Patents

Literature

621results about How to "Solve labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

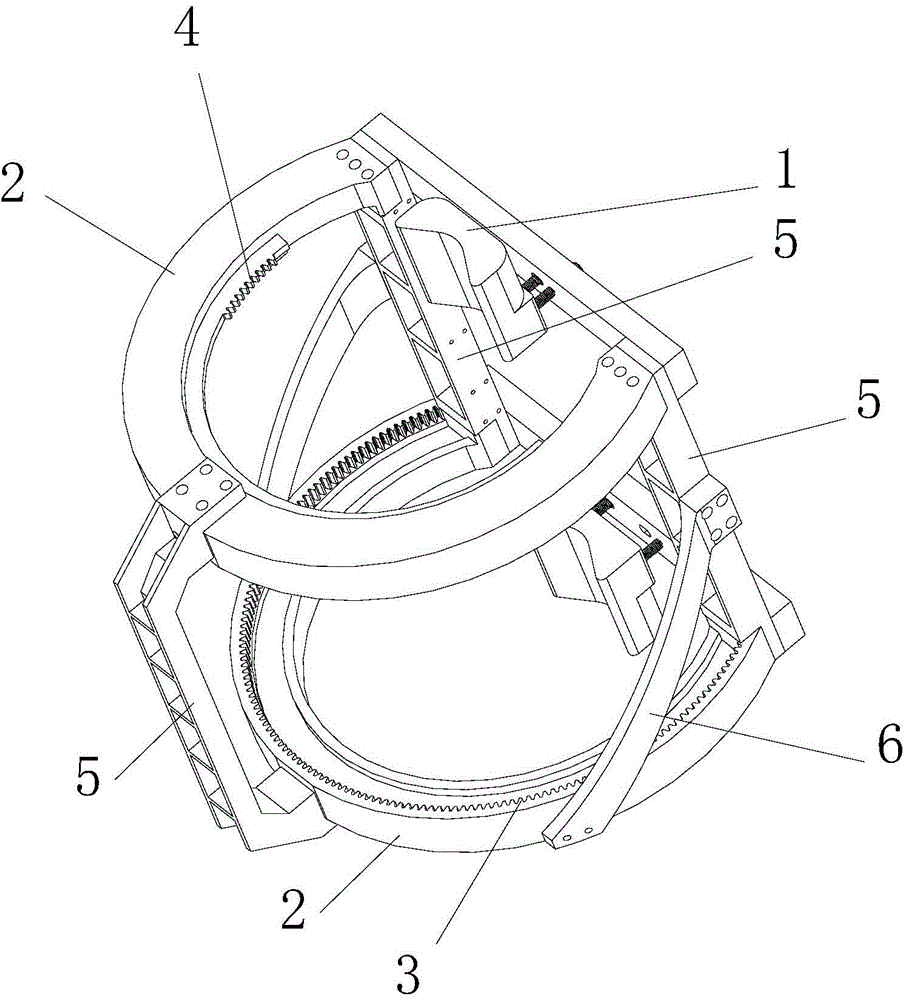

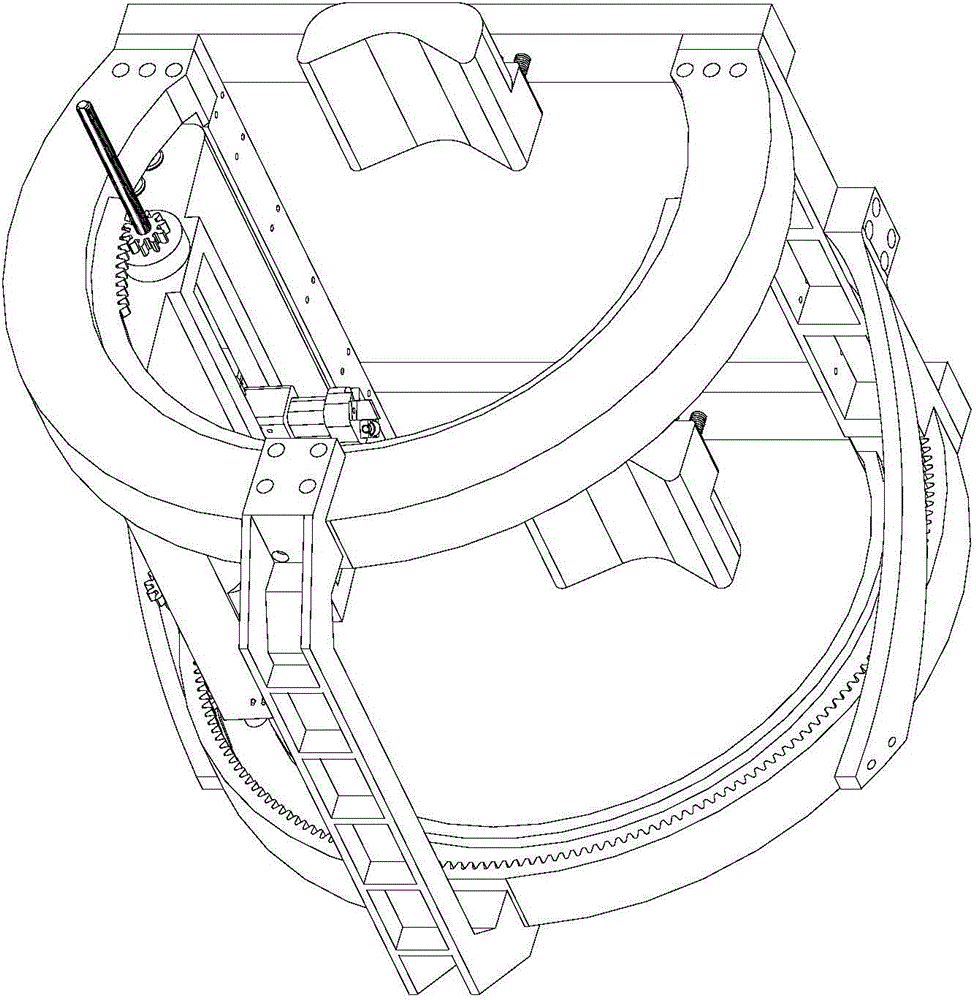

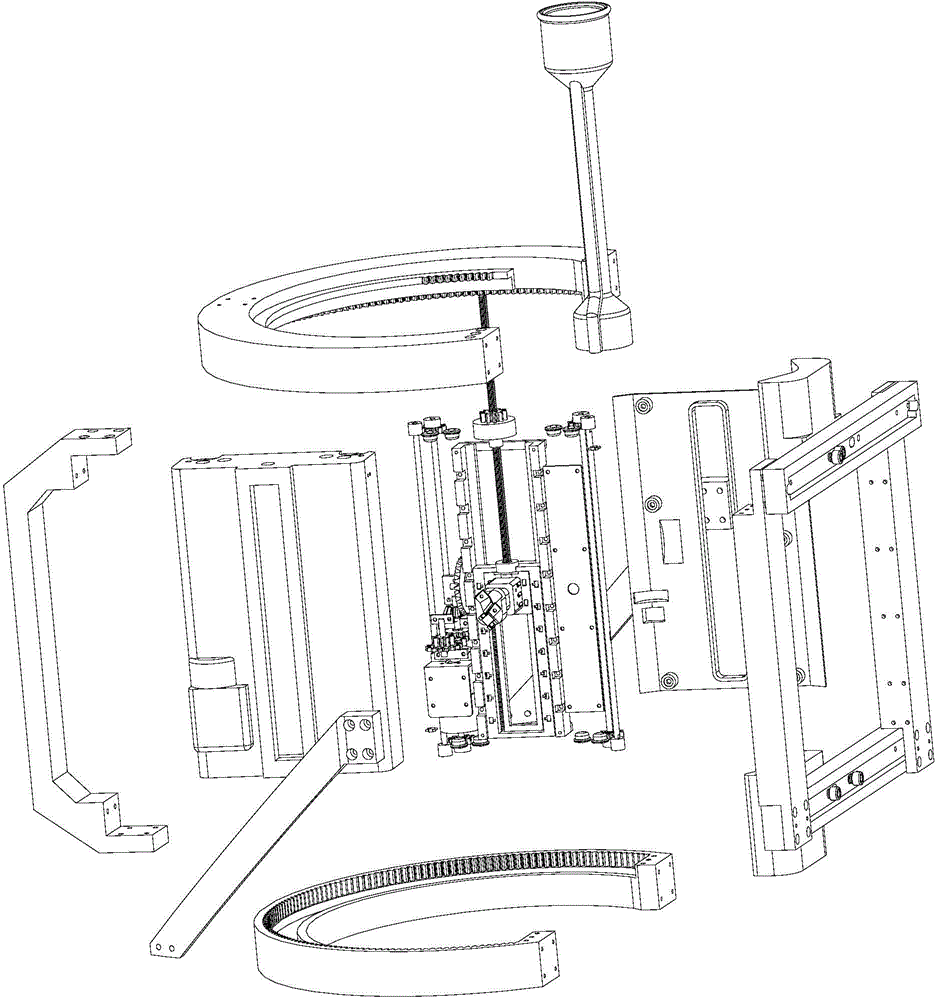

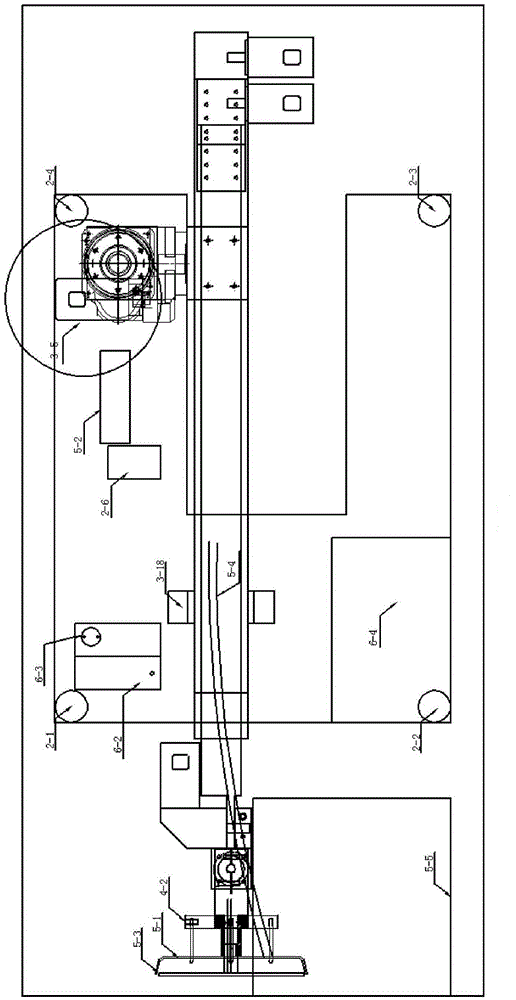

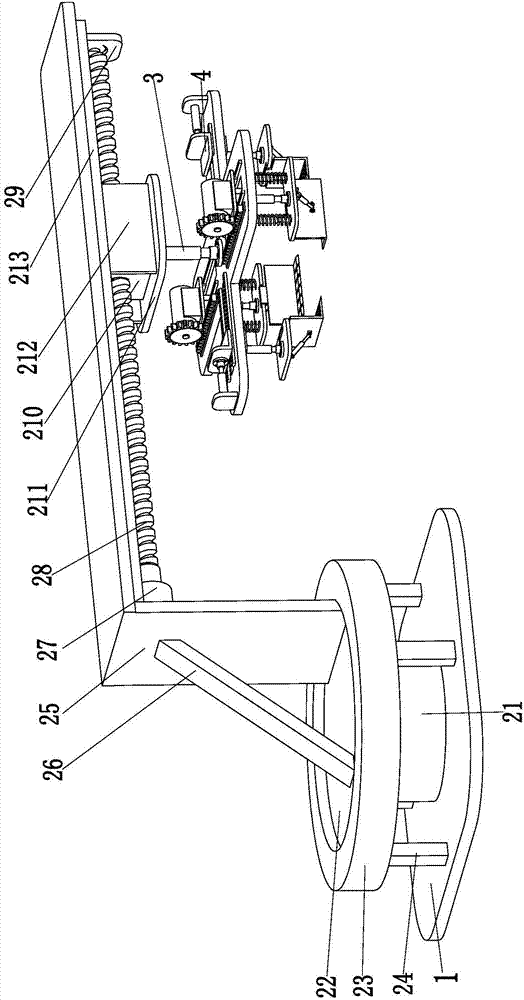

Rubber tapping machine

ActiveCN104429813ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryAutomatic controlControl system

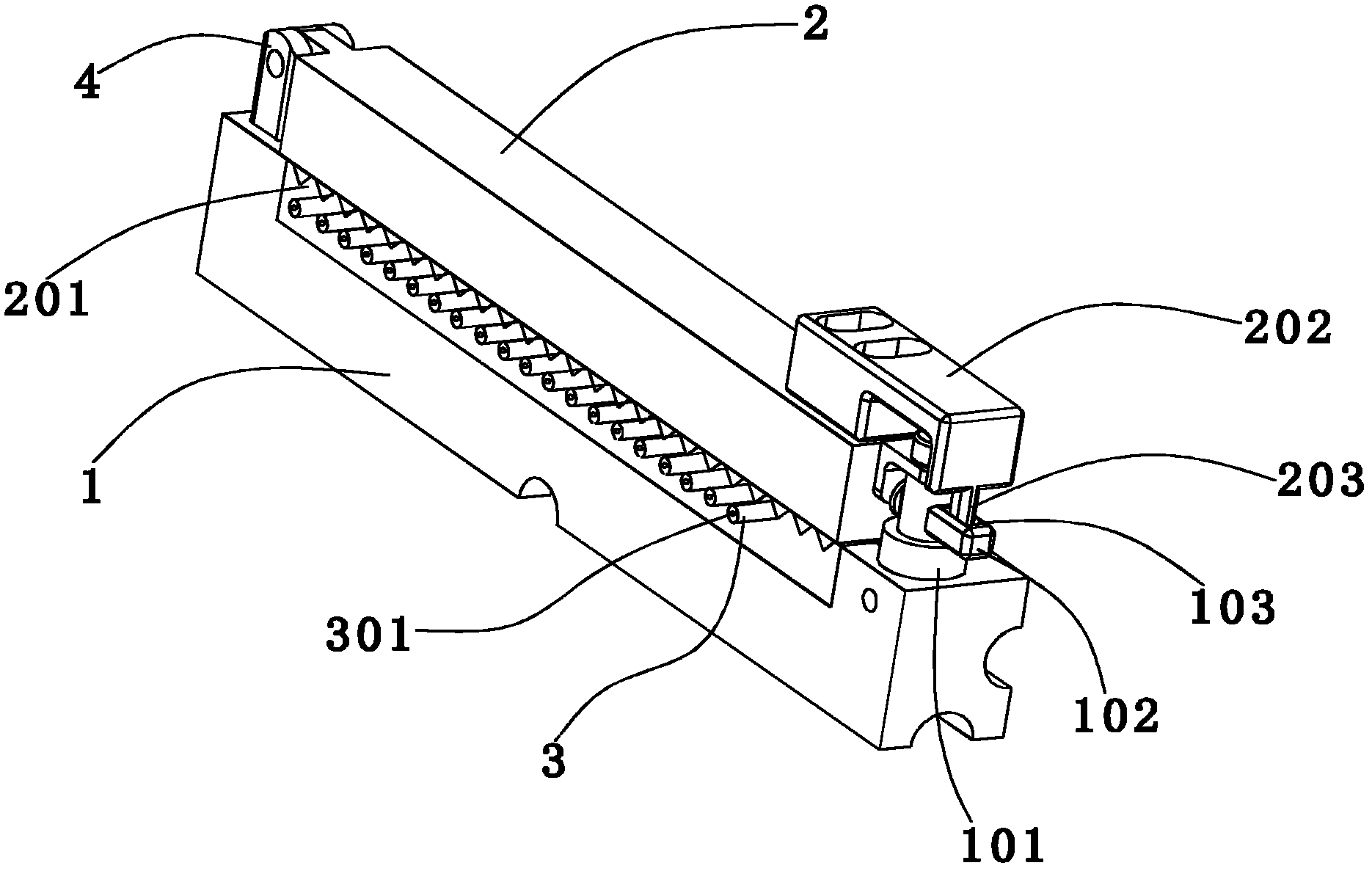

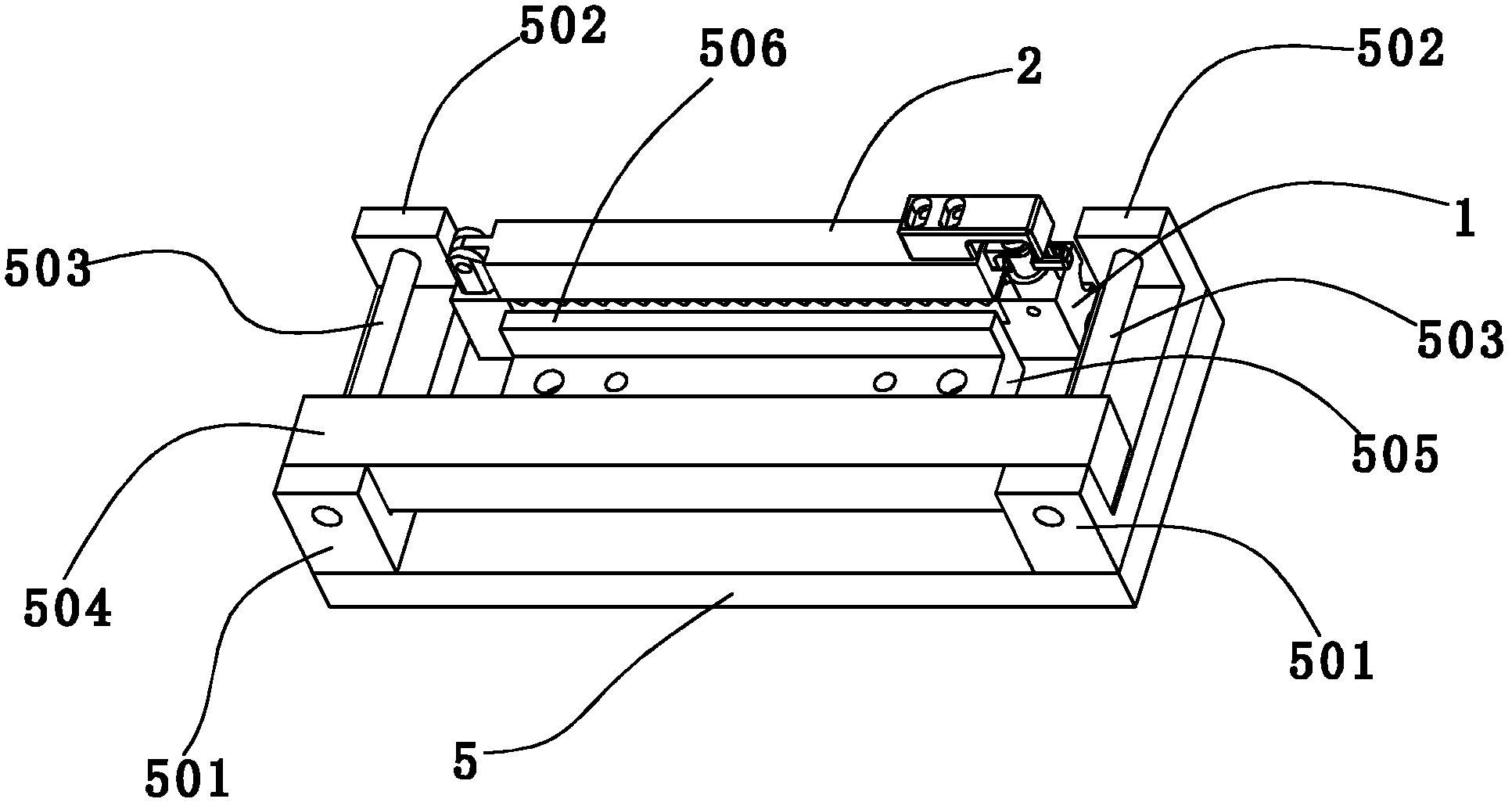

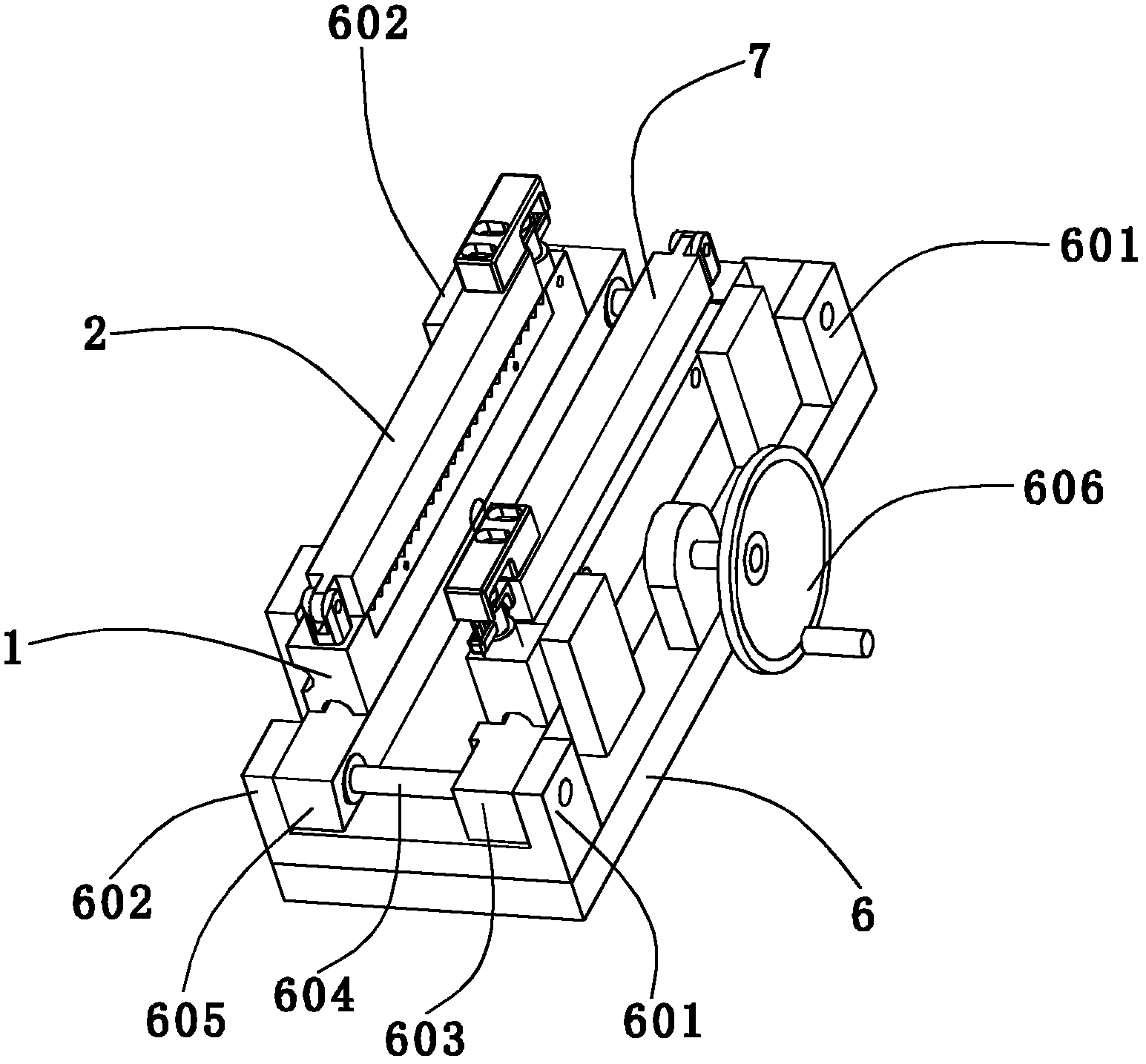

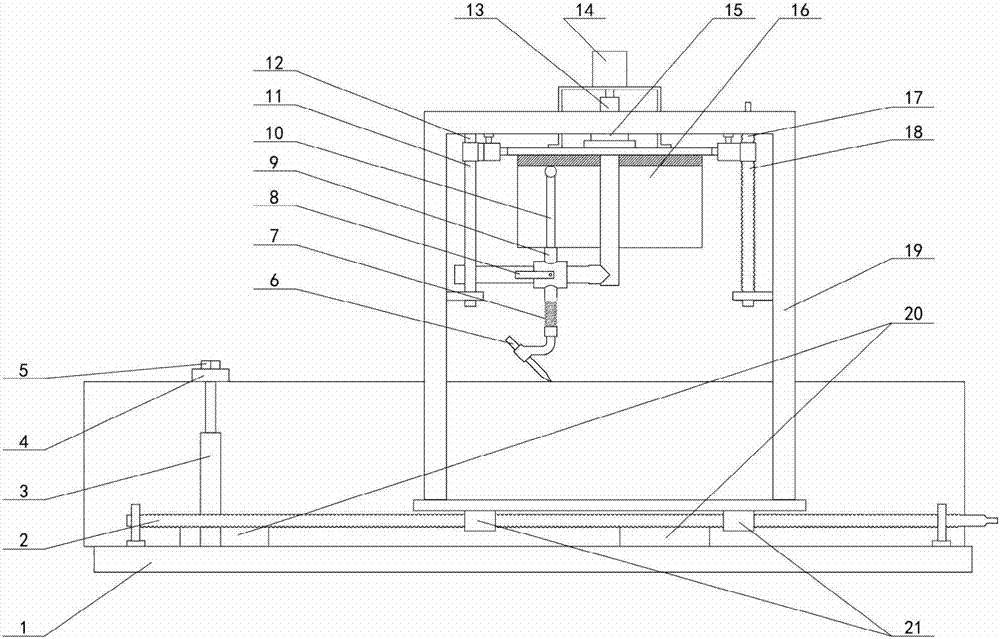

The invention discloses a rubber tapping machine. The rubber tapping machine comprises a tree binding fixing frame and two annular planetary gear outer shells installed at the upper end and the lower end of the tree binding fixing frame respectively. A vector movement knife rest assembly is arranged between the two annular planetary gear outer shells. A gear shaft is arranged on the vector movement knife rest assembly, a motor and a rubber tapping knife rest with a gear rack are arranged in the vector movement knife rest assembly, a rubber tapping knife assembly is arranged in the rubber tapping knife rest, a lead screw is connected to the top end of the rubber tapping assembly, and the rubber tapping knife assembly can vertically move in the rubber tapping knife rest by rotating the lead screw. By means of the rubber tapping machine, manual operation is not needed, and starting, stopping, forward rotating and backward rotating of the motor and starting, stopping, the spraying time and the spraying amount of a catalyst spraying assembly can be controlled by an automatic control system according to a set program. In addition, the automatic control system can be in communication with the exterior through an input-output module, receive a command of an upper computer, update internal program setting and transmit various working states of the rubber tapping machine outwards at any time.

