Patents

Literature

543 results about "Vitreous Bodies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

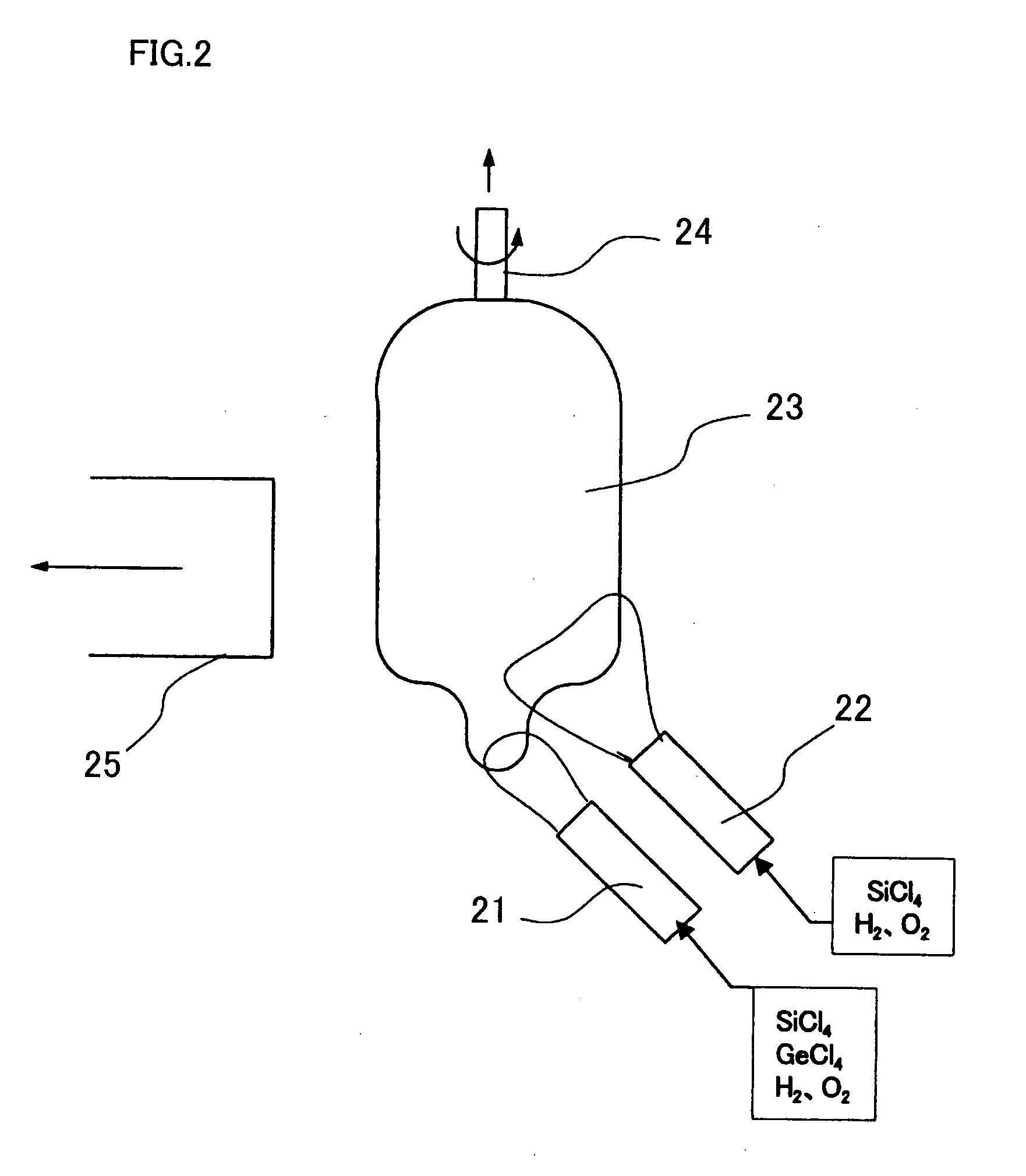

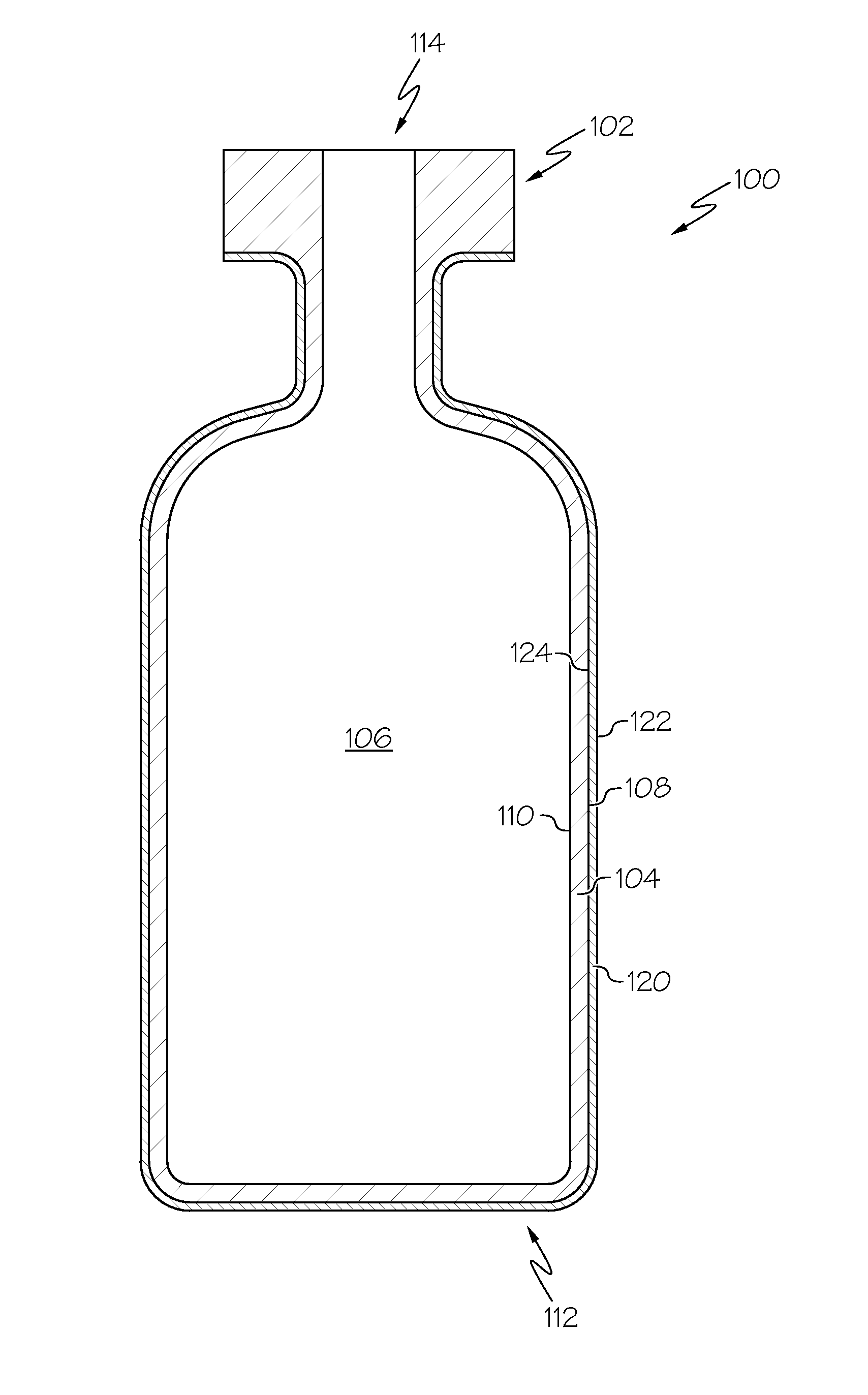

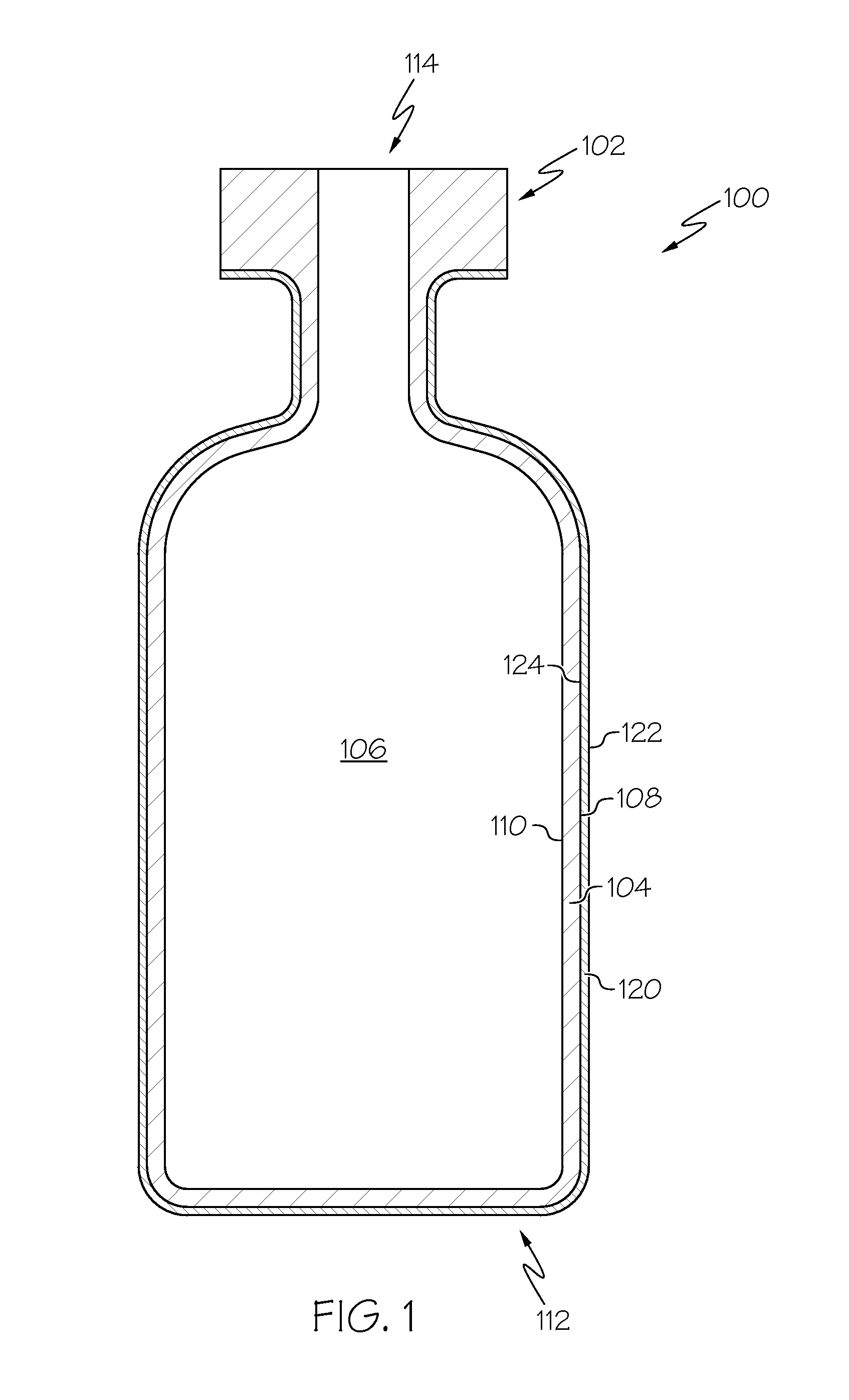

Method of making a hollow, interiorly coated glass body and a glass tube as a semi-finished product for forming the glass body

InactiveUS6200658B1Layered productsLiquid/solution decomposition chemical coatingVitreous BodiesWork in process

Numerous applications for hollow glass bodies made from low melting glass material require an increase in the chemical resistance of the interior surface of the glass body. In order to avoid a disadvantageous de-alkalizing process the hollow glass body must be provided with an interior coating in a comparatively expensive prior art process. In an improved process according to the invention a glass tube acting as a semifinished product from which the hollow glass body is made is provided with an interior coating of oxide material, preferably SiO2, Al2O3, TiO2 or mixtures thereof, having a predetermined coating thickness according to the required chemical resistance or working conditions for forming the glass body and then the hollow glass body is made from the glass tube. The coating is advantageously provided by means of a PICVD process.

Owner:SCHOTT AG

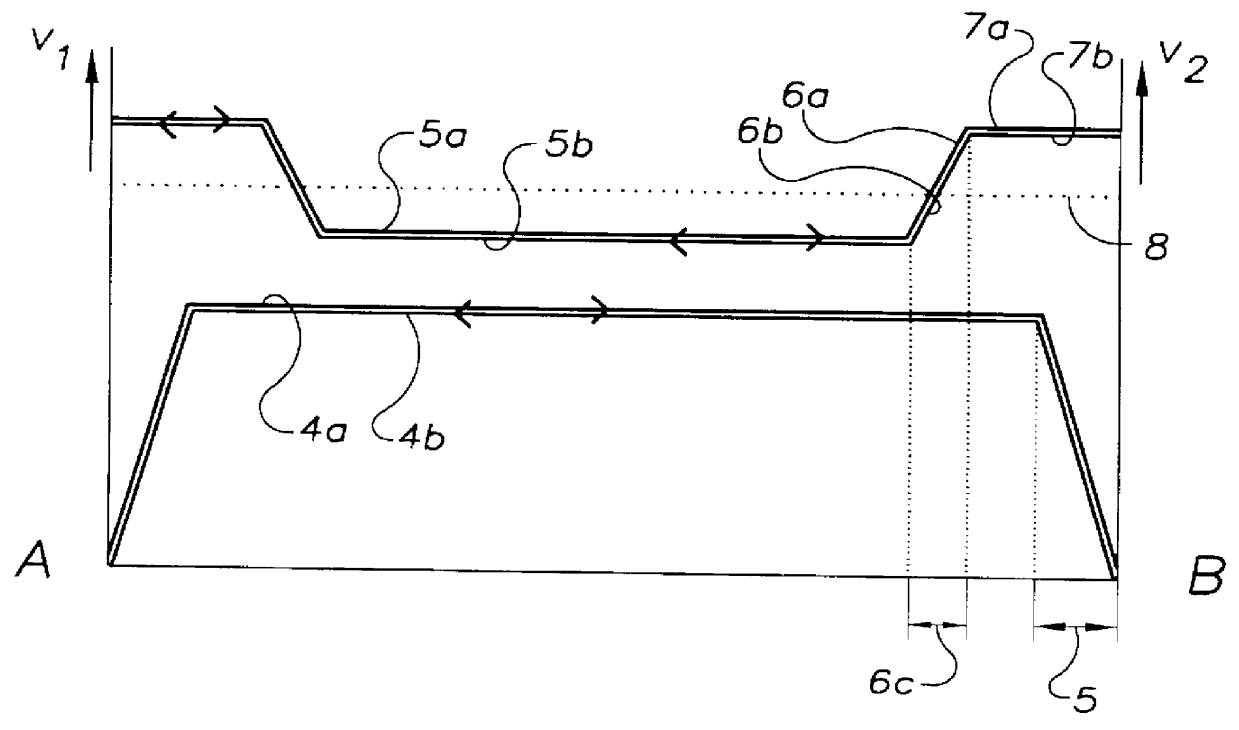

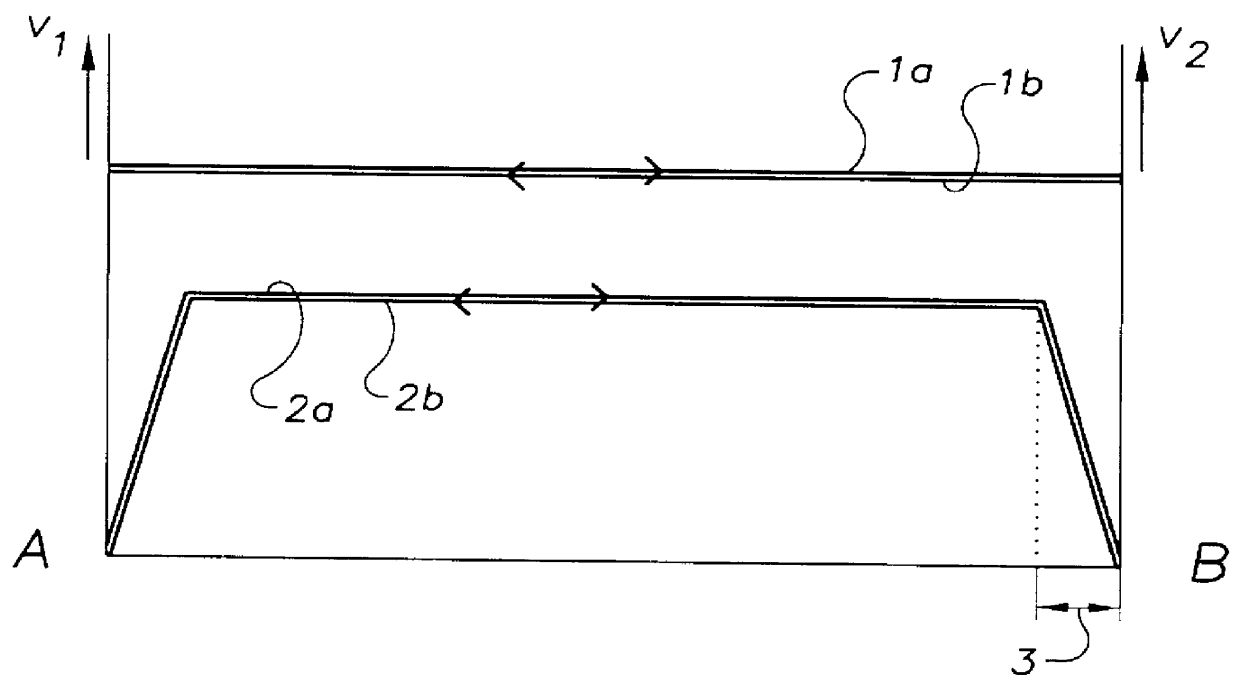

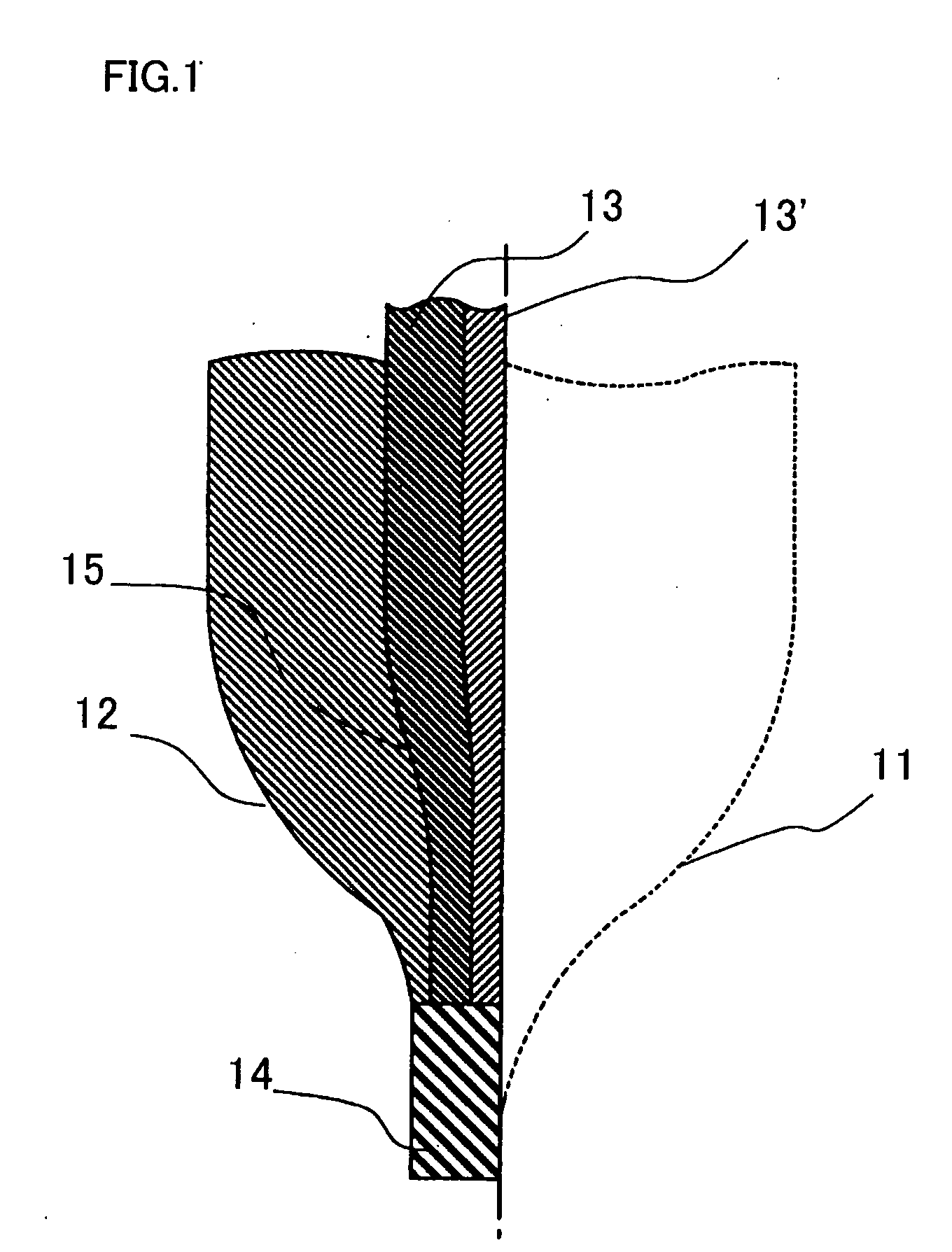

Method of producing quartz glass bodies

InactiveUS6047564AImprove the usefulnessIncrease surface temperatureBlowing machine gearingsGlass deposition burnersVitreous BodiesEngineering

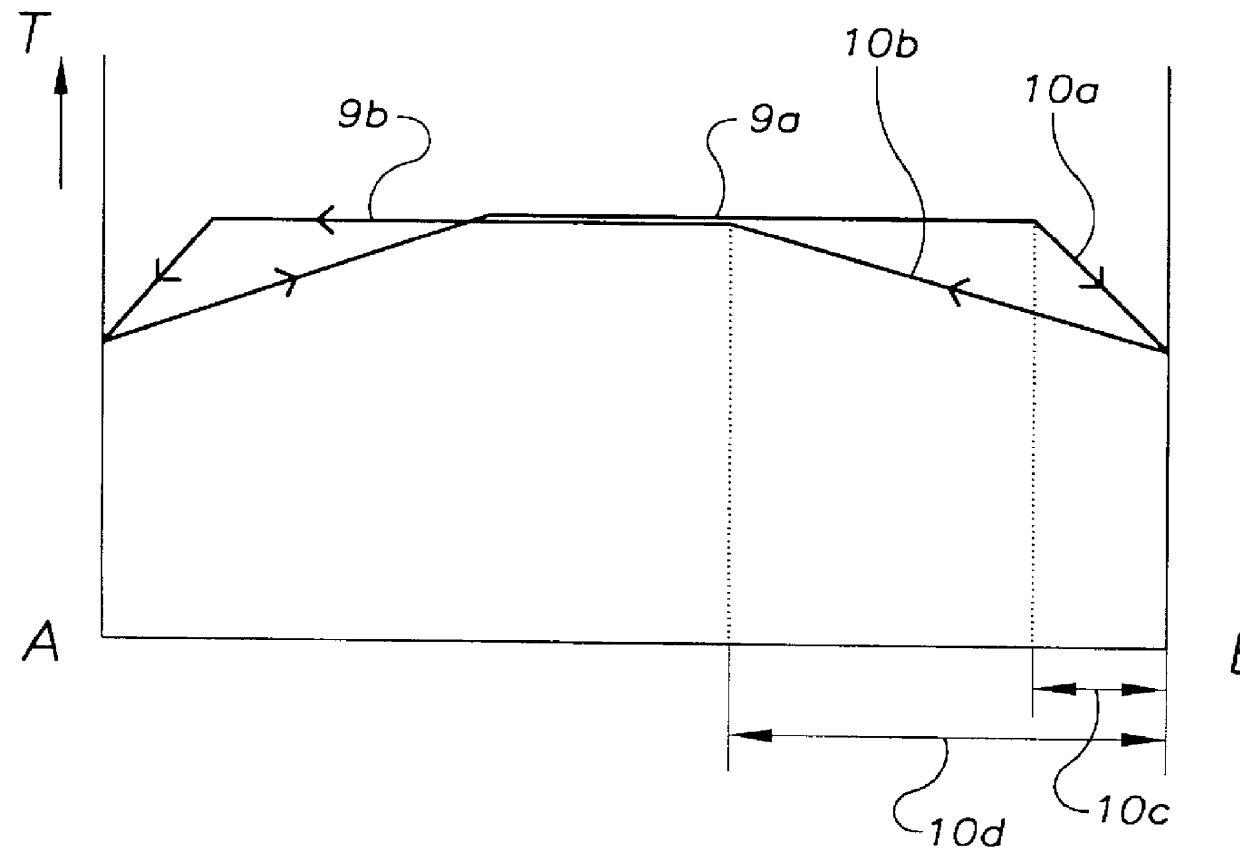

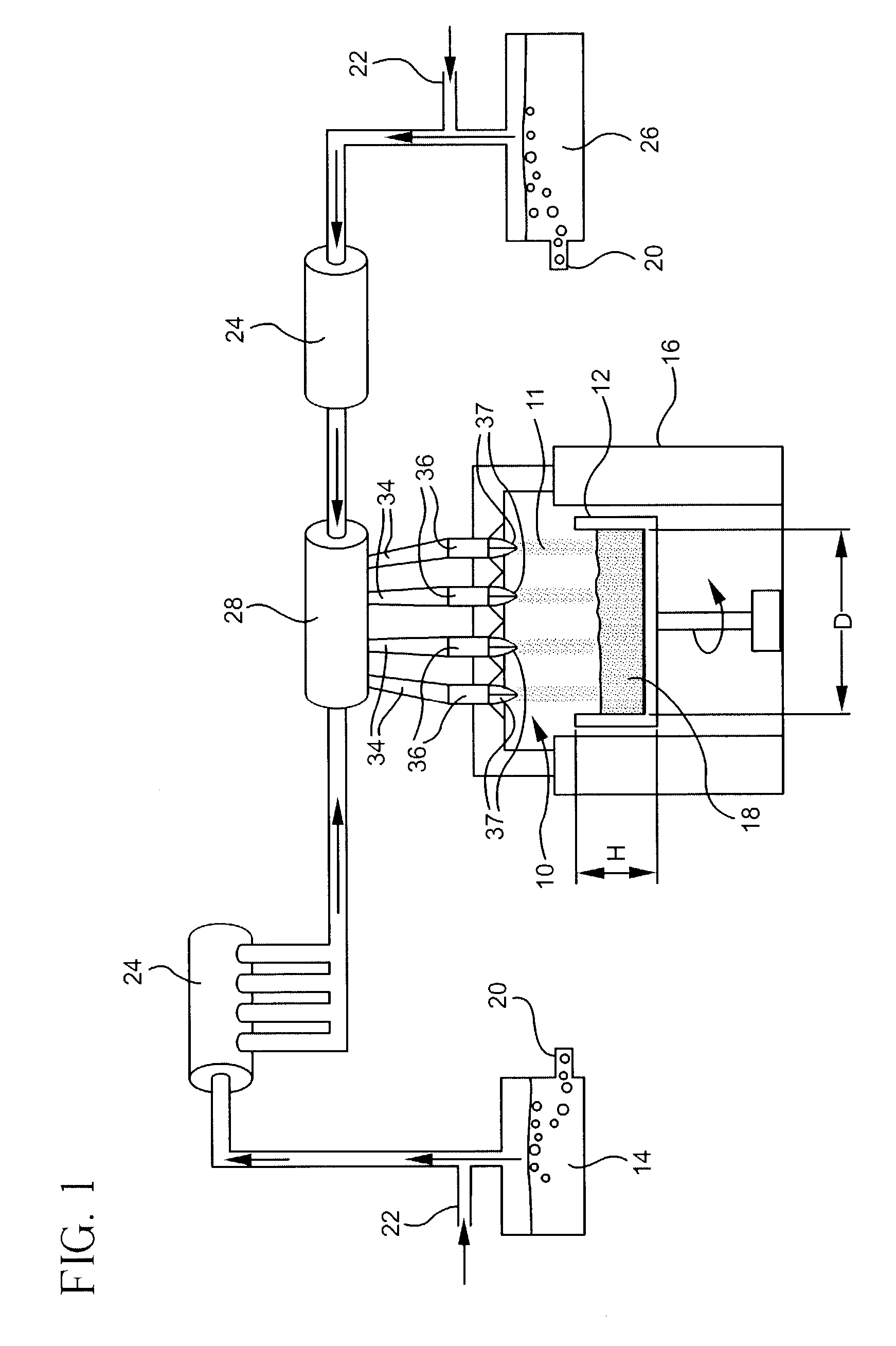

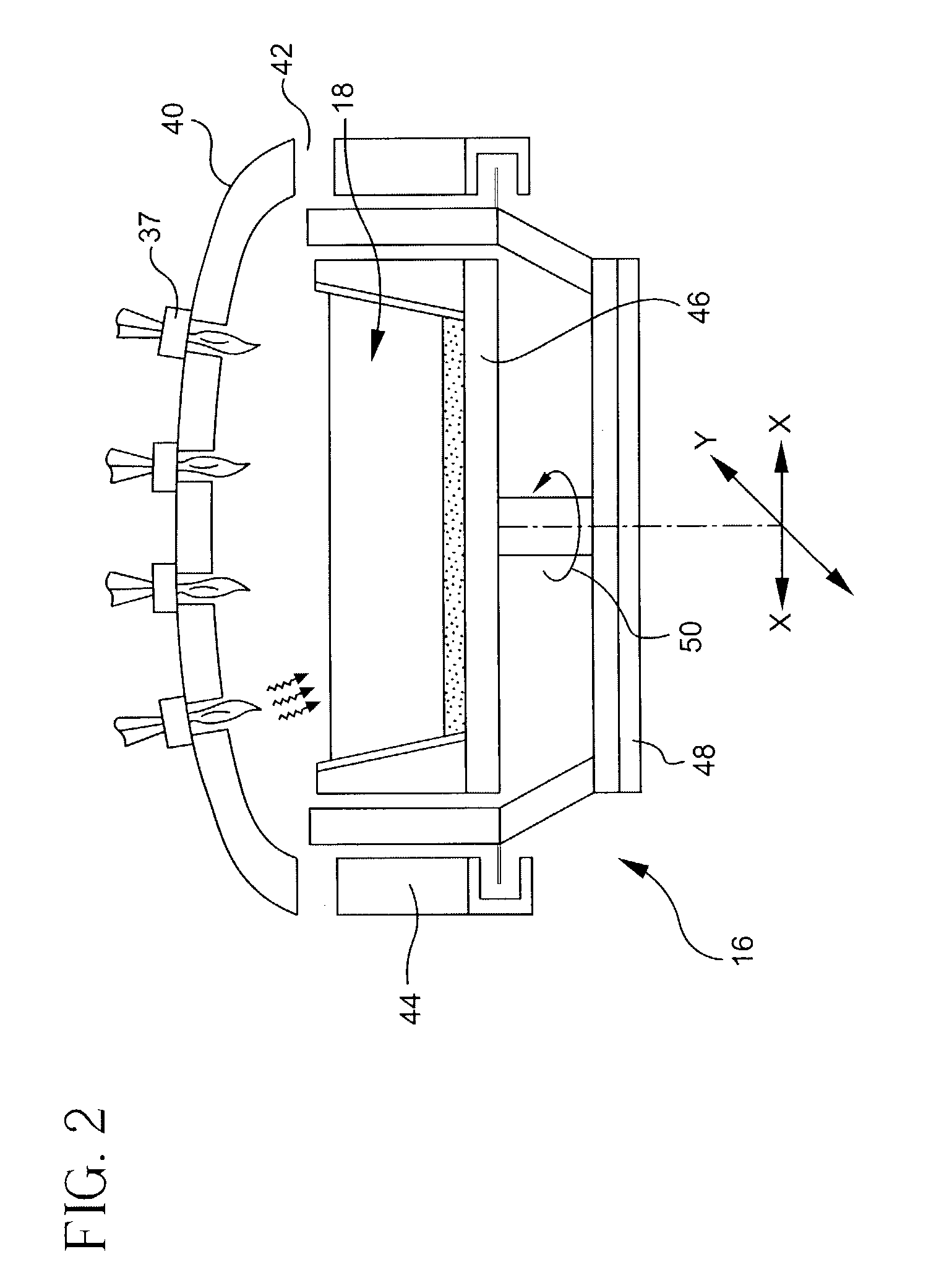

PCT No. PCT / EP97 / 03818 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 17, 1997 PCT Pub. No. WO98 / 03440 PCT Pub. Date Jan. 29, 1998In a known process for the production of quartz glass bodies, SiO2 particles are deposited of the mantle surface of a cylindrical carrier rotating about its longitudinal axis, forming an elongated, porous preform, where the SiO2 particles are formed in a plurality of flame hydrolysis burners which are arranged in at least one burner row parallel to the longitudinal axis of the carrier and are moved at a preset translational speed forward and back between turnaround points at which points their direction of movement is reversed, and in which process the preform is sintered. In order to make available on this basis an easily accomplished process that makes it possible to manufacture a preform which is largely free of localized density variations, the invention proposes on the one hand that the base value of the surface temperature of the preform being formed be kept in a range between 1,050 DEG C. and 1,350 DEG C., that the average peripheral velocity of the preform be kept in the range between 8 m / min and 15 m / min and the average translational velocity of the burner row be kept in a range between 300 mm / min and 800 mm / min. On the other hand, the object is also accomplished according to the invention and on the basis of the known process in that in the area of the turnaround points (A, B) the peripheral velocity of the preform being formed is increased and / or the flame temperature is lowered and / or the distance of the burners from the preform surface is changed.

