Patents

Literature

448 results about "Kovar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

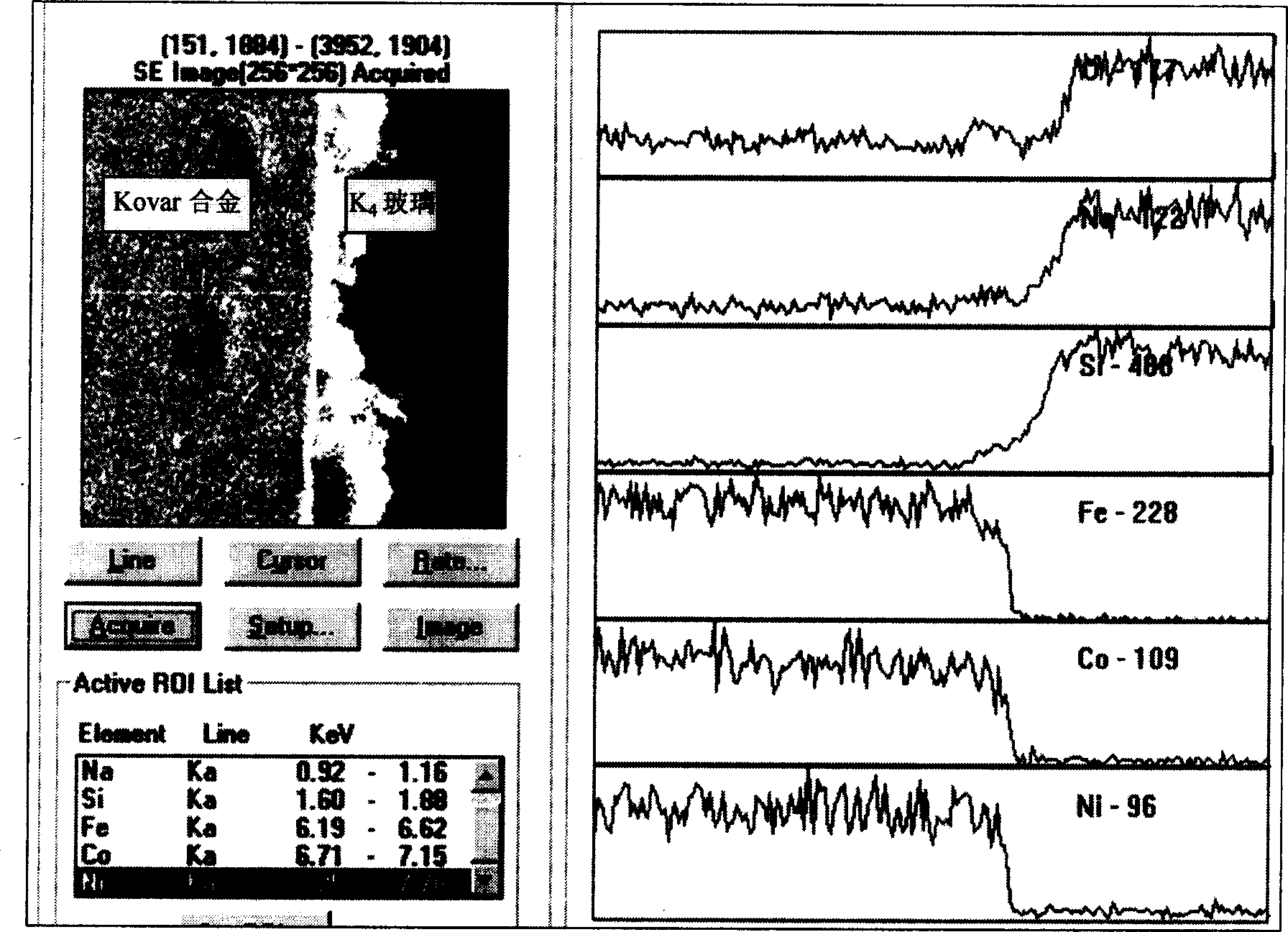

Kovar (trademark of CRS Holdings, inc., Delaware) is a nickel–cobalt ferrous alloy compositionally identical to Fernico 1, designed to have substantially the same thermal expansion characteristics as borosilicate glass (~5 × 10⁻⁶ /K between 30 and 200 °C, to ~10 × 10⁻⁶ /K at 800 °C) to allow a tight mechanical joint between the two materials over a range of temperatures. It finds application in glass-to-metal seals in scientific apparatus, and conductors entering glass envelopes of electronic parts such as vacuum tubes (valves), X-ray and microwave tubes and some lightbulbs.

