Patents

Literature

7280 results about "Manual handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

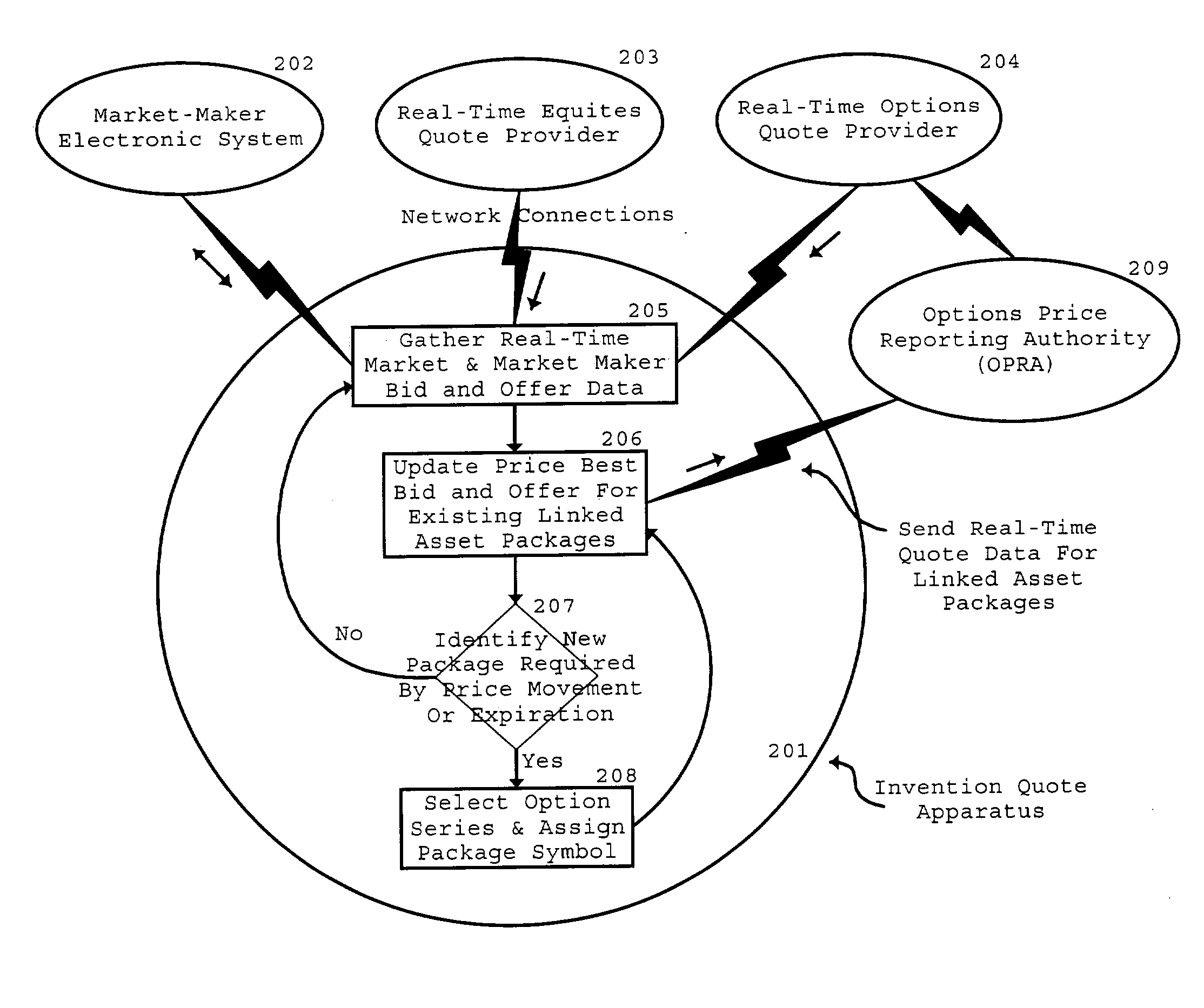

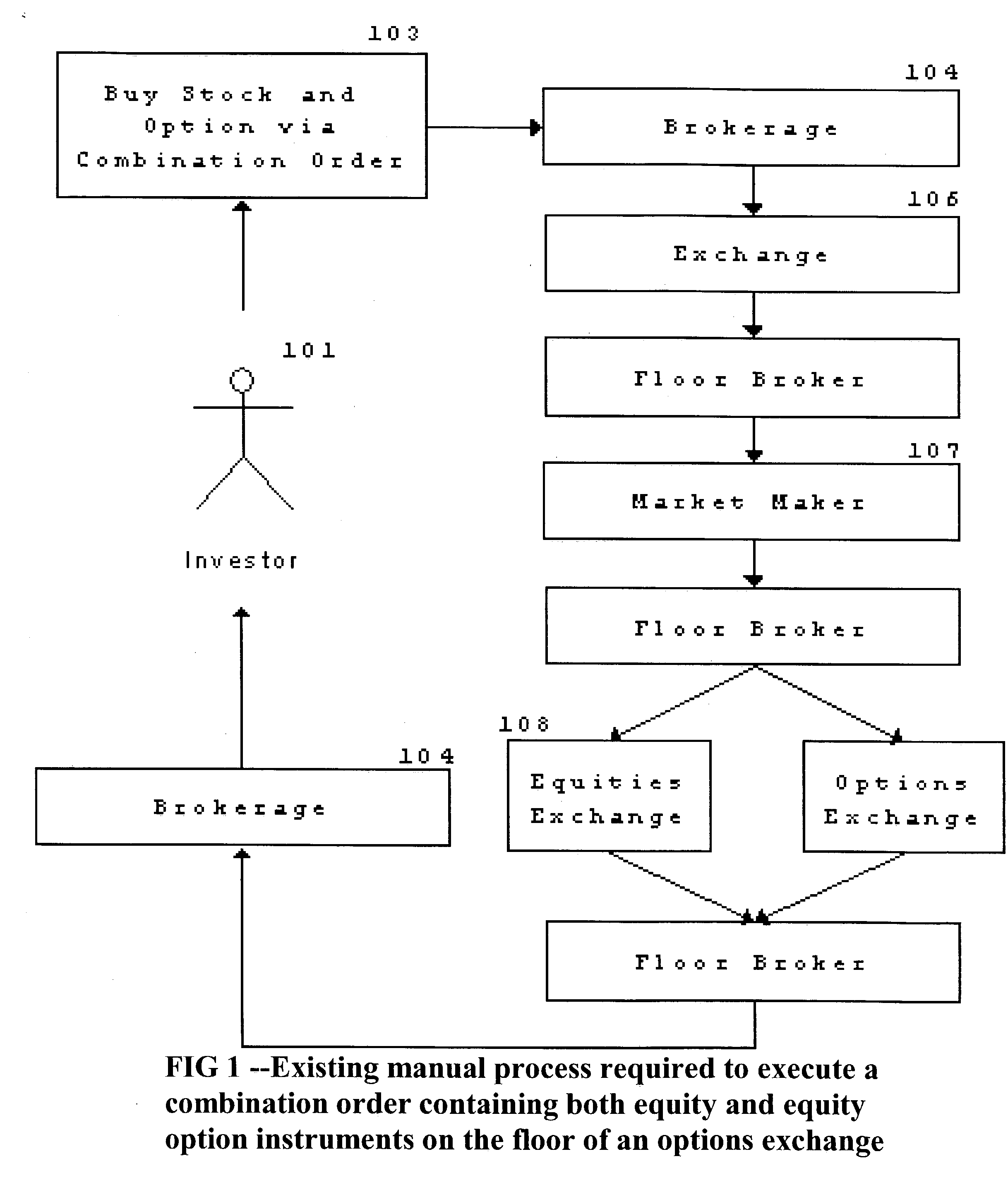

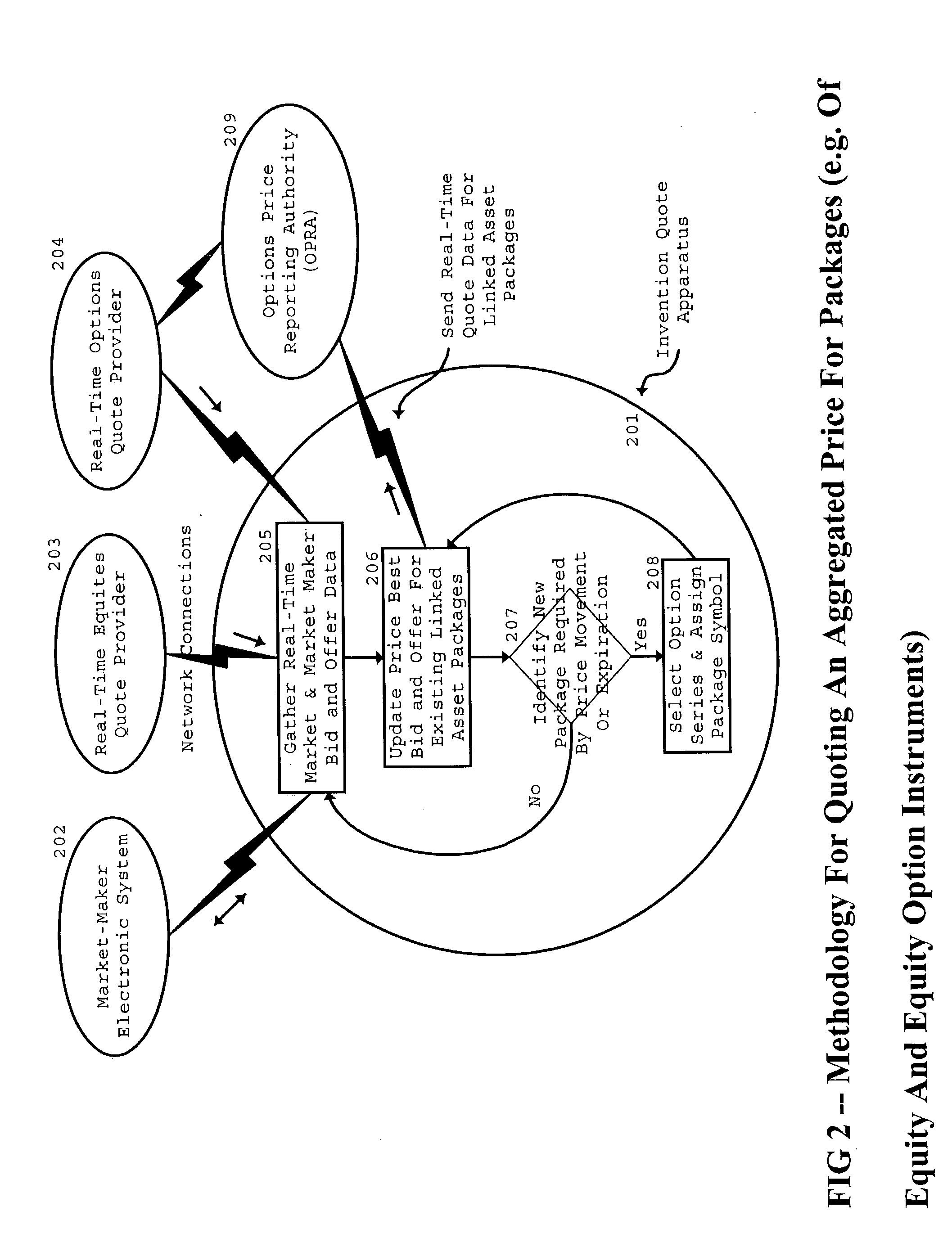

Automated system for aggregated price discovery and electronic trading of linked cash/cash equivalent and their derivative asset packages

InactiveUS20050160024A1Eliminate riskEfficient executionFinanceSpecial data processing applicationsElectronic systemsEngineering

An electronic system for aggregated pricing of linked multi-leg (e.g., equity / option and option / option) asset packages with an additional link to an automated broker system for trading the linked asset packages are disclosed. The invention provides methodology and apparatus to electronically produce aggregated price quotes for packages of instruments designed to represent traditional trading strategies involving cash and their derivatives (e.g., stock and equity options). The system develops packages according to specified strategies, and prices the packages based on the national best bid and offer (NBBO) or direct input from participating market makers and investors. The packages are designed for easy understanding by traditional investors and designed for trading through a single order. These packages are desirable over separately trading the asset and its derivative (e.g., equity and option) instruments because they transfer market volatility risk from the investor to the institution by requiring market makers to agree to the aggregated price of the package prior to executing any trades. Certain linked packages, such as most stocks and options, cannot be traded together on a single floor of an exchange due to restrictions by the Securities and Exchange Commission (SEC) regarding side-by-side trading and integrated market making of most stocks and options. This invention provides an electronic process for synthetic side-by-side trading across separate trading locations (e.g., equity and option exchanges and within the existing rules of the SEC). The electronic process follows traditional rules regarding the manual handling of combination orders involving multiple asset types. The process significantly improves efficiency over manual handling resulting in a system that is scalable to high trade volumes.

Owner:SIDE BY SIDE TRADING

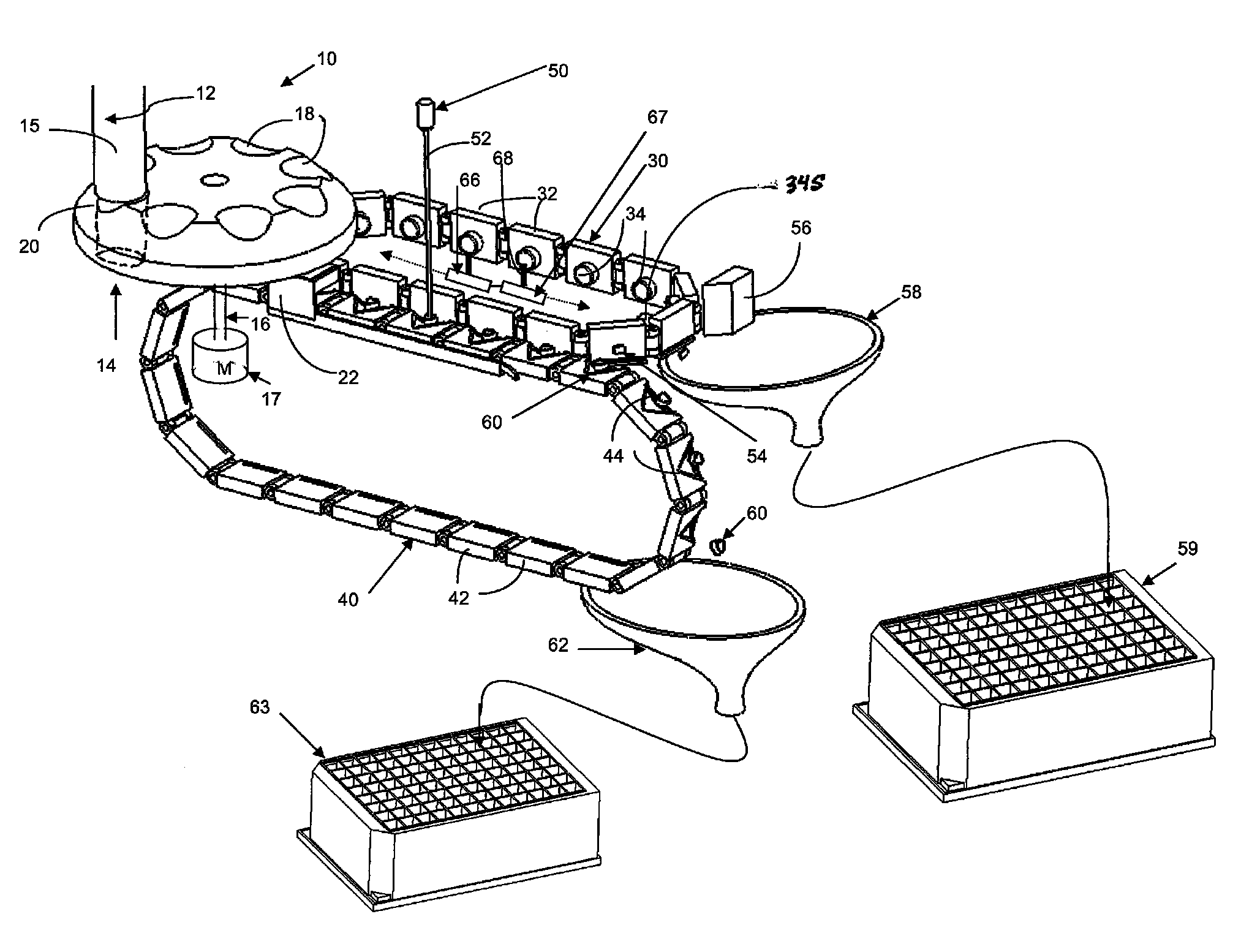

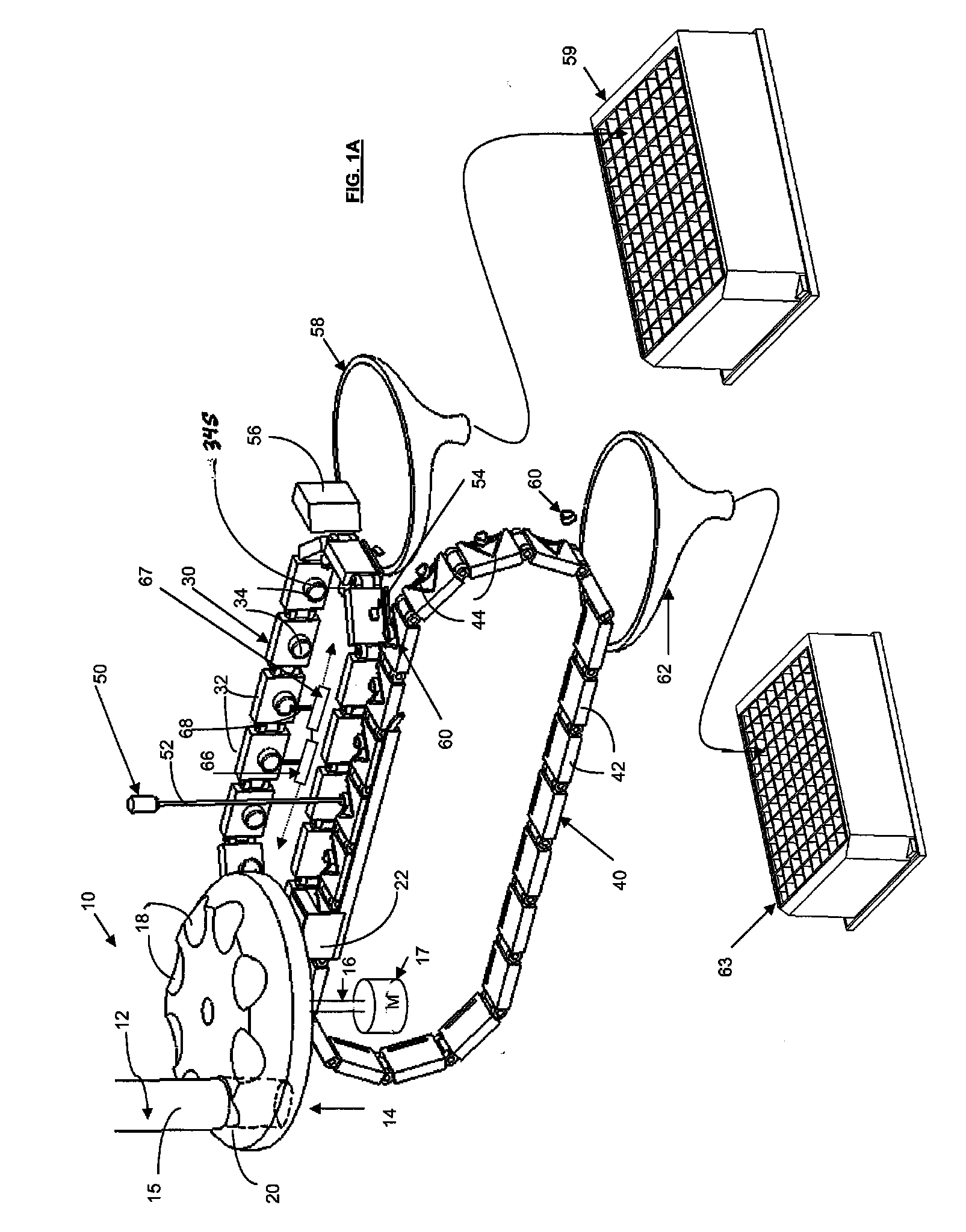

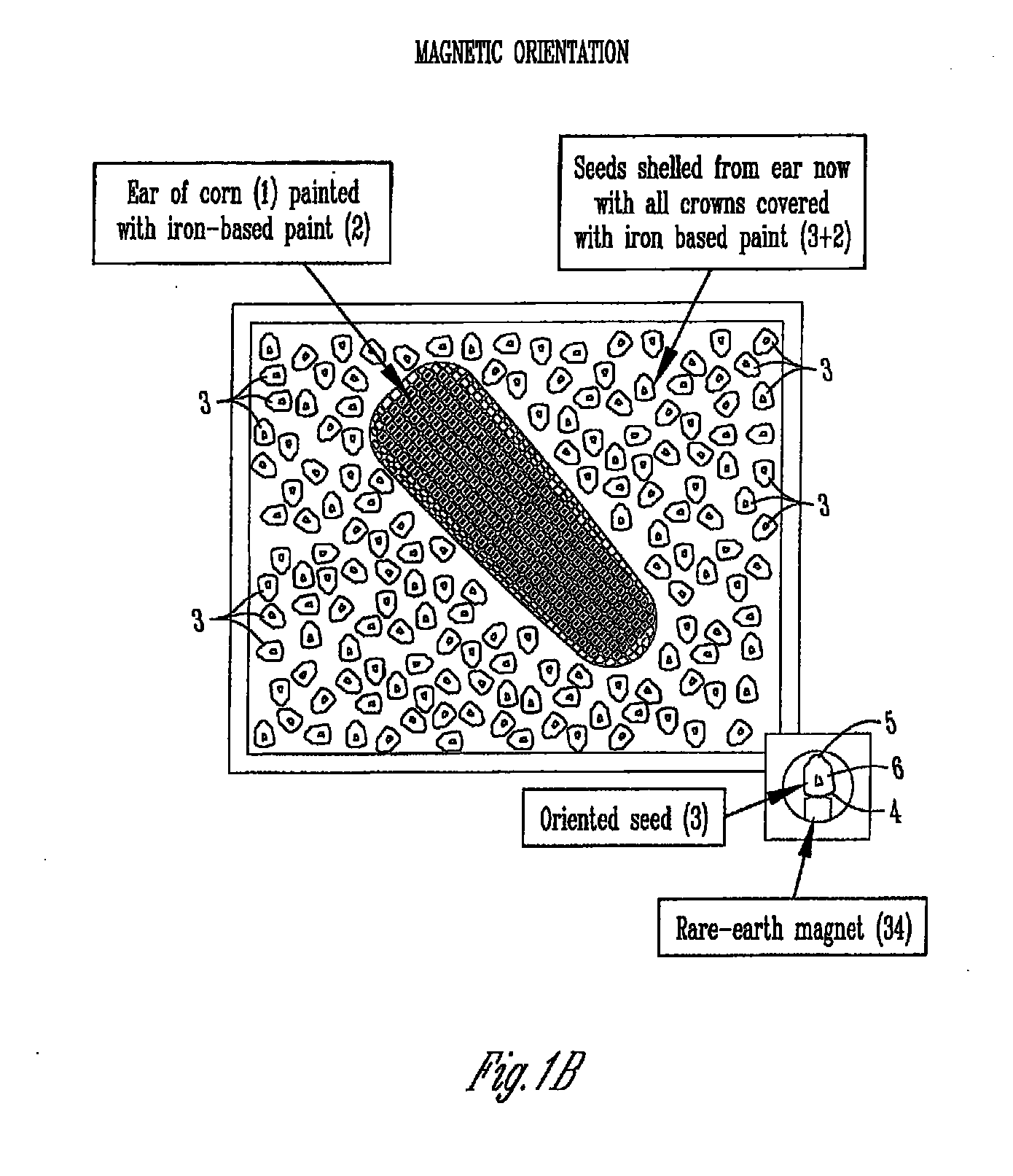

Apparatus, method and system for handling, positioning, and/or automatically orienting objects

InactiveUS20080131254A1Avoid small quantitiesMaximum flexibilityWithdrawing sample devicesPreparing sample for investigationEngineeringComputer vision

A method and apparatus for automatic positioning and / or orientation of an object. The method includes applying a substance or component to an object, or takes advantage of a substance or component already on or associated with an object. The substance or component has a characteristic that can be utilized to automatically attract the substance or component. That characteristic is used to position, move, and / or orient the object automatically, without requiring manual handling. The object can then be further processed or handled. In one embodiment, the substance or component is a magnetically active substance or component. The attraction can be actuated by a magnet.

