Patents

Literature

144 results about "Inconel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inconel is a family of austenitic nickel-chromium-based superalloys. Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high temperature applications where aluminum and steel would succumb to creep as a result of thermally induced crystal vacancies. Inconel's high temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.

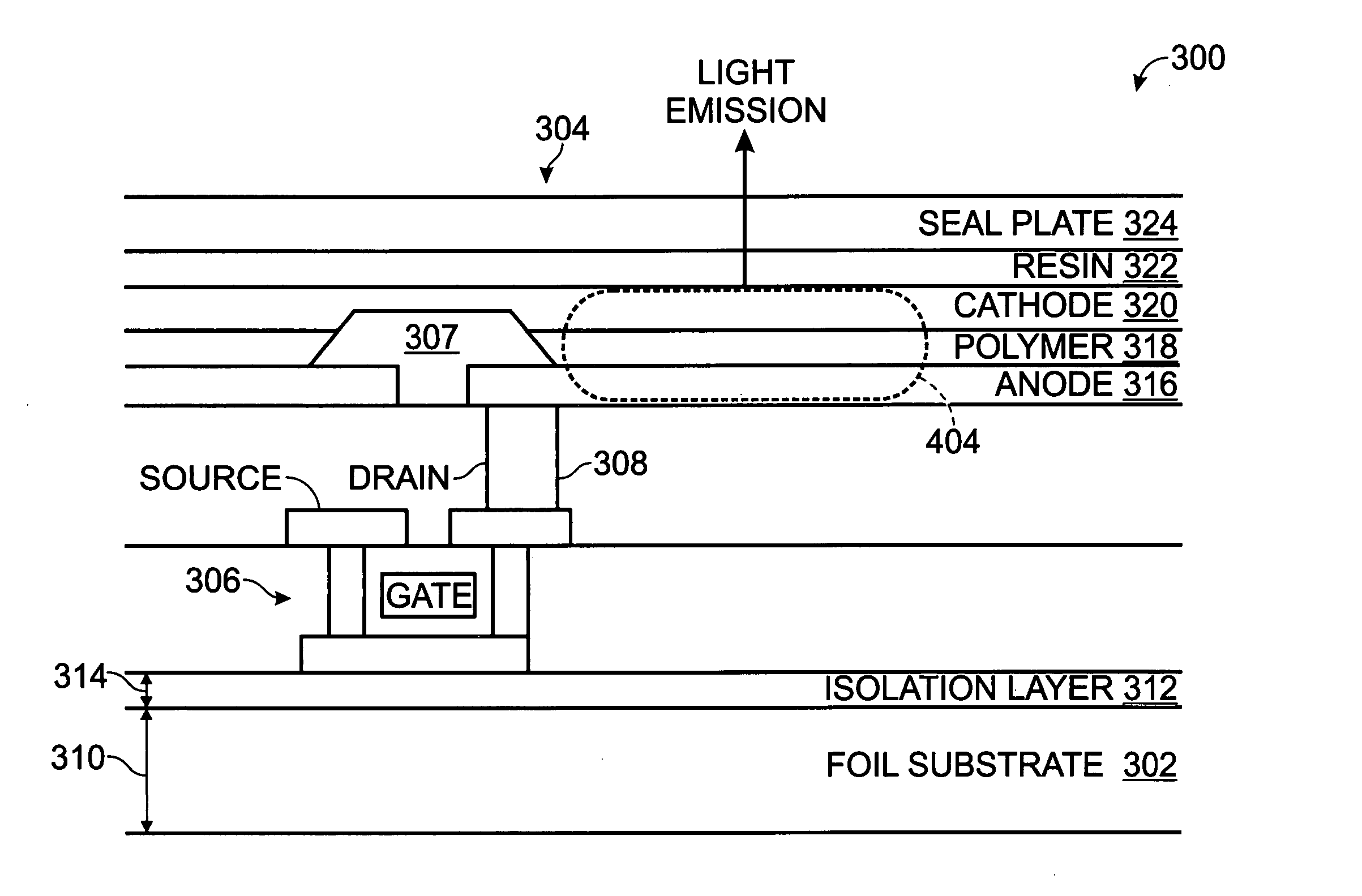

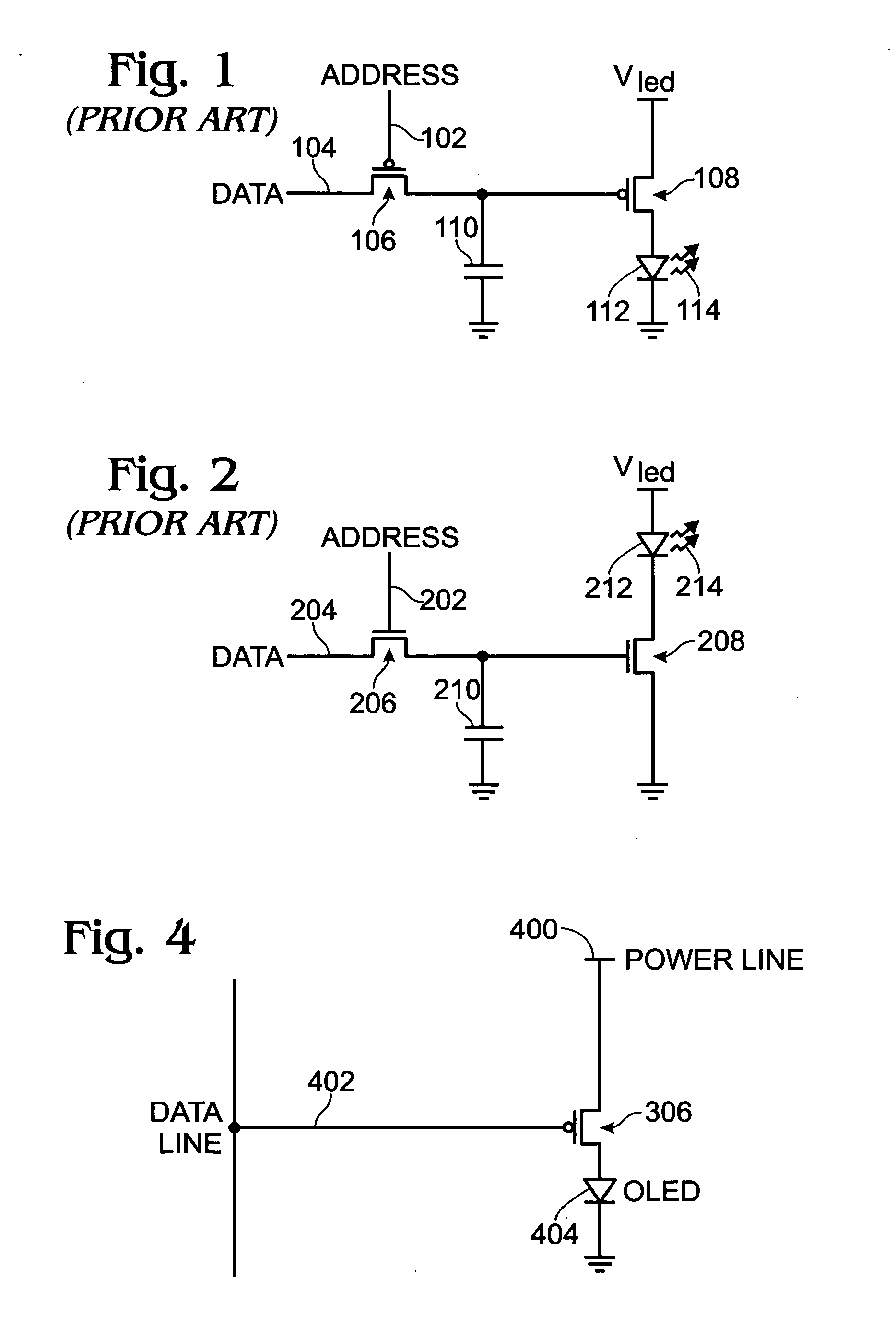

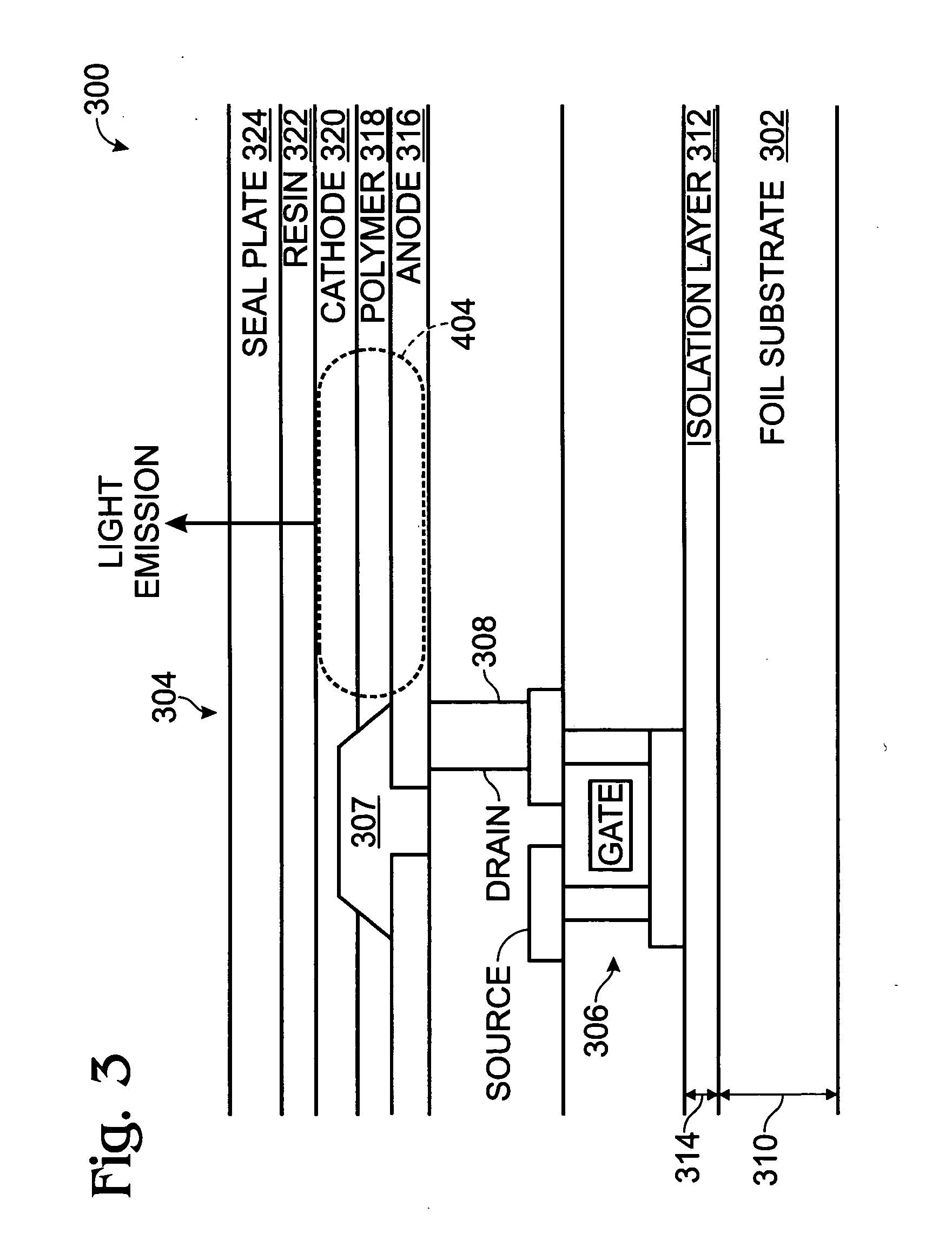

Flexible metal foil substrate display and method for forming same

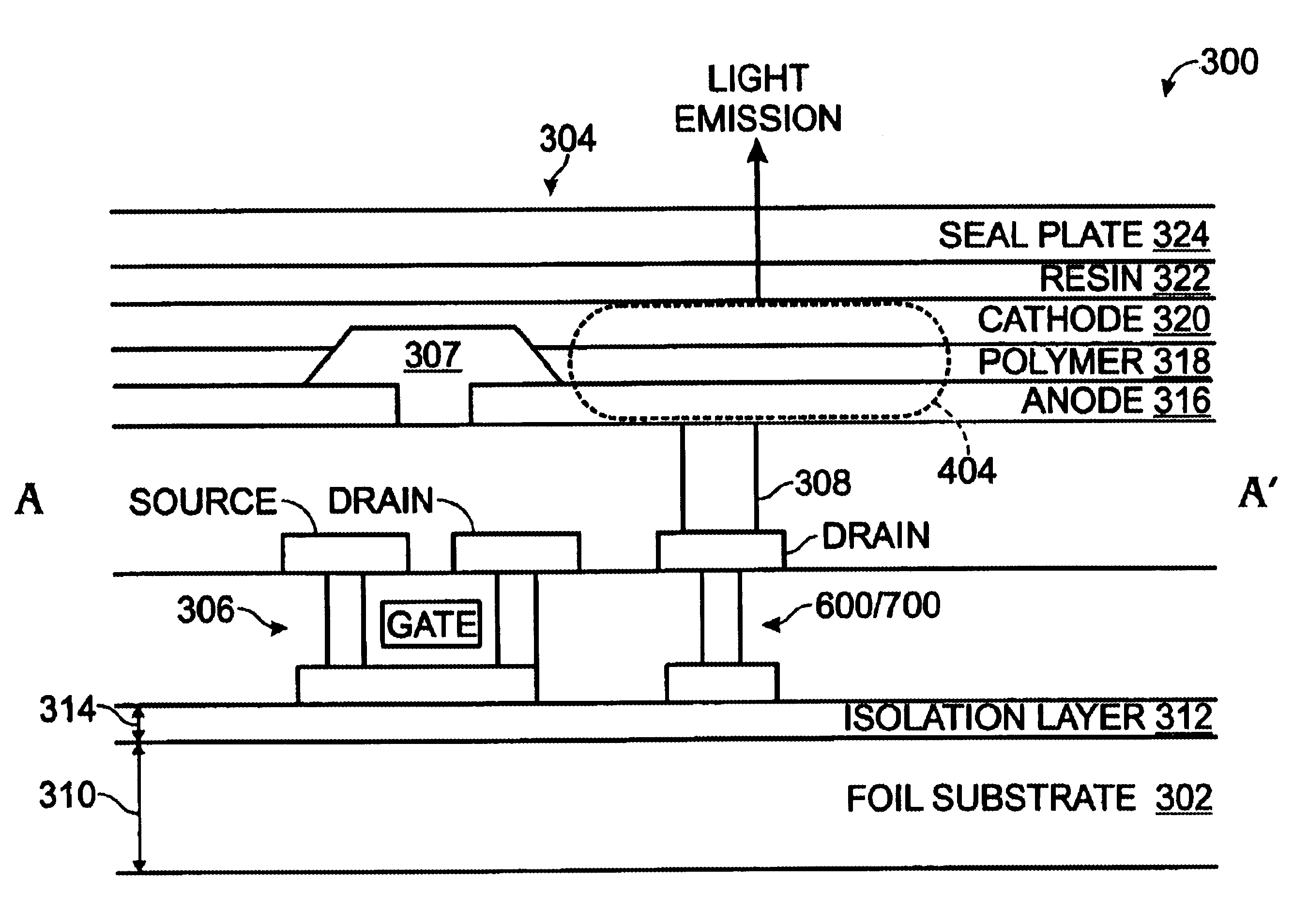

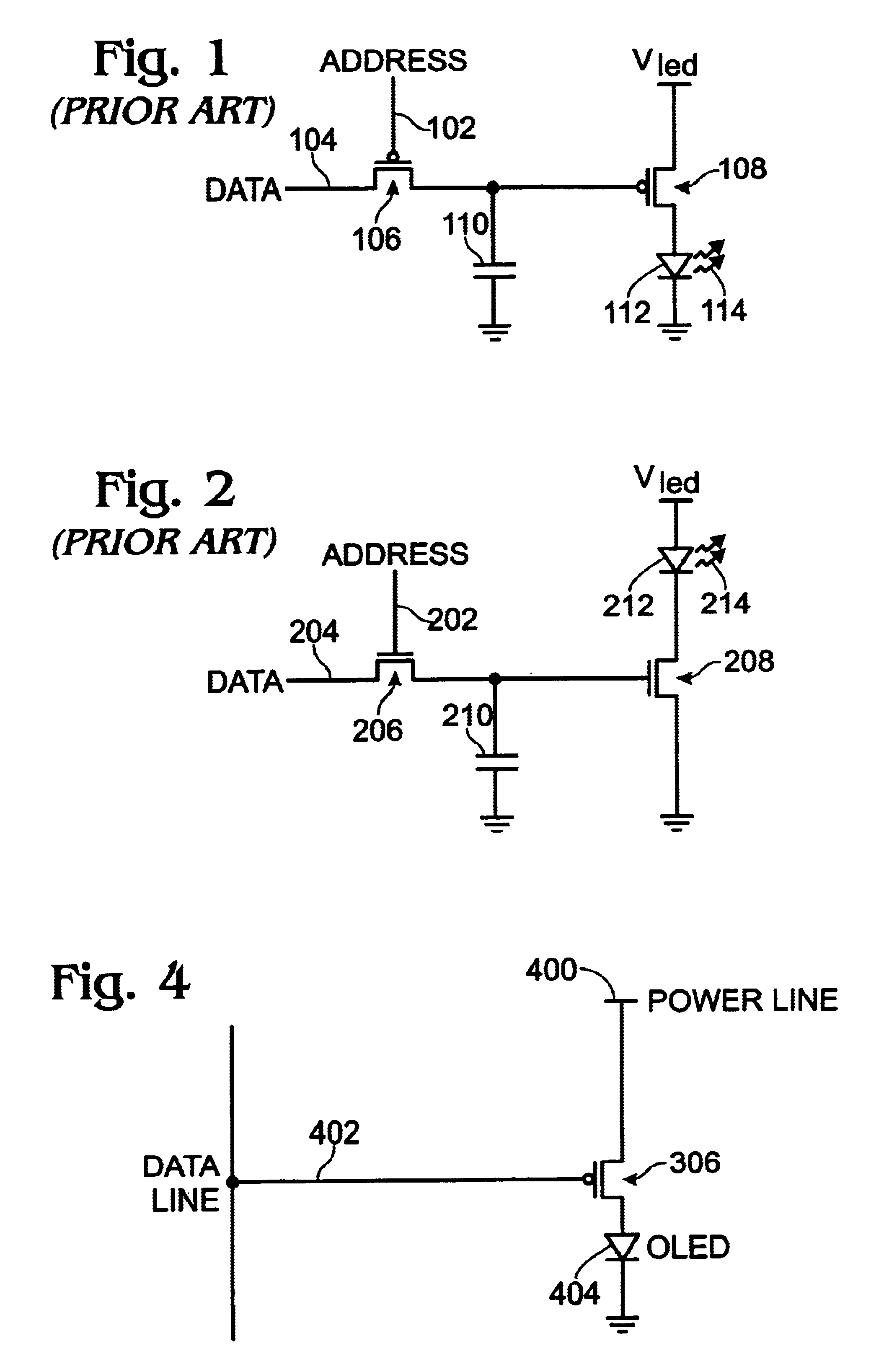

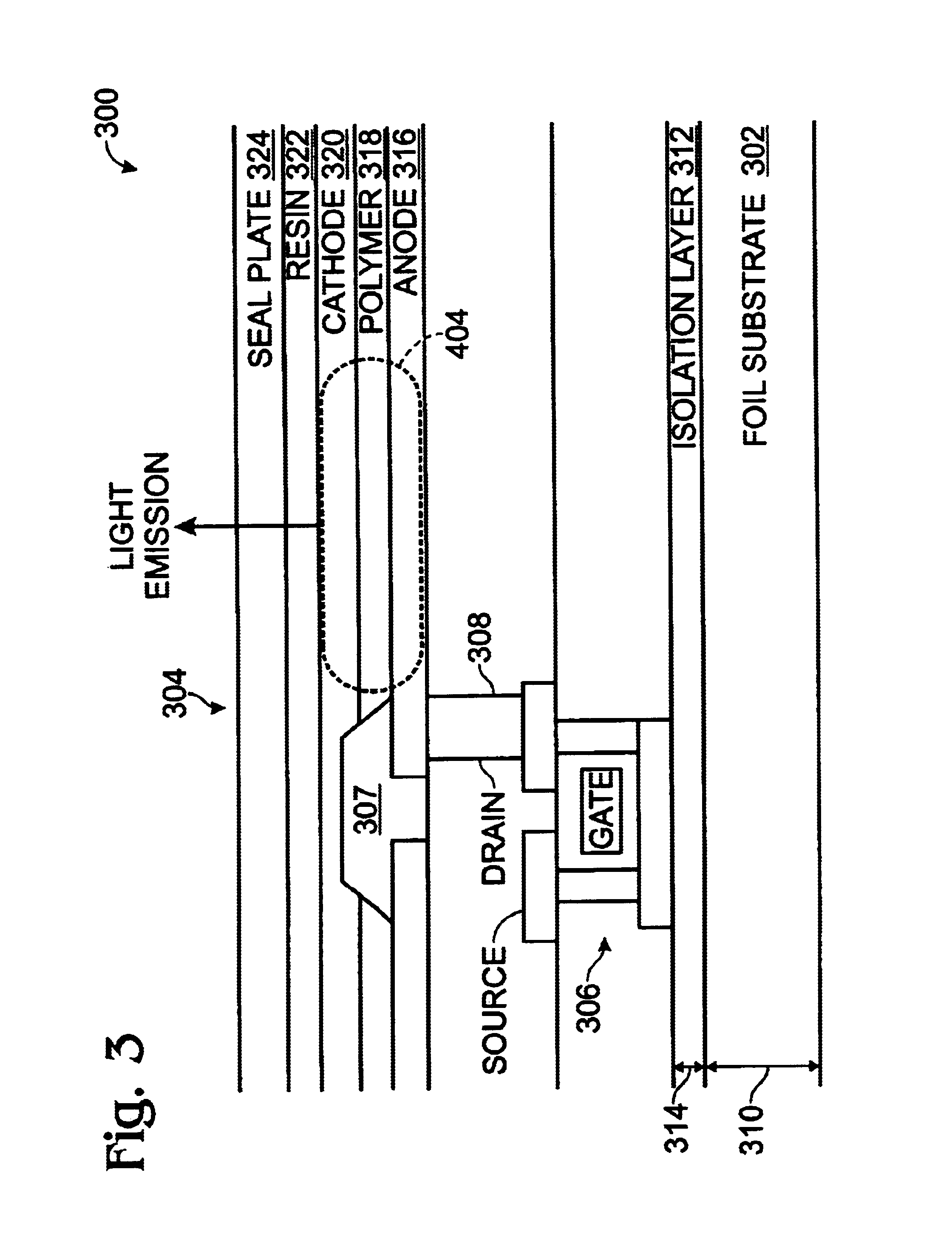

A flexible metal foil substrate organic light emitting diode (OLED) display and a method for forming the same are provided. The method comprises: supplying a metal foil substrate such as titanium (Ti), Inconel alloy, or Kovar, having a thickness in the range of 10 to 500 microns; planarizing the metal foil substrate surface; depositing an electrical isolation layer having a thickness in the range of 0.5 to 2 microns overlying the planarized metal foil substrate surface; depositing amorphous silicon having a thickness in the range of 25 to 150 nanometers (nm) overlying the electrical insulation layer; from the amorphous silicon, forming polycrystalline silicon overlying the electrical insulation layer; forming thin-film transistors (TFTs) in the polycrystalline silicon; and, forming an electronic circuit using the TFTs, such as an OLED display.