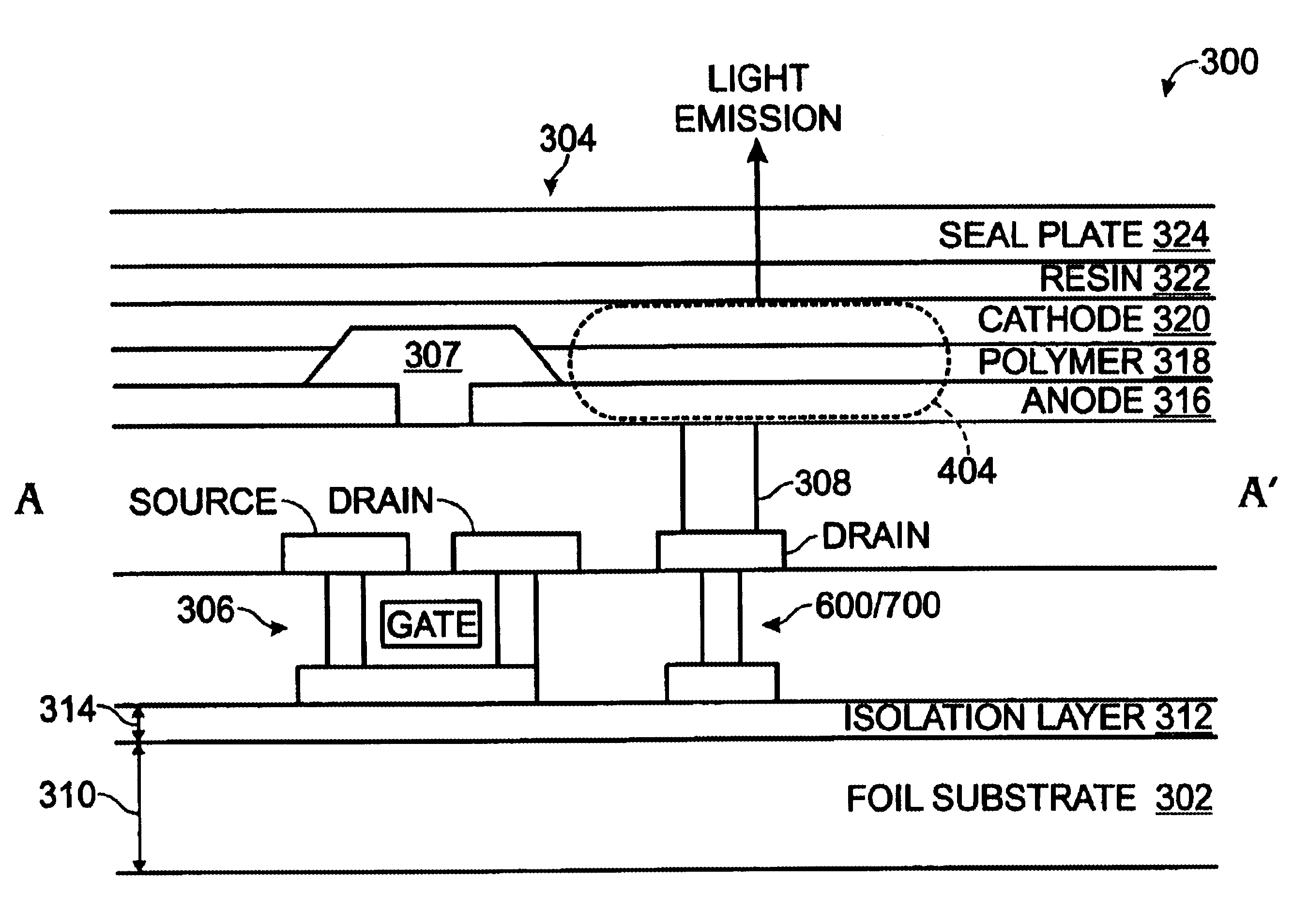

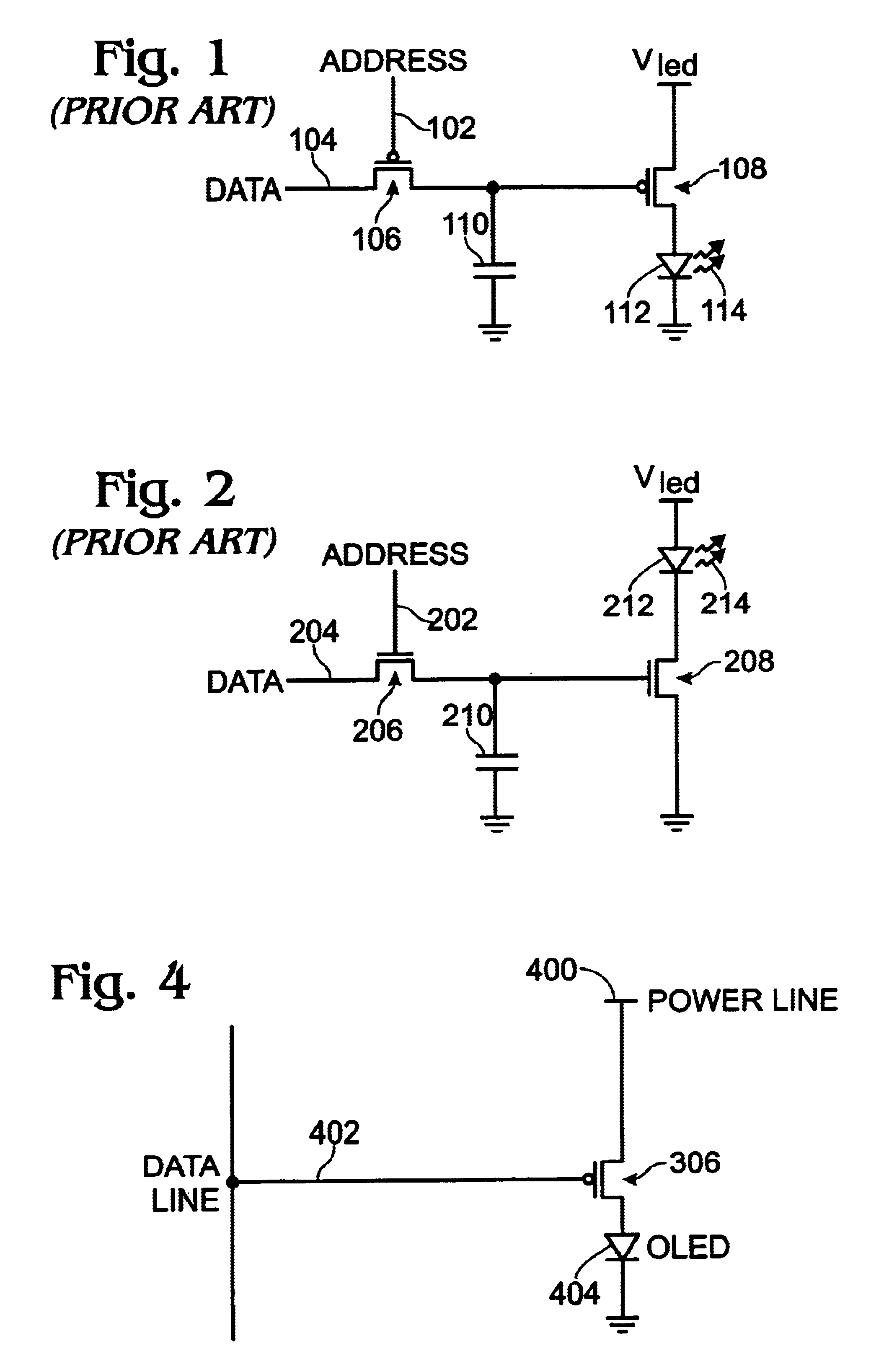

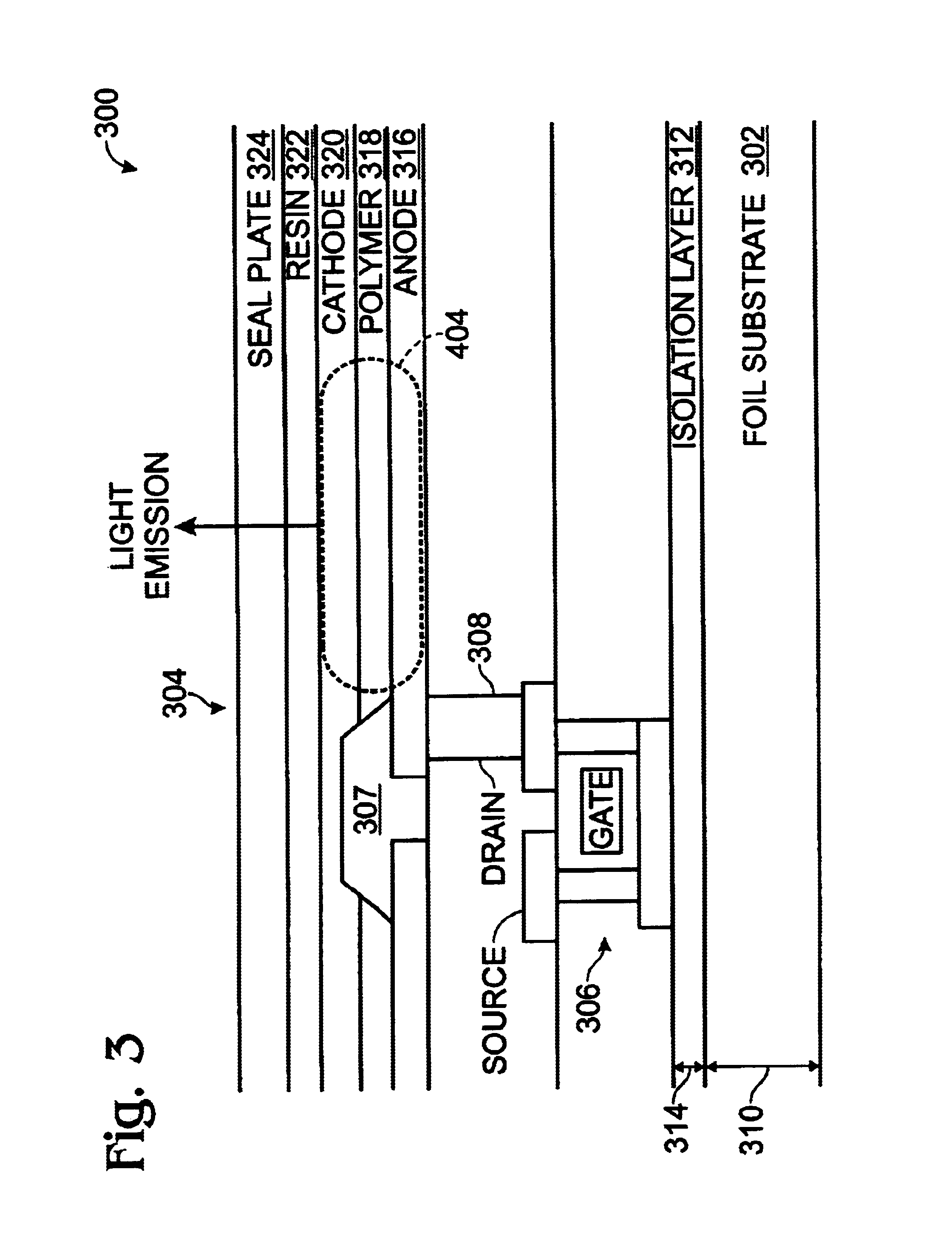

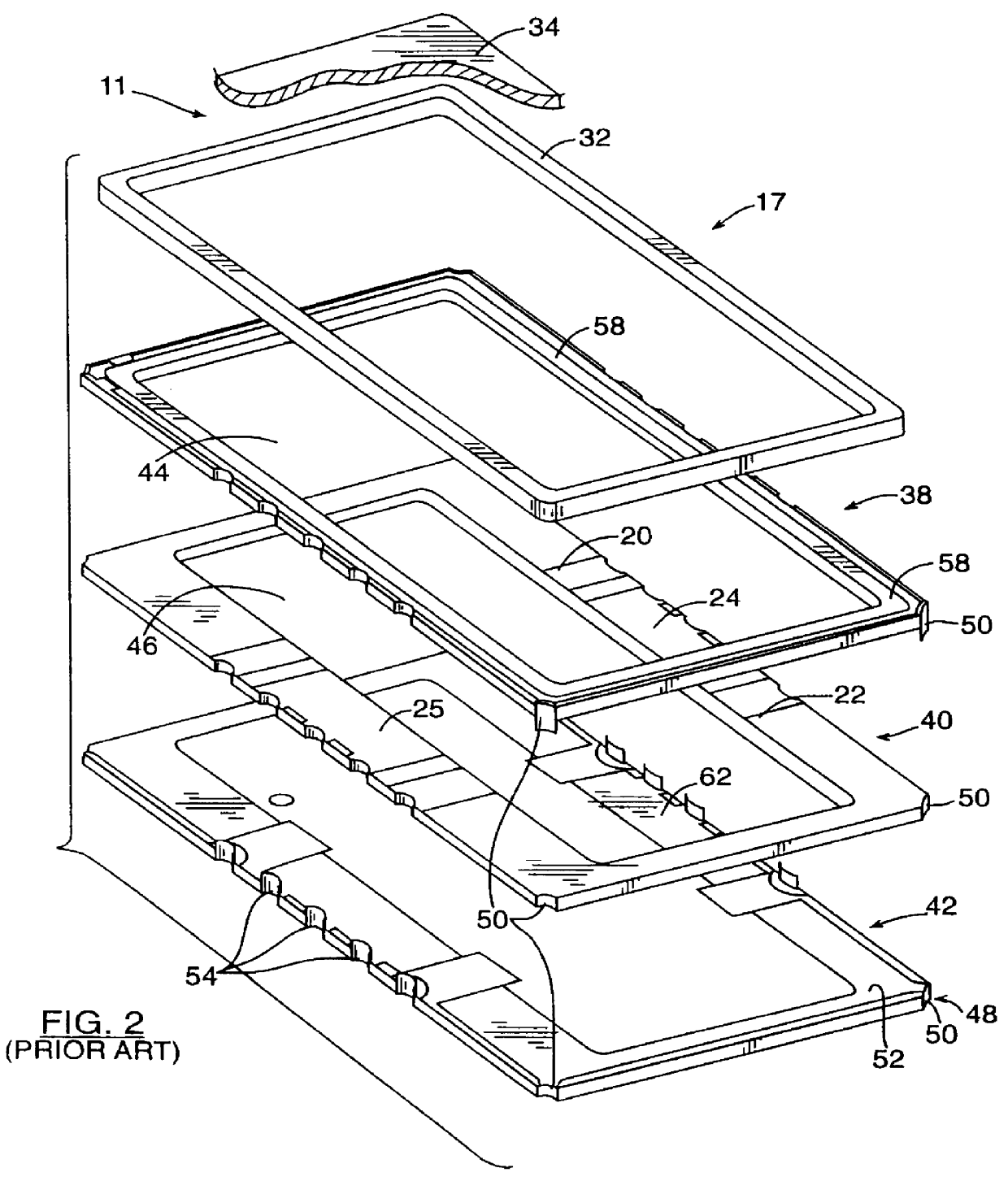

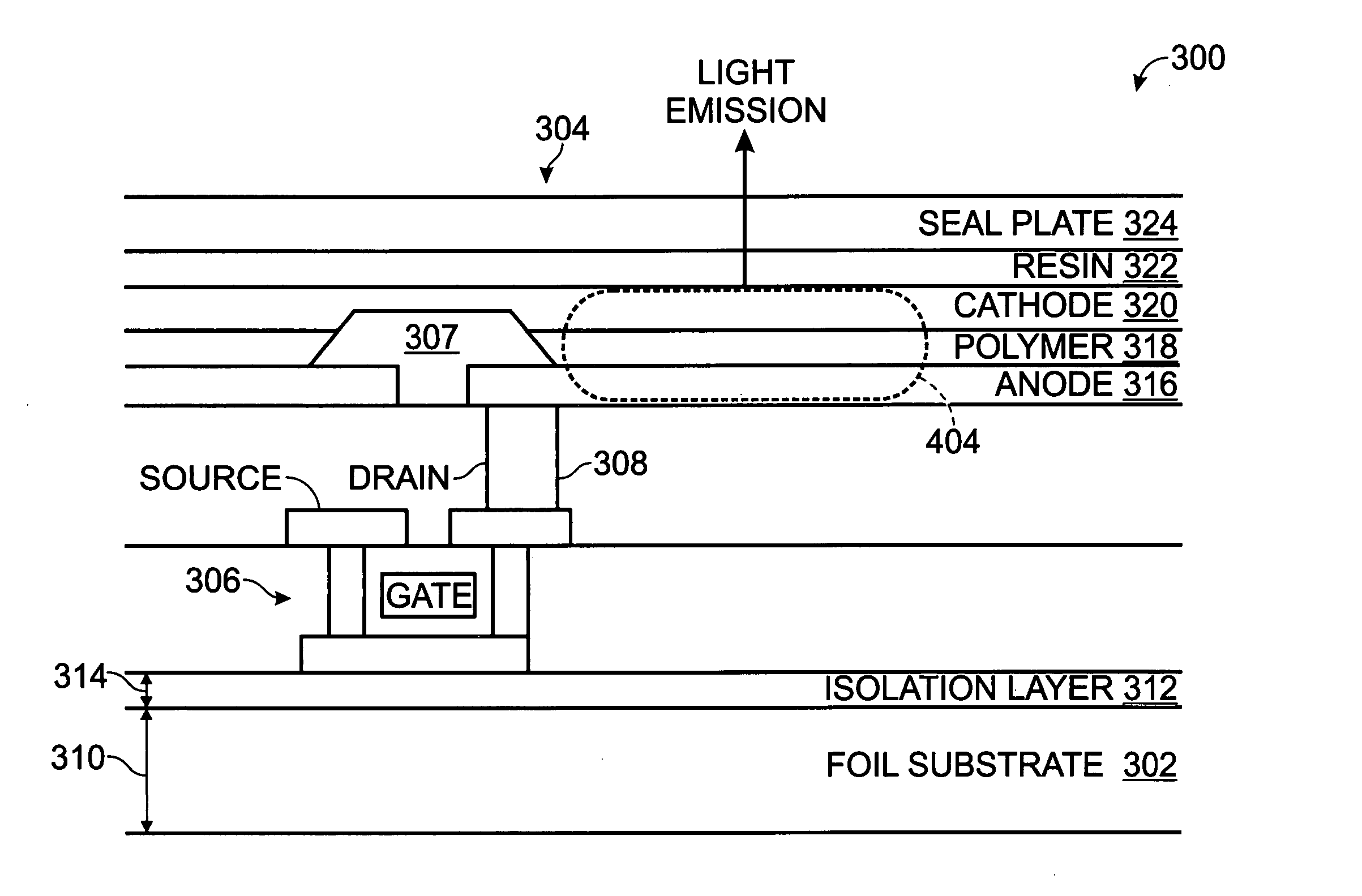

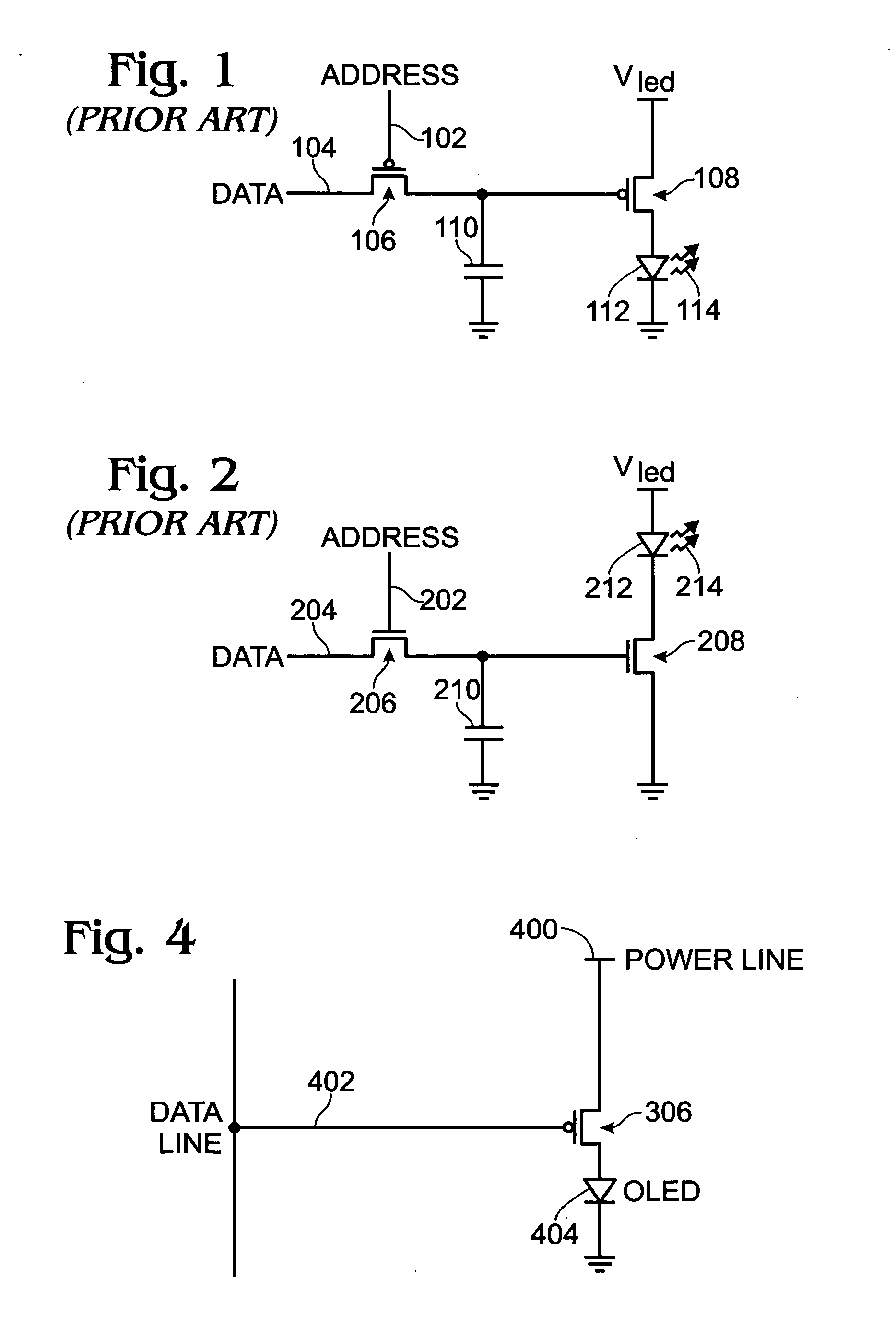

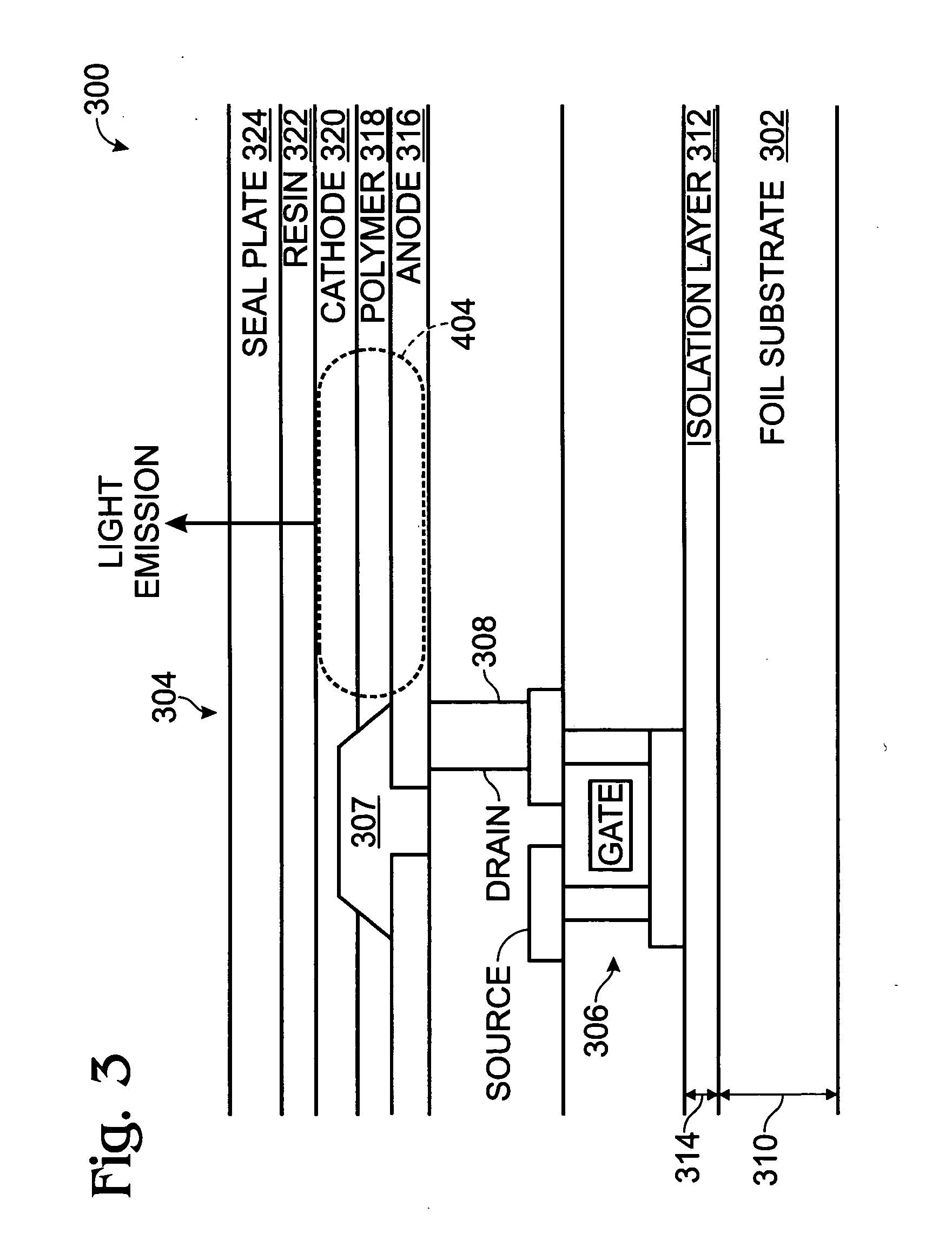

Flexible metal foil substrate display and method for forming same

A flexible metal foil substrate organic light emitting diode (OLED) display and a method for forming the same are provided. The method comprises: supplying a metal foil substrate such as titanium (Ti), Inconel alloy, or Kovar, having a thickness in the range of 10 to 500 microns; planarizing the metal foil substrate surface; depositing an electrical isolation layer having a thickness in the range of 0.5 to 2 microns overlying the planarized metal foil substrate surface; depositing amorphous silicon having a thickness in the range of 25 to 150 nanometers (nm) overlying the electrical insulation layer; from the amorphous silicon, forming polycrystalline silicon overlying the electrical insulation layer; forming thin-film transistors (TFTs) in the polycrystalline silicon; and, forming an electronic circuit using the TFTs, such as an OLED display.

Owner:GLOBAL OLED TECH

Aluminum-free borosilicate glass and applications thereof

InactiveUS20070004580A1Maintain good propertiesGood chemical resistanceSolid cathode detailsGas discharge lamp detailsThermal expansionTitanium alloy

Owner:SCHOTT AG

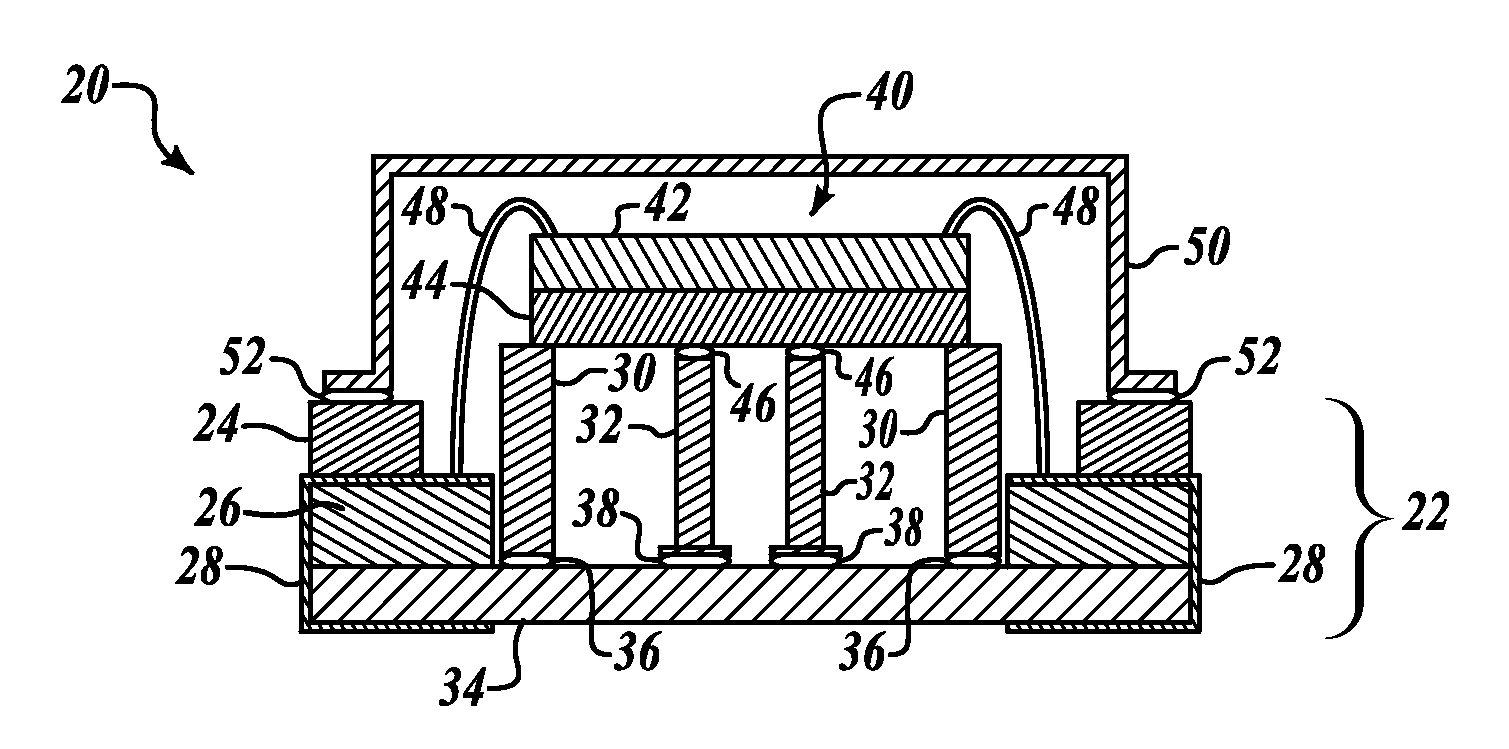

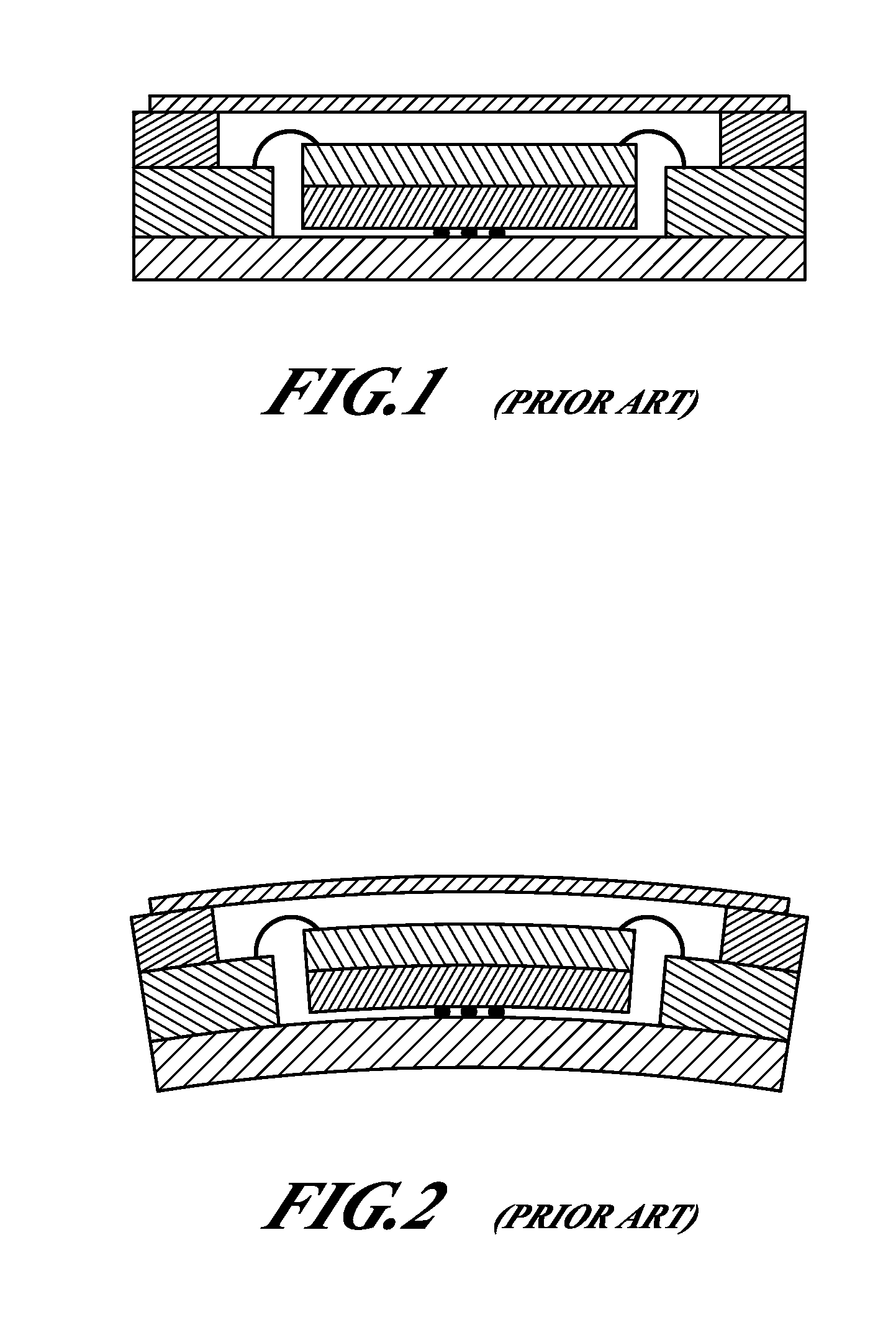

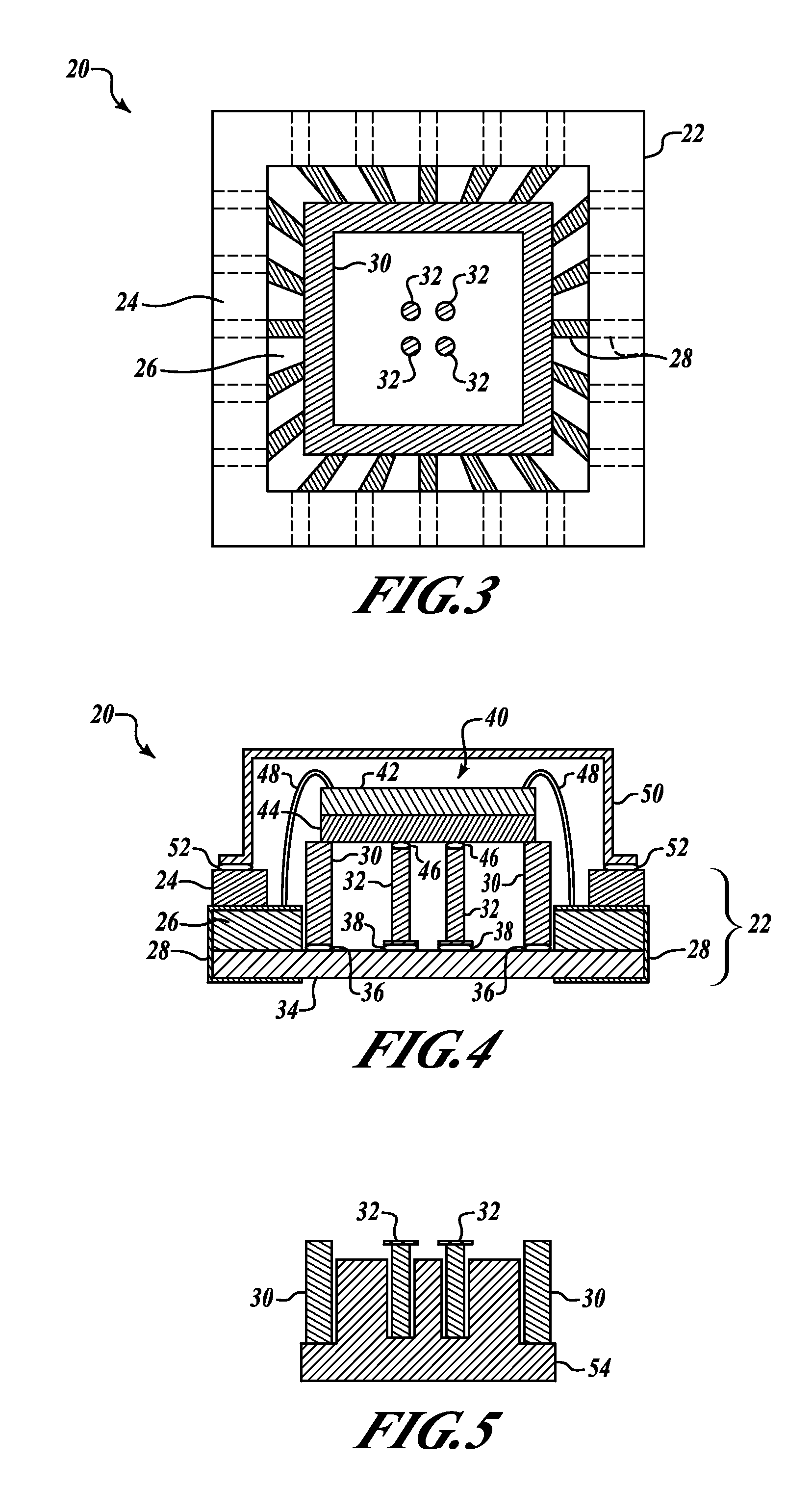

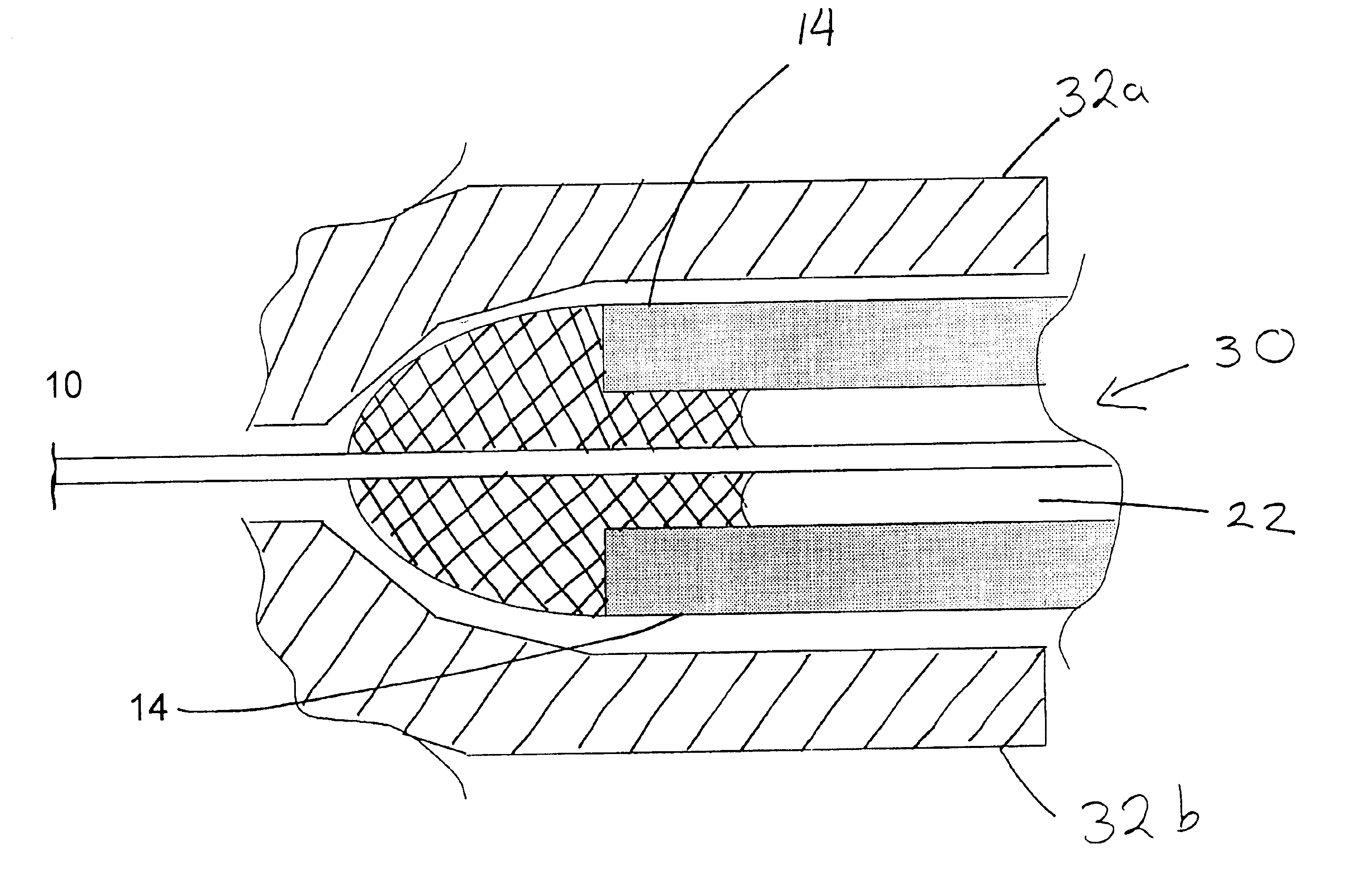

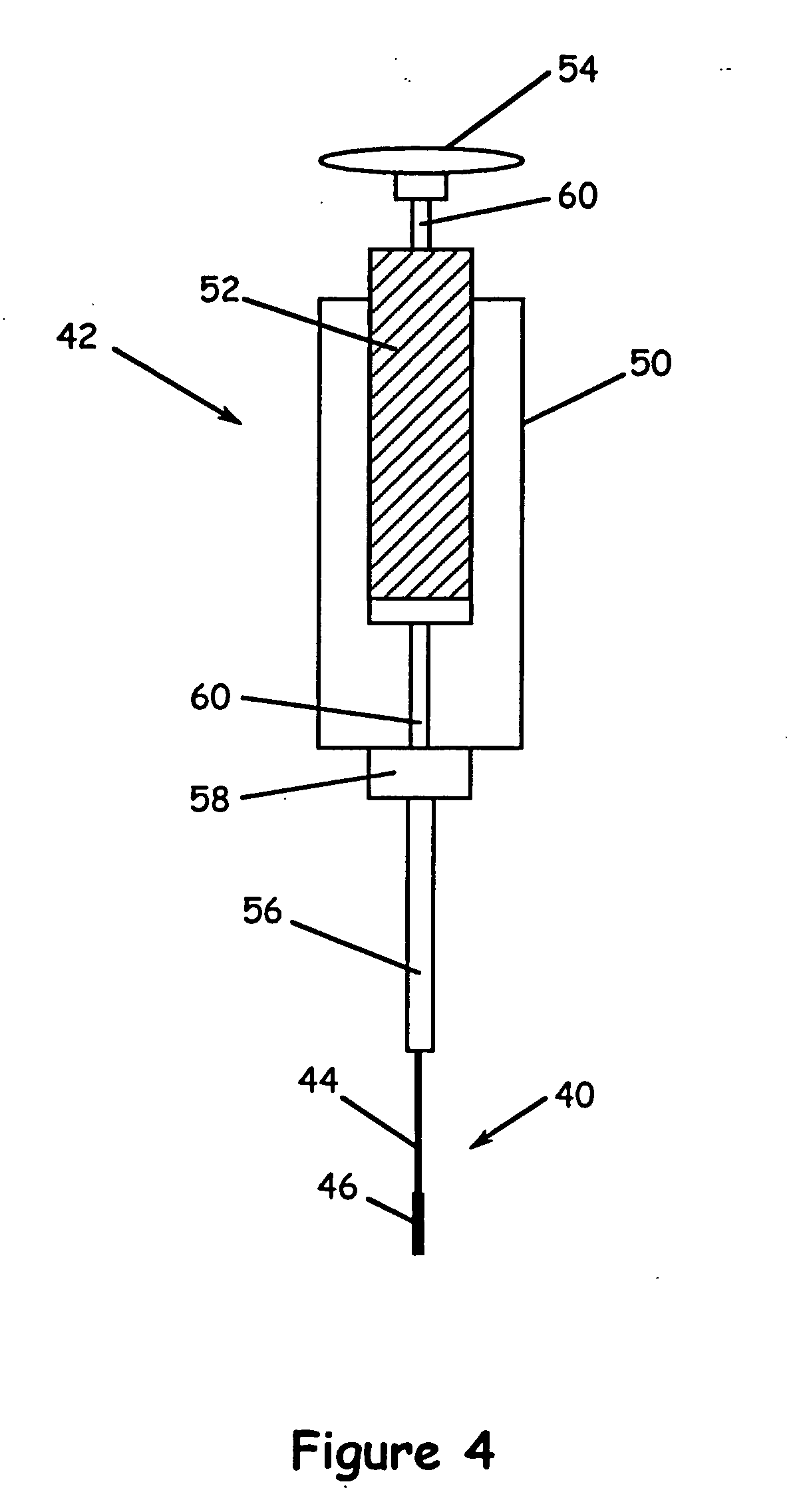

Low-stress hermetic die attach

InactiveUS20080251866A1Reduce thermomechanical stressAcceleration measurement using interia forcesSemiconductor/solid-state device detailsAccelerometerGyroscope

A low-stress hermetic die attach apparatus is disclosed. An example apparatus includes a hermetic package, a device disposed within the hermetic package, and one or more elongated structures greater than 2 thousandths of an inch (mils) in length connected to the package at one end and to the device at the other end. In some embodiments, the apparatus includes elongated structures at least 30 mils long or at least 100 mils long and the device includes a microelectromechanical system (MEMS) die that includes accelerometer or gyro components. In some embodiments, the elongated structures include a column or a pin made of an alloy material such as Kovar. In one embodiment, the Kovar pin is gold plated, attached to the package with a high temperature solder, and attached to the die using gold stud bumps.

Owner:HONEYWELL INT INC

Glass and use of a glass for glass-metal bonds

ActiveUS20110045960A1Simple processImprove carrying capacitySolar heat devicesPV power plantsKovarMetal binding

The glass of the glass-metal bond contains the following ingredients in the following amounts: SiO2, 72-80 wt %; B2O3, 4-<6 wt %; Al2O3, 2-5 wt %; Na2O, 4-7 wt %; K2O, 0-3 wt %; CaO, 2.5-8 wt %; MgO, 0-2 wt %; BaO, 0-4 wt %; TiO2, 0-5 wt %; CeO2, 0-2 wt %; Fe2O3, 0-0.1 wt %; F, 0-2 wt %; and the ratio of the sum total amount of Al2O3 and B2O3 (in mol %) to the sum total amount of MgO, CaO and BaO (in mol %) in the glass is less than 5. The glass-metal bond advantageously includes a KOVAR® alloy and the glass of the aforesaid composition and connects the glass envelope tube with an inner metal absorber tube in a tube collector.

