Patents

Literature

1950results about How to "High transmission precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

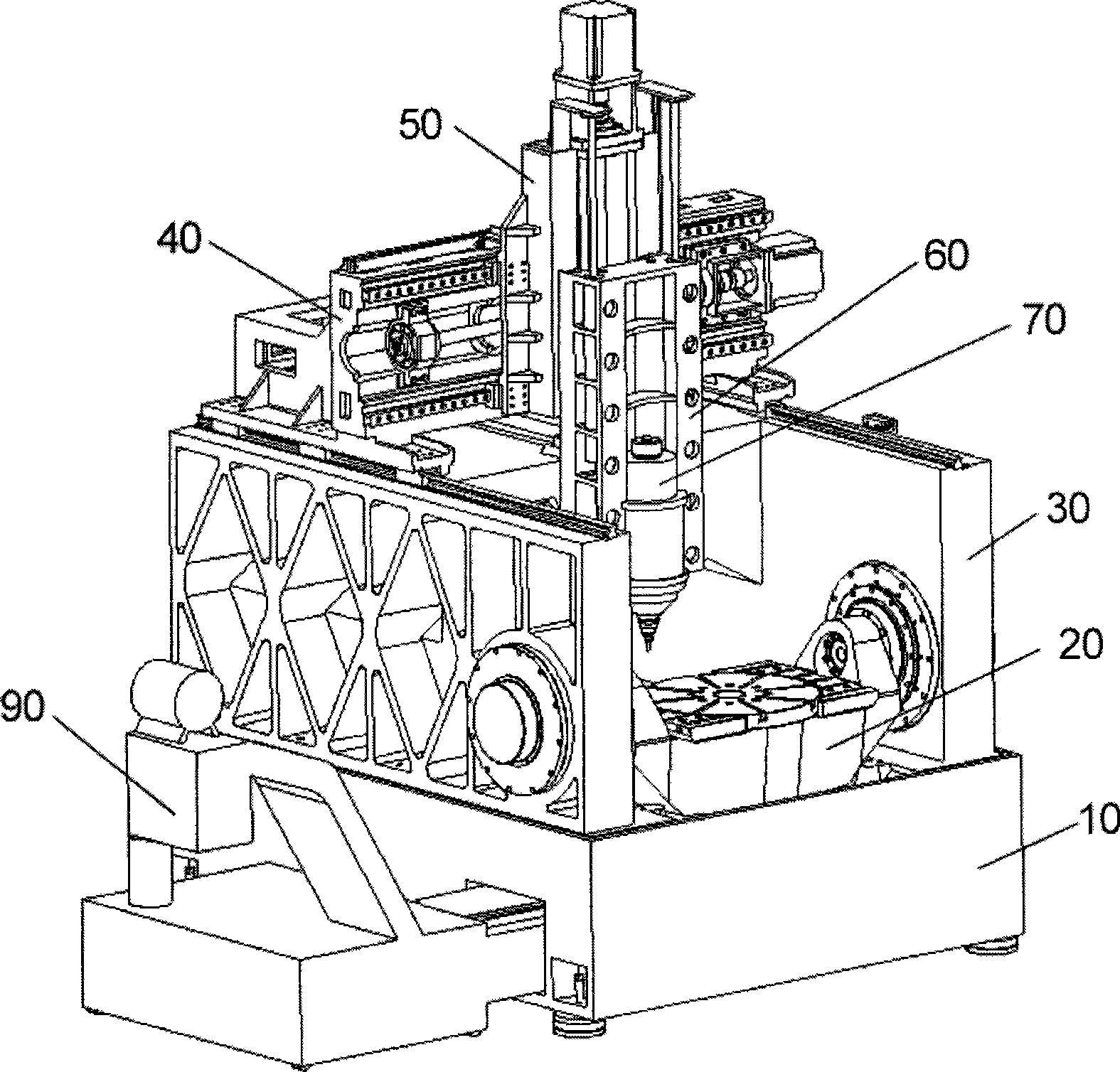

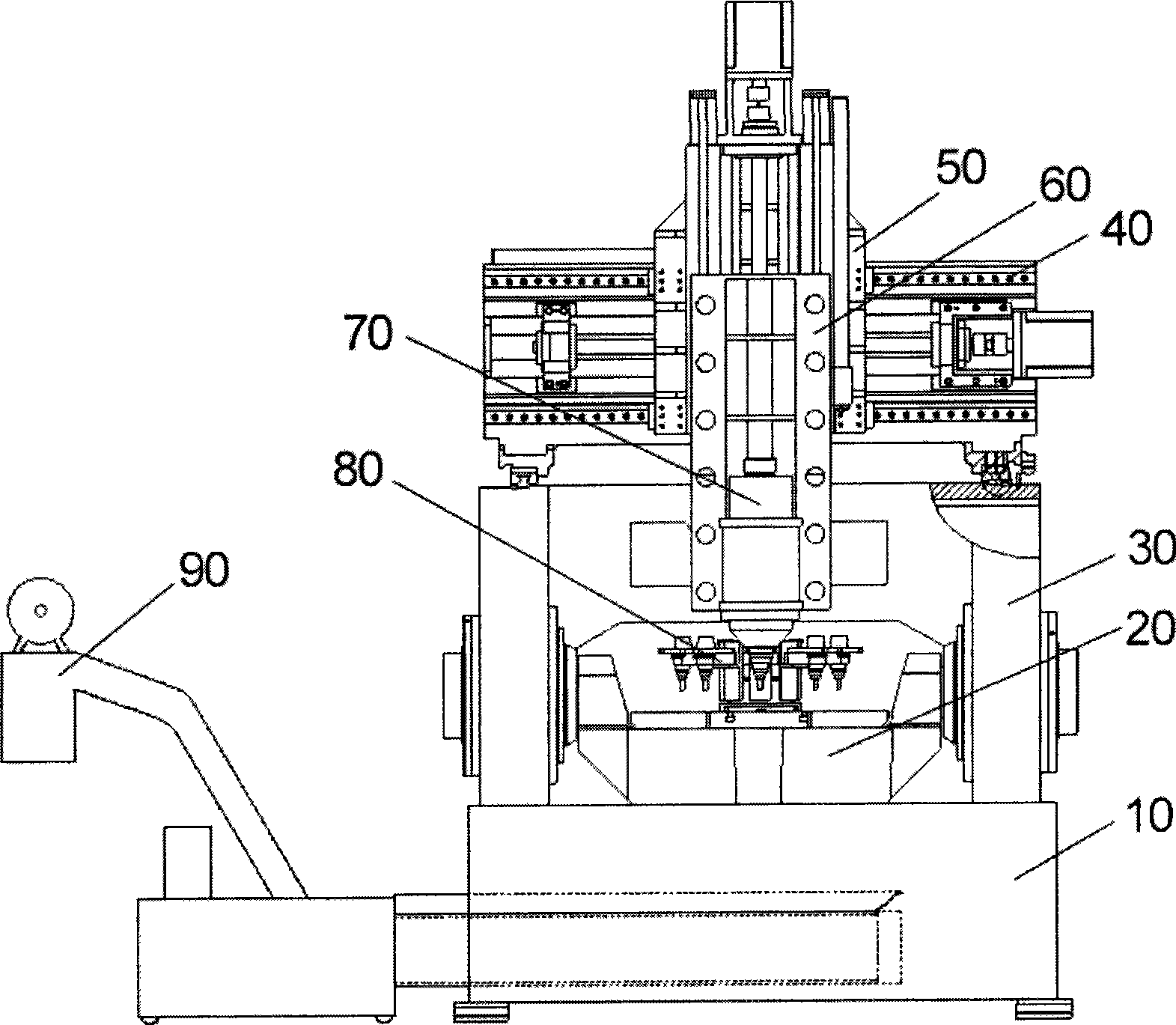

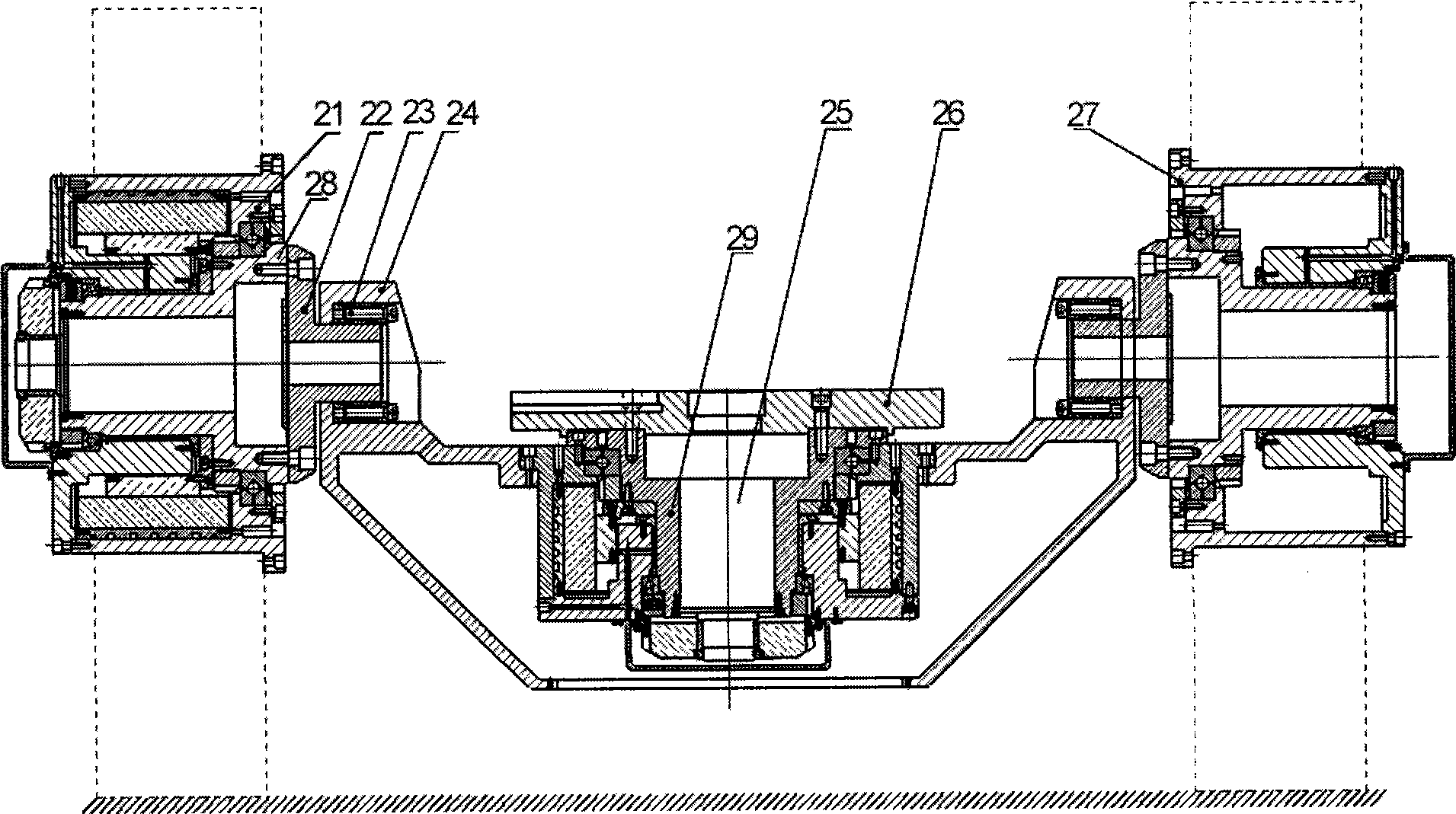

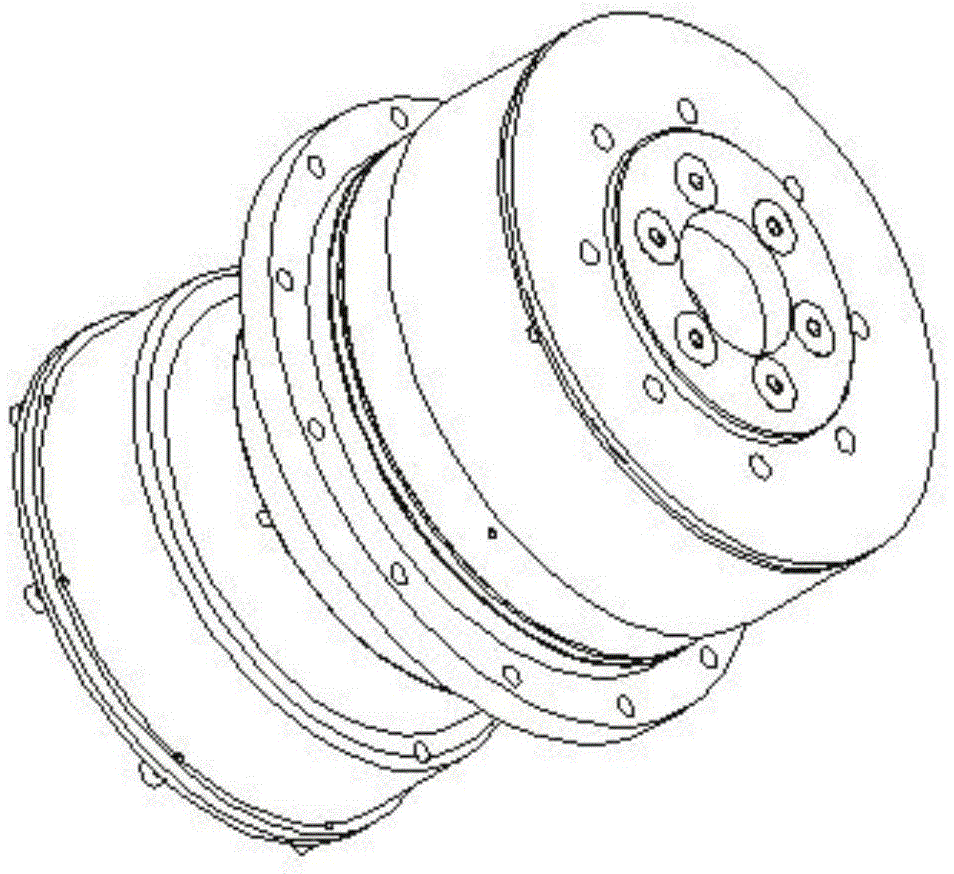

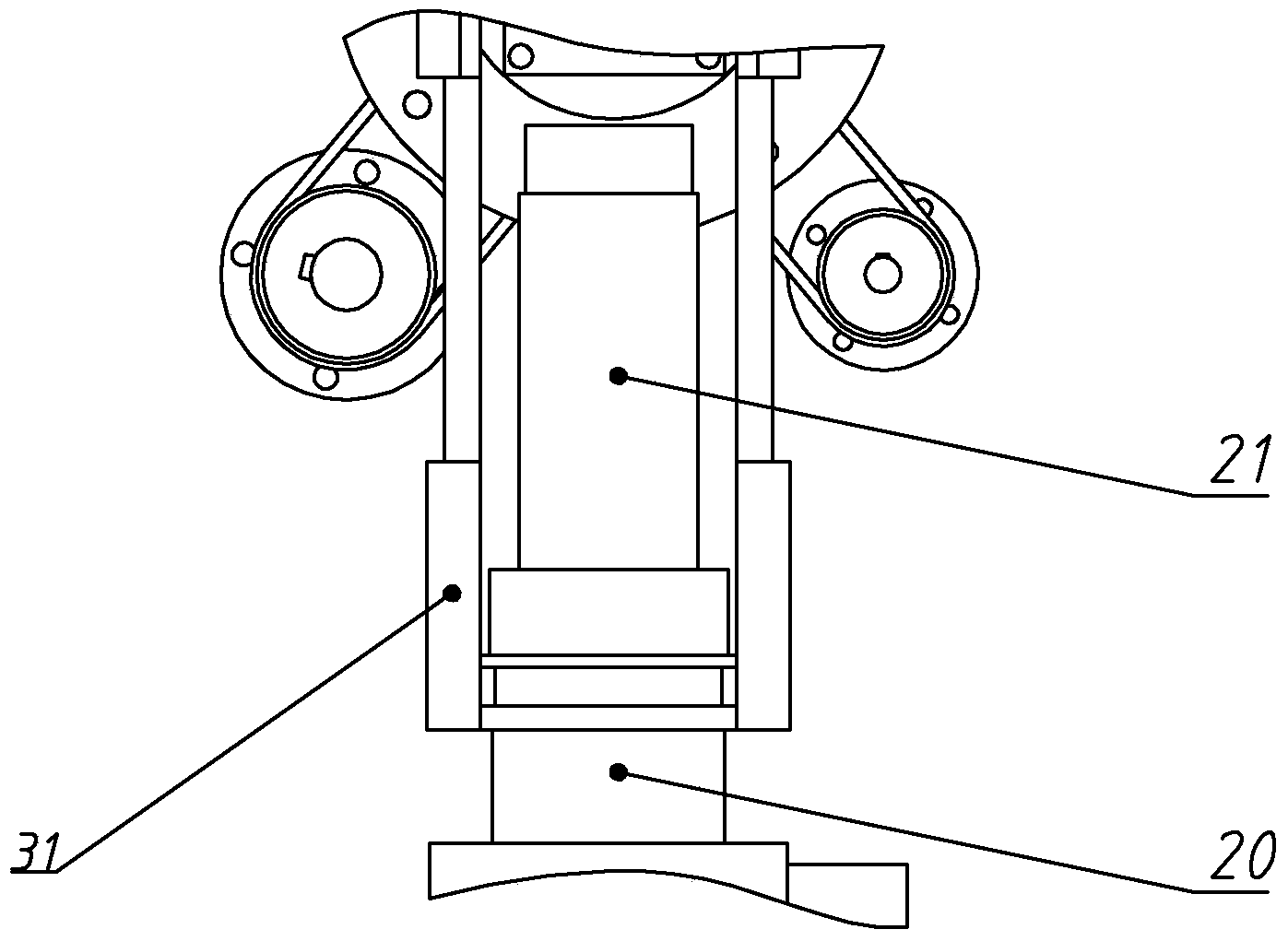

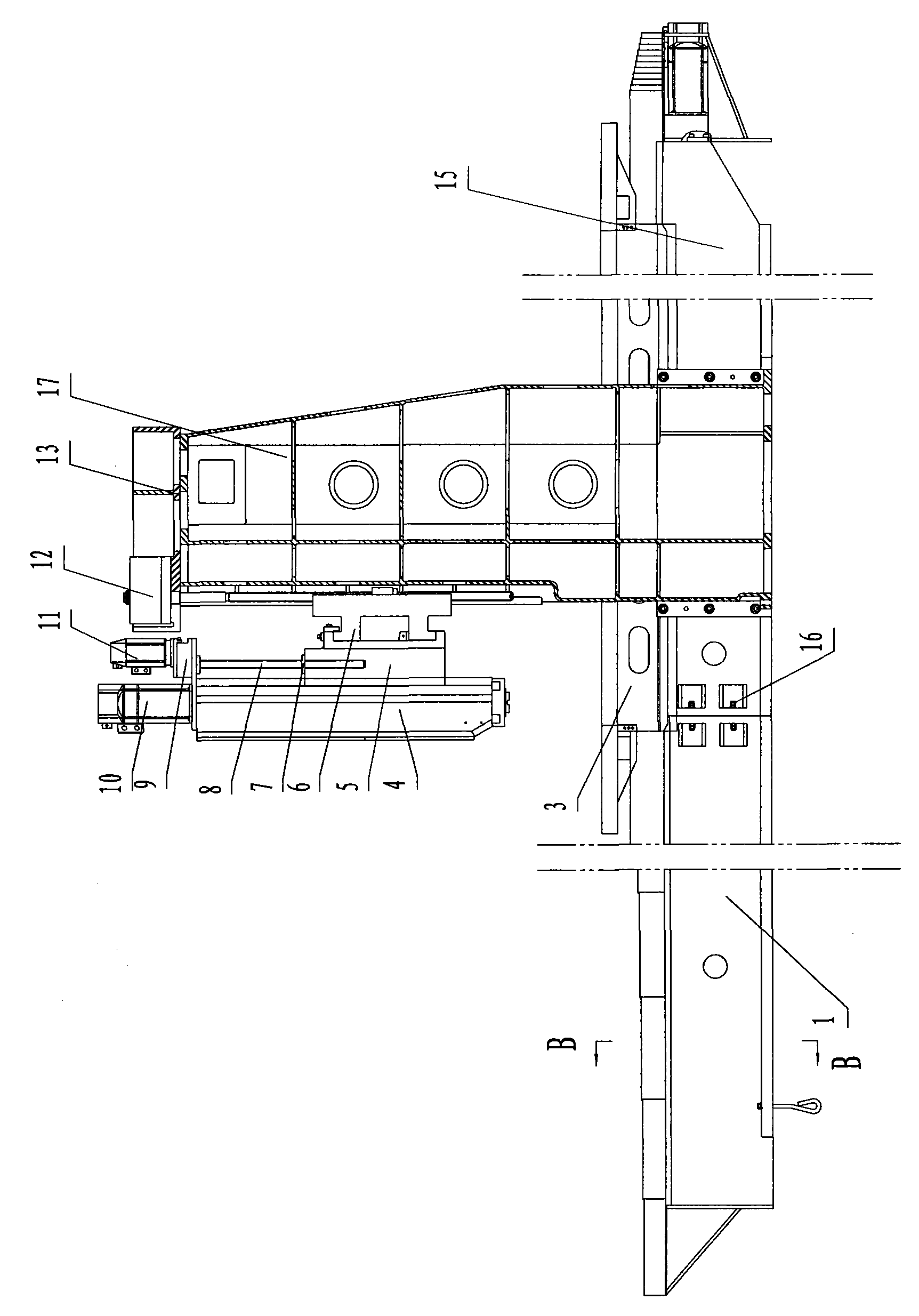

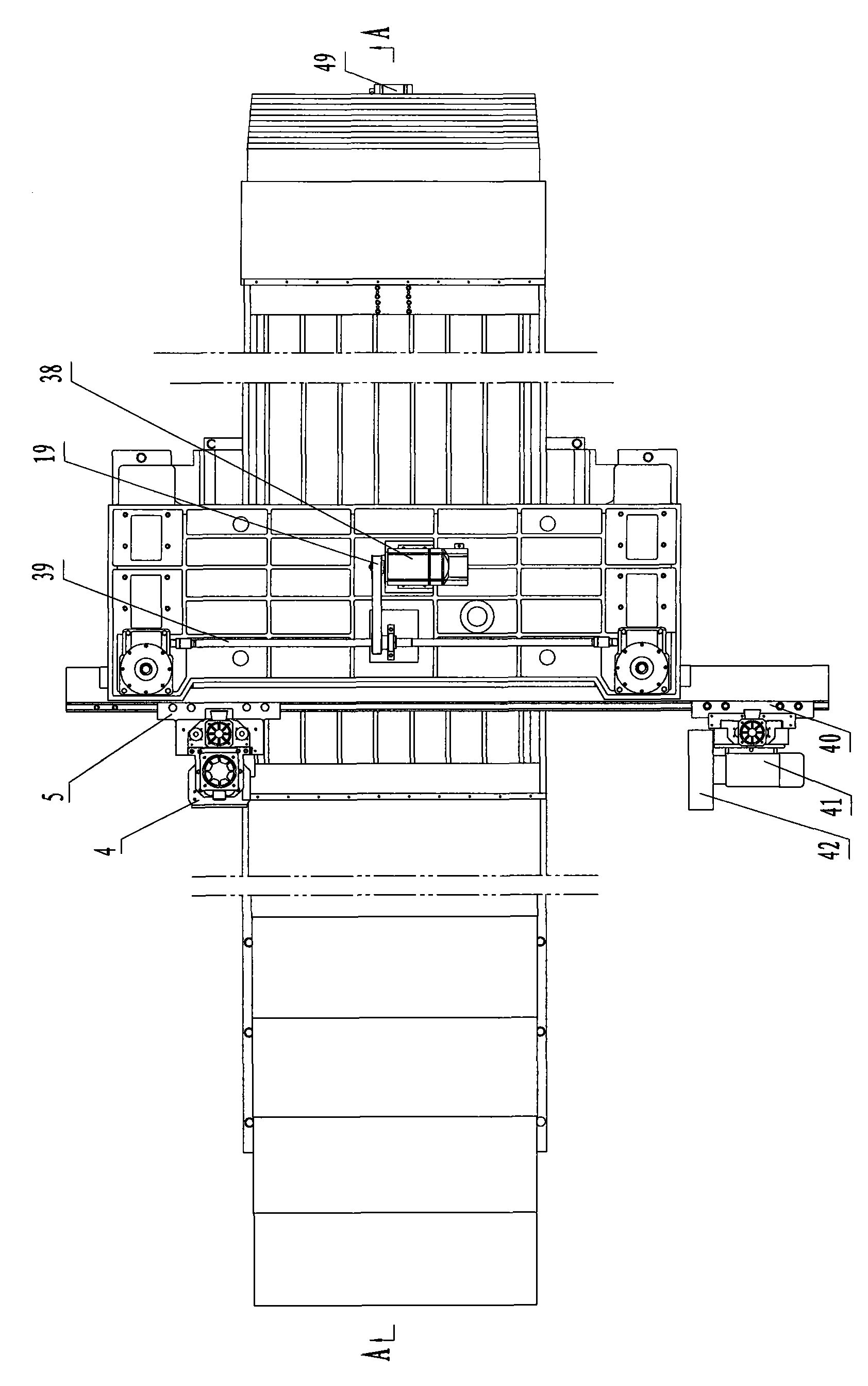

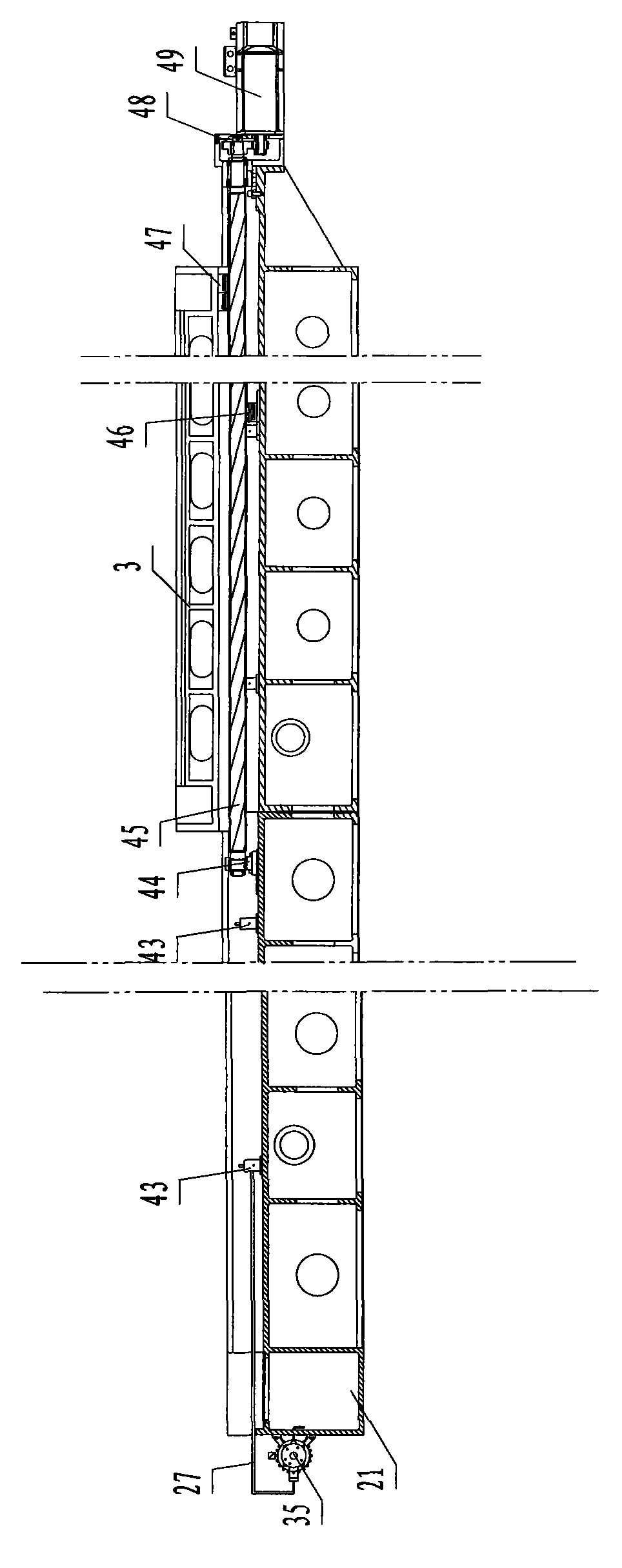

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

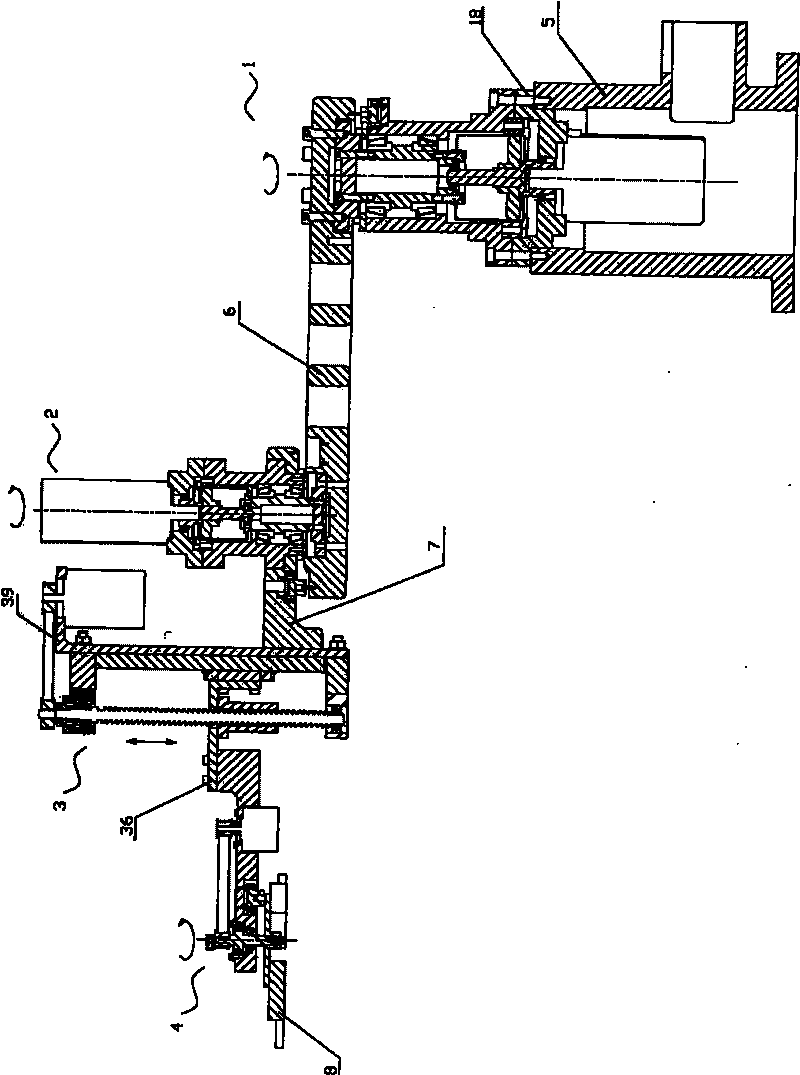

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

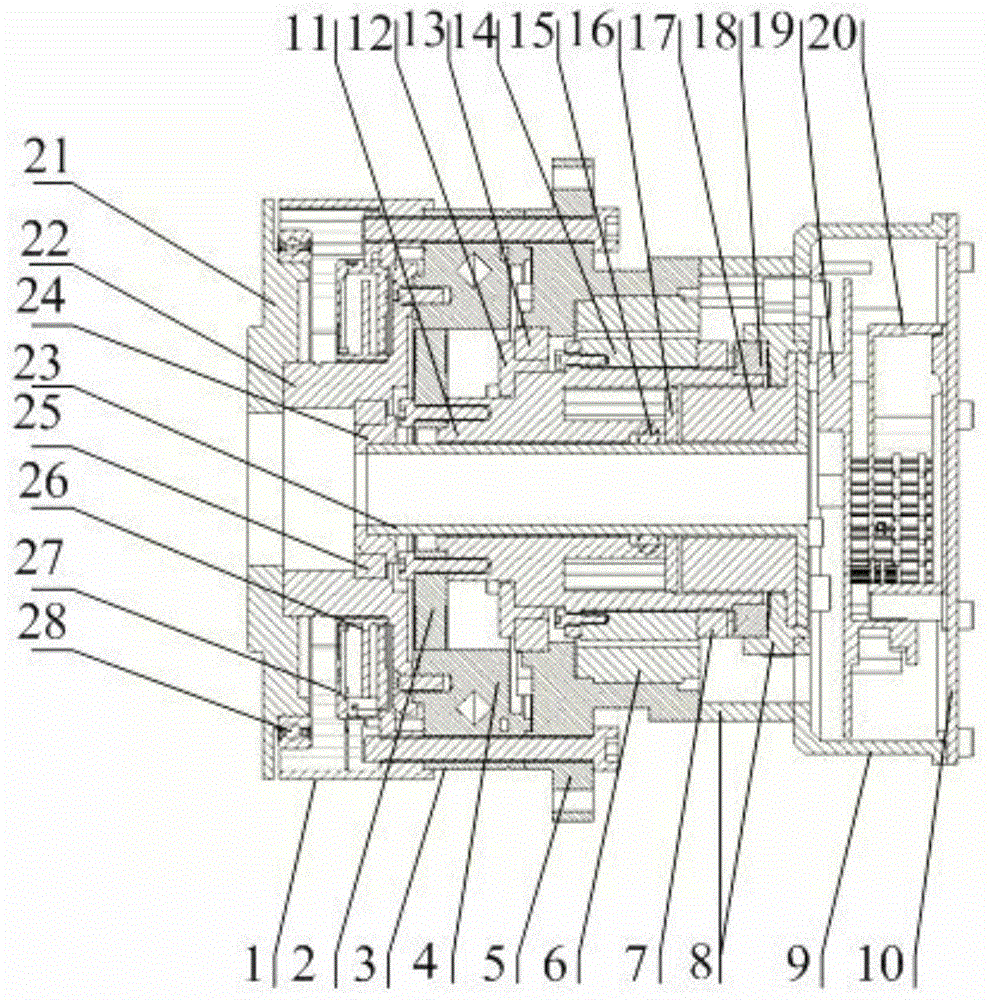

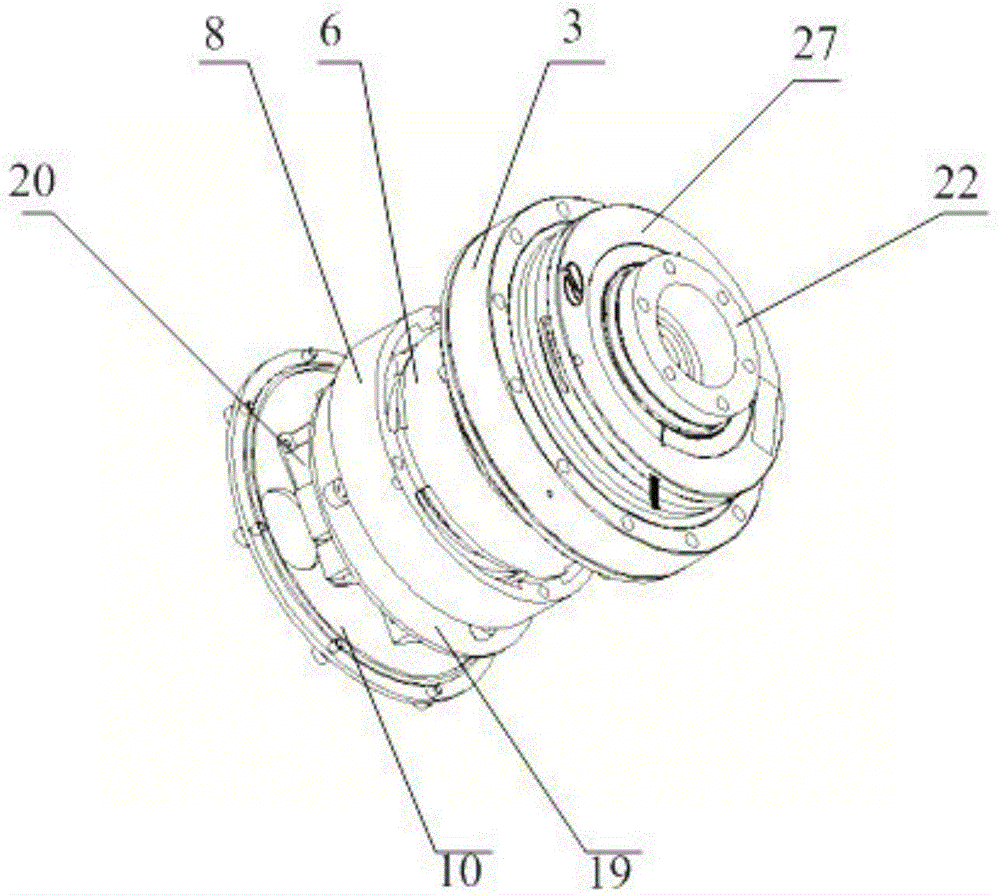

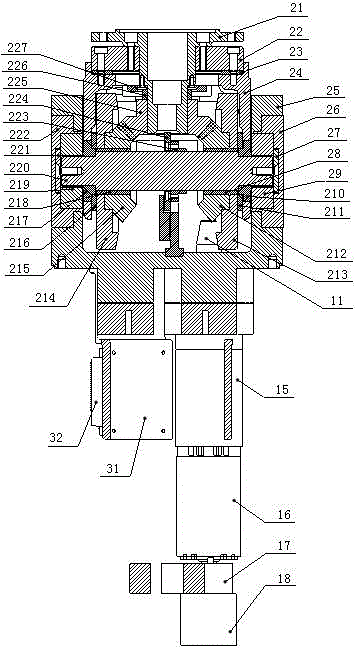

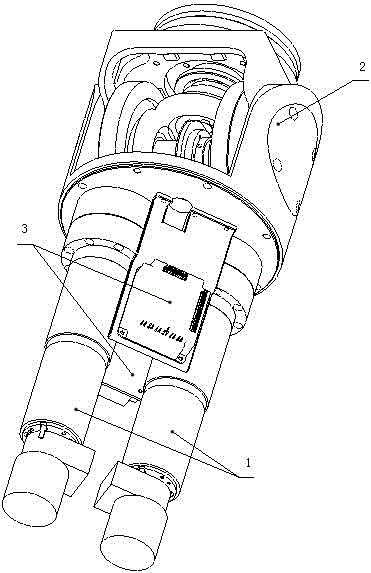

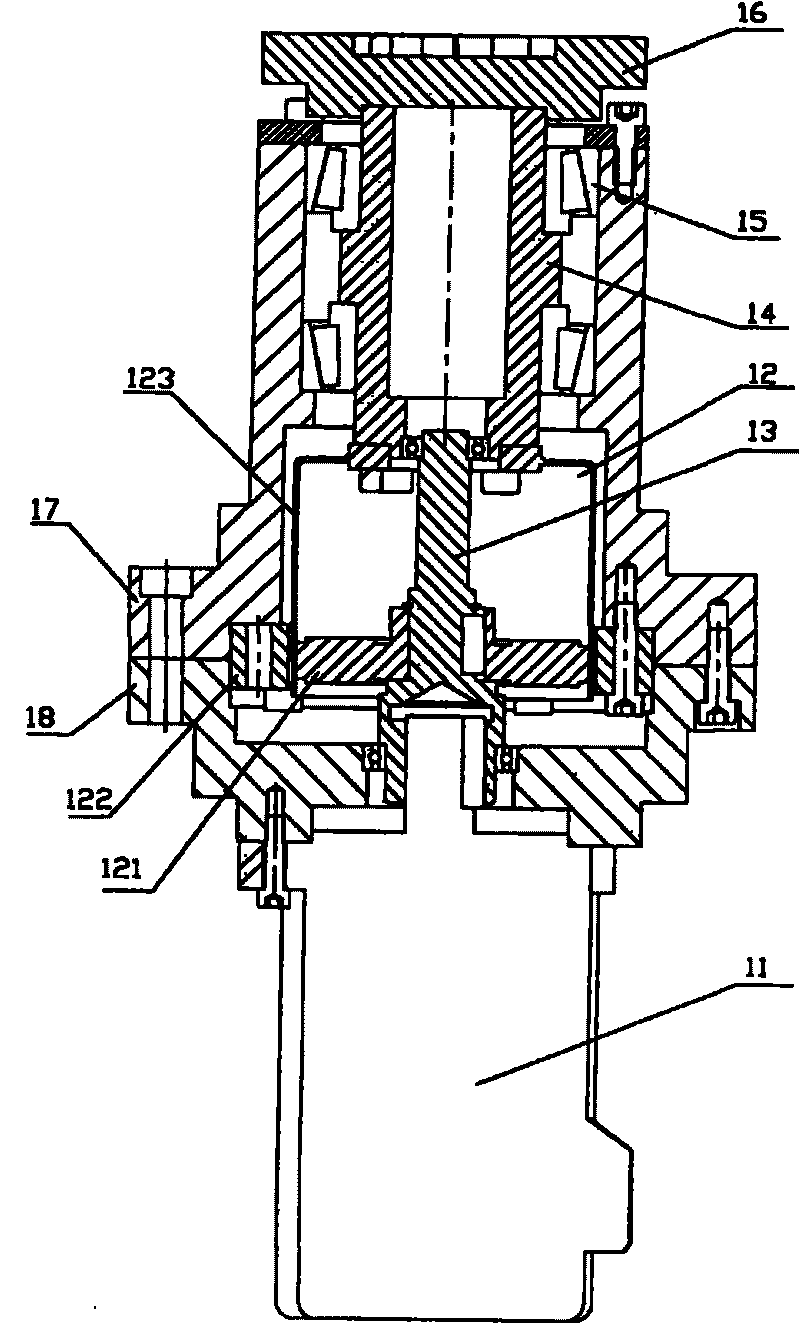

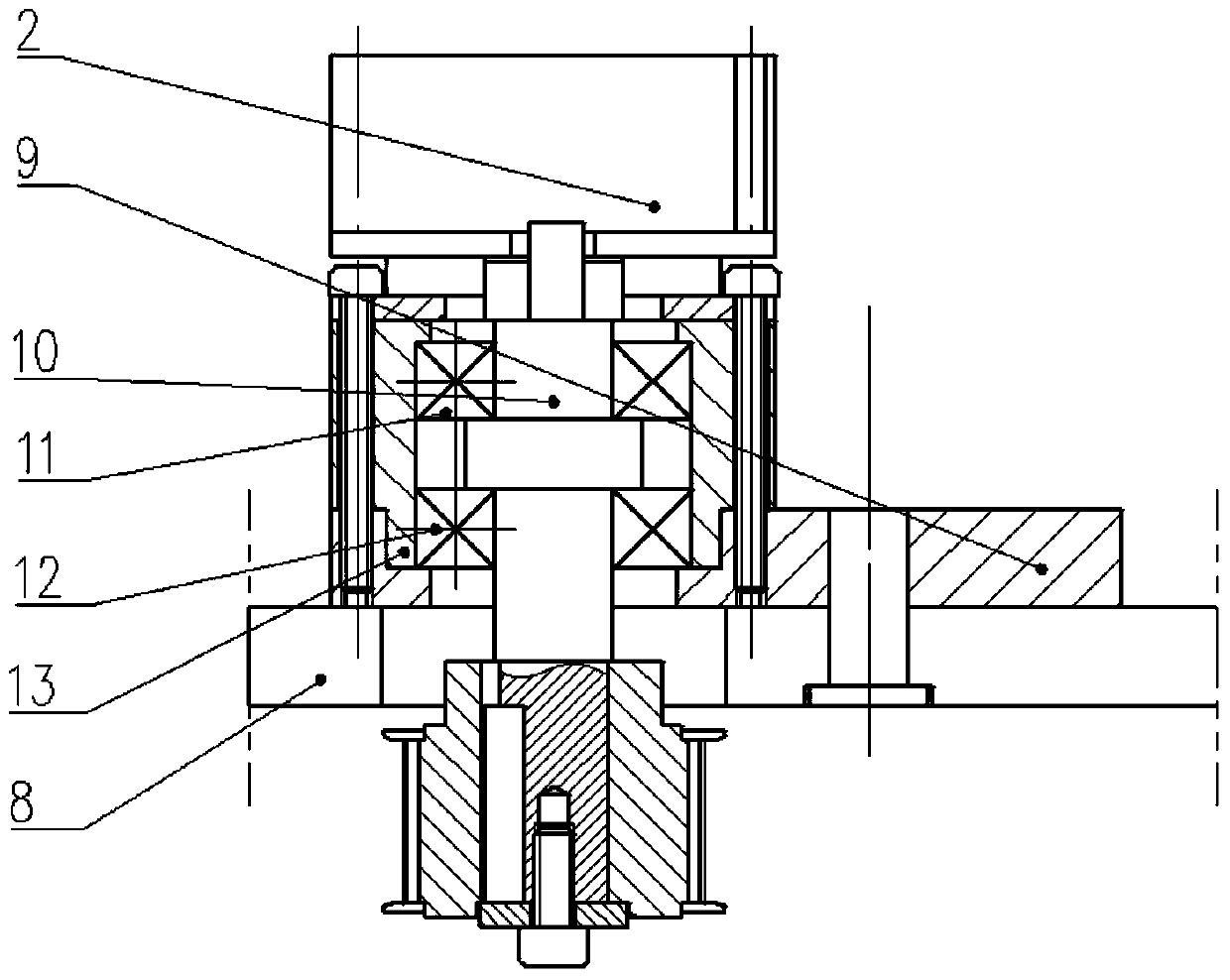

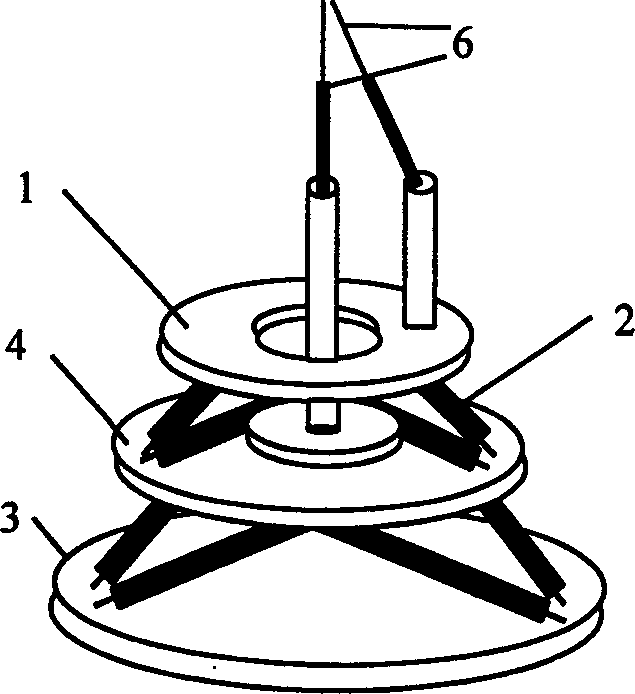

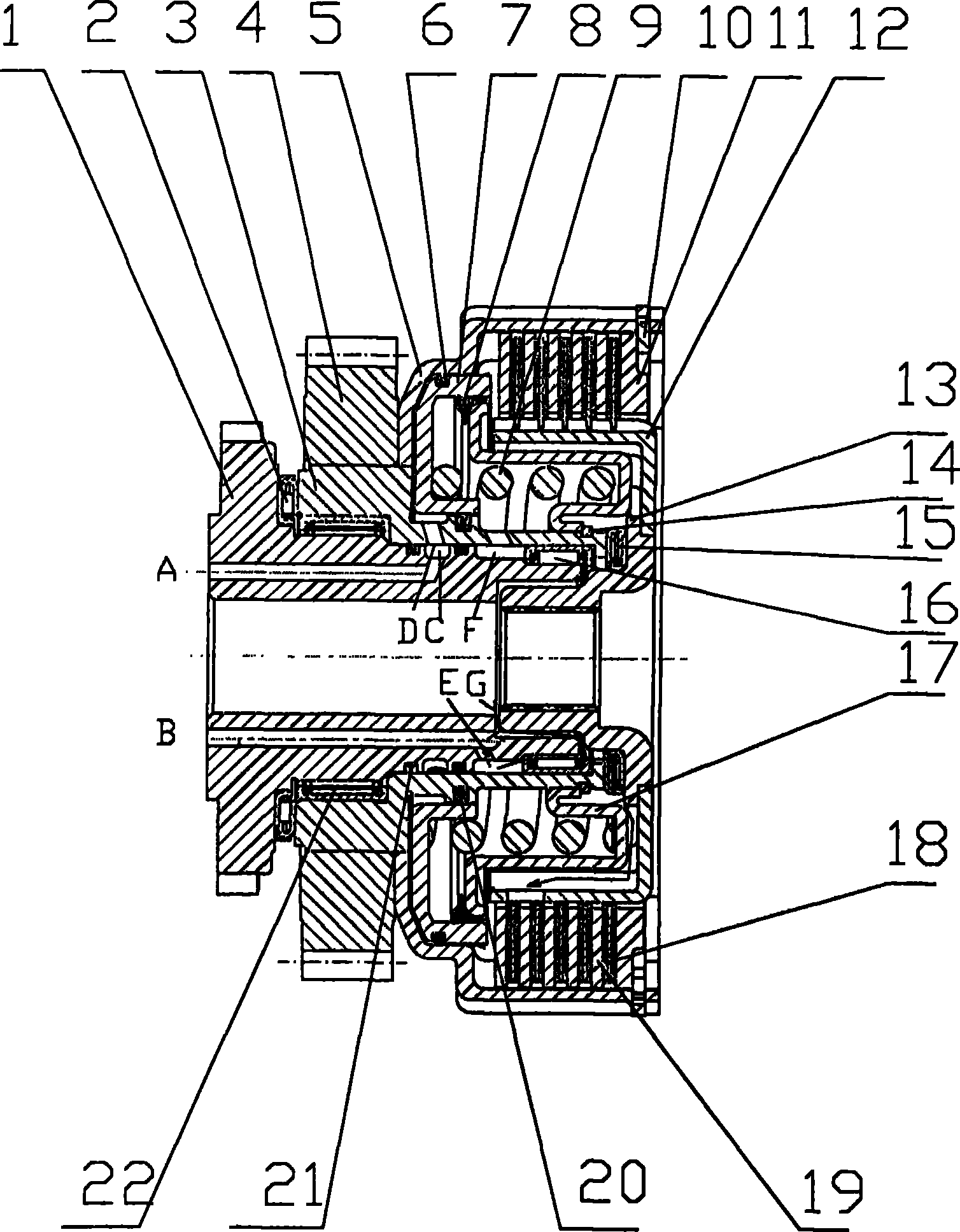

Double-arm robot modularized joint with hollow structure

The invention discloses a double-arm robot modularized joint with a hollow structure, belonging to the field of industrial robots. A mechanical arm is composed of seven similar modularized joints. The joint comprises an input device and an output device, wherein the input device comprises a hollow motor rotor, a rotor axial positioning ring, a third motor bearing, a hollow brake rotor, an O-shaped sealing ring, a motor stator mounting flange, a main transmission shaft, a motor rotor, a second motor bearing, a bearing pressing cover and a harmonic reducer wave generator; the output device comprises a joint output flange, a first output bearing, a mounting flange, an absolute value encoder rotor, a sealing bearing and a harmonic reducer steel wheel; the input device is connected with the output device by the mounting flange. The double-arm robot modularized joint has the advantages that the problems of robot products with more varieties, small batches and complicated structures can be solved; the load dead-weight ratio of the joint can be increased on the basis of meeting the conditions, and the rotation precision of the joint is improved.