Motor rotor and method of manufacturing same

A motor rotor and rotor technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of insufficient sealing of magnetic poles, rust and pulverization of magnetic poles, and reduce the power generation of wind turbines etc. to achieve the effect of reducing cogging torque and torque ripple and reducing manufacturing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical concept of the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the accompanying drawings, the same reference numerals always represent the same components.

[0043] "Axial" mentioned in this article refers to the axial direction parallel to the central rotation axis of the motor rotor, "circumferential" refers to the circumferential direction along the rotor rotation direction, and "radial" refers to the radial direction of the motor .

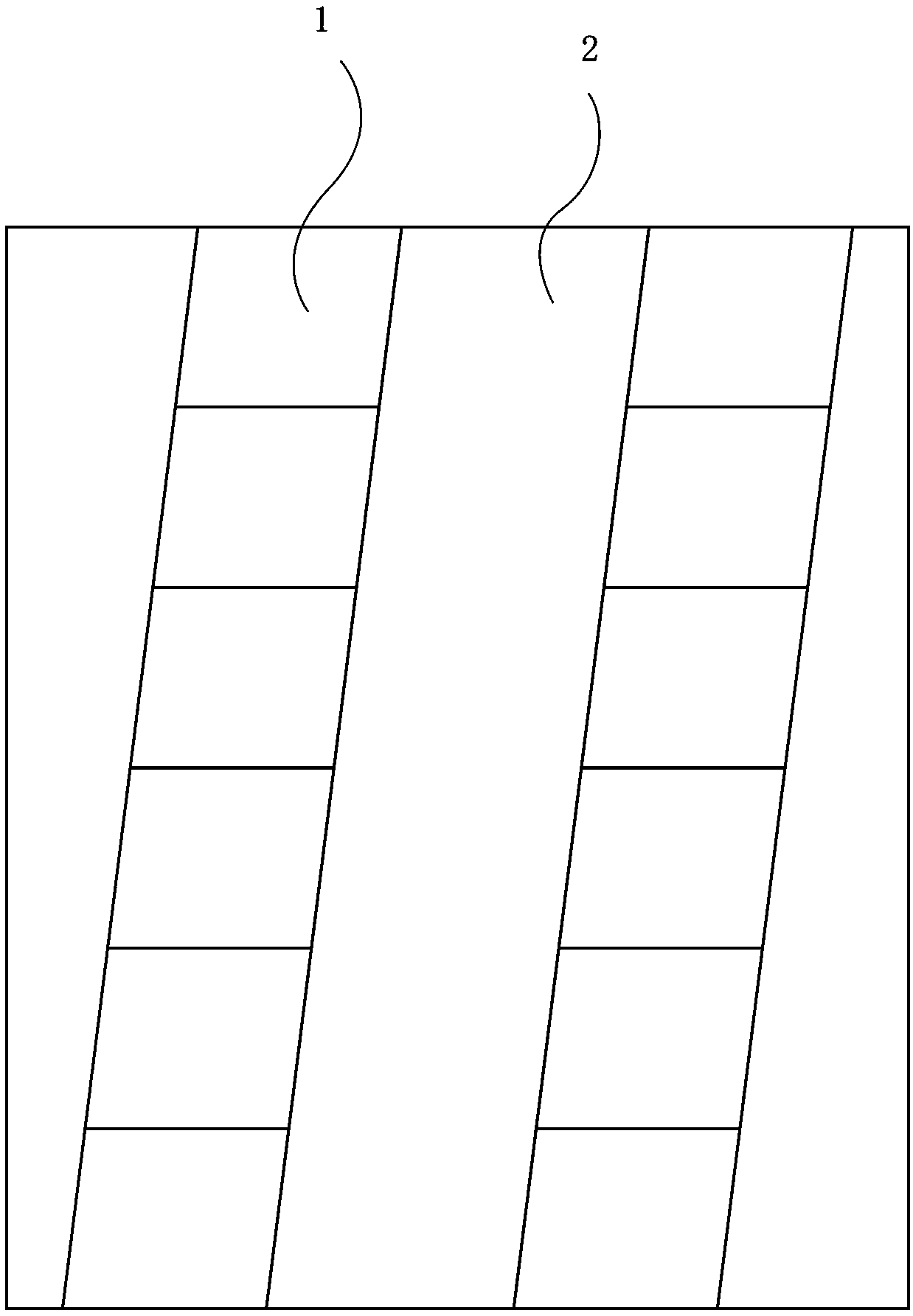

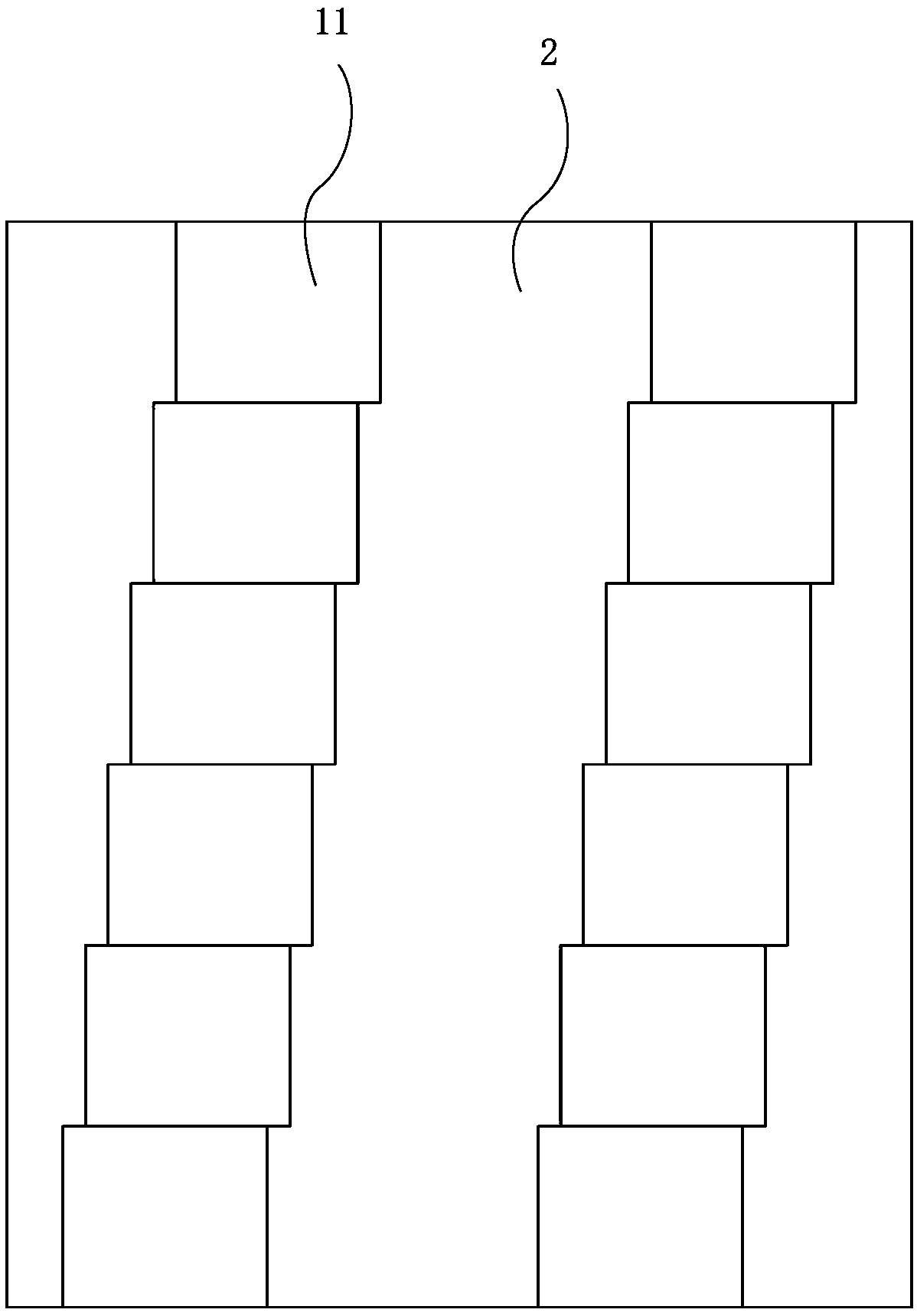