Owner:SCHOTT AG

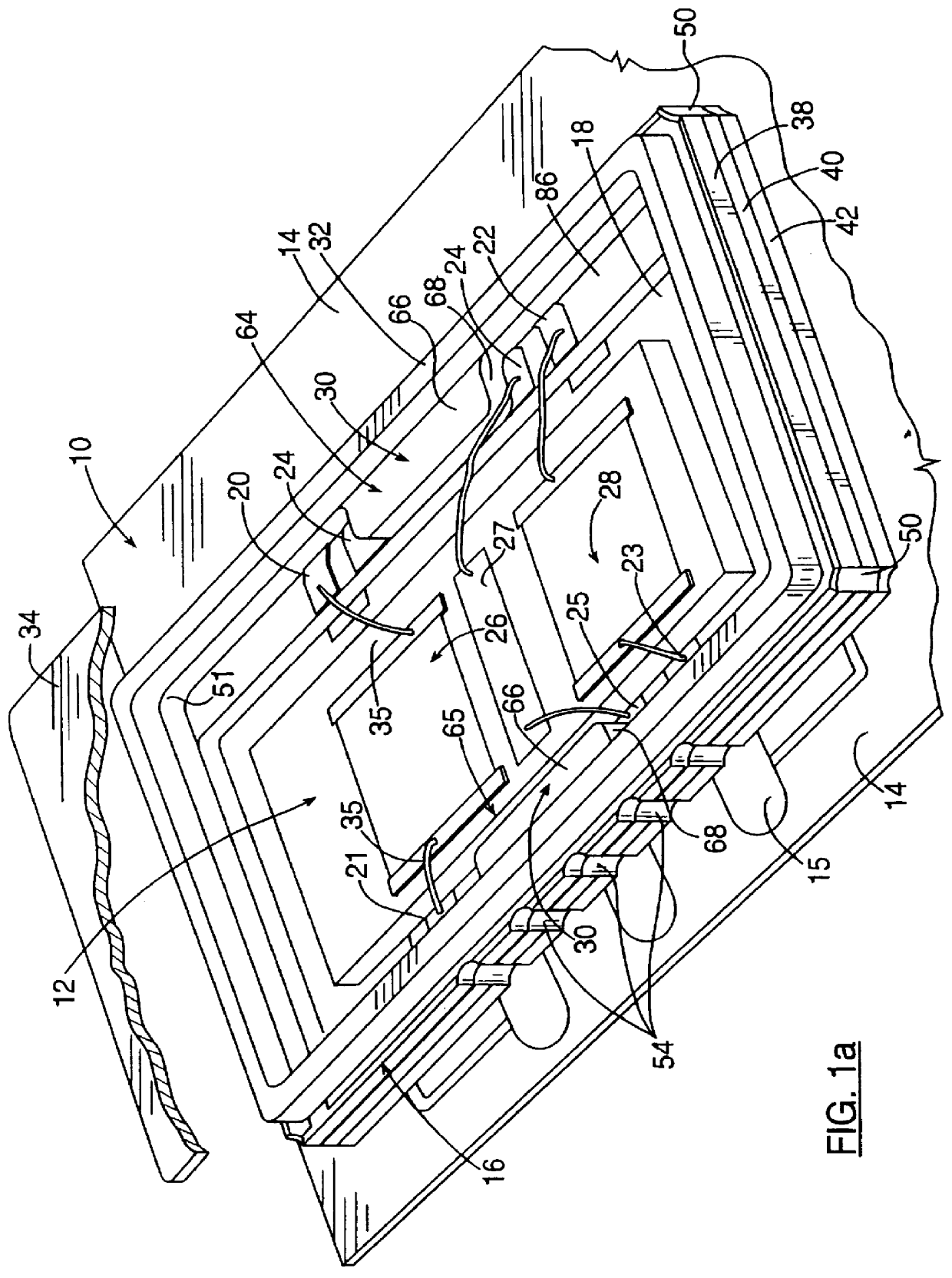

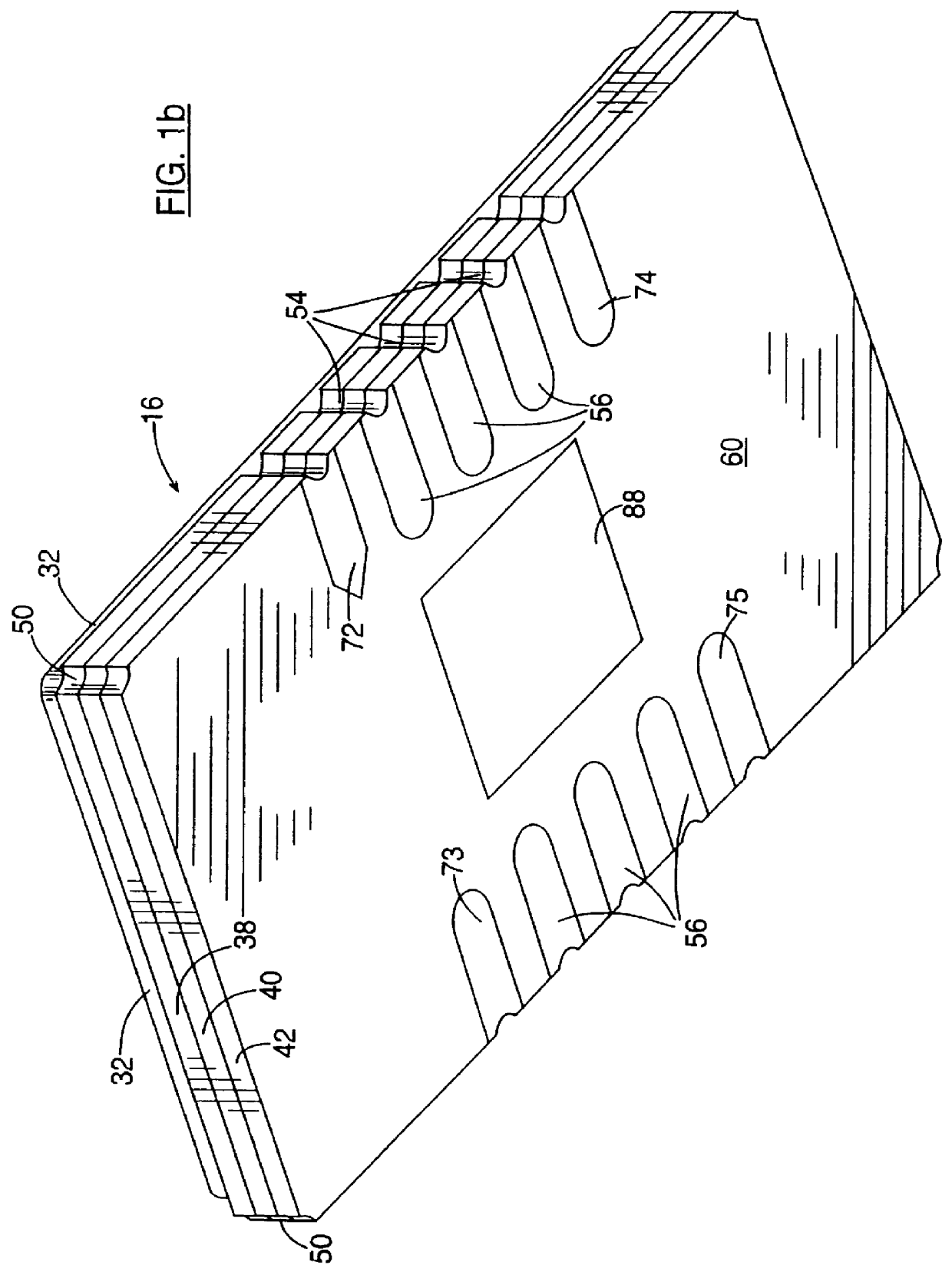

Leadless ceramic chip carrier crosstalk suppression method

InactiveUS6105226AReduce electromagnetic signal effectReduce crosstalkPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblySurface mountingElectrical connection

A leadless ceramic chip carrier useful in surface mounting of SAW devices includes electrically conductive vias and metalization between input and output bond pads for improved crosstalk suppression between input and output device connections. A protrusion extending from a top layer of a multilayer ceramic carrier provides additional electrical contact to a package seal brazed thereto. The vias are positioned between input and output bond pads and connect the metalized protrusion to package ground pads through contact with multiple metalized layers of the package for enhancing the electrical connection between the package Kovar seal ring and customer accessed ground pads. For further suppression of crosstalk, bond pads within the package for connection to the SAW device are spaced at a greater distance from each other than their corresponding pads on the package bottom surface thus maintaining an optimum spacing for package connection to printed circuit board pads for minimizing thermal mismatch effects.

Owner:TRIQUINT

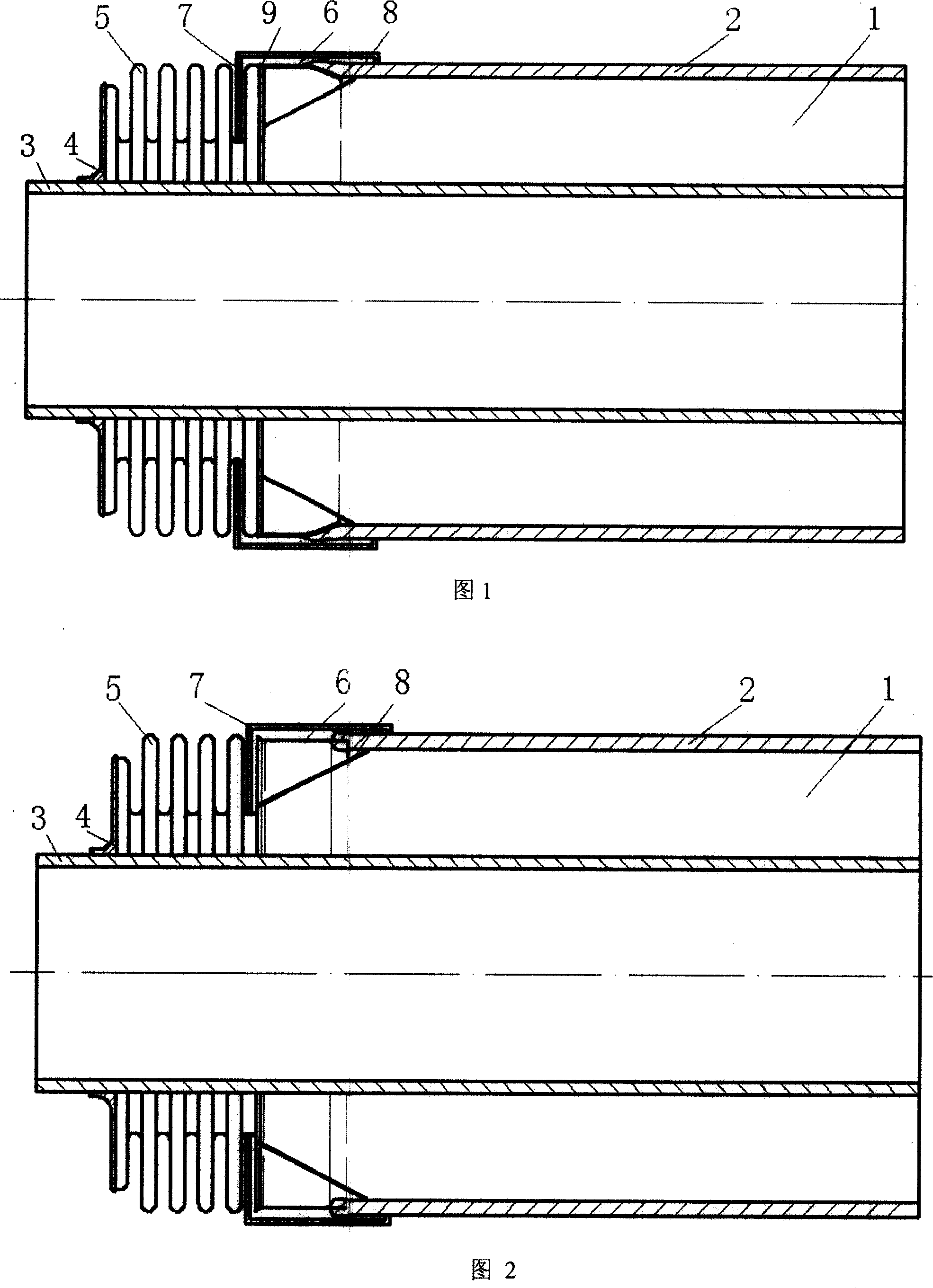

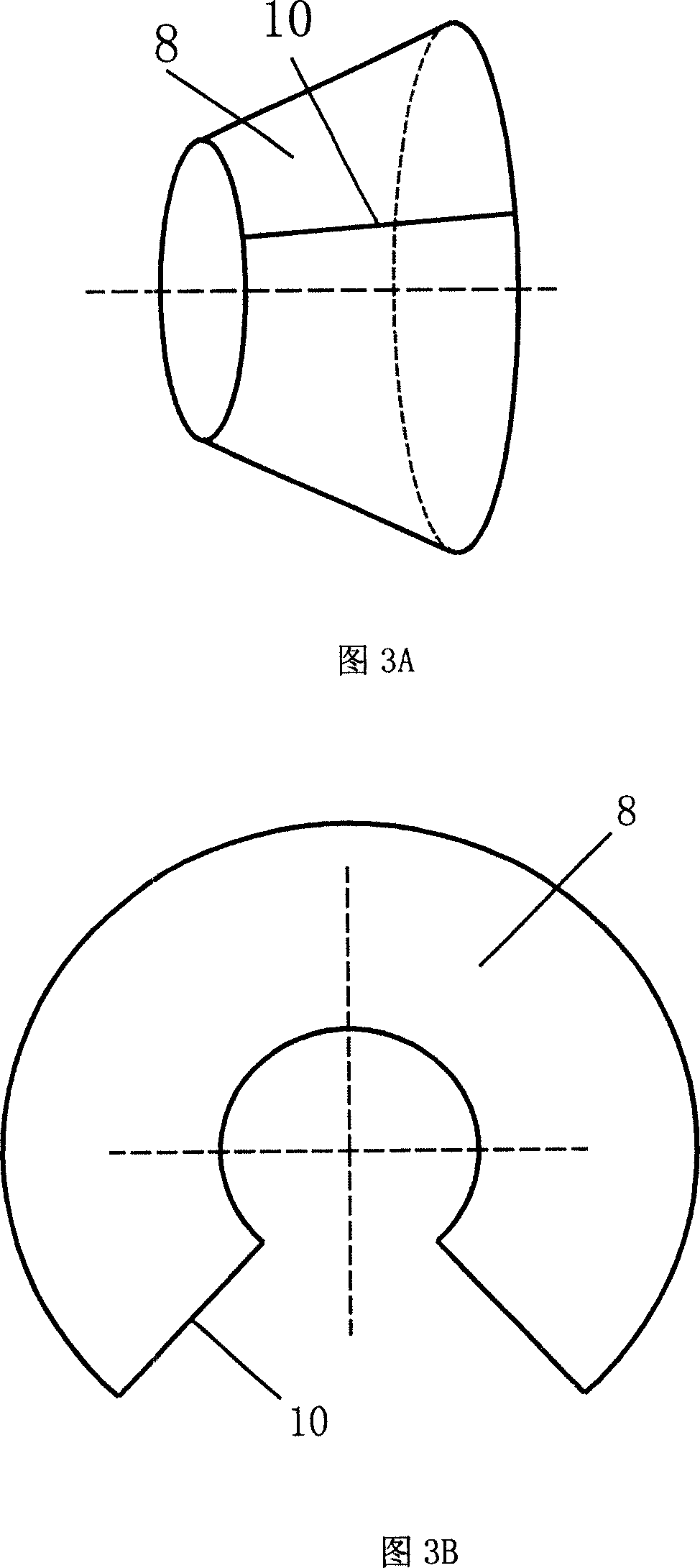

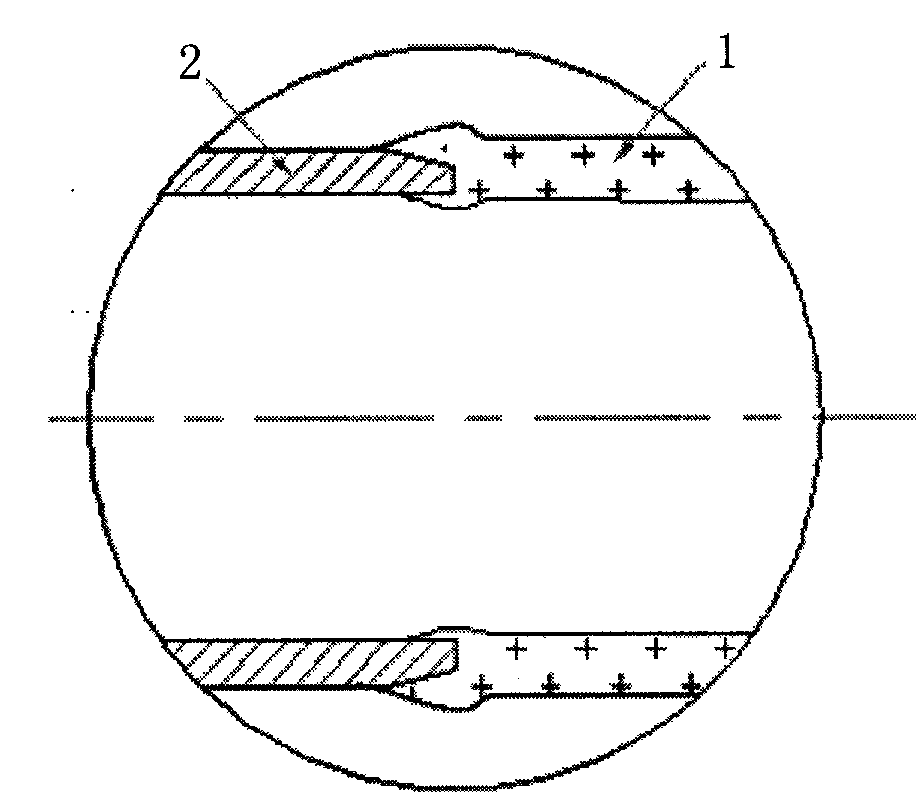

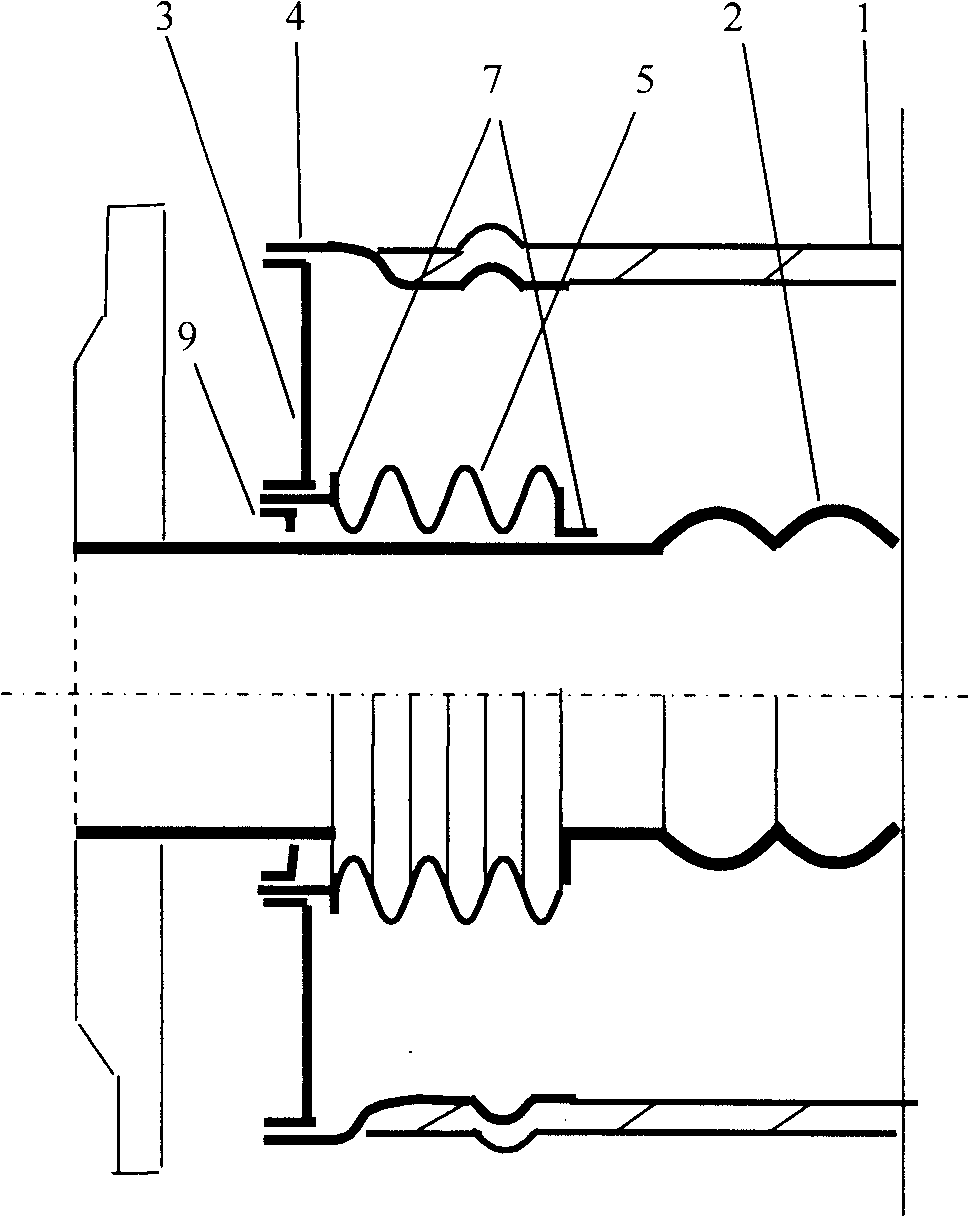

High-temperature solar thermal-collecting tube and manufacturing process thereof

InactiveCN101135501ARadiation immuneExtended service lifeSolar heating energySolar heat devicesEngineeringCobalt

