Patents

Literature

10774 results about "Work in process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Work in process (WIP), work in progress (WIP), goods in process, or in-process inventory are a company's partially finished goods waiting for completion and eventual sale or the value of these items. These items are either just being fabricated or waiting for further processing in a queue or a buffer storage. The term is used in production and supply chain management.

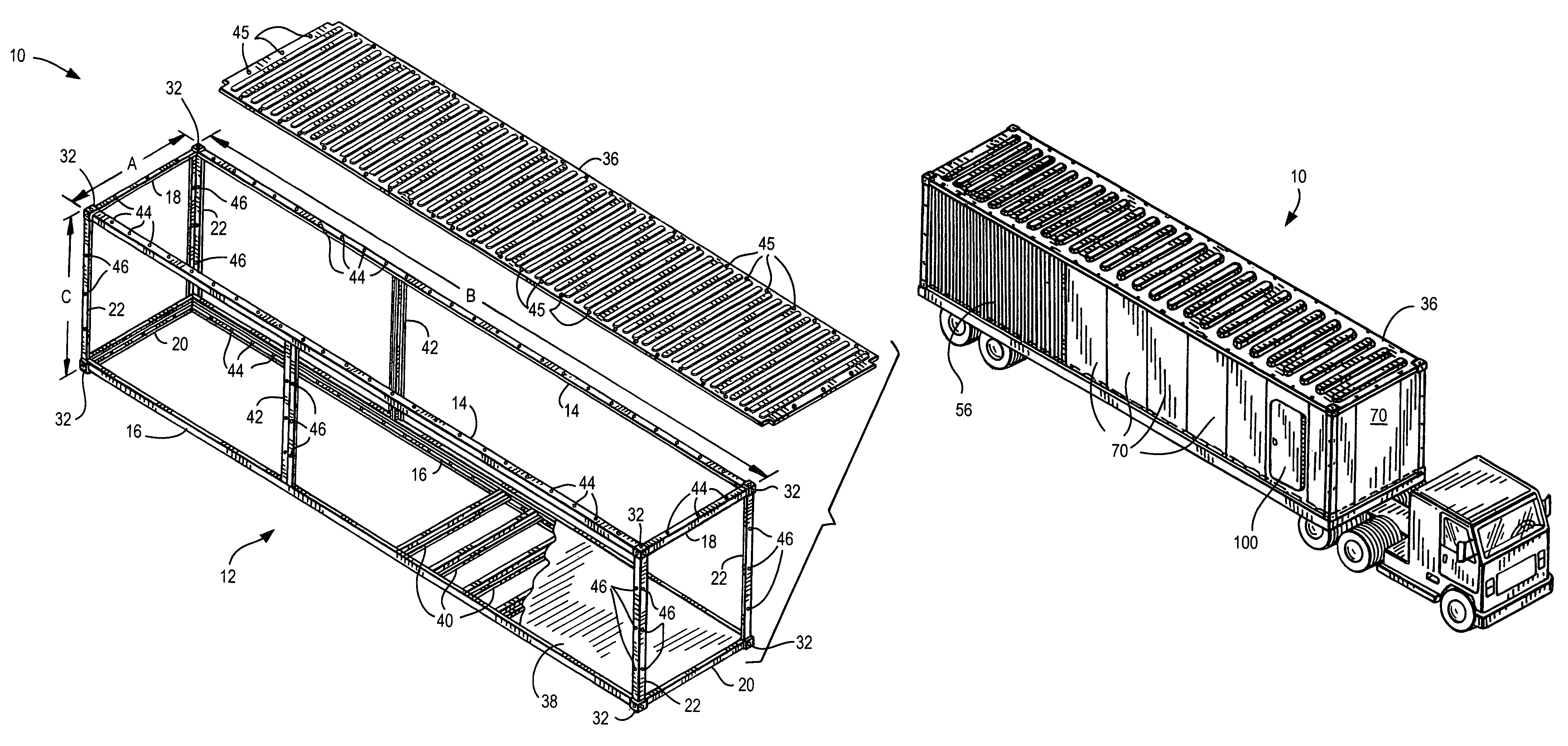

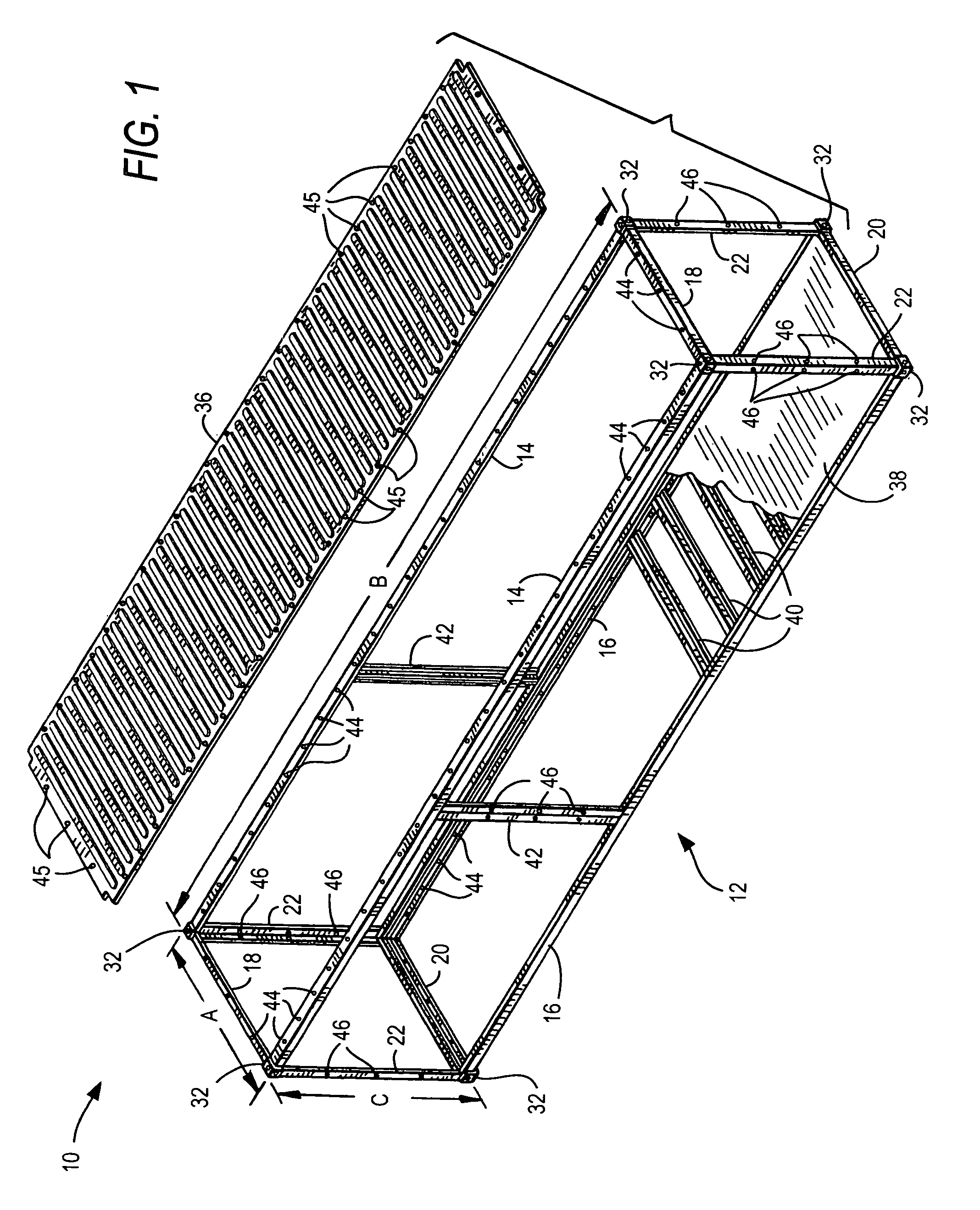

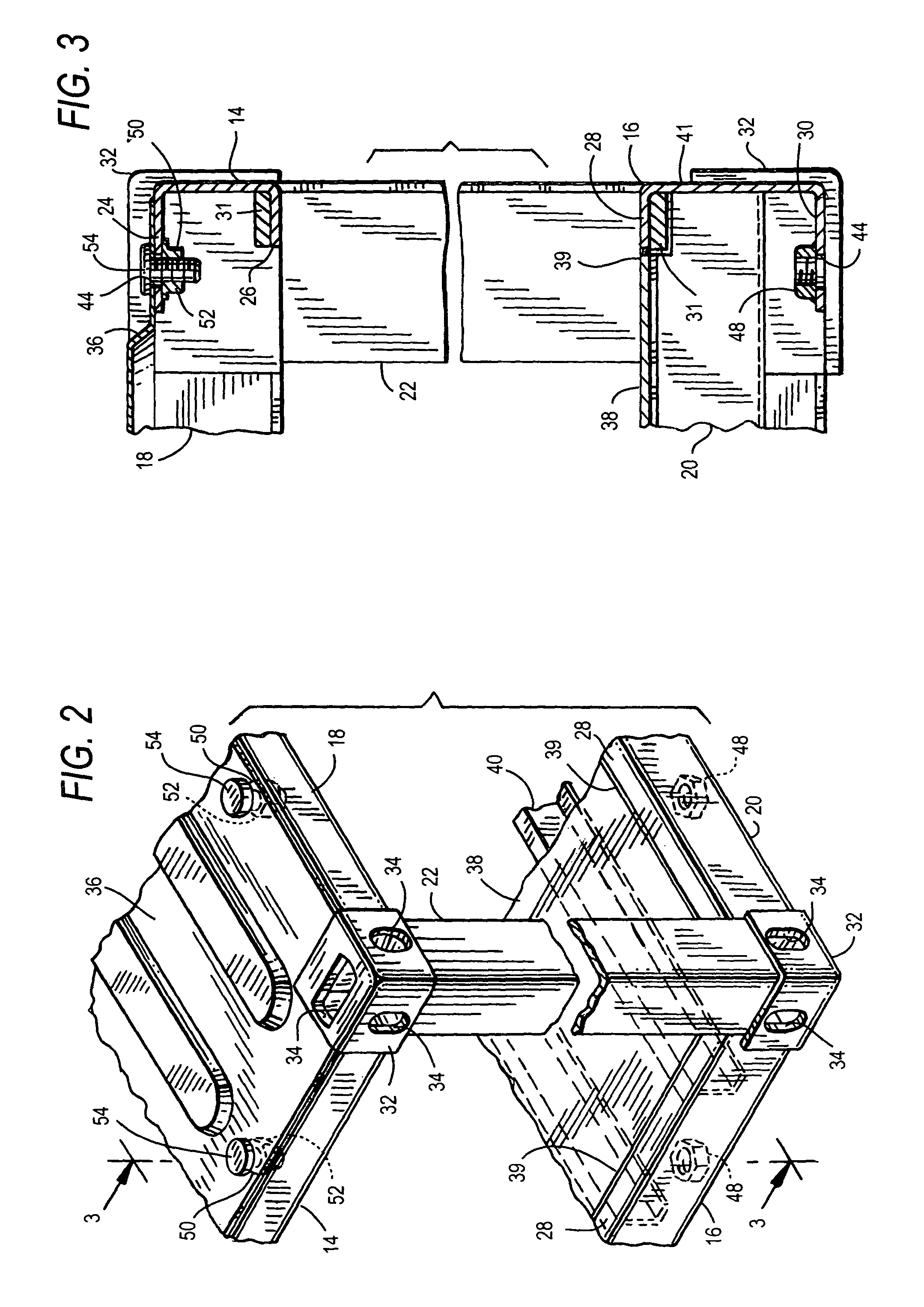

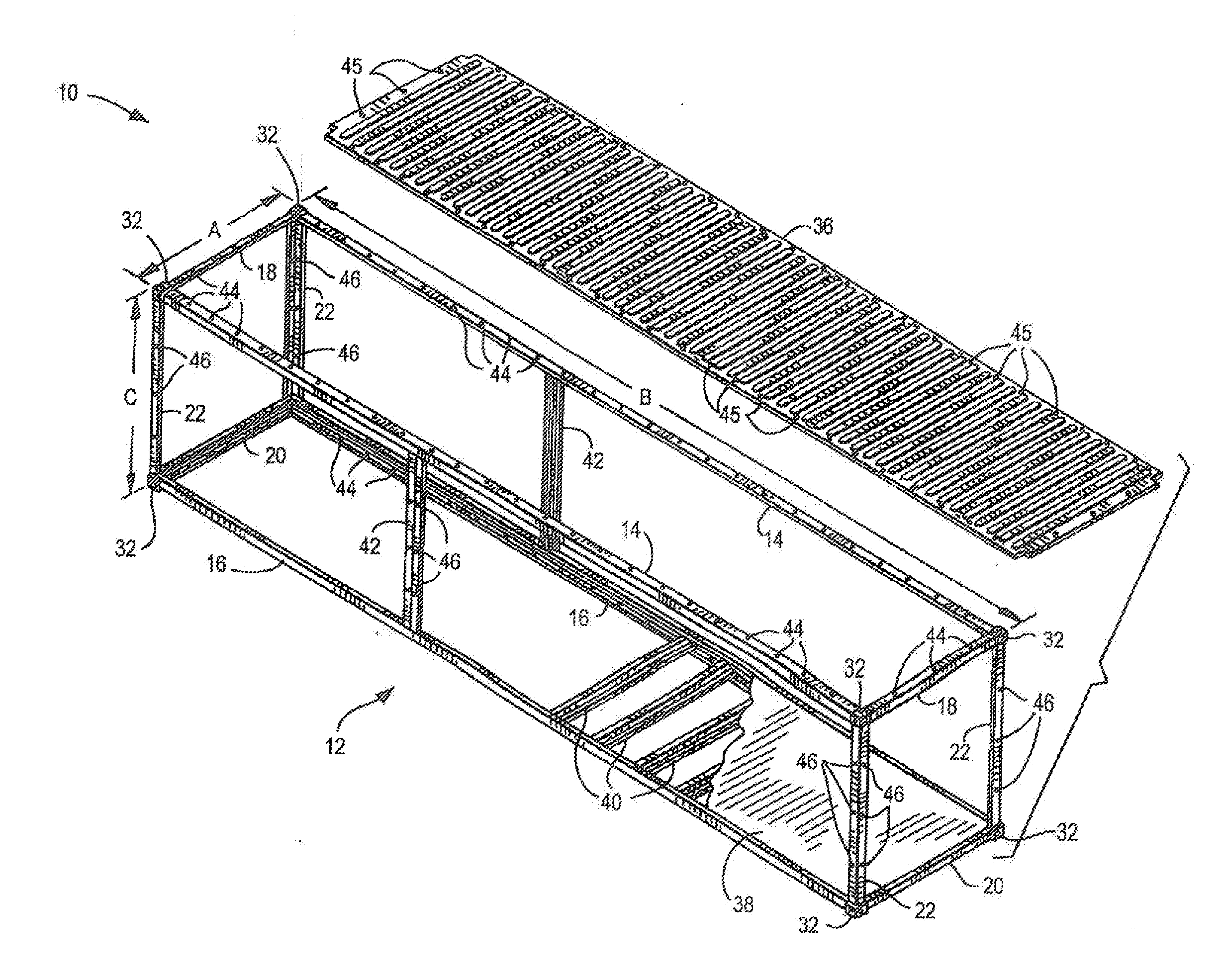

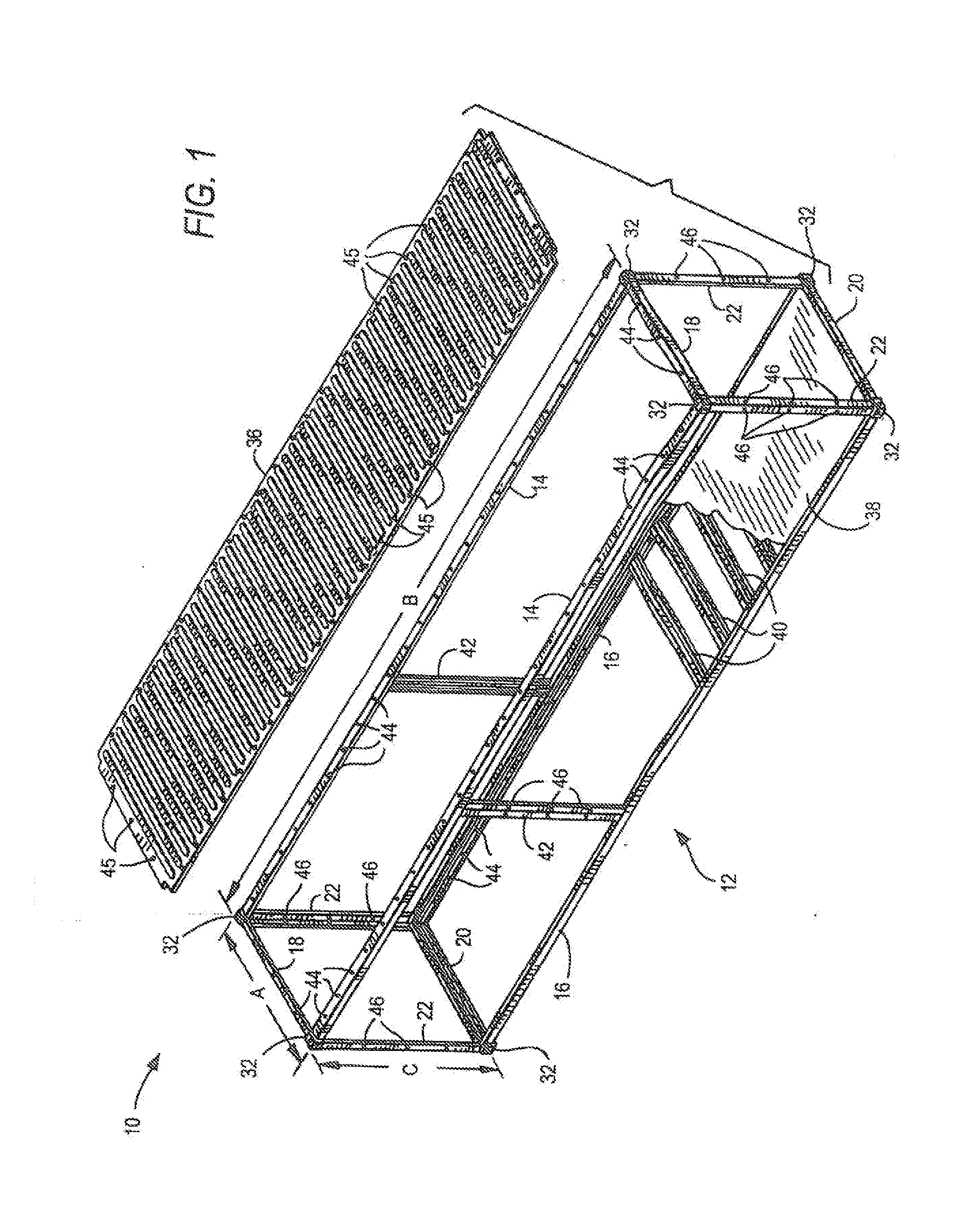

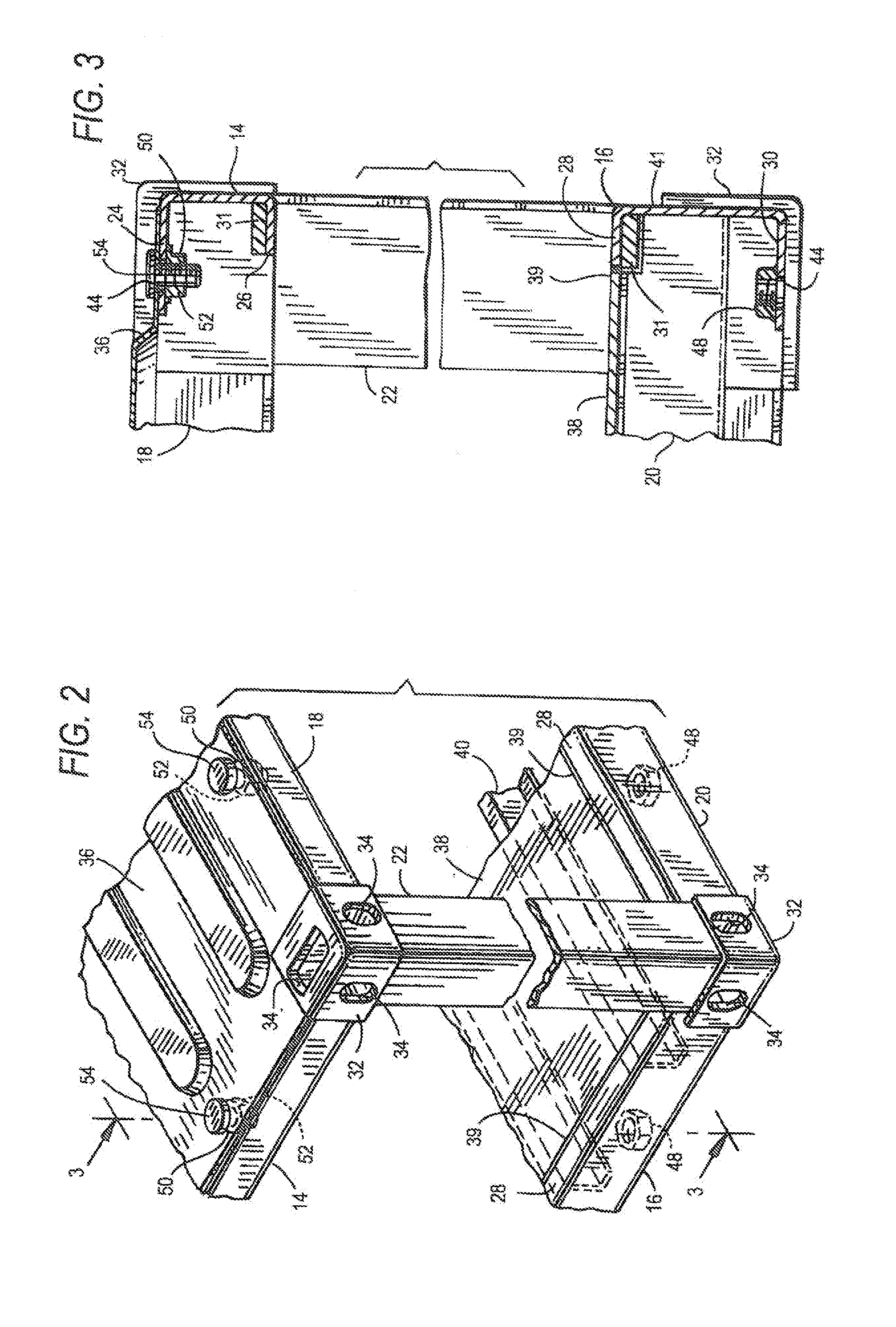

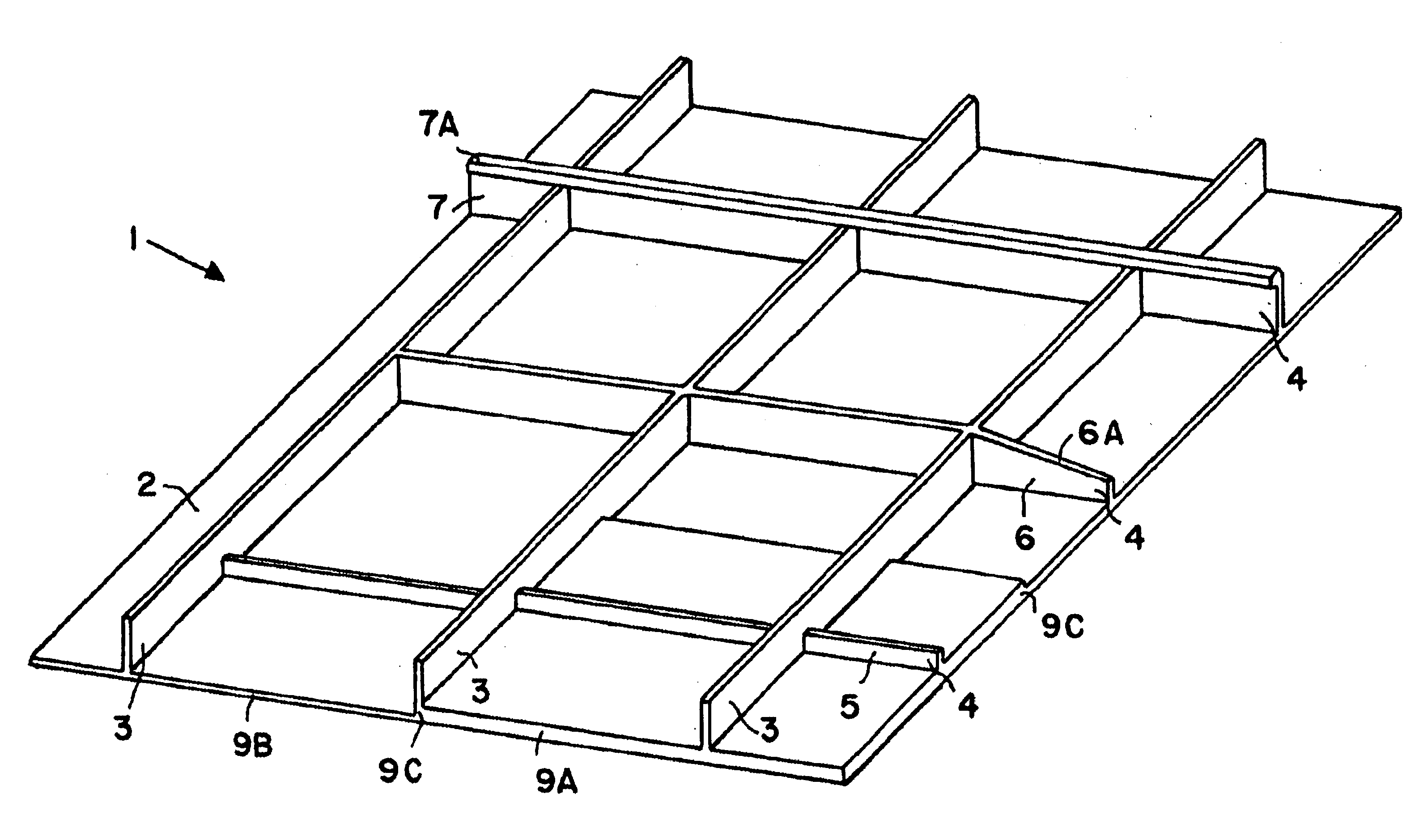

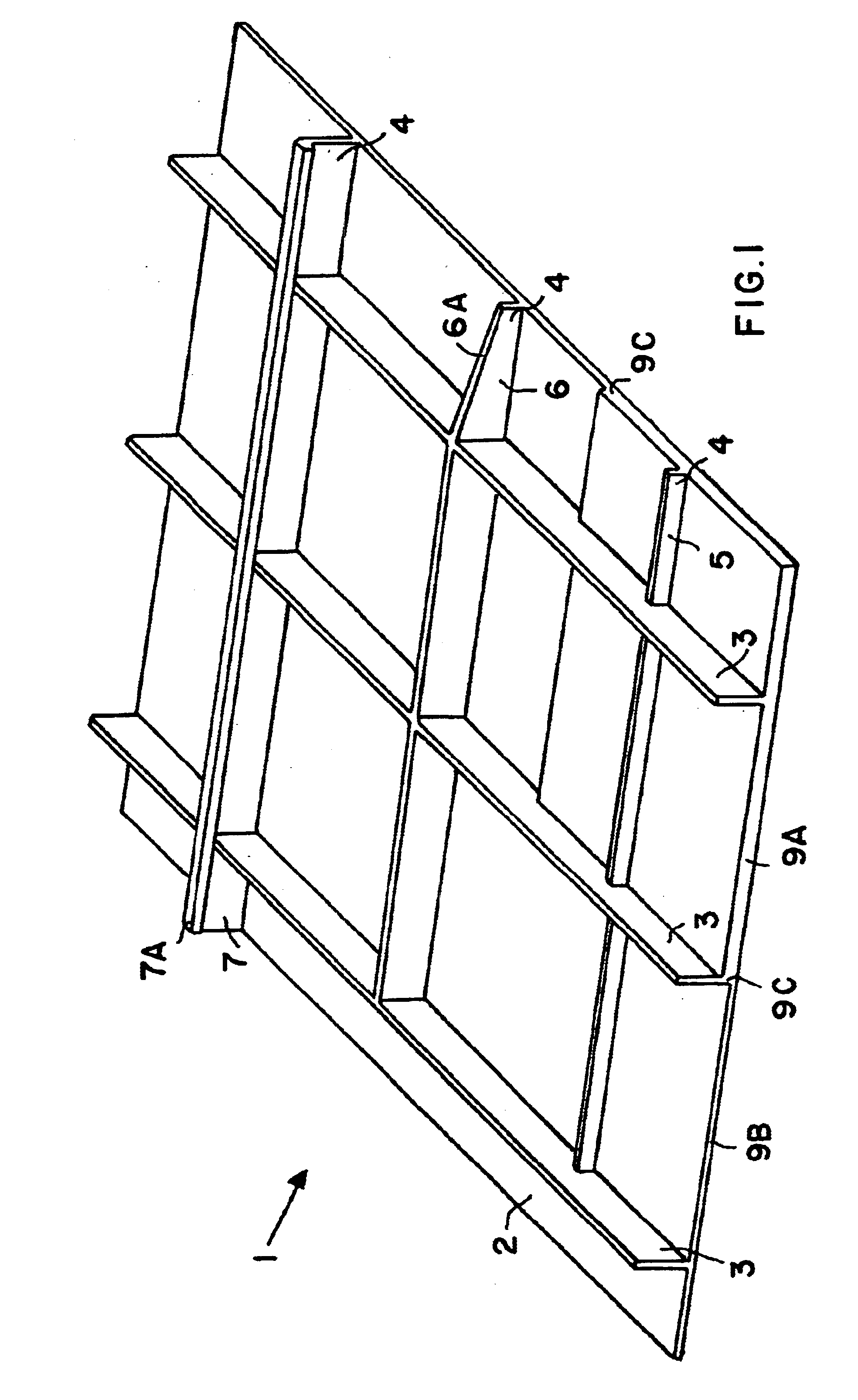

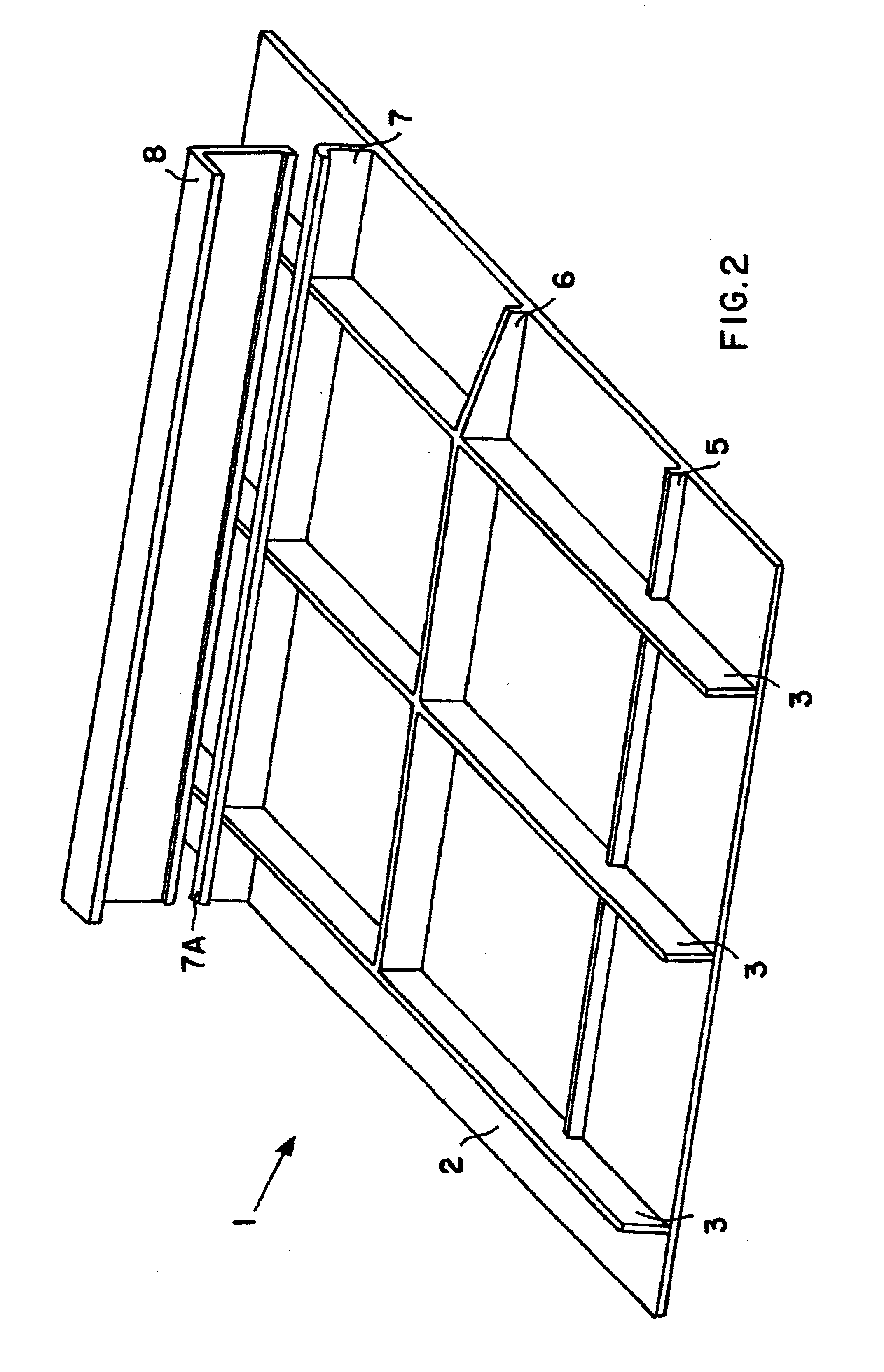

System for modular building construction

InactiveUS7827738B2Good choiceFacilitating selective interconnectionConstruction materialLighting and heating apparatusBuilding unitBuilding construction

Construction systems for erecting building structures comprise a plurality of prefabricated interconnectable modular building units, each unit not meeting at least one of the ISO certification criteria for transport of cargo, but each unit comprising a frame shaped as a rectangular parallelopiped and comprised of framing members and a plurality of nodes, each node situated at a corner of said frame for selective interconnection with other units, the nodes and the exterior dimensions of the frame conforming to ISO shipping standards such that each unit is transportable using the ISO intermodal transportation system, and such that when the units are aggregated horizontally and vertically and adjacent units are interconnected, a building structure comprising at least one habitable space is formed. The modular units are assembled in a factory remote from the job site, and are there constructed to a semi-finished state, including installation of one or more of interior fit-out systems and finishes, exterior envelope systems, plumbing systems, electrical systems, environmental systems, and fire protection systems, following which the semi-finished modular units are transported from the factory to the job site, where they are craned into place and secured to form the structure being erected, a plurality of adjacent pairs of semi-finished modular units also being “stitched” together, and the semi-finished modular units are thereafter constructed to a finished state.