Owner:HERAEUS QUARZGLAS

Highly energy-saving coating glass automatically adjusting light according to environment temperature and multi-layed assembled glass body

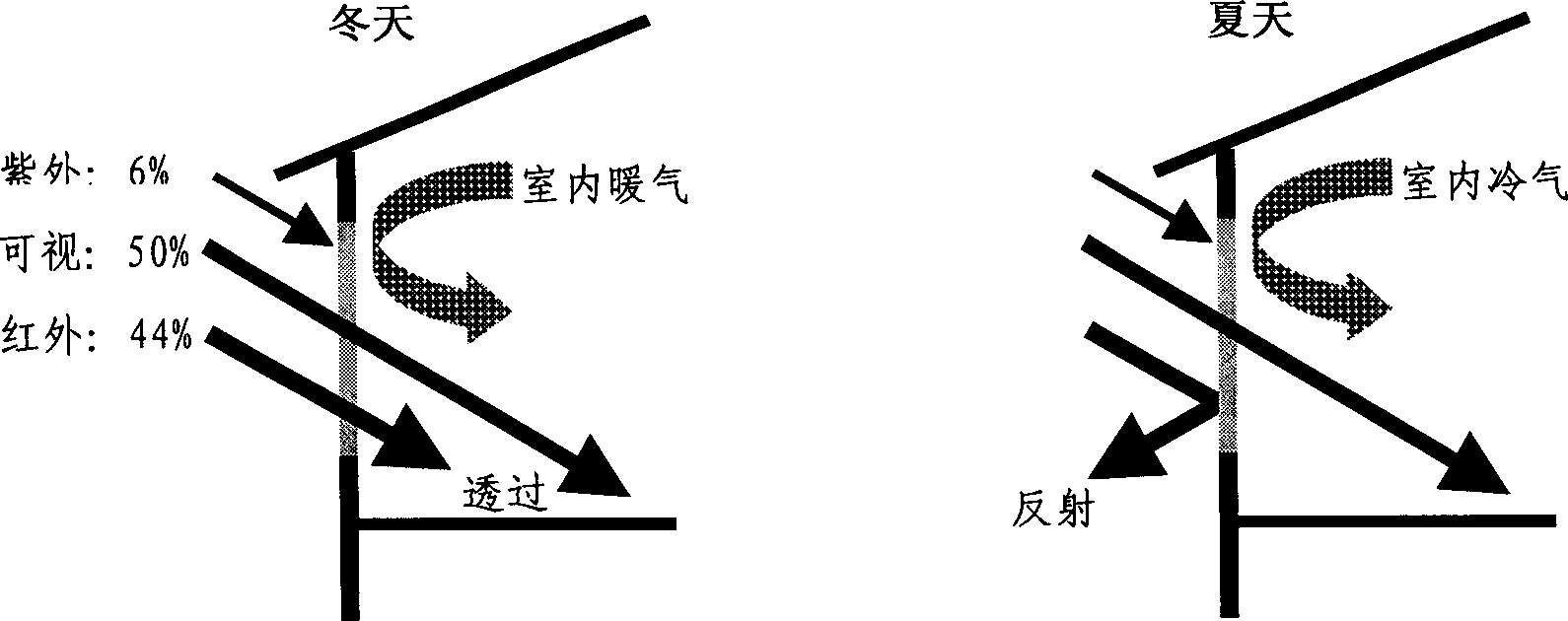

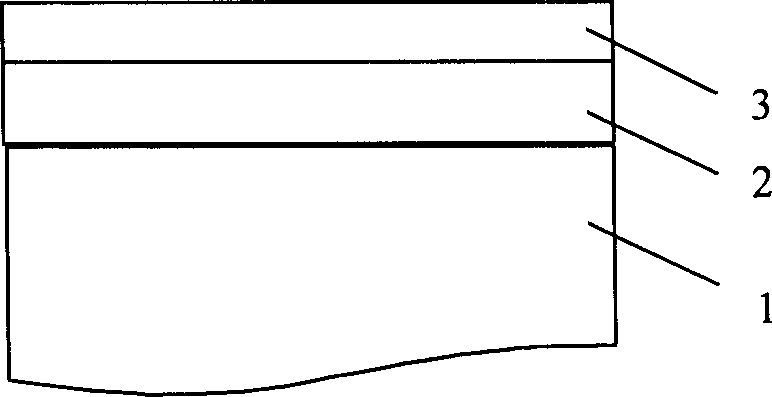

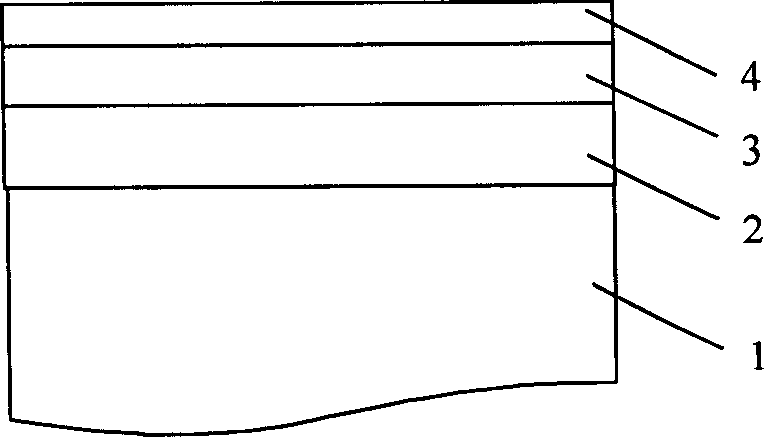

The invention provides a high-efficient energy-saving coating glass of automatic adjusting light with the environmental temperature and a multilayer assembly glass body, and the coating glass comprises: a glass substrate, and an energy-saving multilayer coating on the substrate with a thermalchromic layer of vanadium dioxide thin film and an optical transparent anti-reflection layer with an organic or inorganic thin film. The multilayer assembly glass body is formed by parallelly assembling the multilayer coating glass with gaps. The invention realizes the high adjustment efficiency to solar energy and hot ray reflection mechanism for sunshade in summer and thermal insulation for warm in winter, provides a solid base for VO2 intelligent energy-saving window application, has advantages comprising automatic aperture-control, simple structure, low cost and wear well, at the same time, selecting material appropriately for anti-reflection film can realizes the multi-functionalization for ultraviolet ray, such as absorbing, self-cleaning, sterilizing, anti-atomizating, and the application prospect is great in building energy efficiency.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

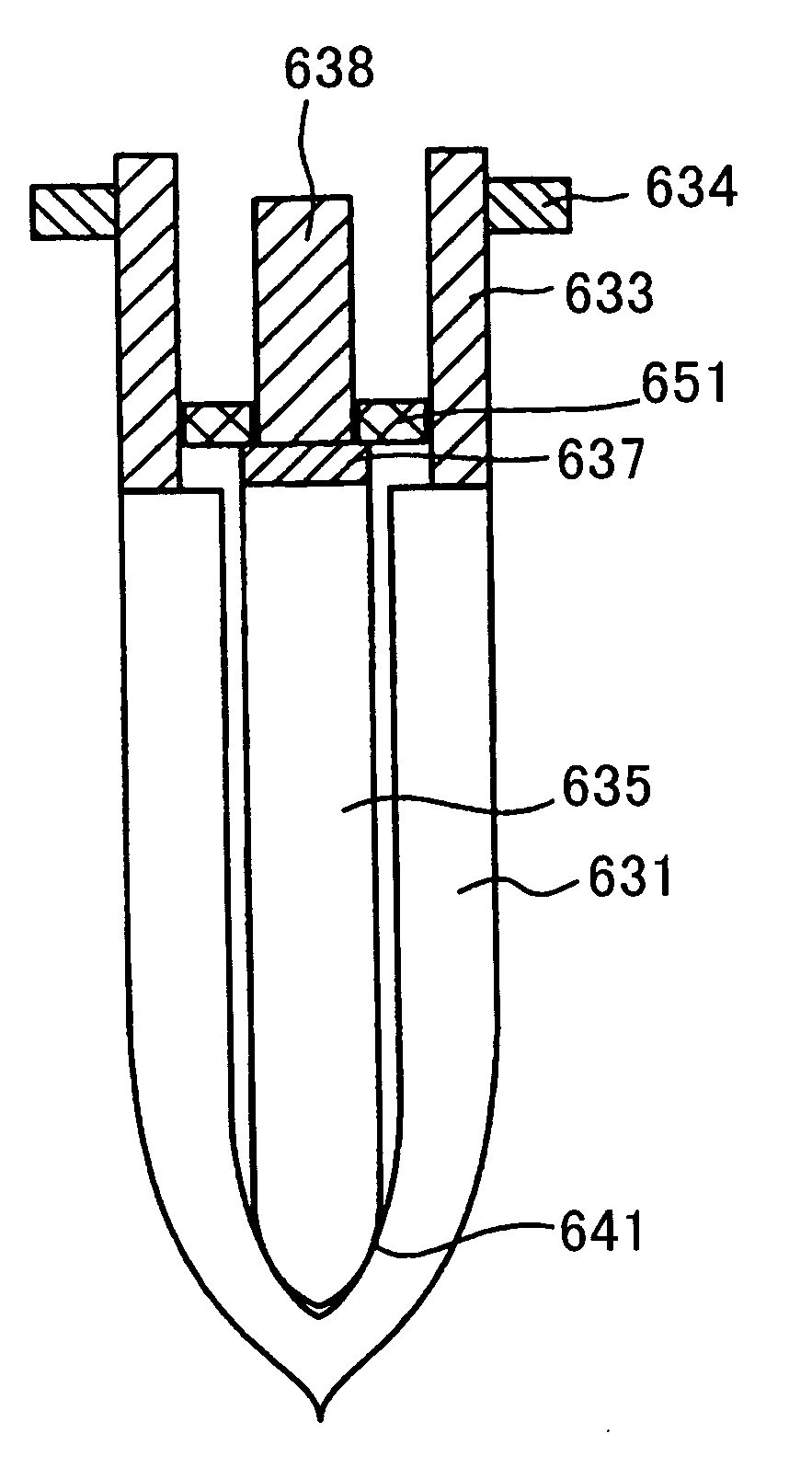

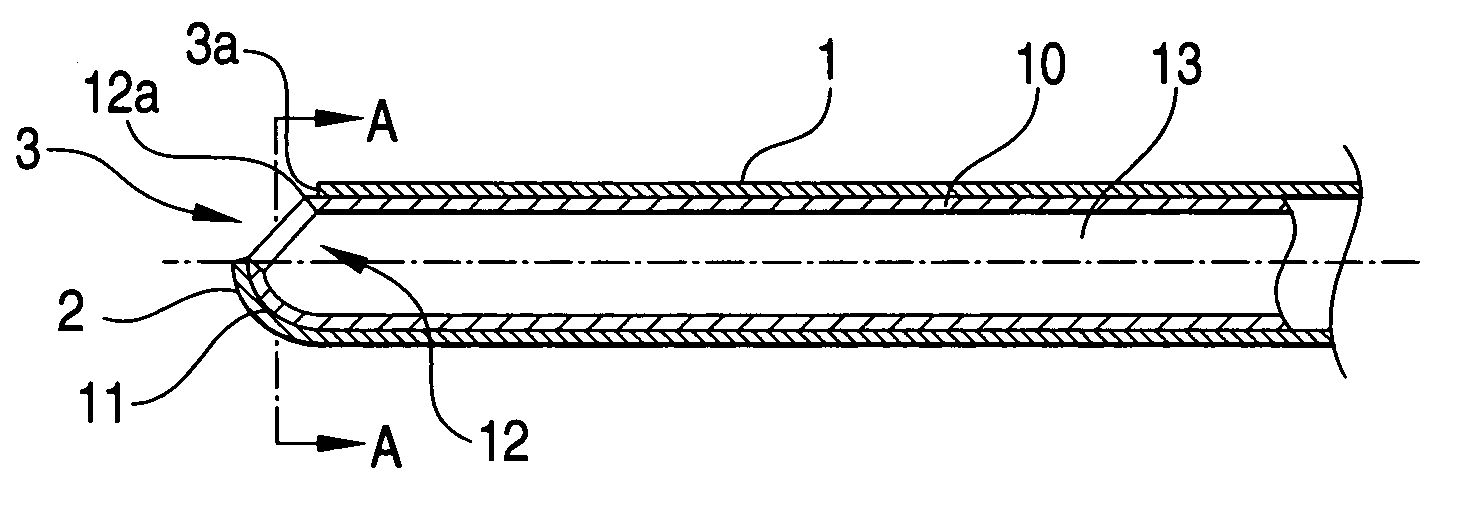

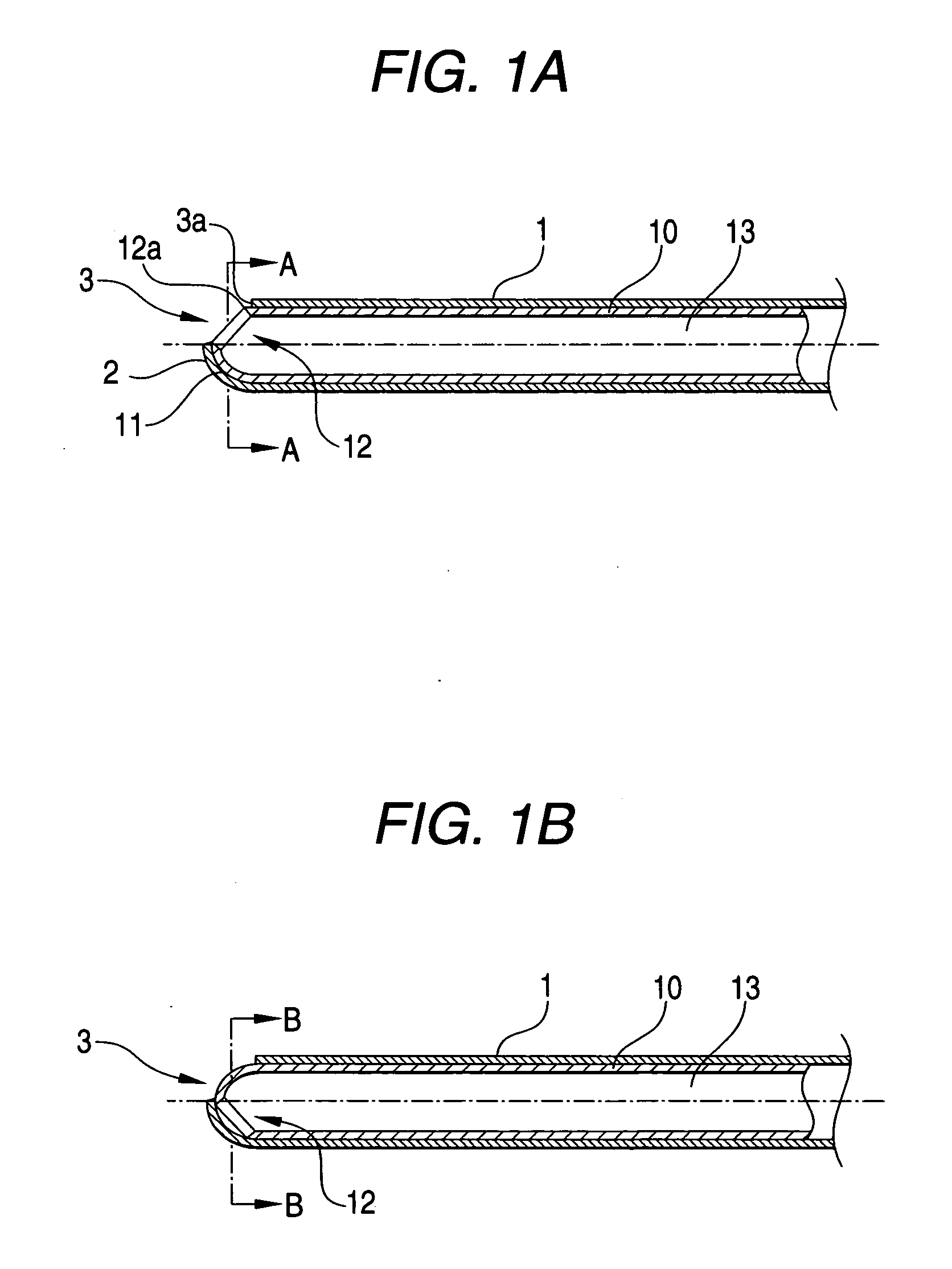

Method for manufacturing optical fiber

InactiveUS20050204780A1Reduce pressureGlass making apparatusCoupling light guidesVitreous BodiesMaterials science

A method of manufacturing an optical fiber, characterized by comprising the steps of forming a glass body having a core, forming a glass tube constituting a clad portion, inserting the glass body into the glass tube, forming the glass body integrally with the glass tube, finishing at least the extraction side end part of the glass tube in a tapered shape and washing the outer surface of the glass tube, characterized in that a difference between the outer diameter of the glass body and the inner diameter of the glass tube is 1.0 to 10.0 mm, and the inner diameter of a support tube fitted to one end of the glass tube is increased more than that of the glass tube or the extraction side end part of the glass tube is sealed with a tapered part provided at least on the inner surface thereof and a spacer is installed so that a clearance between the outer diameter of the glass body and the inner diameter of the glass tube becomes generally constant in the longitudinal direction.

Owner:FURUKAWA ELECTRIC CO LTD

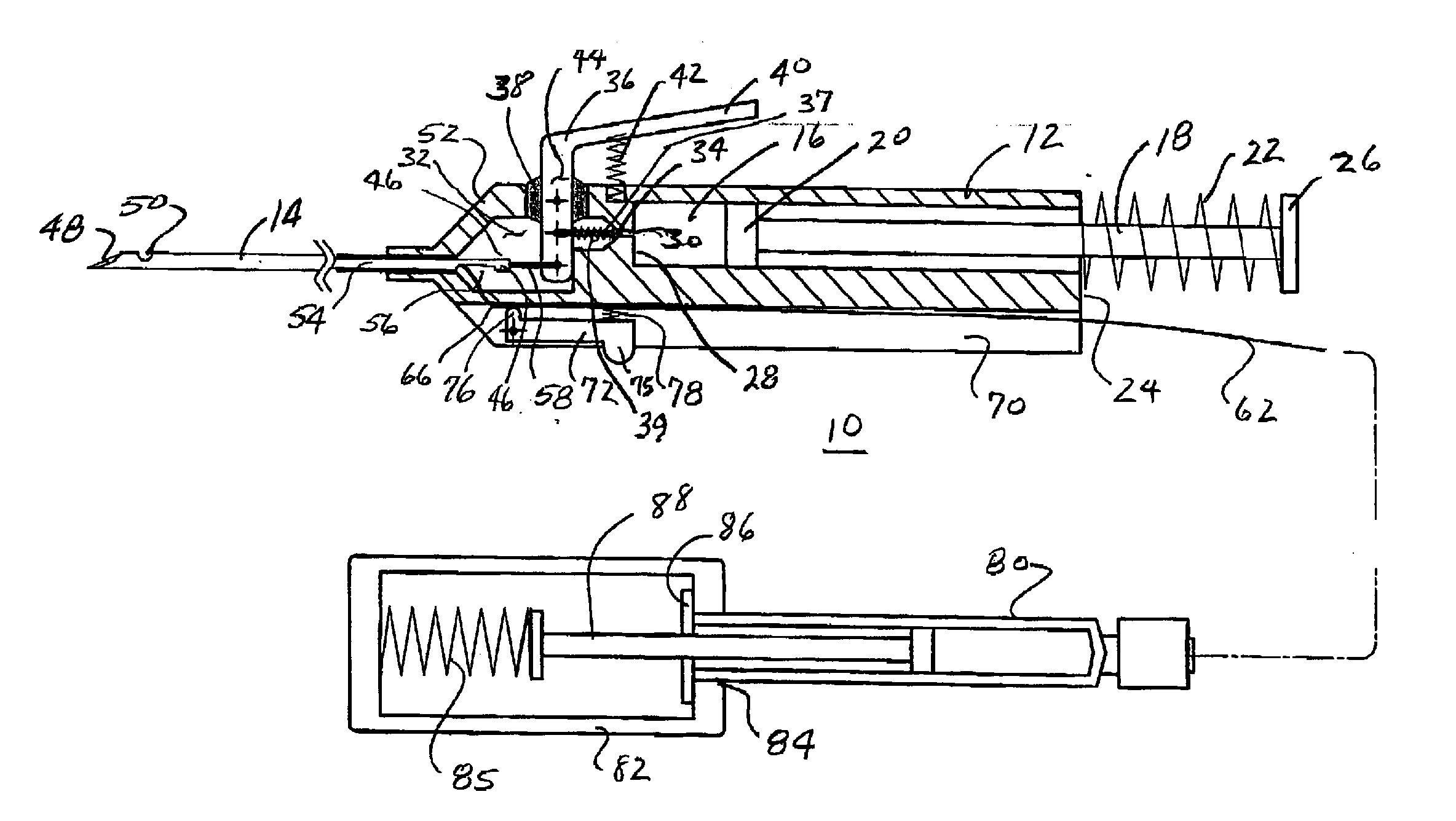

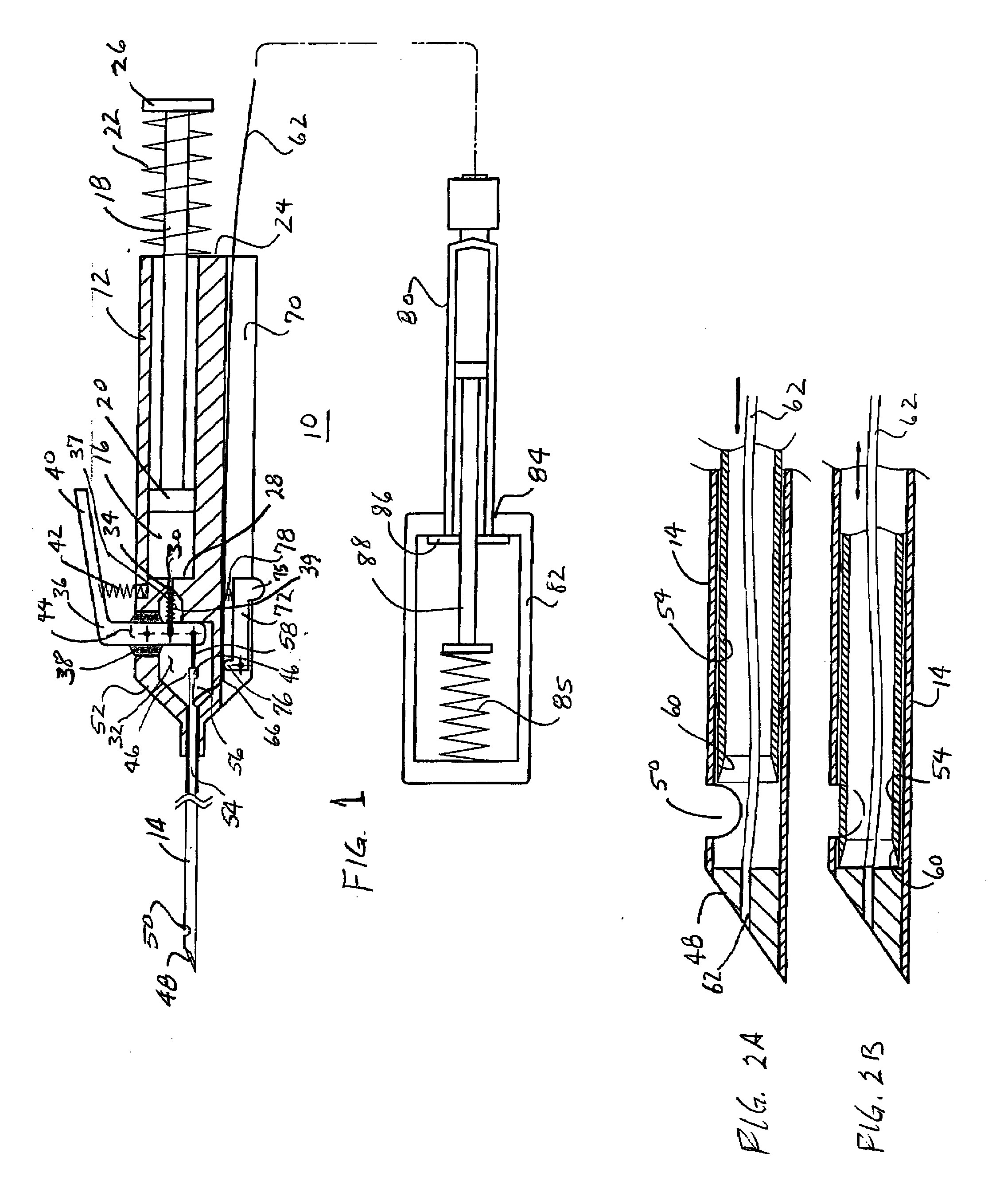

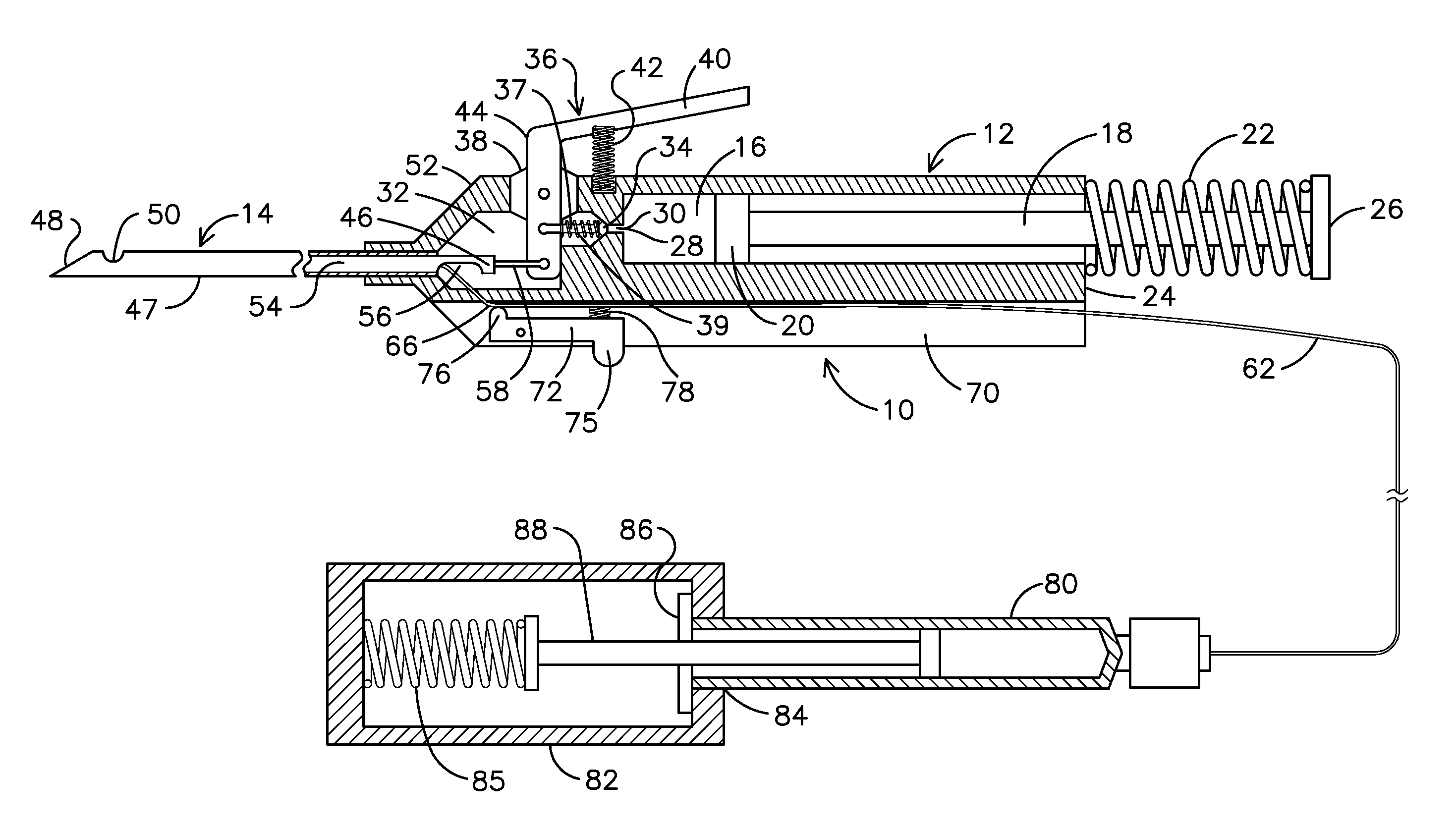

Tool For Extracting Vitreous Samples From An Eye

InactiveUS20070078359A1Prevent undesirable increase in intraocular pressureAvoid cross contaminationEye surgerySurgeryEngineeringAntibiotic Y

A unitary mechanical injector-vitrector hand tool for use in extracting vitreous material from an eye and injecting another fluid into the eye includes a housing body having a proximal end, a distal end and a variable volume cavity in the housing body for establishing a negative pressure or suction. A needle having a sharpened point and a central bore is connected to the proximal end of the housing body. An aperture is formed in a sidewall of the needle near the sharpened end. An inner hollow reciprocal cutter is fitted in the central bore of the needle and has a cutting edge adapted for travel across the aperture. A first manually actuatable lever is pivotably mounted to the housing body and coupled in driving relationship with the reciprocal cutter. A valve assembly is operatively positioned between the needle and the variable volume cavity and arranged to open to apply suction to the needle central bore as the reciprocal cutter travels across the aperture so as to withdraw vitreous material falling into the hollow cutter. A pressurized source of fluid is coupled by a conduit through the central bore of the needle and cutter and selectively actuated to replace the removed vitreous material with other material such as an antibiotic.

