Permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and magnetic steel, which is applied in the direction of synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., which can solve the problem of increasing the difficulty of R&D and design of motor controllers and the difficulty of back electromotive force and other problems, to achieve the effect of easy assembly and production, small cogging torque, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

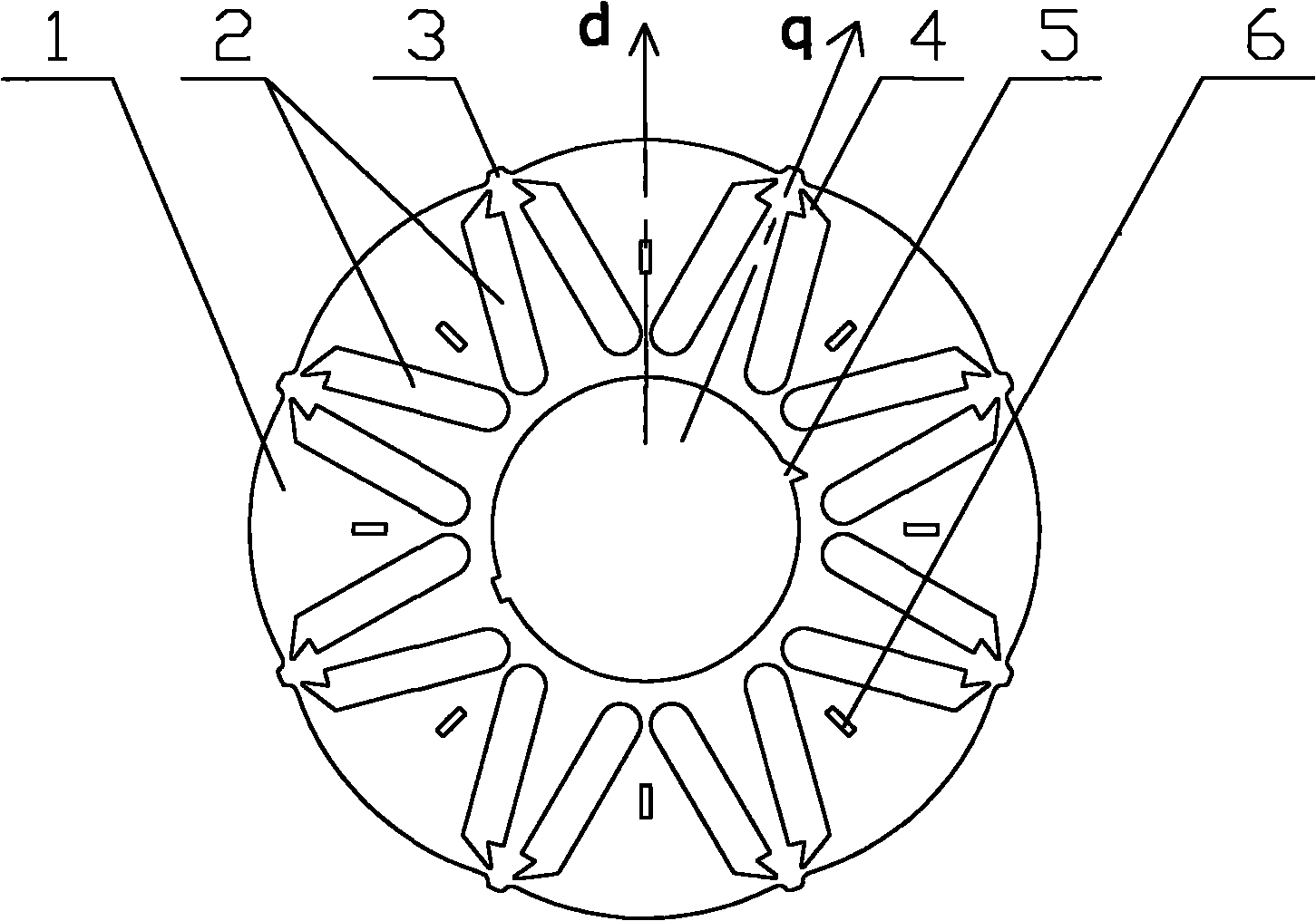

[0021] as attached figure 1 , 1 is the rotor, 2 is the magnetic steel groove, 3 is the protrusion, 4 is the air gap of the magnetic steel groove, 5 is the mark groove, 6 is the positioning riveting point, d is the direct axis of the motor, and q is the quadrature axis of the motor.