Owner:NINGBO CIHEVEA TECH CO LTD

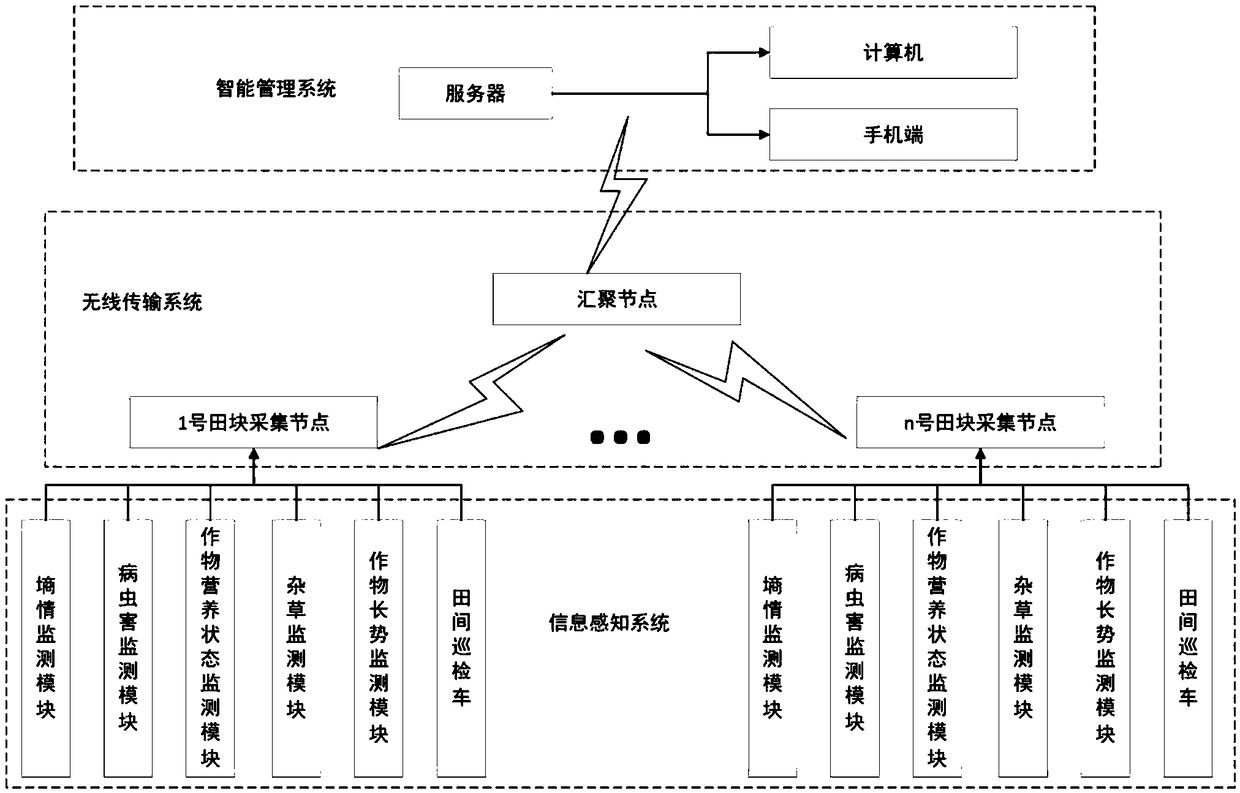

Crop growth information monitoring system and method based on internet of things

InactiveCN109470299ARealize monitoringRealize acquisitionMeasurement devicesDiseaseNutritional status

The invention discloses a crop growth information monitoring system and method based on internet of things. The system comprises an information perception system, a wireless transmission system and anintelligent management system, wherein the information perception system includes a soil moisture content monitoring module, a plant disease and insect pest monitoring module, a crop nutrition statemonitoring module, a weed monitoring module and a crop condition monitoring module. After crop planting, relevant information and threshold values of a crop growth environment are set through an intelligent management system interface, the soil moisture content, diseases and insect pests, nutritional status, weed growth and growth vigor information of growing crops are acquired through the perception system in real time and are sent to a server for data storage, analysis and display, if the information exceed threshold values, workers are remind of corresponding processing, plants are helped to accurately judge the crop growth conditions, real-time effective decision information is provided for accurate operation, the problem is solved that the crop growth conditions in planting field pieces need to be checked regularly in traditional planting process and accordingly the labor intensity is high, the labor cost is reduced, and the operating efficiency and accuracy are improved.