Owner:PIONEER HI BRED INT INC

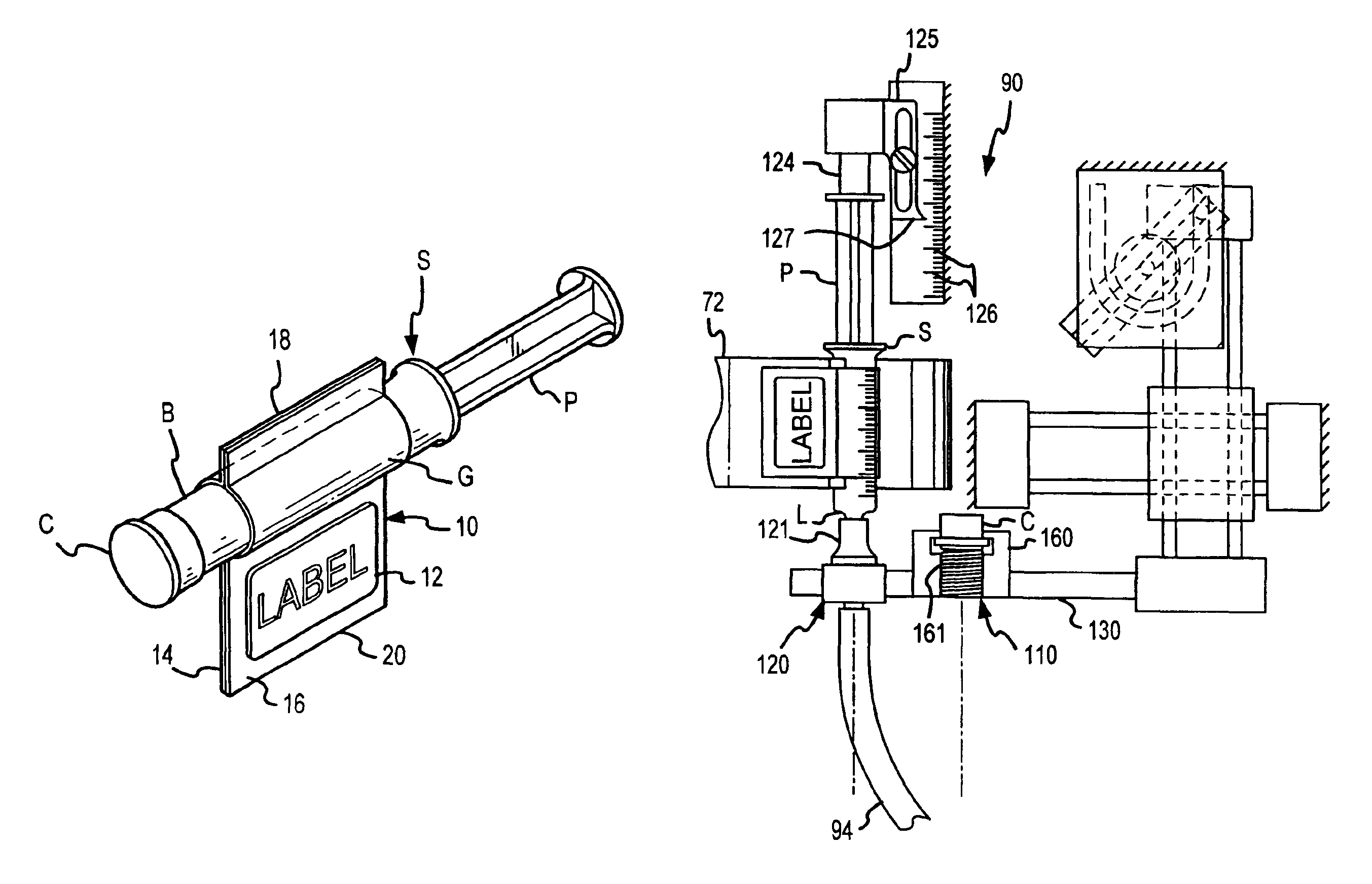

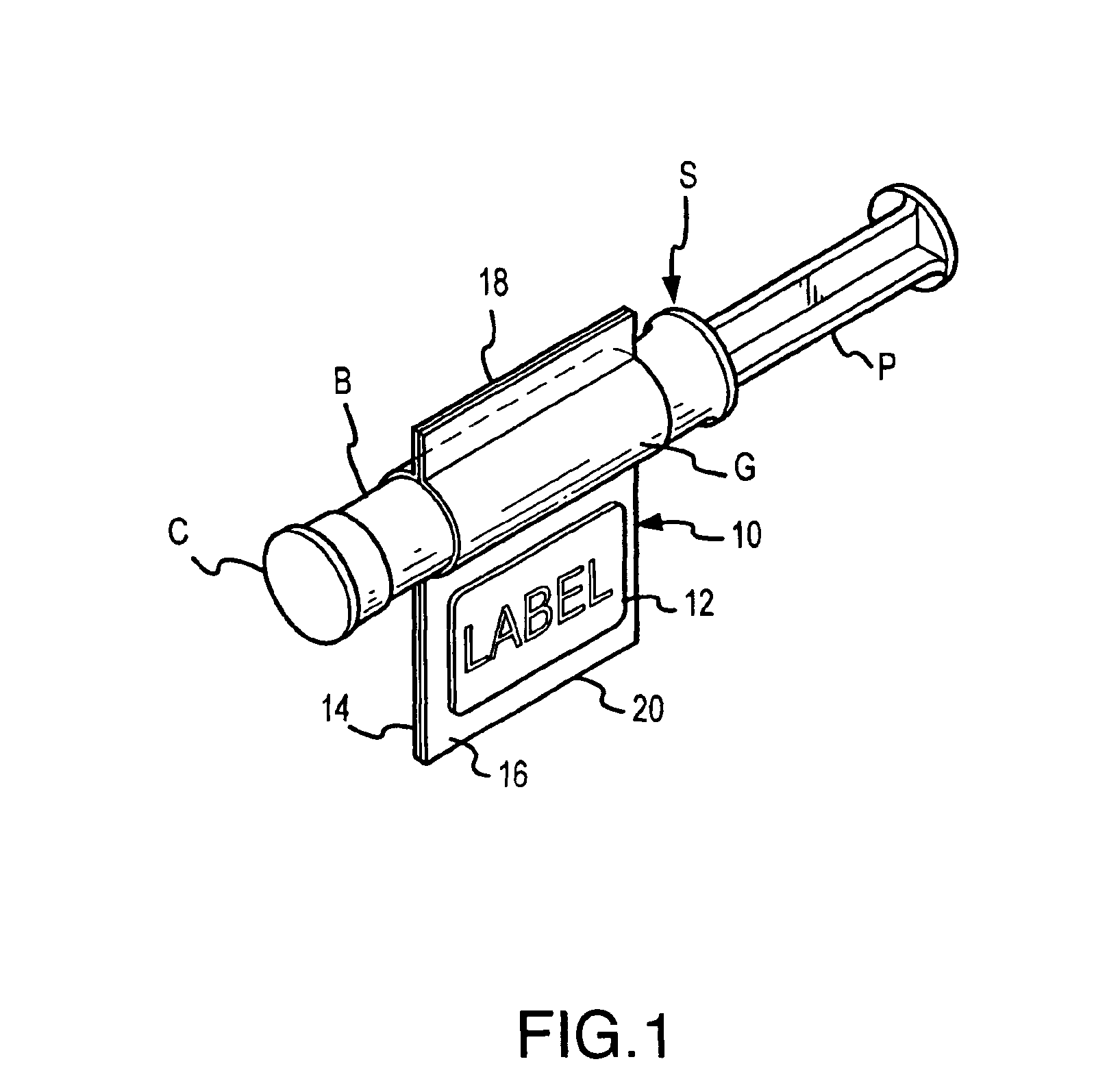

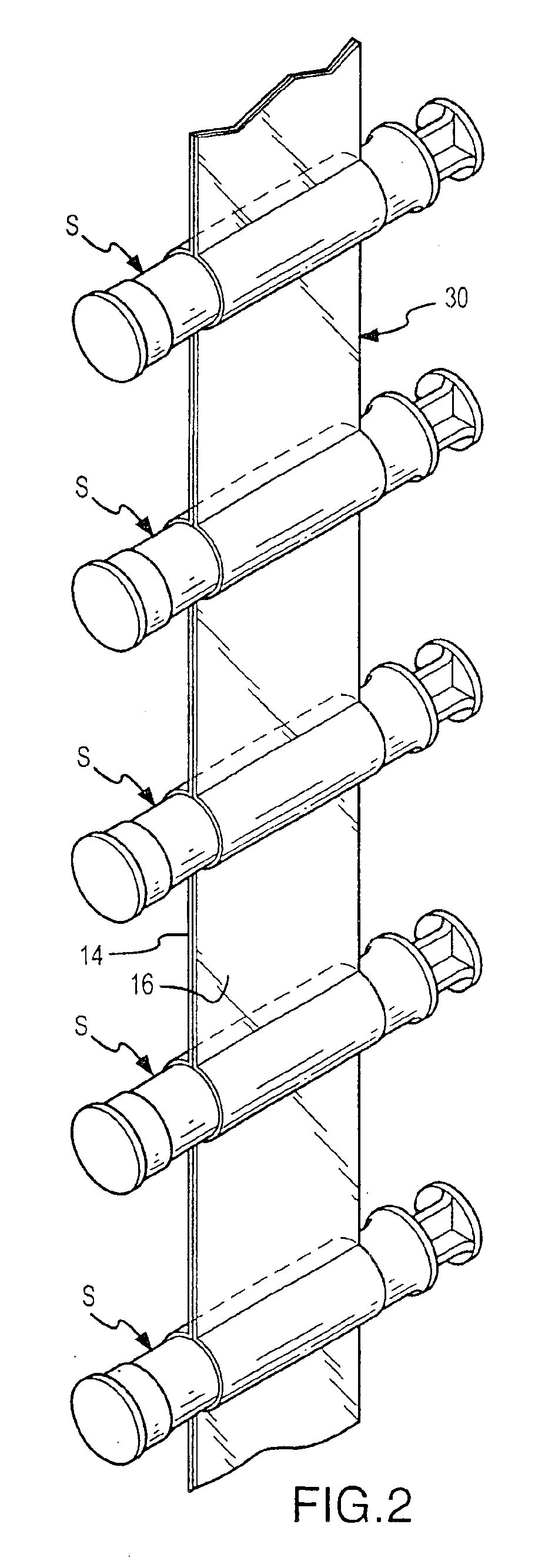

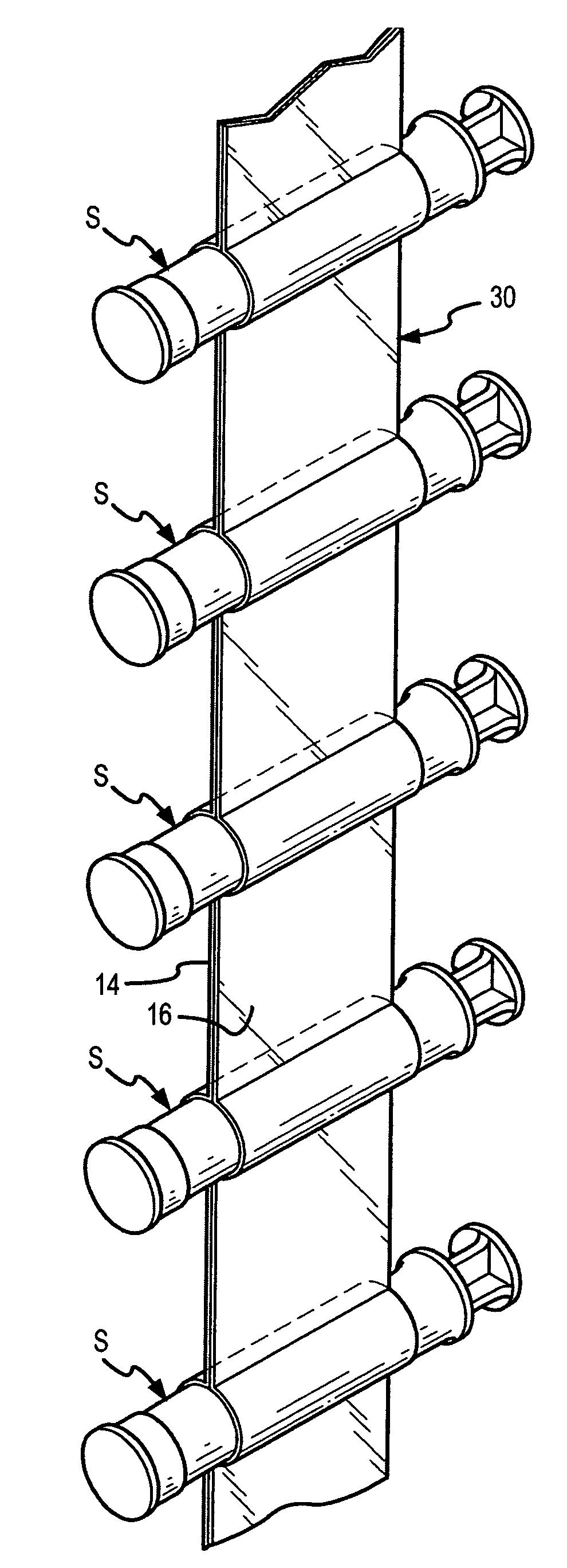

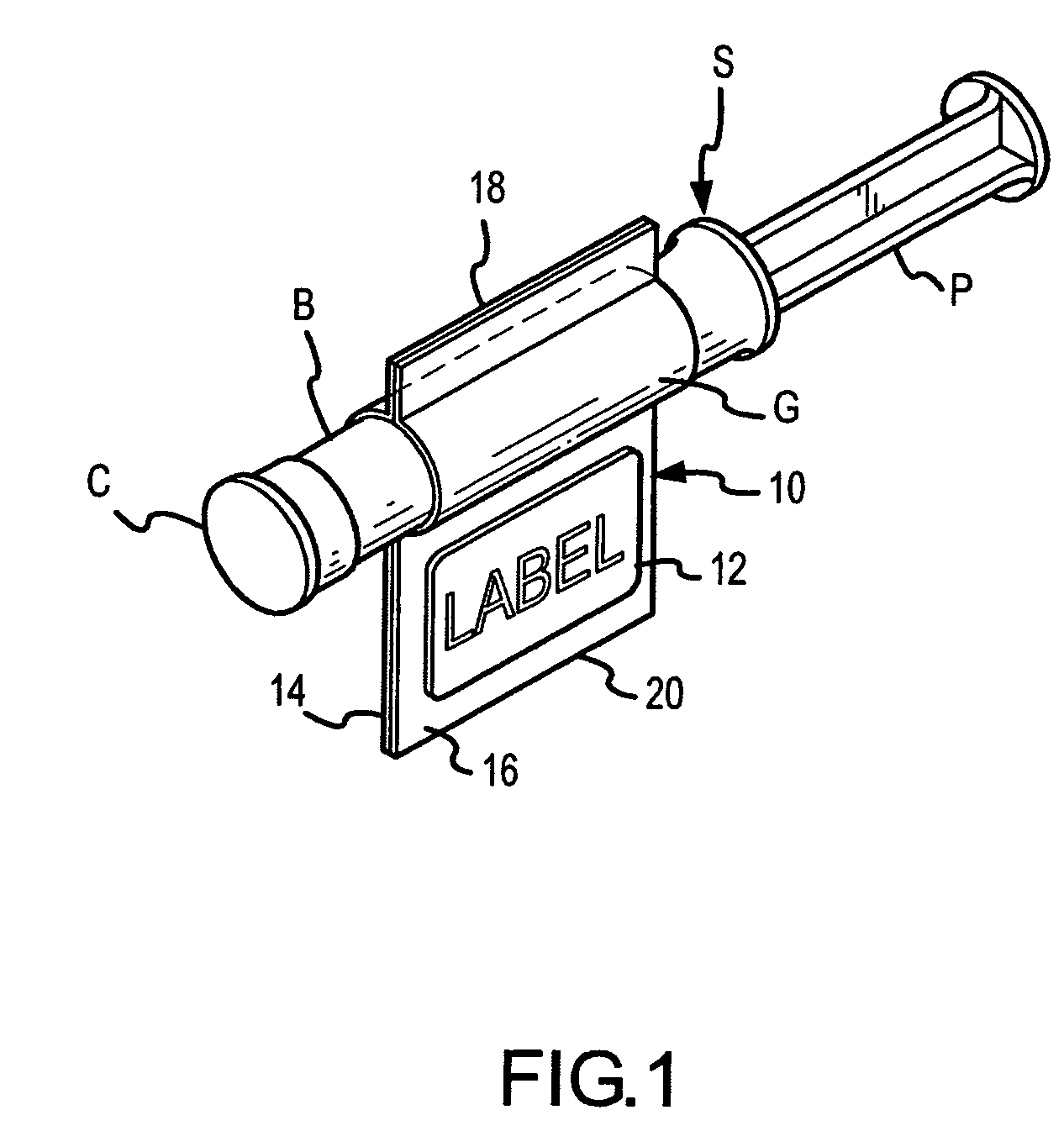

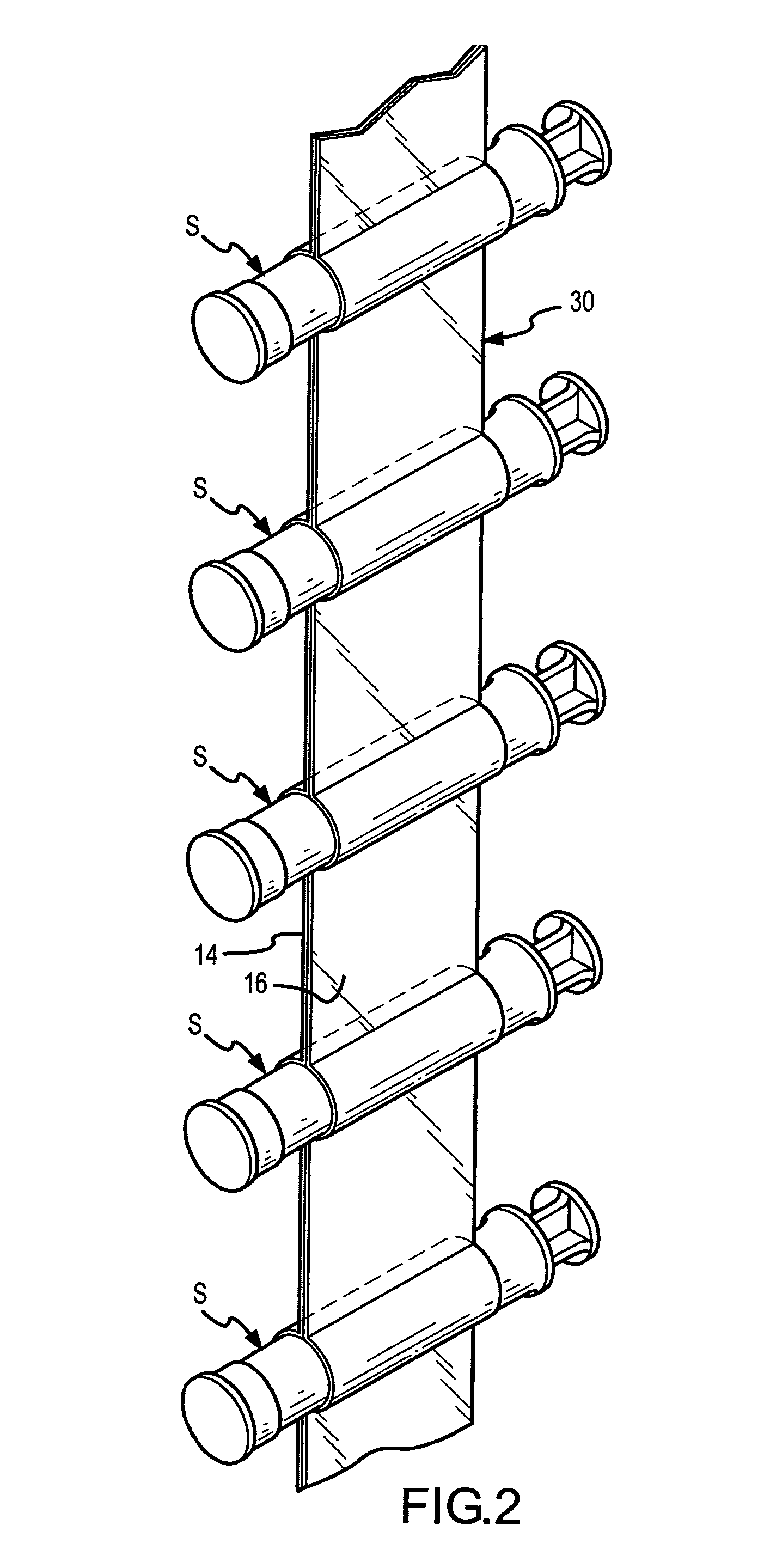

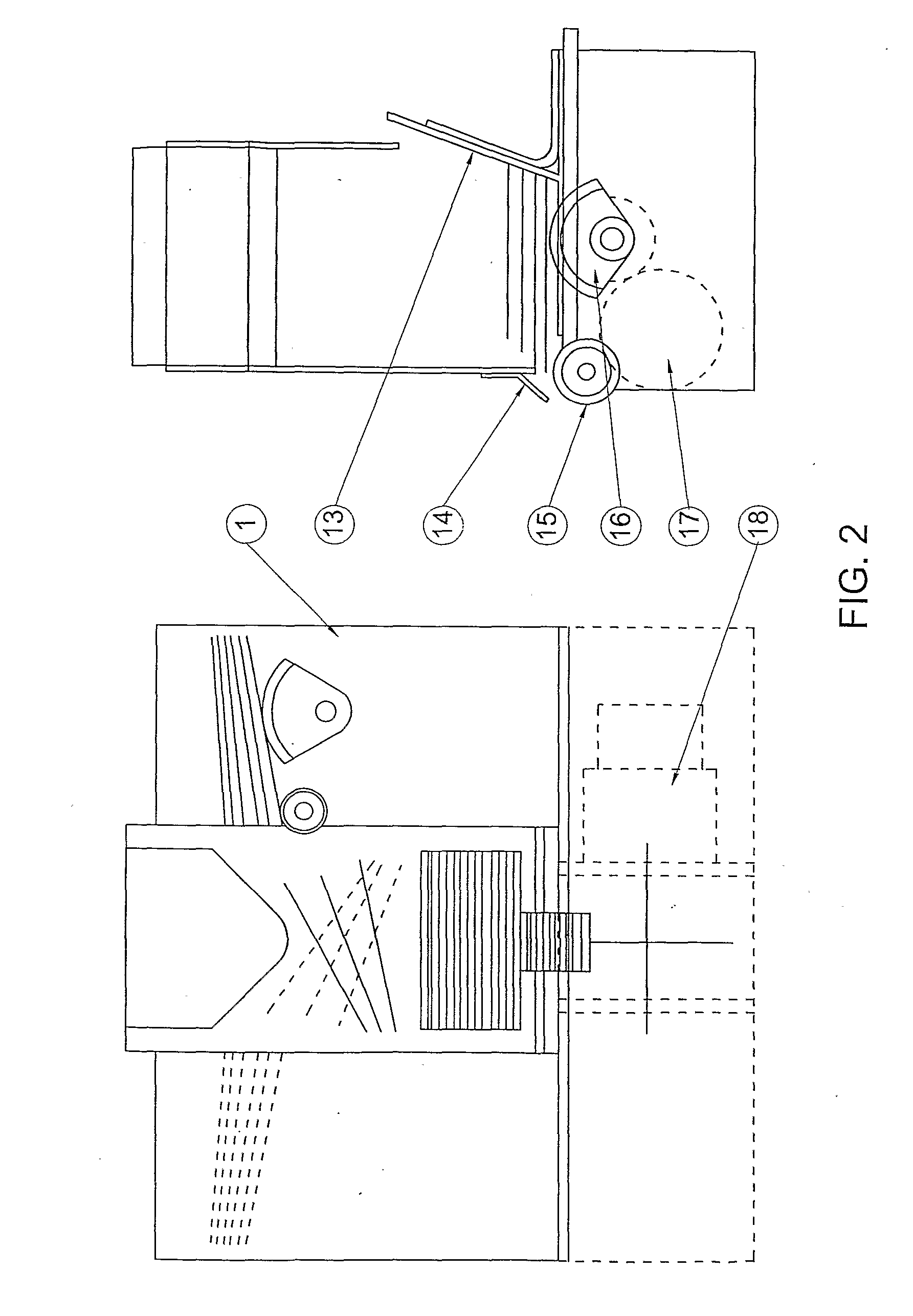

Method for filling and capping syringes

InactiveUS6976349B2Facilitates maintenance of sterilityImproved syringe fillingCapsAmpoule syringesManual handlingBiomedical engineering

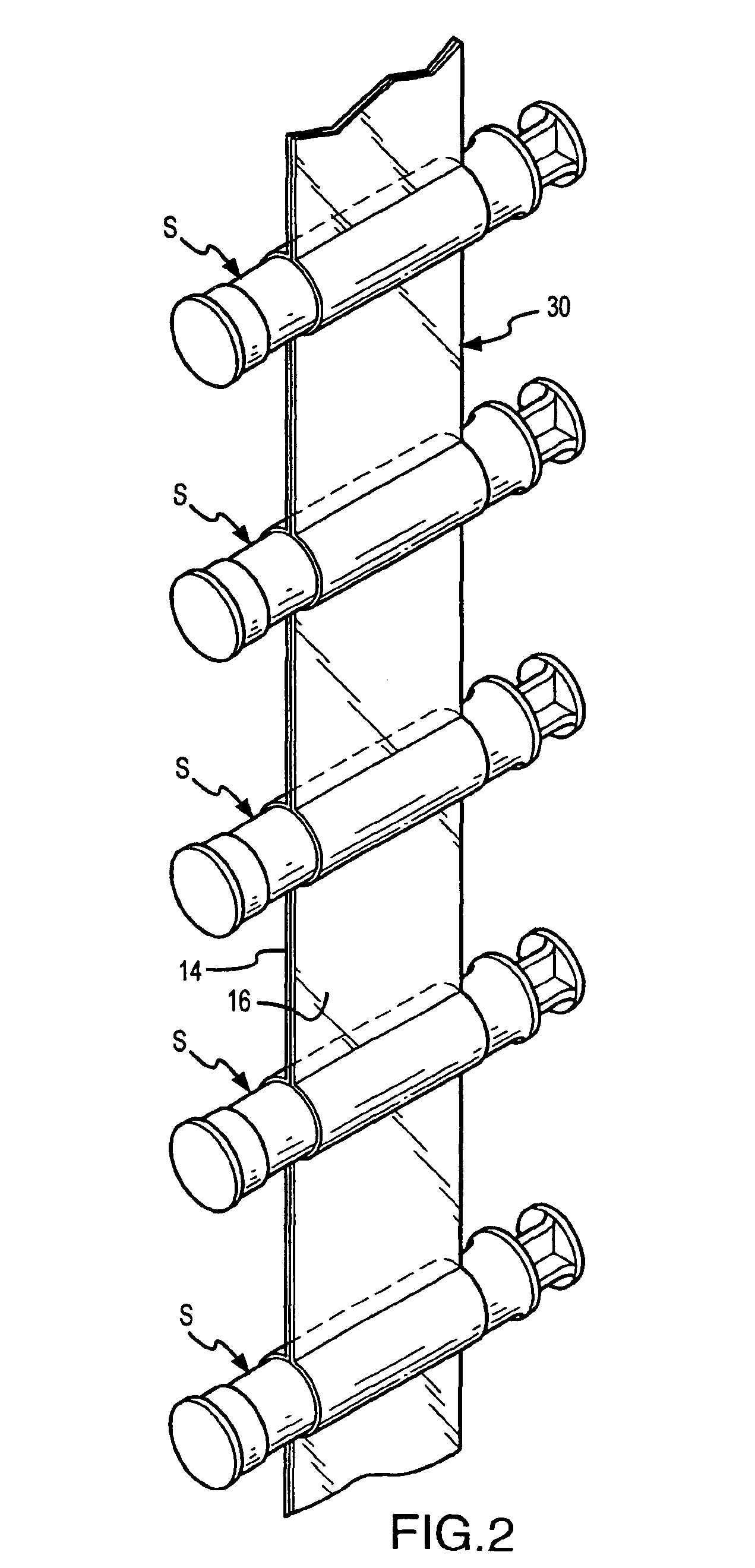

An inventive method, system and apparatus are provided for syringe handling, and more particularly, for syringe labeling, filling and capping operations. To facilitate syringe handling, an inventive apparatus includes a plurality of syringe bodies interconnected in a predetermined orientation by a belt. Such belt may be of pliable construction and may define a predetermined spacing in between adjacent ones of the syringe bodies, such predetermined spacing corresponding with a distance between holders provided in a handling apparatus. The syringe handling apparatus may provide for the placement of contents-related information on belt segments between adjacent syringe bodies and for separating the belt segments, wherein a flap is left interconnected to each syringe body. The syringe handling apparatus may alternatively or also provide for automated filling of the syringe bodies wherein cap removal, filling and cap replacement operations are completed free from manual handling.

Owner:BAXTER ENGLEWOOD

Serial data capture and processing

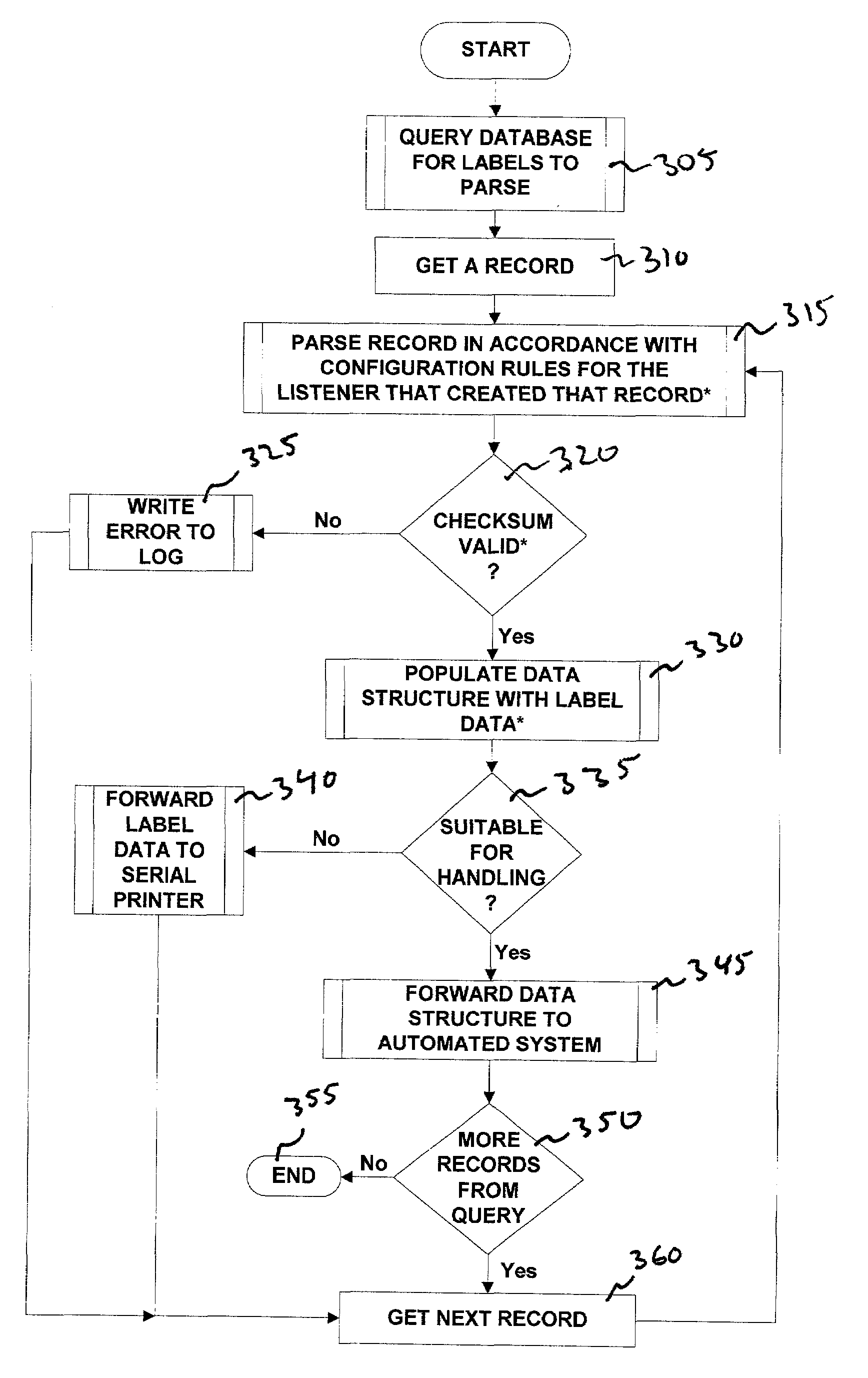

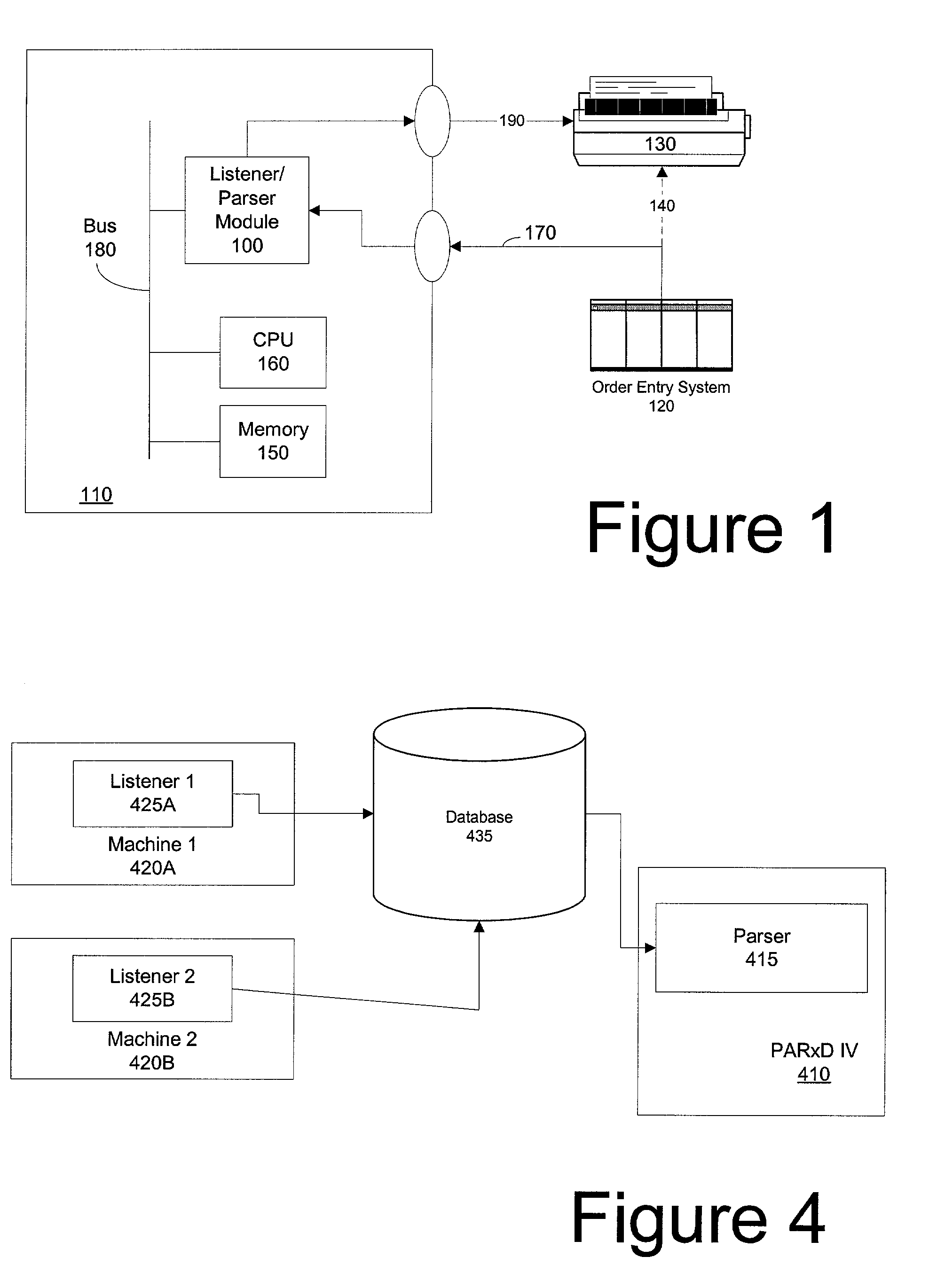

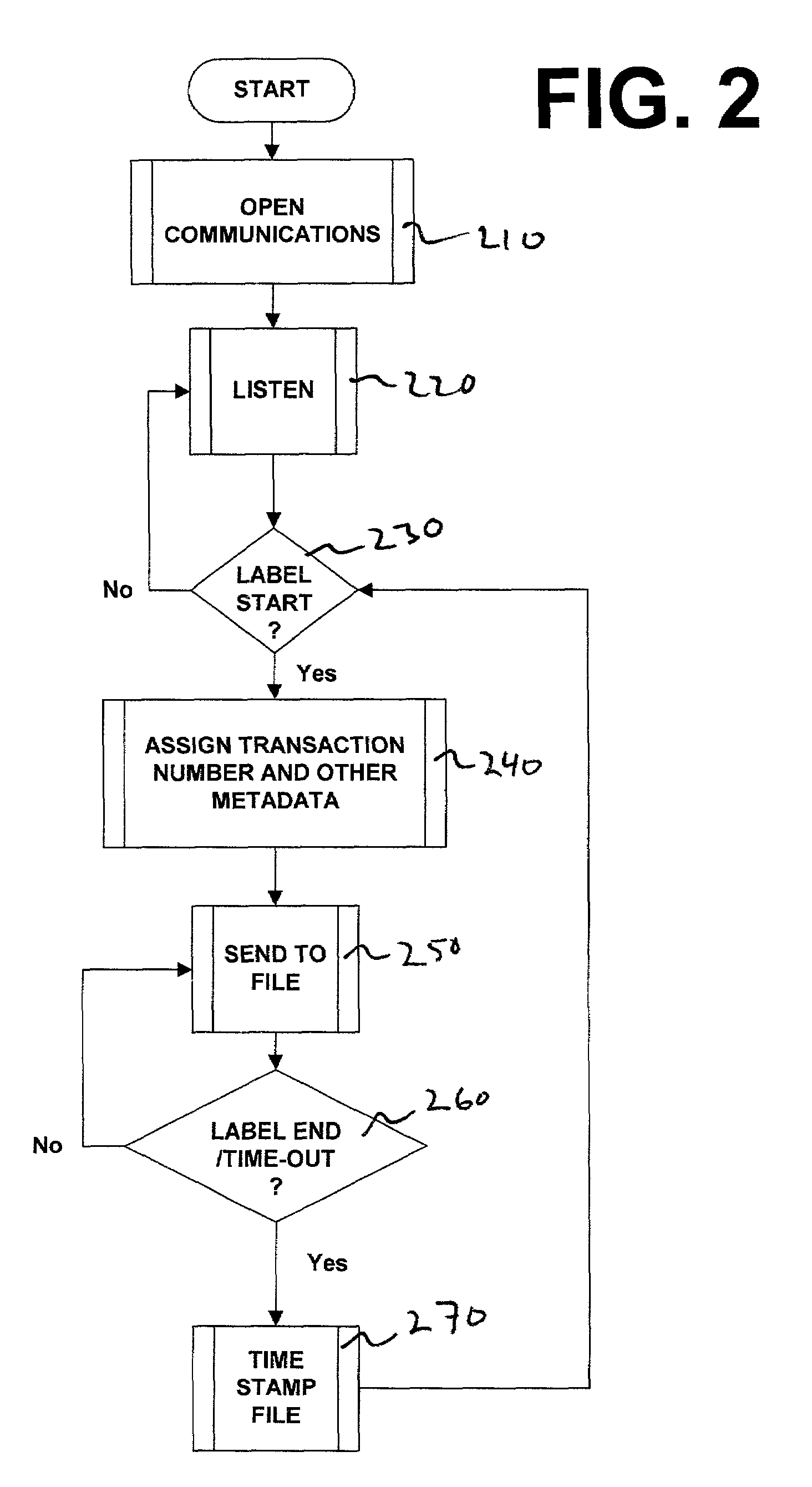

A method and software interface enables serial data streams to be trapped, parsed, tested for suitability for automated handling by a medication preparation system. Only those portions of the serial data stream that are not suitable for such handling are released for printing and manual handling. A serial data interface includes a listener software module (“LSM”) that receives serial data streams and a parser software module (“PSM”) communicatively connectable to the LSM that processes the serial data streams received from the LSM. A set of configuration rules accessible by the PSM defines the manner of processing by the PSM on the serial data streams. A data structure results that enables data handling by an automated medication preparation system.