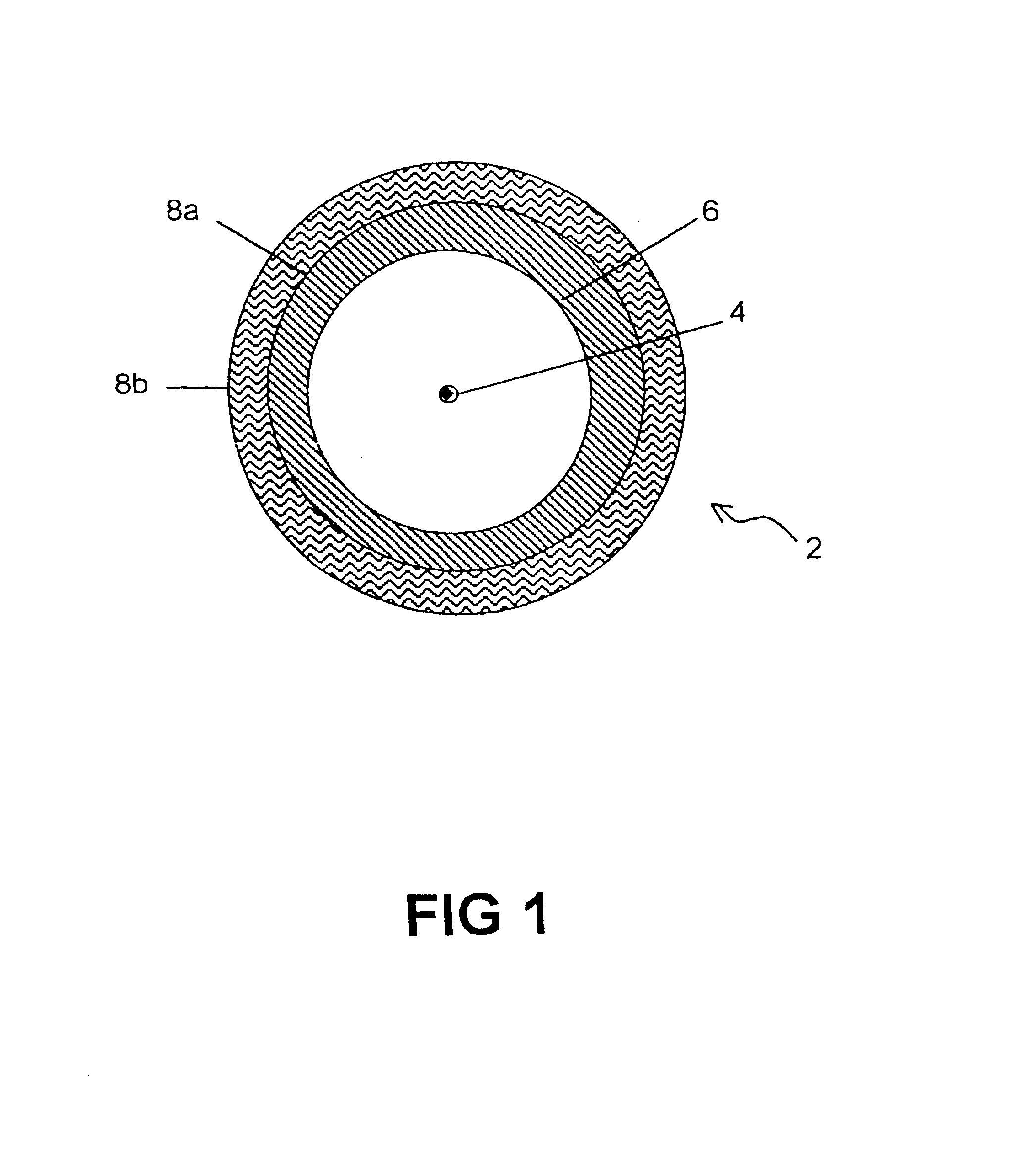

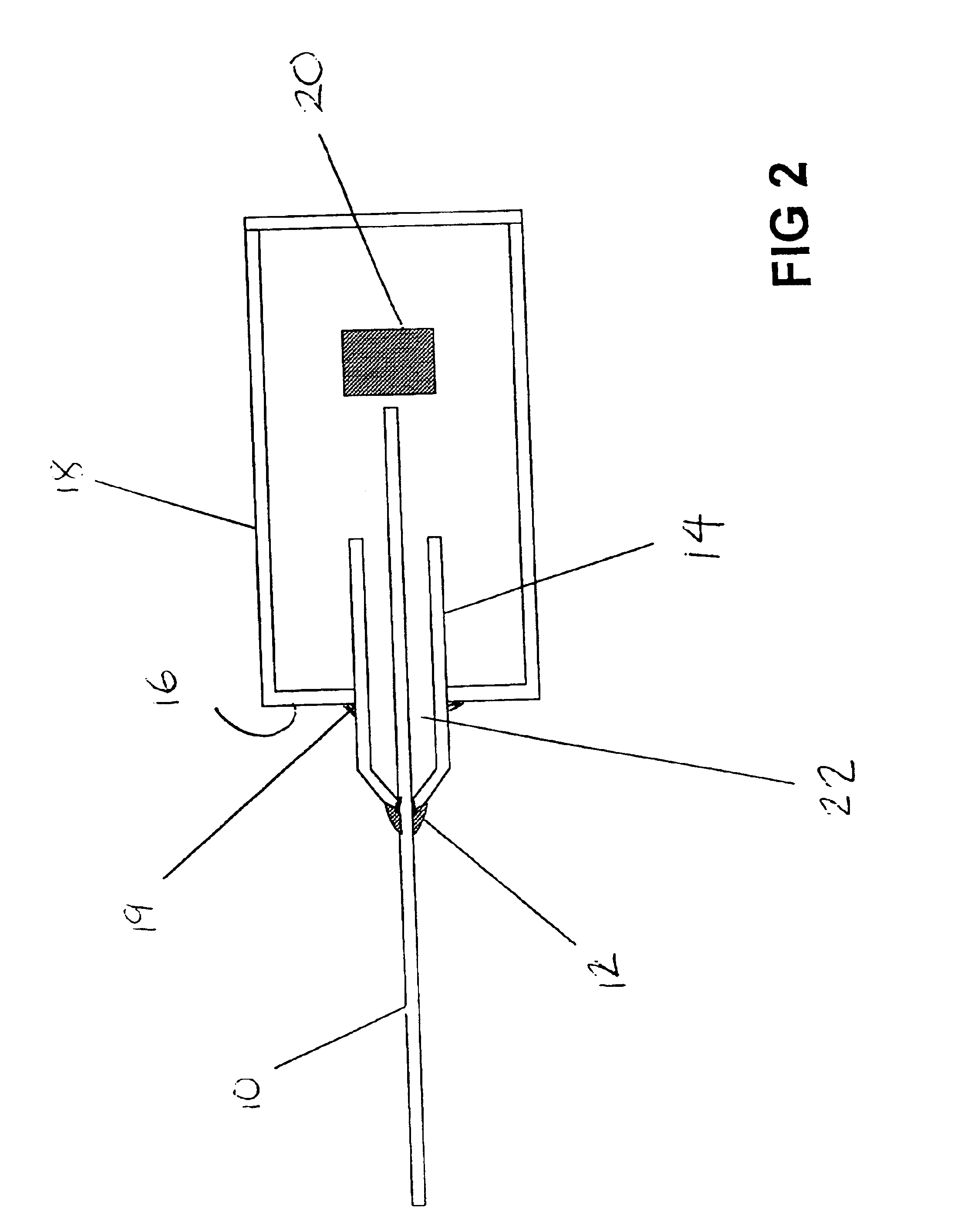

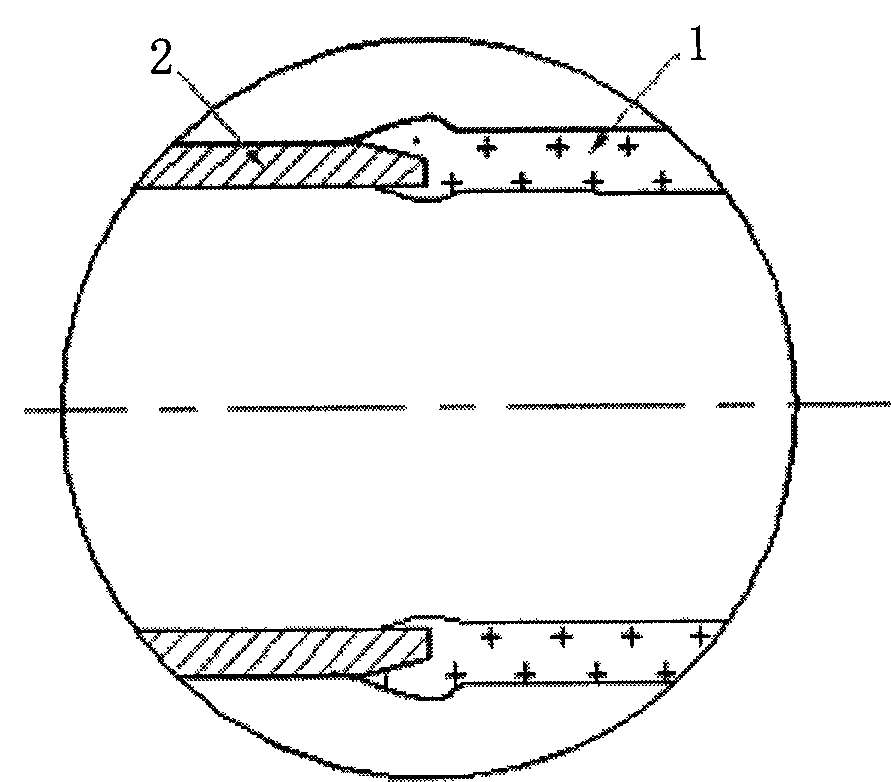

A high temperature solar heat collecting tube and its producing technology mainly applies to tank type solar high temperature heat electric power generation field. The heat collecting tube includes external glass tube and coaxial metal internal tube, corrugated pipe with expansion compensation function is joined with the metal tube by connecting parts, the other end of the corrugated pipe is welded with metal-glass transition parts kovar ring, then the kovar ring is sealed-in with the glass tube, in order to protect glass and glass sealing-in part against radiation, a sunshade hood is mounted at the outer side of sealing-in part, a thin-wall lightproof ring is welded on the corrugated tube. The said glass tube is made of DM308; DM305 or DM320 molybdenum group glass, the kovar ring is made of 4j29 or 4j30 iron-nickel-cobalt low expansion alloy.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

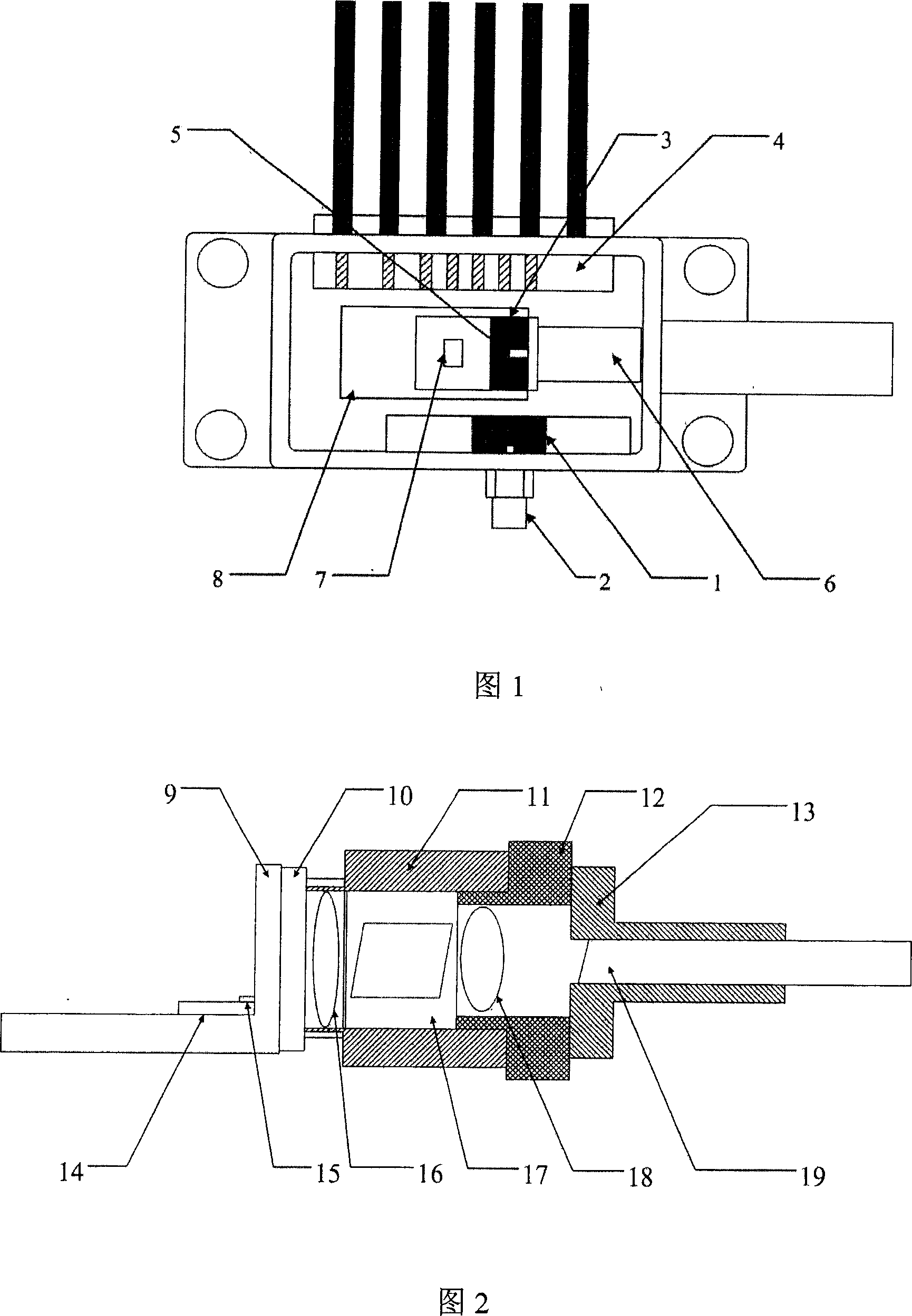

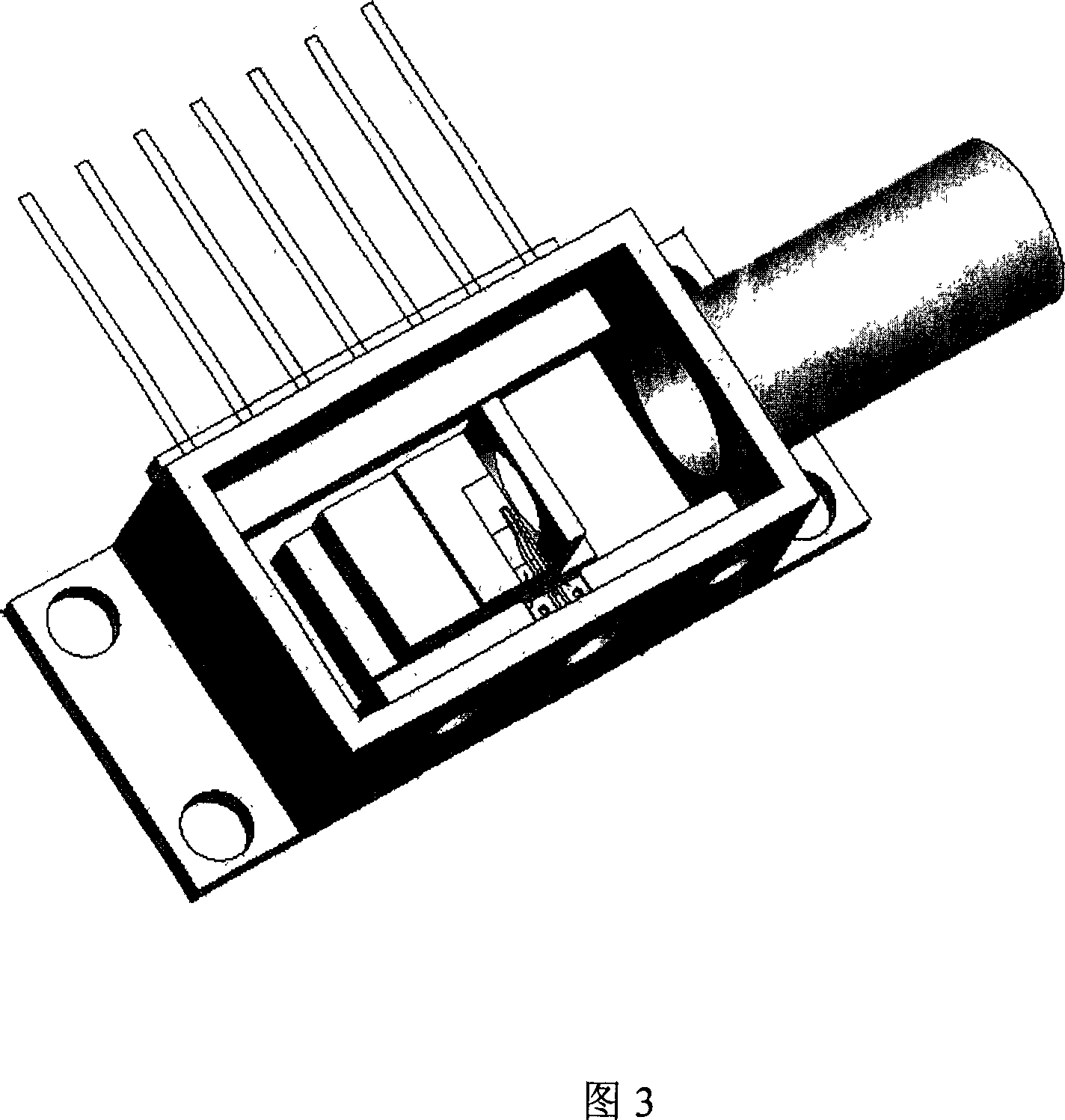

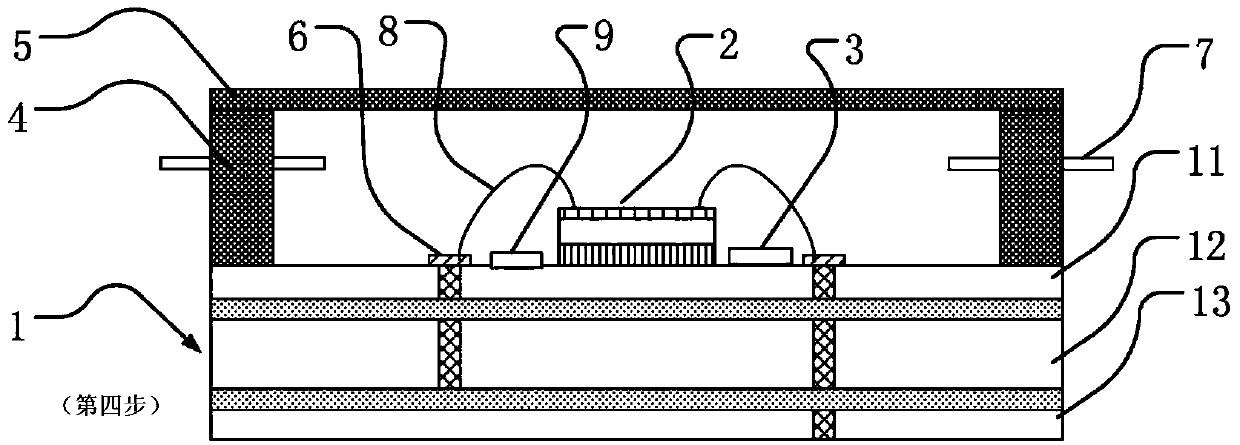

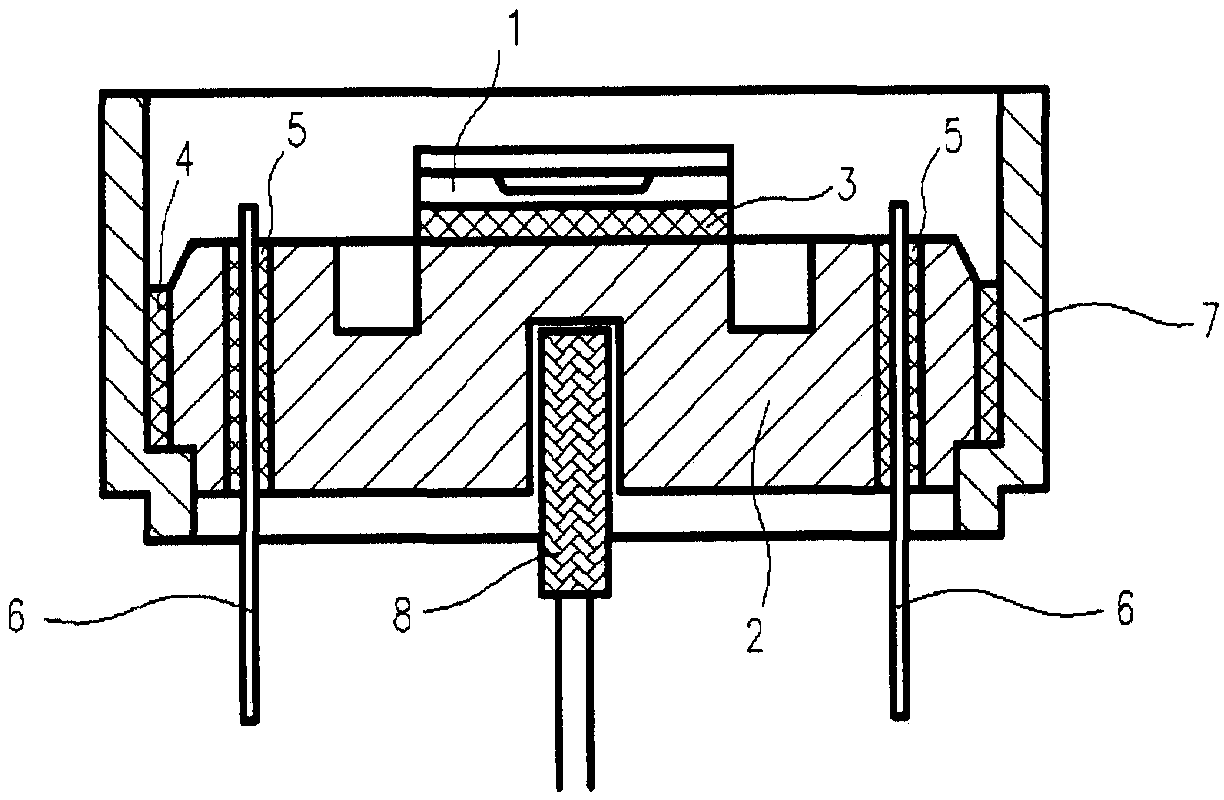

Encapsulation structure and method of the high-speed semiconductor light emission component

InactiveCN101017956AReduce loadEasy to install and debugLaser detailsSemiconductor/solid-state device detailsCoplanar waveguideWorking temperature

The package structure for a high-speed semiconductor light emission assembly comprises: a dish-type case with RF connector, a semiconductor refrigerator to control the work temperature of emission chip, a KOVAR metal heat sink, a medium heat sink substrate, a light emission device, a thermistor, a backlight detector, the metal wire to connect dc connection electrode and case pin, a coplanar waveguide transmission lie on medium substrate, and optical coupling assembly. Wherein, it uses BTF standard package form for dc terminals outside the case.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for forming a flexible metal foil substrate display

A flexible metal foil substrate organic light emitting diode (OLED) display and a method for forming the same are provided. The method comprises: supplying a metal foil substrate such as titanium (Ti), Inconel alloy, or Kovar, having a thickness in the range of 10 to 500 microns; planarizing the metal foil substrate surface; depositing an electrical isolation layer having a thickness in the range of 0.5 to 2 microns overlying the planarized metal foil substrate surface; depositing amorphous silicon having a thickness in the range of 25 to 150 nanometers (nm) overlying the electrical insulation layer; from the amorphous silicon, forming polycrystalline silicon overlying the electrical insulation layer; forming thin-film transistors (TFTs) in the polycrystalline silicon; and, forming an electronic circuit using the TFTs, such as an OLED display.

Owner:SHARP LAB OF AMERICA INC

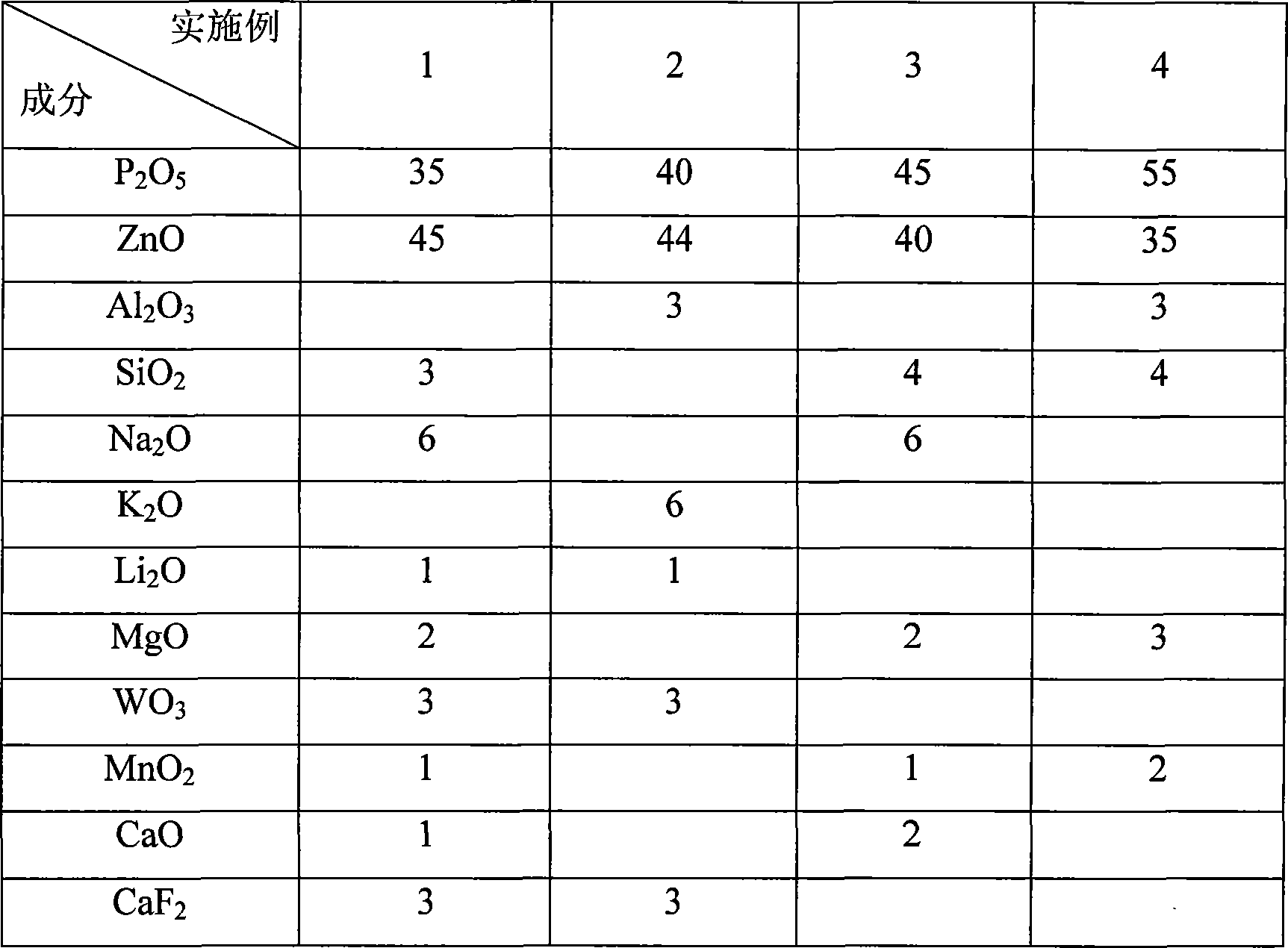

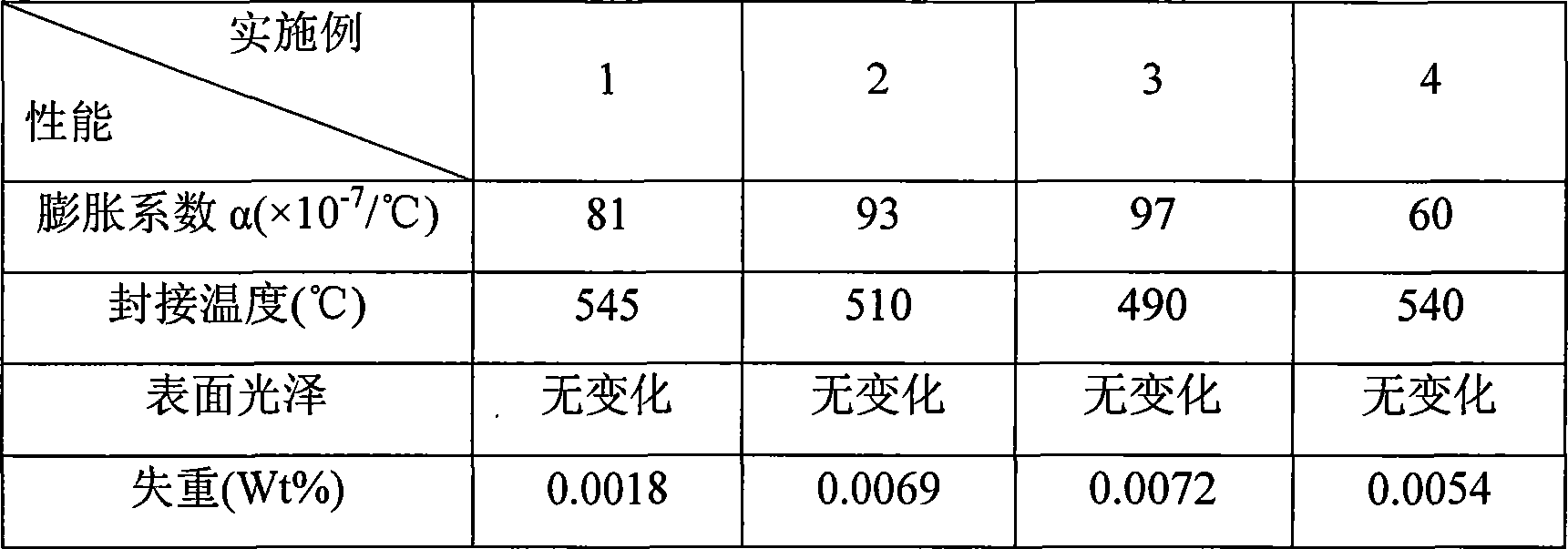

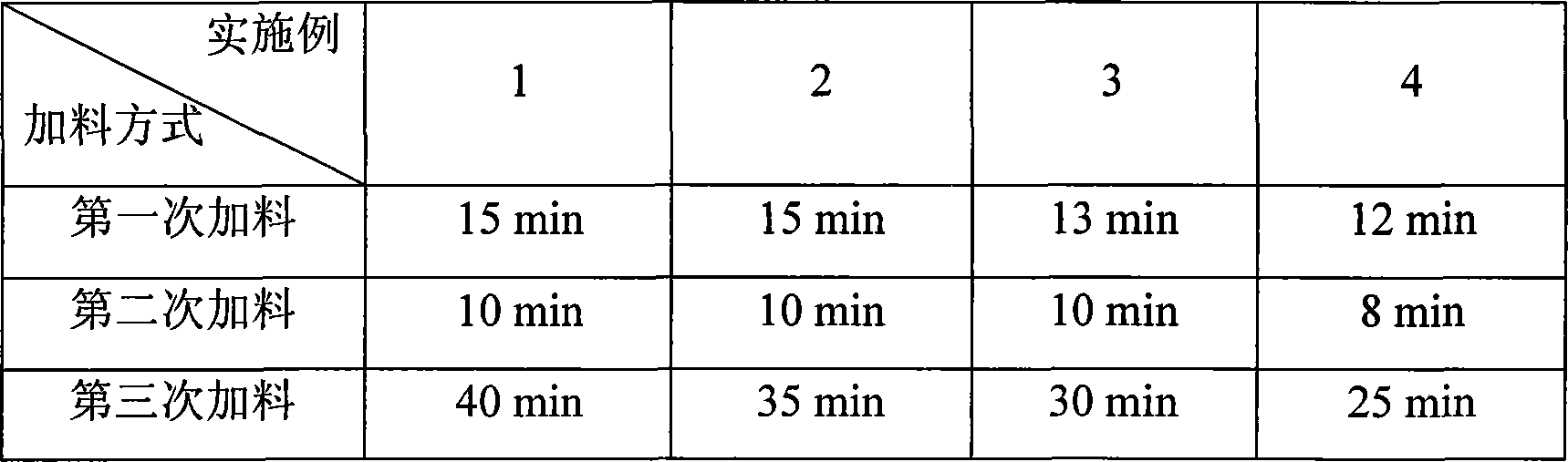

Leadless low-melting glass powder for seal with metal or alloy and preparation method thereof

InactiveCN101113073AEasy to adjust thermal expansion coefficientSuitable softening temperatureVitreous BodiesMixed materials

The invention relates to lead-free glass powders with low melting point for sealing of metal or alloy and preparation methods thereof. The glass powder comprises P2O5, ZnO, Al2O3, SiO2, MgO, MnO2, Li2O, WO3, CaF2, Na2O, K2O and CaO. The preparation thereof is divided into the following steps: (1) raw materials are drawn and fully mixed according to weight proportions to make into mixed materials; (2) the mixed materials are heated and melted for 30 minutes to two hours under a temperature ranging from 1000 DEG C to 1350 DEG C; (3) the melted glass liquid is cooled and cured into glass body. The glass powder not only has comparatively ideal heat expansion coefficient, softening temperature and chemical stability but also has simple preparation process, straightforward operation and low cost, which is applicable to the sealing of glass, ceramic, metal and semiconductor and in particular applicable for the sealing of metals of molybdenum family and tungsten family or alloy such as kovar alloy. Also the glass powder is competitive in lead-free production and has wide market development prospect.