Owner:JIANGSU UNIV

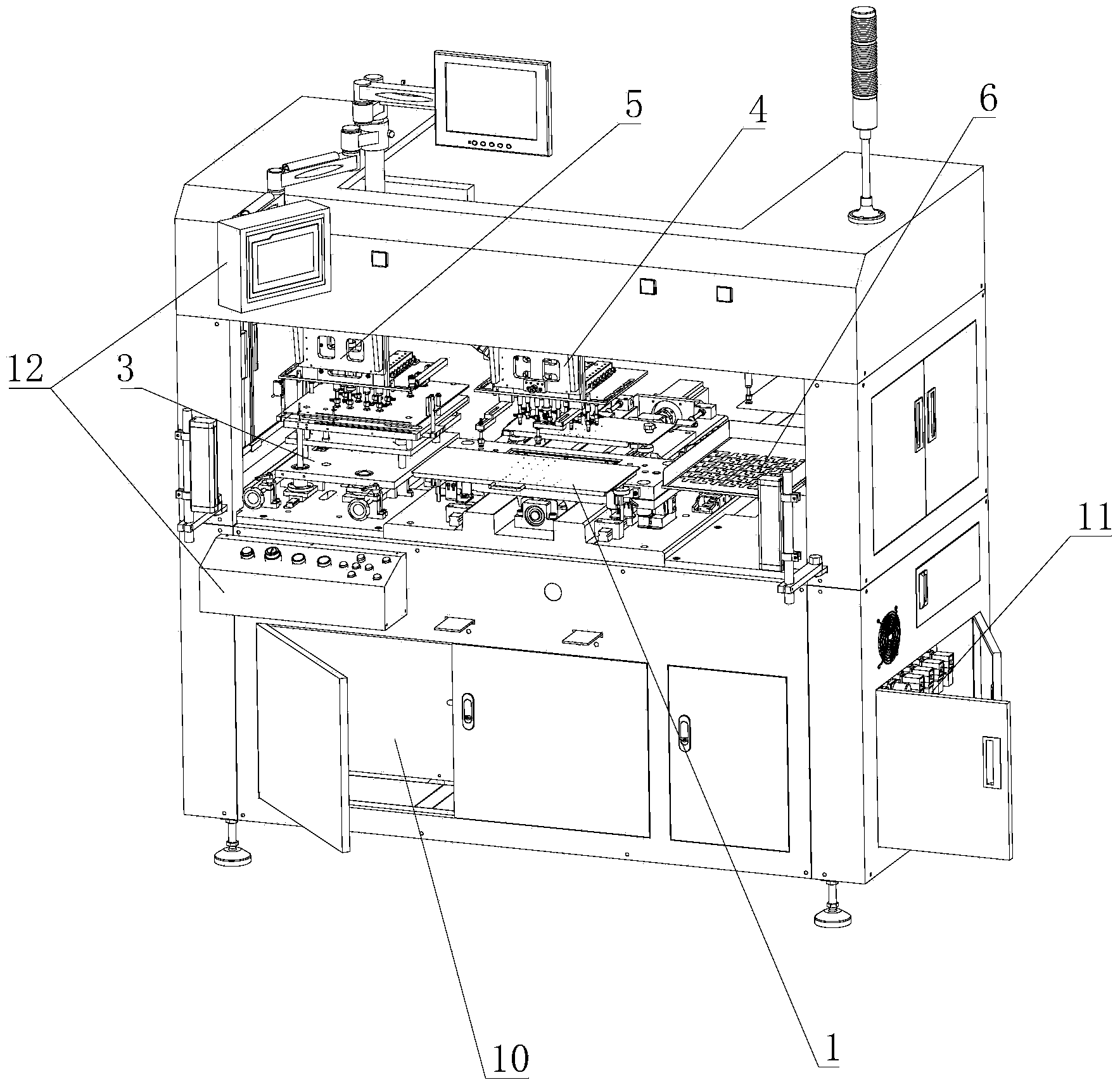

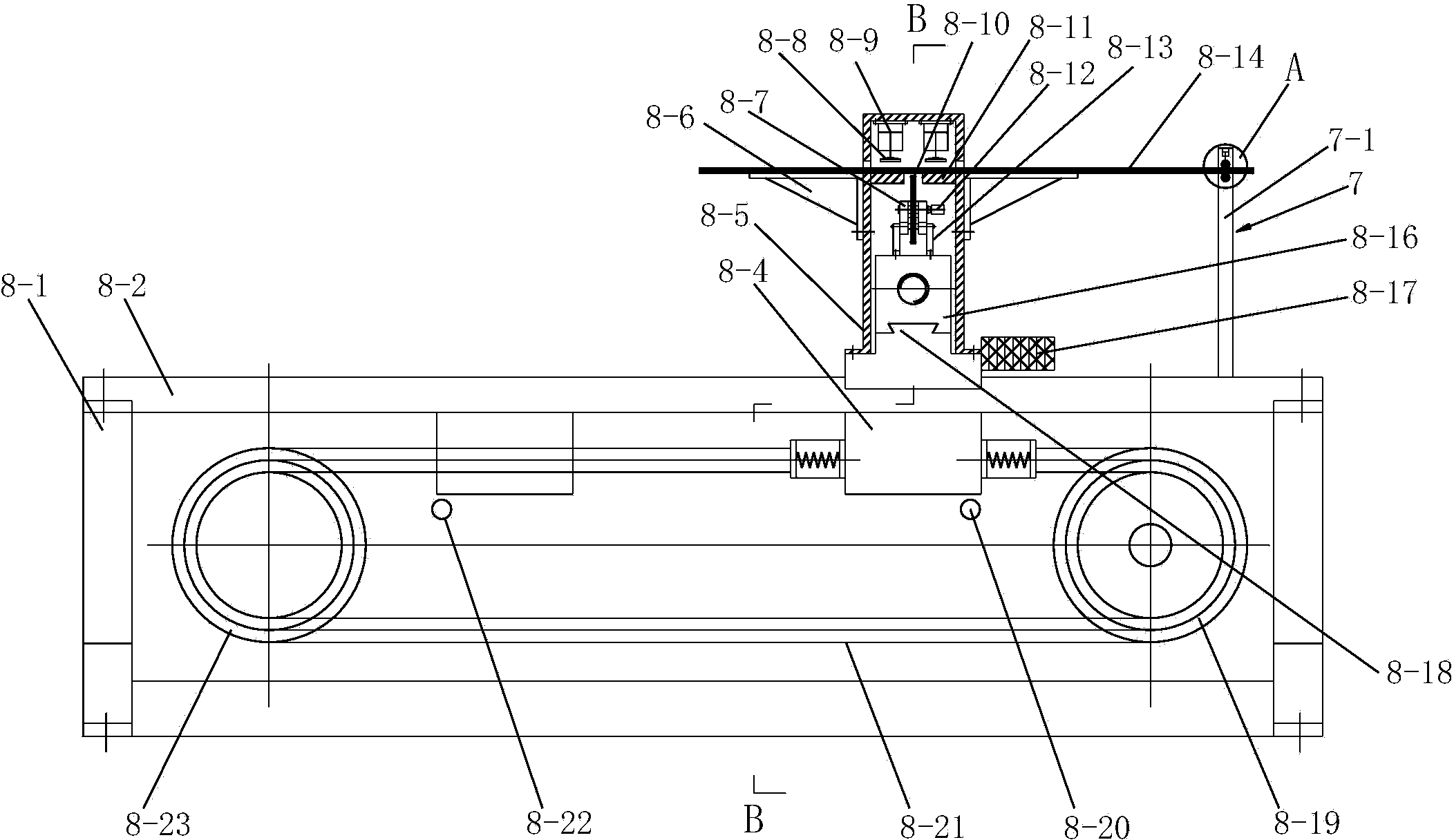

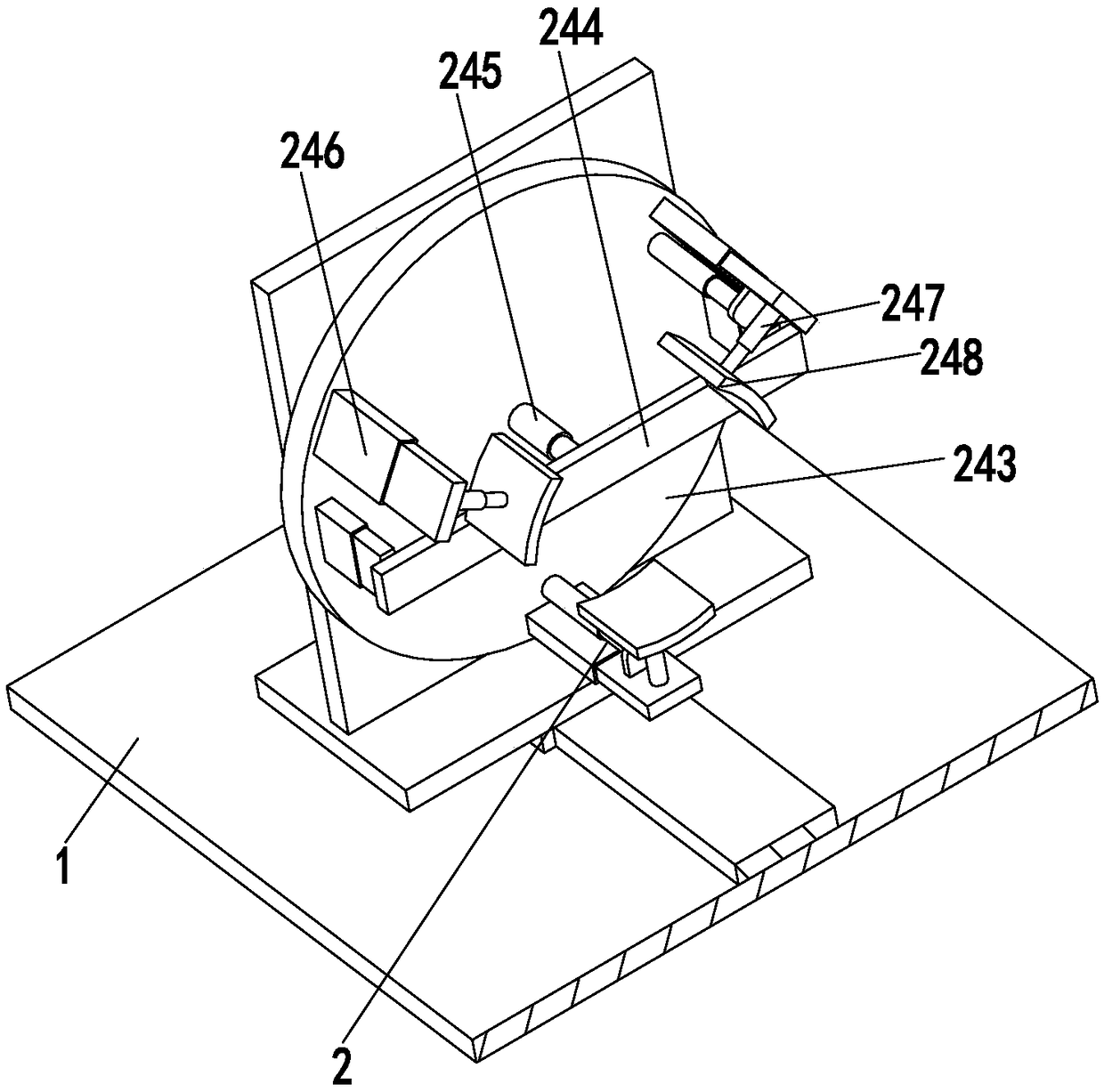

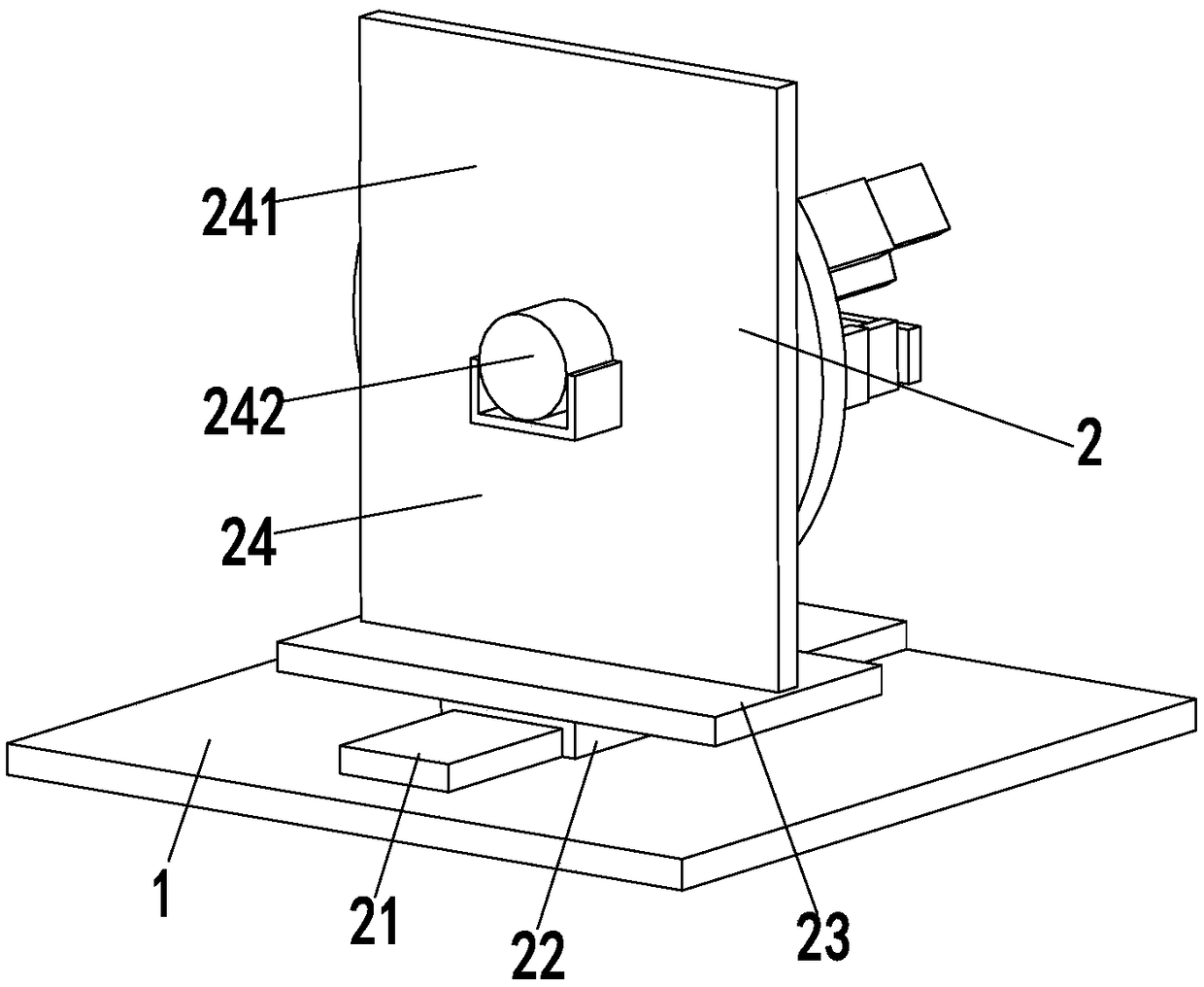

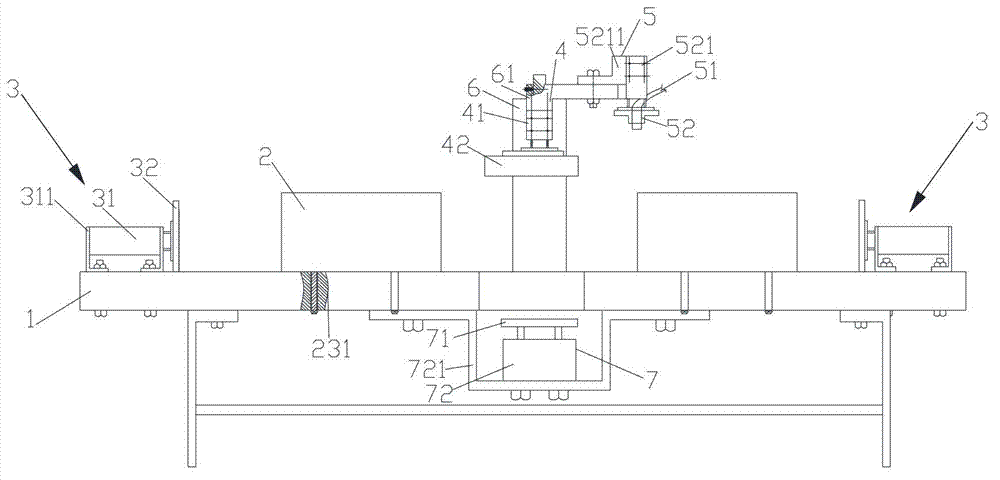

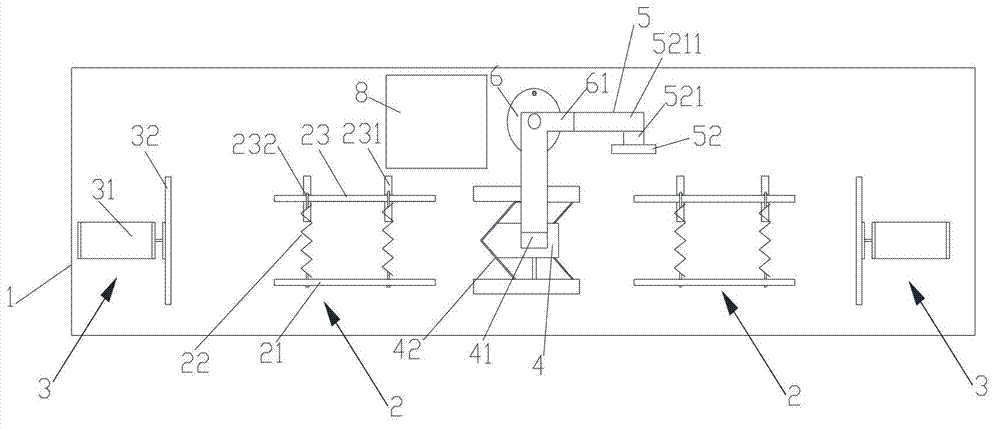

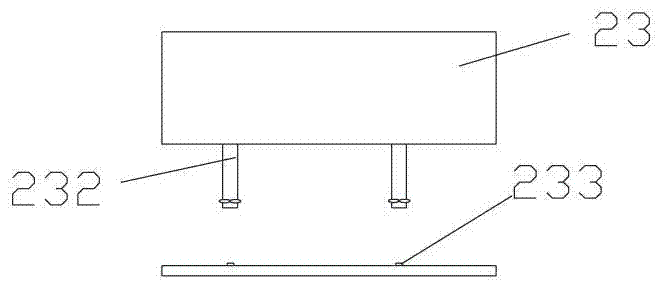

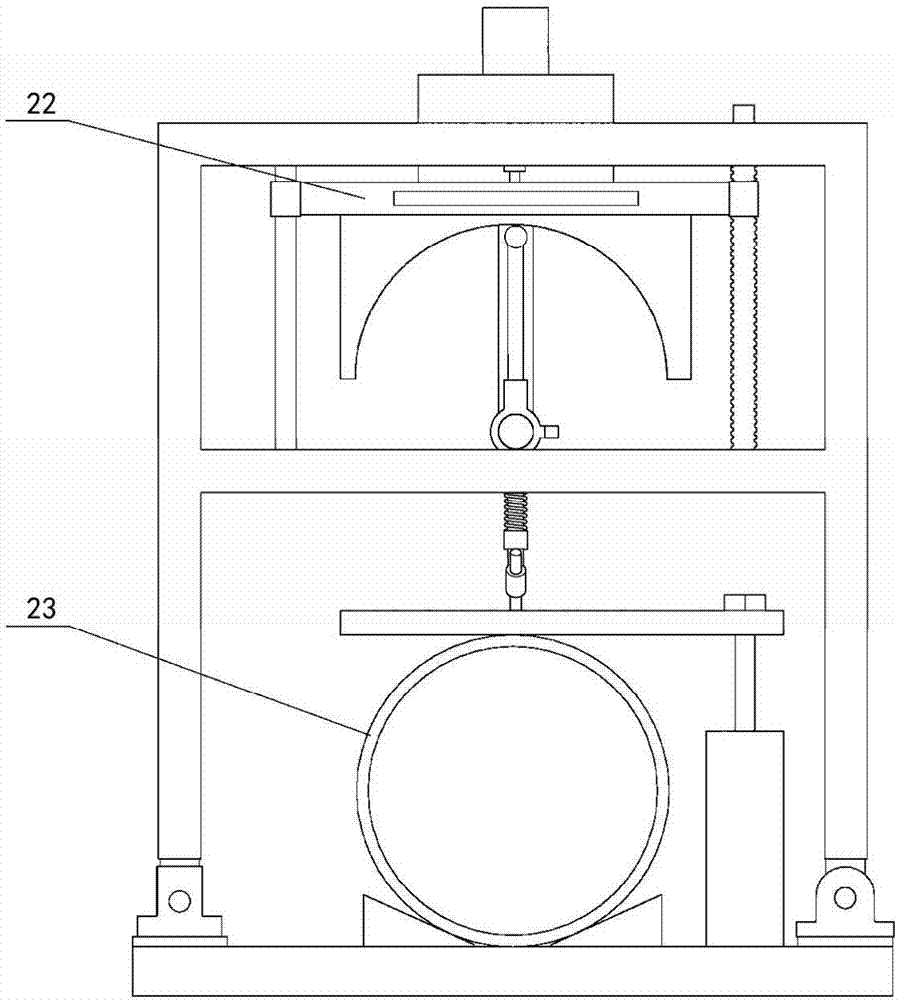

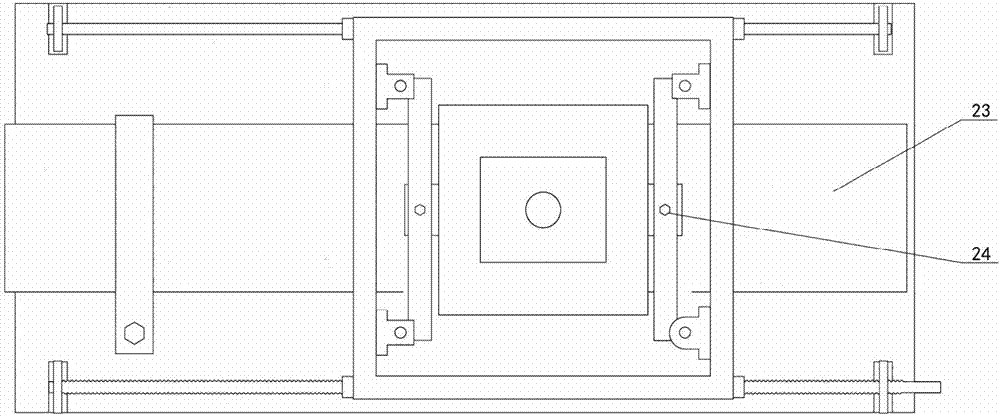

Automatic coin quality detection device

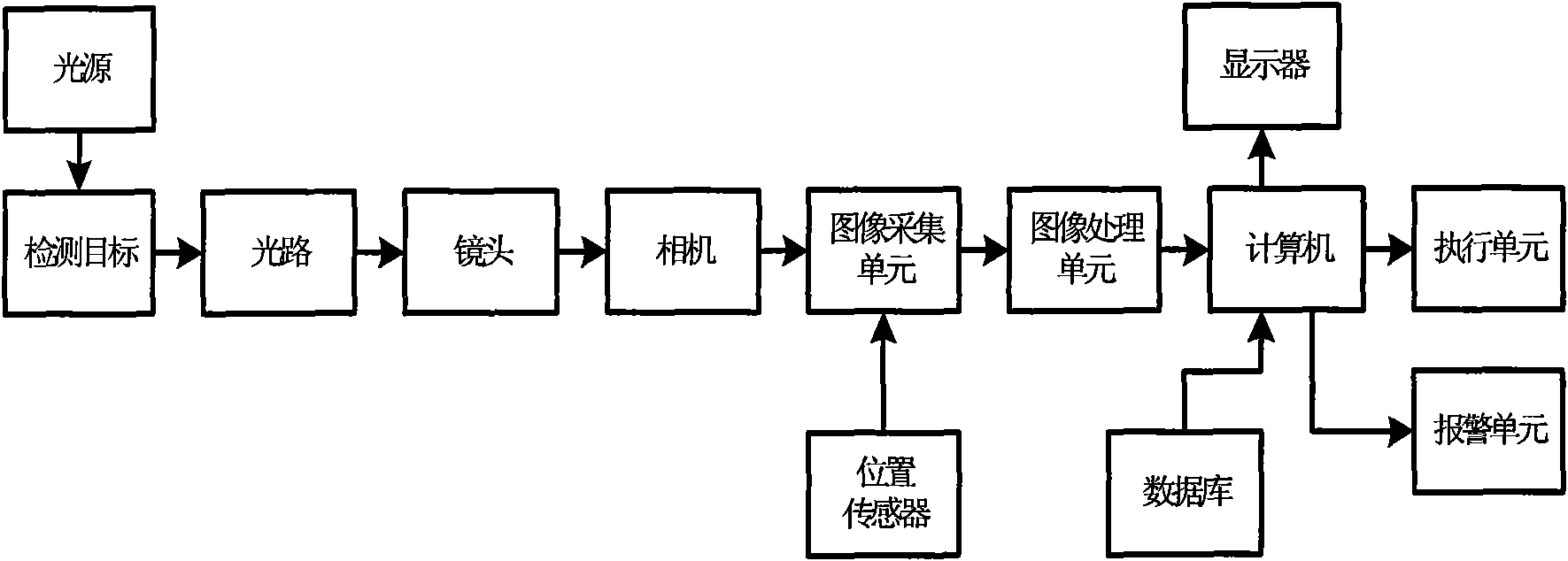

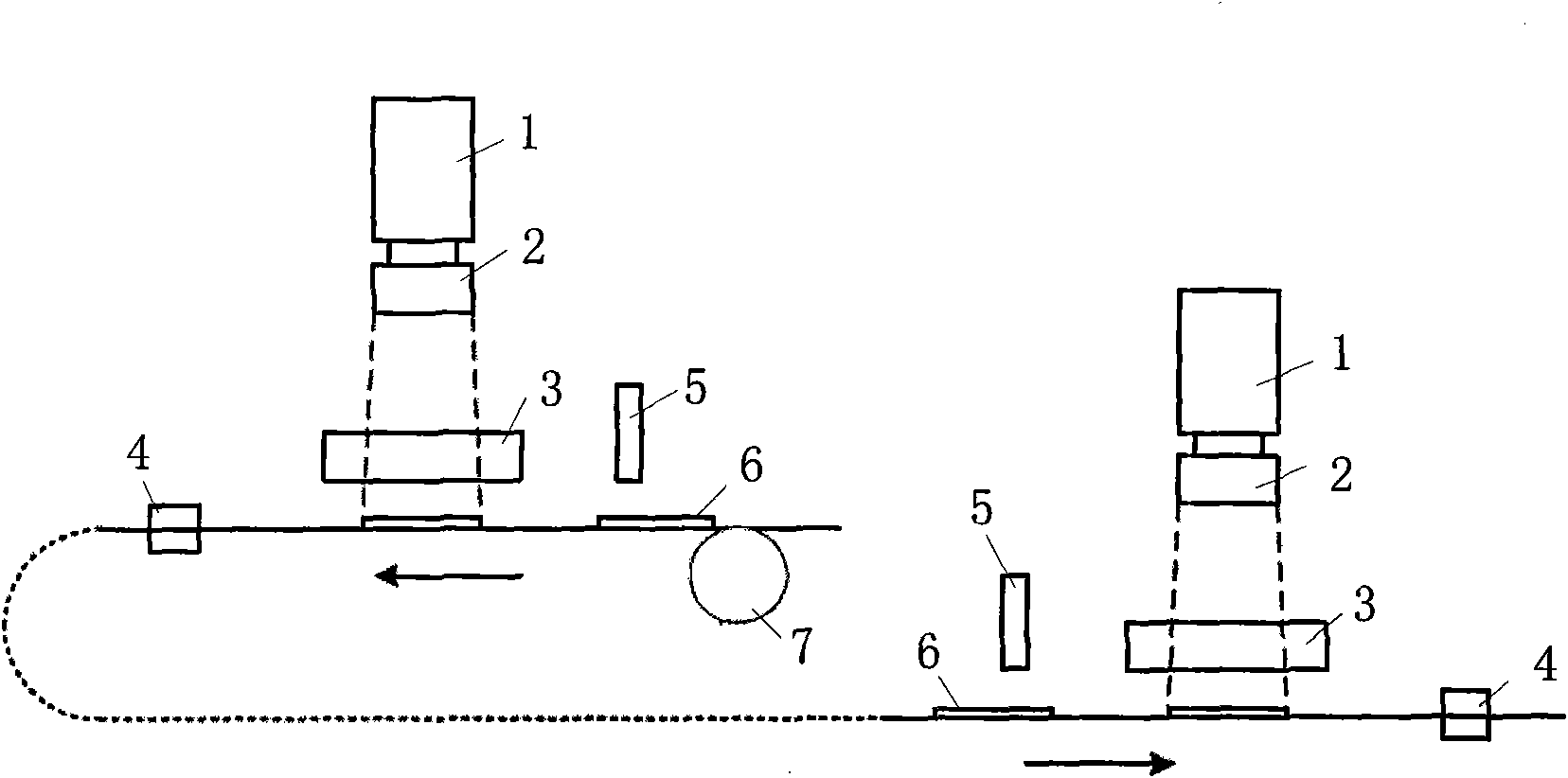

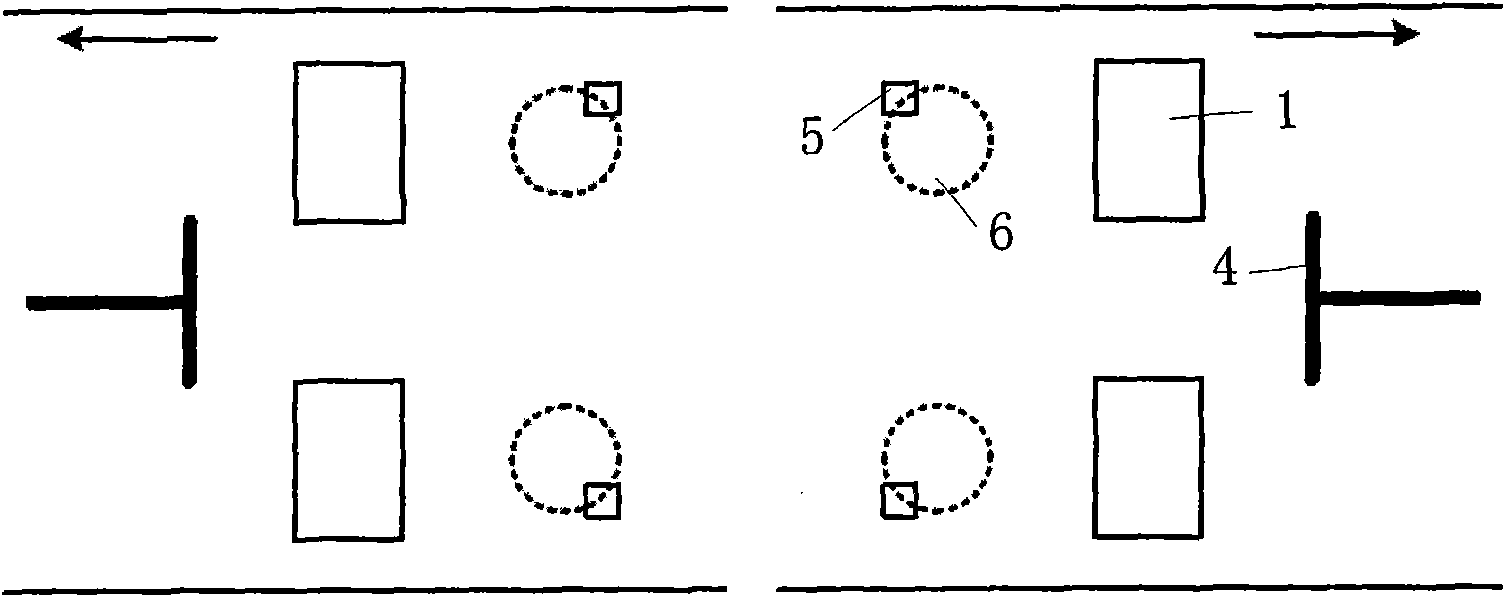

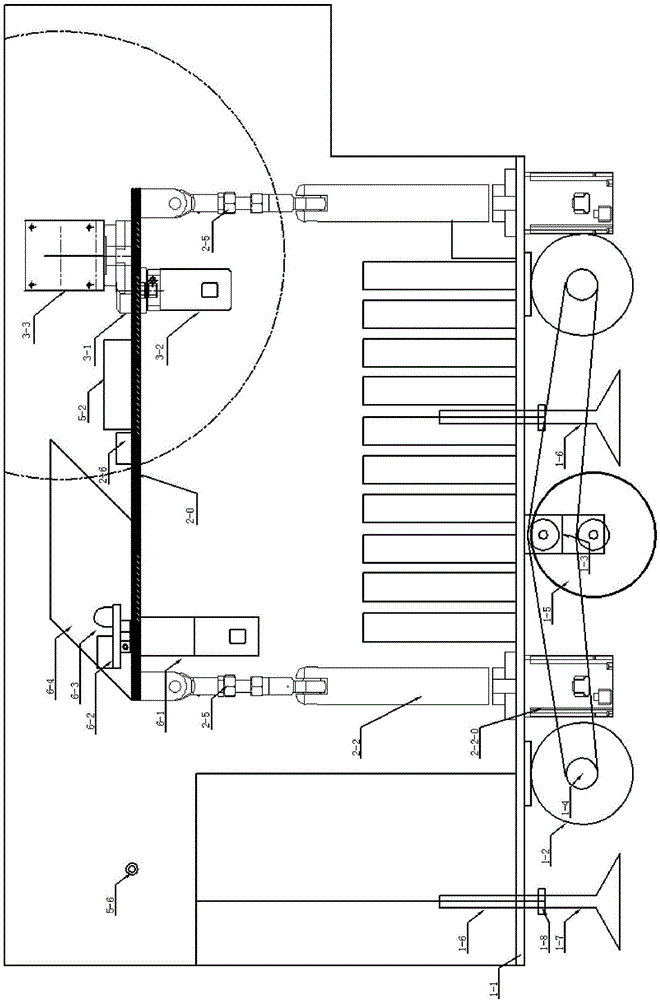

InactiveCN101561948AResolve detectionSolve labor intensityCoin testingCoin countersImaging processingVision based

The invention relates to an automatic coin quality detection device, in particular to a high-precision multifunctional automatic coin production quality detection device based on a visual system, realized by applying an image processing technology. The detection device comprises a combined illumination imaging light source, an image receiving unit, an image processing unit, a result output unit and a damaged coin discarding device, wherein the image receiving unit, the image processing unit, the result output unit and the damaged coin discarding device are sequentially connected; the combined illumination imaging light source adopts a mode that surface light sources at a high angle and a low angle illuminate at the same time; the image receiving unit collects image data on the coin surface; the image processing unit process the collected image data, confirms and discards defective products according to a production standard and transfers real-time detected images and analysis result information to the result output unit; and the damaged coin discarding device discards the ultra-detective products according to the control information of the image processing unit. The invention has the objective detection standard, can quantitatively prescribe, improves the production efficiency, can continuously upgrade the detection speed, emancipates the labor force and improves the automation degree of coinage.

Owner:CHINA BANKNOTE PRINTING & MINTING

Novel production technique of xylose

ActiveCN101392009AReduce the amount of sulfuric acidAvoid environmental pollutionSugar derivativesSugar derivatives preparationRegenerative processXylose

The invention discloses a new manufacturing technique of a xylose and relates to a technique for manufacturing the xylose. The technique adopts the technology of electrodialysis recycling sulphuric acid, a bag adopted by a nanofiltration concentration device and a special nanofiltration separation system concentrates the liquid in the technique for manufacturing the xylose at normal temperature, therefore water and other impurities can be removed from the product; the manufacturing technique comprises: 1. pretreatment, 2. hydrolyzation, 3. decoloration, 4. electrodialysis, 5. ion exchange, 6. nanofiltration, 7. concentration, 8. ferment, 9. crystallization, 10. centrifugation, and 11. drying, then the high purity xylose is obtained. The new manufacturing technique of the xylose can not only recycle 50 percent sulphuric acid in the hydrolyze liquid, but also can recycle waste acid and spent caustic produced in the regenerative process of duolite, therefore the dosage of sulphuric acid can be saved and the environment pollution is avoided. The technique solves the problems of scale formation in device in the neutralizing deacidification technique, large usage of duolite in deacidification technique, large usage of devices, large investment, large consumption of acid and alkali, high costs and the like; thus improving the device utilization rate and the service life, decreasing the ash and the acid contents in the hydrolyze liquid, improving the quality of the hydrolyze liquid and enhancing the product quality and separating efficiency.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

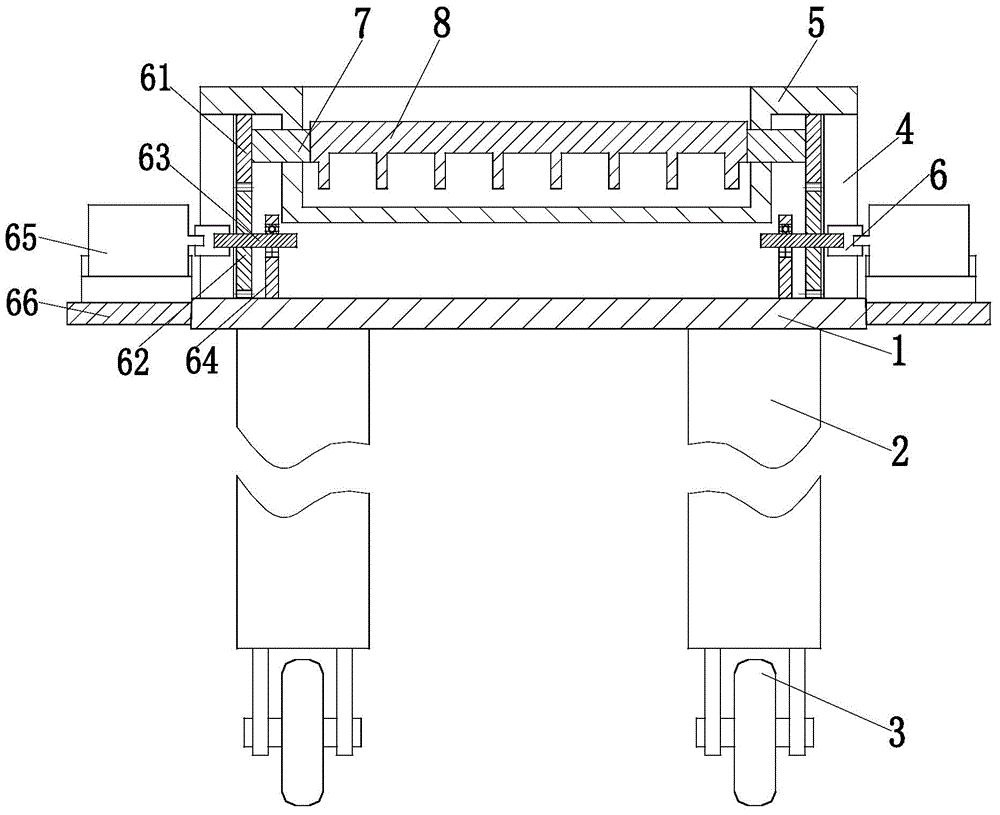

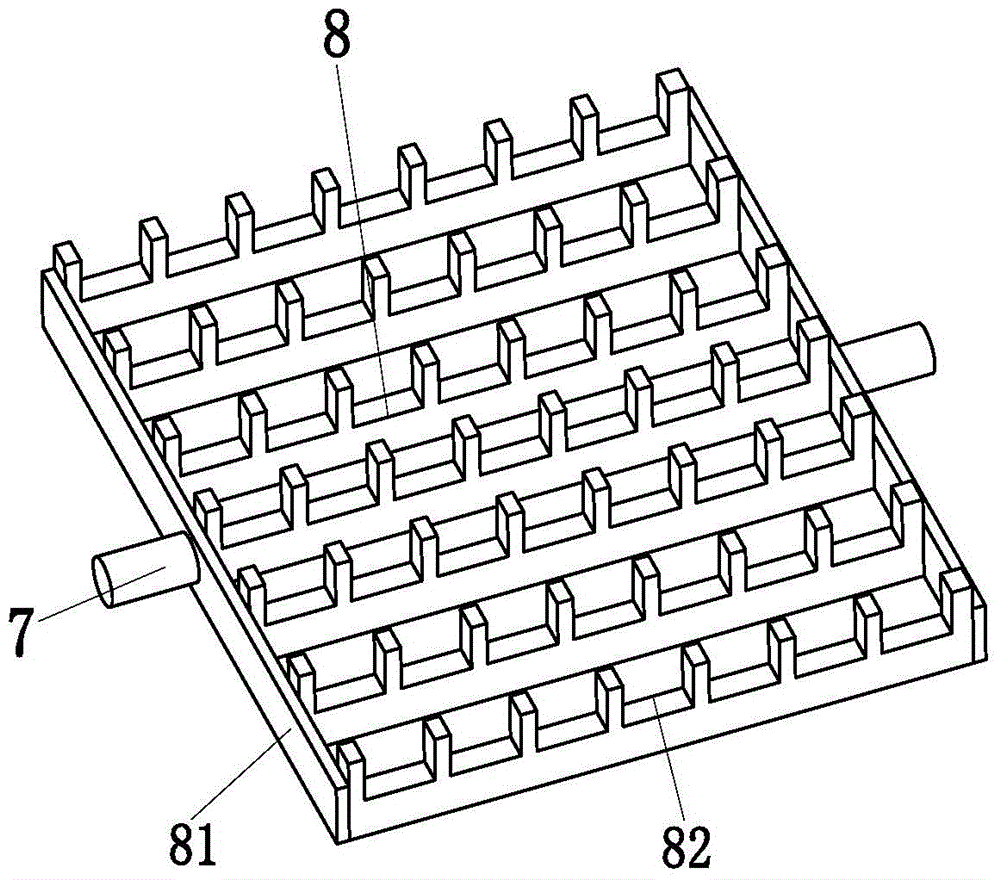

Fully automatic wall surface and shed surface spray coating grinding device

InactiveCN104563458AImprove adaptabilityImprove toleranceBuilding constructionsPlane surface grinding machinesSpray coatingFully automatic

The invention discloses a fully automatic wall surface and shed surface spray coating grinding device, which comprises a moving mechanism, a bearing installing platform and an automatic moving arm, and is characterized in that the moving mechanism adopts a manual moving mechanism or an automatic moving mechanism, a fixing plate of the bearing installing platform is arranged on a regulating bearing or a ball head of the moving mechanism, the regulating bearing or the ball head is connected onto a regulating foot driven by an electric cylinder, the electric cylinder is connected onto the bottom plate of the moving mechanism, the bottom plate is moved by the moving mechanism, the automatic moving arm is arranged on the bearing installing platform, and a spray coating device, a grasping mechanism or an anti-collision grinding dust sucking mechanism is arranged on the front end of the automatic moving arm. The fully automatic wall surface and shed surface spray coating grinding device has the advantages that the flexible splicing layout can be realized according to the room area, wall surface and shed surface coating, trowelling and whole surface flattening and putty grinding dust collection work can be simultaneously completed according to different requirements, and the problems of dust pollution and high work intensity of operators can be thoroughly solved.

Owner:董旺建

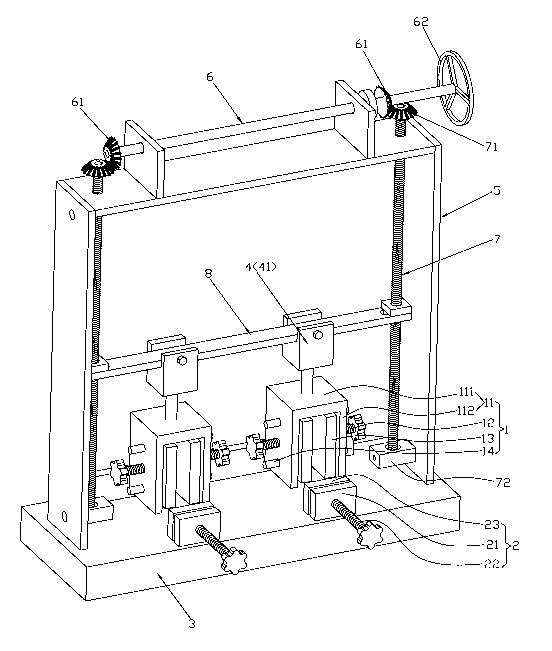

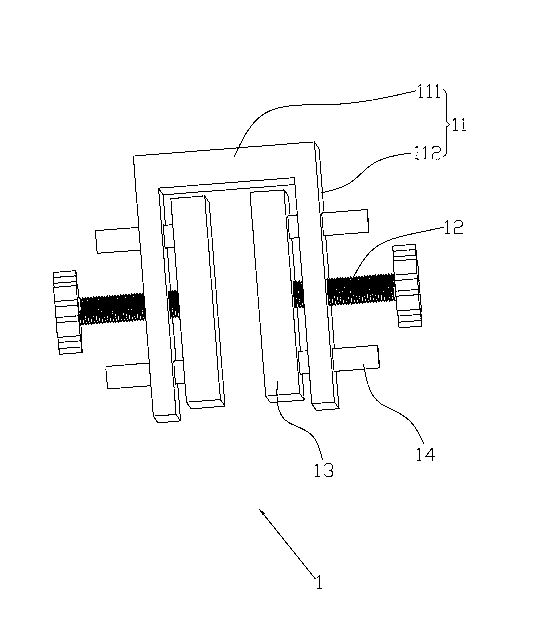

Plug test fixing device of lamp charging plug

InactiveCN103308788AThe solution cannot be used universallyImplement automated testingElectrical testingTest efficiencyEngineering

Provided is a plug test fixing device of a lamp charging plug. The fixing device comprises a pedestal. The pedestal is provided with a first clamping device which is used for fixing charging plugs with different sizes, and a second clamping device which is used for fixing lamps with different sizes. The first clamping device is connected with a drive device which can drive the first clamping device and can move upward and downward along a vertical direction. Compared with the prior art, the plug test fixing device of the lamp charging plug utilizes the drive device to conduct the plug test on the charging plug so that an automated test is realized. The test is high in efficiency and solves problems that a low efficiency and a high labor intensity caused by adopting manual manner to test the service life of the charging plug in the prior art. Besides, the first clamping device of the invention can clamp and fix the charging plugs with different sizes. Therefore, the plug test on the charging plugs with different sizes can be conducted. The plug test fixing device is high in universality and solves a problem that the plug test fixing device of the conventional charging plugs cannot be universally used.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

