Patents

Literature

320 results about "Tooth grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quenching and tempering method in tooth punching process of gear with medium-hard tooth surface

InactiveCN102501035AHigh hardnessReduce pittingSolid state diffusion coatingFurnace typesHobbingTempering

Owner:NANJING JINXIN TRANSMISSION EQUIP

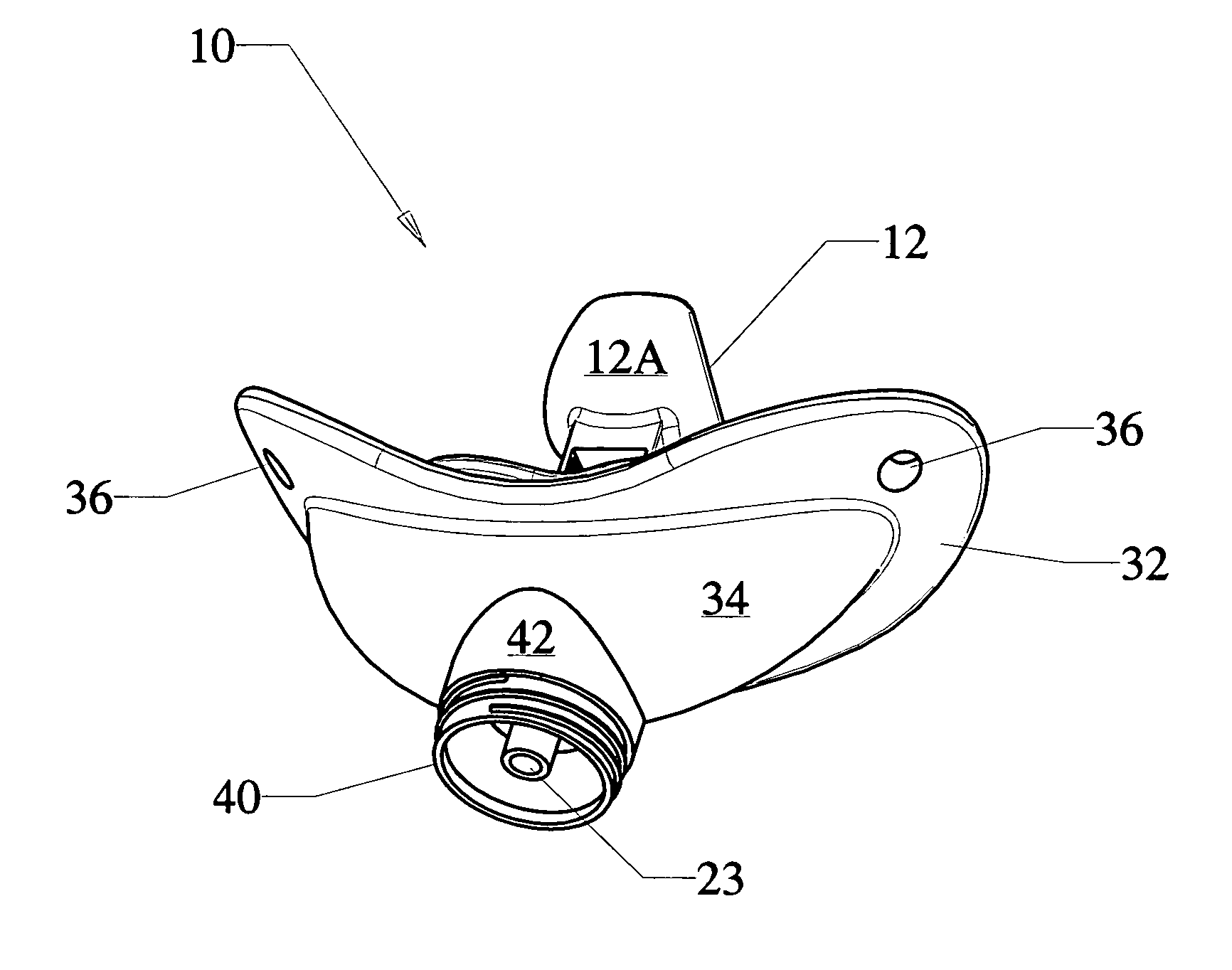

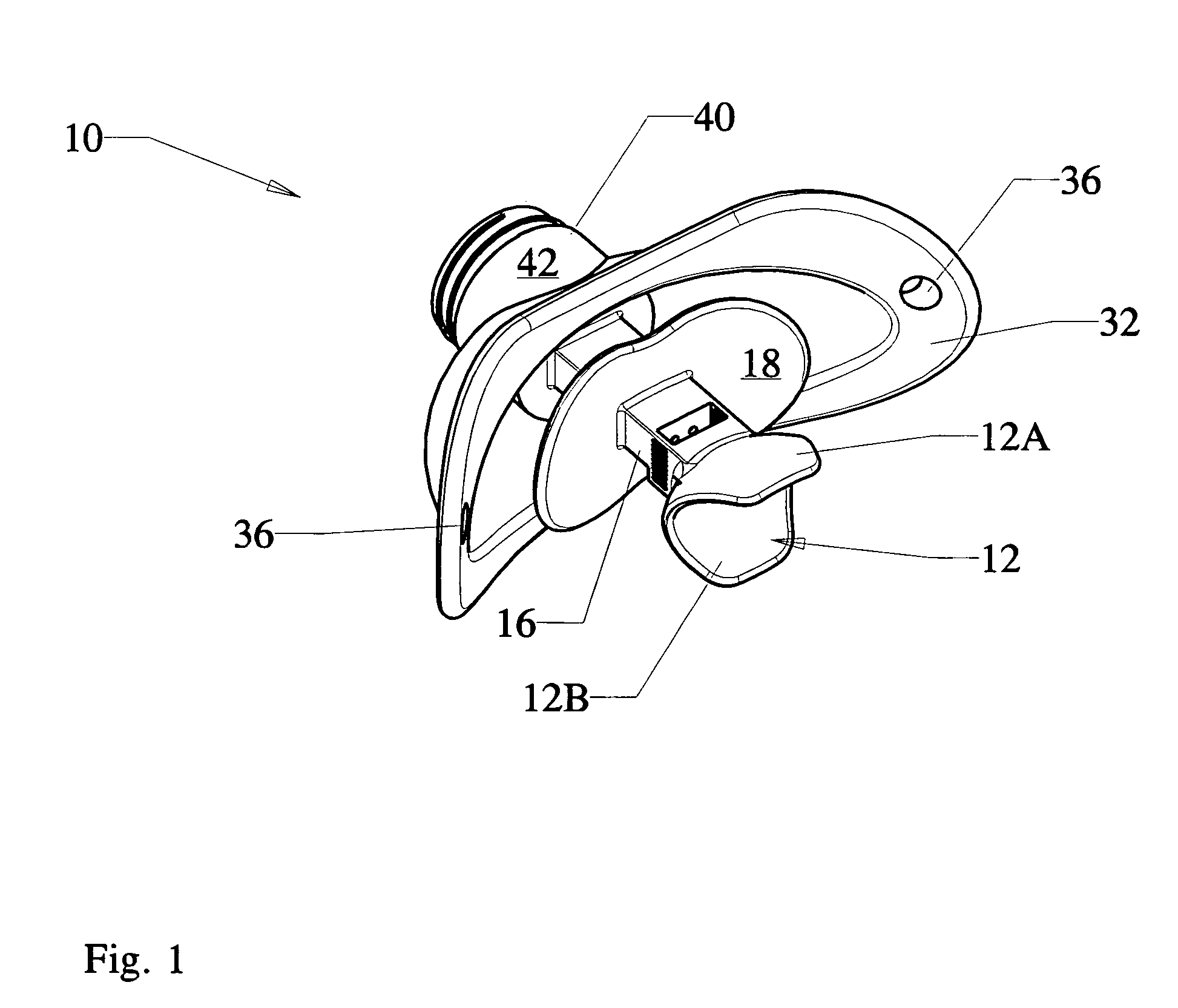

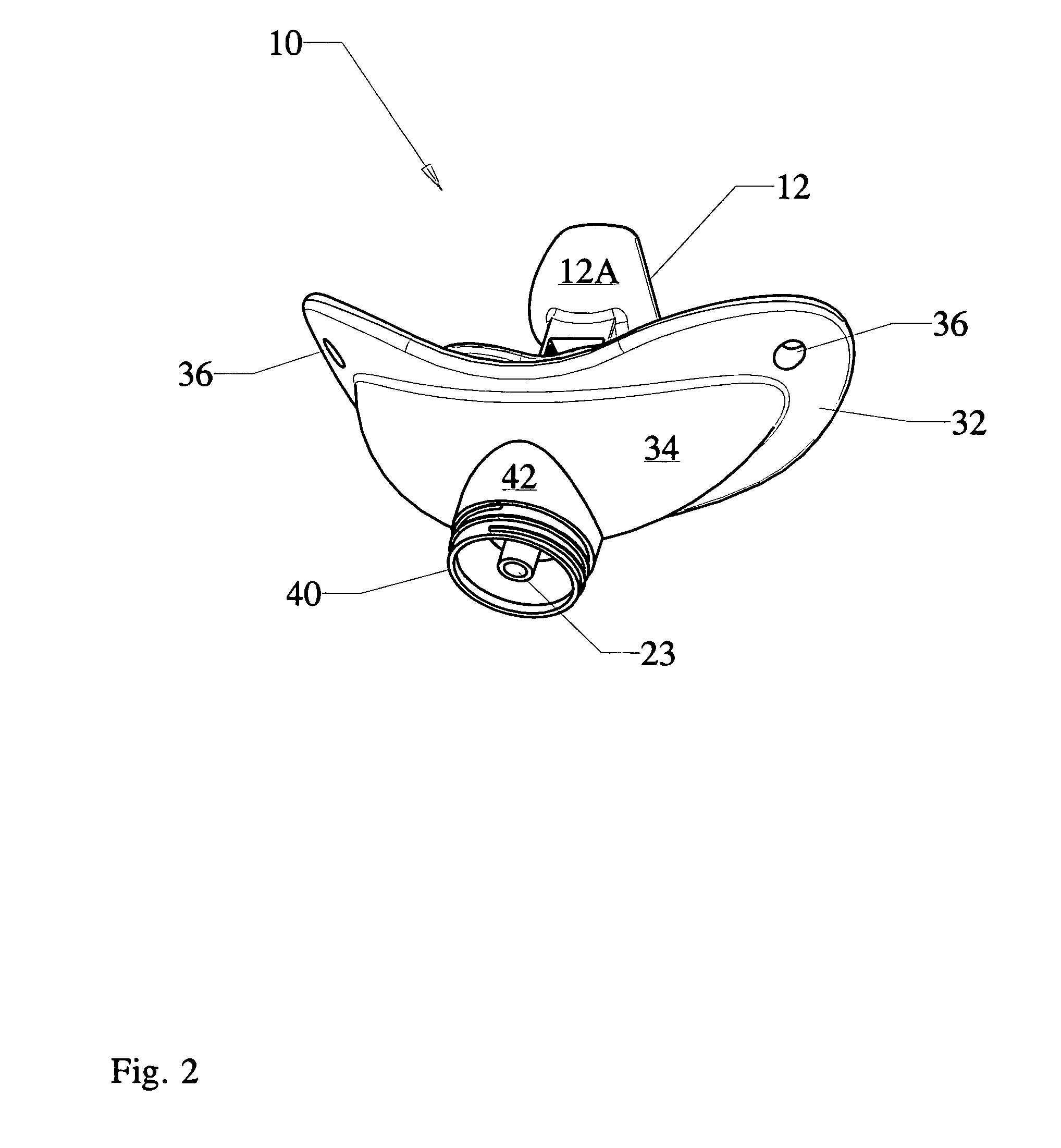

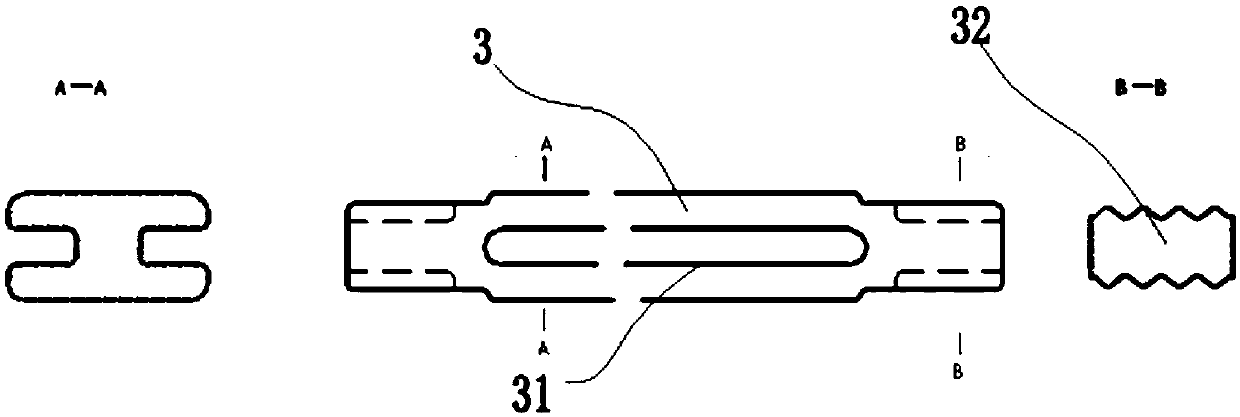

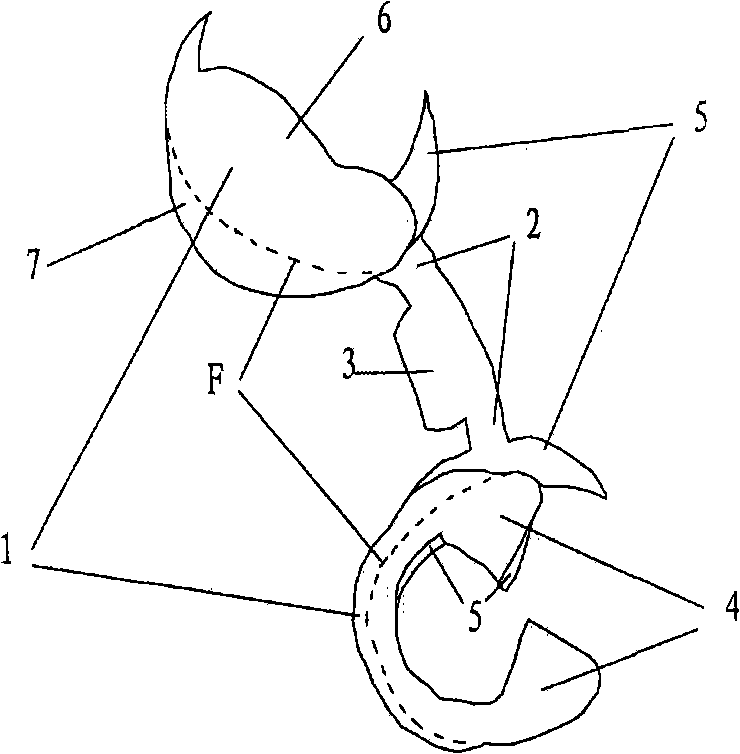

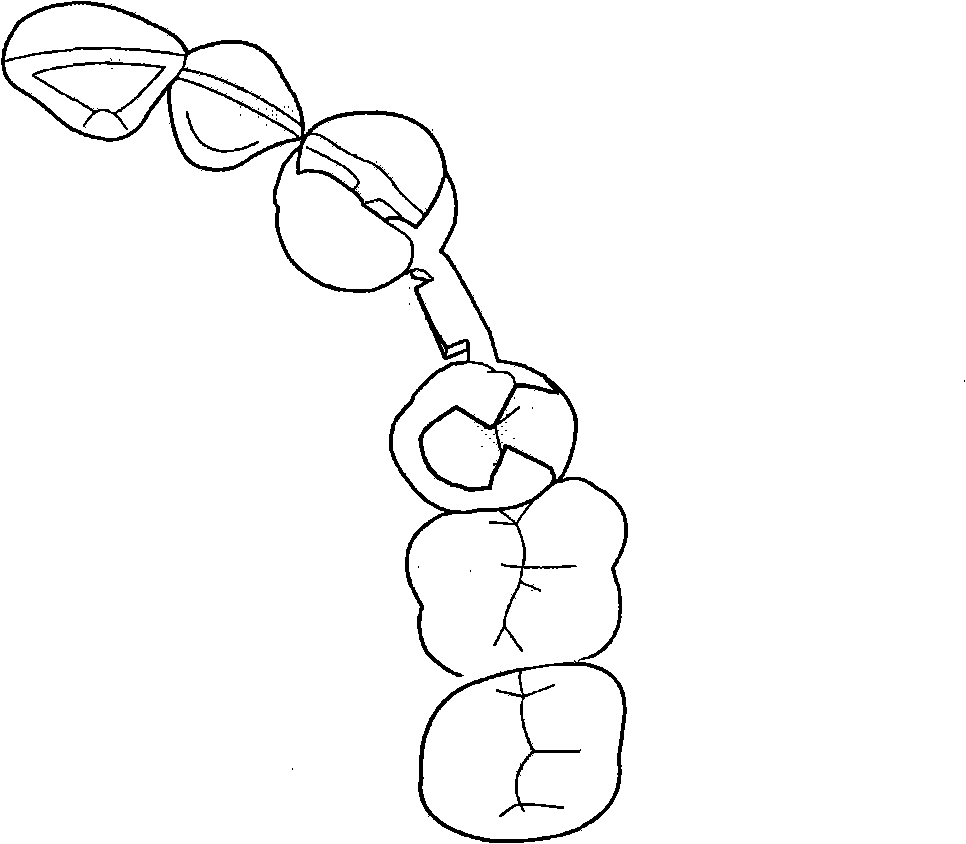

Breathing normalizer apparatus

InactiveUS7137393B2Reduce deliveryPrevent snoringTeeth fillingSnoring preventionOral medicationTeeth grinding

A breathing normalizer for partial insertion within the user's mouth for normalizing breathing patters, prevention of snoring, teeth grinding, and light forms of sleep apnea is disclosed. The device includes an outer plate which is positioned external to the user's mouth when in use, an elongated hollow shaft for connecting the structure to a lip plate adapted to be received between the user's lips and teeth, and a generally C-shaped multi-lobed structure adapted for receiving the user's tongue. The device is positioned within the oral cavity of the user in an operative configuration such that the tongue is retained within the multi-lobed structure, the teeth clamp down upon the connector with the lip plate positioned between the teeth and the inner portions of the upper and lower lips. The outer plate further defines a centrally disposed chamber having an inlet tube in fluid communication with the hollow tubular connector for providing an inlet for breathing air. The inlet tube is adapted for connection to a source of gas, such as oxygen, to assist in delivering the gas to the user through the lungs. In addition, the chamber includes a threaded peripheral edge adapted for threaded engagement with a container of medicine thereby facilitating the delivery of oral medications into the user's oral cavity and preferably the delivery of oral medications below the tongue. A medicine receiving chamber is further provided to allow for medicine received therein to be dispensed and / or evaporated in the user's mouth. As a result of proper application of the apparatus breathing at night is normalized, while snoring, grinding of the teeth, and apena are prevented, and further while medications may be simultaneously delivered orally.

Owner:PIVOVAROV ALEXANDER R

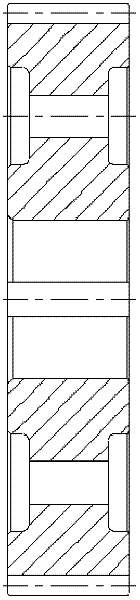

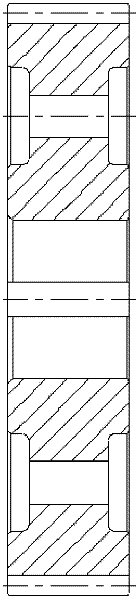

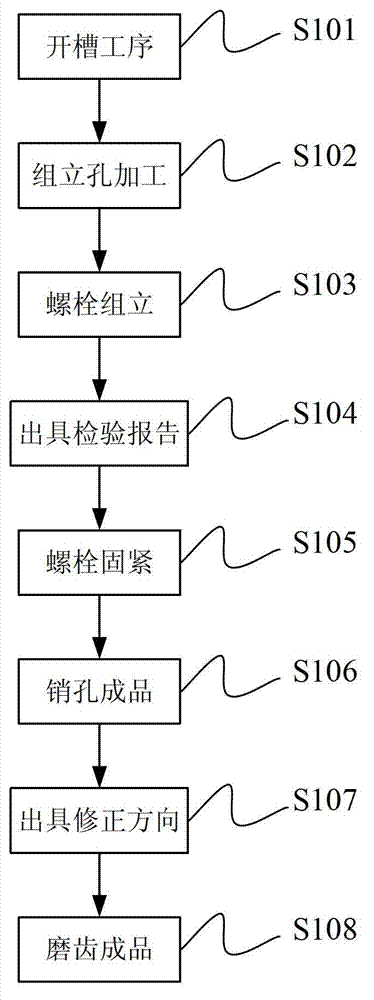

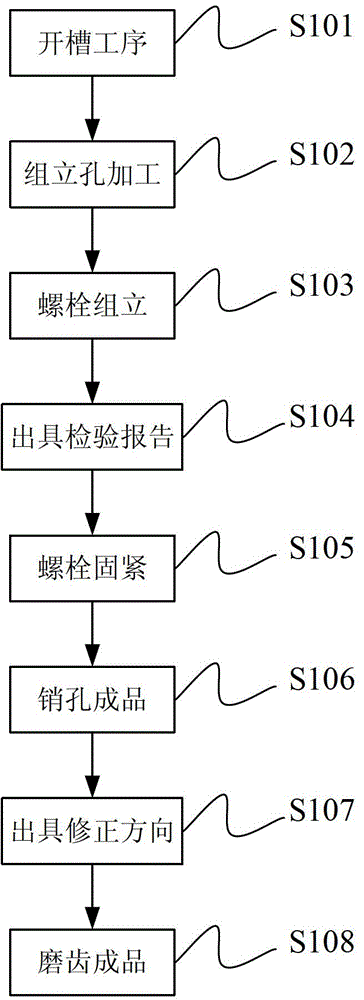

Method for machining combined herringbone tooth part

The invention discloses a method for machining a combined herringbone tooth part. The method includes the steps of machining slots of two helical tooth part and machining an assembly hole on a first helical tooth part; aligning centering errors of the herringbone tooth and machining several assembly holes evenly distributed on a second helical tooth part; aligning centering errors of the herringbone tooth and performing assembly; re-inspecting the centering errors of the herringbone tooth and issuing a centering inspection report; aligning the pitch circle run-out according to the centering inspection report and fastening the pitch circle run-out through a bolt after centering of the herringbone tooth; finishing pinholes on the two helical tooth parts and drilling assembly holes left on the second helical tooth part; re-inspecting the centering errors of the herringbone tooth and providing a correction direction of one of the two helical tooth parts; and decomposing the two helical tooth parts and grinding teeth according to the correction direction to obtain the finished product. According to the method, through three times of alignment of the herringbone tooth centering, two times of error re-inspection of the herringbone tooth centering, tooth grinding, slotting, matching, assembly hole drilling and tooth grinding, drawing design requirements are met.