Owner:BAXTER ENGLEWOOD

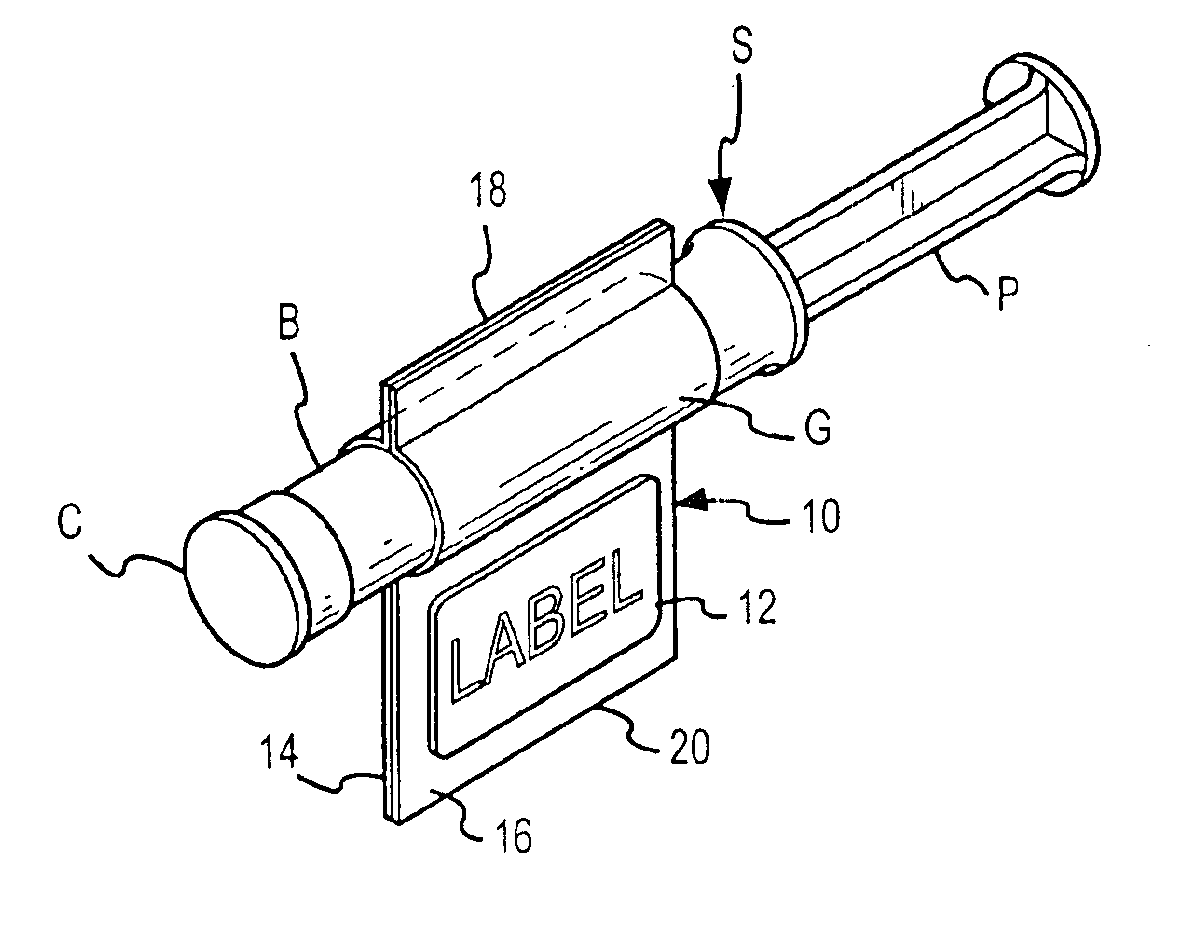

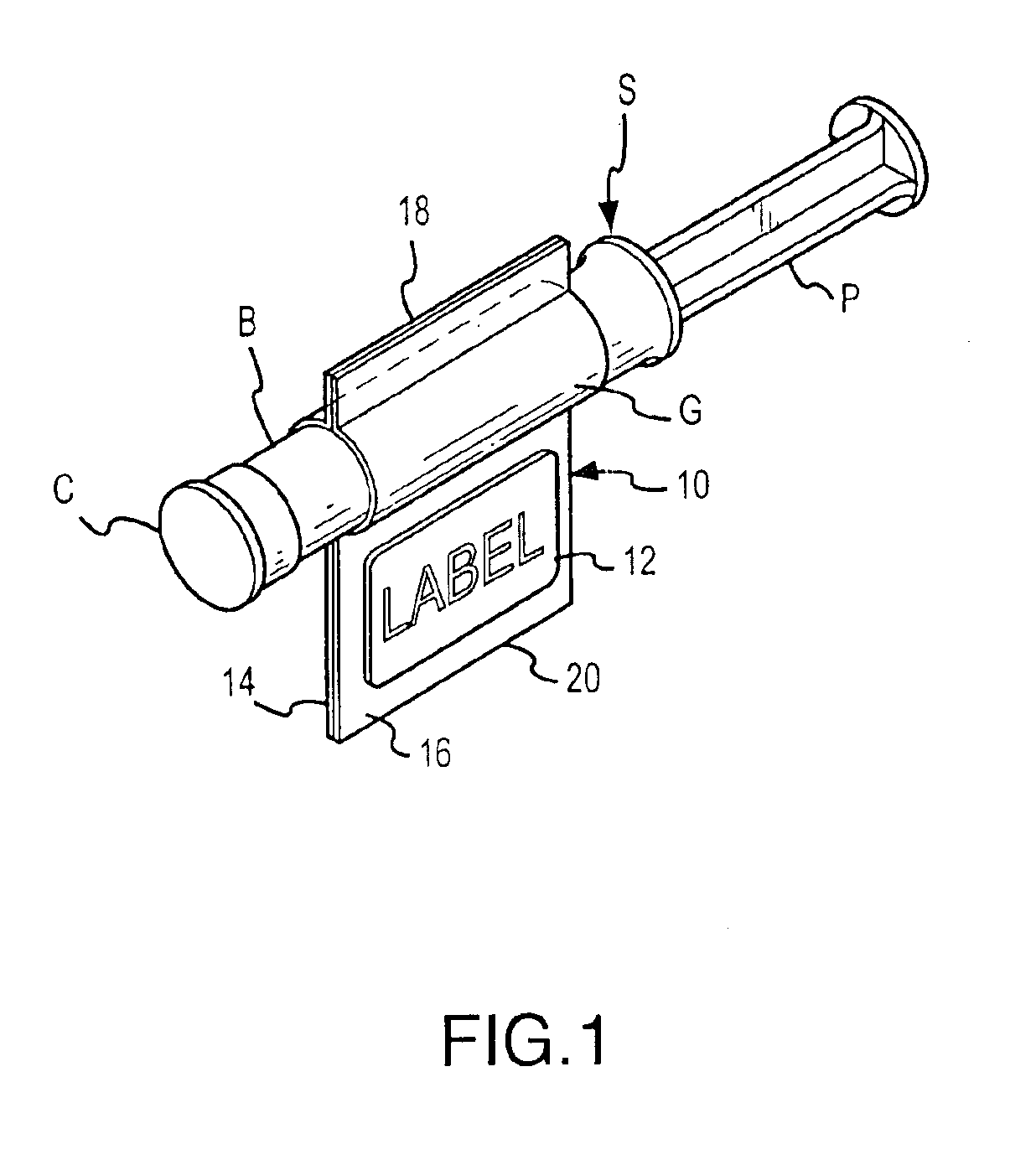

Method and system for labeling syringe bodies

InactiveUS6957522B2Easy to handleEasy to carryPower operated devicesPackage sterilisationManual handlingBiomedical engineering

An inventive method, system and apparatus are provided for syringe handling, and more particularly, for syringe labeling, filling and capping operations. To facilitate syringe handling, an inventive apparatus includes a plurality of syringe bodies interconnected in a predetermined orientation by a belt. Such belt may be of pliable construction and may define a predetermined spacing in between adjacent ones of the syringe bodies, such predetermined spacing corresponding with a distance between holders provided in a handling apparatus. The syringe handling apparatus may provide for the placement of contents-related information on belt segments between adjacent syringe bodies and for separating the belt segments, wherein a flap is left interconnected to each syringe body. The syringe handling apparatus may alternatively or also provide for automated filling of the syringe bodies wherein cap removal, filling and cap replacement operations are completed free from manual handling.

Owner:BAXTER ENGLEWOOD

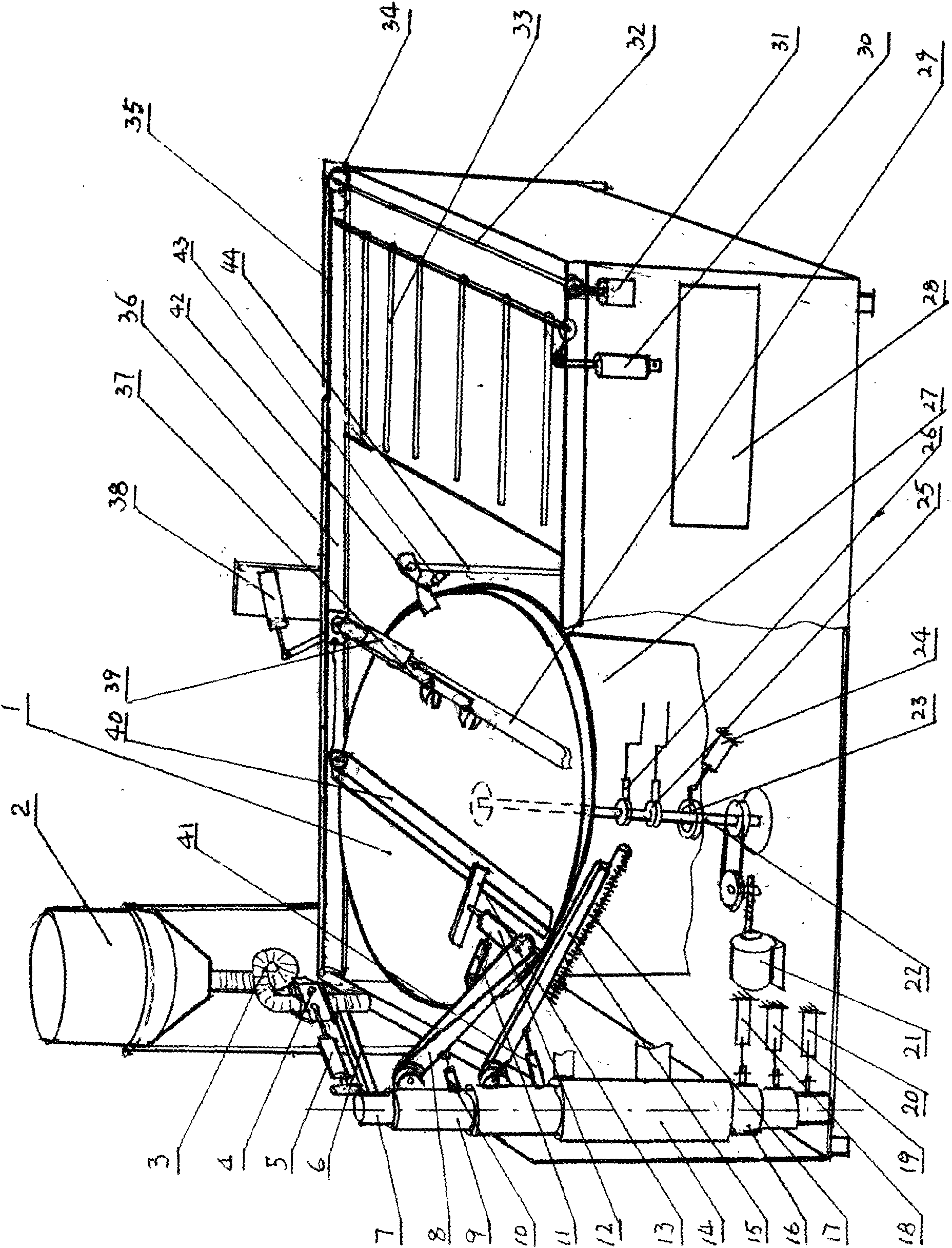

Full-automatic pancake machine

InactiveCN101584352AImprove processing efficiencyReduce labor intensityOil/fat bakingPancakes bakingRobot handElectric machinery

The invention discloses a full-automatic pancake machine, comprising a griddle heating and rotating under the drive of motor, an accumulator, a mechanical hand for polishing by simulating manual pancake making actions, a mechanical hand for feeding paste materials, a spreading mechanical hand, a raising mechanical hand, a pulling mechanical hand, a scraping mechanical hand, a turning-moving mechanical hand and an automatic controller. The automatic controller controls each mechanical hand to run according to program, thereby achieving the actions of simulating manual pancake making of the full-automatic pancake machine. All the manual operation procedures of pancake making in the invention are finished automatically, so that the pancake making is automatized, processing efficiency is improved, and labour intensity is reduced, besides, the made pancake still has the feeling of pancake made manually.

Owner:单传芹

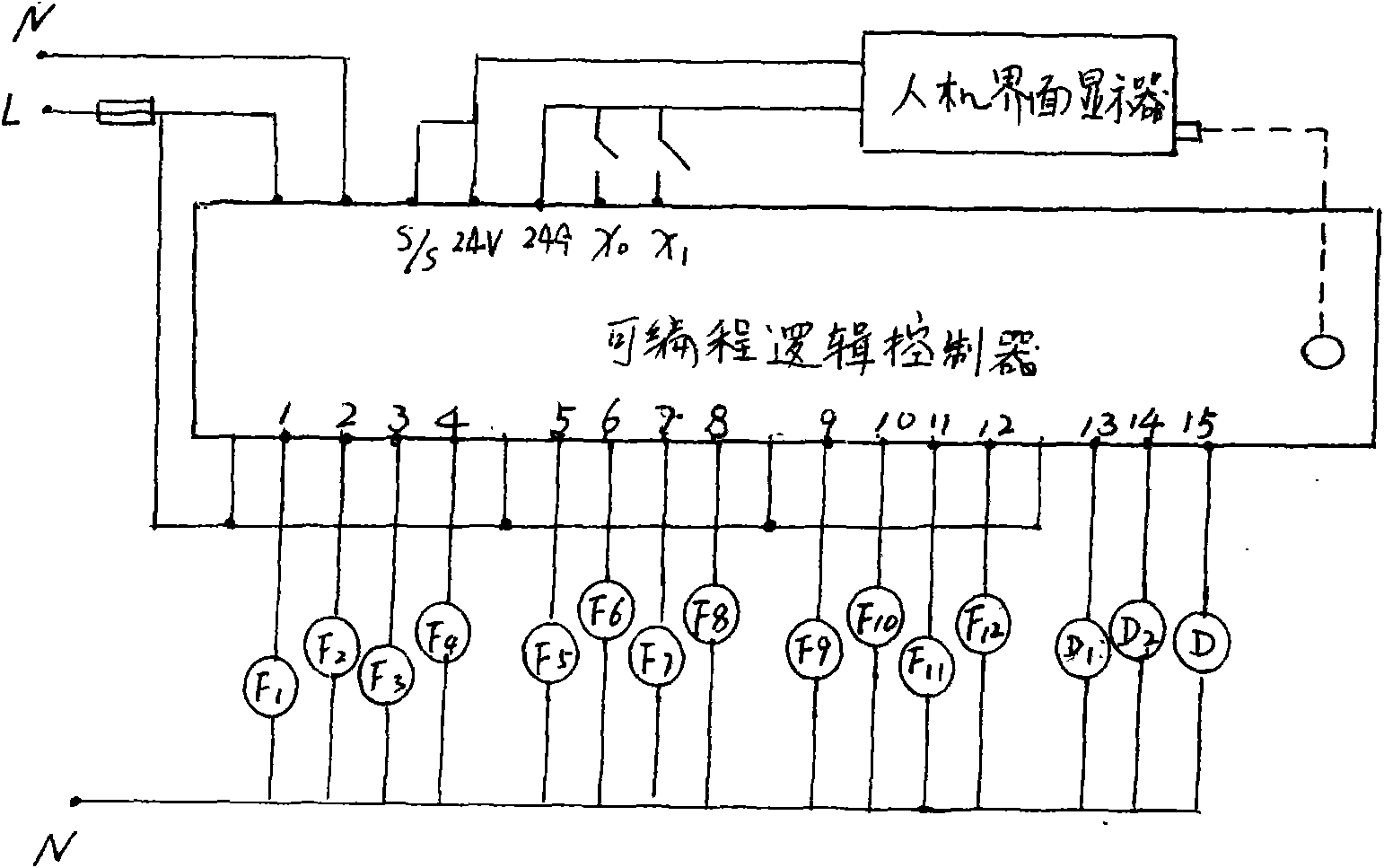

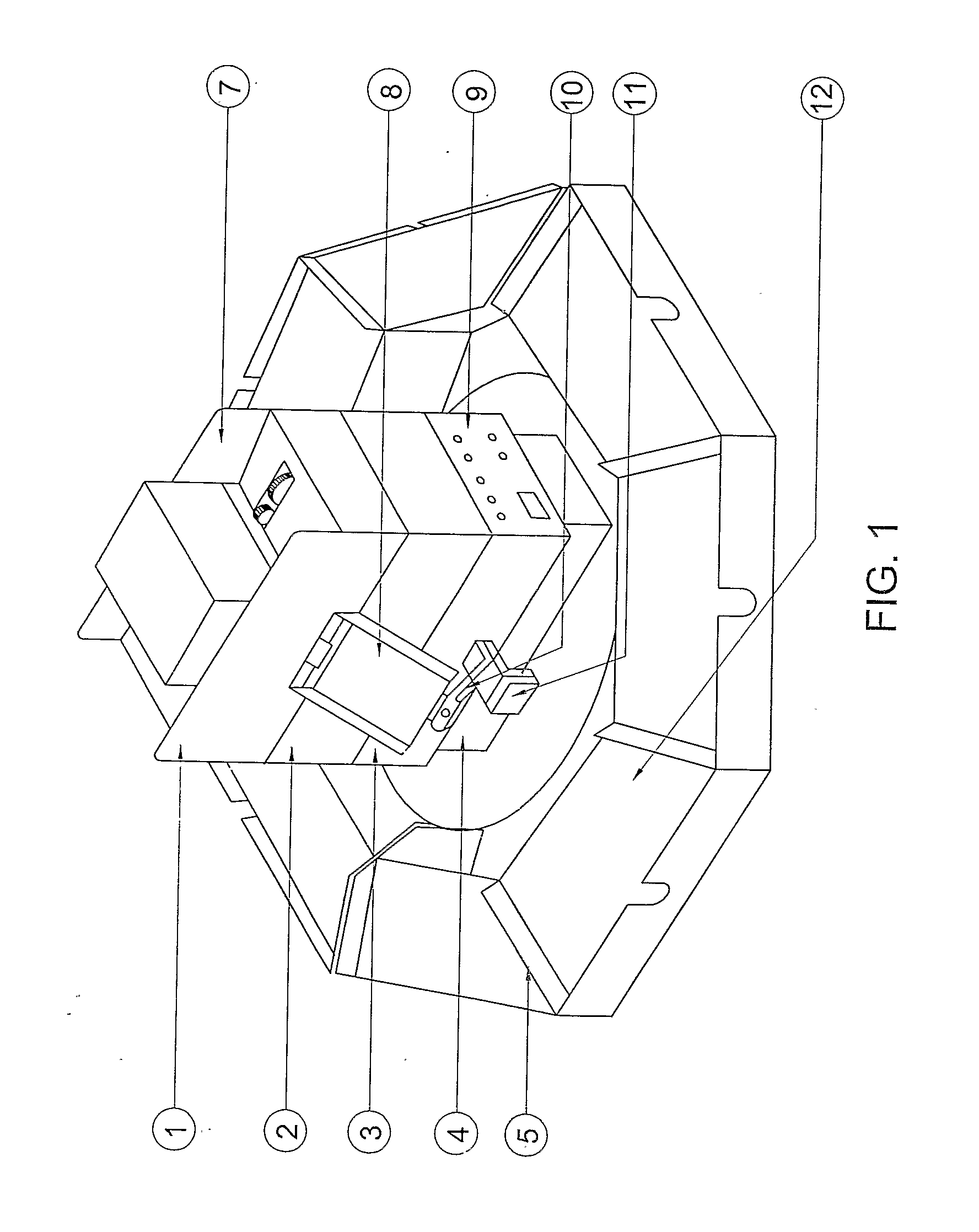

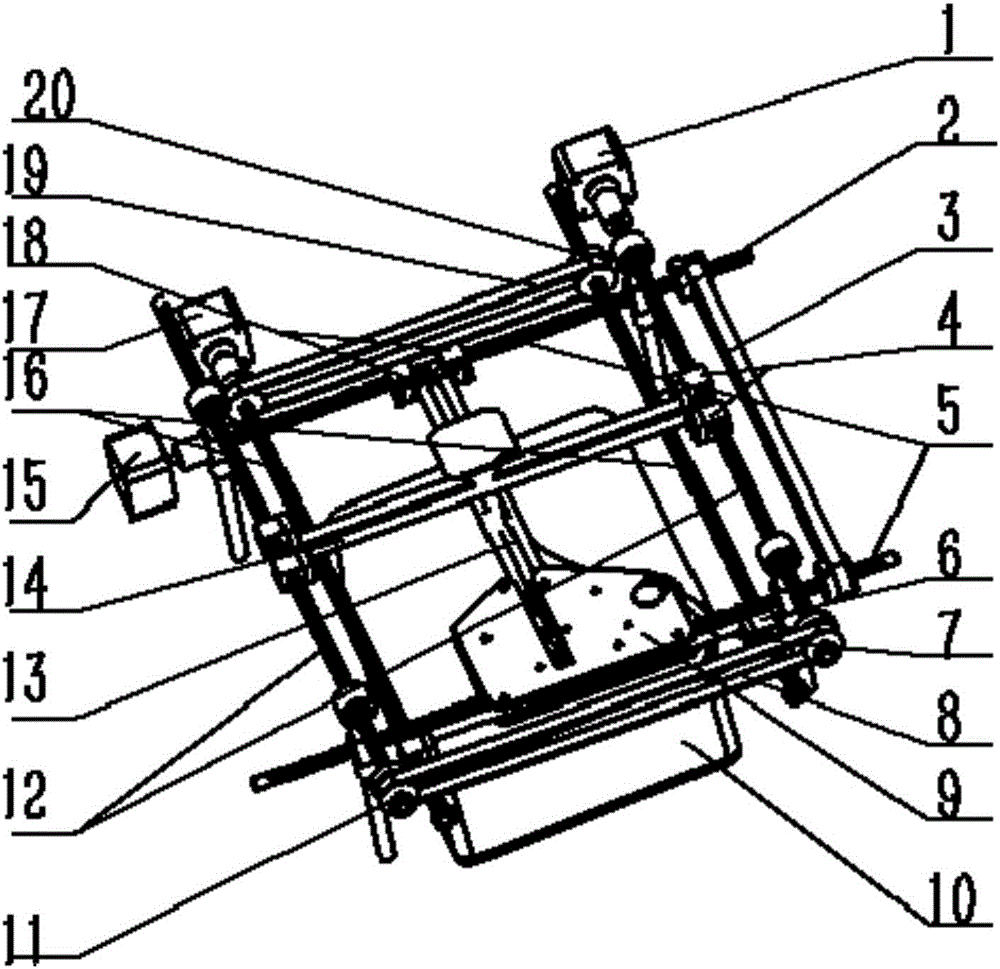

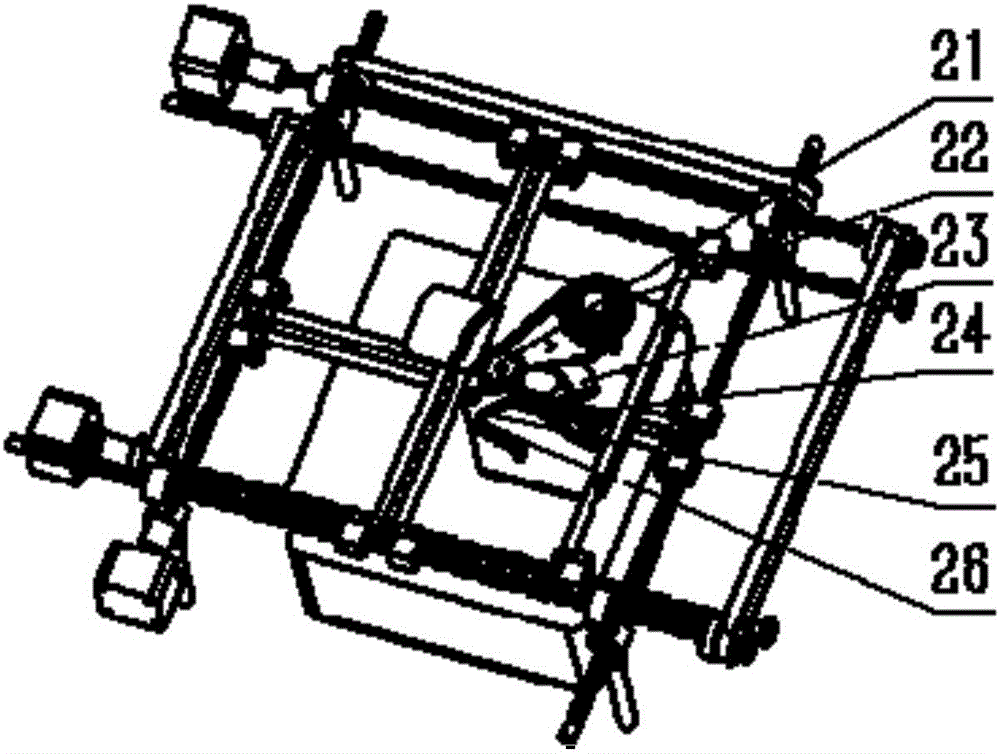

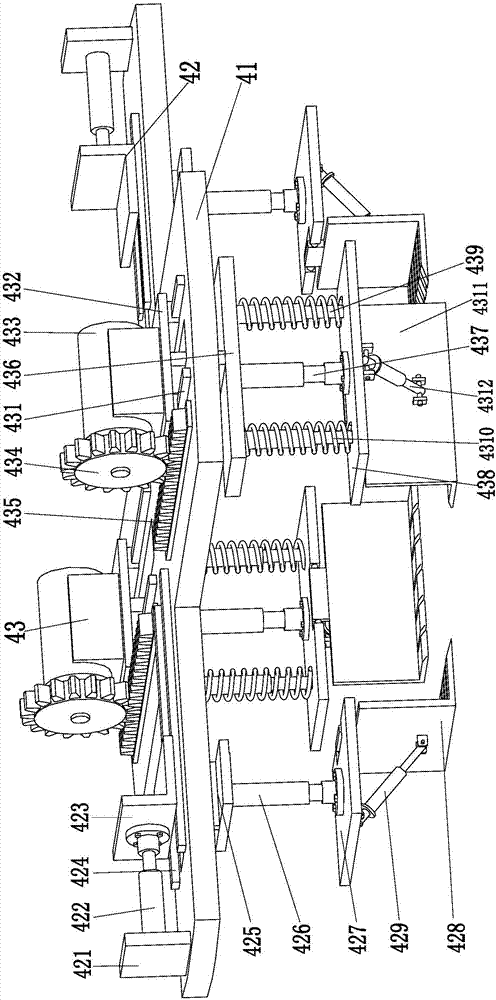

Workpiece stamping intelligent control process and intelligent control manipulator

InactiveCN103252770AImprove work efficiencyImprove securityProgramme-controlled manipulatorMetal-working feeding devicesAutomatic controlMachining process

The invention discloses a workpiece stamping intelligent control process. The workpiece stamping intelligent control process controls automatically and satisfies all actions to be operated coherently to effectively improve working efficiency, no manual work is needed, safety is improved and cost is effectively saved. Product quality is guaranteed to enable products to meet market demands. The invention further provides an intelligent control manipulator implementing the process. Through an efficient, accurate, flexible, safe operation mode flexible in design, the intelligent control manipulator is convenient to operate, production efficiency is greatly improved, structural design is reasonable, design mode is flexible, effects are obvious, process persistence is high, raw materials are saved and energy consumption is quite low; a regulation and control type industrial control process satisfies different demands, the structural design enhances smoothness, swing precision is guaranteed, and machining process is guaranteed to be completed automatically, continuously and effectively; and conventional manual or semi-automatic machining modes are replaced, and resources are saved.