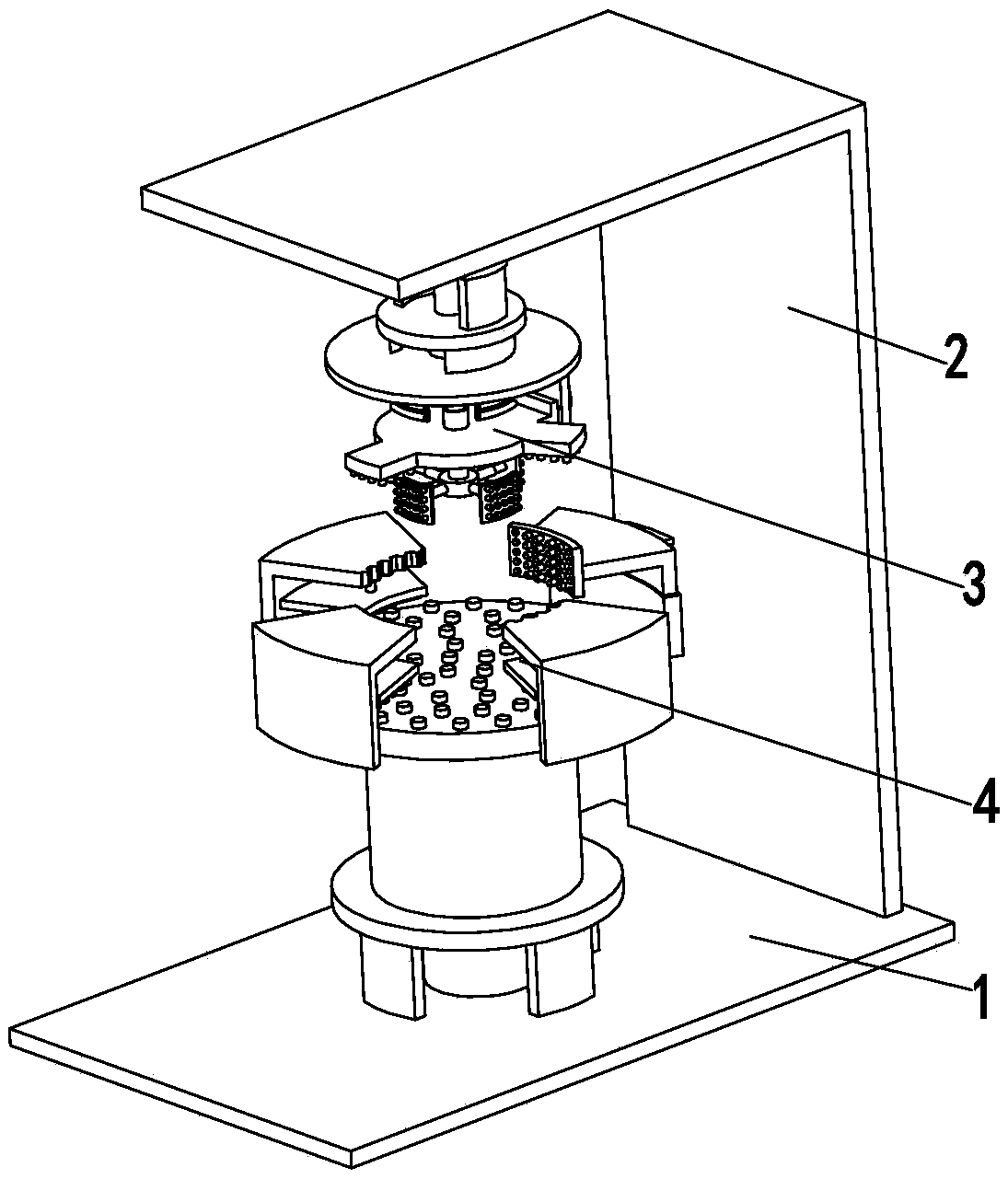

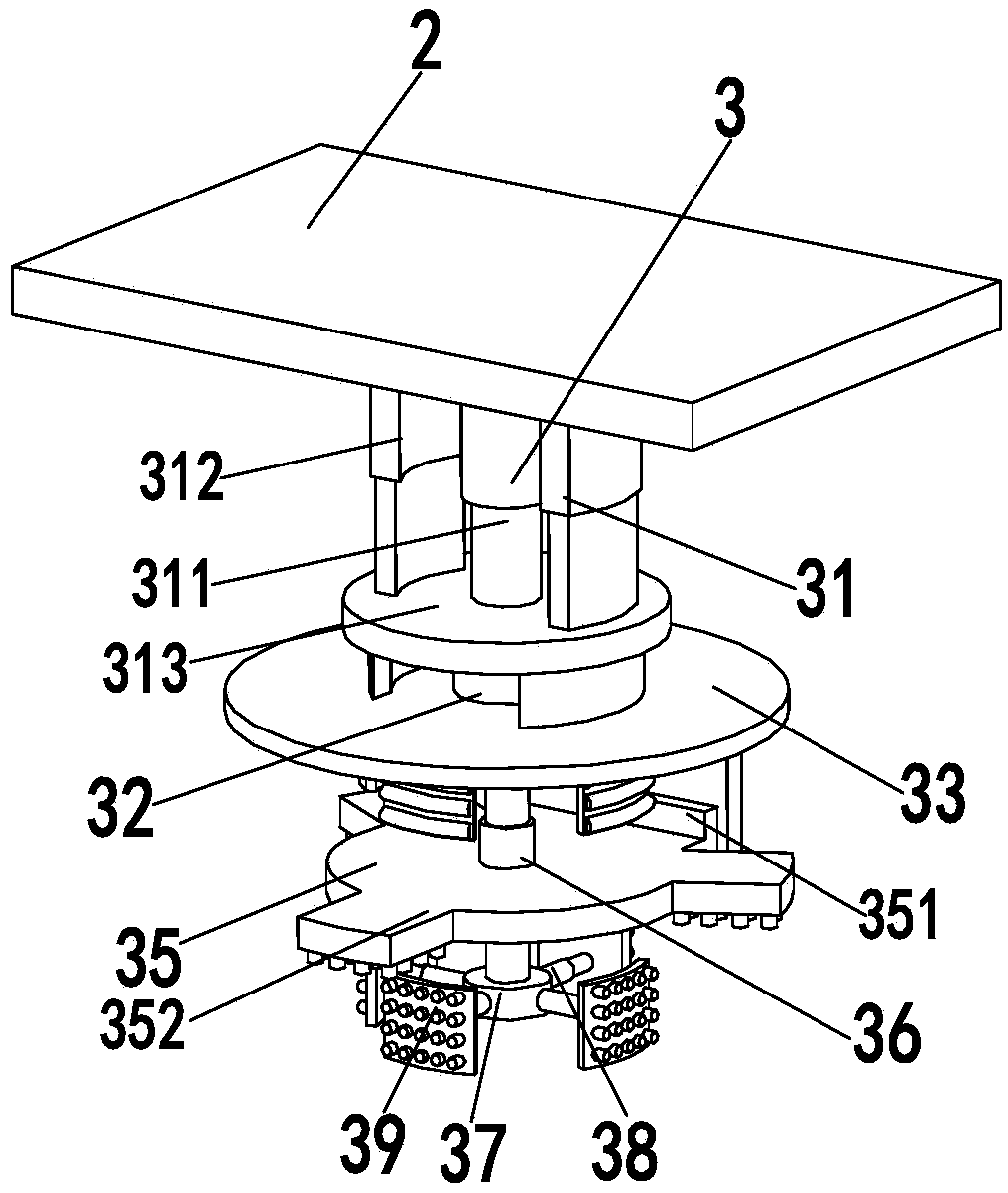

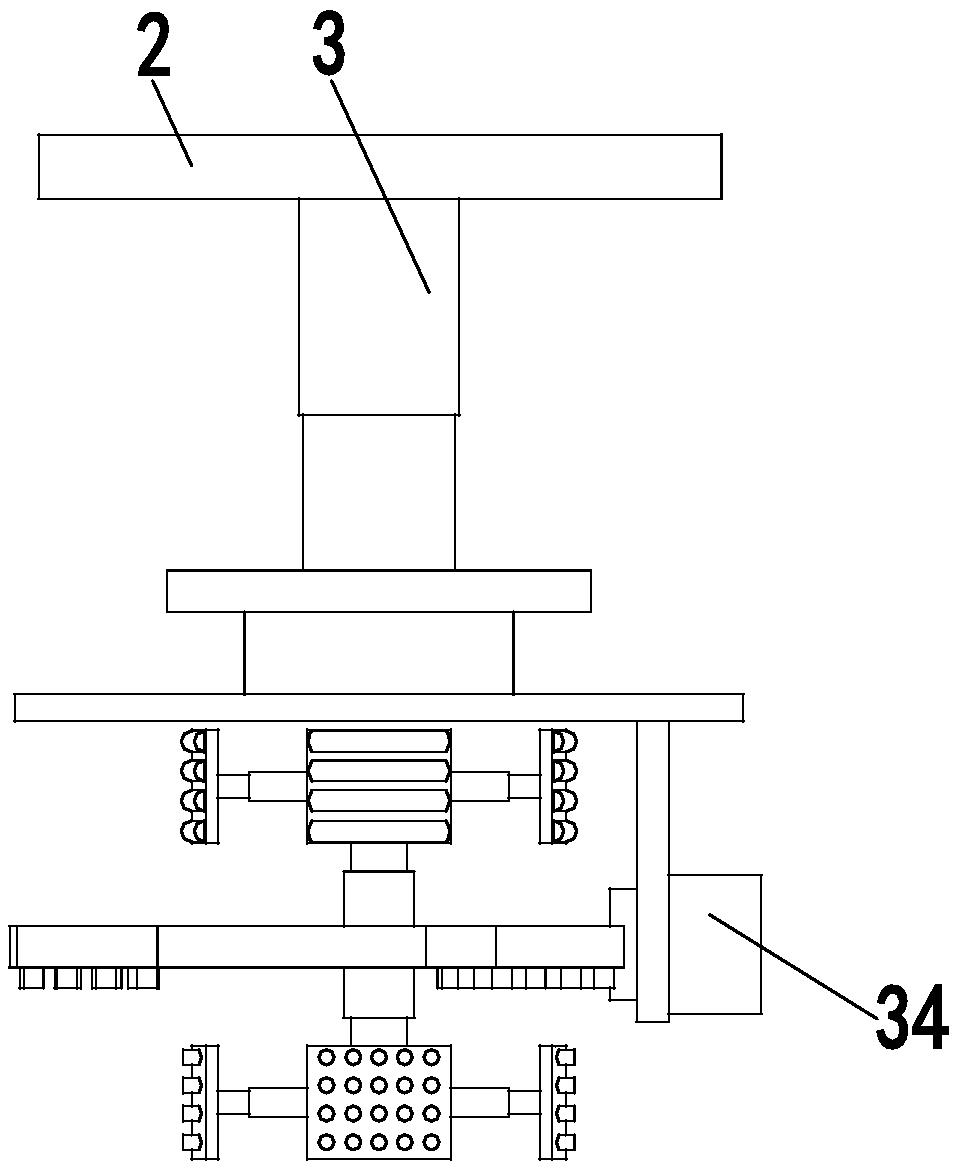

Constructional engineering grab bucket capable of grabbing and carrying bagged cement of different specification

ActiveCN106946035AImprove handling efficiencySolve labor intensityConveyor partsManual handlingFlange

The invention relates to a constructional engineering grab bucket capable of grabbing and carrying bagged cement of different specifications. The grab bucket comprises a bottom plate, a regulating device is installed on the bottom plate, the lower end of the regulating device is provided with a hydraulic lift cylinder, the bottom end of the hydraulic lift cylinder is installed on a gripping device by flanges, the regulating device can drive the gripping device mounted on the hydraulic lift cylinder to adjust positions, the gripping device can grab bagged cement, and the regulating device, the hydraulic lift cylinder and the gripping device cooperate with each other to complete the process of gripping bagged cement. According to the grab bucket provided by the invention, the existing problems, such as high labor intensity, low handling efficiency and complicated operation, caused during manual handling of bagged cement are solved, the operation complication being caused by different requirements on workers by different specifications of bagged cement. And the function of automatic gripping of bagged cement can be realized.

Owner:福建兴旺建设发展有限公司

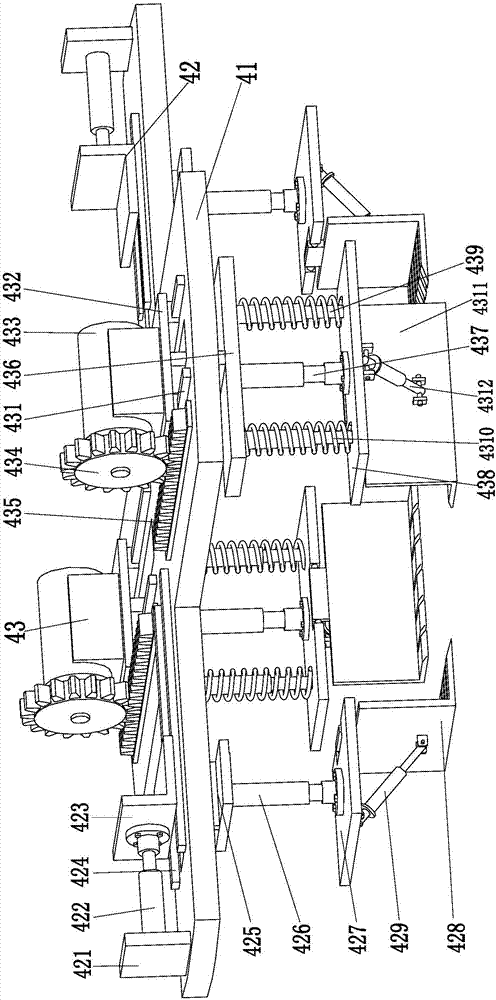

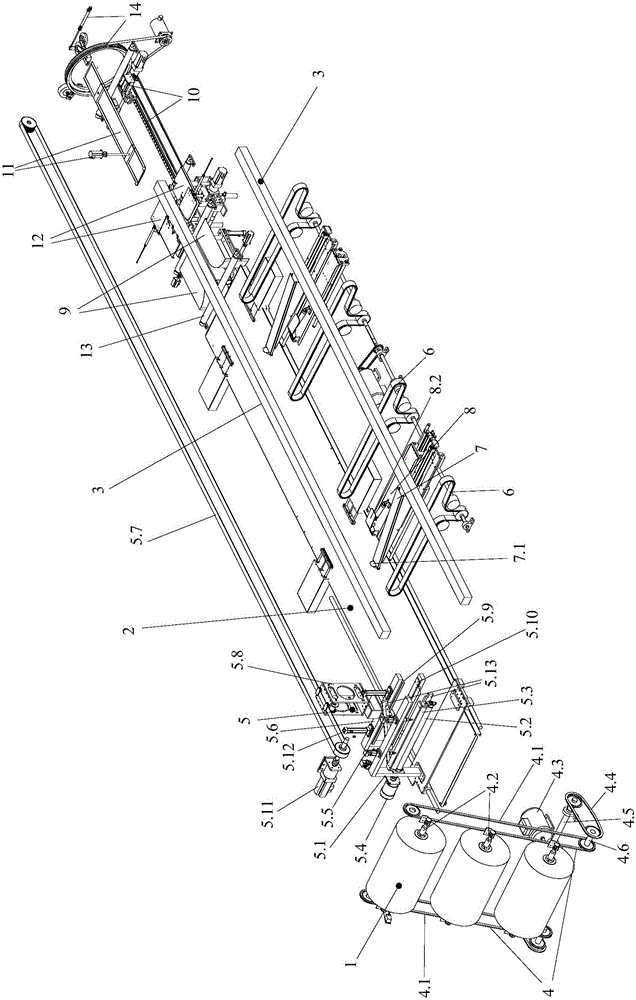

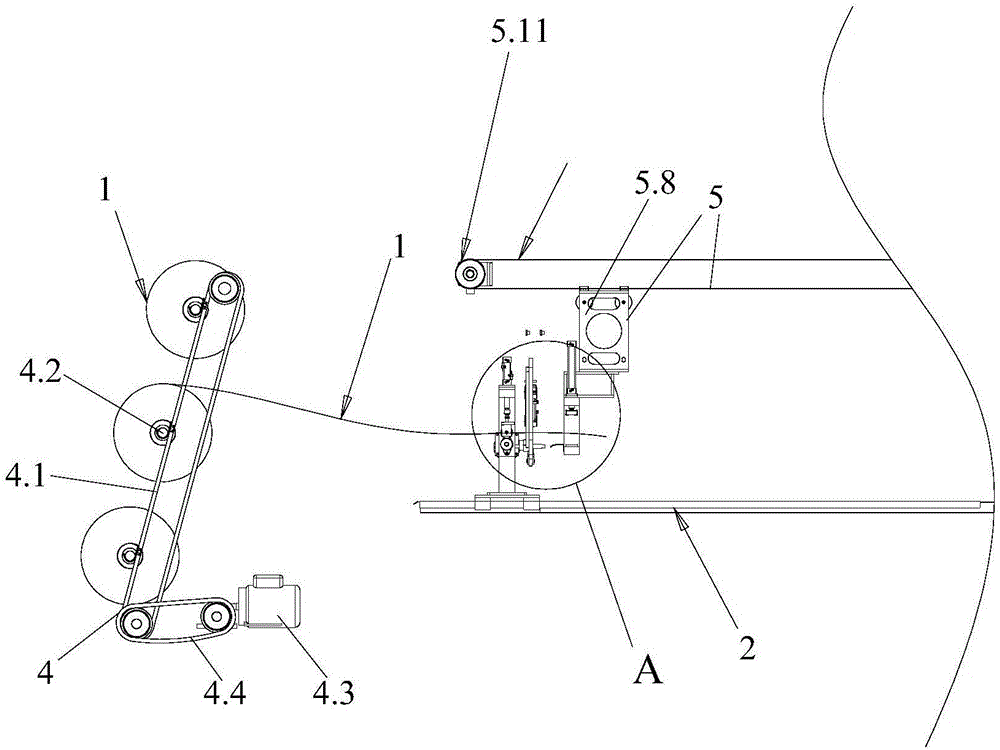

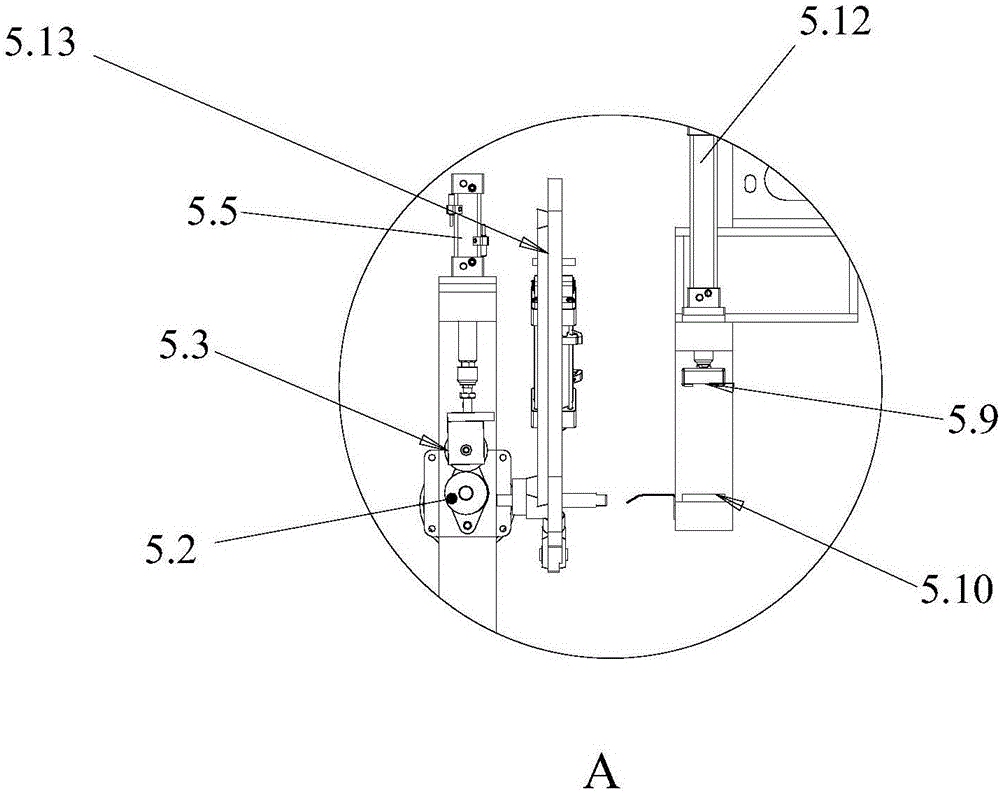

Fully-automatic single blanking mechanical arm

ActiveCN104070558AGet rid of influenceSolve labor intensityMetal working apparatusPunch pressInstability

The invention provides a fully-automatic single blanking mechanical arm. A loading plate device, a loading arm device, a blanking device, a horizontal conveying device, an unloading arm device, an upper partition paper device and a finish product collecting device are mounted on an existing punch press to form an excellent structural design, so that the fully-automatic single blanking mechanical arm can complete operations of loading, conveying, blanking, movement and the like of FPC (flexible printed circuit) boards; the cooperation of all the parts enables the fully-automatic single blanking mechanical arm to meet the requirements of single production, so that the problems existing in the signal production such as high labor intensity, high work-related injury risk, low production efficiency, large worker quantity and personnel instability can be solved.

Owner:SHENZHEN MAKEN M & E

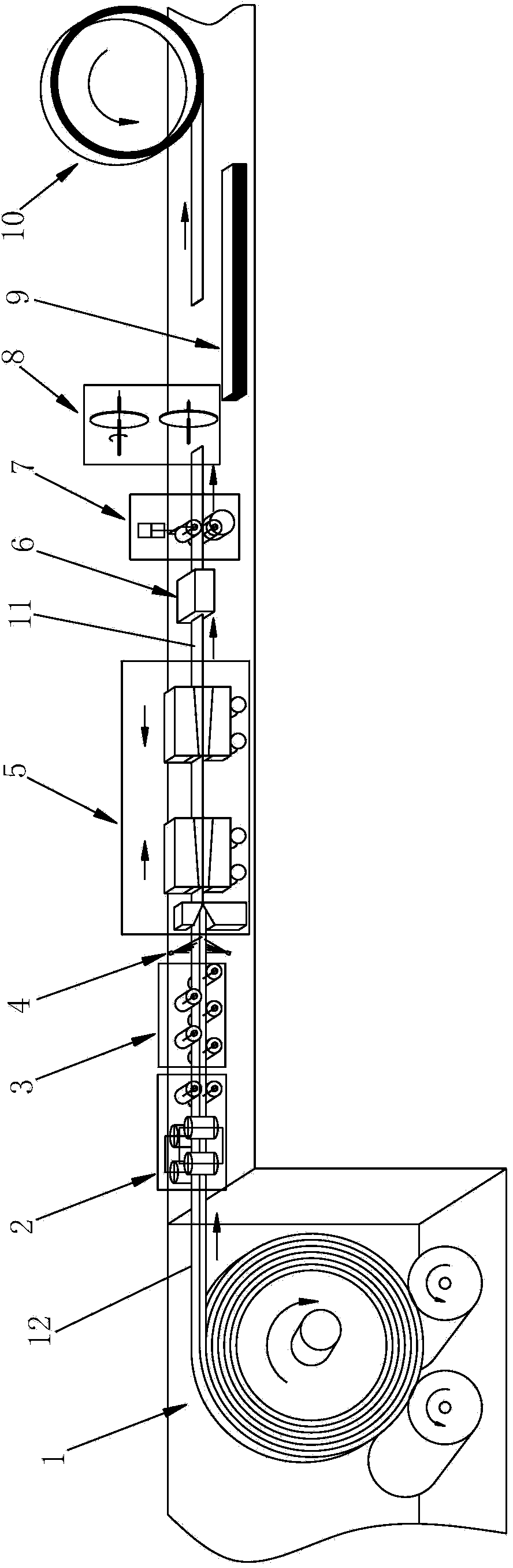

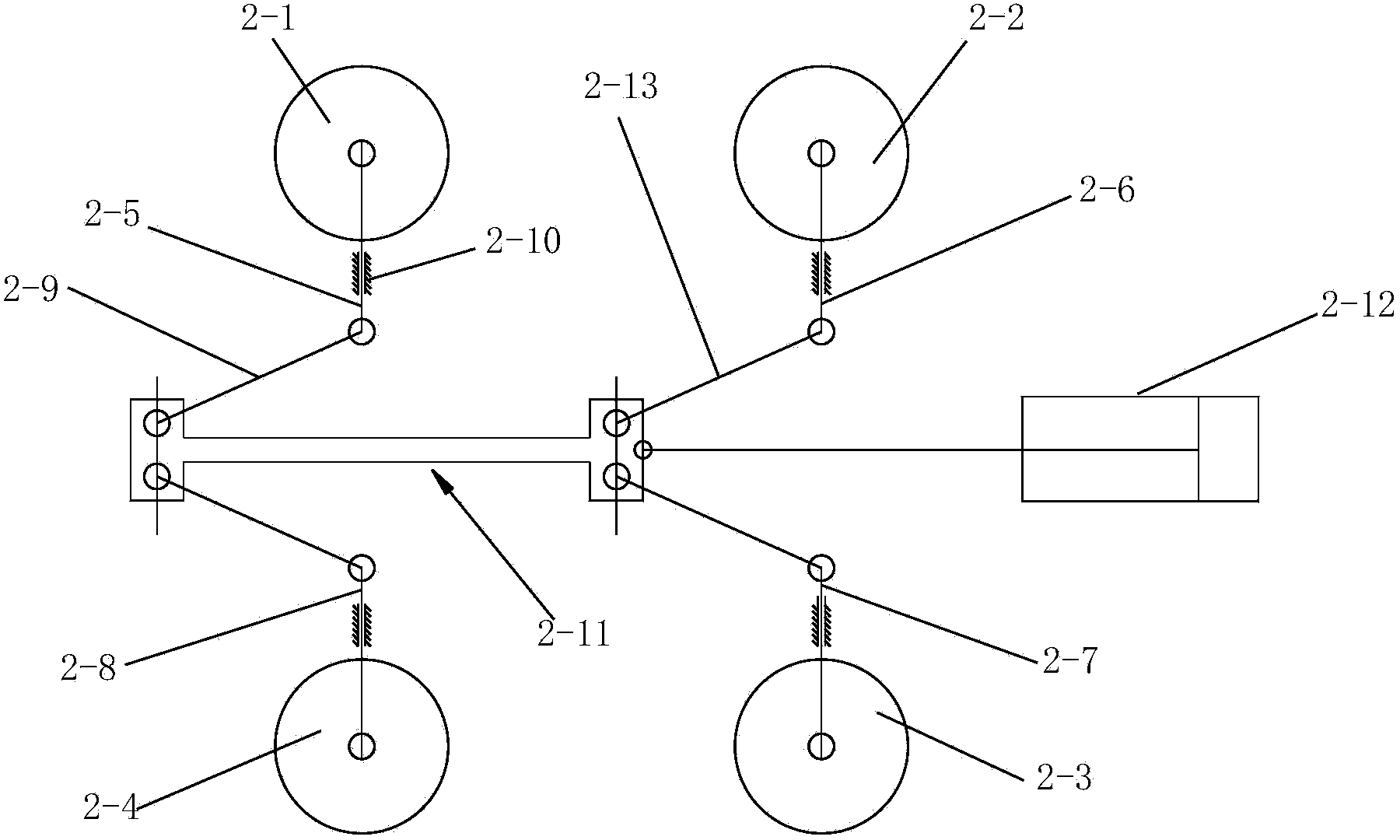

Continuous drawing production line and production method of strip product

ActiveCN103447347ASimple structureNovel and reasonable designMetal sawing devicesMetal sawing accessoriesProduction lineManufacturing engineering

The invention discloses a continuous drawing production line of a strip product. The continuous drawing production line comprises an uncoiler, a straightener, a continuous drawing machine, a length measuring device and a cuttolength saw, as well as a stacking device for stacking the sawn product or a rolling machine for rolling up the sawn product, wherein the uncoiler, the straightener, the continuous drawing machine, the length measuring device and the cuttolength saw as well as the stacking device or the rolling machine are arranged in sequence. The continuous drawing production line provided by the invention has the advantages that the floor space is reduced, the damage and transformation of the products are avoided in hoisting, and the yield is improved. The invention also discloses a production method of the continuous drawing production line of the strip product. The production method comprises the steps of unfolding a pony roll blank to a straight line state, straightening the blank which is unfolded to the straight line state, carrying out continuous drawing processing on the straightened blank to form the product, measuring the length of the product according to the preinstalling length, sawing the product according to the preinstalling length, and stacking the sawn product or rolling up the sawn product. The production method of the continuous drawing production line provided by the invention has the advantages that the production efficiency and the yield are improved.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