Owner:INSIGHT INSTR

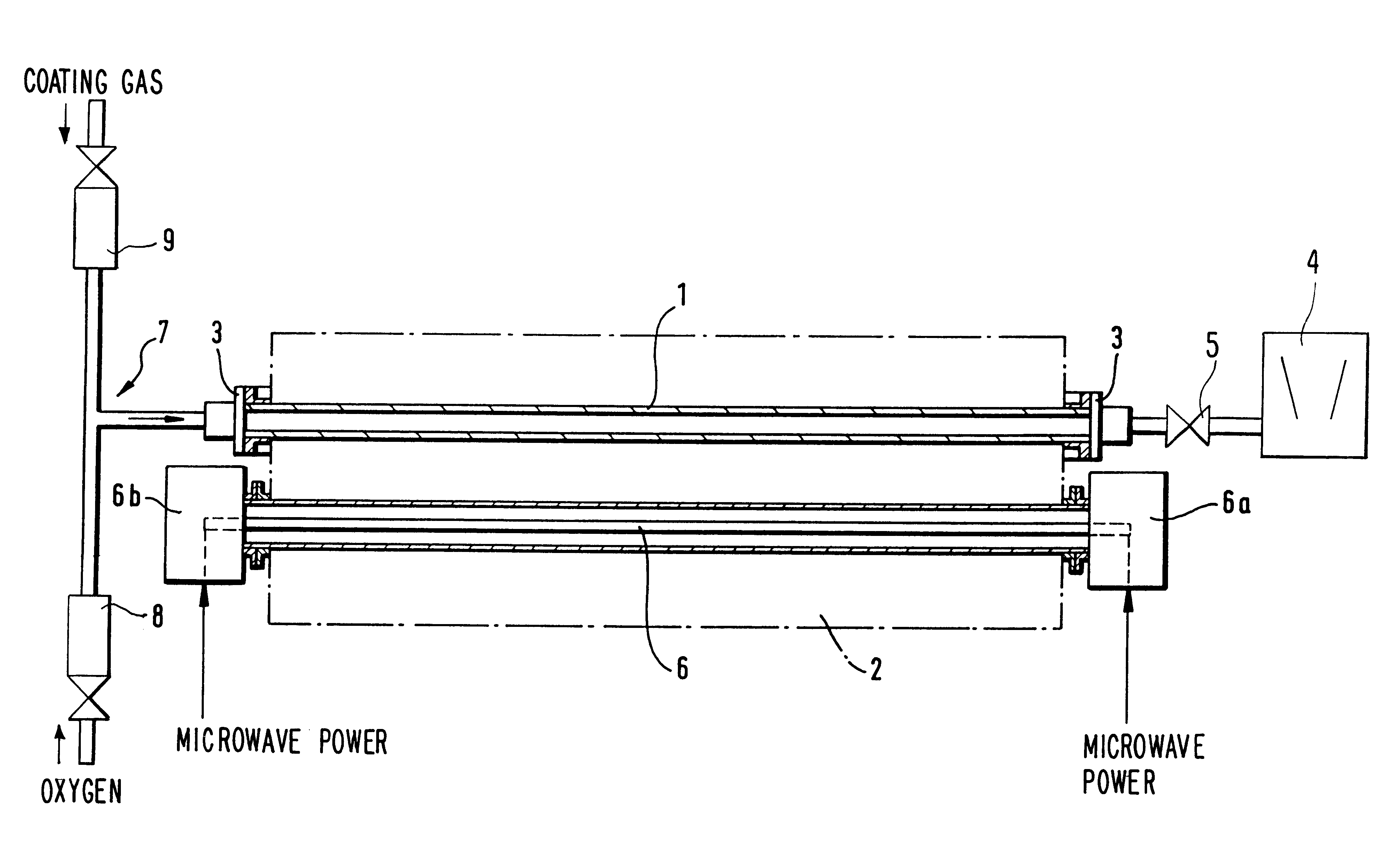

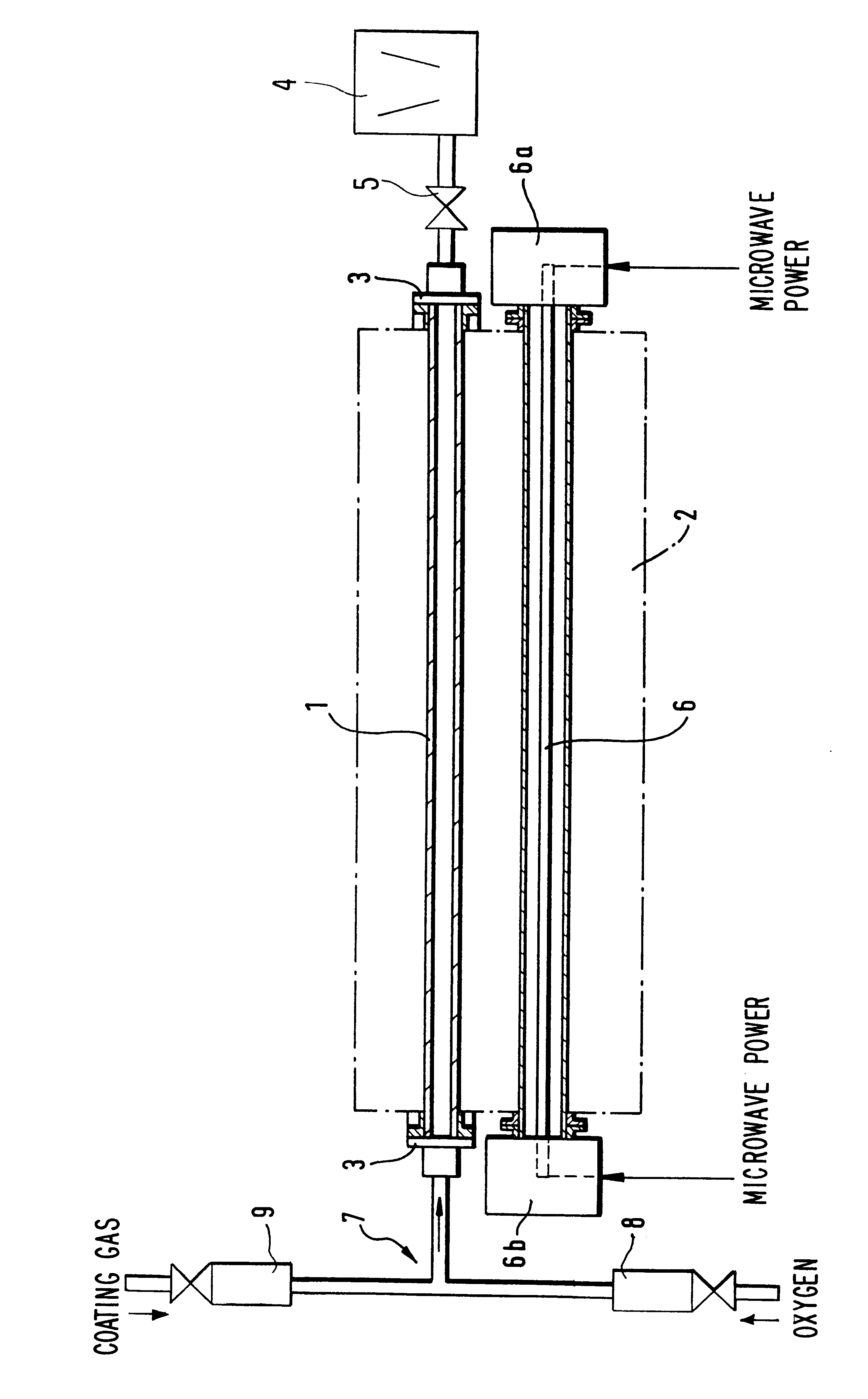

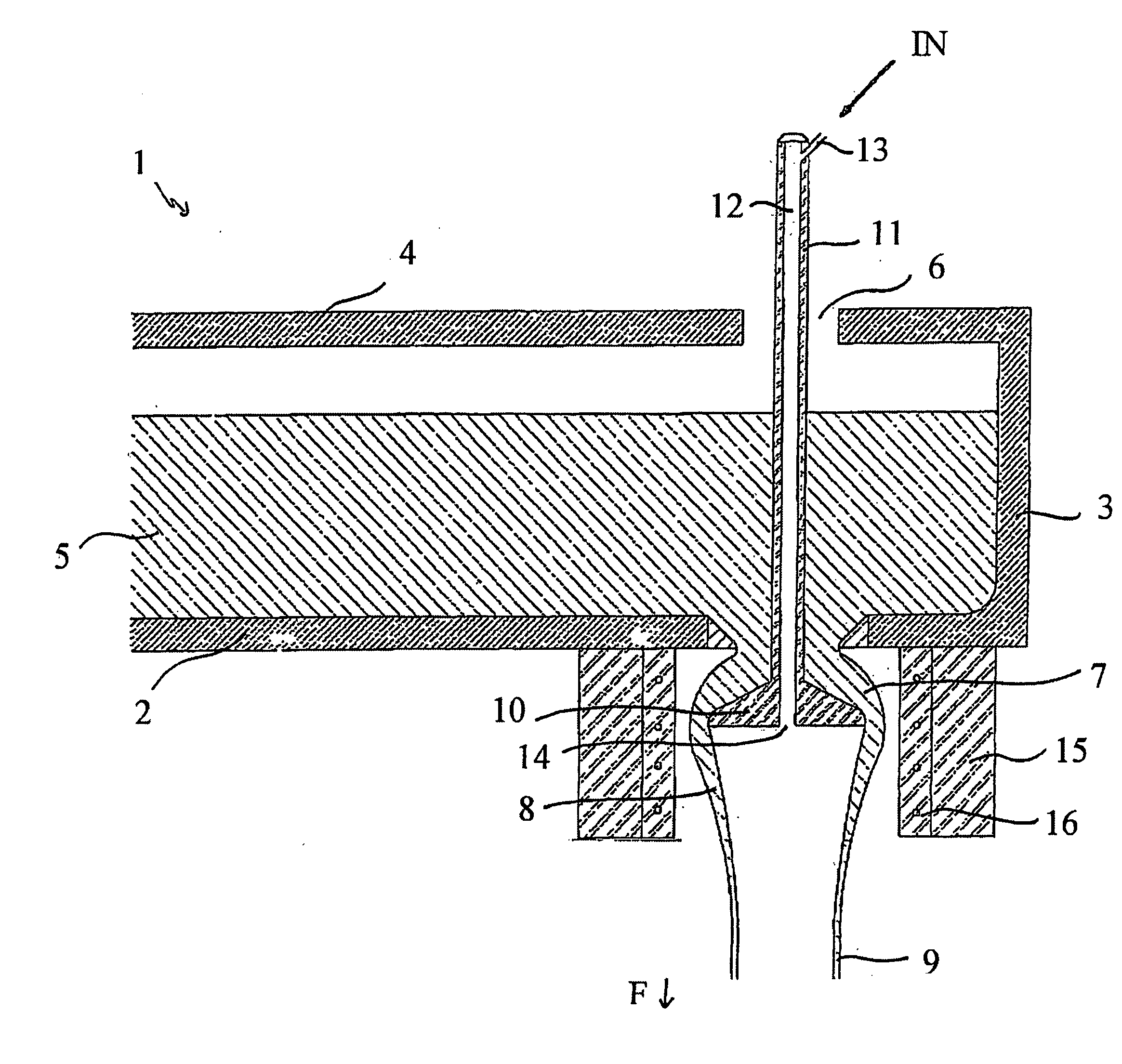

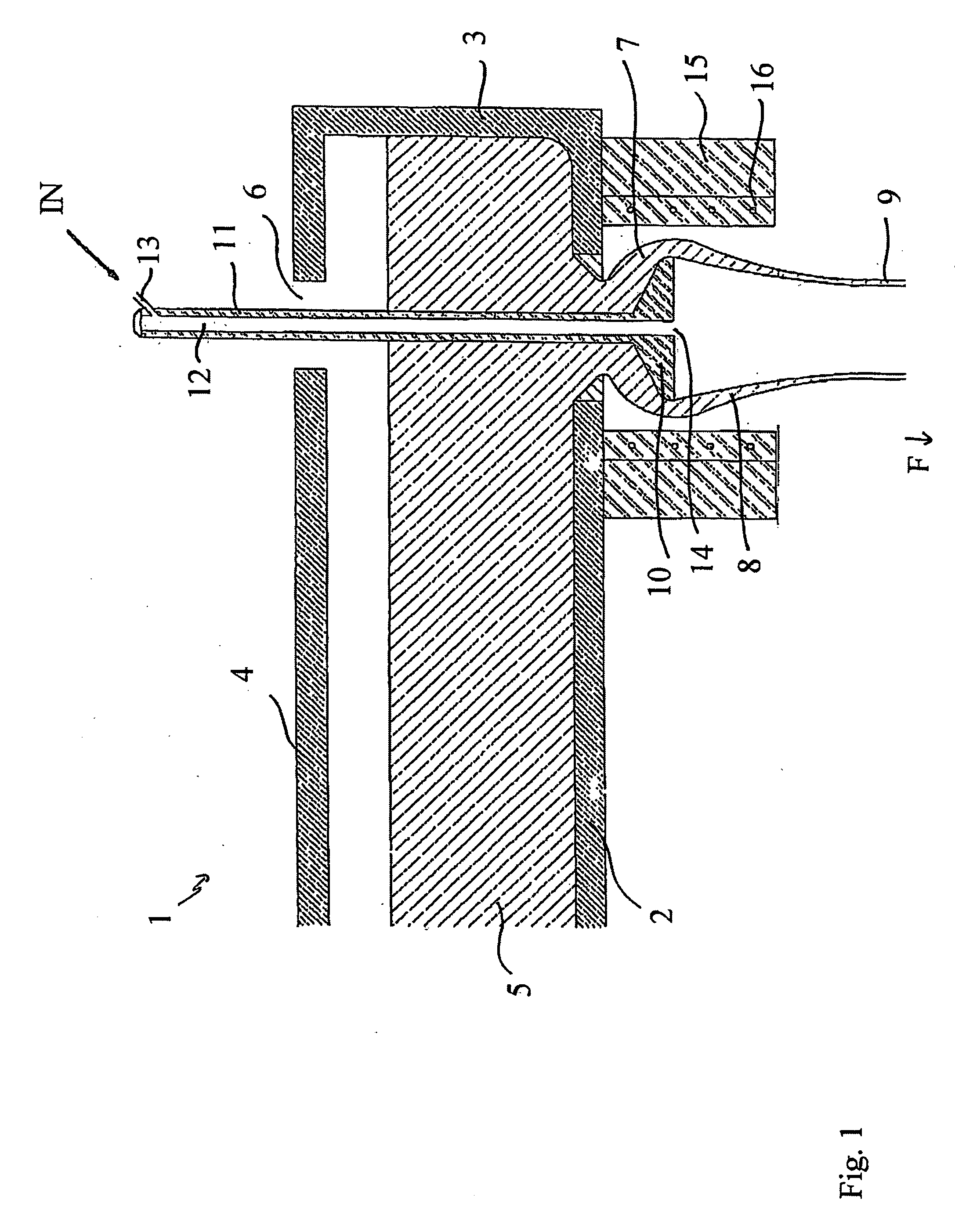

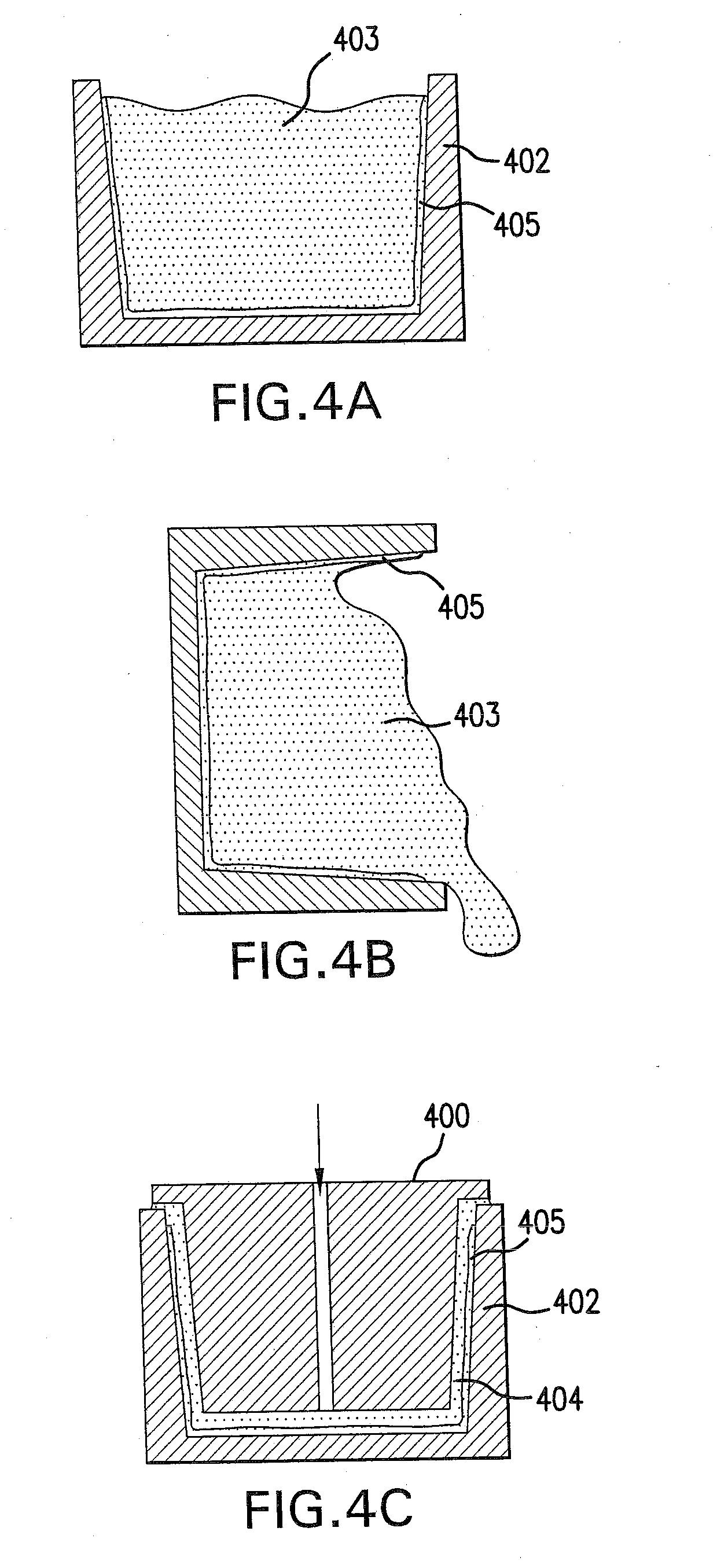

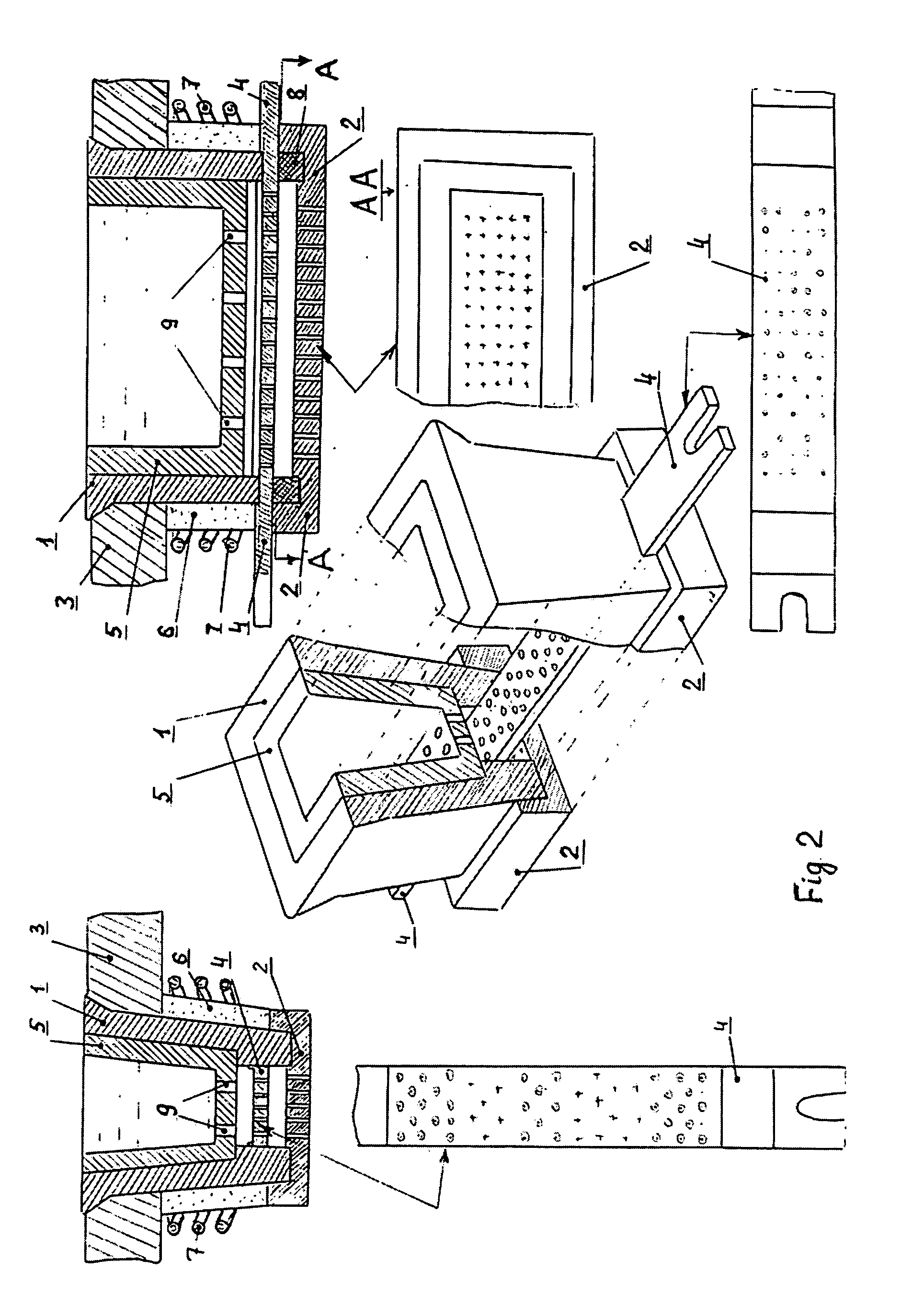

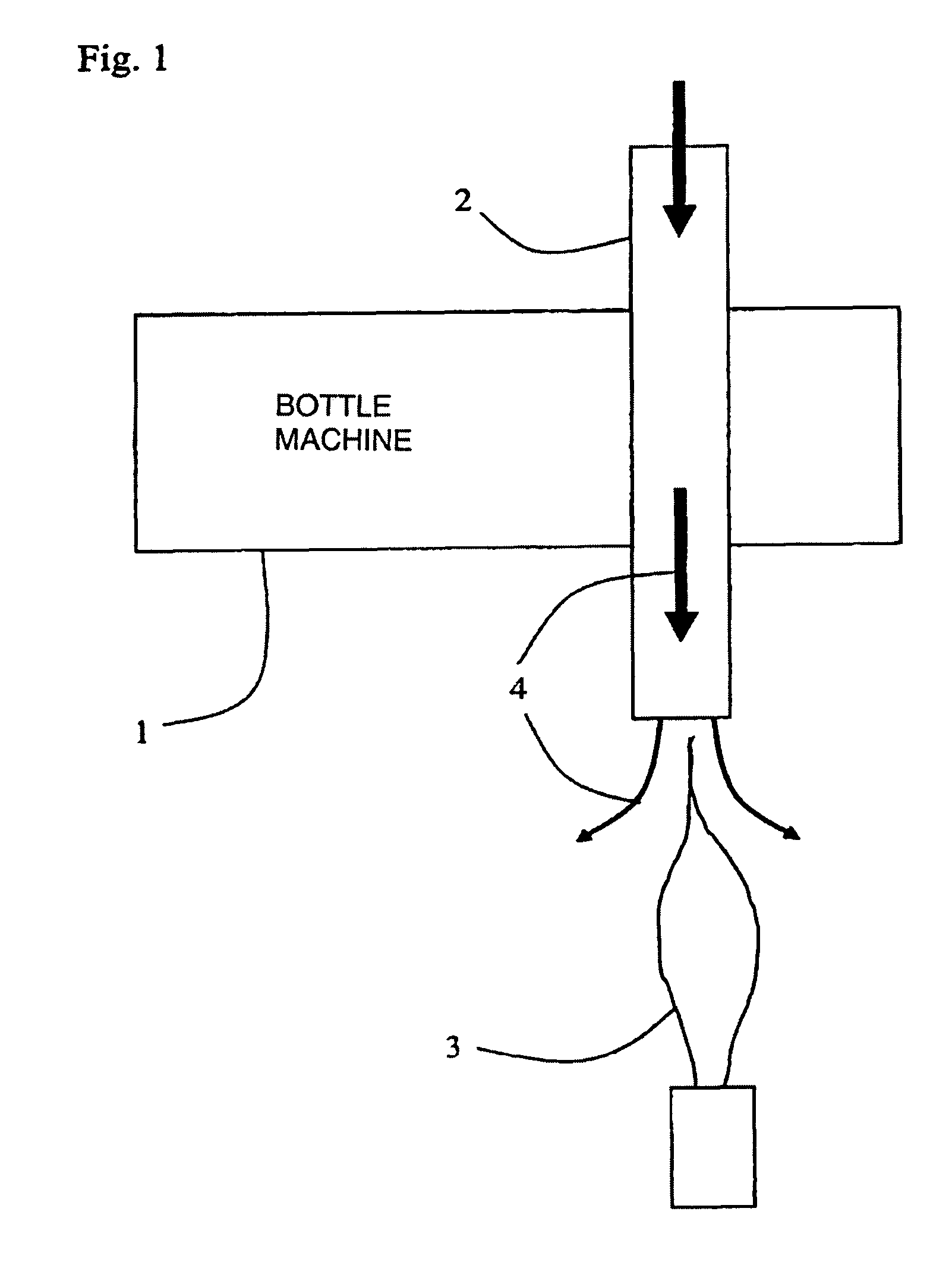

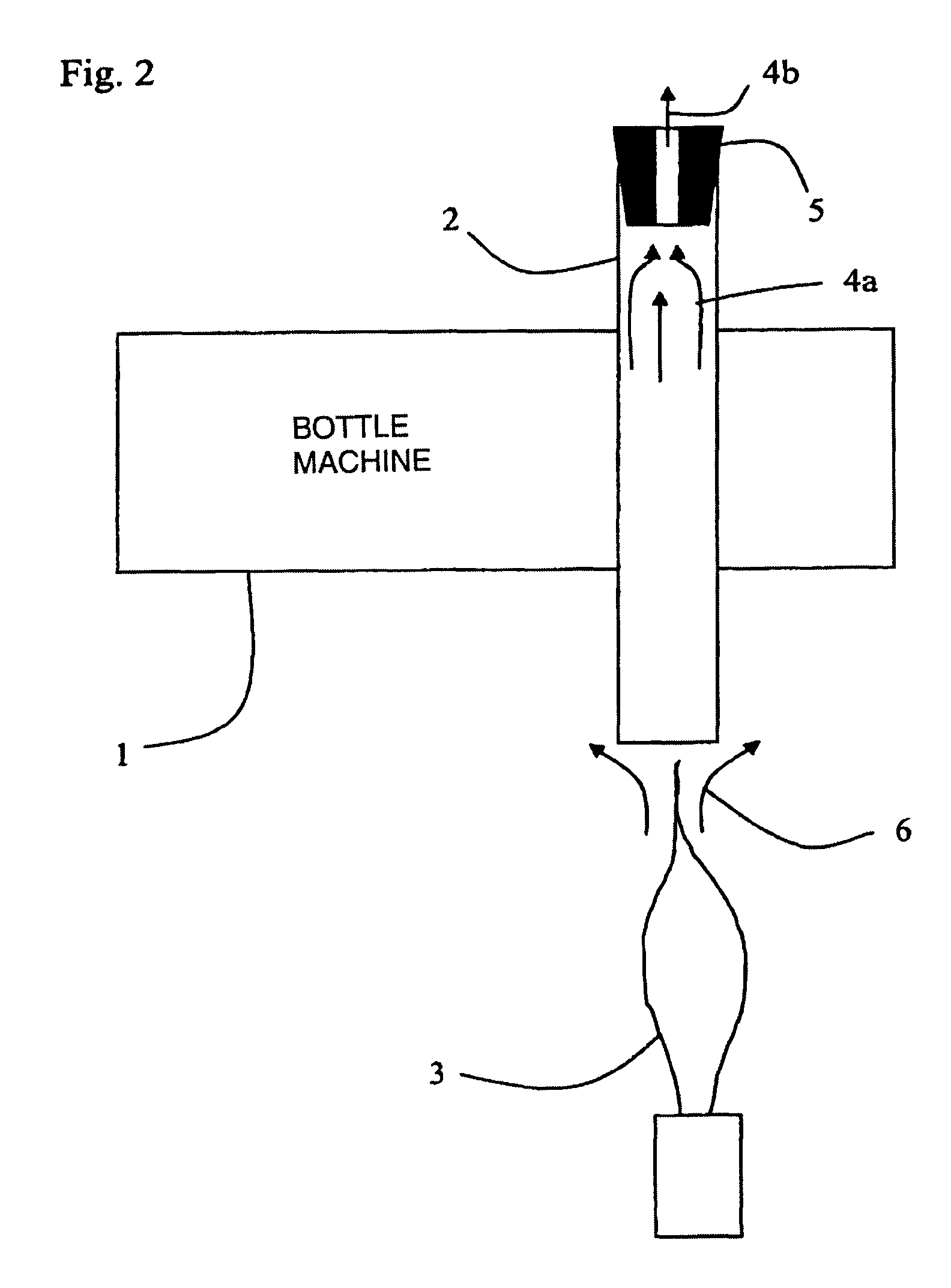

Method and apparatus for manufacturing internally coated glass tubes

InactiveUS20060260360A1Large oxygen contentRapid and complete reactionMaterial nanotechnologyGlass drawing apparatusMetallurgyVitreous Bodies

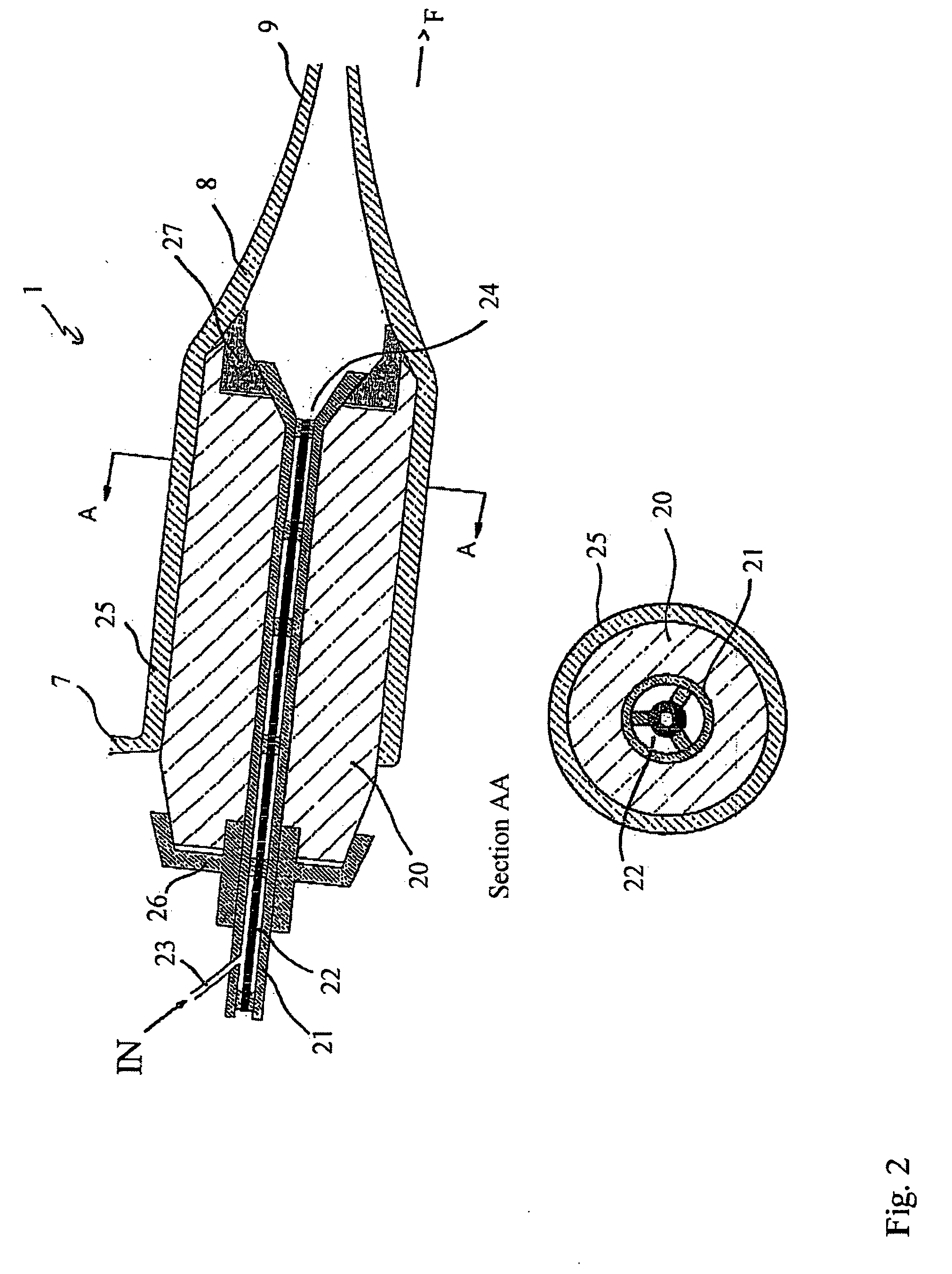

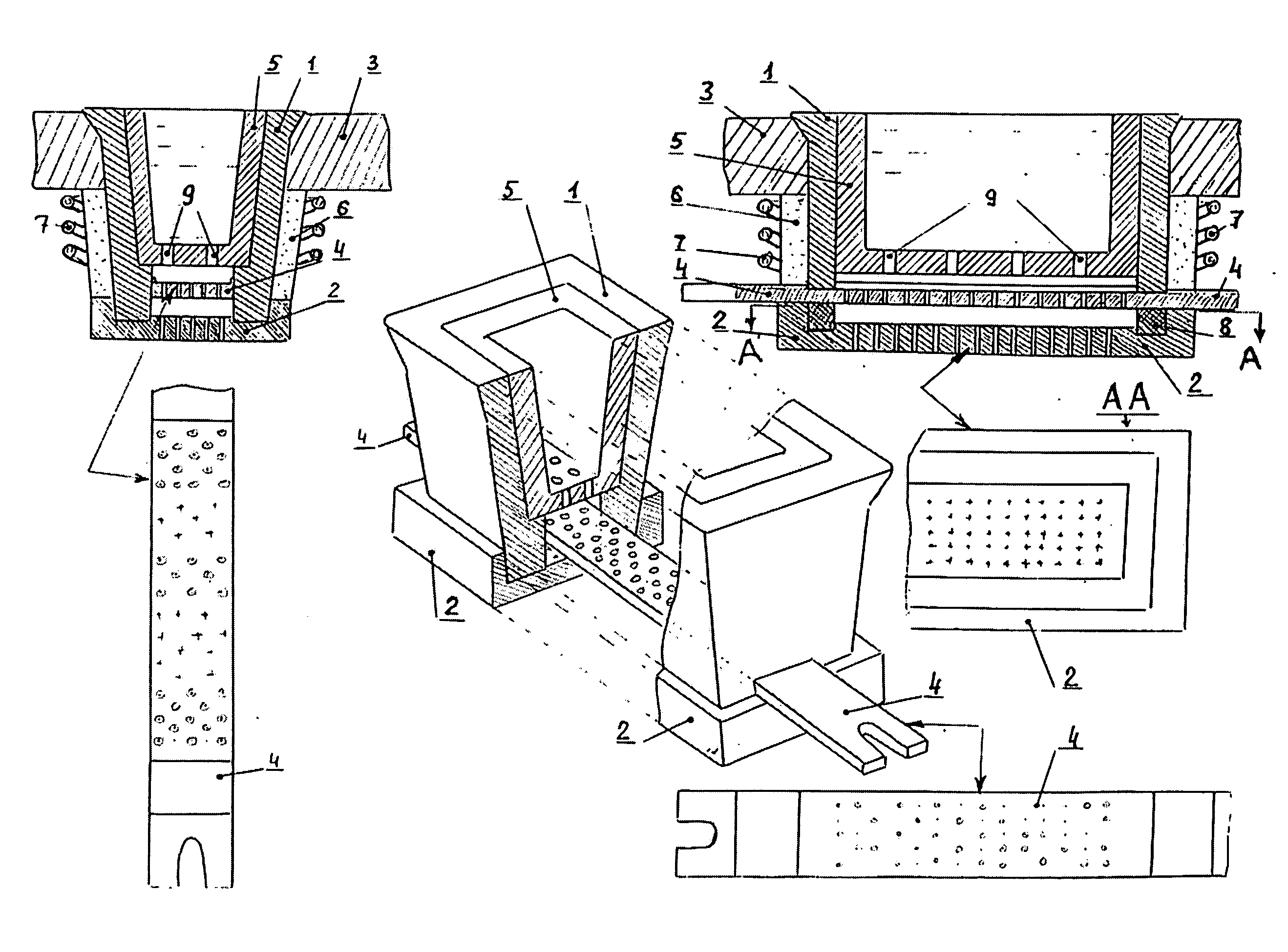

The invention relates to a method for manufacturing a glass tube with a coated inner surface by drawing a glass melt (5) to a bag (8) of softened glass and hot forming to a glass tube (9). During the process a substance is introduced into the bag (8) of softened glass. According to the invention the substance is introduced as an aerosol and the inner surface is coated by means of the substance during the hot forming. The method permits economical internal coating with a continuous glass drawing method. The use of aggressive chemical substances for internal coating can be dispensed with according to the invention. As a result, for example, internally coated glass tubes with improved hydrolytic resistance can be manufactured. The invention also relates to a suitable apparatus for manufacturing internally coated glass tubes and the use of glass tubes manufactured by this means for further processing to a hollow, internally coated formed glass body, for example, as primary packaging in the pharmaceuticals field.

Owner:SCHOTT AG

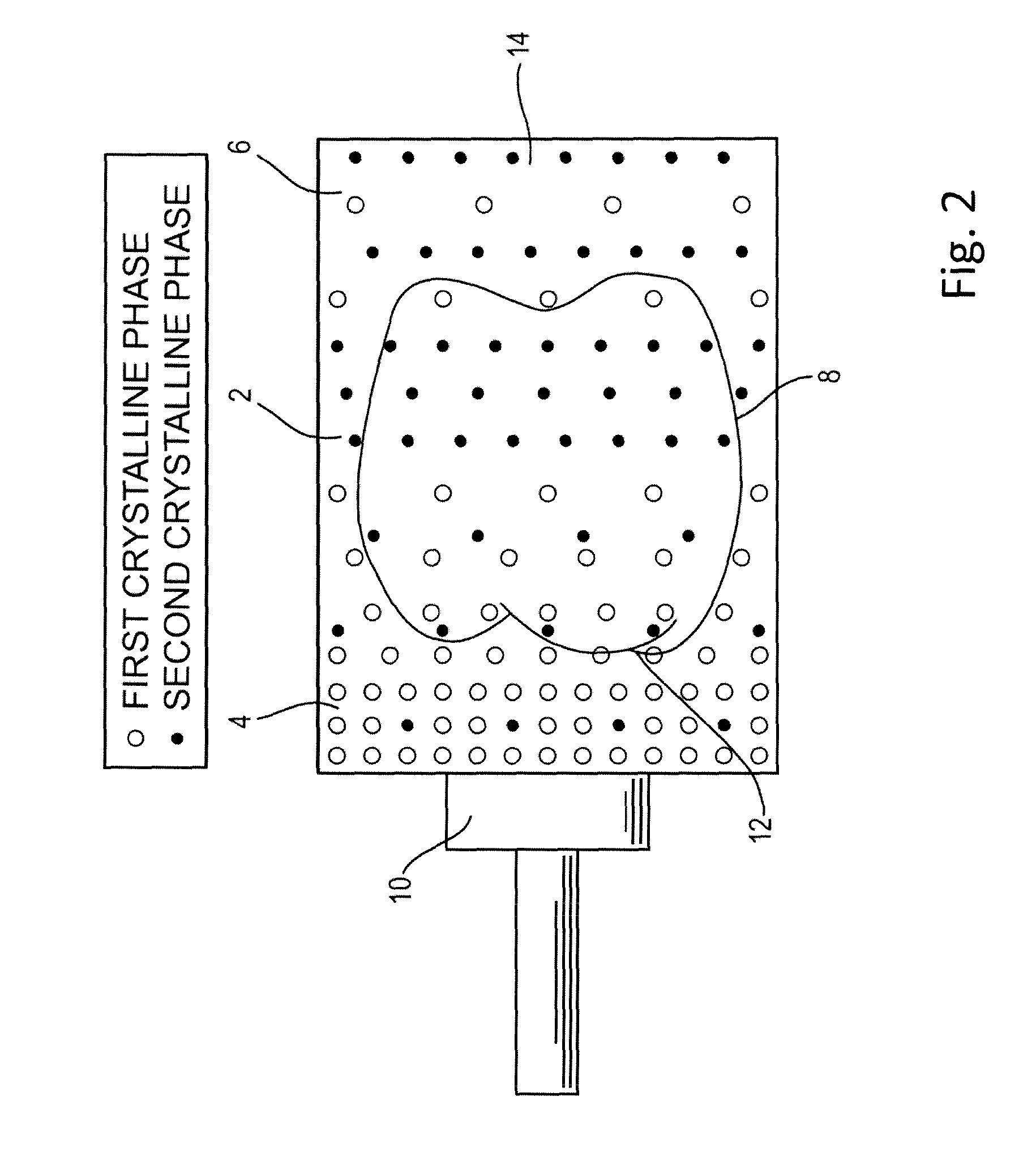

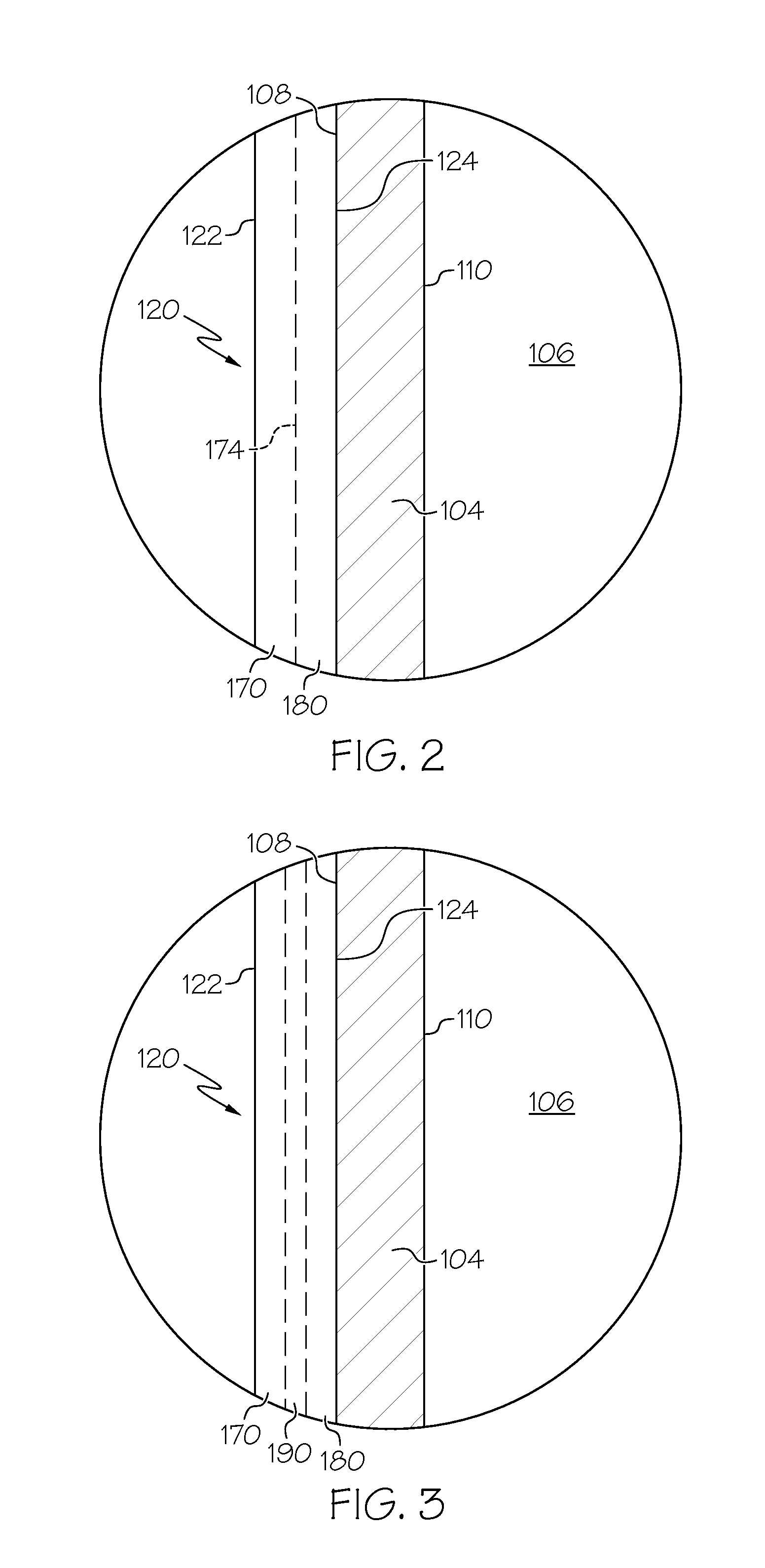

Laser Patterning of Glass Bodies

ActiveUS20100050692A1Decorative surface effectsLaser beam welding apparatusLaser patterningVitreous Bodies

