Patents

Literature

163results about How to "Increase magnetic density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

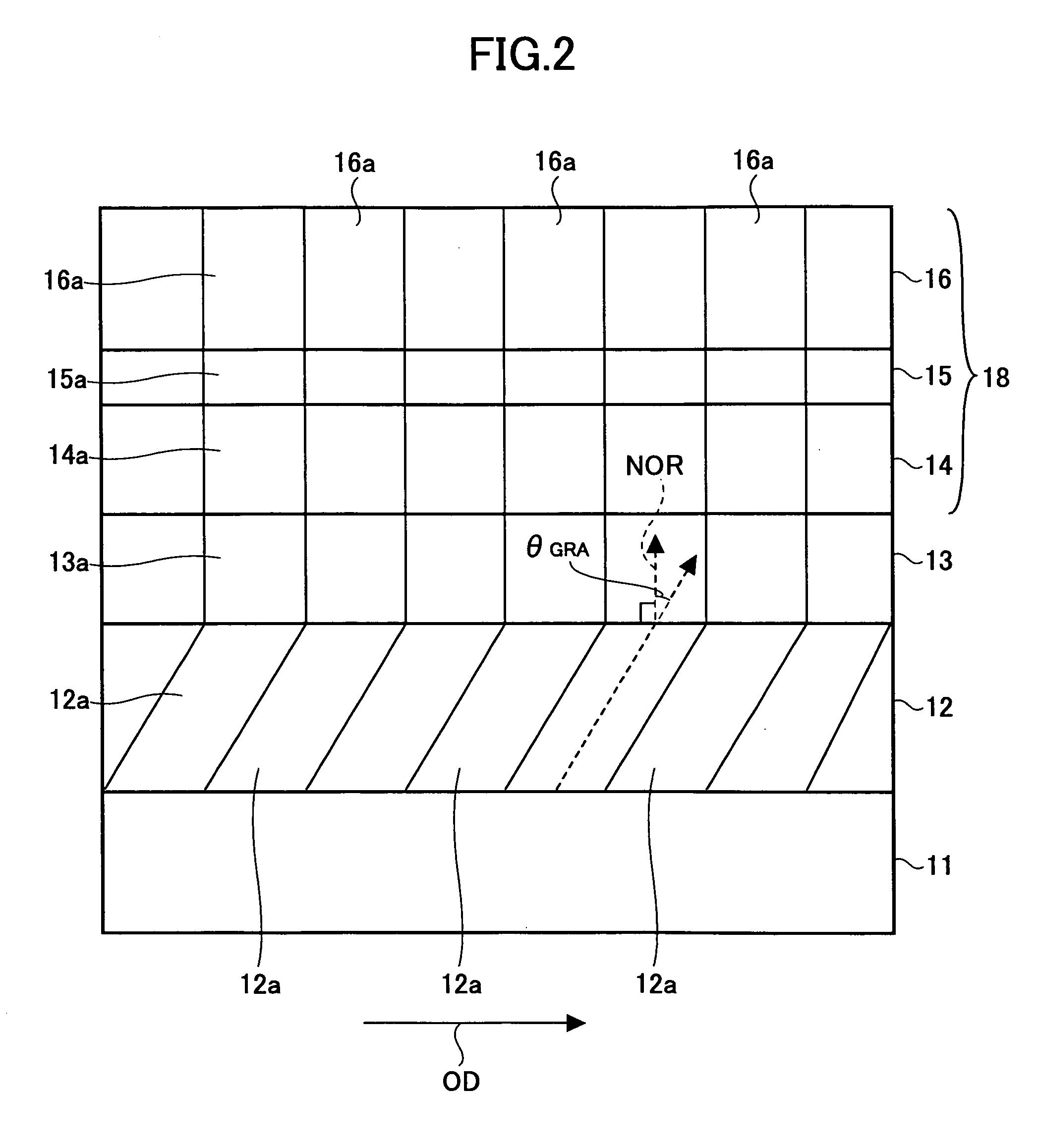

Magnetic recording media

InactiveUS20110151281A1Medium noise is reducedSuitable for useRecord information storageMaterials with non-metallic substancesNon magneticMagnetic layer

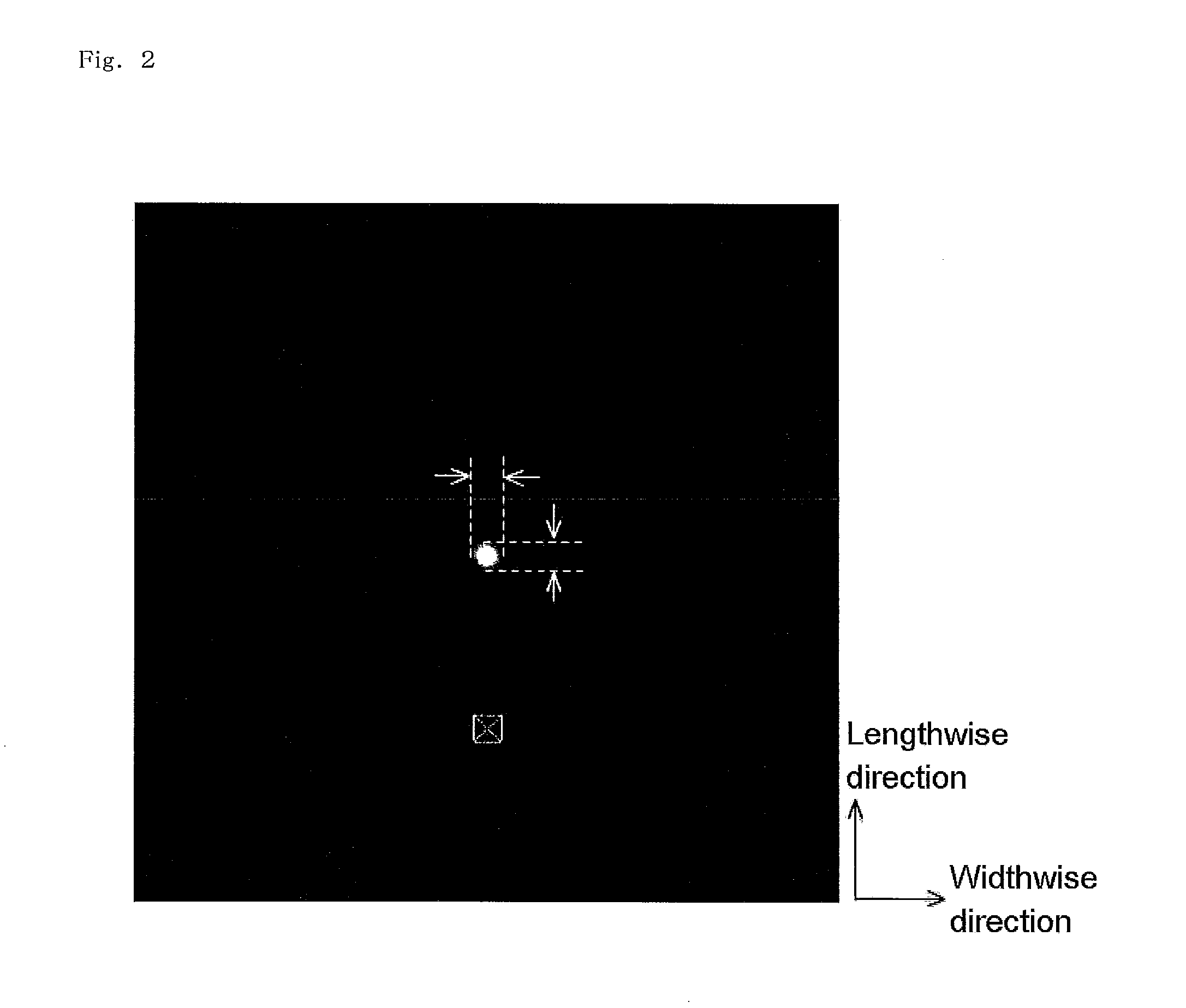

A magnetic recording medium which has a non-magnetic substrate and a magnetic layer formed on the non-magnetic substrate, in which the magnetic layer contains magnetic powder with a particle size of 40 nm or less and a binder, an autocovariance length Ma of the magnetic layer in its lengthwise direction is 70 nm or less, an autocovariance length Mb of the magnetic layer in its widthwise direction is 80 nm or less, and a ratio Ma / Mb is from 0.80 to 1.20.

Owner:HITACHT MAXELL LTD

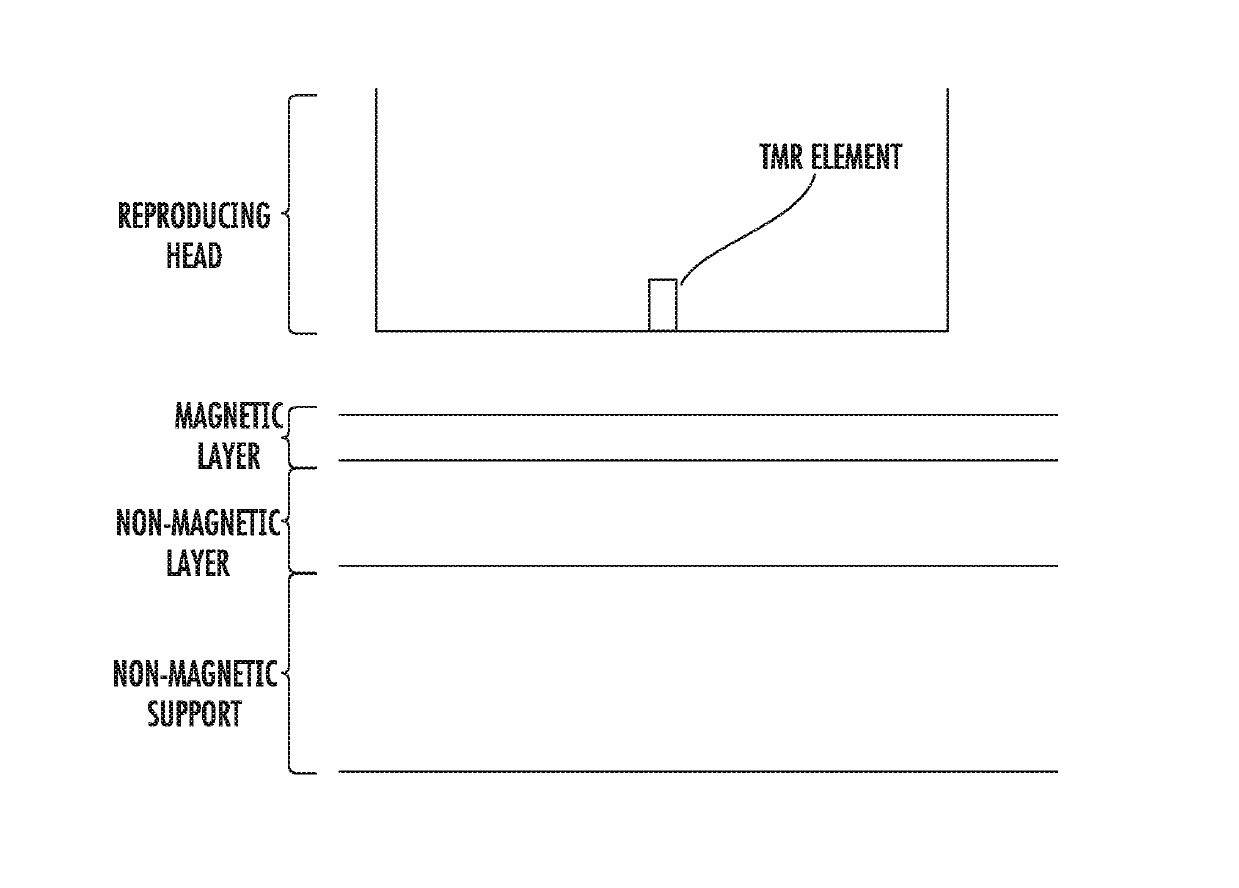

Magnetic tape device and magnetic reproducing method

ActiveUS20180286449A1Improve signal-to-noise ratioIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

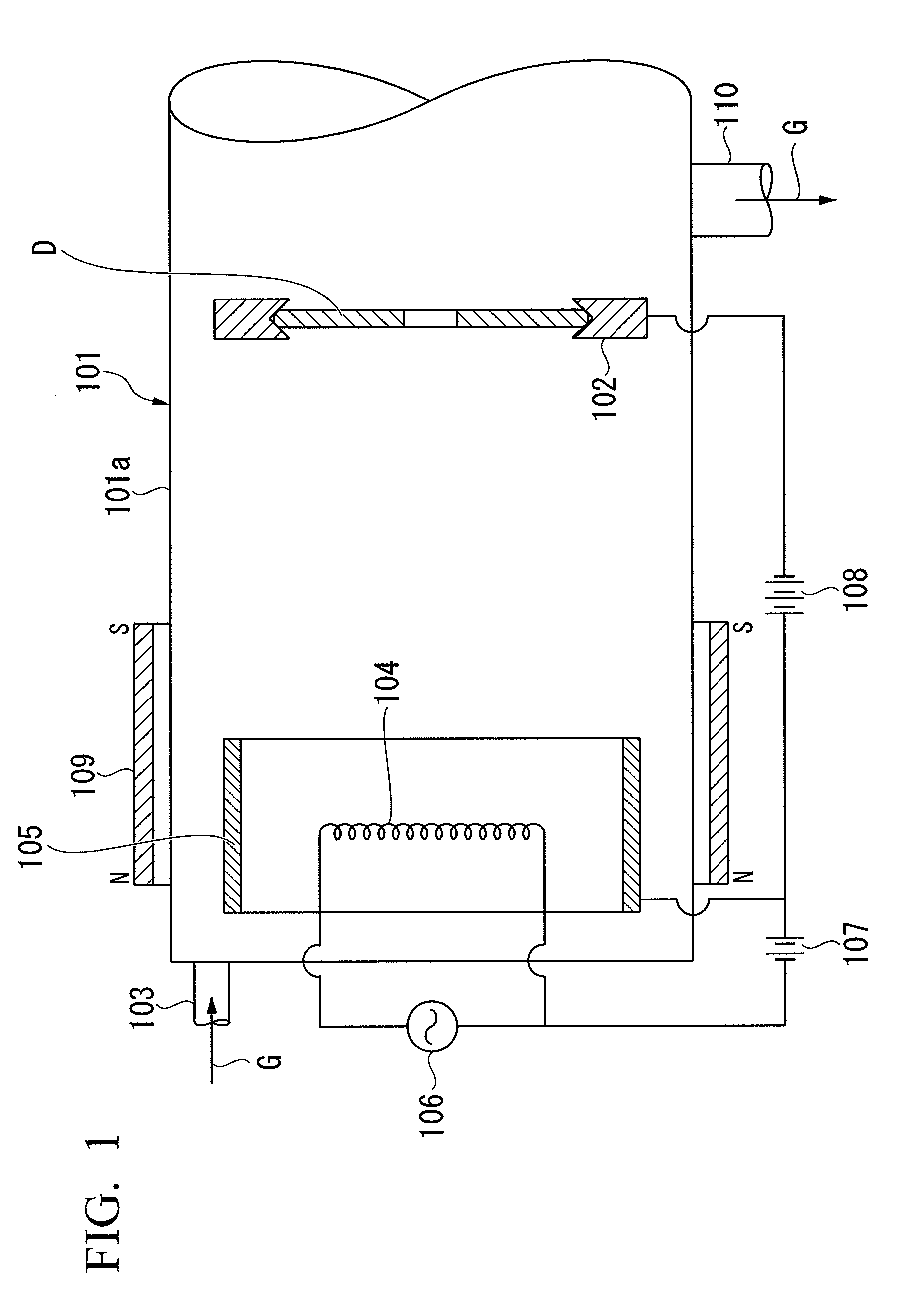

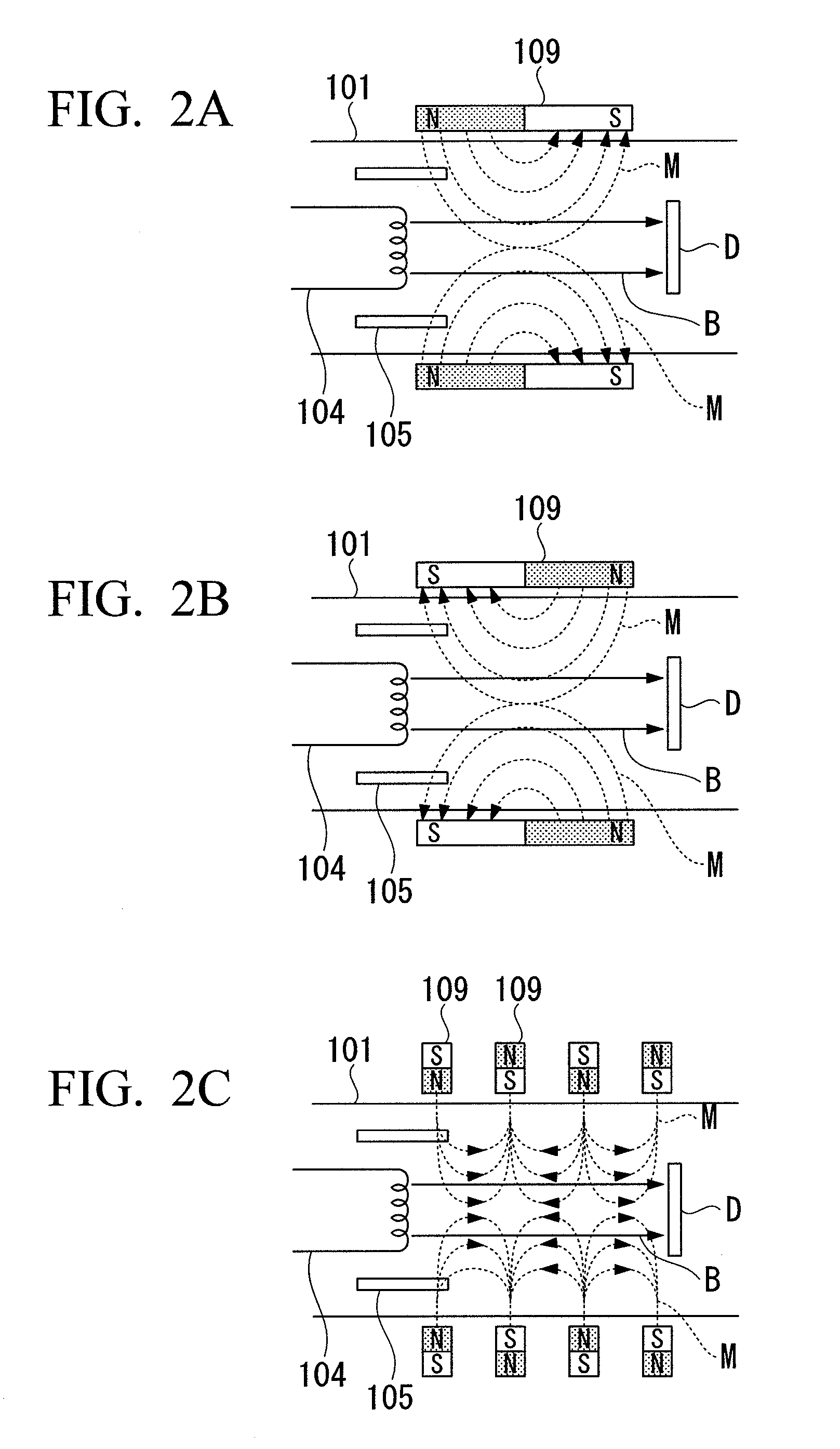

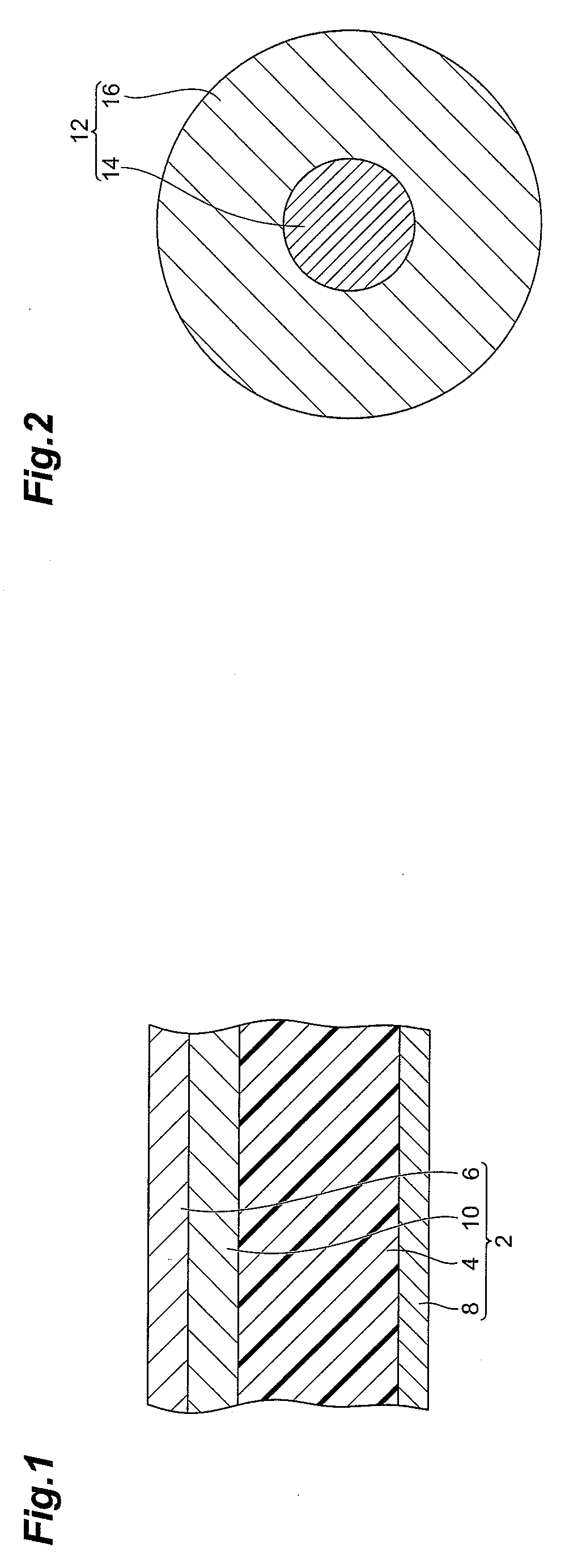

Method of forming carbon film, method of manufacturing magnetic recording medium, and apparatus for forming carbon film

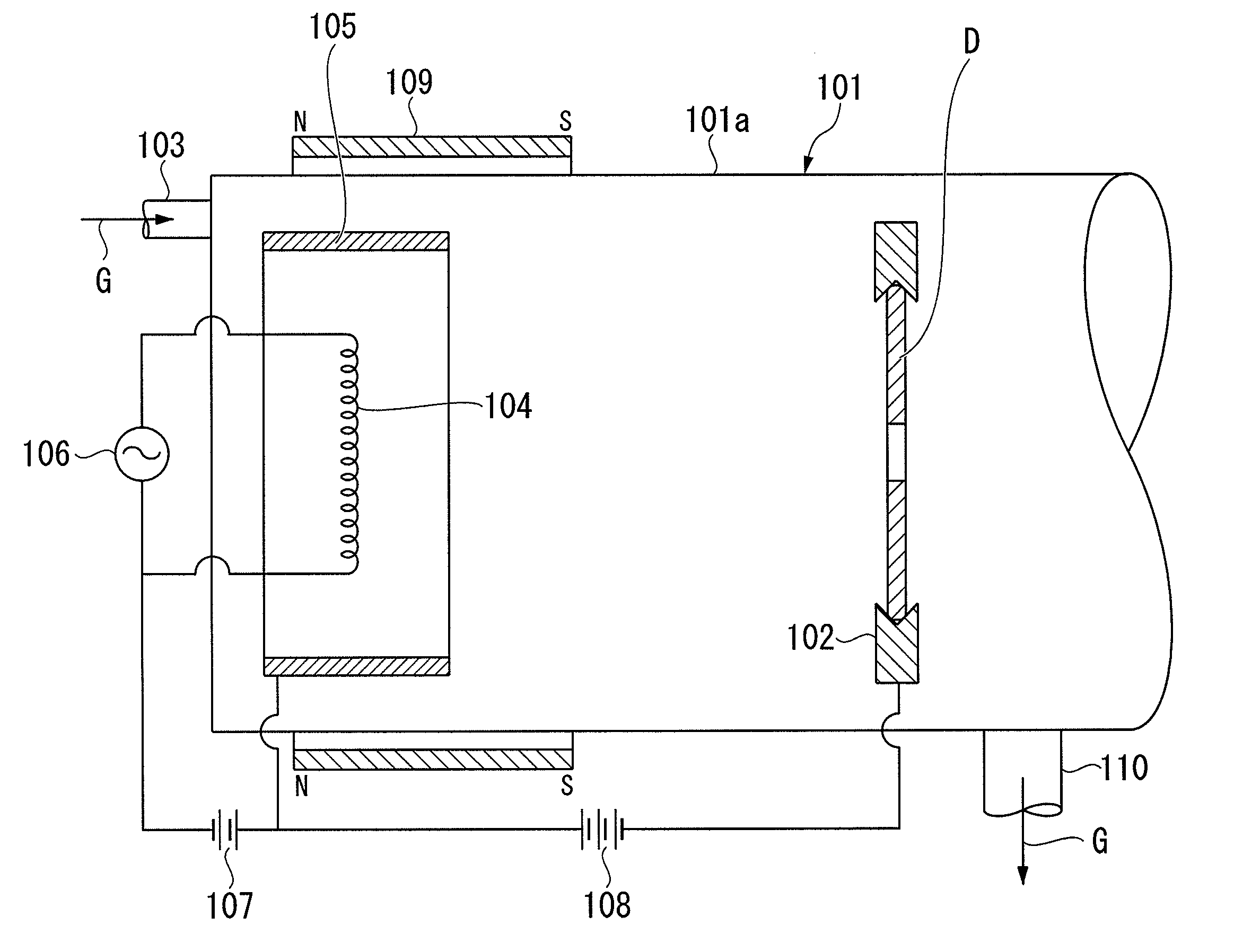

InactiveUS20100028563A1High hardnessReduce thicknessSpark gapsMagnetic layer protectionCarbon filmInternal pressure

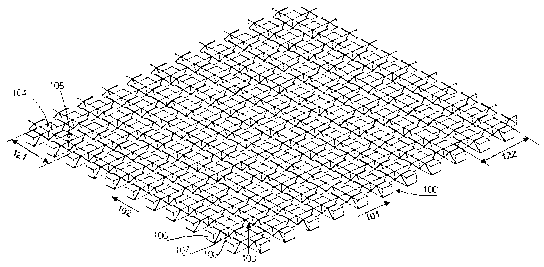

The present invention provides a carbon film forming method capable of forming a dense carbon film with high hardness. The carbon film forming method includes: introducing a raw material gas G including carbon into a deposition chamber 101 whose internal pressure is reduced; ionizing the raw material gas G using a discharge between a filament-shaped cathode electrode 104 heated by electrical power and an anode electrode 105 provided around the cathode electrode; and accelerating and radiating the ionized gas to the surface of a substrate D. A magnetic field is applied by a permanent magnet 109 to increase the ion density of the ionized gas accelerated and radiated to the surface of the substrate D. In this way, it is possible to form a carbon film with high hardness and high density on the surface of the substrate D.