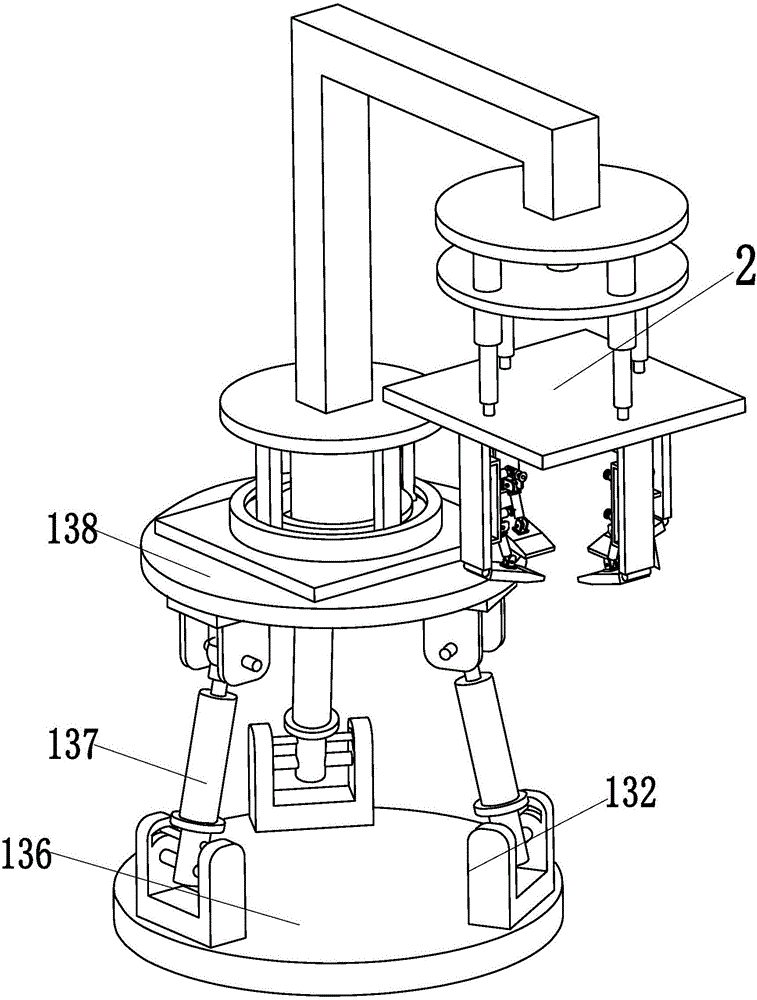

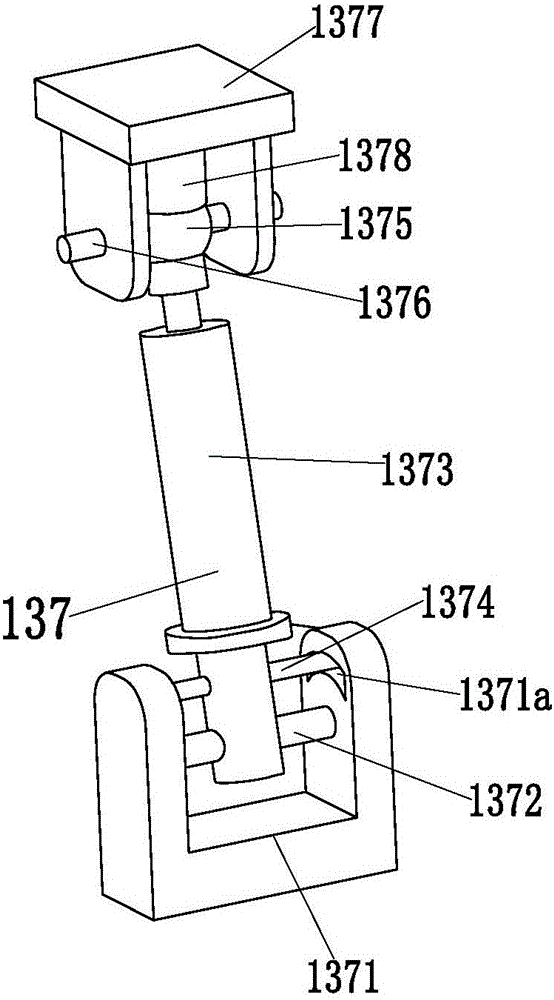

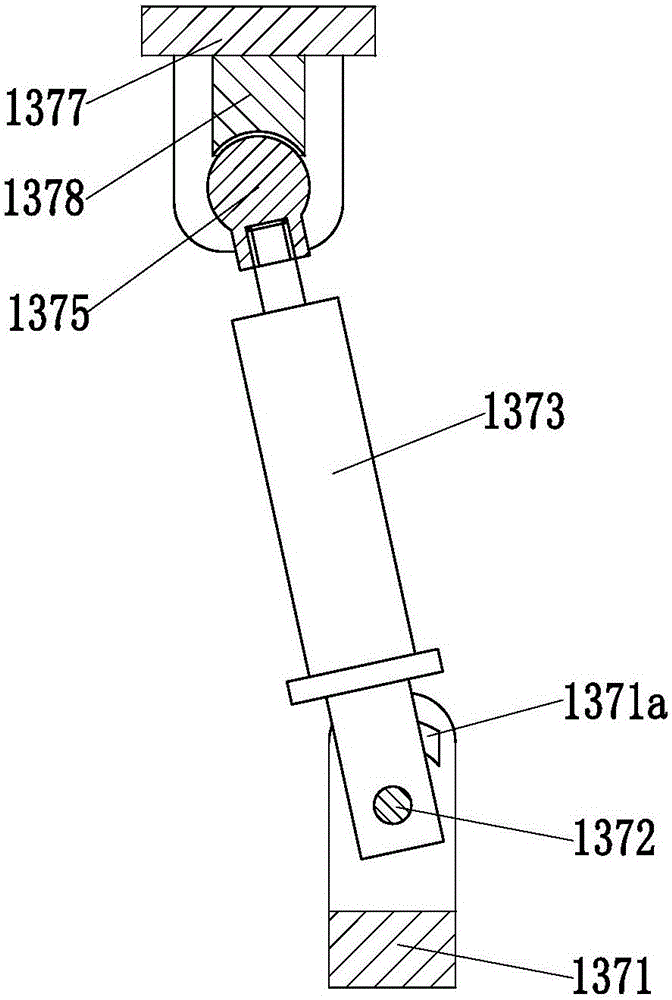

Hydraulic grabbing mechanical arm for anti-collapsing rock-soil retaining wall

InactiveCN106002952AGood dynamic responseIncrease stiffnessProgramme-controlled manipulatorGripping headsHydraulic cylinderLower limit

The invention relates to a hydraulic grabbing mechanical arm for an anti-collapsing rock-soil retaining wall. The hydraulic grabbing mechanical arm comprises a damping supporting mechanism, wherein the damping supporting mechanism comprises a fixed platform; three parallel-connection branch chains are evenly mounted on the upper end face of the fixed platform in the direction of the axis, and the top ends of the three parallel-connection branch chains are mounted on the lower end face of a movable platform; each parallel-connection branch chain comprises a concave support welded to the upper end face of the fixed platform, a lower limiting shaft is mounted between middles of two sides of each concave support, and two arc limiting grooves are symmetrically formed in the inner wall of the upper end of each concave support; each lower limiting shaft is sleeved with a first hydraulic cylinder, two limiting rods are arranged on the two sides of the bottom end of each first hydraulic cylinder, and the tail ends of two limiting rods are connected with corresponding two arc limiting grooves in a sliding fit manner; and a hydraulic grabbing device is mounted at the upper end face of the movable platform. According to the mechanical arm, the stable automatic hydraulic grabbing function of masonry can be achieved, the phenomenon of vertical shaking or left-and-right shaking in the carrying process can be avoided, and stability performance is good.

Owner:JILIN UNIV

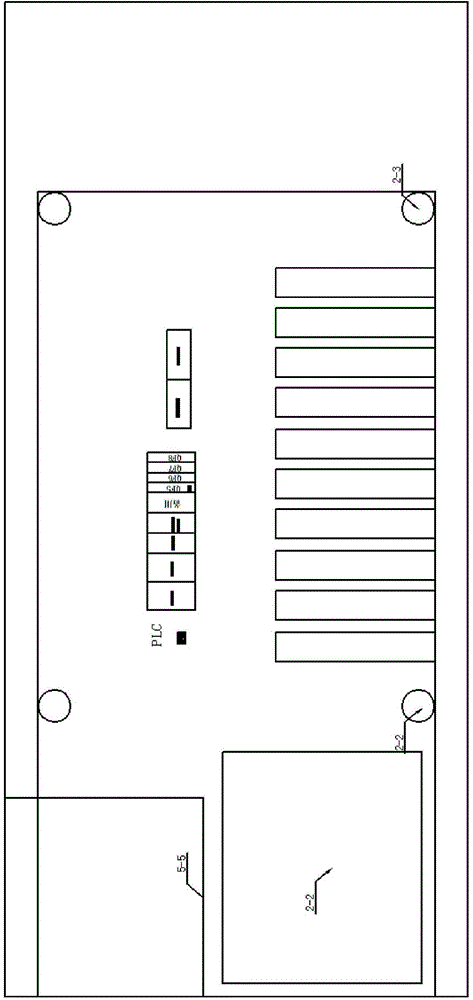

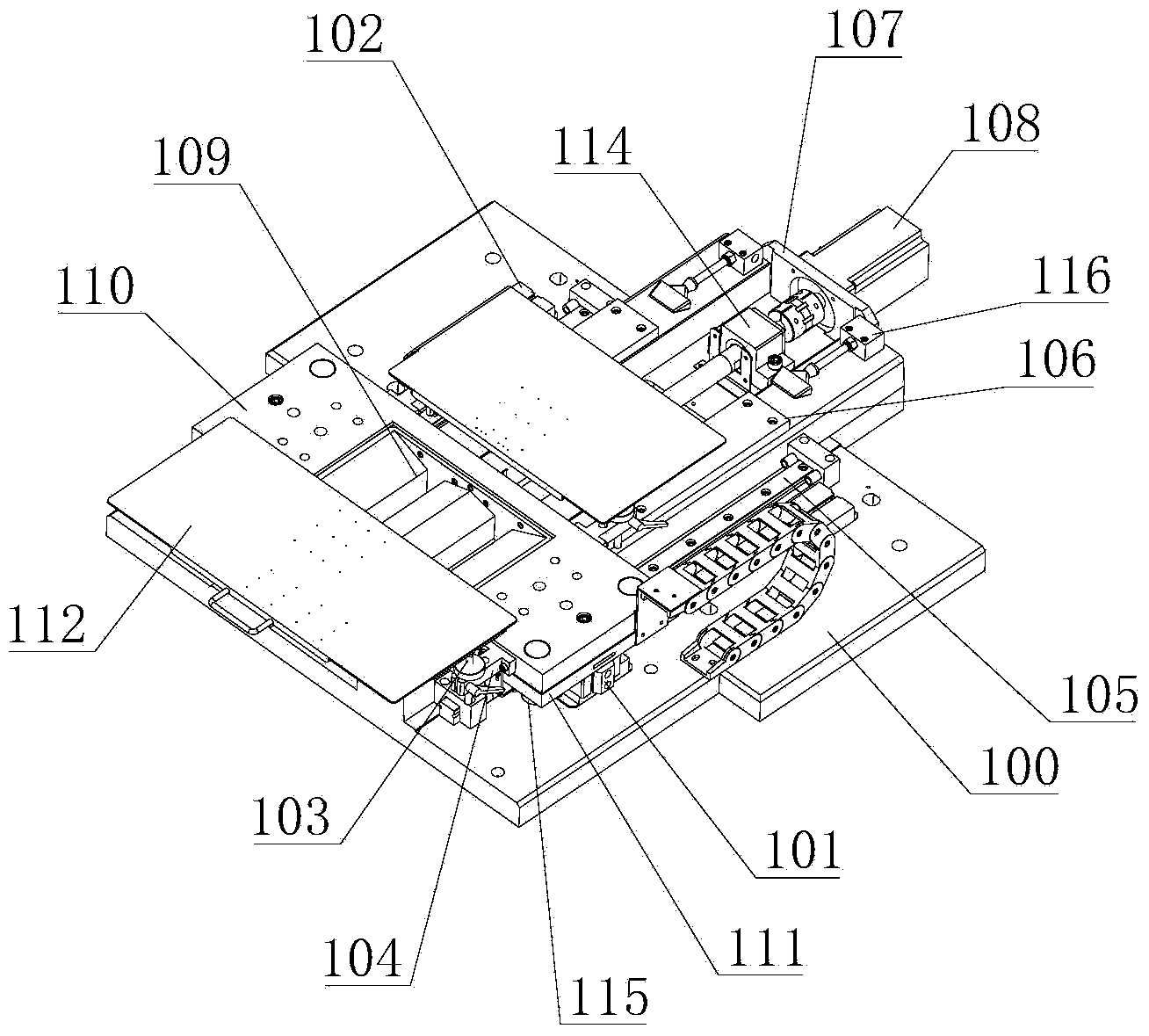

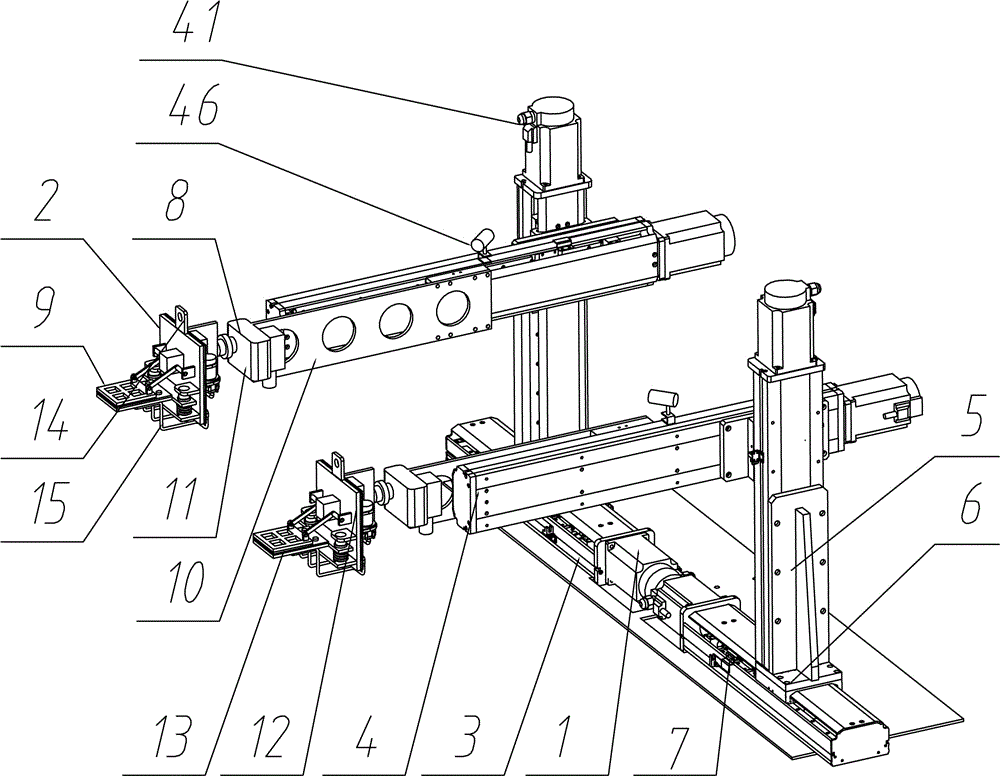

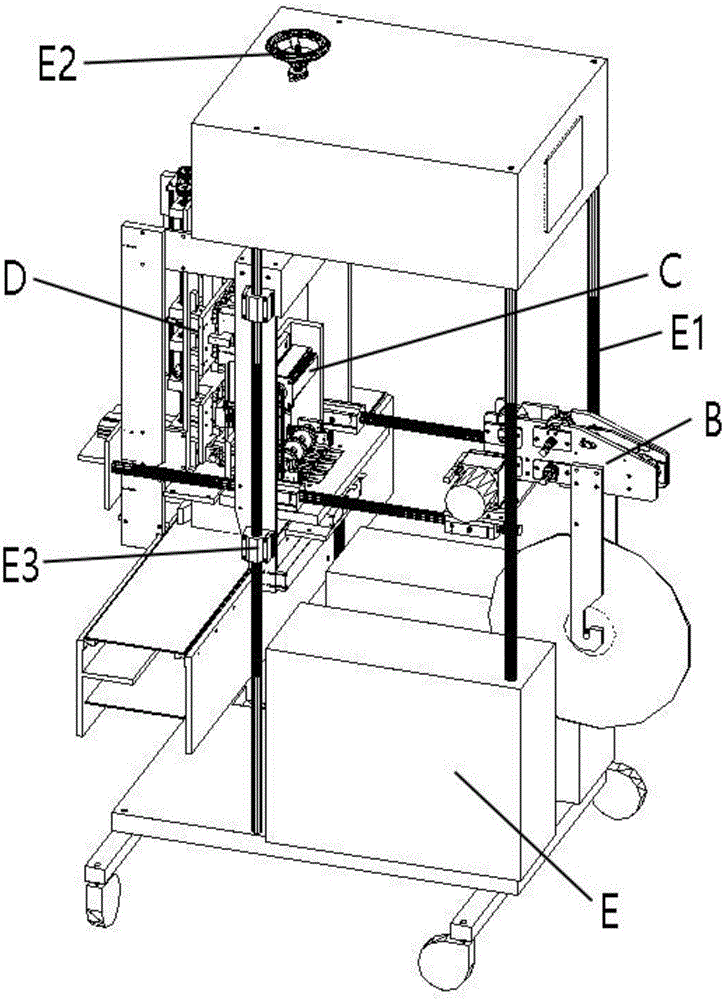

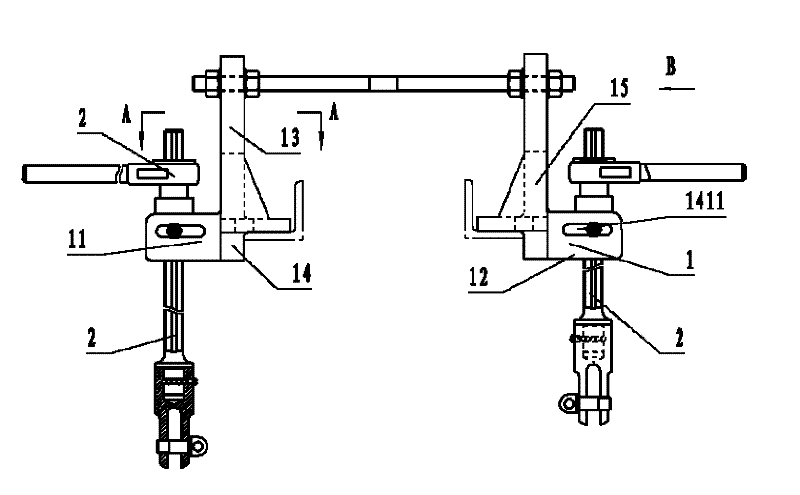

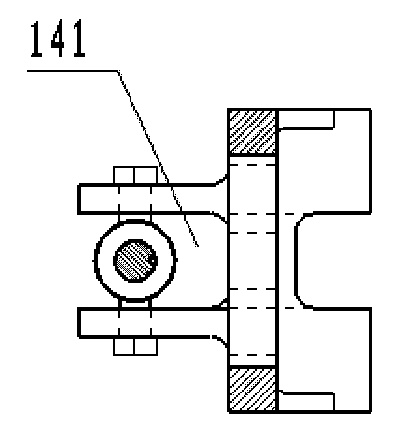

Wiring robot and wiring method for on-site calibration of mutual inductor

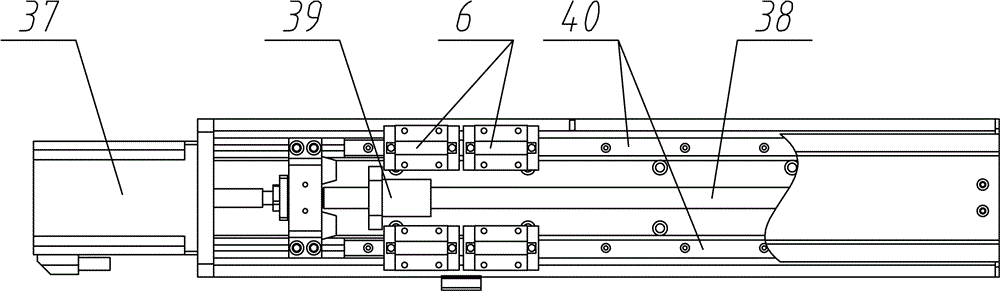

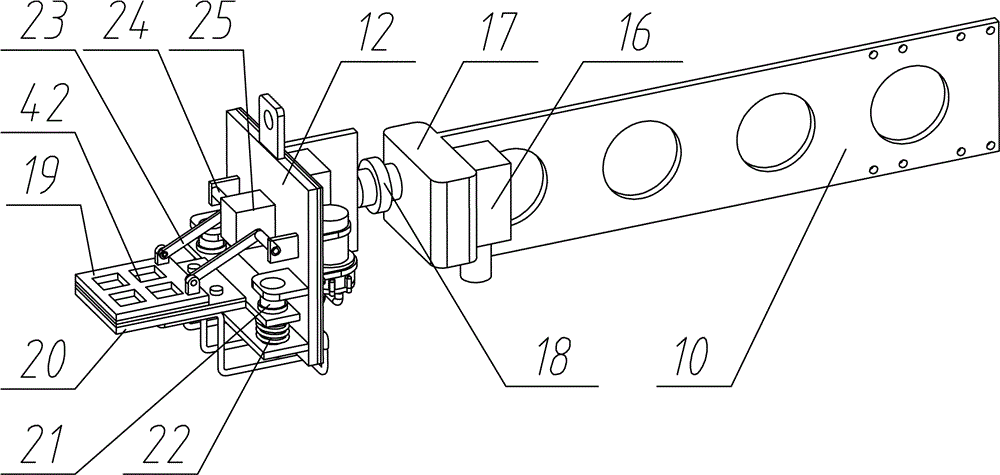

ActiveCN105729484ASolve labor intensitySolve the dangerMeasurement instrument housingManipulatorBall screwInductor

The invention provides a wiring robot and wiring method for on-site calibration of a mutual inductor. The wiring robot for on-site calibration of the mutual inductor mainly comprises a wiring robot body. The wiring robot body comprises two sets of mechanical arms and manipulators. Each set of mechanical arms includes the X-axis mechanical arm, the Y-axis mechanical arm and the Z-axis mechanical arm, wherein the mechanical arms are driven by a ball screw structure to slide relatively. Each manipulator comprises an angle adjustment device and a wiring device, wherein the angle adjusting device comprises a wiring mechanical arm, and the front end of the wiring mechanical arm is connected with the wiring device through a rotating mechanism; and the wiring device comprises an installation base, a clamping mechanism is right arranged at the front end of the installation base, a connecting hole is formed in the upper end of the installation base, and a gluing device is arranged at the lower end of the installation base. According to the wiring robot and wiring method for on-site calibration of the mutual inductor, connection between a port of the mutual inductor and a wire can be completed automatically, and thus a worker is assisted in completing an on-site calibration task of the mutual inductor.

Owner:平邑仁安中医药产业发展有限公司

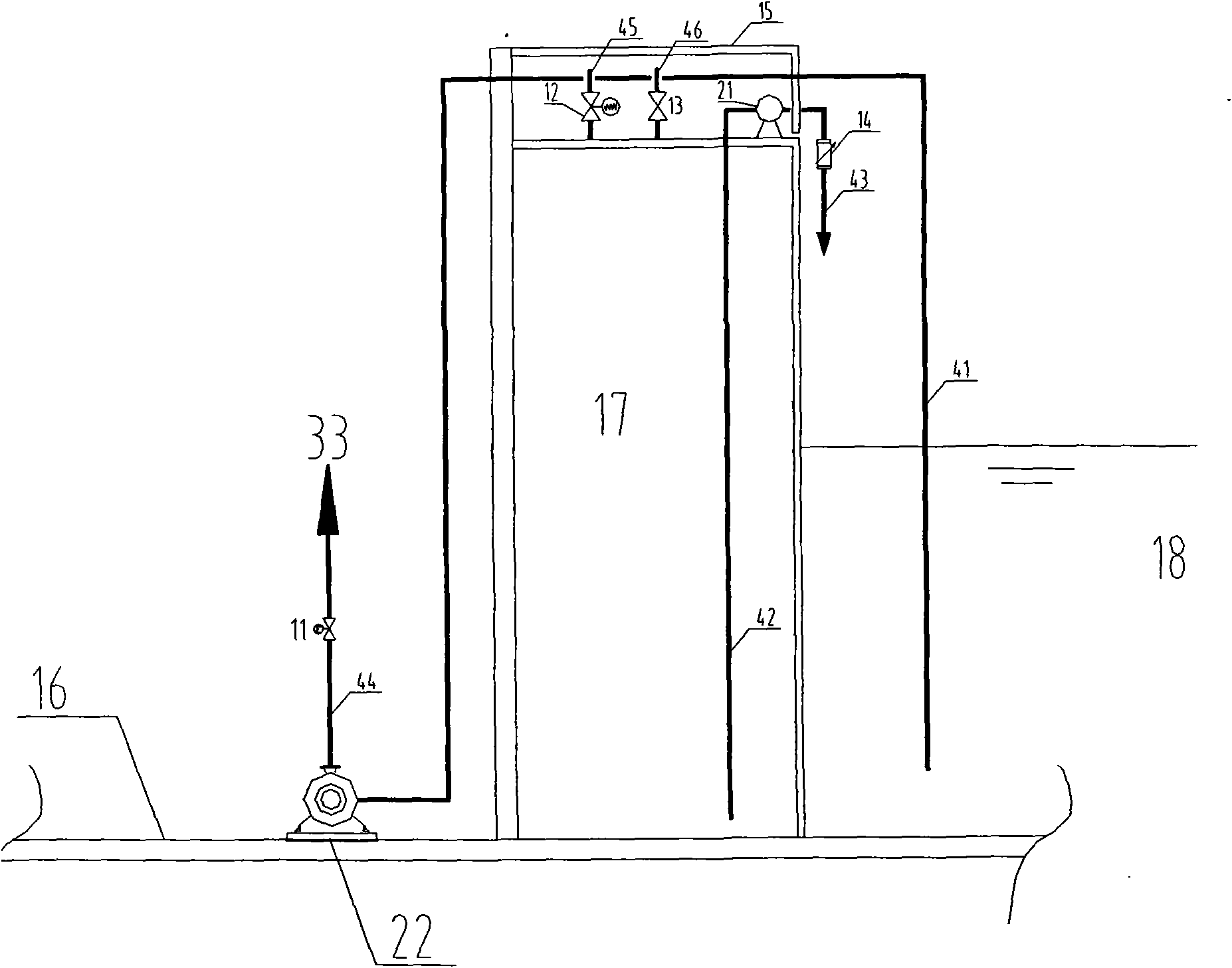

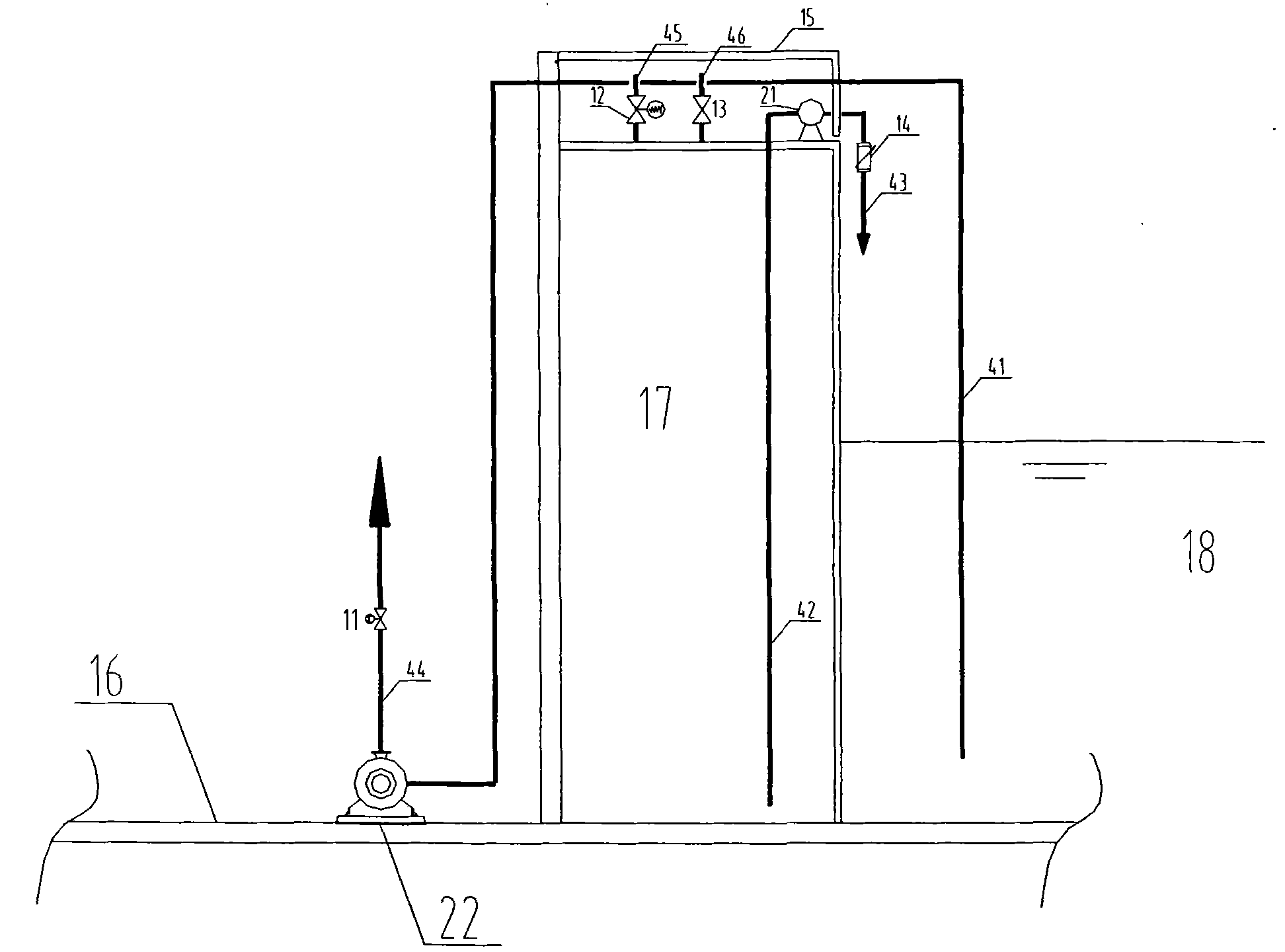

Chemical cleaning method of hollow fiber membrane and device thereof

InactiveCN101829505AGuaranteed fluxImprove stabilitySemi-permeable membranesFiberHollow fibre membrane