Owner:GLOBAL BUILDING MODULES

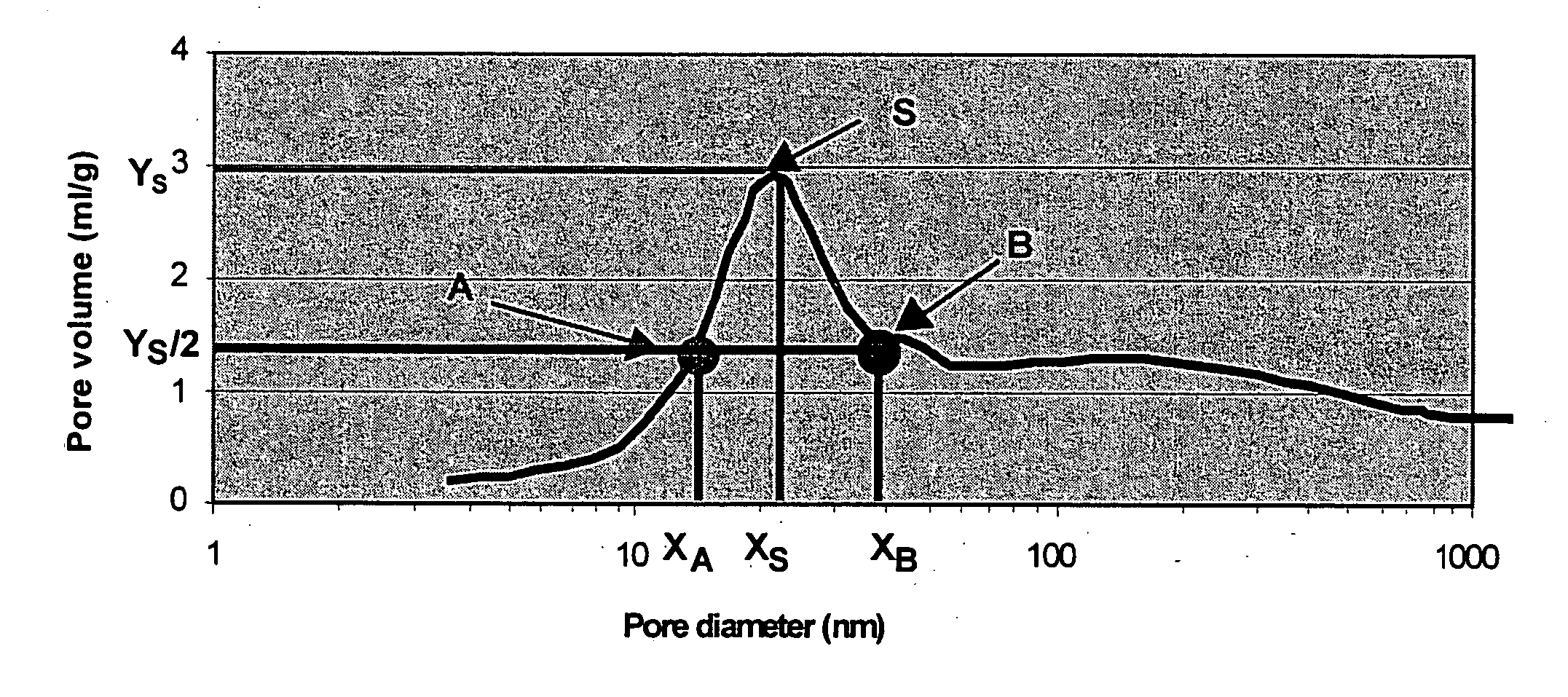

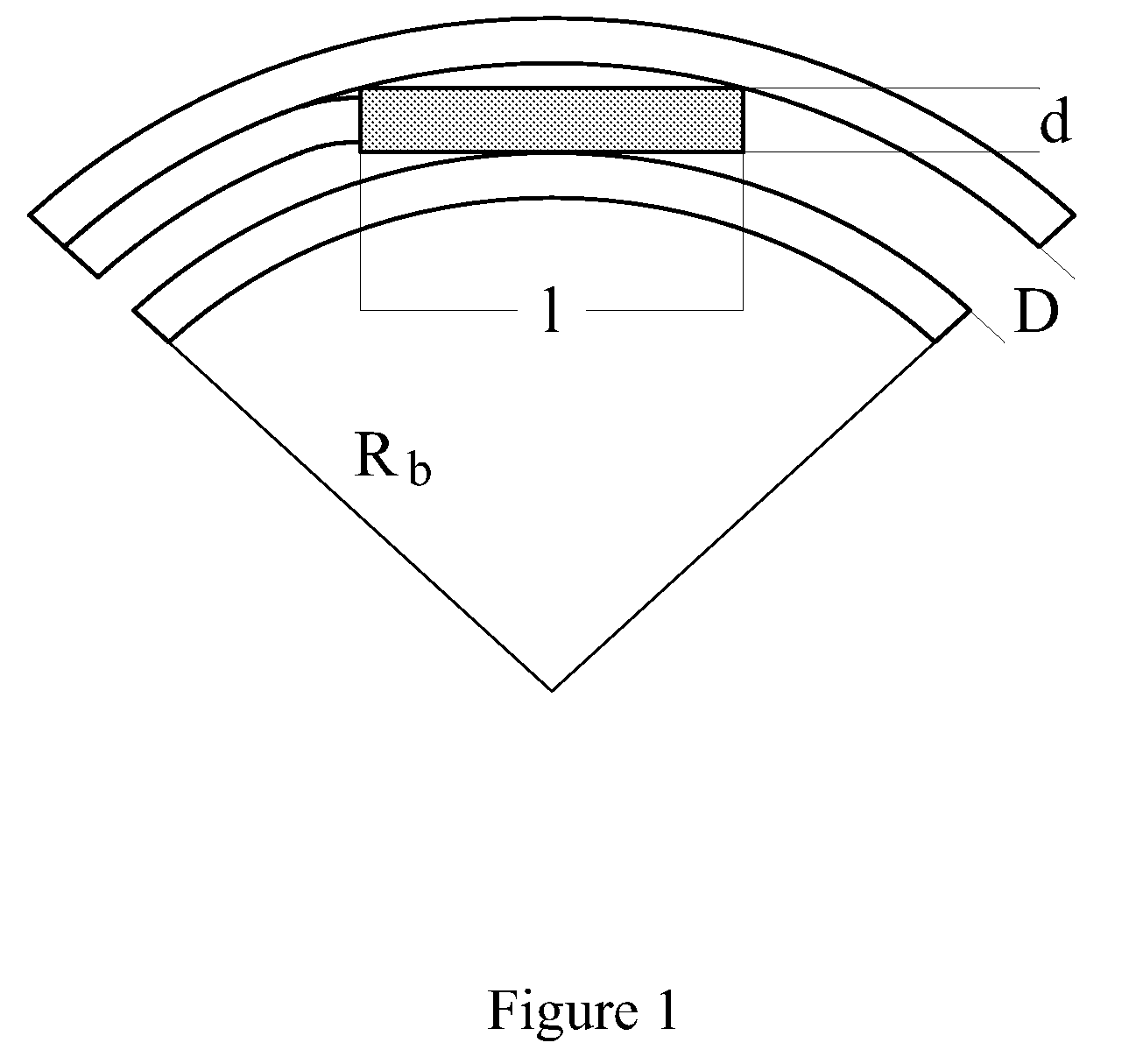

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS20050004297A1Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresElastomerPorosity

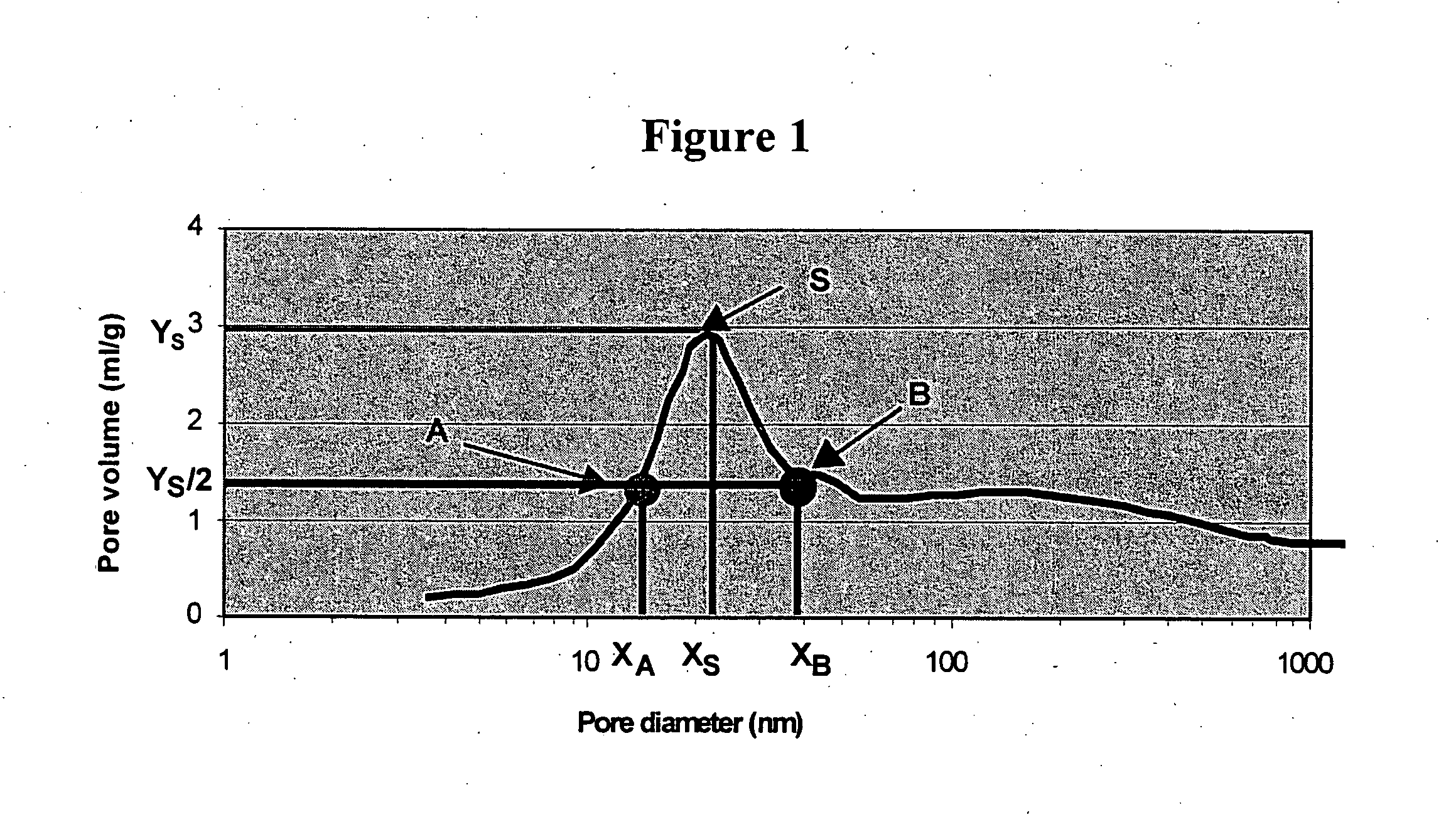

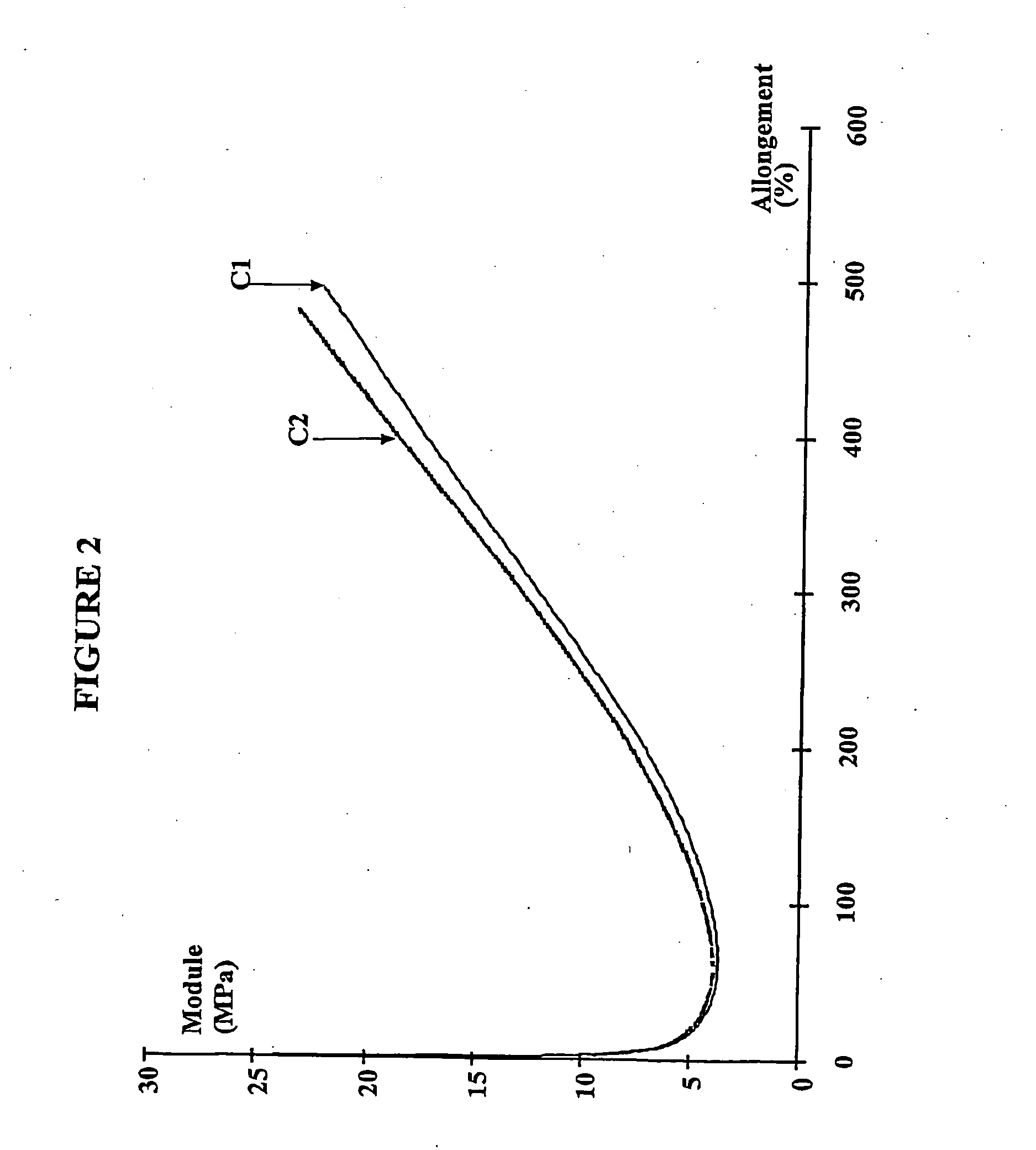

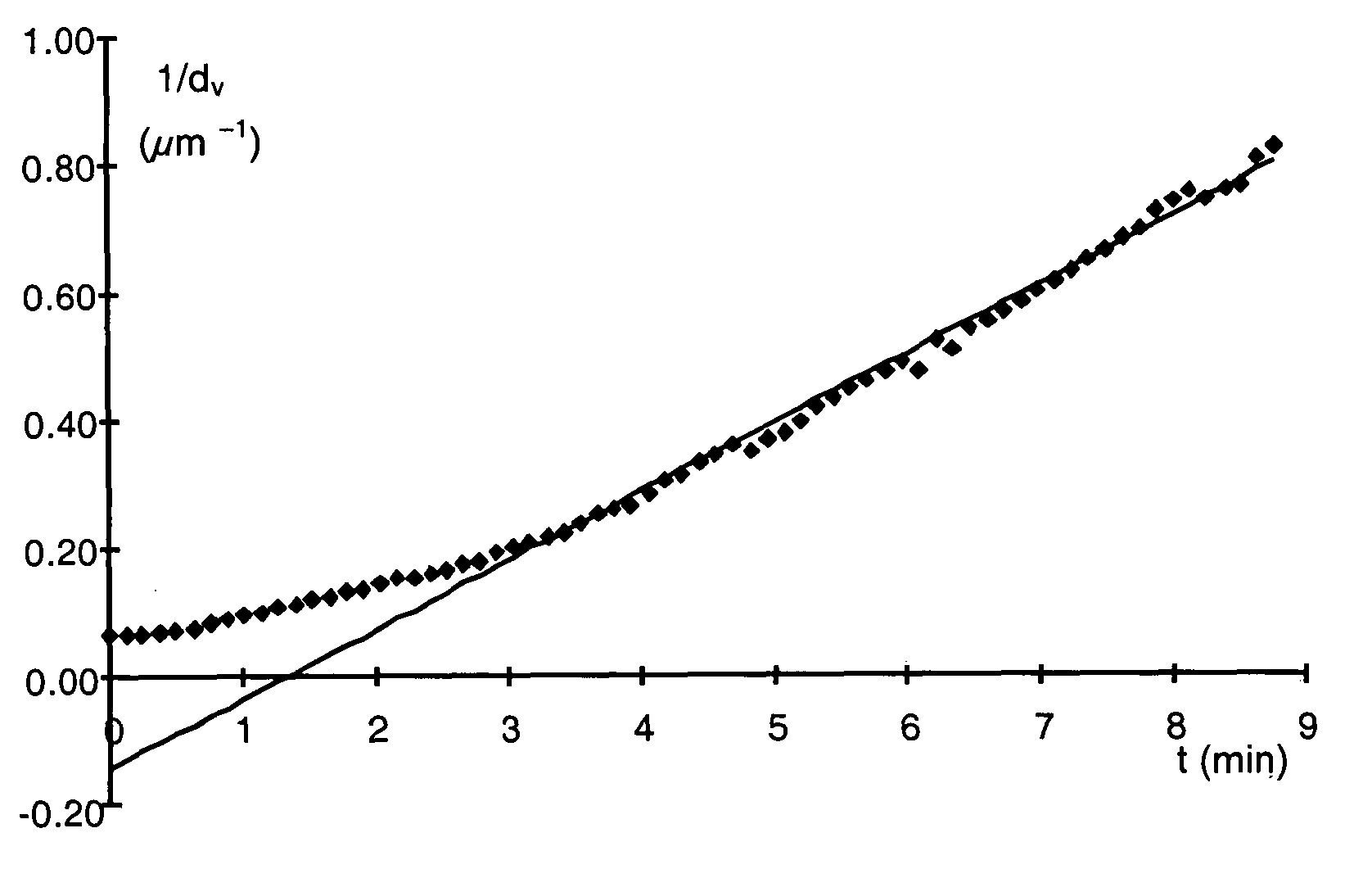

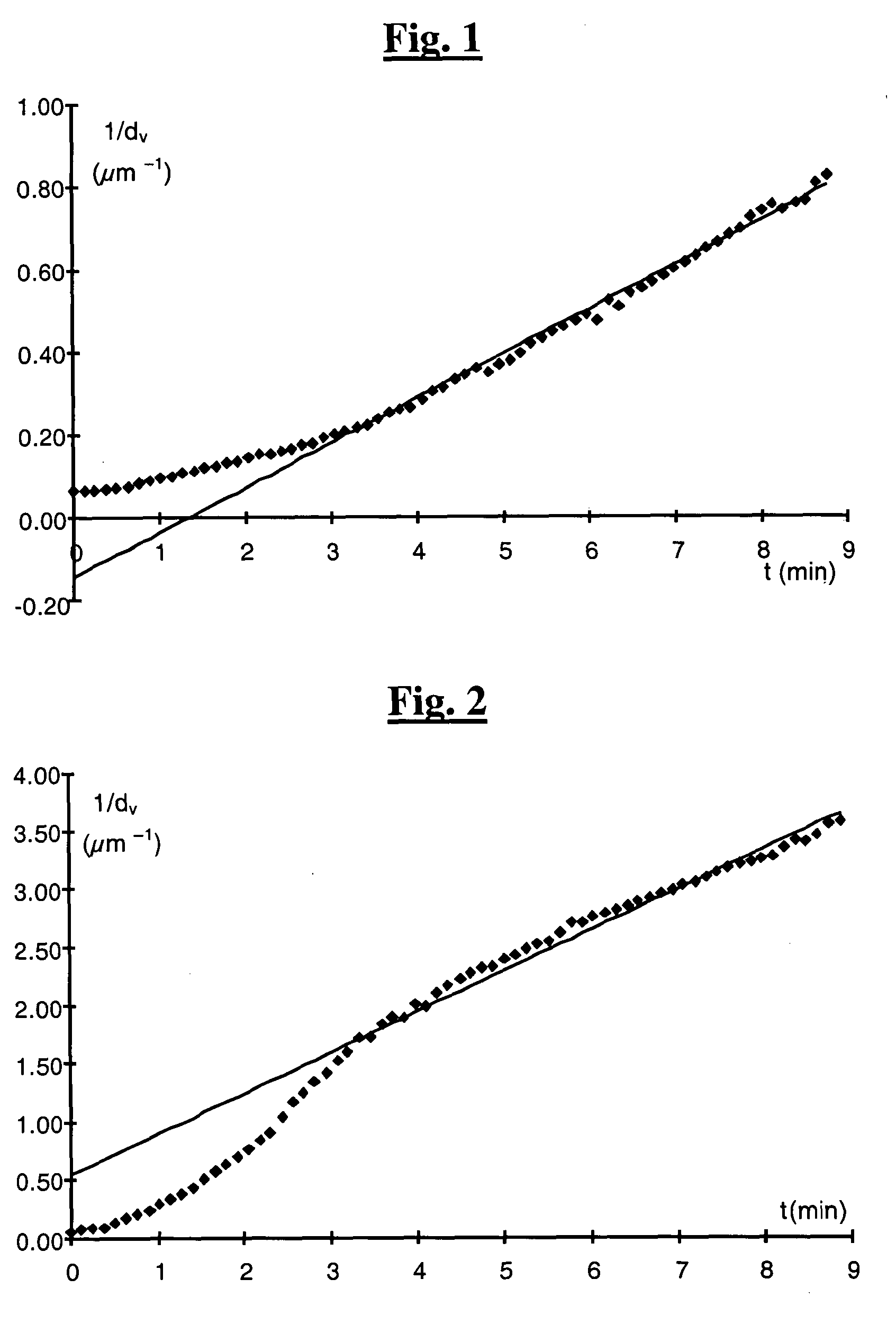

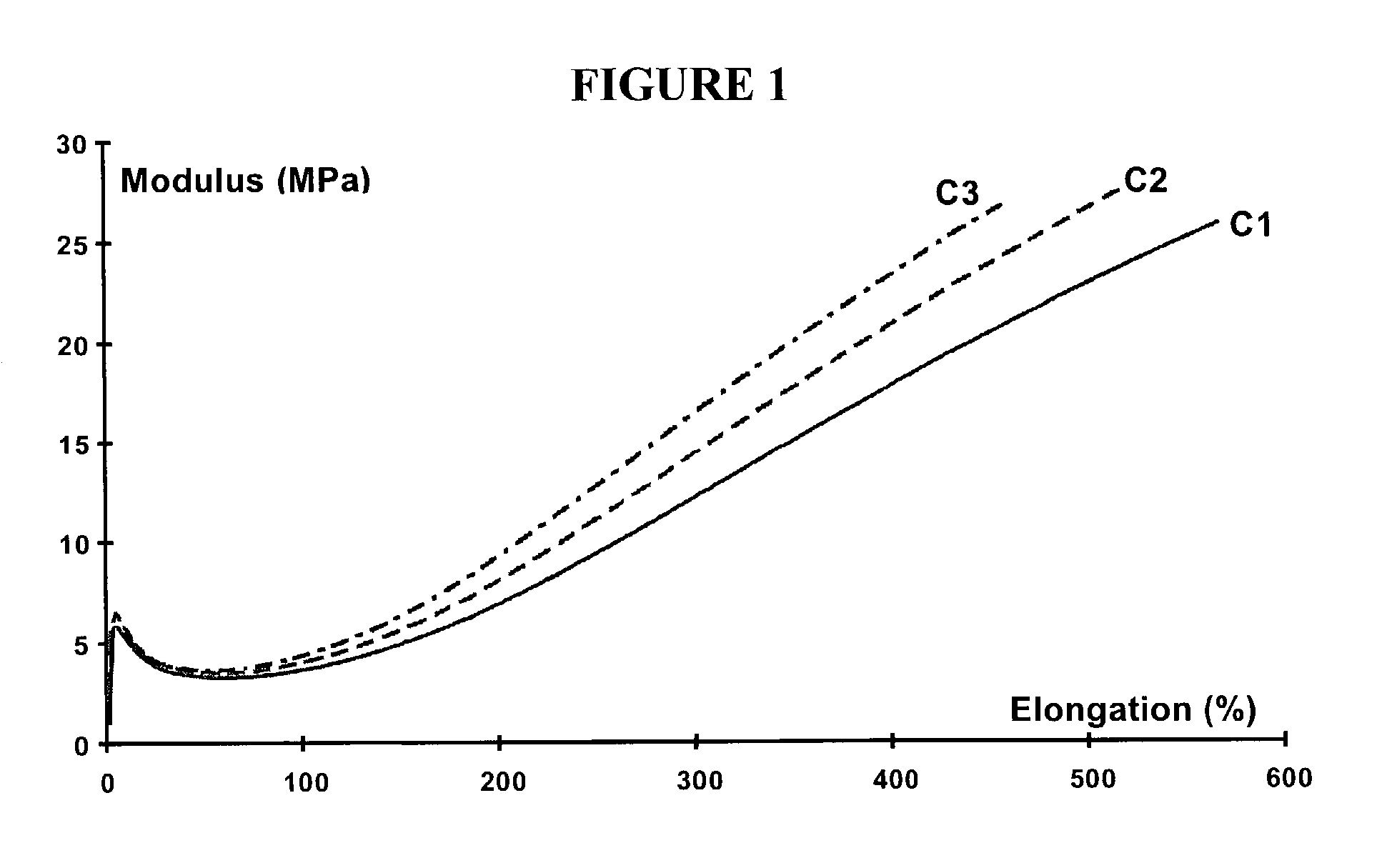

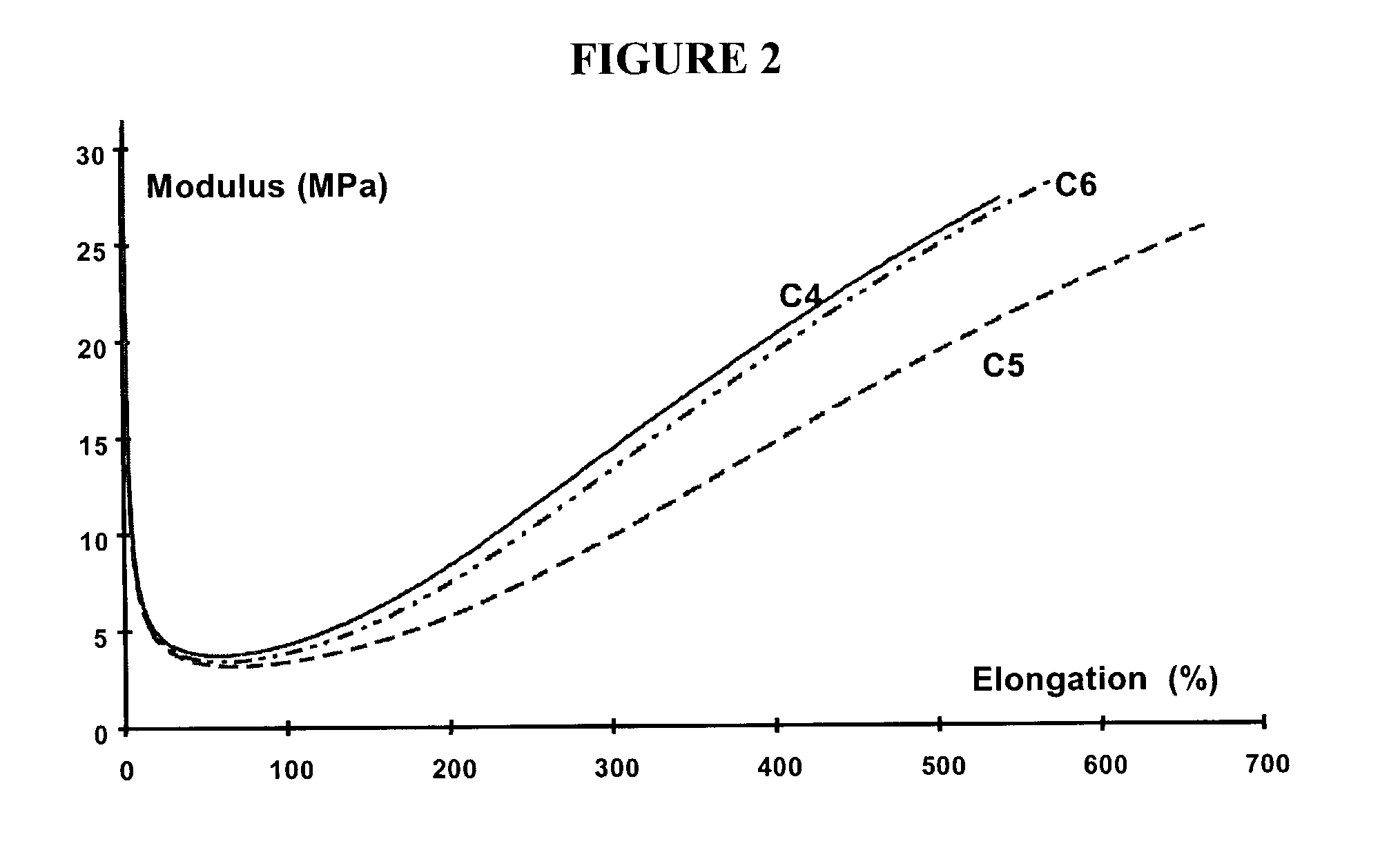

Diene rubber compositions are described containing a diene elastomer, a reinforcing inorganic filler, and a coupling agent wherein the inorganic filler includes a silica having the following characteristics: (a) a BET specific surface area between 45 and 400 m2 / g; (b) a CTAB specific surface area between 40 and 380 m2 / g; (c) an average particle size (by mass), dw, of 20 to 300 nm; and at least one of the following characteristics, preferably two and more preferably all three: (d) a particle size distribution such that dw≧ / CTAB)−30; (e) a porosity which meets the criterion L / FI≧−0.0025 CTAB+0.85; (f) an amount of silanols per unit of surface area, NSiOH / nm2; NSiOH / nm2≦−0.027 CTAB+10.5. These diene rubber compositions can be used for the manufacture of tires or of semi-finished products intended for tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