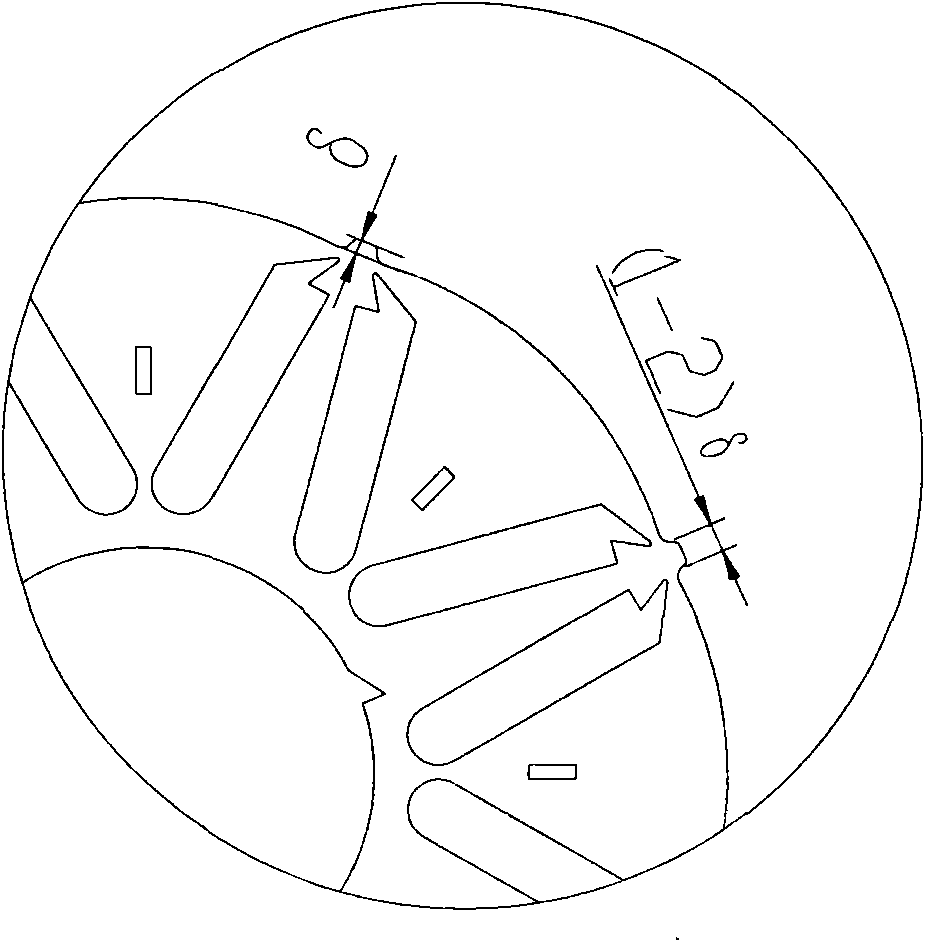

[0022] In a permanent magnet synchronous motor of the present invention, a plurality of magnetic steel slots 2 are evenly distributed on the circumferential surface of the rotor 1, and each magnetic steel slot is independently closed and has no contact with each other. The rotor in this embodiment is provided with 8 poles and 16 magnetic steel slots, two magnetic steel slots are arranged in a V shape, as shown in the figure, the two magnetic steel slots pointed to by 2 are a V-shaped magnetic steel slot group, the V-shaped opening faces the outer circle of the rotor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com