Owner:CHONGQING GEARBOX

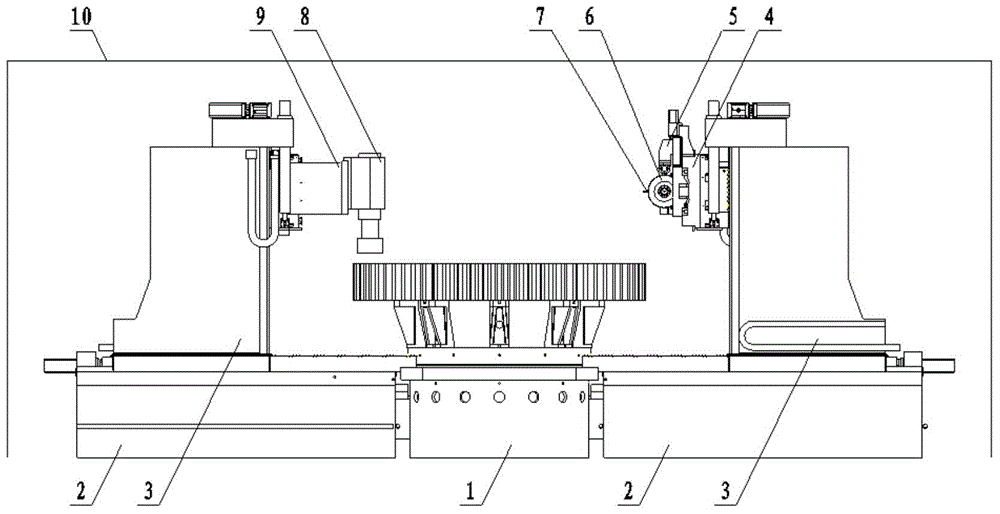

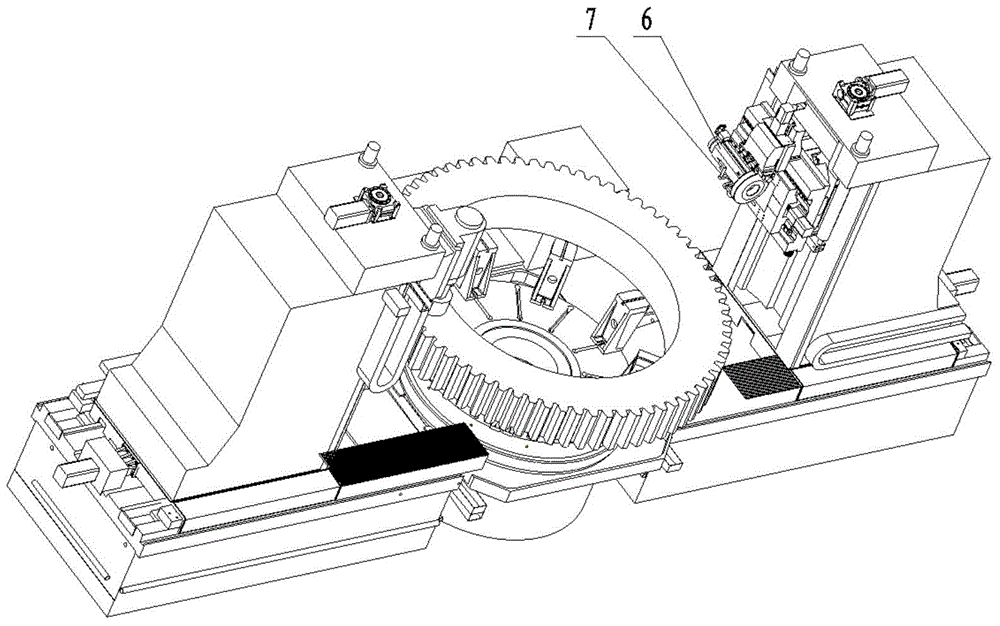

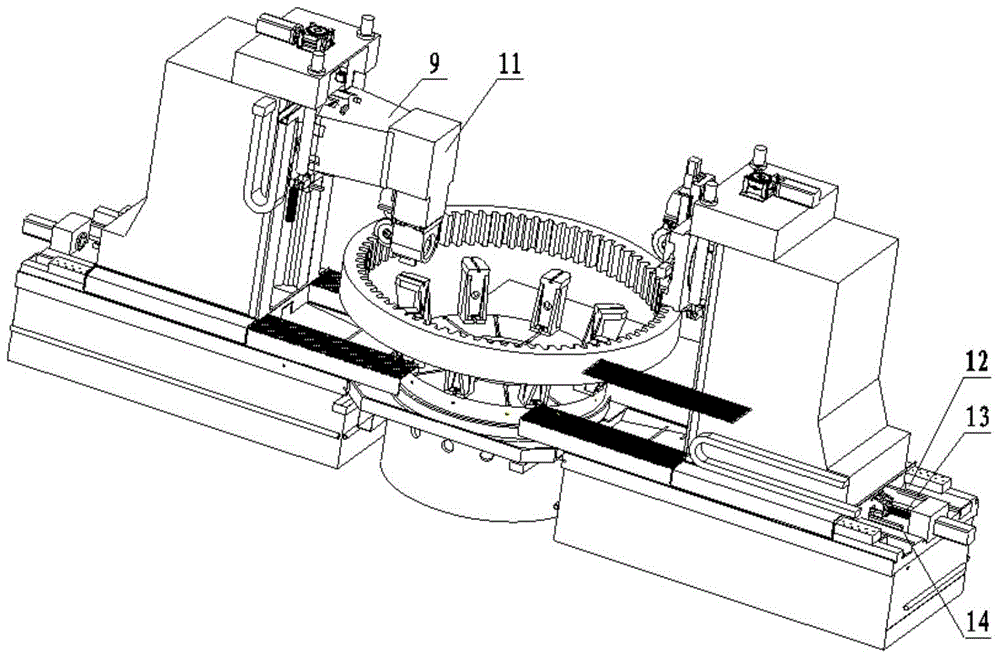

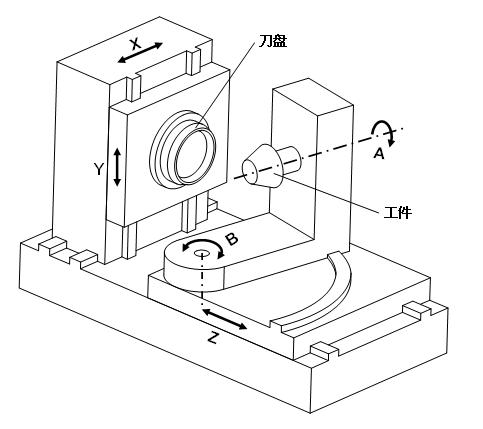

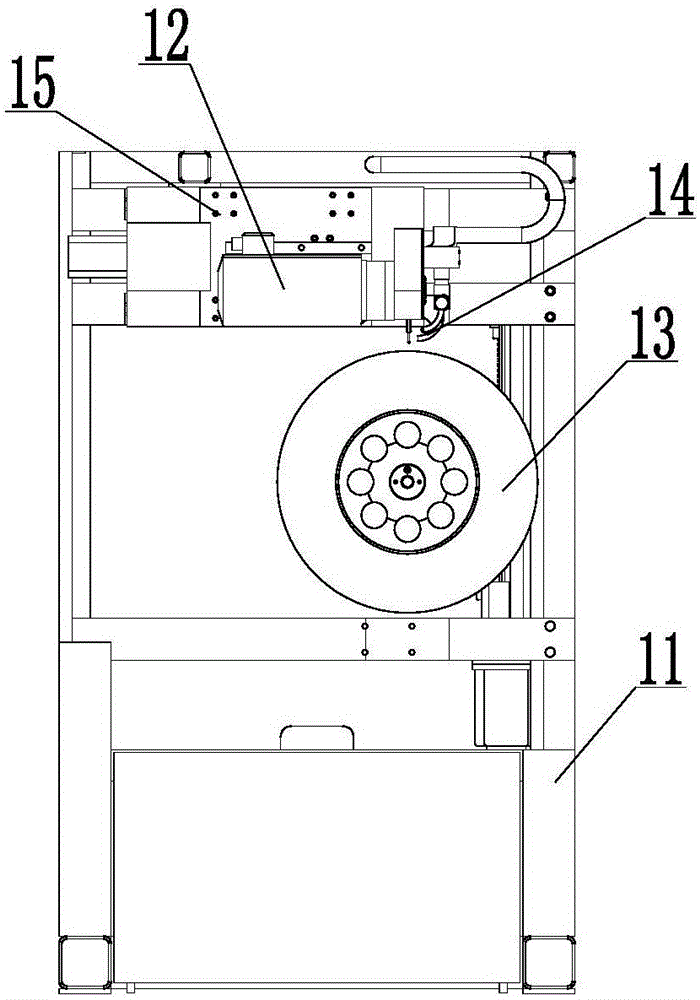

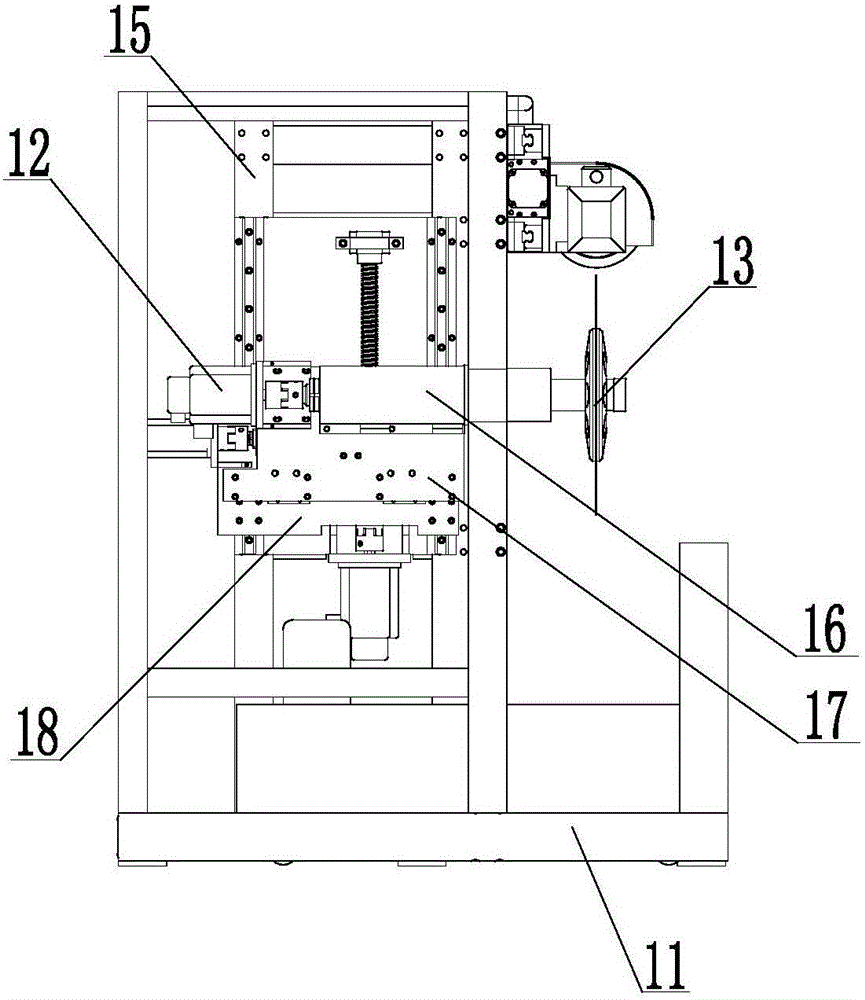

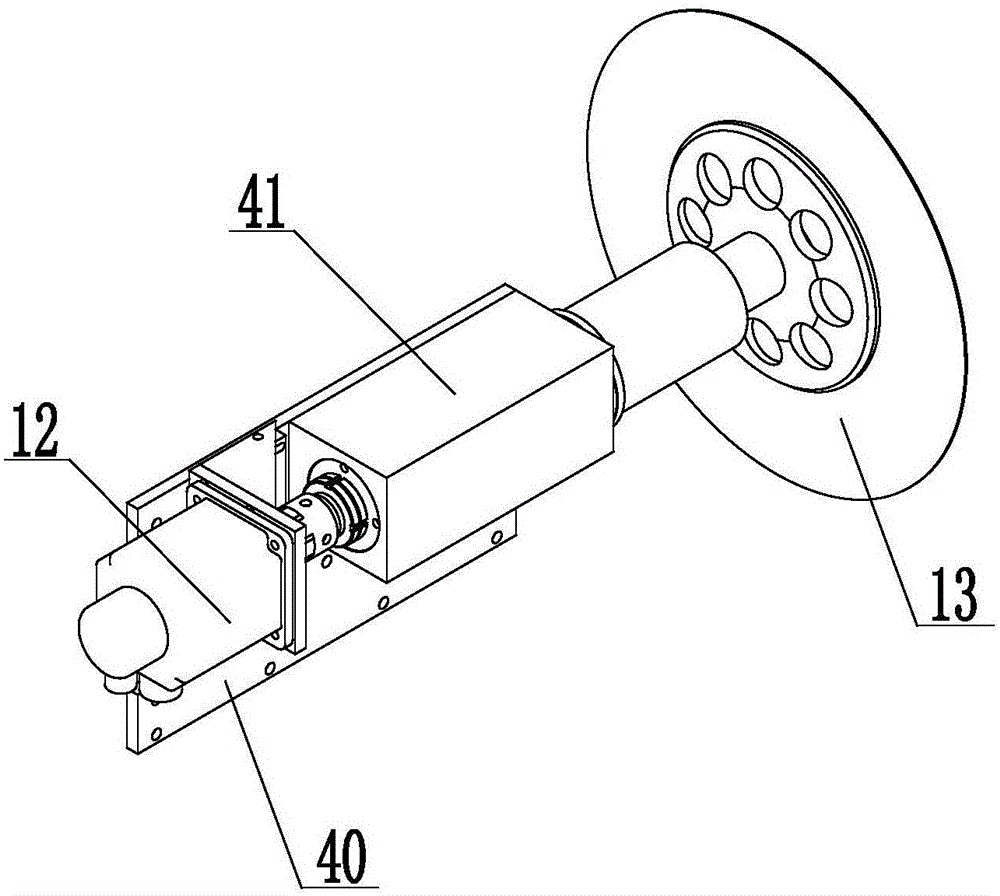

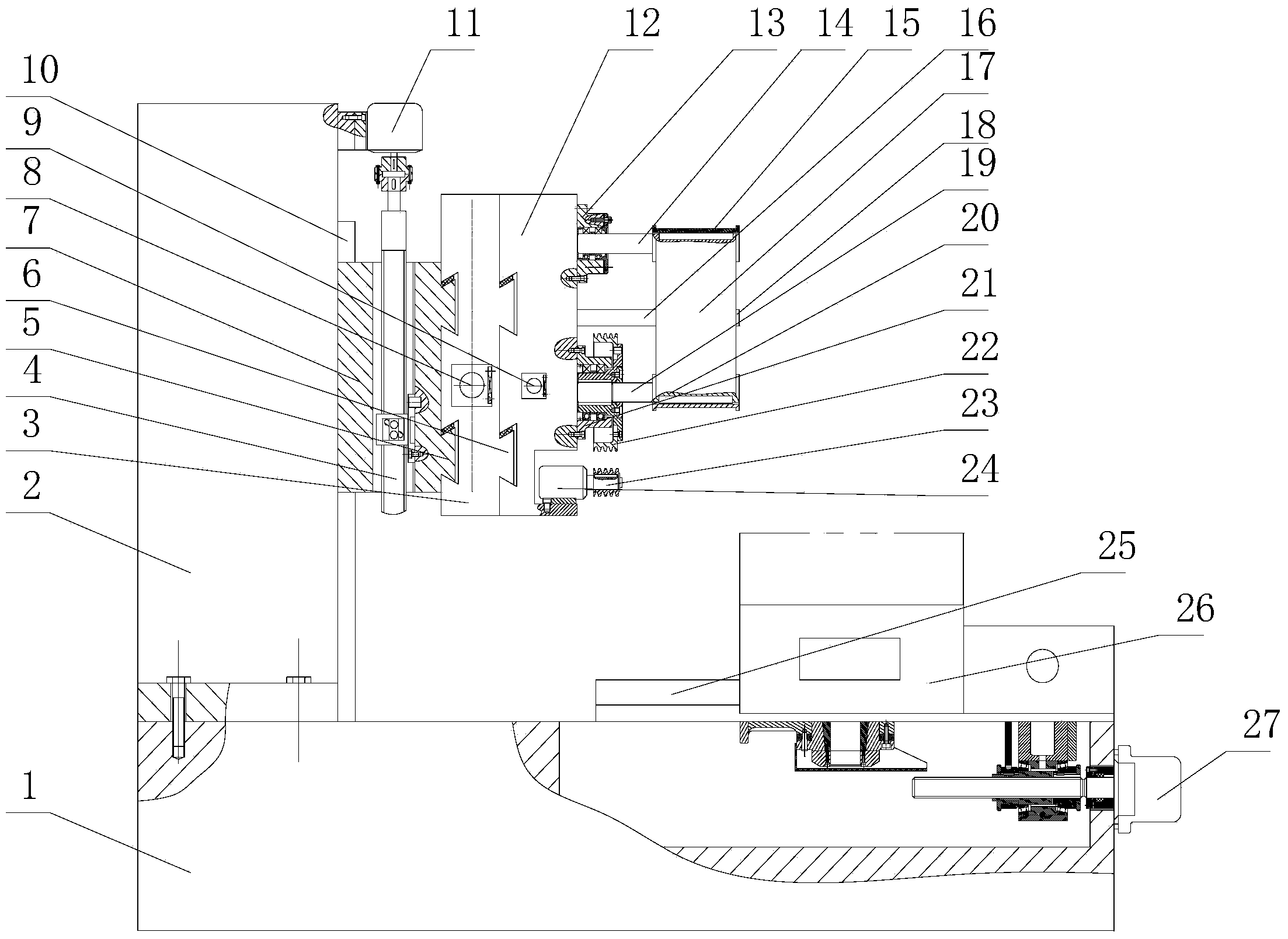

Large high-accuracy gear composite grinding center

ActiveCN104889863AReduce in quantityReduce auxiliary timeGrinding carriagesGrinding feed controlGear wheelMeasuring instrument

Owner:秦川机床工具集团股份公司

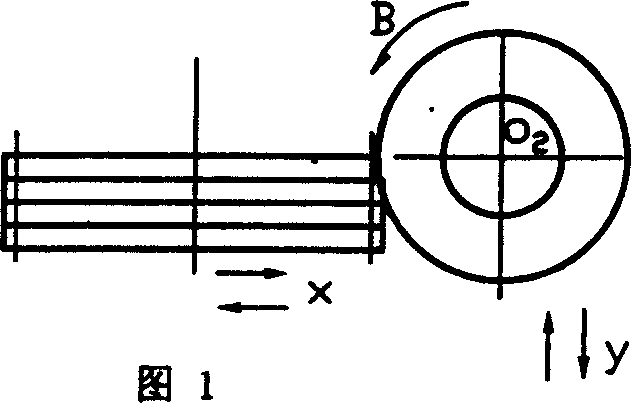

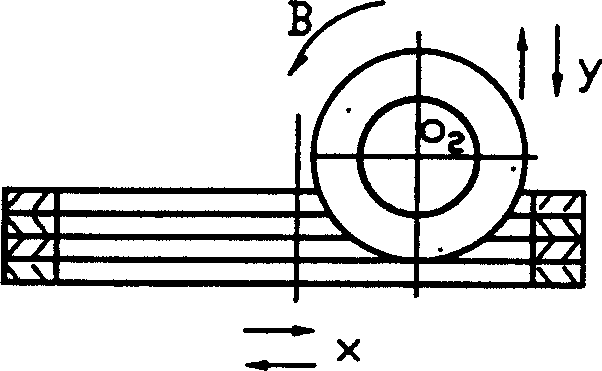

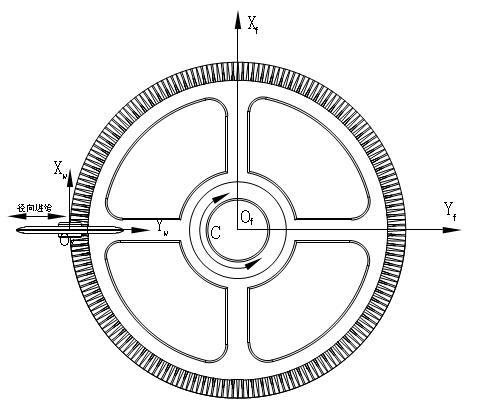

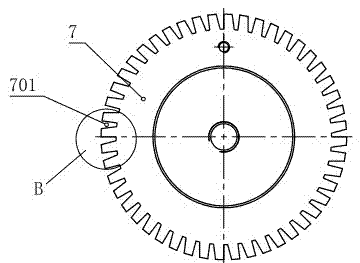

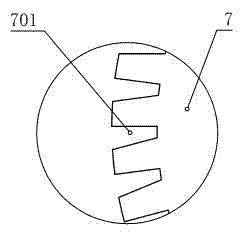

Digital controlled method for grinding teeth of cycloidal gear, and its appts.

