Patents

Literature

451 results about "Material requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

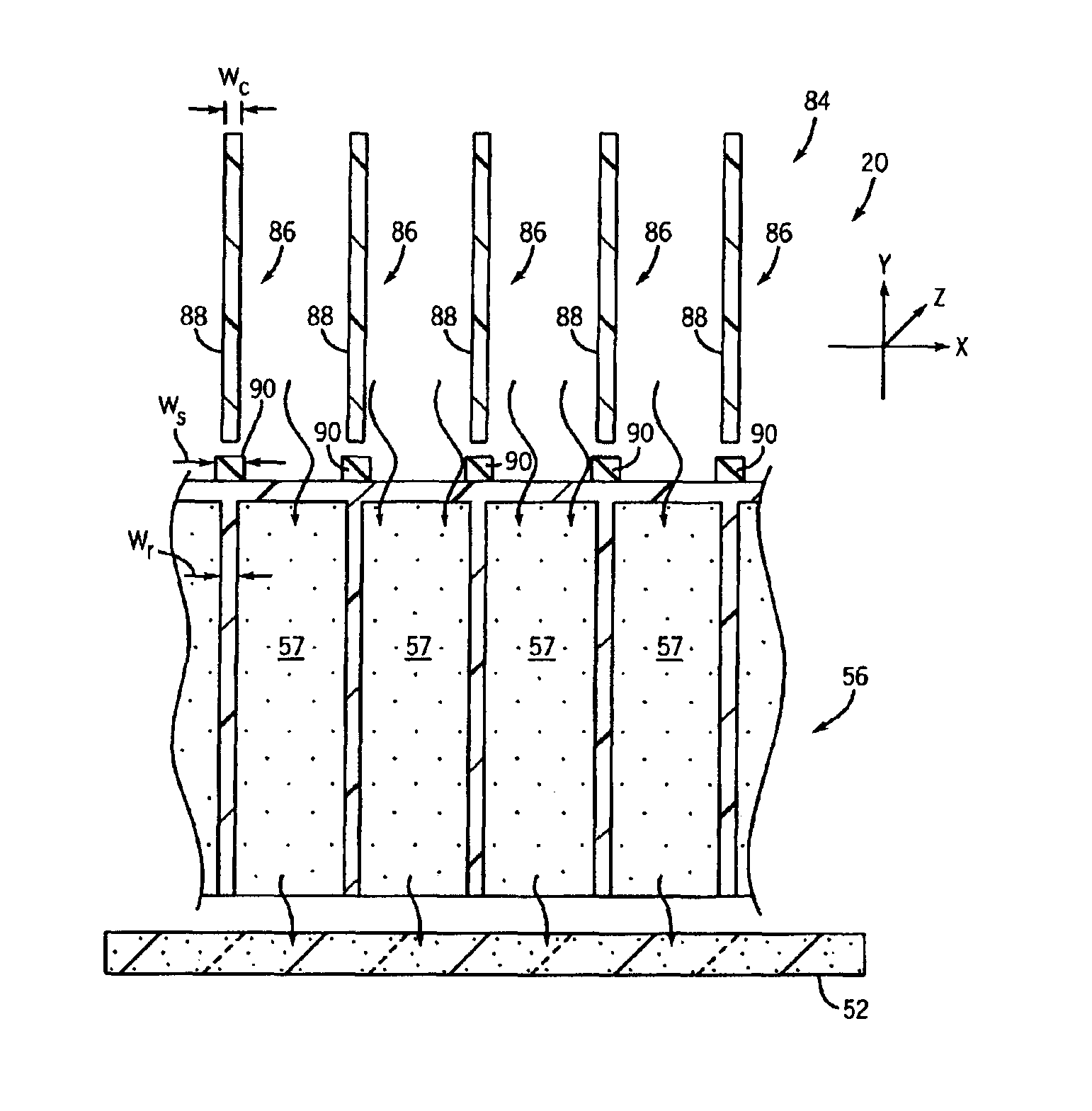

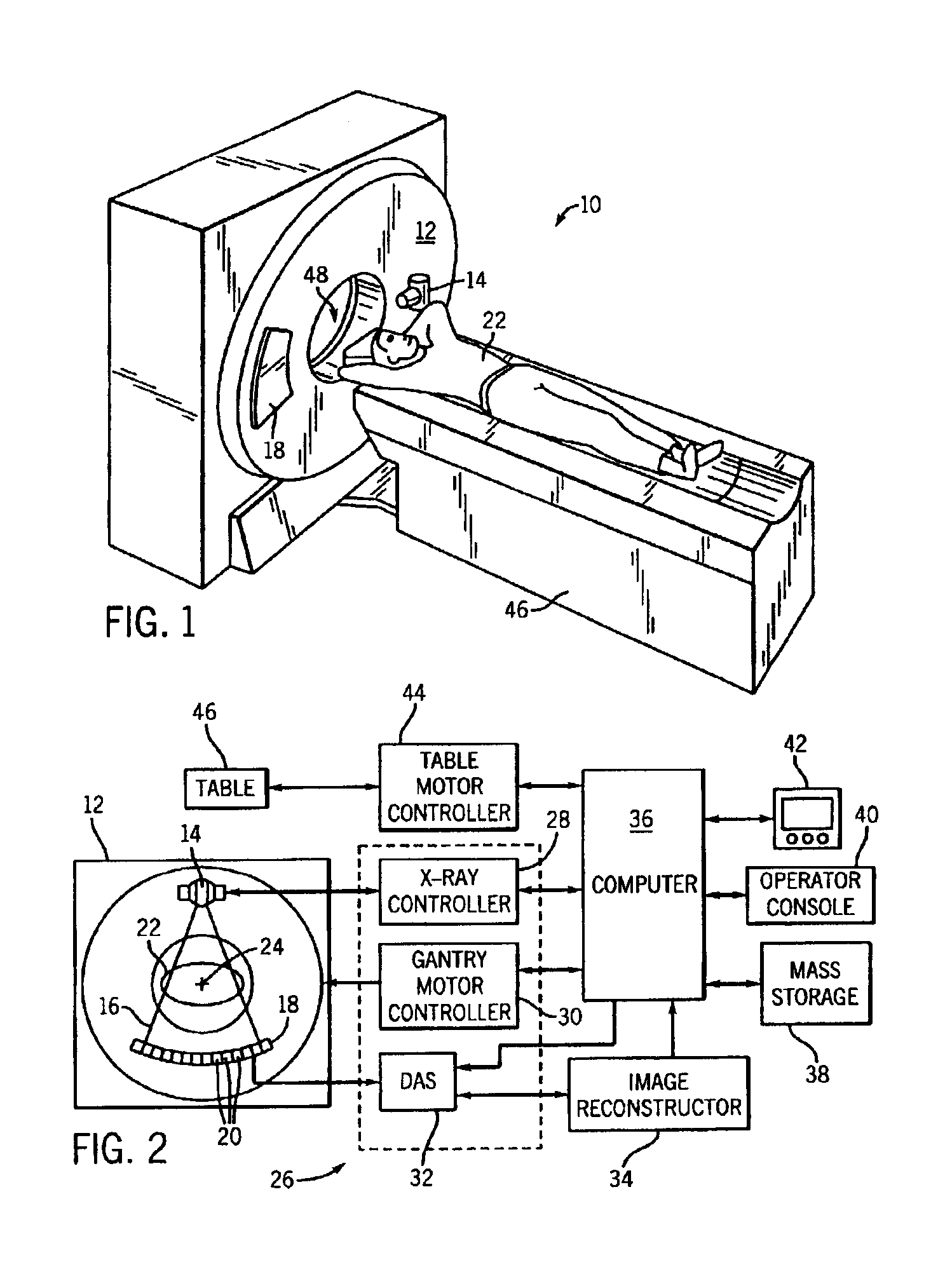

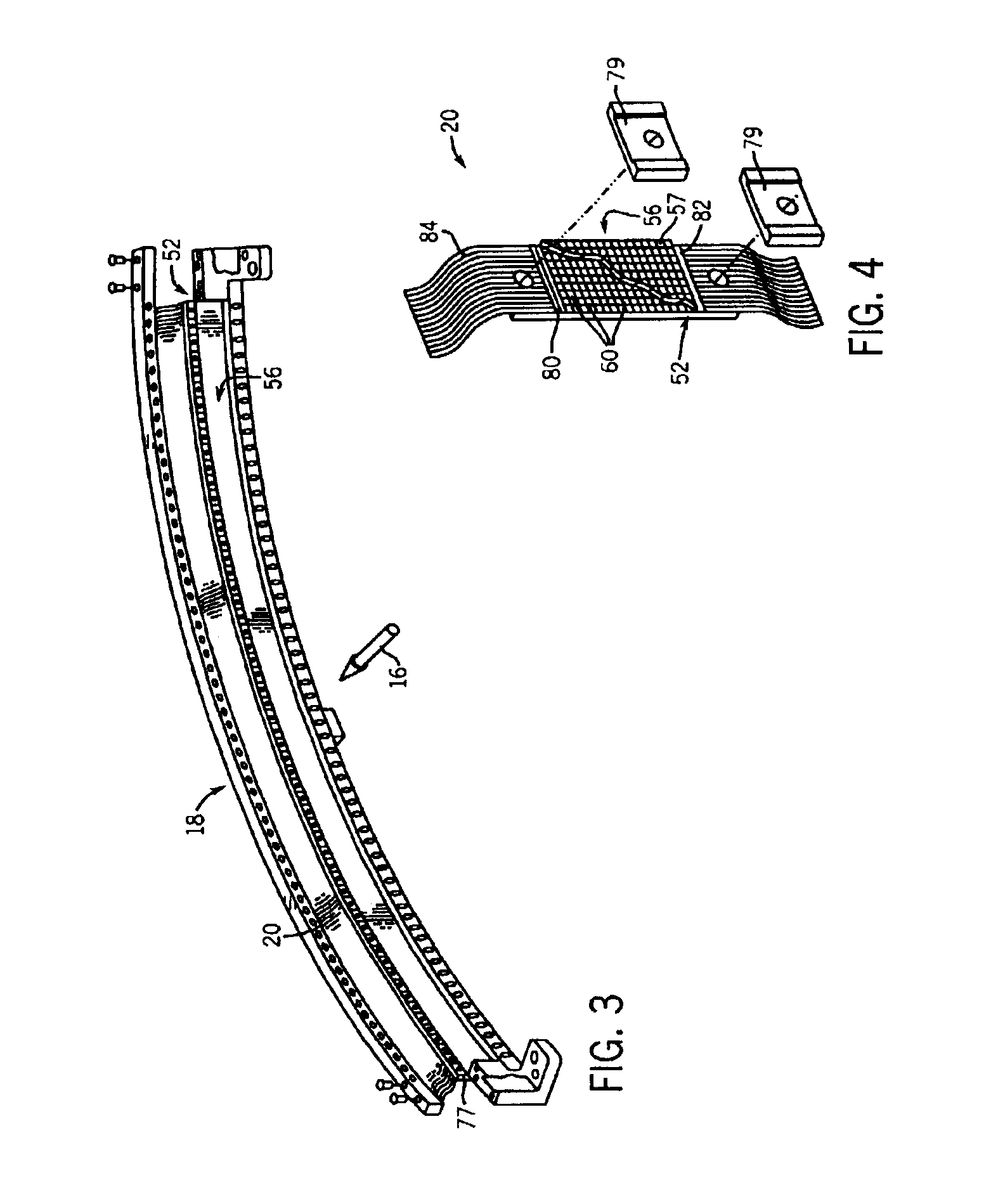

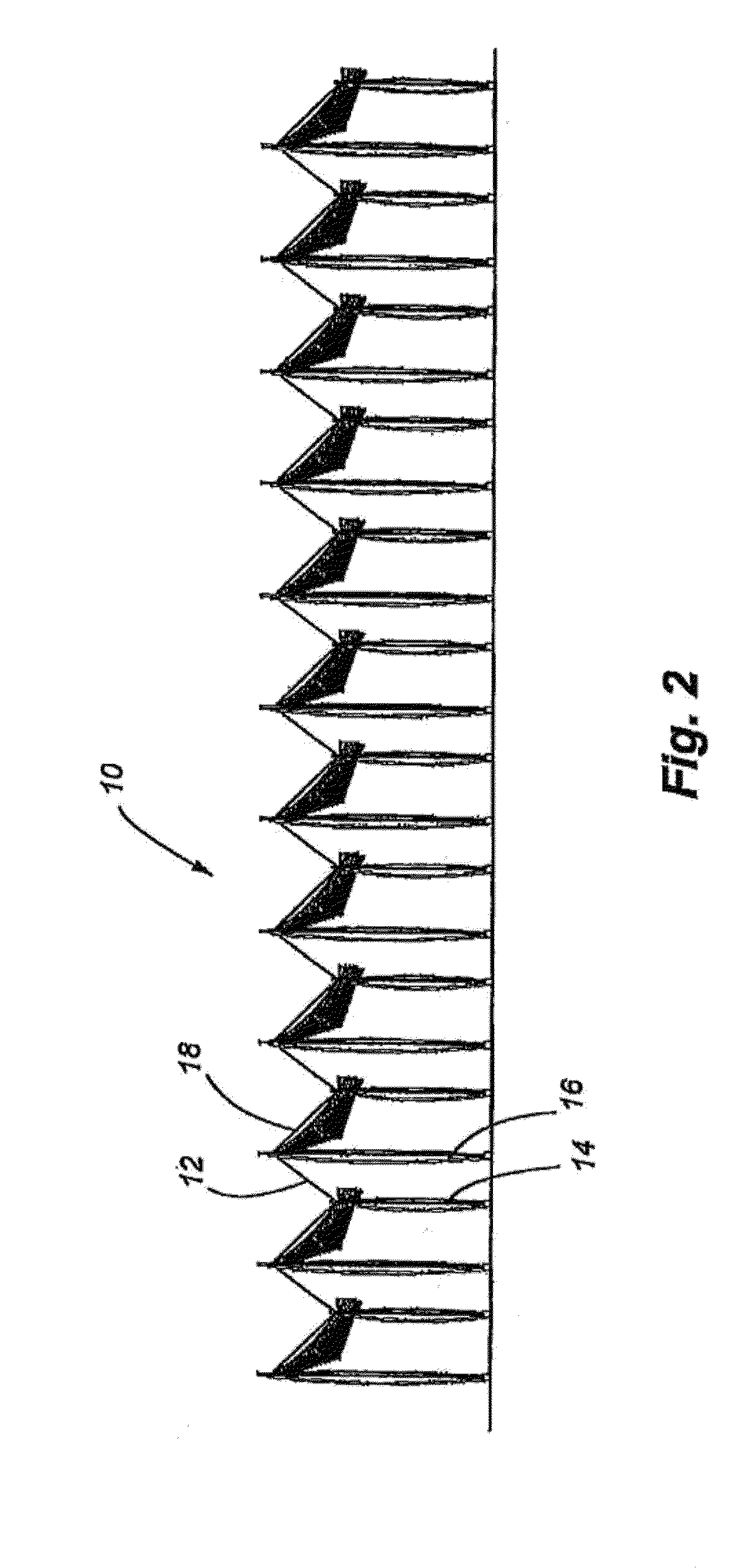

Collimator assembly having multi-piece components

InactiveUS6934354B2Convenient heightReduced material requirementsHandling using diaphragms/collimetersComputerised tomographsEngineeringMaterial requirements

The present invention is directed to a collimator assembly defined by a series of multi-piece collimator elements or plates that extend along at least one dimension of a scintillator pack. Each collimator element has a collimating component and a shielding component that are structurally independent from one another. The collimating components may be connected to the shielding components or separated by a small air gap. The shielding components are wider than the collimating components but the collimating components have a greater height. With this construction, the collimator assembly optimizes collimation and shielding with lower material requirements and reduced overall size.

Owner:GENERAL ELECTRIC CO

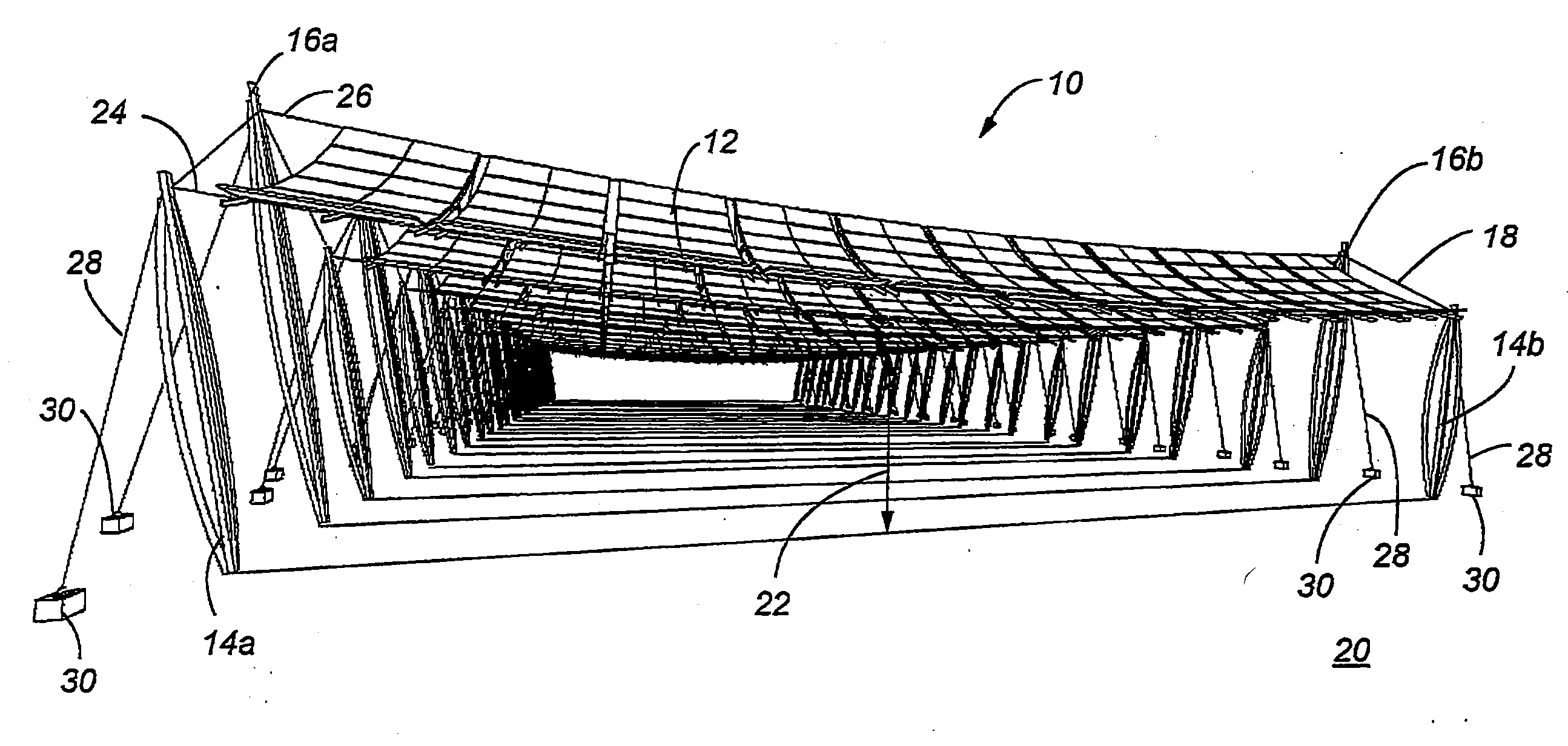

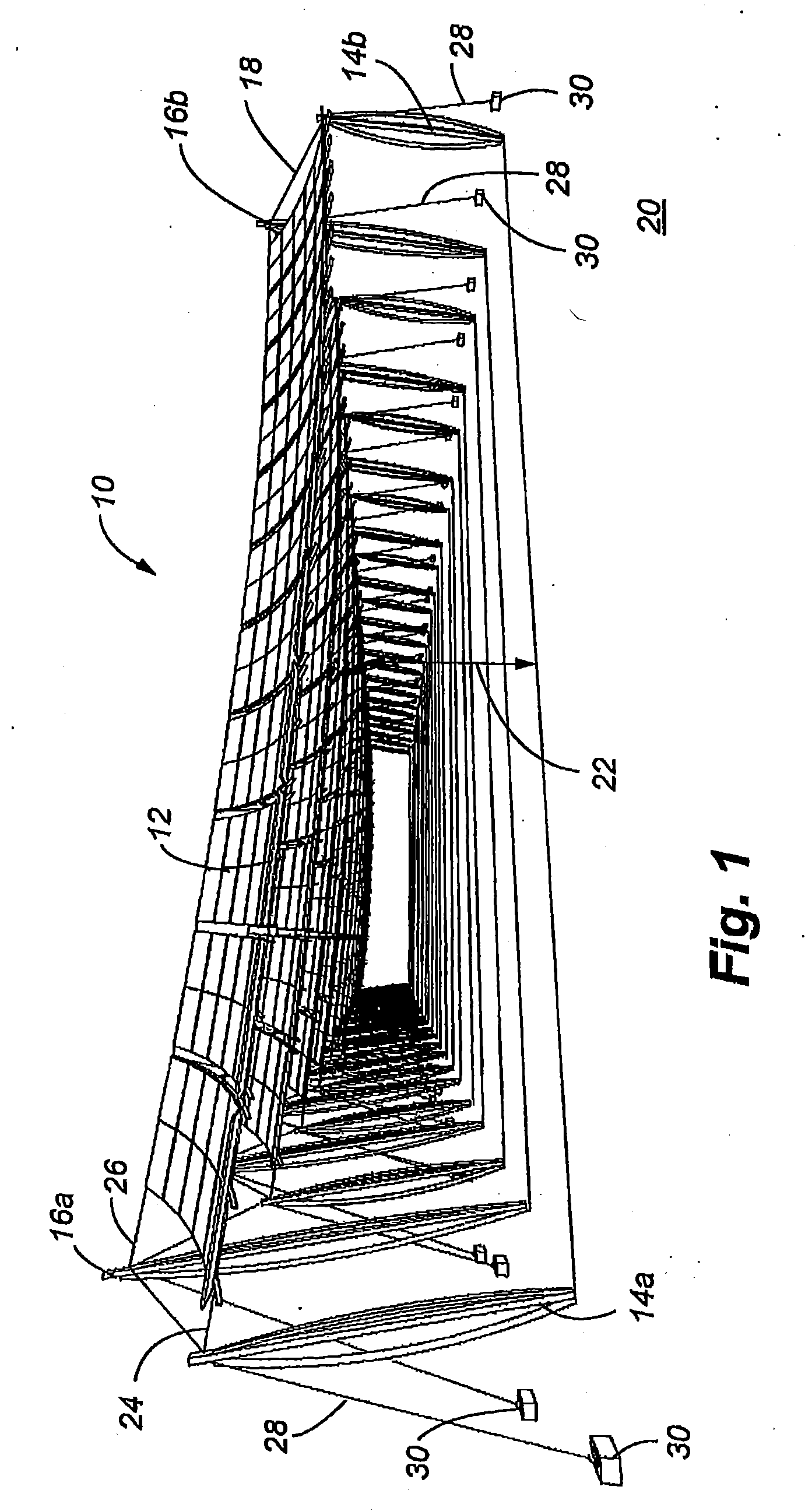

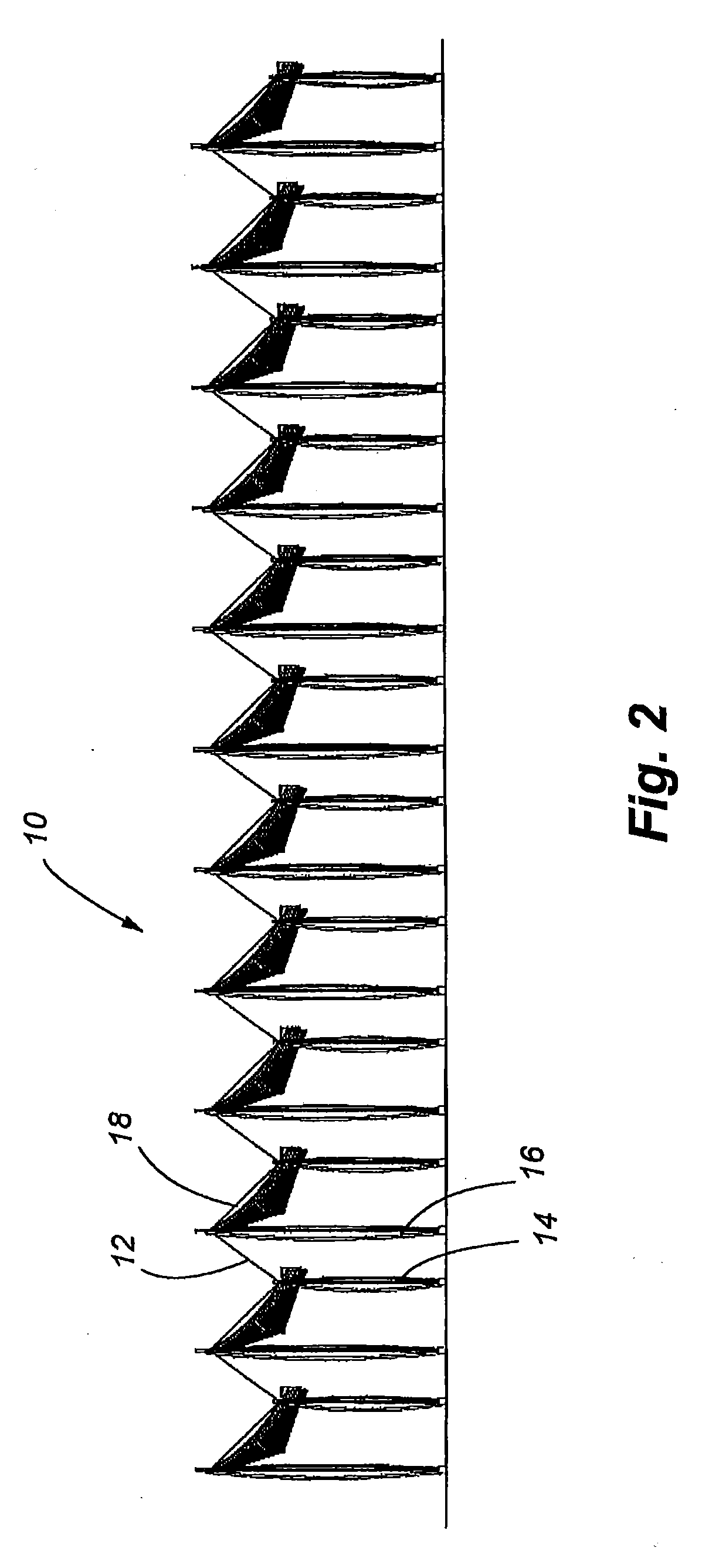

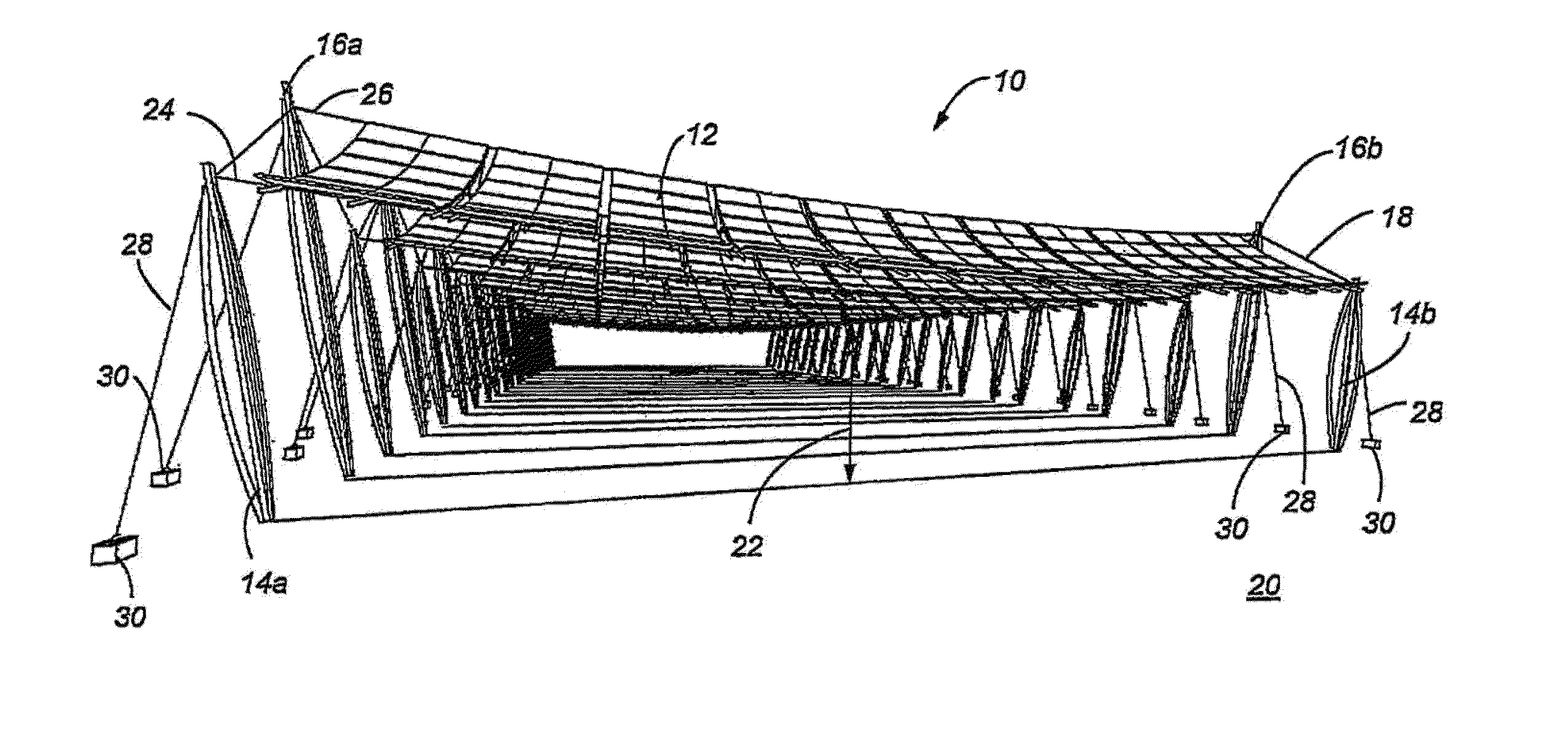

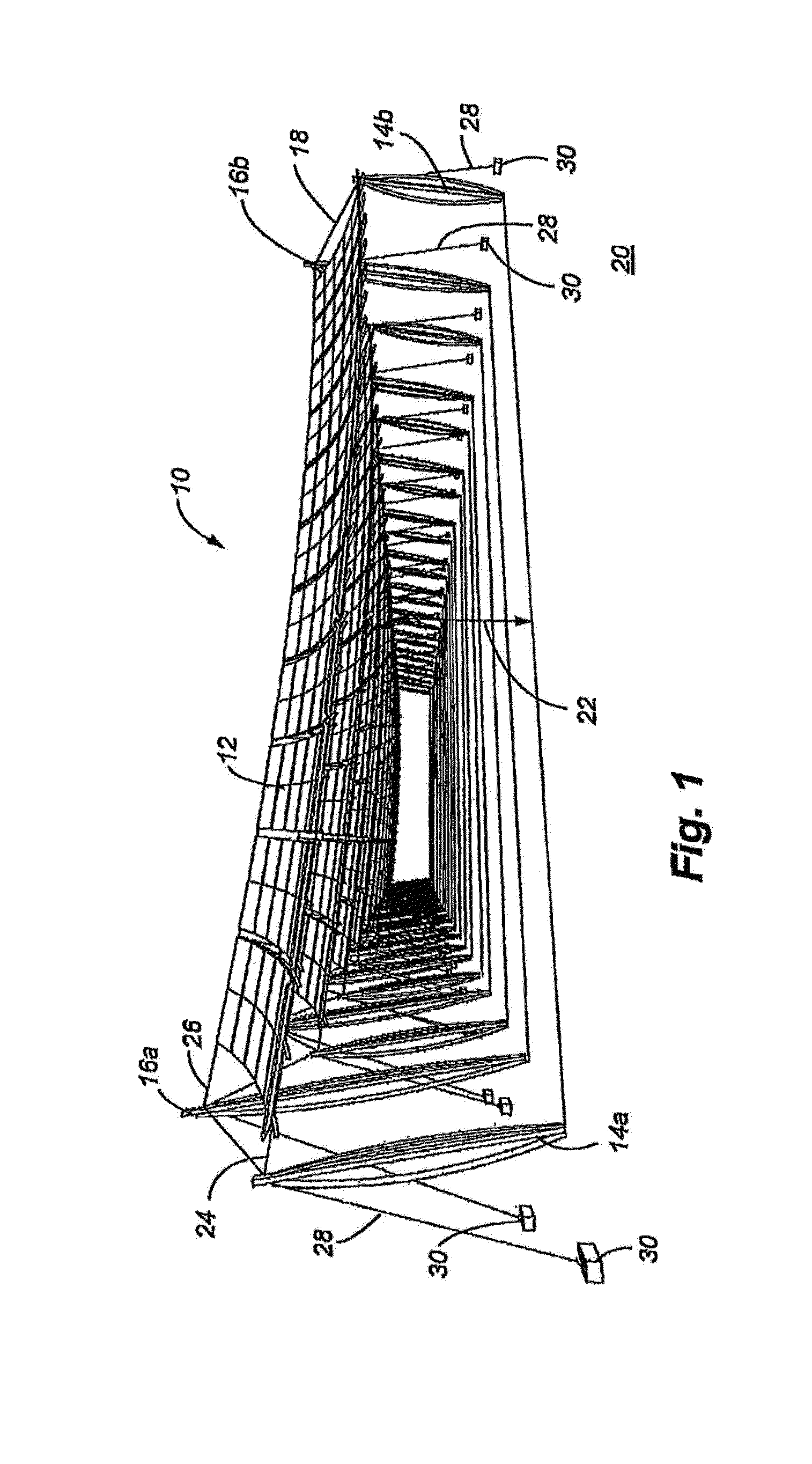

Solar array support methods and systems

InactiveUS20100314509A1Minimizes construction effortMinimizes maintenance needPhotovoltaic supportsSolar heating energyEngineeringLand use