Owner:SHOWA DENKO HD SINGAPORE PTE

Magnetic tape device and magnetic reproducing method

ActiveUS10403317B2Increase recording capacityHigh capacity)Magnetic materials for record carriersRecord information storageMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

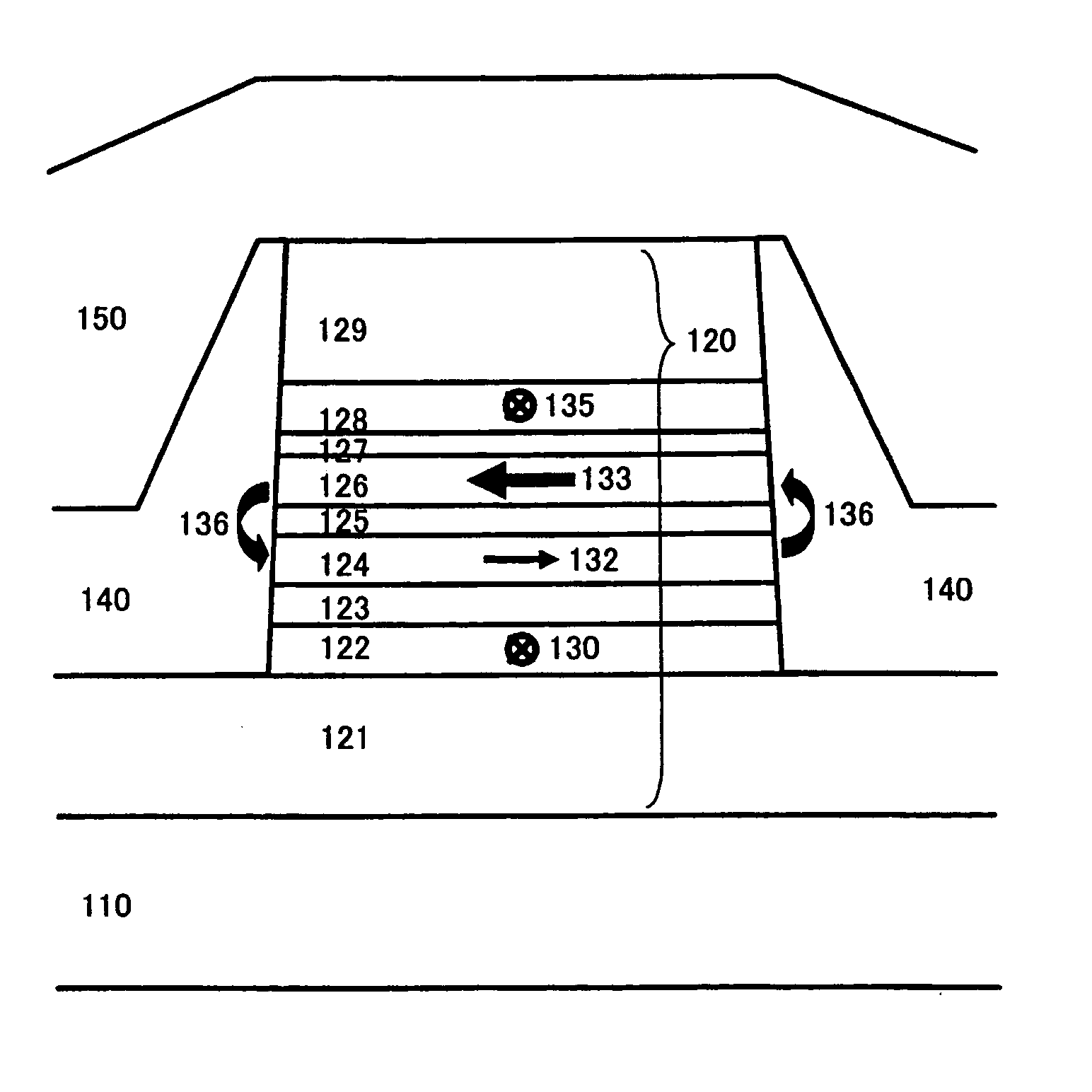

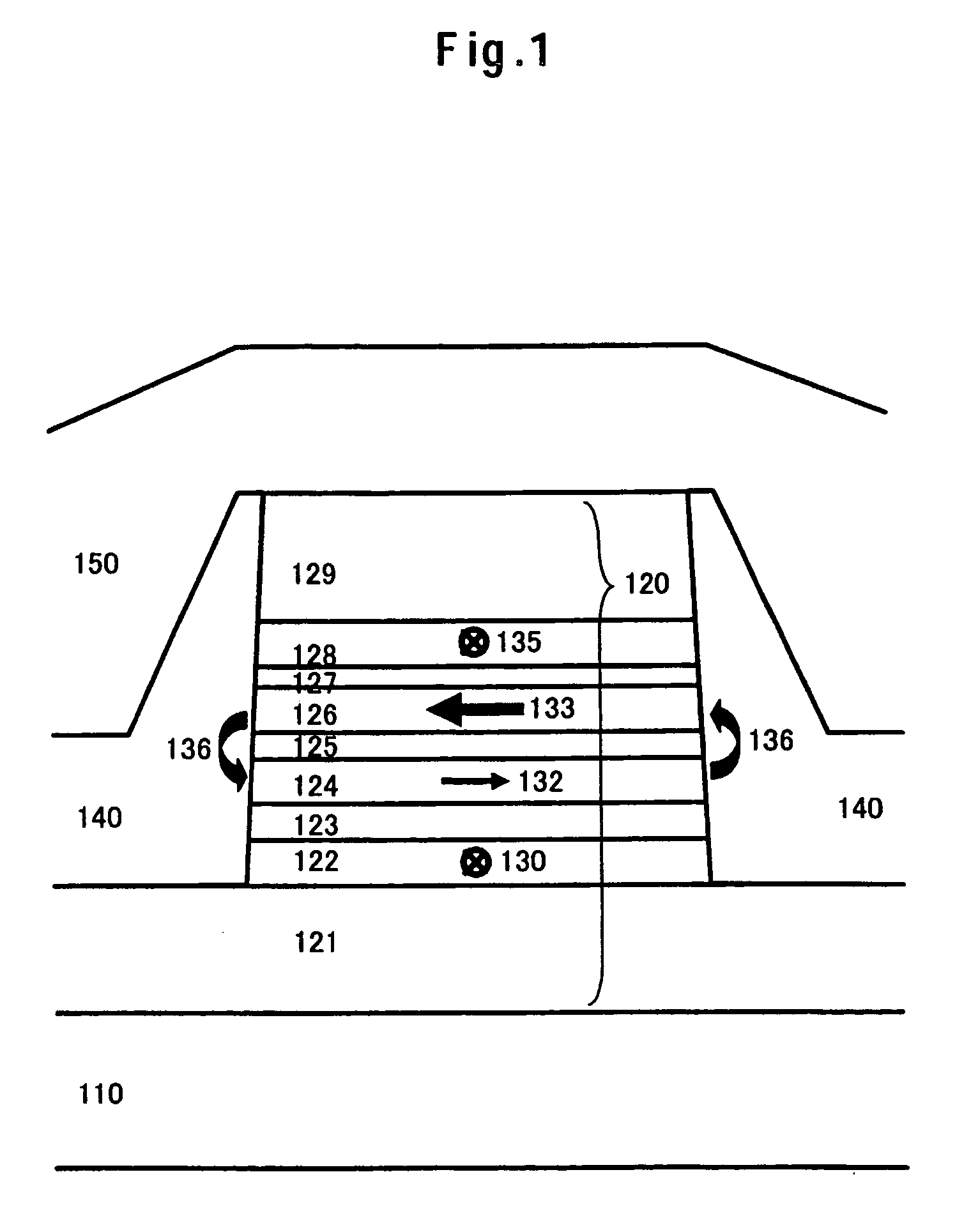

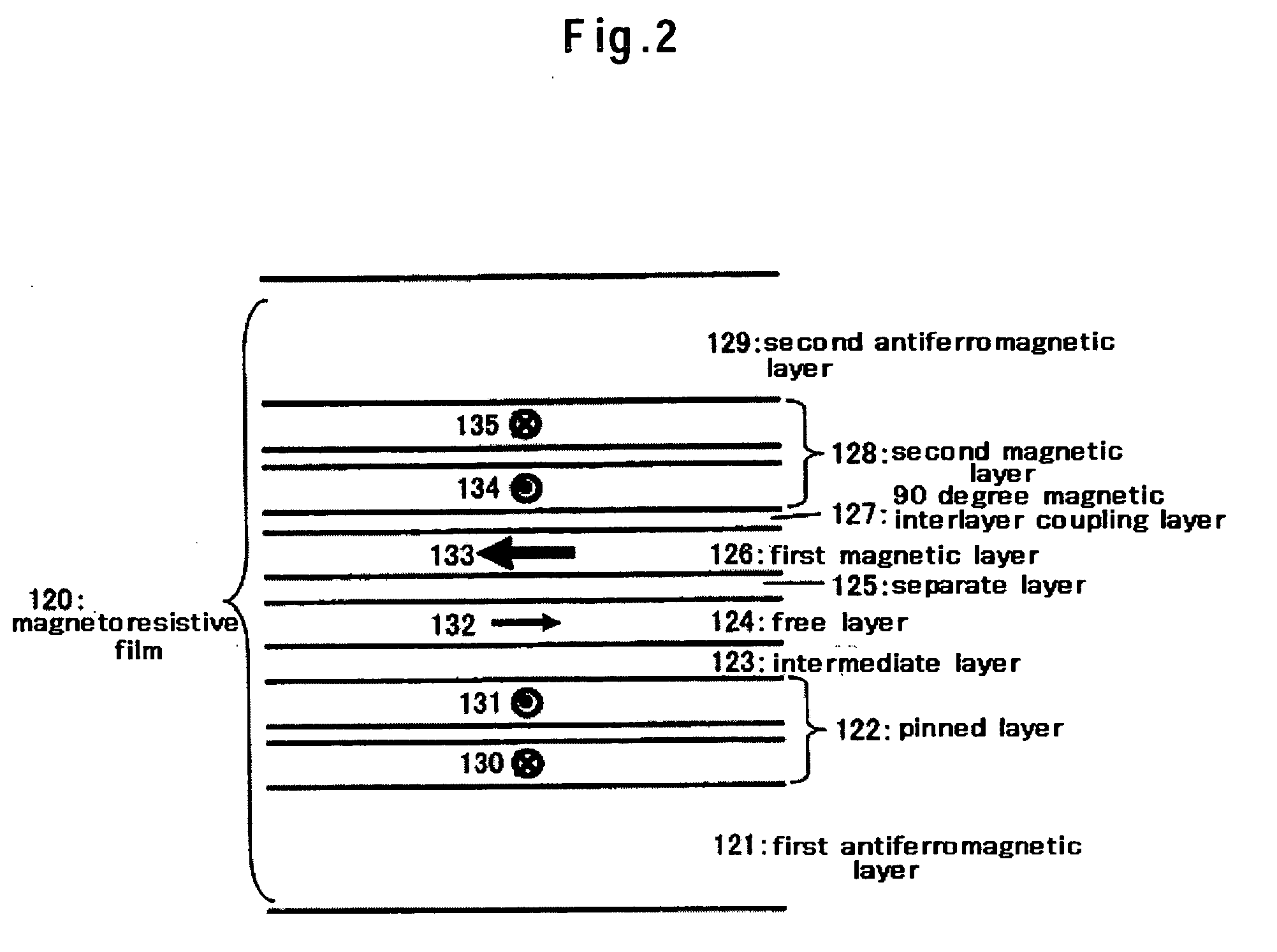

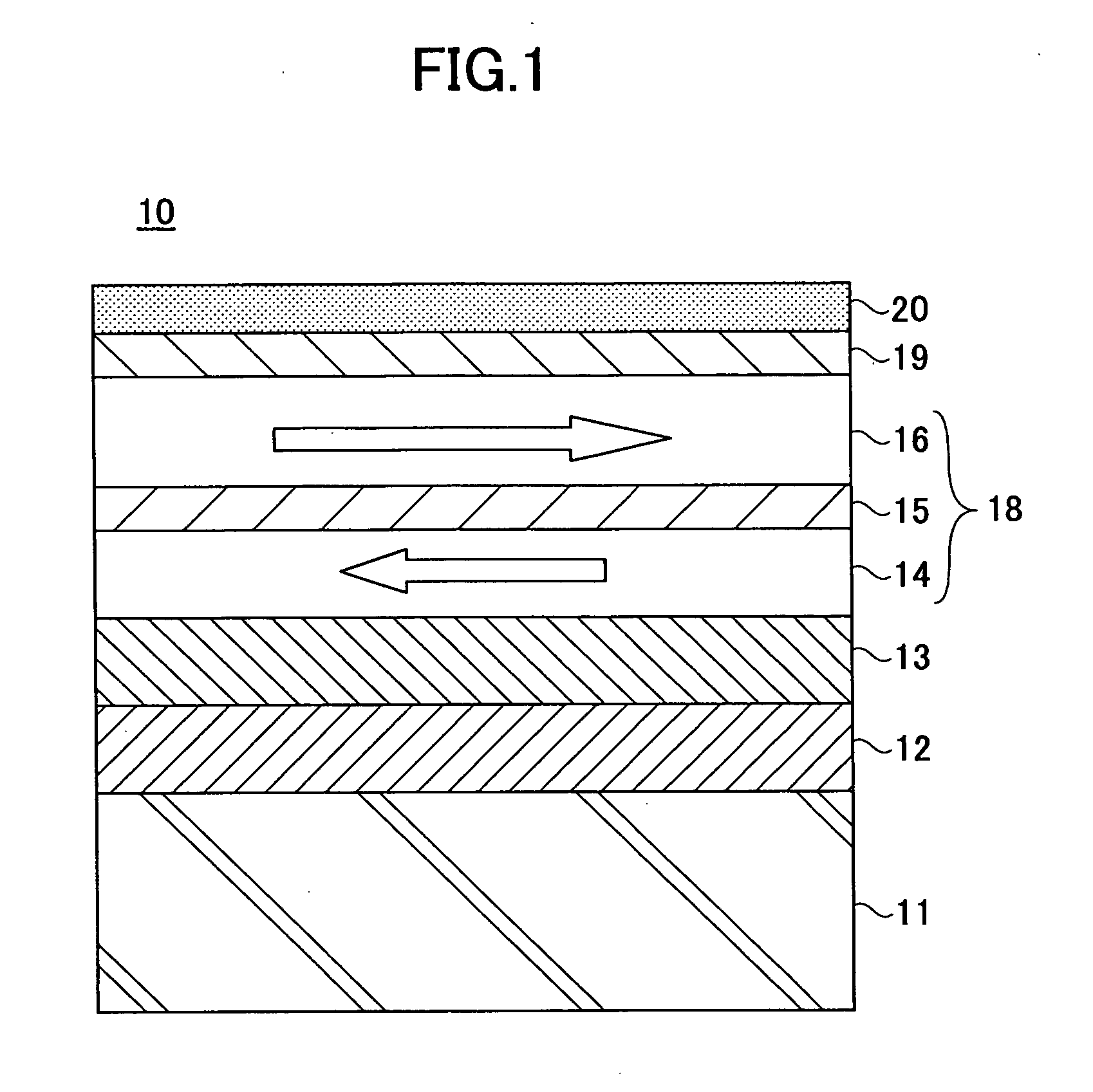

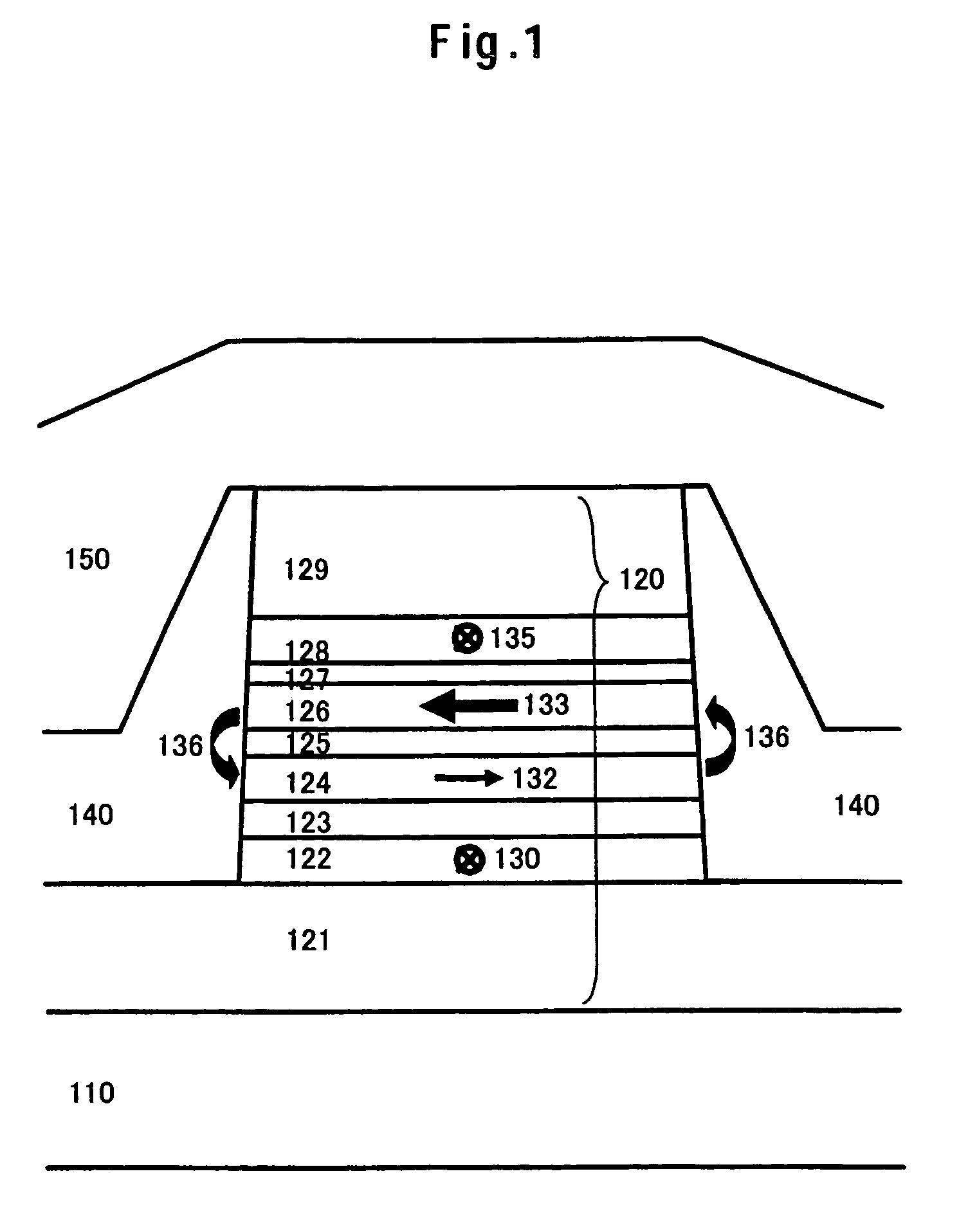

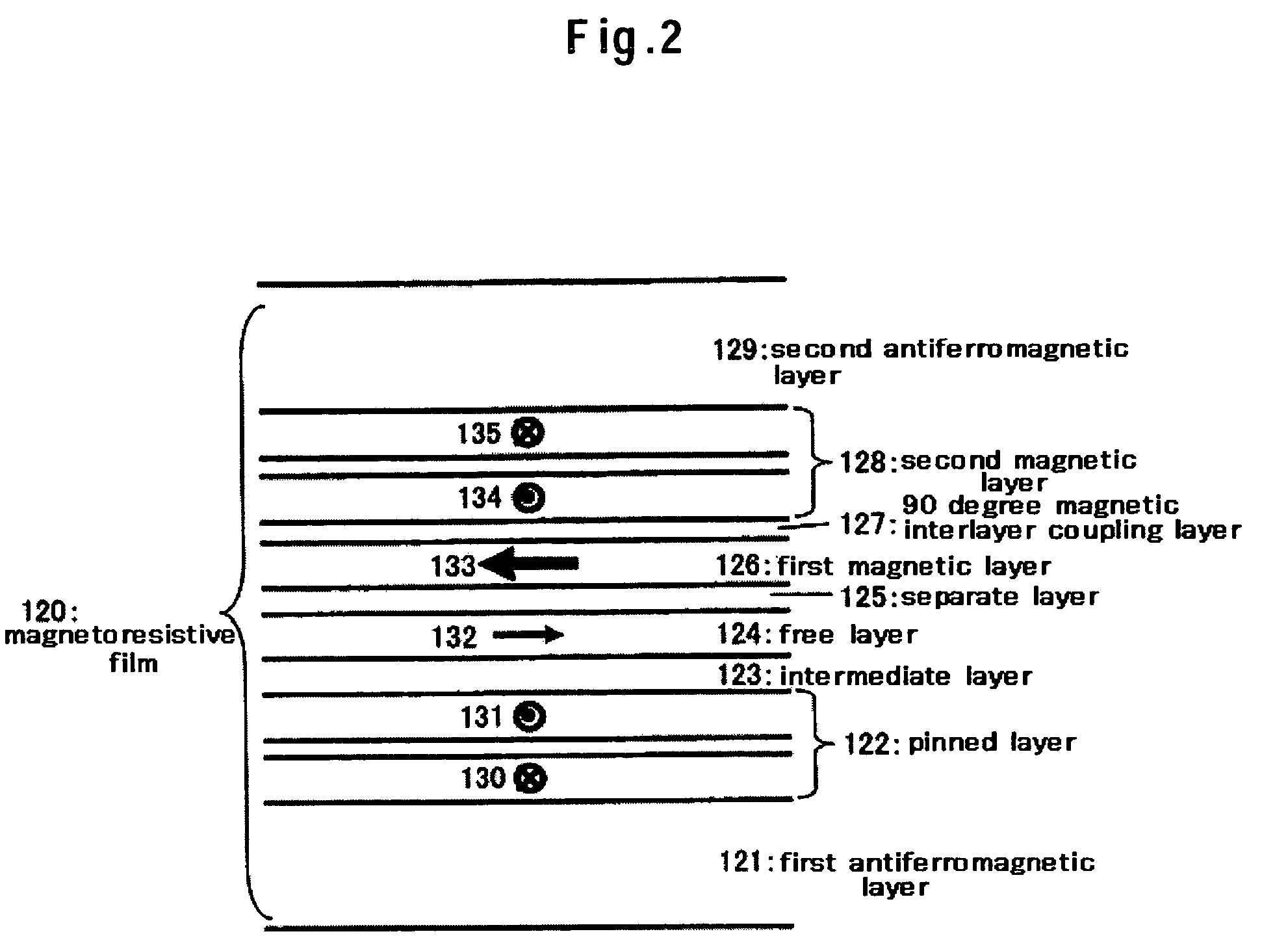

Magnetoresistive head using longitudinal biasing method with 90-degree magnetic interlayer coupling and manufacturing method thereof

InactiveUS20060103991A1Inhibition effectExcellent read sensitivityRecord information storageManufacture of flux-sensitive headsLow noiseMagnetization