Owner:GLOBAL OLED TECH

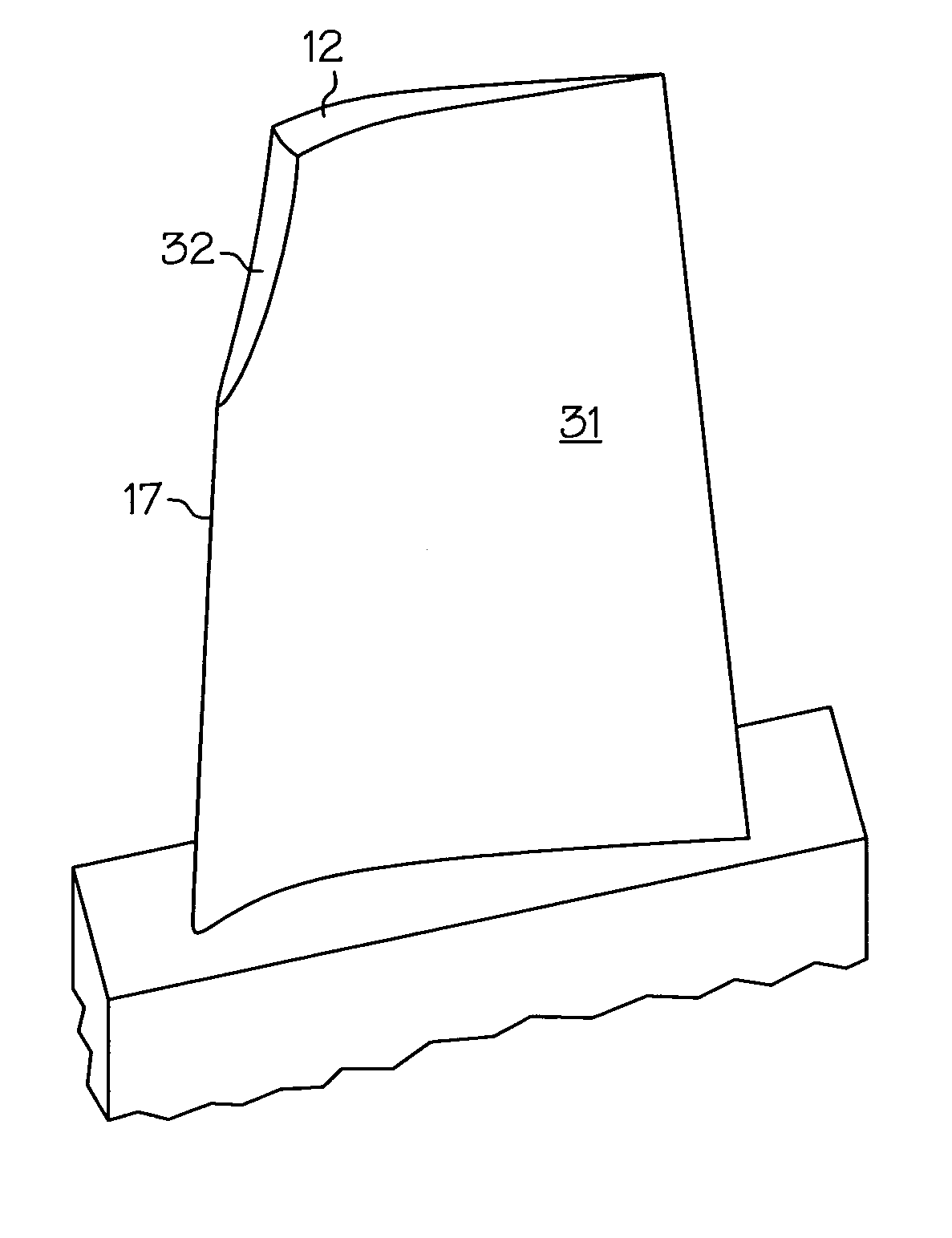

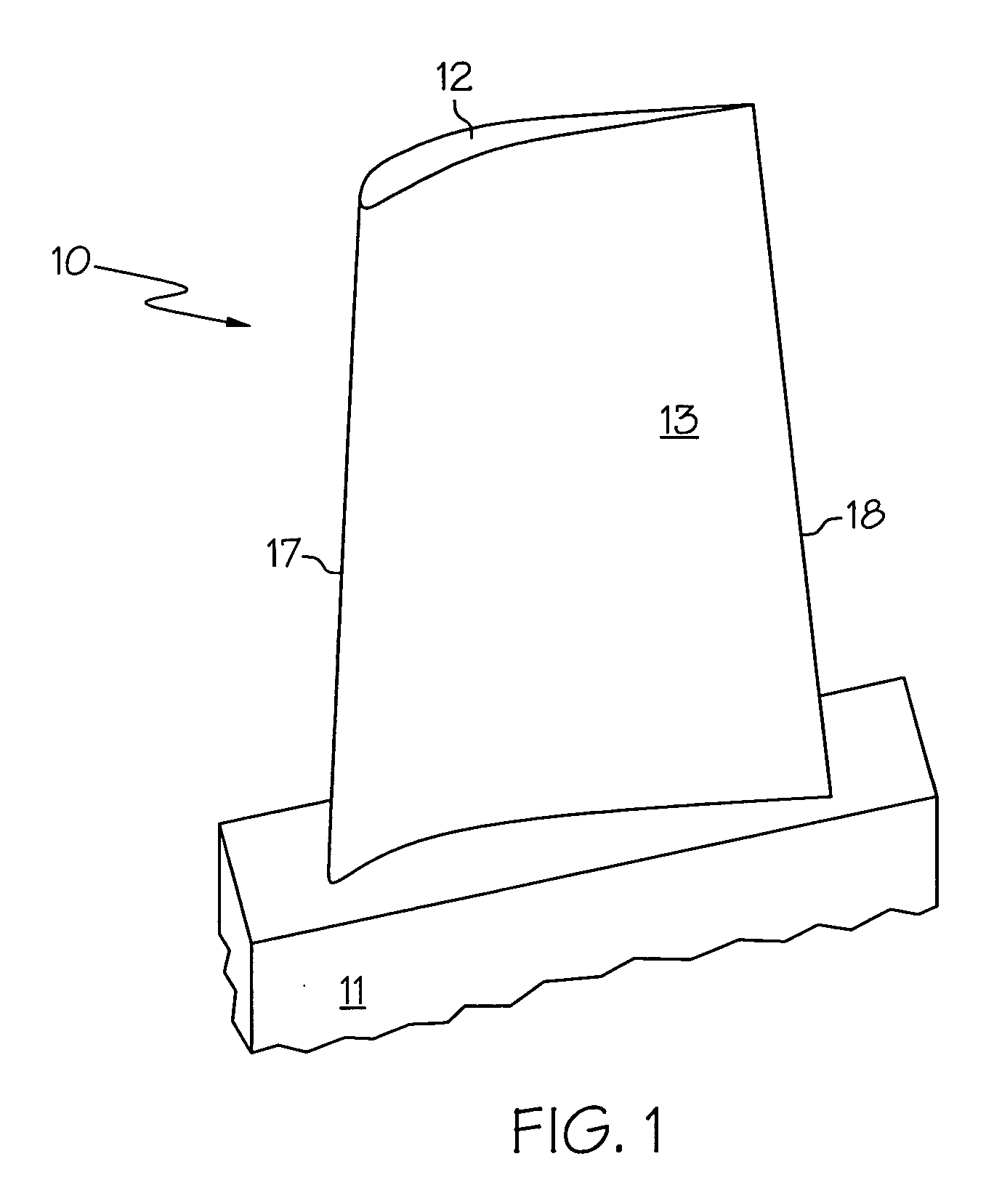

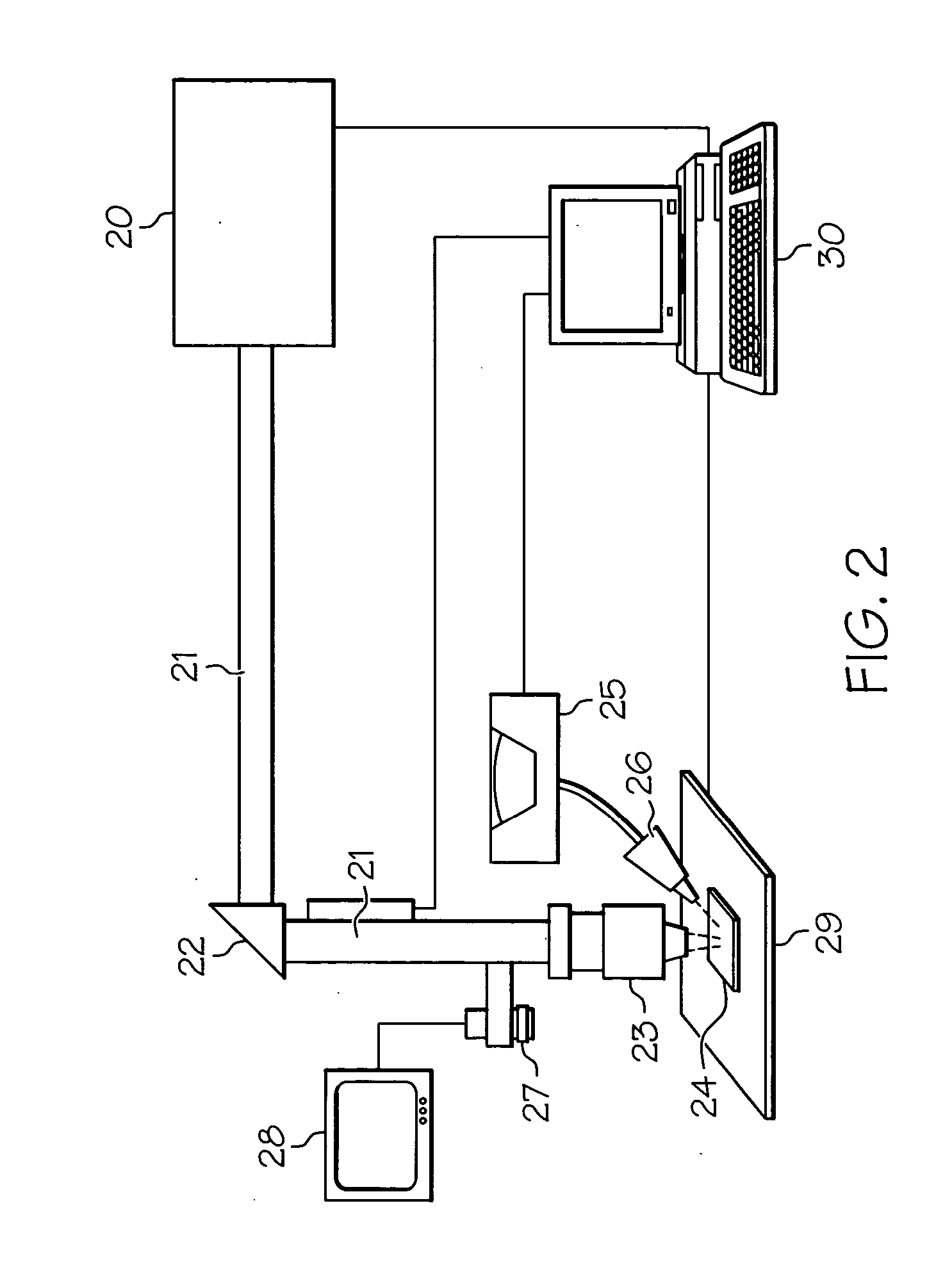

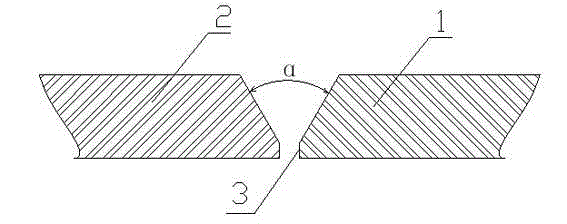

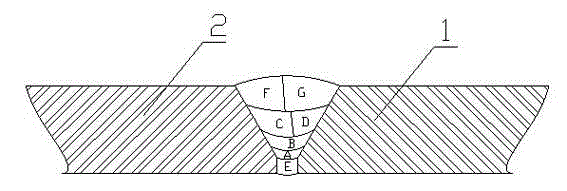

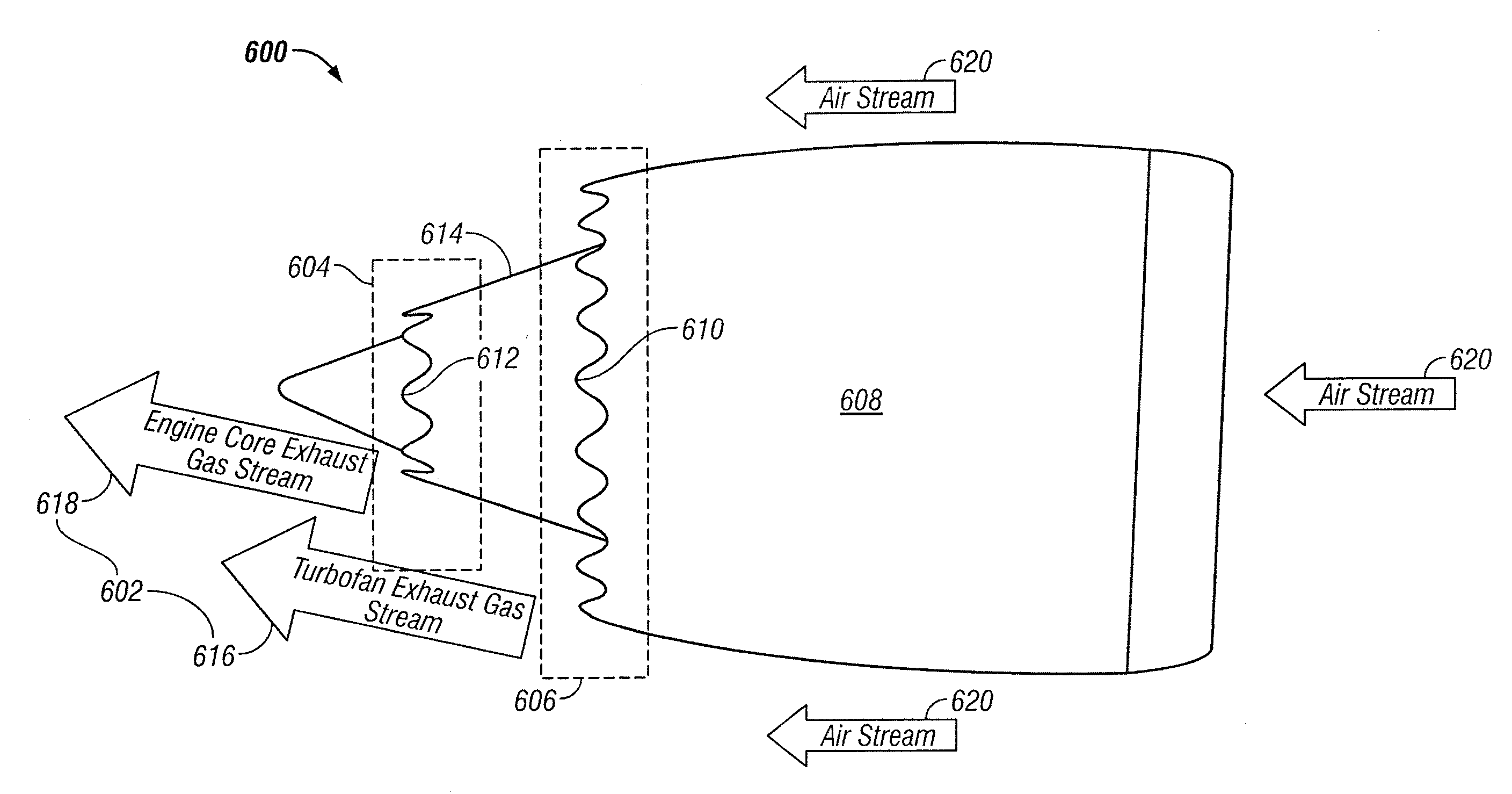

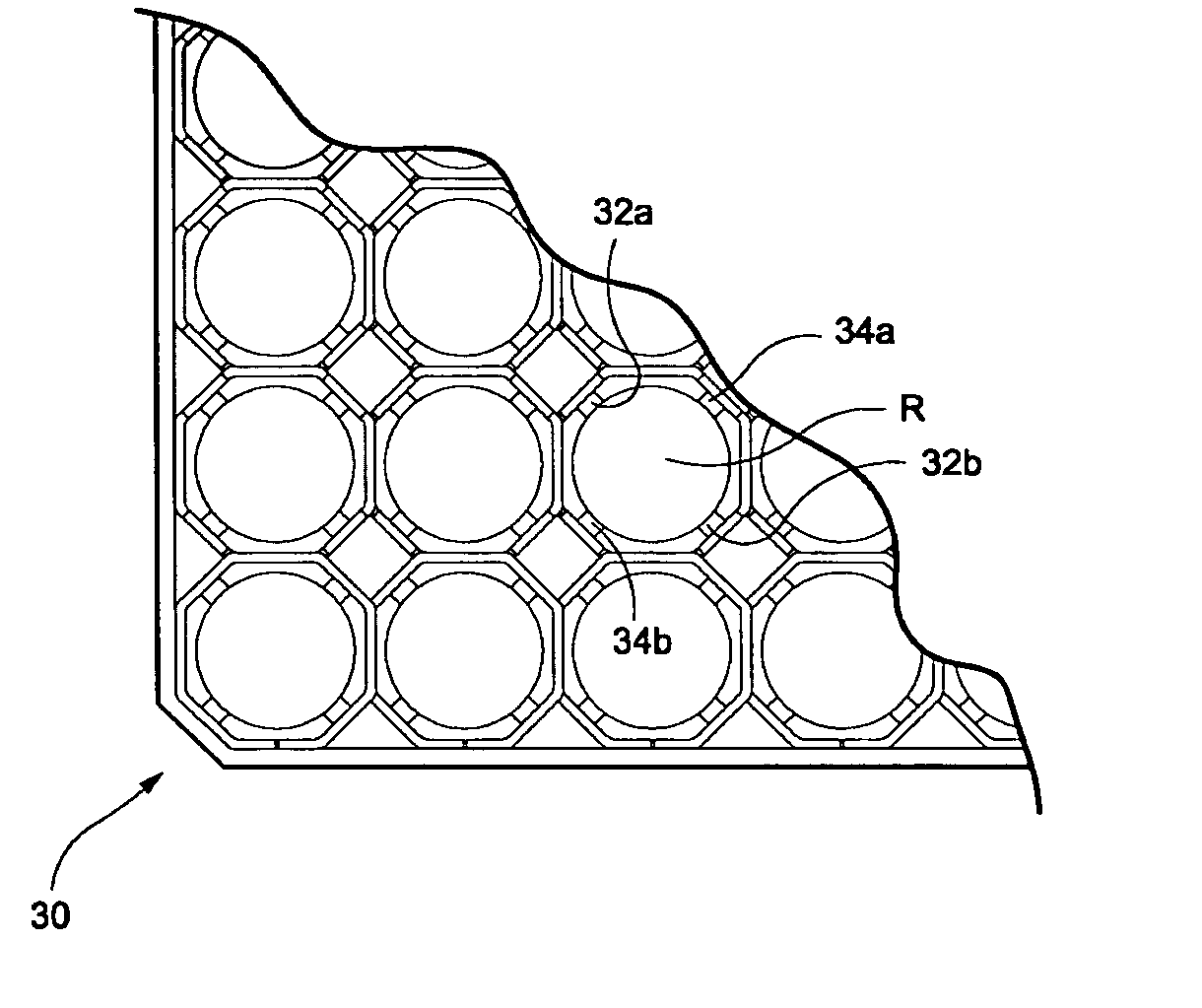

Method to restore an airfoil leading edge

The present invention provides methods and apparatus to restore a blade leading edge on a gas turbine engine component such as an airfoil of a turbine blisk. The method utilizes welding image technology and power control systems in order to provide effective welding with superalloy materials such as Inconel 713 and Inconel 625. The method includes machining away a damaged leading edge and providing a repaired region through successive depositions of superalloy powder filler through laser fusion welding. Deposition material is added until the repaired region exceeds the original dimensions of the airfoil. The airfoil is then machined and finished to return it to original airfoil dimensions.

Owner:HONEYWELL INT INC

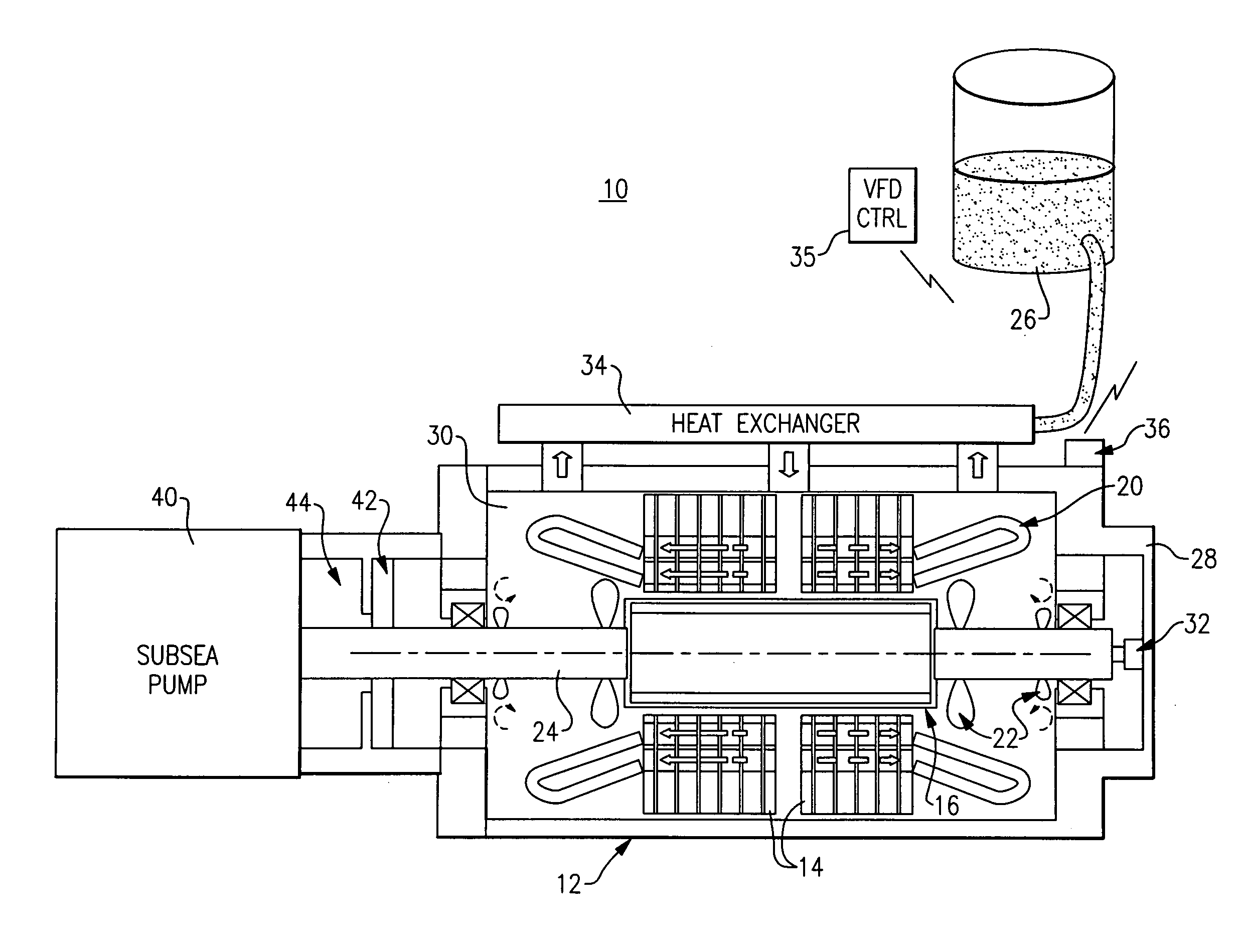

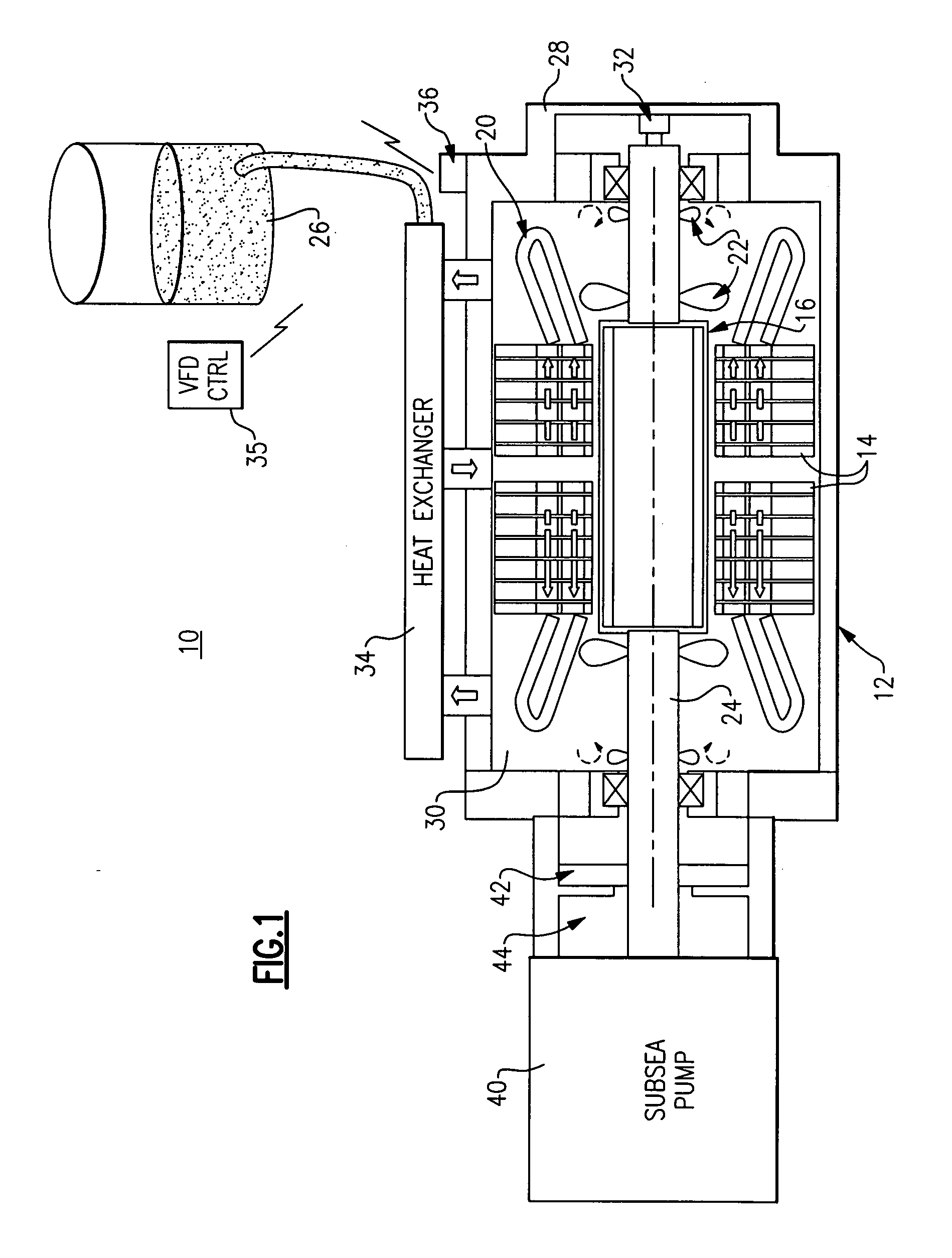

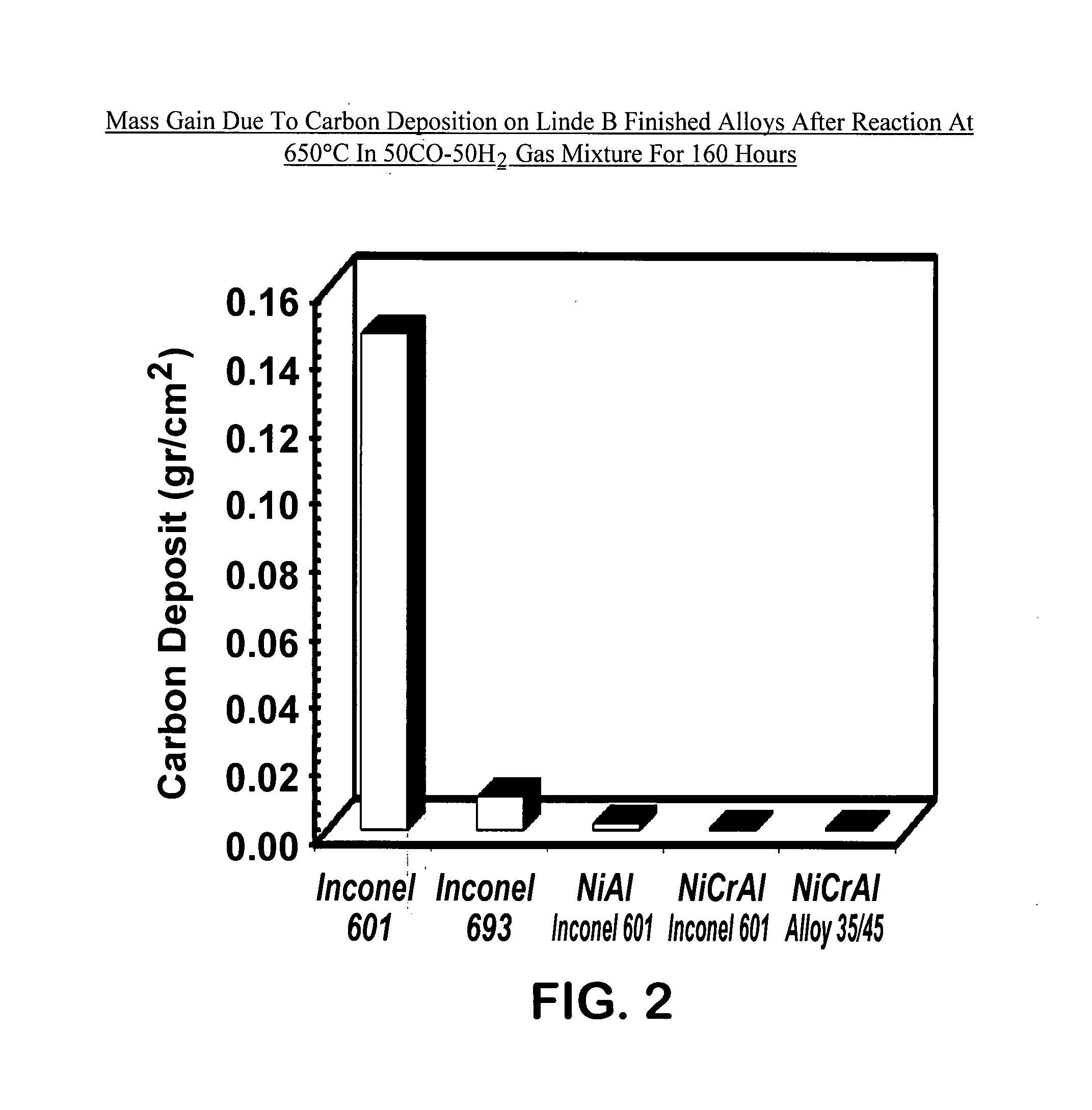

Permanent magnet motor for subsea pump drive

InactiveUS20090232664A1Avoid corrosionPositive displacement pump componentsPump controlPermanent magnet motorInconel

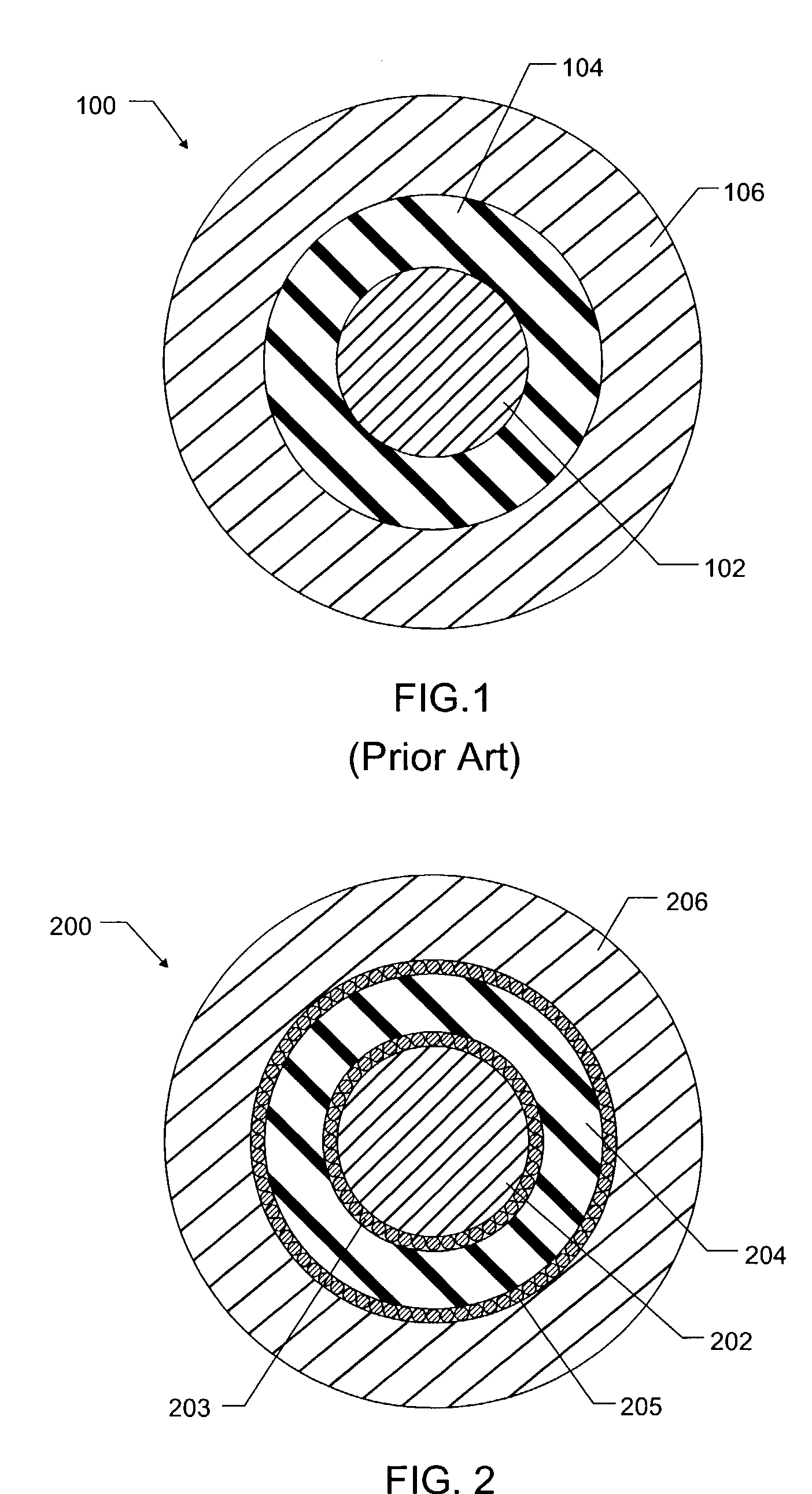

A subsea pump drive employs a permanent magnet (PM) motor to drive a subsea pump. The PM motor rotor in one embodiment is canned with a non-magnetic material such as inconel that can provide a desired level of corrosion protection. The PM motor provides a subsea pump drive that is smaller and more efficient, having a high power factor than a subsea pump drive utilizing a conventional induction motor. The PM motor subsea pump drive eliminates the necessity for a topside storage tank and associated fluid transfer lines when the motor rotor is cooled with processed fluid.

