Patents

Literature

208results about How to "Increase axial length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

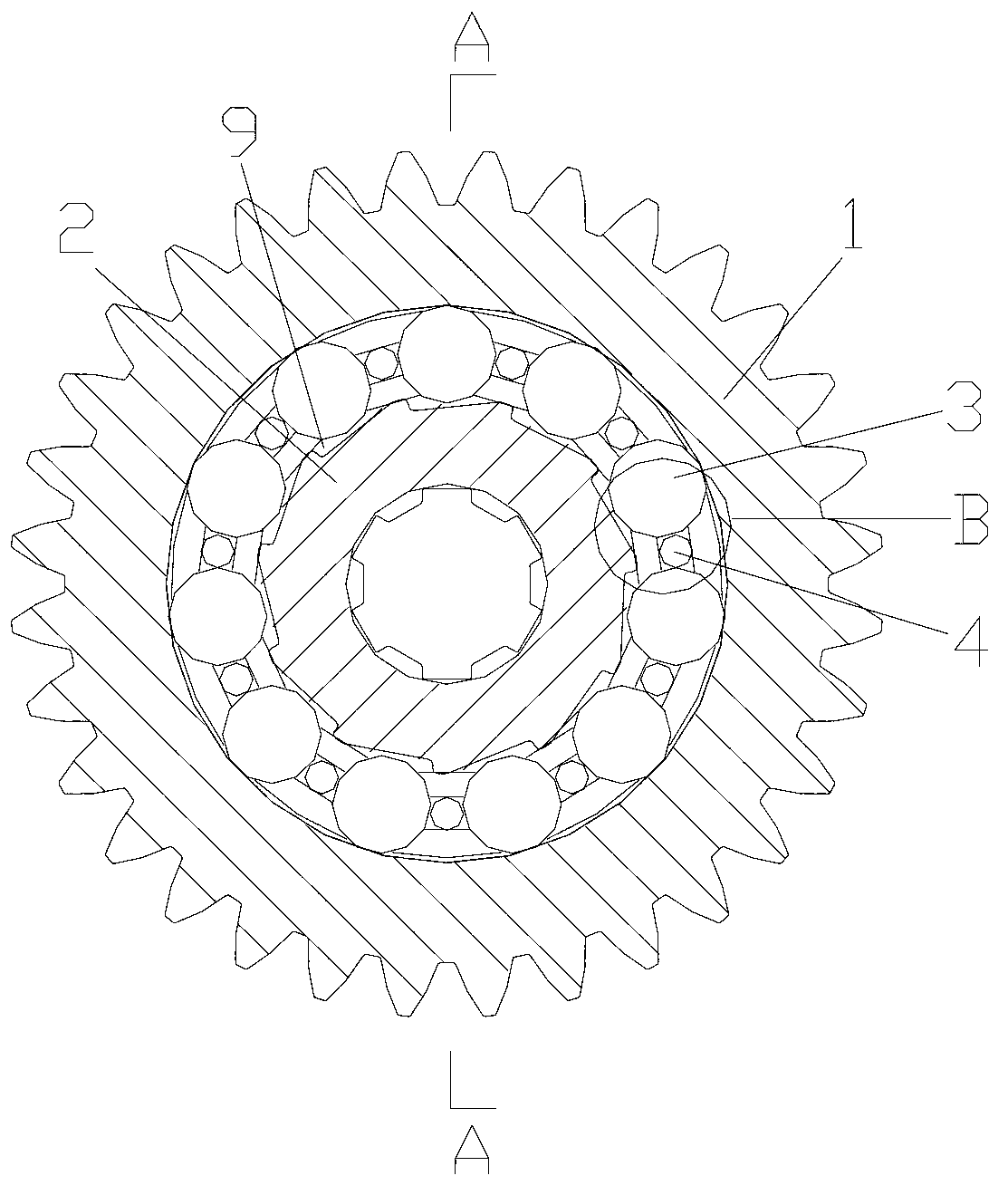

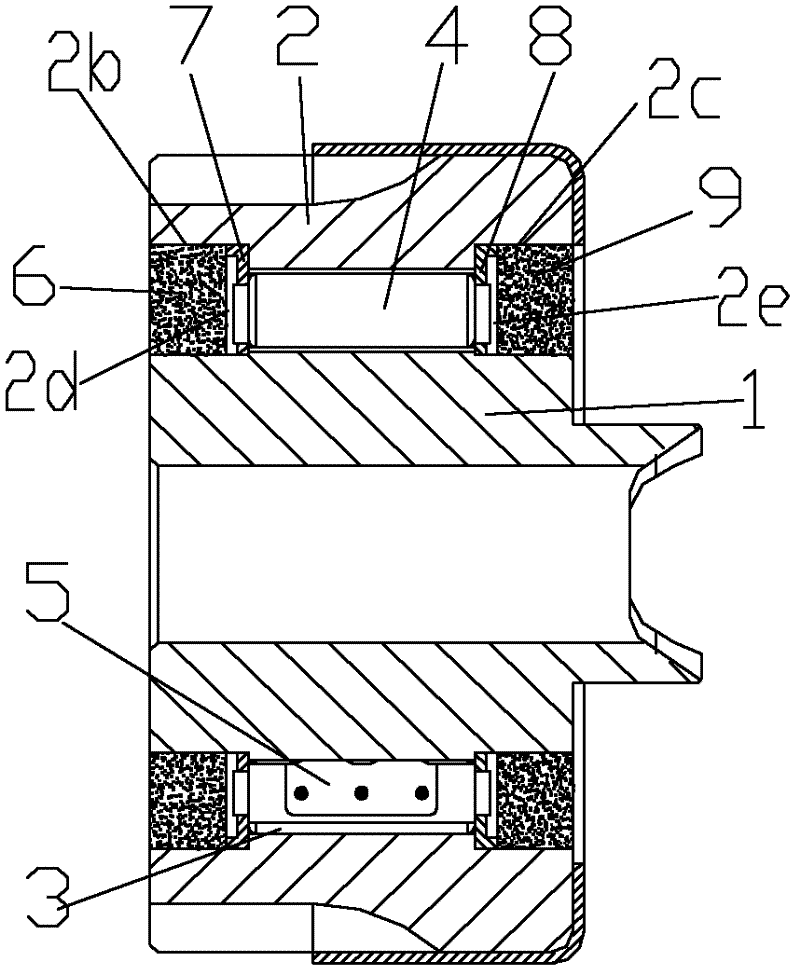

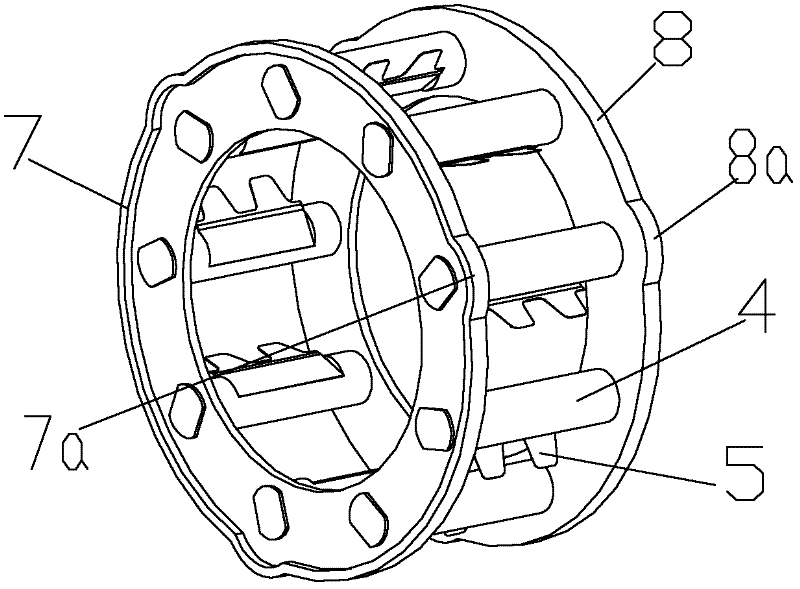

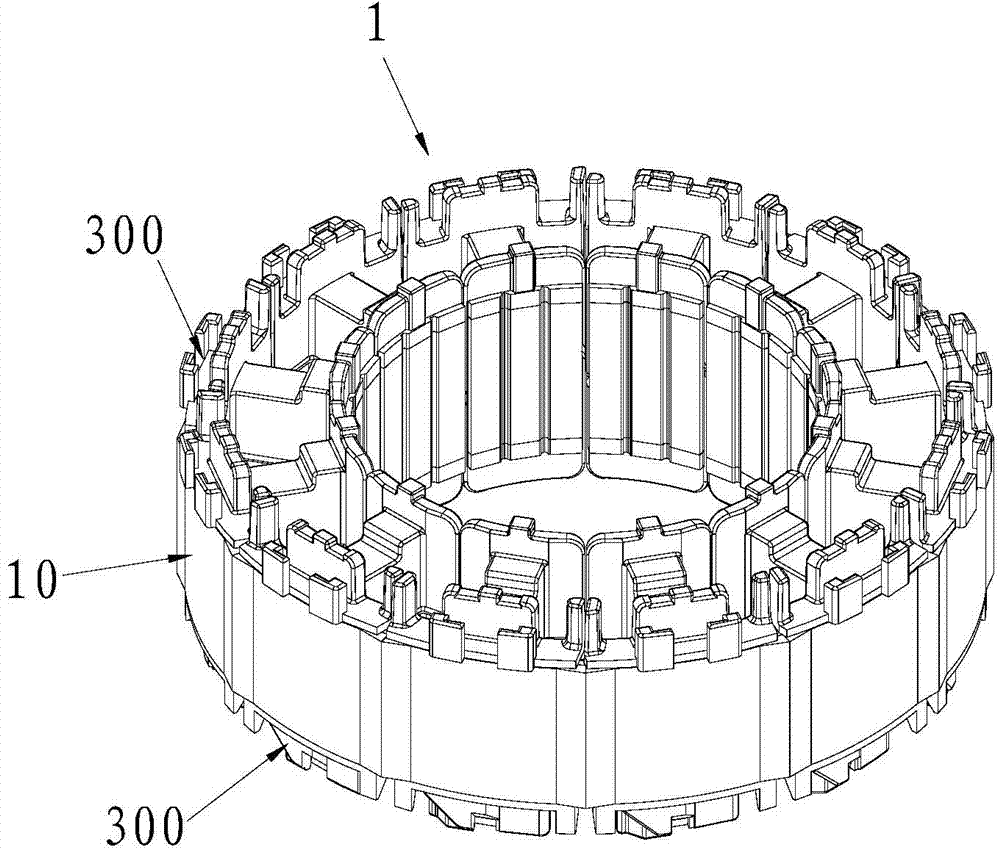

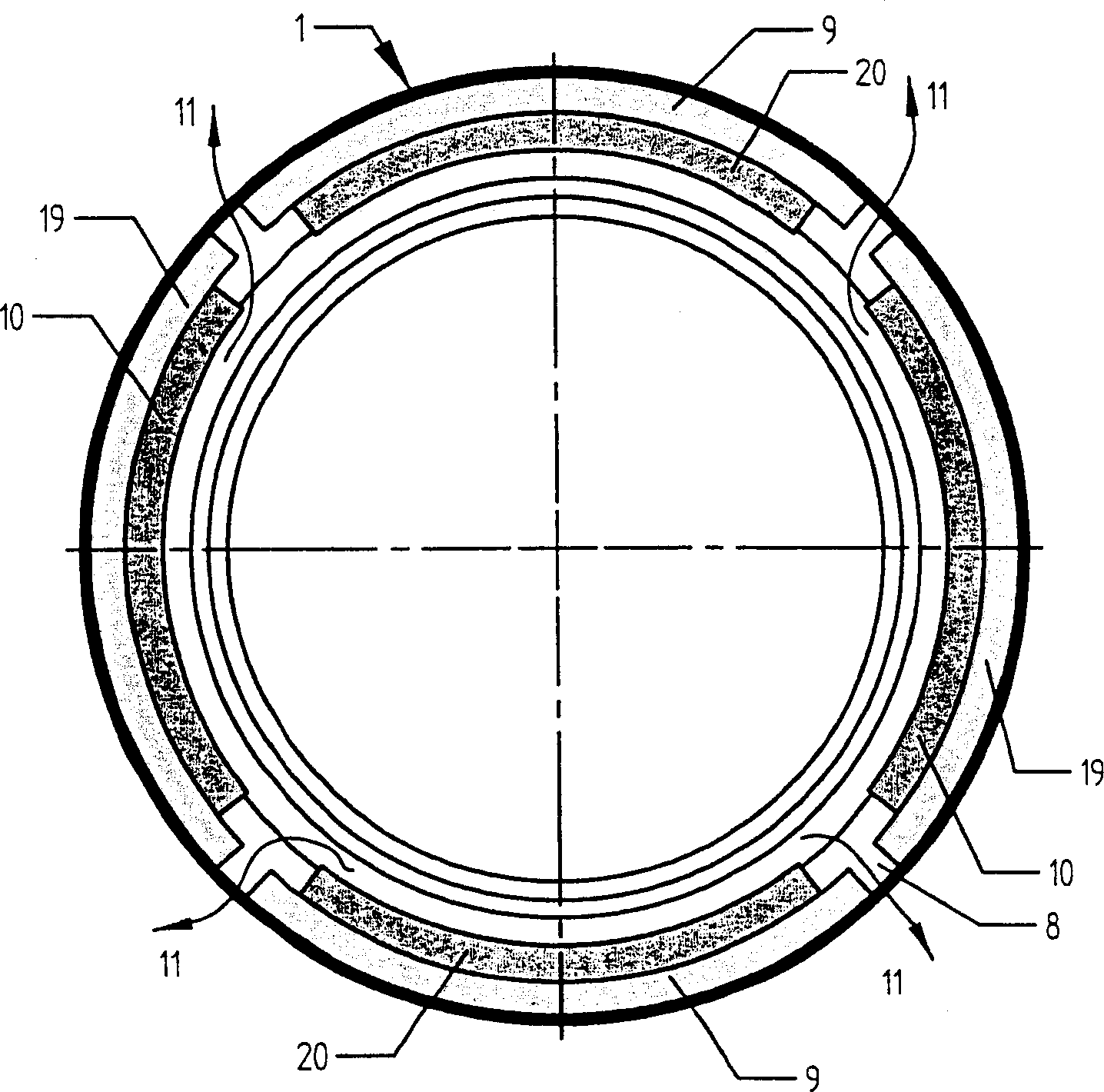

Floating auxiliary roller type overrun clutch

InactiveCN103307140AIncrease axial lengthIncrease the lengthFreewheel clutchesEngineeringMachining process

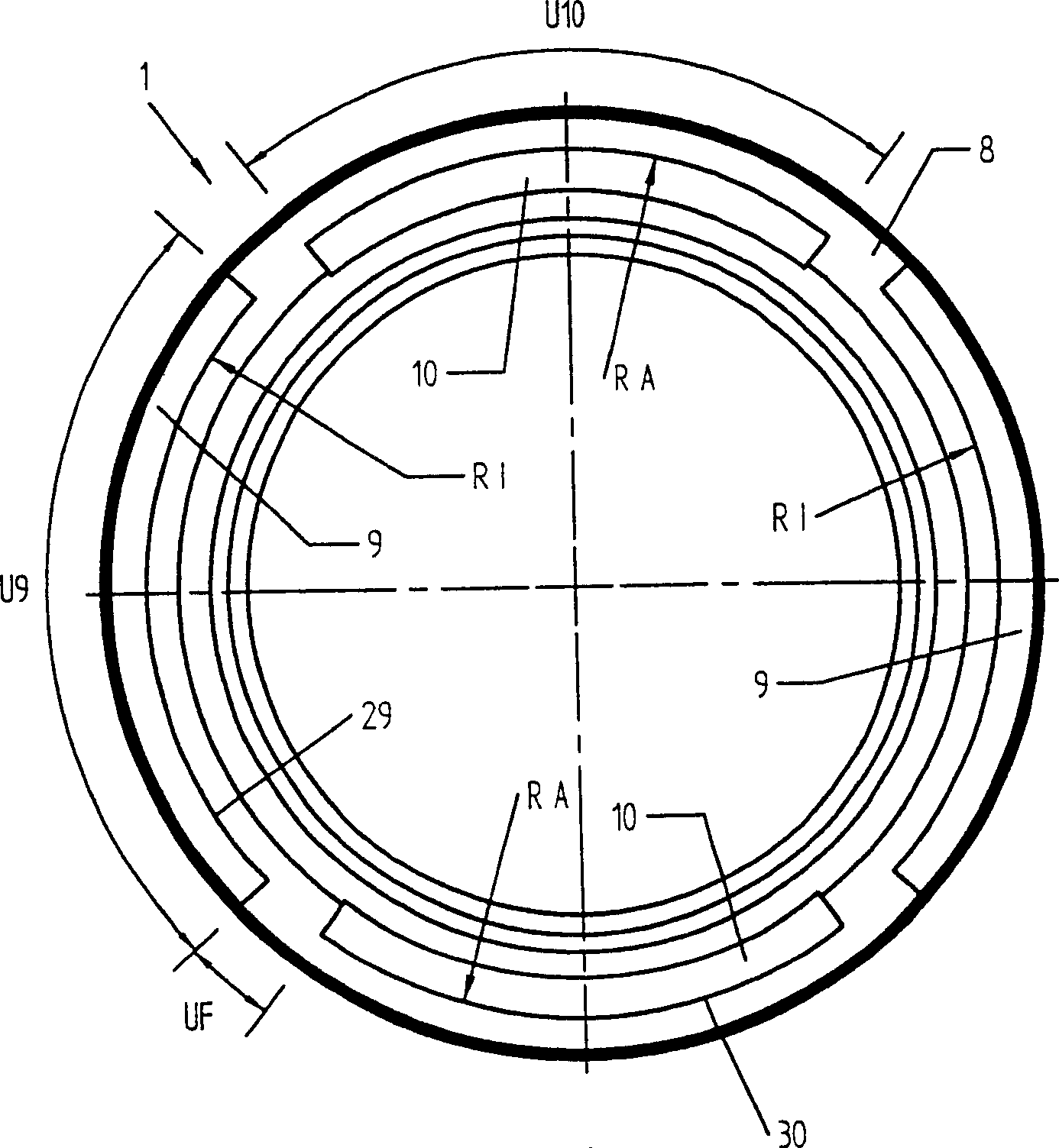

The invention discloses a floating auxiliary roller type overrun clutch which comprises an outer ring, an inner ring, rolling bodies and auxiliary rollers, wherein engagement spaces used for being engaged with or separated from the rolling bodies are formed between the outer ring and the inner ring; the auxiliary rollers are parallel to an axial line of the overrun clutch and are spaced from the rolling bodies; and the auxiliary rollers are arranged between the rolling bodies in such a way that the auxiliary rollers can move in a circumferential direction of the overrun clutch. According to the floating auxiliary roller type overrun clutch, the processing of a limiting seat is avoided, the processing process is simplified, the working efficiency is improved, and the processing cost is reduced; as the auxiliary roller structure is adopted, the axial length of the overrun clutch and the rolling bodies can be theoretically infinitely prolonged, the engagement length is prolonged, the bearing capacity of the overrun clutch is increased, the radial size of the overrun clutch under higher bearing capacity is reduced, and the service life of the overrun clutch is prolonged; and meanwhile, the probability of imbalance caused by application of a pretension force to point contact of each roller in the prior art is removed, thereby enabling each roller to keep parallel to the axial line of the inner ring.