Owner:DONGHUA UNIV

Glass fiber fixative and fixing process

InactiveUS6837075B1Eliminate needGood adhesionGlass making apparatusCoupling light guidesFiberMetallic materials

A glass fixative composition for bonding glass materials to non-glass materials is provided. The fixative composition is selected for its thermal expansion coefficient, its viscosity, its adhesion to glass, melting point, and bond strength. The glass fixative is in particular useful for bonding optical fibers to metallic materials such as Kovar. The low melting point of the glass fixative enables localized heating methods to be used, in particular, as Kovar is a ferromagnetic material, induction heating can be used to form a bond. The bond formed provides a compressive joint which enables the fiber to be hermetically fixed in position.

Owner:LUMENTUM TECH UK LTD

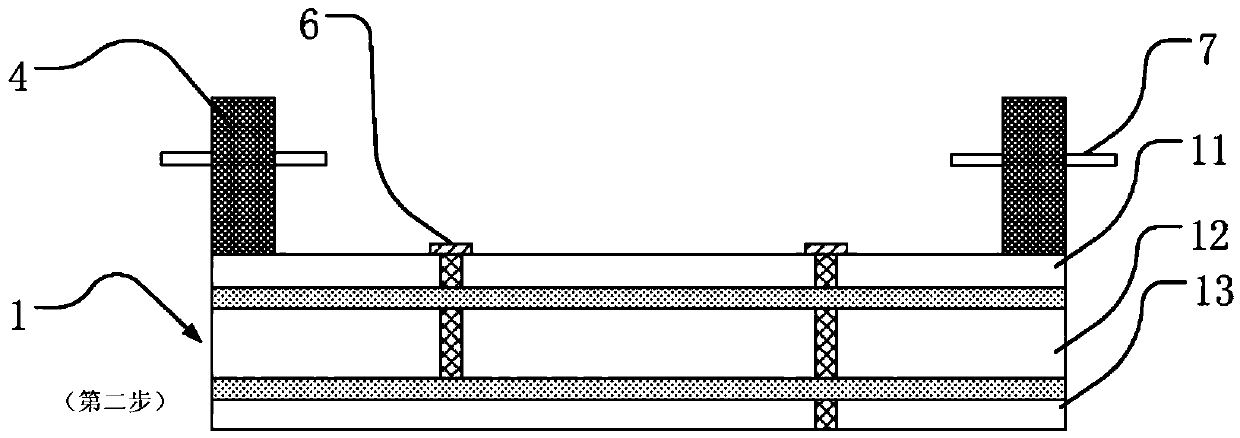

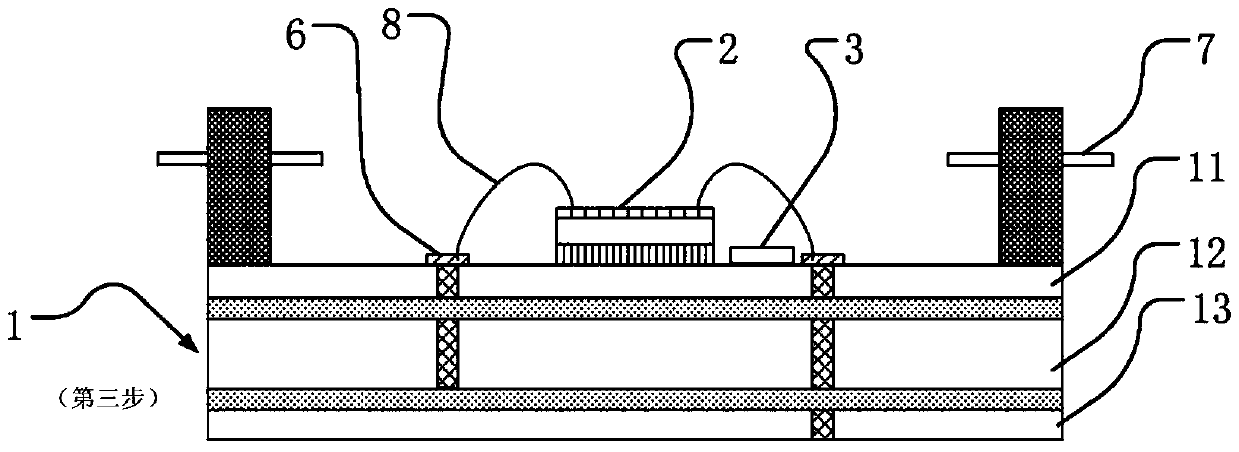

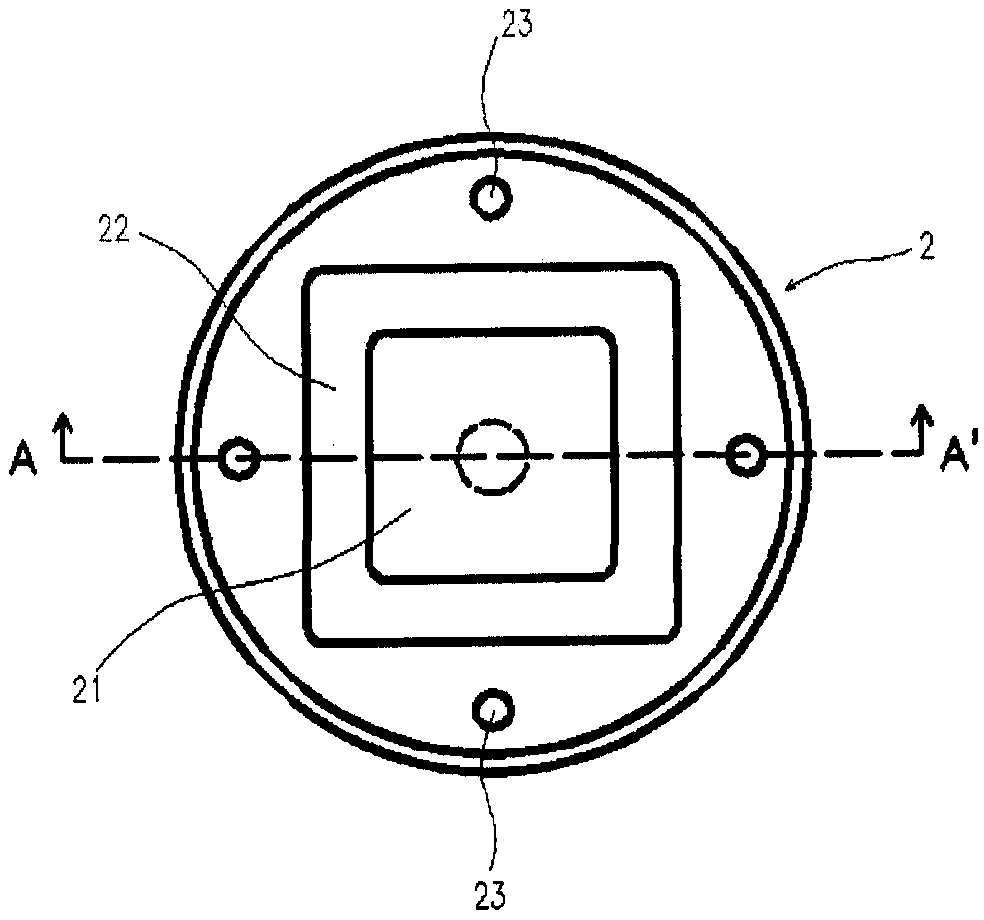

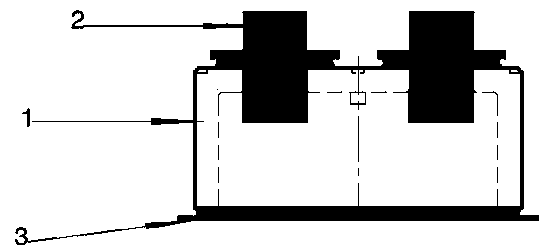

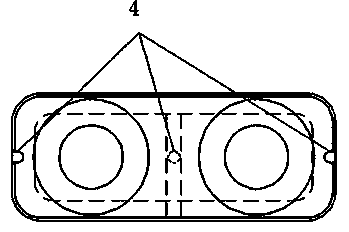

MEMS (Micro-Electromechanical System) sensor encapsulation structure and encapsulation method thereof

ActiveCN103950886ACompact structureReduce electrical connectionsDecorative surface effectsSolid-state devicesHigh densityThermal expansion

The invention relates to an MEMS sensor encapsulation structure and an encapsulation method thereof, which are used for encapsulating an MEMS sensor. The MEMS sensor encapsulation structure is characterized by comprising a ceramic base, a side wall and a top cap, wherein a plurality of metal bonding pads are respectively arranged on a top layer and a bottom layer of the ceramic base; the metal bonding pads on the top layer of the ceramic base are connected with leads of the MEMS sensor; the MEMS sensor is arranged on the ceramic base; the metal bonding pads on the bottom layer of the ceramic base are connected with an external circuit; the ceramic base adopts one-layer or multi-layer perpendicularly interconnected structure; the side wall and the top cap are both made of kovar alloy. According to the invention, the ceramic base of which coefficient of thermal expansion is approximate to that of the MEMS sensor material is selected as the encapsulation material, in order to reduce influence of the base expansion stress to the MEMS sensor; meanwhile, the ceramic base can be utilized to realize one-layer perpendicular interconnection or multi-layer perpendicular interconnection; the system-level integration between the MEMS sensor and the peripheral circuit can be realized within a small area; high-density system-level encapsulation can be realized; the encapsulation flexibility and the expansibility of the MEMS sensor can be realized.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

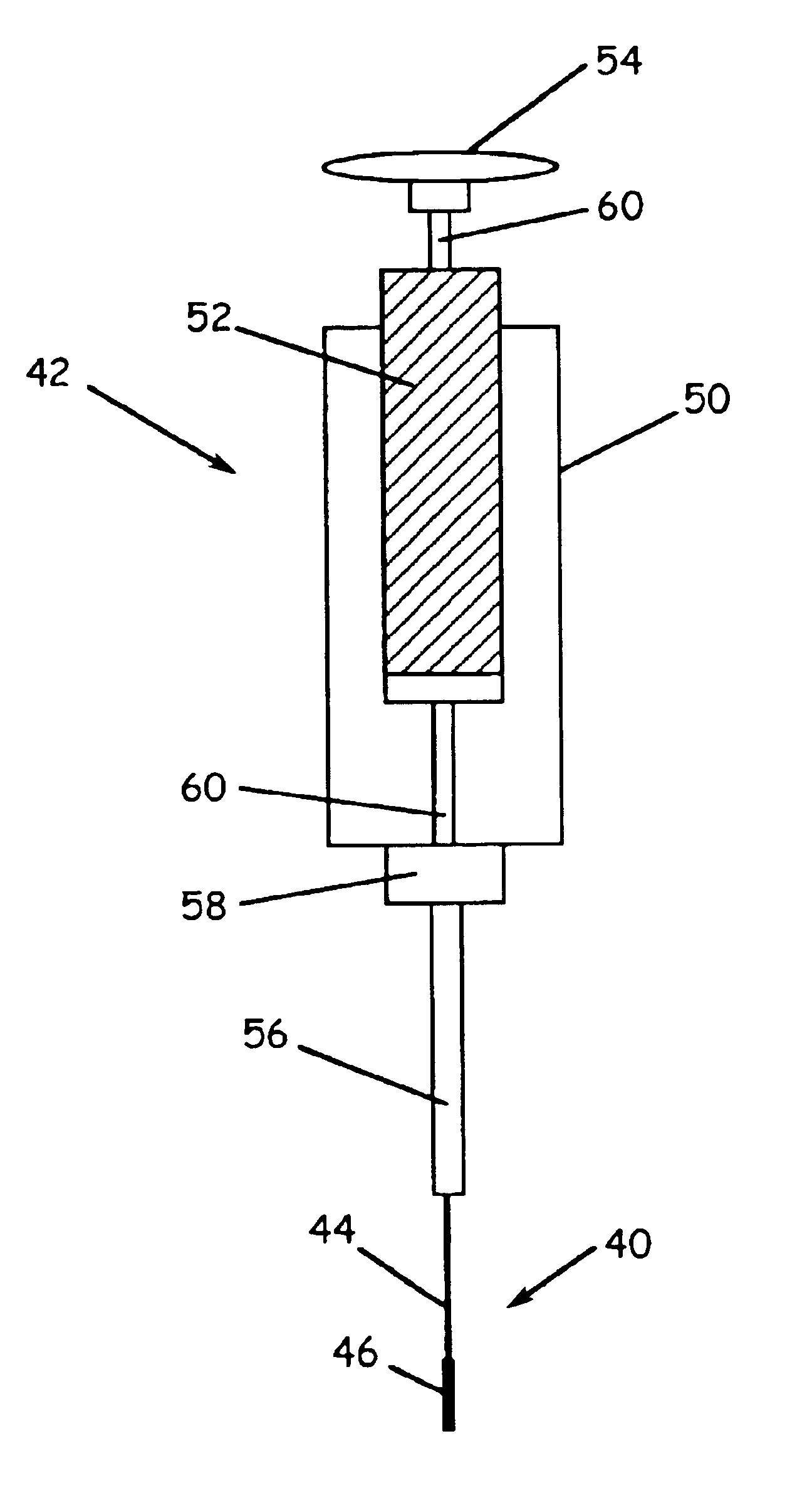

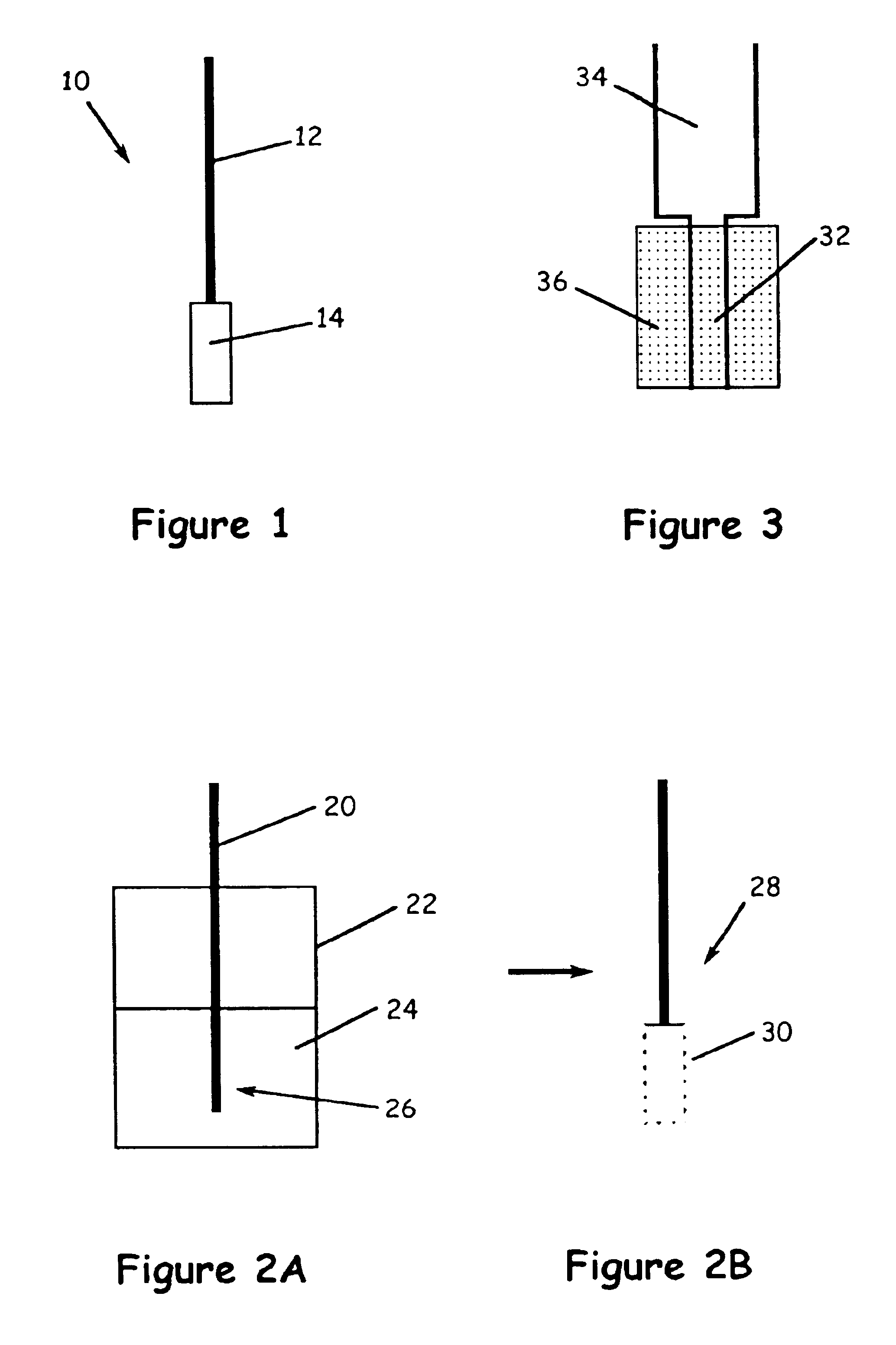

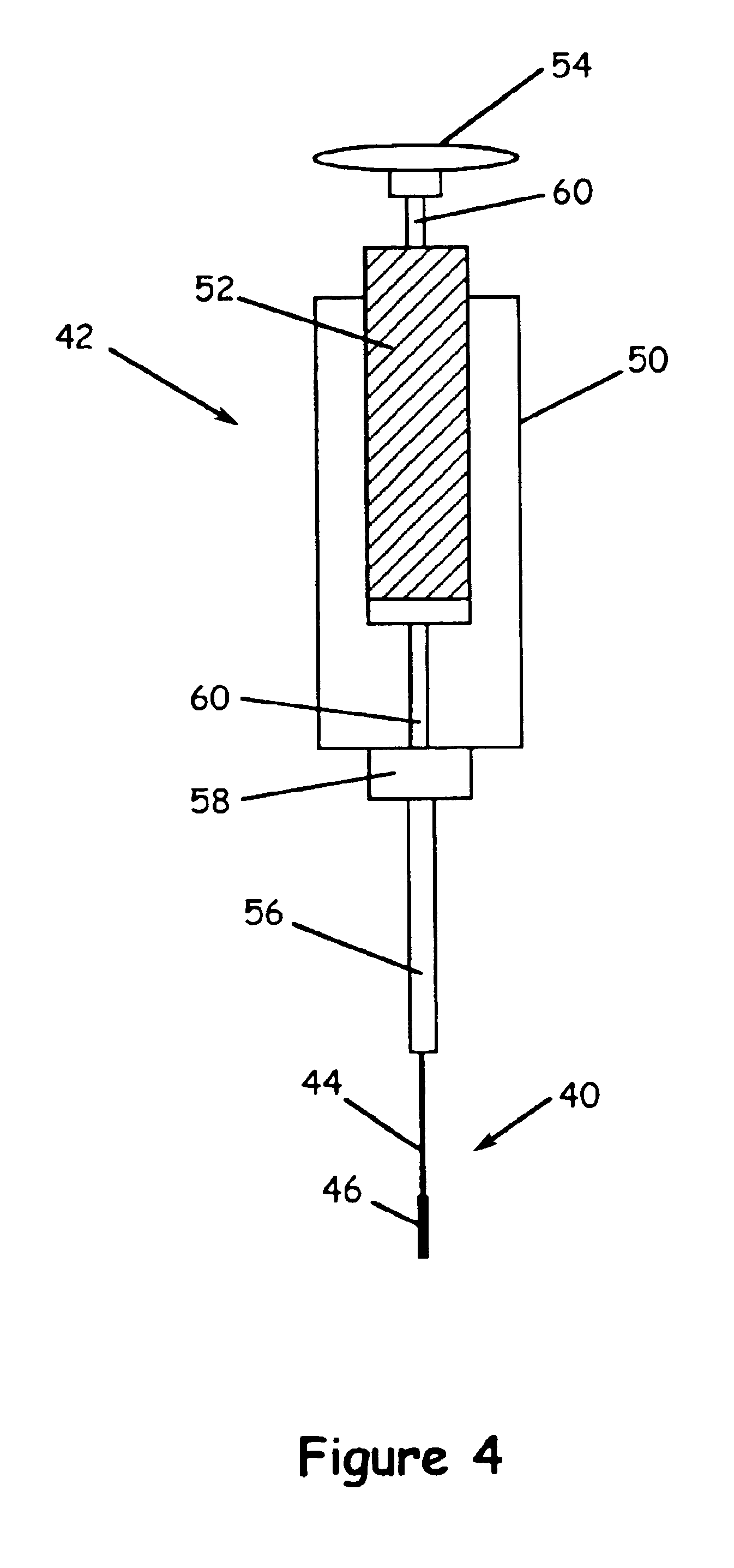

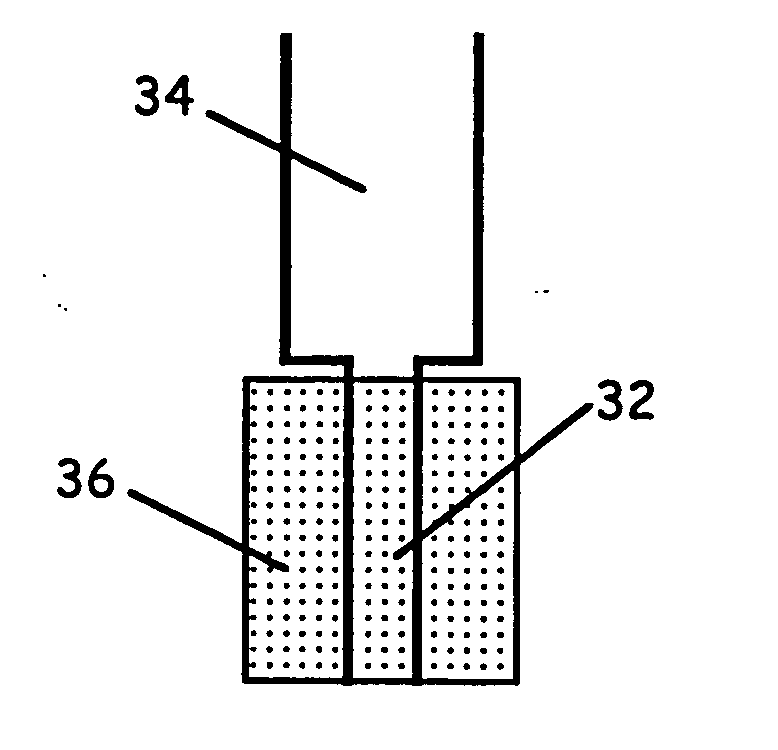

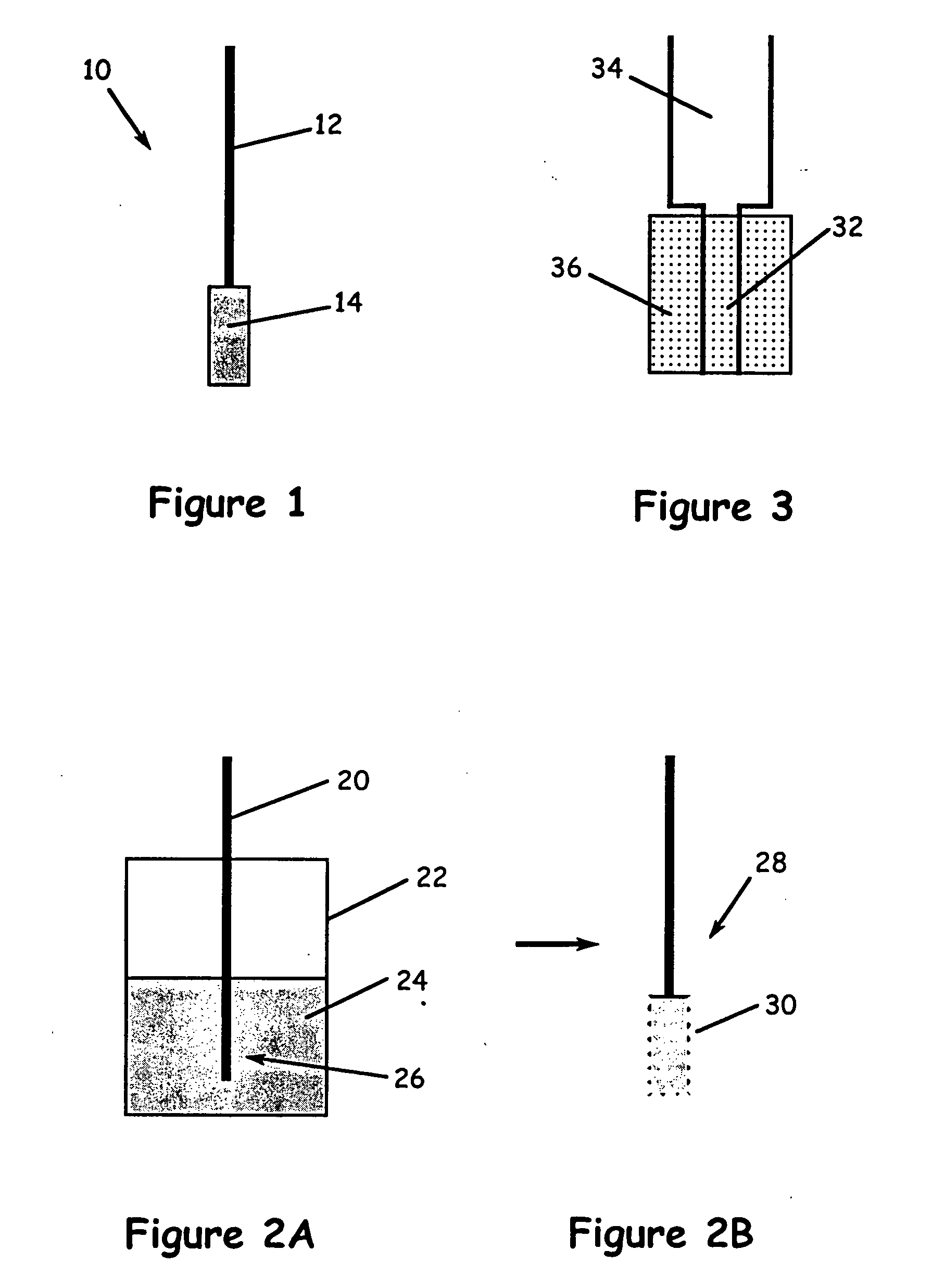

Solid phase microextraction device using aerogel

InactiveUS6905031B1Quick and easy to manufactureEasily toleratedComponent separationSolid sorbent liquid separationSolid-phase microextractionKovar