Owner:FOSHAN DINGFENG ROBOT

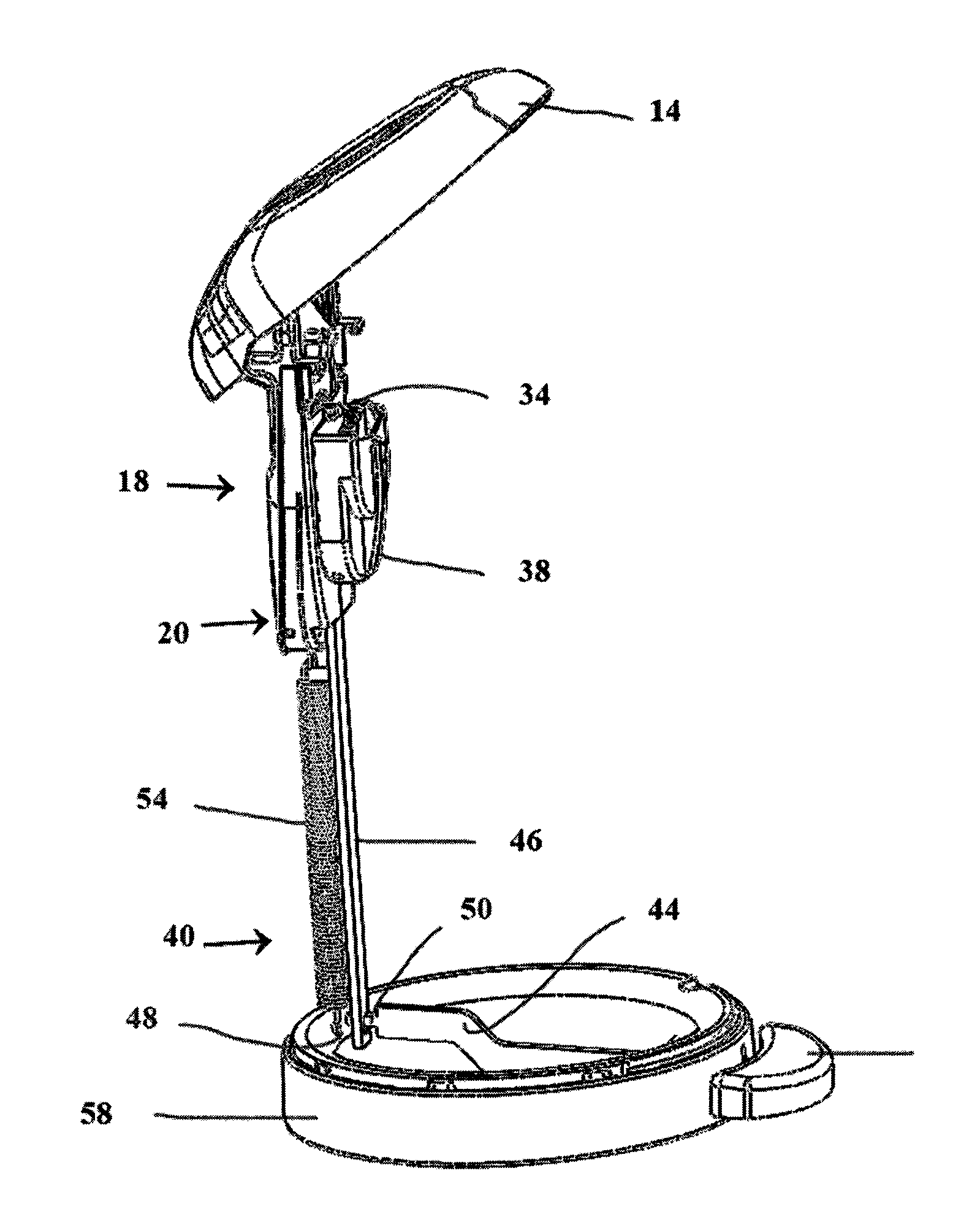

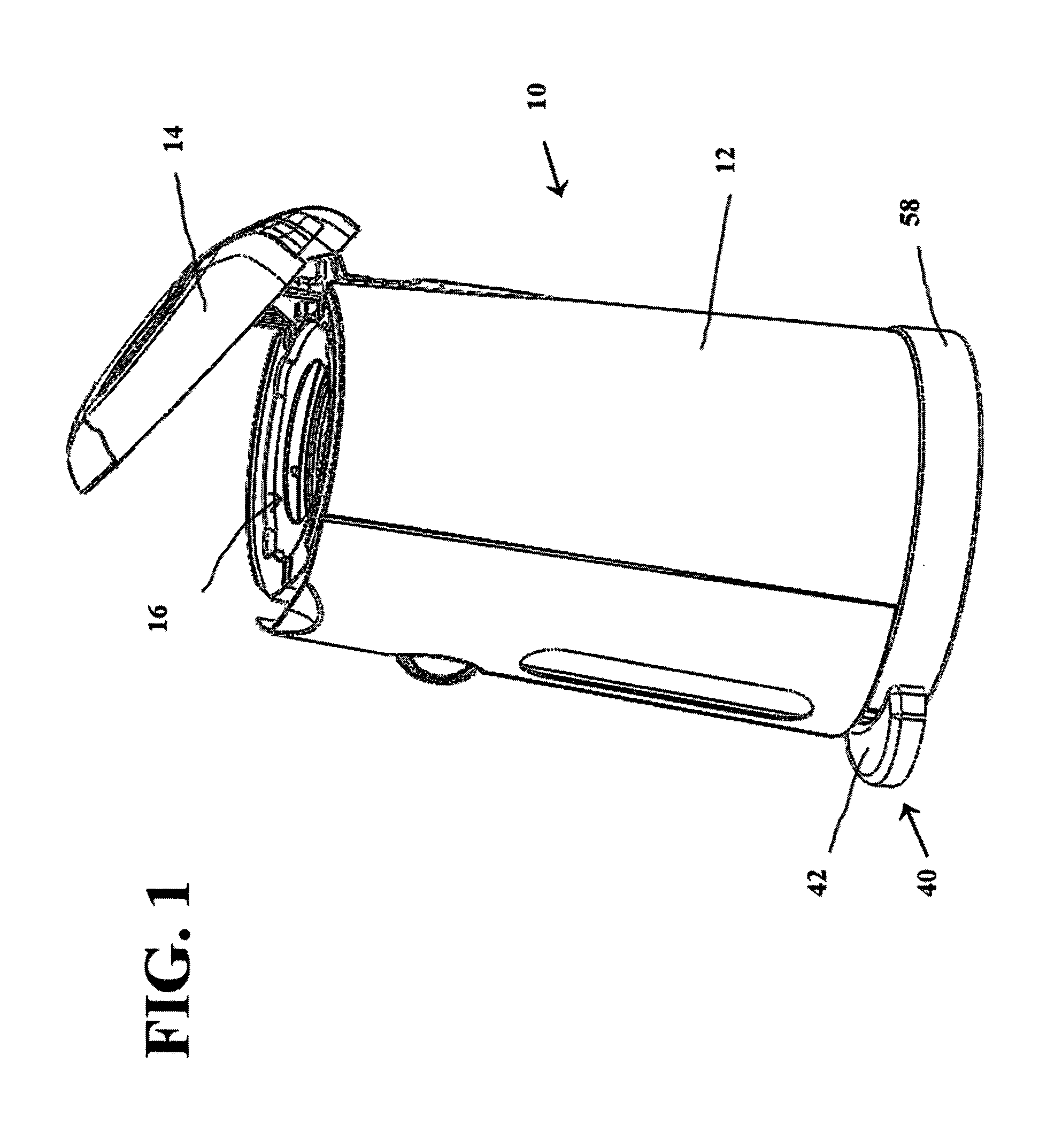

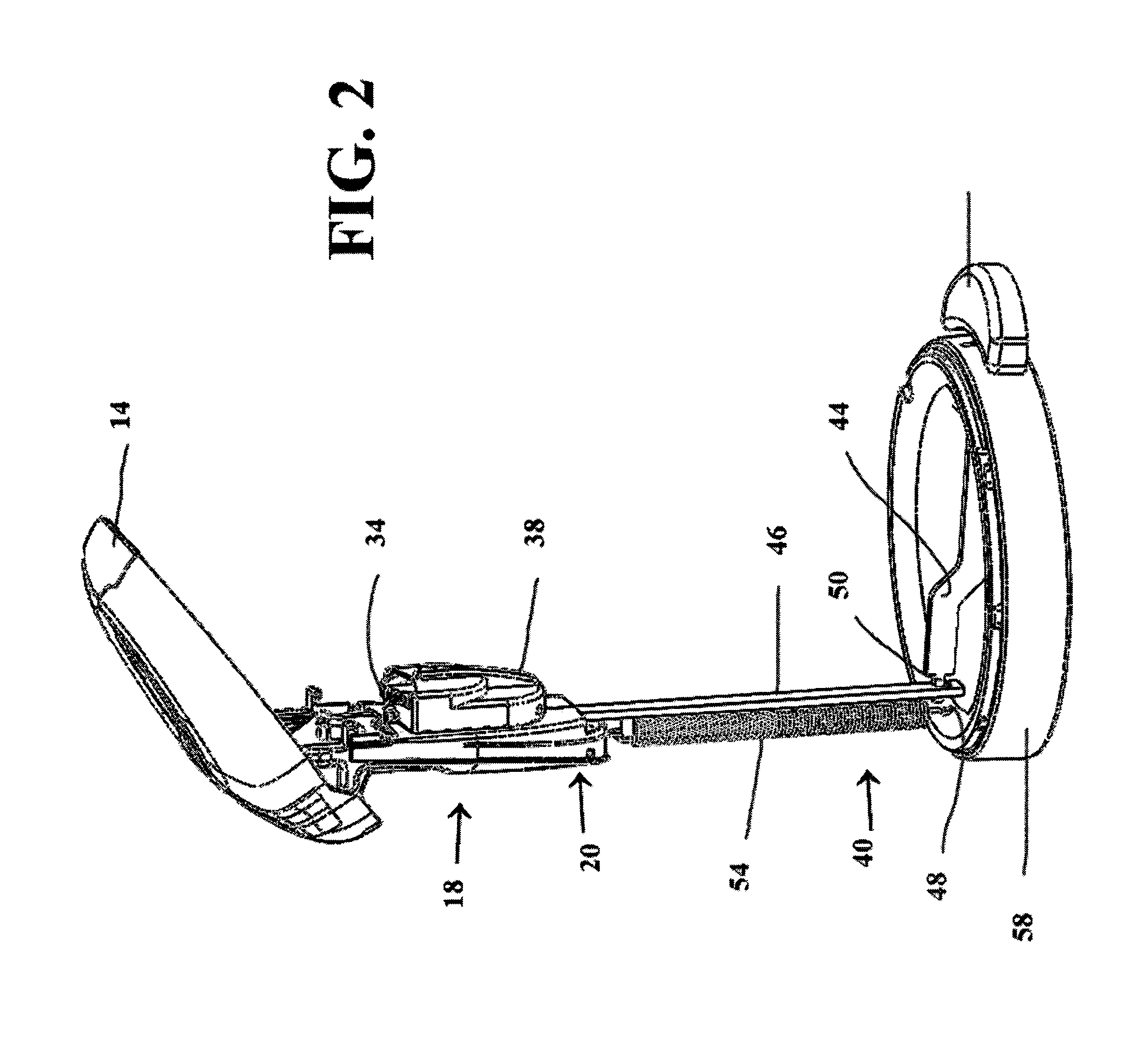

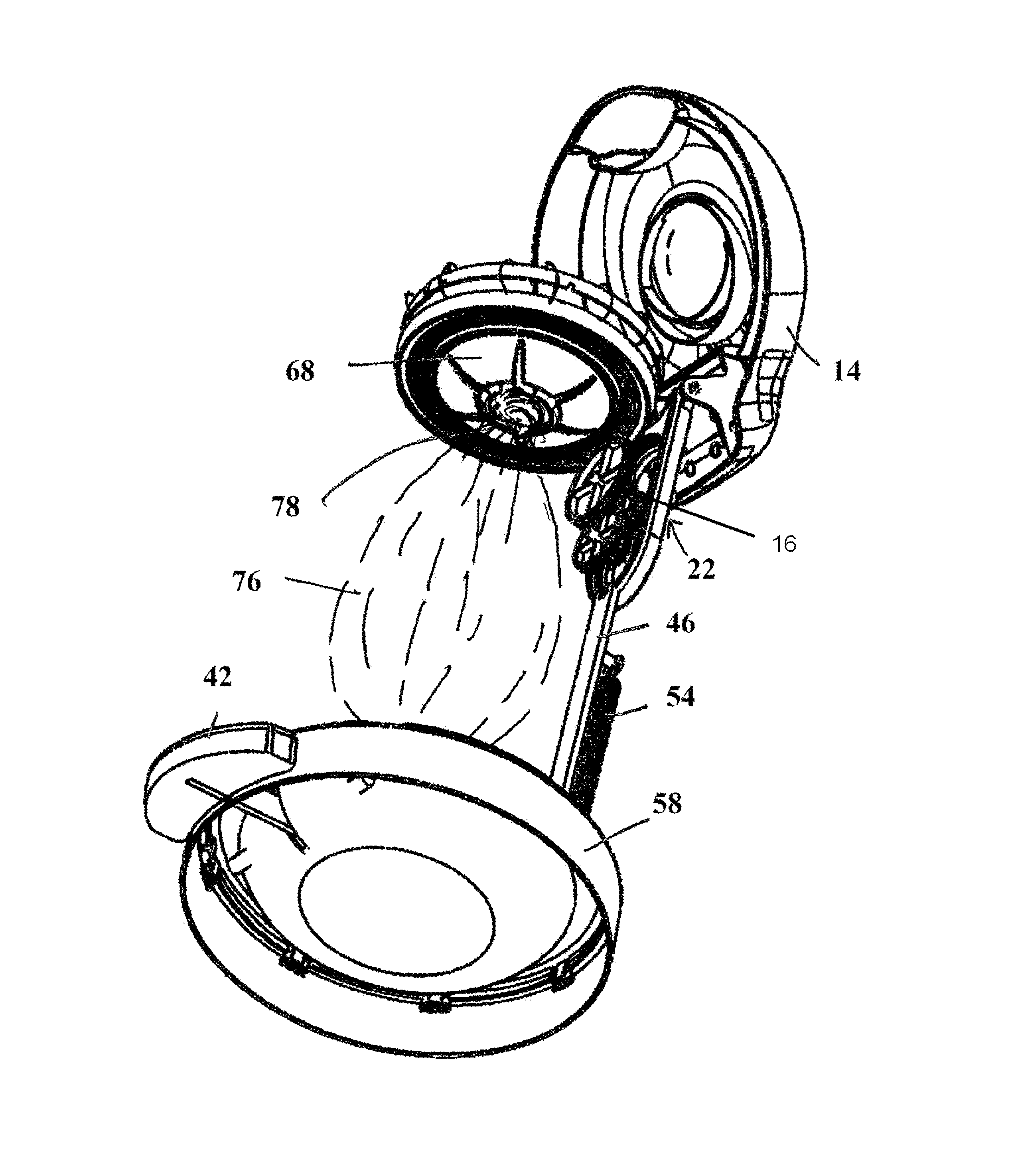

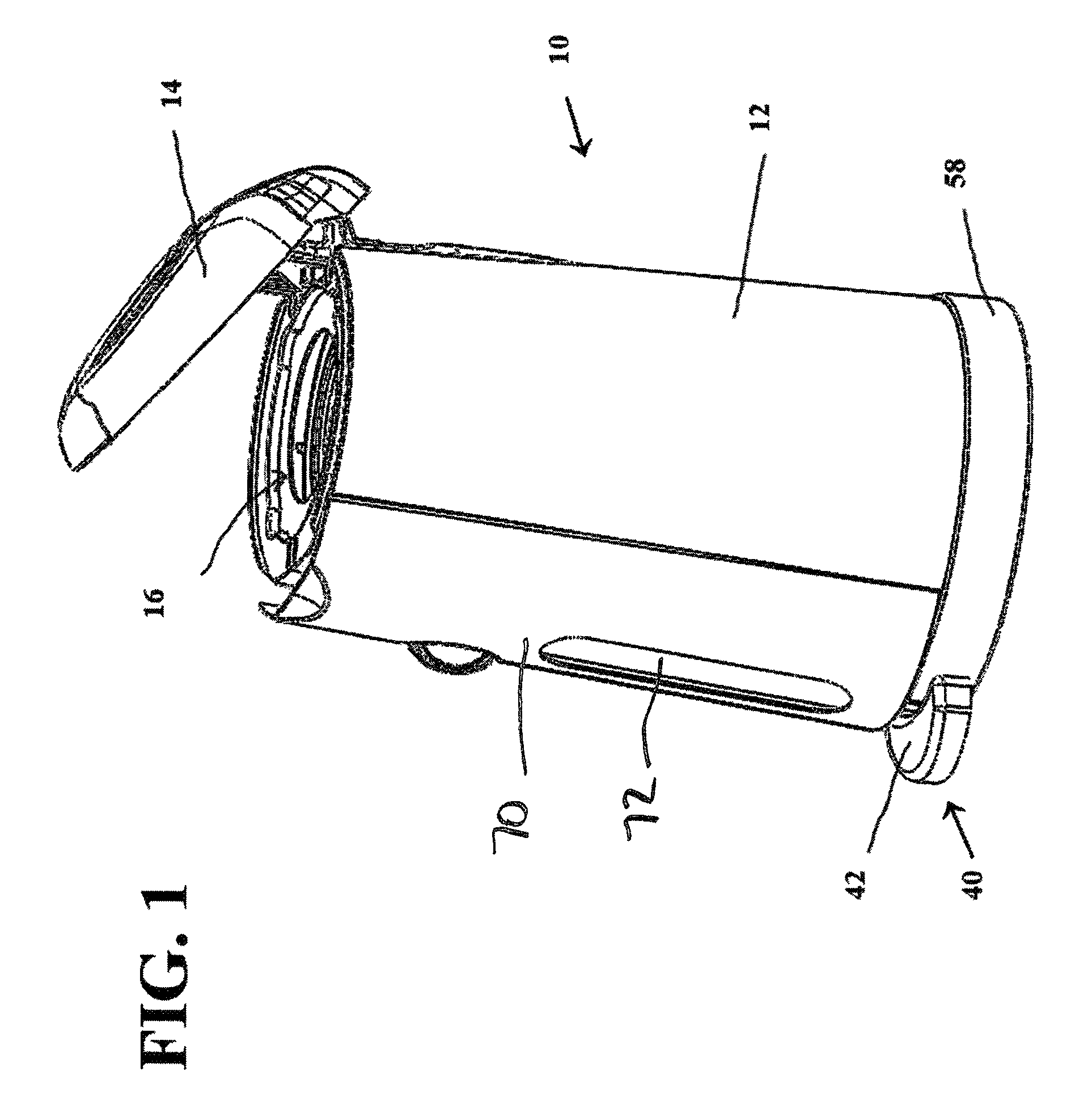

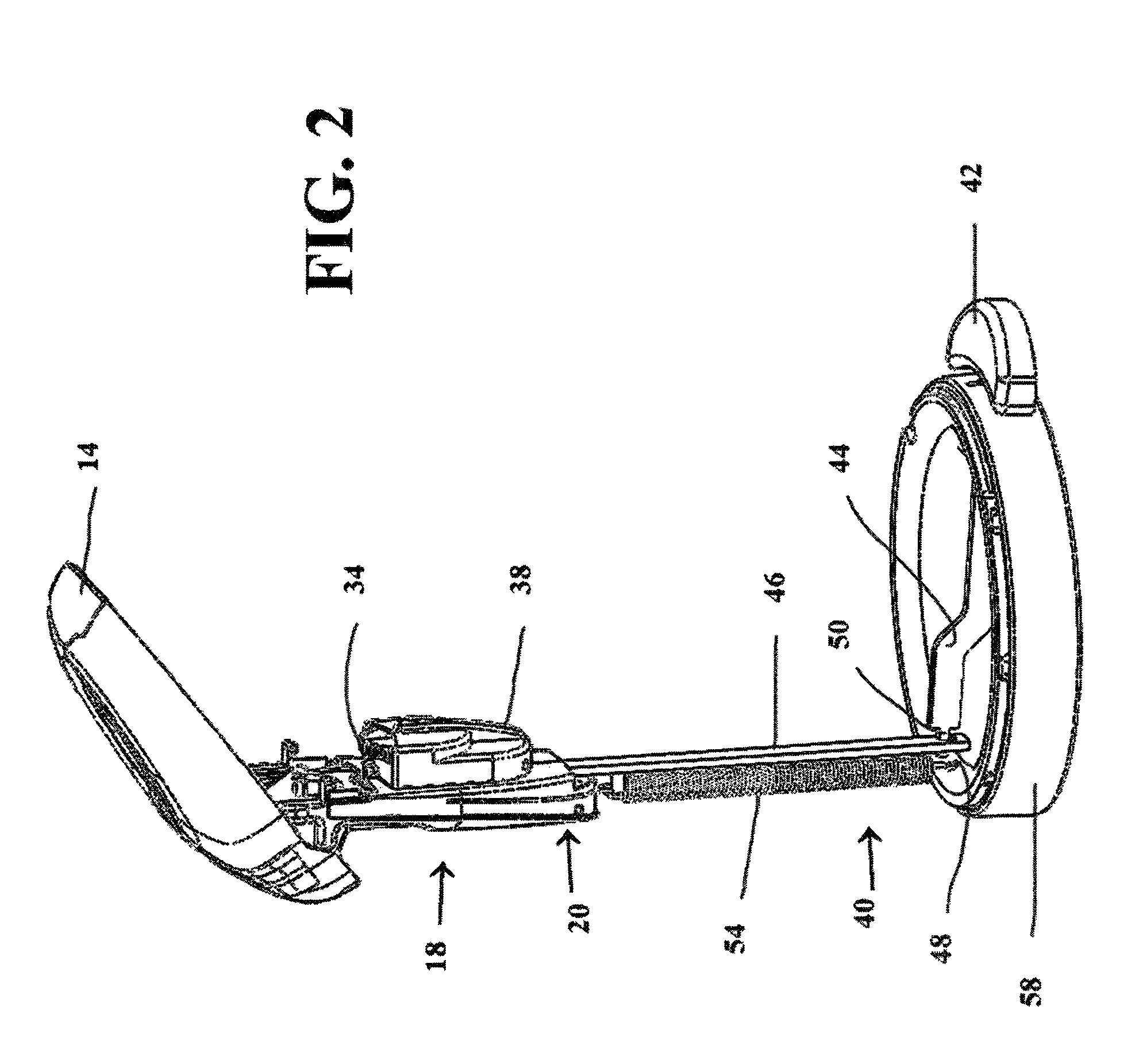

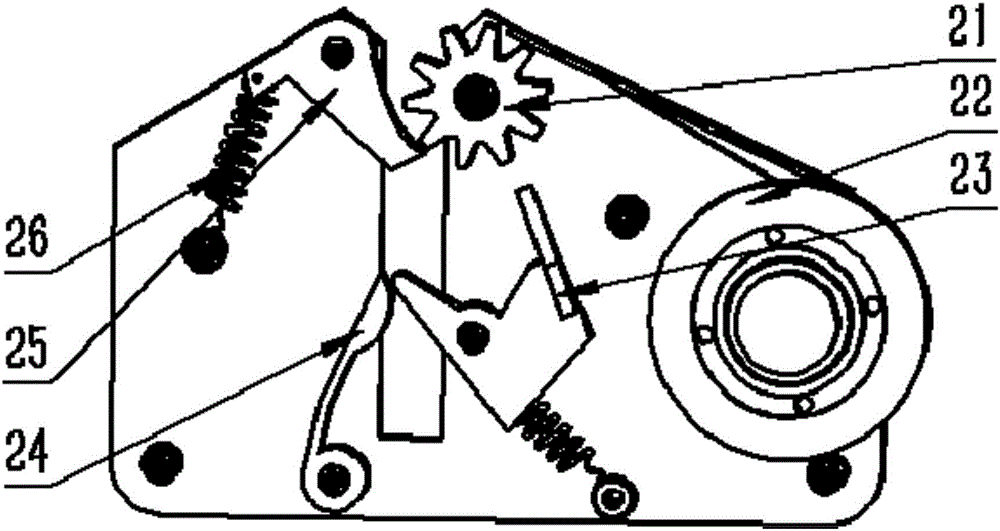

Waste disposal device with self-closing lid

Waste disposal device adapted to receive a waste-containing member includes a container defining a waste-receiving compartment having an opening, a lid connected to the container and lid having a first, closed position covering the opening of the container and a second, open position in which the opening is exposed, and a rotation mechanism arranged in the container to rotate the waste-containing member when present in the container. The rotation mechanism is arranged to rotate the waste-containing member upon closure of the lid without manual handling of the lid.

Owner:DOOLI PROD LLC

Waste disposal device with self-closing lid

Waste disposal device that receives a waste-containing member includes a container defining a waste-receiving compartment having an opening, a lid having a closed position covering the opening and an open position in which the opening is exposed, and a rotation mechanism arranged in the container to rotate the waste-containing member when present. The rotation mechanism is arranged to rotate the waste-containing member upon closure of the lid without manual handling of the lid. A foot pedal assembly includes a depressible foot pedal and a spring, and is arranged to cause both opening of the lid when the foot pedal is depressed and closure of the lid when the pressing force is removed. The spring is moved against its bias upon depression of the foot pedal and returns to its original state when the pressing force is removed to thereby cause closure of the lid and rotation of the waste-containing member.

Owner:DOOLI PROD LLC

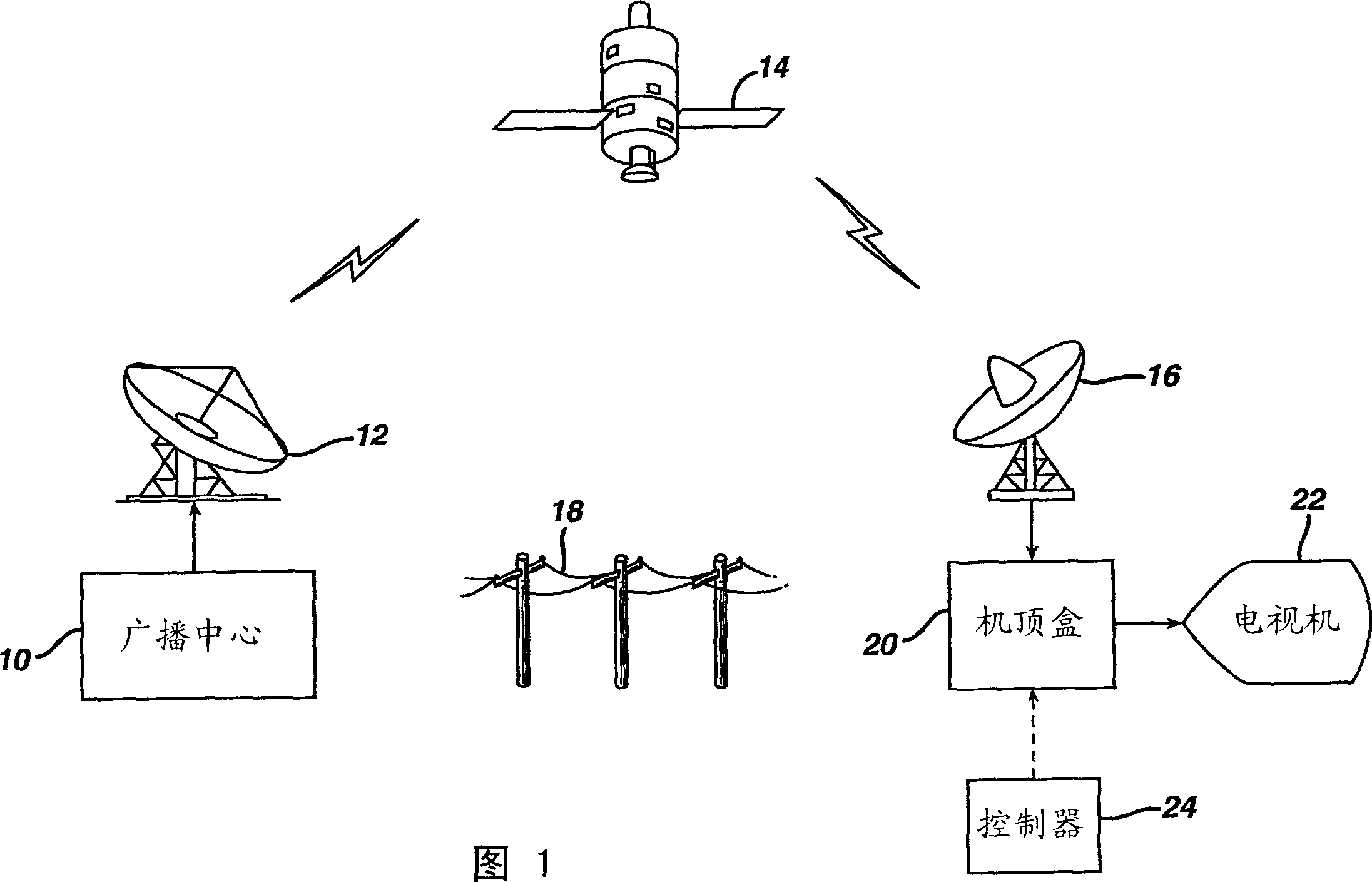

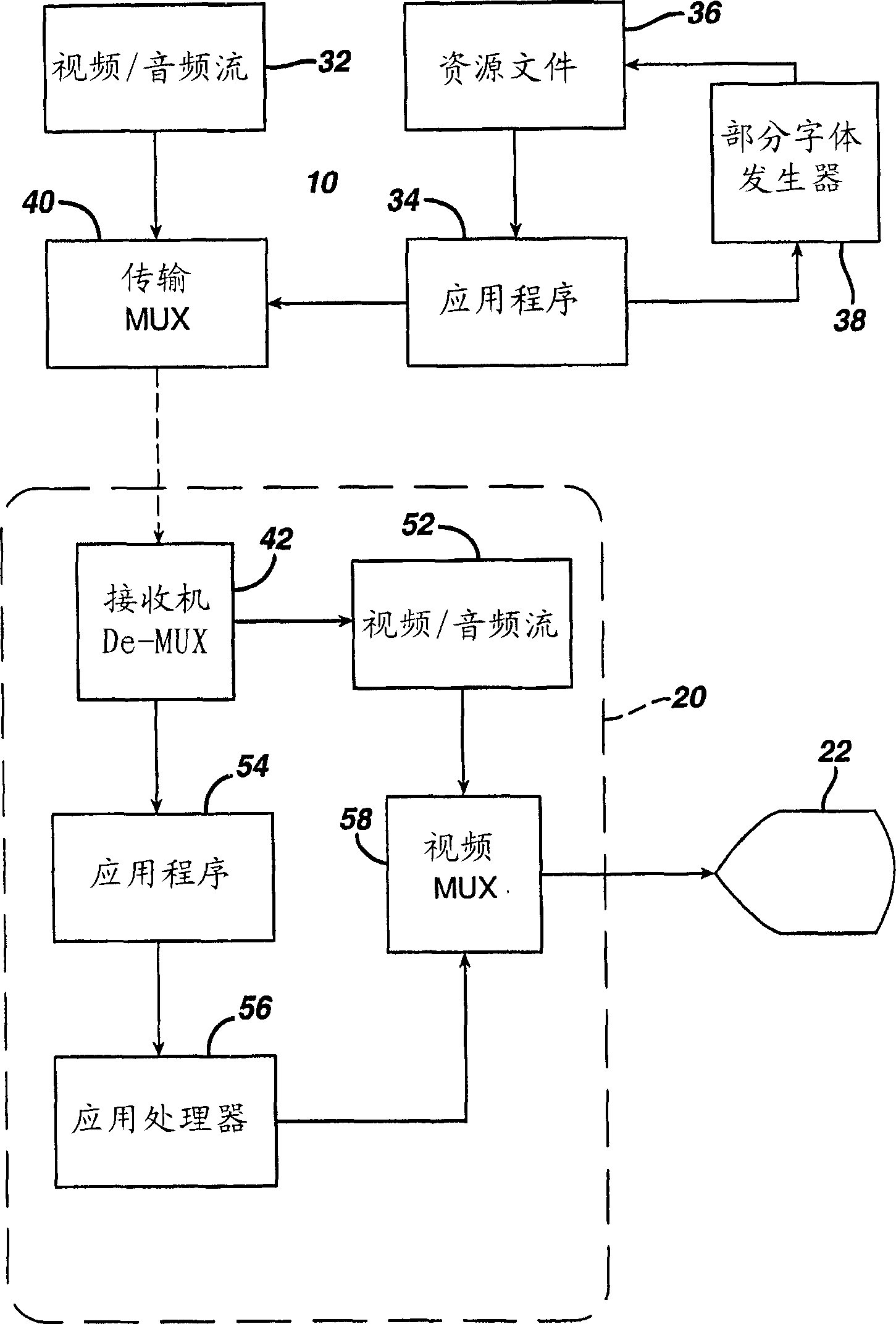

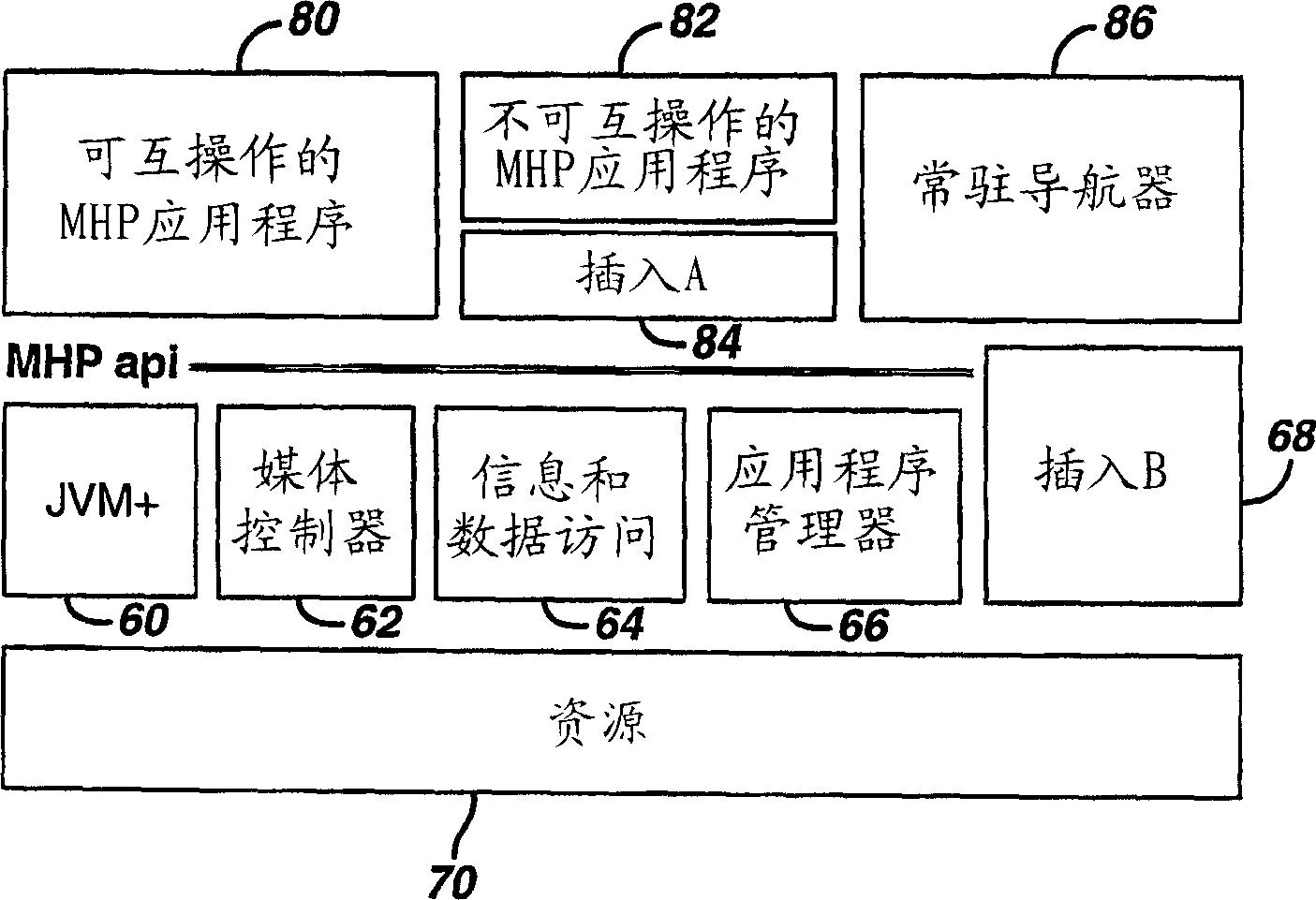

Interactive television system with partial character set generator

InactiveCN1723696AReduce overhead allocationReduce transfer timeTelevision system detailsColor television detailsTelevision systemText display

An interactive television system includes a partial font generator (38) which generates a character font file of only those fonts used by a given application program for text display. The partial font file contains the language character fonts utilized by the application program, but less than the complete character set of the language. Thus, the partial font file thus requires less time or bandwidth to transmit in the allotted transmit intervals. The partial font file may be generated by a manual process, or by an automated analysis of the fonts used by an application program.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

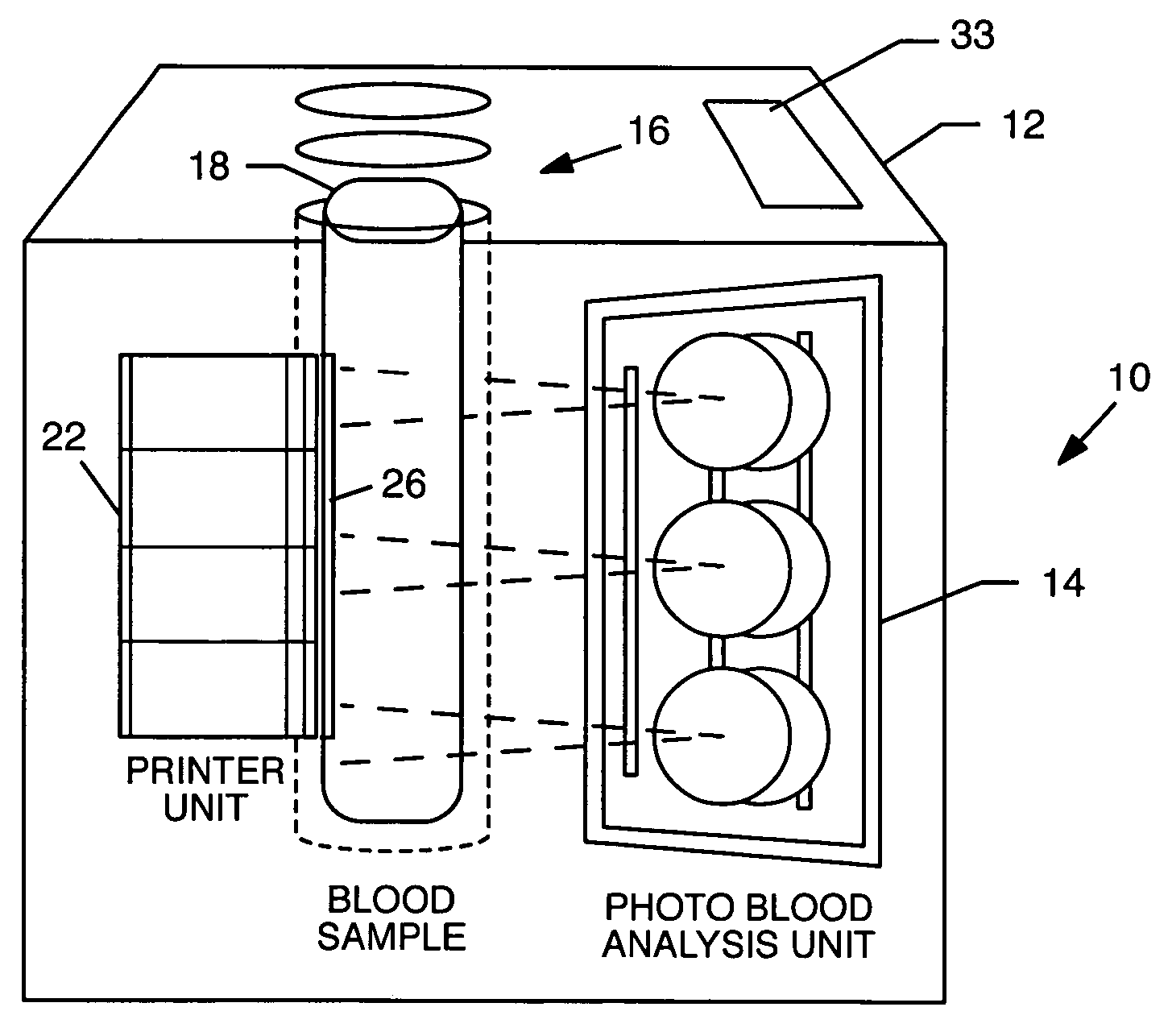

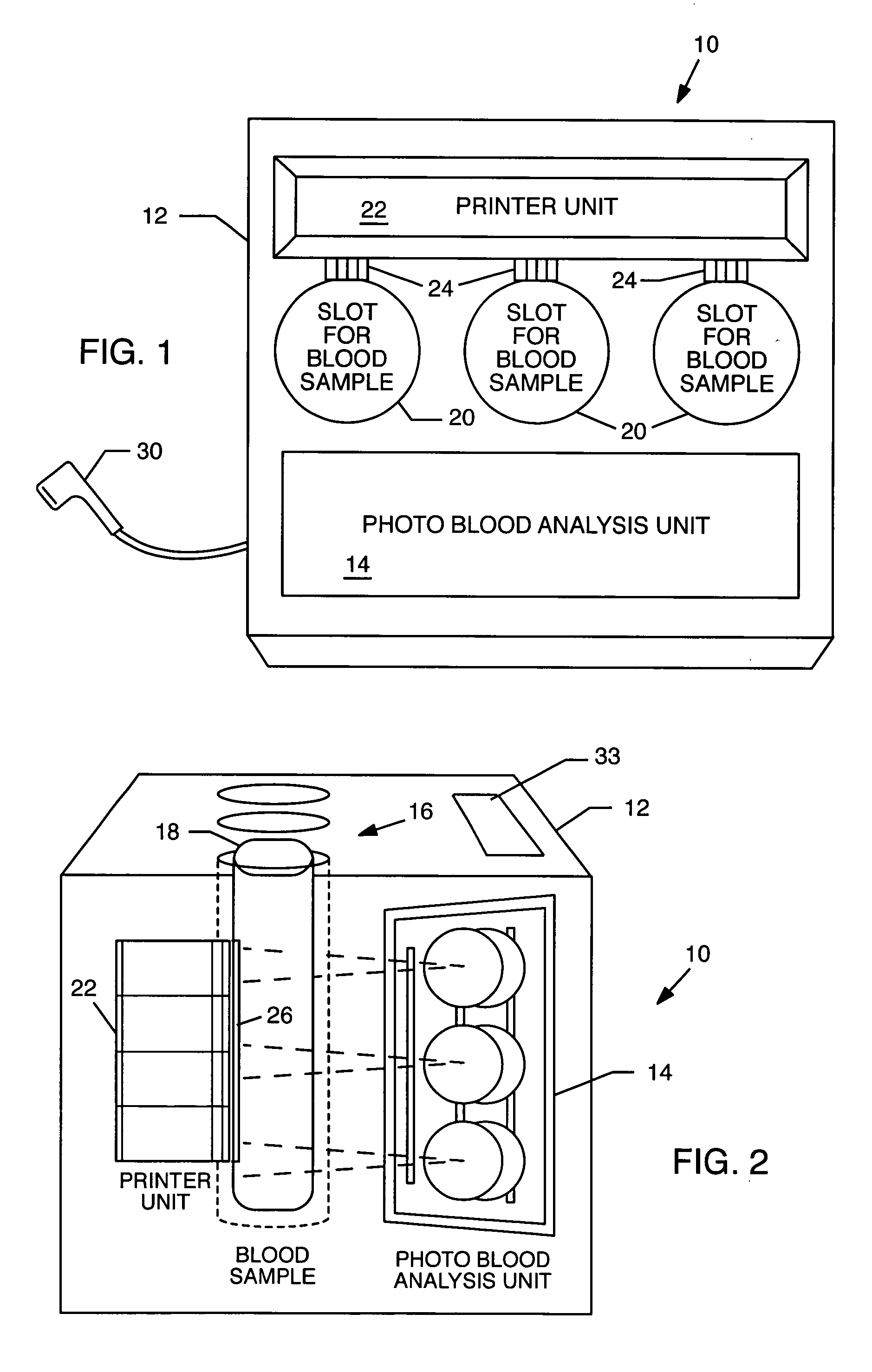

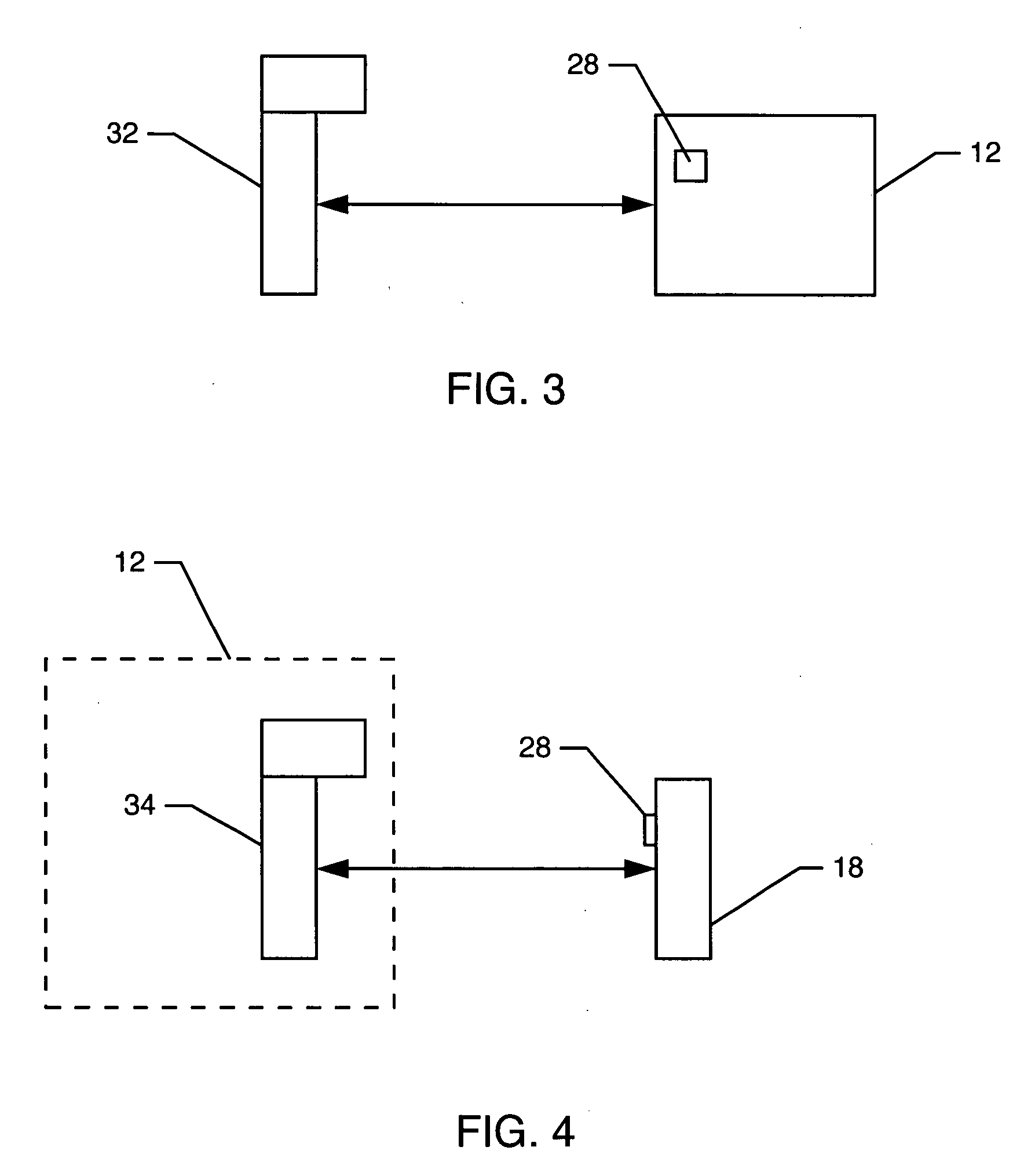

Automatic blood analysis and identification system

InactiveUS20050019943A1Reduces human error factorReduce errorsMaterial analysis by optical meansIndividual particle analysisComputer printingGroup A - blood

An automatic blood analysis and identification system permits patient identification and other vital information, such as blood type and Rh factor, to be automatically printed directly on a container holding a bodily fluid sample almost immediately after the sample has been drawn and analyzed. There is no manual handling of the sample between the draw and the identification. The system includes a carrier unit for holding at least one clear sample container, and a printer disposed within the unit for printing information onto the sample container. A photo-analyzer analyzes a bodily fluid sample within the sample container, and sends information to the printer which prints the information onto the sample container. The system may also be configured to utilize radio frequency identification (RFID) technology to imprint electronic data bearing the information onto a microchip implanted within the sample container.