A magnetoresistive head and a fabricating method thereof accomplishing high read sensitivity and excellent linear response with low noise even if track width narrowing makes progress are provided. In one embodiment, using a magnetoresistive film having a laminated body of a pinned layer / an intermediate layer / a free layer / a separate layer / a first ferromagnetic layer / a 90-degree magnetic interlayer coupling layer / a second ferromagnetic layer, and the magnetizations of both the pinned layer and the second ferromagnetic layer are fixed nearly in the direction along the sensor height. On the other hand, the magnetizations of the first ferromagnetic layer and the second ferromagnetic layer have an interlayer interaction being directed in nearly orthogonal directions to each other through the 90-degree magnetic interlayer coupling layer, and the first ferromagnetic layer has a magnetization directed nearly in the direction along the track width in zero external magnetic field. According to this, the first ferromagnetic layer applies a longitudinal biasing field to the free layer nearly in the direction along the track width.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

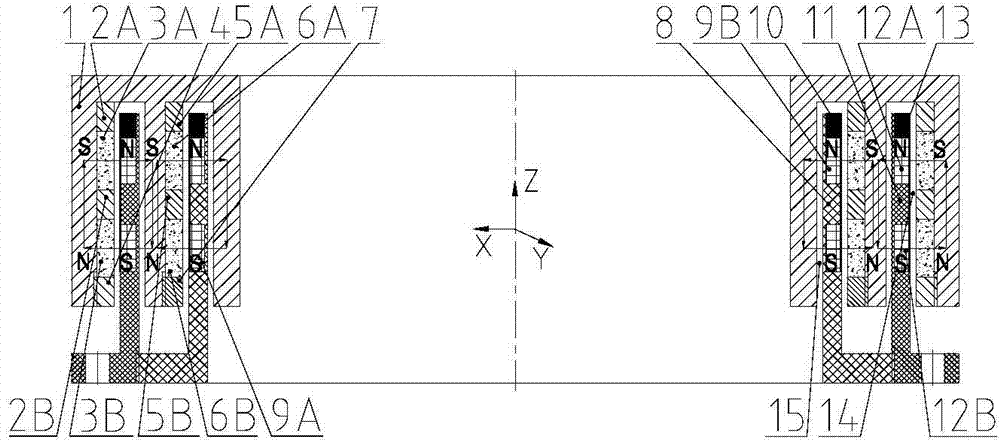

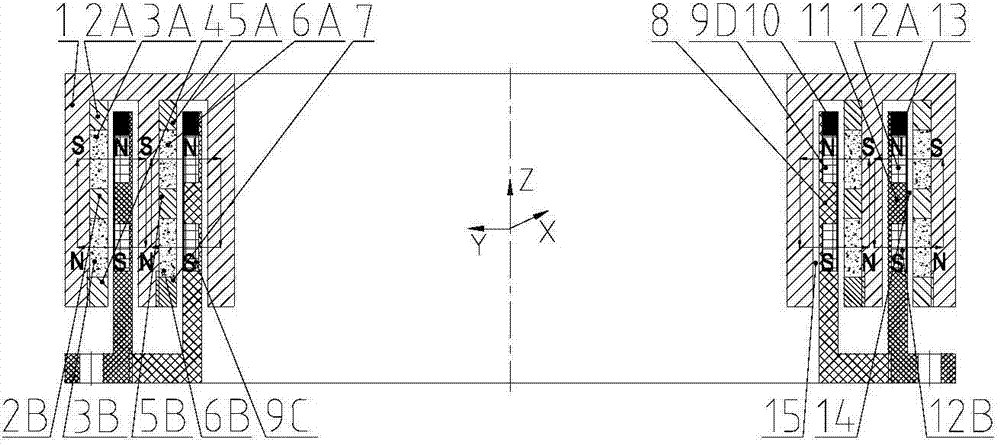

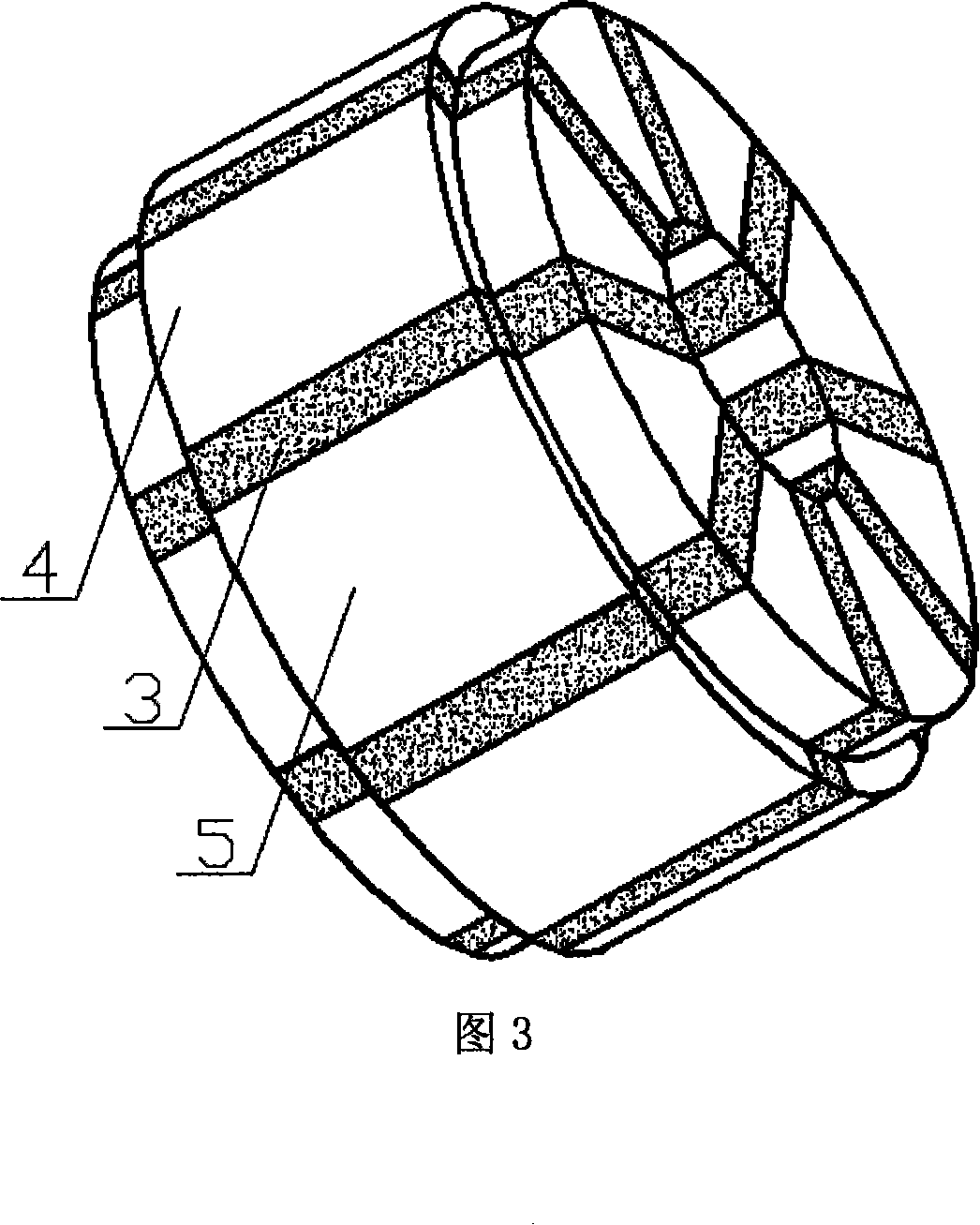

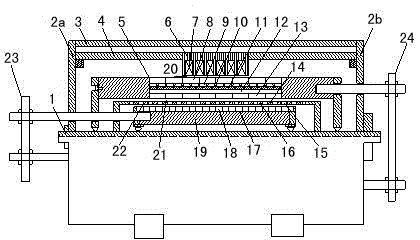

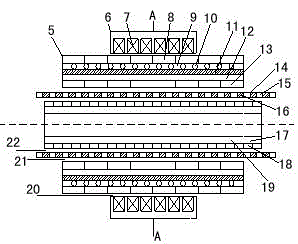

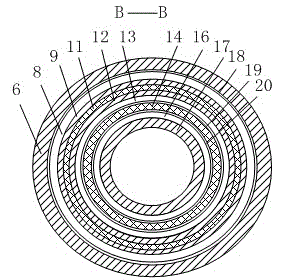

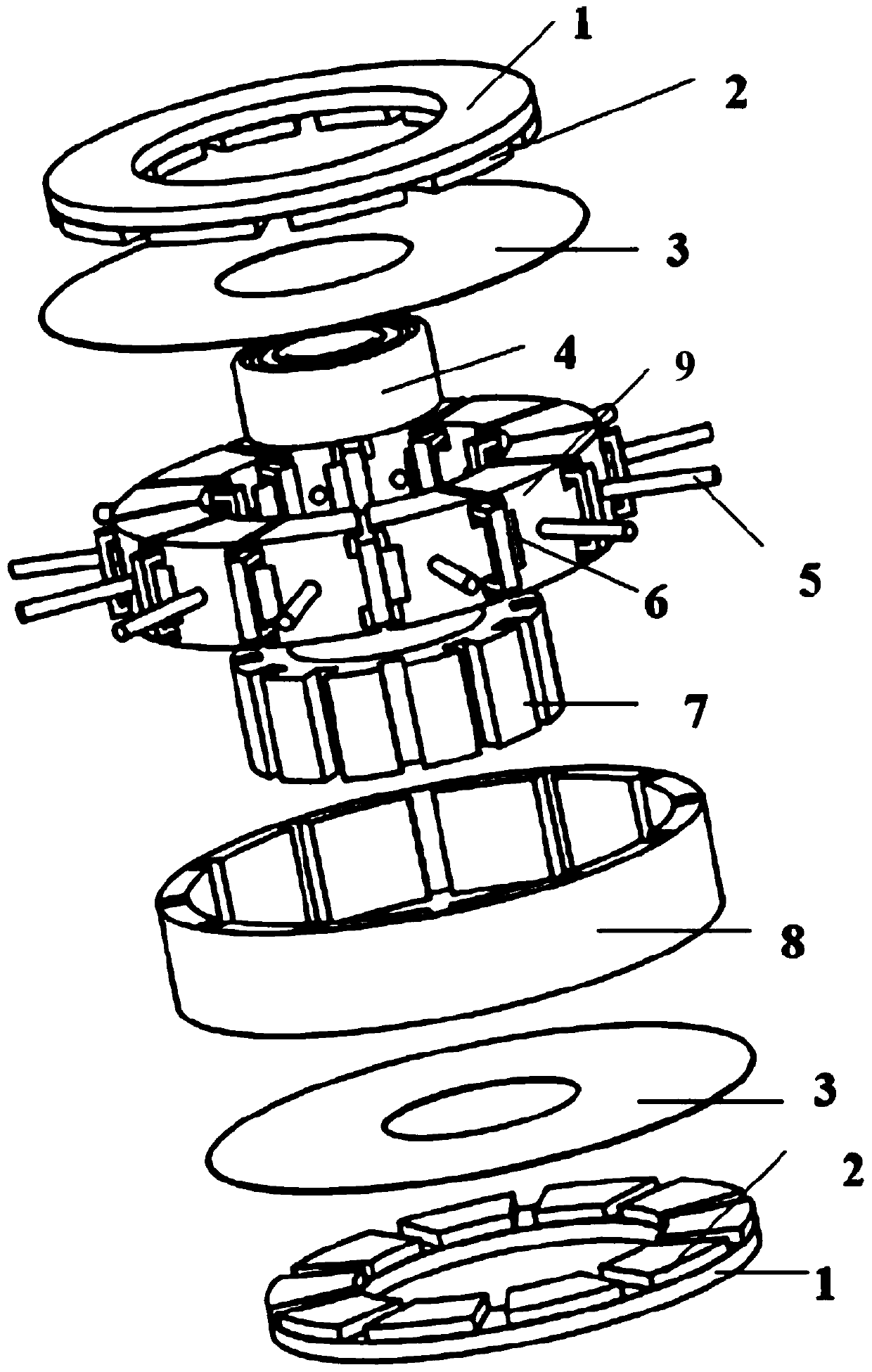

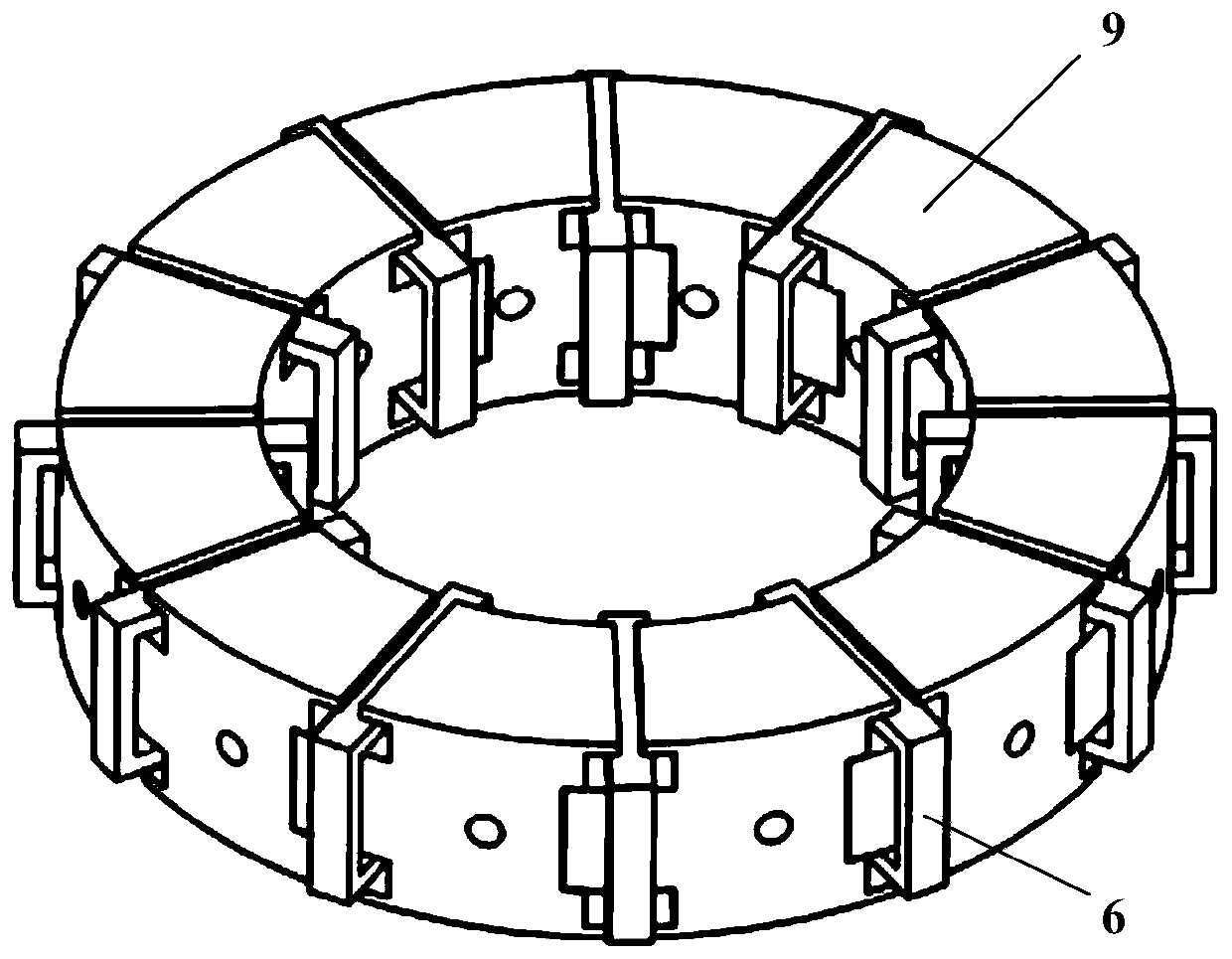

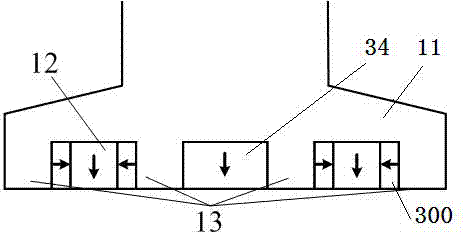

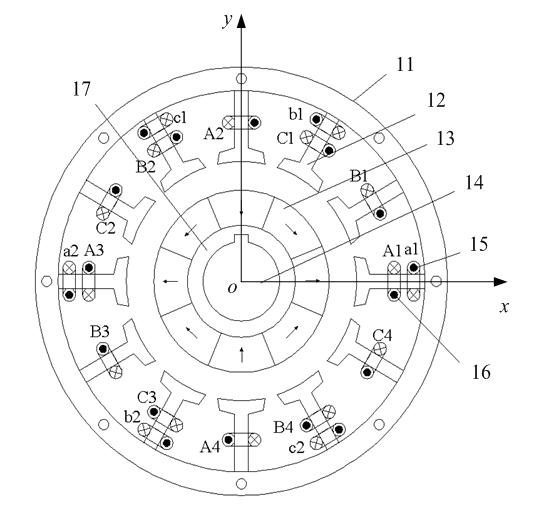

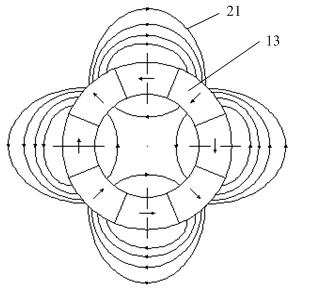

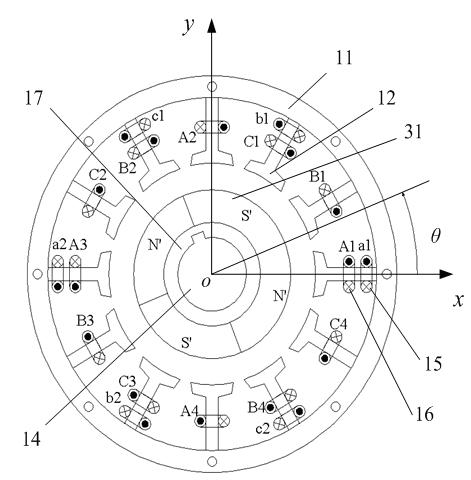

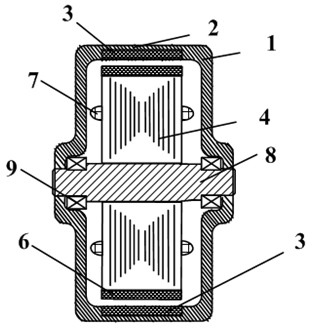

Double-stator three-freedom-degree decoupling lorentz-force magnetic bearing

The invention discloses a double-stator three-freedom-degree decoupling lorentz-force magnetic bearing. The lorentz-force magnetic bearing mainly comprises two parts, namely, a rotor system and a stator system, wherein the rotor system mainly comprises a magnetic-conductive ring, an axial magnetic-isolated ring, an axial magnetic steel, an axial locking nut, a deflection magnetic-isolated ring, deflection magnetic steel and a deflection locking nut; the stator system mainly comprises a deflection stator skeleton, a deflection winding, an axial stator skeleton, an axial winding and epoxy resin glue. The double-stator three-freedom-degree decoupling lorentz-force magnetic bearing disclosed by the invention has the advantages that axial translation and radial two-freedom-degree deflection control can be realized and the translation control and the radial deflection control are completely decoupled, so that the control performance and the control accuracy of the magnetic bearing are improved; simultaneously, since the magnetic flux and the magnetic density in air gaps are constant, outputted force and torque and the control current have the relative good linearity, so that the control accuracy of the magnetic bearing is further improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