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

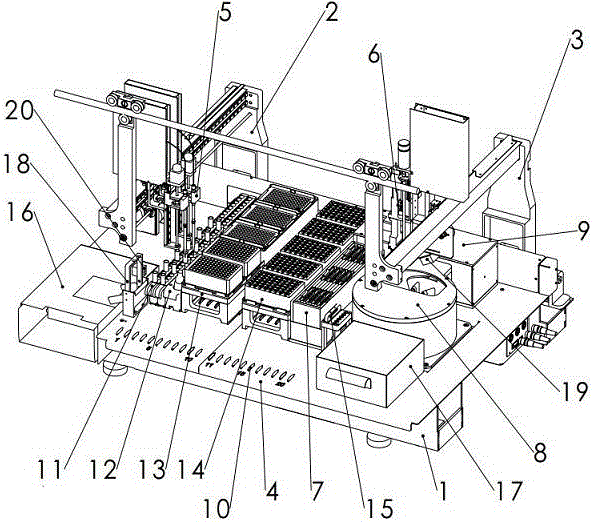

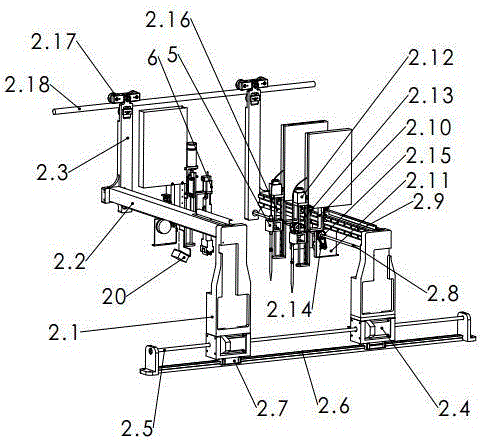

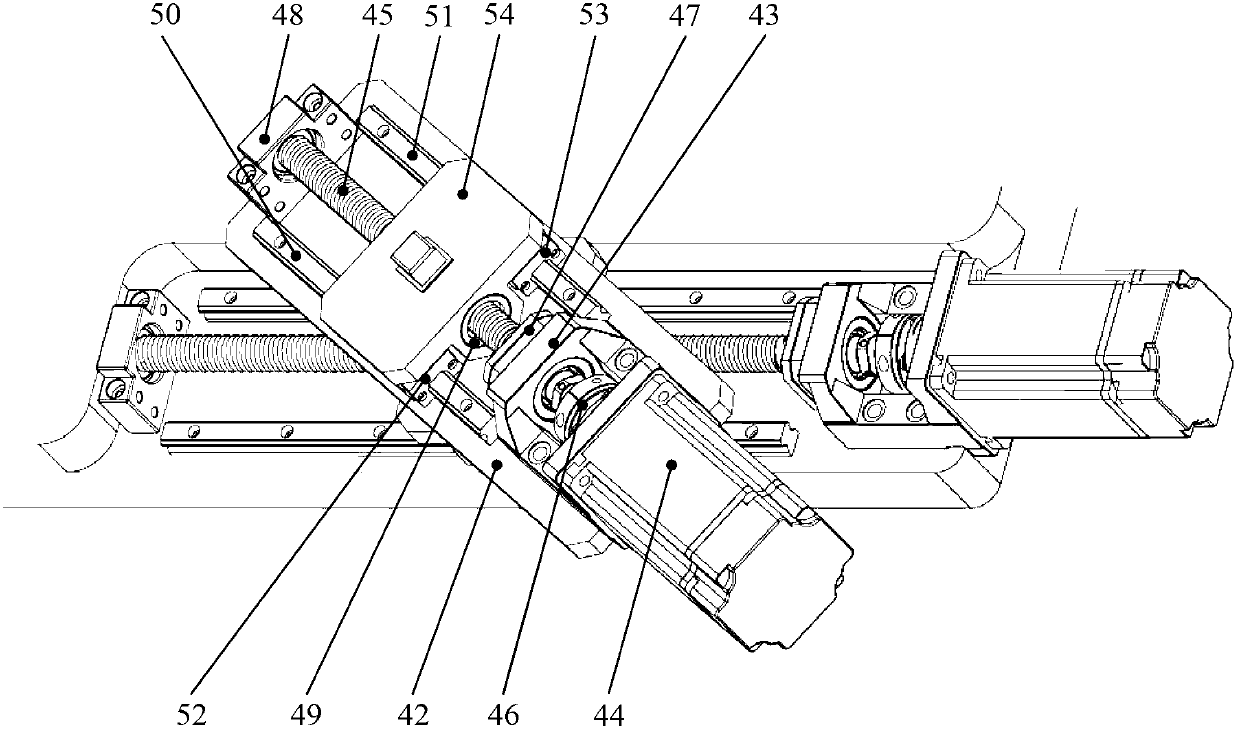

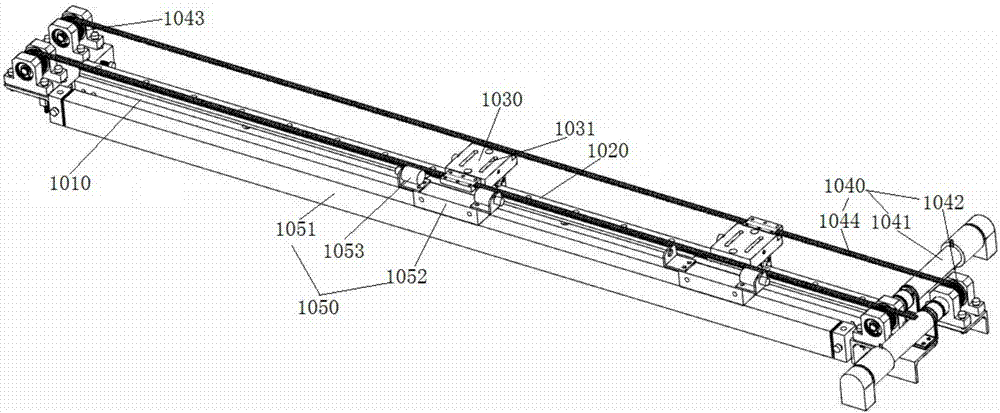

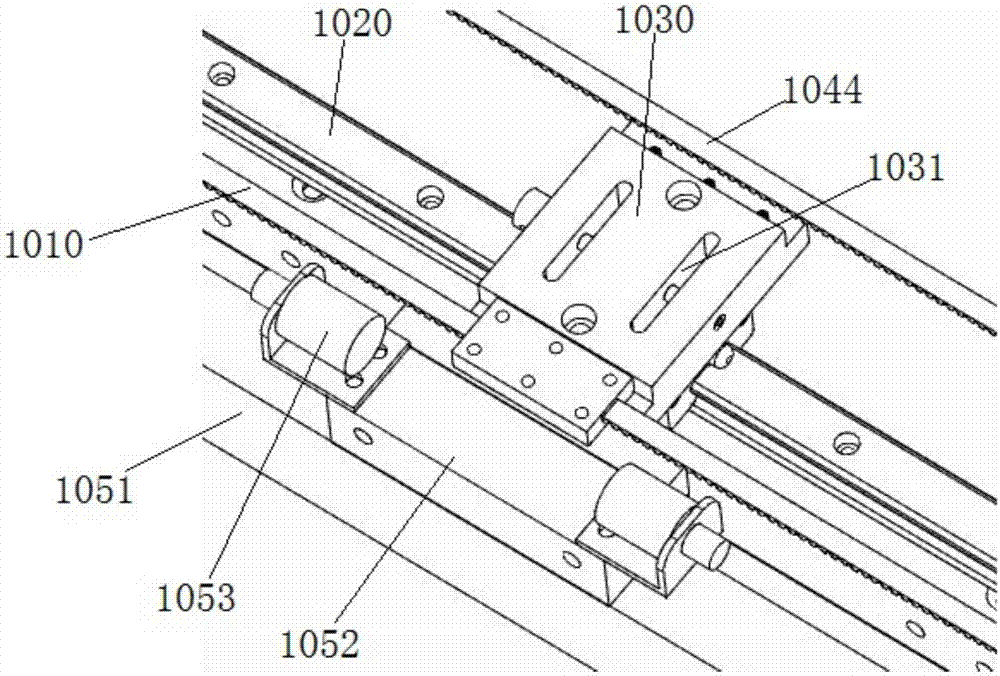

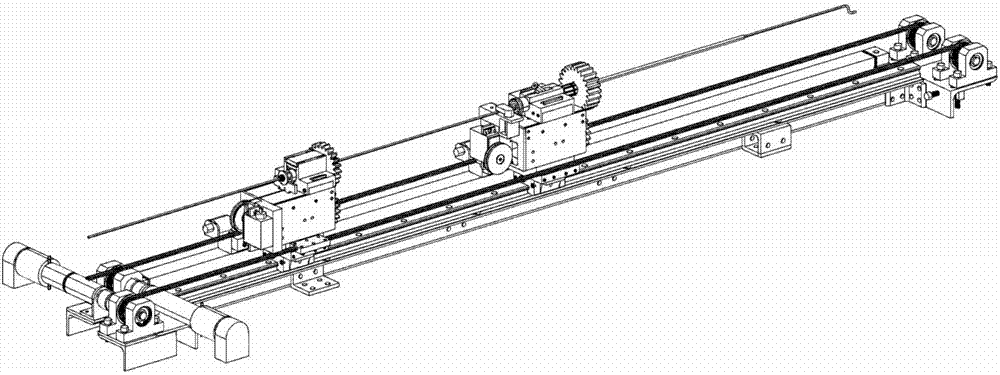

Multi-channel fully automatic blood type analyzer

InactiveCN106596992AHigh transmission precisionExtended service lifeProgramme-controlled manipulatorBiological testingBiochemical engineeringGroup A - blood

The invention relates to the field of medical apparatus and instruments, and in particular, relates to a multi-channel fully automatic blood type analyzer cooperatively used with a microcolumn gel card. The multi-channel fully automatic blood type analyzer includes an analyzer base; a working platform is fixed on the base; the working platform is provided with a sample adding, picking and placing mechanism and a reagent storage mechanism; the sample adding, picking and placing mechanism includes a sample adding mechanical arm and a grasping mechanical arm; the middle part of the working platform is provided with a plurality of groups of loading tracks, the loading tracks are loaded with a sample loading frame, a self-use evenly-mixing reagent loading frame, a gun head loading frame and a microcolumn gel card loading frame in turn side by side. The multi-channel fully automatic blood type analyzer is small in size and compact in design, and flexibly meets the multiple experimental functions of the system. The mechanical arms have high transmission accuracy and long service life.