Owner:PRECISION DYNAMICS CORPORATION

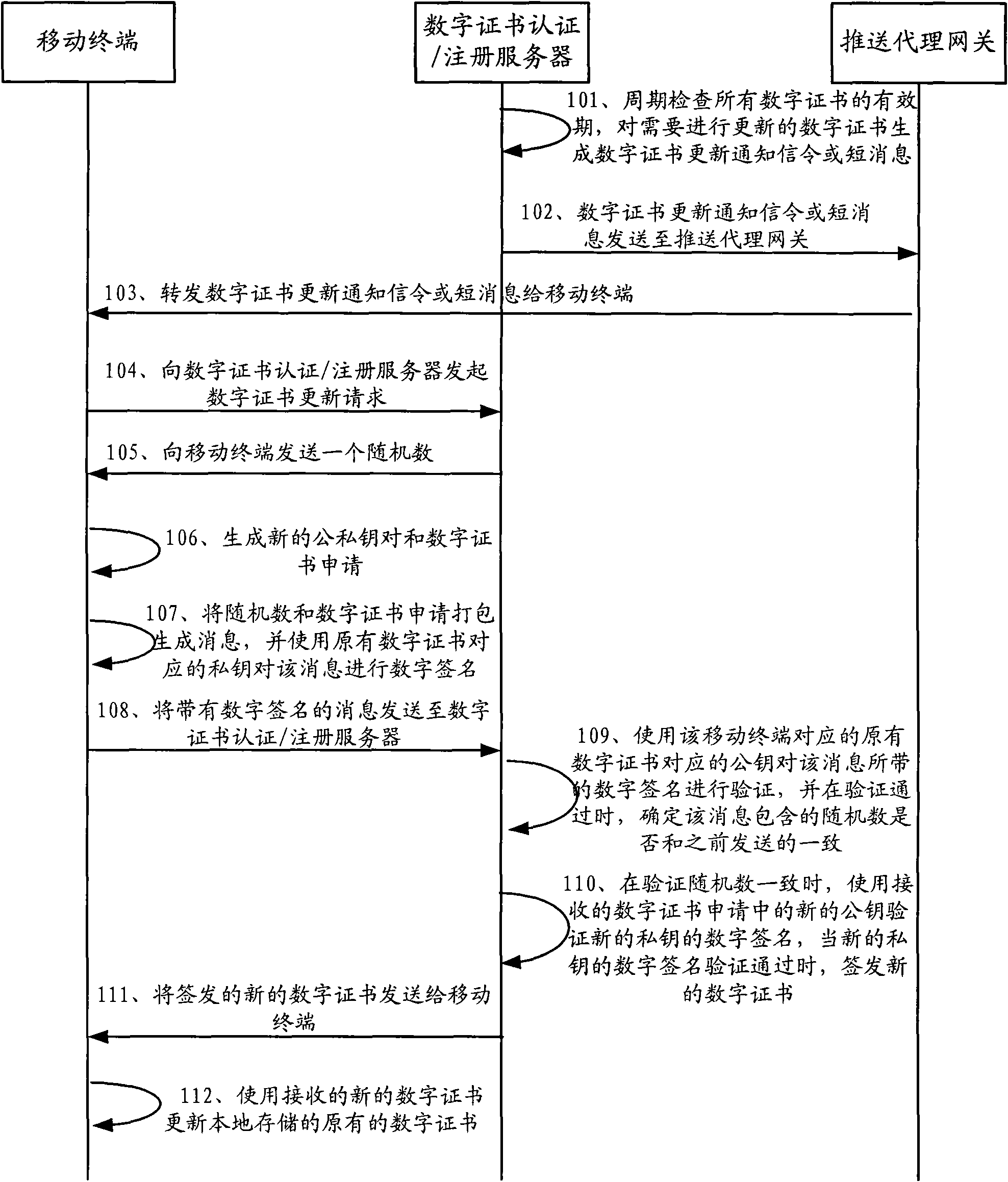

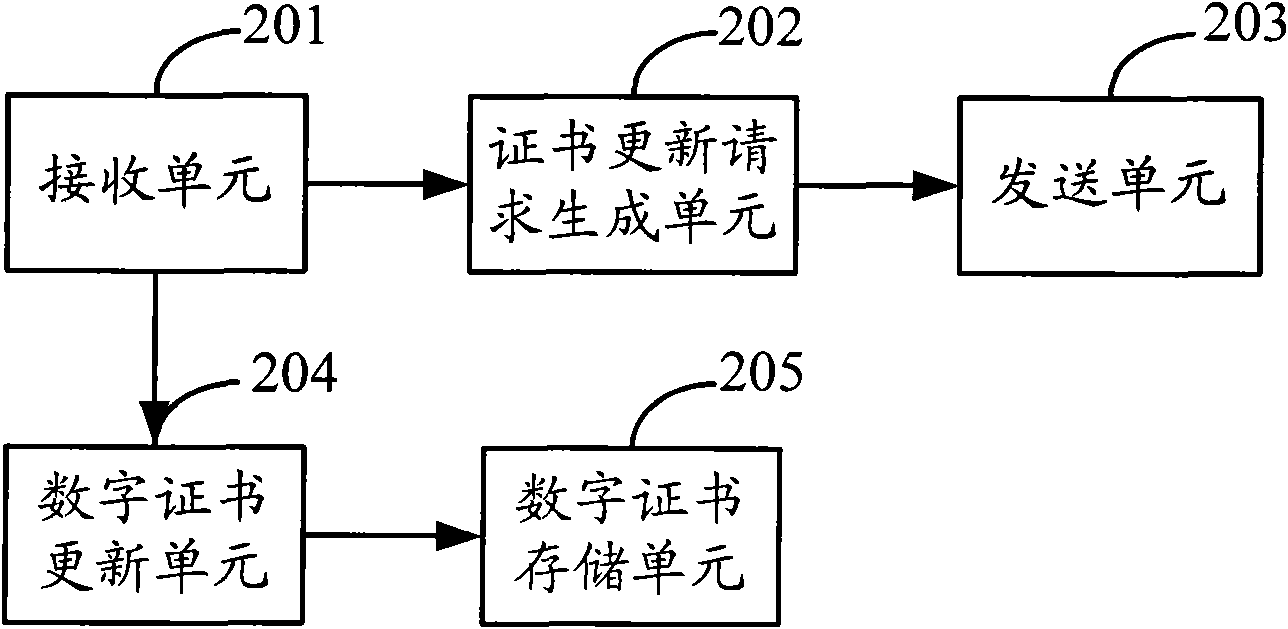

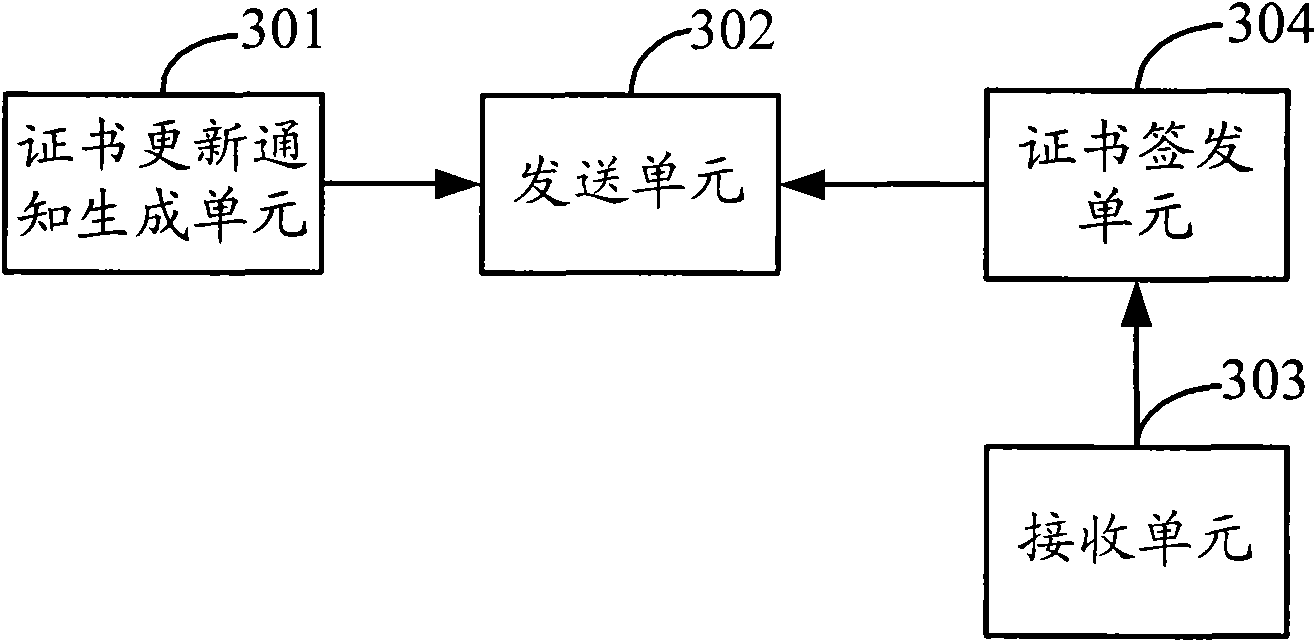

Method, device and system for updating digital certificate

InactiveCN101651540APublic key for secure communicationUser identity/authority verificationComputer networkOperation mode

The invention discloses a method, a device and a system for updating a digital certificate. The method comprises the following steps that: a digital certificate certification / registration (CA / RA) server transmits a digital certificate update notification; the digital certificate certification / registration server receives a digital certificate update request transmitted by a mobile terminal according to the digital certificate update notice; and the digital certificate certification / registration server signs and issues a new digital certificate to the mobile terminal according to the request. The method, the device and the system for updating the digital certificate solve the problems in the prior art that because a mobile terminal user adopts a manual operation mode to update the digital certificate, the operations are complex, the user experience is poor and the update rate of the digital certificate is difficult to guarantee.

Owner:CHINA MOBILE COMM GRP CO LTD

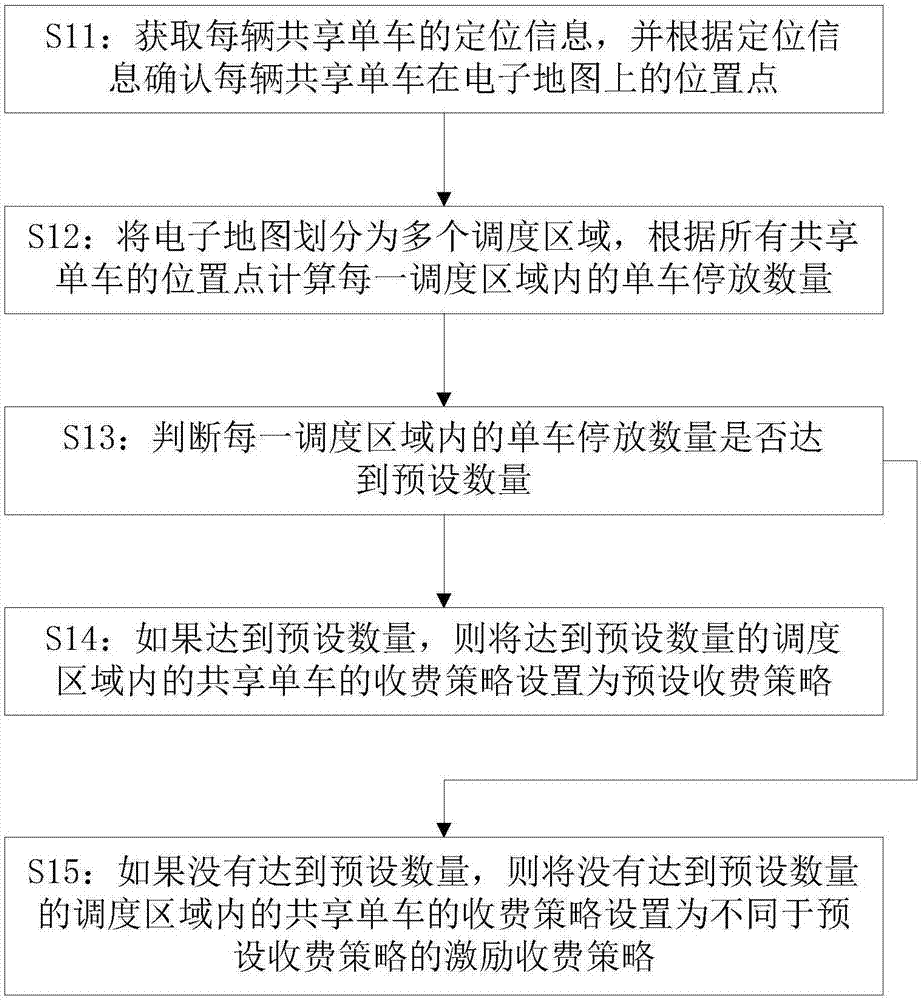

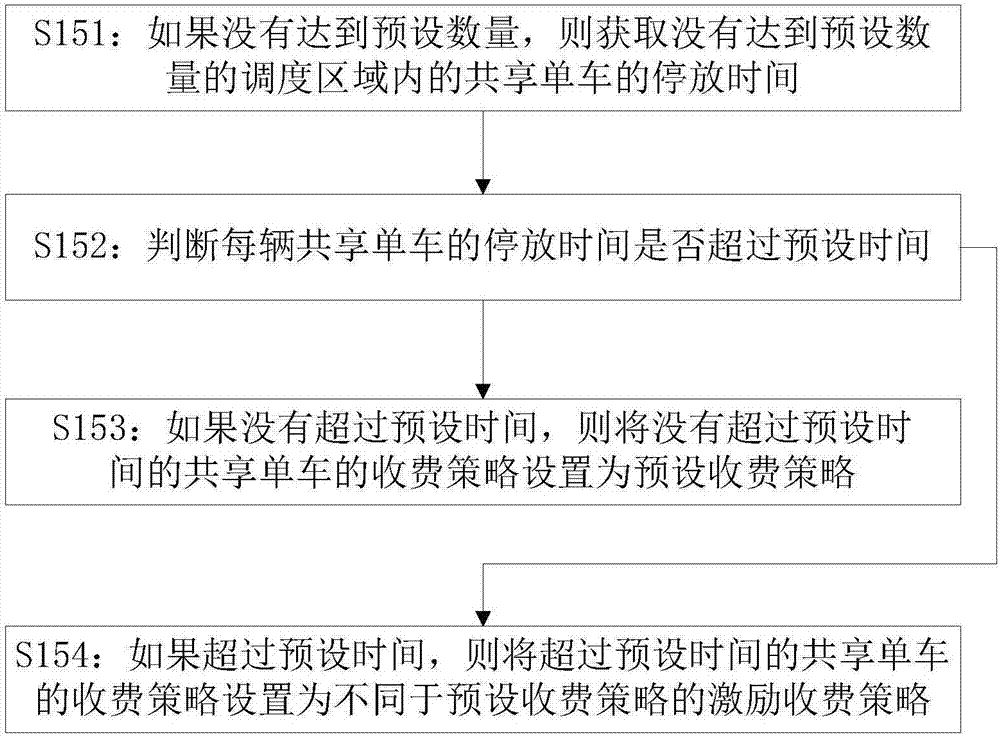

Shared bike scheduling method based on user participation

InactiveCN107093104AReduce manual handling inputReduce scheduling costsMarket predictionsDiscounts/incentivesSingle vehicleUser participation

The invention discloses a shared bike scheduling method based on user participation. Shared bikes are provided with intelligent locks, the positioning information is sent after the intelligent locks are locked. The scheduling method comprises steps that the positioning information of each shared bike is acquired, and the position point of each shared bike on an electronic map is confirmed according to the positioning information; the electronic map is divided into multiple scheduling regions, and the bike parking quantity of each scheduling region is calculated according to the position points of all the shared bikes; whether the bike parking quantity of each scheduling region surpasses preset quantity is determined; if yes, charging strategies of the shared bikes in the scheduling regions with the quantities reaching the preset quantity are set to be preset charging strategies; if not, charging strategies of the shared bikes in the scheduling regions with the quantities not reaching the preset quantity are set to be excitation charging strategies different from the preset charging strategies. The method is advantaged in that manual handling input can be reduced, and scheduling cost is reduced.

Owner:CHENGDU WENGWENG TECH CO LTD

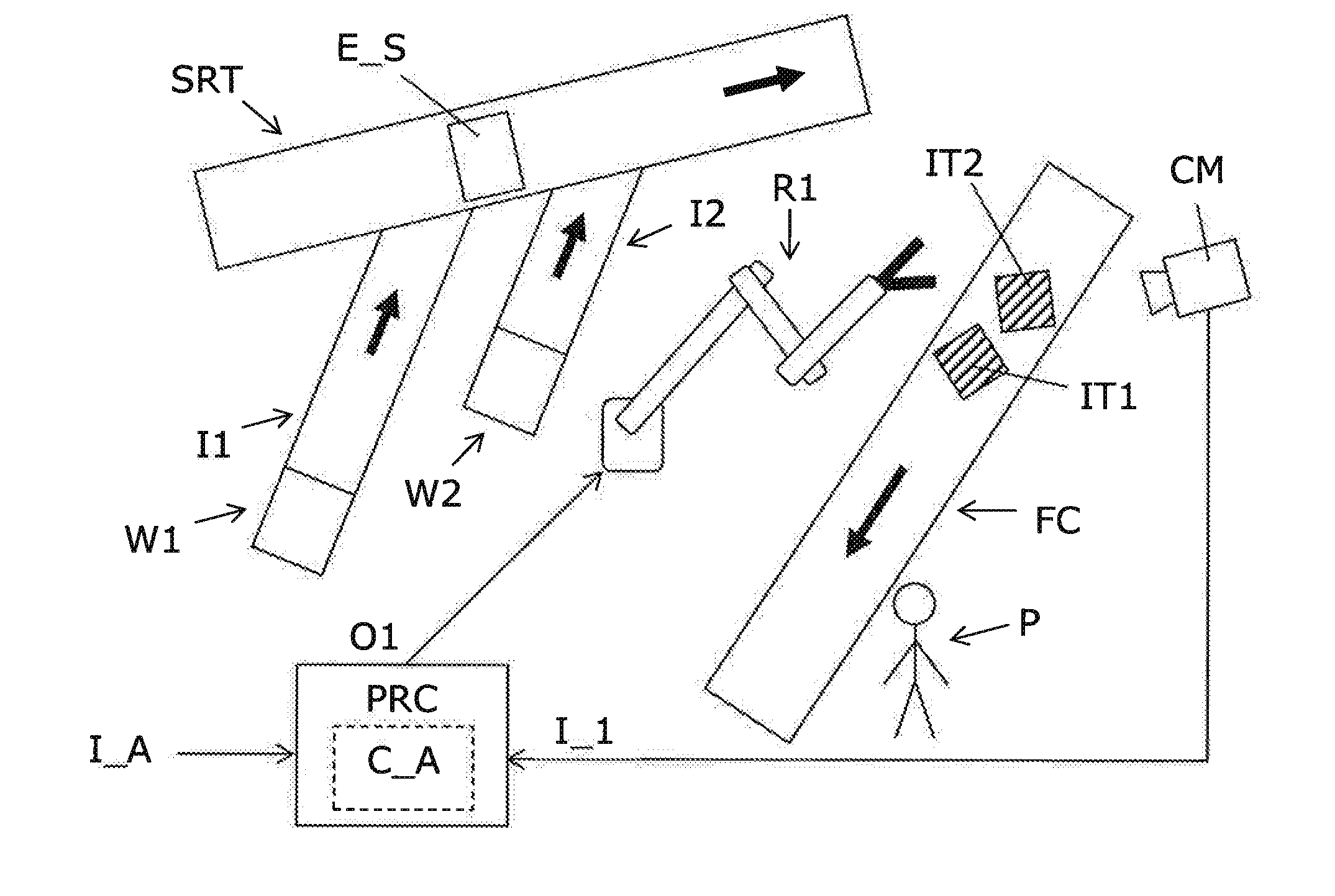

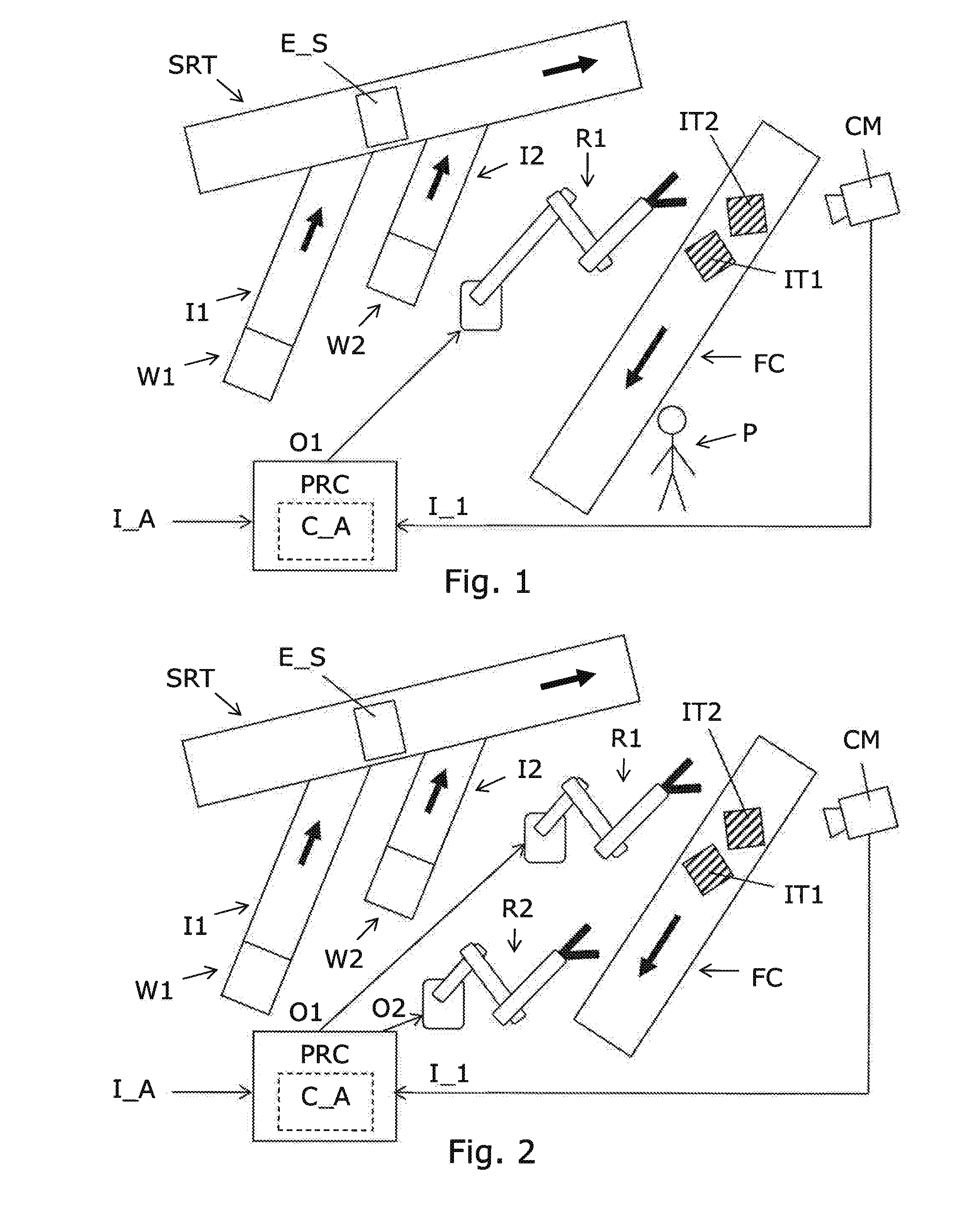

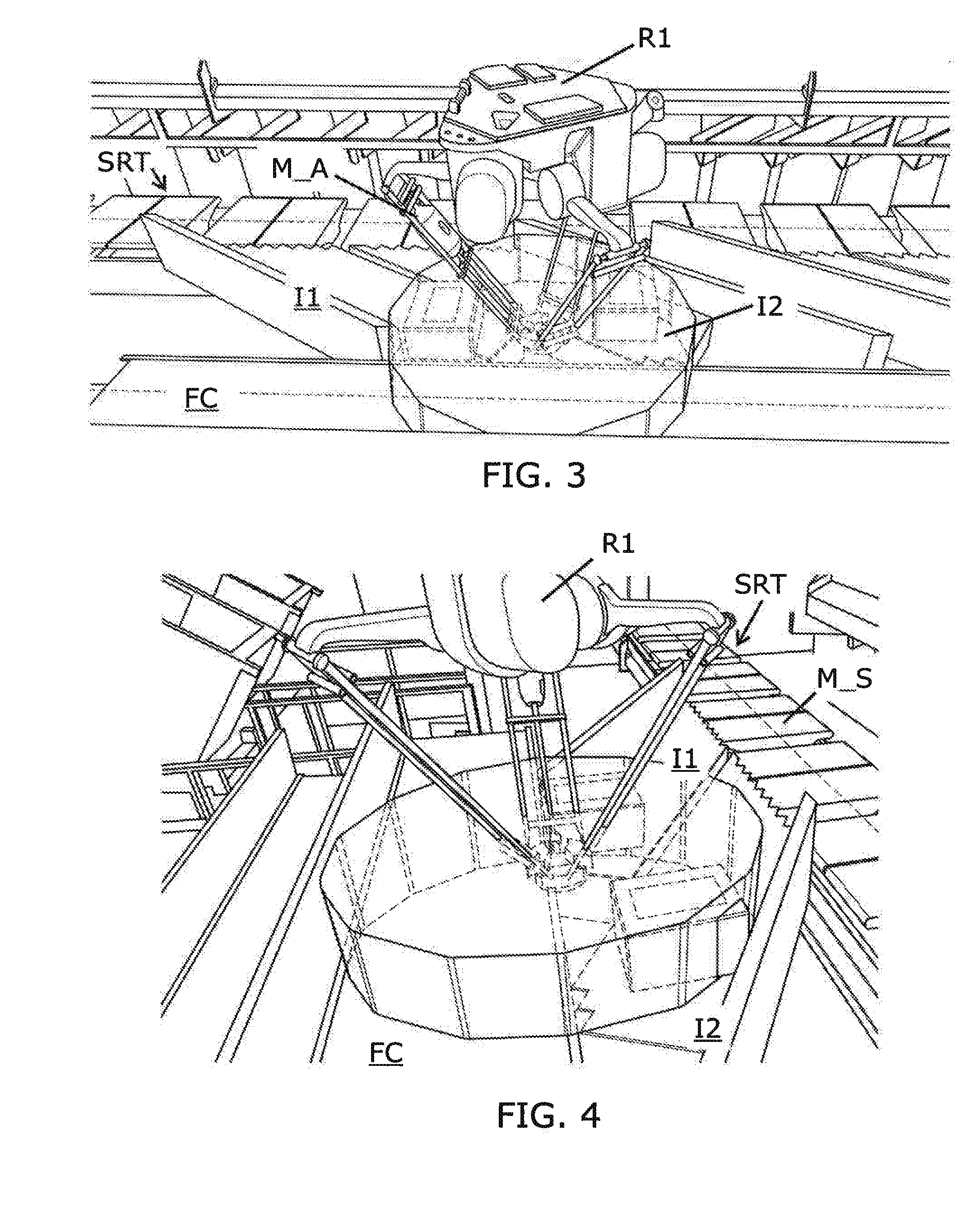

Method for inducting and singulating items to a sorter

ActiveUS20160199884A1Improve sorting effectProgramme-controlled manipulatorDigital data processing detailsManual handlingComputer science

The invention provides a method and a system for inducting items to a sorter (SRT) from a stream of items (IT1, IT2), e.g. mail or parcels, arriving at a feeding conveyor (FC). A processor (PCR) executes a control algorithm (C_A) with at least information (I_1) regarding the stream of items arriving at the feeding conveyor (FC) as input. In response, the control algorithm (C_A) generates an output (O1) indicating where to place an item picked up by a robot (R1) from the feeding conveyor (FC). The control algorithm (C_A) selects between two or more of: 1) a first induction (I1) arranged for transporting items to the sorter (SRT), 2) an empty space (E_S) on the sorter(SRT), 3) the feeding conveyor (FC), e.g. singulating bulk items on the feeding conveyor (FC), and 4) a weighing unit (W1) arranged for weighing items. By controlling the robot (R1) accordingly, it is possible to provide effective use of existing pick-and-place robots as part of a sorter induction system, where a high capacity can be obtained with a small requirement for space. E.g. it may be possible to save space for inductions, compared to what is required for manual handling with the same sorting capacity, especially this may be advantageous for items with a maximum weight of 2-3 kg.

Owner:BEUMER GRP AS

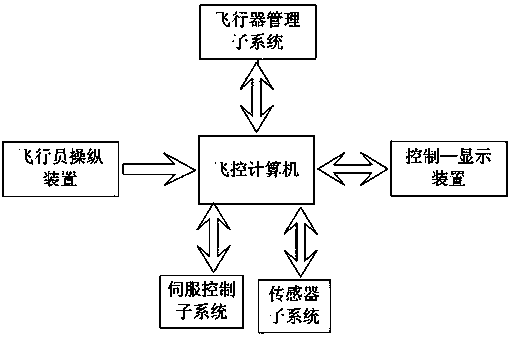

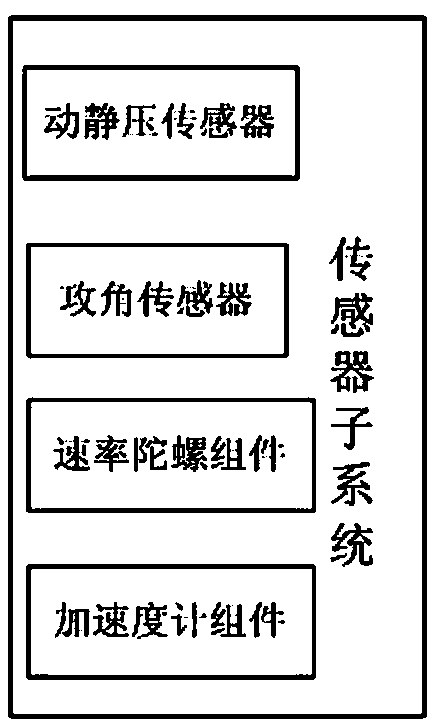

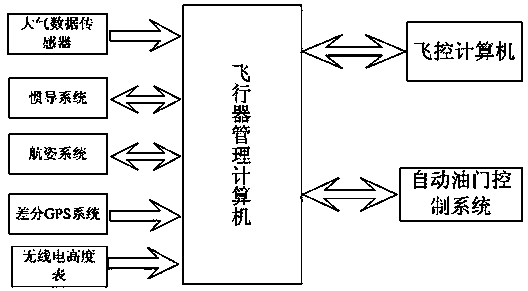

Manned/unmanned selectable dual-mode flight control system

InactiveCN103914077AReduce handling loadReduce catastrophic accidentsPosition/course control in three dimensionsTask completionElectricity

The invention belongs to the technical field of airplane flight control systems, and particularly relates to a manned / unmanned selectable dual-mode flight control system. The manned / unmanned selectable dual-mode flight control system is composed of a fly-by-wire flight control system and an expended aircraft management system. During whole airspace flight, an unmanned control mode can be selected for conducting automatic flight, and an aviator plays the role of a highly-intelligent information identification system to monitor the flight state, the airspace control, external information and the like. An aircraft management subsystem can be used for processing uncertain factors according to predetermined programs or predetermined processing principles, the uncertain factors can influence task completion, online task / flight path planning and task redistribution or threat avoidance are conducted automatically, and under necessary conditions, the aviator can exit the unmanned control mode to perform manual handling. In the aviator control mode, the aircraft management subsystem plays the role of a senior assistant decision-making system to provide flight and task guide information so as to assist the aviator to complete tasks.