Systems and methods for disposing and supporting a solar panel array are disclosed. The embodiments comprise various combinations of cables, support columns, and pod constructions in which to support solar panels. The solar panels can incorporate single or dual tracking capabilities to enhance sunlight capture. The embodiments encourage dual land use in which installation of the systems minimizes disruption of the underlying ground. Supplemental power may be provided by vertical axis windmills integrated with the columns. Special installations of the system can include systems mounted over structures such as parking lots, roads and aqueducts. Simplified support systems with a minimum number of structural elements can be used to create effective support for solar panel arrays of varying size and shapes. These simplified systems minimize material requirements and labor for installation of the systems.

Owner:P4P HLDG

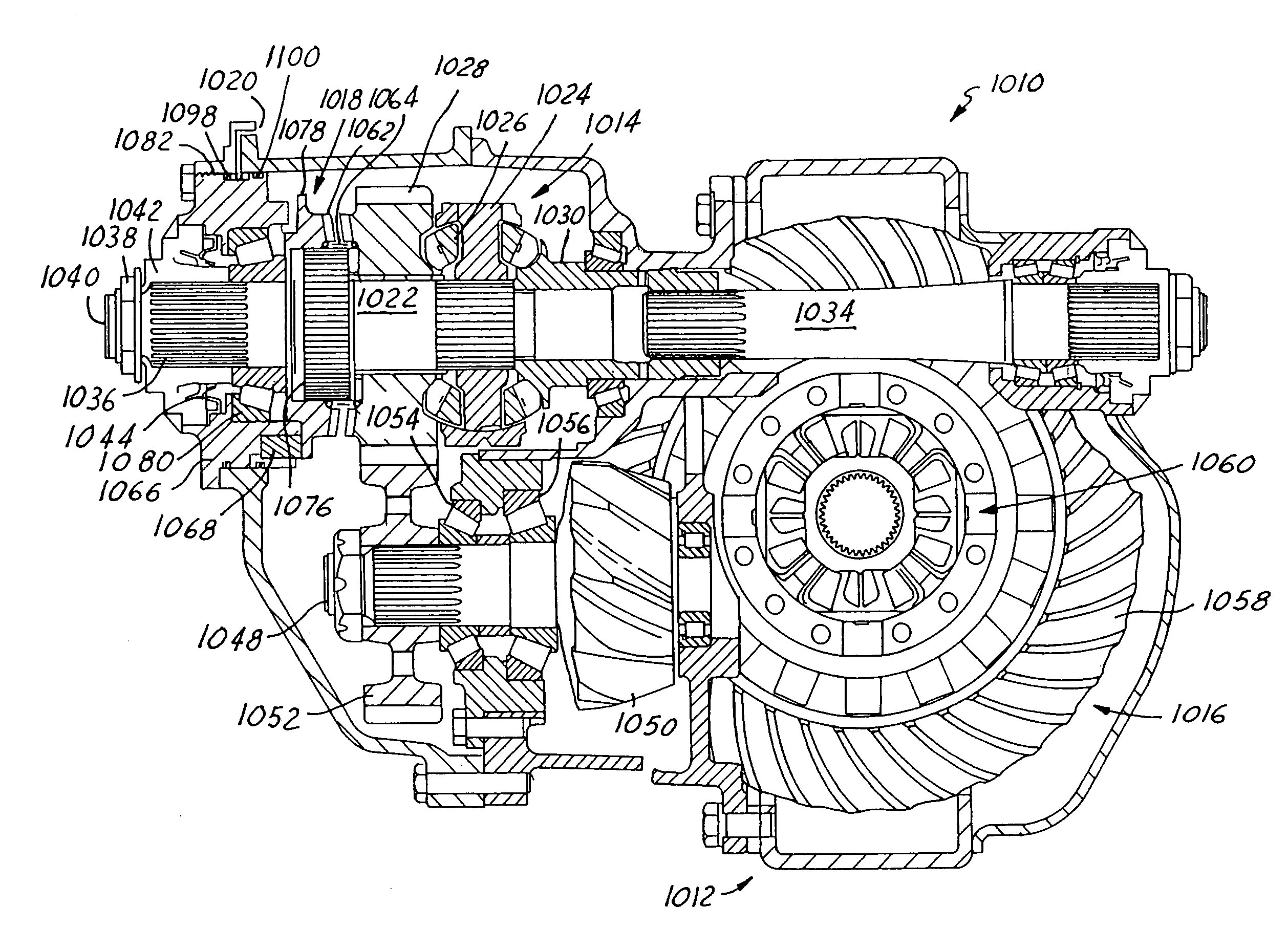

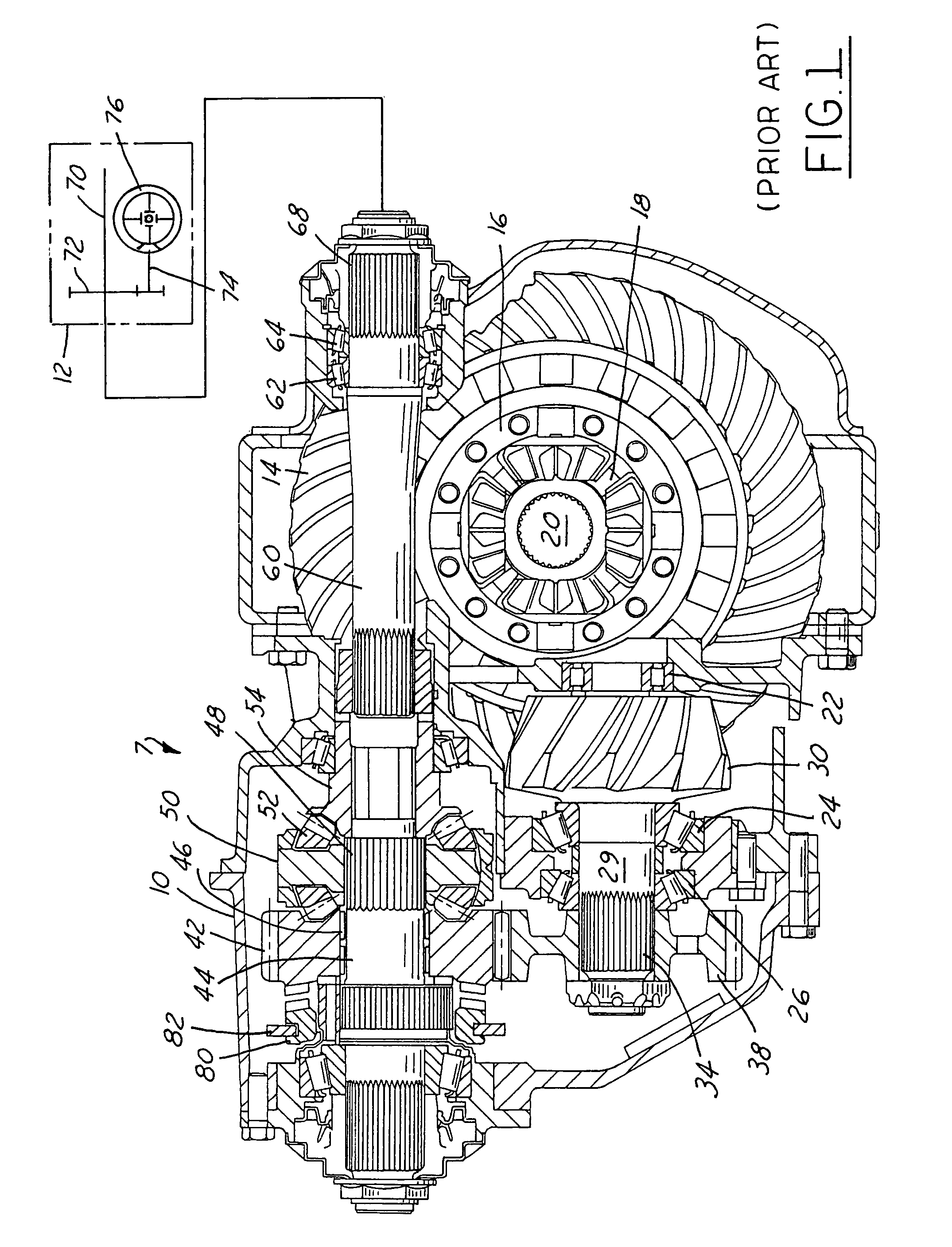

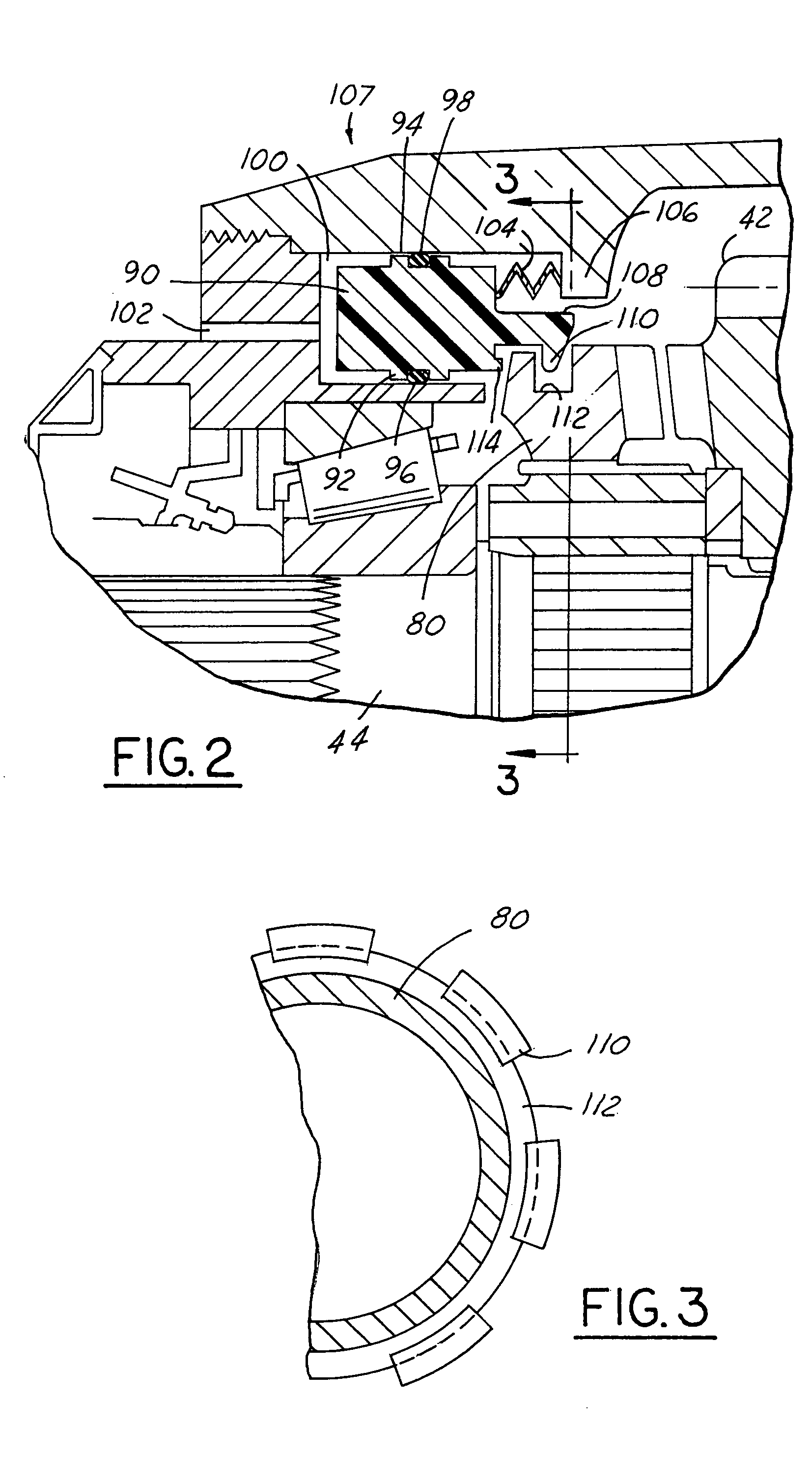

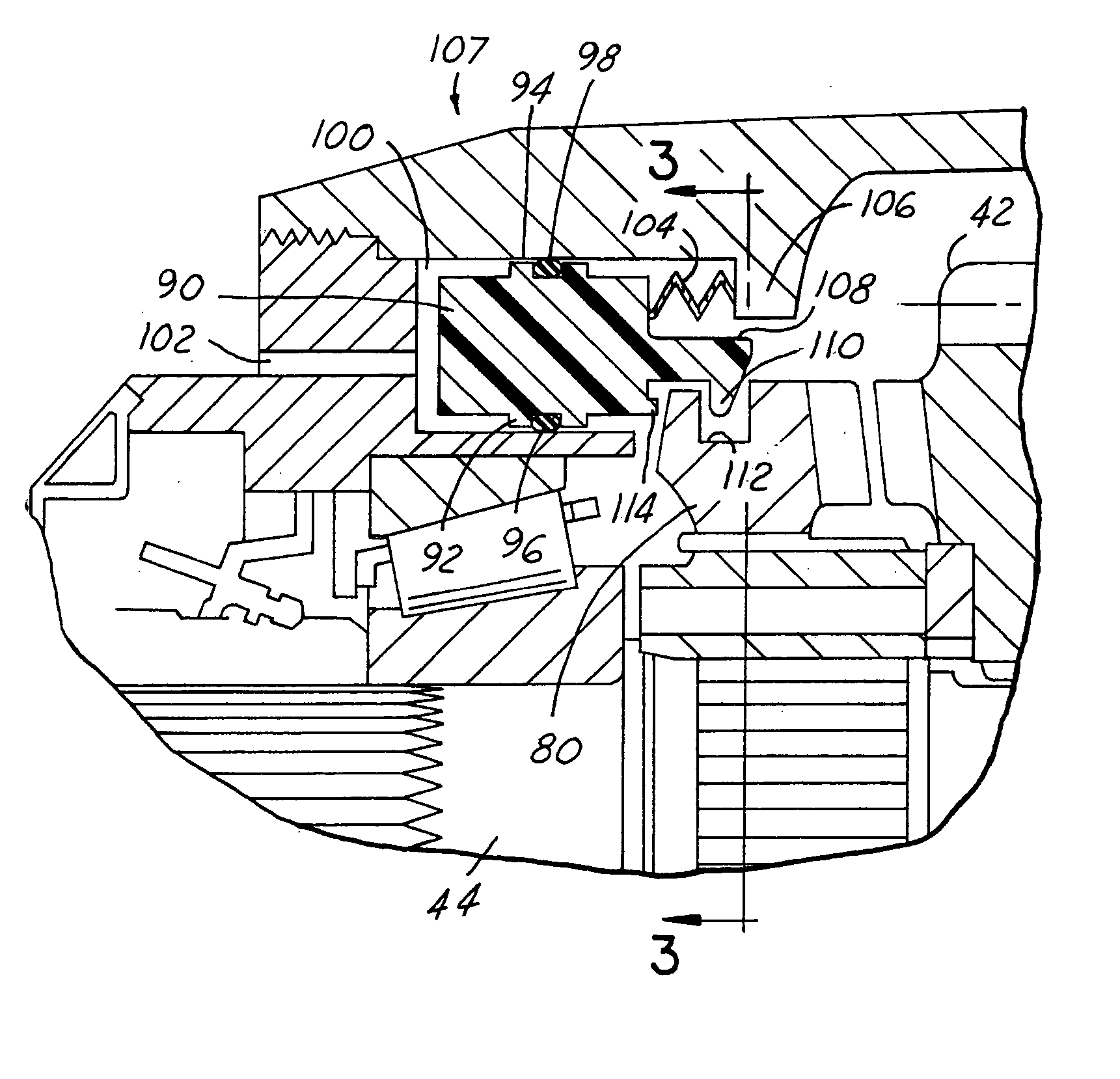

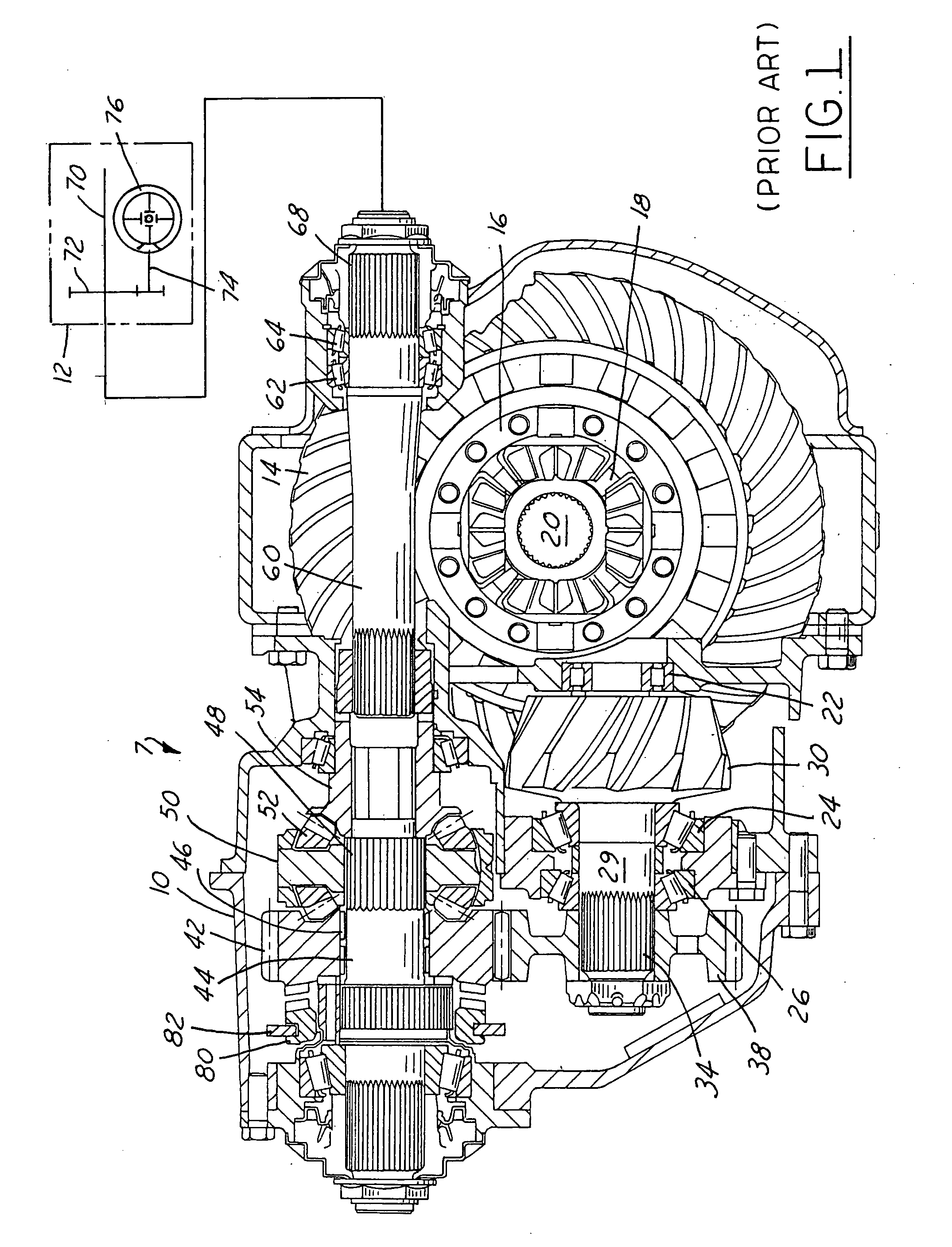

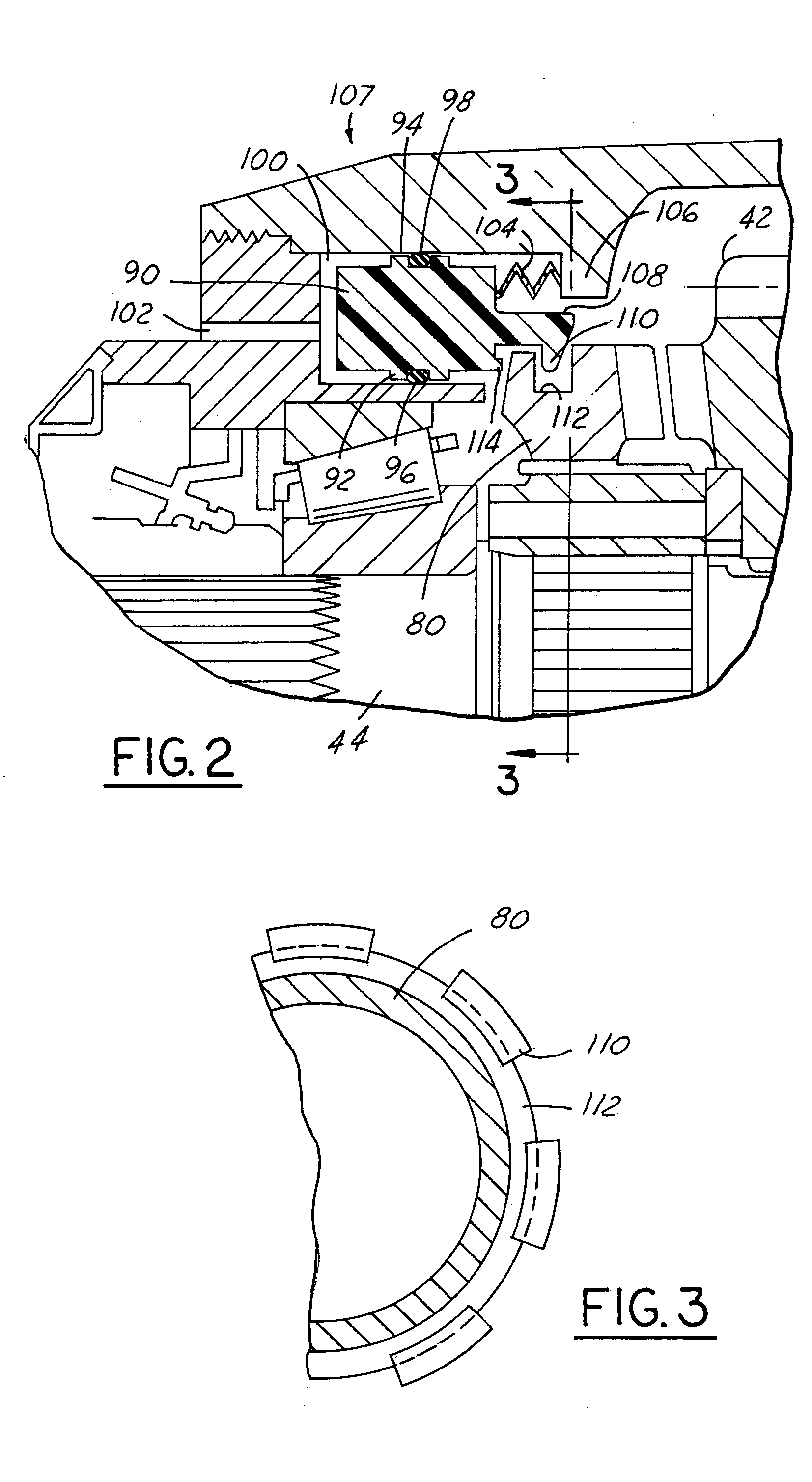

Inter-axle differential lock shift mechanism

InactiveUS7211017B2Reducing space and material requirementLow production costFluid actuated clutchesGear lubrication/coolingGear driveEngineering

An improved inter-axle differential locking clutch is provided that aligns the actuator and the clutch member thereby reducing space and material requirements in the axle assembly housing. The clutch also eliminates the need for a pushrod and shift fork thereby reducing tooling and production costs, as well as eliminating issues associated with misalignment of the piston and pushrod, relative rotation of the shift fork and clutch member, and tipping of the shift fork. The clutch includes one or more pistons disposed within either the axle housing or a carrier supporting the input shaft bearing. Fluid pressure actuates the pistons against a clutch member causing selective engagement between the clutch member and either a side gear driven by the inter-axle differential or a differential case housing the differential gears of the inter-axle differential.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