Owner:SHINVA MEDICAL INSTR CO LTD

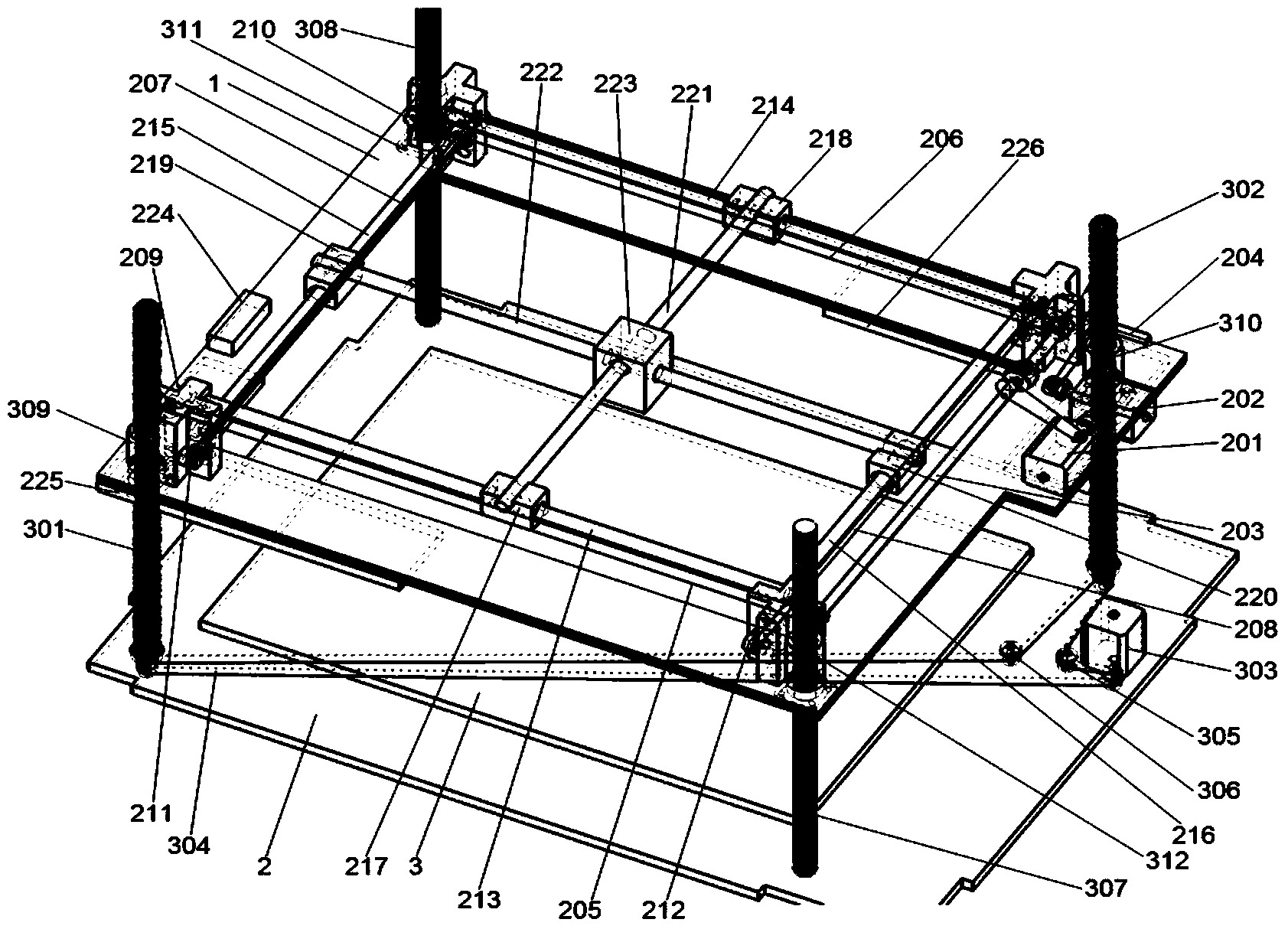

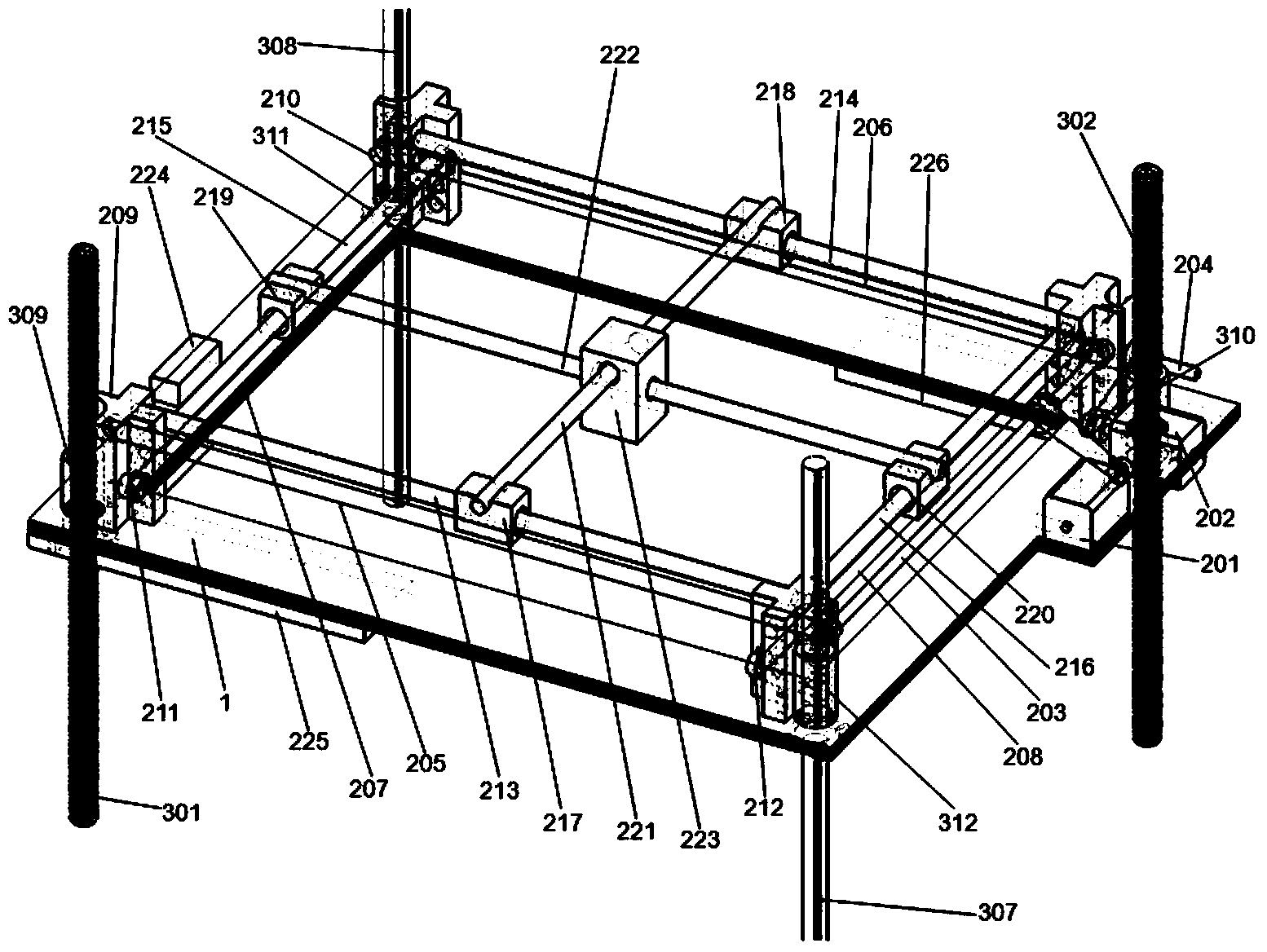

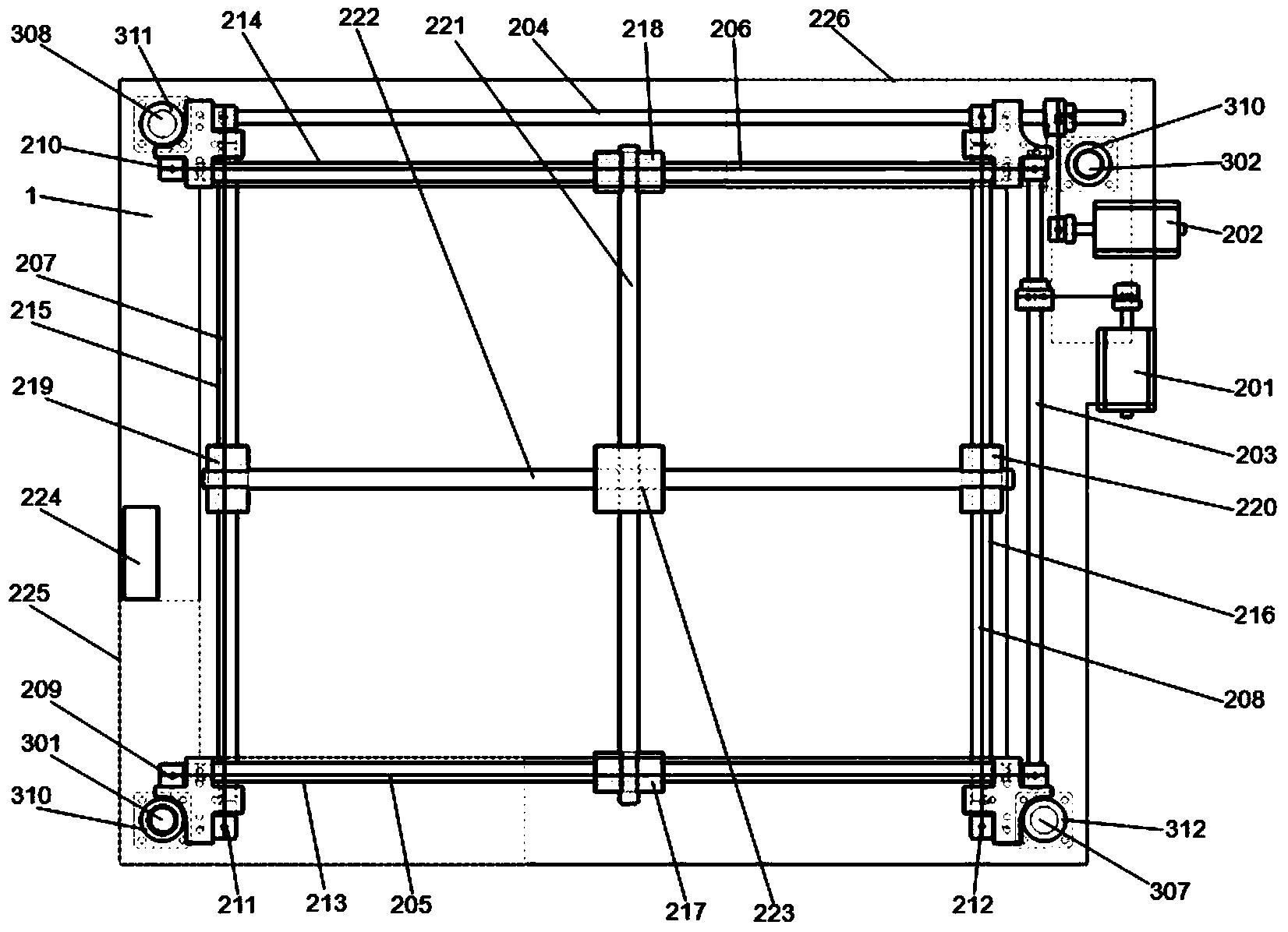

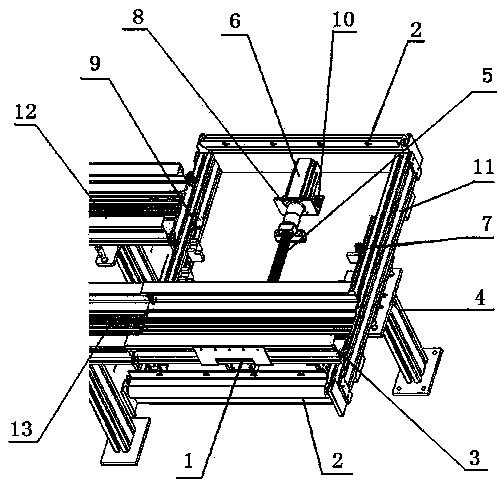

3D (three-dimensional) printing system structure

The invention relates to a 3D (three-dimensional) printing system structure. The 3D (three-dimensional) printing system structure comprises a lifting printing platform, a dual-screw dual-optical-axis Z-shaft driving mechanism, an X-shaft drive mechanism, a Y-shaft drive mechanism as well as a stationary object carrying platform, wherein the printing platform is provided with an X-shaft drive motor and a Y-shaft drive motor; the two motors are respectively connected to a pair of driven bearings by synchronous belts at two ends of the driving shaft; double slide shafts in the X direction and the Y direction are both provided with slide seats; two pairs of slide seats are respectively connected by an X cross beam and a Y cross beam, and the two cross beams respectively penetrate through a 3D printer head; a driving motor of the dual-screw dual-optical-axis driving mechanism and the driving shaft are connected by the synchronous belt; the position of the driving motor can be adjusted randomly. The X-shaft drive mechanism, the Y-shaft drive mechanism and the driving shaft operate individually, so that the motion modulation is reduced; the dual-screw dual-optical-axis driving mechanism has favorable stability, so that the printing platform is stressed in a balance manner; the driving in each direction is stable; the 3D printing precision is improved.

Owner:UNIV OF SCI & TECH OF CHINA

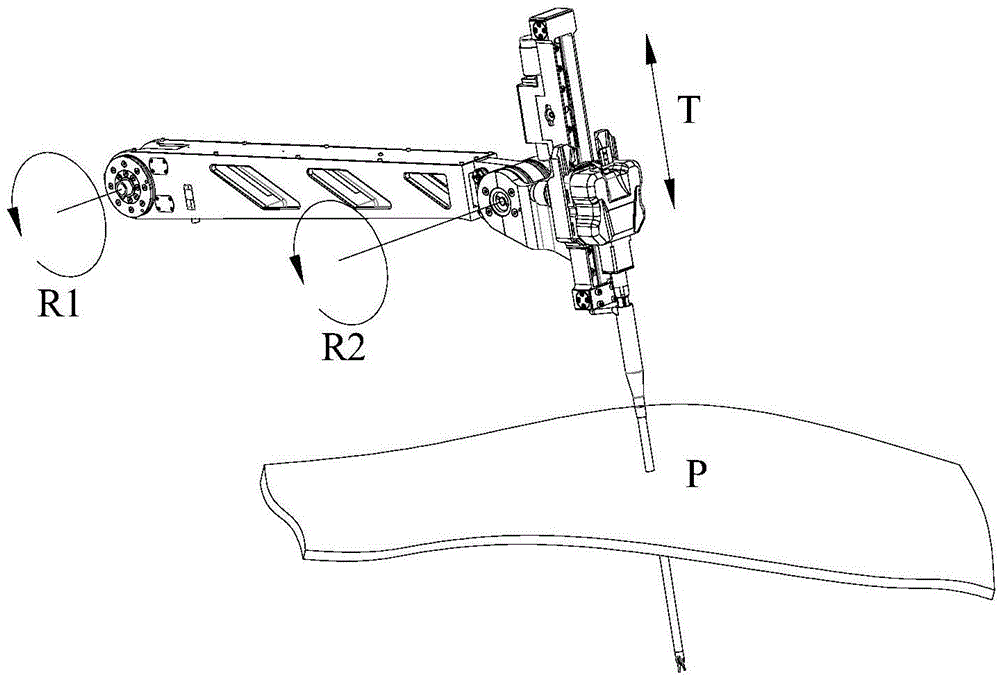

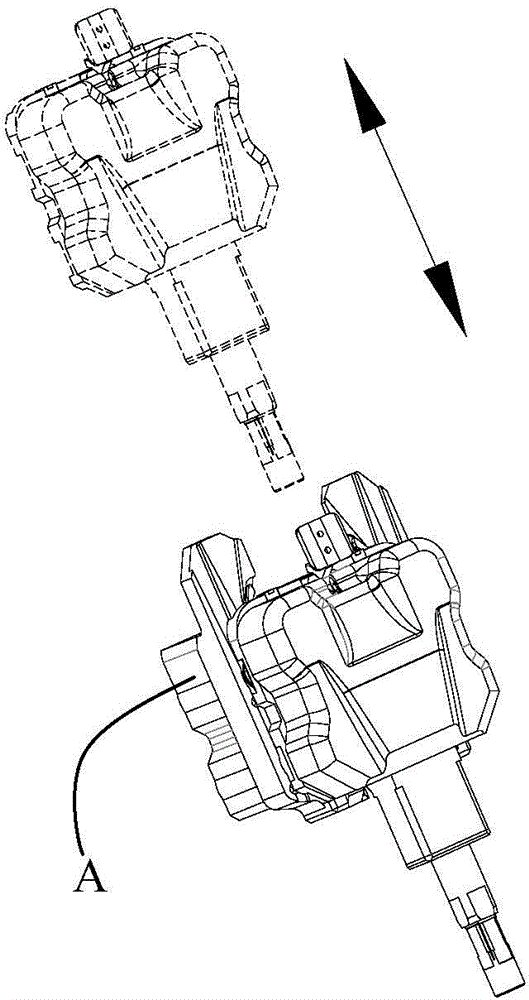

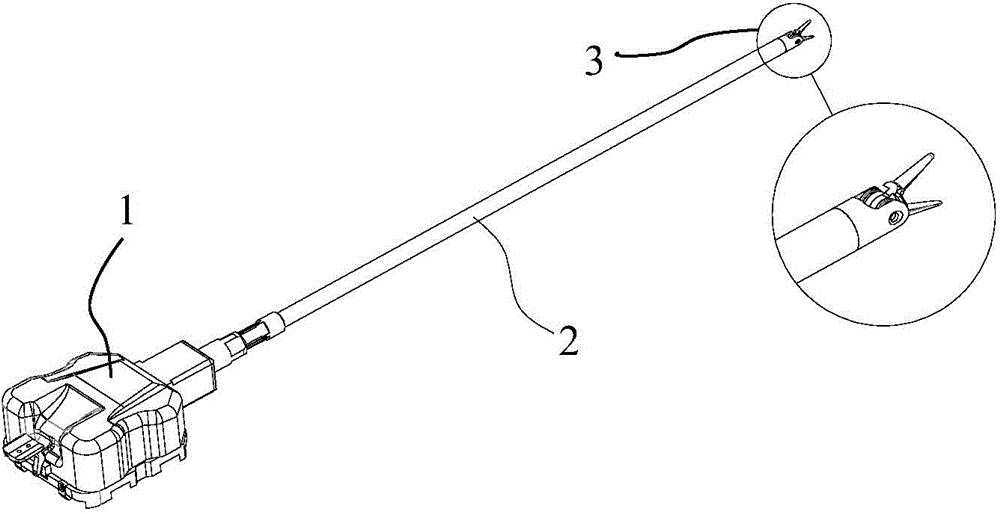

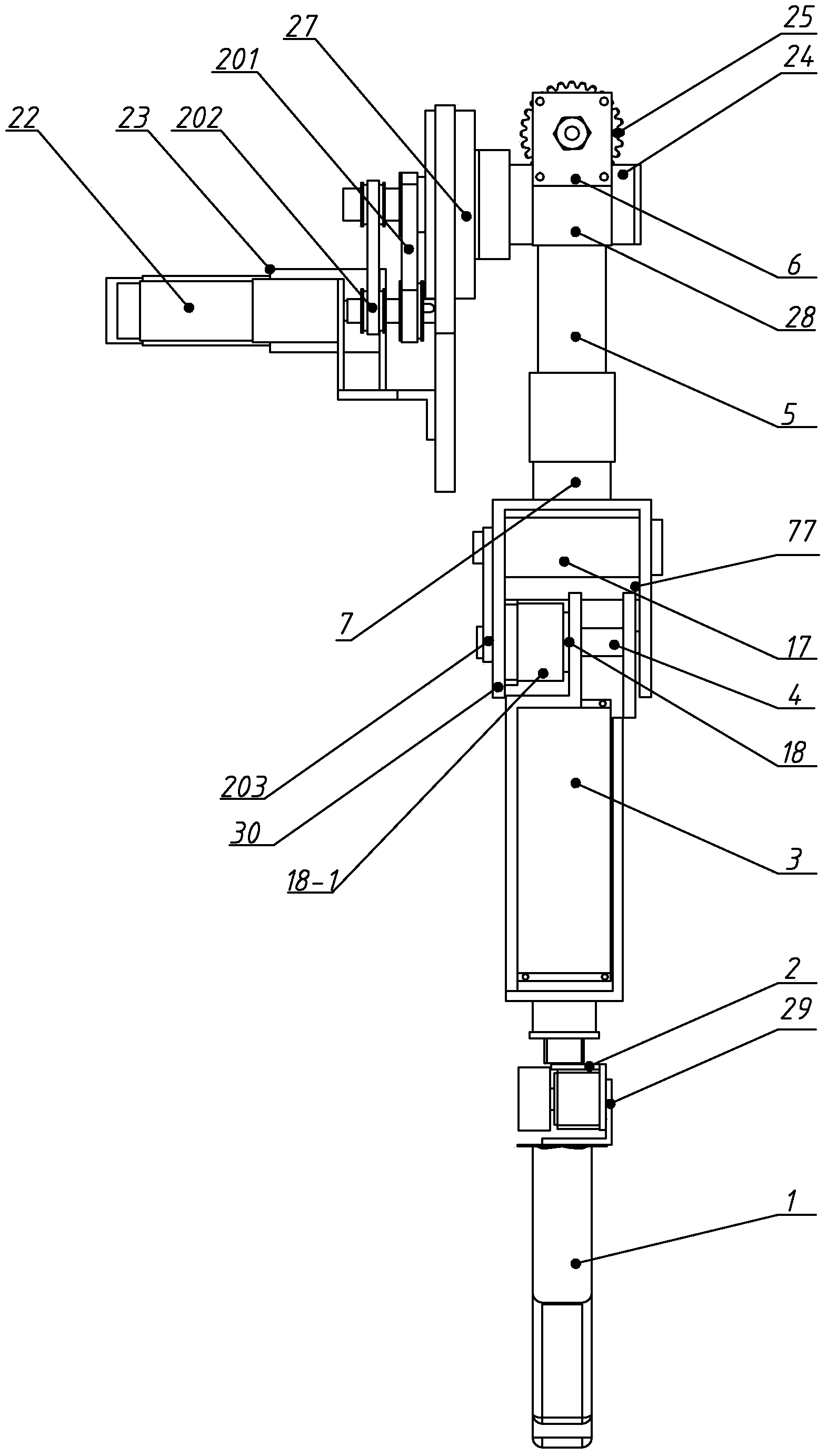

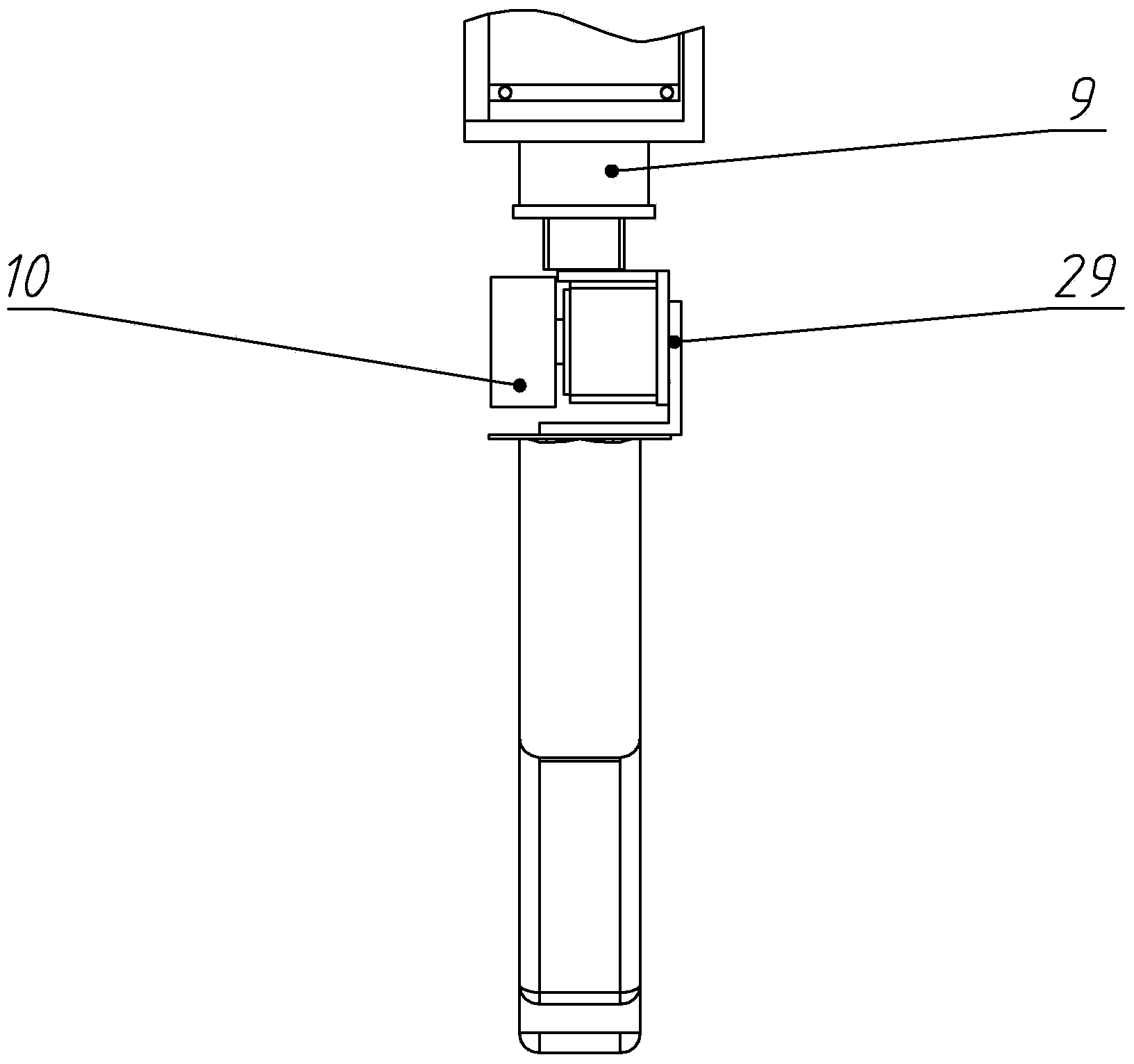

Instrument for robot-assisted micro-invasive surgery

InactiveCN104799891ASave spaceImprove quick change efficiencyDiagnosticsSurgeryLess invasive surgeryDrive shaft

The invention discloses an instrument for a robot-assisted micro-invasive surgery. The instrument comprises a driving device, a connecting guide pipe and a terminal executing device which are sequentially connected; the driving device comprises a base, three driving shafts are rotationally arranged on the base through a bearing, and each driving shaft is fixedly sleeved with a screw roller and a cohesion block; the terminal executing device comprises a clamp seat and an opening and closing clamp, wherein the clamp seat is fixed at the front end of the connecting guide pipe, the opening and closing clamp consists of a left opening and closing clamp body and a right opening and closing clamp body, and the wire rollers connected with the left opening and closing clamp body and the right opening and closing clamp body and the left opening and closing clamp body and the right opening and closing clamp body are arranged on a hinge pin of the clamp seat; the connecting guide pipe, the left opening and closing clamp body and the right opening and closing clamp body are respectively connected with a screw driving system. The instrument provided by the invention is compact in structure, light in weight and high in driving precision, and the quick-changing efficiency of the instrument can be improved.