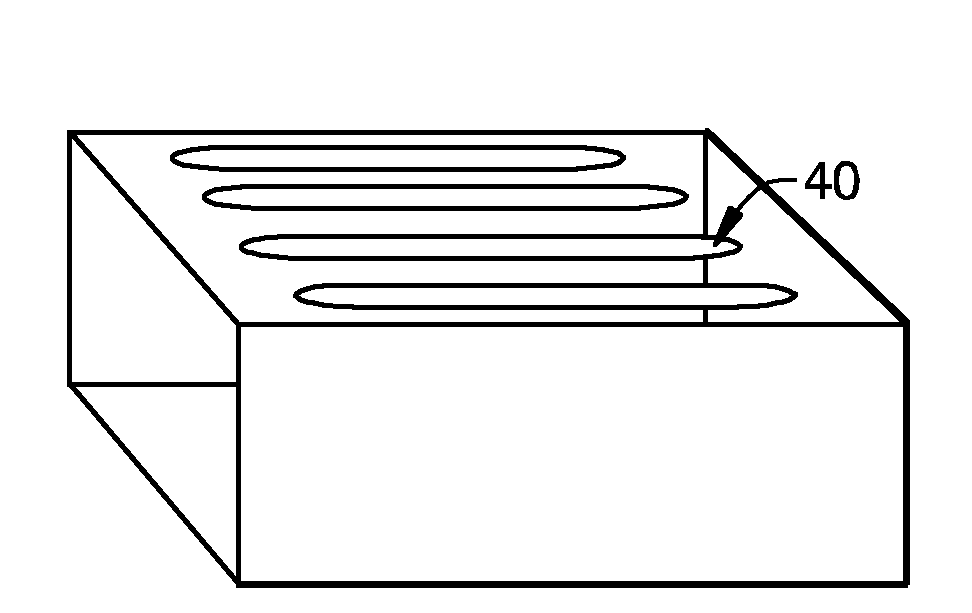

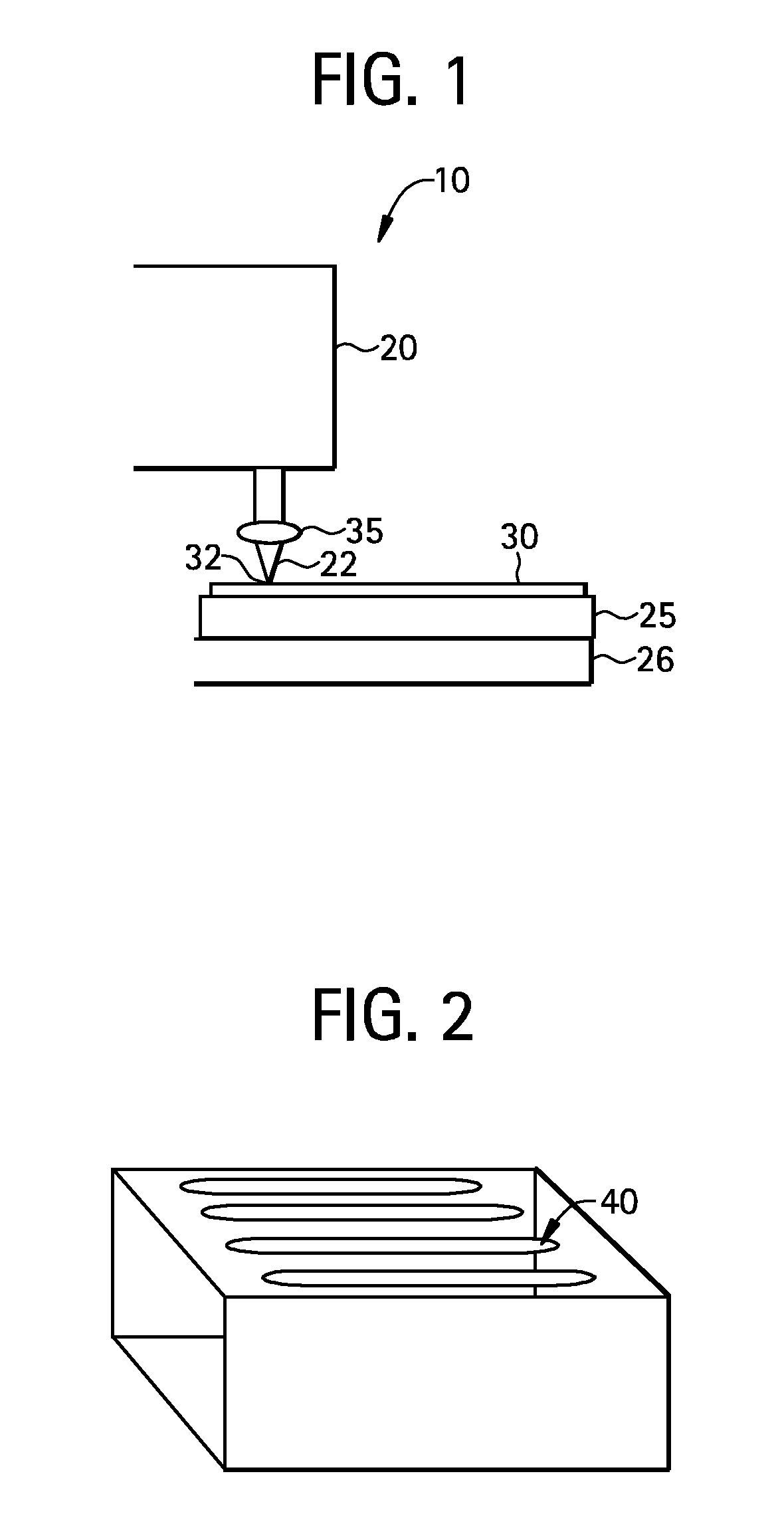

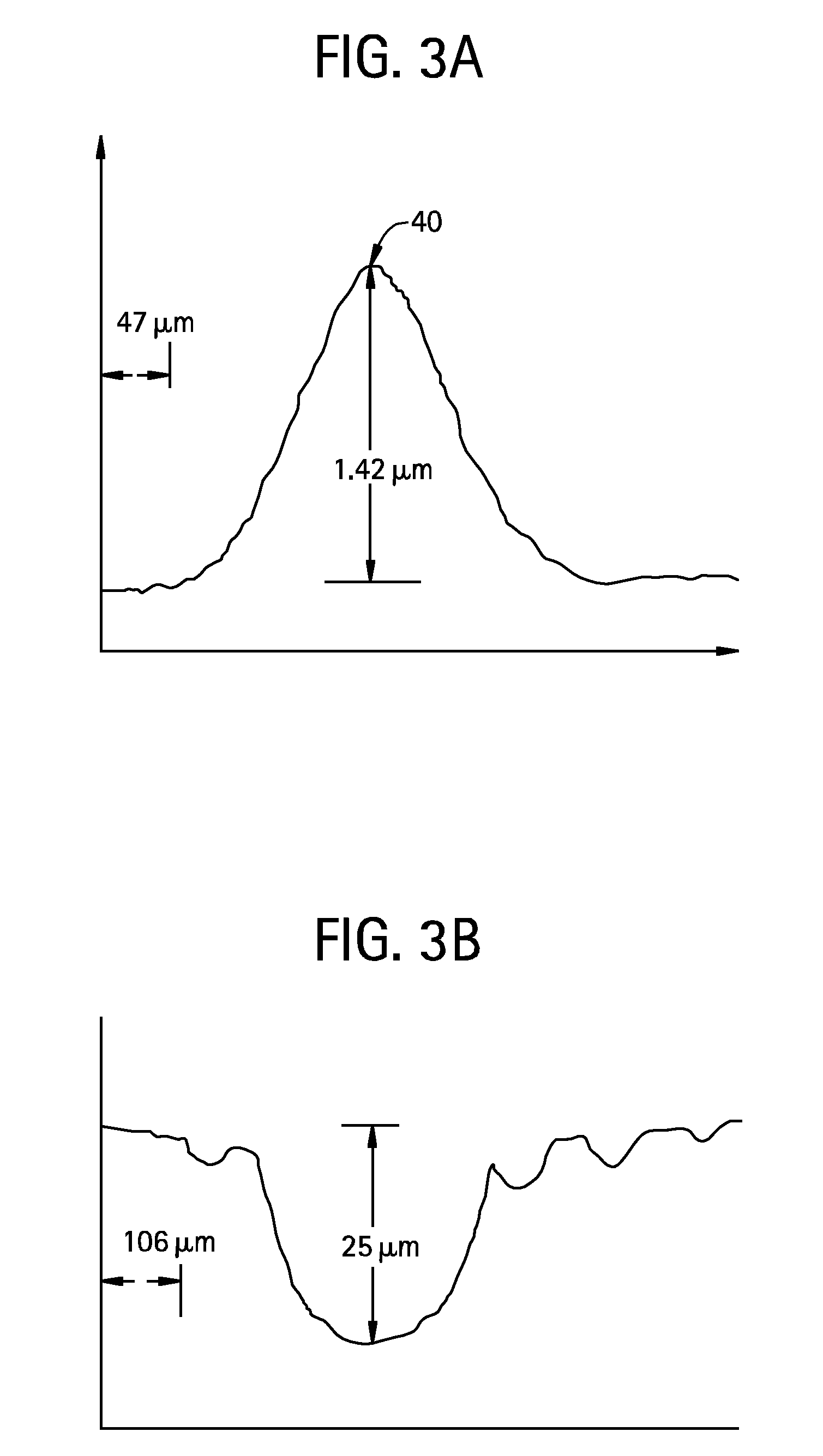

A method for laser patterning of a glass body, the method comprising the steps of:(i) providing a laser, said laser having an output beam at a laser wavelength λ;(ii) providing a glass body having optical density at of at least 1.5 / cm at said wavelength;(iii) directing said laser output beam to (a) impinge on the glass body without ablating said glass, and (b) heat the glass body at a location proximate to said laser output beam so as to form a swell at this location; and(iv) etching this location.

Owner:CORNING INC

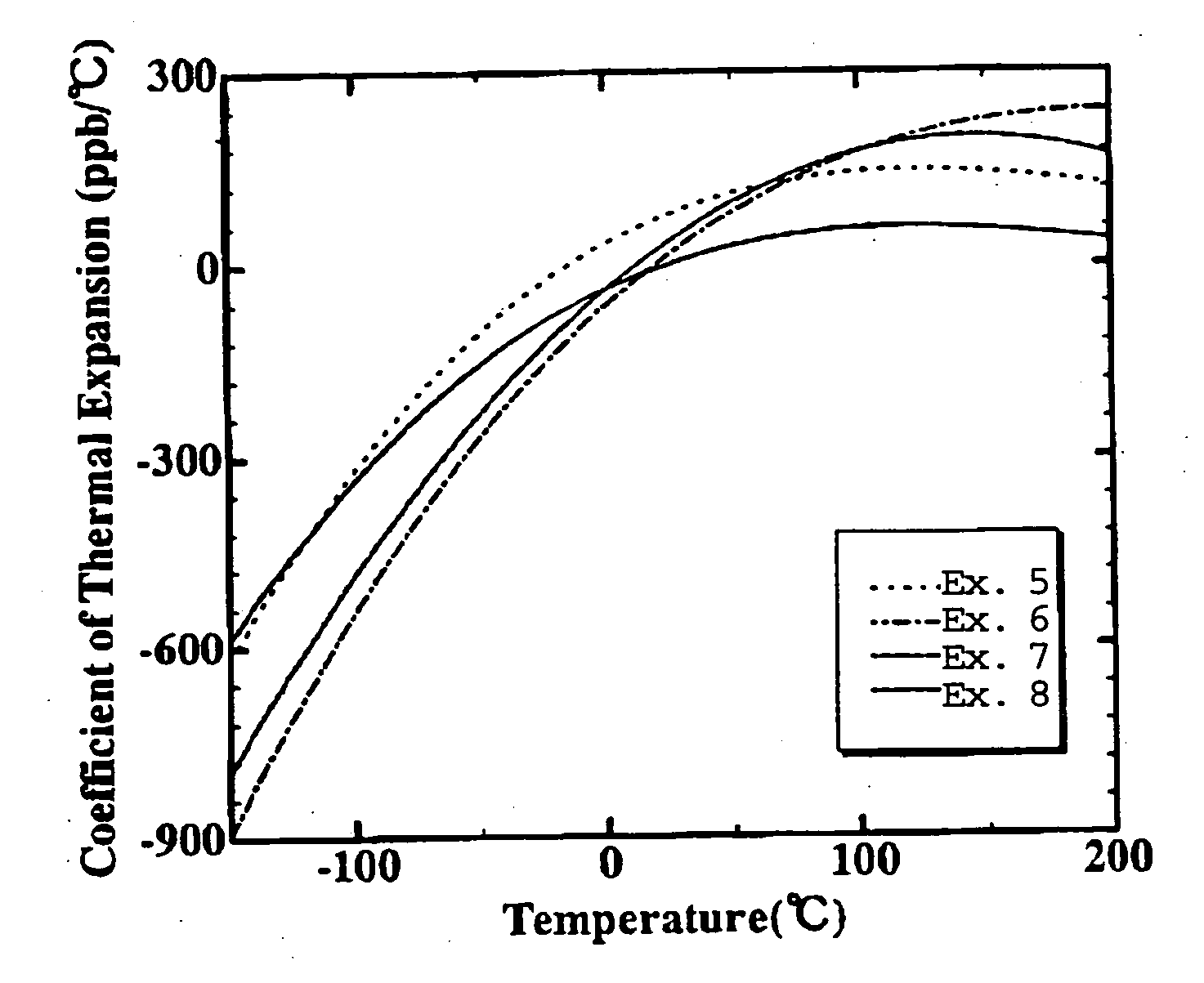

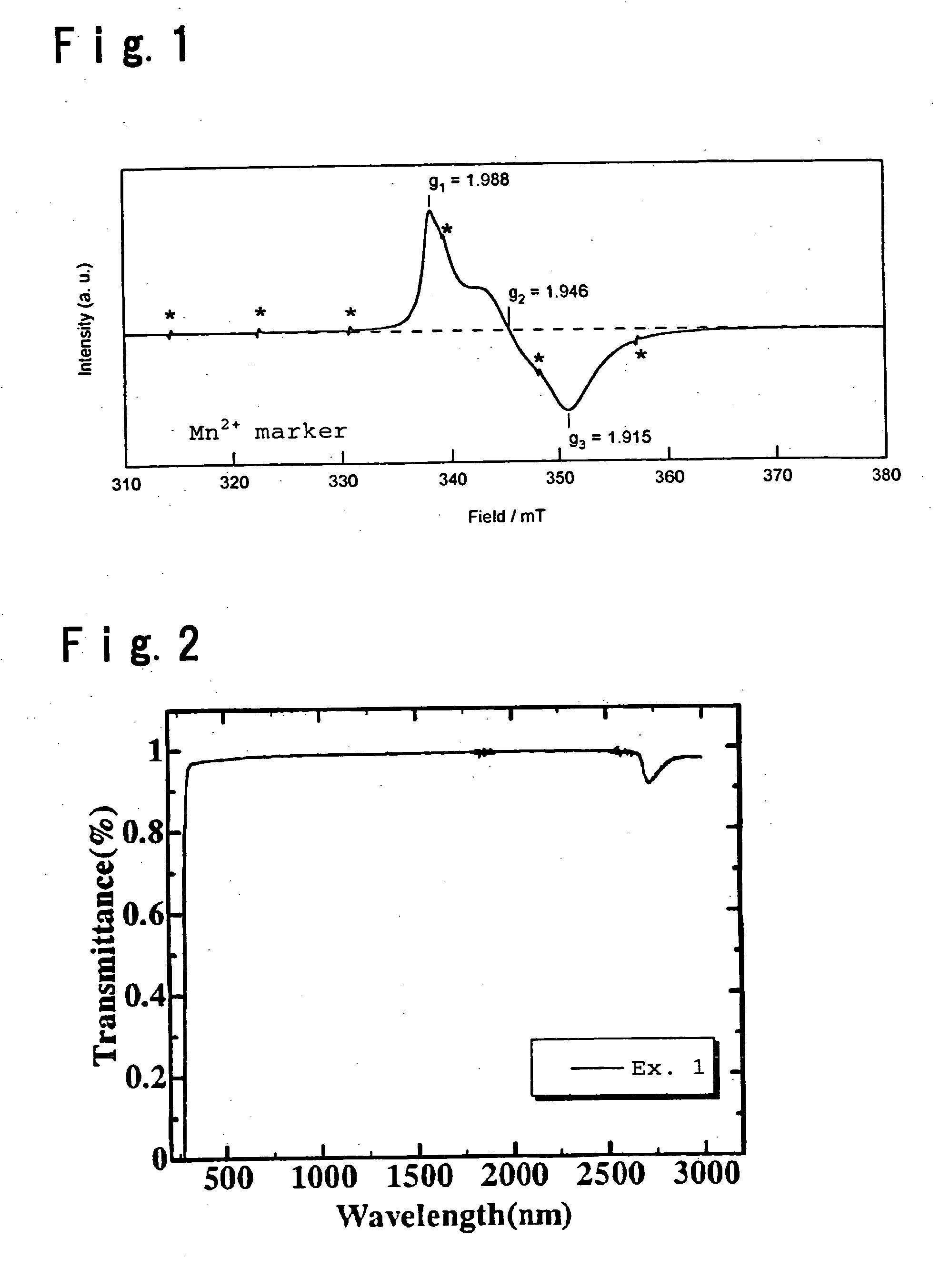

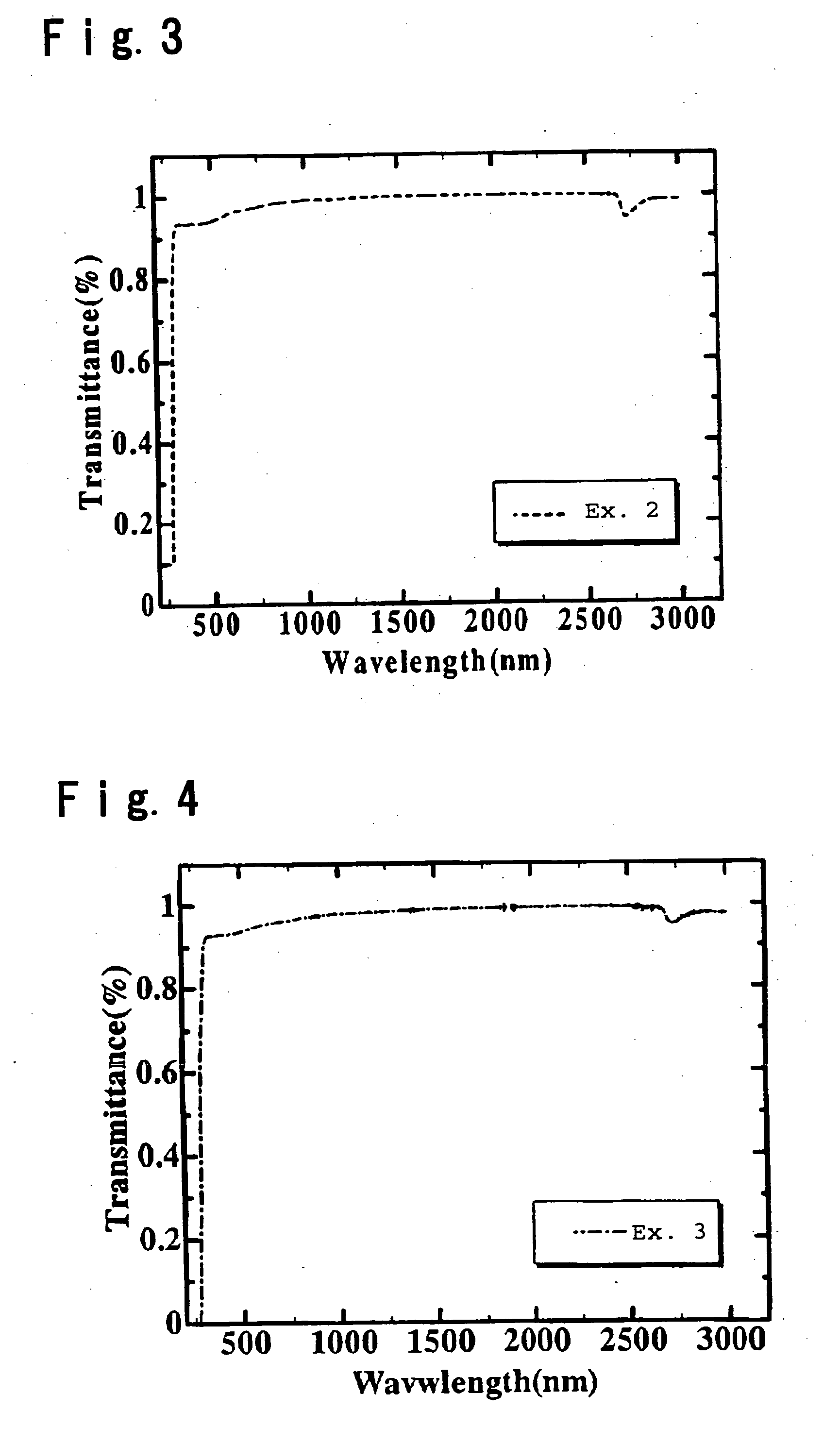

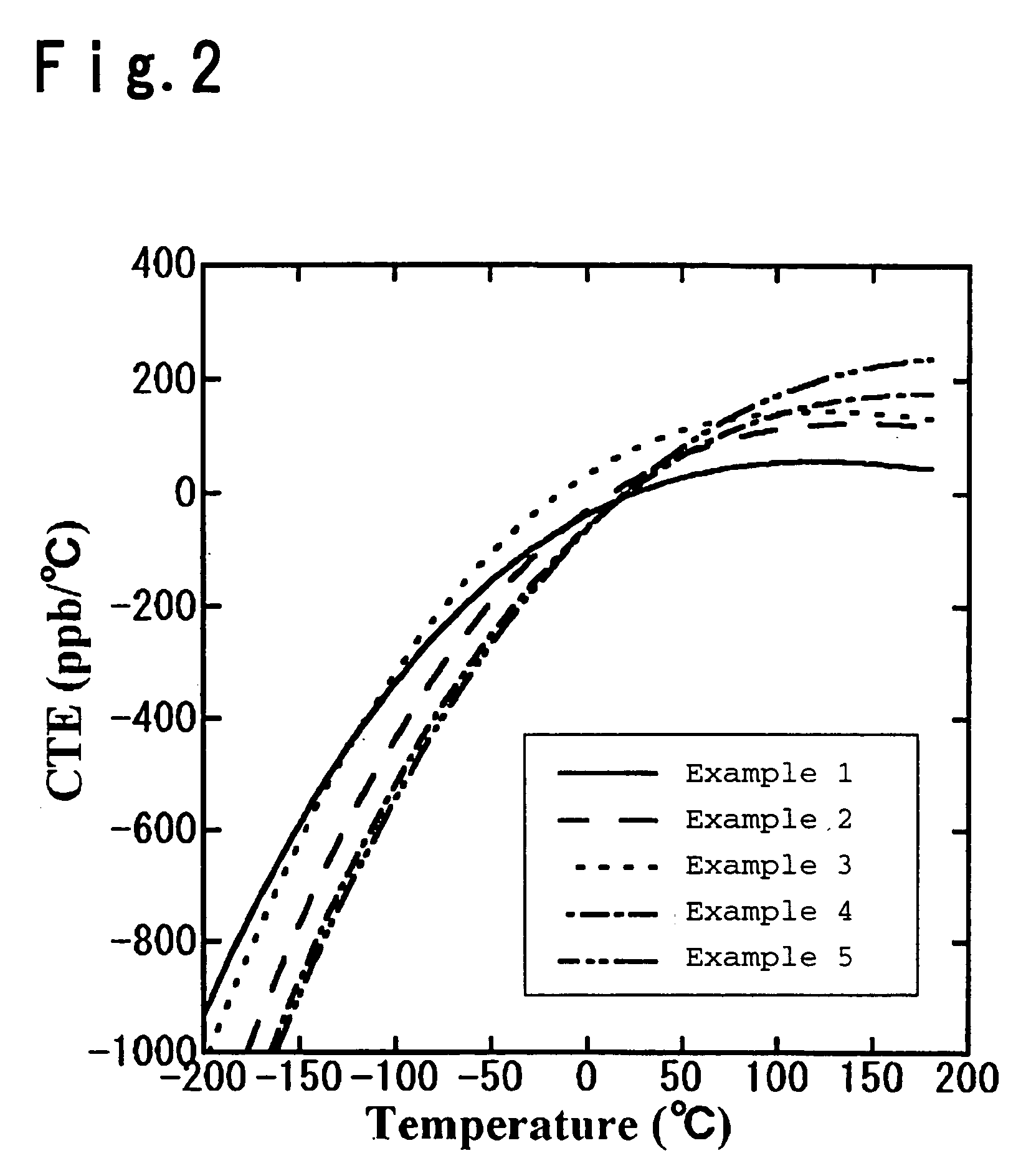

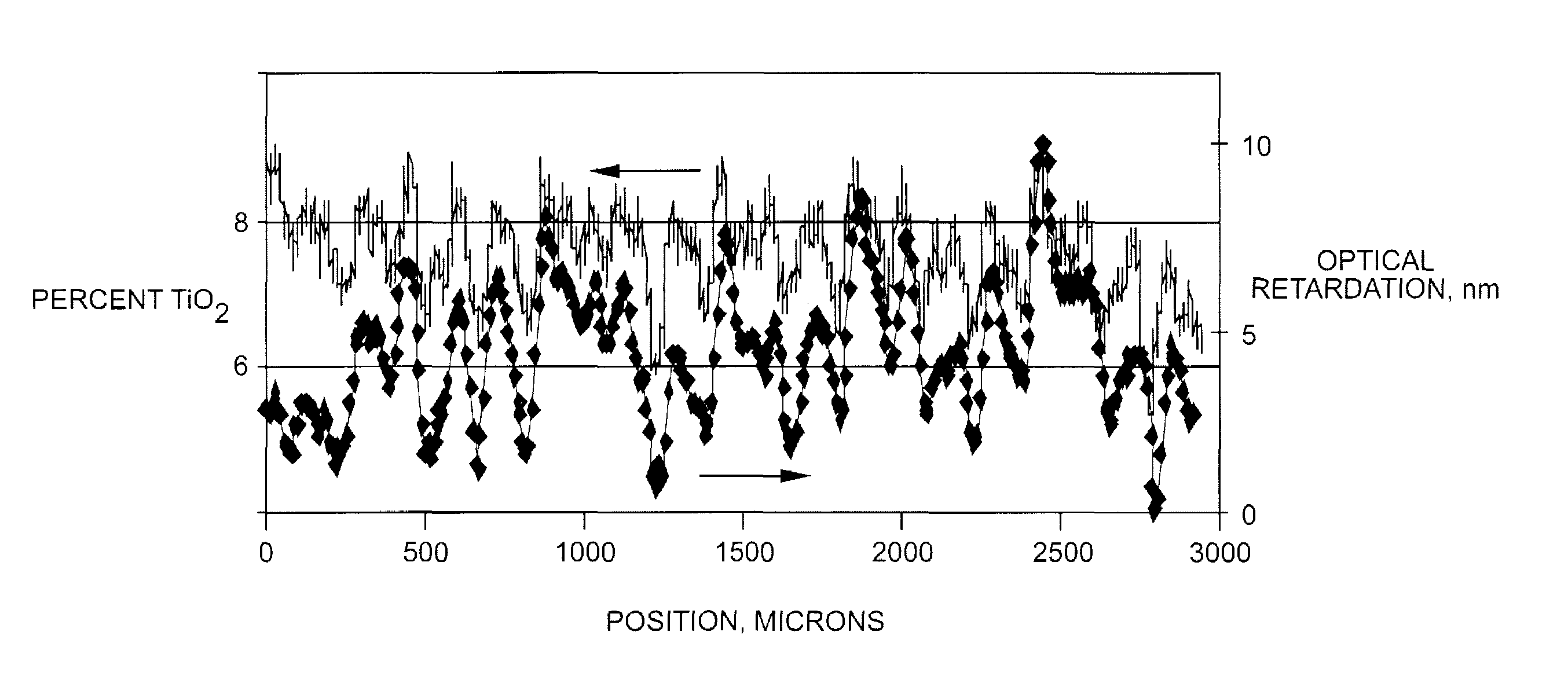

Silica glass containing TiO2 and process for its production

ActiveUS20070042893A1High light transmittanceHigh transparencyCharging furnaceGlass reforming apparatusVitrificationTransmittance

It is to provide a silica glass containing TiO2, having a wide temperature range wherein the coefficient of thermal expansion is substantially zero. A silica glass containing TiO2, which has a TiO2 concentration of from 3 to 10 mass %, a OH group concentration of at most 600 mass ppm and a Ti3+ concentration of at most 70 mass ppm, characterized by having a fictive temperature of at most 1,200° C., a coefficient of thermal expansion from 0 to 100° C. of 0±150 ppb / ° C., and an internal transmittance T400-700 per 1 mm thickness in a wavelength range of from 400 to 700 nm of at least 80%. A process for producing a silica glass containing TiO2, which comprises porous glass body formation step, F-doping step, oxygen treatment step, densification step and vitrification step.

Owner:ASAHI GLASS CO LTD

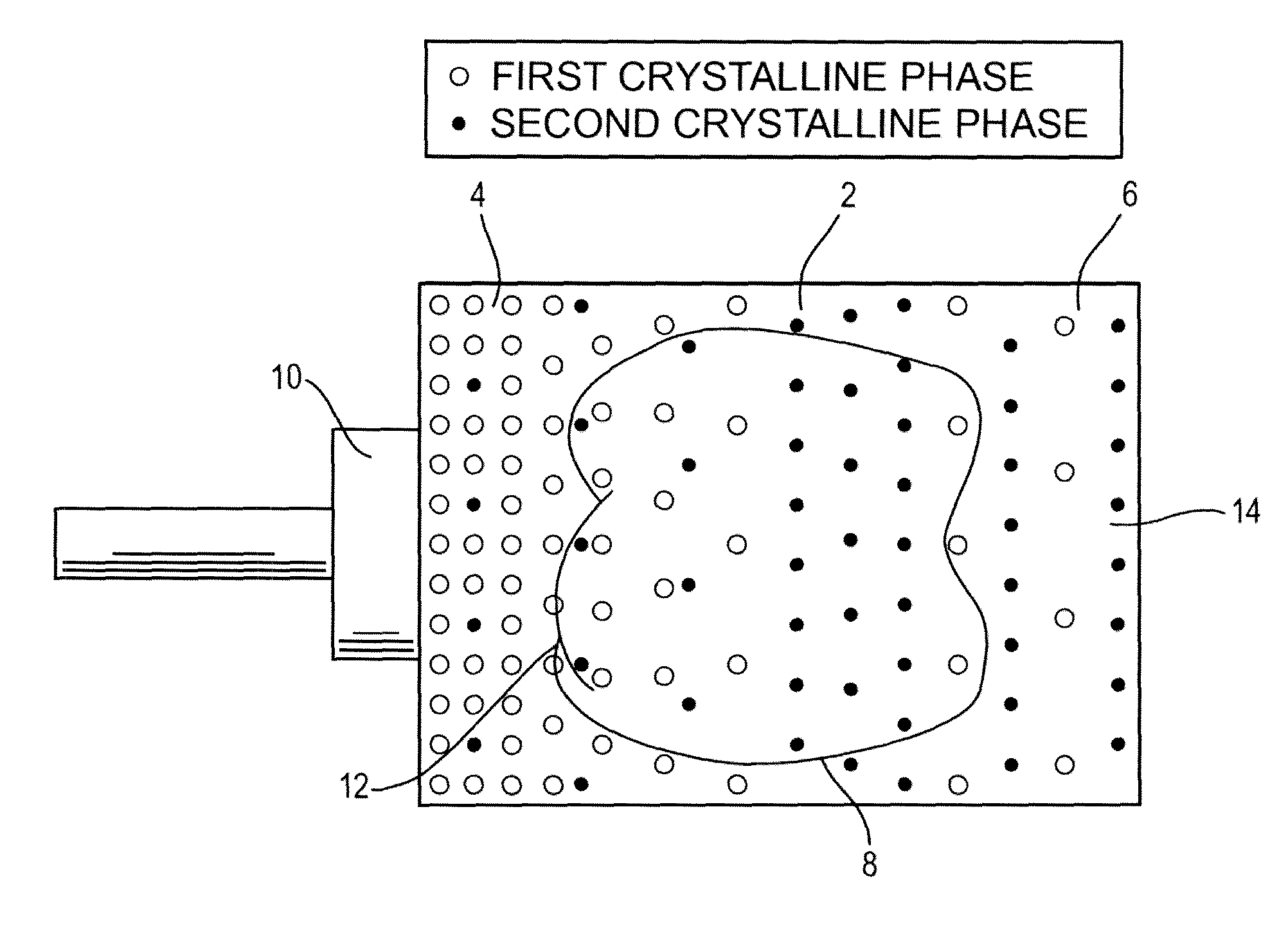

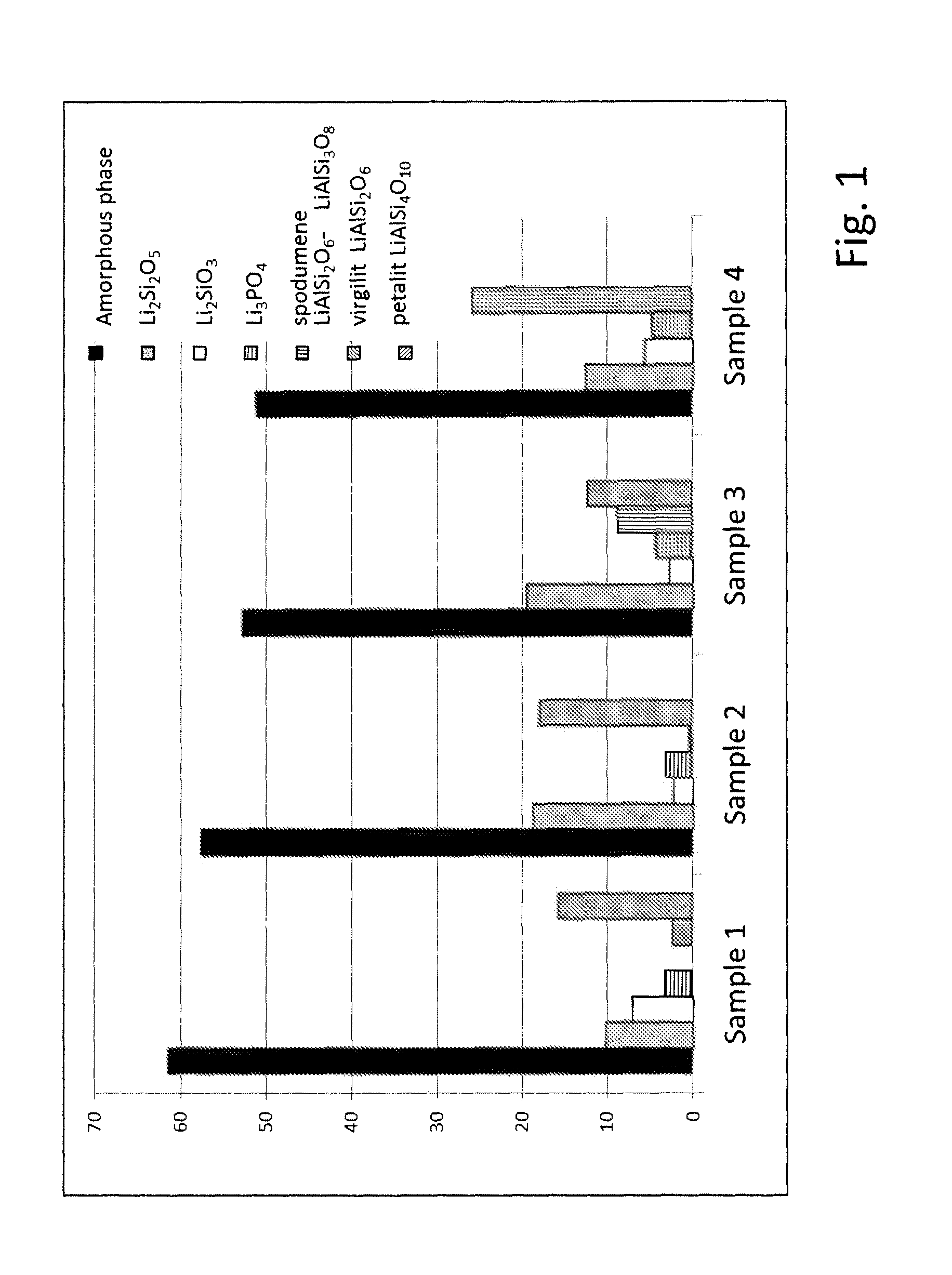

Process for preparing a glass-ceramic body

ActiveUS20140141960A1Improve distributionIncrease bodyDentistry preparationsMedical preparationsVitreous BodiesNucleation

Process for preparing glass-ceramic body including the steps of providing a basic glass body and subjecting the basic glass body to a thermal treatment whereby a crystalline phase embedded in a glass matrix is formed. The basic glass body is made of a composition comprising 65 to 72 wt-% SiO2, at least 10.1 wt-% Li2O and at least 10.1 wt-% Al2O3 based on the total weight of the composition, the proportion of Li2O to Al2O3 being from 1:1 to 1.5:1. The thermal treatment involves a nucleation step followed by several crystallization steps at different temperatures, whereby at least two different crystalline phases are formed.

