Patents

Literature

2275 results about "Tooth part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

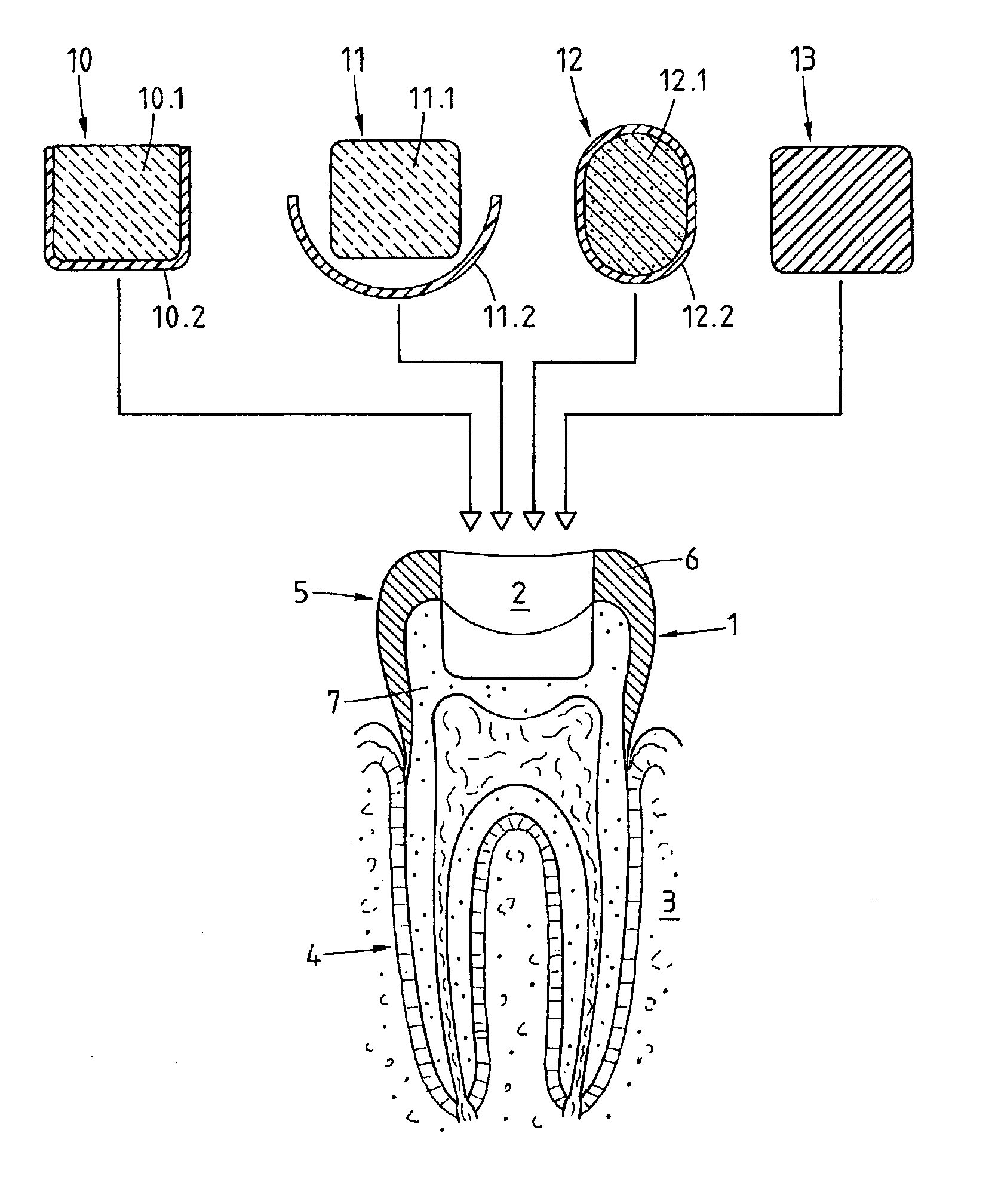

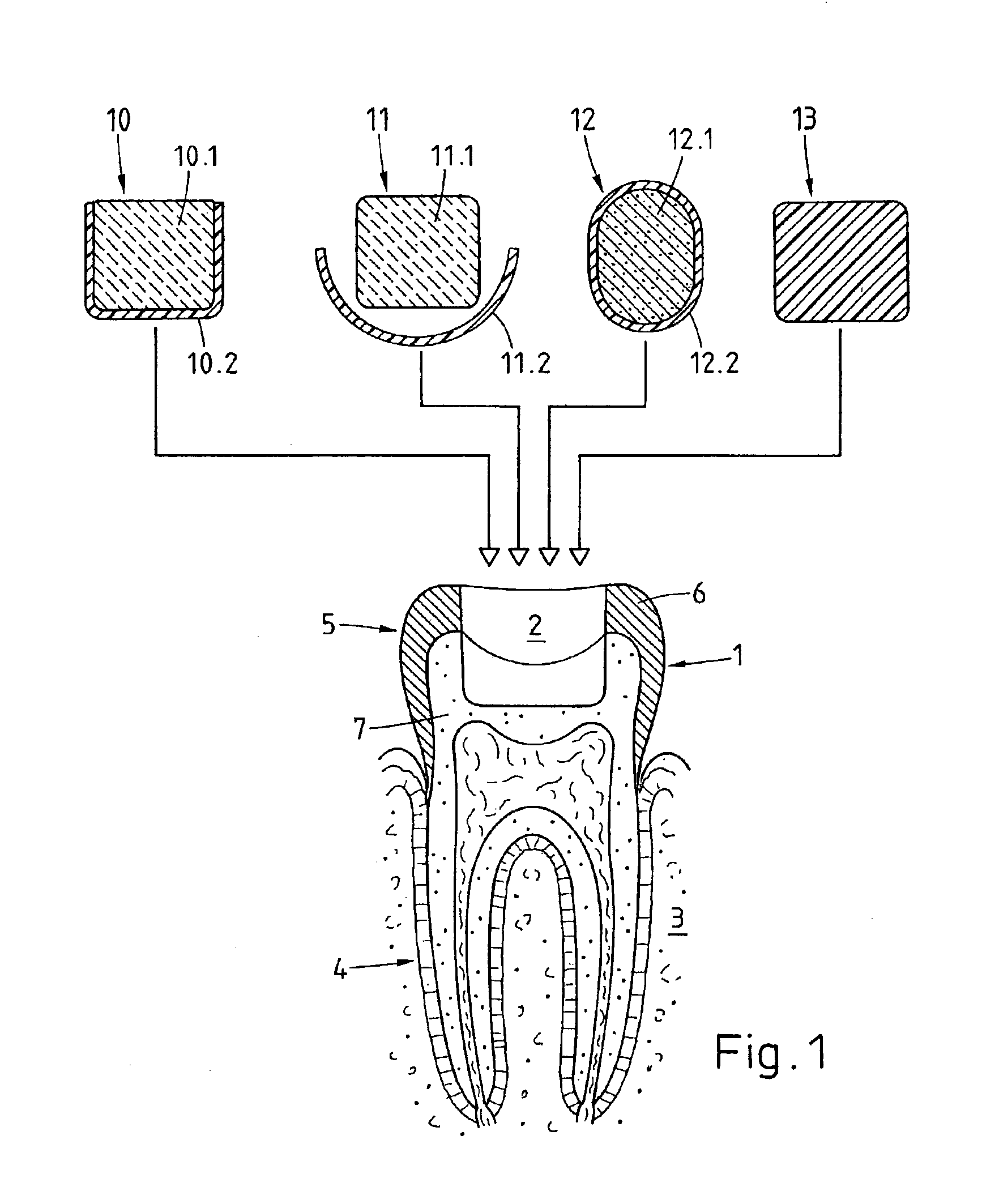

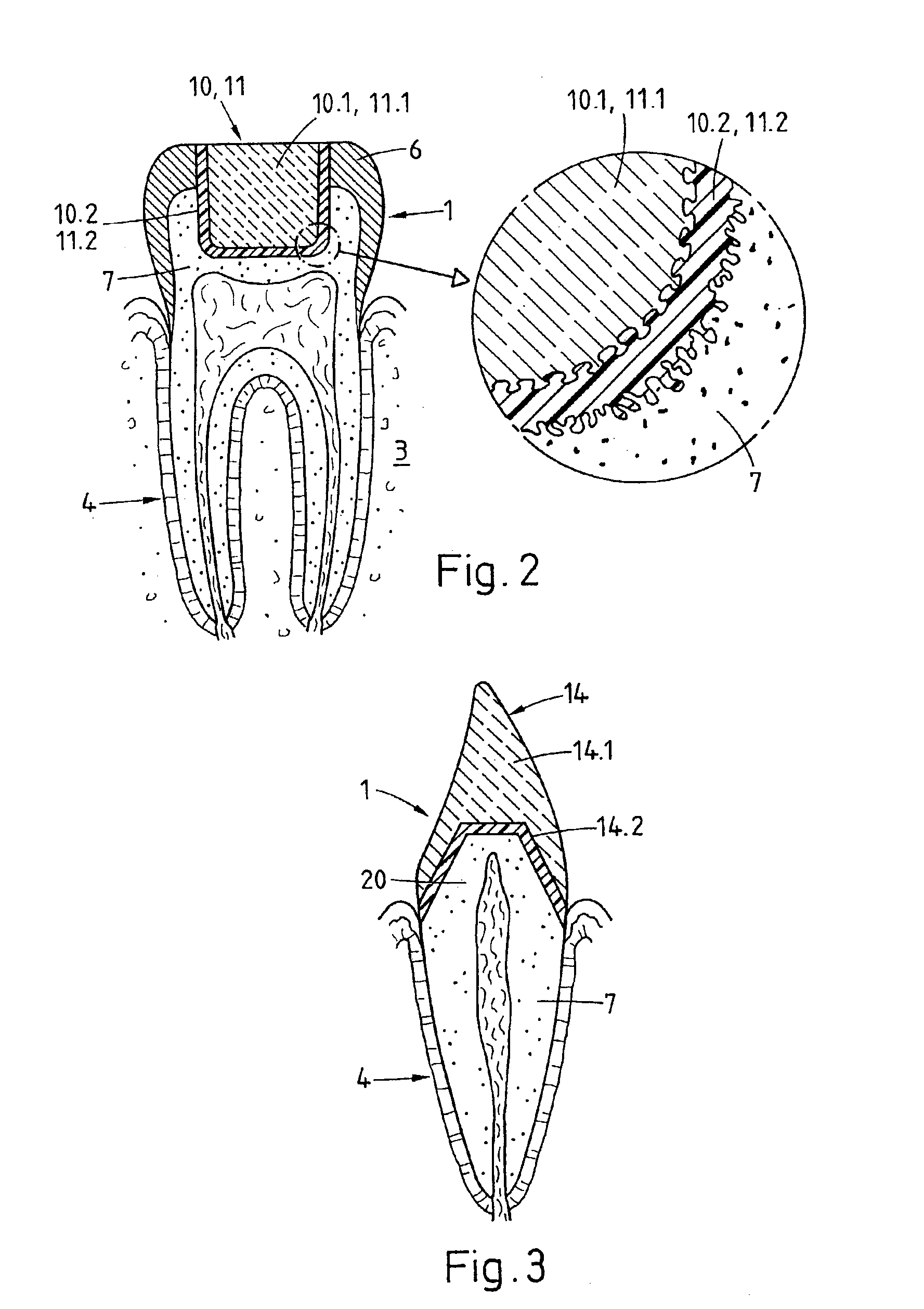

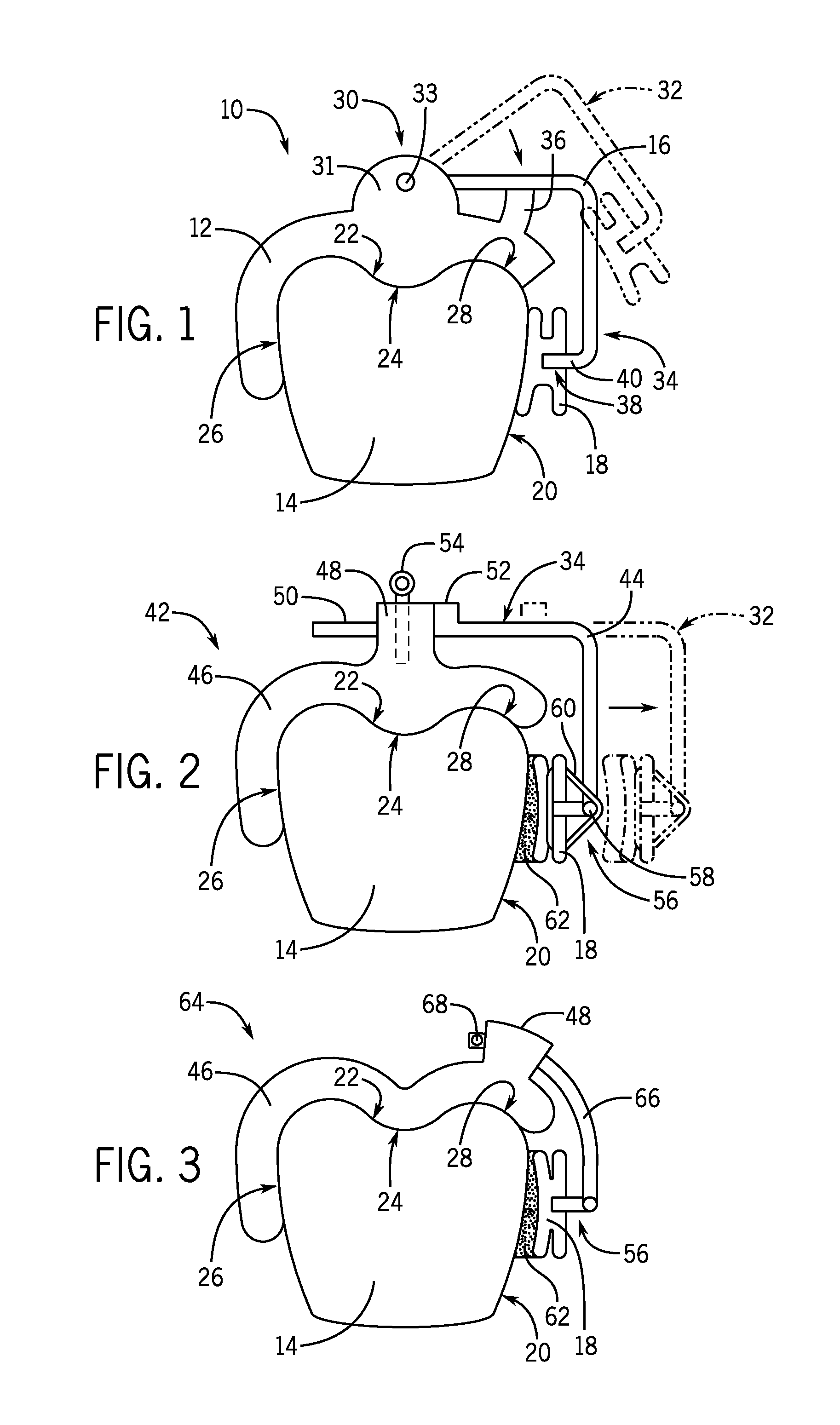

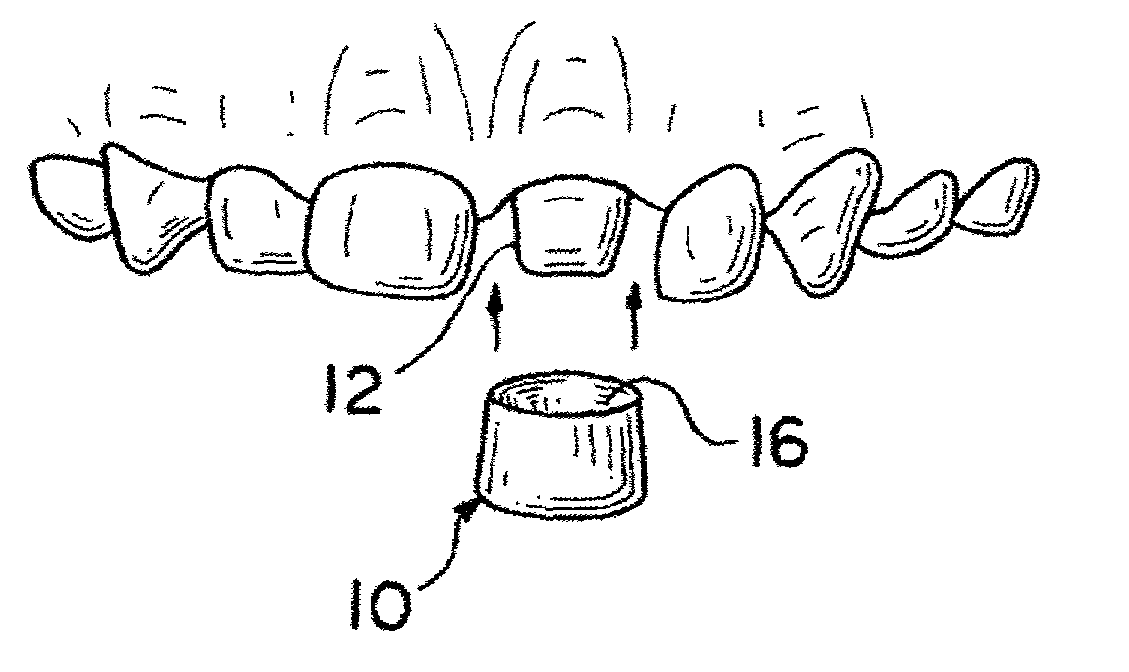

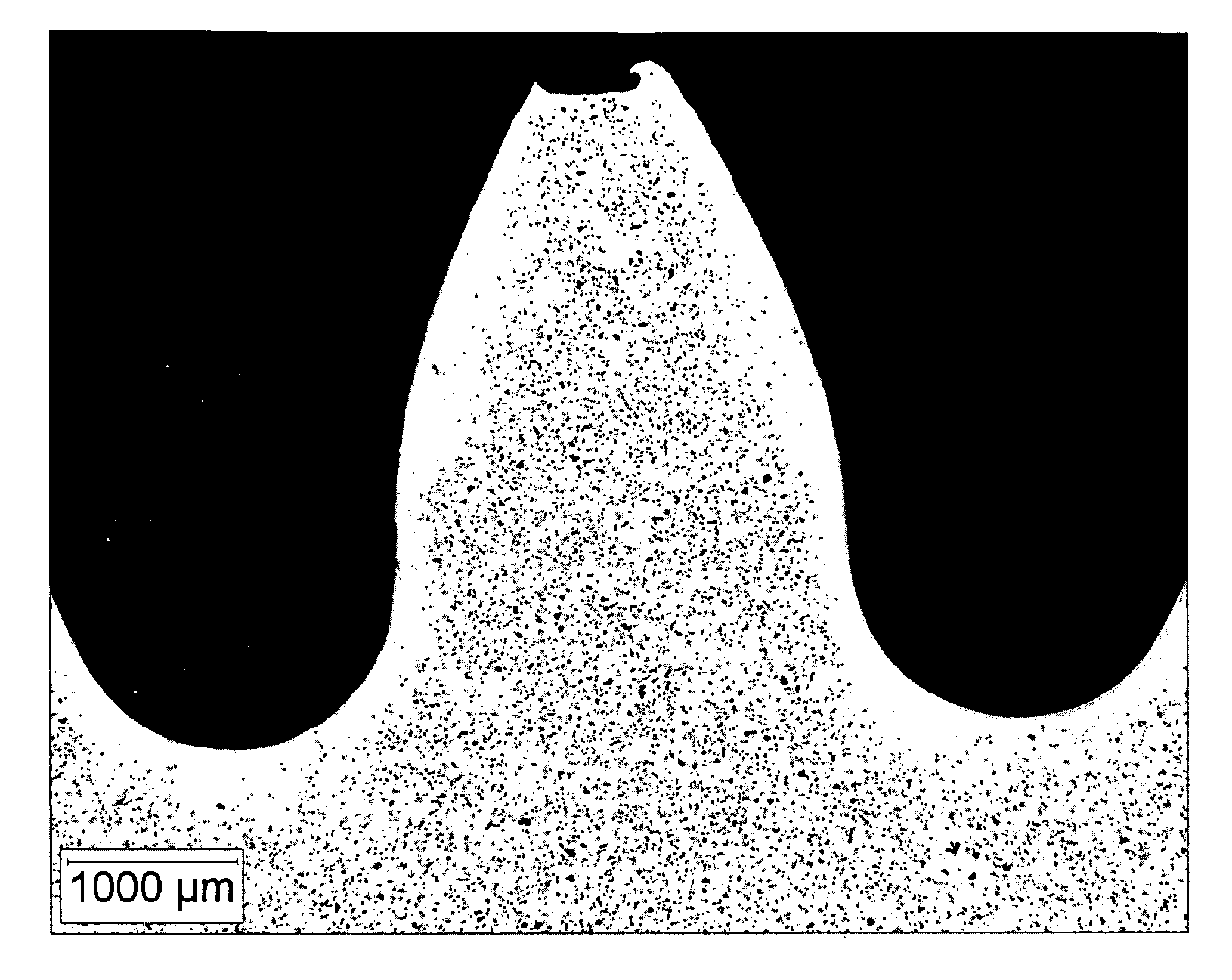

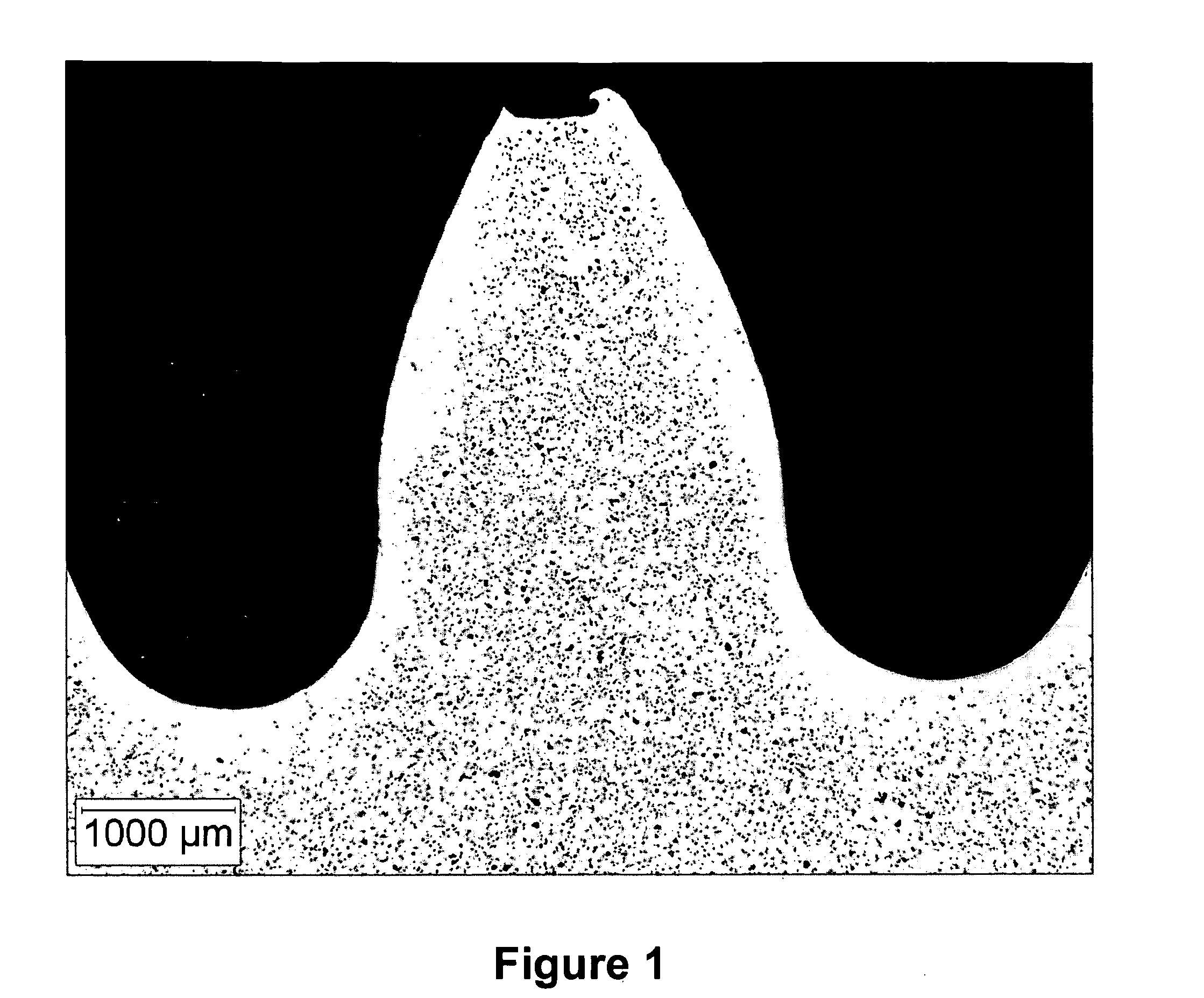

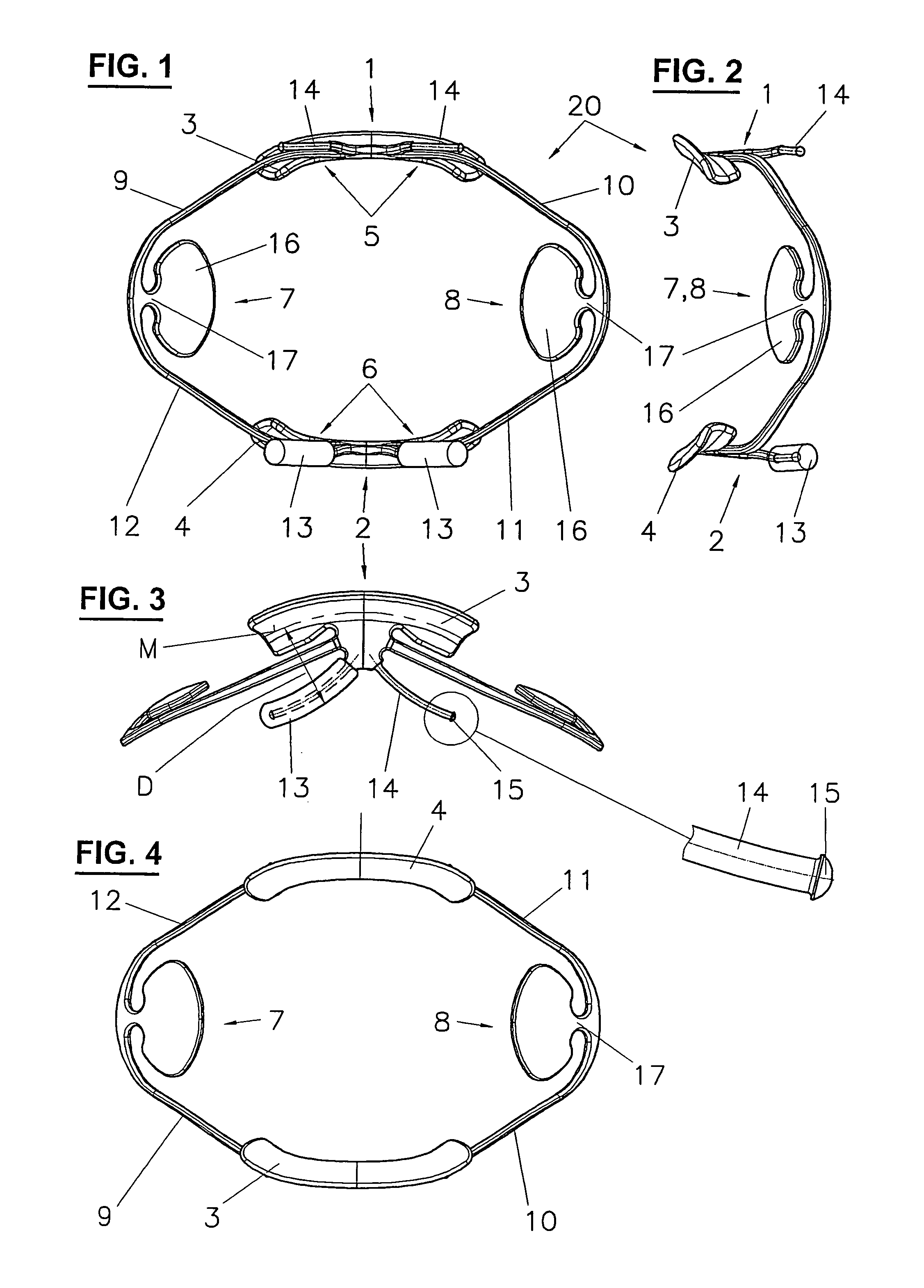

Preparation for being fastened on a natural tooth part or tooth and corresponding fastening method

ActiveUS6955540B2Reduce Shrinkage ProblemsRelieve stressDental implantsImpression capsStress concentrationNatural tooth

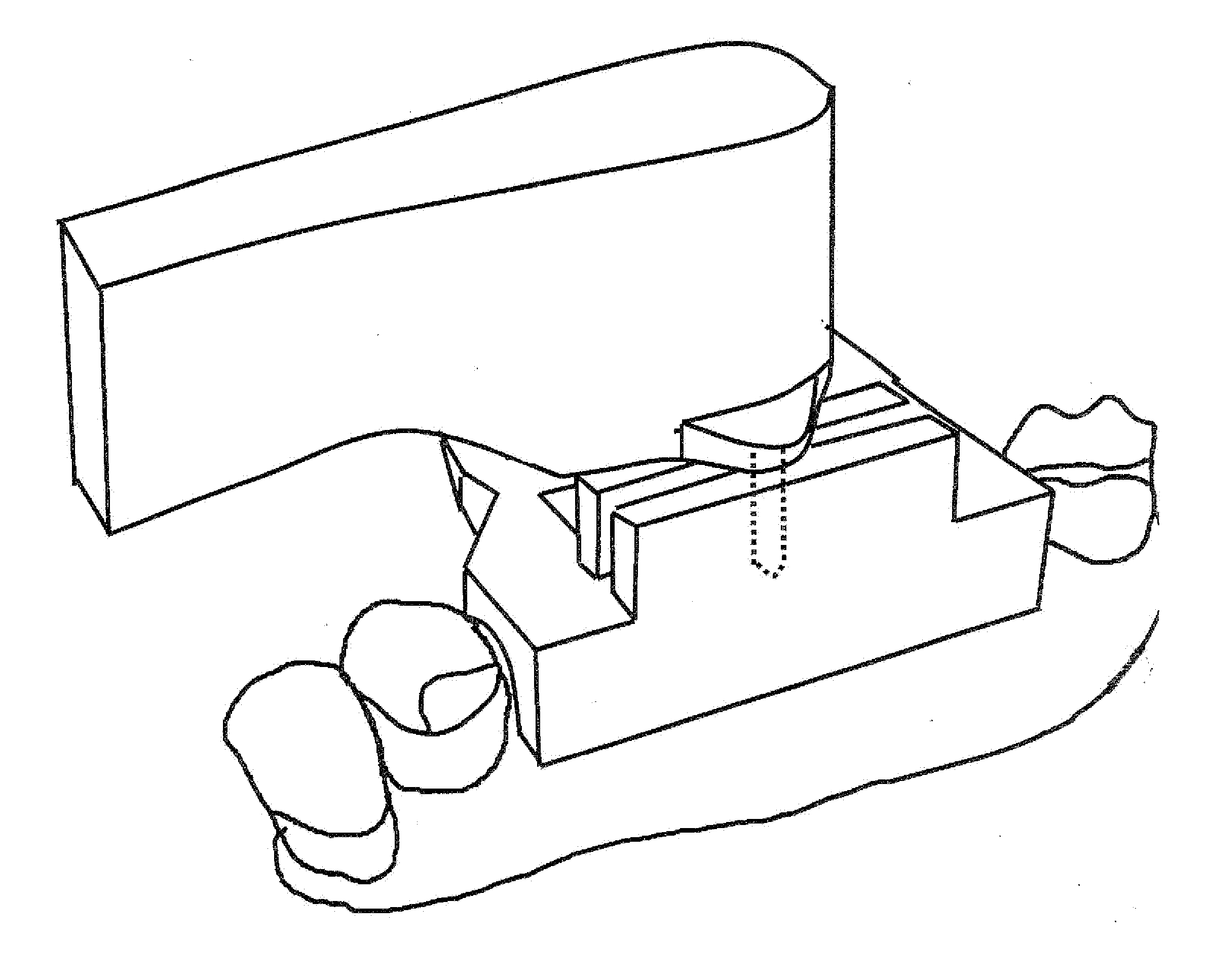

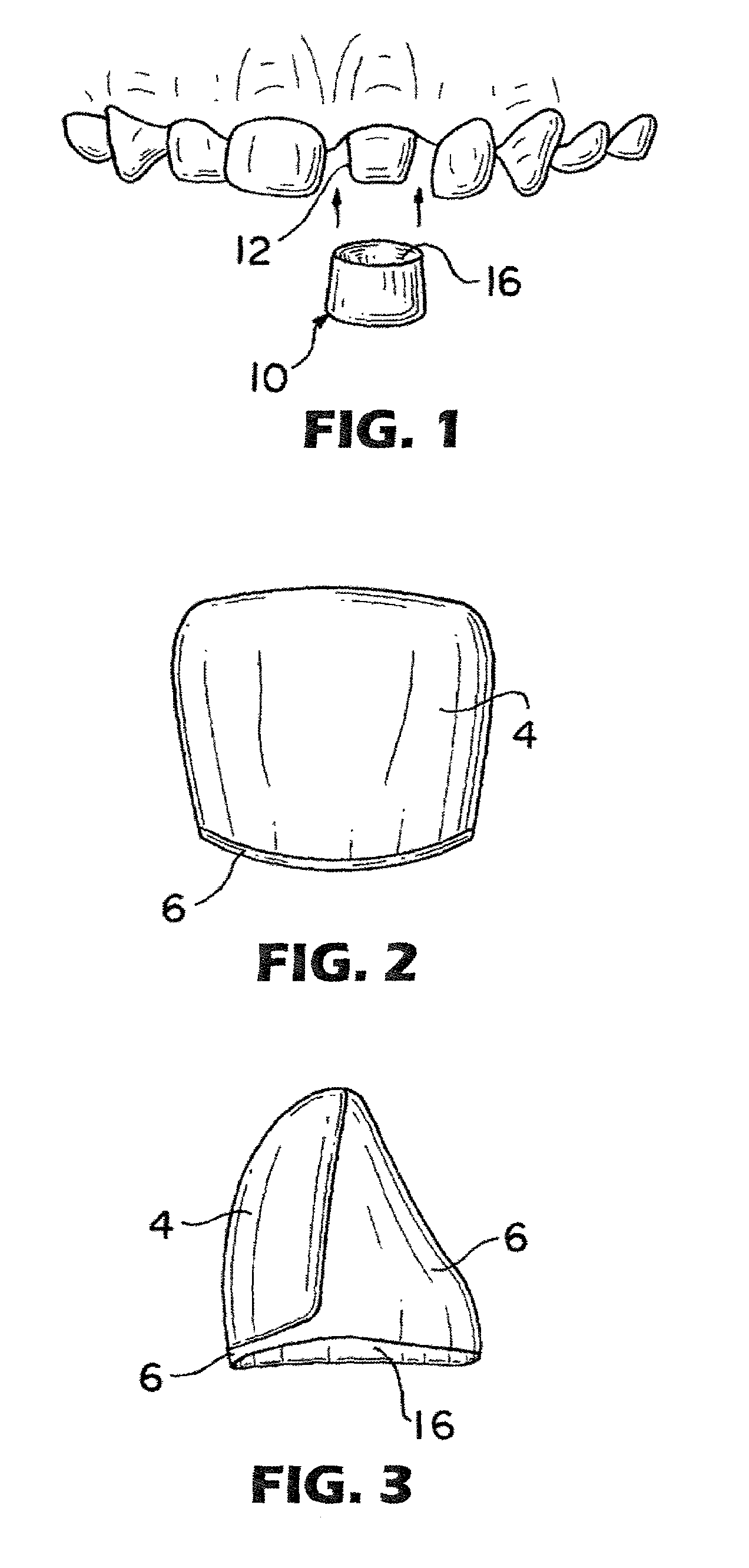

A preparation (10, 11,12,13) to be fixed to a natural tooth part or tooth, in particular for the replacement of a load-bearing tooth part, is for example a filling for a drilled-out tooth (1), a crown, bridge or prosthesis to be placed on a tooth stub, or a tooth pin to be fixed in a tooth root for fastening an artificial tooth, a bridge or a prosthesis. The preparation has surface regions which consist of a material with thermoplastic properties. The preparation (10, 11, 12,13) is designed in a manner such that it has oscillation properties with such low damping losses that for a liquefaction of the material with thermoplastic properties by way of oscillations there are local stress concentrations required, and in a manner such that such stress concentrations only occur in the region of the preparation surface. The preparation is positioned on a suitably prepared natural tooth part in a manner such that the material with the thermoplastic properties is in contact or may be brought into contact with the dentin surface and / or enamel surface. The preparation is then made to mechanically oscillate and is simultaneously pressed against the natural tooth part, whereby the material with the thermoplastic properties is at least partly liquefied and brought into intimate contact with the dentin or enamel surface in a manner such that after solidification it forms a positive fit and / or material fit connection. Teeth restored with such preparations have a high stability and a long life, which in particular is attributed to the fact that the thermoplastic material, in contrast to cements used for the same purpose, shrinks less and has the ability to relieve internal stress by creeping.