Owner:TIANJIN UNIV

Six-degree-of-freedom humanoid robot arm

The invention discloses a six-degree-of-freedom humanoid robot arm, and relates to a robot arm. The invention aims to solve the problems that the existing robot arm is cumbersome in joint structure, heavy in self weight, low in load bearing ratio and complicated to control. A shoulder rotating joint, a shoulder joint, an upper arm, an elbow rotating joint, a elbow swing joint, a fore arm, a wrist rotating joint, a wrist swing and a hand are sequentially arranged from top to bottom, wherein an arm swing motor is connected with a worm by virtue of a conveyor belt, an arm rotating motor is connected with a shoulder swing support by virtue of a conveyor belt, an upper arm shell is arranged between a shoulder joint and an elbow joint, an elbow rotating drive motor and a speed reducer are sequentially arranged in the upper arm shell from top to bottom, an elbow swing joint motor is arranged in an elbow joint shell and is connected with an elbow joint conveyor belt, an elbow joint speed reducer is arranged in the elbow joint shell, a hand connecting support is arranged between the fore arm and the hand, a wrist joint swing motor is arranged on one side of the hand connecting support, and a wrist joint rotating motor is arranged at the upper end of the hand connecting support. The six-degree-of-freedom humanoid robot arm is applied to a humanoid robot.

Owner:HARBIN INST OF TECH

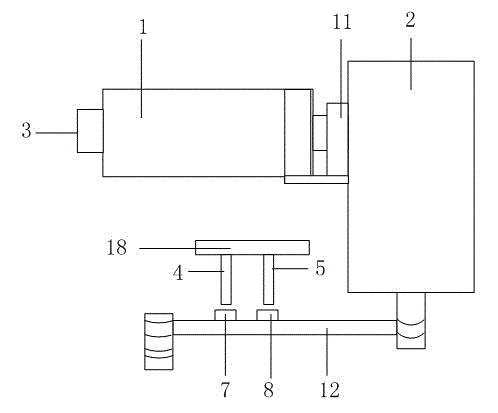

Shunting positioning system of logistic trolley track

The invention relates to a track conversion device suitable for a hospital logistic transmission system. A shunting positioning system of a logistic trolley track comprises a device support, a drive motor and a displacement inductor, wherein the drive motor is a serve motor and connected with one end of a screw rod through a coupler, track change is achieved for a trolley through a relay track, the initial position of the replay track is respectively matched with an initial track on which the trolley runs and a target track, a support slide rail perpendicular to the initial track is arranged below a track support used for bearing the relay track, the relay track is welded to the track support, a transverse rod of the track support is provided with a threaded mechanism which is matched with a threaded mechanism on the screw rod, and the screw rod and the track support form linage integration through the threaded mechanisms. The shunting positioning system of the logistic trolley track solves the problems that an existing shunting positioning system of the logistic trolley track is large in error of track change butt joint and severe in damage to a motor, and is high in accuracy and low in loss of the motor.

Owner:GUANGXI MANCHEBISI AUTOMATION EQUIP

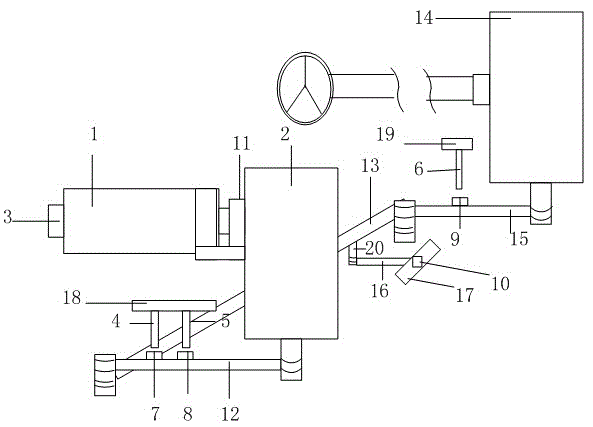

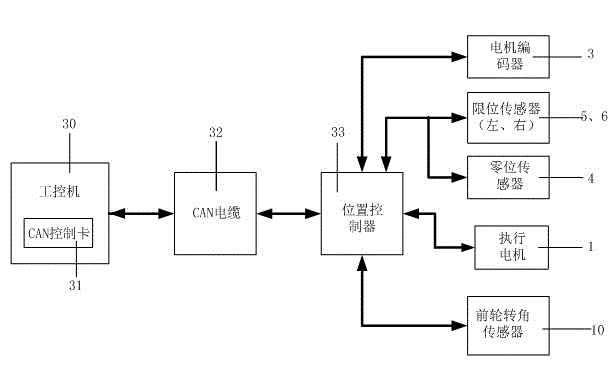

Unmanned vehicle steering system and control method thereof

ActiveCN102941876AHigh precisionImprove transmission efficiency and accuracySteering linkagesAutomatic steering controlSteering systemContact type

The invention discloses an unmanned vehicle steering system and a control method thereof. The system comprises an execution motor, a steering machine, a motor coder, a non-contact type zero position detection mechanism, a non-contact type left limiting detection mechanism, a non-contact type right limiting detection mechanism, a front wheel absolute corner mechanism and a front wheel corner double closed loop control system. The execution motor is a steering driving mechanism, and the input end of the execution motor is connected with the output end of the steering machine. The motor coder is connected with an output shaft at the back end of the execution motor. The unmanned vehicle steering system is favorable for improving steering control accuracy of unmanned vehicles, adopts a selector switch to switch the control process of manual driving / automatic driving, facilitates program debugging and ensures vehicle and personnel body safety under the emergency condition.

Owner:NANJING UNIV OF SCI & TECH

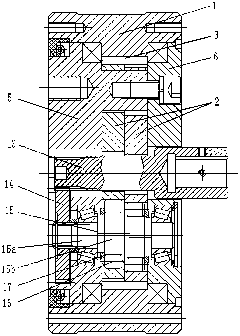

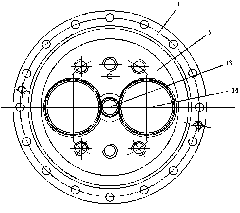

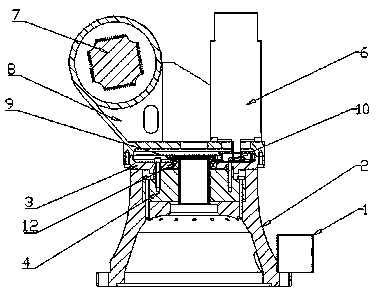

Closed cycloid precision gear reducer

ActiveCN103994184AImprove bending strengthImprove carrying capacityPortable liftingToothed gearingsLeveling effectCarrying capacity

The invention discloses a closed cycloid precision gear reducer. The closed cycloid precision gear reducer comprises an input part, a pin wheel housing, an output part and a small-tooth-difference inside-gear reducing mechanism. Wheel pins used for being meshed with a cycloidal gear of the small-tooth-difference inside-gear reducing mechanism are arranged on the inner ring of the pin wheel housing in the circumferential direction. The inner ring of the pin wheel housing is provided with containing grooves which correspond to the wheel pins in a one-to-one mode and are used for containing the wheel pins. The wheel pins make double-line contact with the inner walls of the corresponding containing grooves. According to the closed cycloid precision gear reducer, the double-line contact characteristic exists between the wheel pins and the containing grooves in the pin wheel housing; as the wheel pins make double-line contact with the corresponding containing grooves in the tooth width direction, the bending strength is enhanced, and carrying capacity is improved; meanwhile, due to the increase of the number of contact lines, the achievement of the error leveling effect is facilitated, transmission accuracy can be improved, and then the requirements for machining errors and assembly errors can be lowered. Compared with an existing RV gear reducer, the return difference of the closed cycloid precision gear reducer is smaller; besides, the closed cycloid precision gear reducer is compact in structure, long in service life, simple in machining process and low in manufacturing cost.

Owner:CHONGQING UNIV

Six-axis degree-of-freedom manipulator

InactiveCN103568002AAvoid jitterCompact structureProgramme-controlled manipulatorControl systemDegrees of freedom

The invention discloses a six-axis degree-of-freedom manipulator. The six-axis degree-of-freedom manipulator comprises a base, wherein the base is in transmission connection with a first transmission mechanism, a second transmission mechanism, a third transmission mechanism, a fourth transmission mechanism, a fifth transmission mechanism and a sixth transmission mechanism in sequence, wherein the six transmission mechanism is in transmission connection with a mechanical palm part. A series of functions such as welding, spraying and handling are combined, the newest servo control system is adopted, and a series of new functions which can meet the industrial production of users are developed on the platform. The conventional complex transmission process is greatly simplified in the aspect of mechanical transmission, and the characteristic that bevel gear mesh type transmission is generally adopted by the conventional six axes is cancelled, so that the manipulator has a compacter structure and higher transmission efficiency, is more accurate in control and can effectively prevent the situation of jitter due to joint movement.

Owner:RIZHAO POLYTECHNIC

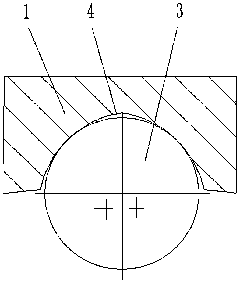

Coarse and fine scanning rotating prism device

InactiveCN102955251ASatisfy rough scan requirementsMeet fine scanning requirementsOptical elementsElectric machineGear wheel

The invention relates to a coarse and fine scanning rotating prism device, which comprises a prism and an inner and outer prism frame assembly, a worm and gear movement mechanism, a rotary motor, a yaw motor and a rotating half shaft assembly, an anti-backlash motor and an anti-backlash gear assembly, a rotary encoder assembly, a deflection encoder assembly, a rectangular frame and a base, wherein the rotary motor drives the prism and the inner and outer prism frame assembly through the worm and gear mechanism to realize full circumferential rotation, and the yaw motor is directly coupled with the rectangular frame to realize the yaw movement of the prism and the inner and outer prism frame assembly; and the whole device is arranged on the base. The prism is driven by the worm and gear mechanism to realize the full circumferential large-range rotation, and the coarse scanning requirements of dynamic beams are met; and a rotary movement mechanism and a yaw movement mechanism are nested to be combined, so that the integration of coarse and fine scanning functions is skillfully realized in a single set of devices, and the problems that the dispersal spatial structure is brought by a coarse and fine scanning separation design and the coarse and fine error term of the system is difficult to separate and traceably amend are avoided.

Owner:TONGJI UNIV

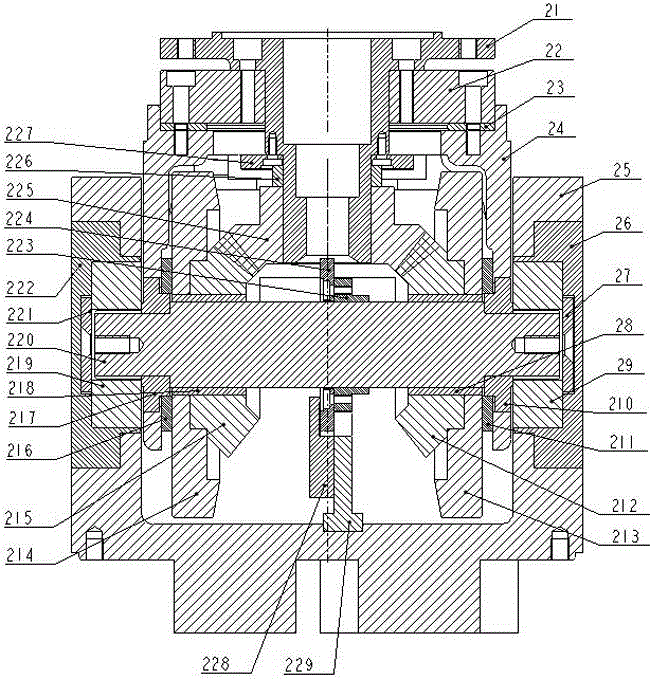

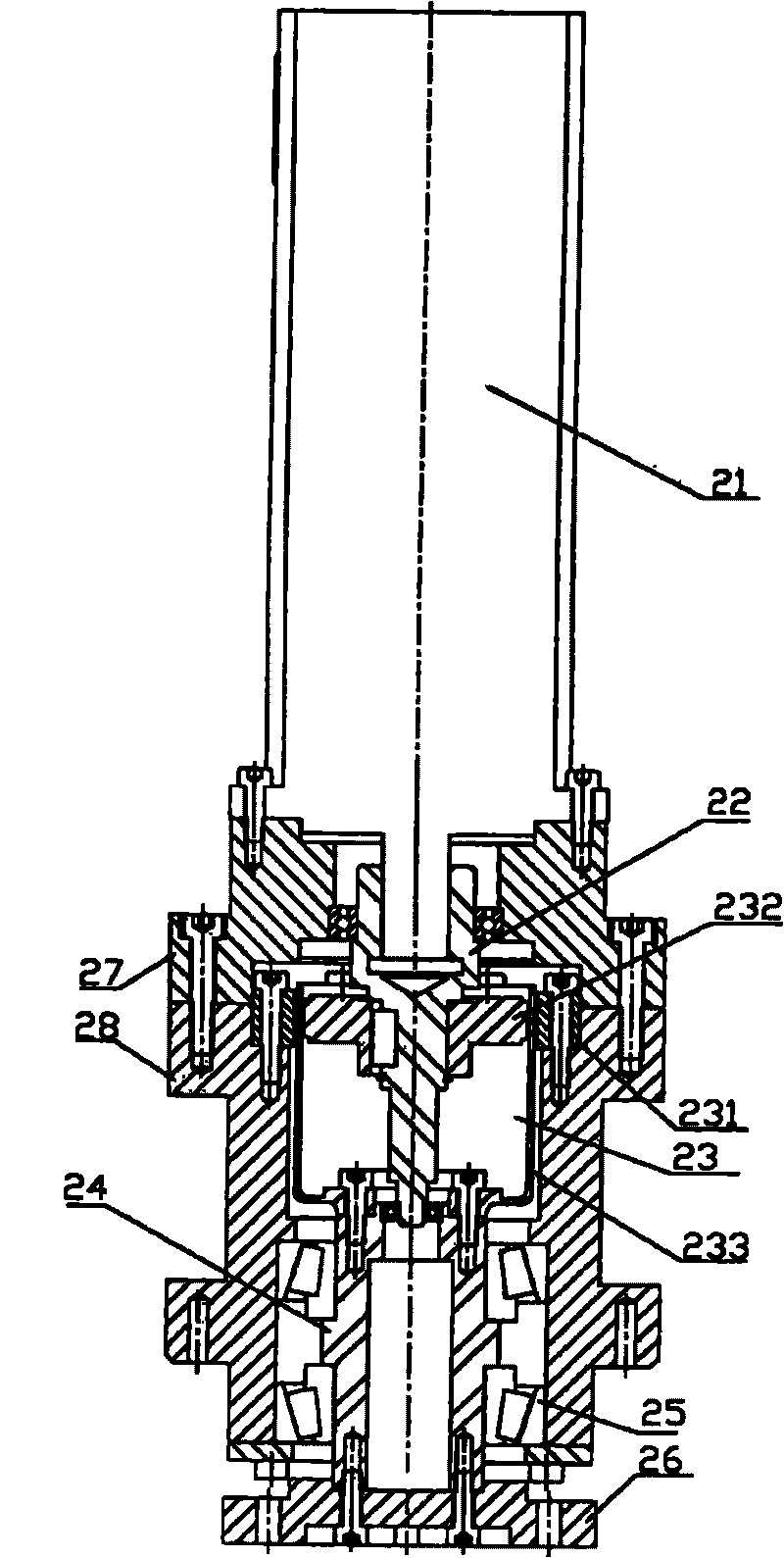

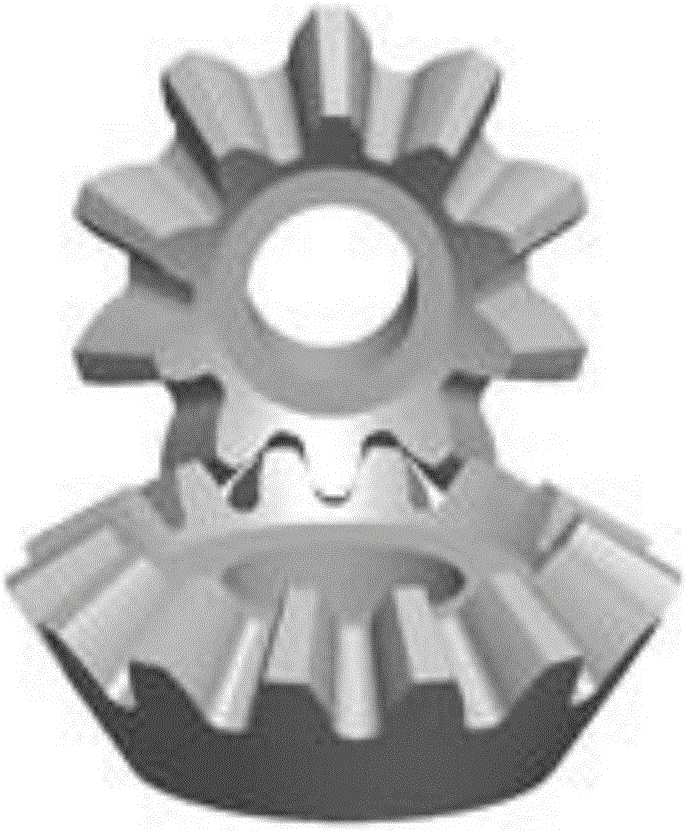

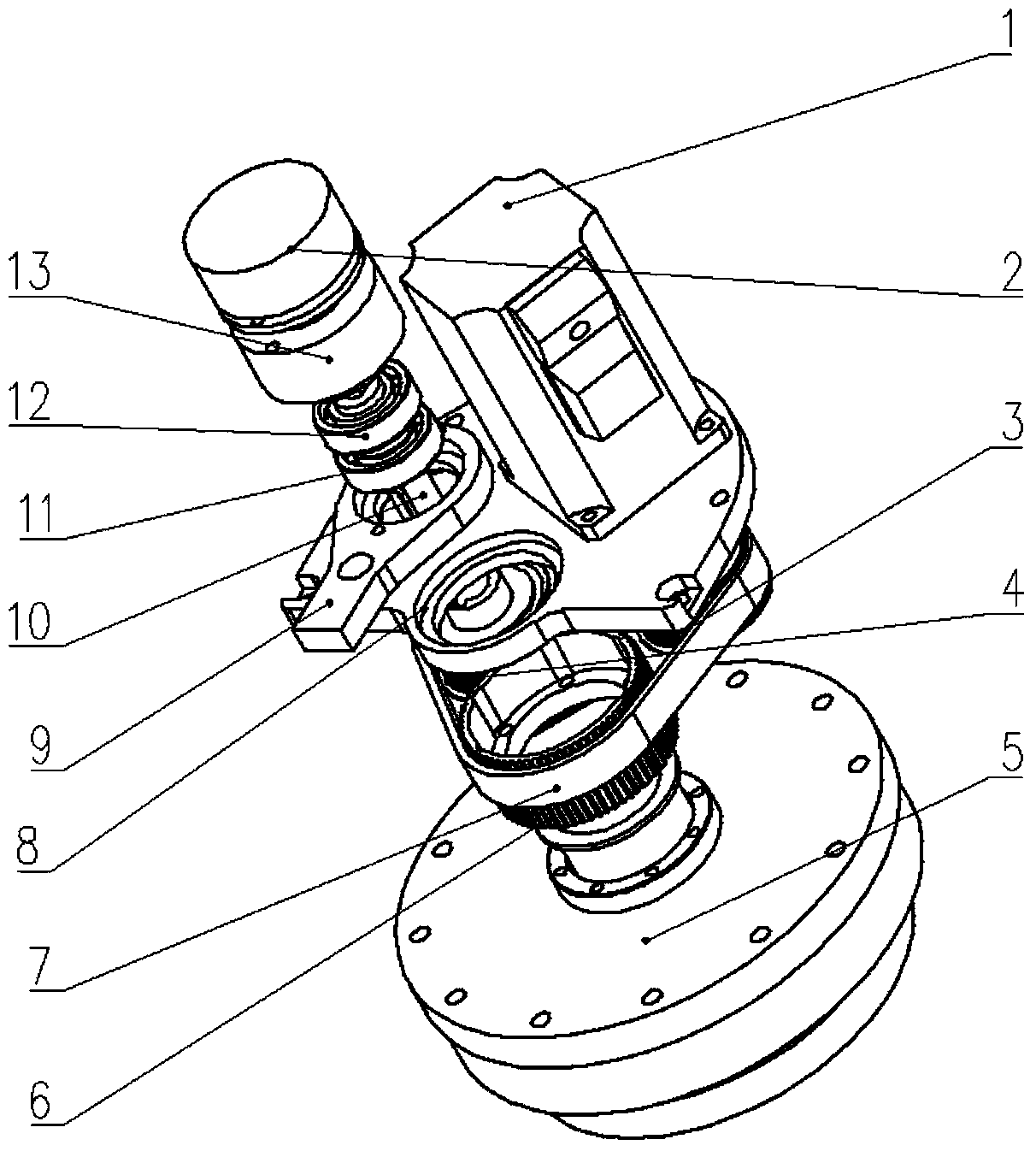

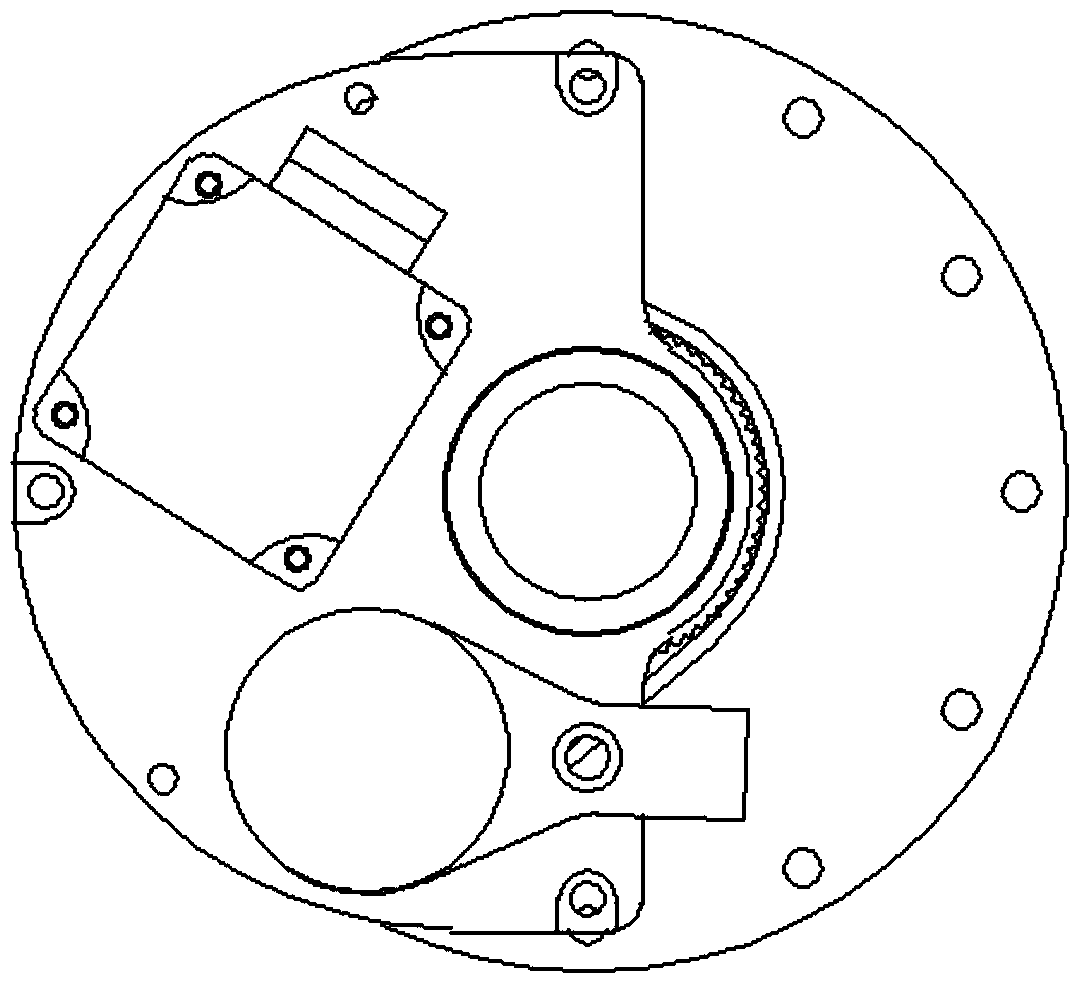

Two-degree-of-freedom joint of space robot

The invention discloses a two-degree-of-freedom joint of a space robot. The two-degree-of-freedom joint comprises two joint driving assemblies and a joint transmission assembly. Two-degree-of-freedom movement of the joint can be achieved. Three movement modes of pitching, rotating and combining of pitching and rotating can be achieved by adjusting the rotating speeds and the rotating angles of two motors. The joint transmission assembly is a differential movement mechanism formed by two input bevel gears and an output bevel gear. The two input bevel gears are fixedly connected with corresponding hypoid gears respectively, and an output flange is fixedly connected with the output bevel gear. First-stage speed reduction is carried out on the torque of the motors through planetary reducers connected with the motors, then second-stage speed reduction is carried out through the hypoid gears, and finally the torque is transmitted to the output end through the bevel gear differential mechanism. As the reduction ratios of two stages of speed reduction are large, the output torque of the mechanism is large, and the high load capacity is achieved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