Owner:SOUTHWEST UNIVERSITY

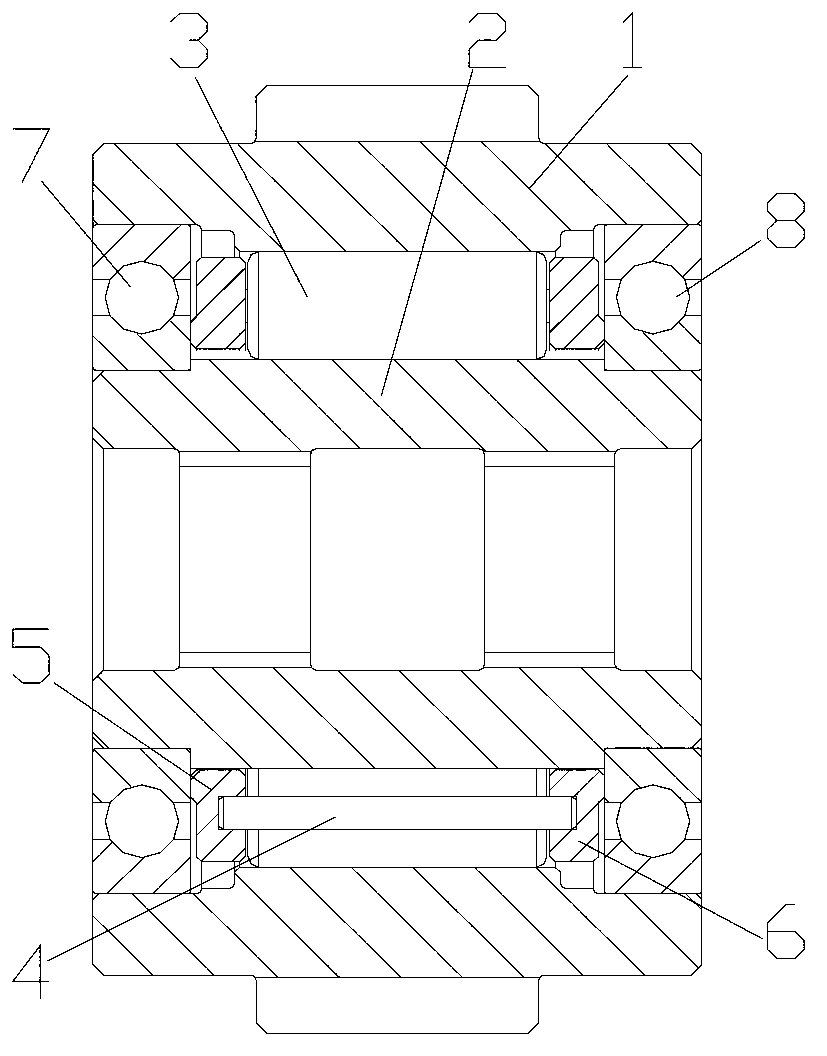

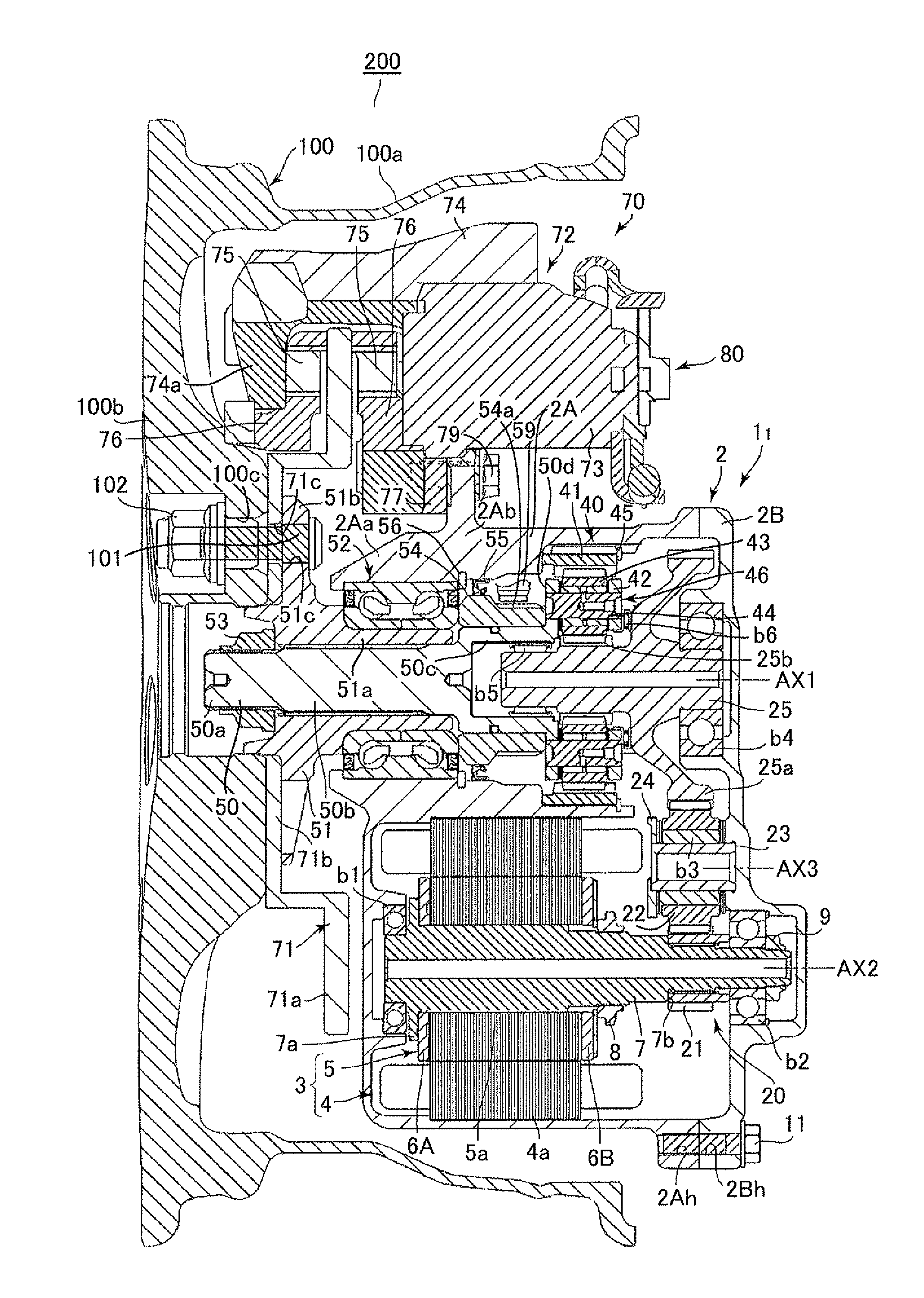

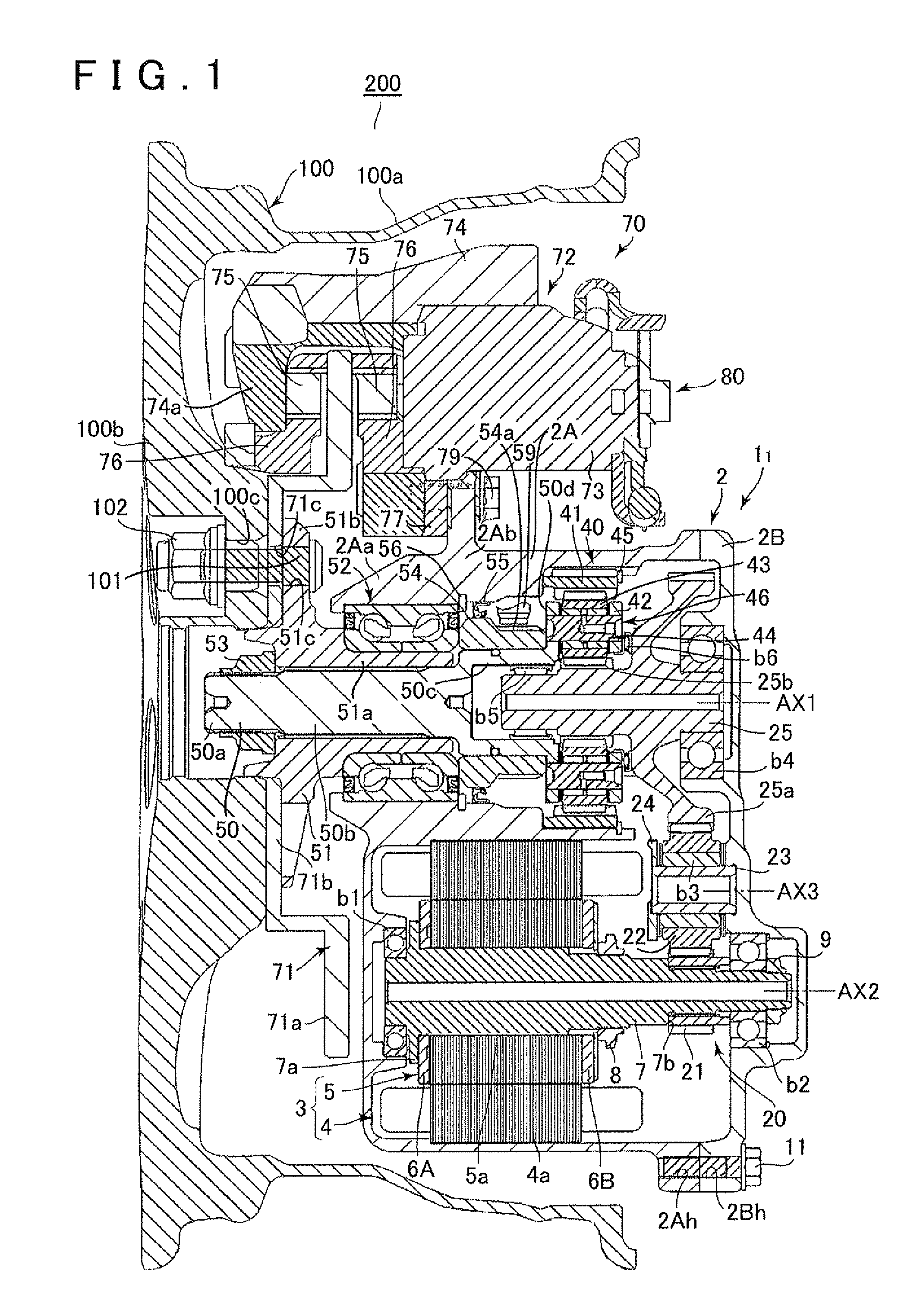

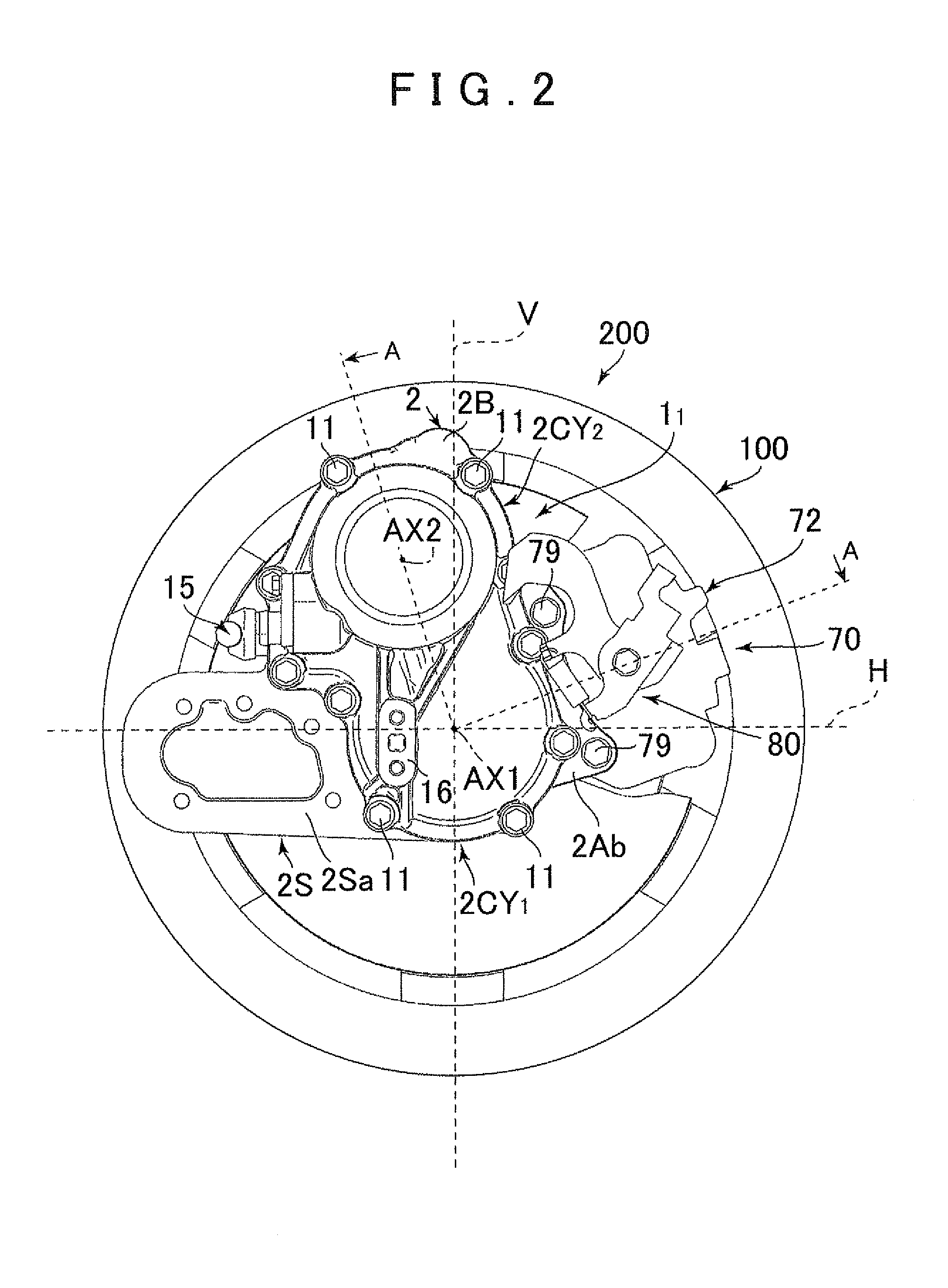

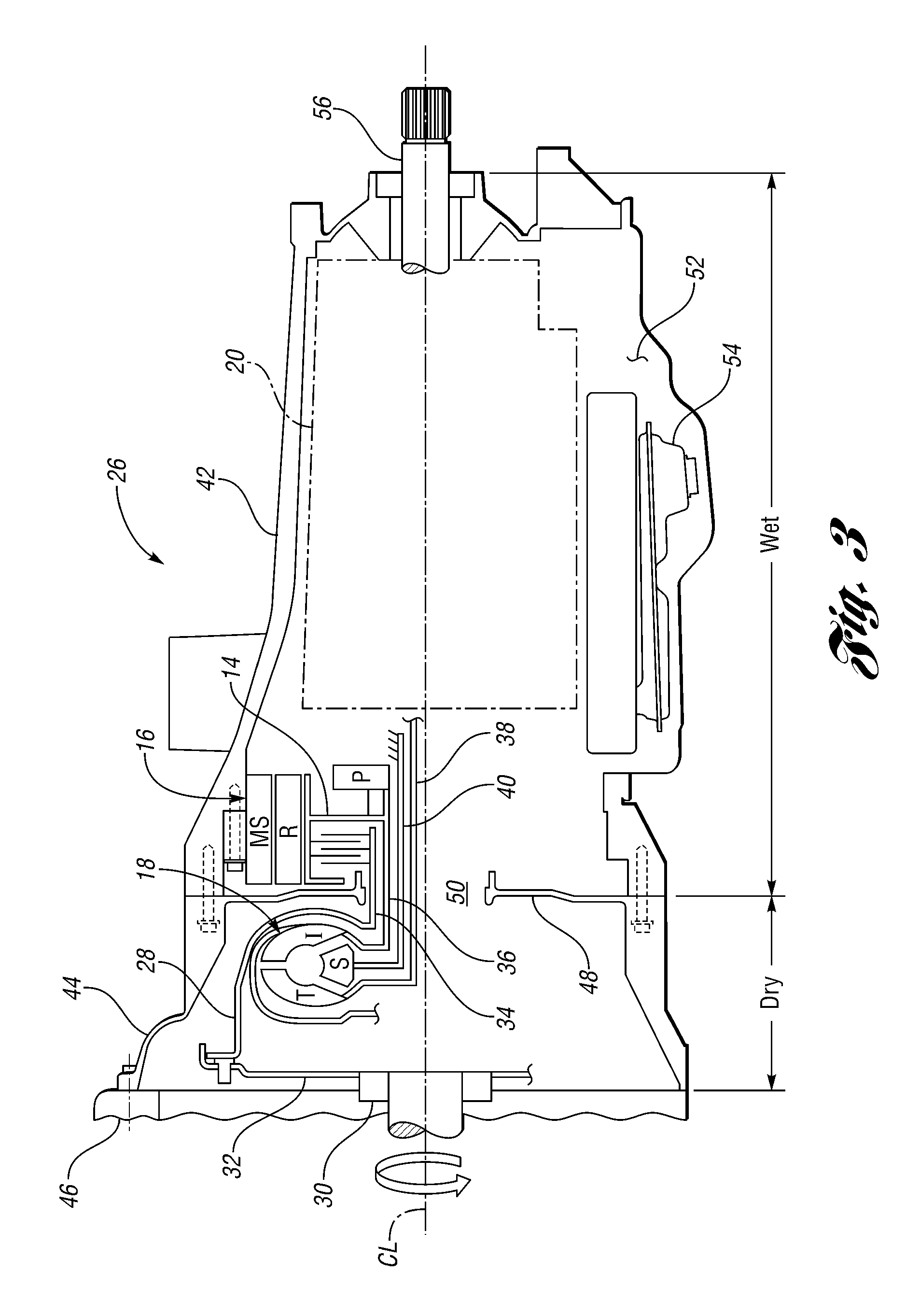

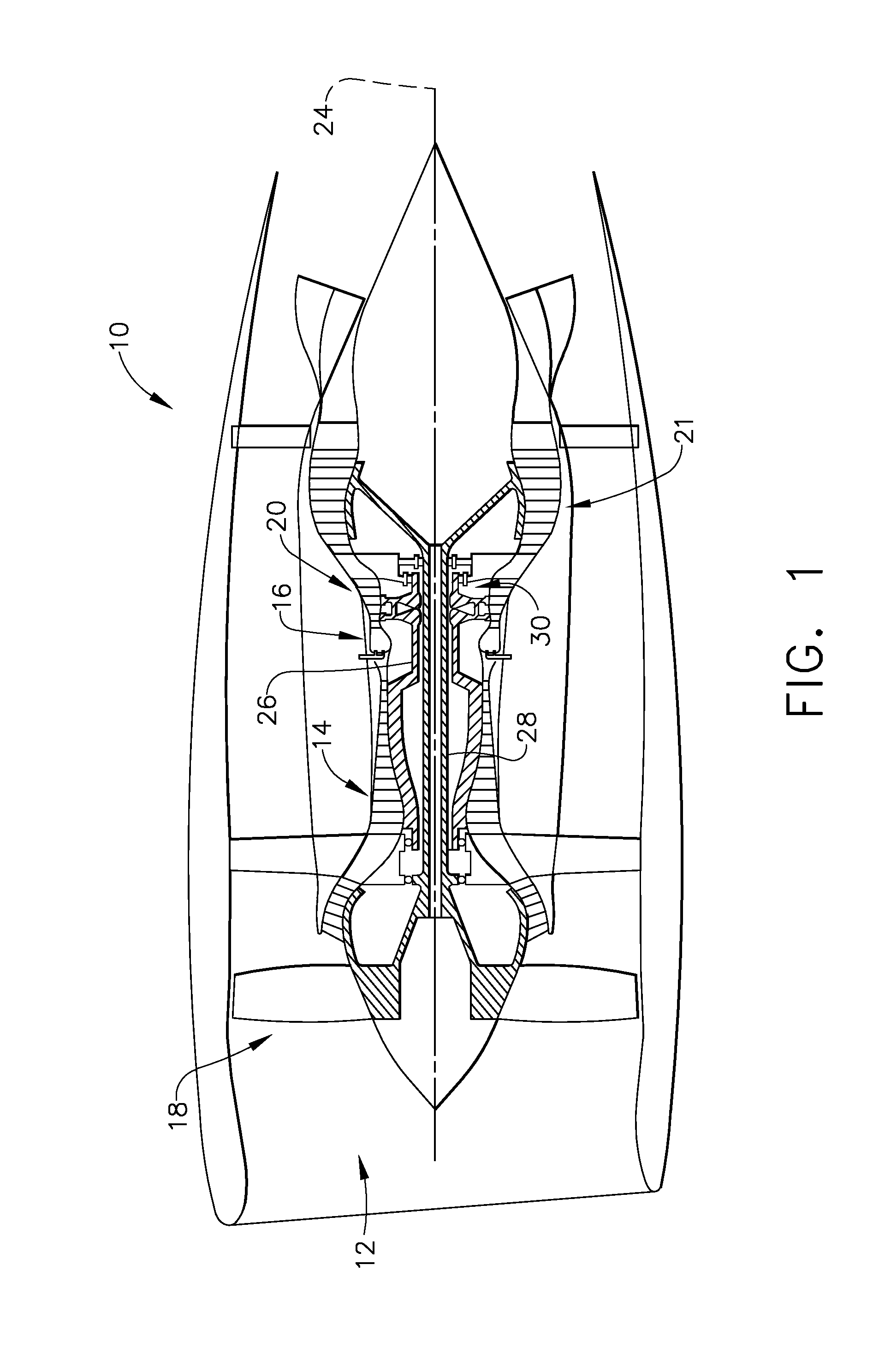

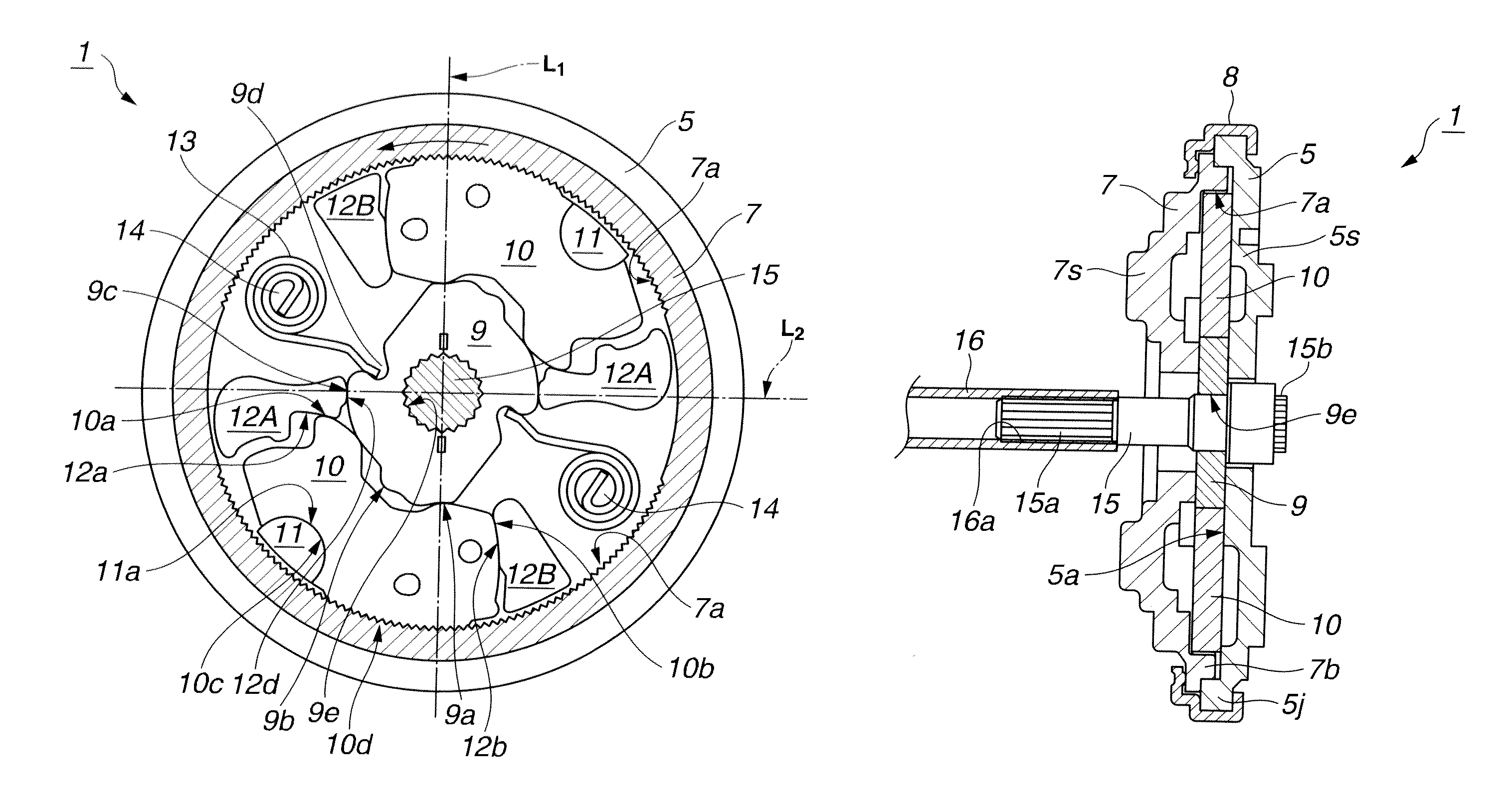

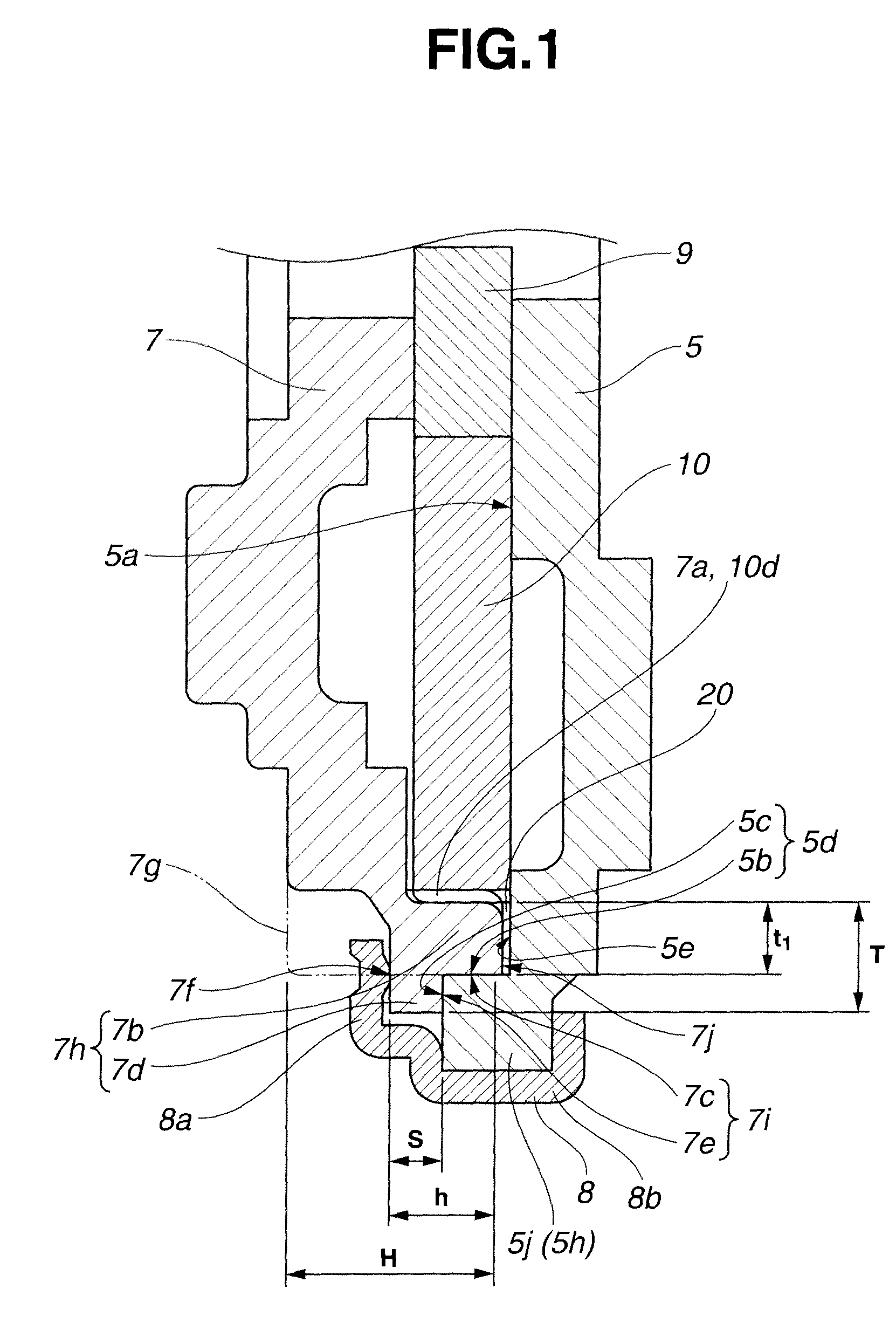

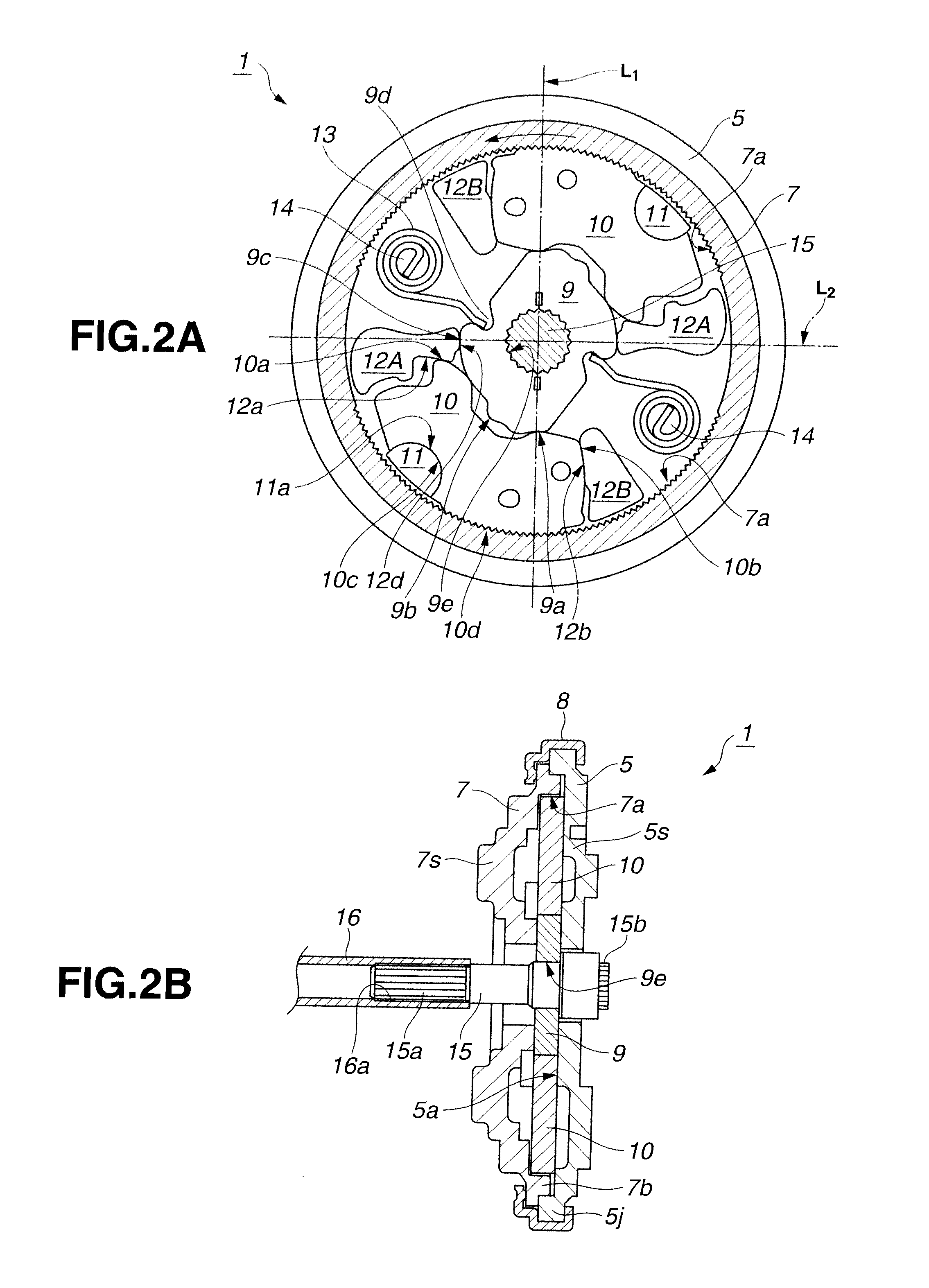

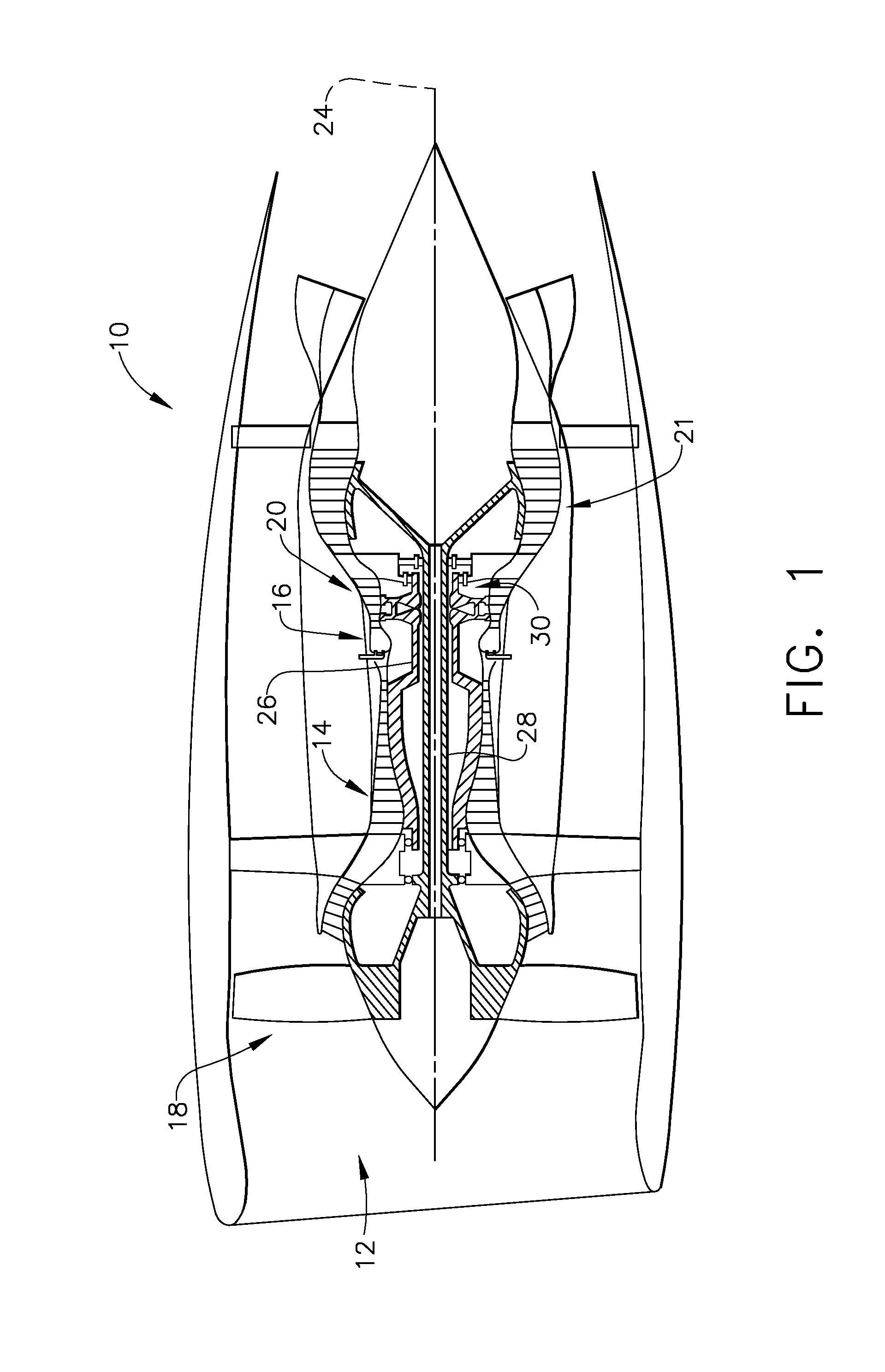

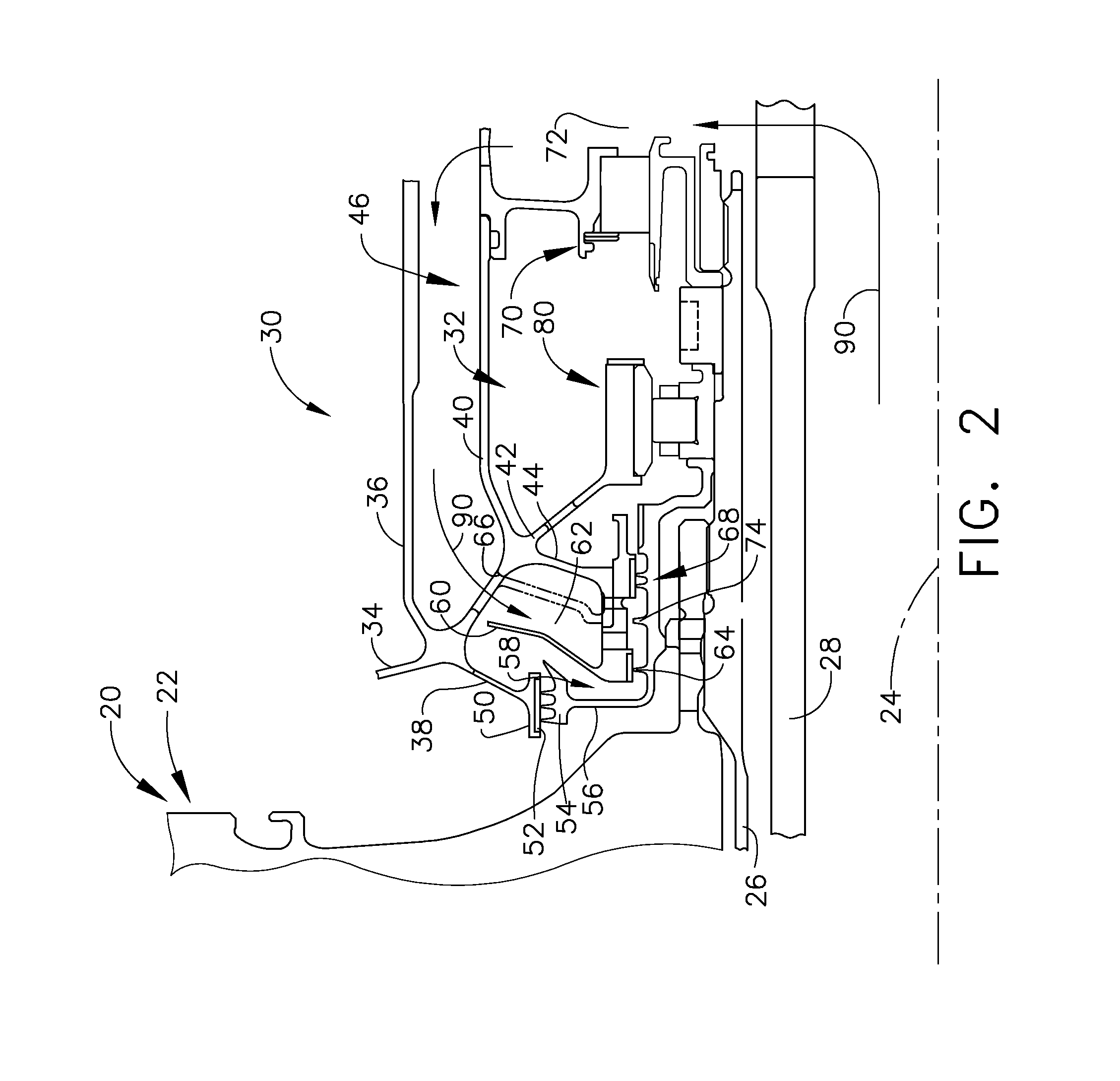

In-wheel motor drive device

ActiveUS8596395B2Increase axial lengthShorten the axial lengthSpeed controllerElectric devicesMotor driveElectric machine

An in-wheel motor drive device is attached to an inner side of a wheel of a vehicle wheel and drives the vehicle wheel. The in-wheel motor drive device includes a rotating electric machine; a transmission mechanism that transmits the rotation of the rotating electric machine; a speed reducing mechanism that reduces in speed the rotation transmitted by the transmission mechanism; and an output shaft that outputs the reduced-speed rotation of the speed reducing mechanism to the wheel. The speed reducing mechanism and the output shaft are disposed on a first axis coaxial with a center of the wheel. The rotating electric machine is disposed on a second axis parallel to the first axis, and the rotating electric machine and the speed reducing mechanism are positioned in a radial cross section perpendicular to the first axis and the second axis.