Owner:JIANGXI HONGDU AVIATION IND GRP

Method, system, and apparatus for handling, labeling, filling, and capping syringes with improved cap

InactiveUS7392638B2Easy to handleEasy to carryCapsDecorative coversManual handlingBiomedical engineering

Owner:BAXTER ENGLEWOOD

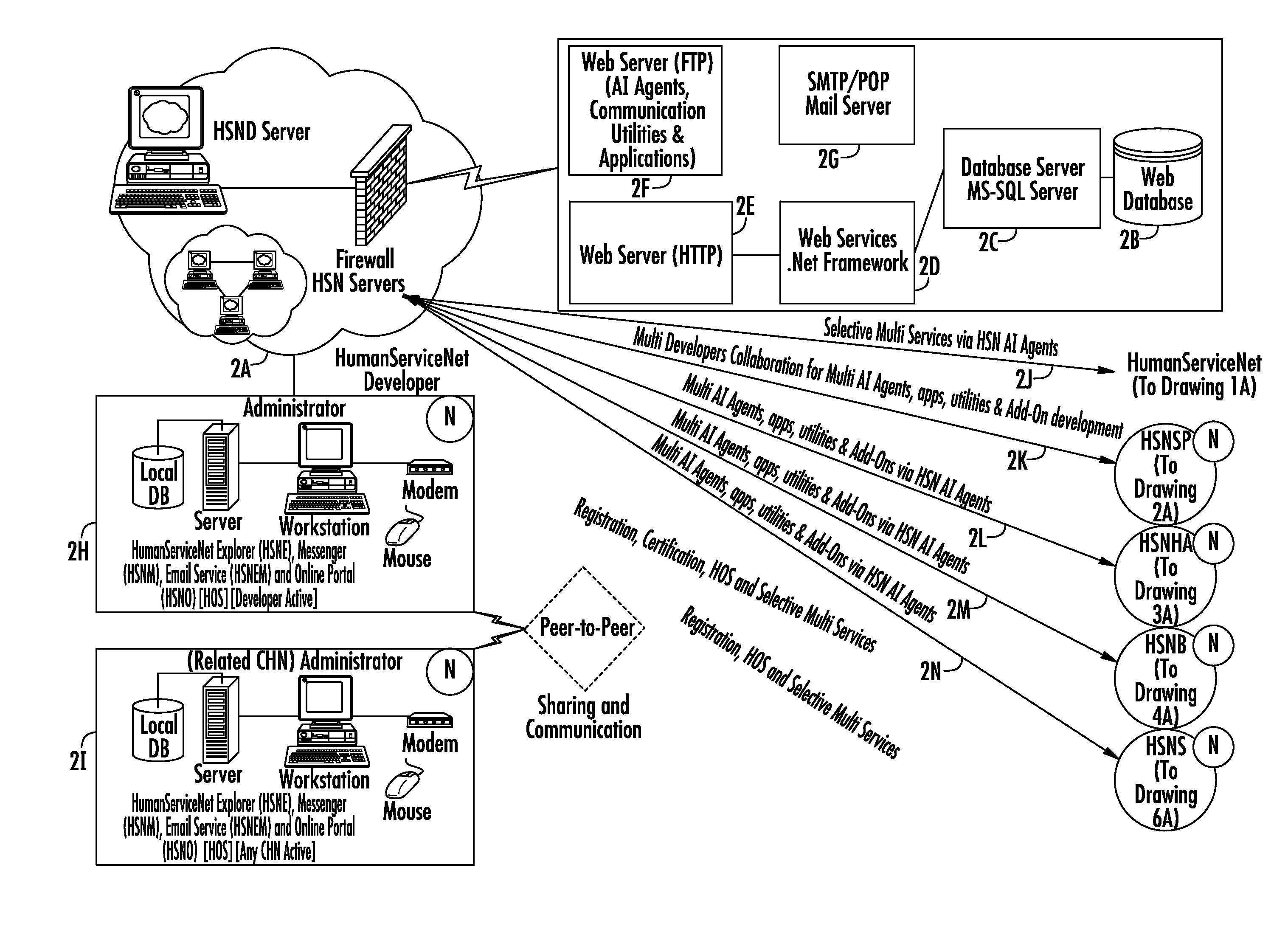

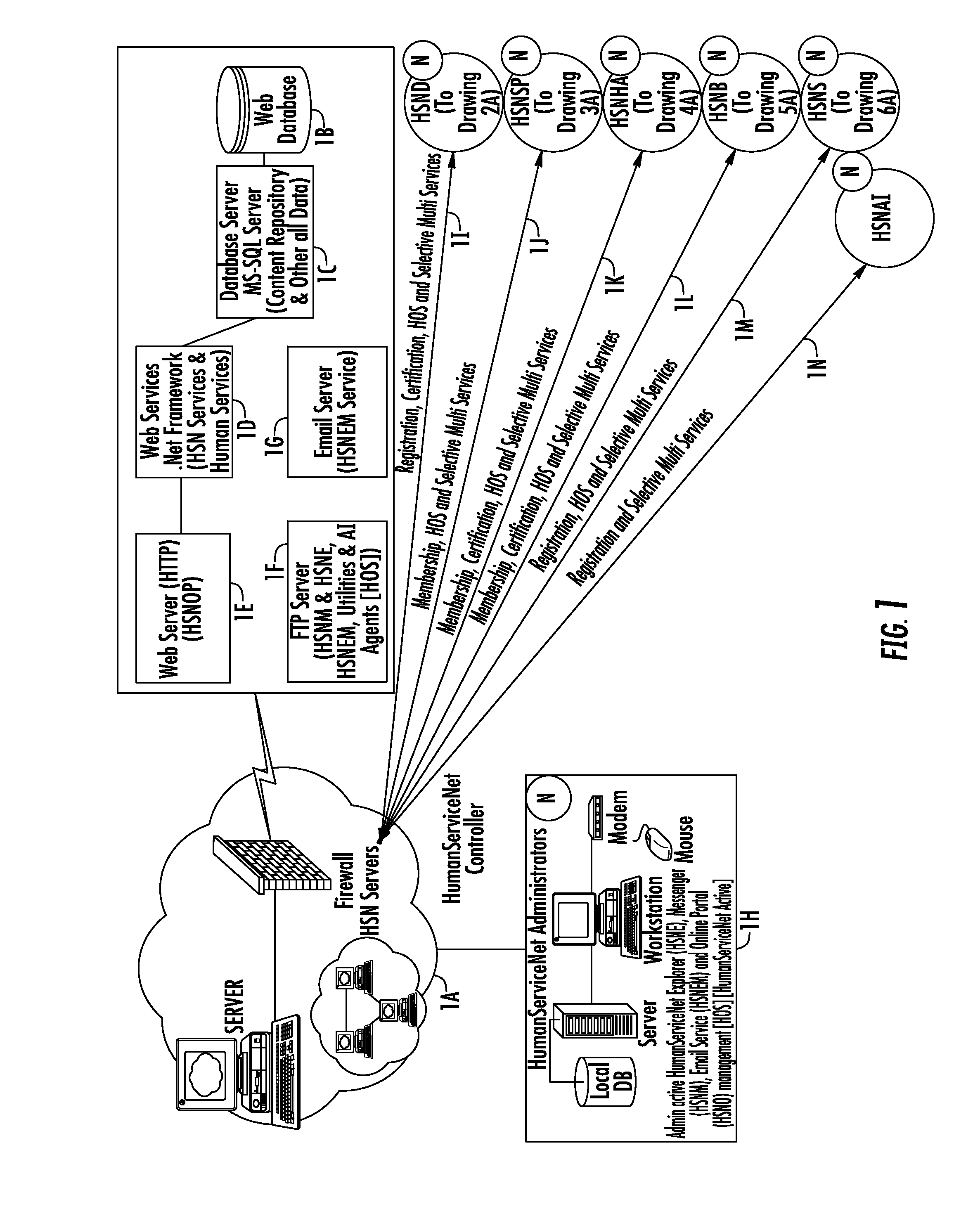

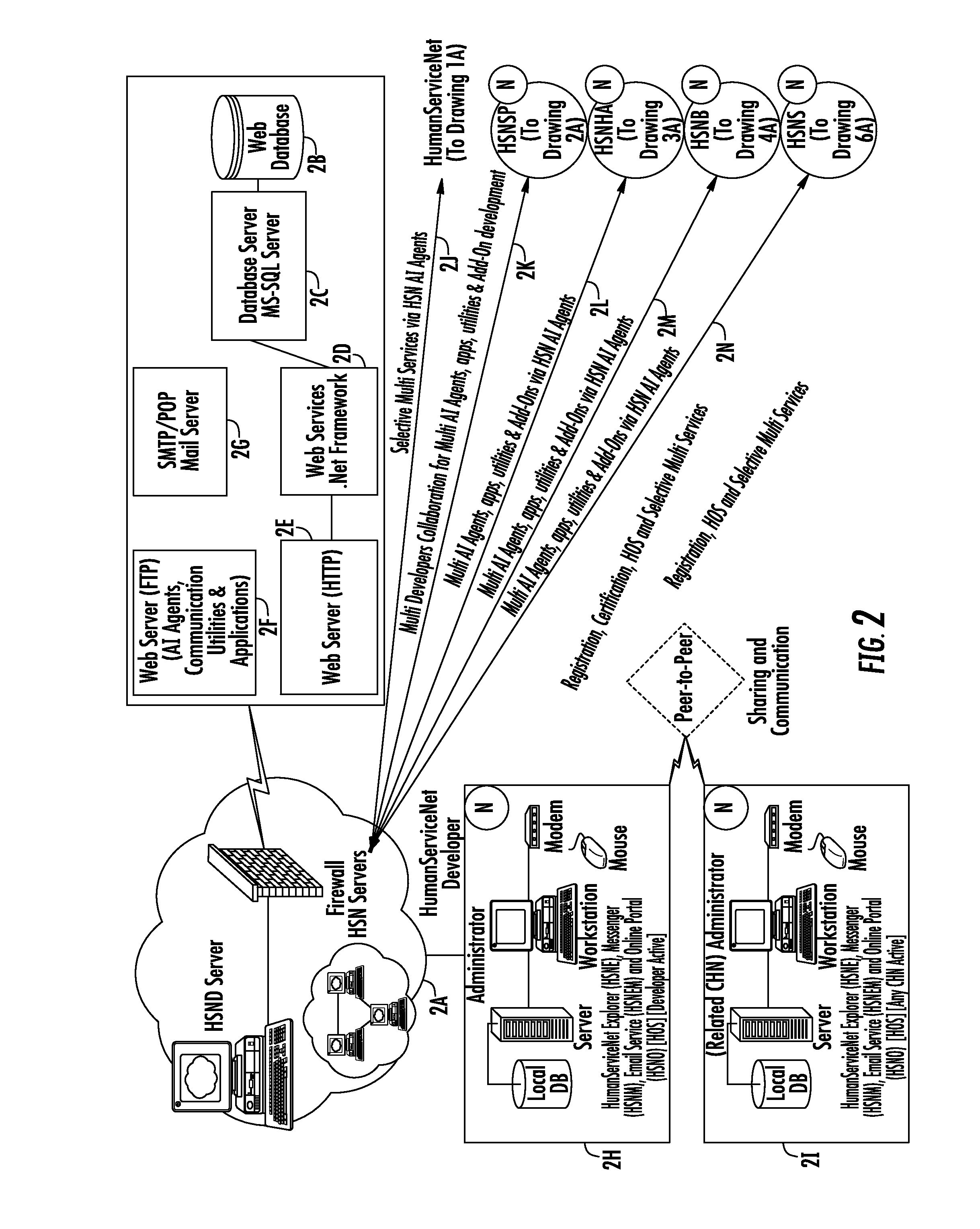

System and method for accessing applications for social networking and communication in plurality of networks

InactiveUS20110078583A1Easy to watchInput/output for user-computer interactionSpecial service provision for substationDigital deviceBlack box

A system for transmission, reception and accumulation of the knowledge packets to plurality of channel nodes in the network operating distributedly in a peer to peer environment via installable one or more role active Human Operating System (HOS) applications in a digital devise of each of channel node, a network controller registering and providing desired HOS applications and multiple developers developing advance communication and knowledge management applications and each of subscribers exploiting the said network resources by leveraging and augmenting taxonomically and ontologically classified knowledge classes expressed via plurality search macros and UKID structures facilitating said expert human agents for knowledge invocation and support services and service providers providing information services in the preidentified taxonomical classes, wherein each of channel nodes communicating with the unknown via domain specific supernodes each facilitating social networking and relationships development leading to human grid which is searchable via Universal Desktop Search by black box search module.

Owner:ONEPATONT SOFTWARE LTD

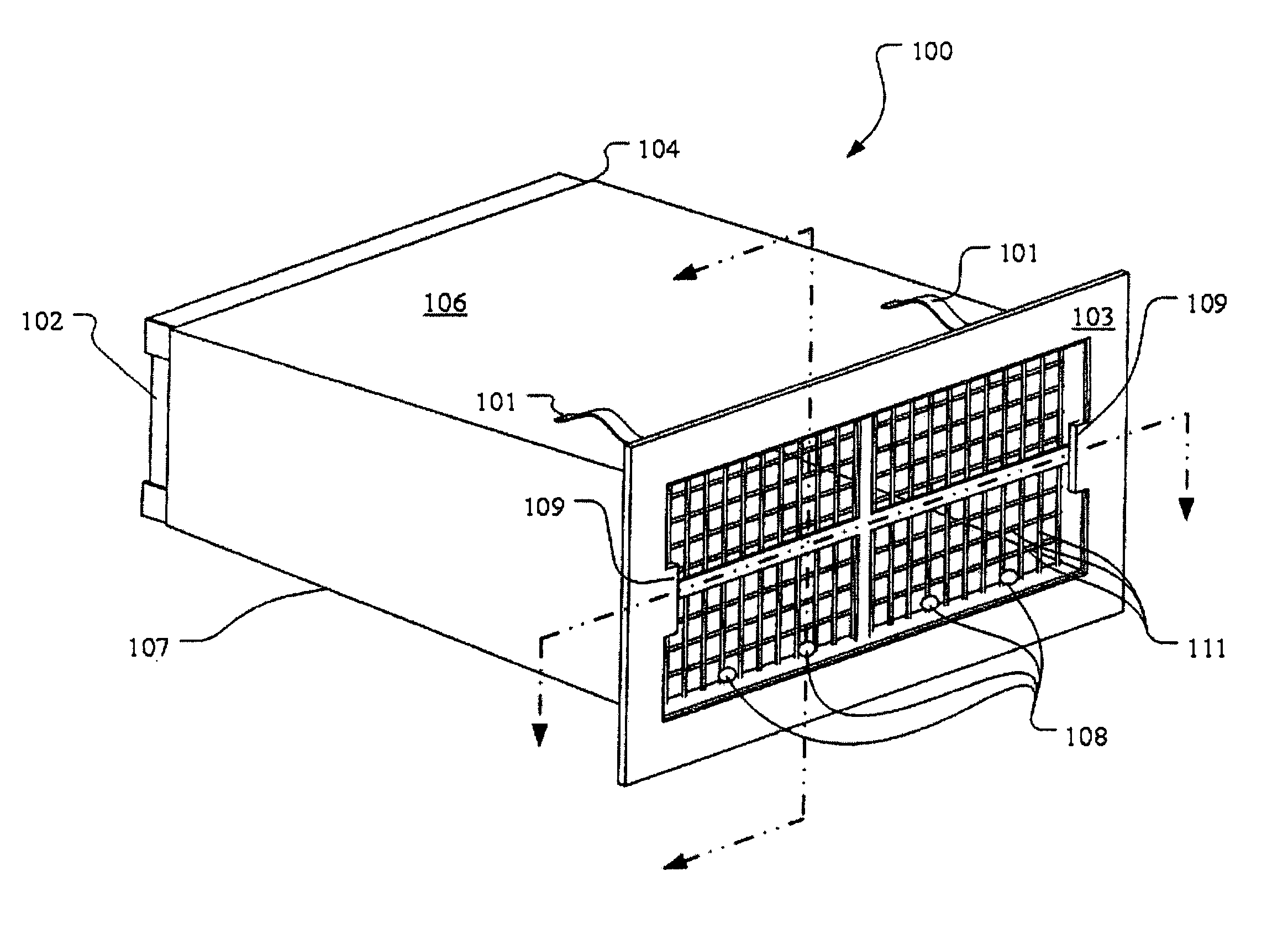

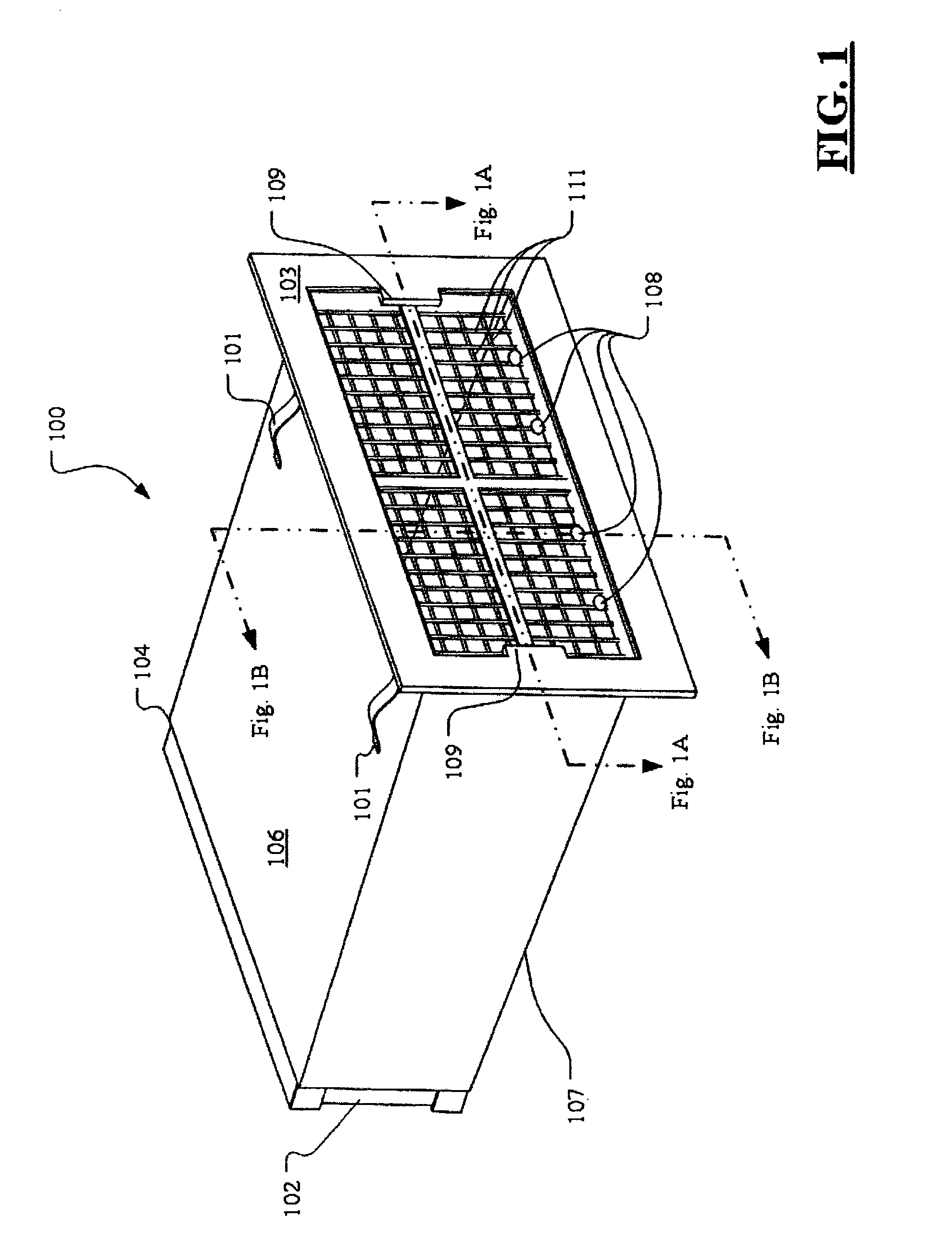

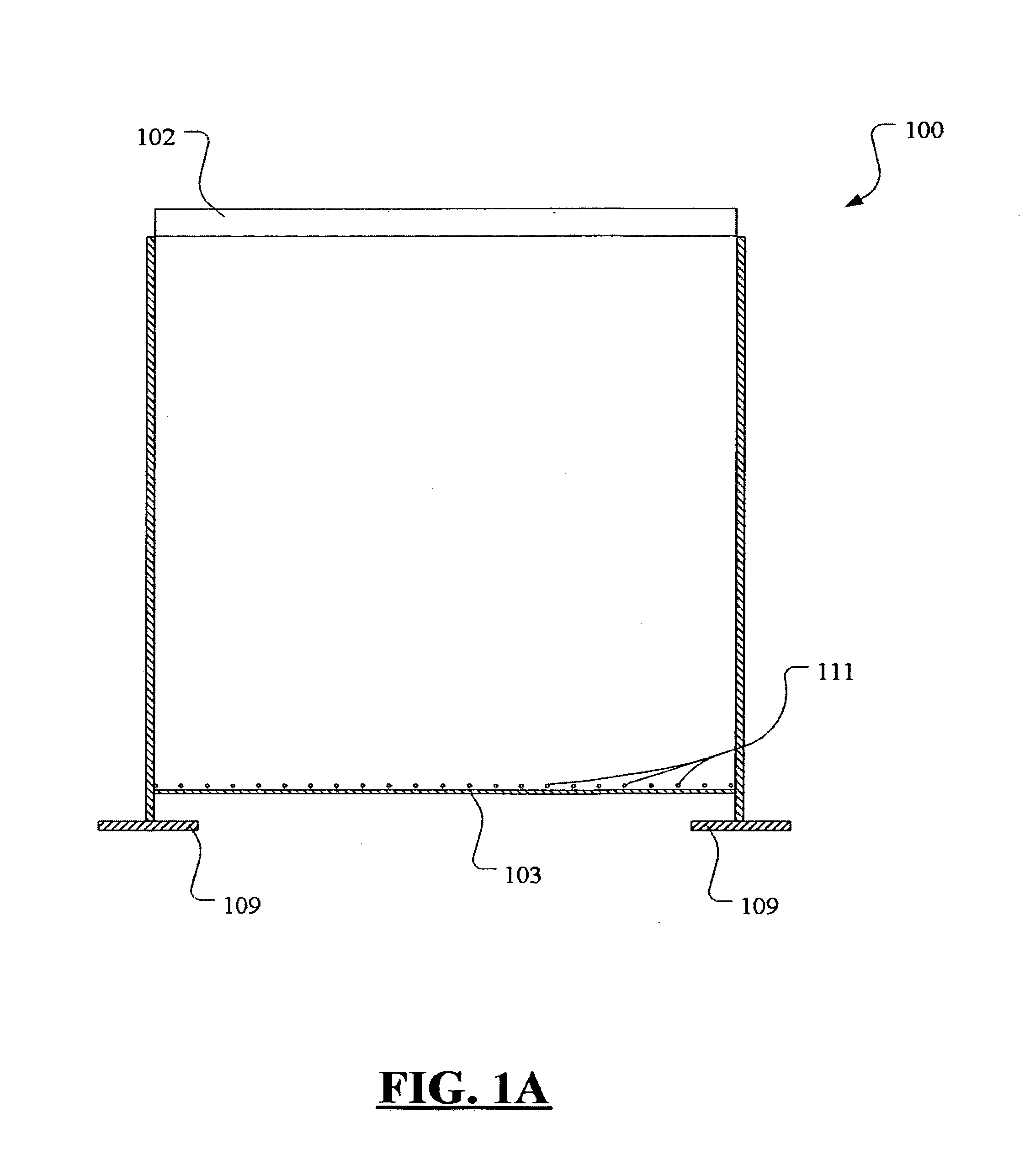

Removable vent having a filter for use in a building foundation

A removable ventilator is equipped to hold an air filter, the ventilator being designed for placement in a building foundation, for example between concrete blocks. The front of the ventilator faces away from the building when the ventilator is installed. The rear of the ventilator faces into the building when the ventilator is installed. At least one securing device is located at the rear of the ventilator, for securing the air filter to the rear. At least one manual handling feature is located at the front of the ventilator, for removing the ventilator from between the concrete blocks.

Owner:A I AIR TECH

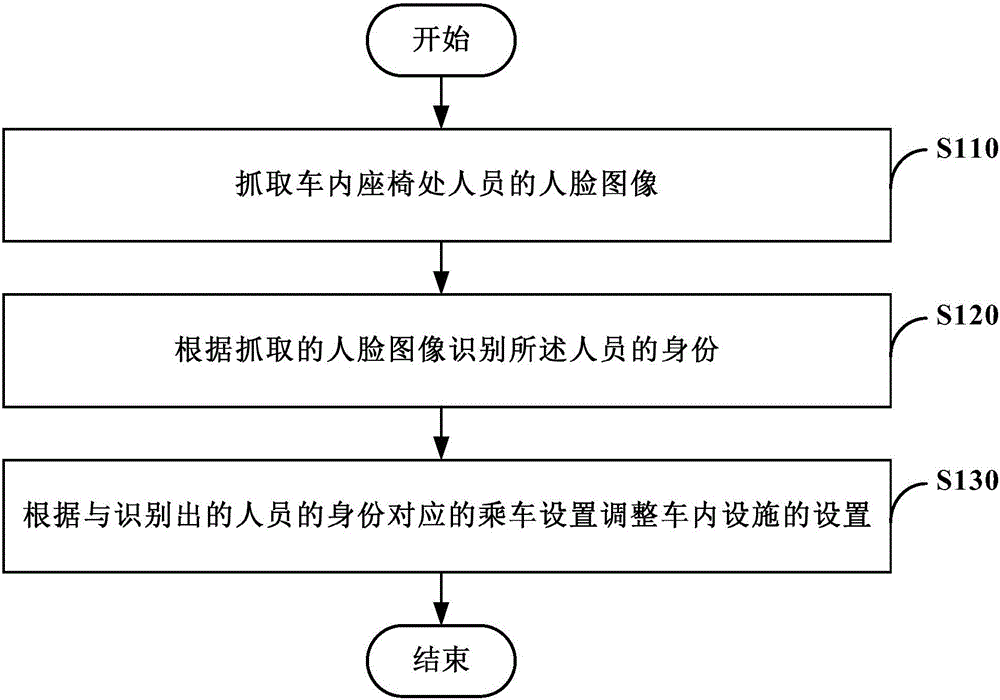

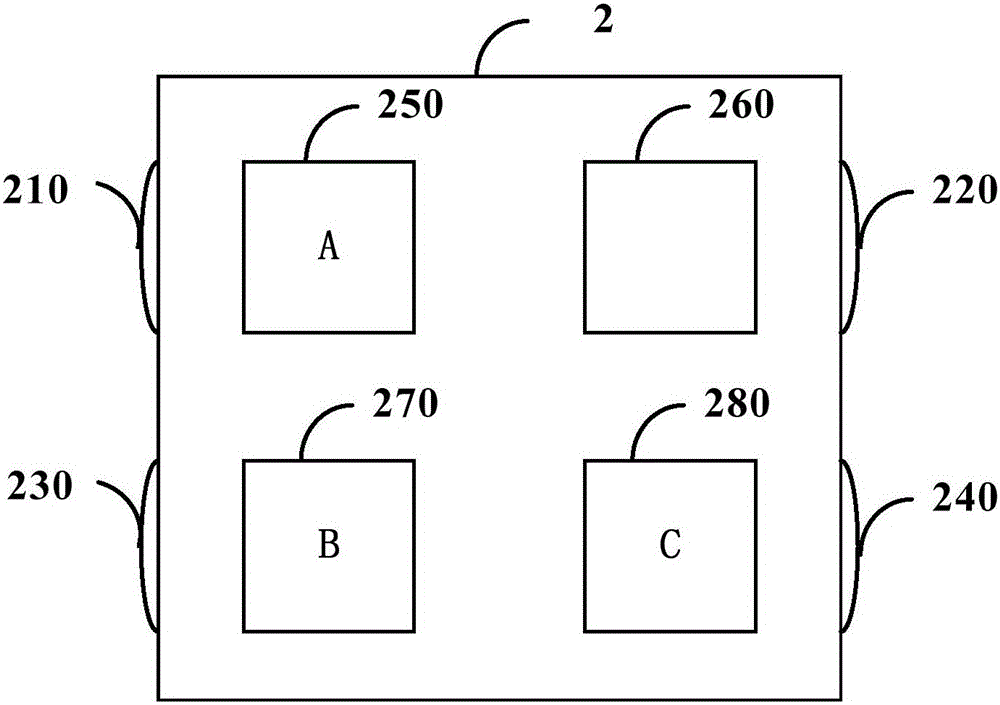

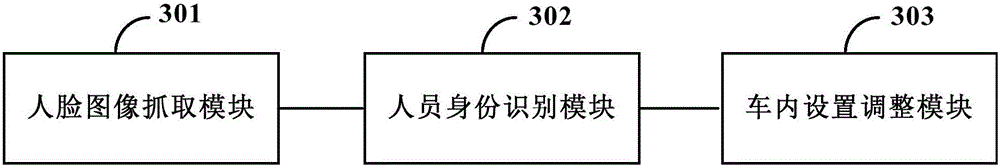

Vehicle setting method and apparatus, and vehicle electronic information system

InactiveCN105843375ARealize active identificationRealize automatic adjustmentInput/output for user-computer interactionCharacter and pattern recognitionElectronic informationSelf adaptive

The invention provides a vehicle setting method and apparatus, and a vehicle electronic information system. The method includes steps of capturing a face image of personnel at a seat in a vehicle; identifying the identity of the personnel according to the captured face image; and adjusting the setting of facilities in the vehicle according to riding setting corresponding to the identified personnel identity. By employing the technical scheme, manual operation is avoided, through the identification of the face image of the personnel at the seat in the vehicle, the setting of the facilities in the vehicle can be automatically adjusted according to the riding setting corresponding to the identified personnel identity so that active identification of the identity of the vehicle riding personnel can be realized, the setting of the facilities in the vehicle can be automatically adjusted according to the riding setting corresponding to the riding personnel identity, good riding experience can be brought to the vehicle riding personnel, and the flexibility of adaptive adjustment of the riding personnel for the vehicle is improved through automatic adjustment of the setting of the facilities in the vehicle.