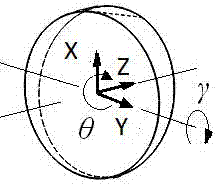

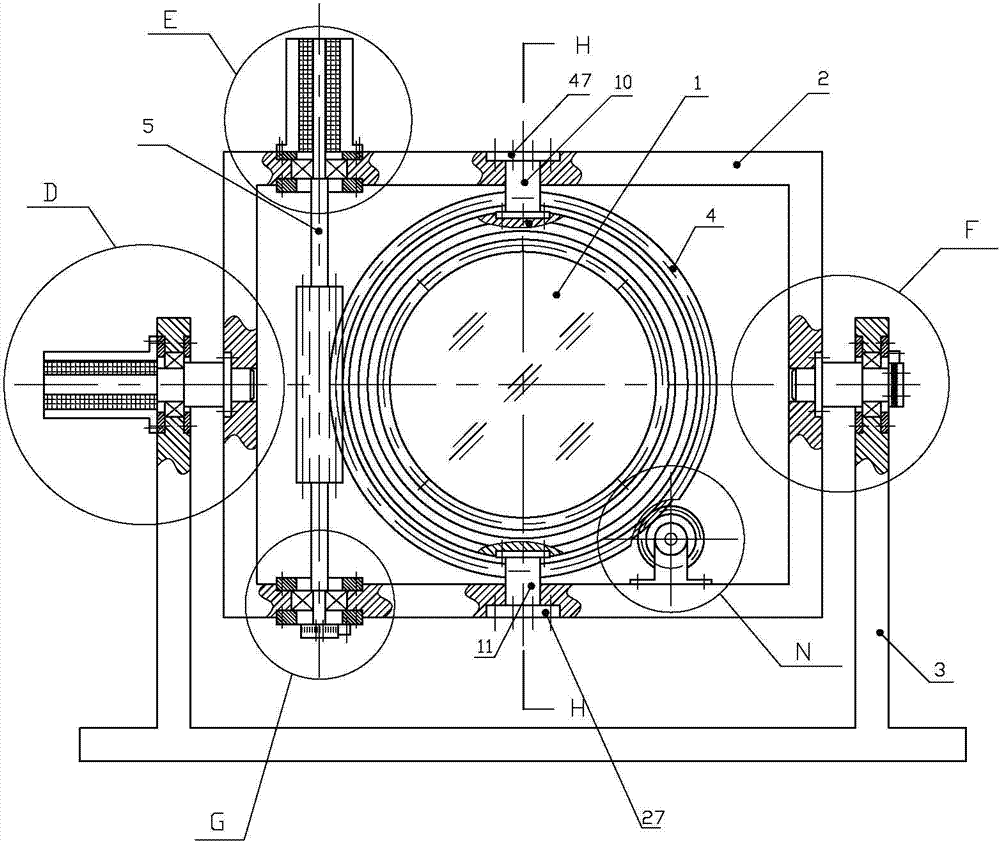

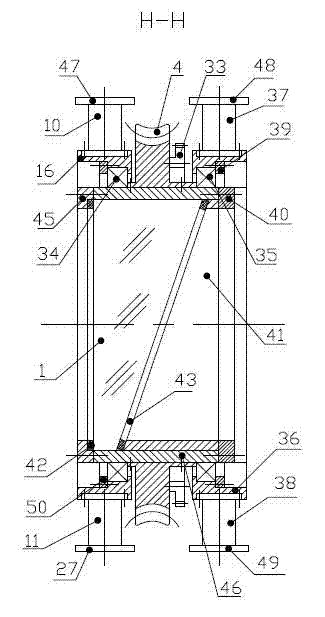

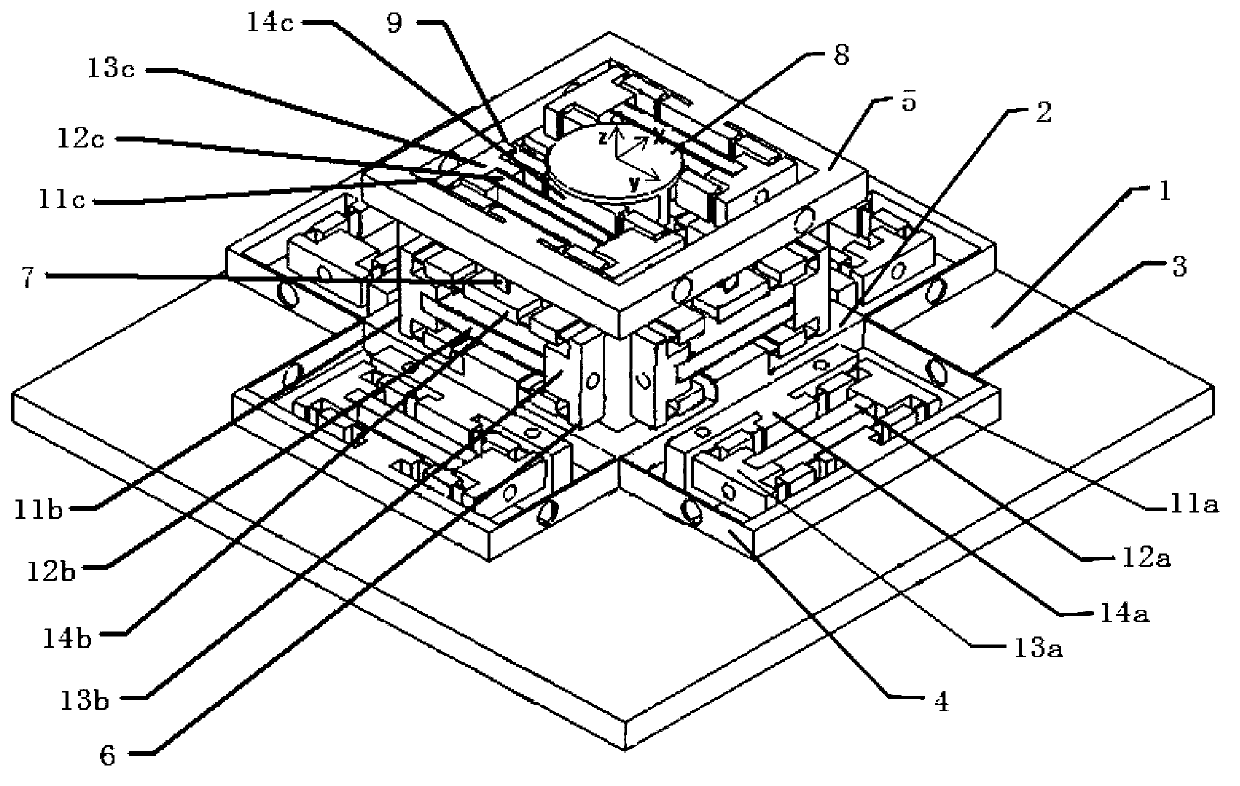

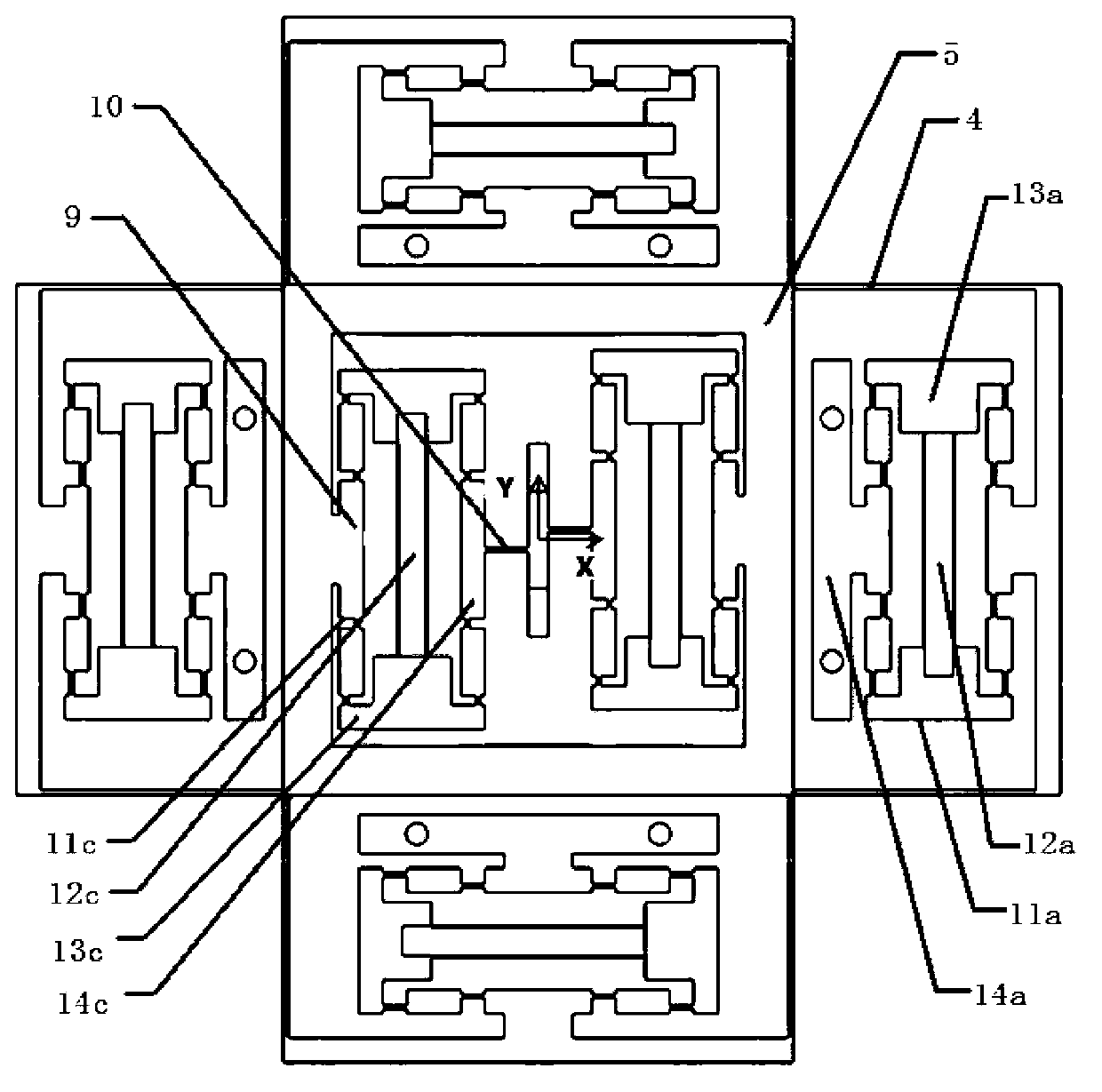

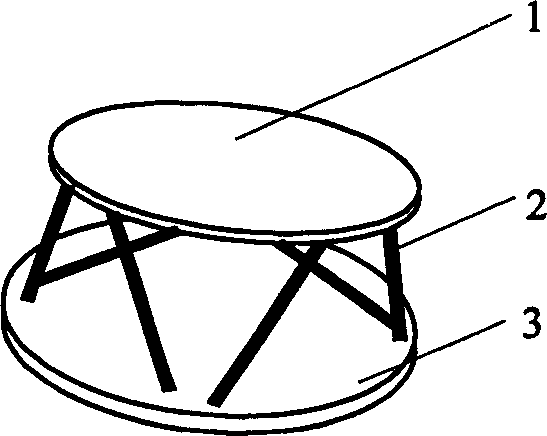

Integrated type six degrees of freedom precision positioning platform

The invention discloses an integrated type six degrees of freedom precision positioning platform. The integrated type six degrees of freedom precision positioning platform comprises a base, a lower platform component, a middle platform component and an upper platform component. The integrated type six degrees of freedom precision positioning platform utilizes a piezoelectric ceramics brake to enable the lower platform component to achieve rectilinear motion along an X direction and a Y direction of a coordinate system, enable the middle platform component to achieve a rectilinear motion along an Z direction of the coordinate system and a rotary oscillation around an axis which is parallel to the X axis and an axis which is parallel to the Y axis, and enables the upper platform component to rotate around the Z axis. The integrated type six degrees of freedom precision positioning platform can achieve precise control position on the six degrees of freedom and effectively avoids displacement coupling among axes due to the fact that the middle platform component and the lower platform component are designed into a symmetric structure. Meanwhile, the transmission platform can achieve integral manufacture, is driven by the piezoelectric ceramics brake, has the advantages of being free from friction and coupling, being high in precision, long in journey and high in resolution rate and can meet complex manufacturing and operation requirements of nanometer science and technology studies.

Owner:CHONGQING UNIV

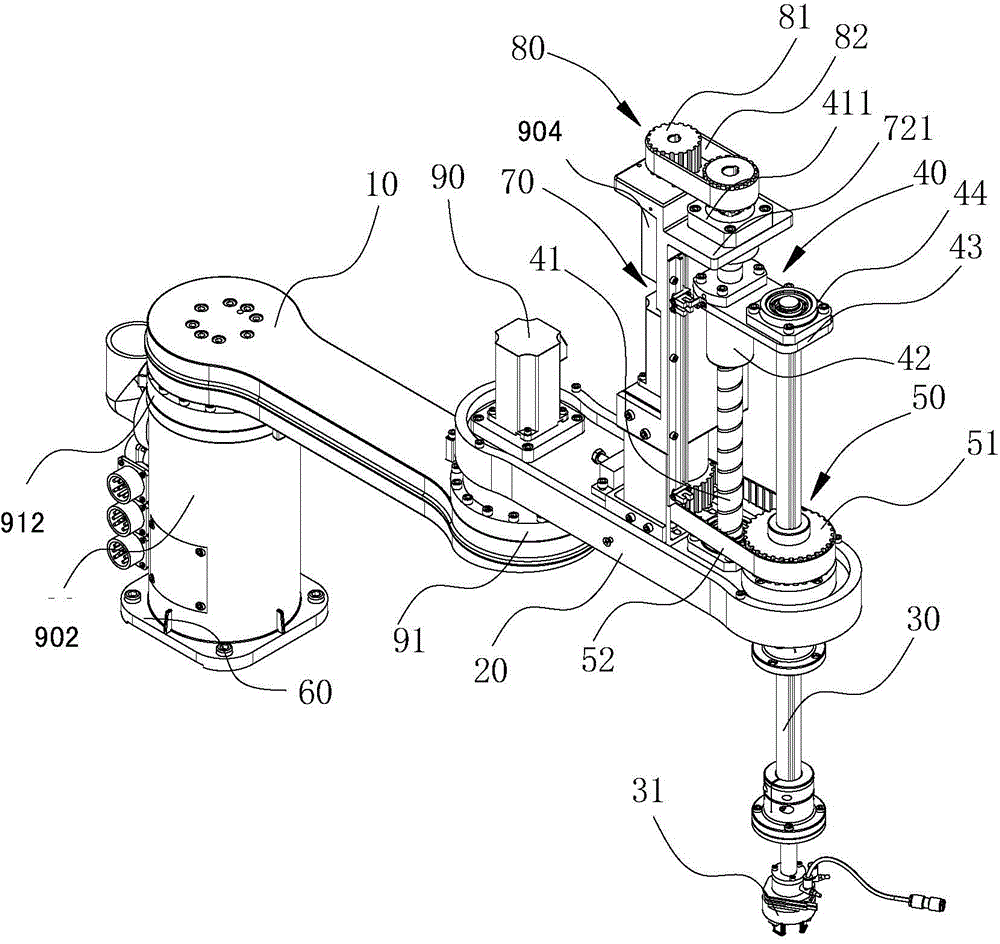

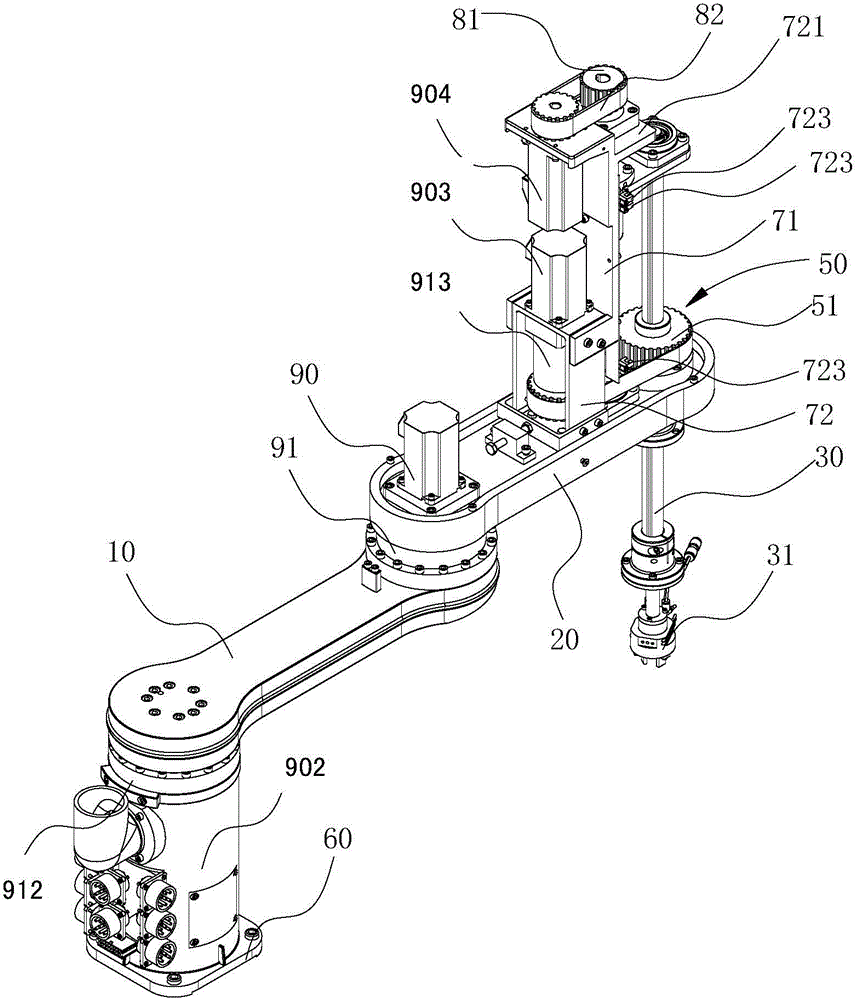

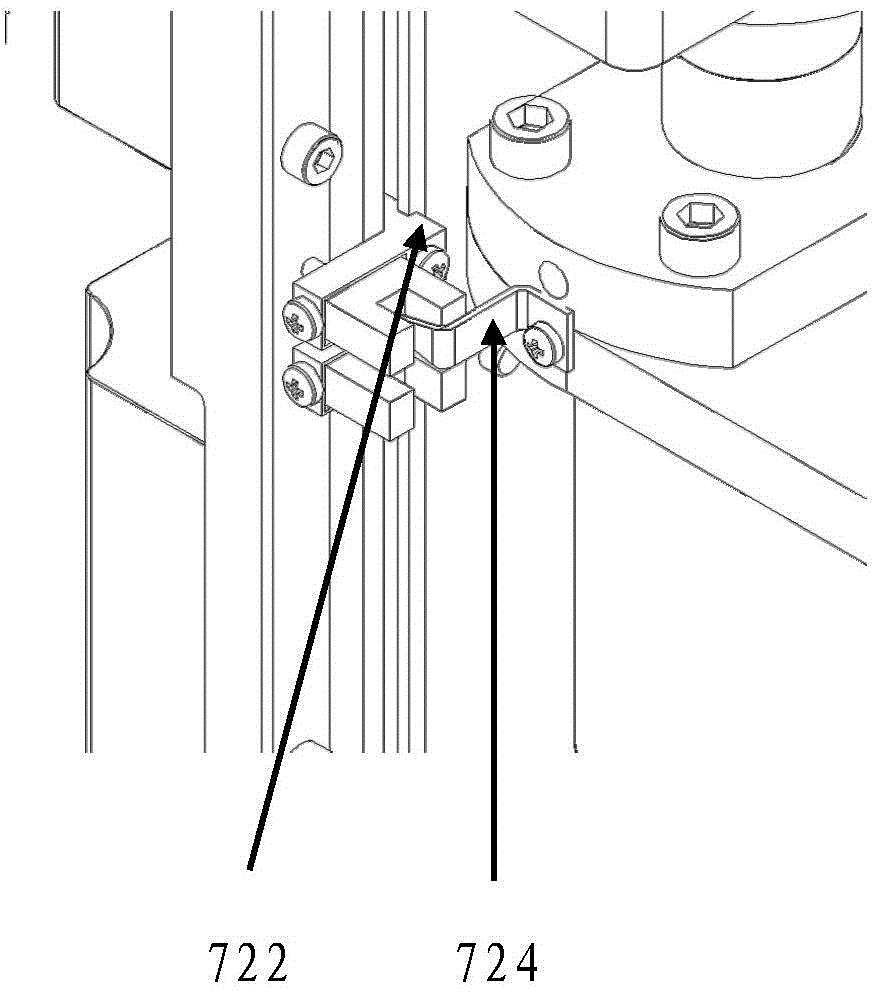

Multi-joint robot

ActiveCN103978477AExtended range of motionSmall endProgramme-controlled manipulatorSacroiliac jointControl theory

The invention provides a multi-joint robot, which comprises a large arm, a small arm, a movement unit and a gripper, wherein the large arm and the small arm are horizontally arranged and are mutually hinged, the movement unit is arranged on the small arm and comprises a lifting mechanism, and the gripper is used for gripping parts, is arranged on the lifting mechanism and can make lifting movement along with the lifting mechanism. The multi-joint robot is small and exquisite and flexible in tail end, compact in structure and good in control performance.

Owner:CHERY AUTOMOBILE CO LTD

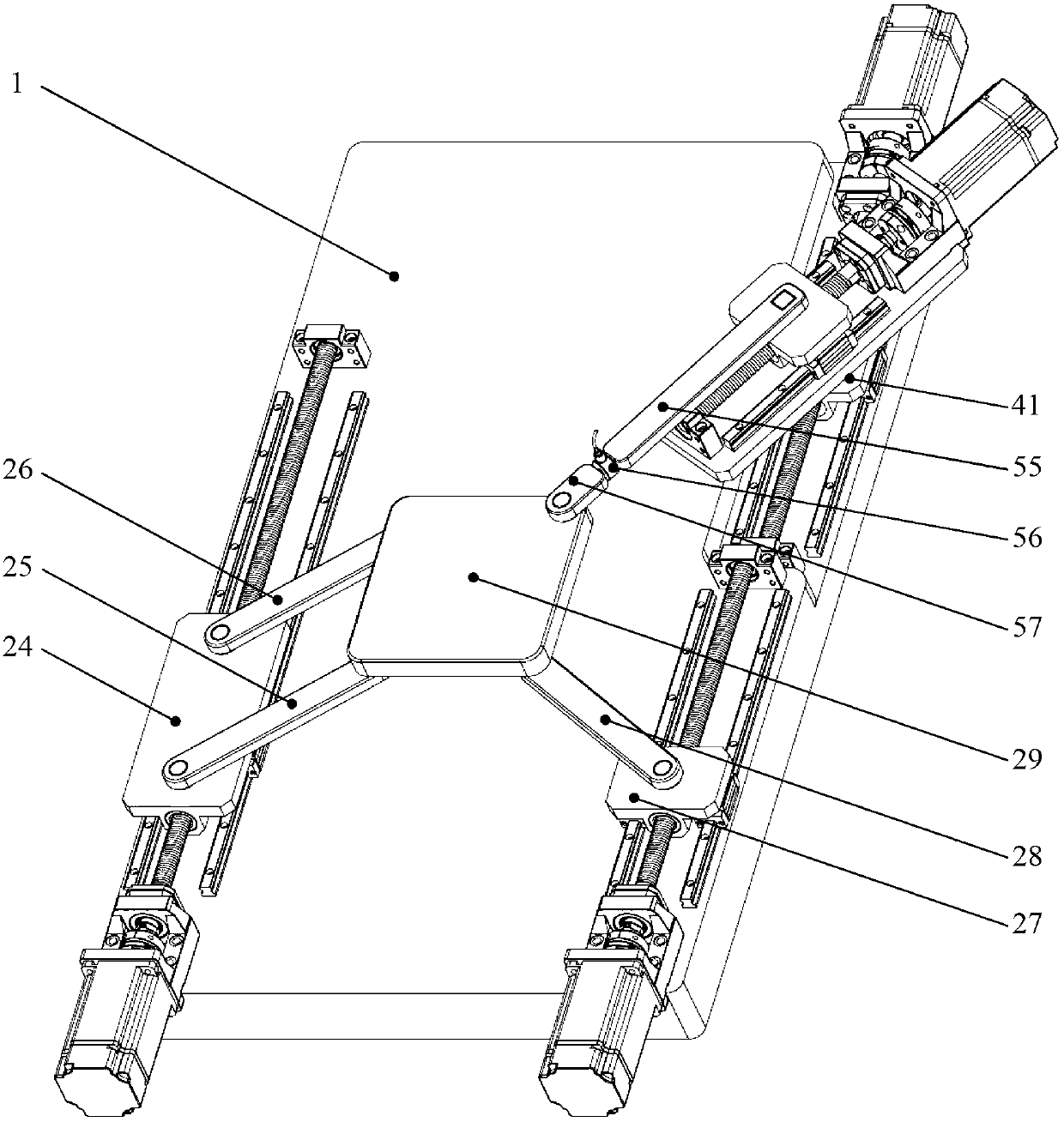

Novel plane two-degree-of-freedom redundant drive parallel moving platform

InactiveCN103101050AIncrease stiffnessImprove dynamic performanceProgramme-controlled manipulatorLoop controlDegrees of freedom

The invention discloses a novel plane two-degree-of-freedom redundant drive parallel moving platform, and belongs to the technical field of mechanical manufacturing. The novel plane two-degree-of-freedom redundant drive parallel moving platform comprises a moving platform, parallel guide rails, three equal-length branch chains, a telescopic branch chain and slide blocks; the positions of the slide blocks on the corresponding guide rails and the lengths of the telescopic branch chains are controlled under driving of a servo motor; and the moving platform has two translation degrees of freedom in the plane. Because a parallel mechanism is adopted, the moving platform has the advantages of high rigidity and good dynamic performance; the telescopic branch chains are taken as the redundant drive branch chains, a pull pressure sensor is installed close to the connection point of the telescopic branch chains and the moving platform, preset pull pressure force can be applied to the moving platform by utilizing the servo motor at the point along the directions of the telescopic branch chains through force enclosed loop control. Through optimizing the size and direction of applied load of the redundant drive branch chains, the rigidity and dynamic performance of the mechanism can be improved further.

Owner:TSINGHUA UNIV

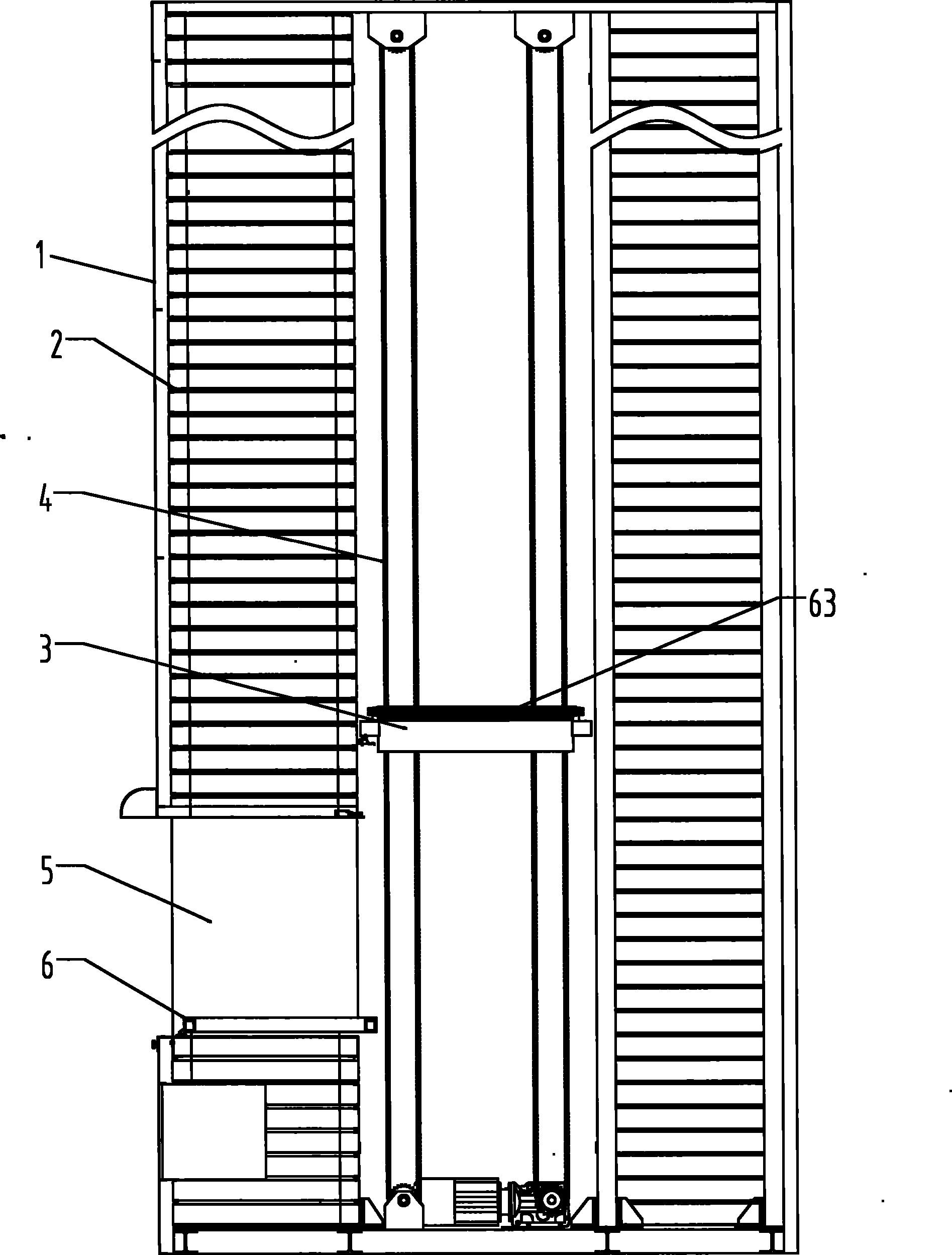

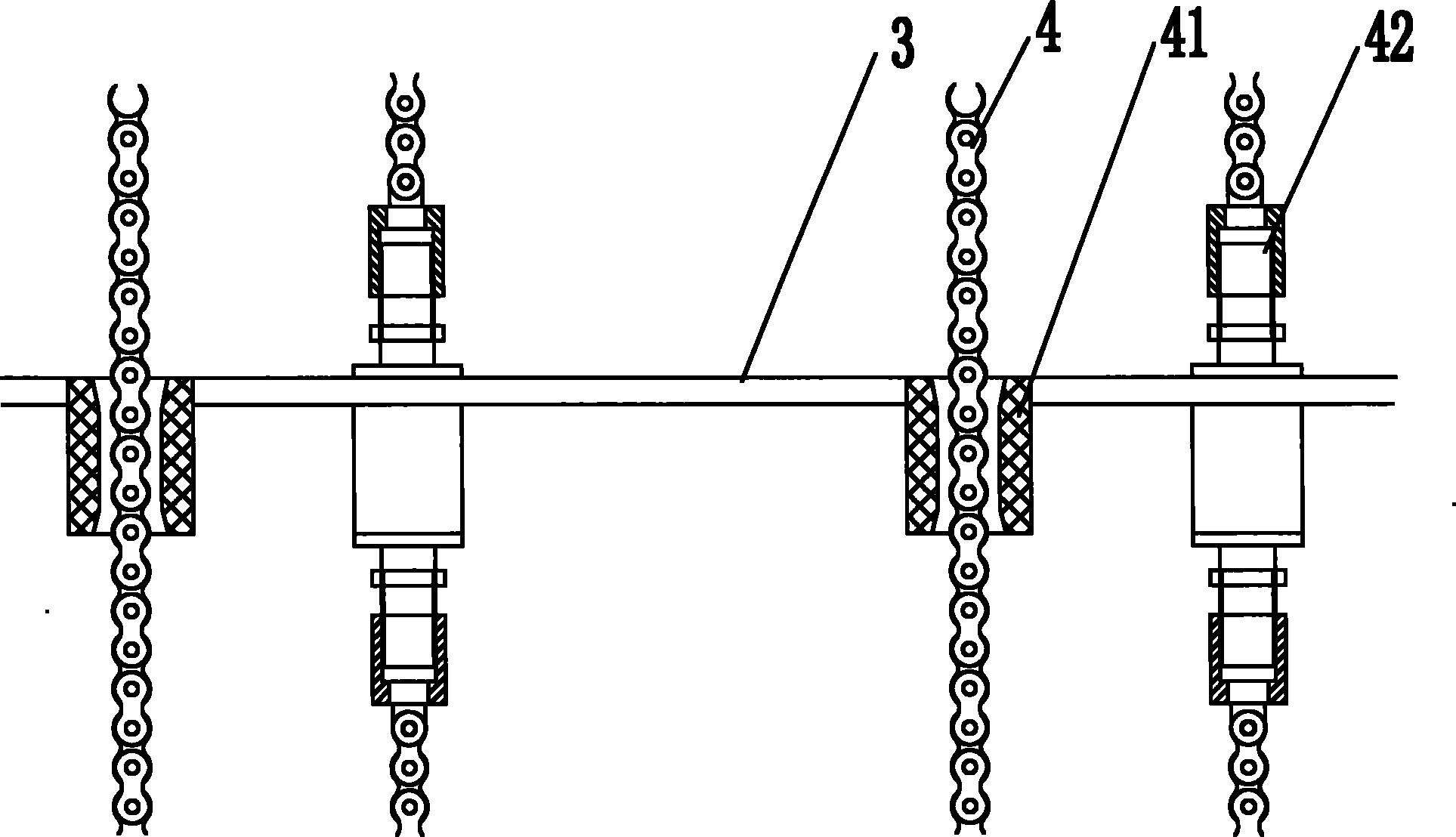

Vertical lifting container

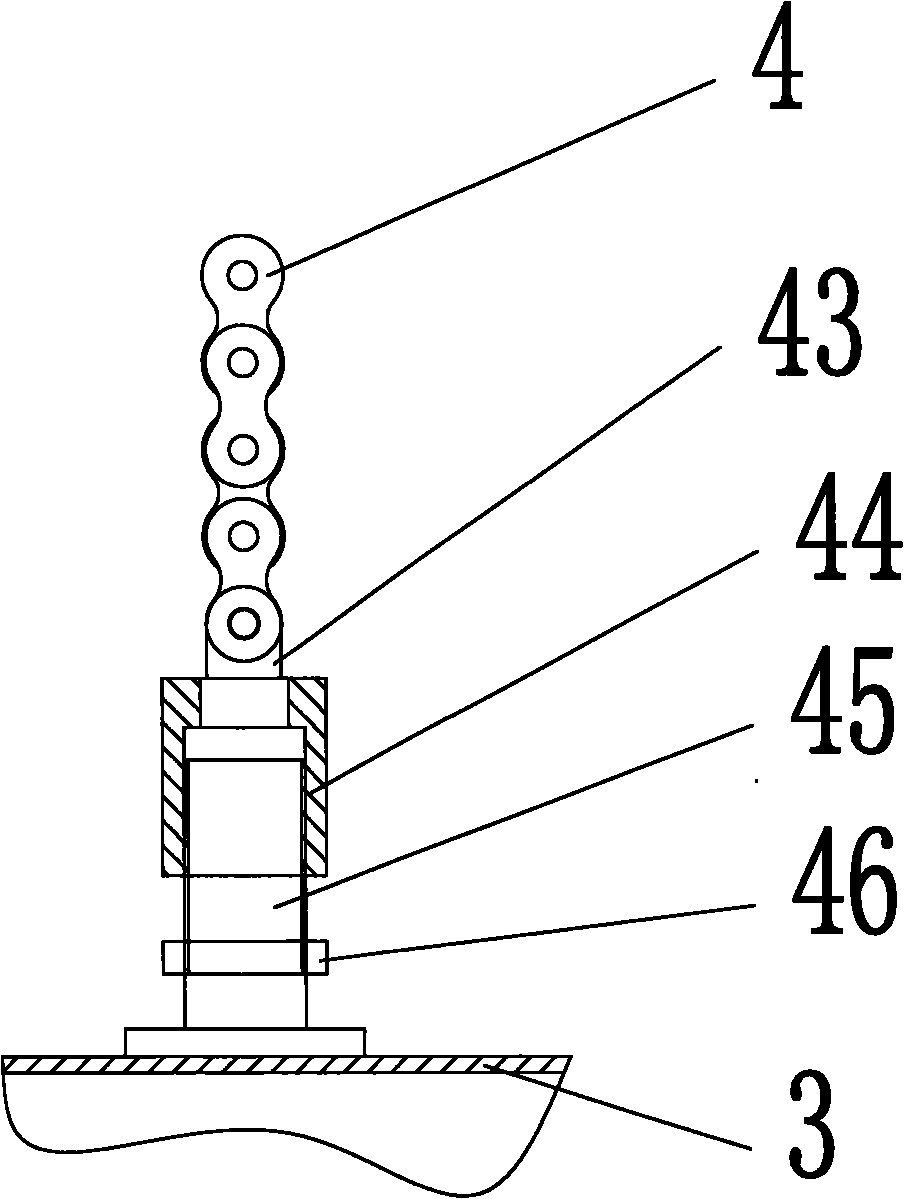

ActiveCN101850884AGuaranteed smoothnessImprove shipping efficiencyStorage devicesSprocketEngineering