A numerally controlled tooth grinding method for cycloid gear features that an abrasive disk is driven by a cranker-connecting rod mechanism to linearly reciprocate for forming an equivalent cylindrical grinding surface and the cycloid gear to be machined is driven by a dual-coordinate numerally controlling system controlled by microcomputer to shift and rotate, so enveloping whole tooth profile of cycloid gear.

Owner:CHONGQING UNIV

Processing method for internally toothed annulus

The invention provides a processing method for an internally toothed annulus, which comprises the following steps: selecting a low-carbon steel tooth billet and carrying out rough lathing after the tooth billet is forged and normalizing treatment is performed; roughly machining the tooth billet into a tooth profile; conducting carburizing, quenching and high temperature tempering on the toothed part, and finally carrying out the shot peening; conducting finish machining on a datum plane; and conducting finish machining on the tooth profile through tooth grinding. The method solves the hardness problem of the toothed surface of the internally toothed annulus, adopts a low carbon steel material, carries out tough tooth punching before heating, and grinds the toothed part after cemented quenching; the hardness of the toothed surface can reach HRC 58 to 62, so as to thoroughly eliminate the pitting corrosion of the toothed surface and prolong the service lives of parts; as the tooth grinding process is carried out after heating, the precision of the toothed annulus can be above 6 grade; as the precision grade of the toothed part is improved after the tooth grinding process, the transmission of the toothed annulus becomes smoother; and as the tooth punching process is carried out before heating, the parts are low in hardness in the normalized condition, which provides convenience for tooth punching and improves the processing efficiency.

Owner:NANJING JINXIN TRANSMISSION EQUIP

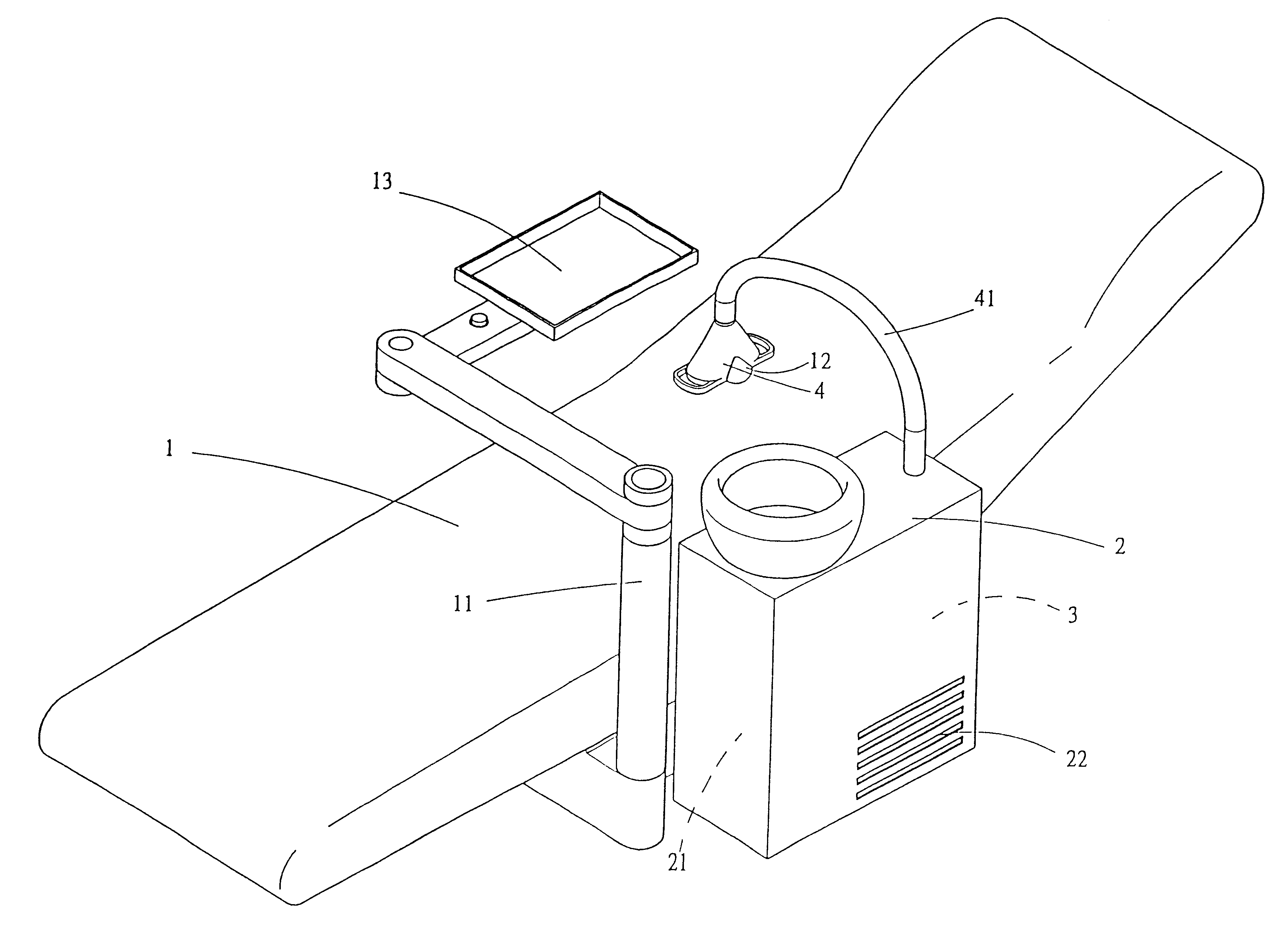

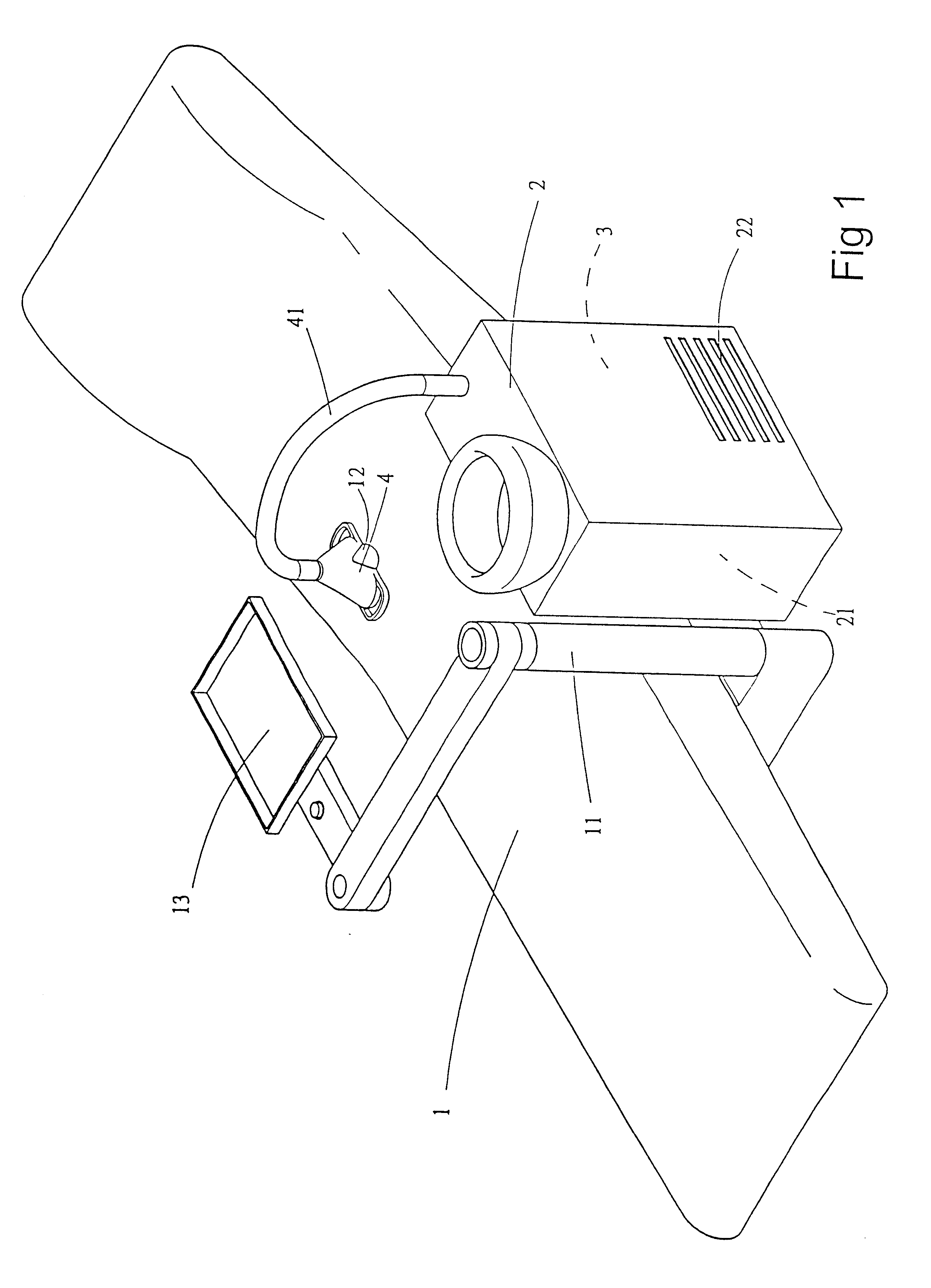

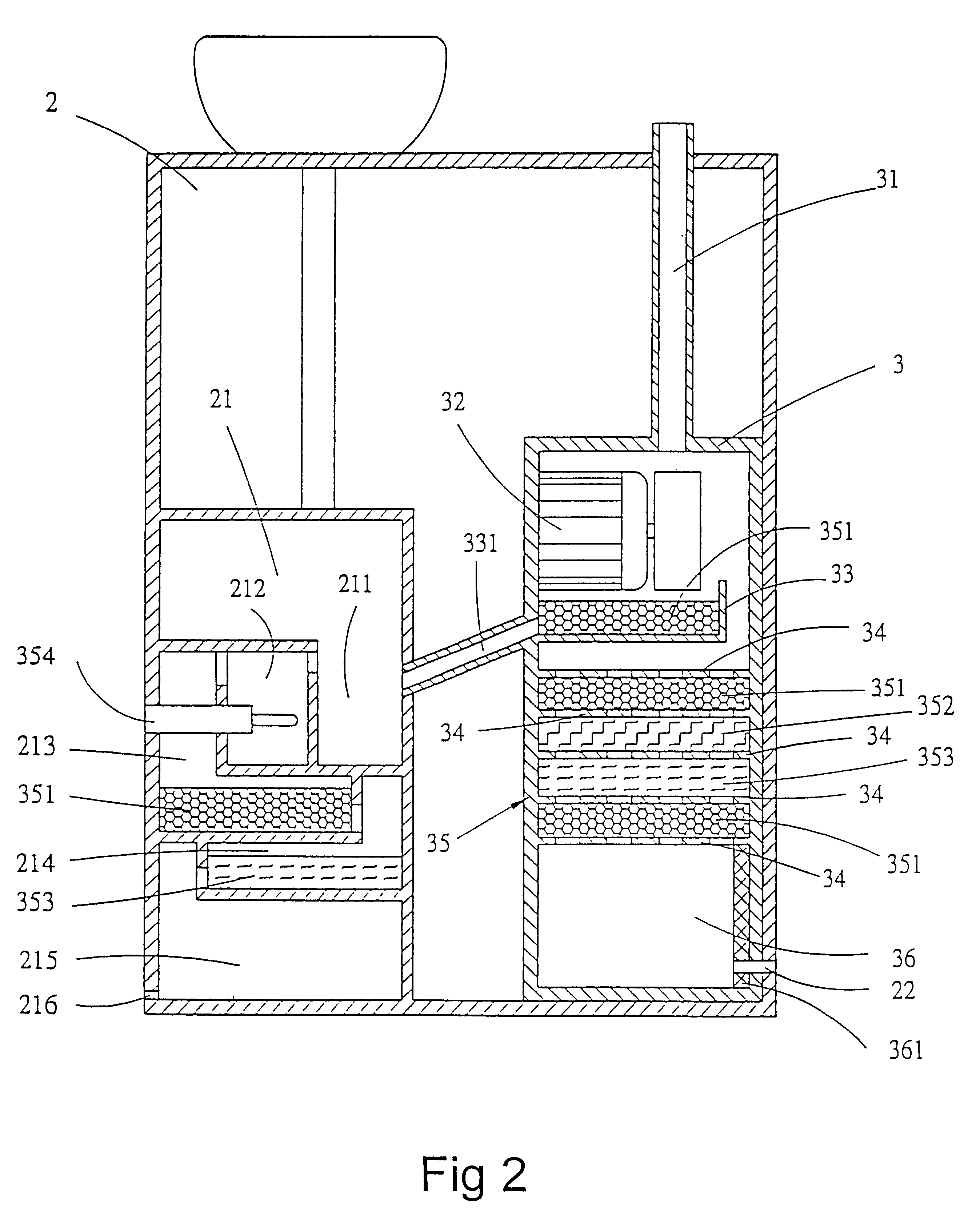

Air-sucking, sterilizing and wastewater treatment method for dental clinic bed

InactiveUS6464499B1Precise positioningAvoid contaminationOperating chairsDental toolsChemical solutionExhaust valve

This is an air-sucking, sterilizing and wastewater treatment method for dental clinic bed. It has an air-sucking and sterilizing device, and a wastewater-treating device below a gargle bench of a dental clinic bed. The air-sucking inlet of the air-sucking and sterilizing device is connected above the bench top to an air-sucking pipe that can be bent to form. At the other end of the air-sucking pipe is an air-sucking mask equipped with a clinical lamp. Utilizing the bendable property of the air-sucking pipe, the dentist can adjust the air-sucking mask with the clinical lamp to an optimum position, to collect germ-carrying flying saliva and volatile chemicals produced in the clinical process, or the flying moisture from the tooth grinding machine in the air-sucking and sterilizing device. Inside the air-exhaust valve is a ion device for purifying purpose to enhance hygienic quality of the entire clinical process, and avoid unnecessary contamination of flying saliva. The wastewater-treating device will clean the patient's mouth and chemical solutions and germ-carrying wastewater, filter and sterilize it thoroughly before discharging it, so the discharged wastewater will not pollute river sources.

Owner:LU LI CHOU

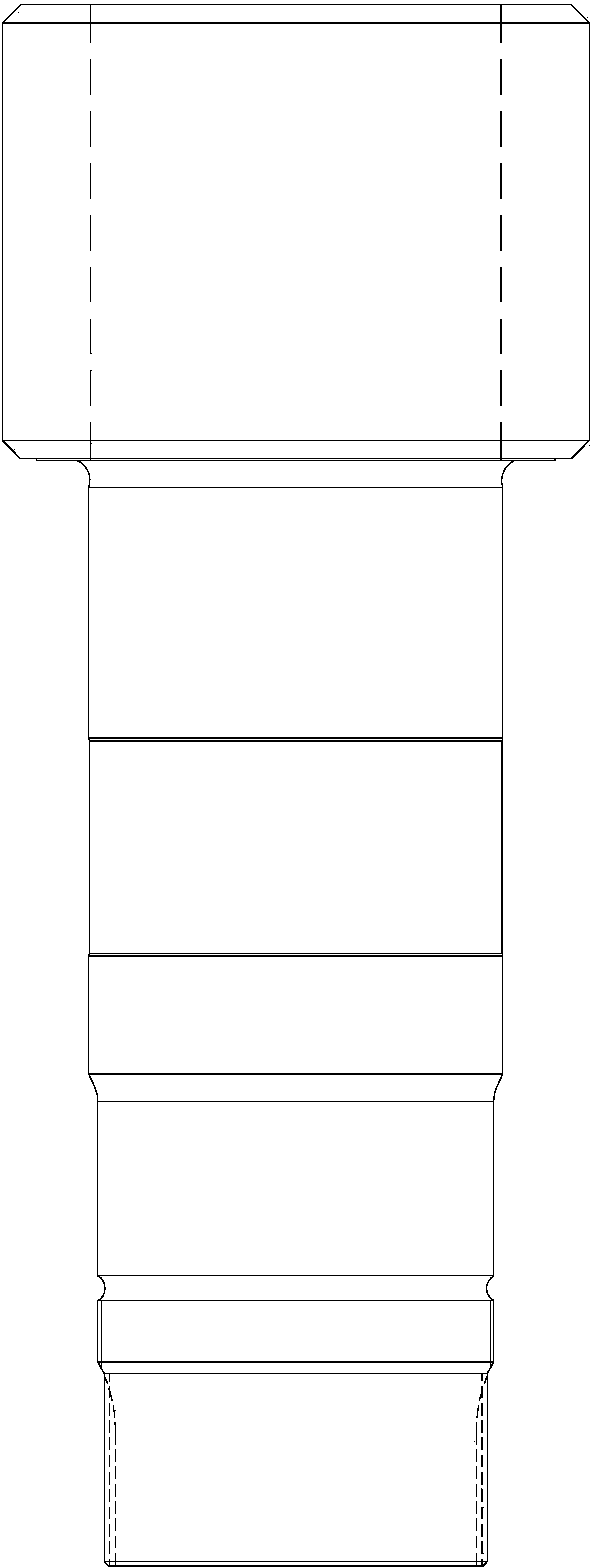

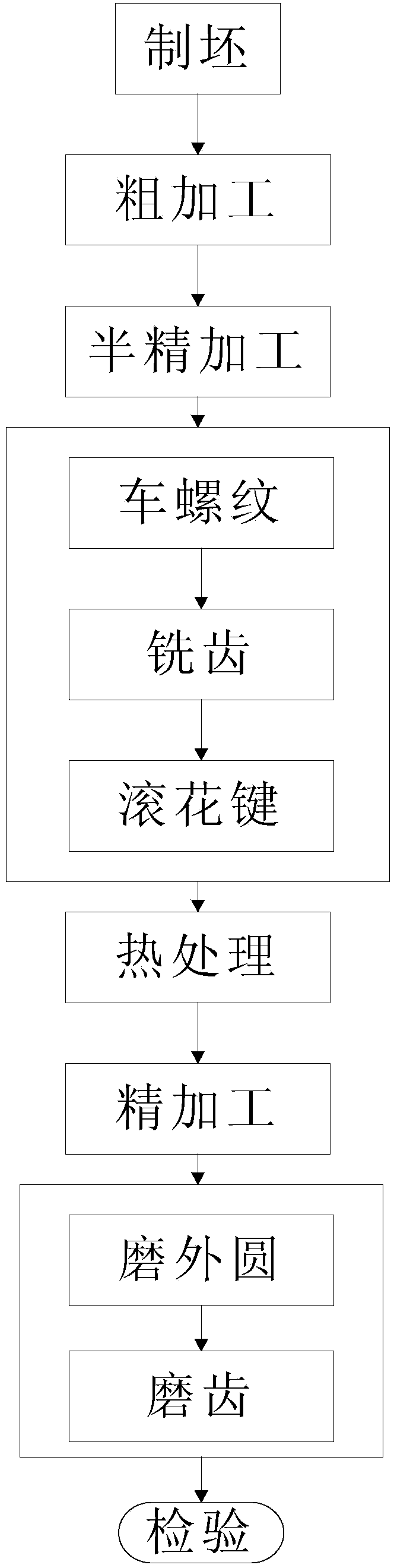

Process for machining gear main shaft of high-power wind turbine generator set

The invention provides a process for machining a gear main shaft of a high-power wind turbine generator set and relates to the adjustment of the sequence of heat treating and machining in the technological process. The specific process includes the steps of carrying out rough machining and semi-finishing machining on a blank, machining a gear and gear teeth, machining a spline, coating anti-seepage agents, carrying out heat treatment, and finally carrying out external grinding and tooth grinding. Accordingly, a part is machined. Meanwhile, in the machining process, imported high-end devices and tools are used in critical procedures and are cooperated with a heat treatment micro-distortion control technology so that specialized complete process machining from the blank to the finished product can be achieved. Through the process for machining the gear main shaft of the high-power wind turbine generator set, a fine metallographic structure and an even carburized layer can be obtained through the heat treatment. Consequently, the strength and accuracy of the spline are improved, the weight of the gear main shaft is reduced, and the service life of the gear main shaft is prolonged.