Owner:GENERAL ELECTRIC CO

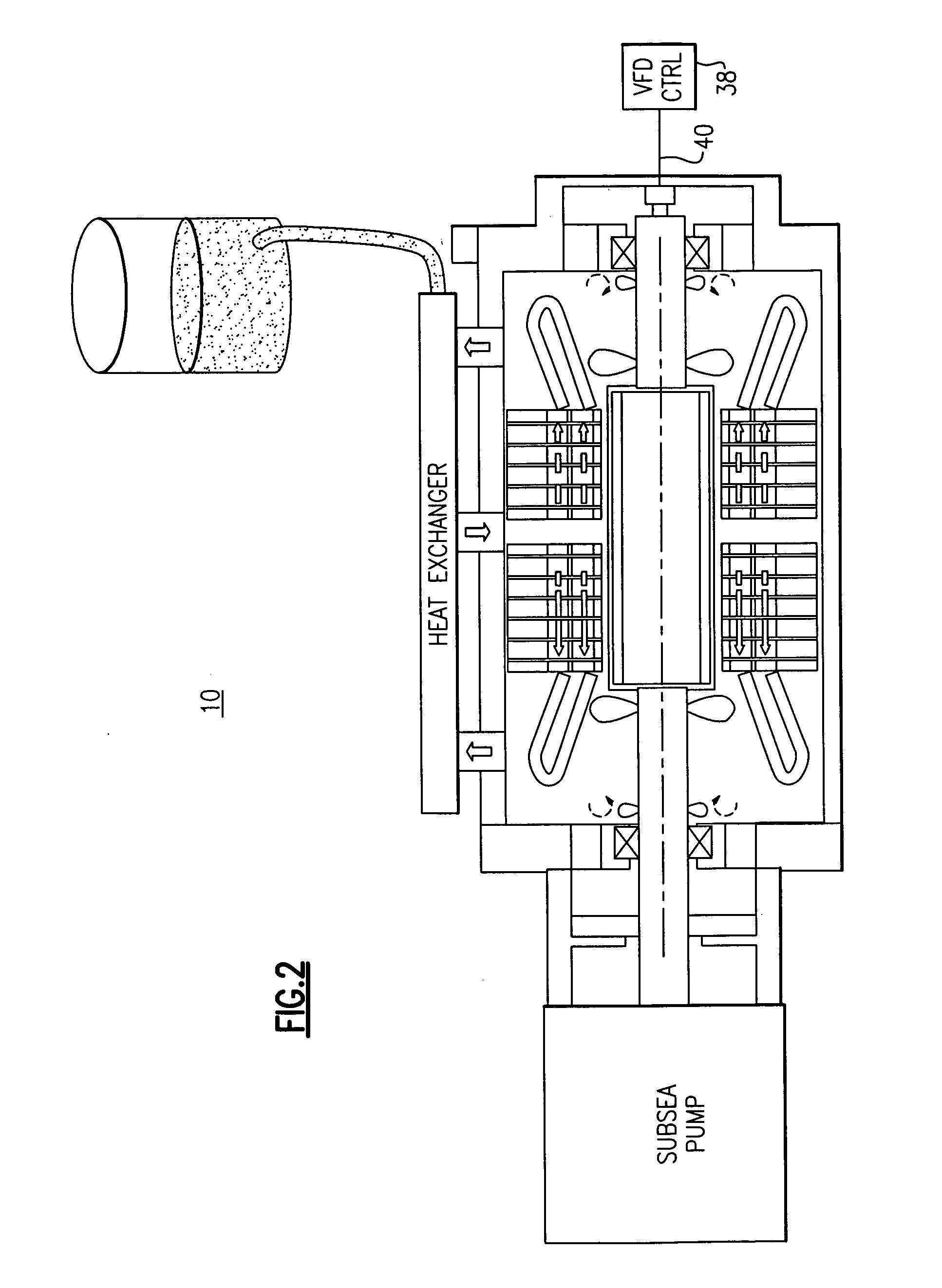

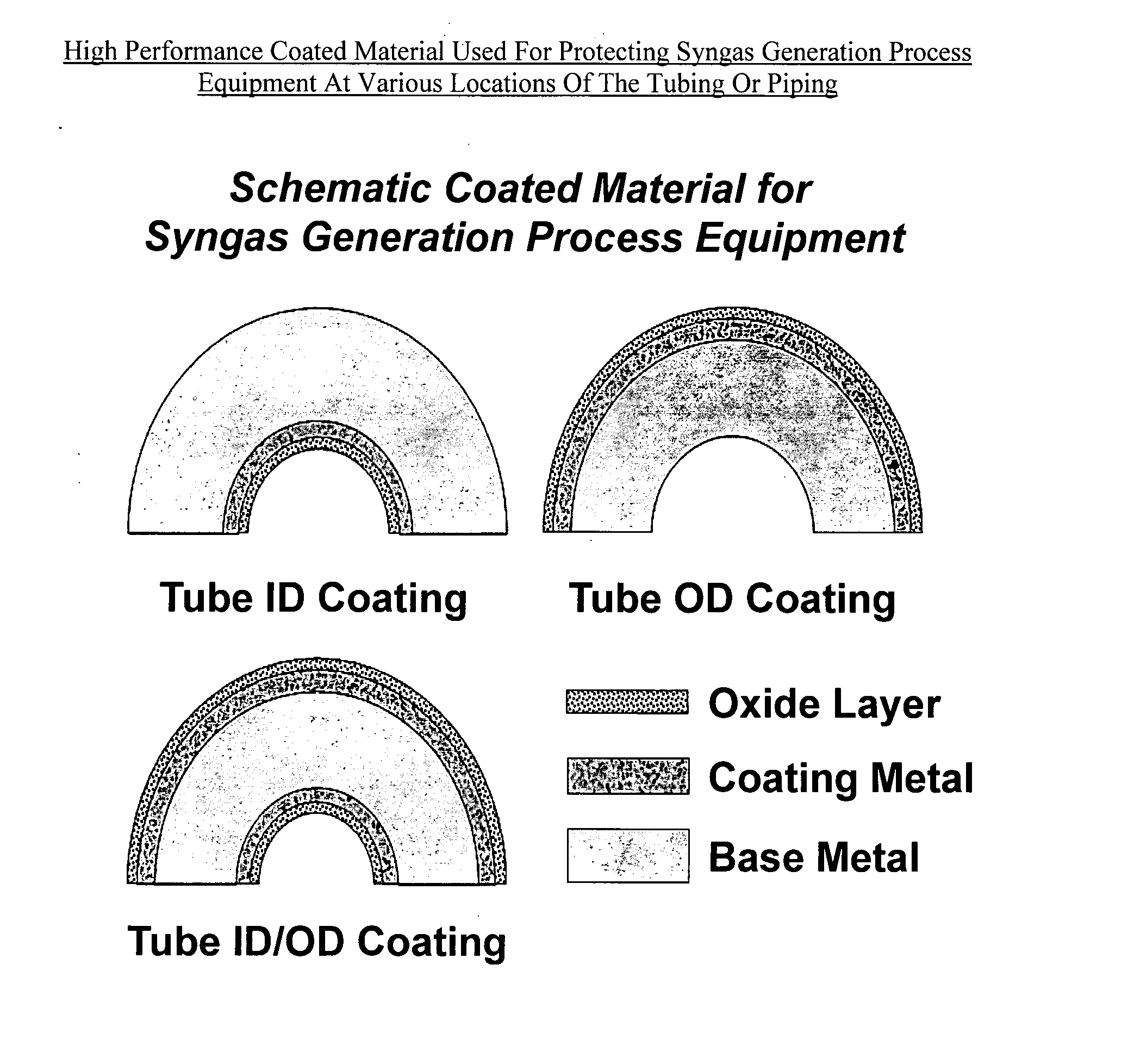

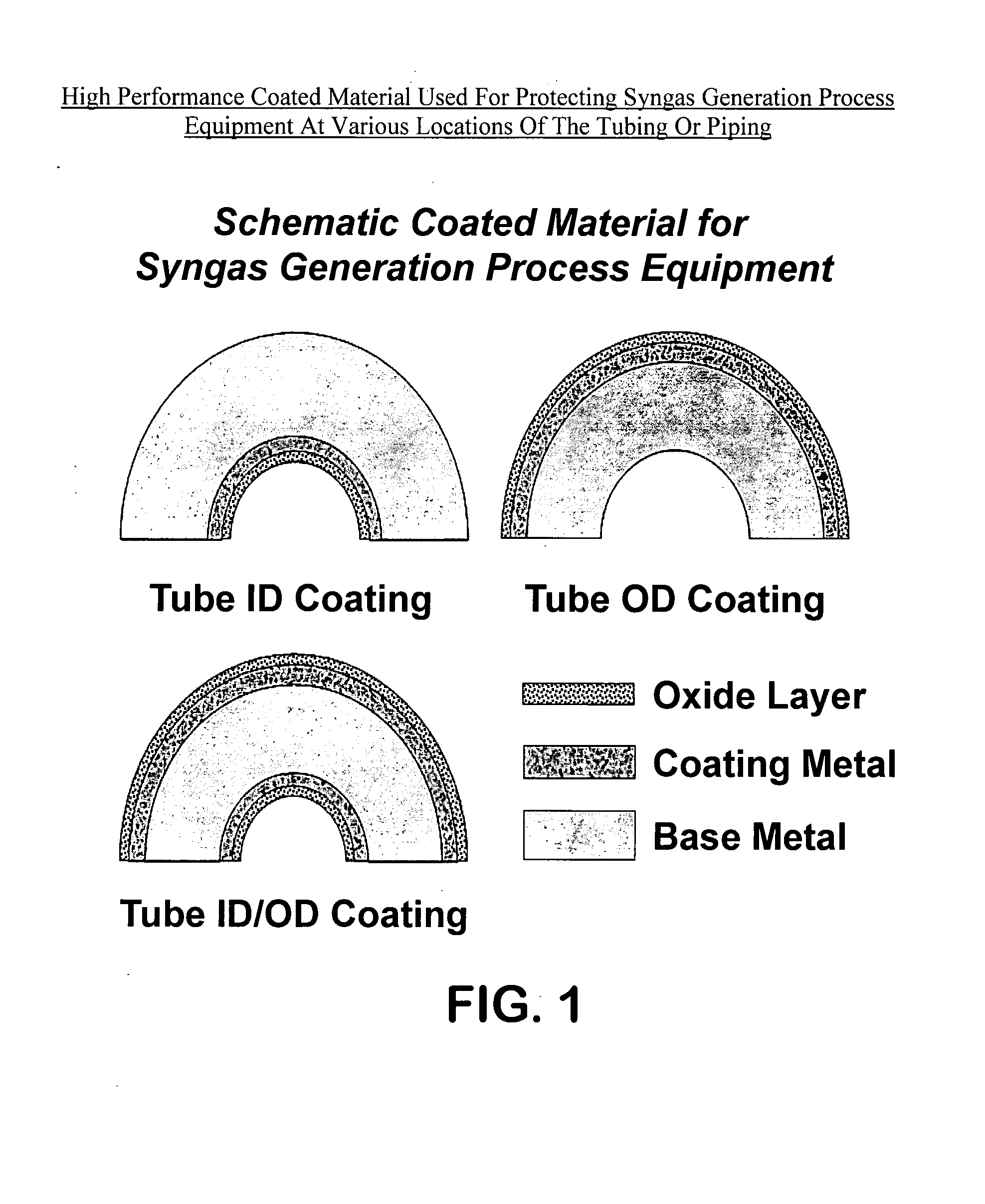

High performance coated material with improved metal dusting corrosion resistance

InactiveUS20080020216A1Improve the immunityReduce carbon depositionAnodisationLiquid surface applicatorsMulliteInconel

High performance coated metal compositions resistant to metal dusting corrosion and methods of providing such compositions are provided by the present invention. The coated metal compositions are represented by the structure (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal. P includes alumina, chromia, silica, mullite or mixtures thereof. Q includes Ni and Al, and at least one element selected from the group consisting of Cr, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof. R is selected from the group consisting of carbon steels, low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys. Advantages exhibited by the disclosed coated metal compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The coated metal compositions are suitable for use in syngas generation process equipment.

Owner:EXXON RES & ENG CO

Argon tungsten arc welding method for nickel-based alloy

ActiveCN102941397AControl generationImprove mechanical propertiesArc welding apparatusInconelWeld seam

The invention discloses an argon tungsten arc welding method for nickel-based alloy. The method comprises the following steps: (1) selecting a solder material, (2) making pre-welding preparation and making a bevel, (3) performing multi-layer multi-pass welding operation under such a condition that the weld inter-layer temperature is not more than 150 DEG C, and setting specific parameters of welding process, and (4) performing post-welding inspection. The method solves the problems of the Inconel 601 nickel-based alloy welding operation, such as high risk of thermal cracks, poor fusion penetration effect and tungsten inclusion, and effectively prevents the formation of air bubbles in weld seams, thereby ensuring that the produced welded joints have good mechanical property, corrosion resistance and attractive appearance. The ideal welding technique method is provided for the manual argon tungsten arc welding operation of Inconel 601 nickel-based alloy.

Owner:WISDRI WUHAN WIS IND FURNACE

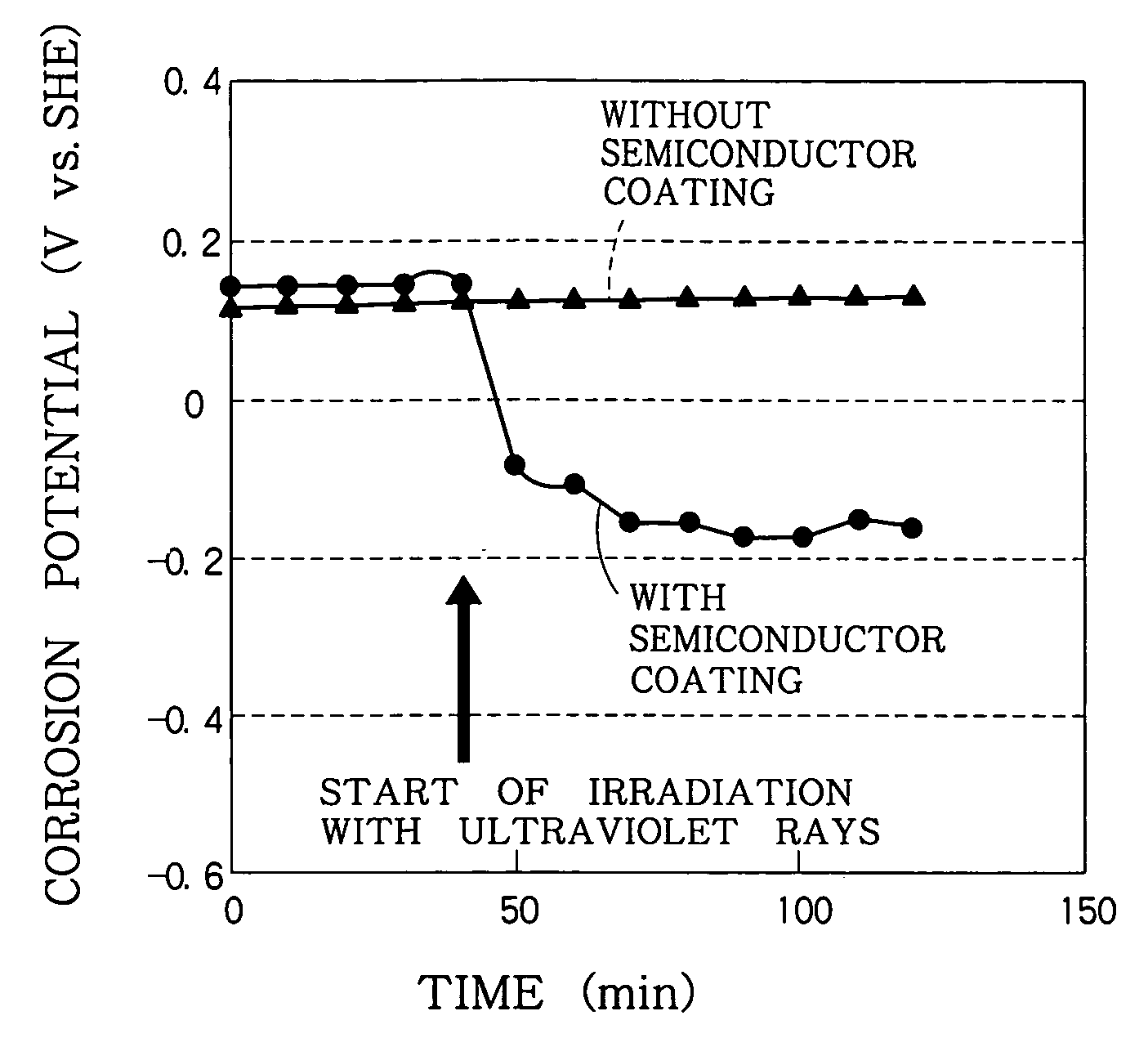

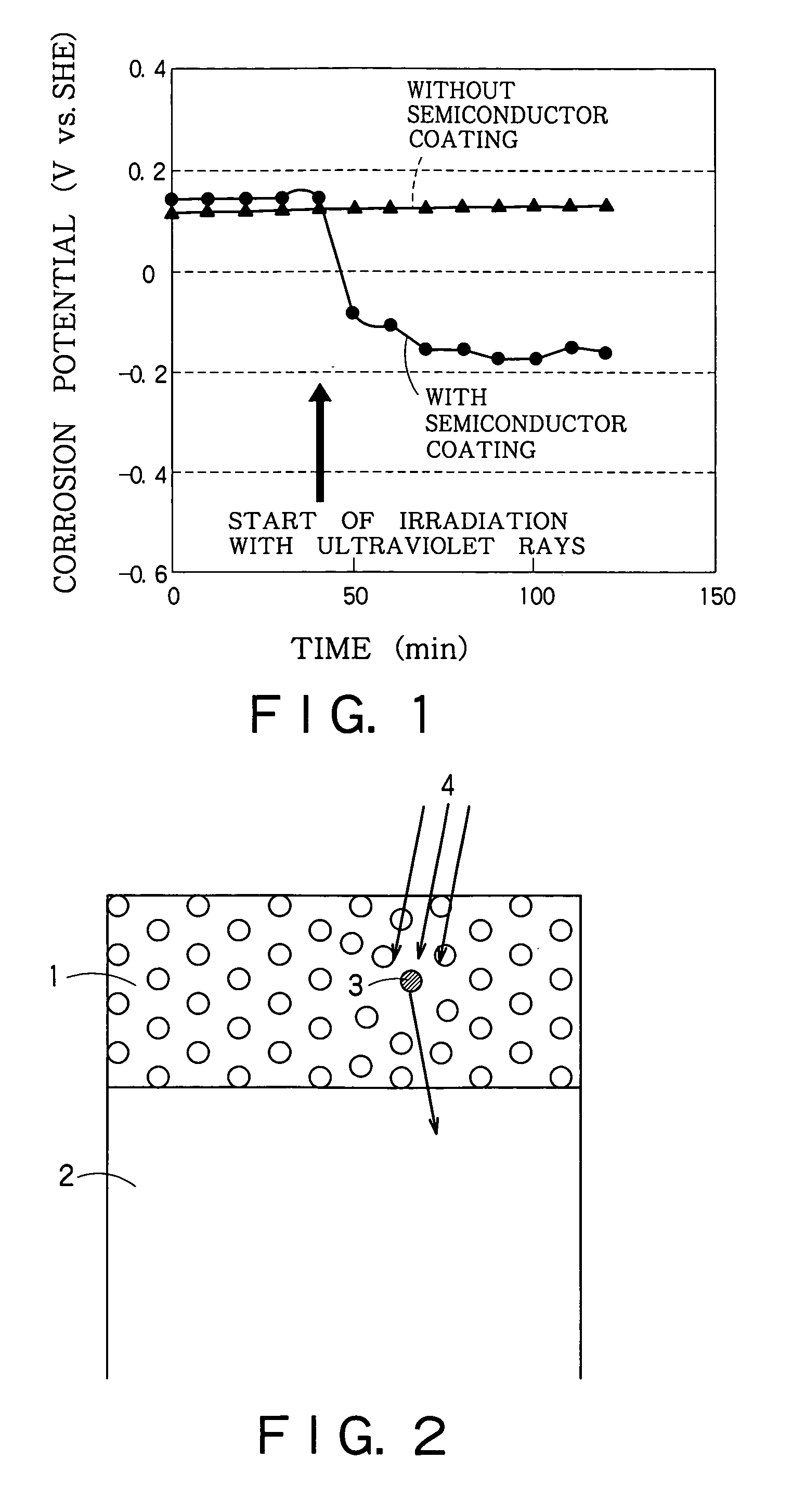

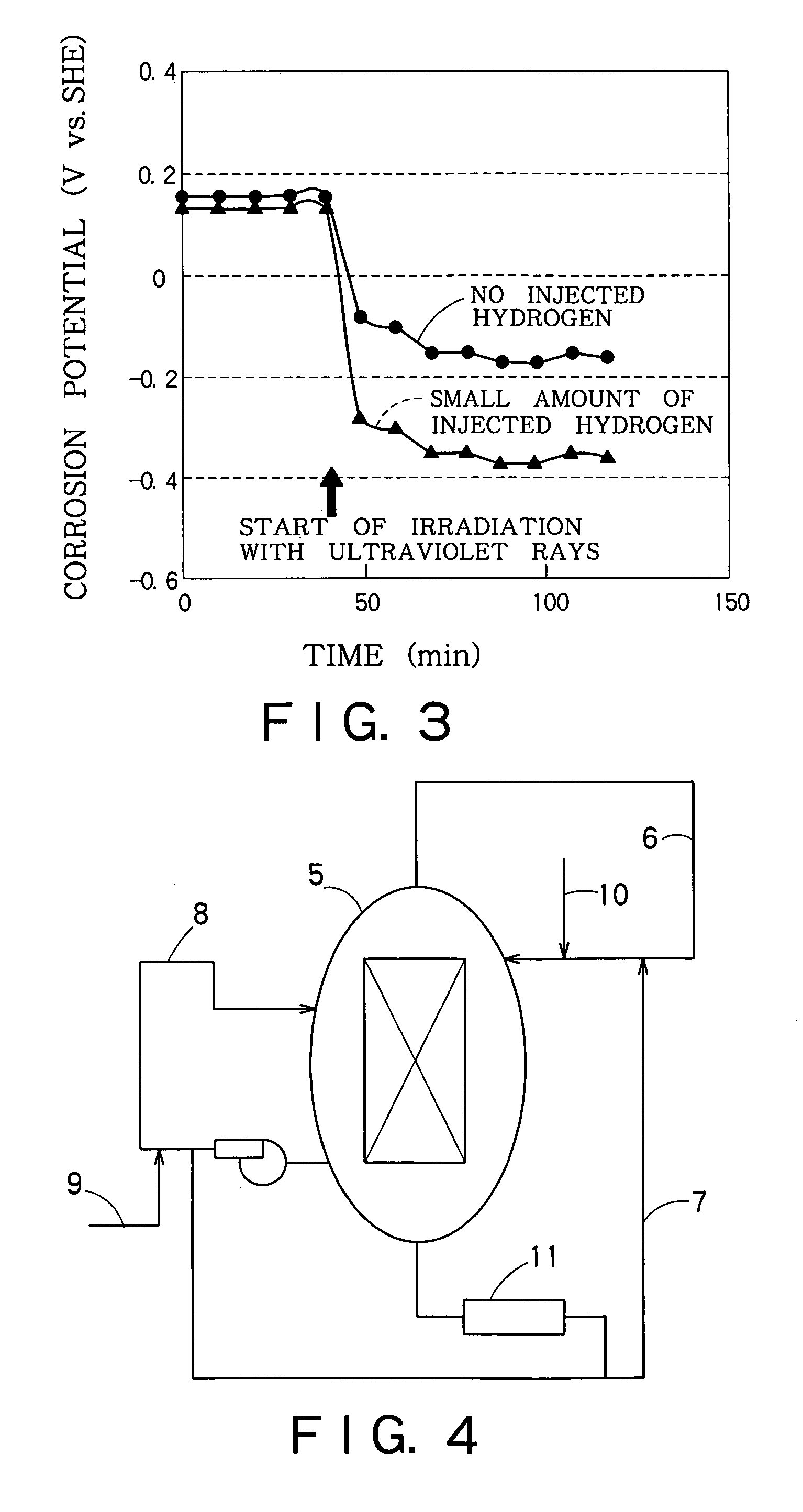

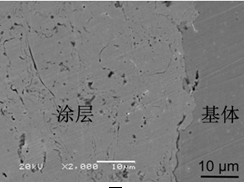

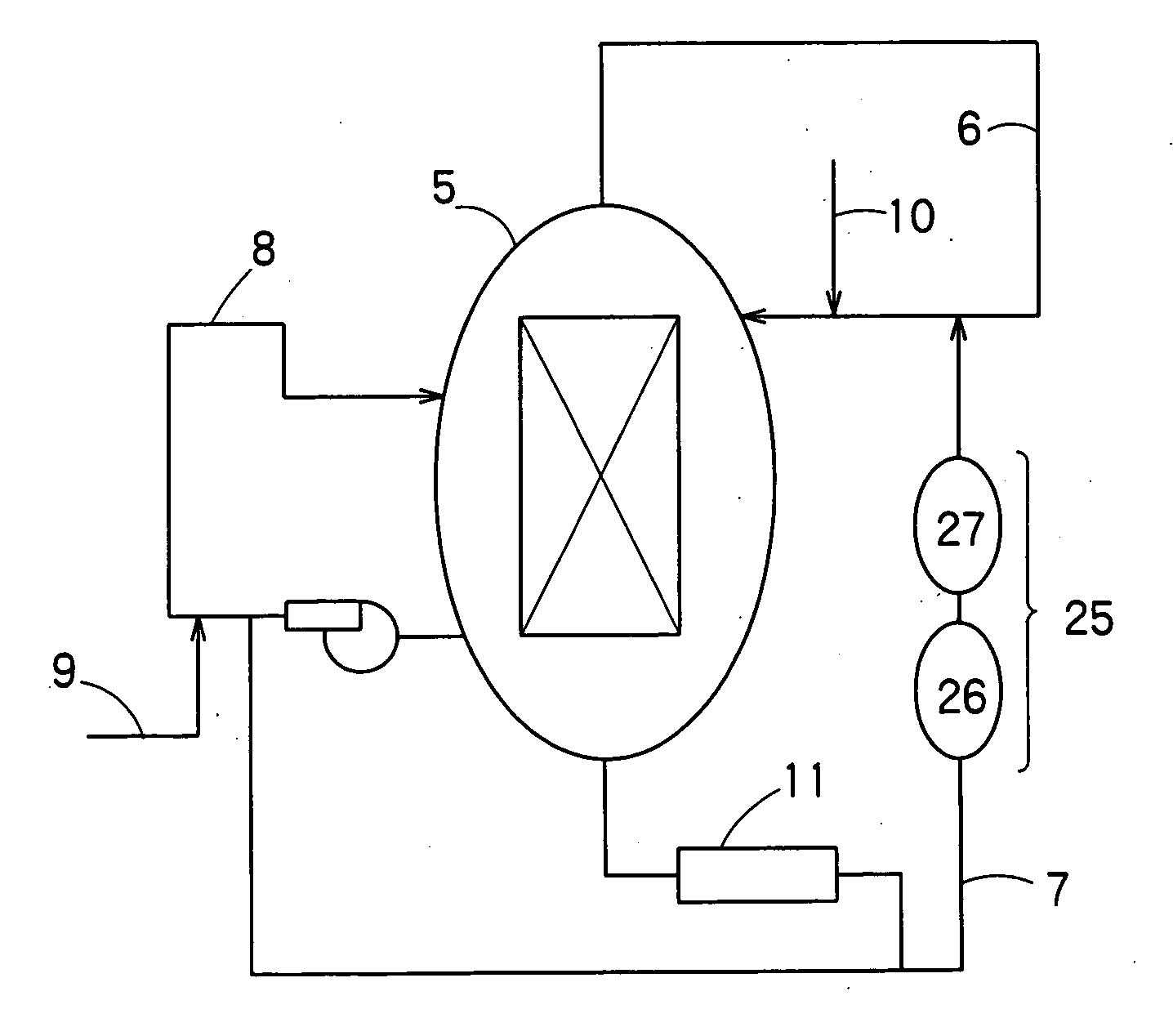

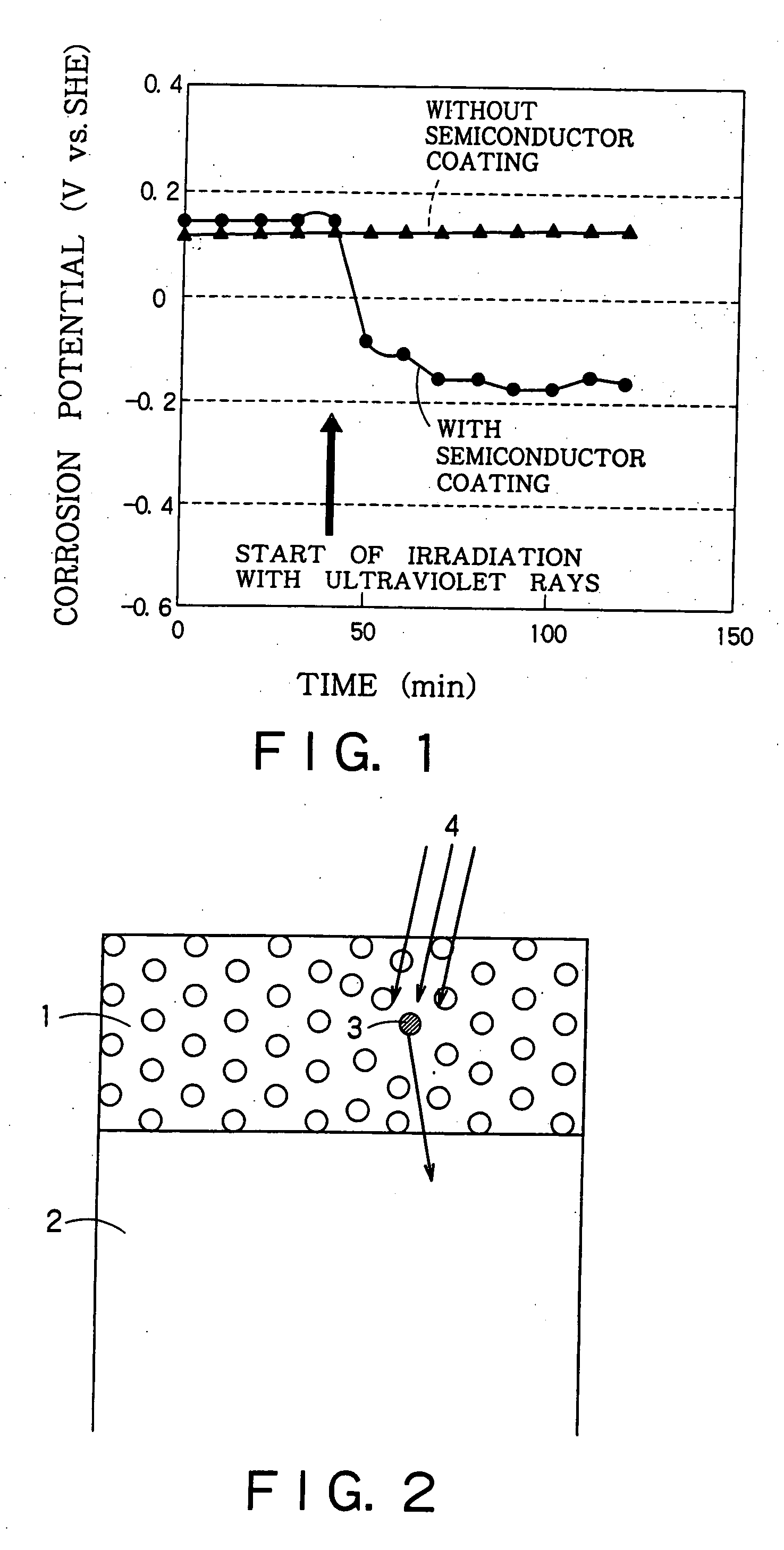

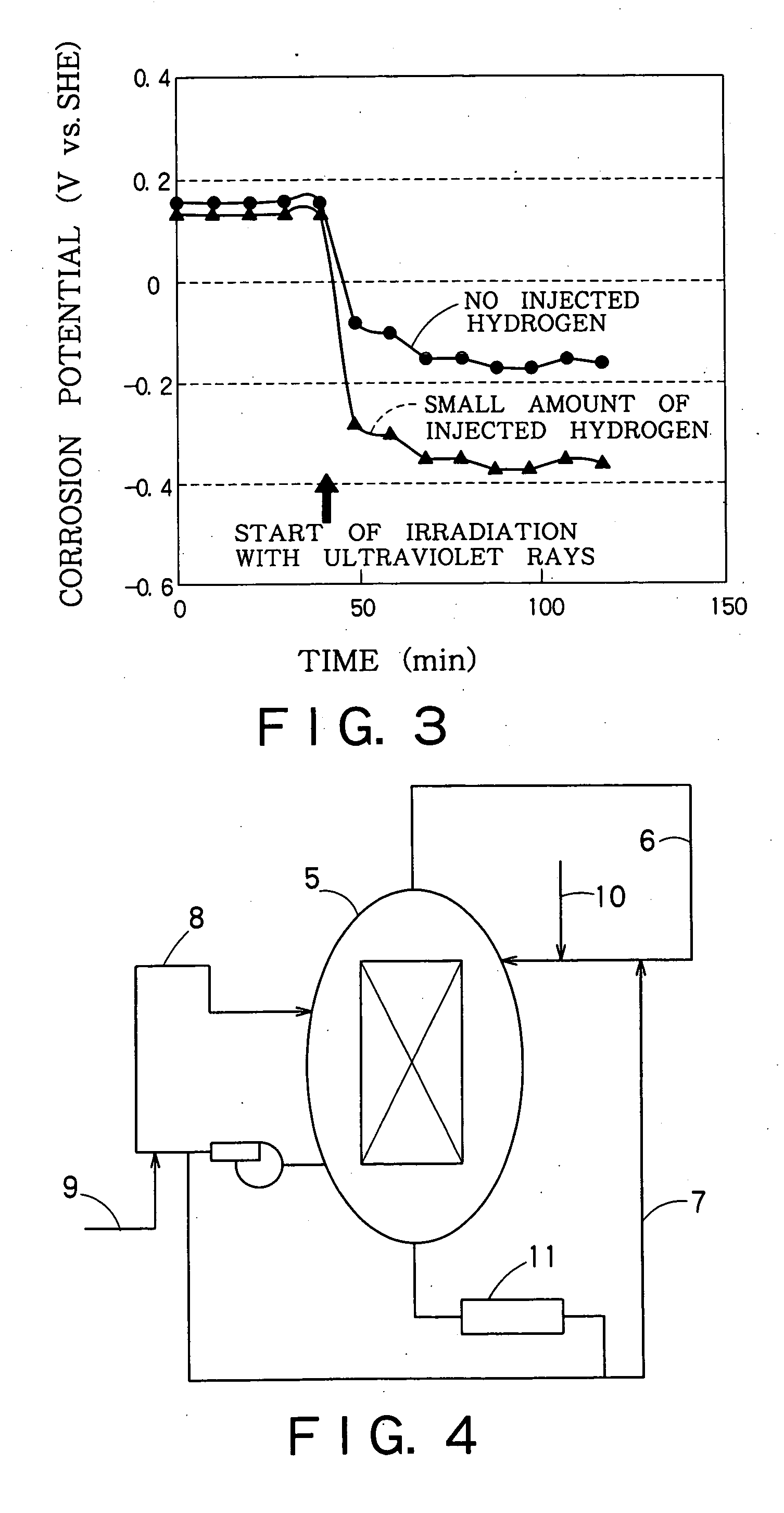

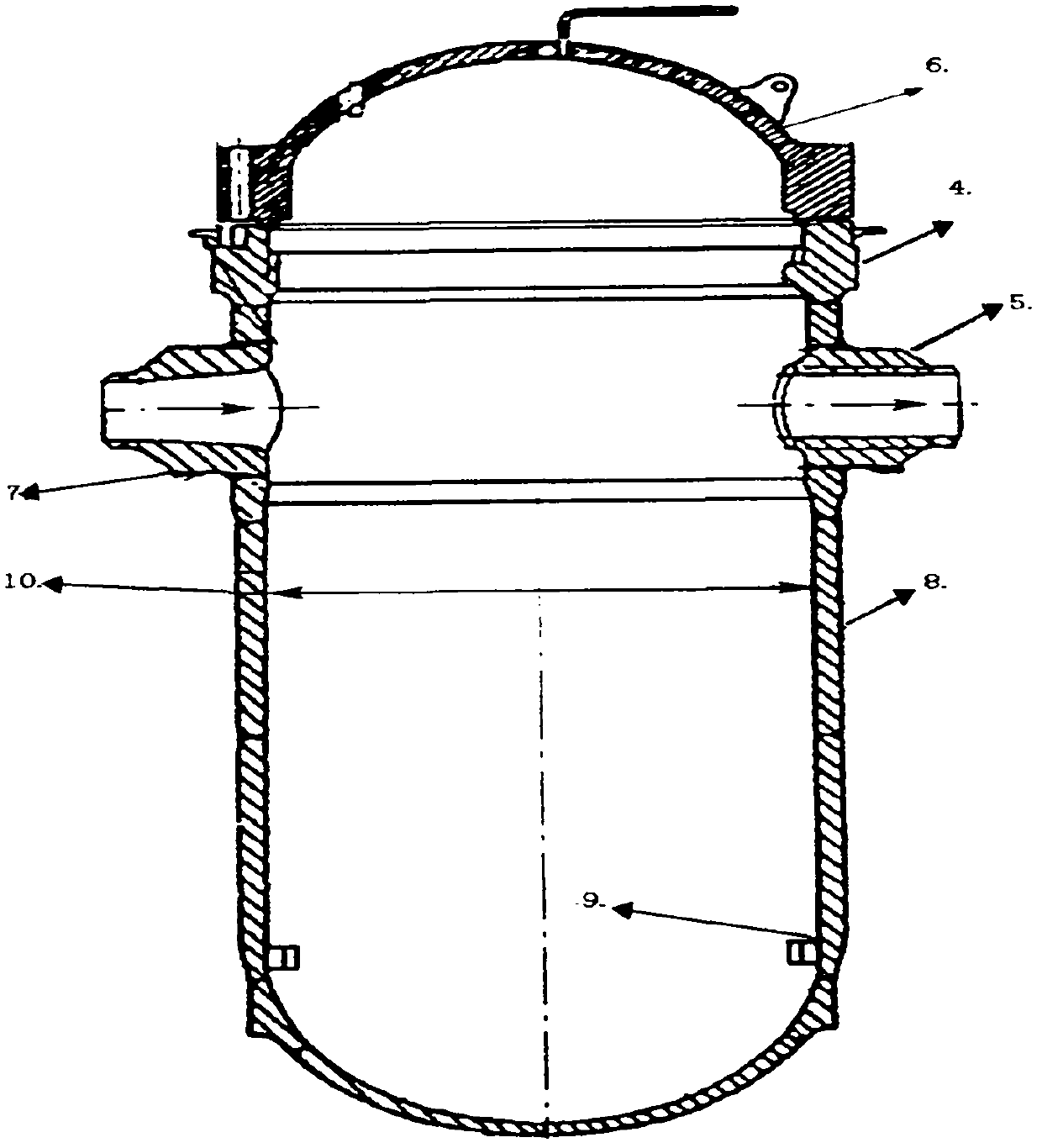

Reactor structural member and method of suppressing corrosion of the same

InactiveUS6940939B1Increase the concentration of hydrogenEffective preventionNuclear energy generationNuclear monitoringHydrogen concentrationNuclear reactor

A photocatalytic substance having the properties of an n-type semiconductor is deposited on a surface of a metal base made of a stainless steel or Inconel. When necessary, the hydrogen concentration of the reactor water is increased. A current produced by the photocatalytic substance when the same is irradiated with light or radioactive rays in a nuclear reactor flows through the metal base to reduce corrosion current. When necessary, the photocatalytic substance is provided on its surface with at least one of Pt, Rh, Ru and Pd.