Owner:WOODWELDING

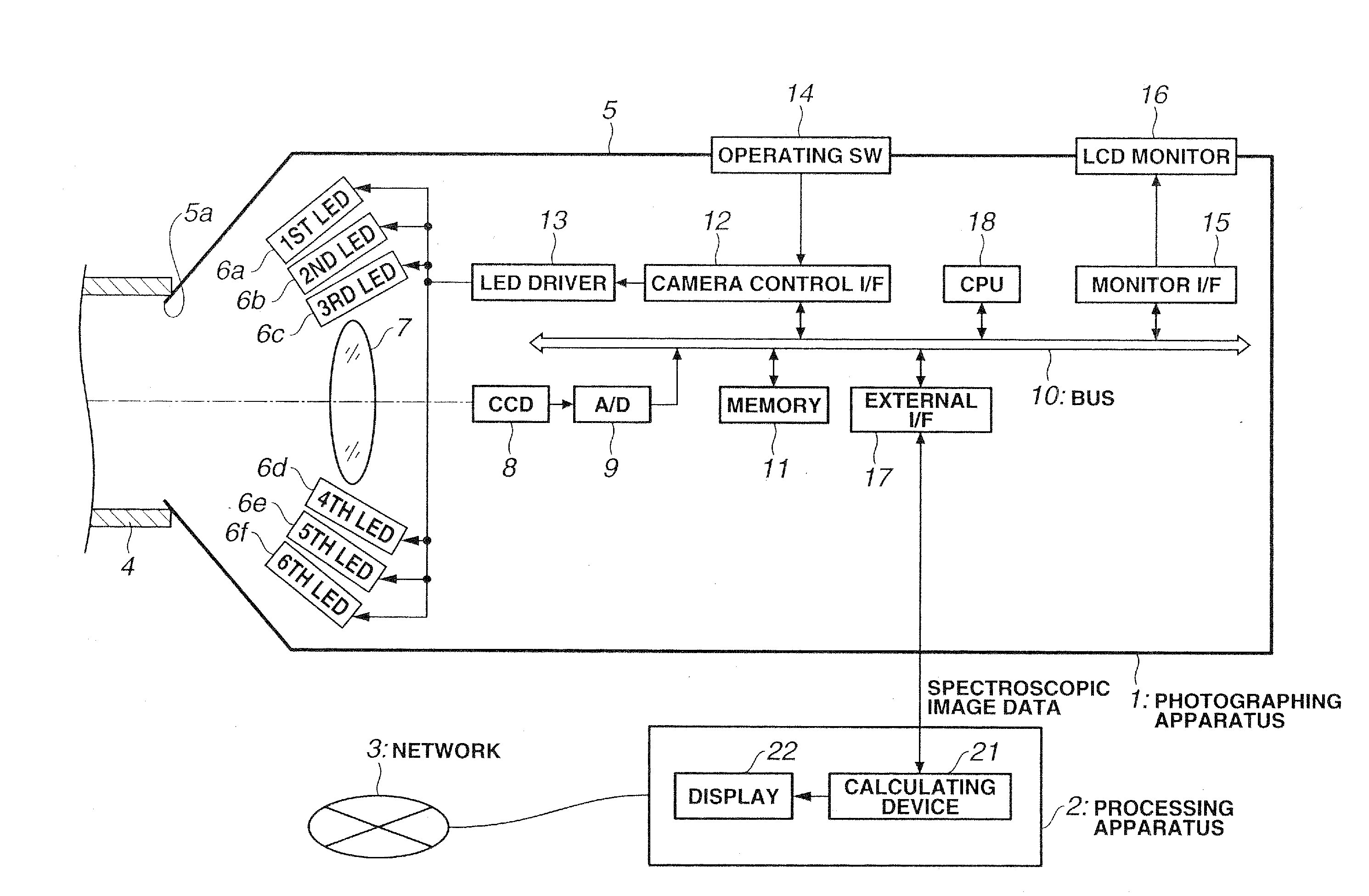

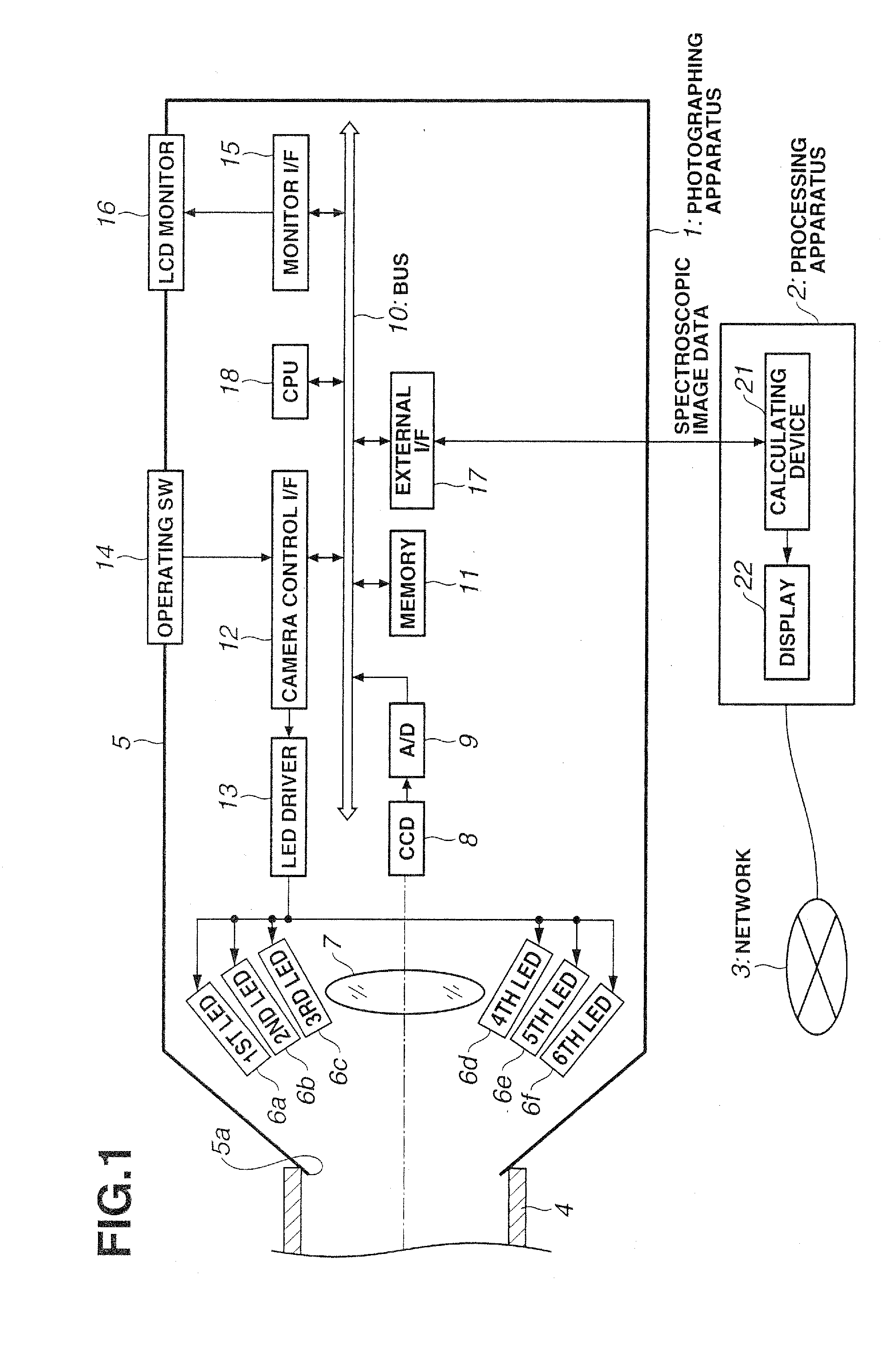

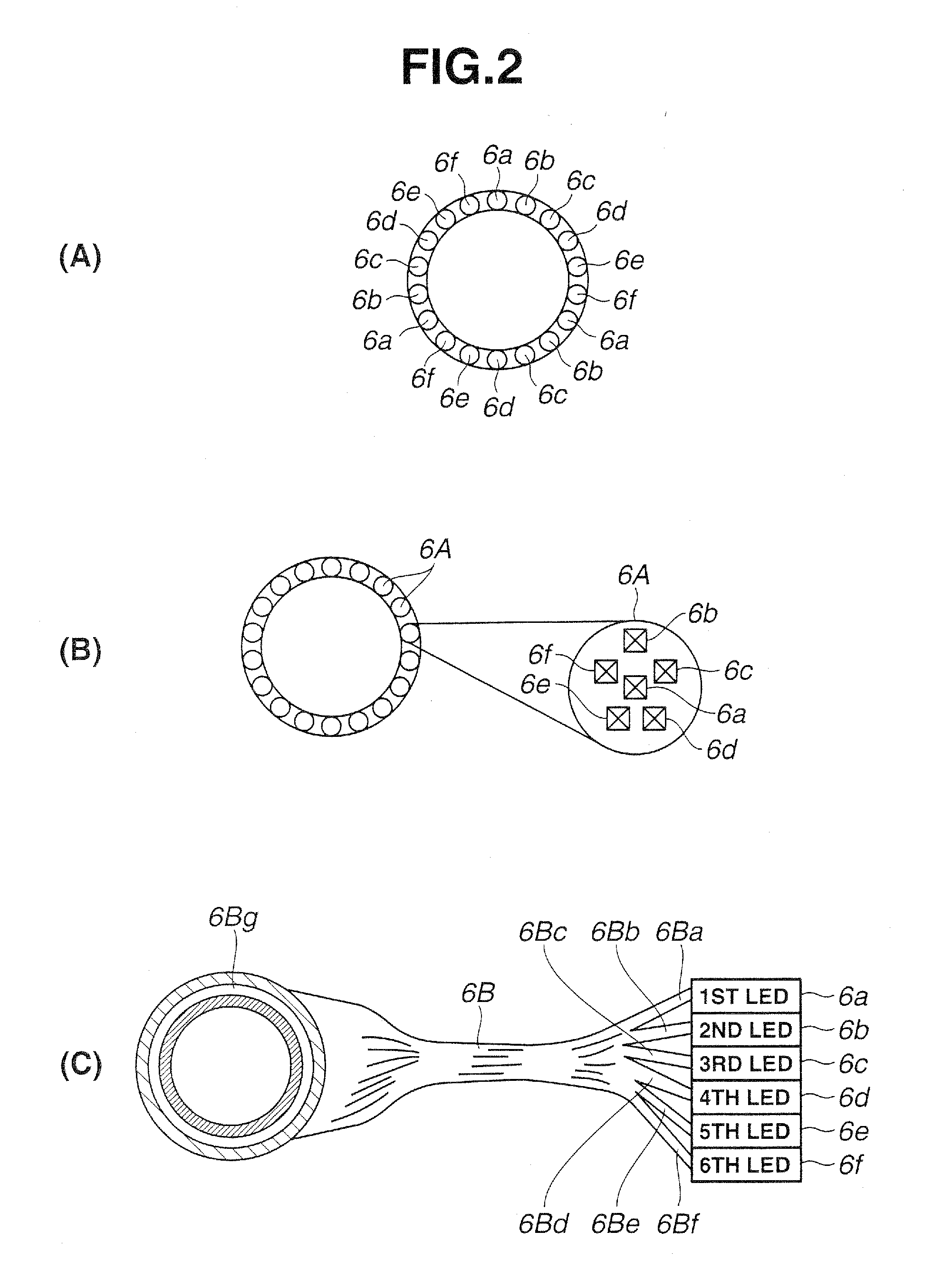

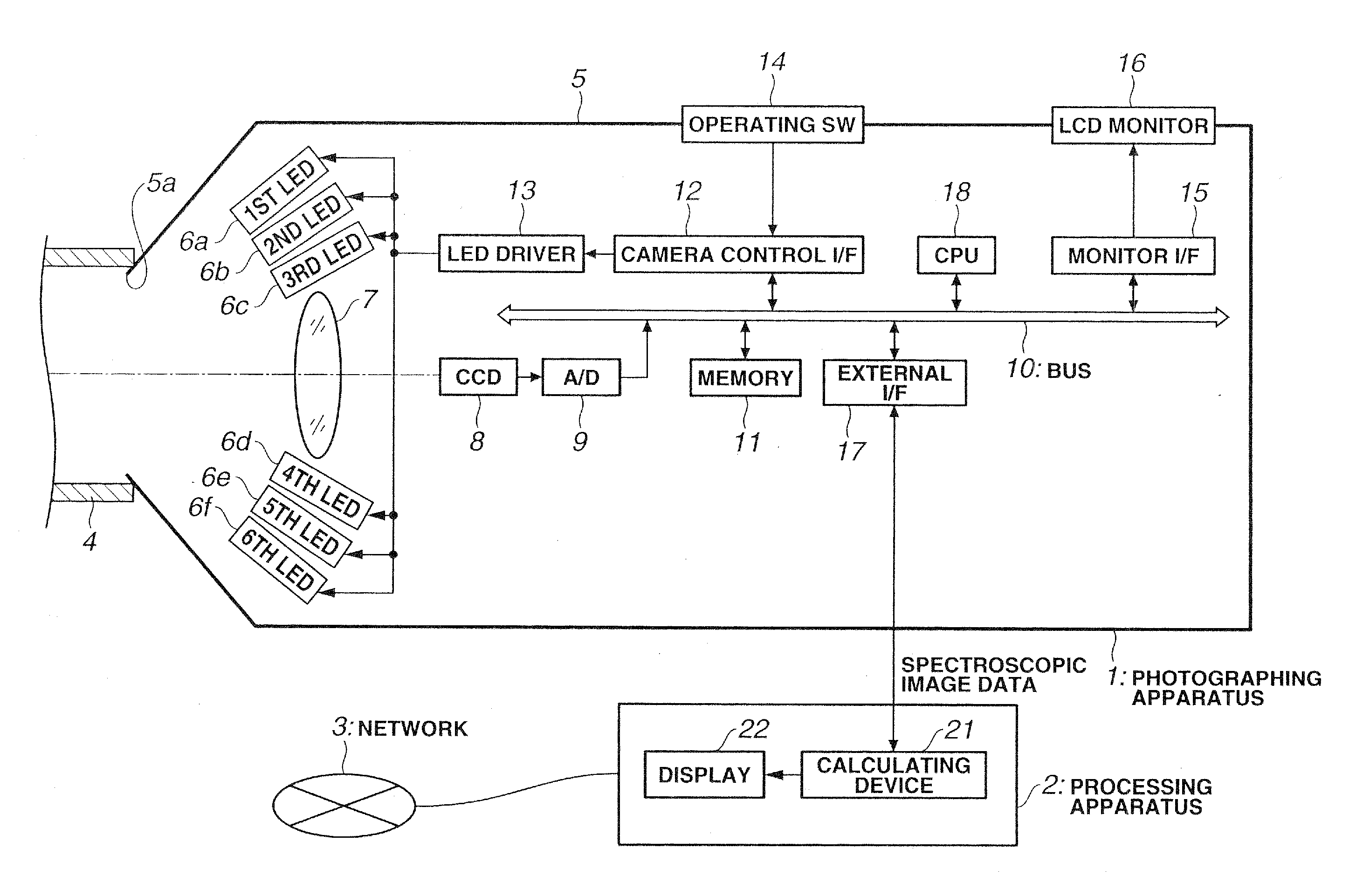

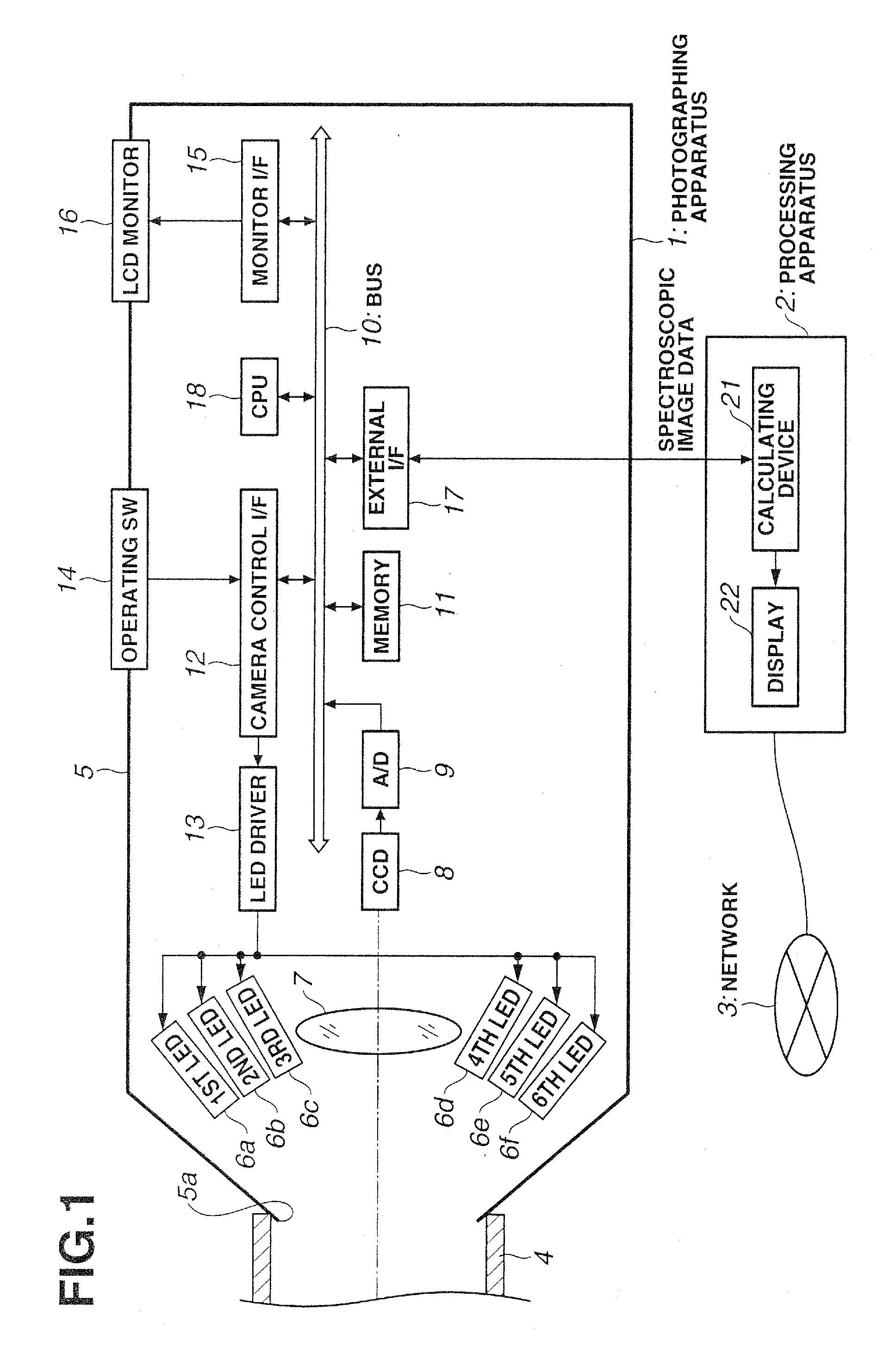

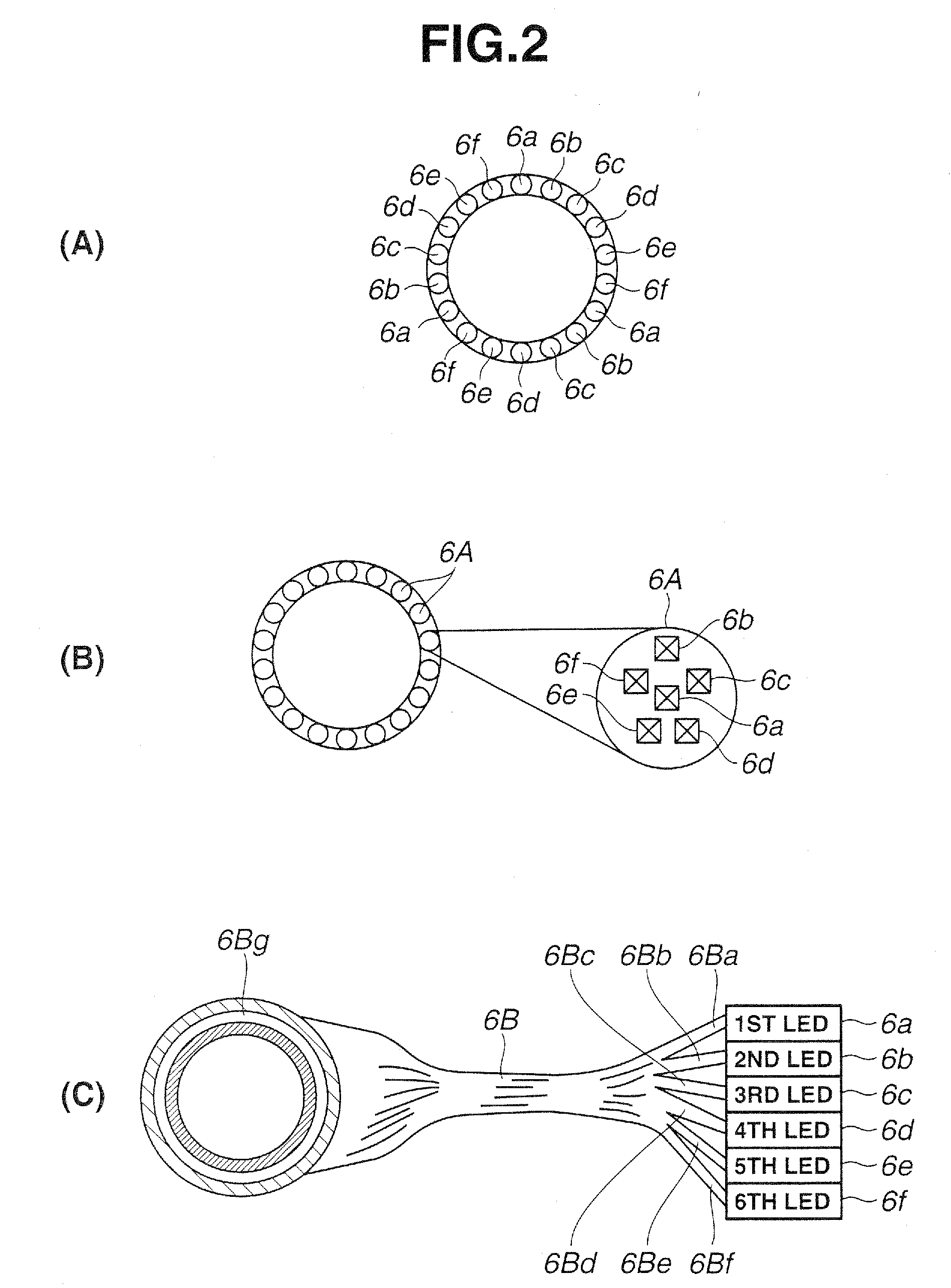

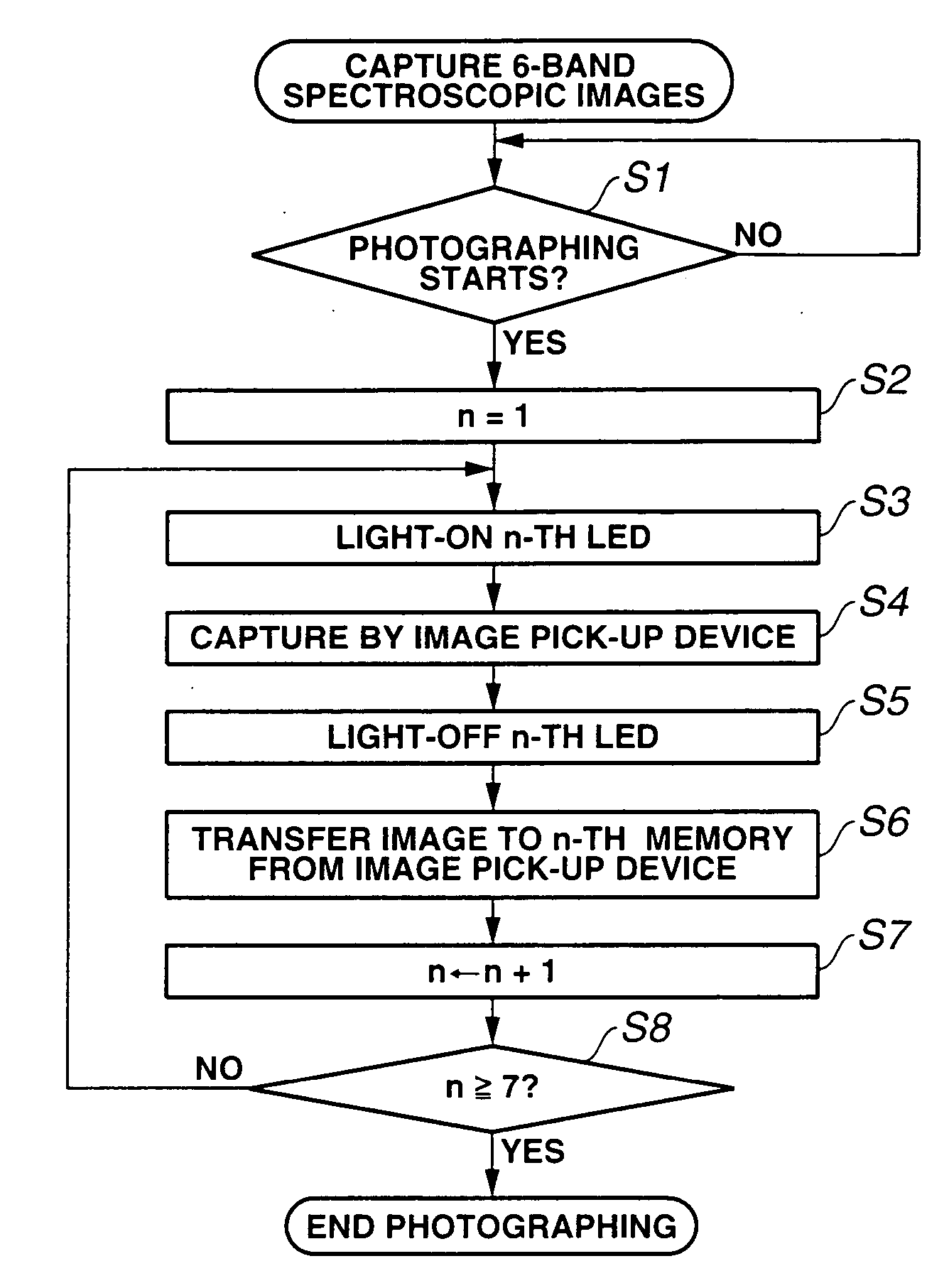

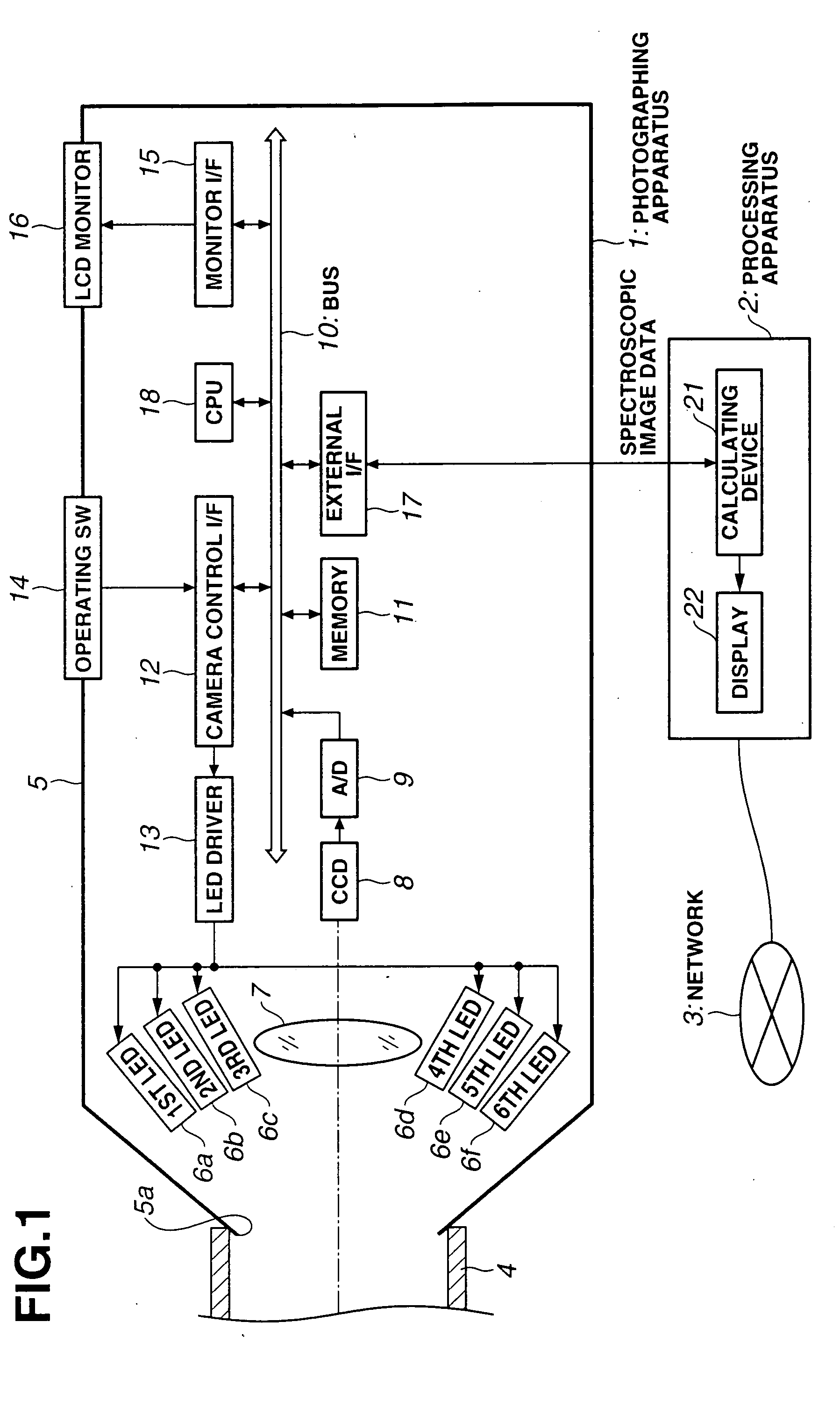

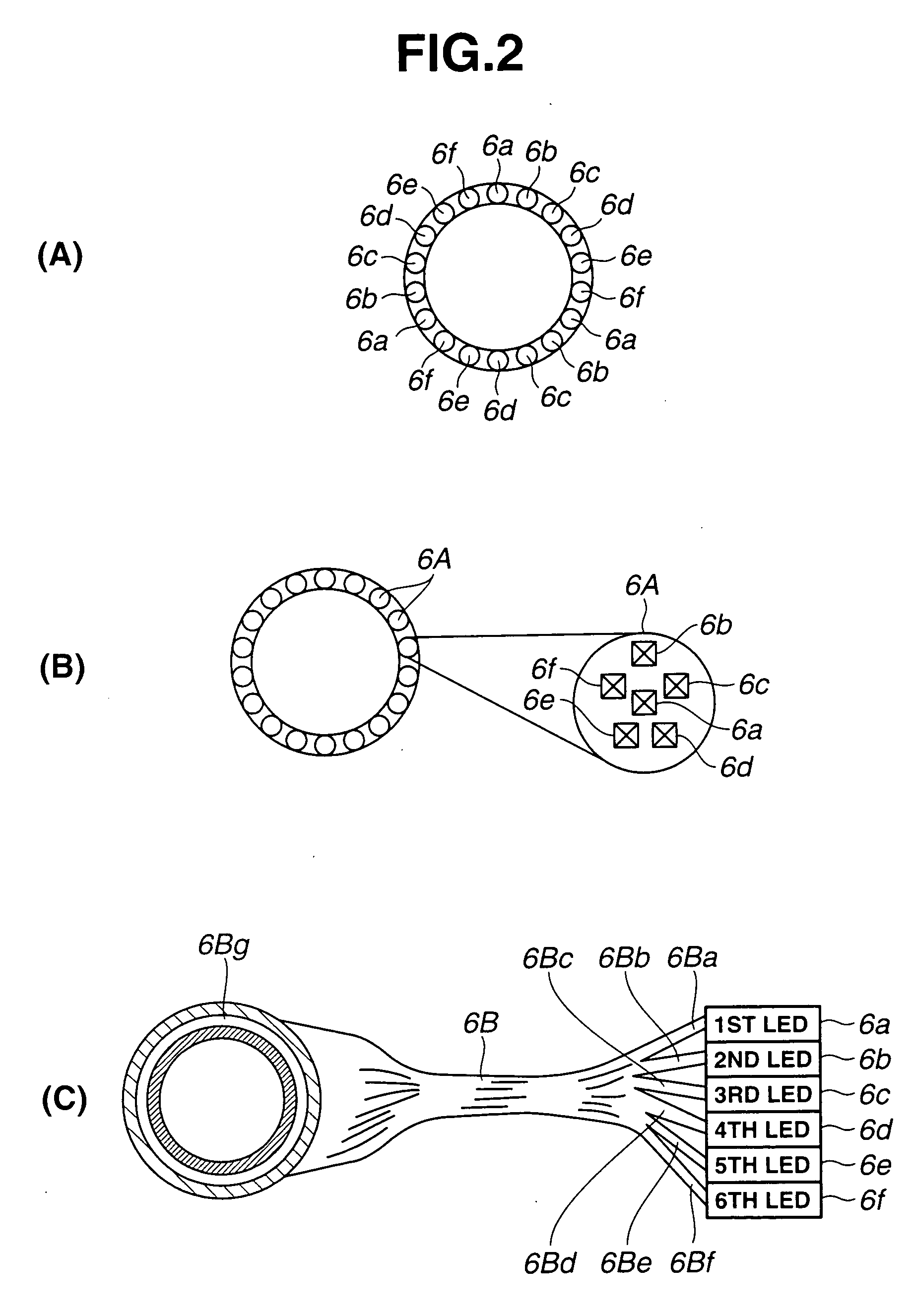

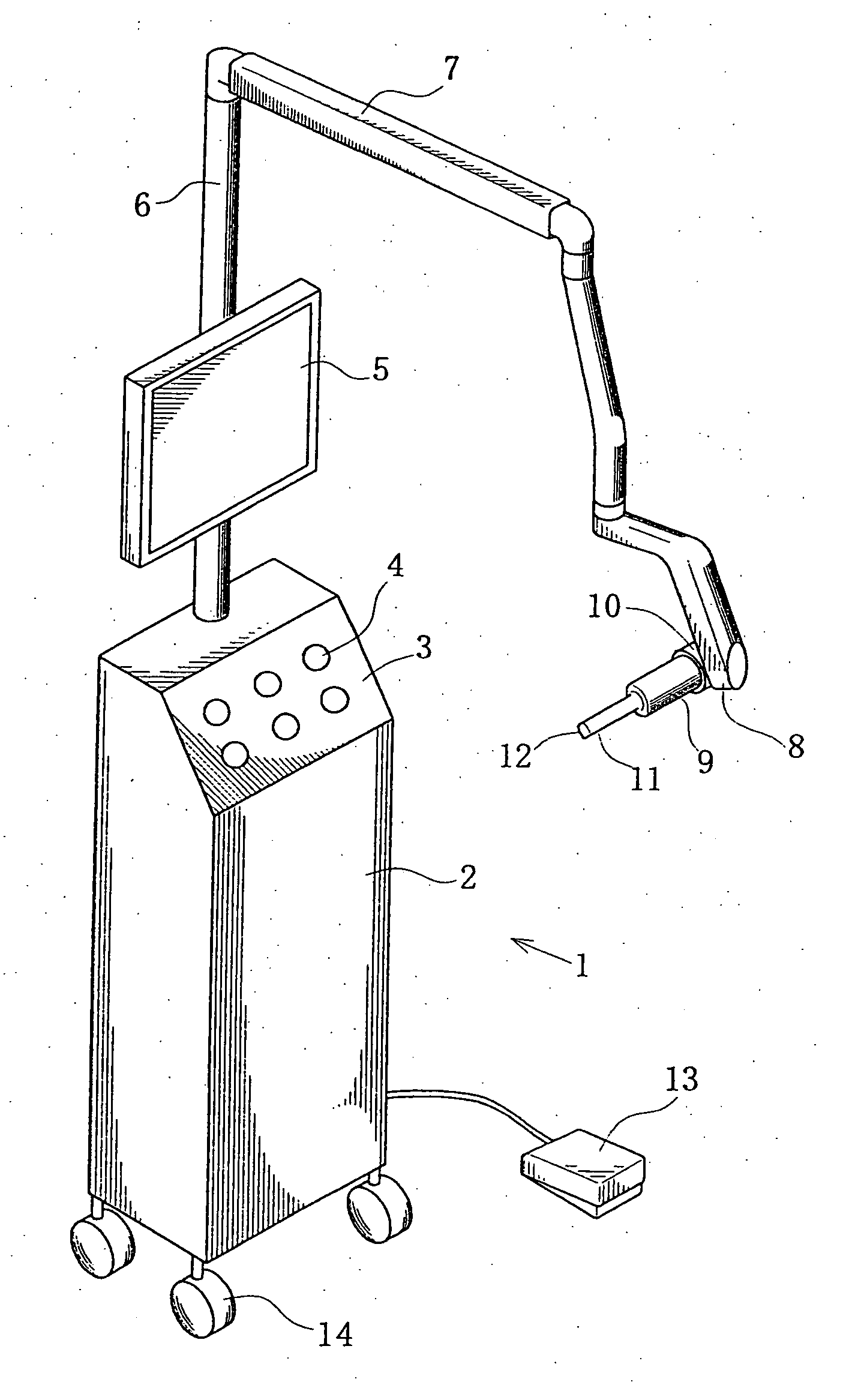

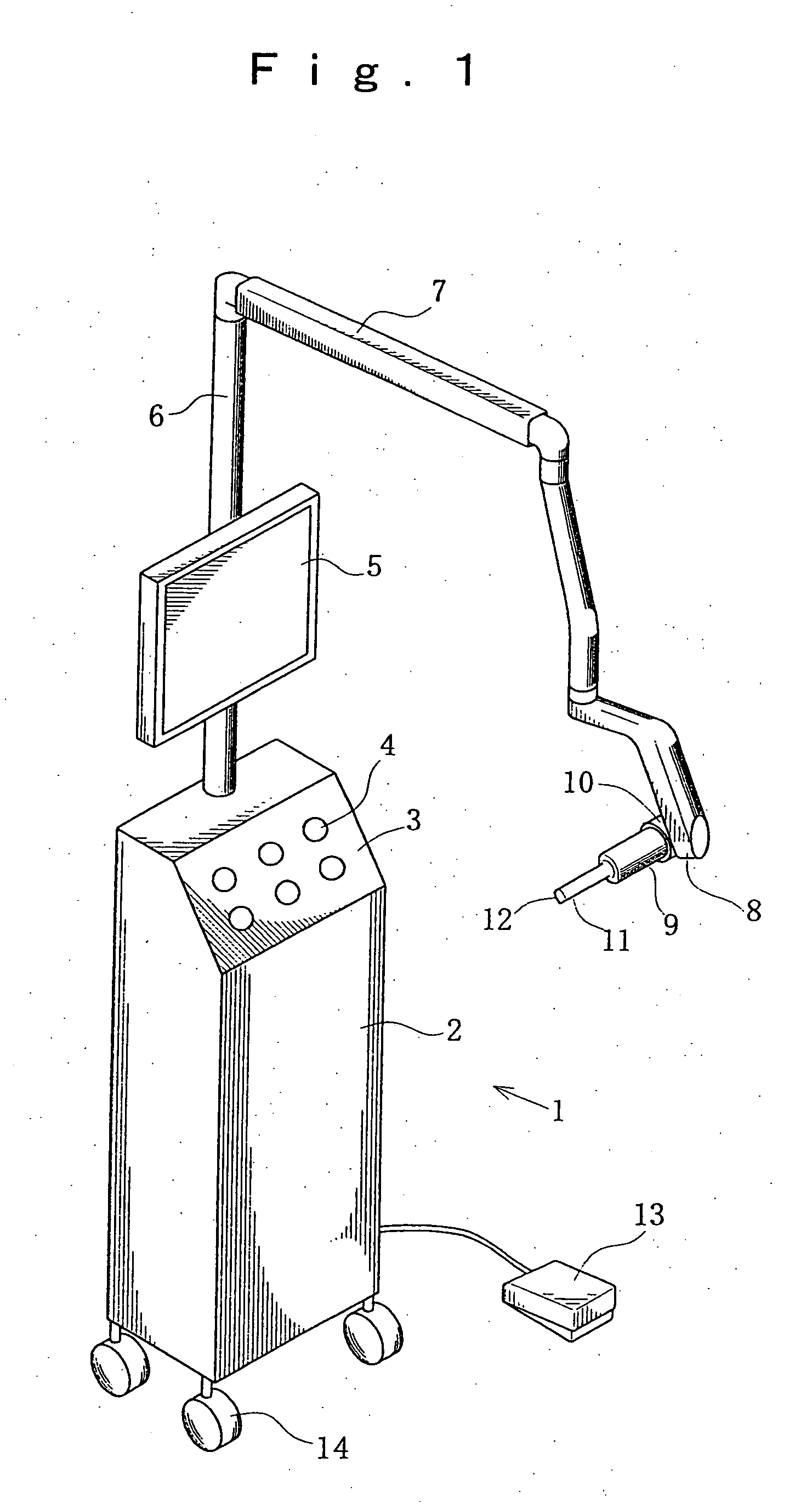

Image processing system which calculates and displays color grade data and display image data

An image processing system is used for dentistry. Upon creating a false tooth of a patient (59), a plurality of illuminating light of LEDs with different wavelengths emit light and a photographing apparatus (1A) photographs a tooth portion of the patient (59), thereby obtaining image data. The image data is sent to a dentistry filing system (2A) serving as a processing apparatus, and color reproducing data is obtained by calculation. The color reproducing data is sent to a dentistry factory (55) via a public line. Data is searched from a database (56) for calculating a ceramic compounding ratio, compound data of the ceramic false tooth is obtained, matching the color of the tooth portion of the patient (59), and the false tooth approximate to the tooth color of the patient (59) is created.