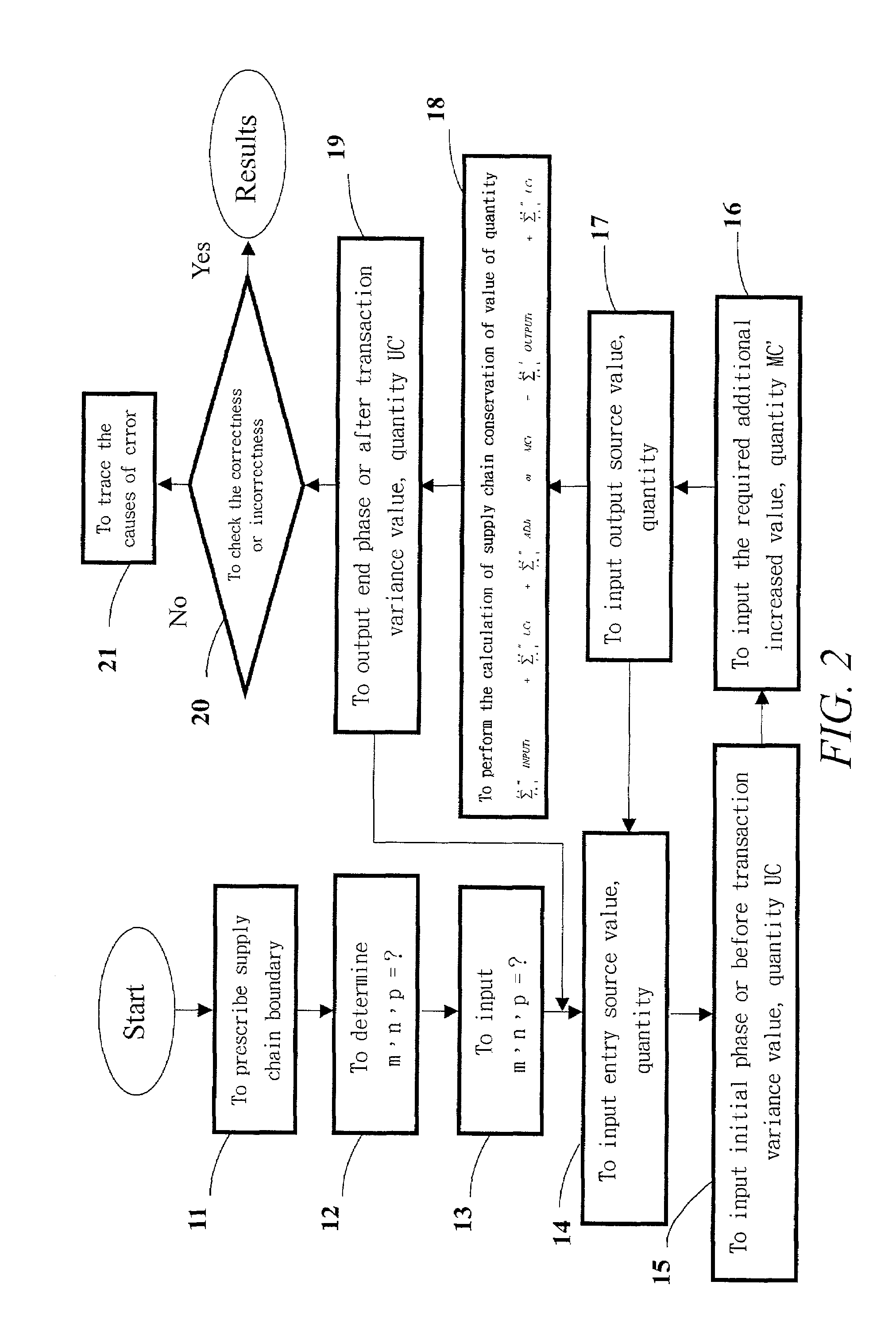

Application of supply chain unit cell or cell group or boundary conservation of value and quantity to computer management system

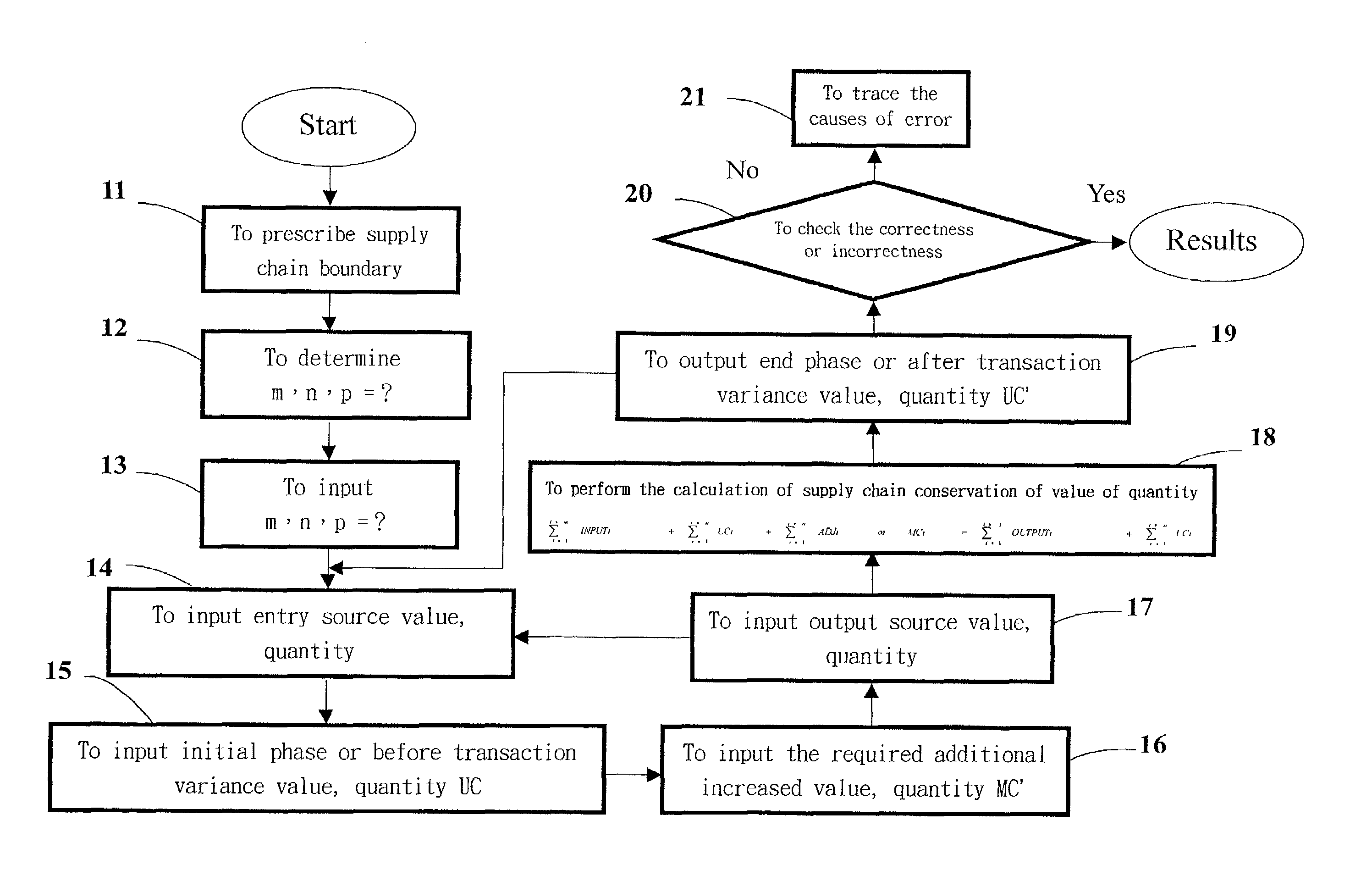

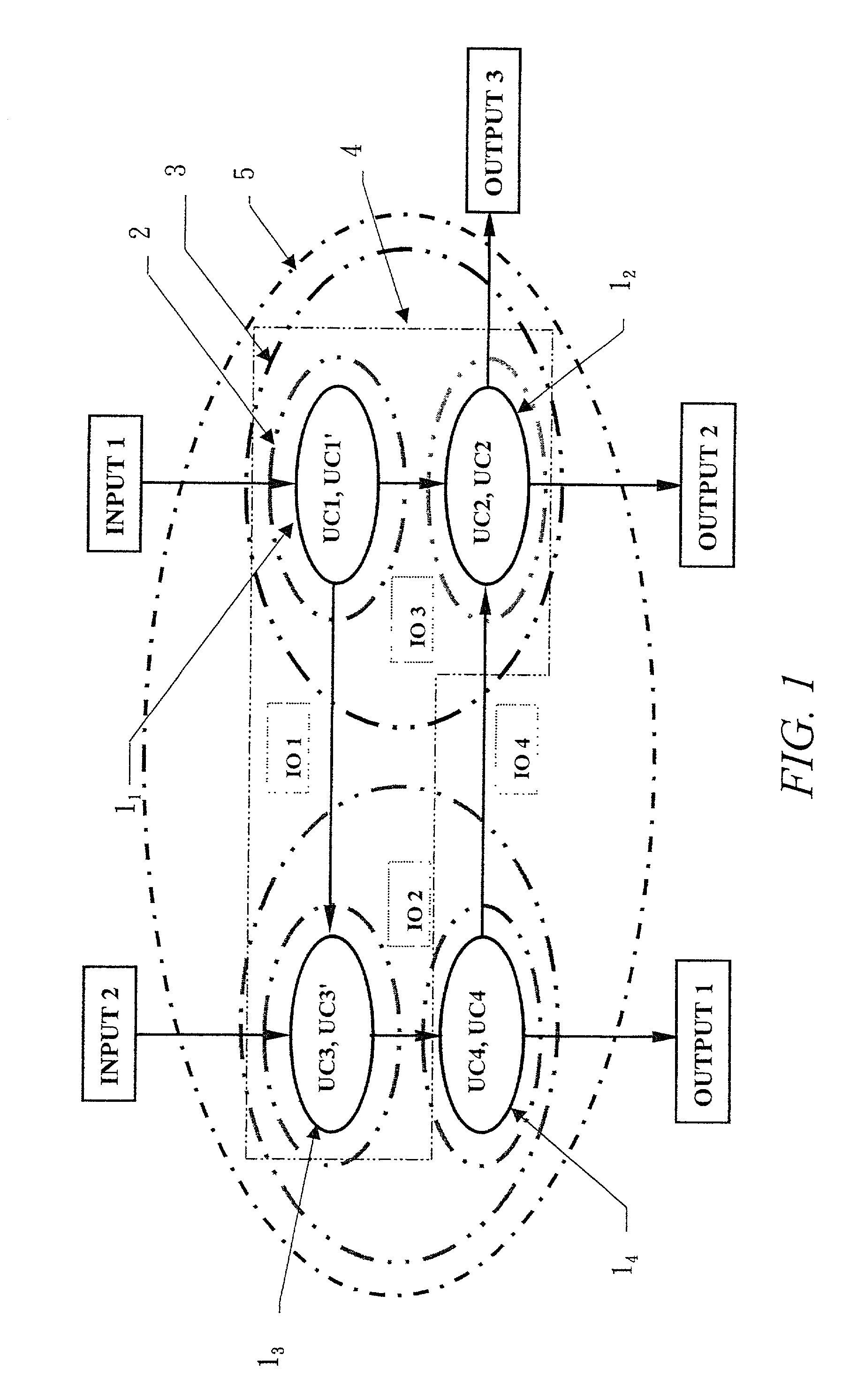

Computer software for execution by a computer management system to supervise and detect a Boundary Conservation of Value and Quantity in at least one Supply Chain Unit Cell or Cell Group. A warning is output when there is an abnormality detected in the value or quantity in a supply chain unit cell or cell group, and corrective information is provided to the computer management system. A mathematical management logic model of supply Chain Boundary Conservation of Value and Quantity is utilized to perform the management of Supply Chain Boundary Change of Quantity or Value to supervise and detect a quantity or value of raw material, semi-products, as well as finished goods.

Owner:WANG WU CHIEH

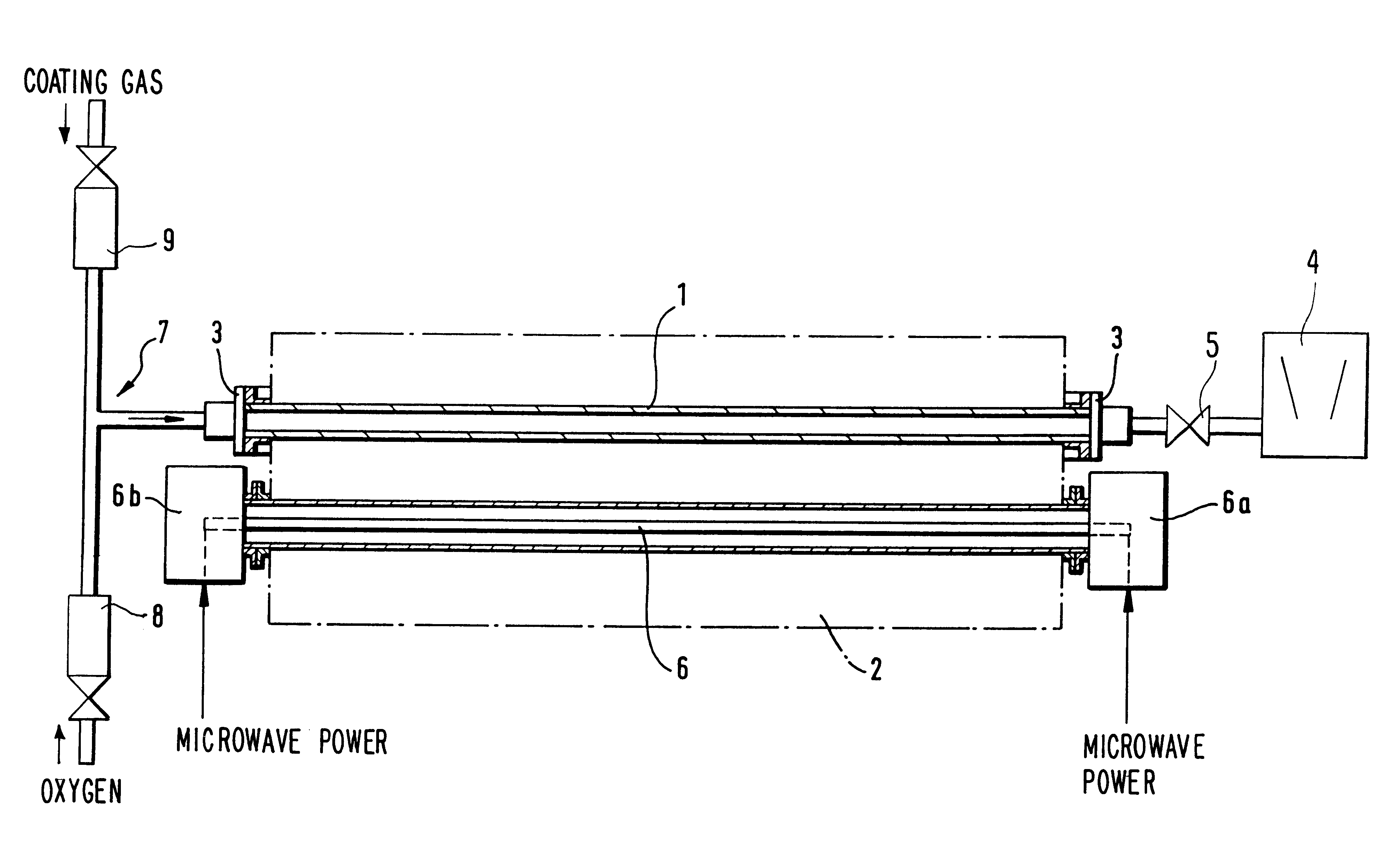

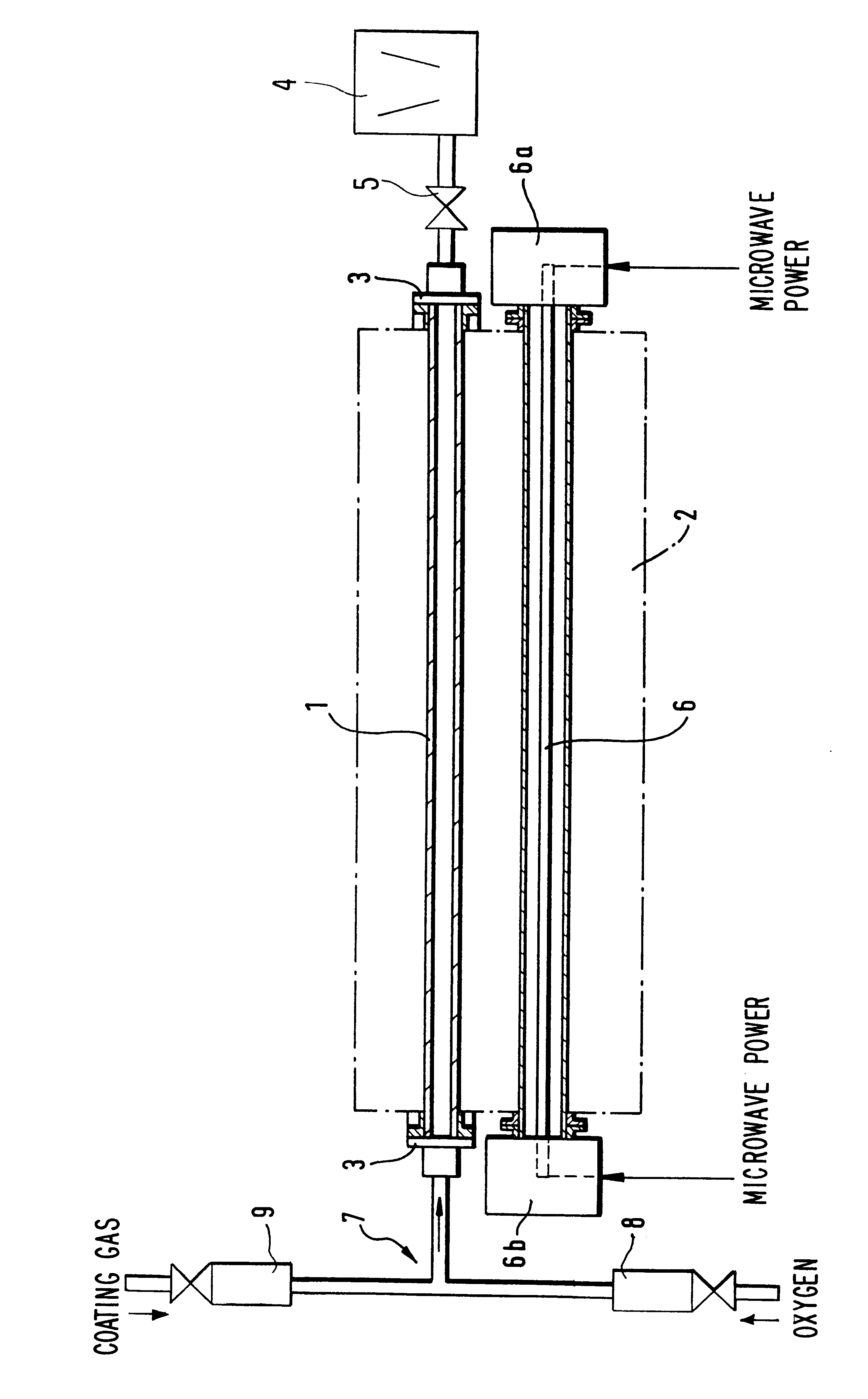

Method of making a hollow, interiorly coated glass body and a glass tube as a semi-finished product for forming the glass body

InactiveUS6200658B1Layered productsLiquid/solution decomposition chemical coatingVitreous BodiesWork in process

Numerous applications for hollow glass bodies made from low melting glass material require an increase in the chemical resistance of the interior surface of the glass body. In order to avoid a disadvantageous de-alkalizing process the hollow glass body must be provided with an interior coating in a comparatively expensive prior art process. In an improved process according to the invention a glass tube acting as a semifinished product from which the hollow glass body is made is provided with an interior coating of oxide material, preferably SiO2, Al2O3, TiO2 or mixtures thereof, having a predetermined coating thickness according to the required chemical resistance or working conditions for forming the glass body and then the hollow glass body is made from the glass tube. The coating is advantageously provided by means of a PICVD process.

Owner:SCHOTT AG

Rubber composition based on diene elastomer and a reinforcing silicon carbide

InactiveUS20040030017A1Improve homogeneityReduce consumptionSpecial tyresTyre beadsElastomerPolymer science

A rubber composition usable for the manufacture of tires, based on at least one diene elastomer, a reinforcing inorganic filler and a coupling agent providing the bond between the inorganic filler and the elastomer, wherein said inorganic filler comprises a silicon carbide having the following characteristics: (a) a BET specific surface area of between 20 and 200 m<2> / g; (b) an average particle size (by mass), dw, of between 10 and 350 nm. Tires or semi-finished products for tires such as treads comprising said rubber composition.

Owner:MICHELIN RECH & TECH SA

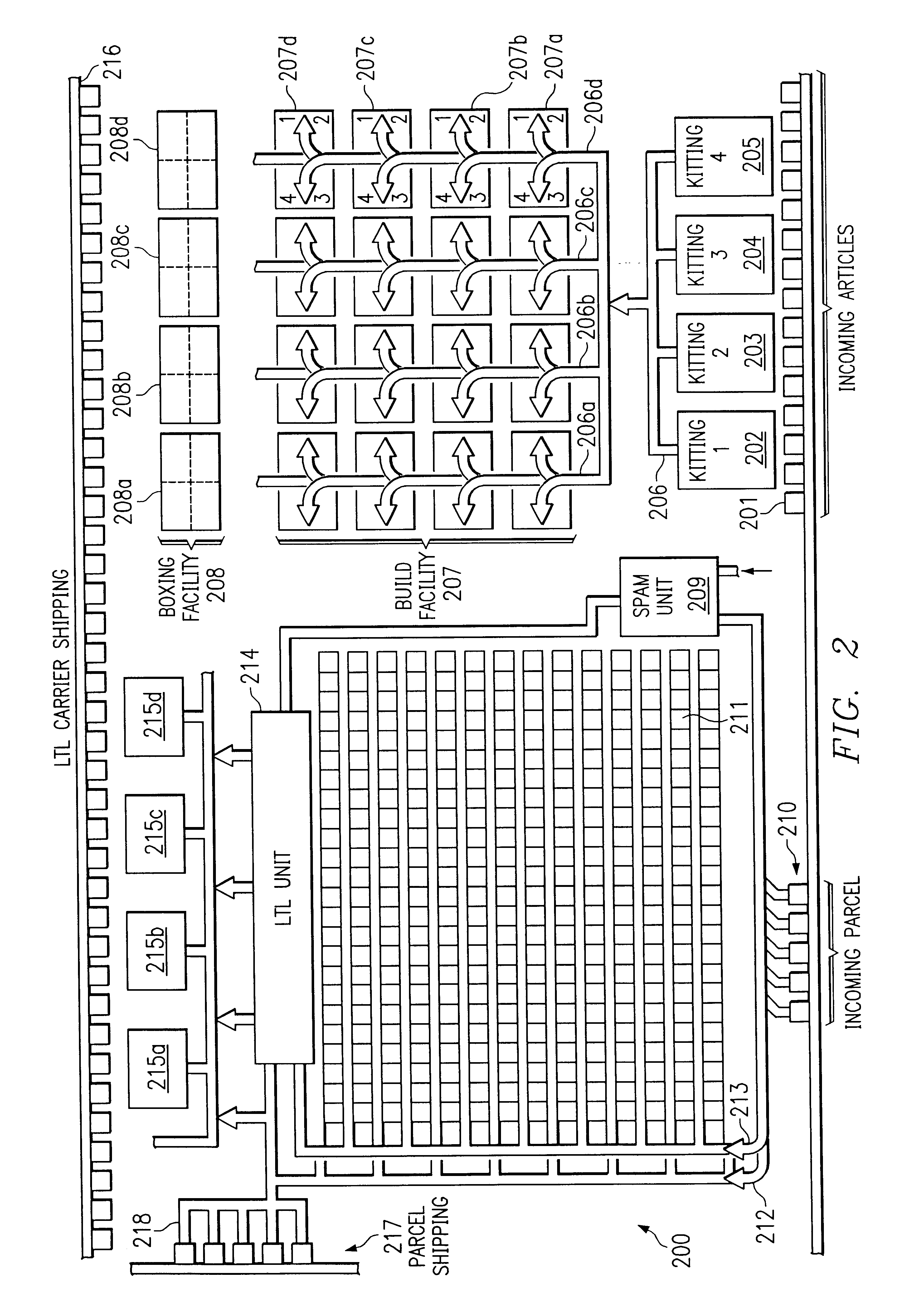

Method, system and facility for controlling resource allocation within a manufacturing environment

InactiveUS6615092B2Low production costDigital data processing detailsResourcesWork in processBuild to order

A method, a system and a facility provide for the control of resource allocation within a build to order manufacturing environment. A system for providing a control center for a manufacturing facility is disclosed. The system includes a plurality of information sources operably associated with manufacturing products within the manufacturing facility. A user interface of the system displays selective information associated with portions of the manufacturing facility within a control center operable to manage production within the manufacturing facility. The system further includes a resource allocator operably coupled to the control center and the plurality of information sources and the resource allocator is operable to monitor work in process within the manufacturing facility.

