Patents

Literature

18800results about "Mechanical conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

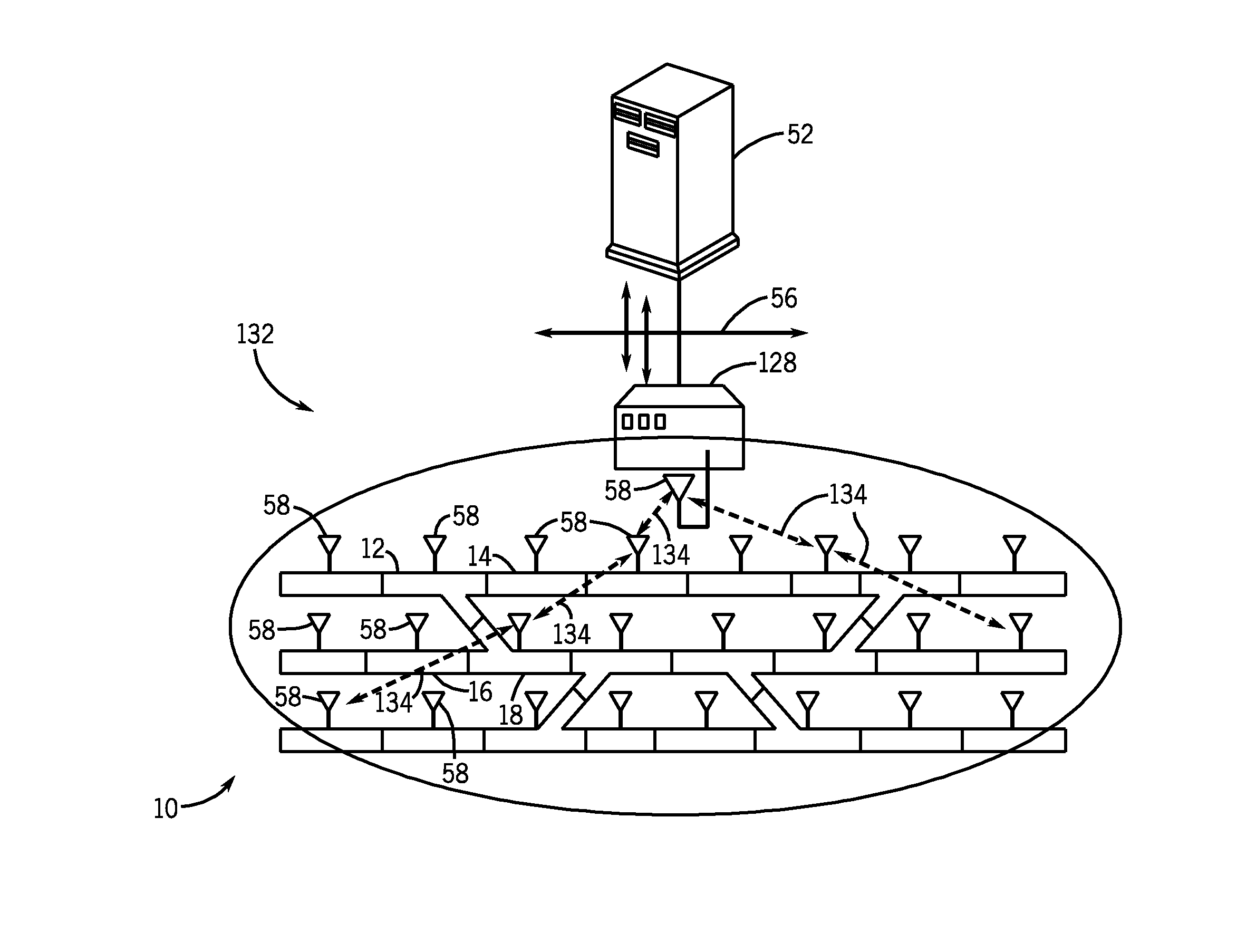

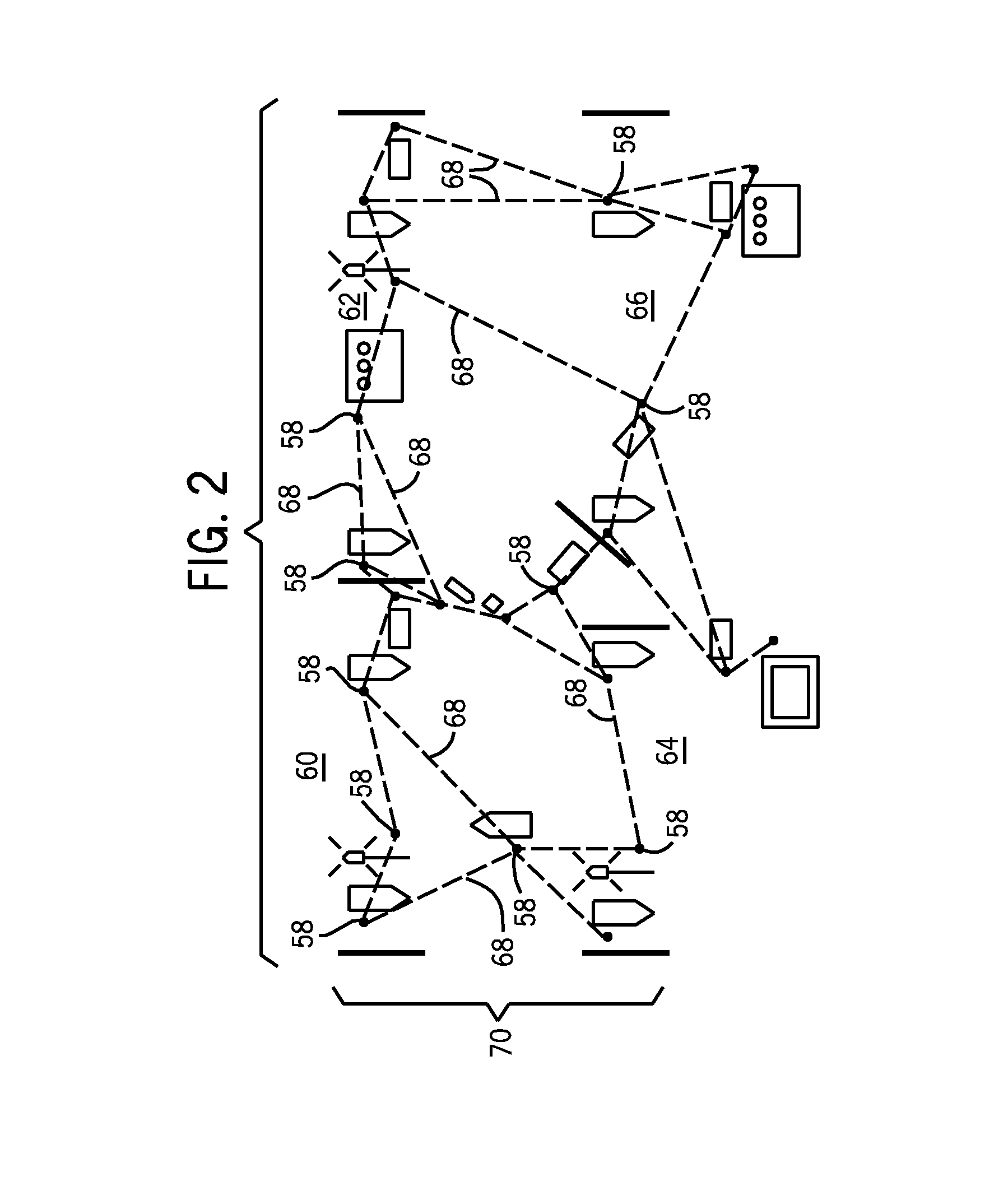

Materials-handling system using autonomous transfer and transport vehicles

ActiveUS20090074545A1High degree of automationEfficient automationDigital data processing detailsLoading/unloadingEngineeringHandling system

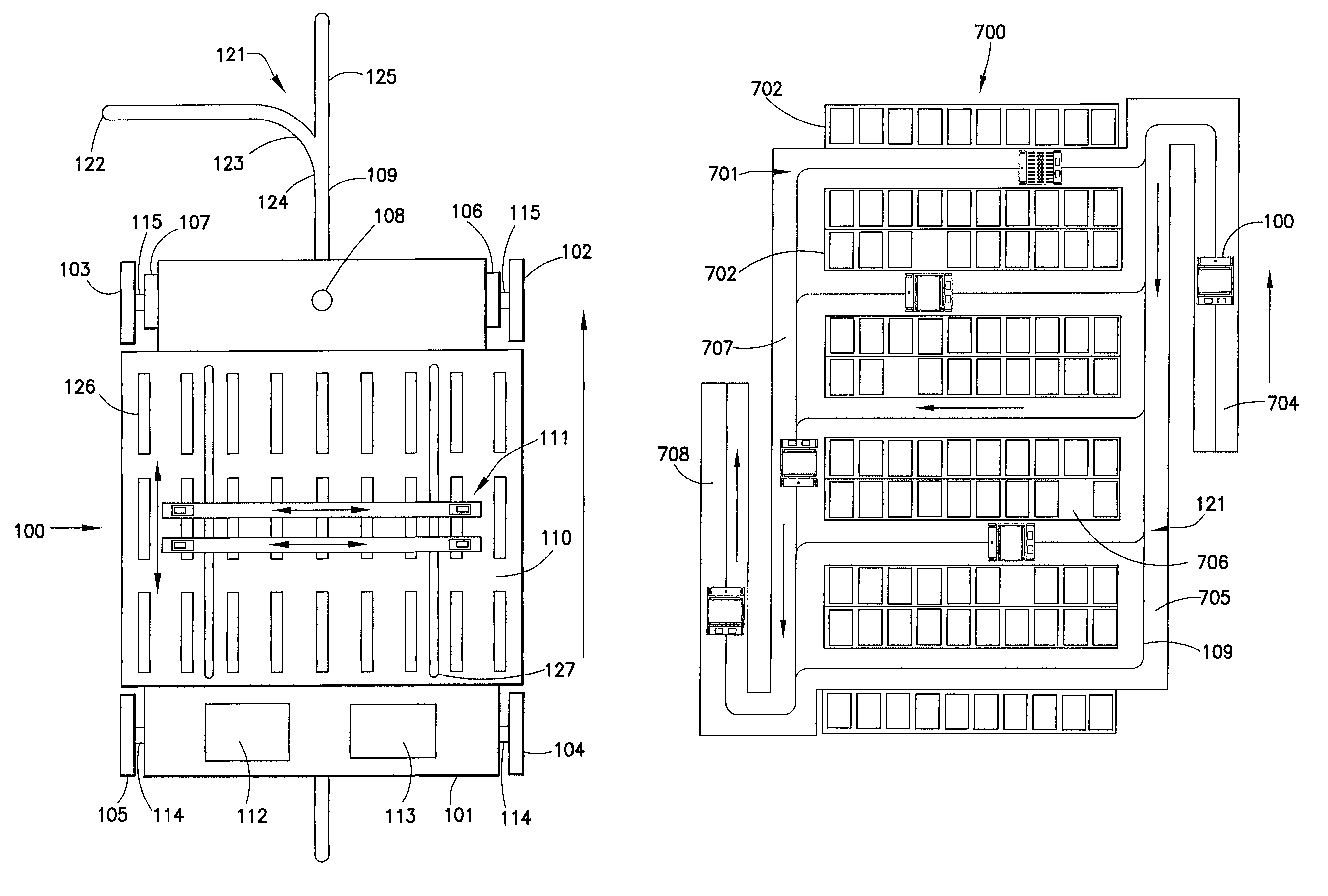

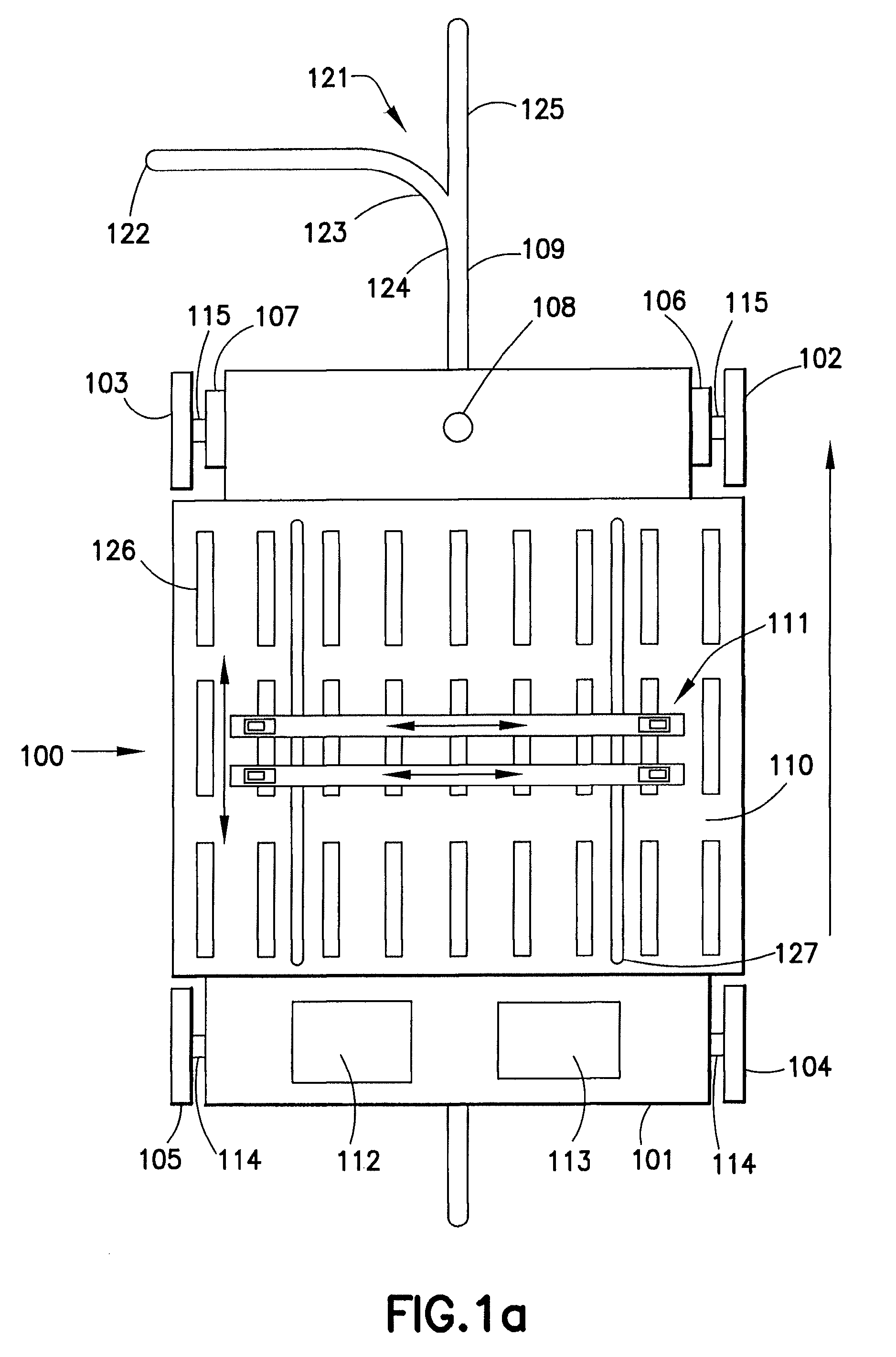

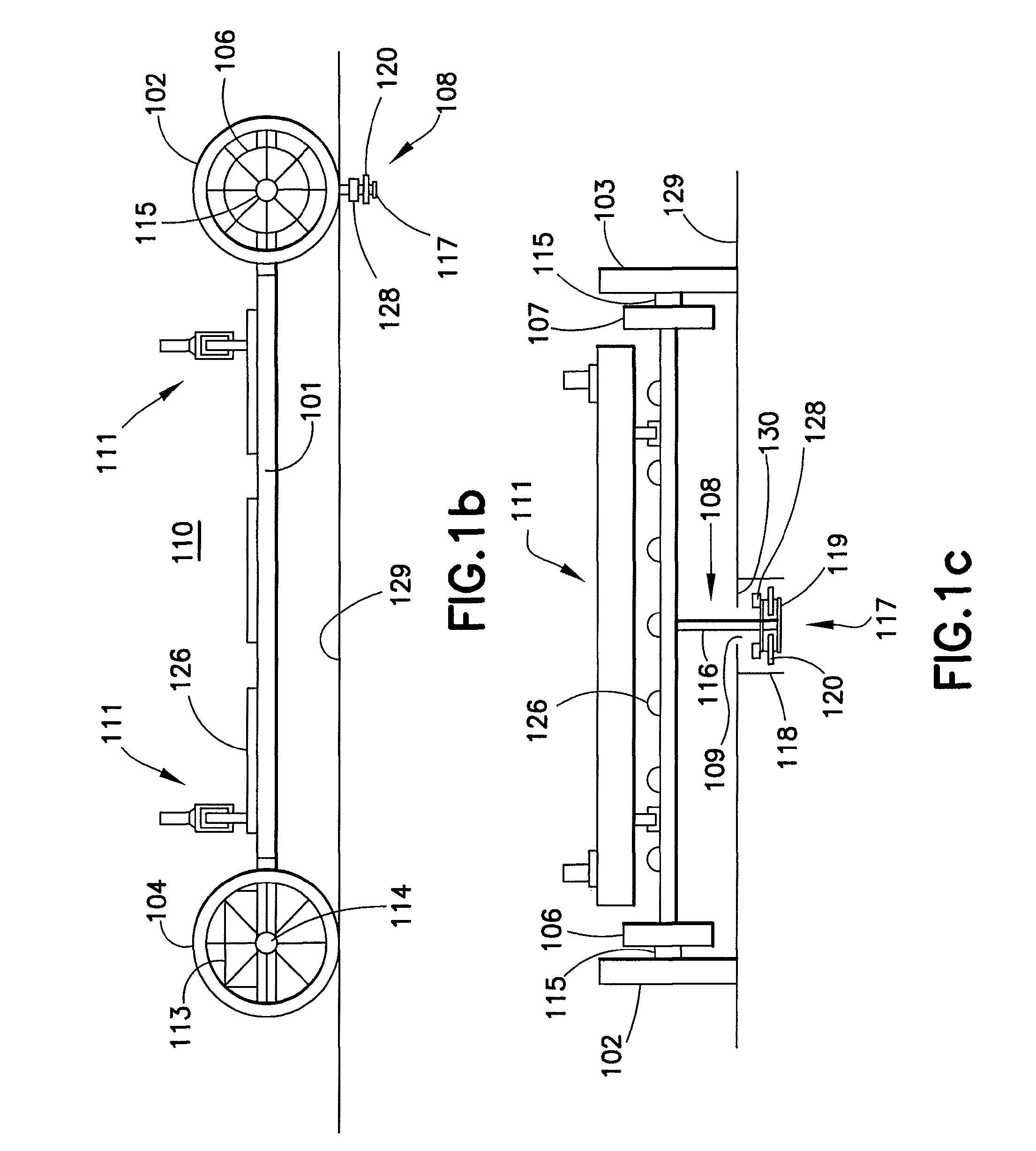

Methods and apparatus for selecting and combining packages in an outbound container by employing autonomous transfer and transport vehicles which move on a network of roadways to carry a plurality of individual cases each containing the same kind of product from a loading station and to a destination station where individual packages are combined in the outbound container. The travel of each vehicle through the roadway network is computer controlled, and each vehicle includes means for automatically loading and unloading packages from predetermined locations on the network.

Owner:SYMBOTIC LLC

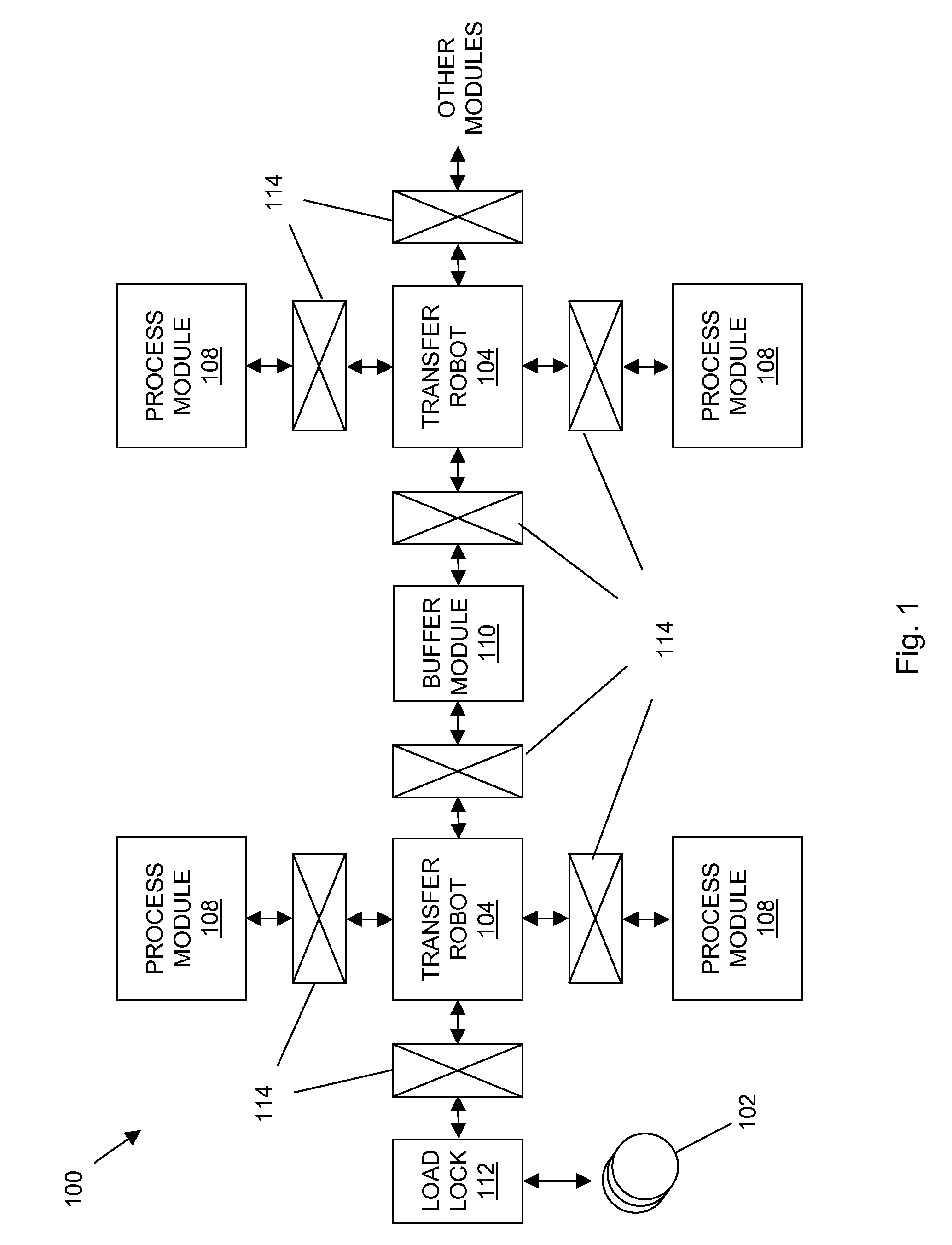

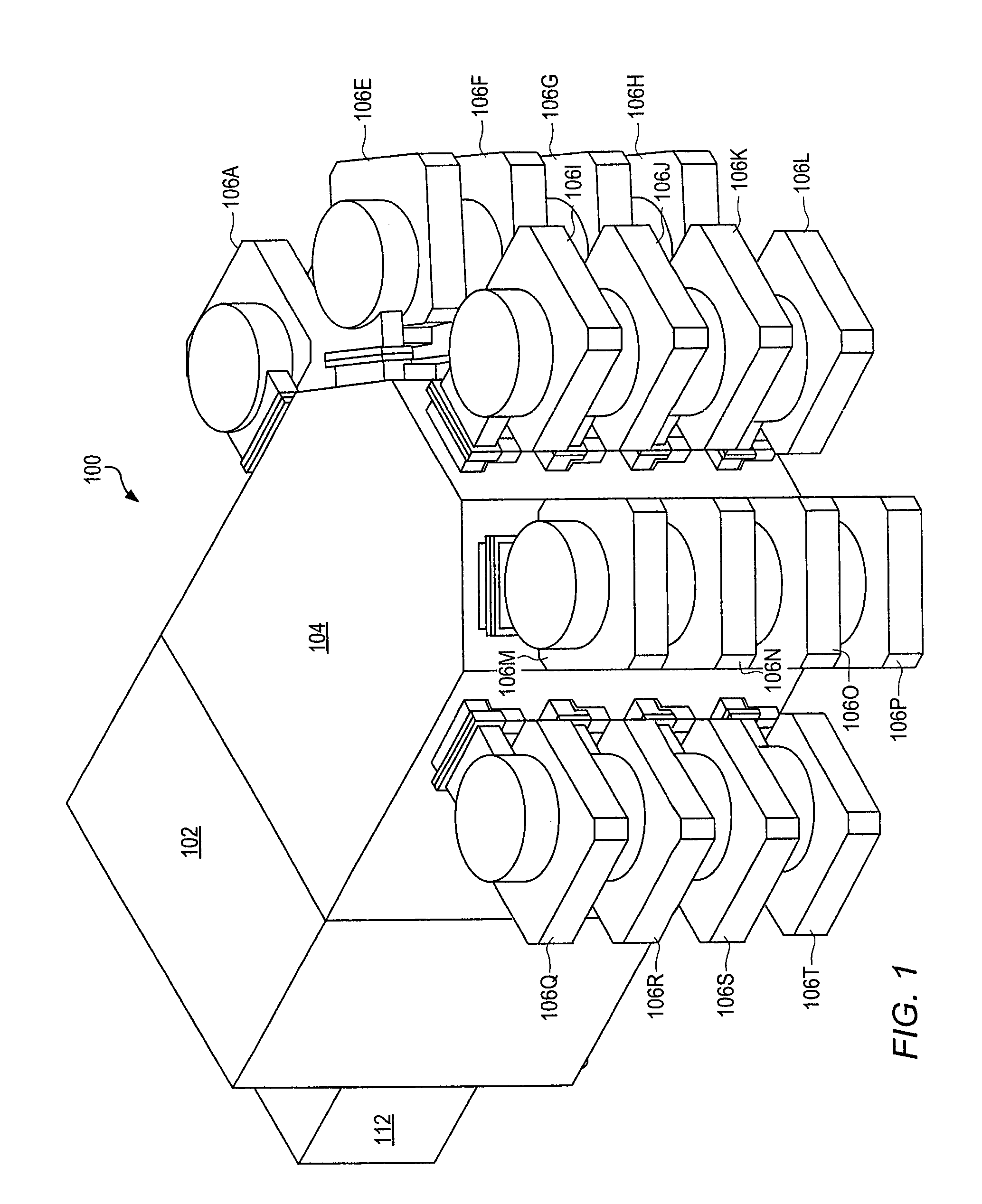

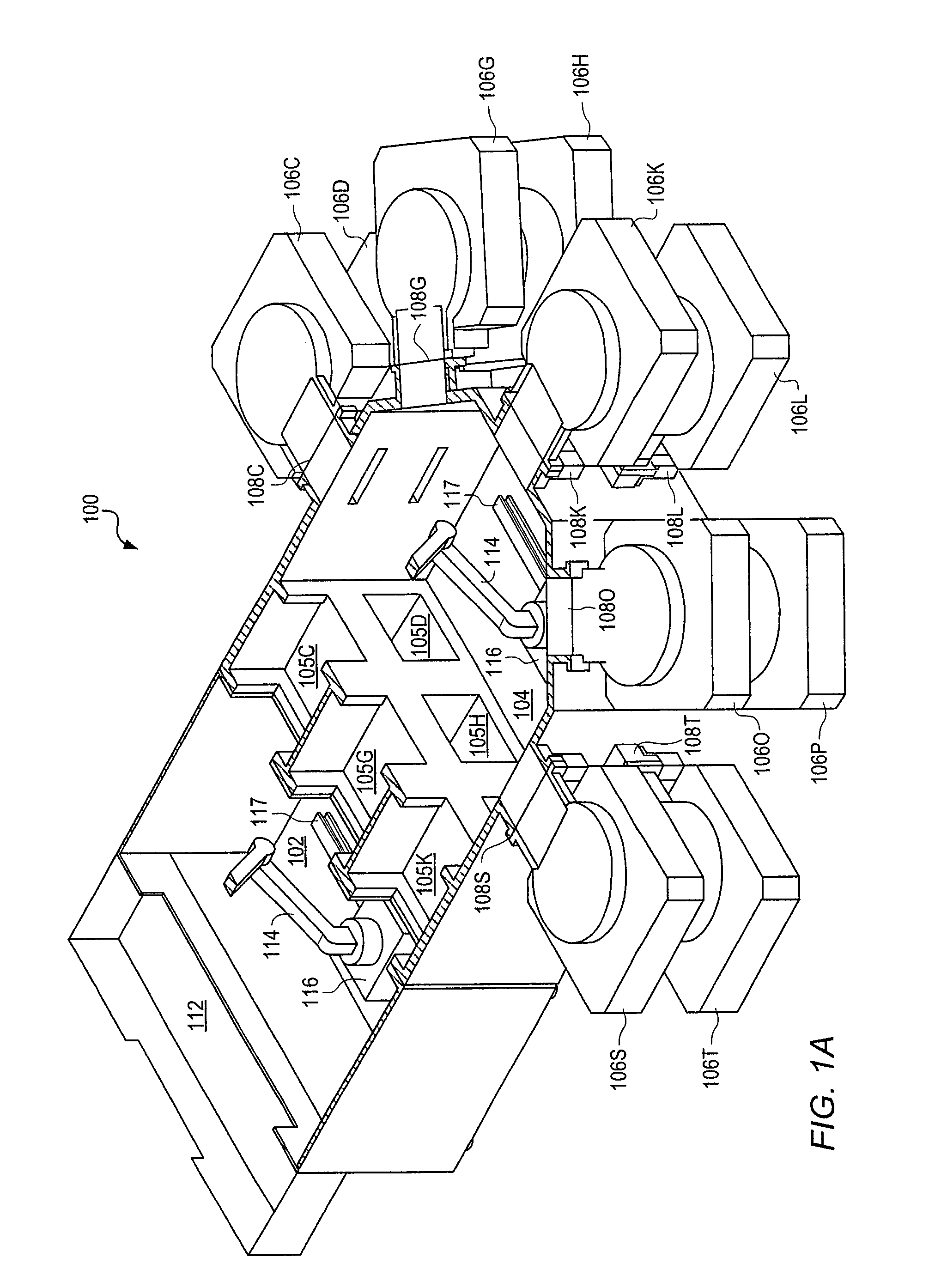

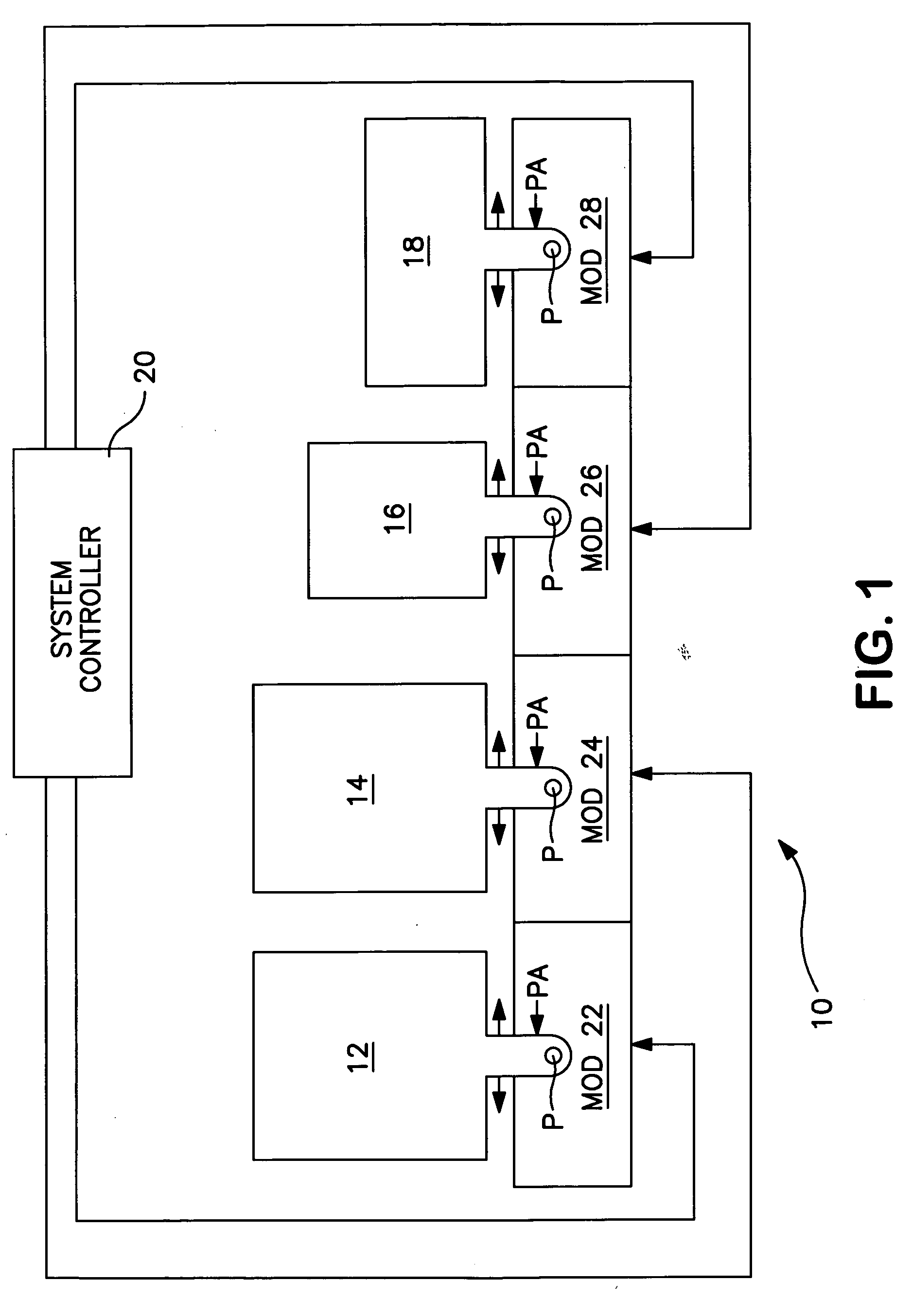

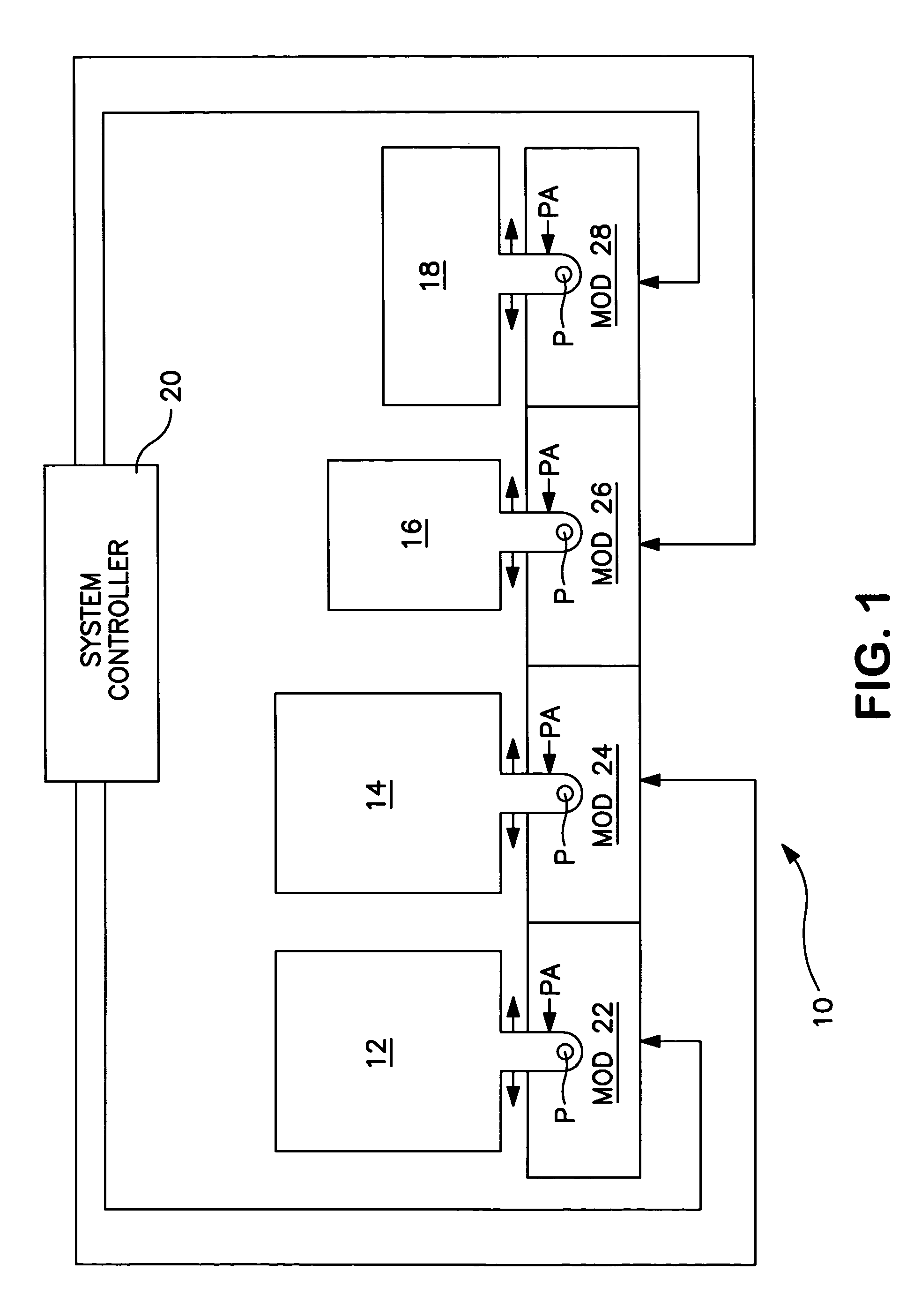

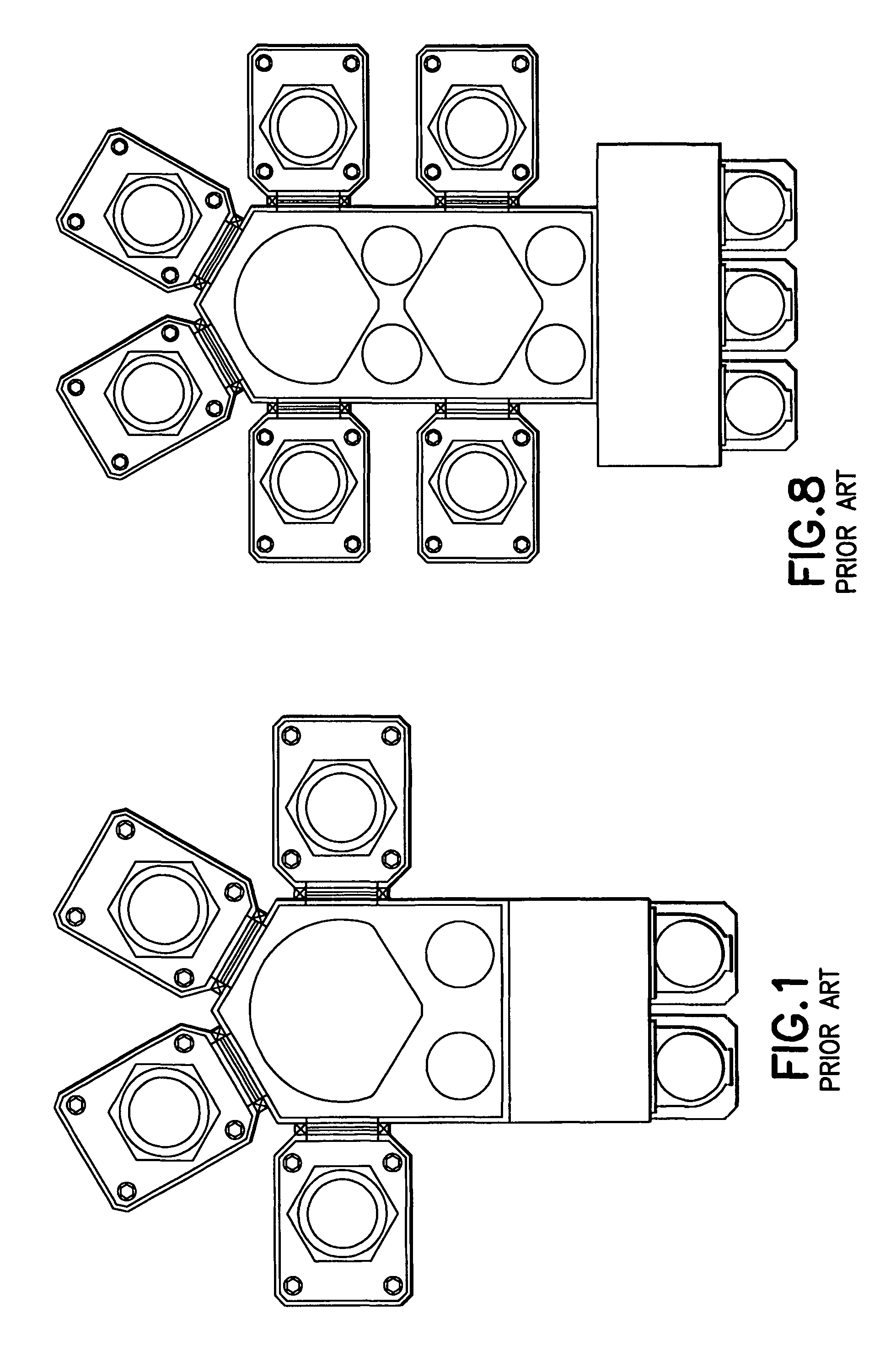

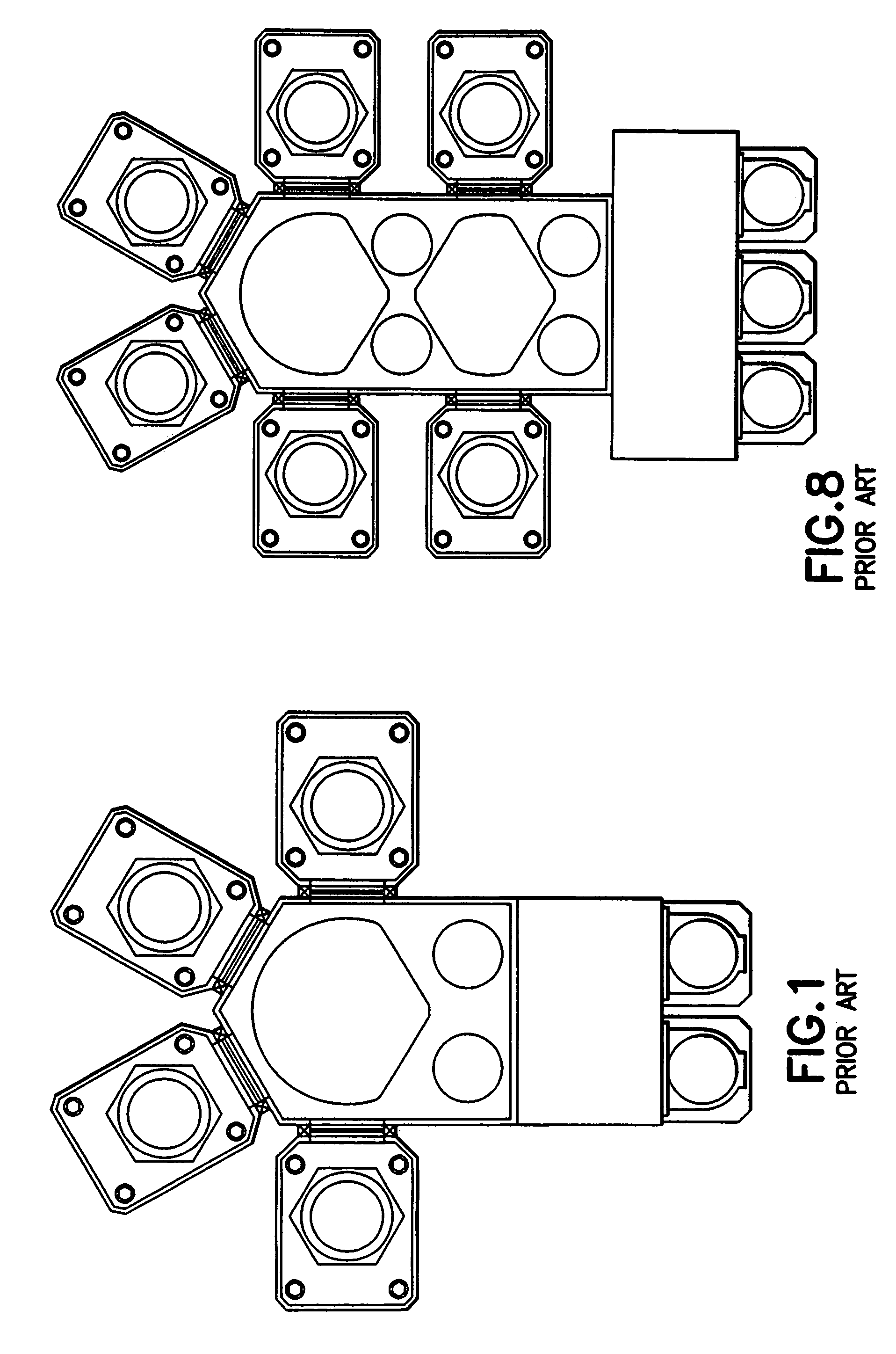

Semiconductor manufacturing process modules

ActiveUS20080124197A1Balance processing loadSemiconductor/solid-state device manufacturingConveyor partsProcess moduleSemiconductor

