Patents

Literature

84results about How to "Reduced risk of demagnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

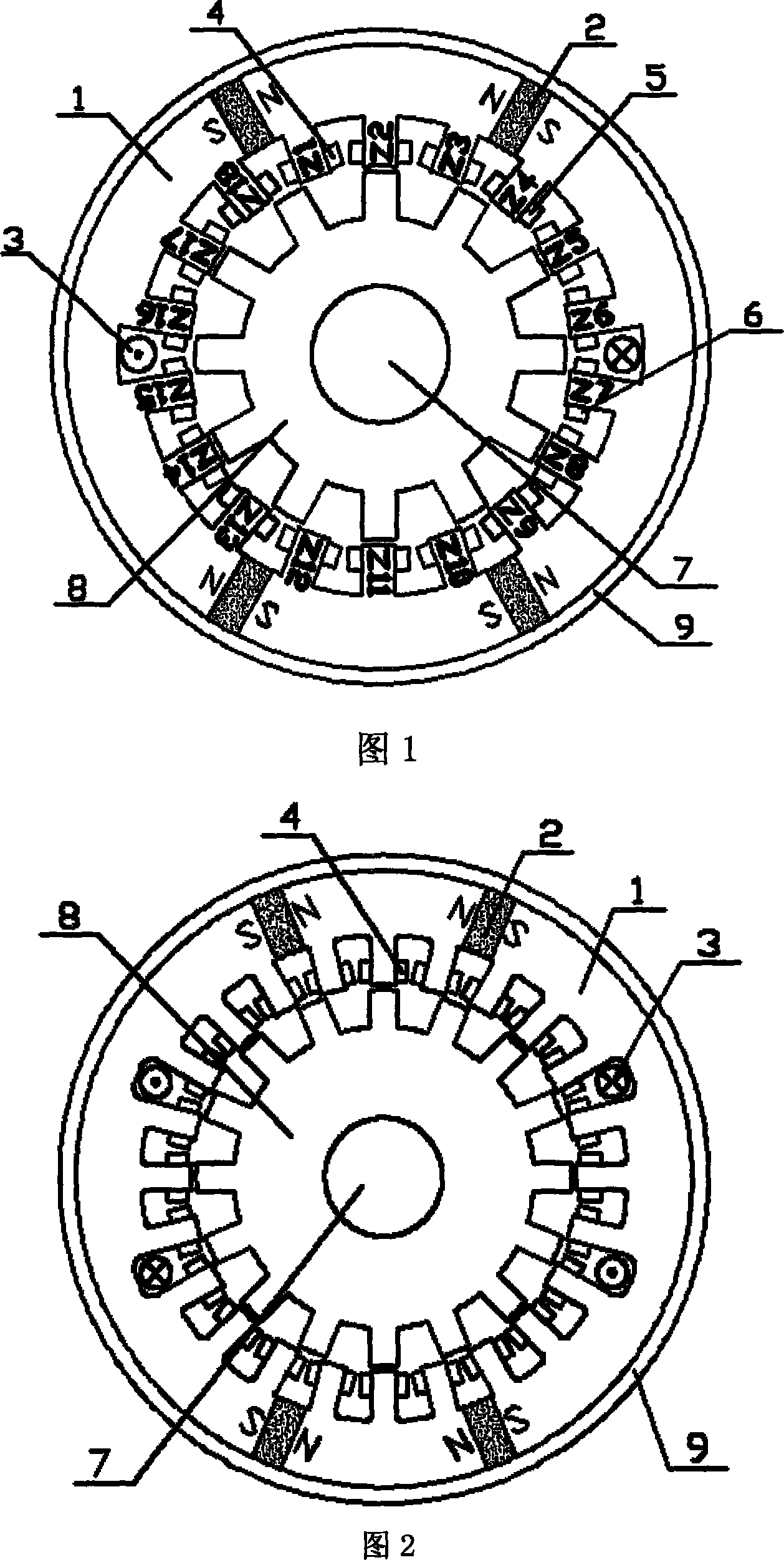

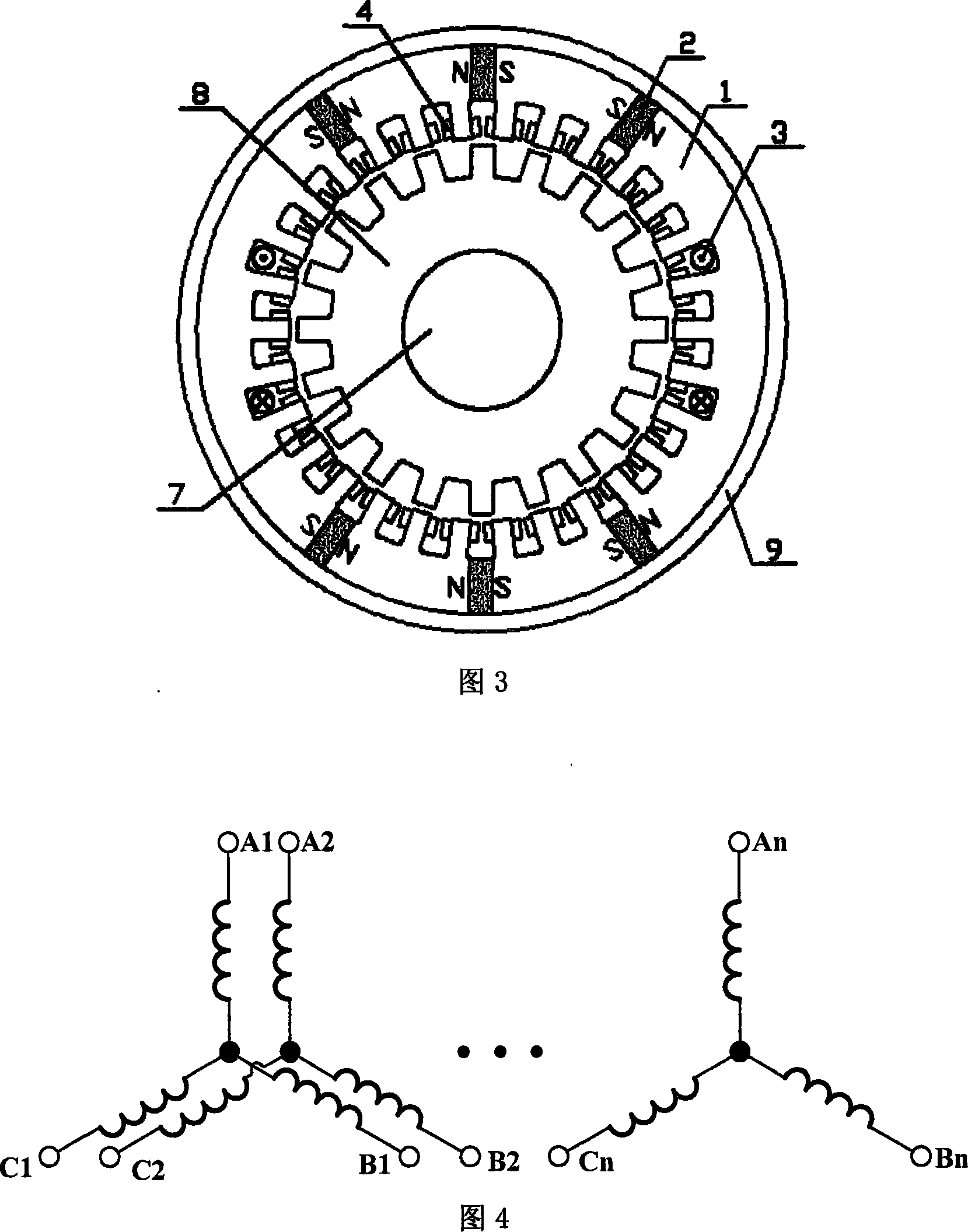

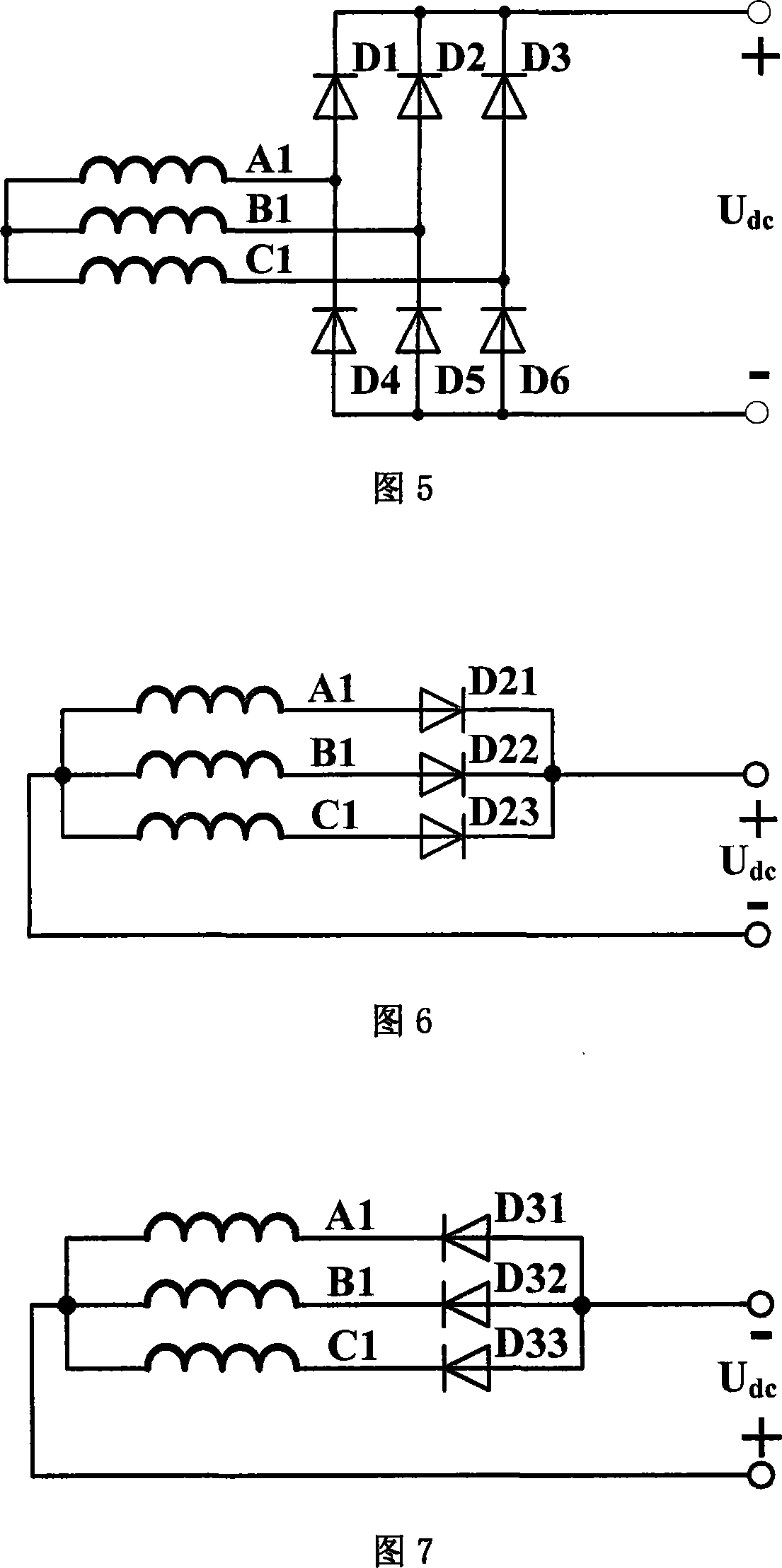

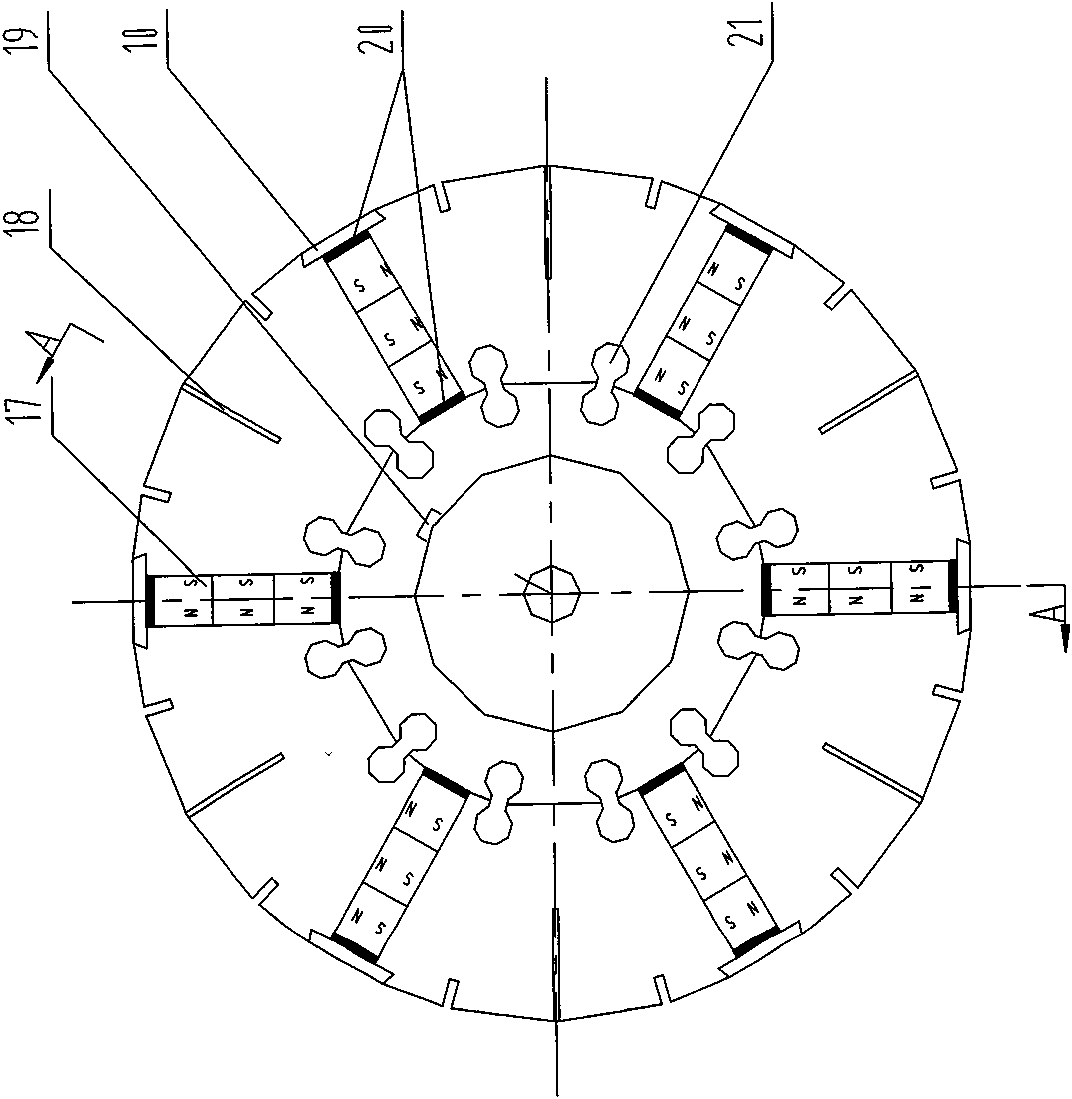

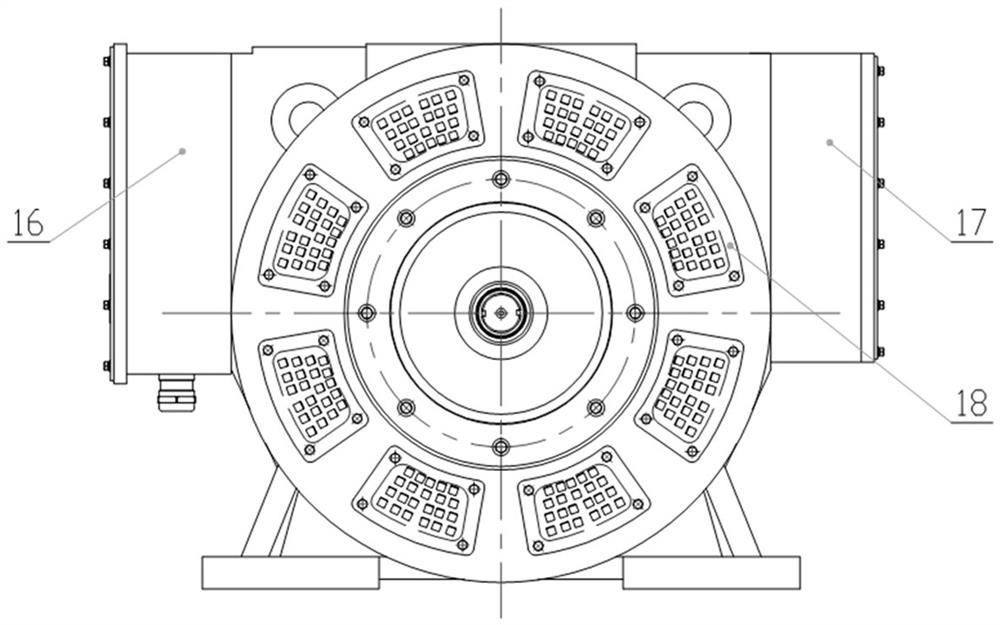

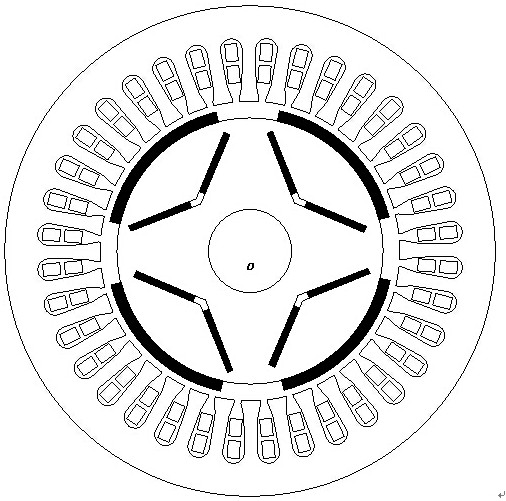

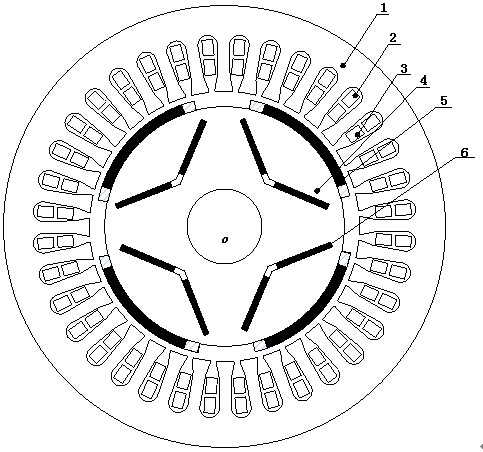

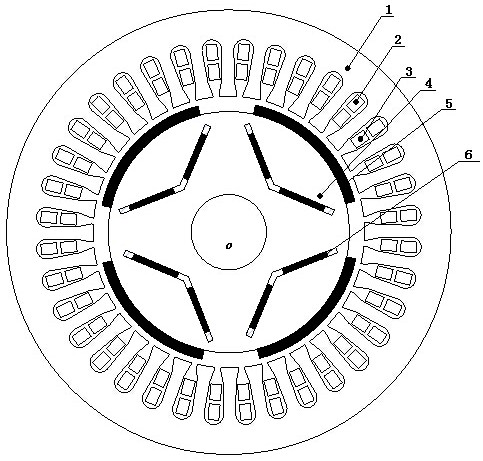

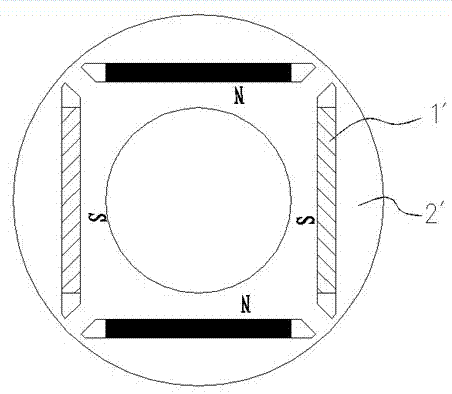

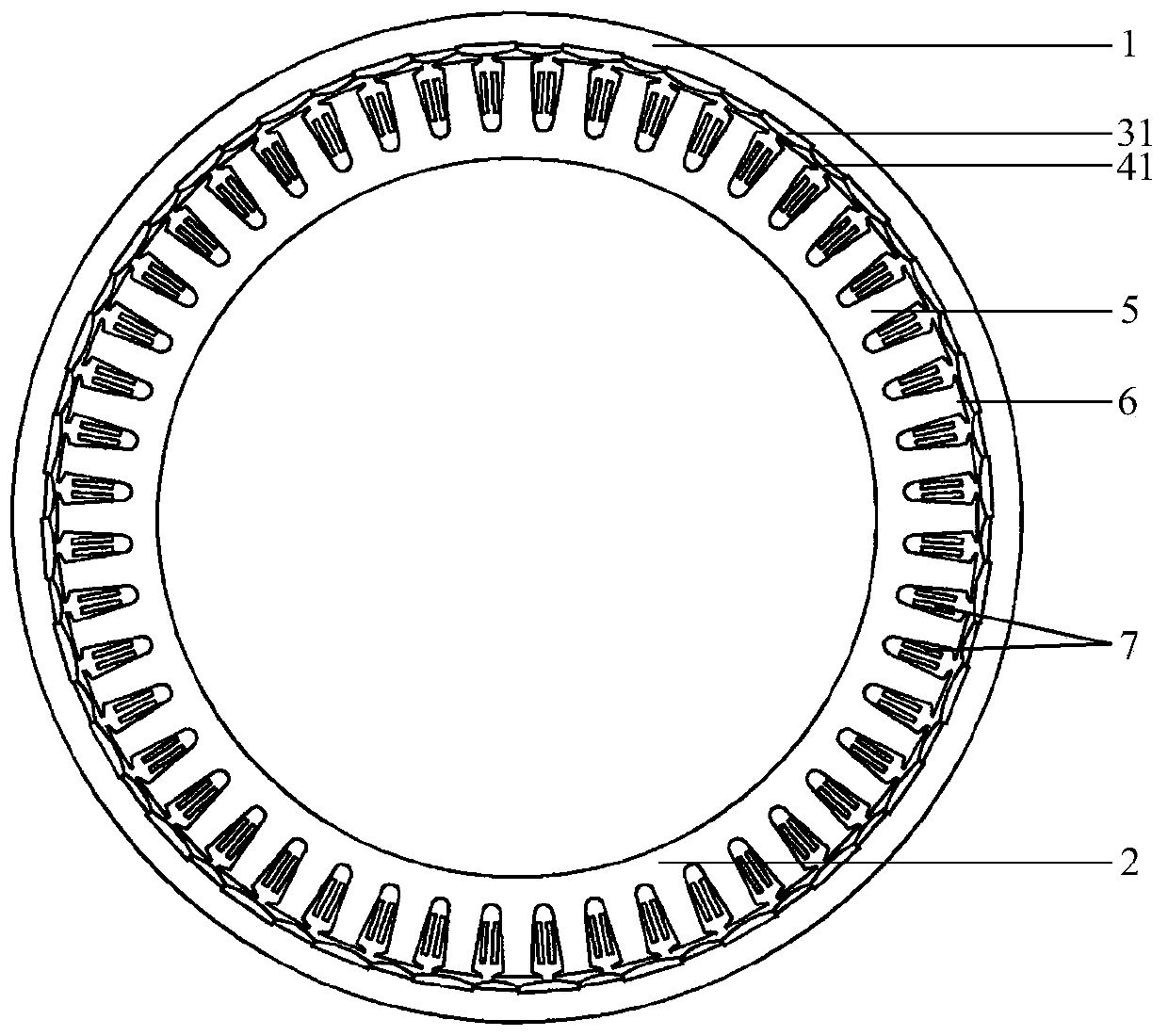

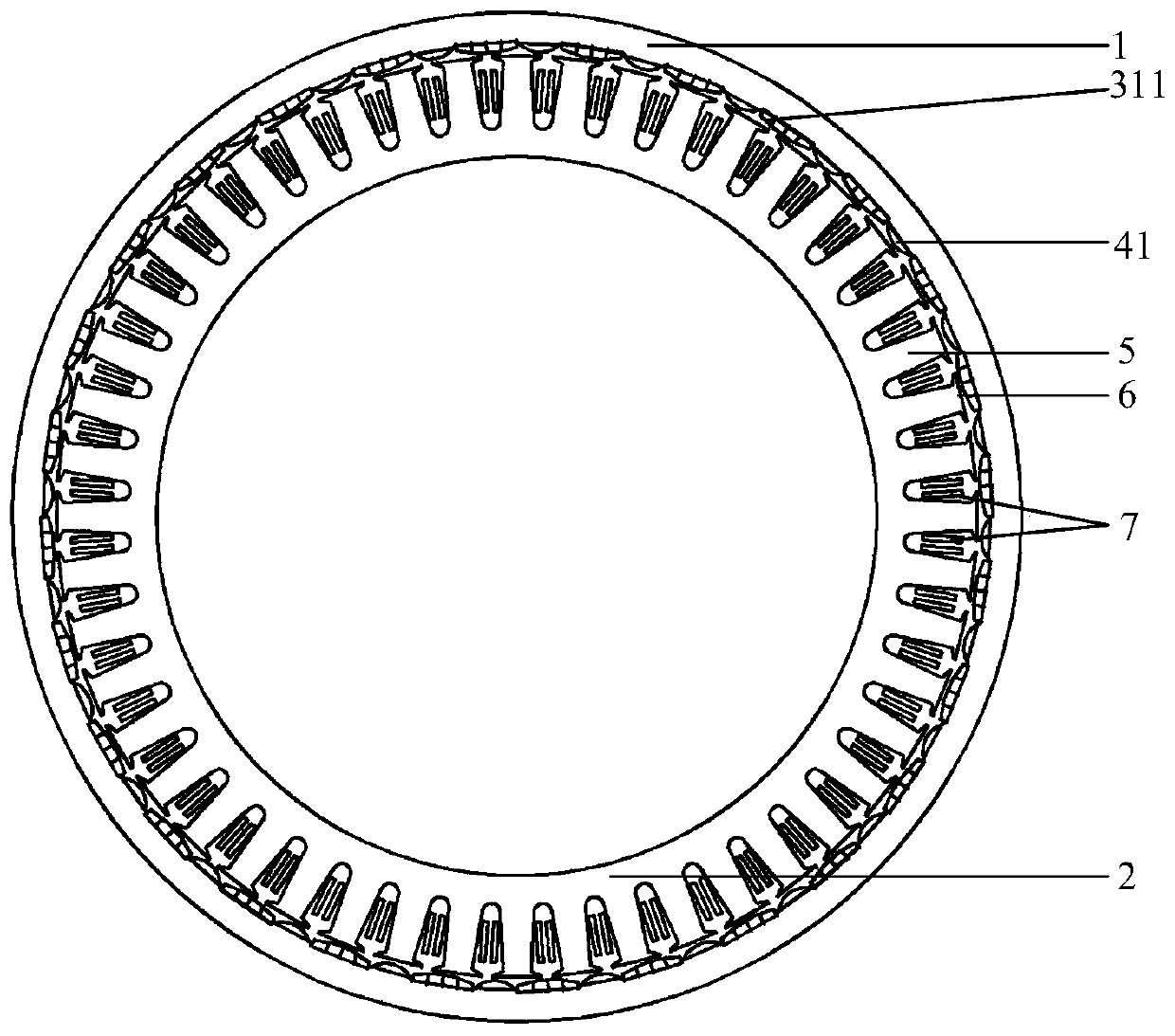

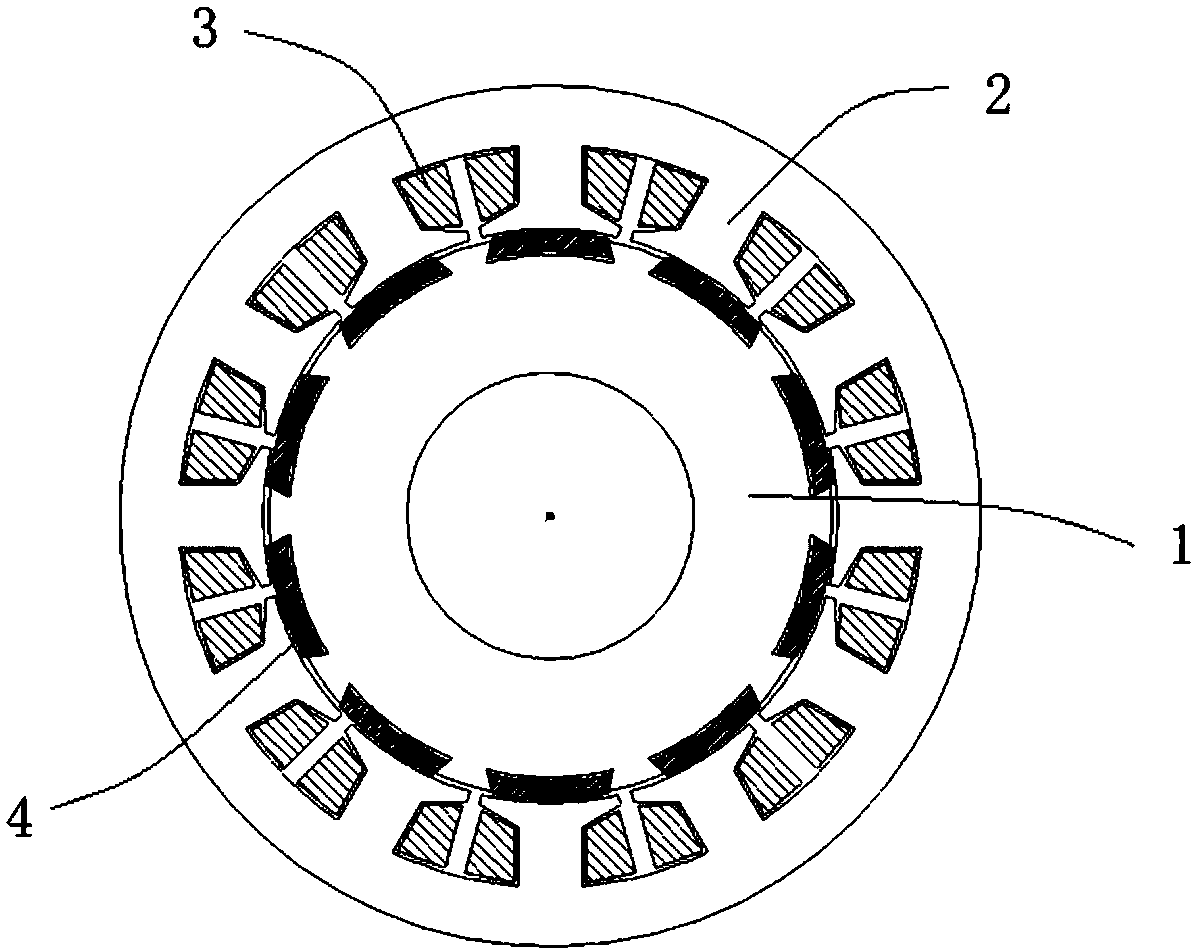

Mixed excitation dual protruding pole brushless DC generator

ActiveCN101127461AReduced risk of demagnetizationMeet the needs of different applicationsMagnetic circuit stationary partsDC commutatorPhysicsMagnetic potential