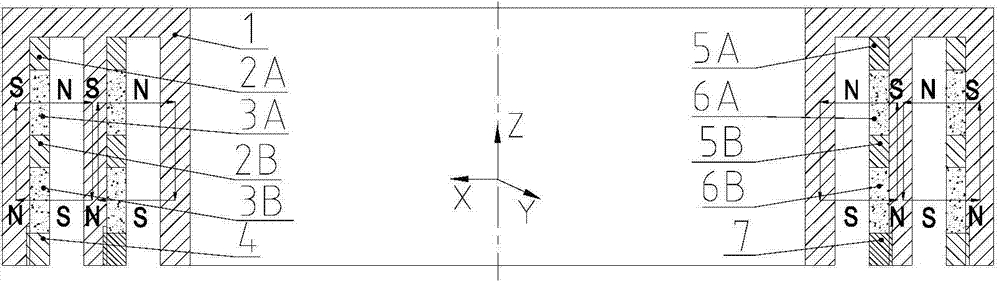

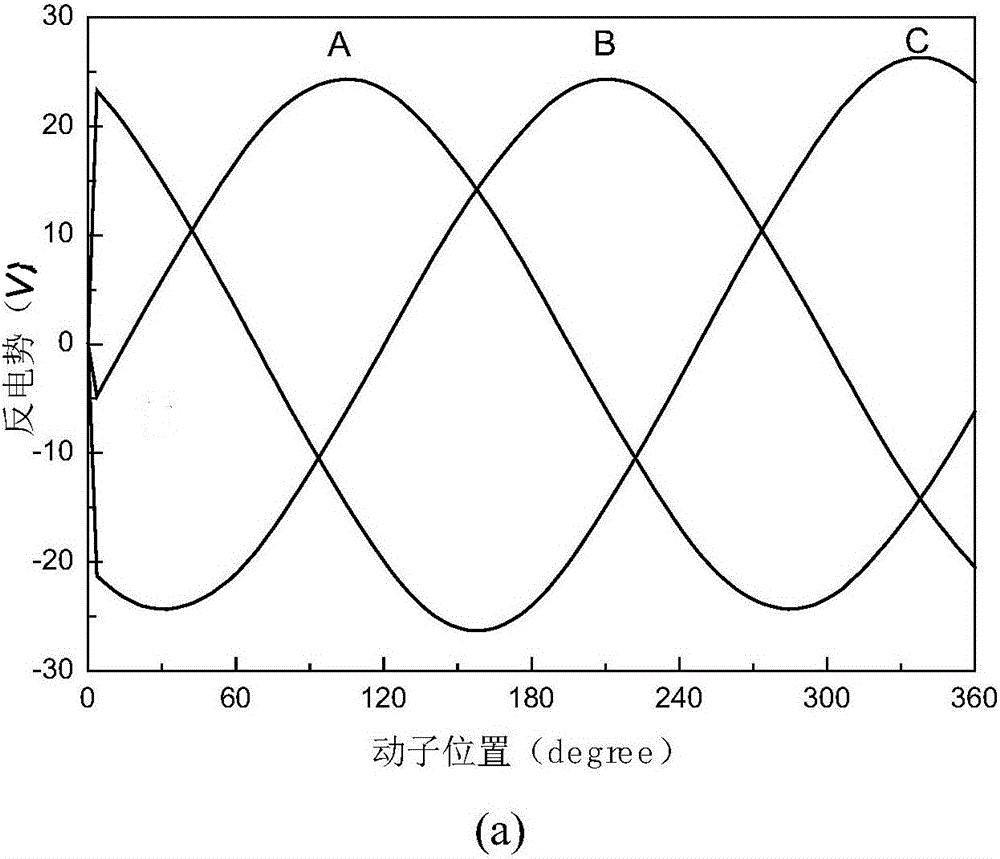

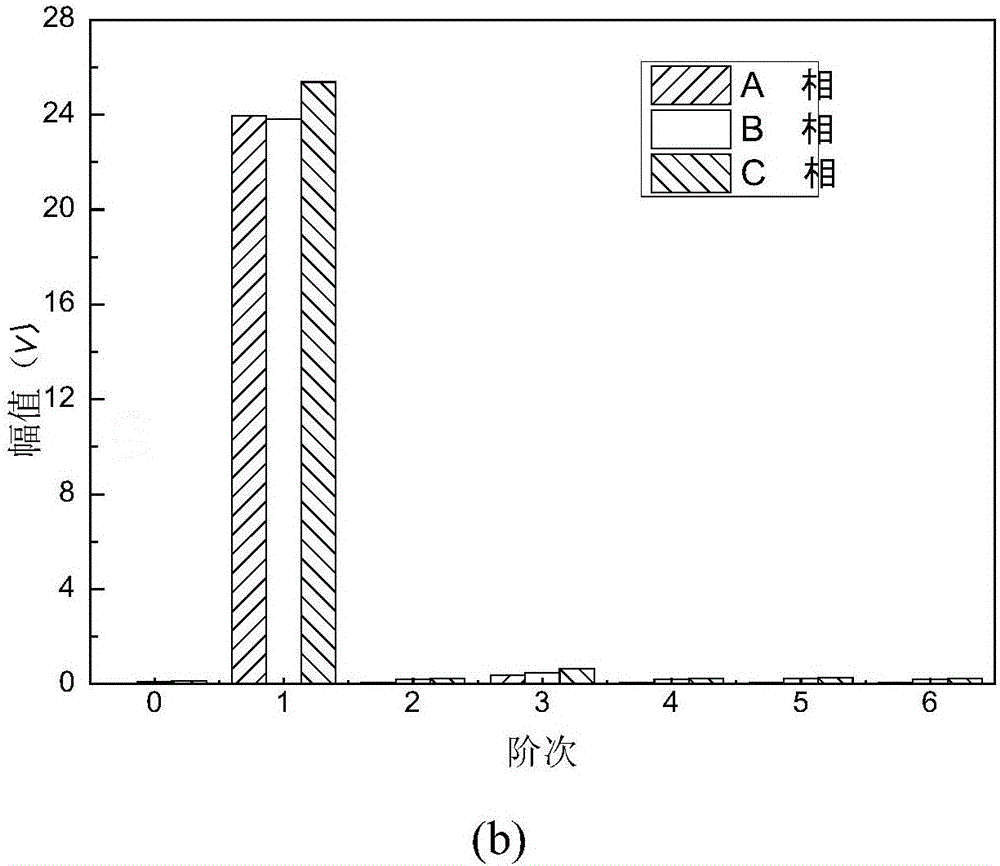

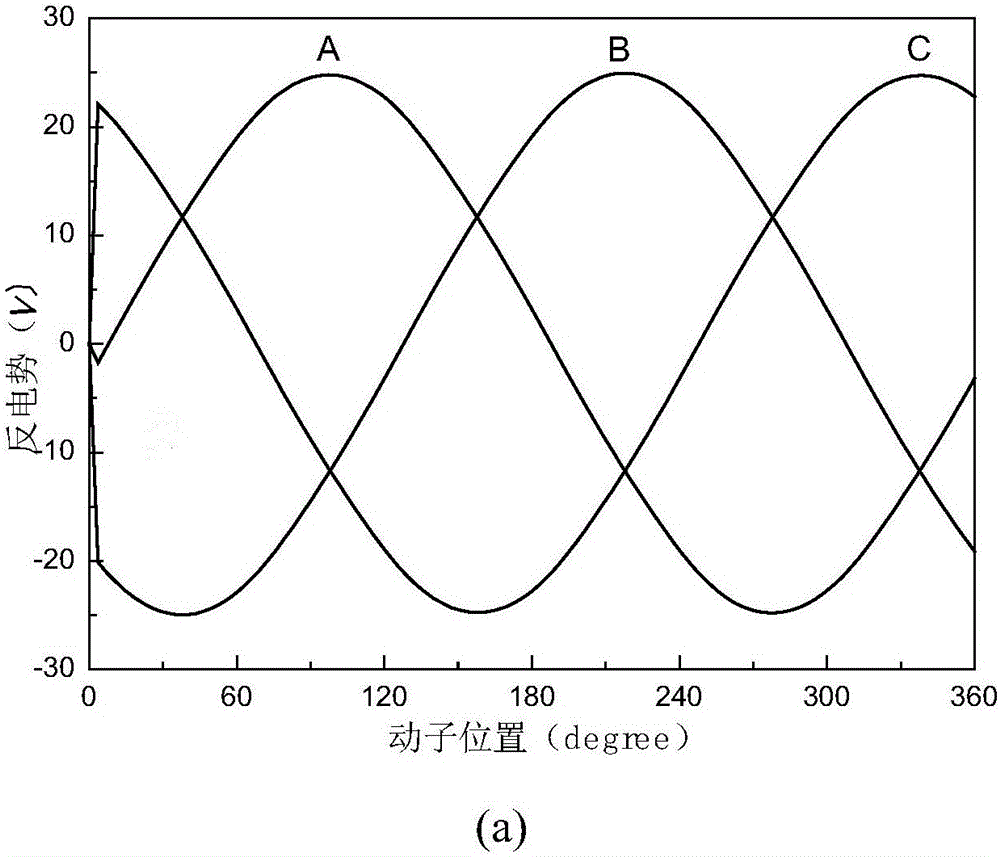

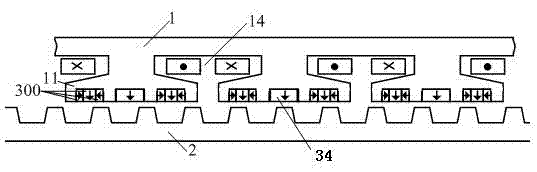

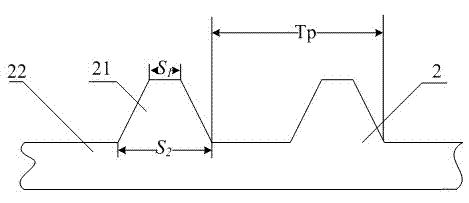

Modular vernier permanent magnetic linear motor based on Halbach permanent magnetic structure

ActiveCN106411096AReduce thrust fluctuationImprove the unbalanced three-phase potential problemPropulsion systemsMagnetic barrierPhase difference

The invention discloses a modular vernier permanent magnetic linear motor based on a Halbach permanent magnetic structure. The modular vernier permanent magnetic linear motor comprises 3k mover modules and one stator, there are air gaps between the two, the stator comprises a permanent magnet which is provided with a stator core, is surface-mounted to the stator core and has a Halbach array structure, armature windings are arranged in grooves of the mover modules, positions of each phase of the armature windings in the different mover modules are different, positions of axles of the same phase of the armature windings in each module correspondingly relative to the stator permanent magnet are maintained consistent, each module can work as an individual complete vernier permanent magnetic linear motor, two adjacent mover modules are connected by use of a magnetic barrier made of a non-magnetic material, the different mover modules respectively generate push forces with certain phase differences with the stator, through modular combination of movers and variation of positions of the windings in the different modules, each phase of the windings is enabled to have a completely symmetric structure in an overall view, and thus the effect of offsetting and weakening thrust fluctuations is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

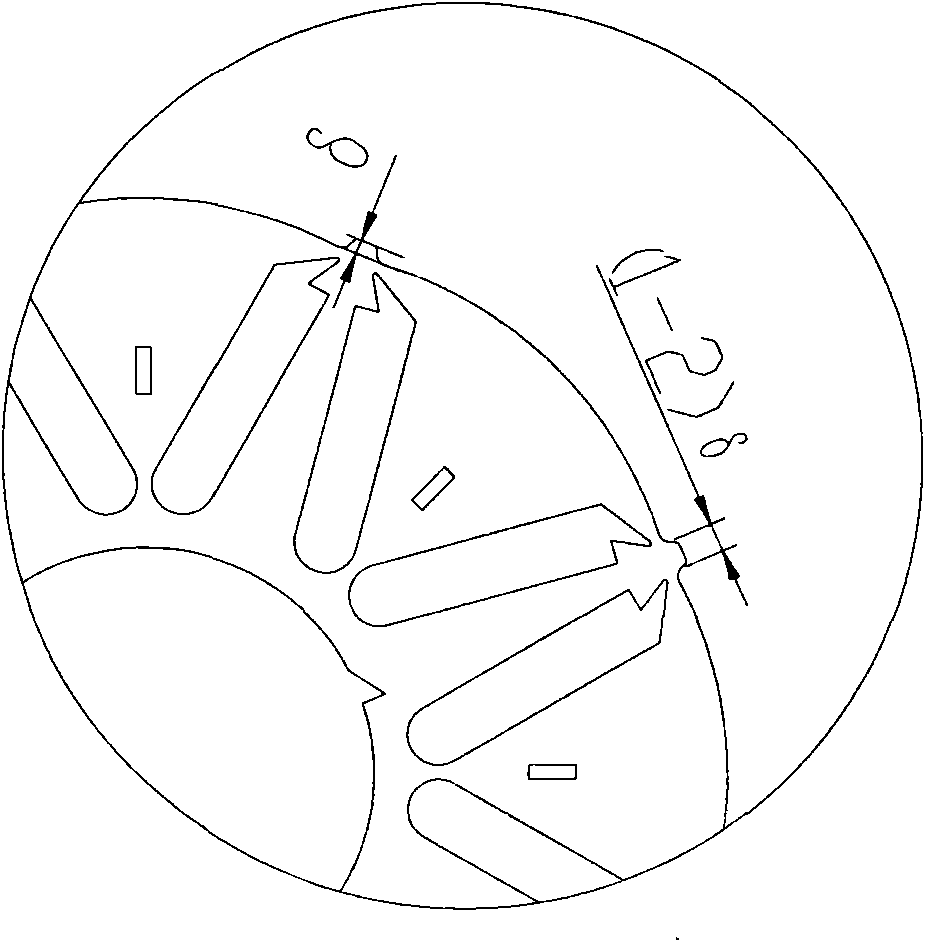

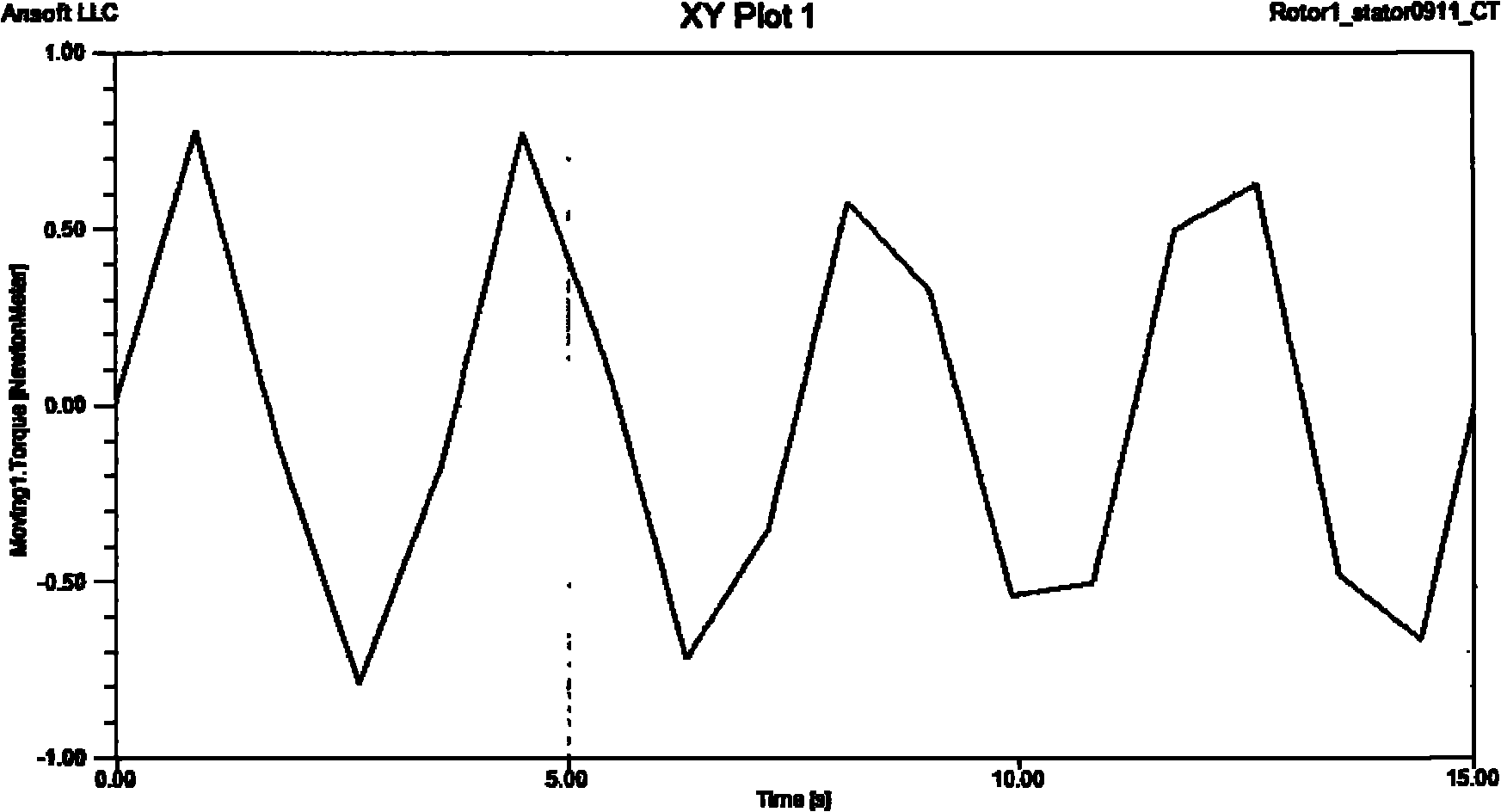

Permanent magnet synchronous motor

InactiveCN102420475AReduce cogging torqueEasy to manufacture and assembleMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorMagnetic poles

A purpose of the present invention is providing a permanent magnet synchronous motor rotor structure which has high air gap flux density and is easy to generate back electromotive force with a sine wave. In a permanent magnet synchronous motor, a circumferential surface of the rotor is uniformly provided with a plurality of magnetic steel grooves which are independently enclosed and do not contact mutually. Every two magnetic steel grooves are arranged to form a V shape, an opening of the V shape faces excircle of the rotor, and a tip of the V shape faces a rotor center. Each magnetic steel groove is provided with magnetic steel. In each group of V-shaped magnetic steel grooves, two magnetic steel facing the excircle of the rotor core have a same magnetic pole, and magnetic poles of magnetic steel facing the excircle of the rotor core in two adjacent groups of V-shaped magnetic steel grooves are opposite with the magnetic pole of the two magnetic steel. The excircle of the rotor goes down toward the center with depth delta and smooth transition at a crossing position of axes, which means that air gap width at the crossing position is less than air gap width at a straight axis position by delta. Through improving the rotor, the permanent magnet synchronous motor rotor has high mechanical strength and a large salient pole ratio, and weakened magnetism speed expansion is facilitated.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

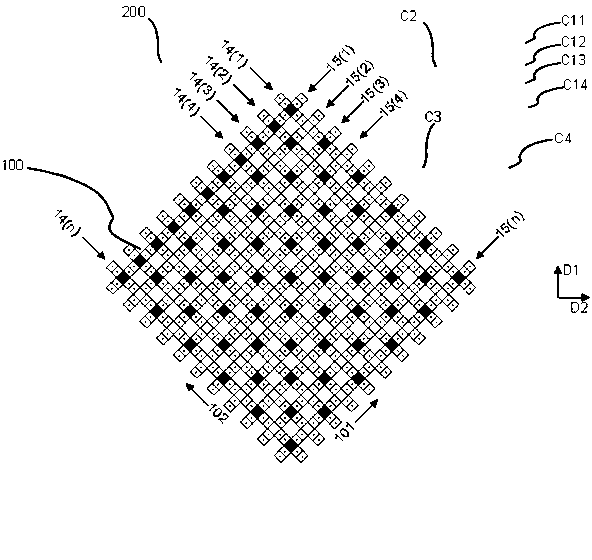

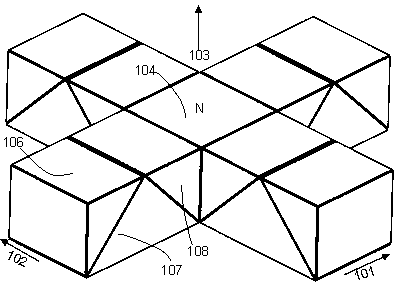

Magnet unit, magnet array, magnetic levitation planar motor and lithographic device using magnetic levitation planar motor

ActiveCN103208867AUnilateral magnetic densityReduce magnetic leakagePhotomechanical exposure apparatusMicrolithography exposure apparatusElectric machinePlanar motor

The invention discloses a cross magnet unit which comprises a first magnet and a second magnet unit surrounding the first magnet. The first magnet is an N-pole magnet or an S-pole magnet. The magnetization direction of the first magnet is the Z-xis direction. The second magnet unit comprises four groups of magnet combinations with identical structure. The four groups of magnet combinations are respectively located in the X-axis direction and the Y-axis direction. The magnetization direction of the magnet combinations points at the N-pole magnet or is far away from the S-pole magnet. Each group of magnet combinations comprise at least two prism magnets, pyramid magnets or pyramid frustum magnets. A magnet array, a magnetic levitation planar motor and a lithographic device using the magnetic levitation planar motor are further disclosed.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

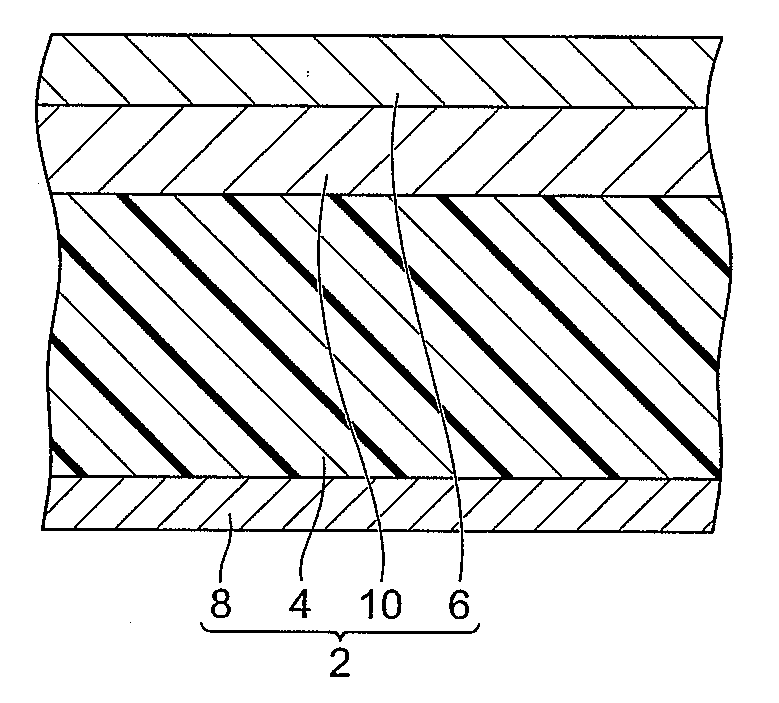

Magnetic recording medium, method of producing magnetic recording medium and magnetic storage apparatus

InactiveUS20050276998A1Promote stratificationIncrease magnetic densityBase layers for recording layersRecord information storageCrystalliteMagnetic storage

A magnetic recording medium has a seed layer provided on a substrate surface, an underlayer provided on the underlayer, and a recording layer provided on the underlayer. Information is recorded in the recording layer by magnetizing the recording layer in a recording direction. The seed layer is formed by a polycrystal of crystal grains made of an alloy material having a B2 crystal structure, and a [100] crystal orientation of the crystal grains are inclined towards one of two sides partitioned by a plane that is formed by the recording direction and a substrate normal which is normal to the substrate surface.

Owner:FUJITSU LTD

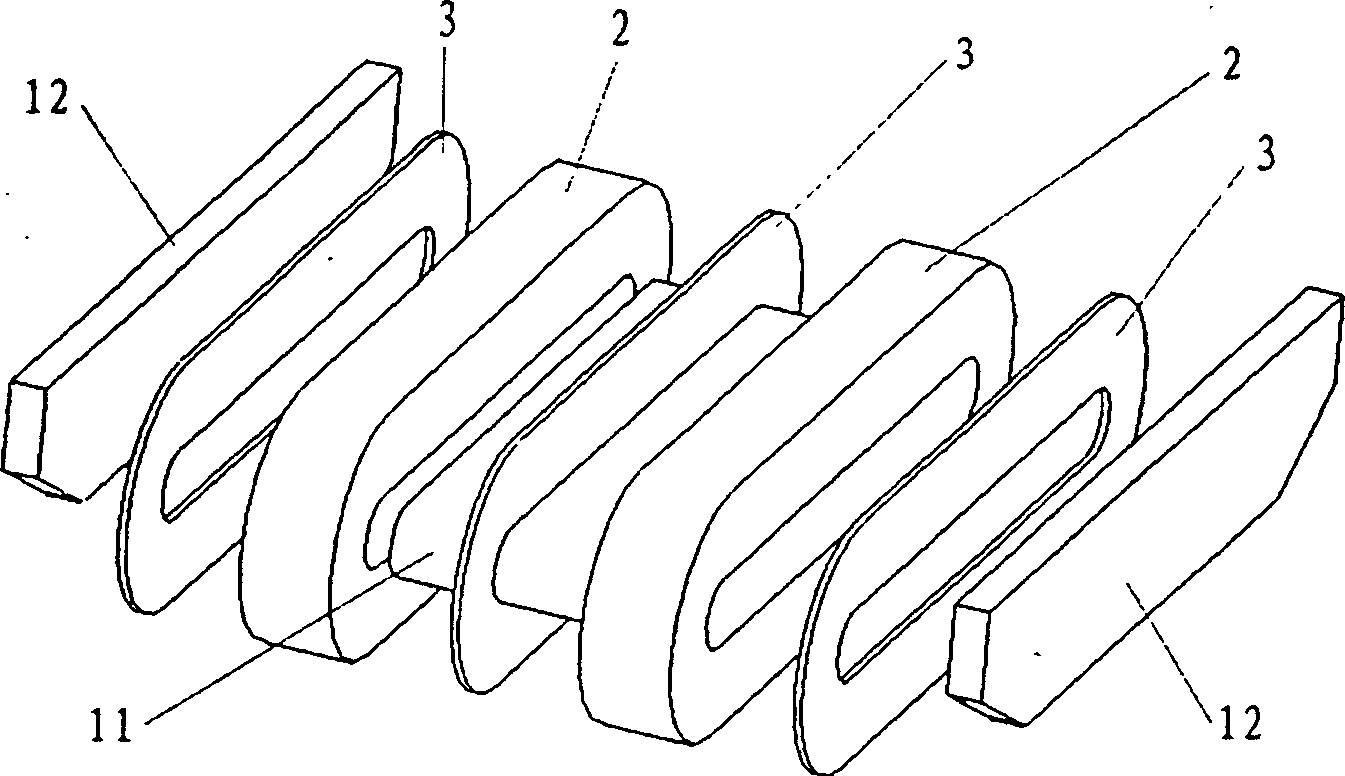

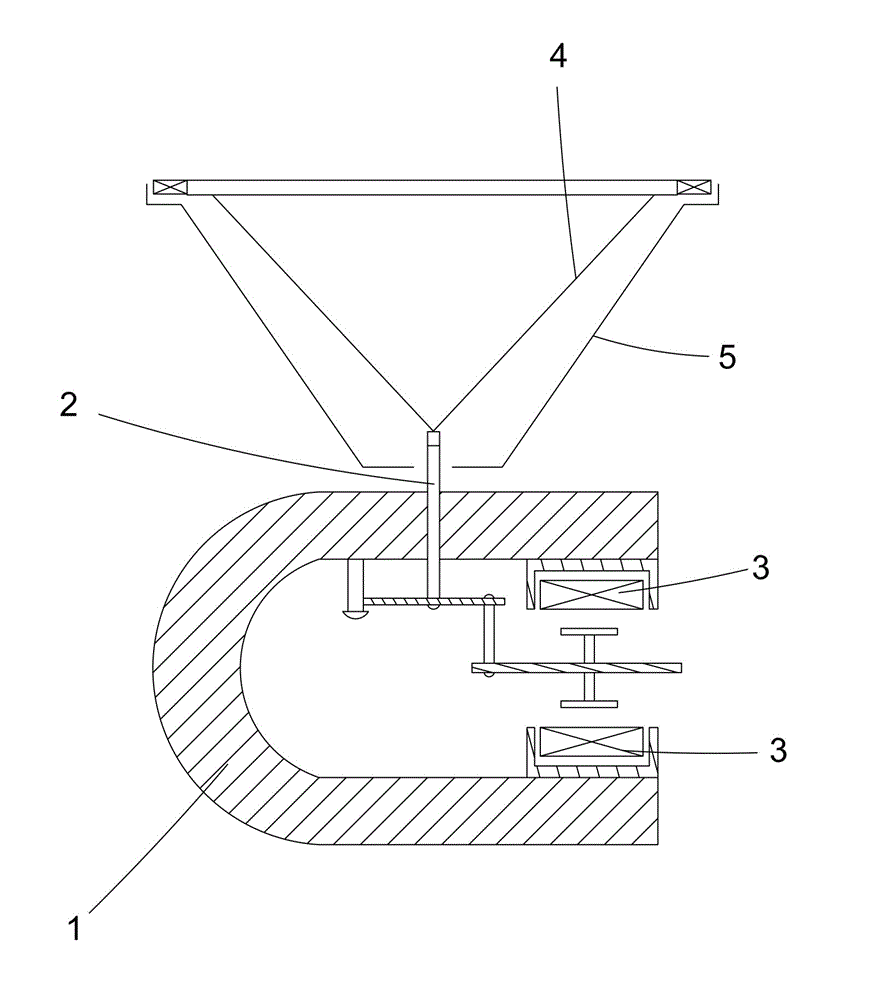

Built-in permanent magnet dual-side flat plate type linear motor

ActiveCN101741214AIncrease effective lengthIncrease magnetic densityPropulsion systemsSurface mountingPermanent magnet linear motor

The invention relates to a built-in permanent magnet dual-side flat plate type linear motor, which belongs to the technical field of motors, and solves the problems of low air gap flux density and low thrust density of the conventional surface-mount permanent magnet dual-side flat plate type linear motor. A secondary pole of the built-in permanent magnet dual-side flat plate linear motor comprises two flat plate type excitation components, a primary pole is positioned between the two flat plate type excitation components of the secondary pole, each secondary iron core is provided with a plurality of pairs of grooves on the air gap side, each permanent magnet is closely matched with the groove in which the permanent magnet is positioned, and two permanent magnets of each pair of grooves and the iron core between the grooves form a magnetic pole; on the lognitudinal cross section of the flat plate type excitation components, the cross section of each groove is a parallelogram, the groove bottoms of the two grooves of each pair of grooves are close to each other and form a V-shape, and the range of the included angle Theta of two adjacent sides of the two grooves in each pair of grooves is not less than 30 degrees and not more than 150 degrees; and the magnetizing direction of each permanent magnet is vertical to the bevel edge of the parallelogram, the magnetizing directions of the two permanent magnet in each magnetic pole are in the same direction or in the opposite directions, and the polarities of the adjacent two magnetic poles are opposite. The invention is a linear motor.