Owner:KK TOSHIBA

Method for forming a flexible metal foil substrate display

A flexible metal foil substrate organic light emitting diode (OLED) display and a method for forming the same are provided. The method comprises: supplying a metal foil substrate such as titanium (Ti), Inconel alloy, or Kovar, having a thickness in the range of 10 to 500 microns; planarizing the metal foil substrate surface; depositing an electrical isolation layer having a thickness in the range of 0.5 to 2 microns overlying the planarized metal foil substrate surface; depositing amorphous silicon having a thickness in the range of 25 to 150 nanometers (nm) overlying the electrical insulation layer; from the amorphous silicon, forming polycrystalline silicon overlying the electrical insulation layer; forming thin-film transistors (TFTs) in the polycrystalline silicon; and, forming an electronic circuit using the TFTs, such as an OLED display.

Owner:SHARP LAB OF AMERICA INC

Process for machining metal and high performance aqueous lubricant therefor

InactiveUS20060172897A1Easy to handleEfficient processingWork treatment devicesBase-materialsEmulsionBoron nitride

A water-dilutable emulsion lubricant for machining, exhibiting improved dispersibility and emulsion stability, by emulsifying an oil system, composed of a base oil and an effective amount of fine particles of boron nitride of a crystalline turbostratic structure, dispersed in the base oil, in a water system, using an emulsifier. The lubricant is free from heavy metals, e.g., molybdenum disulfide and useful for machining difficult-to-cut materials such as Ti alloys and Inconel. The lubricant is effective even at a diluted state comprising 0.001% up to 0.1% by weight of crystalline t-BN.

Owner:YAMAMOTO OSAMU

Composite tube for ethylene pyrolysis furnace and methods of manufacture and joining same

InactiveUS20050058851A1OptimizationSolve the real problemThermal non-catalytic crackingArc welding apparatusHigh resistanceHydrocotyle bowlesioides

A process for making a composite tube uniquely suited for use in ethylene pyrolysis furnaces wherein the tube comprises an outer shell made from a wrought or cast Fe—Ni—Cr heat resistant alloy and an inner core made from INCOLOY® alloy MA956 powder. The outer shell and powder core are heated and simultaneously extruded to form a composite tube. The process is carried out at temperature, and time at temperature, preferably less than 1200° C. so as to prevent recrystalization of the very fine grain structure in the alloy MA956. This un-recrystalized fine grain structure permits pilgering and / or cold drawing of the extruded composite tube to final size. The composite tube provided by the present invention is uniquely suited for use in the petrochemical and chemical process industries, so as to increase the efficiency and productivity of their respective processes. The thin core layer of alloy MA956 provides high resistance to carburization and coke formation heretofore caused by the hydrocarbon feedstock flowing through the composite tube, while the outer shell of Fe—Ni—Cr heat resistant alloy provides overall strength and rigidity to the tube. The use of the outer shell in the composite tube also solves the joining problem heretofore encountered in joining alloy MA956. A root pass or passes using an alloy MA956 filler metal followed by overlay welding passes using a filler metal compatible with the heat resistant alloy, such as INCONEL alloy 617 or FM 25 / 35, joins the outer shells of adjoining composite tubes and, thus, solves the welding problem.

Owner:HUNTINGTON ALLOYS CORP (US)

Preparation method for nickel-based high temperature alloy by using electron beam melting

The invention especially relates to a preparation method for nickel-based high temperature alloy by using electron beam melting, which belongs to the field of metallurgical purification technology. The method comprises the following steps: taking high-purity raw materials respectively corresponding to each element included in Inconel 740 alloy; respectively polishing, cleaning and drying the high-purity raw materials; proportioning the dried high-purity raw materials according to composition of the Inconel 740 alloy; and finally, placing the proportioned high-purity raw materials in an electron beam melting furnace, heating the high-purity raw materials until the raw materials are fused, carrying out melting, closing electron beam current after completion of melting, cooling a melt to obtain an alloy ingot and removing an oxidation film on the top of the alloy ingot so as to obtain the Inconel 740 nickel-based high temperature alloy. According to the invention, through usage of the characteristics of high vacuum, high-energy density and the like of electron beam in vacuum melting and combined utilization of volatilization rules of elements under a vacuum condition, alloy components in a finished product are well controlled, and production efficiency is substantially improved while the purity of the high temperature alloy is guaranteed.

Owner:DALIAN UNIV OF TECH

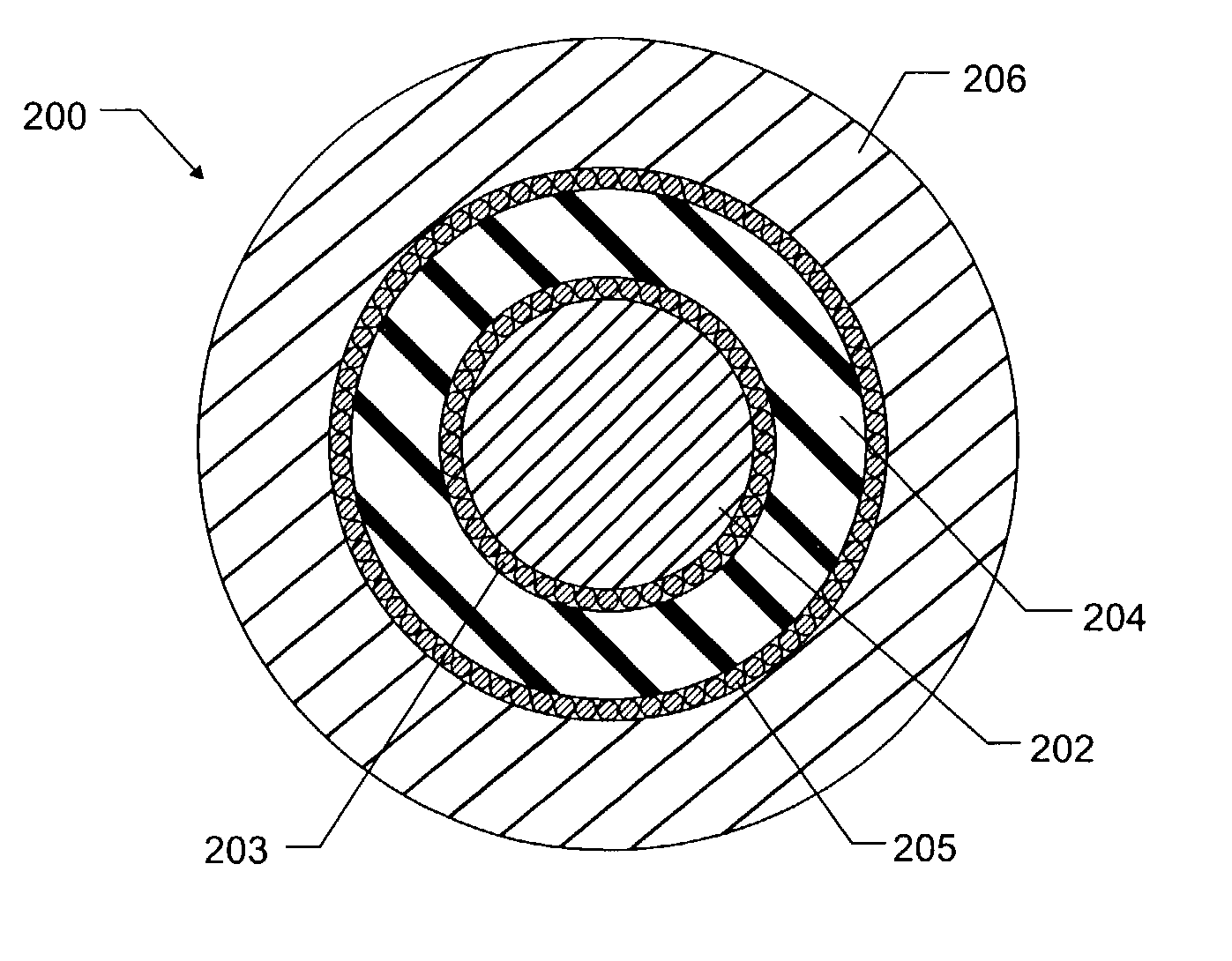

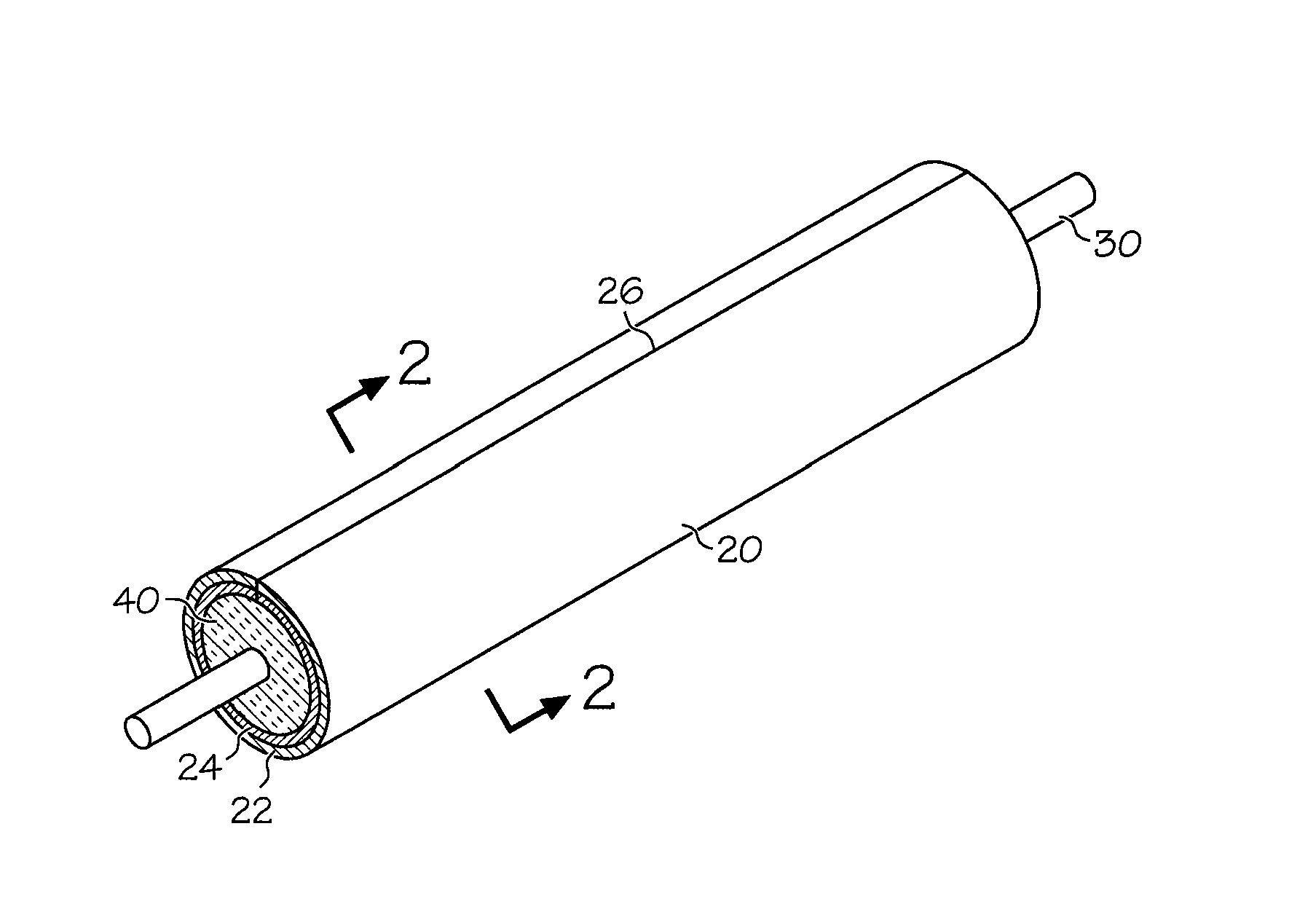

Dual stress member conductive cable

InactiveUS6960724B2Improve conductivityPower cables with screens/conductive layersFlexible cablesEngineeringInconel

A dual stress member electrical cable includes an electrically conductive, load-bearing core, an insulating layer surrounding the core, and an electrically conductive, outer load-bearing member surrounding the insulating layer. The core may be formed of a solid wire of steel, aluminum, or titanium. The insulating layer may be formed of Teflon or PEEK. The outer load-bearing member may be a tube formed of Inconel, stainless steel, galvanized steel, or titanium.

Owner:SCHLUMBERGER TECH CORP

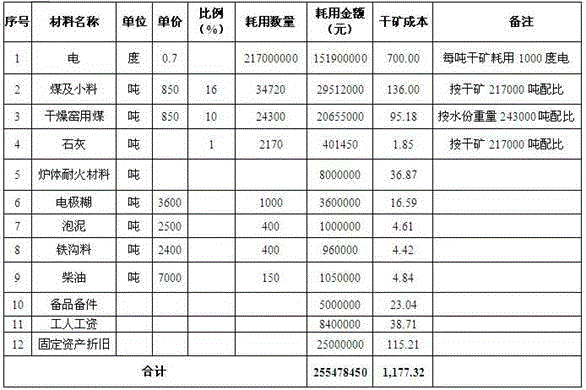

Method for smelting chromium-nickel-iron alloy from stainless steel dust-removing ash

InactiveCN101126138AEasy to recycleReduce pollutionProcess efficiency improvementChromium nickelFerrosilicon

The invention is a stainless steel ash removing method for smelting inconel. The method comprises the steps as follow; 1 make ash removing block, comprising the following three steps; 1) selective mixing; 2) extrusion molding; 3) natural drying; 2 make the master liquid by melting the normal recycled waste steel or stainless slag steel, pre-treated the molten iron, the ash removing block and the chromate nickel sponge iron inside the electric furnace; 3 batch-by- batch restoring, which comprises the following three steps: 1) add the block and the extra coke or coke breeze to smelt after the raw material used as master liquid is fully melted; 2) supply power with 15 to 20 minutes, then stop for conducting the operations of temperature measuring, exampling and analyzing, and add ferrosilicon breeze and lime; 3) the molten iron is remained between 1550 to 1600 DEG C in the smelting process; 4 finally restoring, and the main components of the metal solution after being finally restored are as follow: C percent is more than or equal to 2.50, Si percent is more than or equal to 0.20, P percent is less than or equal to 0.045, Cr percent is more than or equal to 5.0, and Ni percent is more than or equal to 1.5. The invention has the advantages of reducing environment pollution and increasing the metal yield of the ash removing.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

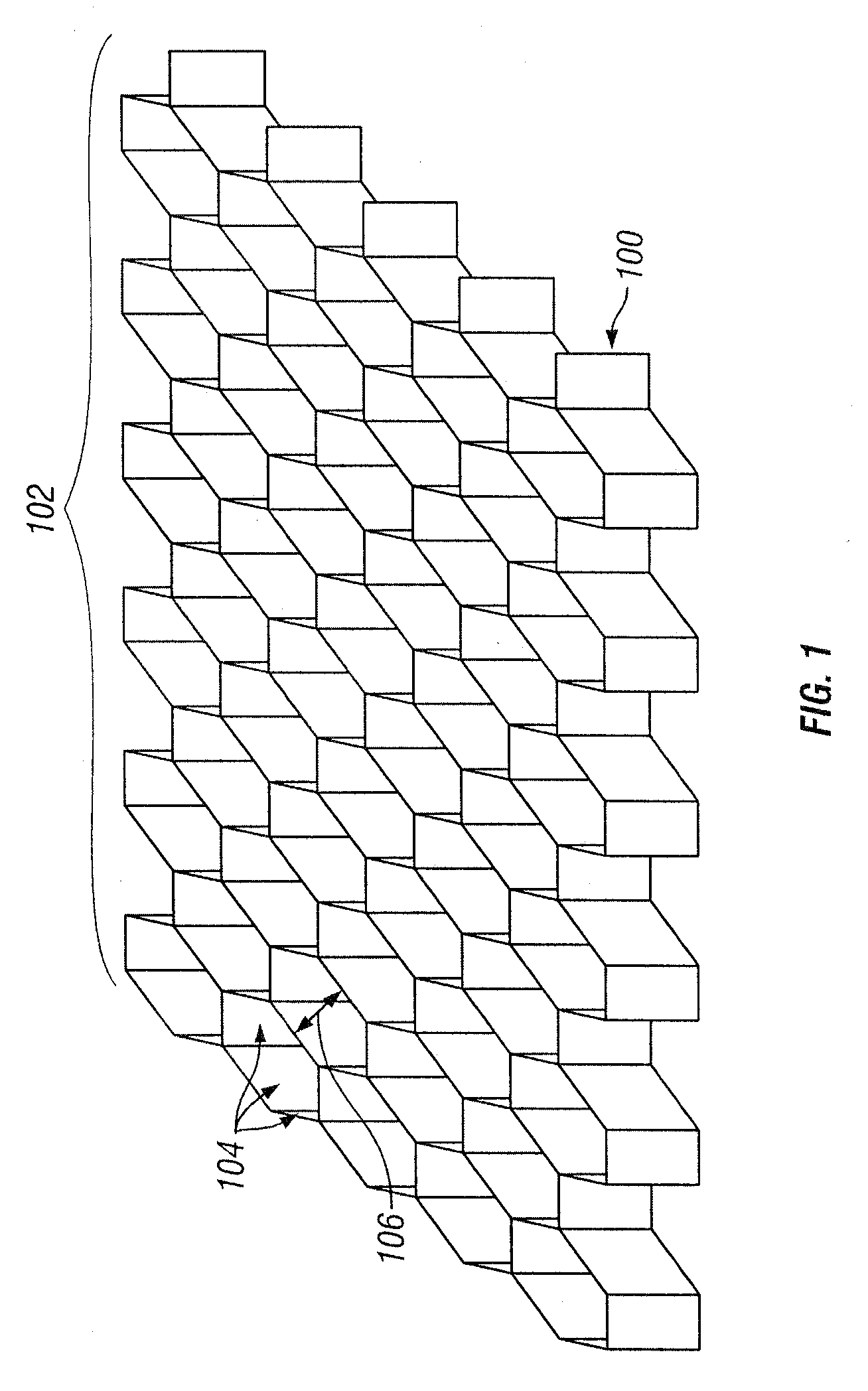

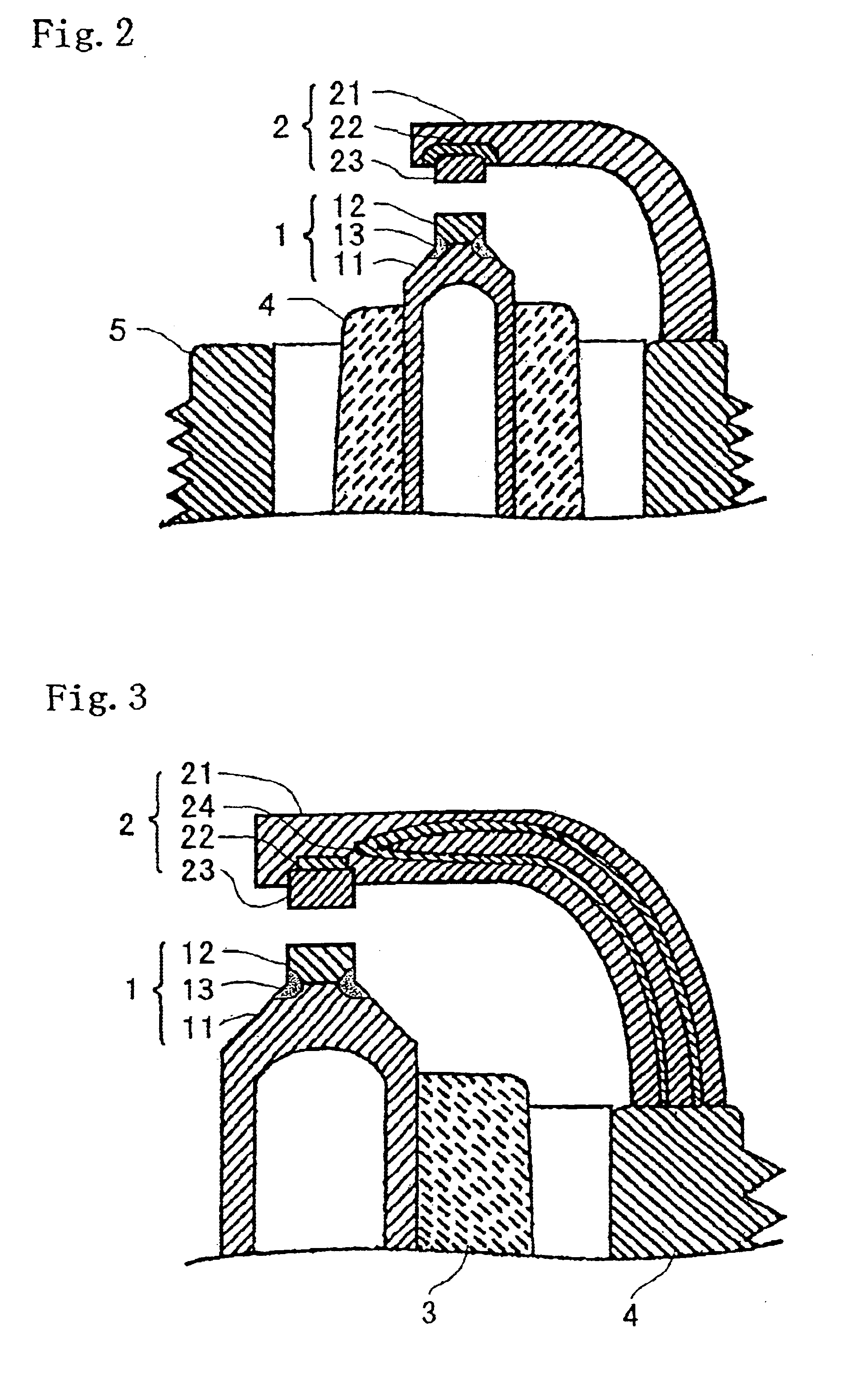

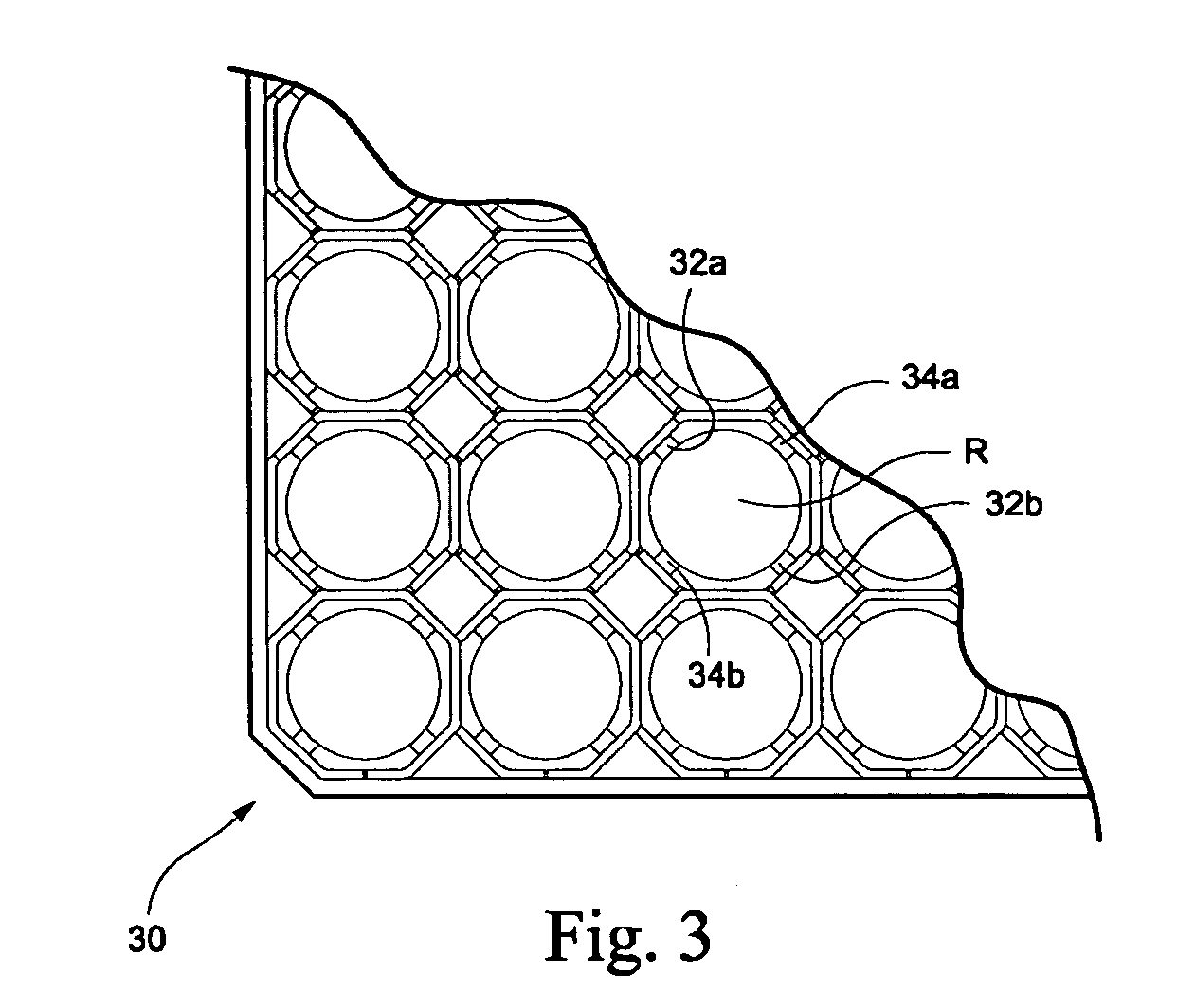

Thermally conductive structure

ActiveUS20090178410A1Reduce thermal deformationReduce and eliminate thermal deformationEngine manufacturePaper/cardboard articlesThermal deformationTemperature difference

A multi-layered honeycomb structure adapted to reduce and / or eliminate thermal deformation is disclosed herein. In some embodiments, walls of the honeycomb structure comprise a first layer, optionally, a second layer, and a core layer adjacent to the first layer or between the first and second layers. The first and second layers may be compositions of Inconel or other high strength materials. The core layer may be copper or another thermally conductive material. The core layer is adapted to transmit heat between a first region of a structure and a second region. In this manner, heat can be transferred from the heated region to an unheated region, thereby reducing the temperature difference between the regions and thus the amount of thermal deformation.