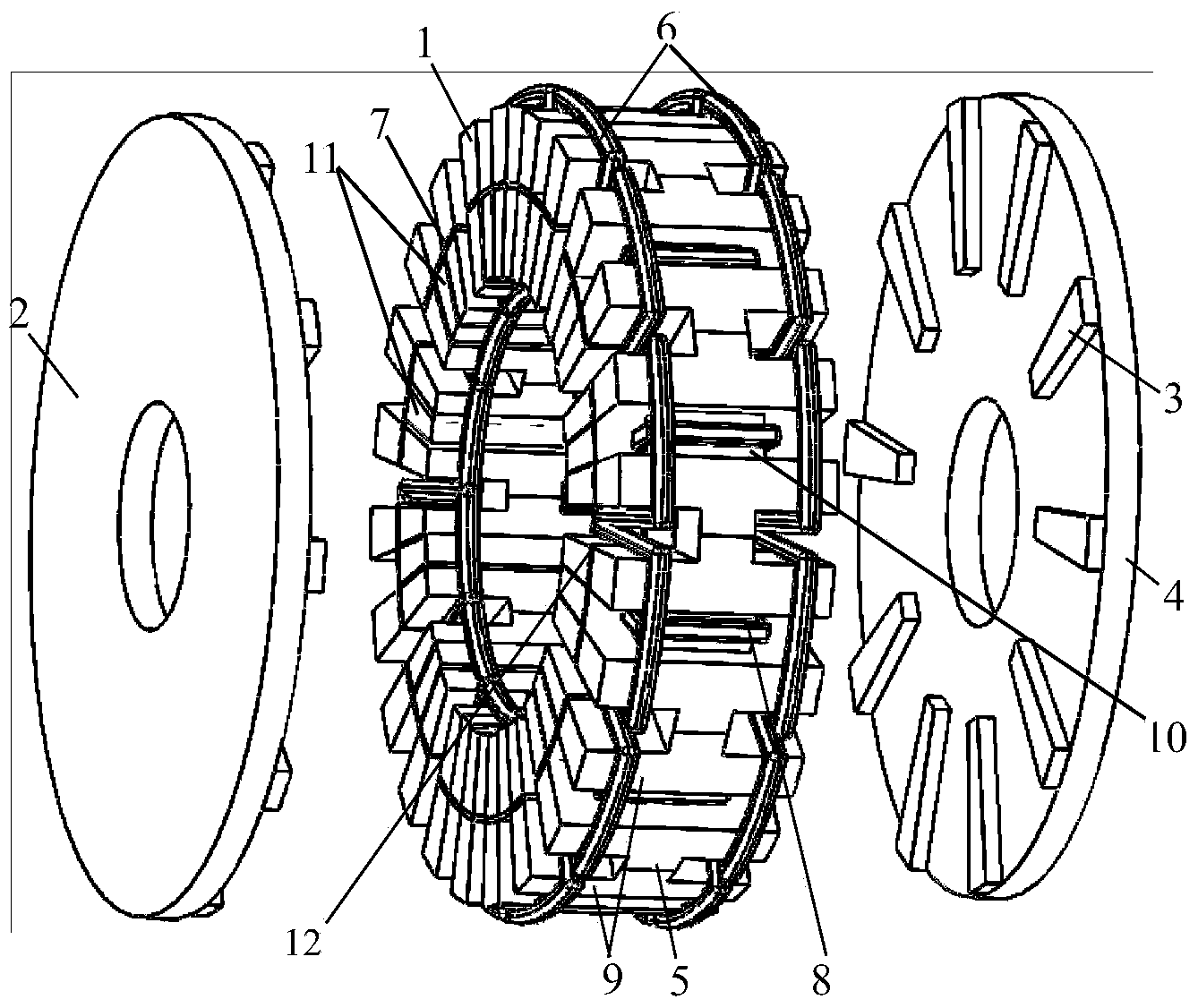

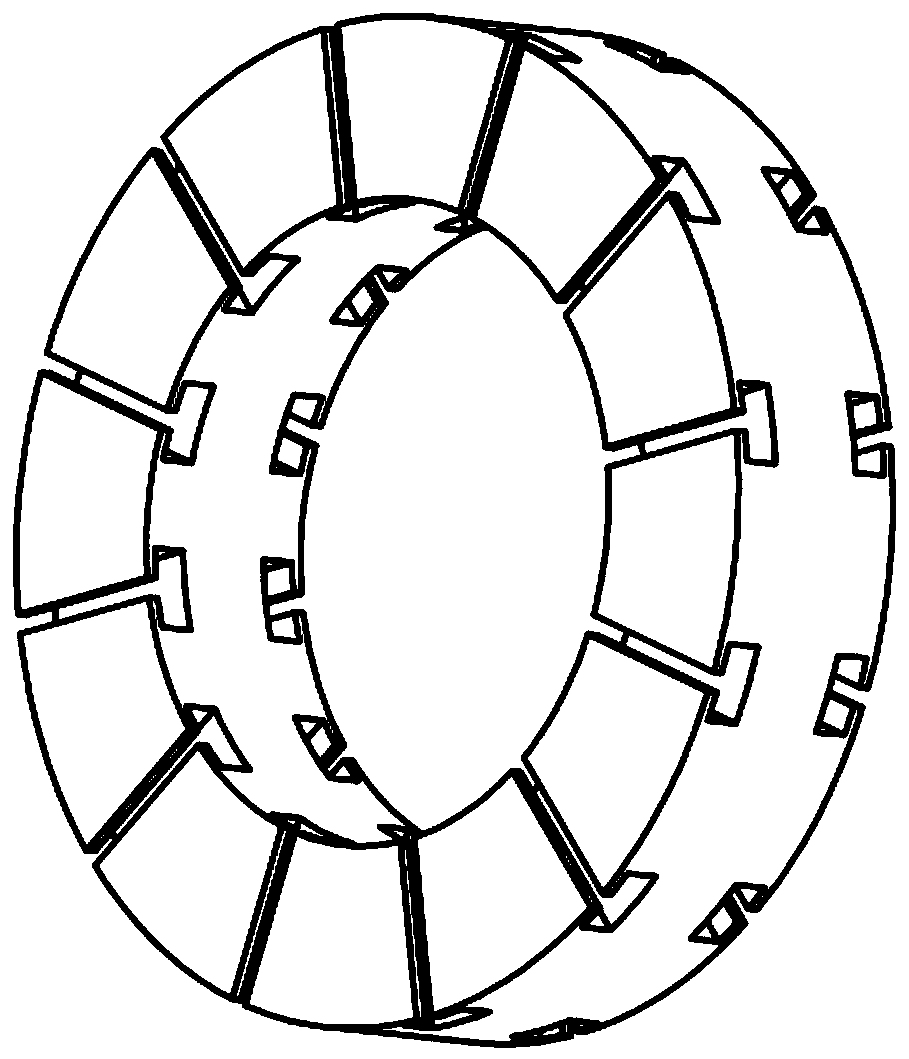

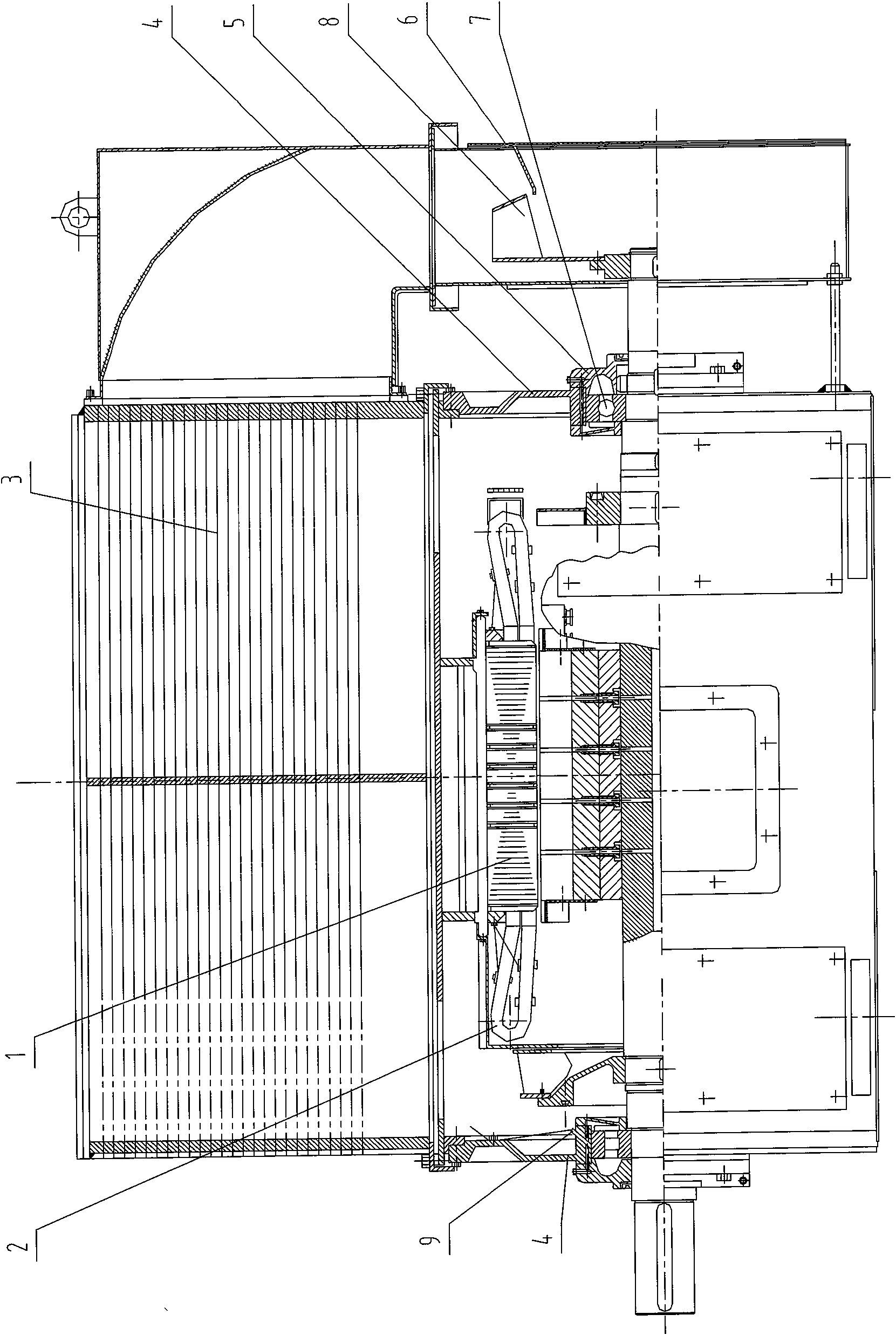

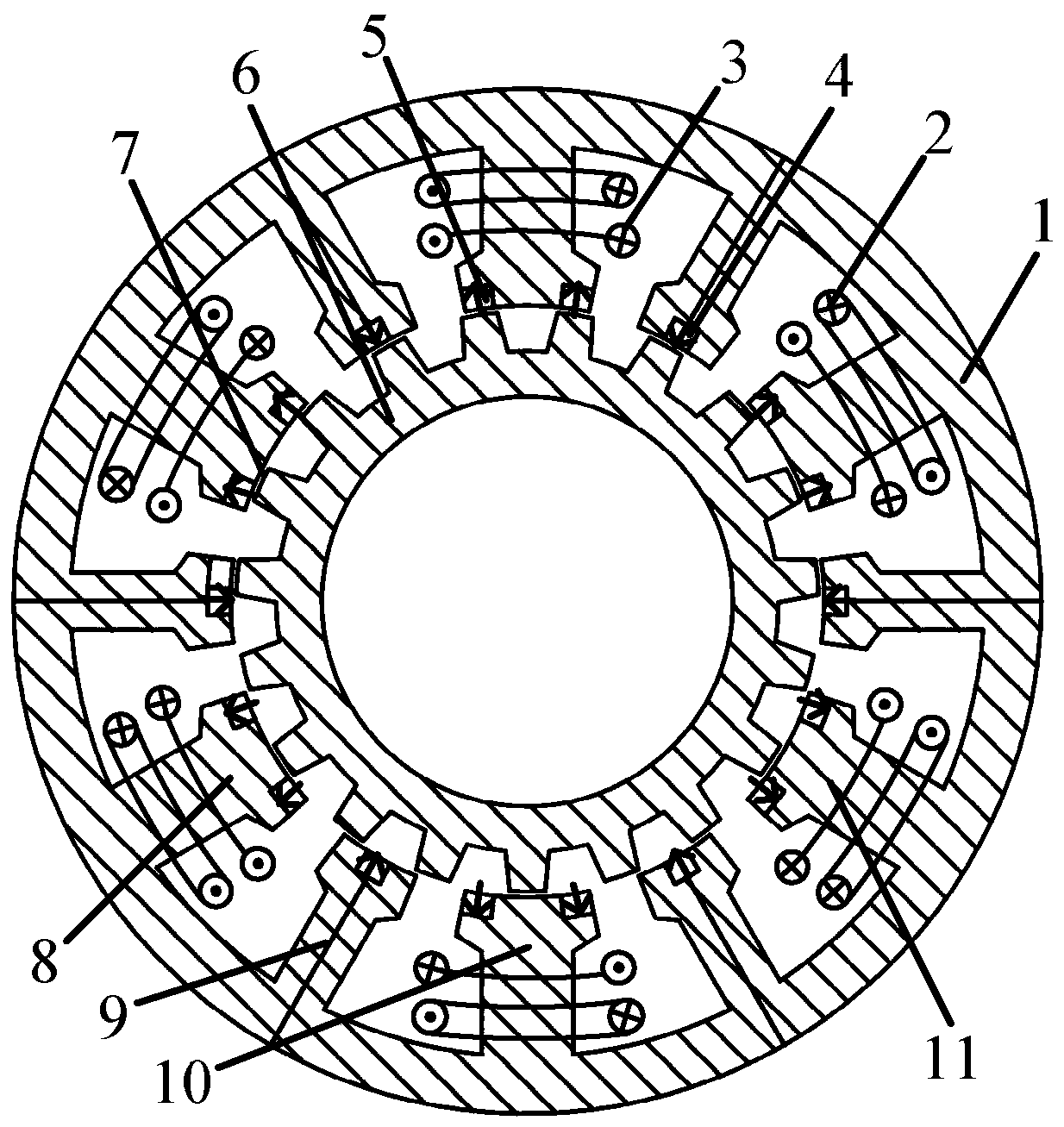

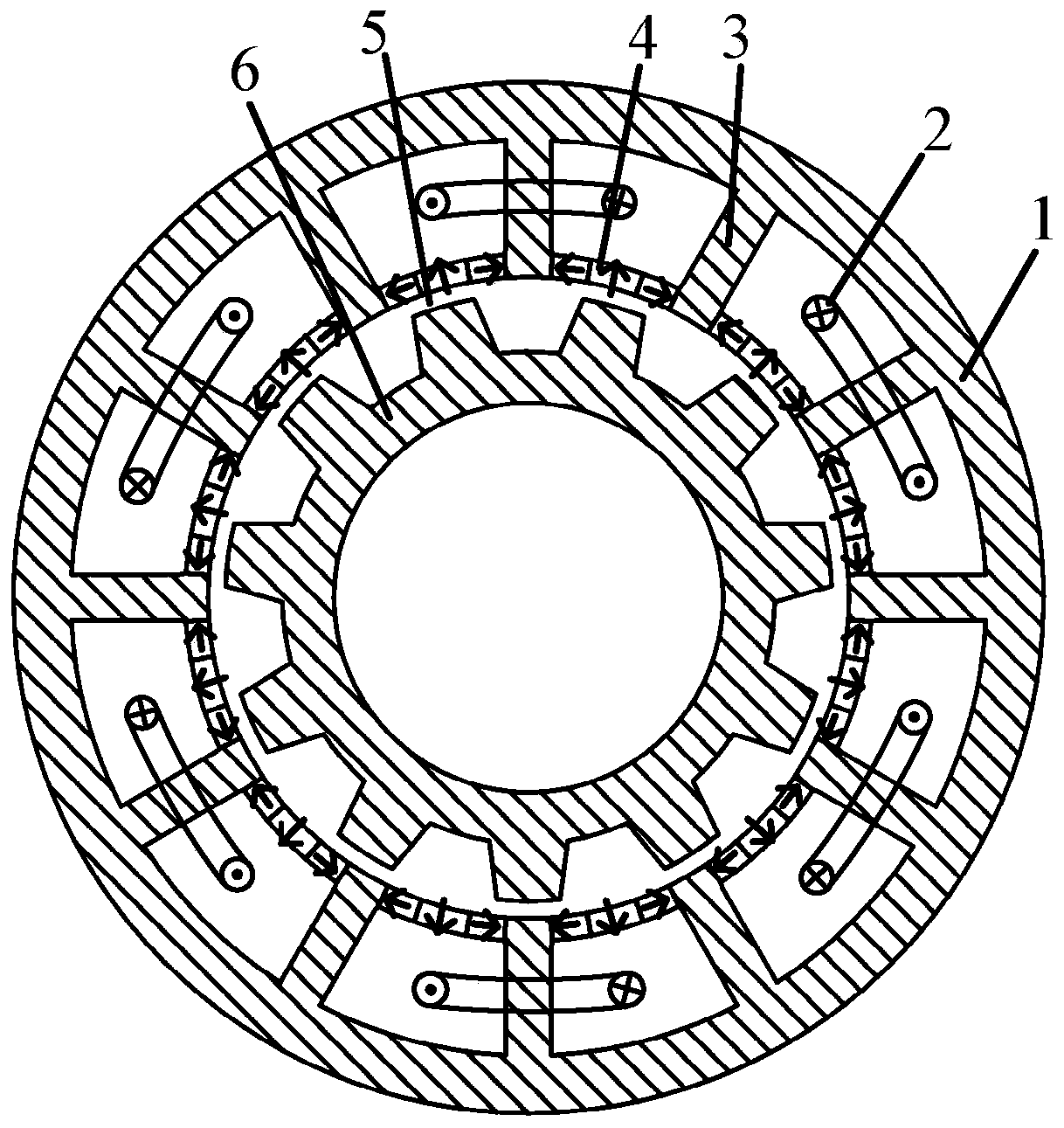

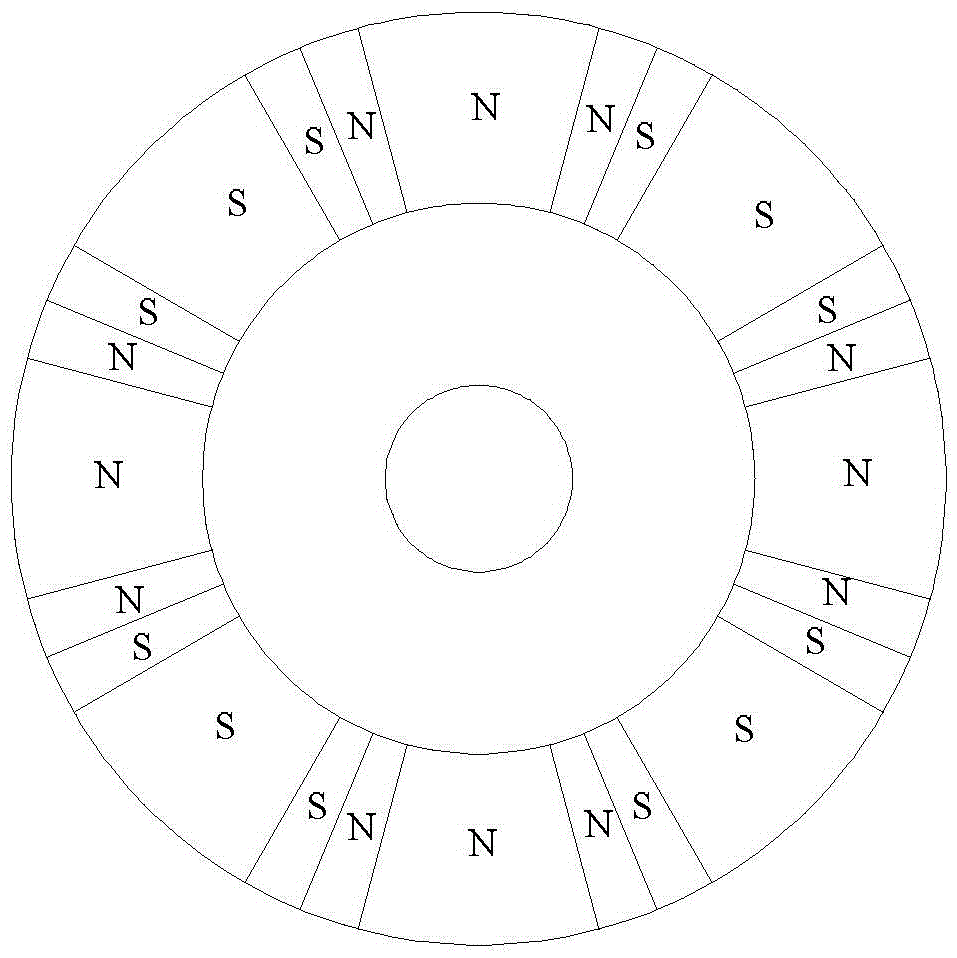

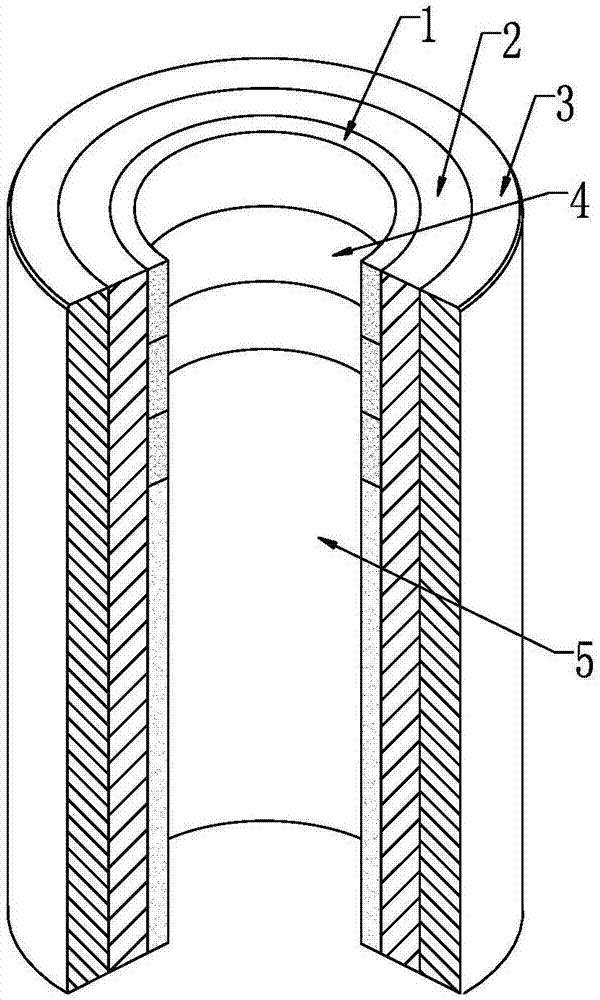

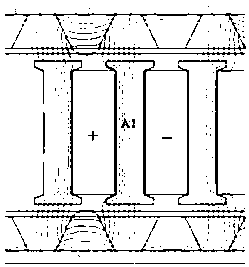

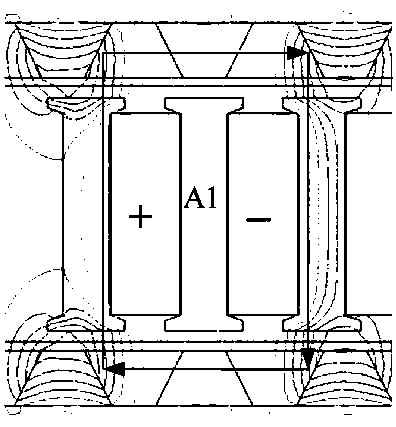

The utility model relates to a brushless direct current generator with hybrid excitation double salient, belonging to double salient motor, which comprises a stator and a rotor, wherein, the stator is composed of a stator core (1), a permanent magnet (2), a magnetizing coil (3) and the armature windings (4),(5),(6); the rotor comprises a rotating shaft (6), a rotor core (7); the yoke of the stator is provided with more than two groups of permanent magnets with symmetrical distribution, moreover the number of each group is more than two, and the neighboring permanent magnets are separated by three stator poles; meanwhile the magnetizing coil with symmetrical distribution is arranged outside the permanent magnets. The utility model has no additional air gap; the magnetic potential of the permanent magnet and the magnetic potential of the excitation make parallel connection so as to avoid the permanent magnet being demagnetized by the magnet potential of the electric excitation. A plurality of sets of armature windings output a plurality of channels of direct current after the rectification; wherein the output of the armature winding (4) sleeved on the stators between the permanent magnets can provide the power supply for the own excitation coil (3) of the motor, which makes the entire motor work in an independent electricity generation condition; therefore the utility model is in particular suitable for the wind power generation situation and other separate supply application situation.

Owner:SUZHOU DSM GREEN POWER LTD

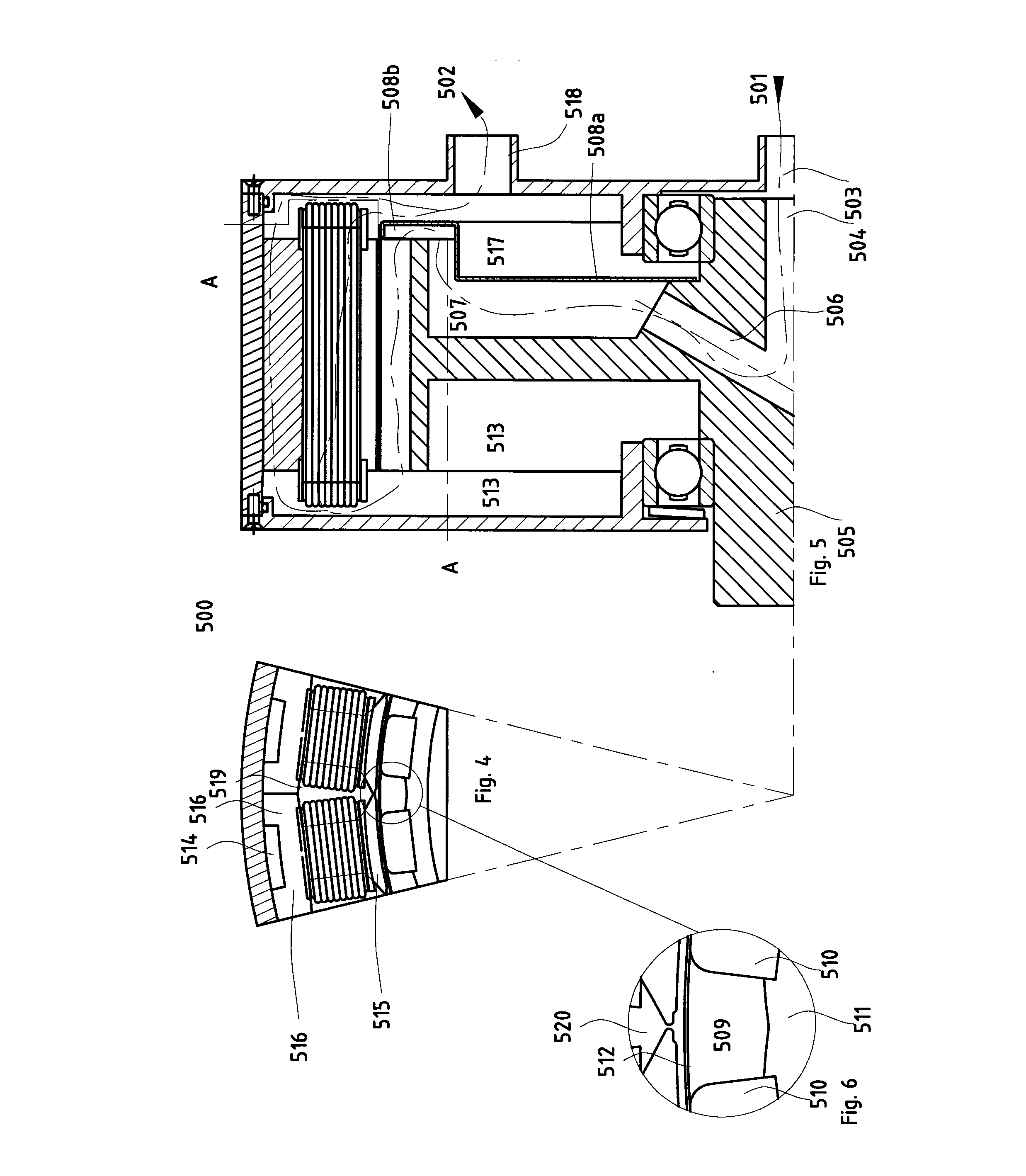

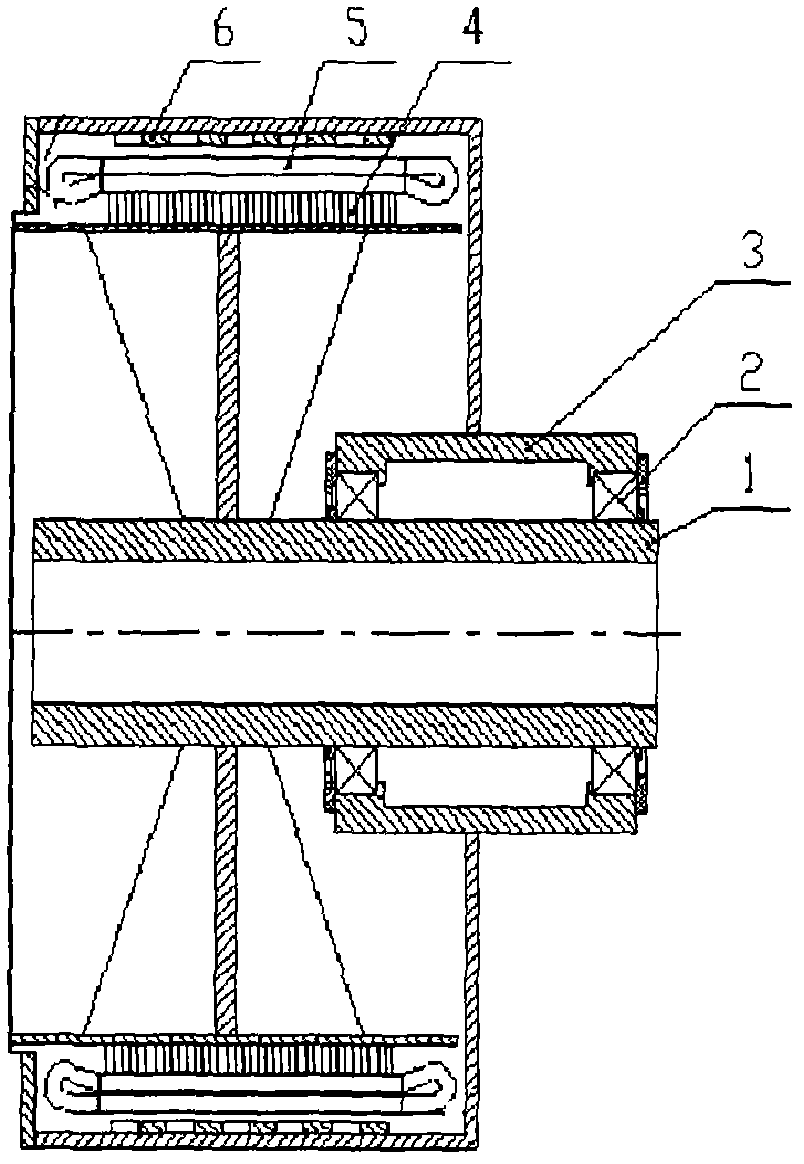

Cooled magnet motor

ActiveUS20130342049A1Reduce thermal resistanceImprove cooling effectMagnetic circuit rotating partsCooling/ventillation arrangementRotor magnetsHigh flux

An electric motor / generator comprises a rotor with magnets mounted on the surface of the rotor, the magnets facing the stator over a gap. The magnets have a very high flux density but a limited ability to withstand high stator currents at high temperatures, preferably magnets made of the N48H material. By providing rotor magnet cooling means that reduces the temperature of the magnets by a cooling fluid, use of magnets with lower maximum working temperature and higher flux density is permitted and thereby higher flux can be obtained from the magnets.