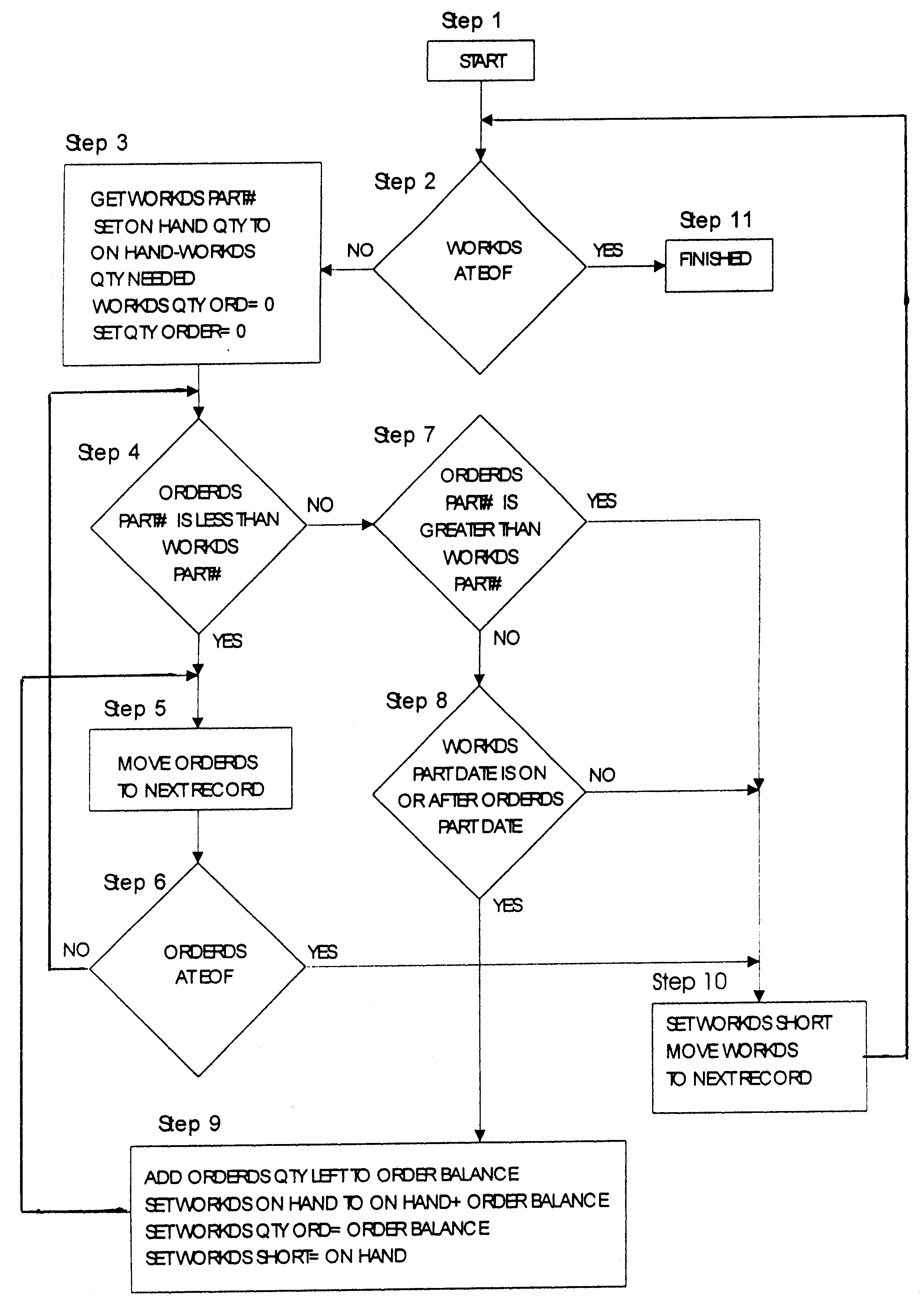

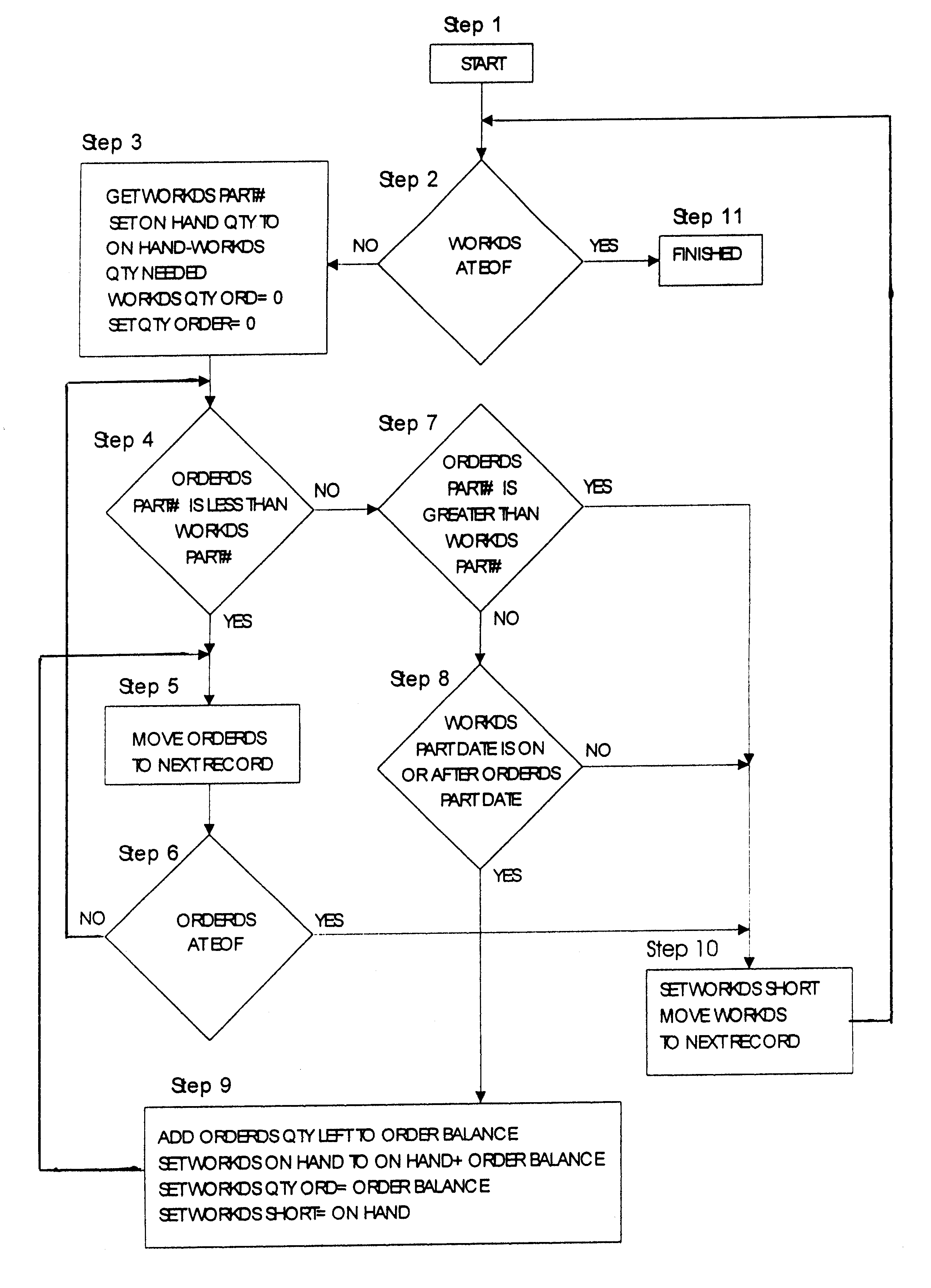

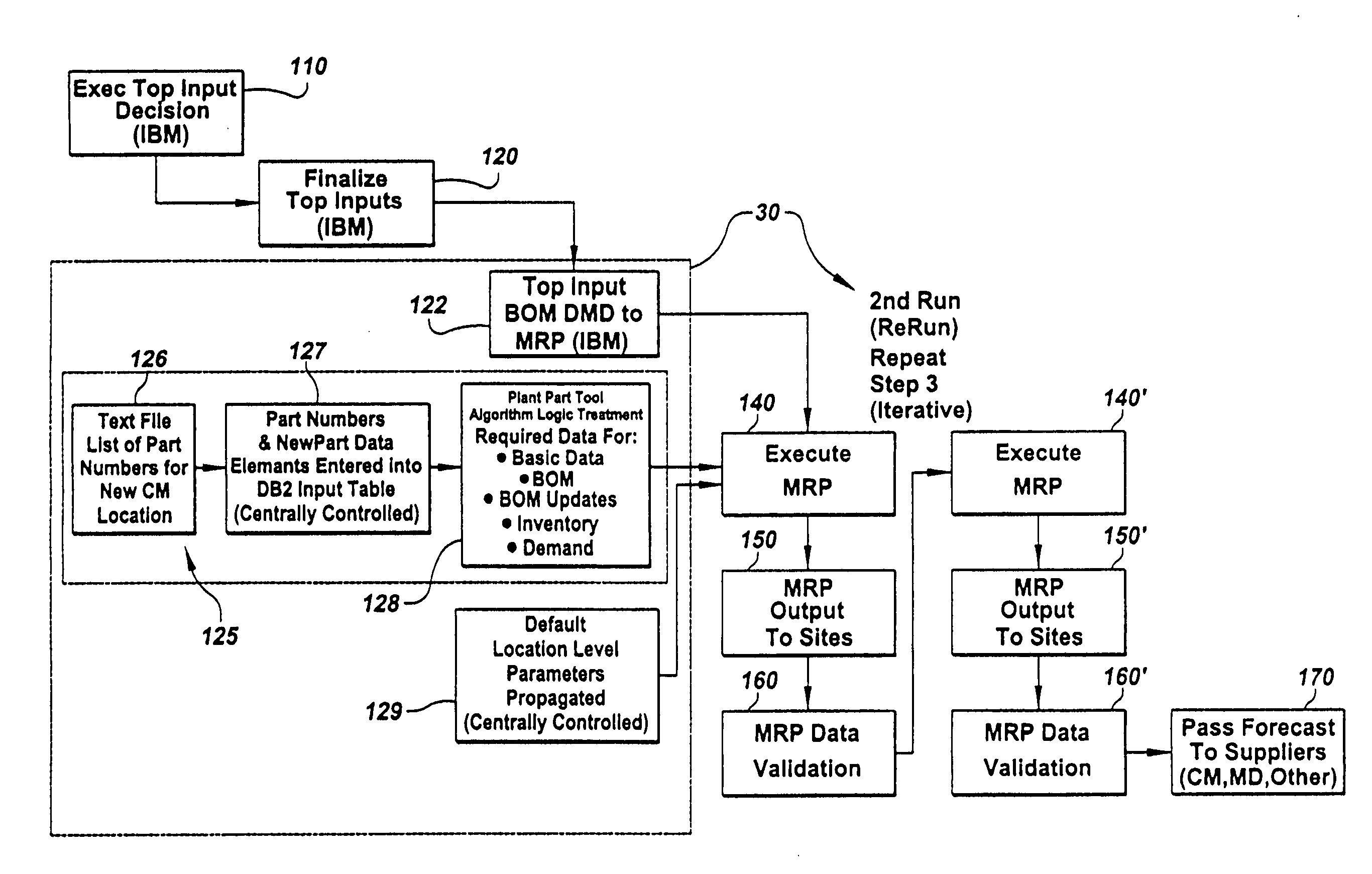

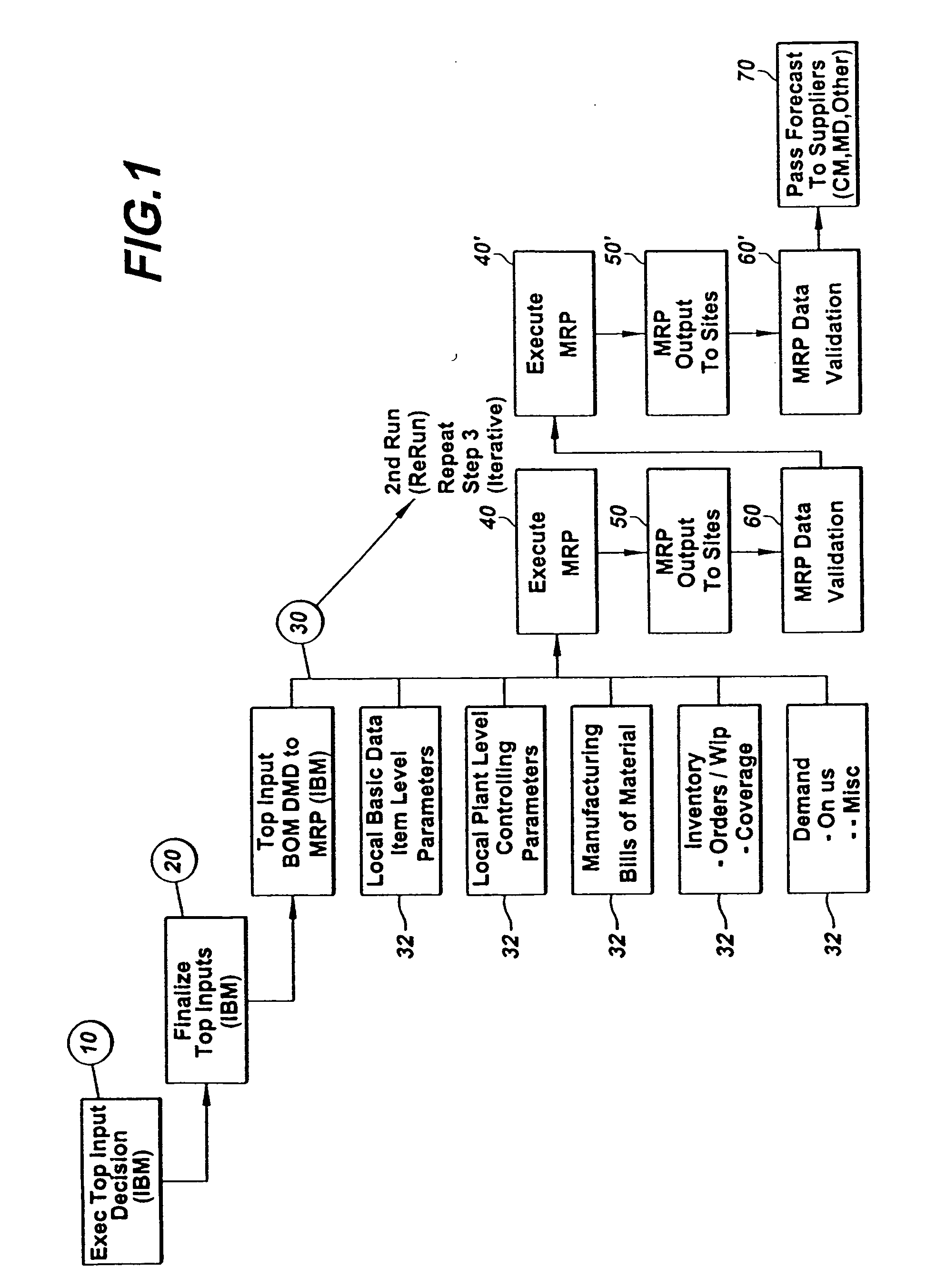

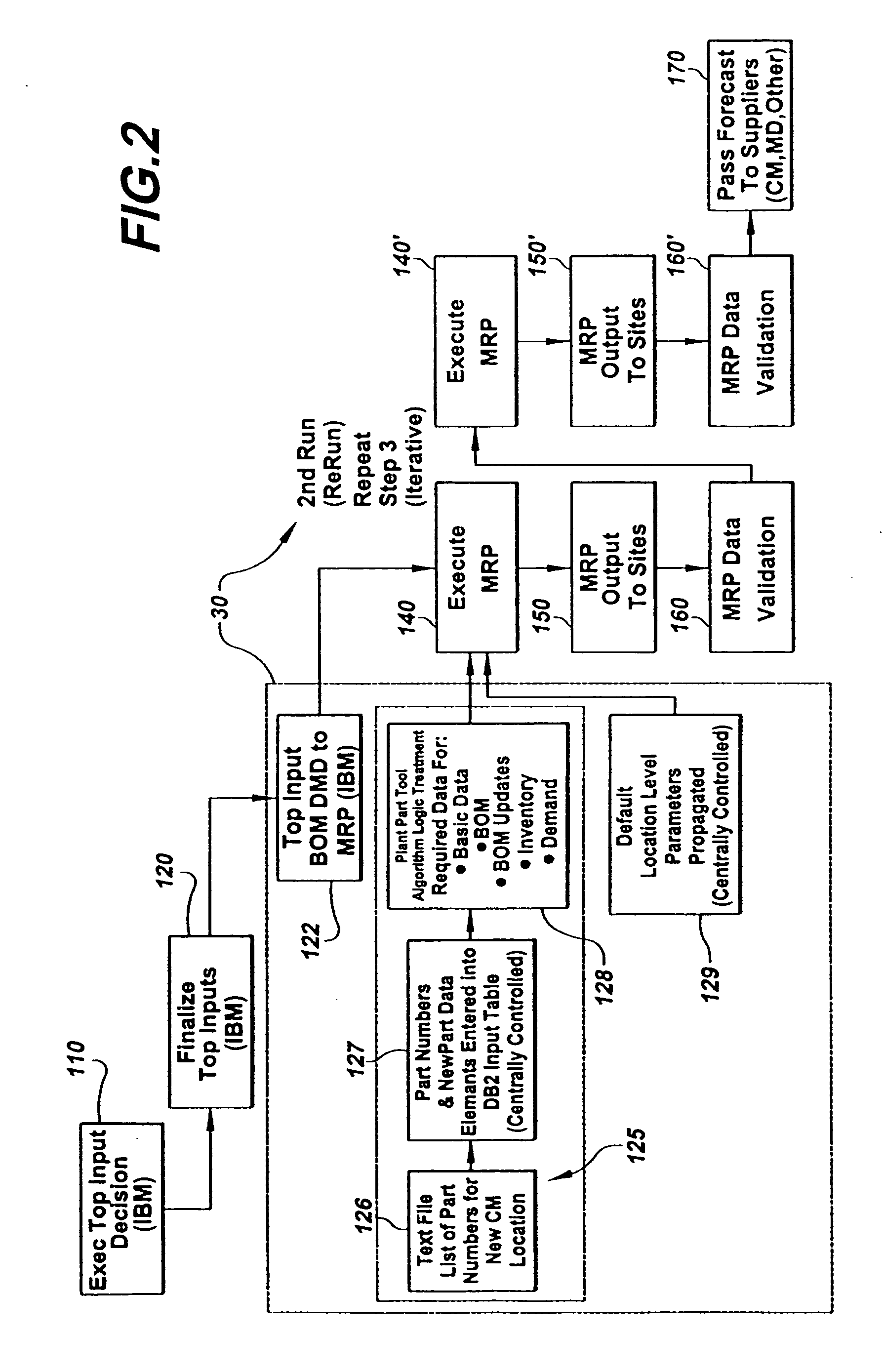

Method and apparatus for material requirements planning

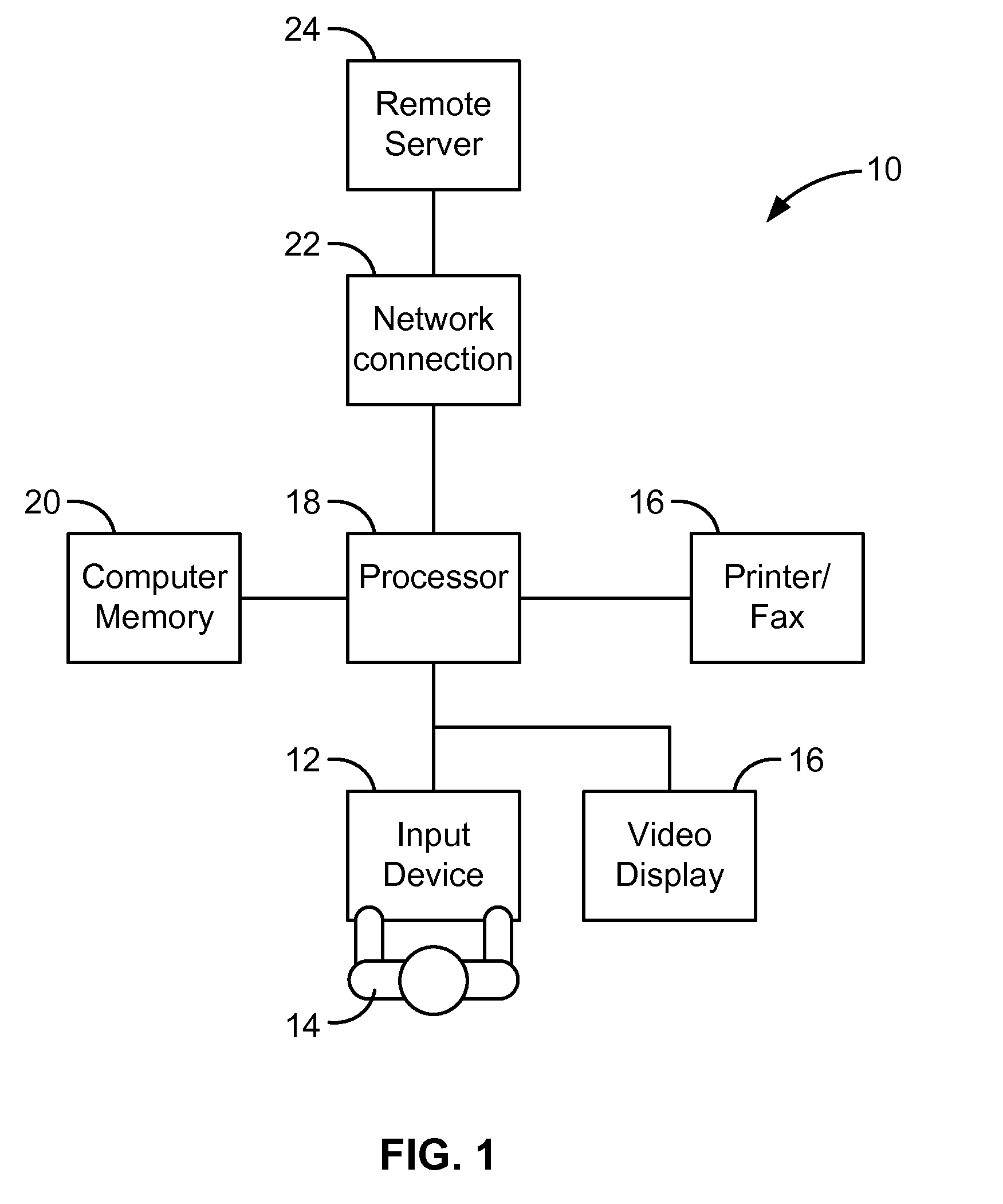

InactiveUS6625616B1Fast data processingAvoid necessary capital expenditureHand manipulated computer devicesDigital data processing detailsNetwork connectionData access

A method and apparatus for materials requirements planning that implements a client / server computer network with an algorithm which enables receiving and preserving input data from the client in a stateless protocol in the server, the input data from a client is preprocessed to determine the MPR state, and stored for each client in the server in a separate side container using stateless protocols. A side container containing a client's data is accessed by distinct SQL and VB code routines to perform specific reports, modification of a required materials order and / or adjustment of material availability for use dates. The preprocessing arranges the input data into record sets of all scheduled material requirements, all currently available and required materials and all unfulfilled ordered materials. The preprocessing is executed via SQL, and the processing is executed via executable code into a temporary record set that is placed into a storage container. The apparatus consists of a server side processor having a network connection and provided with software to supply network server functions, server side general purpose programming functions, and database functions using SQL code. A client side processor connected to the network and provided with software to enable login to the server side processor via the network, and to supply software functions including data access reports and / or modification in order to be able to control server access.