Owner:STRAZA GEORGE C P

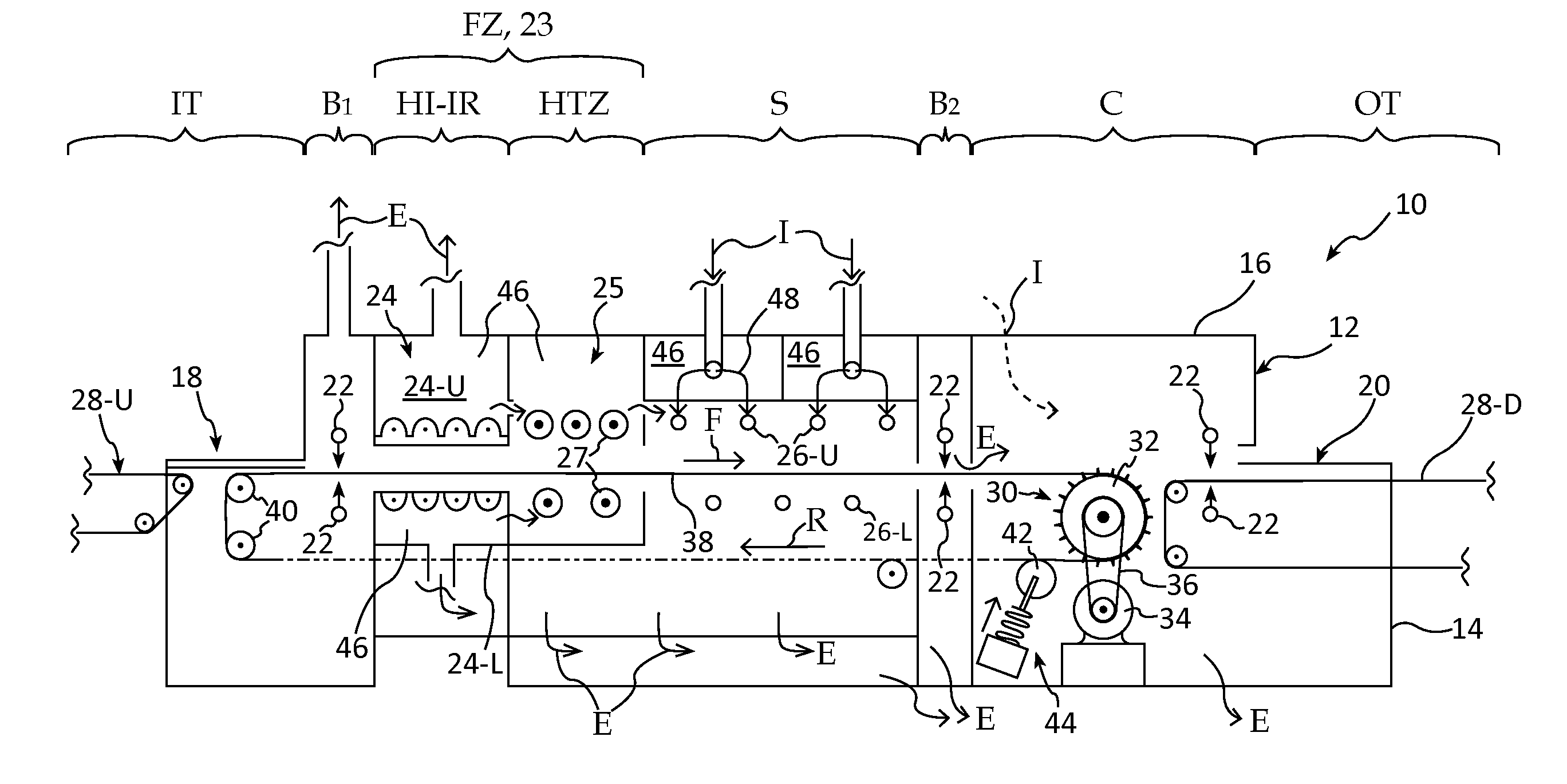

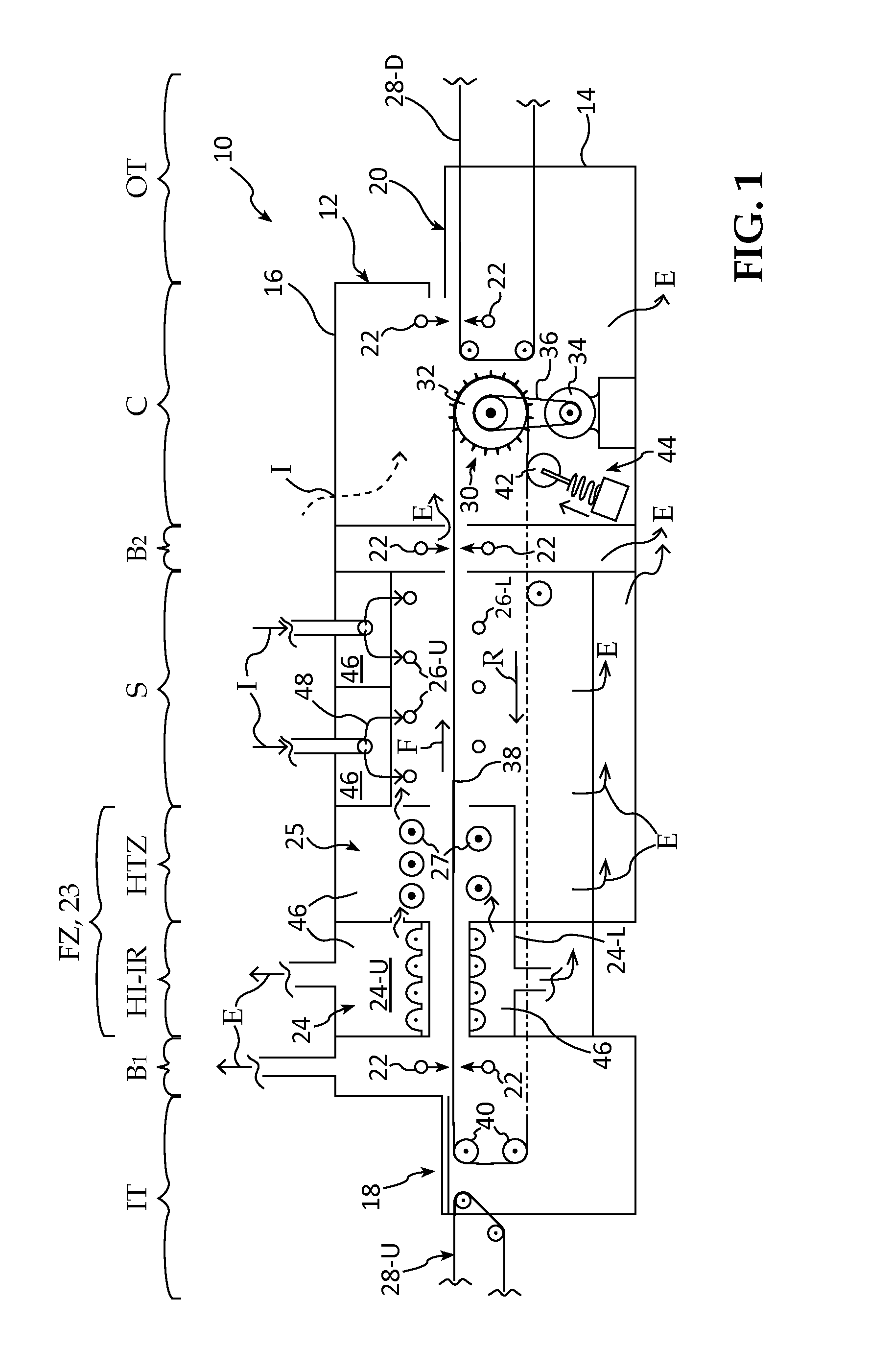

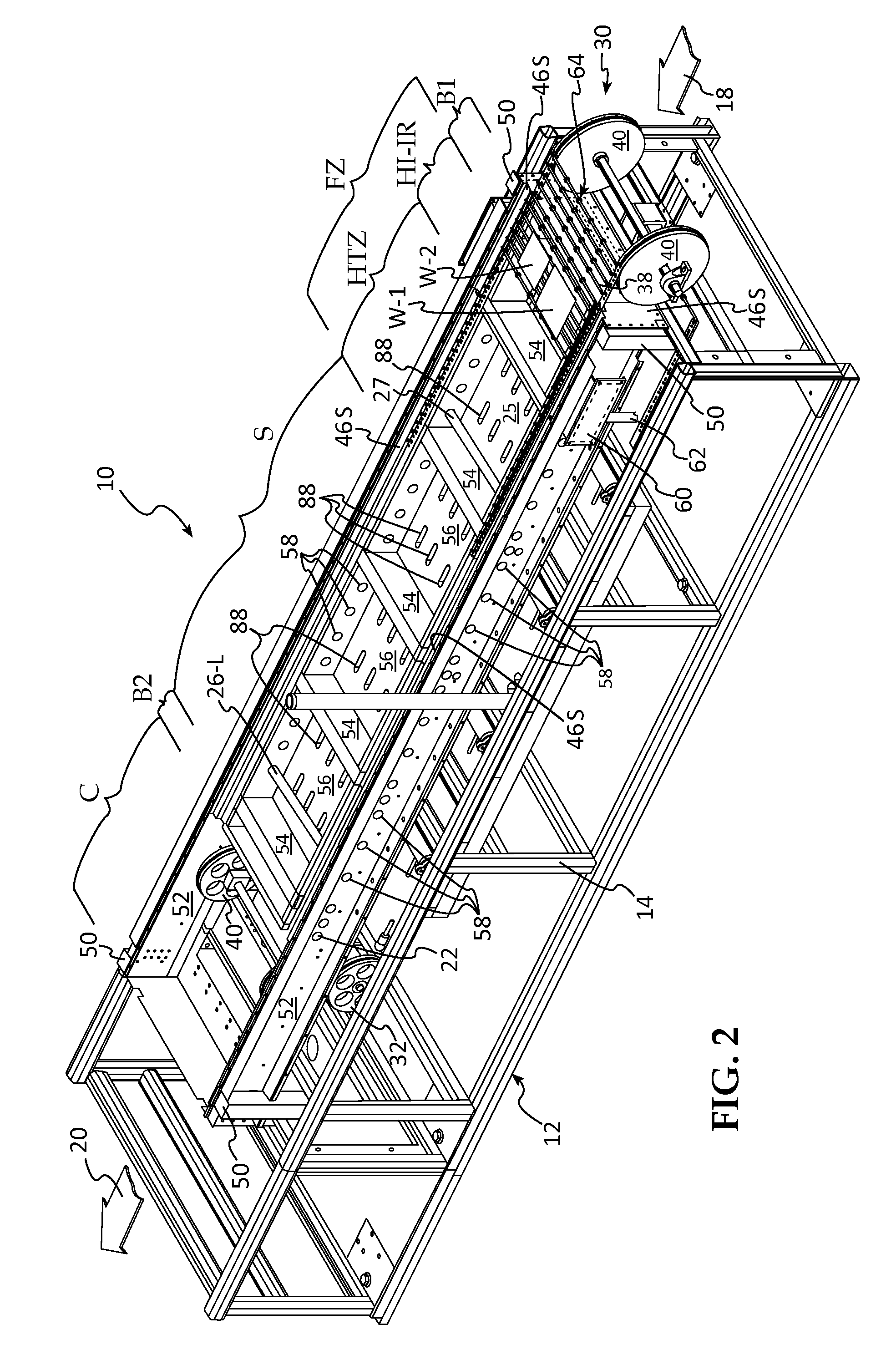

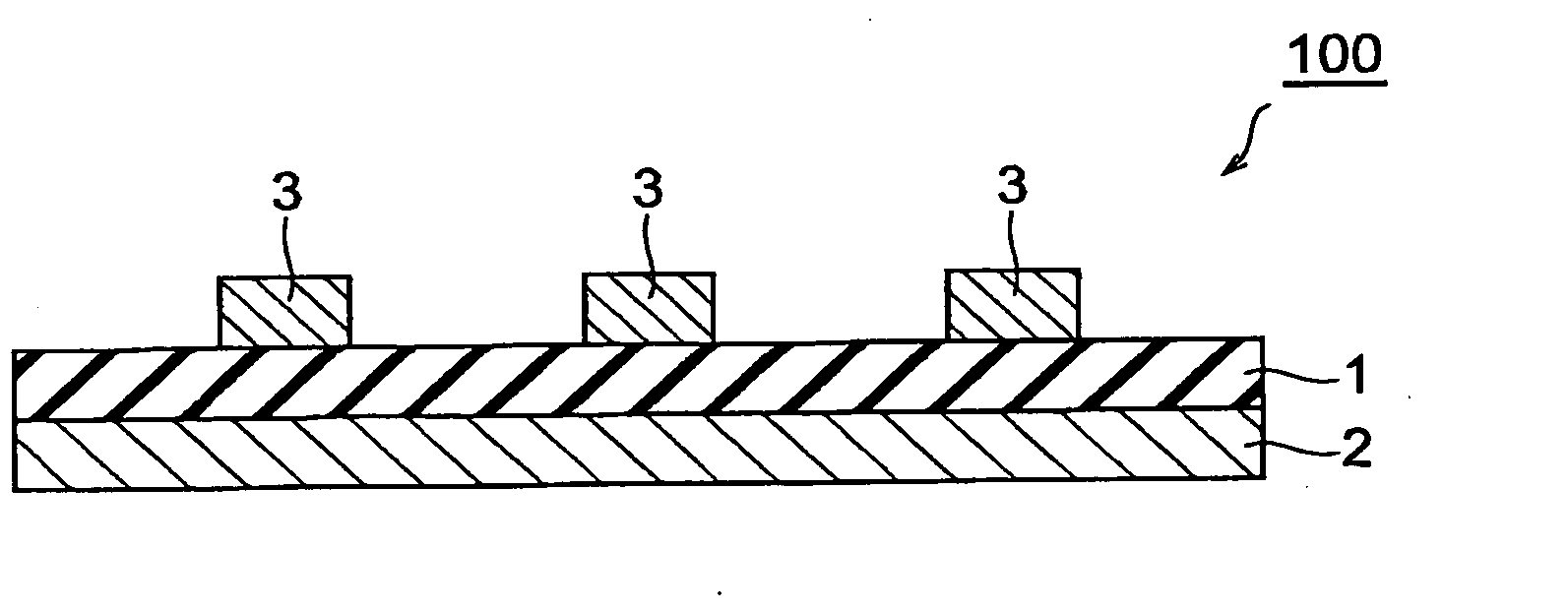

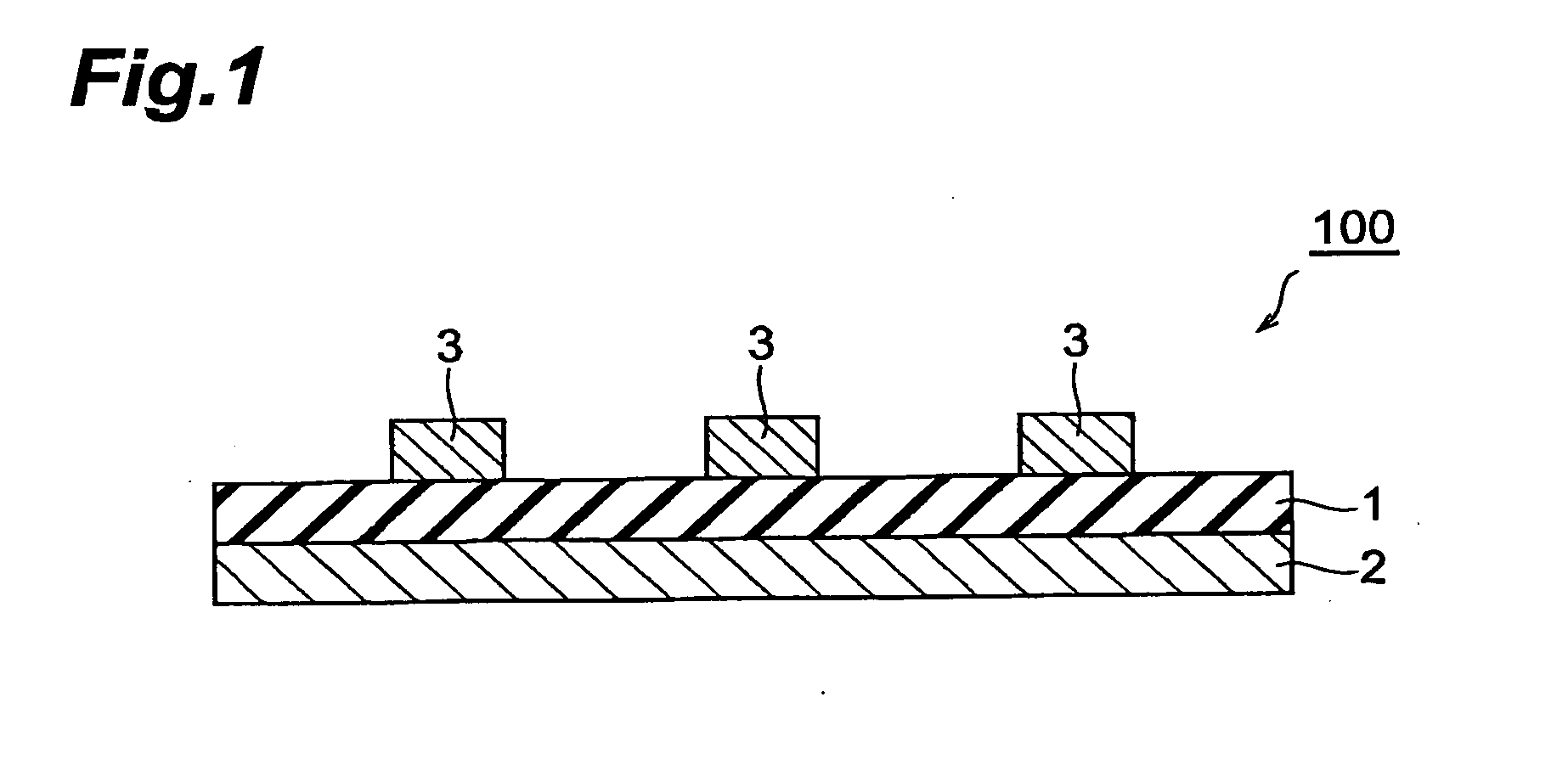

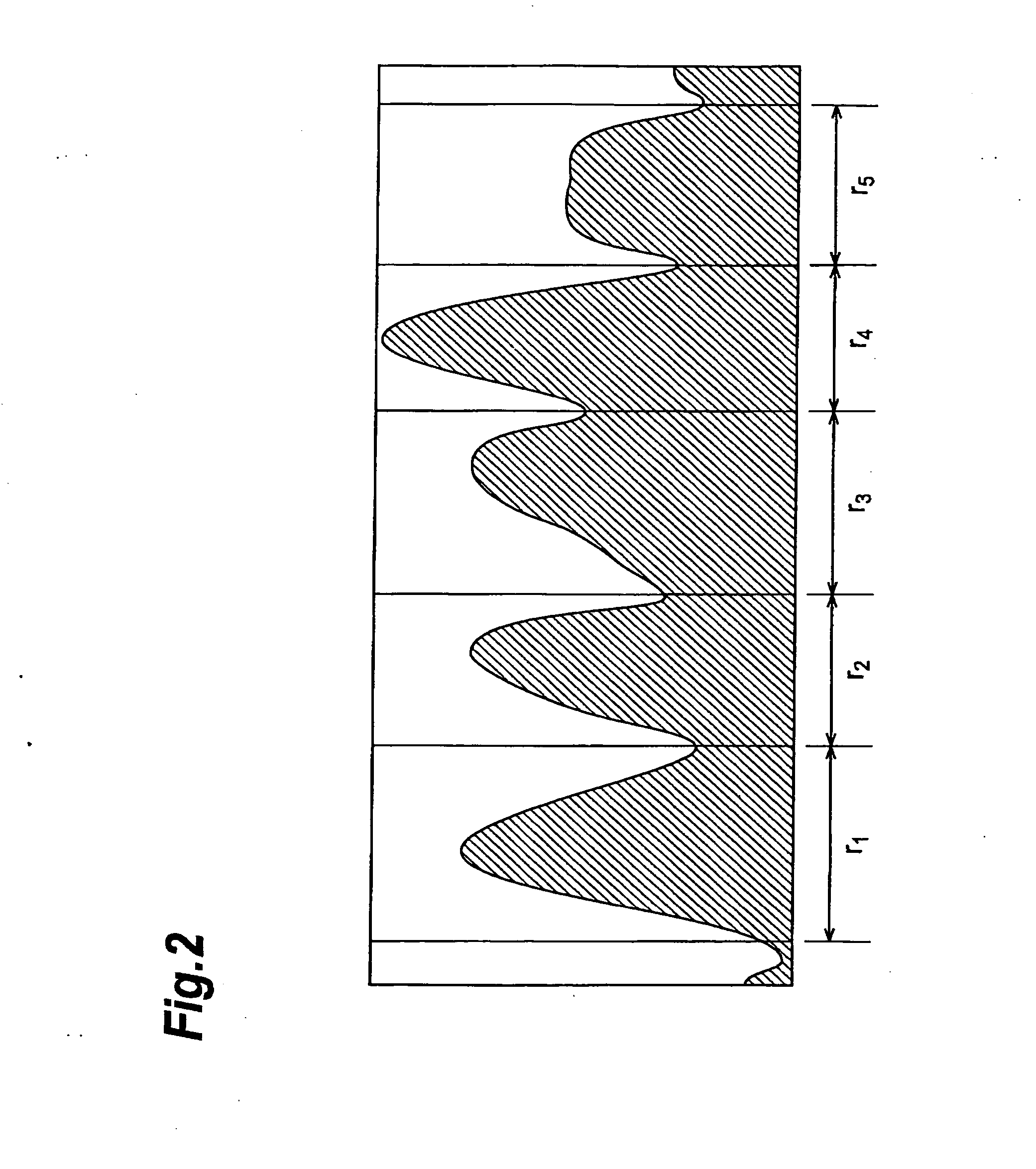

Diffusion Furnaces Employing Ultra Low Mass Transport Systems and Methods of Wafer Rapid Diffusion Processing

InactiveUS20120269226A1Increase heatAccurate temperatureCharge supportsSemiconductor/solid-state device manufacturingTransport systemEngineering

Multi-zone, solar cell diffusion furnaces having a plurality of radiant element (SiC) or / and high intensity IR lamp heated process zones, including baffle, ramp-up, firing, soaking and cooling zone(s). The transport of solar cell wafers, e.g., silicon, selenium, germanium or gallium-based solar cell wafers, through the furnace is implemented by use of an ultra low-mass, wafer transport system comprising laterally spaced shielded, synchronously driven, metal bands or chains carrying non-rotating alumina tubes suspended on wires between them. The wafers rest on raised circumferential standoffs spaced laterally along the alumina tubes, which reduces contamination. The high intensity IR flux rapidly photo-radiation conditions the wafers so that diffusion occurs>3× faster than conventional high-mass thermal furnaces. Longitudinal side wall heaters comprising coil heaters in Inconel sheaths inserted in carrier tubes are employed to insure even heating of wafer edges adjacent the side walls.