Owner:OLYMPUS CORP

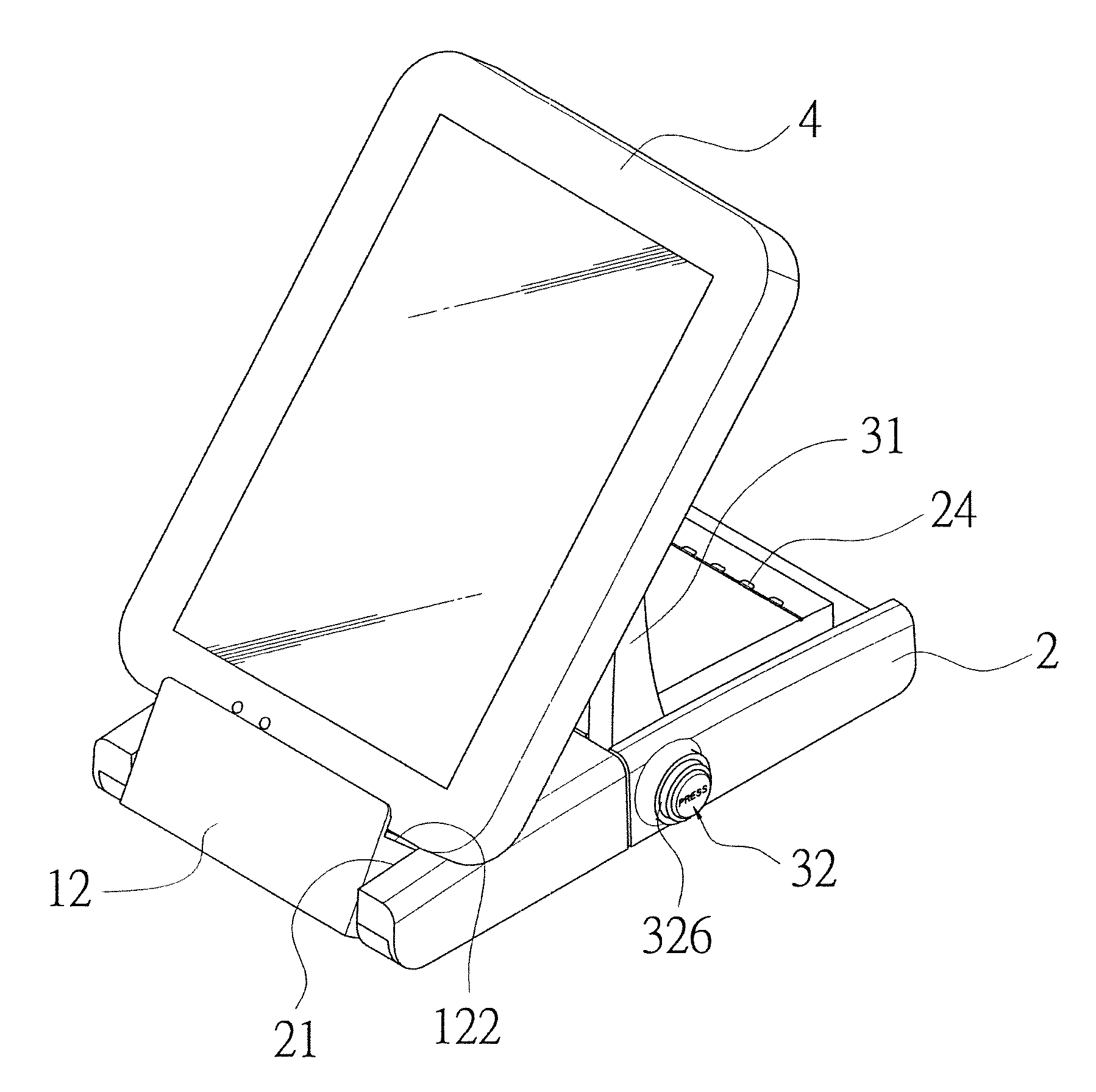

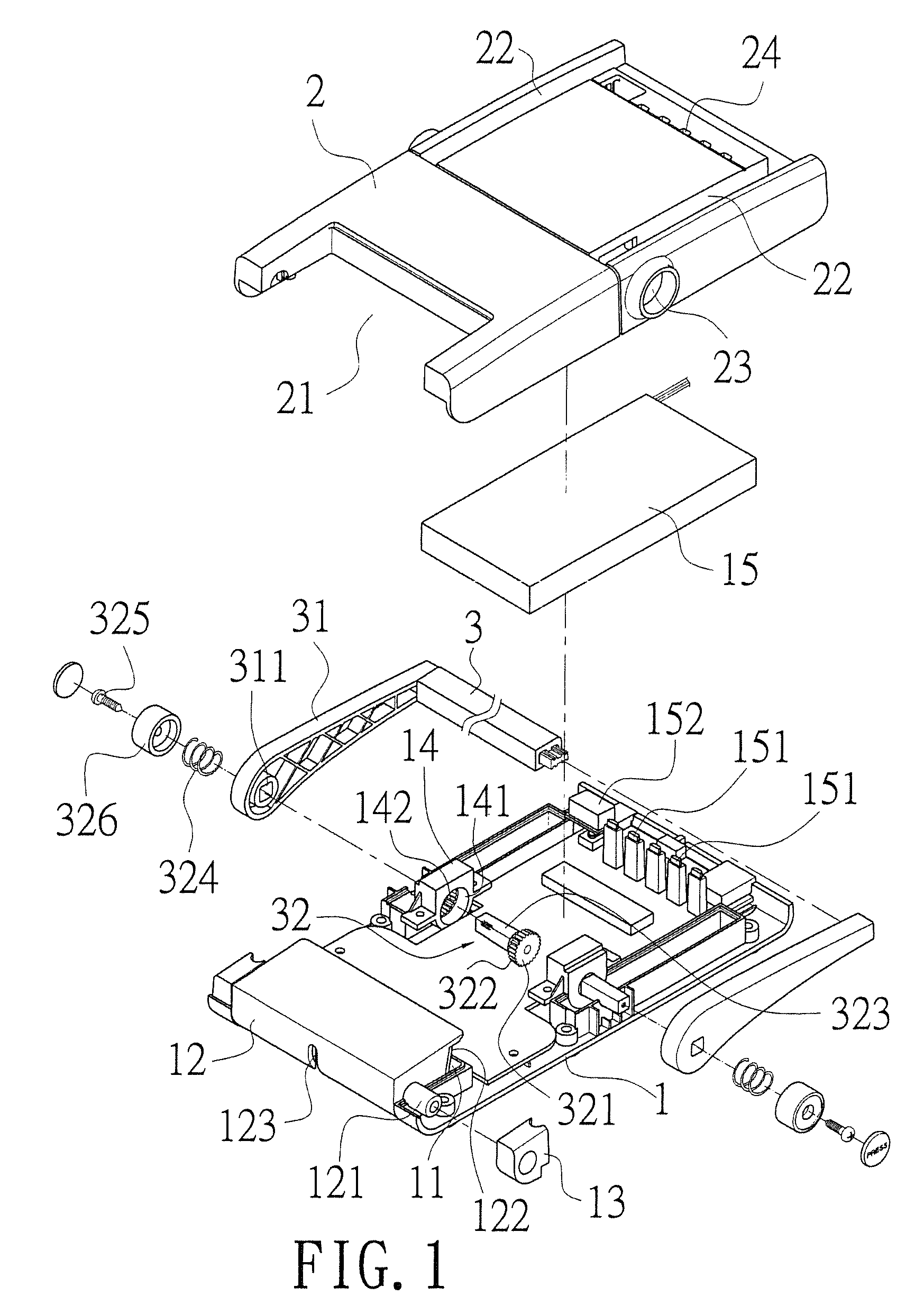

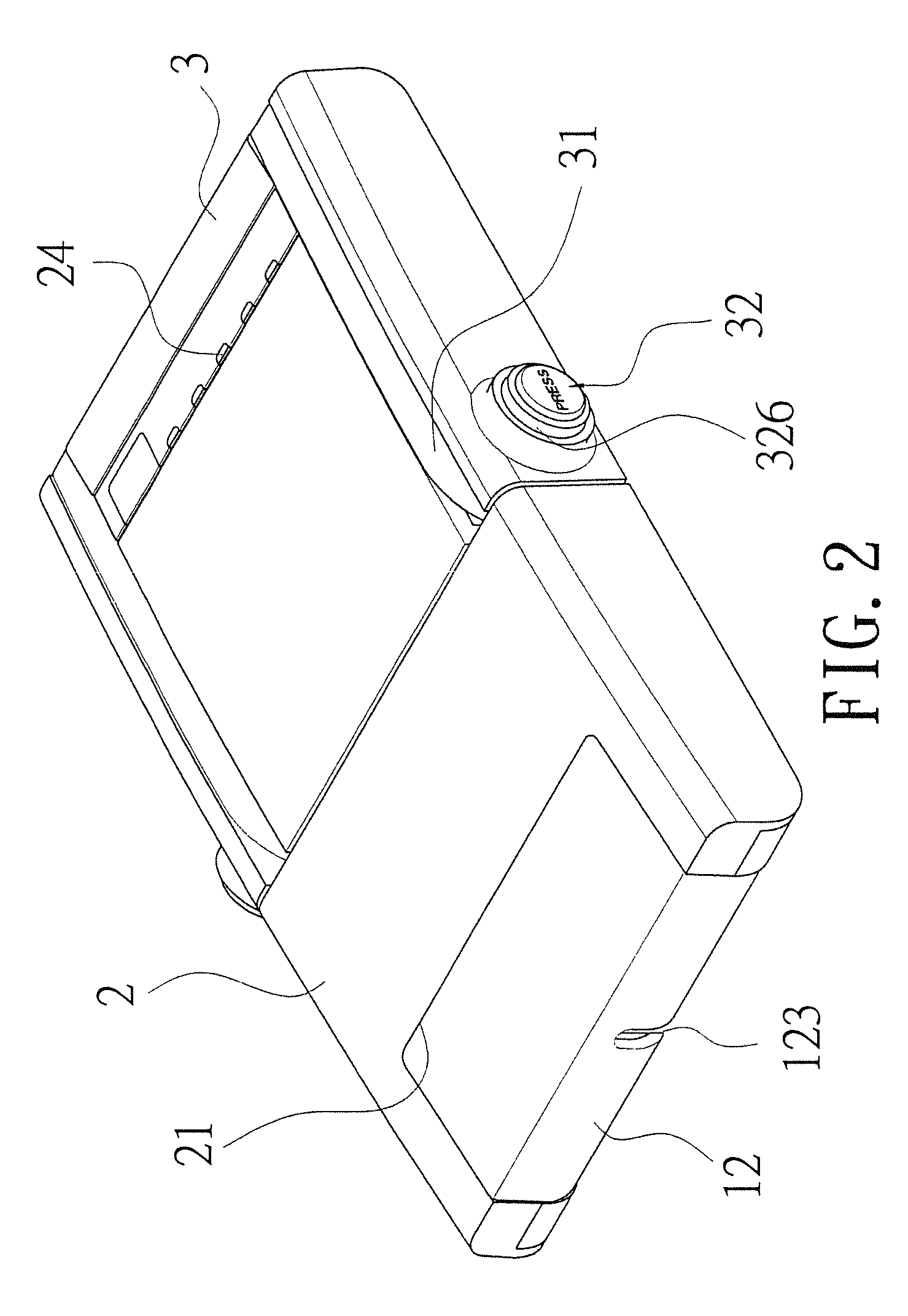

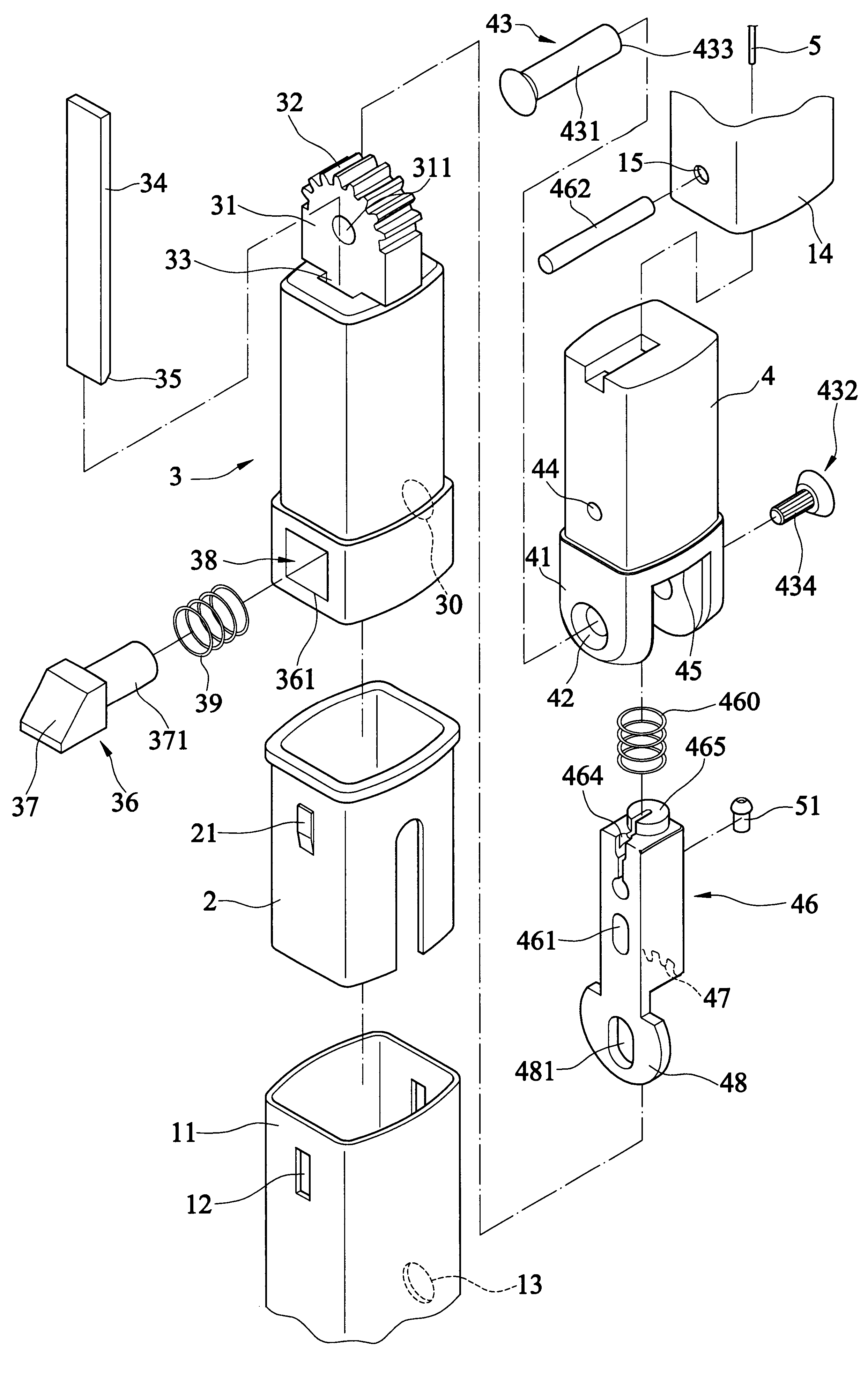

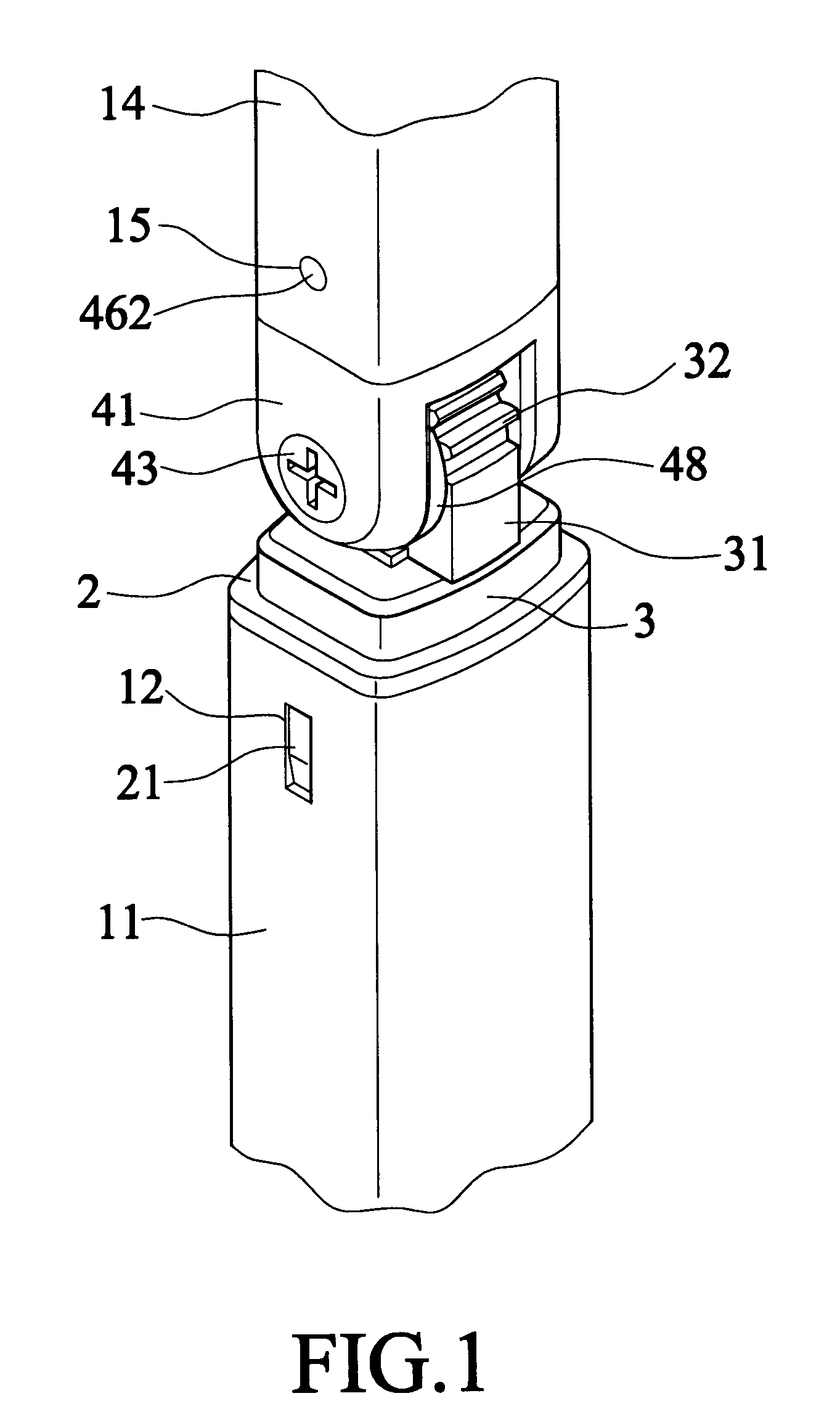

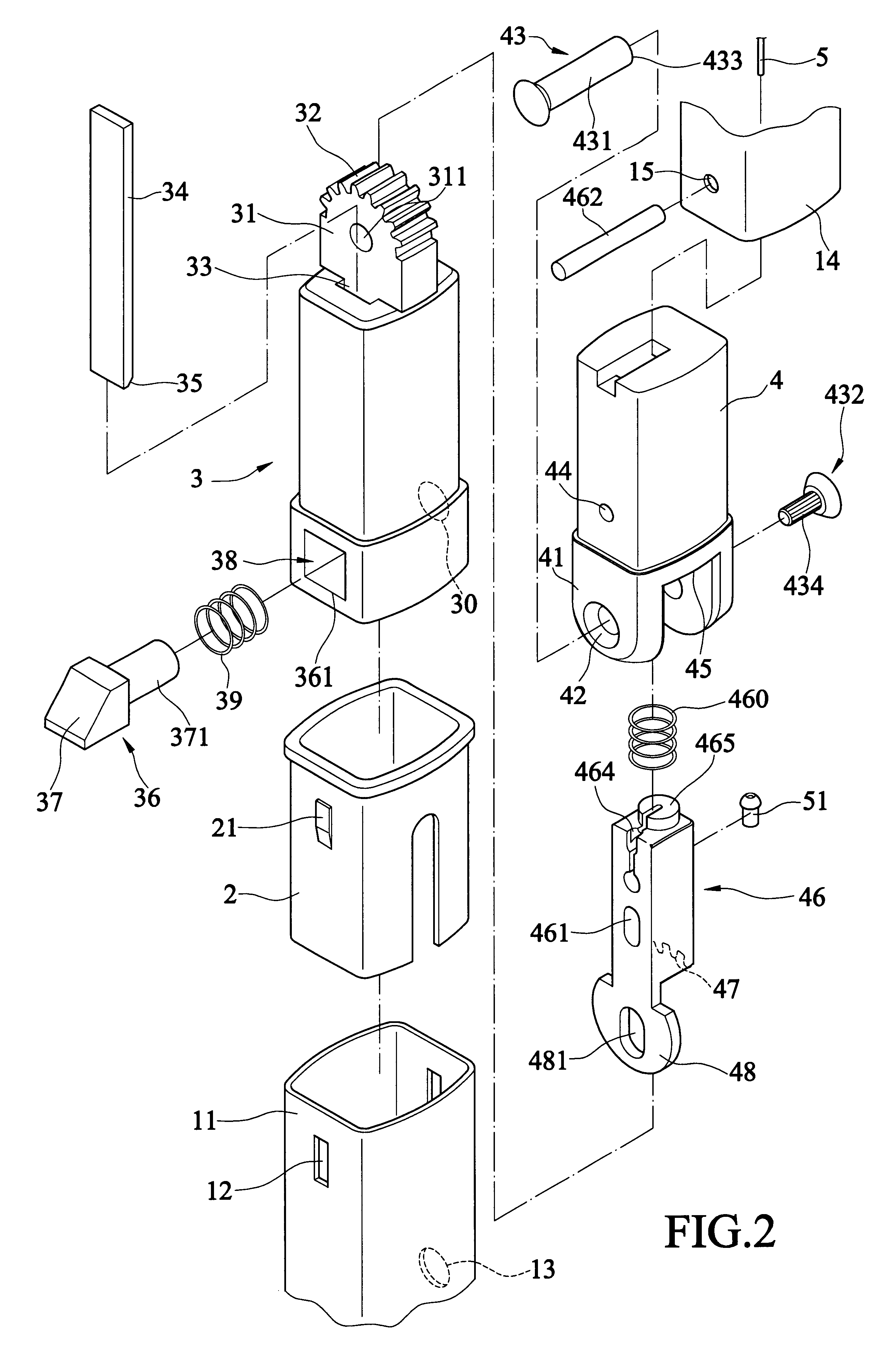

Electronic device holder

An electronic device holder is revealed. The electronic device holder includes a base, a top cover and a support member. In use, a control member of the support member is pressed so that a locking shaft is moved inwards to push a shaft part moving into a pivot hole of an assembly block of the base. And a teeth part around the shaft part is released from teeth of a locking hole. Thus the support member can be rotated to the required position. Without any force applied to the control member, the teeth part of the shaft part is engaged with the teeth of the locking hole again due to the elastic member. Thus the support member is locked, the support block is then rotated to the required position and an electronic device is leaning against the support member. Therefore users can use electronics conveniently, without holding them in hands.

Owner:JOW TONG TECH CO LTD

Image processing system

InactiveUS20080192235A1Improve fidelityTelevision system detailsRadiation pyrometryImaging processingLength wave

An image processing system is used for dentistry. Upon creating a false tooth of a patient (59), a plurality of illuminating light of LEDs with different wavelengths emit light and a photographing apparatus (1A) photographs a tooth portion of the patient (59), thereby obtaining image data. The image data is sent to a dentistry filing system (2A) serving as a processing apparatus, and color reproducing data is obtained by calculation. The color reproducing data is sent to a dentistry factory (55) via a public line. Data is searched from a database (56) for calculating a ceramic compounding ratio, compound data of the ceramic false tooth is obtained, matching the color of the tooth portion of the patient (59), and the false tooth approximate to the tooth color of the patient (59) is created.

Owner:OLYMPUS CORP

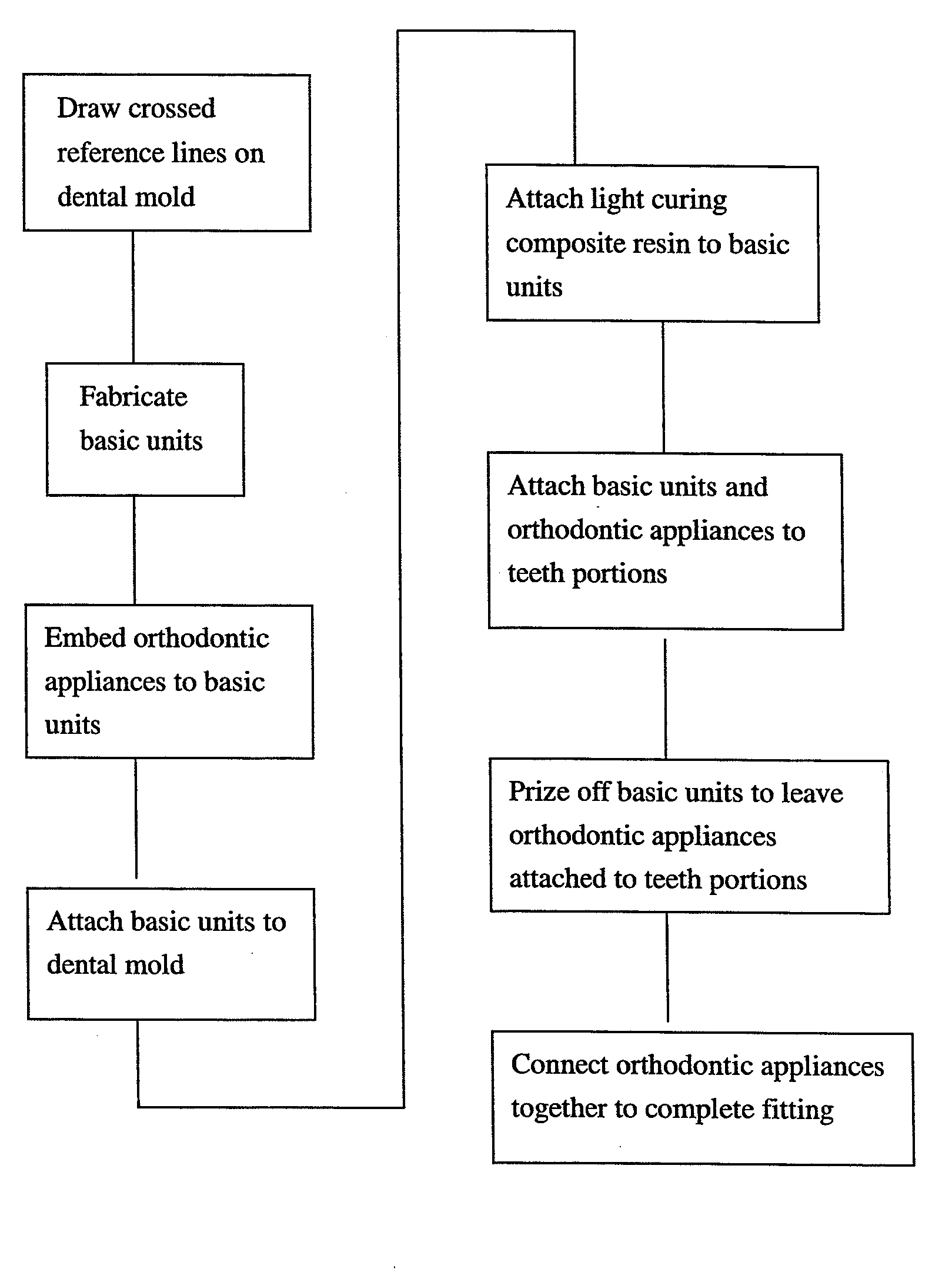

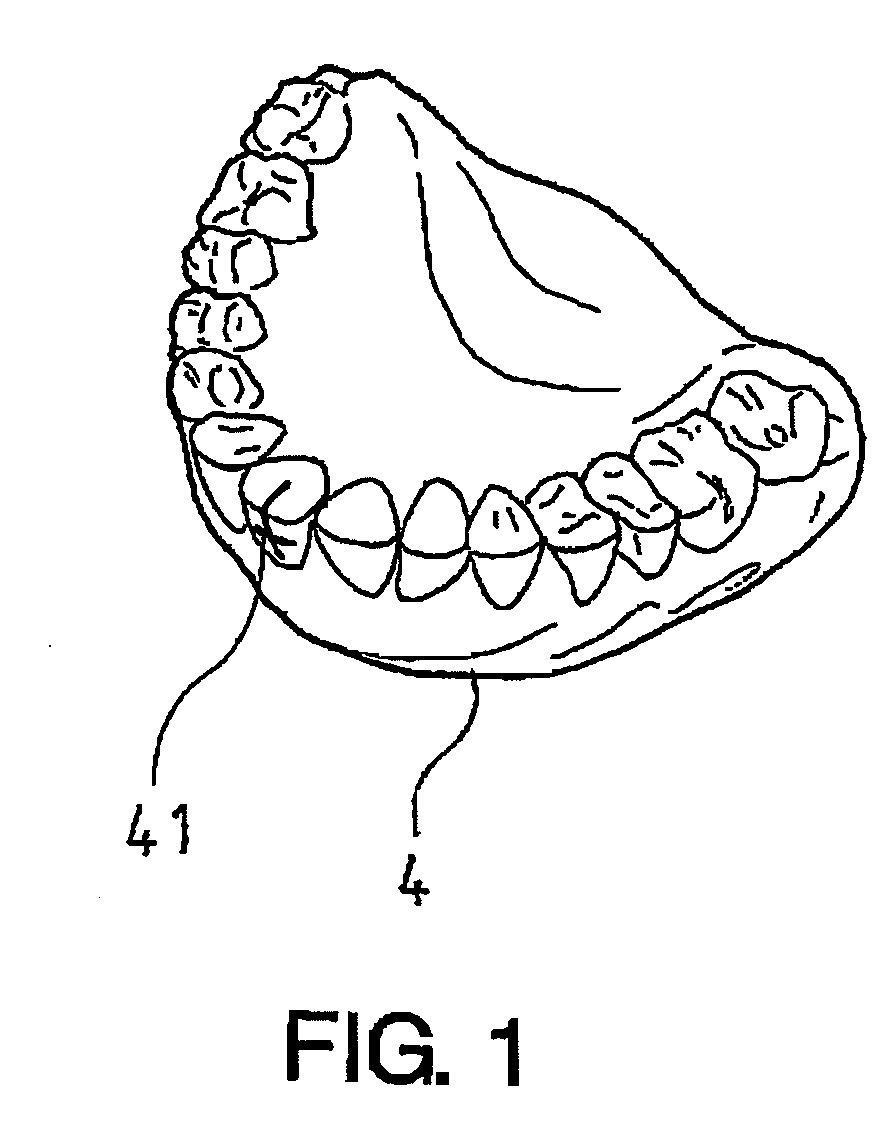

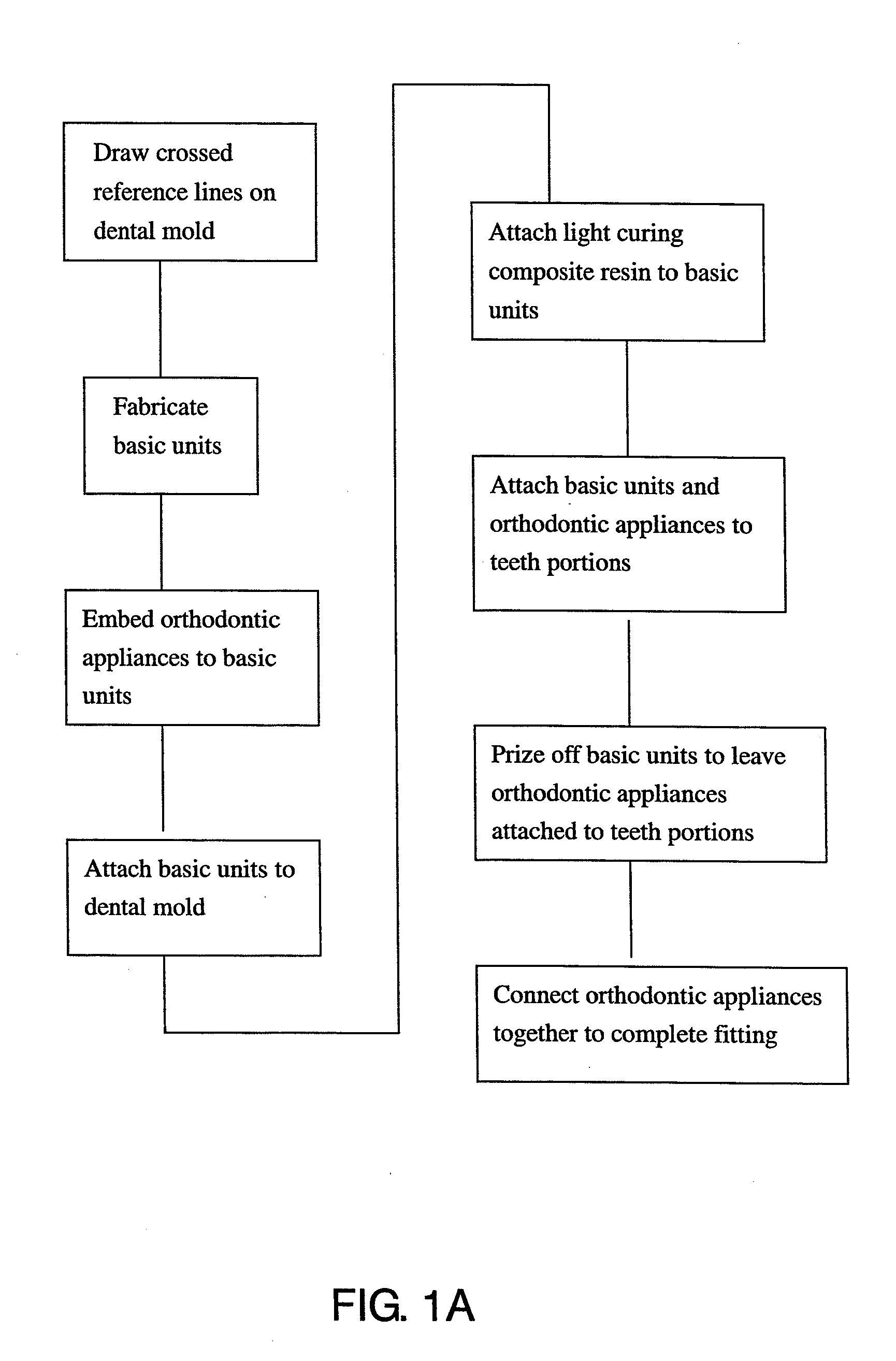

Positioning method for orthodontic appliance and structure thereof

A positioning method for orthodontic appliance and structure, mainly provided with base units molded by plastic injection. During the fabricating process, a crossed reference line is first drawn on a dental mold of the patient, after heating, the orthodontic appliance is embedded to the base unit, and a flexible member is used to bind and fixedly position the orthodontic appliance. Each of the aforementioned base units together with the orthodontic appliance is attached to the dental mold, and then light curing composite resin is attached to each of the base units. Accordingly, after applying an adhesive layer to each of the orthodontic appliances, each of the series connected base units together with the orthodontic appliances bound to the base units is directly attached to the respective teeth portion of the patient requiring straightening, thereby enabling fitting of orthodontic appliances to be more convenient and providing a more efficient fabricating process.