Owner:MRPONLINE COM

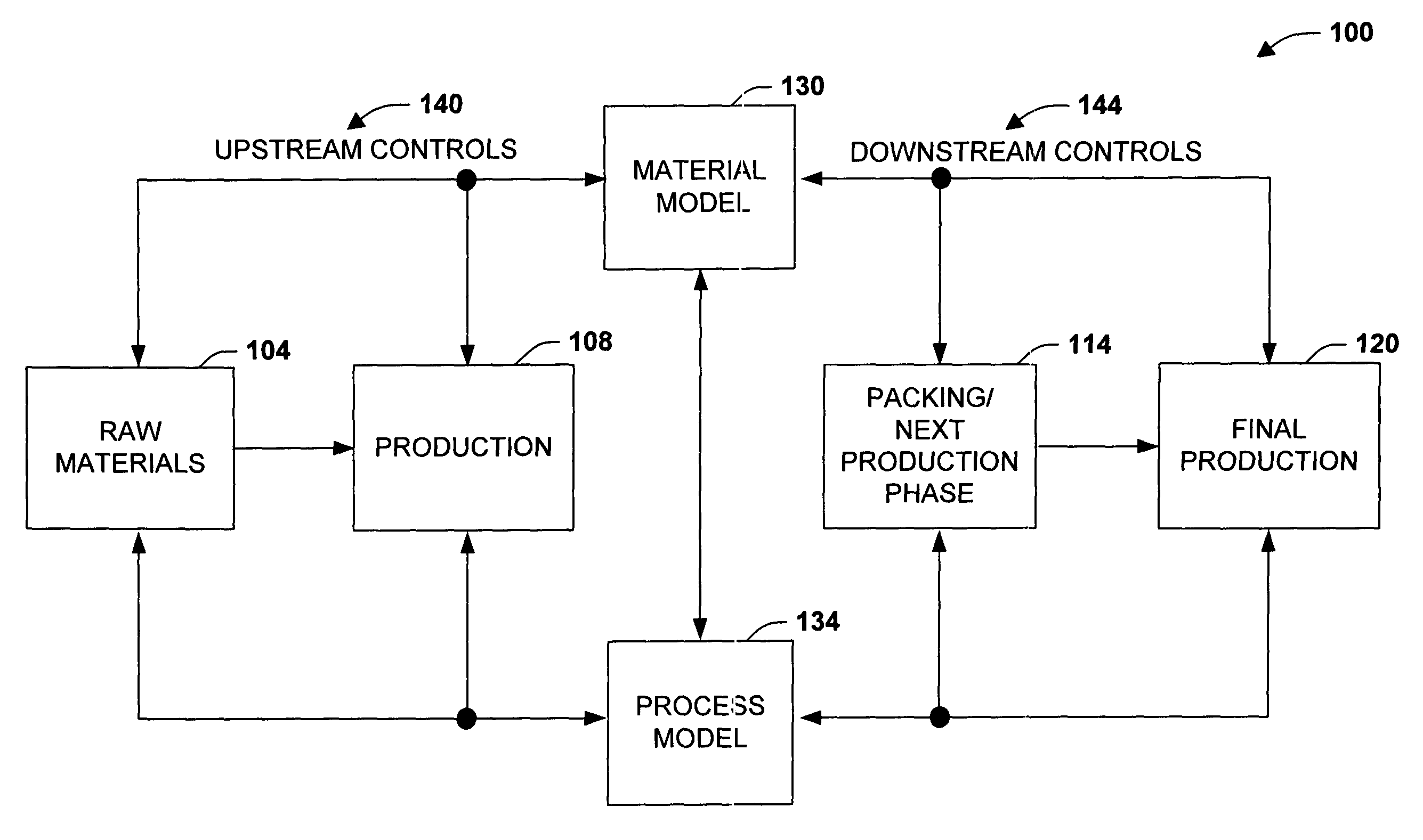

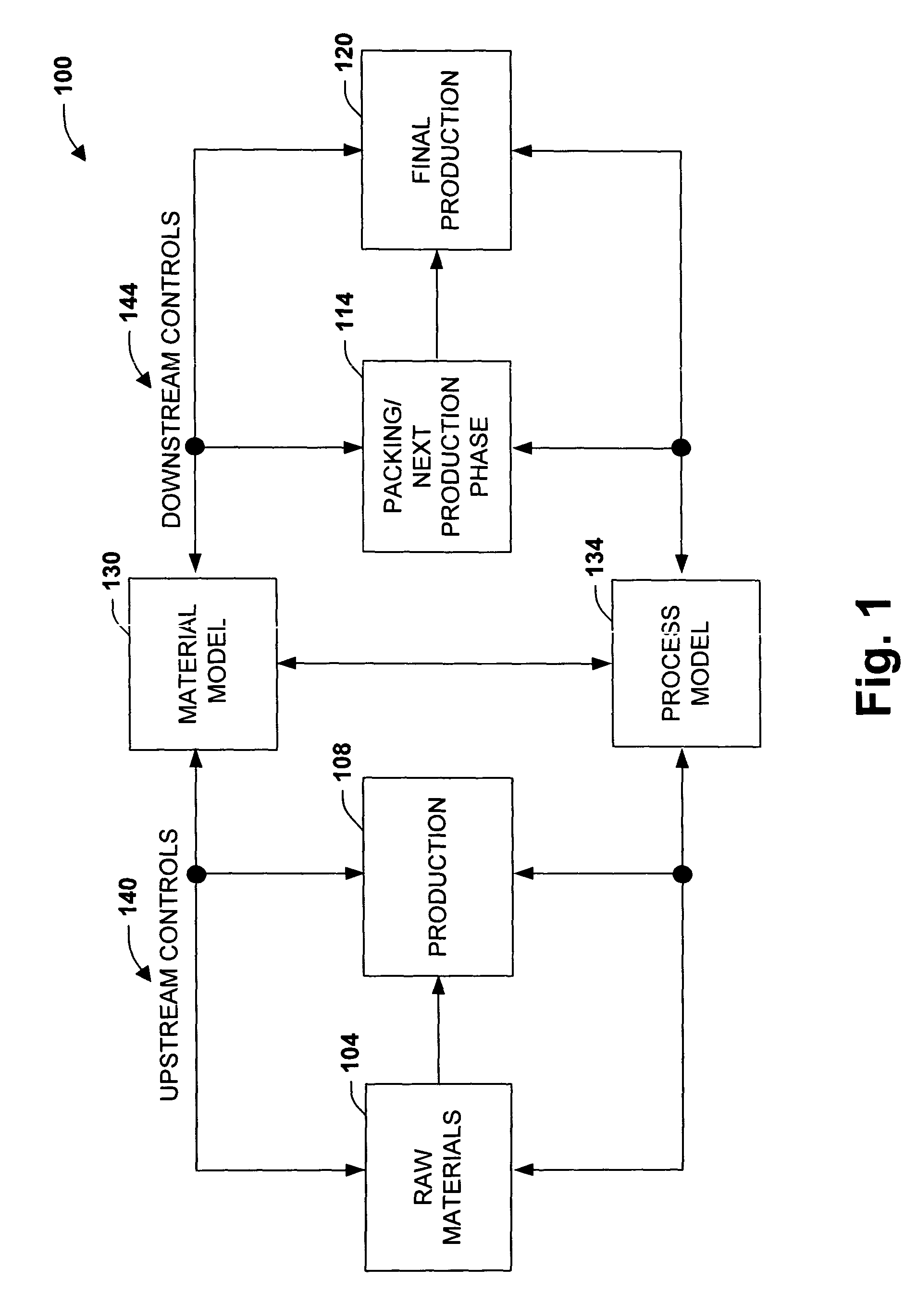

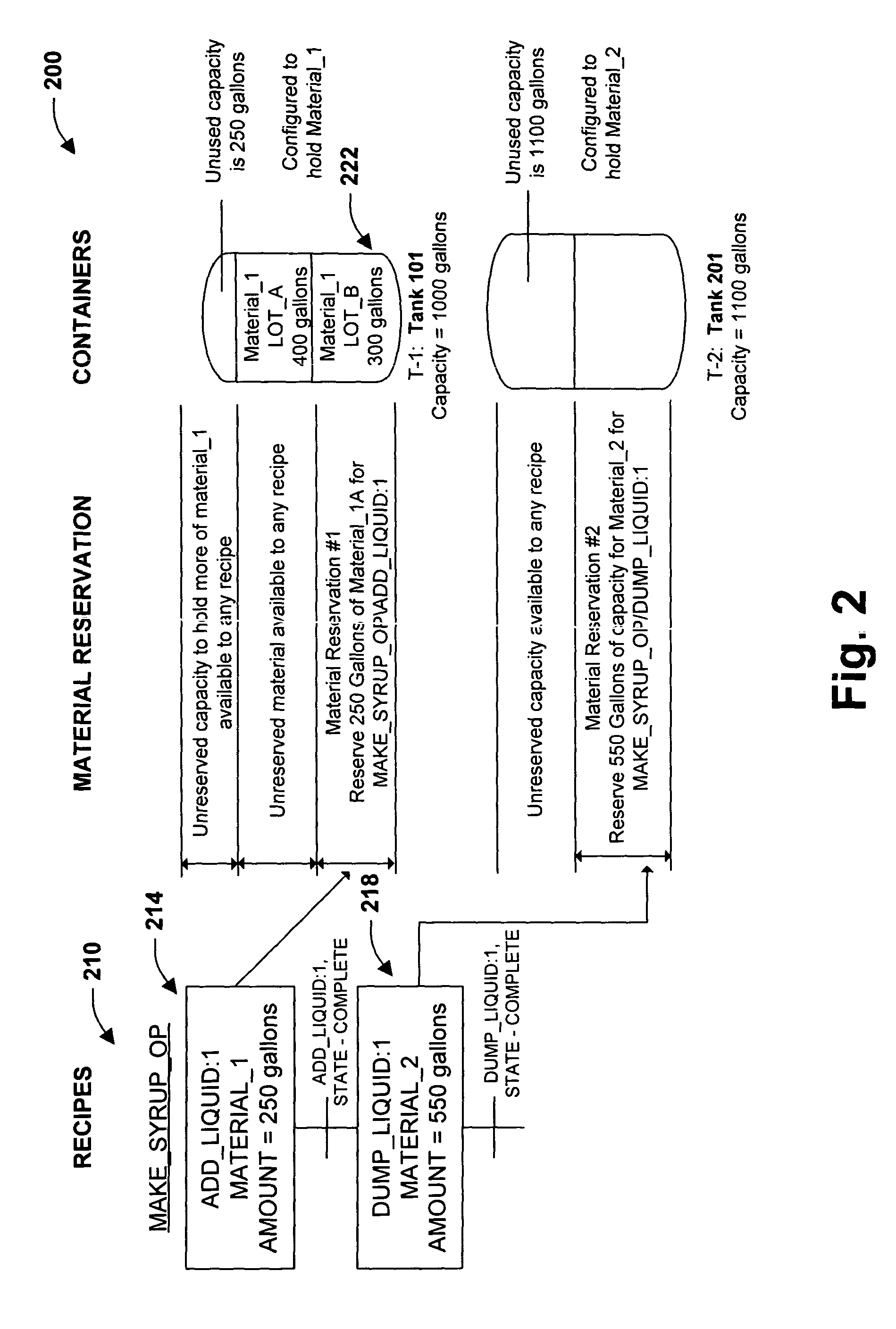

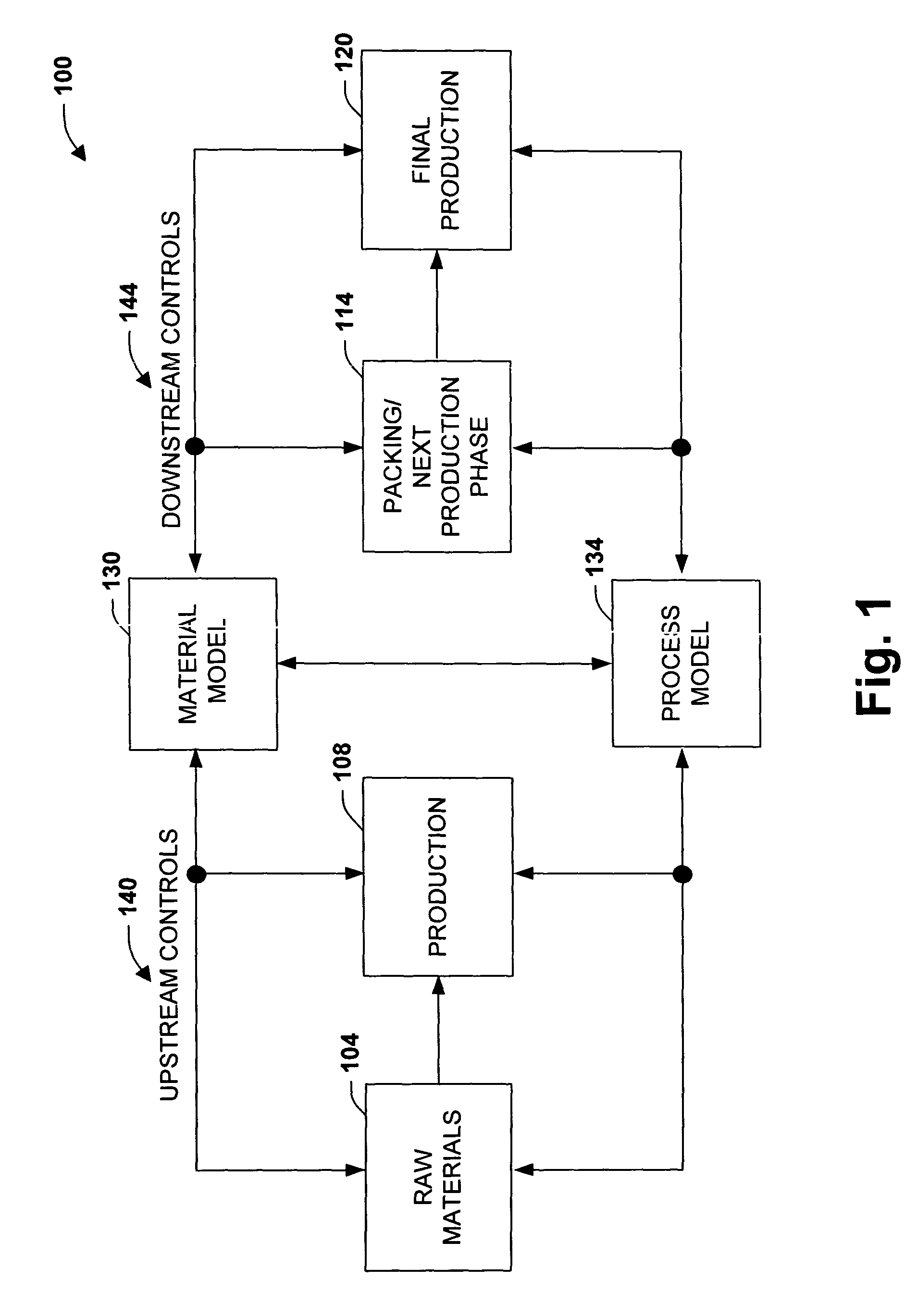

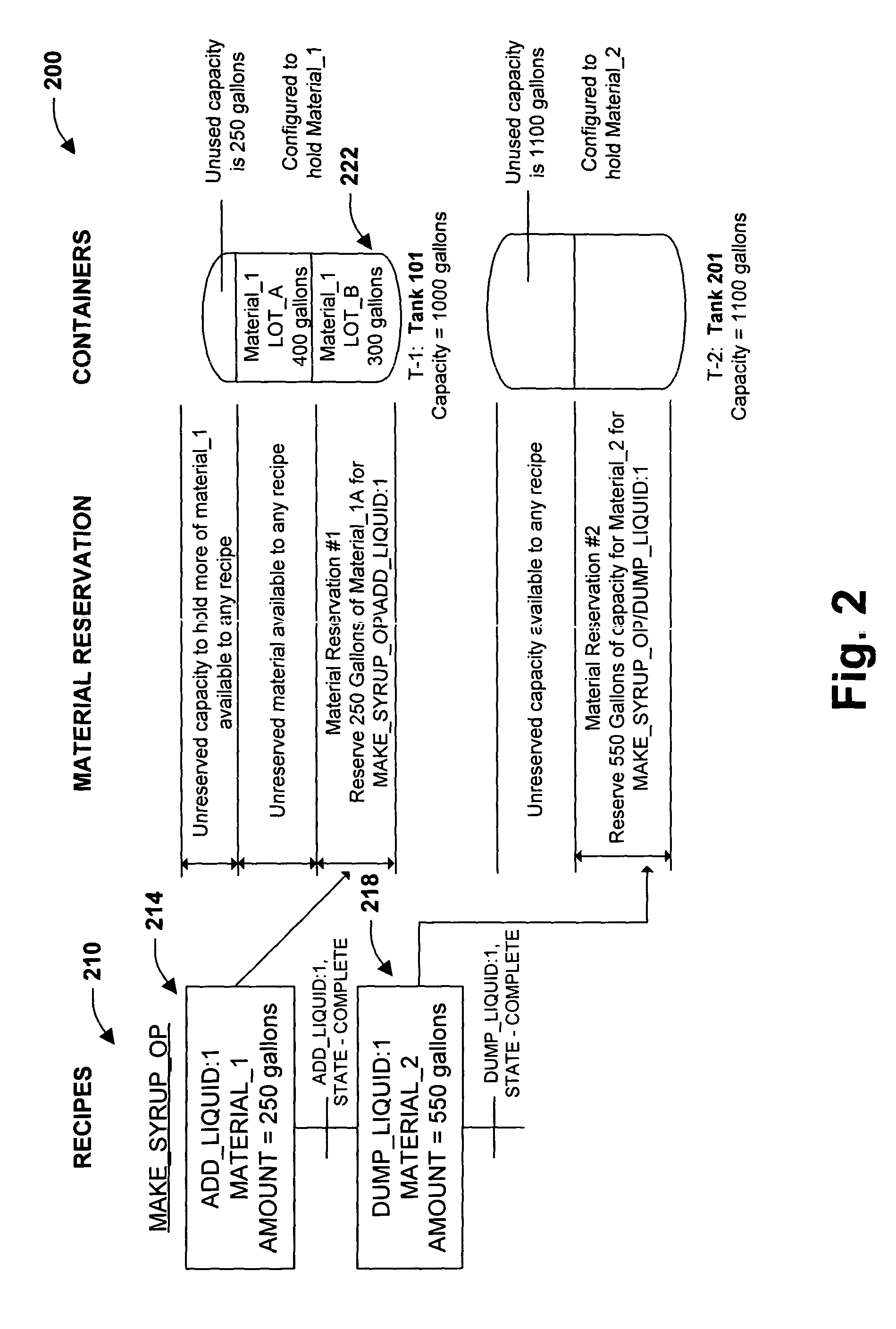

Material reservation distribution system and method

InactiveUS20050065626A1Easy to optimizeEfficient managementProgramme controlHand manipulated computer devicesBatch processingManufacturing operations

The present invention relates to a system and methodology facilitating material-driven processing in an industrial controller environment. Various models supported by database objects are provided to automatically and dynamically map inventory systems / processes to control systems / process such as in batch or recipe operations. A material model is provided that tracks to an inventory database and includes such aspects as defining material types and containers to house such materials. An area model maps the material model to possible units and equipment modules to process the materials. These models include phased-based parameters that define amounts of material that flow into and out of a determined area for processing the materials. Before, during and / or after automated manufacturing operations, object binding operations occur between material-based servers associated with an inventory system and batch servers associated with a process-control system. Such binding includes Just-In-Time or on-demand binding at run time, and relates material requirements of a recipe (or batch) to the units and equipment that are available to produce the recipe.

Owner:ROCKWELL AUTOMATION TECH

Inter-axle differential lock shift mechanism

InactiveUS20040204282A1Reducing space and material requirementLow production costFluid actuated clutchesGear lubrication/coolingGear driveEngineering

An improved inter-axle differential locking clutch is provided that aligns the actuator and the clutch member thereby reducing space and material requirements in the axle assembly housing. The clutch also eliminates the need for a pushrod and shift fork thereby reducing tooling and production costs, as well as eliminating issues associated with misalignment of the piston and pushrod, relative rotation of the shift fork and clutch member, and tipping of the shift fork. The clutch includes one or more pistons disposed within either the axle housing or a carrier supporting the input shaft bearing. Fluid pressure actuates the pistons against a clutch member causing selective engagement between the clutch member and either a side gear driven by the inter-axle differential or a differential case housing the differential gears of the inter-axle differential.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

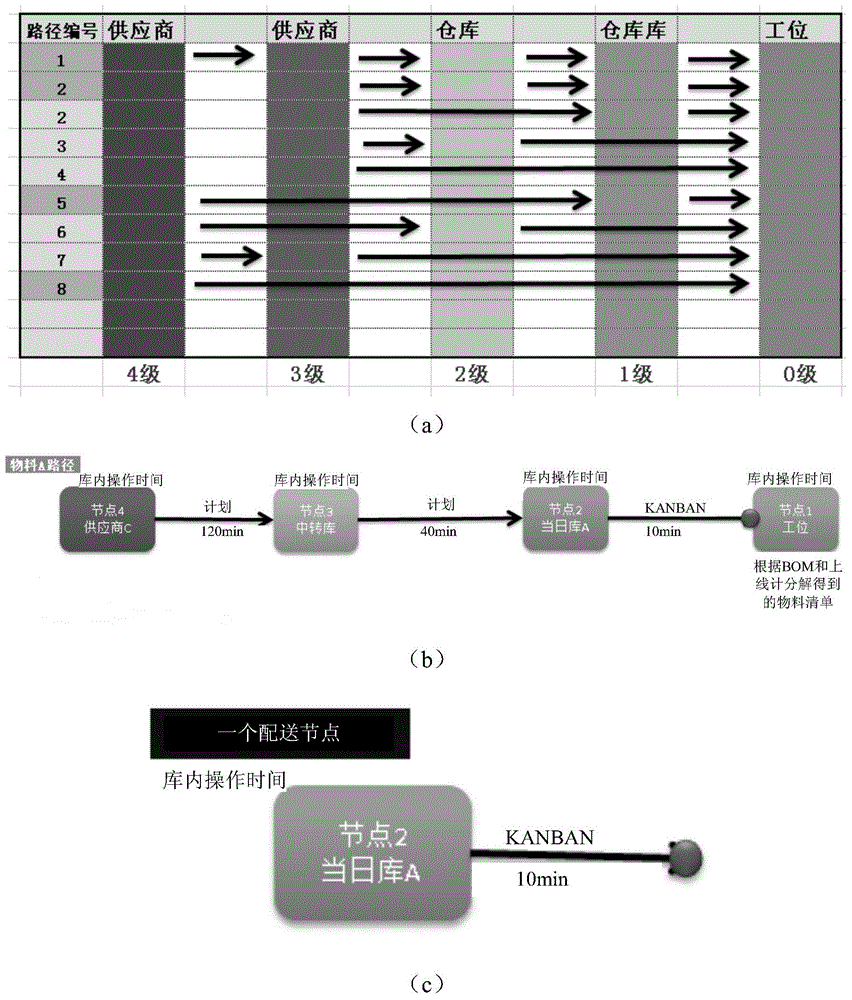

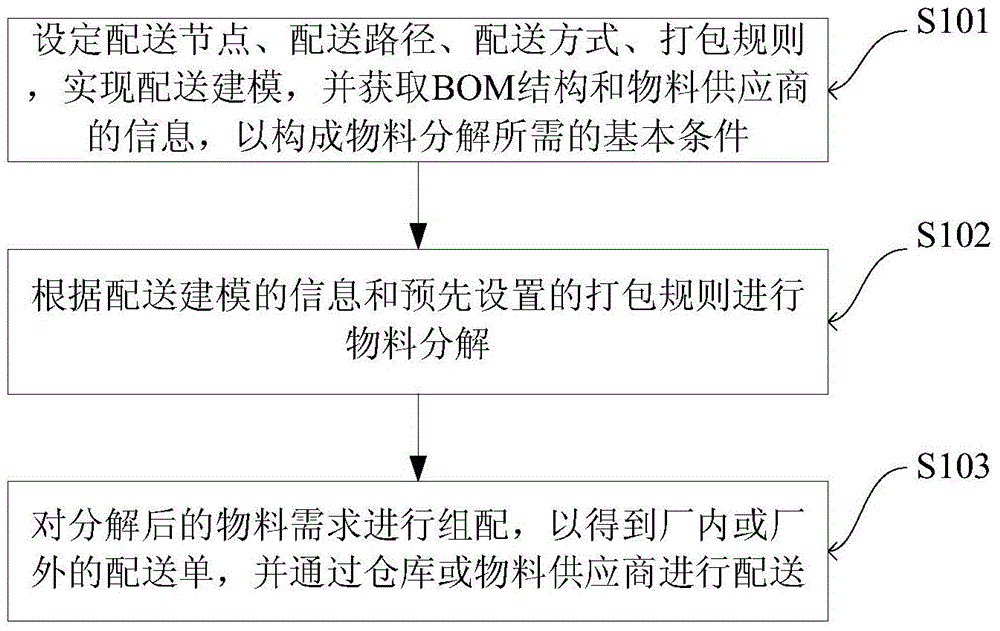

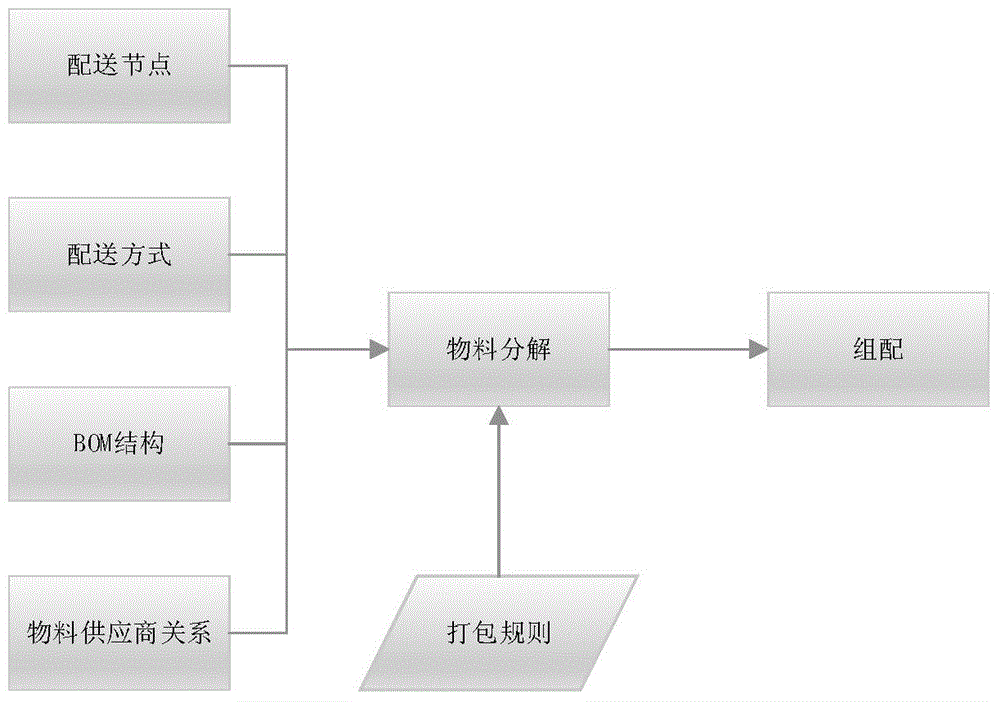

Material distribution method

ActiveCN104463521ARealize real-time decomposition and real-time distributionMeet the needs of pull distributionLogisticsDecompositionDistribution system

The invention discloses a material distribution method. The material distribution method includes the following steps that distribution nodes, distribution paths, distribution modes and a packaging rule are set for achieving distribution modeling; information of a BOM structure and a material supplier is acquired, and then basic conditions required for material decomposition are formed; material decomposition is conducted according to distribution modeling information and the preset packaging rule; decomposed material requirements are assembled, in-plant or out-plant distribution bills are acquired, and the materials are distributed through a warehouse or the material supplier. By the adoption of the method, the complexity of an existing distribution system is lowered, the stability and the timeliness of the system are improved, real-time decomposition and real-time distribution (JIT) of the materials are achieved, and the requirements for material pull type distribution in multi-variety, small-batch and mixed flow production in modern discrete manufacturing are met.

Owner:EPIC HUST TECH WUHAN

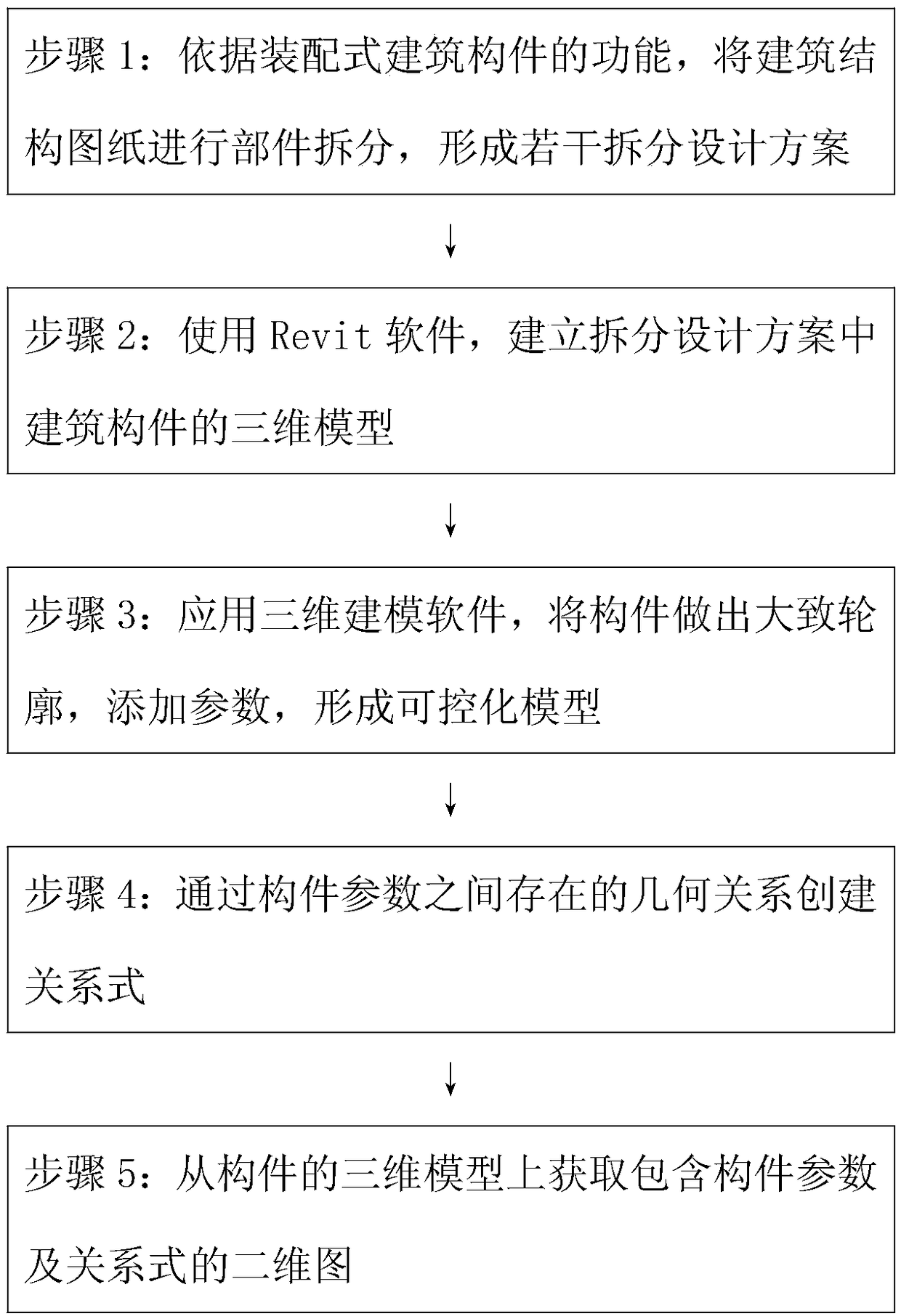

BIM-based fabricated member parametrization design method

InactiveCN108664697AFast and accurate generationMeet factory productionGeometric CADDesign optimisation/simulationTwo-dimensional graphDimensional modeling

The invention provides a BIM-based fabricated member parametrization design method. The method comprises the steps of 1: according to functions of fabricated building members, performing component disassembly on a building structure drawing to form a plurality of disassembly design schemes, wherein the schemes are specifically expressed in a form of "total construction design + BIM issued component disassembly drawing"; 2: by using Revit software, establishing three-dimensional models of the building members in the disassembly design schemes; 3: by applying three-dimensional modeling software,making rough profiles of the members, adding parameters, and forming controllable models; 4: through a geometric relationship between the parameters of the members, creating a relational expression;and 5: from the three-dimensional models of the members, obtaining a two-dimensional graph comprising the parameters of the members and the relationship expression. According to the design, the drawing needed by factory production is quickly and accurately generated, and the material requirement amount can be automatically calculated and summarized according to the parameters in the drawing.

Owner:山东住工装配建筑有限公司

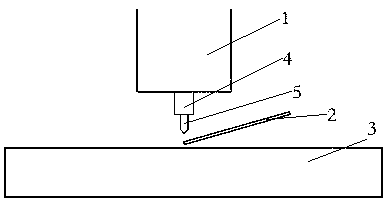

Electric arc additive manufacturing method

InactiveCN108723549AReduce mistakesNo crackElectrode holder supportersWelding accessoriesLoop controlSource type

The invention discloses an electric arc additive manufacturing method which comprises the following steps of (1) selecting a corresponding heat source type, a forming wire material, and a material type of a base plate according to the material requirement of a forming target part; (2) building a computer-aided design (CAD) geometric model of the forming target part, extracting a standard templatelibrary (STL) model, slicing the STL model, generating a G code file required for printing, and transmitting the G code to a printer; (3) setting printing parameters, starting the printer, and printing metal thin layers according to a planned route layer by layer; and (4) after finishing printing all layer sheets through the printer, carrying out arc failure through a welding gun, and obtaining the forming target part. An additive piece printed through the method provided by the invention is less in error and flawless, has the advantage of good surface quality, and is stable in process, high in dimensional accuracy and surface quality, short in processing period, and low in cost at the same time; the printing process is in closed-loop control, so that the automation degree is high, and thelabor intensity of operating personnel can be reduced; and continuous manufacturing can be realized, and the manufacturing efficiency is high.

Owner:HOHAI UNIV CHANGZHOU

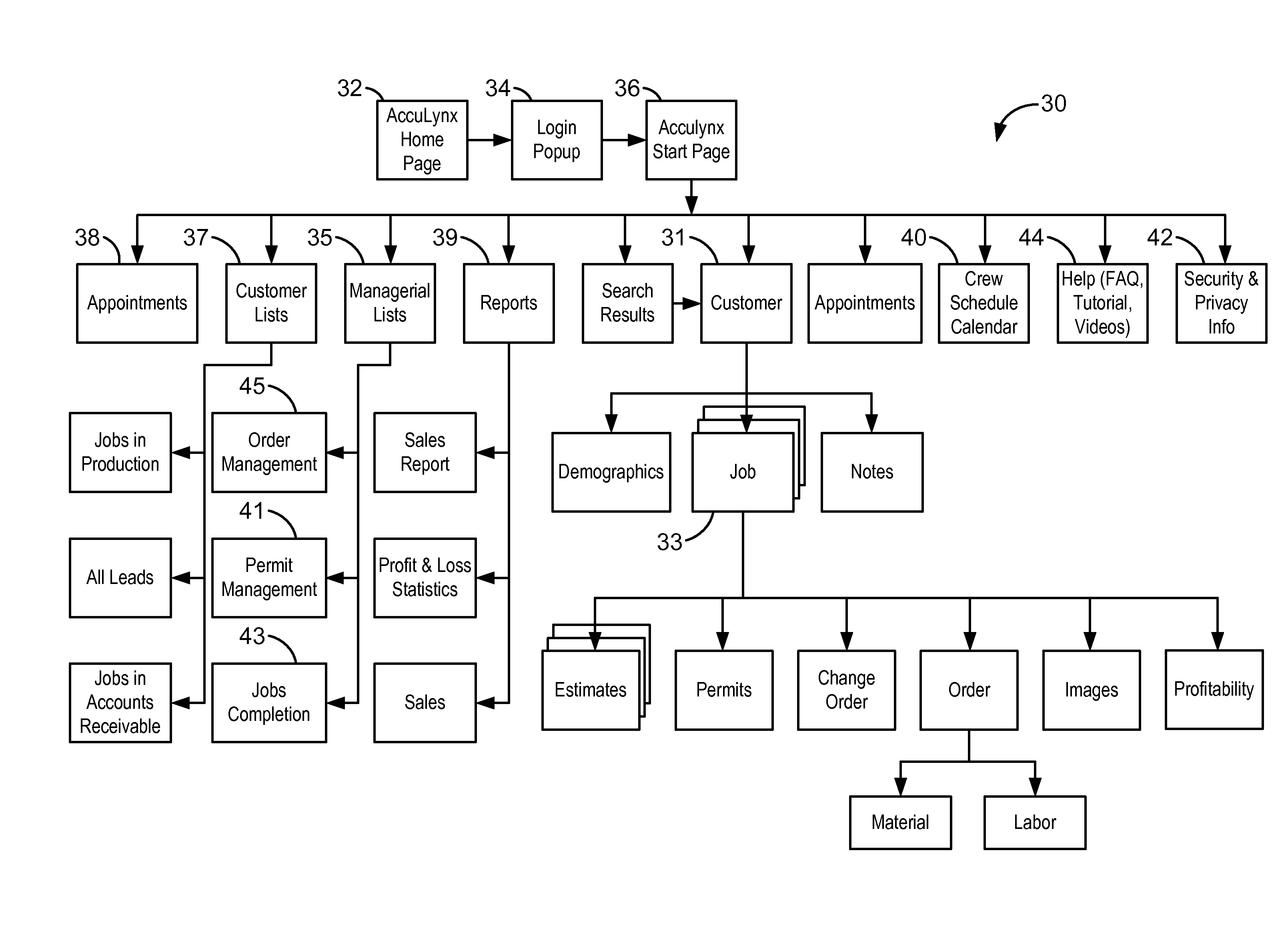

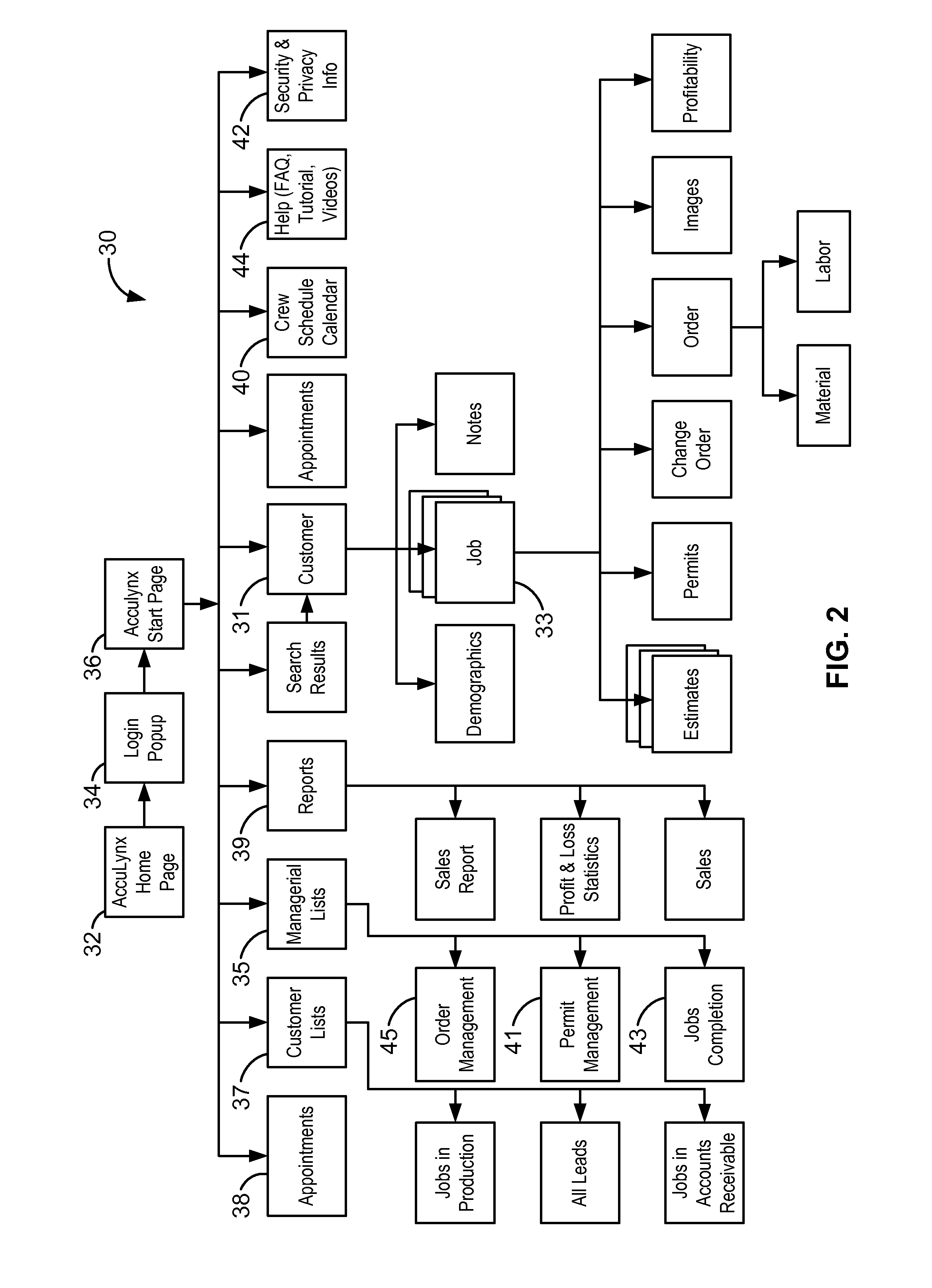

System for the Management of Construction Projects

A computer-based system for managing construction repair project that includes an input device coupled to a processor, an output device coupled to the processor, wherein the processor is programmed to perform certain actions based on user input. The processor is programmed to determine material requirements for the repair project, determine the labor requirement for the repair project, and to generate a cost estimate for the repair project. The processor is also programmed to generate purchase orders for materials based on the material requirements, generate a work crew schedule base on the labor requirements, generate a project schedule that provides a timeline for work to be performed on the repair project, while regularly providing status updates to the user regarding the work performed on the repair project.