A sample collection substrate of aerogel and / or xerogel materials bound to a support structure is used as a solid phase microextraction (SPME) device. The xerogels and aerogels may be organic or inorganic and doped with metals or other compounds to target specific chemical analytes. The support structure is typically formed of a glass fiber or a metal wire (stainless steel or kovar). The devices are made by applying gel solution to the support structures and drying the solution to form aerogel or xerogel. Aerogel particles may be attached to the wet layer before drying to increase sample collection surface area. These devices are robust, stable in fields of high radiation, and highly effective at collecting gas and liquid samples while maintaining superior mechanical and thermal stability during routine use. Aerogel SPME devices are advantageous for use in GC / MS analyses due to their lack of interfering background and tolerance of GC thermal cycling.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

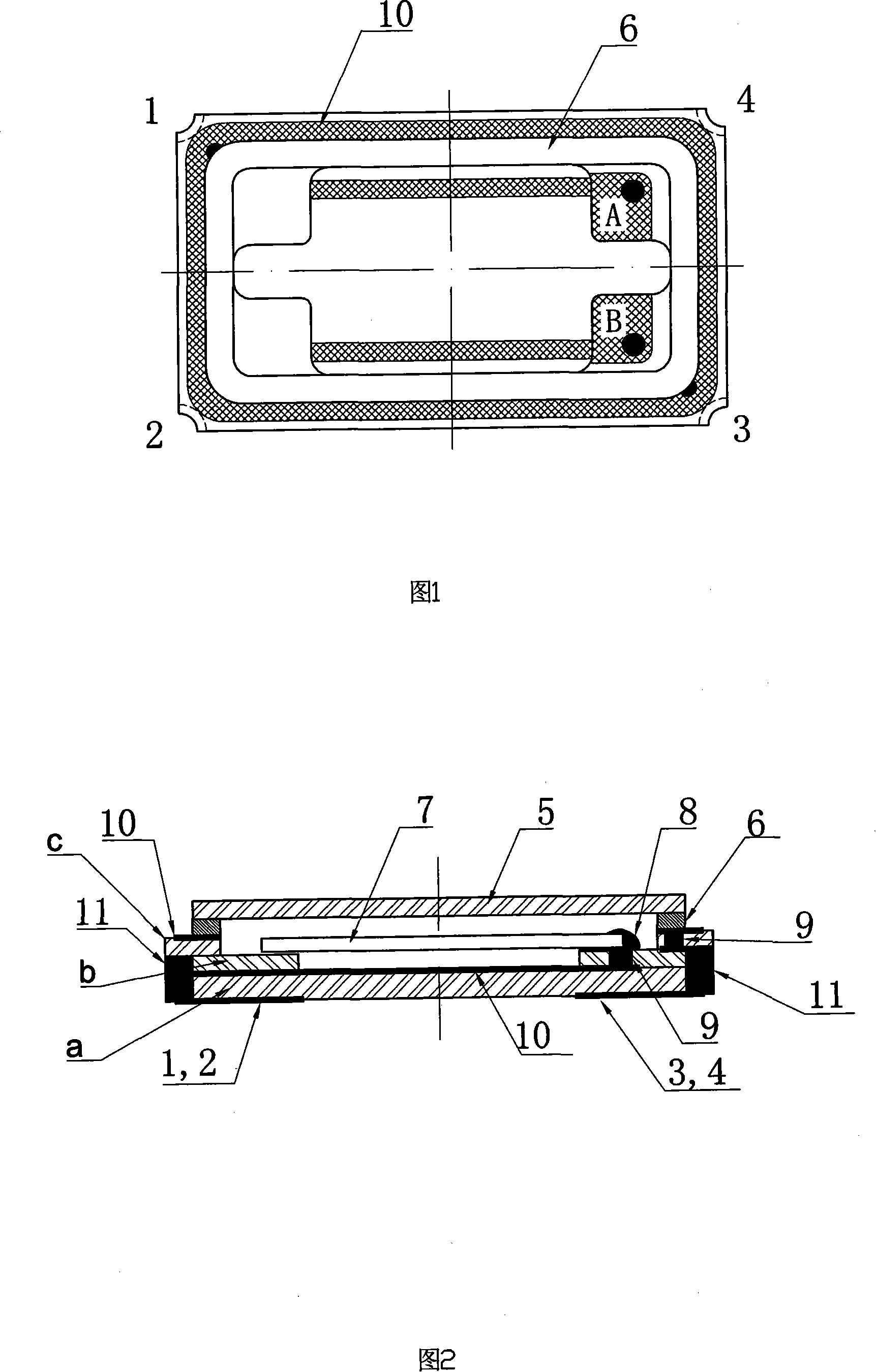

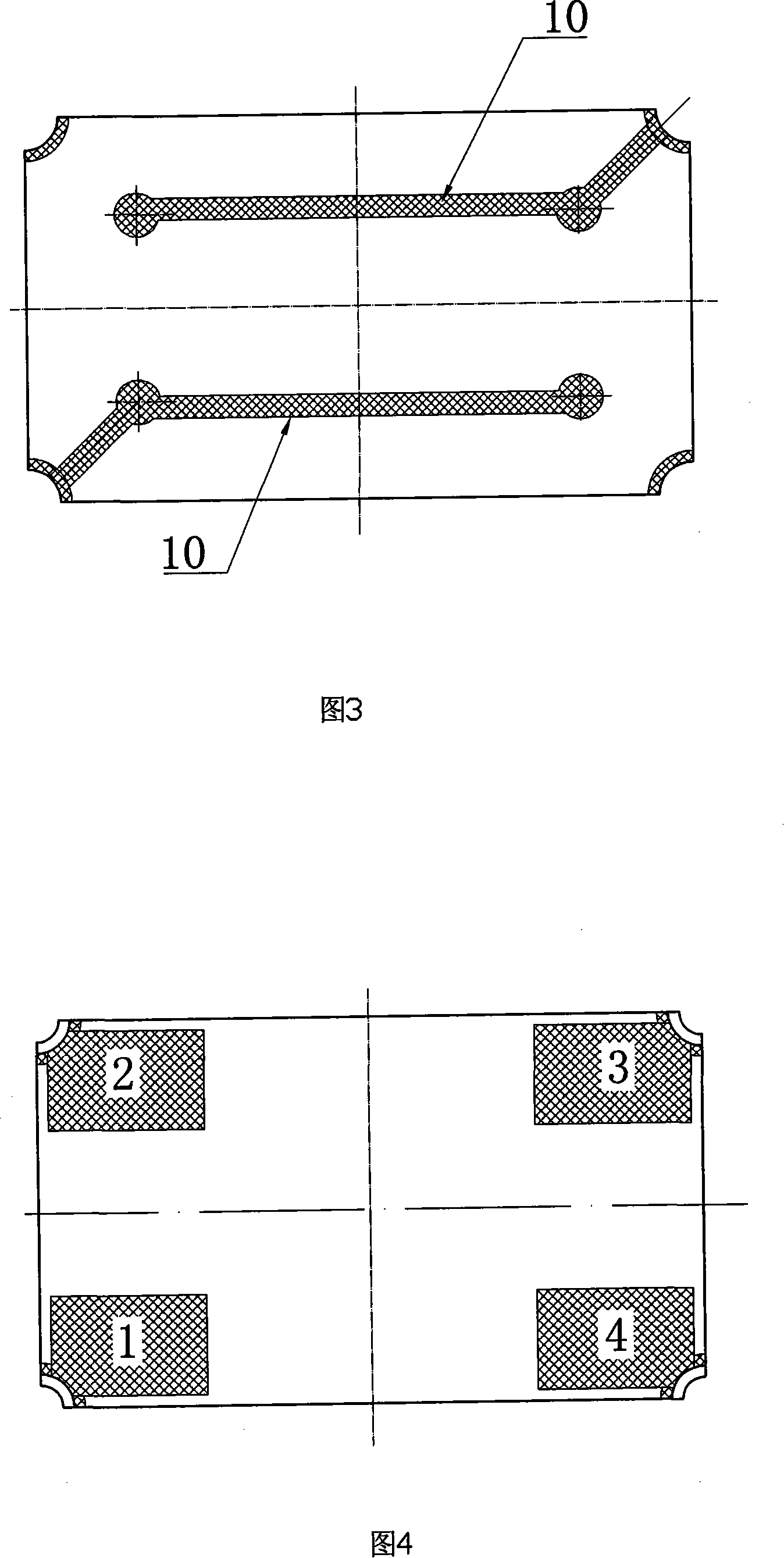

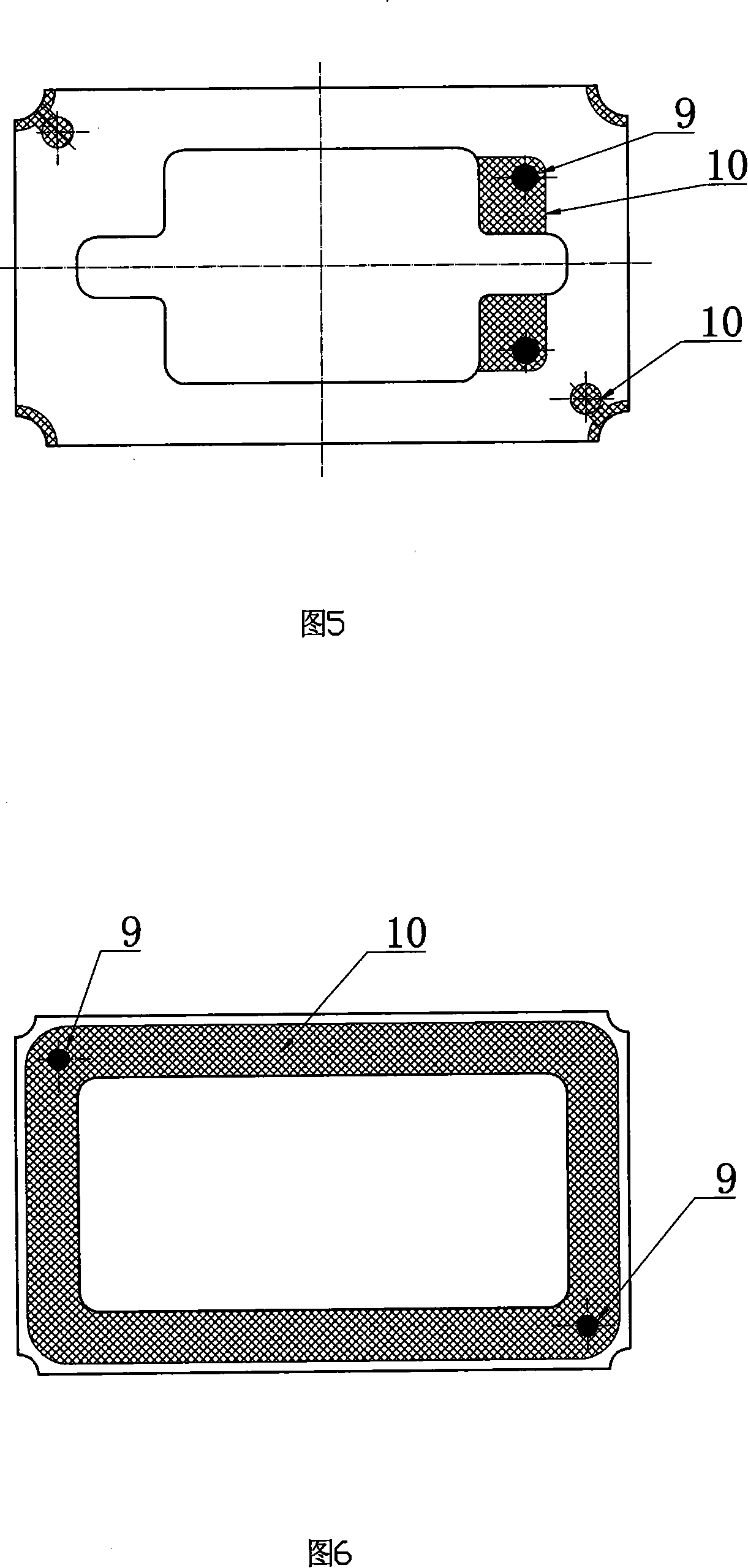

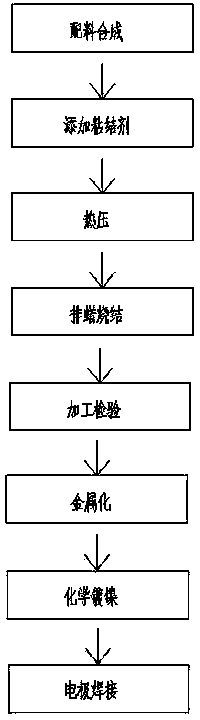

Ceramic packing member used for SMD crystal resonator and manufacturing technique thereof

InactiveCN101132169AThe number of layers of co-fired ceramic plates is reducedReduce manufacturing costImpedence networksSemiconductor/solid-state device detailsShielding gasCarbon Dioxide / Helium

This invention relates to a technique for ceramic packing the transistor resonator, particularly the ceramic package component used for SMD transistor resonator. It is composed of: the co-sintered ceramic layer and the ceramic cover. Said co-sintered ceramic layer comprises the coincided No.1 ceramic layer and No.2 ceramic layer. Over the No.2 layer is the ceramic cover; on the upper surface of the No.1 layer is the printed convex platform, which is used for supporting transistors and guiding the electrodes, through the holes, to the basal plane soldering plate. The advantages are: simple sintering process, low production cost, reducing shielding gas protective soldering, low kovar frame material requirement, low gold-plated area, and short leading wire.

Owner:CHAOZHOU THREE CIRCLE GRP

Anode welding process for metal-glass and metal-ceram

The present invention discloses anode welding method for metal and glass and ceramic and belongs to the field of different material connection technology. Under atmosphere and at low welding temperature, the present invention complete solid connection directly without any added intermediate material. Precision welding may be completed in vacuum, protecting atmosphere and air with less deformation of the workpiece and in simple technological process. The present invention may be used in welding including borosilicate glass, fiber optical glass, quartz and other non-metal material and Kovar, Fe-Ni, Al and other alloy and metal material as well as the sealing of Si, GaAs and other semiconductor material. The said technological process requires high surface processing precision and is used mainly in micro mechanism and mini sensor manufacture, electric vacuum technology, aeronautics and astronautics and other fields.

Owner:XI AN JIAOTONG UNIV

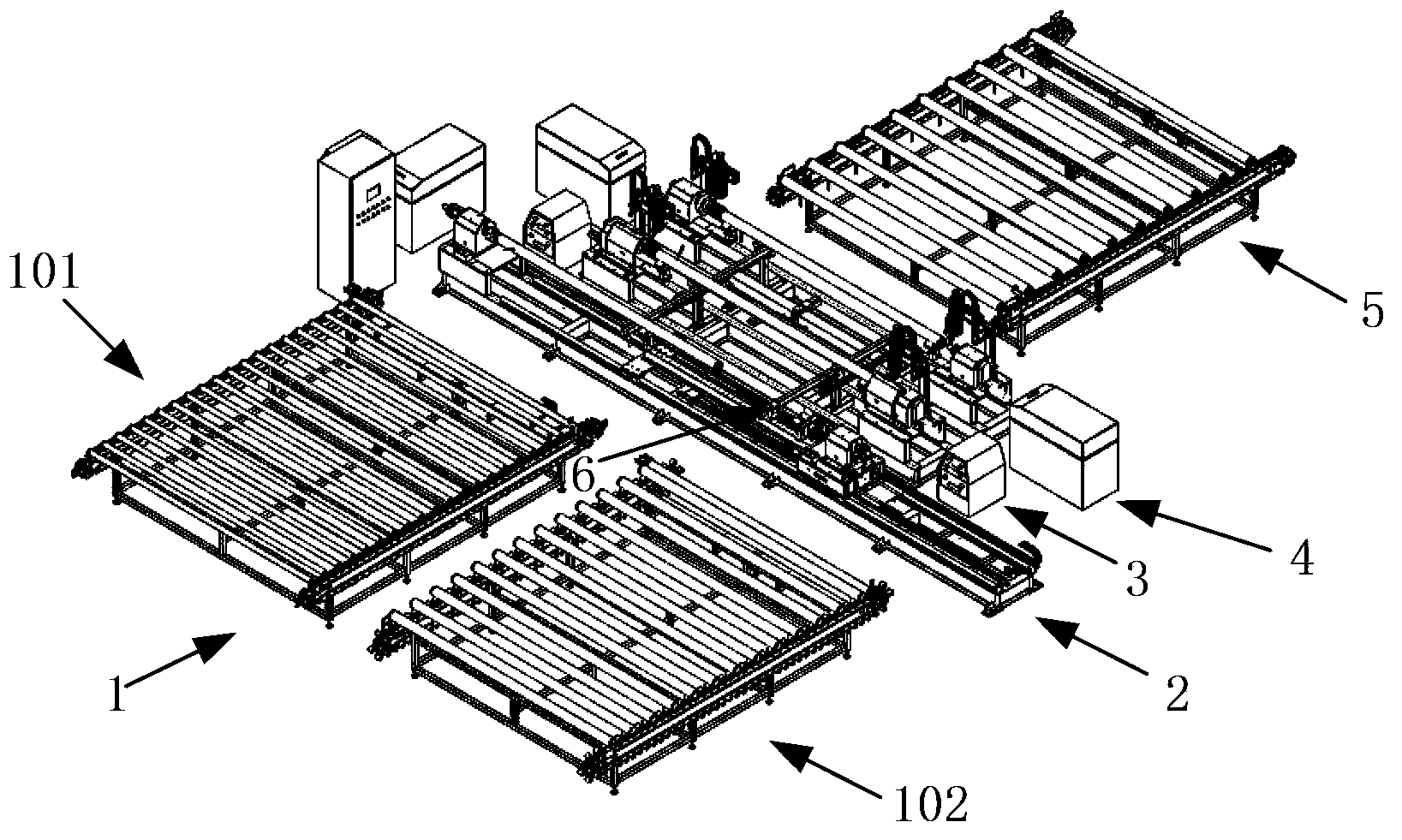

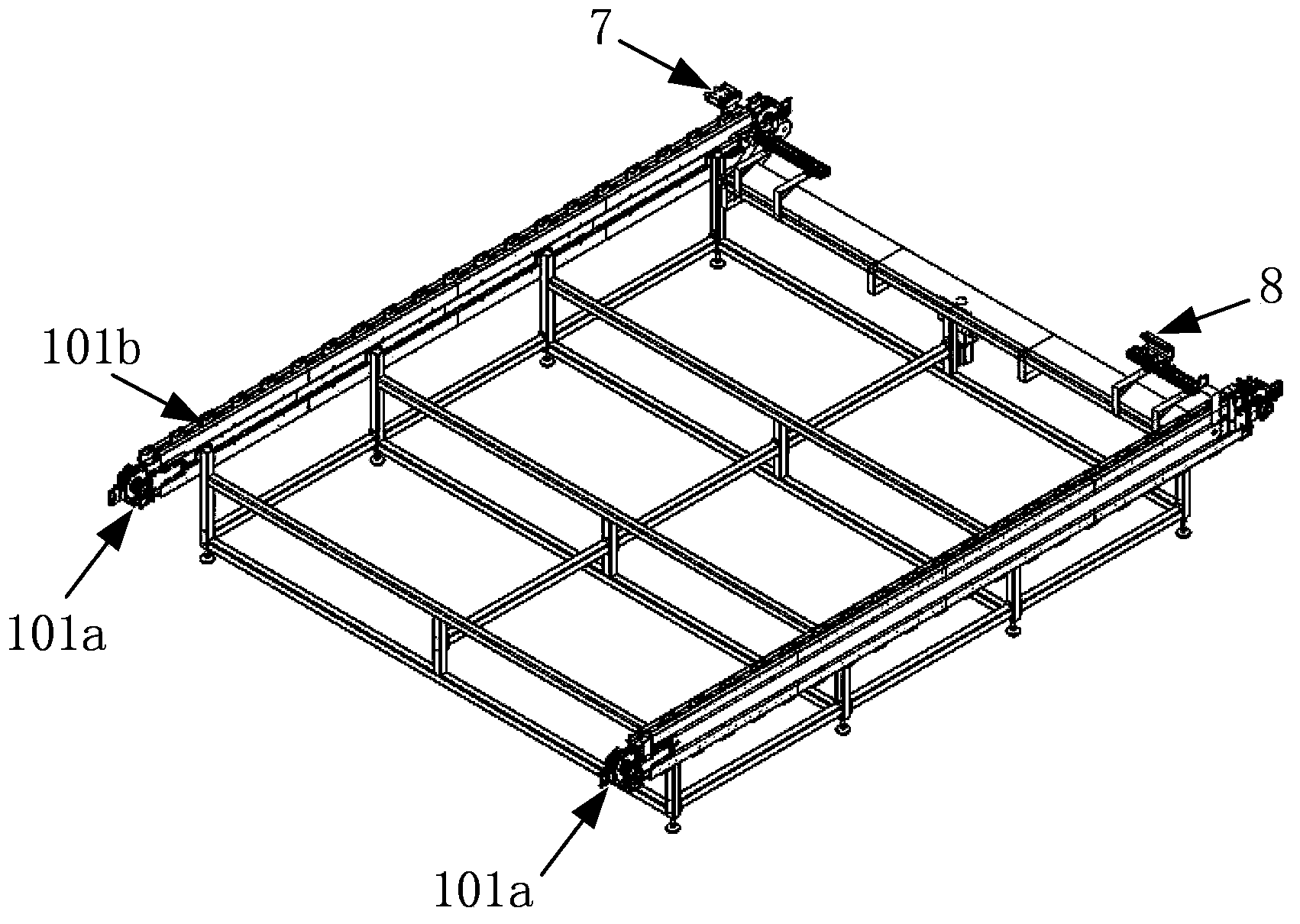

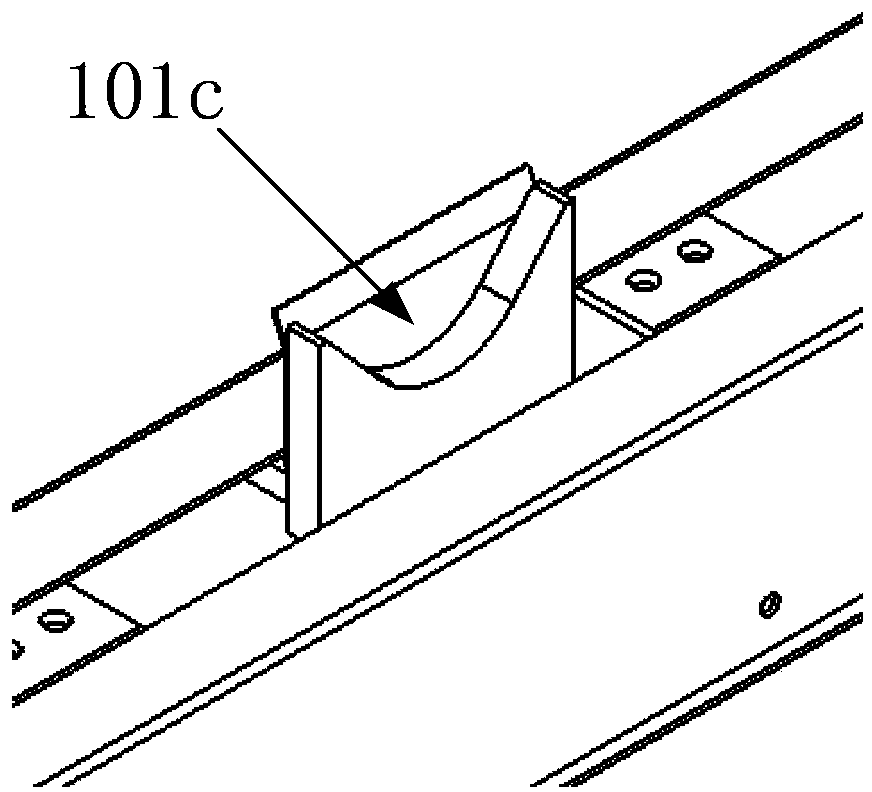

Assembly line of medium-high temperature solar thermal-collecting tube assembly

ActiveCN103433629AHigh degree of automationNo need to manually measureWelding/cutting auxillary devicesArc welding apparatusTransfer procedureEngineering

The invention discloses an assembly line of a medium-high temperature solar thermal-collecting tube assembly. The assembly line of the medium-high temperature solar thermal-collecting tube assembly comprises a feeding conveying mechanism, an assembly spot welding worktable, an argon arc ring welding worktable, a laser ring welding worktable and a finished product conveying line, wherein the feeding conveying mechanism is used for conveying a coated steel tube and a glass tube; during a conveying process, dimensional measurement and positioning installation of a getter and a getter box can be performed by a material measuring mechanism and a tool positioning mechanism; then, the materials are manually lifted to the assembly spot welding worktable to perform assembly positioning, and further, spot welding of Kovar at both ends of a corrugated tube and the coated steel tube and the corrugated tube and the glass tube is realized; then, the materials are automatically fed to the argon arc ring welding worktable to perform automatic argon arc ring welding, are automatically fed to the laser ring welding worktable to perform laser ring welding, and then, are automatically charged to the finished product conveying line to convey a finished product. The assembly line of the medium-high temperature solar thermal-collecting tube assembly disclosed by the invention has the advantages that the degree of automation during an assembly process of the medium-high temperature solar thermal-collecting tube assembly can be improved, and the production efficiency is greatly improved.