The invention discloses a chemical cleaning method of a hollow fiber membrane, comprising the following steps of: (1) preparing a composite chemical cleaning agent with the active chlorine concentration of 10-13%; and (2) back washing the hollow fiber membrane on line by adopting the compounded composite chemical cleaning agent. The invention also discloses a chemical cleaning device of the hollow fiber membrane, which is provided with a composite chemical cleaning agent storage tank and a back washing system comprising a back washing pump; and the upper part of the storage tank is provided with a filling pipe, an electromagnetic valve and an air release valve. The invention can effectively keep the membrane flux of a membrane bioreactor and is matched with the running characteristic of a membrane bioreactor process. The invention solves the problems of large impact on microorganisms in a system, high labor intensity caused by needing to hang a membrane assembly out for cleaning and the like, and difficult running management, can integrate a membrane assembly cleaning system and the membrane bioreactor to improve the control level of automation. By adding a surfactant and regulating the pH value of the system to be greater than 13, the stability of a sodium hypochlorite solution can be improved.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

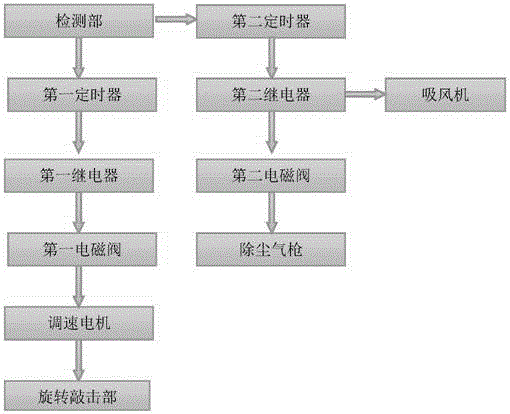

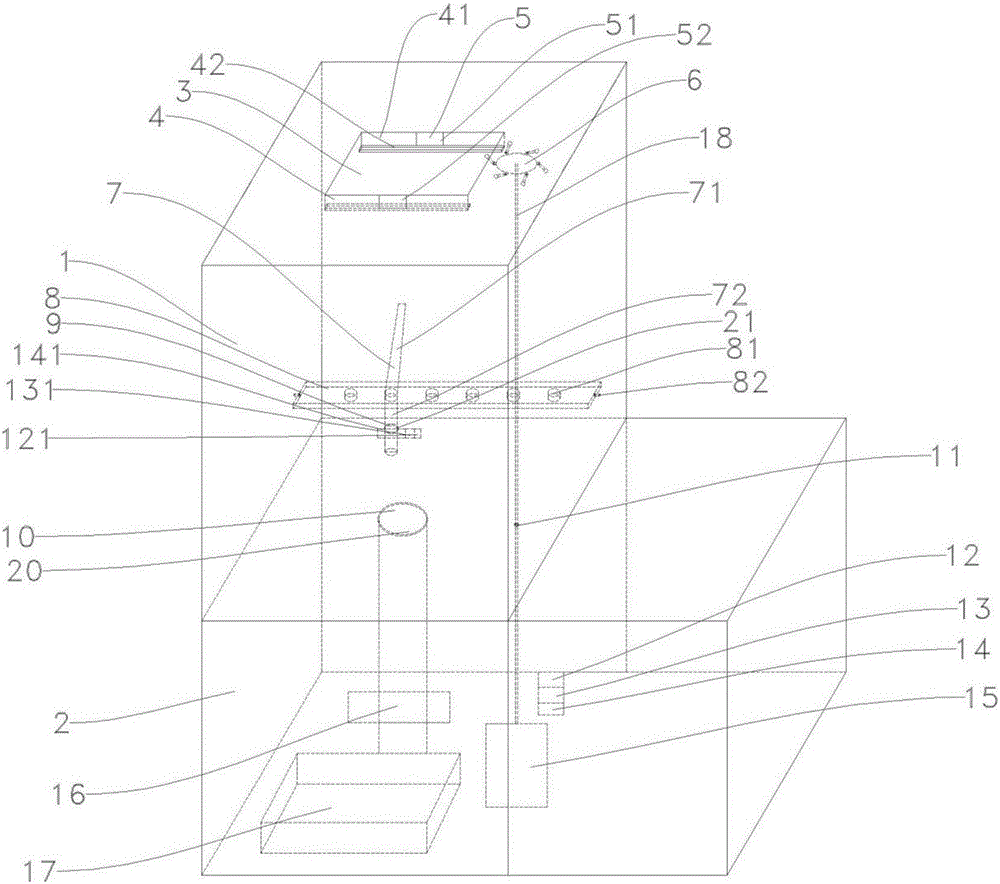

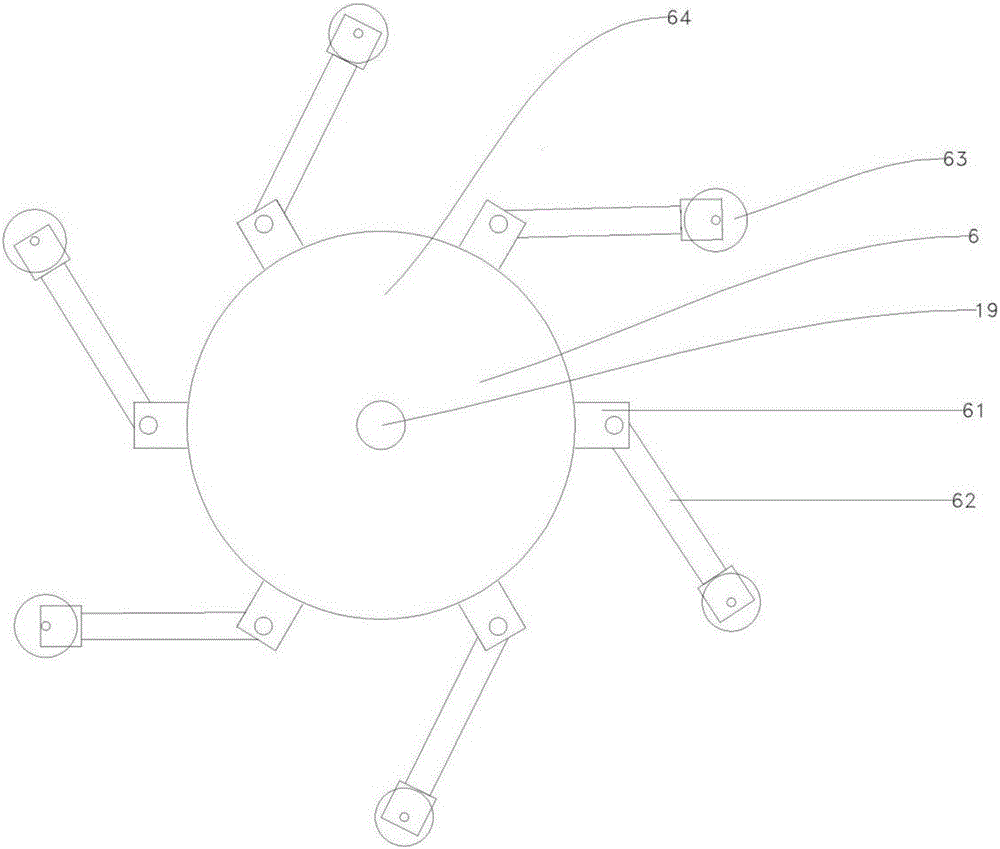

Device for removing dust and solder splash from electricity meter

ActiveCN105149296ARealize tapping to remove tin slagGood effectCleaning processes and apparatusSolenoid valveSolder paste

The invention provides a device for removing dust and solder splash from an electricity meter. The device comprises a first box and a second box which is fixedly connected with the bottom surface of the first box, wherein the upper surface of the first box is provided with a limiting part which is used for placing the electricity meter and a detection part; the first box is internally provided with a dust removing pneumatic gun and a vibration knocking part; and the second box is internally provided with a first timer, a second timer, a first relay, a second relay, a first solenoid valve, a second solenoid valve, an adjustable-speed motor, a suction ventilator and a dust collection bag. The detection part detects the to-be-treated electricity meter, and after a preset period of time, the adjustable-speed motor operates to realize knocking on the to-be-treated electricity meter; and the detection part detects the to-be-treated electricity meter, and after a preset period of time, dedusting on the to-be-treated electricity meter by the dust removing pneumatic gun and dust collection by the suction ventilator are realized. By adopting the device disclosed by the invention, the problems in manually knocking the shell and manually removing the dust with the pneumatic gun that the standard degree is low and the efficiency is low are solved; and the device is simple in structure, simple and convenient to operate, high in automation degree and good in dust and solder splash removing effect.

Owner:LIYANG HUAPENG ELECTRIC POWER METER

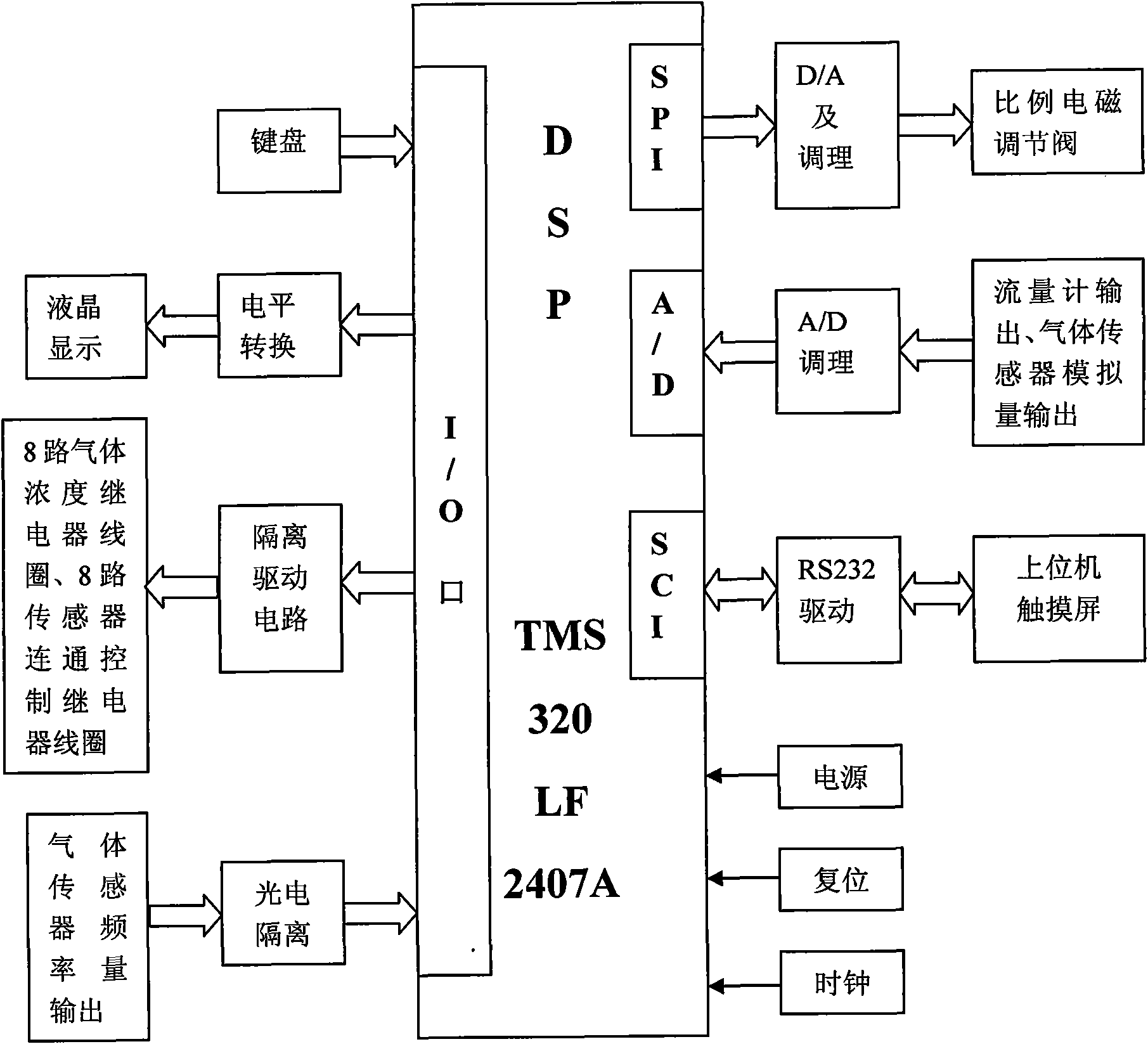

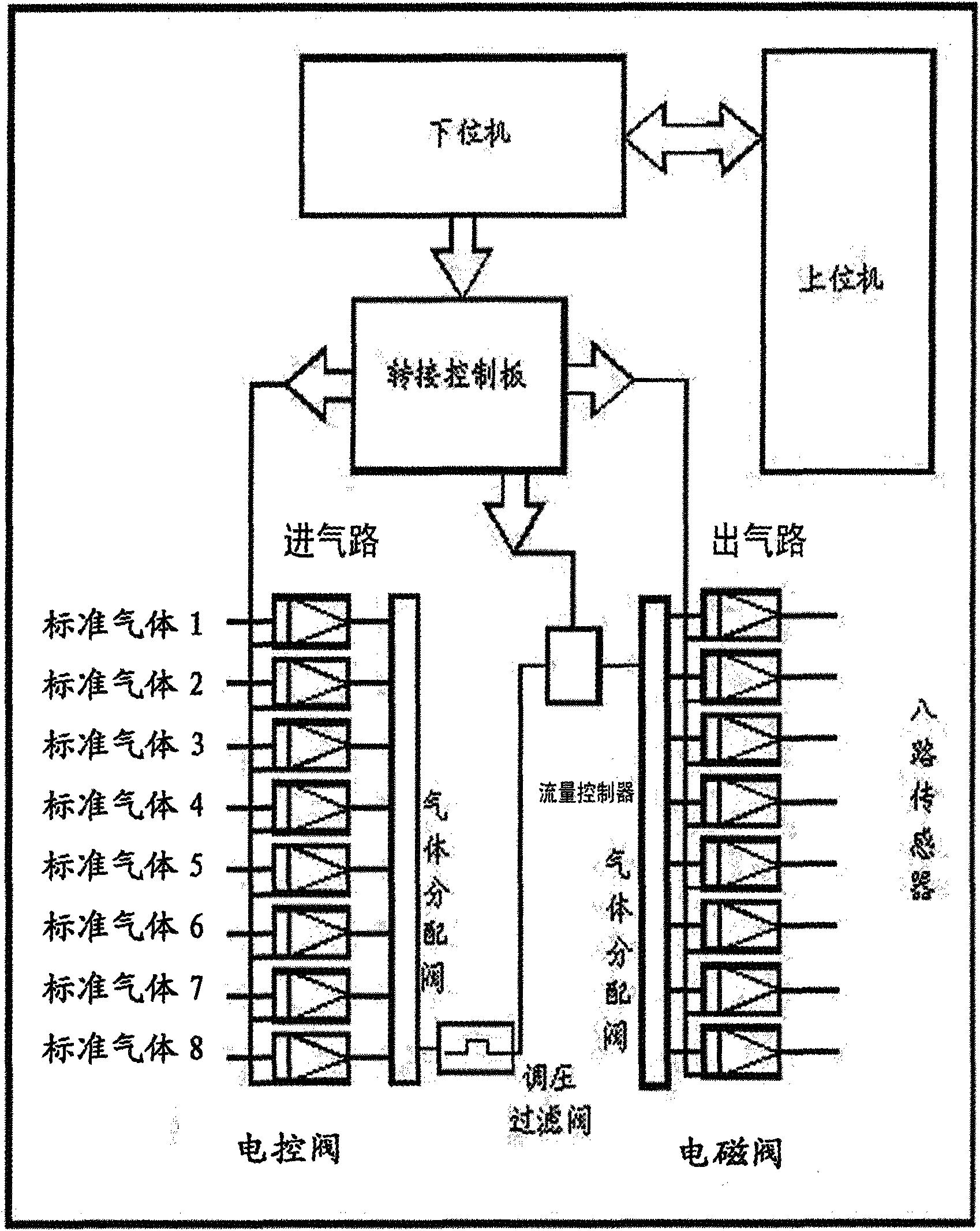

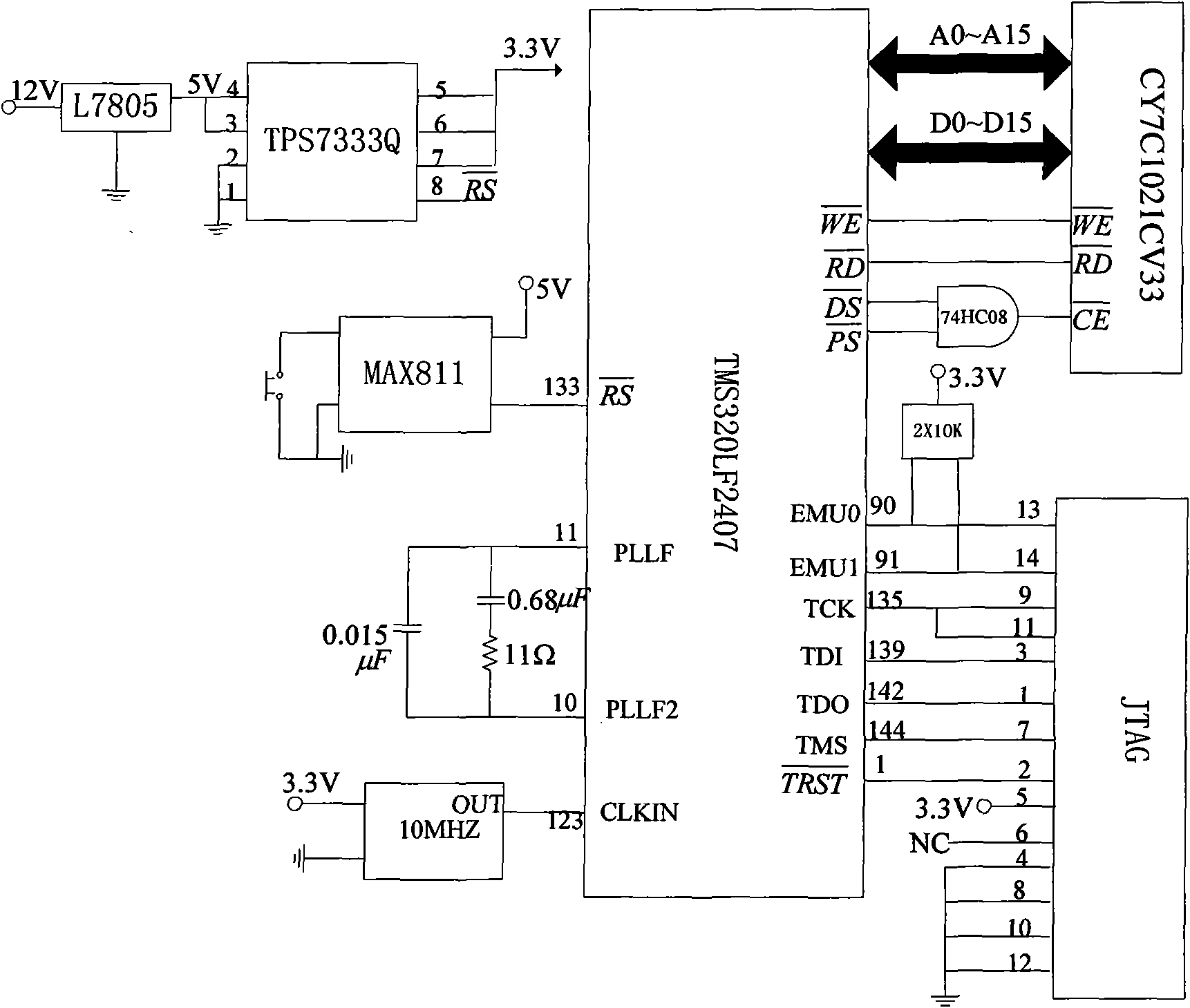

Digital signal processor (DSP)-based intelligent gas sensor checking instrument for mines

InactiveCN101988912ASolve labor intensitySolve efficiency problemsMaterial analysis by electric/magnetic meansDigital signal processingMicrocontroller

The invention provides a digital signal processor (DSP)-based intelligent gas sensor checking instrument for mines, comprising a microcontroller unit, a signal conditioning unit, a communication interface unit, a keyboard display unit, a touch control unit and a gas circuit system; and in the invention, the communication connection is carried out on the units and modules of the checking instrument. In the invention, the existing checking instrument structure is improved, and the central processing unit (CPU) technology, the electronic technology and the control technology are taken as main technologies, thereby solving the problems of low speed, low accuracy and high labor intensity of the existing checking instrument and providing services for underground safety production of coal mines.