Owner:EXACT LOGIX

Solar array support methods and systems

InactiveUS20160065116A1Reduce laborCost-effectivePhotovoltaic supportsSolar heating energySupporting systemMaterial requirements

Systems and methods for disposing and supporting a solar panel array are disclosed. The embodiments comprise various combinations of cables, support columns, and pod constructions in which to support solar panels. Special installations of the system can include systems mounted over structures such as parking lots, roads, aqueducts, and other bodies of water. Simplified support systems with a minimum number of structural elements can be used to create effective support for solar panel arrays of varying size and shapes. These simplified systems minimize material requirements and labor for installation of the systems.

Owner:P4P HLDG

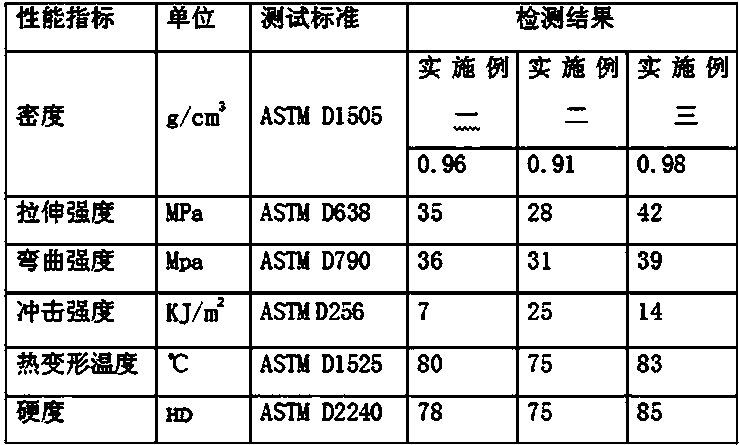

High-impact high-stiffness polypropylene rotational molding material and preparation method thereof

The invention relates to a high-impact high-stiffness polypropylene rotational molding material and a preparation method thereof. The rolling plastic rotational molding material comprises the following raw materials: by weight, 100 parts of polypropylene, 0-30 parts of polyethylene, 0-0.1 part of a crosslinking agent, 0-0.15 part of an auxiliary crosslinking agent, 1-10 parts of an elastomer, 0.1-0.5 part of an antioxidant, 0-10 parts of a nano filler, 0.1-0.5 part of a dispersing lubricant and 0-0.4 part of a surface treatment agent. According to the invention, the crosslinkable polyethylene is added in a polypropylene melt mixing process for melt curing to obtain the high-impact high-stiffness polypropylene modified rotational molding material with a semi interpenetrating network structure, and the high-impact high-stiffness polypropylene modified rotational molding material can meet the material requirements of vehicles and other different fields. The curing reaction of the polyethylene belongs to the in situ curing, the material has the unique semi interpenetrating network structure, different components are mutually bitten or buckled, the compatibility between the polyethylene and polypropylene resin can be improved, and the performance advantages of the both are full played.

Owner:天津市华鑫达投资有限公司

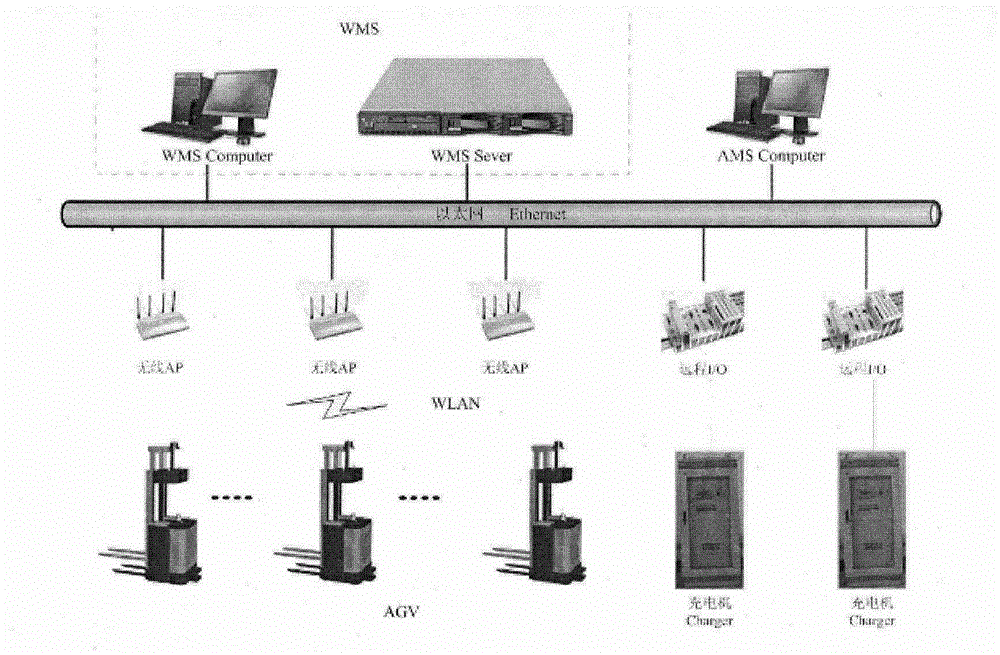

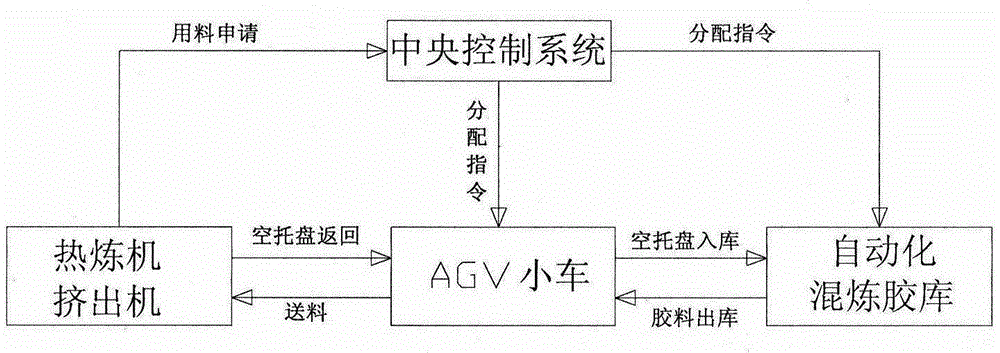

System and method for automatic conveying of tire factory

InactiveCN104944092ARealize the information management of the whole plantReduce manufacturing costControl devices for conveyorsMechanical conveyorsVulcanizationMaterial requirements

The invention provides a system for automatic conveying of a tire factory. The system comprises a rubber compound storage unit, a rolling forming unit, a vulcanization unit and a tire finished product storage unit, wherein product conveying, excess material returning conveying and empty tray recycling conveying are performed between every two adjacent units through an automatic guide vehicle (AGV). The AGV is controlled through a main control computer, and an AGV conveying task is issued to a console according to the site material requirement conditions. The method for applying an AGV technology to tire production enterprises has the advantages of reducing production cost and labor intensity, improving operation accuracy and reducing occupied space, and achieves whole plant information management of the tire production enterprises.

Owner:马涛

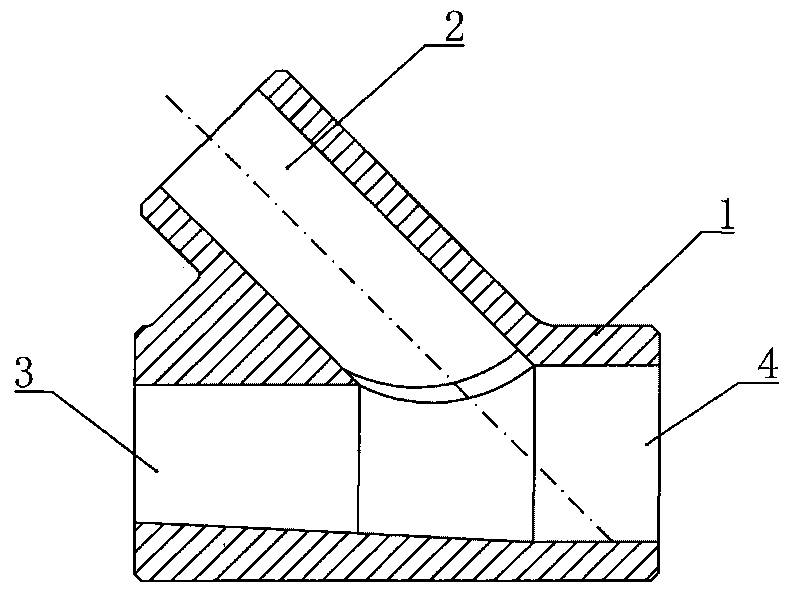

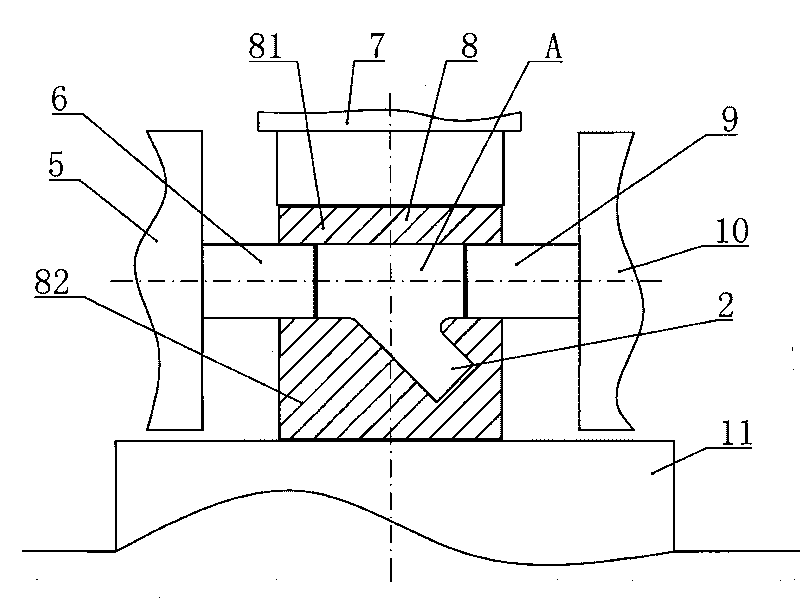

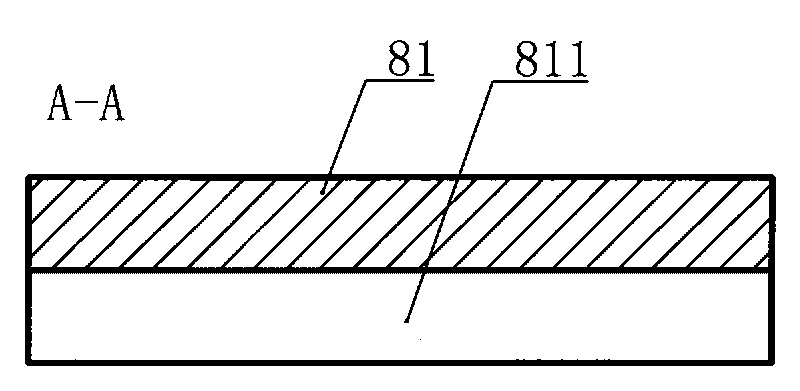

Forging process of large tee and large skew tee

ActiveCN101695739AQuality improvementImprove mechanical propertiesForging/hammering/pressing machinesEngine componentsWater basedGraphite

The invention relates to a forging process of a large tee and a large skew tee, which comprises the steps of: putting cut blanks in a heating furnace to heat to 1200 DEG C; preheating a forging die to 200-250 DEG C, respectively coating water base graphite and glass lubricant on the forging die and the cut blanks; putting the cut blanks on a multi-direction die liquid forging press mould, moving an upper cylinder to enable an upper die to mutually press a lower die; starting an upper oil cylinder, a left oil cylinder and a right oil cylinder of a forging press for forging; releasing pressure to move the mould after molding by the forging die, taking a semi-finished product out to be put into a heat treatment furnace for furnace cooling and annealing, carrying out heat treatment, nondestructive recheck and mechanical behavior check according to the steel material requirement, and preparing for the next machining; and machining the treated semi-finished product according to the drawing requirement. The invention has the advantages of reducing energy resources and improving the production efficiency.

Owner:HEBEI FOCUS PIPING

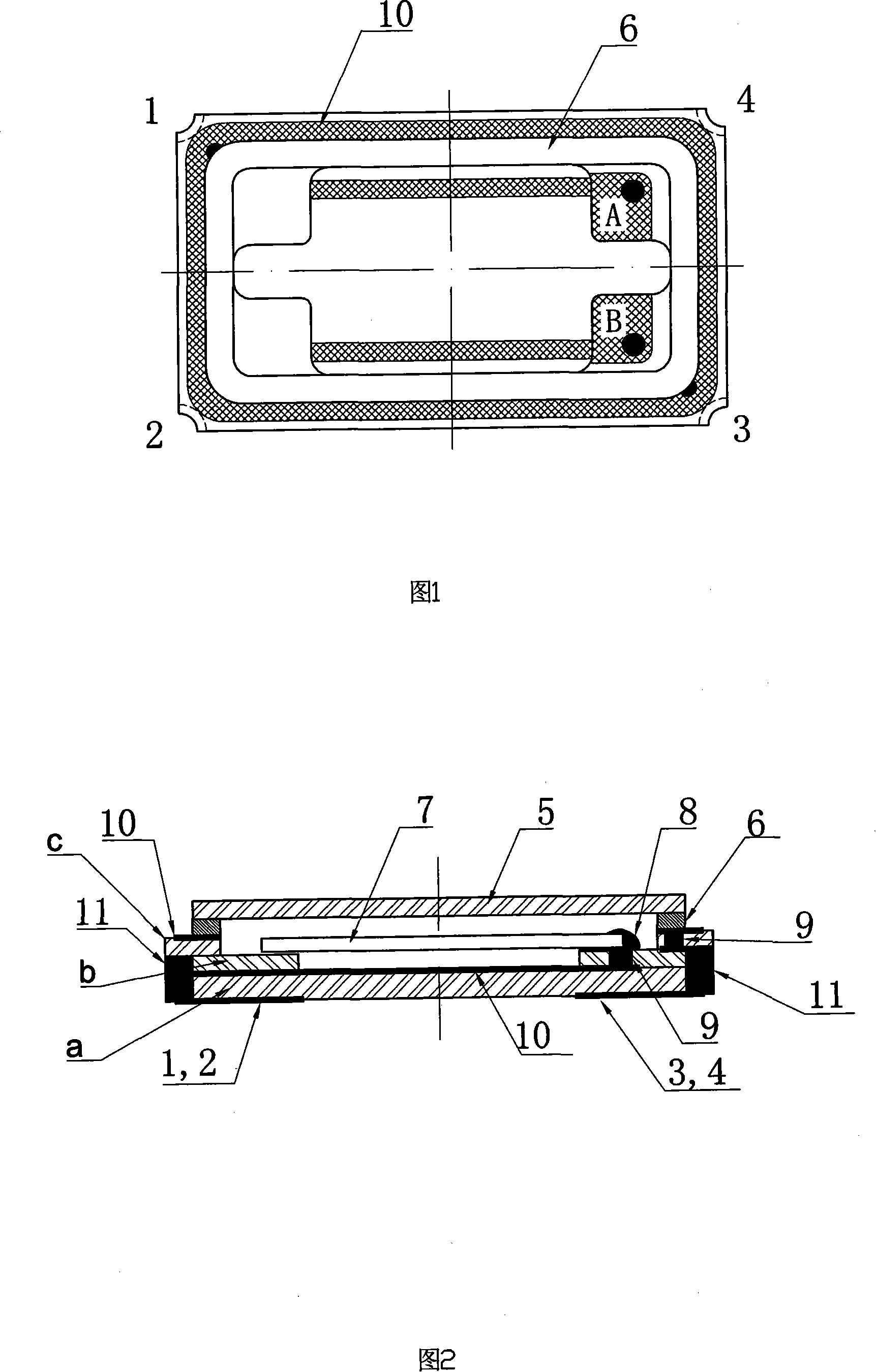

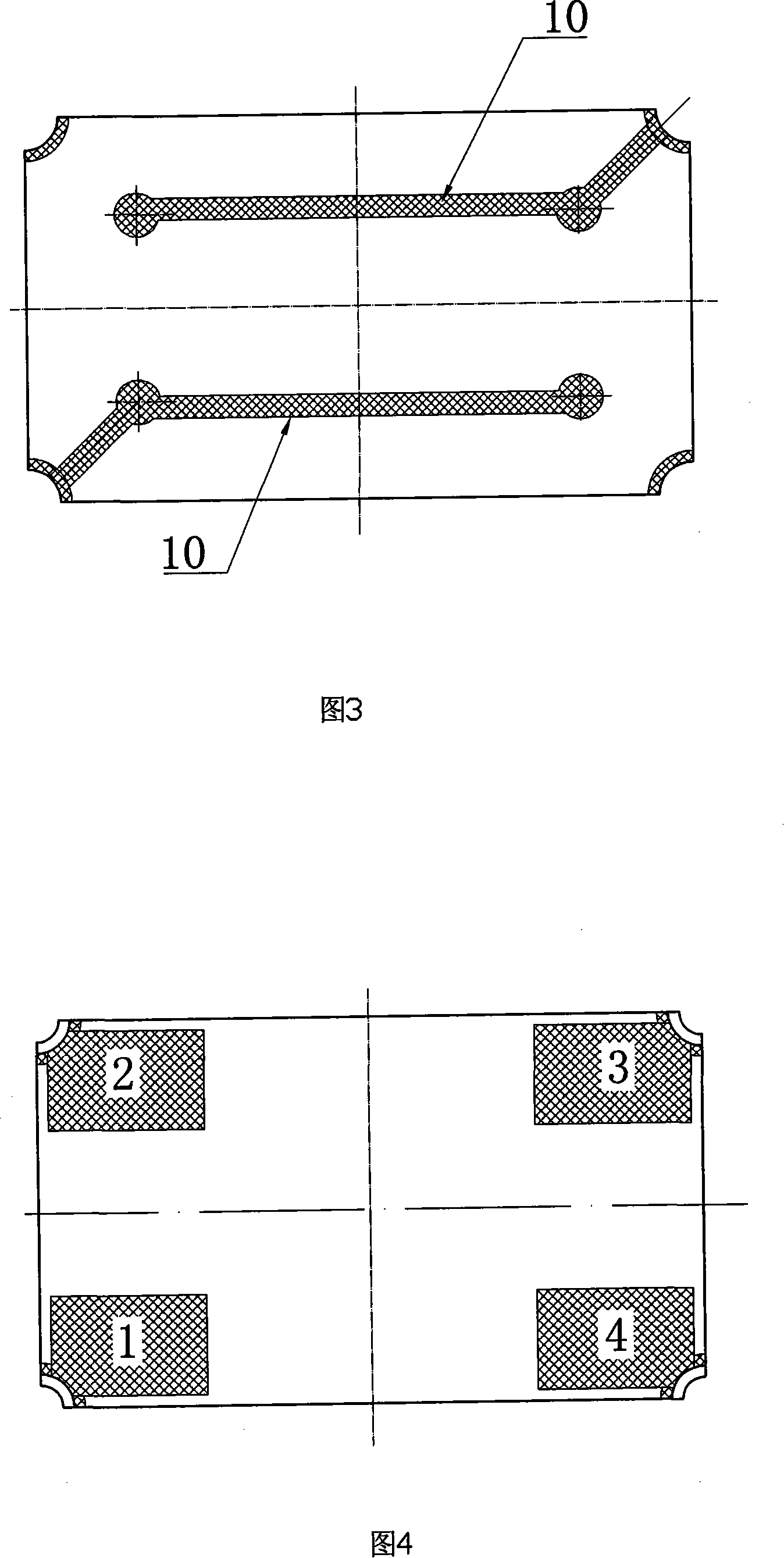

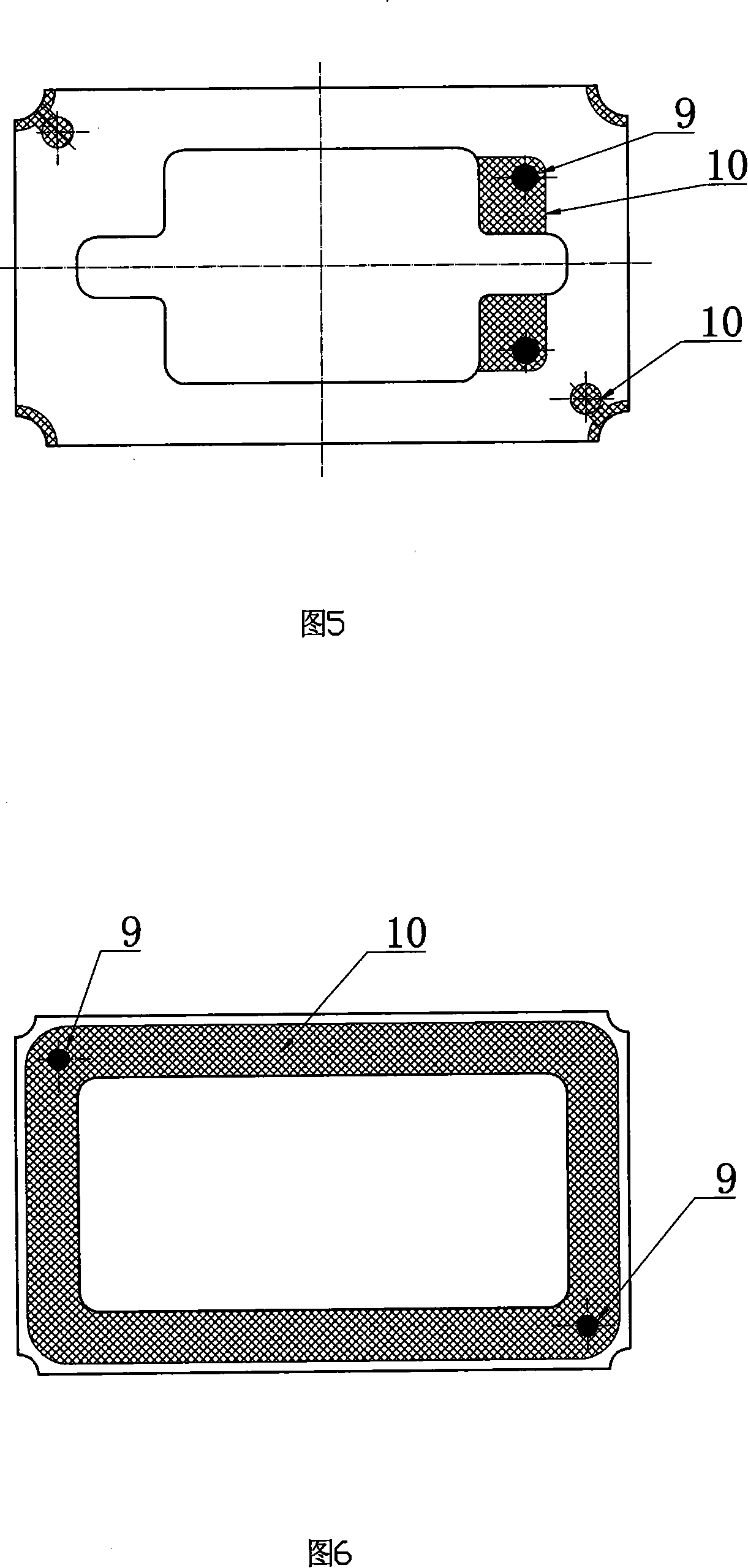

Ceramic packing member used for SMD crystal resonator and manufacturing technique thereof

InactiveCN101132169AThe number of layers of co-fired ceramic plates is reducedReduce manufacturing costImpedence networksSemiconductor/solid-state device detailsShielding gasCarbon Dioxide / Helium

This invention relates to a technique for ceramic packing the transistor resonator, particularly the ceramic package component used for SMD transistor resonator. It is composed of: the co-sintered ceramic layer and the ceramic cover. Said co-sintered ceramic layer comprises the coincided No.1 ceramic layer and No.2 ceramic layer. Over the No.2 layer is the ceramic cover; on the upper surface of the No.1 layer is the printed convex platform, which is used for supporting transistors and guiding the electrodes, through the holes, to the basal plane soldering plate. The advantages are: simple sintering process, low production cost, reducing shielding gas protective soldering, low kovar frame material requirement, low gold-plated area, and short leading wire.