Owner:STRAUMANN HLDG AG

Glass Articles With Low-Friction Coatings

ActiveUS20130224407A1Glass/slag layered productsPreformed elementsChemical compositionVitreous Bodies

Low-friction coatings and glass articles with low-friction coatings are disclosed. According to one embodiment, a coated glass article may include a glass body comprising a first surface and a low-friction coating positioned on at least a portion of the first surface of the glass body. The low-friction coating may include a polymer chemical composition. The coated glass article may be thermally stable at a temperature of at least about 260° C. for 30 minutes. A light transmission through the coated glass article may be greater than or equal to about 55% of a light transmission through an uncoated glass article for wavelengths from about 400 nm to about 700 nm. The low-friction coating may have a mass loss of less than about 5% of its mass when heated from a temperature of 150° C. to 350° C. at a ramp rate of about 10° C. / minute.

Owner:CORNING INC

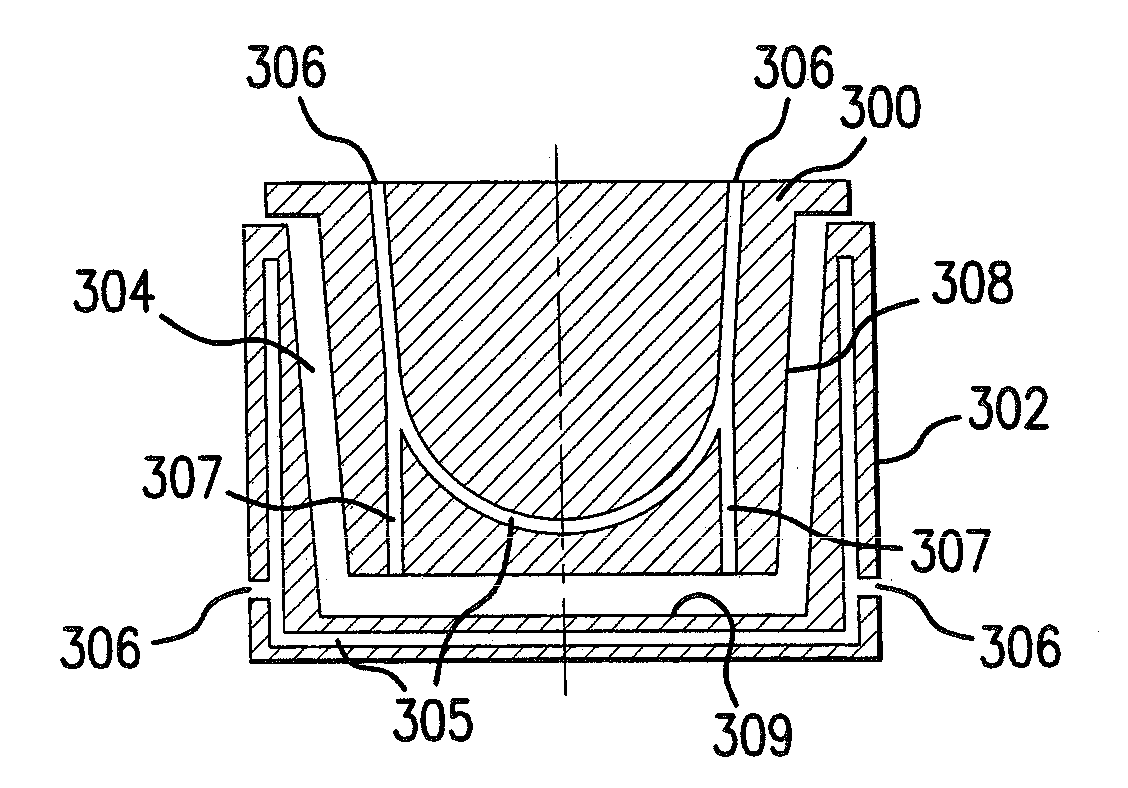

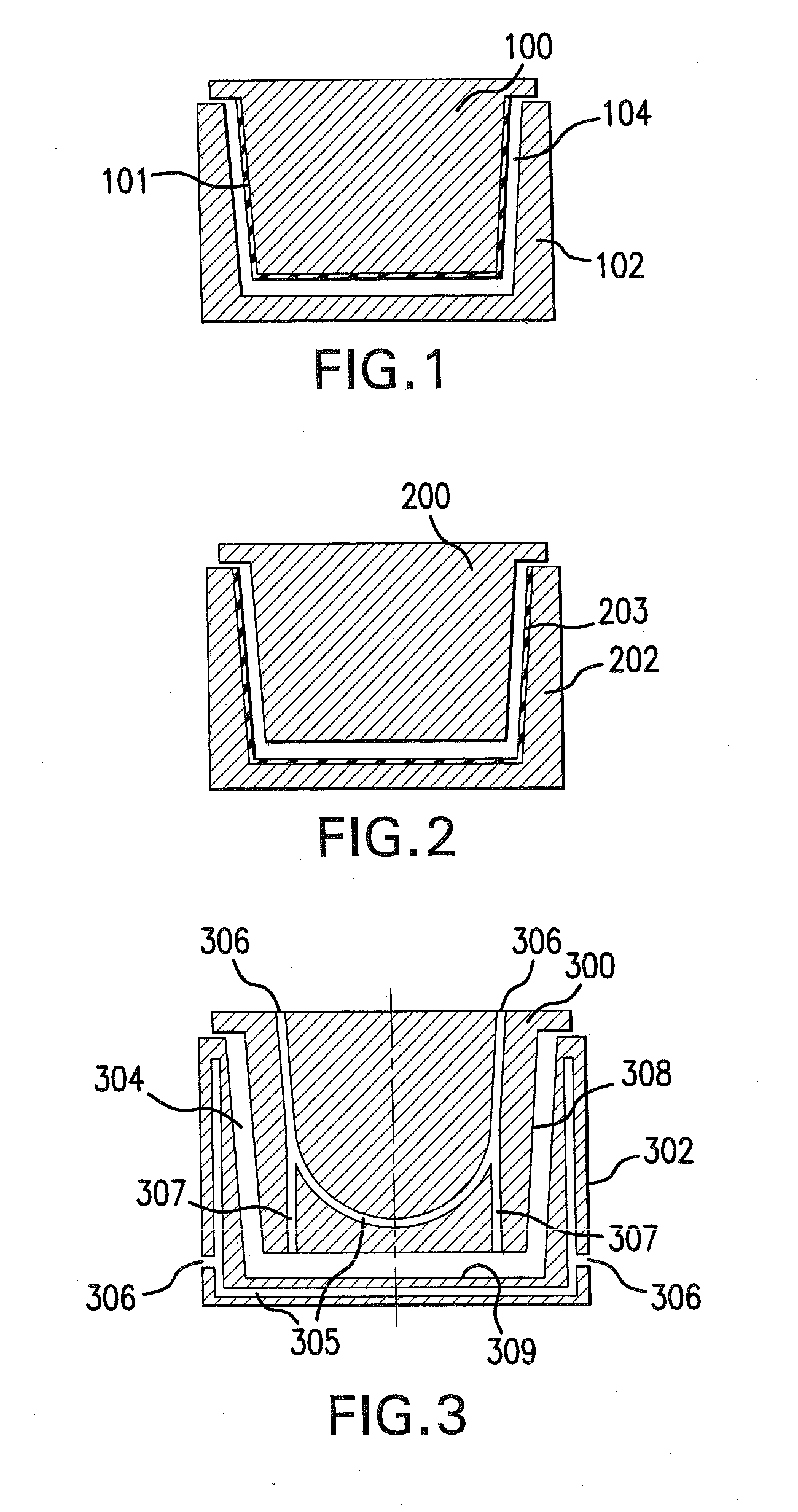

Quartz glass body, method and casting mold for manufacturing same

InactiveUS20080153688A1Low purityLow impurity contentAfter-treatment apparatusFinal product manufacturePorosityVitreous Bodies

The invention includes an improved quartz glass body, especially an improved quartz glass crucible for melting non-metals, non-ferrous metals, or silicon, and a method and casting mold for making it The quartz glass body is made by a method in which a quartz glass-water mixture is supplied to a casting mold comprising an outer part and an inner part, dried in the mold, and put under an overpressure during the drying. Later a resulting green glass body is removed from the mold. At least a portion of the shaping surfaces of the inner part of the mold are surfaces of a water-impermeable substance. The method provides a cast body with a reduced tendency to crack and with a smaller open porosity.

Owner:SCHOTT AG

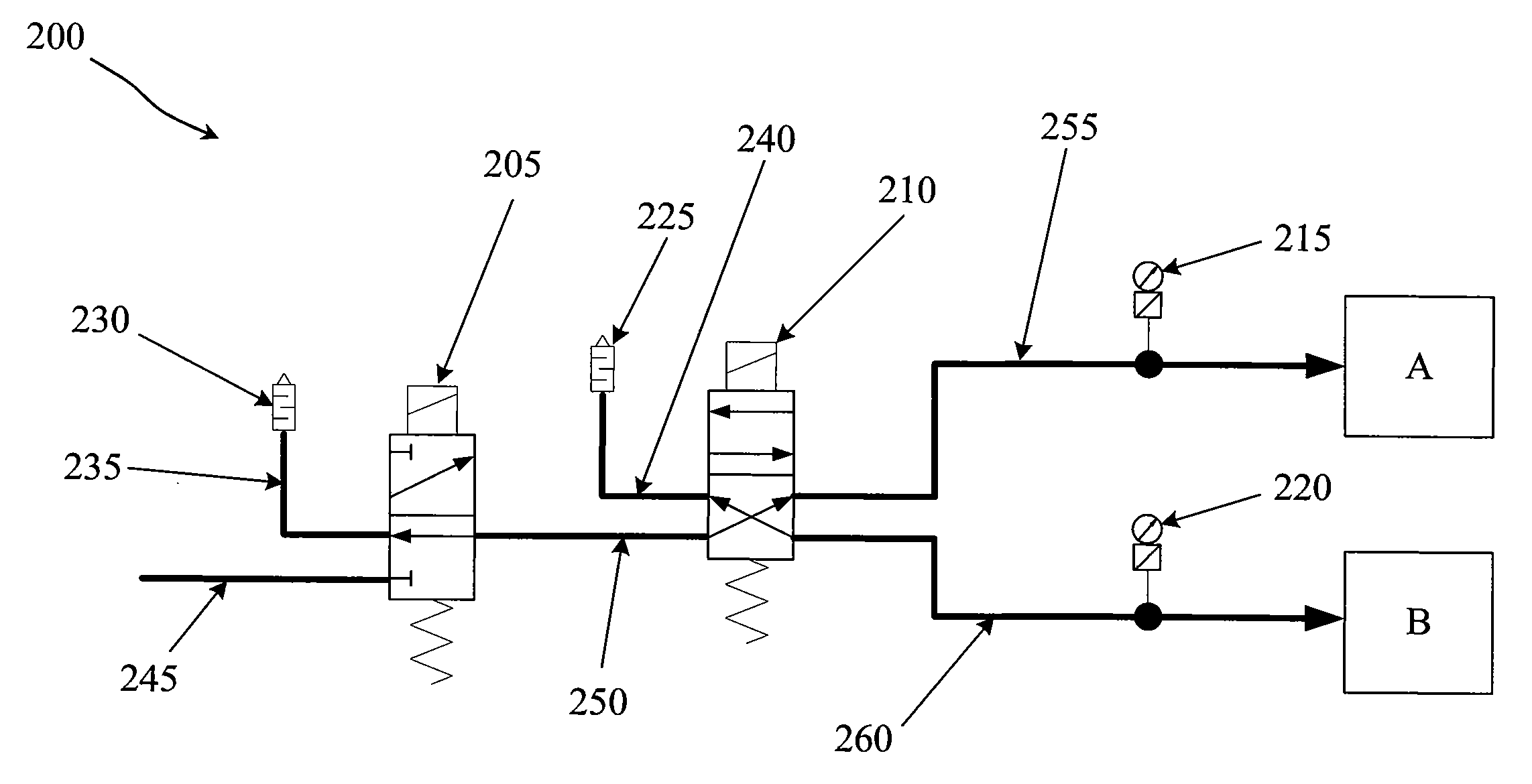

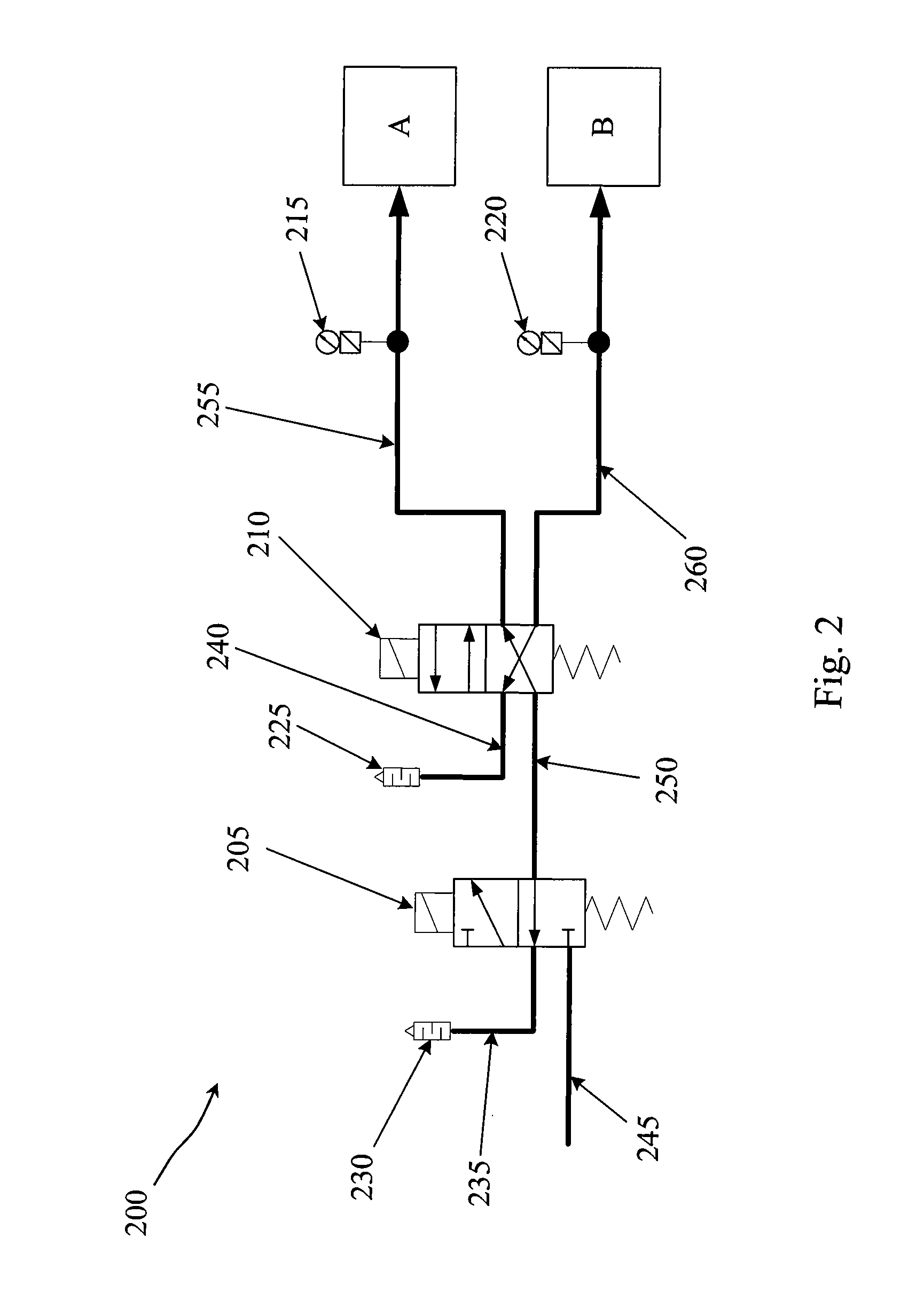

Pressure Monitor for Pneumatic Vitrectomy Machine

A system for a pneumatically-powered vitrectomy machine includes an output port, a venting valve, a venting manifold, a pressure transducer, and a controller. The output port provides pressurized gas to a vitrectomy probe. The venting valve is located close to the output port. The venting manifold fluidly connects the venting valve to a venting port. The venting port vents pressurized gas from the venting manifold. The pressure transducer is located near the output port. The pressure transducer is configured to read a pressure of a gas near the output port. The controller is adapted to receive information about the pressure and activate the venting valve. When the information received from the pressure transducer indicates a fault condition, the controller directs the venting valve to open.

Owner:ALCON INC

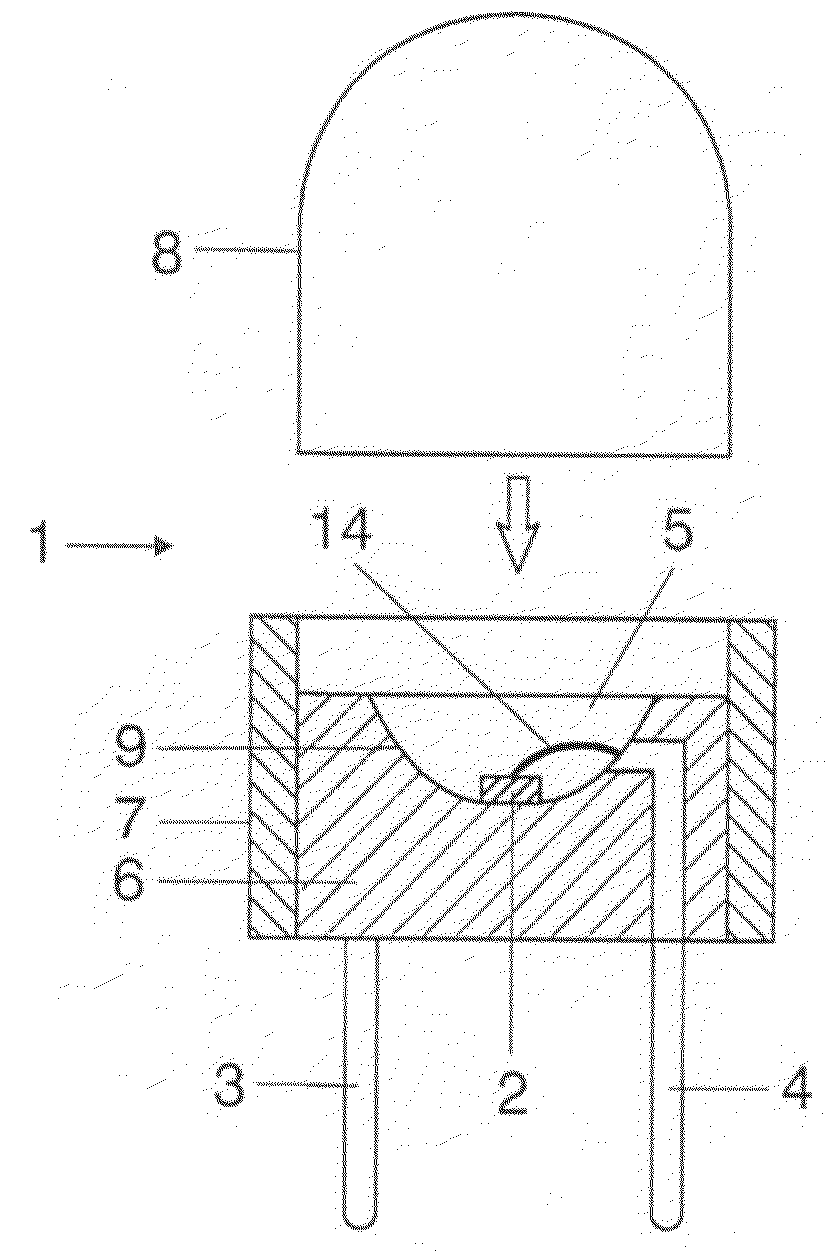

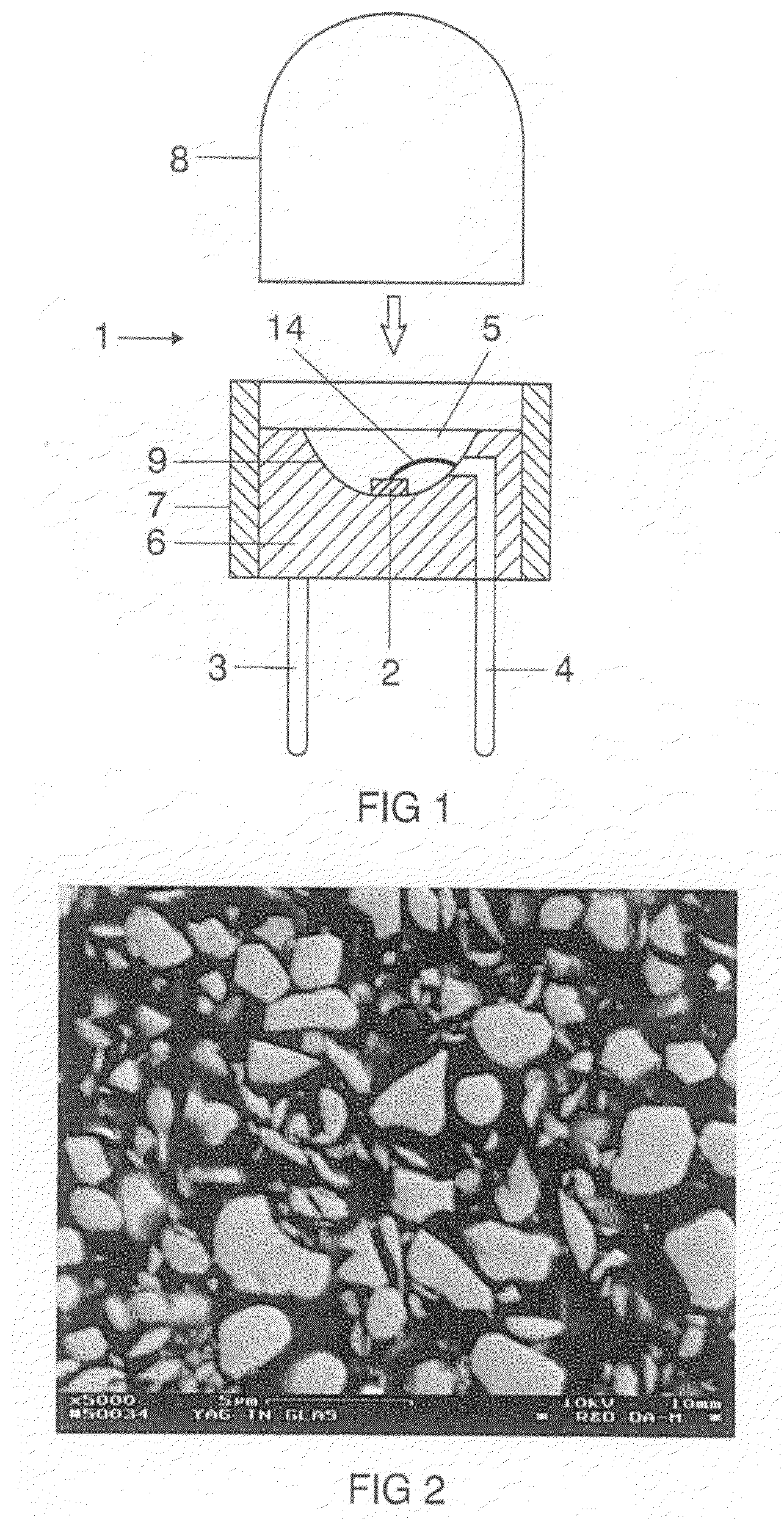

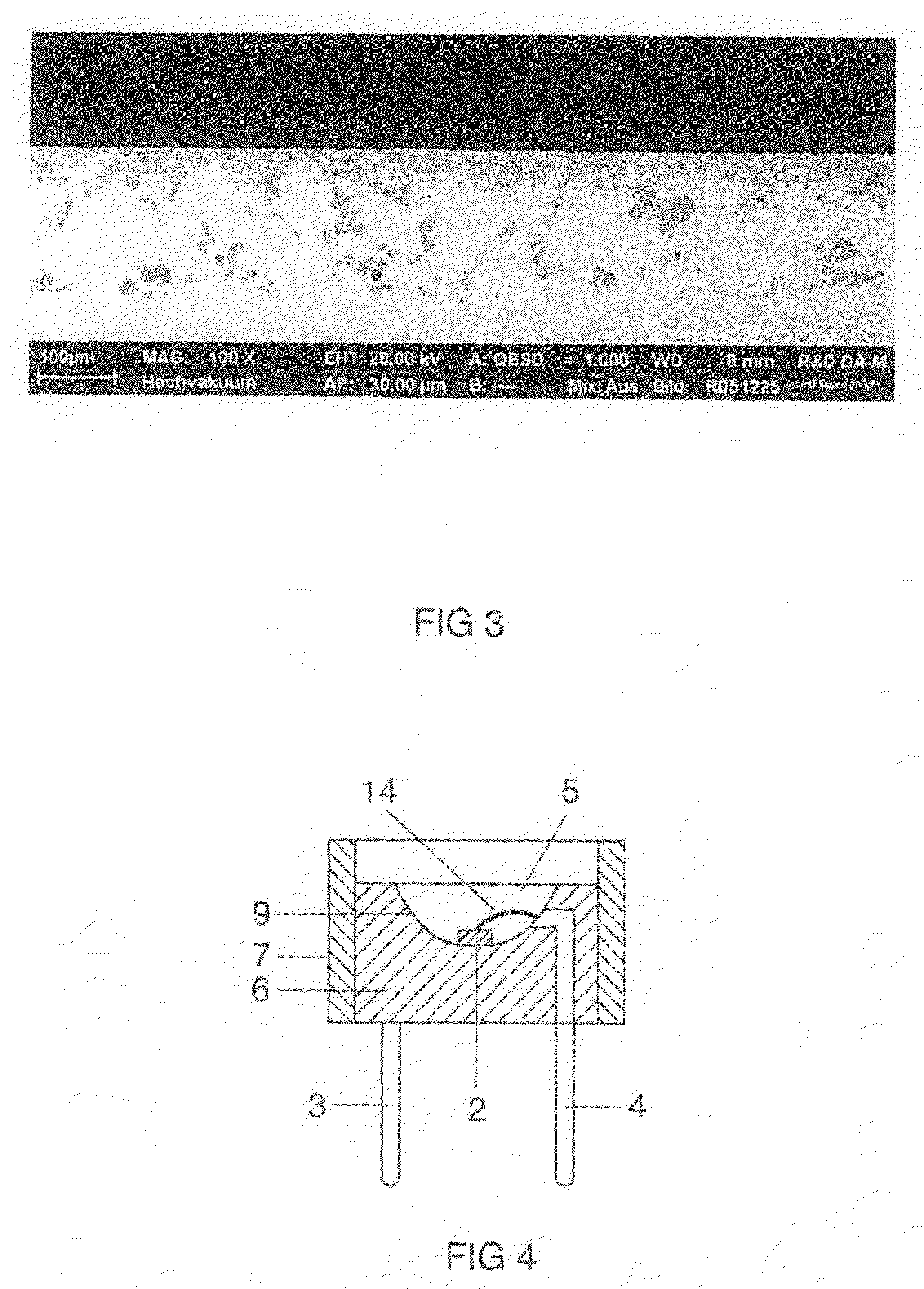

Luminescence conversion led

InactiveUS20090206352A1Improve conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingVitreous BodiesElectrical connection

A luminescence conversion LED having a radiation emitting chip that is connected to electrical connections and is surrounded by a housing that comprises at least a basic body and a cap, the chip being seated on the basic body, in particular in a cutout of the basic body, and the primary radiation of the chip being converted at least partially into longer wave radiation by a conversion element, wherein the cap is formed by a vitreous body, the conversion means being contained in the vitreous body, the refractive index of the vitreous body being higher than 1.6, preferably at least n=1.7.

Owner:OSRAM GMBH +1

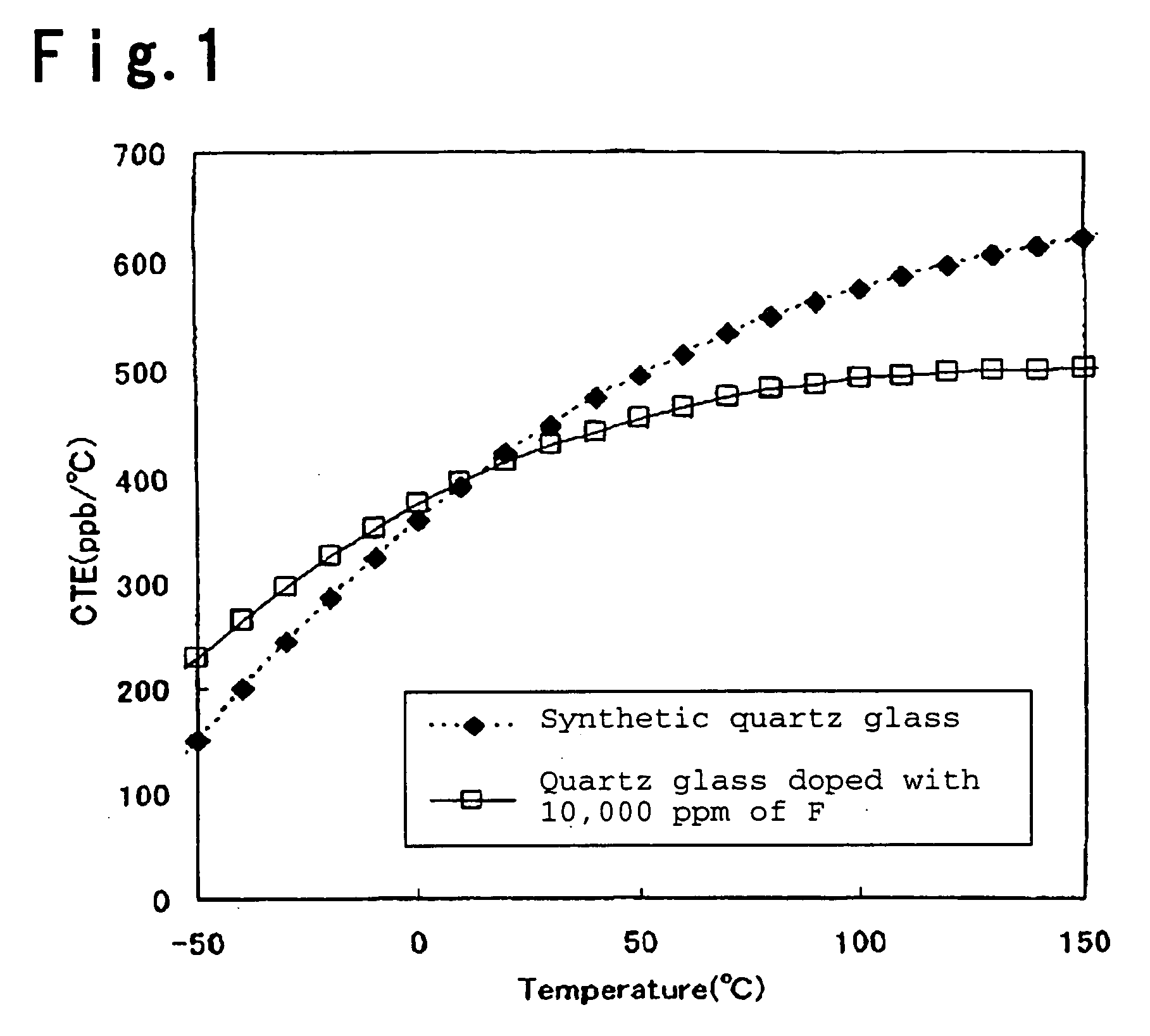

Silica glass containing TiO2 and process for its production

ActiveUS20050272590A1Excellent in of coefficientImprove uniformitySemiconductor/solid-state device manufacturingGlass shaping apparatusVitreous BodiesThermal expansion

A silica glass containing TiO2, which has a fictive temperature of at most 1,200° C., a F concentration of at least 100 ppm and a coefficient of thermal expansion of 0±200 ppb / ° C. from 0 to 100° C. A process for producing a silica glass containing TiO2, which comprises a step of forming a porous glass body on a target quartz glass particles obtained by flame hydrolysis of glass-forming materials, a step of obtaining a fluorine-containing porous glass body, a step of obtaining a fluorine-containing vitrified glass body, a step of obtaining a fluorine-containing formed glass body and a step of carrying out annealing treatment.