Owner:EZBOND DIGITAL CO LTD

Image processing system

InactiveUS20060152586A1Reduces the illuminating unhomogeneityTelevision system detailsPrintersImaging processingLength wave

An image processing system is used for dentistry. Upon creating a false tooth of a patient (59), a plurality of illuminating light of LEDs with different wavelengths emit light and a photographing apparatus (1A) photographs a tooth portion of the patient (59), thereby obtaining image data. The image data is sent to a dentistry filing system (2A) serving as a processing apparatus, and color reproducing data is obtained by calculation. The color reproducing data is sent to a dentistry factory (55) via a public line. Data is searched from a database (56) for calculating a ceramic compounding ratio, compound data of the ceramic false tooth is obtained, matching the color of the tooth portion of the patient (59), and the false tooth approximate to the tooth color of the patient (59) is created.

Owner:OLYMPUS CORP

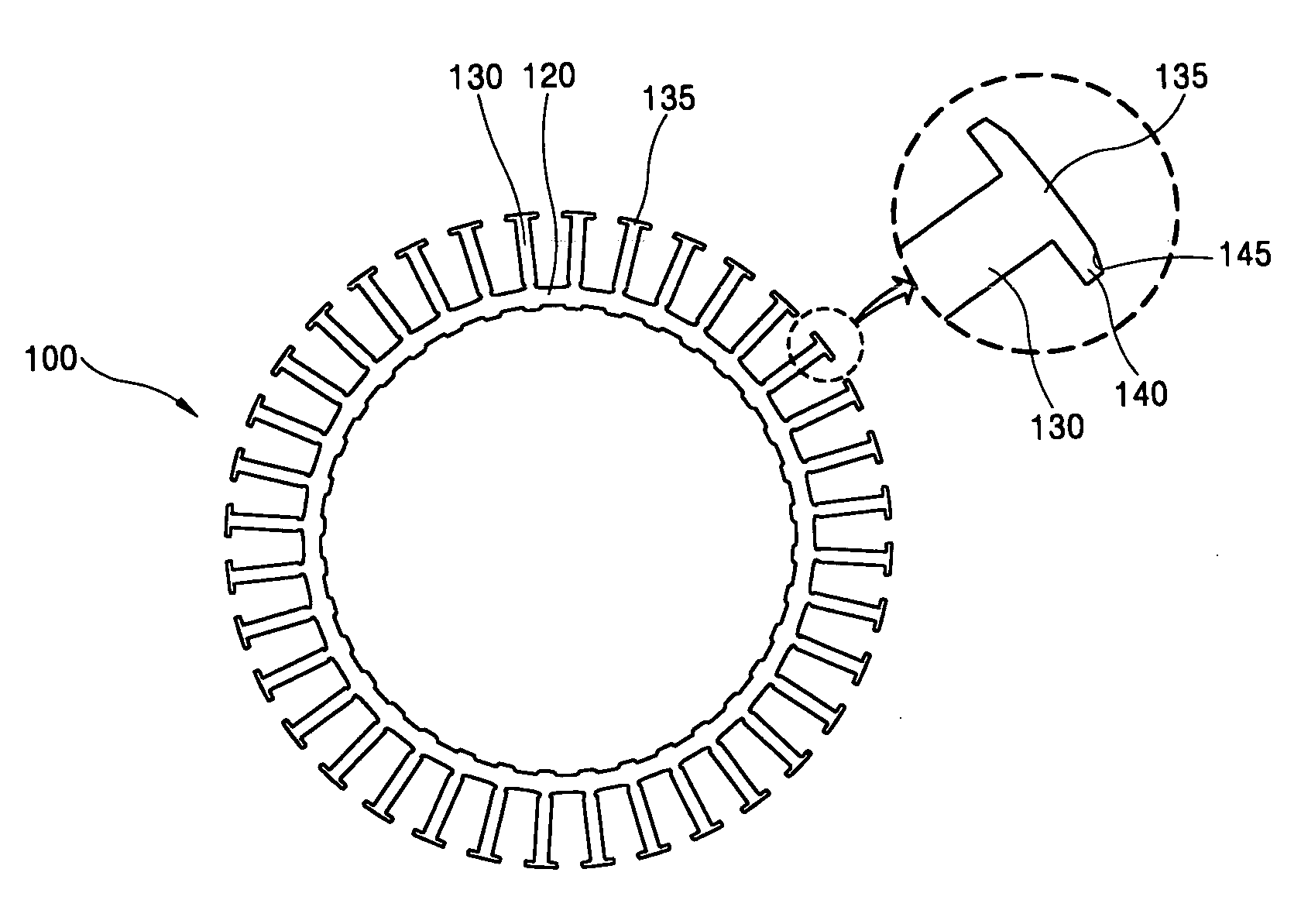

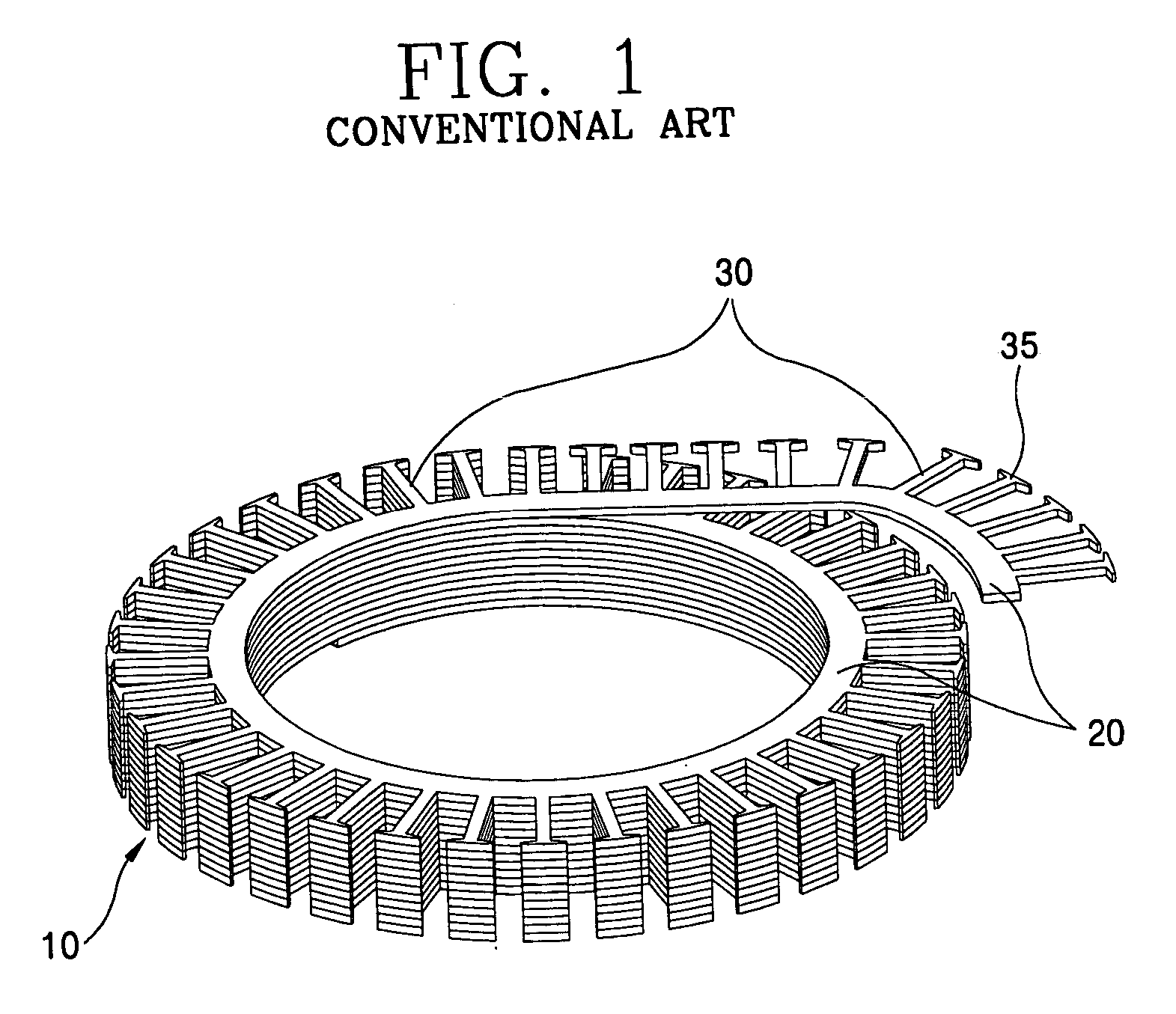

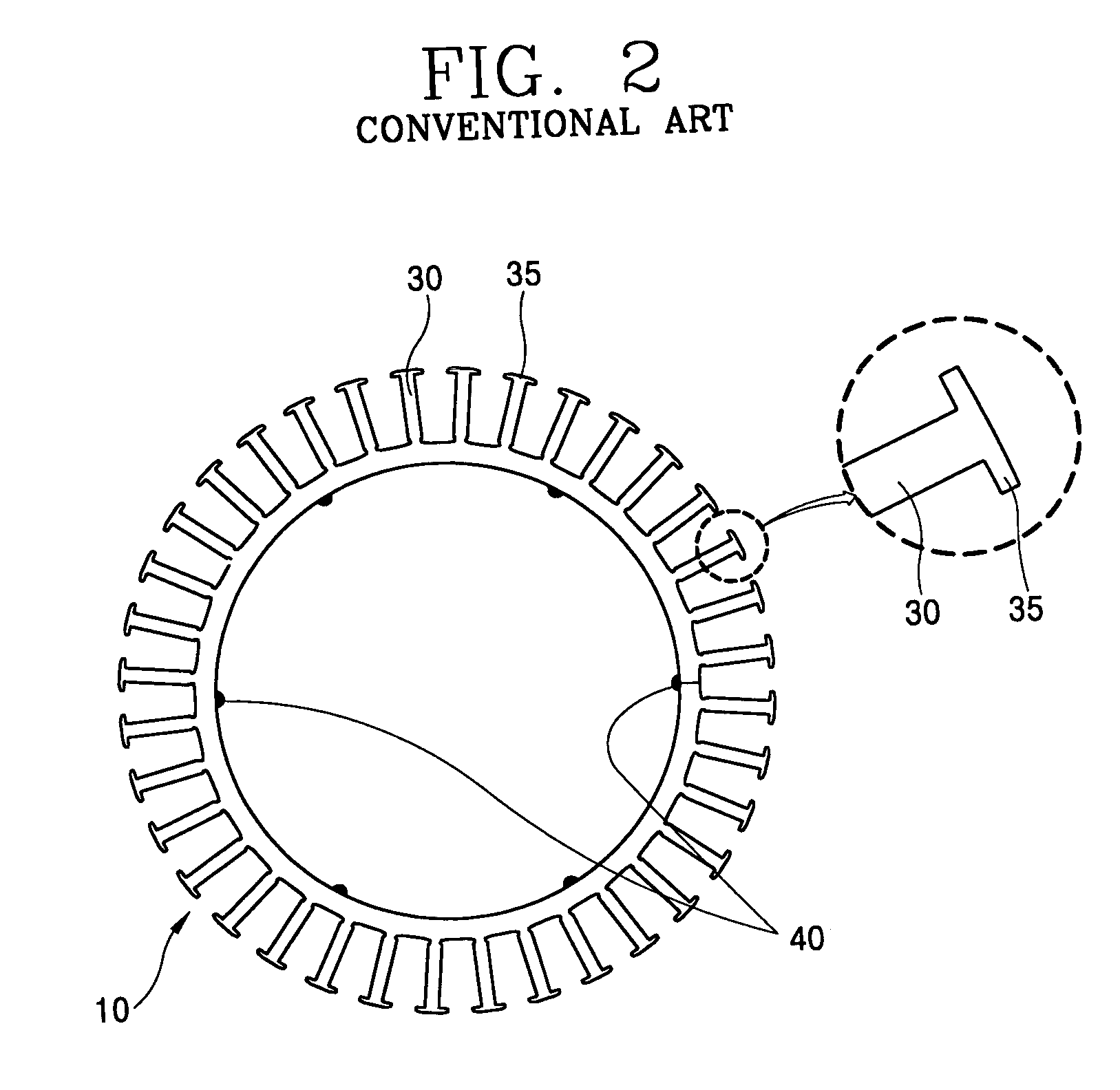

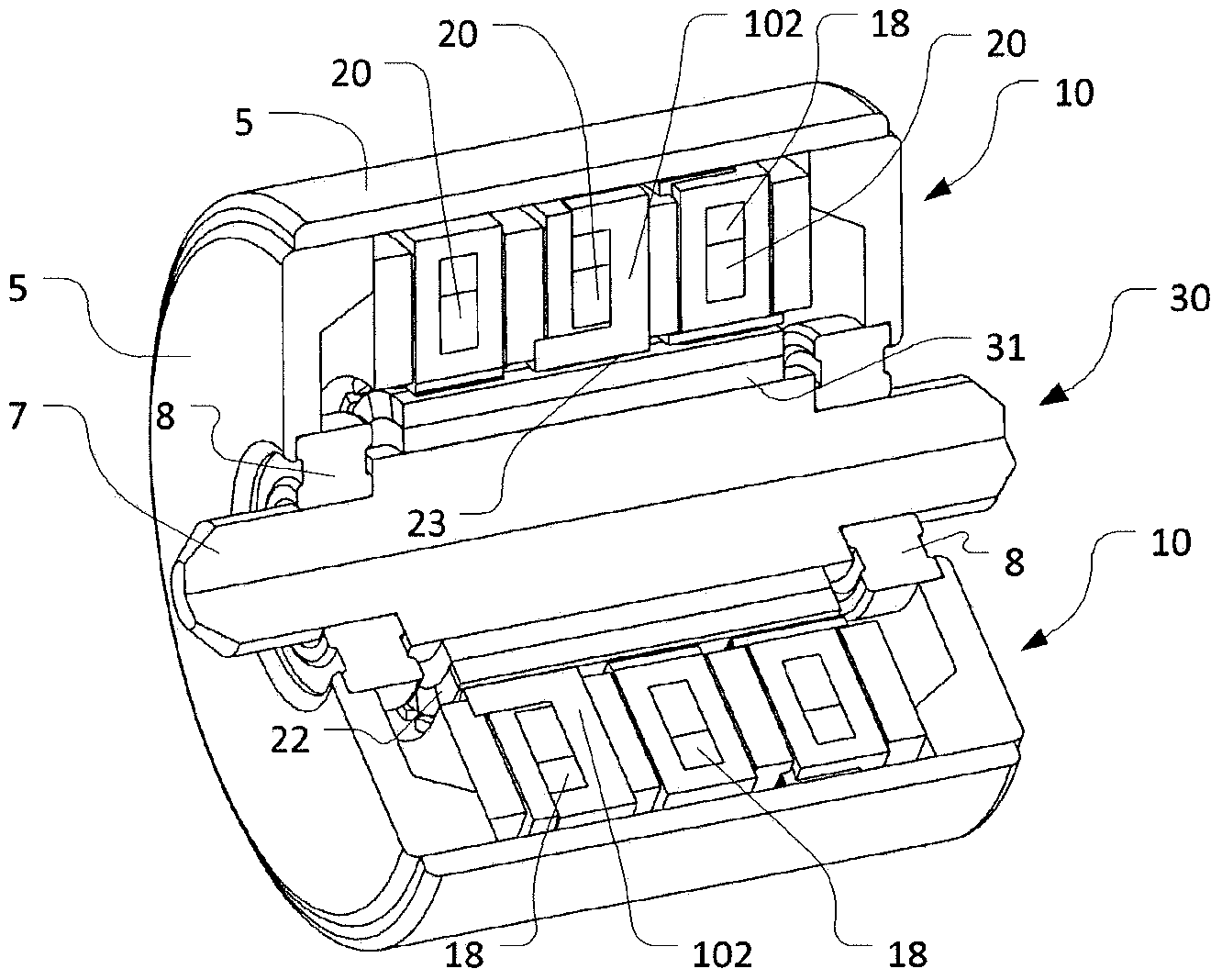

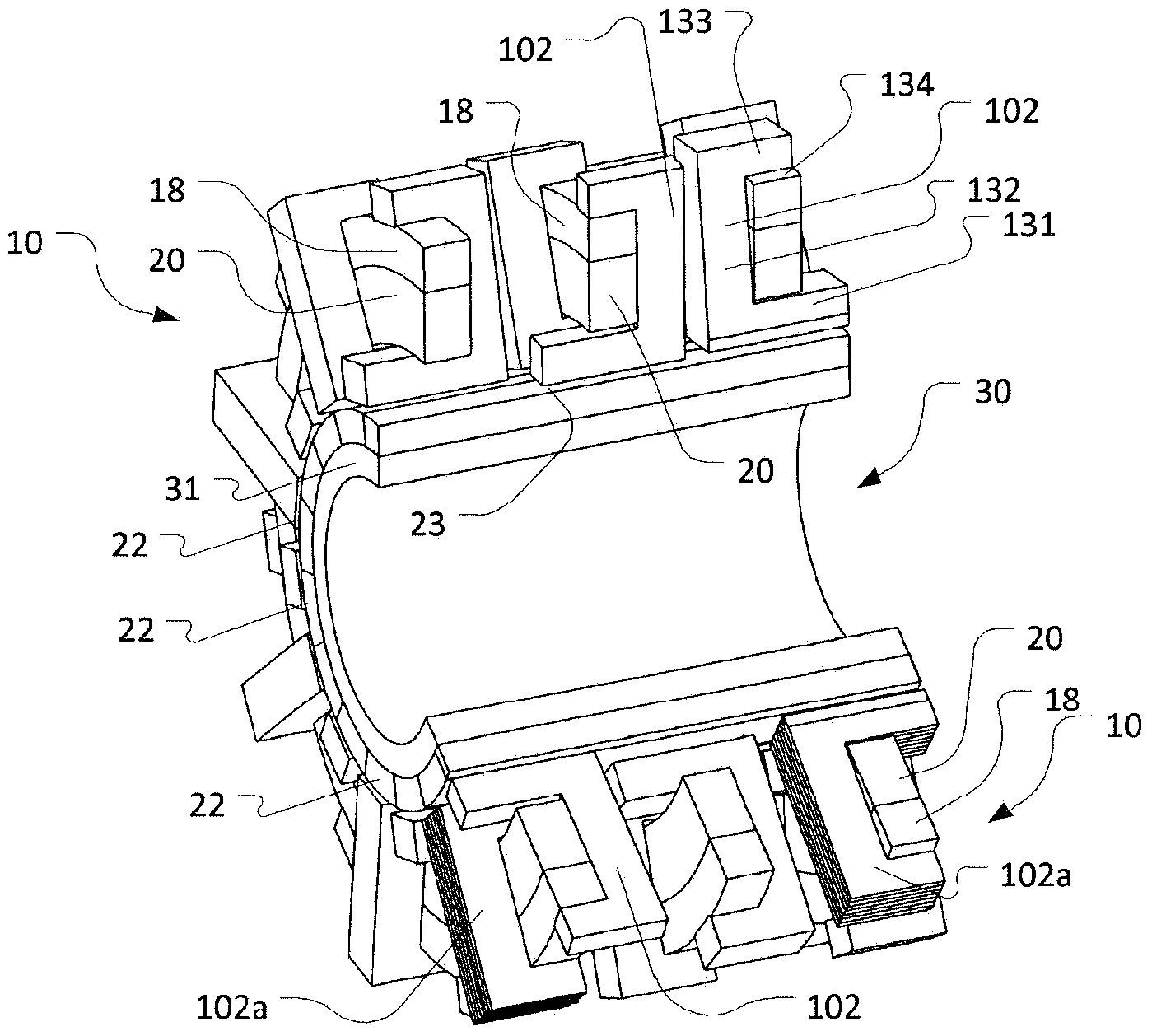

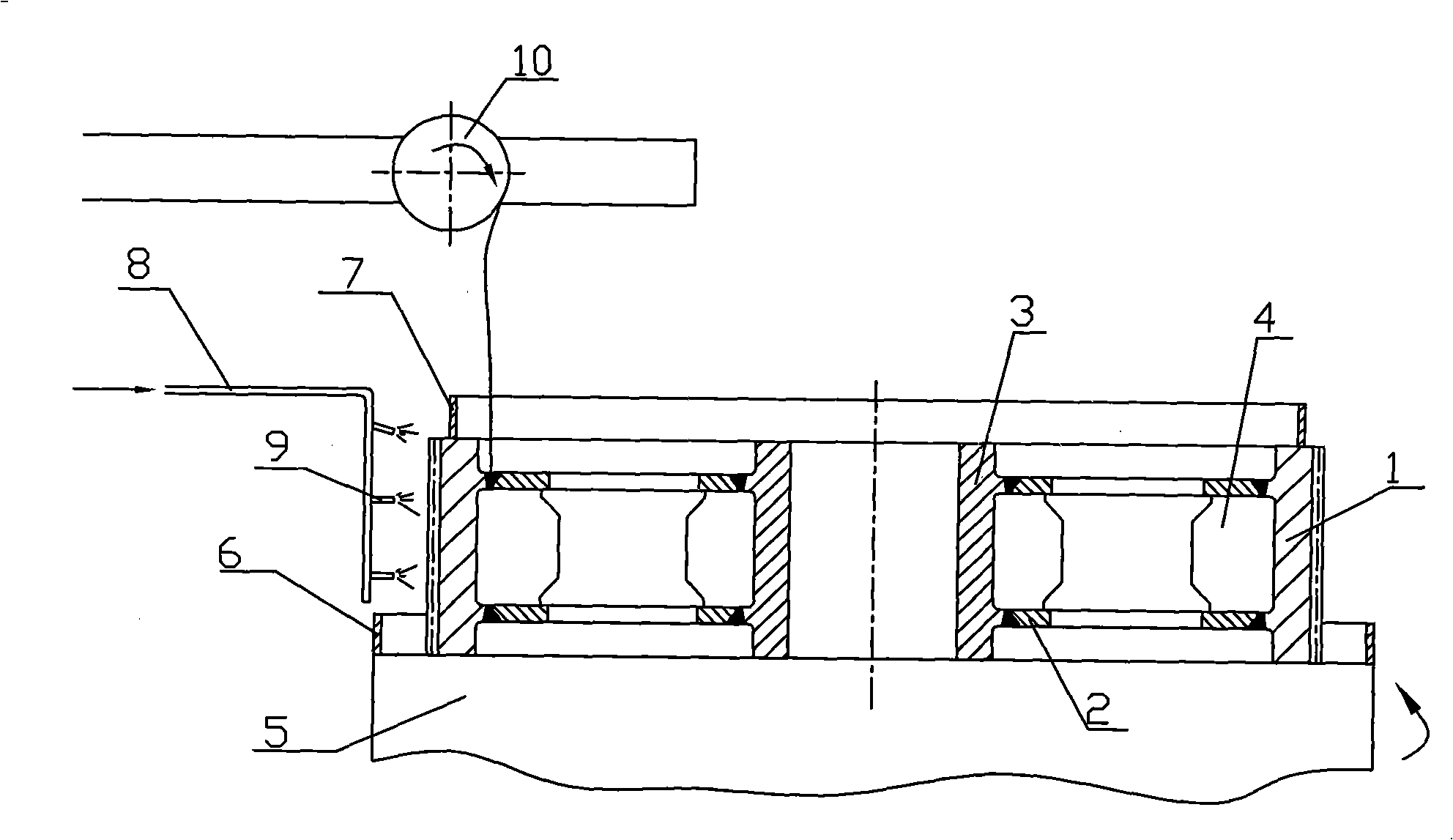

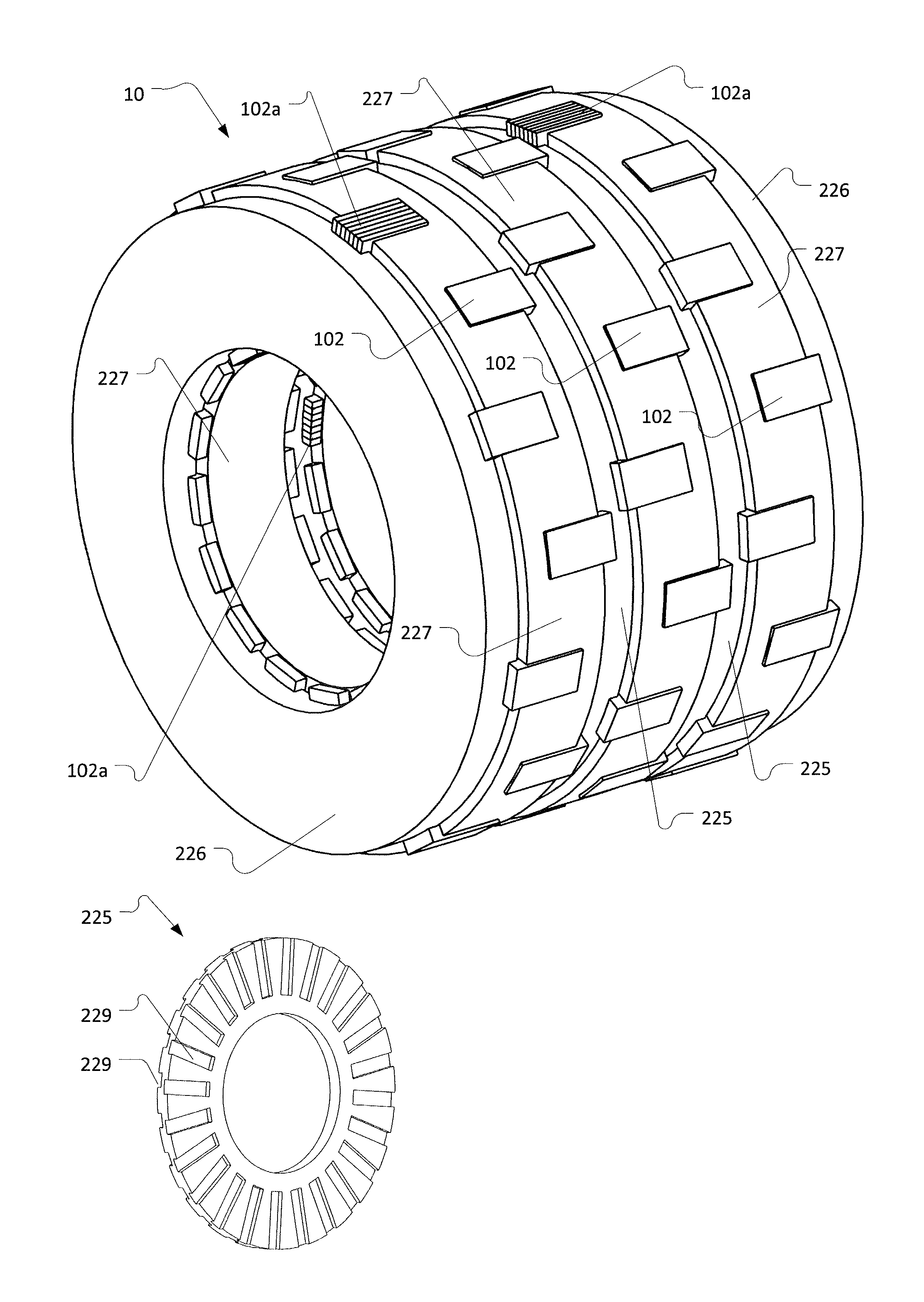

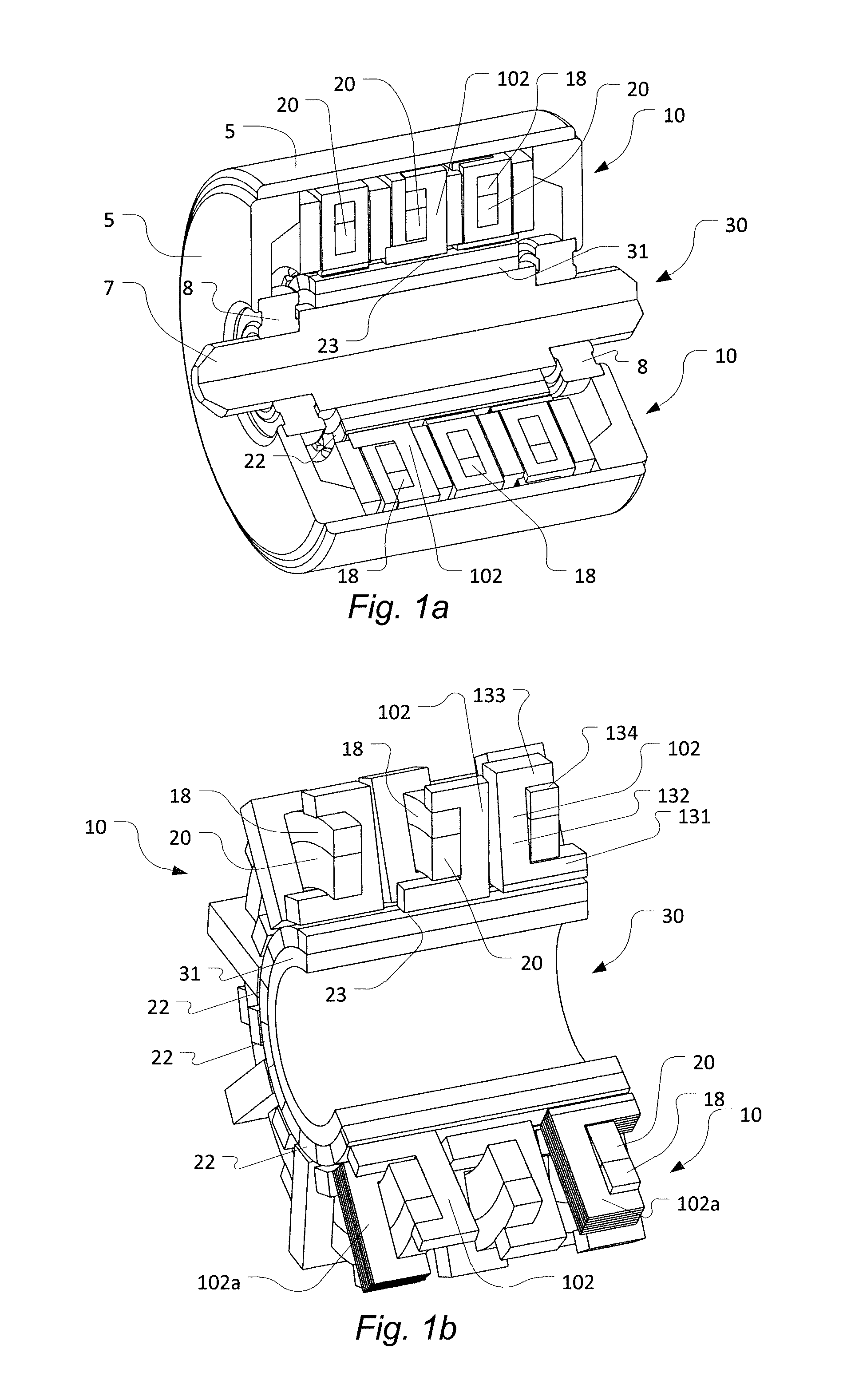

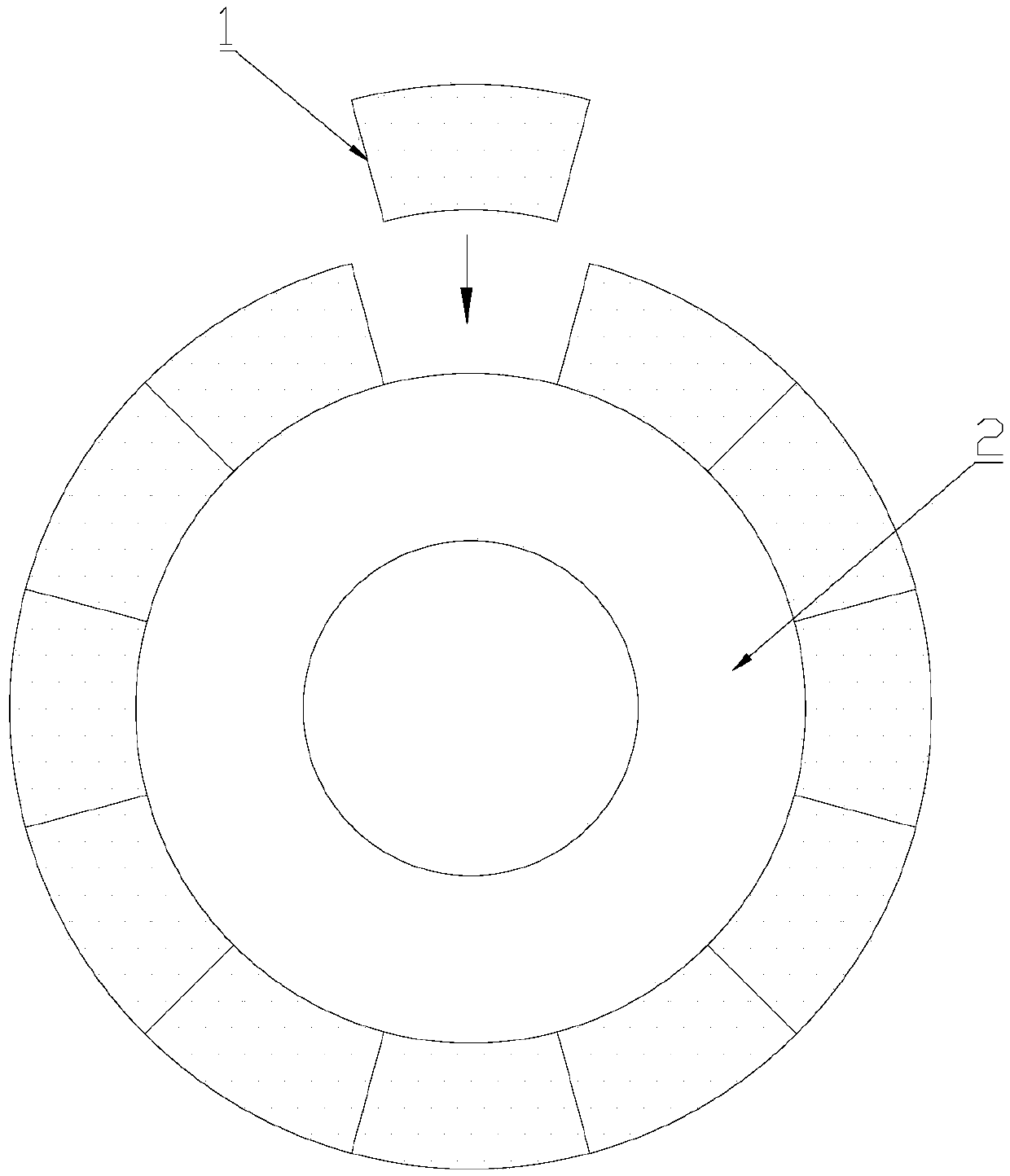

Laminated body of motor and manufacturing method thereof

ActiveUS20050073211A1Reducing cogging torque in operation of motorNo thermal deformationMagnetic circuit stationary partsManufacturing stator/rotor bodiesConductor CoilTooth part

A laminated body of a motor includes: a yoke part having a belt shape with a long length in comparison with its width and spirally laminated to form a hollow cylindrical shape; a plurality of teeth parts protruding from one side edge of the yoke part in a width direction and disposed along a longitudinal direction in an isolated manner at a predetermined distance; a stopping protrusion extendingly formed at a protruding end of the teeth part in a longitudinal direction of the yoke part; and an inclined portion having an inclined surface formed by decreasing a width of the stopping protrusion toward its end so as to reduce cogging torque, so that a minimum passage for a winding nozzle is provided while cogging torque is reduced. A laminated body of a motor includes: a yoke part having a belt shape with a long length in comparison with its width and spirally laminated to form a hollow cylindrical shape; a plurality of teeth parts protruding from one side edge of the yoke part in a width direction and disposed along a longitudinal direction in an isolated manner at a predetermined distance; and a protrusion receiving groove recessed in one side of the teeth part along a thickness direction and a coupling protrusion protruding from its other side along the thickness direction of the teeth part to be inserted and fixed by each other, so that defective measurement and an increase in production time caused by welding operation are prevented.