Owner:CHAOZHOU THREE CIRCLE GRP

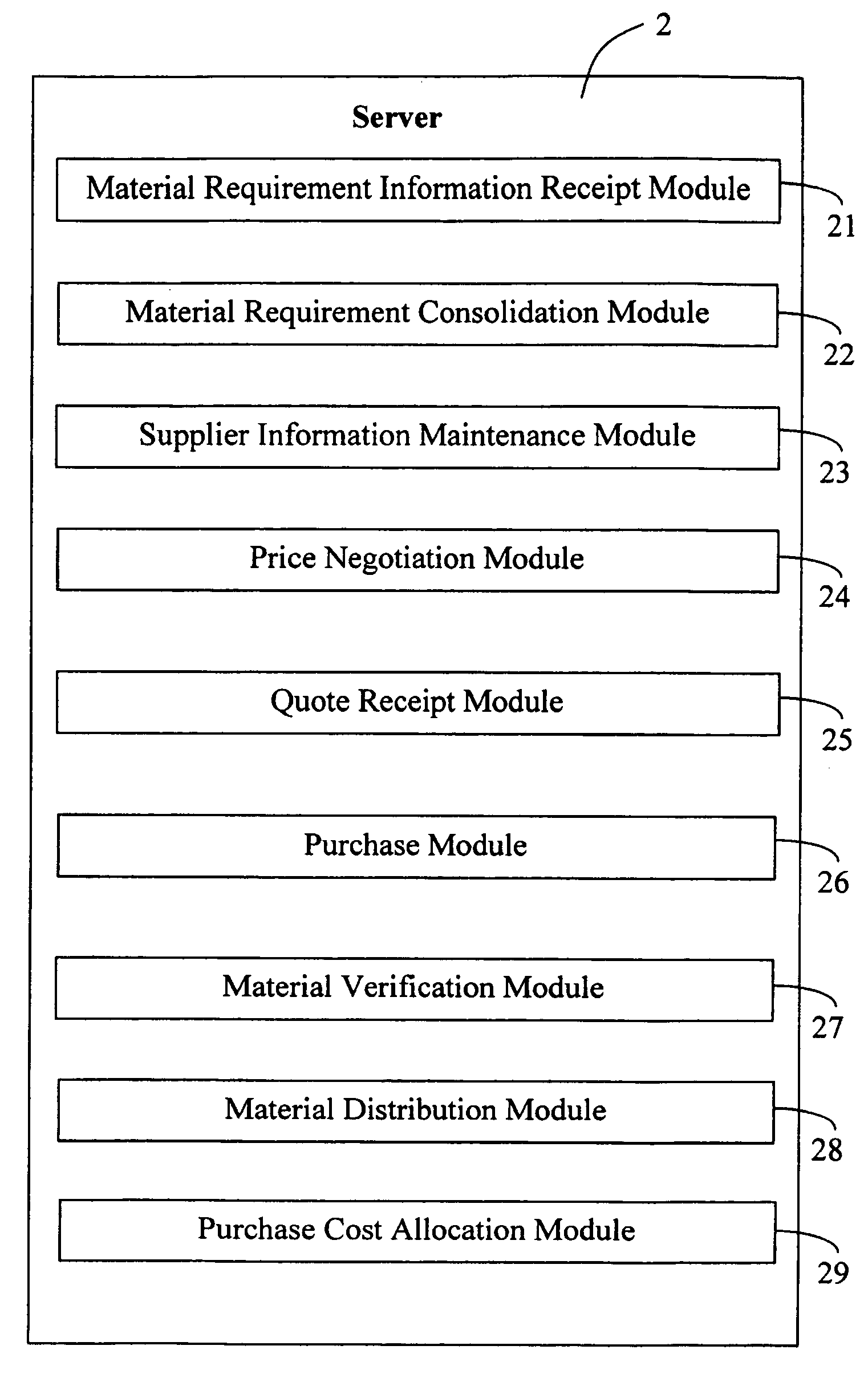

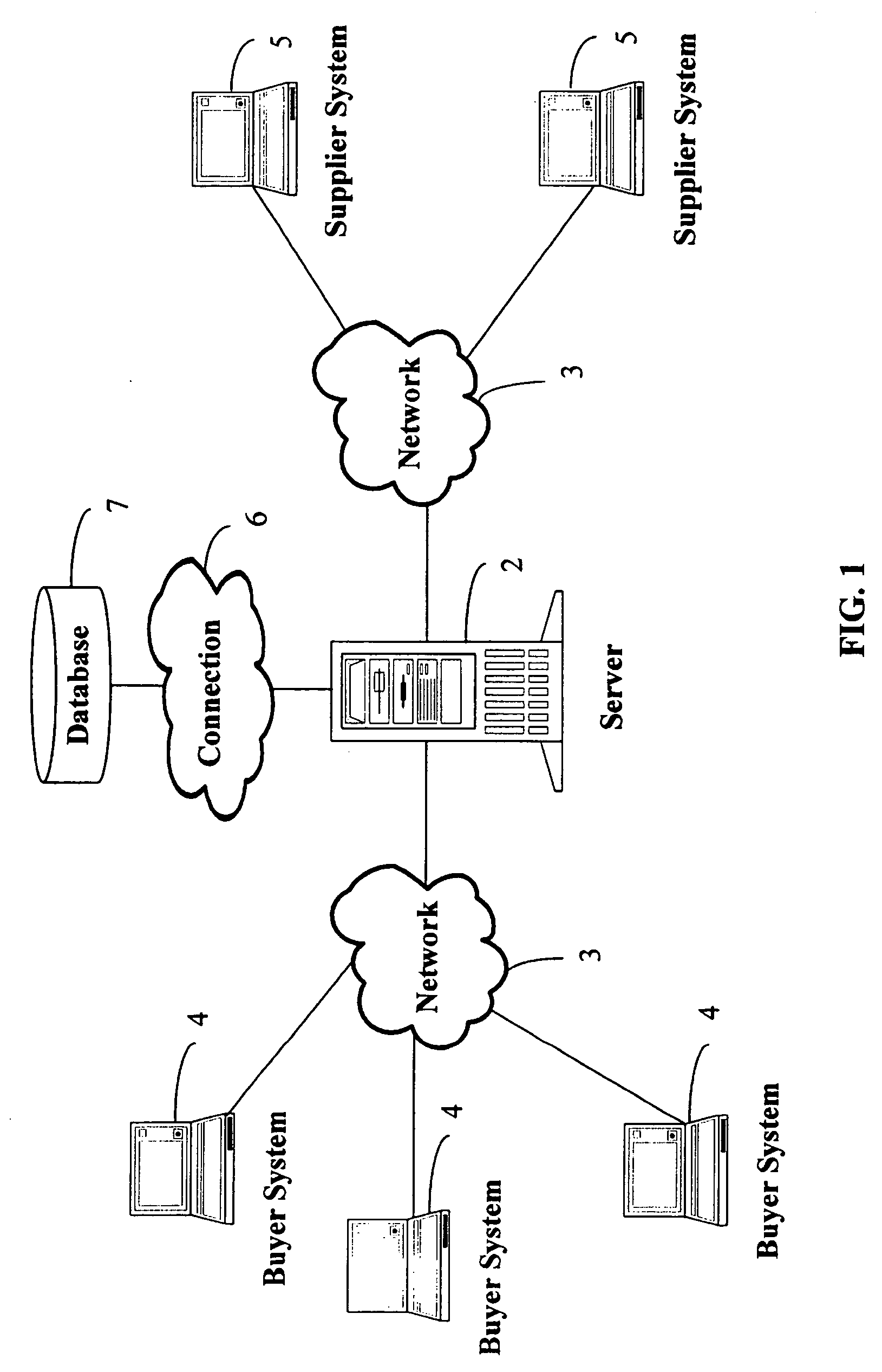

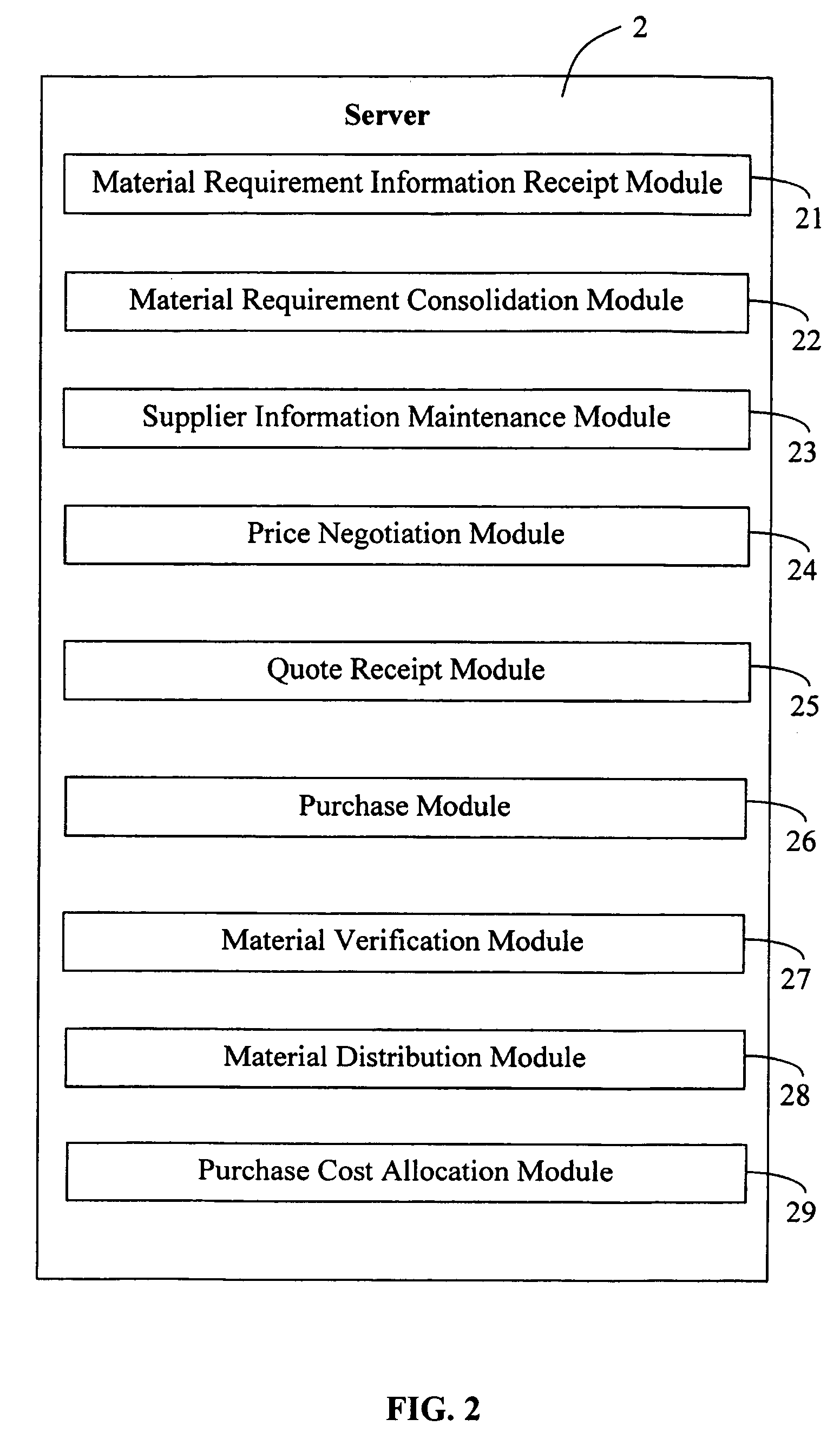

Consolidated procurement management system and method

InactiveUS20050010491A1Reduce expensesLower purchase costResourcesCommerceCost distributionApproaches of management

A consolidated procurement management system includes a server (2), and a plurality of buyer systems (4) and a plurality of supplier systems (5) connected to the server through a network (3). The server includes: a material requirement information receipt module (21) for receiving material requirement information from the buyer systems; a material requirement consolidation module (22) for calculating a total requirement quantity for each material, and generating consolidated material requirement data; a quote receipt module (25) for receiving quotes from the supplier systems; a purchase module (26) for determining one or more winning suppliers from a plurality of suppliers participating in price negotiations, and for generating purchase orders; and a purchase cost allocation module (29) for calculating purchase costs and expenses for each buyer, and for generating purchase cost allocation information. A related consolidated procurement management method is also disclosed.

Owner:HON HAI PRECISION IND CO LTD

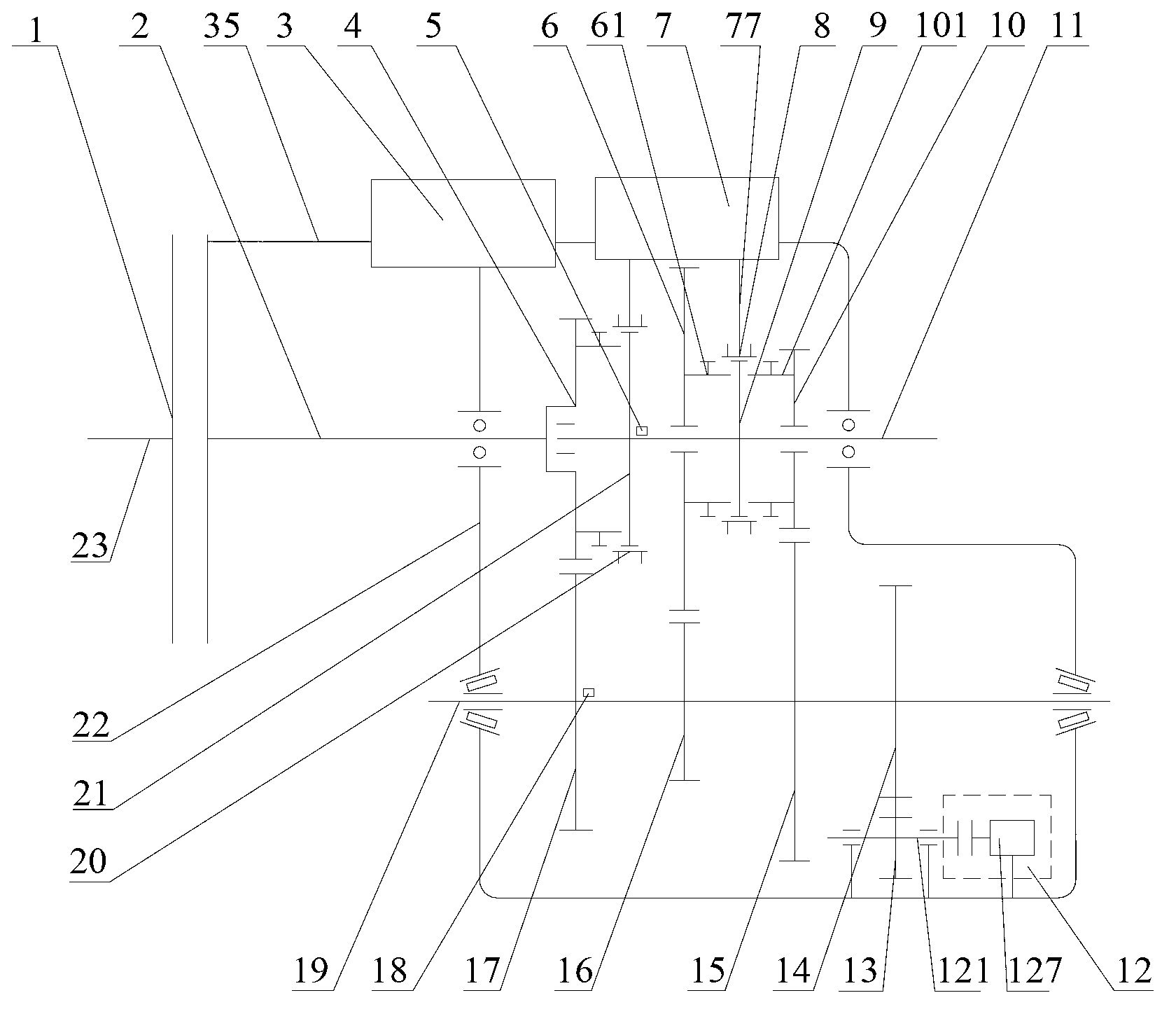

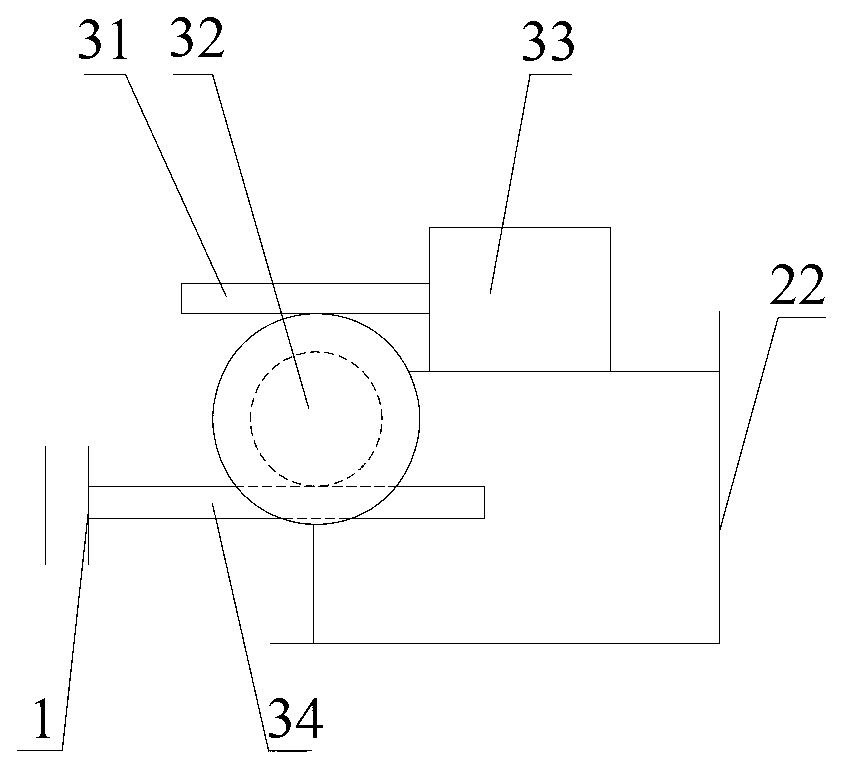

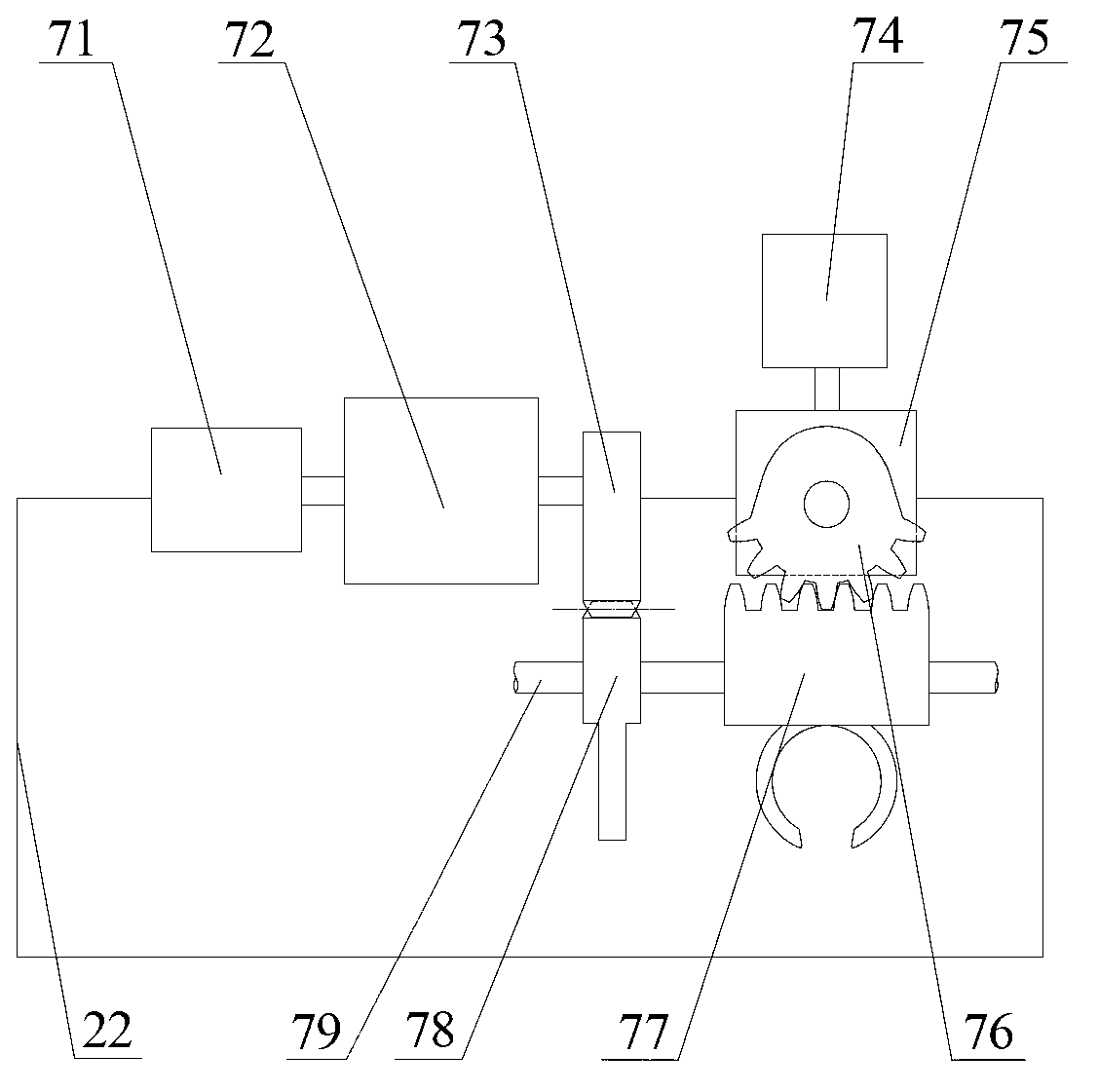

Synchronizer-free shifting system for regulating speed of intermediate shaft of electric automobile

ActiveCN102840309AReduce loadReduced Power RequirementsGearboxesMechanical actuated clutchesElectric machineDrive motor

The invention relates to a front-engine rear-drive automatic mechanical transmission case shifting system for a driving motor, in particular to a synchronizer-free shifting automatic mechanical transmission case for regulating the speed of an intermediate shaft based on a small quantity of gears, belonging to the technical field of automobile control. The system comprises an input shaft, an intermediate shaft, an output shaft, driving and driven gears for each gear, a splined hub, a jointing sleeve, a sensor, a speed regulating motor, a speed regulating motor transmission mechanism, a clutch operating mechanism, a shifting executing mechanism and a controller. According to the system, the rotating speed of the intermediate shaft is regulated through the speed regulating motor, so that synchronization of the jointing sleeve and a target gear during shifting is realized, a synchronizer with high material requirements is eliminated, reduction in the cost is facilitated, and the effect of compatibility among startup, accelerating performance and relatively high-speed running of a small-sized pure electric automobile is realized simultaneously.

Owner:TSINGHUA UNIV +1

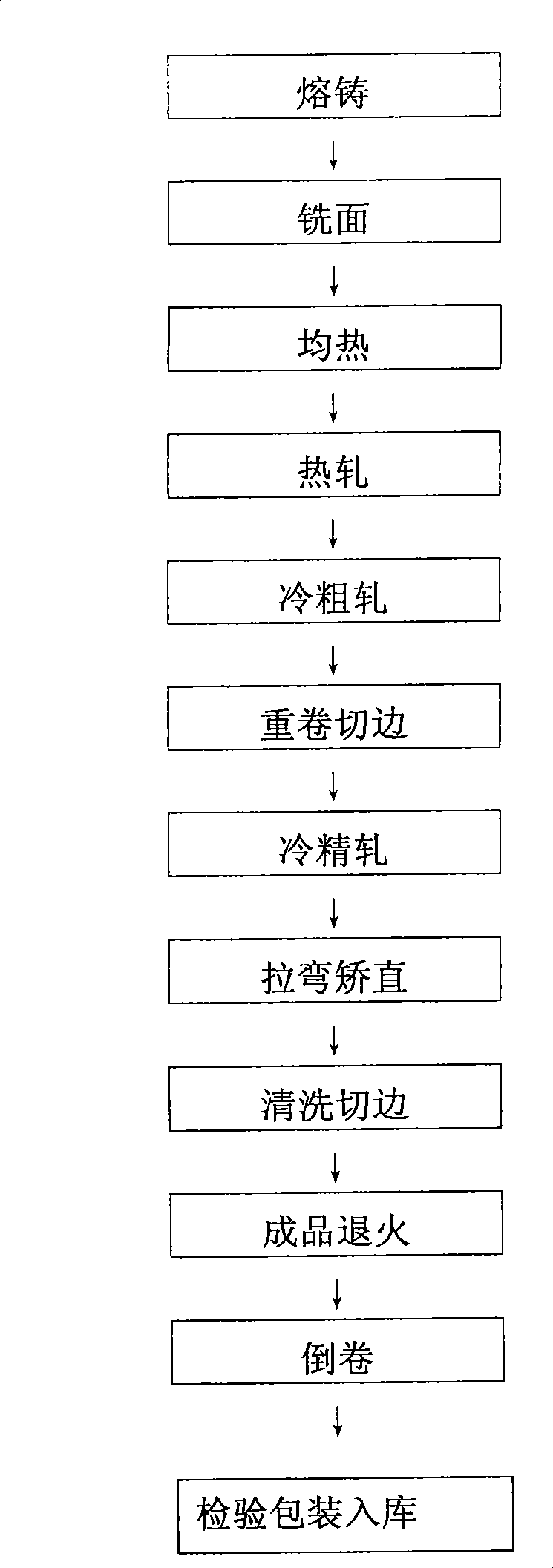

Processing process method of corrosion-resistant copper-zinc-aluminum alloy material

ActiveCN102352452AConvenience for subsequent useGood resistance to multiple corrosionRare-earth elementCerium

The invention discloses a processing process method of a corrosion-resistant copper-zinc-aluminum alloy material. In the processing process method, a copper-zinc-brass alloy is used as a matrix, and elements such as zinc, aluminum, nickel, silicon, boron, manganese and rare earth are added to achieve the aims of high wear resistance, high corrosion resistance, high-temperature resistance and goodmachinability, thus the material requirements of the ocean development and utilization industry, the seawater desalination and heat transfer industry and other special industries can be met; and the energy is saved and the production cost is reduced. The processing process method uses the copper-zinc-brass alloy as the matrix and comprises the following steps: adding nickel, iron, lead, silicon, manganese, aluminum, zinc, boron and at least one of lanthanum and cerium or mixed rare earth elements in turn, dosing, casting, performing saw cutting, heating, performing hot rolling, milling surfaces, performing cold rough rolling, annealing, rolling to obtain a finished product, annealing the finished product, shearing, packaging and warehousing. If the product is required to be in a hard state, the annealing of the finished product is not performed; the corrosion-resistant copper-zinc-aluminum alloy material strip can be prepared, and the important steps are casting, heating and hot rolling; and the processing process is easy, the method is simple, and labor and time can be saved; and the processing process method is convenient to popularize.