The invention discloses a vertical lifting container, which comprises a container body, a corbel for holding a pallet is respectively on the two sides of the container, a passage for the lifting platform to run from top to down is left between the cornels on the two sides of the container body, a lifting platform is hung in the passage through a lifting chain, one side of the container is provided with a goods outlet, the pallet for transporting into or out the goods is arranged in the goods outlet, and a drive device drives the pallet to translate. In the vertical lifting container of the invention, the pallet device is driven by a chain wheel device to smoothly and stably run, a guide device is arranged to further guarantee the smoothness of the pallet during the processes of drawing and withdrawing, so as to improve the operating efficiency of the goods and reduce running noise, and a chain tensioner can adjust the tension of the chain to avoid the swaying phenomenon and to enable the adjustment of the horizontal position of the lifting platform to be convenient. Since a guide upright similar to a guide rail is arranged, the vertical lifting platform can ensure the smoothness of the lifting platform and prevent the surface of the lifting platform from being oblique and shifted.

Owner:南京音飞储存设备(集团)股份有限公司

Charging and blanking robot of punch press

InactiveCN101758497AEasy to adjustImprove work efficiencyProgramme-controlled manipulatorMetal-working feeding devicesPunch pressReduction drive

The invention discloses a charging and blanking robot of a punch press, comprising four joints, a base, two arms and an end effector, wherein the first joint, the second joint and the fourth joint have the degree of freedom of rotation, and the third joint has the degree of freedom of up and down translation; one end of the first joint is connected with the base by an input end shell; the other end of the first joint is connected with one end of the first arm by a first joint output flange; the other end of the first arm is connected with a second joint output flange of the second joint; a third joint connecting plate is connected with the joint rack of the fourth joint; and a fourth joint output rotary table is provided with the end effector. A harmonic transmission mode is adopted by a first joint transmission device and a second joint transmission device of the robot. Aiming at the characteristic that a harmonic speed reducer only can bear torque but can not bear bending moment, a pair of tapered roller bearings is arranged on an output shaft and is used for bearing overturning bending moment. The transmission mode has compact structure, high transmission efficiency, small return difference and high transmission accuracy.

Owner:ZHEJIANG UNIV

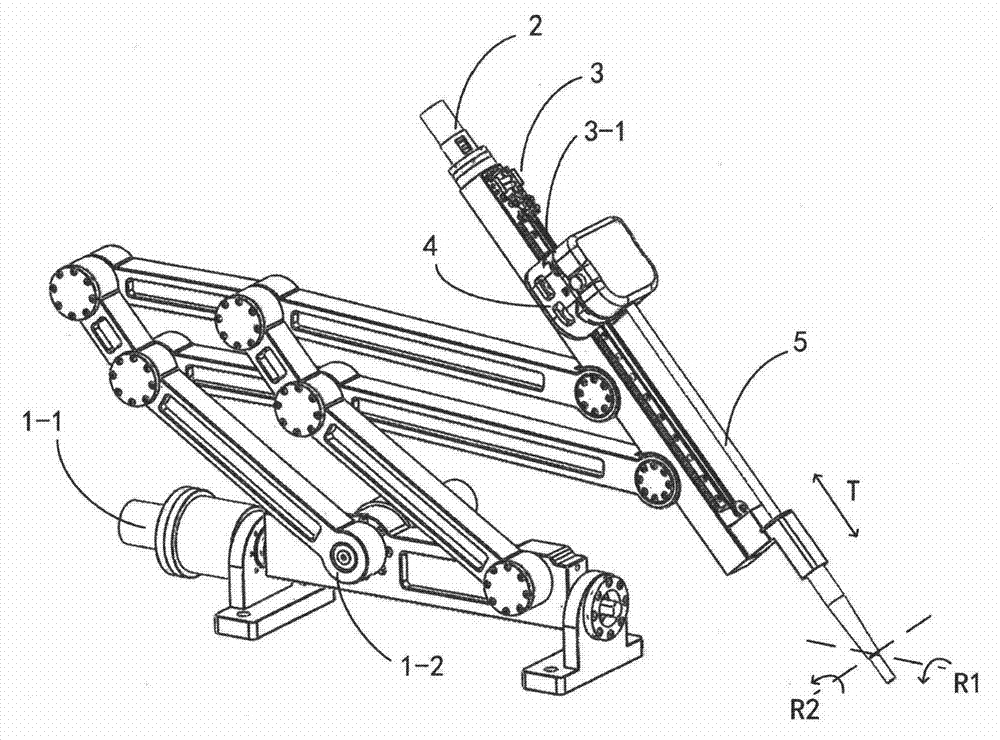

Steel wire rope transmitting linear telescopic mechanism for minimally-invasive surgery robot

The invention discloses a steel wire rope transmitting linear telescopic mechanism for a minimally-invasive surgery robot. The steel wire rope transmitting linear telescopic mechanism mainly comprises a driving system, a steel wire rope transmitting device and a tail end actuating mechanism. The driving system is composed of a rear servo motor, a speed reducer and a coupler, wherein the output shaft of the speed reducer is connected with a ball spline shaft through the coupler to transmit movement to the steel wire rope transmitting system. The steel wire rope transmitting system is composed of a steel wire rope, a ball spline, a spline screw barrel, a guide shaft and a guide wheel. The mutual conversion between the circumferential motion and the linear motion of the steel wire rope is achieved, and the self linear motion direction change of the steel wire rope is obtained. The tail end actuating mechanism is fixed to a telescopic supporting rod, a linear guide rail is arranged on the telescopic supporting rod, the tail end actuating mechanism is connected with the steel wire rope through a fixing screw device, and the linear motion of the steel wire rope can be transmitted to the tail end actuating mechanism. The steel wire rope is arranged in a closed loop mode. The linear telescopic mechanism has the advantages of being small in occupancy, simple in structure, accurate in control, free of hysteresis error and high in transmitting efficiency.

Owner:TIANJIN POLYTECHNIC UNIV

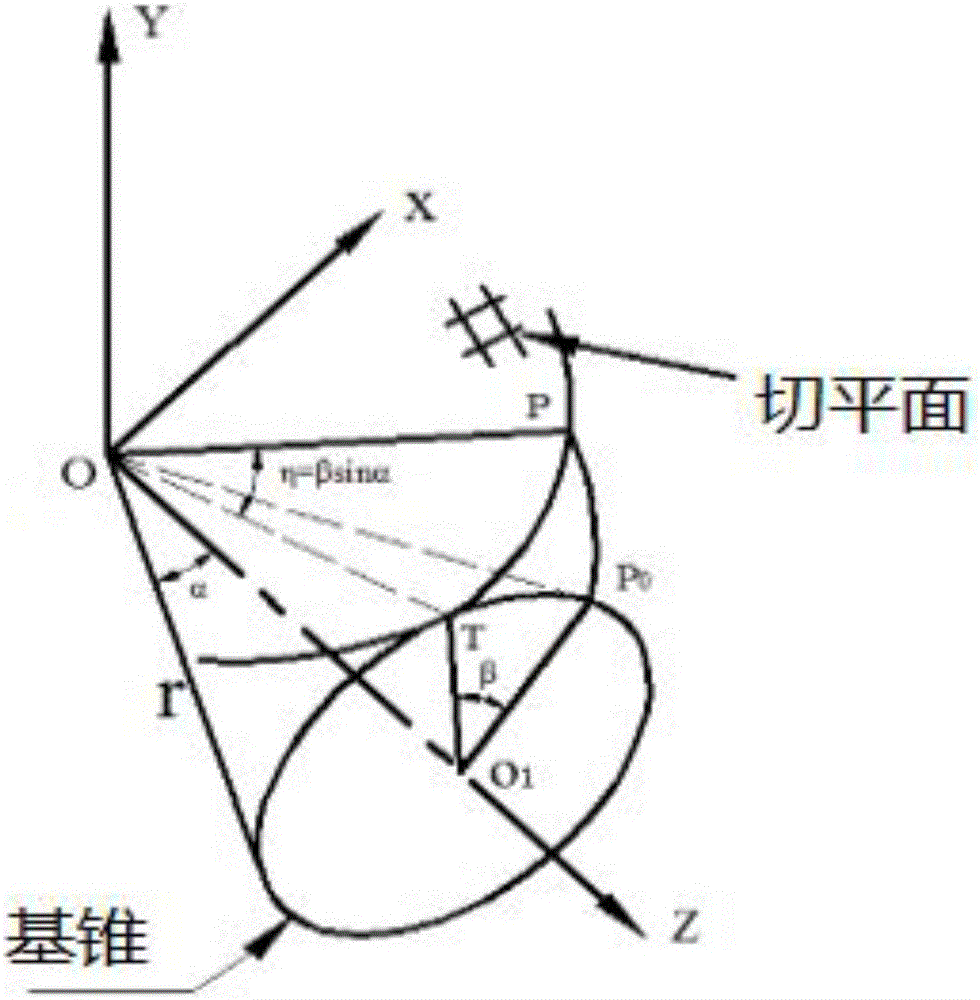

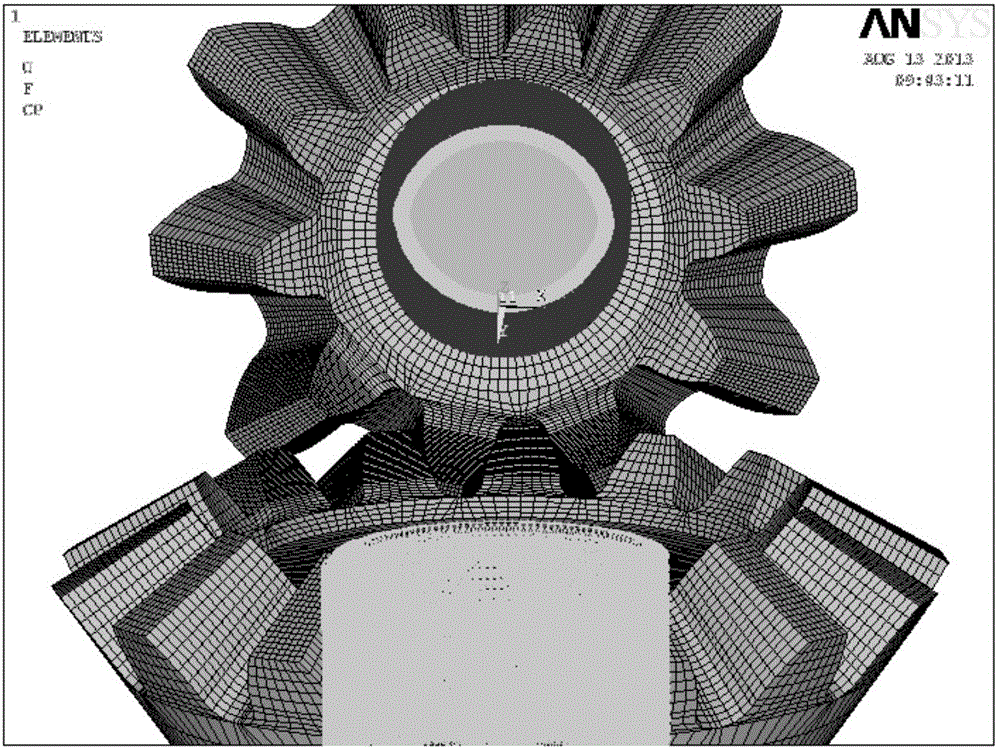

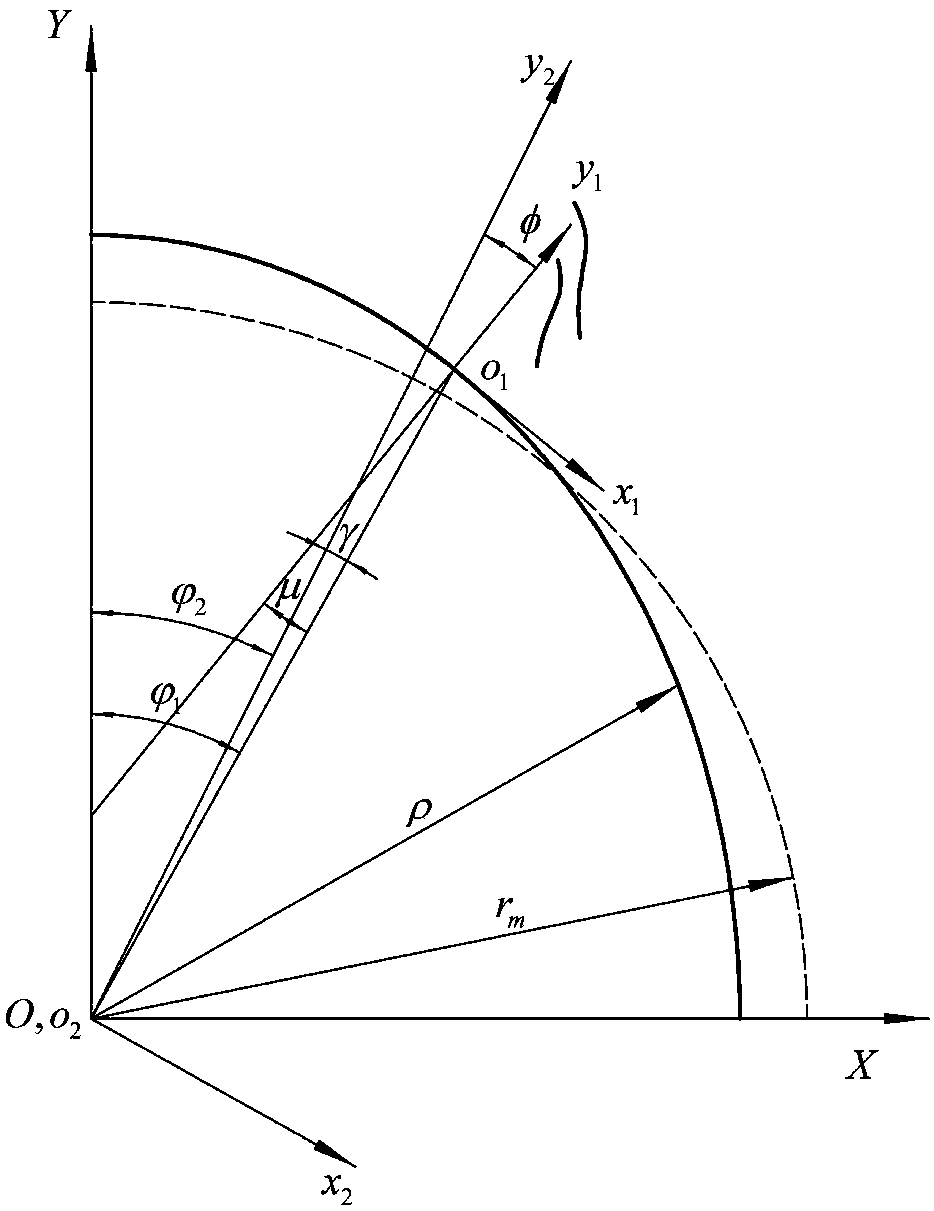

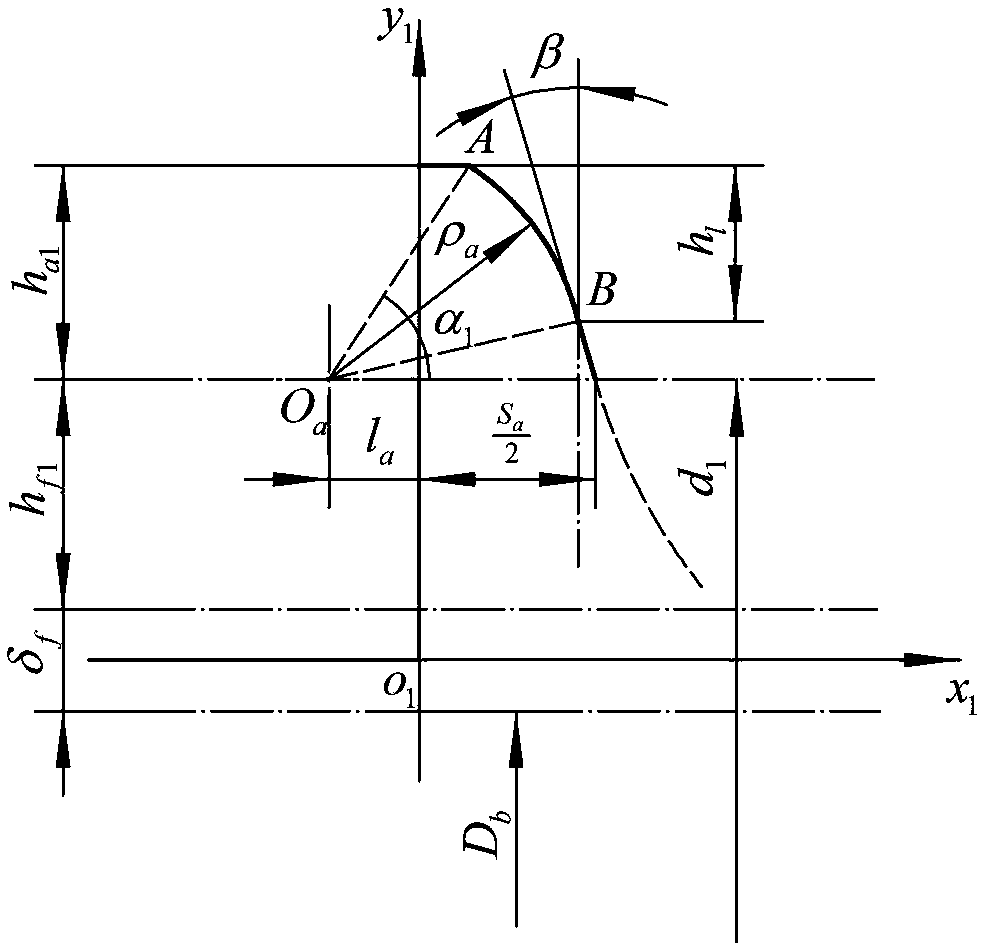

Involute bevel gear tooth end relief and parametric modeling method

ActiveCN105843985AImprove uneven load distributionIncrease stressDesign optimisation/simulationSpecial data processing applicationsStress distributionElement model

The invention disclose s an involute bevel gear tooth end relief and parametric modeling method which includes the steps of building a three-dimensional model of a bevel gear without the relief; building a finite element model of the bevel gear without the relief; determining 4 key engaging positions in the gear engaging process according to the gear engaging period to obtain the gear circumferential displacement difference value and the tooth width-direction equivalent contact stress distribution; determining the relief amount and the relief length of the tooth end relief; building a relief curve equation and a relief tooth surface equation; realizing the primary modeling of the relief curve and the tooth surface after the relief, and building a three-dimensional model of the relief gear; analyzing the gear after the relief by finite element analysis software and comparing the gear after the relief with a gear without the relief. The tooth surface contact condition is improved, the vibration noise in the gear engagement is reduced, and the NVH quality of the gear is improved.

Owner:WUHAN UNIV OF TECH

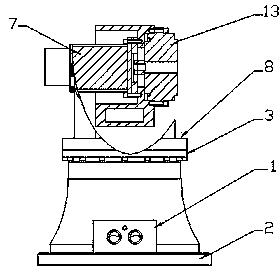

Hollow series-connection mechanical arm

The invention discloses a hollow series-connection mechanical arm. The hollow series-connection mechanical arm comprises a plurality of modularized joints and a base, wherein the rotating end of the first modularized joint is vertically and rotationally connected with the base, the fixed end of the first modularized joint is fixedly connected with the rotating end of the second modularized joint, the fixed end of the second modularized joint is fixedly connected with one end of a first connecting arm, the other end of the first connecting arm is fixedly connected with the fixed end of the third modularized joint, the rotating end of the third modularized joint is fixedly connected with the fixed end of the fourth modularized joint, the rotating end of the fourth modularized joint is fixedly connected with one end of a second connecting arm, the other end of the second connecting arm is fixedly connected with the fixed end of the fifth modularized joint, and the rotating end of the fifth modularized joint is fixedly connected with the fixed end of the sixth modularized joint. The hollow series-connection mechanical arm of the structure is low in self weight, large in weight-power ratio, lower in energy consumption and simple in structure, and the self weight can be reduced easily.

Owner:TIANJIN UNIV

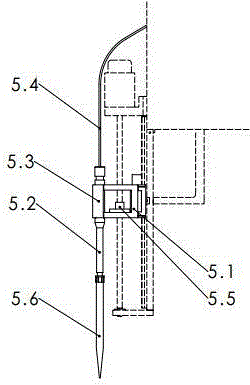

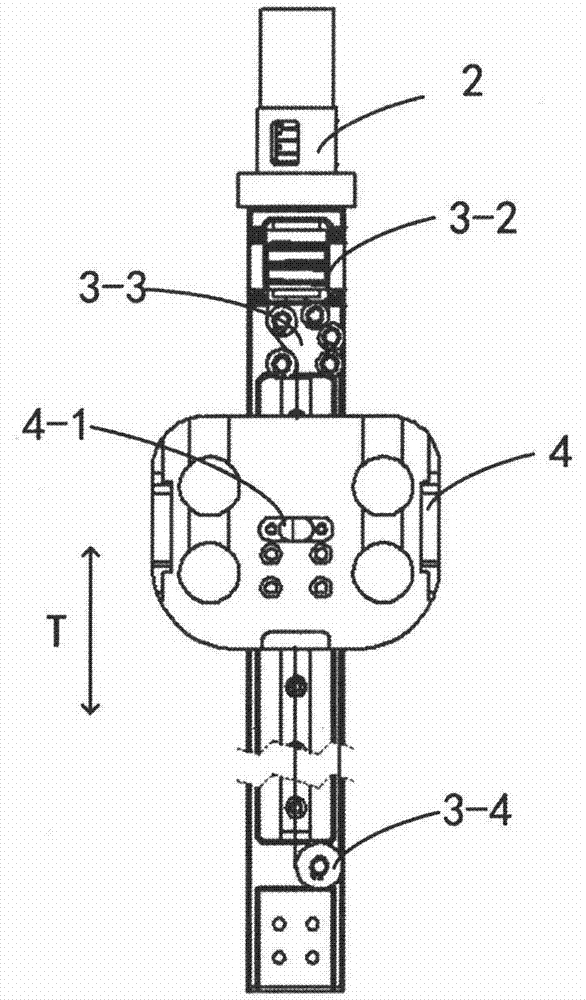

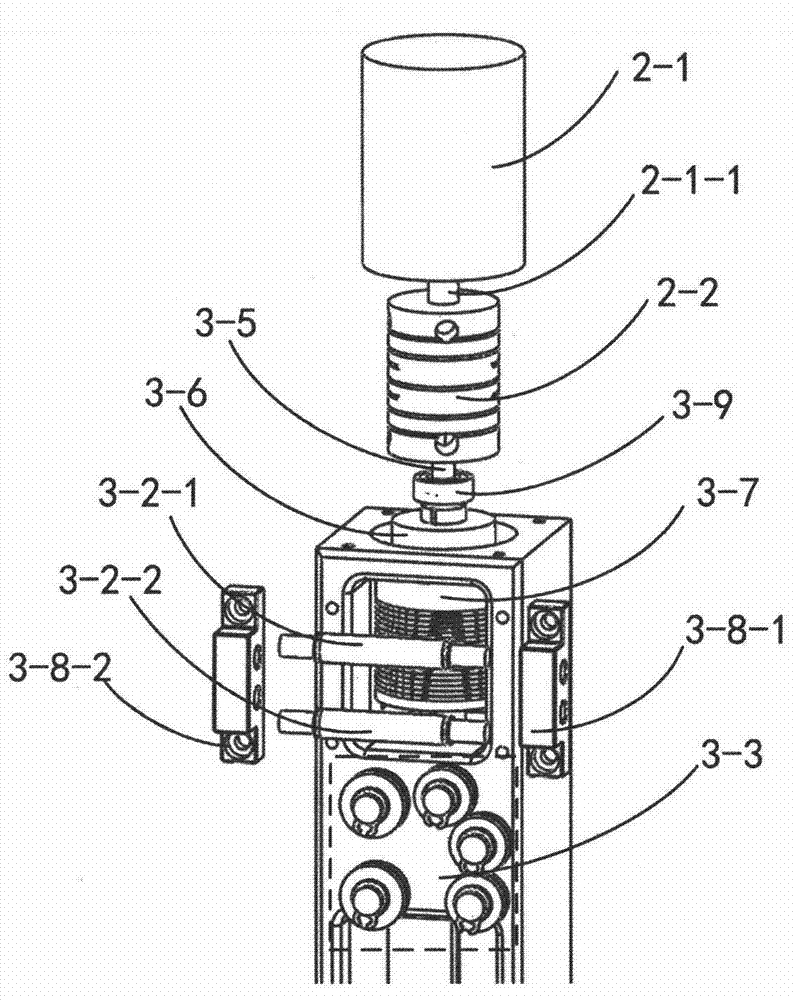

Interventional surgical robot subordinate end and mobile platform and control method of robot subordinate end

ActiveCN107374738AMeet the requirements for collaborative operationHigh transmission precisionDiagnosticsSurgical robotsSurgical robotThree vessels