Owner:DALIAN CLEAN ENERGY HEAVY IND

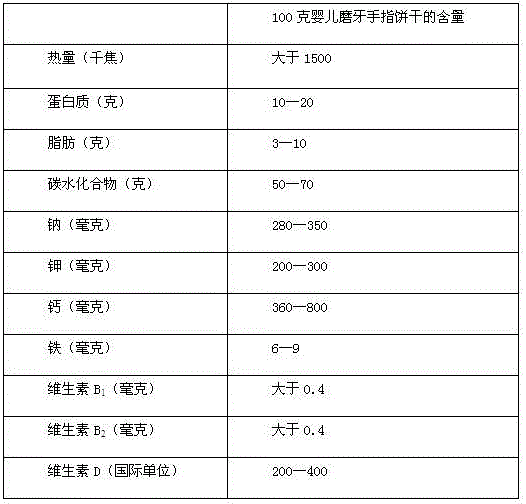

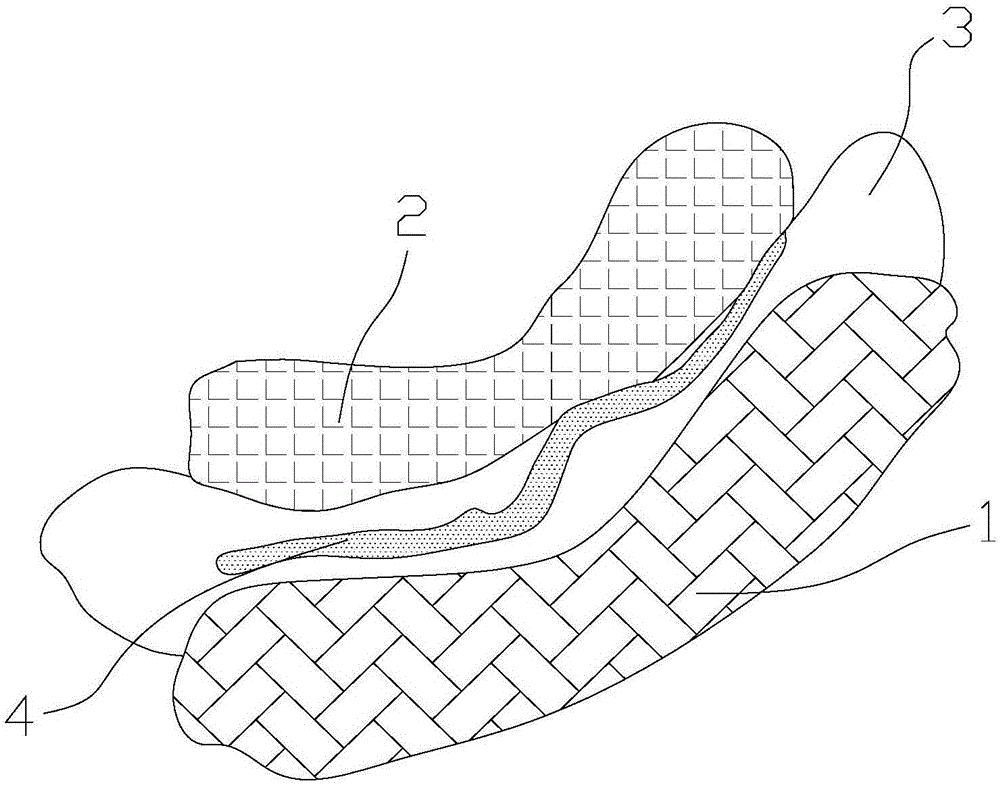

Tooth grinding food

The invention provides a tooth grinding food which is made of a composition comprising wheat meal, grease, sugar and a leavening agent at least. The tooth grinding food is characterized in that the wet gluten content of the wheat meal or the wheat meal and starch is below 20 percent, preferably below 18 percent; and on the basis of 100 parts by weight of the sum of the wheat meal and the starch, the tooth grinding food comprises 14-22 parts of grease, 18-26 parts of sugar and 0.05-0.1 part of leavening agent, and the expansion ratio is between 1.0 and 1.2. The tooth grinding food is produced by a crisp biscuit production process, has proper hardness, is difficult to break and drop, is suitable for an infant to grind teeth and is beneficial to the growth of the teeth of the infant.

Owner:贝因美股份有限公司 +1

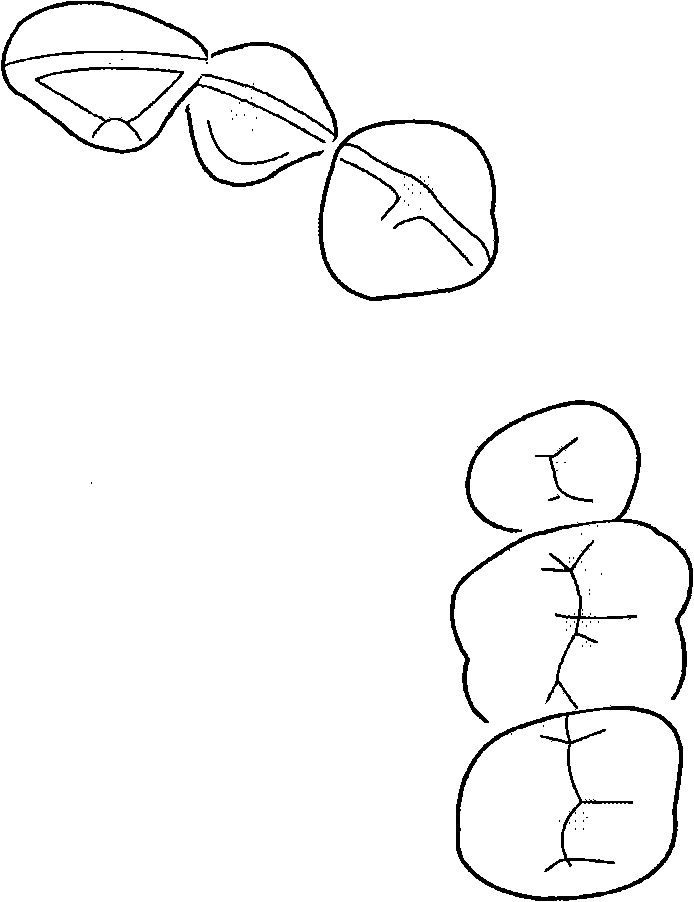

Method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding

The invention relates to the field of dental prosthesis, in particular to a method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding. The method comprises the following steps: a three-dimensional scanner is adopted to scan a dental cast, a three-dimensional stereoscopic image is formed, an ultra-thin veneer with the thickness of less than 0.5 mm is designed on the virtual image, after the ultra-thin veneer is designed, data is output to a 3D (three-dimensional) resin wax forming machine, the ultra-thin veneer is formed in the manners of resin-spraying, irradiation curing and printing, and then the formed resin wax pattern is subjected to embedded casting, grinding adjustment, try-in and glazing. Compared with the prior art, the method adopts a computer to design, and the conventional hand-made wax pattern is replaced by the resin wax pattern processed by the digital resin wax spraying, irradiation curing and printing processing, so that fabrication of porcelain laminate veneer with the thickness of less than 0.5 mm is realized. An aesthetic seeking patient with discolored teeth does not need tooth grinding and can receive tooth-whitening treatment without hurting teeth.

Owner:深圳市金悠然科技有限公司

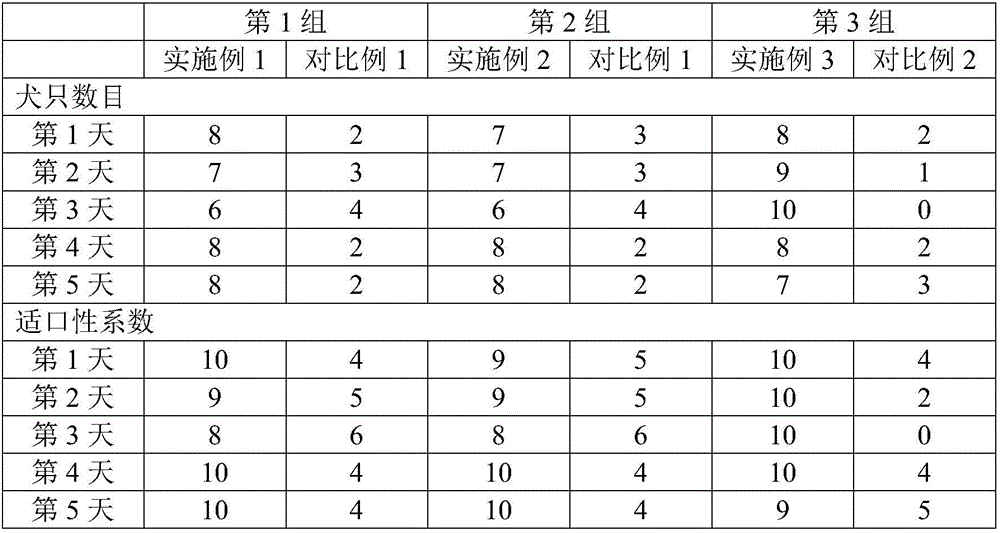

Feed for breeding porcupines

The invention relates to feed for breeding porcupines. The feed contains corn flour, tapioca flour, sweet potato flour, kudzu root powder, peanut powder, silkworm chrysalis powder in parts by weight, cod liver oil in parts by weight, dry yeast in parts by weight, angelica powder in parts by weight, pistachio nut powder in parts by weight and chicken cashew nut powder in parts by weight. According to the formula, the feed provides complete and a plenty of nutrients for porcupine breeding, and the growth feed contains fat, carbohydrates, crude fibers and minerals, so that the growth of the porcupines can be promoted, and the resistance of the porcupines can be improved. Furthermore, the feed is agreeable to the mouth feel of the porcupines, has certain elasticity and chewiness and is suitable for the tooth grinding of the porcupines. The phenomenon that the porcupines disorderly nibble and chew is prevented.

Owner:宁安市宇晨饲料有限公司

Infant molar rod biscuit containing soybean dietary fibers and production method thereof

InactiveCN105660791AImprove developmentPromote digestionDough treatmentBakery productsSodium bicarbonateFiber

The invention belongs to the field of foods and in particular relates to an infant molar rod biscuit containing soybean dietary fibers and a production method thereof. The infant biscuit disclosed by the invention contains soybean dietary fibers and also contains flour, white granulated sugar, eggs, grease, starch, whole milk powder, soy isolate protein, sodium bicarbonate, water and other raw materials, wherein the content of the soybean dietary fibers accounts for 2.5 to 9.3 percent of the weight of the biscuit. According to the invention, the soybean dietary fibers added into the formula have the characteristics of high protein and high fiber, the protein content of quality is improved, soybean protein and wheat protein can be well combined, and formation and structure of gluten can be improved, so that the product is higher in hardness. The soybean dietary fibers have good water absorption properties and can maintain 7-8 times of water, the viscosity of the product is improved, and the measured water absorption amount is less than 10 percent. Therefore, a quality surface layer is wetted and softened to absorb water, and the aims of guaranteeing long-term sucking of the infant and improving the tooth grinding and oral cavity practicing skills are achieved.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Feed for breeding porcupines

The invention relates to feed for breeding porcupines. The feed contains corn flour, tapioca flour, sweet potato flour, kudzu root powder, peanut powder, silkworm chrysalis powder, cod liver oil, dry yeast, angelica powder, pistachio nut powder and chicken cashew nut powder. According to the formula, the feed provides complete and a plenty of nutrients for porcupine breeding, and the growth feed contains fat, carbohydrates, crude fibers and minerals, so that the growth of the porcupines can be promoted, and the resistance of the porcupines can be improved. Furthermore, the feed is agreeable to the mouth feel of the porcupines, has certain elasticity and chewiness and is suitable for the tooth grinding of the porcupines. The phenomenon that the porcupines disorderly nibble and chew is prevented.

Owner:徐玉文

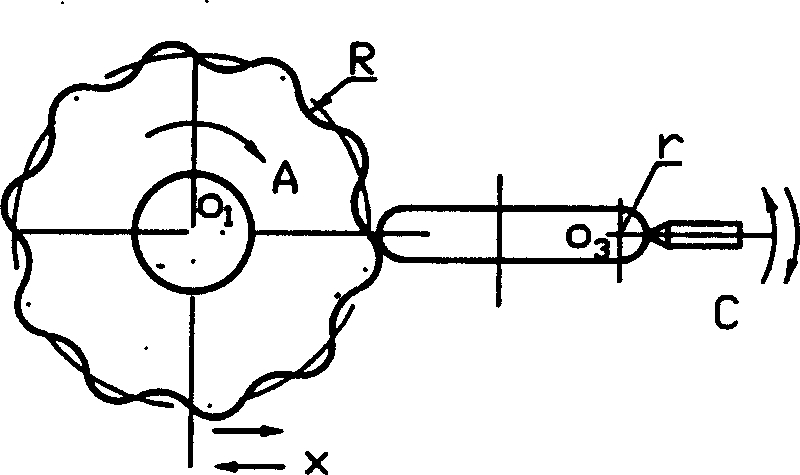

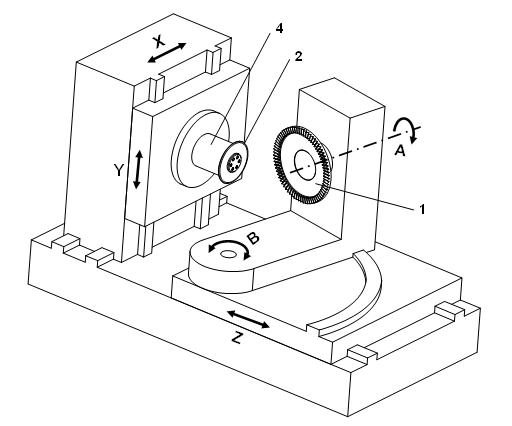

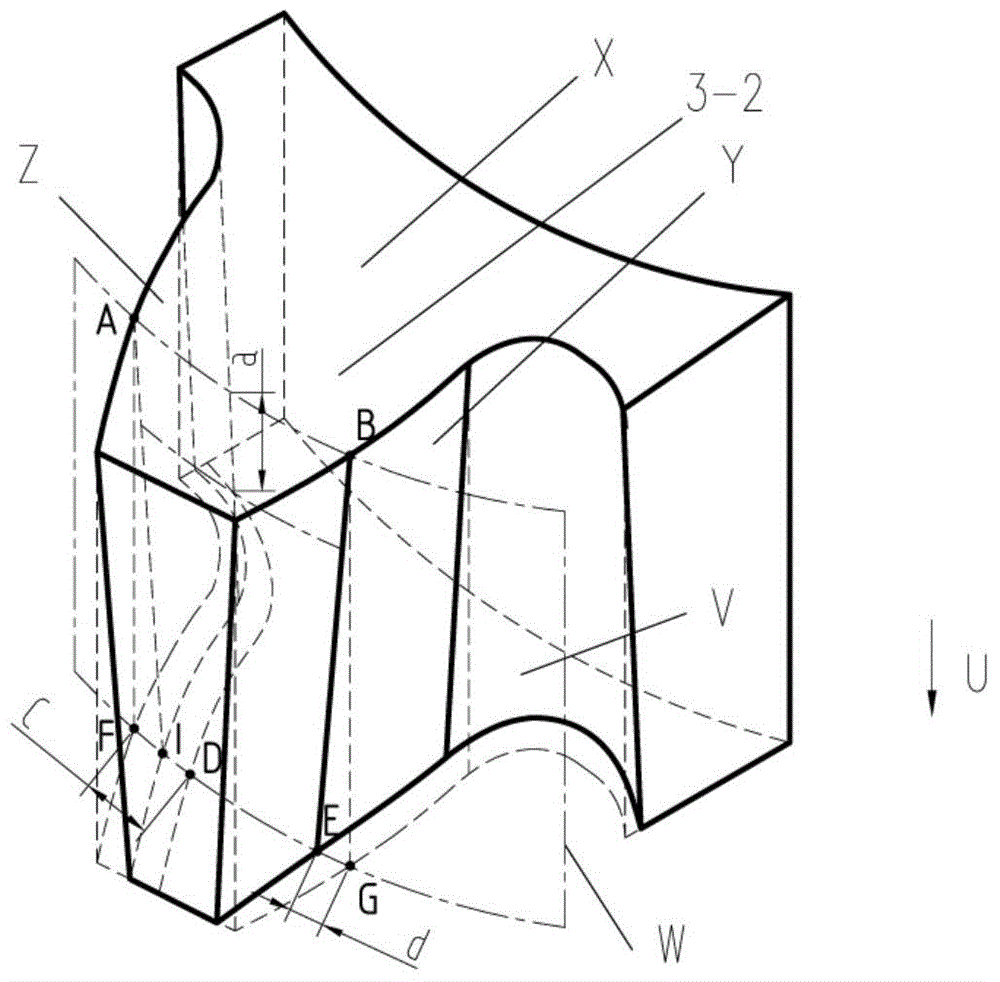

Method for processing face gear

The invention discloses a processing method for realizing face gear teeth milling and high-precision teeth grinding by use of a disc cutter on an existing numerically controlled lathe, which is characterized in that a face gear 1 is installed on a working platform of the lathe, an extended grinding wheel set 4 is installed on top of a lathe spindle, the disc cutter 2 is installed on top of the extended grinding wheel set 4; during processing, the face gear 1 rotates around its axis along with a lathe A rotating shaft while swinging with a lathe B rotating shaft, the disc cutter 2 rotates at a high speed around its axis along with the spindle while making a reciprocating feed movement in the radial direction of the face gear; because of the lathe B-shaft travel limitation, a single-face processing way is adopted, a right tooth face of the face gear is processed firstly, after one whole tooth face is processed, the face gear makes an indexing motion to process the next tooth face till the whole right tooth face of the face gear is processed, and then a left tooth face of the face gear 1 is processed on another station till the whole face gear is processed. By using the existing numerically controlled lathe and the disc cutter, the face gear teeth milling and the high-precision teeth grinding can be processed at the same time without additionally designing or manufacturing a face gear special processing lathe, the manufacturing cost is reduced and the development period is shortened greatly.

Owner:唐进元

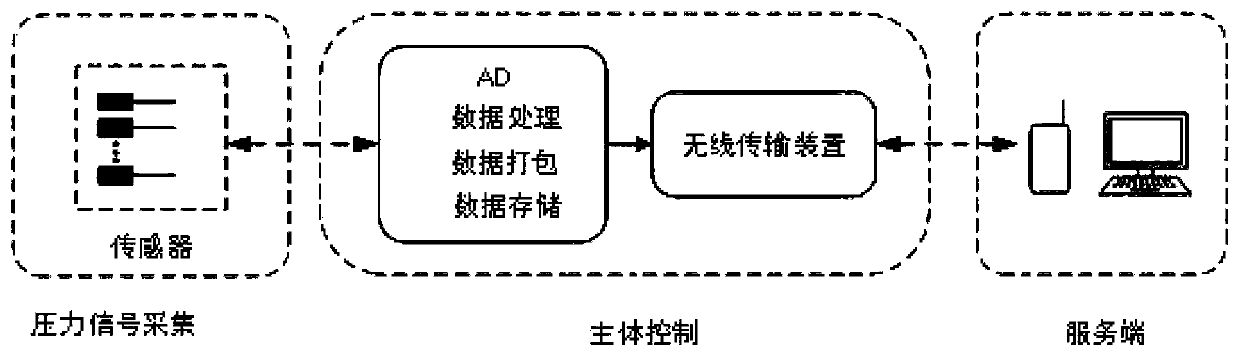

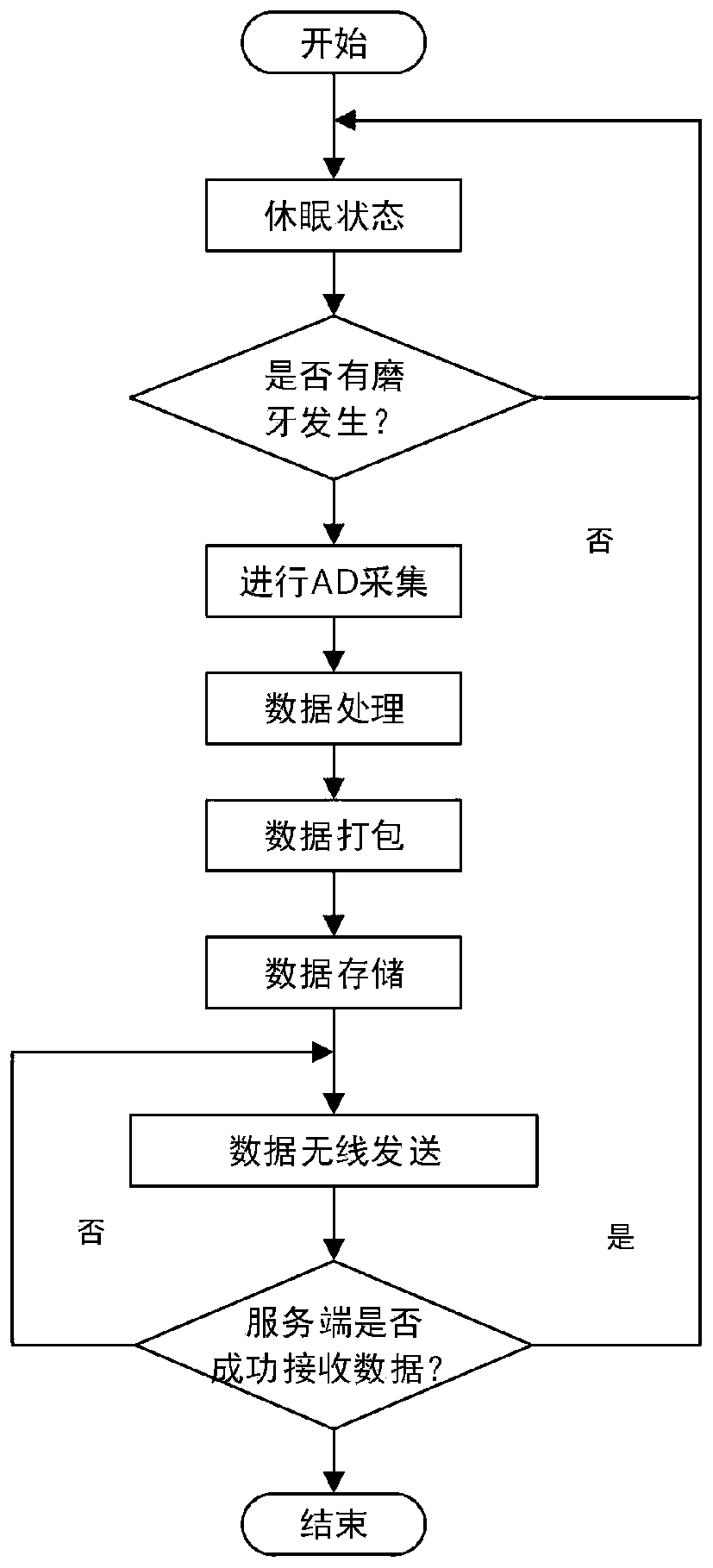

Full-dentition occlusion monitoring and intelligent analysis auxiliary diagnosis and treatment device

ActiveCN109730796ANo discomfortGood curative effectDentistryDiagnostic recording/measuringOriginal dataData information

The invention provides a full-dentition occlusion monitoring and intelligent analysis auxiliary diagnosis and treatment device. The device comprises a pressure acquisition module, a main control module, a wireless transceiving module, a receiving end, a server and a receiving terminal, wherein the pressure acquisition module is used for collecting tooth occlusion force data of a patient; the maincontrol module used for receiving signals of a pressure sensor and controlling processing, storage and packaging of pressure data; the wireless transceiving module is used for wirelessly sending the pressure data processed by the main control module to the receiving end; the receiving end is used for receiving the data of the wireless transceiving module, the receiving end analyzes the packaged data, and the analyzed data is transmitted to the server; the received occlusion force data is processed by the server through an artificial intelligence algorithm, and the original data which is not intelligently processed and results obtained after intelligent processing are transmitted to the receiving terminal; the receiving terminal is used for receiving data information of the server and allowing doctors to check tooth grinding data of the patient and disclose a treatment scheme. The occlusion force information of the tooth grinding patient can be monitored in real time, measured dynamically and intelligently analyzed and processed, and the device has the advantage of being high in instantaneity.