Owner:BOOKS AUTOMATION US LLC

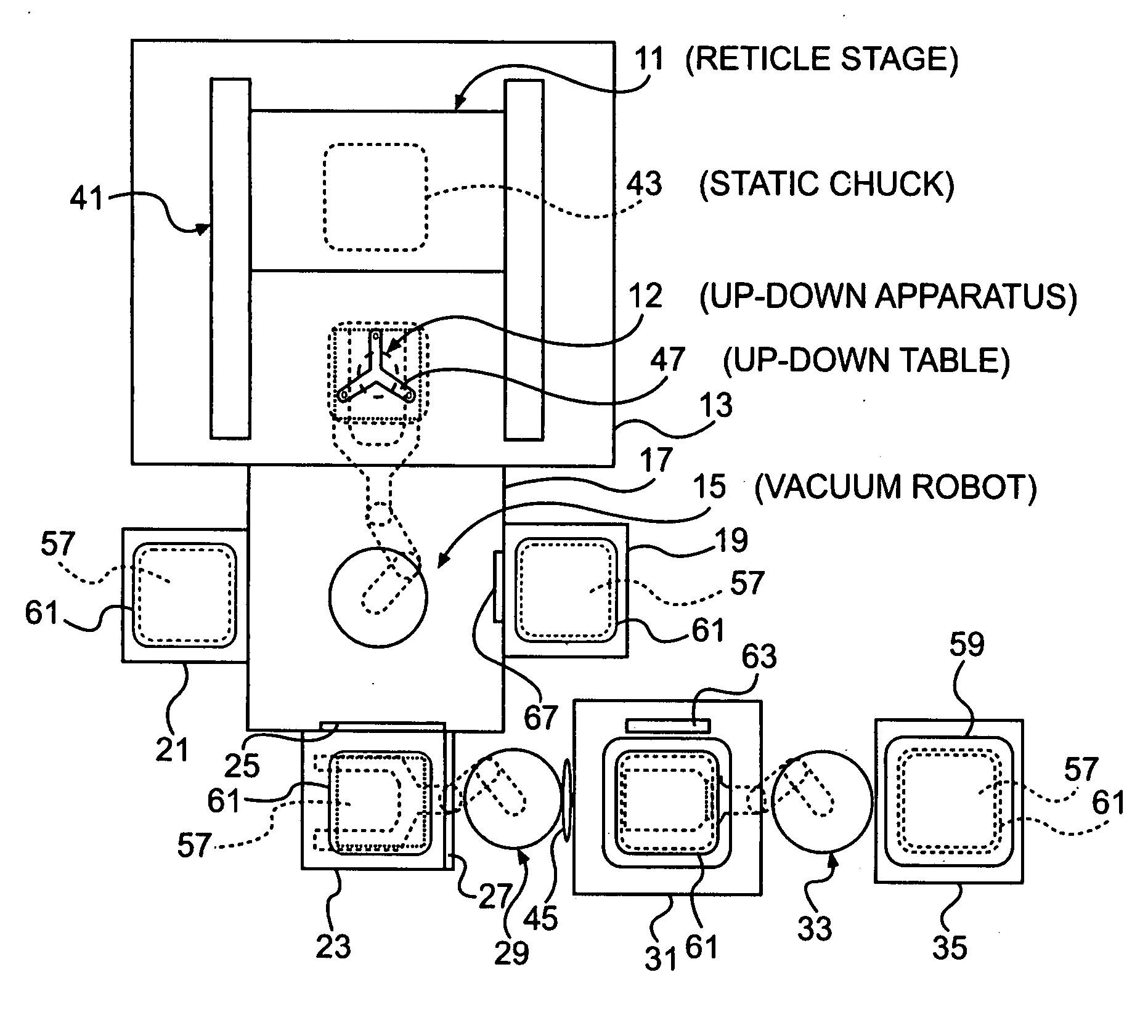

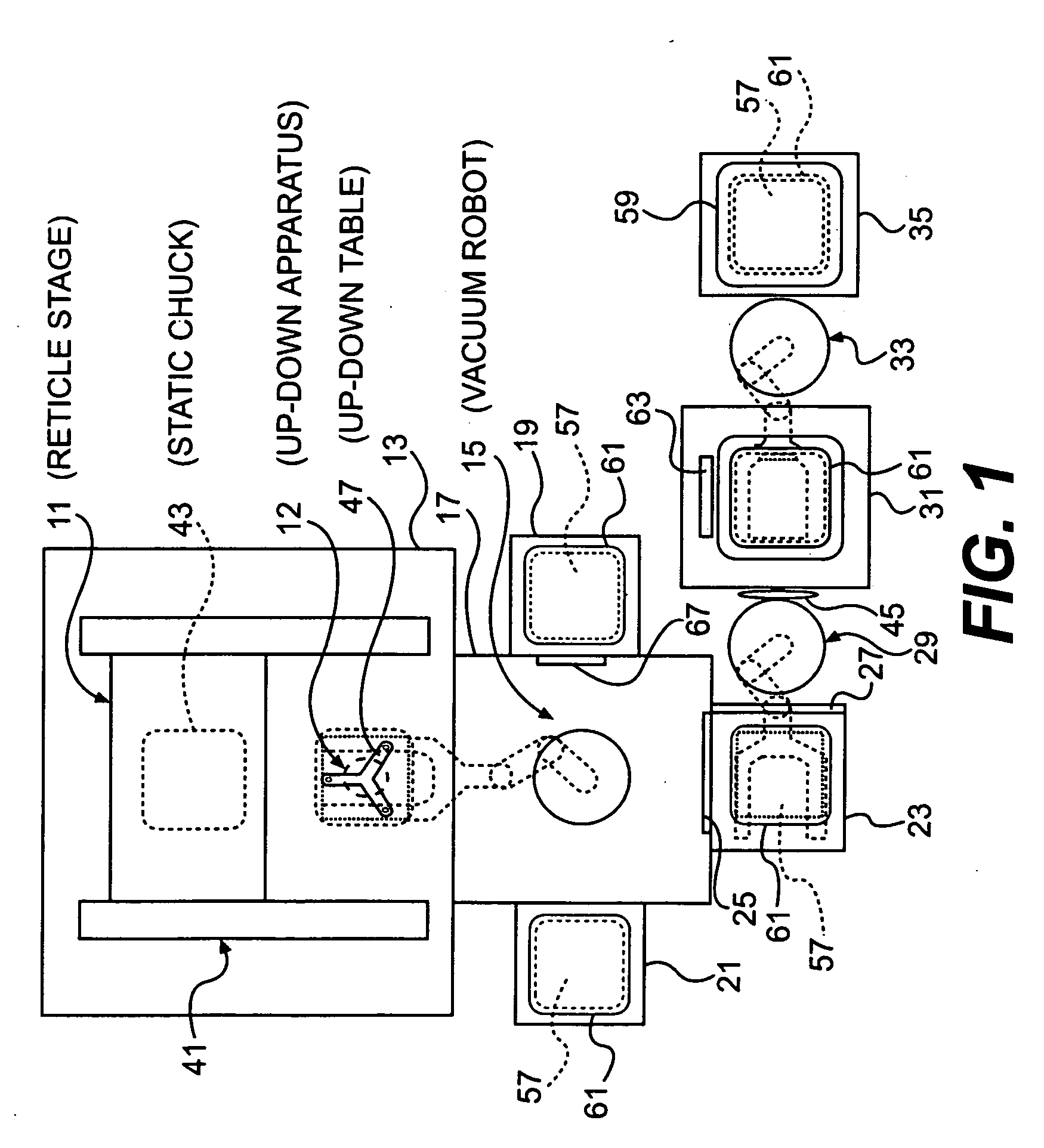

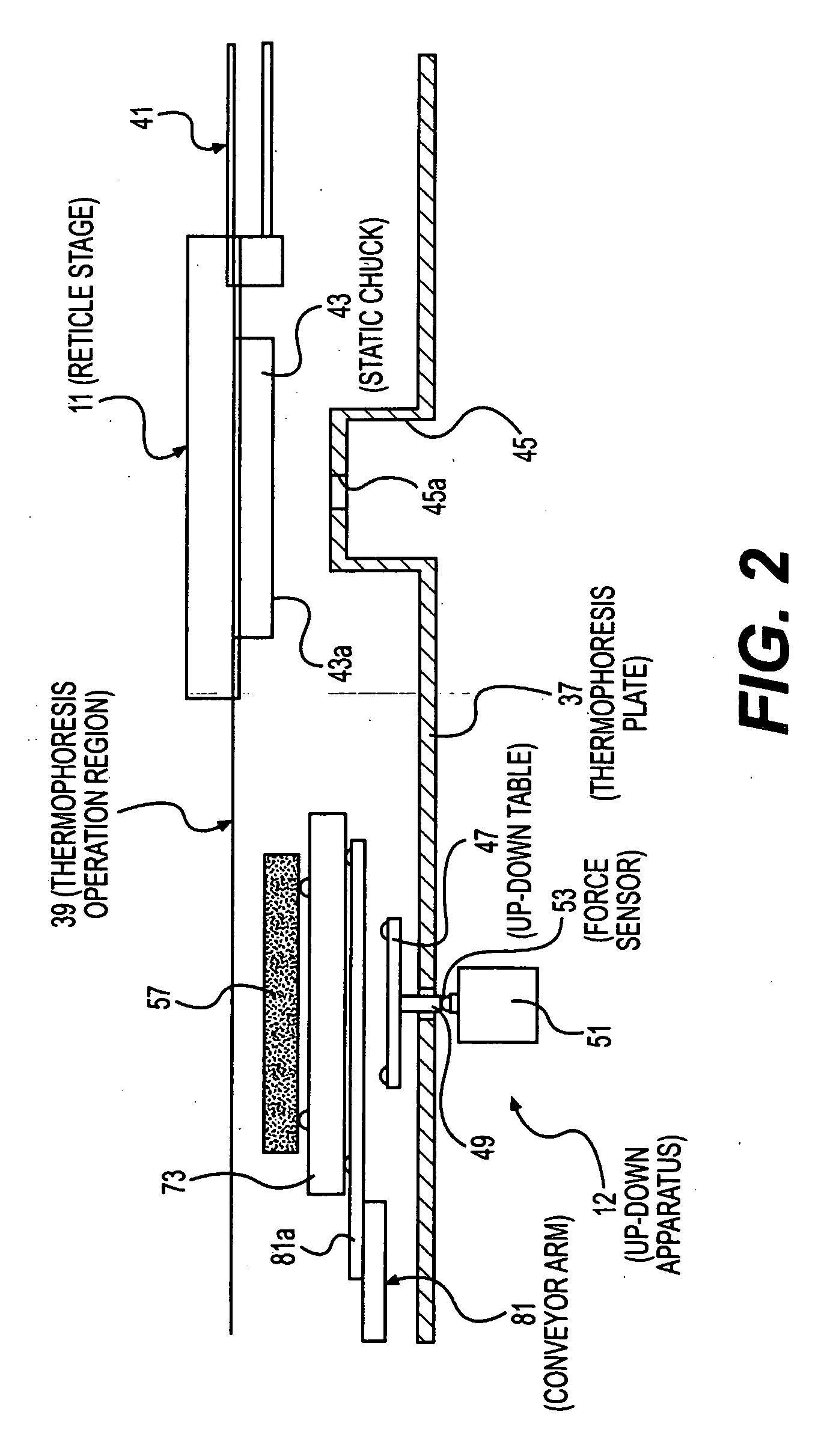

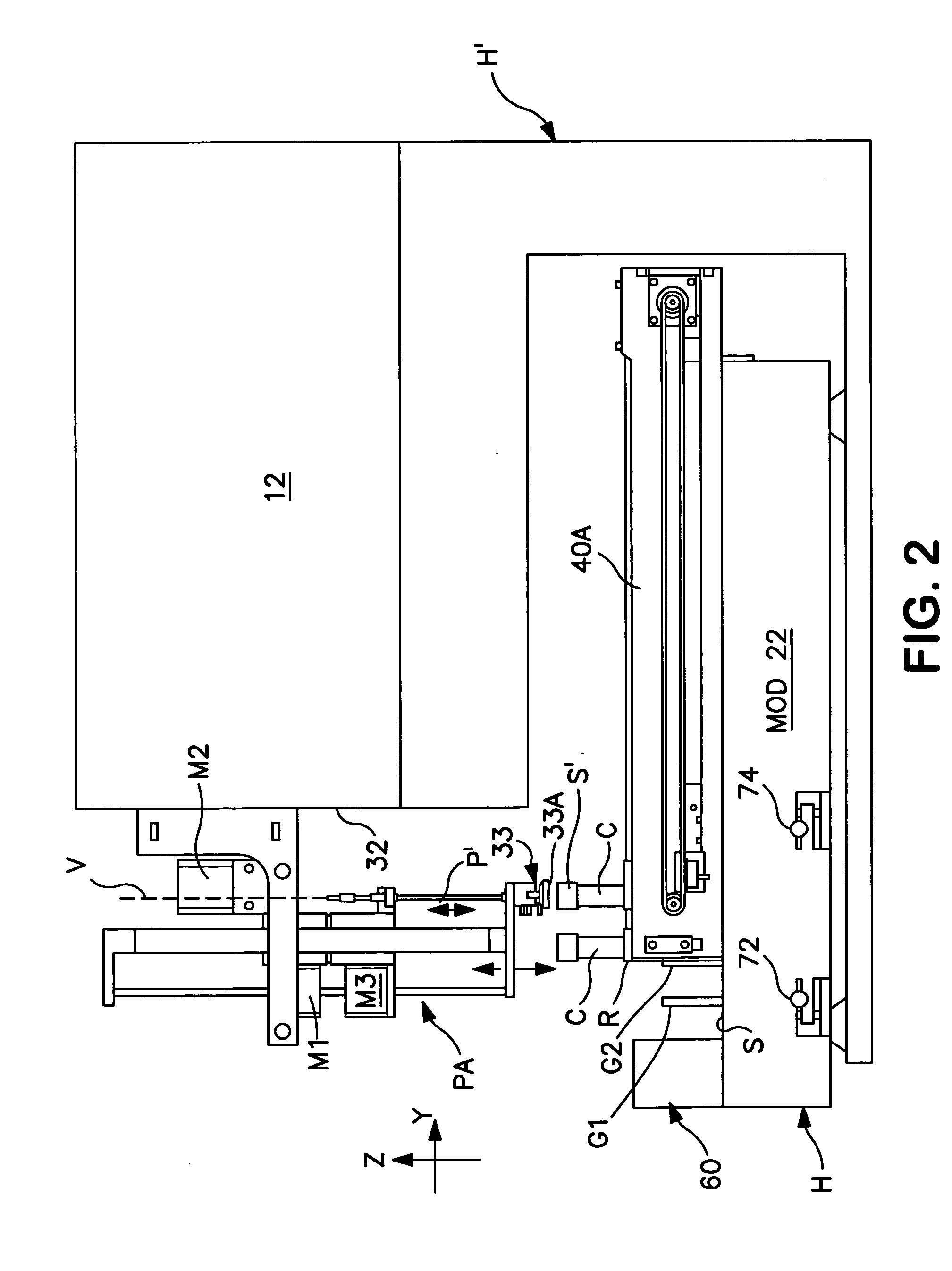

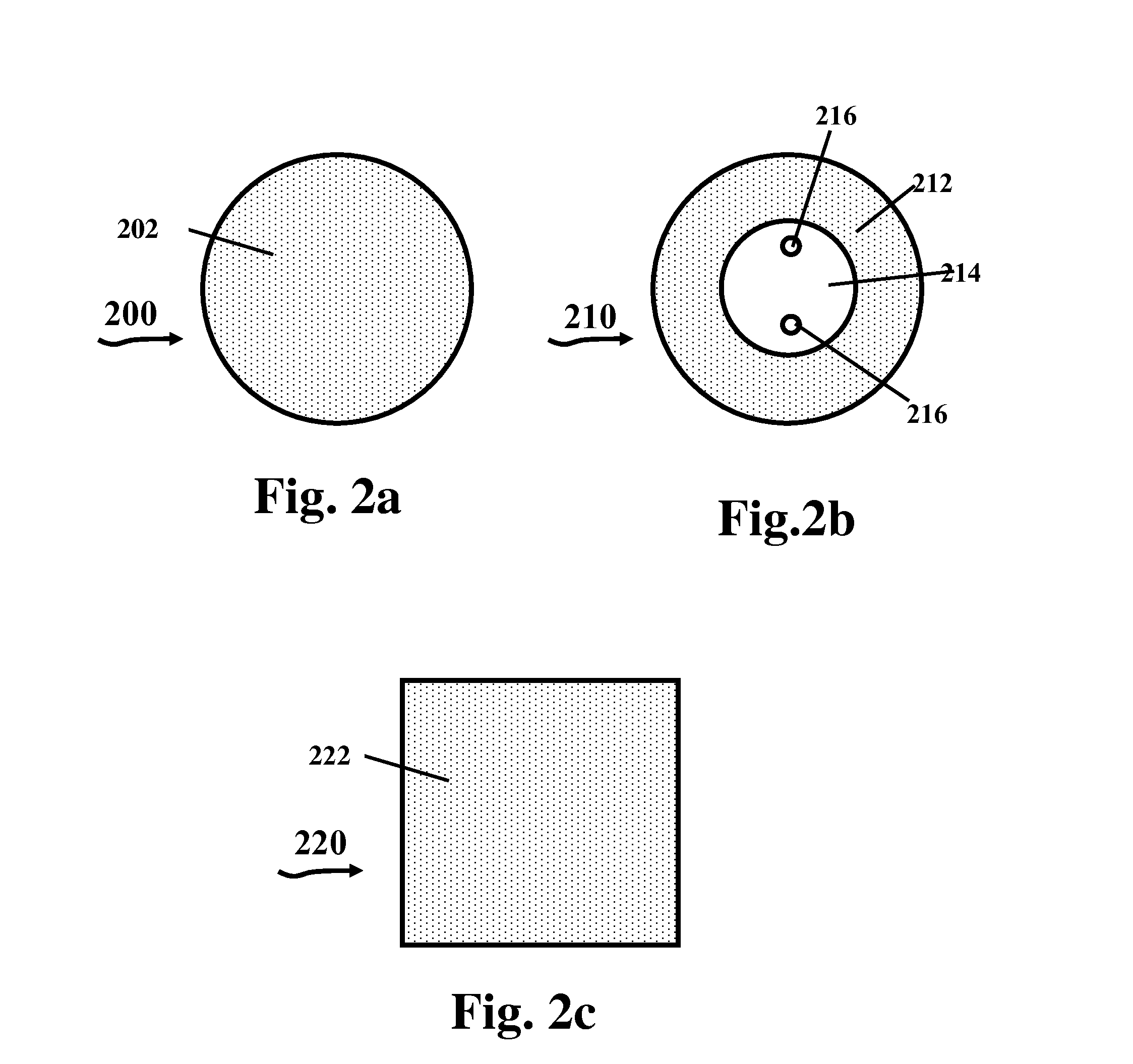

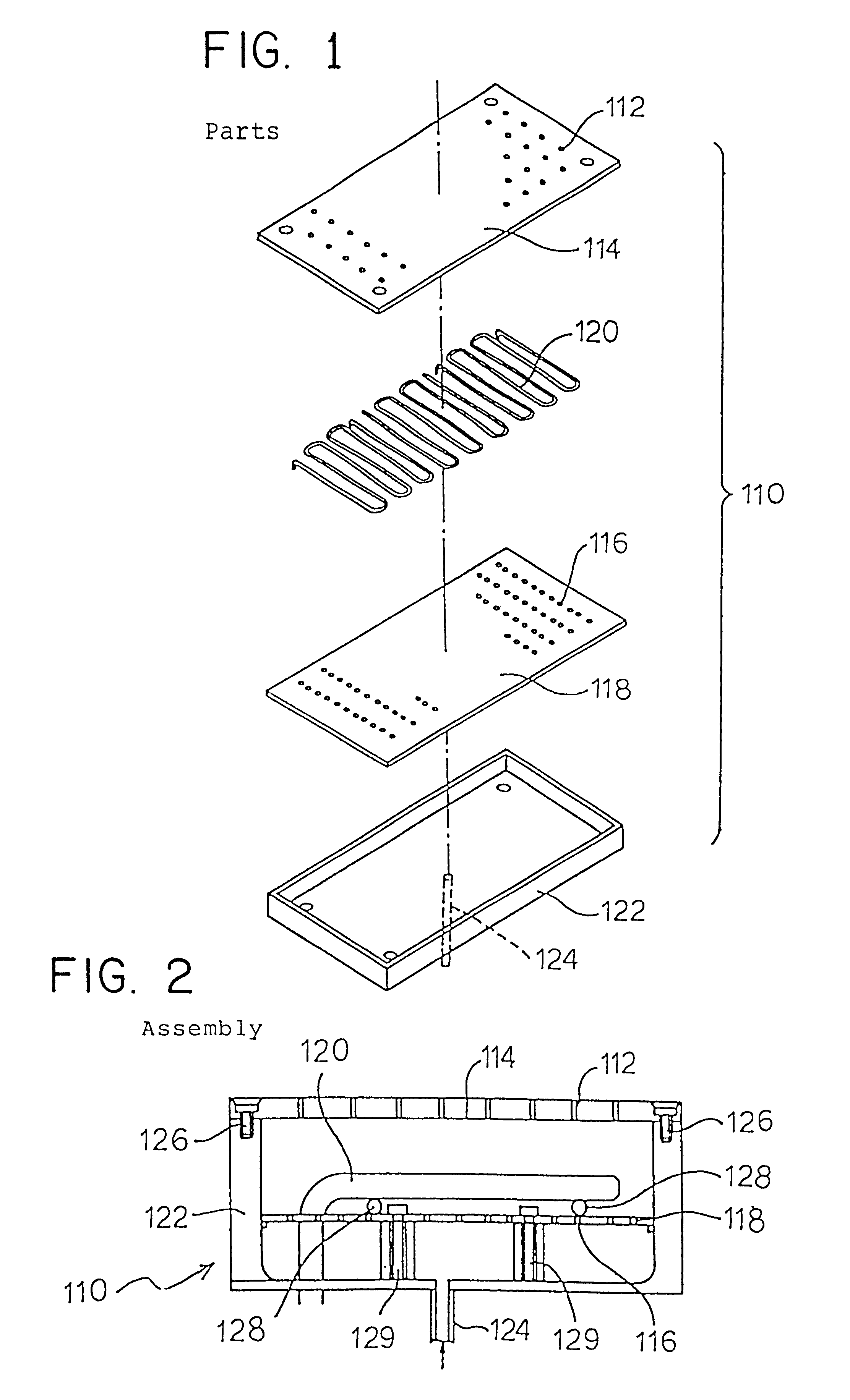

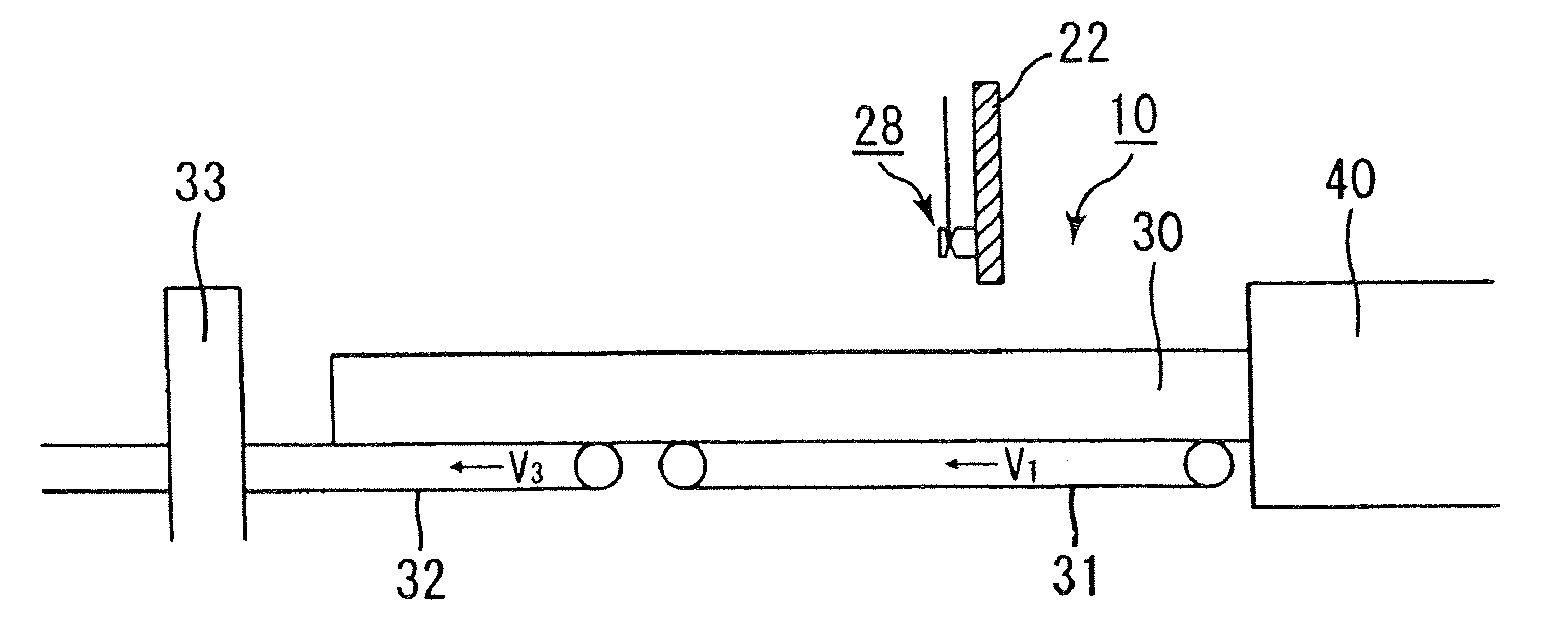

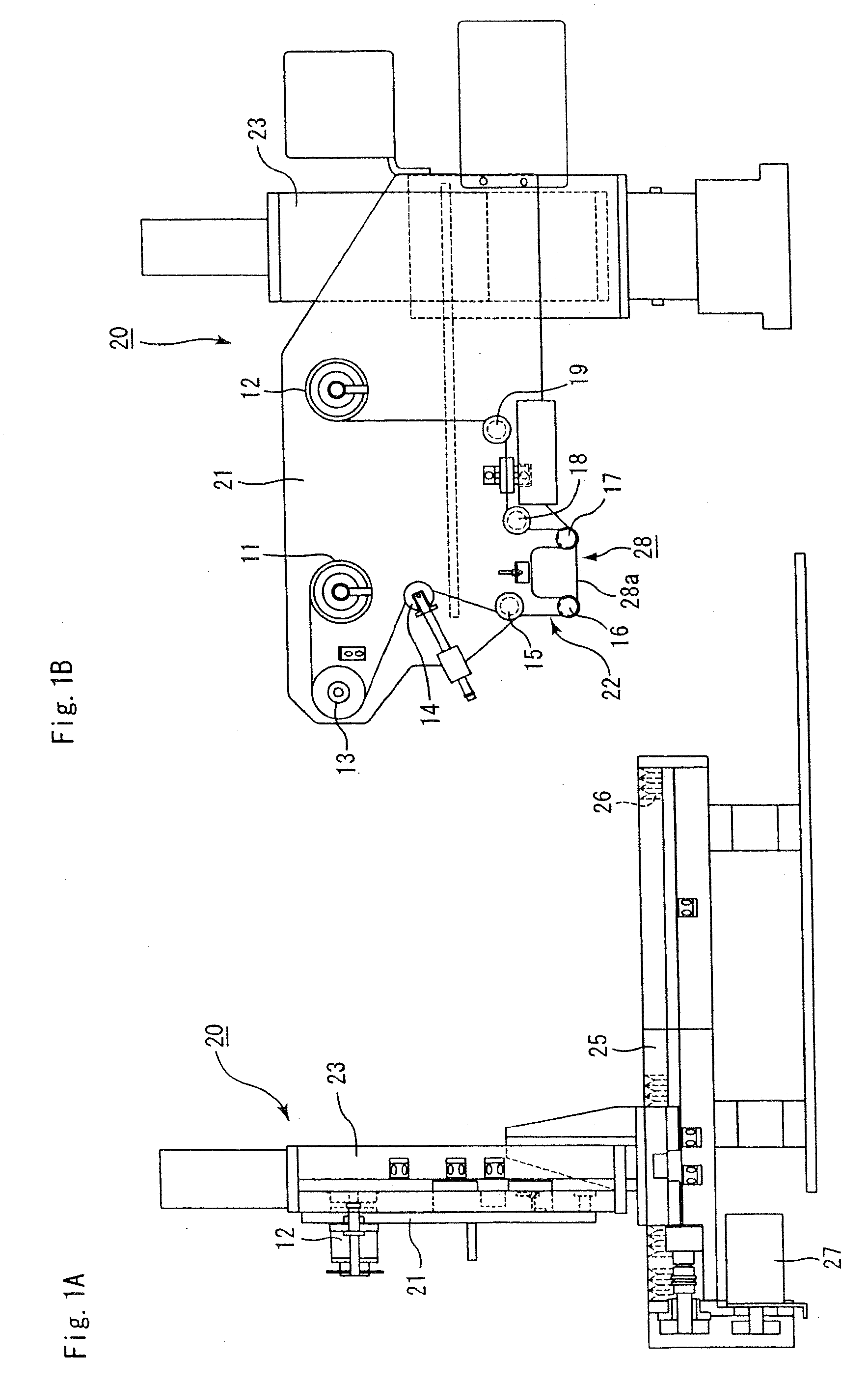

Substrate conveyor apparatus, substrate conveyance method and exposure apparatus

ActiveUS20060291982A1Improve reliabilityStrong adhesionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringReticle

The present invention pertains to a substrate conveyor apparatus that carries a substrate such as a reticle, a substrate conveyance method and an exposure apparatus, with the object of reliably adhering a substrate to the lower surface of a chuck. The present invention is characterized by having a movable stage that can move in the horizontal direction and that is equipped with a chuck having an adhesion surface that faces down for adhering a substrate, an up-down means equipped with an up-down table that is positionable in a position below the substrate and within the movement range of the movable stage, and a conveyance means equipped with a conveyor arm that carries the substrate to the up-down means.

Owner:NIKON CORP

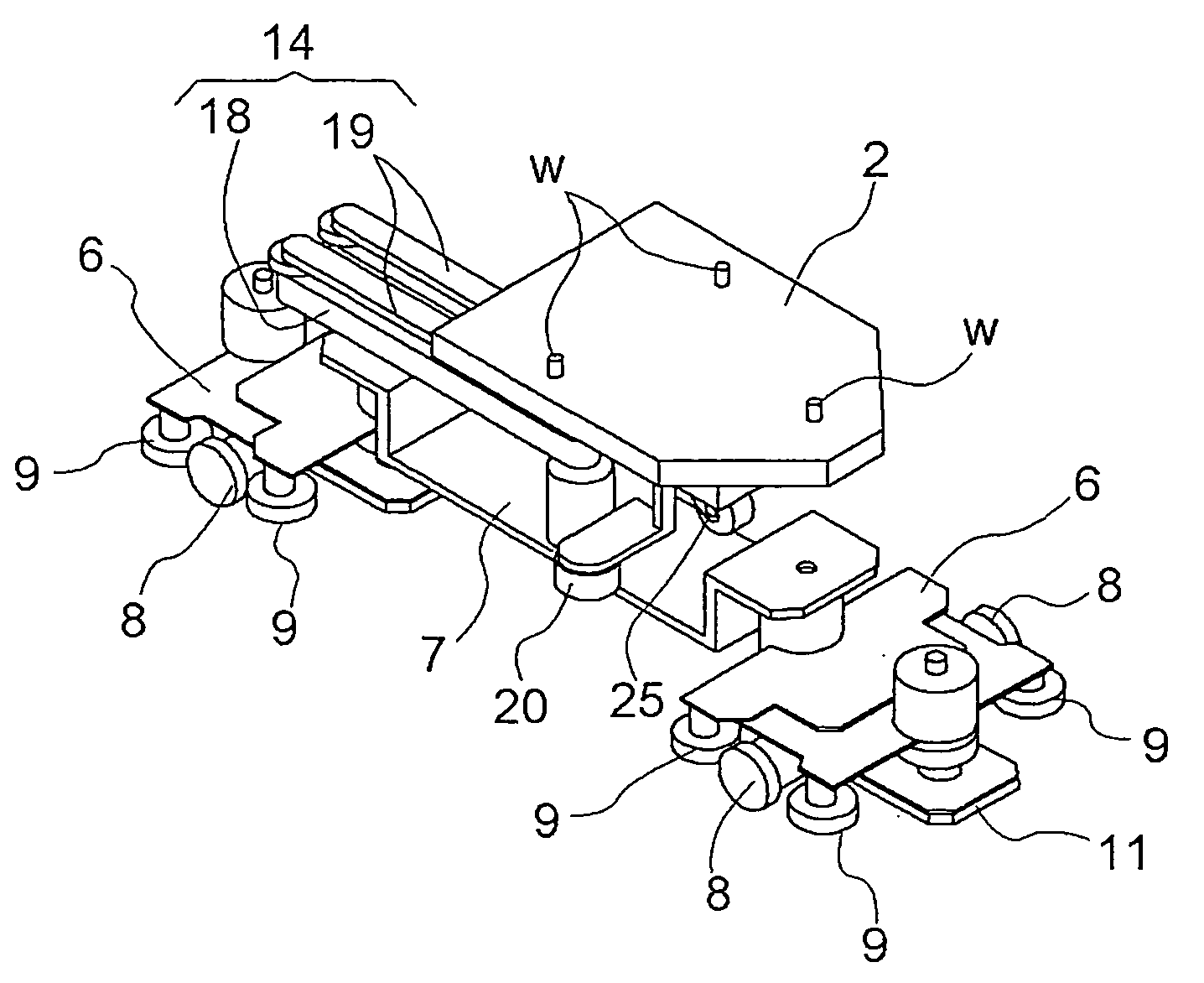

Article transport device

InactiveUS20070034477A1Small and simpleSemiconductor/solid-state device manufacturingControl devices for conveyorsSolid of revolution

Owner:DAIFUKU CO LTD

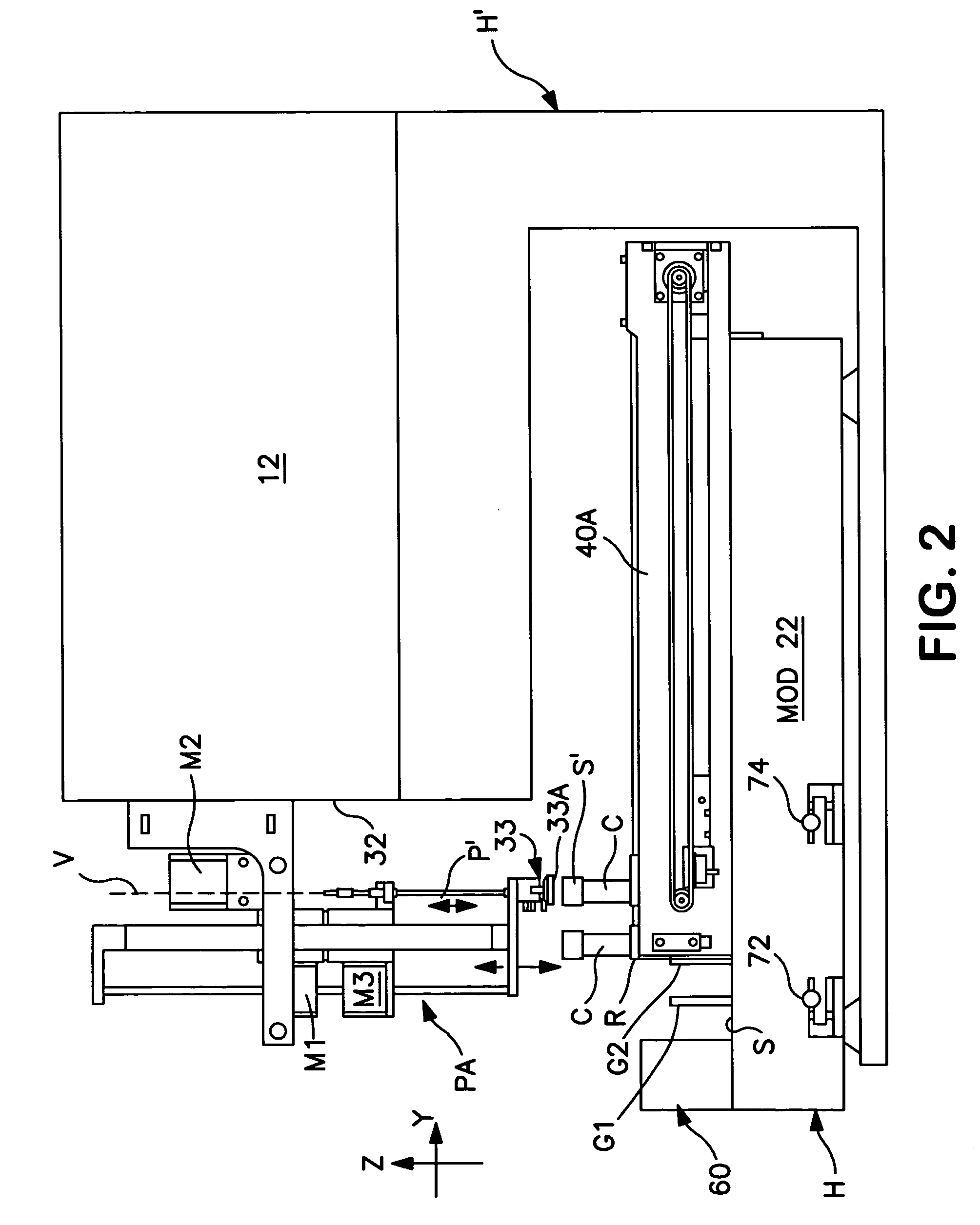

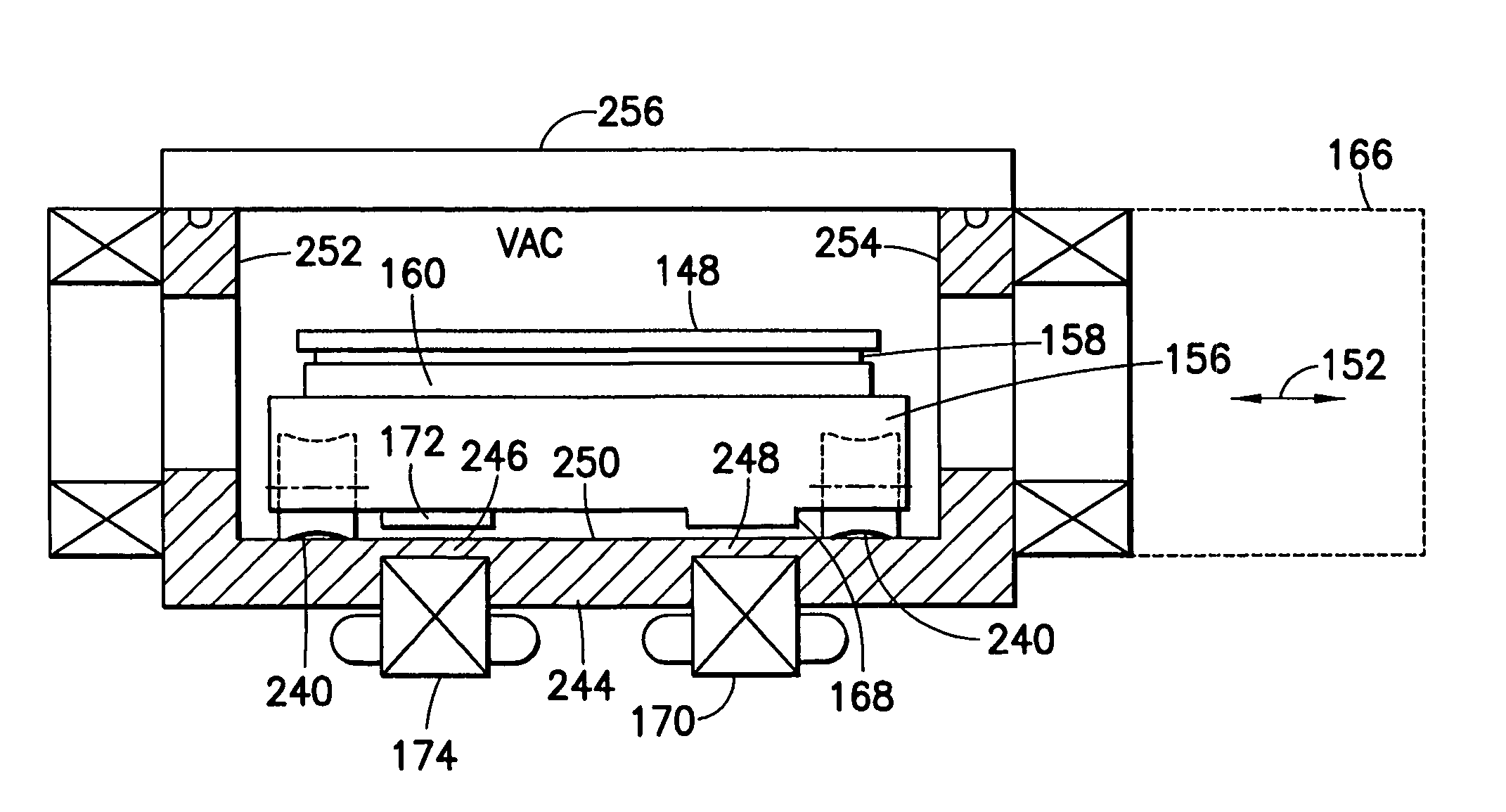

Substrate processing apparatus

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

Materials-handling system using autonomous transfer and transport vehicles

ActiveUS7991505B2High degree of automationEfficient automationDigital data processing detailsLoading/unloadingEngineeringHandling system

Methods and apparatus for selecting and combining packages in an outbound container by employing autonomous transfer and transport vehicles which move on a network of roadways to carry a plurality of individual cases each containing the same kind of product from a loading station and to a destination station where individual packages are combined in the outbound container. The travel of each vehicle through the roadway network is computer controlled, and each vehicle includes means for automatically loading and unloading packages from predetermined locations on the network.