Owner:TP SOLAR OF USA

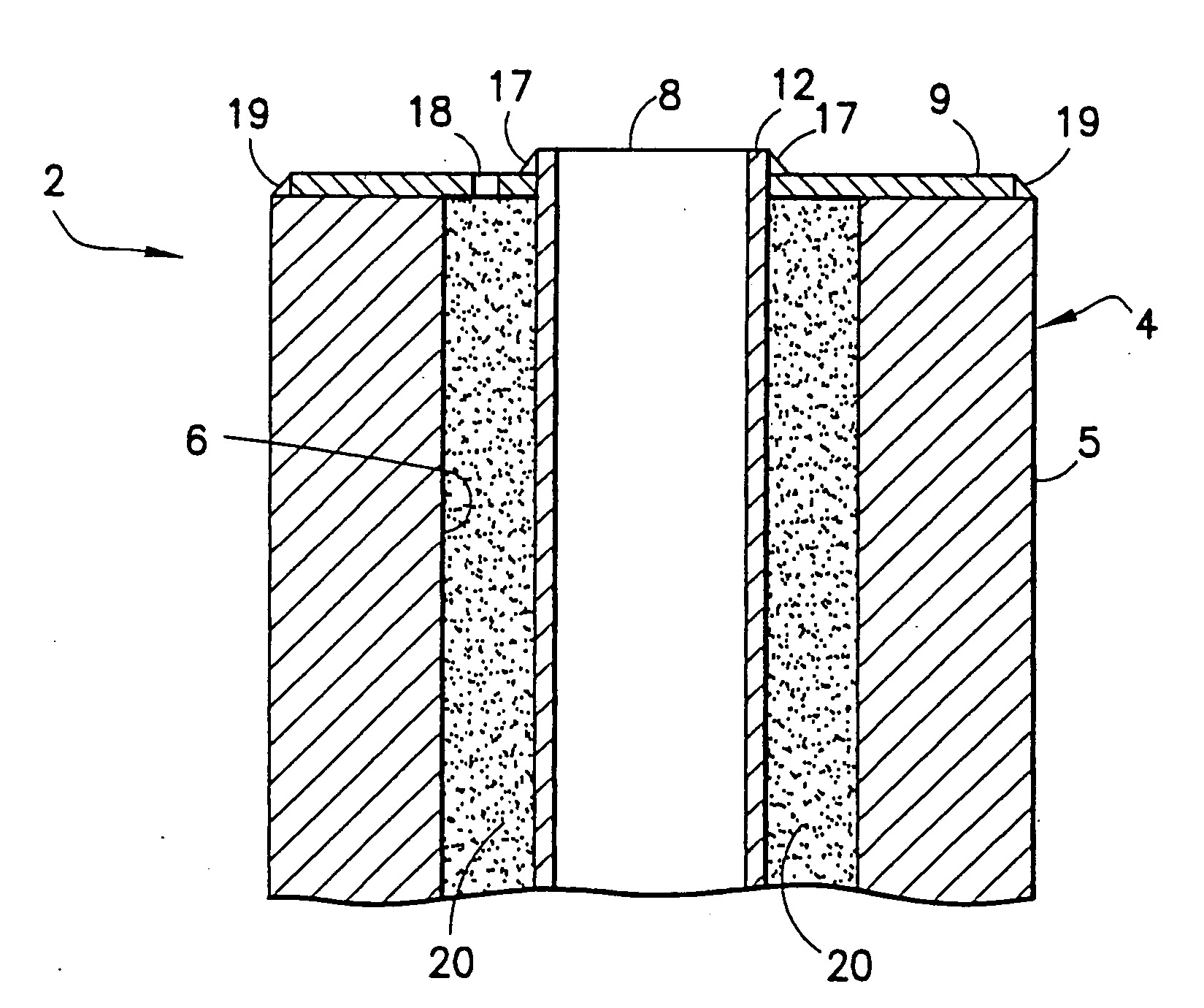

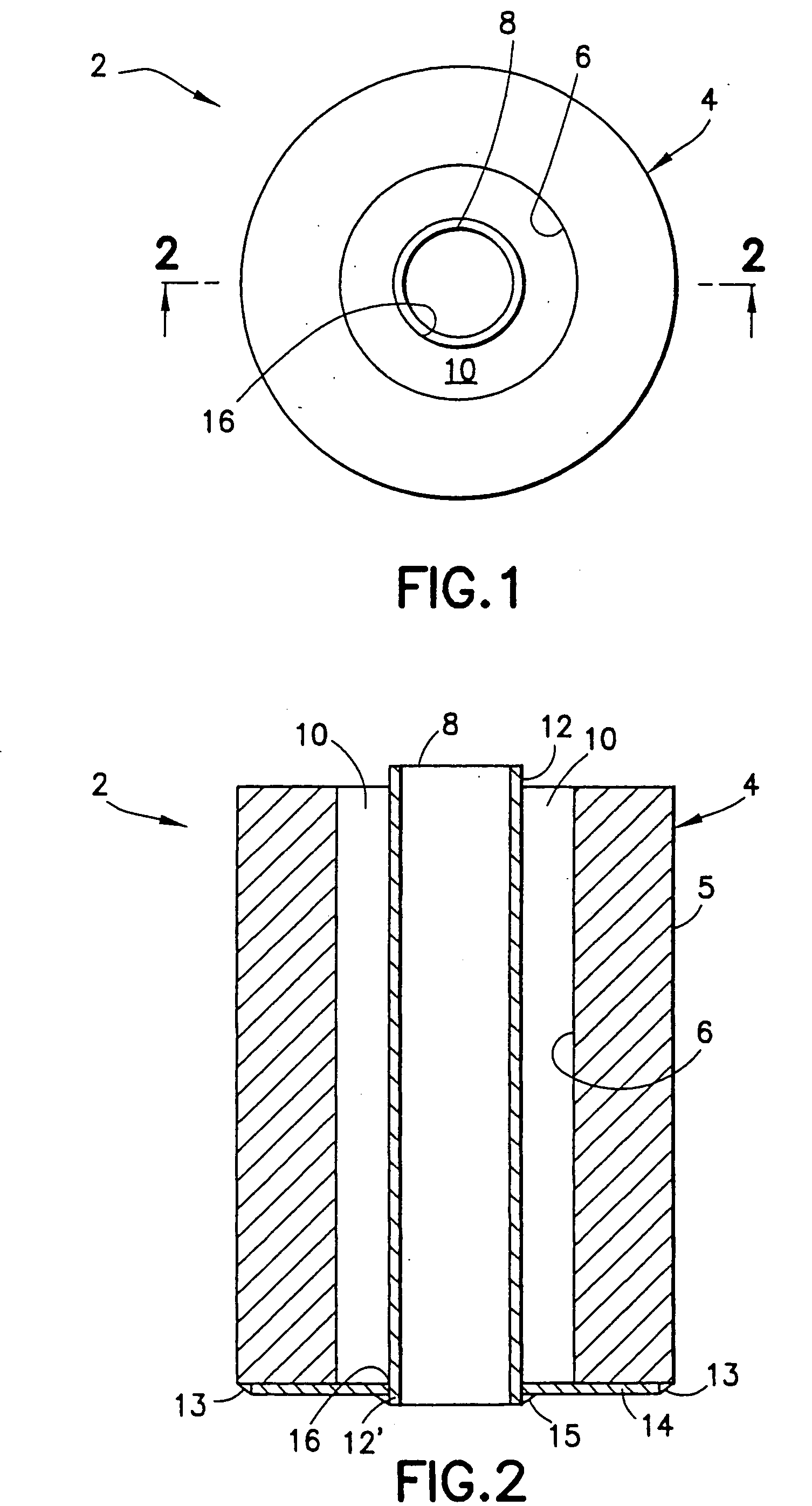

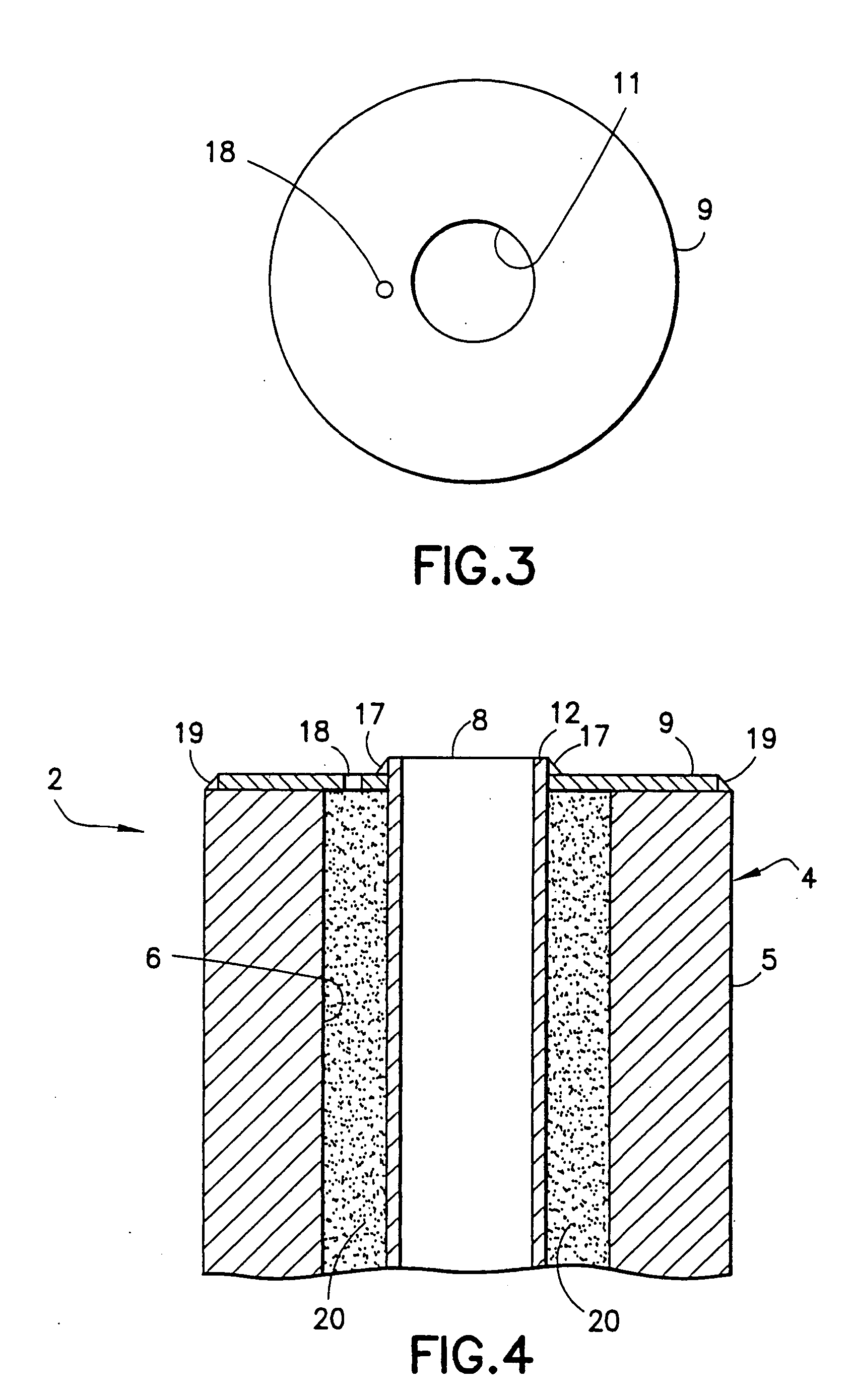

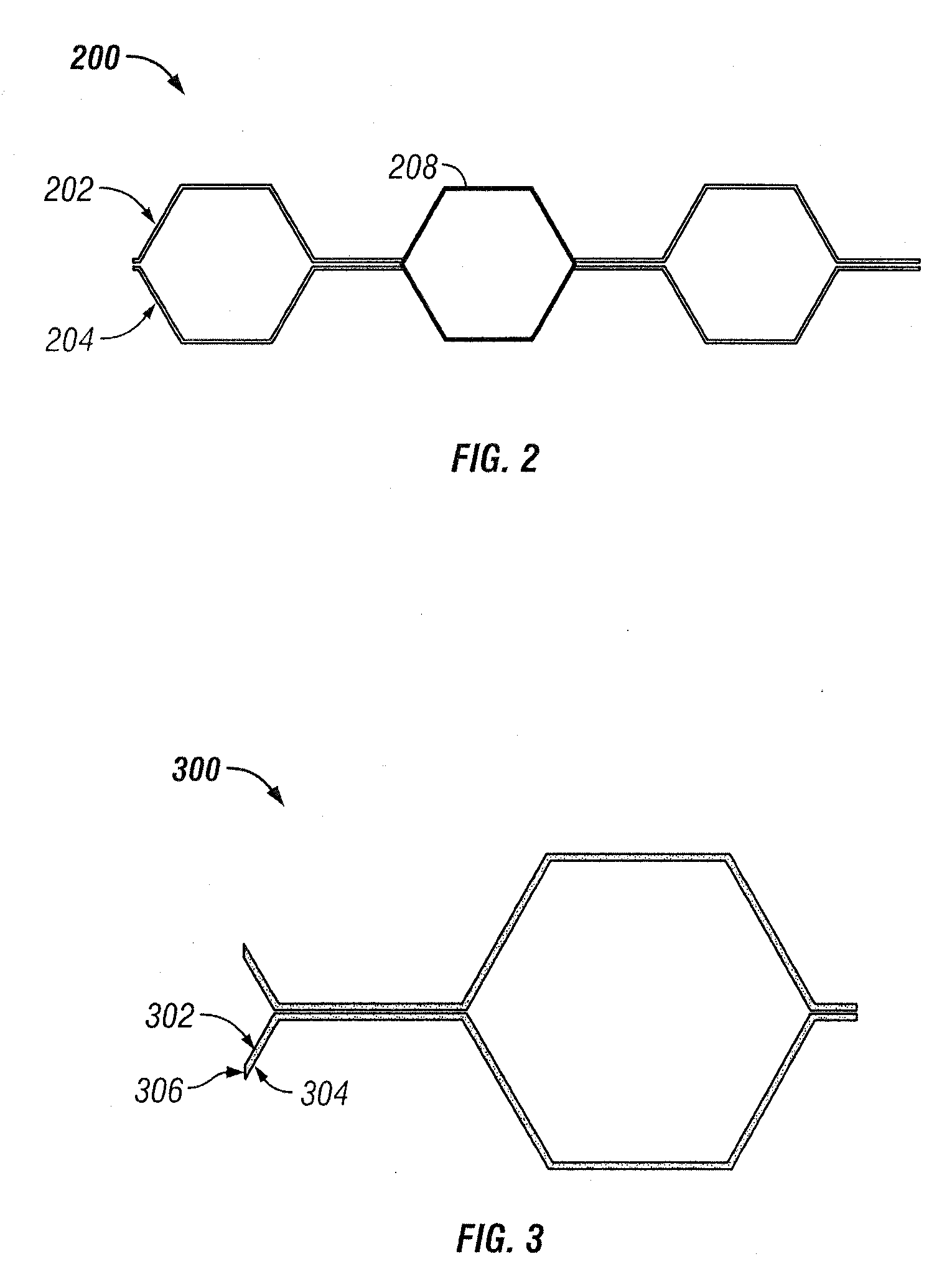

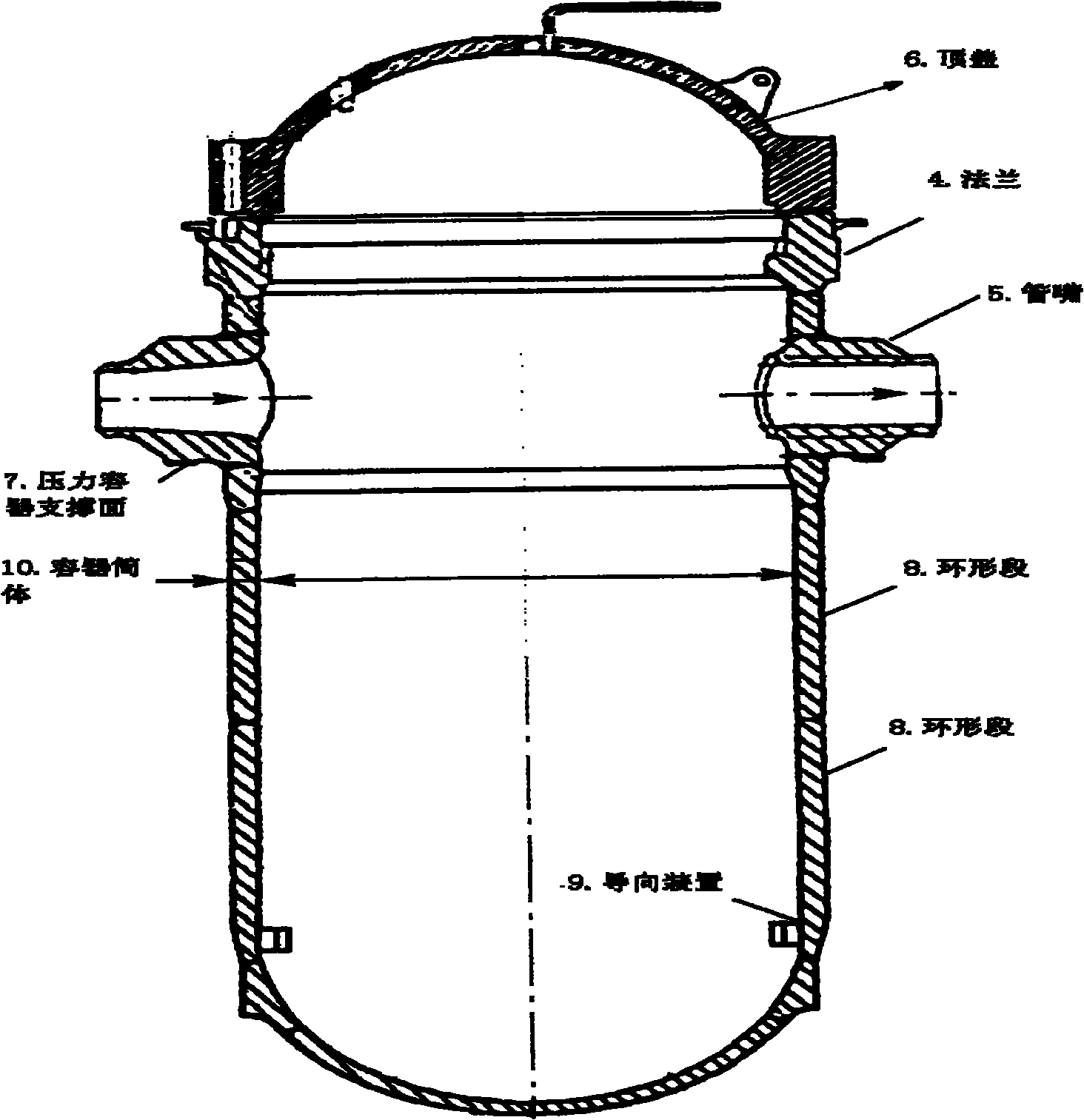

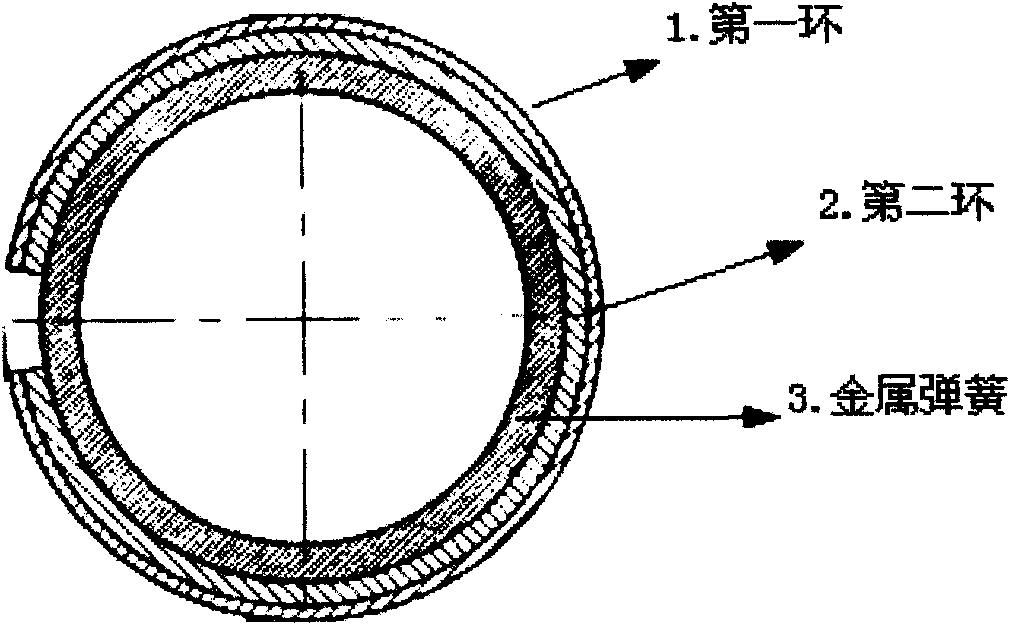

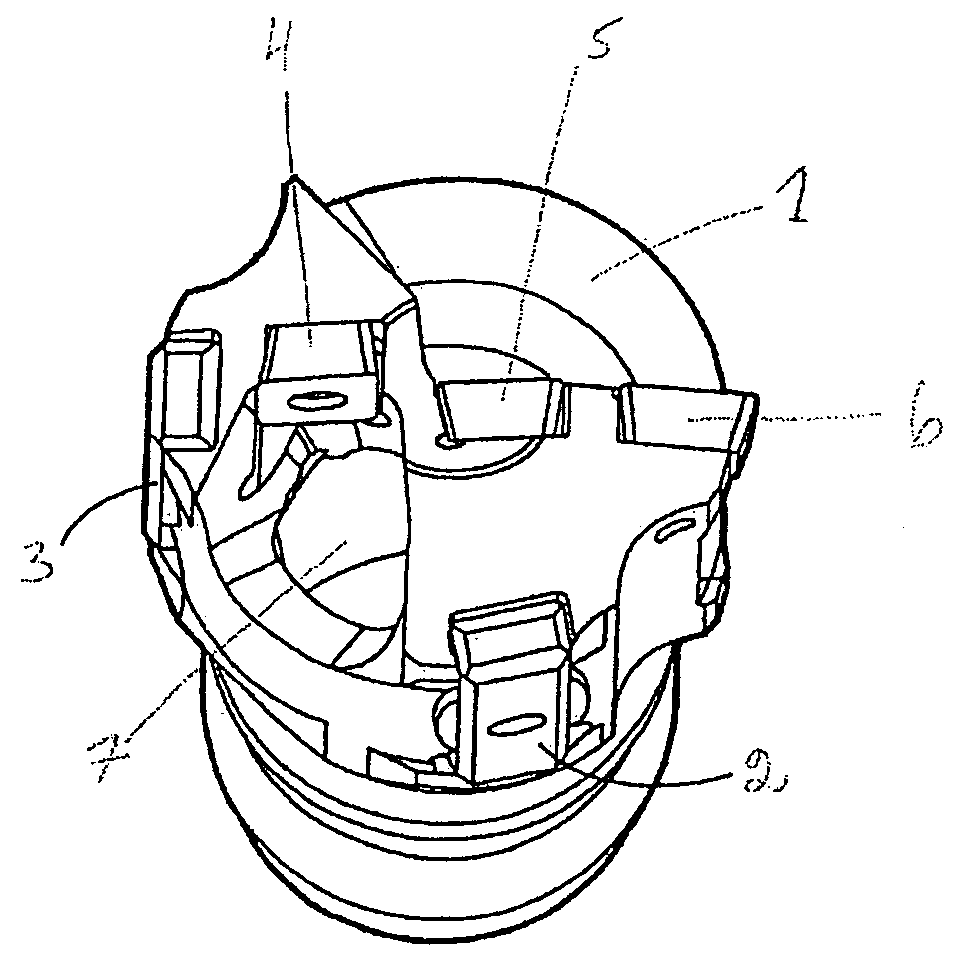

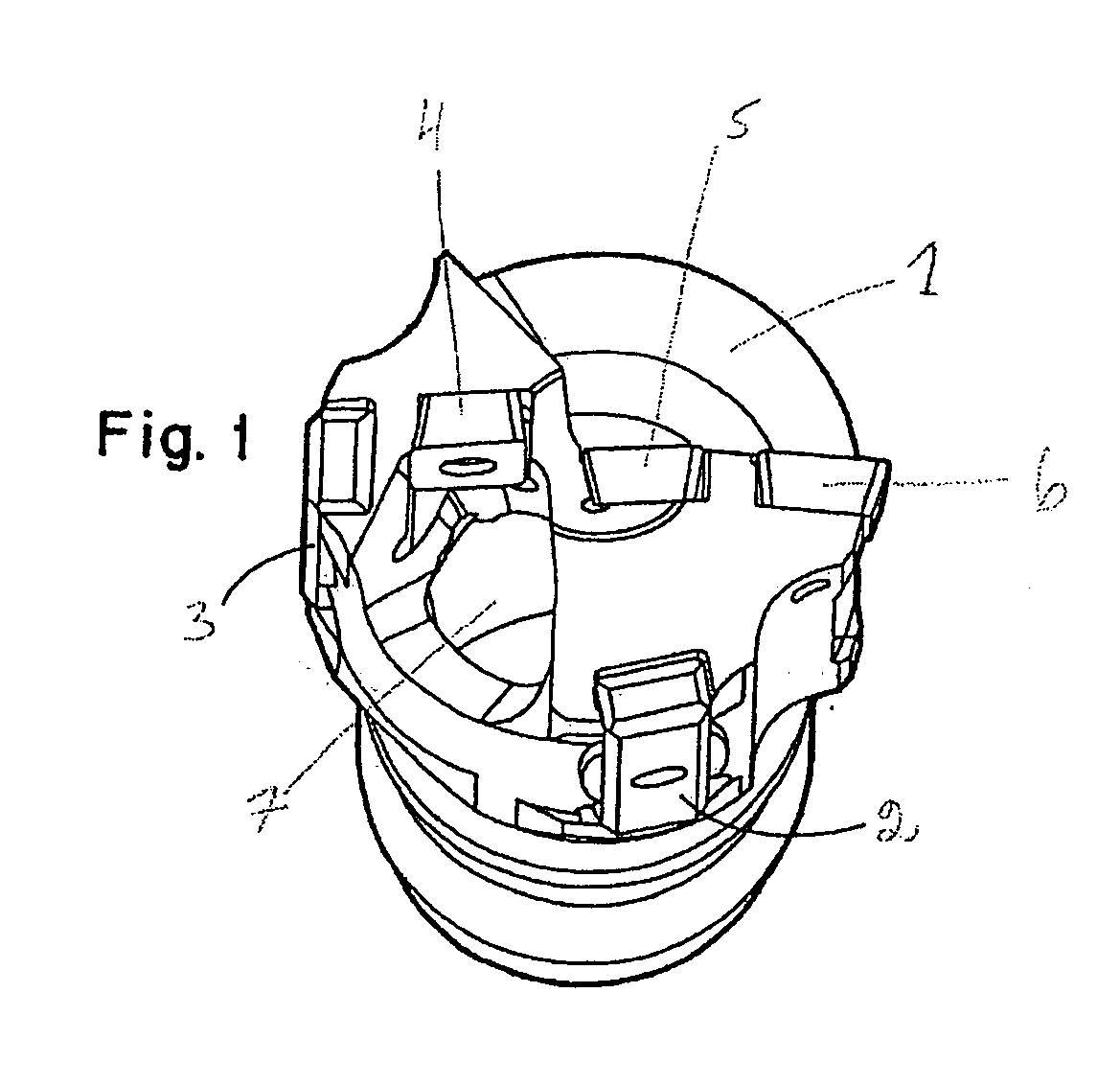

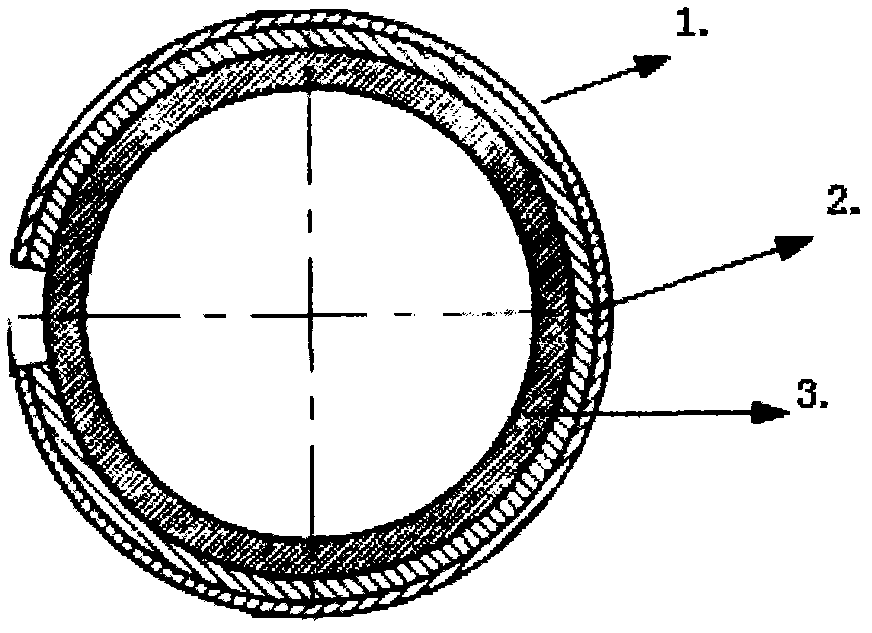

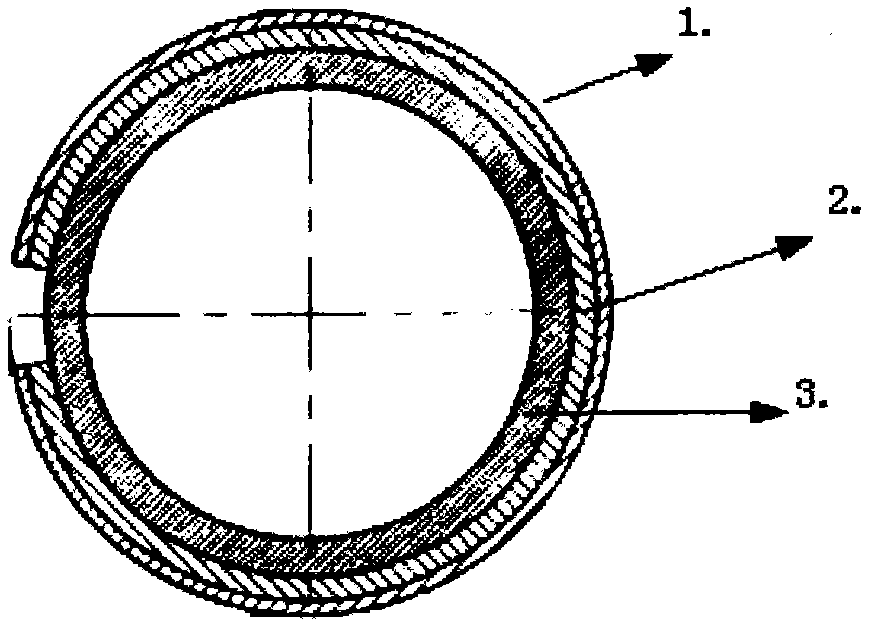

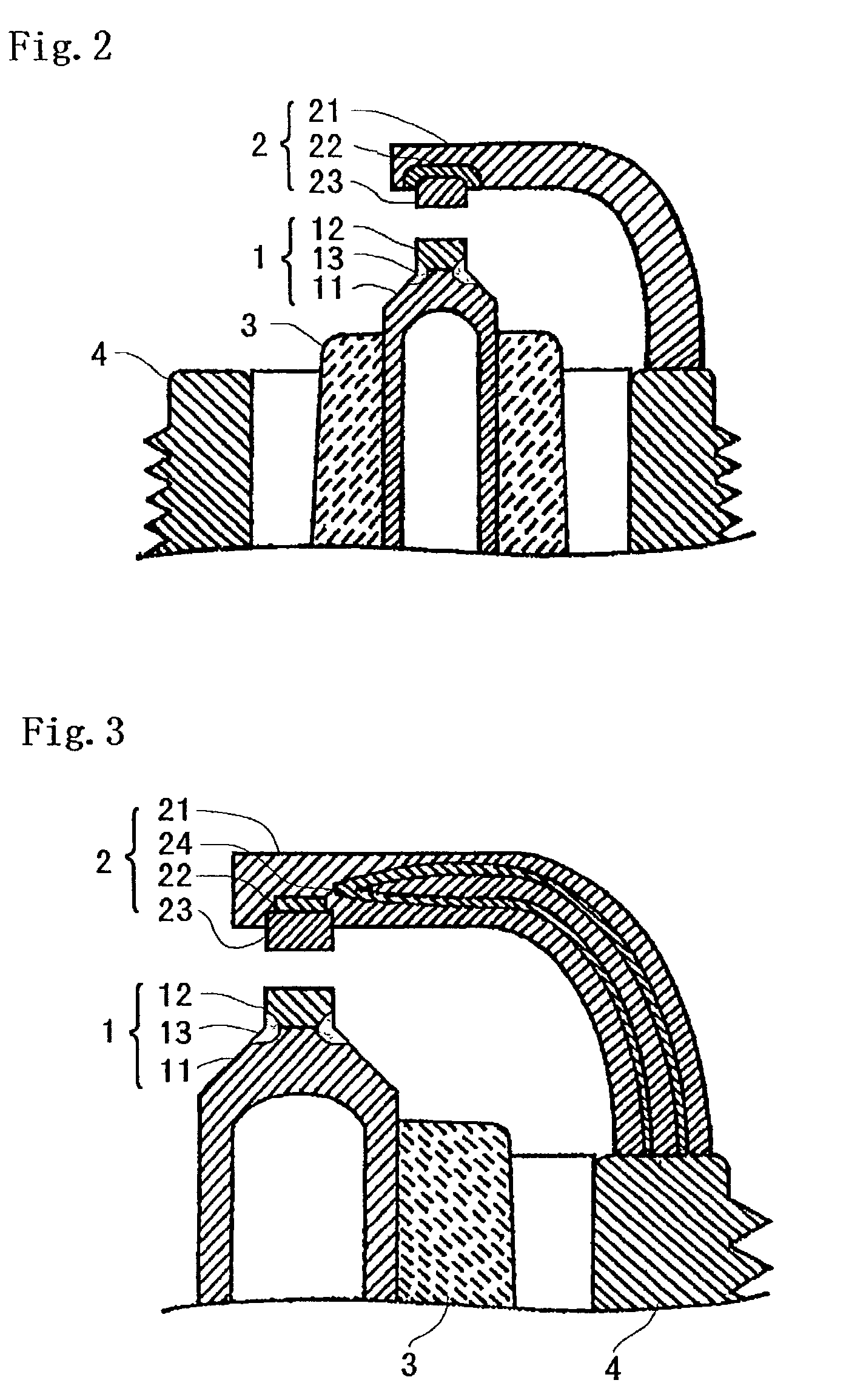

Cladding sealing ring and manufacturing method thereof

The invention discloses a cladding sealing ring and a manufacturing method thereof, wherein the cladding sealing ring consists of three parts of a first ring consisting of inconel 600, a second ring consisting of high purity silver, and a spiral spring which is formed by winding inconel 718 wrapped by the shell of the inconel 600, and an opening is arranged at the peripheral direction of the outside of the sealing ring which is formed by connecting the three parts into a whole body. The section of the ring is of a C shape, and is provided with an outer radial sealing surface and an inner radial sealing surface. When the sealing ring is compressed, each ring of the spiral spring generates an additional bound force to the radial inconel 600, and the high purity silver ring generates plastics deformation, and thereby the minor defect of the sealing surface of a flange is made up. The elastic and plastic combination makes the metal sealing ring have good sealing performance and the capability of compensating the flange deformation and sealing ring looseness caused by temperature and pressure fluctuation.

Owner:NINGBO TIANSHENG SEALING PACKING

Support pads for drill heads

InactiveUS20060045640A1Strong and durableDurable and strongDrilling/boring measurement devicesThread cutting machinesInconelWaspaloy

The present invention relates to a drill head comprising one or more support pads. According to the invention at least one support pad is made of a ceramic material. Such a support pad is particularly useful when drilling in heat resistant materials such as Inconel 718, Inconel 939, Waspaloy, Udimet 720, etc.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

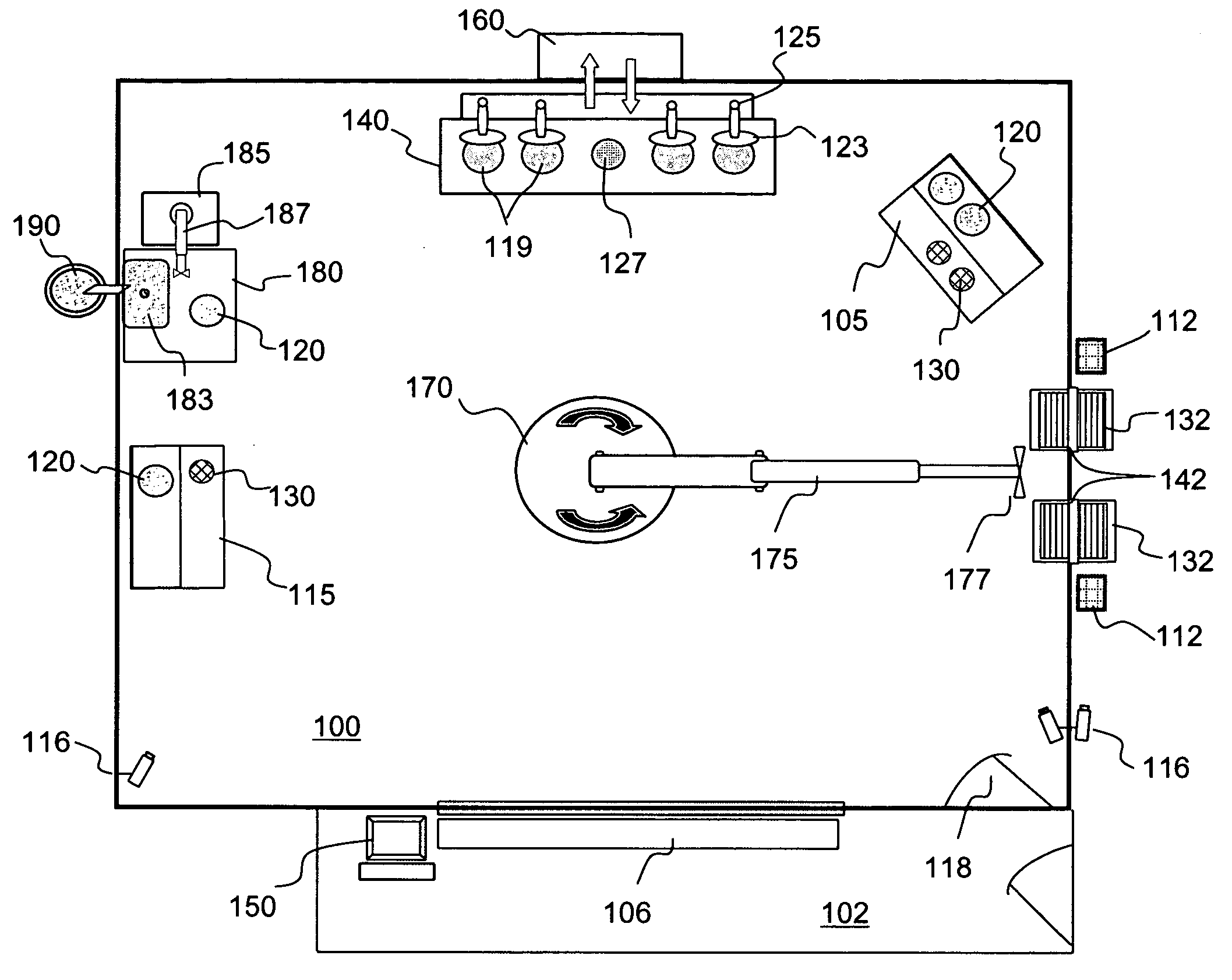

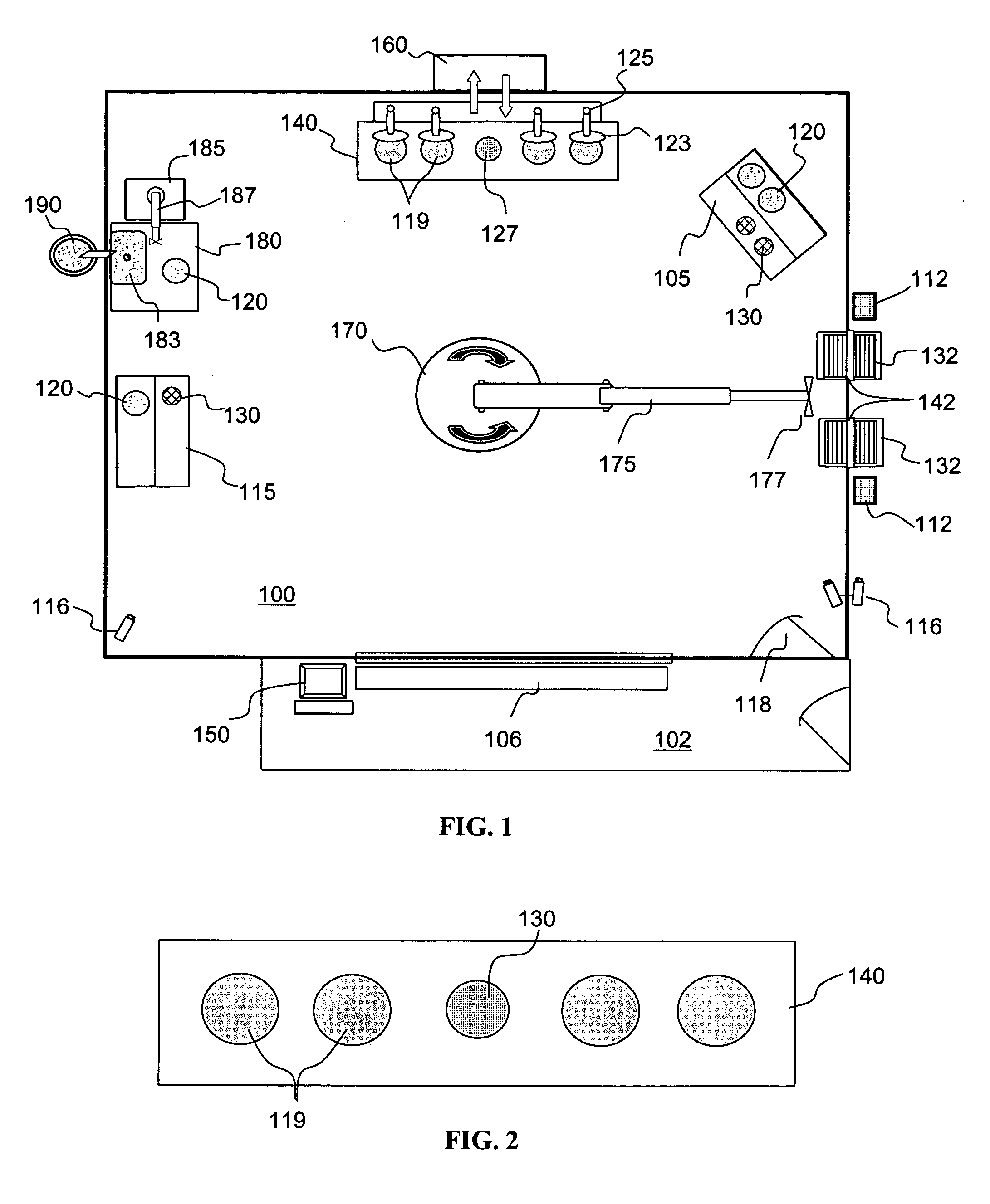

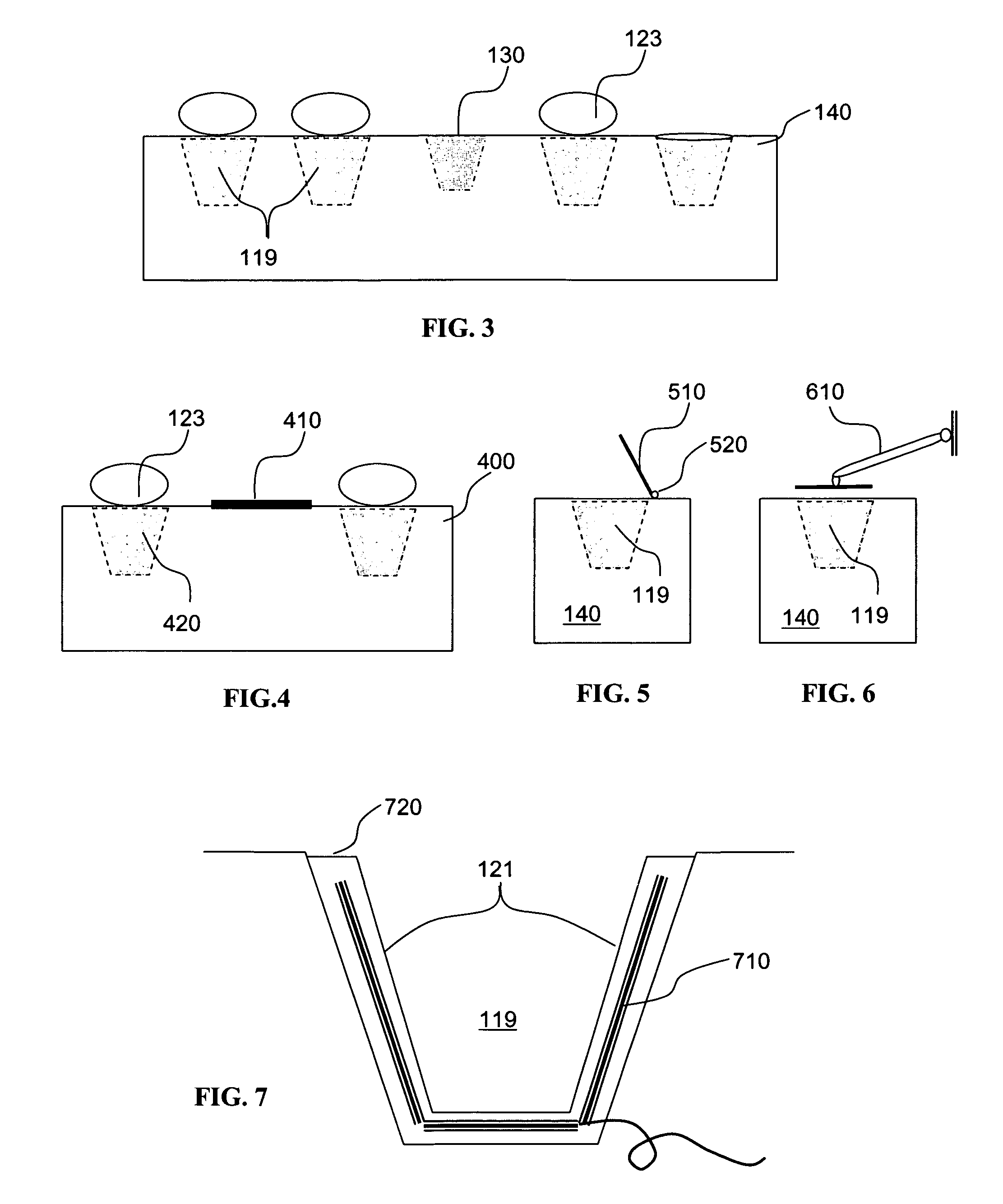

Automated mineral processing systems and methods

InactiveUS20050102061A1Maximum safetyResolved quickly and easilyProgramme-controlled manipulatorComputer controlChemical treatmentEngineering

Mineral processing system performs product movement and processing within a secured room using robotics and computerized automation. A heated chemical processing well provides a hot bath wherein raw mineral is submersed into a separating agent. Used separating agent and residual mineral waste can be automatically disposed of at a chemical dumping station. New separating agent can be automatically loaded into hot baths. Crucibles contain separating agent during mineral processing, and can be used to transport waste from the processing station to the dumping station. A mineral basket can transport and contain mineral during processing. Crucibles and baskets can be made of Inconel, stainless steel, or other material suitable for high temperature processing. A lid / cover includes transducers (e.g., thermal, liquid level) for monitoring processing operations within the well. A separating material delivery port and a vent integrated with the lid / cover that can be used to collect and contain harmful vapors.