Owner:AISIN AW CO LTD

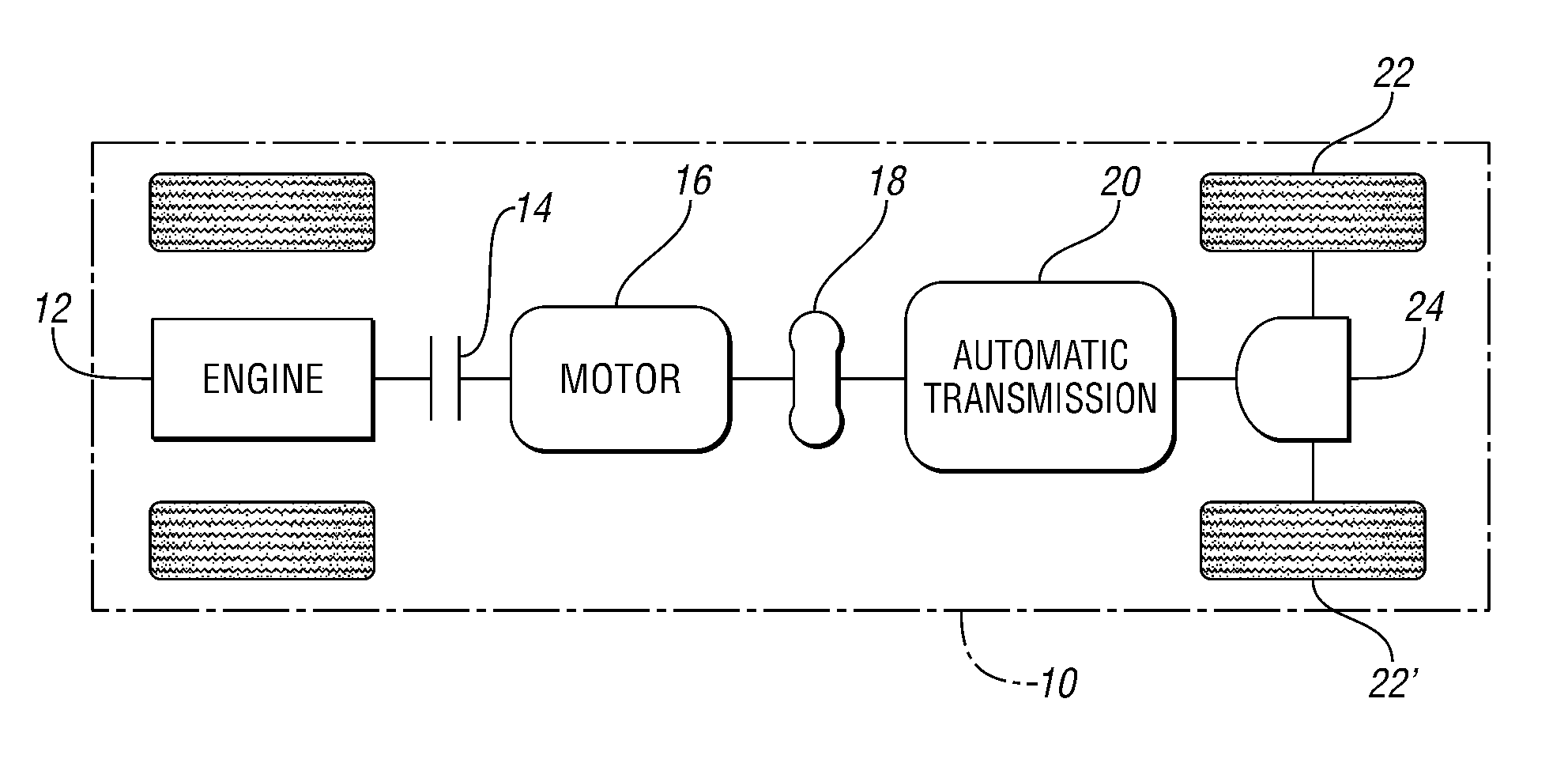

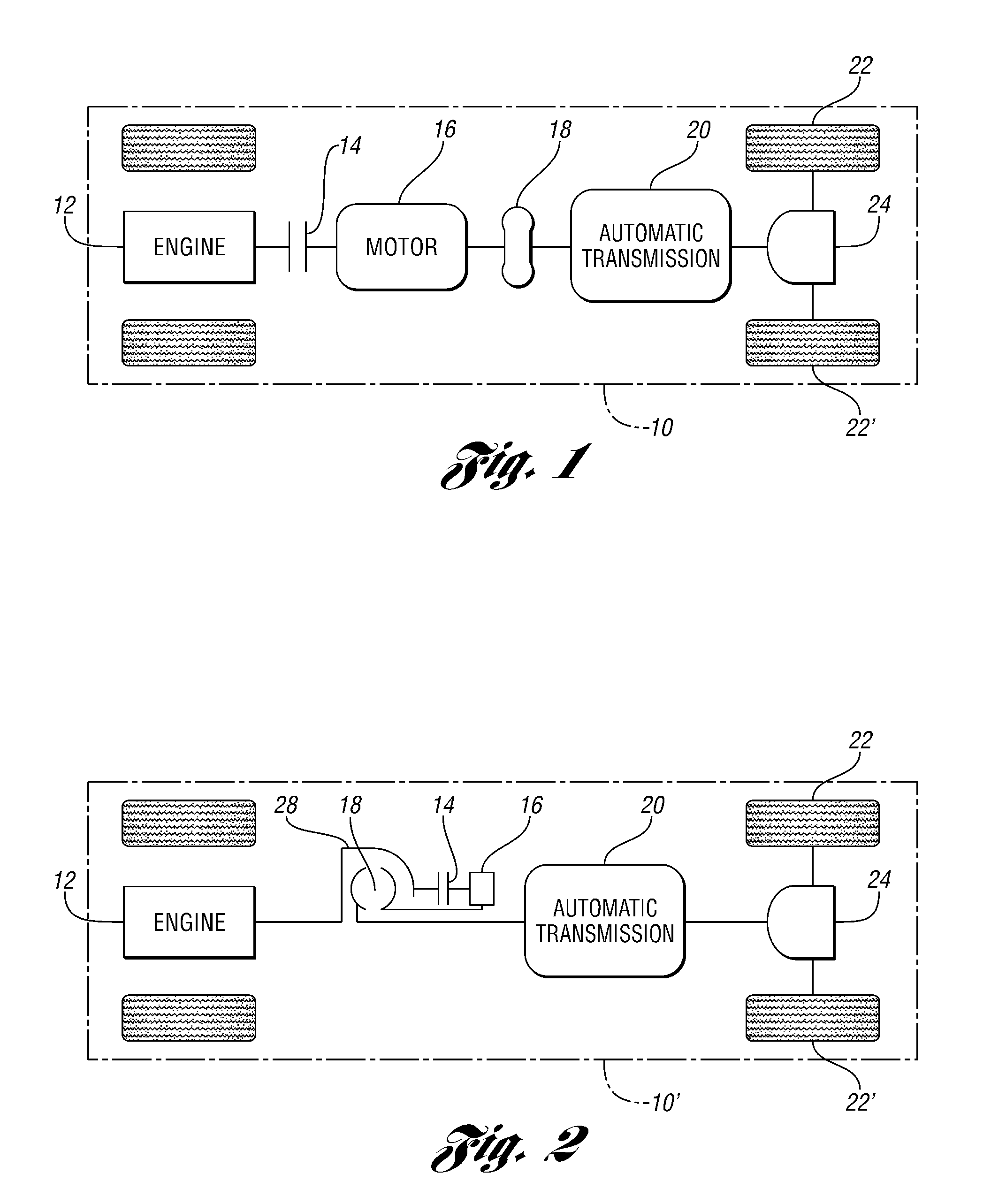

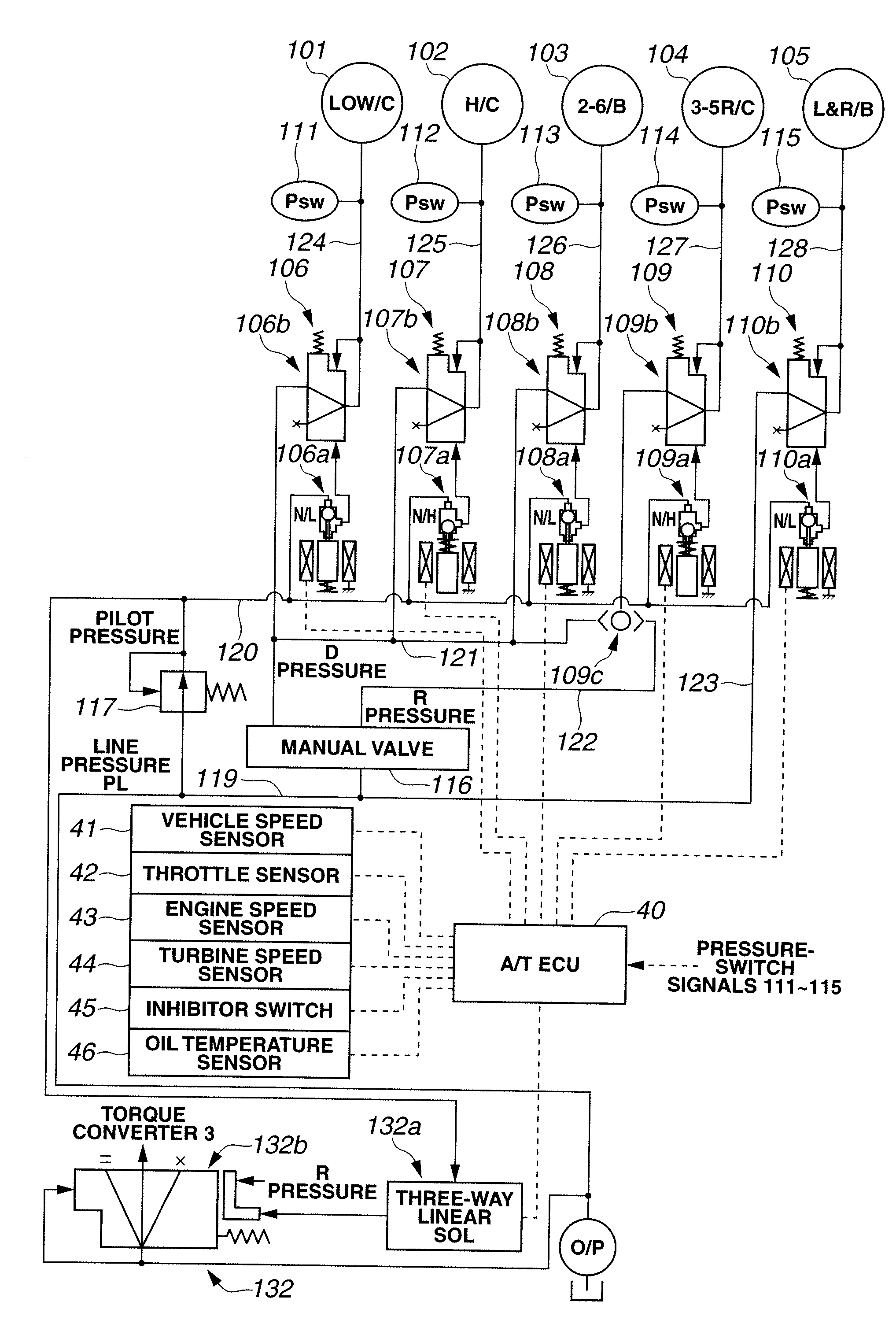

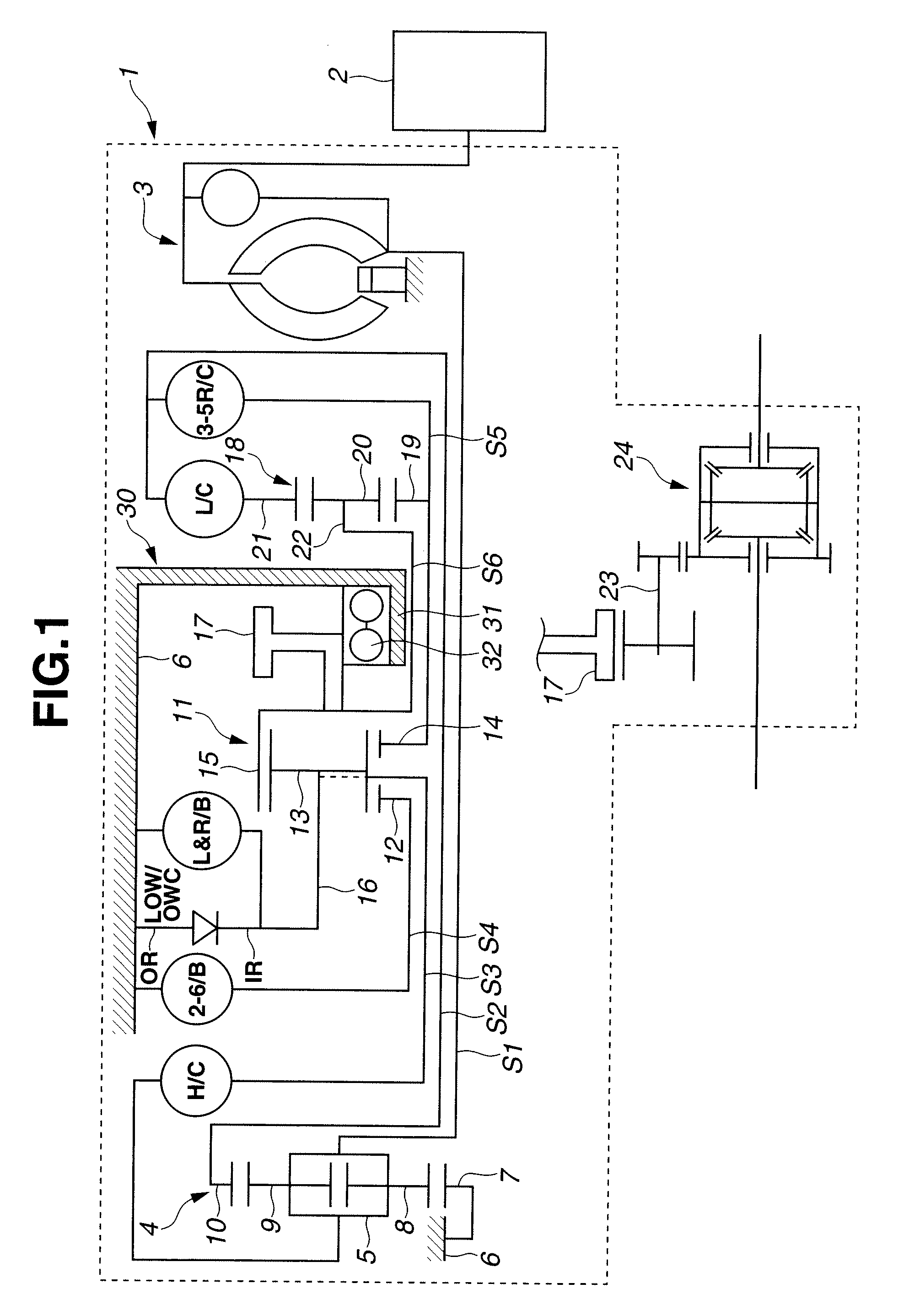

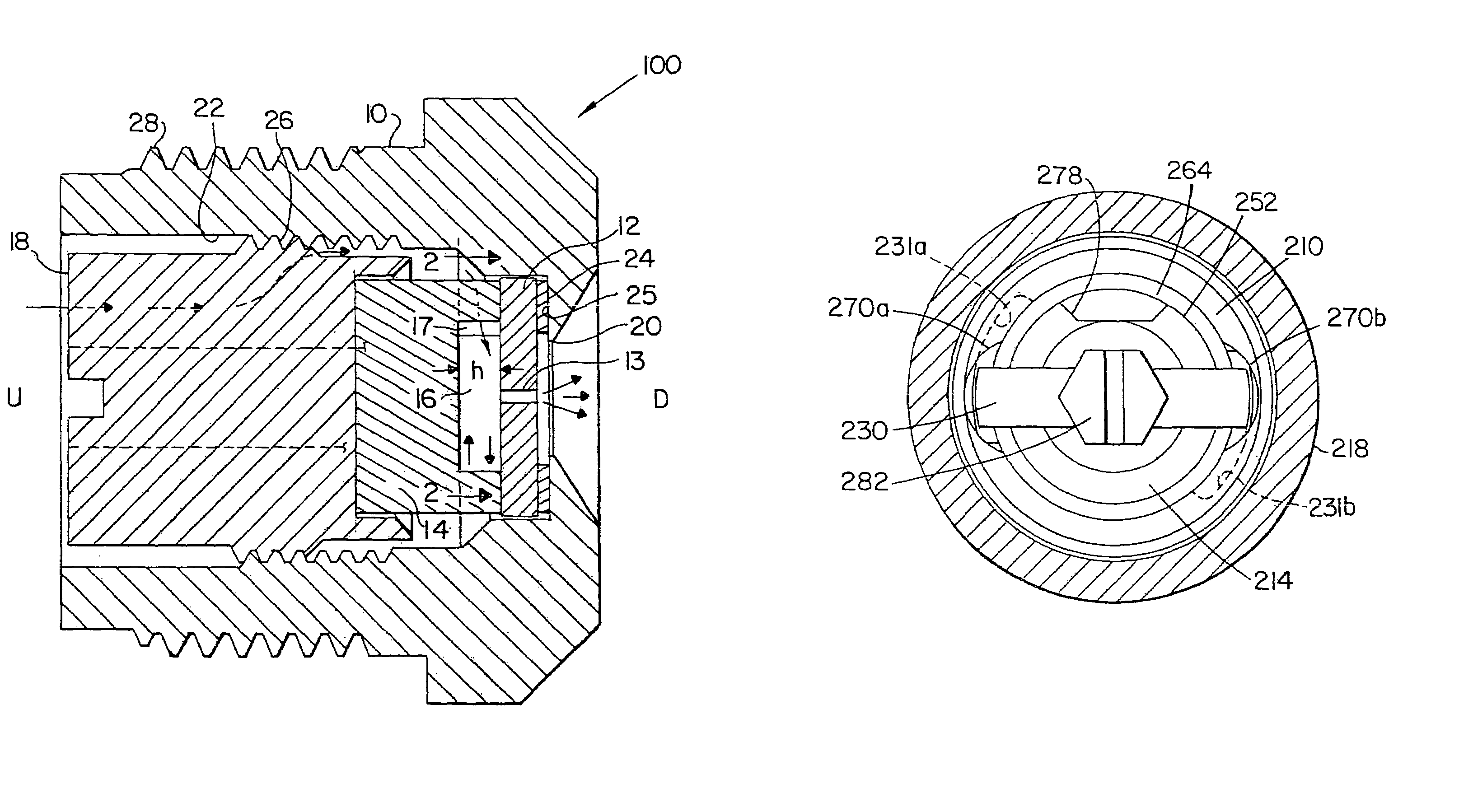

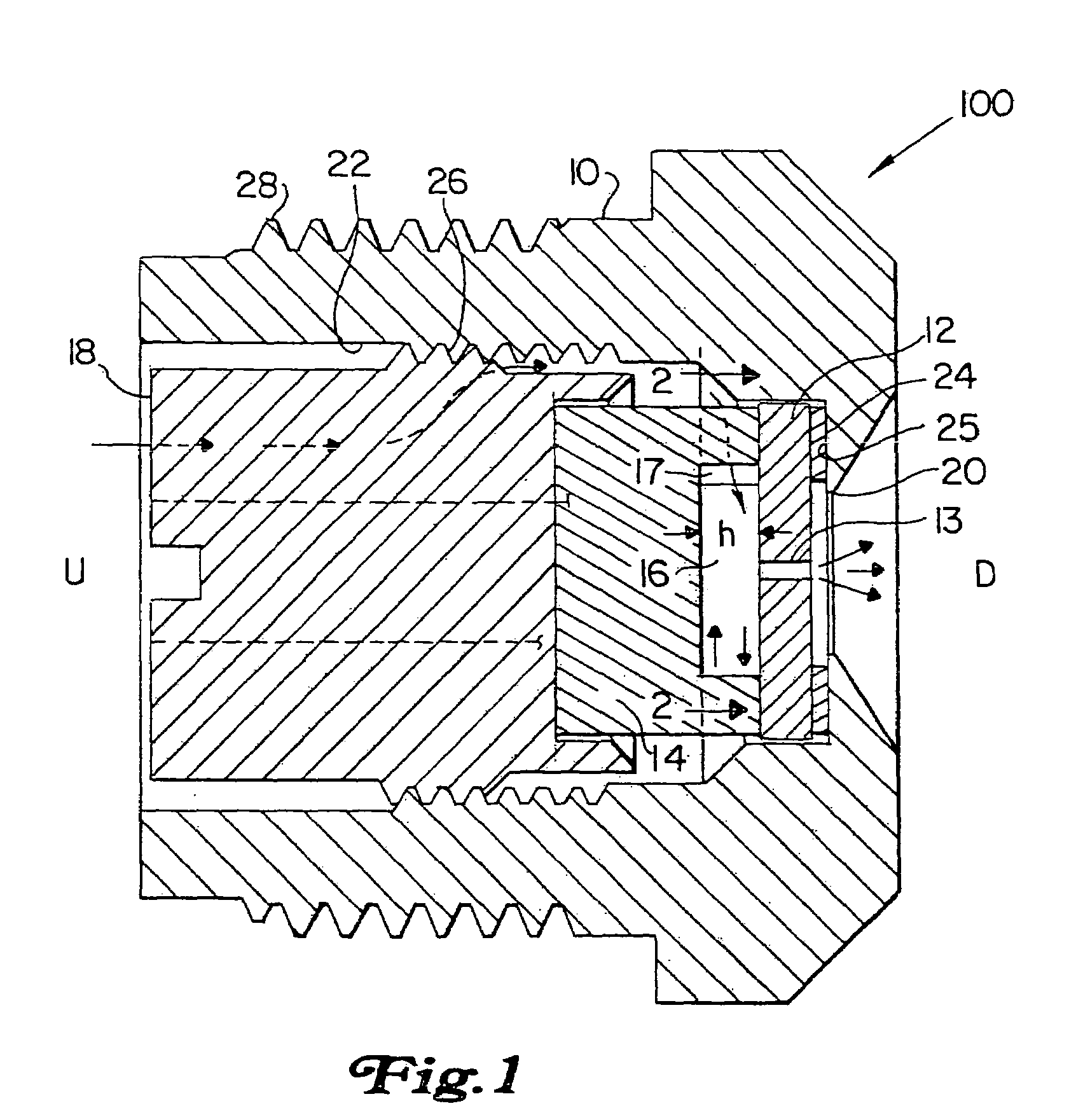

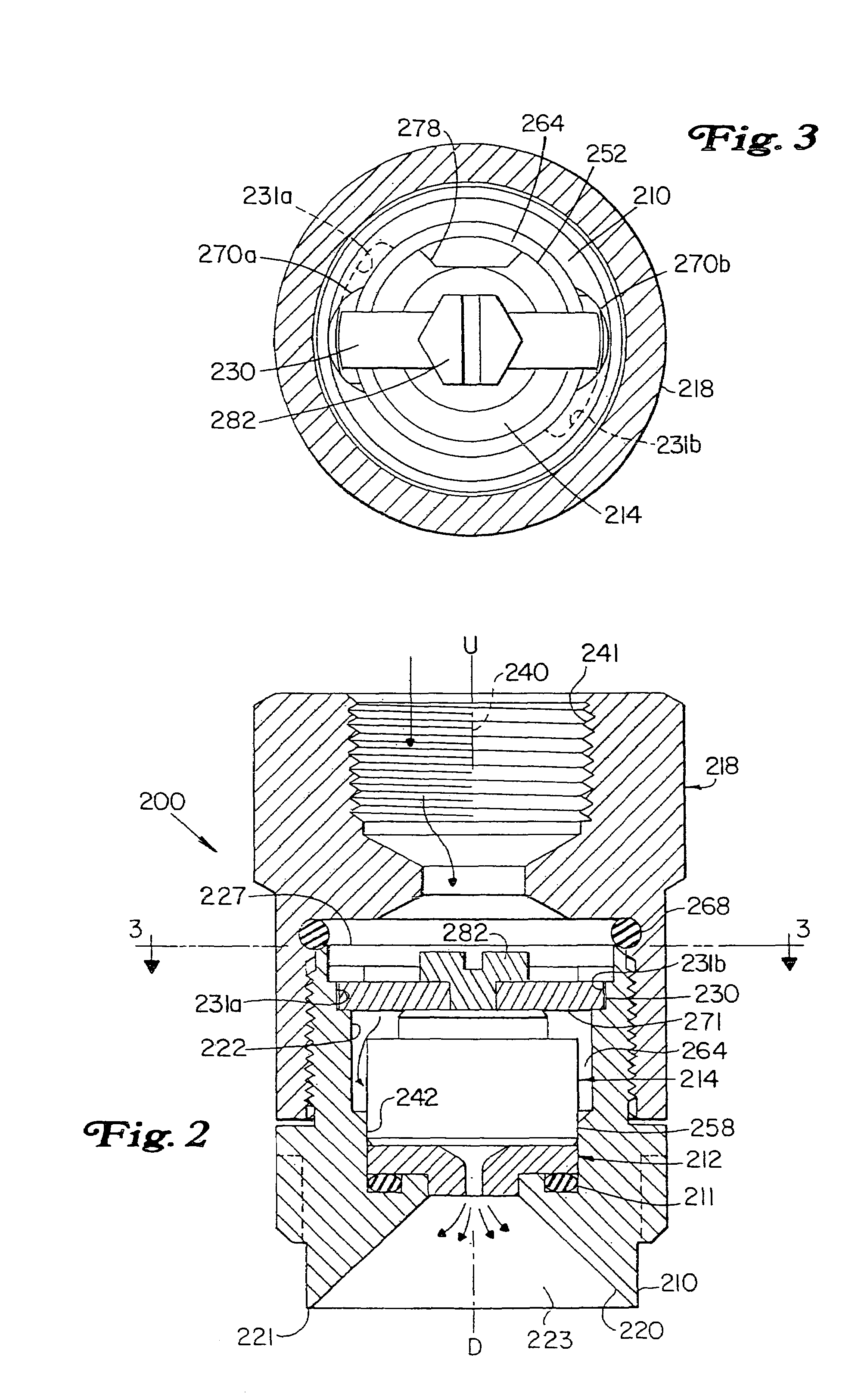

Hydraulic circuit for hybrid electric transmission

ActiveUS20130087225A1Little increase in axial lengthIncrease axial lengthServomotor componentsFluid dynamicsHydraulic circuitControl theory

A hydraulic circuit for a vehicle powertrain includes a first line for carrying fluid to a torque converter, a second line for carrying fluid from the torque converter, a third line for carrying fluid to a balance dam and an electric motor, and a fourth line for supplying actuating pressure to a clutch, said lines being coaxial.

Owner:FORD GLOBAL TECH LLC

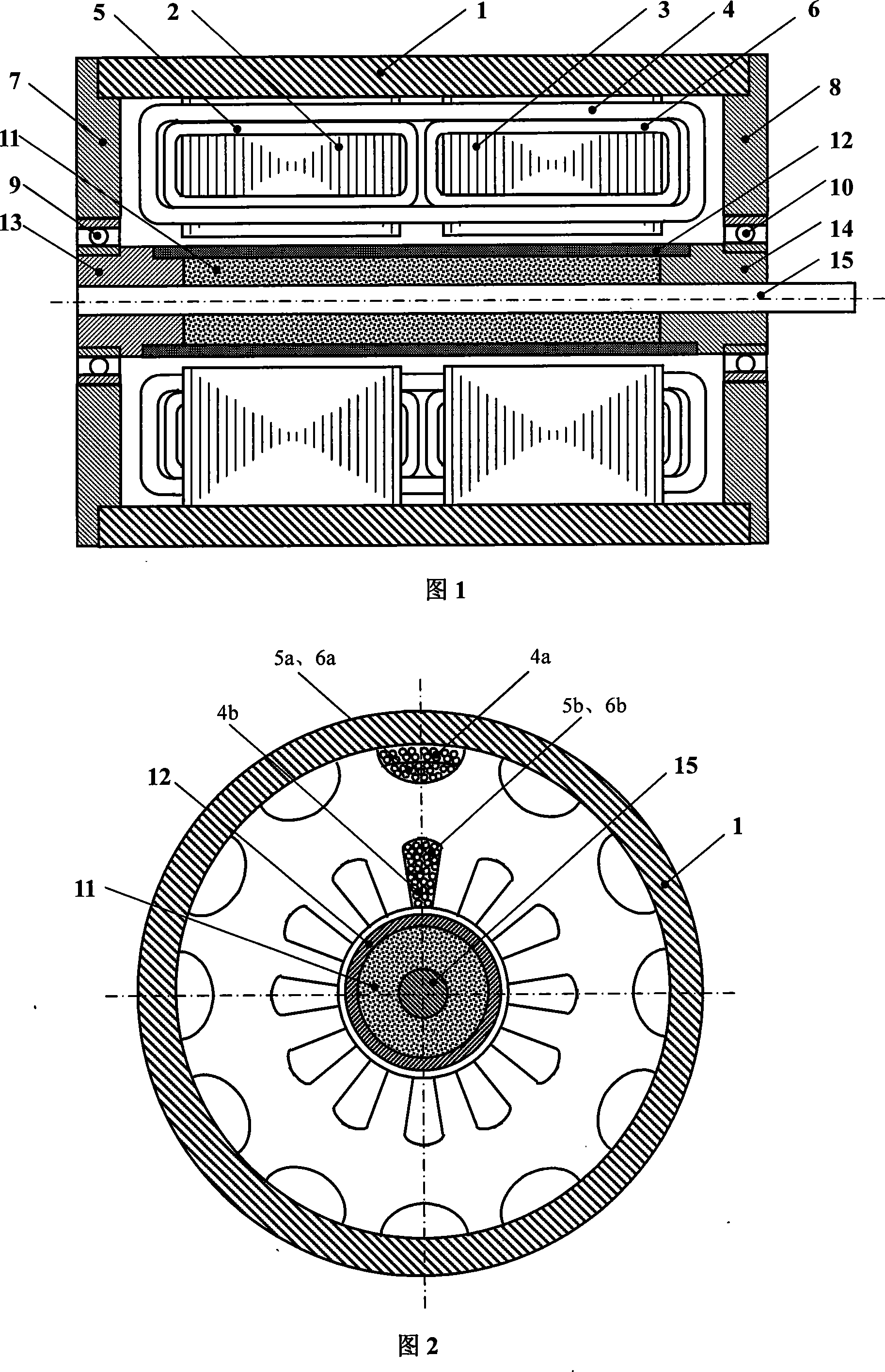

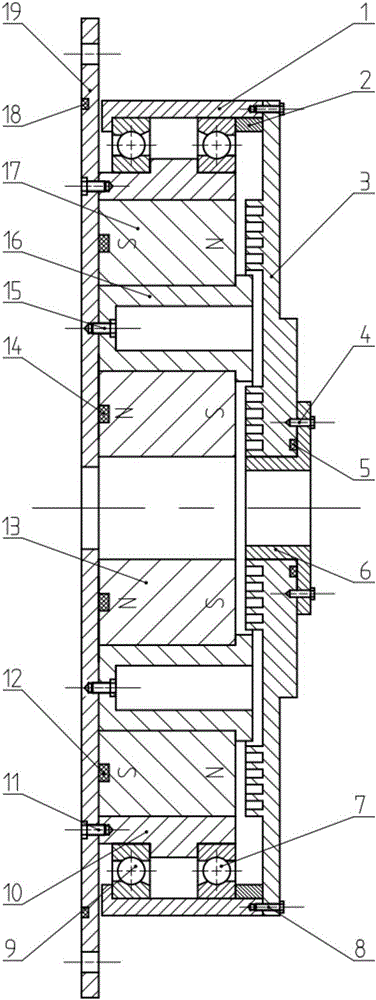

High speed magnetic suspension permanent magnet motor without bearing

InactiveCN101207309ASimple structureIncrease axial lengthMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorEngineering

The invention relates to a high-speed magnetic-suspension bearing-free permanent-magnetic machine, which comprises a shell, a stator core, a stator winding, a permanent-magnetic rotor, a rotating shaft, a left terminal cover, a right terminal cover, a left standby bearing and a right standby bearing. The stator core is divided into a right section and a left section and is provided with a groove that is used for holding the stator winding on the radial inner side and the radial outer side. The stator winding consists of a set of double-pole torque windings that are used for producing the electromagnetic torque and two sets of four-pole magnetic-suspension windings that are used for producing the rotor suspension force. The permanent-magnetic rotor consists of a permanent-magnet of a radial magnet-charging integral structure, a high-strength magnetic-conductive sheath and a fastening piece. The standby bearings are used for supporting the rotor when the high-speed motor is not powered on. The invention integrates the magnetic-suspension bearing and the permanent-magnetic machine, so that the stator and the rotor of the machine not only can produce the electromagnetic torque that drives the rotation of the motor, but also can produce the magnetic-suspension force that supports the weight of the rotor, thereby simplifying the structure of the machine, shortening the axial length of the machine, increasing the stiffness and the critical rotating speed of the rotor of the high-speed machine, and improving the stability of the operation.

Owner:SHENYANG POLYTECHNIC UNIV

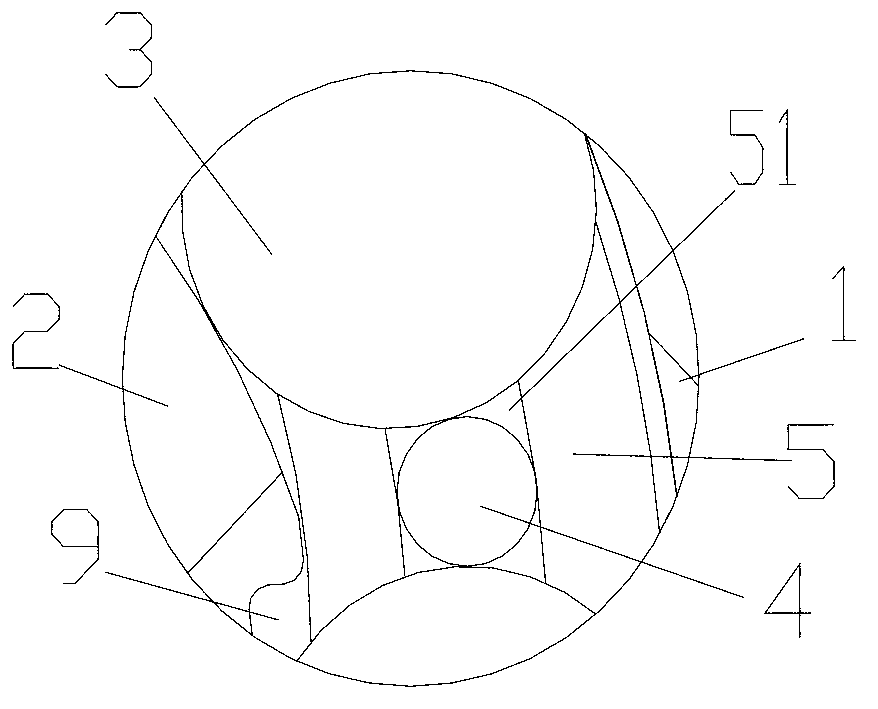

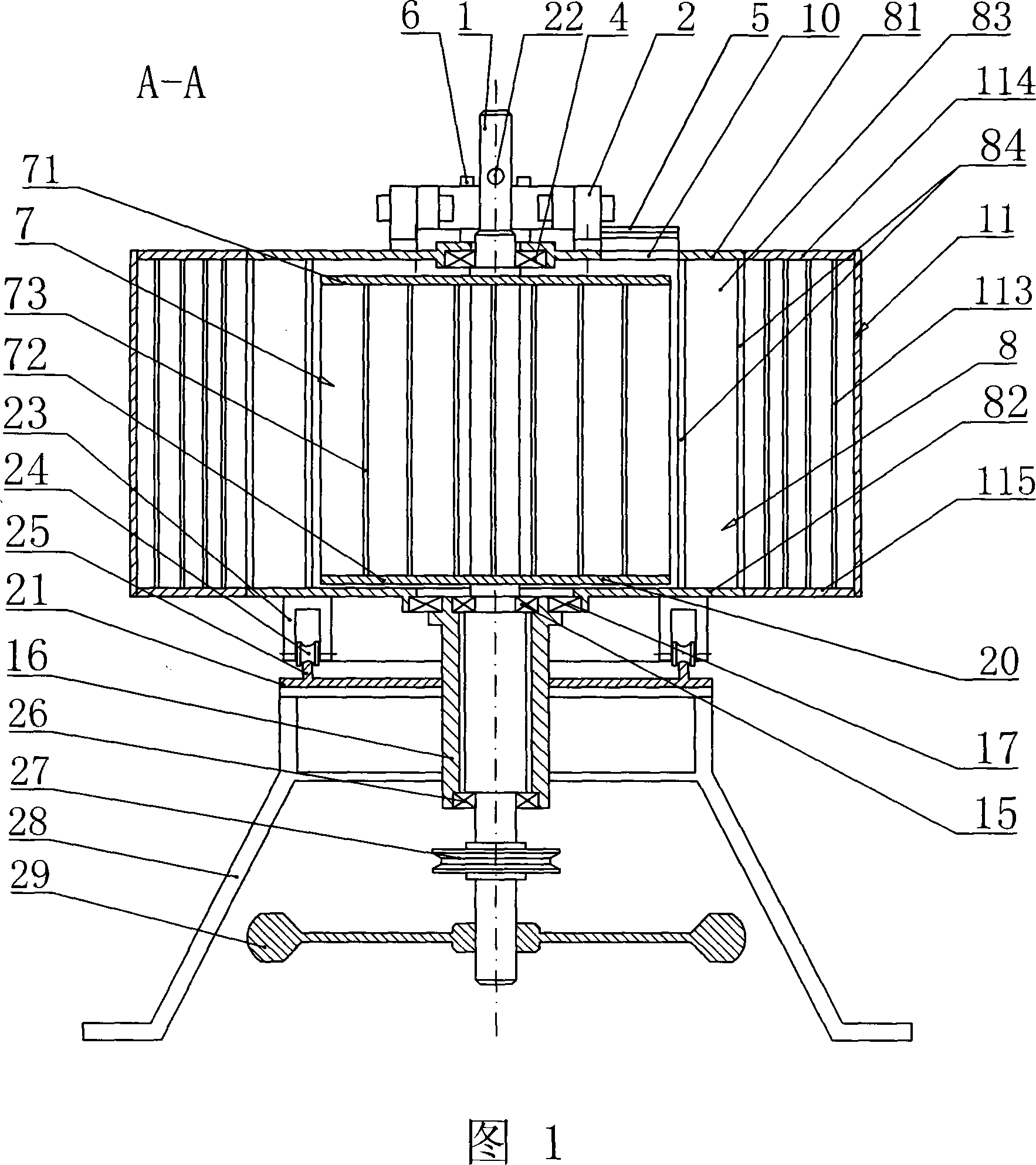

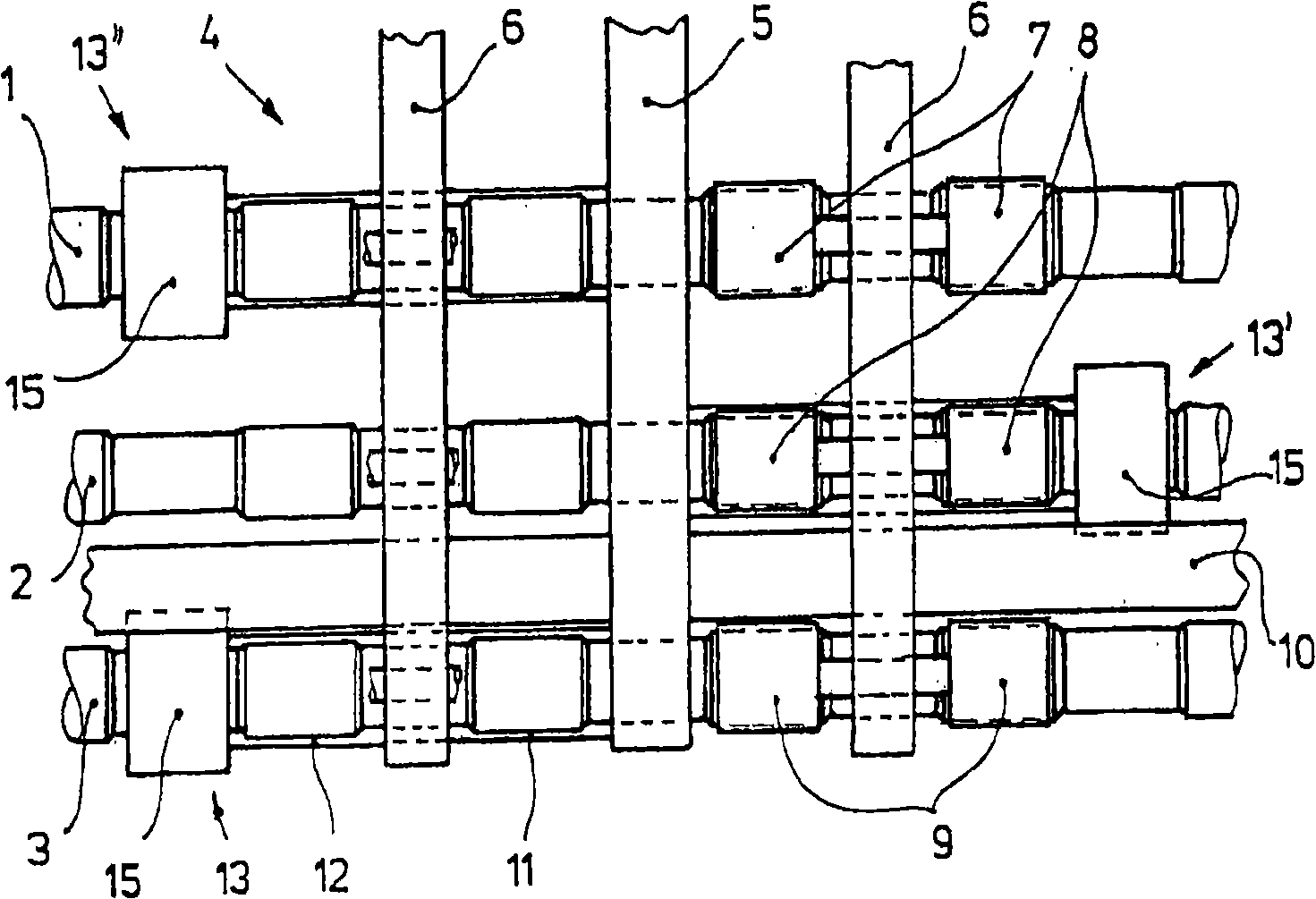

Heavy Duty Overrunning Clutch

The invention discloses a heavy-duty overrunning clutch, which comprises an outer ring, an inner ring, a plurality of rollers and a retaining frame. The retaining frame comprises a support ring I, a support ring II and a plurality of support columns corresponding to the rollers. Spring plates are fixedly arranged on the support columns along the axial direction and are used for applying pre-tightening force on the rollers along the engagement direction of an engagement slot. The direct processing of a limit seat on the outer ring can be avoided, the working efficiency can be increased, the processing cost can be reduced, the service life can be prolonged, and the transmission effect can be guaranteed. Moreover, relevant components can be replaced easily after being damaged, the outer ringneeds not to be rejected as a whole, and the cost of maintenance and use can be reduced. The axial length of the overrunning clutch and the rollers can be increased theoretically indefinitely, the engagement length can be increased, and thus the bearing capacity of the overrunning clutch can be improved. Meanwhile, the pre-tightening force can be applied at multiple points of the rollers according to needs, and the limiting balance for the rollers can be guaranteed while the axial length is ensured, so that the rollers cannot deviate from the axial line of the inner ring. Therefore, the stable operation of the overrunning clutch can be ensured, and mechanical failure can be avoided.

Owner:SOUTHWEST UNIVERSITY

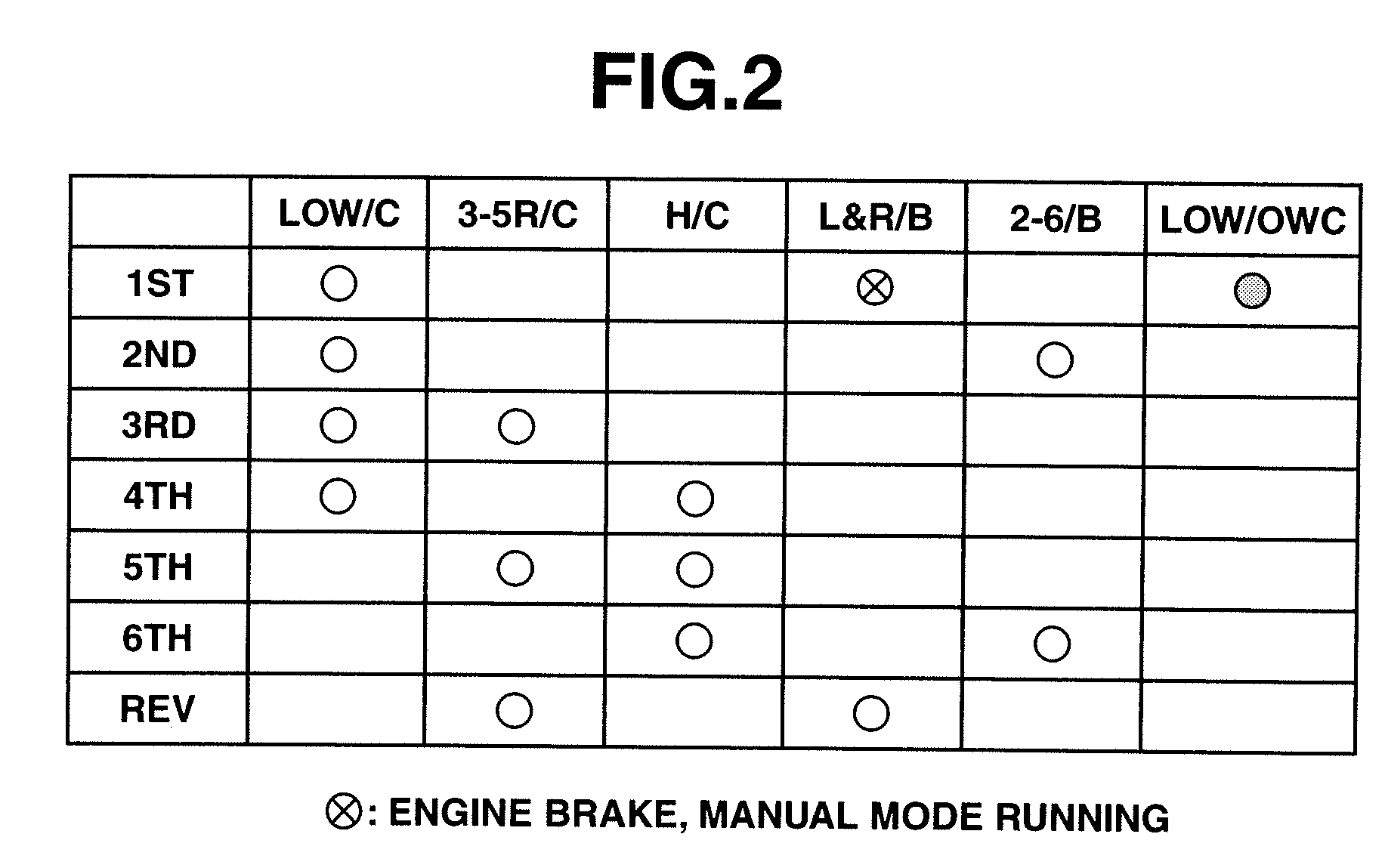

System and method of controlling automatic transmission

ActiveUS20080076632A1Increased torque capacityImprove braking effectDigital data processing detailsToothed gearingsAutomatic transmissionEngineering

In system and method of controlling an automatic transmission that includes a lowest gear-stage friction element and has a lowest gear stage having a largest gear ratio and a gear stage other than the lowest gear stage, the lowest gear stage being established through engagement of the lowest gear-stage friction element, the gear stage other than the lowest gear stage being established while the lowest gear-stage friction element is kept in disengagement, a temperature of working oil in the automatic transmission is sensed, and use of the lowest gear stage is inhibited and use of the gear stage other than the lowest gear stage is allowed when the sensed temperature of the working oil is lower than a first predetermined temperature as a predetermined extremely low temperature at which an engagement failure of the lowest gear-stage friction element is caused.

Owner:JATCO LTD +1

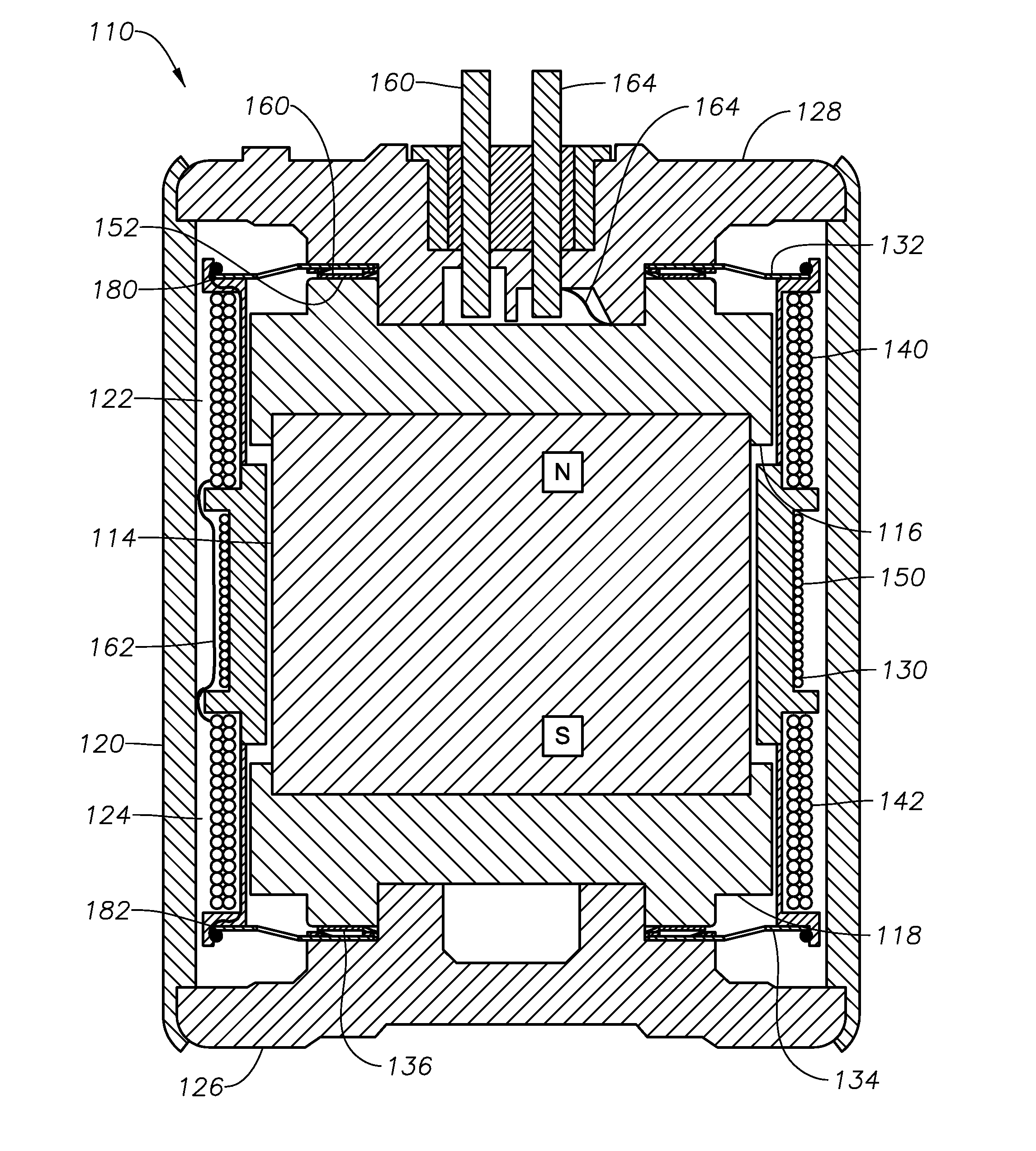

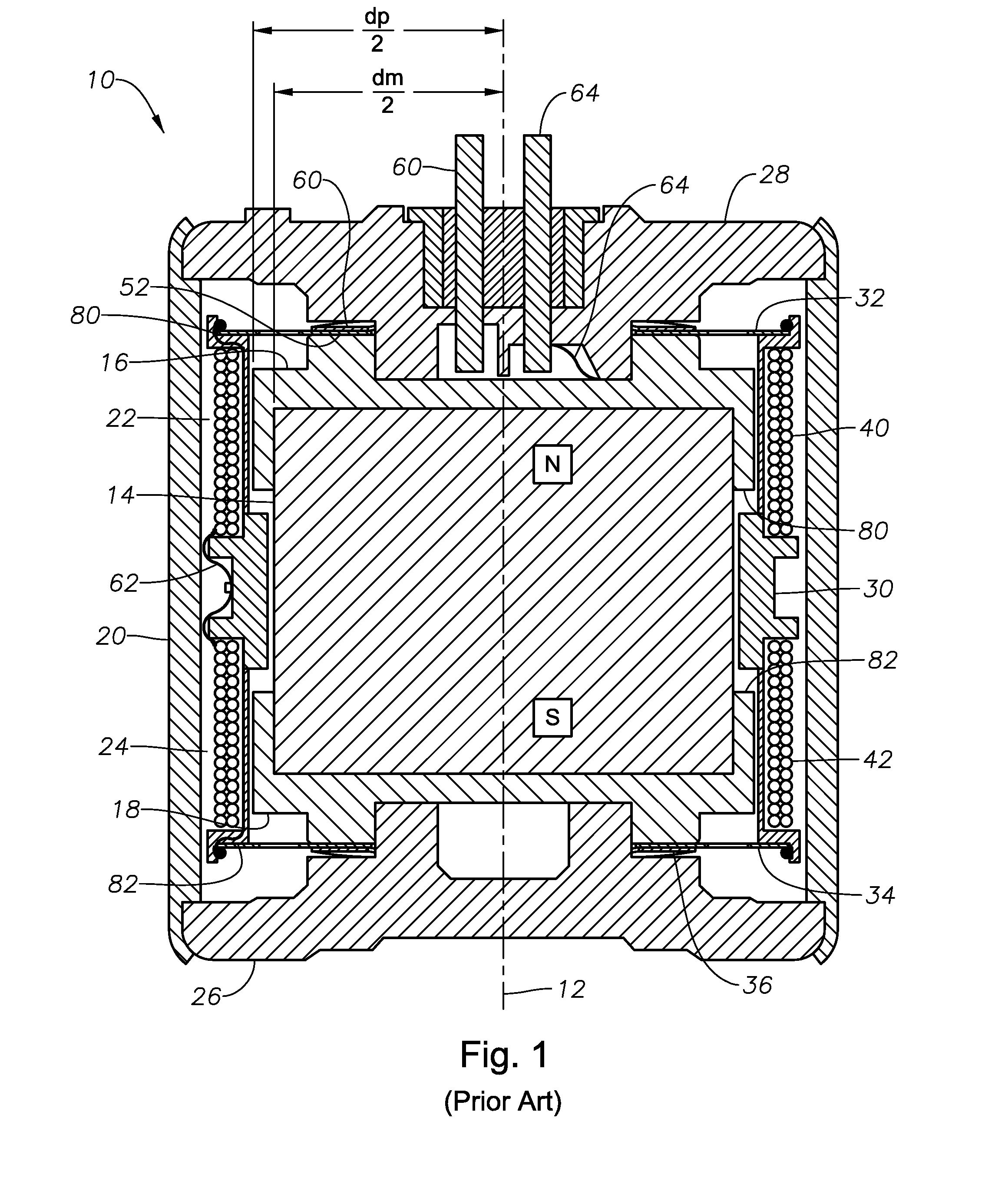

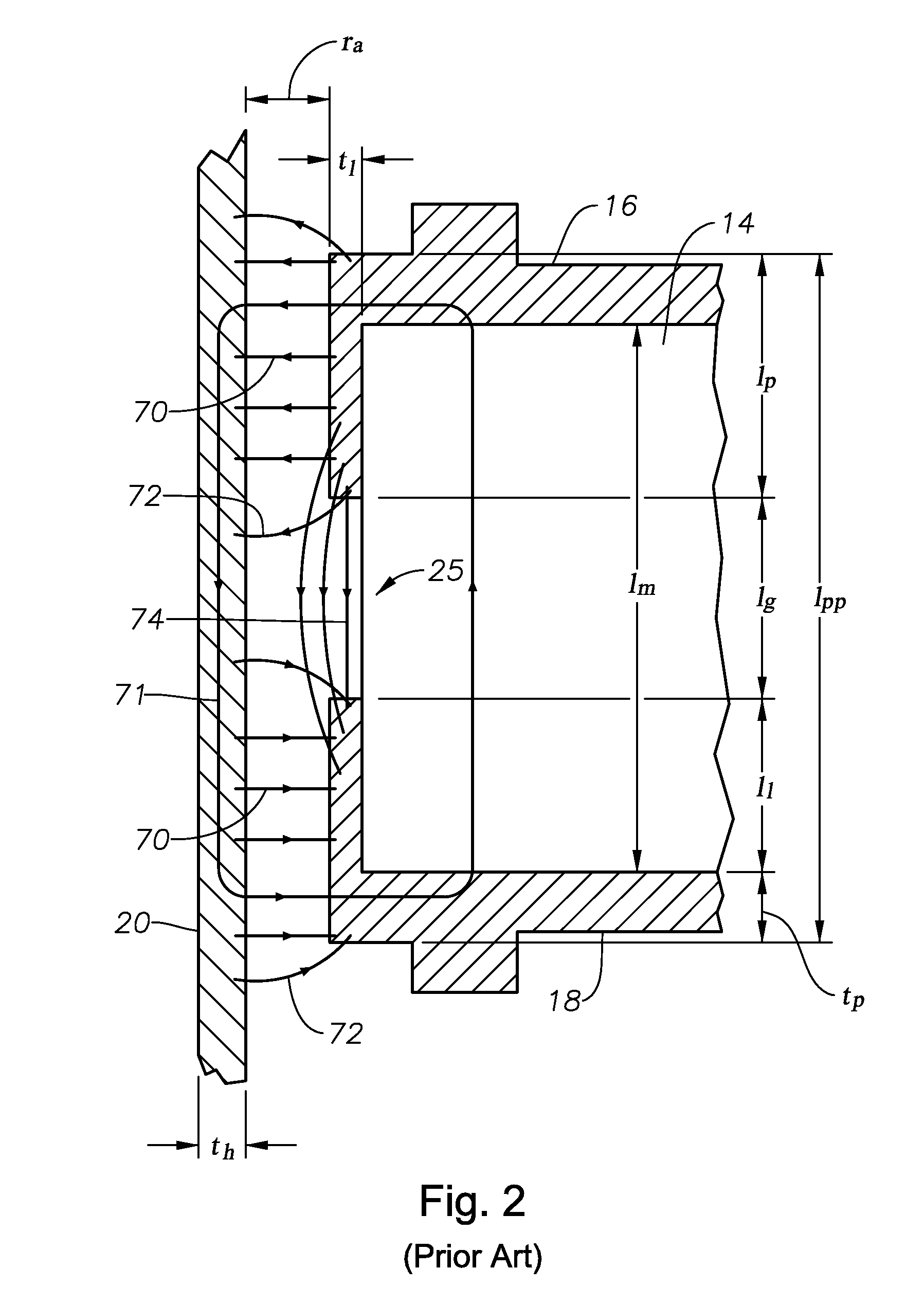

Vertical geophone having improved distortion characteristics

ActiveUS20110007609A1Minimize geophone distortionSimplifies tuningElectrical transducersSeismologyGeophoneEngineering

A vertical geophone that includes a lower frequency spring, which forms part of the geophone electrical circuit, that is positioned directly on the lower end cap This arrangement eliminates the “spring supported by a spring” arrangement of prior art geophones to minimize geophone distortion and simplify tuning of the frequency springs. A contact spring is positioned between the lower frequency spring and the lower pole piece for forming part of the geophone electrical circuit. One surface of contact spring includes a plurality of wiper surfaces that ensure consistent sliding electrical contact against either the bottom surface of the lower pole piece or the upper surface of the lower frequency spring. The obverse surface of the contact spring is preferably spot welded to the other adjacent member.