Owner:山西科致成科技有限公司 +1

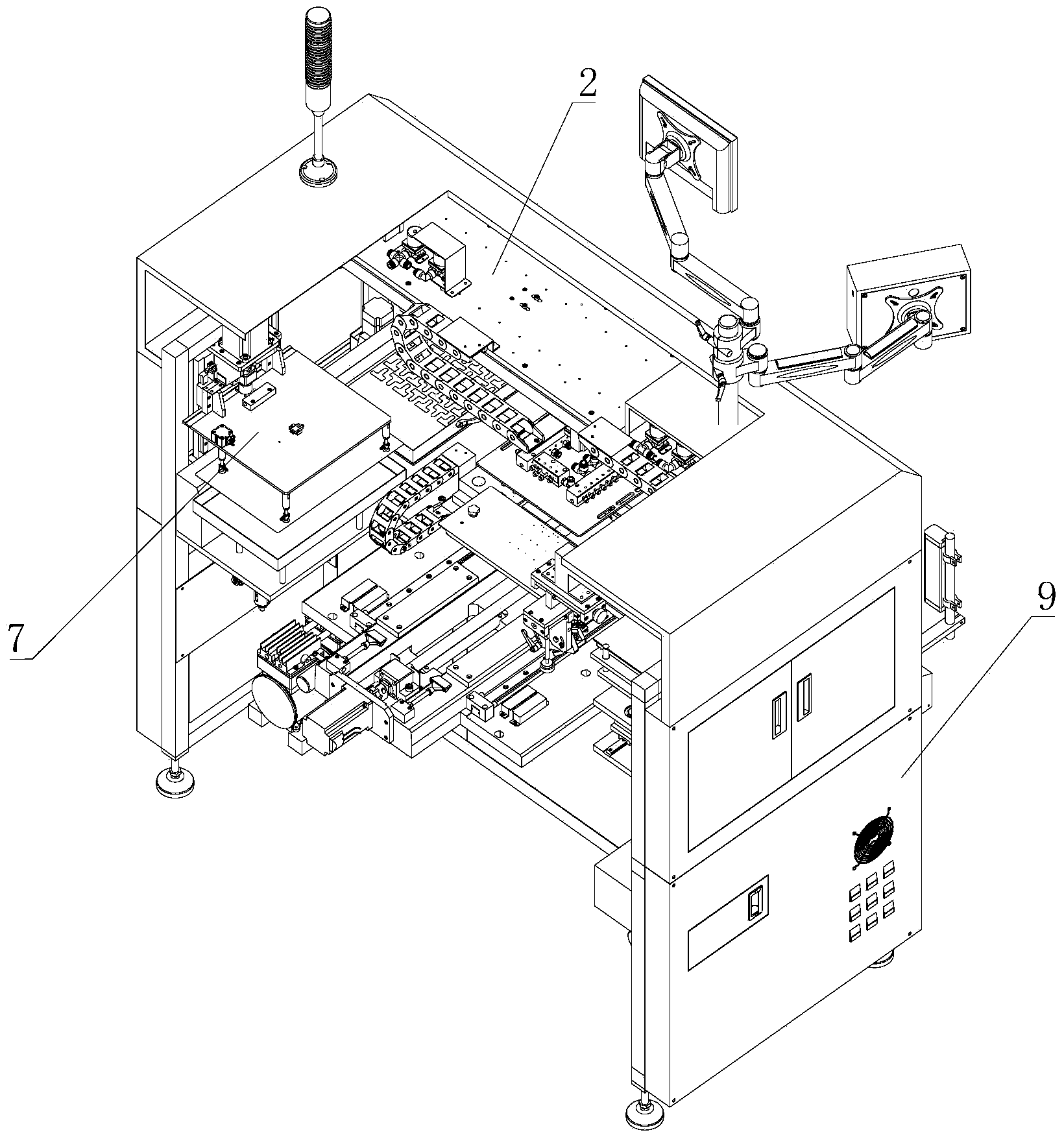

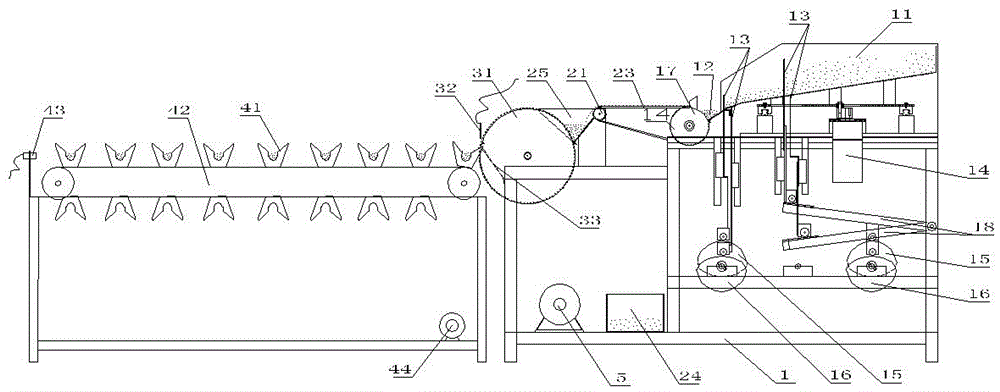

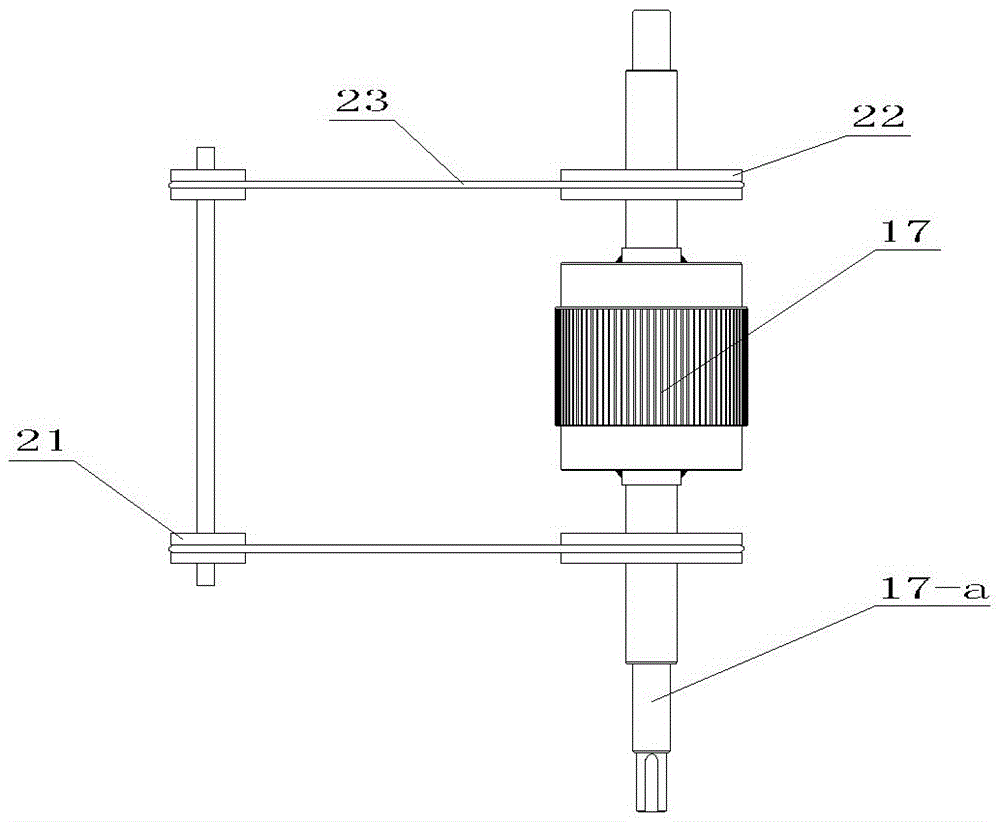

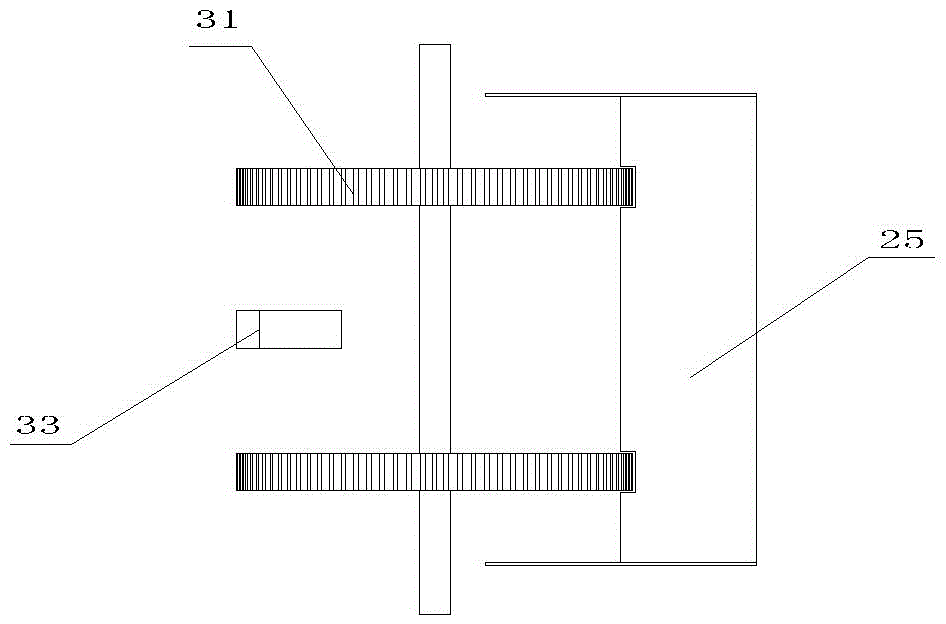

Fully-automatic assembling machine for protective meshes of storage batteries

InactiveCN106450415ASolve labor intensitySolve efficiency problemsAssembling battery machinesFinal product manufactureFully automaticTape drive

The invention provides a fully-automatic assembling machine for protective meshes of storage batteries. The assembling machine comprises a splitting part, a cutting-off part and an assembling part, wherein the splitting part comprises a splitting machine frame, a material tape channel, a splitting knife and a power device; the cutting-off part comprises a cutting-off machine frame, a plurality of narrow material tape channels for narrow protective mesh material tapes to pass through are horizontally arranged on the cutting-off machine frame, and a narrow material tape driving device and a cutting-off device are also arranged in the travelling direction of the narrow protective mesh material tape; the assembling part comprises an assembling machine frame, a mesh clip, a push rod, a mesh clip driving device, a push rod driving device, a mesh tray, a tray driving device, a clip groove clamping device and a storage battery clamping device; and the cutting-off part is arranged in front of the assembling part, and the splitting part is arranged in front of the cutting-off part. The whole working process of the assembling machine has full automation, high efficiency, low labor intensity and stable assembling quality.

Owner:JIANYANG CHAONENG ELECTRONICS

Automatic subpackage machine and method for incense sticks

ActiveCN106314855AControl quantitySmooth connectionConveyorsPackaging automatic controlButt jointContinuous operation

The invention discloses an automatic subpackage machine and method for incense sticks, and belongs to the technical field of incense making. The automatic subpackage machine structurally comprises an arranging and stabilization assembly, a broken incense screening assembly, a counting and quantification assembly, a subpackage and conveying assembly and a control management circuit in sequence. The broken incense screening assembly comprises two parallel conveying belts operating synchronously. A stabilization feeding roller wheel is arranged between the feeding ends of the conveying belts. The receiving position below the feeding roller wheel is in butt joint with a discharging outlet of a vibration feeding hopper, and a discharging point is arranged above the conveying belts to form the linkage of the arranging and stabilization assembly and the broken incense screening assembly. The quantified output automatic subpackage machine is formed by means of the post-processing counting and quantification assembly and the subpackage and conveying assembly. Standard arrangement, broken incense screening, quantified output counting and subpackage of the incense sticks are achieved, and automatic linkage and continuous operation are also achieved. The structure is simple, the efficiency is high, and the repeated operation quality is stable.

Owner:河北古城香业集团股份有限公司

Section bar automatic packaging equipment

ActiveCN106218968AIncrease productivitySolve the low degree of automationWrapper folding/bending apparatusWrappingReciprocating motionUltimate tensile strength

The invention provides section bar automatic packaging equipment. The section bar automatic packaging equipment comprises a packaging paper feeding mechanism, a section feeding mechanism, a vertical folding mechanism, horizontal folding mechanisms, a packaging mechanism, a clamping and feeding mechanism, a pushing mechanism and a control mechanism, wherein the packaging paper feeding mechanism is used for lifting, pulling out and shearing and paving packaging paper on a platform; the section feeding mechanism is used for transferring and locating a section bar in the middle part of the platform where the packaging paper is paved; the vertical folding mechanism is used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform; the horizontal folding mechanisms are used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform and then horizontally folding the upper part of the side edge of the packaging paper, so that the packaging paper wrap the end surface of the section bar; the packaging mechanism is used for winding and sealing the packaging paper which wraps the section bar; the clamping and feeding mechanism is used for a reciprocating motion to transfer the section bar wrapped by the packaging paper to the packaging mechanism; and the pushing mechanism is used for compacting the opening of the packaging paper which wraps the end surface of the section bar. The section bar automatic packaging equipment provided by the invention can solve the problems that the efficiency is low and the labor intensity is great due to a manual operation, so that the packaging efficiency and quality of the section bar are improved.

Owner:佛山市嘉荣智能机械有限公司

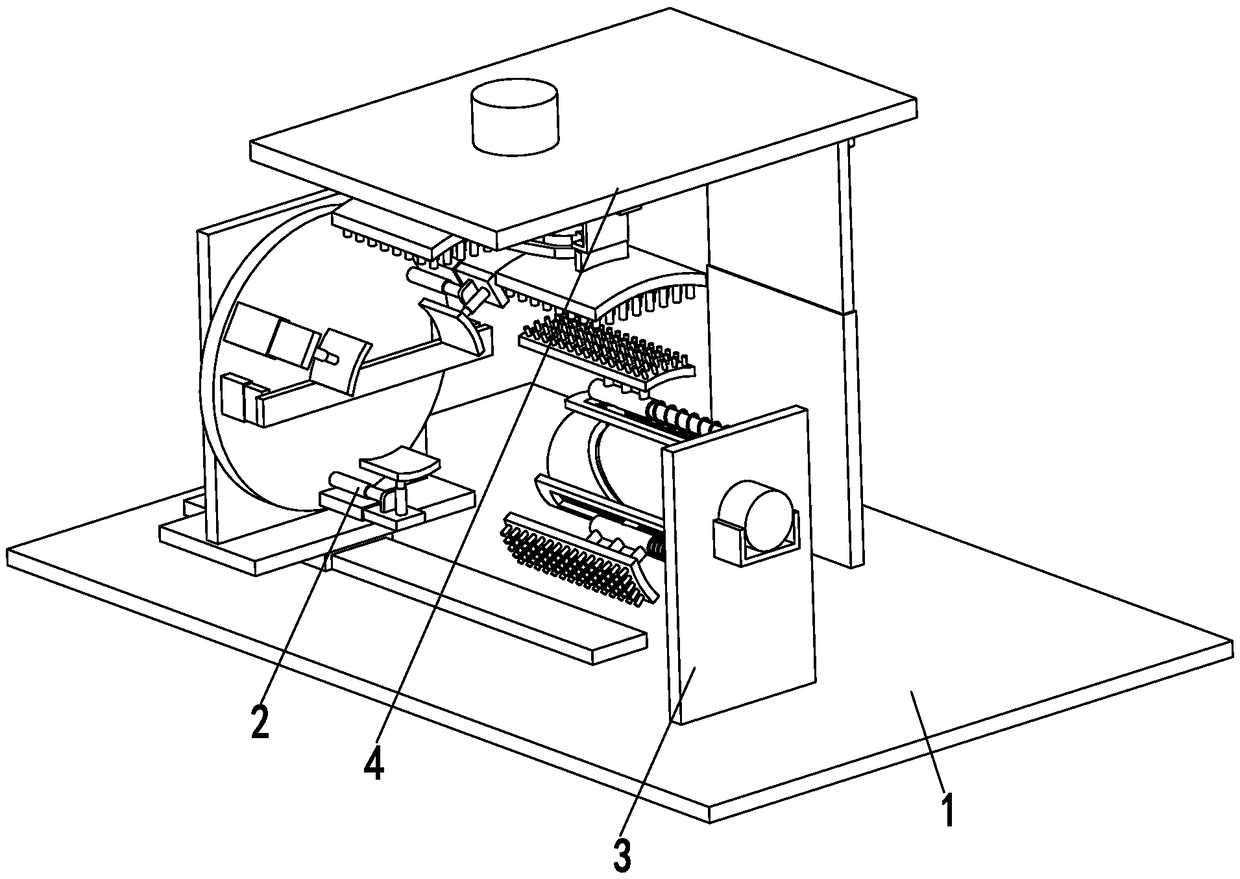

Workpiece grinding machine of numerical-control electric spark machine tool

InactiveCN108789046ASolve the costSolve labor intensityGrinding carriagesGrinding drivesNumerical controlEngineering

The invention relates to a workpiece grinding machine of a numerical-control electric spark machine tool. The workpiece grinding machine of the numerical-control electric spark machine tool comprisesa base plate, a fixing device, an inner wall grinding device and an outer wall grinding device. The fixing device and the inner wall grinding device are sequentially installed on the base plate from left to right. The outer wall grinding device is installed on the back side of the base plate. The inner wall grinding device comprises a fixing plate, a rotating motor, a rotating column, sliding blocks, limiting frames, telescopic rods, springs, adjusting air cylinders and first steel wire brushes. The outer wall polishing device comprises a lifting frame, a rotating motor, a rotating column, a cam, connection sliding blocks, connection frames, guide rails and second steel wire brushes. The workpiece grinding machine of the numerical-control electric spark machine tool can solve the problemsthat in an existing annular workpiece grinding process, the labor cost is high, the labor intensity is high, the work efficiency is low, the grinding difficulty is large, and the adjustability is poor; the automatic grinding function on the annular workpiece can be achieved; and the workpiece grinding machine of the numerical-control electric spark machine tool has the advantages of being low in labor cost, low in labor intensity, high in work efficiency, small in polishing difficulty, good in adjustability and the like.

Owner:浙江芊荷科技有限公司 +1

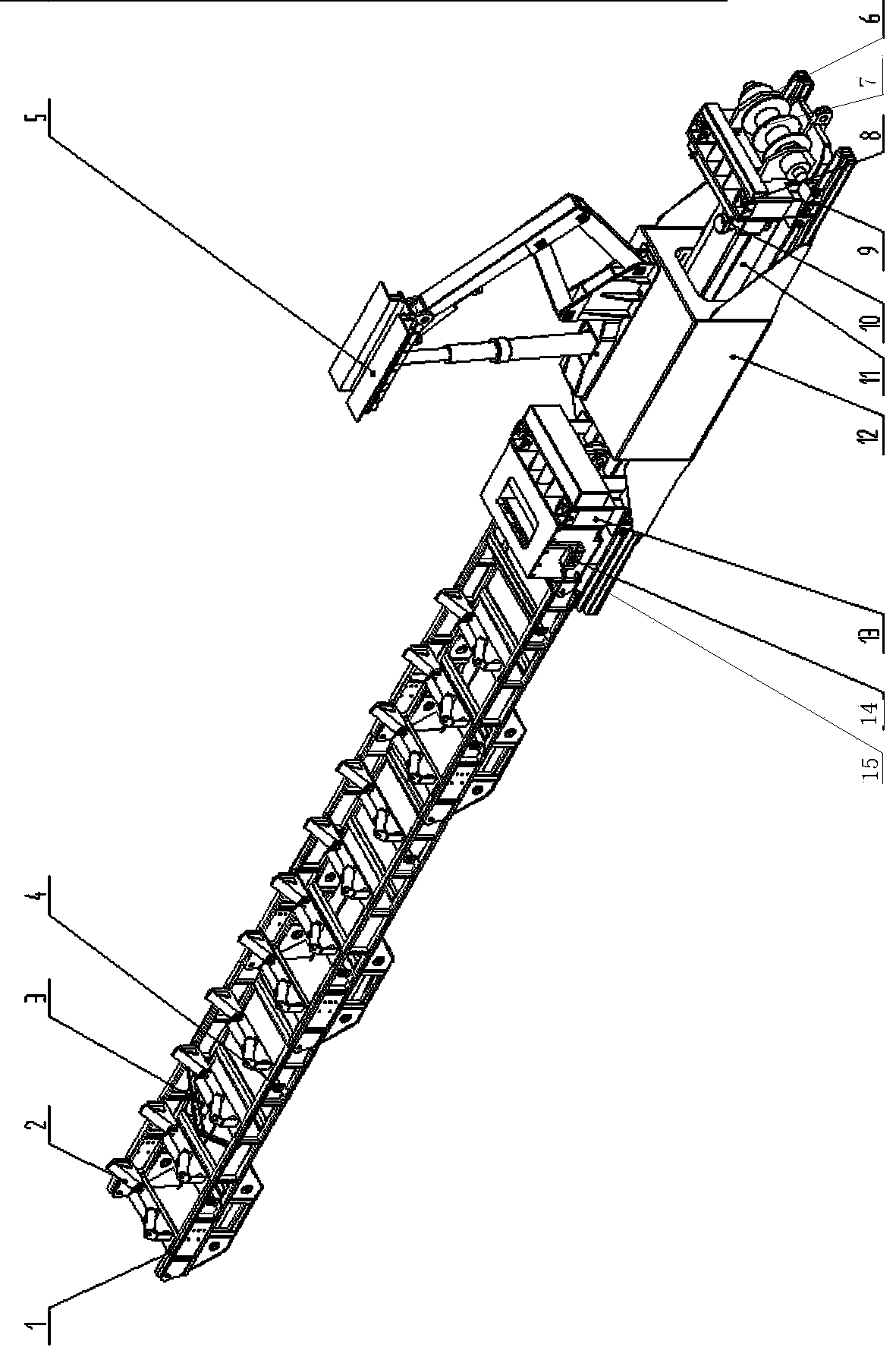

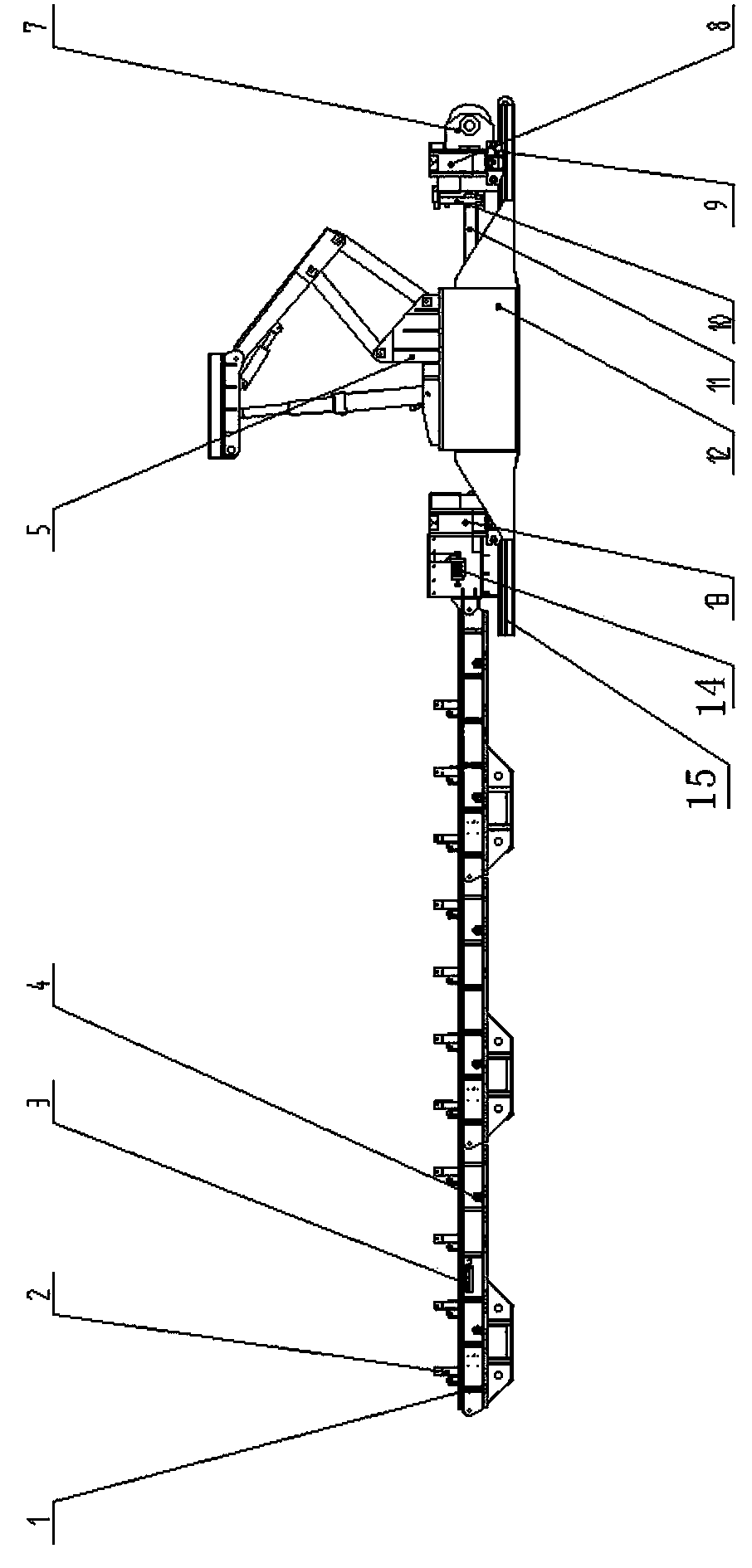

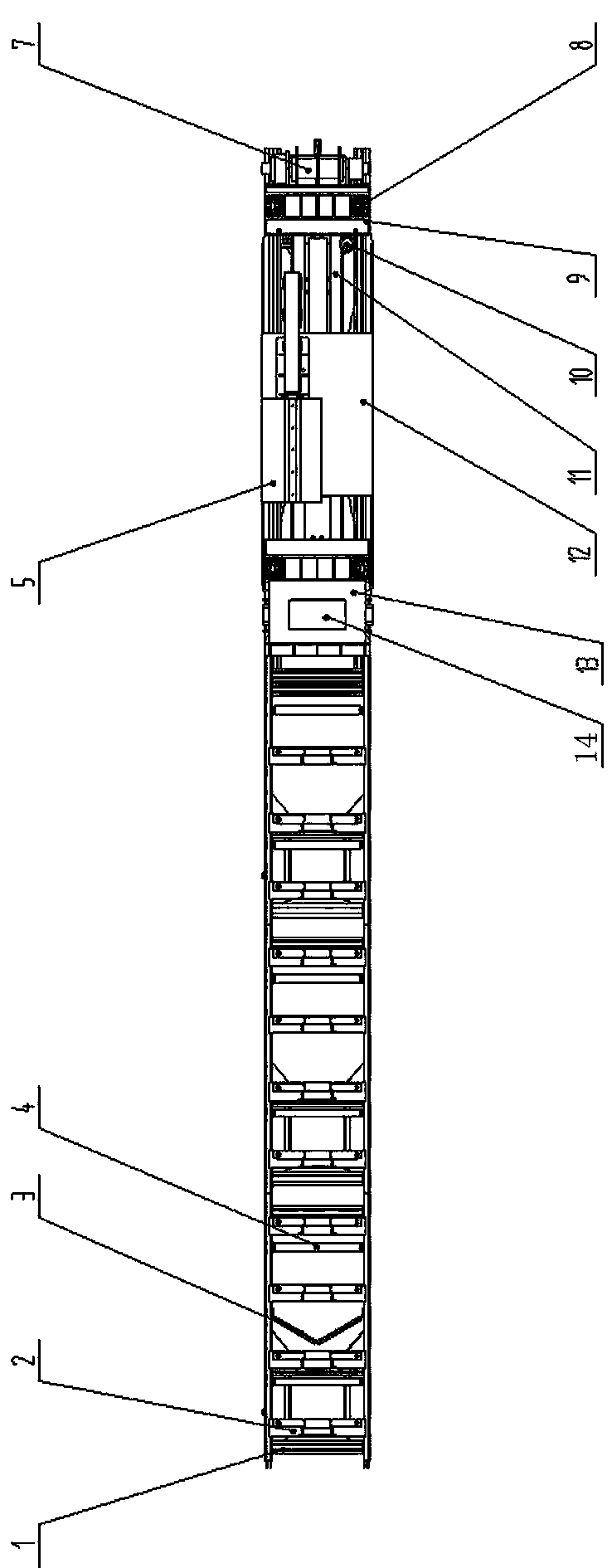

Stepping self-moving rubber belt conveyor tail used for fast driving

The invention belongs to the technical field of designing and manufacturing of driving working face devices in a coal mine and particularly relates to a stepping self-moving rubber belt conveyor tail used for fast driving. The problems existing in the moving mode of an existing driving working face belt conveyor tail are solved. The stepping self-moving rubber belt conveyor comprises a rigid frame, a roller and a rack. The rack comprises a front rack and a back rack, a beam is connected between the front rack and the back rack, a base is arranged between the front rack and the back rack, and guide rails are connected with the bottom of the base. A push moving oil cylinder is arranged on the beam, and a stand column mechanism and a four-bar mechanism are arranged at the top of the base. Roller boxes are arranged on the two sides of the front rack and the two sides of the back rack. The roller boxes are matched with the guide rails in a sliding mode, and lifting oil cylinders are connected inside the roller boxes and arranged in the vertical direction. The stepping mode is unique, and a set of device combines a hydraulic support and the belt conveyor tail to achieve stepping self moving, so that the requirement for fast moving of the device under different working conditions is met. The stepping self-moving rubber belt conveyor tail is simple in structure, convenient to install and flexible in operation.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Seedling grafting machine and grafting method of seedling grafting machine

The invention belongs to the field of planting machinery and provides a grafting machine, which consists of a work table, a cutting engagement device and a seedling positioning device. The invention also provides a grafting method adopting the grafting machine. The seedling grafting machine has the beneficial effects that 1, the grafting mechanization is realized, and the problems of high work intensity and low work efficiency of artificial grafting are solved; 2, when the grafting machine provided by the invention is adopted, the cutting surfaces of stocks and cions are precisely aligned, at least one side of the forming layer is aligned, and the grafting survival rate is high; and 3, a wax coating mode is adopted for fixing the cutting surface combining part of the stocks and the cions, the wound infection is avoided, in addition, the seedling thickness increase is not influenced, and the binding rope unlocking treatment after the traditional grafting is omitted.

Owner:CHINA AGRI UNIV

Surface automatic polishing machine for flange

InactiveCN109465700ASolve the costSolve efficiency problemsEdge grinding machinesGrinding carriagesFlangePetroleum engineering

A surface automatic polishing machine for a flange is proposed, and includes a bottom plate, a mounting frame, an inner wall polishing mechanism and an outer wall polishing mechanism. The mounting frame which is in an inverted L shape is mounted on the bottom plate, the lower end of the mounting frame is provided with the inner wall polishing mechanism, the lower end of the inn wall polishing mechanism is provided with the outer wall polishing mechanism, the outer wall polishing mechanism is installed on the bottom plate, and the inner wall polishing mechanism comprises a lifting frame, a rotating motor, a rotating frame, a steering motor, a steering plate, a bi-directional adjusting cylinder, a working plate, a working cylinder and an adjusting plate. The invention can solve the problemsof high labor cost, low work efficiency, high labor intensity, poor adjustability and poor work stability in the prior flange polishing process, and can realize the function of automatic polishing ofthe flange, and has the advantages of low labor cost, high work efficiency, low labor intensity, good adjustability and high work stability.