Owner:DELL PROD LP

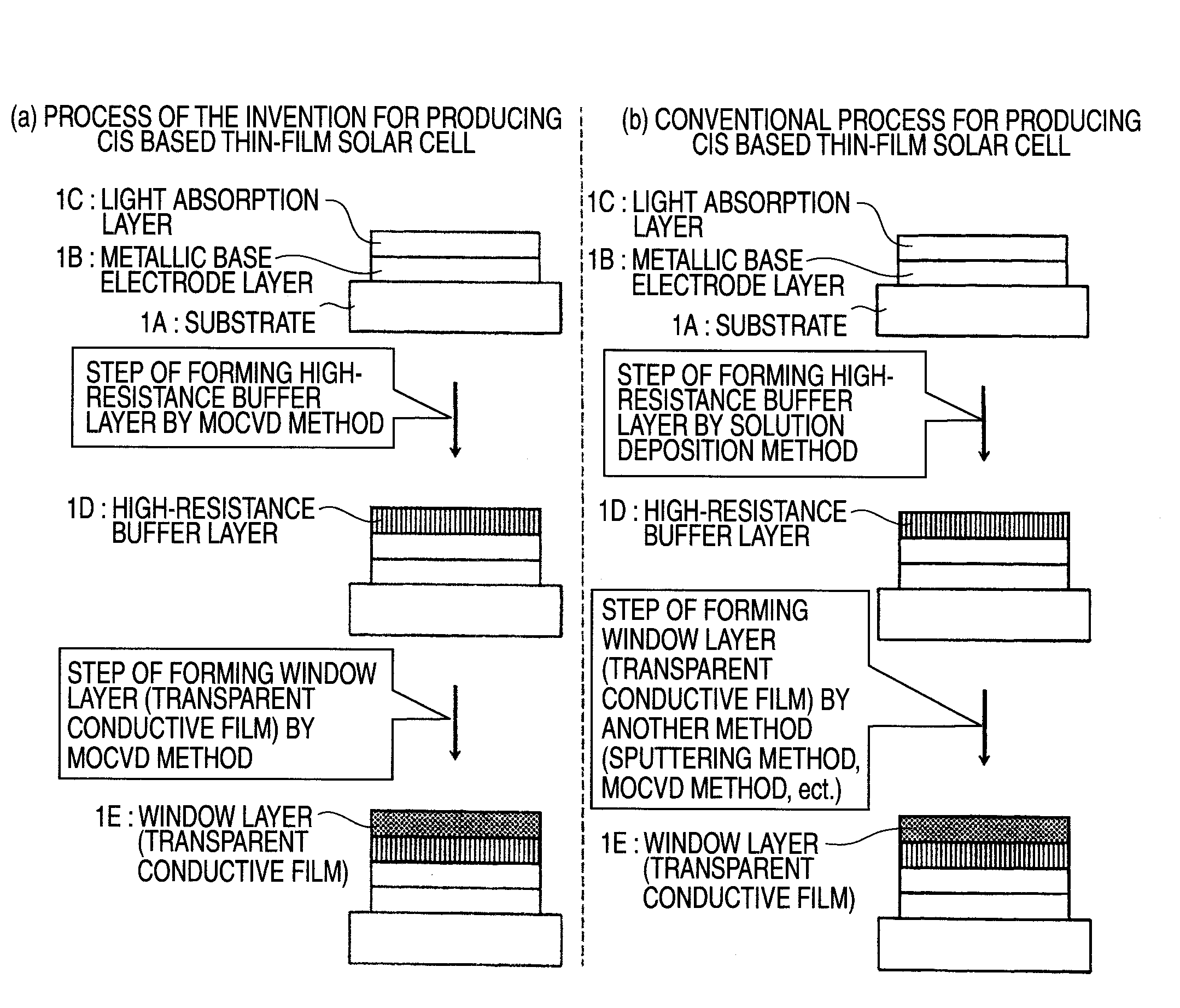

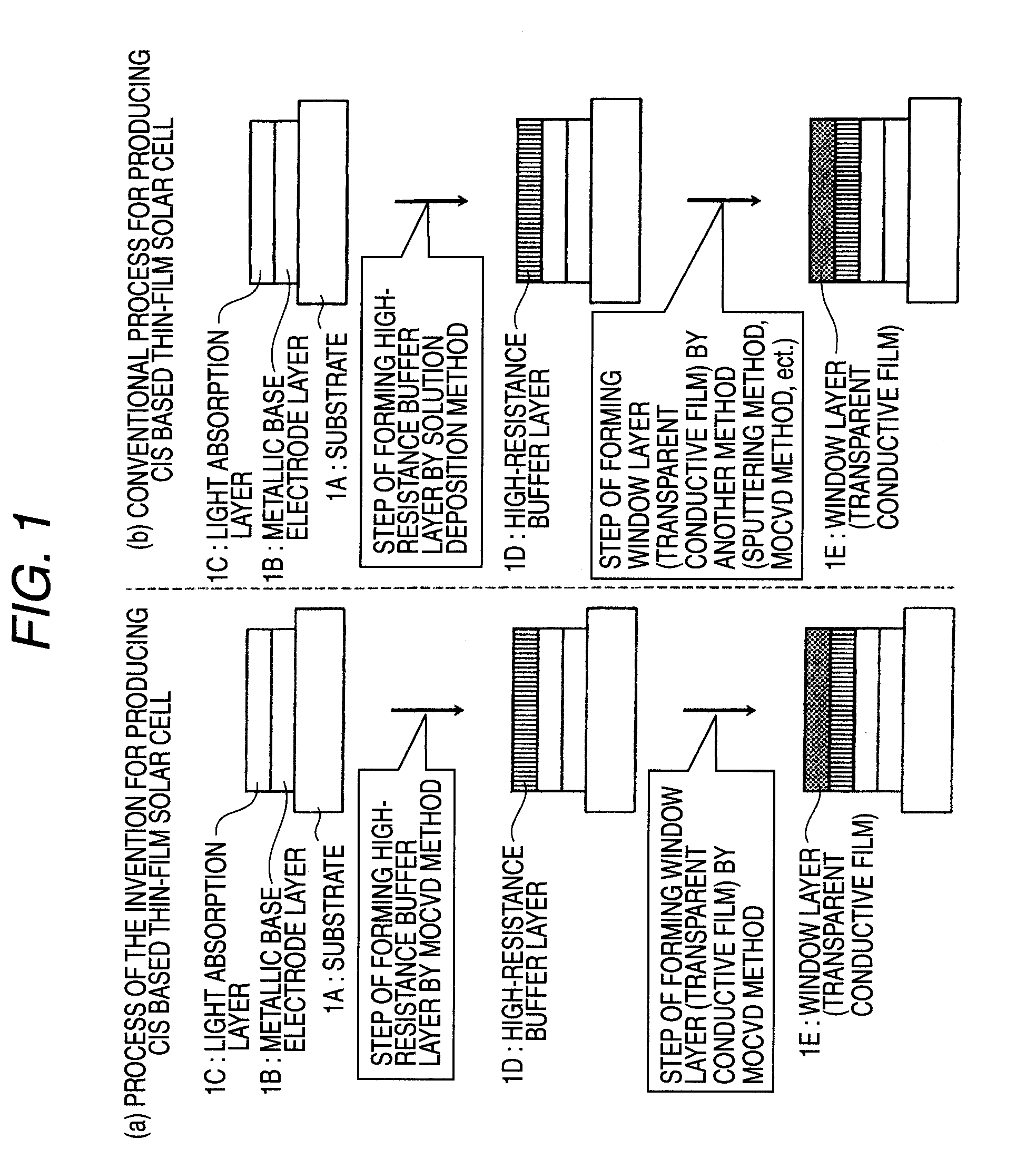

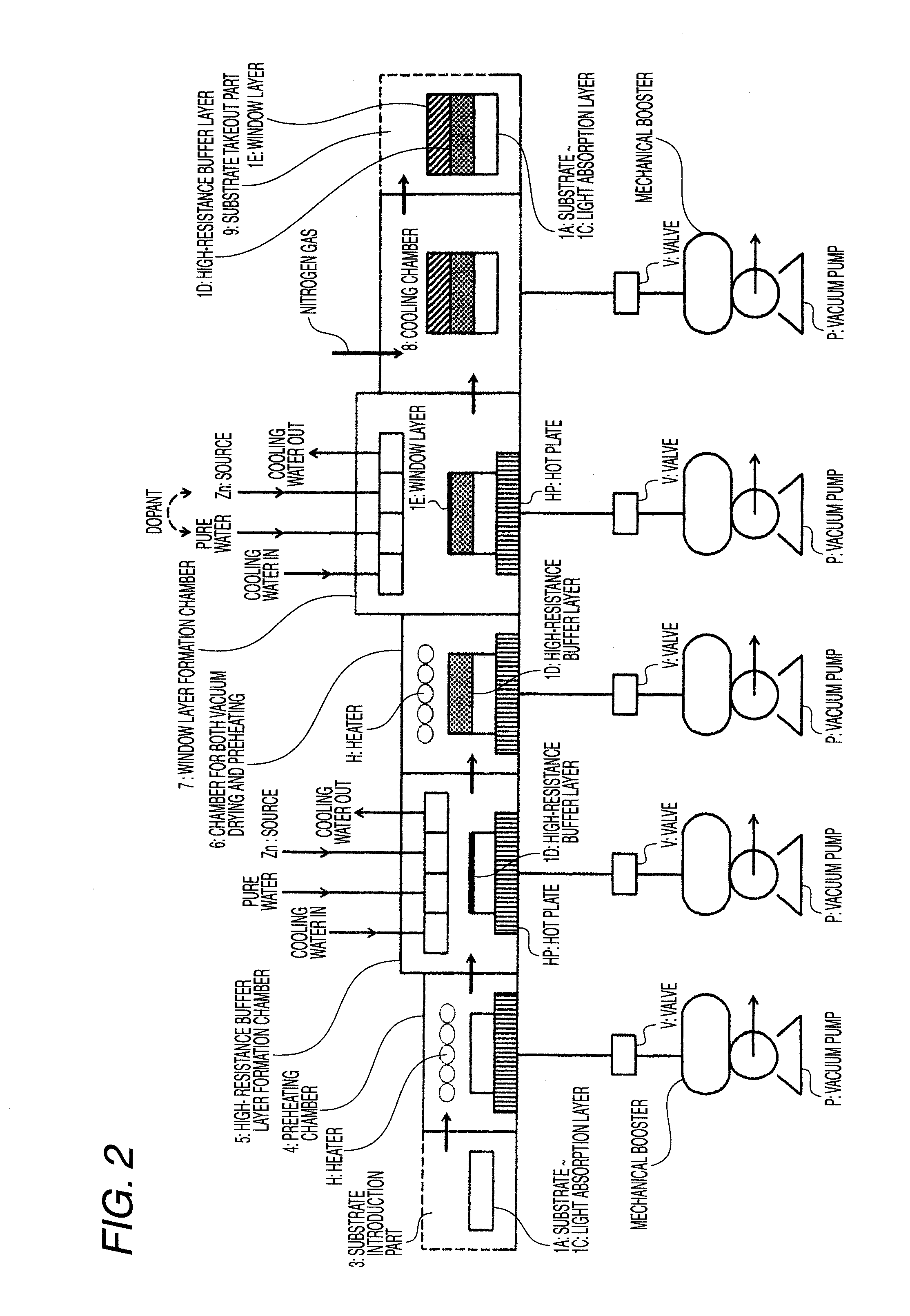

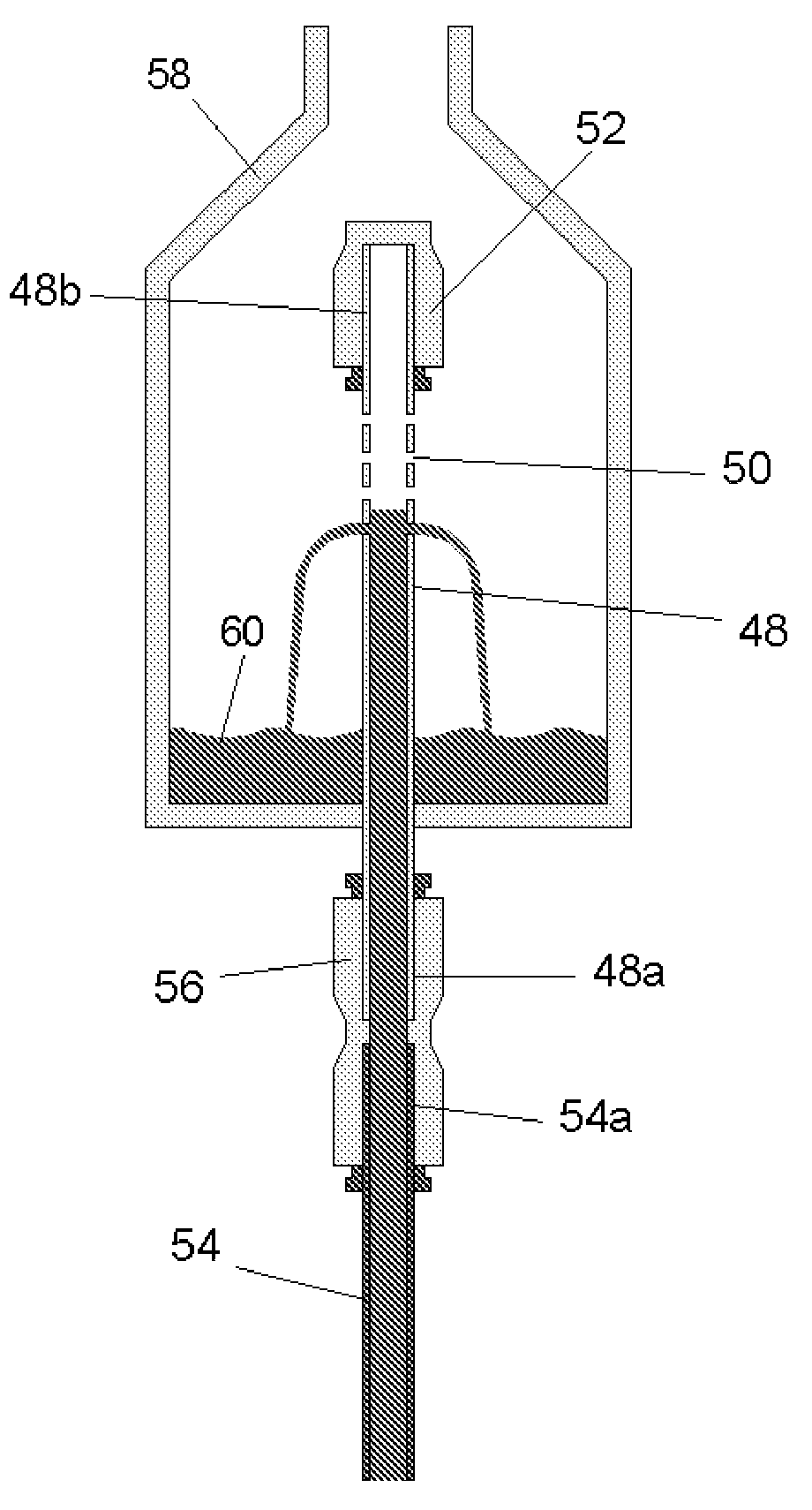

Method of Successive High-Resistance Buffer Layer/Window Layer (Transparent Conductive Film) Formation for CIS Based Thin-Film Solar Cell and Apparatus for Successive Film Formation for Practicing the Method of Successive Film Formation

ActiveUS20090087940A1Reduction in raw-material costLow cost of treatmentFinal product manufactureSemiconductor/solid-state device manufacturingHigh resistanceWork in process

A high-resistance buffer layer and a window layer (transparent conductive film) are successively formed by the MOCVD method to obtain the same output characteristics as in conventional film deposition by the solution deposition method and to simplify a film deposition method and apparatus. Thus, the cost of raw materials and the cost of waste treatments are reduced to attain a considerable reduction in production cost.After a metallic base electrode layer 1B and a light absorption layer 1C are formed in this order on a glass substrate 1A, a high-resistance buffer layer 1D and a window layer 1E are successively formed in this order in a multi layer arrangement on the light absorption layer 1C of the resultant semifinished solar cell substrate by the MOCVD method. Consequently, a film deposition method and apparatus are simplified and the cost of raw materials and the cost of waste treatments can be reduced.

Owner:SOLAR FRONTIER

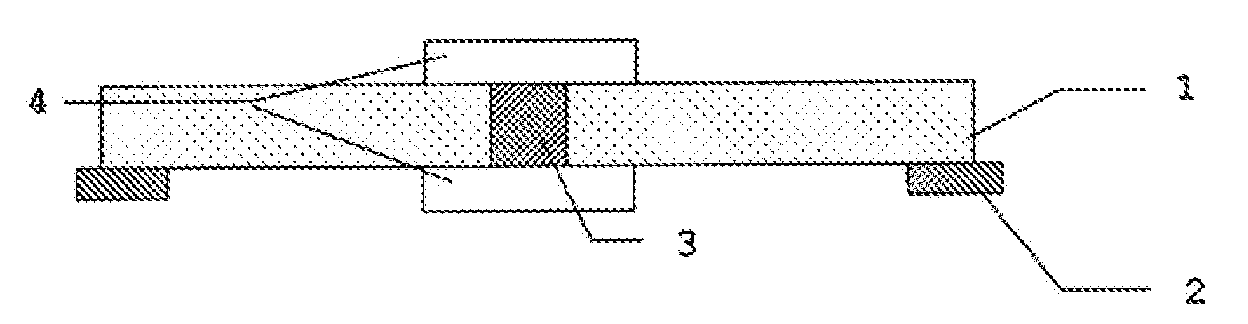

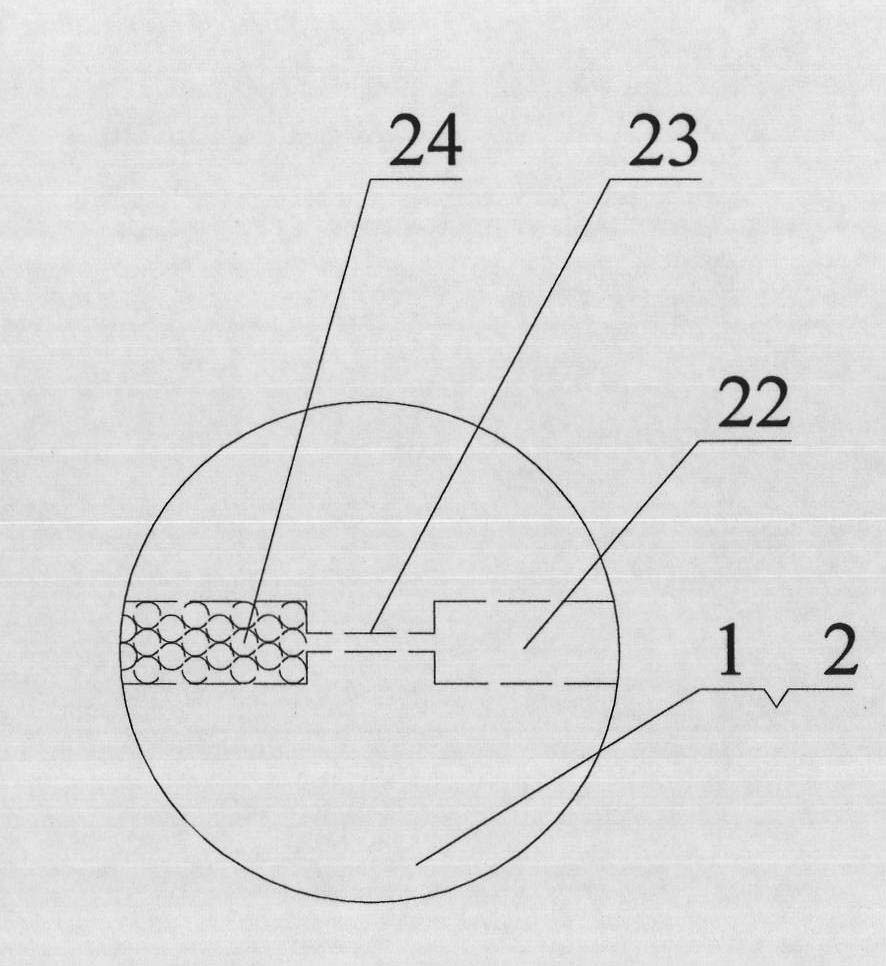

Modified Pre-Ferrulized Communication Cable Assembly and Installation Method

ActiveUS20080317410A1Reduce effortShorten the timeOptical fibre/cable installationCoupling light guidesWork in processEngineering

Disclosed is a modified pre-ferrulized cable assembly that facilitates installation of an optical fiber communication cable through narrow cable guides having sharp bends. The pre-ferrulized cable assembly includes a communication cable having a free, front end, a semi-finished communication connector, and a suction plug. The invention further relates to efficient methods for installing the modified pre-ferrulized cable assembly through a cable guide.

Owner:DRAKA COMTEQ BV

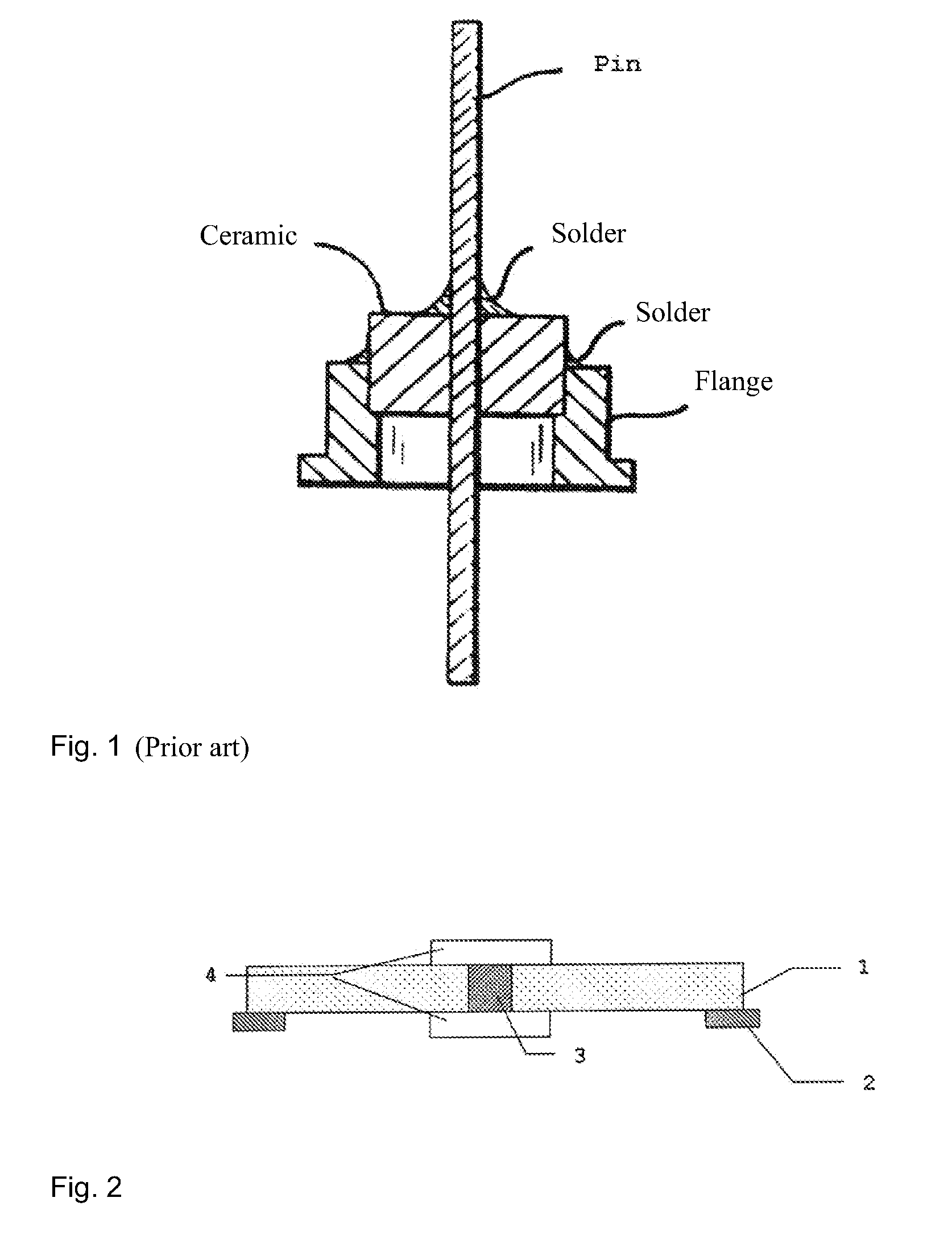

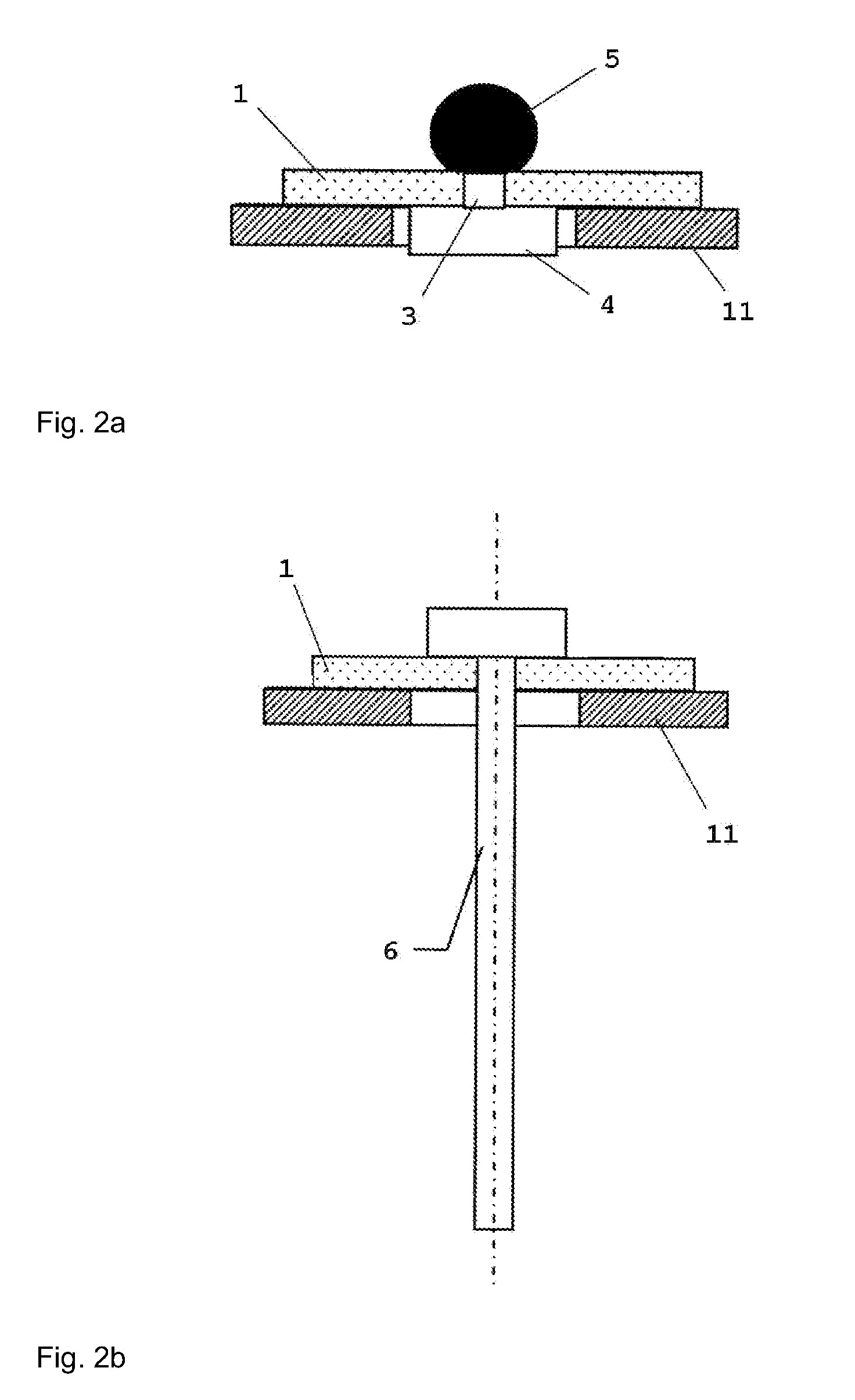

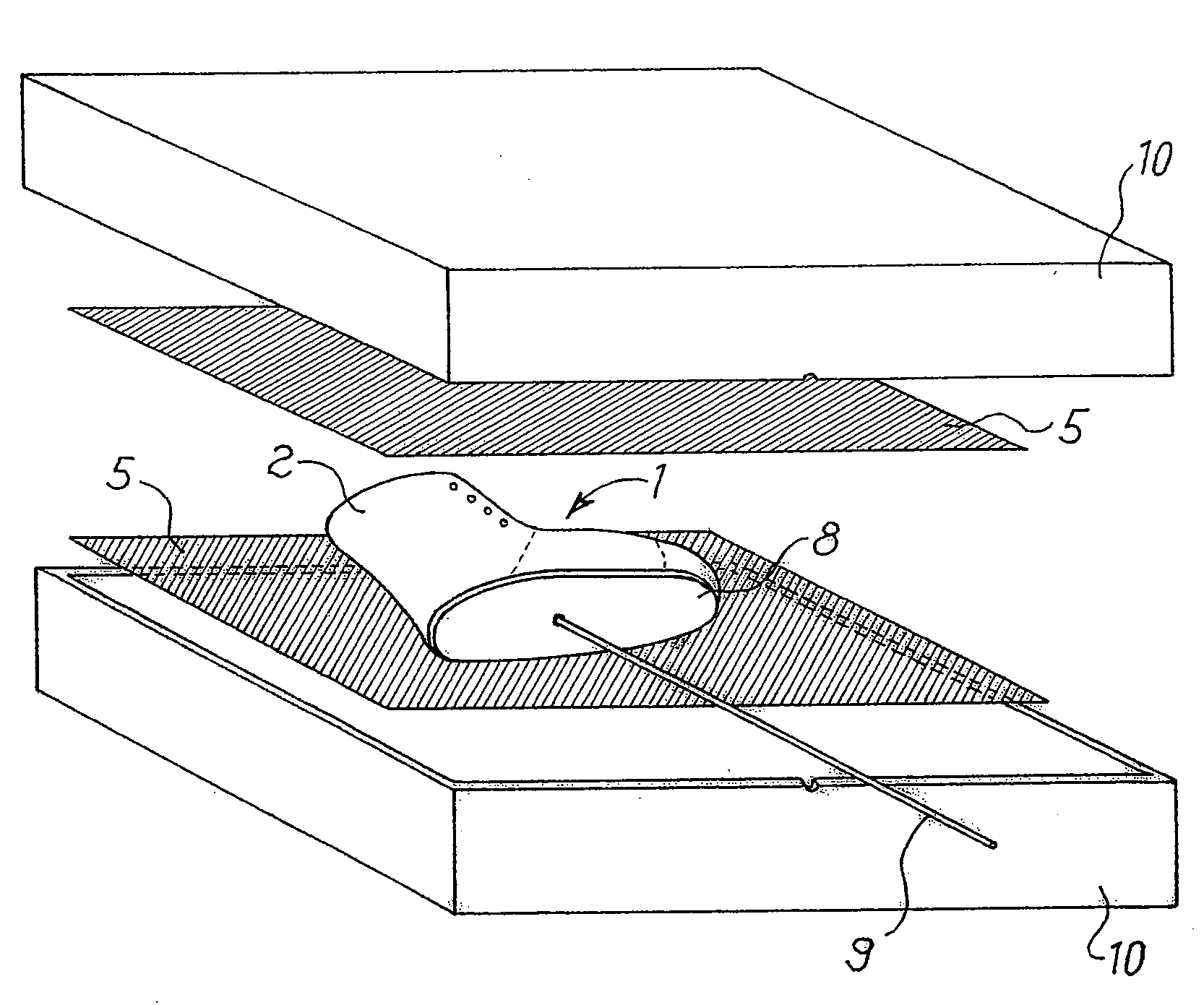

Filter feedthrough for implants

A new hermetically-sealed contact feedthrough for cardiac pacemakers and defibrillators for the connection between internal device electronics and external components, a flat ceramic disk (1) being used as an insulating main carrier, in which openings (3) are situated, into which various electrode embodiments (4, 5, 6, 7) may be inserted as through contacts. Using a metal flange or metal-plated vapor deposition zone (2), the ceramic disk may be soldered directly onto the implant housing (11). In addition, active and passive auxiliary components (8) may be applied directly to the ceramic. The main carrier may be implemented as a multilayer ceramic (9), so that rewiring levels and shielding components (10) may be integrated in the feedthrough. The feedthrough according to the present invention allows novel construction variants, above all things having orientation to multipolar systems, through use of standardized ceramic semifinished products.