Owner:GEOSPACE TECH

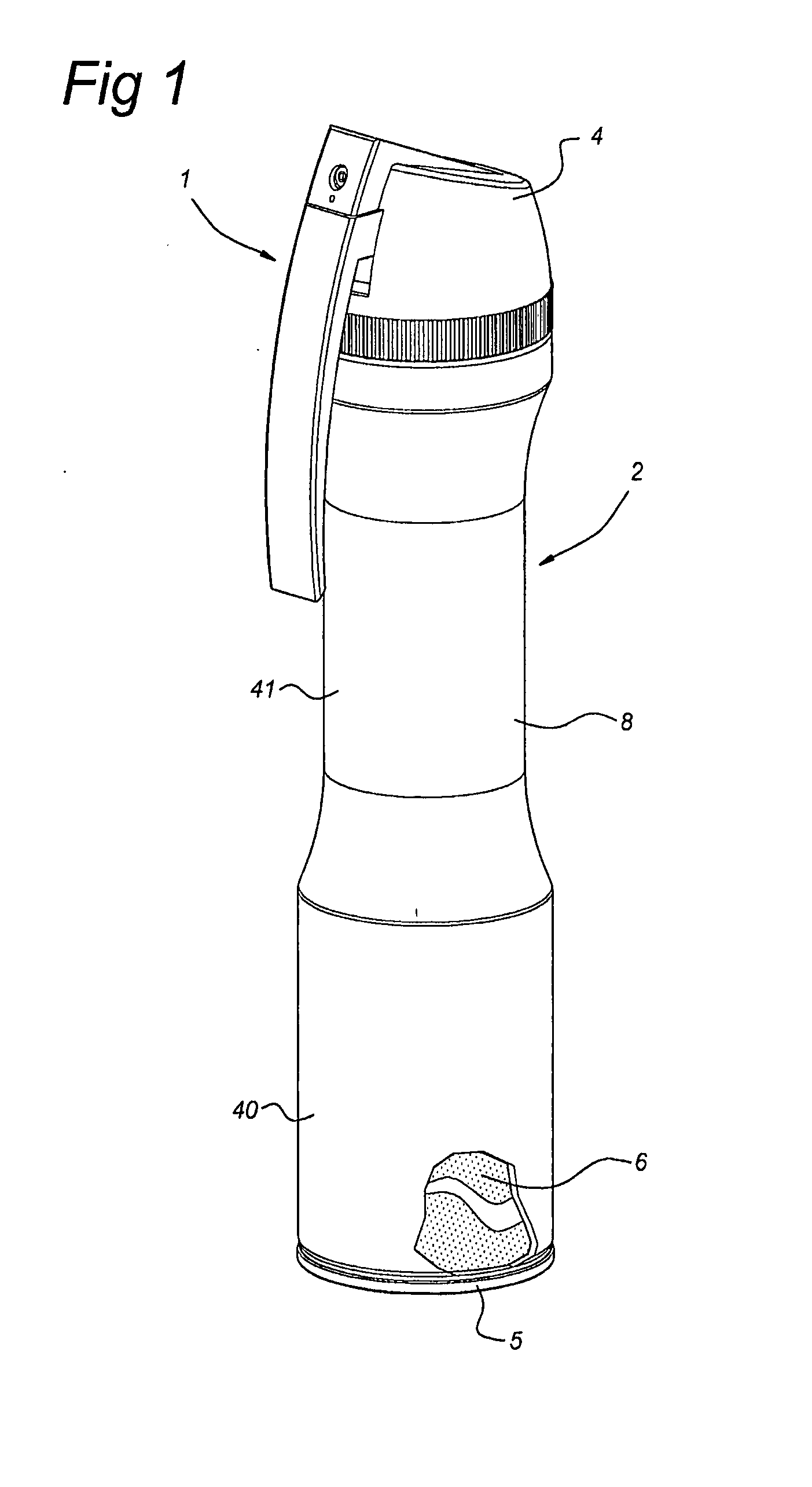

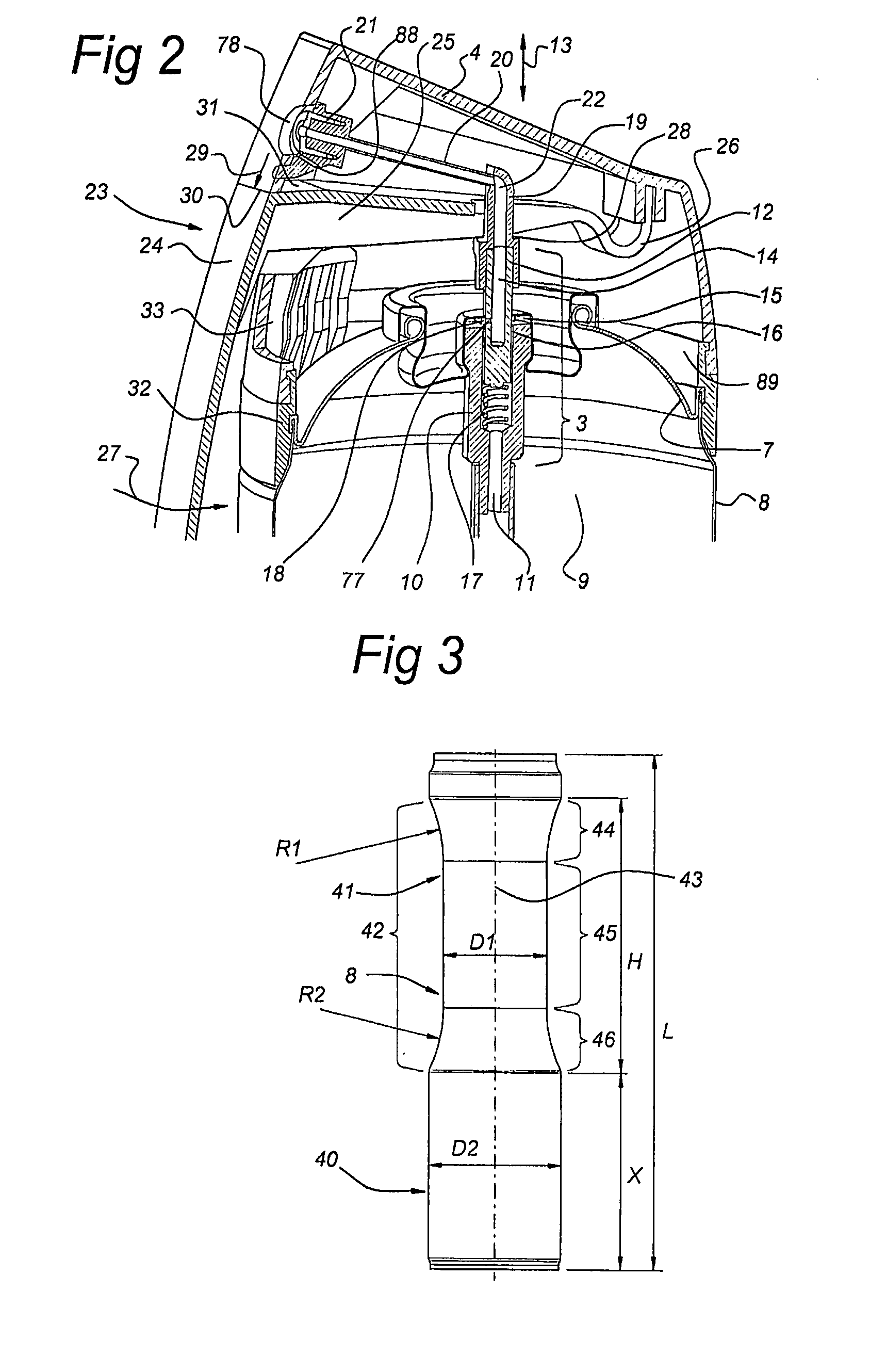

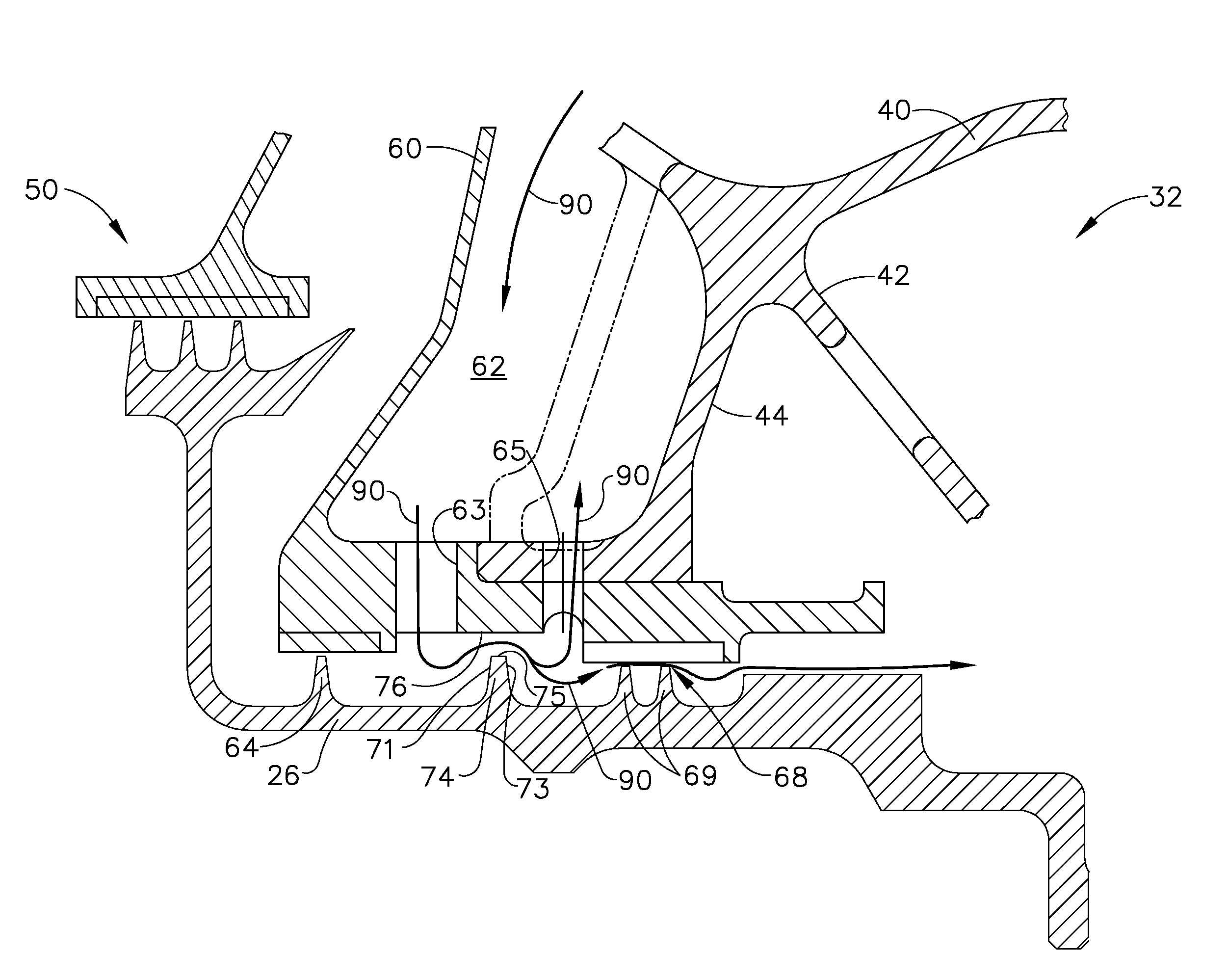

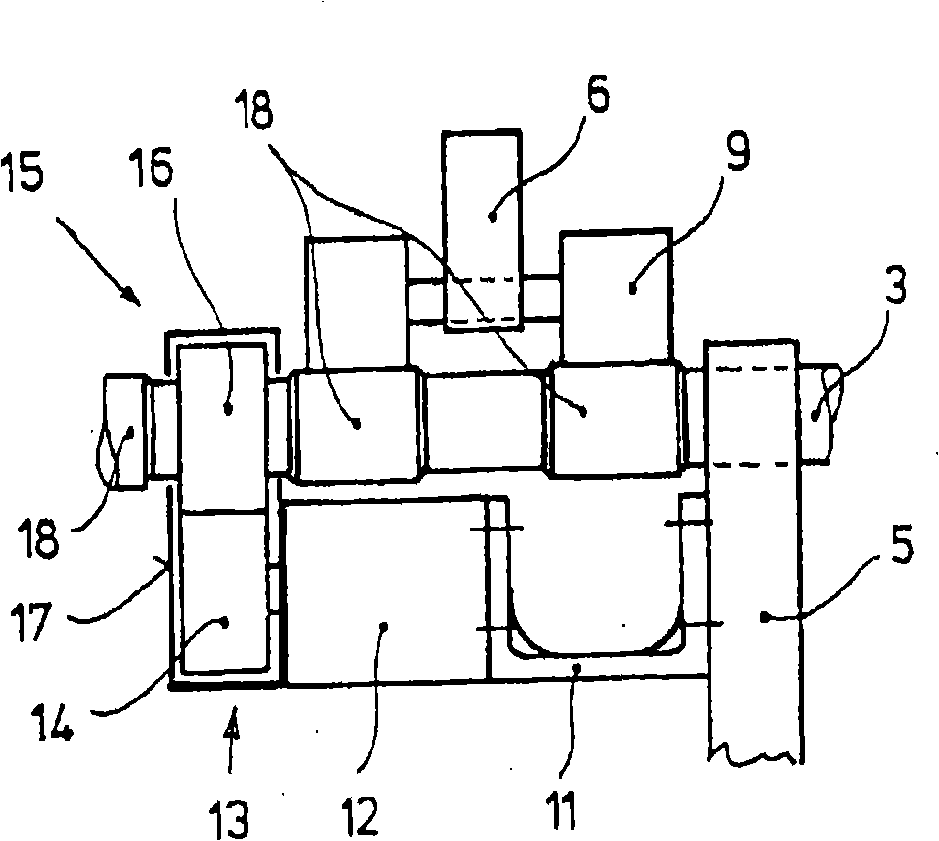

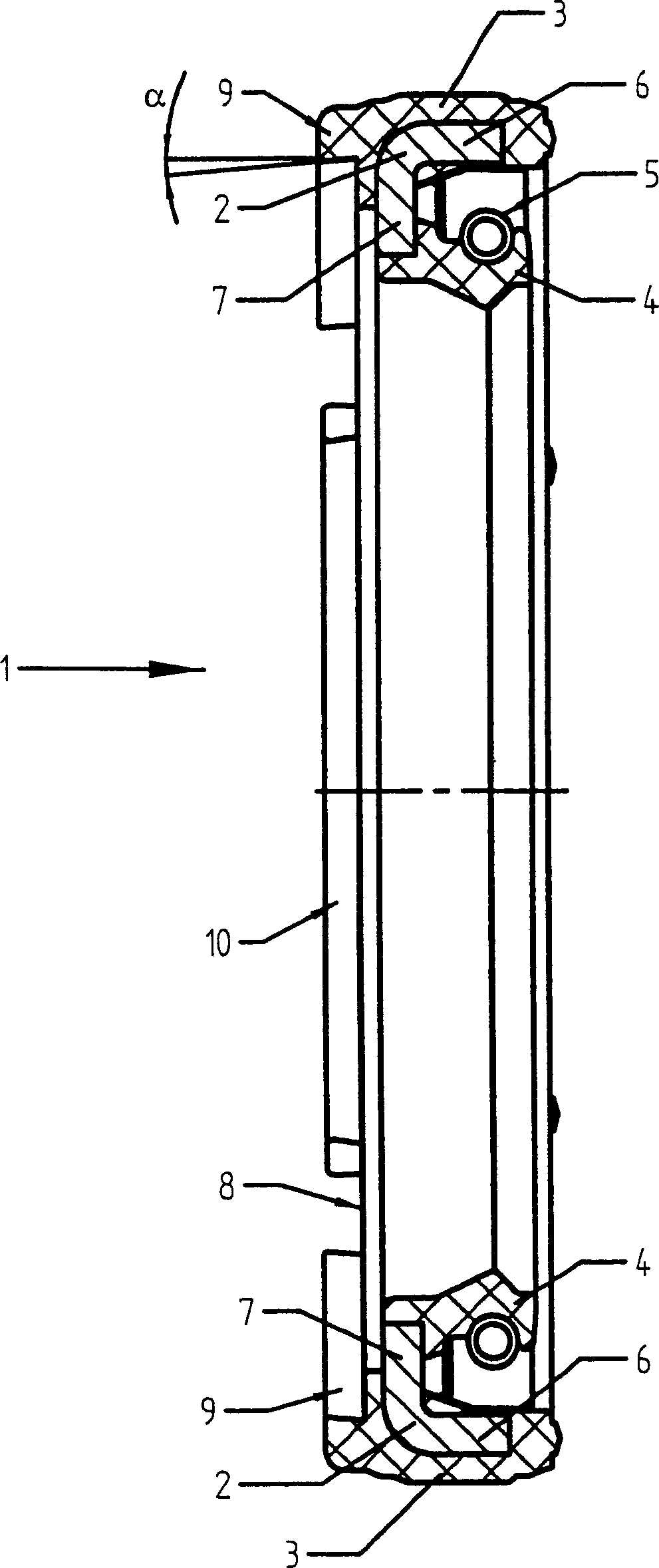

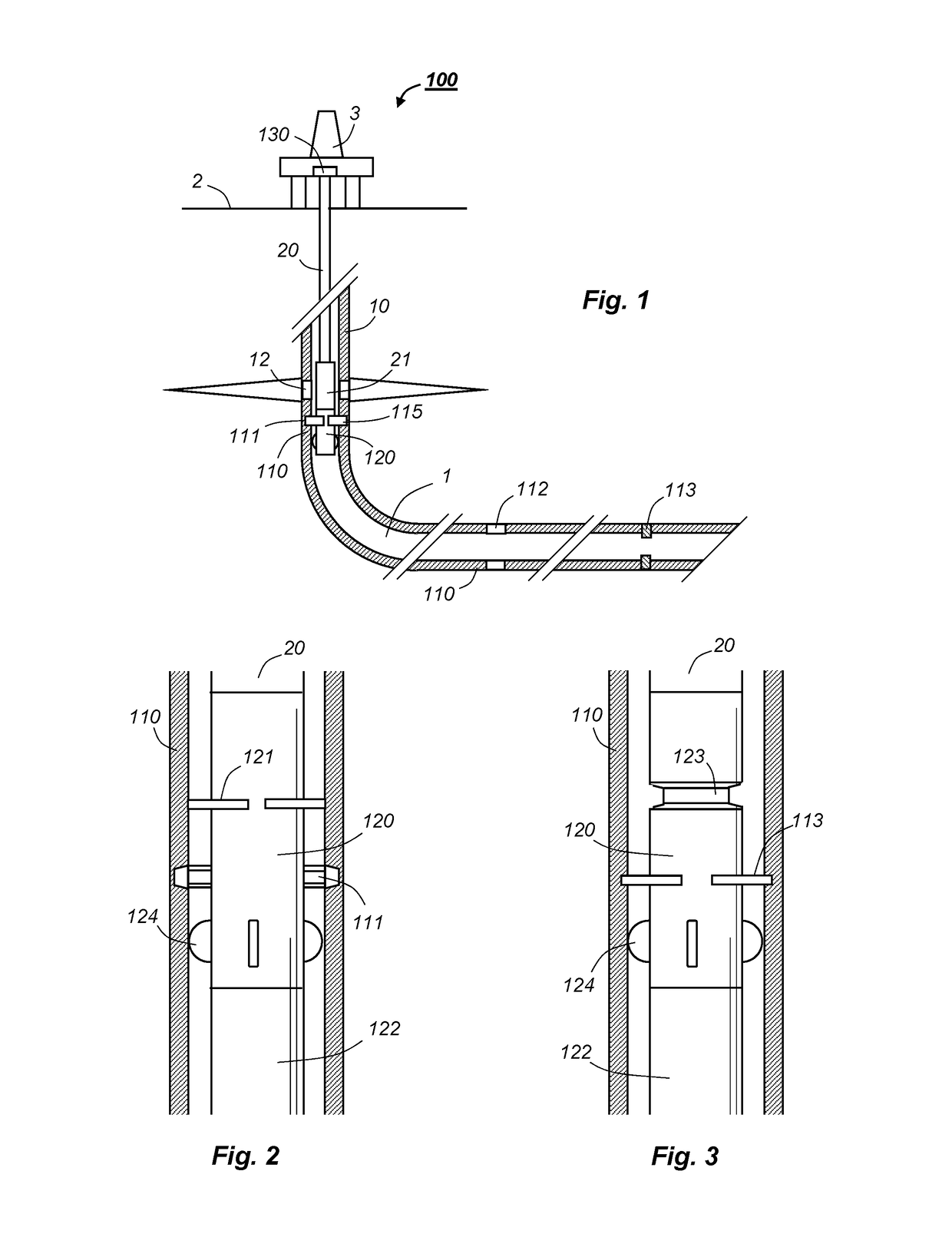

Dispensing device for dispensing a product

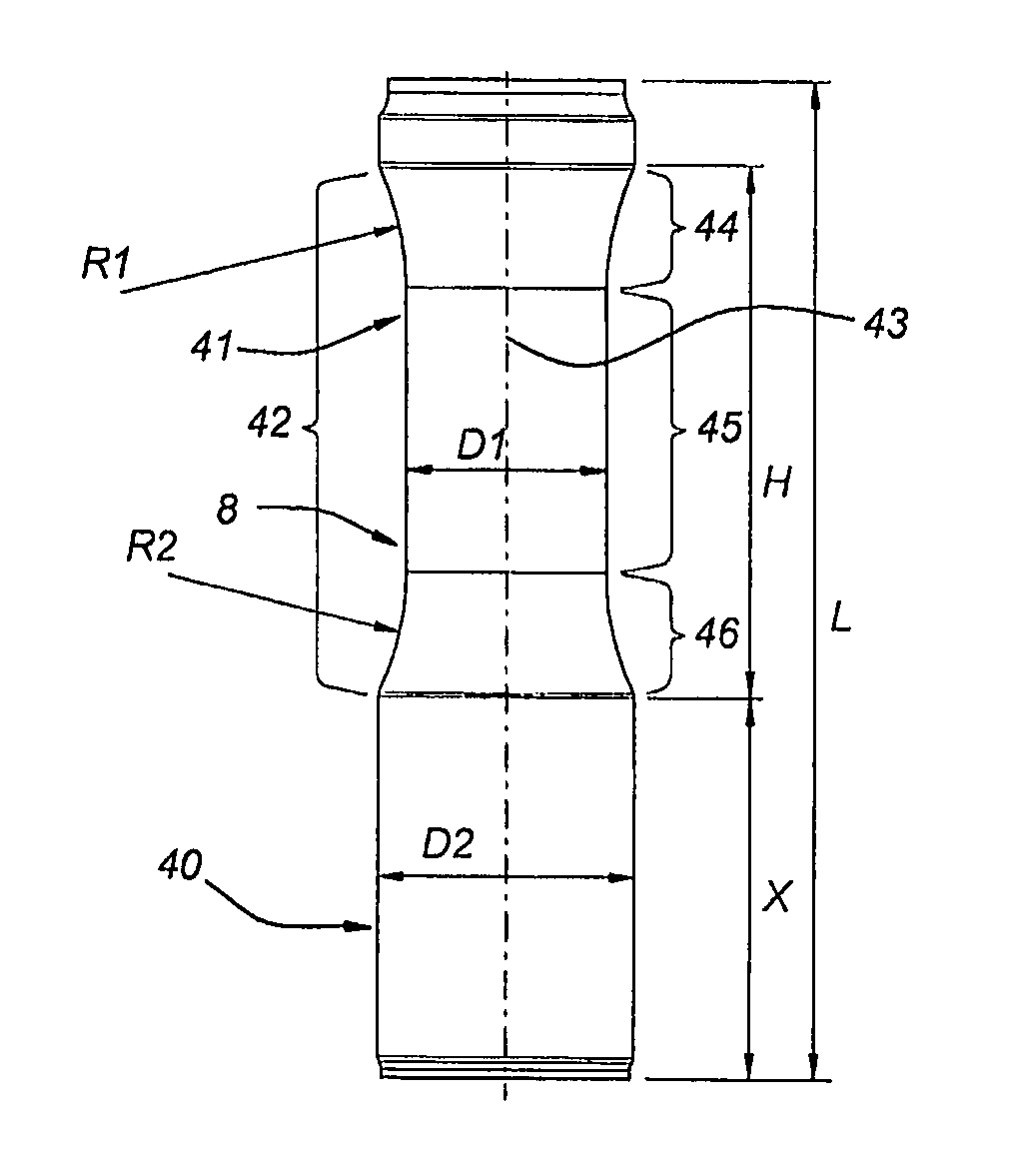

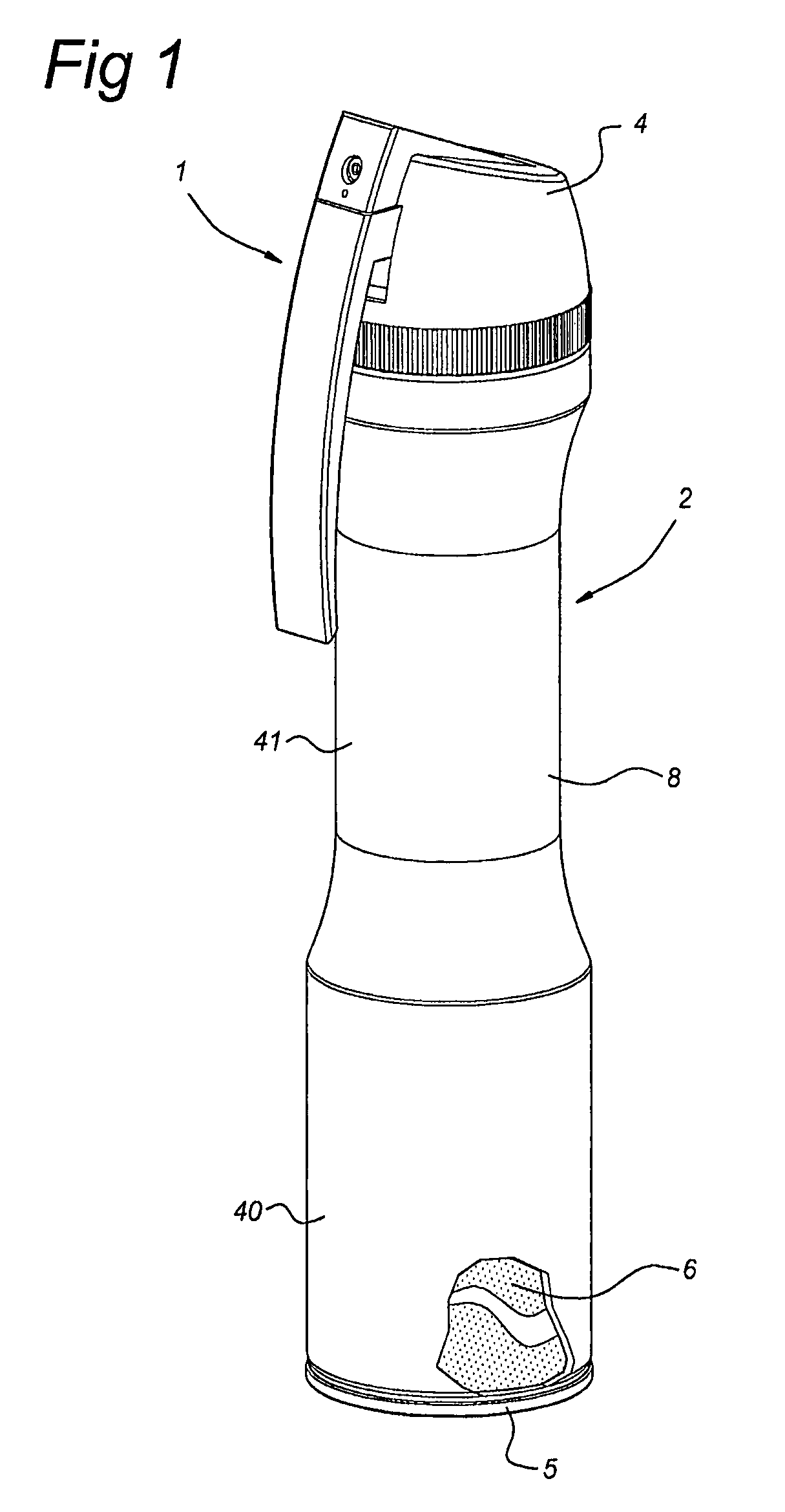

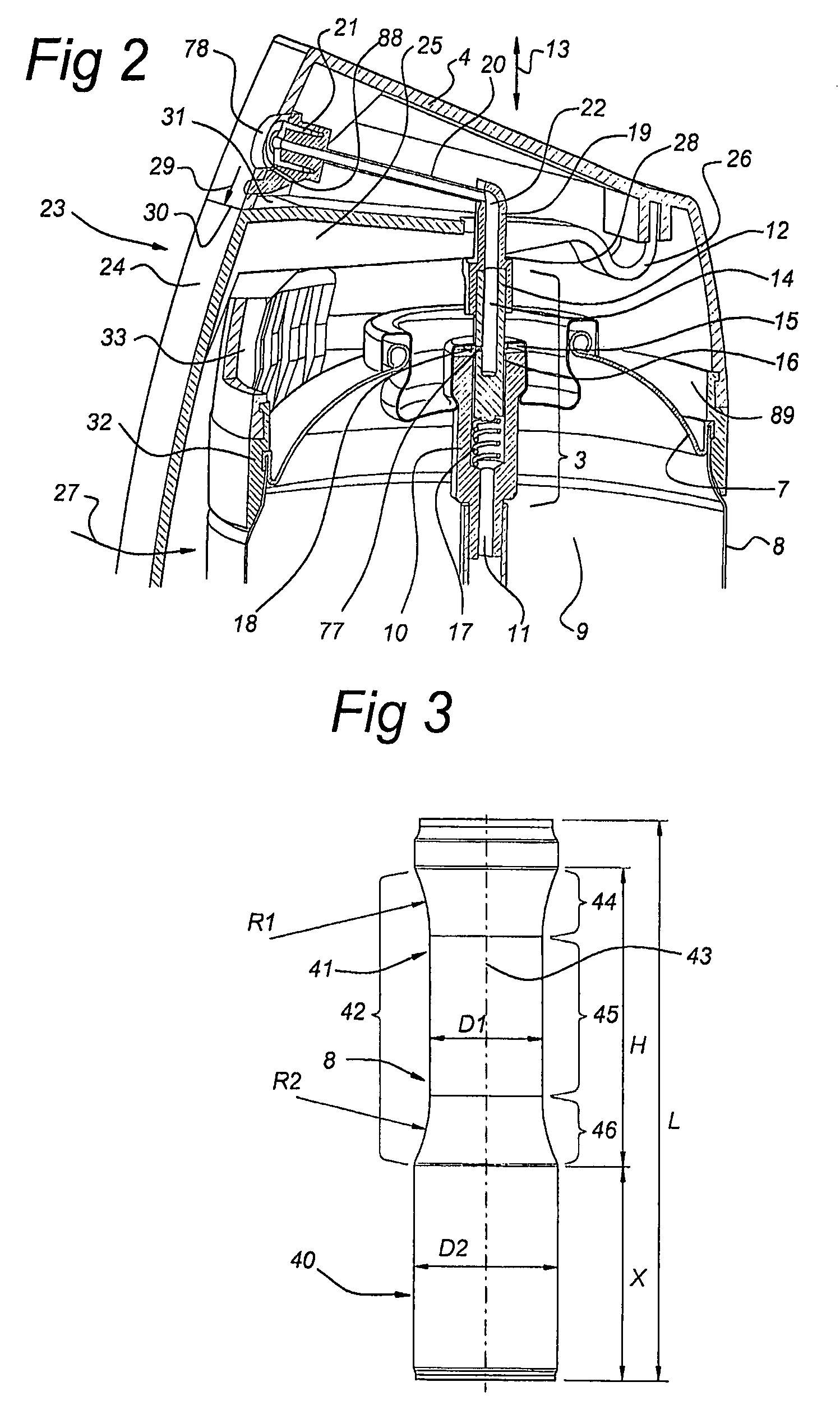

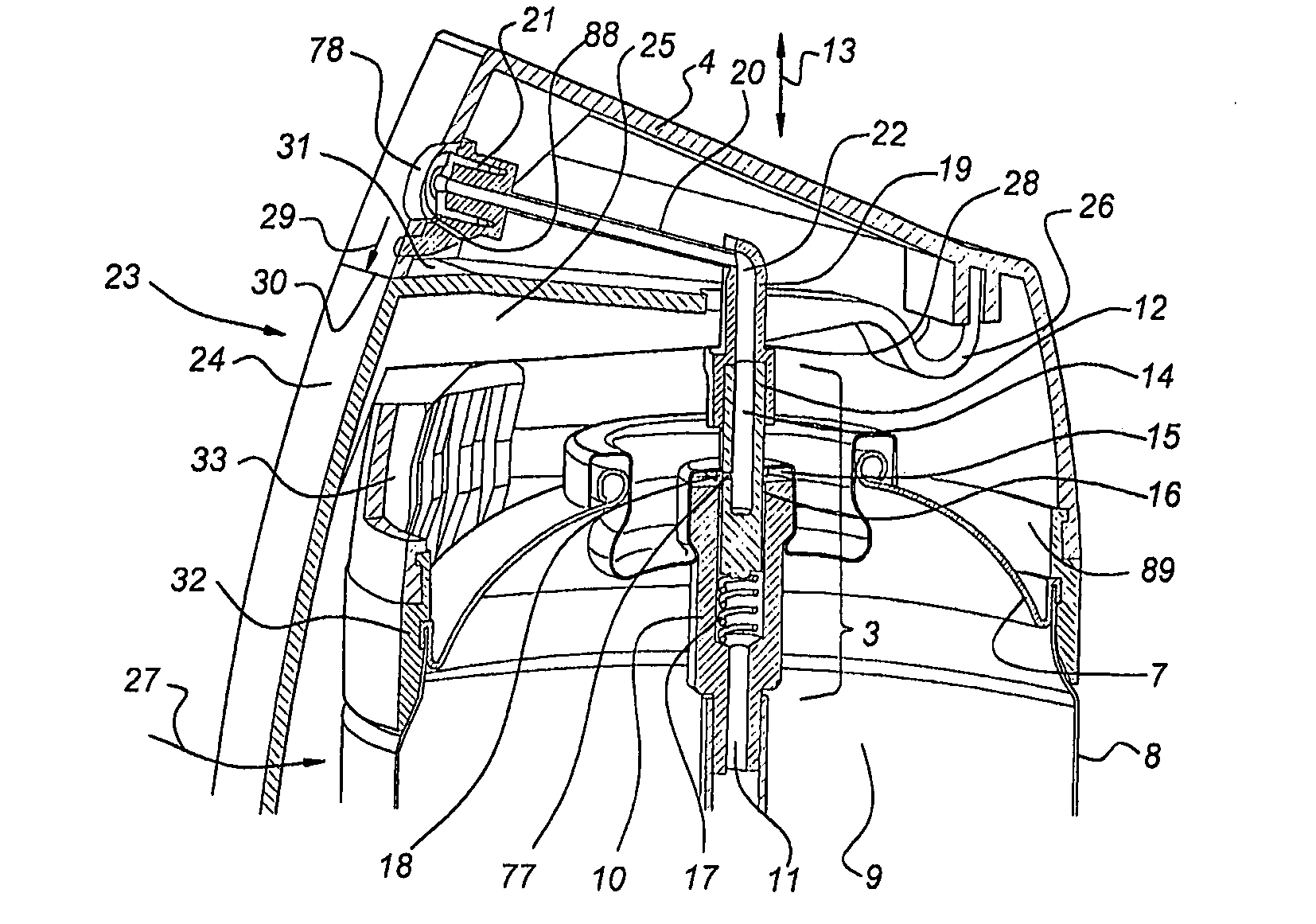

InactiveUS7959040B2Increase axial lengthImprove stabilityLiquid transferring devicesLiquid dispensingEngineeringGuide tube

The invention relates to a dispensing device (1) for dispensing a product. The dispensing device comprises: a container (2) containing the product under pressure, the container having a top (7), bottom (5) and body portion (8), an axial direction being defined between the bottom and top; a valve mechanism (3) mounted at the top of the container, the valve mechanism being movable with respect to the container for pressurized discharge of the product out of the container; and a dispensing cap (4) mounted on the top of the container. The dispensing cap carries: a nozzle (21) debouching outside the cap for spraying the product, the nozzle being connected to the valve mechanism by a conduit; and art actuating member (23) having a horizontal arm (25) and a vertical arm (24). The horizontal arm is hingedly suspended in the cap and engages the valve mechanism to actuate the valve mechanism upon pulling the vertical arm towards the container portion. The body portion of the container has a lower portion (40) and an upper portion (41) providing a one-band grip (42). The vertical arm is arranged to be engageable by at least one finger of a hand gripping the one-band grip. The one-hand grip is constricted in its circumference with respect to the lower portion.

Owner:RUST OLEUM NETHERLANDS

Dispensing Device for Dispensing a Product

InactiveUS20080190968A1Precise aimingAvoid contactLiquid transferring devicesLiquid dispensingEngineeringGuide tube

The invention relates to a dispensing device (1) for dispensing a product. The dispensing device comprises: a container (2) containing the product under pressure, the container having a top (7), bottom (5) and body portion (8), an axial direction being defined between the bottom and top; a valve mechanism (3) mounted at the top of the container, the valve mechanism being movable with respect to the container for pressurized discharge of the product out of the container; and a dispensing cap (4) mounted on the top of the container. The dispensing cap carries: a nozzle (21) debouching outside the cap for spraying the product, the nozzle being connected to the valve mechanism by a conduit; and art actuating member (23) having a horizontal arm (25) and a vertical arm (24). The horizontal arm is hingedly suspended in the cap and engages the valve mechanism to actuate the valve mechanism upon pulling the vertical arm towards the container portion. The body portion of the container has a lower portion (40) and an upper portion (41) providing a one-band grip (42). The vertical arm is arranged to be engageable by at least one finger of a hand gripping the one-band grip. The one-hand grip is constricted in its circumference with respect to the lower portion.