Owner:ASAHI GLASS CO LTD

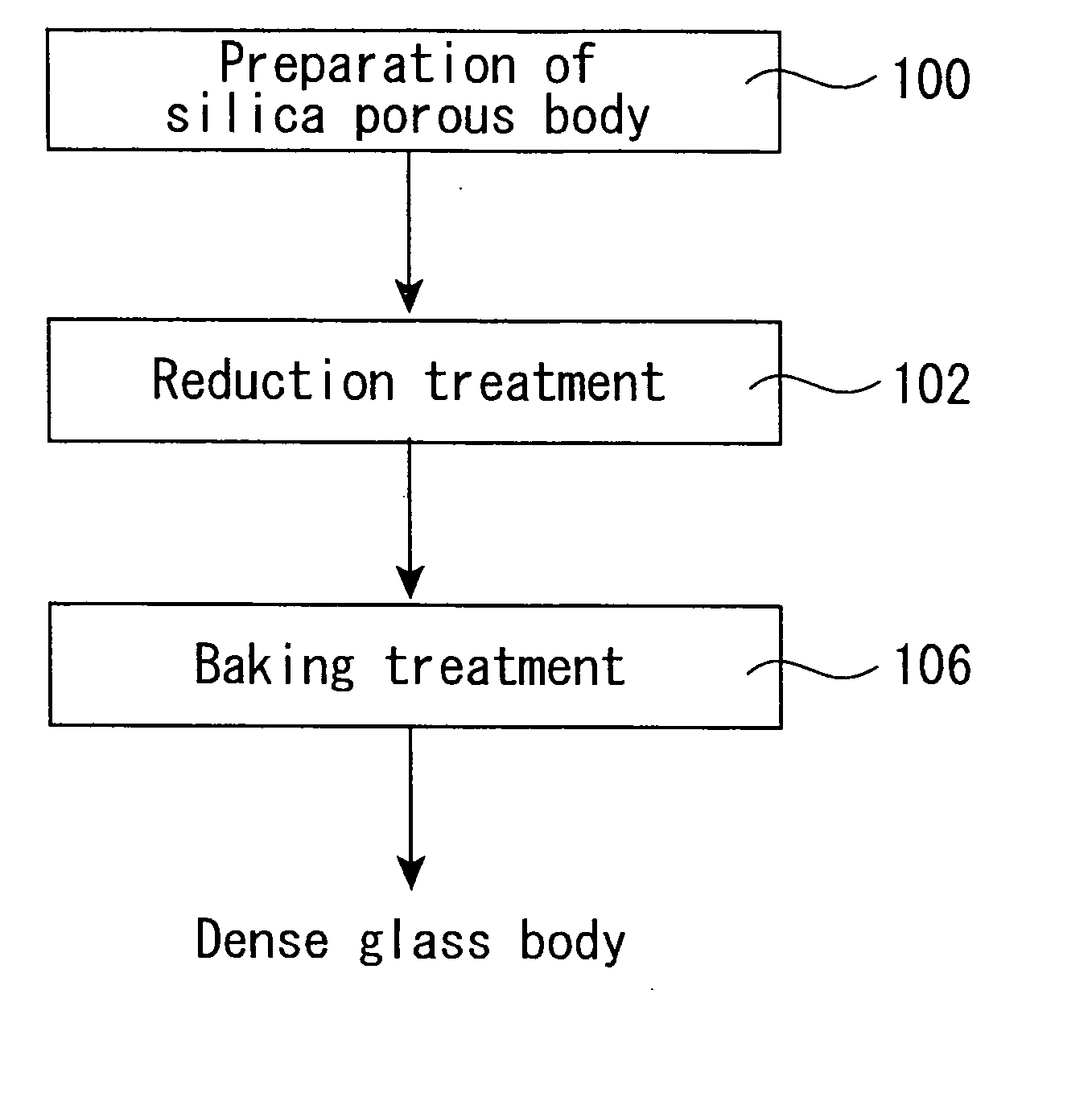

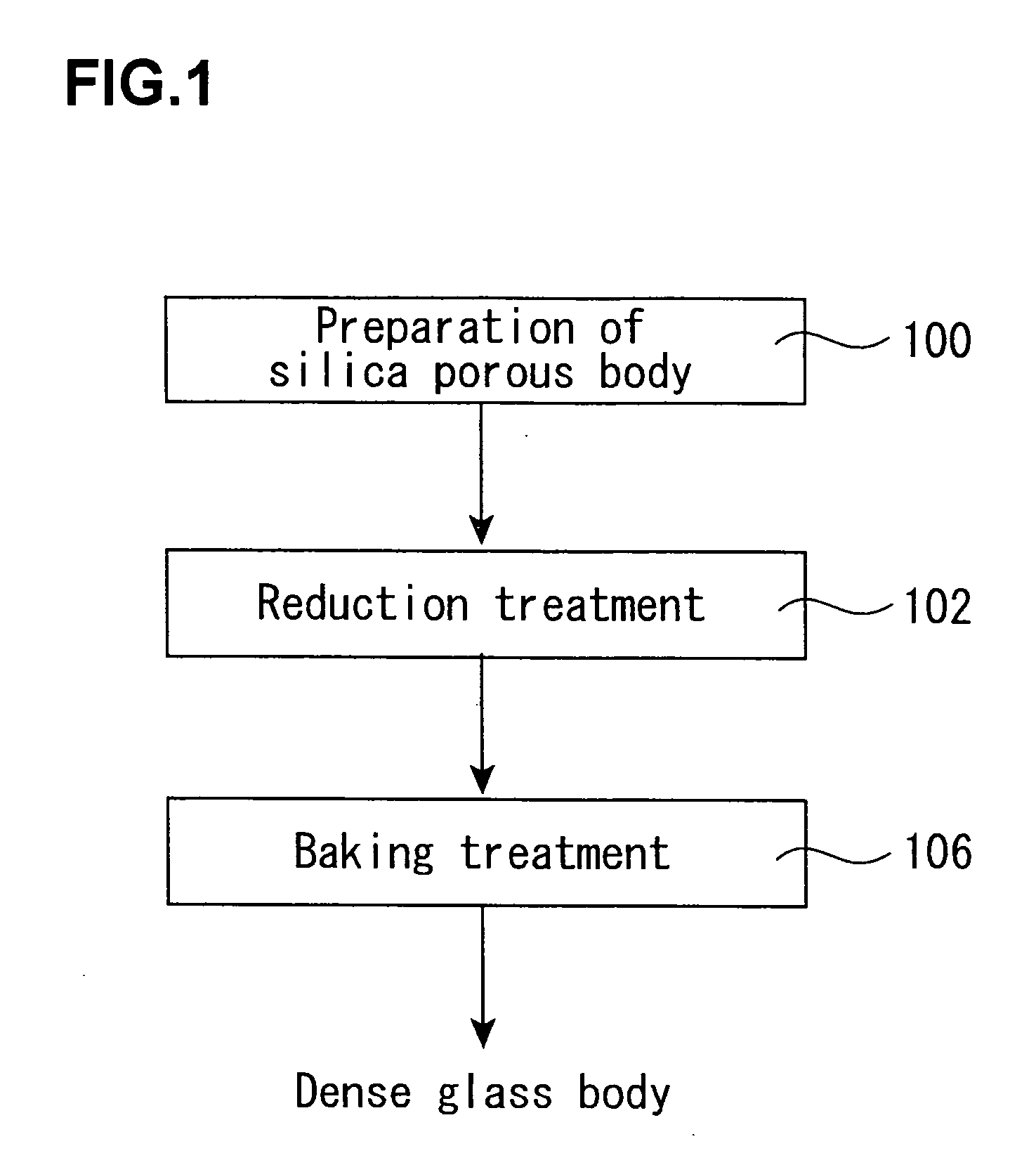

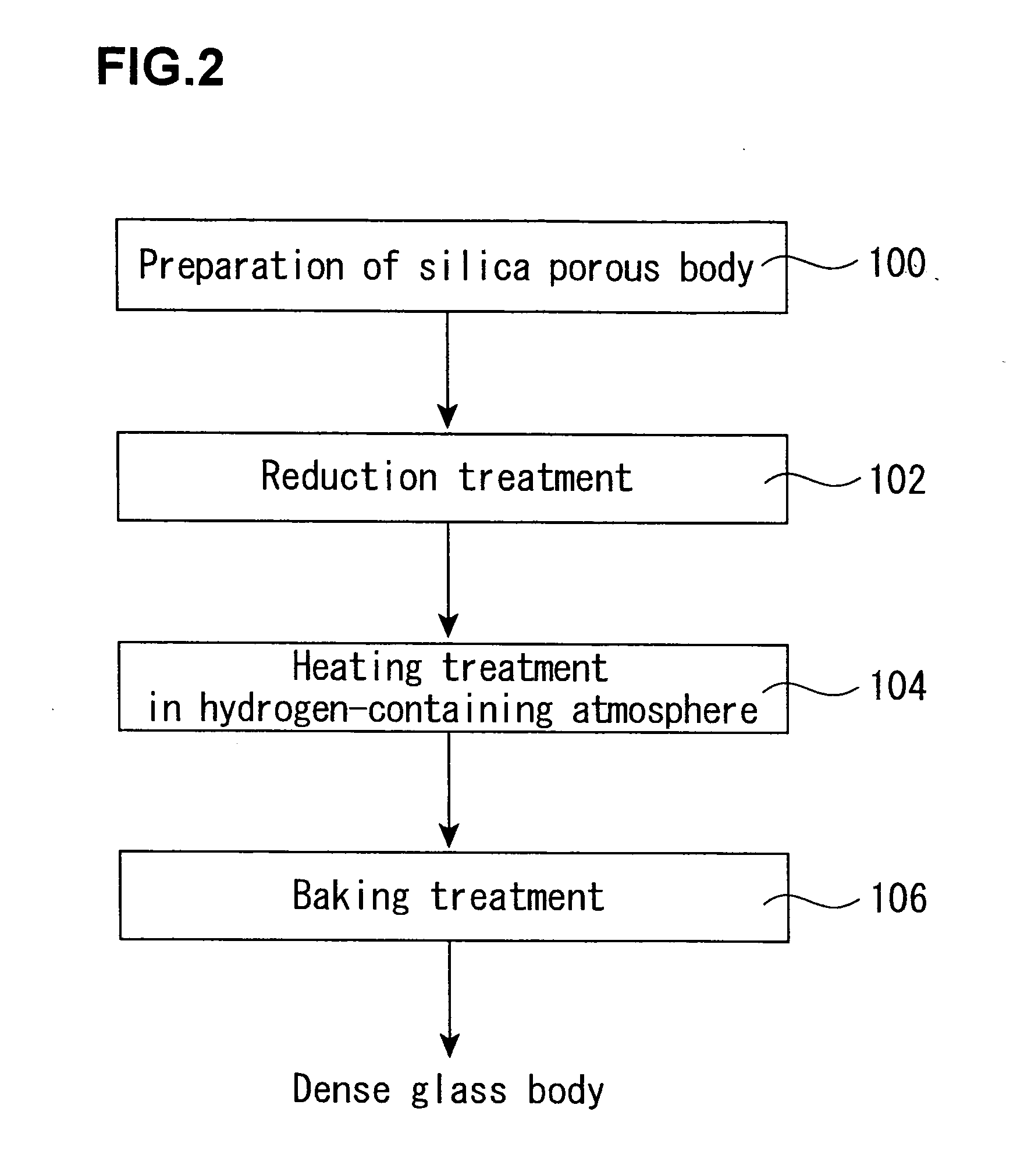

Method for producing synthetic quartz glass and synthetic quartz glass article

ActiveUS20060059948A1High effect for preventing diffusionImprove heat resistanceGlass shaping apparatusGlass severing apparatusReduction treatmentVitreous Bodies

First of all, there is provided a production process of a synthetic quartz glass which has less impurity, has a high-temperature viscosity characteristic equal to or more than that of a natural quartz glass, and hardly deforms even in a high-temperature environment, and especially a production process of a highly heat resistant synthetic quartz glass which is free from the generation of bubbles and is dense. Secondly, there is provided a highly heat resistant synthetic quartz glass body which is easily obtained by the production process of the present invention, and especially a transparent or black quartz glass body which is free from the generation of bubbles, is dense, has high infrared absorption rate and emission rate, and has an extremely high effect for preventing diffusion of alkali metal. The process is a process of producing a highly heat resistant quartz glass body having an absorption coefficient at 245 nm of 0.05 cm−1 or more, and the silica porous body was subjected to a reduction treatment, followed by baking, thereby forming a dense glass body.

Owner:SHIN ETABU QUARTZ PRODS

Reduced striae extreme ultraviolet elements

Titania-containing silica glass bodies and extreme ultraviolet elements having low levels of striae are disclosed. Methods and apparatus for manufacturing and measuring striae in glass elements and extreme ultraviolet elements are also disclosed.

Owner:CORNING INC

Apparatus integrated with ceramic bushing for manufacturing mineral/basalt fibers

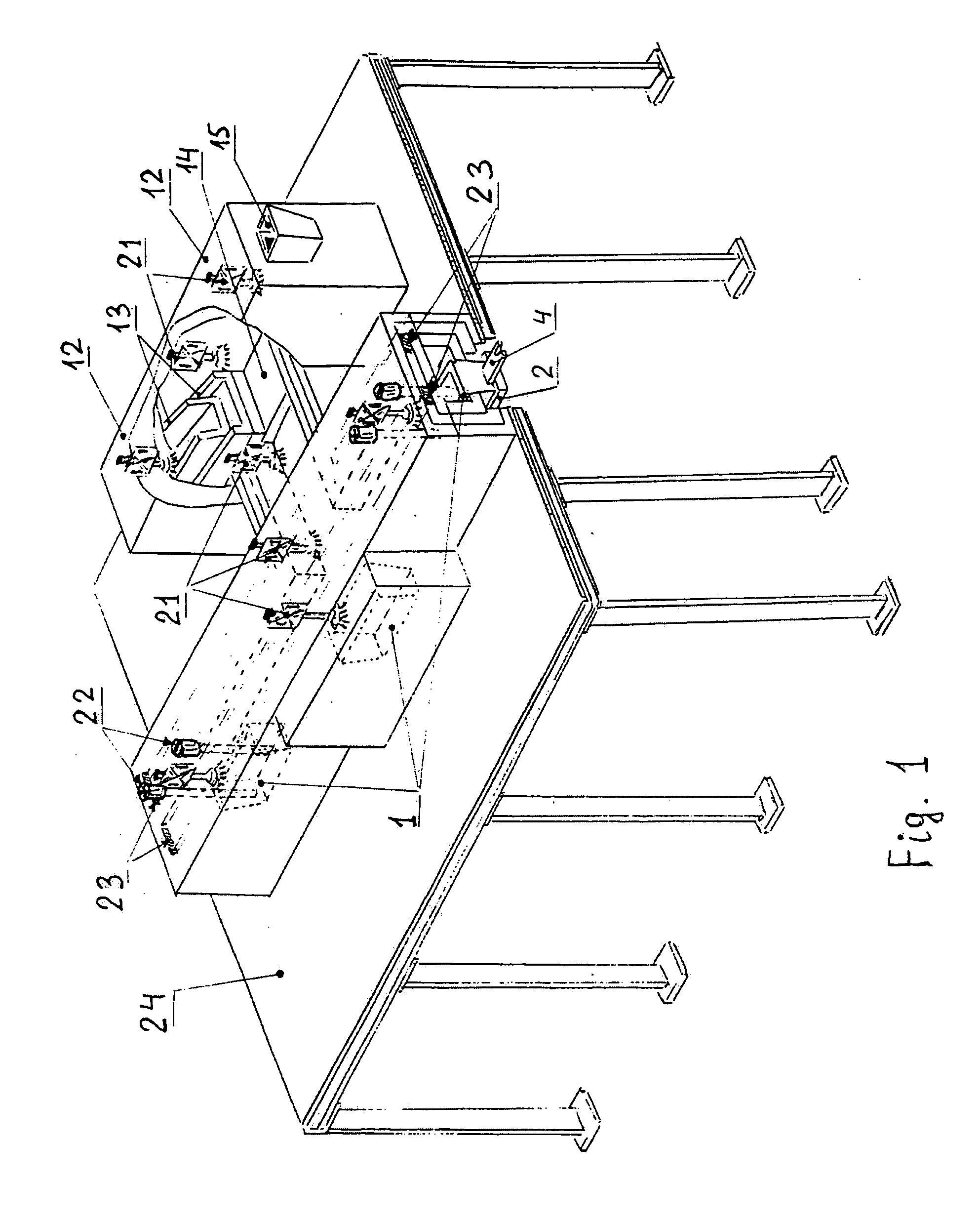

ActiveUS20060218972A1Low costImprove stabilityGlass furnace apparatusRotary drum furnacesComposite applicationMicrometer

The apparatus integrated with ceramic bushing / s for manufacturing mineral / basalt fibers from natural basalt rocks is disclosed. The apparatus and the ceramic bushing / s are integrated into one unit capable provide all operations which are needed: melt basalt rock materials, homogenize basalt glass body suitable for forming fibers to be drawn / attenuated into continuous fibers and gathered into a strand of elemental fibers from 7 to 20 micrometers (μm) in diameter. Also the coarse fibers at the diameters from 20 μm to 100 micrometers (μm) having amorphous structural state which exhibit ductile / flexible properties. The ceramic bushing / s are designed to eliminate precious Pt, Rd metals using instead corrosion resistant ceramic materials to reduce basalt fiber products cost and to increase its commercial compatibility when compared to the other fibers currently been on the market in reinforced concrete / composite applications, including Three Dimension Fiber Reinforced Concrete-3D FRC.

Owner:BLACKBULL IND INC +1

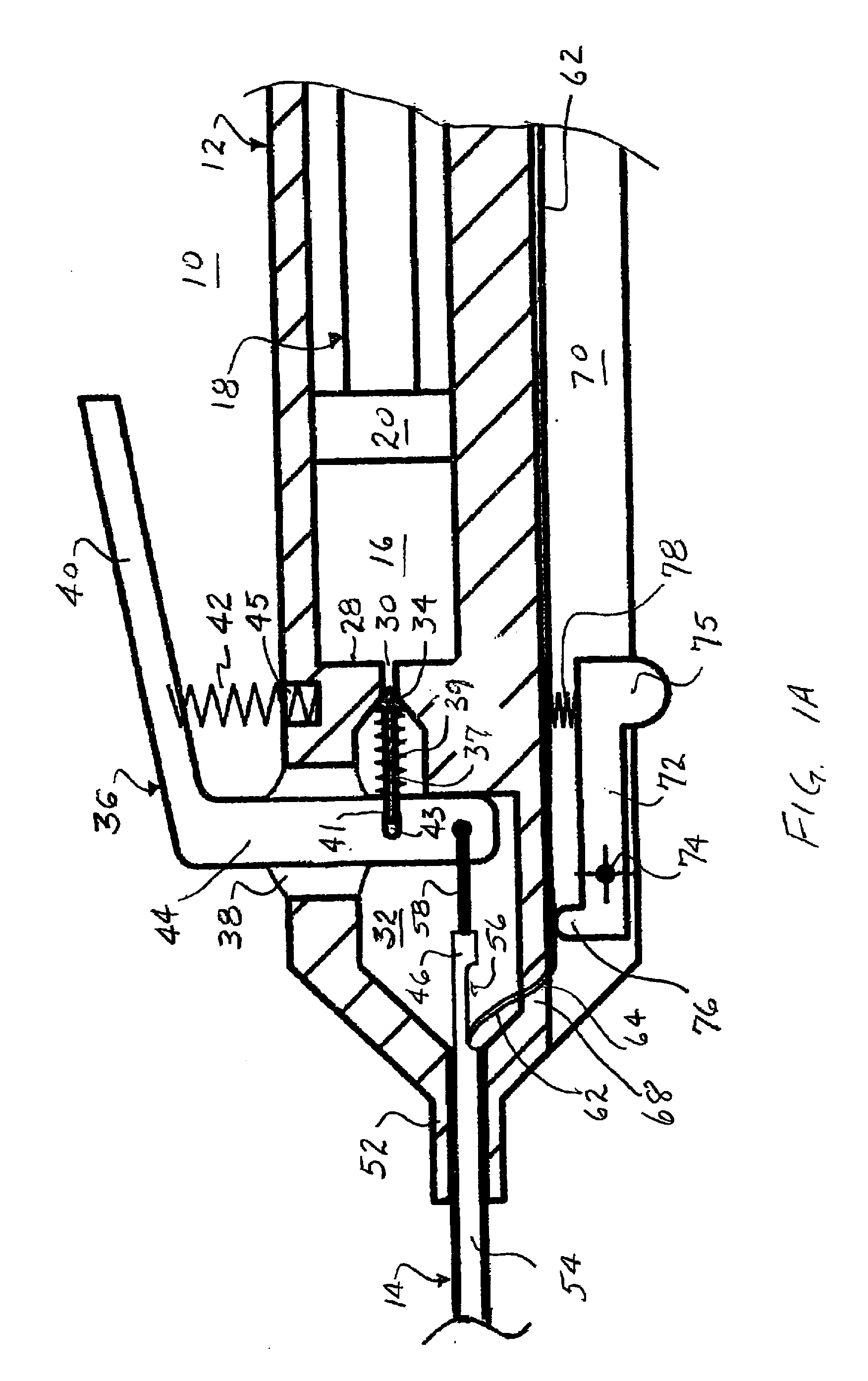

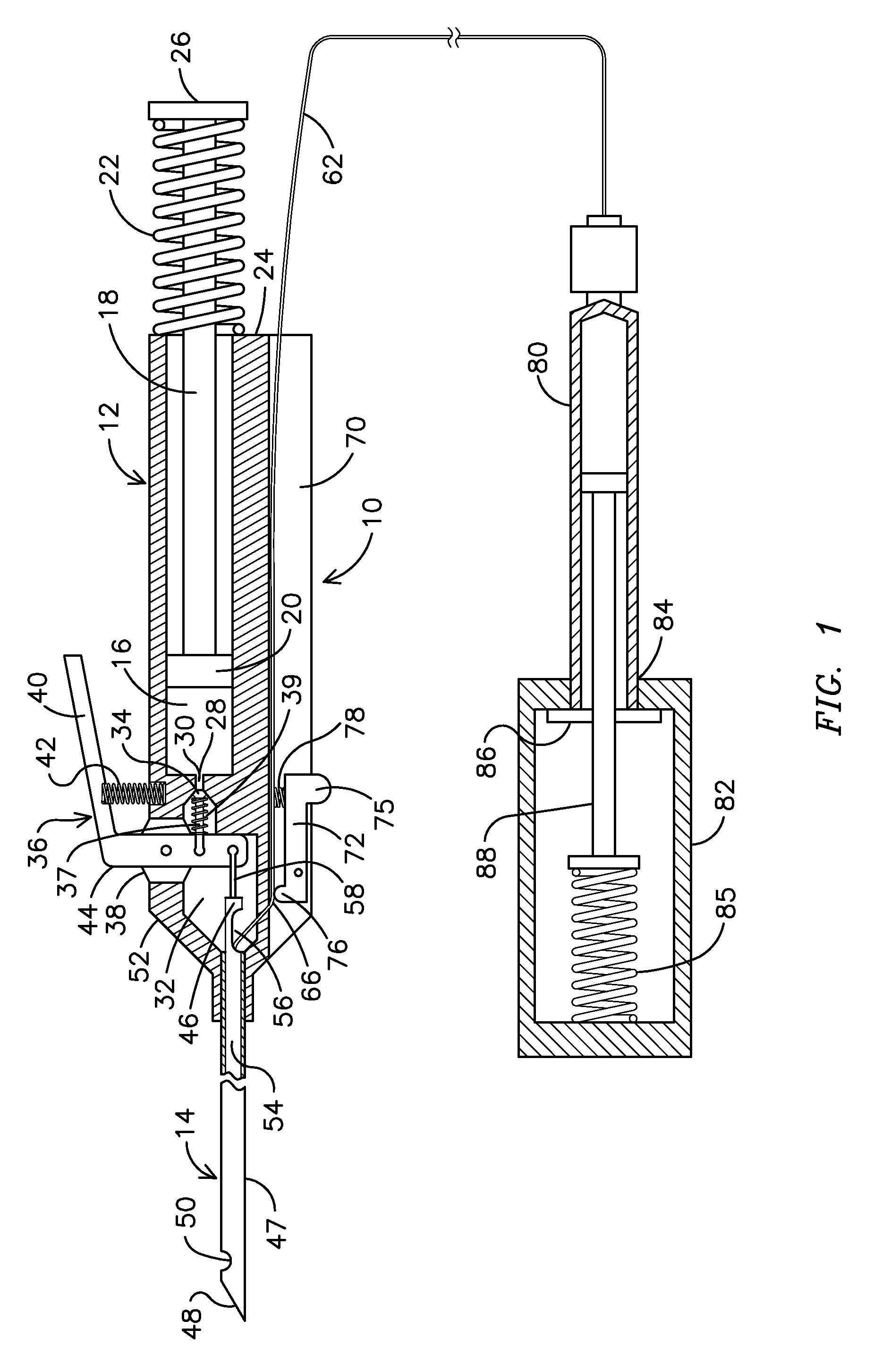

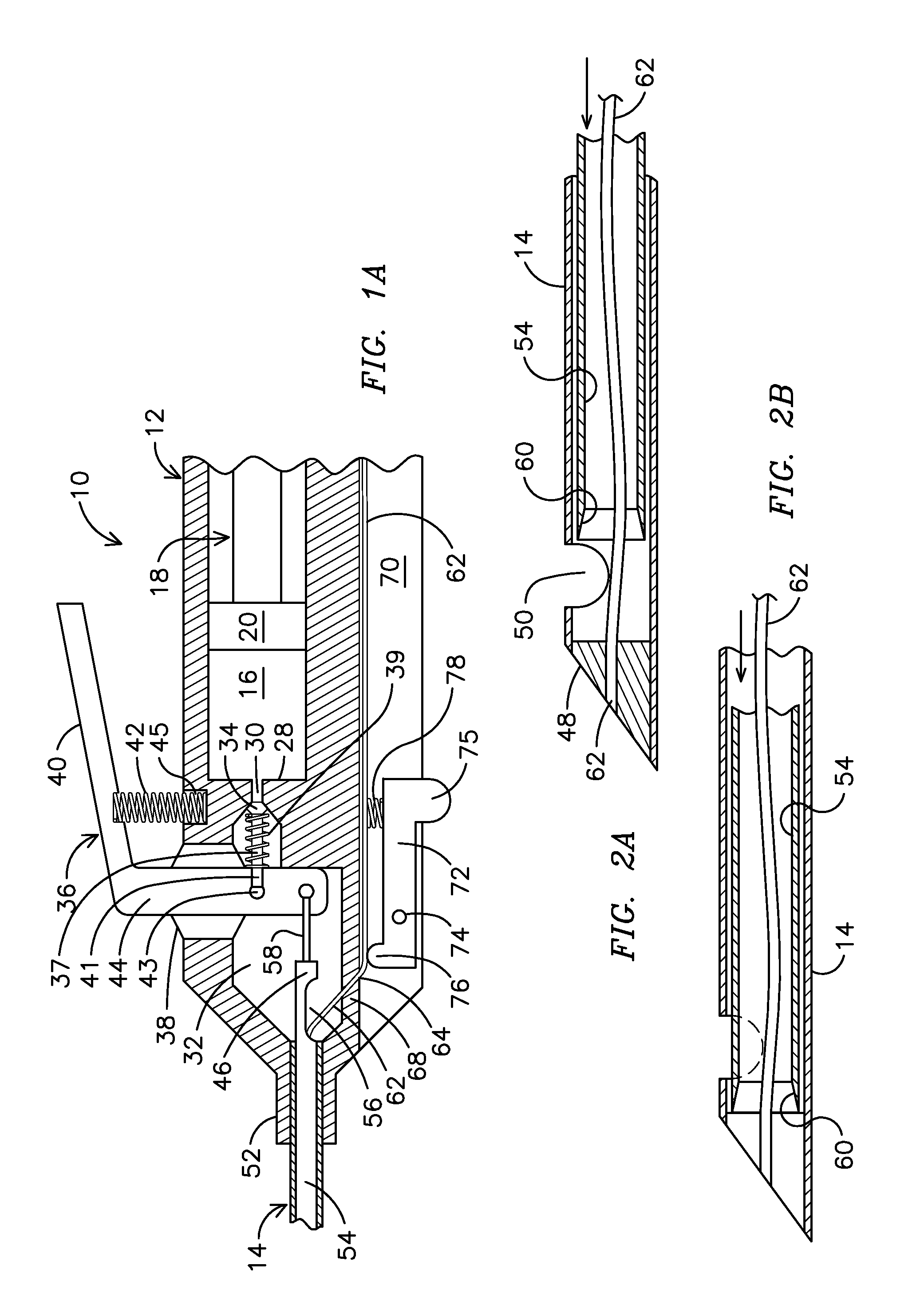

Retractable Tip For Vitrectomy tool

ActiveUS20090234274A1Prevent undesirable increase in intraocular pressureAvoid cross contaminationEye surgerySurgeryAbdominal trocarEngineering

A probe for a vitrectomy tool is provided having a vitreous cutter tube having a blunt tip at a distal end and adapted to be coupled at a proximal end to a handpiece of a vitrectomy tool; a retractable outer trocar tube surrounding the vitreous cutter tube having an open distal end with a sharpened edge; and a retraction mechanism coupled to a proximal end of the outer trocar for selectively extending and retracting the outer trocar tube between a first extended position wherein the sharpened edge of the outer trocar is extended beyond the blunt tip of the vitreous cutter tube to facilitate insertion into the eye and a second retracted position wherein the sharpened edge of the outer trocar is retracted behind the blunt tip of the vitreous cutter tube to facilitate safe operation of the probe. A vitrectomy tool for removing material from an eye of a patient is provided having a housing having a proximal end and a distal end and a probe coupled to the proximal end of the housing.

Owner:INSIGHT INSTR

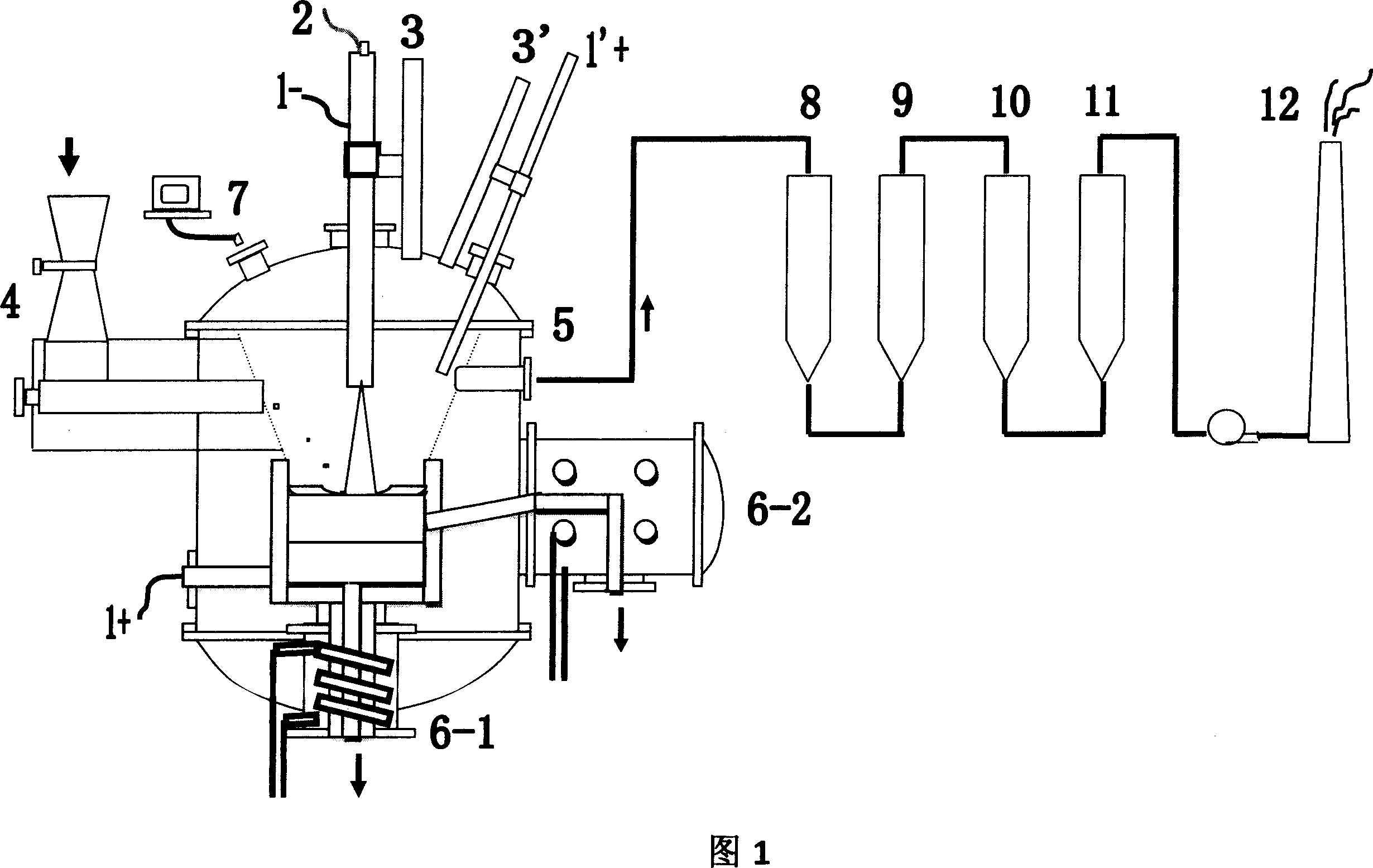

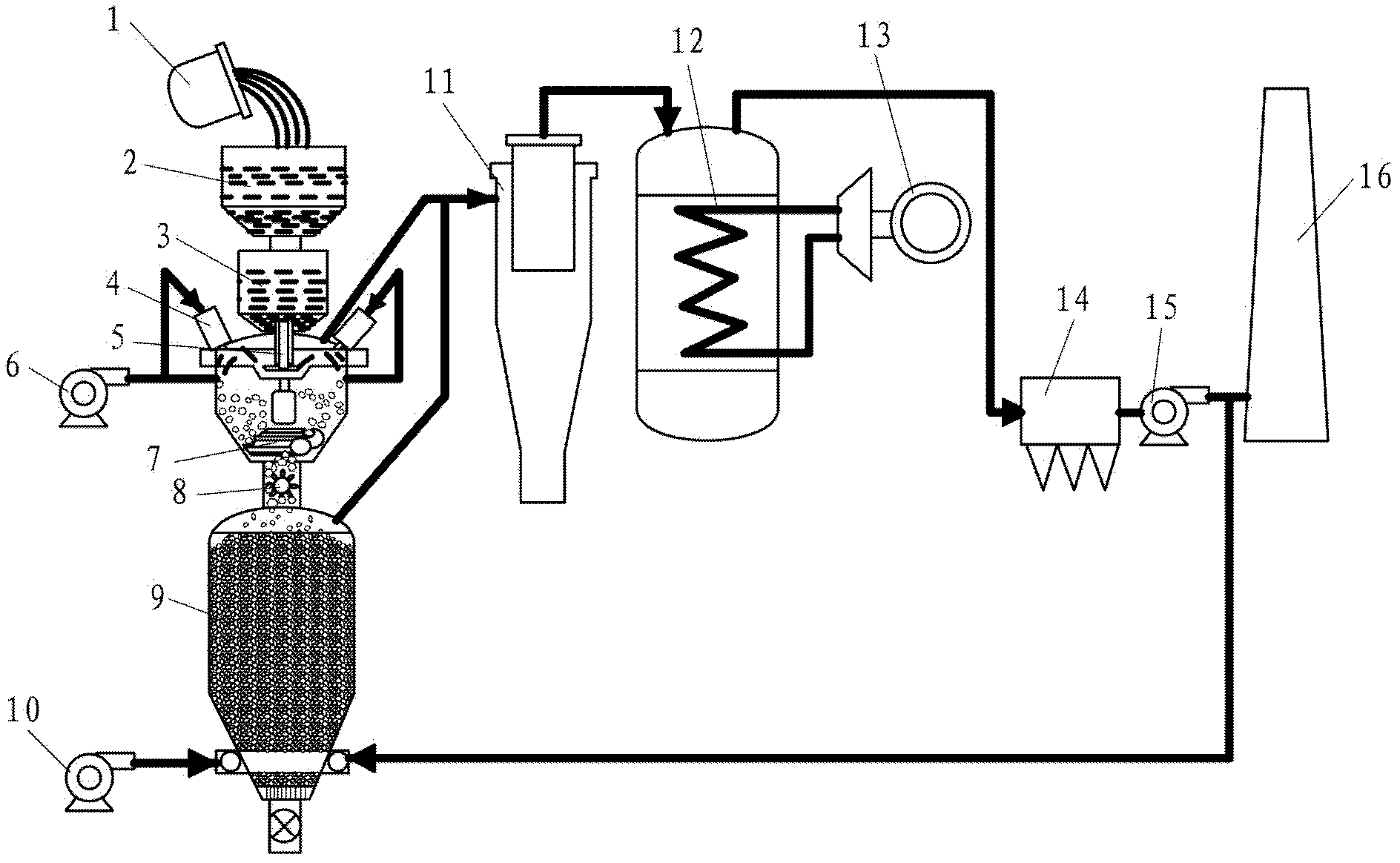

Poisonous waste treating method and special apparatus

InactiveCN101088581AAvoid secondary pollutionReduce processingDispersed particle separationCombined combustion mitigationHigh energyPolychlorinated biphenyl

The present invention relates to poisonous waste treating method and apparatus, and belongs to the field of waste treating technology. The poisonous waste treating apparatus is plasma apparatus comprising a furnace body, a main graphite electrode and an auxiliary graphite electrode connected to the cover of the furnace body, carrier gas supplier connected to the main graphite electrode, a feeder, a vitreous body exhausting heat pump, a metal melt heat pump, a crucible inside the furnace body, a lower electrode in the bottom of the furnace body, a liquid level sensor connected to the sensor controller, and a tail gas exhausting system connected to the furnace body. It is used in treating polychlorinated biphenyl and other high dangerous waste through instantaneous high temperature, and has no secondary pollution, capacity of recovering high energy gas, and capacity of recovering metals.