Owner:XI AN JIAOTONG UNIV

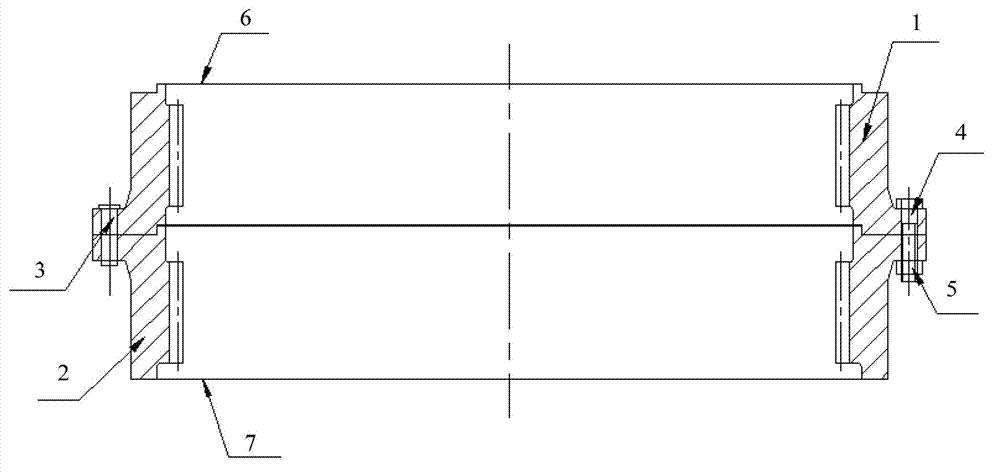

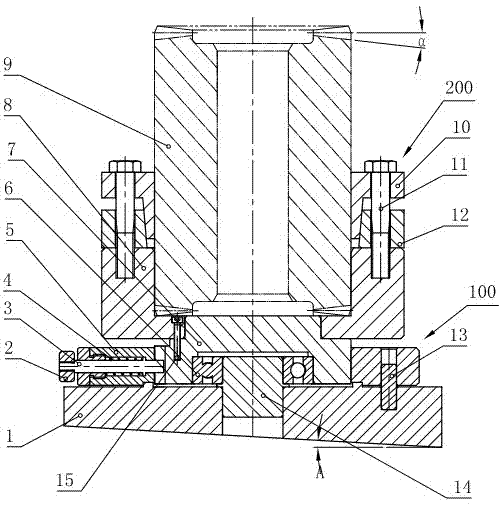

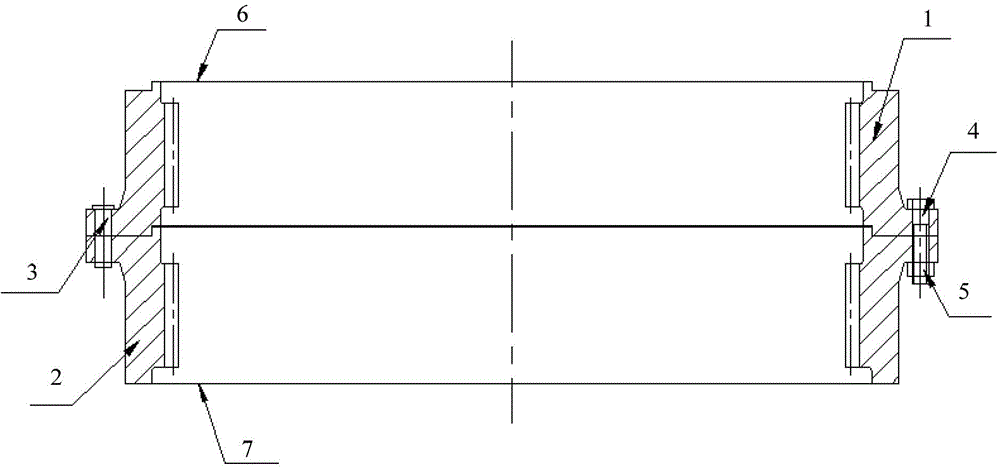

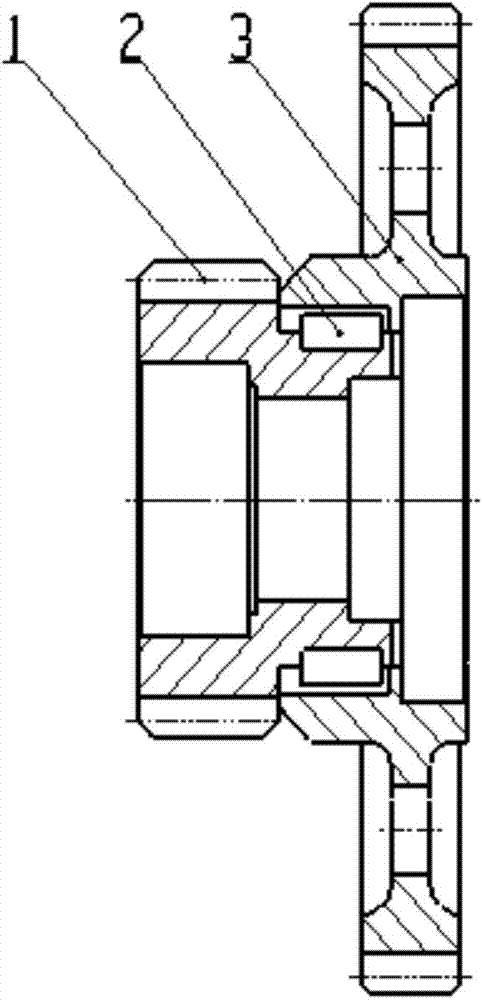

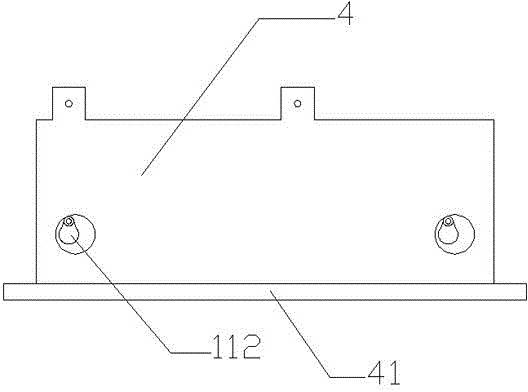

Face tooth grinding fixture

InactiveCN102248229AGuaranteed meshing accuracyExtended service lifeGear-cutting machinesGear teethLine of actionEngineering

The invention relates to a face tooth grinding fixture characterized by comprising a bottom support plate, wherein a dividing device is installed on the bottom support plate, a positioning sleeve is fixedly installed on the dividing device, the positioning sleeve and the dividing device are coaxially installed, a clamping device is arranged at the upper end of the positioning sleeve, an inclined surface is formed on the bottom surface of the bottom support plate, and the angle of the inclined surface is equal to the included angle between the root of the processed face tooth and the theoretical line of action. The face tooth grinding fixture has a simple and compact structure, low manufacturing cost and convenience in operation, can realize grinding of the face tooth only by a common tool grinder without needing extra special equipment, provides a means for grinding the face tooth, meets the requirement on the roughness of the face tooth surface, improves the tooth form accuracy, ensures the accuracy of mesh of the face tooth, prolongs the service life of the face tooth and reduces waste.

Owner:WUXI RL PRECISION MACHINERY

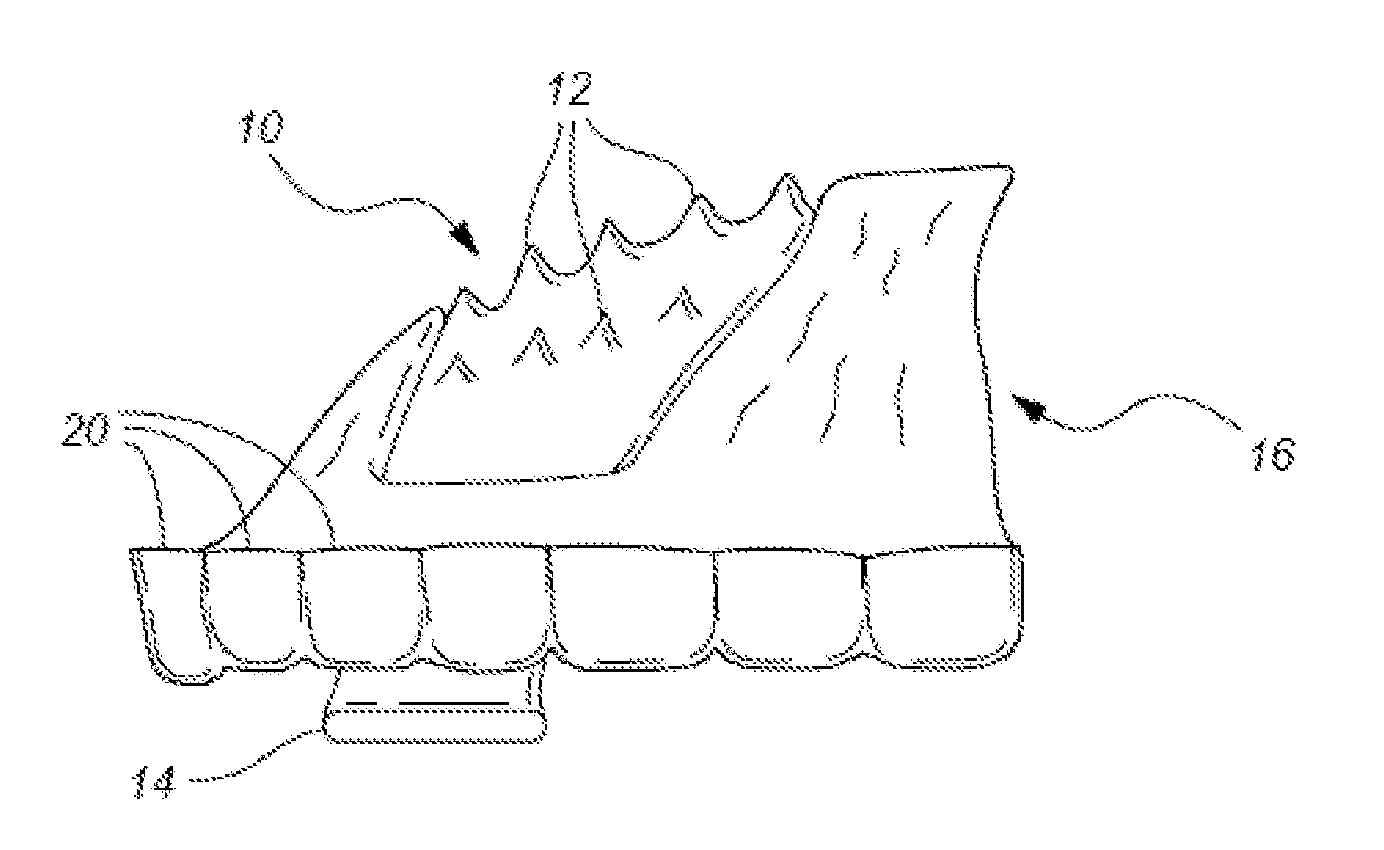

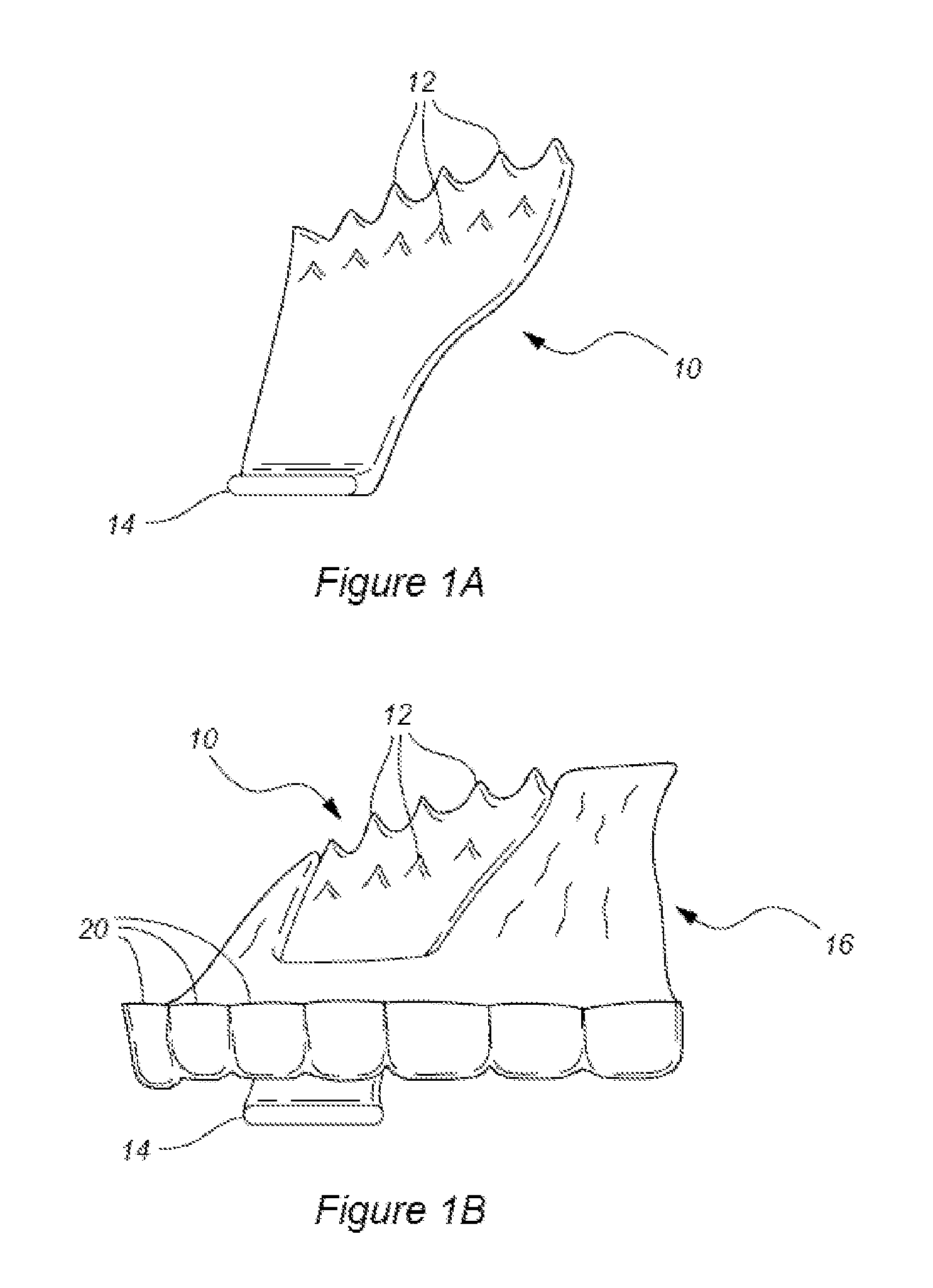

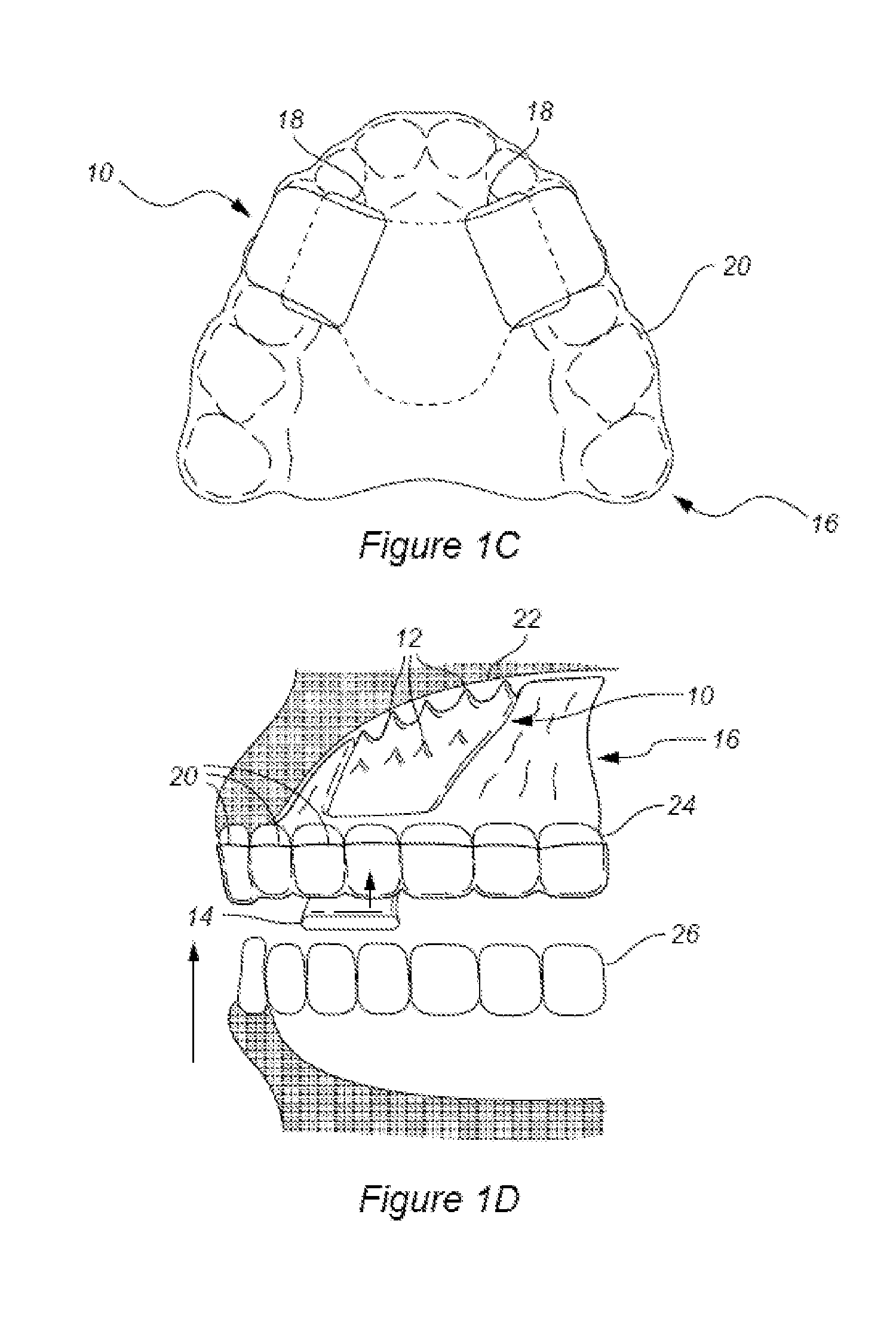

Device and Methods for Treatment of Bruxism and TMJ Disorder

InactiveUS20140190491A1Avoid developmentPreventing of tooth wearSnoring preventionNon-surgical orthopedic devicesIrritationTooth grinding

The present invention relates to a device and method of treating temporomandibular joint disorder (TMJ) and bruxism by placement in the mouth of an individual with a dental mouth guard to produce a minor irritation of the palate of a person suffering from temporomandibular joint disorder (TMJ) and bruxism through one or more irritation teeth or spines that mildly irritate the palate of a wearer when tooth grinding or maxillary pressure occurs. The mouth guard includes an irritation plate and a tooth molding for placement and fitting to a patient's upper dentition. The irritation plate employs irritation spikes whereupon commencing of tooth grinding initiate minor irritation to the palate of a wearer wherein, the wearer is alerted to the occurrence of tooth grinding, whether the wearer is sleeping or awake. The irritation plate also employs use of two “wings” that engage the wearer's teeth upon commencement of tooth grinding.