Owner:RUST OLEUM NETHERLANDS

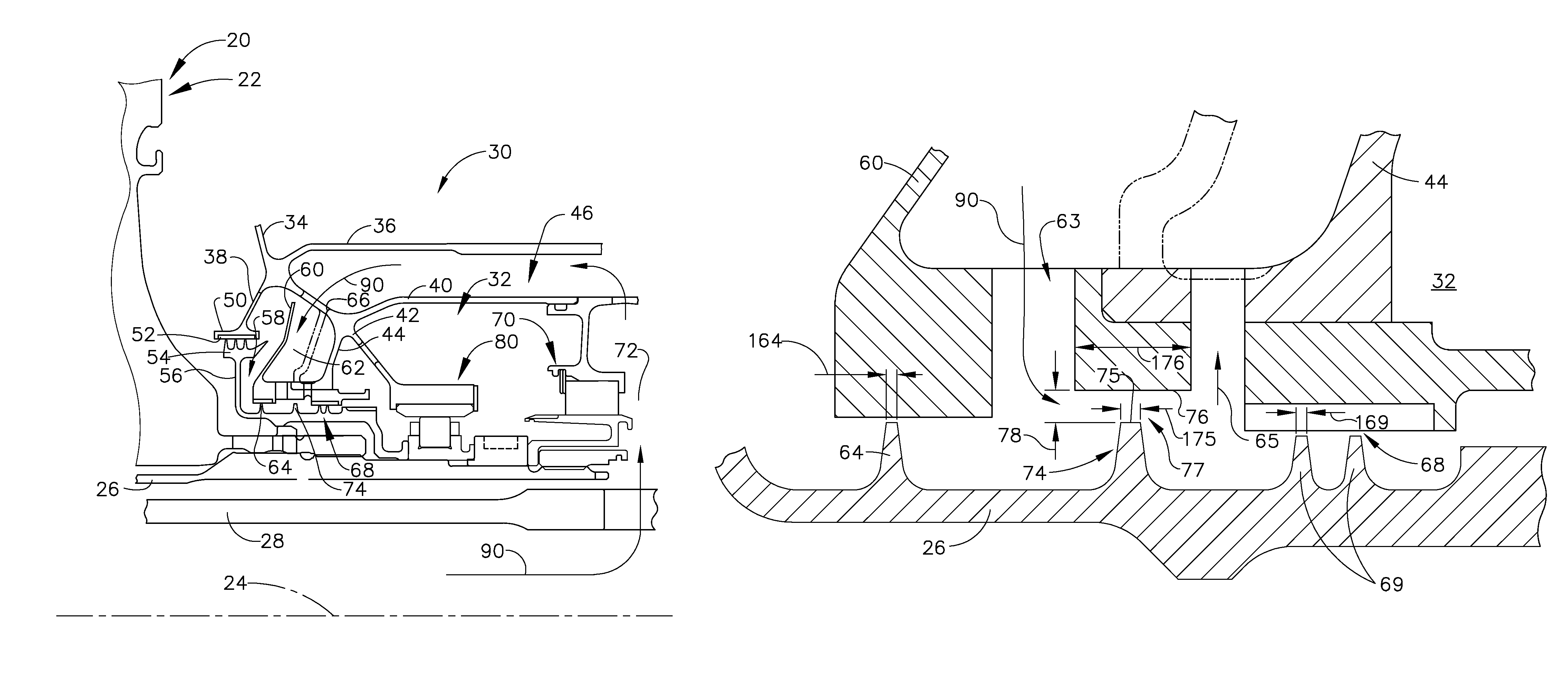

Wide discourager tooth

Owner:GENERAL ELECTRIC CO

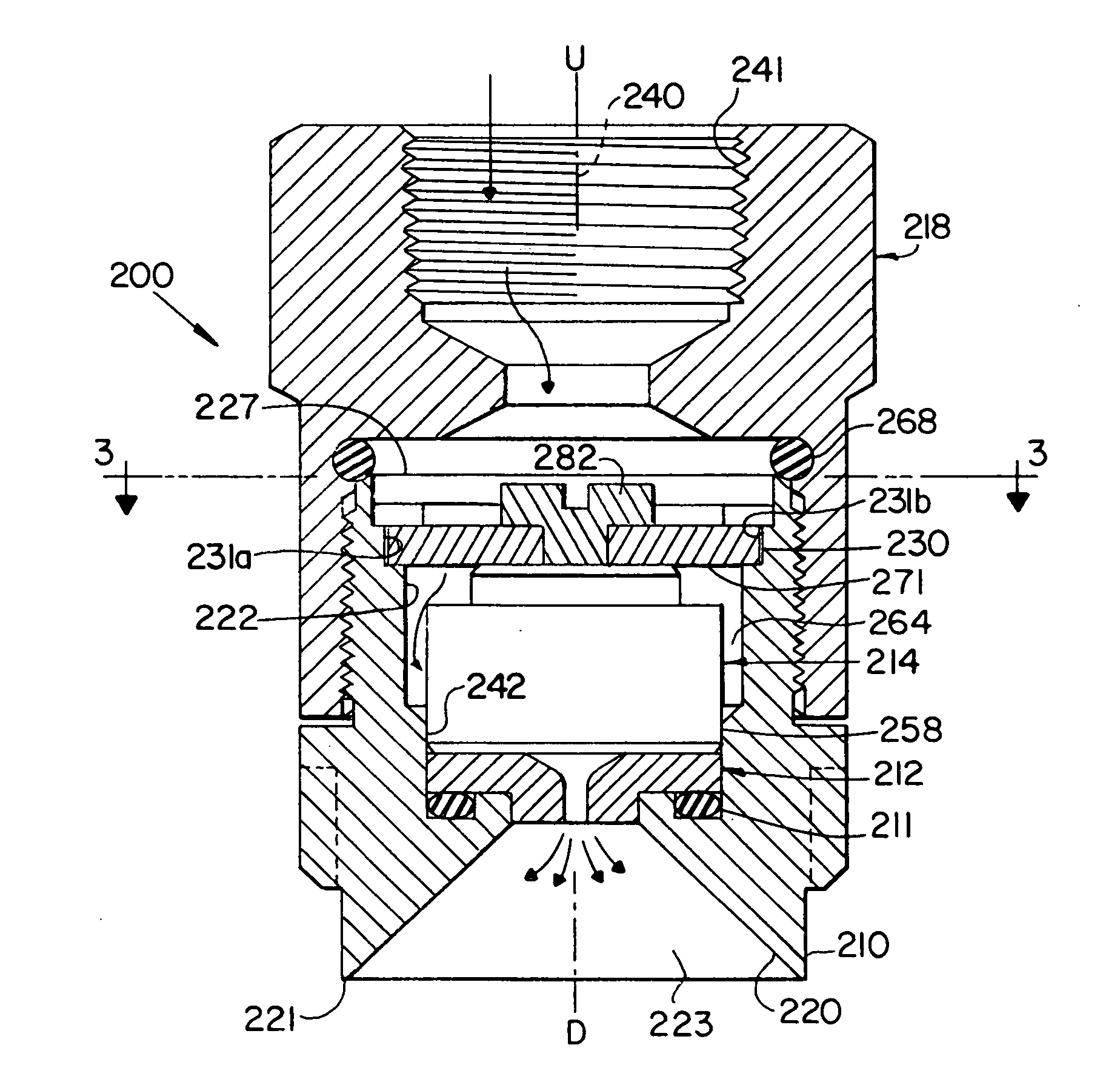

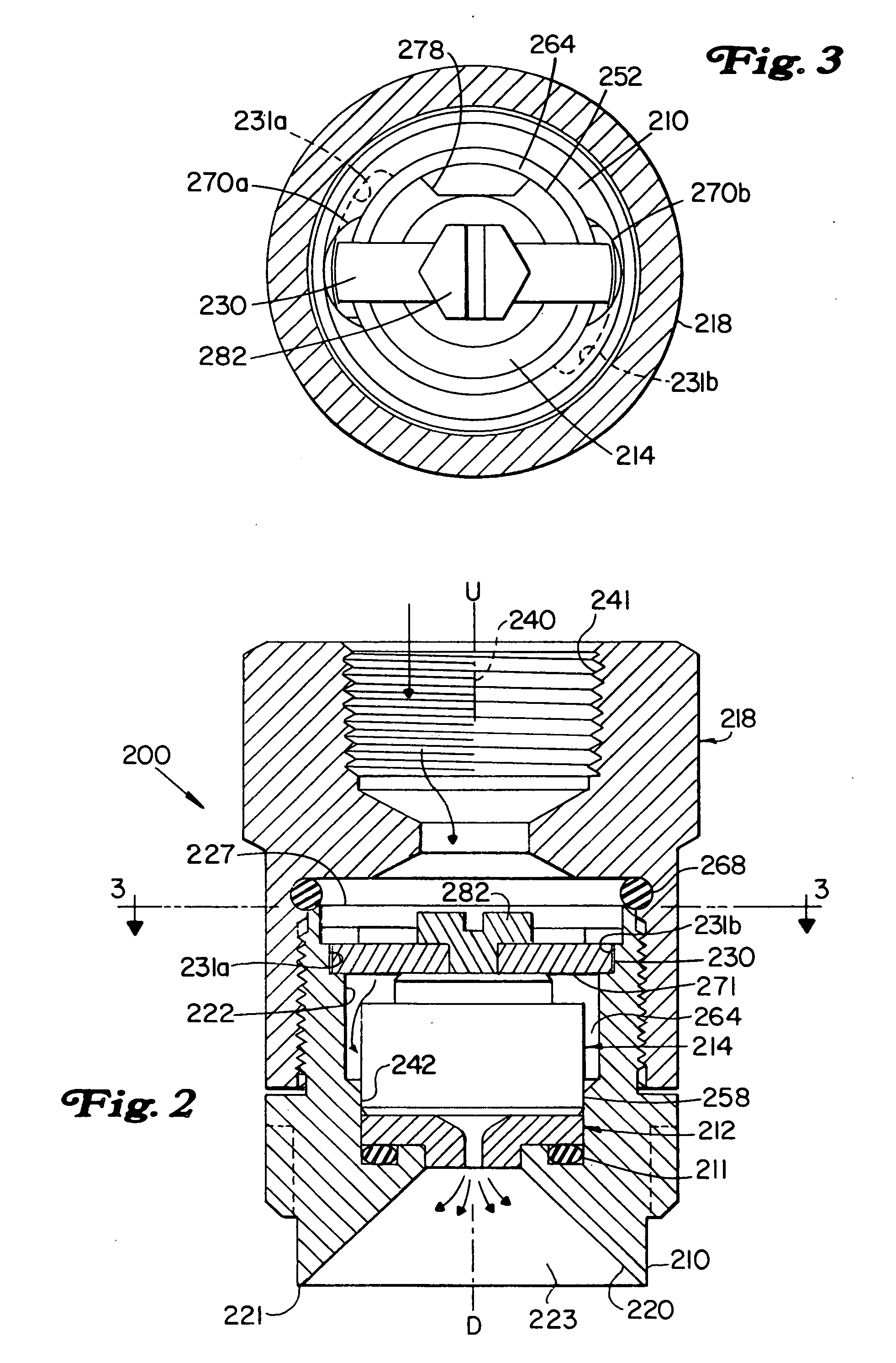

Spray Nozzle

InactiveUS20080217435A1Facilitate fluid communicationFacilitates rotational engagementSpray nozzlesEngineeringNozzle

A spray nozzle (300) which employs a locking and an alignment feature (330) to facilitate the replacement of internal nozzle components. The spray nozzle includes a nozzle body (310), a swirl element (314) and an orifice disc (312). The nozzle body defines a central bore which extends between a fluid receiving section and a fluid discharge section and delineates a central axis and delimits an interior locating surface for swirl element and the orifice disc. The orifice disc includes a protuberance (374) associated with the downstream surface thereof which protrudes into the spray opening of the nozzle body.

Owner:DELAVAN

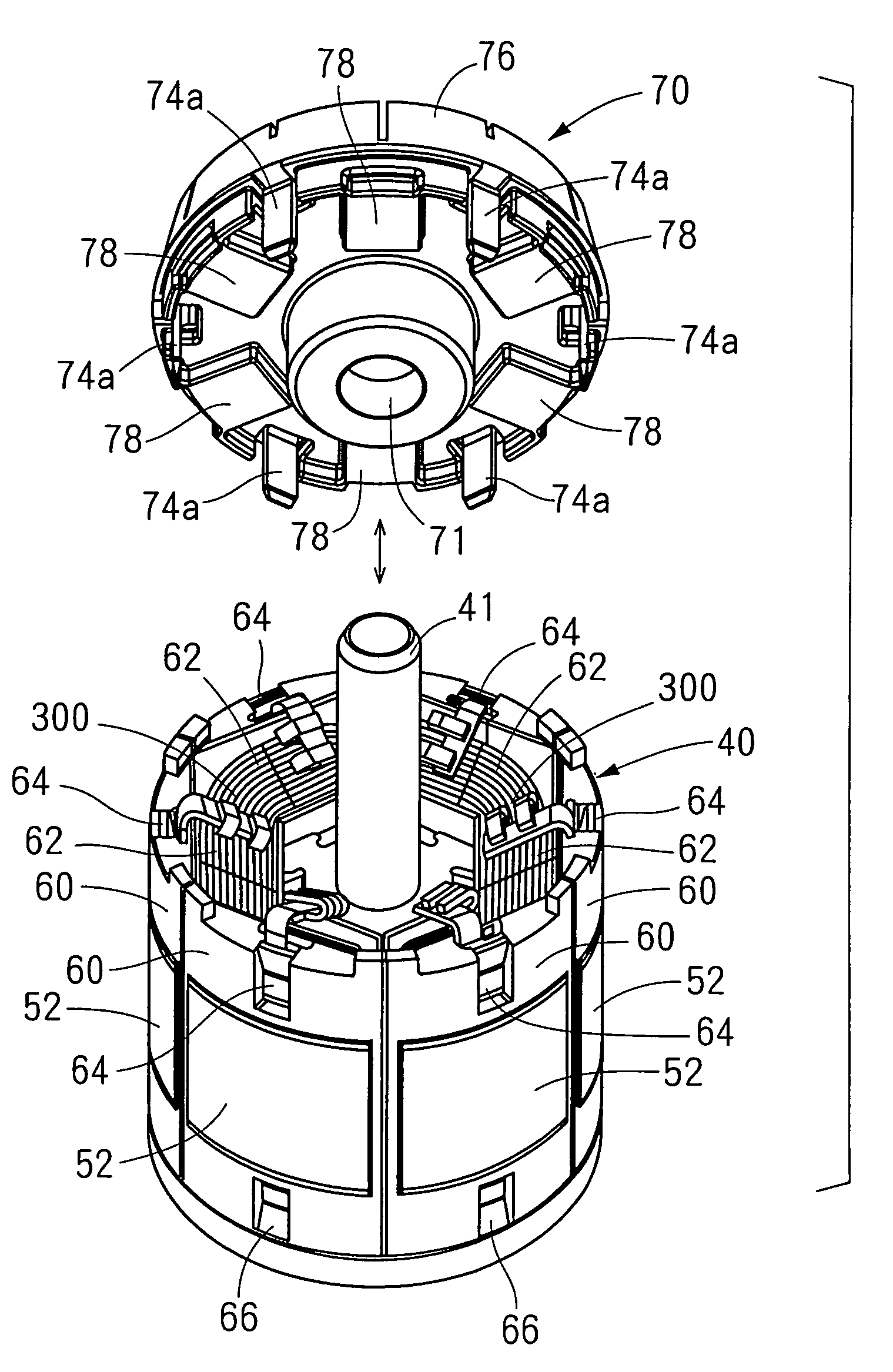

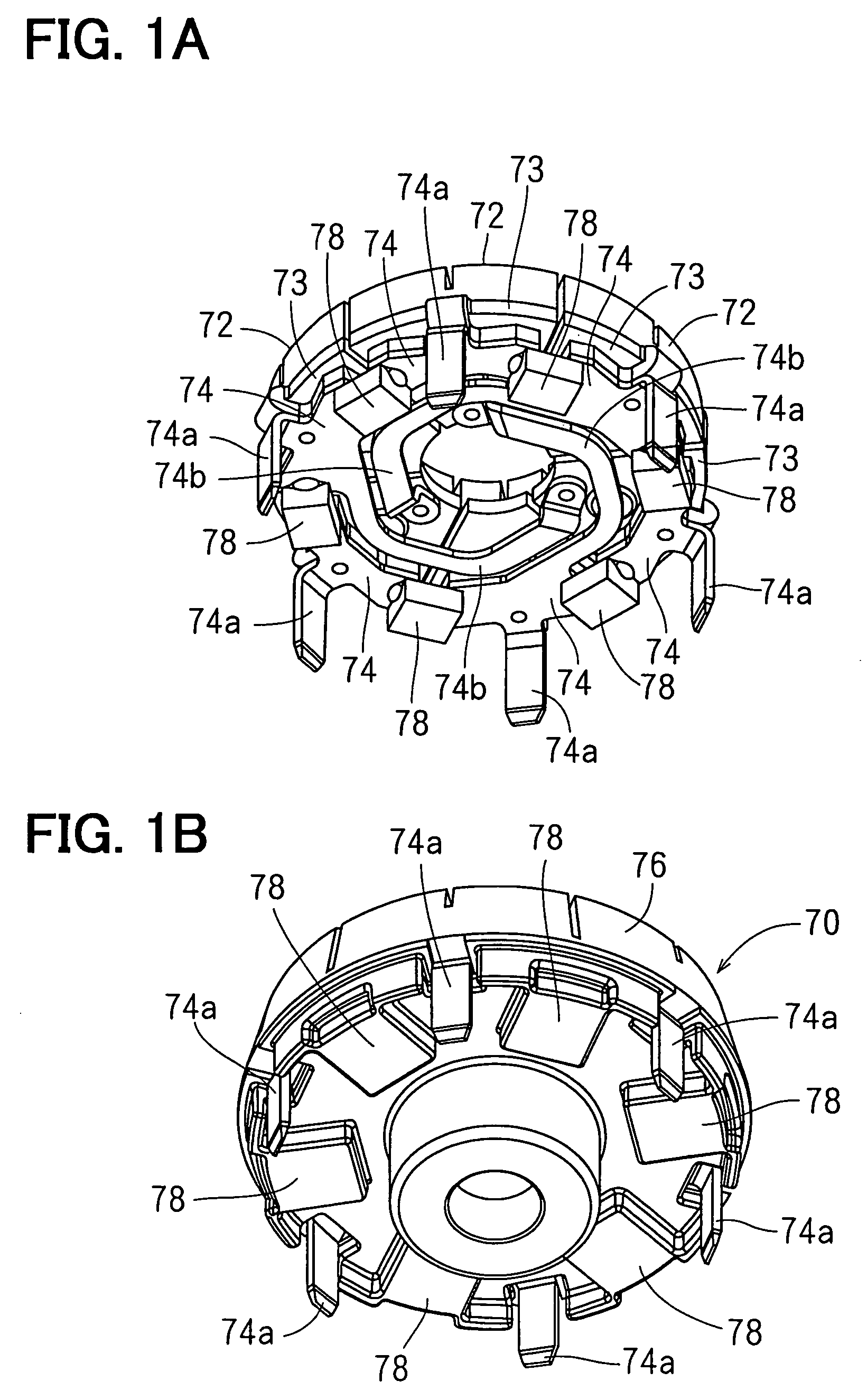

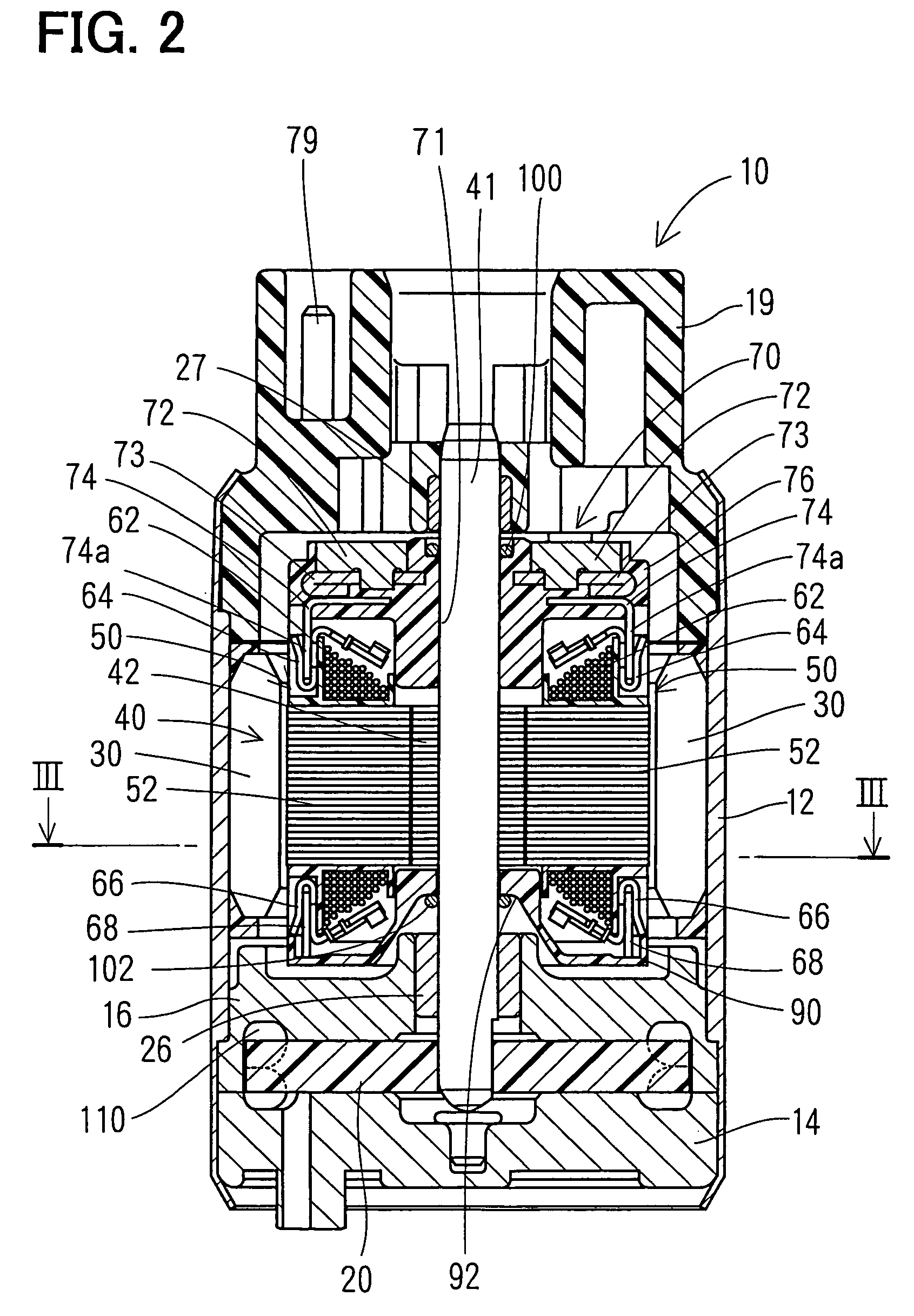

Motor, fuel pump, commutator, and method for manufacturing a commutator

ActiveUS7084547B2Increase overall axial lengthPrevent wearRotary current collectorMagnetic circuit rotating partsEngineeringFuel pump

A commutator includes six segments disposed in the direction of rotation, and is attached to one axial end of an armature. By the commutator rotating together with the armature, each of the segments successively contacts a brush. Each of the segments is electrically connected with terminals through mid-terminals. Three of the six terminals, non-adjacent and alternatingly located in the direction of rotation, are electrically connected directly with mid-terminals facing in radial opposition. Capacitors are electrically connected directly with the terminals adjacent in the direction of rotation. Discharge does not occur between the brush and segments when the brush separates from the segments accompanying rotation of the armature, since electromagnetic energy built up in the coils of the armature is temporarily built up in the capacitors.

Owner:DENSO CORP

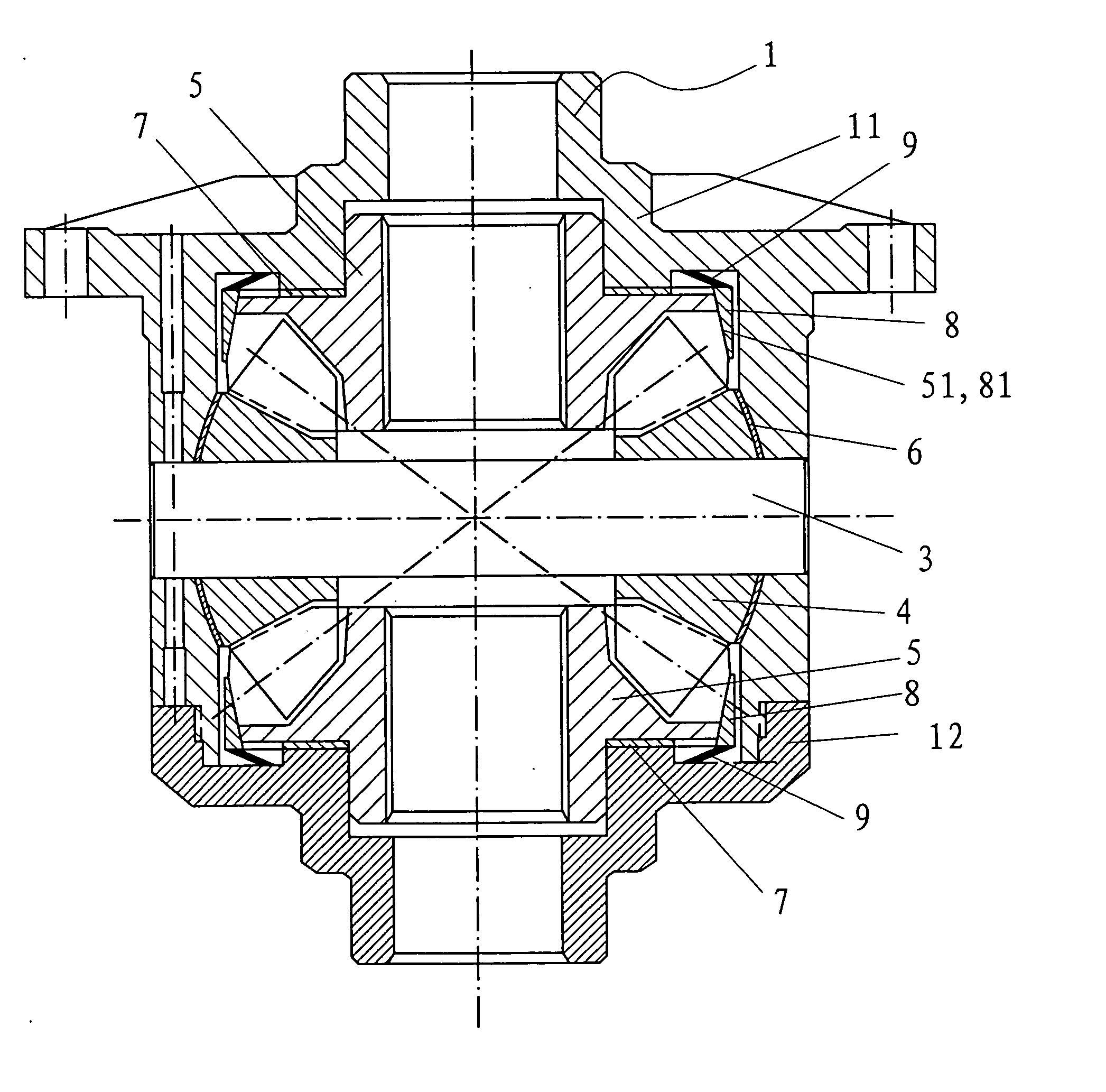

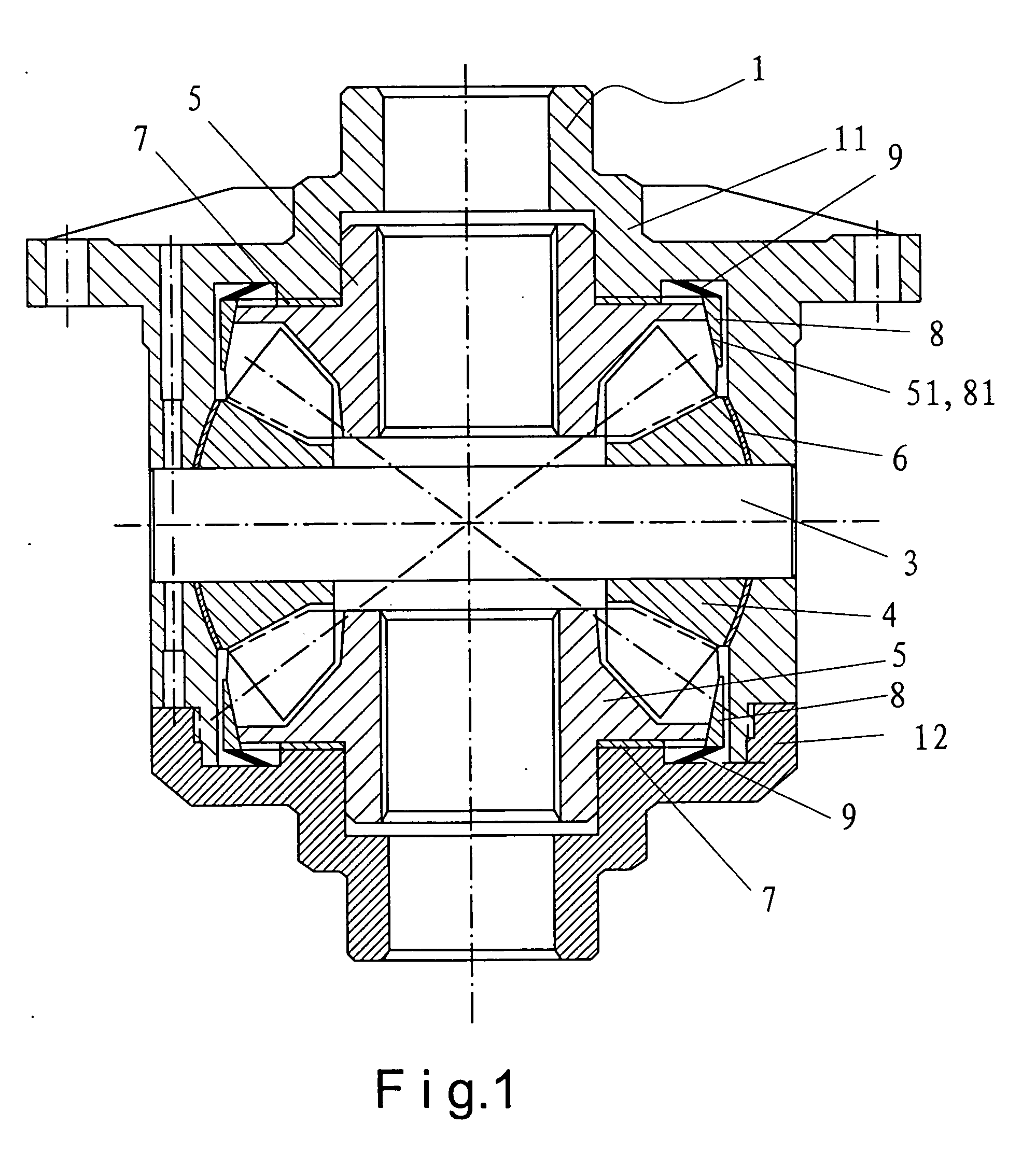

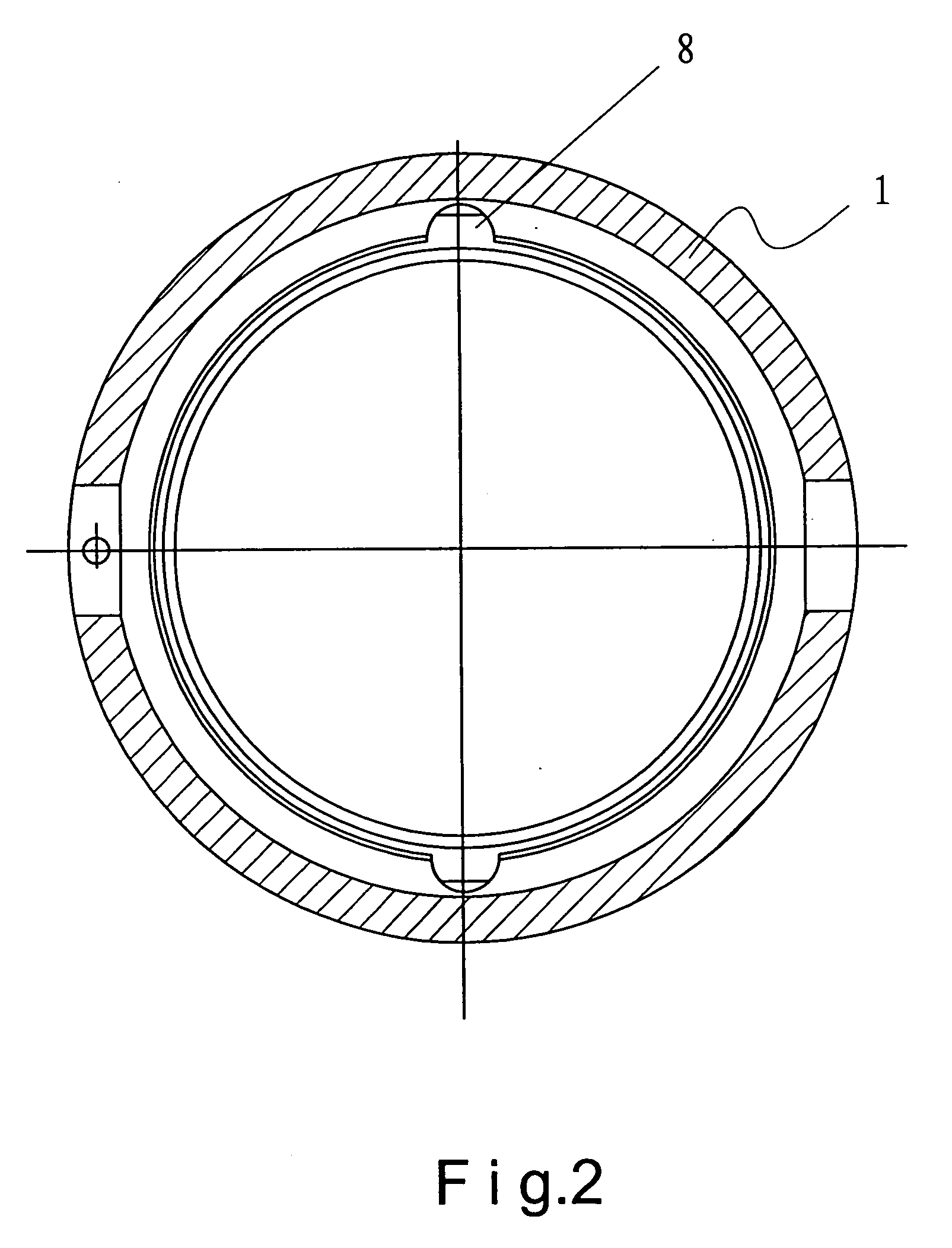

Preload limited-slip differential

InactiveUS20050288144A1High single-wheel tractionLower resistanceDifferential gearingsControl devicesCyclical fluctuationLimited-slip differential

This invention relates to a type of preload limited-slip differential, by means of the friction between the back cone (51) of the side gear (5) and the friction ring (8) to realize the preload function of the differential, thus the length of the differential is not increased, the structure is very compact. Moreover, the gear ratio between the pinions (4) and side gears (5) periodically fluctuates to ensure higher one-wheel traction and lower turning resistance, and the contradictory requirements of good cross-country ability and steering agility are well balanced.

Owner:WANG XIAOCHUN +1

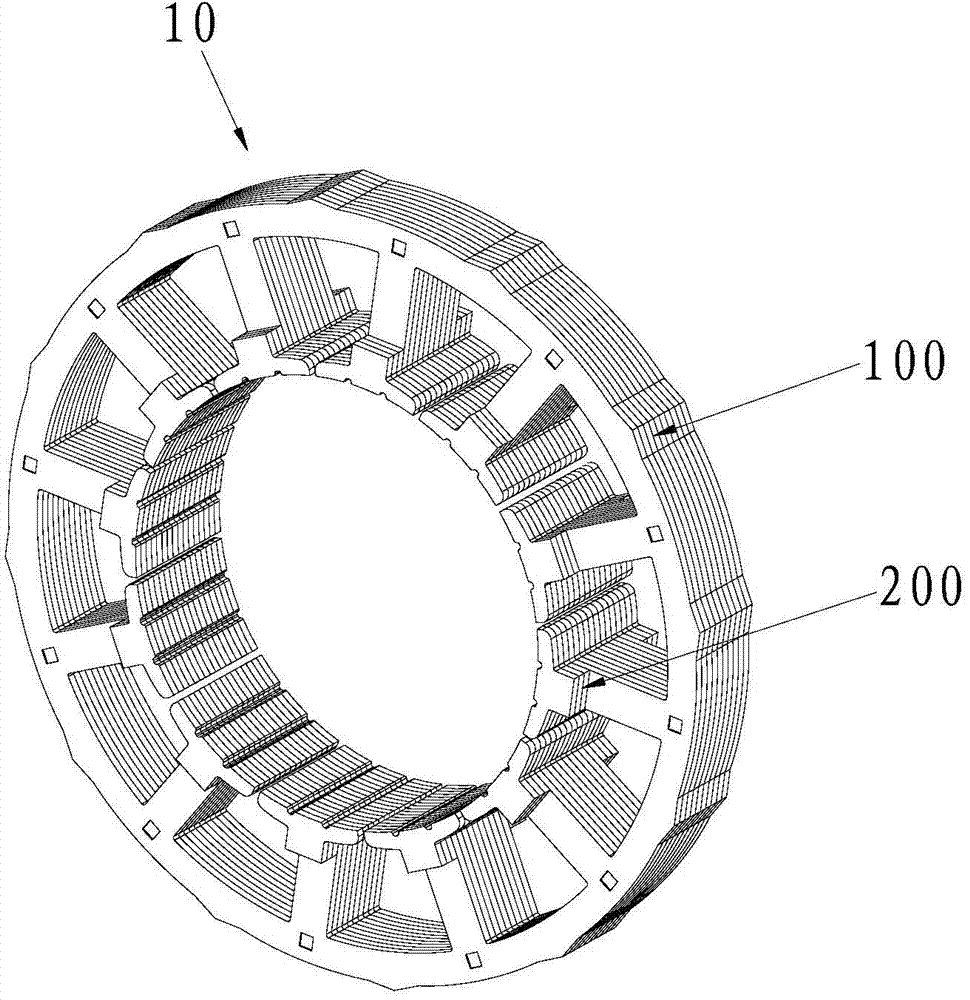

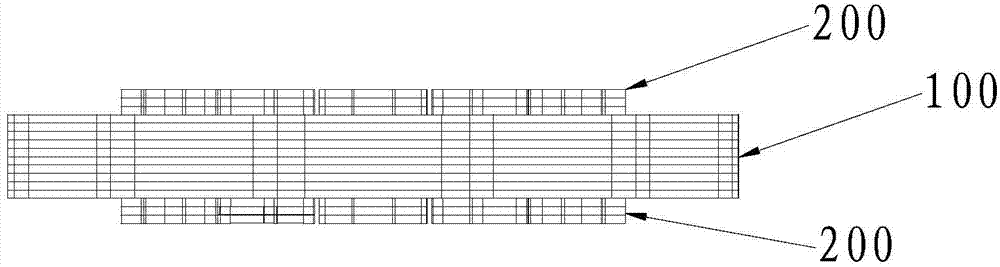

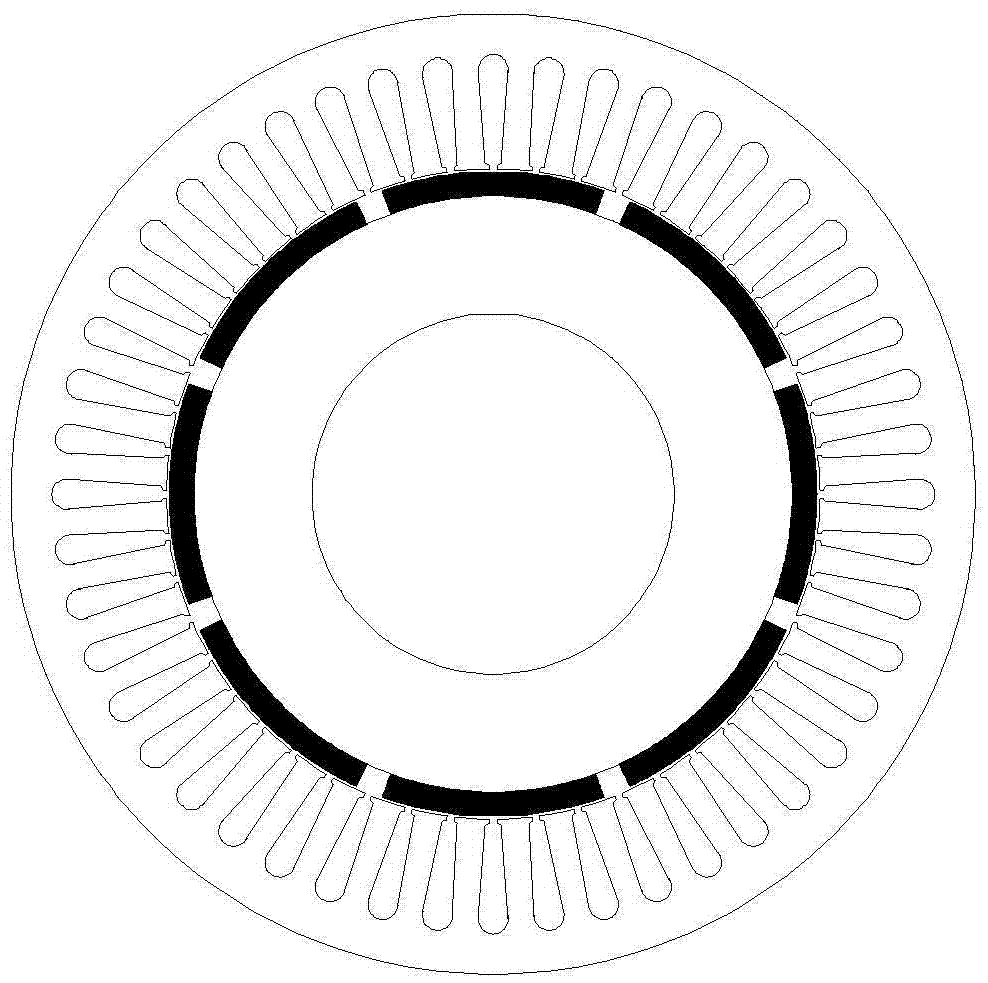

Motor stator iron core, motor stator, motor, and manufacturing method of motor stator