Owner:BIOTRONIK SE & CO KG

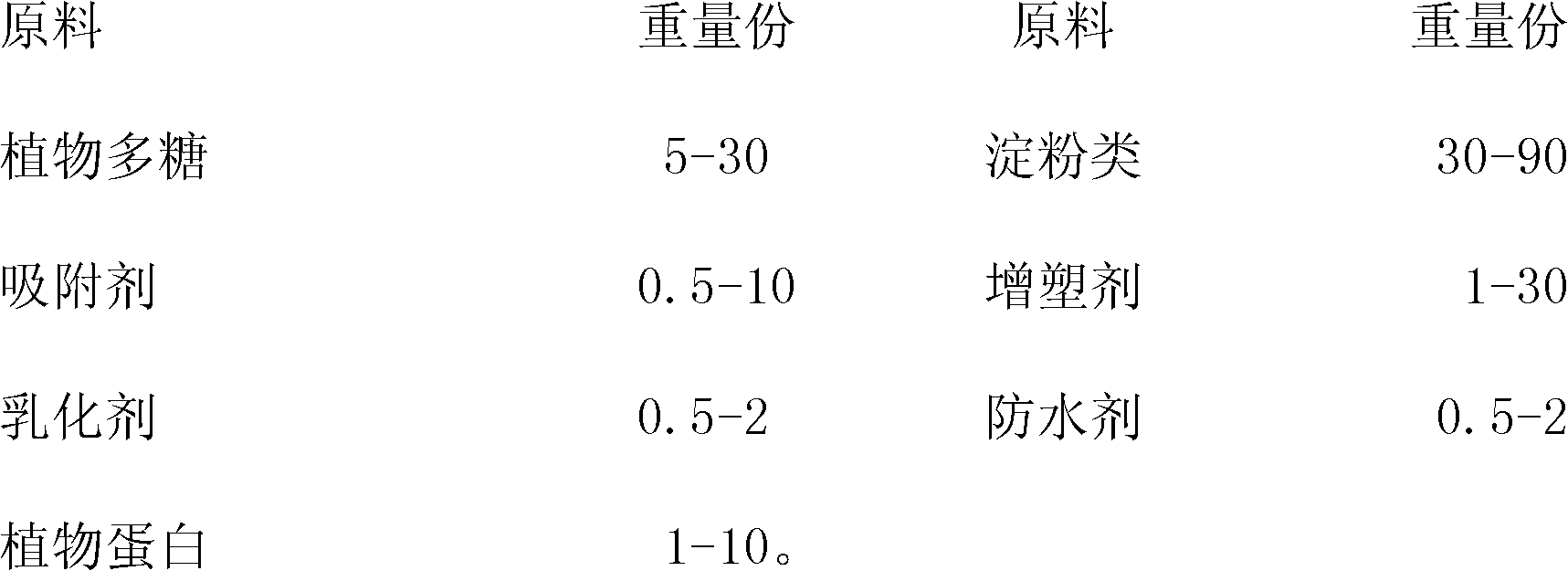

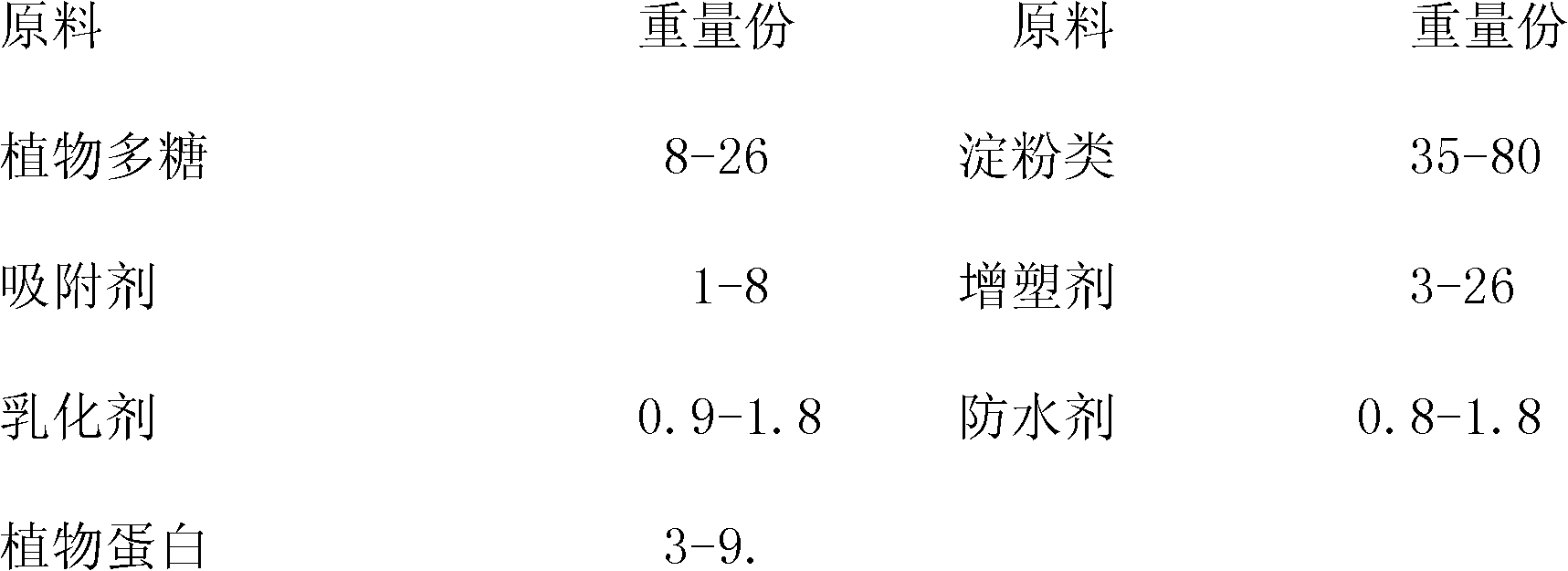

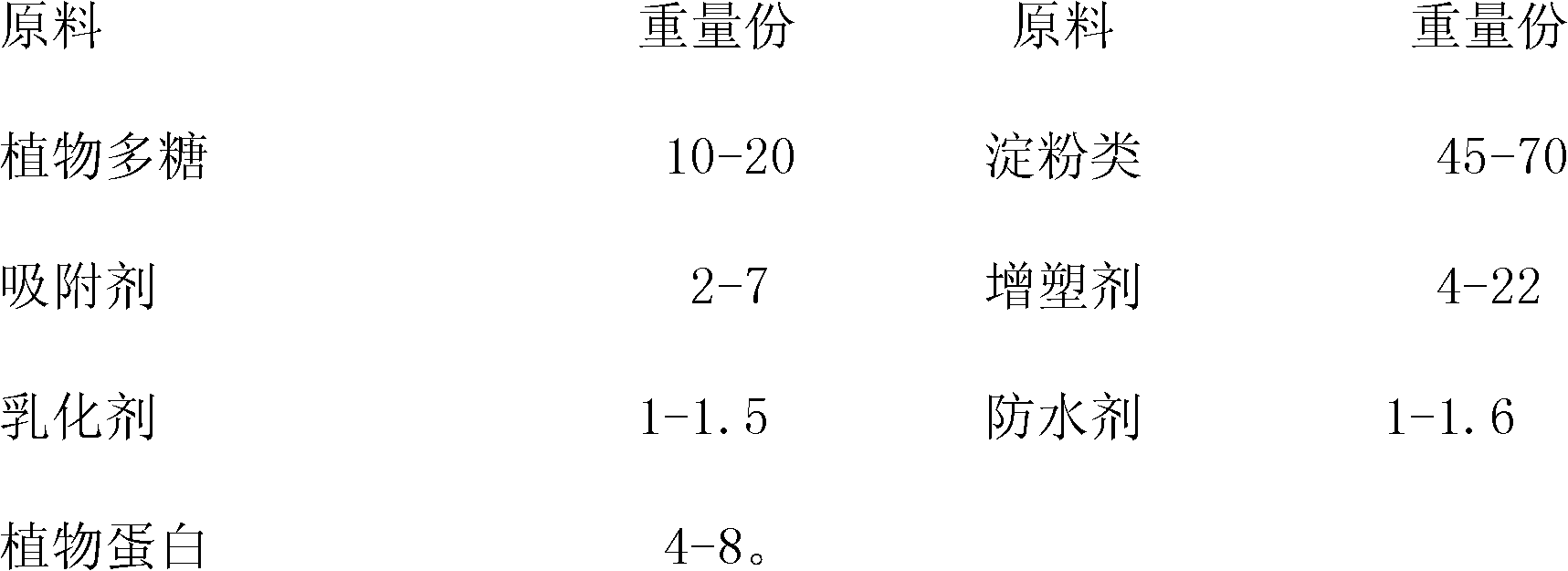

Plant polysaccharide cigarette filter tip and preparation method thereof

The invention discloses a plant polysaccharide cigarette filter tip and a preparation method thereof. Plant polysaccharide, starch, adsorbent, plasticizer, emulsifier, waterproofing agent and plant protein are blended according to a certain proportion, so that the filter tip is prepared. The preparation method includes the following steps: (a) the starch, water and the plasticizer are blended and stirred, so that modified starch solution is obtained; (b) the plant polysaccharide and the modified starch solution are blended; (c) under certain conditions, the emulsifier, the waterproofing agent and the adsorbent are added into the mixture of the plant polysaccharide and the modified starch solution, and after stirring, the mixture is injected into a long cylindrical mold made of anti-freezing, heat-proofing material and molded; (d) the semifinished product is placed into a freezing environment and frozen, i.e. prefreezing; (e) the semifinished product in step d is placed into a freeze dryer and freeze-dried; (f) the porous composite body is taken out of the mold and deburred, and thereby a filter tip stick is obtained. Material resources are rich, the cost is low, and the three wastes cannot be produced. The performance is good, the filter tip can reduce the nicotine content by 40.2 to 84.1 percent, the tar by 26 to 72.1 percent and the nicotinamide by 20 to 39.2 percent, and after use, waste can be biodegraded.

Owner:WUHAN LICHENG BIOTECH +1

System for modular building construction

InactiveUS20160160515A1Facilitating selective interconnectionGood choiceLighting and heating apparatusProtective buildings/sheltersBuddingModular unit

Construction systems for erecting budding structures comprise a plurality of prefabricated interconnectable modular budding units, each unit comprising framing members and a plurality of nodes, each node situated for selective interconnection with other units, the nodes and the exterior dimensions of the frame conforming to ISO shipping standards such that each unit is transportable using the ISO intermodal transportation system, and such that when the units are interconnected, a building structure is formed. The modular units are assembled at a remote location, and are there constructed to a semi-finished state, following which the semi-finished modular units are transported from the remote location to the job site, where they are secured to form the structure being erected, and the semi-finished modular units are thereafter constructed to a finished state.

Owner:GLOBAL BUILDING MODULES

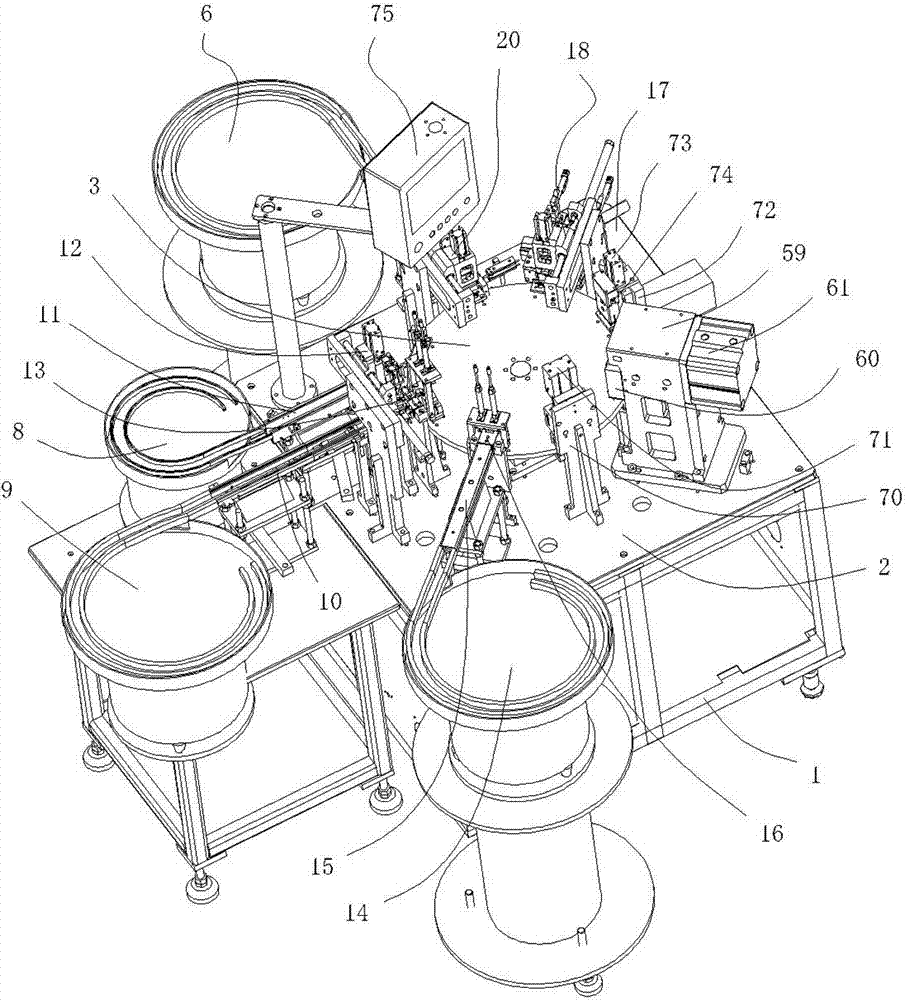

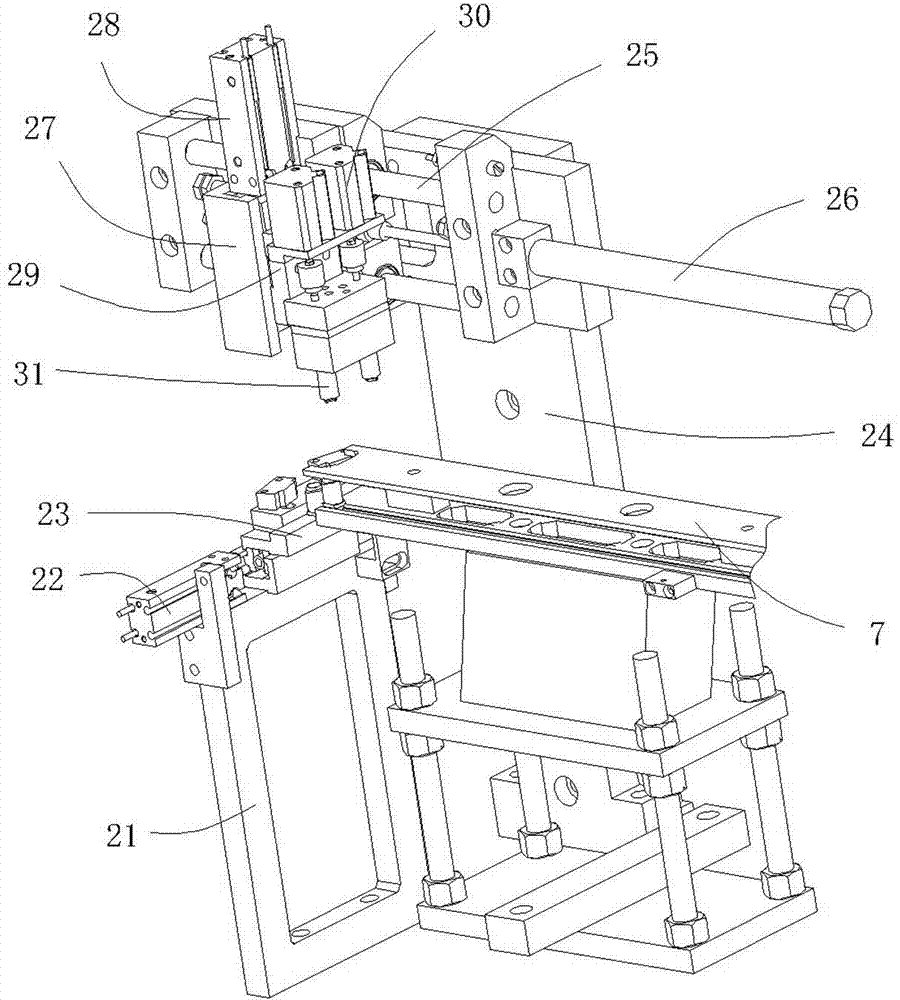

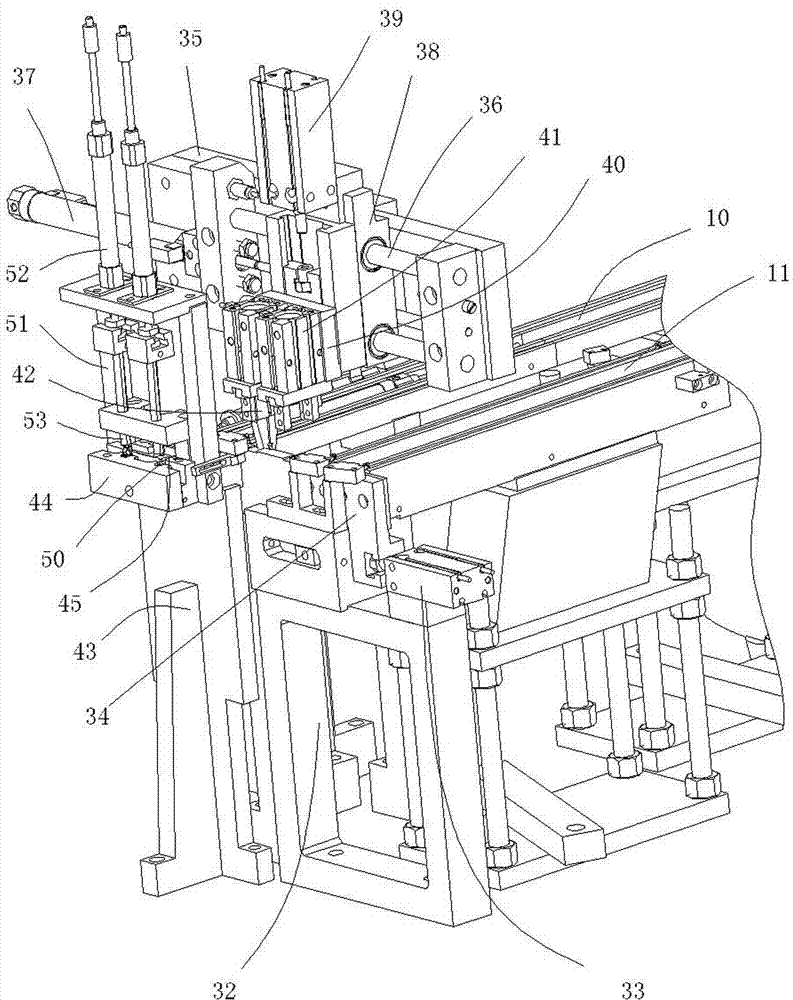

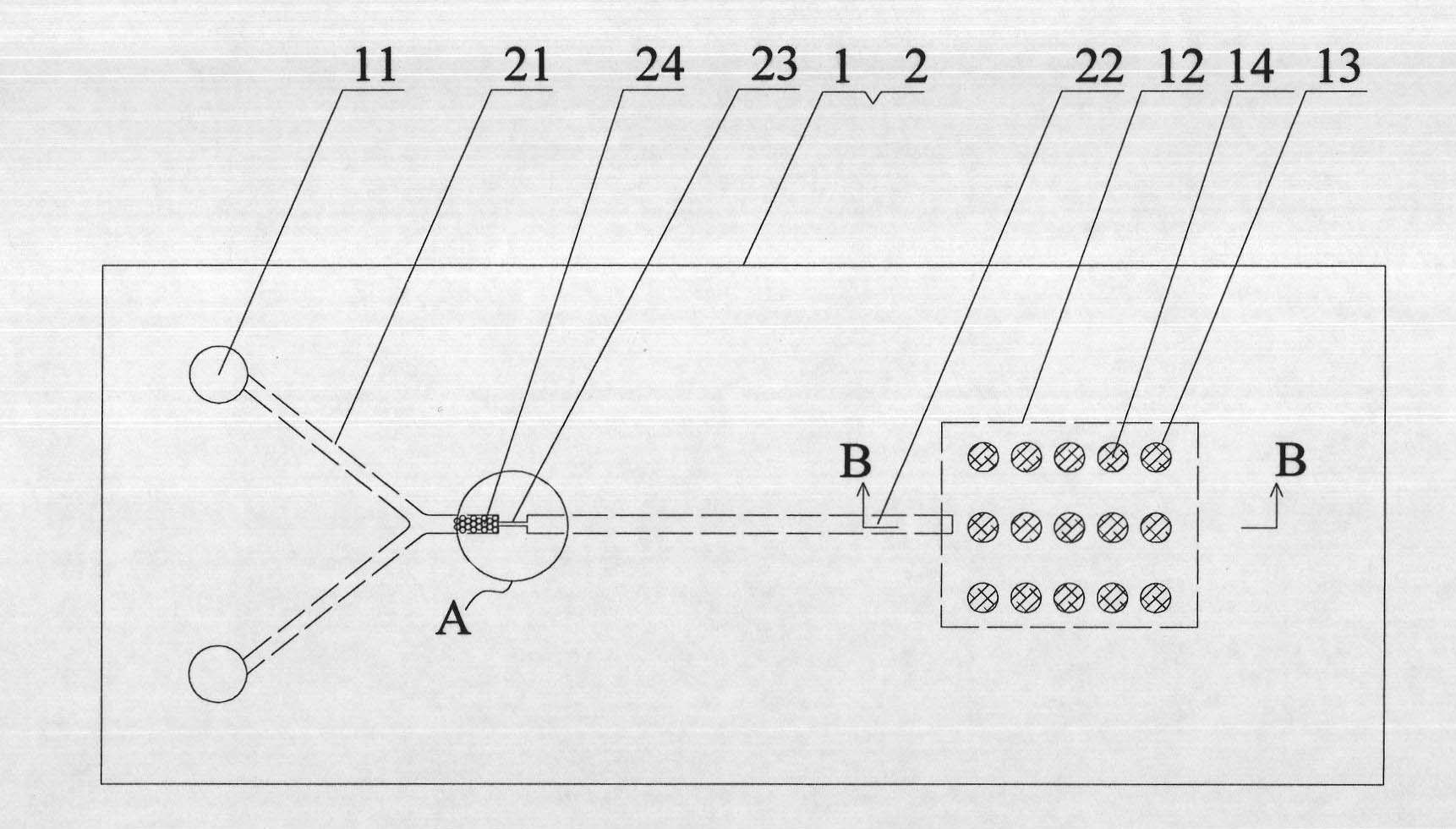

Automatic assembling machine for female joint of television signal line

ActiveCN103481060ARealize automated assemblyIncrease productivityAssembly machinesWork in processEngineering

The invention relates to an automatic assembling machine for a female joint of a television signal line. The automatic assembling machine comprises a frame, a working platform and a multi-station turnplate. A plurality of locating modules are uniformly distributed on the multi-station turnplate, and locating slots are concavely arranged on the positioning modules. An upper shell station, an upper semi-finished product station, an upper insulating sleeve station, a riveting station and a discharge station are uniformly and sequentially distributed above the multi-station turnplate. A shell feed vibrating plate and a shell feed mechanism are arranged outside the upper shell station. A socket spring plate feed vibrating plate, an insulating seat feed vibrating plate, a semi-finished product assembling mechanism and a semi-finished product feed mechanism are arranged outside the upper semi-finished product station. An insulating sleeve feed vibrating plate and an insulating sleeve feed mechanism are arranged outside the upper insulating sleeve station. A riveting mechanism is arranged above the riveting station. A discharge channel and a discharge mechanism are arranged outside the discharge station. With the above structure, automatic assembly of the female joint of the television signal line can be achieved, and the assembling machine is high in production efficiency, low in labor intensity and high in qualification rate.

Owner:NINGBO XINGRUI ELECTRONICS TECH

Method for making coal fine into form coke by microwave energy

InactiveCN101497835AReduce manufacturing costIncrease productivitySolid fuelsMicrowave heatingMicrowaveWork in process

The invention relates to a method for producing formed coke, in particular to a method for preparing coal powder into the formed coke by microwave. The method adopts coal powder as raw material and comprises the following steps: sieving the coal powder for preparing fine coal powder, sending the fine coal powder into a first microwave heating device for dehydration until the water content of the heated fine coal powder is below 1 percent, and sending the heated fine coal powder into a second microwave heating device by a conveying device for dry distillation; performing the dry distillation to the fine coal powder by the second microwave heating device to analyze other materials in the coal powder, preparing carbocoal after the dry distillation, sending the carbocoal into a mixer by the conveying device to prepare the mixture after adding bonding material; sending the mixture to a forming machine by a conveyer for forming so as to prepare a formed coke semi-finished product; sending the reformed coke semi-finished product into a third microwave heating device for being heated and carbonized to prepare red coke, and sending the carbonized red coke into a coke car to prepare a formed coke product. The invention has low production cost, high production efficiency, cleanness and environment protection because coke powder and waste are not produced during the production.

Owner:唐山金强恒业压力型焦有限公司

Micro fluid control chip and preparation method and application thereof

InactiveCN101817495AReduce volumeVolume stabilityPrecision positioning equipmentSolid-state devicesFluid controlVolumetric Mass Density

The invention belongs to the technical field of micro fluid control, particularly disclosing a micro fluid control chip and a preparation method and application thereof. One side of the chip is provided with a plurality of sample introduction holes, each sample introduction hole is communicated with a sample introduction runner; after meeting, each sample introduction runner is communicated with a main runner; the main runner is provided with a narrow runner; a micro-sphere of which the size is 0.5-1.5 mm is filled in front of the inlet of the narrow runner; the outlet of the main runner is communicated to a waste liquid tank arranged at the other side of the chip. The preparation method mainly comprises: firstly preparing a PDMS substrate; then, preparing a PDMS cover plate with an upper groove; sticking the substrate onto the cover plate to obtain a semi-finished product of the chip; carrying out modified treatment on each runner in the semi-finished product of the chip; finally, putting the micro-sphere in, controlling the charge quantity, and finishing production. The micro fluid control chip of the invention has high solution mixing efficiency, stable solution flow rate, small volume, convenient carrying and relatively simple manufacturing; when being used for detecting the density of triphosadenine, the micro fluid control chip has the advantages of high sensitivity, favourable detection effect and the like and can not be affected by environment humidity.

