Method for manufacturing harmonic reducer of robot

A technology of a harmonic reducer and a manufacturing method, which is applied to the manufacturing field of a robot harmonic reducer, can solve the problems of low transmission precision of the harmonic reducer, inability to process gear hobbing tools, and inability to control the amount of deformation, and achieves the qualified rate of finished products. High, prolong the service life, improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

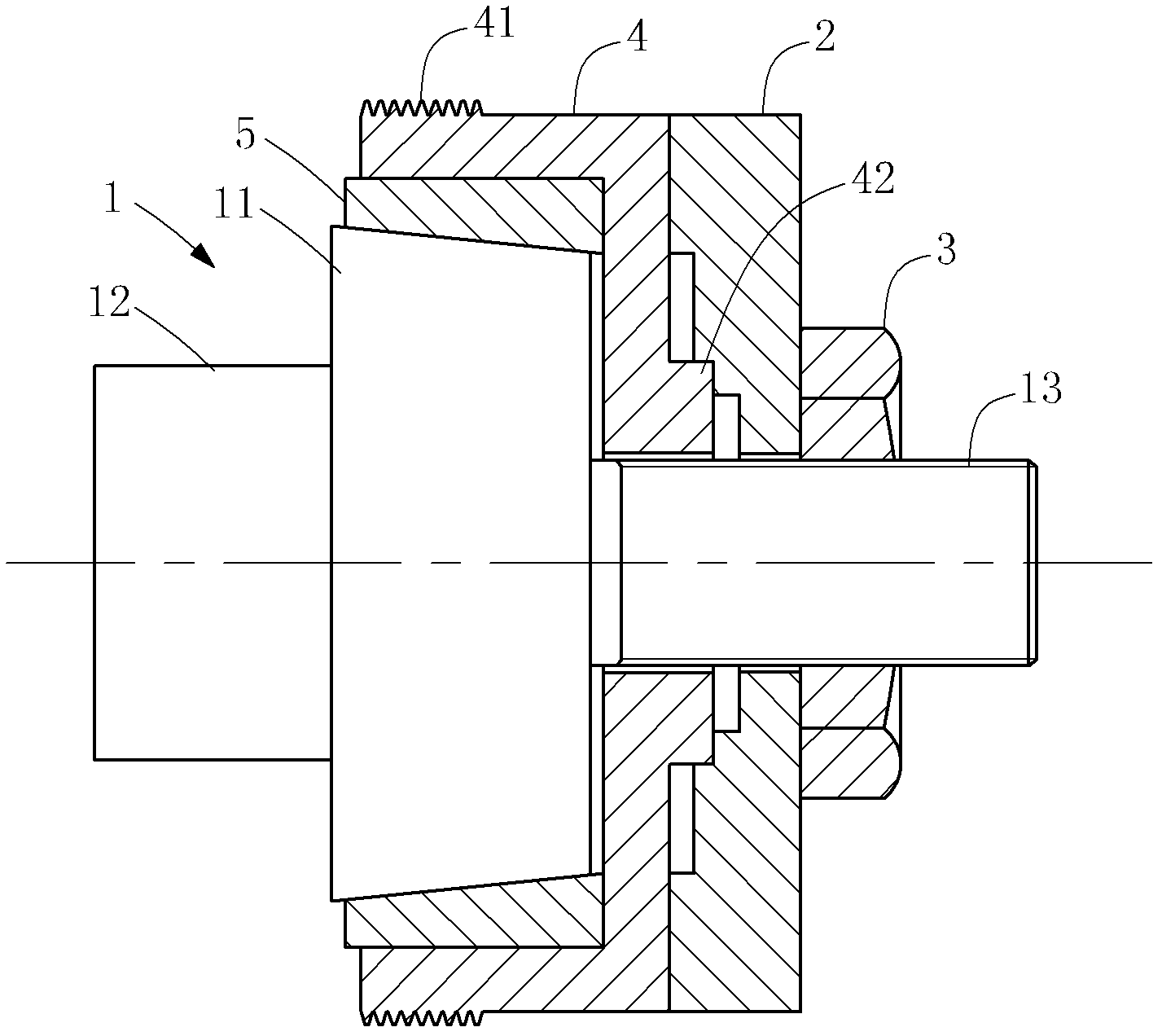

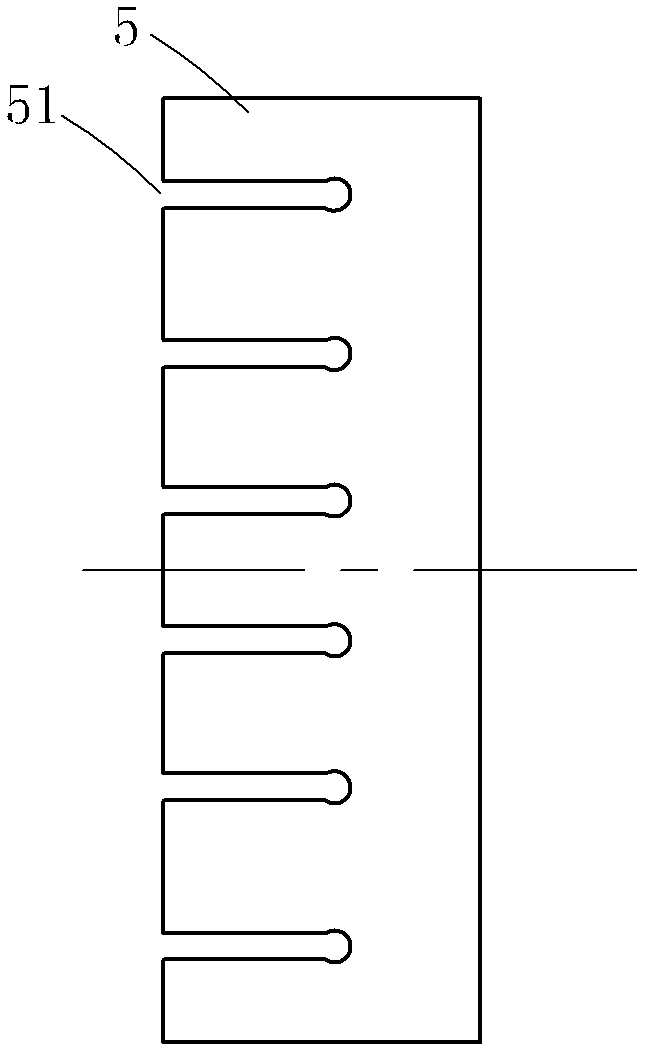

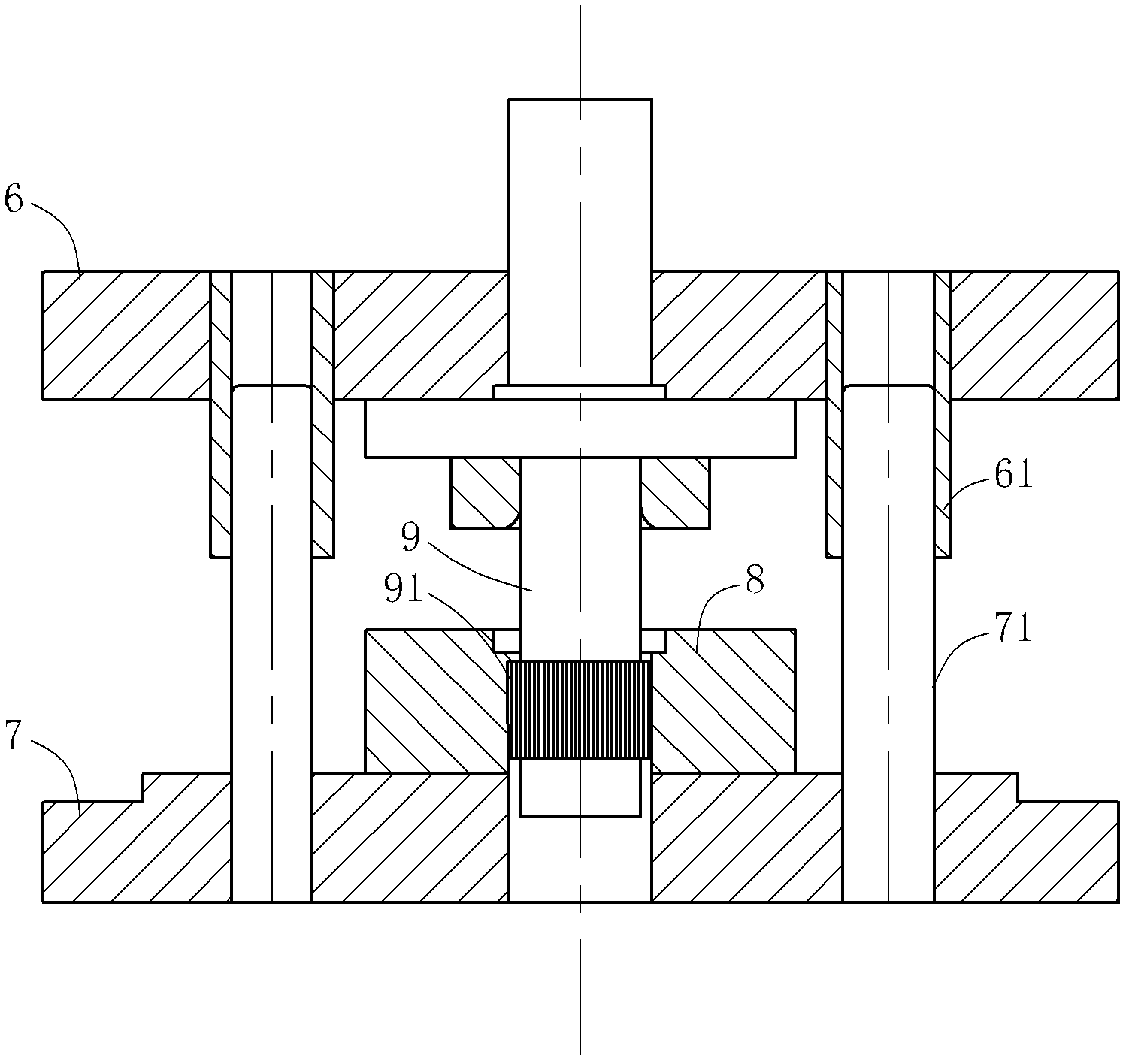

[0023] Such as figure 1 and figure 2 Commonly shown, a manufacturing method of a robot harmonic reducer includes the manufacturing steps of the flexspline, and the manufacturing steps of the flexspline include: (1) the forging step of forging a solid billet of the flexspline; (2) The solid flexspline billet is heat-treated, and the hardness reaches HRC38-40; (3) The heat-treated solid flexspline billet is turned into a thin-walled flexspline semi-finished product; (4) The inner part of the flexspline semi-finished product is supported by a flexspline tensioning fixture (5) Grind the flexspline semi-finished product on the grinding machine to produce the flexspline outer ring gear 41. Through practice, it is found that the working hours of grinding the outer ring gear 41 by the grinding machine are shorter than the working hours of rolling the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com