ActiveCN104734376AImprove performanceIncrease magnetic densityMagnetic circuit stationary partsManufacturing stator/rotor bodiesConductor CoilMagnet

The invention belongs to the technical field of motors and discloses a motor stator iron core, a motor stator, a motor and a manufacturing method of the motor stator. The motor stator comprises the motor stator iron core. The motor comprises the motor stator and the motor stator iron core. According to the motor stator iron core, one end or two ends of an iron core body are provided with tooth boot boss portions, the purpose of increasing the axial length of the motor stator iron core can be achieved, and the turn length of a winding is not increased; besides, the flux of a magnet on a rotor can be guided to stator teeth through the tooth boot boss portions, the magnetism gathering effect is better, the flux density of the stator iron core can be improved, the material utilization rate is higher, and the weight of the motor stator iron core is reduced. Meanwhile, the turn length of the winding of the motor stator is reduced, the weight of the winding is reduced, the length of the end of the motor is reduced, and the motor is high in performance and low in cost.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

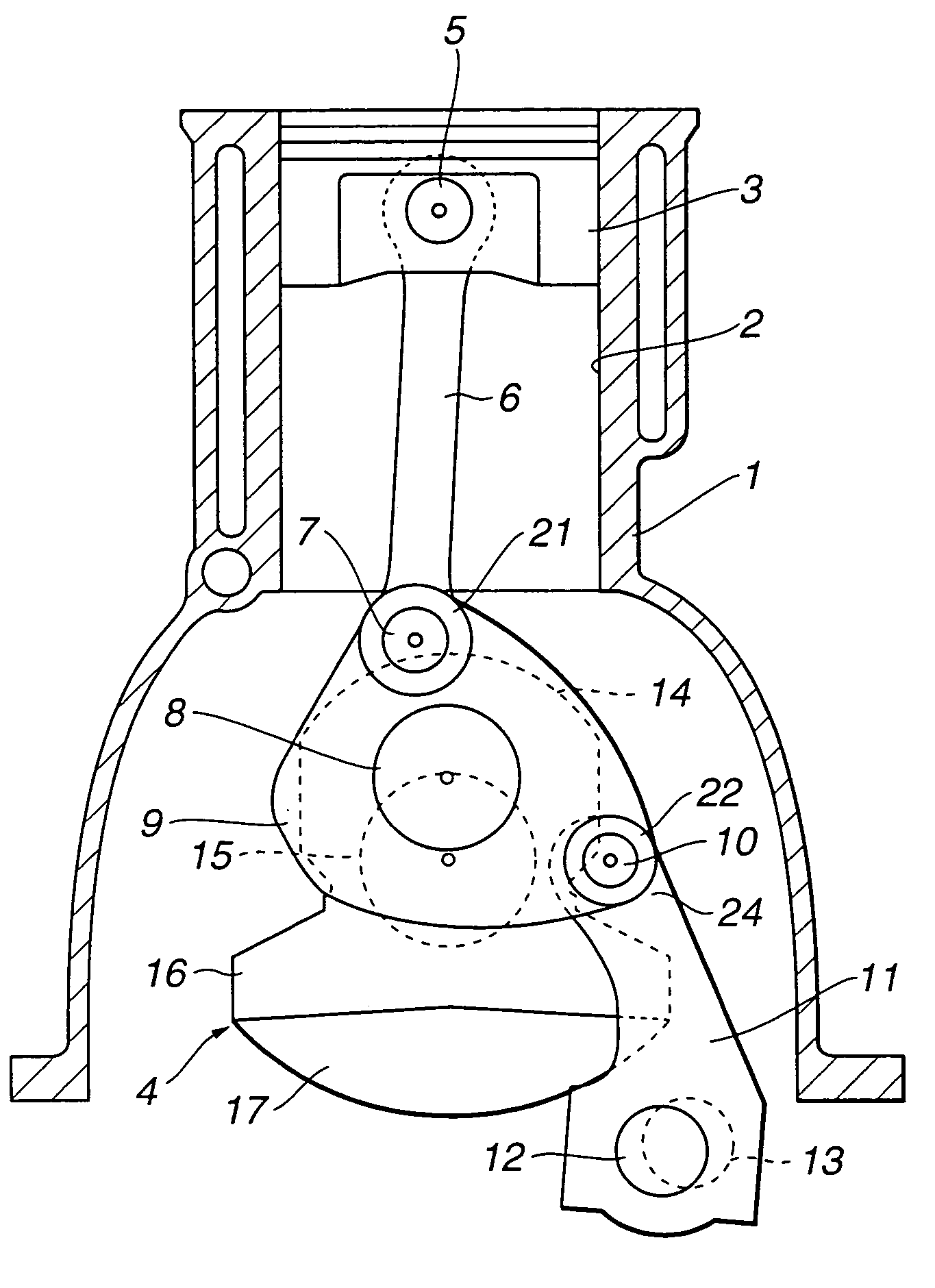

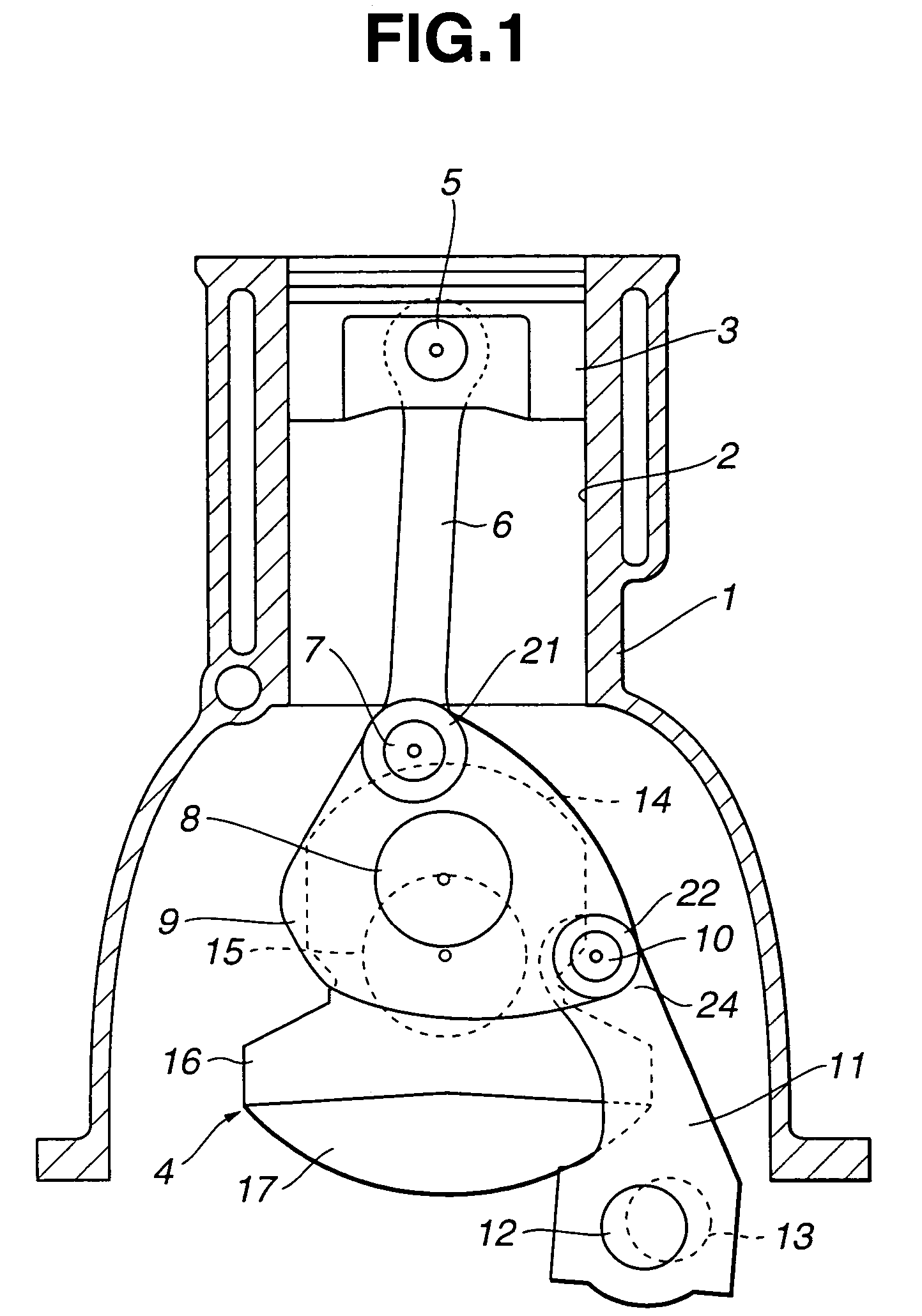

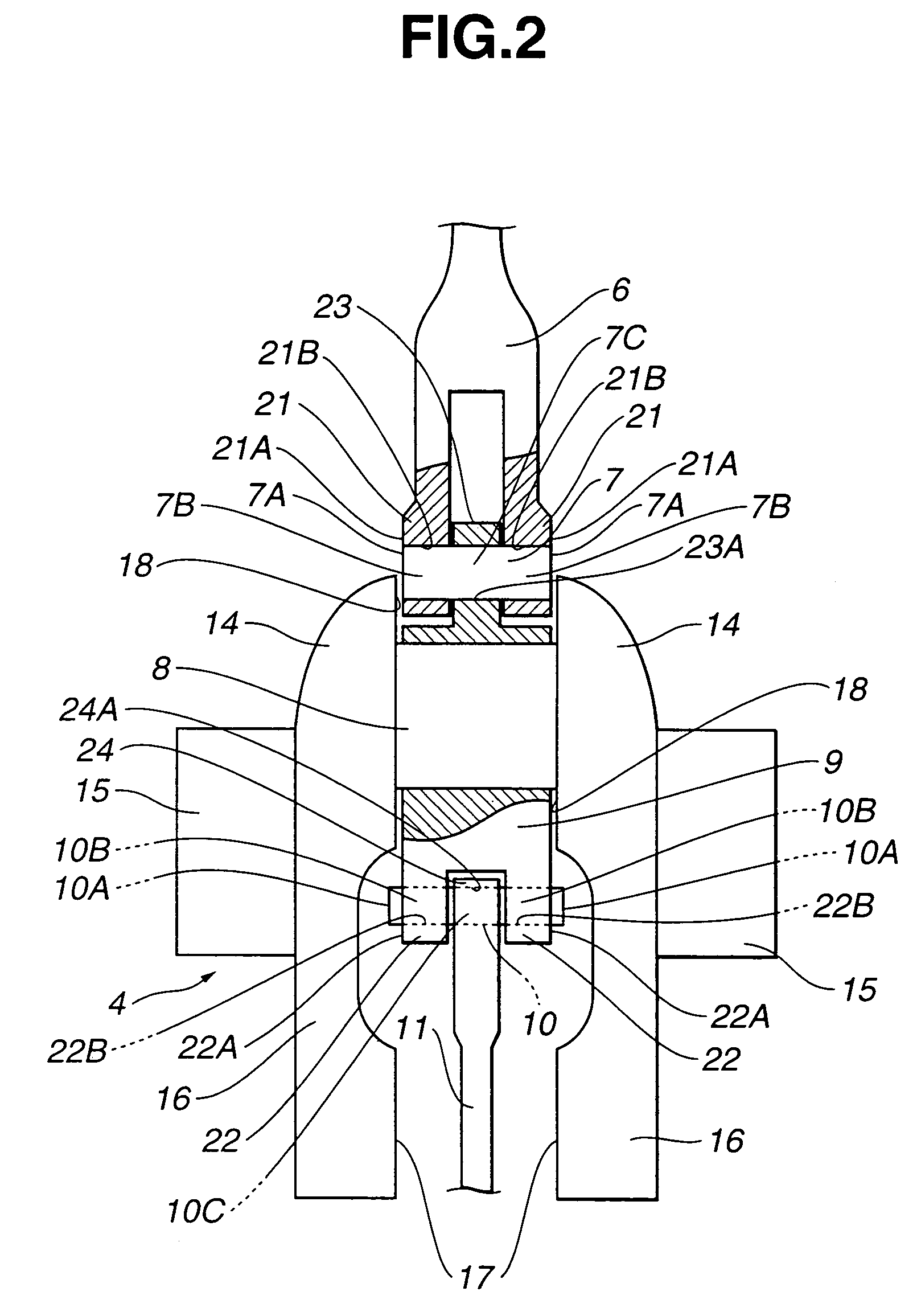

Multi-link piston crank mechanism for internal combustion engine

ActiveUS7121251B2Optimization mechanismAvoid interferenceConnecting rodsGearingMulti linkInternal combustion engine

A multi-link piston crank mechanism for an internal combustion engine, including a crankshaft having a crank pin, and crank webs connected with each other through the crank pin. A pair of thrust surfaces are formed on the crank webs so as to be opposed in a direction of a center axis of the crank pin. A first link pivotally supported on the crank pin is coupled to a second link through a connection pin located in a space between the thrust surfaces. The connection pin is moveable about the crank pin to form a circular trace along which the thrust surfaces extend. The end surfaces of the connection pin and the thrust surfaces come into mutual contact to prevent the connection pin from falling out of the space between the thrust surfaces.

Owner:NISSAN MOTOR CO LTD

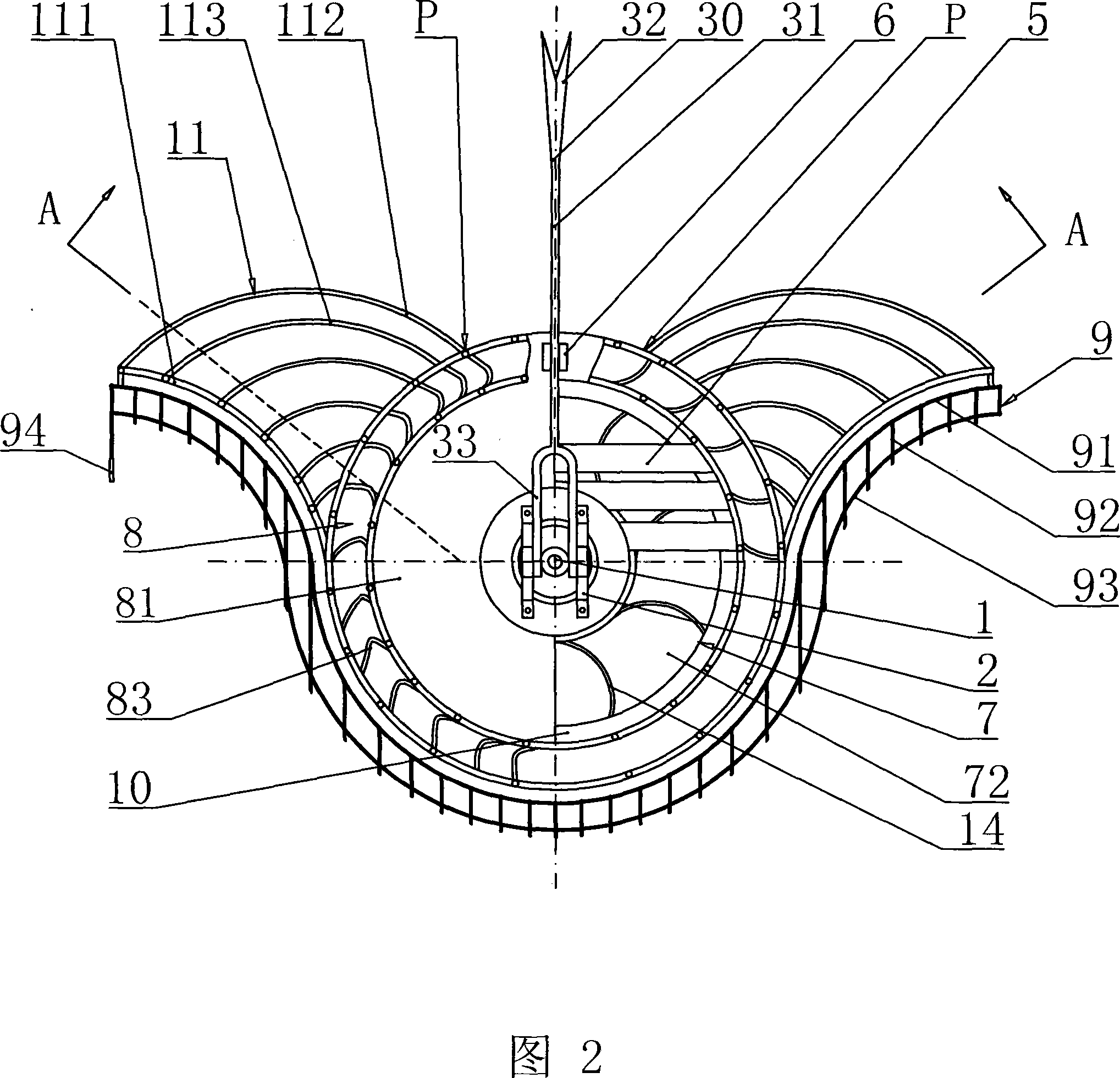

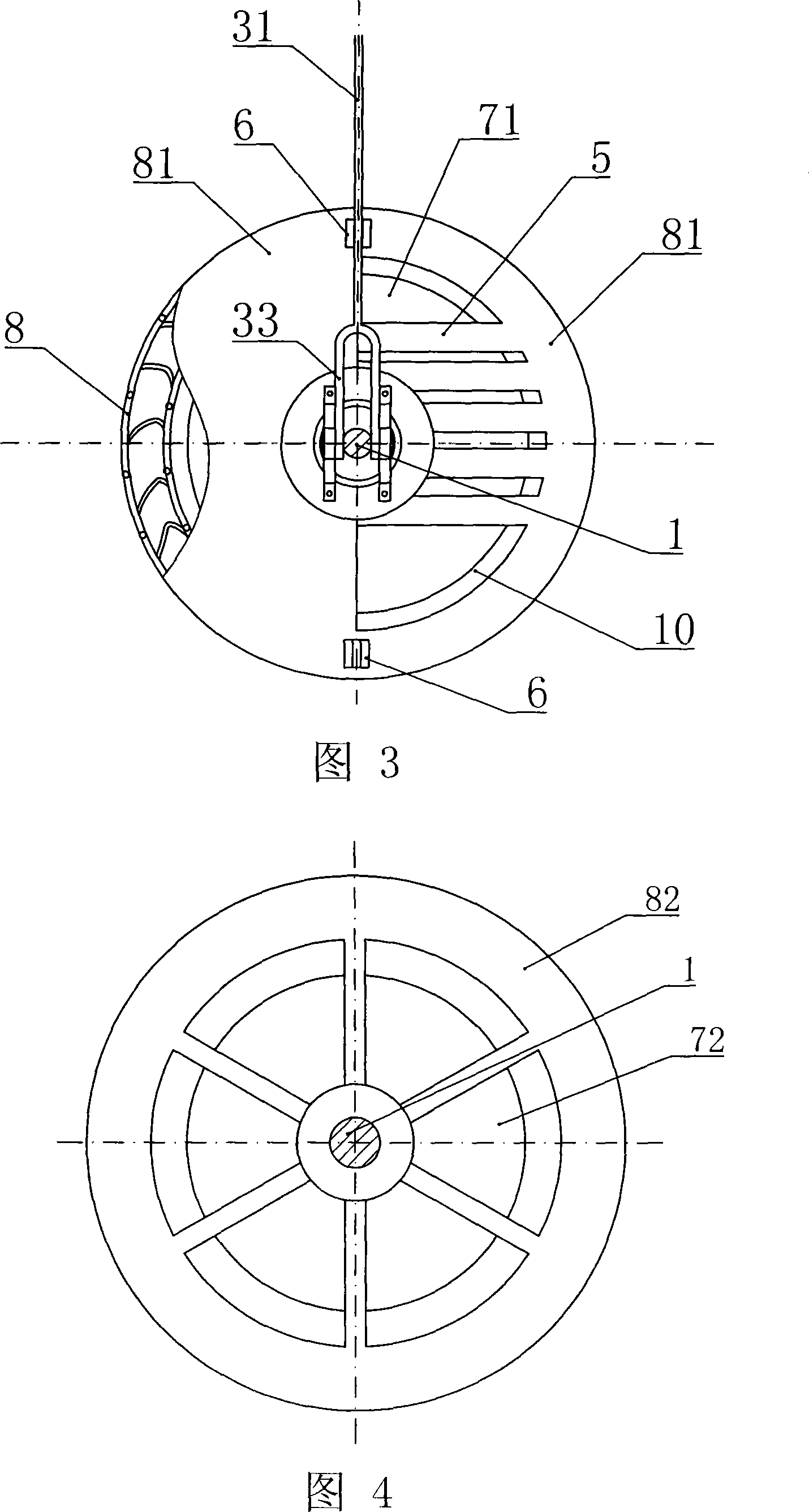

Large power wind-gathering current-guiding wind power machine

InactiveCN101169102AAvoid destructionIncrease output powerWind motor controlWind motor combinationsElectricityImpeller

The invention provides a high-power wind-gathering airflow-guiding air operated machine, which includes a machine base, a main shaft, an impeller, wind-gathering covers, a rear helm, and a power outputting wheel. An annular airflow-guiding bracket around the peripheral outline of the impeller is arranged outside the impeller, the center of the upper cover of the airflow-guiding bracket is rotationally connected with the main shaft, and the center of the lower cover of the airflow-guiding bracket is rotationally connected with the machine base. The wind-gathering covers are two covers which are respectively arranged on the outer sides of the airflow-guiding bracket, and the two covers extend towards the rear and the two wings. The rear helm is arranged along the back and forth direction, the front end of the rear helm is hinged with the upside of the airflow-guiding bracket through a hinge shaft horizontally arranged. The invention integrates manifold advantages, can gather maximum wind power, can guide the airflow to form tornado type rotary airflow, can ensure that the rotor blades receive force continuously in 360 DEG C to accelerate, can generate electricity normally in 2-3 DEGC wind force, can control the wind volume, and can stabilize the rotation speed. The rear helm which can turn for 180 DEG C can resist the typhoon, and is safe and reliable. Large-diameter inertial wheel can cushion the impact of the blasts, and can enable the impeller to operate stably.

Owner:黄金德 +1

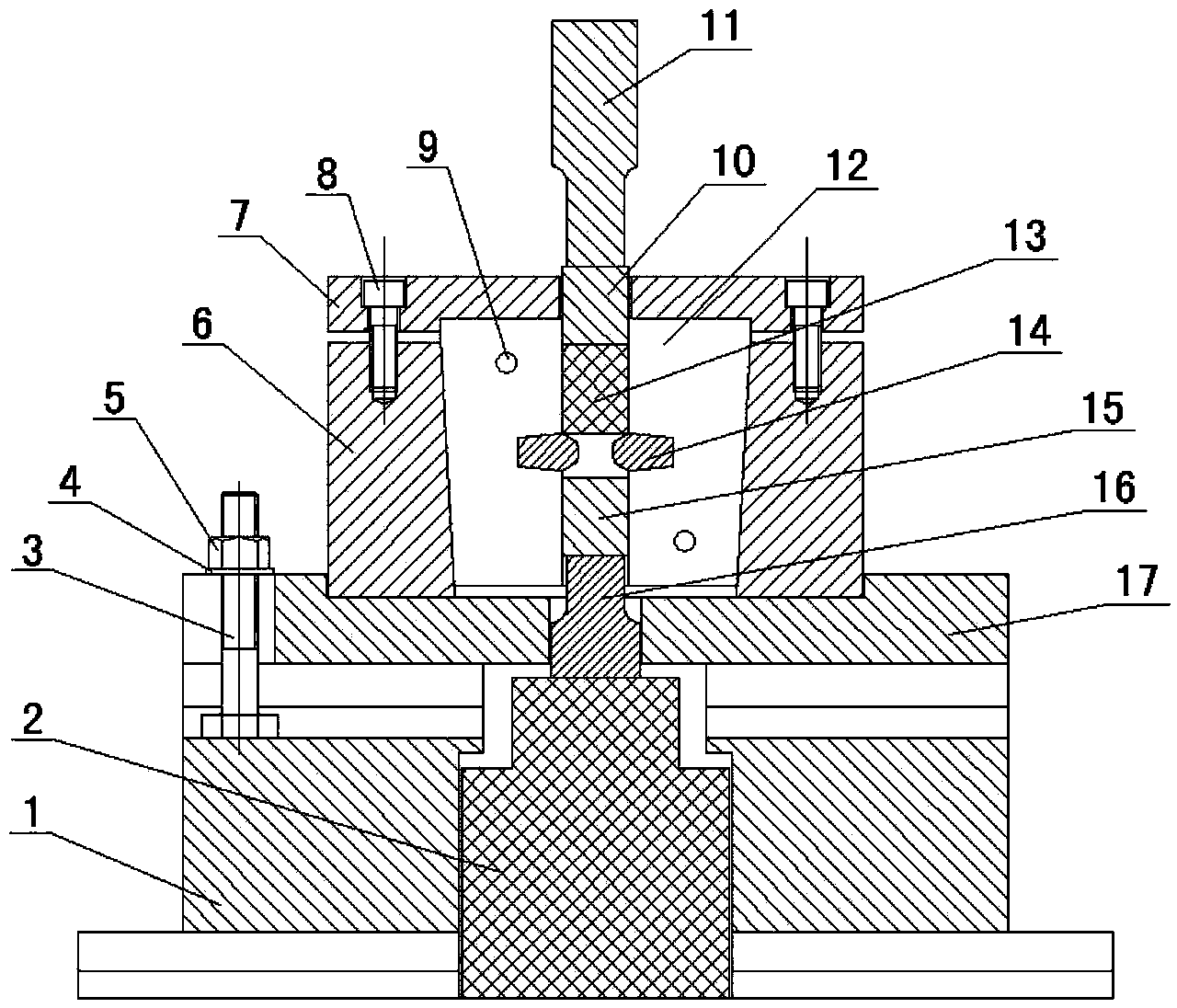

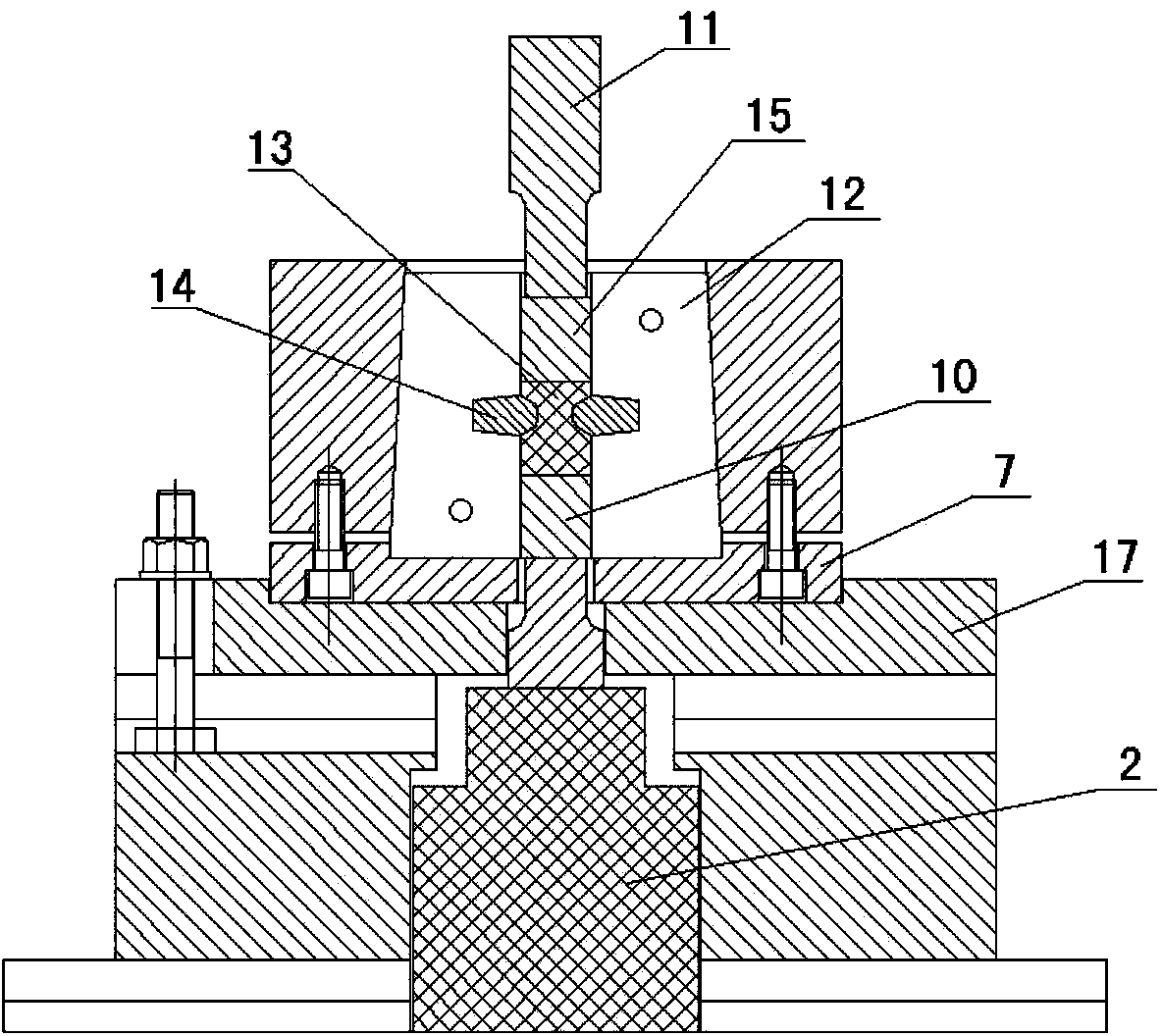

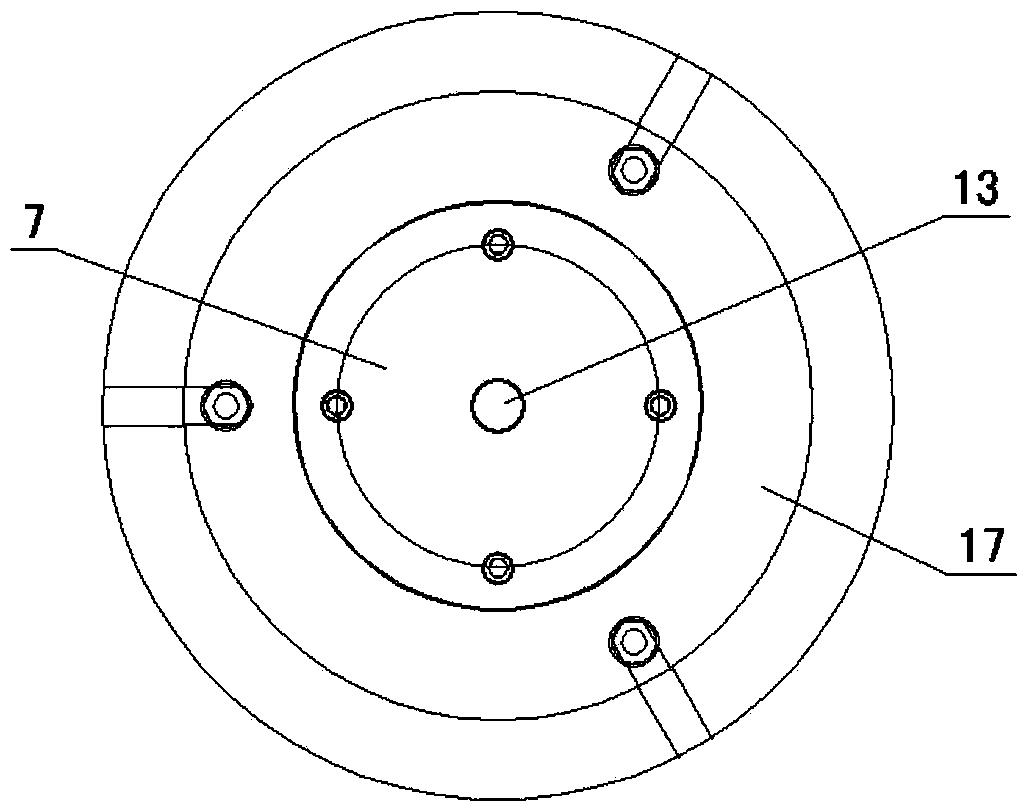

Device for realizing reciprocating extrusion process on one-way hydraulic press

The invention discloses a device for realizing a reciprocating extrusion process on a one-way hydraulic press. The device is characterized in that a hollow cylindrical cavity is formed in an annular extrusion cylinder; an upper male die and a lower male die which can be in axial sliding in the hollow cylindrical cavity are respectively arranged at the top and the bottom of the hollow cylindrical cavity; a cylindrical blank is placed in the hollow cylindrical cavity; a die core inserted block is clamped and embedded into a groove in the inner cylinder wall of the annular extrusion cylinder to form an annular reduced section; the circumference of the annular extrusion cylinder is fixedly sleeved with a pre-tightening ring; a female die pressing plate is fixedly connected to the top of the pre-tightening ring and is propped against the top surface of the annular extrusion cylinder; a female die composed of the annular extrusion cylinder, the female die pressing plate, the pre-tightening ring and the die core inserted block is formed in the manner that the bottom surface of the pre-tightening ring or the top surface of the female die pressing plate is placed in a downward-concave platform on the top surface of a female die fixing plate to form an upright-placing or inverted state; an nitrogen spring in the hollow cavity of a base forms underpropping to the lower male die. According to the invention, the reciprocating extrusion technology on the one-way hydraulic press is realized in an assisting way, reciprocating extrusion deformation under different extrusion ratios can be satisfied, and the fine and equiaxed fine-grain tissues can be achieved.

Owner:HEFEI UNIV OF TECH

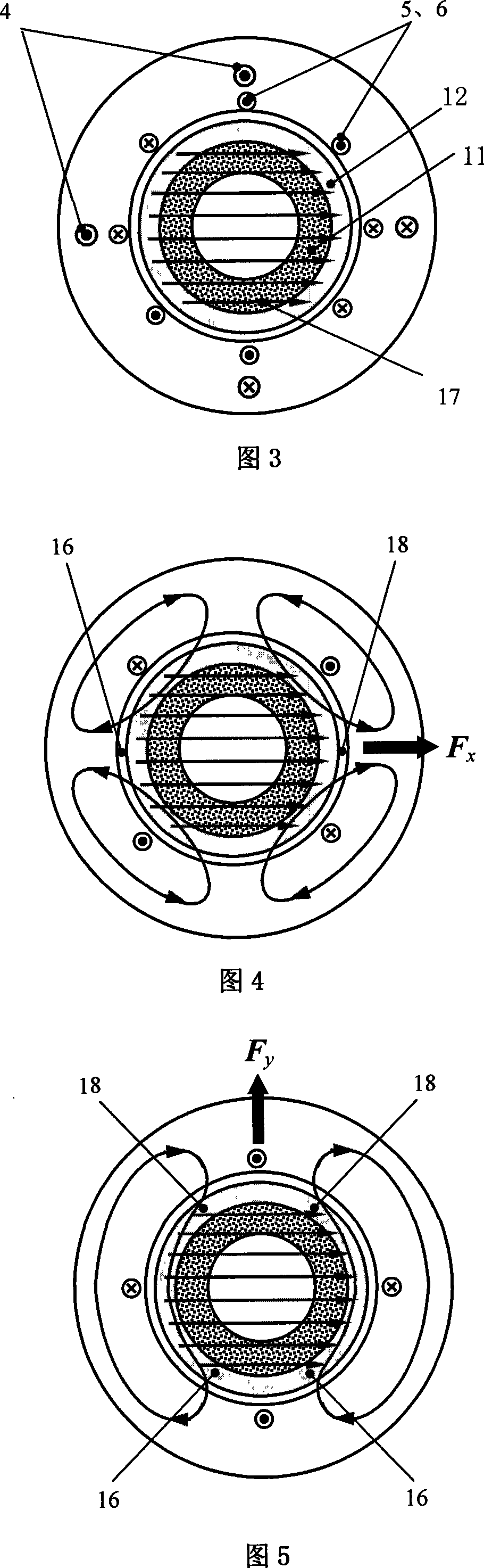

Radial rotary sealing device for magnetic liquid

InactiveCN105221753AAvoid collision damageIncrease axial lengthEngine sealsEngineeringMagnetic liquids

The invention discloses a radial rotary sealing device for magnetic liquid and belongs to the field of mechanical engineering sealing. By means of the radial rotary sealing device for the magnetic liquid, the problems that when an existing sealing device is in use, it is difficult to add or replace magnetic liquid, and machining accuracy and assembly accuracy are too high due to the fact that the axial length is large are solved. According to the sealing device for the magnetic liquid, radial sealing is adopted, the axial dimension is reduced by increasing the radial dimension, a first magnetic disc is connected with a shell through screws, and detachment is convenient. Moreover, the invention provides a novel mode for designing the rotary sealing device for the magnetic liquid.

Owner:BEIJING JIAOTONG UNIV

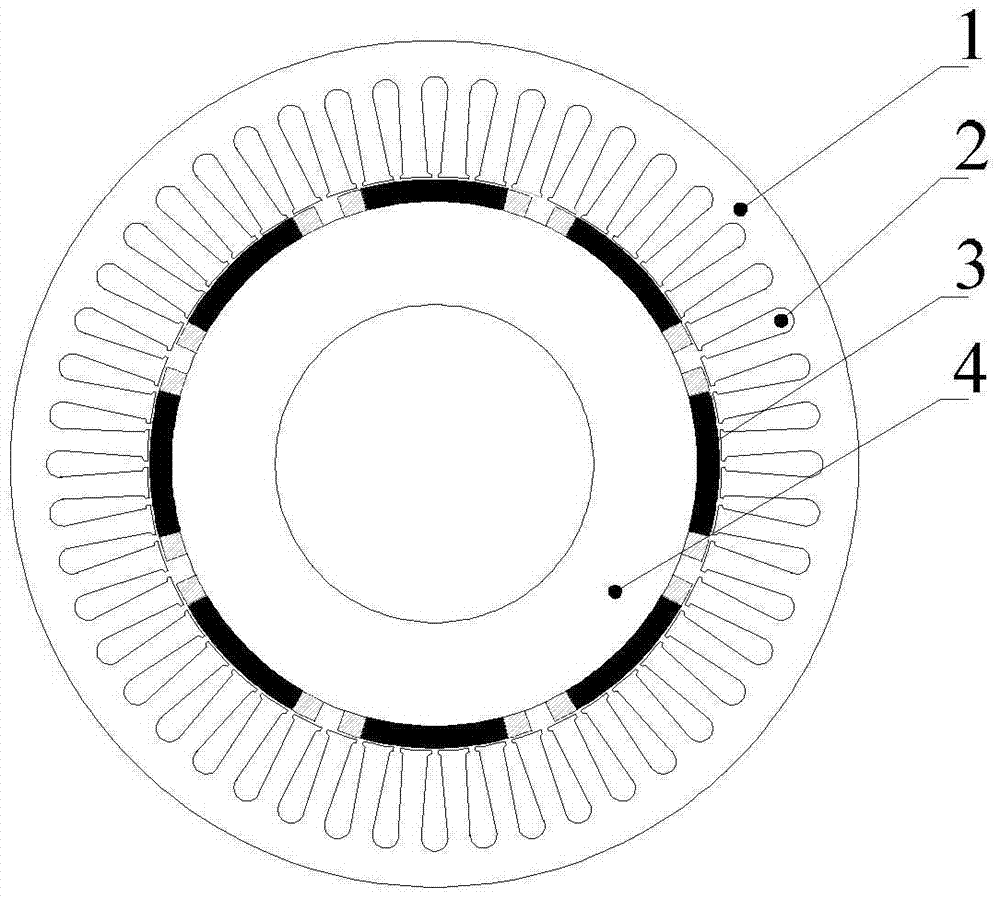

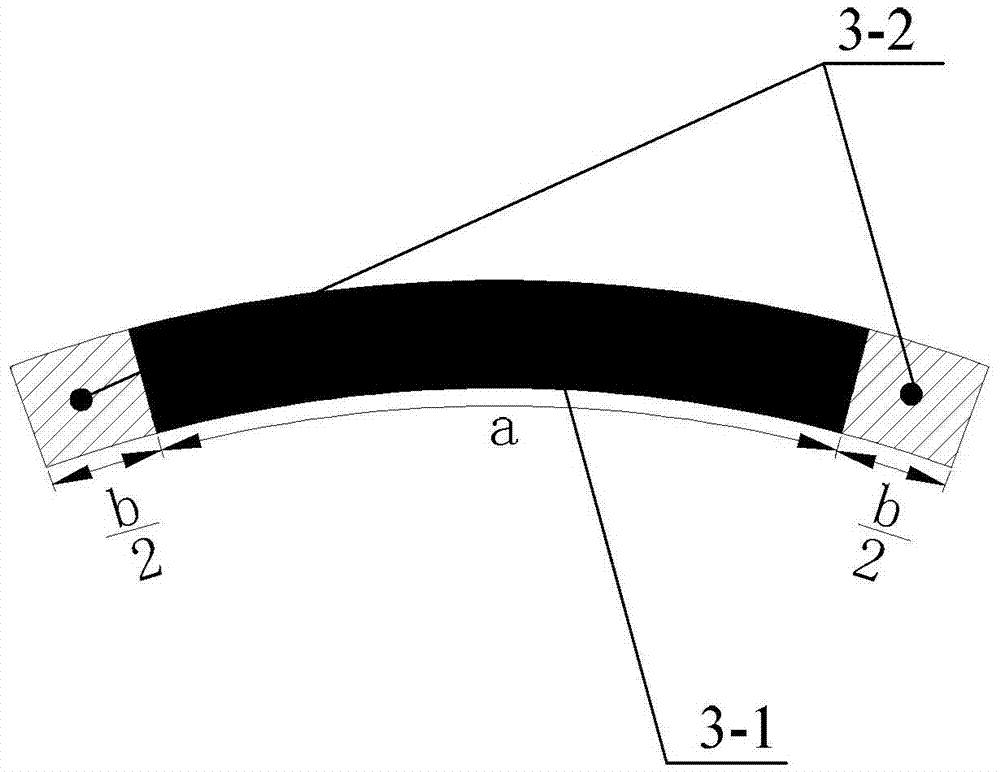

Composite magnetic pole type surface-mounted permanent magnet synchronous motor

ActiveCN105449968AAir gap magnetic density waveform distortion rate is smallIncrease axial lengthMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSurface mountingPermanent magnet synchronous motor

The invention discloses a composite magnetic pole type surface-mounted permanent magnet synchronous motor, which belongs to the field of permanent magnet motors. The composite magnetic pole type surface-mounted permanent magnet synchronous motor aims to solve the problems that harmonic wave is in the presence in a sinusoidal-current-driven rare earth permanent magnet synchronous motor air gap magnetic field and local irreversible demagnetization always happen. The composite magnetic pole type surface-mounted permanent magnet synchronous motor comprises a rotor and a stator, wherein the rotor is arranged in the stator; a radial air gap is formed between the rotor and the stator; the excircle surface of the a rotor iron core is evenly provided with a plurality of rotor magnetic pols in a surface-mounted way; each rotor magnetic pole comprises a rare earth permanent magnetic pole and two ferrite permanent magnetic poles, wherein the left end surface and the right end surface of the rare earth permanent magnetic pole are independently provided with one ferrite permanent magnetic pole; the rare earth permanent magnetic pole and two ferrite permanent magnetic poles form a continuous circular-arc magnetic pole structure; and the magnetization directions of the rare earth permanent magnetic pole and two ferrite permanent magnetic poles are all radial magnetization and are the same. The permanent magnet synchronous motor of the structure causes the harmonic content of the air gap magnetic field to be lowered, motor efficiency is improved, the ferrite permanent magnet material is low in price, and cost is lowered.