Owner:HUNAN UNIV

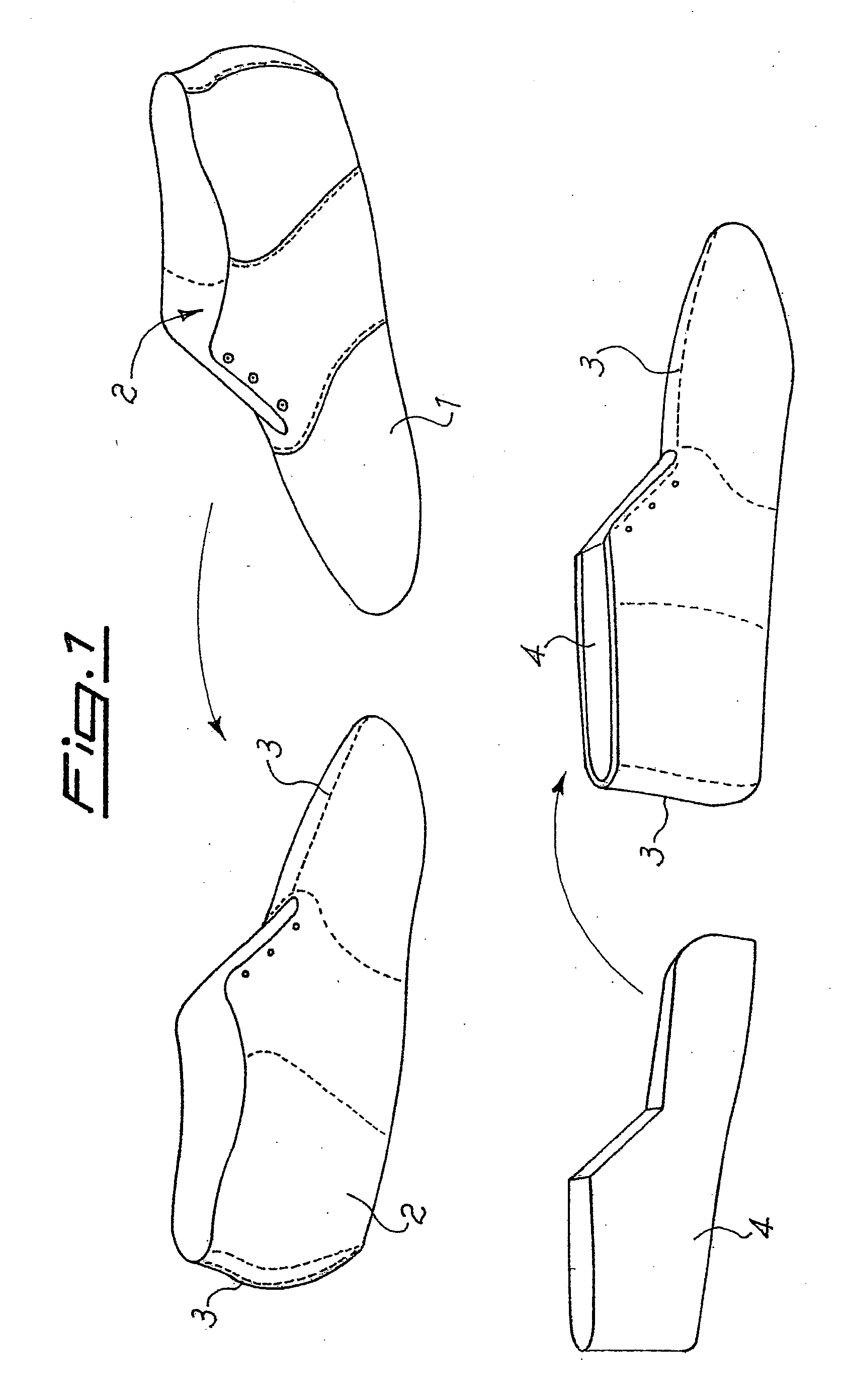

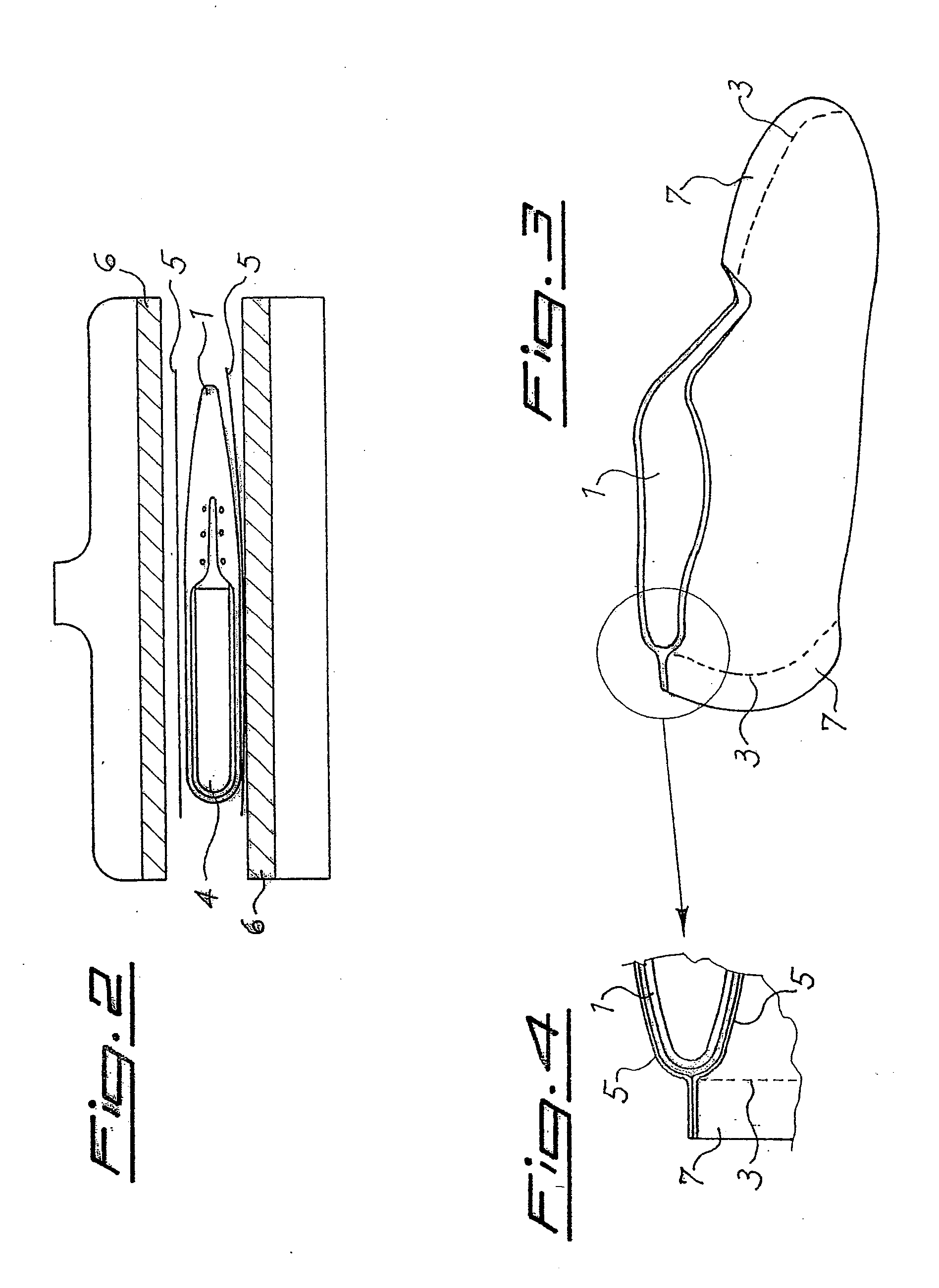

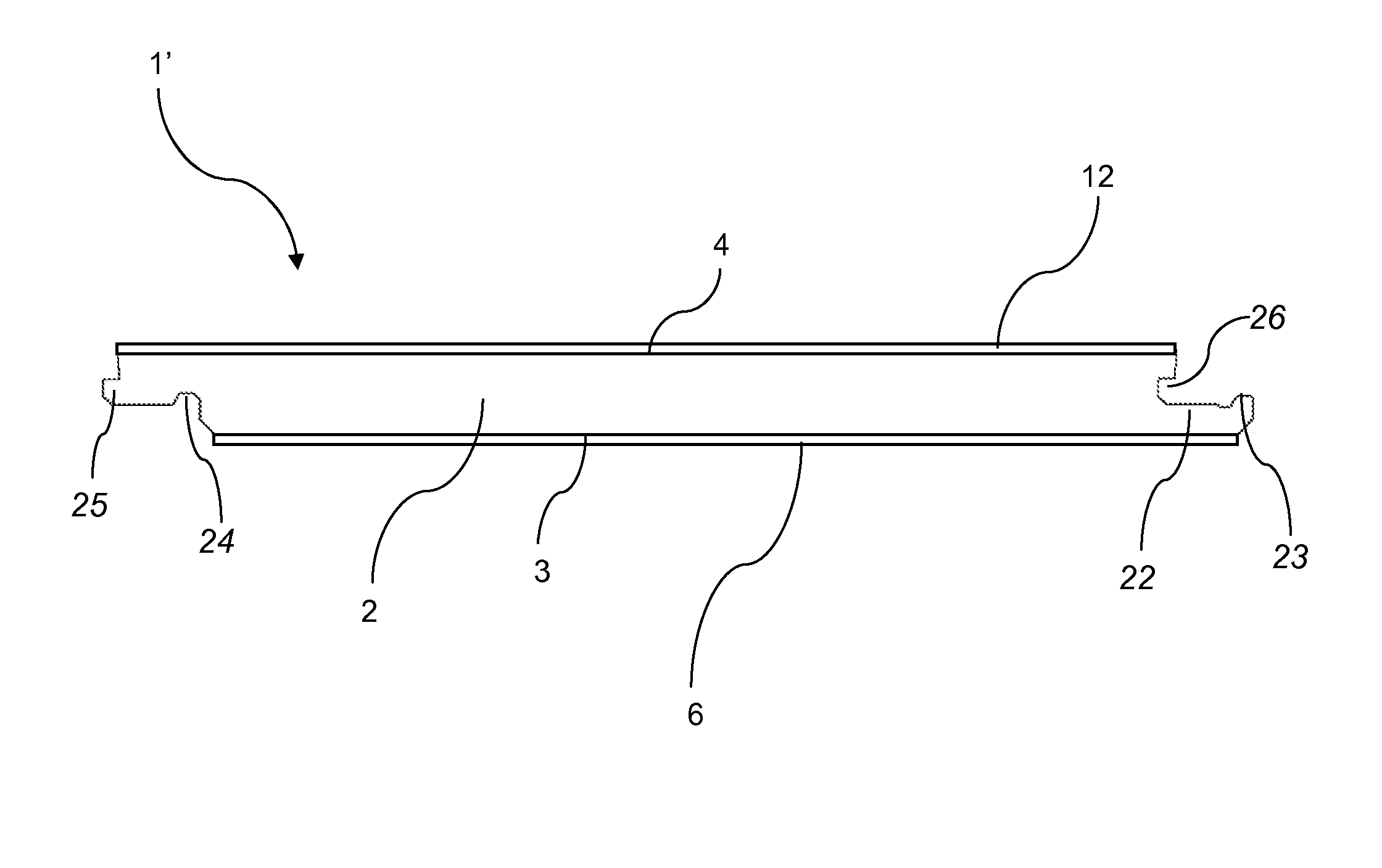

Semimanufactured Waterproofed Products, Particularly Shoes, Clothing Items and Accessories

InactiveUS20080127426A1Improve adhesionPhysical treatmentInsolesWork in processBiomedical engineering

Owner:OUTDRY TECH

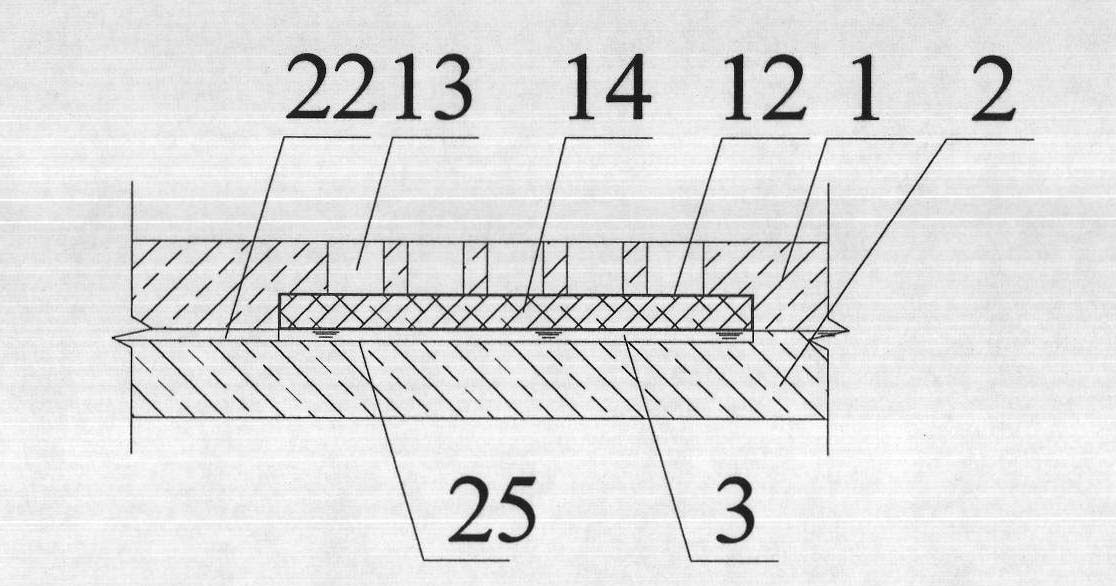

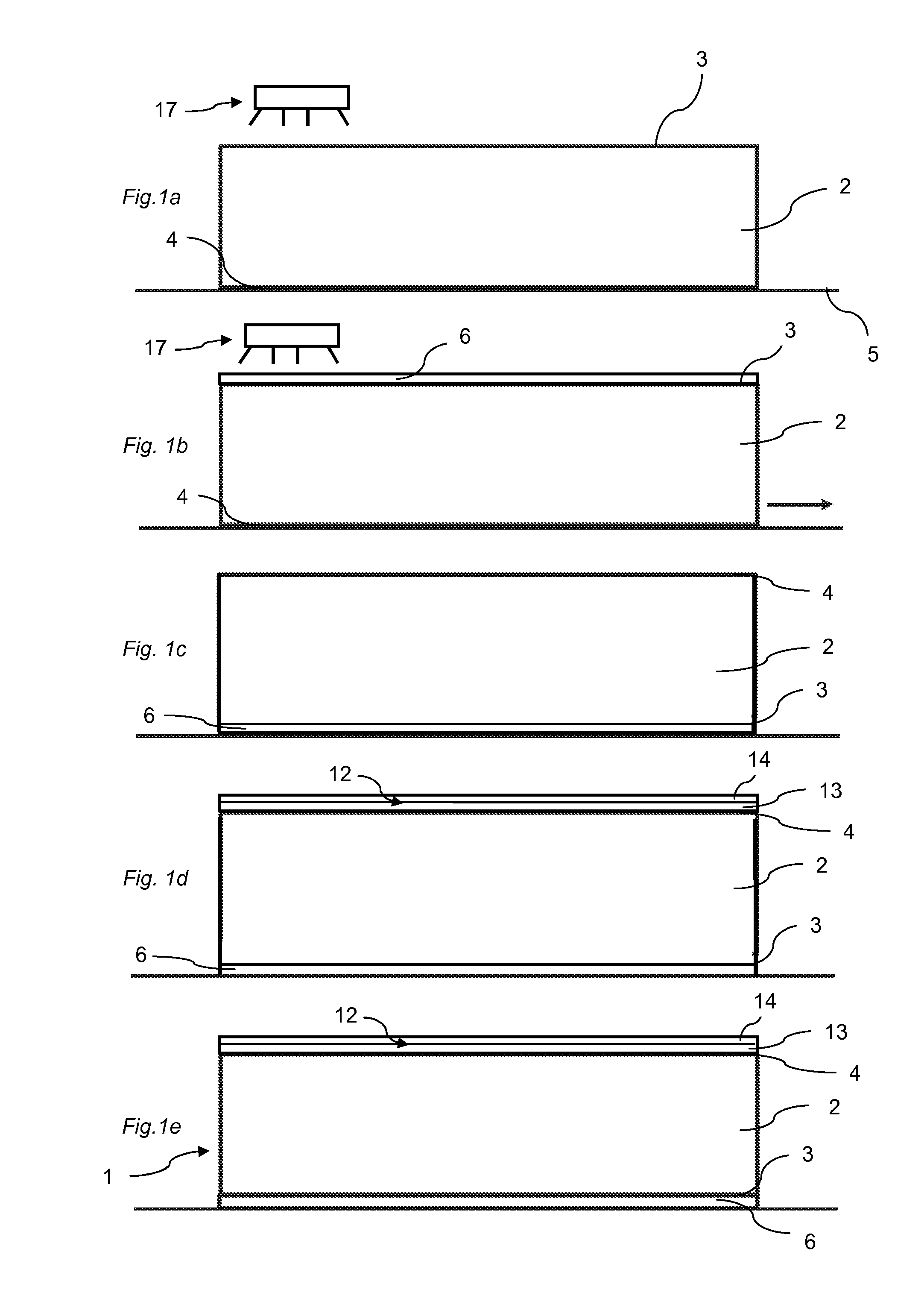

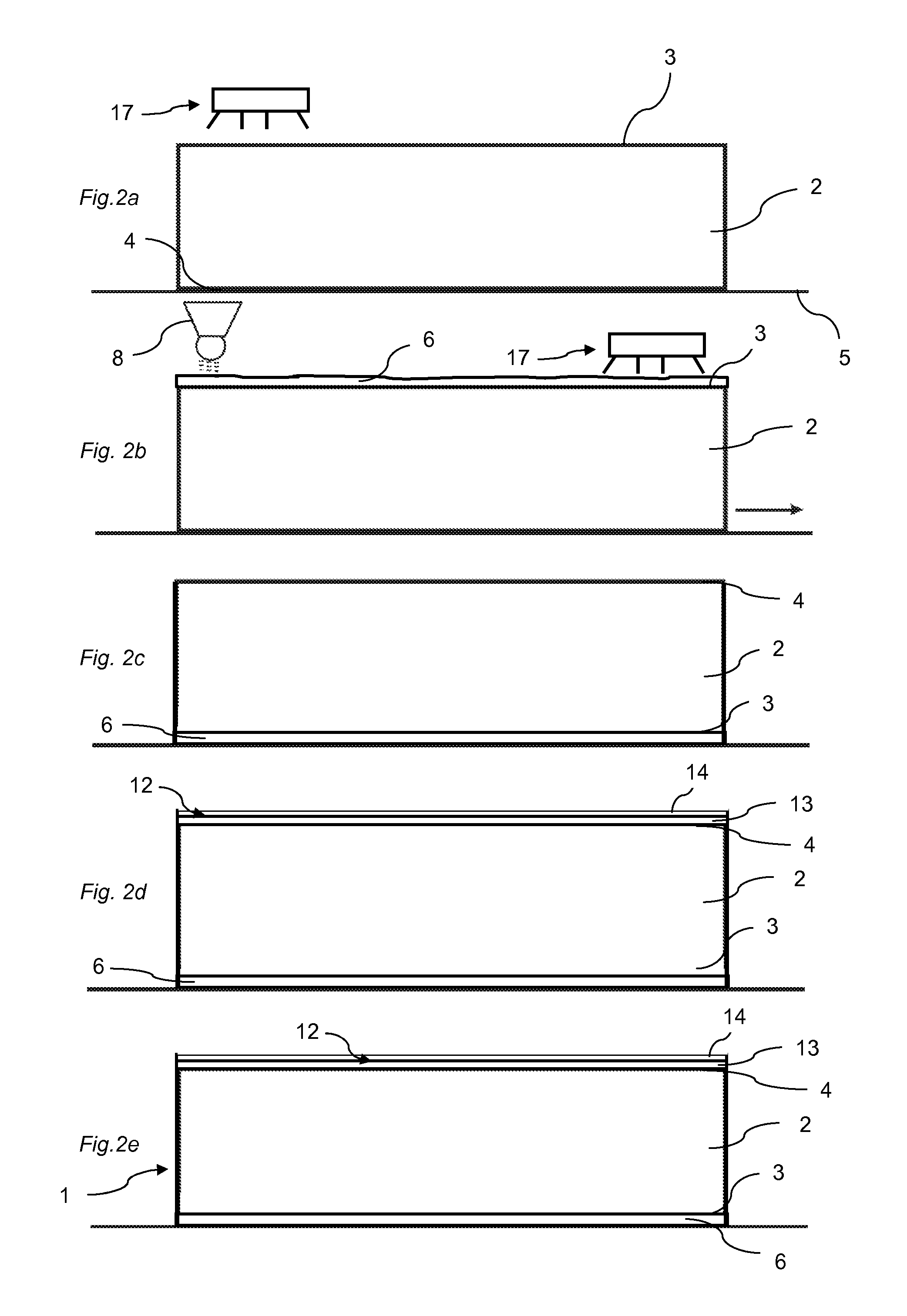

Method of producing a building panel and a building panel

ActiveUS20140199558A1Large shrinking forceReduce the amount requiredConstruction materialSynthetic resin layered productsSurface layerEngineering

A method of producing a building panel (1), including: providing a core (2), applying a balancing layer (6) having a first moisture content on a first surface (3) of the core (2), the balancing layer (6) comprising a sheet impregnated with a thermosetting binder, applying a surface layer (12) having a second moisture content on a second surface (4) of the core (2), the surface layer (12) comprising a thermosetting binder, adjusting the first moisture content of the balancing layer (6) such that the first moisture content of the balancing layer (6) is higher than the second moisture content of the surface layer (12) prior to curing, and curing the surface layer (12) and the balancing layer (6) by applying heat and pressure. Also, a semi-finished product adapted to be cured for forming a building panel (1).

Owner:VÄLINGE INNOVATION AB

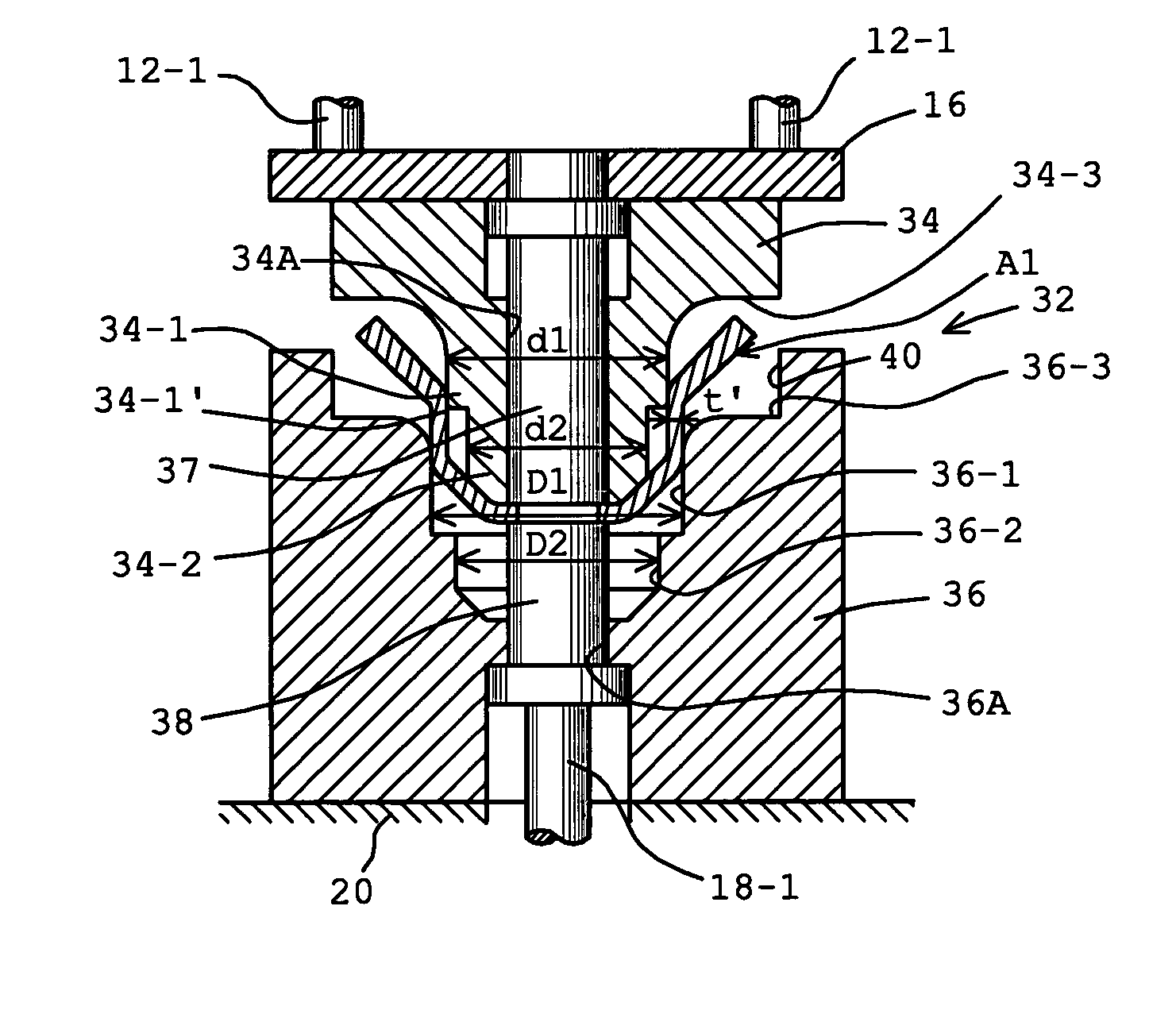

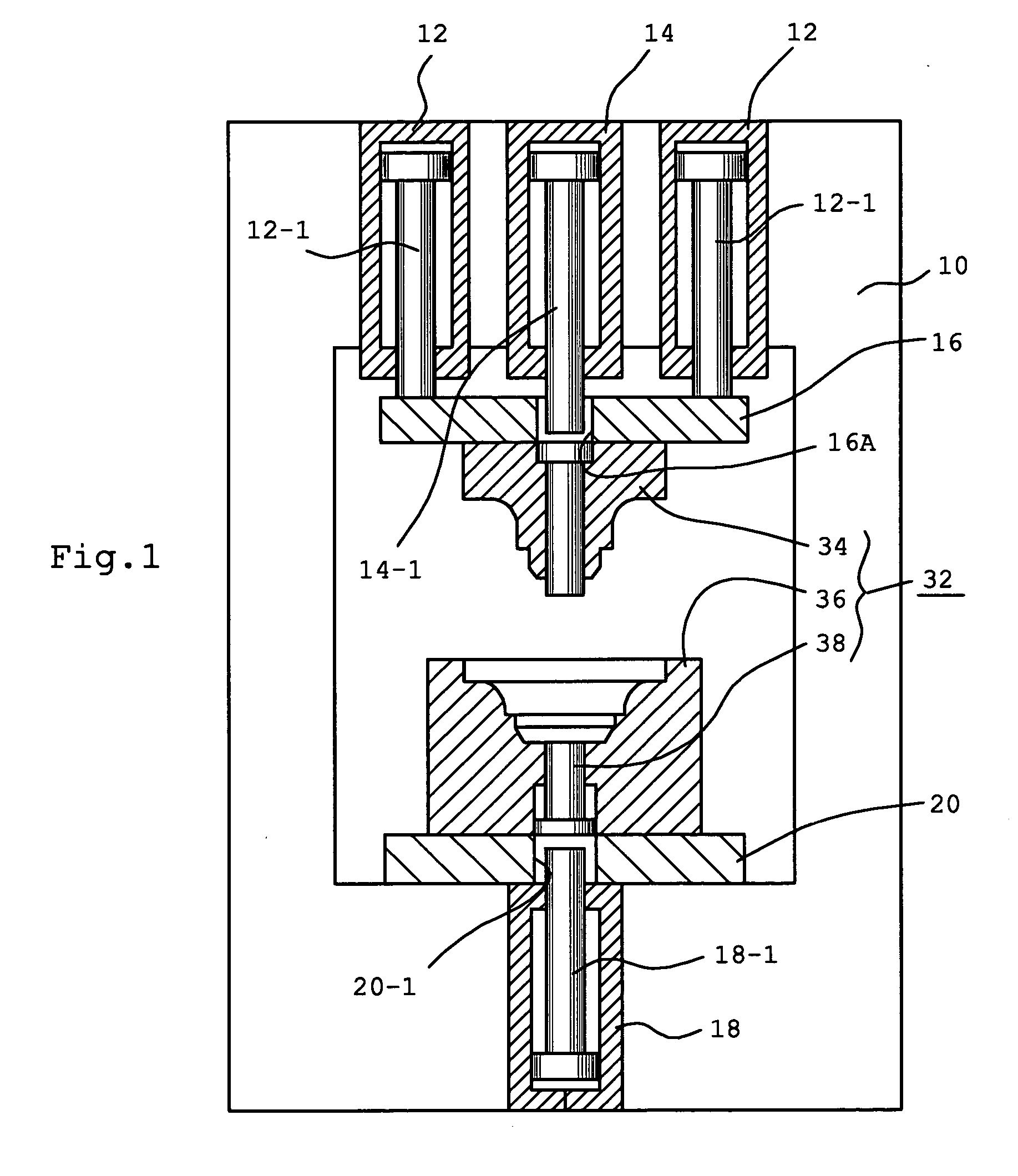

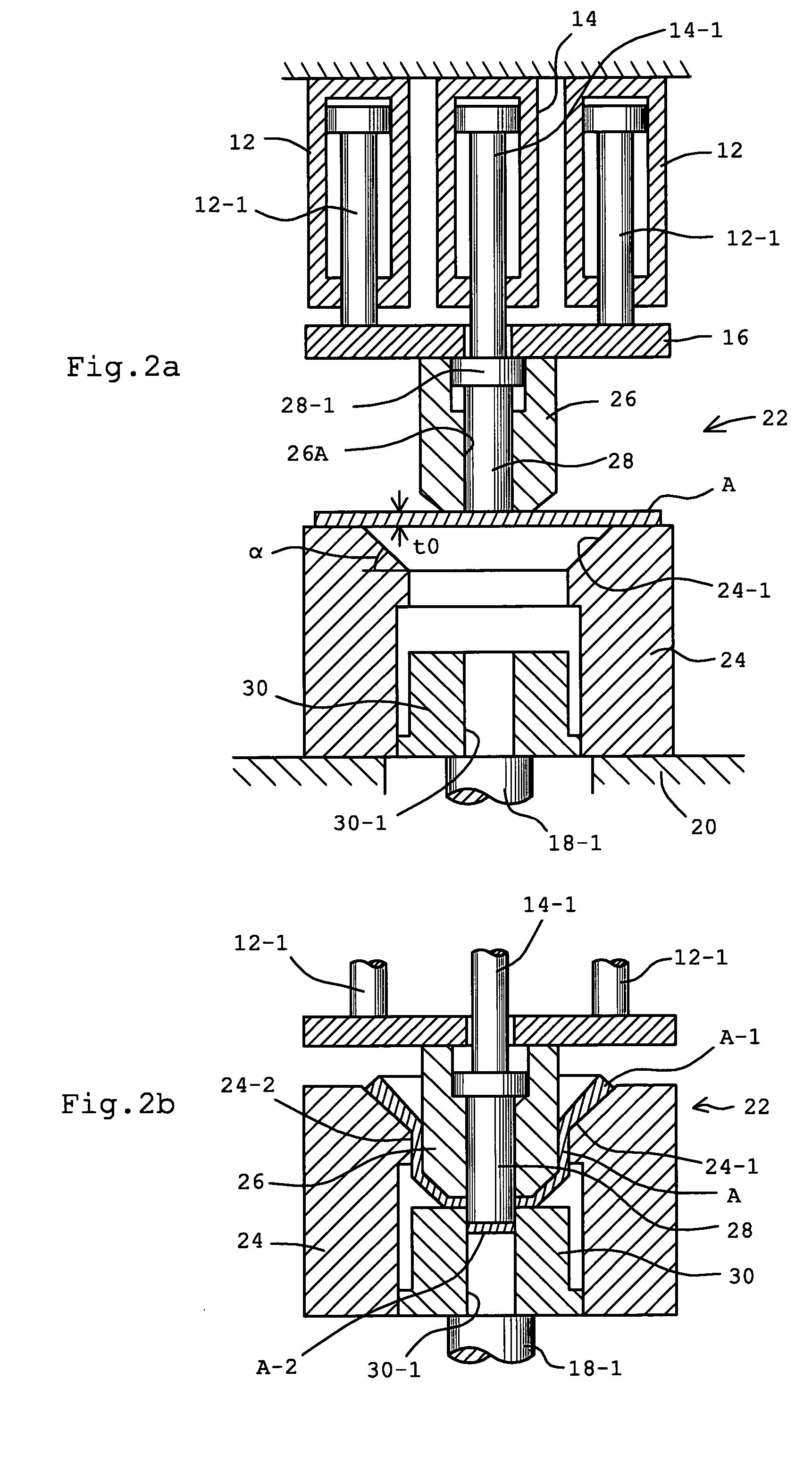

Method and apparatus for producing thin walled tubular product with thick walled flange

InactiveUS20040244459A1Forging/hammering/pressing machinesDomestic articlesMetalworkingWork in process

Method and apparatus for producing a thin walled tubular product with thickened flange. A first stage metalworking (drawing) of a circular plate material A is done by using a first die set 22 having a conical die 24 and a drawing punch 26 is done in a manner that the end of the blank plate is remained on the conical surface 24-1 of the die, so that a semi-finished tubular product A1 with a inclined flange A1-1 is obtained. Then, a second stage metalworking (drawing) of the semi-finished tubular product A1 is done by a second die set 32 having a shaping punch 34 and a restraint die 36. The semi-finished tubular product A1 is held by the restraint die 36 and the shaping punch 34 is introduced into the semi-finished tubular product A1 for effecting a wall thickness reduction under ironing principle while forming a stepped portion. Simultaneous with the execution of the second stage drawing, a flattening of the flange is done while restriction diameter expansion by a wall 40, thereby obtaining a thickened flattened flange A2-3.