Owner:SYMBOTIC LLC

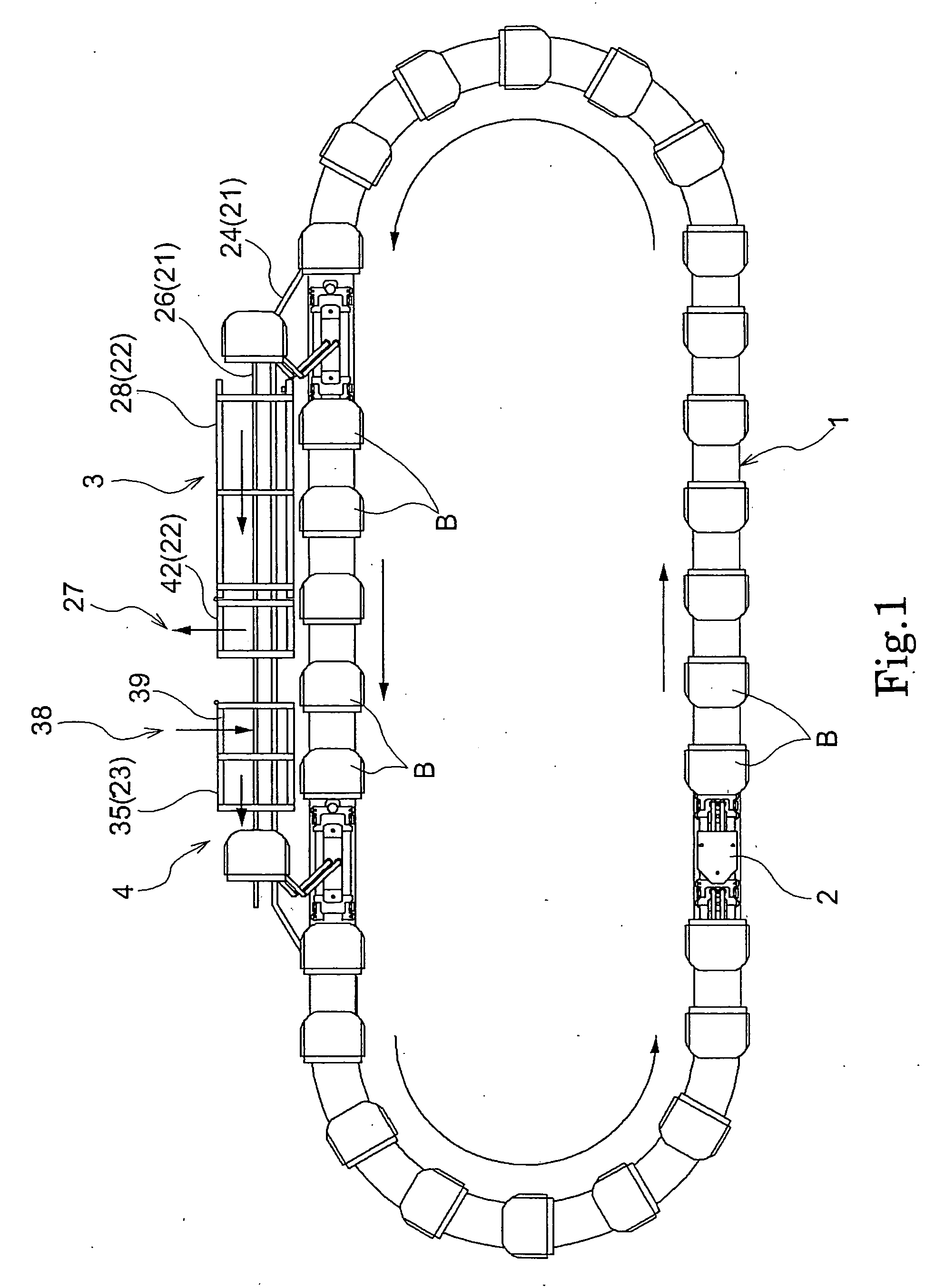

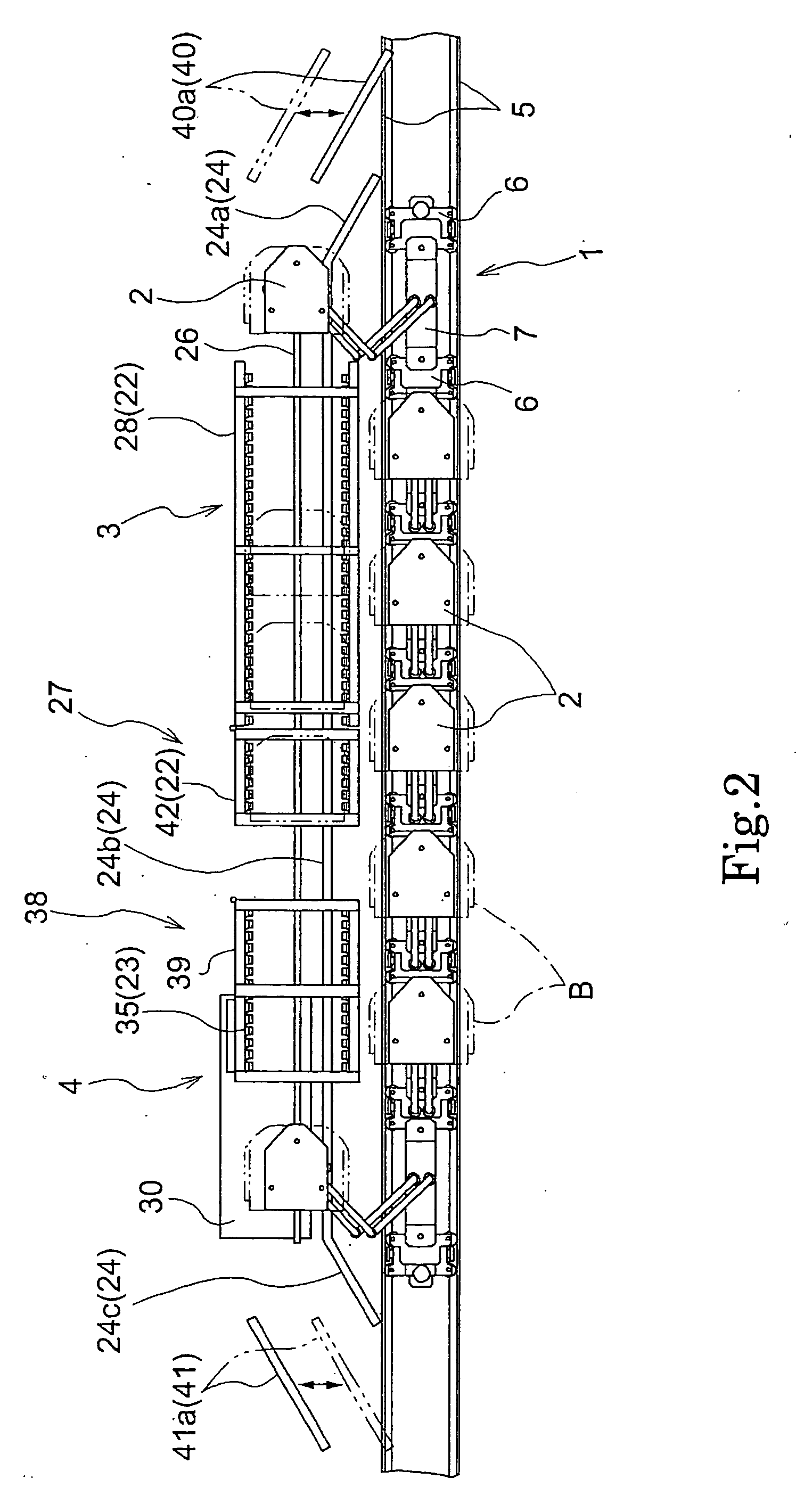

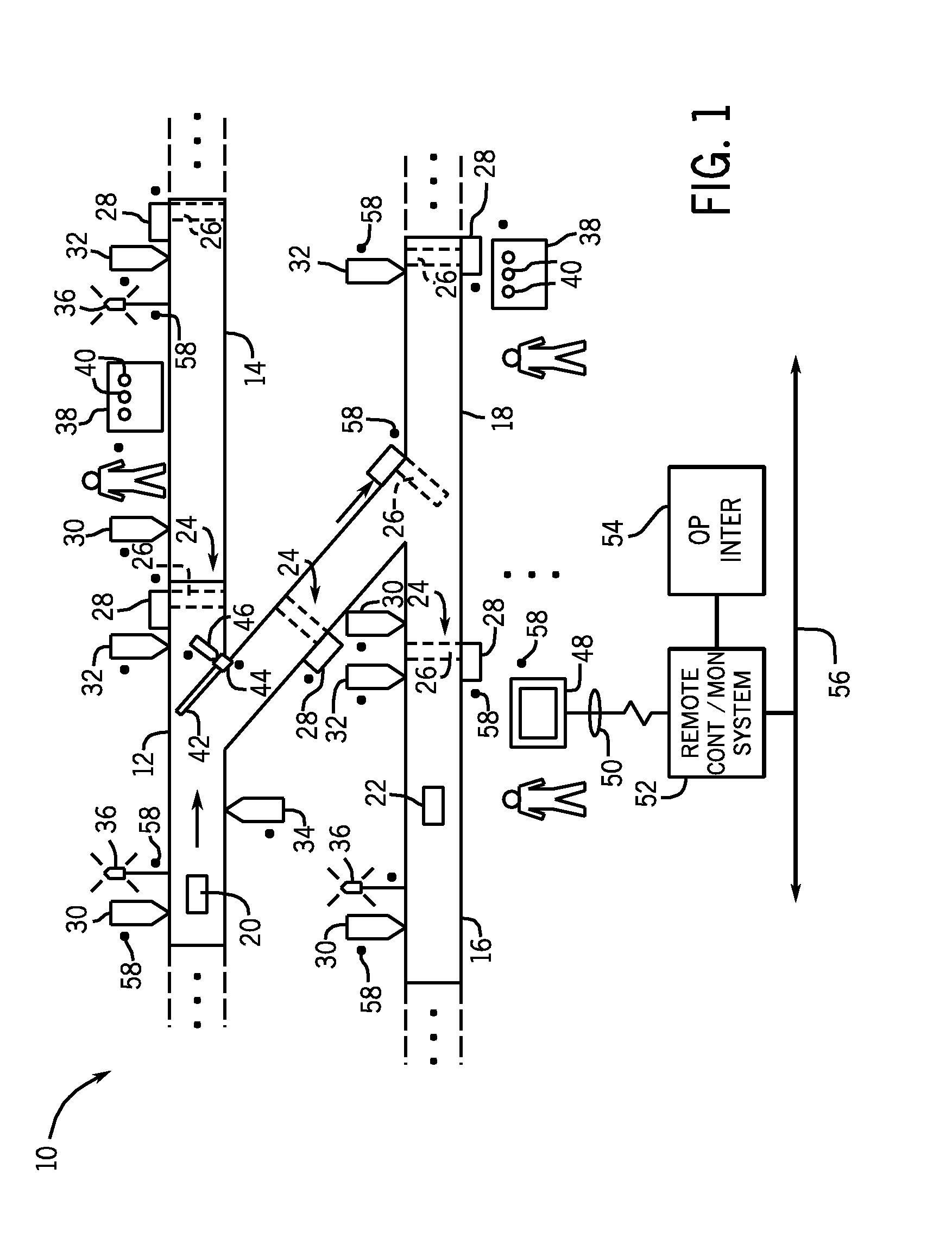

Method and apparatus for sorting items

A method and apparatus are provided for sorting items to a plurality of sort destinations. The items are loaded onto one of a plurality of independently controlled delivery vehicles. The delivery vehicles follow a track that guides the delivery vehicles to the sort destinations, which are positioned along the track. Once at the appropriate sort destination, the delivery vehicle ejects the item to the sort destination and returns to receive another item to be delivered.

Owner:OPEX

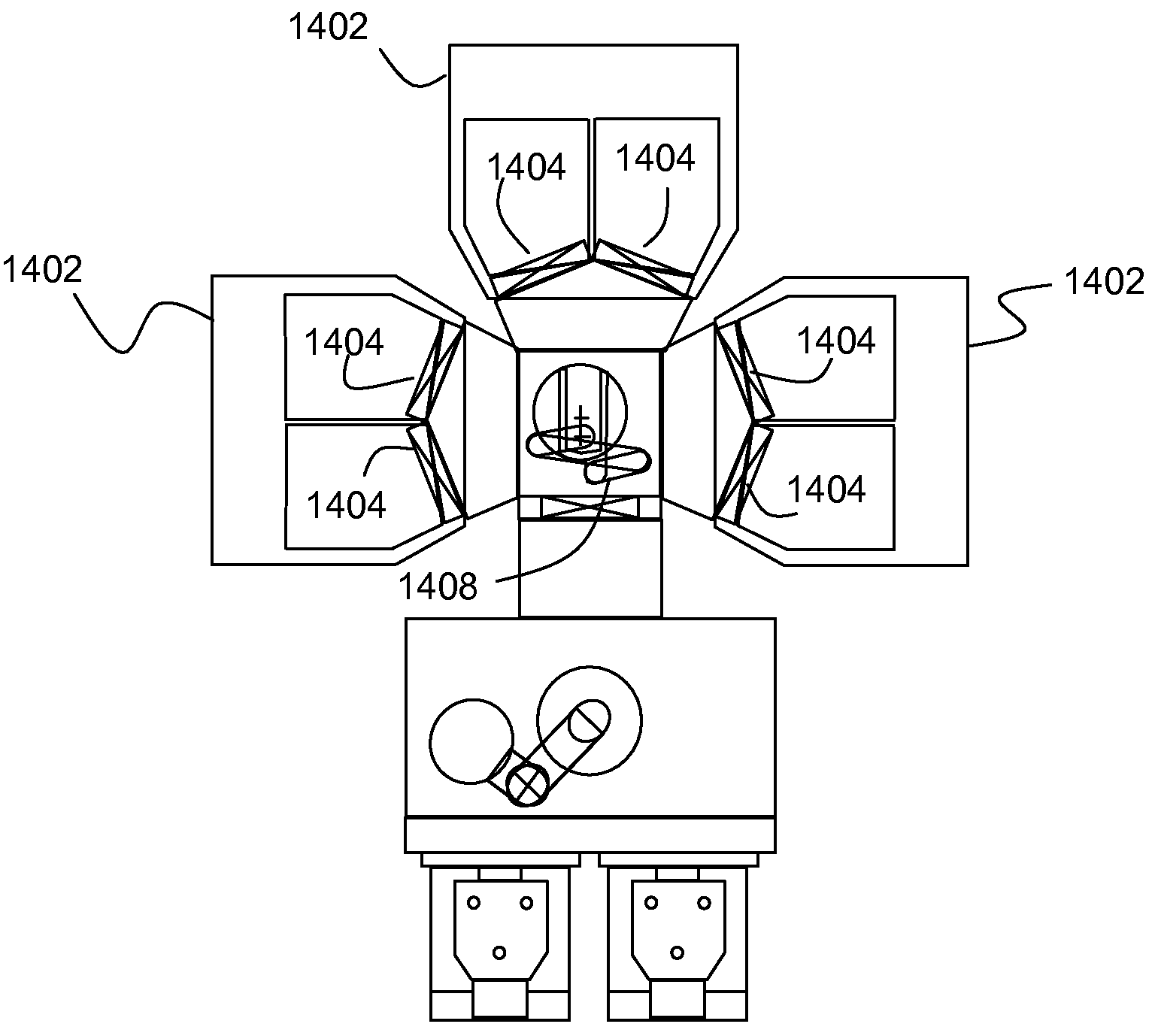

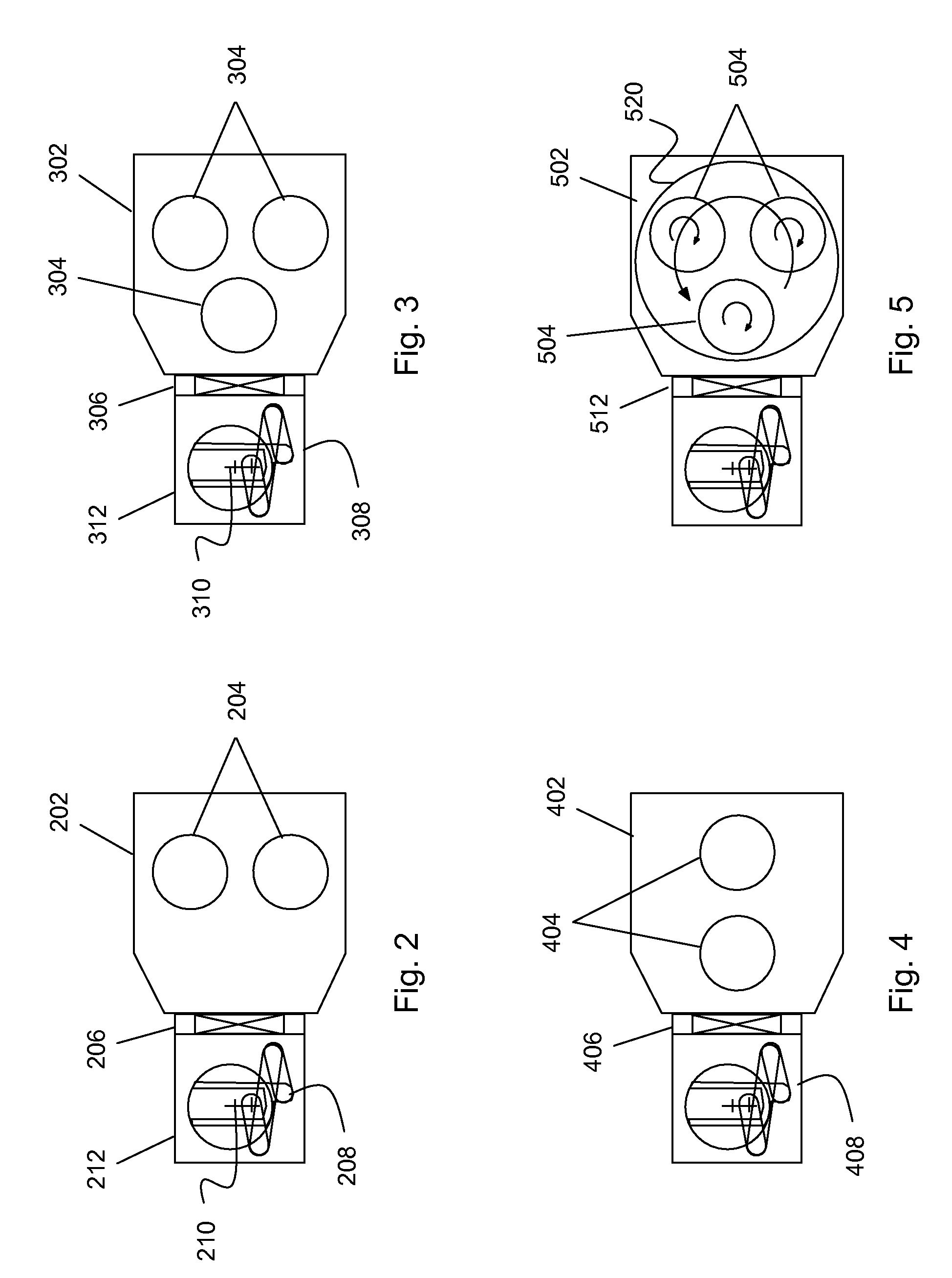

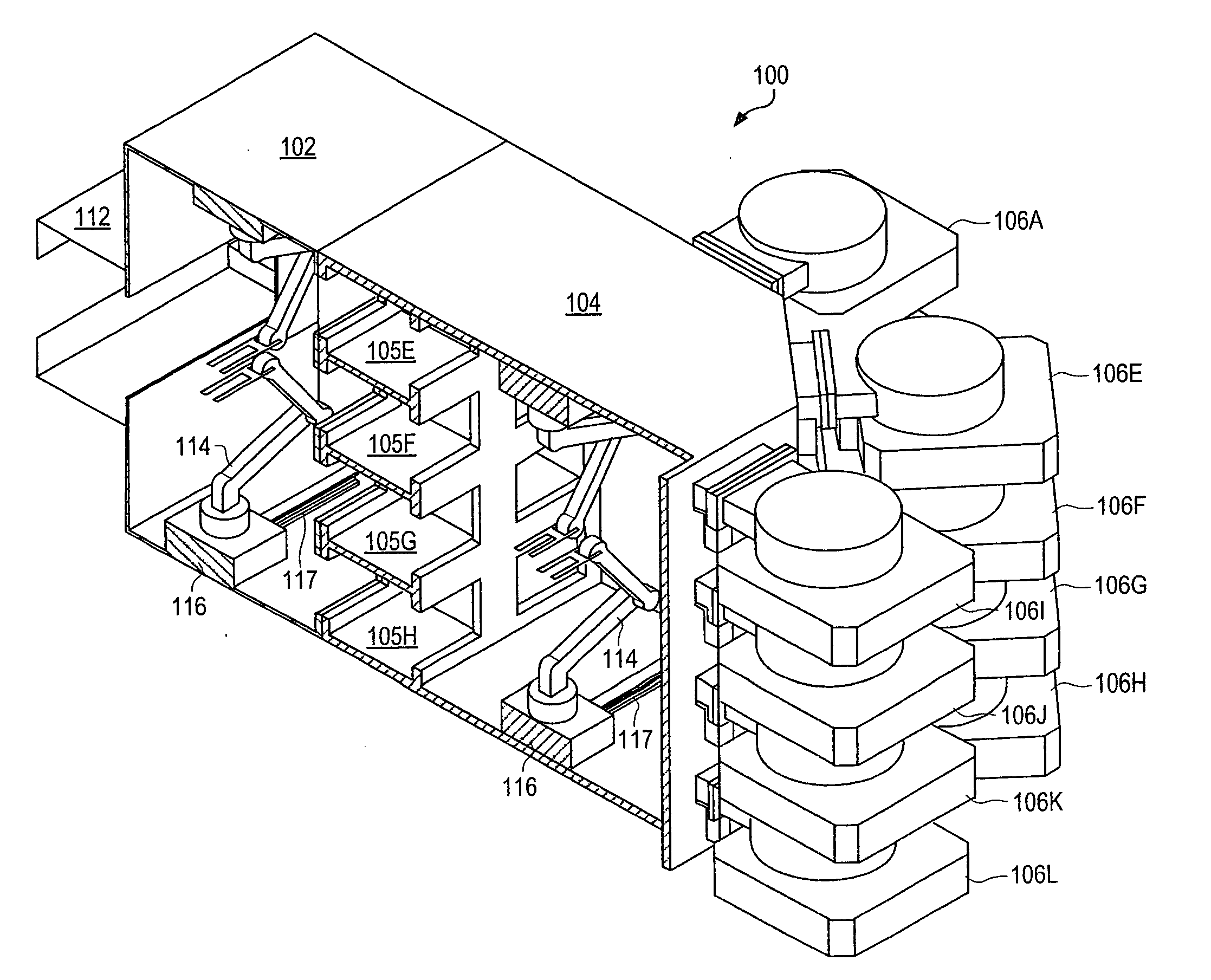

Stacked process chambers for substrate vacuum processing tool

InactiveUS20080202892A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingRobotic armSemiconductor

A substrate processing apparatus is described. The apparatus includes a substrate load lock chamber. A substrate transfer chamber is vacuum coupled to the substrate load lock chamber. A plurality of process chamber modules are vacuum coupled to the substrate transfer chamber. At least two of the process chamber modules are horizontally clustered around the substrate transfer chamber. In addition, at least two of the process chamber modules are vertically arranged with one process chamber module above the other process chamber module. The substrate transfer chamber includes one or more robotic arms for transferring semiconductor substrates between the substrate load lock chamber and the plurality of process chamber modules.

Owner:SMITH JOHN M +2

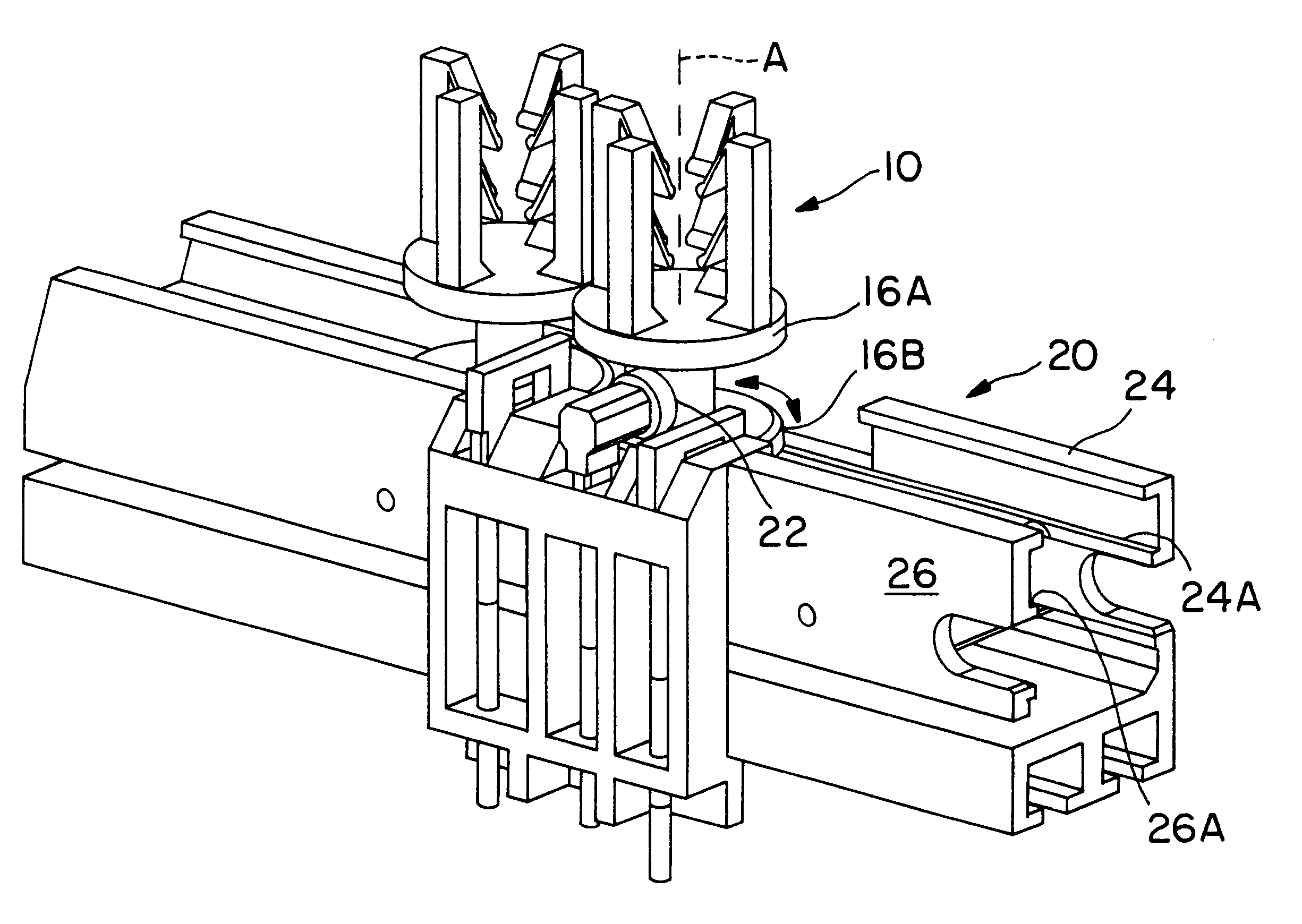

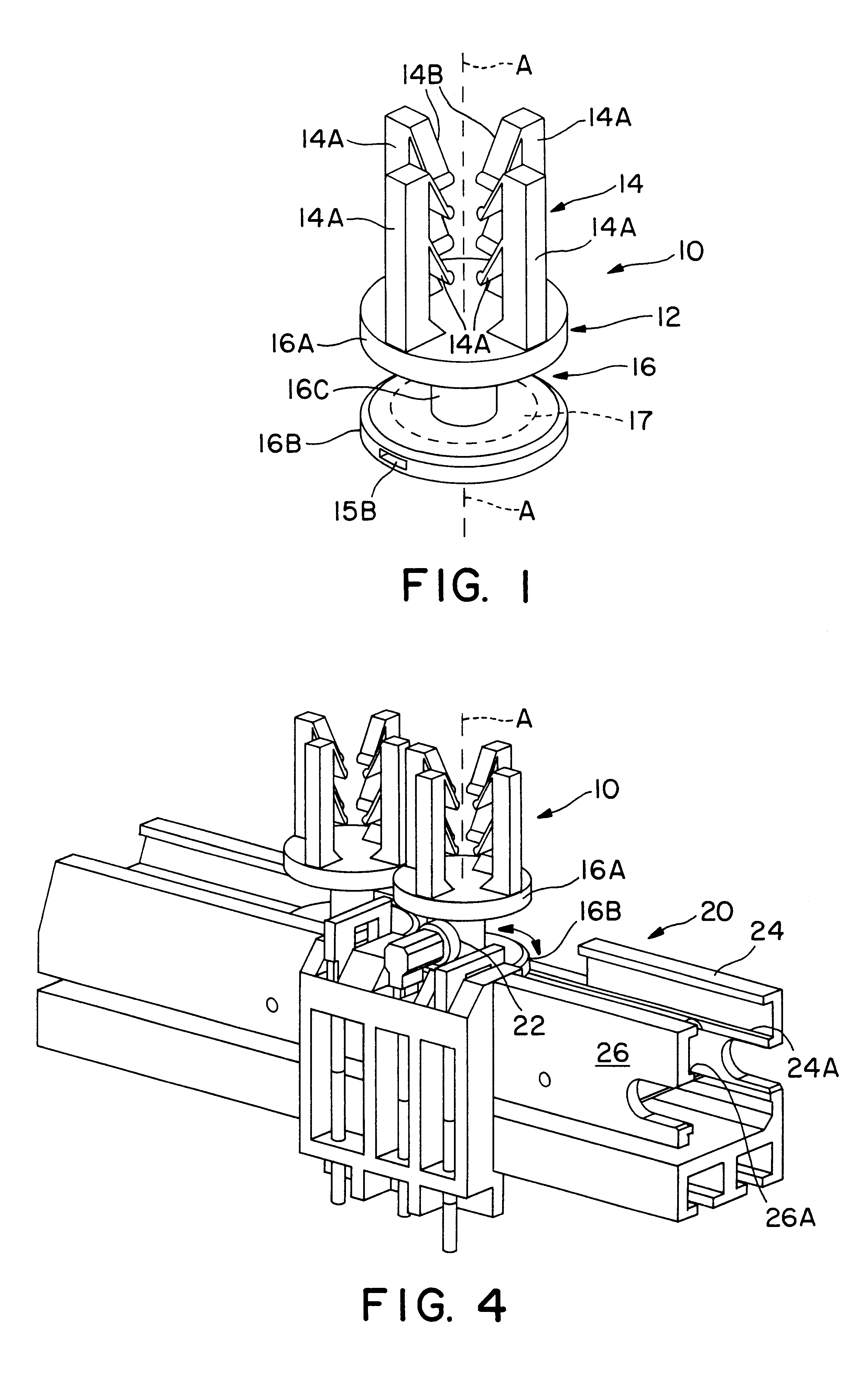

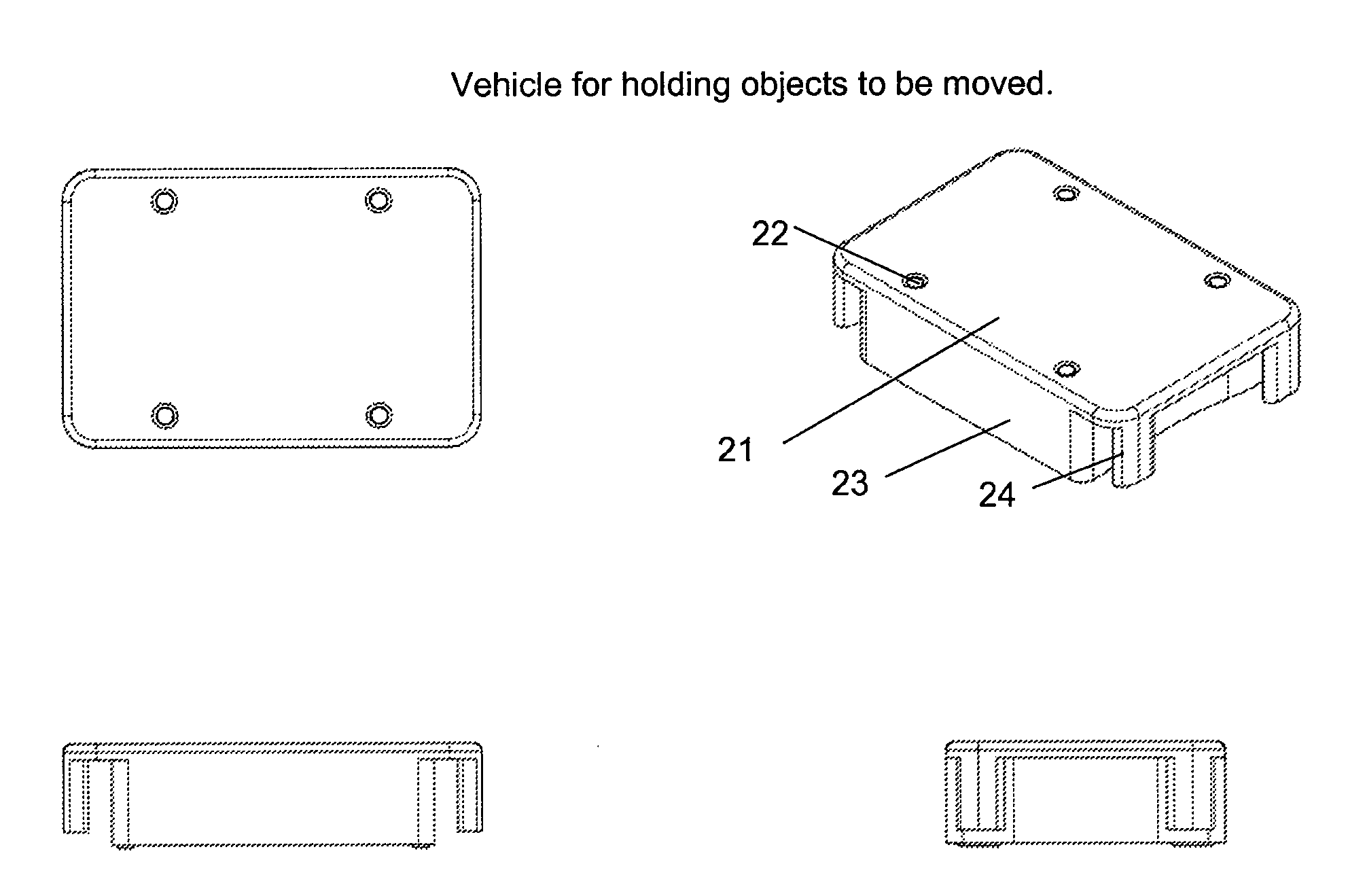

Specimen carrier for automated transport system and method and apparatus for identifying same

A specimen carrier comprises a unitary structure for receiving and retaining a specimen container in an upright orientation. Such unitary structure is defined by a pedestal having upper and lower platforms connected by a stem. Extending upwardly from the upper platform is a plurality of rigid members which support a plurality of opposing flexible fingers adapted to engage and press upon the side wall of a specimen container received by the carrier. Preferably, the specimen carrier of the invention has a chamber formed therein for housing a pre-programmed, programmable or otherwise radio-frequency (RF) identification tag in the form of an RF transponder. Upon being energized by a suitable RF field provided by an RF reader antenna or sensor positioned adjacent the carrier's intended path of movement, the tag transmits a unique identification code, such code being received by the antenna or sensor and decoded by the reader.