Owner:EVERGRANDE FF INTELLIGENT AUTOMOTIVE GUANGDONG CO LTD

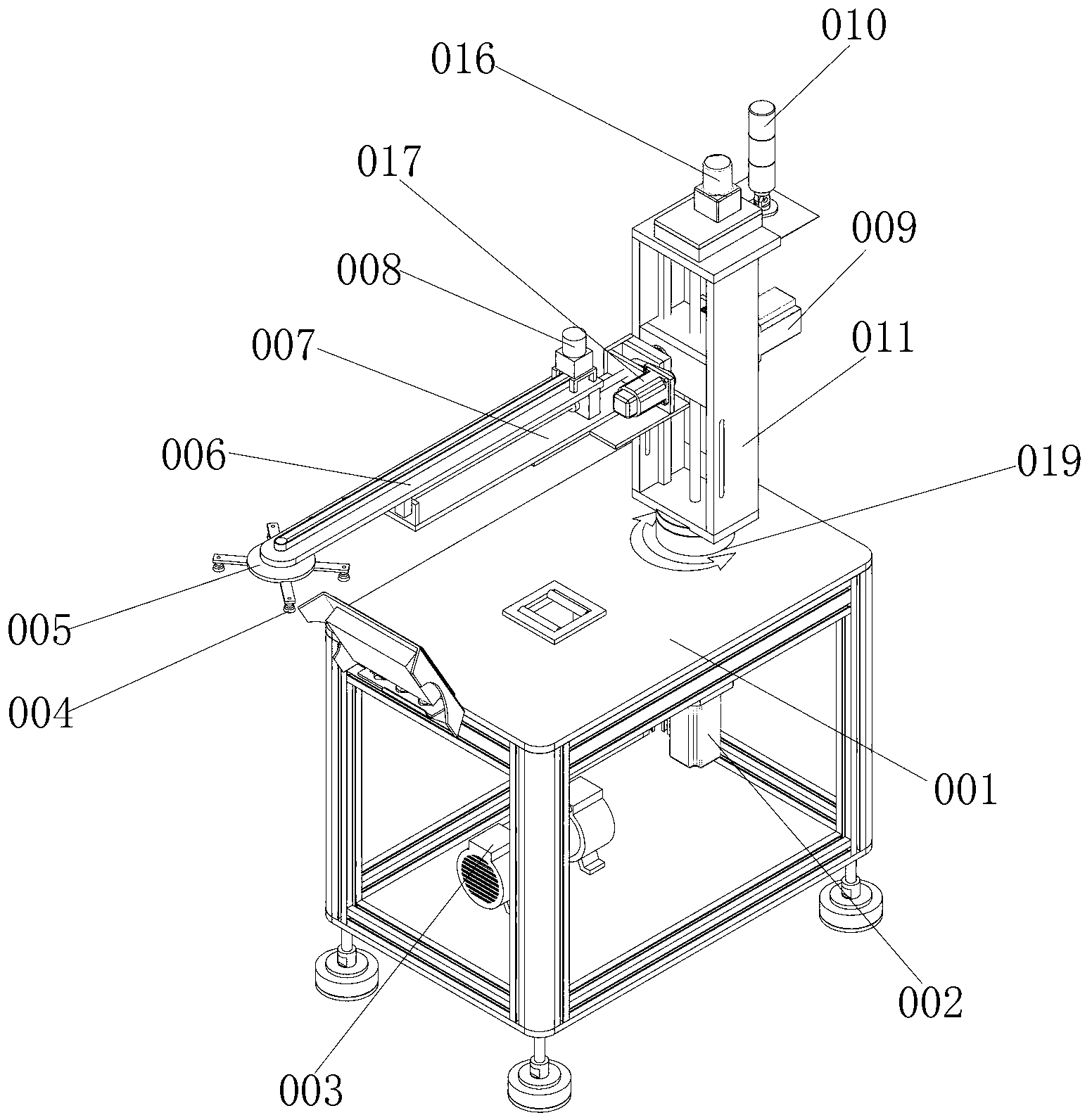

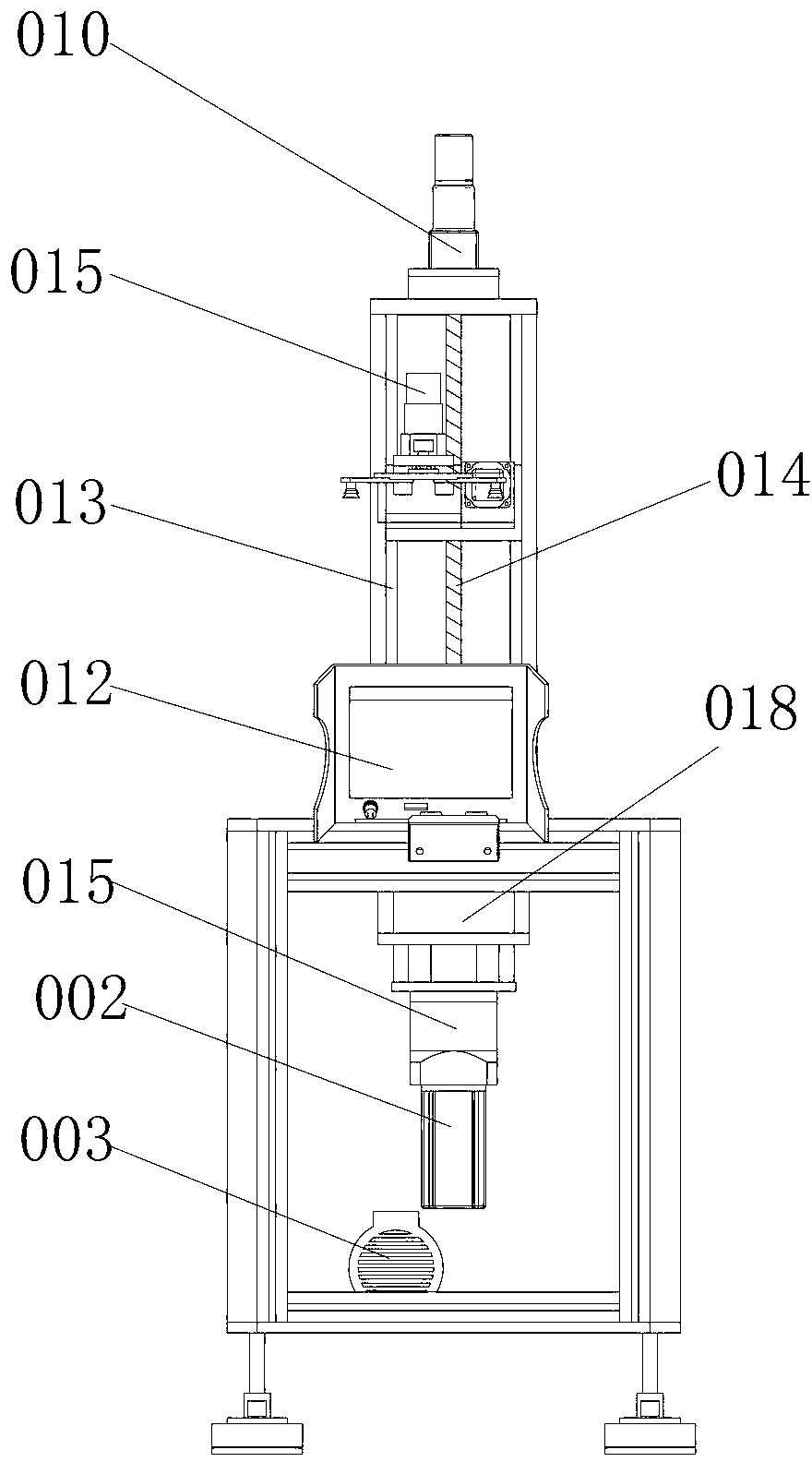

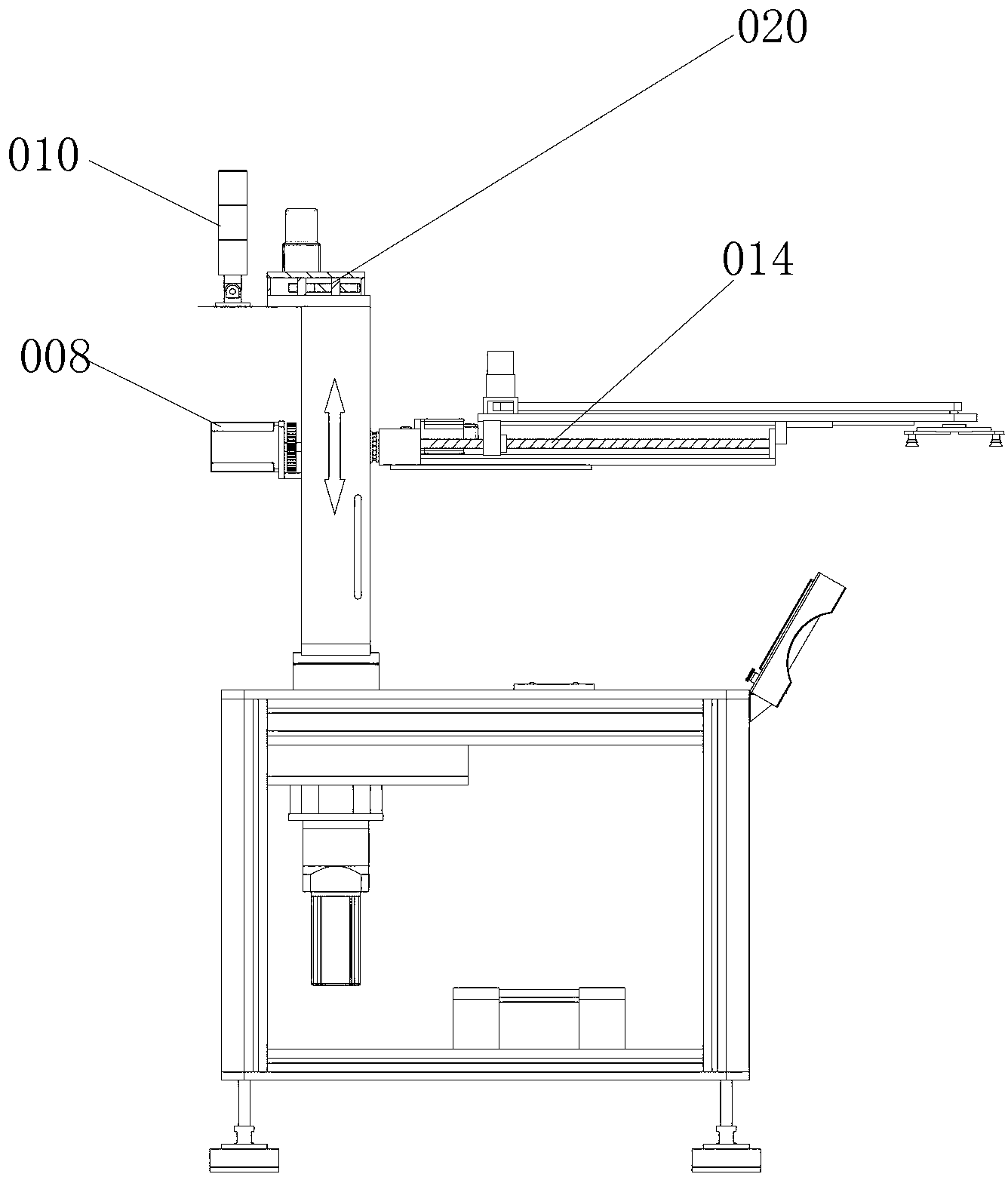

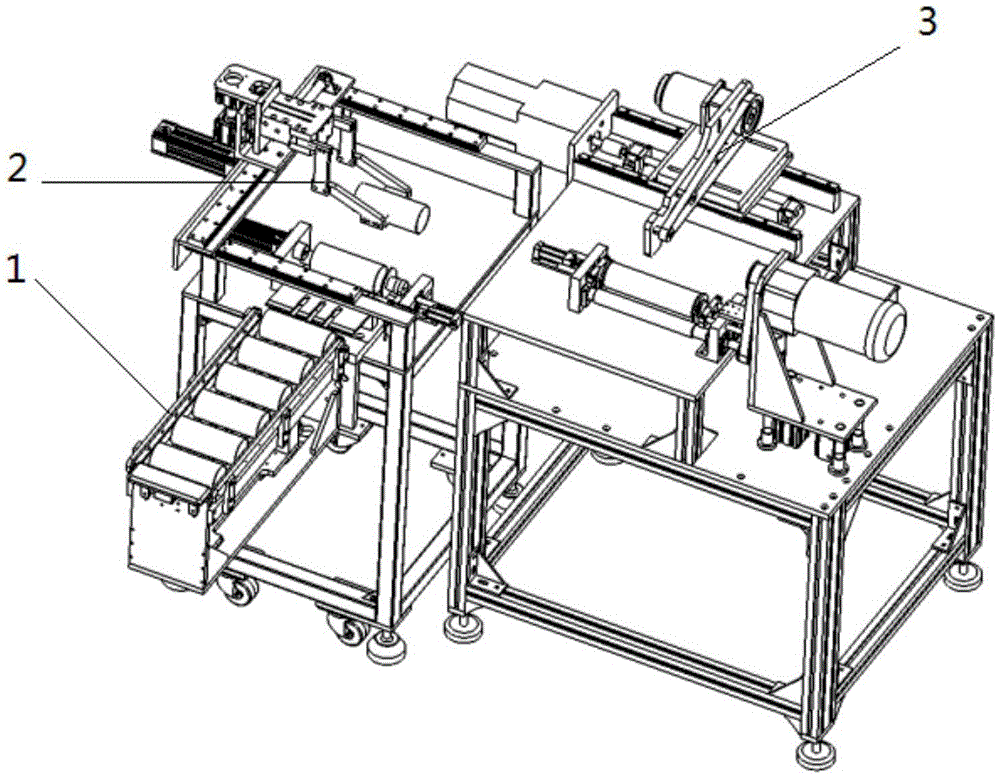

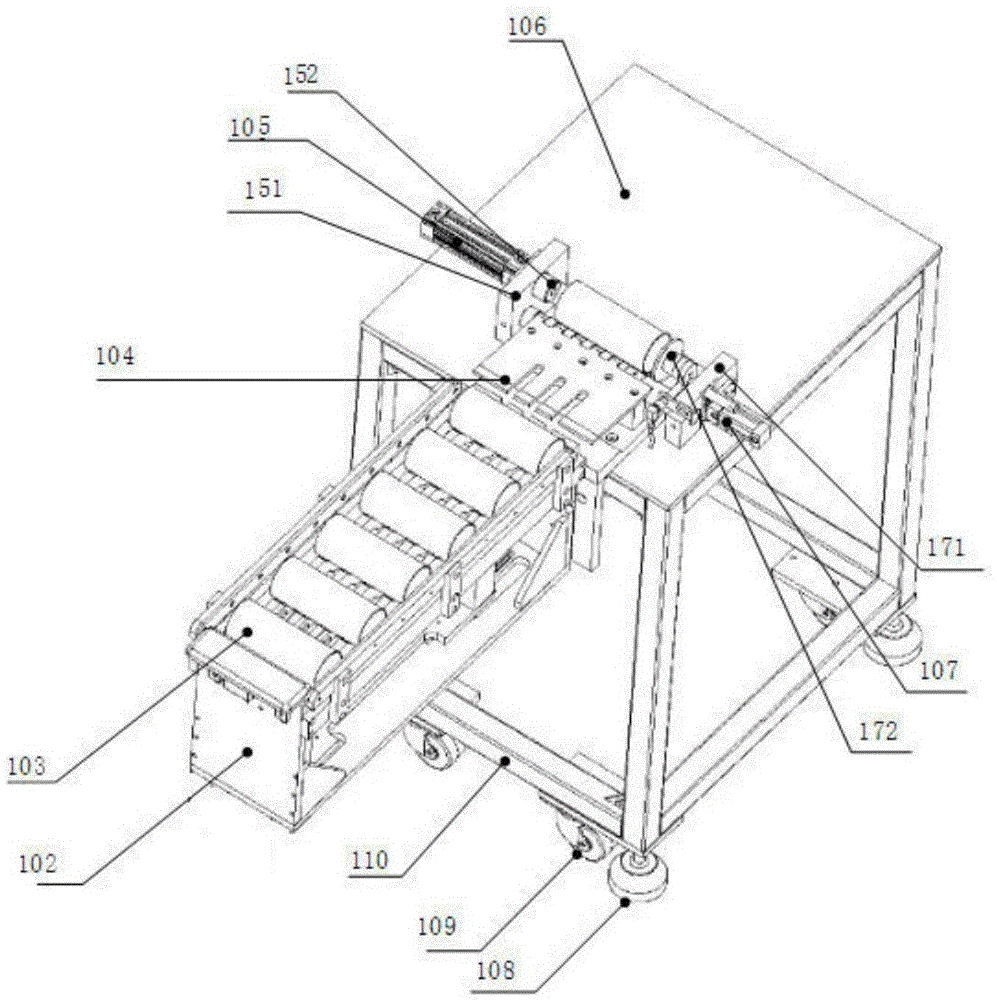

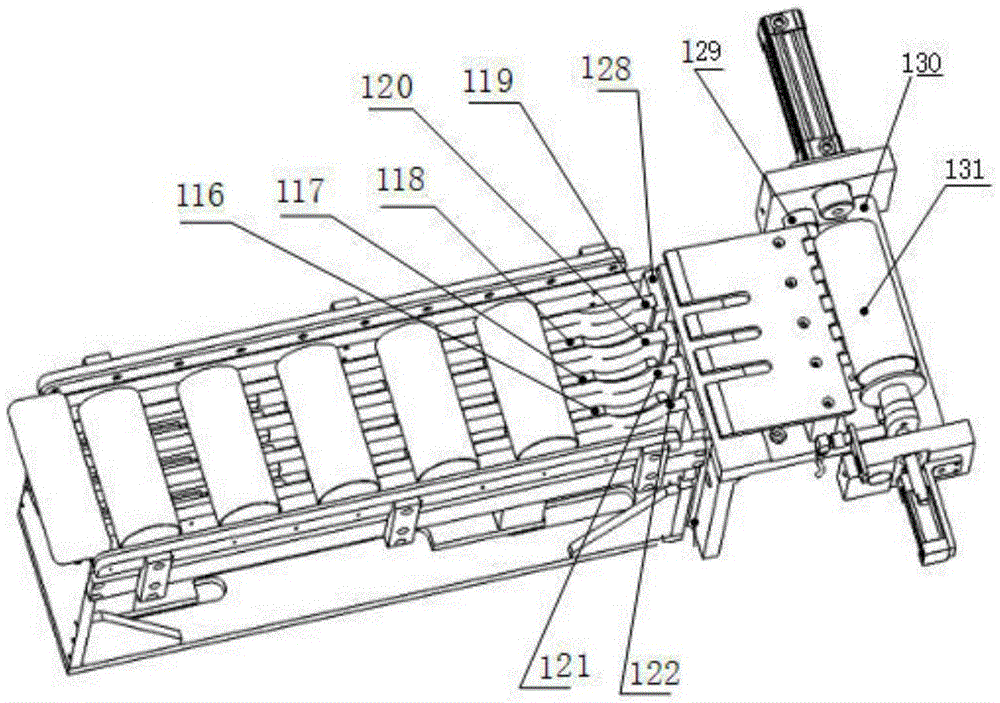

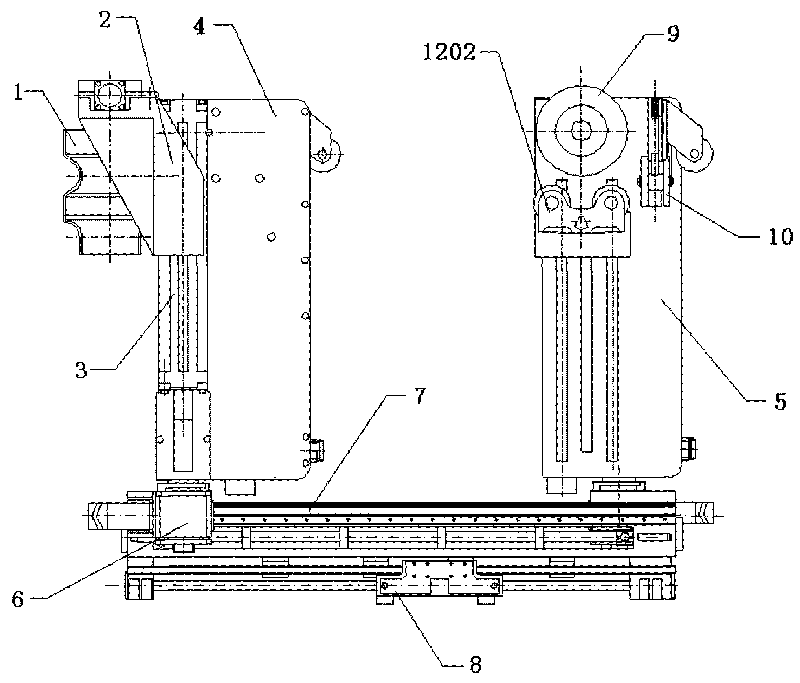

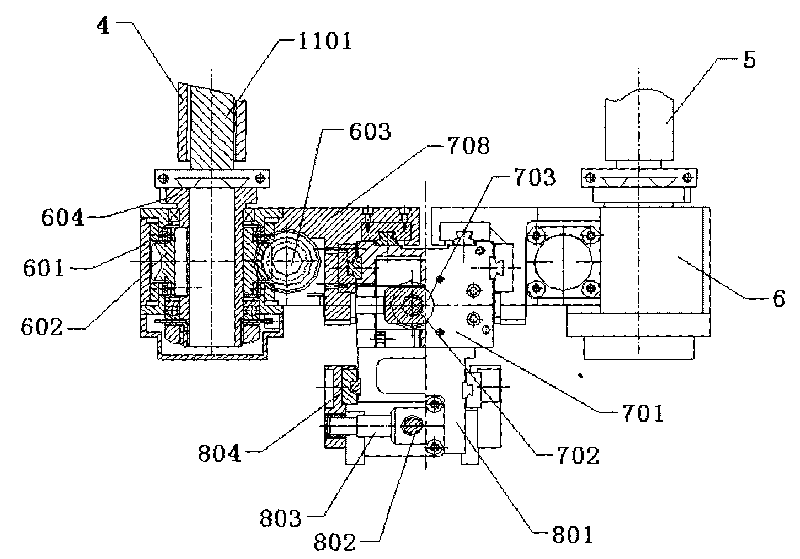

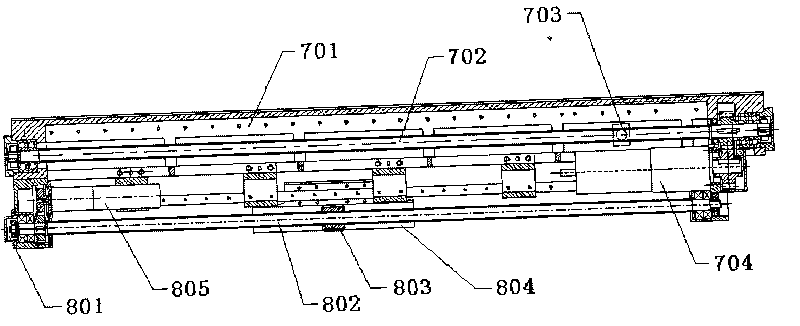

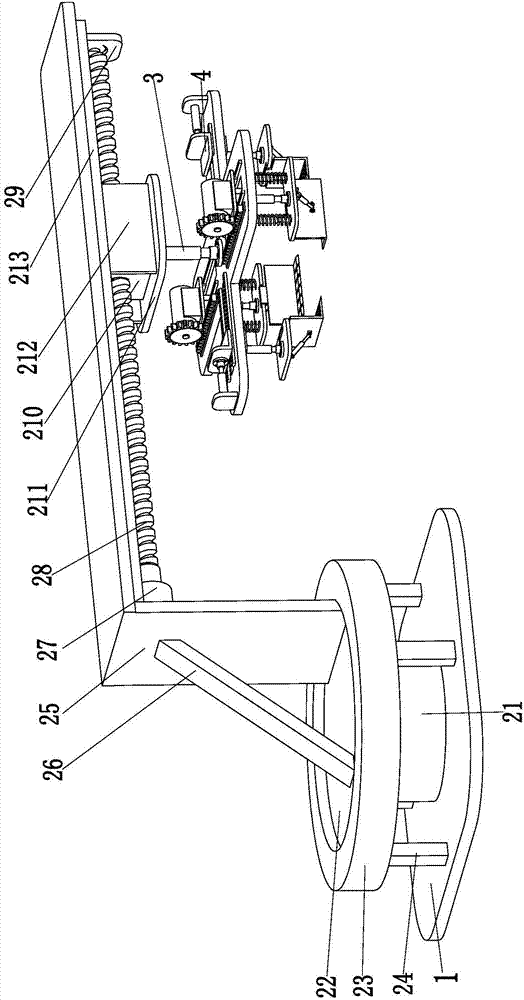

Automatic polishing system for cylindrical workpiece

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

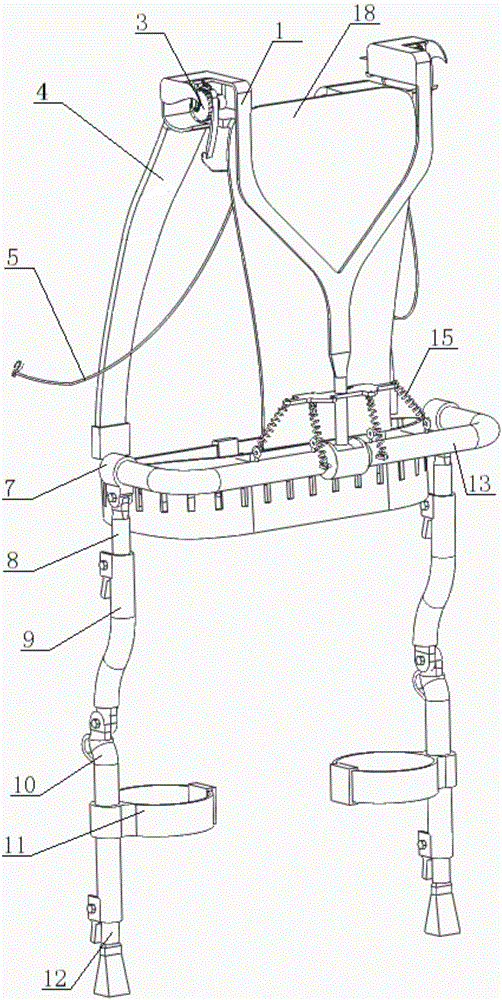

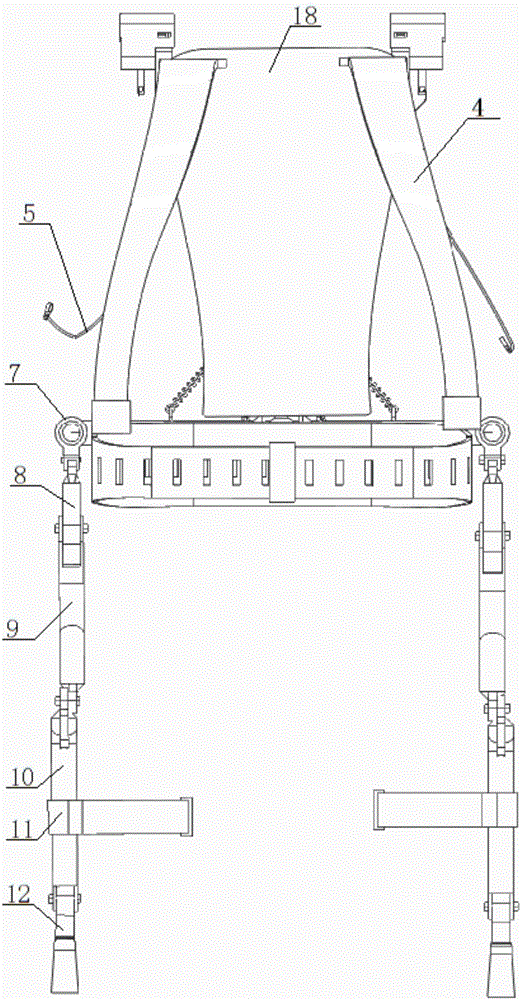

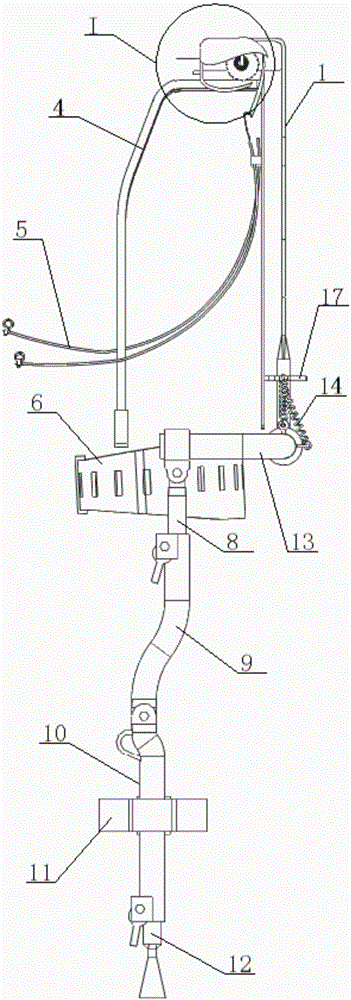

Wearable handling assistor

ActiveCN105856190AReduce loadReduce the burden onProgramme-controlled manipulatorEngineeringMechanical design

The invention provides a wearable handling assistor and belongs to the technical field of mechanical design. Leg assemblies are arranged on the two sides of a waist bent rod, and thigh inner rods of the leg assemblies are connected to the waist bent rod through revolute pairs; suspension belt and ratchet mechanisms are arranged on the two sides of the top of a back bearing plate, ratchet wheels of the suspension belt and ratchet mechanisms are arranged coaxial with coiled springs and are fixed to shafts through key grooves, suspension belt shafts are fixed and wind around the shafts, one ends of the coiled springs wind around the shafts, the other ends of the coiled springs are fixed to racks, one ends of pawl springs are fixed to the racks, the other ends of the pawl springs are connected to pawls, and the tail ends of the pawls are connected to pull wires controlling the pawls to be retracted or released; a connecting rod with a spherical hinge is provided with a ring groove, a back connecting plate is connected to the connecting rod with the spherical hinge through a revolute pair, springs on the two sides are fixed to the back connecting plate and the waist bent rod, a middle spring is fixed to the back connecting plate and the waist bent rod, and the connecting rod with the spherical hinge is connected to the waist bent rod through a spherical pair. The wearable handling assistor is mainly used for assisting in manual handling.

Owner:枣庄华亿矿业集团有限公司

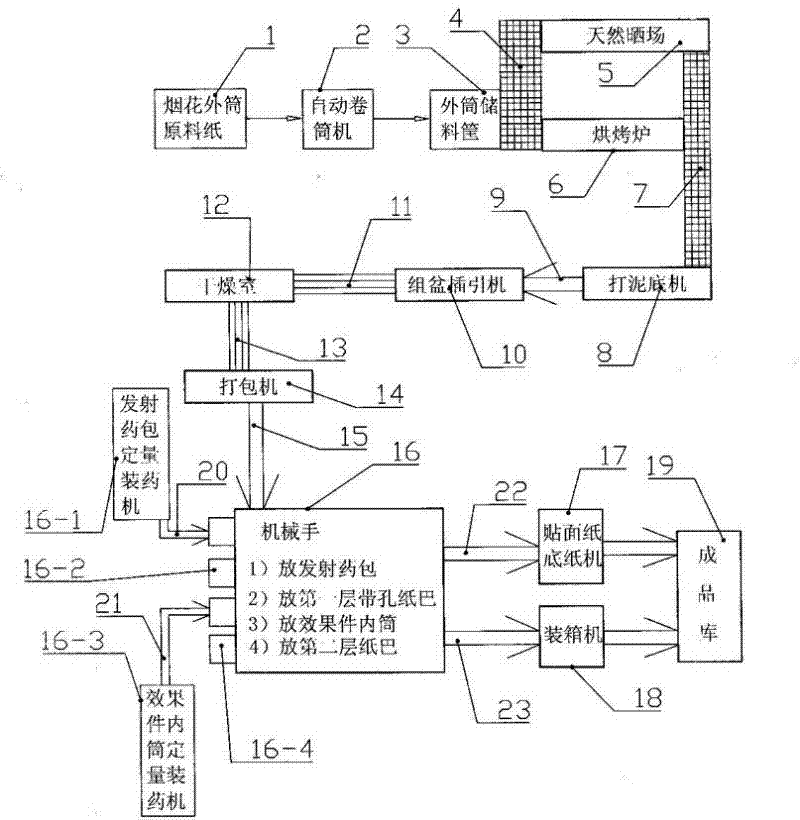

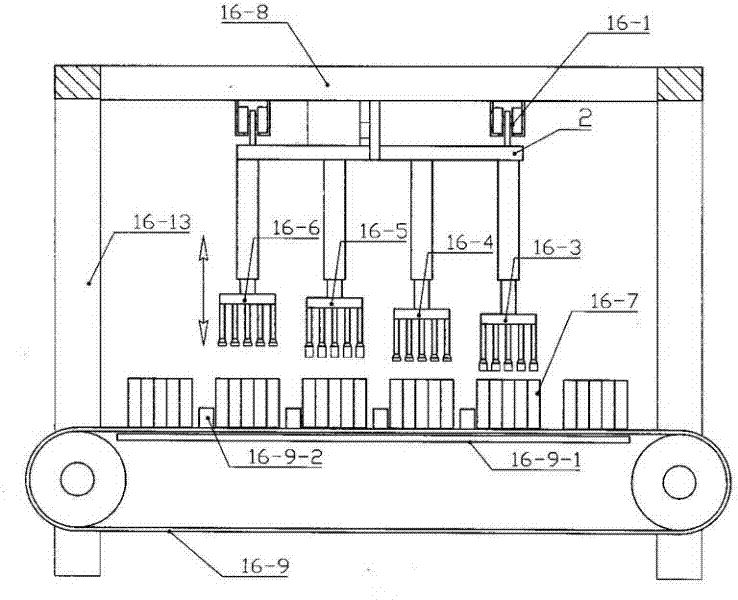

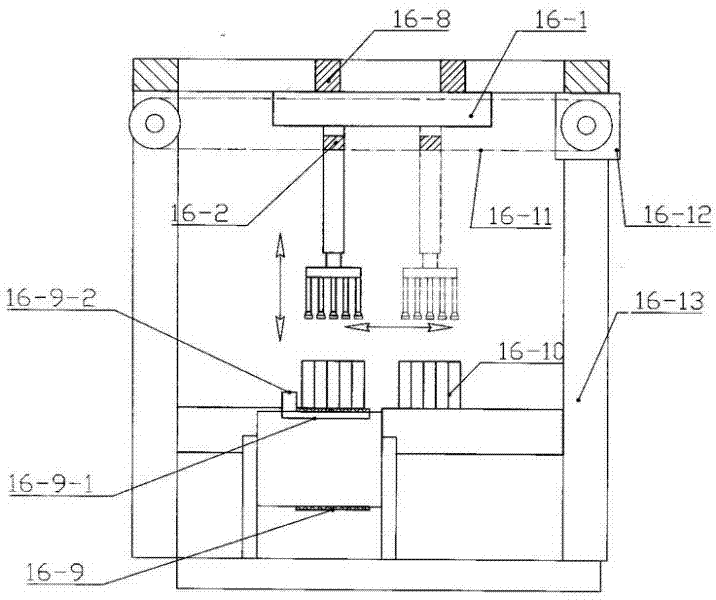

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

Robot for de-icing of power transmission lines

ActiveCN101728803ASo as not to damageGood deicing effectOverhead installationManipulatorEngineeringHigh pressure

The invention relates to a troubleshooting device for high-voltage power transmission lines, in particular to a robot for de-icing of the power transmission lines. The robot is creatively provided with a de-icing mechanism on a front arm, the de-icing mechanism is connected on the front arm through a lifting mechanism, the action of the de-icing mechanism is to carry out the de-icing through the rotation of a de-icing knife and the extrusion of a plurality of the power transmission lines by a walking mechanism and a pressing mechanism during the process that the robot walks along the power transmission lines, and the robot can automatically cross barriers without the need of manual handling, thereby having the advantages of good de-icing effect, high efficiency, wide range of applications and high safety factor.

Owner:GUANGDONG KEYSTAR INTELLIGENCE ROBOT CO LTD

Playing cards shuffling and dealing machine

The invention presents a methodology and device for distribution of playing cards. Automatic operation without manual intervention is its main theme. This eliminates the likely manipulations, monotony, errors associated with manual handling of playing cards. The device has provision of conventional automatic shuffling prior to distributing. Playing cards shuffled in more elaborate manner by other suitable devices also can be used on the invented device. There are many user friendly features of the invented device. These include compact size, portability, ease of operation and maintenance, adaptability to any card games. Optional operation of this device by a remote control enhances its utility Standard playing cards of Bridge or Poker size can be used with this device. The invented device is said to be useful to group of players in homes, club houses, casinos and at out-doors.