Owner:HDD SERVO MOTORS

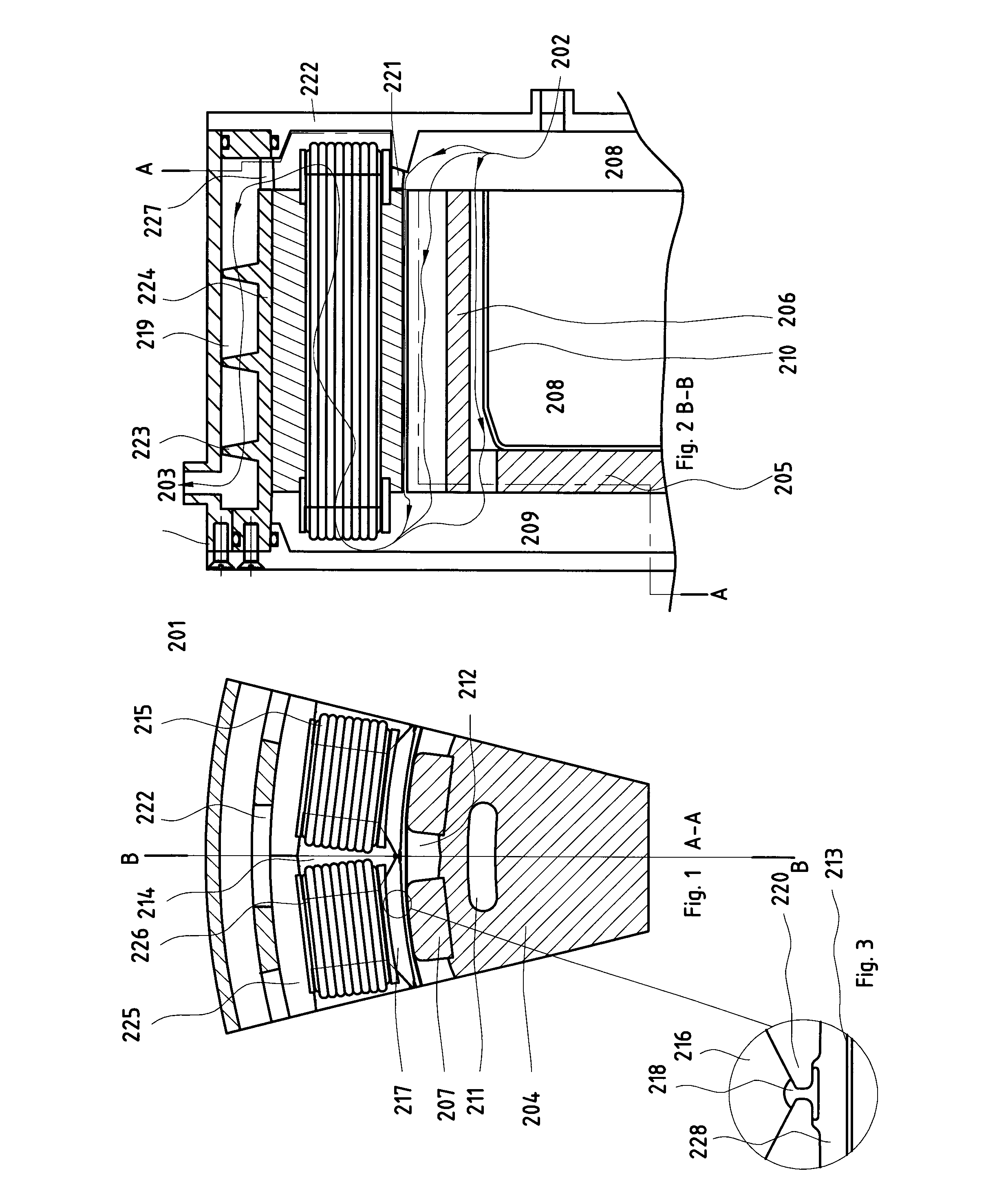

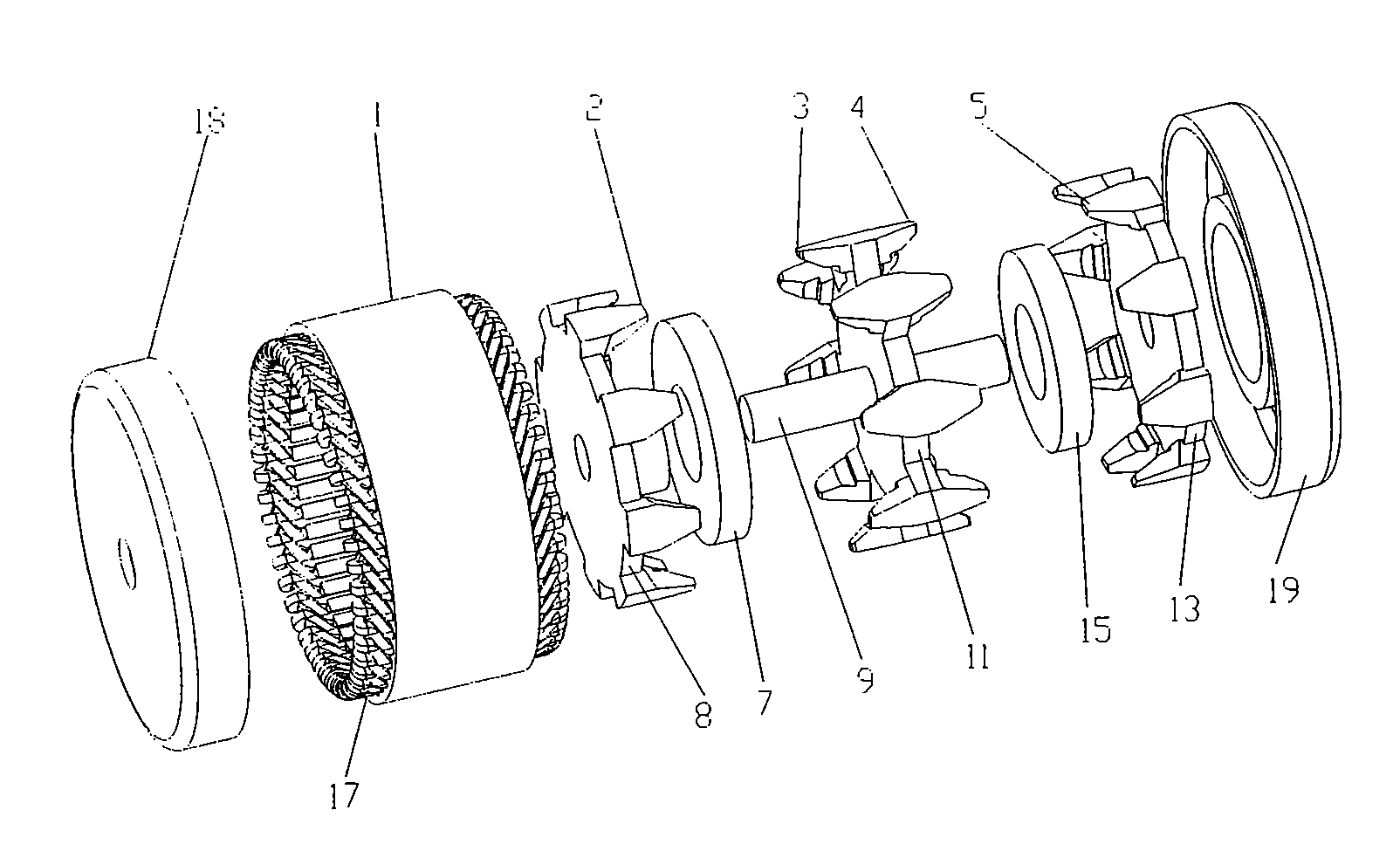

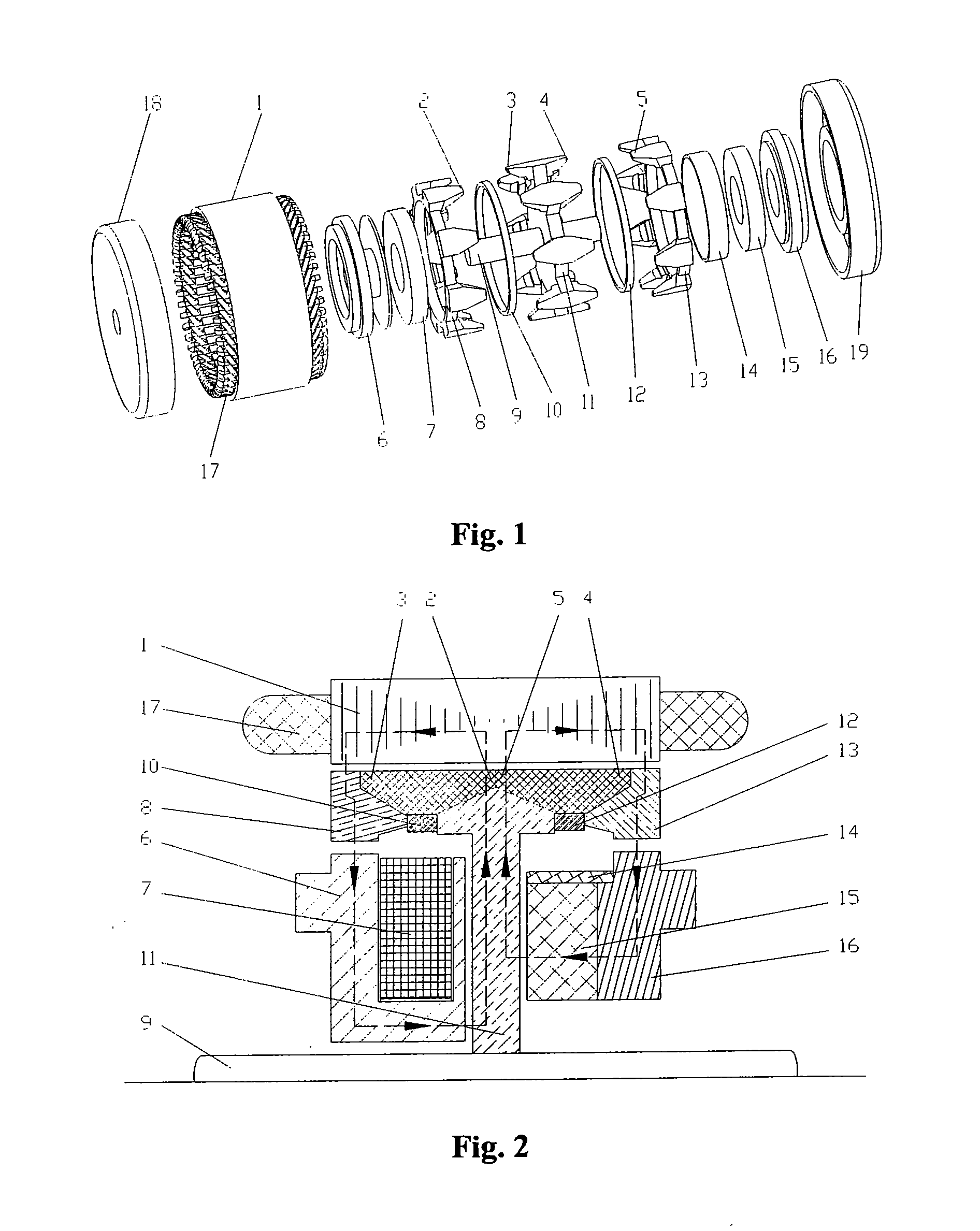

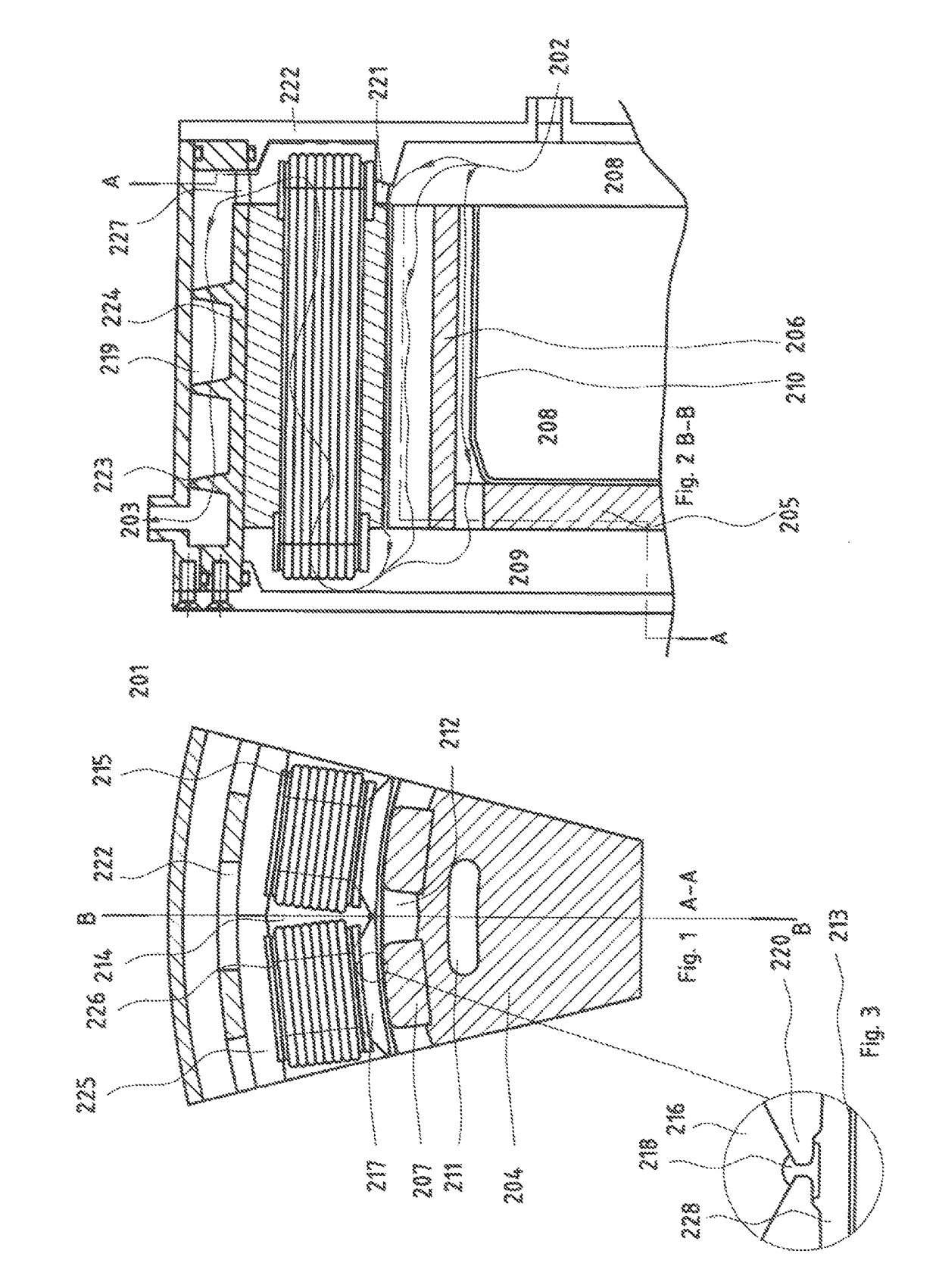

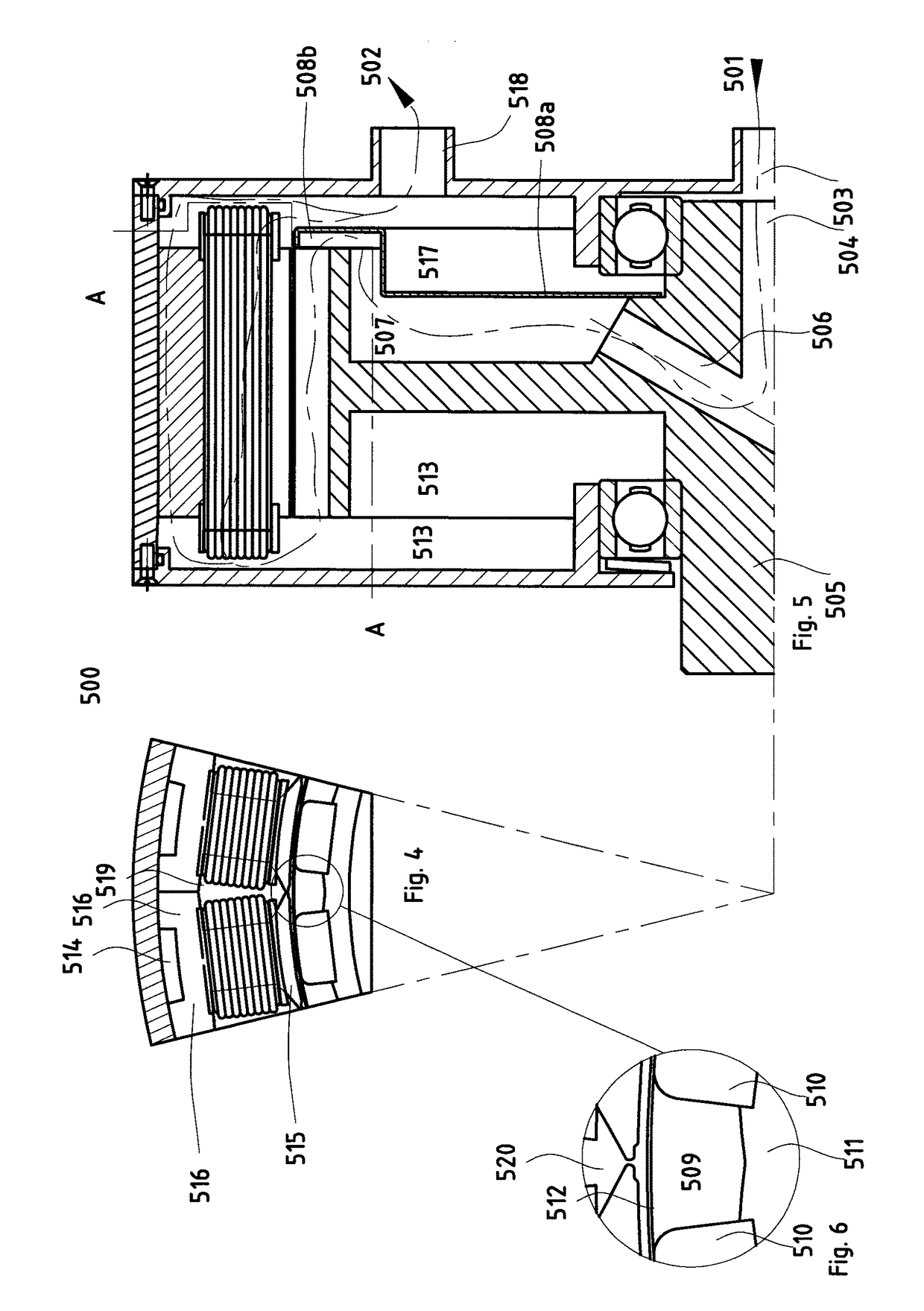

AC Electric Machine With Claw Poles

ActiveUS20120056502A1Increase main magnetic flux magneticIncrease magnetic magnetic energy productSynchronous generatorsWindingsLow speedElectric machine

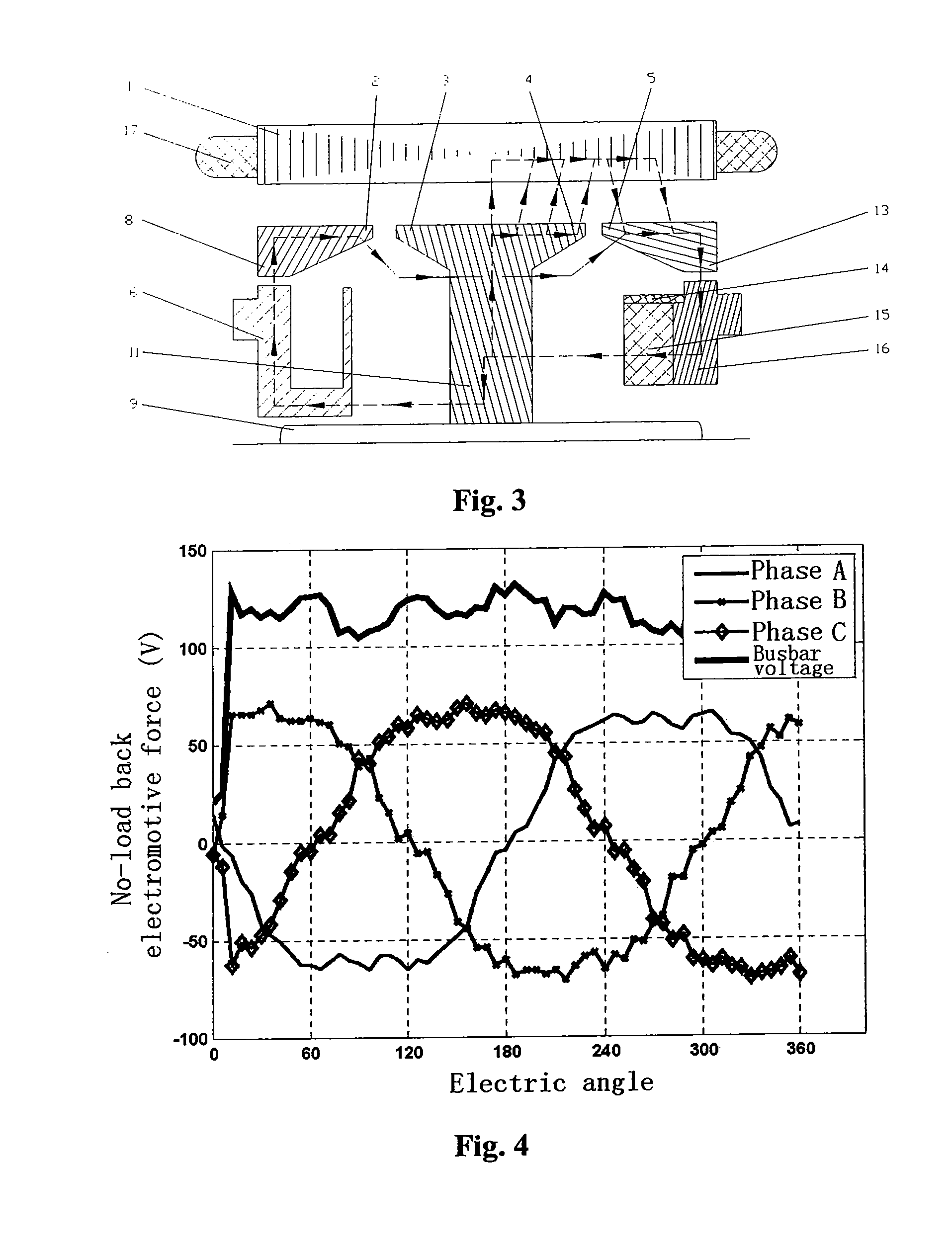

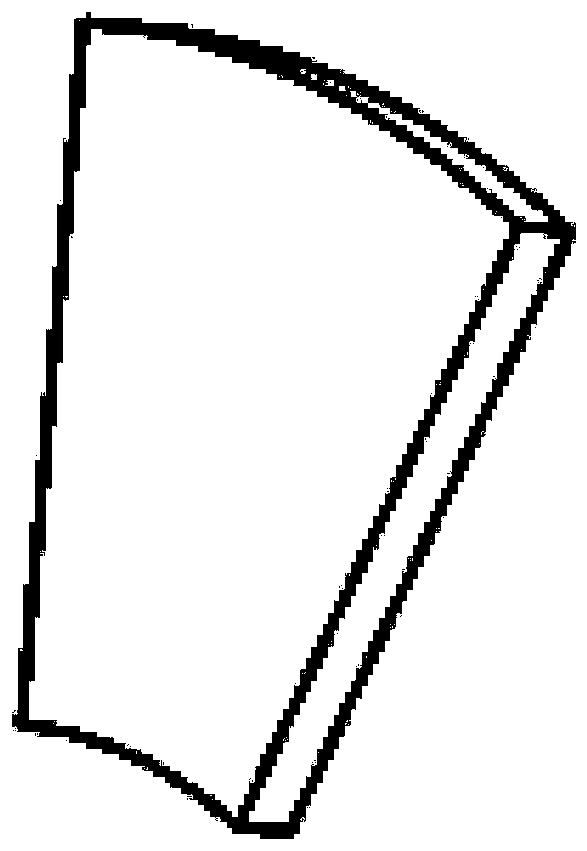

An AC claw-pole electric motor includes a casing, a stator connected with the casing, a rotor and two exciting parts. The rotor includes a rotor shaft (9), a center magnetic yoke (11), a first side magnetic yoke (8), a second side magnetic yoke (13), and claw poles (2, 3, 4, 5) provided on the center magnetic yoke (11), the first side magnetic yoke (8) and the second side magnetic yoke (13). The two exciting parts are respectively provided in spaces formed by the center magnetic yoke (11), the first side magnetic yoke (8), the second side magnetic yoke (13) and the claw poles (2, 3, 4, 5). The axial exciting magnetic fluxes of the two exciting parts are opposite in direction. Thus, the main magnetic flux and the magnetic energy product of the electric motor are increased, and the output and the operation efficiency of the electric motor at a low speed are improved.