Owner:COULTER INTERNATIONAL CORPORATION

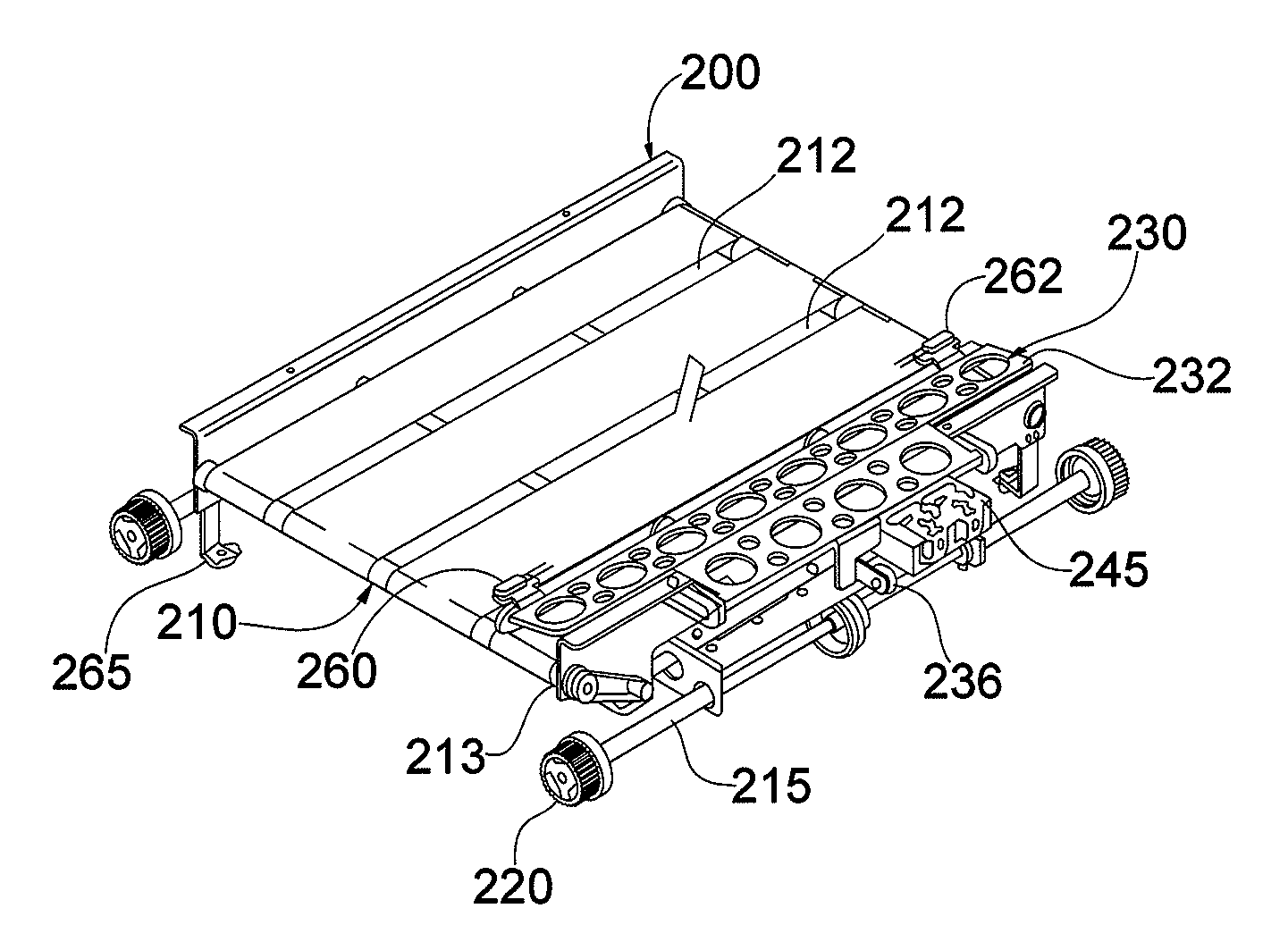

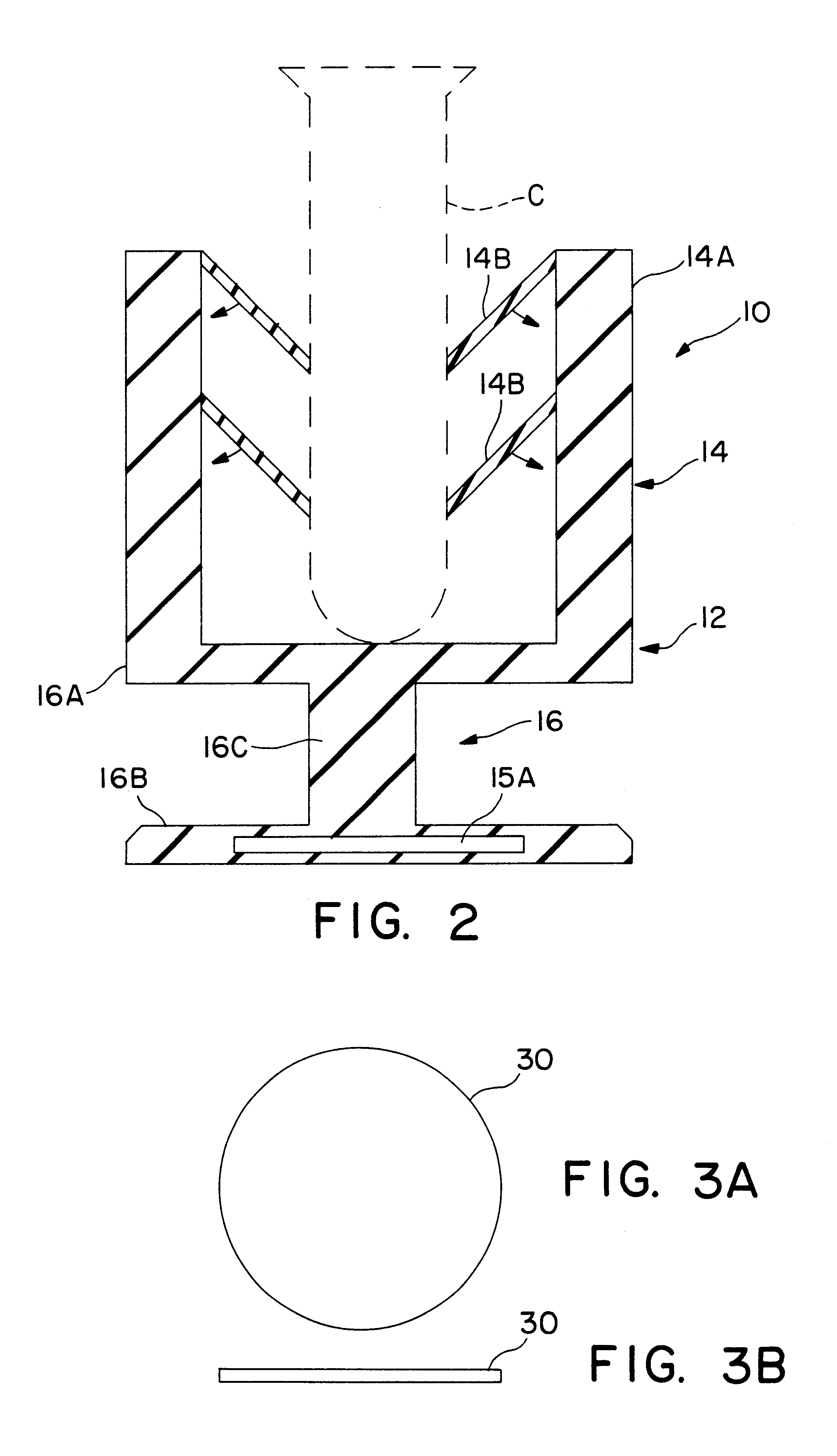

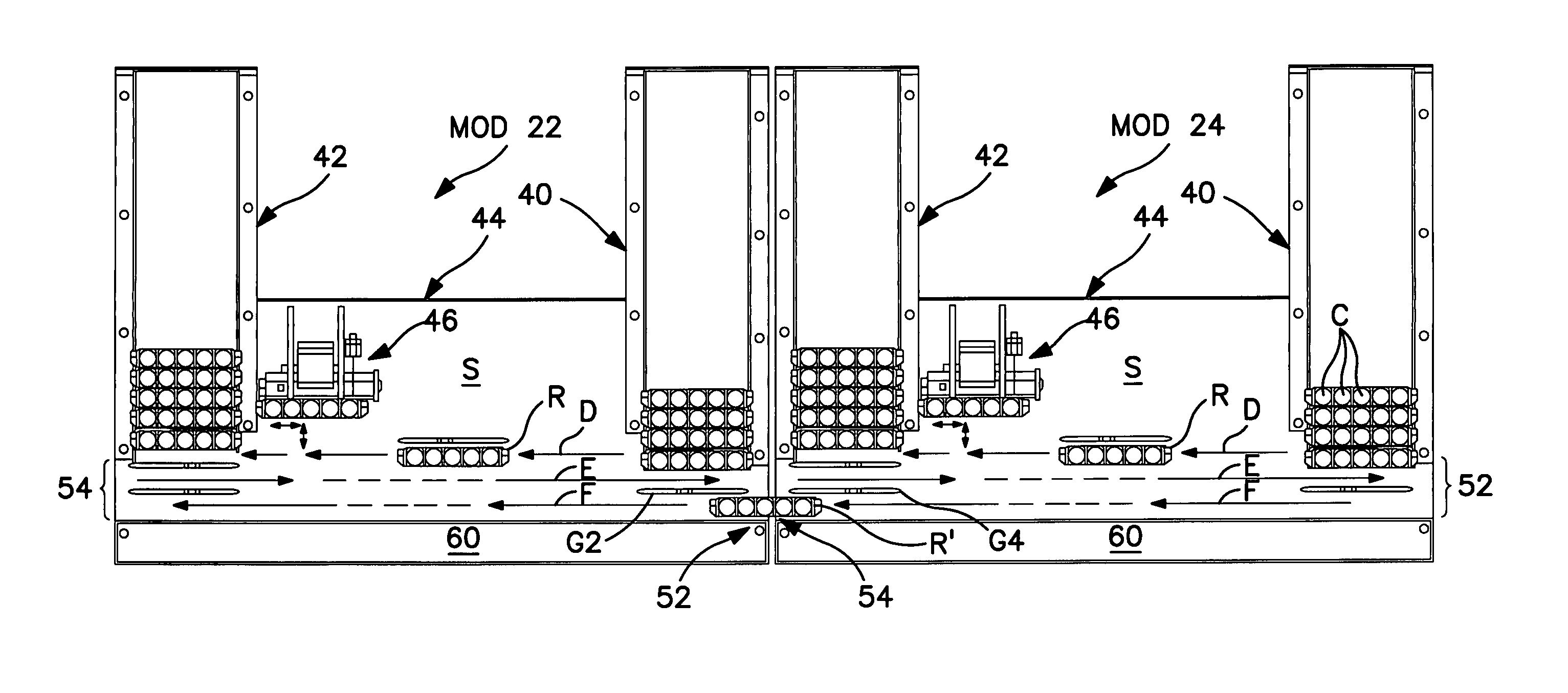

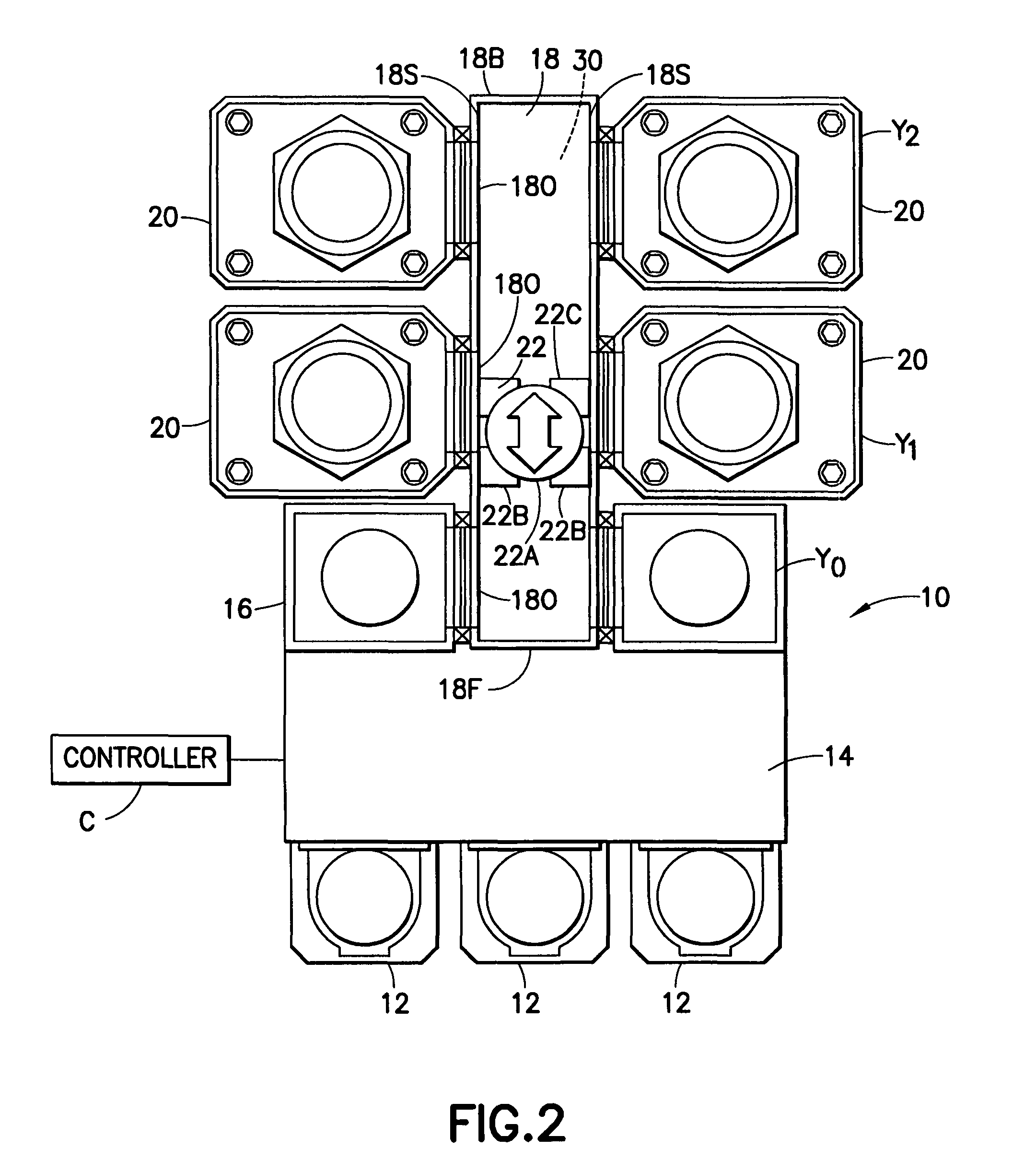

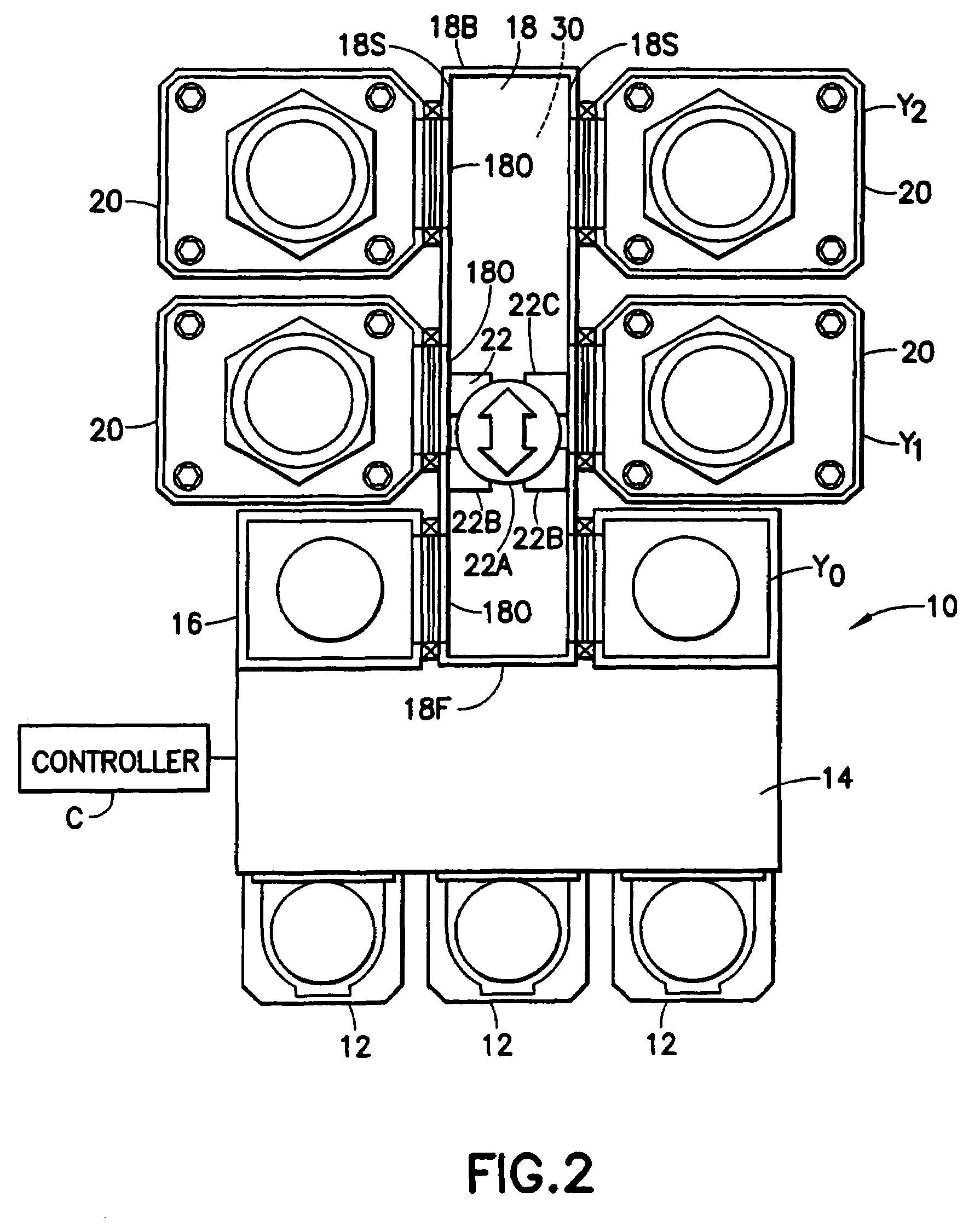

Specimen-transport module for a multi-instrument clinical workcell

ActiveUS20050196320A1Simpler and reliable resultEliminate needMaterial analysis by optical meansCharge manipulationWorkcellTransfer system

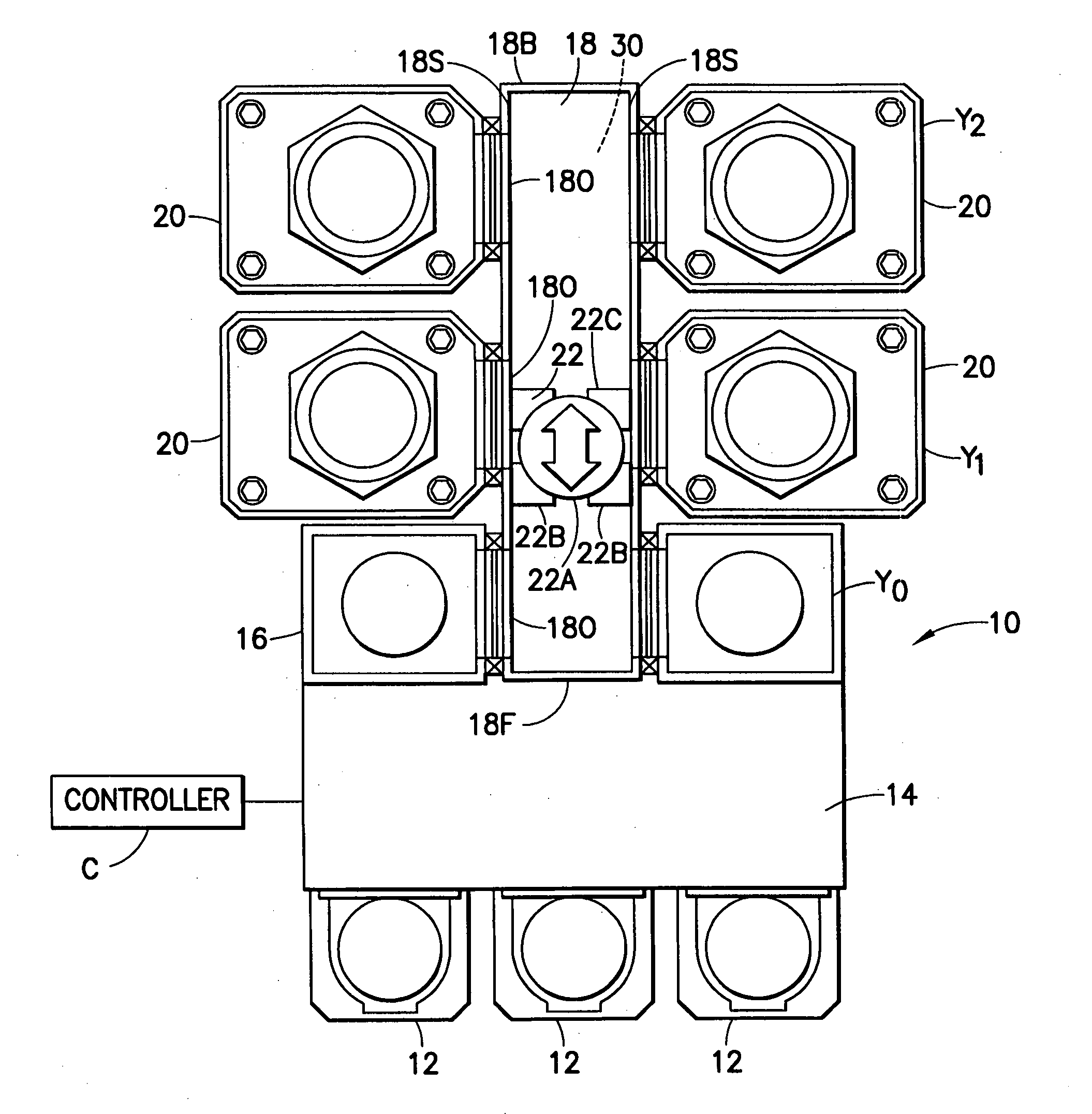

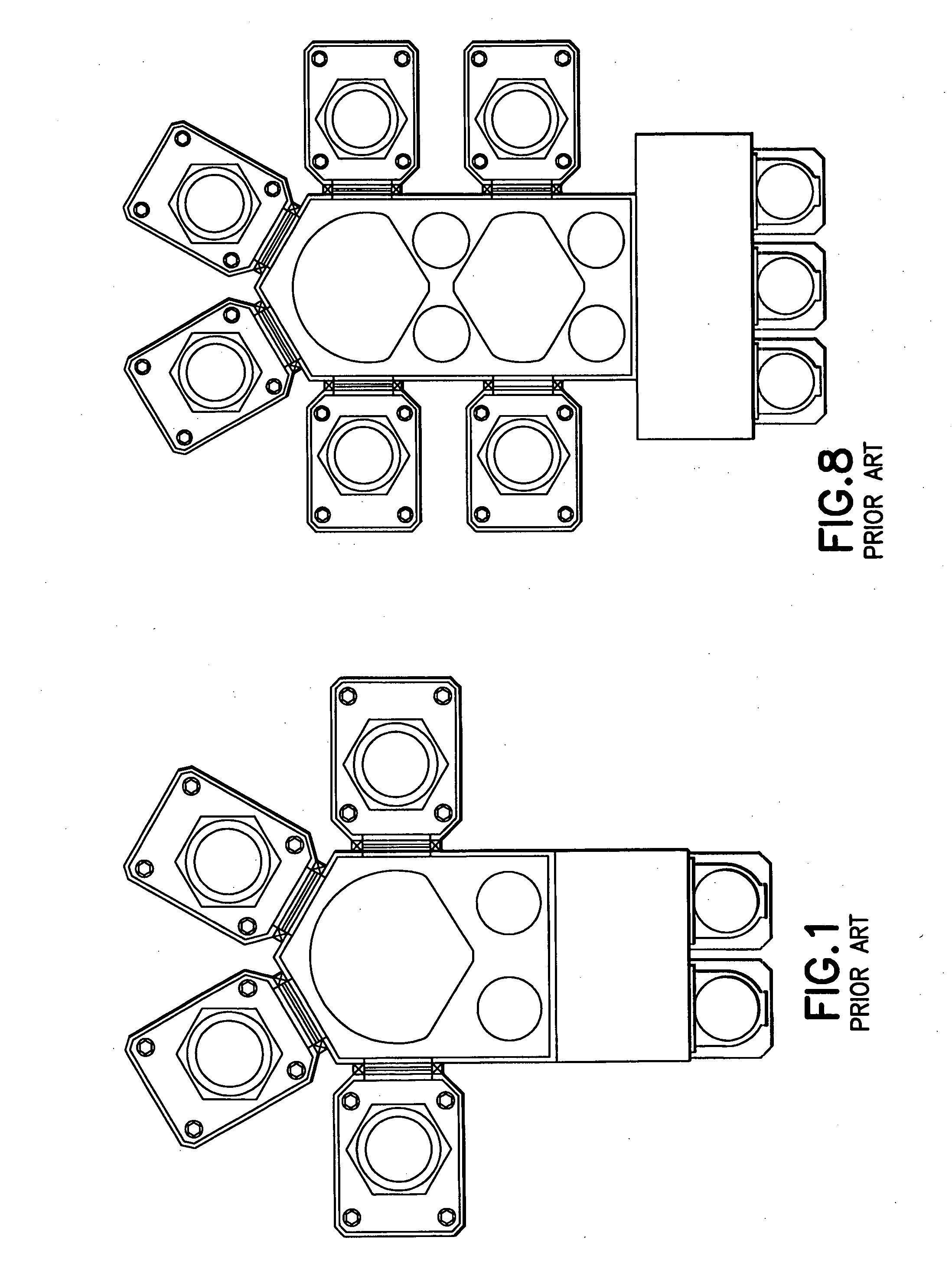

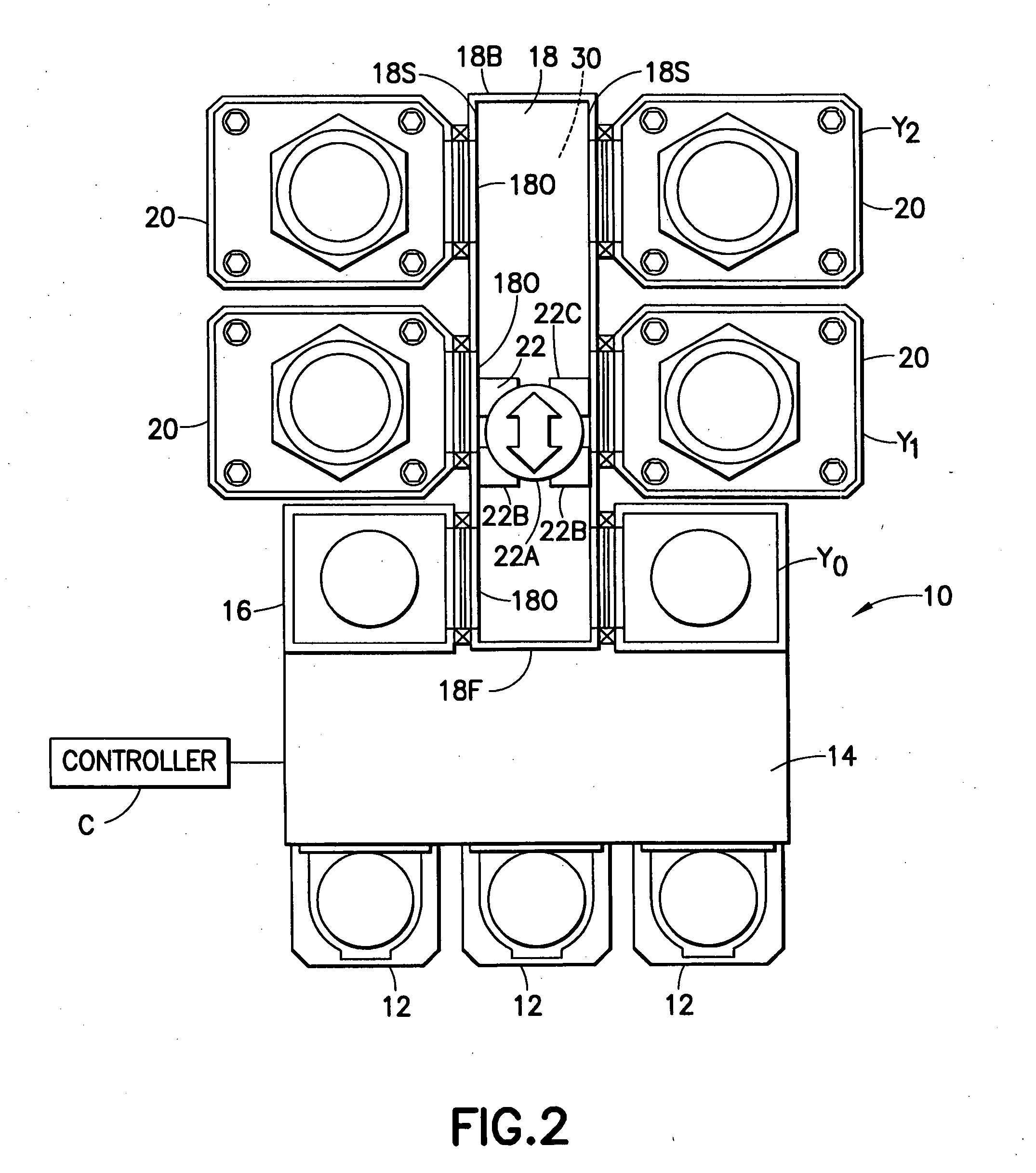

A specimen-transport module adapted for use with each of a plurality of specimen-processing instruments of a multi-instrument clinical workcell. Such module is adapted to transport individual racks of specimen-containers relative to a specimen-aspiration probe of an associated instrument in a workcell, as well as to transfer selected racks of specimen-containers to an adjacent and identical specimen-transport module associated with another clinical instrument of the workcell. Since the same transport system is used to both present specimens for aspiration and to transfer specimens between instruments, there is no need for two independent conveyances as is characteristic of the prior art. Preferably, the specimen-transport module includes a magnetic X / Y transport system that operates beneath a rack-supporting surface to advance racks in mutually perpendicular directions across a supporting surface via magnetic forces.

Owner:BECKMAN COULTER INC

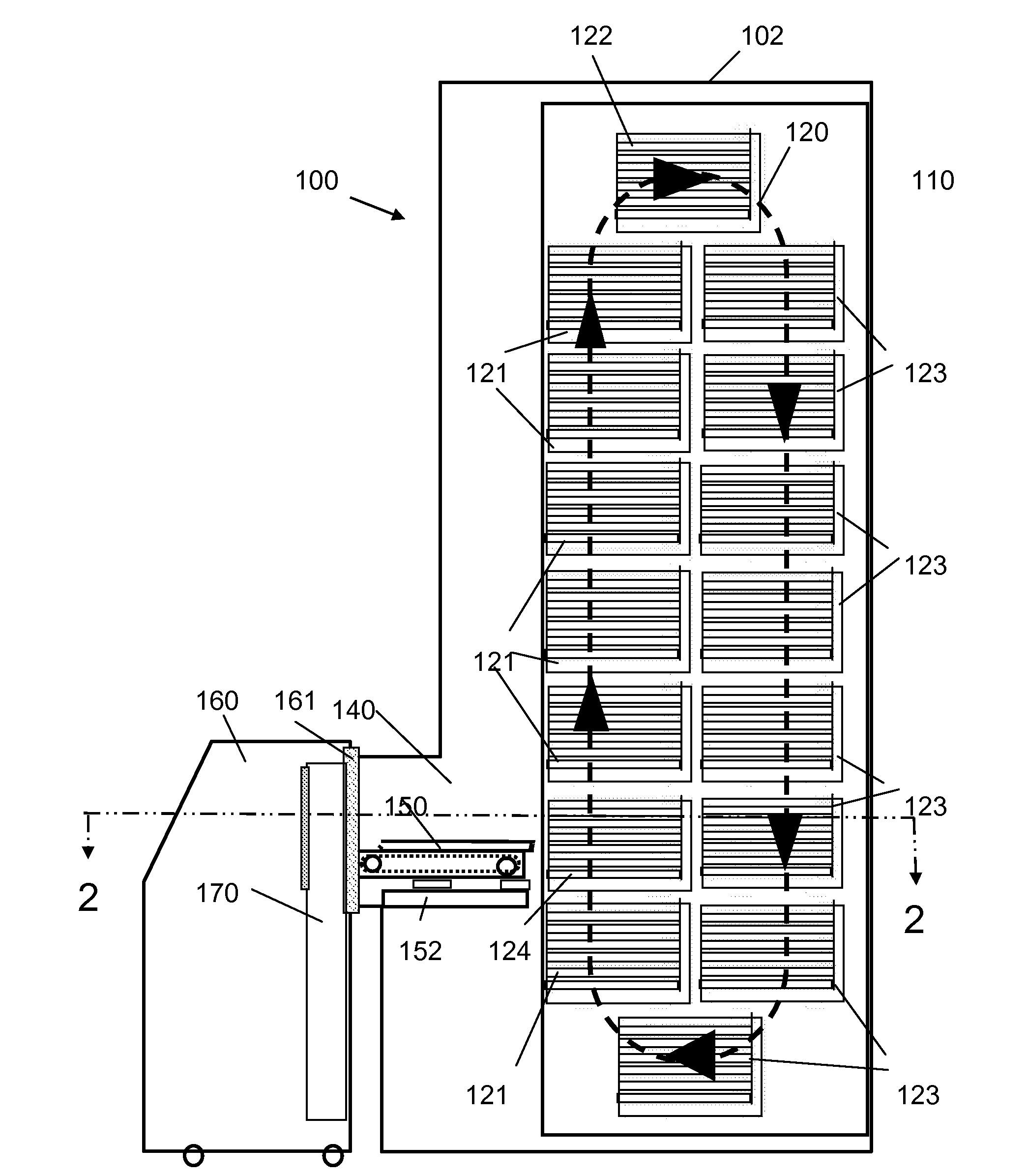

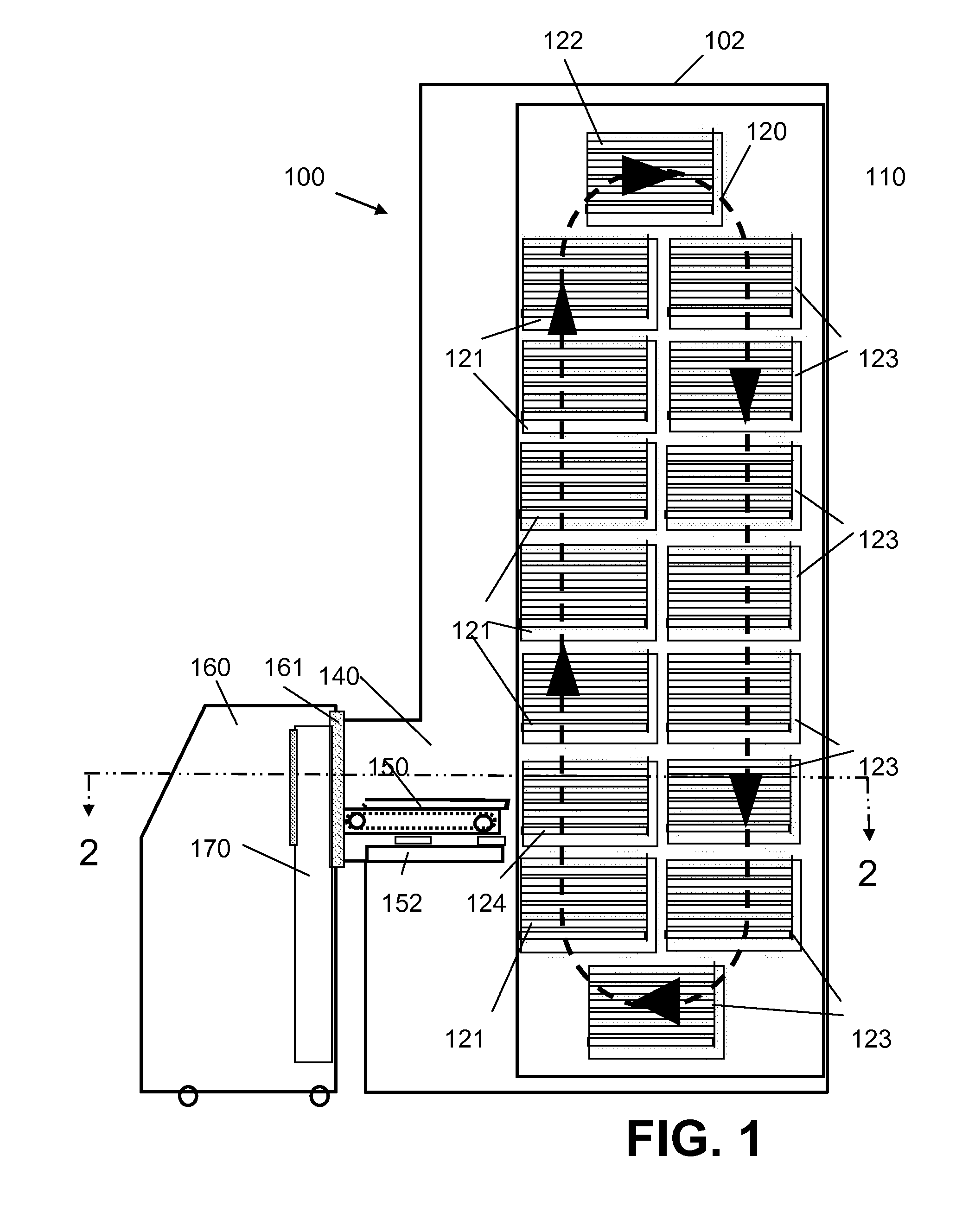

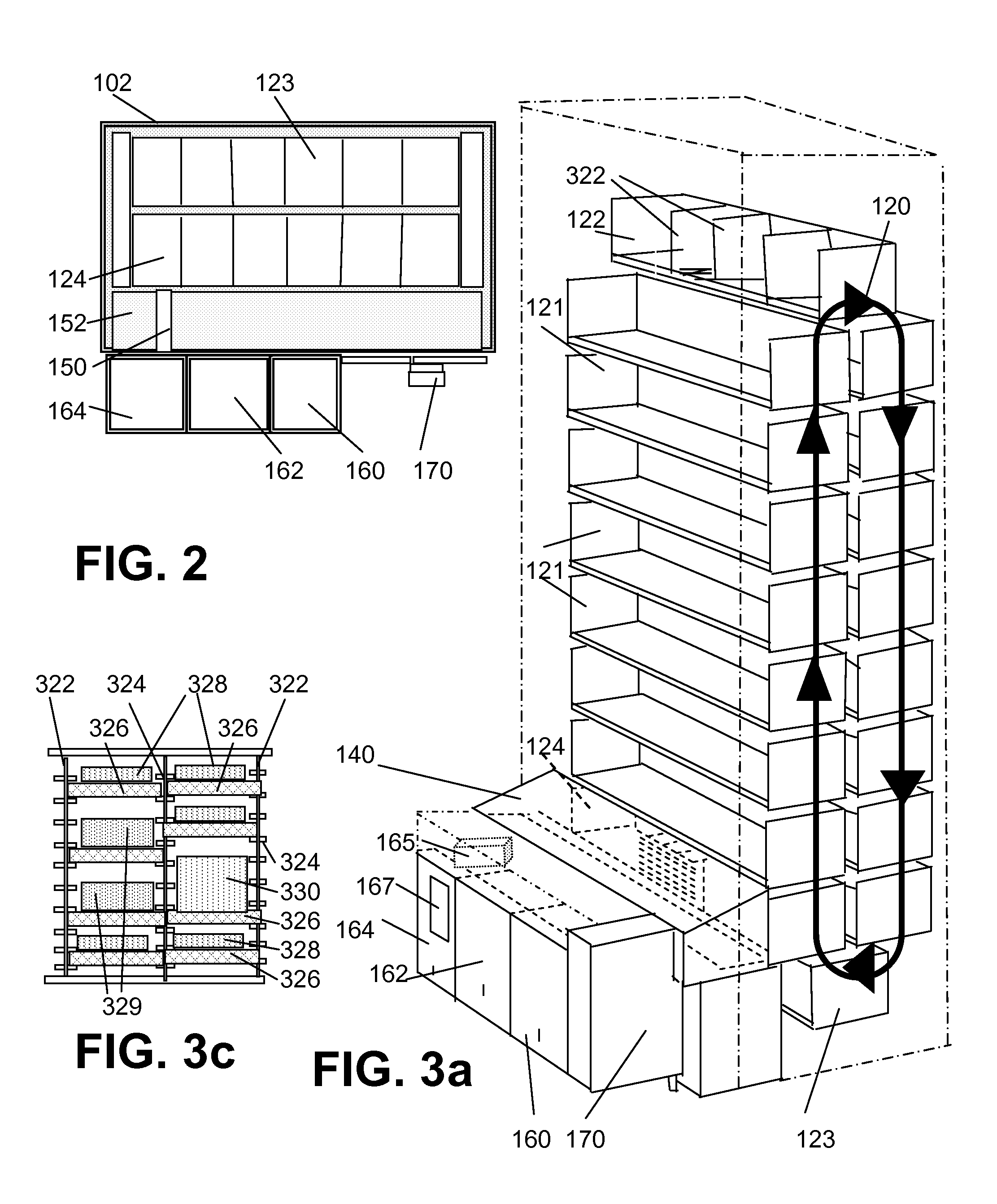

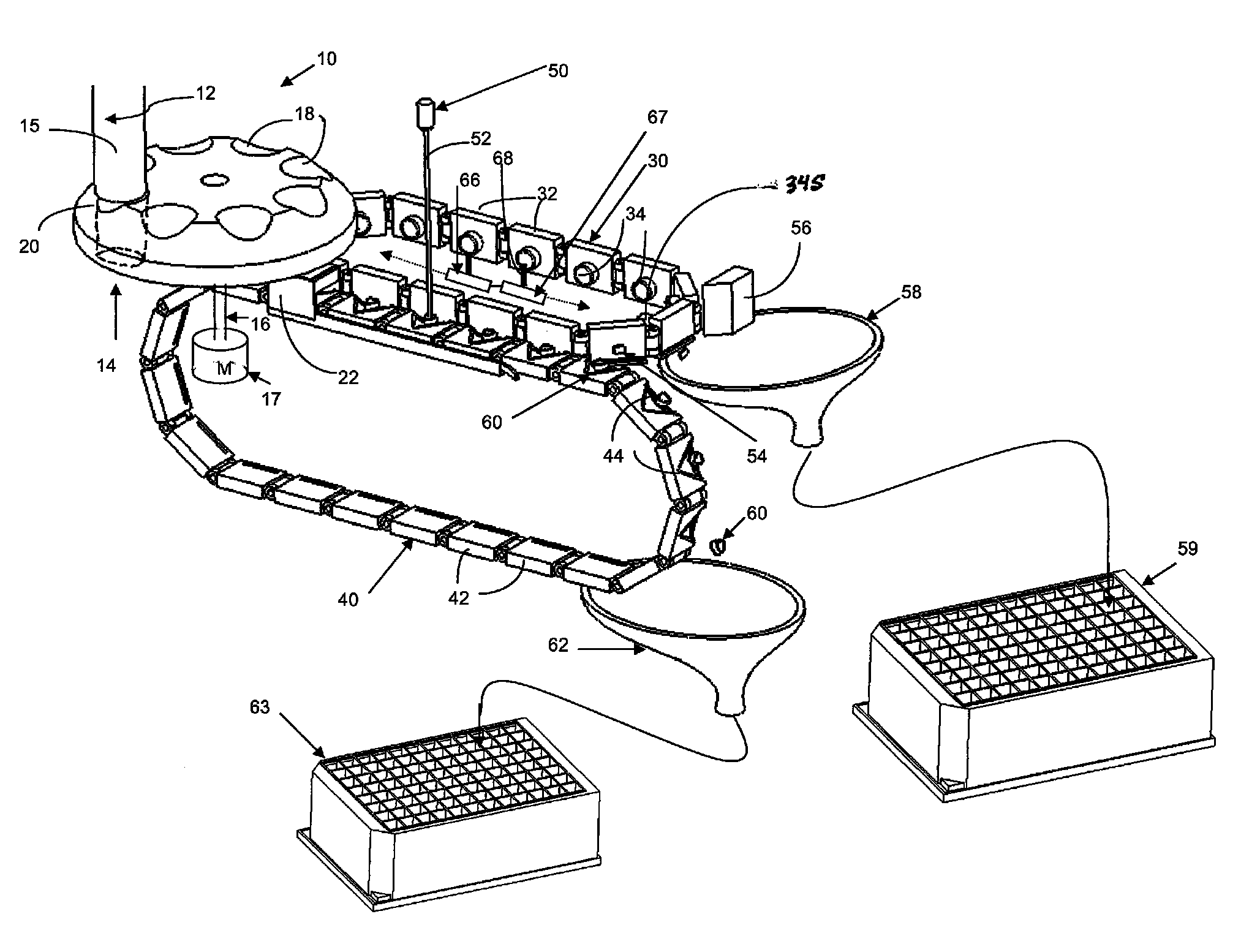

Automated system for storing, retrieving and managing sample

ActiveUS20070172396A1Eliminate needMinimized in sizeAnalysis using chemical indicatorsDomestic cooling apparatusEngineeringHolding room

An automated storage system for storing large quantities of samples in trays includes a storage compartment, a tray shuttle compartment abutting the storage compartment on one side and a plurality of independent modules on the other side. The modules perform processing of samples that are retrieved from the storage compartment by a tray shuttle, including extraction of selected samples from retrieved source trays and transfer of the selected samples into a separate, destination tray that can be further processed or removed from the system for use. The independent operation of the modules permits handling and processing to be performed simultaneously by different modules while the tray shuttle accesses additional samples within the storage compartment. In one embodiment, a vertical carousel is used to vertically align a desired tray with the tray shuttle, while the tray shuttle operates within a horizontal plane.