Owner:GARCIA RENE

Tooth grinding hotdog for pets and preparation method of tooth grinding hotdog

ActiveCN106720946APrevent obesityReasonable collocationAnimal feeding stuffAccessory food factorsHydrolysateFish oil

The invention discloses a tooth grinding hotdog for pets. The tooth grinding hotdog is prepared from an inner-layer sausage, interlayer stuffing and an outer-layer pork skin, wherein the inner-layer sausage is prepared from a first meat material, a component A and a component B; the interlayer stuffing is prepared from a second meat material, a component C and a component D; the component A is prepared from rice flour, vegetable protein, white granulated sugar, yeast hydrolysate, sweet potato flour, table salt, citric acid, garlic powder and functional auxiliary materials; the component B is prepared from glycerol and smoking spice; the component C is prepared from starch and table salt; the component D is prepared from glycerol and fish oil. The tooth grinding hotdog for the pets, disclosed by the invention, has balanced nutrients, bright color and very good layering, has the effects of cleaning teeth and grinding the teeth, and can also be used for improving digestion and refreshing the breath. The invention further discloses a preparation method of the tooth grinding hotdog for the pets; the preparation method has the advantages of a few of steps, simple flow and safety in operation.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

Plastic-injected tooth-cleaning pet chew food for pets and preparation method thereof

ActiveCN107927407APromote digestionPromote absorptionAnimal feeding stuffAccessory food factorsMechanical equipmentBone shape

The invention belongs to the field of pet food, in particular to a plastic-injected tooth-cleaning pet chew food for pets and a preparation method thereof. The sandwich layer of the food is in a porkrib shape or a knot-bone shape, and a meat layer rolls up or wraps the sandwich layer, so that the food is unique in appearance and more attractive to the pets, and has more interestingness. The foodhas good toughness and chewiness and strong biting resistance, and is suitable for pet tooth grinding. The food of the invention is easy to digest and absorb for the pets, and mechanical equipment ina processing process is often adopted so as to reduce labor, reduce cost and improve processing efficiency. Leather pet food (cattle hide and pigskin products) needs to be washed with chemical agentsto clean leather, which causes pollution to environment. The food of the invention replaces the leather food, and relieves environmental protection pressure.

Owner:烟台好氏宠物食品科技有限公司

Heat treatment method for medium-modulus and large-modulus gears

PendingCN109097533AUniform surfaceImprove quality stabilitySolid state diffusion coatingFurnace typesCarbon potentialEconomic benefits

The invention discloses a heat treatment method for medium-modulus and large-modulus gears. The heat treatment method comprises the following stages: preheating, heating, carburizing, diffusing, cooling, quenching, tempering and the like. In combination with design of a carburizing tool, according to the characteristics of the medium-modulus and large-modulus gears, through the temperature, the time and the carbon potential for heat treatment, the surface carburizing layer depth and the intrinsic quality are guaranteed; meanwhile, the quenching type selection and the oil temperature are scientifically adjusted; each factor affecting the carburizing and quenching deformation amount is considered to obtain a carburizing and quenching technological method suitable for the medium-modulus and large-modulus gears; the tooth surface accuracy of the medium-modulus and large-modulus gears treated by the heat treatment method provided by the invention can be guaranteed in GB7-GB9 grade, and thetooth surface accuracy can be not required to be corrected by a tooth grinding process after the heat treatment; by the heat treatment method, the surface of a gear product is guaranteed to be uniform, the quality stability is improved, the technological steps are optimized, the production time is effectively shortened, large-scale and batch production can be achieved, the production efficiency isimproved, and economic benefits are achieved.

Owner:HANDE AXLE (ZHUZHOU) GEAR CO LTD

Method for machining combined herringbone tooth part

The invention discloses a method for machining a combined herringbone tooth part. The method includes the steps of machining slots of two helical tooth part and machining an assembly hole on a first helical tooth part; aligning centering errors of the herringbone tooth and machining several assembly holes evenly distributed on a second helical tooth part; aligning centering errors of the herringbone tooth and performing assembly; re-inspecting the centering errors of the herringbone tooth and issuing a centering inspection report; aligning the pitch circle run-out according to the centering inspection report and fastening the pitch circle run-out through a bolt after centering of the herringbone tooth; finishing pinholes on the two helical tooth parts and drilling assembly holes left on the second helical tooth part; re-inspecting the centering errors of the herringbone tooth and providing a correction direction of one of the two helical tooth parts; and decomposing the two helical tooth parts and grinding teeth according to the correction direction to obtain the finished product. According to the method, through three times of alignment of the herringbone tooth centering, two times of error re-inspection of the herringbone tooth centering, tooth grinding, slotting, matching, assembly hole drilling and tooth grinding, drawing design requirements are met.

Owner:CHONGQING GEARBOX

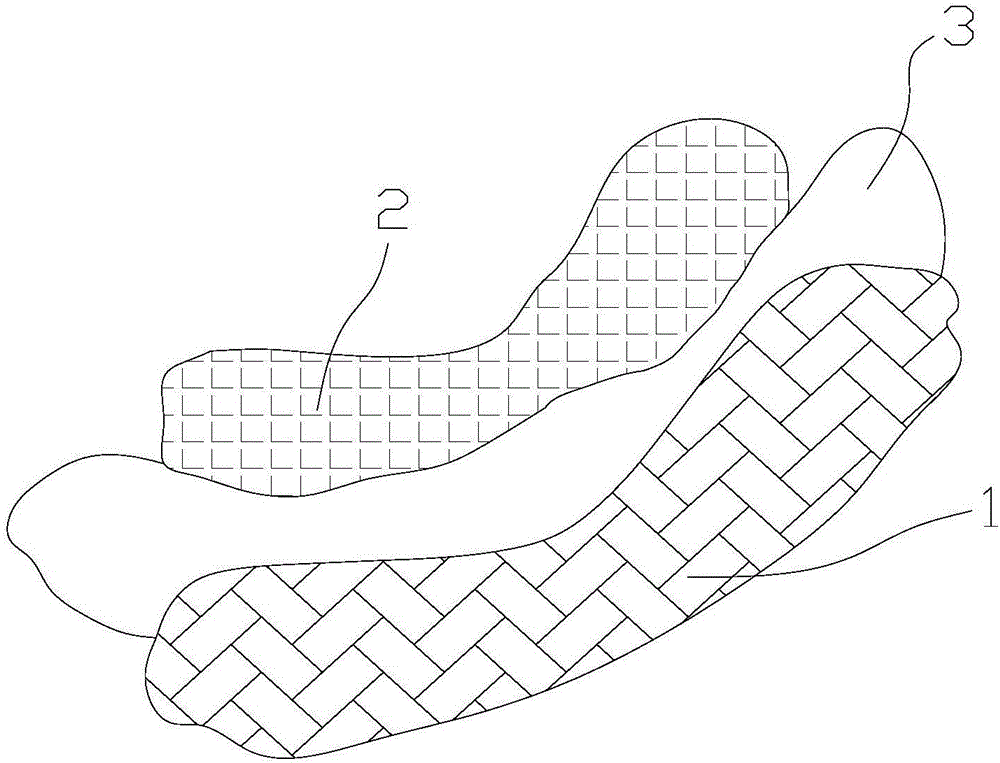

Split tooth prosthesis for fixing and repairing deficient toot and production method thereof

The invention provides a fission-typed dental prosthesis used for fixedly restoring lost tooth, comprising a whole bracket and a key way typed bridge tooth; the whole bracket is fixedly bonded to enamel used for abutment teeth at two sides of the lost tooth; the key way typed bridge tooth is fixedly bonded to the whole bracket in a zigzag way by a concave trough which is concave internally and arranged at the bottom of the key way typed bridge tooth, and forms a concave-surface contact with the adjacent surface of the abutment tooth. The preparation method of the fission-typed dental prosthesis of the invention is characterized in that non-functional area and inverted concave area of the abutment teeth at two sides of the lost tooth are analyzed on a model; wax-pattern is directly prepared on the copied original model; a suspension casting sprue is directly embedded so as to prepare the whole bracket by embedding, scorification and casting; subsequently, the key way typed bridge tooth is prepared. The fission-typed dental prosthesis needs no surgical operation, leads the manual denta prothesis to be firmly fixed on adjacent abutment teeth on the basis of no tooth-grinding or little tooth-grinding so as to bear the engaging force along all directions and uniformly disperse the force onto the abutment tooth, has good and natural appearance, good function, low cost, short treatment period, good fixing effect, and eliminates the black triangle area of adjacent teeth at the same time.

Owner:李奎范 +1

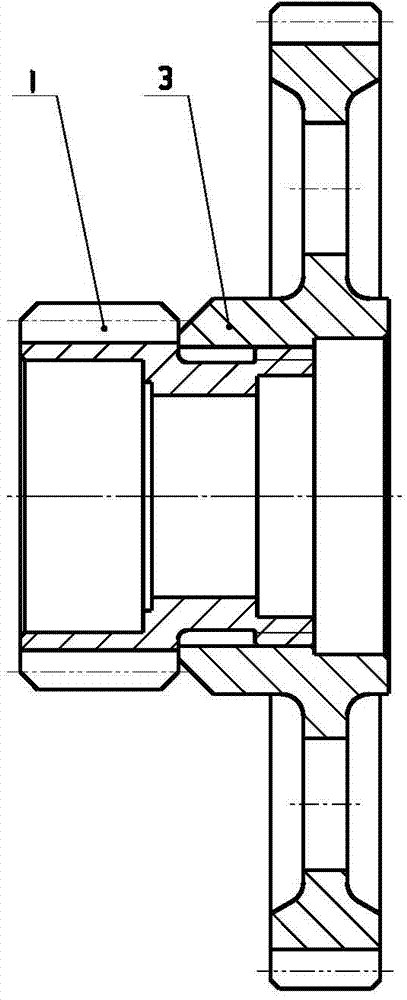

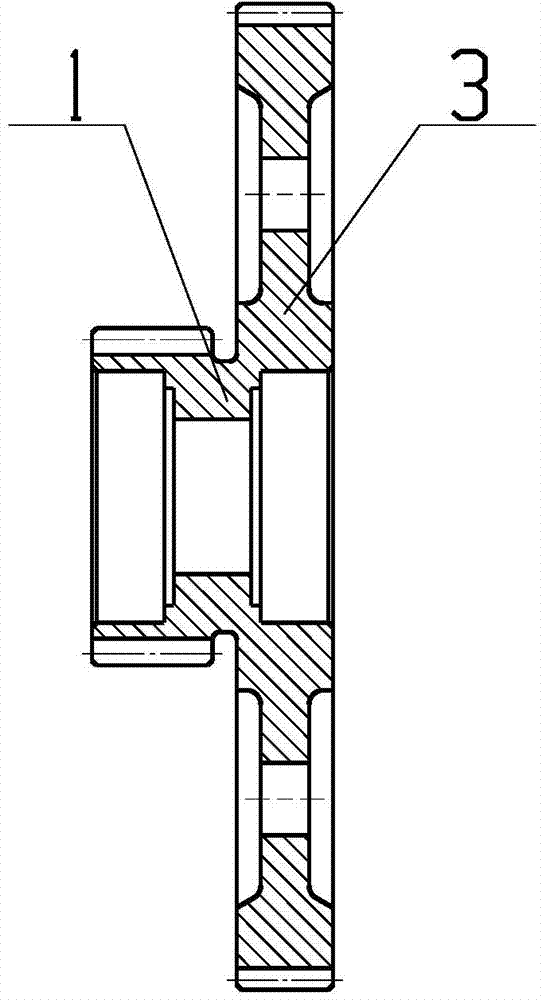

Method for forming splined connection type dual gears

The invention discloses a method for forming splined connection type dual gears. The method is used for solving the technical problem of low transmission precision of dual gears formed by an existing method for forming the dual gears. The technical scheme includes that the method comprises manufacturing and grinding teeth of a small-end gear and machining an external spline; machining an outer circle of a large-end gear, and manufacturing an internal spline; heating the large-end gear in an oil furnace and keeping the temperature of the oil furnace unchanged; taking out the large-end gear from the oil furnace, instantly sleeving the internal spline of the large-end gear onto the external spline of the small-end gear to form an assembly, enabling the internal spline to be in interference fit with the external spline and cooling the assembly in a cooling oil groove; manufacturing teeth of the large-end gear on the basis of a basic hole of the small-end gear after the assembly is cooled, and performing hobbing and tooth grinding machining on the large-end gear. The method has the advantages that the splined connection type dual gears are subjected to hot-press, the internal spline on the large-end gear is in interference fit with the external spline on the small-end gear, accordingly, the dual gears can be firmly connected with each other, and the transmission precision of the dual gears is improved to be higher than a fifth level from the seventh level in the prior art.