The invention discloses an interventional surgical robot subordinate end and a mobile platform and a control method of the robot subordinate end and belongs to the technical field of minimally invasive blood vessel interventional operations. The mobile platform comprises a platform main beam, and platform connection blocks are arranged on the platform main beam through a linear guide rail pair D; the platform connection blocks are driven by a platform driving mechanism and used for installing a catheter controller or a guide wire controller. The interventional surgical robot subordinate end comprises the catheter controller, the guide wire controller and the mobile platform; the catheter controller and the guide wire controller are mounted on the two platform connection blocks respectively. According to the interventional surgical robot subordinate end, the catheter controller and the guide wire controller are installed on the mobile platform, and the problem is solved that it is difficult for an existing robot to complete co-operating of a catheter and a guide wire.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

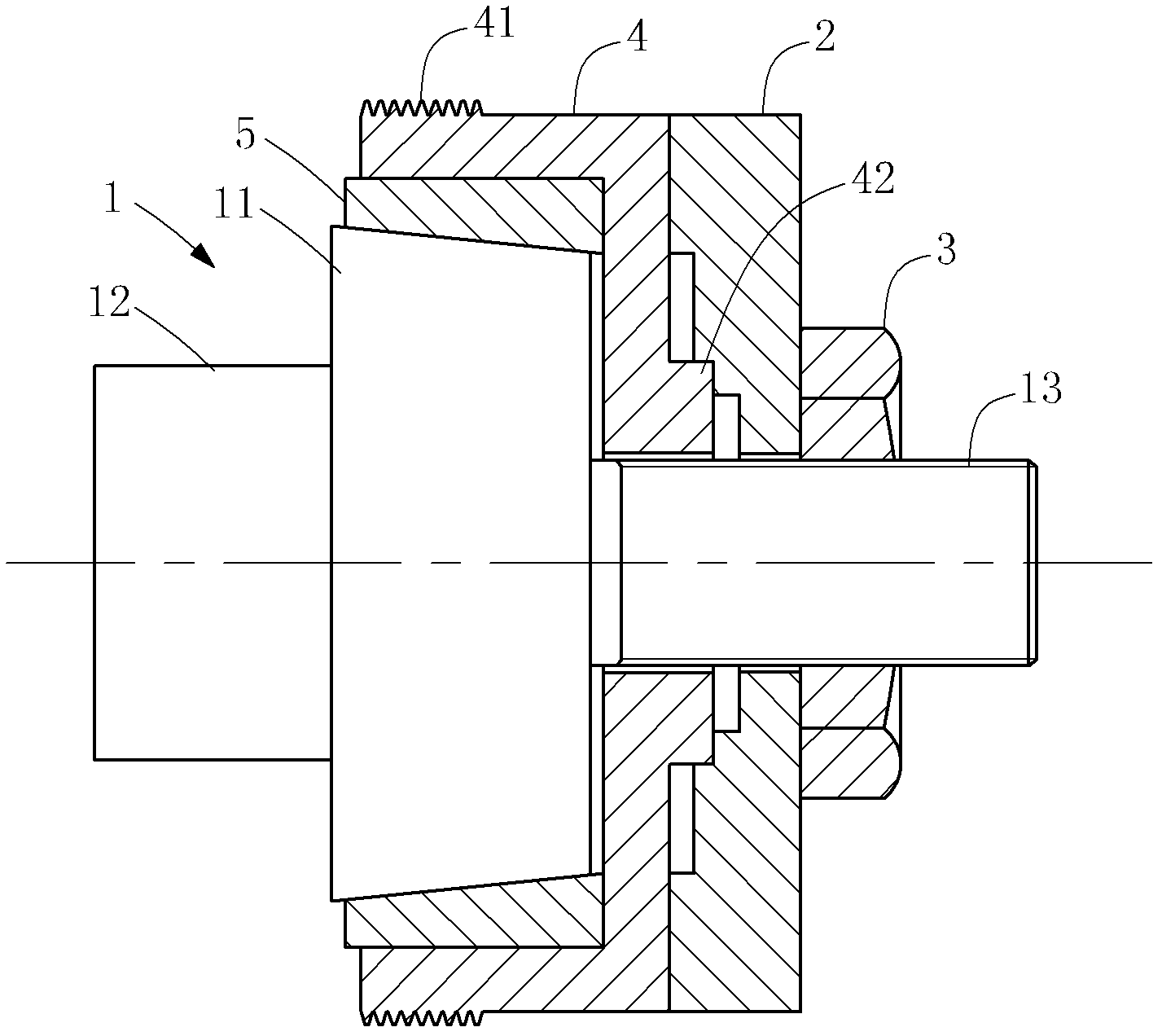

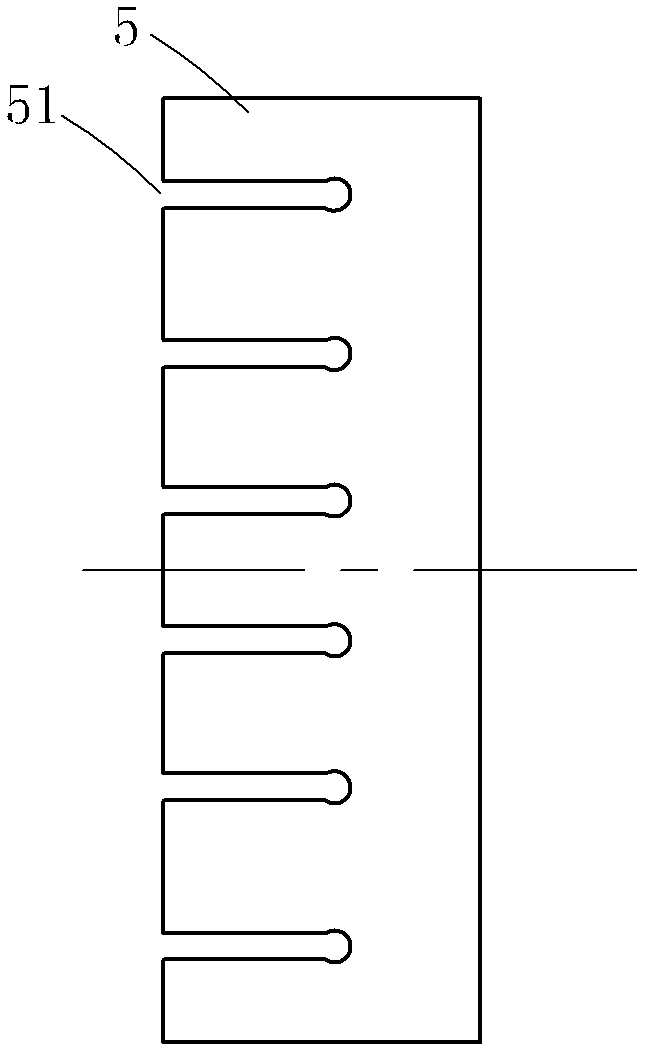

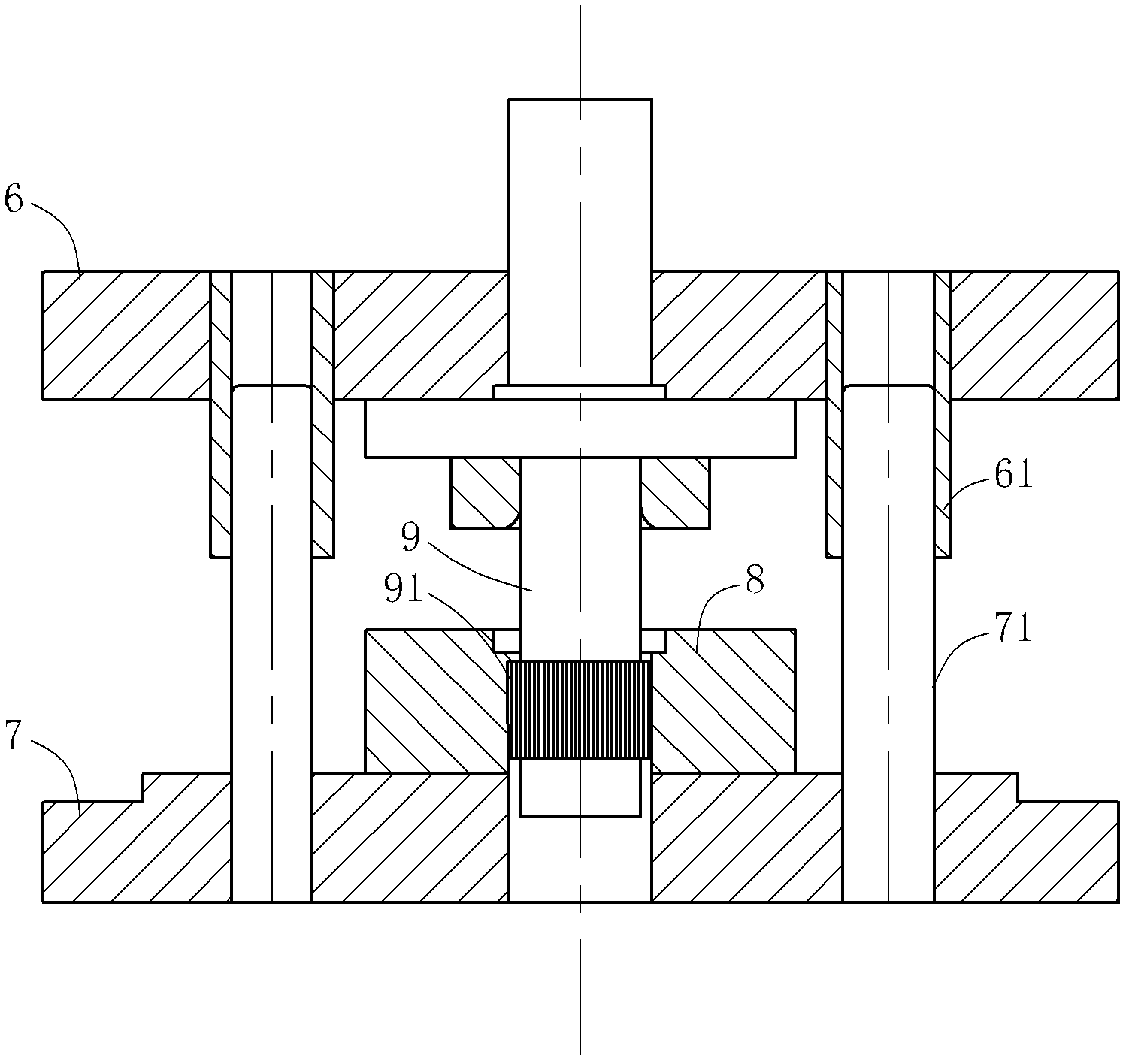

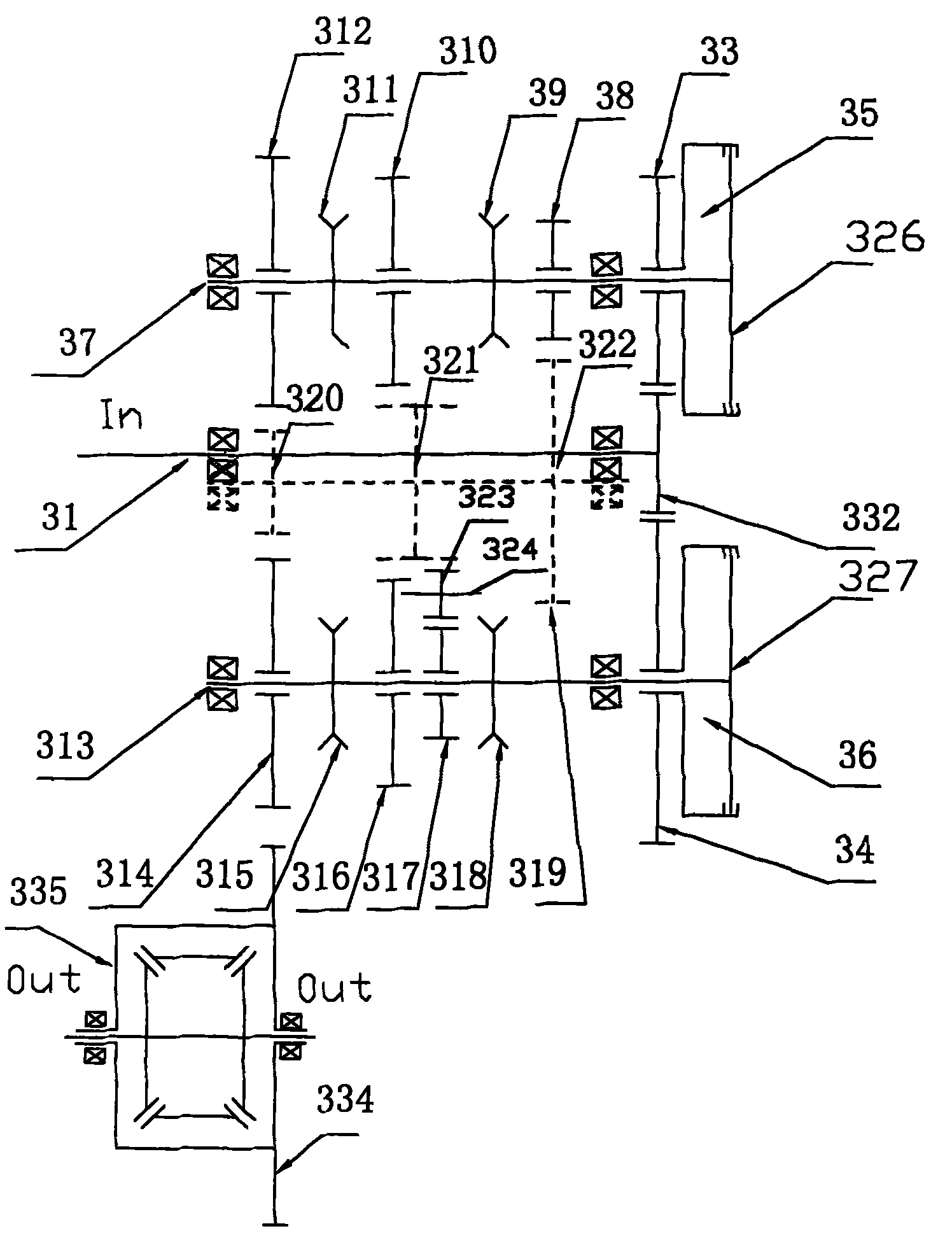

Screw-nut gear-shifting mechanism for automatic two-gear transmission of electric car

InactiveCN103557316AImprove transmission efficiencyEliminate axial playGearingGearing controlGear driveAutomatic transmission

The invention relates to a screw-nut gear-shifting mechanism for an automatic two-gear transmission of an electric car. The mechanism comprises an input shaft, an intermediate shaft and a fork gear-shifting mechanism, wherein the input shaft and the intermediate shaft are parallel to each other; a first-gear driving gear and a second-gear driving gear are fixedly arranged on the input shaft respectively; a second-gear driven gear, a first-gear driven gear, a main reduction driving gear and a synchronizer are sequentially arranged on the intermediate shaft respectively; the first-gear driving gear and the first-gear driven gear are normally engaged, and the second-gear driving gear and the second-gear driven gear are normally engaged; a main reduction driven gear is arranged to be matched with the main reduction driving gear, and during installation for usage, the main reduction driven gear is fixed on a differential mechanism flange plate through bolts; and a fork of the fork gear-shifting mechanism is sleeved with a joint sleeve of the synchronizer. According to the mechanism, a screw and screw-nut mechanism is adopted, so that the accuracy and the reliability of gear shifting are improved; and the mechanism is simple in structure, convenient to install and small in size, has a self-locking function and can prevent gears from loosening.

Owner:HEFEI UNIV OF TECH

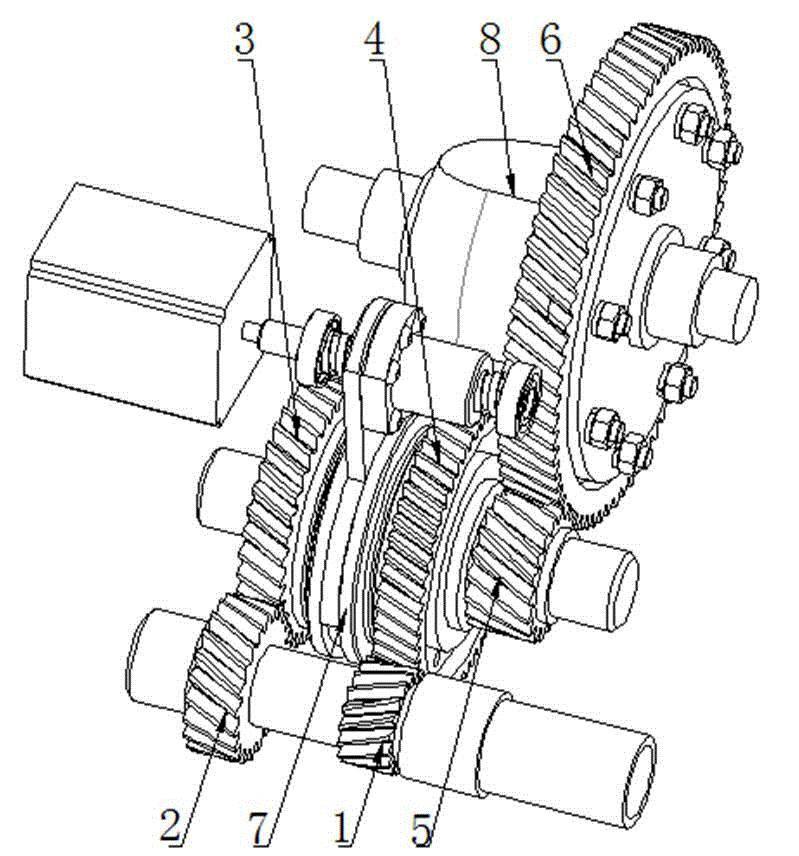

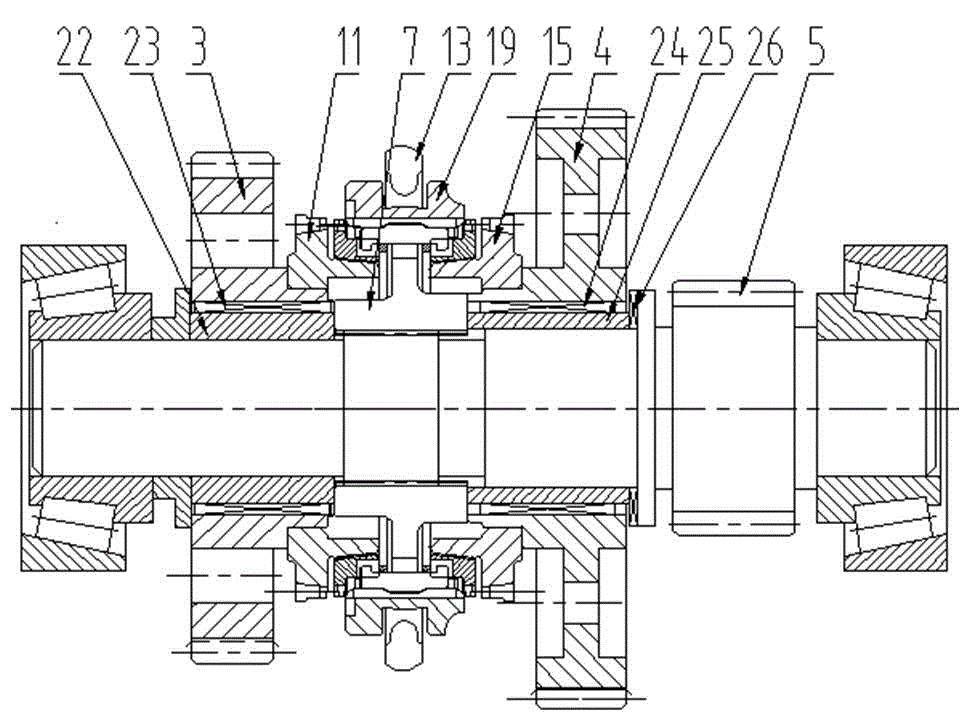

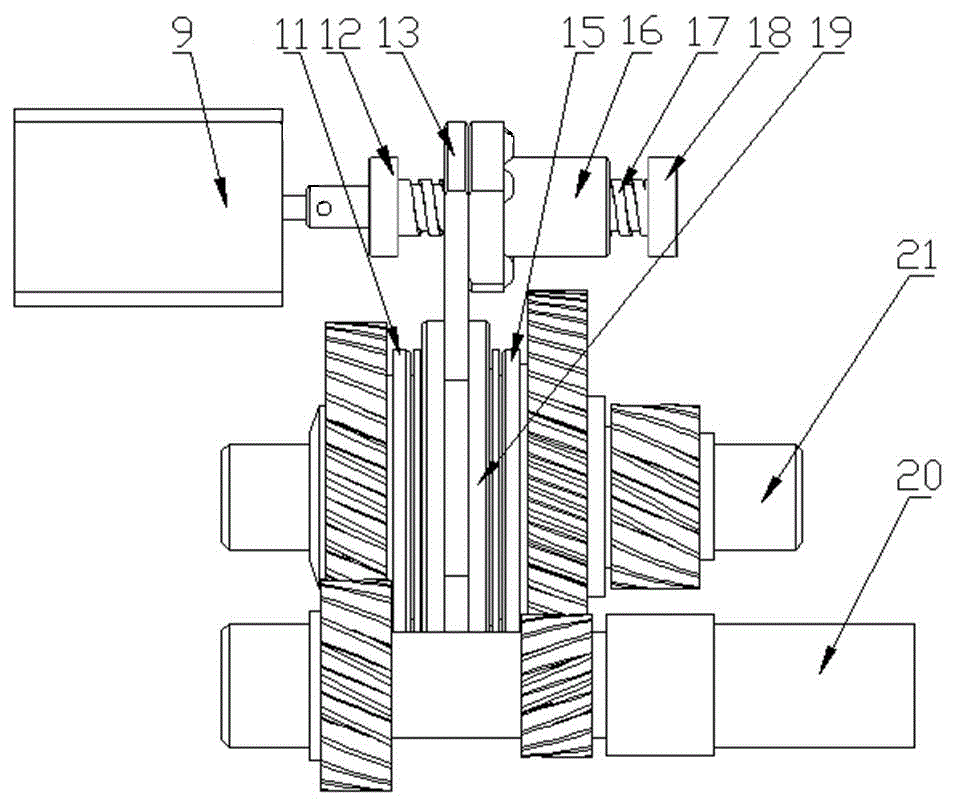

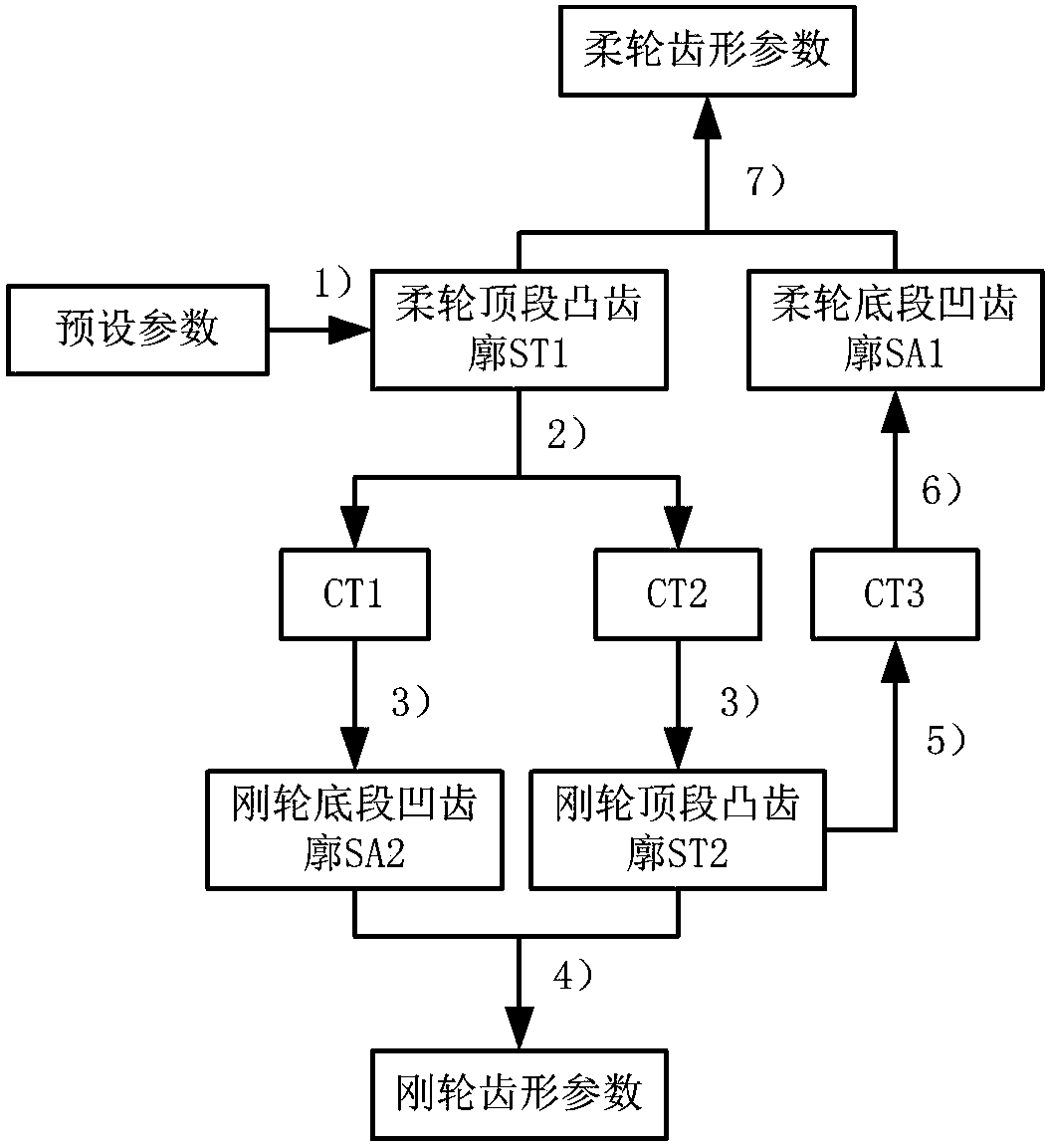

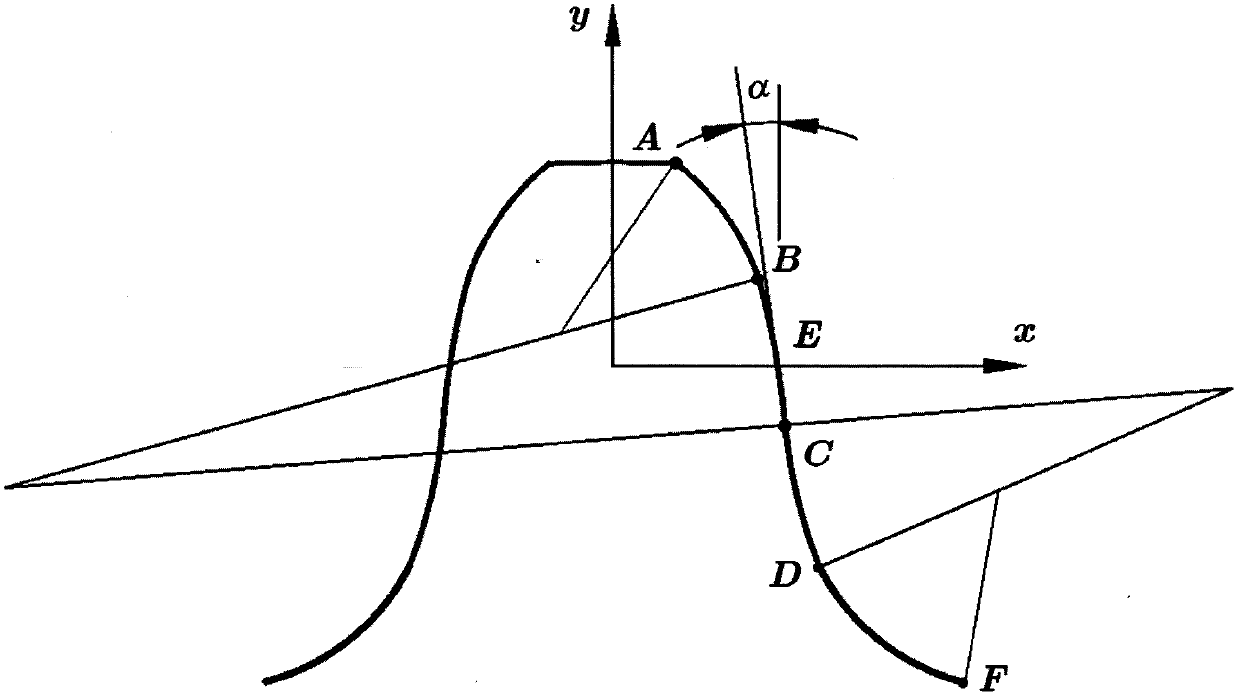

Bidirectional conjugate tooth profile design method for harmonic gear drive

ActiveCN108533715AIncrease logarithmReduce contact stressPortable liftingGearing elementsGear driveReduction drive

The invention relates to a bidirectional conjugate tooth profile design method for harmonic gear drive. The bidirectional conjugate tooth profile design method for harmonic gear drive comprises the steps of firstly, expressing a flexible wheel top-section convex tooth profile coordinate through a parameter equation, converting to a rigid wheel coordinate system, solving to obtain discrete point coordinates of a theorical conjugate concave tooth profile and a concave tooth profile of a flexible wheel top-section convex tooth profile, determining the working tooth depth of a rigid wheel tooth profile through least square fit, determining a fitted curve section to be a rigid wheel bottom-section concave tooth profile and a rigid wheel top-section concave tooth profile, and calculating to accomplish a tooth profile design of a rigid wheel; and then expressing a rigid wheel top-section convex tooth profile coordinate through a parameter equation, converting to a flexible wheel coordinate system, solving to obtain discrete point coordinates of a theorical concave conjugate tooth profile in a flexible wheel bottom-section range, determining the tooth depth of a flexible wheel through least square fit, determining a fitted curve to be a flexible wheel bottom-section concave tooth profile, and calculating to obtain a flexible wheel working tooth profile. According to the bidirectional conjugate tooth profile design method for harmonic gear drive provided by the invention, the flexible wheel tooth profile and the rigid wheel tooth profile with bi-conjugate and secondary-conjugate phenomena are directly obtained, so that a conjugate contact area and a meshing zone are increased, the tooth surface contact stress is reduced, and the drive accuracy of a harmonic reducer is improved.