Owner:北京天瑞星光热技术有限公司

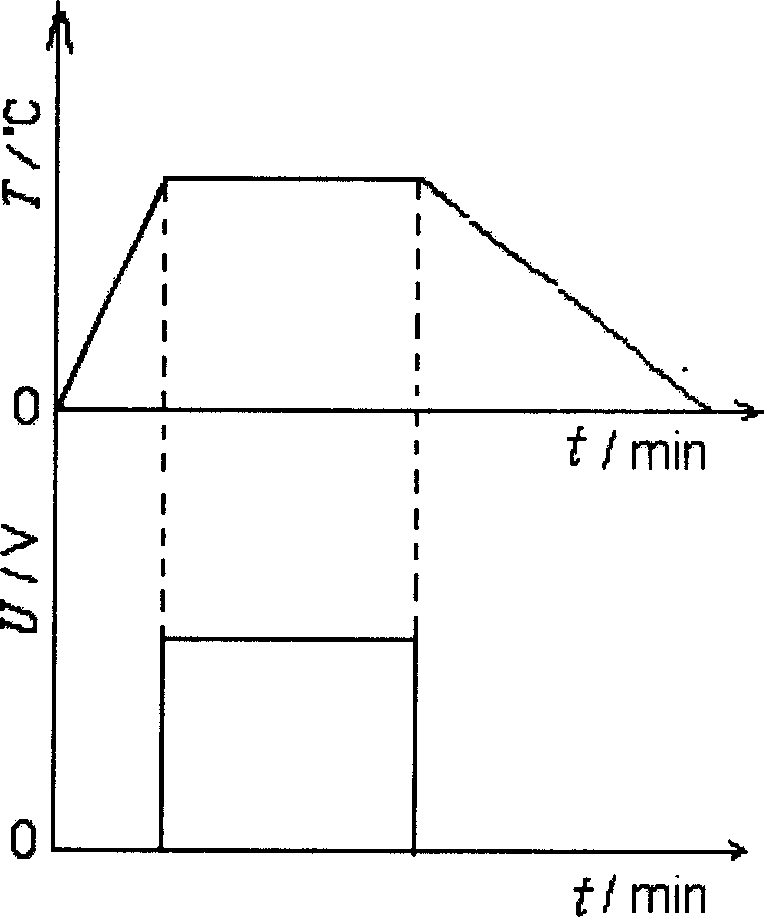

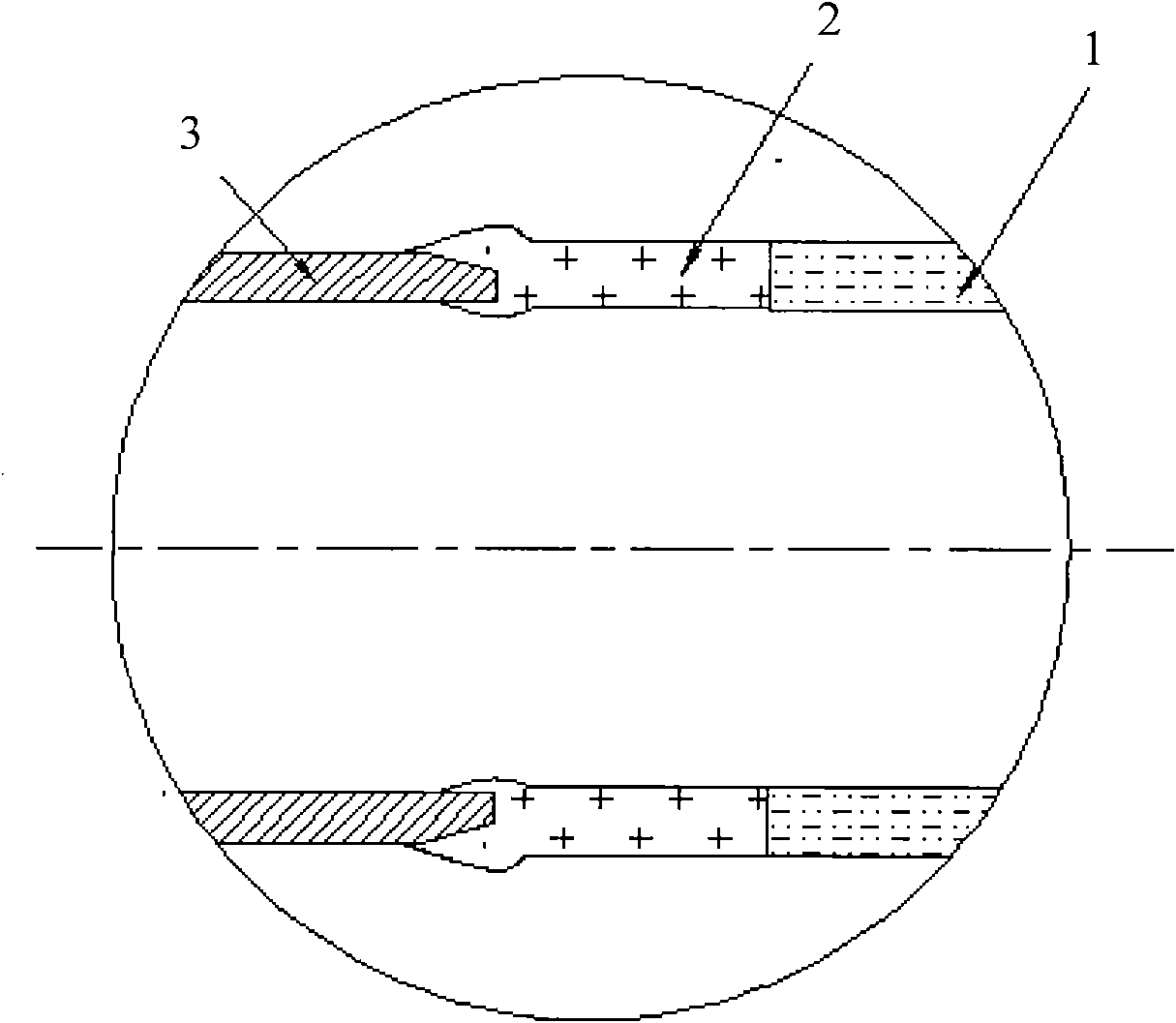

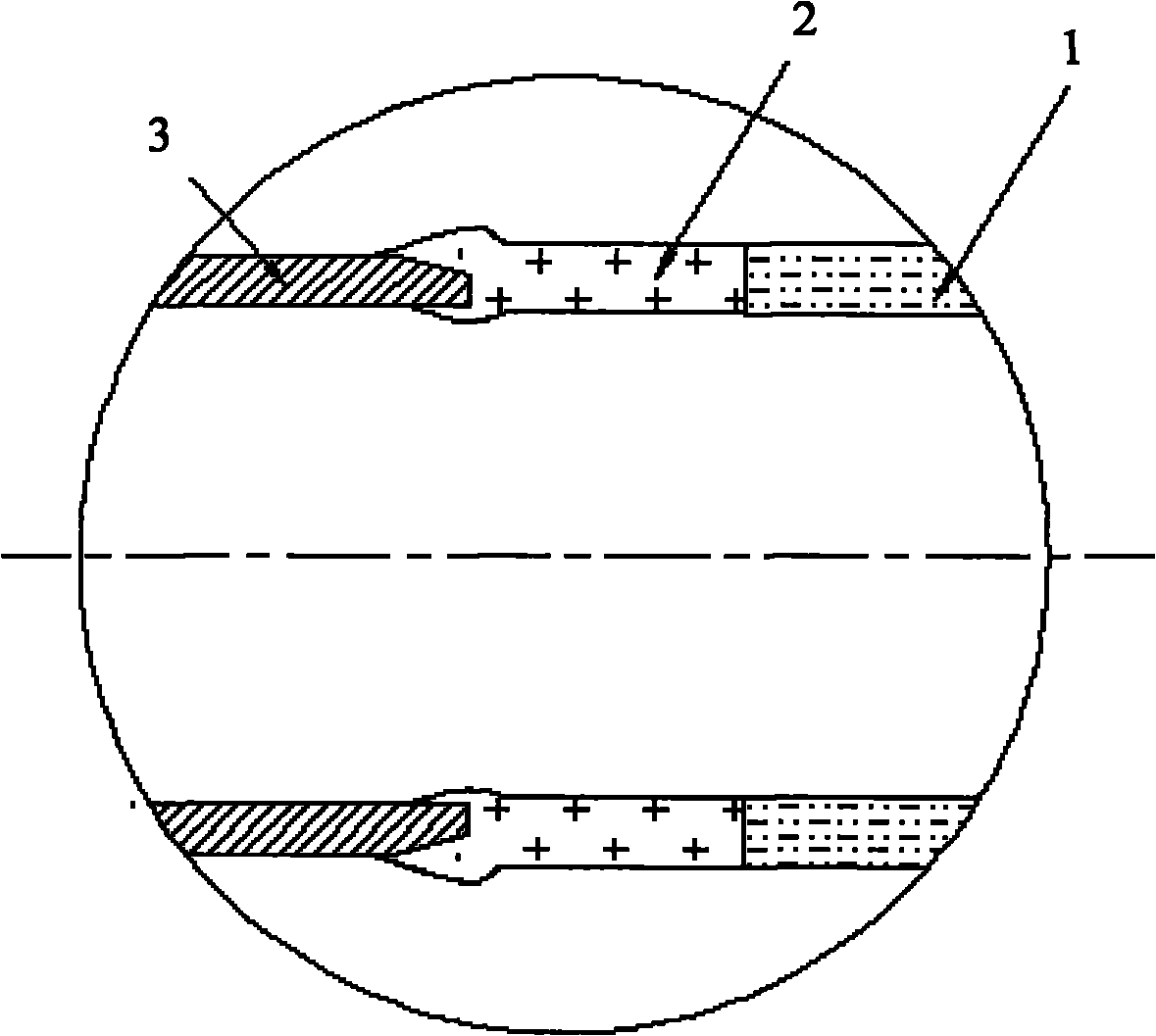

Sealing connection method of metal and glass of novel medium-high temperature solar energy heat collection pipe

The invention discloses a sealing connection method of metal and glass of a novel medium-high temperature solar energy heat collection pipe, which relates to a method for matched sealing connection of two materials: the metal of kovar alloy and the glass of neutral borosilicate glass with the similar thermal expansion coefficients. The invention provides a novel method for manufacturing the metal glass medium-high temperature solar energy heat collection pipe. In the method, the difference of the thermal expansion coefficient of the kovar alloy and the thermal expansion coefficient of the neutral borosilicate glass is in a range between 5 percent and 10 percent, the difference of the thermal expansion coefficient of the transition section glass and the thermal expansion coefficient of the neutral borosilicate glass is in a range between 5 and 10 percent, the sealing connection temperature of the neutral borosilicate glass and the transition section glass is between 600 and 1000 DEG C, the heating temperature of the sealing connection region of the kovar alloy and the transition section glass is between 600 and 1200 DEG C, the length of the sealing connection opening is between 3 and 8 mm, and the whole sealing connection section of the neutral borosilicate glass, the transition section glass and the kovar alloy after the sealing connection carries out the annealing processing at the annealing temperature between 450 and 600 DEG C for 10 to 60 minutes.

Owner:北京天瑞星光热技术有限公司

A high temperature pressure sensor packaging structure

ActiveCN106134489BReduce the impactMinimize adverse effects on high temperature performanceSemiconductor/solid-state device detailsSolid-state devicesMems pressure sensorNitrogen

The invention relates to a package structure of a high-temperature pressure sensor, comprising a silicon carbide sensitive chip, an aluminum nitride base, a stress buffer substrate, a high-temperature sealing glass, a lead post, a Kovar outer cover and a thermocouple, wherein the aluminum nitride base is There is a boss on the surface, a stress buffer substrate is placed on the boss, and a silicon carbide sensitive chip is placed on the stress buffer substrate; the periphery of the boss is a stress isolation groove, and there are two or more through holes on the periphery of the stress isolation groove. The column passes through the through hole and is sintered by high-temperature sealing glass to realize the fixed connection between the lead column and the aluminum nitride base. The thermocouple is installed on the lower surface of the aluminum nitride base, and the aluminum nitride base is placed on the Kovar housing through the positioning steps. In addition, the aluminum nitride base and the Kovar cover are sintered and connected through high-temperature sealing glass. The packaging structure is resistant to high temperature, effectively reduces the influence of process stress and high temperature thermal stress on the sensitive chip of the MEMS pressure sensor, and further improves the high temperature measurement accuracy of the sensor.

Owner:BEIJING RES INST OF TELEMETRY

Integrated metal-glass sealing method

The invention relates to an integrated metal-glass sealing method, which belongs to the metal-glass sealing field. The processing steps of the invention is that: a Kovar base plate and a lead-through to be sealed are cleaned in acetone and alcohol and then are dried; the dried Kovar base plate and lead-through are directly assembled with a hard borosilicate glass; the assembled product is first oxidized for 1-50 minutes in wet N2 under the temperature of 450-700 DEG C, then heated up at the speed of 5-15 DEG C per minute and heat preserved for 5-60 minutes under the weakly reducing atmosphere of 900-1050 DEG C, and finally cooled to 250-200 DEG C at the speed of 5-15 DEG C per minute. The invention has the advantages that the high temperature decarburizing gas outlet procedure in the traditional metal-glass sealing process is saved; the procedures of oxidation and sealing by fusing are integrated into a process to be completed; the integrated metal-glass sealing method can be used for the matched seal of the Kovar base plate with hard borosilicate glasses such as DM305, DM308, BH-G / K and Elan19; the airtightness of seals is good, the bonding strength of the seals is high and the product consistency is good; the operation is convenient, the production process can be better controlled, the production cost is lowered, and the production efficiency is improved.

Owner:UNIV OF SCI & TECH BEIJING +1

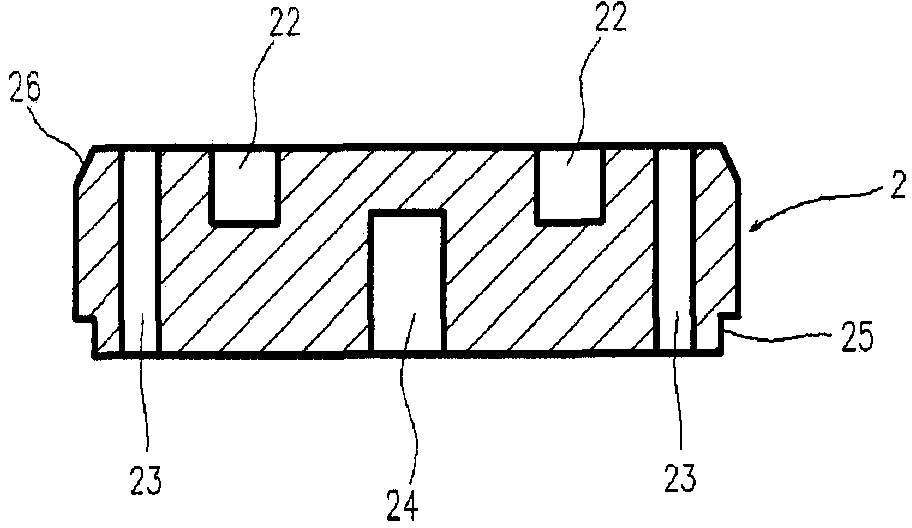

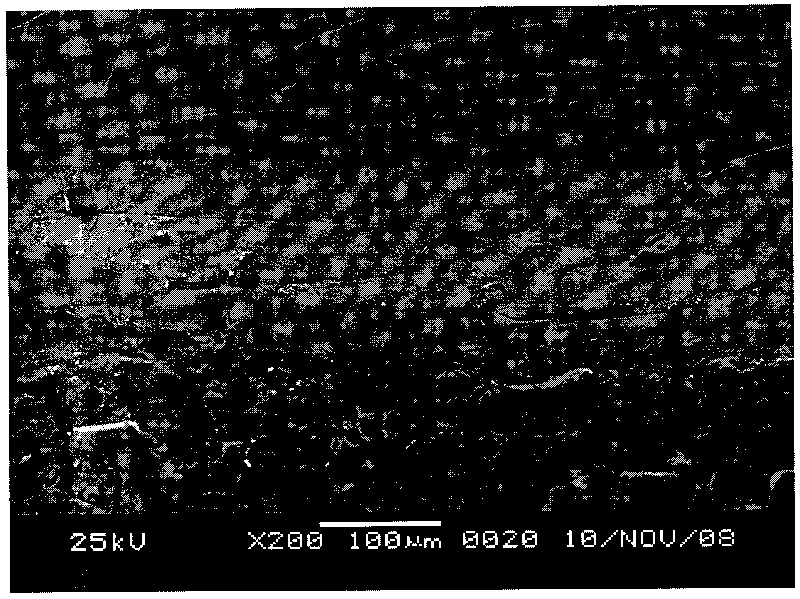

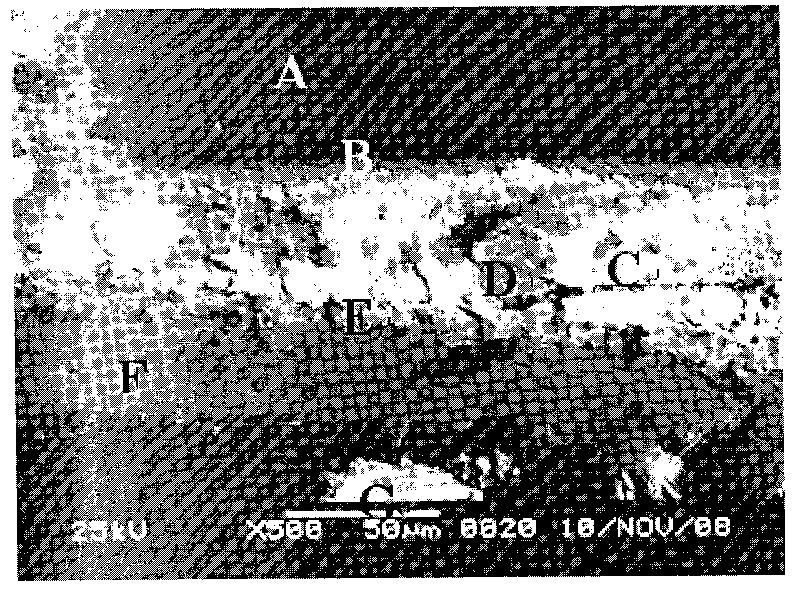

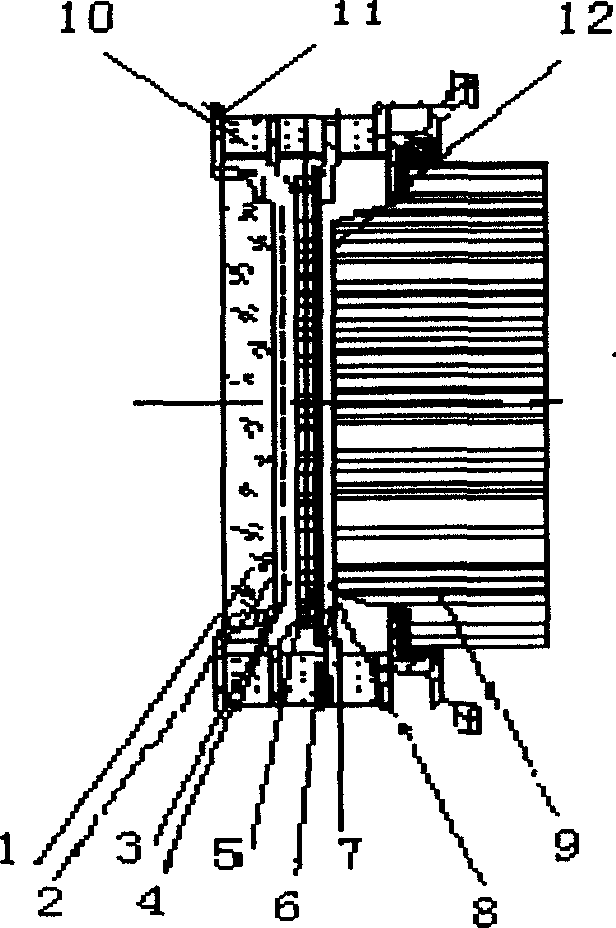

Hard soldering method of high volume fraction SiC particle-reinforced Al matrix composite and kovar alloy dissimilar material

The invention discloses a hard soldering method of high volume fraction SiC particle-reinforced Al matrix composite and a kovar alloy dissimilar material, relating to a hard soldering method of a dissimilar material. The invention solves the problem that welding cost is high because the existing hard soldering of the dissimilar material needs metalizing treatment. The method of the invention comprises the following steps: after cleaning master batches and foil-shaped brazing filler metal, putting the foil-shaped brazing filler metal between the master batches, and then putting into a vacuum furnace for soldering to finish hard soldering of the master batches. The method of the invention obtains soldering seams with compact issue and forms firm metallurgical bonding. The invention does not need to carry out metallization processing on the master batch, thus lowering welding cost.

Owner:HENAN POLYTECHNIC UNIV

Soldering method of high volume fraction SiC particle-reinforced Al matrix composite and kovar alloy

The invention discloses a flame soldering method of a high volume fraction SiC particle-reinforced Al matrix composite and kovar alloy, relating to a soldering method of a dissimilar material. The invention solves the problem of small possibility of welding engineering structure because the strength of the welding joint of SiCp / Al composite and kovar alloy melting is low. The method of the invention is characterized in that Ni-p is chemically plated on the surface of the high volume fraction SiC particle-reinforced Al matrix composite, and then soldering is carried out under the soldering acid and protective atmosphere after a piece to be soldered is assembled. The solder, the kovar alloy and a nickel coating of the invention mutually diffuse to form compact metallurgical bonding. In the method of the invention, the shear strength of joint connected by SiCp / Al of which the SiC particle volume fraction is 55% with kovar alloy 4J29 is 225 MPa.