Owner:LG ELECTRONICS INC

Swivel draw bar structure of a suitcase

InactiveUS6409207B1Precise rotationCarriage/perambulator accessoriesOther accessoriesUpper jointEngineering

A swivel draw bar structure of a suitcase. A fixing sleeve is installed at the top end of the lower joint tube of the draw bar. A projective arc plate is joined at the center of the top surface of the fixing sleeve. A plurality of teeth are formed on the top surface of the arc plate. A downward straight groove is formed on the top surface of the fixing sleeve. A slide sheet is inserted in the straight groove. The bottom end of the slide sheet is a bevel joined with a bevel of a retractable button so that the retractable button can slide in a transversal groove of the fixing sleeve. The projective part of the retractable button can penetrate through the transversal groove and protrude out of a hole of the fixing sleeve to be locked in a hole of the lower joint tube. A swivel sleeve seat is joined at the bottom end of the upper joint tube. A pair of auriform sheets having holes extend downwards from the swivel sleeve seat. The holes of the auriform sheets are joined a central hole of the arc plate via a spindle. An upward longitudinal groove is formed on the bottom surface of the swivel sleeve seat for insertion of a slide retaining element. The slide retaining element is connected to the swivel sleeve seat through pin connection. The top end of the slide retaining element is joined with a drive element to drive the slide retaining element to move upwards or downwards. A tooth part is formed on the bottom surface of the slide retaining element to mesh with the teeth of the arc plate. A retaining sheet extends from the bottom surface of the slide retaining element. The bottom end of the retaining sheet contacts with the top end of the slide sheet to push the retractable button to be positioned in the lower joint tube.

Owner:CHAW KHONG TECH

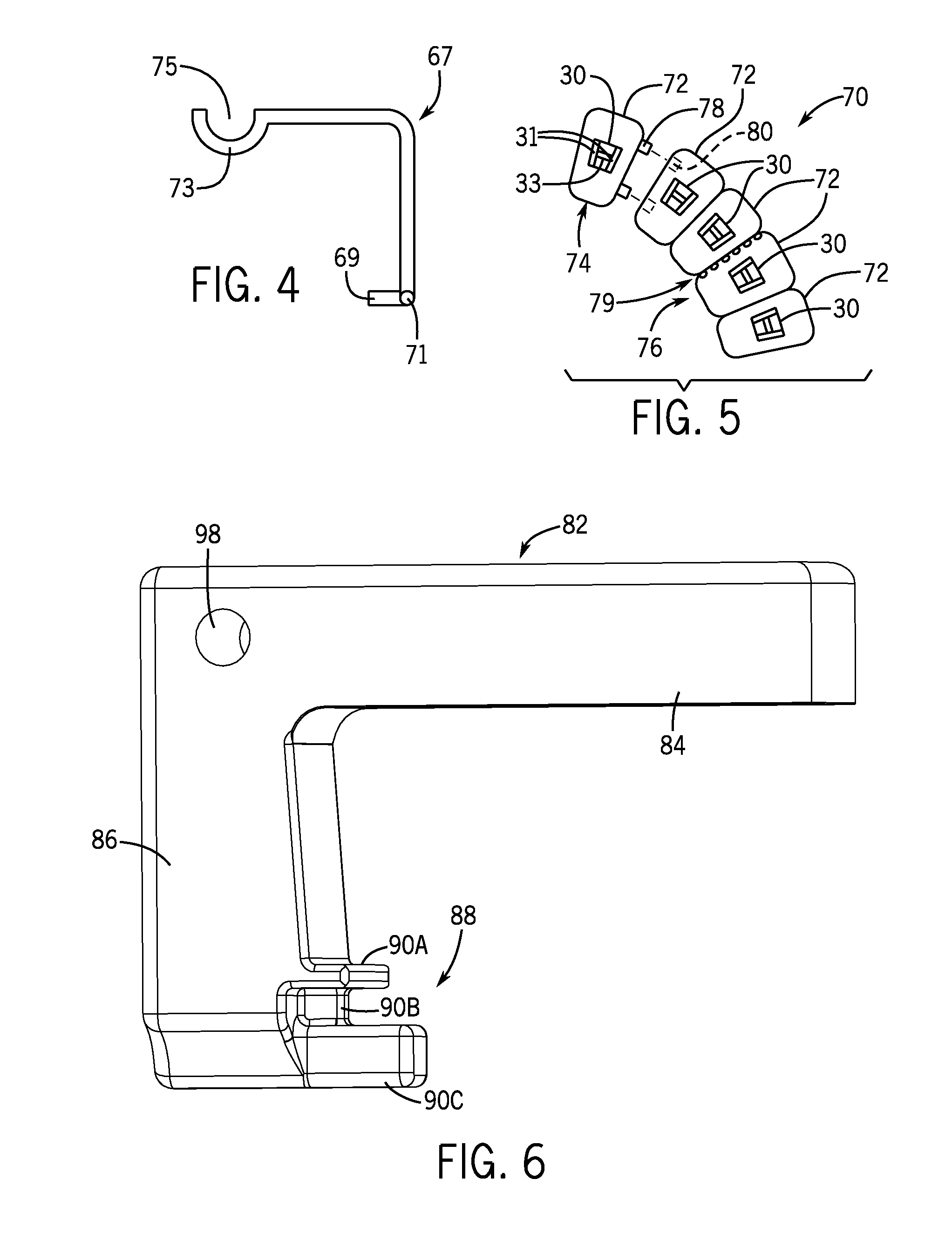

Dental tool and guidance devices

ActiveUS20140248577A1Precise preparationSimpler and reliable and convenientTeeth fillingDental toolsDental instrumentsEngineering

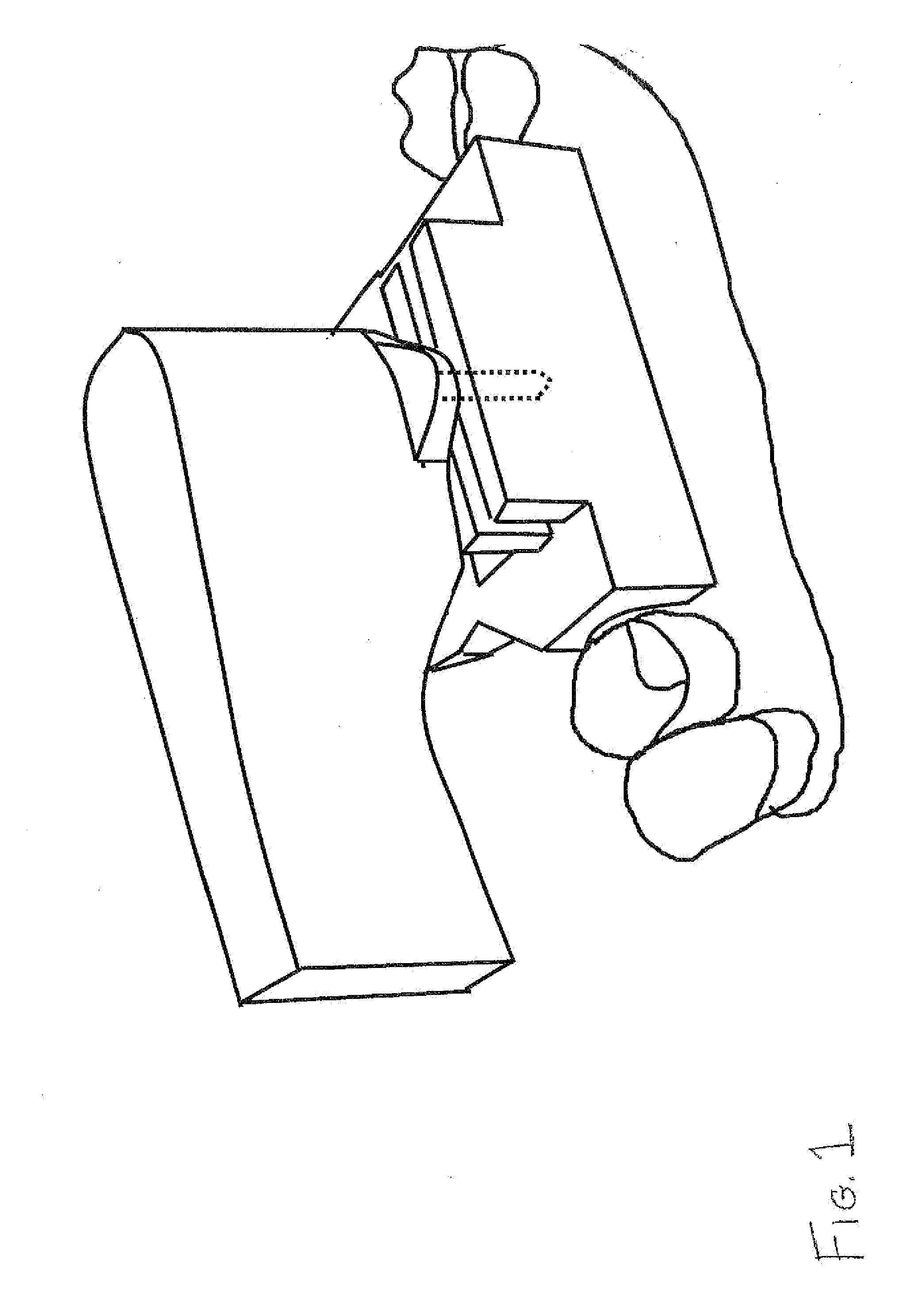

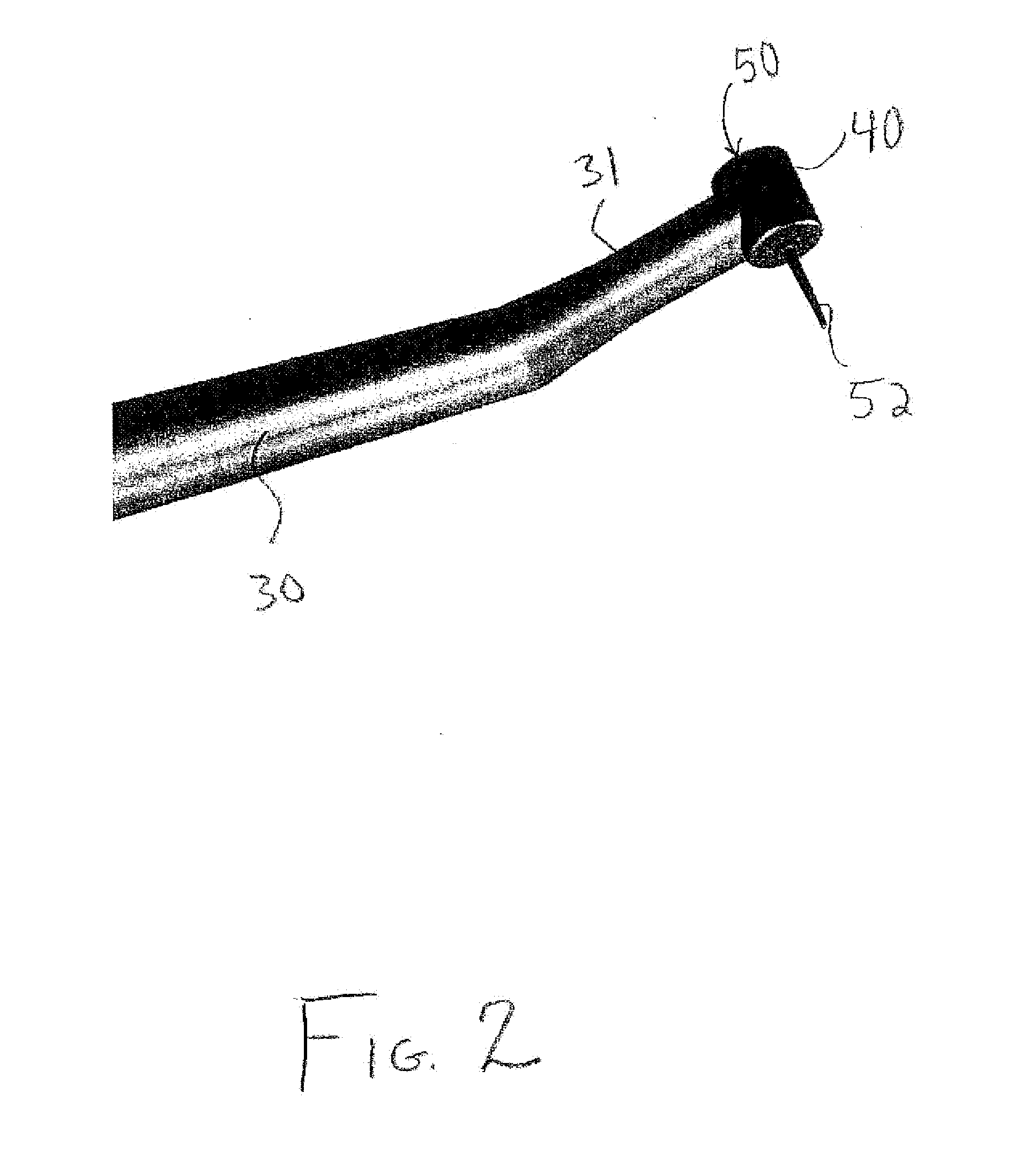

The present invention is directed to a system of devices and a method for preparing a tooth to receive a restoration. The system includes a dental instrument for removal of portions of a tooth in the mouth of a patent and an overlay for guiding the dental instrument during the step of tooth removal. The overlay is designed for temporary installation into the mouth of the patient to guide the dental instrument to remove tooth material. The overlay has one or more sets of guide walls, with a predetermined configuration capable of contacting one or more guide projections of the dental instrument, and a receptacle capable of receiving and attaching to the dental instrument.

Owner:VIAX DENTAL TECH LLC

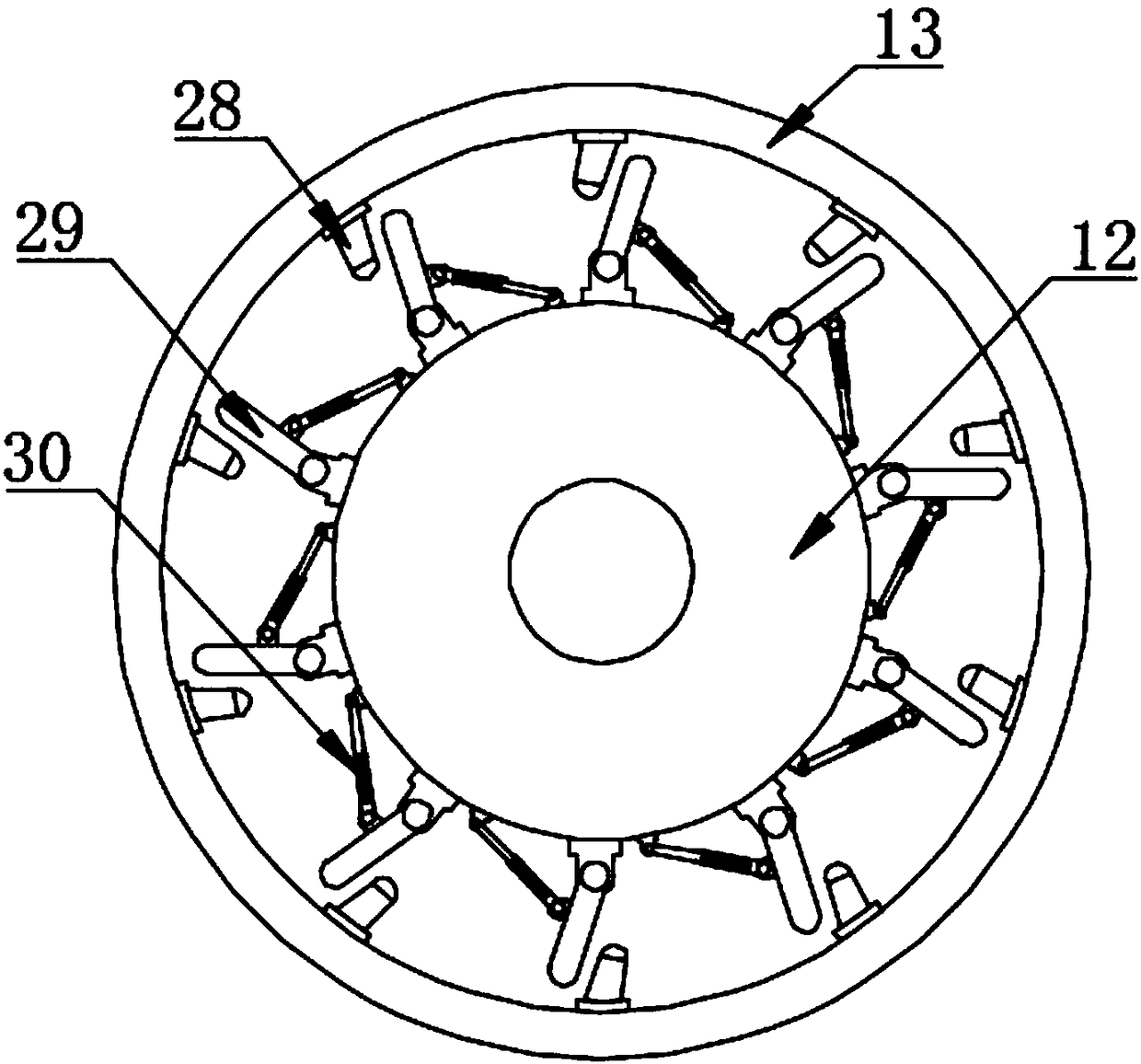

Indirect Bonding Tray and Method of Manufacture Thereof

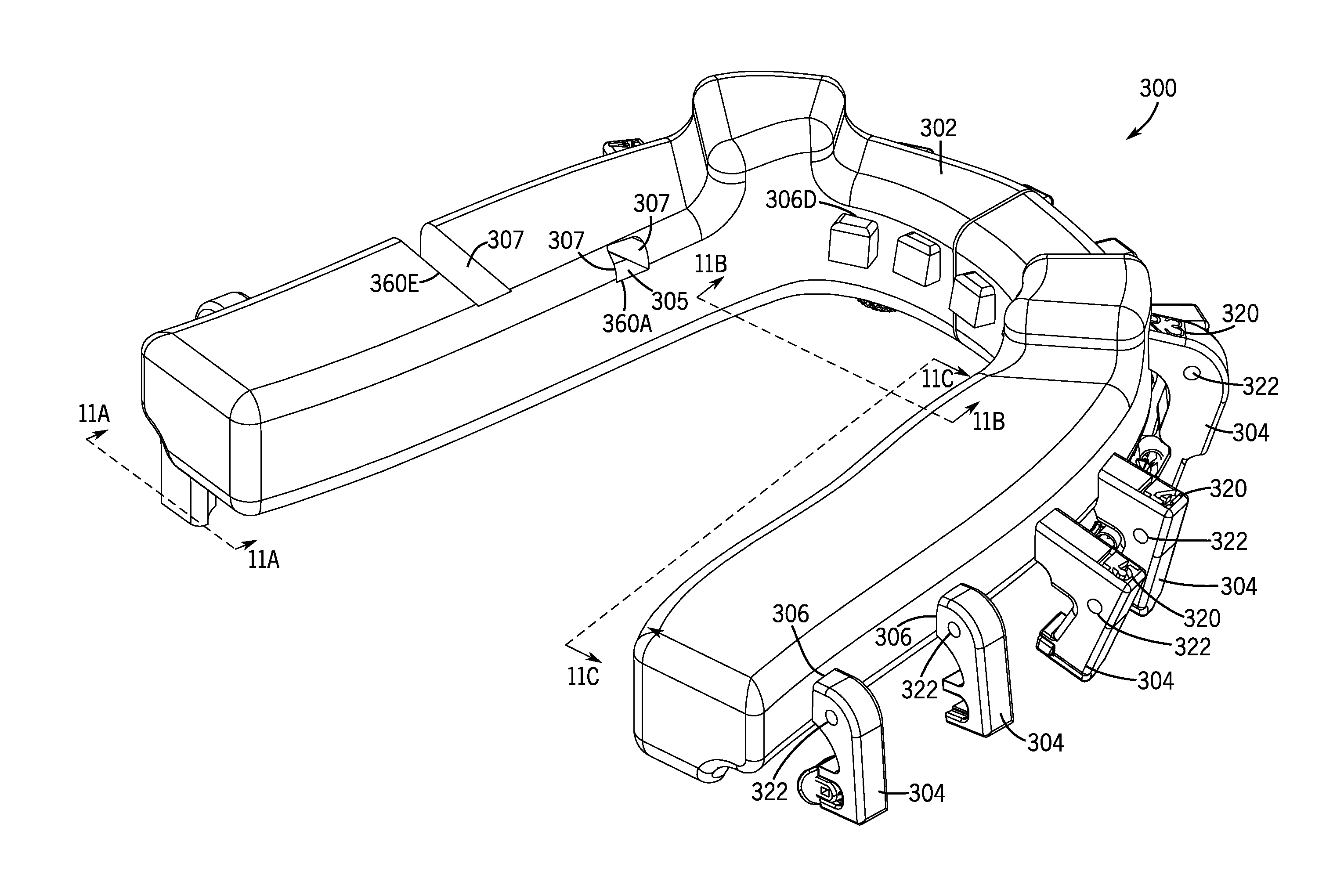

An indirect bonding tray includes a least one tooth portion. Each tooth portion includes an occlusal surface that conforms to an occlusal surface of an associated tooth of a patient's dentition. At least one arm includes an arm tip configured to engage an orthodontic bracket. The at least one arm is movably attached to at least one tooth portion to move between a first position and second position relative to a bonding surface of the associated tooth. In the second position, the arm is in a position configured to hold an orthodontic bracket in a predetermined treatment position relative to the bonding surface of the associated tooth.

Owner:AMERICAN ORTHODONTICS

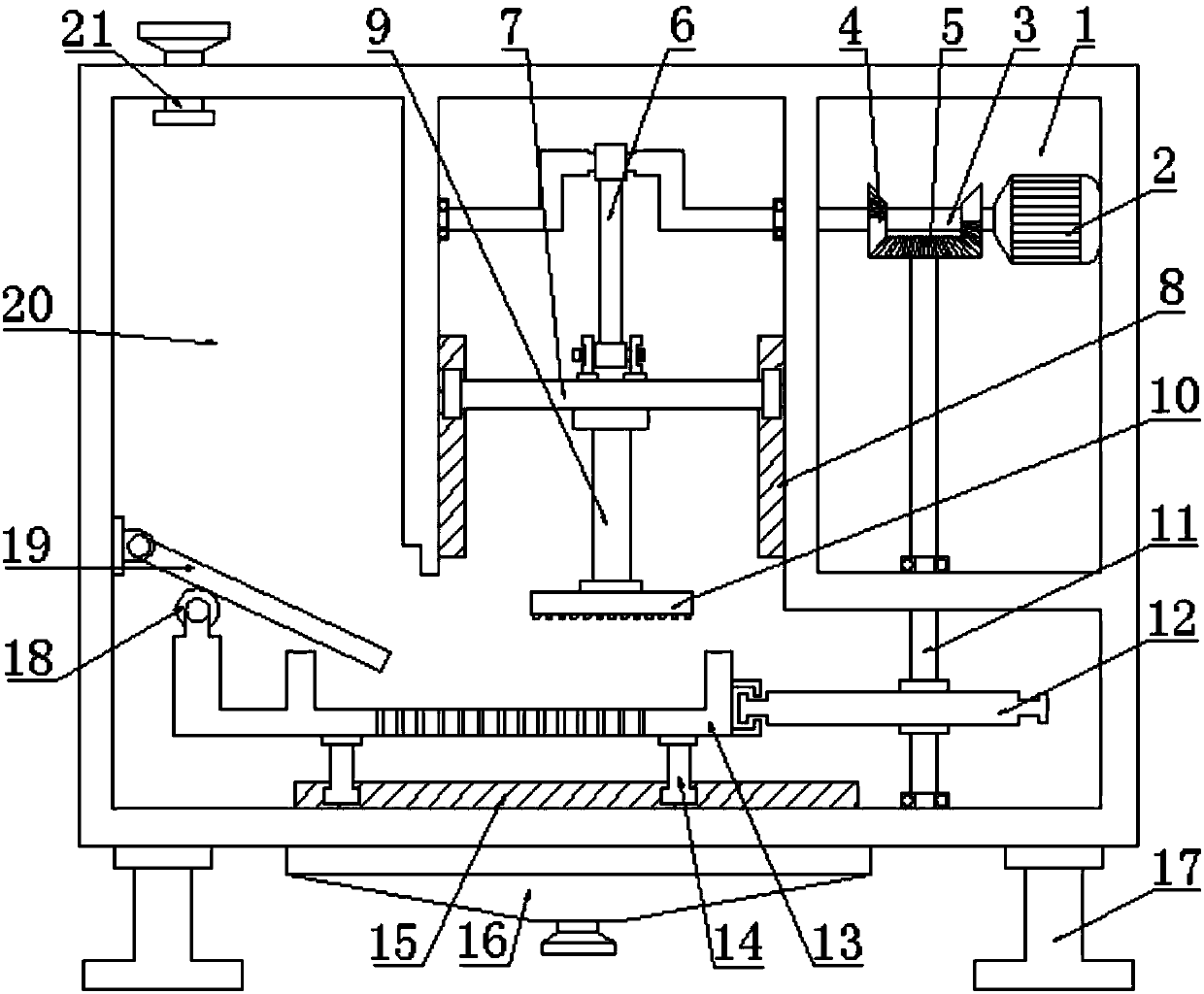

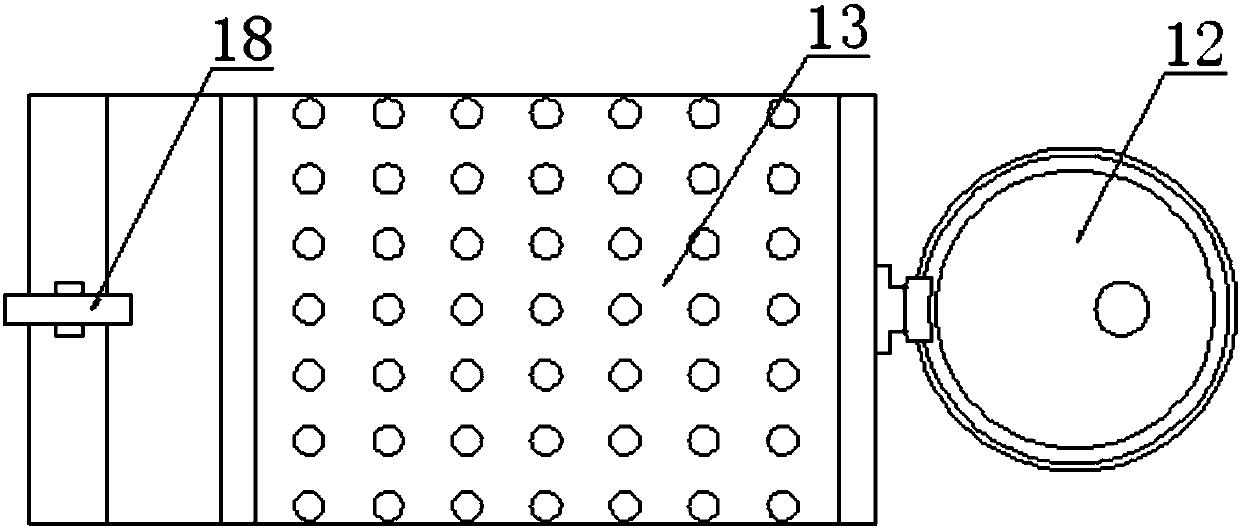

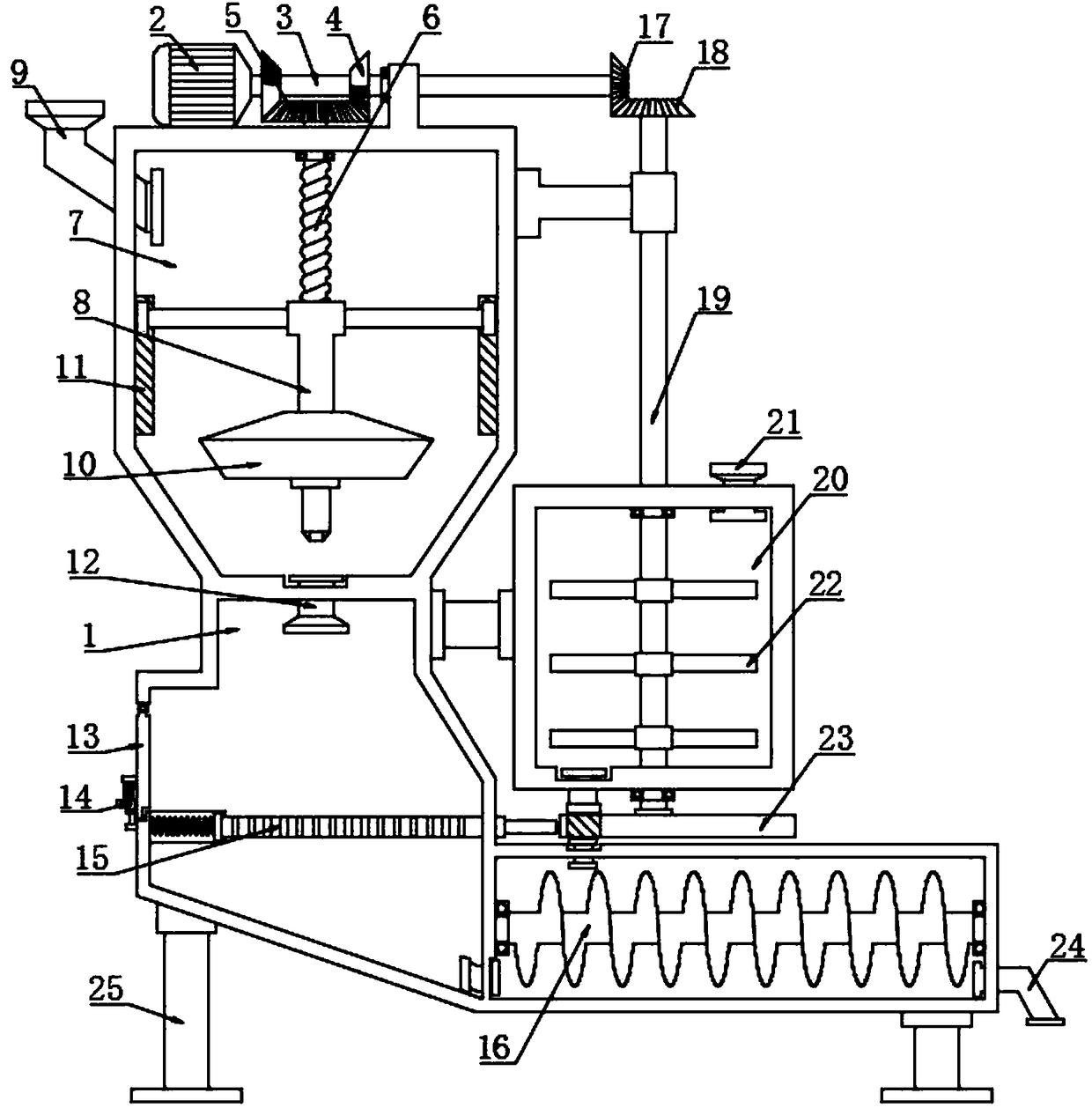

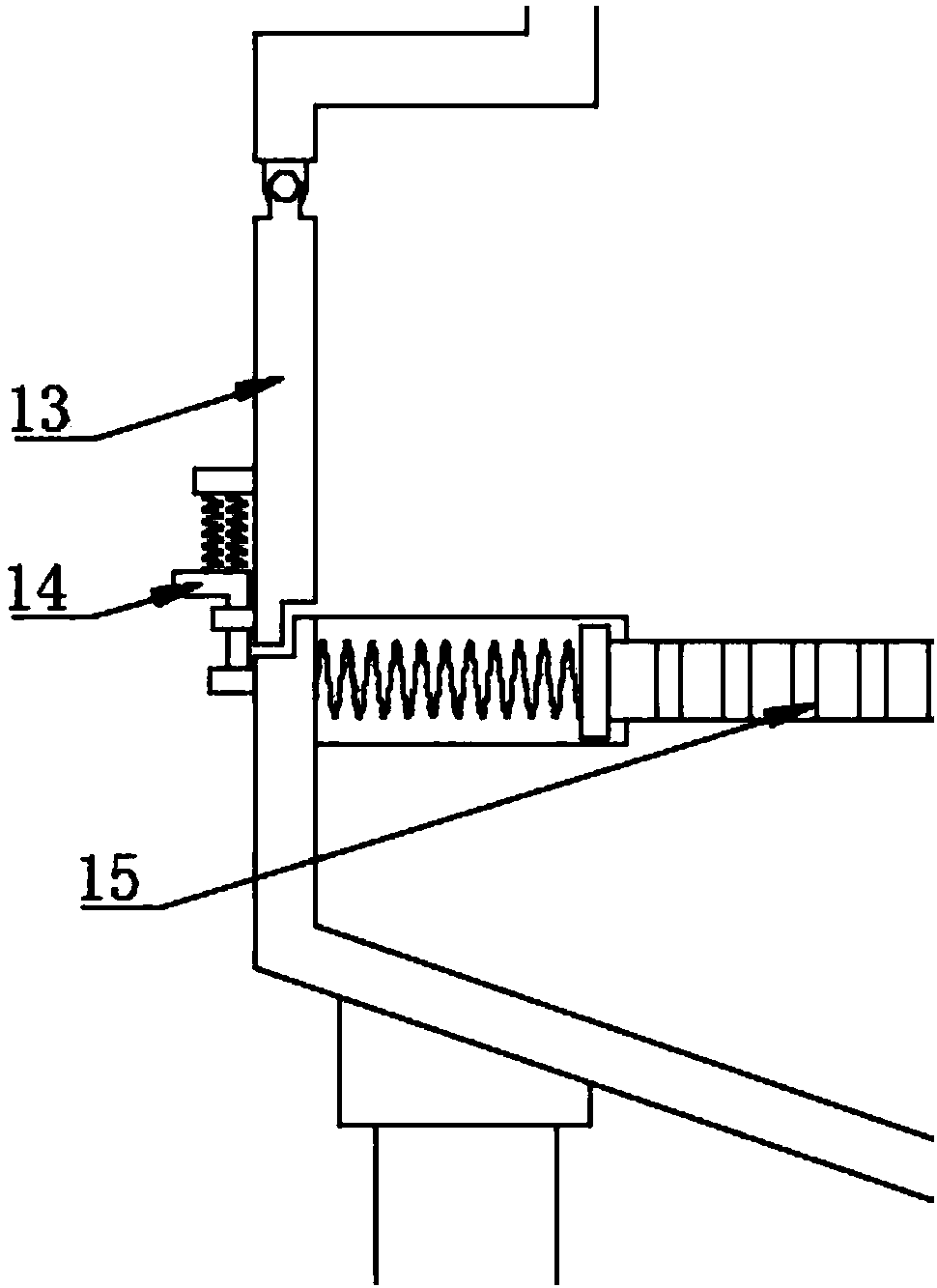

Reciprocating smashing device for Chinese herbal medicines

InactiveCN107837859AImprove mashing efficiencyReasonable structural designSievingScreeningGear wheelDrive shaft

The invention discloses a reciprocating smashing device for Chinese herbal medicines. A crankshaft bearing is rotationally connected with a device body. The middle of a crankshaft is connected with the upper end of a connecting rod in a sleeved mode. The lower end of the connecting rod is rotationally connected with the upper surface of the middle of a transverse plate. The two sides of the transverse plate are connected with guide grooves in a sliding mode. The guide groove in the left end is fixedly connected with the outer wall of a storage box, and the guide groove in the right end is fixedly connected with the device body. The lower end of the transverse plate is fixedly connected with the upper end of a vertical supporting rod, and the lower end of the vertical supporting rod is fixedly connected with a press head. The right portion of the crankshaft is fixedly connected with two semicircular bevel gears, and the semicircular bevel gears are provided with tooth parts engaged witha bevel gear. According to the reciprocating smashing device for Chinese herbal medicines, the crankshaft drives the connecting rod to push the press head to reciprocate up and down so that Chinese herbal medicines on a screening plate can be smashed, the bevel gear drives a driven shaft to rotate forwards and backwards in a reciprocating mode, the rotating driven shaft drives a sheave to do eccentric movement and further drives the screening plate to reciprocate left and right, a roller wheel moves left and right to drive a bottom plate to open and close in a reciprocating mode, and therefore the intermittent discharging function is realized. The reciprocating smashing device for Chinese herbal medicines is reasonable and practical in structure design, the smashing efficiency of Chineseherbal medicines is greatly improved, the automation degree is high, and labor is saved.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

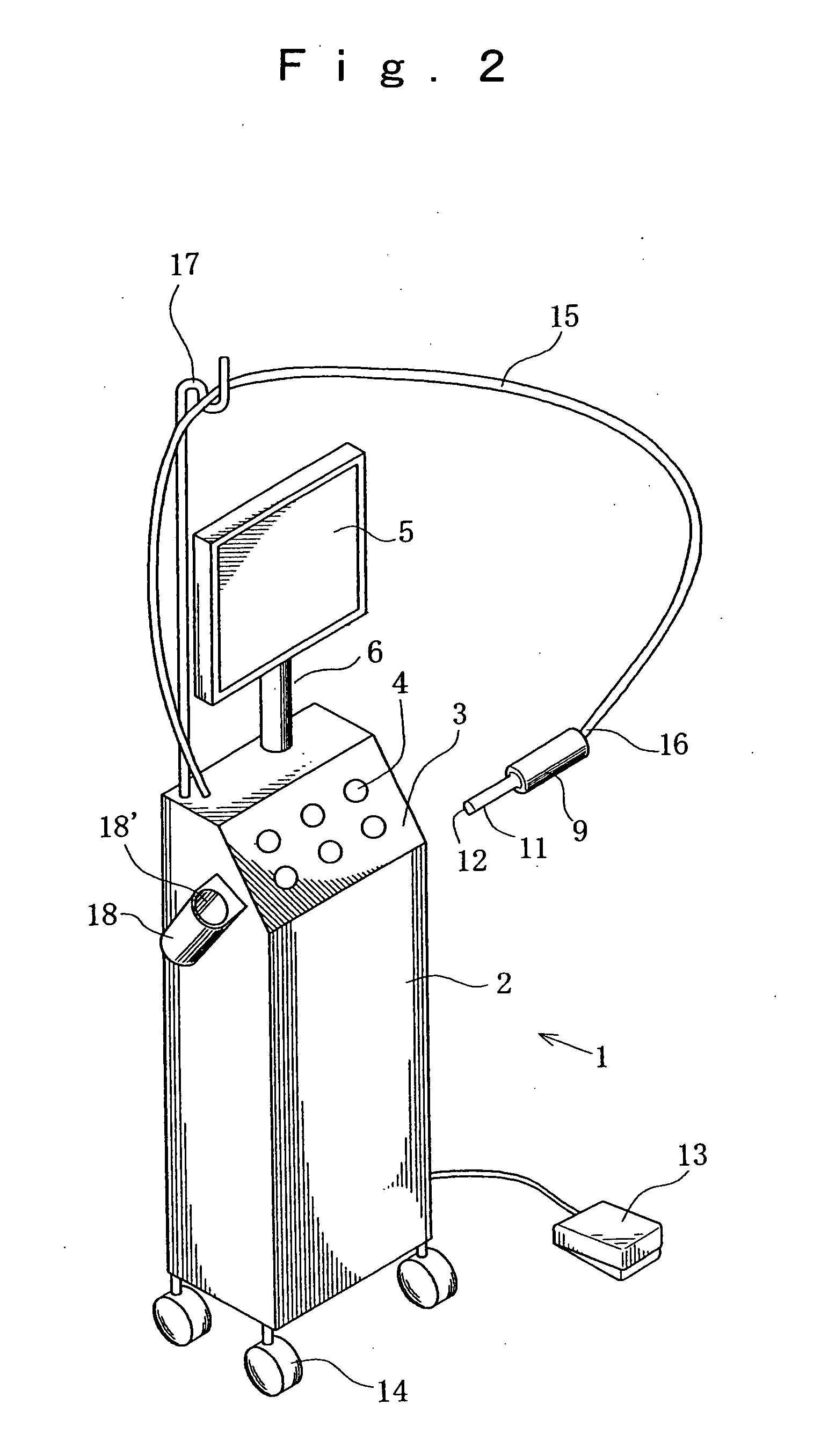

Dental Optical Diagnostic Apparatus

Owner:J MORITA TOKYO MFG CORP

Stainless steel dental crowns with a polyester/epoxy coating

InactiveUS7008229B2Improve aestheticsExtended wear timeImpression capsTooth crownsPolyesterDental crowns

