Combination magnetic pole surface mount permanent magnet synchronous motor

A permanent magnet synchronous motor, combined magnetic pole technology, applied in synchronous machine, synchronous motor with static armature and rotating magnet, magnetic circuit shape/style/structure, etc., can solve harmonics, irreversible demagnetization, motor performance degradation and other problems, to achieve the effect of reducing stator iron loss and torque fluctuation, reducing anti-demagnetization ability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

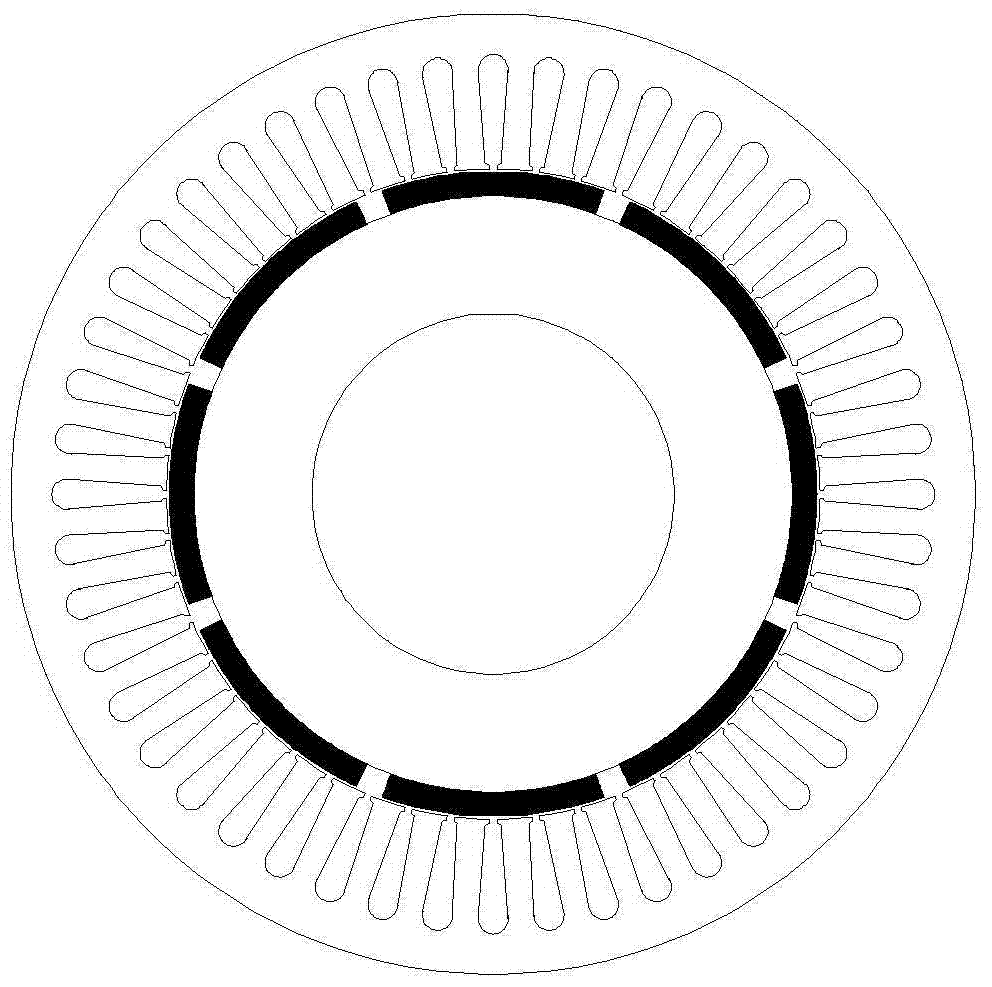

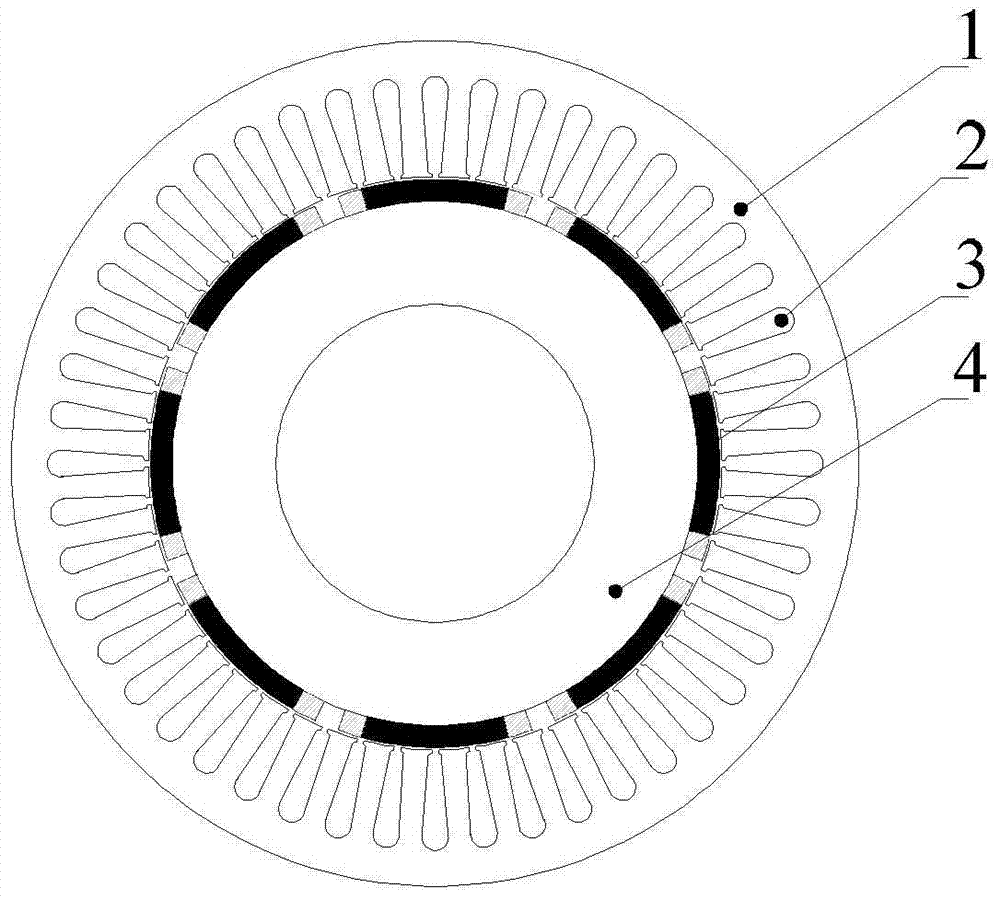

[0012] Specific implementation mode one: the following combination Figure 2 to Figure 4 This embodiment is described. The combined magnetic pole surface-mounted permanent magnet synchronous motor described in this embodiment includes a rotor and a stator. The rotor is arranged inside the stator. A radial air gap is left between the rotor and the stator. The stator includes a stator core 1 and a The stator winding 2 is arranged in the inner stator slot of the stator core 1; the rotor includes a plurality of rotor poles 3 and a rotor core 4, and the outer circular surface of the rotor core 4 is uniformly provided with a plurality of rotor poles 3;

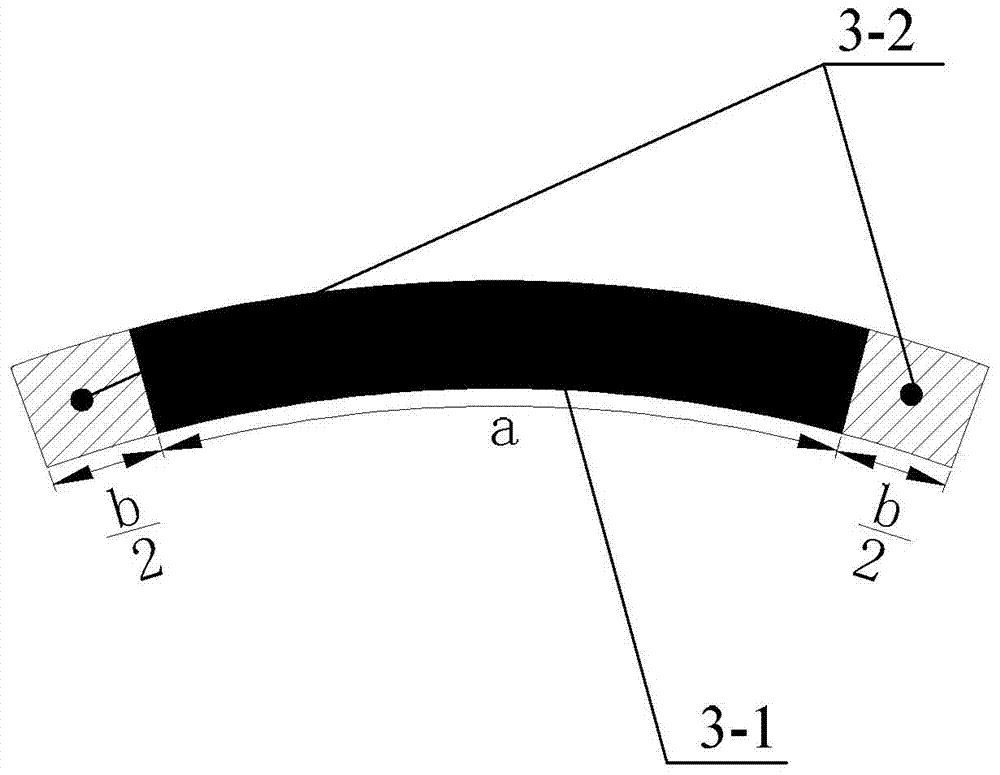

[0013] The rotor pole 3 includes a rare earth permanent magnet pole 3-1 and two ferrite permanent magnet poles 3-2; the two left and right end faces of the rare earth permanent magnet pole 3-1 are respectively provided with a ferrite permanent magnet pole 3-2, and the rare earth The permanent magnet pole 3-1 and the two ferrite perm...

specific Embodiment approach 2

[0017] Specific embodiment two: this embodiment further explains embodiment one, the arc length of the rare earth permanent magnet pole 3-1 is a, and the arc length of the ferrite permanent magnet pole 3-2 is b / 2, both of which meet the following conditions :

[0018]

[0019] In the formula: c is the pole pitch of the rotor pole 3;

[0020] Br 2 is the remanence density of the rare earth permanent magnet pole 3-1 at the working temperature; Br 1 is the residual magnetic density of the ferrite permanent magnet pole 3-2 at the working temperature; and satisfies Br 2 >Br 1 .

[0021] According to the above formula, the size of the rare earth permanent magnet pole 3-1 and the ferrite permanent magnet pole 3-2 are reasonably proportioned to make it produce the best sine wave of the air gap magnetic field, which is beneficial to reduce iron loss and torque fluctuation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com