Owner:MALI VASANT DATTATRAYA

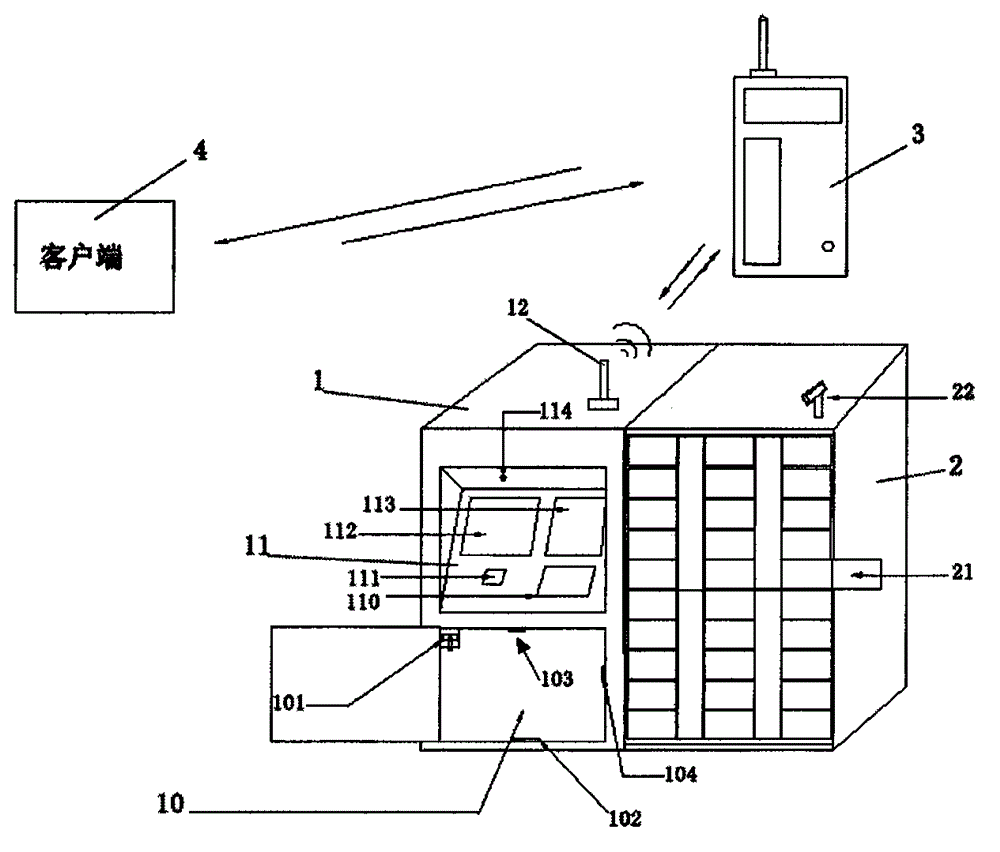

Unattended logistics transceiving system and method

InactiveCN103186843AEasy and flexible deliveryHigh speedLogisticsData switching networksClient-sideElectromagnetic lock

The invention discloses an unattended logistics transceiving system. The unattended logistics transceiving system is characterized by comprising a site operation cabinet (1), a site storage cabinet (2), a server (3) and a client-side (4), wherein a manual operation table (11) is arranged at the upper part of the site operation cabinet (1), and comprises an electronic display screen (110), a 2nd-generaiton ID (identity) card reader (111), a liquid crystal touch screen (containing a micro machine) (112), an operation prompting diaphragm (113) and a pinhole camera (114); and a package processing tool cabinet (10) is arranged at the lower part of the site operation cabinet (1), and comprises a bar code machine (101), a weighing table (102), an illuminating lamp (103) and an electromagnetic lock (104). Aiming at the disclosed unattended logistics transceiving system, the invention also discloses a dispatching and receiving method. The unattended logistics transceiving system and the unattended logistics transceiving method provided by the invention have the advantages of low construction cost, simplicity and flexibility in operation, labor and time conservation, and high safety and reliability, and can be widely applicable to places needing to dispatch and receive express deliveries frequently, such as office buildings.

Owner:深圳市收立方科技有限公司

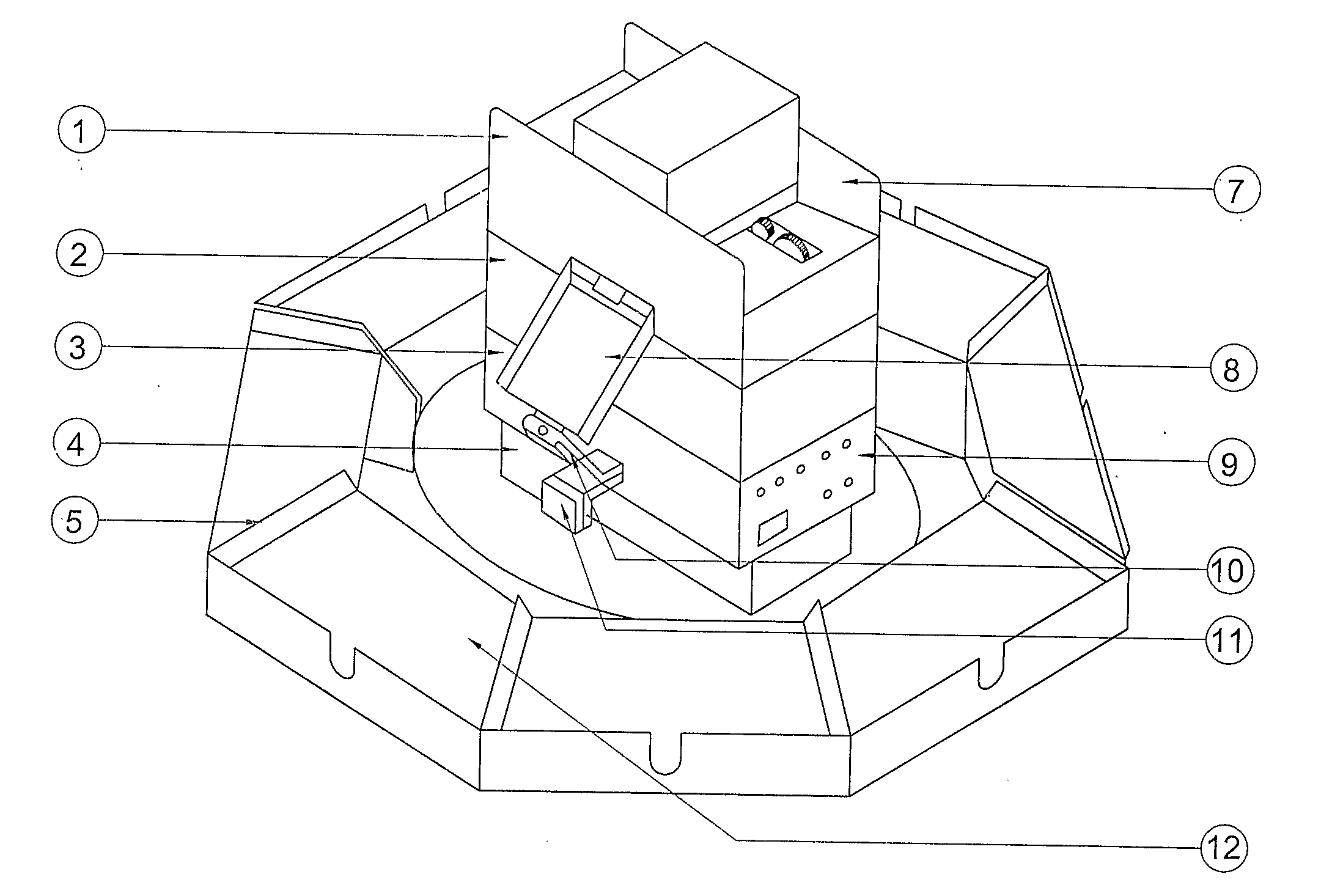

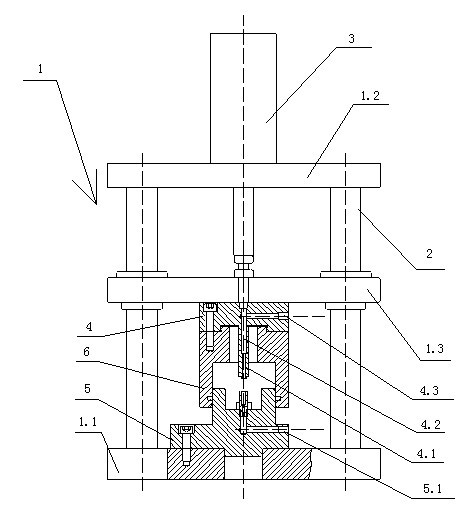

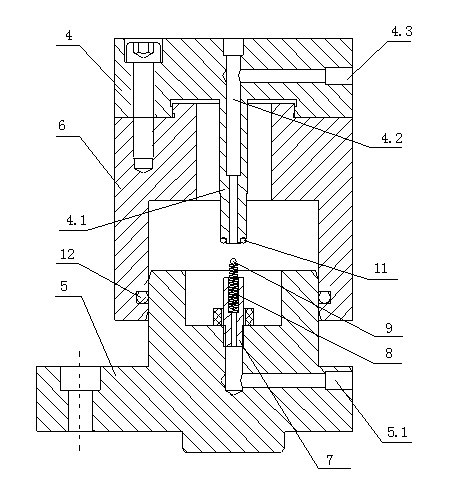

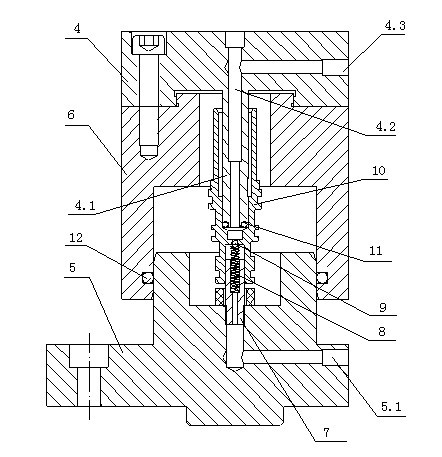

Valve element airtightness testing device

ActiveCN102128707AImprove detection efficiencyEasy to operateDetection of fluid at leakage pointTest efficiencyAir tightness

The invention relates to a valve element airtightness testing device and belongs to the technical field of testing clamps. The valve element airtightness testing device is characterize by comprising a pressing device (1), wherein the pressing device (1) comprises a bottom plate (1.1), a top plate (1.2) and a movable beam (1.3); the top plate (1.2) is provided with an air cylinder (3); a pluralityof guide posts (2) are arranged between the bottom plate (1.1) and the top plate (1.2); the movable beam (1.3) is sleeved on the guide posts (2); a pressure block (4) is arranged at the bottom of themovable beam (1.3); a base (5) is arranged on the bottom plate (1.1); and a sealed barrel (6) is fixed below the pressure block (4). The valve element airtightness testing device can provide stable and adjustable pressing force, so the airtightness of the valve element can be tested more accurately, and the test efficiency is improved; and the operation is convenient, the structure is simple, thetest efficiency is high, and the manual operation intensity is lowered.

Owner:WUXI YINGBEI PRECISION BEARING

Automatic packing system for garbage can and using method of automatic packing system

ActiveCN106241110ARealize automatic sealingNo need for manual packingRefuse receptaclesEngineeringMechanical engineering

The invention discloses an automatic packing system for a garbage can and a using method of the automatic packing system. The automatic packing system for the garbage can comprises bundle clamping mechanisms and an automatic sealing mechanism which are positioned above the garbage can, wherein the bundle clamping mechanisms comprise a first bundle clamping mechanism which moves in the X-axis direction and a second bundle clamping mechanism which moves in the Y-axis direction; the first bundle clamping mechanism is positioned above the second bundle clamping mechanism; and the automatic sealing mechanism is positioned between the first bundle clamping mechanism and the second bundle clamping mechanism. According to the technical scheme, a garbage bag is clamped into a bundle and then is automatically sealed with glue, automatic garbage packing is realized, manual operation is not required, meanwhile, clamping packing precision can be guaranteed, and the circumstance of inadequate packing is prevented.

Owner:GUANGZHOU UNIVERSITY

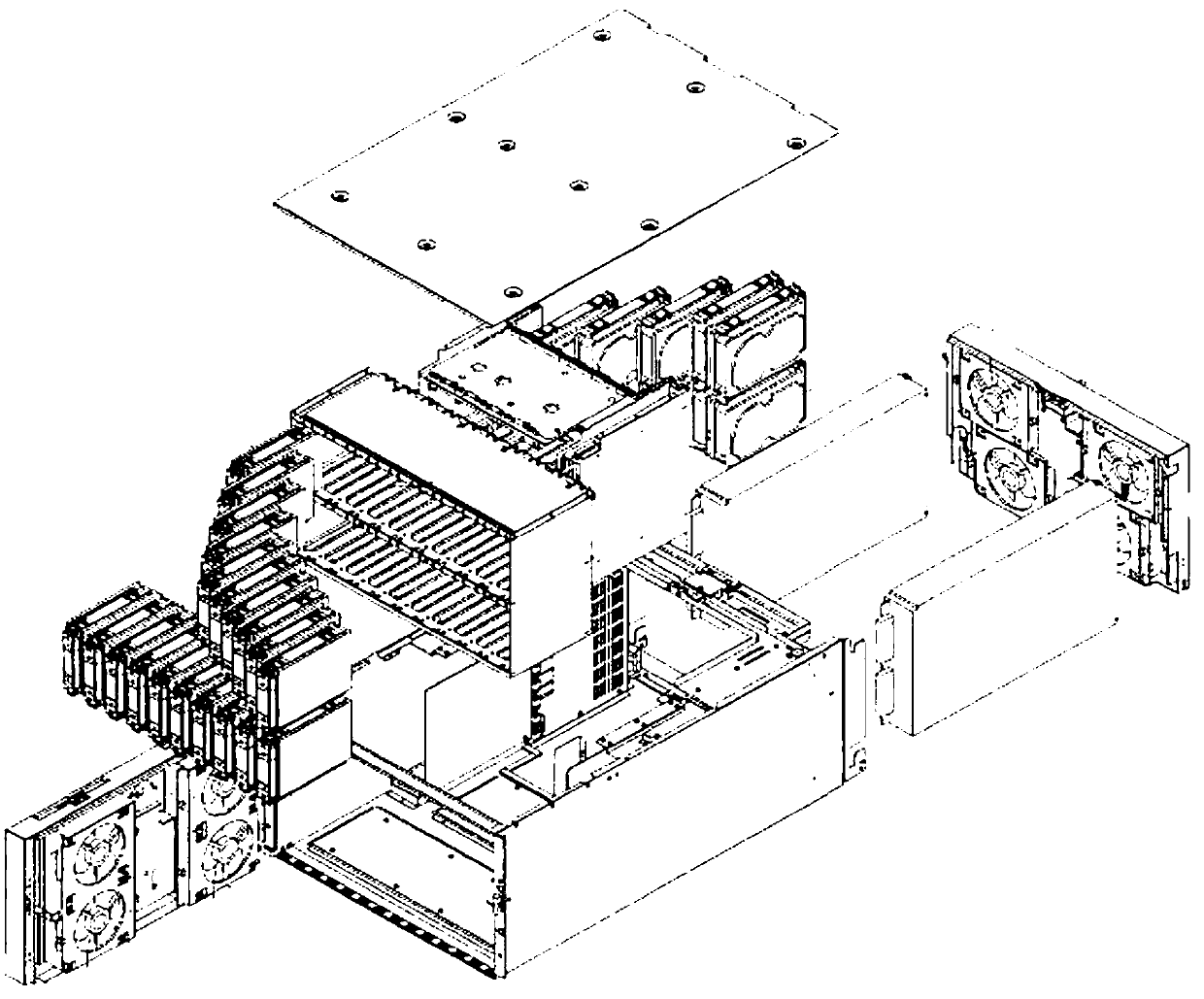

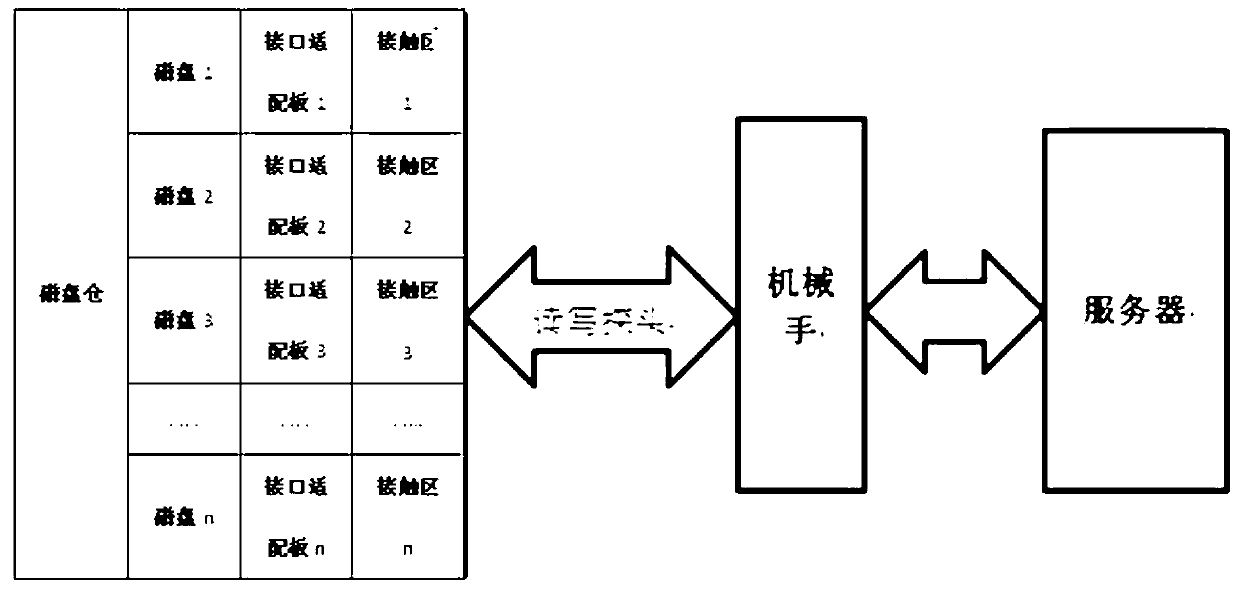

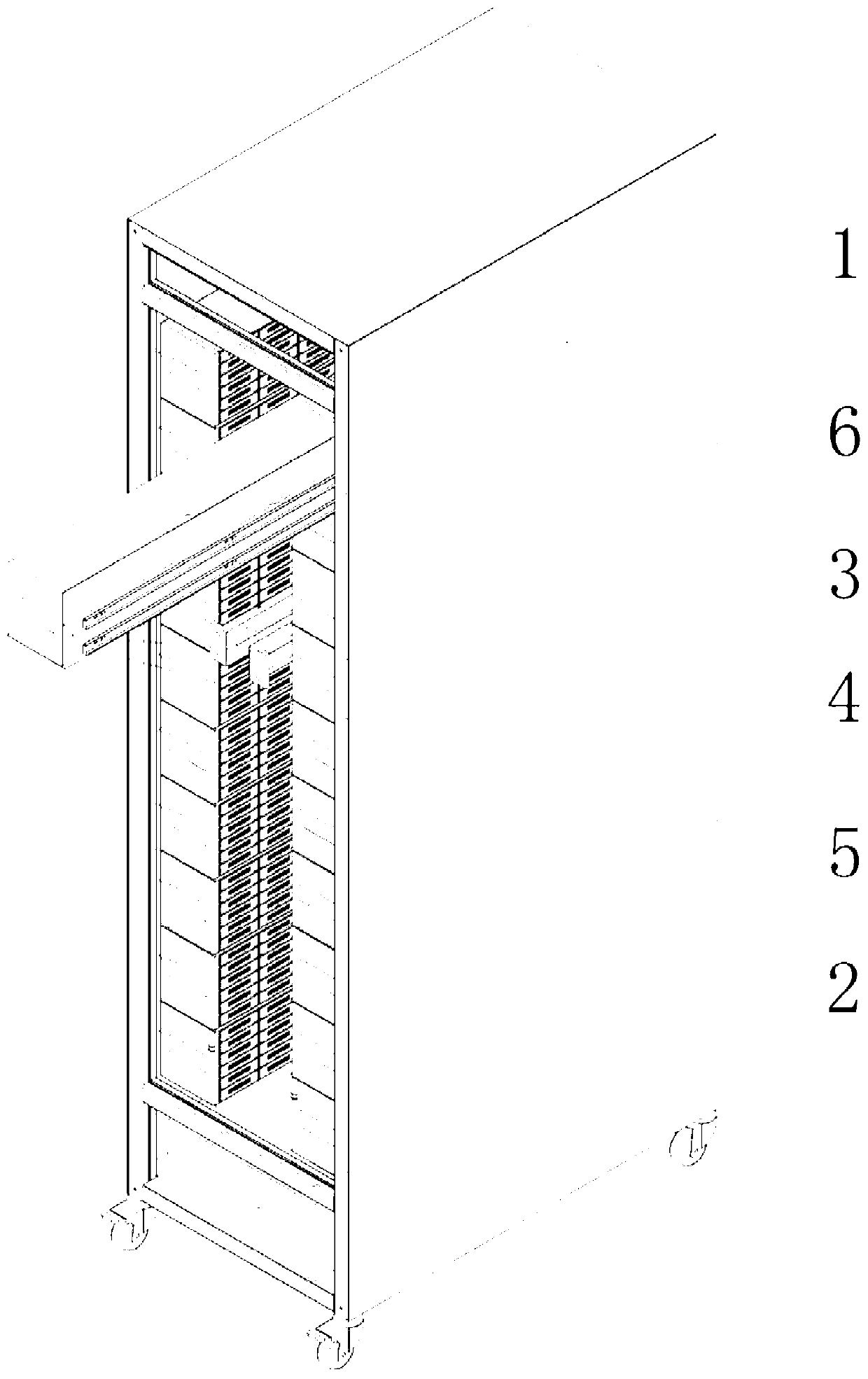

Near-line disk base

ActiveCN103280228AExtended service lifeRealize the purpose of moving the line without moving the diskApparatus modification to store record carriersRecord information storageEngineeringManipulator

The invention discloses a near-line disk base which comprises a cabinet, a server, a manipulator and a plurality of disk storage drawers, wherein the disk storage drawers are in sliding connection with the cabinet through a sliding rail in a drawing mode, the disk storage drawers are longitudinally arranged on one side or two sides of the manipulator, disk storages are installed in the disk storage drawers, a plurality of containing grooves are formed in each disk storage in an array mode, disks are arranged in the containing grooves in an inserting mode, the drawing end of each disk is connected with an interface adaptive board through a first inserting interface in an inserting mode, disk contact points and manipulator contact points which are electrically connected are distributed on each interface adaptive board, the disk contact points and the corresponding disks are broken over, and the manipulator is provided with a probe component which is capable of moving horizontally and vertically. The near-line disk base is free of manual operation, all the disks can be managed automatically in a near-line mode only by the disk storages, the manipulator, the read-write probe and the server, the principle is simple, the near-line disk base is safe and reliable, and all relevant problems caused by the manual operation are solved at the same time.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

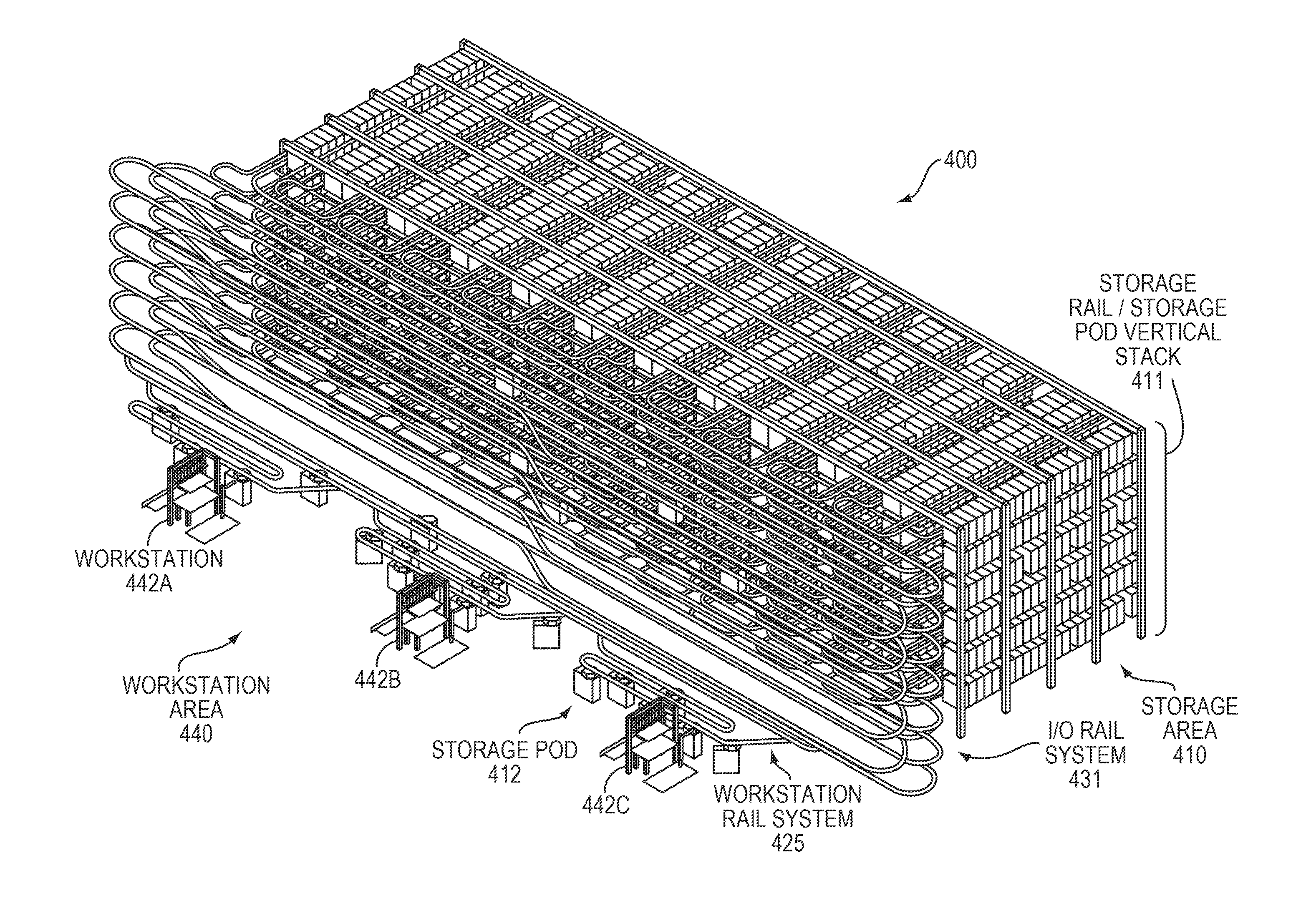

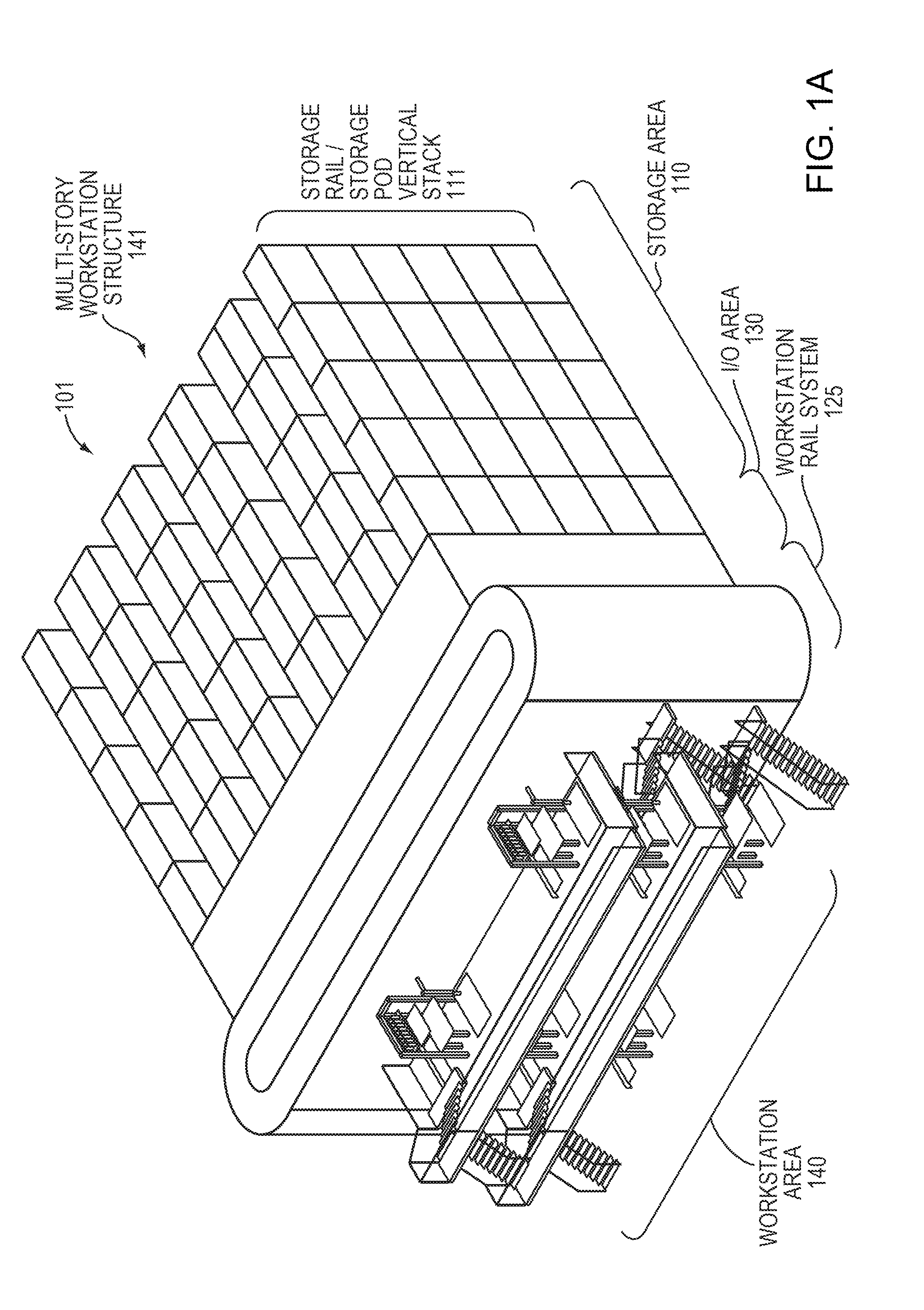

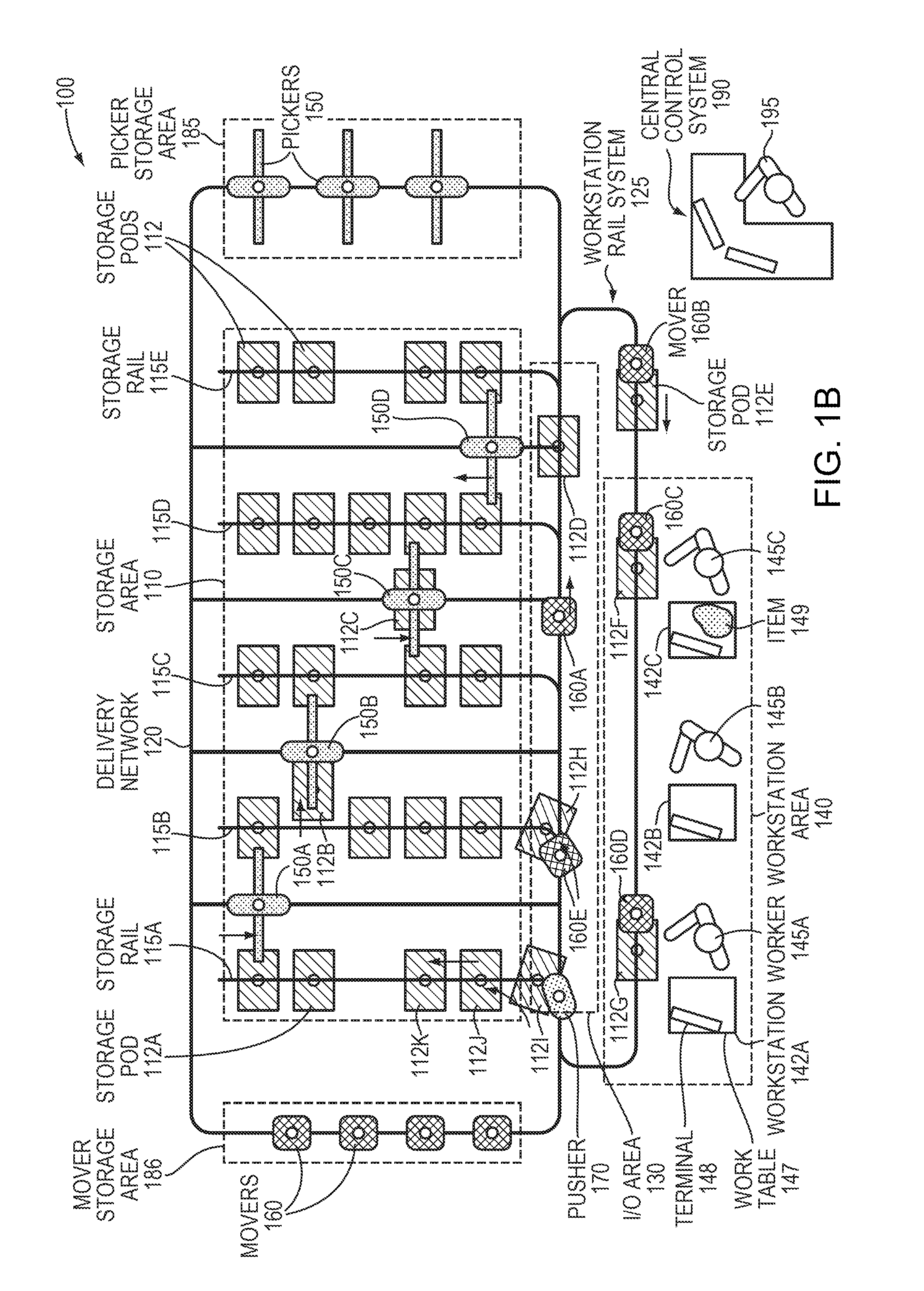

Automated Storage And Retrieval

An automated storage system provides for storing and retrieving items at a common storage space, such as a warehouse. The system includes an arrangement of storage rails that support storage containers. A delivery rail network extends adjacent to the storage rails and to human worker-operated workstations. Picker devices, maneuvering along the delivery rail system, operate to locate a selected storage container, decouple the container from the storage rail system, and transport the storage container along a segment of the delivery rail network. A mover device then receives the selected storage container from the picker device and transports the storage container to a workstation, where items can be retrieved from (and / or added to) the storage container by the human worker.

Owner:SHENZHEN EXTREFFICIENT INTELLIGENCE LTD

Constructional engineering grab bucket capable of grabbing and carrying bagged cement of different specification

ActiveCN106946035AImprove handling efficiencySolve labor intensityConveyor partsManual handlingFlange

The invention relates to a constructional engineering grab bucket capable of grabbing and carrying bagged cement of different specifications. The grab bucket comprises a bottom plate, a regulating device is installed on the bottom plate, the lower end of the regulating device is provided with a hydraulic lift cylinder, the bottom end of the hydraulic lift cylinder is installed on a gripping device by flanges, the regulating device can drive the gripping device mounted on the hydraulic lift cylinder to adjust positions, the gripping device can grab bagged cement, and the regulating device, the hydraulic lift cylinder and the gripping device cooperate with each other to complete the process of gripping bagged cement. According to the grab bucket provided by the invention, the existing problems, such as high labor intensity, low handling efficiency and complicated operation, caused during manual handling of bagged cement are solved, the operation complication being caused by different requirements on workers by different specifications of bagged cement. And the function of automatic gripping of bagged cement can be realized.

Owner:福建兴旺建设发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com