Owner:JING JIN ELECTRIC TECH CO LTD

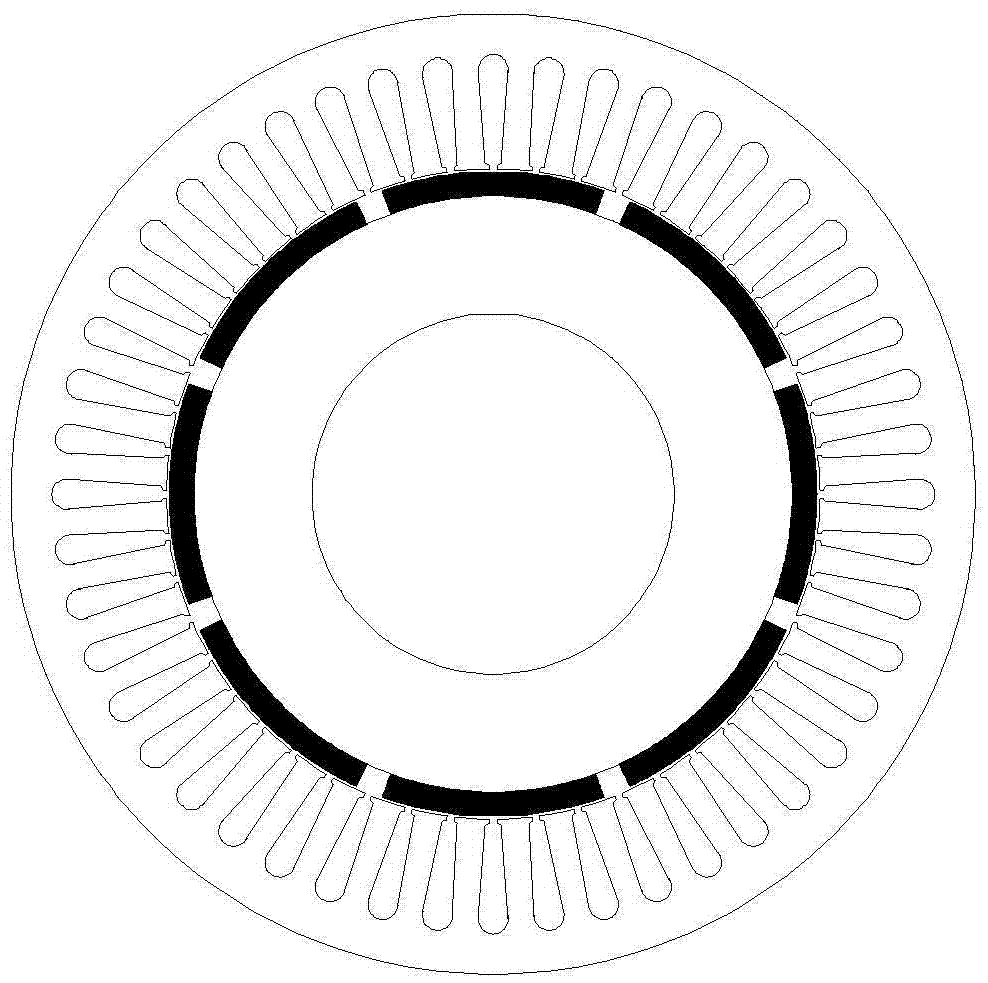

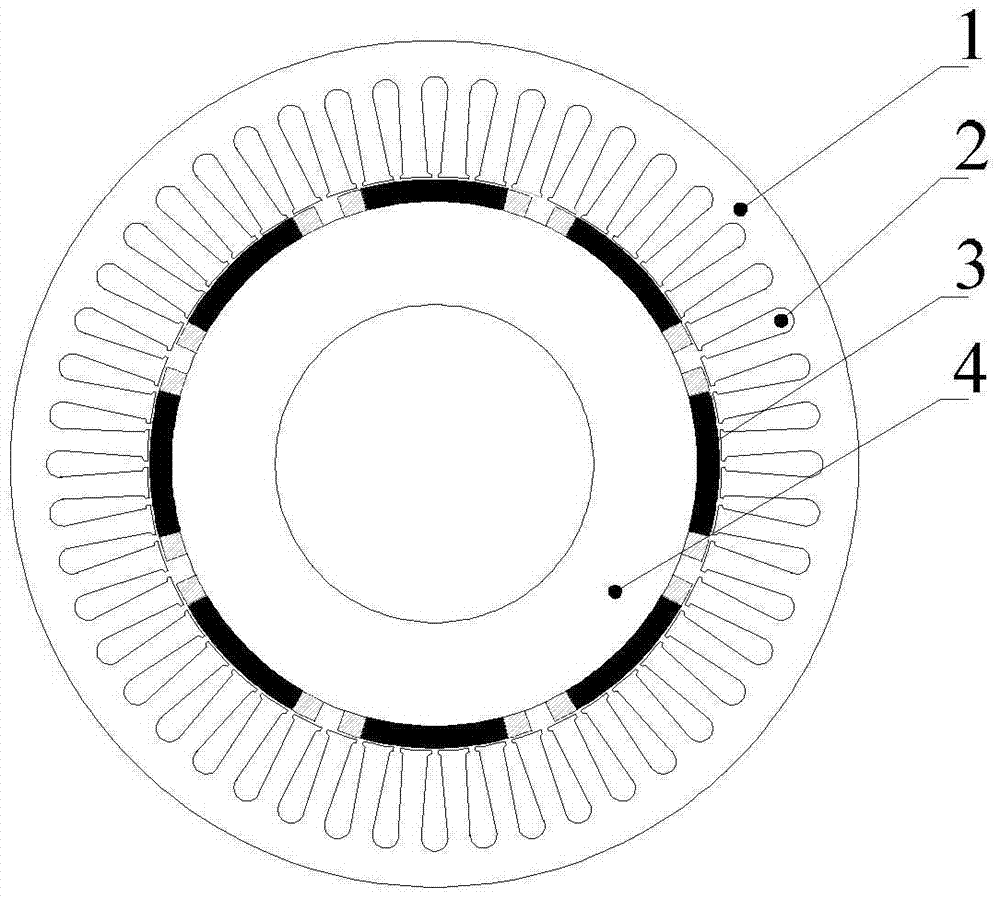

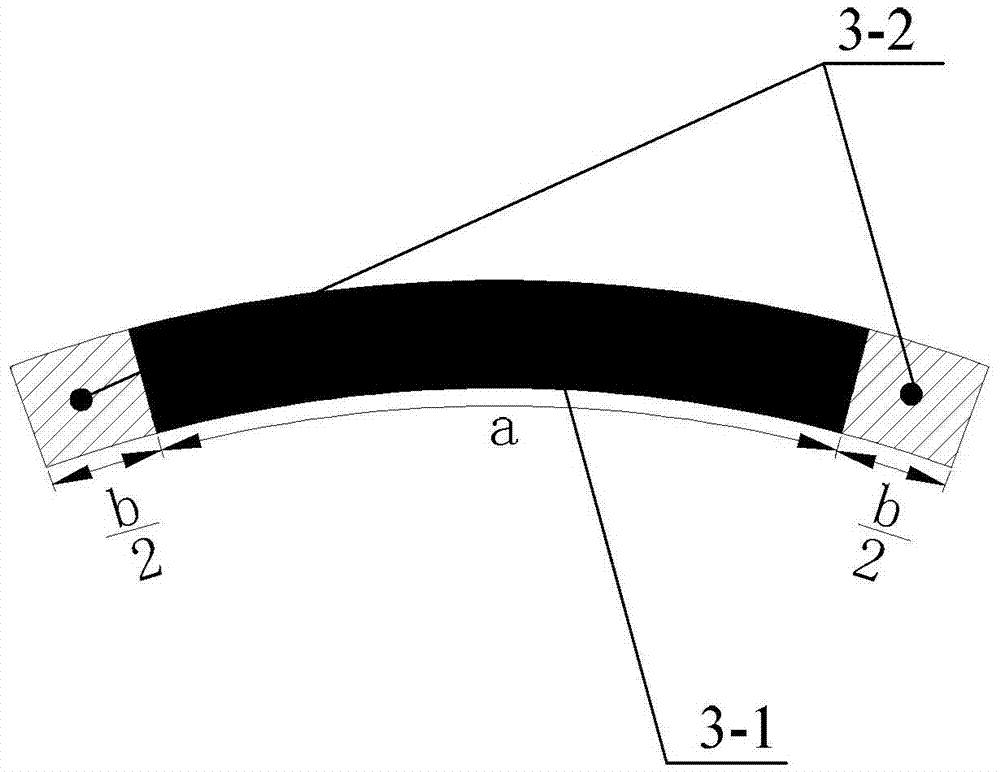

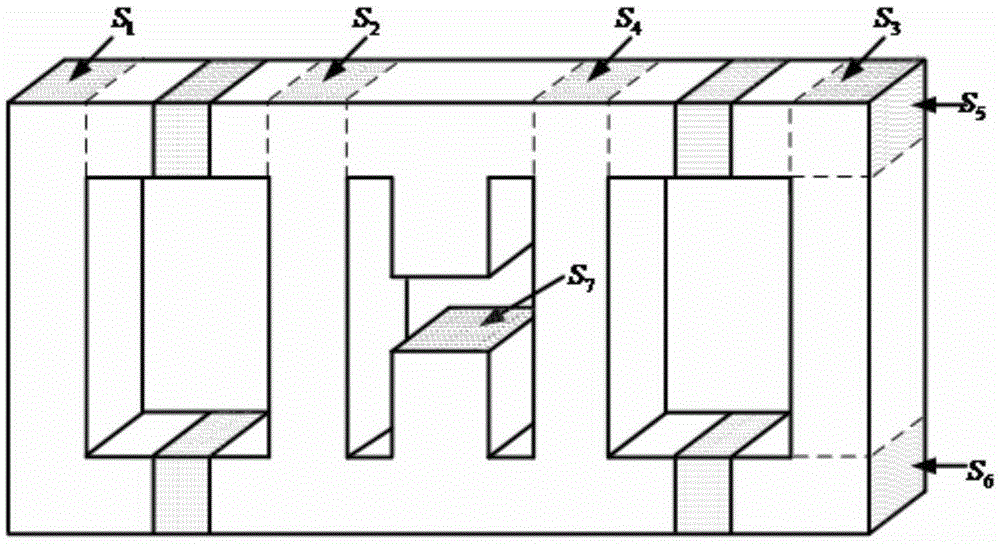

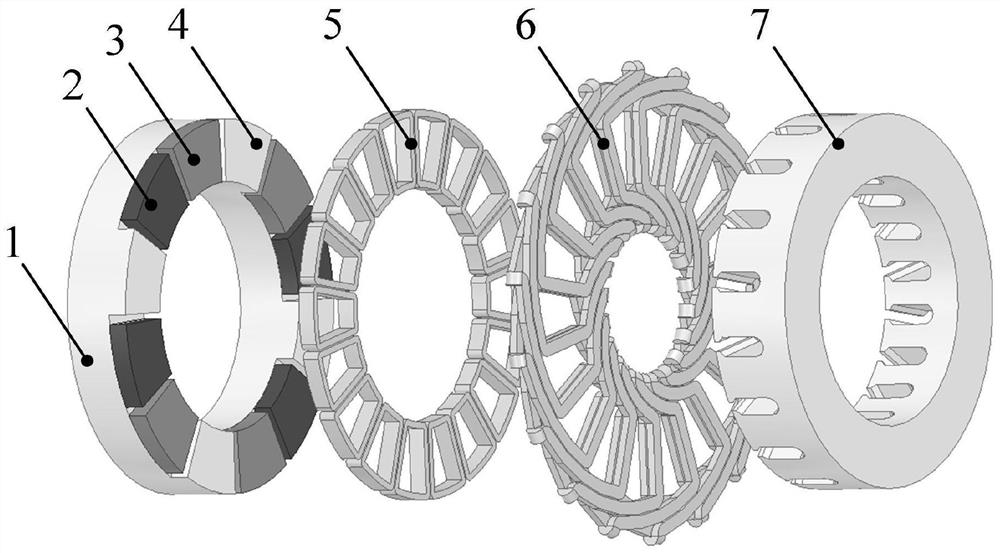

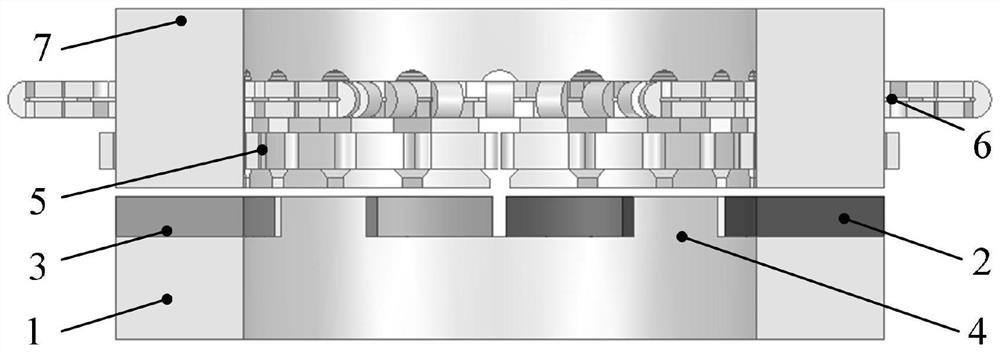

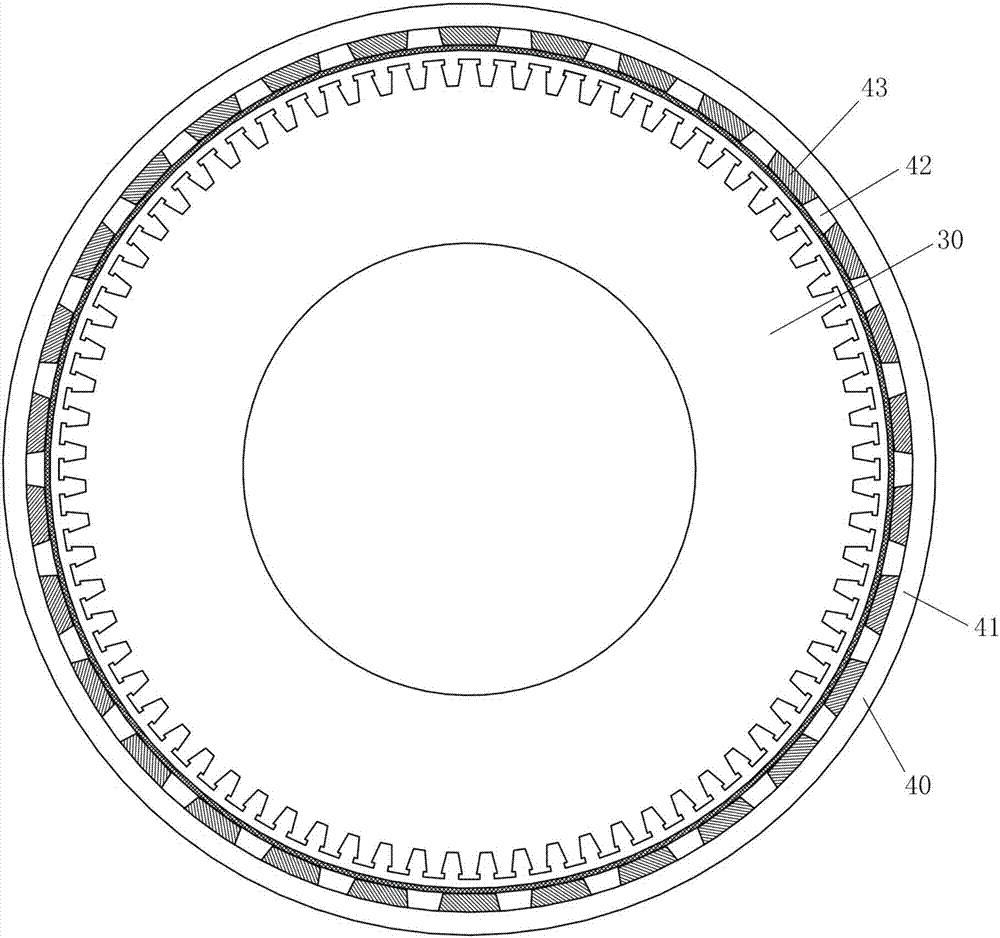

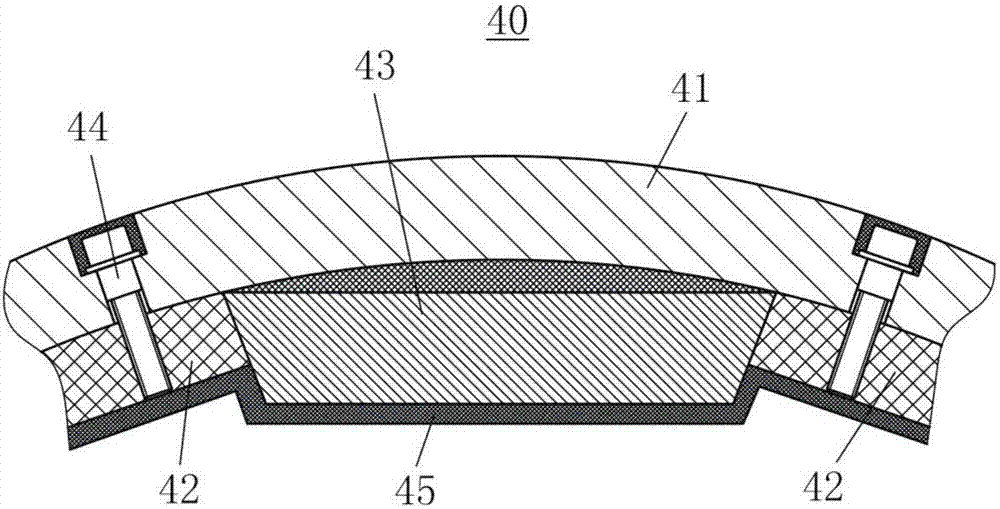

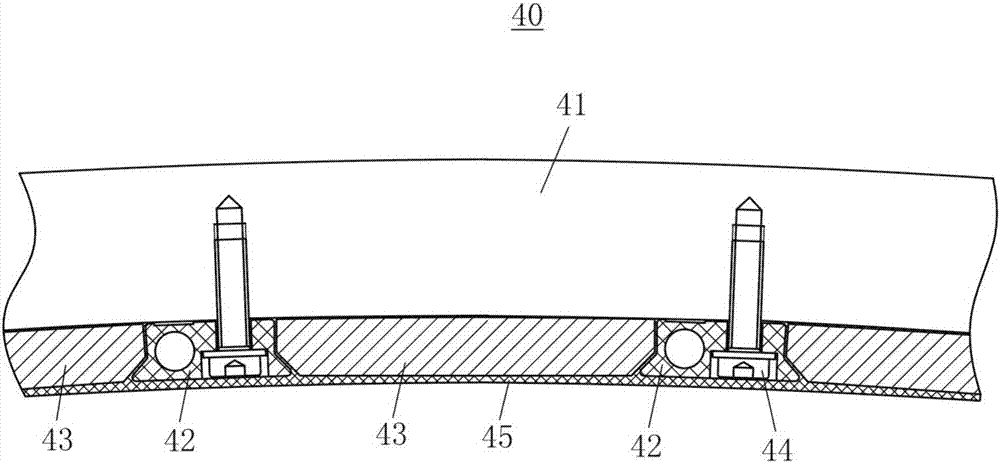

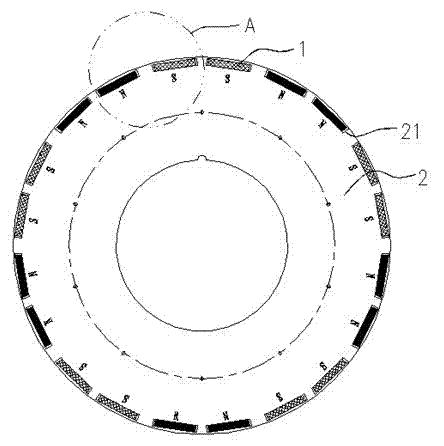

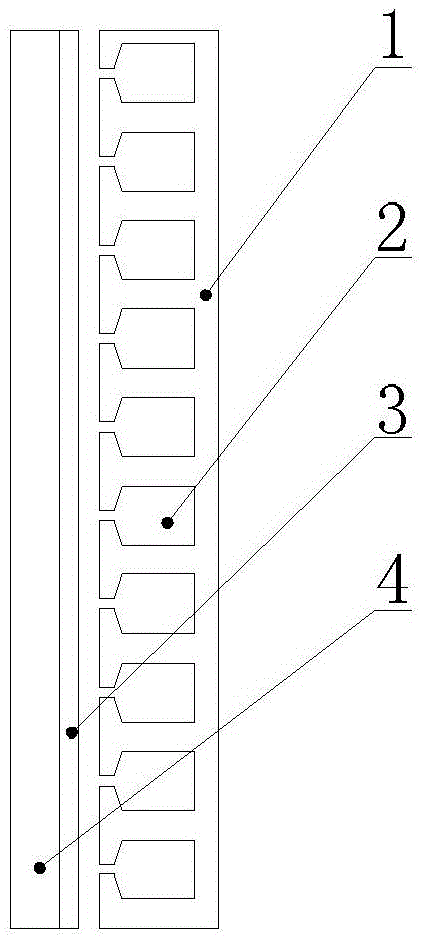

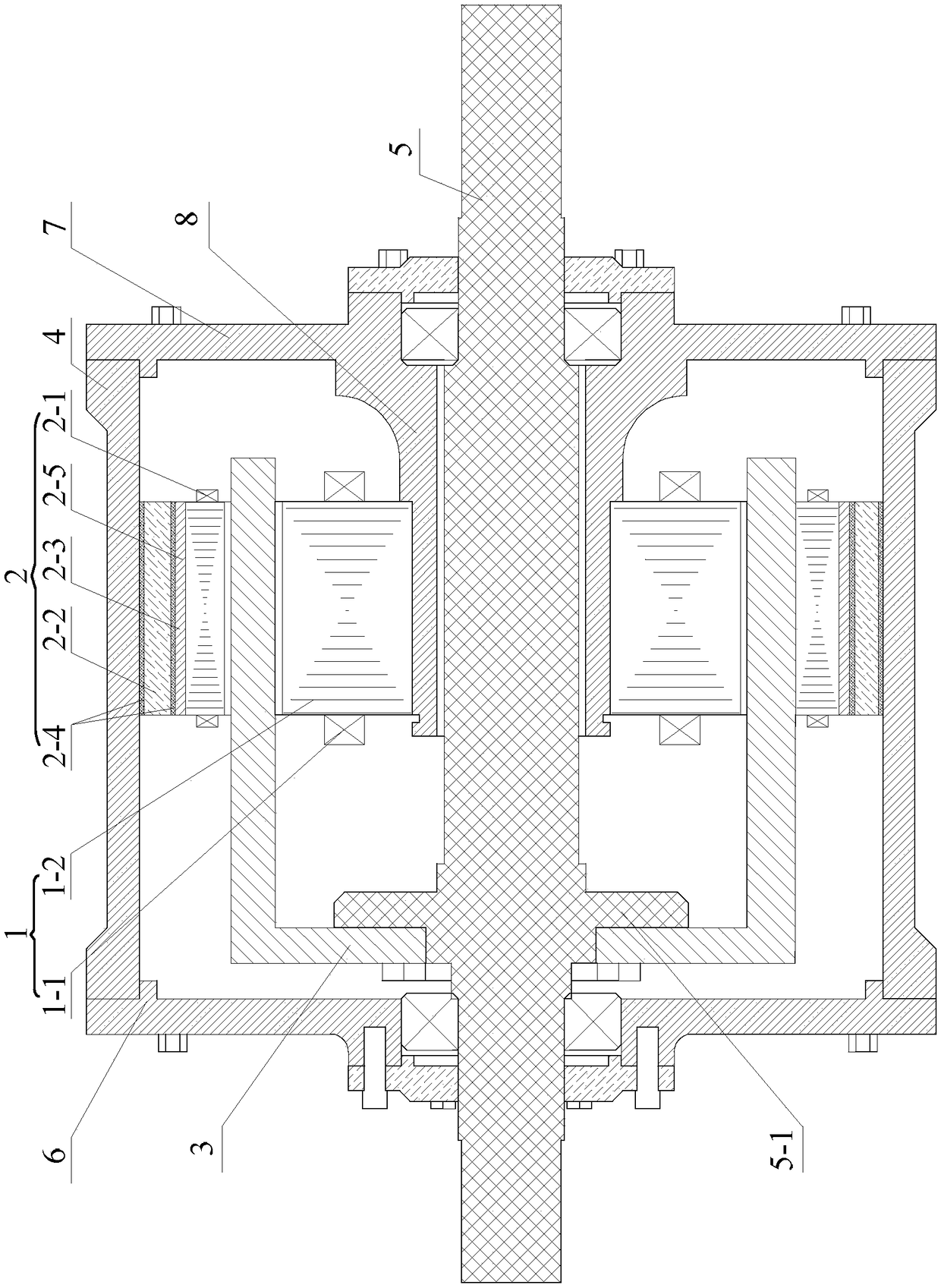

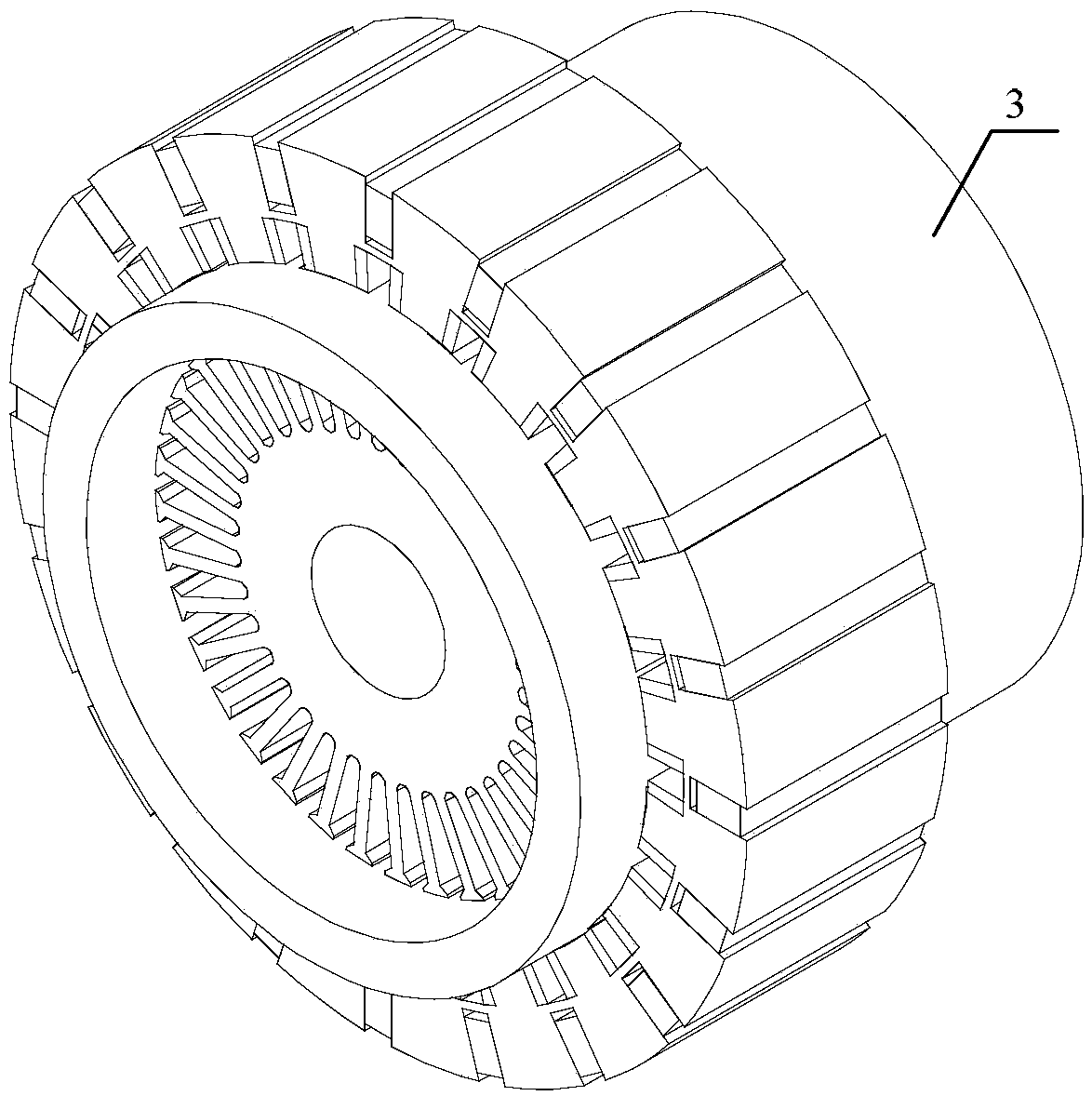

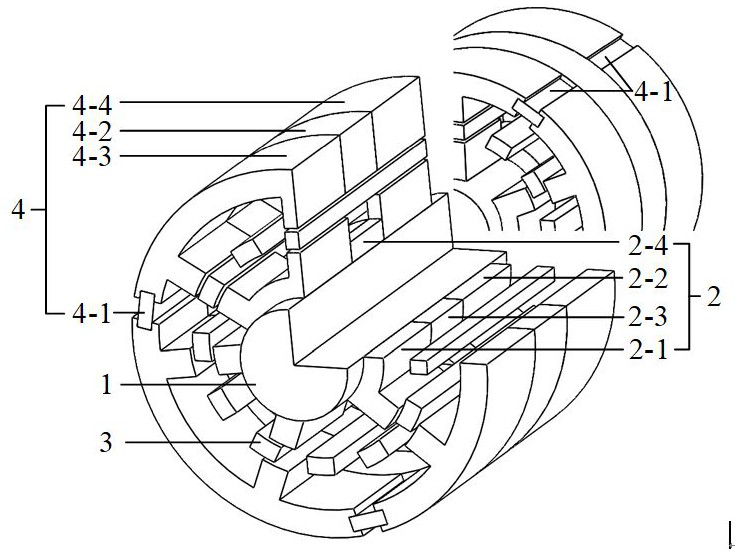

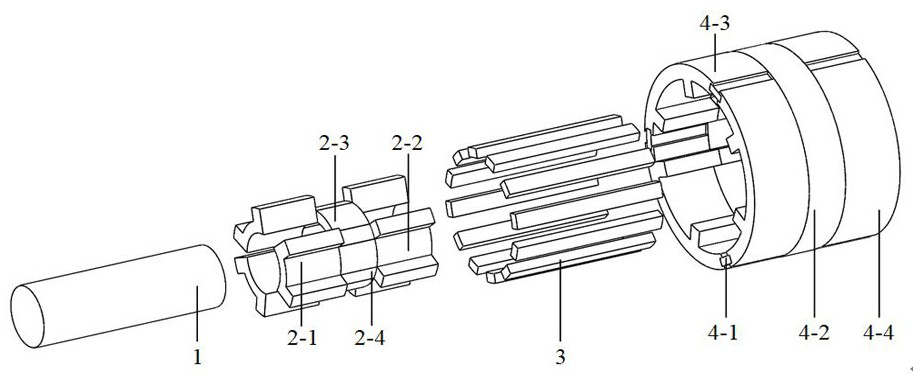

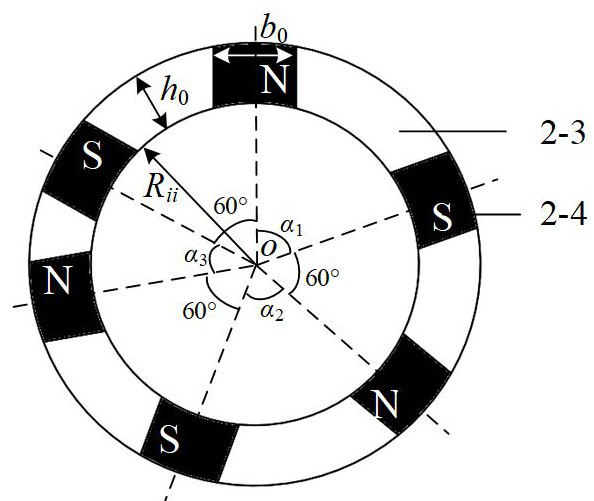

Stator division type axial flux switching type mixed excitation synchronous motor

InactiveCN103490583ALower resistanceReduced risk of demagnetizationDynamo-electric machinesPhysicsSynchronous motor