Owner:中铝洛阳铜加工有限公司

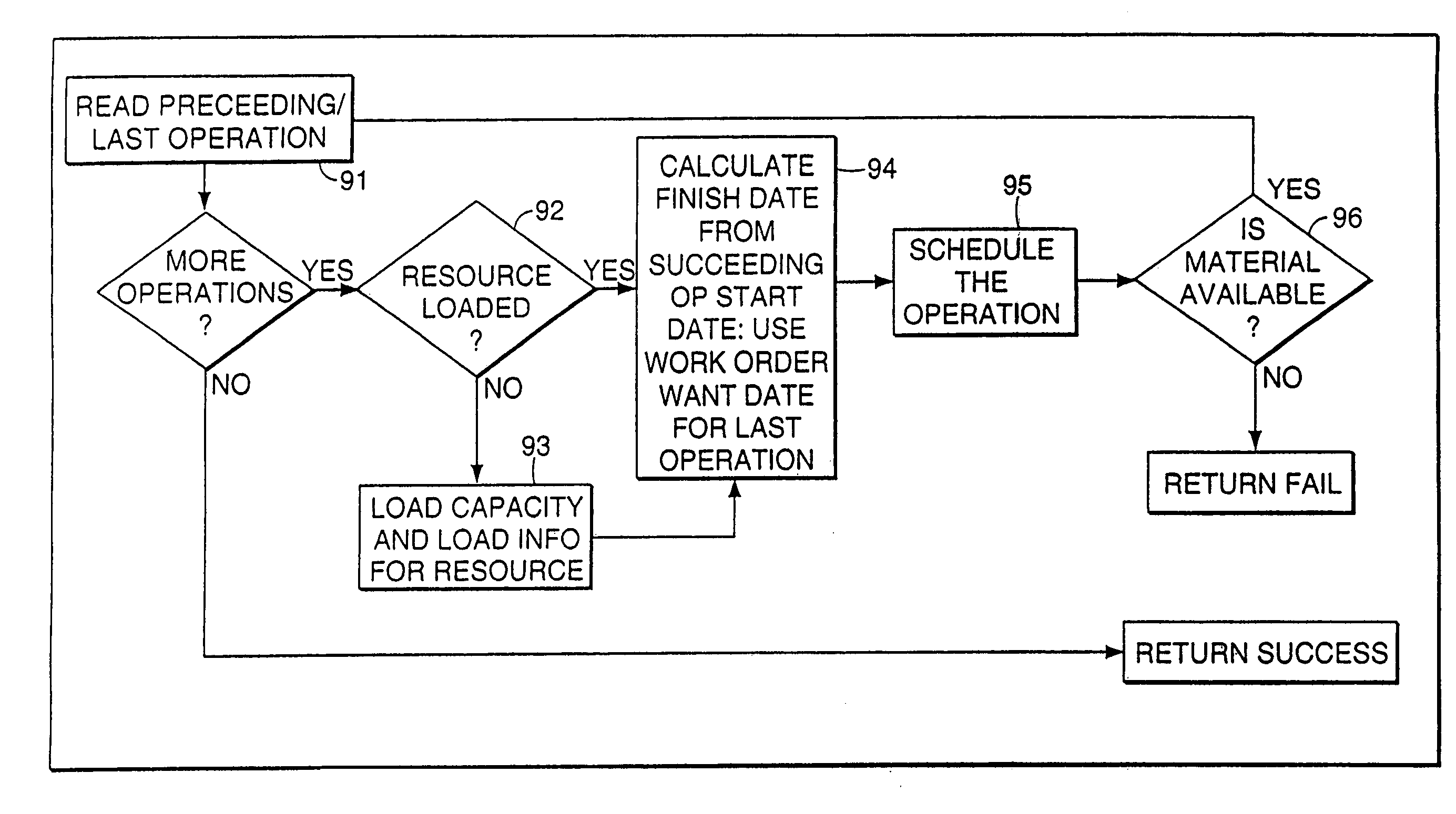

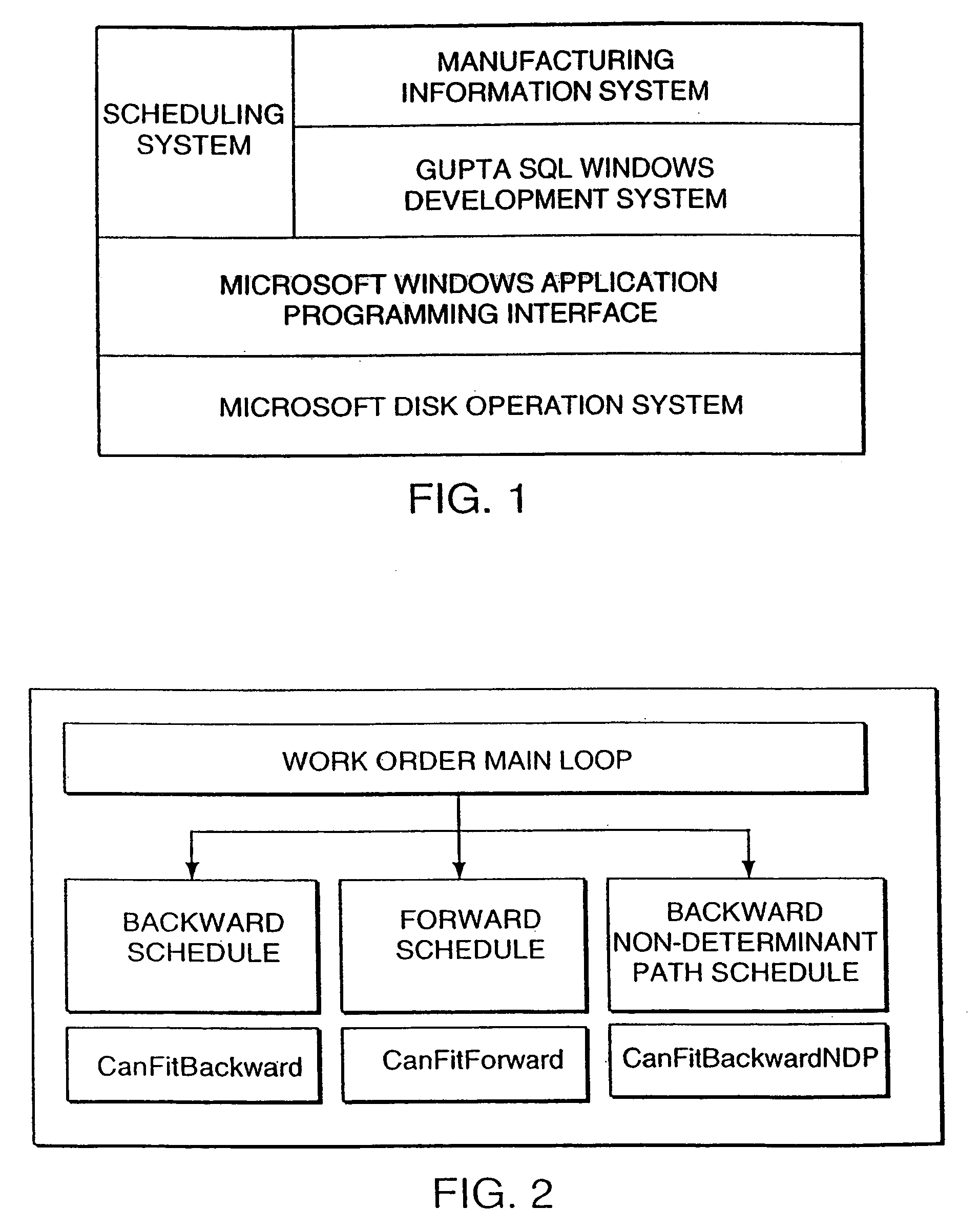

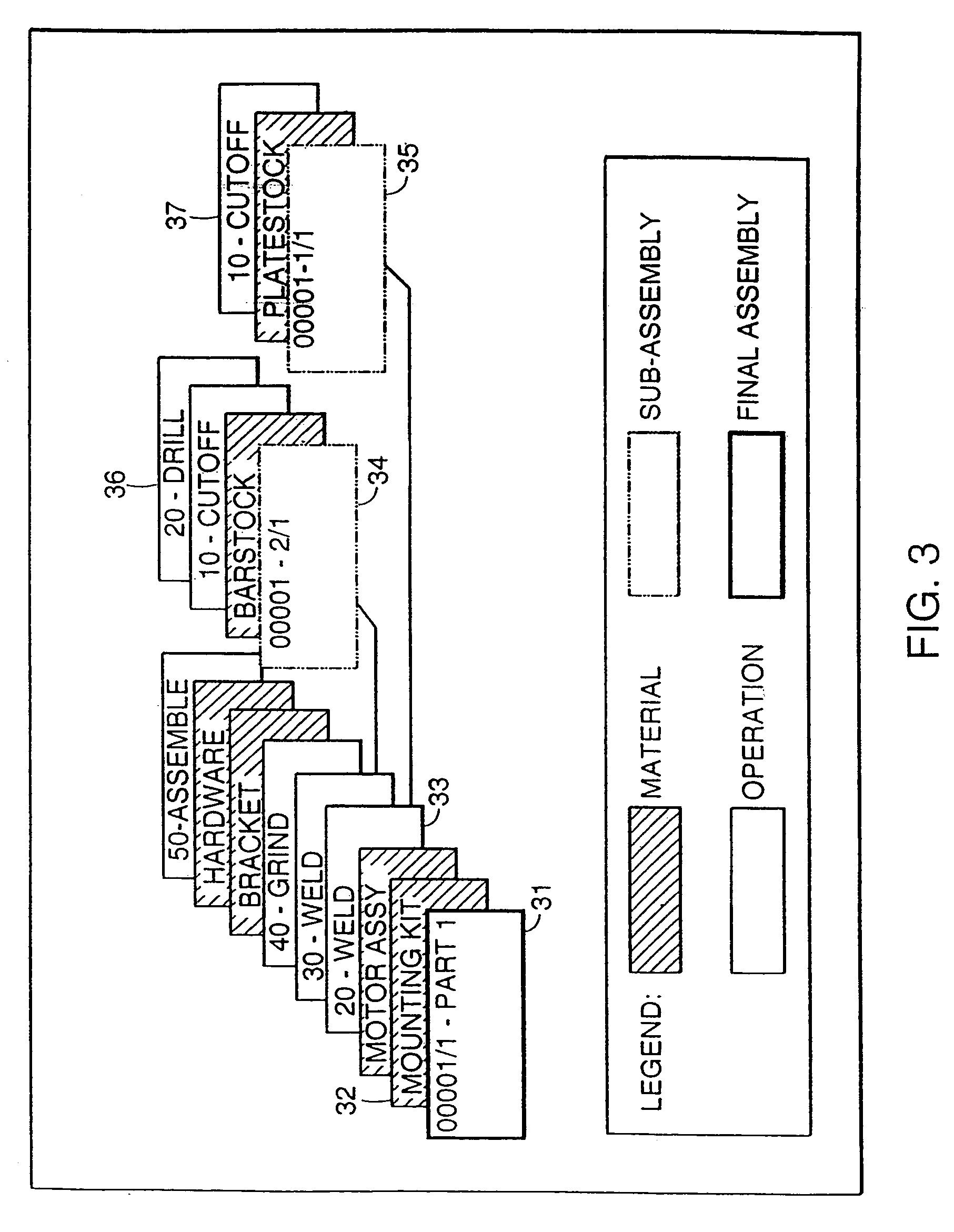

Method and apparatus for scheduling work orders in a manufacturing process

InactiveUS7089071B2Improve overall utilizationResourcesTotal factory controlGraphicsComputerized system

A computerized system is provided for scheduling a plurality of work orders in a manufacturing process. Each work order to be scheduled specifies a set of operations to be performed using a plurality of resources and materials. Data including resource availability information for each resource used in the manufacturing process, material availability information for each material used in the manufacturing process, and work order information is received and stored in a computer. The work order information includes a release date for the work order, a want date for the work order, operations information, and material requirements information. The operations information includes the identity and sequence of operations to be performed for the work order, the identity of the resources needed to perform each operation, a minimum resource capacity needed to perform each operation, and the time needed to perform the operation. The materials information includes the identity of the materials needed to perform each operation and the quantity of each material needed for the operation. Resource capacity and a start date / time and a finish date / time are assigned to each operation based upon the resource availability information, the material availability information, and the work order information. The assigned resource-capacity, the assigned start date / time, and the assigned finish date / time for each operation are displayed on a computer screen in a graphical format.

Owner:INFOR VEENENDAAL

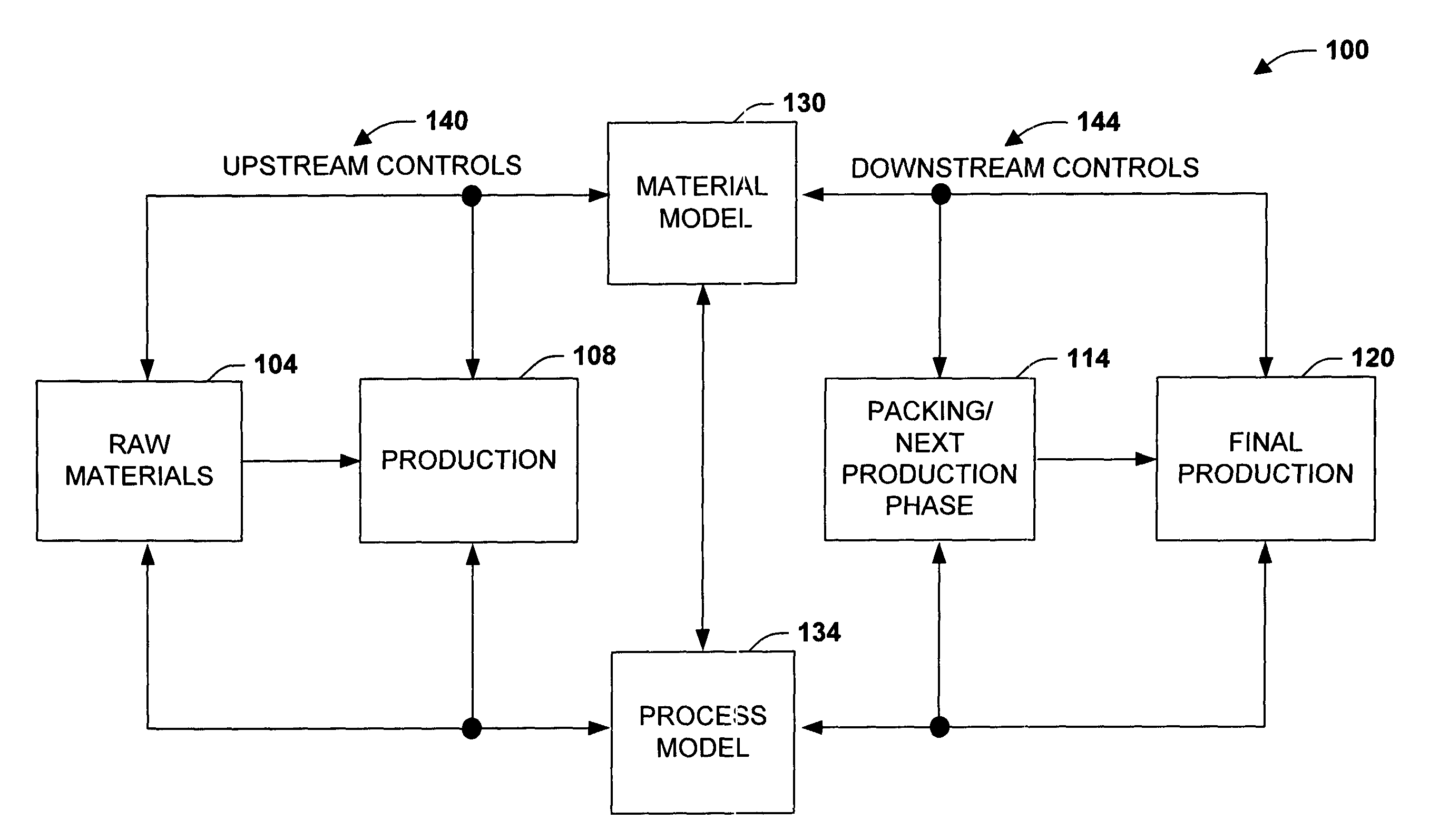

Material reservation distribution system and method

InactiveUS7031782B2Efficient managementEasy to processProgramme controlHand manipulated computer devicesMaterial typeControl system

The present invention relates to a system and methodology facilitating material-driven processing in an industrial controller environment. Various models supported by database objects are provided to automatically and dynamically map inventory systems / processes to control systems / process such as in batch or recipe operations. A material model is provided that tracks to an inventory database and includes such aspects as defining material types and containers to house such materials. An area model maps the material model to possible units and equipment modules to process the materials. These models include phased-based parameters that define amounts of material that flow into and out of a determined area for processing the materials. Before, during and / or after automated manufacturing operations, object binding operations occur between material-based servers associated with an inventory system and batch servers associated with a process-control system. Such binding includes Just-In-Time or on-demand binding at run time, and relates material requirements of a recipe (or batch) to the units and equipment that are available to produce the recipe.

Owner:ROCKWELL AUTOMATION TECH

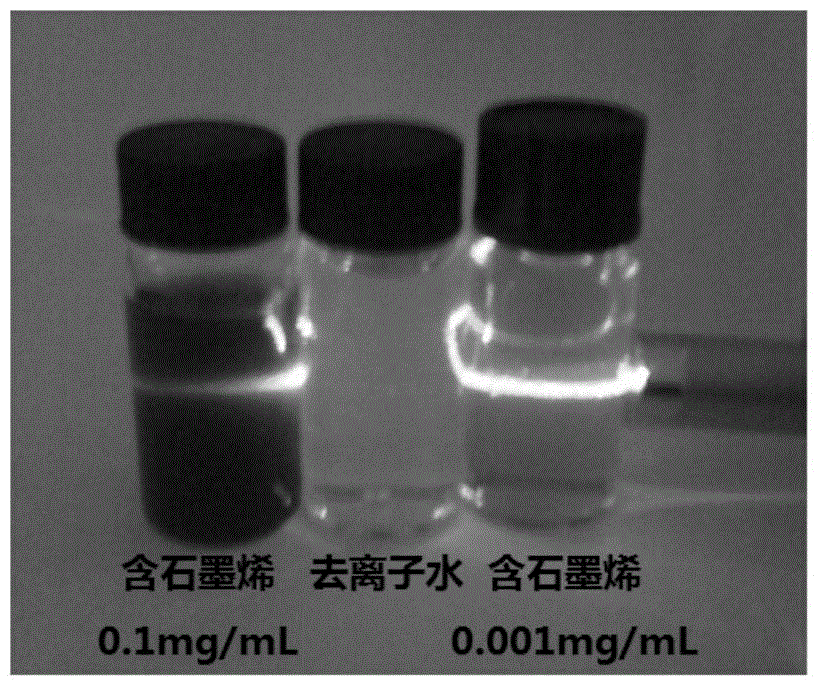

Graphene, graphene colloidal sol, graphene powder and preparation method and preparation device

The invention provides graphene, graphene hydrosol, and graphene powder obtained by drying the graphene hydrosol, wherein the edge of the graphene comprises active groups, and the active groups comprise amino groups. The preparation method of the graphene hydrosol comprises the following steps: (1), performing electrochemical intercalation and exfoliation on graphene to obtain graphene dispersed in electrolyte; the electrolyte after electrochemical intercalation and exfoliation contains both inorganic salt and amino acid; after intercalation, removing free inorganic salt and amino acid compounds from the solution to obtain the graphene hydrosol. According to the graphene, graphene colloidal sol, graphene powder and the preparation method and the preparation device, provided by the invention, the graphene hydrosol is provided, the use of a great deal of an organic solvent in the graphene hydrosol based on the organic solvent is reduced, the stability is good, the preparation method is simple, the operation is easy, the equipment and material requirements are low, the environmental friendliness is achieved, and the industrialization is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Sales order BOM-based method for tracking material and calculating material requirements

InactiveCN101706912AResolve product numberSolve the problems of numerous product bomResourcesOrder formMaterial requirements

The invention provides a sales order BOM-based method for tracking a material and calculating material requirements, which is the method for tracking the material and calculating the material requirements based on the sales order BOM. The method comprises the following steps of: building a sales order model, a sales order BOM model, and a product material requirement calculation result table model; and product material requirement calculation and tracking are realized according to the algorithm summarization. The method not only solves the problem of a large number of product codes and product BOMs, but also meets the requirements of tracking the material needed by the product and effectively calculating the material requirements by building a sales order BOM algorithm model.

Owner:INSPUR COMMON SOFTWARE

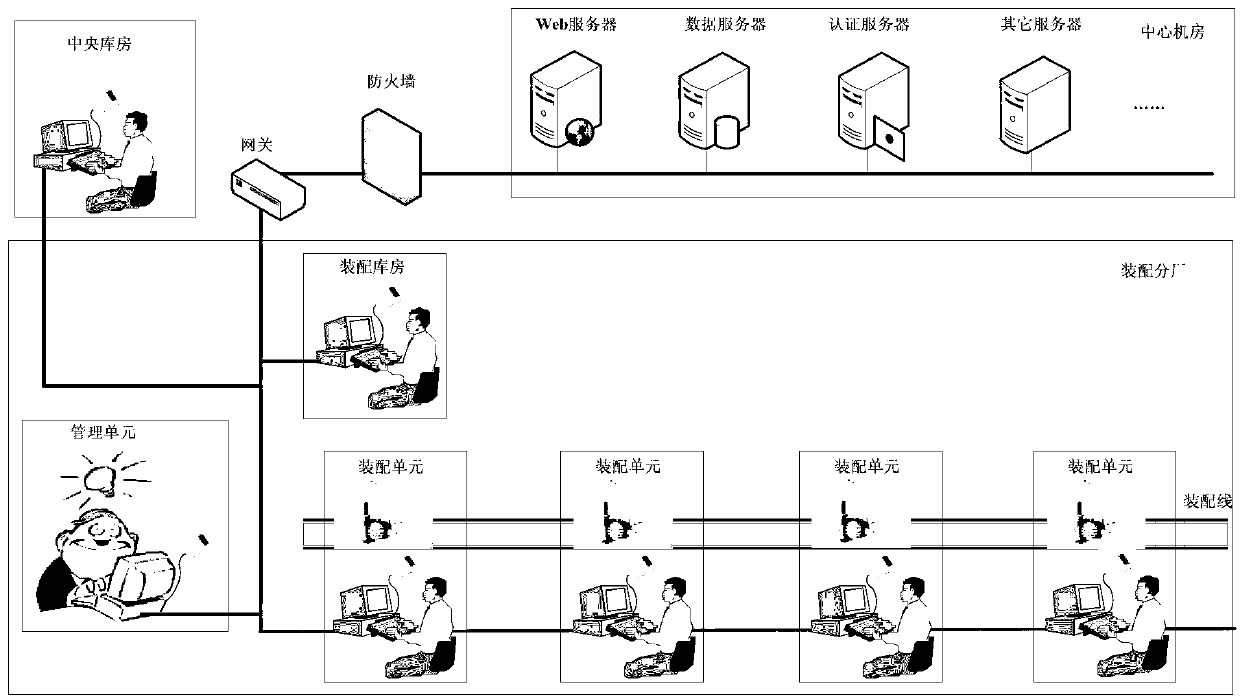

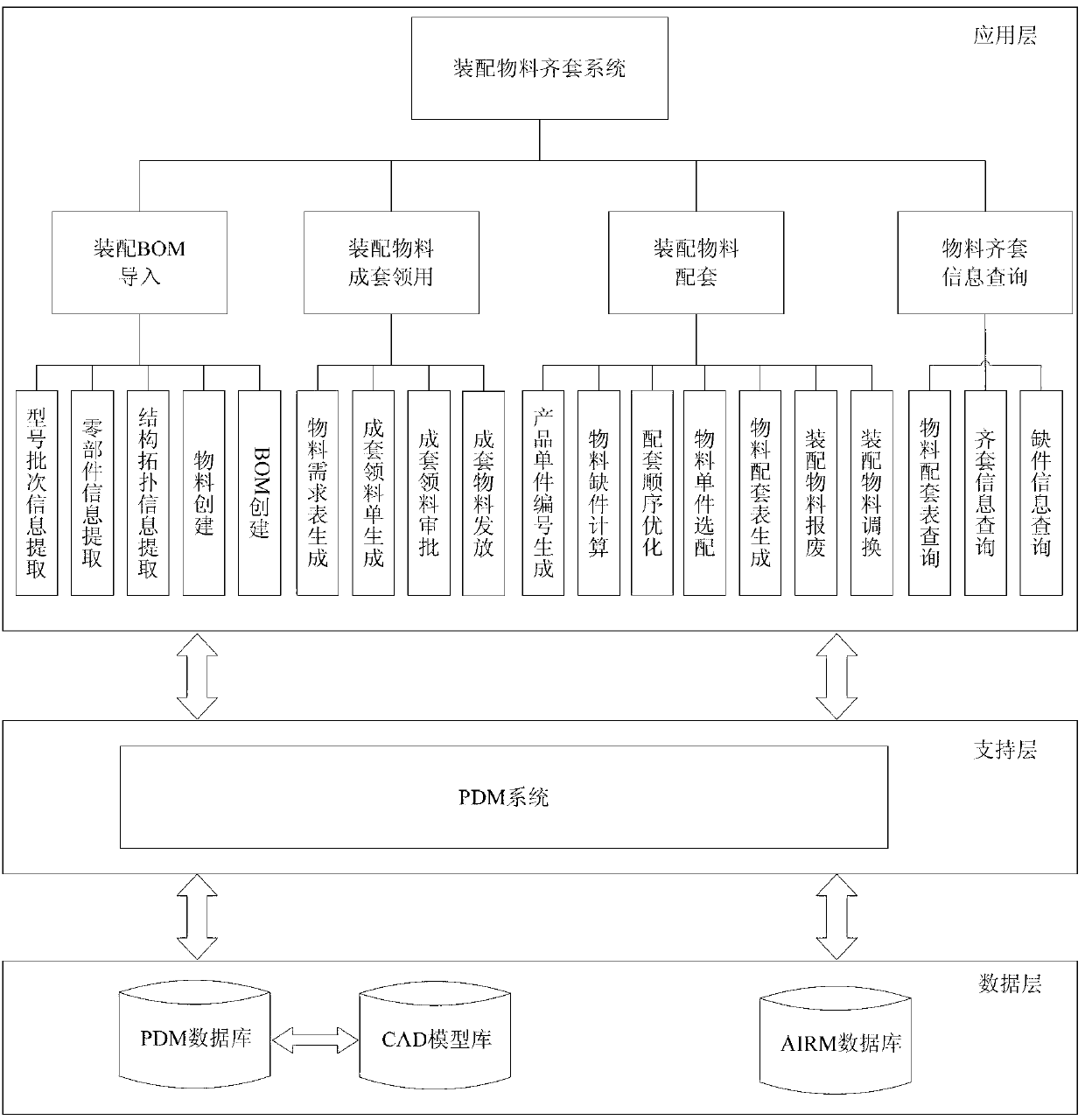

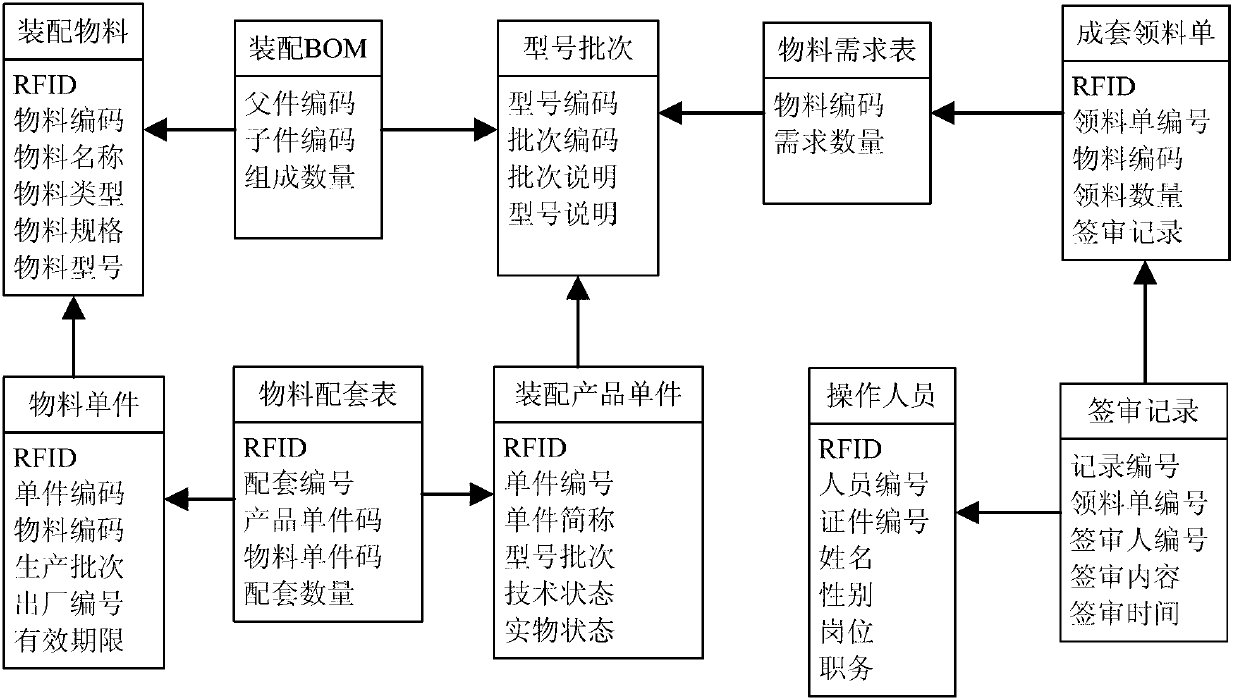

Automatic matching method for high-precision complex product assembling materials

ActiveCN103279613AQuick searchFully automatedSensing record carriersLogisticsComputer Aided DesignBill of materials

The invention discloses an automatic matching method for high-precision complex product assembling materials. The method is characterized by including: traversing and extracting unstructured assembling CAD (computer-aided design) model information through recursive algorithm, and automatically fast building a structured product assembling BOM (bill of material); iterating node layers of the assembling BOM to automatically calculate independent material requirements and related material requirements, and fast and accurately generating material requirement tables; acquiring materials in a matched manner through material requirement table separation, automatic material acquisition list circulation, online signing and examining, single material acquisition registration, and FRID (radio frequency identification); automatically and accurately calculating material shortage lists through assembling BOM iteration and reading of matched material acquisition lists and material matching lists; intelligently optimizing matching sequence through particle swarm optimization, and fast performing optimized material matching; automatically acquiring material information and automatically tracking single material through convenient RFID; and fast inquiring product material matching information through multi-condition optional combination vague inquiry. By the method, automation and intelligence of assembling material matching is increased, and assembling time is shortened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Method for supplier collaboration and data accuracy

InactiveUS20070162171A1Easily and quickly updatingEasily and quickly and correctingAnimal feeding devicesOffice automationBill of materialsMaterial requirements

Methods, systems and apparatus for supplier collaboration and data accuracy within a materials requirement planning scenario. An external supplier is easily integrated into an inter-enterprise planning engine by generating uniquely modified external supplier input files that only include demand information, inventory coverage, and bills of material data associated with the external supplier. This modified external supplier data is used to integrate the external supplier into the planning engine, and for generating a requirements build that fulfills a build plan input into the planning engine. The planning engine is preferably an online planning engine, such that, the requirements build may be validated by inputting the most currently available supplier input data into the planning engine for generating a new, updated requirements build online substantially in real time for fulfilling the build plan.