Owner:3M INNOVATIVE PROPERTIES CO

Mat with puzzle function

InactiveUS8806822B1Reduce waste generationLow production costCovering/liningsIndoor gamesEngineeringTooth part

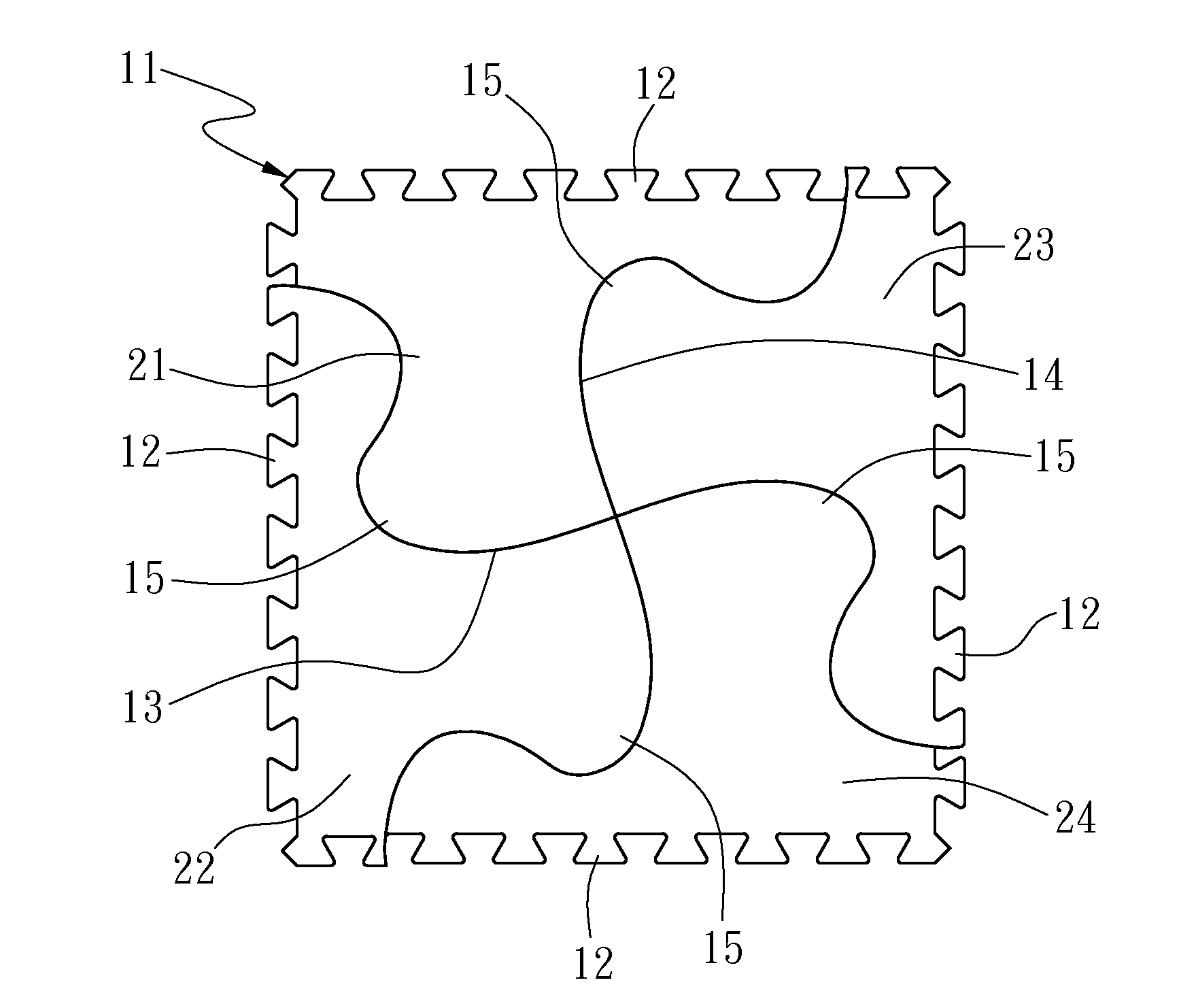

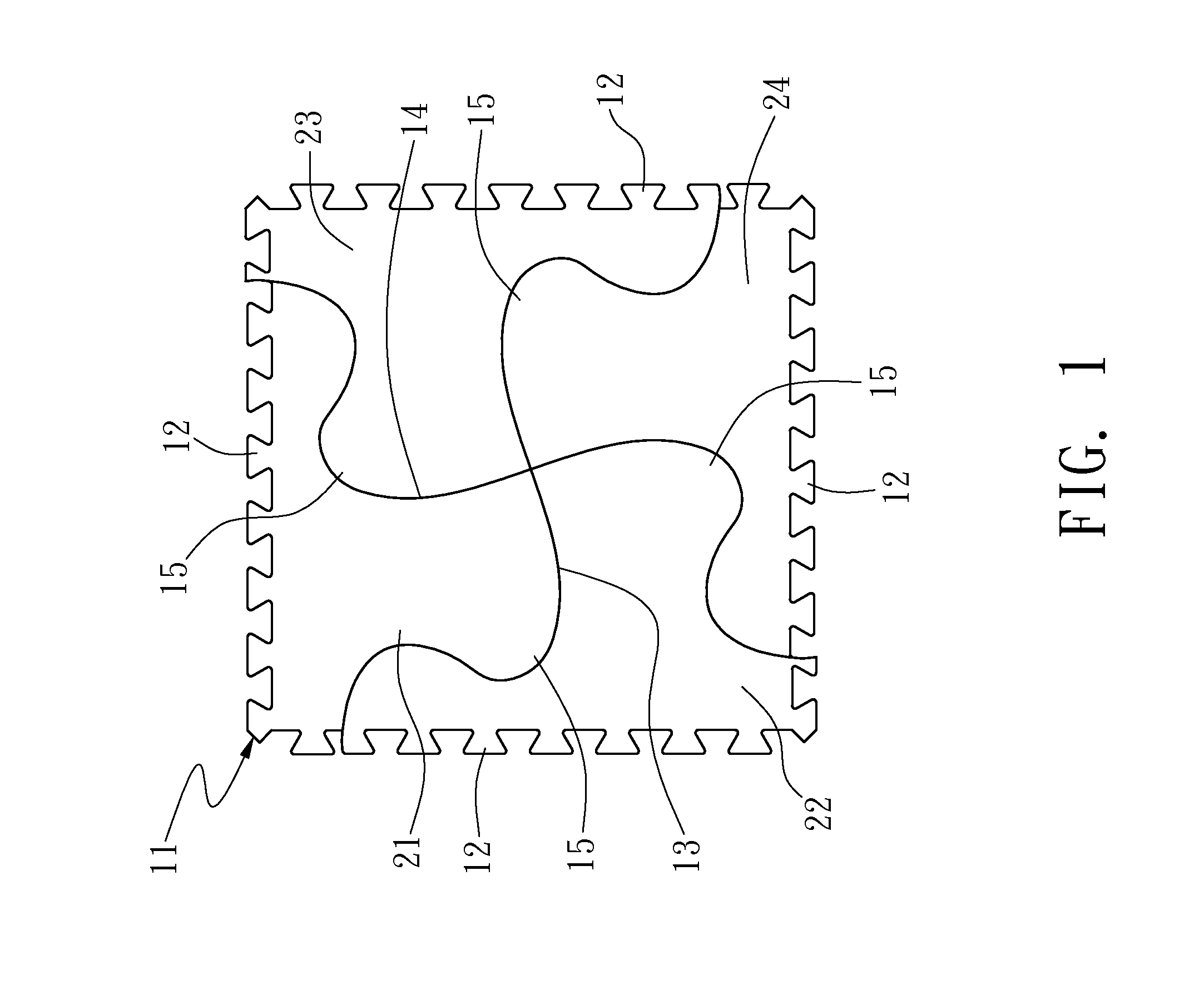

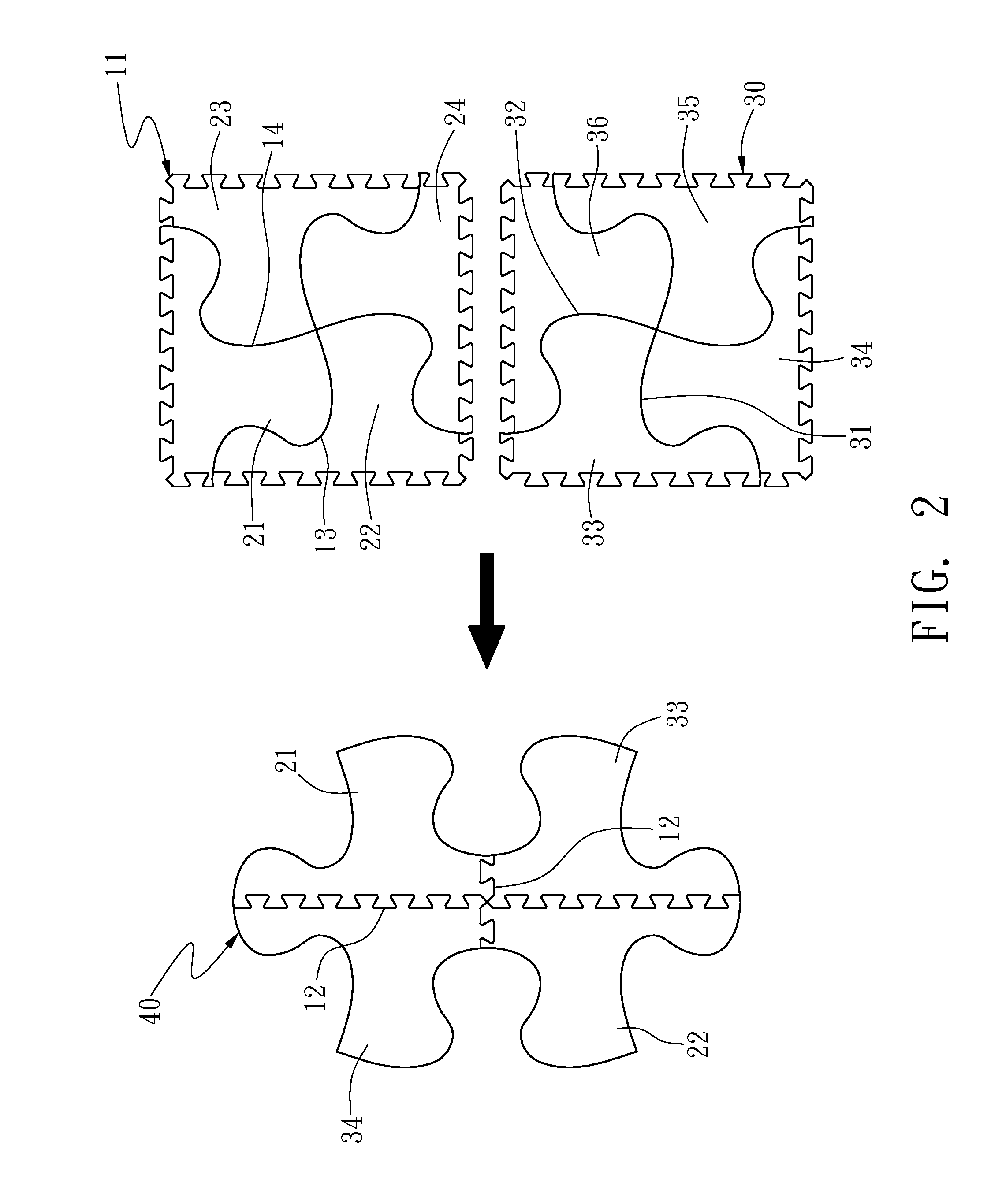

A mat with puzzle function is a four-sided pad. Each side has a tooth part with a succession of teeth. At least two cutting lines divide the mat into four blocks, in such a way that each block has an assembling part with the complementary shape to connect with others. The block of each mat can engage with another block of the mat to form a puzzle mat set.

Owner:WANG WEN PING

Carburization-like overloading tooth component tooth surface laser cladding powder material and repairing method thereof

InactiveCN101100746AImprove repair qualityImprove performanceMetallic material coating processesLaser beam welding apparatusLaser power densityAlloy

A process for laser powder-melting onto the surfaces of the teeth parts that are of heavily loaded cemented steel to be repaired is disclosed herewith. The powder of grains = (-140-+260 mesh) comprises (mass%): C 0.80-1.10, Mn 7.50-9.00, Cr 0.90-1.30, Mo 0.20-0.35, B 2.00-3.50, Si 2.50-3.50, and balanced with Fe with impurities of P not more than 0.06 and S not more than 0.04. Laser power density is equal to 1.0 X 108W-109W / m2 per unit of time. The said powder has good re-melting property, self-enhancing and fatigue-resistance performances, so that it can be used to repair worn gears.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

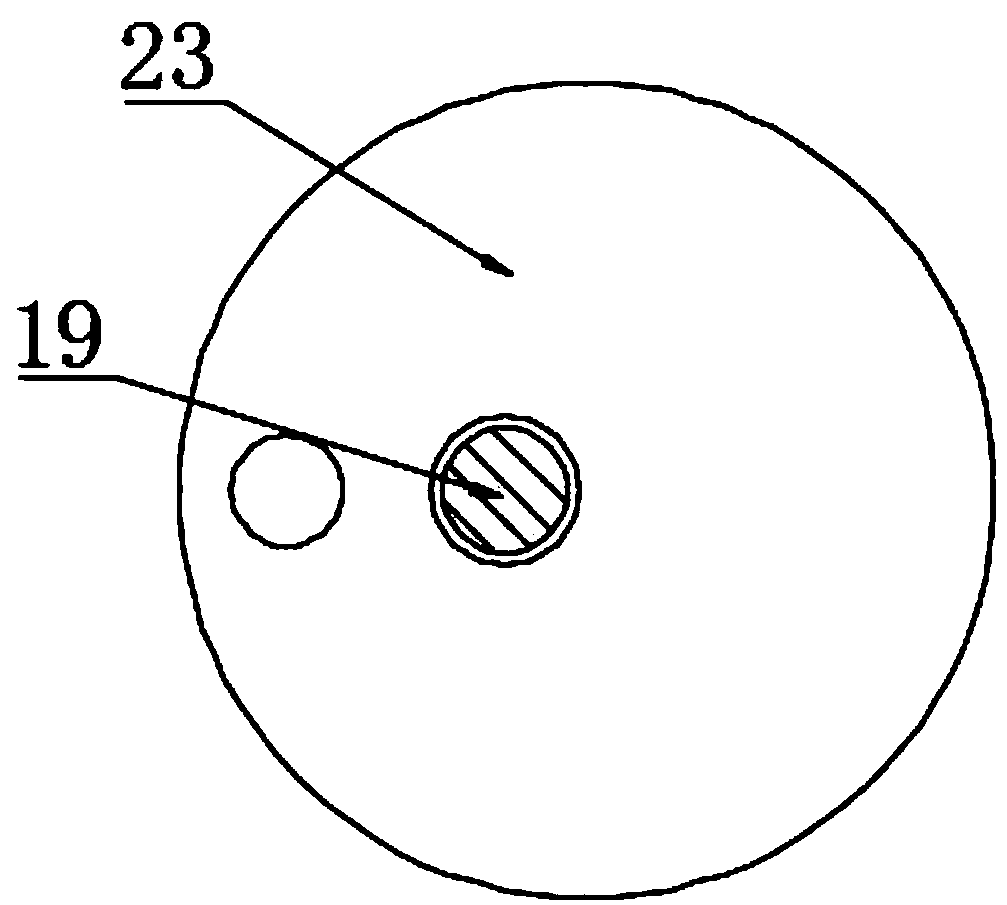

Remediation device for arsenic-contaminated soil

ActiveCN108212284AImprove crushing efficiencySolve pollutionTransportation and packagingRotary stirring mixersGear wheelDrive shaft

The invention discloses a remediation device for arsenic-contaminated soil. According to the remediation device, tooth parts of semi-conical gears mesh with a first cone gear, a storage box is arranged at the upper end of the left side of a device body, the lower end of the first cone gear is fixedly connected to the upper end of a screw rod, the screw rod is connected to the upper end of the device body in a rotating mode through a bearing, the lower end of the screw rod I is connected to a sleeve in a threaded mode, the two sides of the sleeve are connected to guide grooves in a sliding mode, the guide grooves are fixedly connected to the side wall of the storage box, the lower end of the sleeve is fixedly connected to a compression roller, the bottom of the storage box communicates witha material guide pipe, the right side of a driving shaft is fixedly connected to a second cone gear, and the second cone gear meshes with a third cone gear. The remediation device has the advantagesthat the first cone gear is driven to rotate forward and reversely in a reciprocating mode through the toothed parts of the semi-conical gears so as to drive the screw rod to rotate forward and reversely, the screw rod drives the sleeve to move up and down in a reciprocating mode along the guide grooves under the action of threads so as to drive the compression roller to move up and down, the compression roller which moves up and down in a reciprocating mode drives a plug column to block the material guide pipe in a reciprocating mode so as to realize intermittent feeding, and meanwhile, the compression roller which moves up and down crushes soil blocks at the bottom of the storage box.

Owner:黄石市环境投资有限责任公司

Stator and rotor for an electric machine

InactiveCN104272559AMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineCore component

Owner:HOGANAS AB

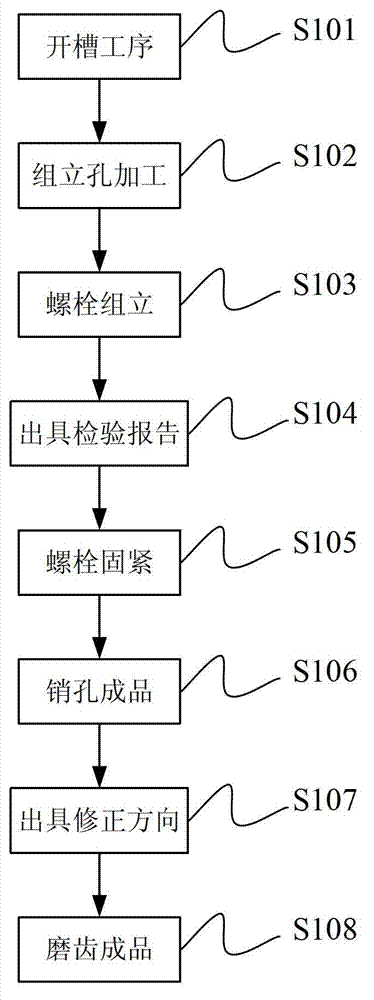

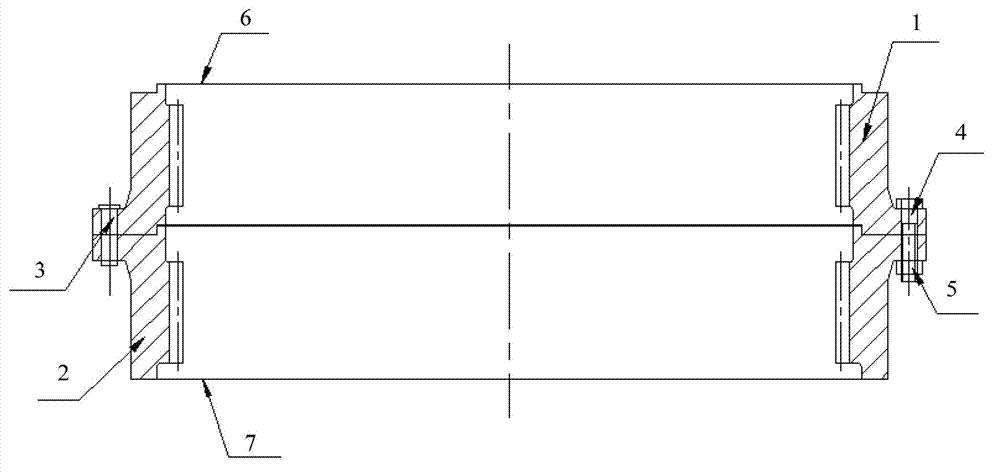

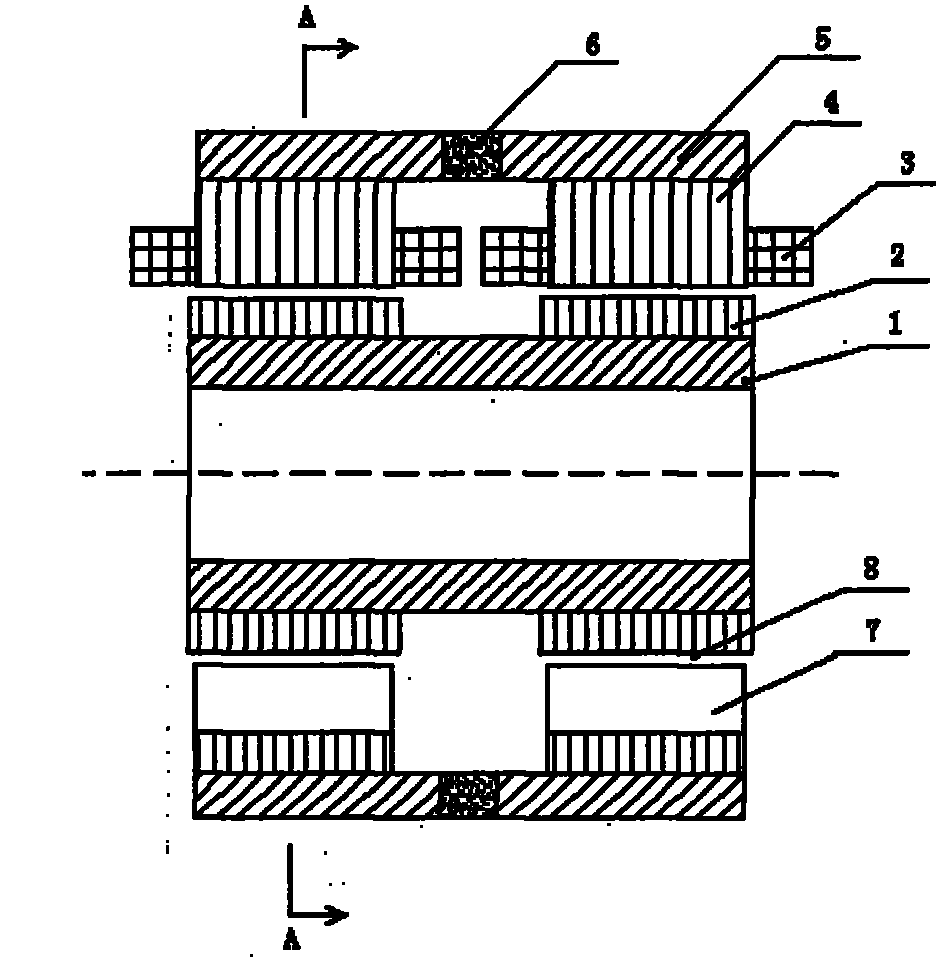

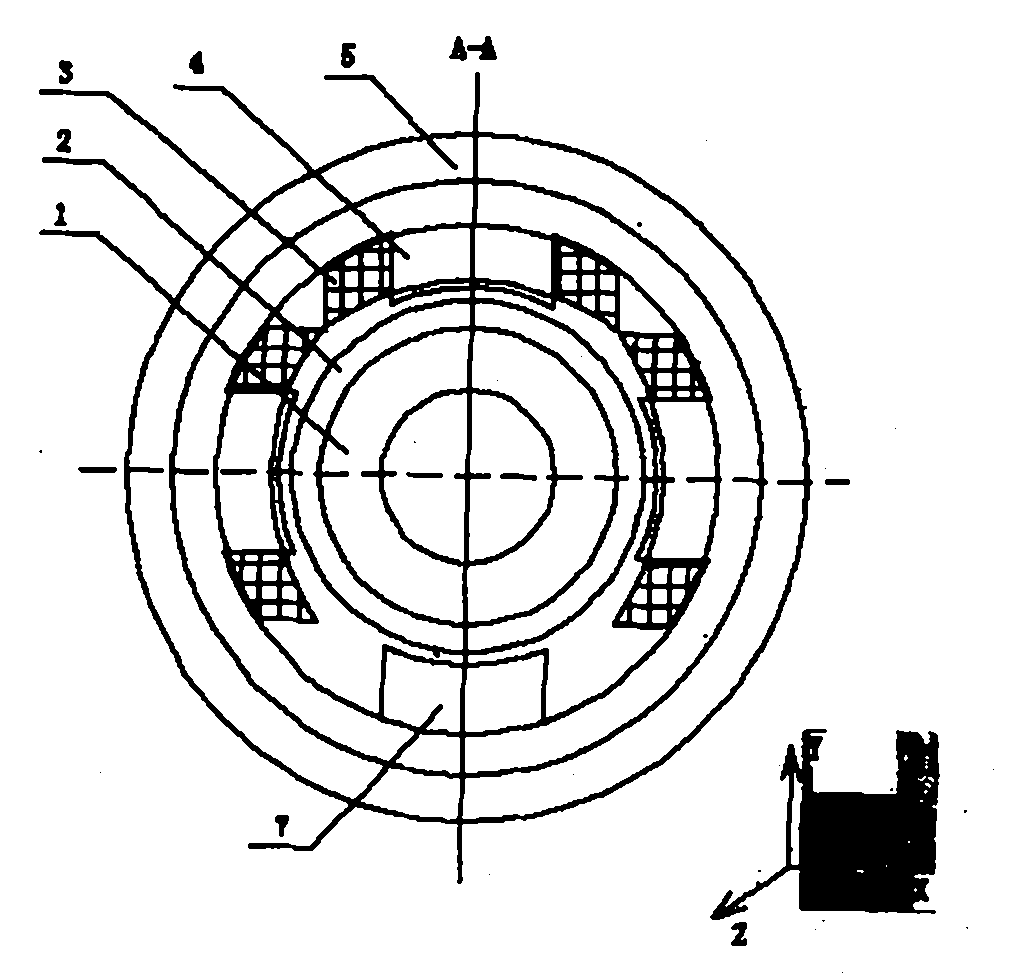

Method for machining combined herringbone tooth part

The invention discloses a method for machining a combined herringbone tooth part. The method includes the steps of machining slots of two helical tooth part and machining an assembly hole on a first helical tooth part; aligning centering errors of the herringbone tooth and machining several assembly holes evenly distributed on a second helical tooth part; aligning centering errors of the herringbone tooth and performing assembly; re-inspecting the centering errors of the herringbone tooth and issuing a centering inspection report; aligning the pitch circle run-out according to the centering inspection report and fastening the pitch circle run-out through a bolt after centering of the herringbone tooth; finishing pinholes on the two helical tooth parts and drilling assembly holes left on the second helical tooth part; re-inspecting the centering errors of the herringbone tooth and providing a correction direction of one of the two helical tooth parts; and decomposing the two helical tooth parts and grinding teeth according to the correction direction to obtain the finished product. According to the method, through three times of alignment of the herringbone tooth centering, two times of error re-inspection of the herringbone tooth centering, tooth grinding, slotting, matching, assembly hole drilling and tooth grinding, drawing design requirements are met.

Owner:CHONGQING GEARBOX

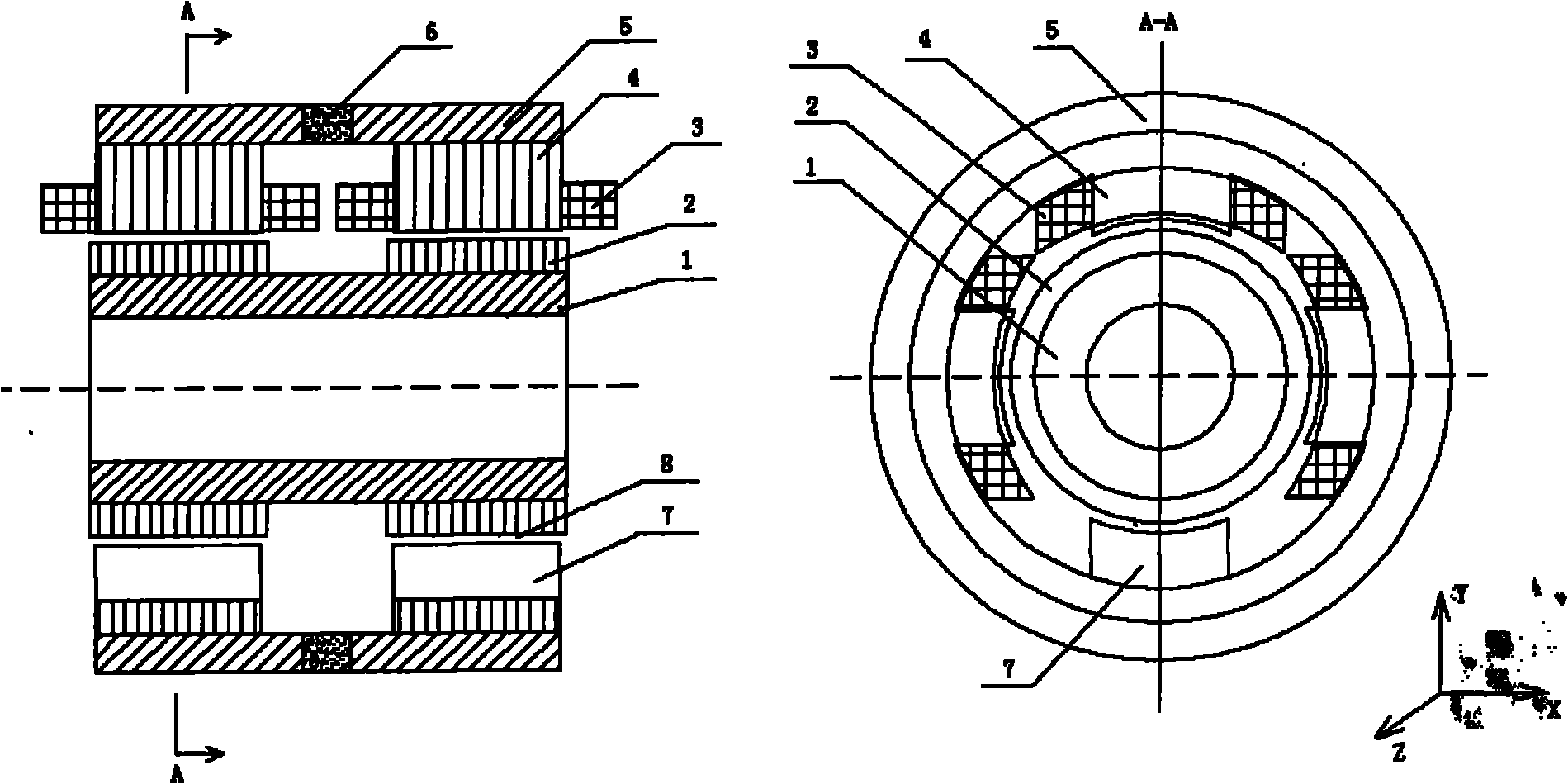

Low-power consumption large-bearing capacity permanent-magnet bias mixed radial magnetic bearing

The invention discloses a low-power consumption large-bearing capacity permanent-magnet bias mixed radial magnetic bearing, which is characterized by comprising a stator and a rotor. The stator core is of an asymmetric structure and comprises asymmetric stator magnetic poles; the stator is provided with 8 stator teeth which are distributed at the left and right ends to form stator tooth parts in the positive and negative directions of an X axis and a Y axis respectively; the stator teeth in the negative direction of the Y axis at each end are made from non-magnetic conductive material, and other stator teeth are made from magnetic conductive material; thus, the permanent magnetic circuit is only closed by the magnetic poles in the + / -X and +Y directions; the outer surface of the stator core consists of two magnetic conductive rings; and the permanent magnet is clamped between the two magnetic conductive rings along the axial direction. Through the invention, the permanent magnetic circuit is not symmetric, and only a +Y magnetic pole is magnetic conductive in the Y direction, when the bearing capacity is provided in the Y direction, the attractive force of the stator teeth in the -Y direction to the rotor is zero, so the stator teeth in the +Y direction do not need to provide additional force to cancel out the attractive force in the -Y direction; therefore, the coil current in the Y direction is reduced, the power consumption is reduced, and large bearing capacity can be provided in the Y direction.

Owner:北京奇峰聚能科技有限公司

Technique for processing welded structure cement carbon quenching gear

ActiveCN101407017AAvoid deformationReduce hardnessSolid state diffusion coatingFurnace typesHarmonic vibrationHardness

The invention discloses a process for processing a carburizing and quenching gear with a welding structure. The process is performed according to the following steps: the inner circle, the outer circle and the two end surfaces of a gear ring are processed, a hub and a radial plate are processed, and the margins are kept on the inner hole and the two end surfaces of the hub; the tooth form of the gear ring is coarsely processed, and the margins are kept; the gear ring is carburized, quenched, oil-cooled and low-temperature tempered; the radial plate and the hub are group-welded, and the gear ring and the radial plate are group-welded on a rotary work table of an automatic welding machine, the gear ring is pre-heated before welding, in the turning process when the gear ring is pre-heated and welded, the tooth part is cooled by cooling fluid through a cooling device, so that the temperature of the tooth part is below 200 DEG C; the ultrasonic crack detection of the welding seam is preformed; the stress is eliminated by the spectral harmonic vibration; and the precision machined step is performed. The process can ensure the hardness and the performance of the tooth surface of the gear as well as the quality of the welding seam after the gear ring is carburized and quenched, thereby solving the problem of the crack of the welding seam; moreover, by adopting the vibration stress eliminating process to eliminate the welding stress, the environment is protected, and the energy consumption is greatly lowered.