Owner:LENT JOHN H

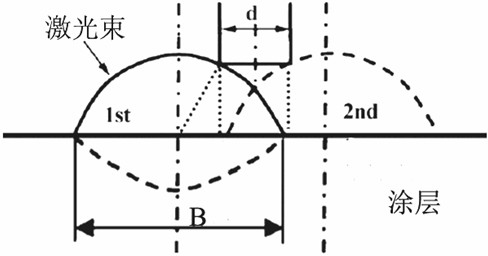

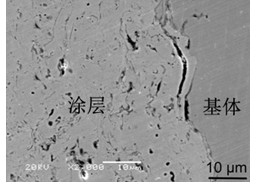

Preparation method for inconel alloy based self-lubricating corrosion and wear resistant coating

InactiveCN102424943AFulfill the needs of serviceTightly boundMolten spray coatingCoated surfaceThermal spraying

The invention discloses a preparation method for an inconel alloy based self-lubricating corrosion and wear resistant coating. The method comprises the steps of: spraying Ni-based diamond alloy powder on a matrix so as to obtain a primary coating; scanning the primary coating with a laser beam so as to obtain a final coating. In the invention, through laser scanning treatment, a dense antifriction lubricating oxide film is formed on the coating surface of an inconel alloy workpiece, and the coating is dense and is closely combined with the matrix interface. The method of the invention meets the service demand of the coating in a high wearing and corrosive medium, and the laser scanning treatment also greatly improves its surface hardness. The method of the invention broadens the engineering application scope of thermal spraying coatings, and provides a new method for developing cogeneric high-end products.

Owner:ANHUI TIANYI HEAVY IND

Reactor structural member and method of suppressing corrosion of the same

InactiveUS20060050833A1Simple structurePrevents stress corrosion crackingNuclear energy generationNuclear monitoringHydrogen concentrationNuclear reactor

A photocatalytic substance having the properties of an n-type semiconductor is deposited on a surface of a metal base made of a stainless steel or Inconel. When necessary, the hydrogen concentration of the reactor water is increased. A current produced by the photocatalytic substance when the same is irradiated with light or radioactive rays in a nuclear reactor flows through the metal base to reduce corrosion current. When necessary, the photocatalytic substance is provided on its surface with at least one of Pt, Rh, Ru and Pd.

Owner:KK TOSHIBA

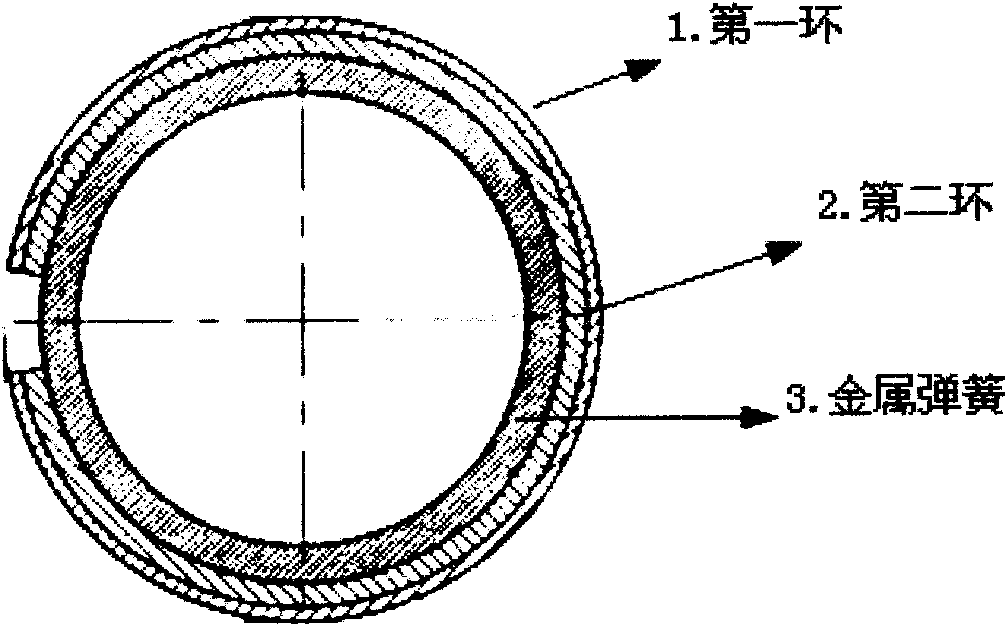

C-shaped cladding sealing ring of built-in spring and manufacturing method thereof

InactiveCN102168757AImprove homogeneityImprove sealingEngine sealsWelding apparatusWhole bodyInconel

The invention discloses a cladding sealing ring of a built-in spring and a manufacturing method thereof, wherein the cladding sealing ring consists of three parts of a first ring consisting of high purity silver, a second ring consisting of inconel 600, and a spiral spring which is formed by winding inconel 750 wrapped by the shell of the inconel 600, and an opening is arranged at the peripheral direction of the outside of the sealing ring which is formed by connecting the three parts into a whole body. The section of the ring is of a C shape, and is provided with an outer radial sealing surface and an inner radial sealing surface. When the sealing ring is compressed, each ring of the spiral spring generates an additional bound force to the radial inconel 600, and the high purity silver ring generates plastics deformation, and thereby the minor defect of the sealing surface of a flange is made up. The elastic and plastic combination enables the metal sealing ring to have good sealing performance and the capability of compensating the flange deformation and sealing ring looseness caused by temperature and pressure fluctuation.

Owner:NINGBO TIANSHENG SEALING PACKING

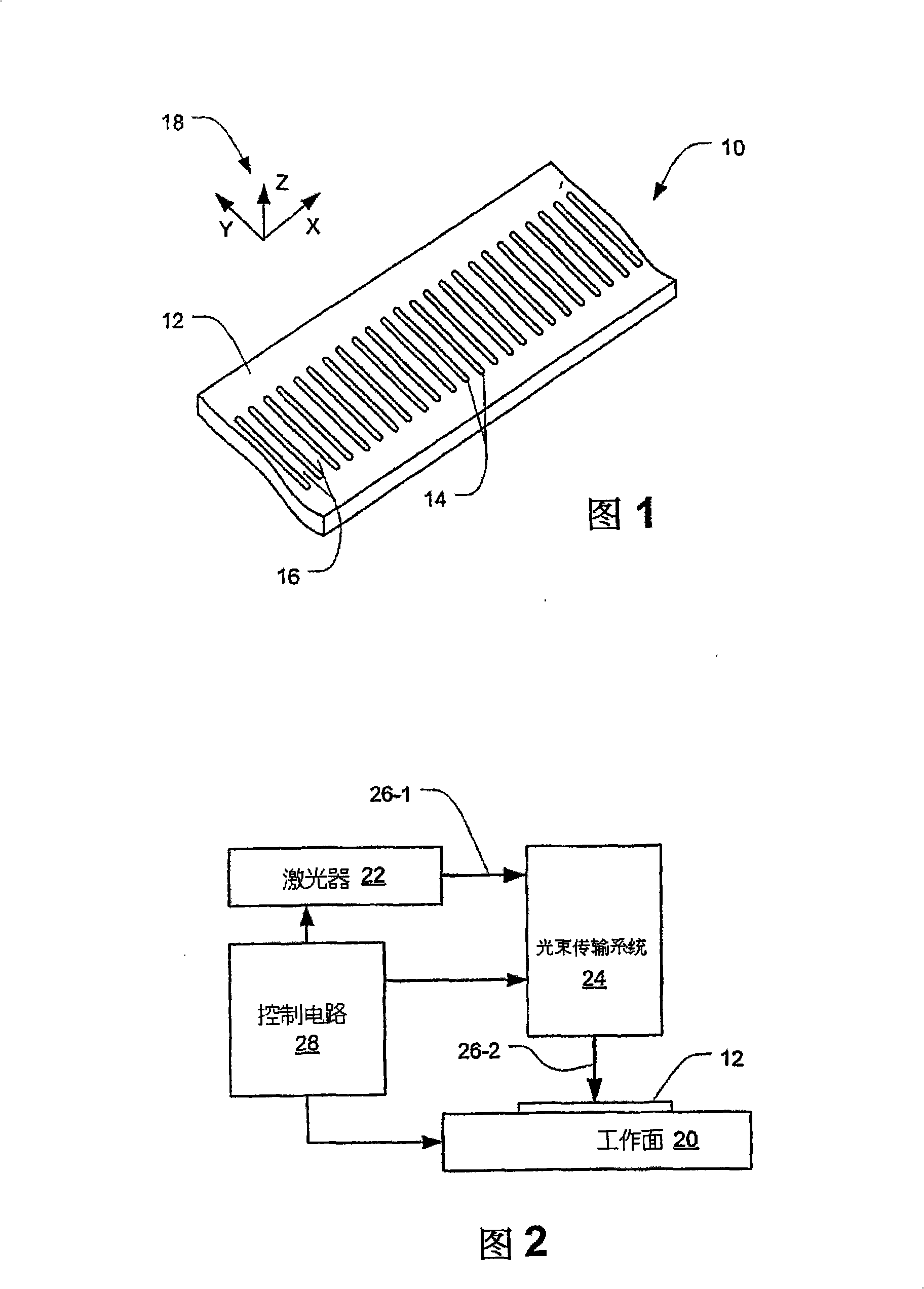

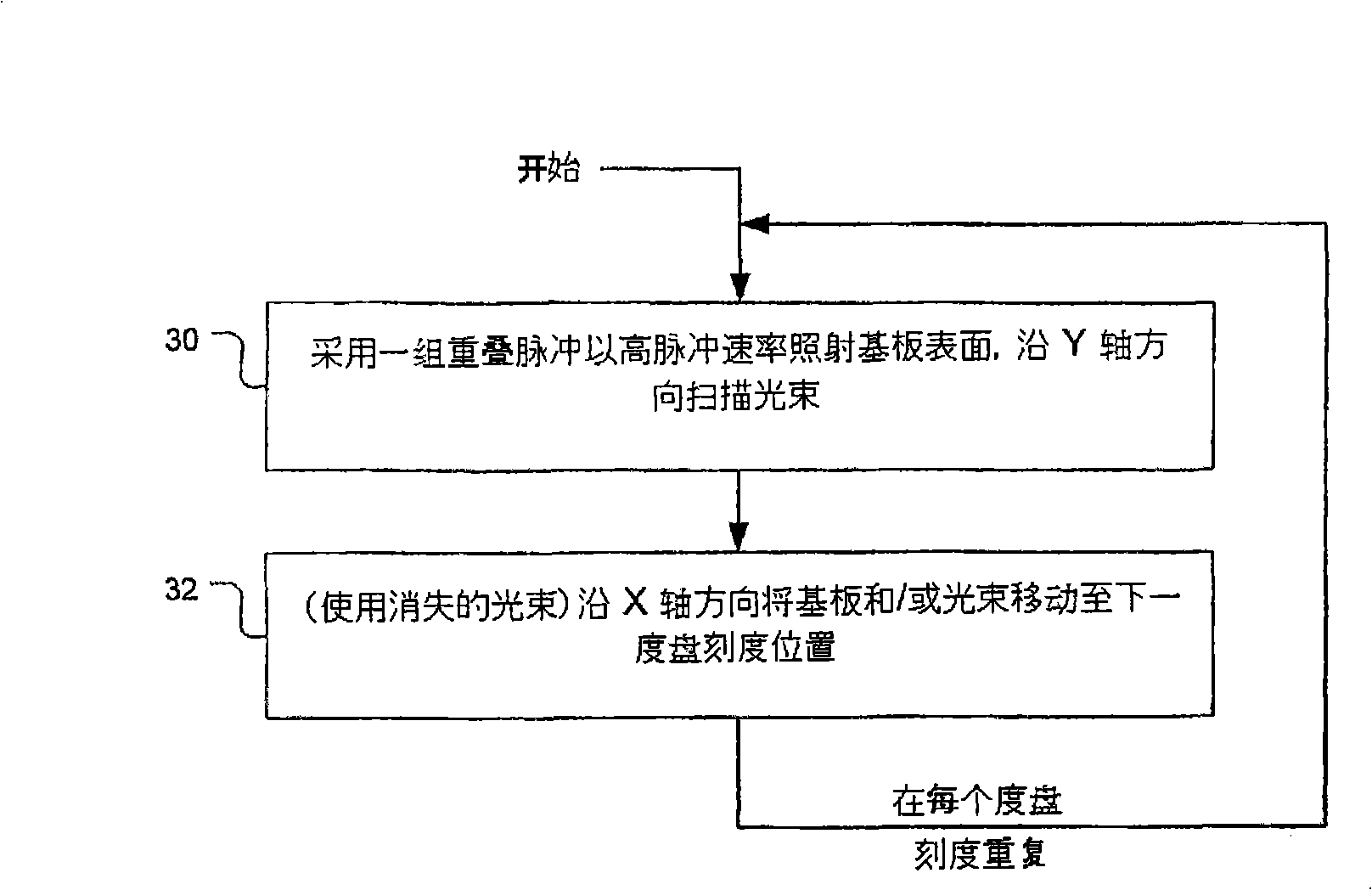

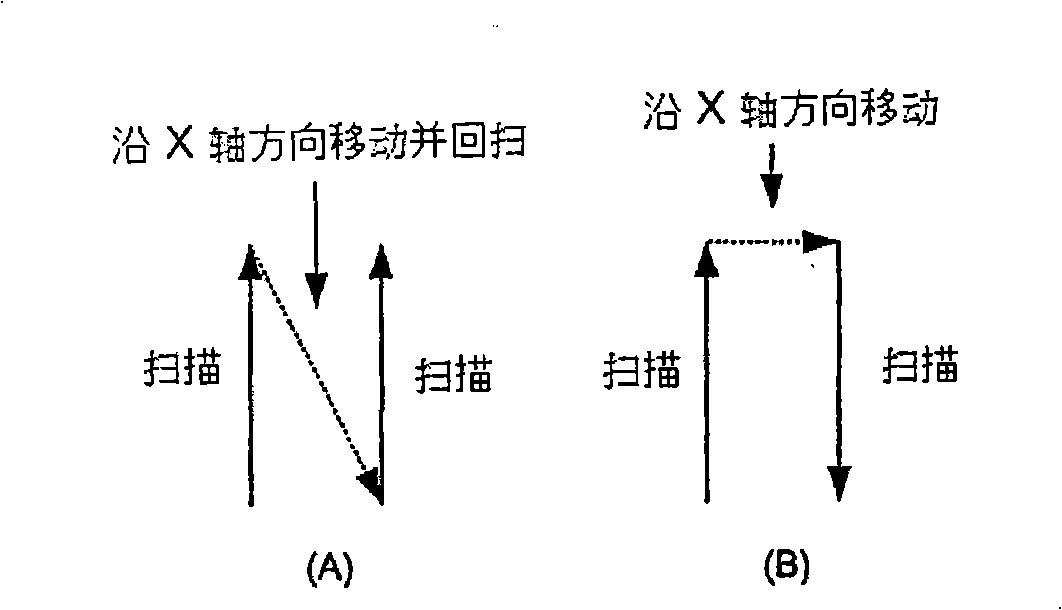

Optical metrological scale and laser-based manufacturing method therefor

InactiveCN101356304AAblative recordingWelding/soldering/cutting articlesOptical reflectionMetal alloy

A reflective metrological scale has a scale pattern of elongated side-by-side marks surrounded by reflective surface areas of a substrate, which may be a nickel-based metal alloy such as Invar TM or Inconel TM and may be a thin and elongated flexible tape. Each mark has a furrowed cross section and may have a depth in the range of 0.5 to 2 microns. The central region of each mark may be rippled or ridged and may be darkened to provide an enhanced optical reflection ratio with respect to surrounding reflective surface areas. A manufacturing method includes the repeated steps of (1) creating a scale mark by irradiating a surface of the substrate at a mark location with a series of overlapped pulses from a laser, each pulse having an energy density of less than about 1 joule per cm<2>, and (2) changing the relative position of the laser and the substrate by a displacement amount defining a next mark location on the substrate at which a next mark of the scale is to be created.

Owner:THE GSI GRP LLC

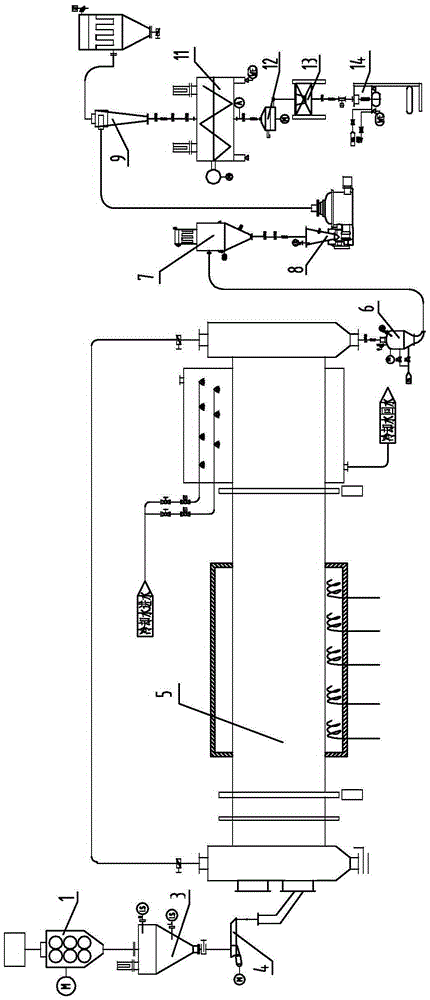

Intelligent production process for lithium battery positive electrode material

ActiveCN105428589AAvoid introducingAvoid stickingElectrode manufacturing processesLi-accumulatorsIron removalMixed materials

The invention discloses an intelligent production process for a lithium battery positive electrode material. The process comprises the following steps of: 1) automatically and accurately proportioning lithium battery positive electrode preparation raw materials and then mixing; 2) enabling the mixed raw materials to enter a rolling granulator for rolling to form elliptic particles; 3) feeding the particles into a rotary furnace for sintering through a vibratory feeder, wherein the inner wall of the rotary furnace is made from a Cr-Ni-Fe alloy with a designation of Inconel 602 or the inner surface of the inner wall of the rotary furnace is welded and covered with a ceramic sheet; 4) enabling the sintered material to enter a mechanical grinder or a jet mill for grinding; 5) enabling the ground fine material to enter a batch mixing device for mixing; and 6) finally enabling the mixed material to enter an automatic packaging system for packaging after passing through a screening device and an electromagnetic iron removal machine. According to the process, the continuous rotary furnace is adopted, so that the sintering capacity is greatly increased; and by adding a process step of rolling before sintering, the positive electrode material powder is made into the elliptic particles, so that the material can be prevented from being adhered to the wall during sintering.

Owner:JIANGSU NDZ LITHIUM INTELLIGENT EQUIP

Method for preparing inconel by using heavy metal sludge

The invention belongs to the reutilization field of heavy metal sludge and particularly relates to a method for preparing inconel by using heavy metal sludge. The method comprises the following steps: mixing stainless steel sludge, electroplating sludge, chrome sludge and fly ash generated in the production process of inconel with laterite-nickel ore, predrying, carrying out reduction roasting and smelting to finally obtain inconel. In the whole production process, fly ash and smelting slag are both recyclable, thereby avoiding secondary pollution, saving resources and energy to the greatest extent, lowering the production cost and further achieving remarkable economic benefit.