Owner:MATSUOKA MINAKO +2

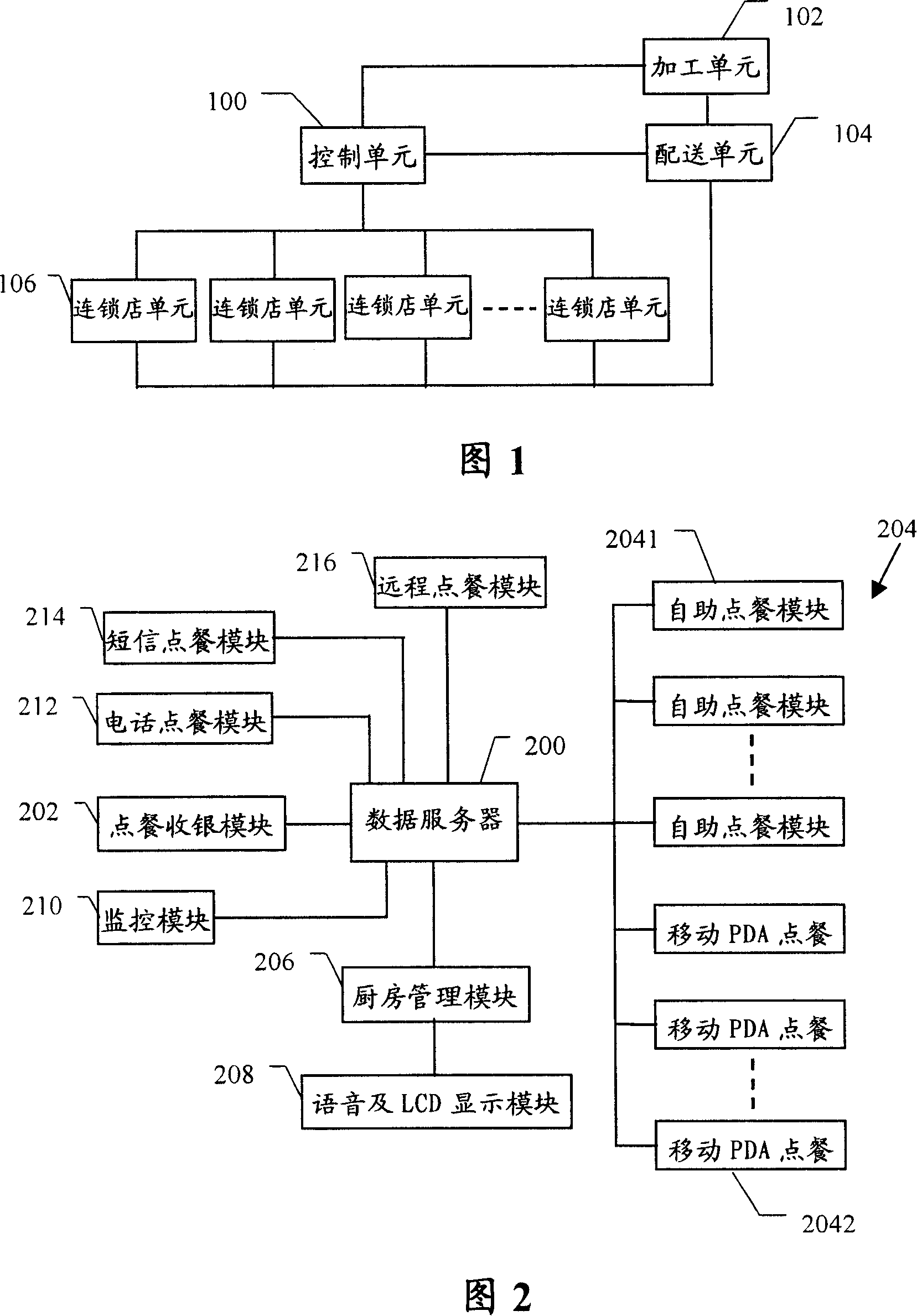

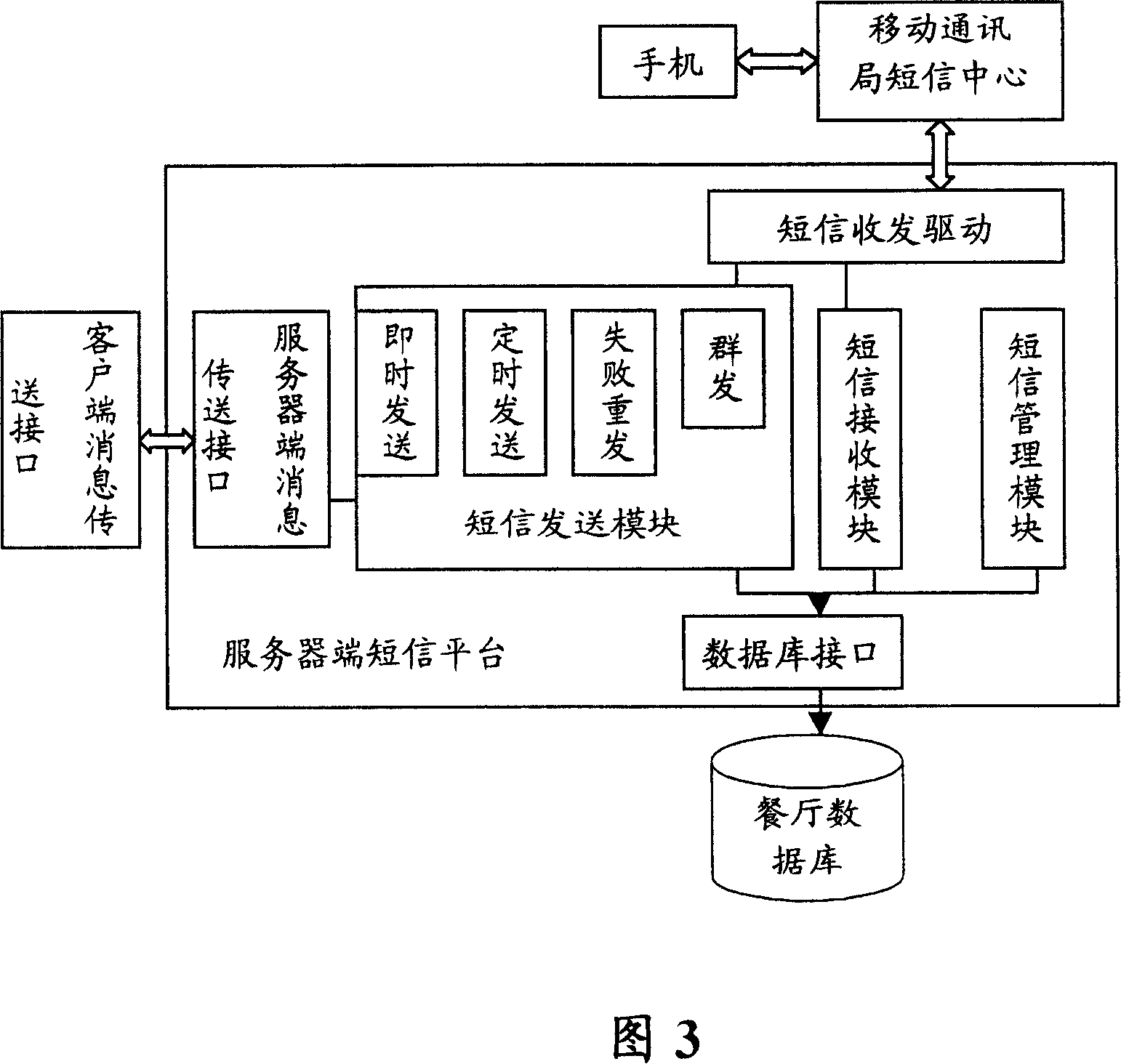

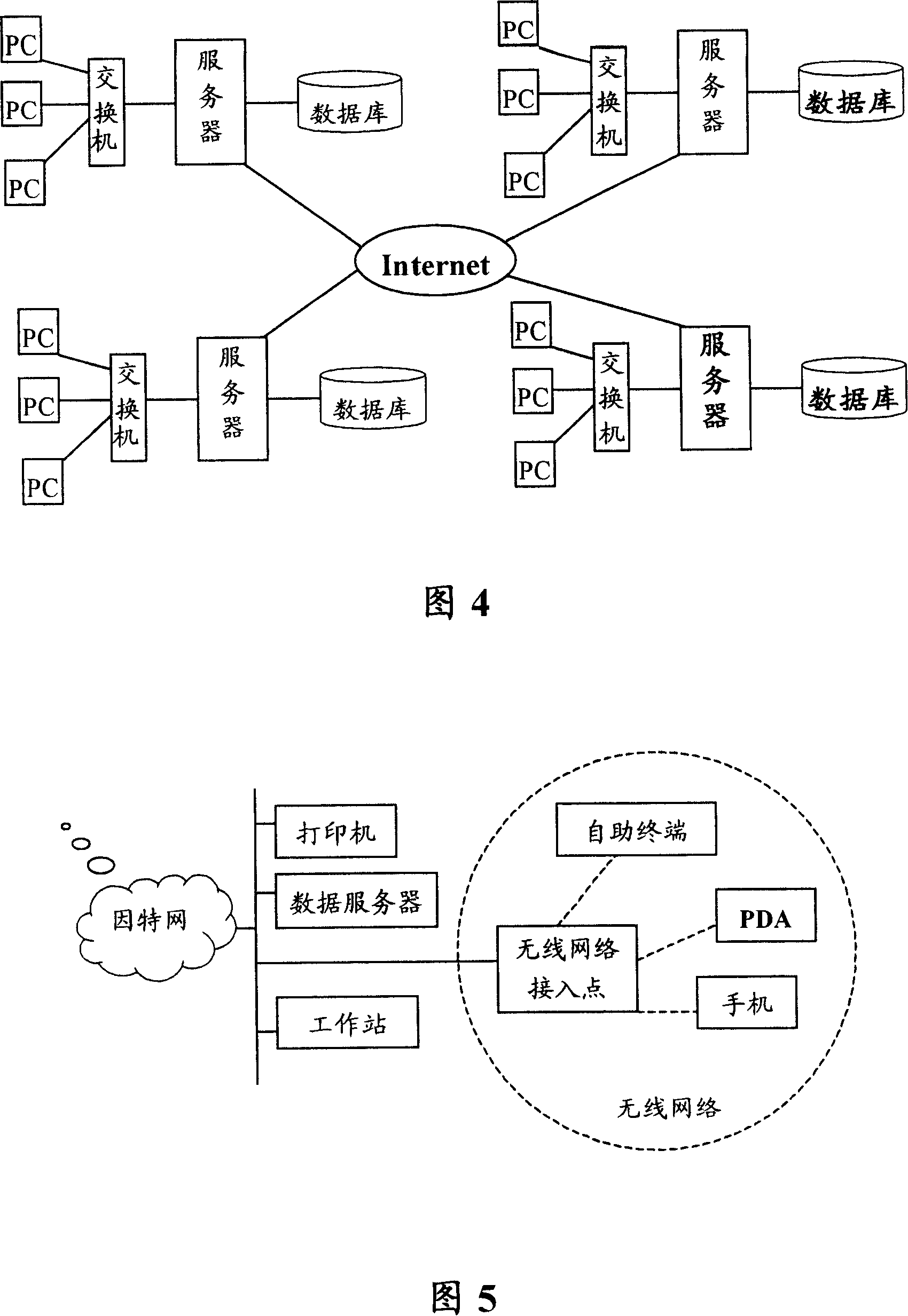

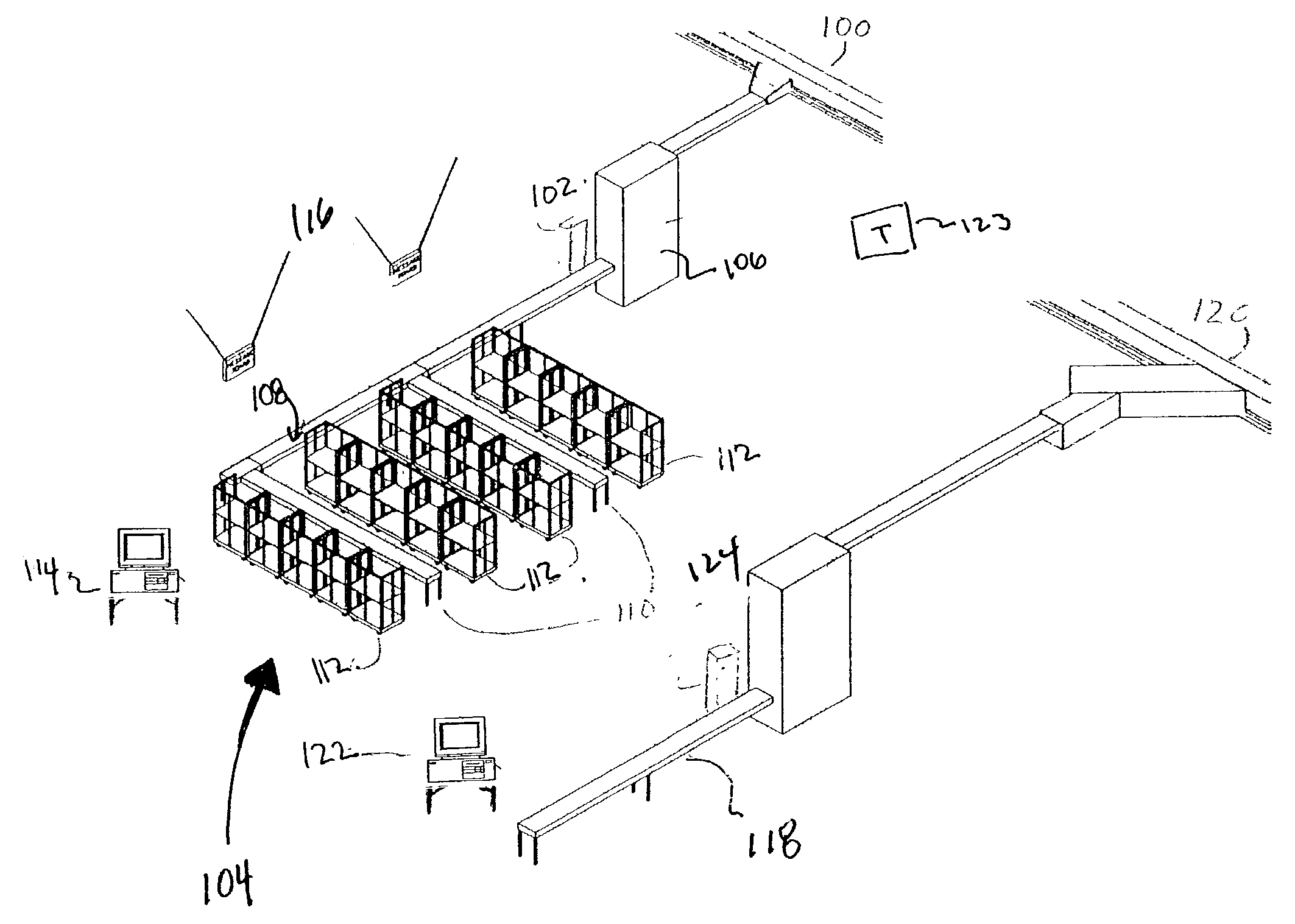

Restaurant chain store management system

InactiveCN101110110AHigh data transfer ratePerfect network functionData processing applicationsStatistical analysisServer allocation

The invention discloses a chain restaurant management system, which comprises a control unit data server that is applied to deploy data in different units, process data and distribute it to different units, a processing unit data server that is applied to examine the real-time demand and stock data of different chain restaurants to control raw material purchase and production and share the data generated to the control unit data server, a distribution unit data server that is applied to examine the real-time demand and stock data of different chain restaurants, the data about the semi-finished products and finished products completed by the processing unit according to the authority distributed by the control unit data server, so as to arrange distribution for different chain restaurants, at least one chain restaurant management unit that is applied for customer order and to get statistics on the operation data of chain restaurants and then provide the data to the control unit data server. Therefore, the invention can be applied for the control and management of raw material purchase, processing and distribution, stock and sales, product quality and service quality in chain restaurants.

Owner:吴鑫

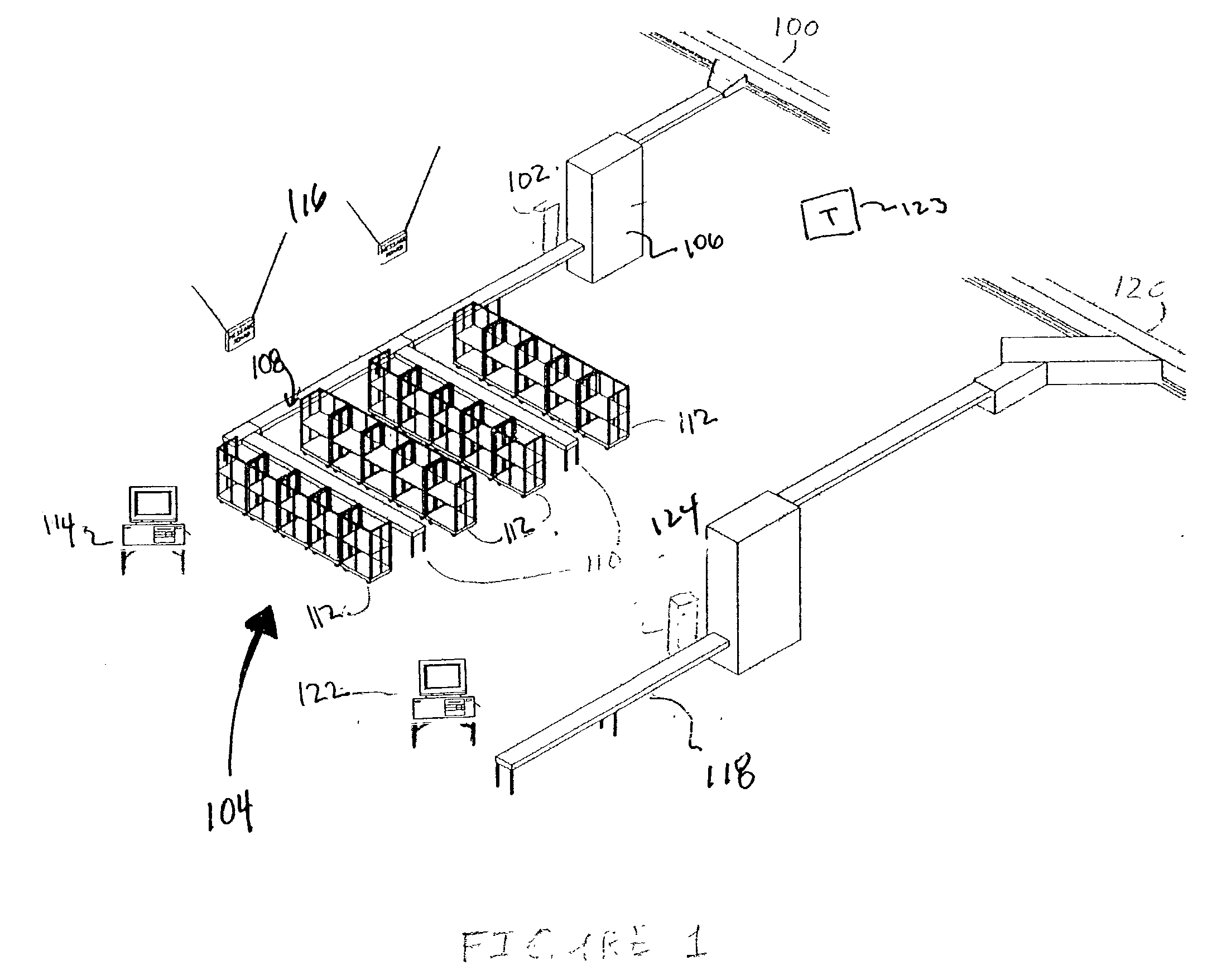

Inventory management of products

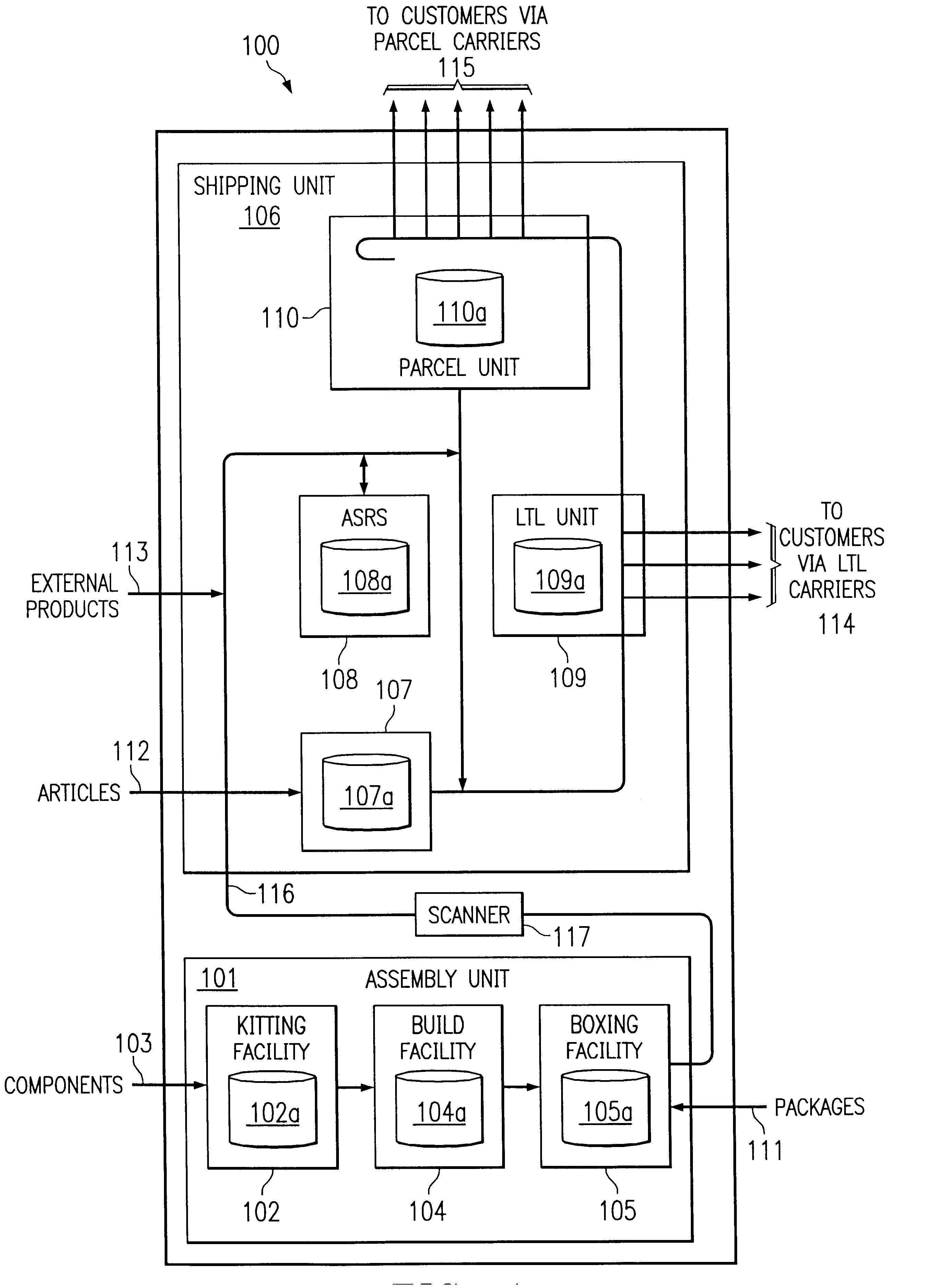

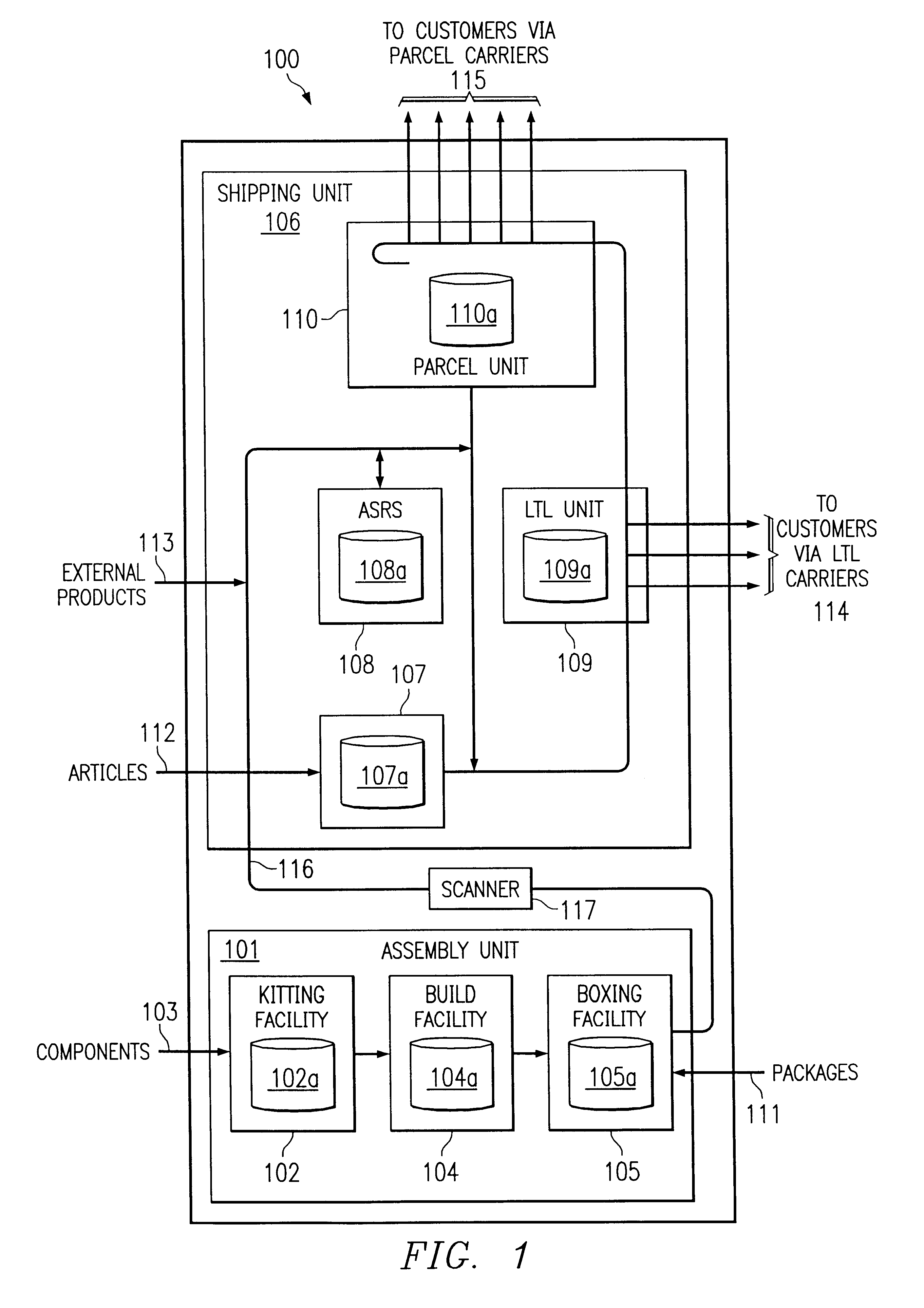

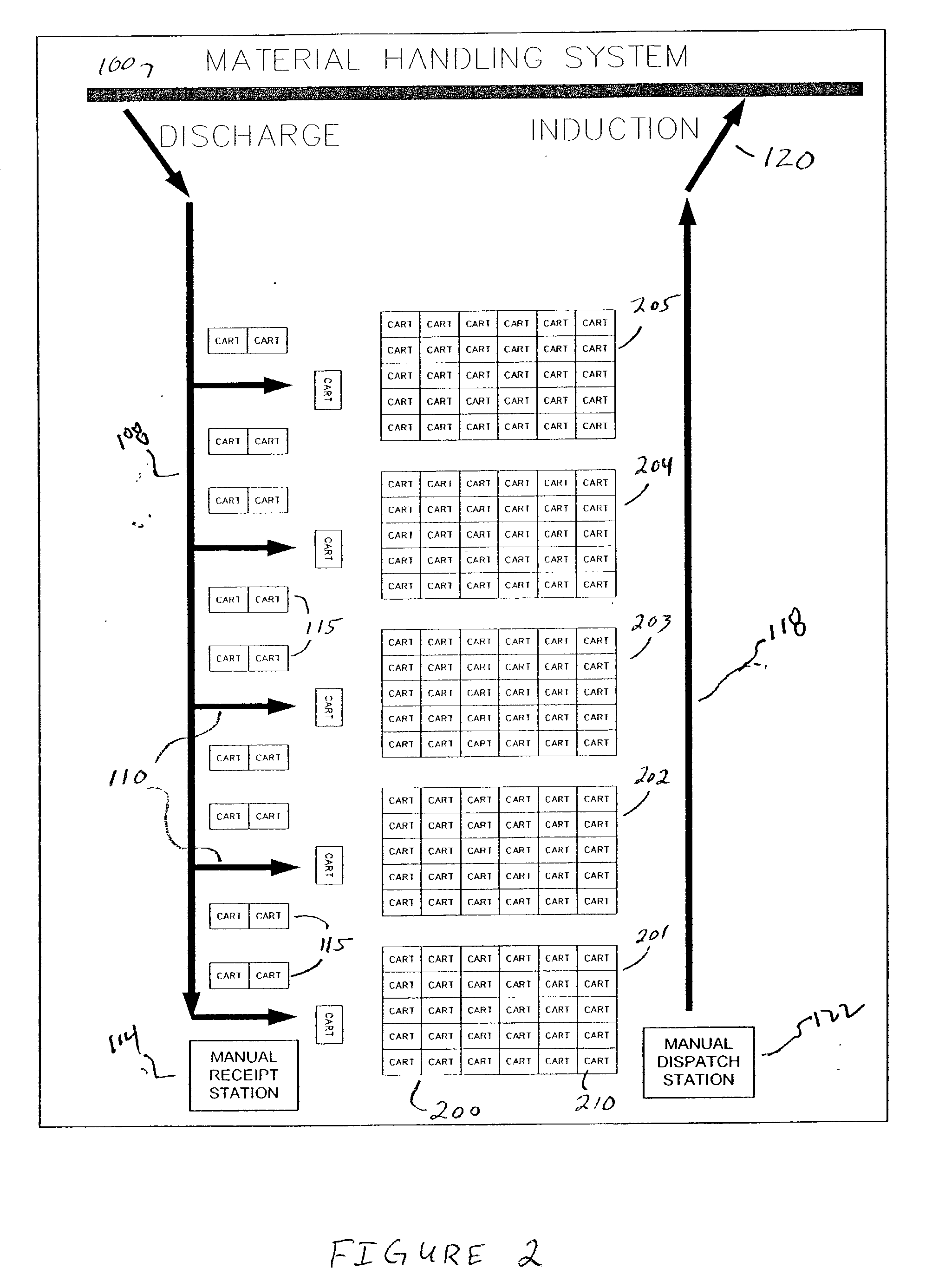

Inventory management of work-in-process (WIP) inventory within a processing facility is accomplished with a staged holding area in concert with control systems. Receiving of material into the staging area is tracked by scanning mechanisms such as Radio Frequency ID (RFID) or bar coding methods. Aggregation of material is recorded by cart sizing factors into the automatic control system. Carts are stored temporarily in locations arranged in a pre-determined grid fashion. The grid location information for a cart is made known to the automatic control system for reference or reporting to production supervisors. Down-stream processing can request staged inventory material from staging operators via overhead message boards or computer screens. Requests may be by particular types of material or by specific cart grid location. Manual entry or manual release of material is also accommodated including manual corrections of staged materials. Release of entire cart contents to down-stream processing is converted to actual material counts

Owner:LOCKHEED MARTIN CORP

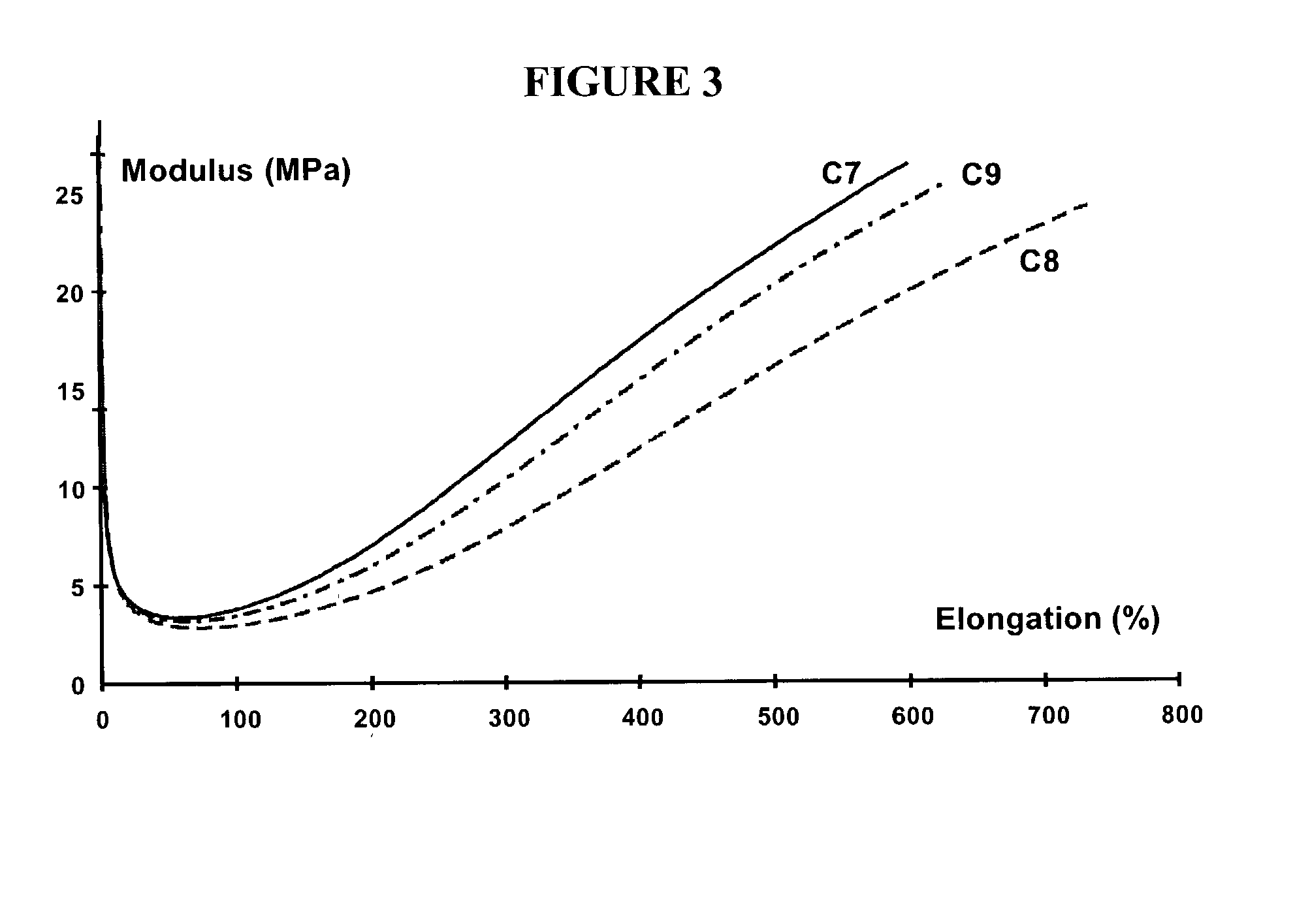

Rubber composition for a tire comprising a reinforcing inorganic filler and an (inorganic filler/elastomer) coupling system

InactiveUS6984689B2Improve efficiencyReduce in quantityOther chemical processesSpecial tyresGuanidine derivativesElastomer

The present invention is directed to a rubber composition that is useful for the manufacture of tires, where the composition is based on a diene elastomer, a reinforcing inorganic filler, and a coupling system. The coupling system comprises a polysulfurized alkoxysilane (“PSAS”) coupling agent (inorganic filler / diene elastomer) associated with a 1,2-dihydropyridine and a guanidine derivative. The present invention is further directed to tires and semi-finished products for tires comprising a rubber composition according to the invention. The invention is also directed to a coupling system (inorganic filler / diene elastomer) for a rubber composition based on a diene elastomer reinforced by an inorganic filler, where the coupling system comprises a polysulfurized alkoxysilane (PSAS) coupling agent in association with a 1,2-dihydropyridine and a guanidine derivative.