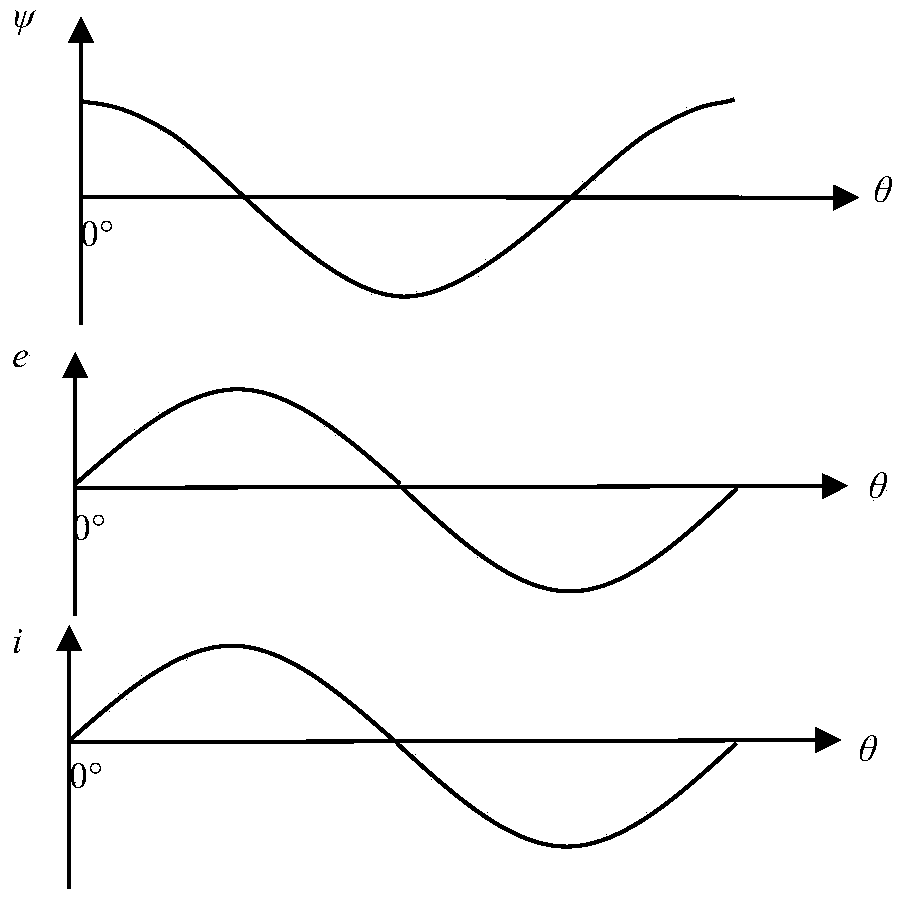

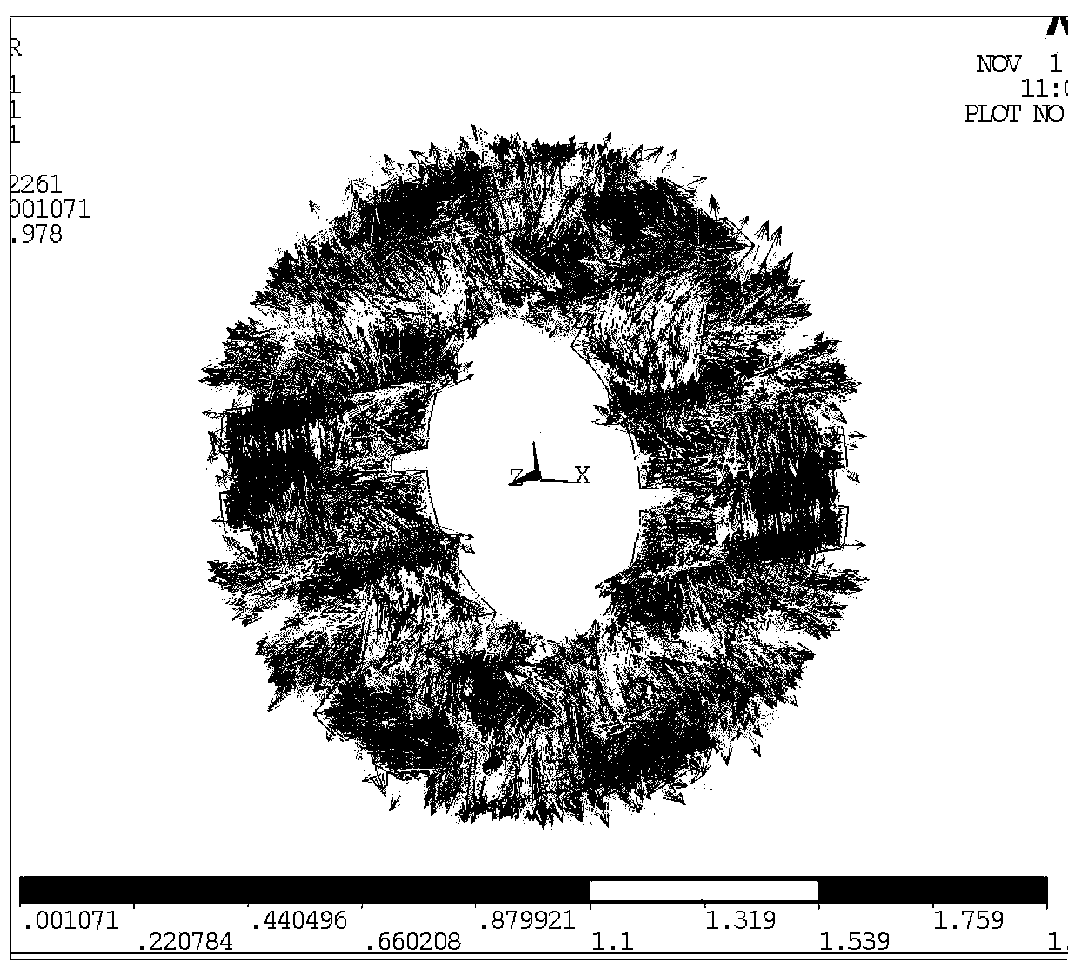

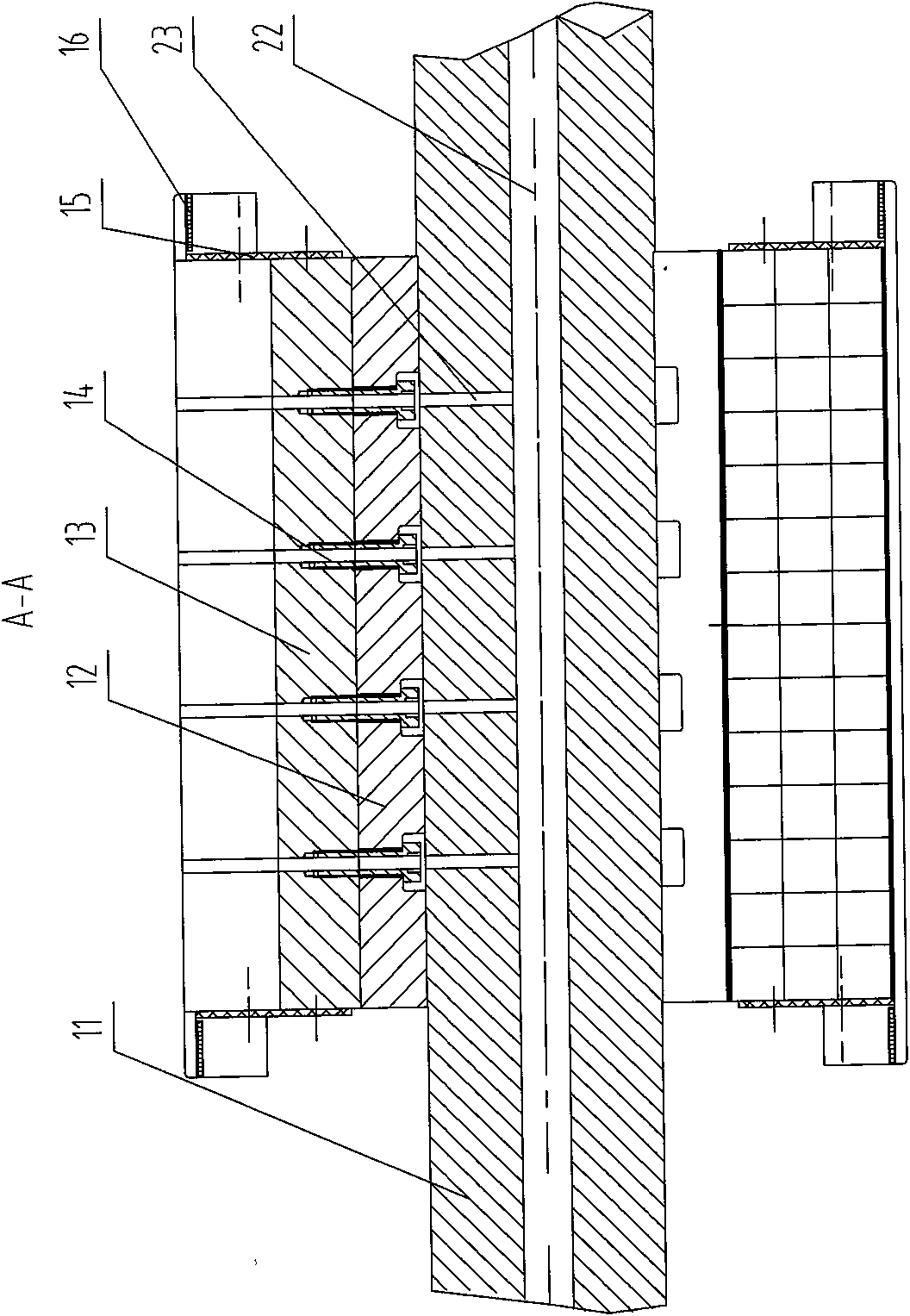

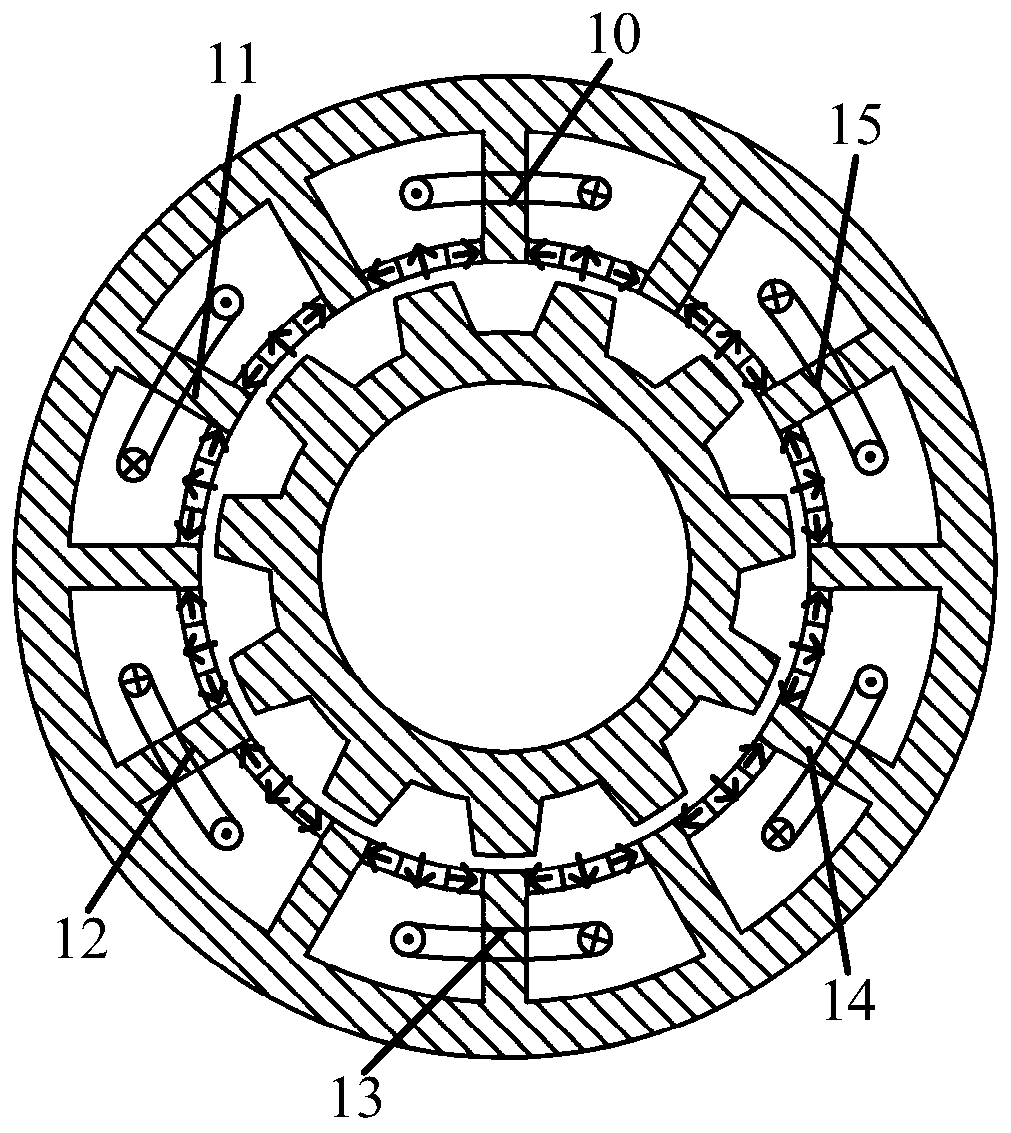

A stator division type axial flux switching type mixed excitation synchronous motor comprises a stator and a rotor. According to the stator, an inner layer H-shaped unit stator iron core and an outer layer H-shaped unit stator iron core are connected to form two wound concentric rings in a splicing mode, a magnetism separation ring separates the two concentric rings, armature windings are concentrated windings and wind stator teeth of the two adjacent H-shaped unit stator iron cores, permanent magnets are distributed between the adjacent H-shaped unit stator iron cores in an N-pole-and-S-pole-alternating mode. The permanent magnets and a stator groove are of a rectangular structure. An excitation support is placed right above the permanent magnets and is separated by the magnetism separation ring. An excitation winding winds the excitation support axially. The rotor is of a disc type structure and comprises a rotor magnet yoke and rotor poles which are evenly fixed on the surface of the rotor magnet yoke in a radial mode. The stator and the rotor are connected coaxially. The magnetism separation ring is used for separating the stator into an inner portion and an outer portion, so that an electro-magnetic circuit and a permanent magnet magnetic circuit are completely connected in parallel, coupling of the two magnetic circuits is lowered, using rate of the permanent magnets is greatly improved, and motor efficiency is obviously improved.

Owner:JIANGXI UNIV OF SCI & TECH

Composite magnetic pole type surface-mounted permanent magnet synchronous motor

ActiveCN105449968AAir gap magnetic density waveform distortion rate is smallIncrease axial lengthMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSurface mountingPermanent magnet synchronous motor

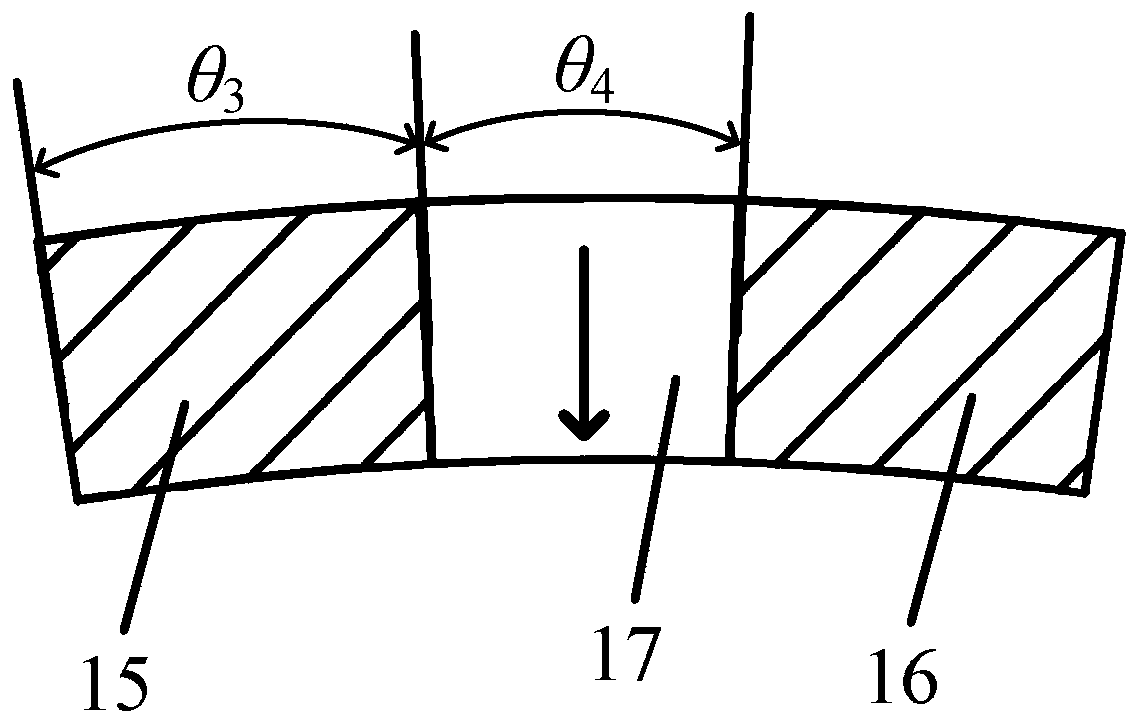

The invention discloses a composite magnetic pole type surface-mounted permanent magnet synchronous motor, which belongs to the field of permanent magnet motors. The composite magnetic pole type surface-mounted permanent magnet synchronous motor aims to solve the problems that harmonic wave is in the presence in a sinusoidal-current-driven rare earth permanent magnet synchronous motor air gap magnetic field and local irreversible demagnetization always happen. The composite magnetic pole type surface-mounted permanent magnet synchronous motor comprises a rotor and a stator, wherein the rotor is arranged in the stator; a radial air gap is formed between the rotor and the stator; the excircle surface of the a rotor iron core is evenly provided with a plurality of rotor magnetic pols in a surface-mounted way; each rotor magnetic pole comprises a rare earth permanent magnetic pole and two ferrite permanent magnetic poles, wherein the left end surface and the right end surface of the rare earth permanent magnetic pole are independently provided with one ferrite permanent magnetic pole; the rare earth permanent magnetic pole and two ferrite permanent magnetic poles form a continuous circular-arc magnetic pole structure; and the magnetization directions of the rare earth permanent magnetic pole and two ferrite permanent magnetic poles are all radial magnetization and are the same. The permanent magnet synchronous motor of the structure causes the harmonic content of the air gap magnetic field to be lowered, motor efficiency is improved, the ferrite permanent magnet material is low in price, and cost is lowered.

Owner:HARBIN INST OF TECH

Axial magnetic flux concentrated winding type hybrid excitation motor

ActiveCN110460175AReduce electricity lossReduced risk of demagnetizationMagnetic circuit rotating partsSynchronous machine detailsElectric machineMagnetic poles

The invention diskloses an axial magnetic flux concentrated winding type hybrid excitation motor. The motor includes a stator disk and two rotor disks, wherein the stator disk includes a stator core,an armature winding, an exciting winding and a magnetic ring, the rotor disks respectively include a rotor back yoke, a magnetic pole block and a permanent magnet, left and right sides of the stator core of the stator disk are provided with stator slots, the armature winding is installed on a magnetic yoke of the stator core, two rotor disks are arranged on both sides of the stator disk, the number of rotor poles matches the number of the stator slots to form a concentrated winding motor structure, the permanent magnets and the magnetic pole blocks are alternately installed on the rotor disks,the two rotor disks are staggered and installed on both sides of the stator disk, the magnetic pole blocks extend outward in the radial direction and form an additional air gap of an excitation fieldin the axial direction with the magnetic ring on the stator core. The motor is advantaged in that the motor has high power density and wide magnetic field adjustment range, and has important application prospects in electric vehicle driving systems, hybrid power generation systems and aviation electric propulsion systems.

Owner:NANJING UNIV OF SCI & TECH

Permanent magnet synchronous motor

InactiveCN101626185AControl temperature riseExtend your lifeMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorMagnetic poles

The invention discloses a permanent magnet synchronous motor consisting of a stator component and a rotor component. The stator component consists of a casing, a stator iron core and a armature winding, wherein a rotor shaft is a hollow shaft, and an internal ventilation hole with two communicated ends are arranged inside the hollow shaft; the rotor shaft is provided with an external ventilation hole communicated with the internal air through hole in the hollow shaft along a radial direction of the rotor shaft; a magnetic shield is provided with a ventilation hole of the magnetic shield along the radial direction; a magnetic pole is provided with a ventilation hole of the magnetic pole along the radial direction; the ventilation hole of the magnetic shield and the ventilation hole of the magnetic pole are communicated with the internal ventilation hole, and the three ventilation holes form a radiant-type radiating structure with the axial direction crossed with the radial direction. Compared with the prior art, the invention excellently controls the temperature rise of the motor in operation, reduces the demagnetization danger of an Nd-Fe-B permanent magnet, and reduces vortex heating and prolongs the service life of the normal operation of the motor at the same time.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

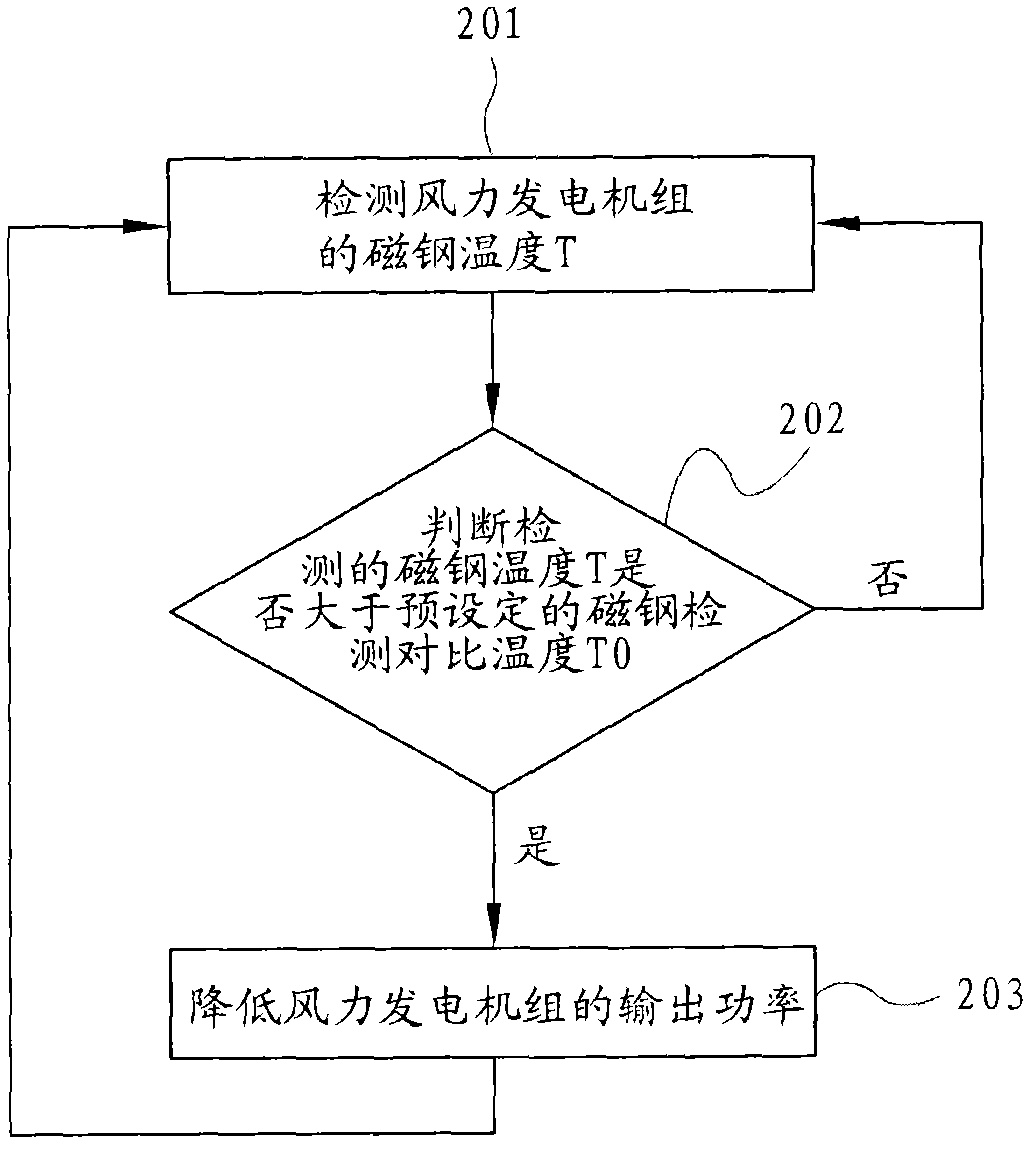

Wind generating set

ActiveCN102352815AReduced risk of demagnetizationWind motor controlMachines/enginesEngineeringWind force

Owner:XINJIANG GOLDWIND SCI & TECH

Stator modular hybrid excitation consequent pole flux reverse motor

InactiveCN111082548AImprove armature winding factorIncreased torque densityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineTorque density

The invention discloses a stator modular hybrid excitation consequent pole flux reverse motor. The motor comprises a plurality of modular stators and an inner rotor, the plurality of modular stators are tightly attached in sequence to form a complete outer stator; an independent air gap is formed between the outer stator and the inner rotor; a plurality of stator grooves are formed in the outer stator; and stator teeth are formed between adjacent stator grooves. The stator teeth are divided into large stator teeth and small stator teeth according to the size; the large stator teeth and the small stator teeth are arranged adjacently; permanent magnets are attached to the surface of each large stator tooth and the surface of each small stator tooth, the width of each permanent magnet is smaller than that of the surface of the corresponding stator tooth, the polarity of the permanent magnet on each large stator tooth is opposite to that of the permanent magnet on the adjacent small statortooth, and an armature winding and a direct-current excitation winding are wound on each large stator tooth. According to the invention, the problems of low torque density and permanent magnet demagnetization of the flux reversal motor are solved, the electromagnetic performance and the operation reliability of the motor are improved, and the processing cost of the motor is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-power high-speed magnetic suspension permanent magnet motor

InactiveCN112242778AIncrease speedHigh powerMagnetic circuit rotating partsMagnetic circuit stationary partsLubricationMagneto

The invention relates to a high-power high-speed motor, in particular to a high-power high-speed magnetic suspension permanent magnet motor. In the motor, an active magnetic suspension bearing is adopted and is composed of two radial bearings, an axial bearing and two position sensors. Meanwhile, the auxiliary bearings are installed at the transmission end and the non-transmission end respectively, active control can be achieved, the dynamic performance of the shafting can be adjusted within the whole rotating speed range, contact is completely avoided, lubrication is not needed, and the service life is long. In the motor, by the adoption of the active magnetic suspension bearing, overall loss can be reduced, a cooling device is omitted, the overall service life is prolonged, and maintenance is convenient. The high-power high-speed magnetic suspension permanent magnet motor has the characteristics of high rotating speed, high power, elimination of a reduction gearbox and the like; theservice life, reliability, noise and vibration are greatly improved; the electrical and mechanical structures are reliable.

Owner:CRRC YONGJI ELECTRIC CO LTD

Surface-mounted-built-in bearingless permanent magnet synchronous motor based on combined magnetic poles

PendingCN112366838ASimple structureReduced risk of demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorTorque ripple

The invention discloses a surface-mounted built-in bearingless permanent magnet synchronous motor based on combined magnetic poles. The motor comprises a rotor and a stator; the rotor is arranged in the stator; an air gap is reserved between the rotor and the stator; the stator comprises an iron core and a stator winding; the stator winding is arranged in an internal stator slot of the stator core; the stator winding comprises a torque winding and a suspension force winding; the rotor comprises a rotor structure body, built-in permanent magnets and surface-mounted permanent magnets, wherein the built-in permanent magnets and the surface-mounted permanent magnets can be both of combined magnetic pole structures. The permanent magnet synchronous motor is simple in structure; the permanent magnets of the motor are easy to machine; the air gap flux density waveform distortion rate of the motor is reduced; and the air gap flux density waveform of the combined magnetic pole type surface-mounted built-in bearingless permanent magnet synchronous motor is more sinusoidal than that of a traditional surface-mounted built-in bearingless rare earth permanent magnet synchronous motor, and therefore, the stator iron loss, the torque ripple and the suspension force ripple are reduced; and due to the strong demagnetization resistance of a ferrite material, the demagnetization risk during the operation of the motor is reduced, and the reliability of the motor is improved.

Owner:HANGZHOU ZHOUJU ELECTRONICS TECHNOLOGICAL

DC bias type flux reverse permanent magnet motor

ActiveCN111181266AReduce the effective air gapIncreased torque densityMagnetic circuit rotating partsElectric machinesDC - Direct currentDc current

The invention discloses a DC bias type flux reverse permanent magnet motor, which comprises a permanent magnet stator and a salient pole iron core rotor. An independent air gap is formed between the permanent magnet stator and the salient pole iron core rotor; the permanent magnet type stator comprises a stator yoke part and a plurality of stator teeth, wherein the stator yoke part and the plurality of stator teeth form a plurality of stator slots; armature windings are placed in the stator slots; bias direct current is injected into the armature windings; a permanent magnet is arranged at theslot opening of each stator slot; the permanent magnets and the adjacent stator teeth form a pair of magnetic poles; and the number and the magnetizing modes of the permanent magnets at the slot openings of the stator slots are the same. Multi-harmonic simultaneous work of the stator armature windings can be achieved, motor magnetic field adjustment is achieved by controlling positive and negative injected direct currents, and the motor is quite suitable for high-power demand occasions such as wind power generation and electric vehicles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

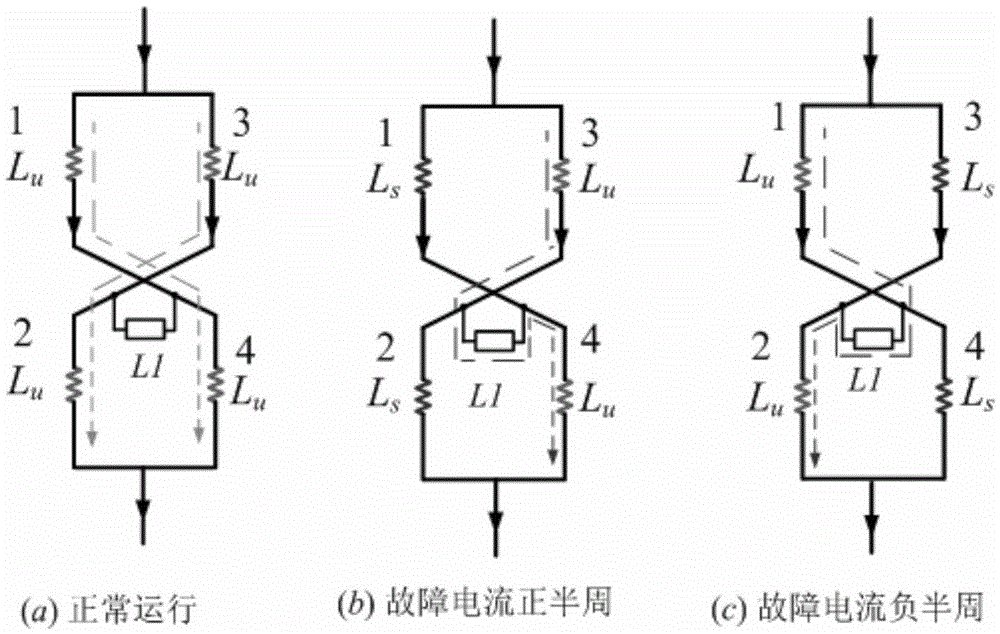

Mixed type magnetic saturation fault current limiter

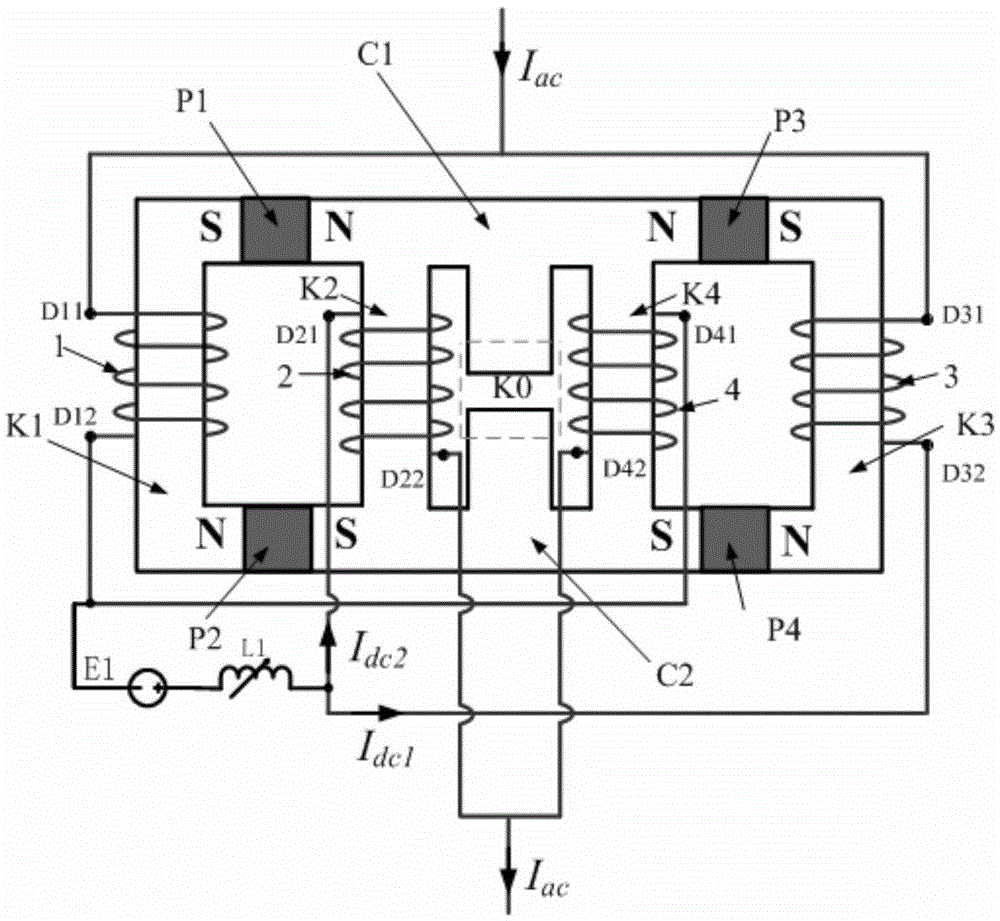

ActiveCN105262072AReduced risk of demagnetizationLower requirementTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresPhysicsFault current limiter

The invention discloses a mixed type magnetic saturation fault current limiter. The current limiter comprises an iron core, coil windings, a direct current power supply and a current-limiting reactor. A permanent magnet and a direct current coil winding are jointly used as an excitation bias source, so that the demand on the direct current bias source is effectively reduced, the demagnetization risk of the permanent magnet is reduced, the reliability of an apparatus is improved, and the consumption and the cost of the apparatus are reduced as well; by adoption of a bridge type structure, the alternating current and the direct current can share the winding, so that the volume of the apparatus can be effectively reduced, and the consumption can be lowered at the same time; the fault current is limited by the current-limiting reactor in a direct current bias loop, so that the current-limiting effect is ensured, and the current-limiting level can be controlled as well; and four coil windings are serially connected through an ingenious connection manner, so that the current in each coil winding is reduced by half while the normal work of the fault current limiter is ensued, the consumption of the current limiter in the normal operation is reduced, and the reliability of the apparatus is improved.

Owner:WUHAN UNIV

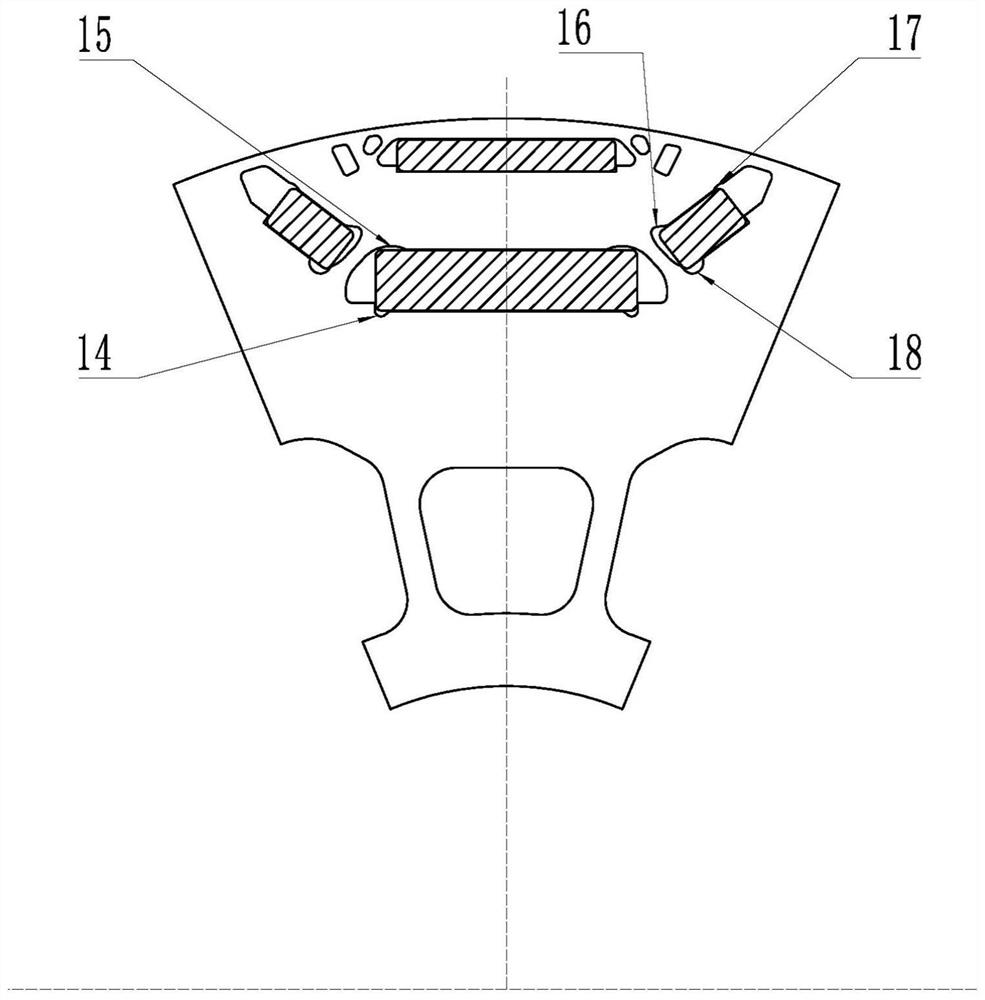

Built-in tangential-type rotor core, built-in tangential-type rotor, and motor

InactiveCN106100180AAvoid demagnetizationImprove reliabilityMagnetic circuit rotating partsEngineeringMechanical engineering

The invention discloses a built-in tangential-type rotor core, a built-in tangential-type rotor and a motor, and belongs to the technical field of motors, and aims at solving a problem of rotor demagnetization in the prior art. The rotor core comprises an iron core main body and a plurality of magnetic tile grooves extending in the radial direction of the iron core main body. The interior of at least one magnetic tile groove is provided with at least two magnetic tile fixing structures. The two adjacent magnetic tile fixing structures in each magnetic tile groove are at least partly isolated from each other. The rotor comprises a magnetic tile, and also comprises the above rotor core. The interior of at least one magnetic tile groove of the iron core is provided with at least two independent magnetic tiles, and each magnetic tile is disposed in one magnetic tile fixing structure. According to the invention, the magnetic tile fixing structures in the rotor core, the rotor and the motor can employ rotor magnetic tiles with different performances, and improve the utilization rate of the rotor magnetic tiles. The problem of rotor demagnetization of a motor rotor can be effectively solved in an operation process of the motor, and the reliability of the motor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Axial magnetic field consequent pole brushless hybrid excitation motor

ActiveCN113078792ALow costRealize brushless excitationMagnetic circuit rotating partsSynchronous motorsElectric machineEngineering

The invention discloses an axial magnetic field consequent pole brushless hybrid excitation motor, which comprises an axial rotor, and is characterized in that permanent magnet N poles distributed in an array are fastened in one side of the axial rotor, permanent magnet S poles distributed in an array are fastened on one side of the axial rotor, one side of the axial rotor is fixedly provided with iron core poles which are distributed in an array mode, one side of the axial rotor is provided with an axial stator, the axial rotor and the axial stator are coaxial, an air gap is formed between the axial rotor and the axial stator, one side of the axial stator is provided with an armature winding in a fastening mode, and the armature winding is close to the air gap. An alternating-current excitation winding for realizing brushless excitation is fastened between the armature winding and the axial stator, the armature winding and the alternating-current excitation winding are wound on the axial stator, and the armature winding and the alternating-current excitation winding are coaxial. According to the motor, the alternating-current excitation winding is adopted, an electric brush and a slip ring are omitted, brushless excitation is achieved, the cost of the motor is reduced, and the reliability is improved.