Owner:XI AN JIAOTONG UNIV

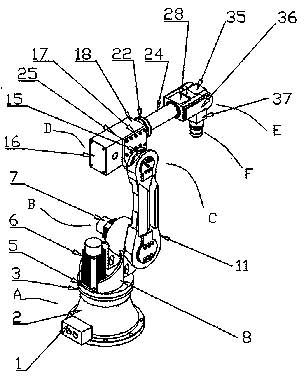

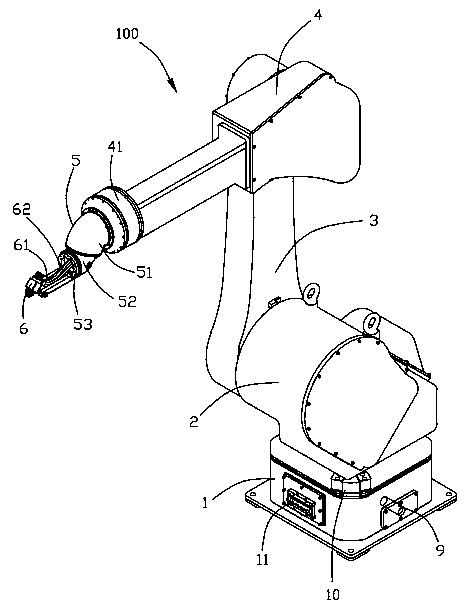

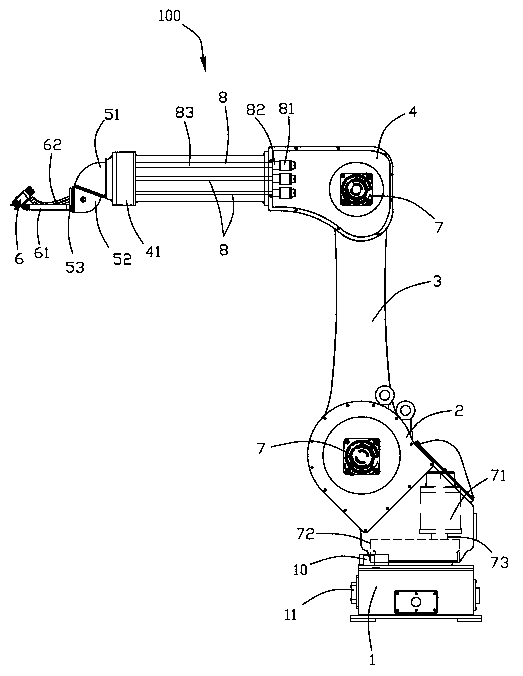

Six-freedom-degree spray coating robot

InactiveCN103538053AHigh transmission precisionImprove precision controlProgramme-controlled manipulatorJointsDrive shaftSpray coating

The invention provides a six-freedom-degree spray coating robot which comprises a base, a waist joint, a big arm joint, a small arm joint, a three-freedom-degree obliquely crossed wrist, a spray gun support, flanges, bearings, a plurality of first drive mechanisms and second drive mechanisms, wherein the waist joint is movably fixed to the base, the big arm joint is movably fixed to the waist joint, the small arm joint is movably fixed to the big arm joint, the three-freedom-degree obliquely crossed base is movably fixed to the small arm joint, the spray gun support is connected to the tail end of the three-freedom-degree obliquely crossed wrist, and the flanges and the bearings are movably connected among all the joints or between the joints and the wrist. The first drive mechanisms are used for driving the waist joint, the big arm joint and the small arm joint to work, and the second drive mechanisms are used for driving the three-freedom-degree obliquely crossed wrist to work. Each first drive mechanism comprises a first servo motor and an RV speed reducer. Each second drive mechanism comprises a second servo motor, a planetary reducer, a hollow transmission shaft and a gear pair, wherein the planetary reducer is connected with the second servo motor, the hollow transmission shaft is connected with the planetary reducer in a matched mode, and the gear pair is arranged in the three-freedom-degree obliquely crossed wrist and connected with the hollow transmission shaft.

Owner:HUAHENG WELDING

Method for manufacturing harmonic reducer of robot

The invention discloses a method for manufacturing a harmonic reducer of a robot, which belongs to the technical field of harmonic reducer processing and includes the steps of manufacturing flexible gears and the steps of manufacturing rigid gears. The steps of manufacturing the flexible gears include: forging solid billets of the flexible gears; performing heat treatment for the solid billets of the flexible gears to reach the hardness of HRC (Rockwell hardness) 38-40; turning the solid billets of the flexible gears after heat treatment into thin-wall semi-finished flexible gears; supporting inner cavities of the semi-finished flexible gears by a flexible gear tensioning fixture; and grinding the supported semi-finished flexible gears to form external gear rings of the flexible gears on a grinder. By the method, the efficiency and the precision of machining the flexible gears and the rigid gears are improved, the hardness of the flexible gears is enhanced, the service life of the harmonic reducer is prolonged, and the method is widely applied to production of harmonic reducers.

Owner:SHANDONG SHKE MACHINERY MFG

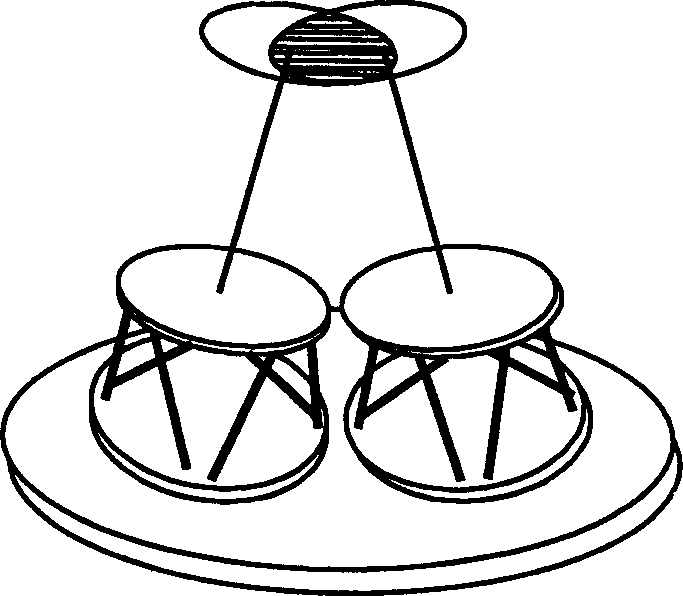

Series-parallel micro operation parallel-connection robot mechanical apparatus

InactiveCN1454753AReduce volumeGreat effortProgramme-controlled manipulatorComputer control systemMicro-operation

Disclosed is a parallel robot set to assemble diminutive machine. The robot comprises two same three-dimensional parallel frames which are in series. The parallel frame has three active links that comprise two Huke gemels and a micro displacement amplifier. The computer control system drives the displacement output of the piezoelectricity equipment. The undersides of the three active links are connected with the middle plate, and another side is connected with the work plate in a parallel frame group.In another group, the undersides of the three active links are connected with the underpan, and another side is connected with the middle plate. The middle plate is hung under the underpan. The two fingers of the robot are set on the work plate and the middle plate, which can work just like the human fingers.

Owner:BEIJING UNIV OF TECH

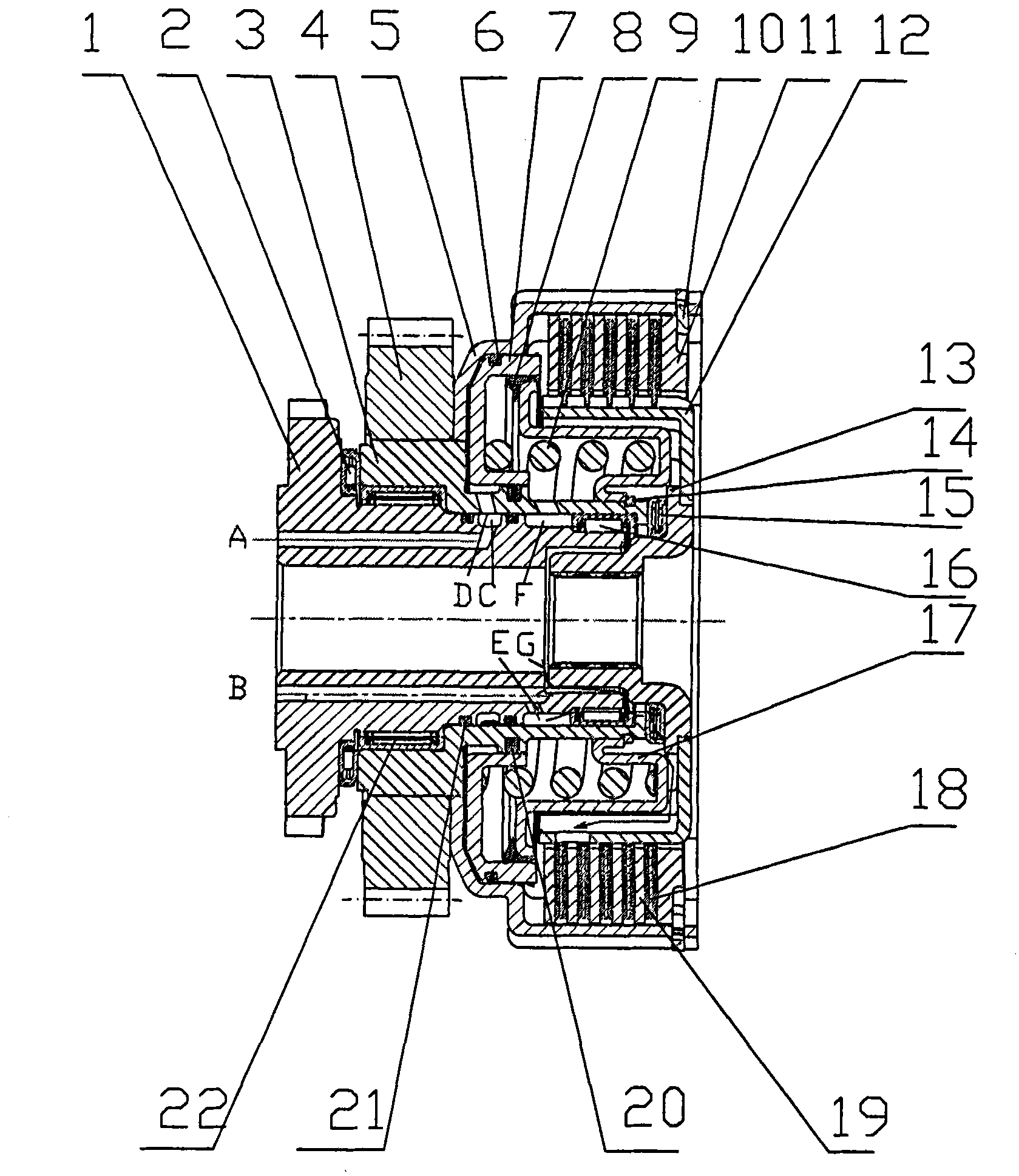

Dual-clutch automated transmission

ActiveCN101979898ASimplify the difficulty of production and processingLow costFluid actuated clutchesToothed gearingsAutomatic transmissionLayshaft

The invention relates to a dual-clutch automated transmission. An input shaft gear is arranged on an input shaft of an engine. The dual-clutch automated transmission comprises two independent monomer clutches, wherein the driving gear of the odd-gear clutch and the driving gear of the even-gear clutch are meshed with the input shaft gear in different transmission ratios respectively; the driving gear of the odd-gear clutch is fixed on a first secondary shaft; the driving gear of the even-gear clutch is fixed on a second secondary shaft; and the first secondary shaft and the second secondary shaft are arranged on two sides of the input shaft respectively and are parallel to the input shaft. In the dual-clutch automated transmission, an integrated dual-clutch is separated into two monomer clutches and the coaxial structure of the traditional dual-clutch transmission is transformed into a parallel structure, so that the manufacturing and processing difficulty of the dual-clutch transmission is simplified and the cost is reduced.

Owner:HEFEI CHANGAN AUTOMOBILE +1

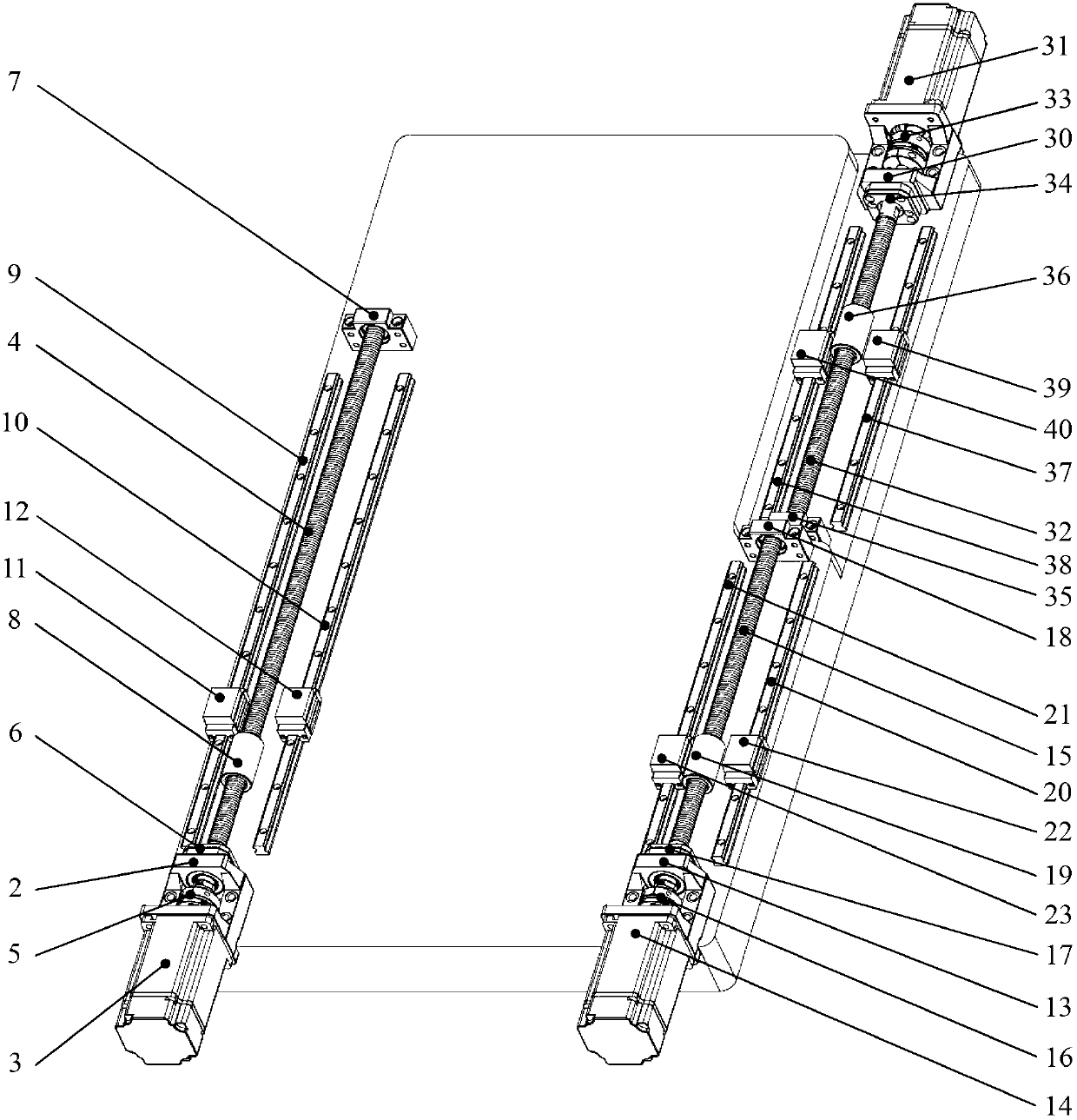

Gantry numerical-control milling and grinding integrated lathe of fixed column and movable beam type

ActiveCN101856789AVersatileGuaranteed accuracyOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a gantry numerical-control milling and grinding integrated lathe of a fixed column and movable beam type, comprising a lathe bed (2), a worktable (3), a left column (17), a right column (14), a beam (6), a spacing beam (22), a top beam (13), an electrical cabinet (33), a system control panel (32) and a tool clamp. The beam (6) is arranged on the left column (17) and the right column (14) through a beam-driving device, a boring and milling head (4) and a universal grinding head (41) are respectively arranged on the beam (6), the boring and milling head (4) is driven by a boring and milling head left-and-right driving device and a boring and milling head up-and-down driving device, the universal grinding head (41) is driven by a grinding head left-and-right driving device and a grinding head up-and-down driving device, and the worktable (3) is arranged on the lathe bed (2) through a ball screw pair (34). On the lathe, after once clamping, a workpiece can be processed by milling, boring, drilling, grinding, rigidly tapping and other continuous working procedures with high accuracy.

Owner:山东大侨发展股份有限公司

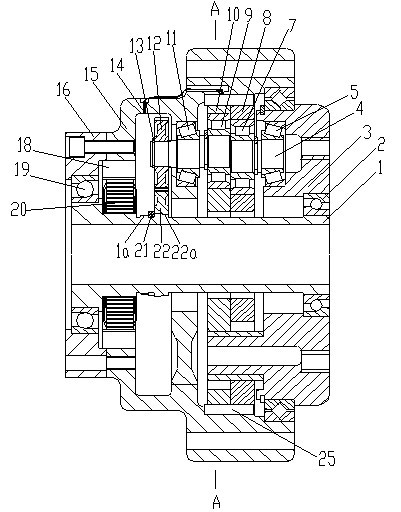

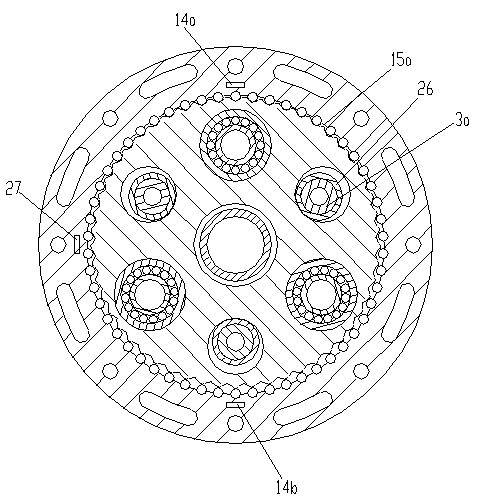

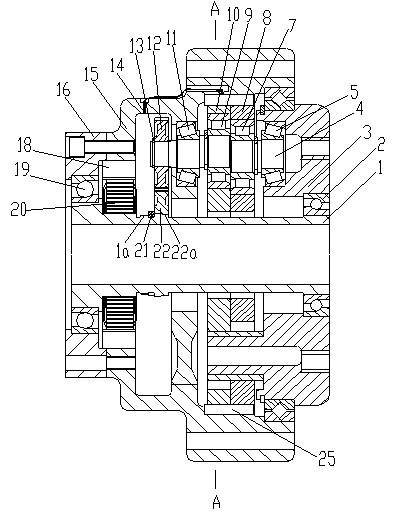

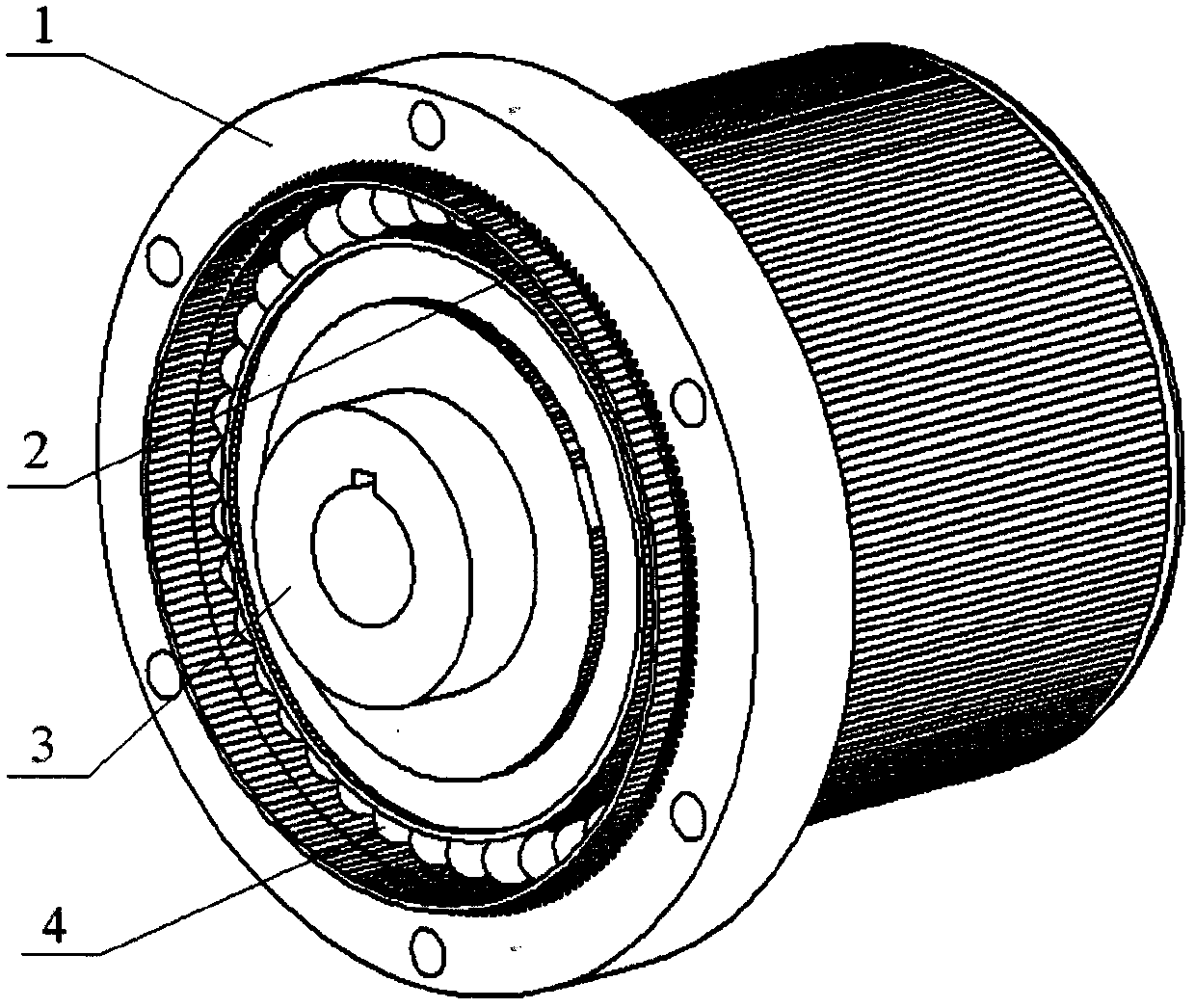

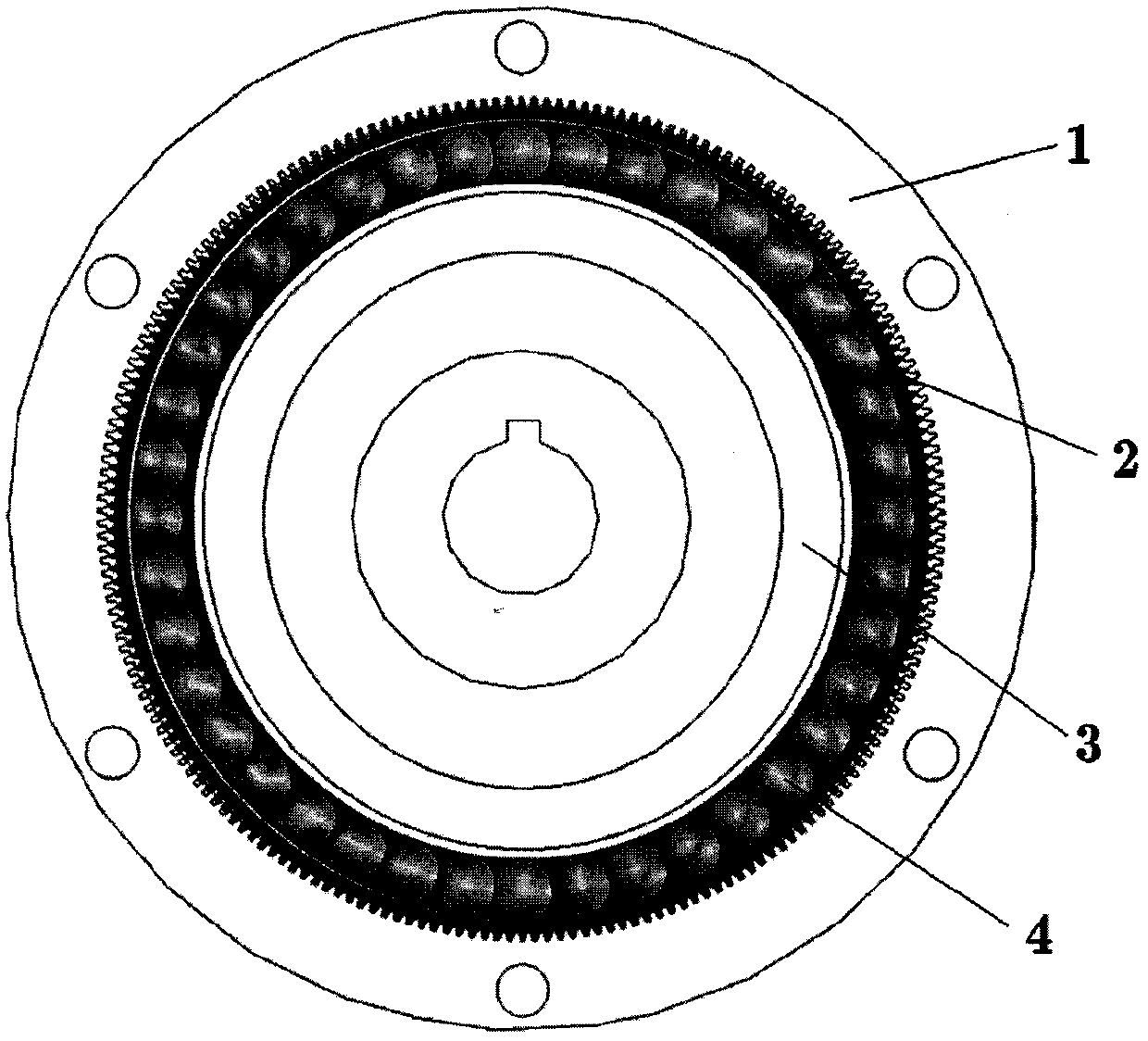

Electromechanically-integrated cycloidalpin wheel drive device

InactiveCN102278425ASave intermediate joinsReduce install targetingGearboxesToothed gearingsCouplingEngineering

The invention discloses an electromechanically-integrated cycloidalpin wheel drive device which comprises a cycloidalpin wheel speed reducer assembly, a high-speed cylindrical gear meshing pair, a servo motor, a speed and temperature sensor, a hollow input shaft and an output shaft with a flange. According to the invention, a planetary speed reducer assembly with three eccentric shafts, an external meshing gear pair, the servo motor and the sensor are integrated into a whole, a coupler is omitted, thus the electromechanically-integrated cycloidalpin wheel drive device has the advantages of compact structure, energy consumption reduction and reduced transmission angle and displacement error between the shafts and improved system precision. The sensor detects an operation state online and feeds back the operation state to a signal processing center, therefore accidents are immediately prevented and controlled. Therefore, the electromechanically-integrated cycloidalpin wheel drive device has the advantages of no need of replacement of lubricating agents, compact structure, strong instantaneity, long service life, high transmission efficiency, strong bearing capacity, low vibration, high precision, convenience for maintenance and the like, and can be widely applied to fields of robots, ships, vehicles and the like.

Owner:CHONGQING AEROSPACE POLYTECHNIC COLLEGE

Design for three-circular-arc tooth profiles of continuous conjugate cup-shaped or silk-hat-shaped harmonic gear

ActiveCN107191570AImprove carrying capacityHigh transmission precisionSustainable transportationGearingGear wheelRooted tooth

The invention provides a cup-shaped or silk-hat-shaped harmonic gear with three-circular-arc tooth profiles in consideration of the axial taper deformation of a flexible gear body. The cup-shaped or silk-hat-shaped harmonic gear is composed of a rigid gear body, the flexible gear body and a wave generator; the flexible gear body is a straight-tooth cylindrical external gear body with the three-circular-arc tooth profile; and the rigid gear body is a straight-tooth cylindrical inner gear body with the three-circular-arc tooth profile. The invention further provides a design method for the tooth profiles of the cup-shaped or silk-hat-shaped harmonic gear with the three-circular-arc tooth profiles. According to the design method, parameters of the three-circular-arc tooth profile of the flexible gear body are selected according to the design criterion that the envelope existence interval is the largest on a design section; the circular-arc tooth profiles of a tooth root and a tooth top of the rigid gear body adopt outer envelope fitting calculation of the movement tracks of the tooth profile of the flexible gear body on the front cross section and the rear cross section of a gear ring of the flexible gear body; and a middle section adopts circular-arc fitting so as to improve the fitting flexibility of the tooth profiles. Compared with a harmonic gear with double-circular-arc tooth profiles, the harmonic gear with the three-circular-arc tooth profiles has a wider envelope existence interval, a wider conjugate meshing tooth surface and a more uniform backlash, and therefore the bearing capacity and the transmission precision of the harmonic gear can be improved.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com