Owner:IBM CORP

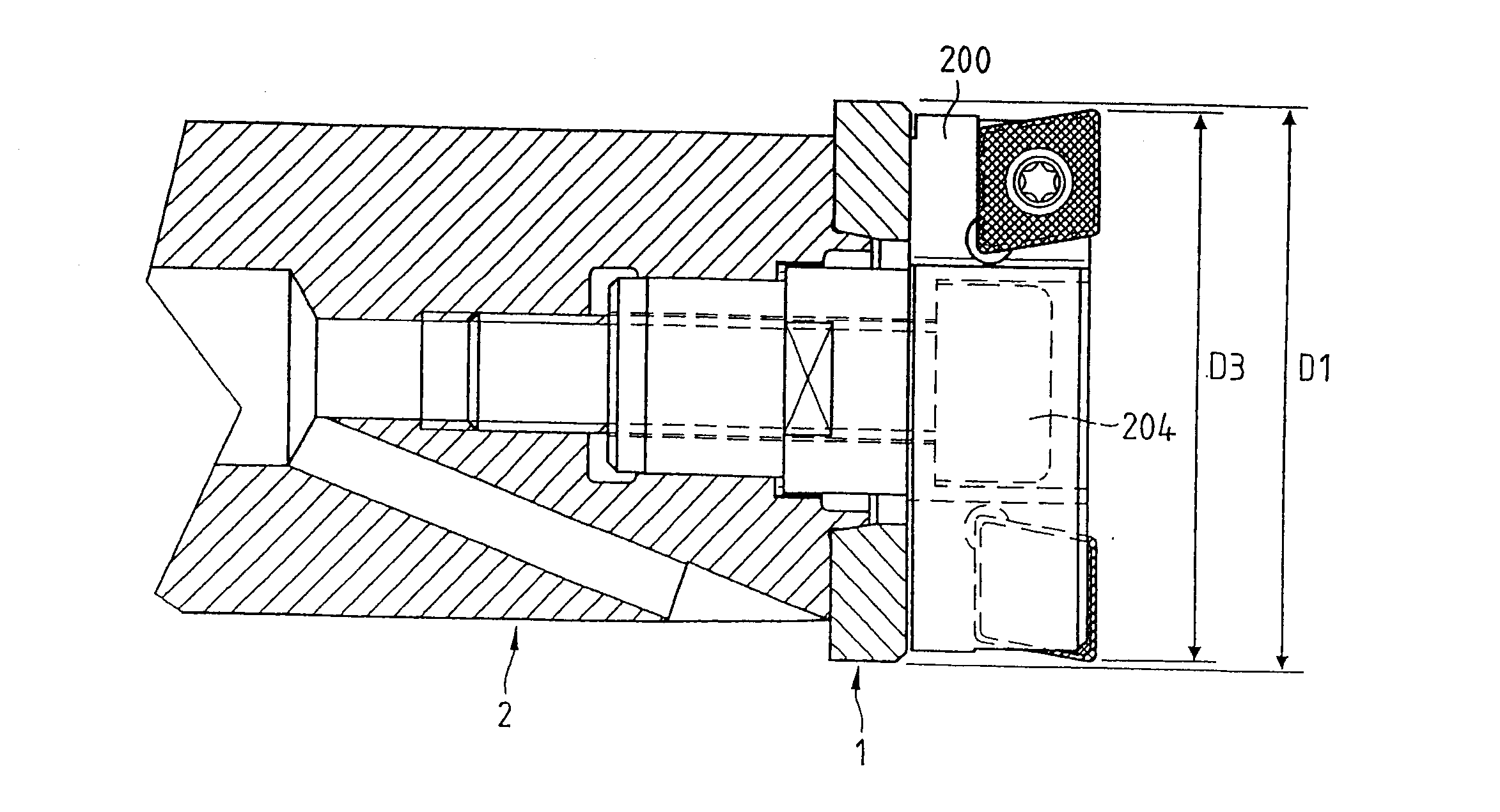

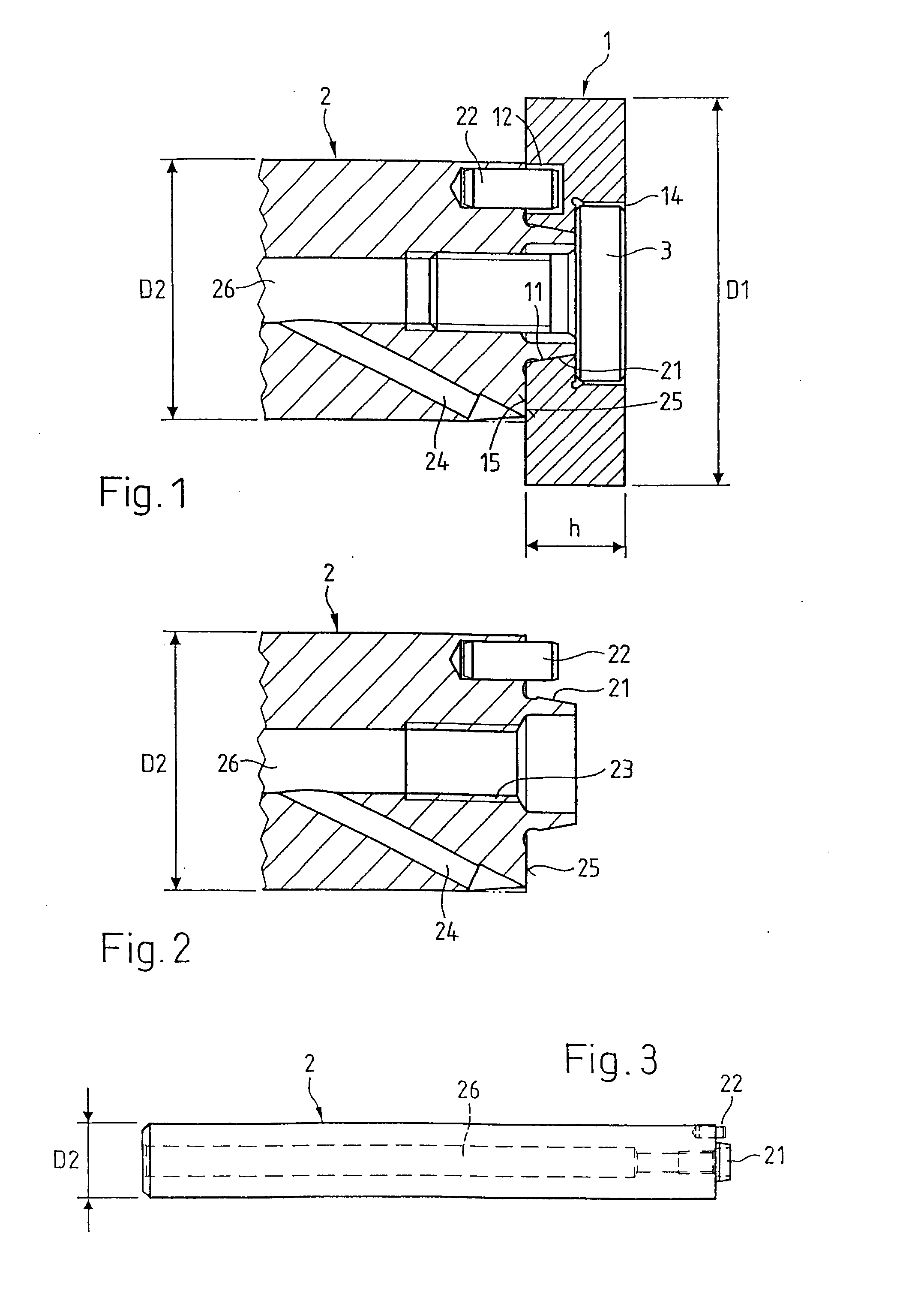

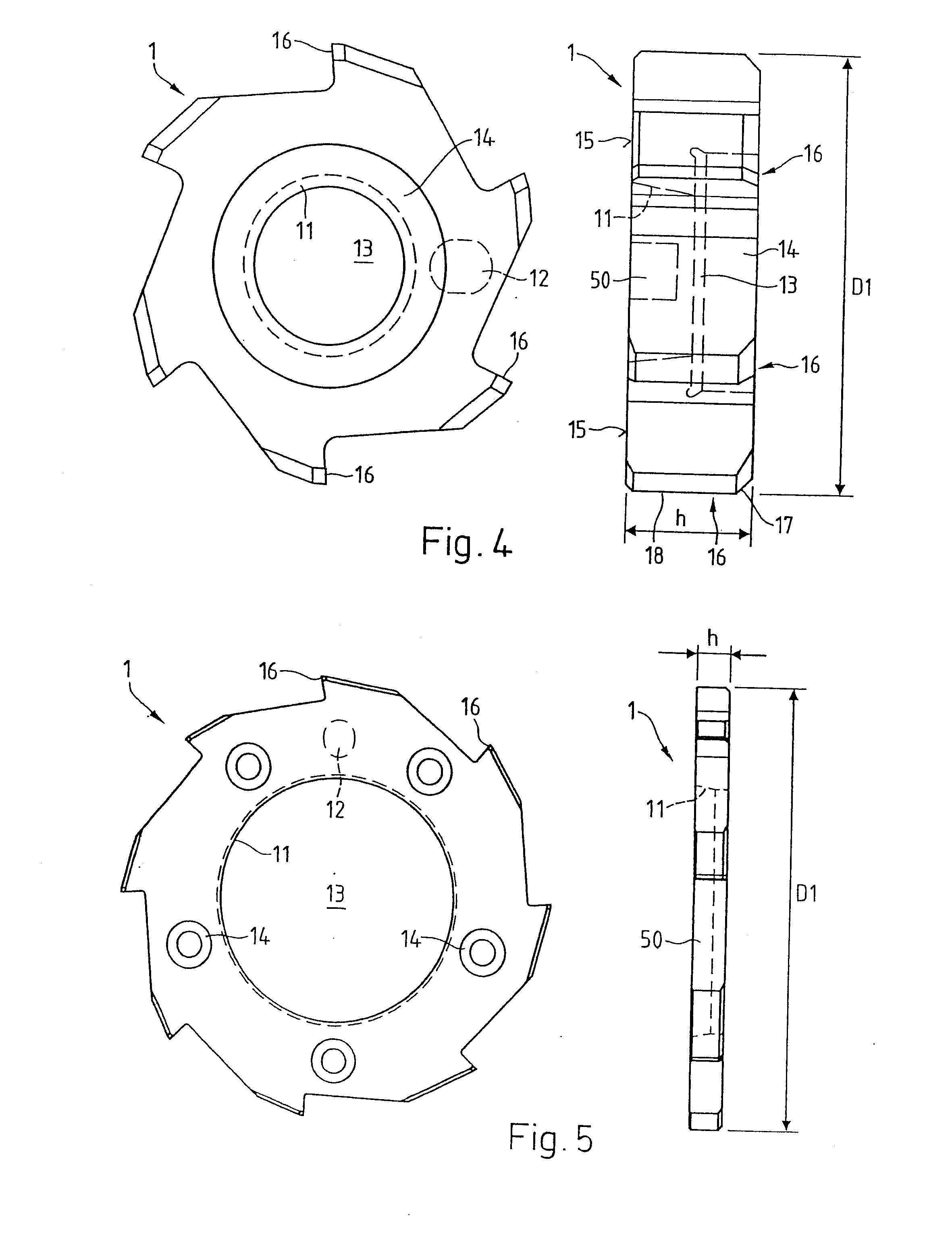

Machine friction tool, interchangeable head and shaft

ActiveUS20070067979A1Reduce manufacturing costSimple designTransportation and packagingAttachable milling devicesMaterial requirementsMillimeter

A machine reaming tool comprises a reaming head or interchangeable head (1) and a shaft (2), wherein the interchangeable head (1) is of one piece and may be exchanged, and in the axial direction and at each location, thus including means for the exchange adaptation, is thinner than a maximal thickness hmax, wherein this maximal thickness hmax is computed in millimetres from a diameter D1 of the interchangeable head in millimetres as hmax =6 mm+(1 / 10)·(D1−12 mm). On account of this, a guide portion (18) for cutters of the reaming head (1) becomes very much shorter than usual, but despite this ensures an adequate quality of machining. In a preferred embodiment of the invention, the interchangeable head (1) in a plane shaft-side end-face side end-face (15) comprises cutout (11) for the centring fastening on the shaft (2). The shaft (2) on an end-side plane surface (25) comprises a connection lug (21) which projects out of this plane surface in the axial direction and to which the cutout (11) of the interchangeable head (1) corresponds. The interchangeable head (1) thus has no axially projecting lug. The material requirement is further reduced, the manufacture of the interchangeable head (1) is simplified, and the material and manufacturing costs are reduced on account of this.

Owner:URMA

Aluminum alloy strip assembly for umbrella framework and machining technique thereof

The invention provides an aluminum alloy strip assembly for the backbone of an umbrella and the technique for processing the same, and the aluminum alloy strip comprises the following components by weight: Fe less than or equal to 0.35%, Si less than or equal to 0.25%, Cu less than or equal to 0.1%, Mn less than or equal to 0.1%, Mg of 2.3-2.7%, Zn less than or equal to 0.1%, Cr of 0.15-0.25%, all the foreign matters less than or equal to 0.15% and Al of the rest; all the component percentage is 100%; the processing technique is characterized by processes of fusion casting, face milling, soakage, hot rolling, cold rough rolling, stretch-bending and aligning, cleaning and edge-cutting, finished product annealing and the like; the aluminum alloy strip assembly of the invention has characteristics of satisfying the material requirements of high-grade umbrella backbones, having good mechanical performances and a short process flow.

Owner:中铝河南铝业有限公司

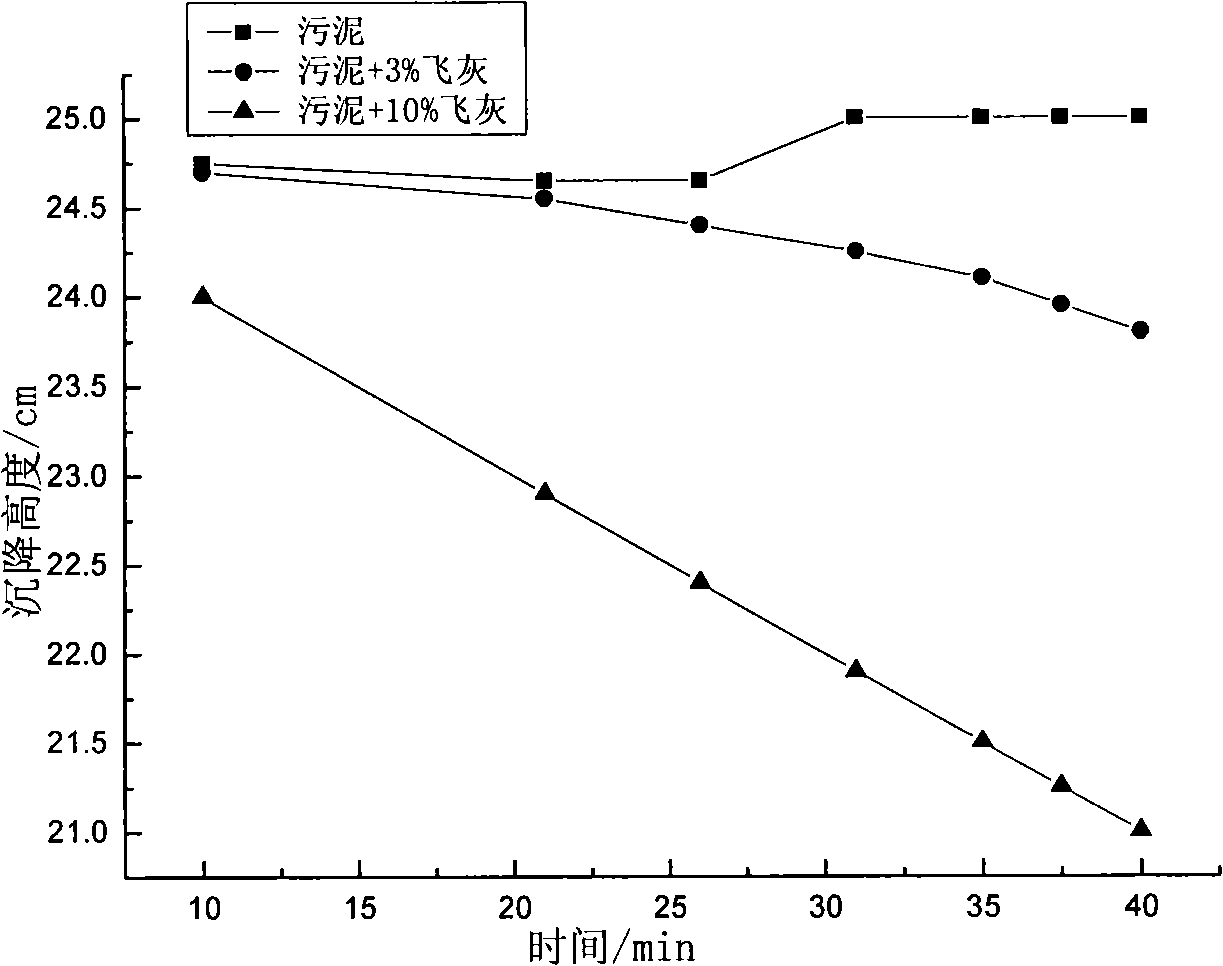

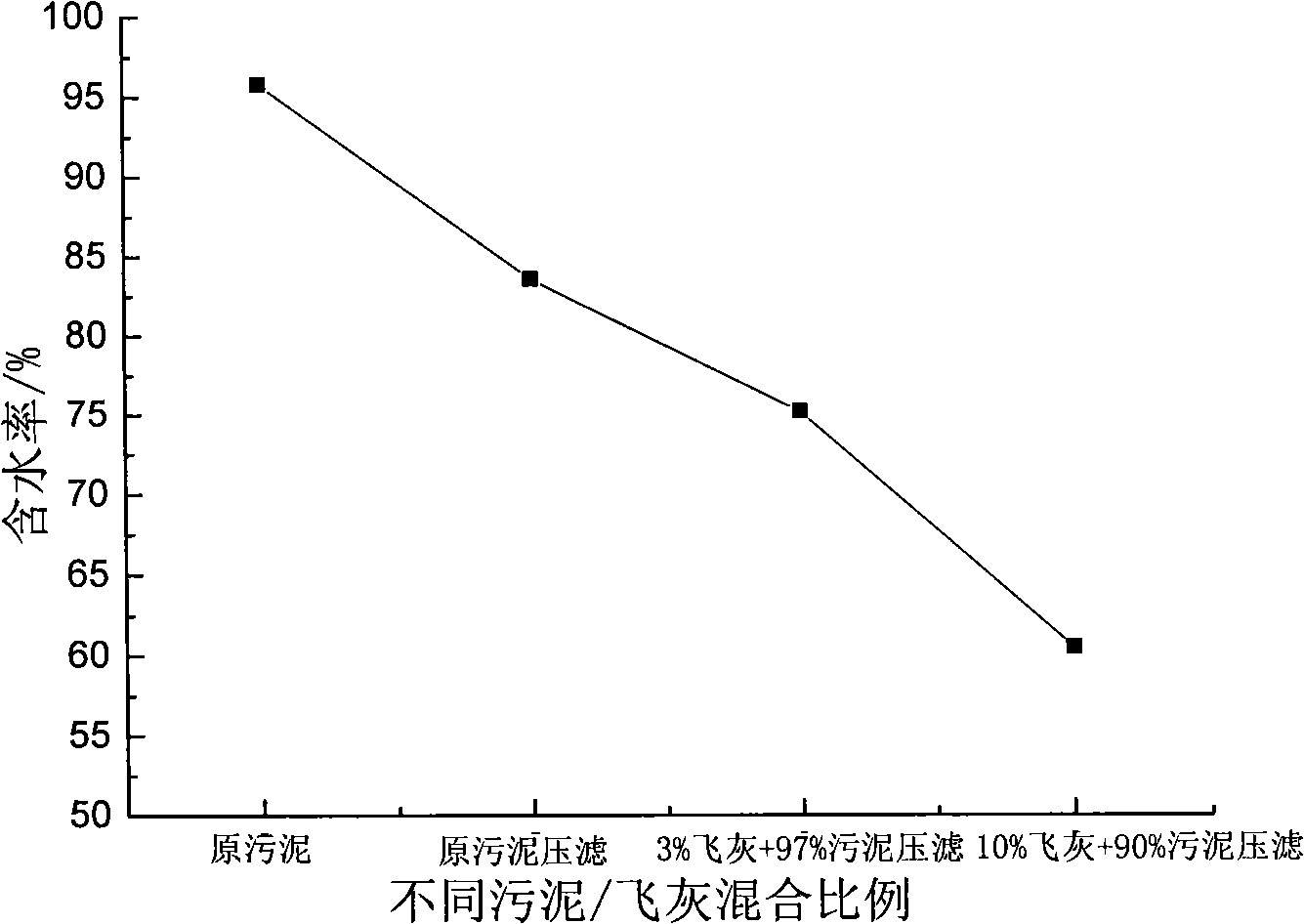

Method for cooperative reclaiming flyash and sludge in refuse incineration

InactiveCN101279825AReduce moisture contentHigh calorific valueSludge treatmentSolid waste managementIon contentResource utilization

The invention relates to a method for fly ash and sludge disposal resource utilization from refuse incineration, which belongs to the environmental engineering technique field. The method adopts the following processes: fly ashes and sludge are mixed in proportion of 1: 10-1: 50 under the normal temperature, wherein the mass unit of fly ashes is gram and the volume unit of sludge is milliliter, proper heavy metal stabilizer is added to the mixture for fully mixing and agitation for fifteen to thirty minutes, and the control range of the pH value is between 9 and 12. The fly ash and sludge mixture can be obtained by washing, pressure filtration and drying. The water content of the sludge is reduced, the heat value is increased and the chloride ion content in the fly ashes is reduced through the synergistic disposal. The treated fly ash and sludge mixture can meet the material requirements of the cement production, thereby realizing the fly ash / sludge synergistic resource utilization.

Owner:SHANGHAI UNIV

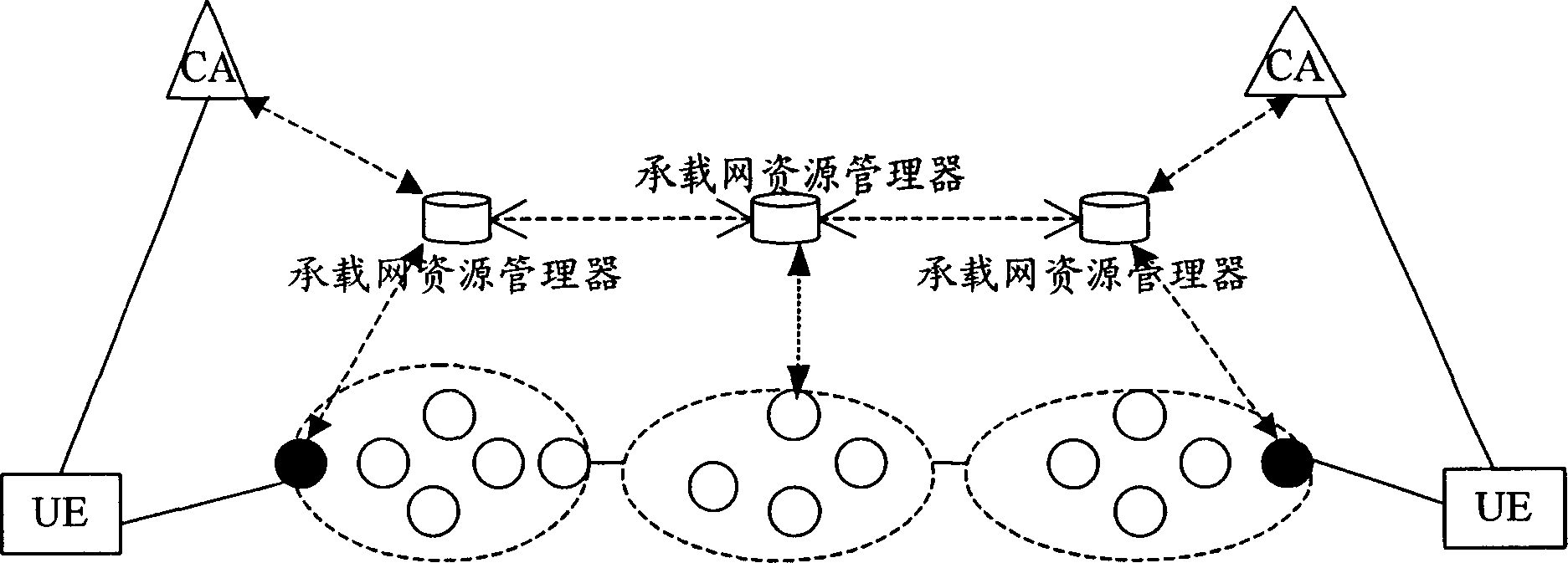

Method of implementing resource allocation in bearer network

InactiveCN1808986AImprove the quality of operationRealize resource allocationData switching networksControl layerMaterial requirements

This invention discloses one method to realize load network materials distribution, which comprises the following steps: dividing the LSP area into at least two Quos class and setting business type and each Quos class relation; then CA is as current business flow to send materials requirement to the load control layer; the load layer receives the requirement and determines the type relative class and judges the class relative LSP materials is enough, if yes, then dispatching the current business flow with relative LSP materials and then sends the successful message and starts mapping order; otherwise, sending the failure message to the linkage.

Owner:HUAWEI TECH CO LTD

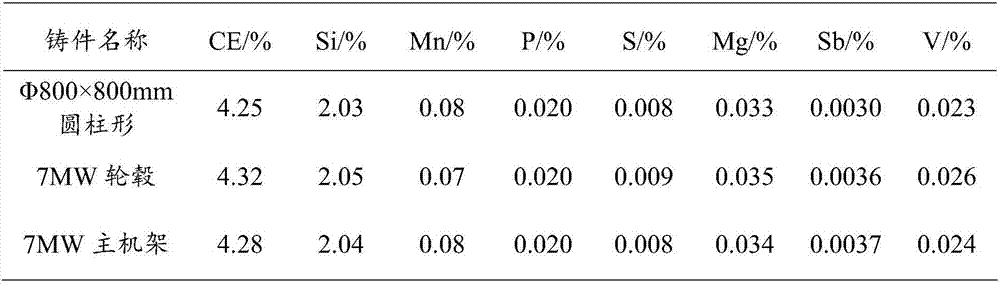

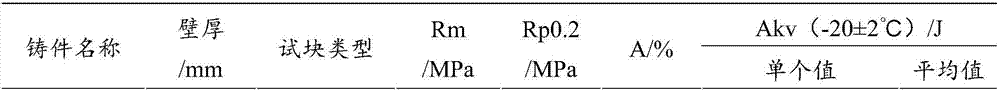

Ultrathick large low-temperature ductile cast iron and preparation method thereof

The invention discloses ultrathick large (wall thickness not less than 200 mm) low-temperature ductile cast iron. The ultrathick large low-temperature ductile cast iron comprises the following components: 4.2-4.4 wt% of CE, 1.9-2.1 wt% of Si, Mn not more than 0.15 wt%, P not more than 0.025 wt%, 0.006-0.012 wt% of S, 0.030-0.045 wt% of Mg, 0.003-0.005 wt% of Sb, 0.02-0.03 wt% of V, and the balance of Fe and impurities carried in the preparation process. The invention further discloses a preparation method of the ultrathick large low-temperature ductile cast iron. The ultrathick large low-temperature ductile cast iron is excellent in heart structure, generates no such special-shaped graphite as fragment graphite, satisfies -20 DEG C impact requirements when satisfying the tensile strength, the yield strength and the ductility, and satisfies the material requirements by high-power development of wind power castings.

Owner:JIANGSU JIXIN WIND ENERGY TECH

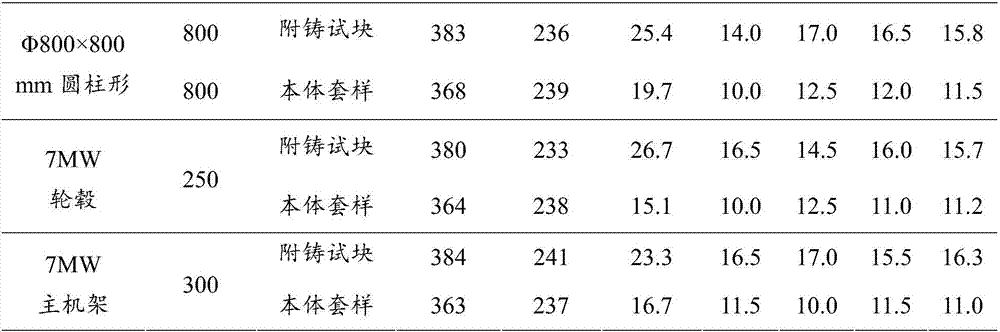

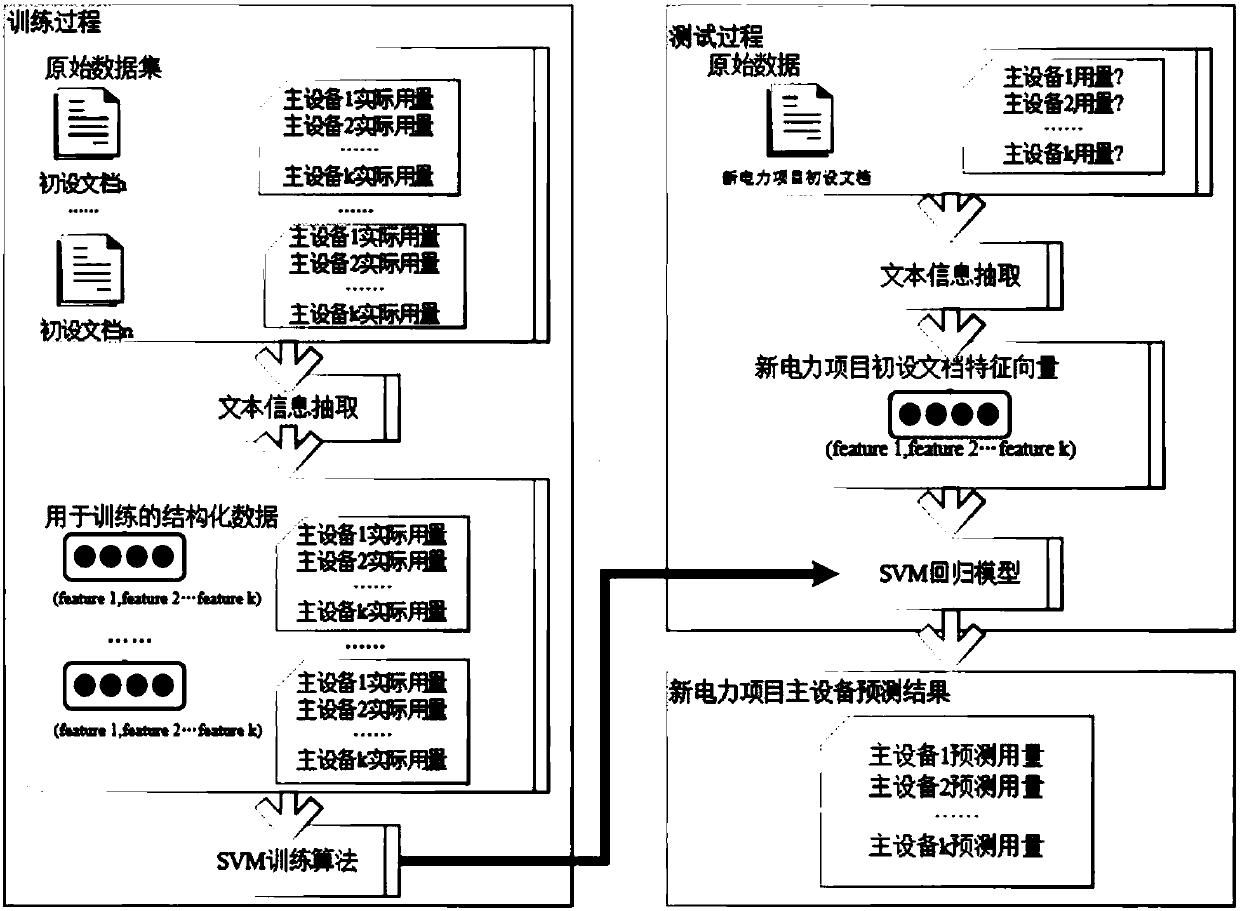

Power material demand prediction method based on text information extraction

ActiveCN107798435ARich varietyForecast data actualForecastingCharacter and pattern recognitionText categorizationMaterial requirements

The invention discloses a power material demand prediction method based on text information extraction. The power material demand prediction method includes a two-step algorithm of power material demand prediction, wherein the first step is used for processing a preliminary design document based on the text information extraction technology, and extracting the engineering attribute information which has important value for predicting the demand quantity of main equipment to realize the structural expression of the preliminary design document, and then realizing the requirement prediction of the main equipment by utilizing an SVM regression algorithm. In the second step, the dense vector expression of a primary design document is learned through a convolutional neural network by utilizing atext classification technology, the demand information of the main equipment is fused with the demand information of the main equipment, and the demand of non-main equipment is predicted through a multi-layer neural network. Compared with the existing calculation, the method can be used for predicting various types of materials. The prediction data tend to be actual, the attributes have more expression, and the method has good practicability. The material demand prediction method conforms to actual application requirements, and can be used for predicting the material requirements after the initial design is completed.

Owner:GUIZHOU POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com