Owner:HOOTECH

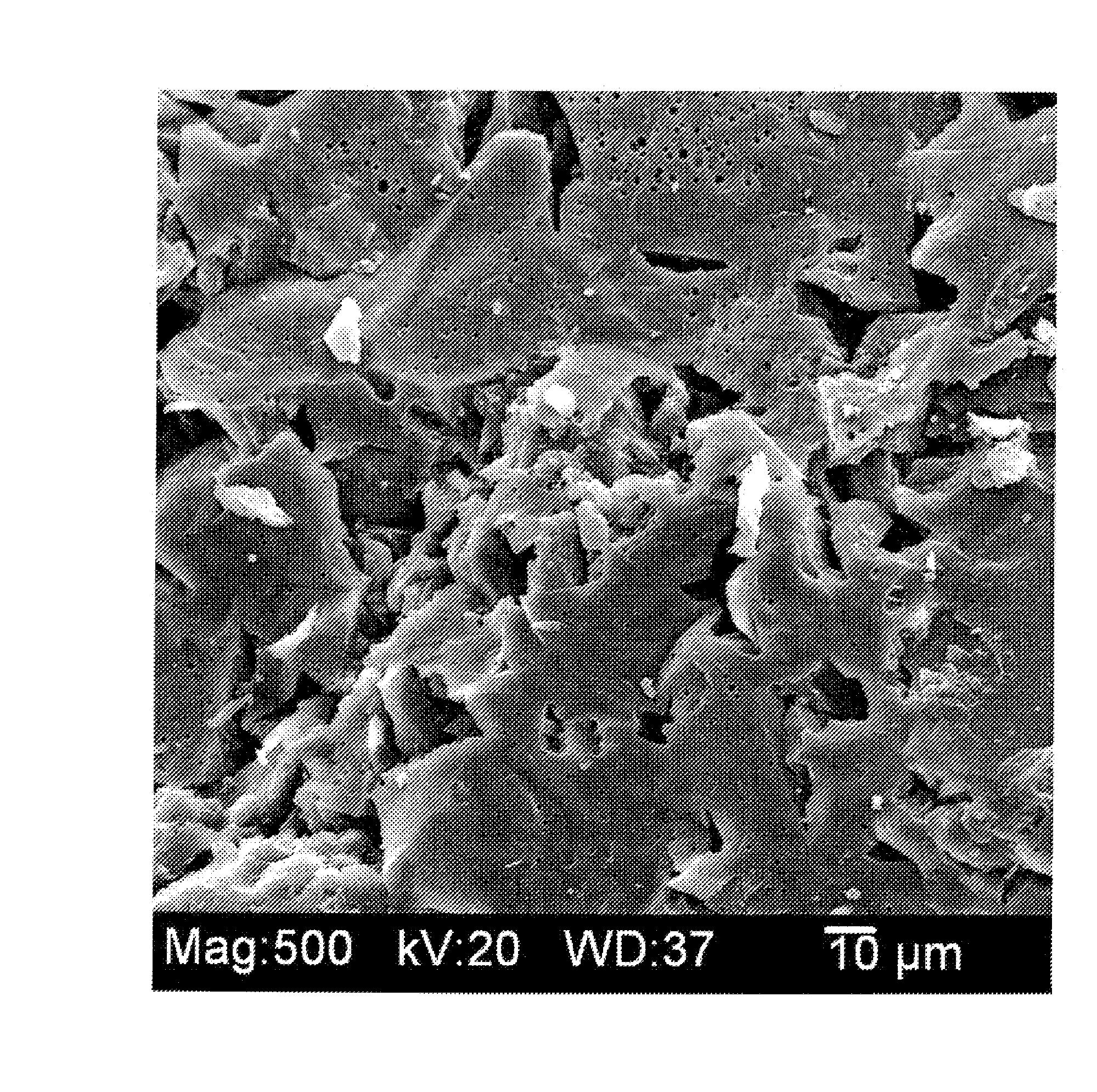

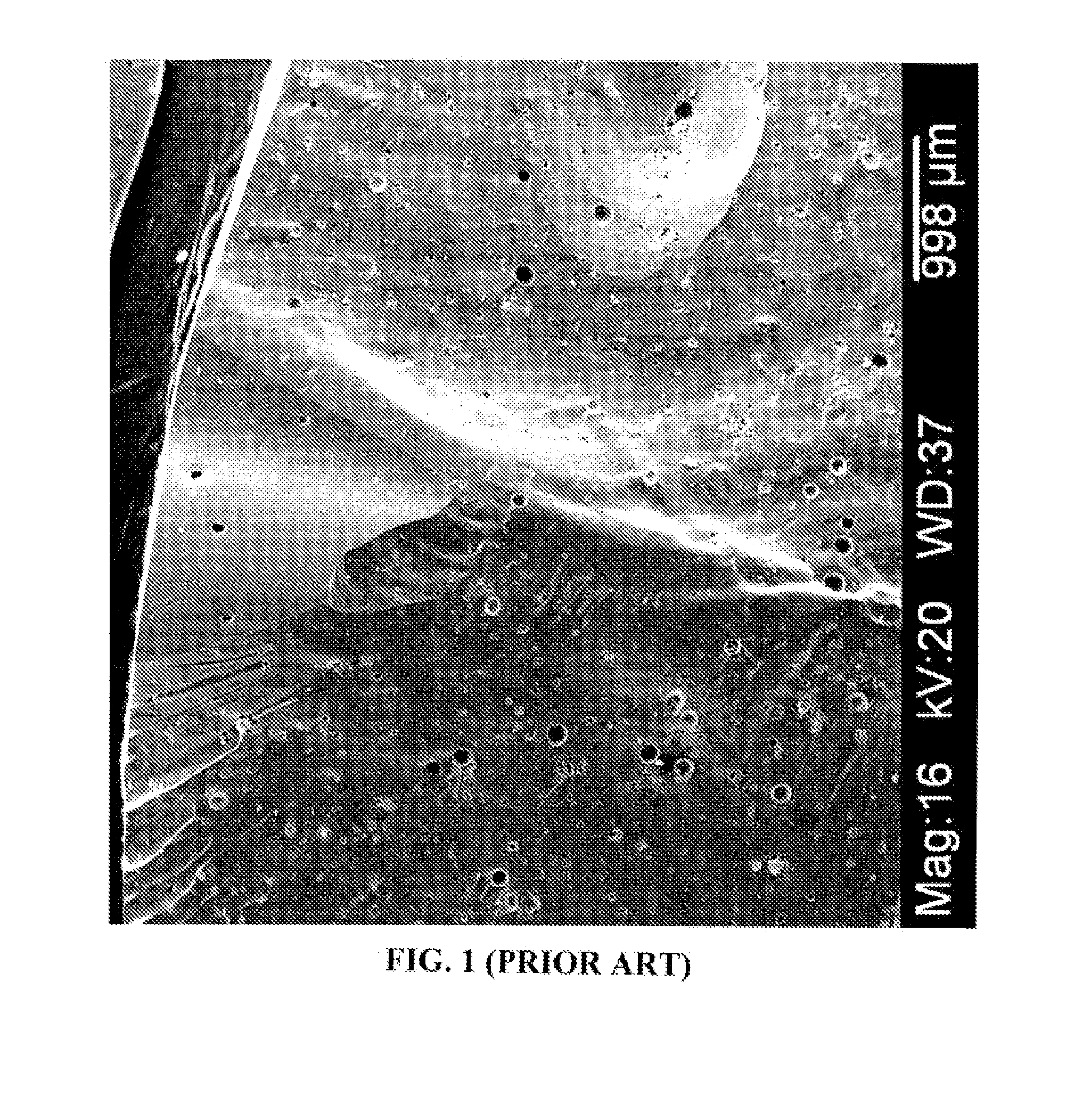

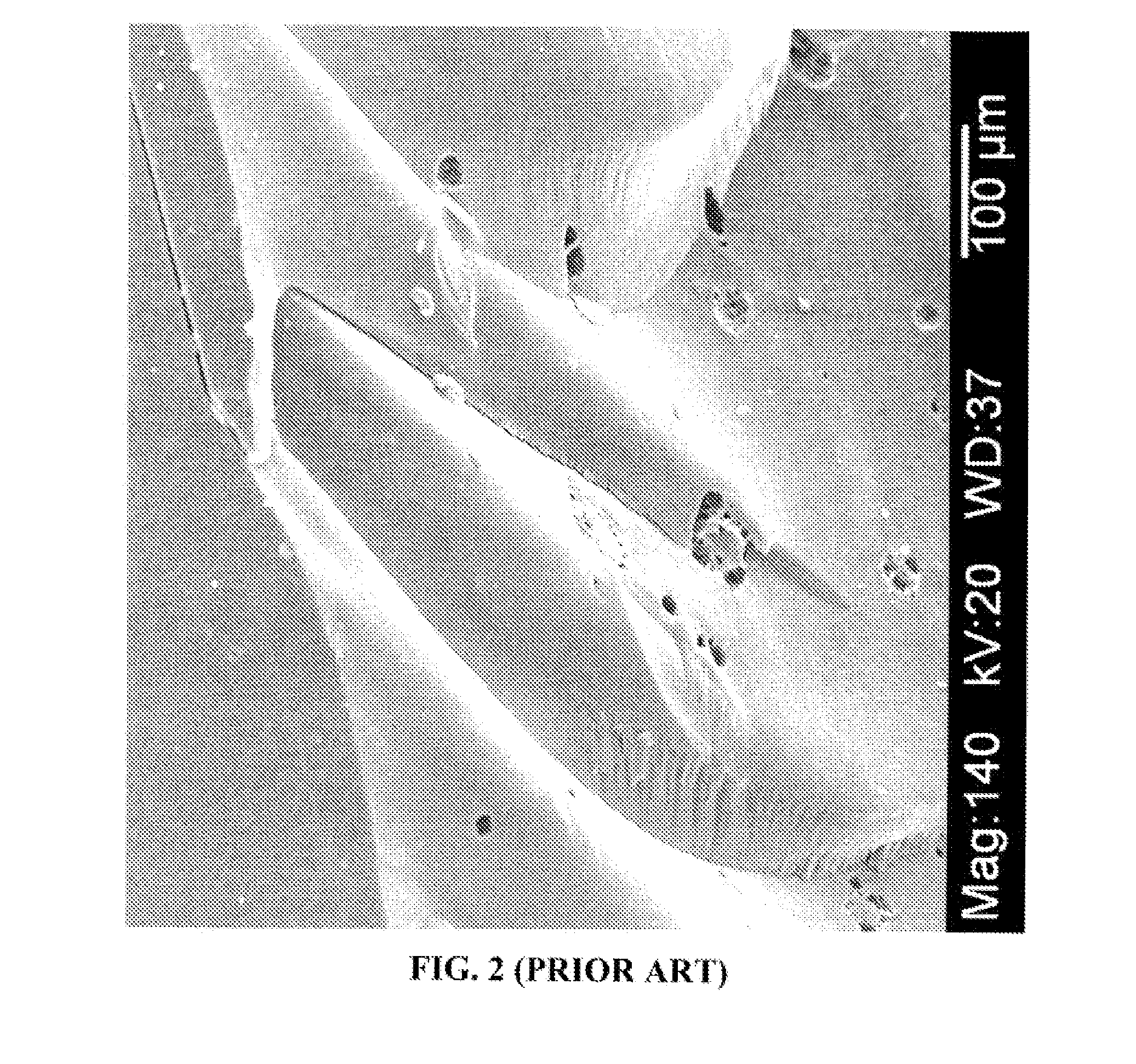

Biphasic nanoporous vitreous carbon material and method of making the same

A biphasic nanoporous vitreous carbon material with a cementitious morphology characterized by presence of non-round porosity, having superior hardness and tribological properties, as useful for high wear-force applications. The biphasic nanoporous vitreous carbon material is produced by firing, under inert atmosphere, of particulate vitrified carbon in a composition containing (i) a precursor resin that is curable and pyrolyzable to form vitreous carbon and, optionally, (ii) addition of one or more of the following: solid lubricant, such as graphite, boron nitride, or molybdenum disulfide; a heat-resistant fiber reinforcement, such as copper, bronze, iron alloy, graphite, alumina, silica, or silicon carbide; or one or more substances to improve electrical conductivity, such as dendritic copper powder, copper “felt” or graphite flake, to produce a superior vitreous carbon that is useful alone or as a continuous phase in reinforced composites, in relation to conventional glassy carbon materials.

Owner:CARBON CERAMICS CO LLC

Method for preventing contamination of an inner surface of a hollow glass body by alkali compounds and glass container, especially for medicinal purposes

InactiveUS7980096B2Preventing and avoiding contaminationBlock compoundPharmaceutical containersGlass drawing apparatusVitreous BodiesContamination

In order to avoid deposition of evaporating alkali compounds on an inner surface of a hollow glass body during thermal processing to form a glass container from the hollow glass body, an overpressure is provided in the hollow glass body during the thermal processing. Either rinsing the hollow glass body with a gas, such as air, or at least partially closing the glass body at one end so that sufficiently rapid pressure equilibration is avoided, can provide this overpressure. The glass containers made by these methods are especially suited for food or pharmaceuticals because they have a reduced alkali release from their inner surfaces, for example at most about 2.0 mg / l sodium oxide.

Owner:SCHOTT AG

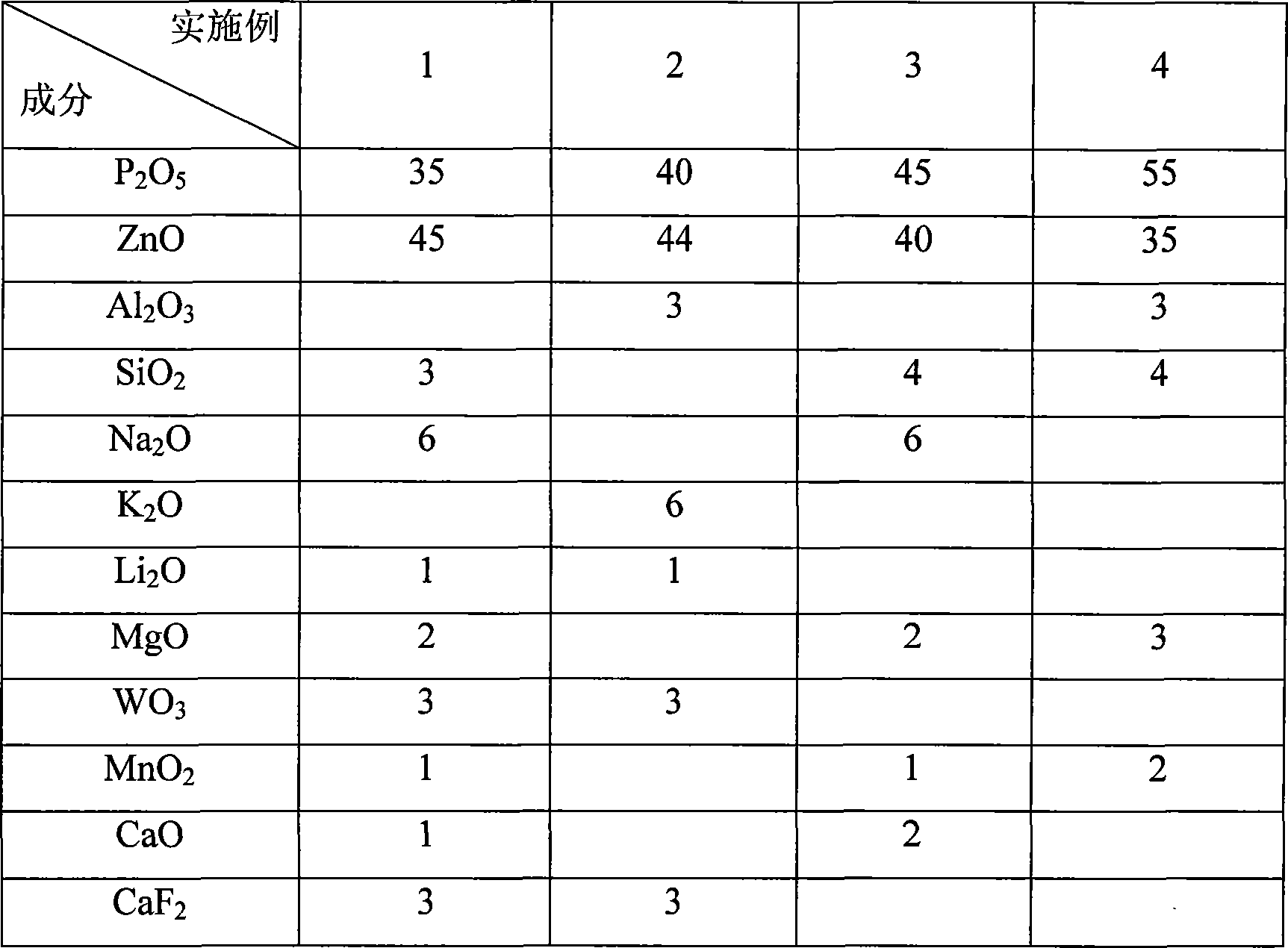

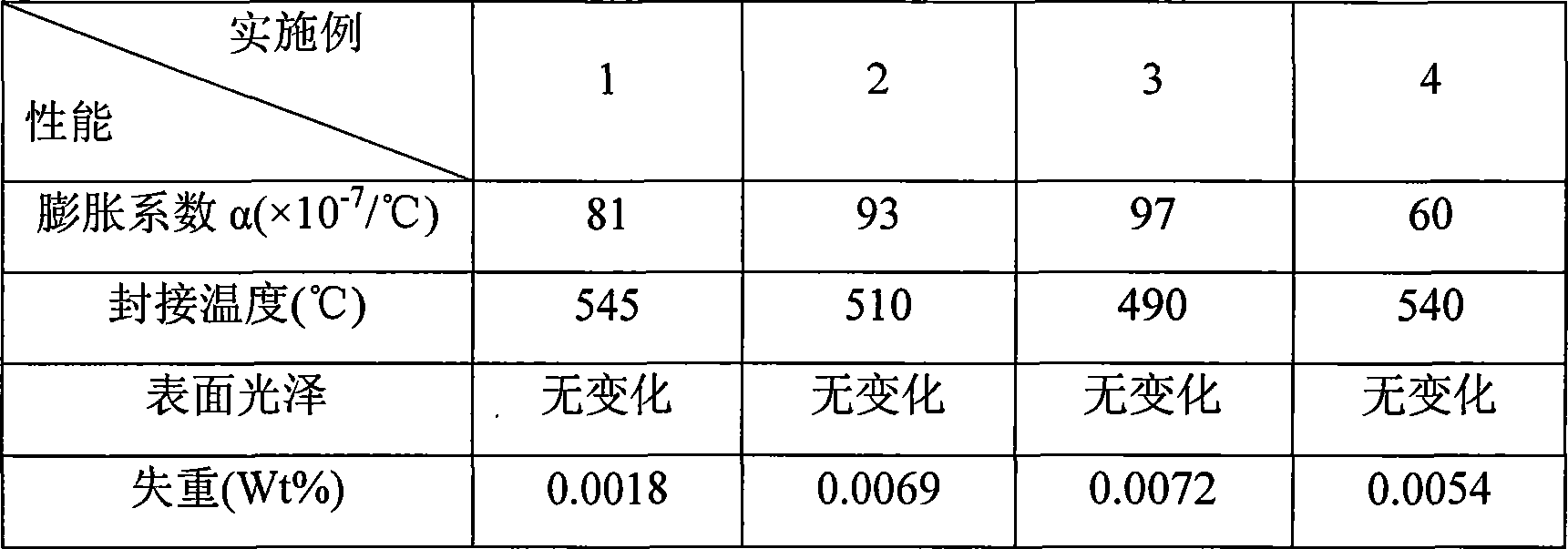

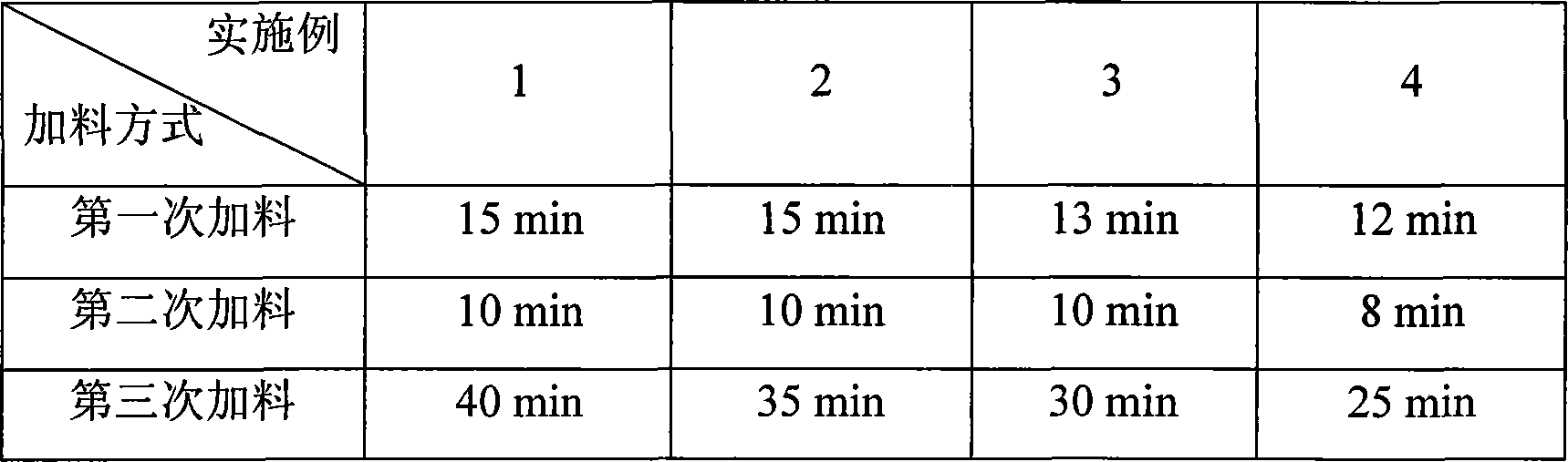

Leadless low-melting glass powder for seal with metal or alloy and preparation method thereof

InactiveCN101113073AEasy to adjust thermal expansion coefficientSuitable softening temperatureVitreous BodiesMixed materials

The invention relates to lead-free glass powders with low melting point for sealing of metal or alloy and preparation methods thereof. The glass powder comprises P2O5, ZnO, Al2O3, SiO2, MgO, MnO2, Li2O, WO3, CaF2, Na2O, K2O and CaO. The preparation thereof is divided into the following steps: (1) raw materials are drawn and fully mixed according to weight proportions to make into mixed materials; (2) the mixed materials are heated and melted for 30 minutes to two hours under a temperature ranging from 1000 DEG C to 1350 DEG C; (3) the melted glass liquid is cooled and cured into glass body. The glass powder not only has comparatively ideal heat expansion coefficient, softening temperature and chemical stability but also has simple preparation process, straightforward operation and low cost, which is applicable to the sealing of glass, ceramic, metal and semiconductor and in particular applicable for the sealing of metals of molybdenum family and tungsten family or alloy such as kovar alloy. Also the glass powder is competitive in lead-free production and has wide market development prospect.

Owner:DONGHUA UNIV

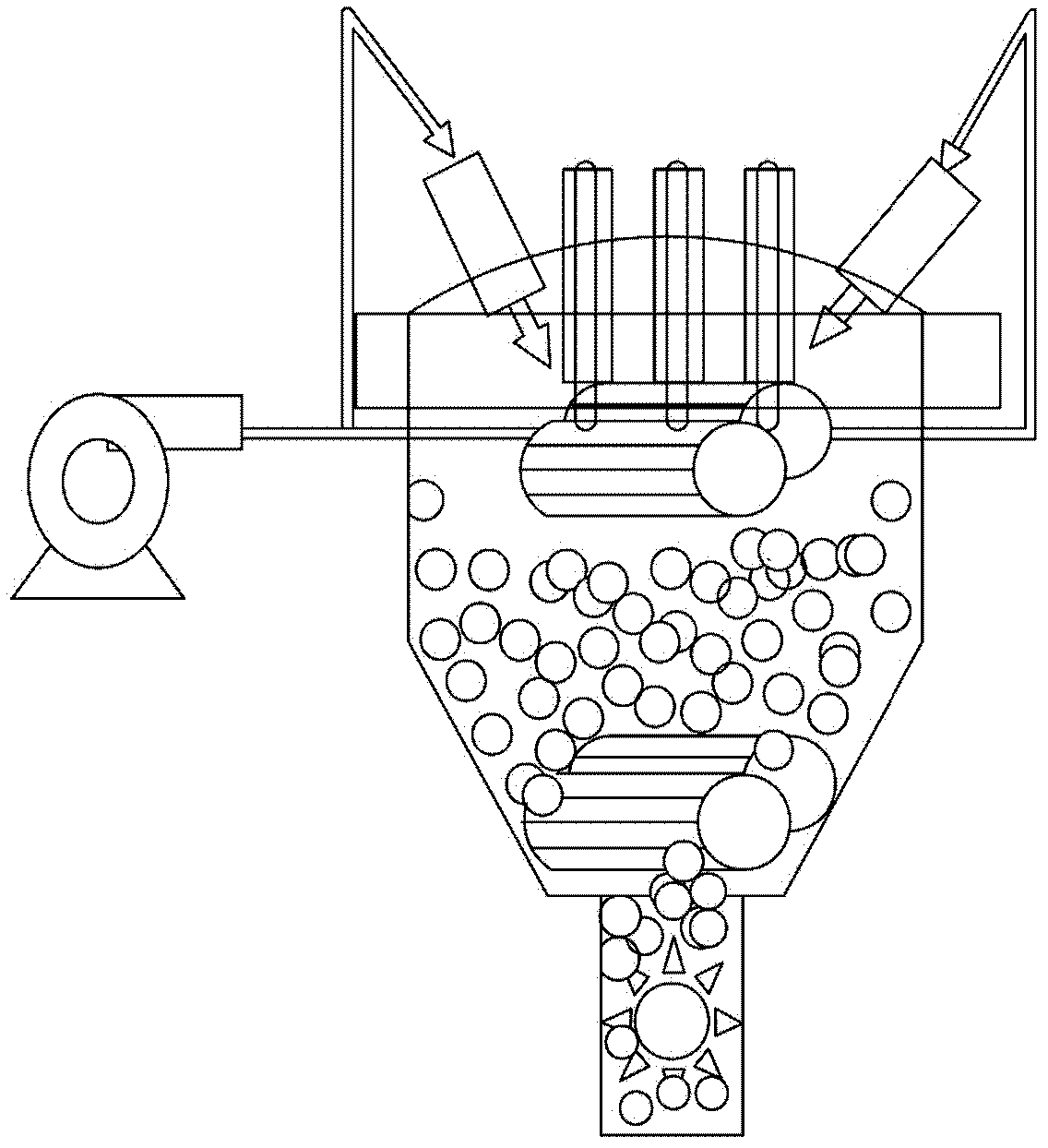

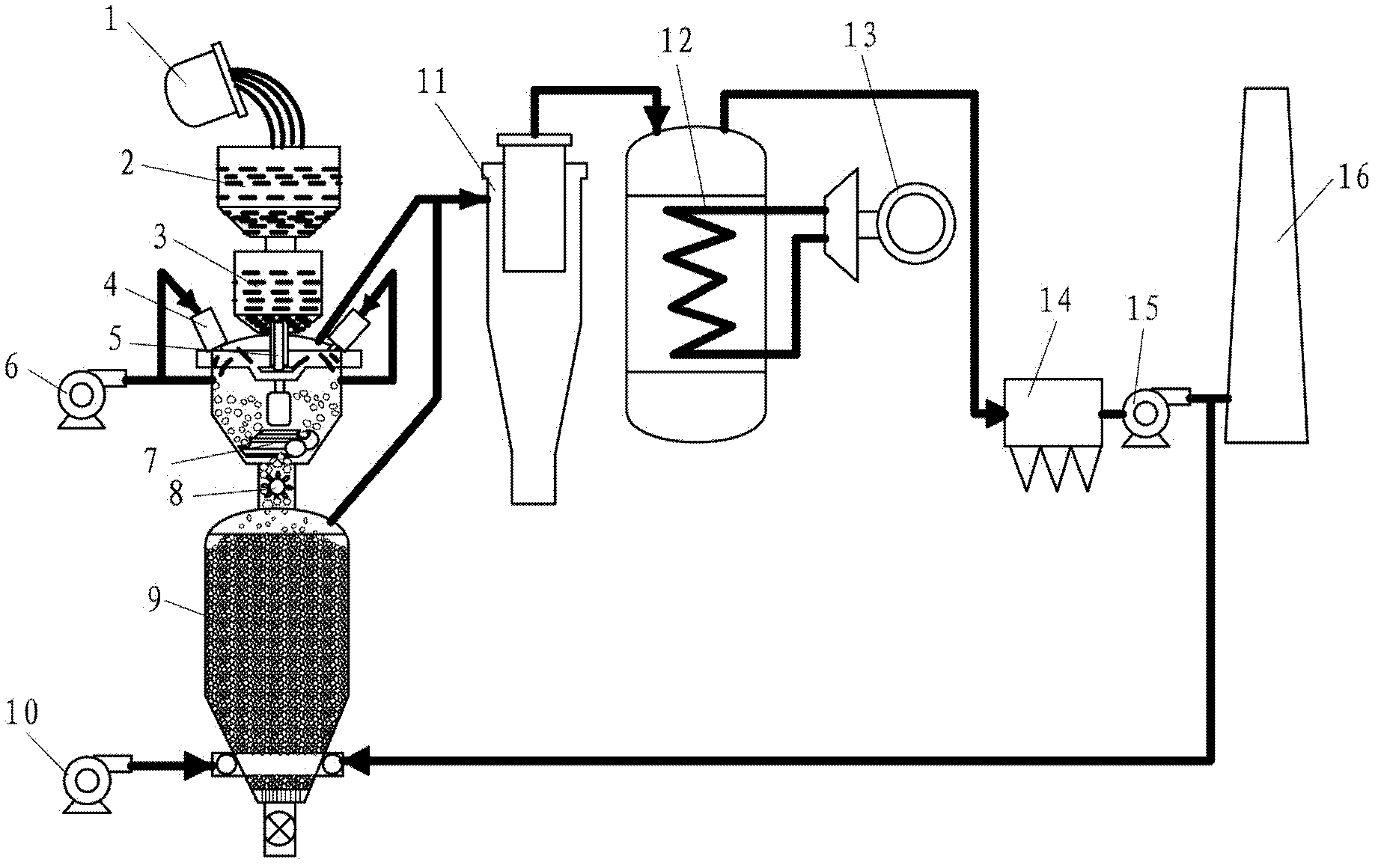

Slag granulating and waste heat recovery device

InactiveCN102424867ARecycling and recovery technologiesProcess efficiency improvementSlagShaft furnace

The invention provides a slag granulating and waste heat recovery device, comprising a slag pot, a slag ladle, a granulating device, a primary cooling fan, a discharge device, a secondary cooling fan, a heat exchange shaft furnace, a cyclone dust collector, a waste heat boiler, a dust collector and a chimney, wherein the slag pot is used for containing slag; a water port is arranged at the lower part of the slag ladle; the granulating device is used for granulating the slag in the slag ladle; the primary cooling fan is used for providing primary cooling air; the discharge device is used for discharging granulated slag; the secondary cooling fan is used for providing secondary cooling air; the heat exchange shaft furnace is used for performing heat exchange between the granulated slag discharged by the discharge device and the secondary cooling air; the cyclone dust collector is used for removing fine particle slag from the primary cooling air and the secondary cooling air; the waste heat boiler is used for generating high-temperature stream; the dust collector is used for collecting dust in the tail gas generated by the waste heat boiler; and the chimney is used for discharging the tail gas after dust collection. By using the slag granulating and waste heat recovery device according to the invention, no new water is consumed in the slag granulating process, the slag waste heatcan be effectively recovered for power generation, and the slag vitreous body after treatment can be used as a construction raw material.