Owner:ZHONGYUAN ENGINEERING COLLEGE

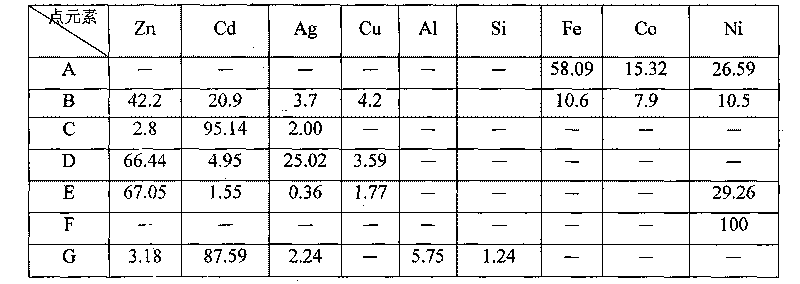

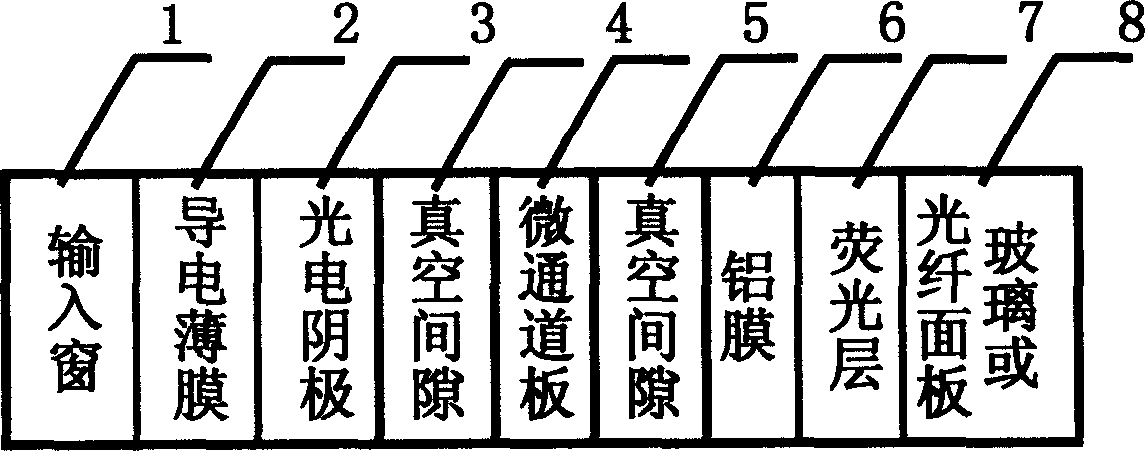

Ultraviolet imaging enhancer

InactiveCN1854761AEasy to identifyReduce false alarm rateElectromagnetic wave reradiationPhotocathodeUltraviolet

An intensifier of ultraviolet image is prepared as setting input window at front end of shell and screen at back end of shell, forming vacuum airtight structure by sealing in input window with kovar alloy 4J50 cathode plate in utilizing low melting point glass powder, sealing photoelectric cathode and micro channel plate as well as screen in shell with excellent vacuum air tightness, coating a layer of conductive film with ultraviolet ray transmission ability and conductivity on internal surface of input window and setting photoelectric cathode on said conductive film.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for preparing a solid phase microextraction device using aerogel

InactiveUS20050233085A1Quick and easy to manufactureEasily toleratedComponent separationOther chemical processesGlass fiberAnalyte

A sample collection substrate of aerogel and / or xerogel materials bound to a support structure is used as a solid phase microextraction (SPME) device. The xerogels and aerogels may be organic or inorganic and doped with metals or other compounds to target specific chemical analytes. The support structure is typically formed of a glass fiber or a metal wire (stainless steel or kovar). The devices are made by applying gel solution to the support structures and drying the solution to form aerogel or xerogel. Aerogel particles may be attached to the wet layer before drying to increase sample collection surface area. These devices are robust, stable in fields of high radiation, and highly effective at collecting gas and liquid samples while maintaining superior mechanical and thermal stability during routine use. Aerogel SPME devices are advantageous for use in GC / MS analyses due to their lack of interfering background and tolerance of GC thermal cycling.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

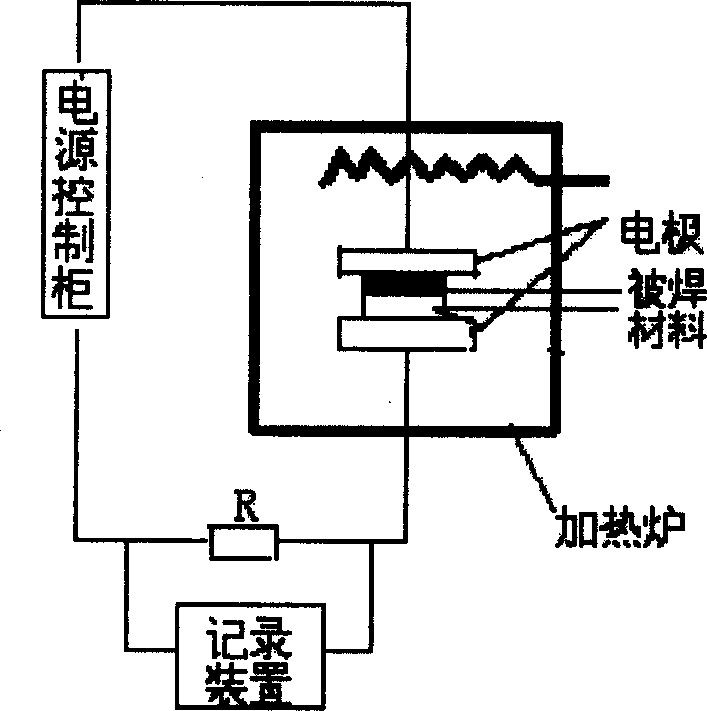

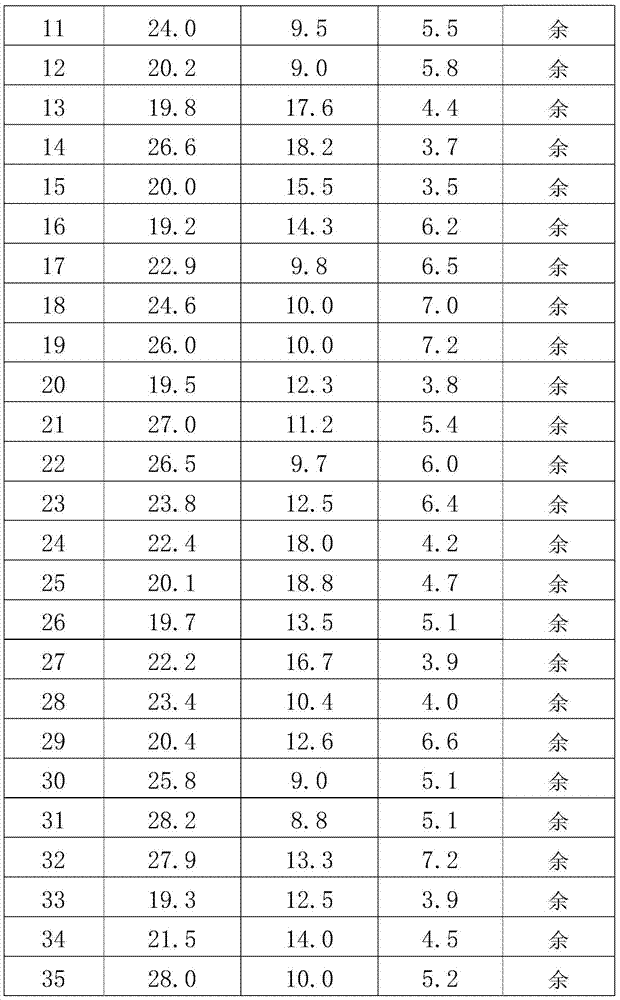

Method for laser sealing glass and kovar alloy

InactiveCN103212812AOptimizing Process ParametersControl pulse widthLaser beam welding apparatusRoom temperatureLight beam

The invention discloses a method for laser sealing glass and kovar alloy. The method includes that (a) clean treatment is carried out on the glass, and derosination treatment and deoiling treatment are carried out on the kovar alloy; (b), the glass is placed on the kovar alloy and is contacted with the kovar alloy tightly; (c) straight-line radiation is carried out with a laser device, the focus of a laser beam is positioned in the junction of the glass and the kovar alloy to obtain a sealing body; and (d) the sealing body is moved to a heating furnace of 100-300 DEG C, stress relief annealing is carried out, and after cooled to room temperature along with the furnace, the sealing body of the glass and the kovar alloy can be obtained. According to the method, due to the fact that technological parameters are optimized, a heat action area and temperature distribution in the area are accurately controlled, and the pulse width, frequency, scanning speed and the temperature of the stress relief annealing are controlled, so that the low-stress and large-size sealing body of the glass and the kovar alloy is obtained, the sealing body can be applied to the construction industry, and the service life of a product is improved substantially.

Owner:SUZHOU UNIV +1

Sealing method of borosilicate glass and kovar alloy of solar collector tube

ActiveCN101786805AIncrease profitReduce manufacturing costSolar heat devicesSolar thermal energy generationKovarHeating temperature

The invention discloses a sealing method of borosilicate glass and kovar alloy of a solar collector tube, which relates to the matching sealing between the borosilicate glass and the kovar alloy under the condition of no transitional glass, and provides a novel method for the production of the metal glass middle-high temperature vacuum solar collector tube. In the method, the difference range of expansion coefficients of the kovar alloy and the borosilicate glass is 5 to 50 percent; the heating temperature at the sealing area is 300 to 1200 DEG C; the length of the sealing interface is about 3 to 8 mm; and the annealing treatment on the borosilicate glass and the kovar alloy are undertaken,the annealing temperature is 300 to 600 DEG C, and the time is 10 to 60 minutes. The method is free from utilizing a glass transitional section, so the production cost is saved, and the utilization rate of the solar collector tube is also improved while the sealing reliability is improved.

Owner:北京天瑞星光热技术有限公司

Vacuum-sealed high-capacity direct-current relay ceramic shell and manufacturing method thereof

The invention discloses a vacuum-sealed high-capacity direct-current relay ceramic shell and a manufacturing method thereof. The relay ceramic shell comprises a ceramic piece, a copper electrode and a kovar alloy cover plate. The ceramic piece is made of five-element ceramic materials. The five-element ceramic materials comprise Al2O3, CaCO3, Cr2O3, SiO2 and MgO. The upper end face and the lower end face of the ceramic piece are partially provided with metal manganese molybdenum layers in a silk printing mode, the metal manganese molybdenum layers are sintered at high temperature to be combined with ceramic, chemical nickel plating is conducted on the metal manganese molybdenum layers, the metal manganese molybdenum layers and metal such as alloy and oxygen-free copper can be welded after chemical nickel plating, and welding drawing force can reach more than 90 Mpa / cm<2>. According to the vacuum-sealed high-capacity direct-current relay ceramic shell and the manufacturing method of the vacuum-sealed high-capacity direct-current relay ceramic shell, existing ceramic is metallized, ceramic materials and metallized materials are improved, metal materials are added to the ceramic, original three-element materials are changed into the five-element materials, the strength and rigidity of the ceramic are greatly improved, and the brittleness is lowered.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

Sealing-in method for glass and kovar alloy and sealed body

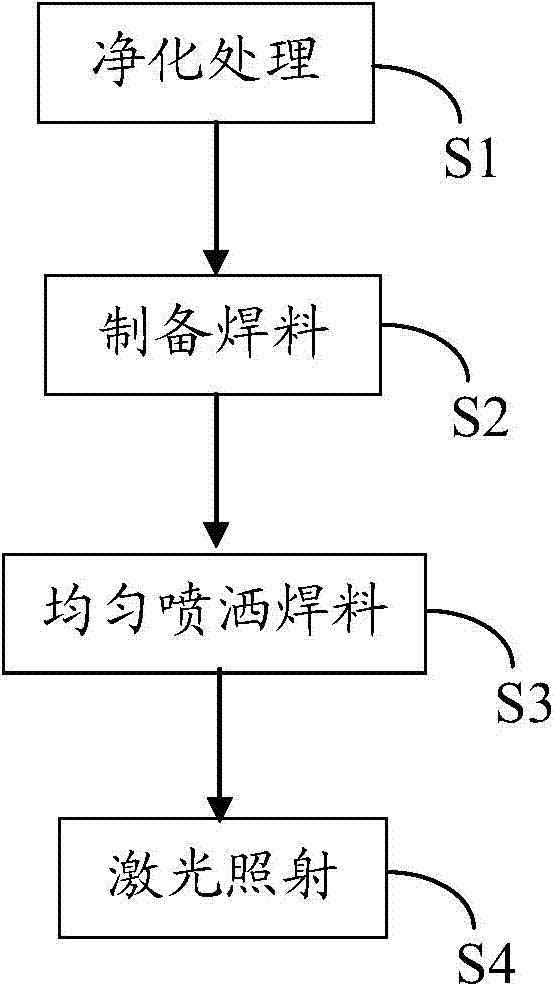

The invention discloses a sealing-in method for glass and a kovar alloy and a sealed body. The sealing-in method comprises the following steps of S1, purifying the glass to be sealed and the kovar ally to be sealed; S2, providing glass powder and metal powder which have the particle sizes of 150-200 meshes, and mixing and grinding the powder to prepare a welding flux; S3, uniformly spraying the welding flux in the step S2 to the surrounding edge of the kovar ally to be sealed; and putting the glass to be sealed on the kovar alloy, wherein the glass and the kovar alloy are in tight contact; S4, irradiating the welding flux at an intersection of the glass to be sealed and the kovar alloy to be sealed through laser to obtain the sealing body formed by the glass and the kovar alloy. According to the sealing-in method for the glass and the kovar alloy, the welding flux is added to the intersection of the glass and the kovar alloy, and the intersection of the glass and the kovar alloy is straightly irradiated with laser, so that the problem of laser processing difficulty caused by high glass laser transmittance rate is solved, and the glass and the kovar alloy can be tightly connected and sealed.

Owner:SUZHOU UNIV

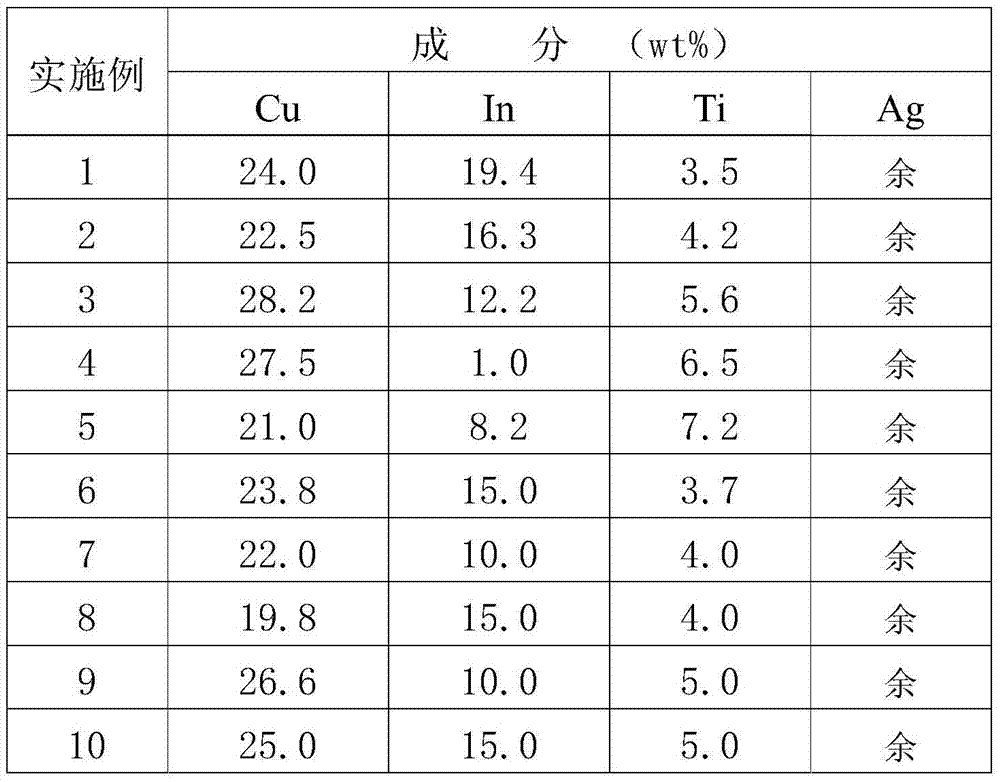

Silver-copper-indium-titanium middle-temperature brazing filler metal

InactiveCN105436741AHigh activityPromote wetting and spreadingWelding/cutting media/materialsWelding/soldering/cutting articlesIndiumNiobium

The invention belongs to the technical field of welding, and relates to a silver-copper-indium-titanium brazing filler metal used for connecting SiO2f / SiO2 composite ceramics and metals (such as tungsten, molybdenum, tungsten-molybdenum alloy, niobium, niobium-molybdenum alloy, invar alloy and kovar alloy). The silver-copper-indium-titanium brazing filler metal is characterized by comprising, by weight percentage, 19.2-28.2% of Cu, 8.2-19.4% of In, 3.5-7.2% of Ti, and the balance Ag. The brazing filler metal is good in machinability, and can be machined into strips, and required brazing temperature is lower than that of a traditional Ag-Cu-Ti brazing filler metal by about 100 DEG C, so that the silver-copper-indium-titanium brazing filler metal has a great significance in the field of ceramic and metal brazing connection in the aspect of reducing post-welding residual thermal stress of joints. The brazing filler metal not only is suitable for connecting the SiO2f / SiO2 composite ceramics and metals, and is also suitable for connecting ceramics, or connecting ceramics and metals, or connecting metals owing to excellent activity of the brazing filler metal.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

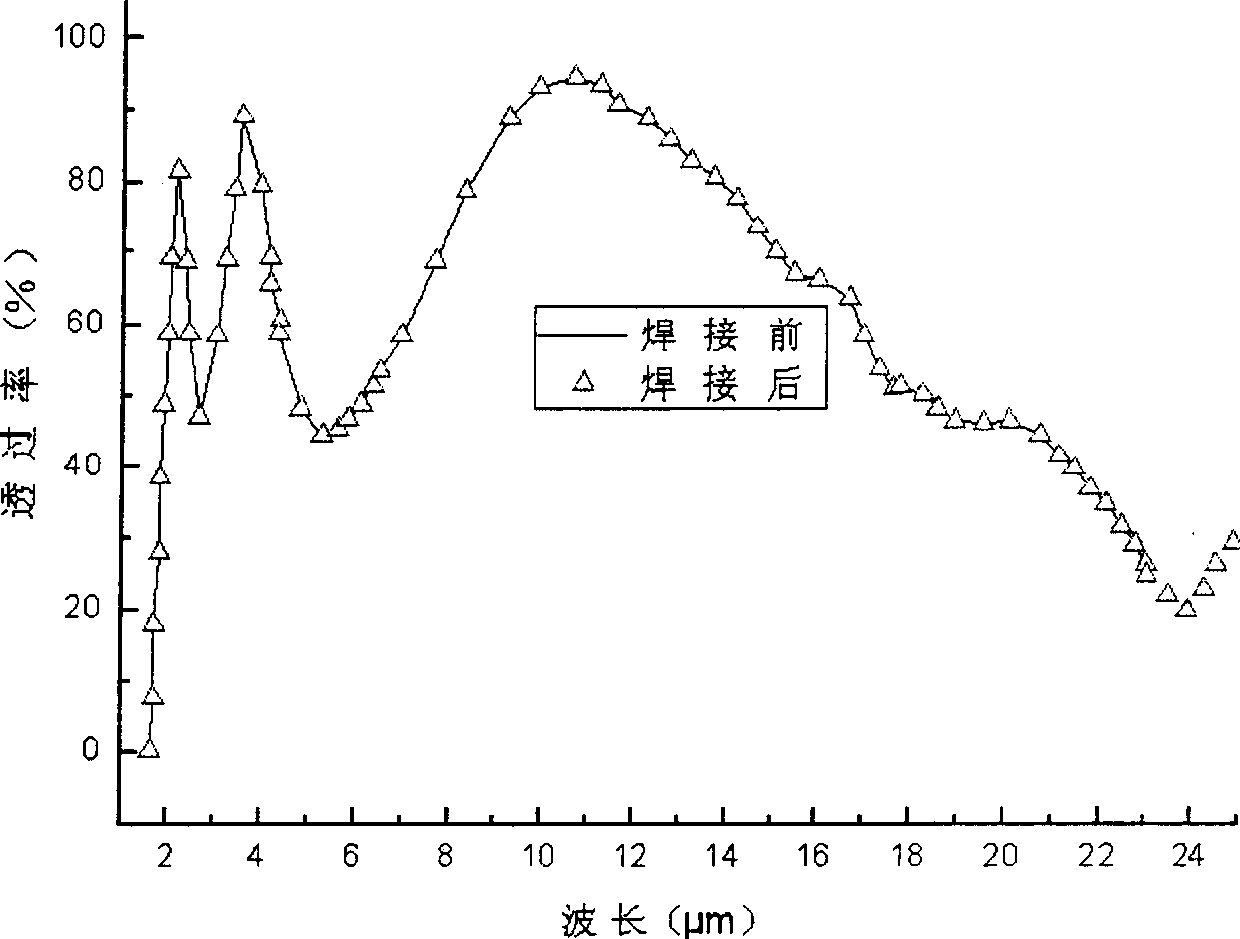

Vacuum seal welding method for window and optic window of low temperature metal Dewar

InactiveCN1820885AExcellent air leakage rateLow outgassing rateVacuum evaporation coatingSoldering apparatusIndiumInfrared window

The present invention discloses the method of low temperature vacuum sealing and welding between the window frame and the optical window of metal Dewar. In the welding between the window frame of kovar alloy material and the optical window of infrared transmitting material, the optical window is first vacuum plated to form Cr / Au coating as the transition layer in the parts to be welded, and the welding in performed with In as welding material at low temperature. The present invention has the outstanding advantage of low temperature welding producing no negative effect on the antireflective coating in the infrared window. Using soft In as the welding material can buffer the difference between the optical window material and the kovar alloy material in expansion coefficient. The metal Dewar has gas leakage rate superior to 3E(-12) torr.liter / sec and gas releasing rate far lower than that of traditional technological process.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

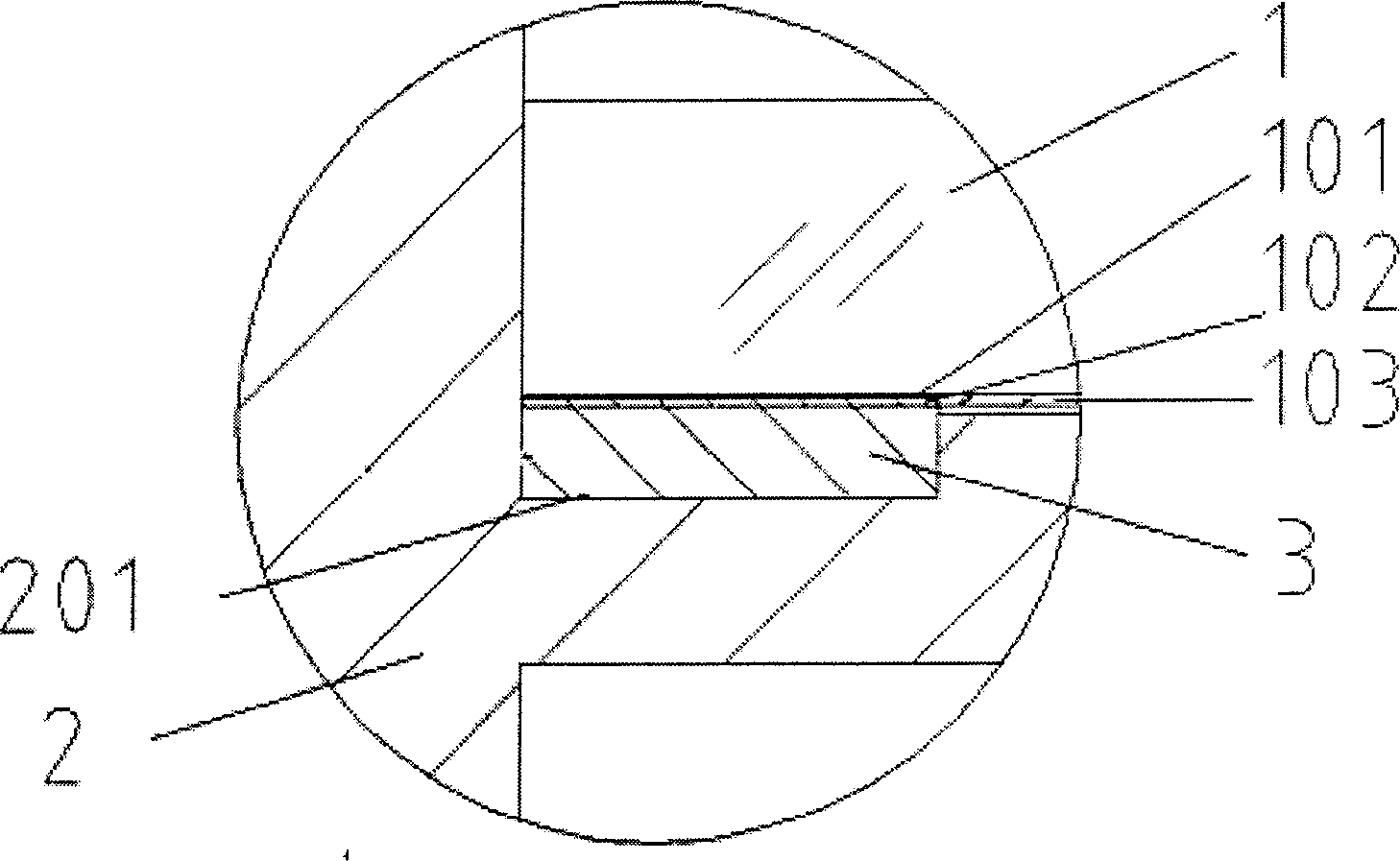

Line focusing solar vacuum heat-collecting tube sealing structure and unloading device

InactiveCN101290168AImprove stabilityImprove reliabilitySolar heating energyGeneral water supply conservationMulti materialEngineering

Owner:中金盛唐新能源科技(北京)有限公司

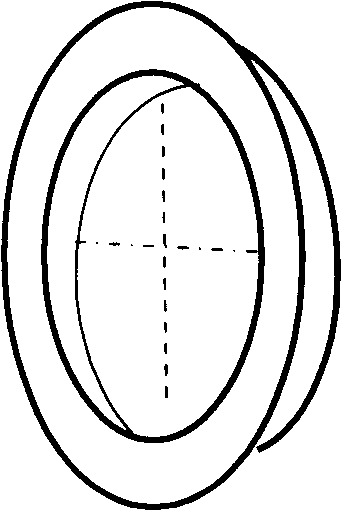

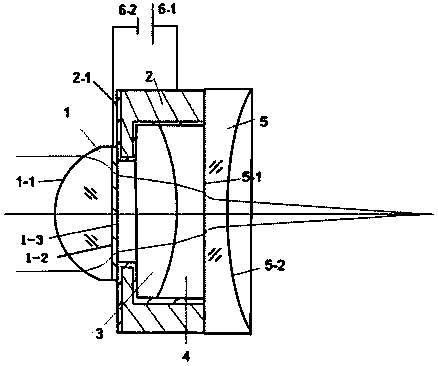

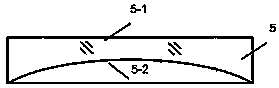

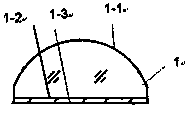

Electrowetting-type variable-focus liquid lens comprising gradient index material

ActiveCN104391345ACompensation for spherical aberrationImprove image qualityLensImaging qualityRefractive index

The invention discloses an electrowetting-type variable-focus liquid lens comprising a gradient index material and belongs to the technical field of optics. The main characteristics are that the front and back surfaces of the liquid lens adopt a plano-convex lens and a plano-concave lens which are made of the gradient index materials respectively and are easy to process; and through reasonably selecting gradient index coefficients A, B and C matched with the two lenses, spherical aberration and chromatic aberration are compensated, and thus the imaging quality of the liquid lens is improved. Besides, a cavity of the liquid lens is made of Kovar materials, so that electrodes can be led out from the cavity directly without plating metal electrodes on the inner wall of the cavity, and the cavity and the two lenses can be welded by utilizing a high-frequency welding method, and thus the seal performance of the liquid lens is effectively improved. The liquid lens overcomes the defect that a common liquid lens can only change focal length but cannot eliminate chromatic aberration and aberration simultaneously; and the liquid lens has the advantages of being excellent in image quality, being capable of forming an optical system independently in application, being small in size, and not needing other elements to participate in imaging.

Owner:西安应用光学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com