Composite magnetic pole type surface-mounted permanent magnet synchronous motor

A technology for permanent magnet synchronous motors and combined magnetic poles, which is applied to synchronous machines, synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, etc., and can solve harmonics, irreversible demagnetization, and motor performance degradation and other problems, to achieve the effect of reducing stator iron loss and torque fluctuation, reducing anti-demagnetization ability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

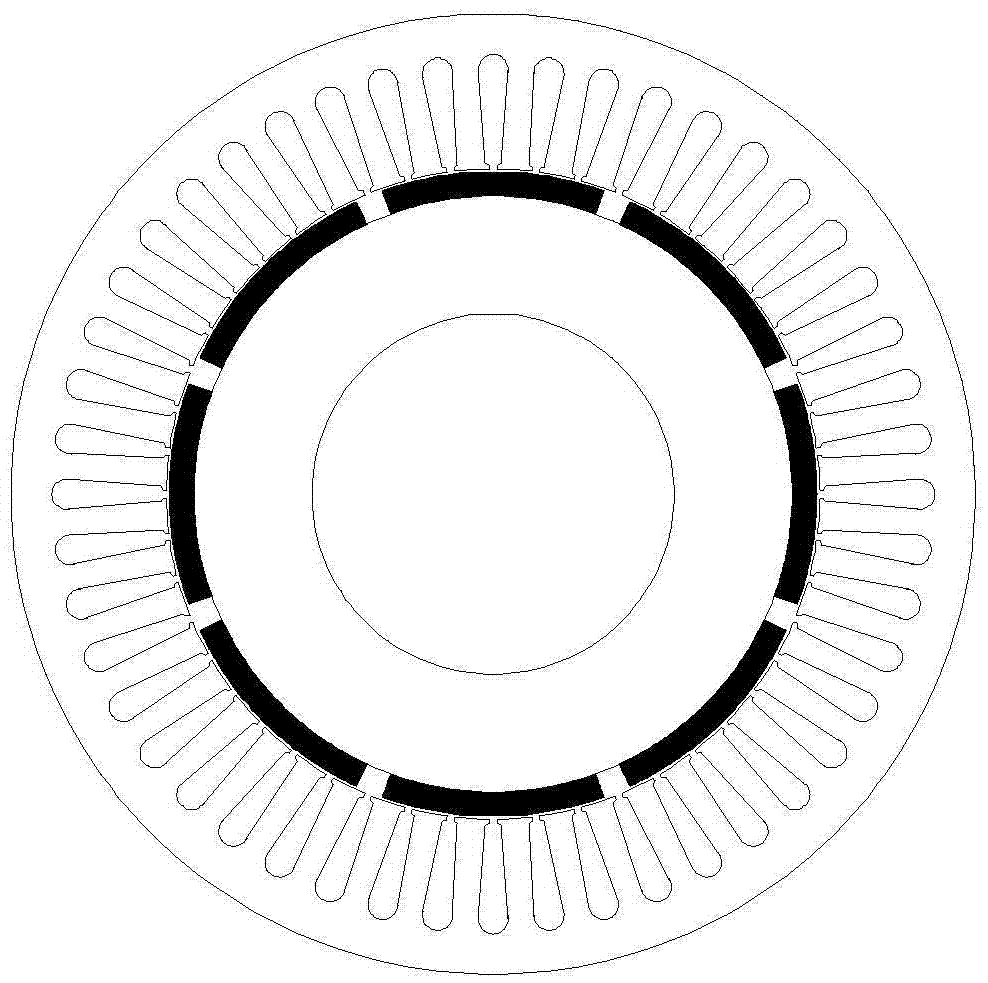

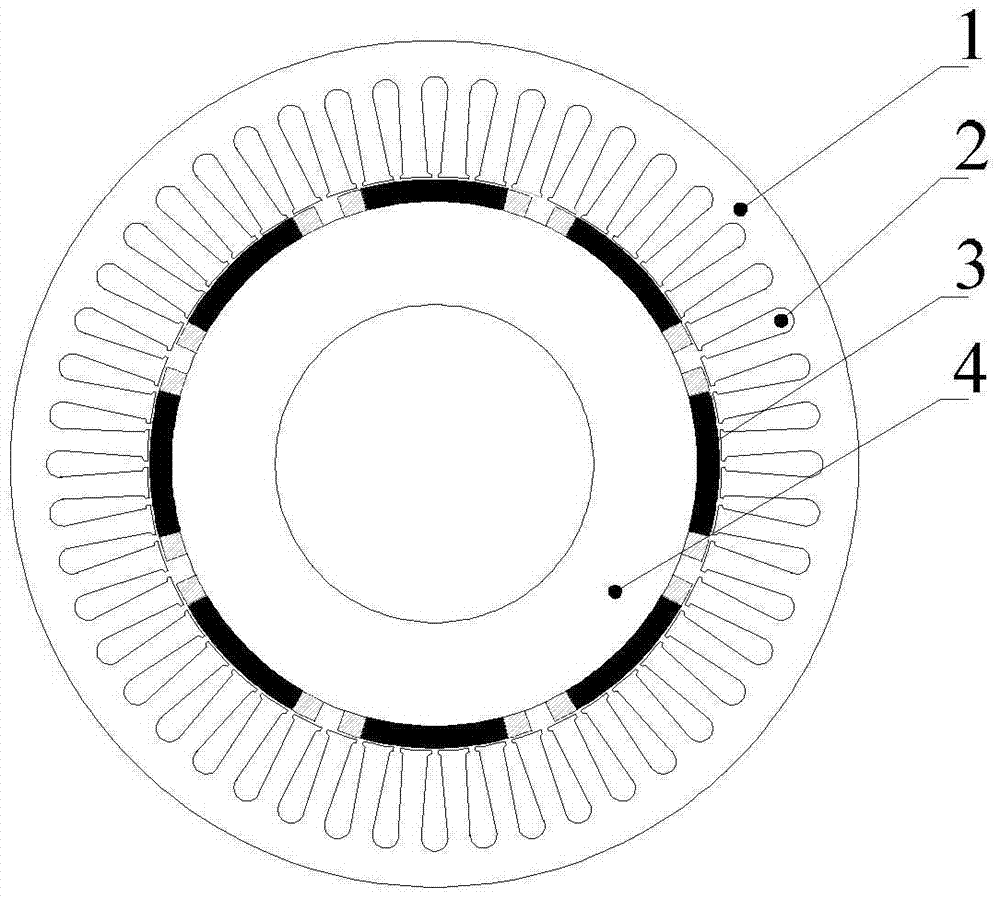

[0012] Specific implementation mode one: the following combination Figure 2 to Figure 4 This embodiment is described. The combined magnetic pole surface-mounted permanent magnet synchronous motor described in this embodiment includes a rotor and a stator. The rotor is arranged inside the stator. A radial air gap is left between the rotor and the stator. The stator includes a stator core 1 and a The