Owner:HARBIN INST OF TECH

Vehicle seat reclining apparatus

A vehicle seat reclining apparatus comprises a base member to be connected to one of a seat cushion and a seat back, a rotation member which is to be connected to the other of the seat cushion and seat back, which is arranged to rotate relative to the base member and which includes an internal gear, a regulating member to regulate axial movement of the rotation member relative to the base member, and a locking setup which includes an external gear and which is arranged to move between a lock position to engage the external gear with the internal gear and an unlock position for disengagement. The base member includes an outer circumferential portion defining a circular recess, the rotation member includes an outer circumferential portion including a cylindrical portion fit rotatably in the outer circumferential portion of the base member. The outer circumferential portion of the rotation member further includes a flange portion which projects radially outwards from the cylindrical portion, which is placed axially between the regulating member and the outer circumferential portion of the base member and which includes a side surface facing away from the base member and servings as a sliding regulation surface set in sliding contact with the regulating member.

Owner:TF METAL CO LTD

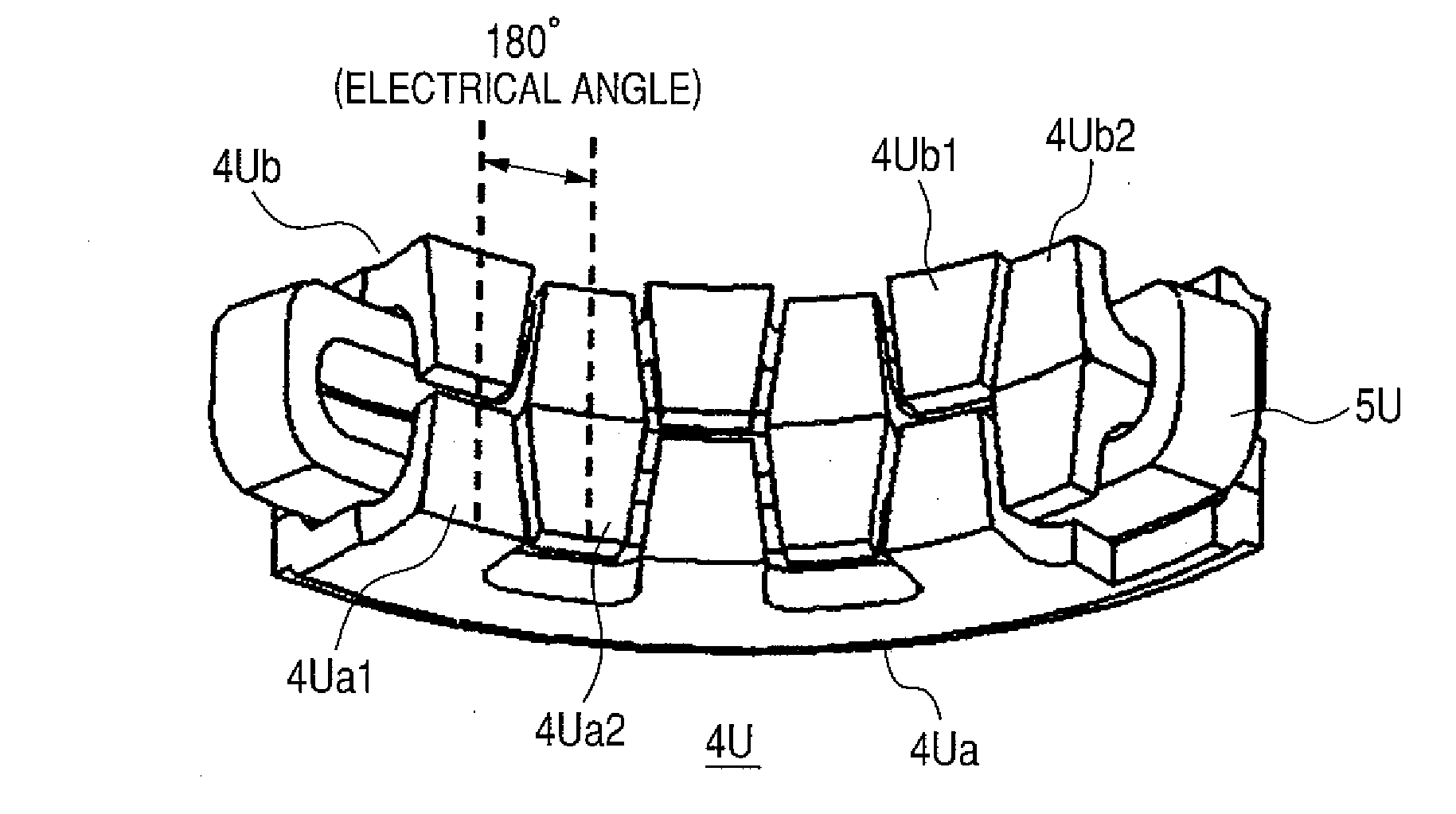

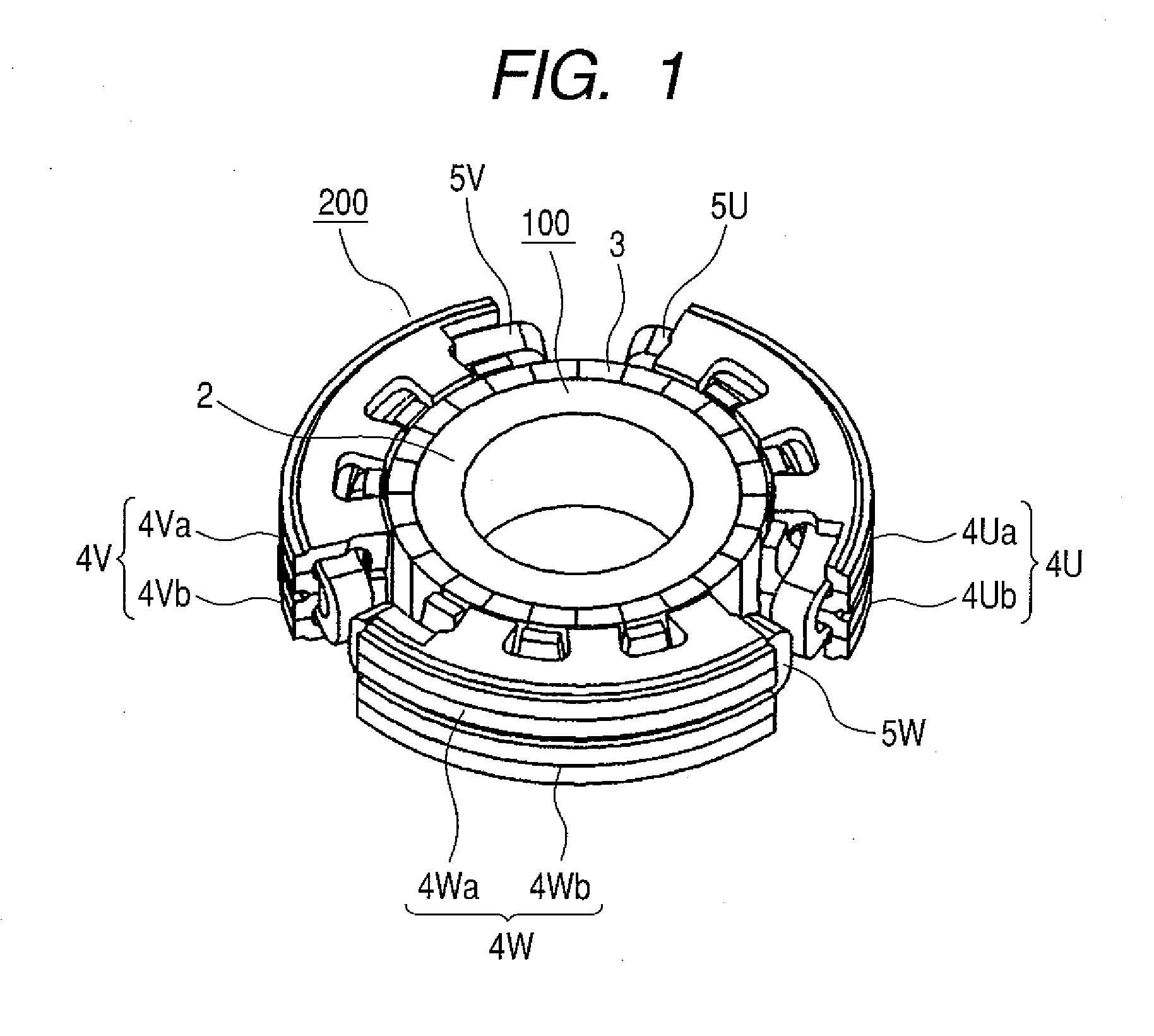

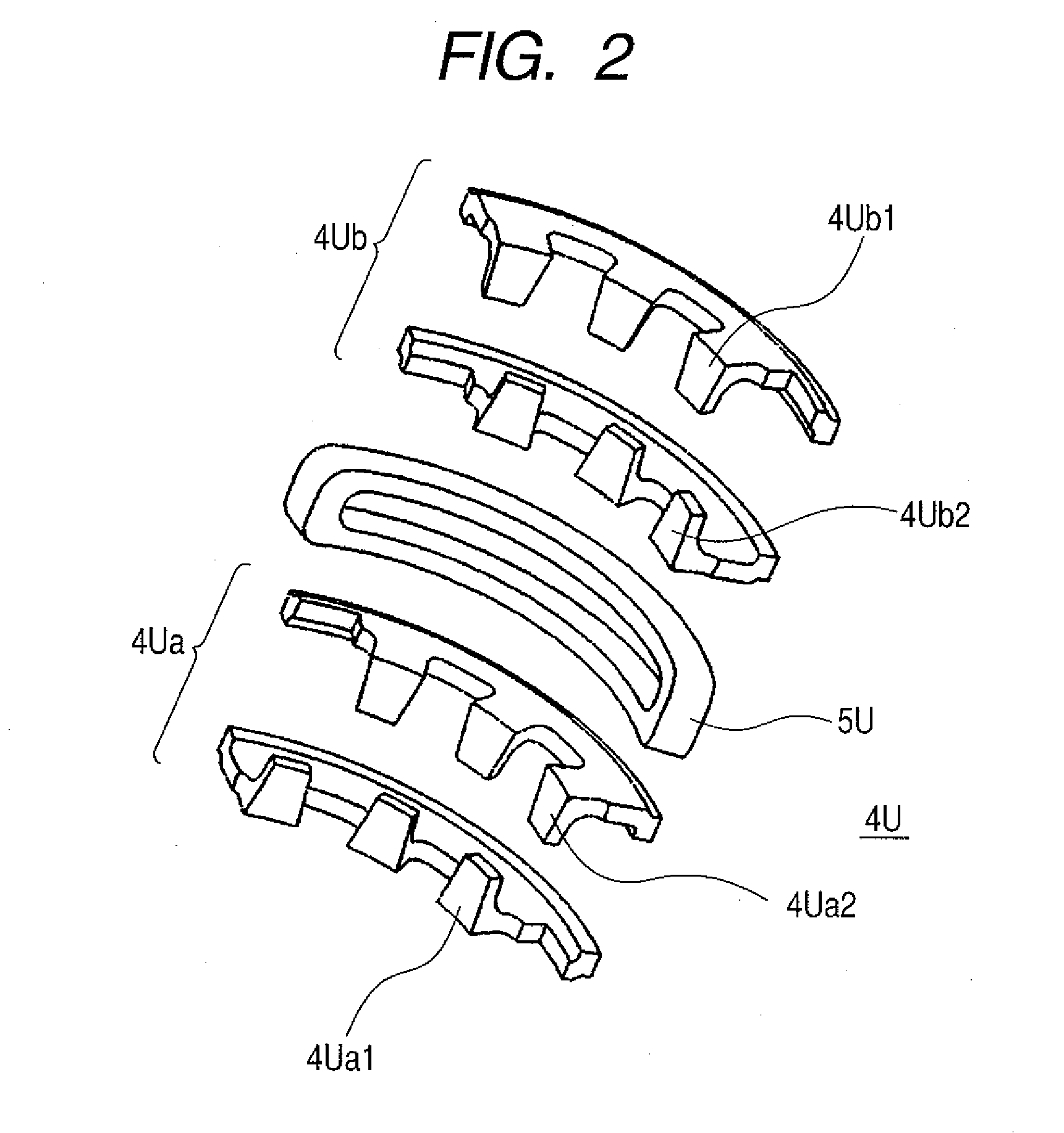

Permanent-magnet synchronous motor

InactiveUS20100253178A1Increase the number of coilsIncrease axial lengthMagnetic circuit rotating partsMagnetic circuit stationary partsRotational axisSynchronous motor

The present invention can achieve a highly efficient permanent-magnet synchronous motor that can obtain output in a high-speed area without prolonging the axis of the permanent-magnet synchronous motor.The present invention provides a highly efficient permanent-magnet synchronous motor that can obtain output in a high-speed area without prolonging the axis of the permanent-magnet synchronous motor, in which stator magnetic poles are formed by dividing a magnetic pole in each phase into a plurality of parts and placing them in a circumferential direction with respect to a rotational axis, at least one divided stator magnetic pole being made movable in the circumferential direction with respect to the rotational axis, and the phase of the movable stator is controlled.

Owner:HITACHI LTD

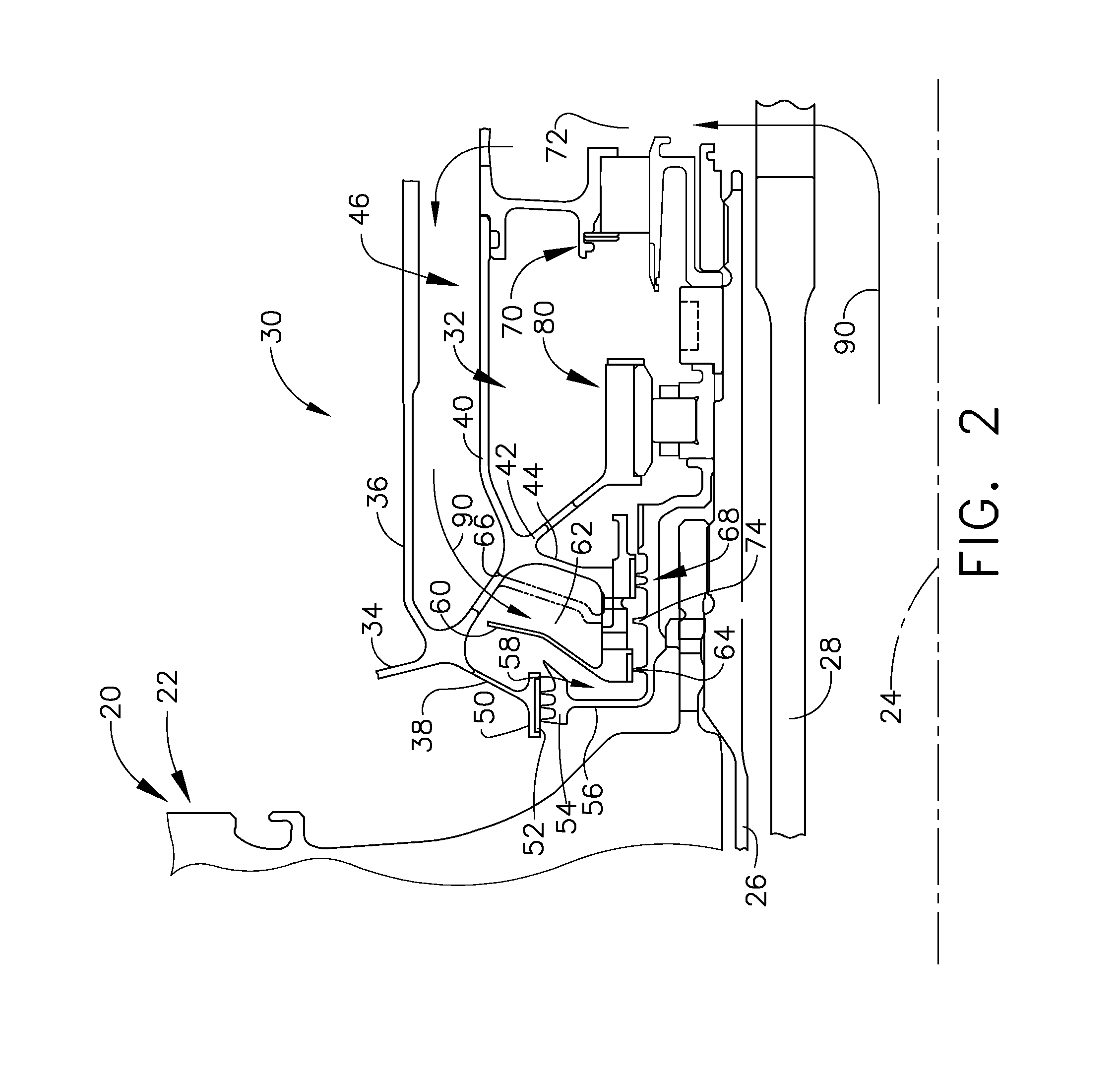

Wide discourager tooth

Oil sump seal pressurization apparatus for turbine engines are disclosed. An example oil sump seal pressurization apparatus may include a non-rotating oil sump housing a bearing; an oil seal isolating an interior of the oil sump; a passage arranged to supply pressurization air to an outward side of the oil seal; a drain arranged to allow draining of oil and venting of at least some of the pressurization air, the drain being positioned axially between the passage and the oil seal; a wide discourager tooth disposed on the shaft and extending radially outward towards a non-rotating land, which may be disposed axially between the passage and the drain, the wide discourager tooth being spaced apart from the land in a radial direction by a gap, the wide discourager tooth including an upper surface; and / or an adjacent tooth disposed on the shaft and extending radially outward from the shaft.

Owner:GENERAL ELECTRIC CO

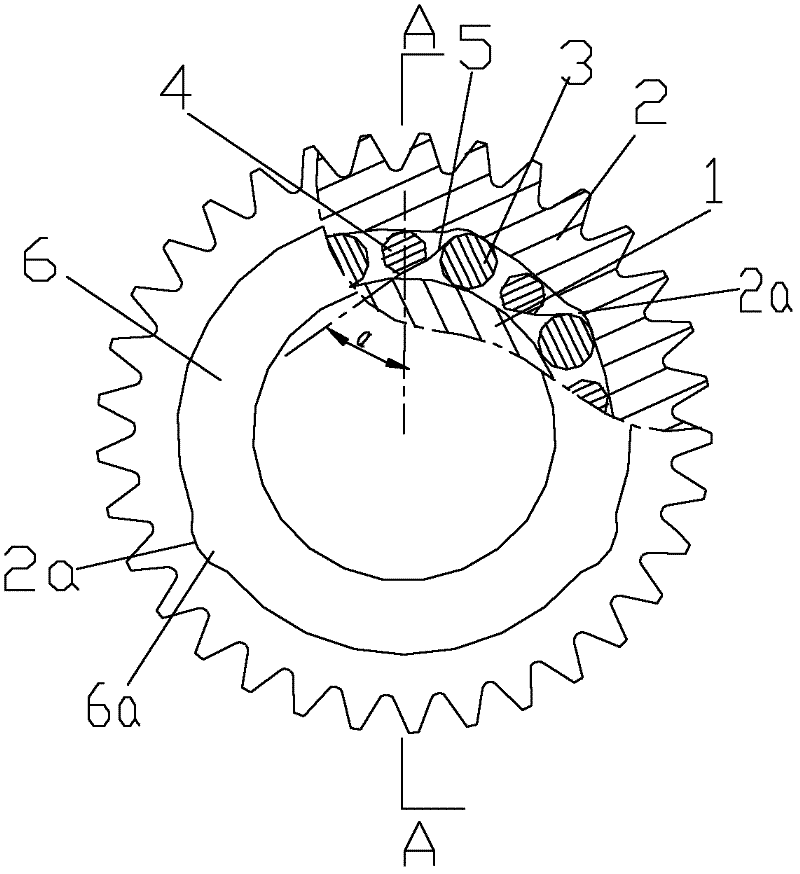

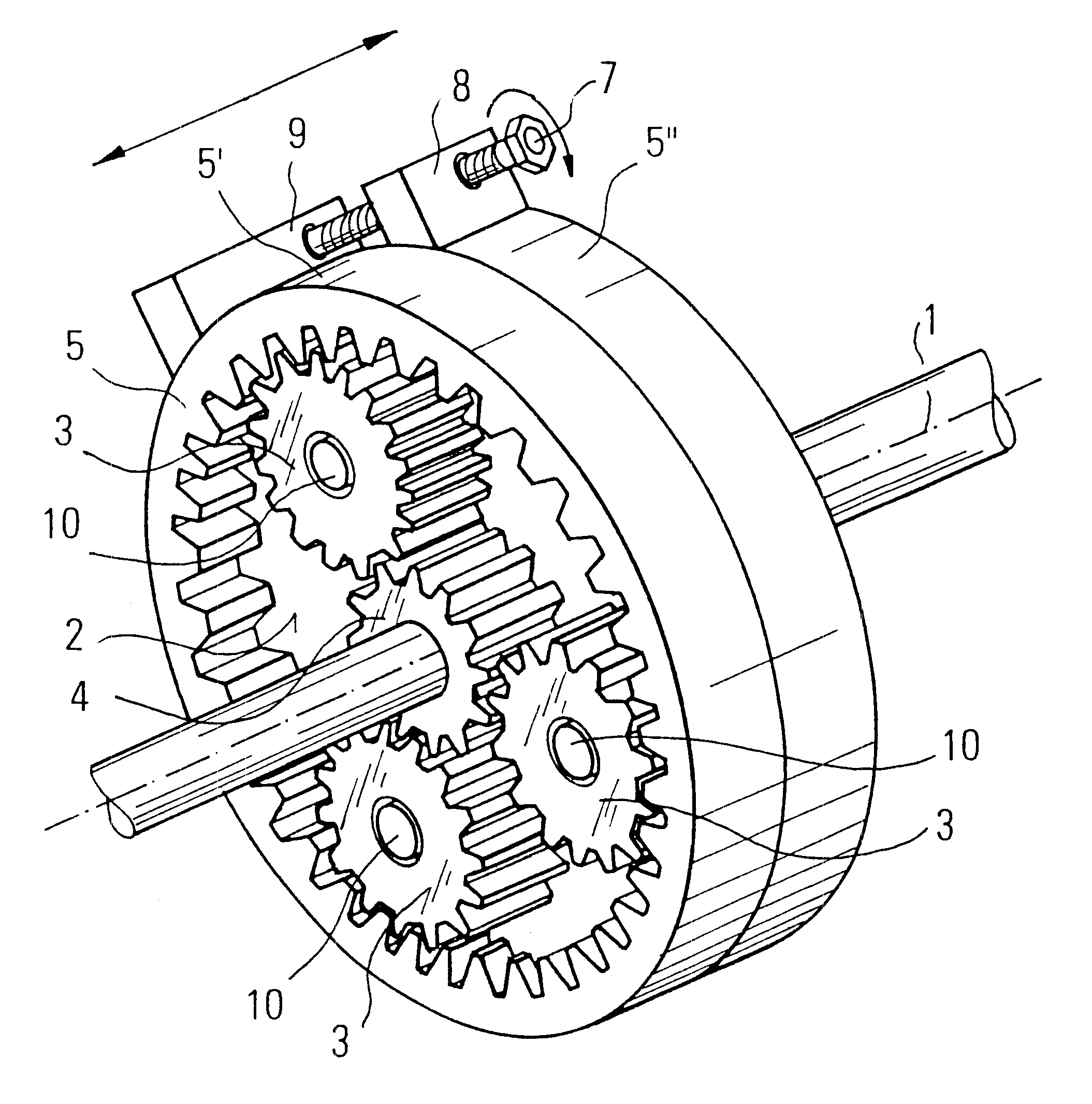

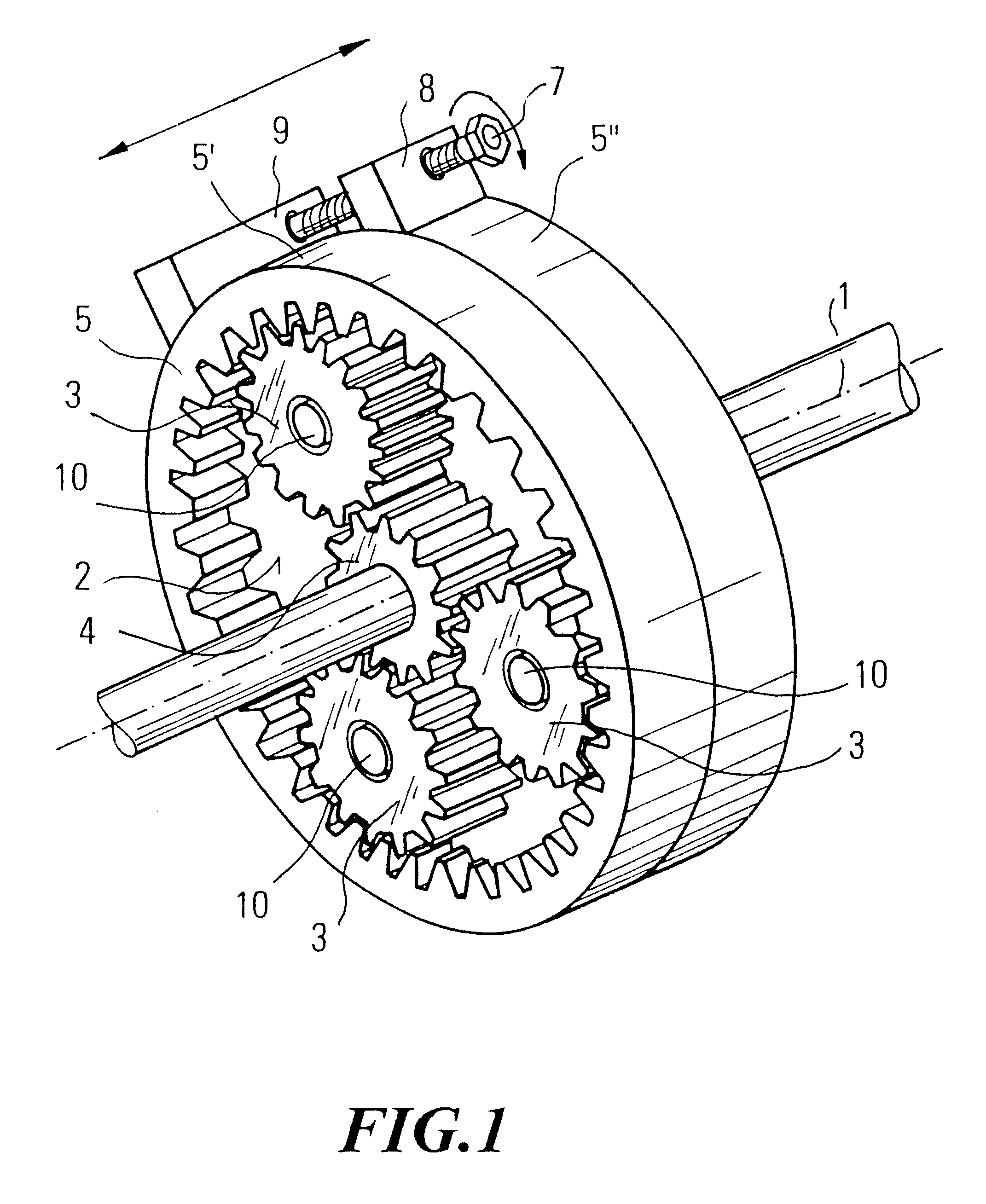

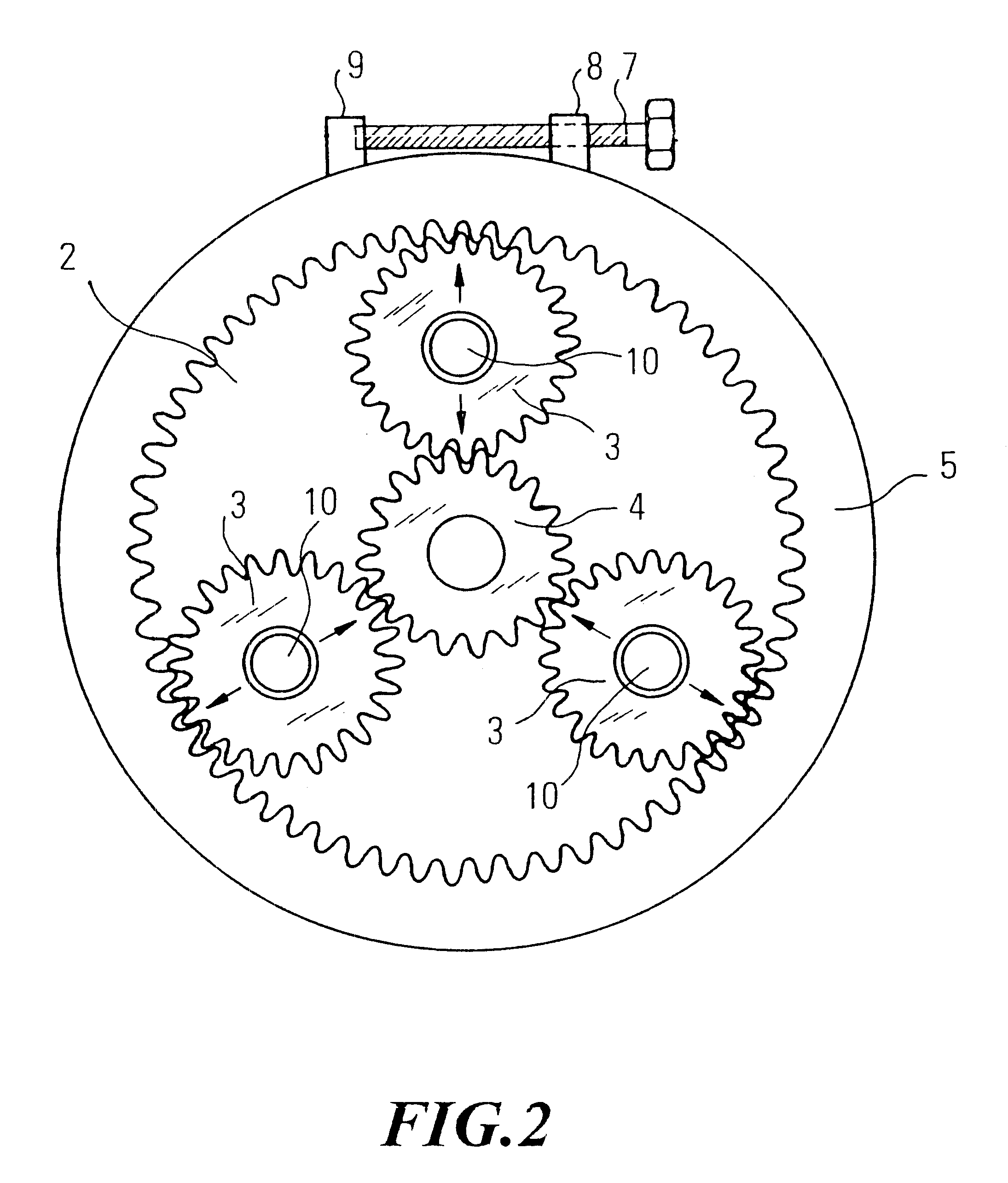

Planet gear

InactiveUS6676558B2Reduce reboundIncrease axial lengthPortable liftingToothed gearingsEngineeringMechanical engineering

The invention relates to a planet gear having a planet carrier rotatable around an axis of rotation, comprising at least one planet wheel arranged on the planet carrier, a sun wheel and a ring gear, wherein the planet wheel is arranged in a movable manner at least radially with respect to the axis of rotation of the planet carrier. To minimize the backlash of a planet gear of this type, it is further provided that the ring gear is formed in two pieces on a plane perpendicular to the axis of rotation of the planet carrier, wherein the two halves of the ring gears can be rotated against each other and thereby effect a radial shift of the planet wheel in the direction towards the sun wheel in order to reduce backlash.