Owner:HARBIN INST OF TECH

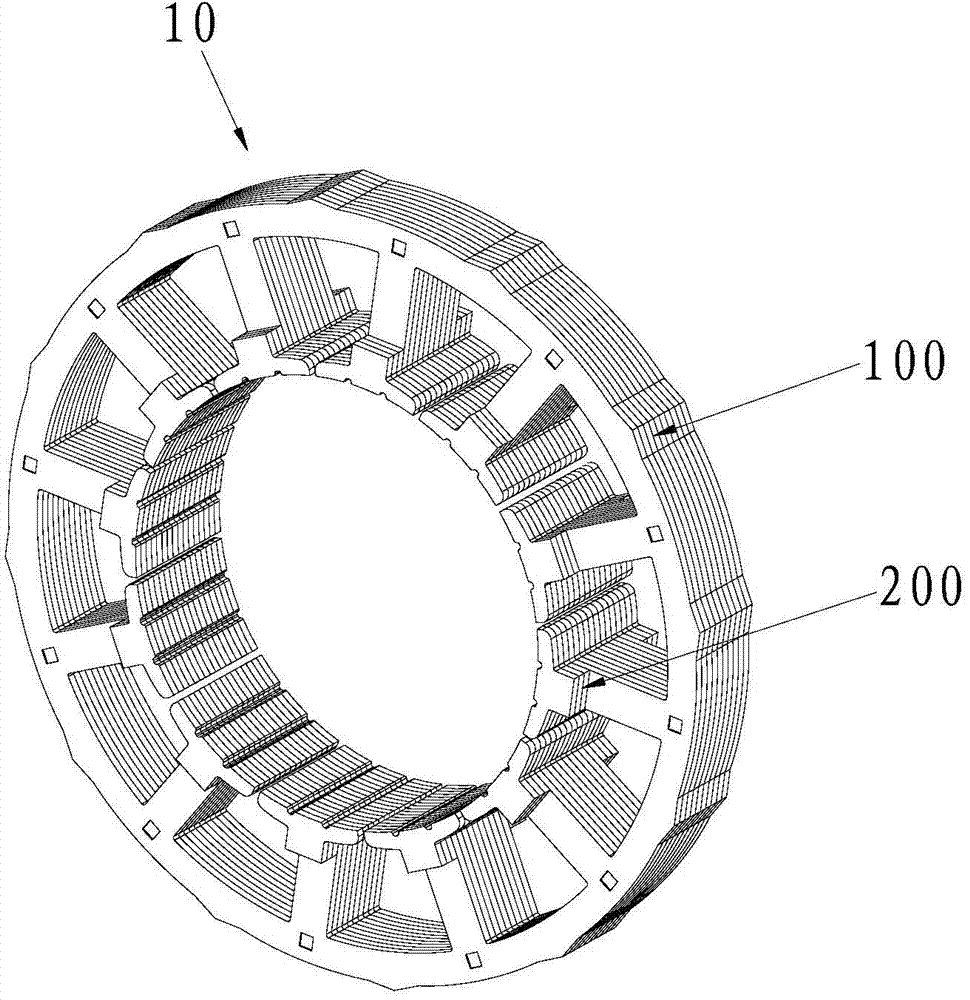

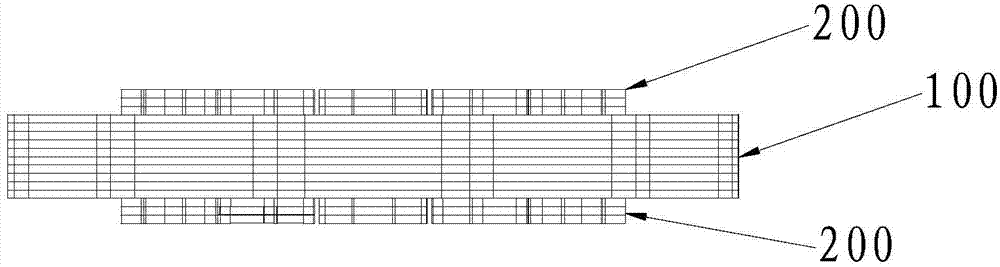

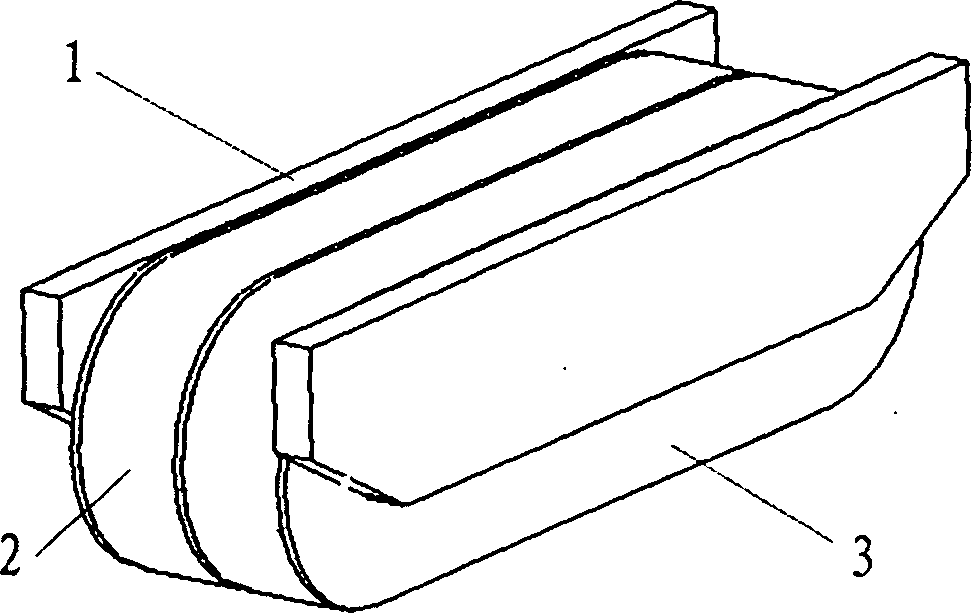

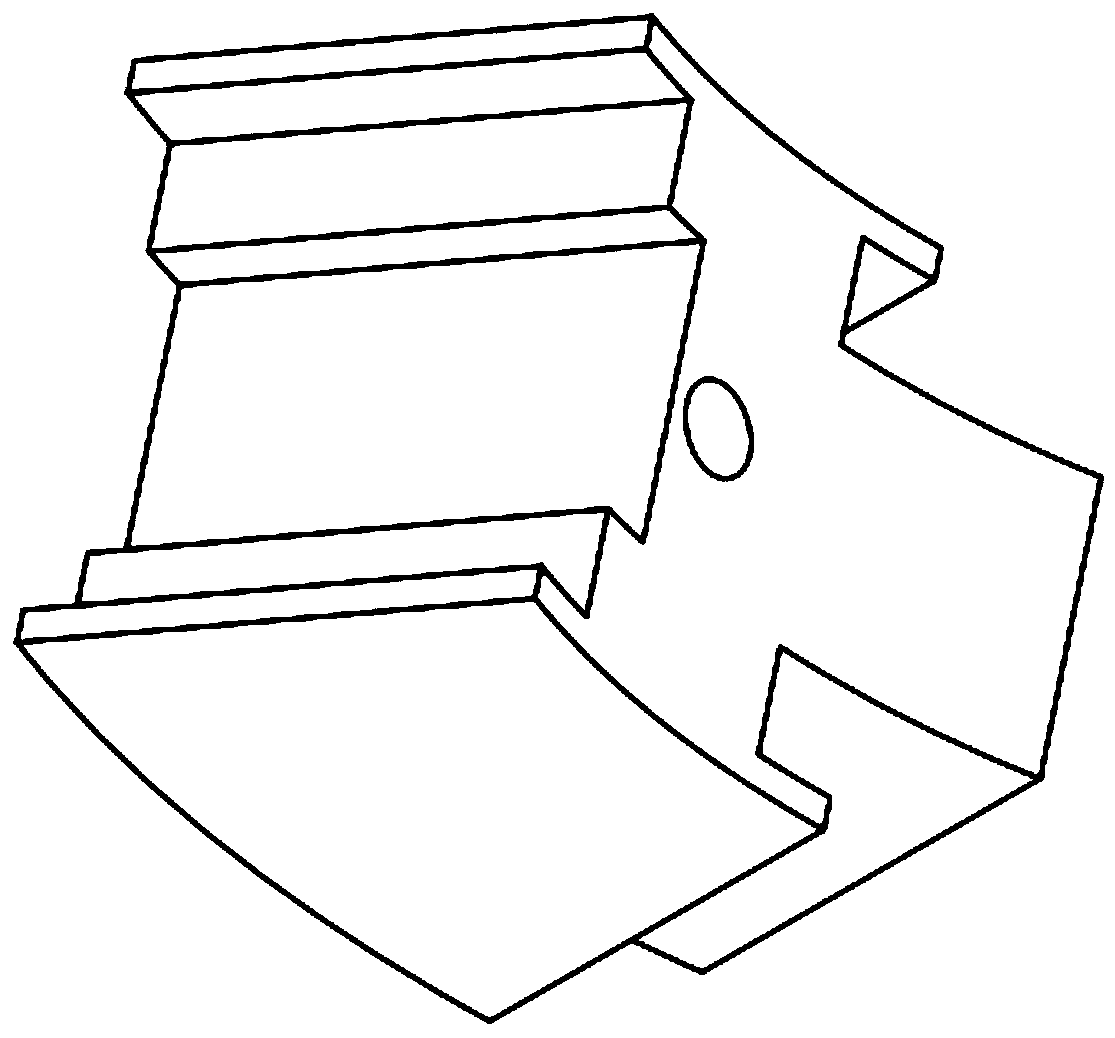

Motor stator iron core, motor stator, motor, and manufacturing method of motor stator

ActiveCN104734376AImprove performanceIncrease magnetic densityMagnetic circuit stationary partsManufacturing stator/rotor bodiesConductor CoilMagnet

The invention belongs to the technical field of motors and discloses a motor stator iron core, a motor stator, a motor and a manufacturing method of the motor stator. The motor stator comprises the motor stator iron core. The motor comprises the motor stator and the motor stator iron core. According to the motor stator iron core, one end or two ends of an iron core body are provided with tooth boot boss portions, the purpose of increasing the axial length of the motor stator iron core can be achieved, and the turn length of a winding is not increased; besides, the flux of a magnet on a rotor can be guided to stator teeth through the tooth boot boss portions, the magnetism gathering effect is better, the flux density of the stator iron core can be improved, the material utilization rate is higher, and the weight of the motor stator iron core is reduced. Meanwhile, the turn length of the winding of the motor stator is reduced, the weight of the winding is reduced, the length of the end of the motor is reduced, and the motor is high in performance and low in cost.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