Owner:FUJIAN NONNON RENEWABLE RESOURCES TECH

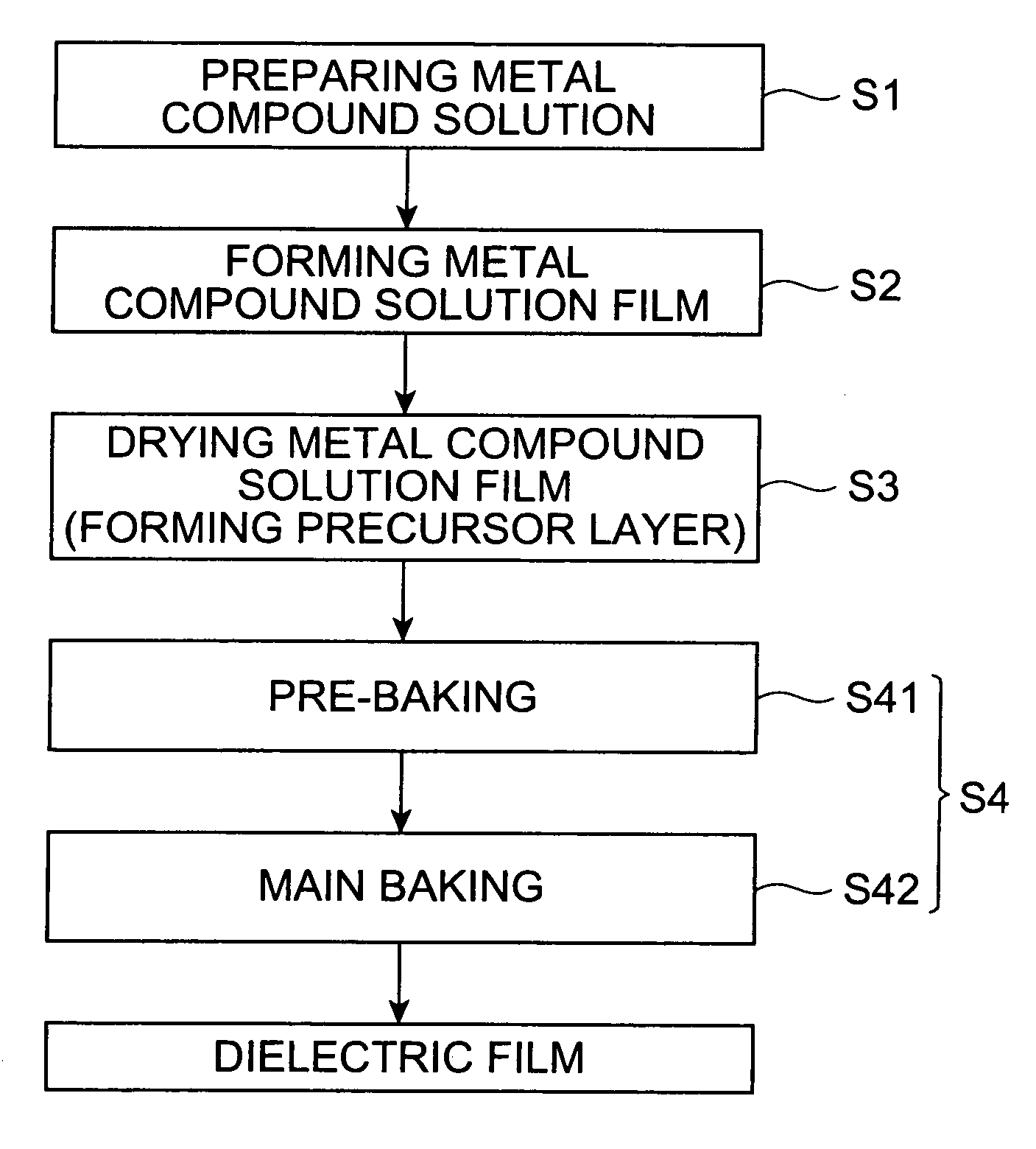

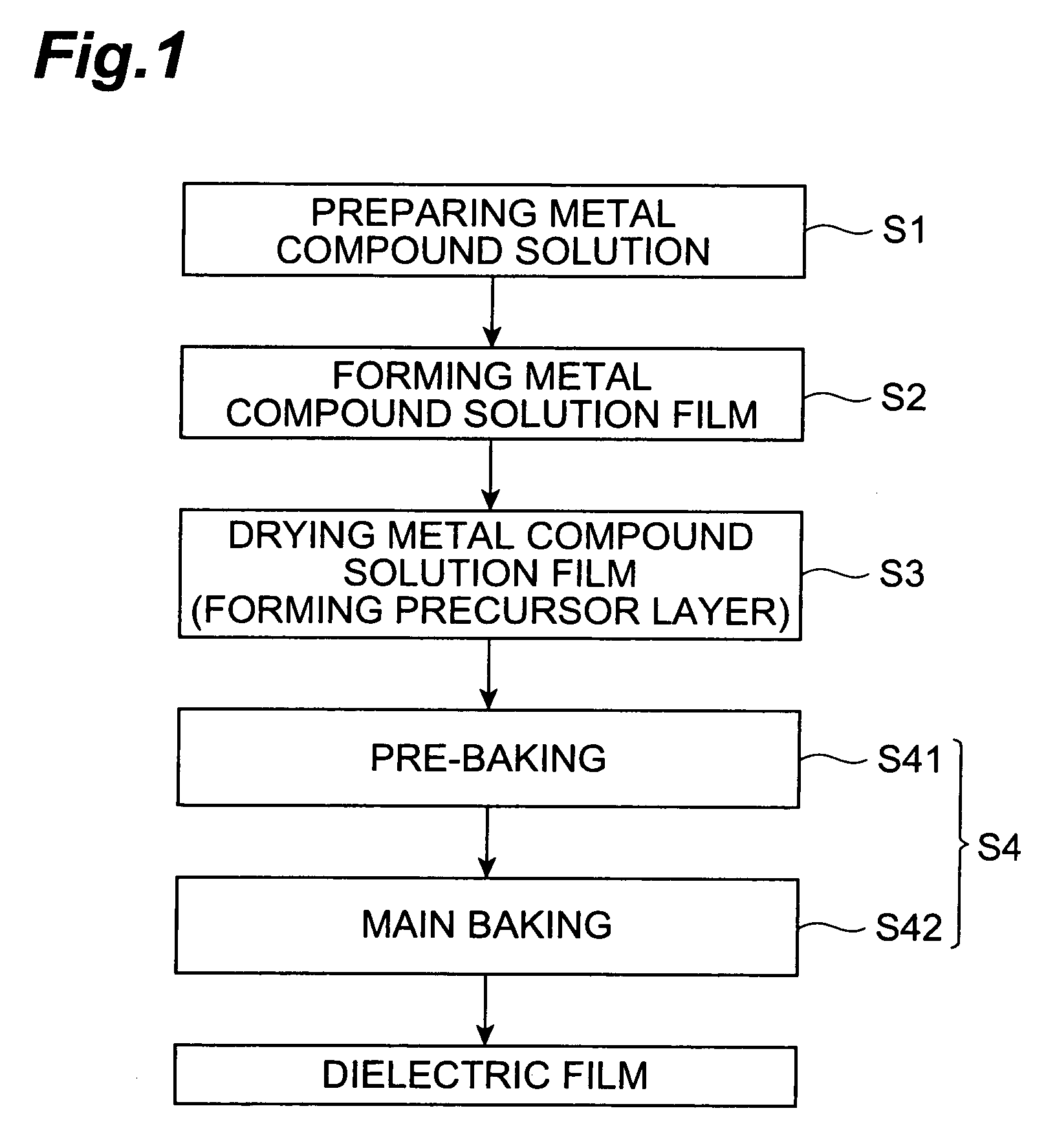

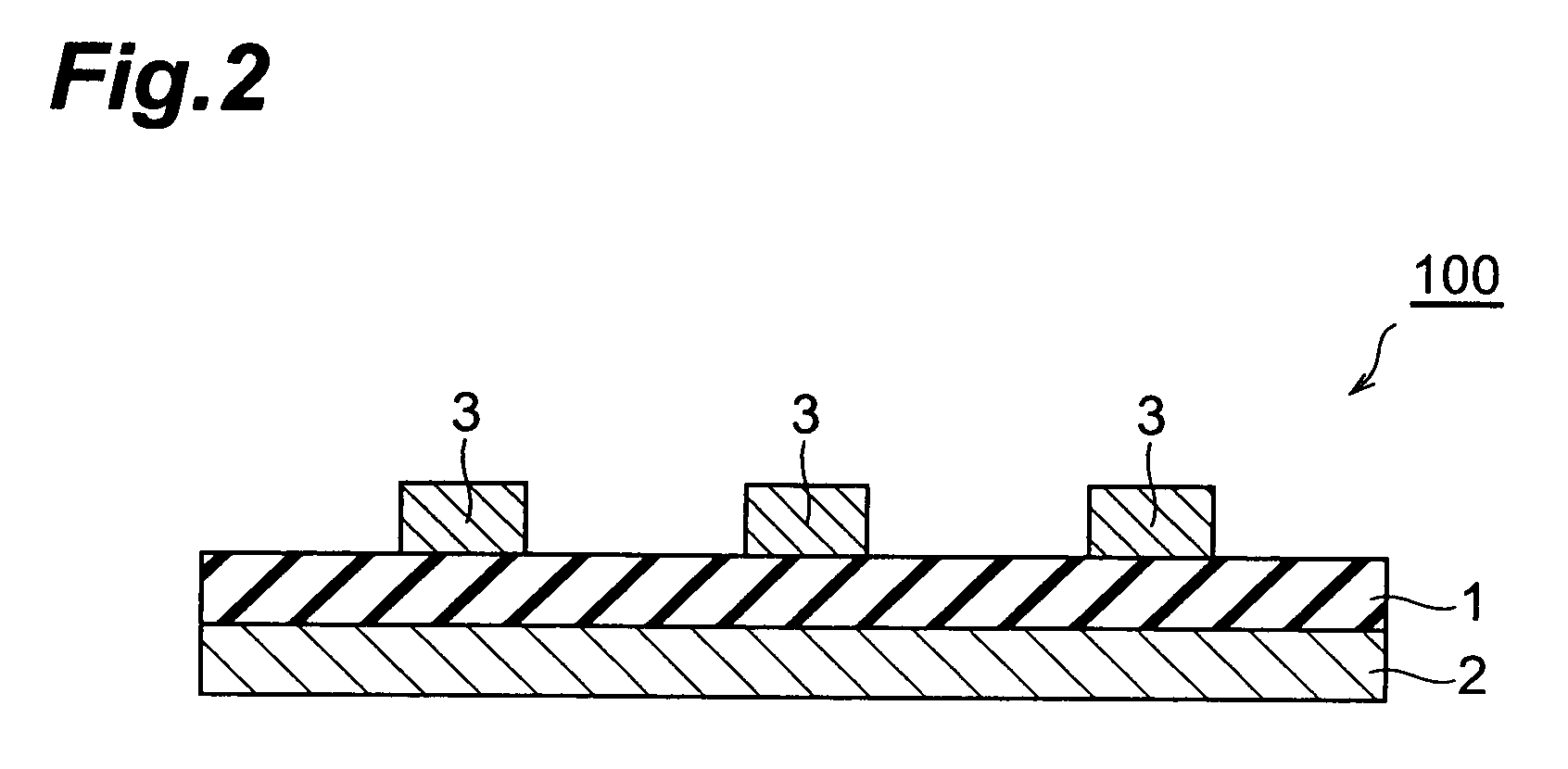

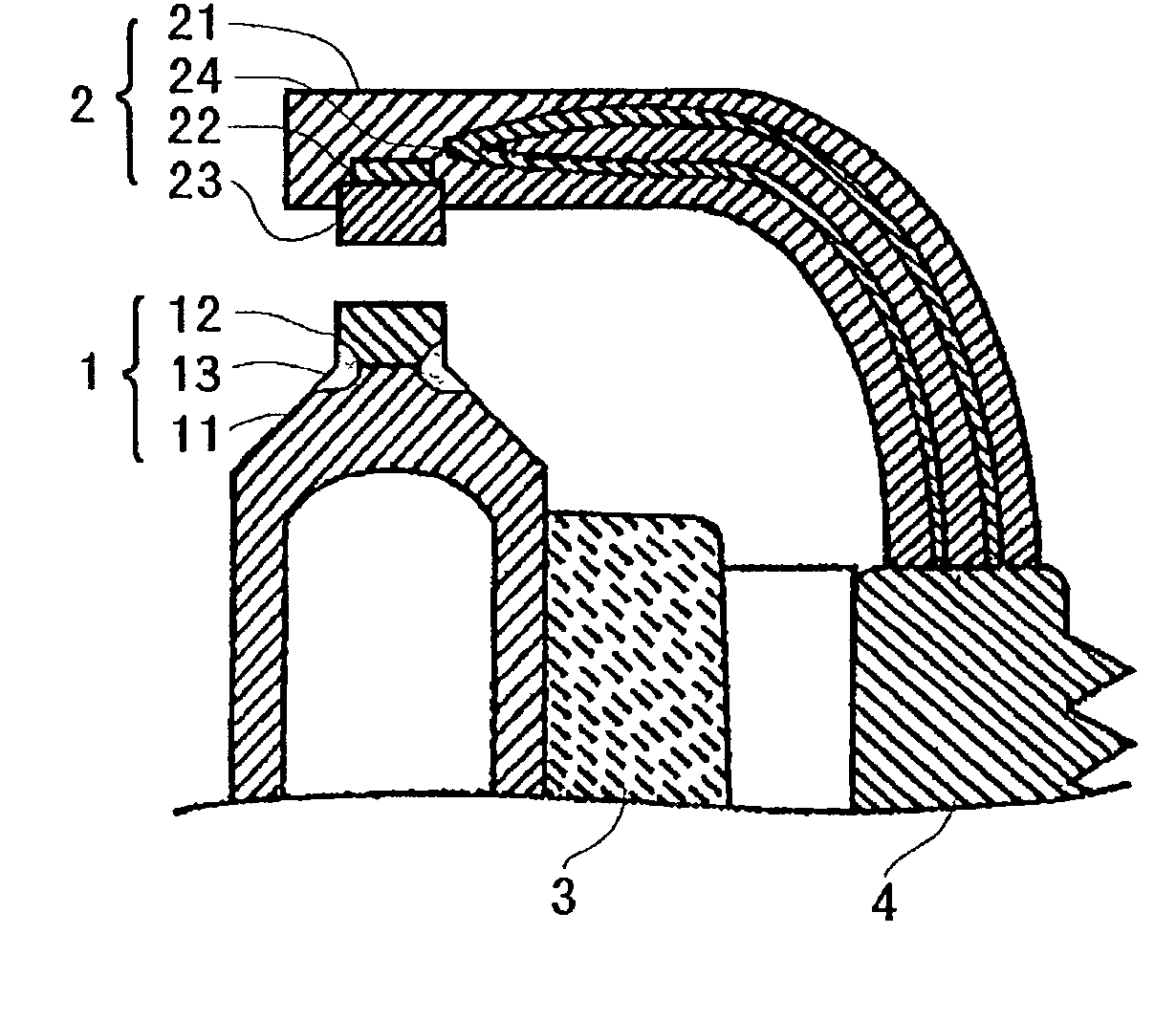

Dielectric film and process for its fabrication

ActiveUS20070049026A1High dielectric constantExcellent leak characteristicSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingMetallurgyInconel

A dielectric film production process comprising a baking step in which a dielectric film is formed by heating a precursor layer formed on a metal layer, wherein the metal layer contains at least one type of metal selected from the group consisting of Cu, Ni, Al, stainless steel and inconel, and during at least part of the baking step the precursor layer is heated in a reduced pressure atmosphere.

Owner:TDK CORPARATION

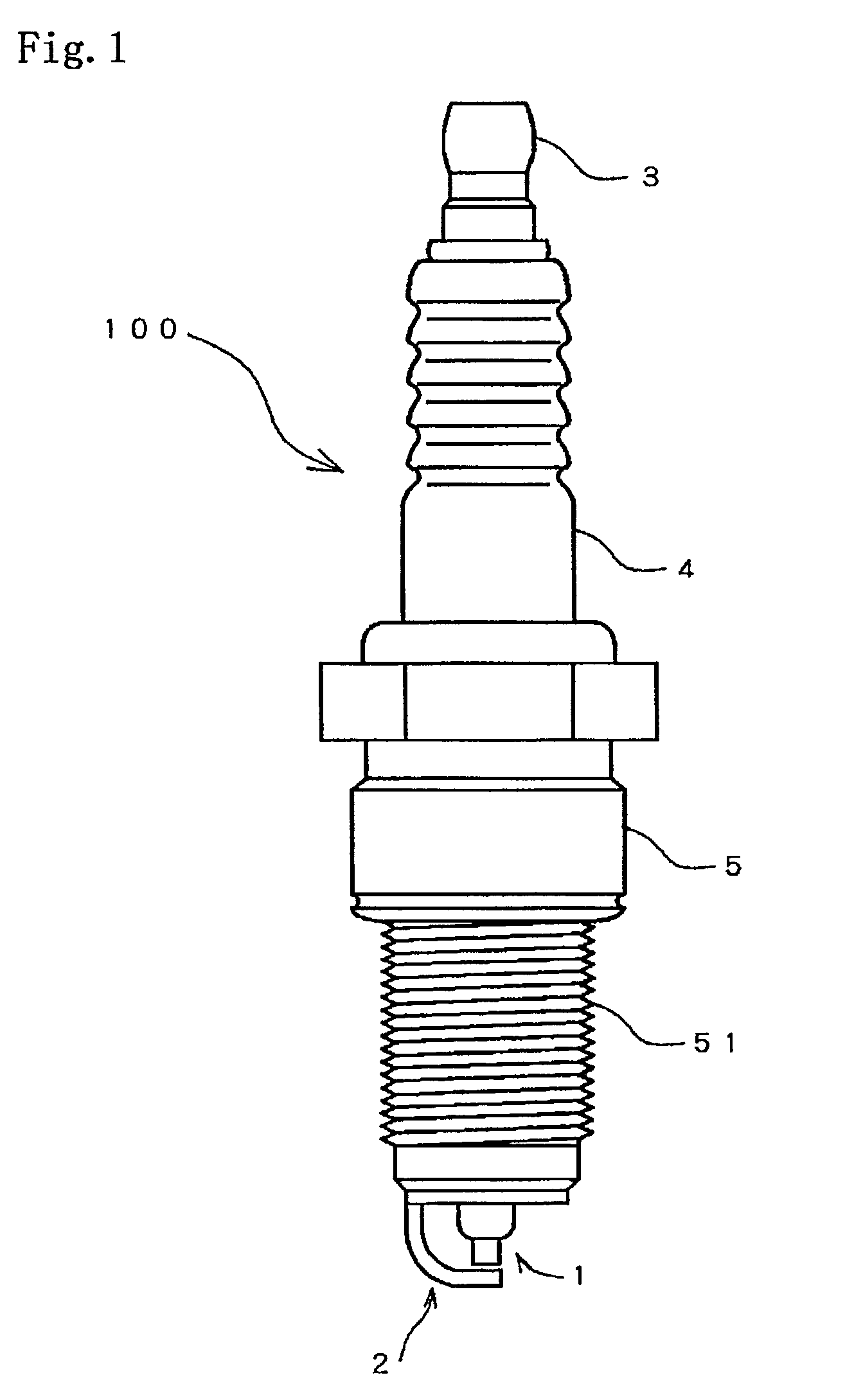

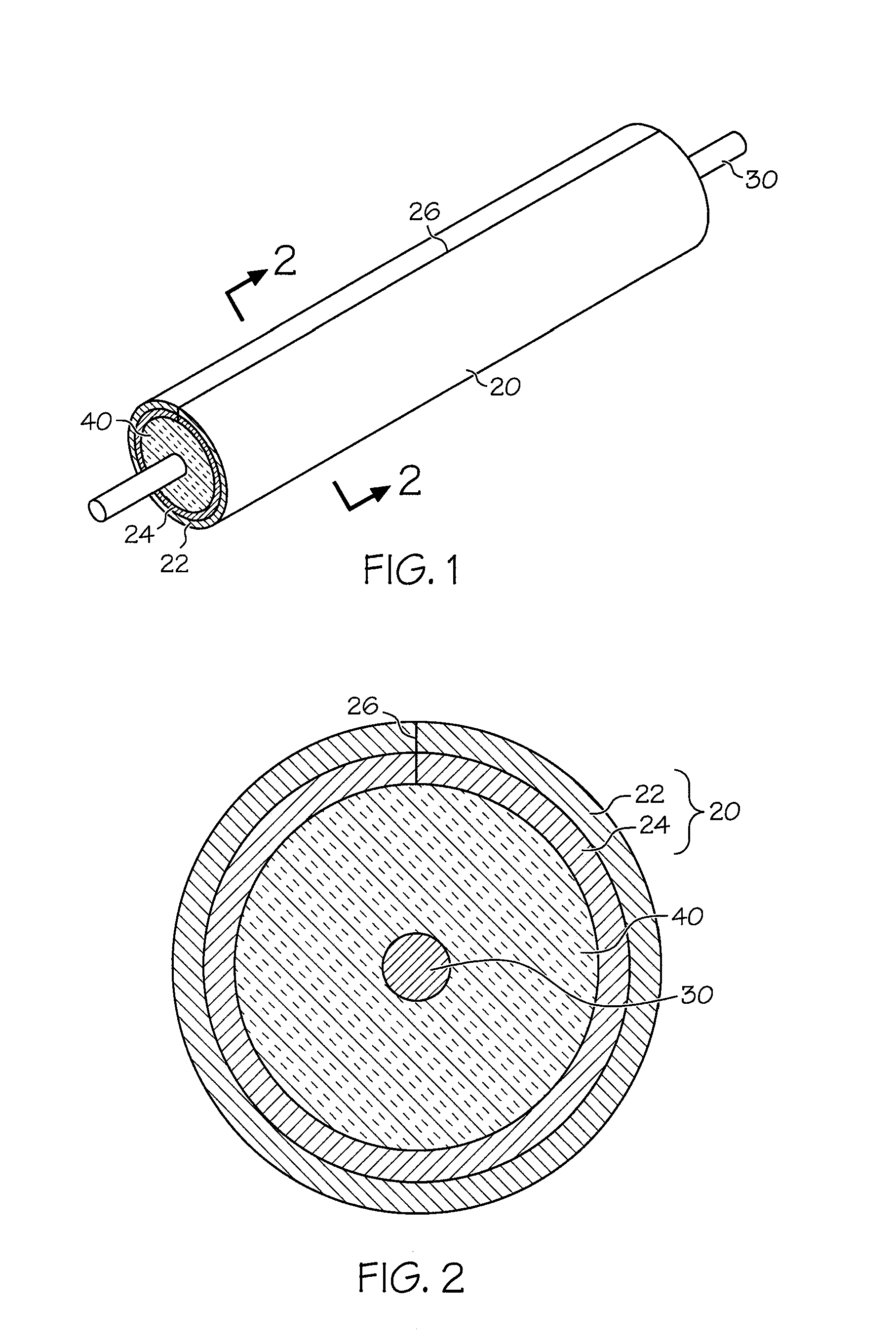

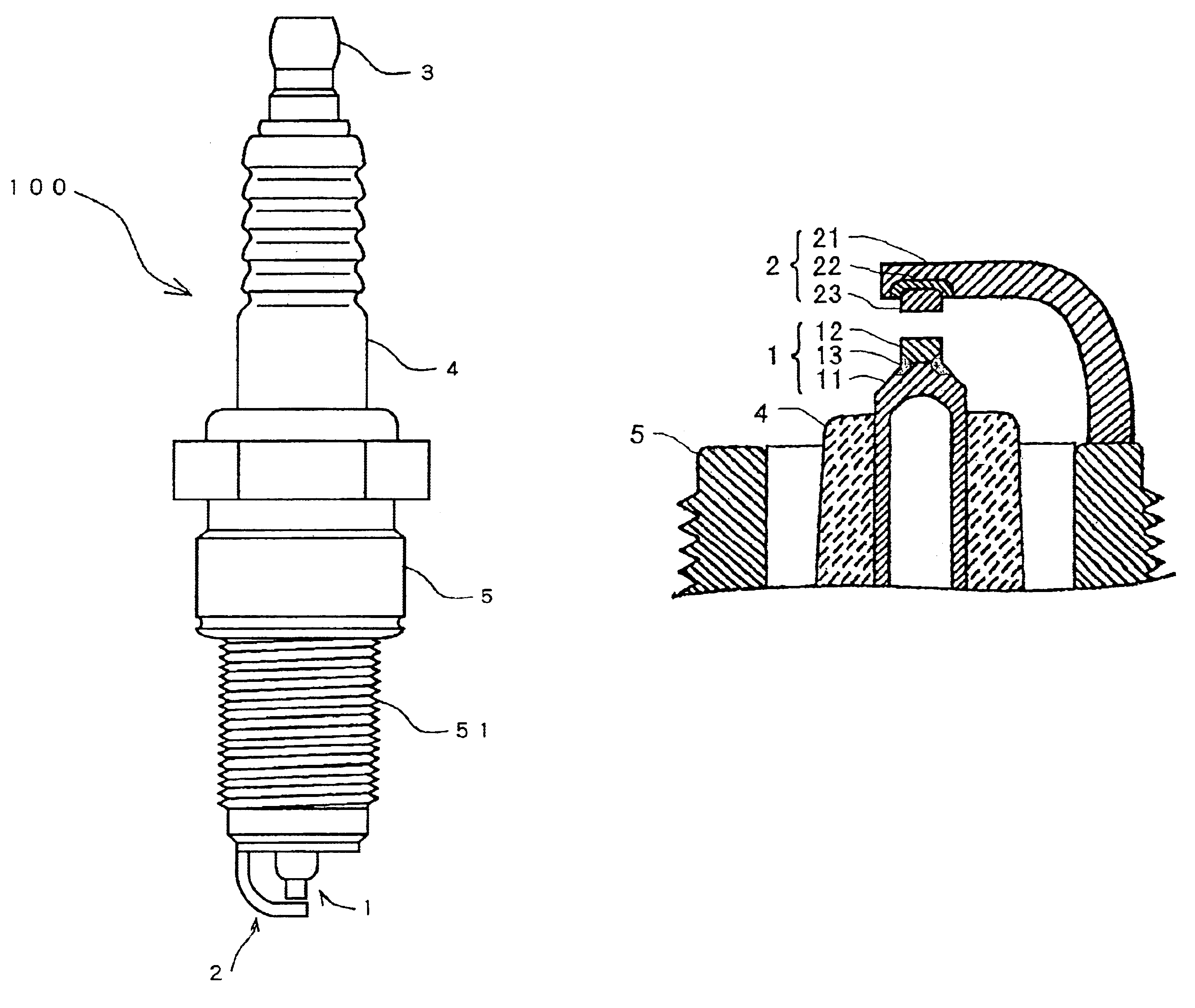

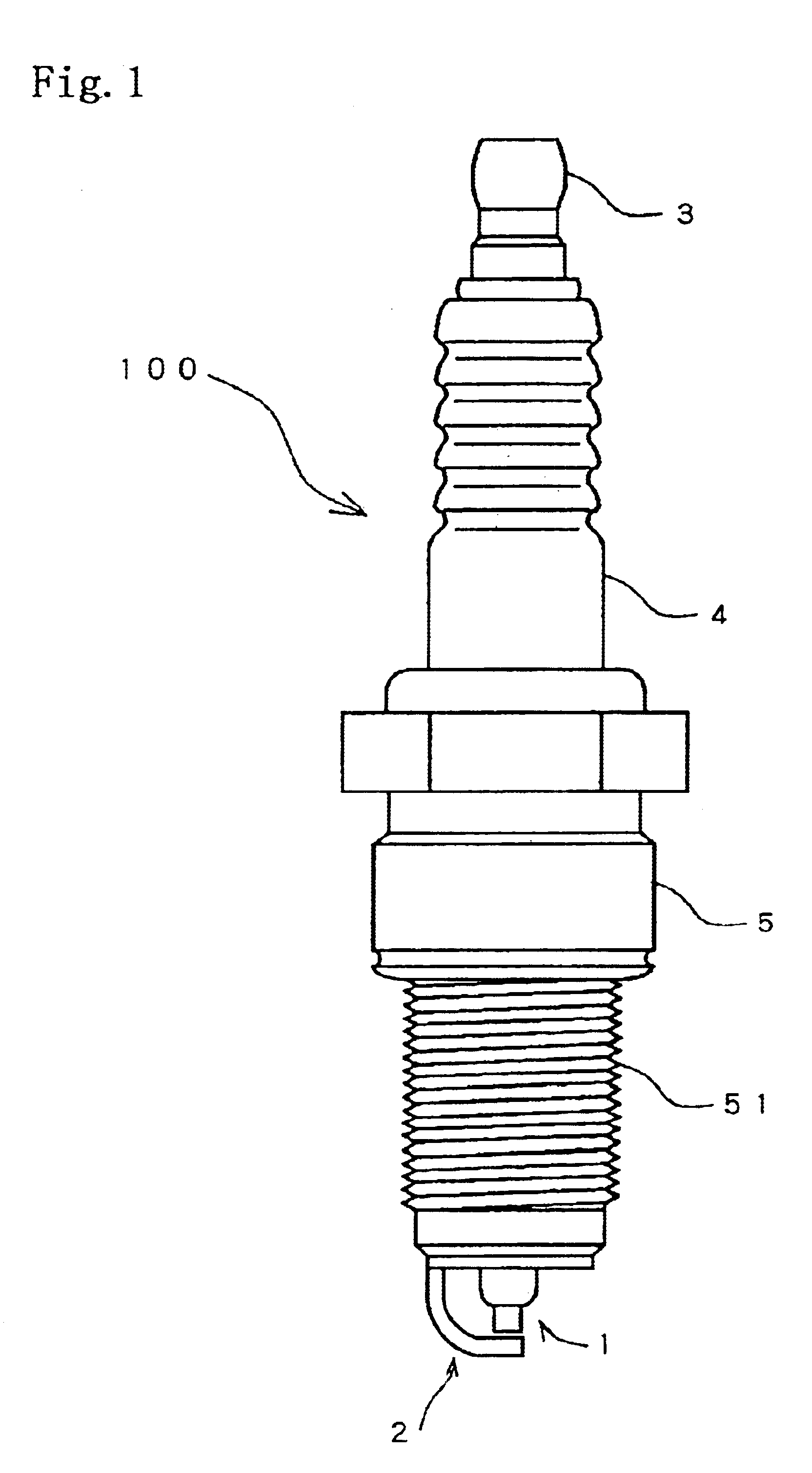

Spark plug internal combustion engine

InactiveUS20030015951A1Prevent peelingNecessity to repair the buckling is slightSparking plugsDissolutionInconel

A spark plug of the present invention is made of an Ir alloy including a specific amount of (1)Rh, (2)Pt, or (3) Rh and Pt or Rh and Ru. The spark plug comprises tips for a center electrode and for a ground electrode that are each 0.6 to 1.8 mm in diameter and 0.2 to 0.7 mm in thickness and for an interlayer made of an Ir alloy including Ni of 40 mass % that has a diameter slightly larger or smaller than that of each tip for the center electrode and for the ground electrode and has a thickness of 0.1 to 0.6 mm. These tips can be manufactured according to the powder processing method, the dissolution method, and so on. The tip for the center electrode is joined to the end surface of the basic body of the center electrode, which is made of a Ni alloy (Inconel 600), according to laser welding. The tip for the interlayer and the tip for the ground electrode are brought into contact with a predetermined position of the ground electrode, and are joined while being pressed according to electric resistance welding. Other parts, such as an insulator and main metal fittings, are each made of general materials and have a general structure. This spark plug is excellent in resistance to lead corrosion, and the tip for the ground electrode is prevented from peeling and falling off from the base because of a thermal expansion difference.

Owner:NGK SPARK PLUG CO LTD

Heating element sheaths

The present invention is directed to a nickel-based alloy, such as INCOLOY or INCONEL, clad stainless steel sheath tubing material for heating elements. This clad material is designed to minimize the cost of heating elements generally constructed entirely of nickel-based alloys alone while providing necessary material requirements of weldability, hot strength, corrosion resistance, thermal shock resistance, and formability.

Owner:ENGINEERED MATERIALS SOLUTIONS

Spark plug internal combustion engine

InactiveUS6710523B2Prevent peelingNecessity to repair the buckling is slightSparking plugsThermal expansionDissolution

A spark plug of the present invention is made of an Ir alloy including a specific amount of (1) Rh, (2) Pt, or (3) Rh and Pt or Rh and Ru. The spark plug comprises tips for a center electrode and for a ground electrode that are each 0.6 to 1.8 mm in diameter and 0.2 to 0.7 mm in thickness and for an interlayer made of an Ir alloy including Ni of 40 mass % that has a diameter slightly larger or smaller than that of each tip for the center electrode and for the ground electrode and has a thickness of 0.1 to 0.6 mm. These tips can be manufactured according to the powder processing method, the dissolution method, and so on. The tip for the center electrode is joined to the end surface of the basic body of the center electrode, which is made of a Ni alloy (Inconel 600), according to laser welding. The tip for the interlayer and the tip for the ground electrode are brought into contact with a predetermined position of the ground electrode, and are joined while being pressed according to electric resistance welding. Other parts, such as an insulator and main metal fittings, are each made of general materials and have a general structure. This spark plug is excellent in resistance to lead corrosion, and the tip for the ground electrode is prevented from peeling and falling off from the base because of a thermal expansion difference.

Owner:NGK SPARK PLUG CO LTD

Non shadow forming spacers and hardware for a BWR fuel assembly

InactiveUS20060045232A1Improve corrosion resistanceReduces and eliminates shadow formationNuclear energy generationFuel element assembliesInconelNickel alloy

A new type of coated component for use in boiling water reactor (“BWR”) fuel assemblies, particularly Zircaloy spacers, having protective coatings applied to selected surfaces of the spacers in order to prevent the formation and propagation of “shadow corrosion” on adjacent zirconium alloy structures. In its broader aspects, the coating material is applied to those surfaces of the BWR components having electro-chemical characteristics that differ from zirconium alloys, such as Inconel spacers or springs. The new coatings impart an electro-chemical potential to the surfaces of the components that is substantially similar to the adjacent zirconium alloy, thereby preventing or significantly inhibiting shadow corrosion.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

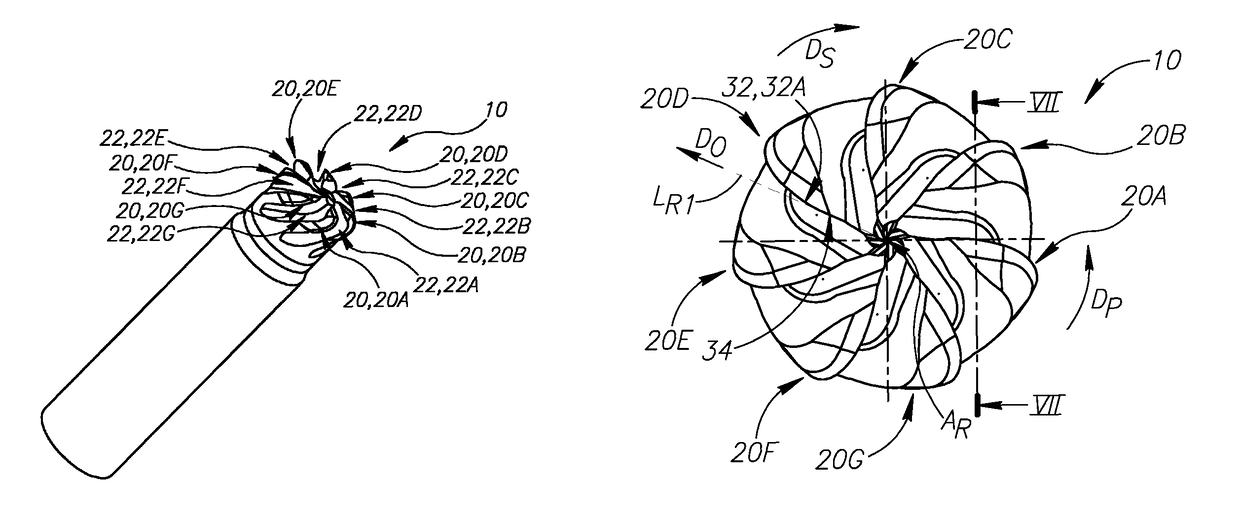

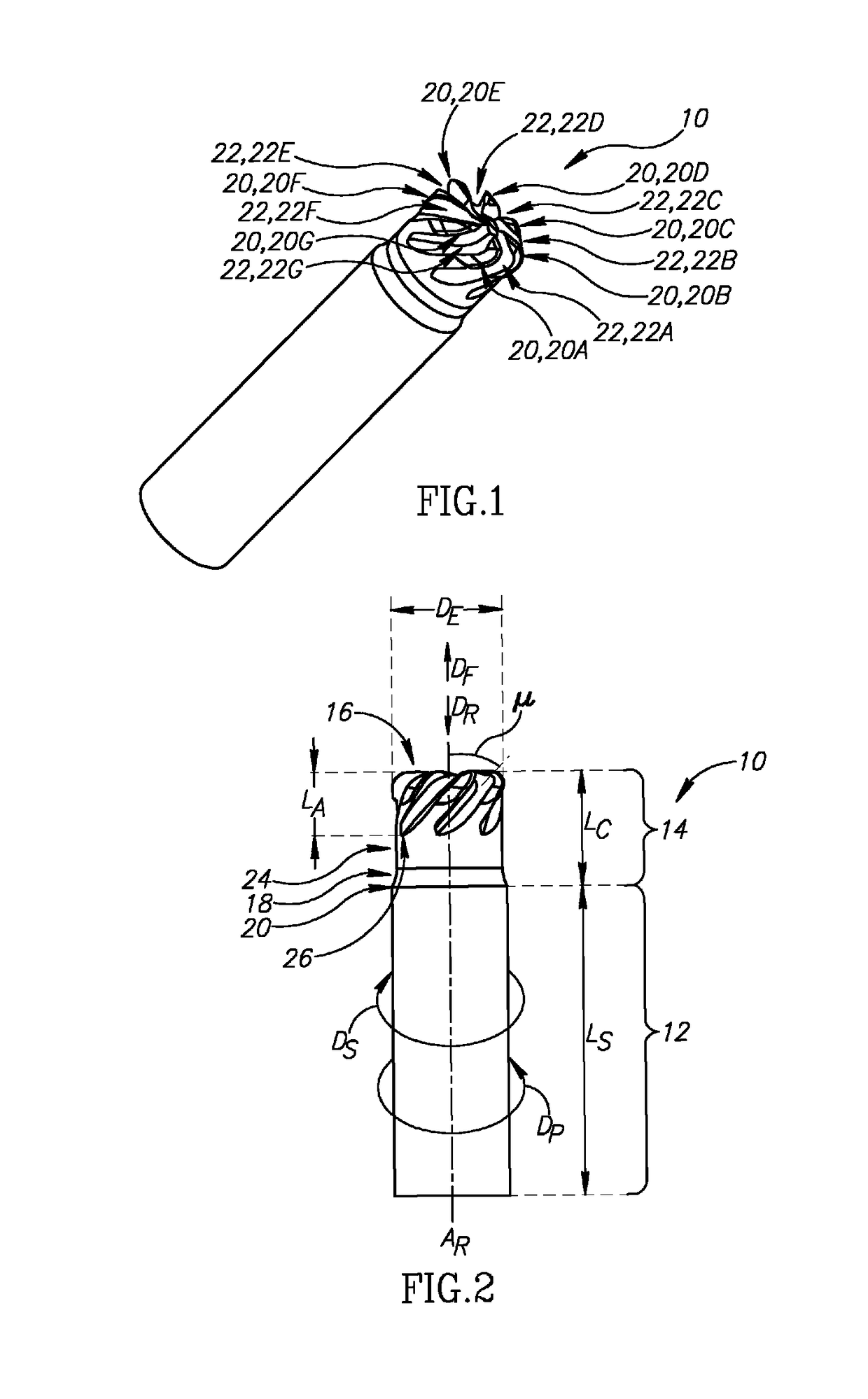

Ceramic face mill with circular arc profile for machining Inconel

A face mill includes a circular arc profile and is configured for machining Inconel. In particular the cutting portion is made of a ceramic material, and has an axial sub-edge with a positive axial rake angle α to increase tool life.

Owner:ISCAR LTD

Dielectric film production process and capacitor

ActiveUS20070025059A1High dielectric constantLower average currentFixed capacitor electrodesElectrolytic capacitorsOptoelectronicsInconel

A capacitor provided with a dielectric film, and a first electrode and second electrode formed sandwiching it and facing each other, wherein the dielectric film has a density exceeding 72% of the theoretical density calculated based on the lattice constant, and either or both of said first electrode and said second electrode contain at least one metal selected from the group consisting of Cu, Ni, Al, stainless steel and inconel.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com