Owner:NEXUS BIOSYSTEMS INC

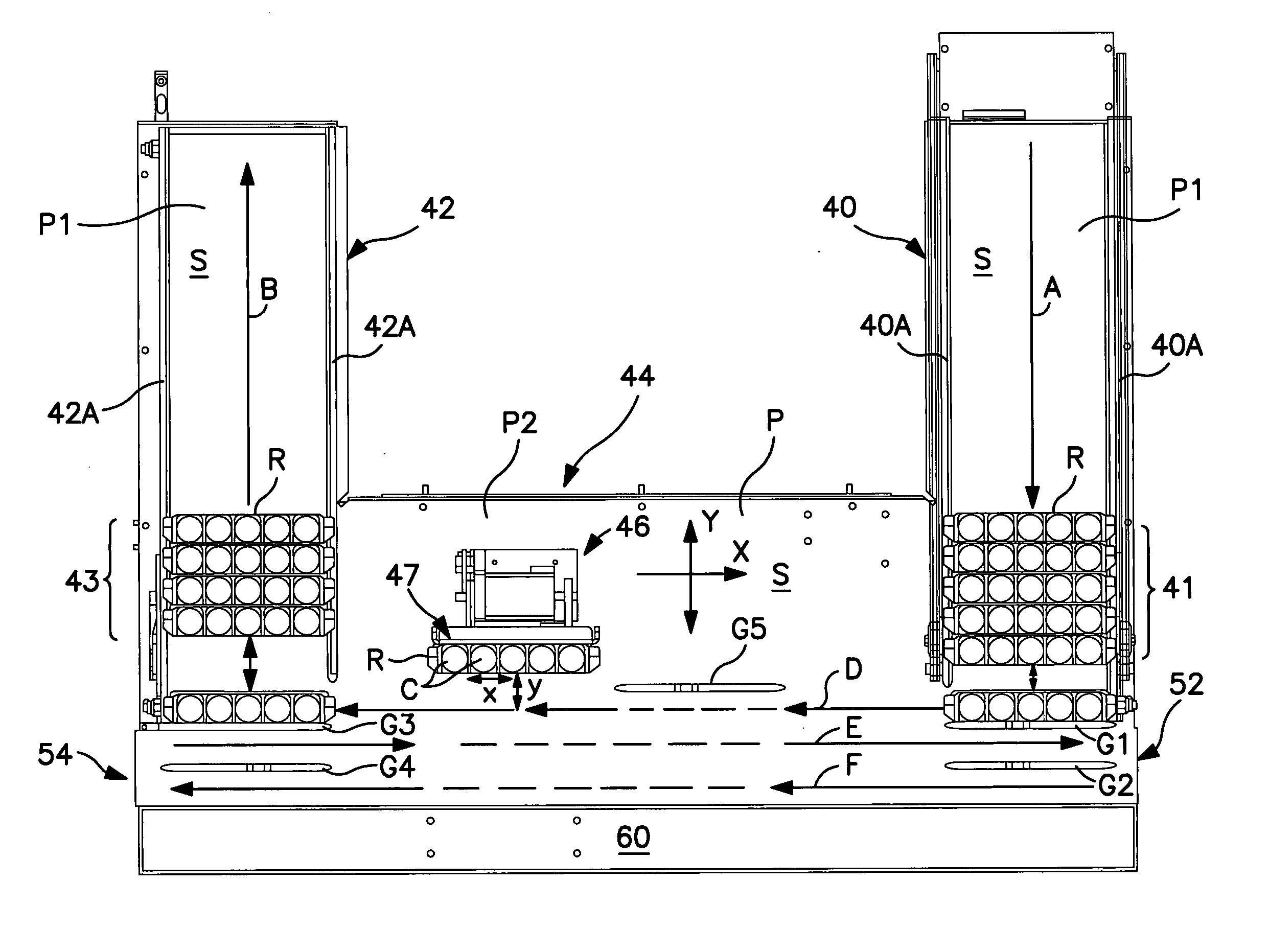

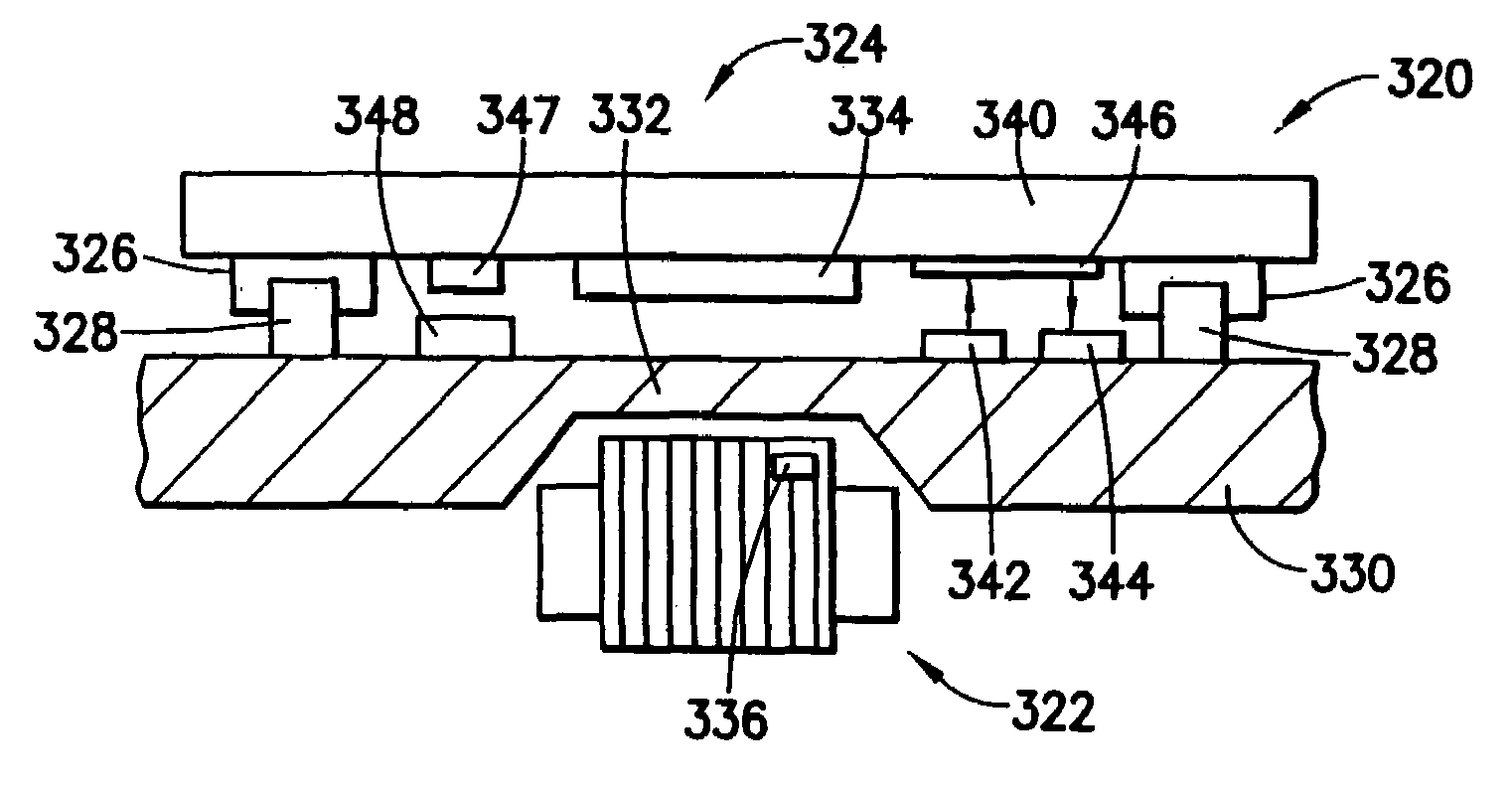

Magnetic specimen-transport system for automated clinical instrument

A magnetic specimen-transport system for transporting racks of specimen-containers to or within an automated clinical instrument for analysis and / or processing. The magnetic specimen-transport system that is adapted to transport magnetically-attractable racks of specimen-containers in mutually perpendicular (X / Y) directions across a rack-supporting surface, whereby the racks can be transported among various non-linearly aligned positions on such surface.

Owner:BECKMAN COULTER INC

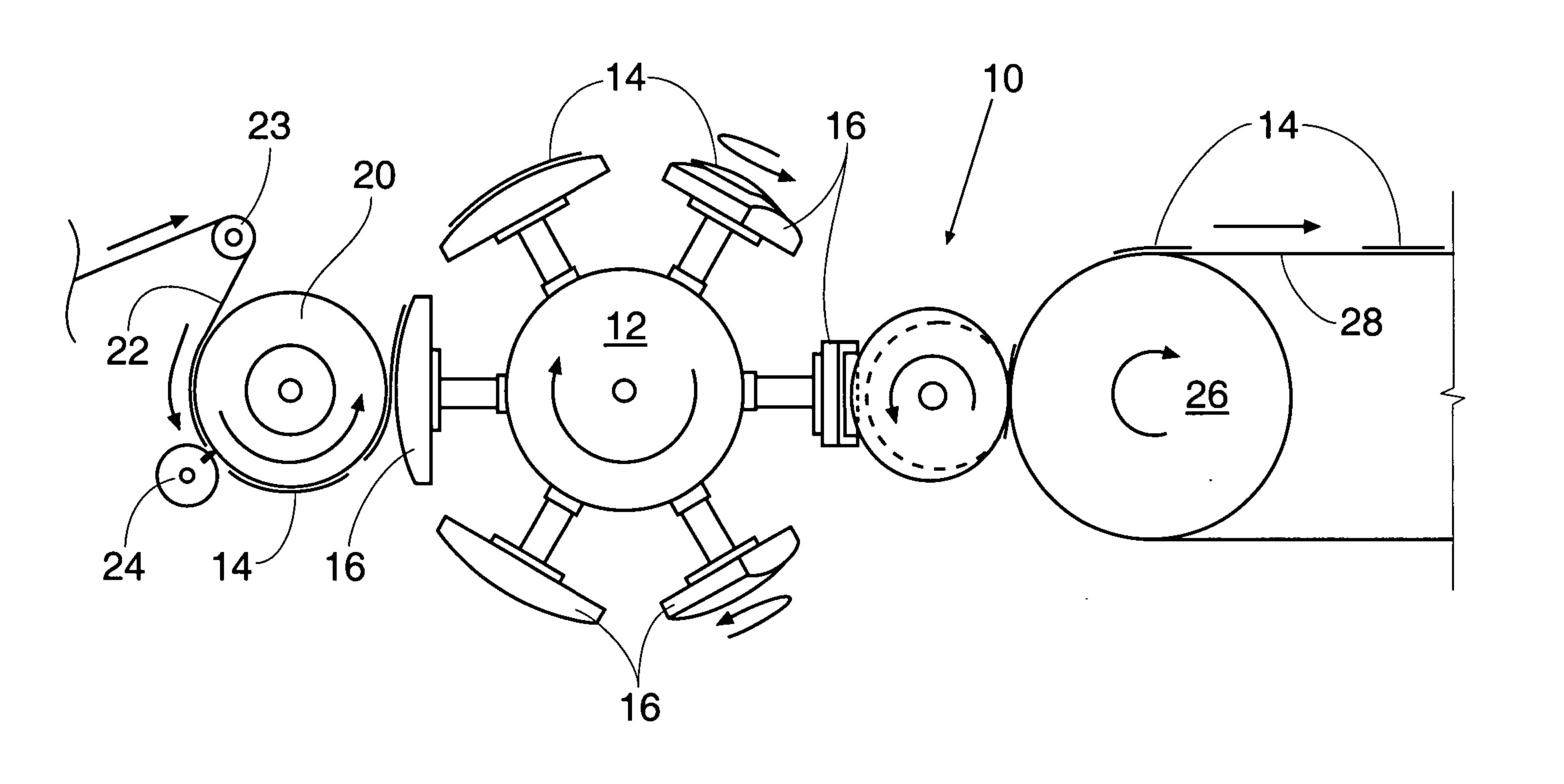

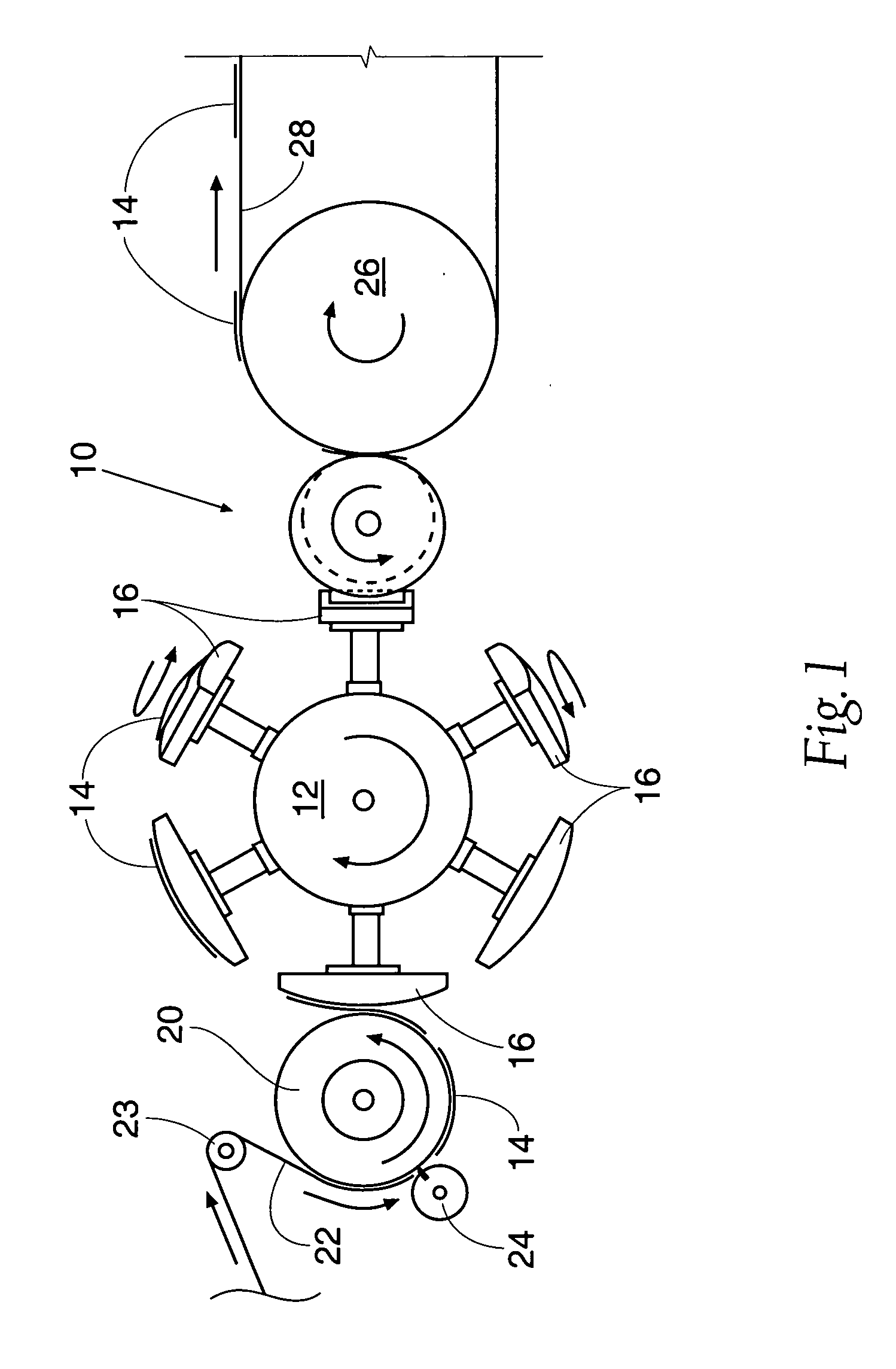

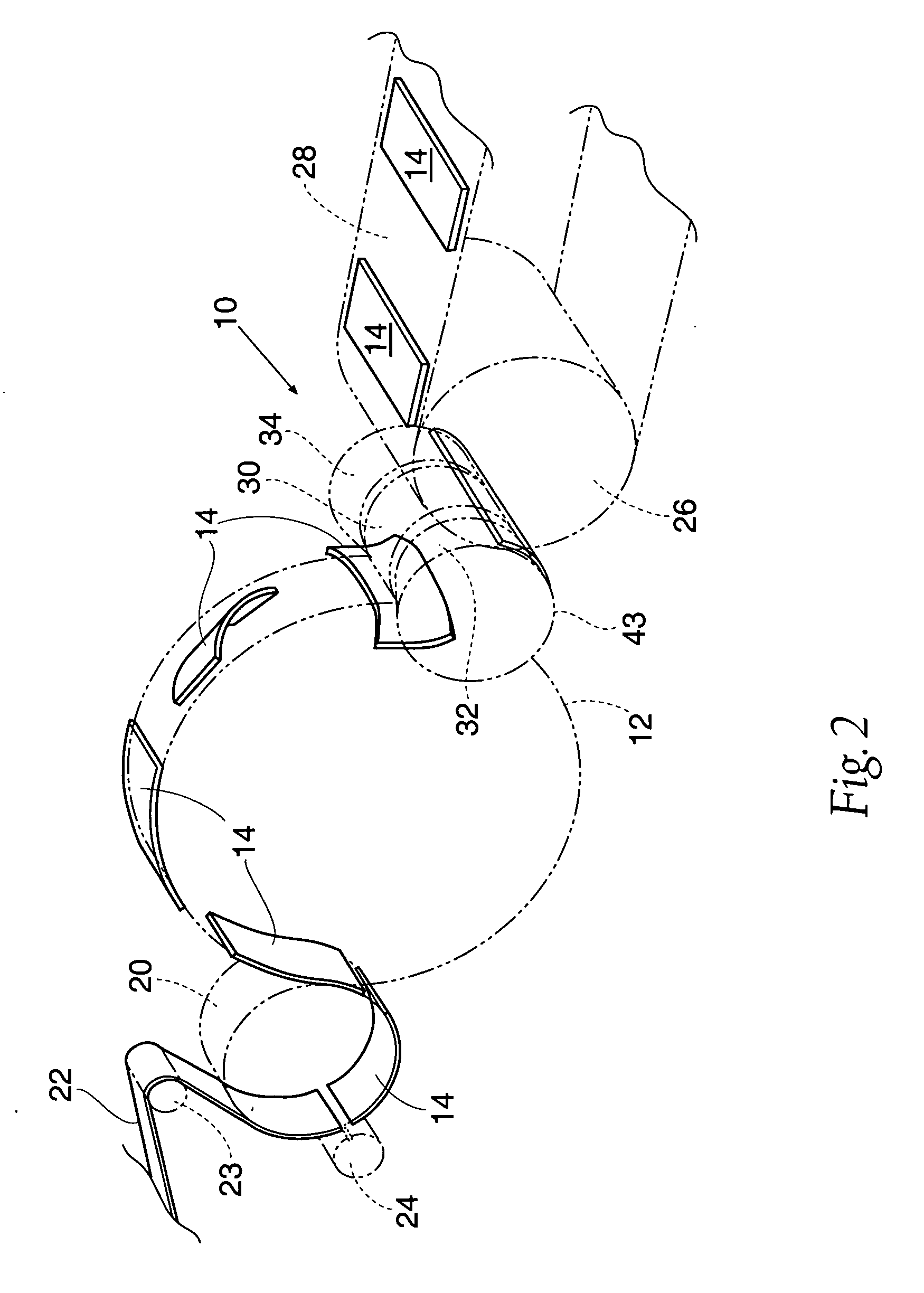

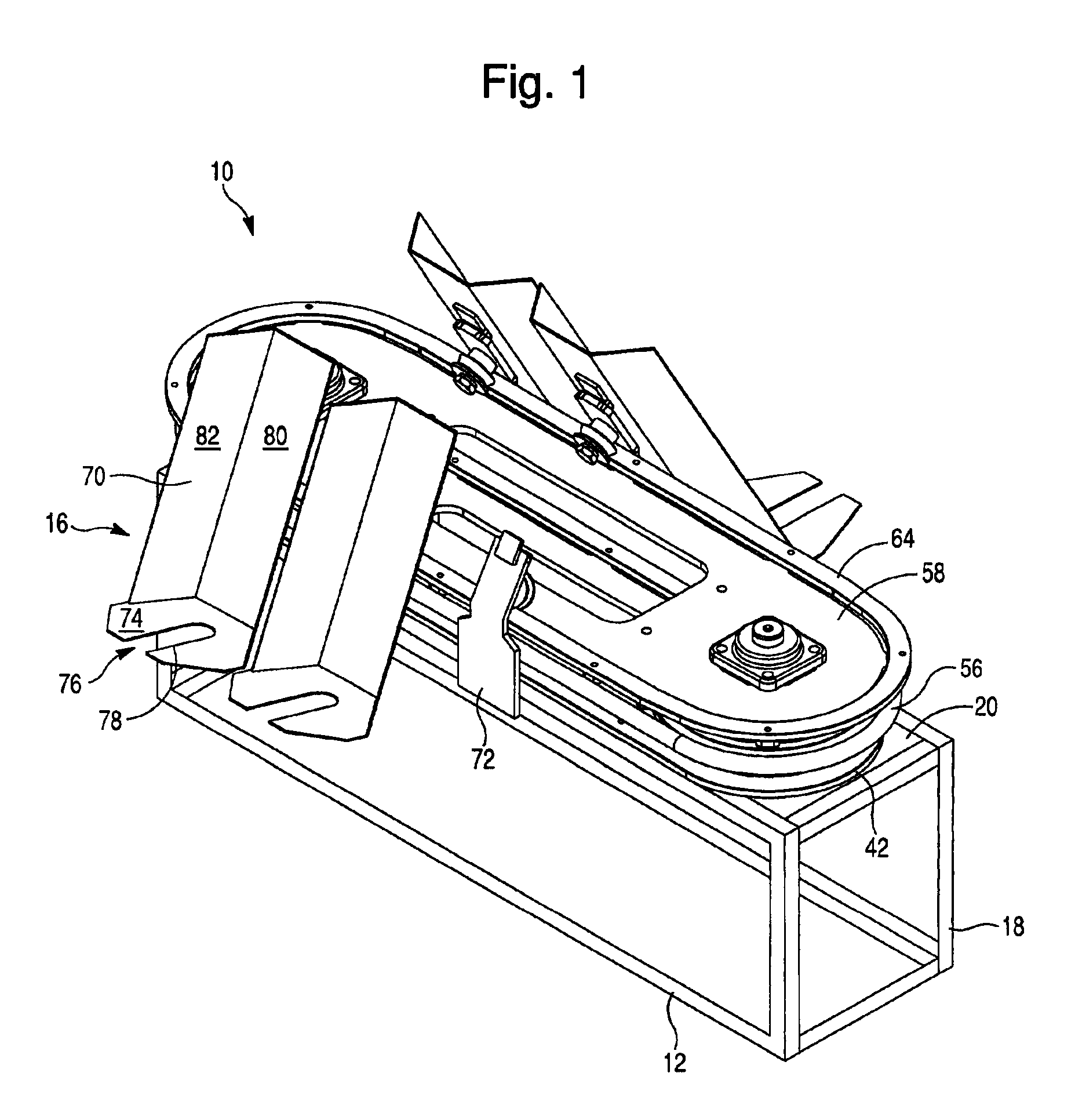

Article transfer and placement apparatus

ActiveUS20070074953A1Reduce the amount requiredEasy transferAbsorbent padsArticle feedersEngineeringElectrical and Electronics engineering

An apparatus for transferring articles such as absorbent cores or disposable diaper chassis components from a rotary mechanism, such as a pad turner, to a linear mechanism, such as a conveyor, for further processing. The invention provides a device for picking an article from the outside of a toroidal surface, thence extending transversely under tension the article to be transferred so that at the point of deposition the article is held flat and at full length. Further, the invention allows for apparatus to match the velocity of both the first and second transfer points, even if these velocities are not the same. The device is of particular benefit where an article to be transferred is subject to internally biasing elastic forces.

Owner:CURT G JOA

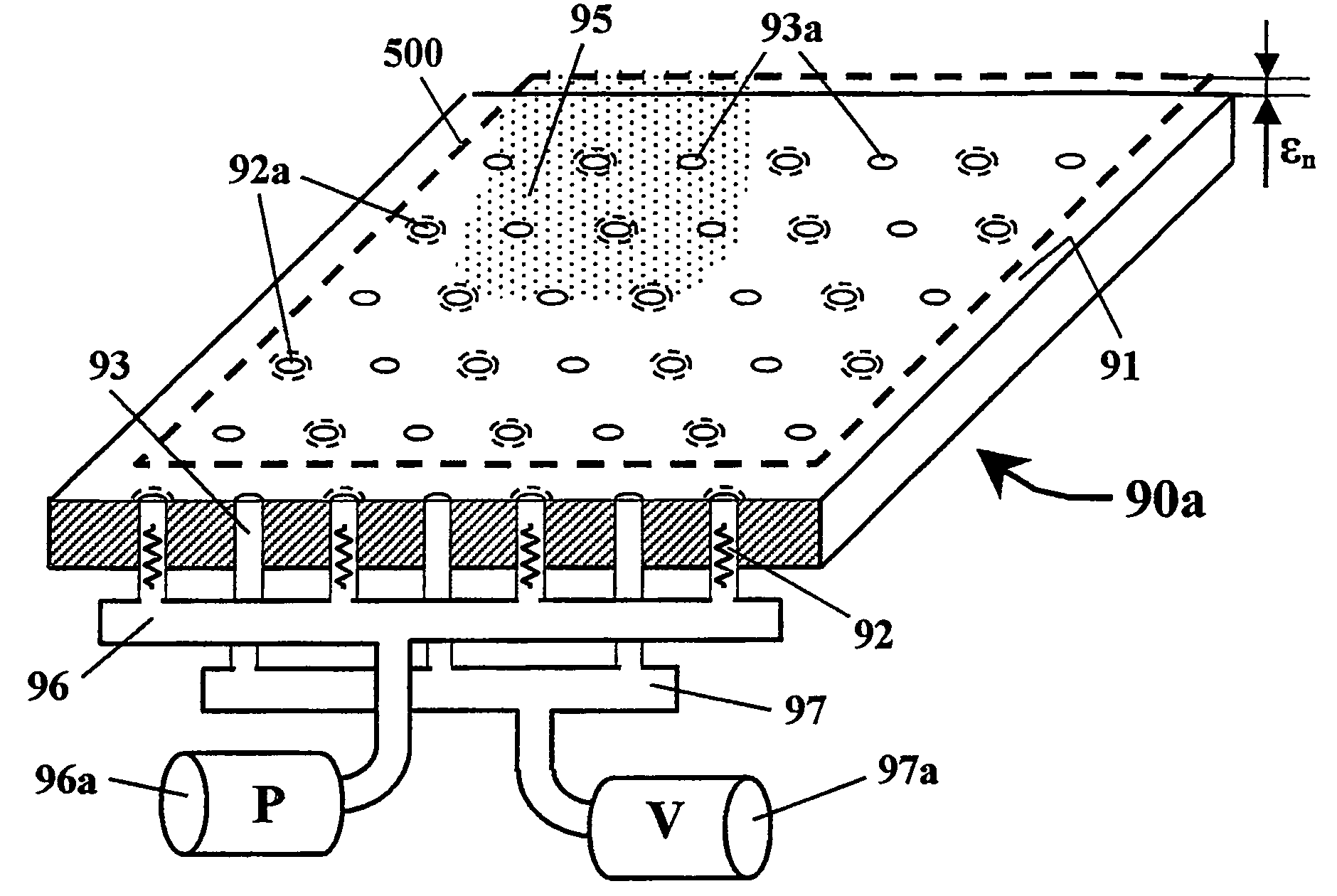

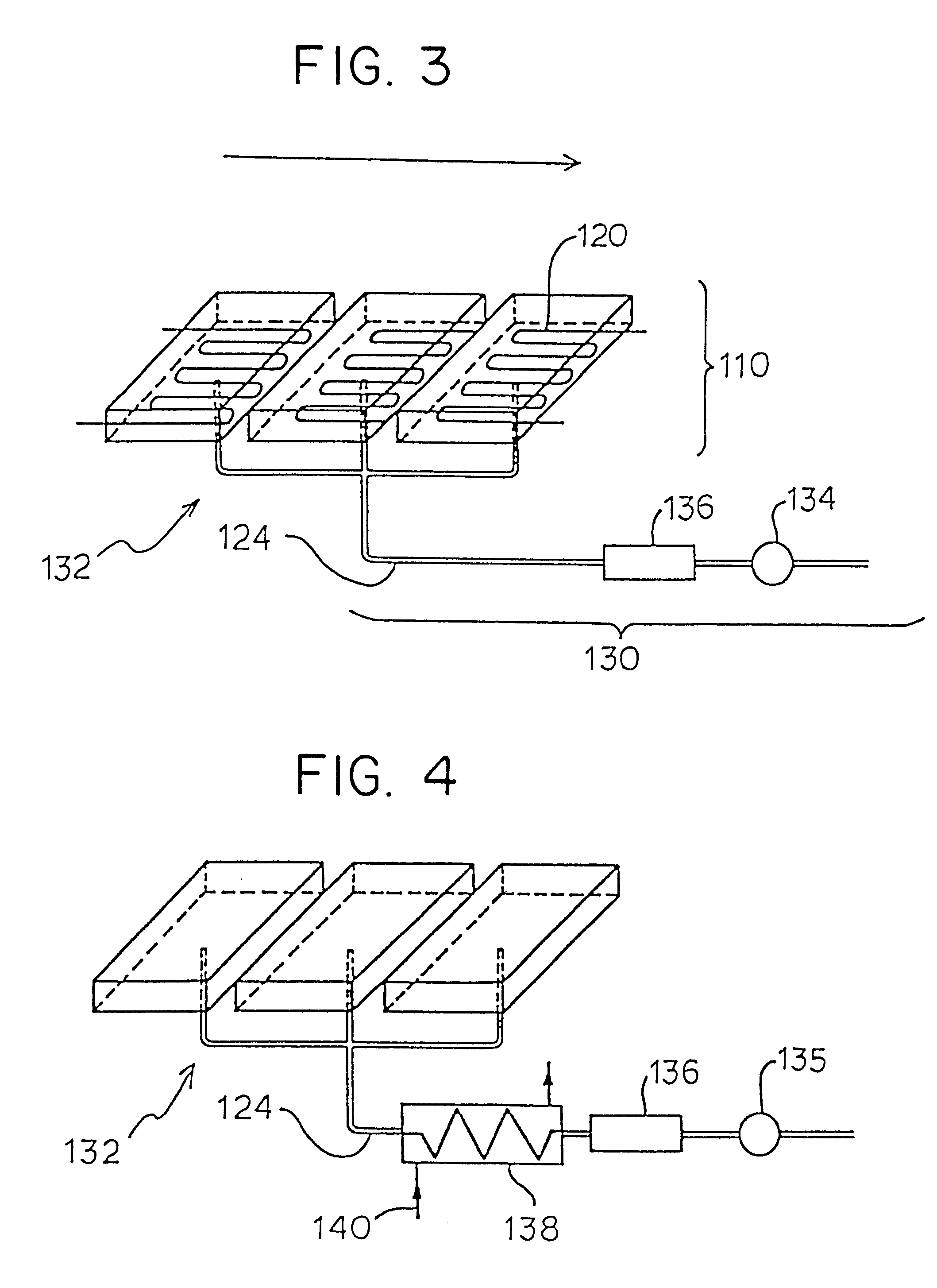

High-Performance non-contact support platforms

InactiveUS7530778B2Improve performanceLinear bearingsSemiconductor/solid-state device manufacturingAmbient pressureEngineering