Owner:XIAN KUNLUN IND GRP

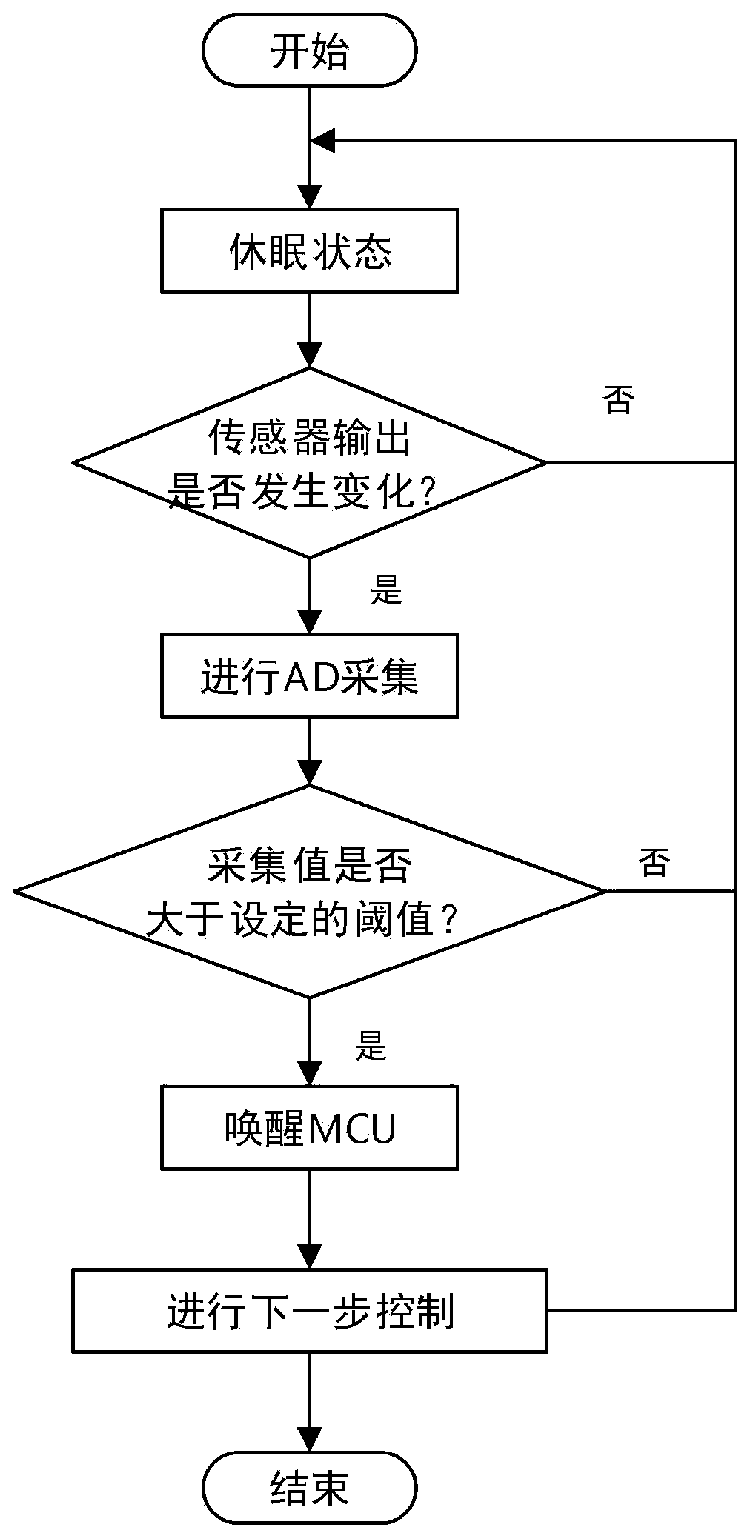

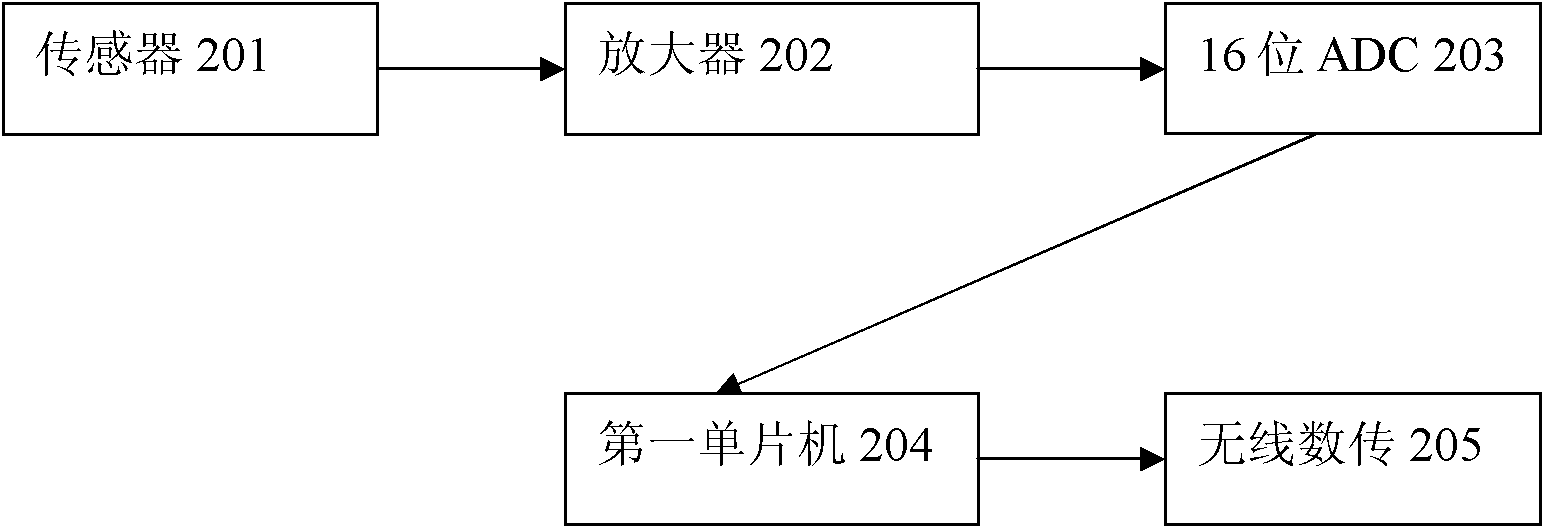

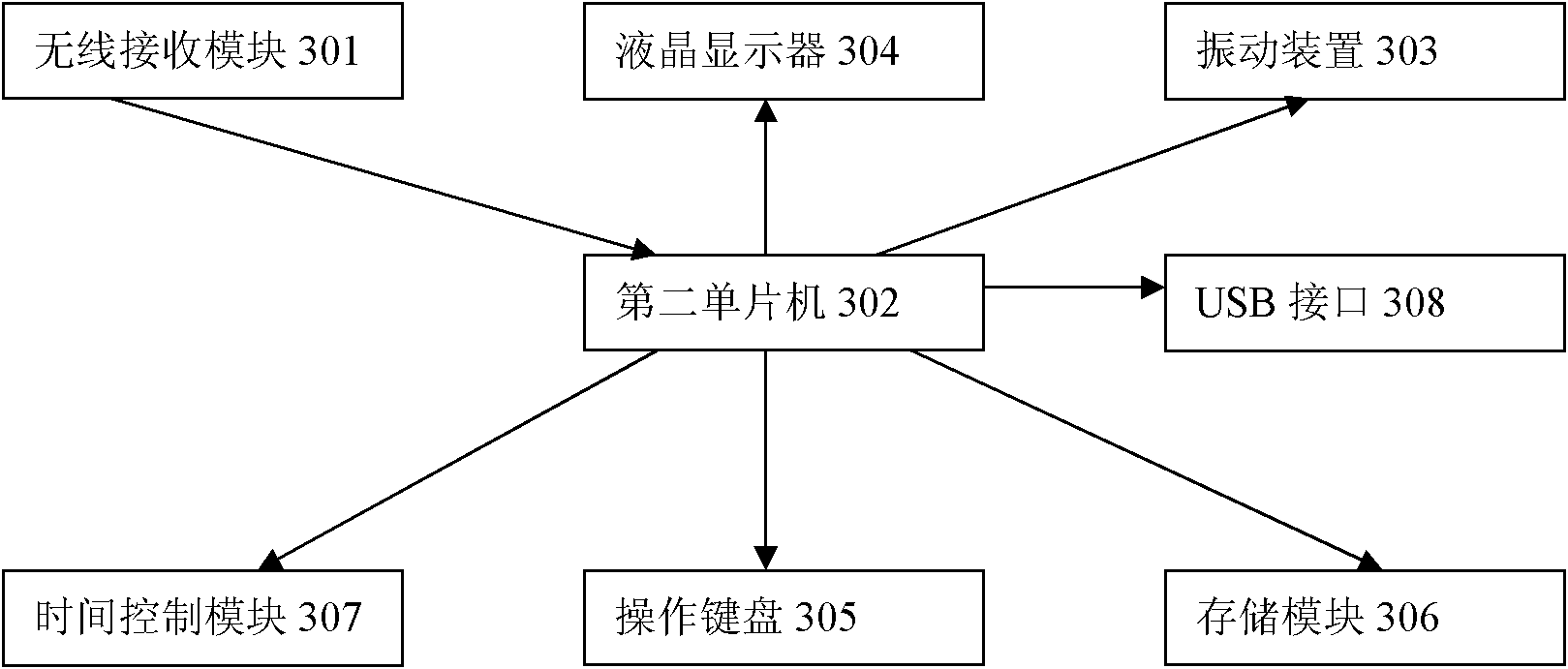

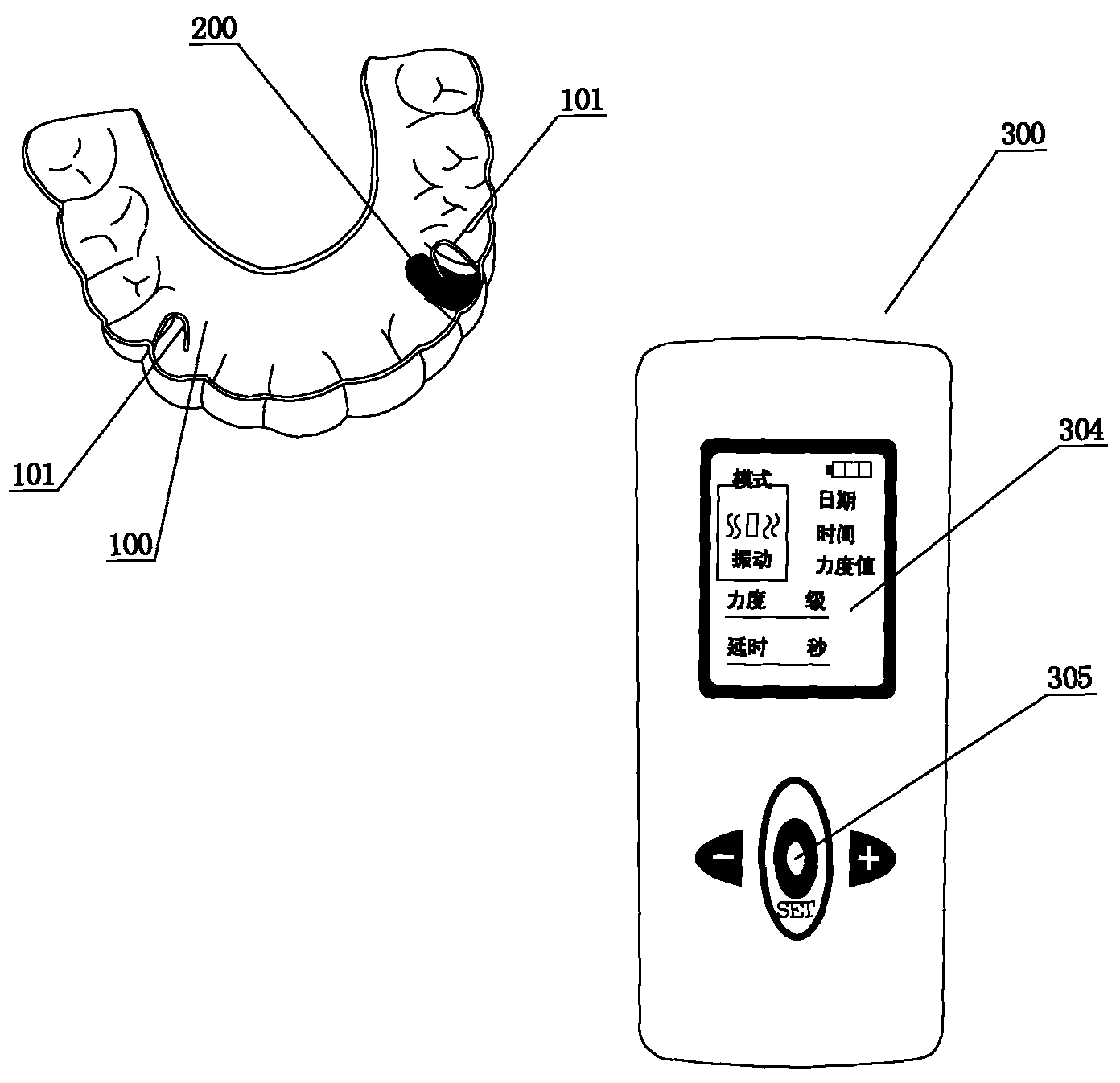

Biofeedback apparatus for treating odontoprisis

InactiveCN102178575AImprove anti-interference abilityFeedback data is accurateNon-surgical orthopedic devicesSleep inducing/ending devicesEngineeringBiofeedback

The invention provides a biofeedback apparatus for treating odontoprisis, which comprises an upper jaw biteplate (100), a sensing transmitting device (200) and a receiving controller (300), wherein the sensing transmitting device (200) is arranged in the upper jaw biteplate (100); and the sensing transmitting device (200) and the receiving controller (300) are connected. The biofeedback apparatus for treating odontoprisis is designed on the basis of two main factors, namely biting and nerves, directly monitors and acquires the signal of a pressure produced by an tooth grinding action, slightly wakes a patient by means of vibration and can be carried and used at home to provide objective and scientific data for the treatment and monitoring of the odontoprisis.

Owner:魏小龙 +2

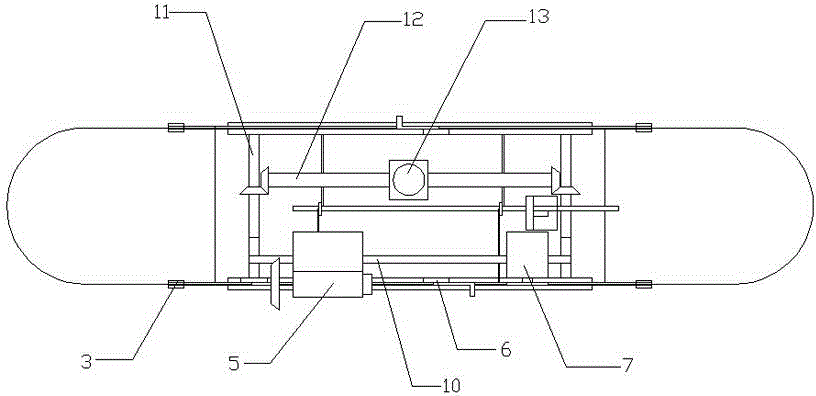

Automatic tooth grinding machine

ActiveCN105081467APrevent splashImprove grinding qualitySawing tools dressing arrangementsCircular sawEngineering

The invention discloses an automatic tooth grinding machine. The automatic tooth grinding machine comprises a machine frame. A grinding head motor is arranged on the machine frame and provided with a circular saw blade. The circular saw blade is connected with the grinding head motor through a rotating mechanism. The machine frame is provided with a front angle adjustment left-and-right movement mechanism. The grinding head motor is connected with the front angle adjustment left-and-right movement mechanism. The machine frame is further provided with a chamfer front-and-back movement mechanism. The chamfer front-and-back movement mechanism is connected with the front angle adjustment left-and-right movement mechanism. The machine frame is further provided with a tooth grinding up-and-down movement mechanism. The tooth grinding up-and-down movement mechanism is connected with the chamfer front-and-back movement mechanism. According to the automatic tooth grinding machine, high-speed automatic tooth grinding of the circular saw blade is achieved, and the saw blade tooth grinding quality and the saw blade tooth grinding efficiency are improved correspondingly; the circular saw blade and a grinding wheel can be controlled to move more flexibly, and the working efficiency is greatly improved.

Owner:浙江缙云韩立锯业有限公司

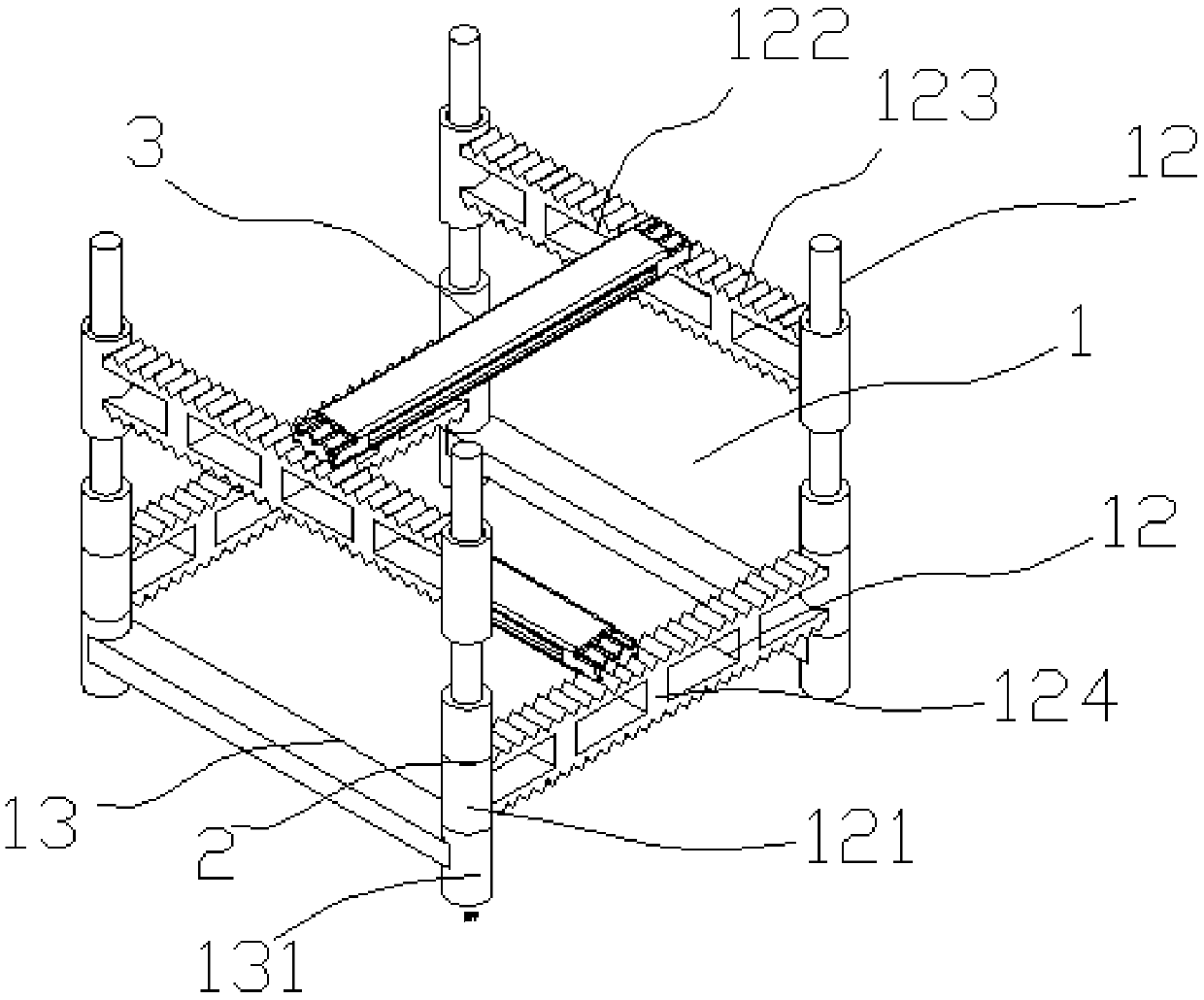

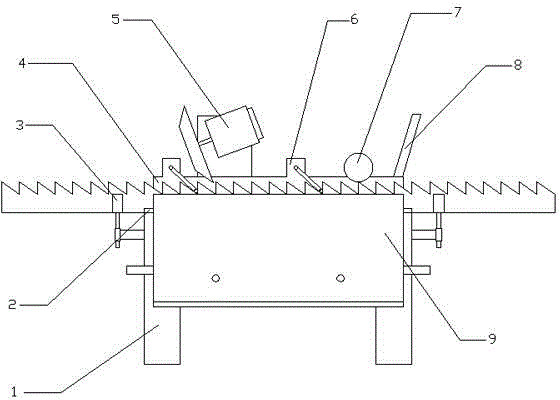

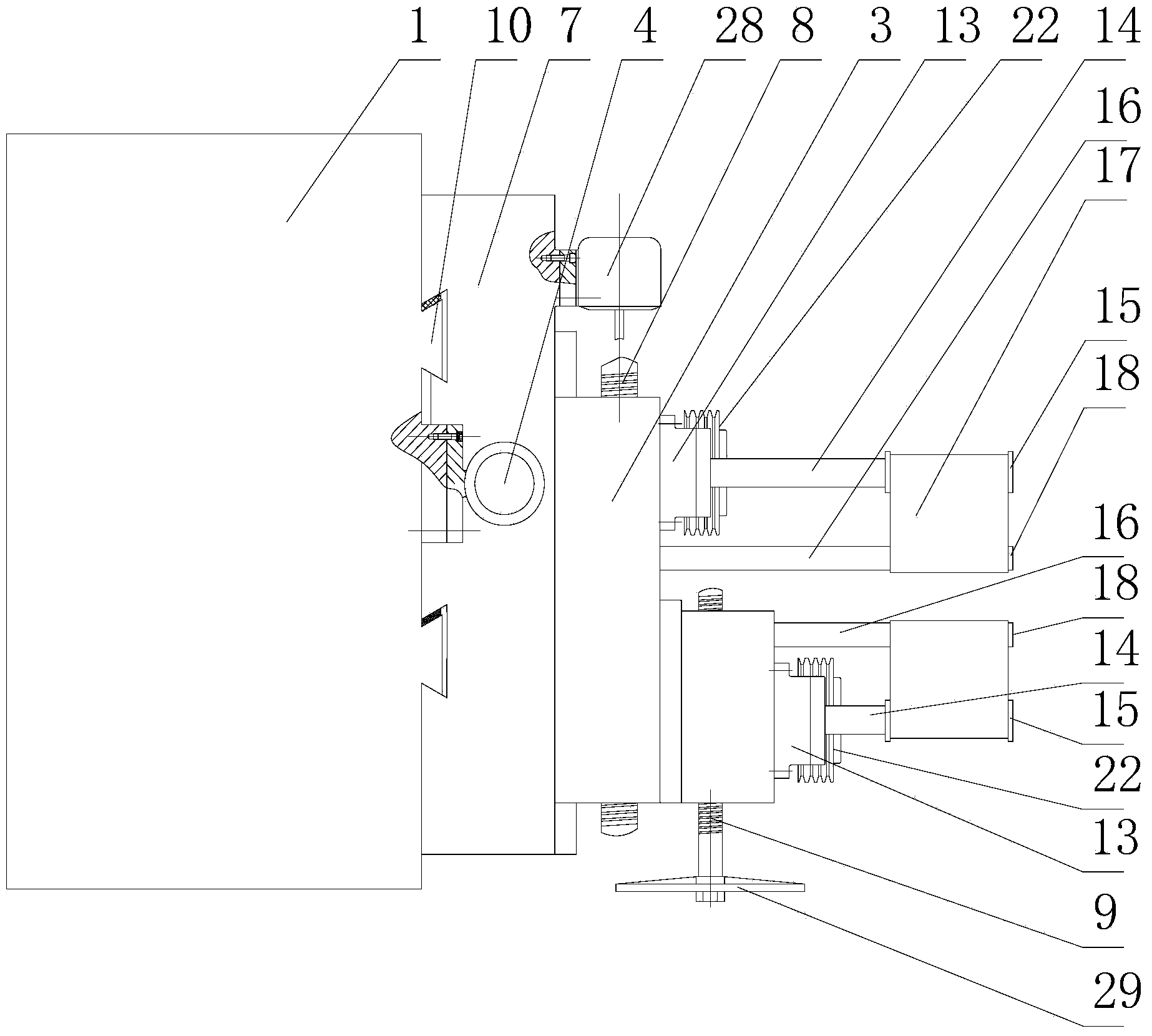

Full-automatic saw grinding and tooth pressing machine

InactiveCN104607719AHigh speedImprove work efficiencySawing tools dressing arrangementsArchitectural engineeringDrive motor

The invention provides a full-automatic saw grinding and tooth pressing machine which comprises a machine tool frame body, a worktable used for holding a band saw is arranged at the upper end of a machine tool frame, a tooth grinding portion and a tooth pressing portion are arranged on the worktable on one side, a drive motor and a transmission rod are arranged in the middle of the machine tool frame, the two ends of the transmission rod are provided with two transmission transverse rods perpendicular to the transmission rod, and the two ends of the transmission rod are in transmission with the transmission transverse rods through conical gears. By means of the machine, grinding, poking, tooth pressing and a series of procedures can be automatically finished on sawteeth of the band saw, the step that the sawteeth need to be staggered manually after the teeth are ground through a traditional saw grinding machine is omitted, and the saw grinding and saw trimming speed can be effectively increased.