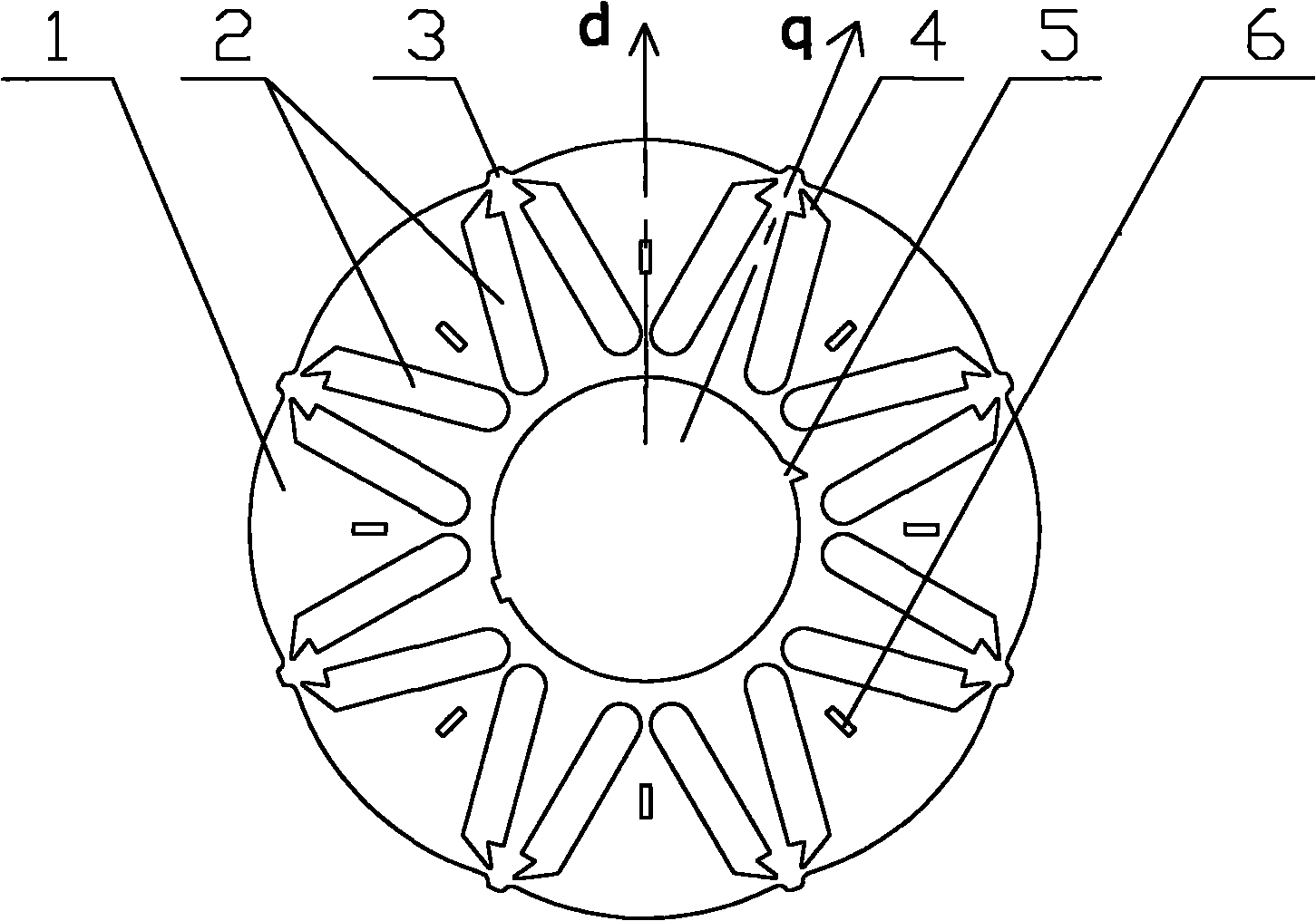

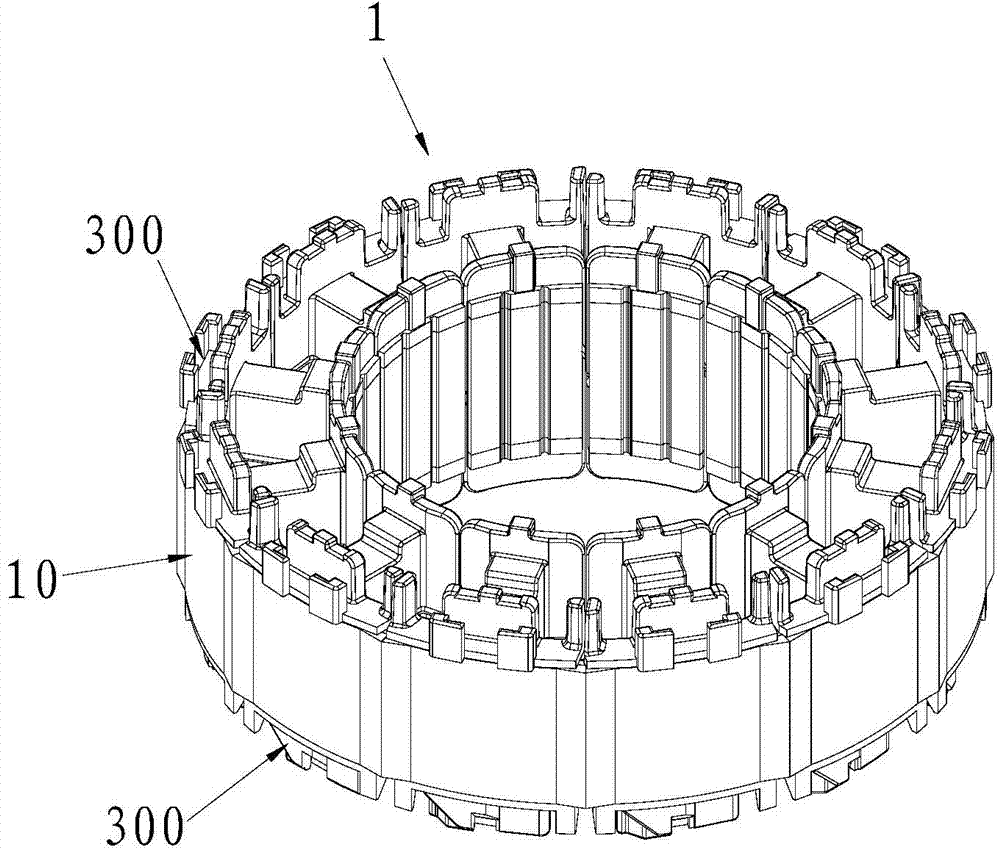

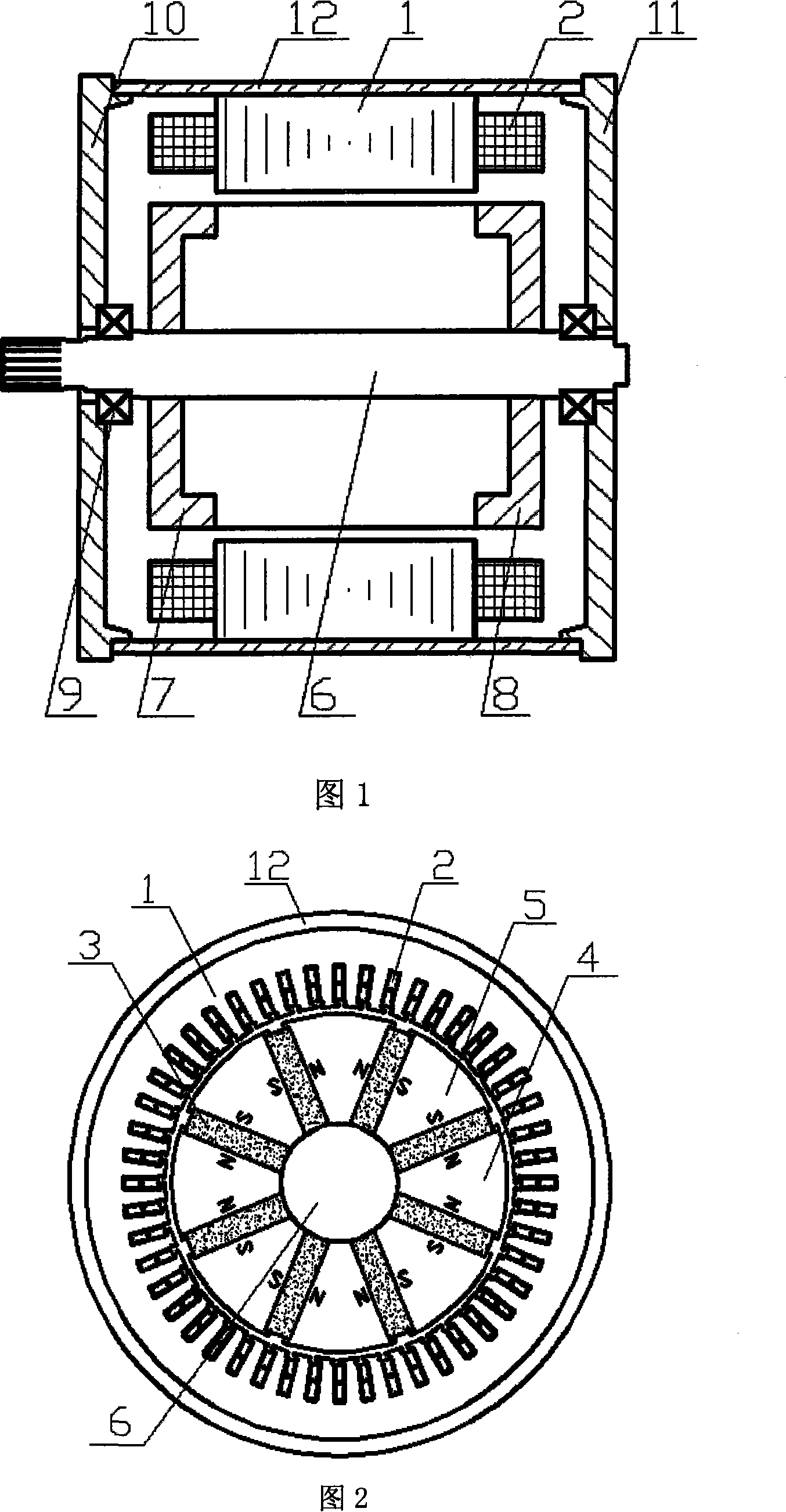

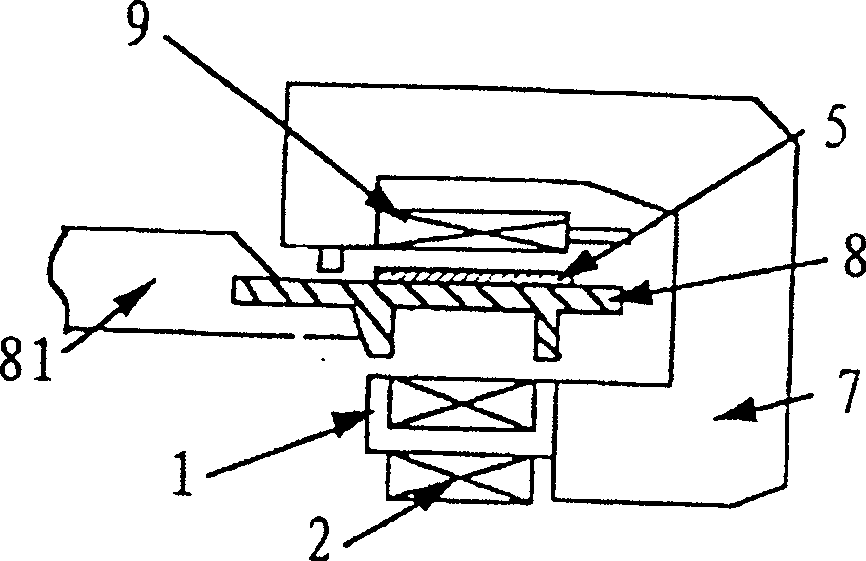

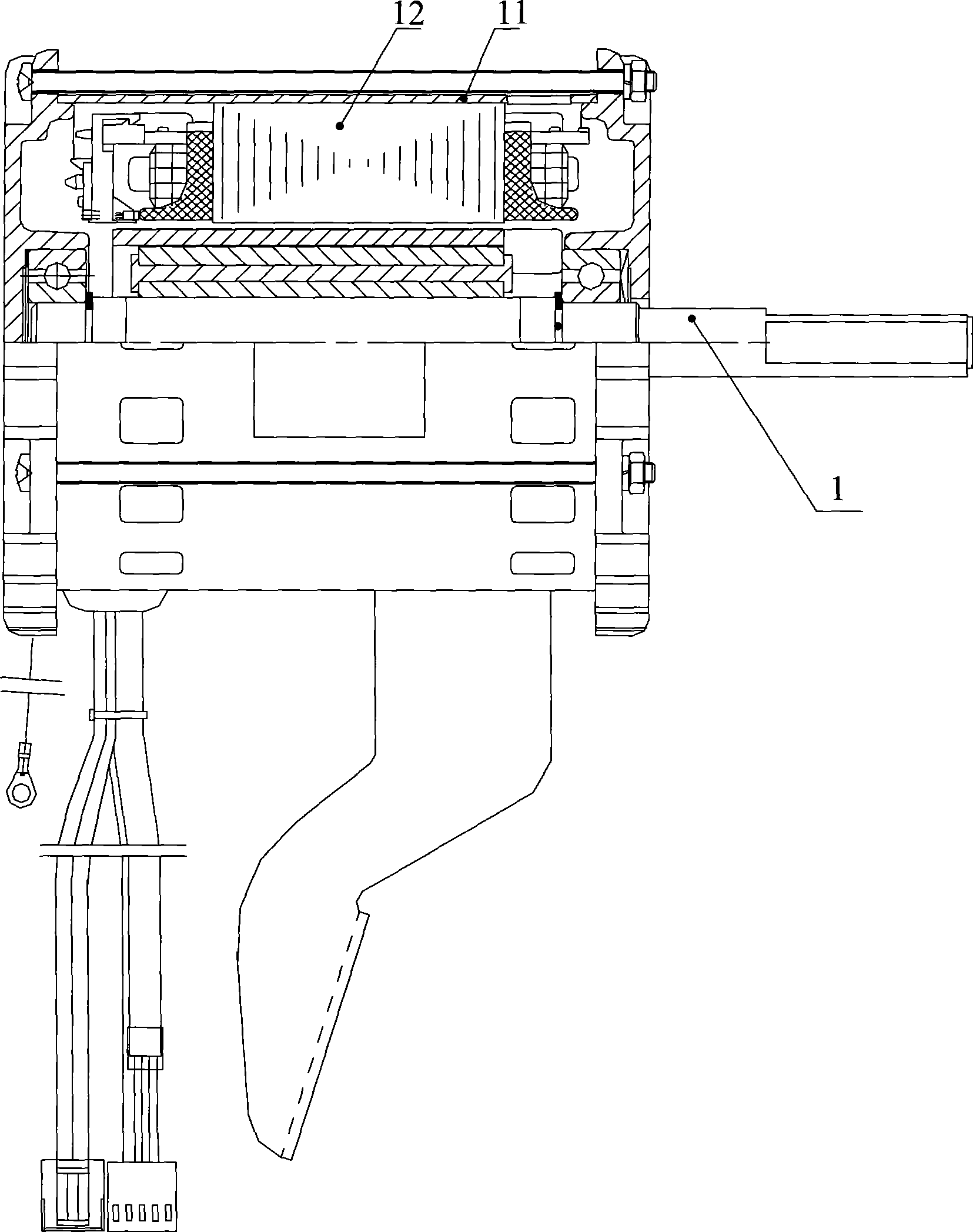

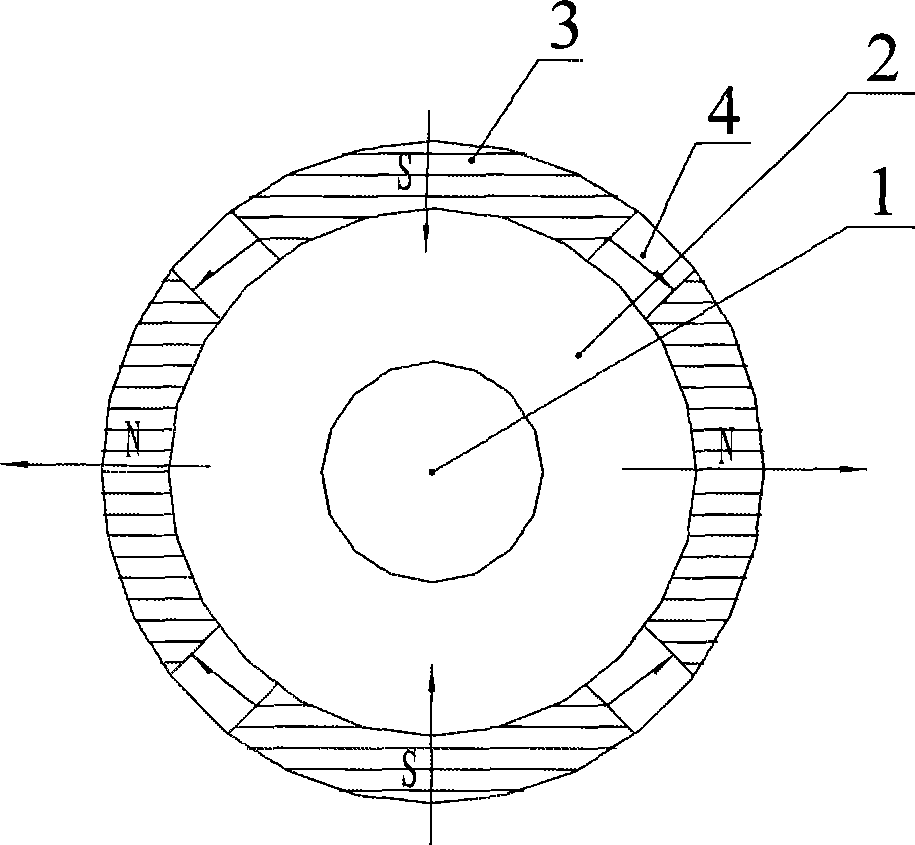

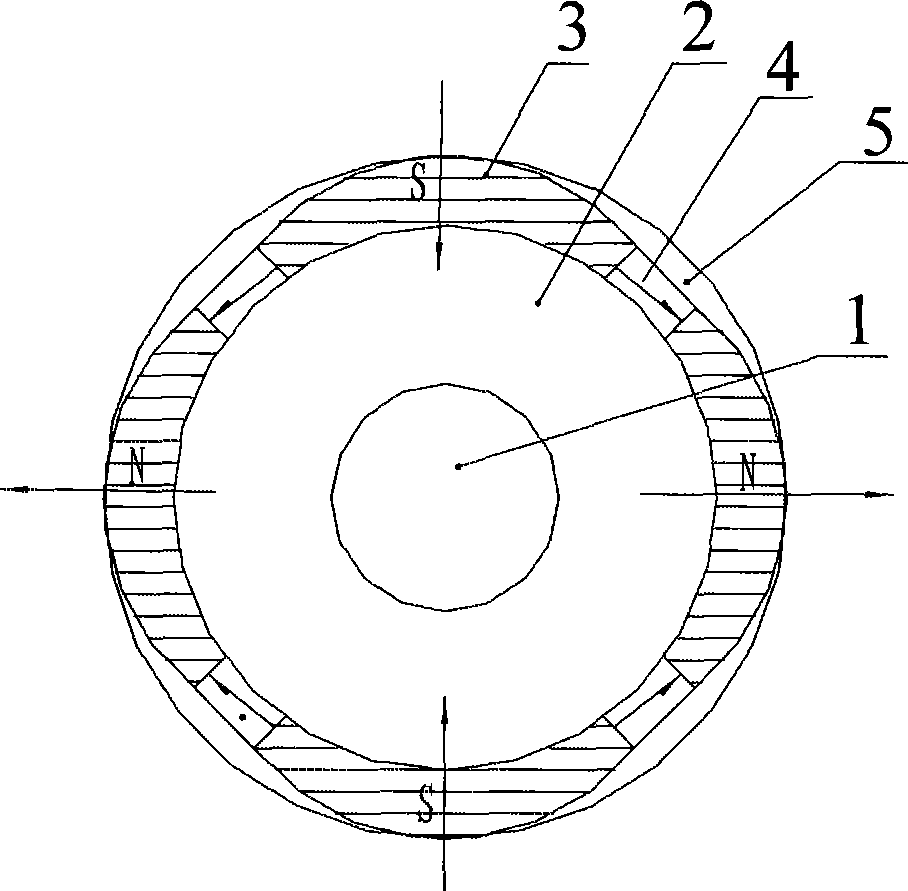

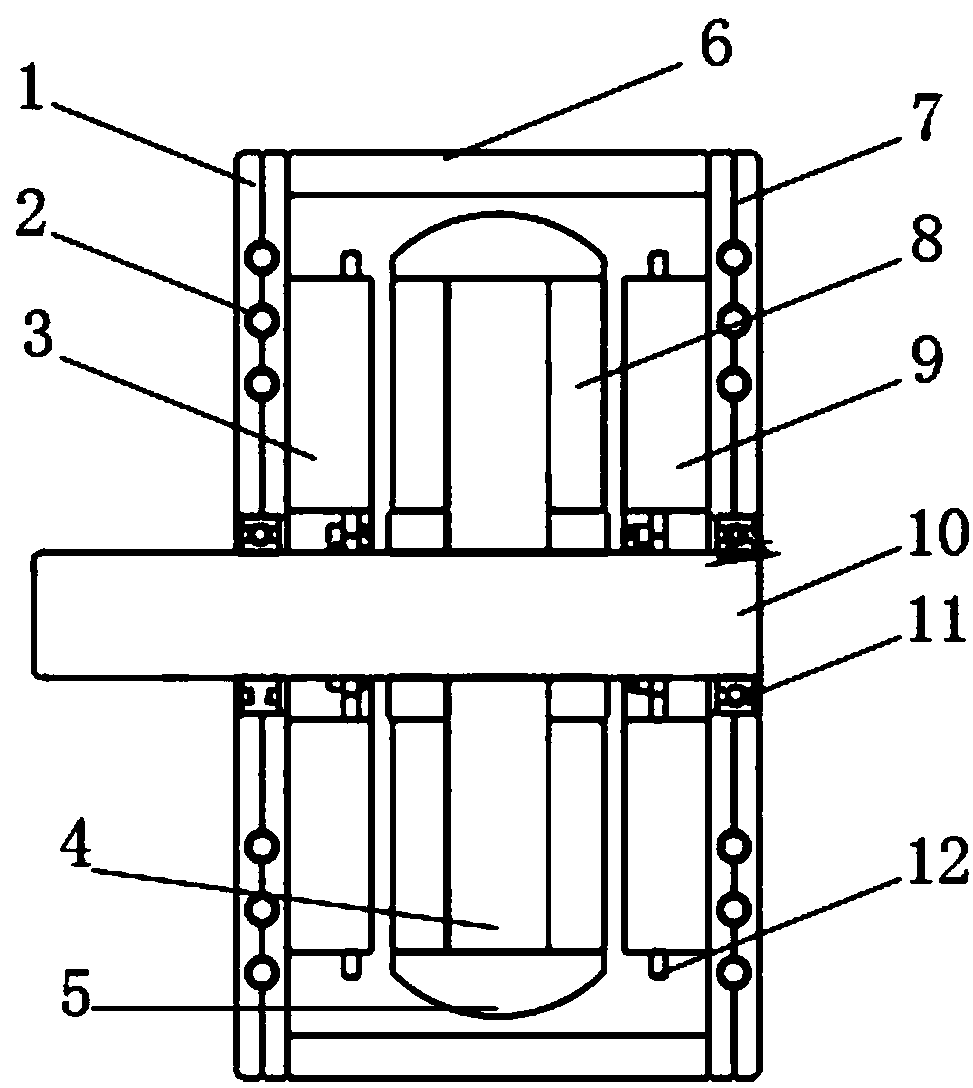

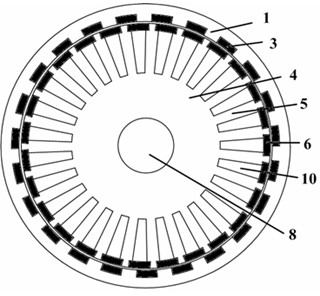

Tangential-set magnet permanent synchronization motor

ActiveCN101123386AIncrease output powerIncrease magnetic densitySynchronous machines with stationary armatures and rotating magnetsElectric machineSynchro

The invention provides a tangential steel magnet permanent magnetism synchro motor, which belongs to the permanent-magnet motors. The motor comprises a stator consisting of a stator core (1) and an armature winding (2), and a rotor consisting of a tangential magnetization permanent magnet (3), a North Pole magnetizer of the rotor (4), an S-pole magnetizer (5) of the rotor, a fixed cover (7) arranged on a driving end, a fixed cover (8) arranged on a non-driving end (8), an axis of rotation (6) and a bearing (9). The rotor and the stator are arranged in a front end cover (10), a back end cover (11) and an enclosure (12). The axial length of the tangential magnetization permanent magnet (3), the North Pole magnetizer of the rotor (4) and the S-pole magnetizer (5) of the rotor (5) is larger than the axial length of the stator core (1); the end connection length can be used effectively. Due to the axial magnetic concentration action of the rotor core, the air-gap induction of the motor is increased; and the power density of the permanent-magnet motor is further increased. The utility model is highly valuable in application in aerospace and civil occasions requiring high performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

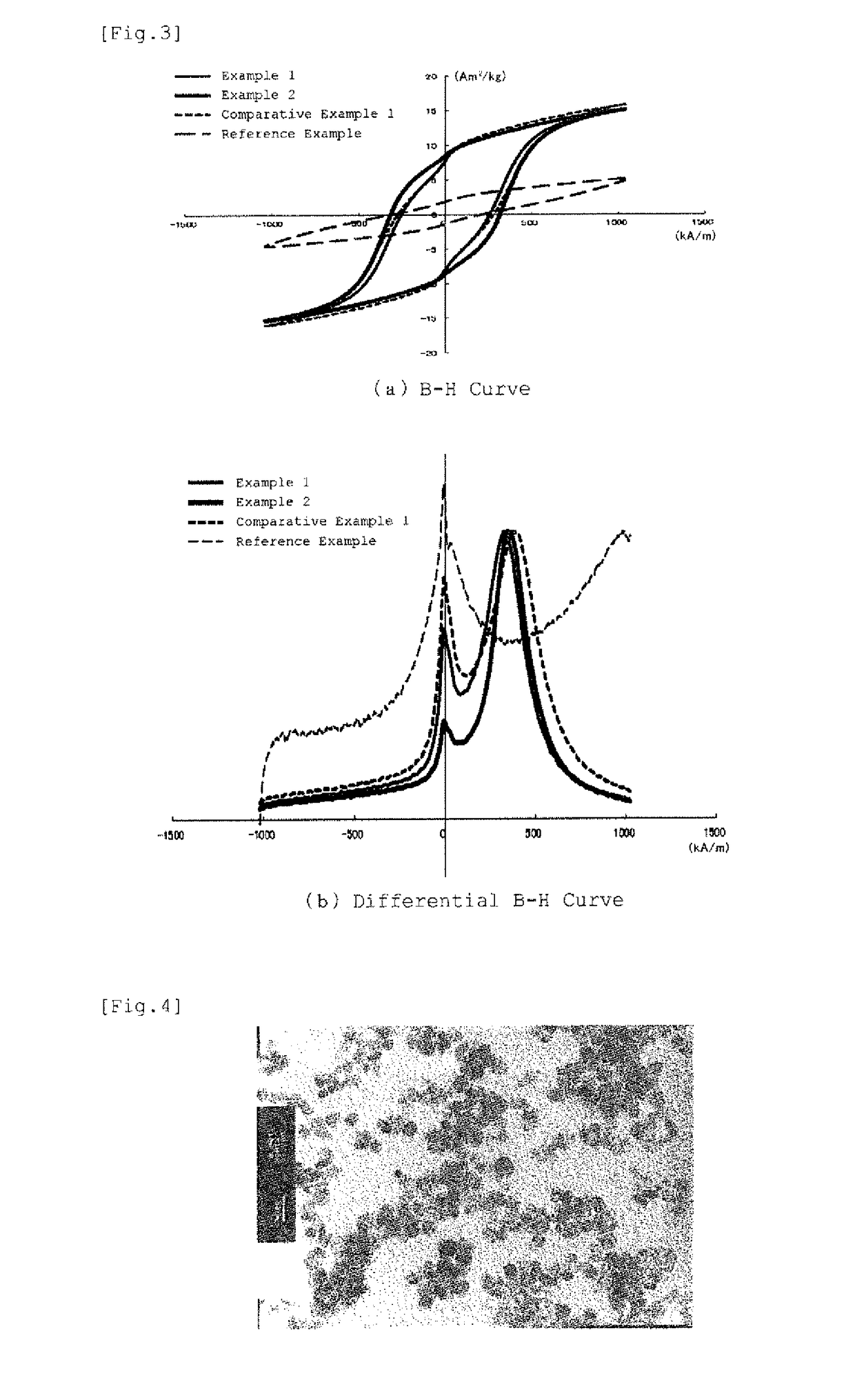

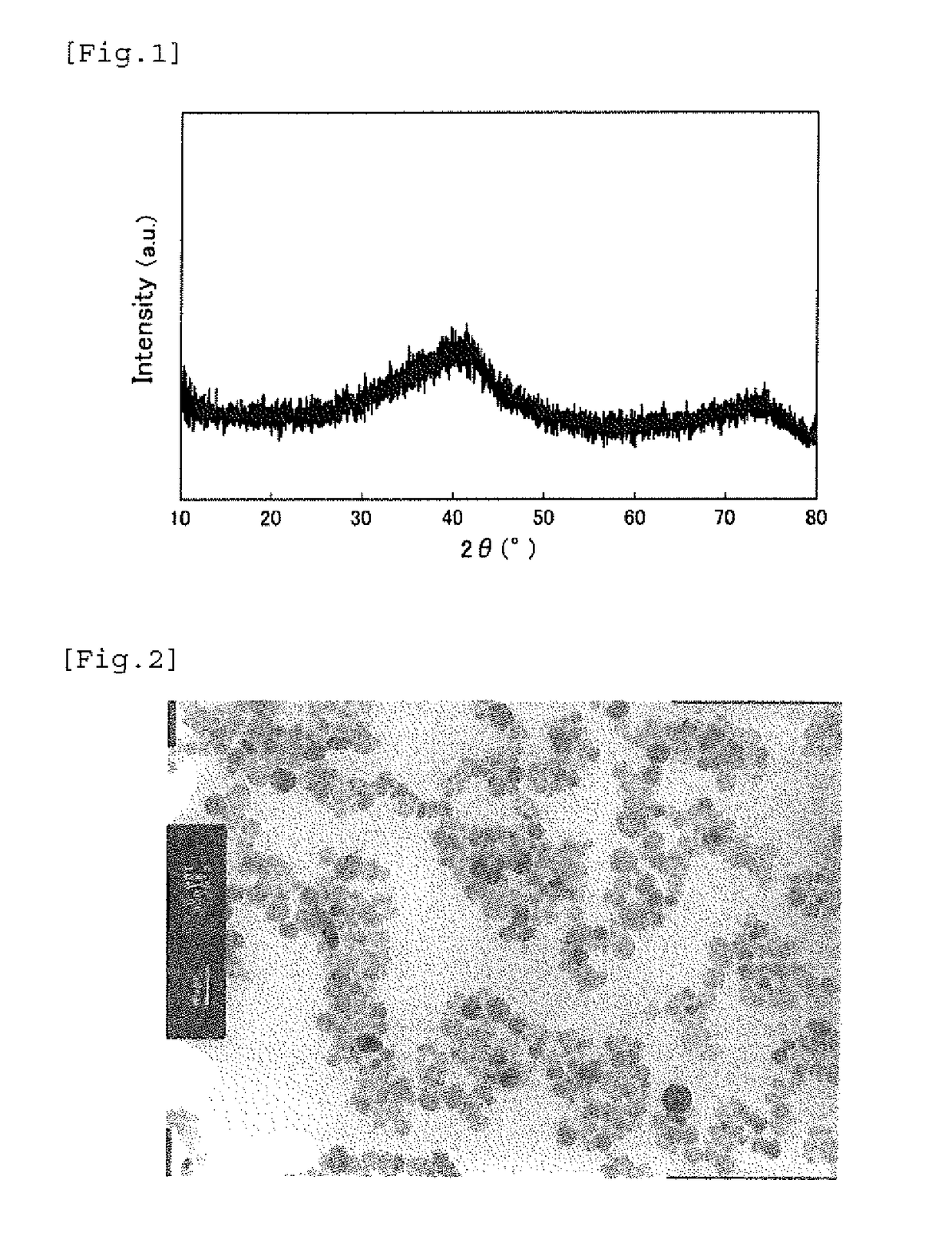

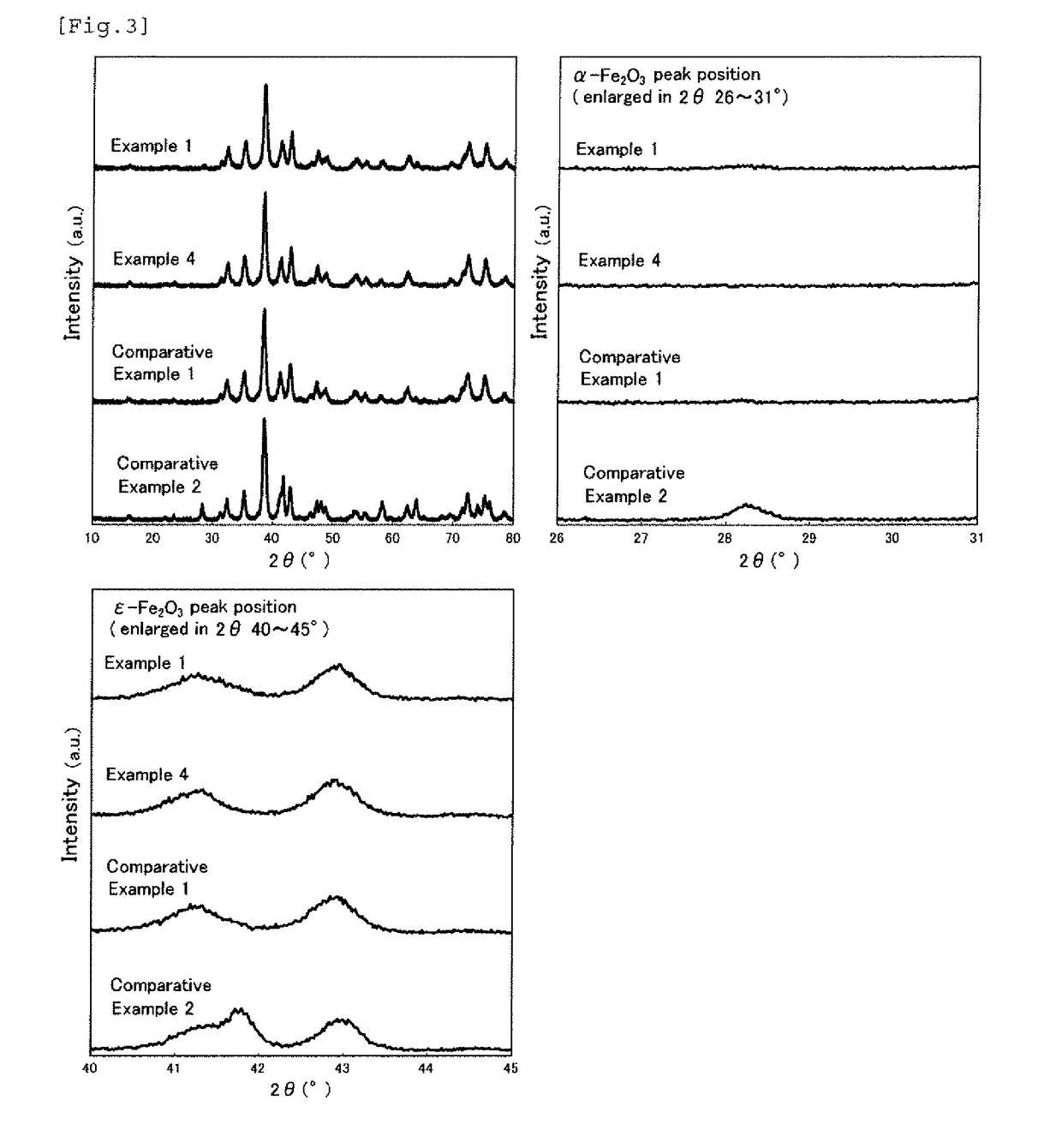

Iron-based oxide magnetic particle powder and method for producing iron-based oxide magnetic particle powder

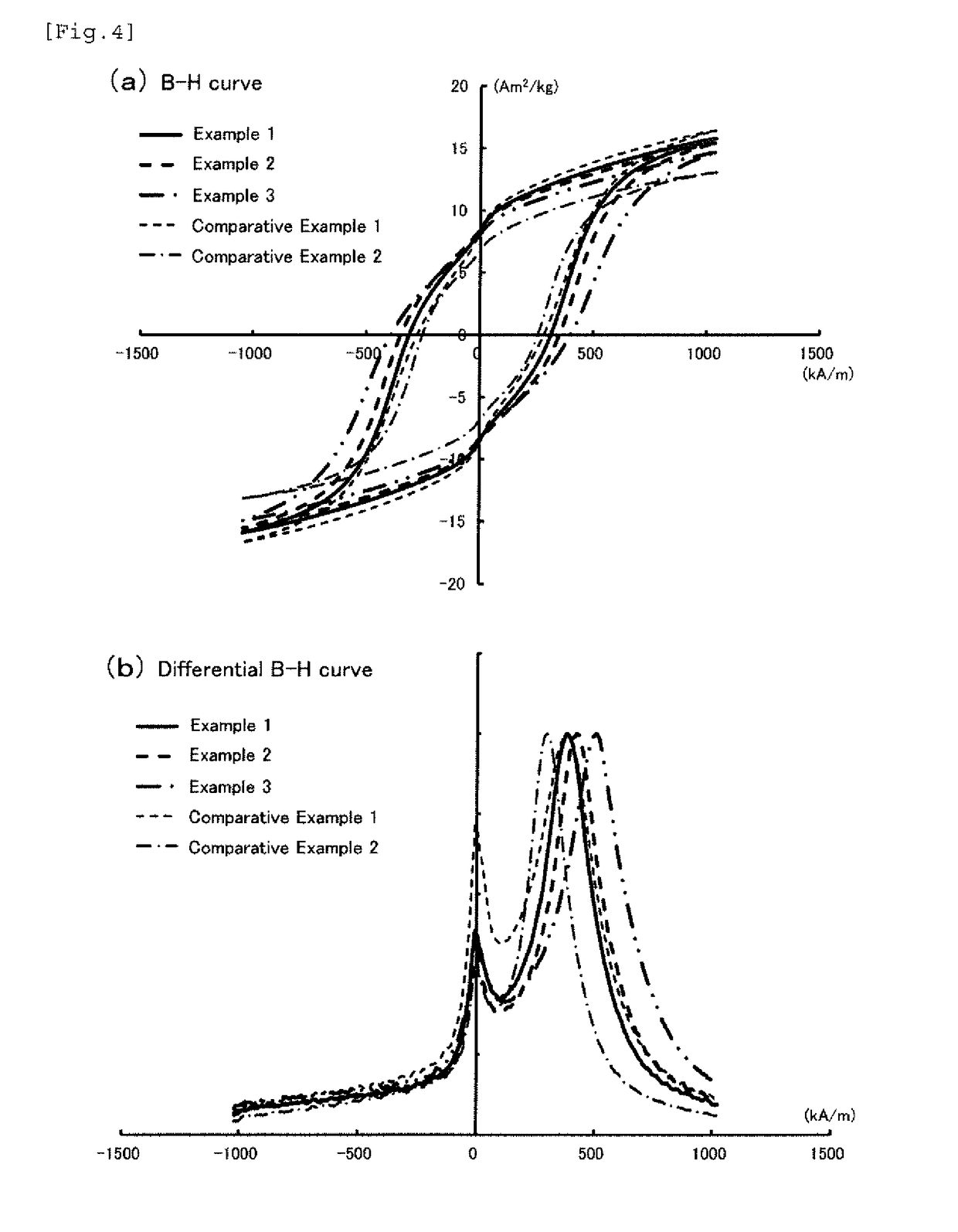

ActiveUS20170287516A1Enhancing magnetic recording characteristicNarrow coercive force distributionMaterial nanotechnologyNanomagnetismCarboxylic acidMicroparticle