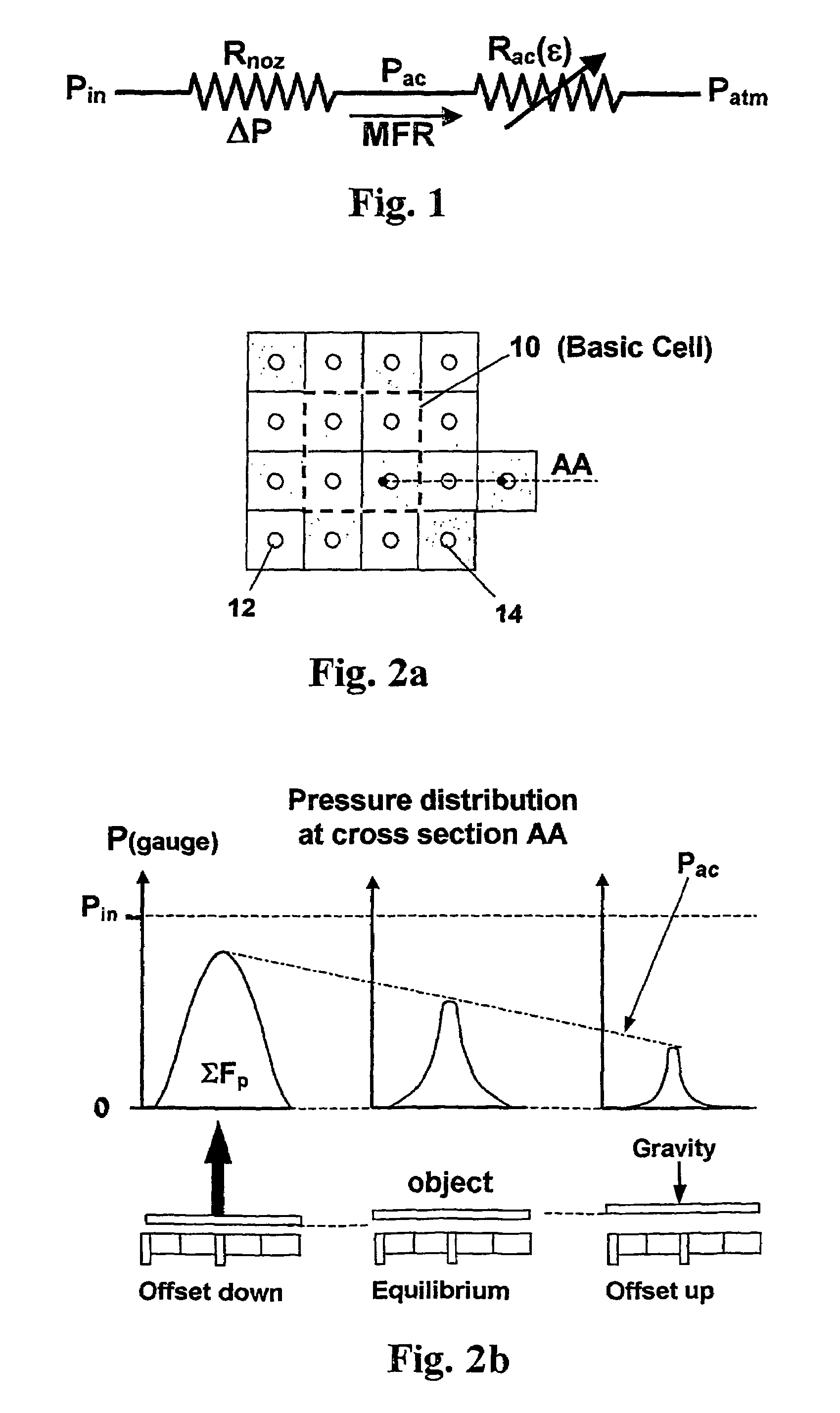

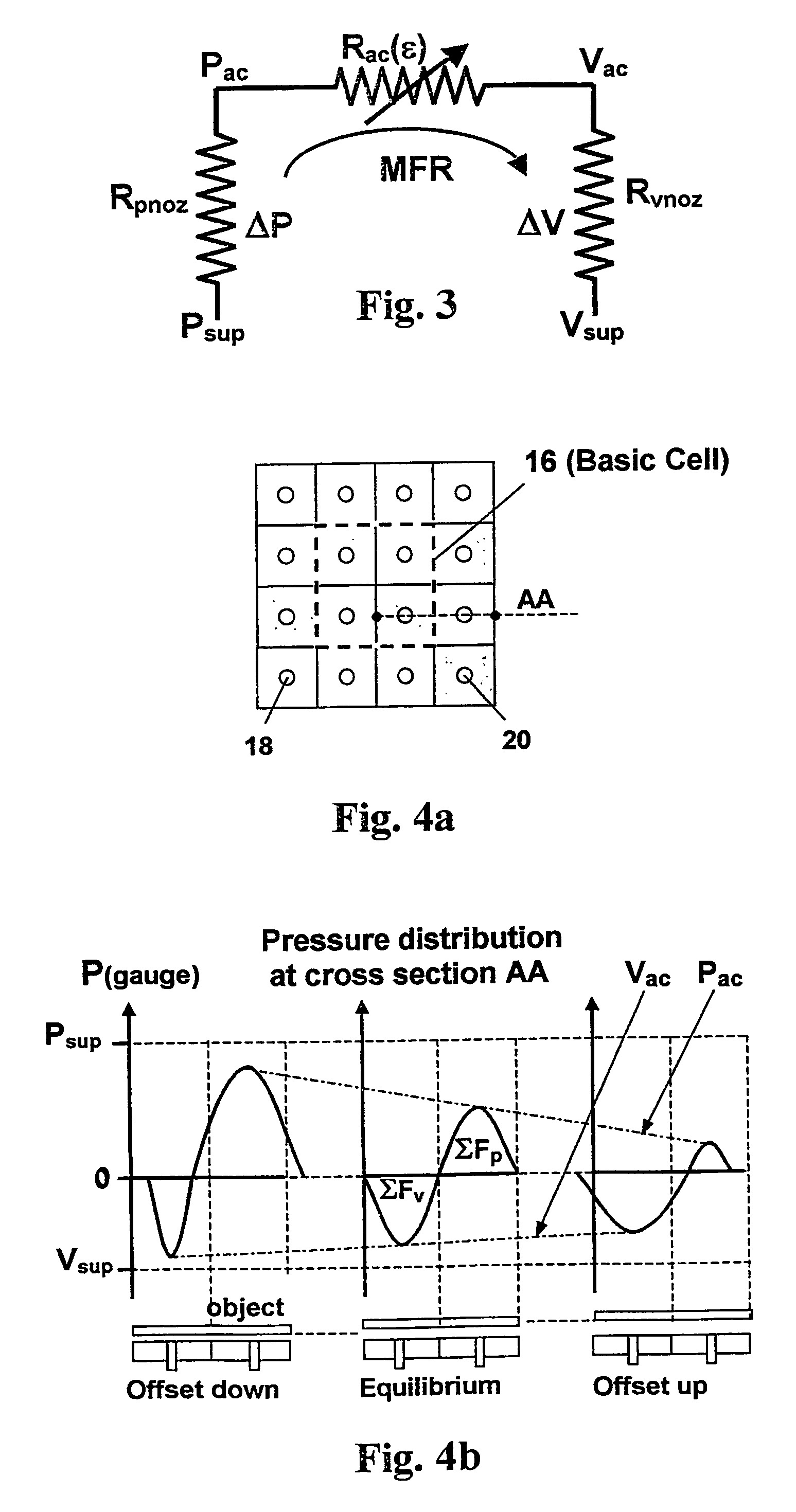

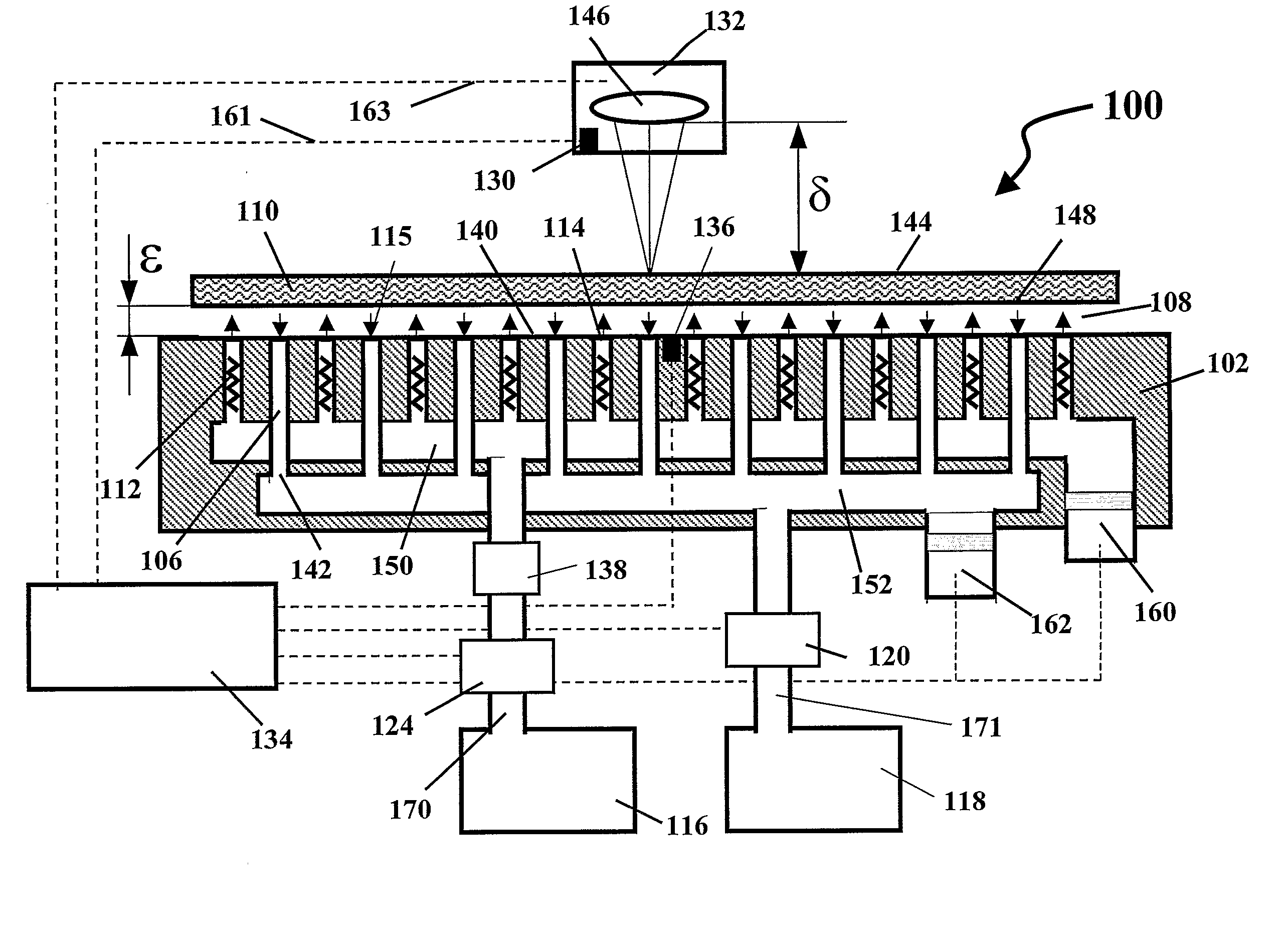

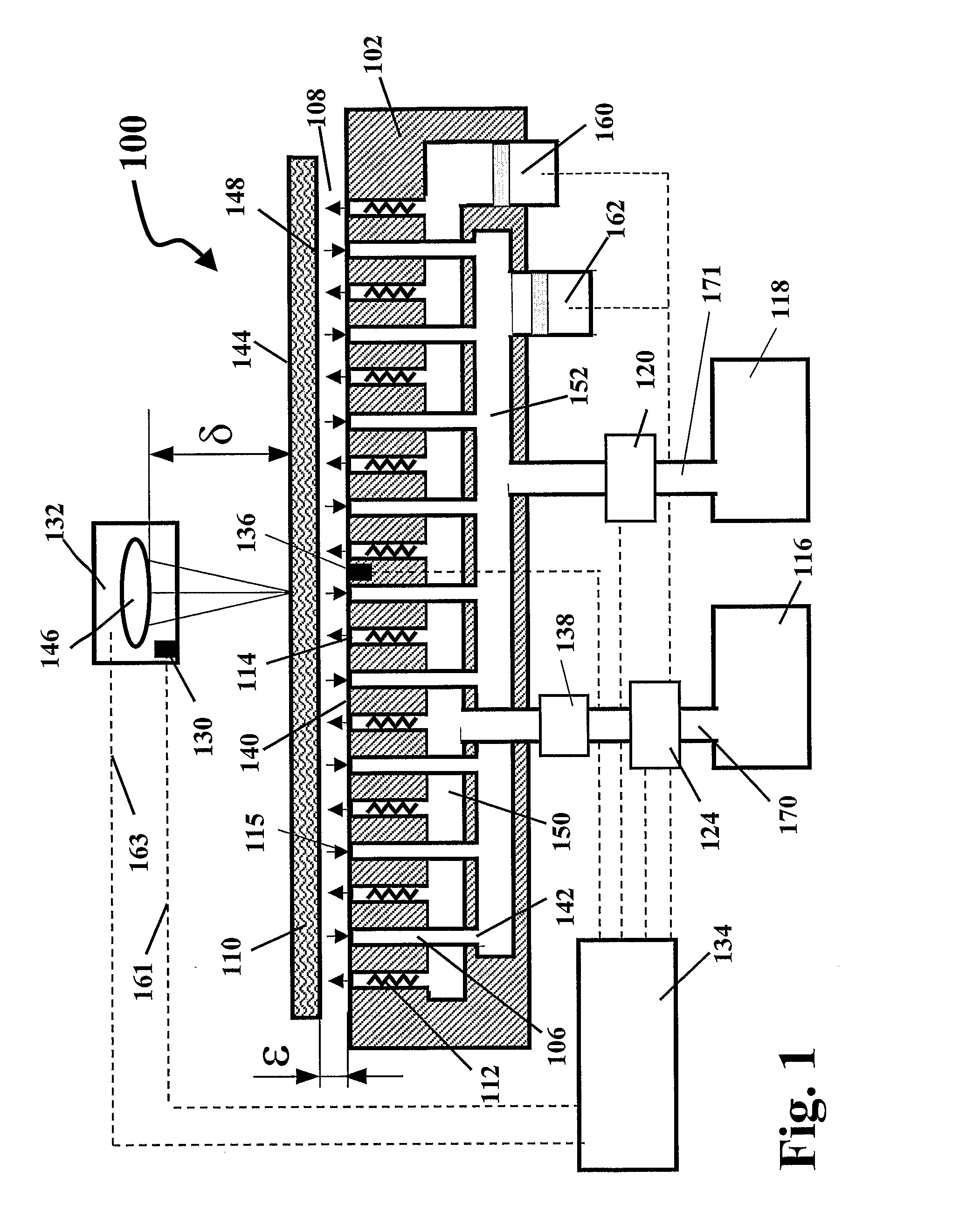

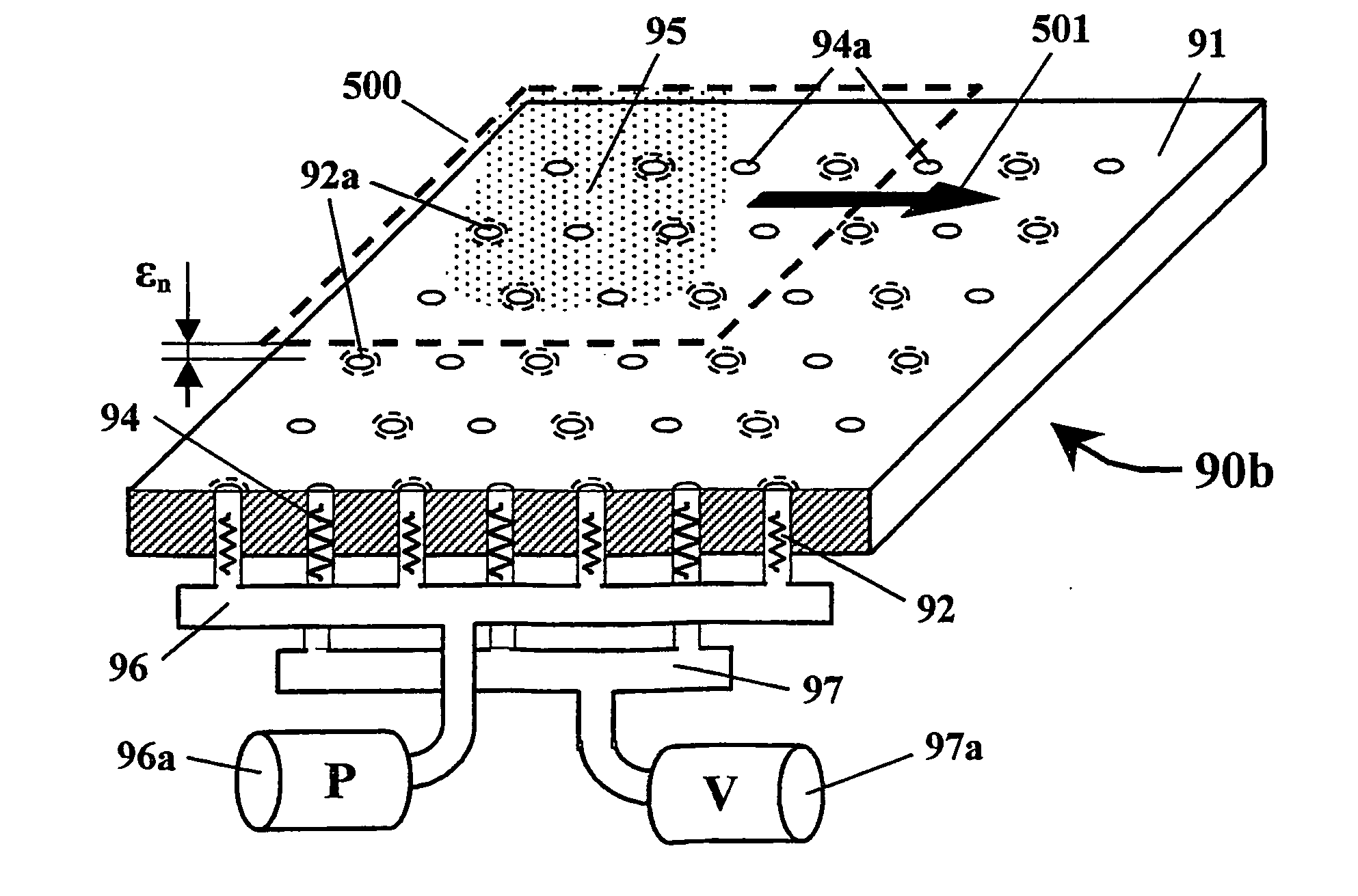

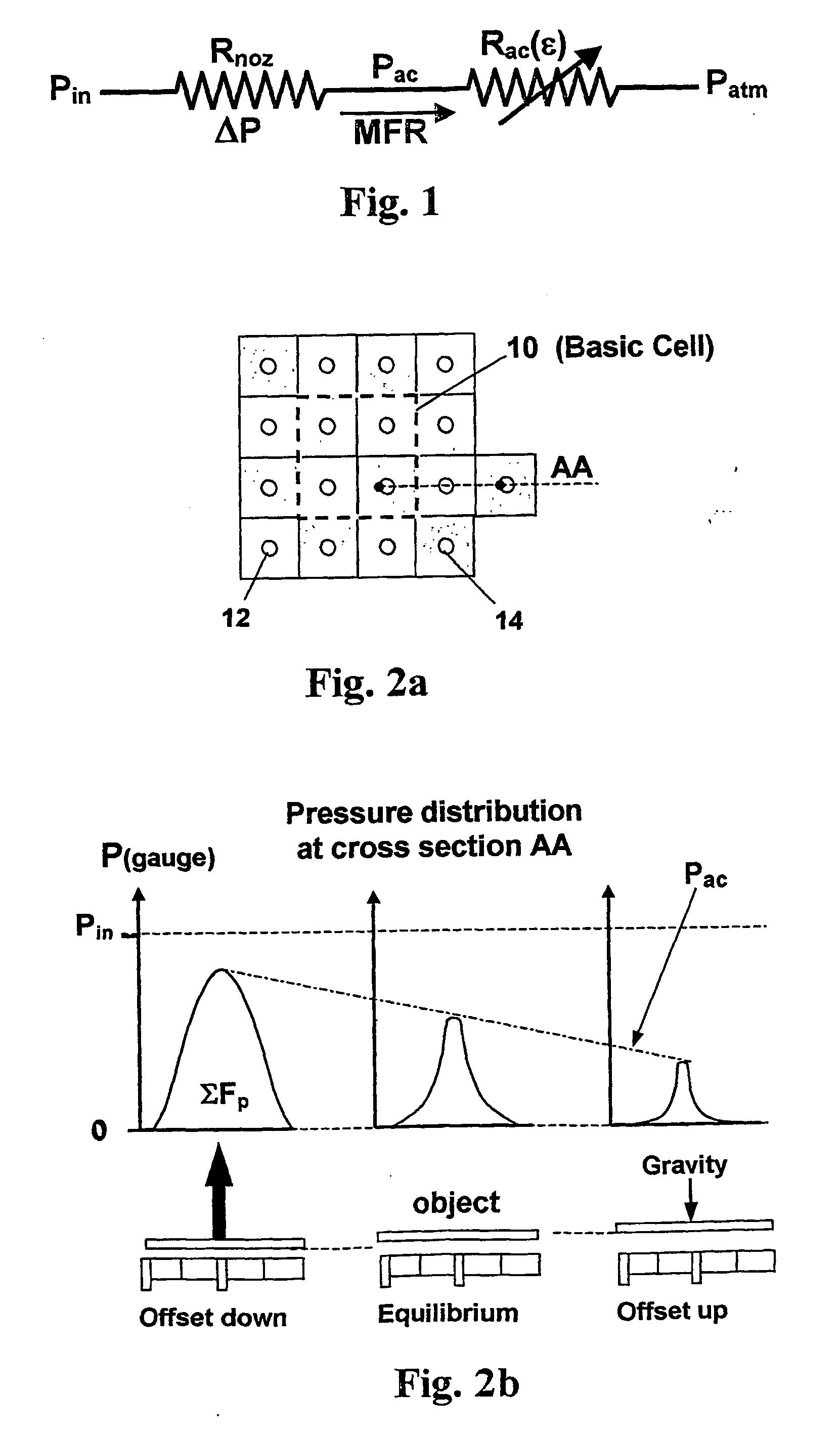

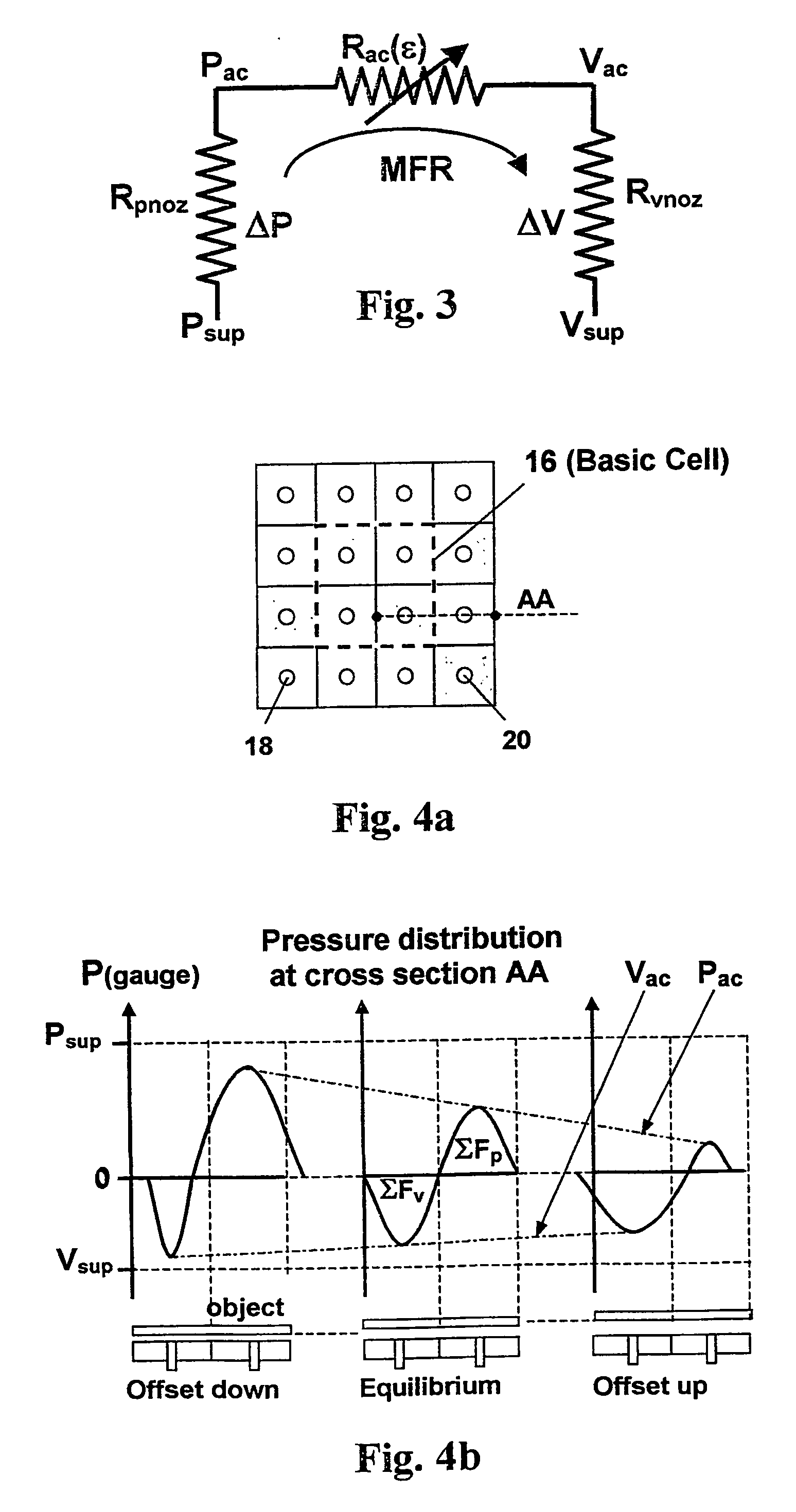

A non-contact support platform for supporting without contact a stationary or traveling object by air-cushion induced forces, the platform comprising at least one of two substantially opposite support surfaces, each support surfaces comprising at least one of a plurality of basic cells each having at least one of a plurality of pressure outlets and at least one of a plurality of air-evacuation channels at least one of a plurality of outlets, and one of a plurality of air-evacuation channels, each of the pressure outlets fluidically connected through a pressure flow restrictor to a high-pressure reservoir, the pressure outlets providing pressurized air for generating pressure induced forces, maintaining an air-cushion between the object and the support surface, the pressure flow restrictor characteristically exhibiting fluidic return spring behavior; each of said at least one of a plurality of air-evacuation channels having an inlet and outlet, the inlet kept at an ambient pressure or lower, under vacuum condition, for locally discharging mass flow, thus obtaining uniform support and local nature response.

Owner:COREFLOW

Non-contact support platforms for distance adjustment

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

Linear substrate transport apparatus

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

High-performance non-contact support platforms

InactiveUS20060054774A1Improve performanceLinear bearingsSemiconductor/solid-state device manufacturingAmbient pressureEngineering

A non-contact support platform for supporting without contact a stationary or traveling object by air-cushion induced forces, the platform comprising at least one of two substantially opposite support surfaces, each support surface comprising at least one of a plurality of basic cells each having at least one of a plurality of pressure outlets and at least one of a plurality of air-evacuation channels at least one of a plurality of outlets, and one of a plurality of air-evacuation channels, each of the pressure outlets fluidically connected through a pressure flow restrictor to a high-pressure reservoir, the pressure outlets providing pressurized air for generating pressure induced forces, maintaining an air-cushion between the object and the support surface, the pressure flow restrictor characteristically exhibiting fluidic return spring behavior; each of said at least one of a plurality of air-evacuation channels having an inlet and outlet, the inlet kept at an ambient pressure or lower, under vacuum condition, for locally discharging mass flow, thus obtaining uniform support and local nature response.

Owner:COREFLOW

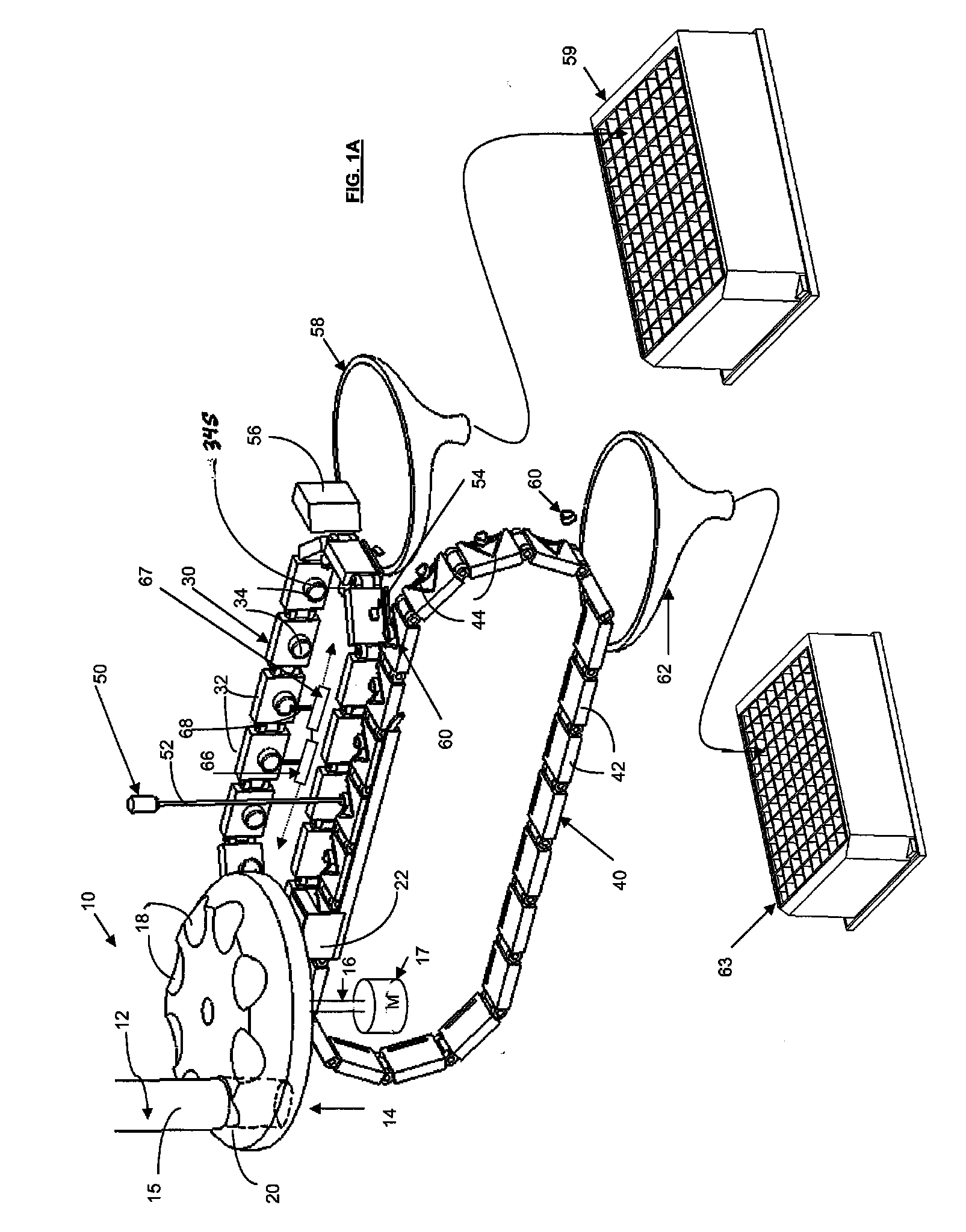

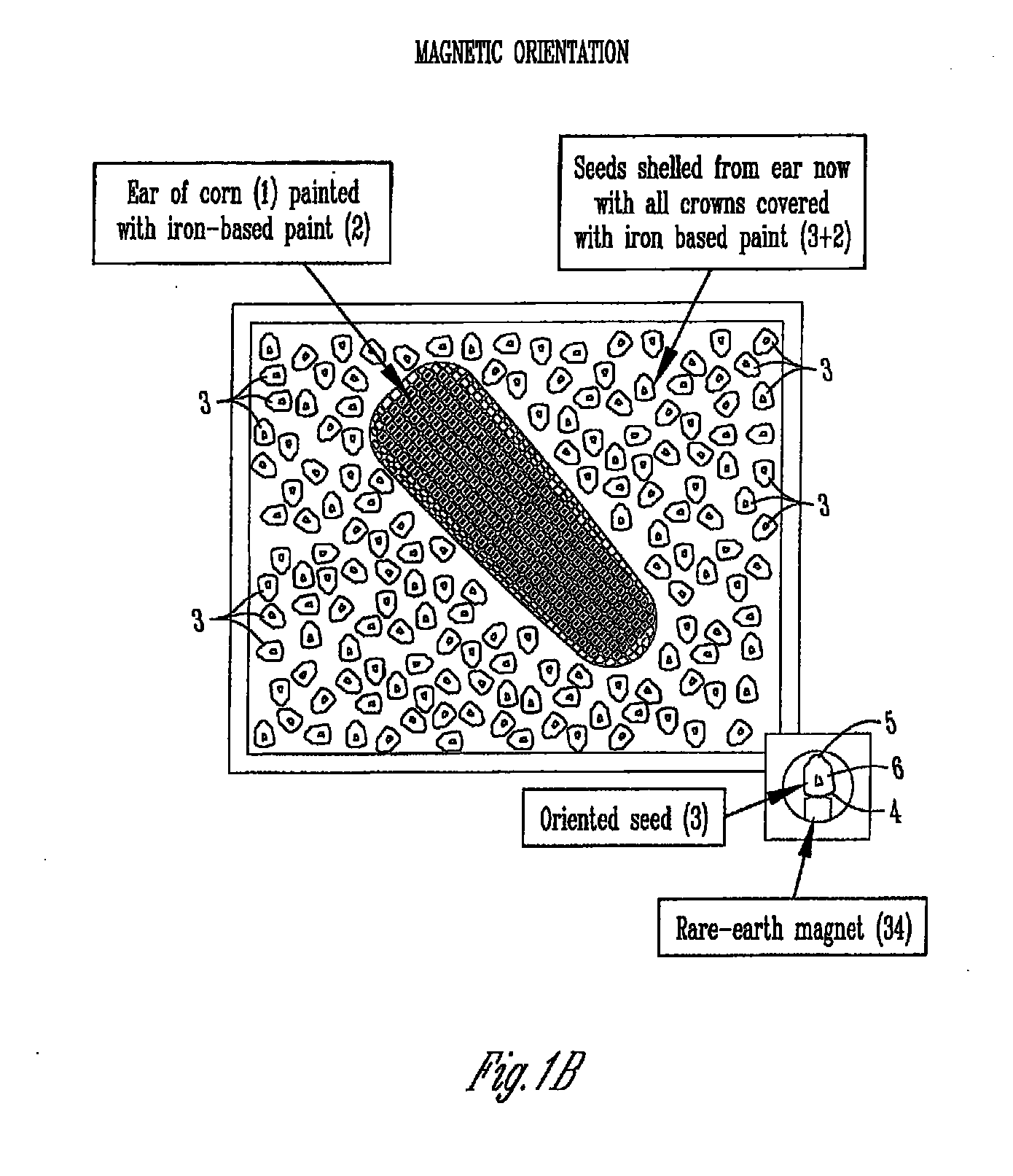

Apparatus, method and system for handling, positioning, and/or automatically orienting objects

InactiveUS20080131254A1Avoid small quantitiesMaximum flexibilityWithdrawing sample devicesPreparing sample for investigationEngineeringComputer vision

A method and apparatus for automatic positioning and / or orientation of an object. The method includes applying a substance or component to an object, or takes advantage of a substance or component already on or associated with an object. The substance or component has a characteristic that can be utilized to automatically attract the substance or component. That characteristic is used to position, move, and / or orient the object automatically, without requiring manual handling. The object can then be further processed or handled. In one embodiment, the substance or component is a magnetically active substance or component. The attraction can be actuated by a magnet.

Owner:PIONEER HI BRED INT INC

Substrate processing apparatus

A semiconductor workpiece processing apparatus having a first chamber, a transport vehicle, and another chamber. The first chamber is capable of being isolated from an outside atmosphere. The transport vehicle is located in the first chamber and is movably supported from the first chamber for moving linearly relative to the first chamber. The transport vehicle includes a base, and an integral semiconductor workpiece transfer arm movably mounted to the base and capable of multi-access movement relative to the base. The other chamber is communicably connected to the first chamber via a closable opening of the first chamber. The opening is sized to allow the transport vehicle to transit between the first chamber and the other chamber through the opening.