Owner:CHONGQING GEARBOX

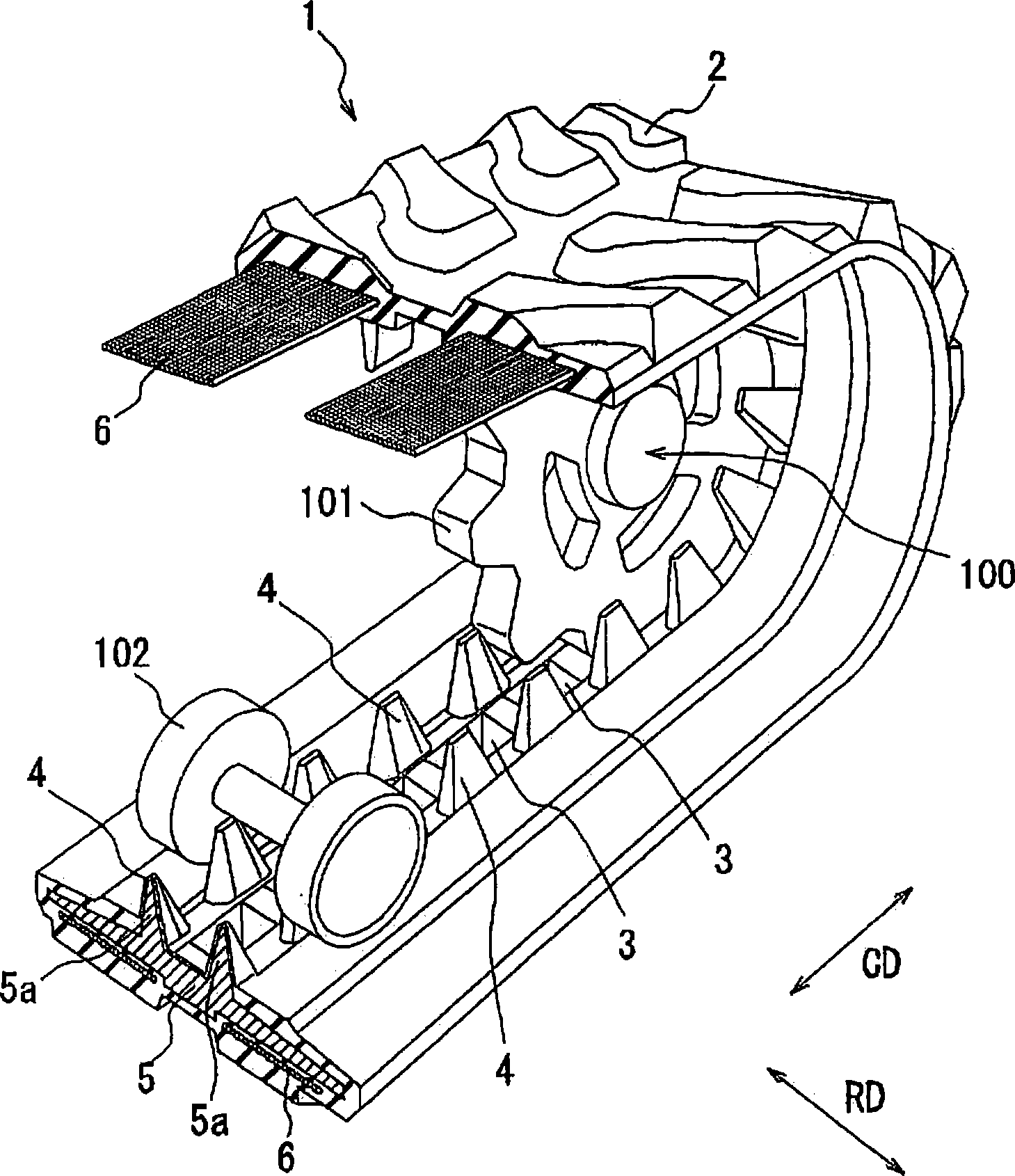

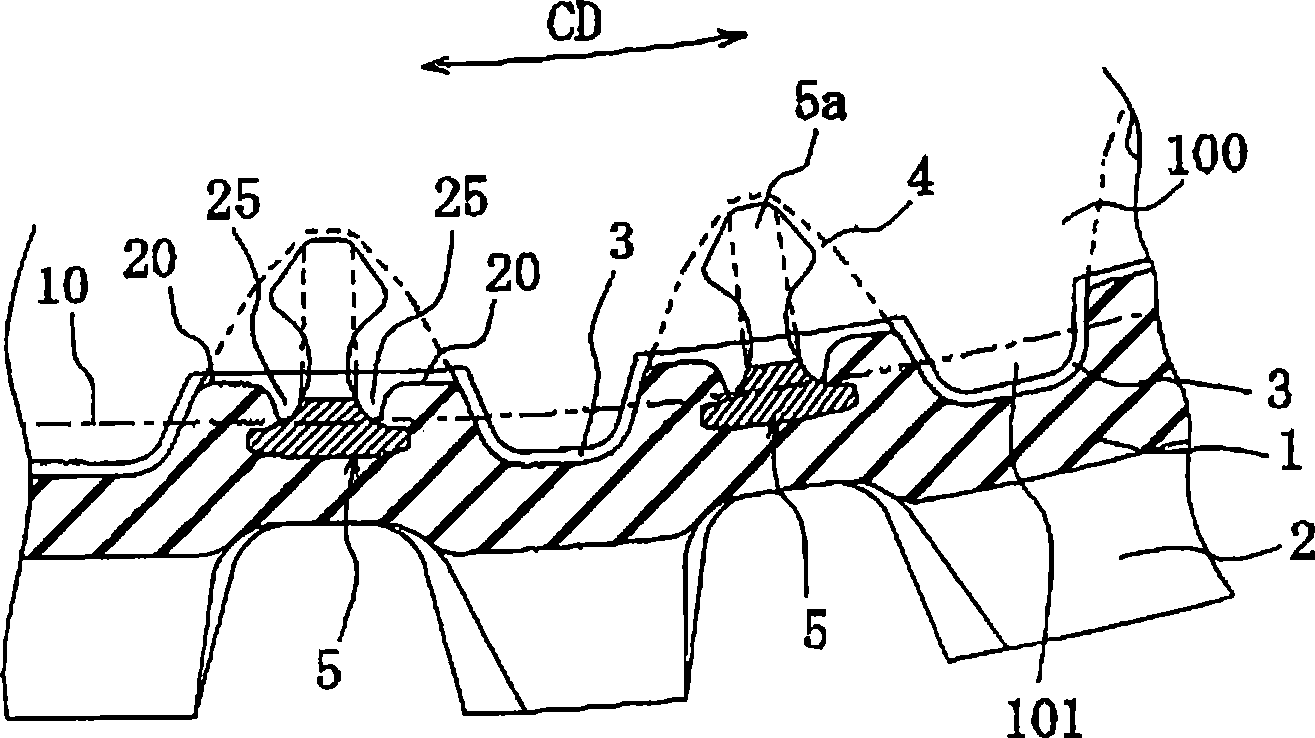

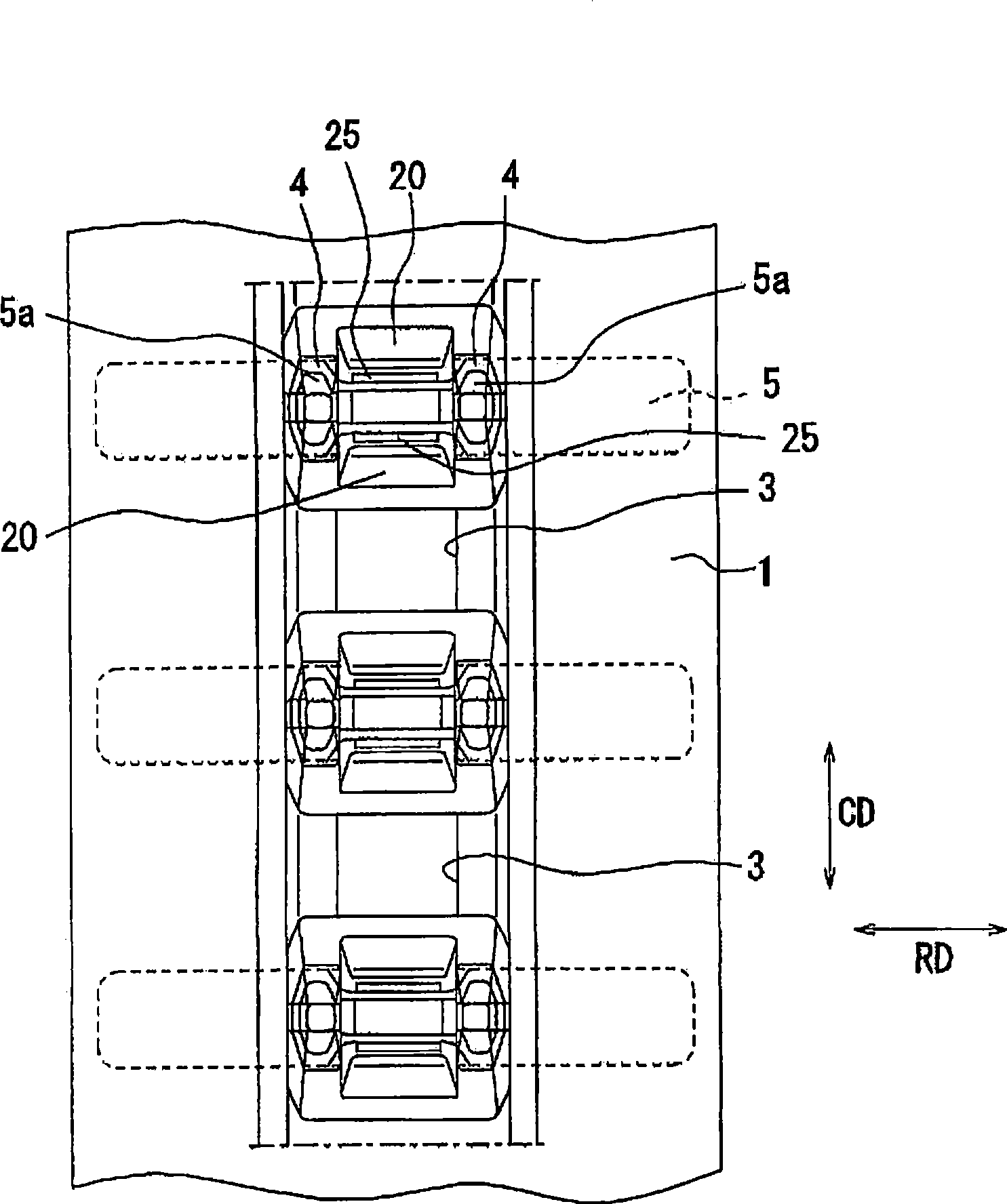

Rubber track and chain wheel suitable for rubber track and core iron for rubber track

The invention provides a rubber track, a chain wheel suitable for the rubber track, and a core rod for the rubber track. The outer peripheral face of the rubber track (1) is provided with a projecting part (2), and the inner peripheral face is provided with a driving clamping part for transferring a driving force which is transferred through clamping of the chain wheel (100) and the driving clamping part, wherein the driving clamping part comprises hard clamping components (5) embedded in the circumferential direction of the rubber track by a certain pitch, and a concave part (3) arranged among the clamping components (5) to receive a tooth part of the chain wheel. According to the rubber track, the tooth part of the chain wheel is clamped with the concave part between the hard clamping components; therefore, compared with the prior condition that the tooth part is abutted with a driving protrusion projecting on the inner peripheral face, damage can be inhibited. Moreover, the shape of the concave part is properly changed to increase the area blocking with the tooth part, so as to reduce surface pressure.

Owner:BRIDGESTONE CORP

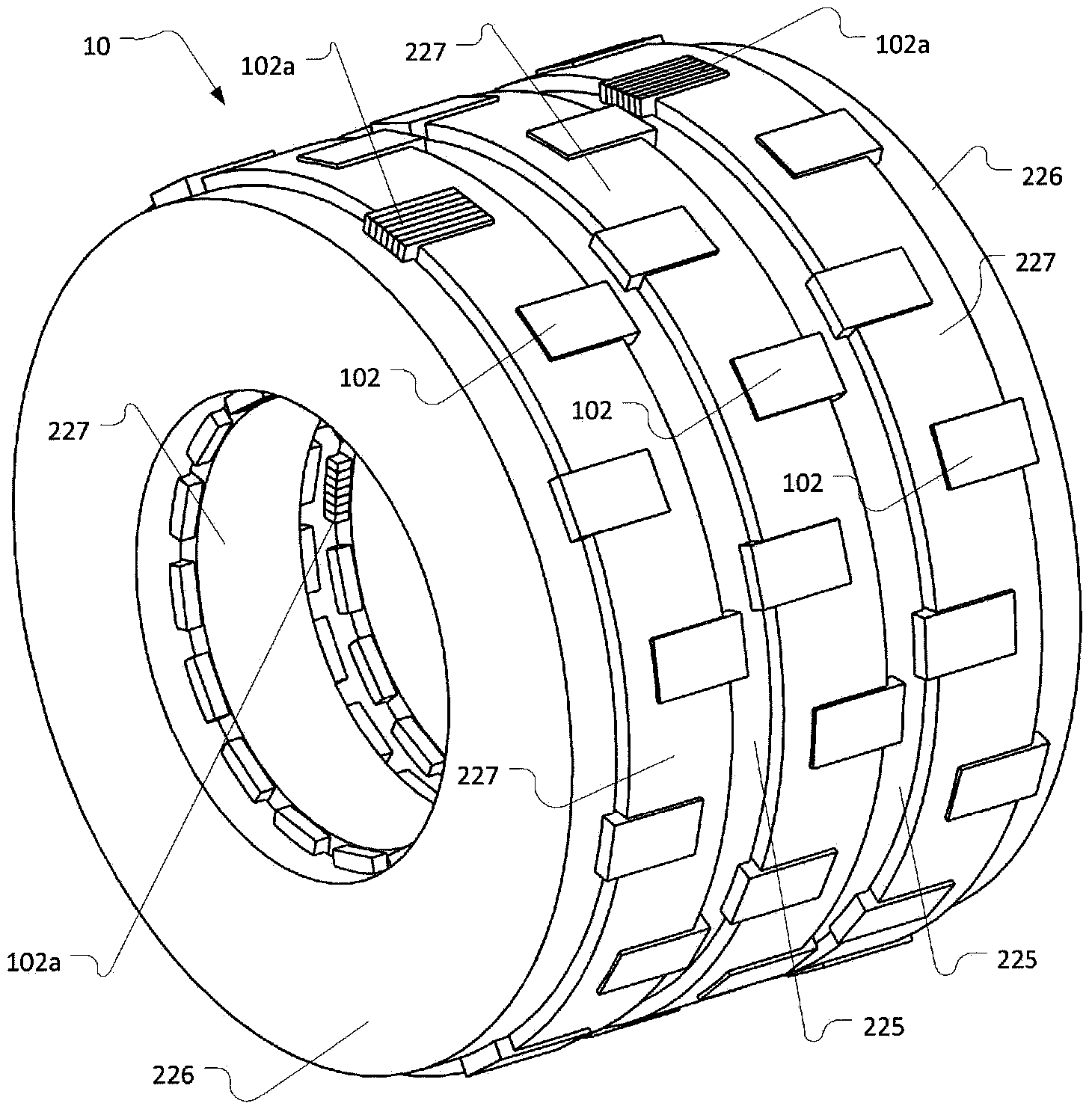

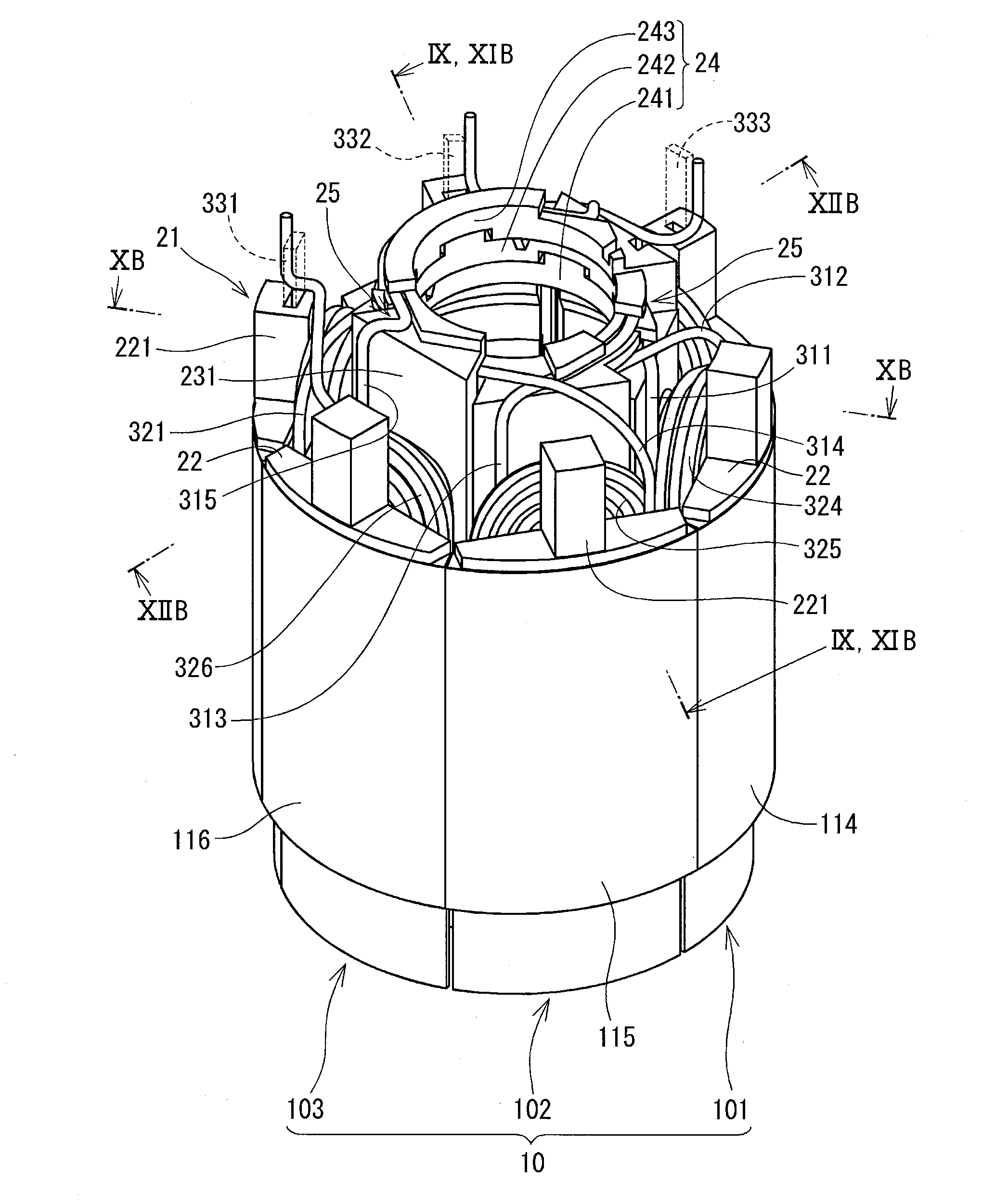

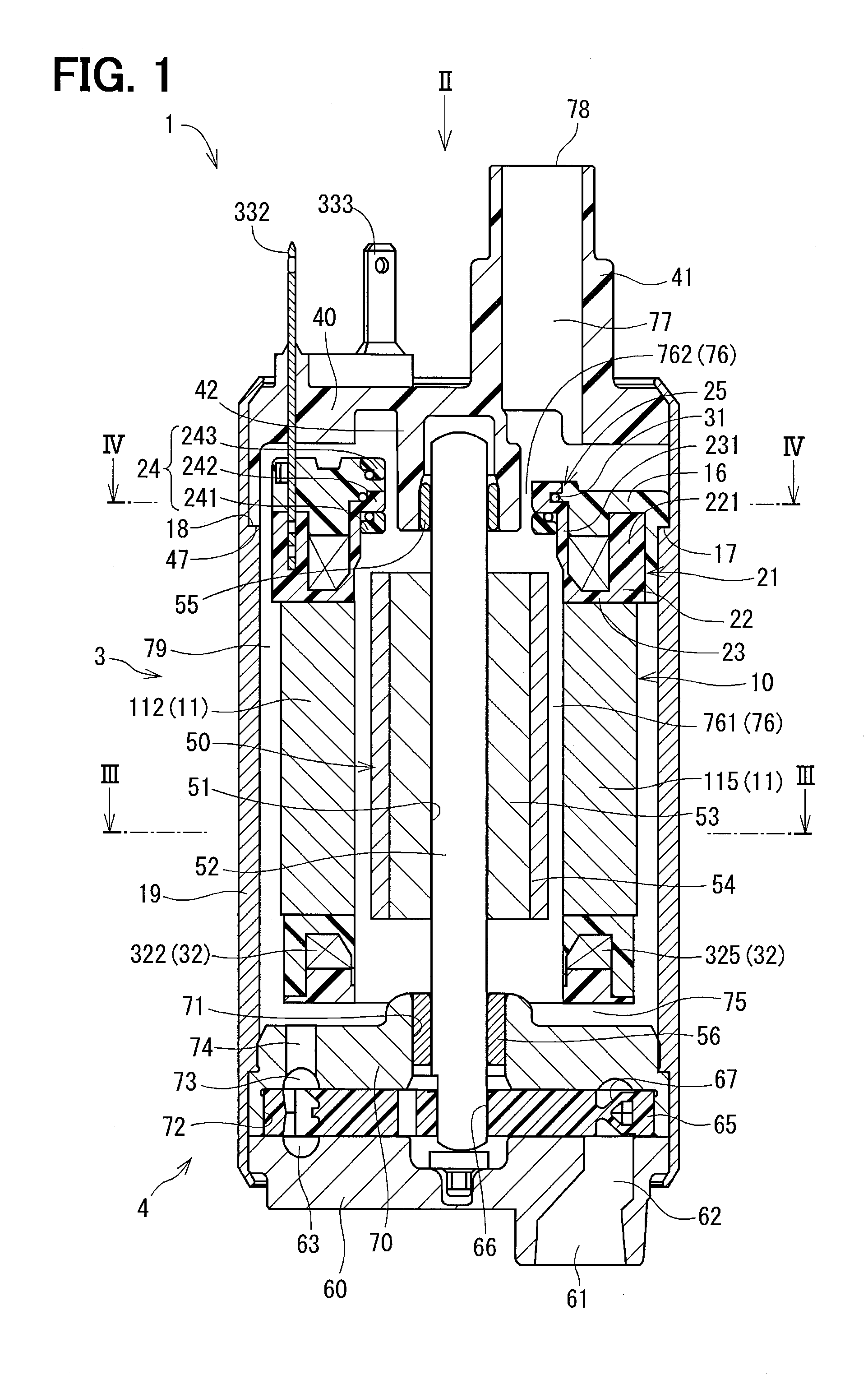

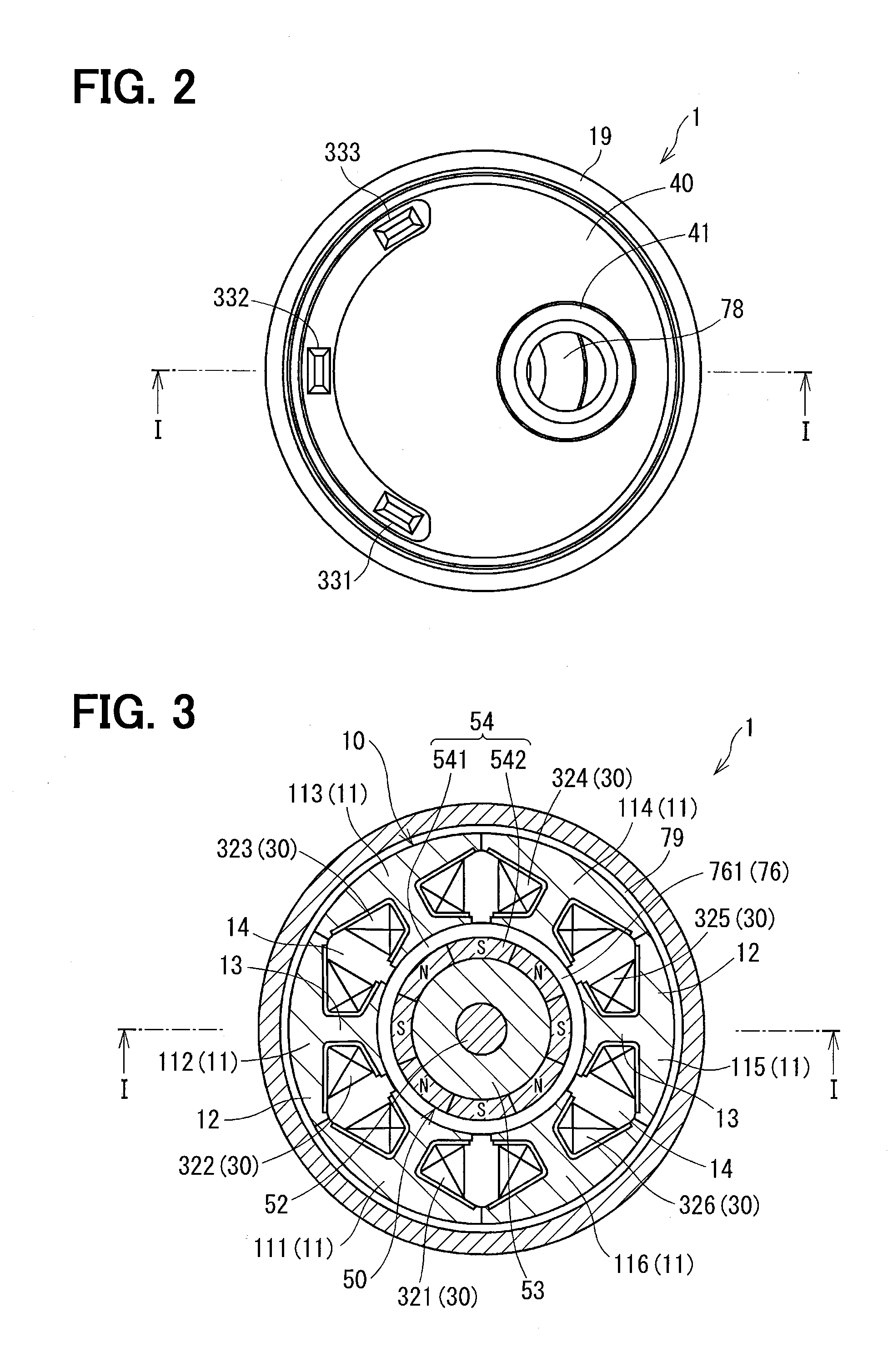

Brushless motor

ActiveUS20130162098A1Windings insulation shape/form/constructionSupports/enclosures/casingsBrushless motorsEngineering

A motor part of a fuel pump is a brushless motor having a stator and a rotor. The stator has a core, a coil set and an insulator, which holds the core and the coil set in an insulated manner. The coil set has a plurality of coils wound about a tooth part and a plurality of crossing wires connecting the coils. The insulator is formed by stacking central ring parts of a plurality of stator units in an axial direction. At least one of crossing wire holder parts is formed of a combination of guide projections, which are formed on the different central ring parts. The length of the brushless motor in the axial direction can thus be shortened.

Owner:AISAN IND CO LTD

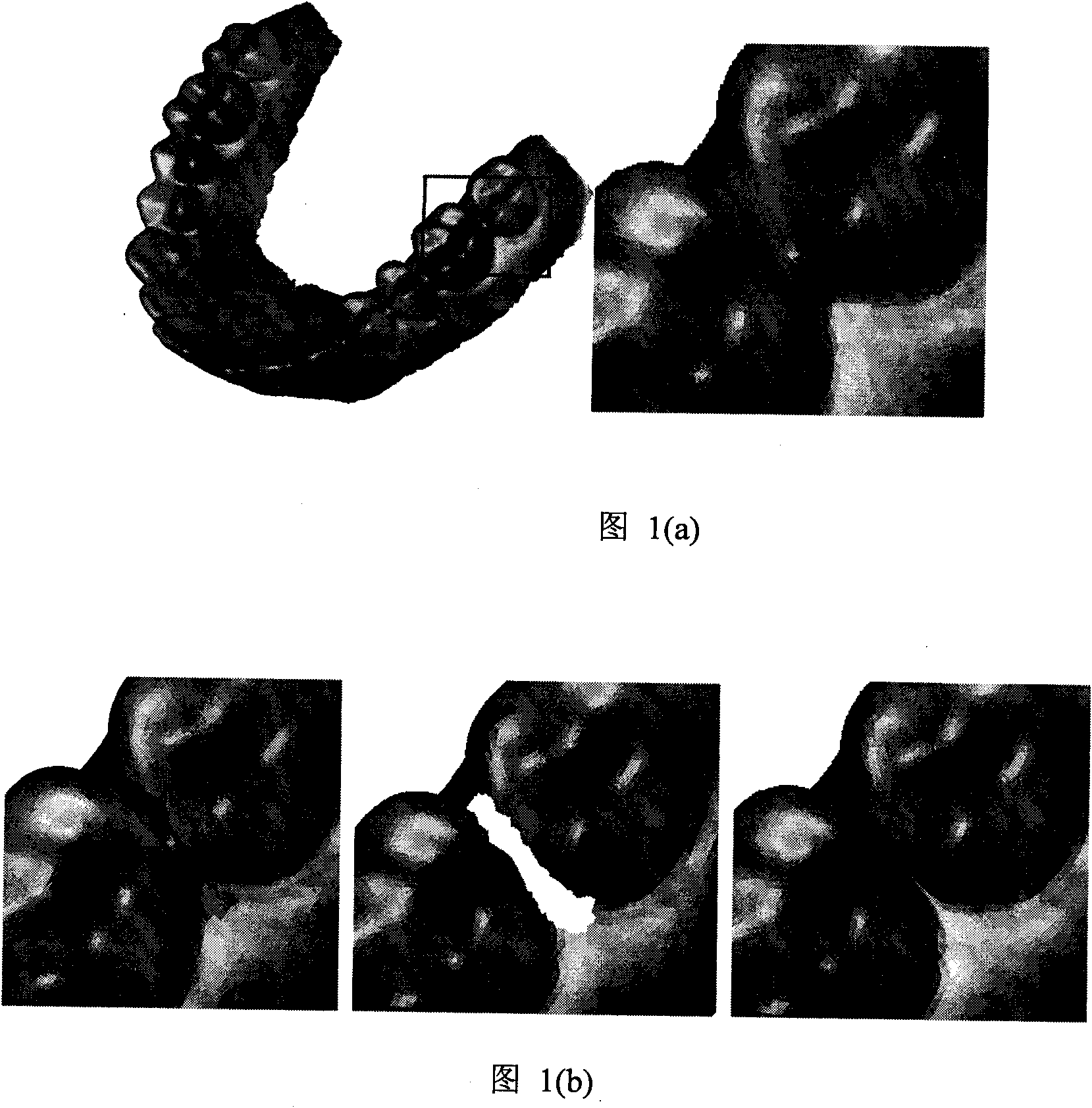

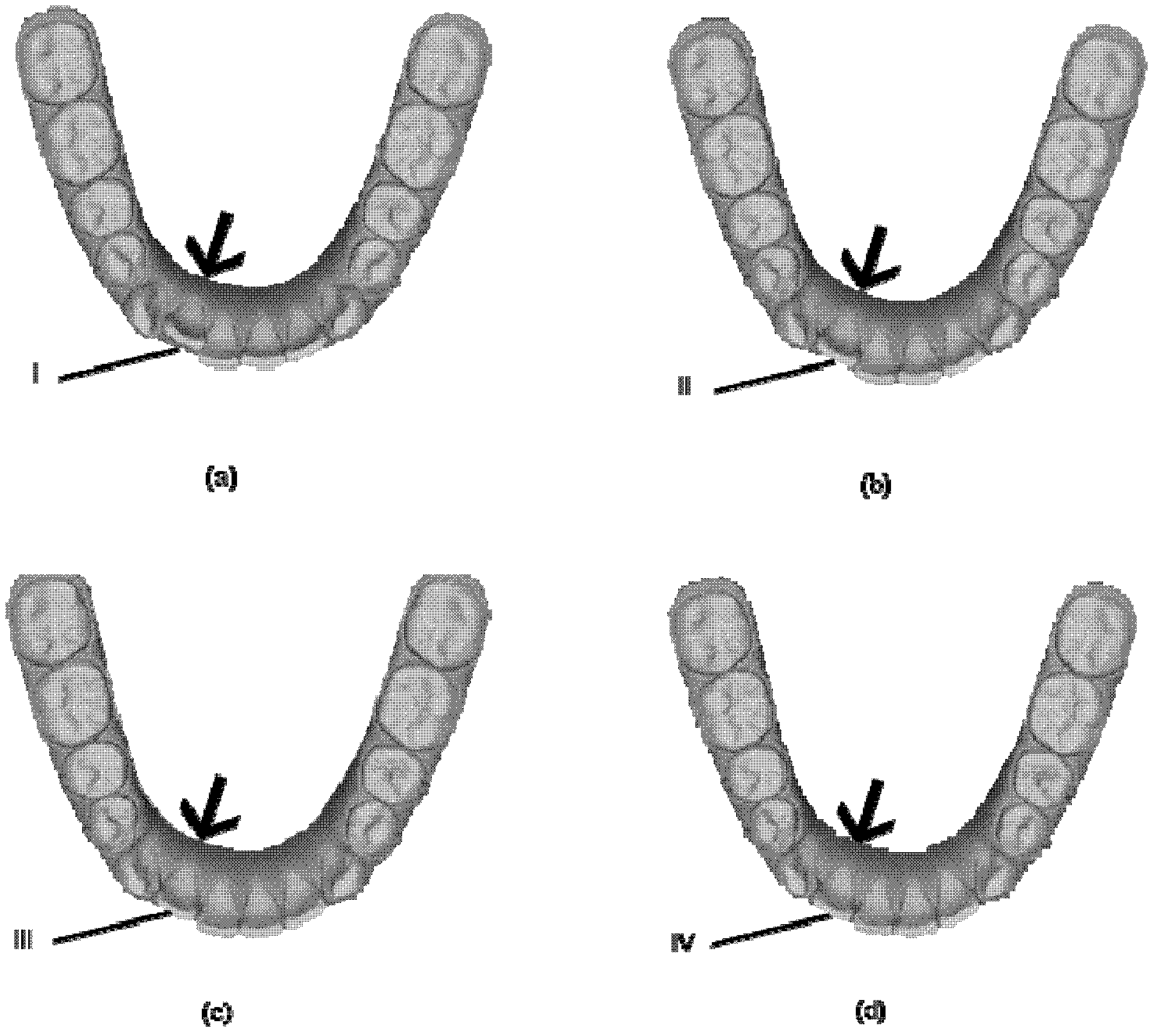

Method for accurately recovering single tooth form on three-dimensional tooth-mandible model

InactiveCN101604354APromote recoveryAutomatic recoverySpecial data processing applicationsComputer-aidedComputer aid

The invention discloses a method for accurately recovering a single tooth form on a three-dimensional tooth-mandible model, and belongs to the field of computer-aided biomedical engineering. The method mainly comprises the following steps: (1) identifying and deleting a fusion part between teeth; and (2) according to hole boundary information generated after deleting the fusion part, constructing a curved surface sheet which accords with a practical spatial position relation between the teeth and can synchronously reflect local characteristics of corresponding tooth parts. The method of the invention only comprises simple human-computer interaction operation, has high automation degree, mainly carries out linear computation, can quickly, stably and accurately recover the form of a deletion part of the single tooth on the three-dimensional tooth-mandible model, and has important application value in the field of computer-aided oral orthodontics.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

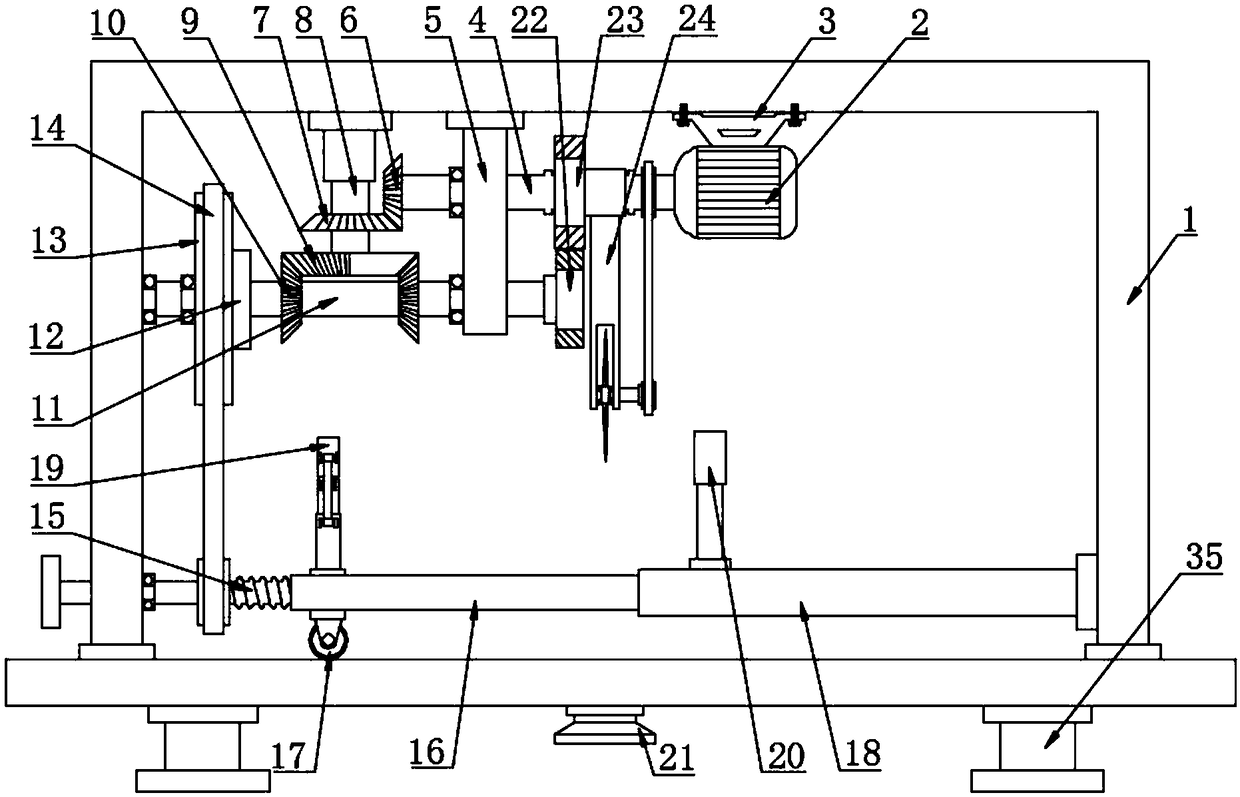

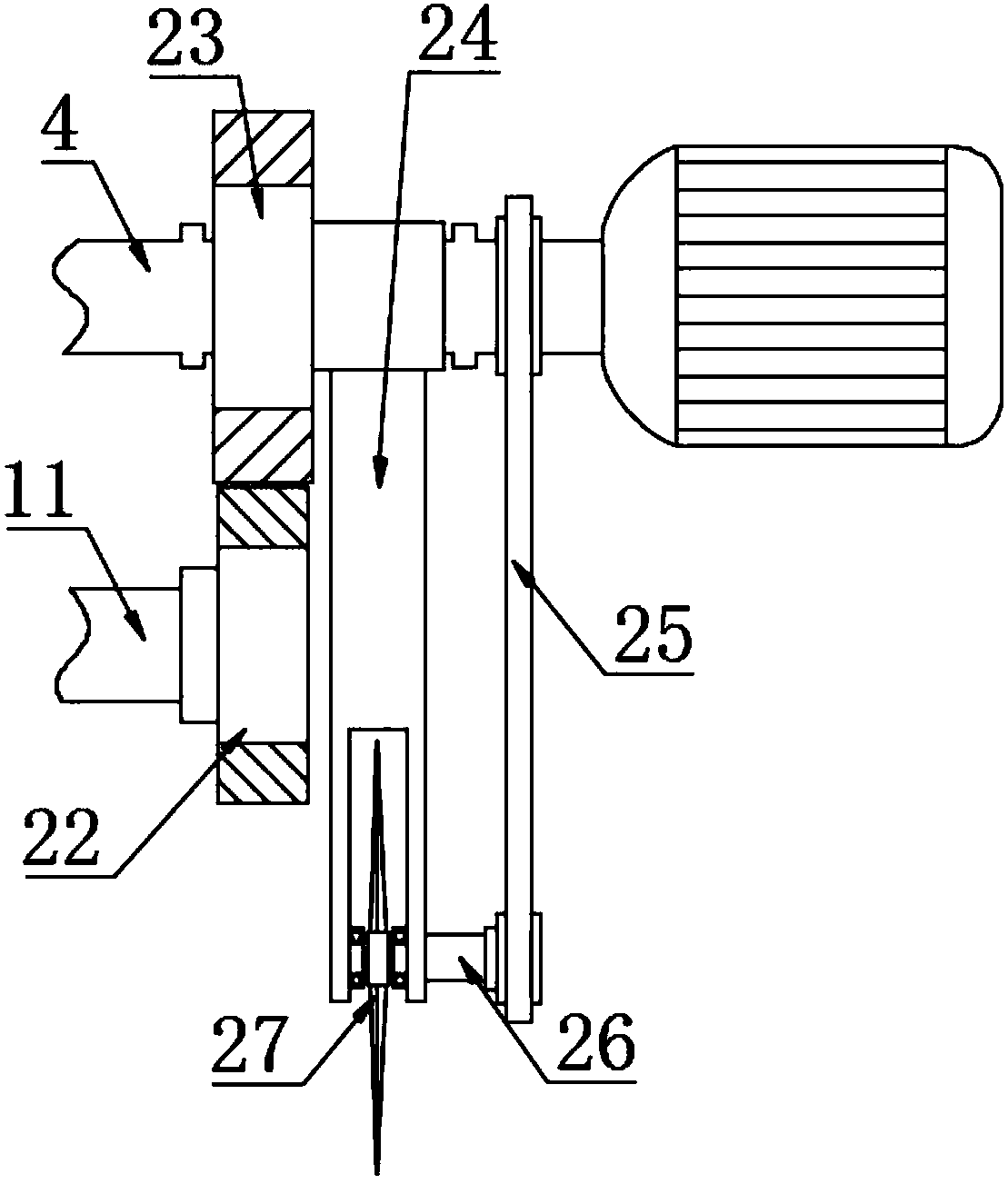

Swinging steel pipe equidistance cutting device

ActiveCN108581025AAchieve equidistant cutting effectAchieve intermittent feed functionTube shearing machinesShearing machine accessoriesPipe fittingDrive shaft

The invention discloses a swinging steel pipe equidistance cutting device. The left end of a driving shaft is fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the second bevel gear is fixedly connected with the middle part of a driven shaft; the lower end of the driven shaft is fixedly connected with a semi-bevel gear; the semi-bevel gear is provided with teeth on one half and no tooth on the other half; third bevel gears are arranged on the two sides below the semi-bevel gear, and are fixedly connected with rotating shafts; the tooth part ofthe semi-bevel gear is engaged with the third bevel gears; the right ends of the rotating shafts are fixedly connected with small gears; the small gears are engaged with large gears; the right sidesof the large gears are fixedly connected with the upper ends of swing rods; and cutting blades are arranged at the middle parts of the lower ends of the swing rods. The device uses the small gears fordriving the swing rods to swing back and forth; when the swing rods swing, a first transmission belt drives the cutting blades to rotationally cut to realize swing cutting; and a fixed disc and a ratchet are used for realizing intermittent one-way rotation of a lead screw to achieve intermittent feeding function of pipes so as to finally achieve equidistance cutting effect of pipe fittings.