Owner:SOUTHEAST UNIV

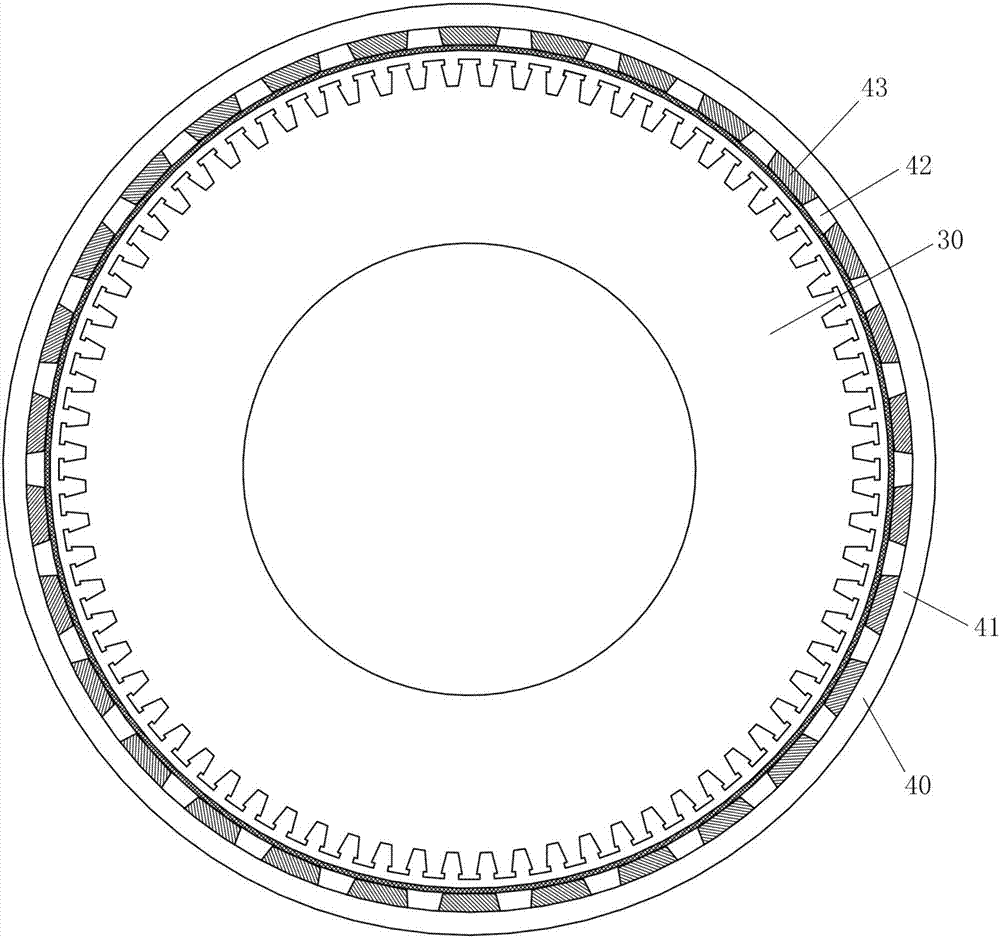

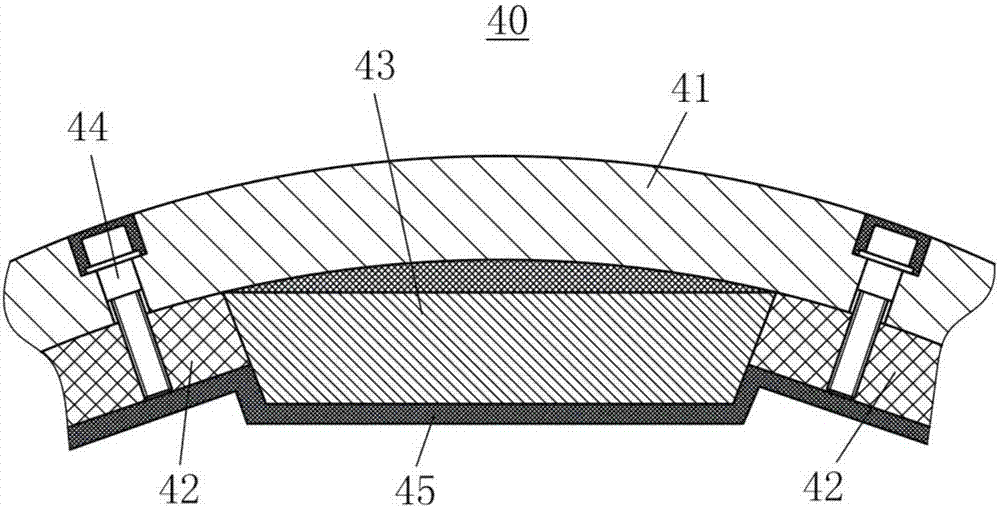

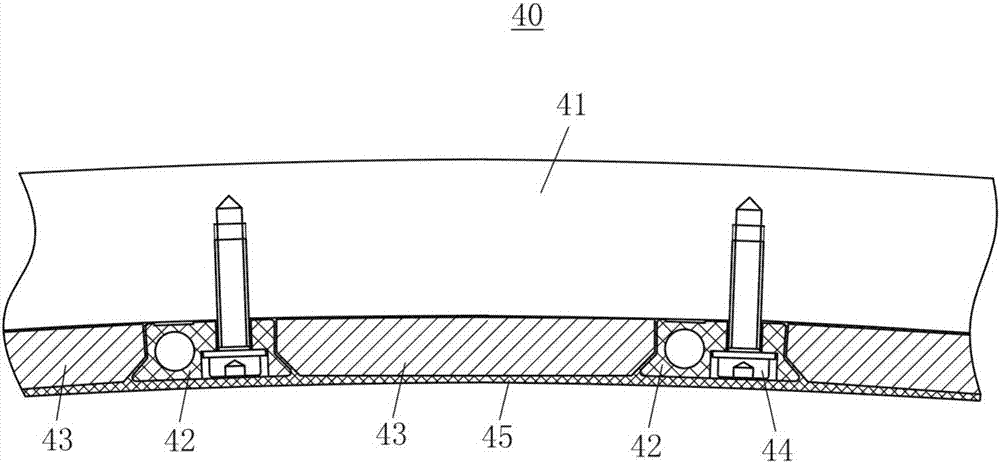

Process equipment and method for curing and formation of magnetic pole protection coating layer

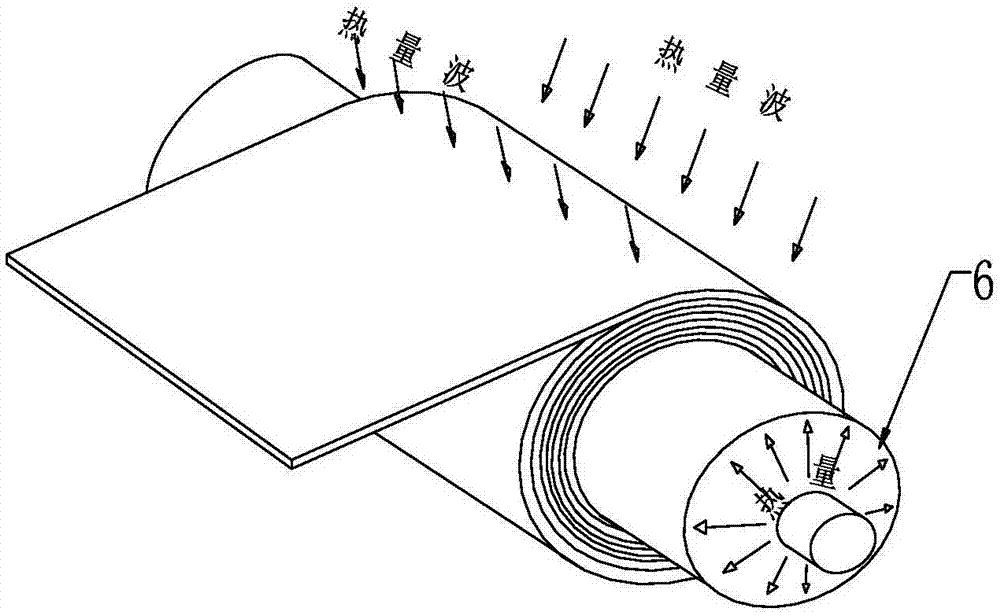

ActiveCN108011481AAvoid relative motionUniform temperature distributionManufacturing dynamo-electric machinesEnergy transferProcess equipment

The invention provides process equipment and method for curing and formation of a magnetic pole protection coating layer. The process equipment comprises a first energy transfer system and a second energy transfer system, wherein the first energy transfer system comprises a first radial limitation support part, a first elastic cavity part and a first fluid medium supply system, the first radial limitation support part faces a first surface of a magnetic yoke, a predetermined distance is reserved between the first radial limitation support part and a magnetic pole to form a first accommodatingspace, the first elastic cavity part is a flexible sealing cavity, is arranged on the first radial limitation support part and is arranged in the first accommodating space, and the first fluid mediumsupply system communicates with the first elastic cavity part and is used for supplying a pressurized fluid medium to the first elastic cavity part or pressurizing and heating the fluid medium. According to the process equipment provided by the technical scheme of the invention, the target of temperature rising control consistency and temperature distribution uniformity of magnetic pole protectionformation quality is achieved, the stress of a magnetic pole protection layer during the formation process is eliminated, the formation quality is ensured, and the risks of stripping and breakage caused by the stress during the subsequent application process are reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

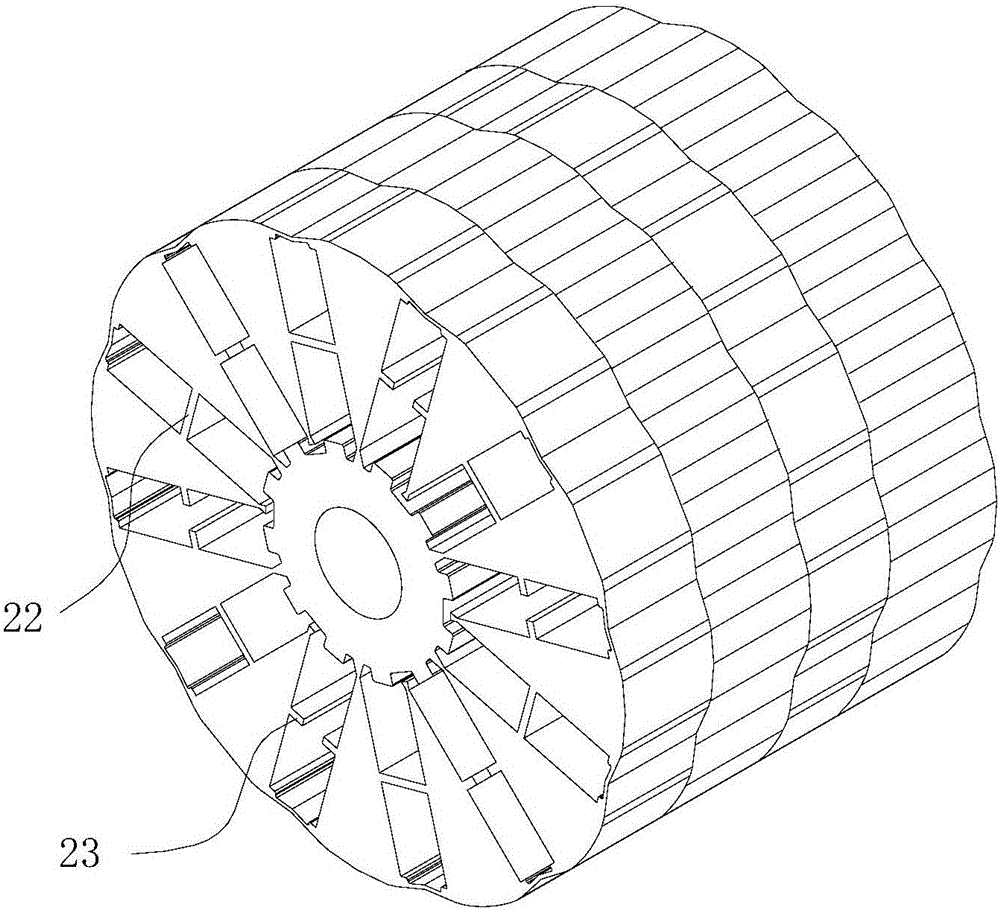

Rotor core and high-efficiency frequency conversion speed regulating permanent magnet synchronous motor

InactiveCN102790455AEvenly distributedImprove performanceMagnetic circuit rotating partsCooling/ventillation arrangementFrequency conversionPermanent magnet synchronous motor

The invention discloses a rotor core and a high-efficiency frequency conversion speed regulating permanent magnet synchronous motor. The rotor core comprises a core body and a plurality of N pole and S pole permanent magnet magnetic steels, wherein 2n magnetic steel slot groups are uniformly distributed on the outer surface of the core body around the center, wherein n is a positive integer; a homopolar permanent magnet magnetic steel is arranged in each magnetic steel slot in the same group; and the permanent magnetic steels between every two groups are sequentially and are alternatively arranged according to the S pole and N pole. The rotor core disclosed by the invention has the characteristics of high strength, material economization, simple manufacturing process and the like. The high-efficiency frequency conversion speed regulating permanent magnet synchronous motor disclosed by the invention has the characteristics of simple structure, high reliability, high efficiency, low cost and the like.

Owner:CHANGYING XINZHI TECH CO LTD

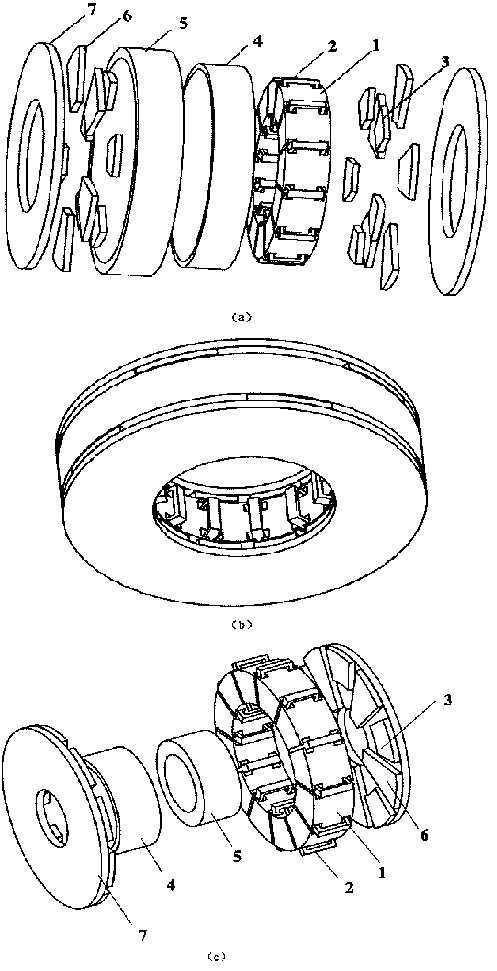

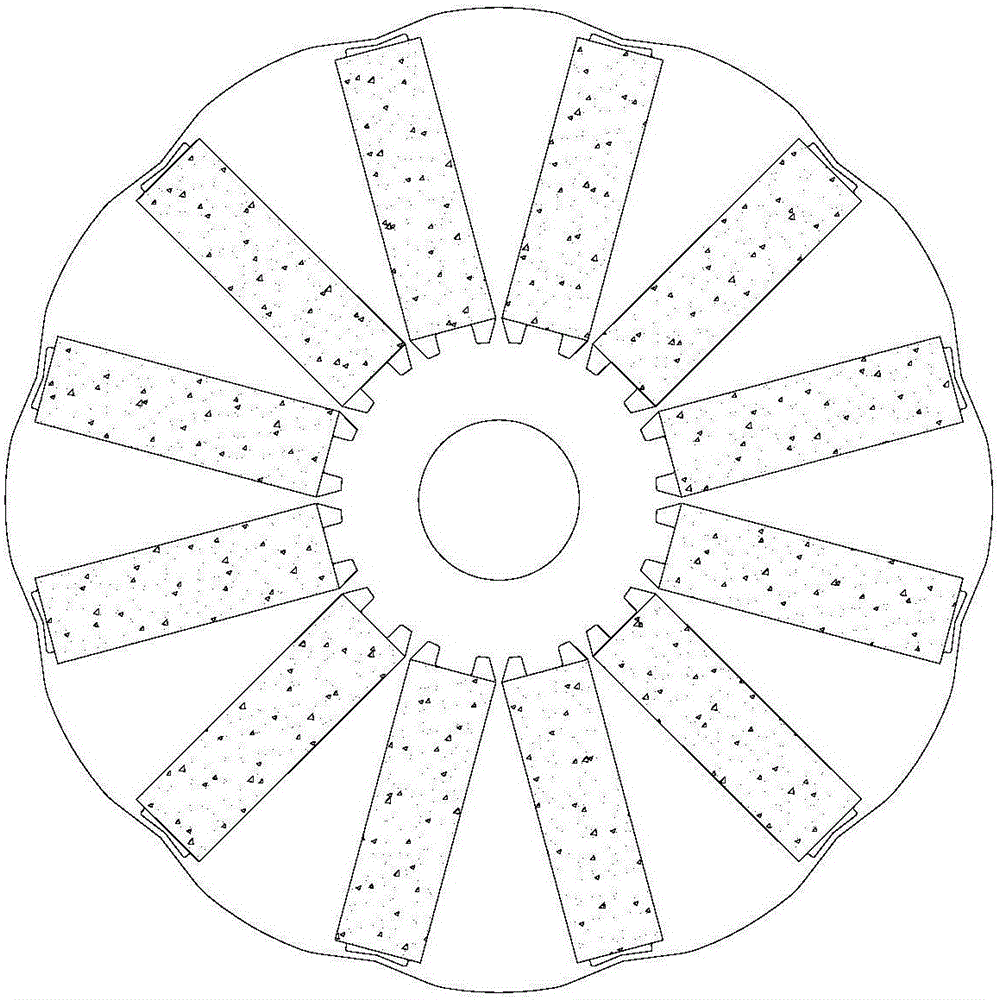

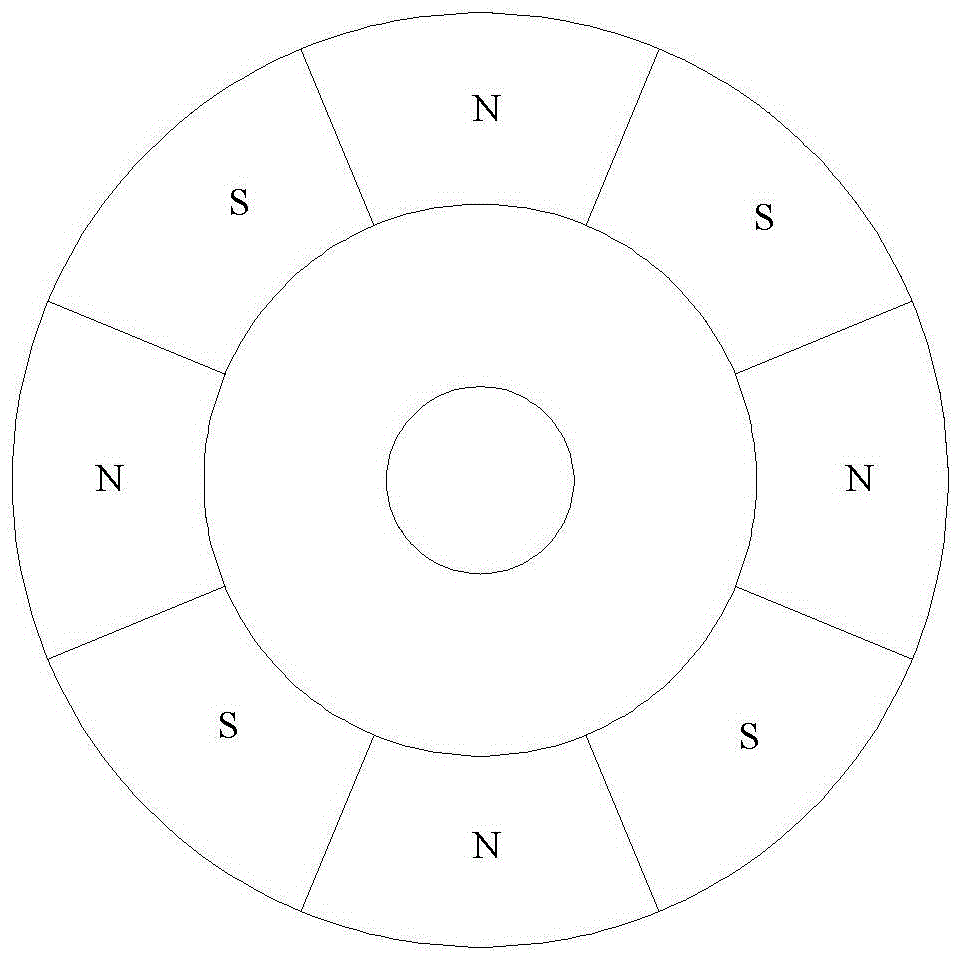

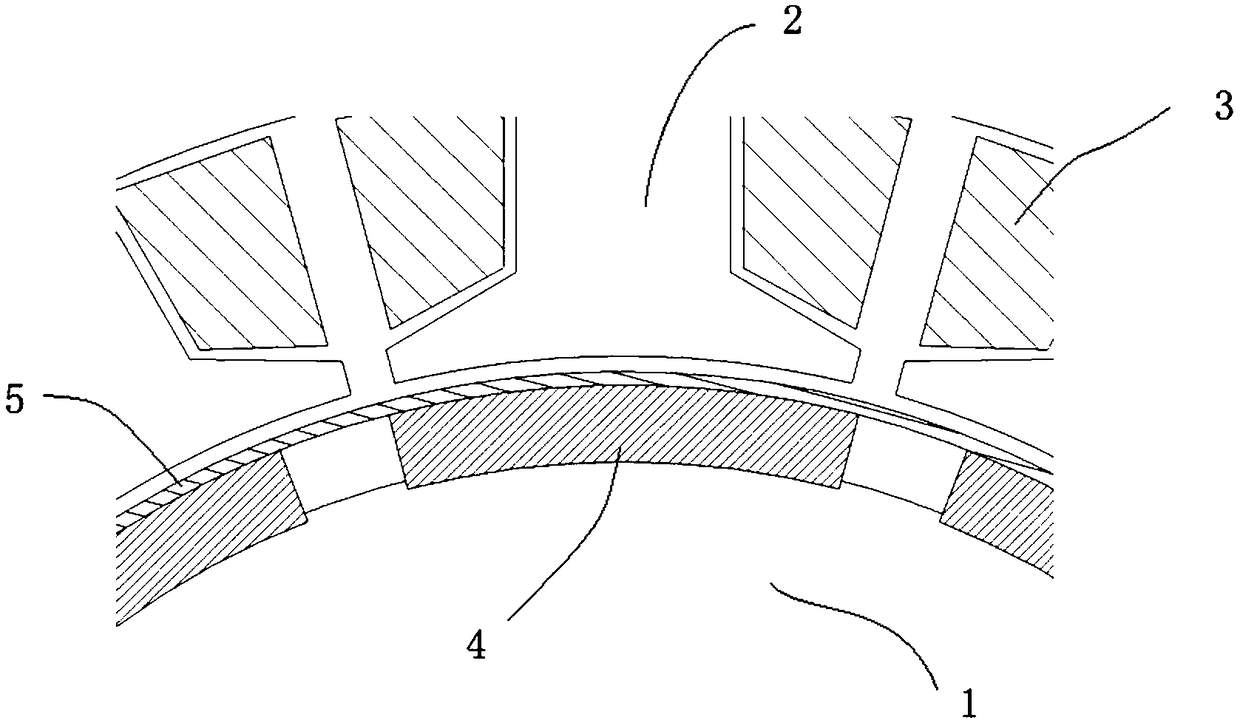

Composite magnetic pole type axial-flux permanent magnet synchronous motor

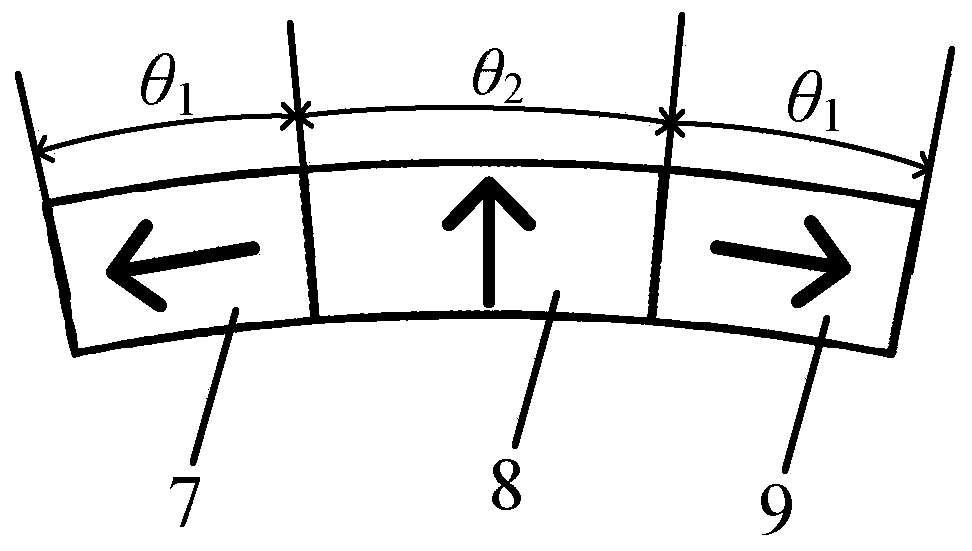

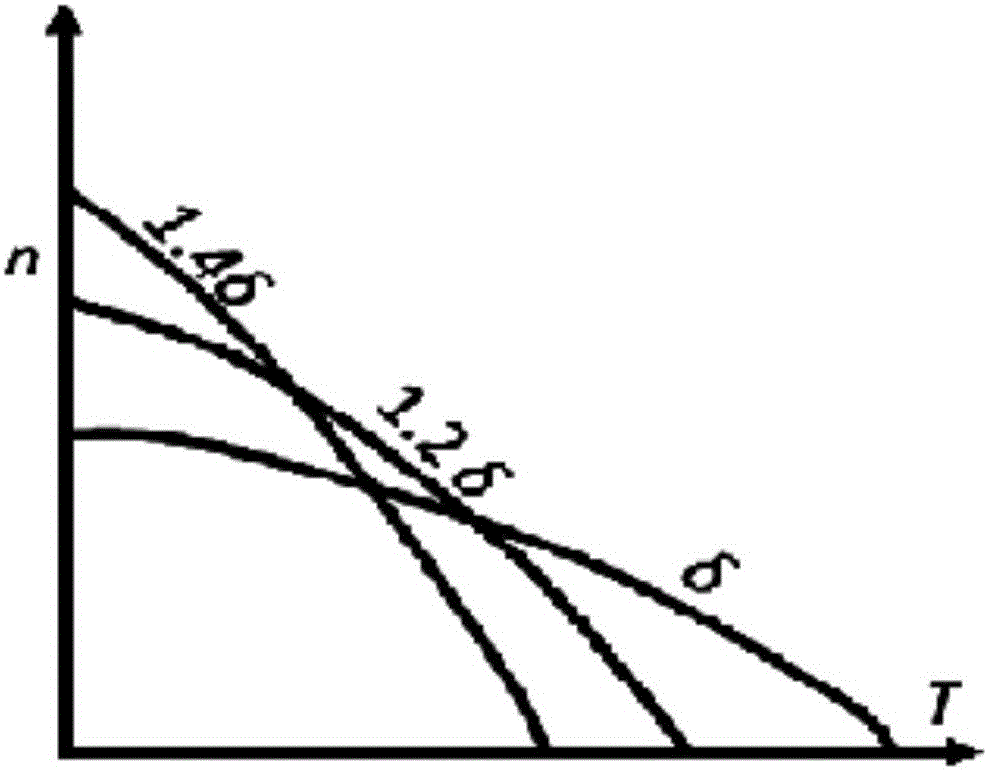

ActiveCN105429409AReduced risk of demagnetizationImprove reliabilitySynchronous machinesMagnetic circuit characterised by magnetic materialsSurface mountingHarmonic

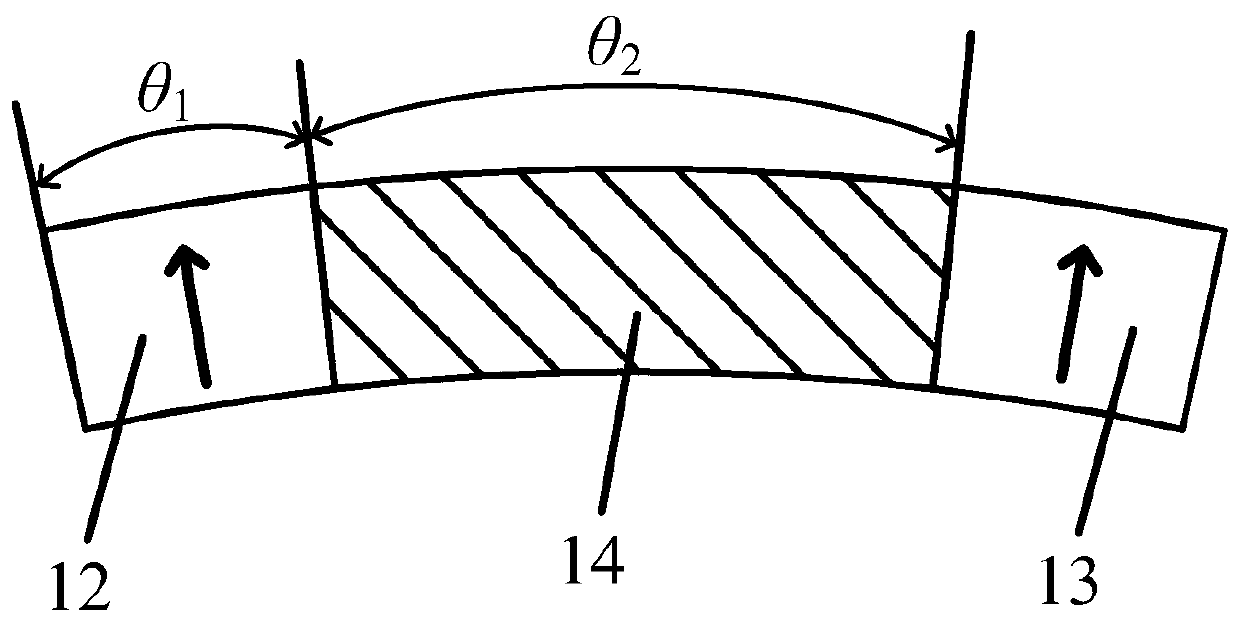

The invention discloses a composite magnetic pole type axial-flux permanent magnet synchronous motor, belongs to the field of permanent magnet motors, and aims at solving the problems that a harmonic wave exists in an air-gap magnetic field of a sine wave-driven rare-earth permanent magnet synchronous motor and local irreversible demagnetization easily occurs. The composite magnetic pole type axial-flux permanent magnet synchronous motor comprises a rotor and a stator, wherein the rotor and the stator are oppositely arranged in parallel; a plurality of rotor poles are evenly arranged on the surface, facing the stator, of a rotor core along the peripheral direction in a surface-mounted manner; the rotor poles are in an arc structure; each rotor pole comprises a rare-earth permanent magnet pole and two ferrite permanent magnet poles; one ferrite permanent magnet pole is arranged on each of the left end surface and the right end surface of each rare-earth permanent magnet pole; each rare-earth permanent magnet pole and each two ferrite permanent magnet poles form a continuous arc magnetic pole structure; and the magnetizing directions of the each rare-earth permanent magnet pole and each two ferrite permanent magnet poles all adopt axial magnetization and are the same. According to the permanent magnet synchronous motor with the structure, the harmonic content of the air-gap magnetic field is reduced; the motor efficiency is improved; meanwhile, the ferrite permanent magnet material is low in price; and the cost is reduced.