Owner:BOOKS AUTOMATION US LLC

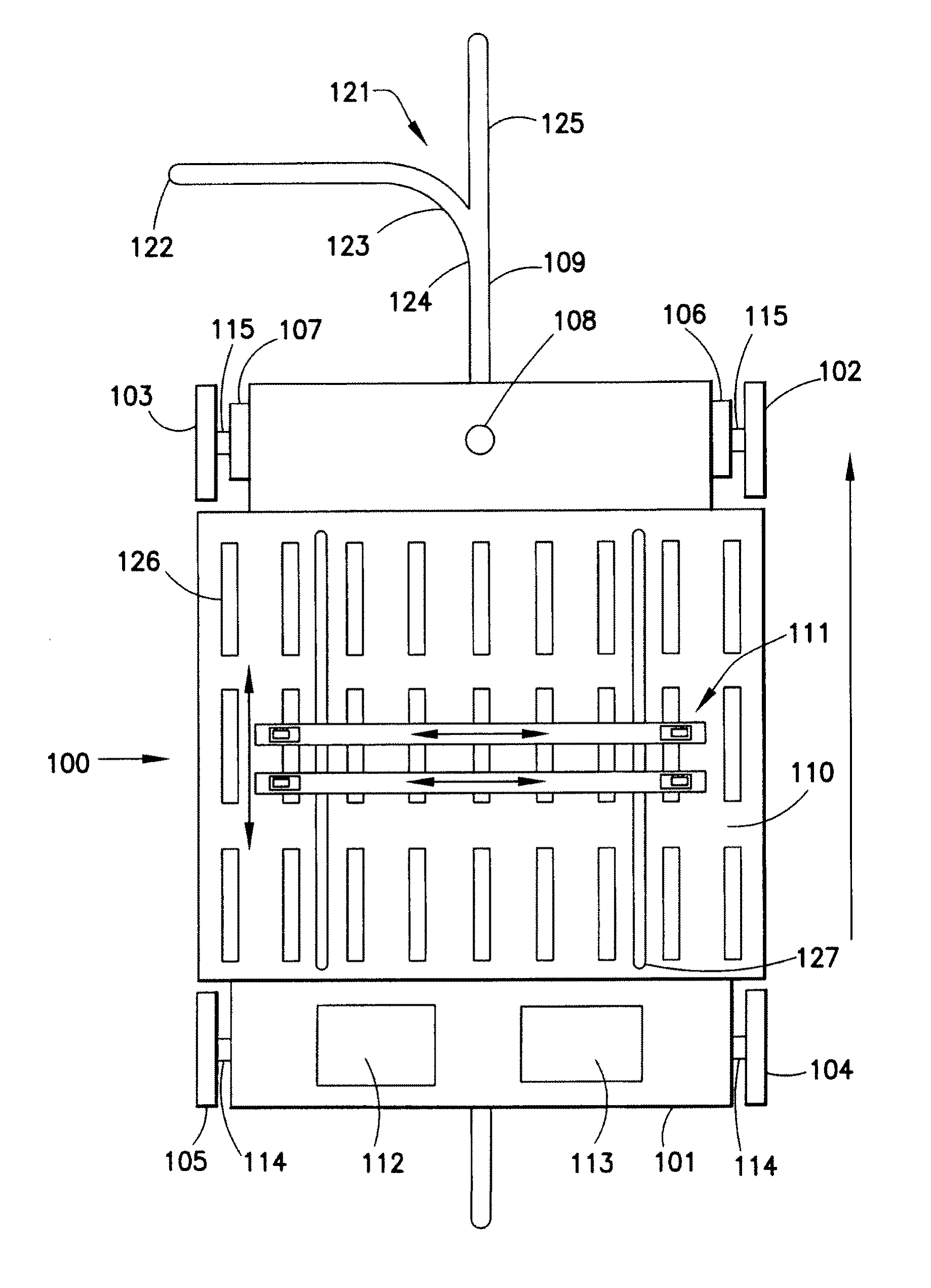

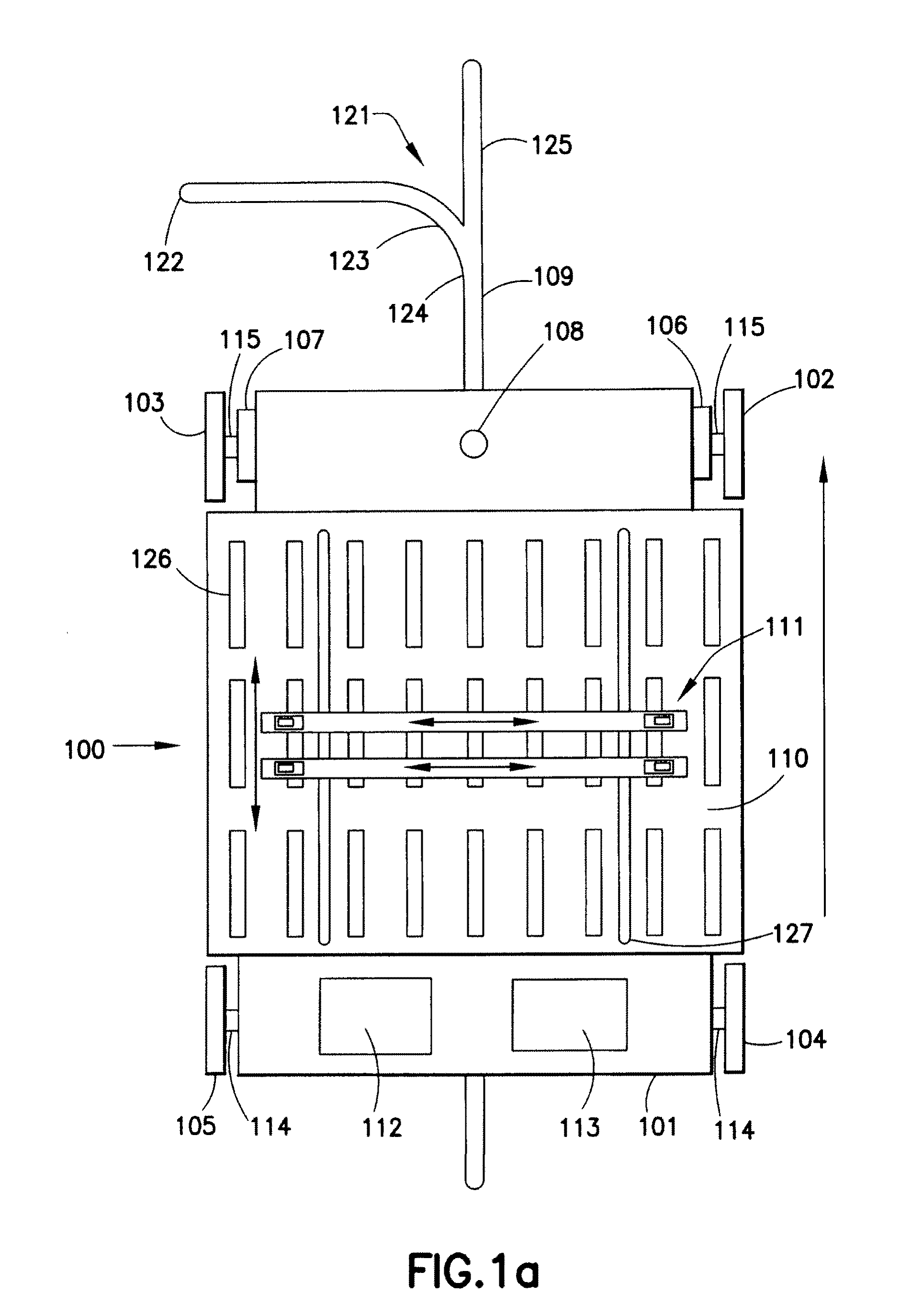

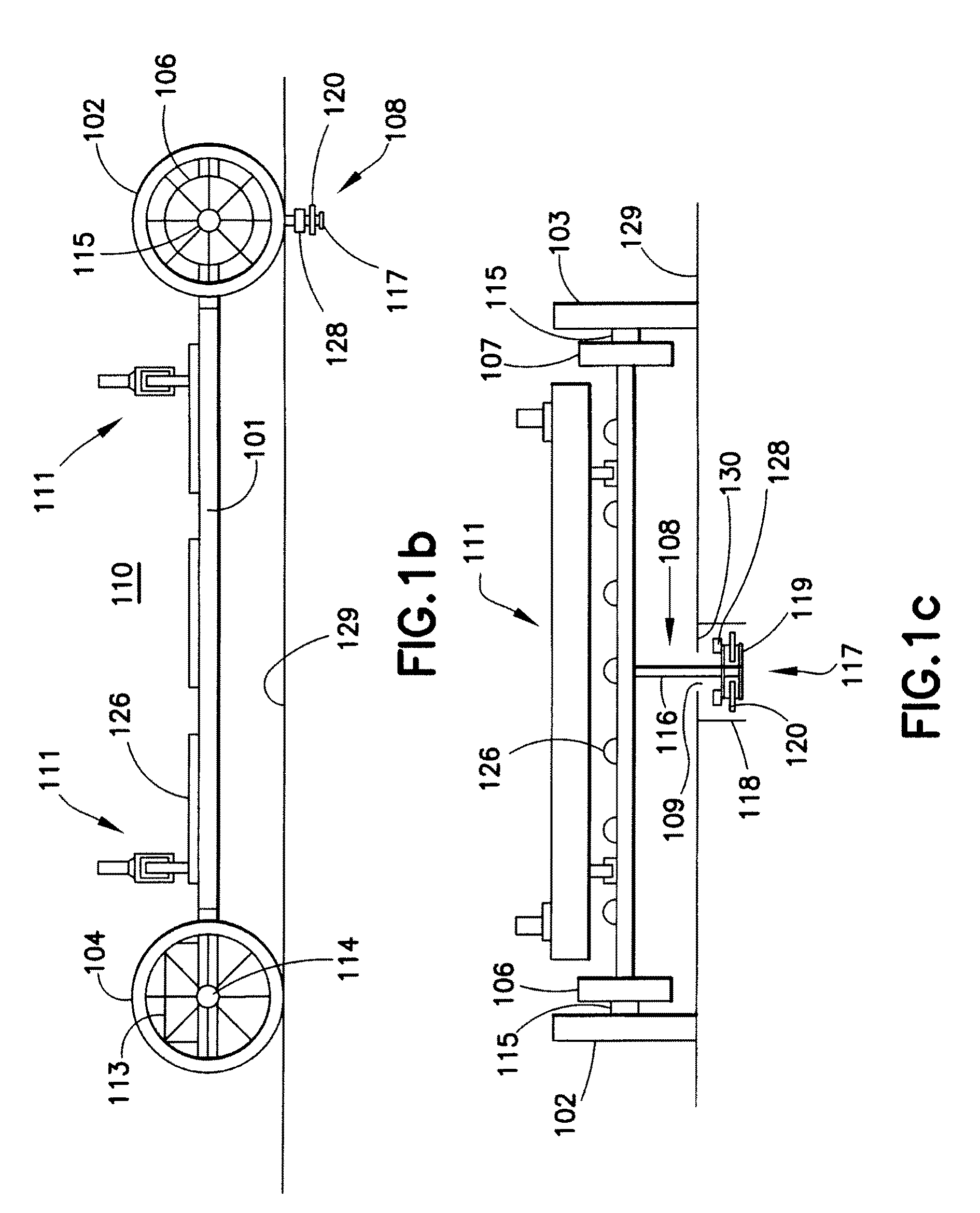

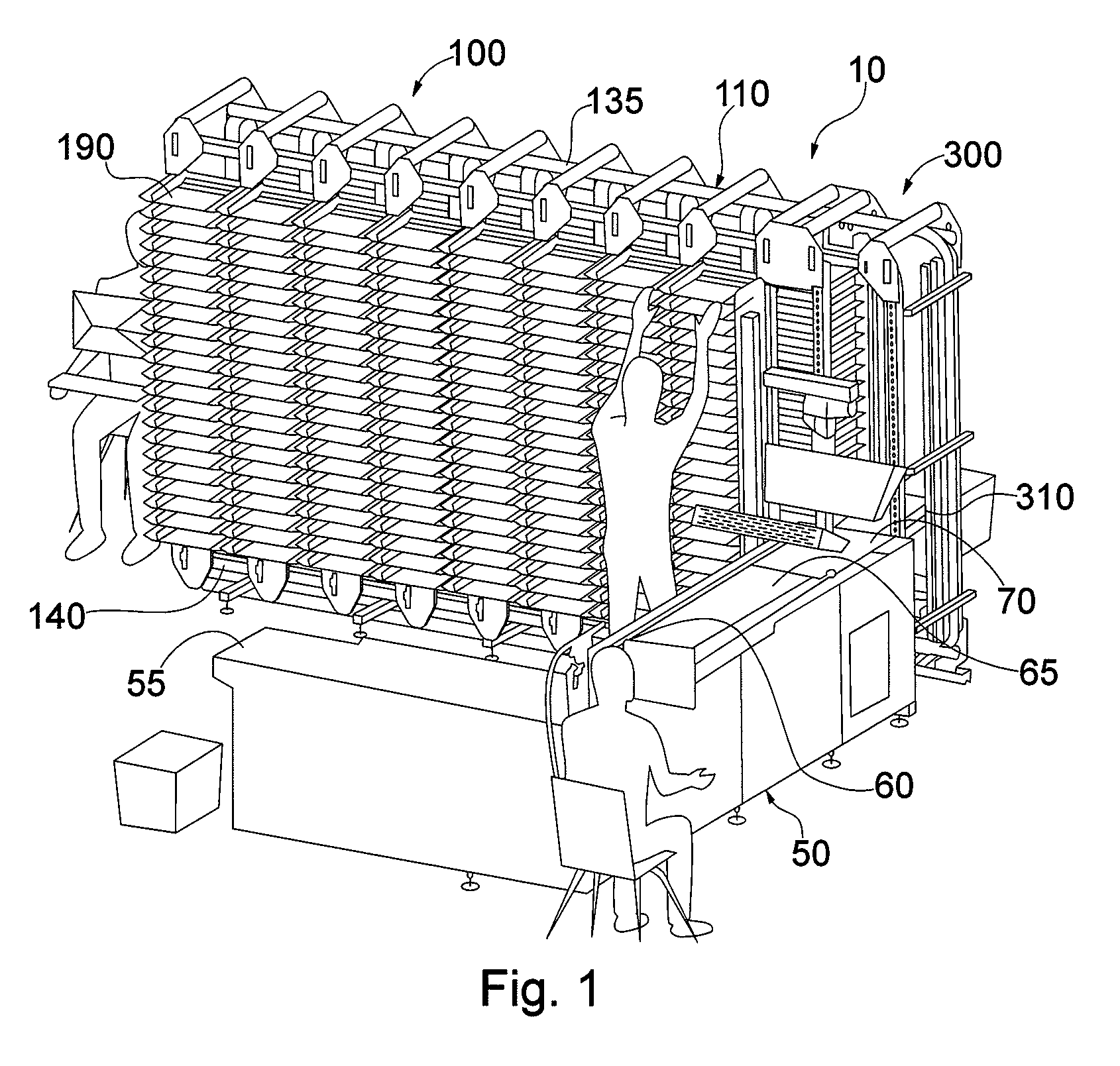

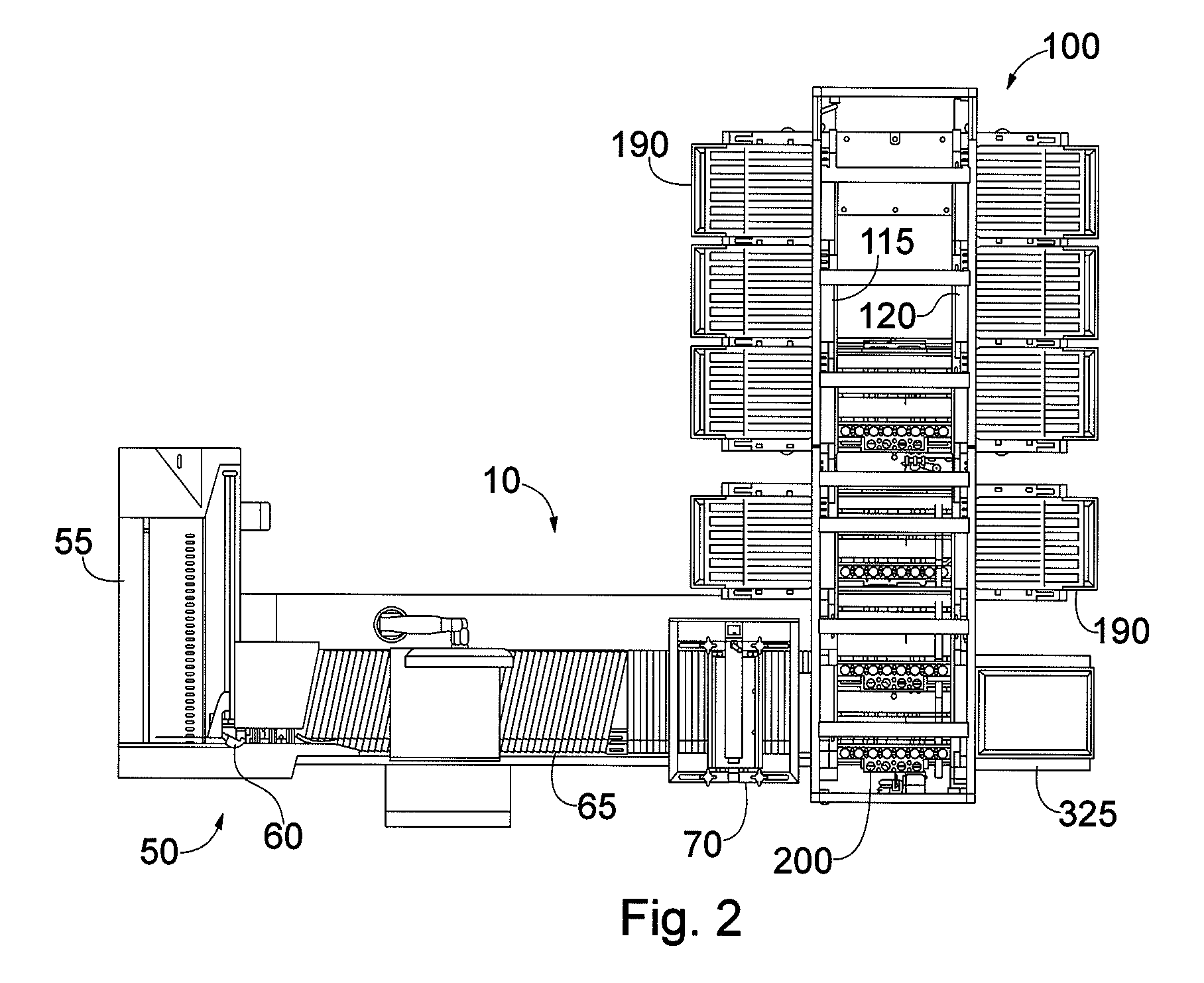

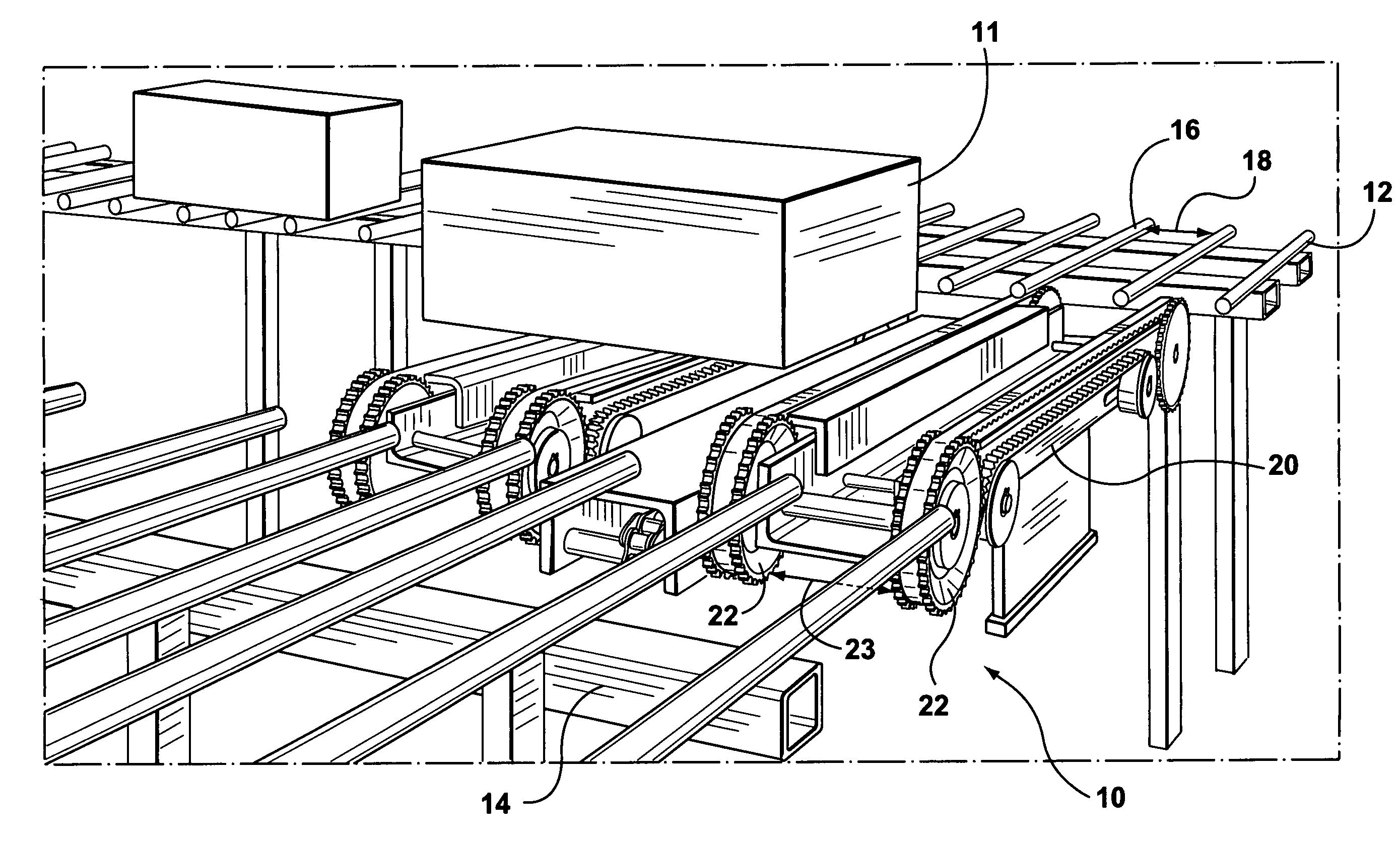

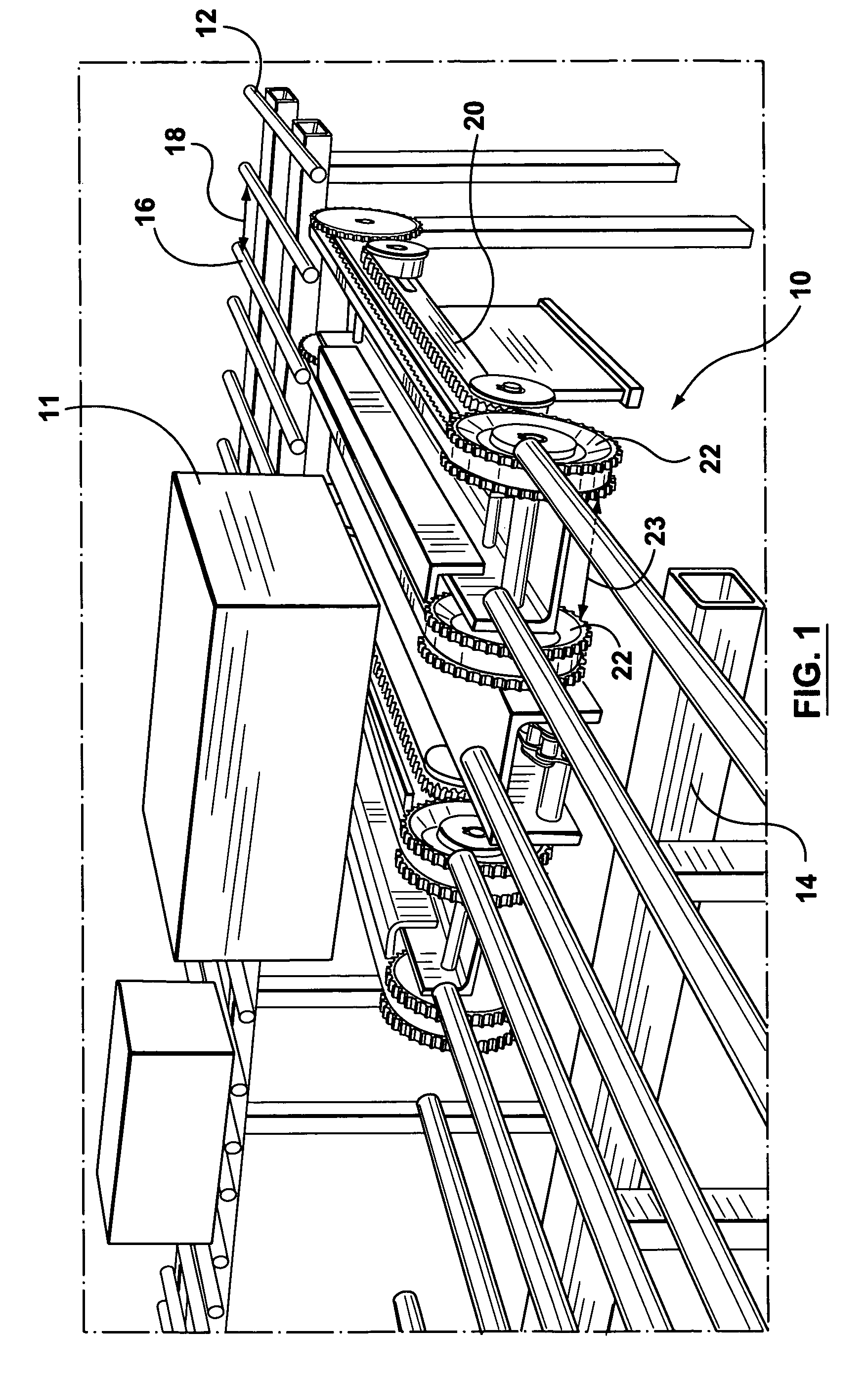

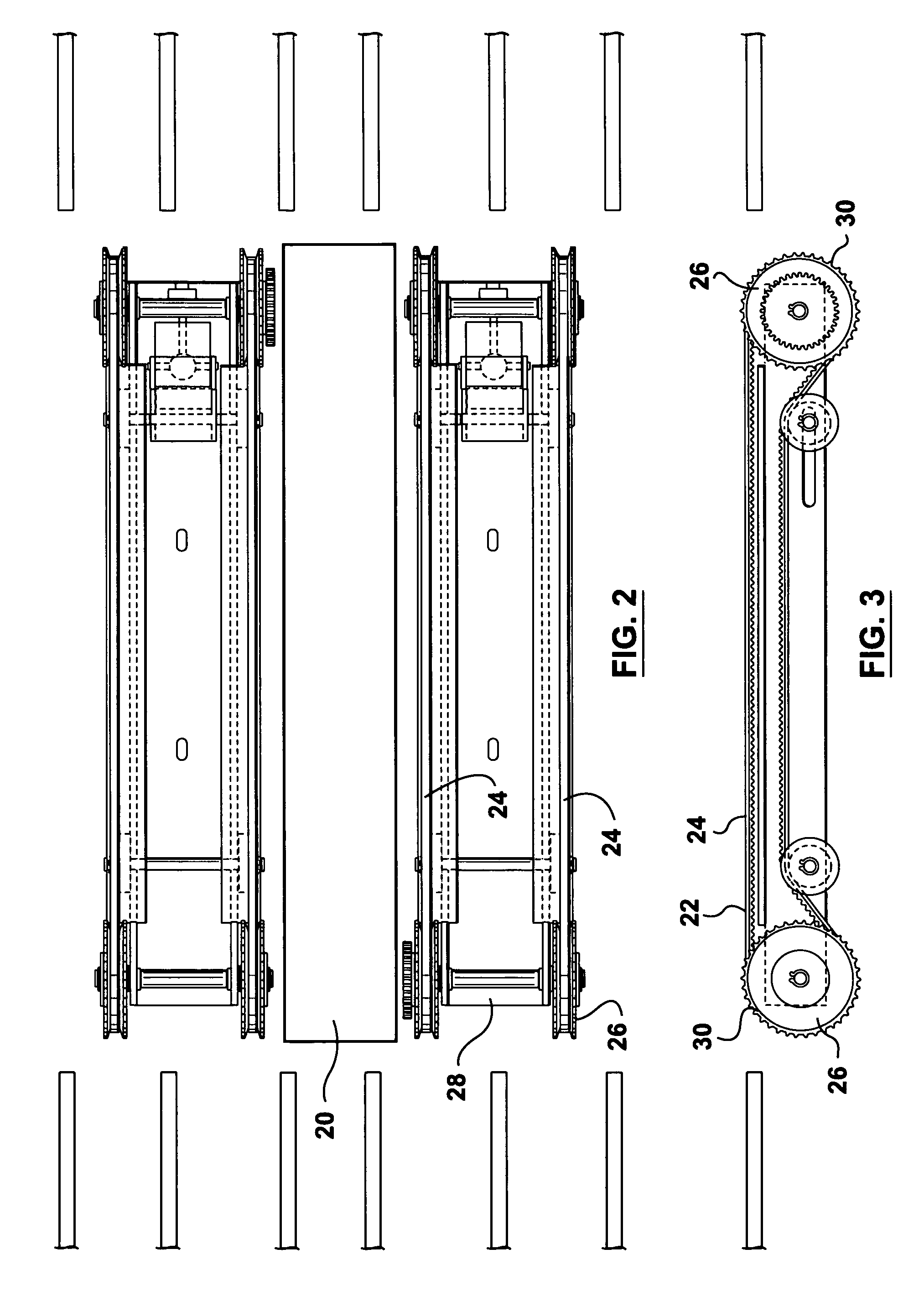

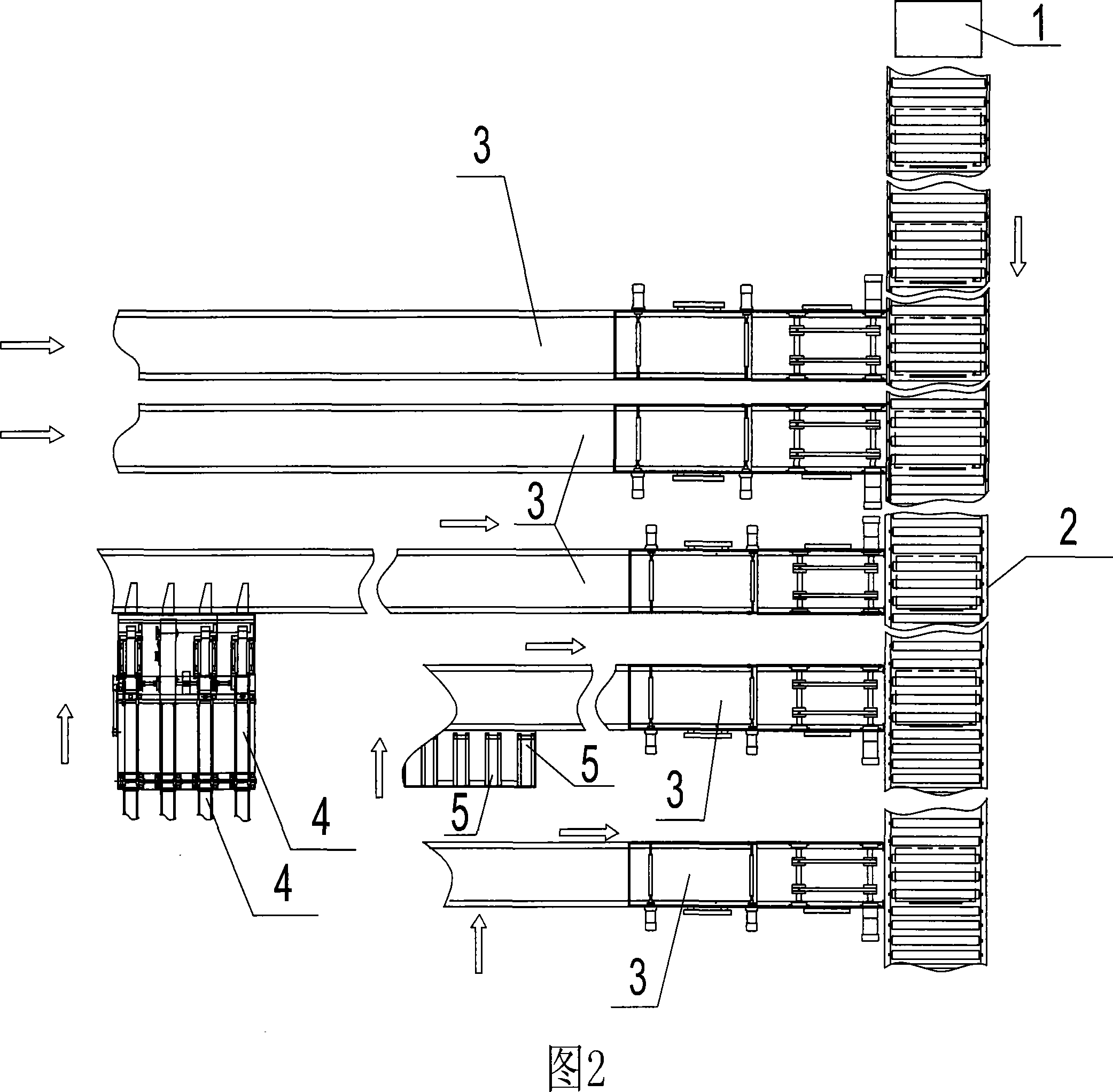

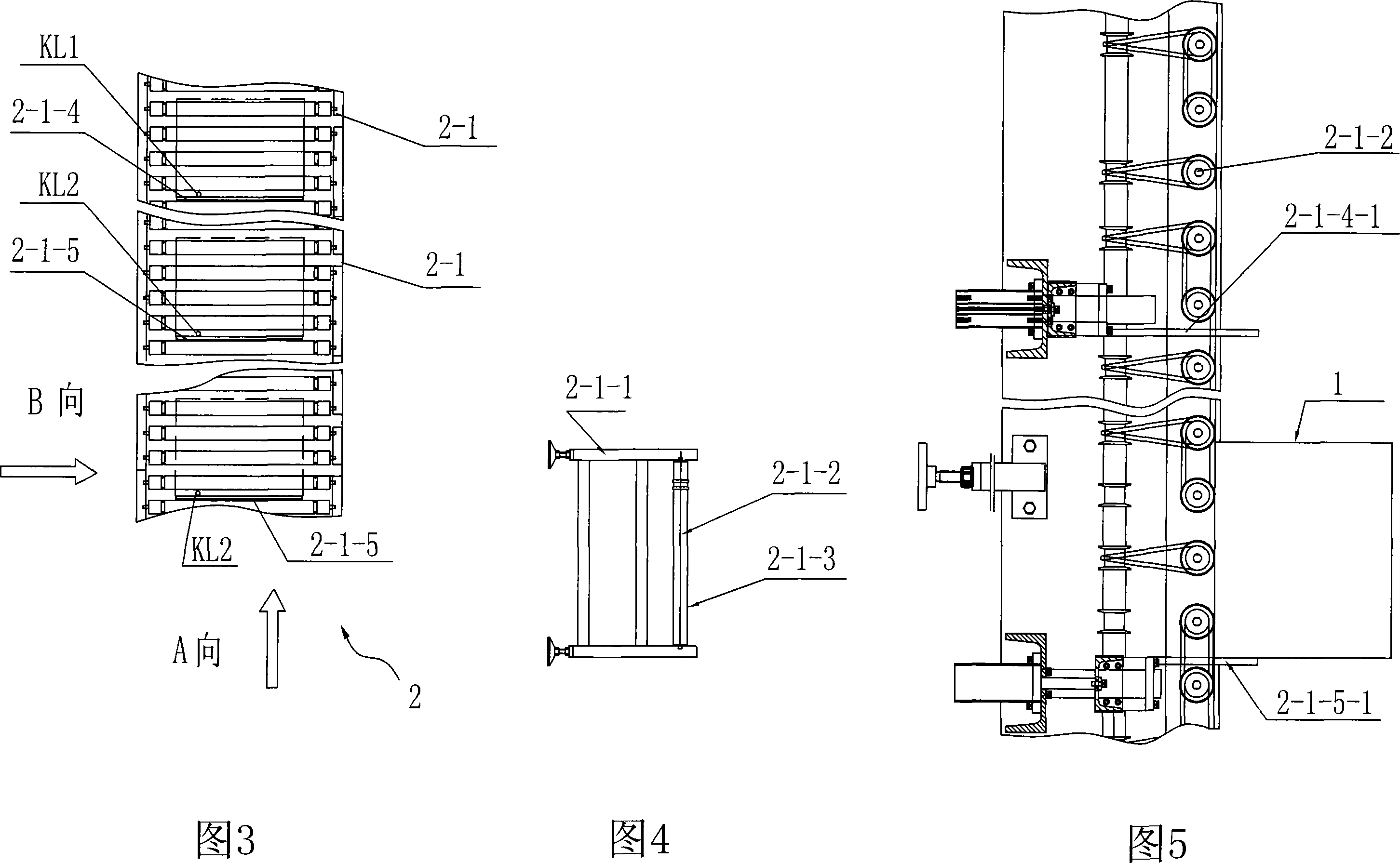

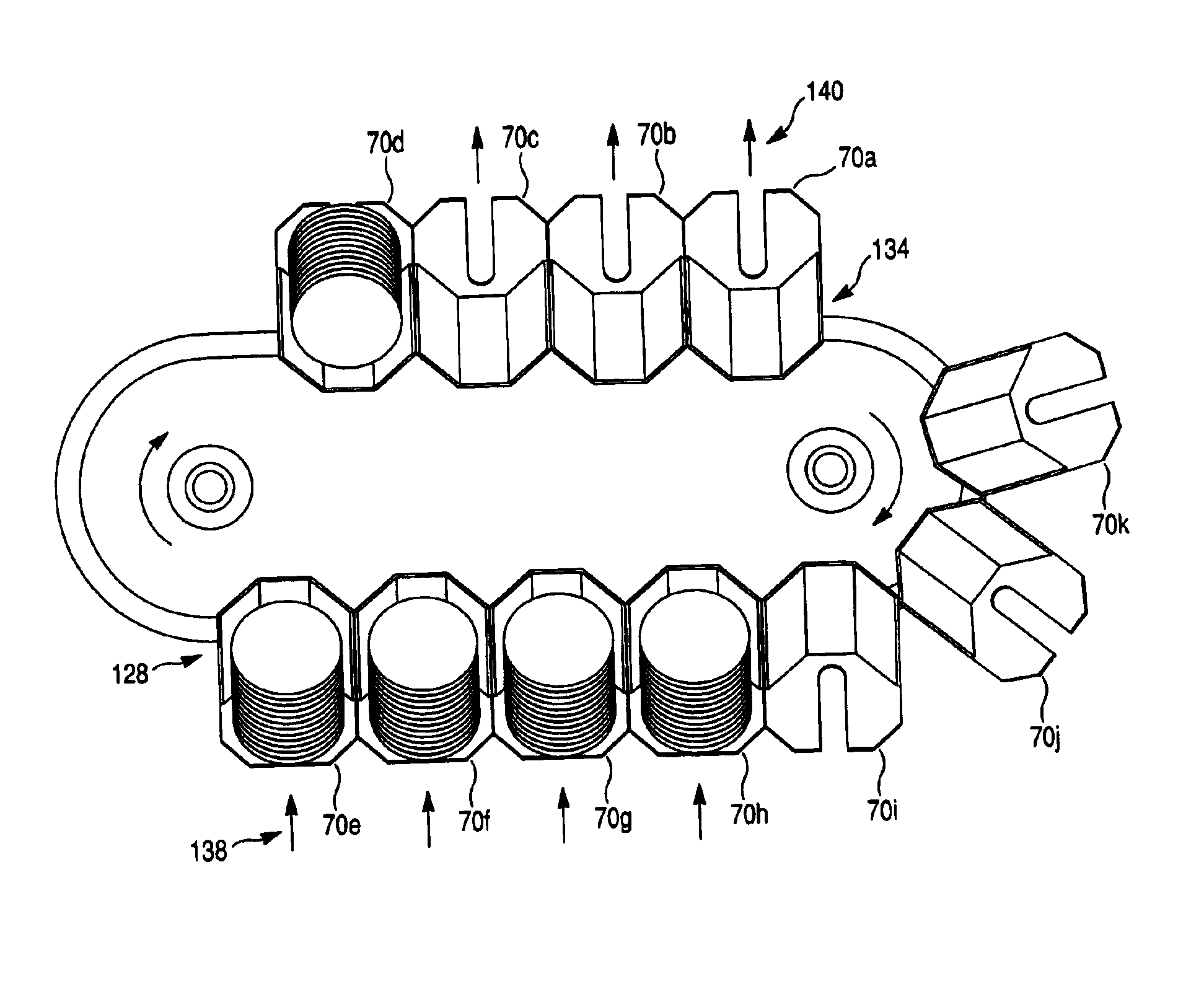

Rack, conveyor and shuttle automated pick system

ActiveUS7686560B2Improve accuracyImprove efficiencyLoading/unloadingStorage devicesEngineeringMechanical engineering

A rack and conveyor shuttle system for placing and retrieving articles of various sizes including a rack system having a shelving framework of at least two tubes spaced apart from one another at a distance, wherein the distance between the tubes is sufficient to support the article in a single stack and a motorized, conveyor shuttle system having at least two finger-like conveyors spaced apart from one another at a distance, wherein the distance between the finger-like conveyors is sufficient to move in between the two tubes so as to engage the article wherein the conveyor shuttle system is adapted to interlace in between the rack system for both placing and retrieving the article.

Owner:CONESTOGA COLD STORAGE

Gas floating apparatus, gas floating-transporting apparatus, and thermal treatment apparatus

InactiveUS6336775B1Large heat capacityWaste of energyGlass transportation apparatusSemiconductor/solid-state device manufacturingEngineeringThermal treatment

A gas floating-transporting apparatus transports a material to be treated along a predetermined direction in a thermal space so as to thermally treat the material to be treated. The apparatus includes a gas floating mechanism and a transporting mechanism. The gas floating mechanism includes a gas ejection device which expels the gas toward a portion of the material to be treated on which a floating force is acted so as to float the material to be treated, and a gas supply device which supplies the gas to the gas ejection means. The transporting mechanism includes an abutting member which abuts a trailing end of the floated material to be treated and moves along the predetermined direction, and which pushes the material to be treated by the movement thereof, whereby the floated material to be treated is moved along the predetermined direction.

Owner:PANASONIC CORP

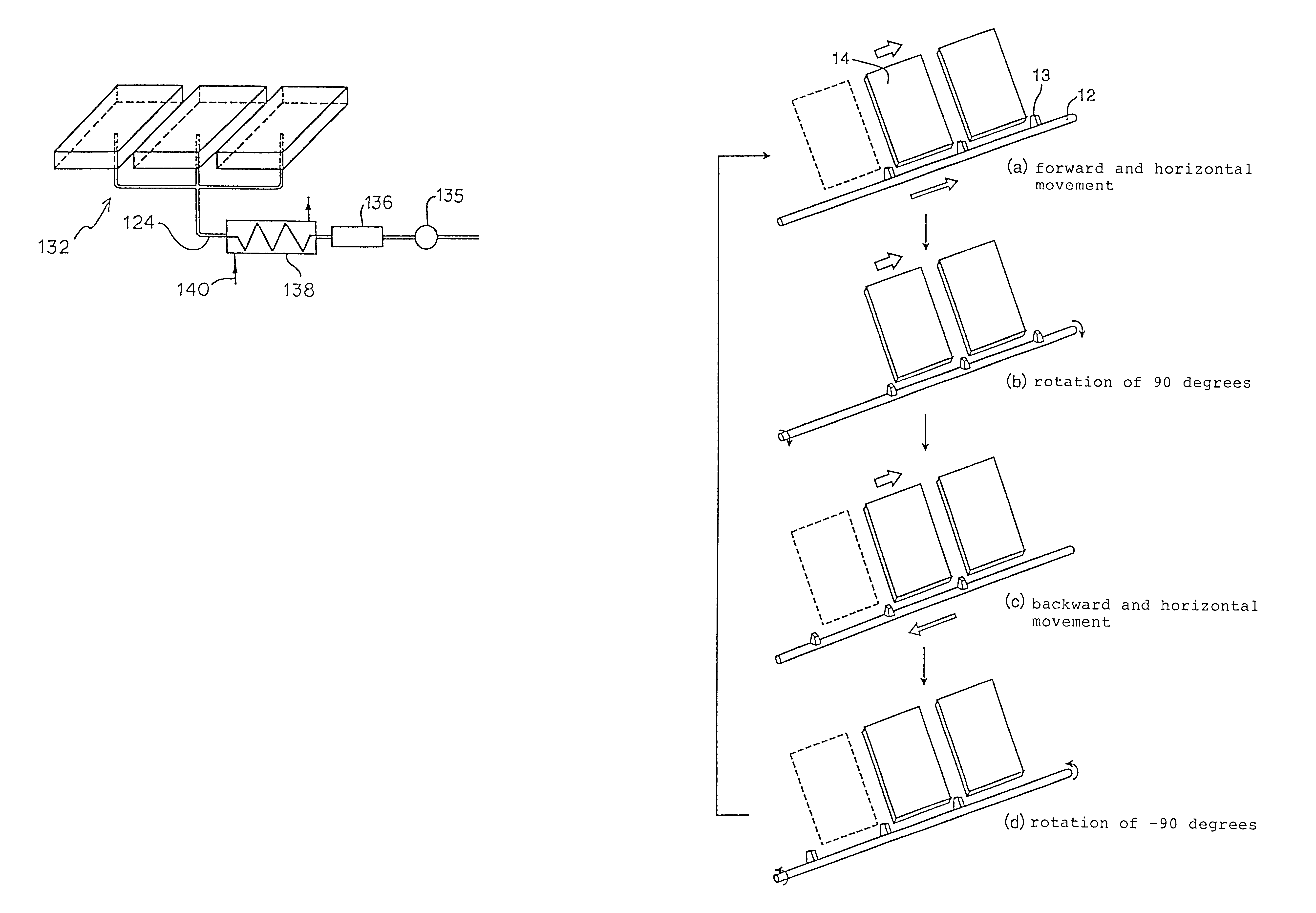

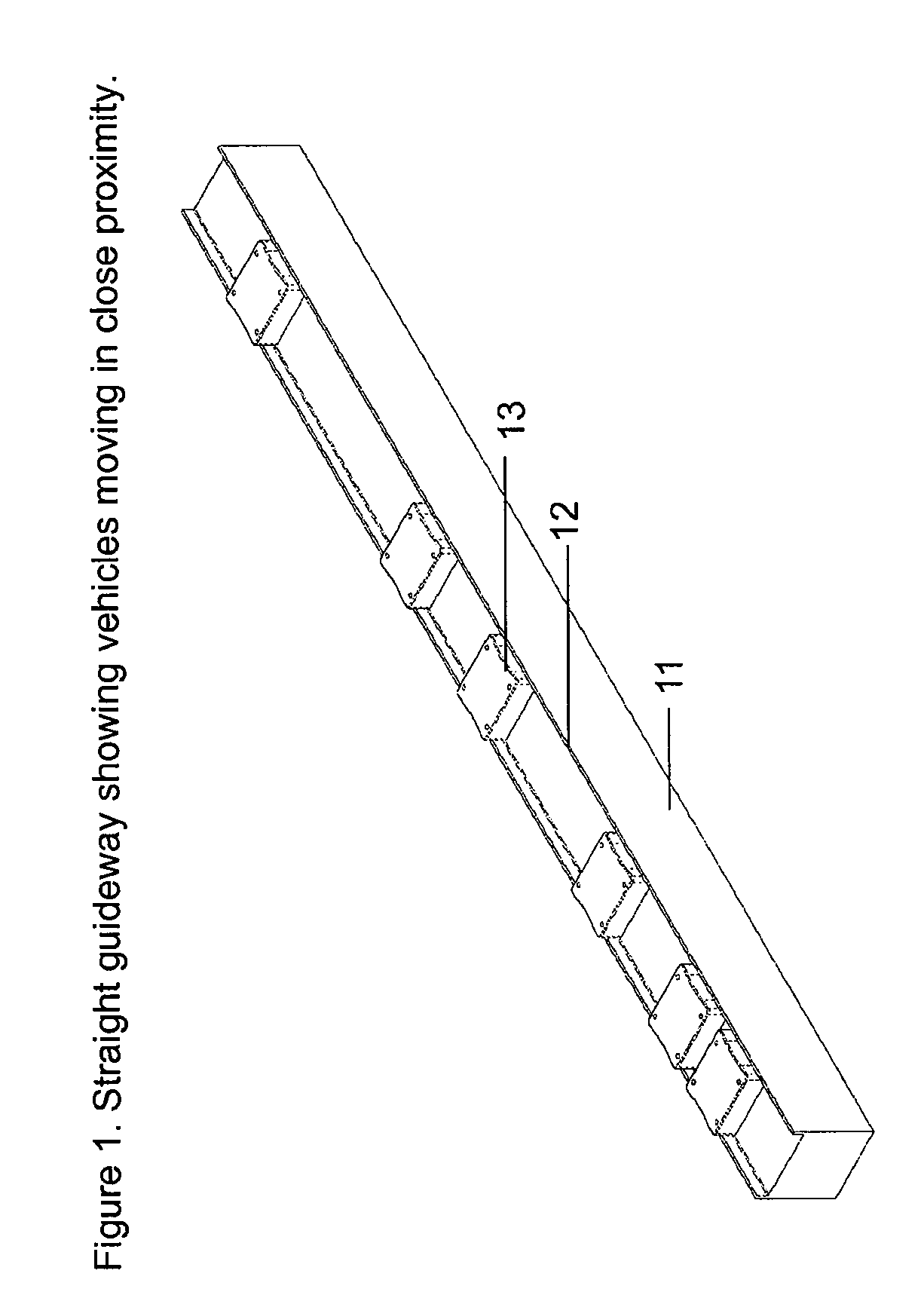

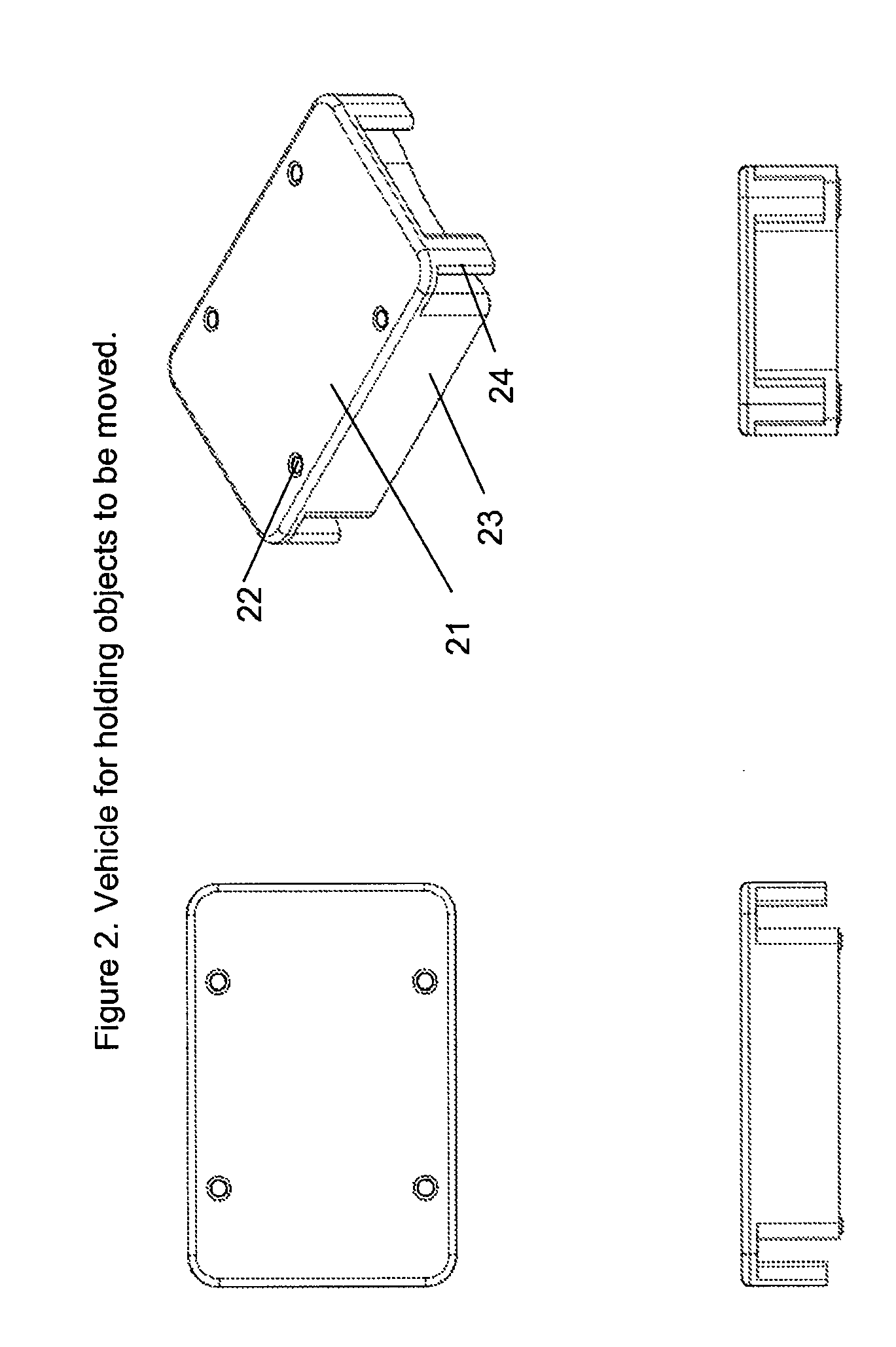

Transport system powered by short block linear synchronous motors

Aspects of the invention provide a transport system powered by short block Linear Synchronous Motors (LSMs). The use of short blocks allows vehicles to move under precise control even when they are in close proximity to each other. The design allows the vehicles to be propelled and guided while negotiating sharp turns and negotiating merge and diverge switches. A coreless LSM can be used to create propulsive force without attractive force so as to allow a relatively high drag vehicle suspension, such as a vehicle sliding on a smooth surface.

Owner:ROCKWELL AUTOMATION

Modular wireless conveyor interconnection method and system

ActiveUS20090084657A1Control devices for conveyorsMultiple digital computer combinationsElectrical batteryComputer module

A modular conveyor system is disclosed in which components of each conveyor module is designed for wireless mesh communication. The communications may be within a module or between modules. Certain of the components may be powered by battery, such that the components may be completely wireless. The network may be entirely self-configuring such that the modules may be assembled and the network established in a straightforward manner.

Owner:ROCKWELL AUTOMATION TECH

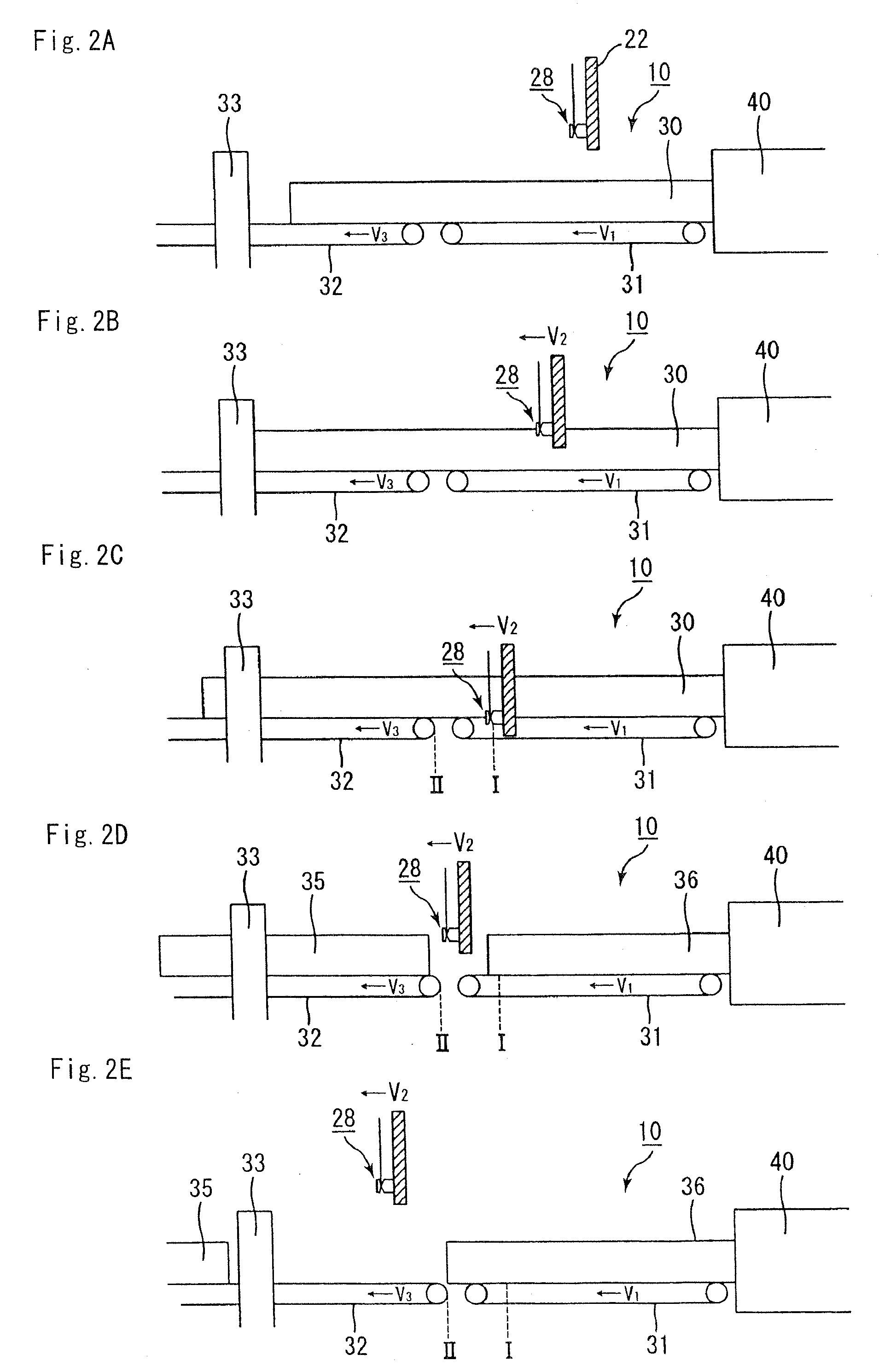

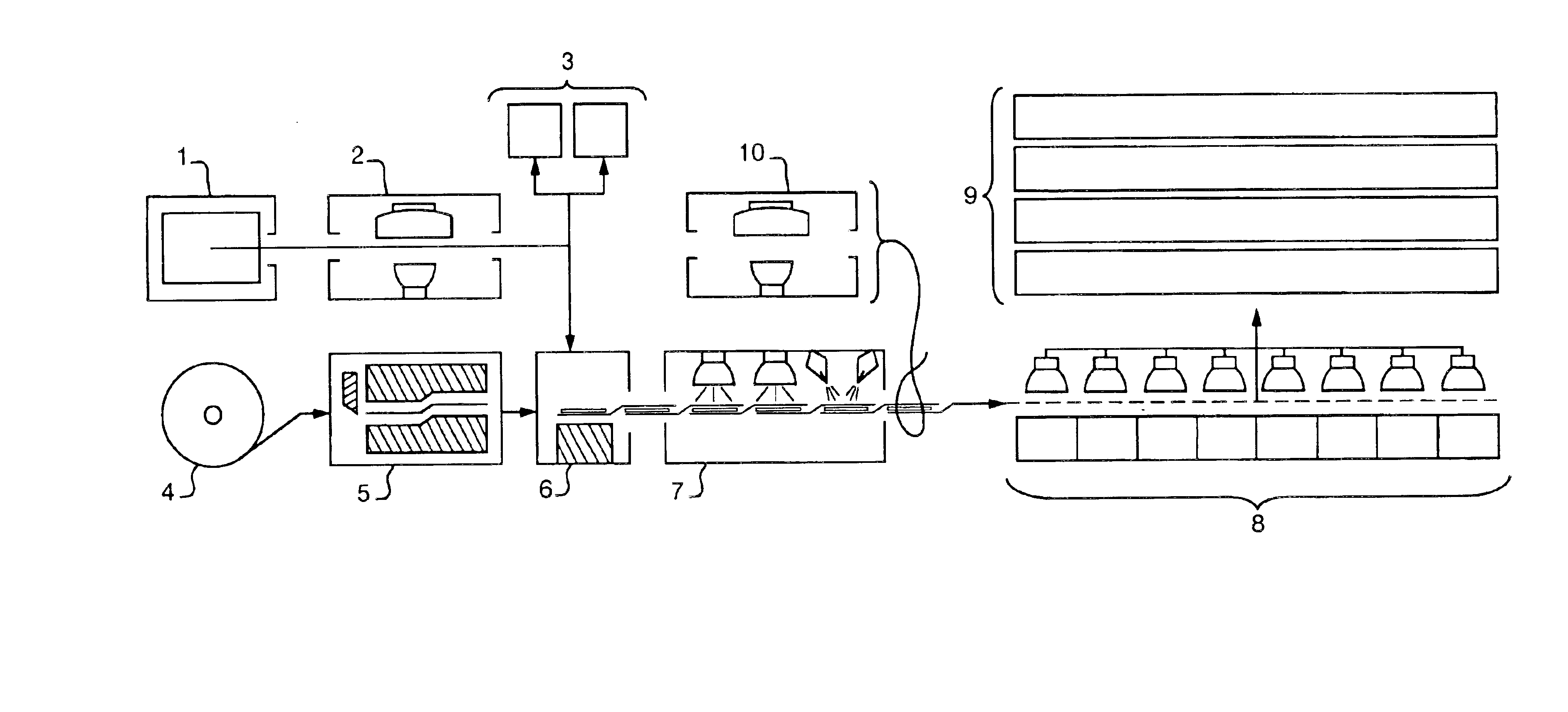

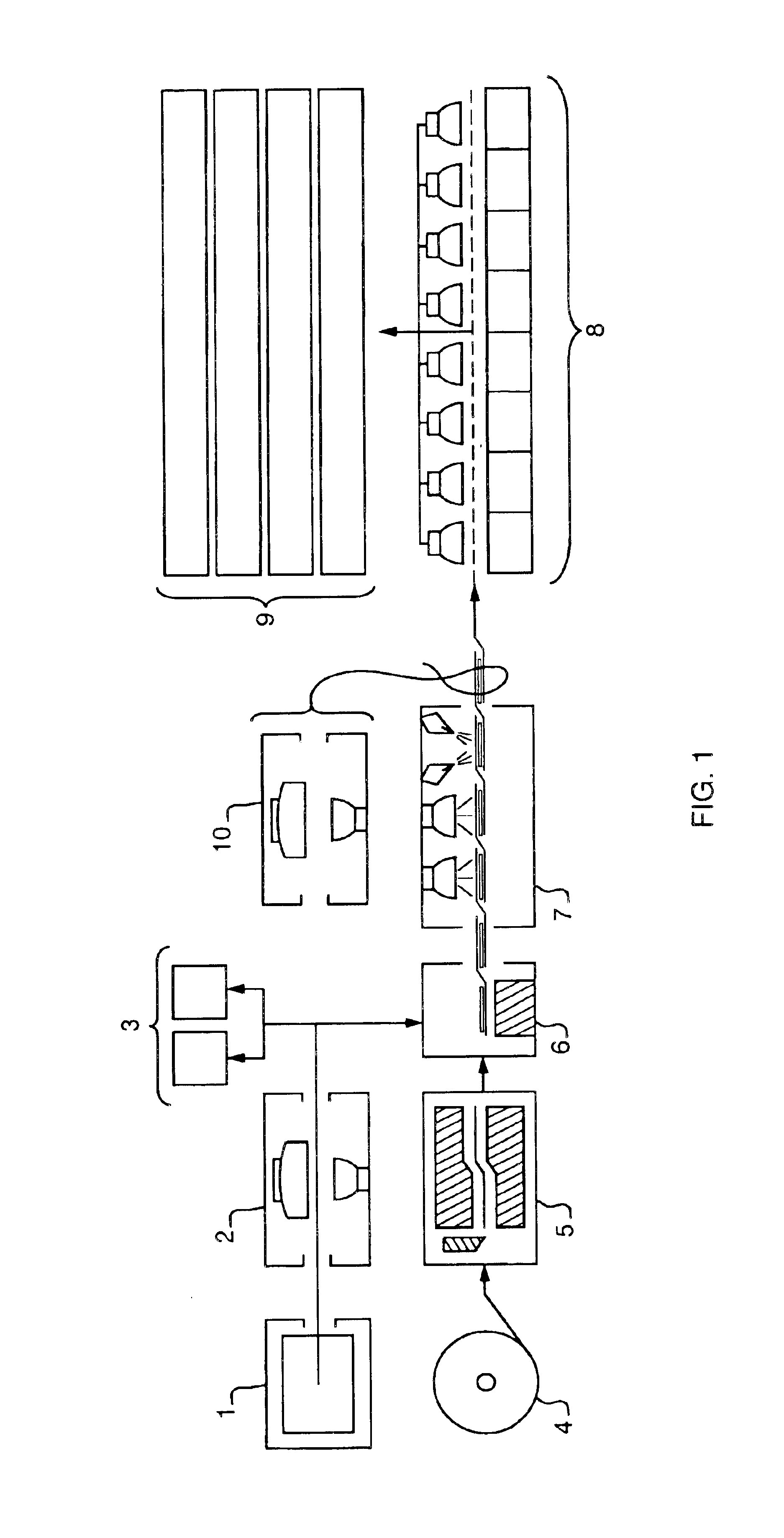

Molded body cutting apparatus, method for cutting ceramic molded body and method manufacturing honeycomb structured body

A molded body cutting apparatus according to the present invention comprising a first conveyer member that conveys an extrusion-molded pillar-shaped ceramic molded body a cutting member that moves in a direction parallel to a movement direction of the above mentioned first conveyer member while moving also in a vertical direction, and cuts the above mentioned ceramic molded body to a predetermined length by passing through the interior of the above mentioned ceramic molded body and a second conveyer member that conveys a cut ceramic molded body cut to a predetermined length by the above mentioned cutting member, wherein a conveyance speed of the above mentioned first conveyer member and a movement speed of the above mentioned cutting member in the above mentioned parallel direction are almost the same, before the above mentioned ceramic molded body is cut, and each of the conveyance speed of the above mentioned first conveyer member, the movement speed of the above mentioned cutting member in the above mentioned parallel direction, and a conveyance speed of the above mentioned second conveyer member becomes faster toward the latter, after the above mentioned ceramic molded body is cut.