An e-type iron-based oxide magnetic particle powder has narrow particle size distribution and has a low content of fine particles which do not contribute to magnetic recording characteristics. As a result, a narrow coercive force distribution is achieved and the powder is suitable for increasing recording density of a magnetic recording medium. The powder containing substituting metal elements can be obtained by: adding an alkali to an aqueous solution containing trivalent iron ions and ions of the metals for partially substituting Fe sites to neutralize the aqueous solution to a pH of 1.5 to 2.5; then adding a hydroxycarboxylic acid; further adding the alkali to neutralize the aqueous solution to a pH of 8.0 to 9.0; washing with water a precipitation of an iron oxyhydroxide containing the substituting metal elements produced; and coating the iron oxyhydroxide containing the substituting metal elements with a silicon oxide and heating the resultant.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

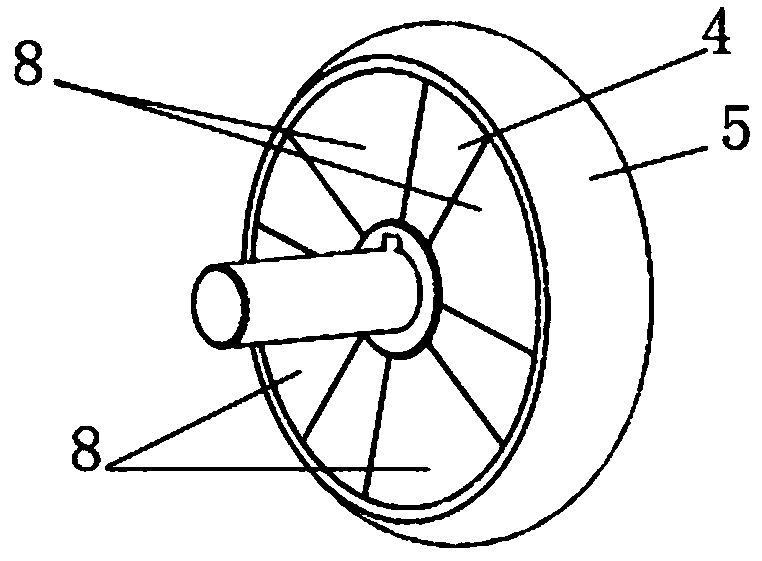

Cylindrical-type linear magnetic-gear composite permanent magnet motor

InactiveCN104883027AIncrease magnetic densityReduce adverse effectsMechanical energy handlingPropulsion systemsMagnetic tension forceLow speed

The invention discloses a cylindrical-type linear magnetic-gear composite permanent magnet motor, and aims at solving a problem of thrust ripple of a conventional magnetic-gear composite motor. Especially for load disturbance or the starting or braking of a motor, the motor improves the operation stability. The motor comprises a brushless DC linear motor and a linear magnetic gear. The motor is also provided with double mechanical ports, and is in a three-layer gap structure. The motor comprises a main armature winding and an auxiliary damping winding, and can achieve the bidirectional transmission of electromechanical energy. The brushless DC linear motor and the linear magnetic gear respectively employ a cylindrical-type structure for coaxial integration. In other words, a double-stator double-rotor structure is formed through a low-speed rotor (17) and an inner stator (14) which form the magnetic gear, and a high-speed rotor (5) and an outer stator (6) which form the brushless DC linear motor.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

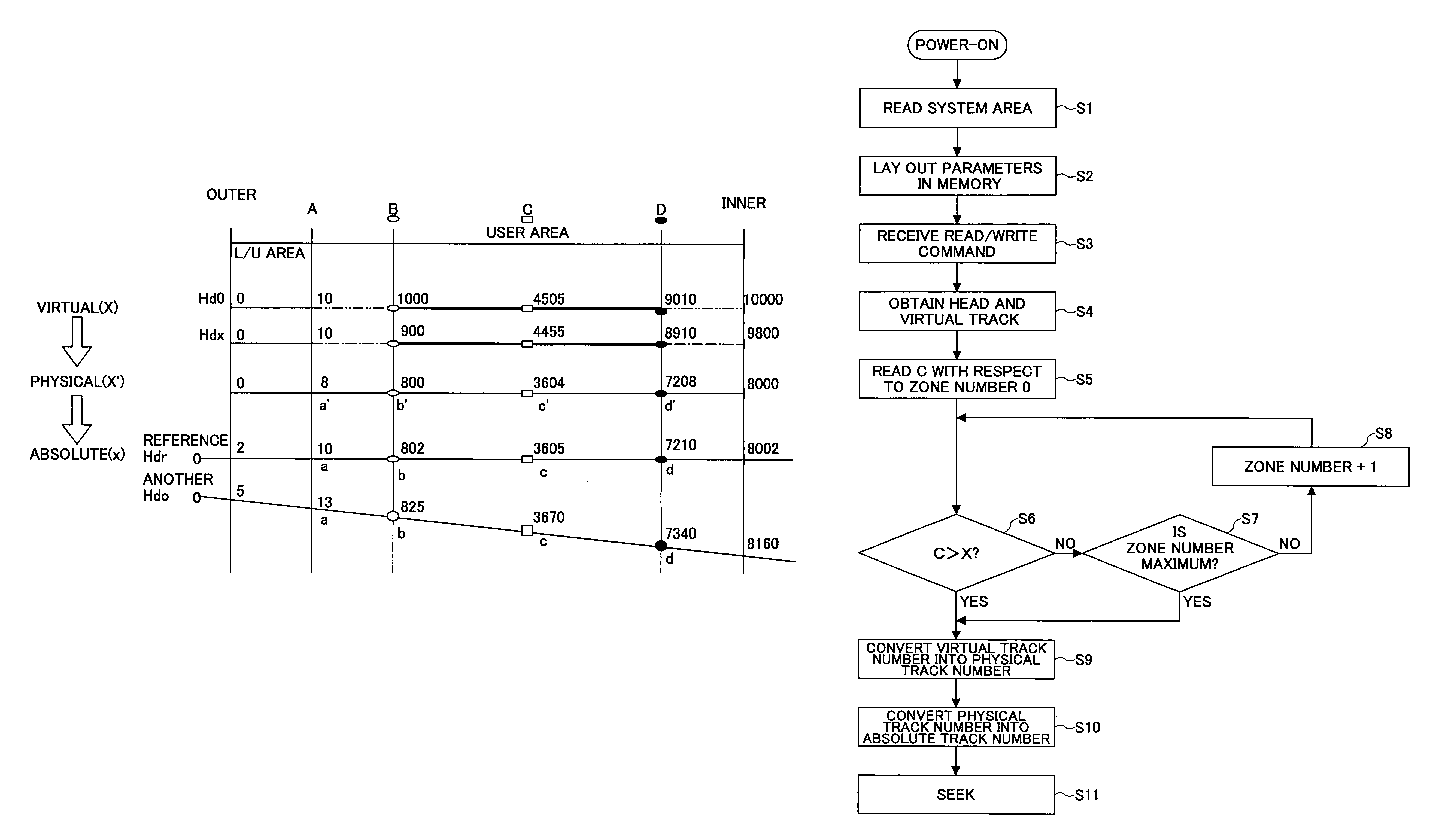

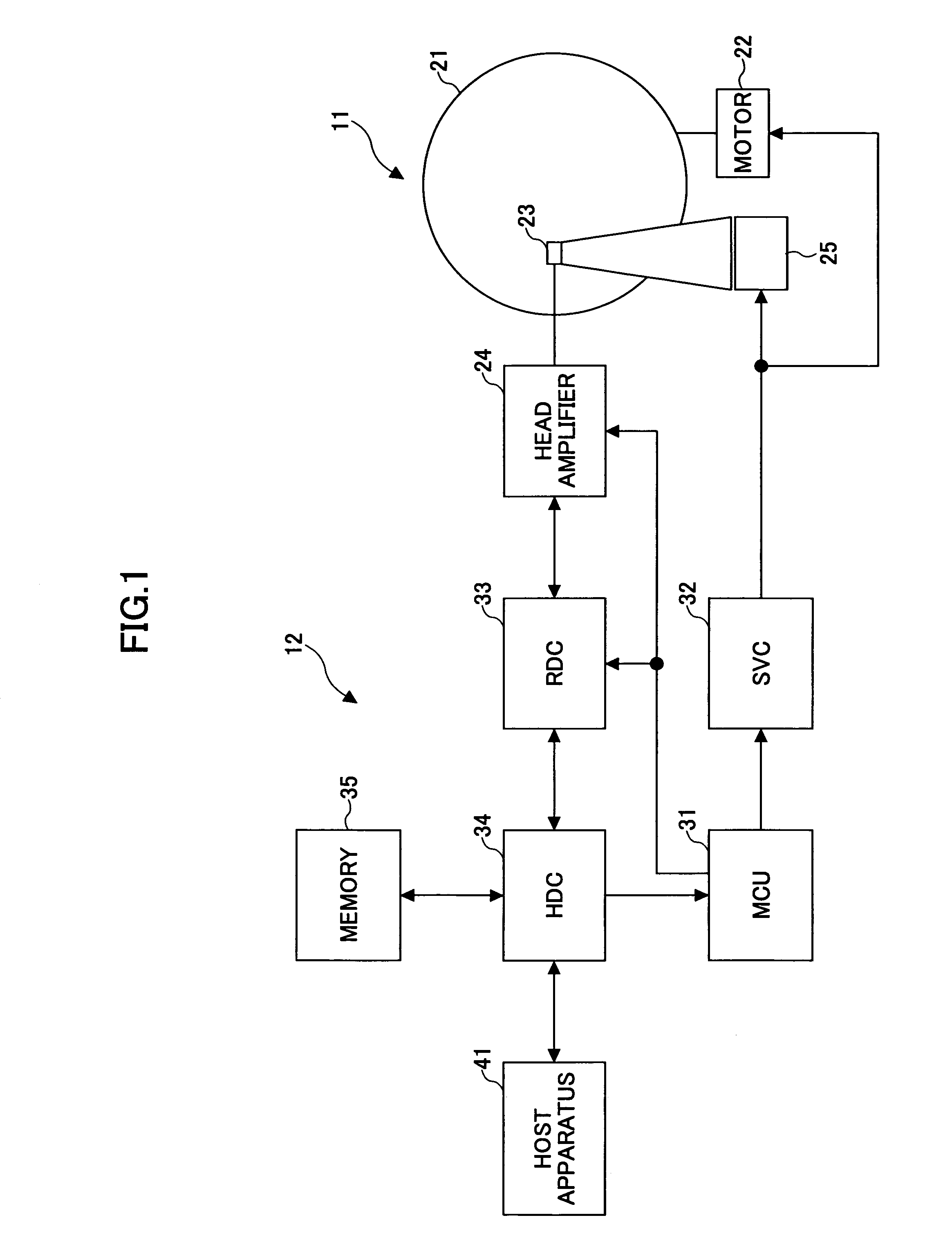

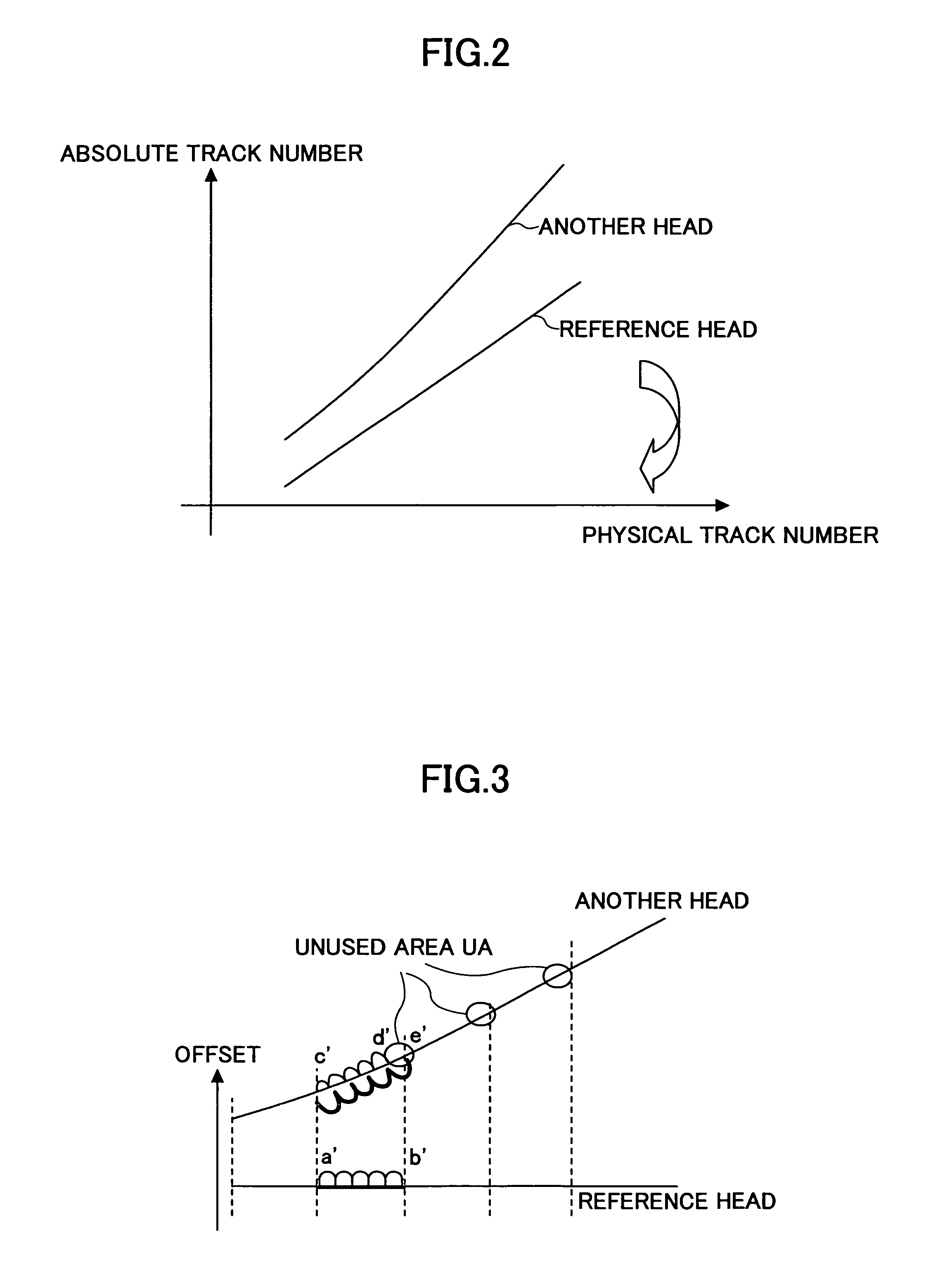

Magnetic disk apparatus suppressing adjacent track influence

InactiveUS7242550B2Increase magnetic densitySignal processing to reduce distortionsRecord information storageElectrical and Electronics engineeringMagnetic disks

A magnetic disk apparatus is configured such that a physical track number is converted into an absolute track number by making a track pitch in an absolute track area formed by a given magnetic head wider by a given amount than a track pitch in a corresponding absolute track area formed by a reference magnetic head if the number of absolute tracks is larger in the absolute track area formed by the given magnetic head than in, the absolute track area formed by the reference magnetic head although the number of physical tracks is identical in corresponding physical track areas between different magnetic disks. The given amount is commensurate with an unused area corresponding to a difference in the number of absolute tracks between the absolute track area formed by the given magnetic head and the absolute track area formed by the reference magnetic head.

Owner:TOSHIBA STORAGE DEVICE CORP

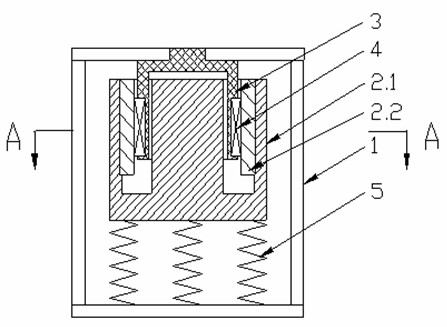

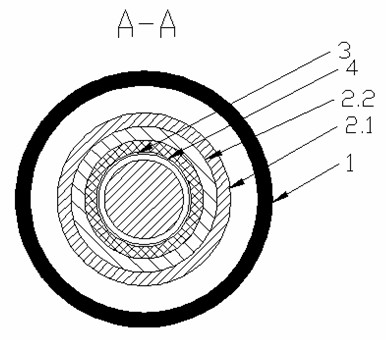

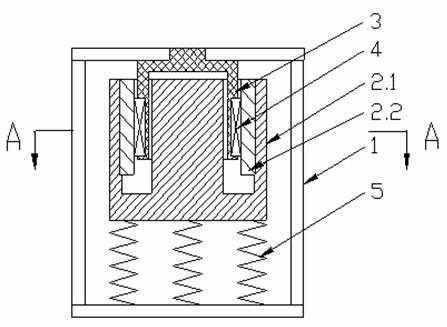

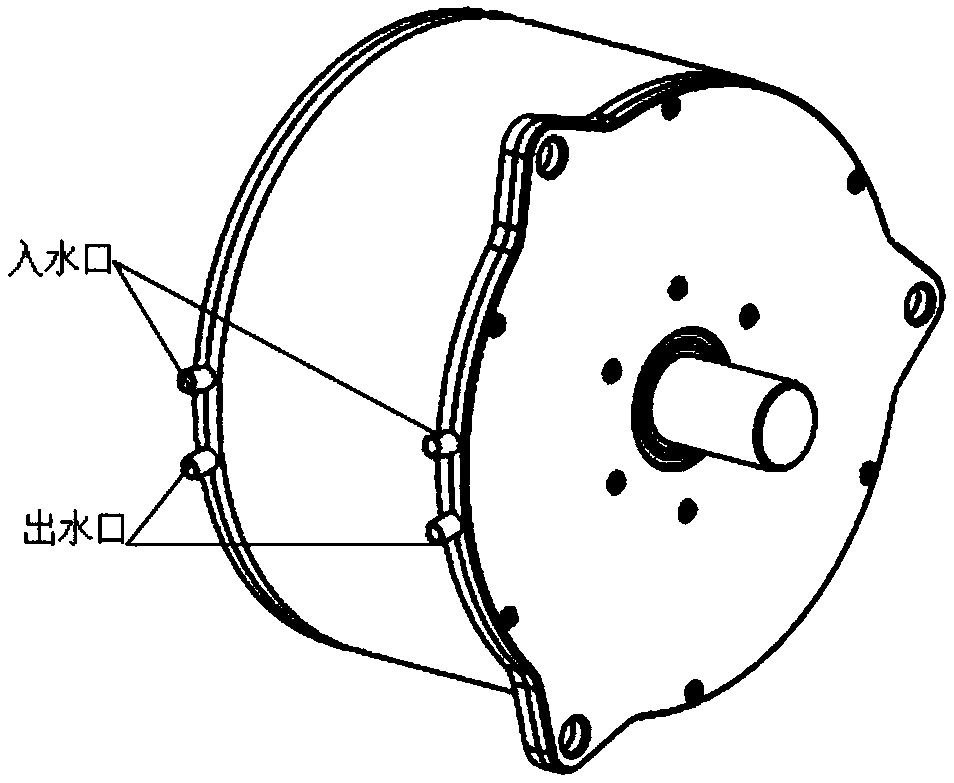

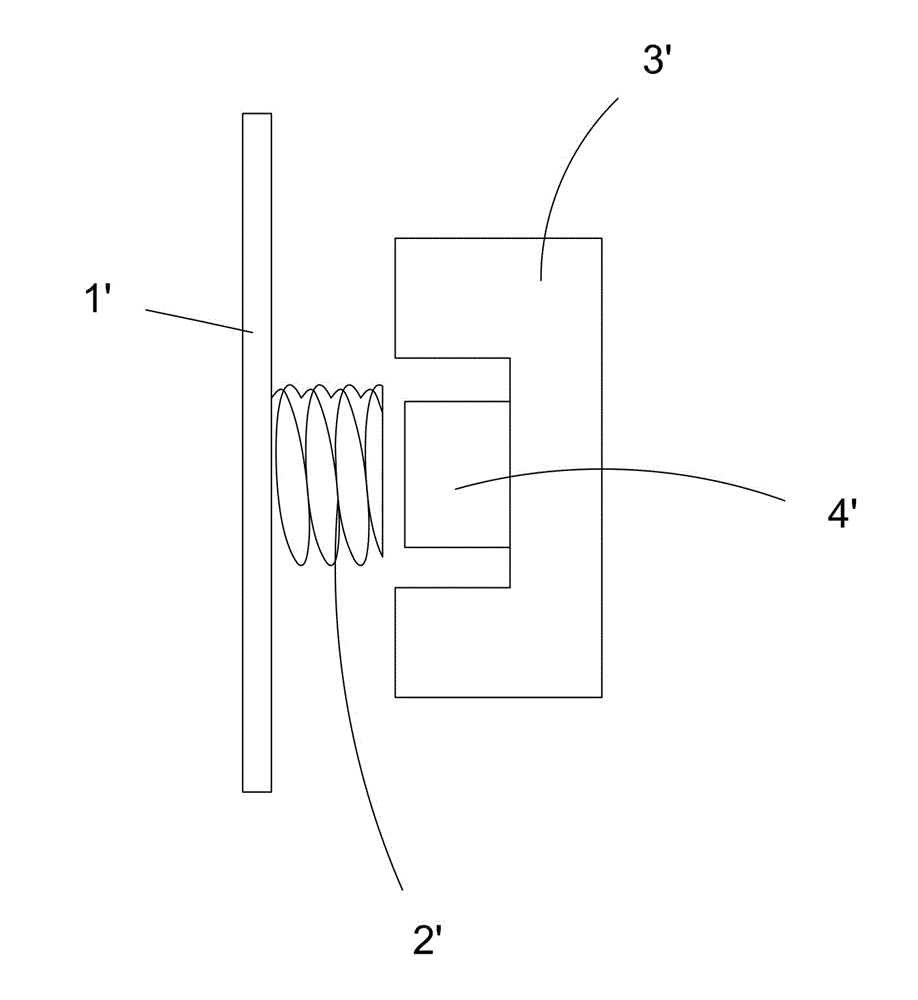

Electromagnetic oscillation energy collection device

InactiveCN102104311ASmall magnetic resistanceIncrease magnetic densityDynamo-electric machinesOuter coreConductor Coil

The invention discloses an electromagnetic oscillation energy collection device. The device comprises a shell, an insulated cup-shaped rotor, a stator, a coil winding and a spring, wherein the rotor is arranged in the shell and consists of a magnetic conductive iron core and a permanent magnet; the magnetic conductive iron core is a whole formed by connecting the bottoms of a cylindrical inner core and an annular outer core in a concentric type, and is provided with an E-shaped longitudinal cross section; the permanent magnet is positioned between the inner core and the outer core of the magnetic conductive iron core and is fixed to the inner surface of the outer core; the bottom of the magnetic conductive iron core is connected with one end of the spring; the other end of the spring is pressed against the bottom of the shell; the cup-shaped stator is fixed with the inner top surface of the shell; the annular cup body of the cup-shaped stator is placed into an annular air gap formed between the inner core and the outer core of the magnetic conductive iron core; the outer surface of the stator is provided with an annular groove along the circumferential direction; and the coil winding is fixed in the annular groove of the stator. The device has a simple structure and reliable operation, and can convert oscillation energy in environment into utilizable electric energy.

Owner:ZHEJIANG UNIV

Suspended magnetic iron structure of magnetic suspension vehicle and its production mehtod

ActiveCN1736761AMachining and manufacturing process simplificationFirmly connectedElectromagnetsElectric propulsionExcitation currentEngineering

Disclosed is a suspending magnet structure of magnetic levitation vehicle, which contains an iron core and a coil and is characterized in that: the coil is prepared with aluminum foil of thicken of 0.15- 0.30mm and insulation film of thicken of 0.01- 0.03mm; the two-side of the coil being separately equipped with copper coolant jacket, inside which is equipped with coiling passage and outside of which is equipped with a pipe connector connecting separately with the two ends of the passage. The invention makes the coil of the suspending magnet cool down effectively and improves the number of turns of coil and the property of resisting big current.