Owner:HARBIN INST OF TECH

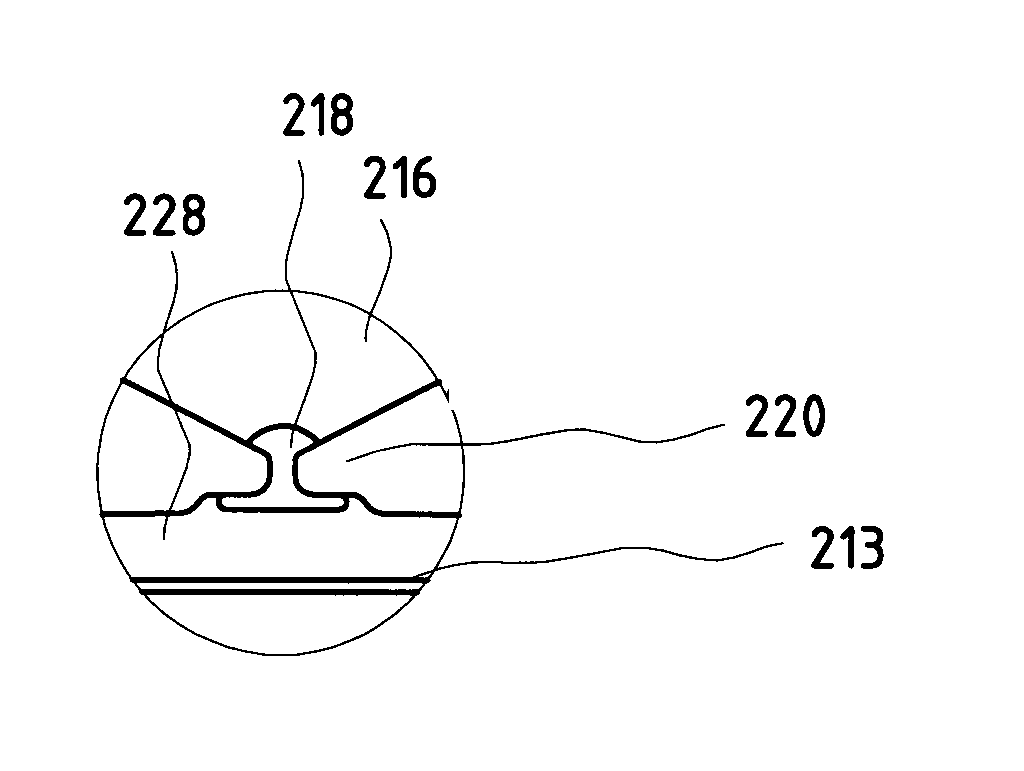

Process device and method for magnetic pole shield coating solidification and molding

ActiveCN108000906AAvoid relative motionUniform temperature distributionApplying solid insulationEnergy transferProcess equipment

The invention provides a process device and method for magnetic pole shield coating solidification and molding. The process device includes a first energy transfer system and a second energy transfersystem, wherein the first energy transfer system includes a first radial limiting support member, a first elastic cavity member, and a first fluid medium supply system; the first radial limiting support member faces a first surface of a magnet yoke and is disposed at a preset distance from poles to form a first accommodation space; the first elastic cavity member is a flexible sealed cavity and isdisposed on the first radial limiting support member and is located in the first accommodating space; and the first fluid medium supply system communicates with the first elastic cavity member and isused for supplying a pressurized fluid medium or a pressurized heating fluid medium to the first elastic cavity member. According to the technical scheme, the goal of unification of temperature risecontrol and unification of temperature distribution of the pole shield molding quality is achieved, the stress of the pole shield coating self-molding process is eliminated, the molding quality is ensured, and the peeling and breakage risks caused by the stress in the later use process are reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Composite material flywheel rotor and manufacturing method thereof

PendingCN107979221AReduce eddy current lossReduce heat dissipationAc network load balancingMechanical energy handlingFiberStress concentration

The invention provides a composite material flywheel rotor, which is formed by winding a magnetic powder fiber layer on the inner layer and a composite fiber layer on the outer layer; the outer side of the magnetic powder fiber layer is a composite material layer which is formed by sequentially winding a plurality of composite fiber materials; an upper magnetic pole and a lower magnetic pole withdifferent structures are formed after the magnetic powder fiber layer is magnetized, the upper half part of the magnetic pole is used as a rotor part of a radial magnetic suspension bearing, and the lower half part of the magnetic pole is used as an excitation magnetic pole of the motor. The invention further provides a manufacturing method of the composite material flywheel rotor, which comprisesthe following steps: 1) respectively manufacturing and winding the magnetic powder fiber layer and the other composite layers; 2) respectively magnetizing the upper portion and the lower portion of the magnetic powder fiber layer, using a cylindrical tire shaft when the composite layer is wound, and adopting a bidirectional heating method for curing while winding. According to the composite material flywheel rotor and the manufacturing method in the invention, the circumferential stress concentration problem and the problem of large heating amount loss of the rotor eddy current are solved; and the rotor can be used for manufacturing the higher-rotation-speed flywheel energy storage device.

Owner:DUNSHI MAGNETIC ENERGY TECH

Air-gap-adjustable disc-type motor and control method thereof

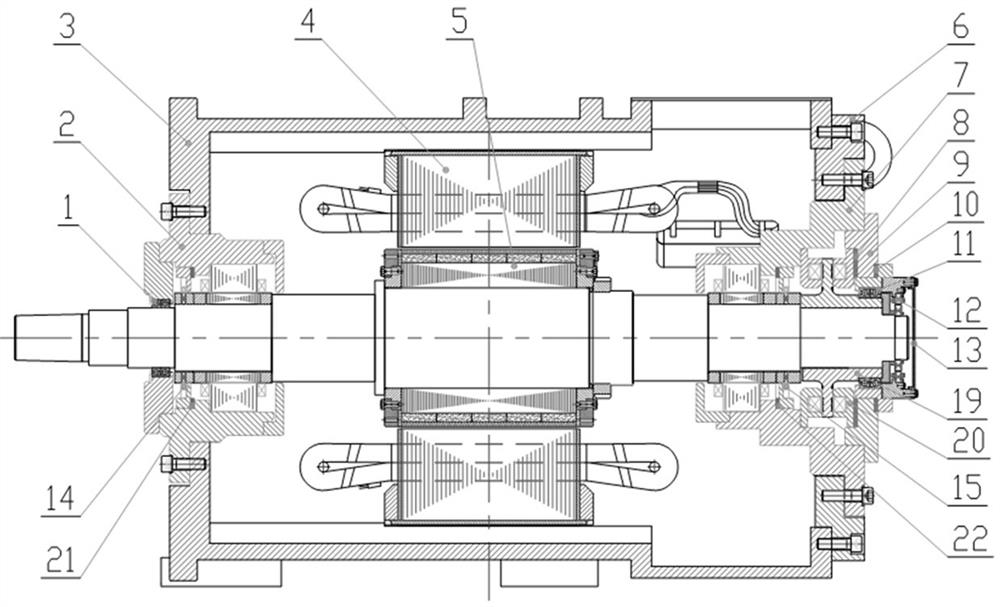

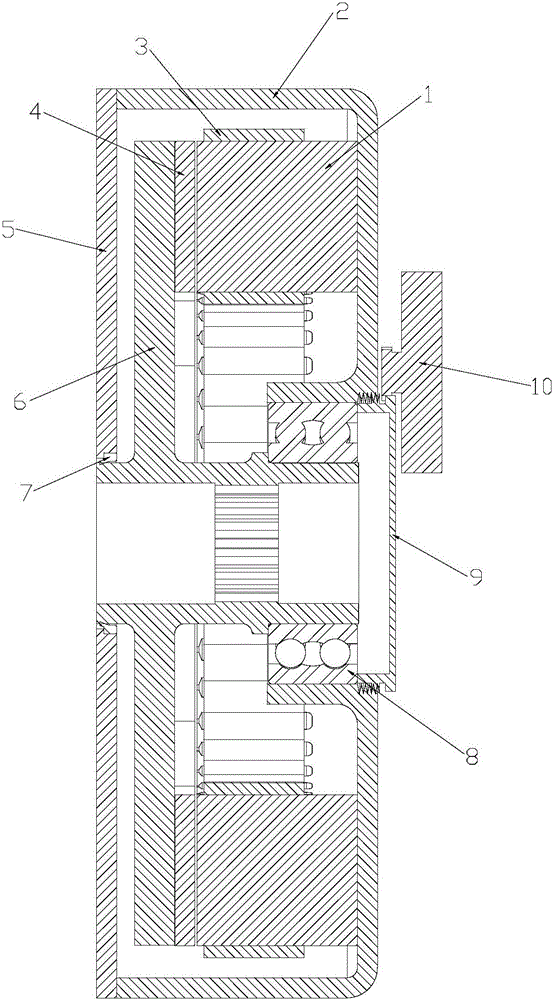

InactiveCN104993647AImprove performanceImprove climbing abilitySingle motor speed/torque controlMechanical energy handlingConductor CoilTurbine

The invention discloses an air-gap-adjustable disc-type motor and a control method thereof, belongs the field of a motor device and a control method thereof, and is to solve the problem that it is inconvenient to adjust an air gap of an existing disc-type motor and the like. The air-gap-adjustable disc-type motor comprises a housing, a stator arranged in the housing, a stator winding sleeved outside the stator, a rotor arranged coaxially with the stator, a bearing connected with the rotor, a bearing cap arranged outside the housing and connected with the bearing, a turbine motor for driving the bearing cap to rotate, a permanent magnet arranged between the stator and the rotor, and an end cover, wherein the end cover and the housing form a cavity. The invention also provides the control method of the air-gap-adjustable disc-type motor. The air-gap-adjustable disc-type motor is convenient to use, high in reliability and low in manufacturing cost. The control method of the air-gap-adjustable disc-type motor is high in control precision and good in control effect.

Owner:华英汽车集团有限公司

Bidirectional magnetic circuit coupling type magnetic field modulation direct drive motor for electric automobile

InactiveCN108777538ARealize low-speed high-torque outputLow-speed high-torque characteristics are obviousElectric machinesMagnetic circuit stationary partsForce linesPower flow

The invention discloses a bidirectional magnetic circuit coupling type magnetic field modulation direct drive motor for an electric automobile, and relates to the field of hybrid excitation of magnetic field modulation type composite motors. The bidirectional magnetic circuit coupling type magnetic field modulation direct drive motor solves the problems that the permanent magnetic field of an existing permanent magnet motor for an electric automobile is difficult to adjust and insufficient in low-speed and high-torque characteristic. According to the bidirectional magnetic circuit coupling type magnetic field modulation direct drive motor, 2n outer stator teeth are uniformly arranged on the inner circumferential surface of an outer stator core in the circumferential direction, an outer stator direct-current exciting winding is wound around each outer stator tooth, the current directions of every two adjacent outer stator direct-current exciting windings are opposite, 2n permanent magnet grooves are uniformly formed in the outer circumferential surface of the outer stator core in the circumferential direction, a permanent magnet is arranged in each permanent magnet groove, magneticisolation bridges are arranged on the two sides, facing groove bottoms and groove openings, of the permanent magnets, the part, corresponding to the bottoms of the permanent magnet grooves, of the outer stator core is served as a magnetic conduction bridge, the magnetizing directions of every two adjacent permanent magnets are opposite, the direction of the magnetic force lines of the permanent magnets is the tangential direction of the outer stator core, and the direction of the magnetic force lines of the outer stator direct-current exciting windings is the radial direction of the outer stator core.

Owner:HARBIN UNIV OF SCI & TECH

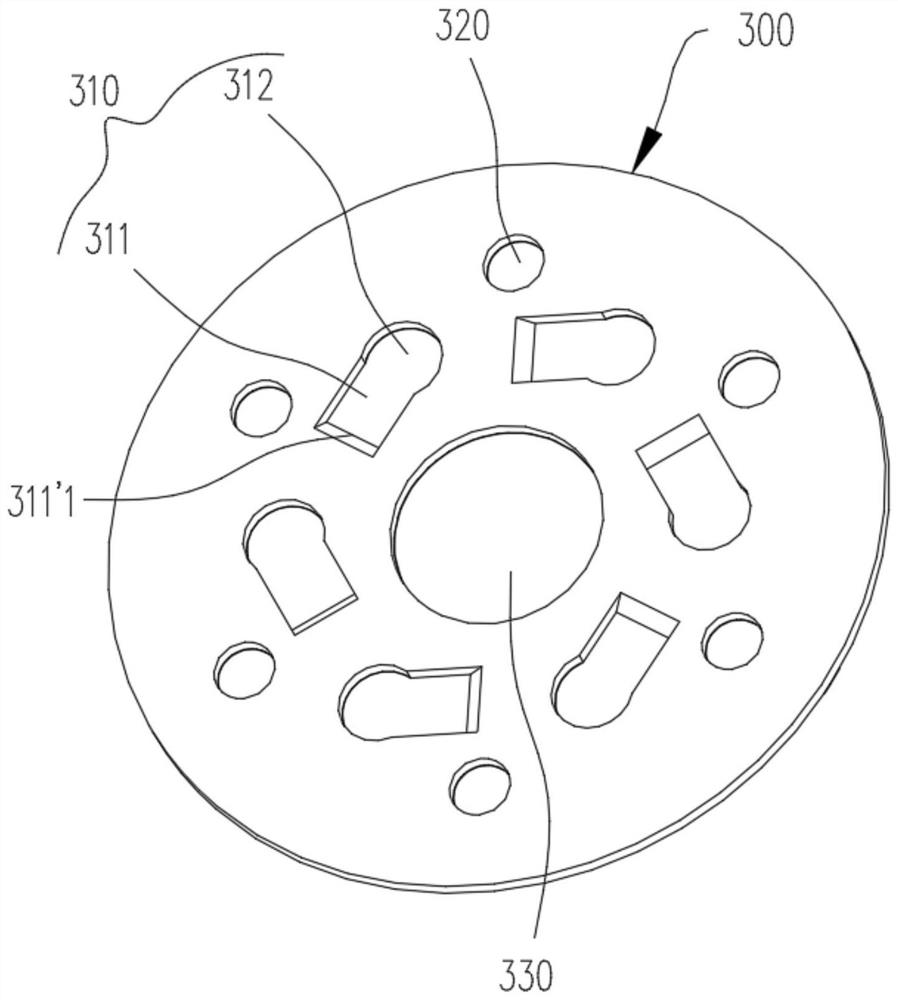

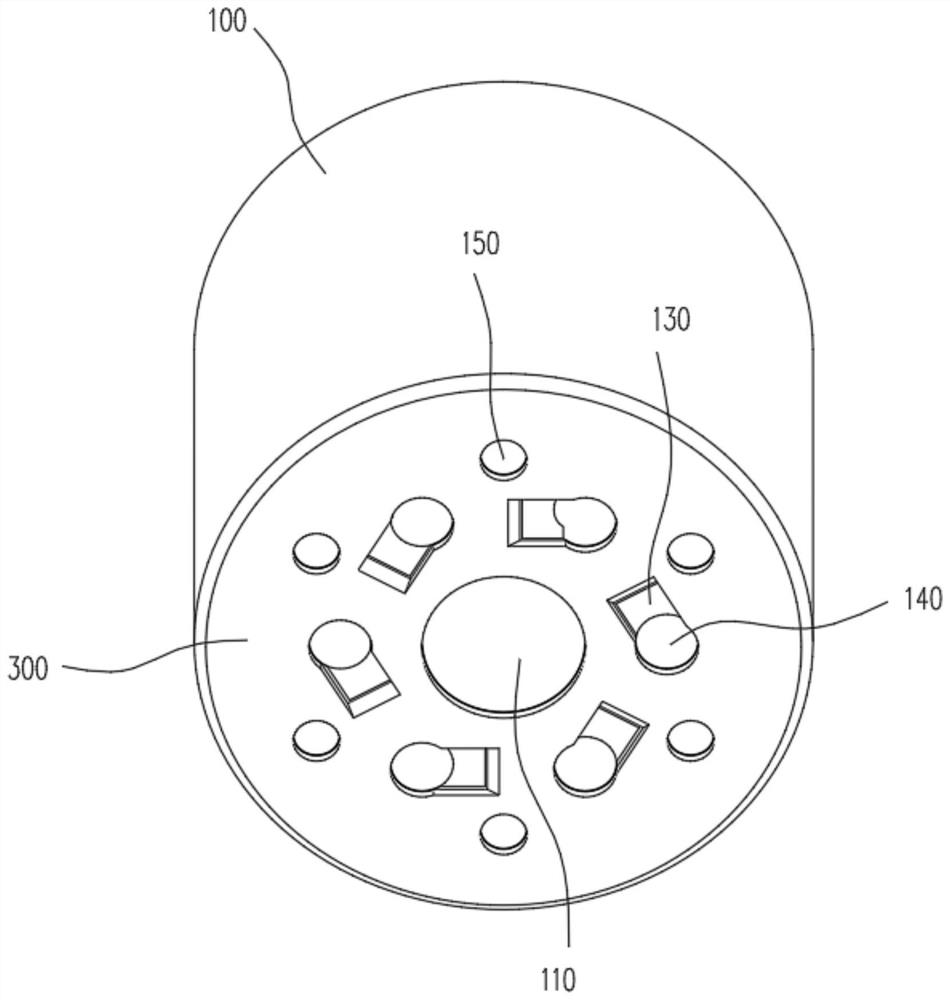

Rotor assembly, motor, compressor and refrigerating device

PendingCN112072814ASpeed up the flowImprove cooling effectMagnetic circuit rotating partsElectric machineEngineering

The invention generally relates to the field of household appliances, in particular to a rotor assembly, a motor, a compressor and a refrigerating device, the rotor assembly comprises a rotor iron core, the rotor iron core is provided with a rotor hole and a magnetic steel groove, the rotor iron core is provided with a circulation hole for refrigerant circulation and a diversion trench formed in the bottom end of the rotor iron core. The circulation hole is communicated with the diversion trench, and one side, far away from the circulation hole, of the diversion trench is provided with an inclined diversion wall, so as to guide a refrigerant to flow into the circulation hole from the tangential direction and the radial direction of the rotor core, thereby accelerating the flowing speed ofthe refrigerant when the refrigerant enters the circulation hole, and improving the heat dissipation effect of the rotor core. The demagnetization risk of the permanent magnet is reduced, and the motor performance is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

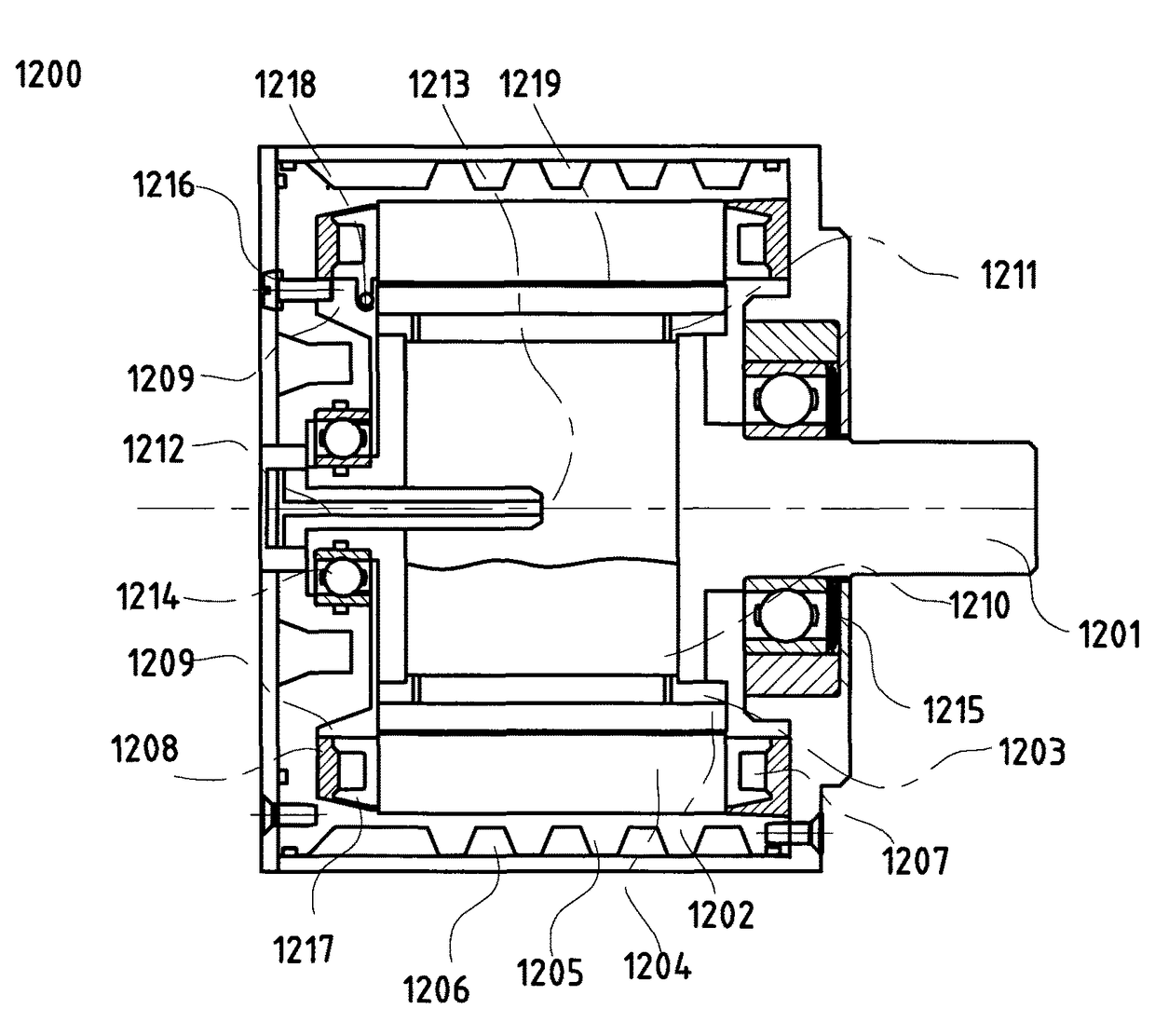

Cooled magnet motor

ActiveUS9735654B2Reduced risk of demagnetizationMagnetic circuit rotating partsCooling/ventillation arrangementRotor magnetsPower flow

An electric motor / generator includes a rotor with magnets mounted on the surface of the rotor, the magnets facing the stator over a gap. The magnets have a very high flux density but a limited ability to withstand high stator currents at high temperatures, preferably magnets made of the N48H material. By providing rotor magnet cooling means that reduces the temperature of the magnets by a cooling fluid, use of magnets with lower maximum working temperature and higher flux density is permitted and thereby higher flux can be obtained from the magnets.