Owner:MAXON MOTOR AG

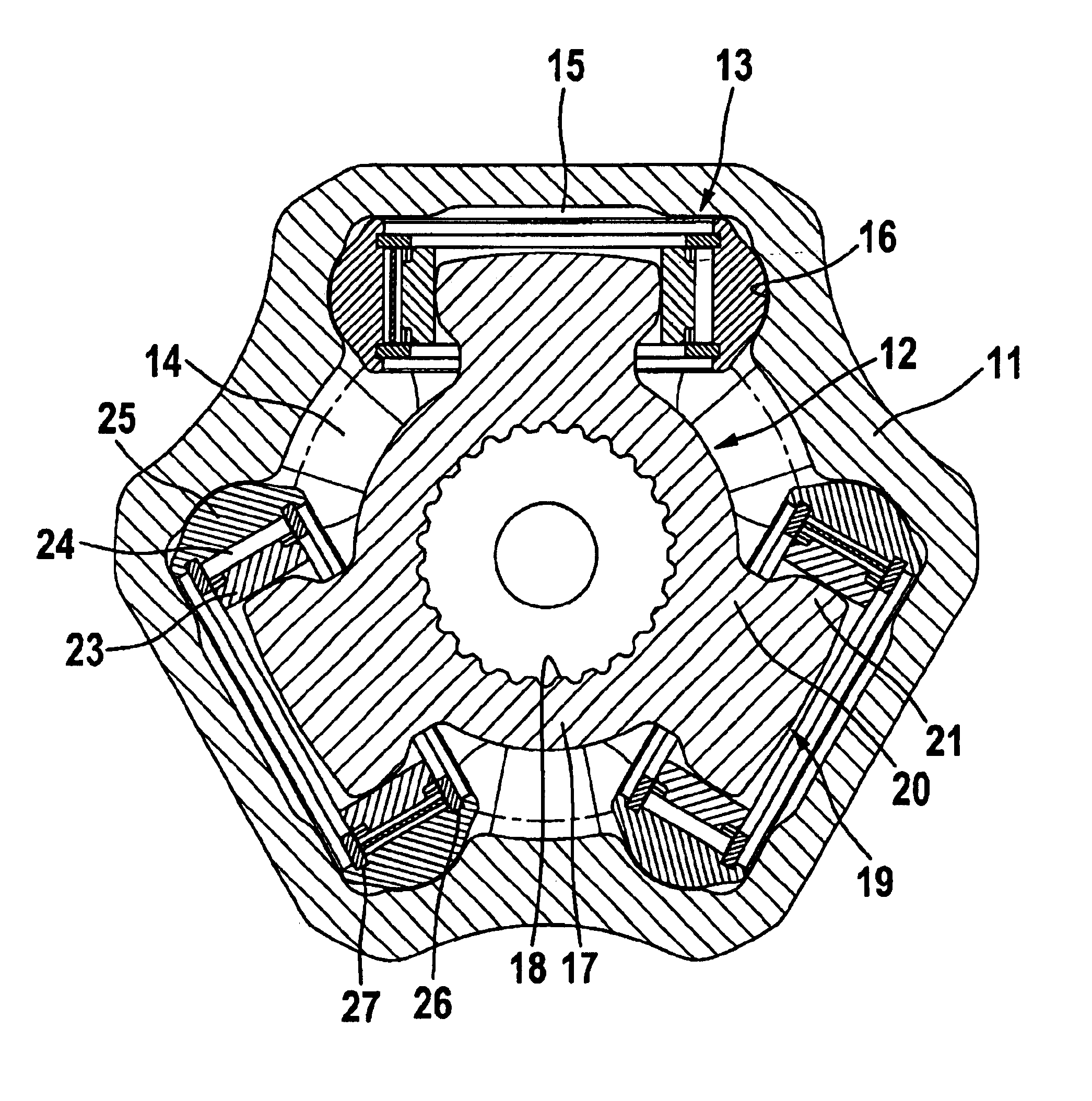

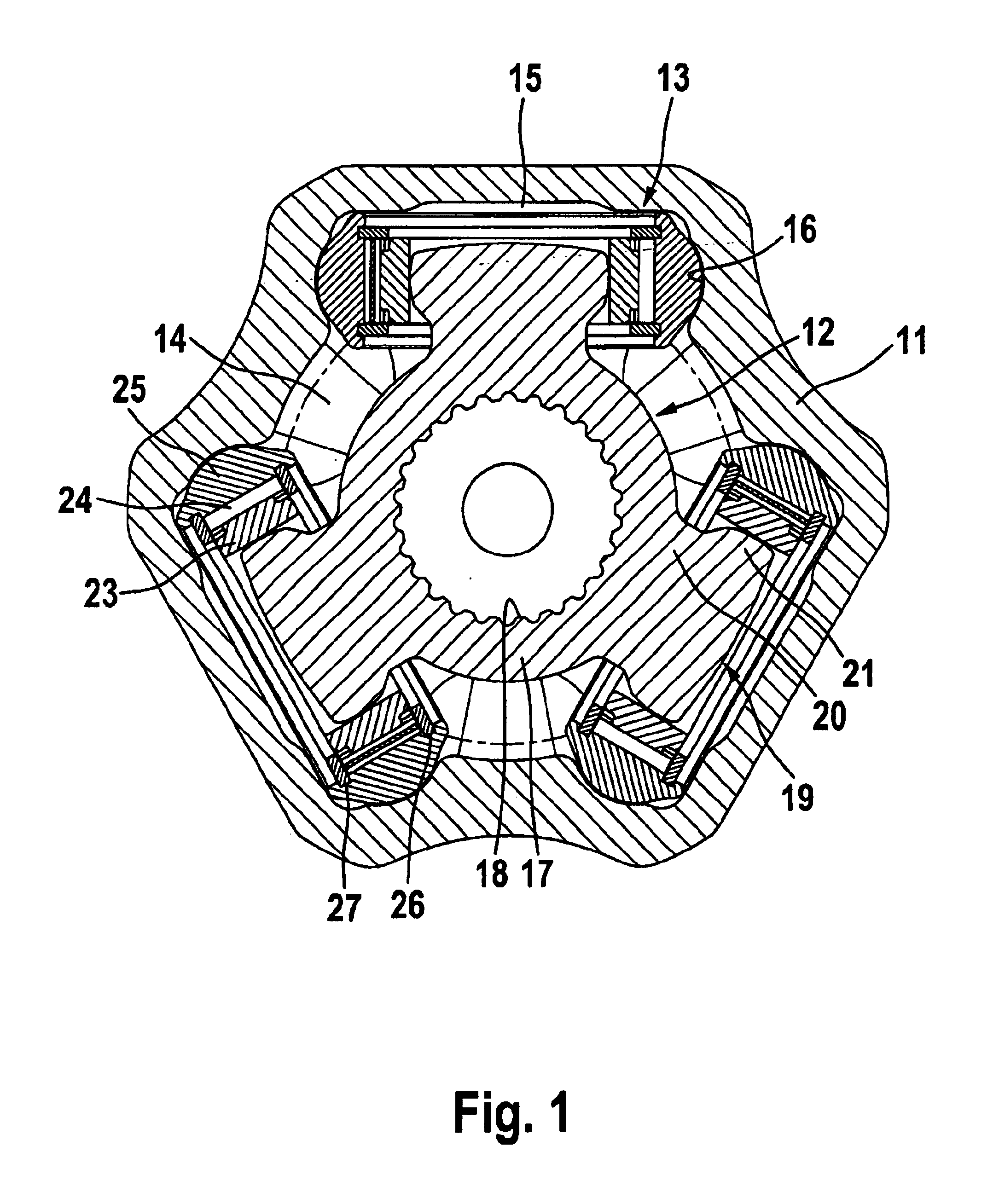

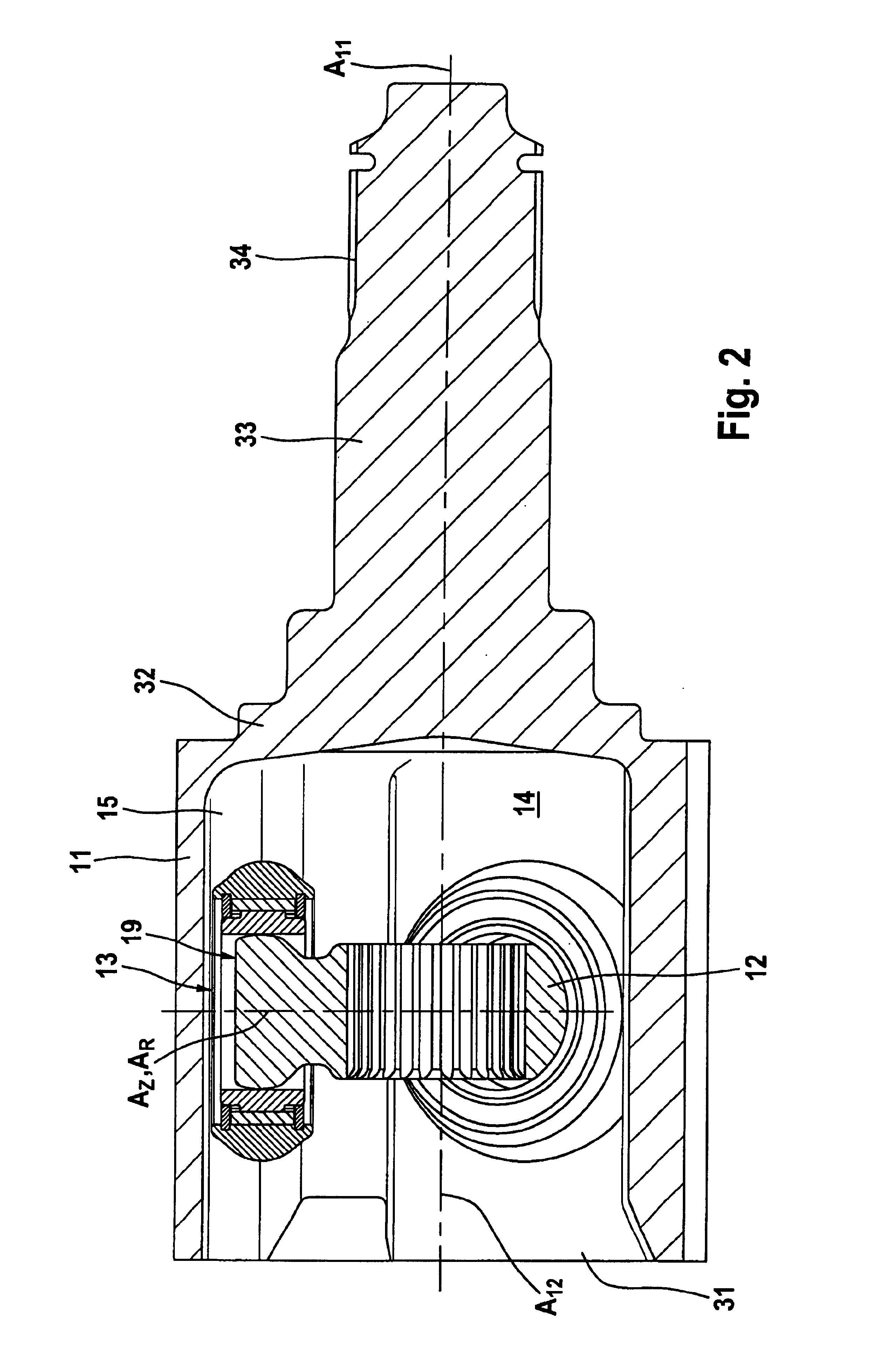

Tripode joint for increased articulation angles

InactiveUS6958016B2Large articulation angleIncrease axial lengthYielding couplingRotary machine partsAxial displacementEngineering

A tripode joint having an outer joint part (11) having three uniformly circumferentially distributed recesses (15) which forms pairs of circumferentially opposed tracks (16) for receiving a roller assembly (13). Each roller assembly (13) is carried on an arm (19) of a tripode star (12). Each arm head has a spherical surface portion. Each roller assembly (13) includes an annular roller carrier (23, 123), bearing needles (24) rotating on the roller carrier (23, 123), and rollers (25) which are rotatably supported on the bearing needles (24). The roller carriers (23, 123) include stop collars which delimit the needle contact face, and which are held with an axial displacement clearance in the direction of the roller axes between axial securing members (26, 27) in such a way that they are secured against being lost relative to the rollers (25).

Owner:GKN DRIVELINE DEUTSCHLAND GMBH

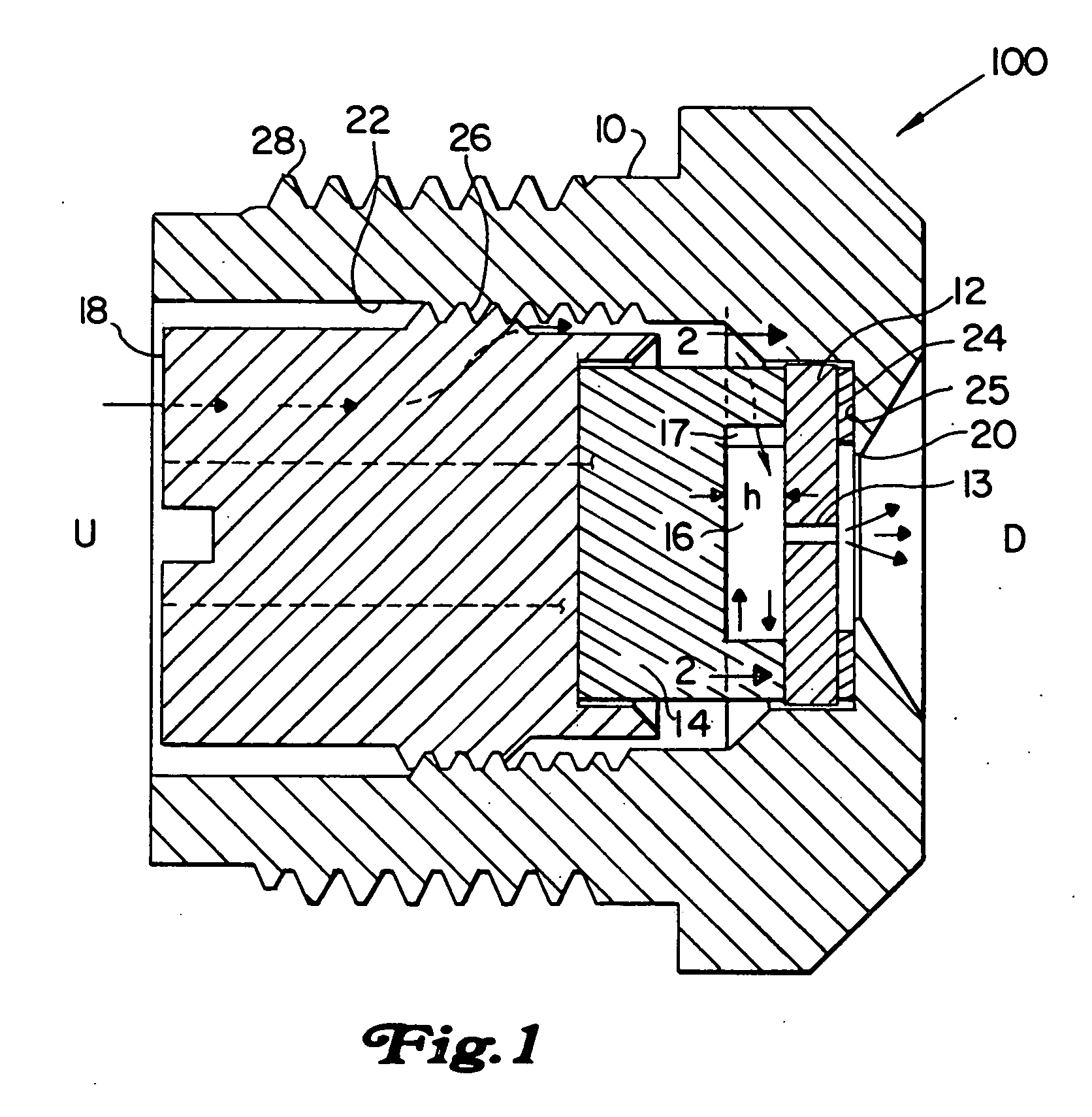

Spray nozzle

InactiveUS7611079B2Reduce total pressure lossFacilitate communicationDust removalFire preventionSpray nozzleEngineering

A spray nozzle which employs a locking and an alignment feature to facilitate the replacement of internal nozzle components. The spray nozzle includes a nozzle body, a swirl element and an orifice disc. The nozzle body defines a central bore which extends between a fluid receiving section and a fluid discharge section and delineates a central axis and delimits an interior locating surface for swirl element and the orifice disc. The orifice disc includes a protuberance associated with the downstream surface thereof which protrudes into the spray opening of the nozzle body.

Owner:DELAVAN

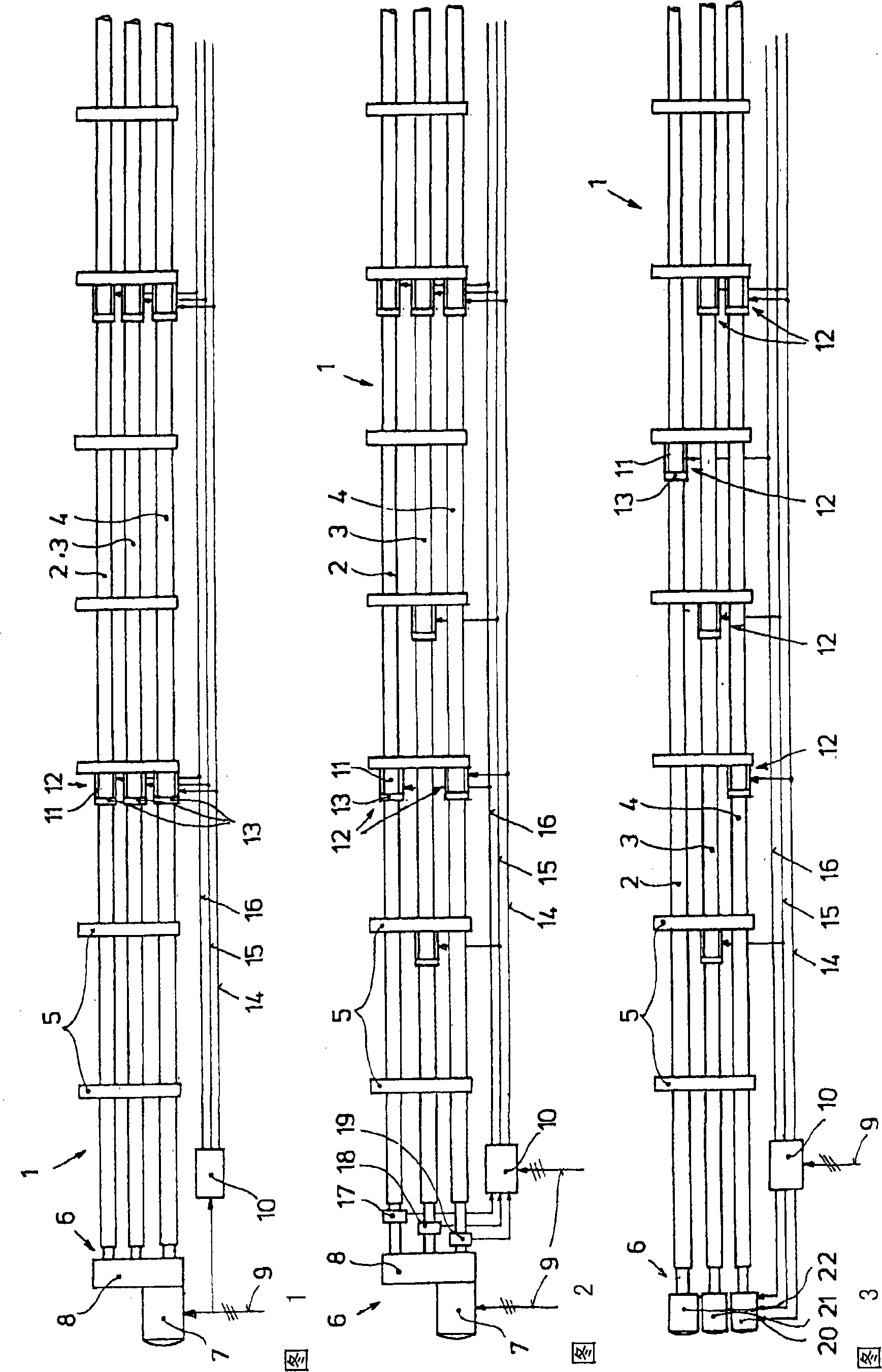

Ring spinning frame comprising drawing systems

ActiveCN101310052ASimplified implementationSimplify its power loadingContinuous wound-up machinesSynchronous motorEngineering

The invention relates to a ring spinning frame comprising drawing systems that are provided with several drawing rollers which can be driven at speeds causing predetermined drawings by means of main drawing system drive units. Auxiliary drawing roller drive units are assigned to the drawing rollers at a distance from the main drawing system drive unit.; The inventive ring spinning frame is characterized in that drawing rollers (2, 3, 4) are equipped with several auxiliary drawing roller drive units (12) which are distributed along the length of the drawing system (1) and impinge the drawing roller with torque that at least reduces torsion thereof such that torques preventing or at least reducing torsion of drawing rollers can be introduced also between the ends of very long drawing rollers without increasing the division of the ring spinning frame at said points or interrupting the sequence thereof and without having to use synchronous motors.

Owner:SAURER GERMANY GMBH & CO KG

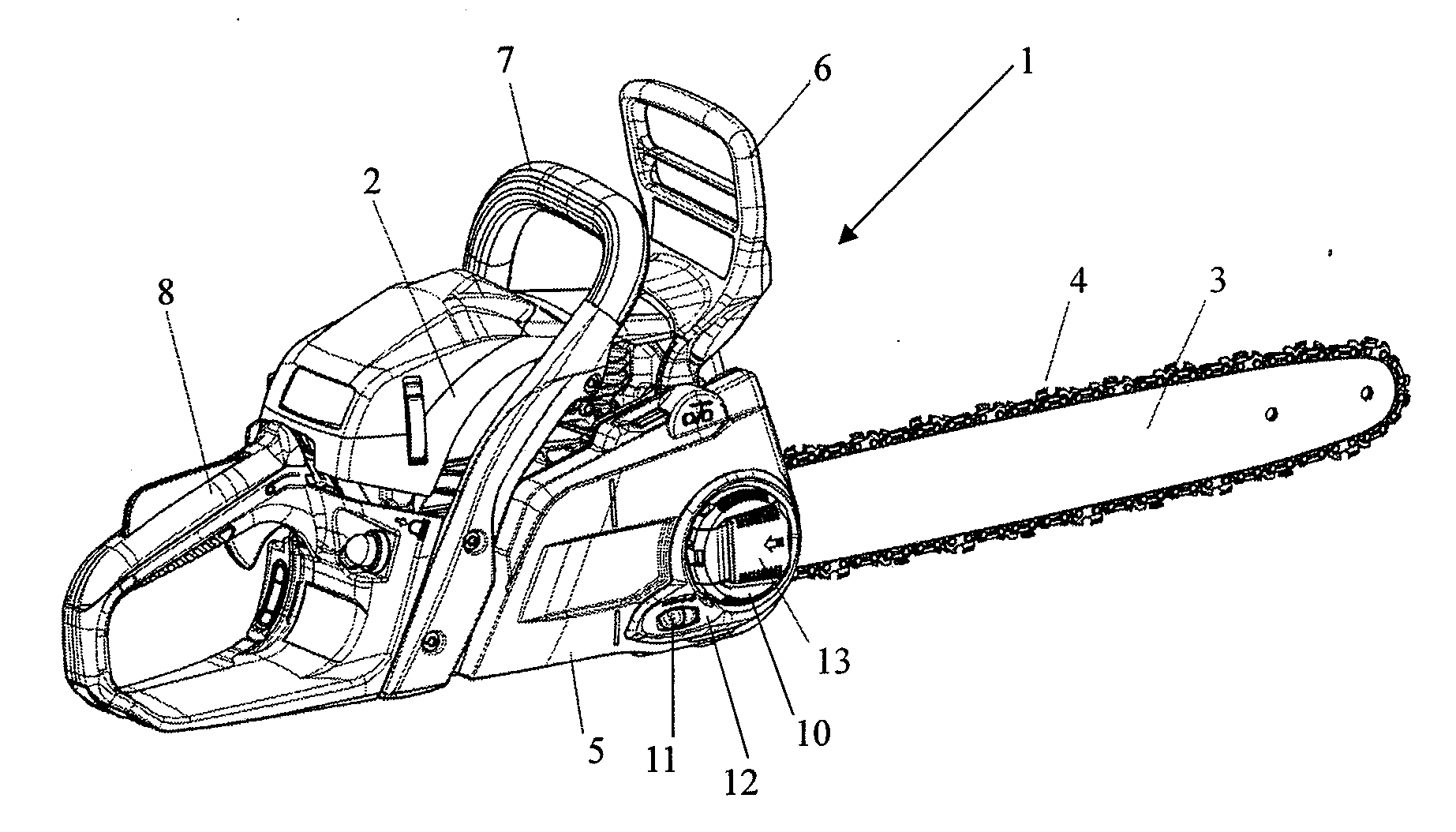

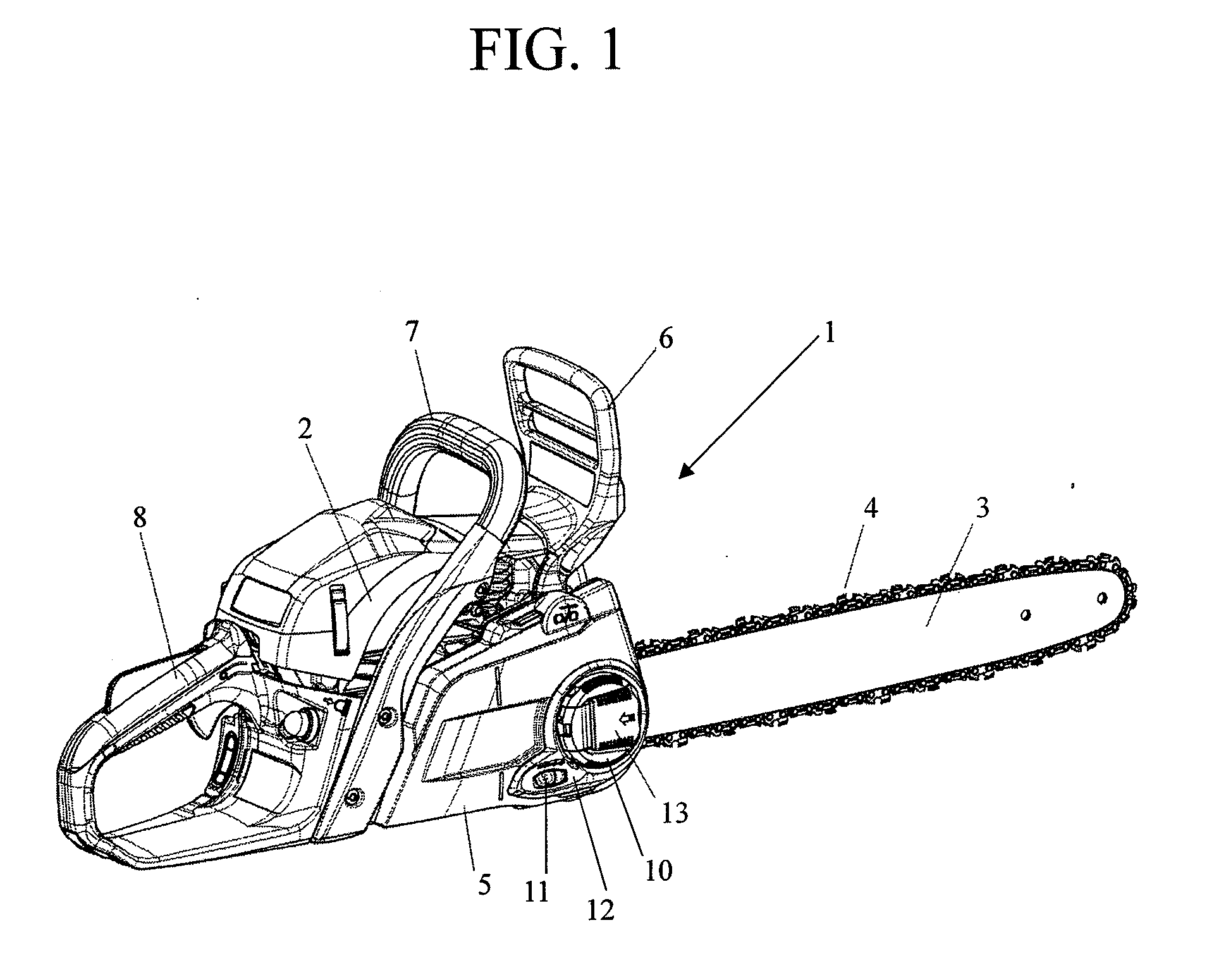

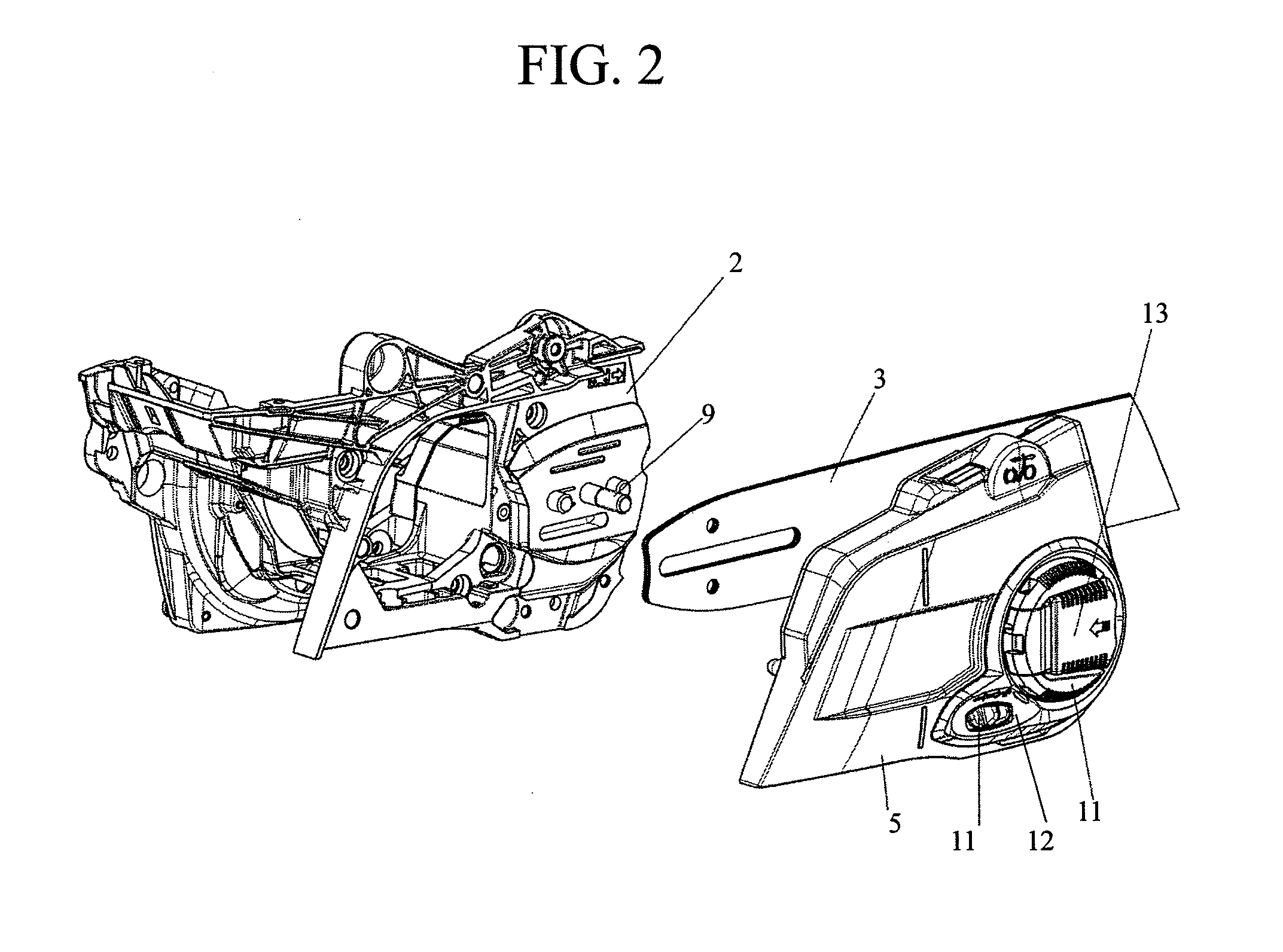

Guide bar fastening device for chain saw

ActiveUS20140290075A1Improve fastening forcePrevent excessive operating forceMetal sawing devicesMetal sawing accessoriesEngineeringChain saw

To provide an operation lever including a first lever that has a base end portion swingably supported to a peripheral portion of a nut member for fastening a guide bar in a chain saw, and a second lever that is engaged with the first lever in a manner slidable in an axial direction. The operation lever can be placed in a receiving portion of the nut member with an axial length thereof shortened, and can be manipulated to rotate the nut member by being gripped on an outer end portion of the second lever in a state in which the operation lever is lifted out from the receiving portion and the axial length is lengthened. Thus, a sufficient fastening force for the guide bar can be obtained, and operability can be improved.

Owner:MAKITA CORP

Radial lip seal device

Owner:CARL FREUDENBERG KG

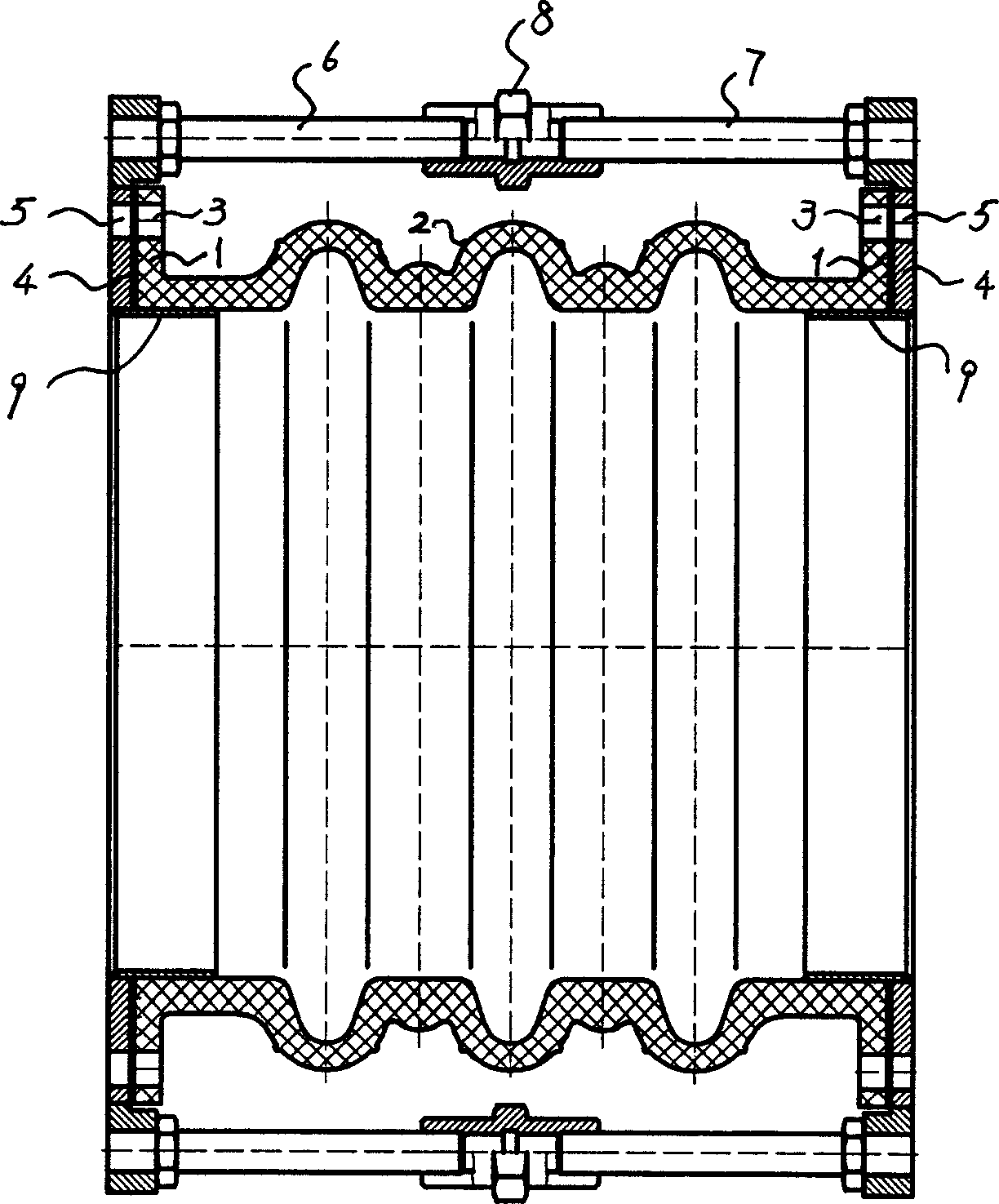

Adjustable bending rubber joint

InactiveCN1614289AInstallation saves time and effortTime-saving and labor-saving disassemblyPipeline expansion-compensationEngineeringUltimate tensile strength

Owner:刘运章

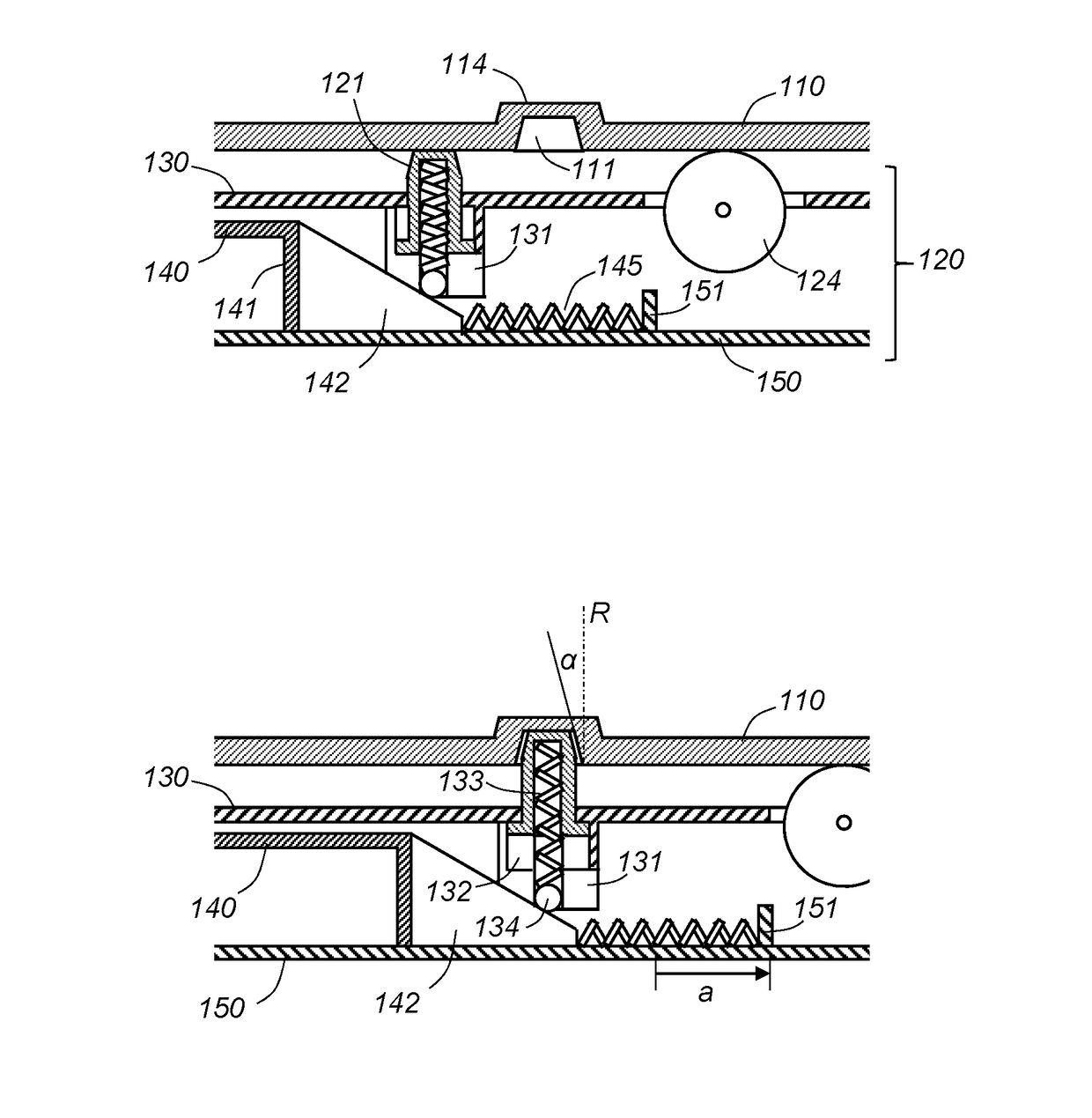

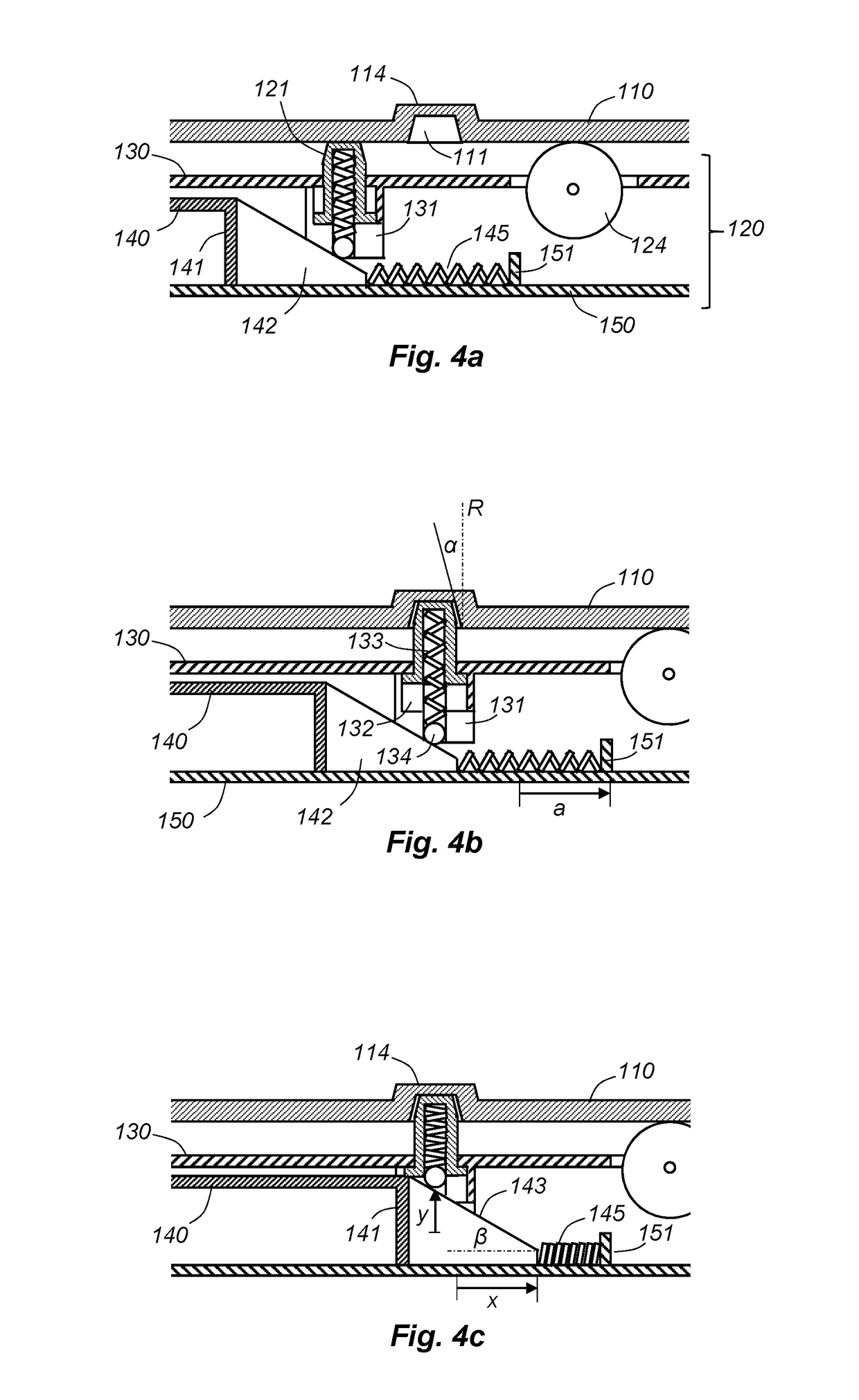

Positioning system

ActiveUS20180156000A1Increase axial lengthReduce the effects of frictionSurveyDrilling rodsMechanical engineeringPositioning system

A system (100) for positioning a working tool (21) in a wellbore (1). The positioning system (100) comprises a casing element (110) with a marker (111, 112, 113) provided on an inner surface, the marker (111, 112, 113) having a distinct diameter different from the inner diameter of the casing element (110). The system further comprises a positioning tool (120) with a latching element (121, 122) adapted to form a latch (115) with the marker (111, 112, 113), and a force detector (130) adapted to detect an axial latching force (FL) applied to a tubing string (20) from the latch (115) when the casing element (110) is located within the wellbore (1) and the force detector (130) is located at a surface (2) outside the wellbore (1).

Owner:COMITT WELL SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com