Owner:无锡市幸昌热能设备有限公司

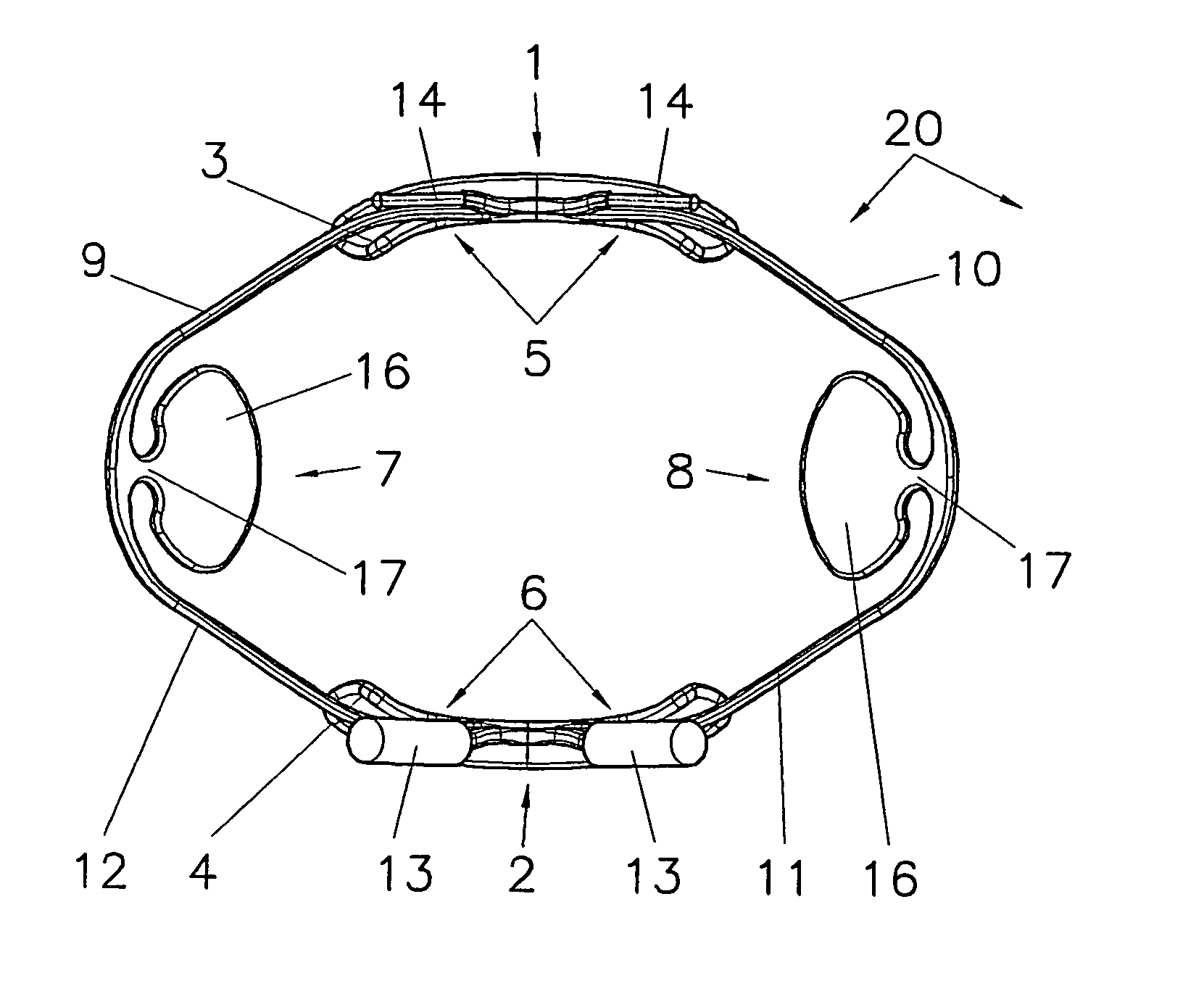

Cheek and lip retractor for dentistry

The cheek and lip retractor for dentistry comprises respective cheek portions and lip portions for the upper and lower lip, the lip portions comprising a lip shield and mucous pads which are separate and spaced apart from the lip shield, the cheek portions and lip portions being connected to each other by flexible connecting elements, and the connecting elements being disposed between the lip shield and the mucous pad. Such a retractor allows a largely free treatment of the tooth portions to be treated and provides a comfortable fit for the patient.

Owner:KERRHAWE

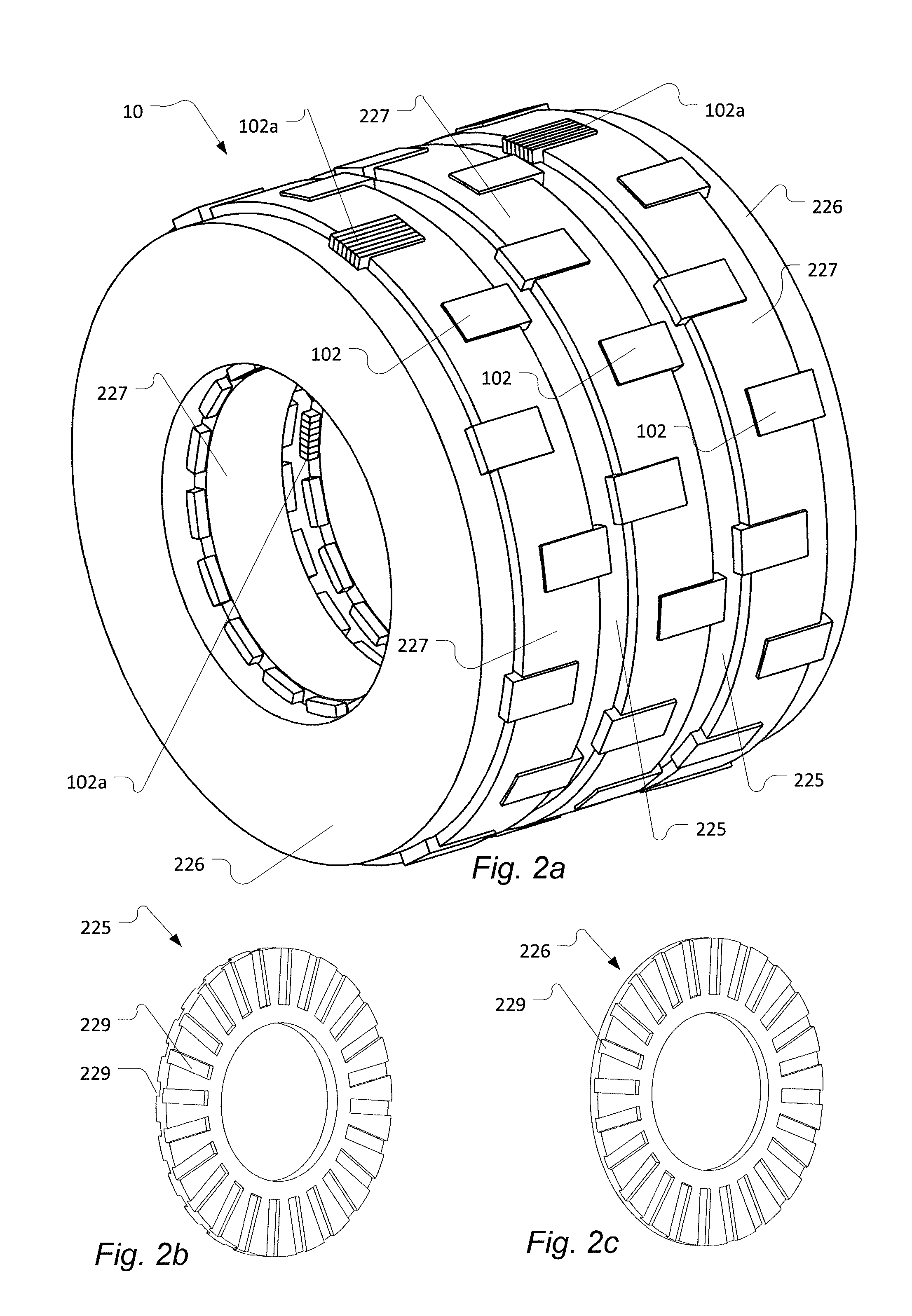

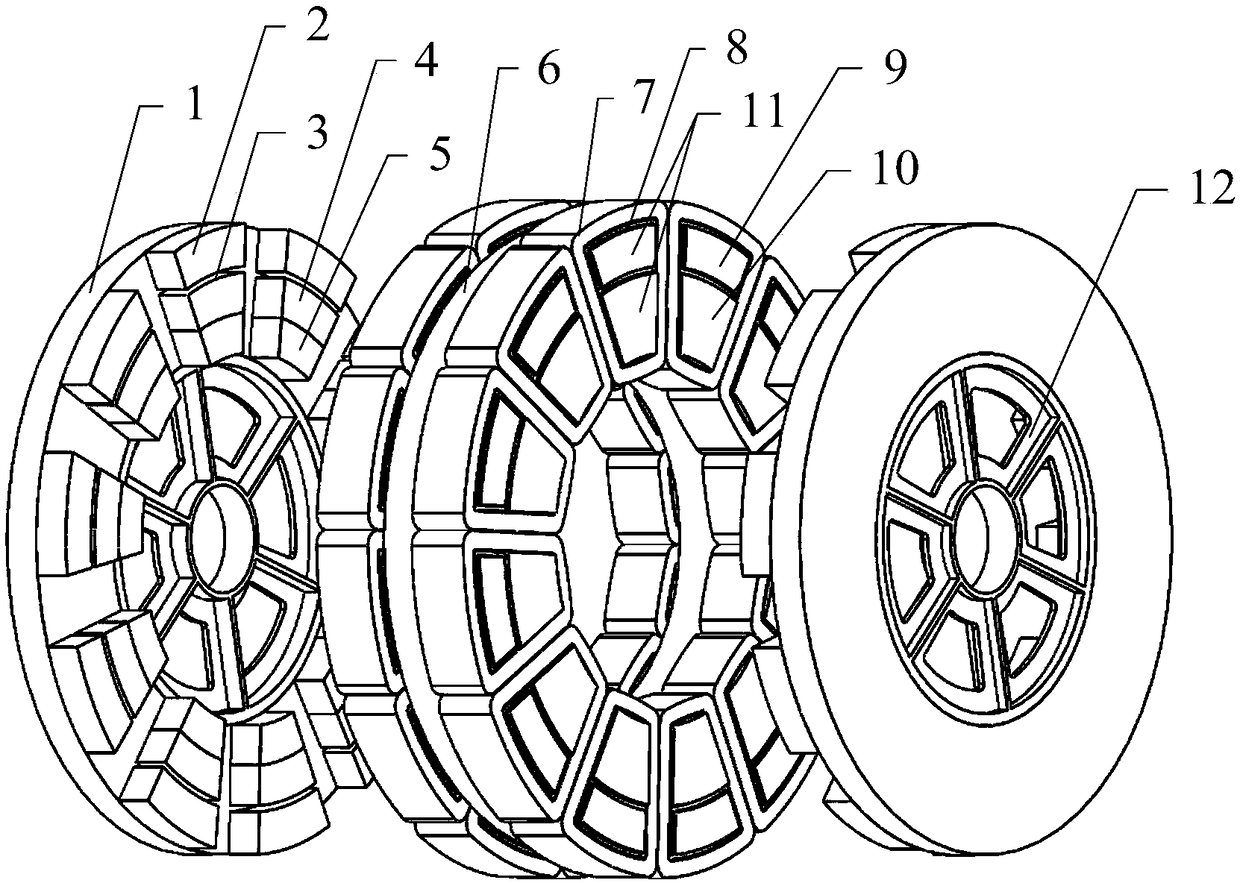

Stator and rotor for an electric machine

InactiveUS20150048708A1Robust constructionEasy constructionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineCore component

A stator for an electric machine, the stator including a stator core and a winding. The stator core including an annular stator core back component providing a magnetic flux path in a circumferential direction and in an axial direction of the annular stator core back component; and a plurality of stator pole components each including a mounting part mounted to the stator core back component, an interface part defining an interface surface facing an active air gap between the stator and a rotor of the electrical machine; and a radially oriented tooth part extending radially from the annular stator core component and connecting the interface part with the mounting part.

Owner:HOGANAS AB

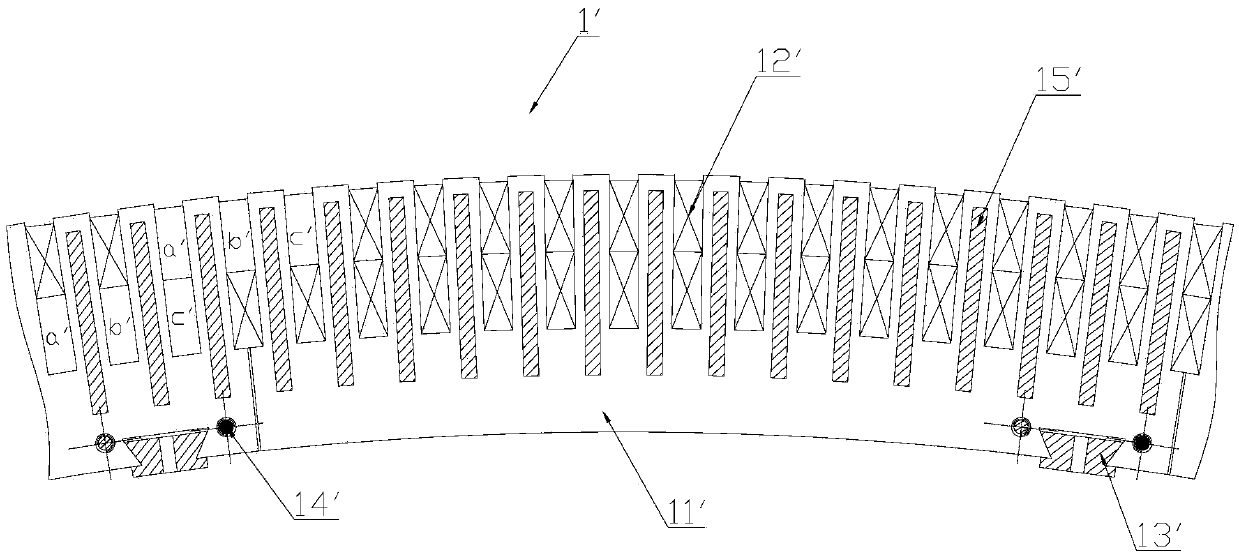

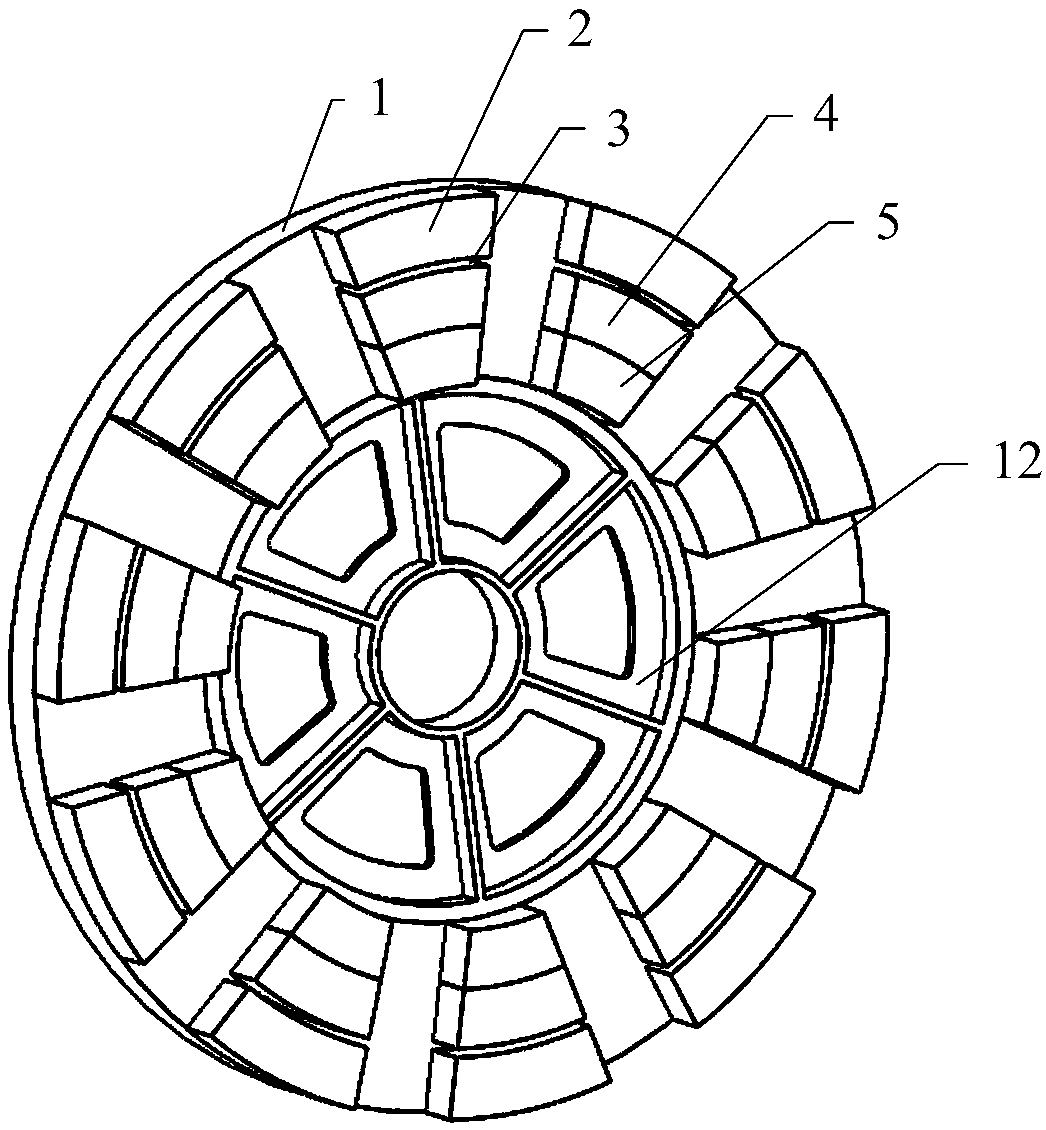

Stator of generator

ActiveCN105515230AEasy to processLow costMagnetic circuit stationary partsWindings conductor shape/form/constructionEngineeringConductor Coil

An embodiment of the invention provides a stator of a generator. The stator of the generator includes a plurality of stator units, each stator unit includes an iron core module and a winding arranged on the iron core module, the iron core module includes a stator iron core which has a yoke part and at least one tooth part fixedly arranged on the yoke part, each tooth part is provided with a winding in one-to-one correspondence, the yoke is provided with grooves along an axial direction of the stator, fixed keys are arranged inside the grooves, and mounting holes are arranged on the fixed keys. The fixed keys at the bottom of the yoke of the stator can realize fixed connection with a support, thereby enabling manufacture to be relatively simple, and effectively reducing cost.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

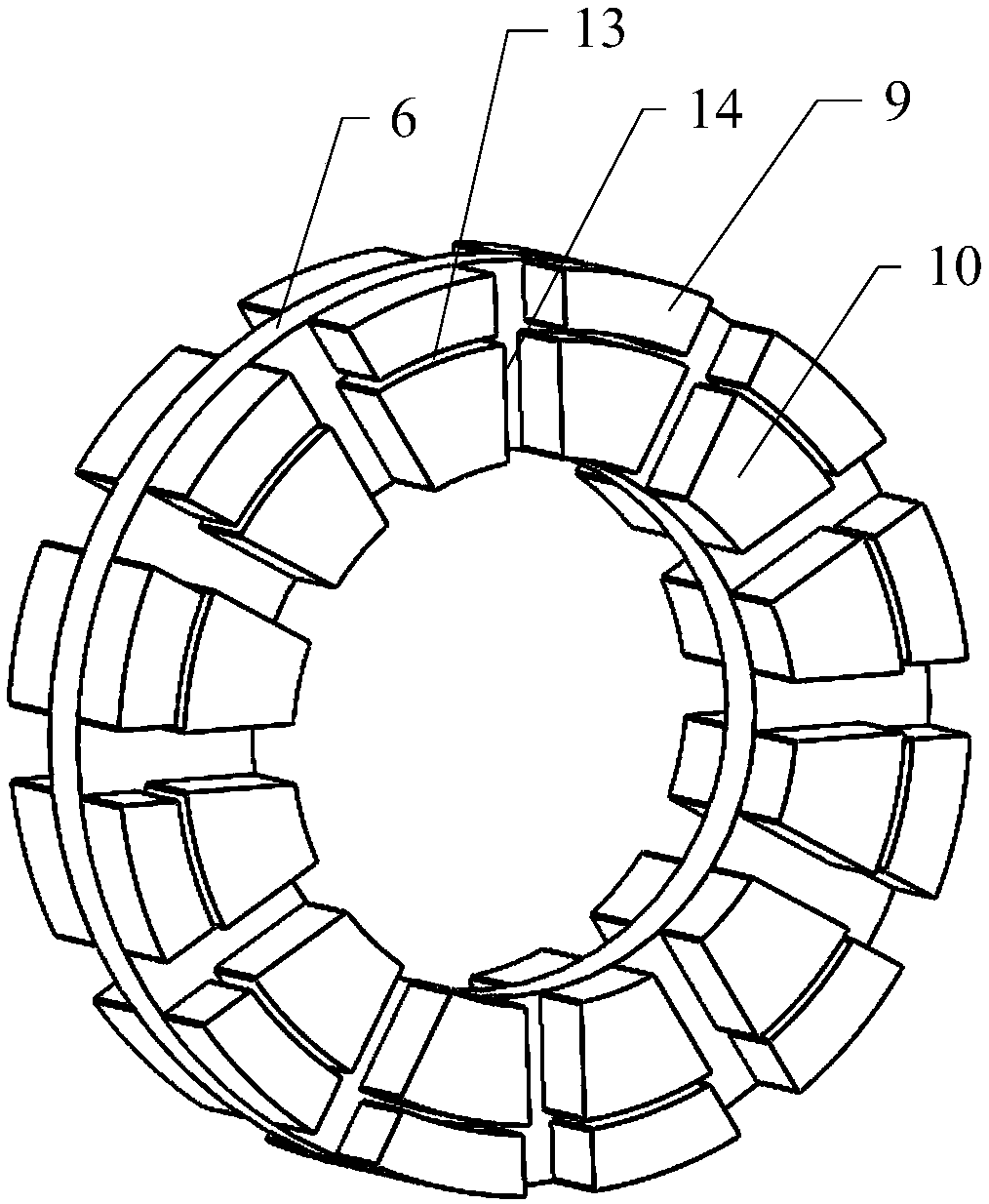

Compound amorphous alloy axial flux motor

ActiveCN109274240AChange sizeHazard of demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesAlloy

A composite amorphous alloy axial flux motor is provided. A plurality of inner tooth portions and an outer tooth portion of the stator are uniformly distributed on the stator yoke portion in the circumferential direction, the stator core is embedded in the housing, A DC excitation win is wound around that outer tooth portion, each outer tooth portion and the inner tooth portion inside of the outertooth portion are integrally wound with an armature winding, The rotor is mounted on a rotating shaft, A permanent magnet and a first soft pole are circumferentially uniformly mounted on a side of the rotor yoke close to the stator, A permanent magnet is in contact with the first soft pole, The permanent magnet and the first soft magnetic pole correspond to the circumferential position of the inner tooth part, the second soft magnetic pole corresponds to the circumferential position of the outer tooth part, the second soft magnetic pole is separated from the permanent magnet in the circumferential direction by a magnetic isolation region, end caps are respectively provided at both ends of the housing, and the rotating shaft of the motor is supported at the center of the end caps by bearings. The permanent magnet and the first soft magnetic pole correspond to the circumferential position of the inner tooth part. The invention not only inherits the characteristics of high power density,high torque density and high efficiency of the axial flux permanent magnet motor, but also has the advantages of smooth and adjustable air gap magnetic field of the electric excitation motor and thelike.

Owner:SHENYANG POLYTECHNIC UNIV

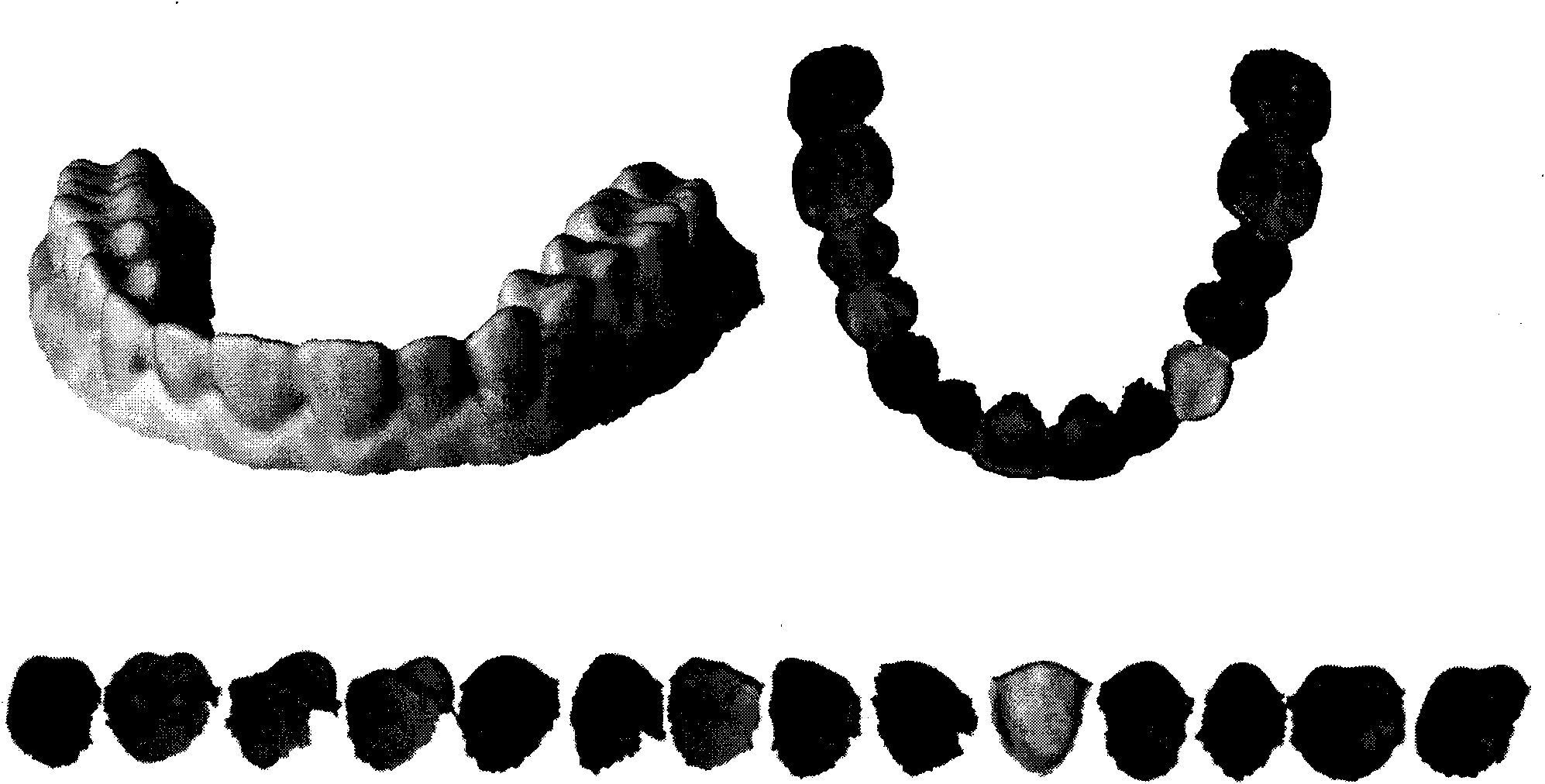

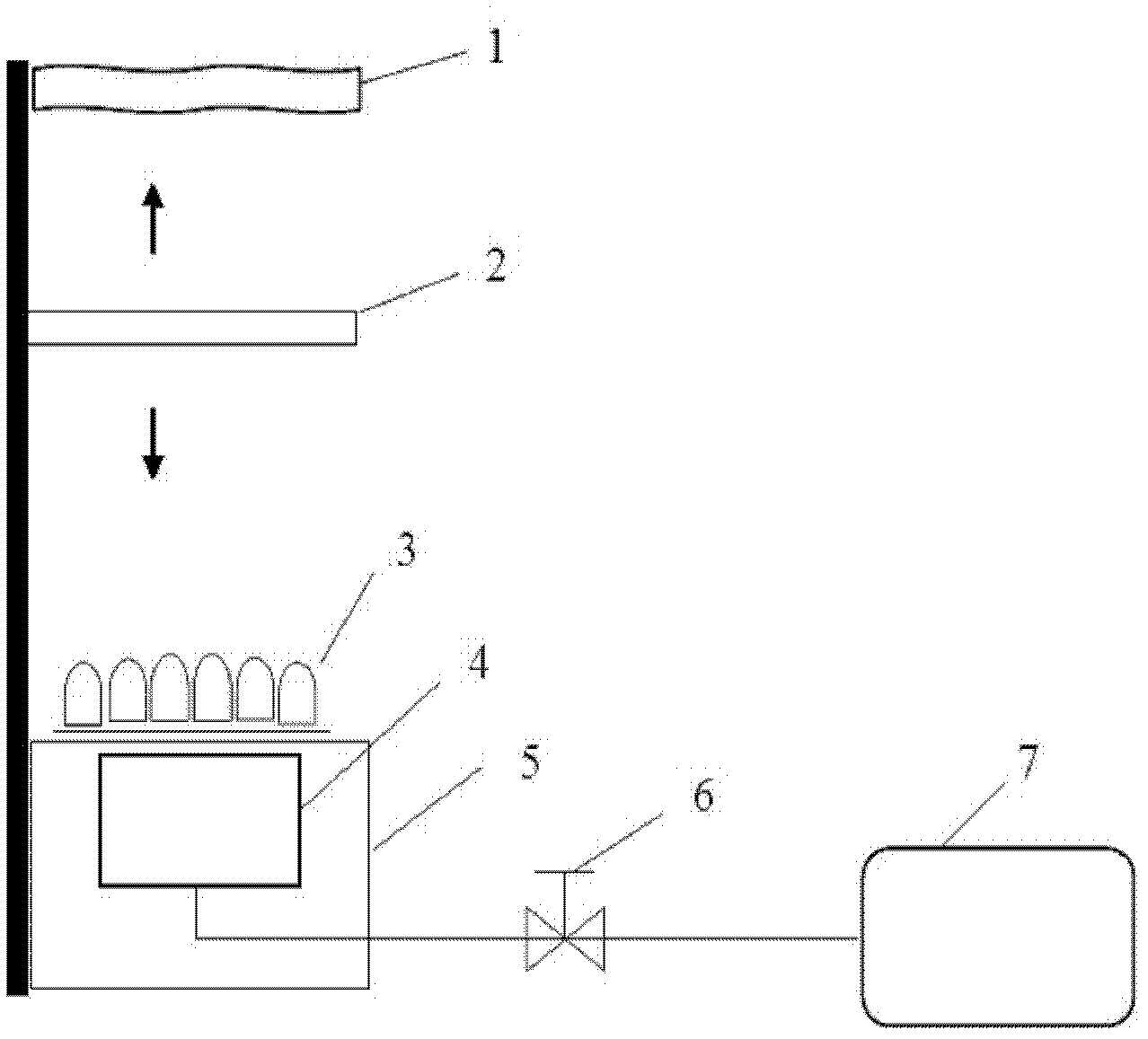

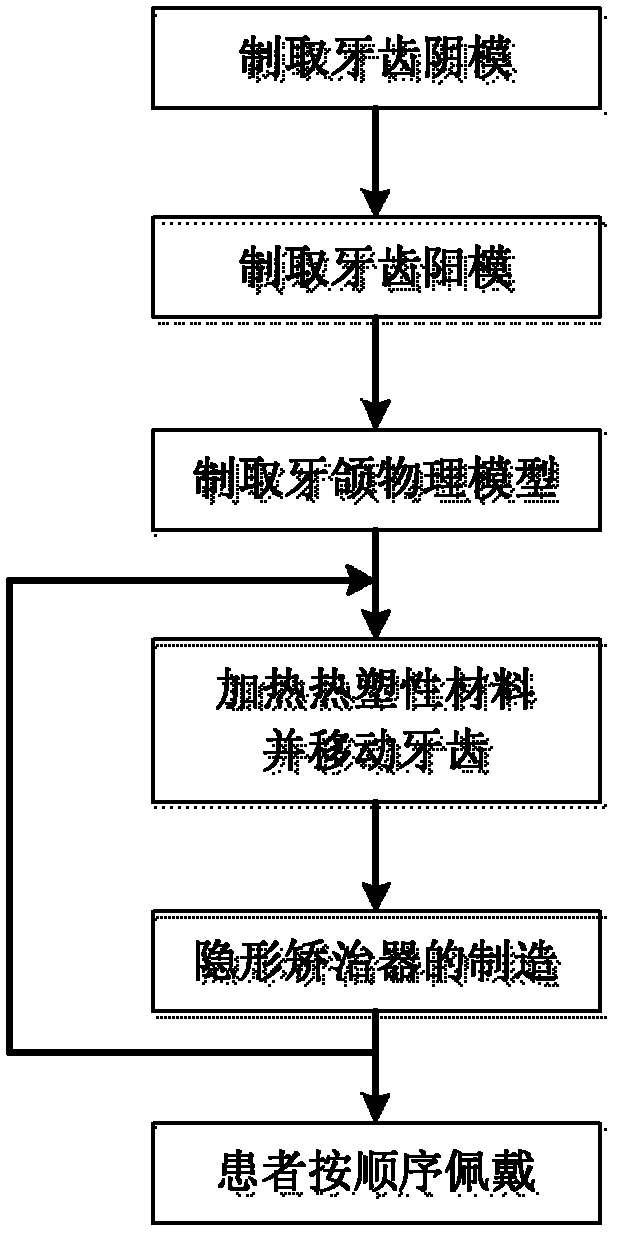

Manufacturing method for invisible orthotic device and product thereof

ActiveCN102512251AMeet manufacturing and processing requirementsEasy to makeOthrodonticsPhysical modelEngineering

The invention discloses a manufacturing method for an invisible orthotic device and a product thereof. The manufacturing method comprises the following steps of: obtaining a tooth female die model of a patient with malformed teeth; filling a thermoplastic material and gypsum on the gypsum to mold teeth to obtain a tooth jaw physical model; heating the thermoplastic material on the tooth part to be corrected in the tooth jaw physical model to be softened, and moving the tooth jaw physical model to a target correcting position; and cooling the thermoplastic material on the tooth part to be corrected to be hardened, and using an orthotic sheet to form a series of invisible orthotic devices by using the tooth jaw physical model as a mother mold. By the method, the invisible orthotic device which is directly operated and is low in cost and cheap in material can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com