Owner:MICHELIN RECH & TECH SA

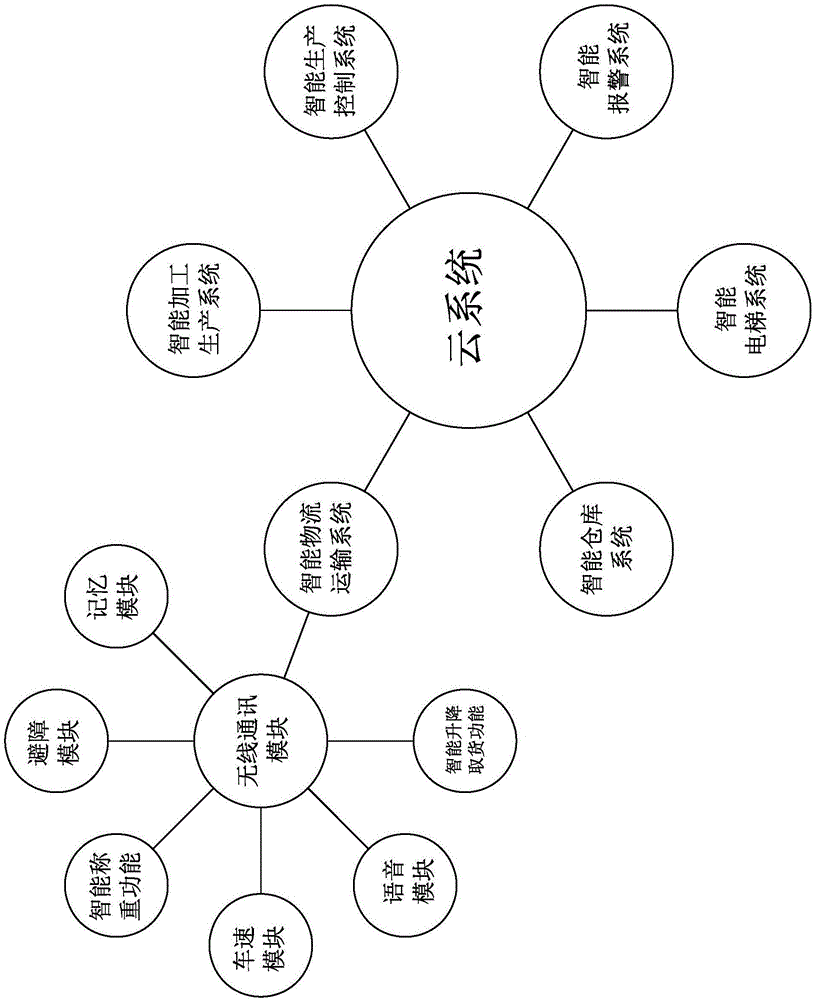

Factory intelligent workshop real-time scheduling system

ActiveCN106056298AIntelligent Management ScienceManagement scienceResourcesProduction control systemStorage garage

The invention relates to a factory intelligent workshop real-time scheduling system, and is designed to solve the technical problem that a management system of an existing factory intelligent workshop needs further improvement. The system is mainly characterized in that an intelligent processing production line of the scheduling system finishes research and purchase as well as installation and debugging of workshop machining equipment; an intelligent warehouse and logistics transportation system carries out scientific classification, storage and transportation on raw materials and substances, management of finished and semi-finished products, and analysis and management on storage data of the raw materials, the semi-finished products and the finished products; an intelligent production control system, by fully utilizing information technology, carries out control in multiple dimensions of production plan issuing, material delivery, production scheduling, completion confirmation, standard operation guidance, quality control and finished product bar code acquisition, and accurately conveys on-site information to a production manager and a decision maker in real time through a network; and an intelligent alarm system is used for monitoring environment and temperature and reminding a transfer robot to return, avoid obstacles and charge.

Owner:宁波赛夫科技有限公司

Integral structural shell component for an aircraft and method of manufacturing the same

A structural panel component, such as an aircraft fuselage shell component, includes a single integral part having longitudinal and crosswise stiffening elements integrally arranged on a skin sheet. This integral component has been formed by a high speed milling chip removal process applied to a solid plate-shaped semi-finished starting material. The skin sheet has areas of differing thicknesses, and the height, thickness, and spacing of the stiffening elements varies as needed, depending on the local loading conditions that will prevail on the finished structural component. The configuration of the component can be optimized to minimize the weight while satisfying all load strength requirements. The manufacturing method is very simple and economical.

Owner:AIRBUS OPERATIONS GMBH

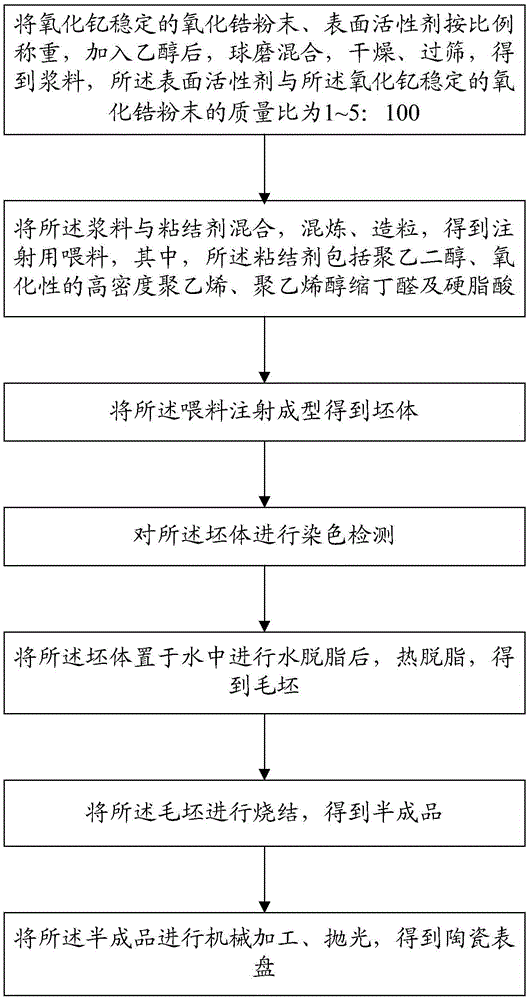

Preparation method of mobile telephone shell

ActiveCN105541324AHigh strengthAvoid breakingTelephone set constructionsLow-density polyethylenePolyethylene glycol

The invention discloses a preparation method of a mobile telephone shell. The preparation method comprises weighing yttrium oxide-stabilized zirconia powder and a surfactant according to a mass ratio of the surfactant to yttrium oxide-stabilized zirconia powder of 1-5: 100, adding ethanol into the weighed materials, carrying out ball milling mixing, carrying out drying and sieving to obtain slurry, mixing the slurry and a binder, carrying out mixing and granulation to obtain feed for injection, wherein the binder comprises polyethylene glycol, oxidizing high density polyethylene, polyvinyl butyral and stearic acid, carrying out injection molding on the feed to obtain a green body, carrying out staining detection on the green body, putting the green body into water, carrying out water debinding, carrying out thermal debinding to obtain a blank, sintering the blank to obtain a semifinished product, and carrying out machining and polishing on the semifinished product to obtain the mobile telephone shell. The mobile telephone shell has high strength, is not easily broken and has high density and uniform apertures. The preparation method has simple processes, operation easiness and high production efficiency.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Method for preparing acid-resistant pressing crack supporting agent from red mud

The invention discloses a method for preparing acid- proof fracturing propping agent with red mud. The comprised raw materials and their weight proportion are as follows: red mud 20- 60%, aluminium-containing substance 20- 60%, barium- containing substance 5- 35%, plasticizing agent 5- 15%. The method comprises following steps: (1) putting red mud and aluminium- containing substance into ball grinding tank for grinding respectively; (2) adding barium- containing substance and plasticizing agent into material got in steps (1), feeding it into ball grinding tank for grinding; (3) preparing material got in step (2) into semi- product particle; (4) calcinating material got in step (3) for 1- 3 hours, getting acid- proof crack propping product. The invention develops new way for red mud application, and provides effective method for increasing acid- proof performance for crack propping agent.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

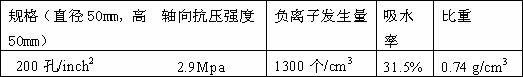

Tourmaline monolithic honeycomb ceramic and preparation method thereof

ActiveCN102285816AImprove adsorption capacityEnhance the efficacy of toxic and harmful substances in liquidsCeramicwareMicrowaveHoneycomb

The invention discloses a tourmaline integral honeycomb ceramic and the ceramic mainly comprises the following components by weight percent: 10-75% of tourmaline, 2-20% of clay, 2-40% of fluxing agent and 1-30% of auxiliary material. The preparation method of the tourmaline integral honeycomb ceramic comprises the following steps: adding tourmaline, clay, the fluxing agent, the auxiliary materialand a dry powder forming agent in a medium mill in proportion to grind and mix so as to obtain a mixture, then adding a appropriate amount of water and a liquid forming agent in the mixture to knead and obtain mud, granulating the mud, aging, extruding to obtain mud sections, moulding the mud sections, performing microwave forming, drying to prepare a semi-finished product, and placing the semi-finished product in a kiln at 500-850 DEG C to fire. Compared with the existing tourmaline products, the characteristics of the existing honeycomb ceramics, namely large specific surface area and porescan be ensured, the effect of tourmaline can be extremely exerted, the amount of tourmaline can be greatly reduced and the ceramic has good energy-saving effect. The energy consumption of the tourmaline integral honeycomb ceramic is one tenth of the energy consumption of the tourmaline ball fired at the same temperature.

Owner:曹南萍

Method for preparing silicon-free or low-silicon acidproof ceramic fracturing propping agent

The invention discloses a method for preparing a silicon-free or low-silicon acidproof ceramic fracturing propping agent, which comprises the following steps of: (1) preparing the following raw materials in percentage by weight: 30 to 95 percent of alumina, 5 to 70 percent of barium carbonate and 0 to 10 percent of sintering aid, wherein the sintering aid is one or more of titanium dioxide, boric acid, calcium carbonate, magnesium oxide and dolomite; (2) performing ball milling on the raw materials in the step (1) in a ball mill for 24 to 48 hours; (3) preparing the raw materials obtained in the step (2) into semi-finished product particles; and (4) sintering the semi-finished product particles obtained in the step (3) at the temperature of between 1,500 and 1,800 DEG C for 1 to 3 hours, and cooling to the room temperature. The method has simple process; the barium carbonate is decomposed at high temperature to generate barium oxide, and the barium oxide is fully reacted with alumina to generate stable barium aluminate; and the barium aluminate has strong acidproof performance and protects other components in the finished product against corrosion of acid liquor, so the acidproof performance of the finished product is greatly improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

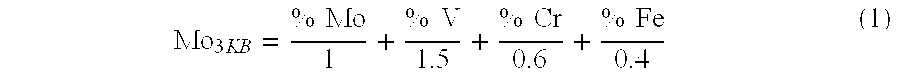

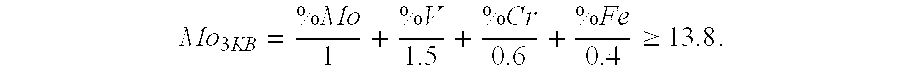

Titanium-based alloy and method of heat treatment of large-sized semifinished items of this alloy

The inventive titanium alloy comprises, expressed in mass %: aluminium 4.0-6.3; vanadium 4.5-5.9; molybdenum 4.5-5.9; chromium 2.0-3.6; ferrum 0.2-0.5; the rest being titanium. An equivalent molybdenum content is determined as corresponding to Moequiv≧13.8. The inventive method for heat treatment consists in heating to tβ⇄α+β−(30-70)° C., conditioning during 2-5 hrs, air or water cooling and age-hardening at a temperature ranging from 540° C. to 600° C. during 8-16 hrs. Said alloy has a high volumetric deformability and is used for manufacturing massive large-sized forged and pressed pieces having a high strength level, satisfactory characteristics of plasticity and fracture toughness.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO KORPORATSIJA VSMPO AVISMA

Controlled-forging controlled-cooling processing technology of bearing ring prepared by GCr15

The invention relates to a controlled-forging controlled-cooling processing technology of a bearing ring prepared by GCr15, comprising the following steps of: quenching the bearing ring in cooling fluid at final forging temperature of 850-950 DEG C and at fluid outlet temperature of 350-550 DEG C; when heating the bearing ring to the temperature of 450-550 DEG C, after preserving the temperature for 1h-3h, discharging the bearing ring from a boiler and cooling the bearing ring to room temperature; when heating the bearing ring to the temperature of 650-690 DEG C again, preserving the temperature for 1h; when continuously heating the bearing ring to the temperature of 740-780 DEG C, after preserving the temperature for 2-3h, cooling the bearing ring to the temperature of 680-690 DEG C and preserving the temperature for 2-4 hours; finally, when cooling the bearing ring to the temperature of 550-600 DEG C at the speed of 10 DEG C / h, cooling o the bearing ring to the room temperature along with the boiler by air; quenching a machined semi-finished bearing ring; when heating to the temperature of 810-830 DEG C, after preserving the temperature for 45-60min, discharging the machined semi-finished bearing ring from the boiler and quenching the machined semi-finished bearing ring in oil; and when heating the machined semi-finished bearing ring to the temperature of 160-200 DEG C after being quenched, preserving the temperature of the machined semi-finished bearing ring for 4h, discharging the machined semi-finished bearing ring from the boiler and cooling the machined semi-finished bearing ring to the room temperature by air. According to the invention, carbides, martensite crystals and austenite crystals of the bearing ring are refined, network carbides are improved or eliminated and impact ductility and fatigue life are improved.

Owner:LUOYANG BEARING RES INST CO LTD

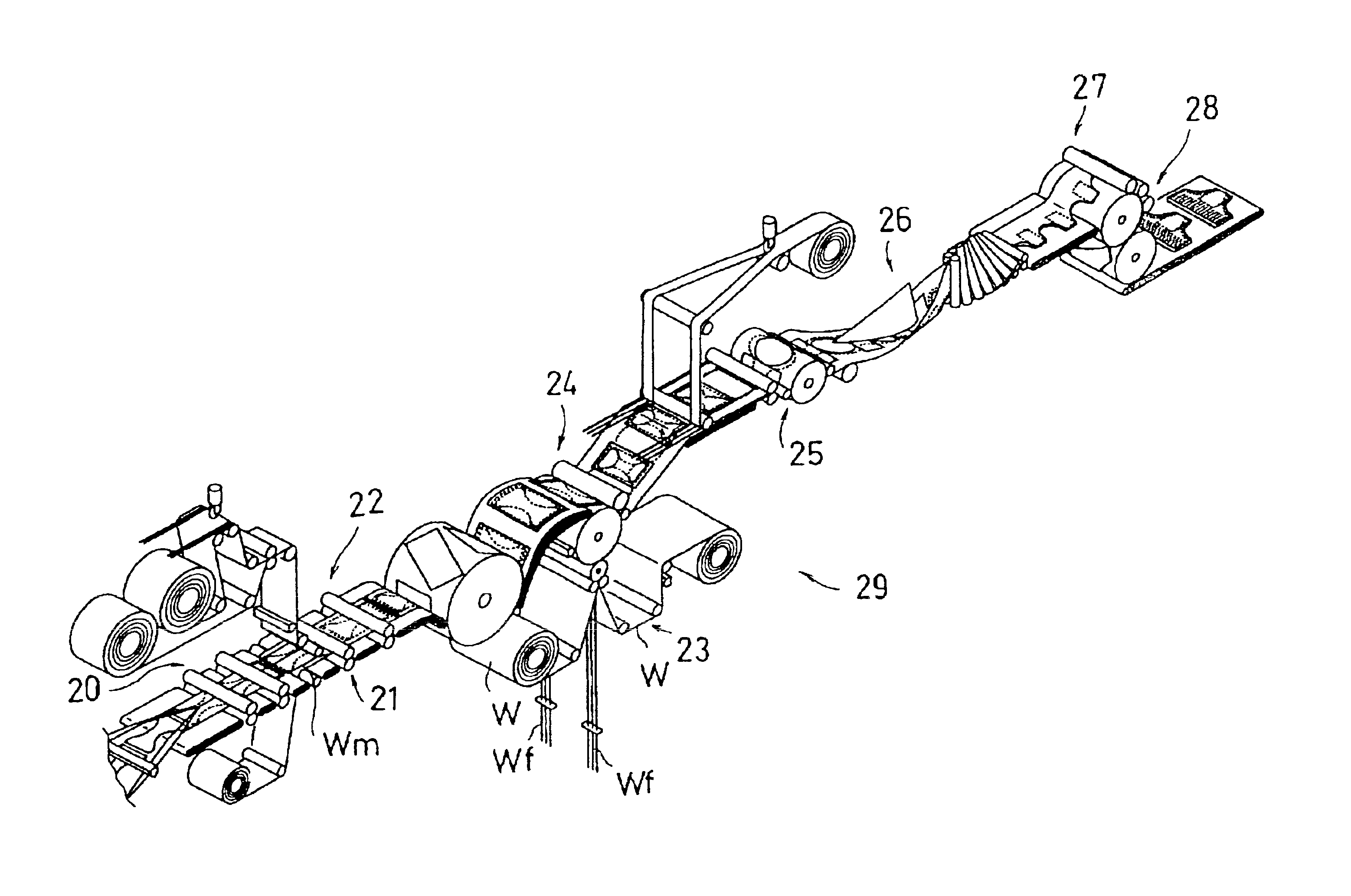

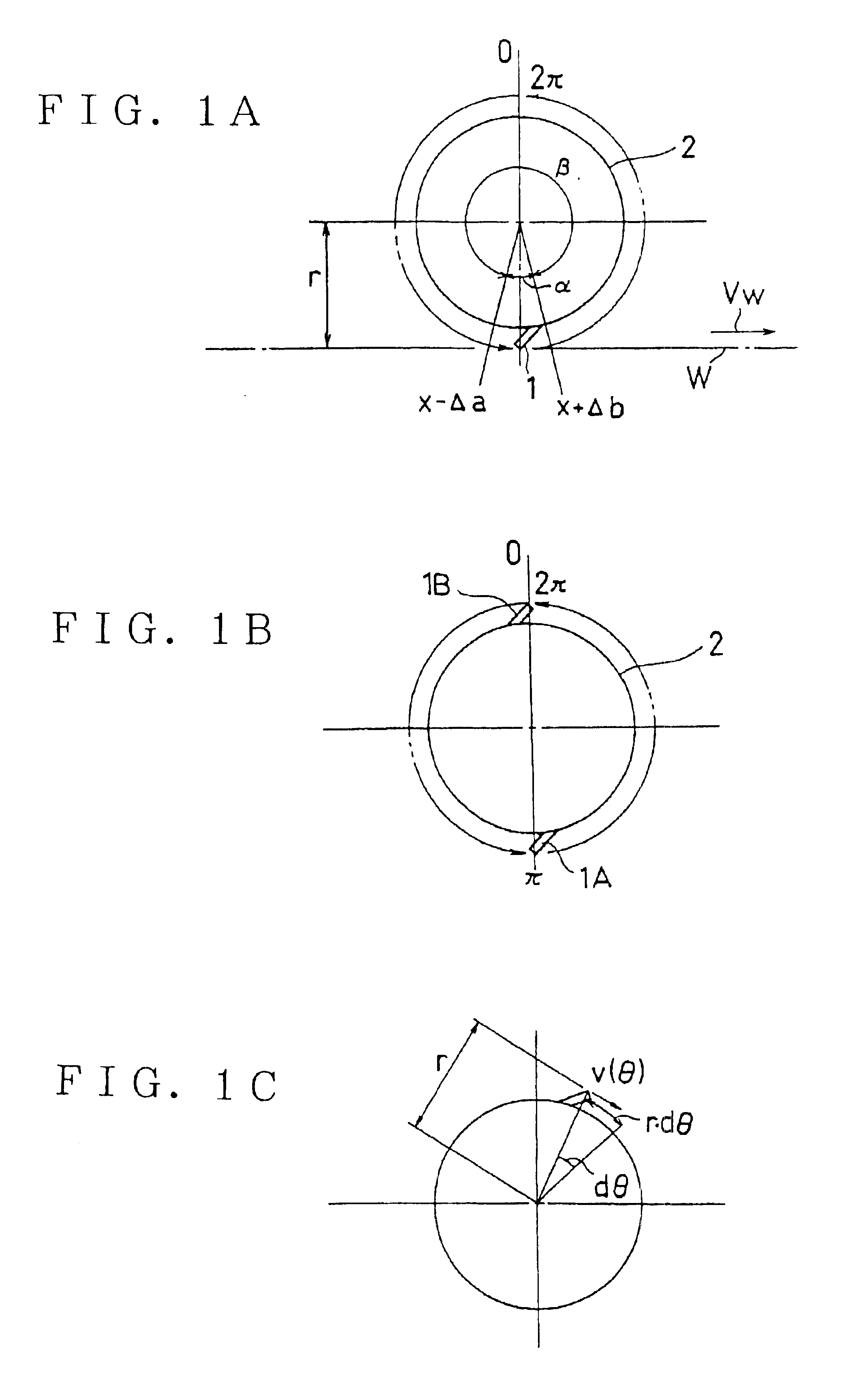

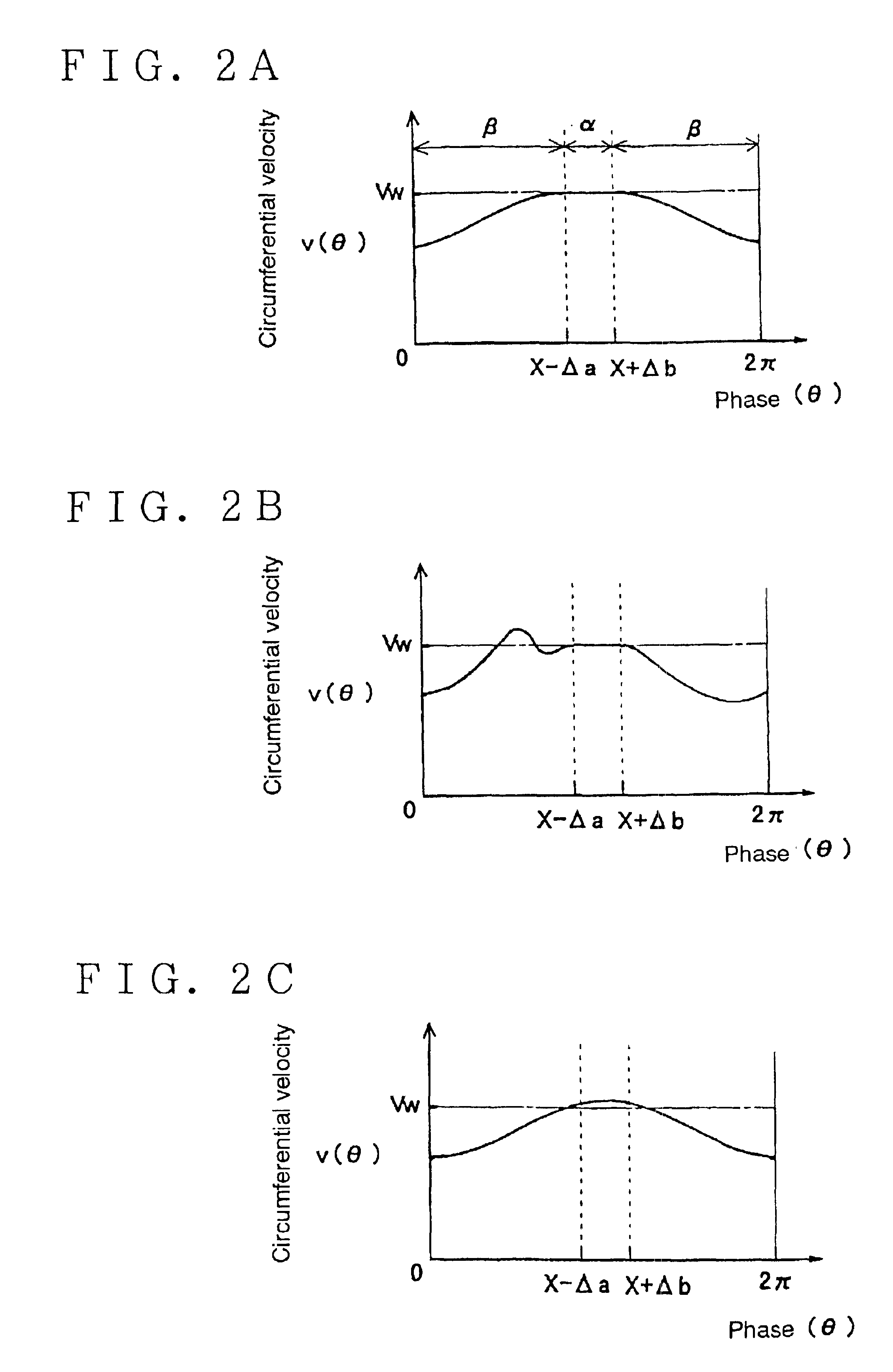

Article production method

The production method for producing an article, comprises the step of rotating a rotating member so as to machine a semi-finished product with a machining section included in the rotating member. A circumferential velocity of the rotating member can be changed according to a size of the semi-finished product during one cycle in which the semi-finished product is machined.

Owner:ZUIKO CORP

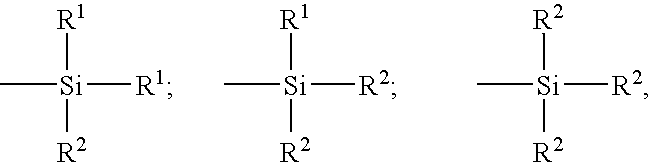

Rubber composition for a tire comprising a multifunctional polyorganosiloxane as coupling agent

InactiveUS6878768B2Reduce rolling resistanceImprove wear resistanceSpecial tyresDyeing processElastomerDouble bond

The present invention relates to a sulfur-cross-linkable elastomeric composition that is useful for the manufacture of tires. This elastomeric composition is based on at least one isoprene elastomer (in particular natural rubber), a reinforcing inorganic filler (in particular, silica), and an (inorganic filler / isoprene elastomer) coupling agent. The coupling agent is a multifunctional polyorganosiloxane (POS), which comprises functions denoted as “Y” and “X”, wherein the Y function is at least one hydroxyl or hydrolyzable function grafted to the silicon atoms of the coupling agent and the X function is a group bearing at least one activated ethylene double bond and is grafted to the silicon atoms of the coupling agent. This POS is, in particular, a POS having an imide, acid or ester function, the ethylene double bond of which is activated by at least one adjacent carbonyl group (—C═O). The present invention further relates to a tire comprising the composition described above as well as semi-finished products for tires, in particular, treads, where the tires comprise a rubber composition according to the present invention.

Owner:MICHELIN RECH & TECH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com