Owner:CENT IRON & STEEL RES INST

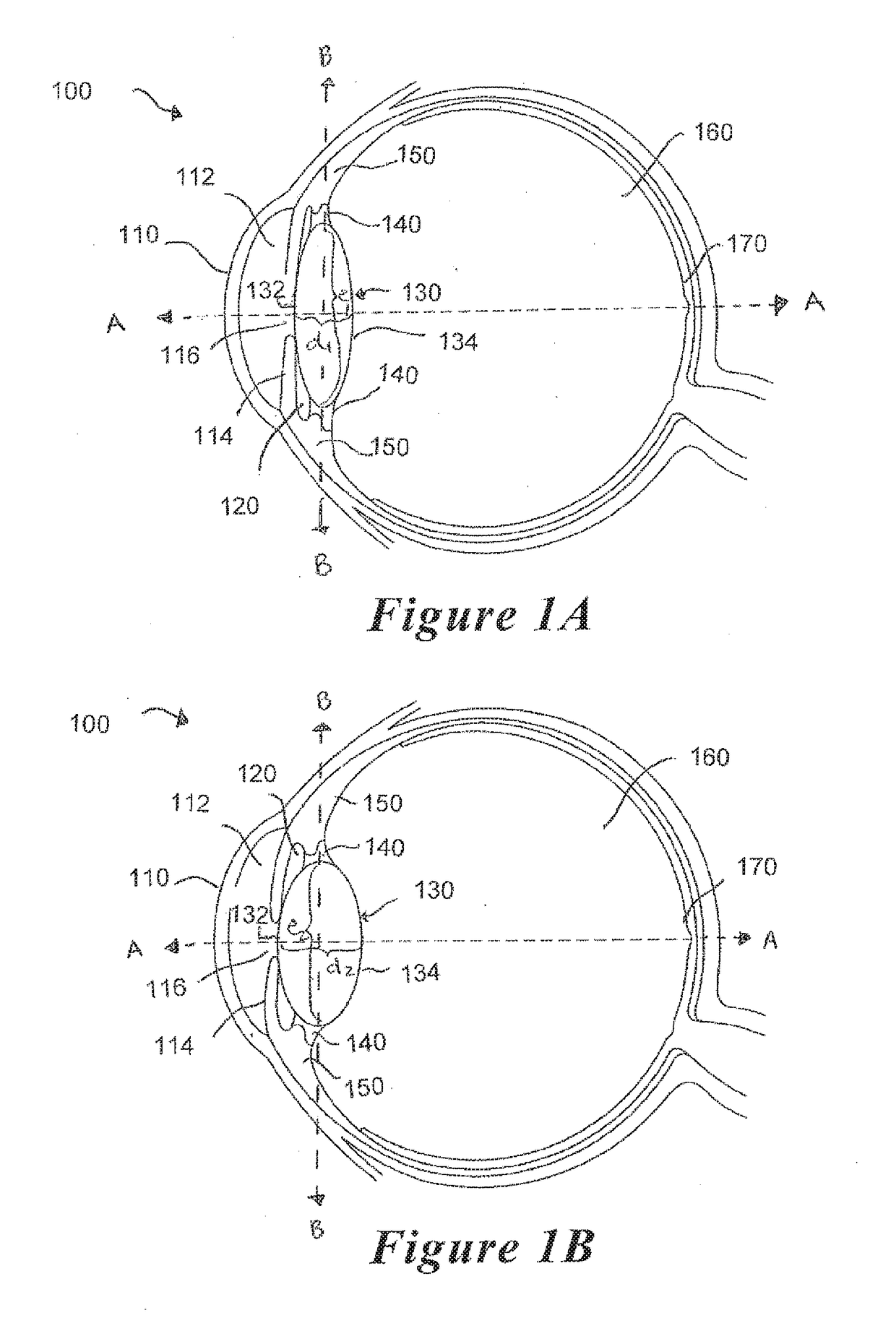

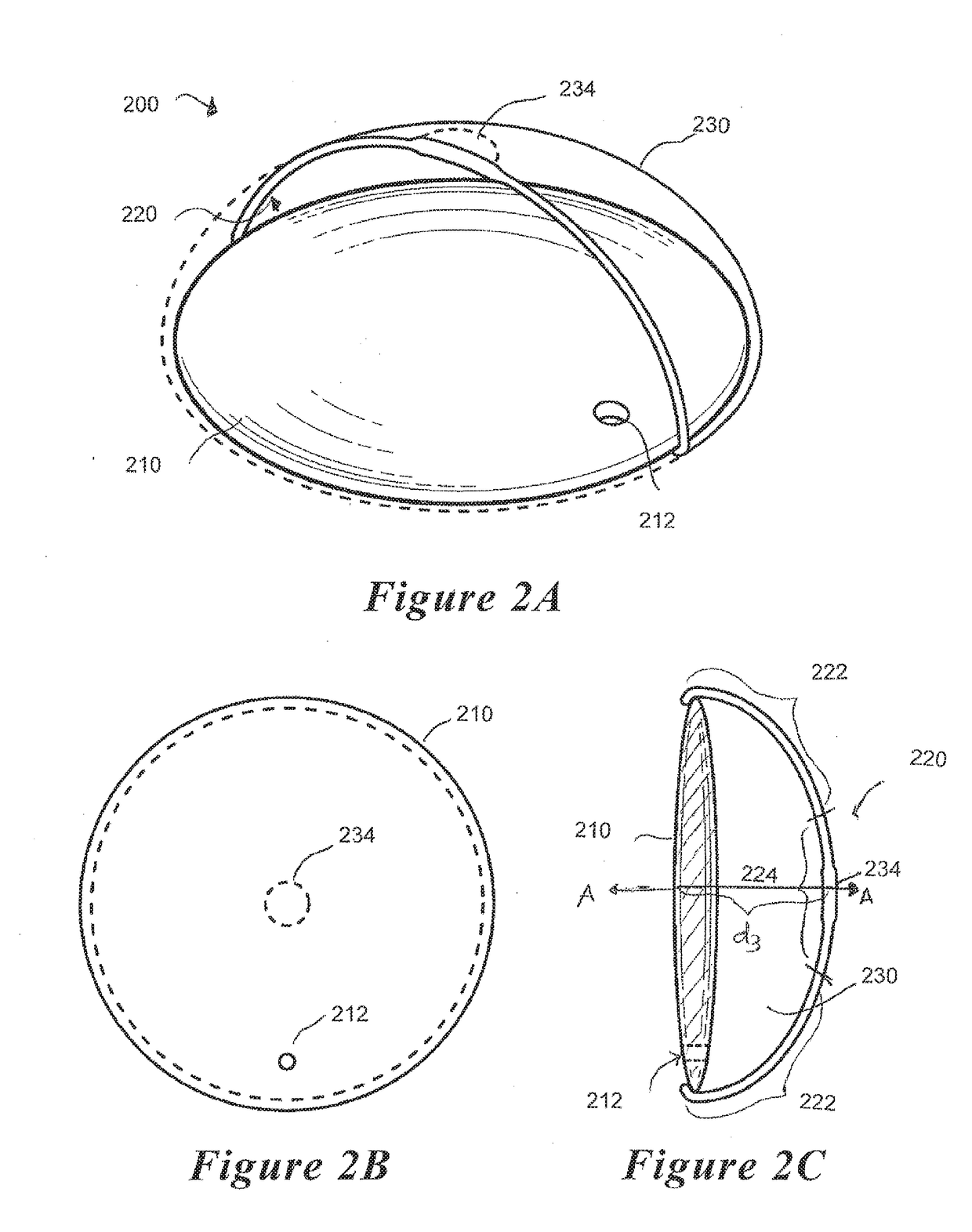

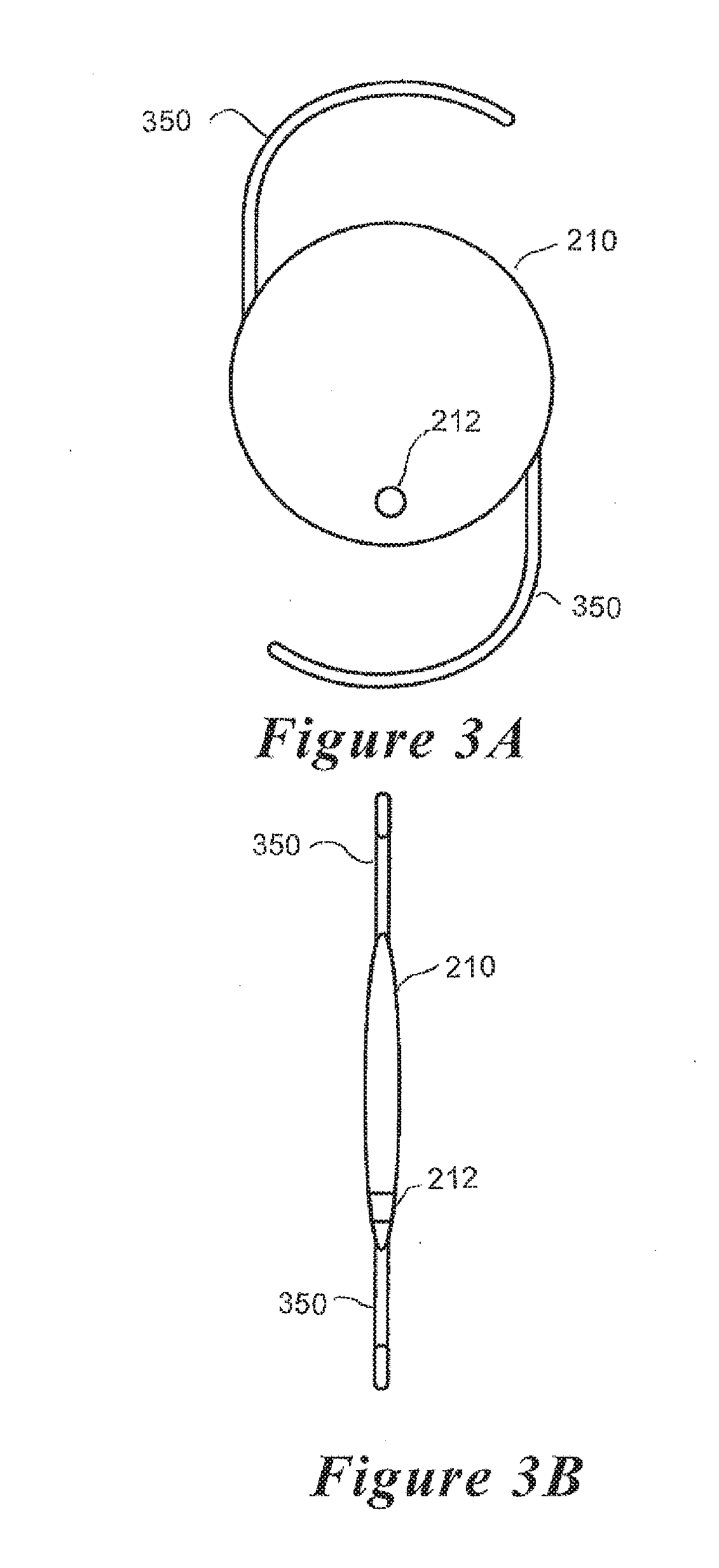

Accommodating intraocular lens

An accommodating intraocular lens (IOL) device adapted for implantation in the lens capsule of a subject's eye. The IOL device includes an anterior refractive optical element and a membrane coupled to the refractive optical element. The anterior refractive optical element and the membrane define an enclosed cavity configured to contain a fluid. At least a portion of the membrane is configured to contact a posterior area of the lens capsule adjoining the vitreous body of the subject's eye. The fluid contained in the enclosed cavity exerts a deforming or displacing force on the anterior refractive optical element in response to an anterior force exerted on the membrane by the vitreous body. The IOL device may further include a haptic system to position the anterior refractive optical element and also to engage the zonules and ciliary muscles to provide additional means for accommodation.

Owner:LENSGEN INC

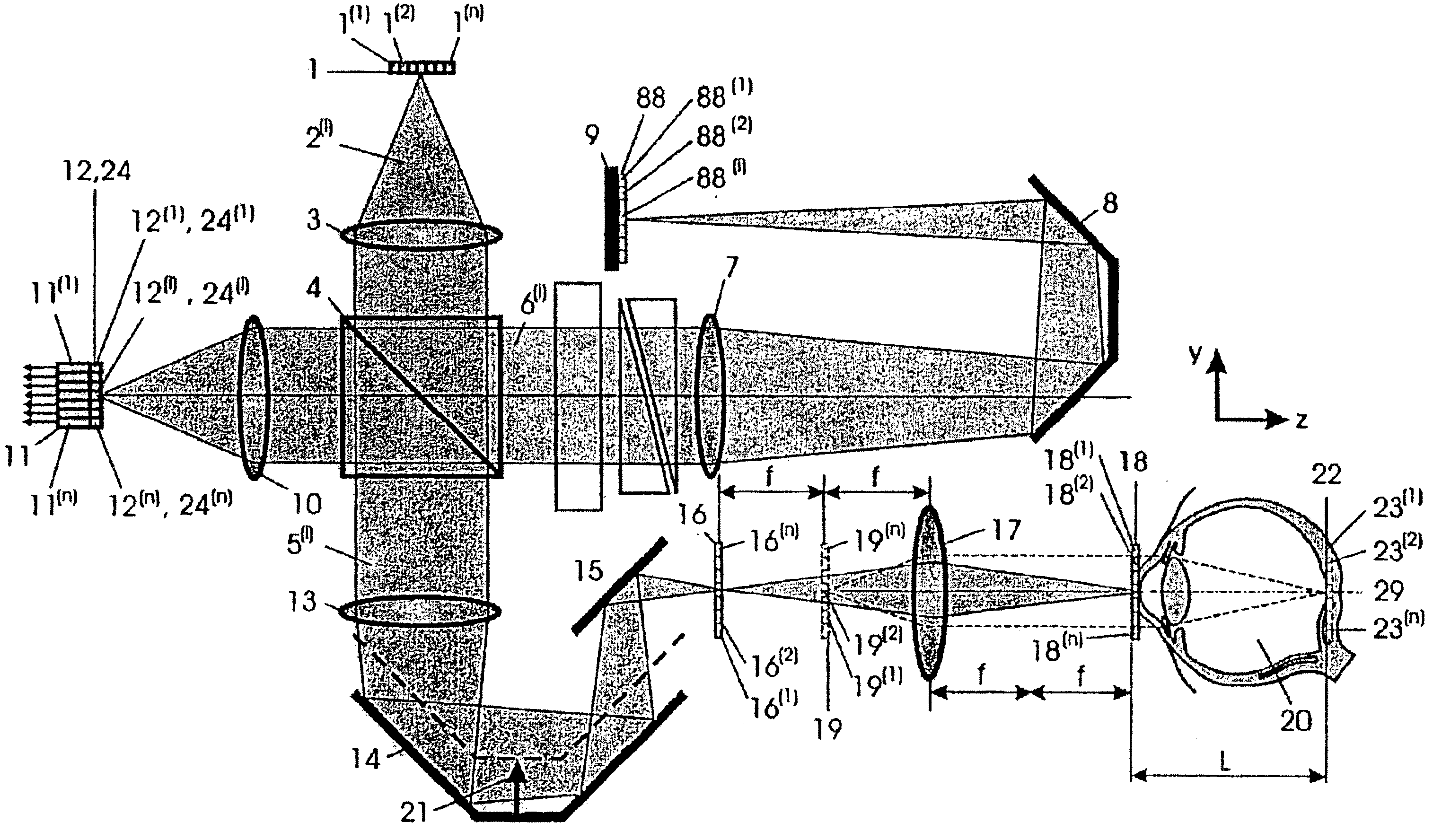

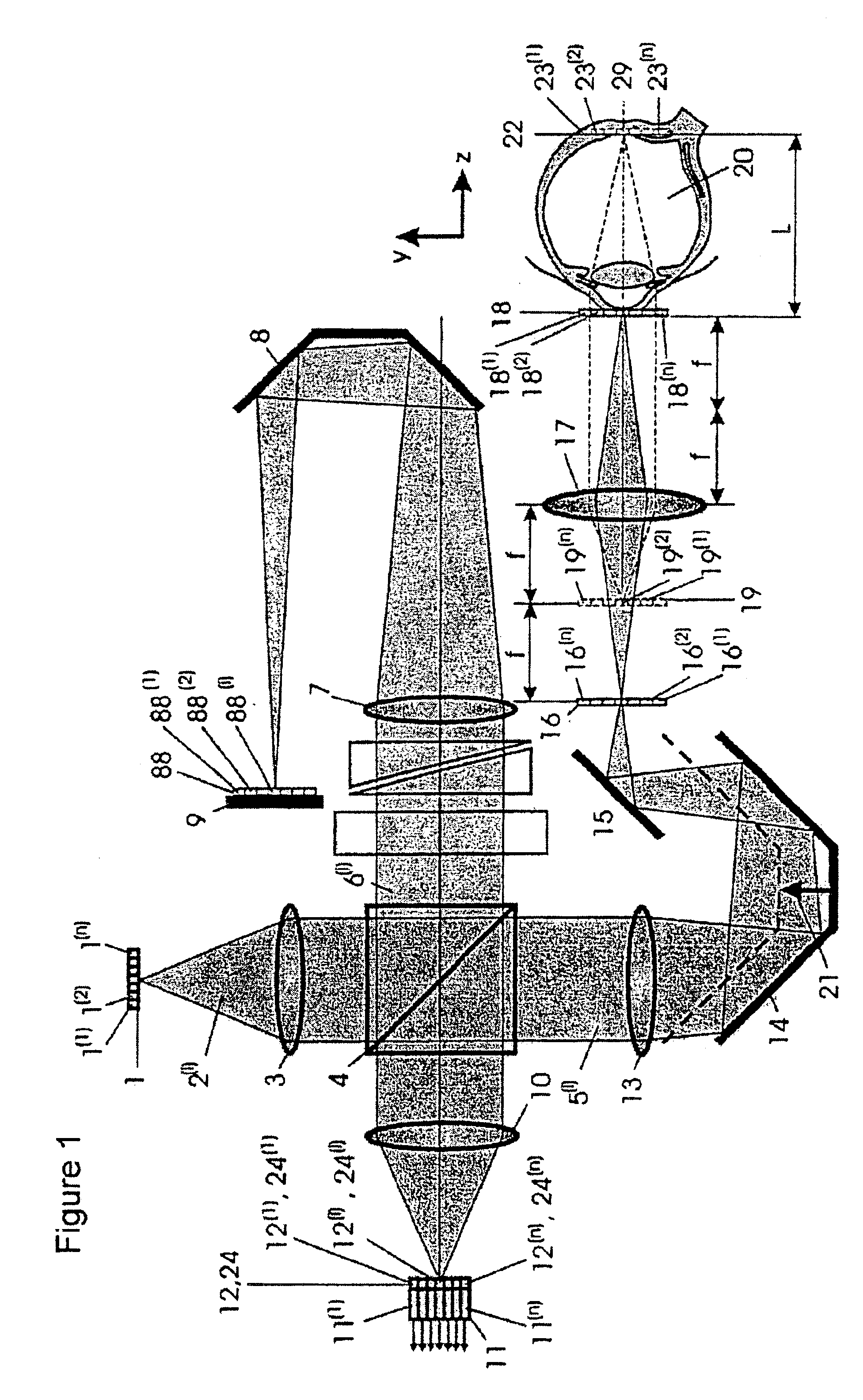

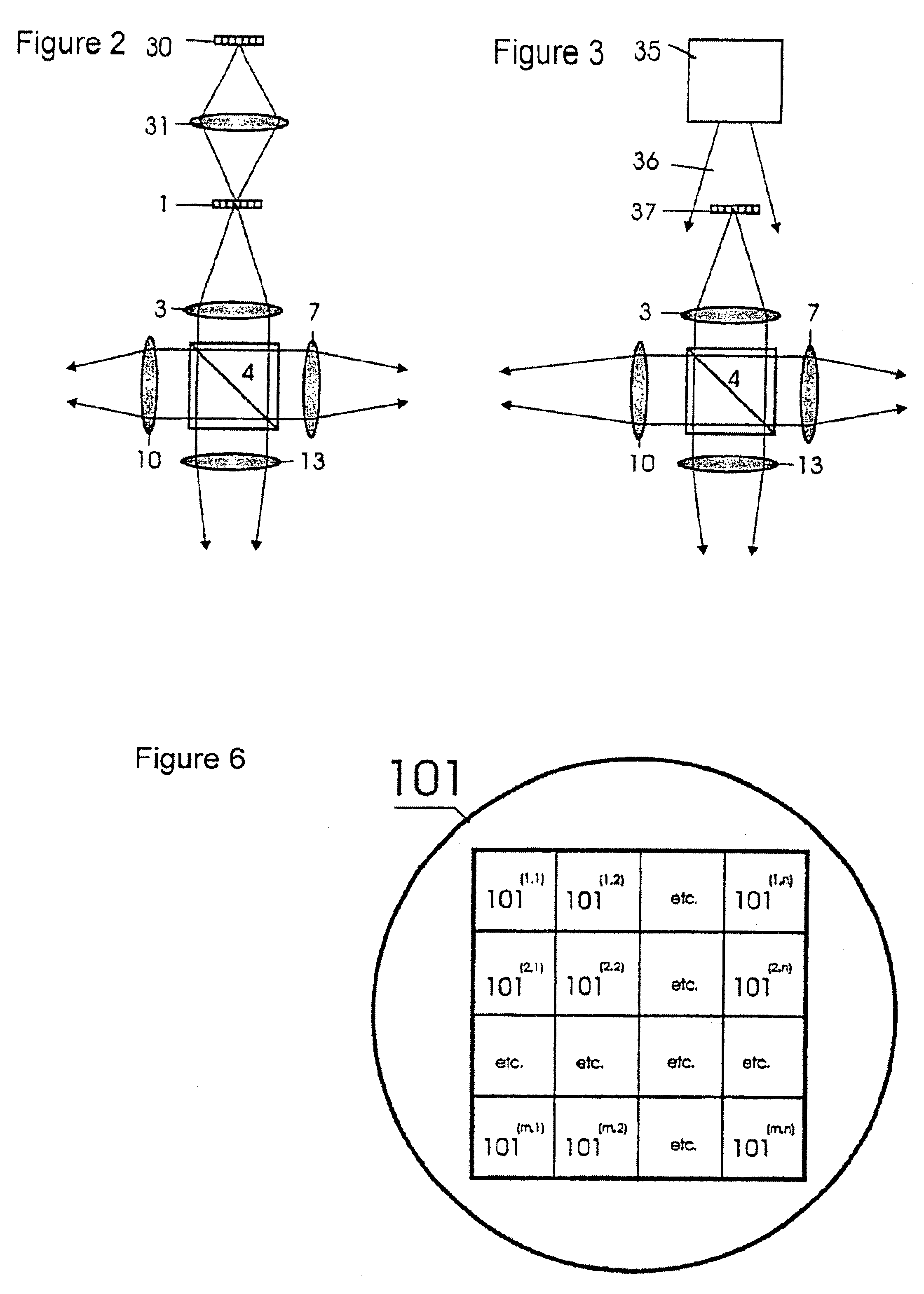

Optical multiplex short coherence interferometry on the eye

The invention is directed to the detection and imaging of the internal geometry of the eye, particularly of the important components for imaging in the eye such as the cornea, lens, vitreous body and retinal surface, by multichannel short coherence interferometry. A method and arrangement for obtaining topograms and tomograms of the eye structure by many simultaneously recorded interferometric depth scans through transversely adjacent points in the pupil using spatially coherent or spatially partially coherent light sources. The depth scan is carried out by changing the optical length of the interferometer measurement arm by means of a retroreflector. By continuously displacing the retroreflector, the z-position of the light-reemitting point in the eye can be determined by means of the occurring interference. It is possible to record depth scans simultaneously through the use of spatially coherent or spatially partially coherent light beams comprising a plurality of partial beams.

Owner:CARL ZEISS MEDITEC AG

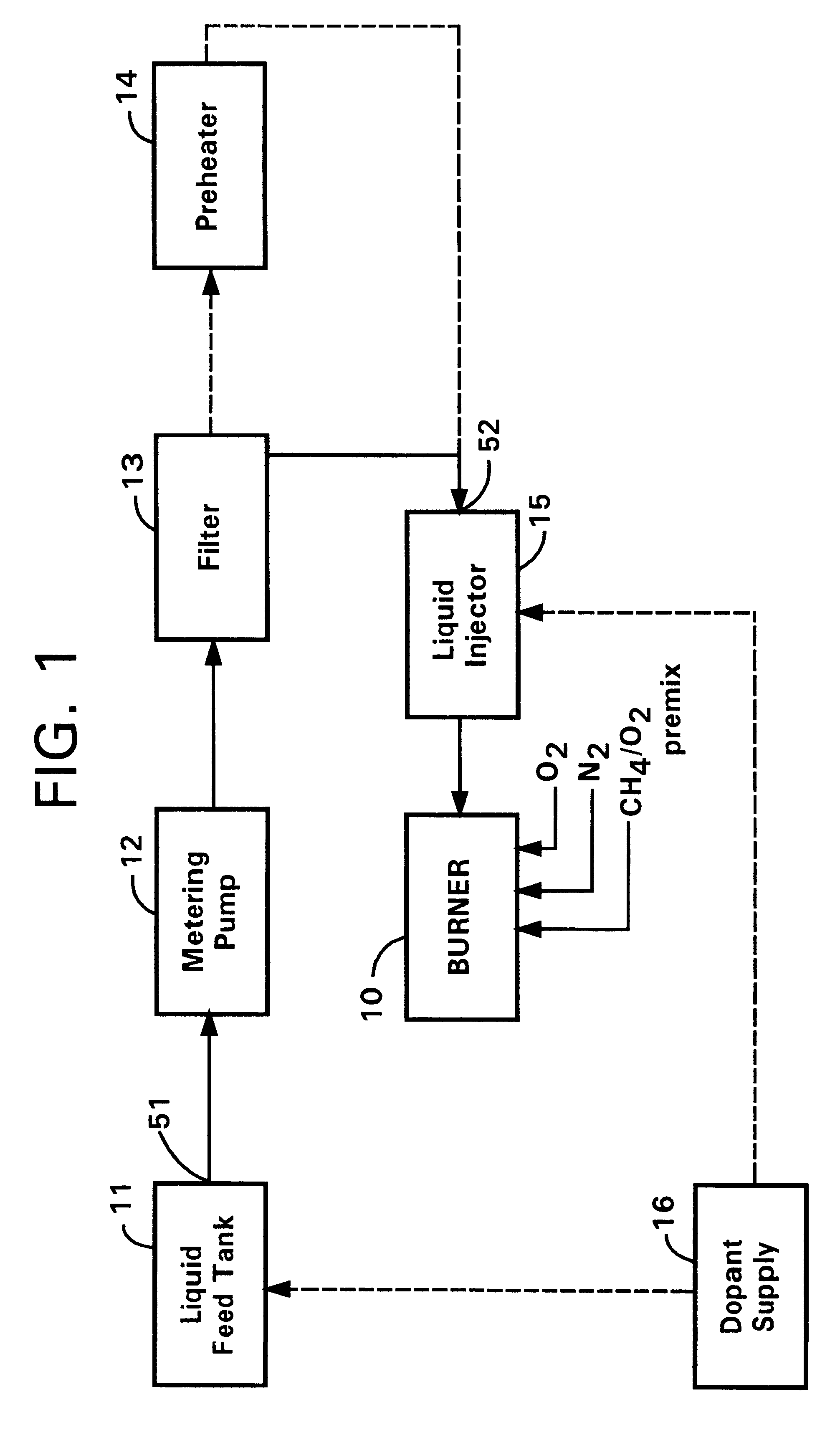

Method and apparatus for forming fused silica by combustion of liquid reactants

InactiveUS6565823B1High concentricityPrevents burner buildupSilicaSpray nozzlesCombustorDecomposition

The present invention is directed to a method for making fused silica glass. A liquid, preferably halide-free, silicon-containing compound capable of being converted by thermal oxidative decomposition to SiO2 is provided and introduced directly into the flame of a combustion burner, thereby forming finely divided amorphous soot. The amorphous soot is deposited on a receptor surface where, either substantially simultaneously with or subsequently to its deposition, the soot is consolidated into a body of fused silica glass. The invention further relates to an apparatus for forming fused silica from liquid, preferably halide-free, silicon-containing reactants which includes: a combustion burner which, in operation, generates a flame; an injector for supplying a liquid silicon-containing compound to the flame to convert the compound by thermal oxidative decomposition to a finely divided amorphous soot; and a receptor surface on which the soot is deposited.

Owner:CORNING INC

Ophthalmic visualization compositions and methods of using same

InactiveUS20070218007A1Facilitate and enhance visualizationReduce riskUltrasonic/sonic/infrasonic diagnosticsPowder deliveryVitreous BodiesContrast medium

Compositions and methods useful for at least assisting in visualizing vitreous bodies of eyes of humans or animals are provided. Such compositions include a contrast component and a carrier component and are substantially free of any therapeutic agent effective to have pharmacological activity in an eye in which the composition is placed. Methods of using such compositions as visualization devices are also provided.

Owner:ALLERGAN INC

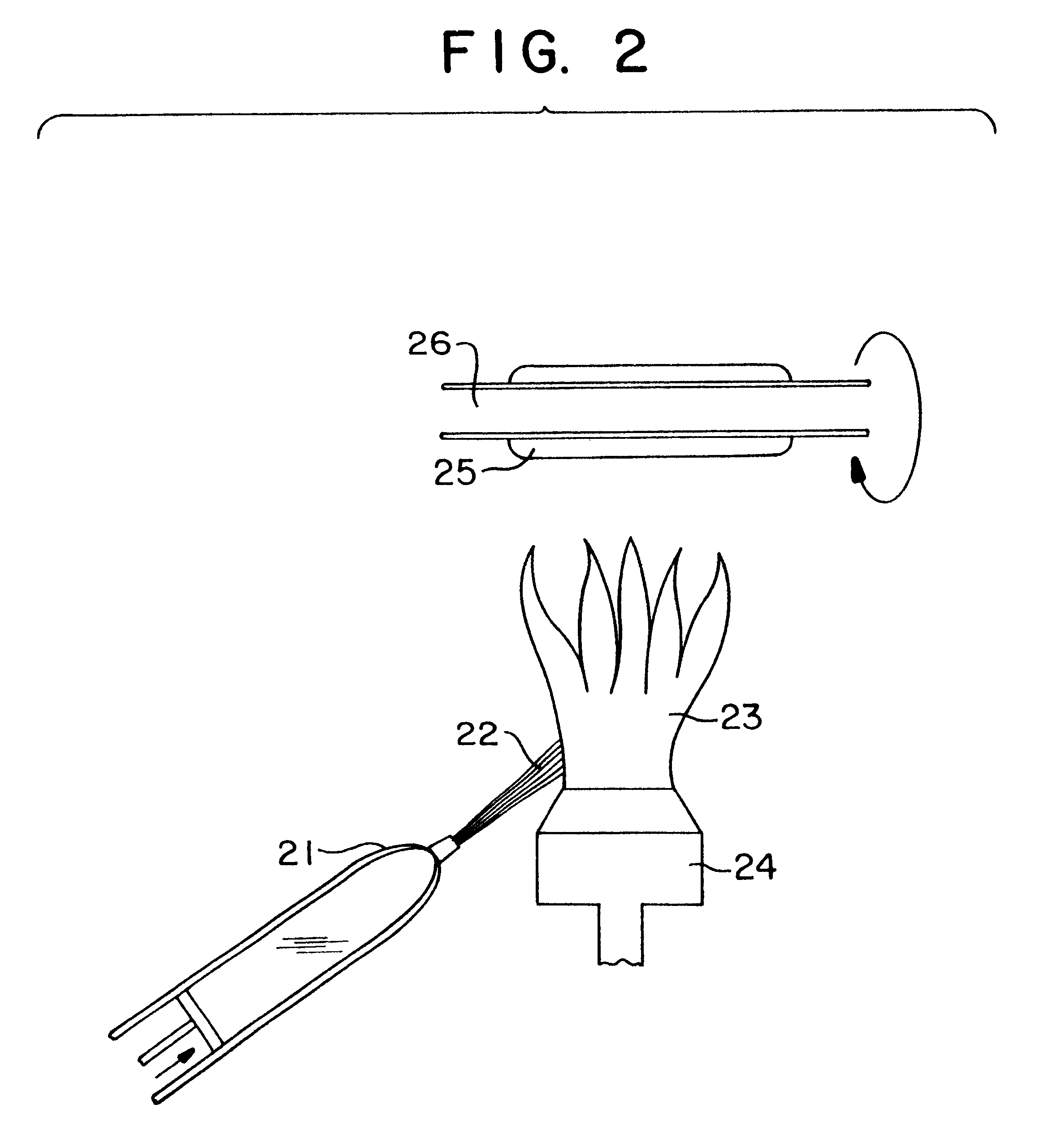

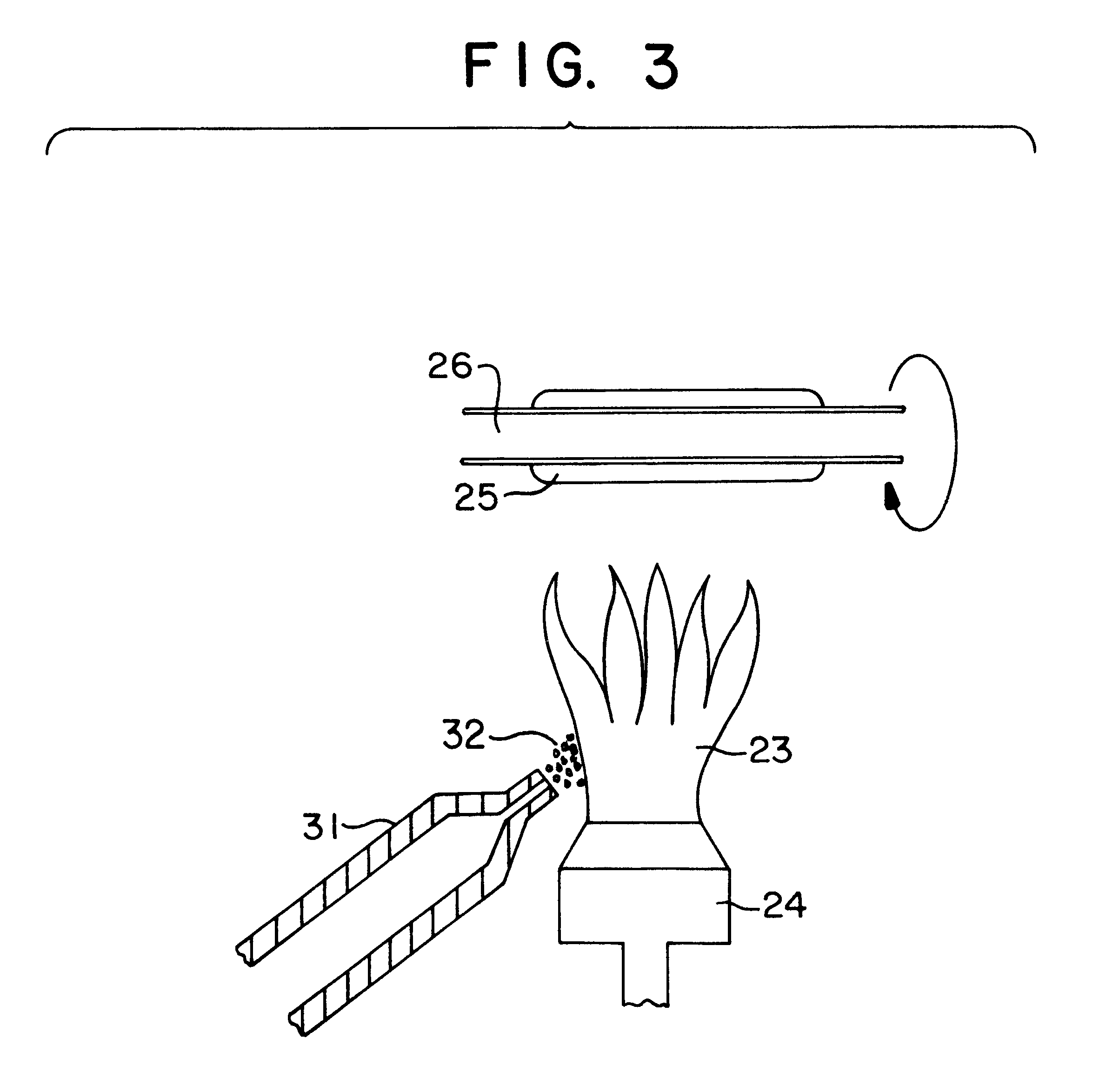

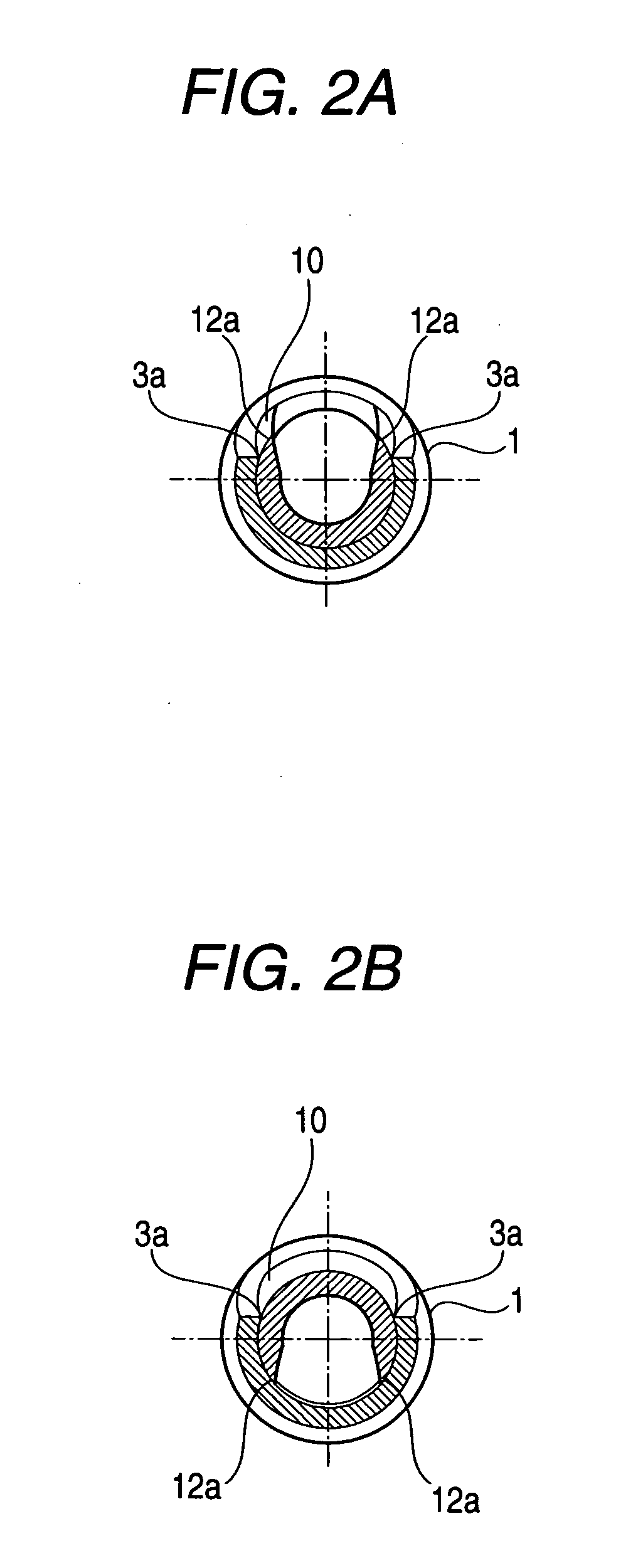

Vitreous body cutter and vitreous body surgical equipment having the same

A vitreous body cutter for cutting a vitreous body in an eye includes: an inner cylindrical blade having a first suction hole and a suction path; an outer cylindrical blade having a second suction hole, the outer cylindrical blade holding the inner cylindrical blade to be rotatable about a center axis thereof; a main body fixed with the outer cylindrical blade; a diaphragm arranged in the main body, the diaphragm being linearly advanced to a distal end side of the blades in a direction of the center axis by supplying compressed gas into a gas chamber formed by the diaphragm and the main body; and a converting-and-transmitting mechanism which converts linearly advancement of the diaphragm into a rotation about the center axis and transmits the rotation to the inner cylindrical blade to rotate the inner cylindrical blade about the center axis.

Owner:NIDEK CO LTD

Vitreous antimicrobial agent and antimicrobial product

InactiveUS20060127498A1Exhibit some effectImprove antibacterial propertiesPowder deliveryBiocideMicrobial agentVitreous Bodies

The object is to provide a vitreous antimicrobial agent that can exhibit excellent antimicrobial properties when added to various types of resins, that has excellent discoloration resistance and hot water resistance, and that can easily be produced at a commercial scale. It is also to provide an antimicrobial resin composition and an antimicrobial product including the vitreous antimicrobial agent. The present invention relates to a vitreous antimicrobial agent that includes, relative to 100 mass % of total glass components, 0.1 to 2 mass % of Ag2O, 40.5 to 49 mass % of ZnO, 6 to 9.5 mass % of SiO2, 30.5 to 39.5 mass % of B2O3, 2 to 10 mass % of an alkaline earth metal oxide, and 6 to 7.5 mass % of Na2O; a vitreous antimicrobial agent comprising, in addition to these, 0.01 to 5 mass % of CeO2 as necessary; an antimicrobial resin composition that includes the vitreous antimicrobial agent; and an antimicrobial product that includes the vitreous antimicrobial agent.

Owner:TOAGOSEI CO LTD

Sintered materials

InactiveUS20050220692A1Improved capillary structureImprove pore structureSilicaGlass shaping apparatusVitreous BodiesSilicon dioxide

Owner:MANGOLD HELMUT +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com