Owner:IBIDEN CO LTD

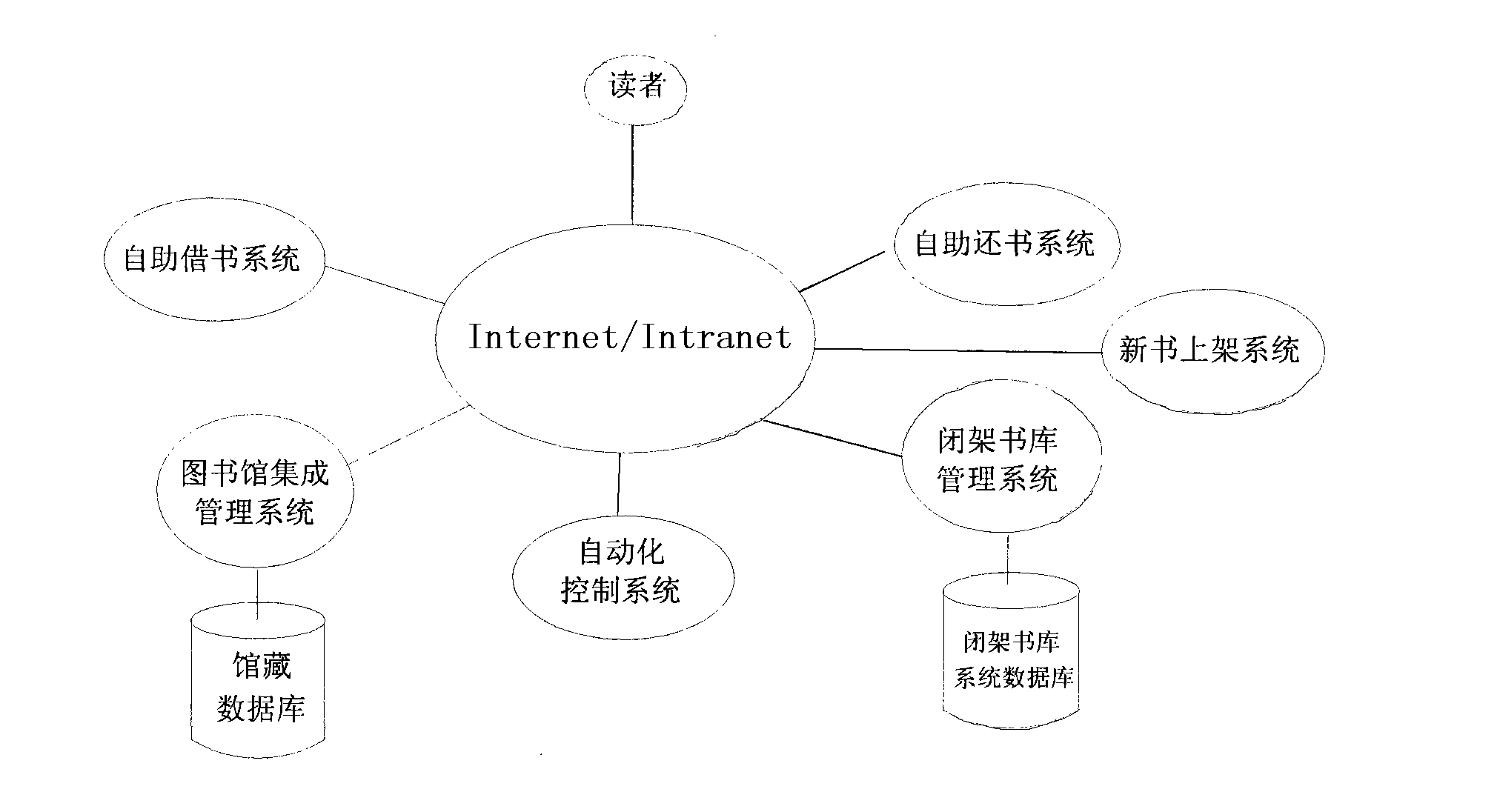

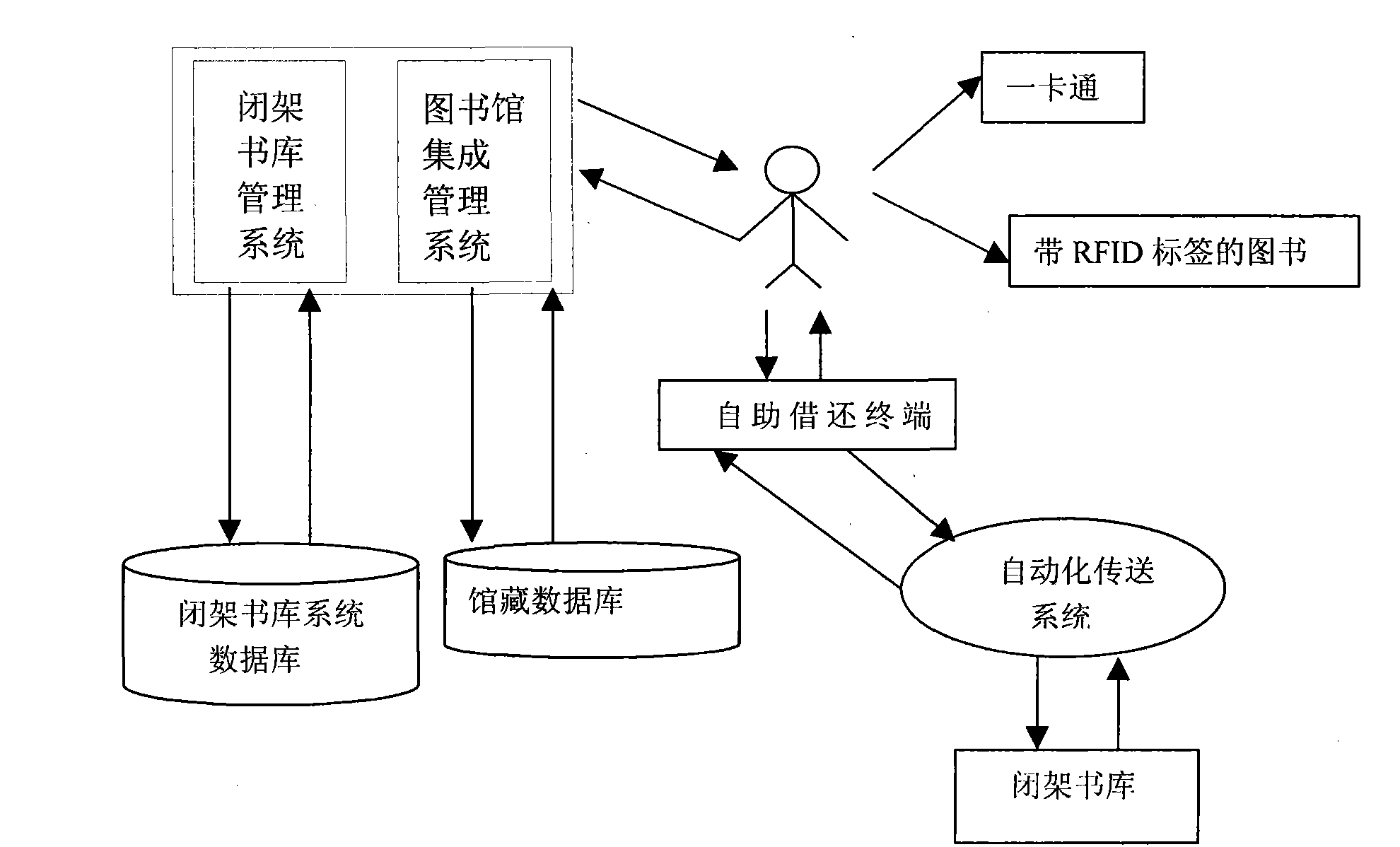

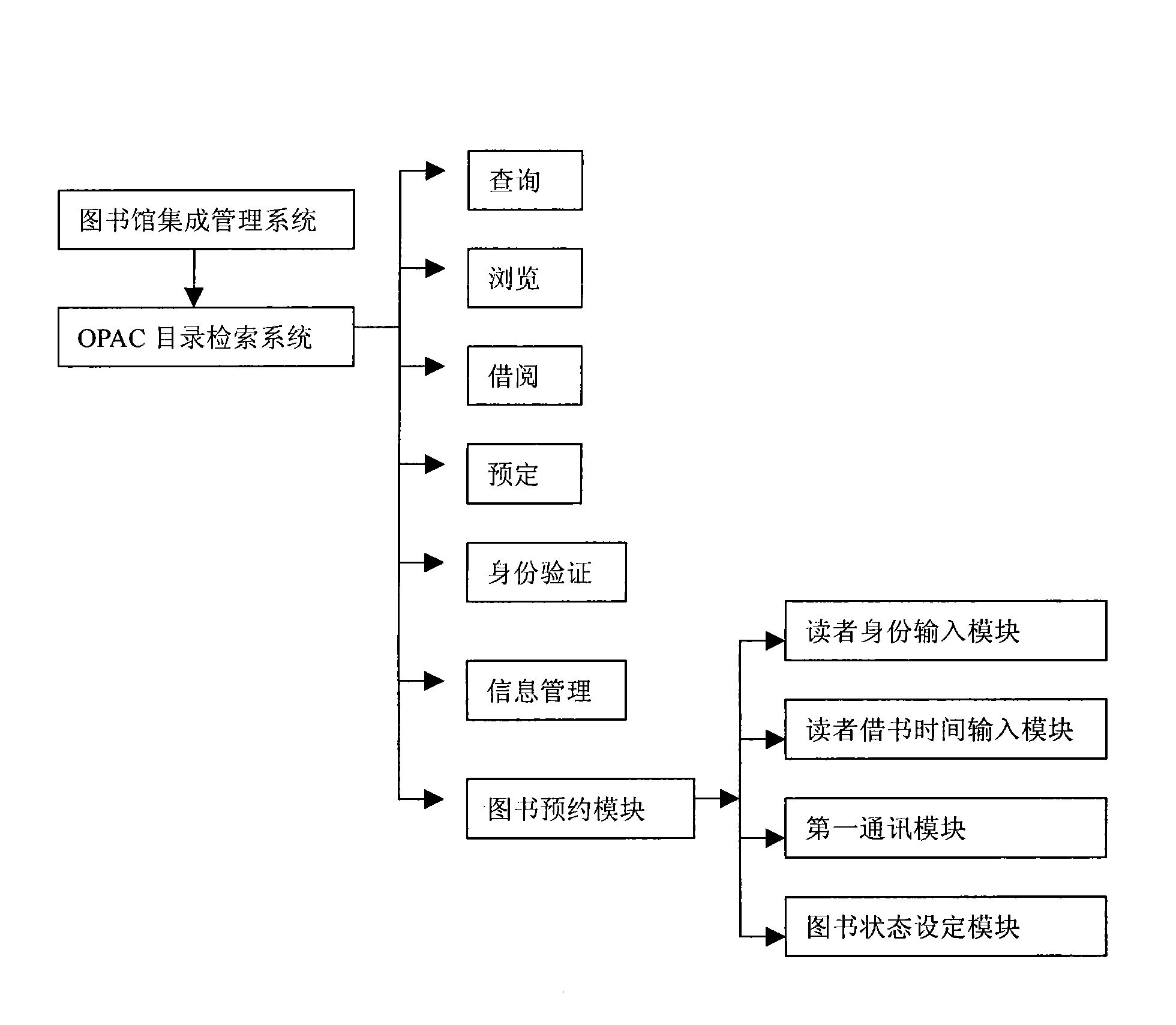

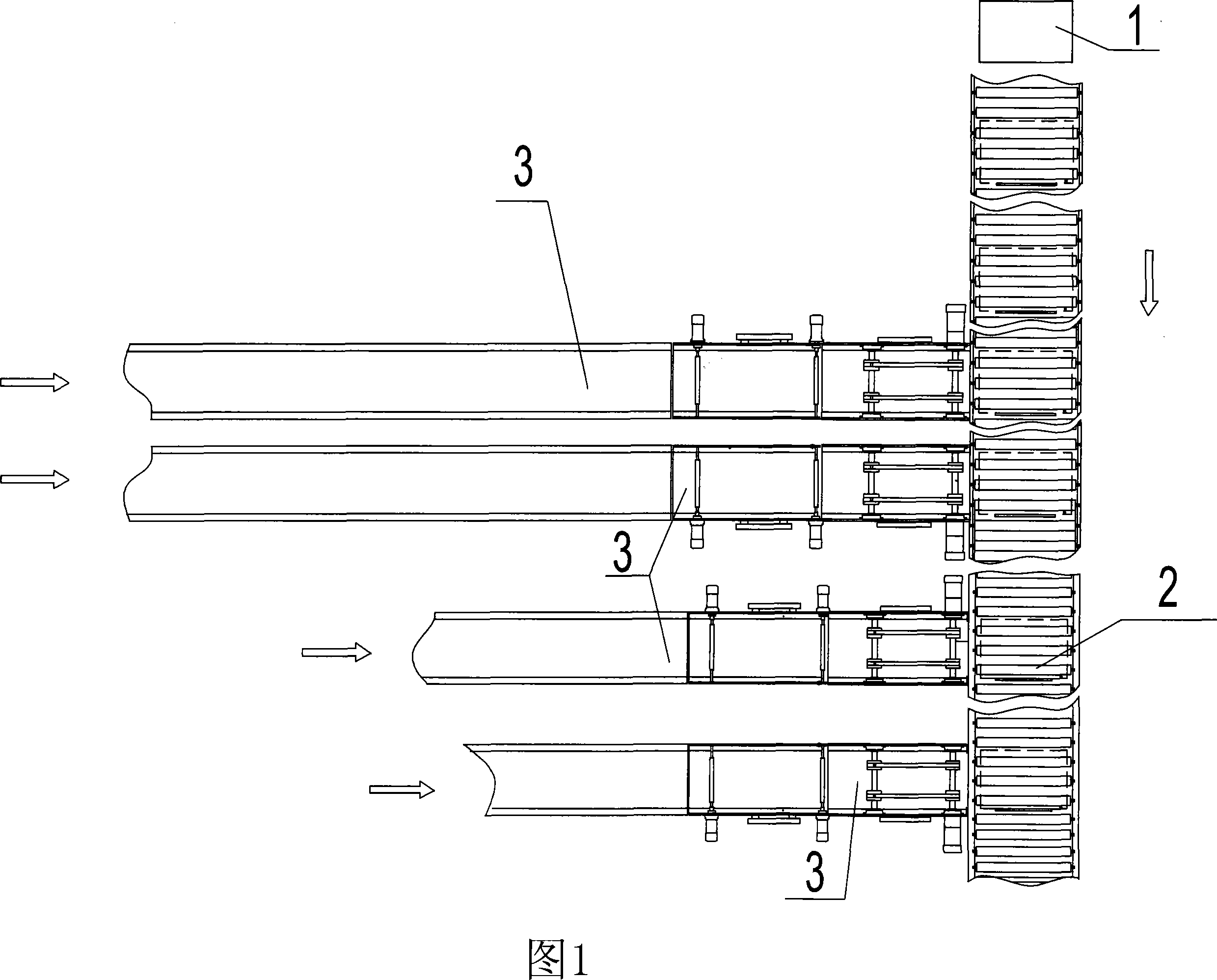

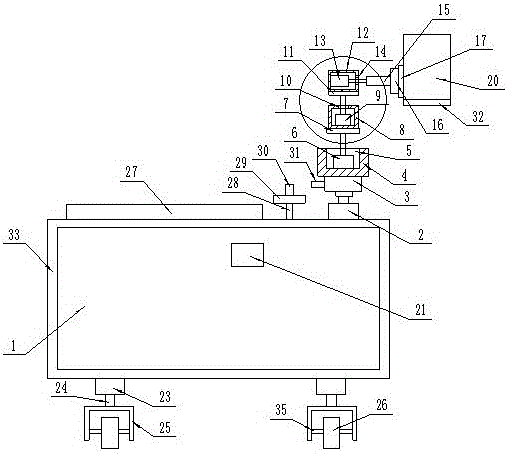

Automatic book management system based on closed stacks

InactiveCN101515391ARealize unmanned management functionImprove securityData processing applicationsCash registersReturn functionTransfer system

The invention discloses an automatic book management system based on closed stacks, which combines the original library management systems, realizes automatic borrowing and returning functions of books, lowers the labor intensity of the workers in the library and effectively improves the quality of the library in serving readers. The automatic library system adopts RFID technology, mechanical automation, network and computer technologies. The book management system of the invention comprises shelves, a library integrated management system, books with RFID chips, a self-service borrowing and returning terminal, a management system of closed stacks, a self-service borrowing system, a self-service returning system and an automatic transfer system which realizes that books automatically go in and out of the closed stacks; wherein, the management system of closed stacks operates the information of the database of the closed shelf system to realize information interaction between the library integrated management system and the automatic transfer system, thus finally realizing the automatic management functions of books.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

Solar cell stringing machine

Owner:GTAT CORPORATION

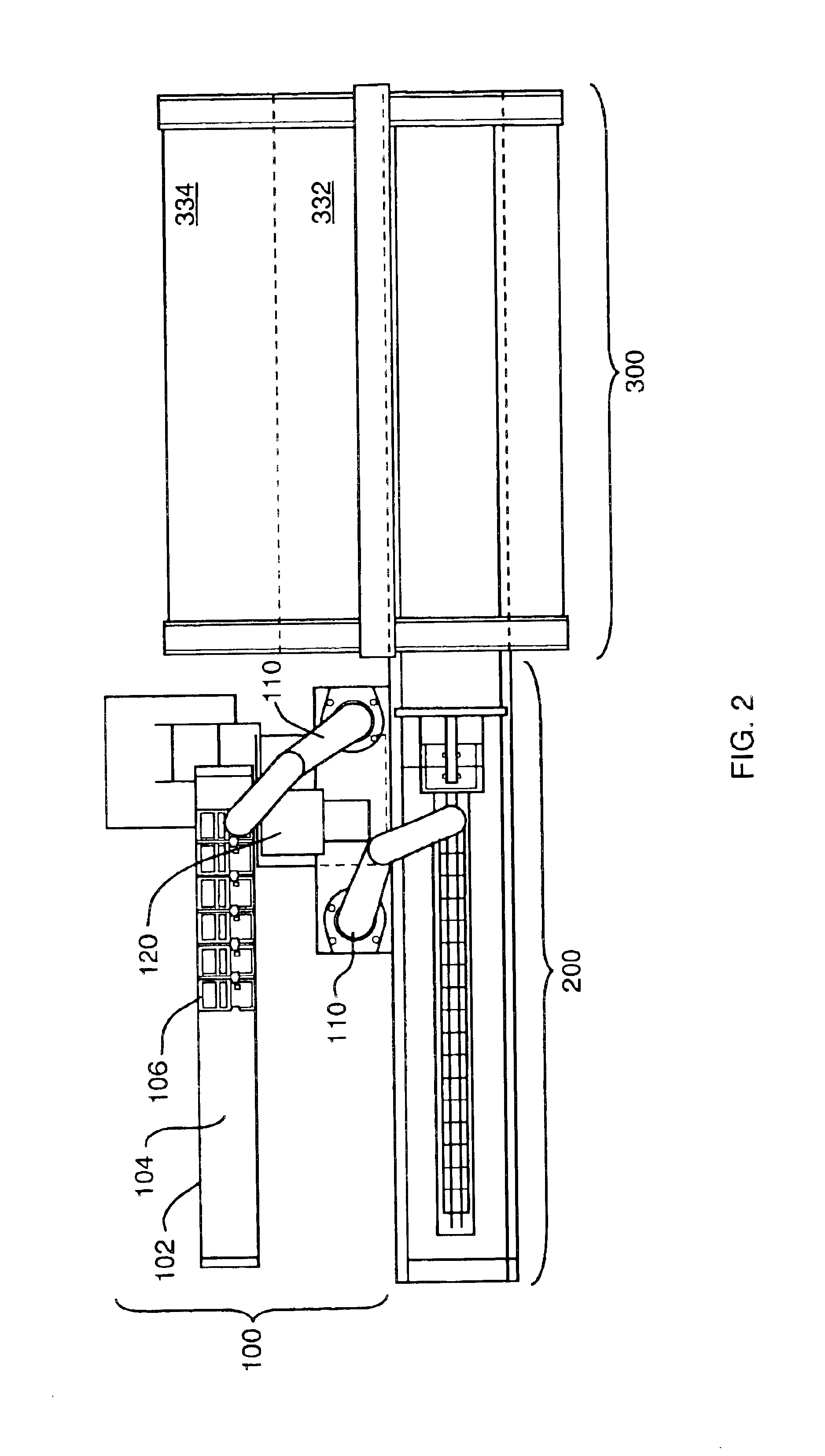

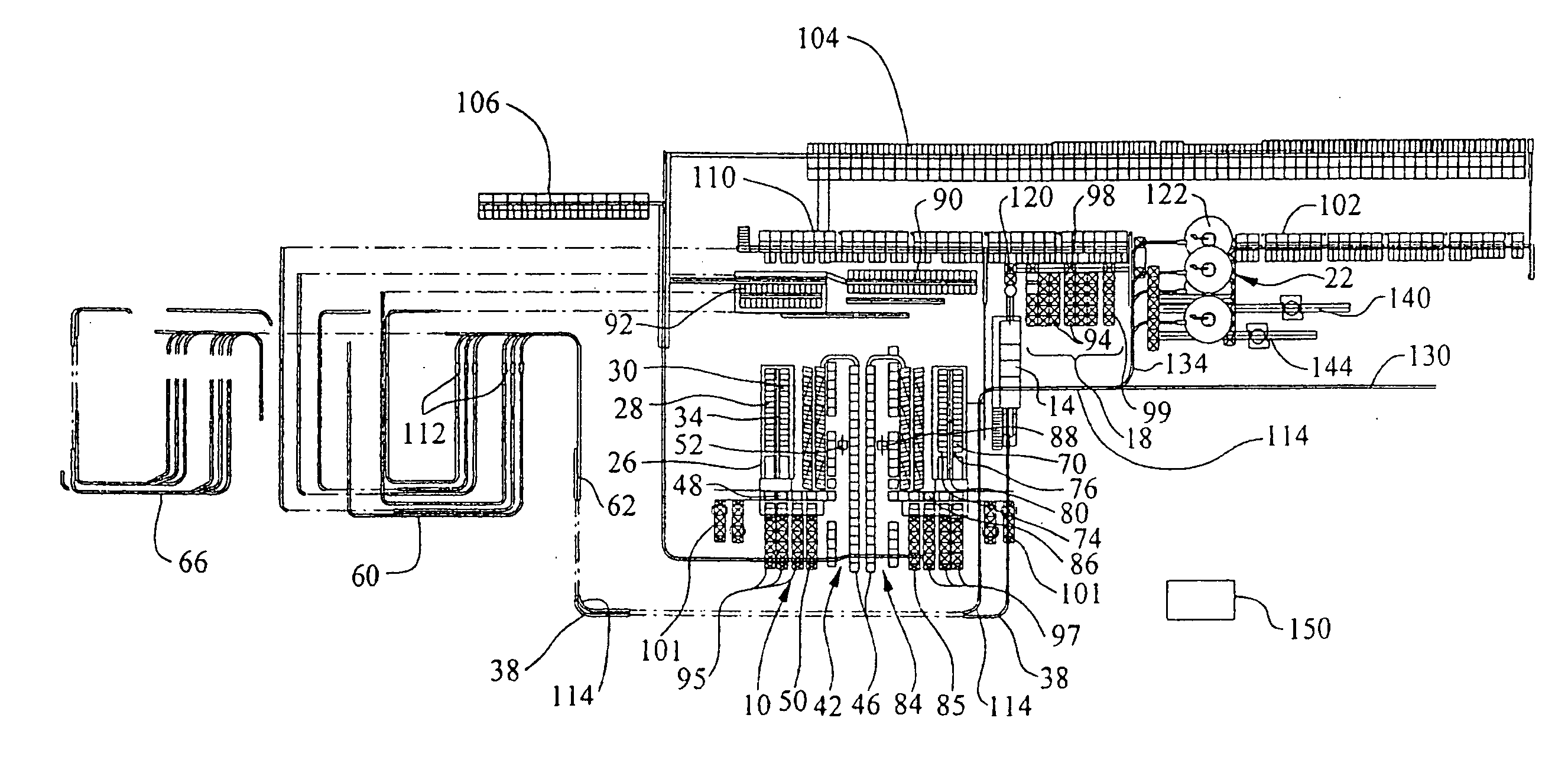

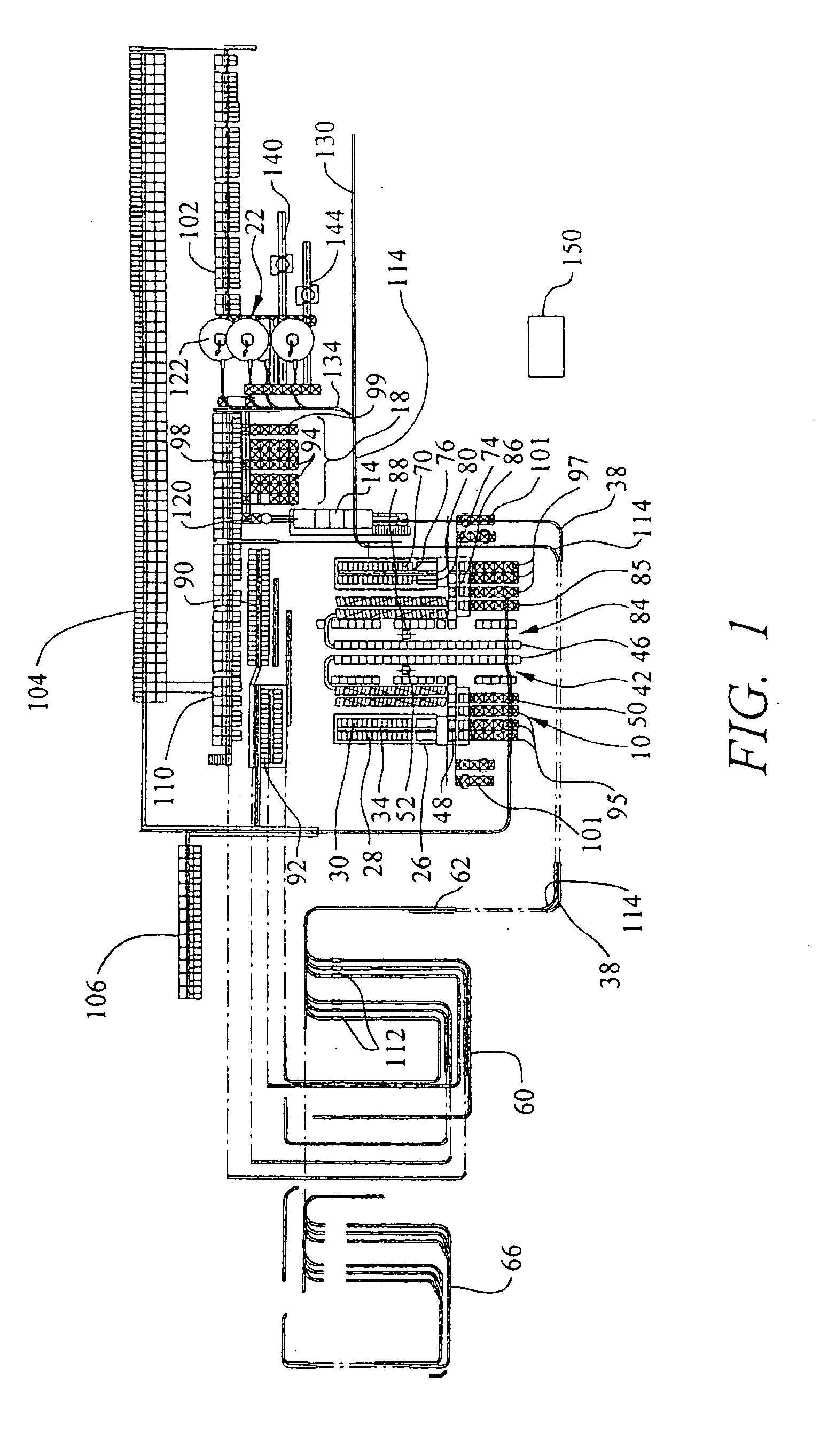

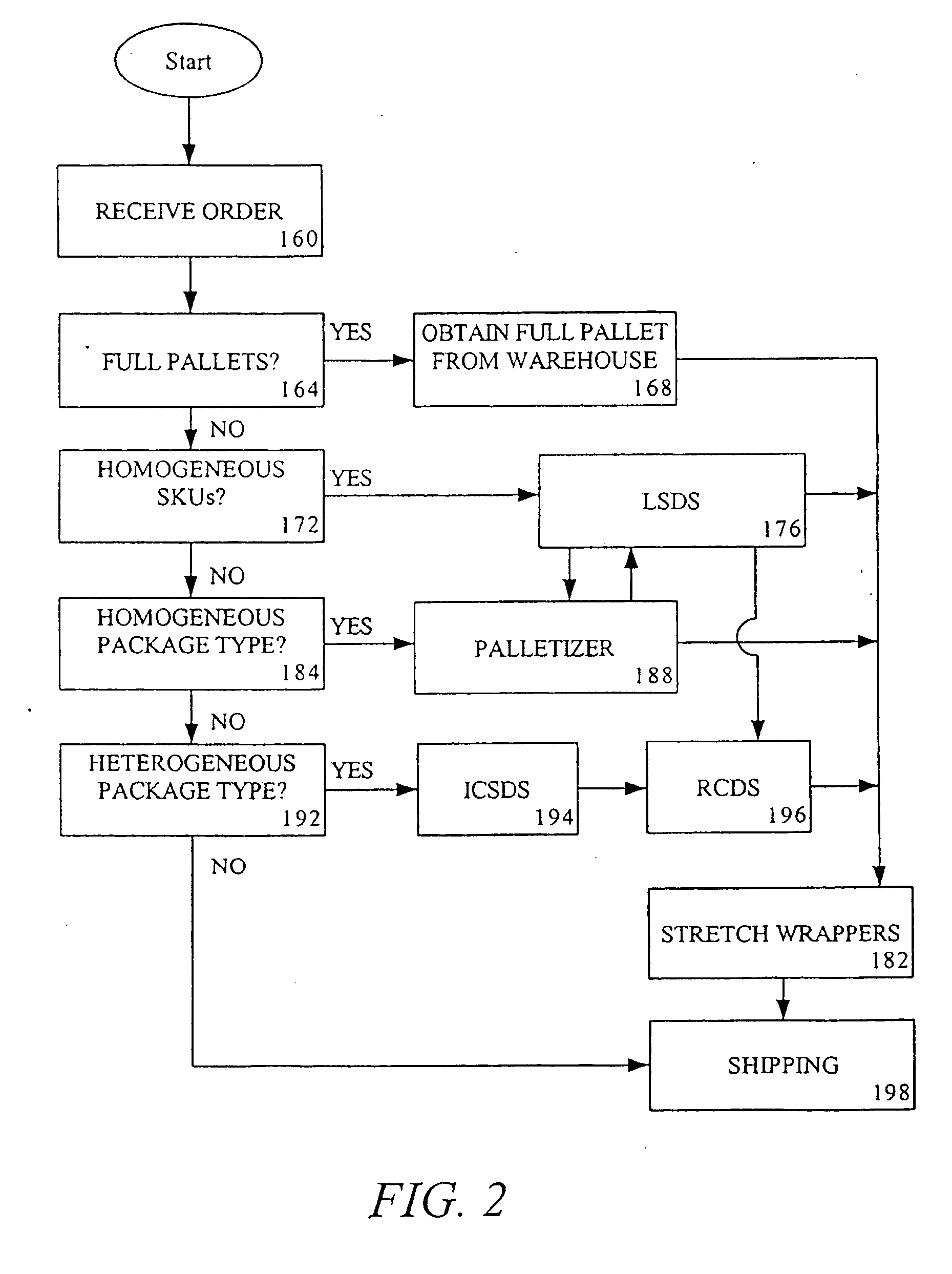

Automated container storage and delivery system

A material storage and delivery system includes an individual container storage and delivery system (ICSDS). A palletizer is provided for placing containers from the ICSDS on a pallet. A layer storage and delivery system (LSDS) places full layers of containers on a pallet. A robotic container delivery system (RCDS) places individual containers on a pallet. A conveyor system conveys containers and pallets between at least two of the ICSDS, the palletizer, the LSDS and the RCDS. A method for storing and delivering containers is also disclosed.

Owner:STINGEL FREDERICK J III +2

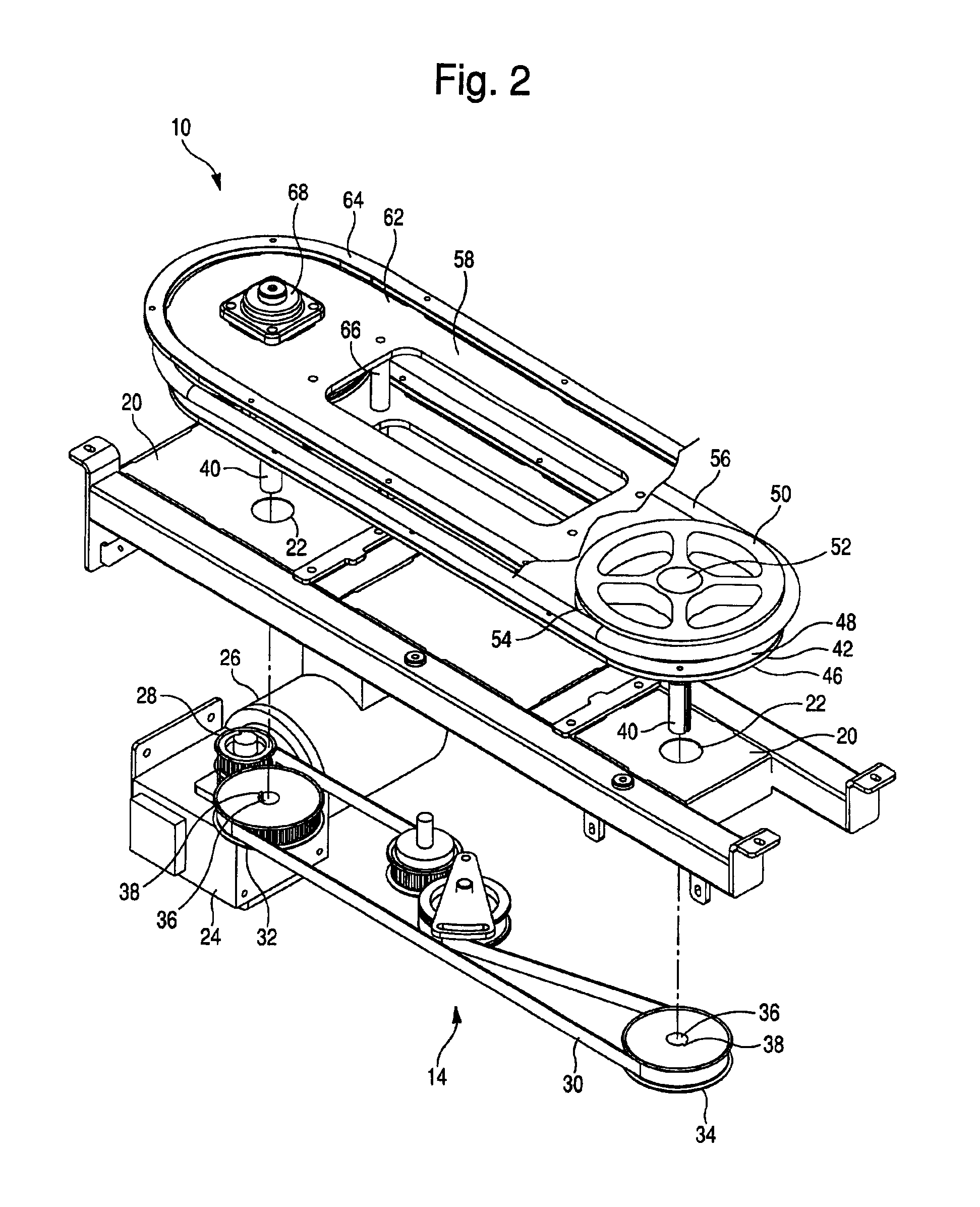

Method and apparatus for buffering a flow of objects

InactiveUS6957941B2Good flexibilityMinimize the numberPackaging meatCharge manipulationEngineeringPackaging machine

A buffer device for buffering a flow of stacks of discrete objects between a stacking machine and a packaging machine is disclosed which buffer includes a plurality of individual trays mounted on carriers which carriers are mounted on a frame and driven about the periphery of the frame by a drive. A first number of stacks of objects is placed on a first number of carriers on a first side of the frame and a second number of stacks are removed from a second number of carriers on a second side of the frame where the first number can be greater than, less than or equal to the first number. The carriers clamp onto a continuously moving drive belt in a manner that allow the drive belt to slip through the carrier clamps when motion of the carriers is obstructed. A method of using the buffer device is also disclosed.

Owner:F R DRAKE

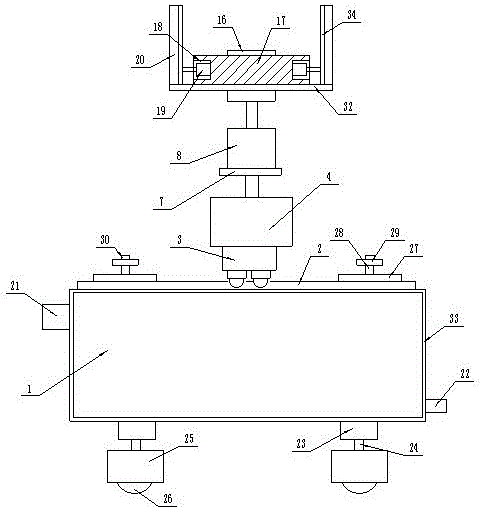

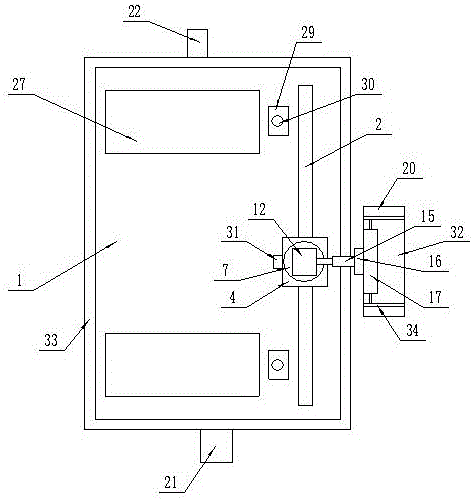

Medical appliance carrying apparatus

ActiveCN106044205AEasy to operateReduce maintenance costsNursing accommodationConveyor partsElectricityHydraulic cylinder

The invention discloses a medical appliance carrying apparatus which comprises a working table. A vertical slide rail is arranged on one side of the upper surface of the working table; an electric trolley is arranged on the vertical slide rail and provided with a mount on the upper surface; a circular groove is formed in the center of the upper surface of the mount; a rotating motor with an upward rotating end is arranged in the circular groove; the rotating end of the rotating motor is provided with a circular supporting plate matched with the circular groove; a first installation box is arranged on the upper surface of the circular supporting plate; a controller is arranged on the front surface of the working table; a mains supply interface is arranged on the back surface of the working table; a power terminal of the controller is connected with a mains supply interface via a conductor wire; an output end of the controller is connected with the electric trolley, the rotating motor, a hydraulic cylinder, an electric pusher and a micro linear motor via conductor wires respectively. The medical appliance carrying apparatus has the advantages of high carrying capacity, high carrying speed, capability of liberating manpower and improving work efficiency, small size, and high movability.

Owner:平邑经济开发区投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com