Owner:李振英

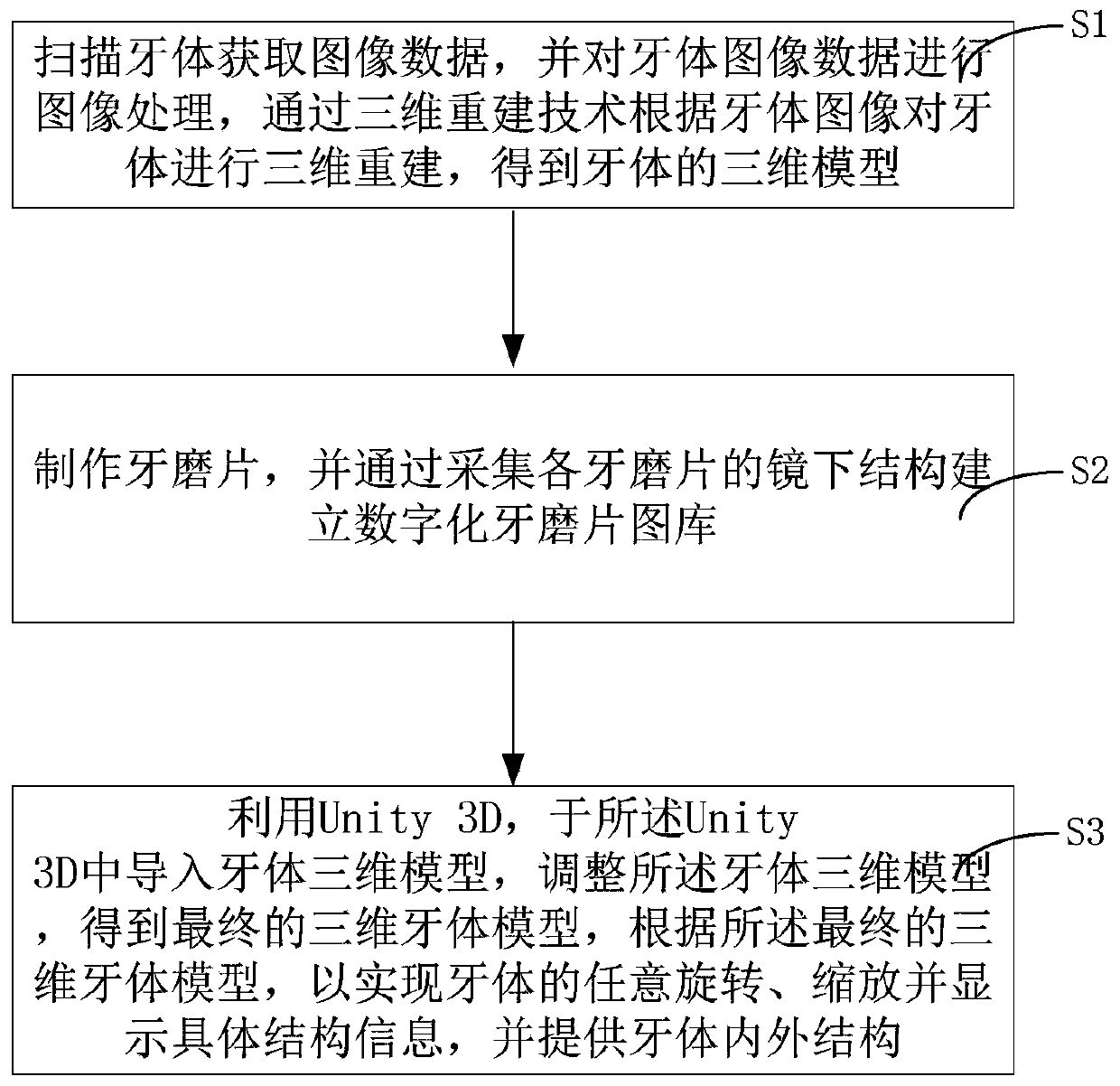

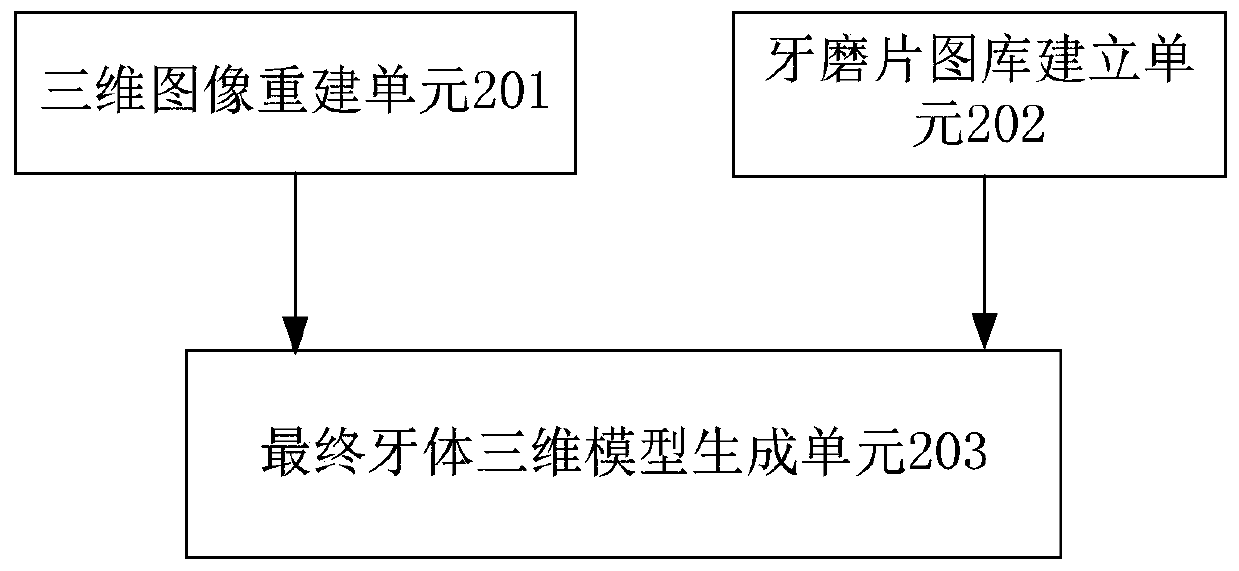

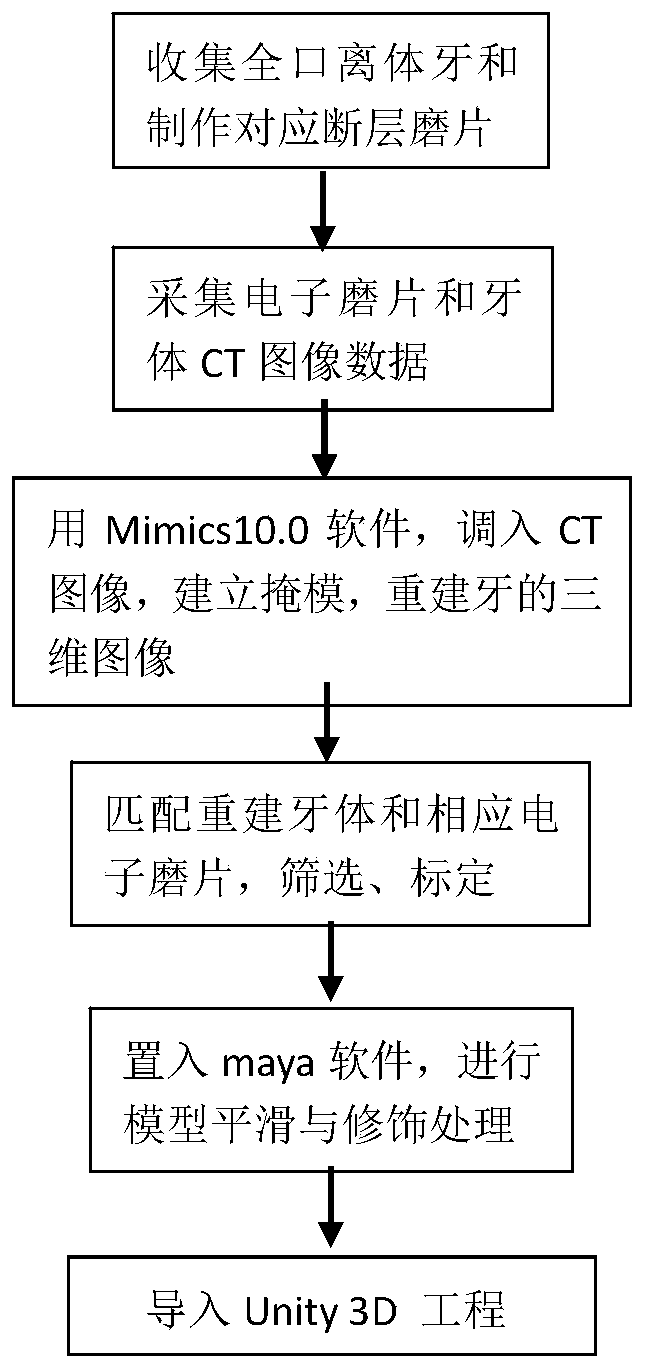

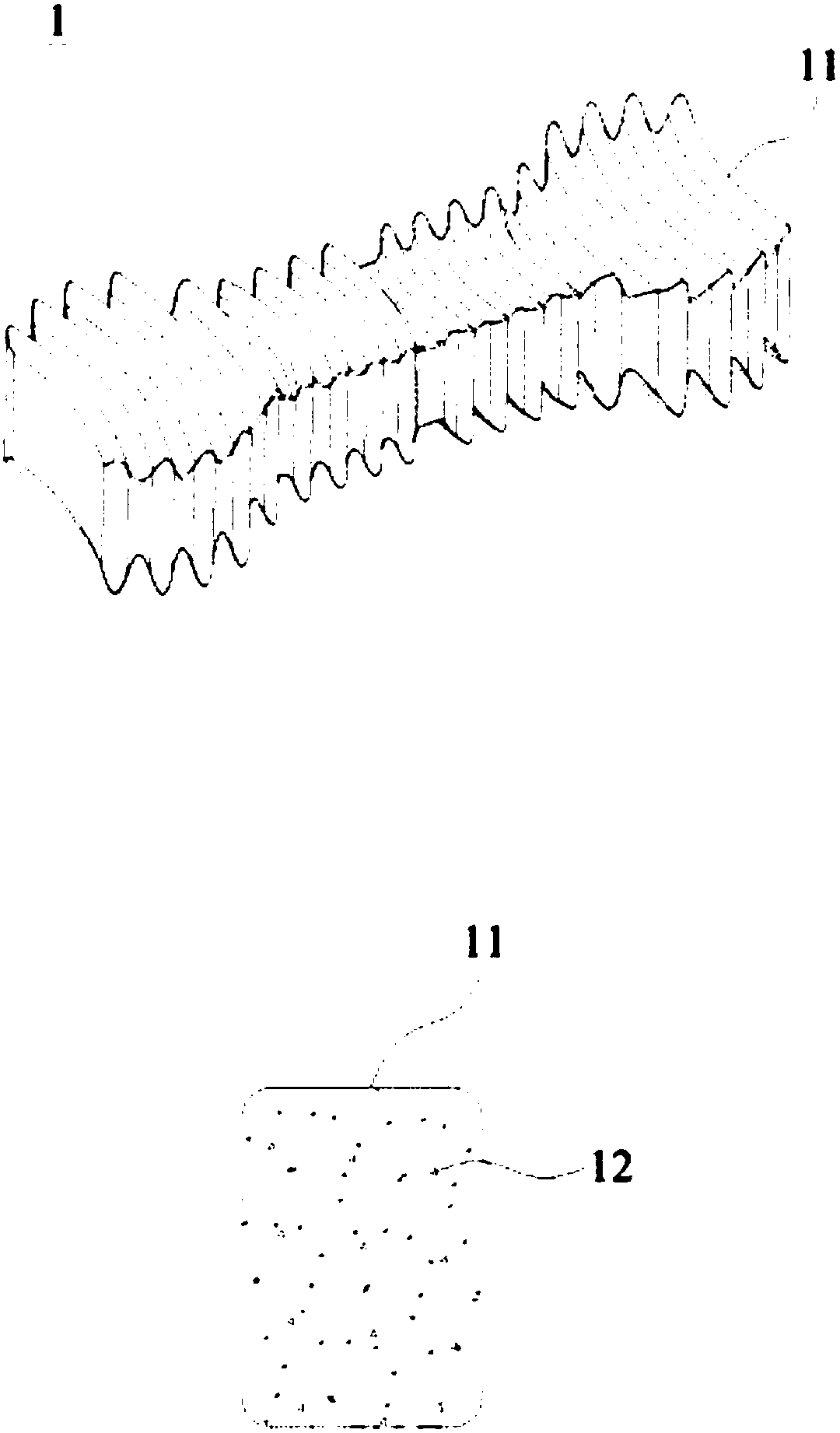

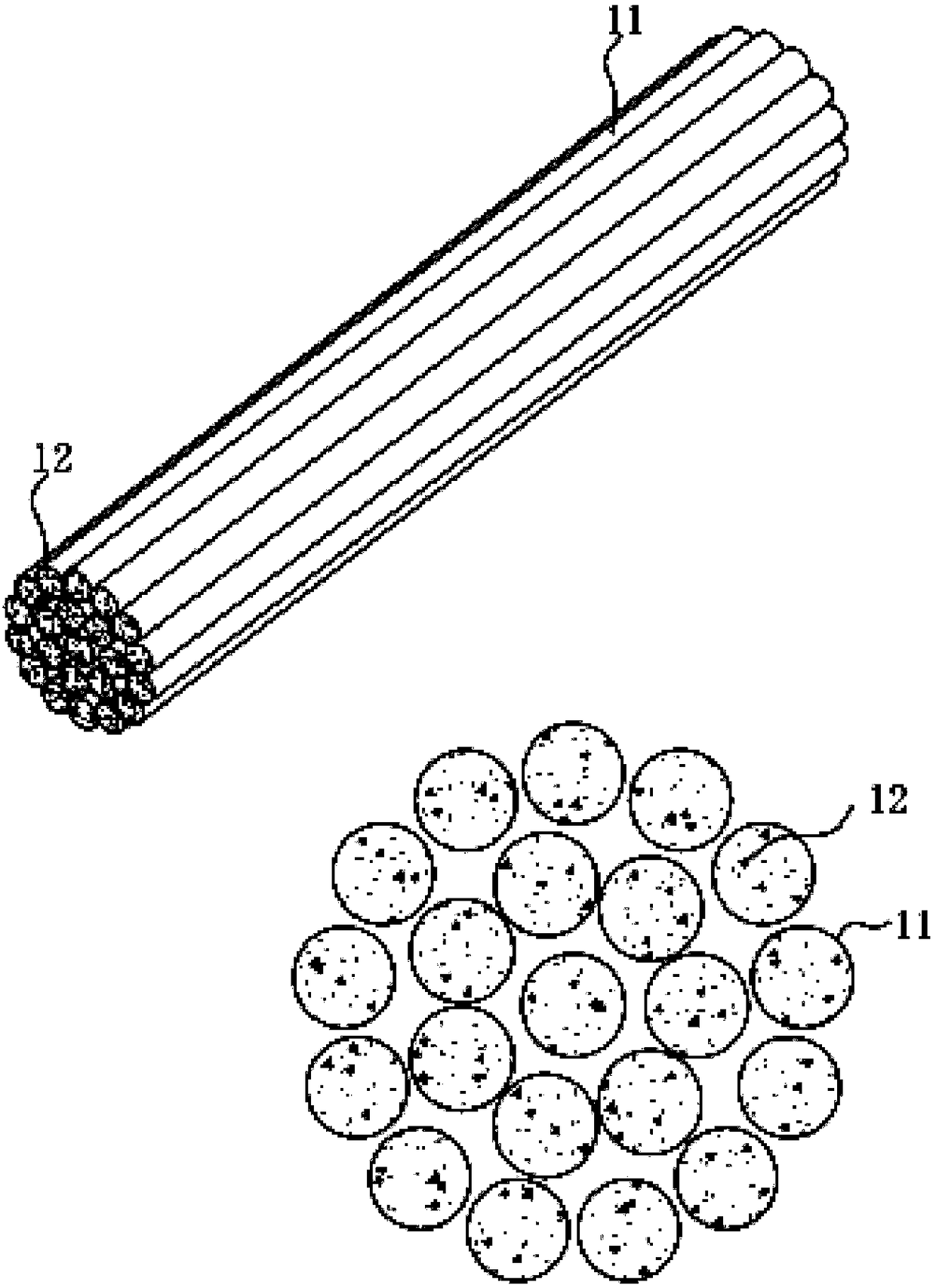

A three-dimensional tooth model construction method and system based on Unity 3D

ActiveCN109920047AClear structureQuality improvementImage analysis3D modellingImaging processingBody images

The invention discloses a three-dimensional tooth model construction method and system based on Unity 3D. The method comprises the following steps: step S1, scanning a tooth body to obtain image data,carrying out image processing on the tooth body image data, and carrying out three-dimensional reconstruction on the tooth body according to a tooth body image through a three-dimensional reconstruction technology to obtain a three-dimensional model of the tooth body; S2, manufacturing tooth grinding sheets, and establishing a digital tooth grinding sheet image library by collecting the submirrorstructure of each tooth grinding sheet; Step S3, utilizing the Unity 3D, introducing a tooth body three-dimensional model into the Unity 3D, adjusting the three-dimensional model of the tooth body; obtaining a final three-dimensional tooth model. according to the three-dimensional tooth model, achieving random rotation, zooming and display of specific structure information of the tooth accordingto the final three-dimensional tooth model, providing an internal and external structure of the tooth. The method can solve the problems that a laboratory is lack of the tooth model and students are difficult to collect the tooth with complete tooth positions and typical structures.

Owner:HOSPITAL OF STOMATOLOGY SUN YAT SEN UNIV

Pet chews with tooth-care effect and preparation method thereof

ActiveCN108243988AFlexibleMalleableAnimal feeding stuffAccessory food factorsAdhesivePathogenic bacteria

The invention discloses a pet chews with a tooth-care effect and a preparation method thereof and belongs to the field of pet tooth-care toys. The pet chews comprises a carrier, an adhesive, probiotics and prebiotics, wherein the probiotics are human intestinal prebiotics flora beneficial to human bodies. The pet chews has the advantages that the tooth-grinding-liking nature of pets is utilized, the probiotics and the prebiotics are added into the pet chews, and pet teeth can be cleaned when a pet chews the pet chews for a long time; in addition, the probiotics and the prebiotics are mixed through the adhesive, a lot of the probiotics and the prebiotics are adhered to the oral cavity of the pet, the prebiotics promote the planting of the probiotics to form the dominant prebiotics flora, the growth of oral cavity pathogenic bacteria and germs harmful to human bodies is inhibited, pet oral cavity health can be maintained, and pet oral cavity odor can be eliminated.

Owner:GONGLIN IND SHENZHEN

Large gear adhesive belt tooth grinding machine

The invention provides a large gear adhesive belt tooth grinding machine, and relates to a large gear machining device. The large gear adhesive belt tooth grinding machine comprises a machine base, a stand column, a rotating working table, a servo motor, a ball screw I and a power head, and is characterized in that the rotating working table is assembled at one end of the upper portion of the machine base, the stand column is assembled at the other end of the upper portion of the machine base, the power head is assembled on the stand column through a swallow-tail-shaped guide rail I, the servo motor is assembled on the stand column and connected with the ball screw I on the power head so as to drive the power head to move up and down along the swallow-tail-shaped guide rail I, and the rotating working table is assembled on the machine base through the guide rail, connected with a rapid oil cylinder on the machine base and driven by the rapid oil cylinder to move leftward and rightward along the guide rail. The large gear adhesive belt tooth grinding machine has the advantages of being novel in structure, easy and convenient to machine, convenient to use, high in grinding efficiency, high in adaptability, high in machined product quality, short in auxiliary time and the like, and therefore the large gear adhesive belt tooth grinding machine is a novel large gear adhesive belt tooth grinding machine which integrates economical efficiency and practicability.

Owner:DALIAN JIAOTONG UNIVERSITY

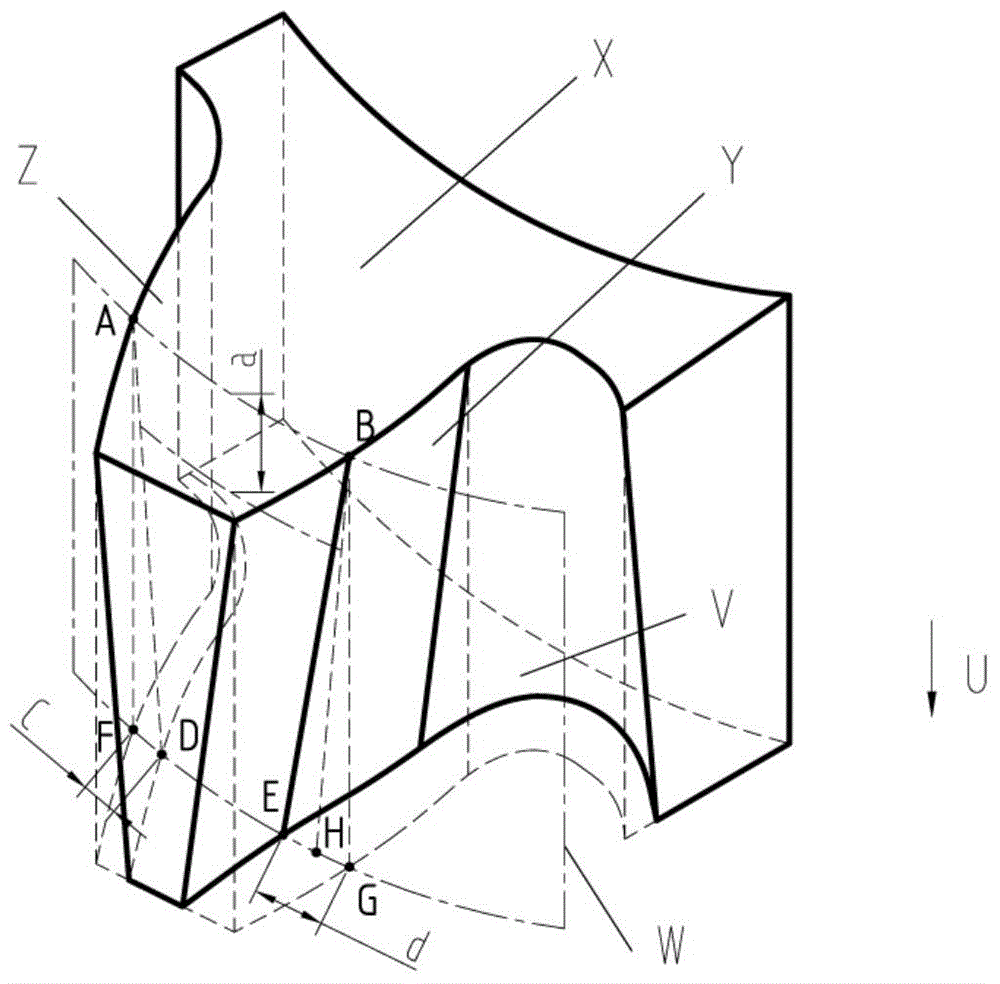

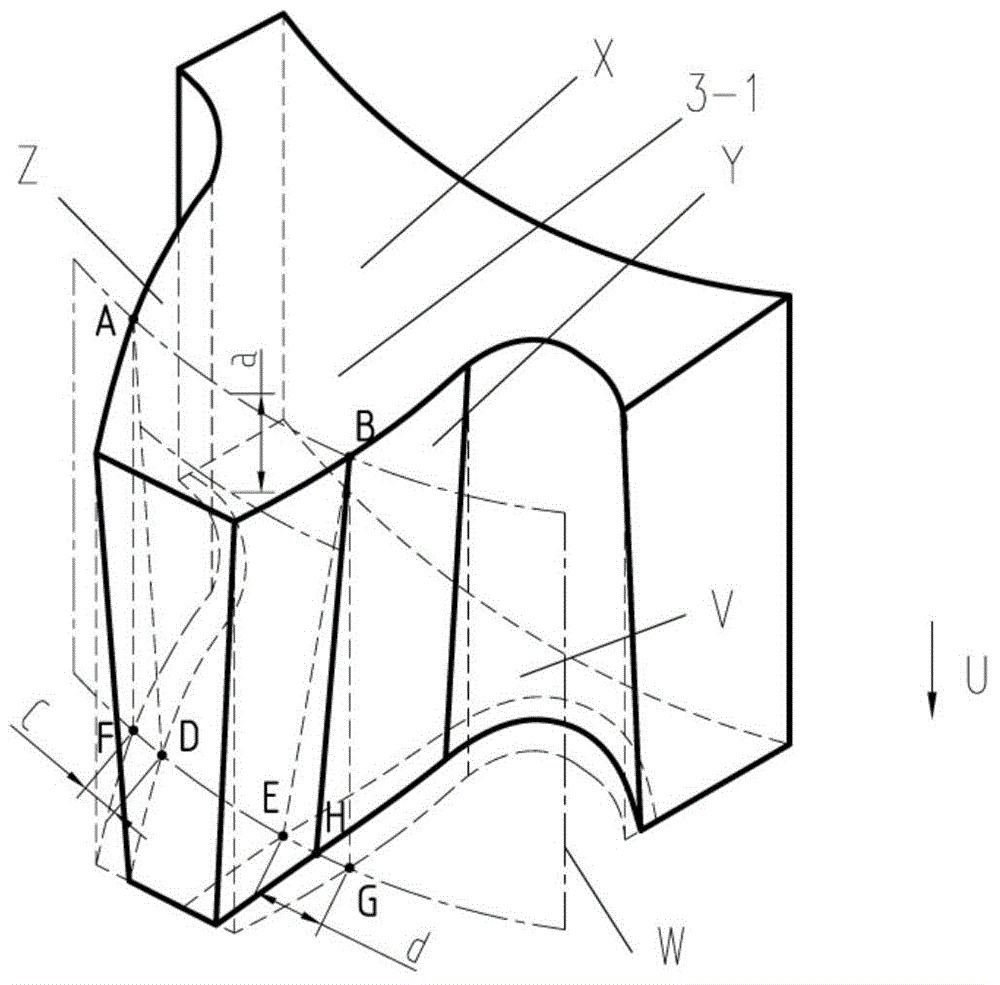

Design method of large axial modification amount gear and large axial modification amount gear

ActiveCN104565289AAvoid Hardness LossAvoid defects such as deep enoughPortable liftingGearing elementsHardnessEngineering

The invention provides a design method of a large axial modification amount gear and the large axial modification amount gear. The design method comprises the steps of determining the design parameters of the large axial modification amount gear according to conditions based on the parameters and the axial modification amount of a set basic gear model, determining the tooth surfaces of the first non-modified gear model and the second non-modified gear model of the large axial modification amount gear before modification, performing axial modification on the tooth surfaces of the first non-modified gear model and the second non-modified gear model, and then obtaining the large axial modification amount gear so that the axial modification amount of one side of the left and right tooth surfaces is 0, while the axial modification amount of the other side is the absolute value of d-c; as a result, a tooth grinding lug boss is avoided, the tooth surface hardness and the depth of a carburized layer are improved, and the reliability of the gear is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com