stator winding 2 is arranged in the inner stator slot of the stator core 1; the rotor includes a plurality of rotor poles 3 and a rotor core 4, and the outer circular surface of the rotor core 4 is uniformly provided with a plurality of rotor poles 3;

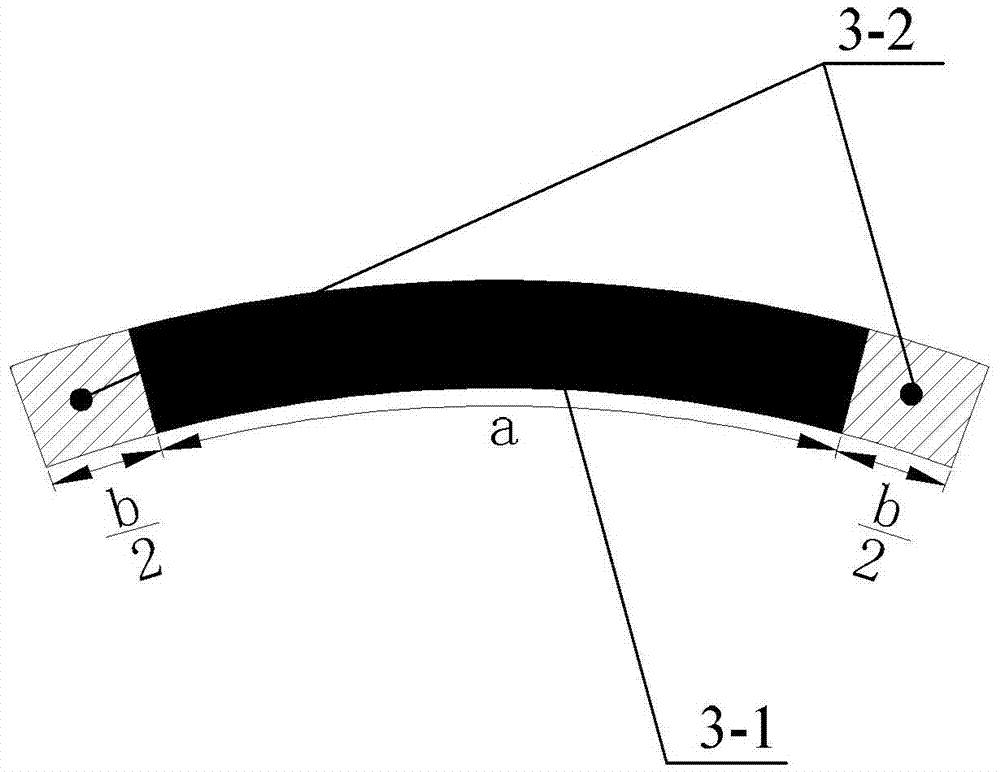

[0013] The rotor pole 3 includes a rare earth permanent magnet pole 3-1 and two ferrite permanent magnet poles 3-2; the two left and right end faces of the rare earth permanent magnet pole 3-1 are respectively provided with a ferrite permanent magnet pole 3-2, and the rare earth The permanent magnet pole 3-1 and the two ferrite perm...

specific Embodiment approach 2

[0017] Specific embodiment two: this embodiment further explains embodiment one, the arc length of the rare earth permanent magnet pole 3-1 is a, and the arc length of the ferrite permanent magnet pole 3-2 is b / 2, both of which meet the following conditions :

[0018] a ( Br 2 ) 2 + b ( Br 1 ) 2 c - 2 π { 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com