Owner:HDD SERVO MOTORS

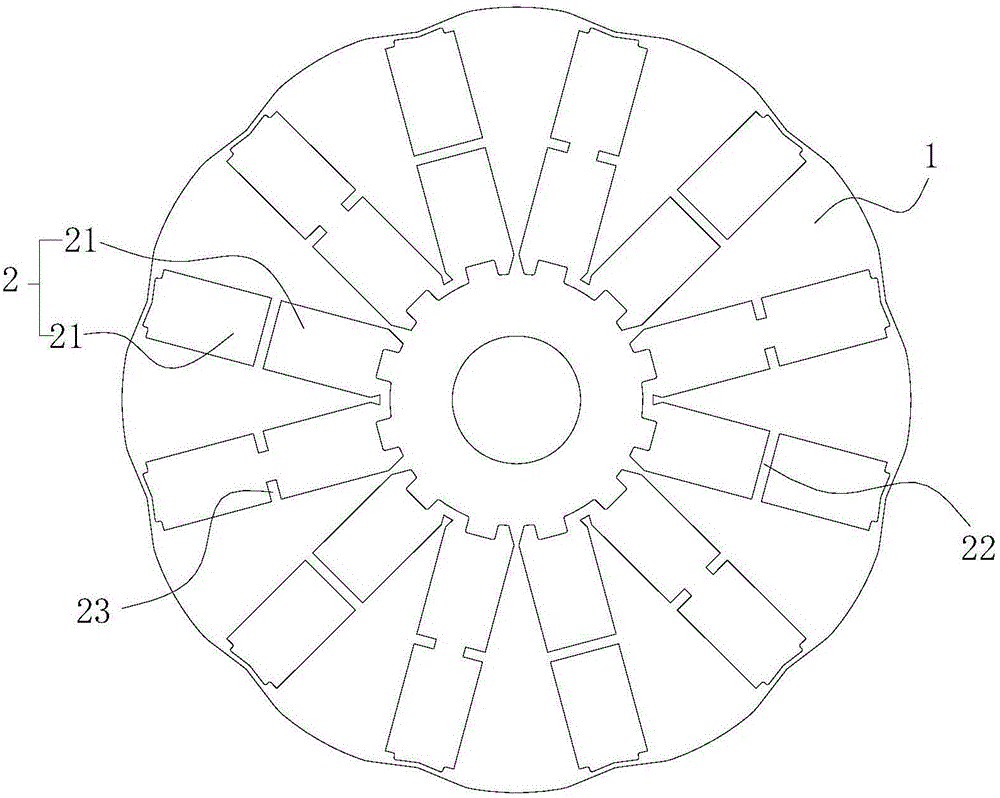

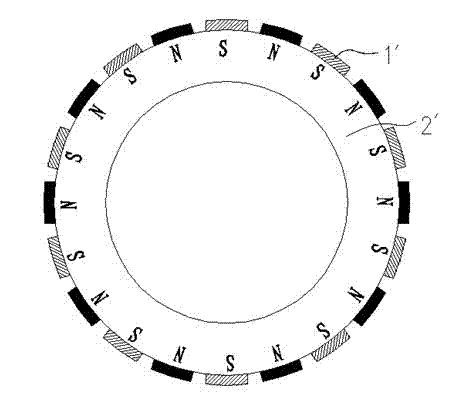

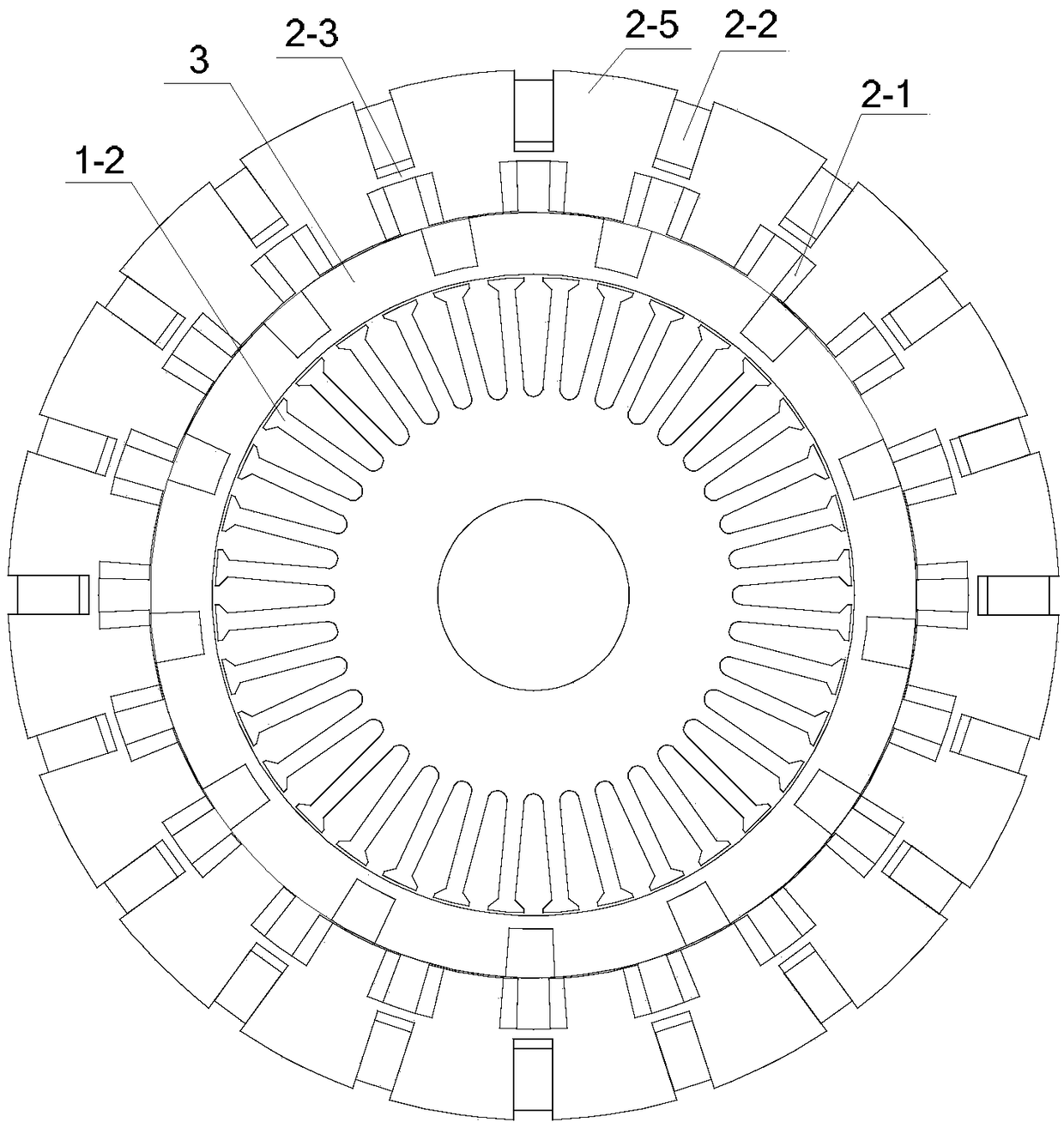

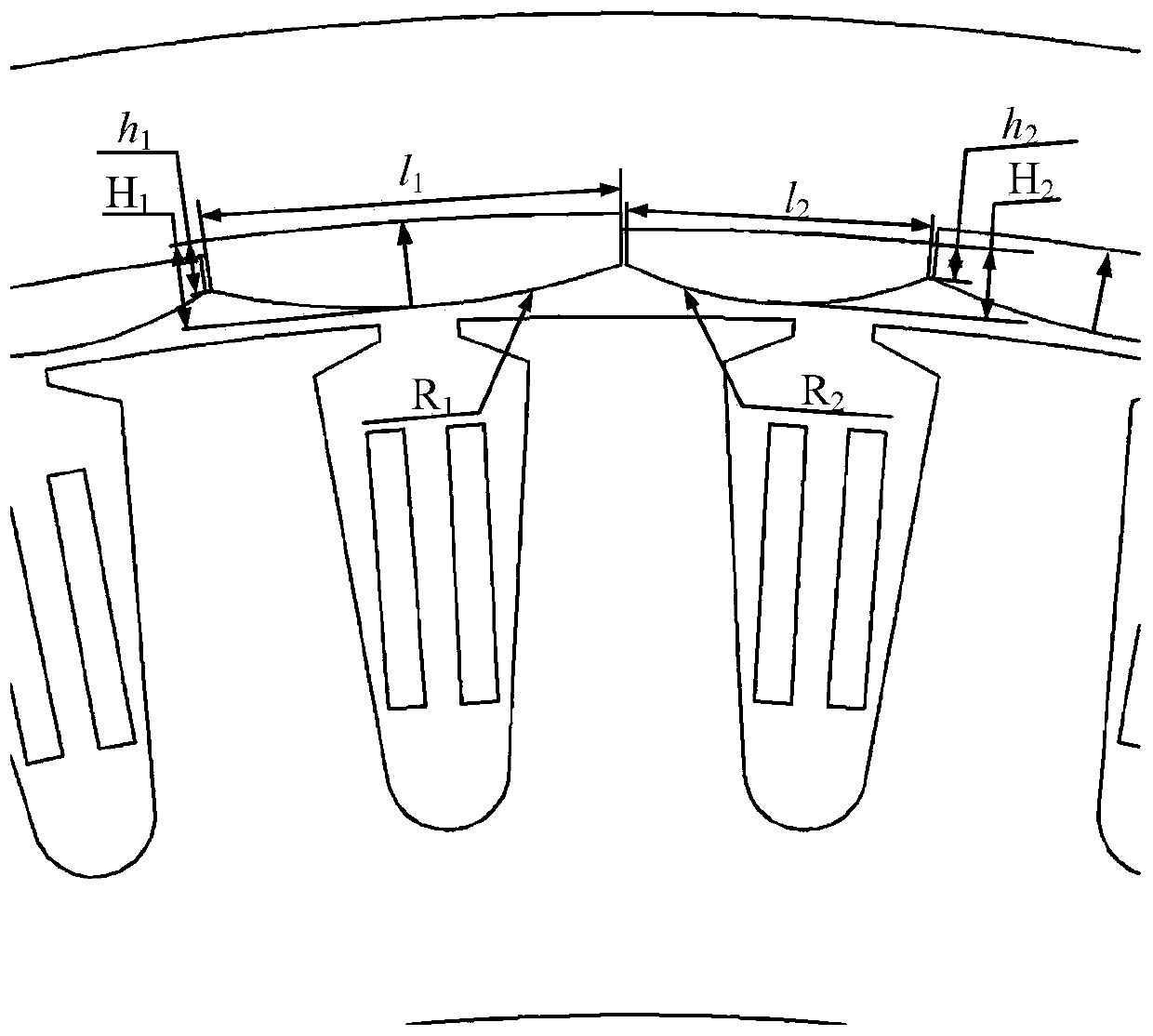

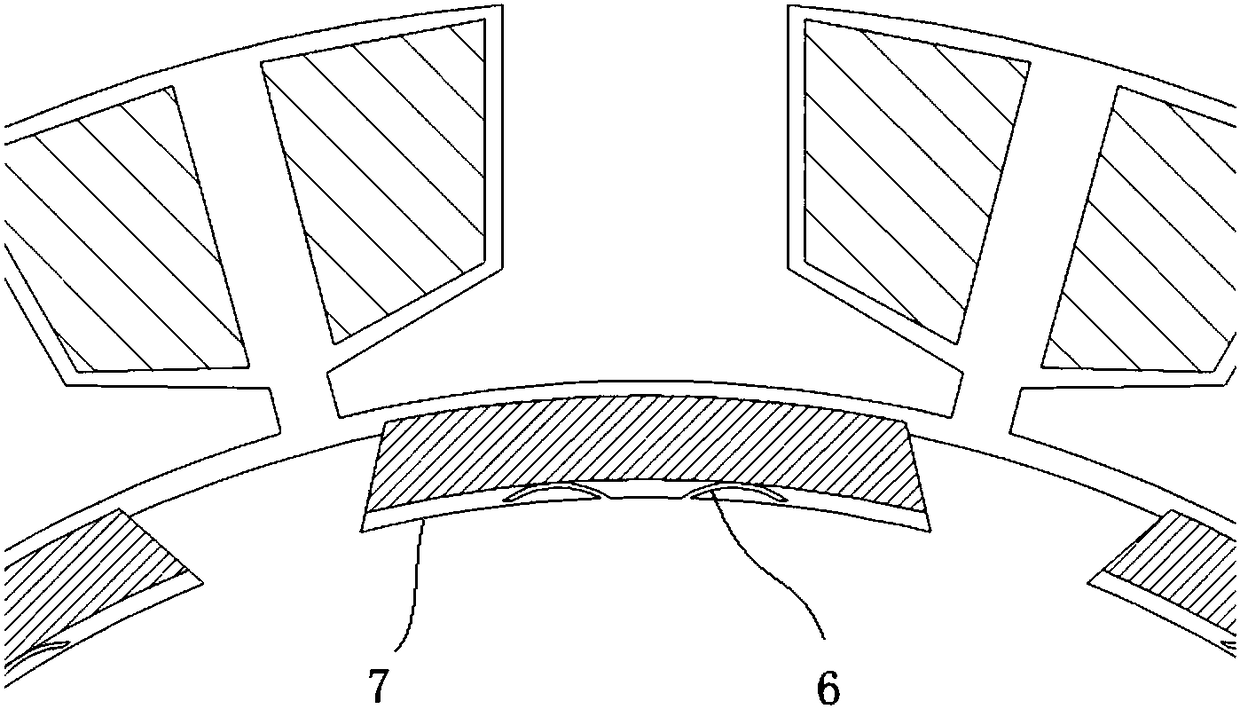

Low-cost alternating pole permanent magnet hub motor for electric vehicle drive

ActiveCN110690803AElectromagnetic properties are comparableLow costMagnetic circuit rotating partsElectric machinesElectric machinePermanent magnet motor

The invention discloses a low-cost alternating pole permanent magnet hub motor for electric vehicle drive, and belongs to the field of motor body design and manufacturing. The motor comprises a coaxial outer rotor 1 and an inner stator 2. The permanent magnets on the outer rotor adopt an alternating pole structure, and the magnetizing directions of the permanent magnets are the same along the radial direction, i.e. uniformly pointing to or deviating from the center of the circle along the radial direction.The salient pole iron cores between the permanent magnets act as virtual poles, the permanent magnets and the virtual poles are alternately and uniformly distributed on the inner circumference of the outer rotor, and the inner stator 2 includes armature teeth 5 and tooth shoes 6. The electromagnetic performance of the motor is equivalent to the permanent magnet motor performance of the conventional N-Spole array, and the usage of the permanent magnets is greatly reduced and thus the cost of the motor is effectively reduced.

Owner:JIANGSU UNIV

Rotor and method for manufacturing same

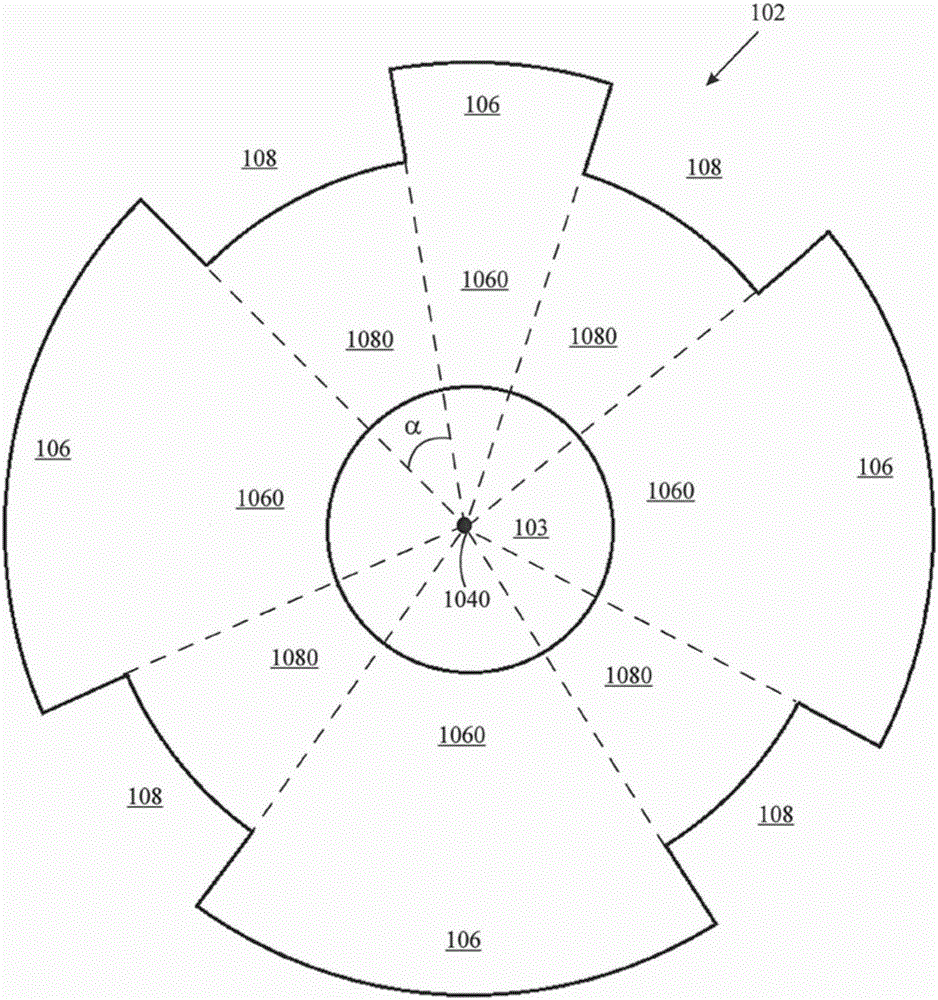

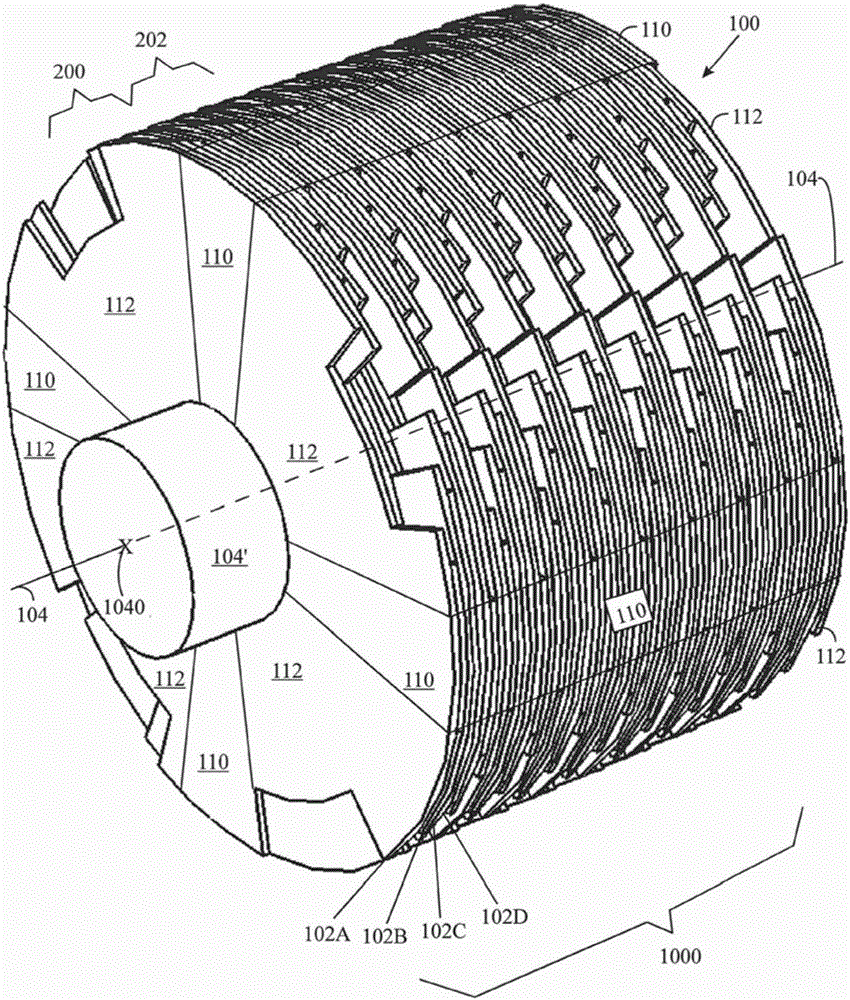

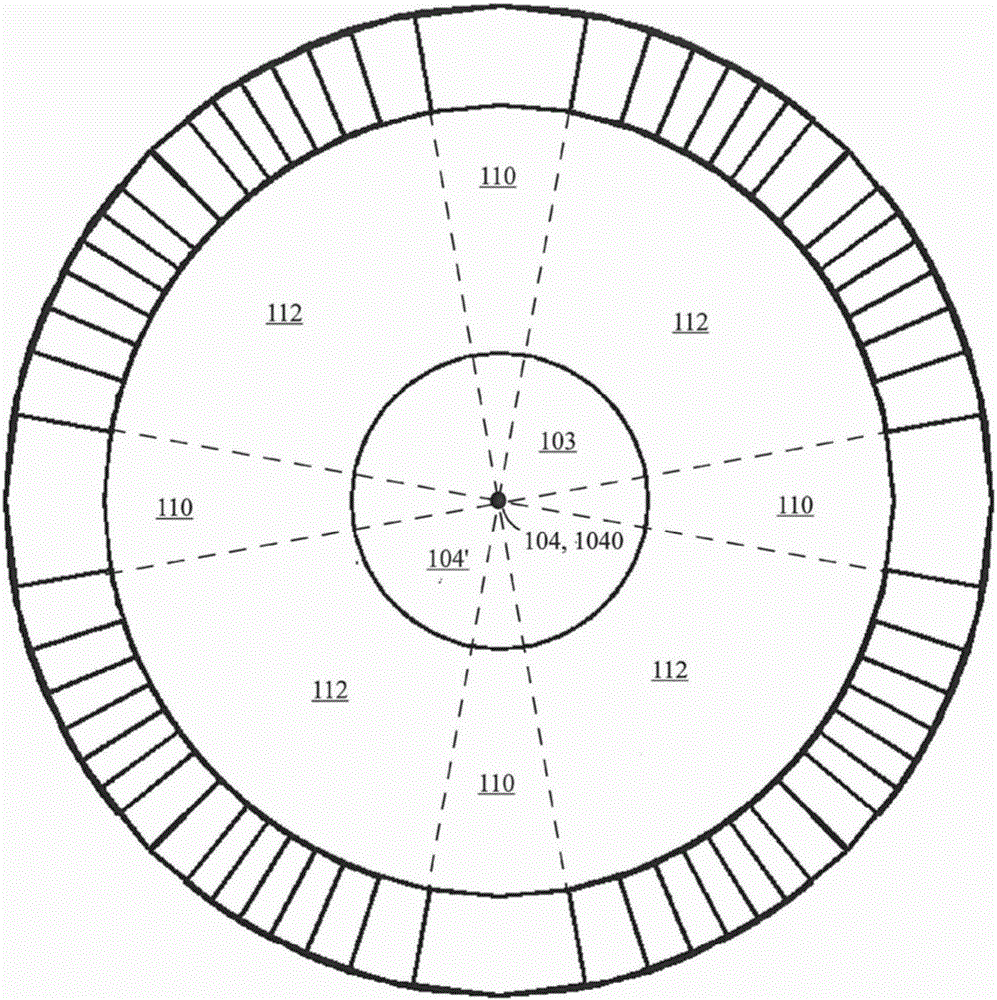

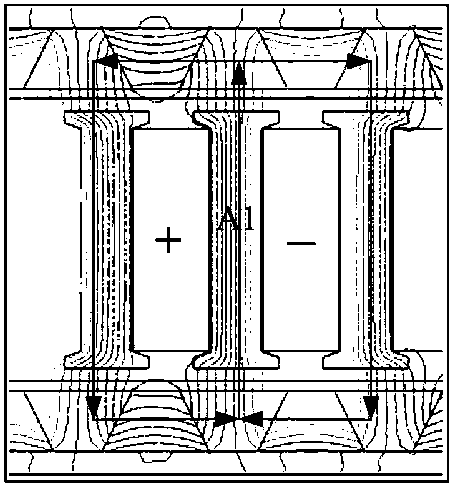

ActiveCN106612025ASimple Salient DesignSimple structureMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMagnetic flux

The invention relates to a rotor and a method for manufacturing the same. A rotor (100) of an electric motor (102) comprises a rotor shaft hole (103), first fan-shaped component parts (106), and second fan-shaped component parts (108). The first fan-shaped component parts and the second fan-shaped component parts are alternately distributed around a rotation axis (104) of the rotor (100). The distance from the outer contour of the second fan-shaped component parts (108) to the rotation axis (104) is shorter than that from the outer contour of the first fan-shaped component parts (106) to the rotation axis (104). When observed along the direction of the rotation axis (104), the second fan-shaped component parts (108) overlap the first fan-shaped component parts (106) of other rotor elements (102). The rotor (100) comprises magnetic flux guide pieces (150, 150', 152, 154, 154', 156, 158) which are configured to extend and pass through the rotor (100) between the rotor shaft hole (103) and the periphery of the protruding part of the rotor (100) when observed along the direction of the rotation axis (104).

Owner:ABB (SCHWEIZ) AG

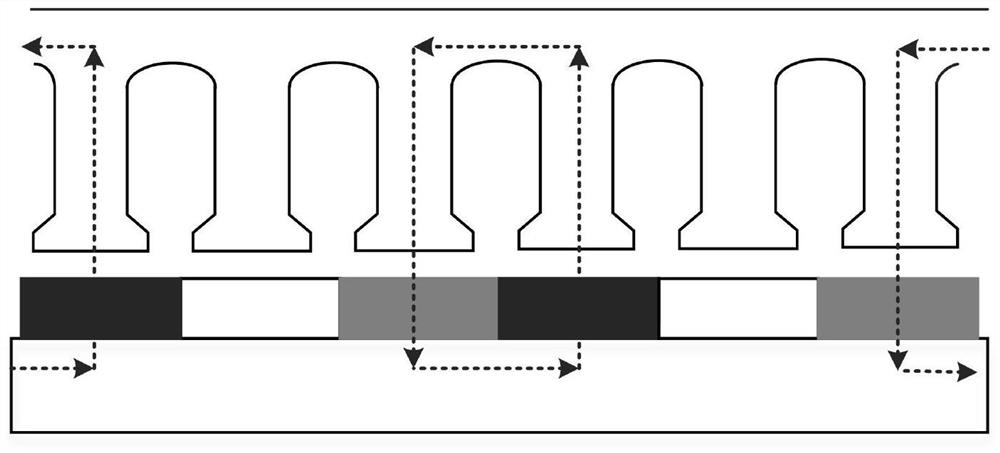

Primary and secondary yoke-free permanent-magnetic linear synchronous motor with double-side secondary structure

ActiveCN109728705AReduced chance of saturationReduce the possibility of saturationPropulsion systemsSynchronous motorProtein secondary structure

The invention relates to a primary and secondary yoke-free permanent-magnetic linear synchronous motor with a double-side secondary structure, and relates to the field of motor equipment. The motor comprises primary and secondary sides, the secondary side comprises upper and lower secondary sides, the upper secondary side is arranged over the primary side, the lower secondary side is arranged under the primary side; the primary side comprises 2m+1 magnetic conductive teeth and m coils, the 2m+1 magnetic conductive teeth are arranged side by side in parallel from left to right successively andnumbered as first, second, third to (2m+1)th magnetic conductive teeth successively, and the mth magnetic conductive tooth is sleeved by a coil. Secondary permanent magnets are arranged in a Halbach manner, secondary back iron is cancelled, the air gap flux density can be improved substantially, and the motor thrust is improved. The secondary permanent magnets arranged in the Halbach manner and the primary magnetic conductive teeth for a serial magnetic circuit, the installation space of an armature winding is increased, and the thrust density of the motor can be improved greatly.

Owner:HARBIN INST OF TECH

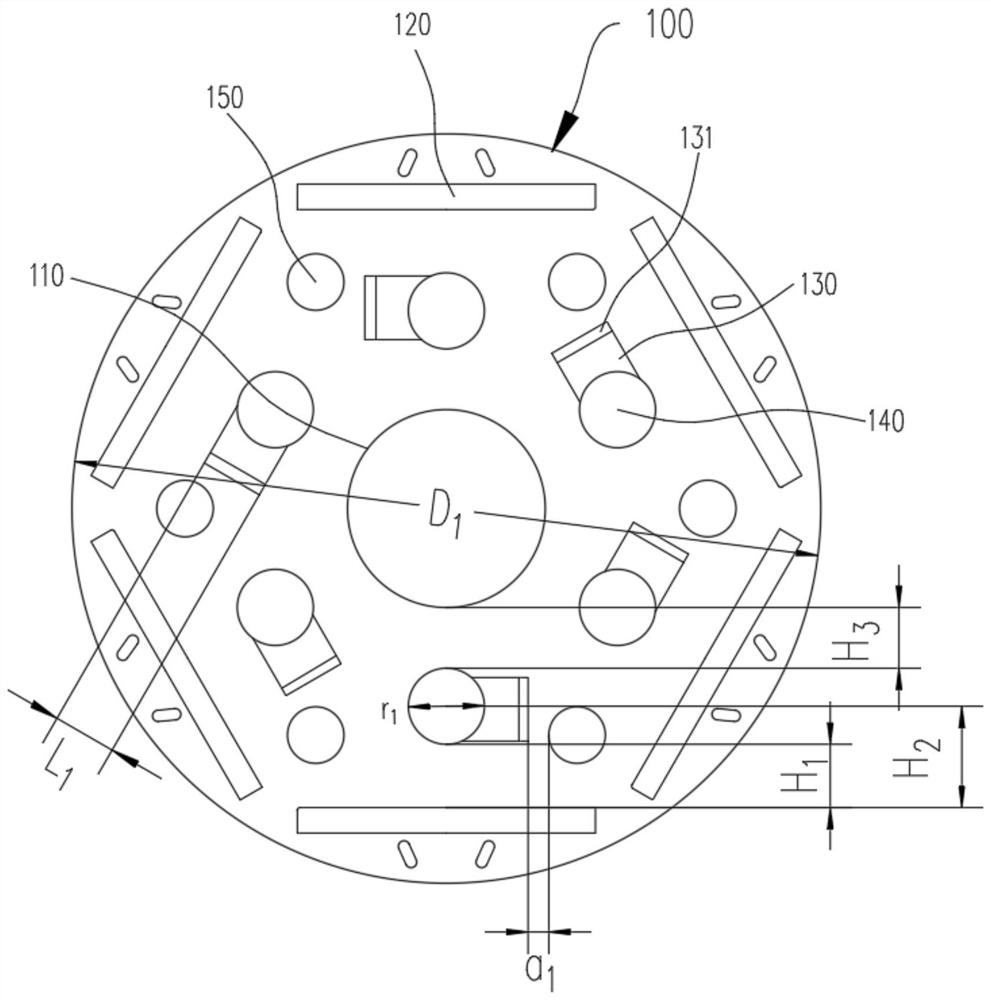

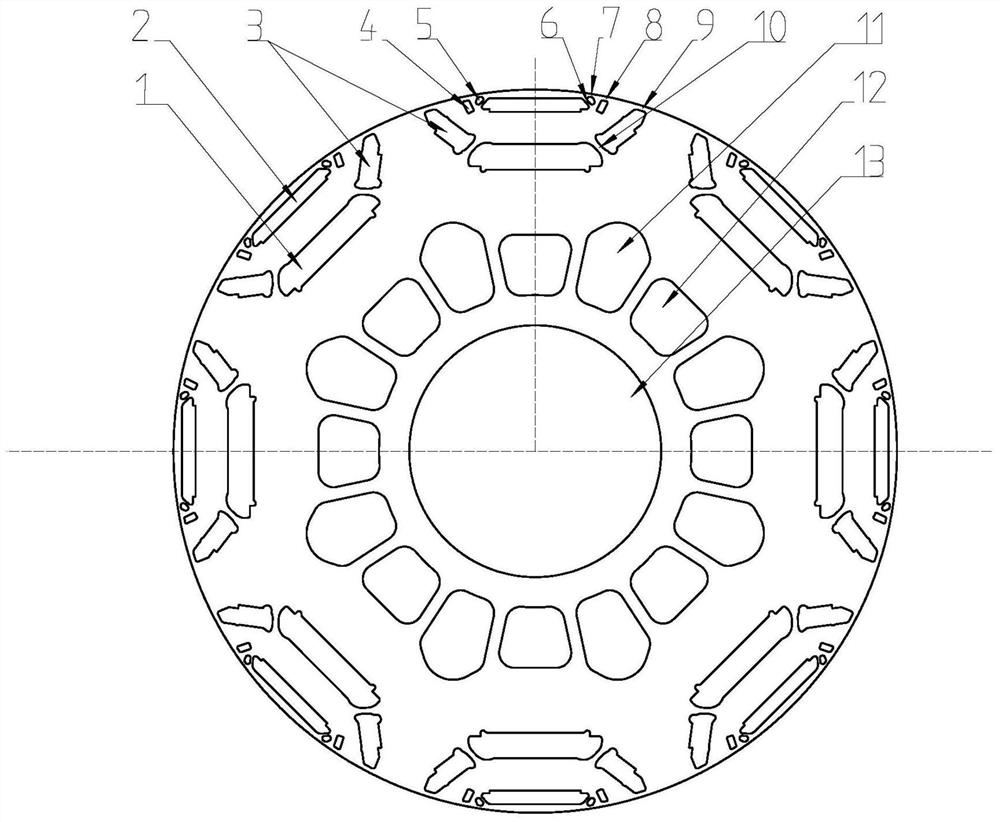

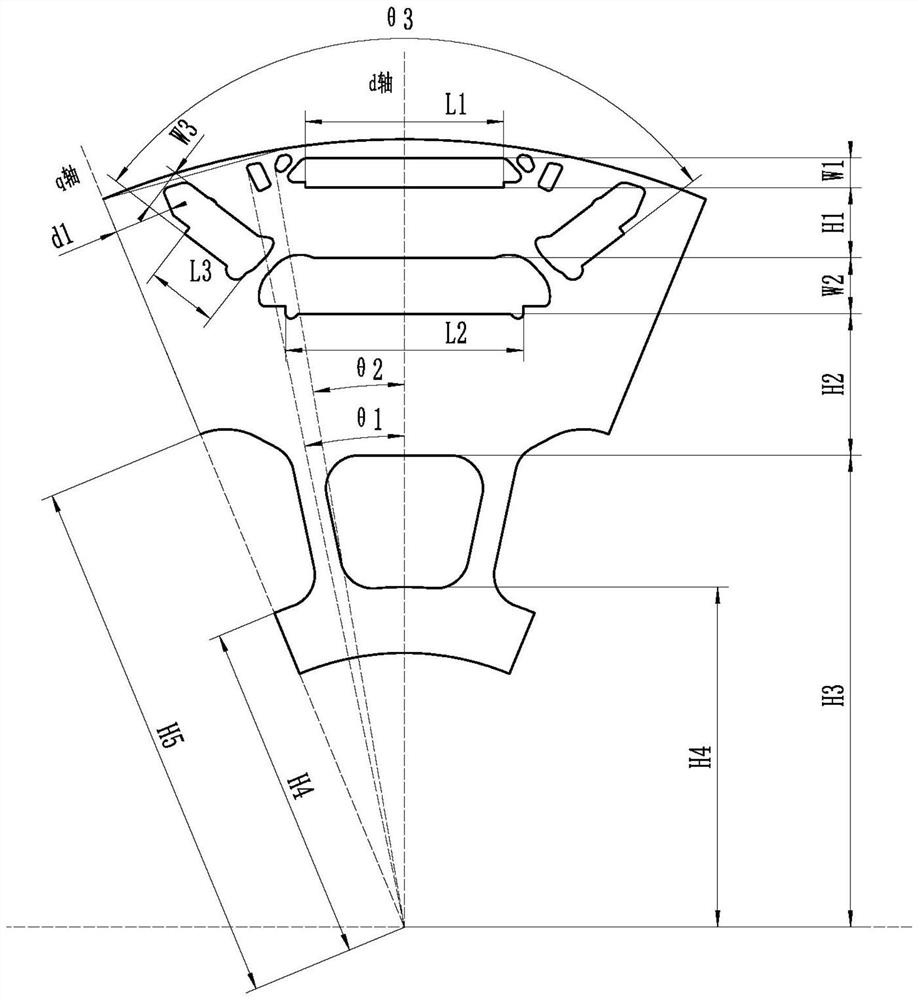

Rotor punching sheet, rotor and motor using rotor punching sheet and rotor

PendingCN113949184AGreat effortIncrease the proportionMagnetic circuit rotating partsElectric machinesPunchingElectric machine

The invention discloses a rotor punching sheet, which comprises a plurality of magnetic pole areas distributed along the circumference, first magnetic steel grooves and second magnetic steel grooves are arranged in the magnetic pole areas, the first magnetic steel grooves are located at the outer sides of the second magnetic steel grooves, and the midperpendicular of the first magnetic steel grooves and the midperpendicular of the second magnetic steel grooves coincide, and the rotor punching sheet also comprises two third magnetic steel grooves, the two third magnetic steel grooves are distributed at the two ends of the second magnetic steel groove and are symmetrically arranged in a V shape, values of the width L1 of the first magnetic steel groove, the width L2 of the second magnetic steel groove and the width L3 of the third magnetic steel grooves meet the following relation, r1 is the radius of the outermost circle of the rotor punching sheet, and p is the number of pole pairs of the motor; the value of the thickness W1 of the first magnetic steel groove, the value of the thickness W2 of the second magnetic steel groove and the value of the thickness W3 of the third magnetic steel groove meet the following relation: 0.16 * L1 < = W1 < = 0.2 * L1 < = W2 < = 2 * W1 < = W3 < = W2; and on the basis of ensuring the output torque of the motor, the production cost of the motor can be reduced, the sine degree of an air-gap magnetic field is effectively improved, harmonic waves are reduced, and the vibration noise problem is improved, so that the high-performance and low-cost motor design is realized.

Owner:ZHEJIANG ZHONGCHE SHANGCHI ELECTRIC CO LTD

Surface-mounted permanent magnet motor rotor and motor

InactiveCN108667174AEasy to fixEasy to useMagnetic circuit rotating partsSurface mountingPermanent magnet motor

The invention discloses a surface-mounted permanent magnet motor rotor and a motor, wherein the motor rotor comprises a rotor body; the outer surface of the rotor body is provided with a permanent magnet groove for arranging a permanent magnet; elastic piece is arranged on the bottom edge and / or side edge of the permanent magnet groove; one end of the elastic piece is connected with the groove edge in a whole; and the other end of the elastic piece is disconnected from the groove edge to be in a freely movable state. When the permanent magnet is mounted, the permanent magnet is extruded intothe permanent magnet groove; the elastic piece is extruded; the distance between the free moving end of the elastic piece and the bottom edge of the groove is reduced; elastic deformation is generated; and the permanent magnet is tightly pressed into the permanent magnet groove by elastic forcegenerated by elastic deformation of the elastic piece. According to the surface-mounted permanent magnetmotor rotor and motor, the permanent magnet can be conveniently fixed; the use of the sheath is removed; the use of the filler is reduced or even eliminated; vibration borne by the permanent magnet is reduced; and demagnetization of the permanent magnet is avoided.

Owner:NANJING UNIV OF SCI & TECH +1

Hybrid excitation double-stator switched reluctance motor

ActiveCN112087114AImprove power densityLarge output torqueSynchronous machine detailsMagnetic circuit stationary partsElectric machineExcitation current

The present invention discloses a hybrid excitation double-stator switched reluctance motor. Six magnetism isolating blocks and six inner stator permanent magnets are embedded in a staggered mode in the circumferential direction to form a cylinder, and the left inner stator and the right inner stator which are the same in structure are arranged on the two axial end sides of the magnetism isolatingblocks and the two axial end sides of the inner stator permanent magnets respectively and are symmetrical in the axial direction. The left side inner stator and the right side inner stator are each composed of three inner stator blocks which are the same in structure and are unevenly arranged in the circumferential direction, and the left side outer stator and the right side outer stator which are the same in structure are arranged on the axial end side of the middle outer stator respectively, are symmetrical in the axial direction and are each composed of three outer stator blocks arranged in the circumferential direction. Side teeth are arranged at the end of each outer stator block in the circumferential direction, an outer stator permanent magnet is fixedly embedded between every twoadjacent side teeth, each outer stator permanent magnet is magnetized in the tangential direction of the circumference, an inner winding is wound on each inner stator salient pole tooth, and an outerwinding is wound on each outer stator salient pole tooth. Under the condition that the same exciting current flow in, the output torque is increased, and the motor power density is improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com