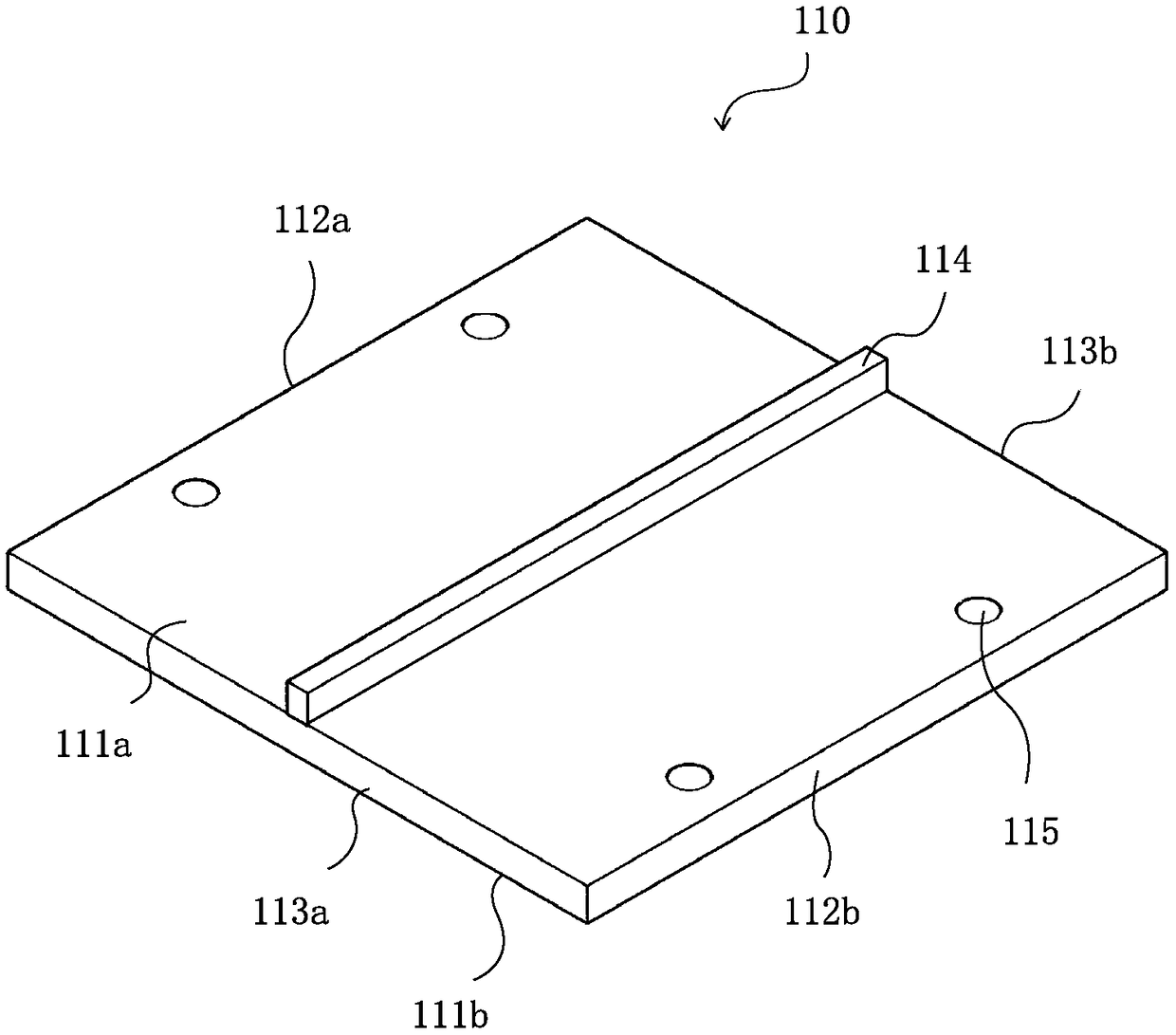

[0044] Figure 3 to Figure 9 A pole module 100 according to a first embodiment of the present invention and a motor rotor 1000 including the pole module 100 are shown. refer to Figure 3 to Figure 8 In other words, the pole module 100 may mainly include a base plate 110 , a pair of pole units (a first pole unit 120 and a second pole unit 130 ), and a case 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com