Owner:TONGJI UNIV

Modular axial flux permanent magnet motor

InactiveCN110611379AReduce stressHigh mechanical strengthWindingsMagnetic circuit rotating partsFlywheel energy storageCooling effect

The invention discloses a modular axial flux permanent magnet motor. The motor comprises a stator, double rotors and a bearing. The stator comprises a stator iron core, a stator winding, stator iron core fixing pins and a stator sealing plate. The stator iron core adopts a modular structure, the stator winding is wound on a yoke part of the stator iron core, and the stator iron core fixing pins radially penetrate through the stator iron core and are fixed on a fixed ring. The stator sealing plate is used for sealing stator cooling oil to improve the cooling effect. The rotors comprise rotor back yokes and rotor permanent magnets which are symmetrically installed on two sides of the stator, the rotor permanent magnets are fixed to the rotor back yokes, and inner circumferences of the rotorback yokes are fixed to the bearing. Equal air gaps are kept between the double rotors and the stator to generate a magnetic field. The modular axial flux permanent magnet motor has the advantages ofhigh air gap flux density, high stator structural strength, high torque density and good cooling effect and is suitable for being applied to electric propulsion, wind power generation and high-speed flywheel energy storage occasions.

Owner:NANJING UNIV OF SCI & TECH

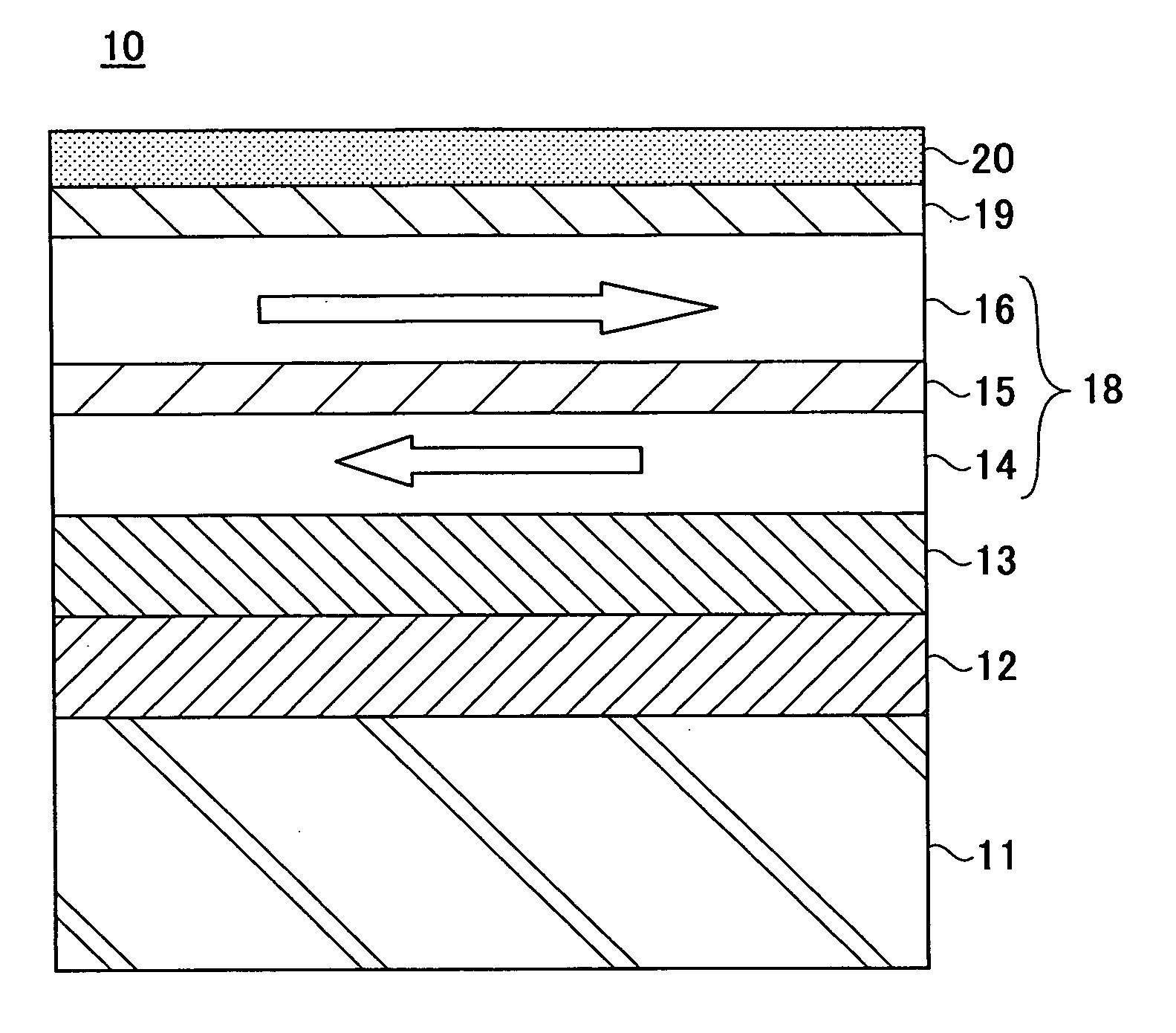

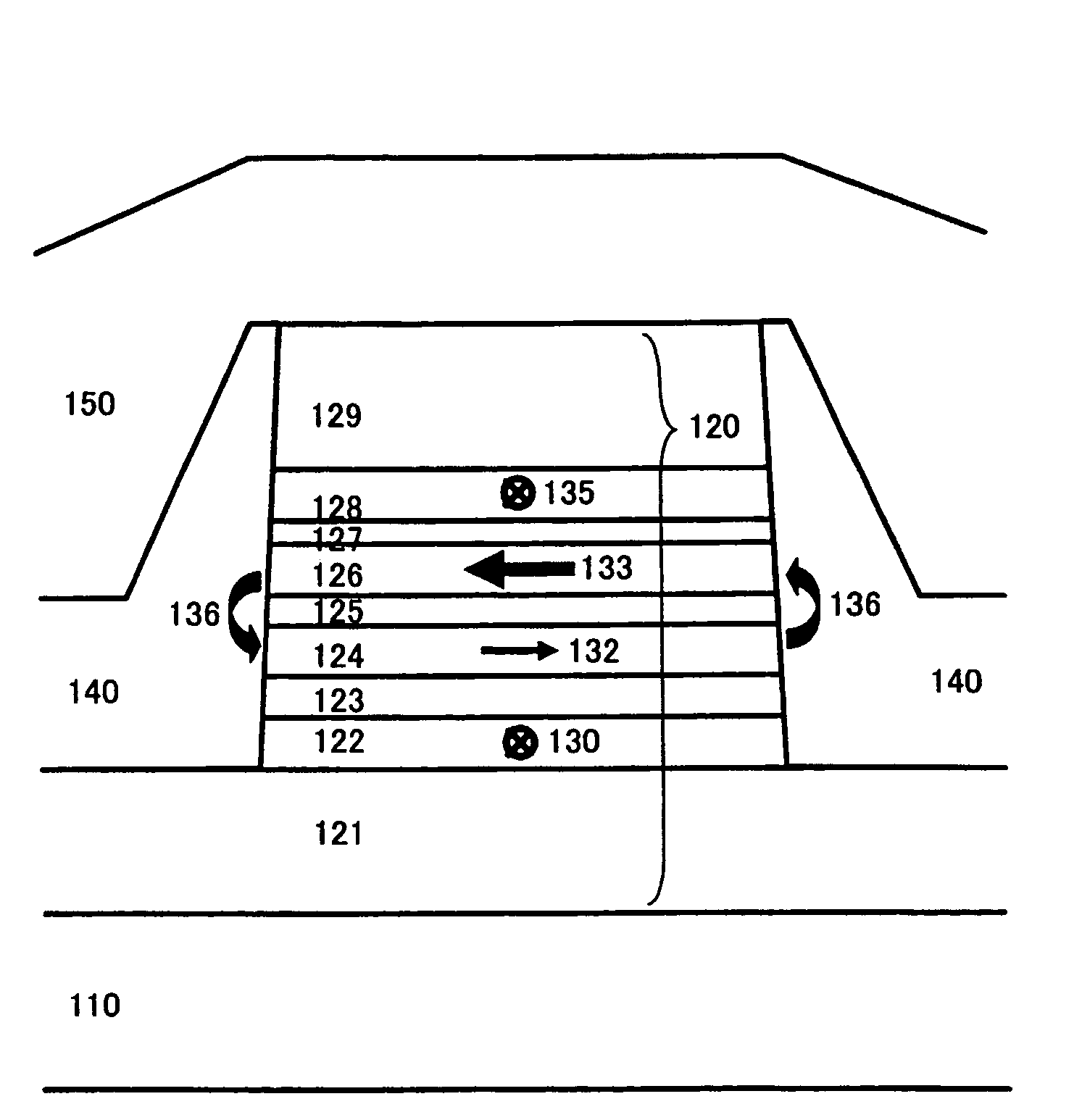

Magnetoresistive head using longitudinal biasing method with 90-degree magnetic interlayer coupling and manufacturing method thereof

InactiveUS7440241B2Increase magnetic densityNarrow widthRecord information storageManufacture of flux-sensitive headsLow noiseMagnetization

A magnetoresistive head and a fabricating method thereof accomplishing high read sensitivity and excellent linear response with low noise even if track width narrowing makes progress are provided. In one embodiment, using a magnetoresistive film having a laminated body of a pinned layer / an intermediate layer / a free layer / a separate layer / a first ferromagnetic layer / a 90-degree magnetic interlayer coupling layer / a second ferromagnetic layer, and the magnetizations of both the pinned layer and the second ferromagnetic layer are fixed nearly in the direction along the sensor height. On the other hand, the magnetizations of the first ferromagnetic layer and the second ferromagnetic layer have an interlayer interaction being directed in nearly orthogonal directions to each other through the 90-degree magnetic interlayer coupling layer, and the first ferromagnetic layer has a magnetization directed nearly in the direction along the track width in zero external magnetic field. According to this, the first ferromagnetic layer applies a longitudinal biasing field to the free layer nearly in the direction along the track width.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Production method for low-energy-consumption neodymium-iron-boron magnetic material

ActiveCN104851544AHigh strengthImprove coercive forceInorganic material magnetismRare-earth elementManufacturing cost reduction

The invention discloses a production method for low-energy-consumption neodymium-iron-boron magnetic material. The permanent magnet material comprises an alloy component of (YxNd1-x)a(Fe1-y-zNiySiz)100-a-b-cBbNbc, wherein the x ranges from 0.46 to 0.53, the y ranges from 0.20 to 0.22, the z ranges from 0.03 to 0.05, the a ranges from 25 to 28, the b ranges from 1.5 to 1.8 and the c ranges from 2 to 5. The production method has the advantages that Nd is replaced by Y through doping, and proper raw material proportions are set, so that saturation magnetization and coercivity of the permanent magnet material are improved while production cost is reduced, and the problems of low saturation magnetization and coercivity both caused by excessive rare earth elements Y and non-magnetic contents B in existing magnetic materials are solved; the magnetic energy product of a magnet is improved by a secondary compaction process, a secondary tempering process is adopted during sintering, and accordingly, the coercivity of the material is further improved; silicon high in electrical resistivity is doped in the material to improve internal resistance of the material, and magnetic density is improved effectively through secondary pressurization of the magnetic material, so that the magnetic material has high temperature stability and magnetic induction intensity and has much lower power loss than the prior art.

Owner:佛山市福斯曼医疗科技有限公司

Low noise fast response permanent magnet DC brushless motor for constant wind control

InactiveCN101459370AImprove qualityReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseBrushless motors

The invention provides a low noise fast response permanent magnet direct current brushless motor for controlling constant air volume, which comprises a shell, a stator and a rotor in the shell, wherein the stator comprises a stator iron core and a stator winding which are fixed on the inner wall of the shell, the rotor comprises a main shaft and a rotor iron core, the external circumferential direction of the rotor iron core is evenly fixed with rotor magnetic poles which comprise radial magnetized magnetic steel and tangential magnetized magnetic steel, the radial magnetized magnetic steel is a main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is a side magnetic pole. Or, the inner circumferential direction of the rotor iron core is evenly embedded with built-in radial magnetized rectangular strip magnetic steel which is the main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is the side magnetic pole. The low noise fast response permanent magnet direct current brushless motor gathers magnetic through two ways of radial and tangential direction, thereby observably increasing the air gap flux density, greatly reducing the mechanical time constant, increasing fast response, controlling the constant air volume in a high performance, which leads a motor to steadily operate in high efficiency, saving energy, low fluctuation, low noise, frequent starting and rapid response, and the low noise fast response permanent magnet direct current brushless motor can achieve the miniaturization and lightening of the motor.

Owner:苏州和鑫电气股份有限公司

Magnetic recording medium and process for production of magnetic recording medium

InactiveUS20090136783A1Prevent oxidationGood weather resistanceLayered productsMaterials with cobaltWeather resistanceNanoparticle

The invention provides a magnetic recording medium with both weather resistance and high recording density. The magnetic recording medium of the invention has a magnetic layer comprising at least SmCo-based magnetic fine particles and a hydrophobic binder, wherein the SmCo-based magnetic fine particles include a core composed of SmCo-based nanoparticles and a hydrophilic polymer covering at least a portion of the surface of the core.

Owner:TDK CORPARATION

Stator permanent magnet type cursor motor structure for reducing positioning force

ActiveCN103490534AAdded complexity and costIncrease manufacturing costMagnetic circuit stationary partsMagnetPermanent magnet motor

The invention discloses a stator permanent magnet type cursor motor structure for reducing positioning force. The structure comprises a primary portion and a secondary portion, wherein an air gap is formed between the primary portion and the secondary portion, a plurality of virtual slots and a plurality of virtual teeth are arranged at the tooth end of each tooth of the primary portion in the moving direction of a motor, the number of the virtual teeth is N1, the number of the virtual slots is N2, the relation of N1 and N2 is N1=N2+1, and the N2 is an odd number larger than 1; a fourth permanent magnet is embedded in the virtual slot right in the middle, and magnetism gathering modules are embedded in the other virtual slots; the magnetizing direction of the fourth permanent magnet is perpendicular to the moving direction of the motor and is towards the air gap; each magnetism gathering module is formed by sequentially and tightly attaching three permanent magnets, wherein the magnetizing direction of the middle permanent magnet is perpendicular to the moving direction of the motor and is towards the air gap, the two permanent magnets on the two sides are relatively magnetized, and the magnetizing direction is the same as the moving direction of the motor; due to the matching of the permanent magnets and the magnetism gathering modules, the positioning force can be reduced, and meanwhile performance indexes such as no-load counter electromotive force, thrust output and the dosage of the permanent magnets are not affected.

Owner:JIANGSU UNIV

Method for producing iron-based oxide magnetic particle powder

ActiveUS20180208479A1Improve featuresNarrow distributionMaterials with cobaltRecord information storageMicroparticleSilicon oxide

To provide iron-based oxide magnetic particle powder that has a narrow particle size distribution and a small content of fine particles that do not contribute to the magnetic recording characteristics, which result in a narrow coercive force distribution, and is suitable for the enhancement of the recording density of the magnetic recording medium, and a method for producing the same. An alkali is added to an aqueous solution containing a trivalent iron ion and an ion of the metal substituting a part of Fe sites to neutralize the aqueous solution to pH of 1.0 or more and 3.0 or less; a hydroxycarboxylic acid D is added in an amount providing a molar ratio D / Fe with respect to the amount of the trivalent iron ion or a molar ratio (D / (Fe+M)) with respect to the total amount of the trivalent iron ion and the ion of the metal M in the case where the substituting metal ion is contained of 0.125 or more and 1.0 or less; an alkali is further added to neutralize to pH of 7.0 or more and 10.0 or less; and then the iron oxyhydroxide containing the substituting metal element is coated with a silicon oxide and heated, so as to provide ε-type iron-based oxide magnetic particle powder containing the substituting metal element.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Bearingless brushless direct current motor and control method thereof

ActiveCN102368657AIncrease magnetic densityReduce weightMagnetic circuit rotating partsVector control systemsLoop controlDC - Direct current

The invention discloses a bearingless brushless direct current motor and a control method thereof. The motor is characterized in that: a permanent magnet is uniformly distributed on a surface of a rotor iron core with a Halbach array; both a torque winding and a suspension force winding employ a short pitch winding structure and are wound round a stator tooth together; coils of each two suspension force windings are separated by a stator tooth; through a difference between a given rotating speed and an actual rotating speed and through a PI regulator, a current given value of the torque winding is outputted to control torque winding input current, and rotating speed closed loop control is realized; through a difference between a given rotor radial displacement and a detected actual displacement and through the PI regulator, a suspension force given value is outputted to control suspension force winding input current, and rotor radial displacement closed loop control is realized. By employing the method in the invention, effective control of bearingless brushless direct current motor torque and suspension force are realized, permanent magnetism material is saved, and a motor weight is reduced.

Owner:ZHENJIANG YUANDONG ELECTRIC MOTOR

Stator permanent magnet vernier motor with modules evenly distributed at circumference

InactiveCN103490577AIncreased torque densityImprove power densitySynchronous machinesMagnetic circuit stationary partsConductor CoilPower density

The invention discloses a stator permanent magnet vernier motor with modules evenly distributed at the circumference. The stator permanent magnet vernier motor comprises an inner stator and an outer rotor. The multiple unit modules which are distributed along the circumference of an air gap are fixed to the outer ring of the inner stator. The side walls of every two adjacent unit modules are tightly attached together. Each unit module is composed of a permanent magnet and a magnetizer which are the same in size, wherein the side wall of the permanent magnet and the side wall of the magnetizer are tightly attached together. The permanent magnets are magnetized in a radial mode. The number P of pole-pairs of magnetic field distribution produced by the permanent magnets corresponds to the number of the unit modules and the number of rotor teeth. The magnetizer in each unit module can be replaced by another identical permanent magnet, and after replacement, the two permanent magnets in the same unit module are opposite in magnetizing direction. Due to the mutual cooperation of the unit modules, the limited notch space, near the stator, of the air gap is reasonably utilized, flux density in a magnetic circuit is increased effectively, counter potential in a winding is effectively improved, output torque and power density of the motor are improved, and the size is reduced correspondingly.

Owner:JIANGSU UNIV

Ultrahigh-speed permanent magnet disk motor and installation method thereof

PendingCN109904951AEasy to installReduce axial effective air gapMagnetic circuit rotating partsMechanical energy handlingMagnetElectrical and Electronics engineering

The invention relates to an ultrahigh-speed permanent magnet disk motor. The motor comprises a first stator core, a second stator core, a stator winding, an enclosure, a heat dissipation pipeline, a front end cover, a rear end cover, a high-speed rotor and ceramic bearings, wherein the high-speed rotor comprises a high-speed rotor core, permanent magnets, a rotor sheath and a rotor shaft; and thehigh-speed rotor core is installed on the rotor shaft in a sleeving mode, permanent magnet wedge-shaped installing slots are processed in the radial direction to install the permanent magnets, the permanent magnets are installed at the two axial sides of the high-speed rotor core, and the rotor sheath is installed on the high-speed rotor core. The motor has high mechanical strength and is suitablefor ultrahigh-speed running; and moreover, a good heat dissipation system is designed, and the situation that the permanent magnets are demagnetized during ultrahigh-speed running of the disk motor is prevented. The invention not only provides an ultrahigh-speed permanent magnet motor scheme but also discloses a motor assembling method.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

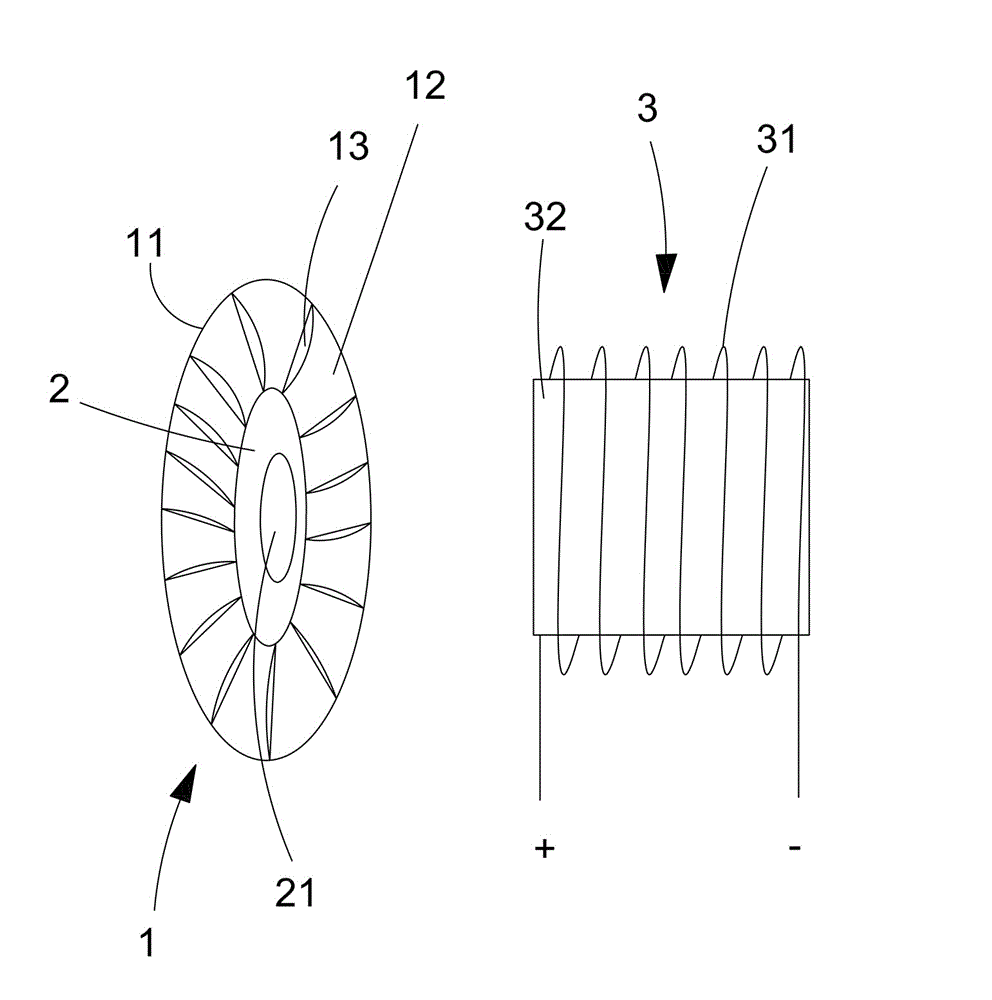

Electromagnetism transient magnetic loudspeaker

InactiveCN103152679AReduce weightLighter and thinnerElectrical transducersMagnetizationSound quality

The invention provides an electromagnetism transient magnetic loudspeaker, which comprises a vibrating diaphragm, wherein a magnetizer is arranged on the vibrating diaphragm; an electromagnetic device is arranged on an opposite position of the magnetizer, and comprises a coil opposite to the magnetizer, and a magnetic bar; and the magnetic bar penetrates through an inner opening of the coil so as to be opposite to the magnetizer. The weight of the vibrating diaphragm is reduced; due to the removal of a voice coil, the axial movement of the voice coil in a magnetic gap is avoided; an electromagnetic type power structure is adopted, so that compared with an existing permanent magnet, the magnetic density is higher, a sound signal can be performed at high speed; a plane vibrating diaphragm design is adopted, so that voice frequency can be parallely transmitted, the defect of emission of voice frequency of a bowl type vibrating diaphragm is overcome, and the sound signal can be highly positioned; and a nickel ring has the characteristics of magnetization, inoxidizability, acid and alkali corrosion and the like, so that the service life of the loudspeaker is greatly prolonged, the problems that the magnetic force of a permanent magnet is reduced, and the tone quality is affected are solved, and graceful sound with high sound quality, clearness, enriched detail and wonderful layering performance is realized.

Owner:胡宗科

Permanent magnet direct-driven vernier motor

InactiveCN102545514ACompact structureReduce volumeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineryEngineering

The invention discloses a permanent magnet direct-driven vernier motor which comprises an outer rotor, an outer rotor permanent magnet, a stator, a stator permanent magnet, windings, a motor shaft and a bearing, wherein the outer rotor is rotatably connected with the motor shaft through the bearing, the motor shaft is fixedly connected with the stator; the outer rotor permanent magnet is embedded in a rotor yoke; the stator is provided with stator teeth along the circumference, two sides of the top of the stator teeth are respectively provided with notches, a stator slot is formed between the adjacent two stator teeth; the windings are wound on the stator teeth; the end face of the stator permanent magnet is embedded in the notch of the adjacent two stator teeth; the stator permanent magnet and the outer rotor permanent magnet adopt radial magnetization, and the magnetization directions of the stator permanent magnet and the outer rotor permanent magnet are same; clearances are reserved between the stator permanent magnet and the outer rotor, as well as the stator teeth and the outer rotor, and the sum of the number of pole pairs (nr) of the outer rotor permanent magnet and the number of pole pairs (np) of the windings is the number (ns) of the stator teeth. The motor has simplified components and compact structure and can reduce the magnetic flux leakage and improve the motor efficiency.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com