Owner:西安科技成果转化工程有限公司

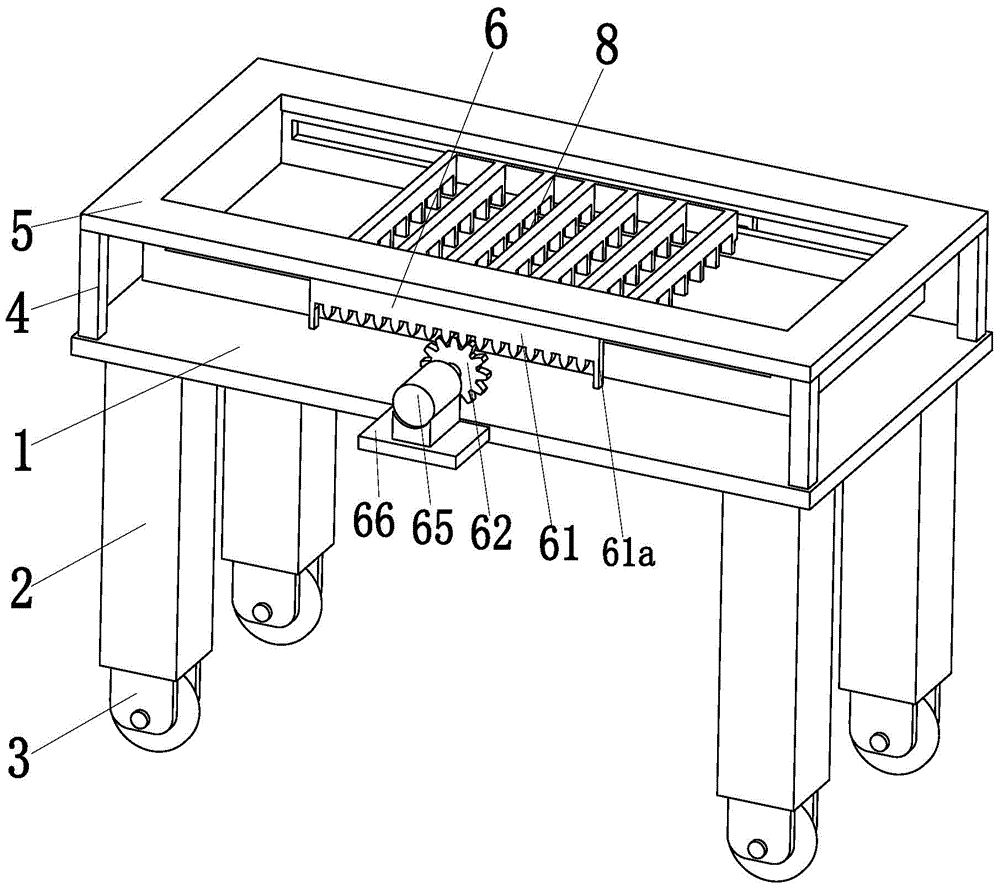

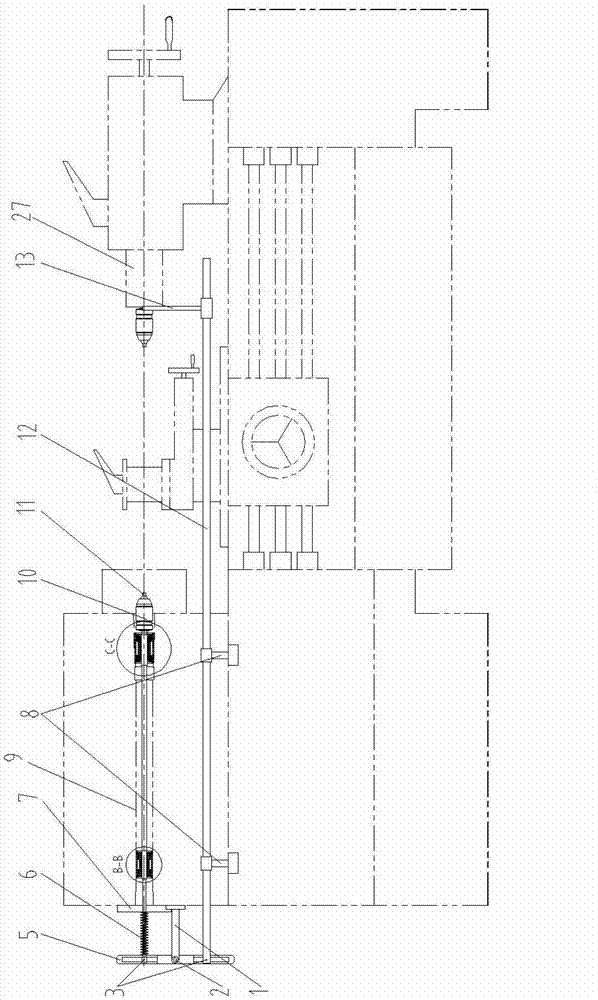

Airing device for white spirit fermented grains

InactiveCN104893902ASpread evenlyReduce labor intensityAlcoholic beverage preparationCouplingDrive motor

The invention relates to an airing device for white spirit fermented grains. The airing device comprises a bottom plate, wherein four supporting columns are symmetrically welded to the bottom of the bottom plate; a universal wheel is arranged at the lower end of each supporting column; the top of the bottom plate is symmetrically welded with four ejector rods; a tray is erected on the four ejector rods; two driving mechanisms are symmetrically arranged at two sides of the tray; two limiting grooves are symmetrically formed in two sides of the tray; a sliding shaft is placed in each limiting groove; an airing rack is welded between the two sliding shafts; each driving mechanism comprises a rack; the lower end of each rack meshes with a gear; each gear is arranged on a rotating shaft through a key; the right end of each rotating shaft is connected with a mounting column through a bearing; the mounting columns are welded to the bottom plate; the left end of each rotating shaft is connected with an outputting end of the driving motor through a coupling; each driving motor is arranged on a supporting plate through a motor seat. A quick airing for white spirit fermented grains can be fulfilled. The airing device has the advantages of easiness and convenience in operation, high airing speed, low labor intensity, high airing uniformity, high work efficiency and the like.

Owner:ANHUI ANQING JINHUI LIQUOR IND

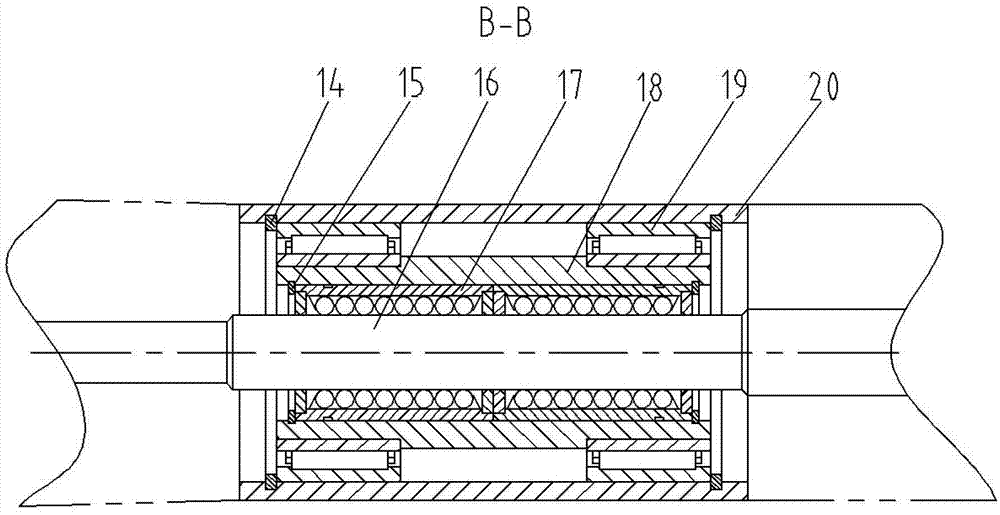

Processing device for double-center hole punching of common lathe

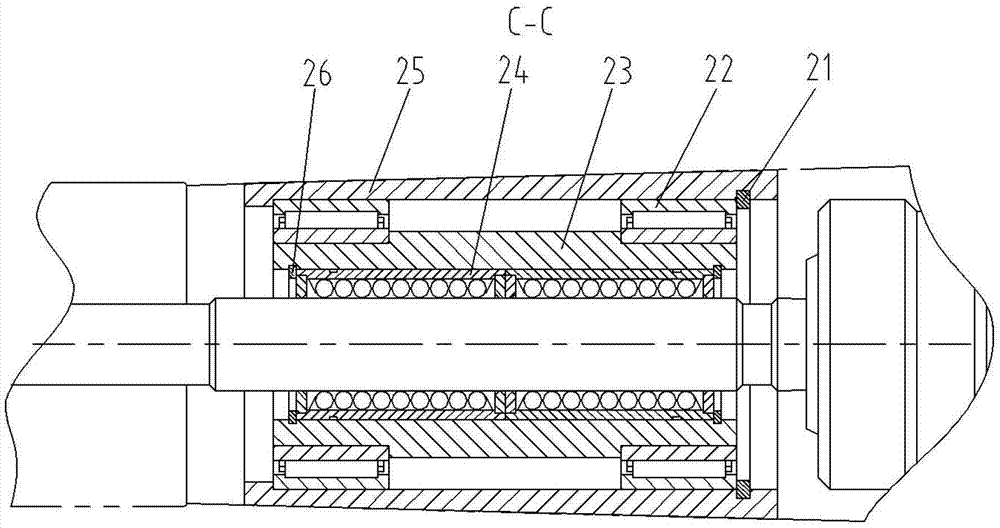

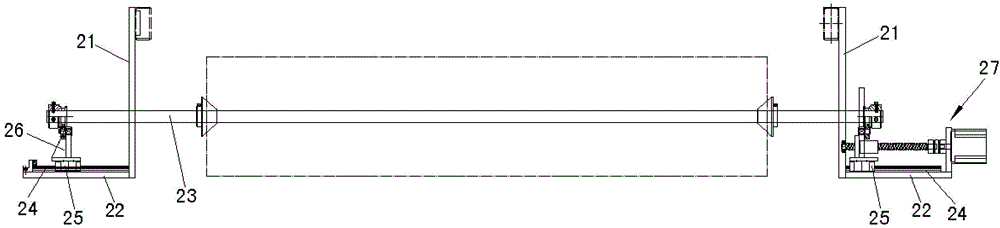

InactiveCN102784946APerformance is not affectedDoes not interfere with normal operationAttachable boring/drilling devicesNeedle roller bearingBall bearing

The invention discloses a processing device for double-centre hole punching of a common lathe. The processing device comprises a proportional reversing feeding device, two groups of shaft hole feeding devices arranged in main shaft holes, a drill chuck connecting rod, a drill chuck and a central drill, wherein the central drill is arranged at a front end of the drill chuck connecting rod through the drill chuck; two groups of shaft hole feeding devices are respectively arranged at front and back parts of the drill chuck connecting rod; each group of the shaft hole feeding devices structurally comprises a liner sleeve, needle rolling bearings, an shaft sleeve and a linear ball bearing which are arranged in the main shaft holes, wherein the linear ball bearing is tightly sleeved on the drill chuck connecting rod; the shaft sleeve is tightly sleeved on the linear ball bearing; the needle rolling bearings are respectively arranged at two ends of the shaft sleeve; and the liner sleeve tightly arranged in the main shaft hole is sleeved on the needle rolling bearing; and one end of the proportional reversing feeding device is connected with a rear end of the drill chuck connecting rod, and the other end of the proportional reversing feeding device is connected with a tail seat of a lathe main body for arranging the drill chuck. By adopting the processing device to punch centre holes at two ends of parts, such as shafts, clamping time can be reduced, efficiency can be improved, precision can be improved, the precision of coaxiality of processing workpieces can be ensured, and meanwhile, workpieces with central holes with different depth and different types at a left end and a right end can be processed through a left central drill and a right central drill with different-ratio feeding rate and feeding volume.

Owner:GUANGXI UNIV

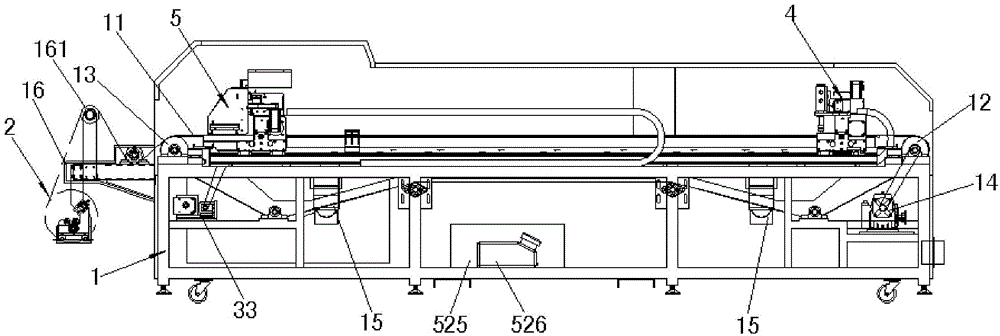

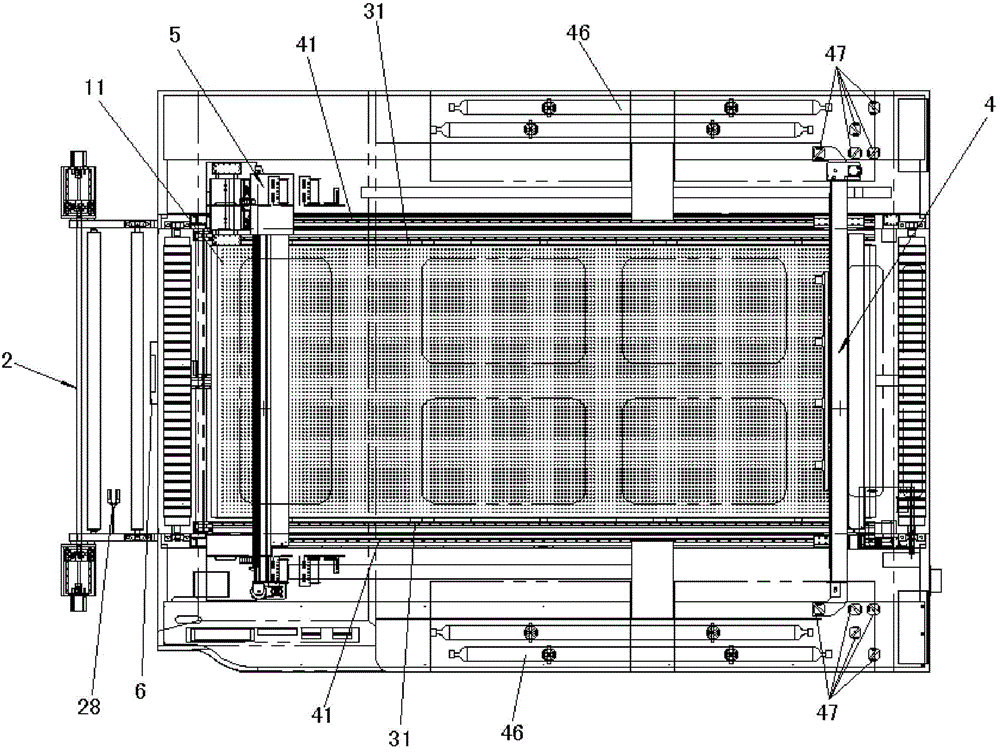

Full-automatic leather printing and cutting machine and printing and cutting method implemented by same

InactiveCN104818350ASolve processabilitySolve the large number of laborLeather clicking/perforating/clickingTypewritersComputer control systemGraphics

The invention discloses a full-automatic leather printing and cutting machine which comprises a framework, an automatic rectifying mechanism, an automatic feeding manipulator, an automatic laser cutting mechanism, an automatic printing mechanism and a control system. A frame and a frame shaft are arranged at the front end of the framework, the frame shaft is arranged on the frame, the automatic rectifying mechanism is arranged at the front end of the framework, the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism are arranged on the framework, and the control system is arranged in the framework and is connected with the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism. The full-automatic leather printing and cutting machine has the advantages that manual production can be truly replaced by machines, accordingly, the leather processing efficiency and processing precision can be greatly improved, and the processing cost can be reduced; optional patterns can be accurately printed by the printing mechanism by the aid of the computer control system, and the problem of asymmetric pattern printing in existing leather processing procedures can be effectively solved.

Owner:DONGGUAN DEL LASER TECH

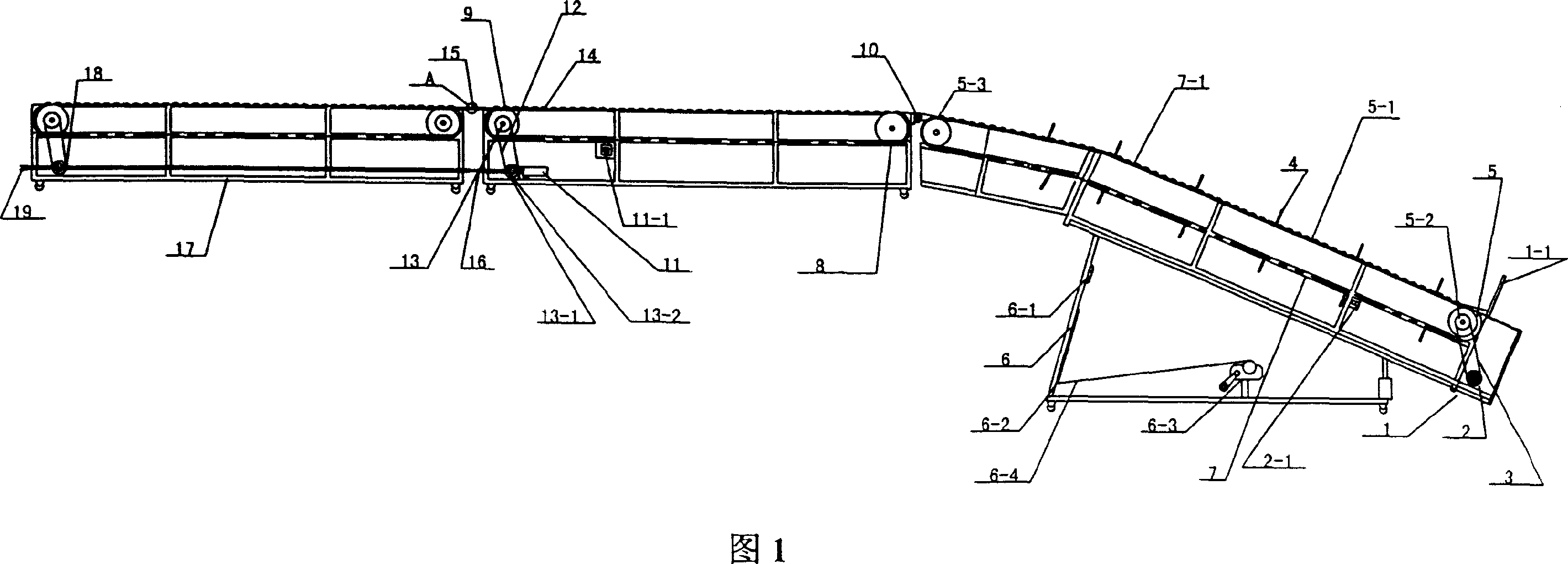

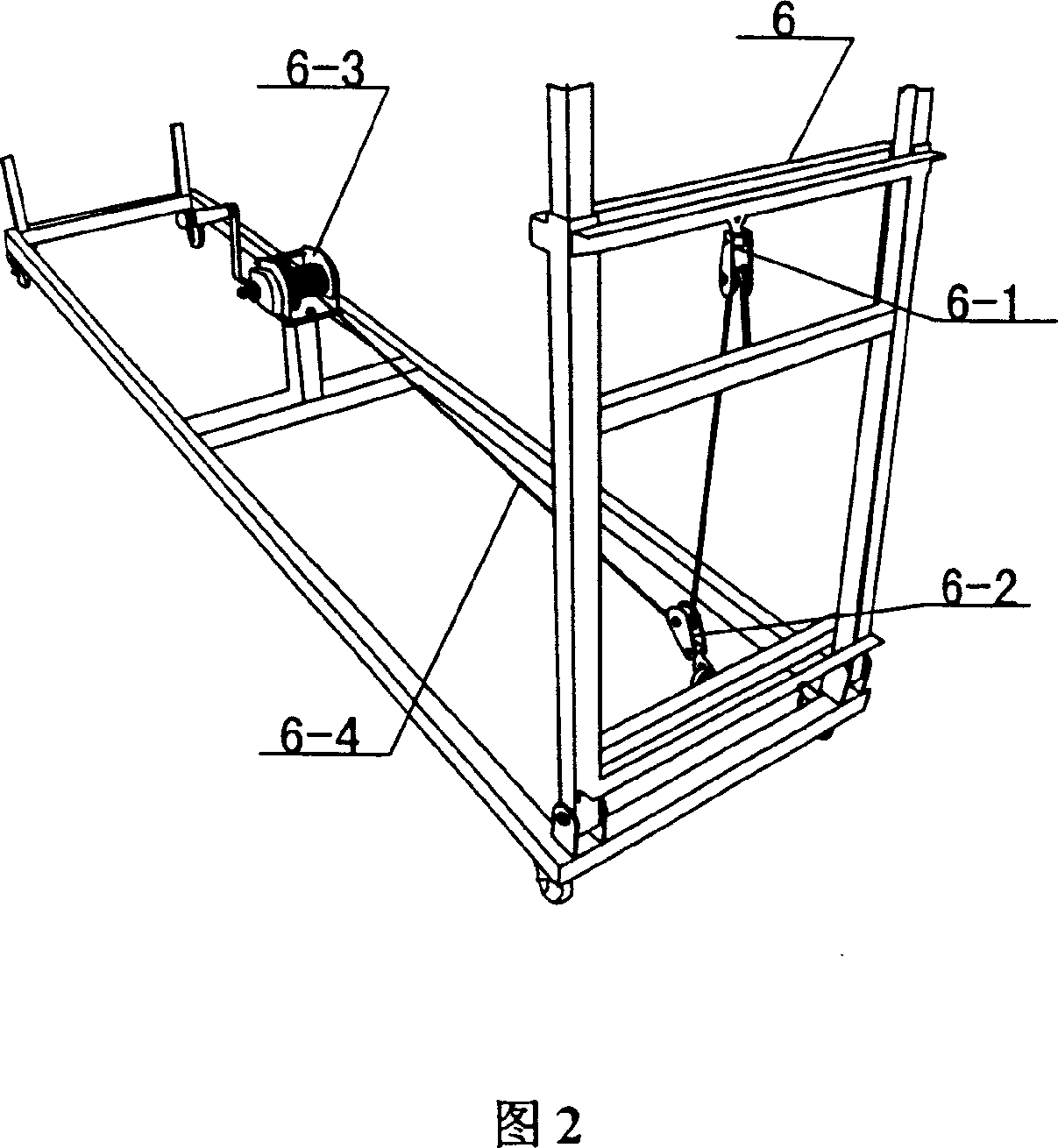

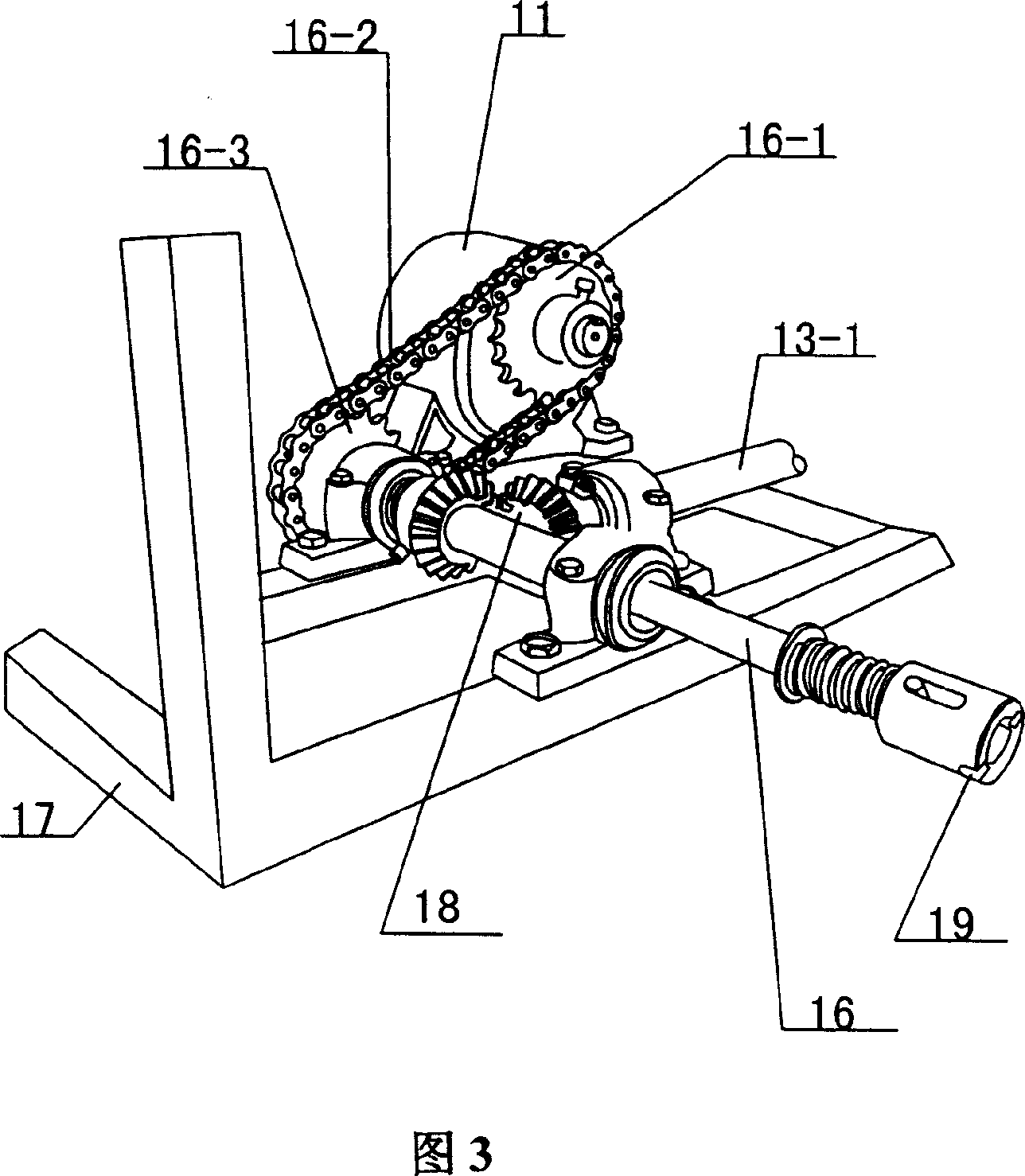

Dismountable conveyer

InactiveCN1944202ASolve labor intensitySolve technical problems with low work efficiencyConveyorsSupporting framesDrive shaftSemi automatic

The dismountable conveyer consists of one slope conveying assembly and one parallel conveying assembly with separate transmission mechanisms, and one jointing device between the slope conveying assembly and the parallel conveying assembly. The slope conveying assembly includes slope conveying frame, motor A, slope transmission chain, driving chain wheel, chain, conveying chain wheel, driven chain wheel, conveying belt with supporting boards and carriers on the frame. The parallel conveying assembly includes parallel conveying frame, motor B, driving shaft, automatic jointing mechanism and semi-automatic jointer capable of being connected fast. The present invention is used in conveying packing box.

Owner:高佳

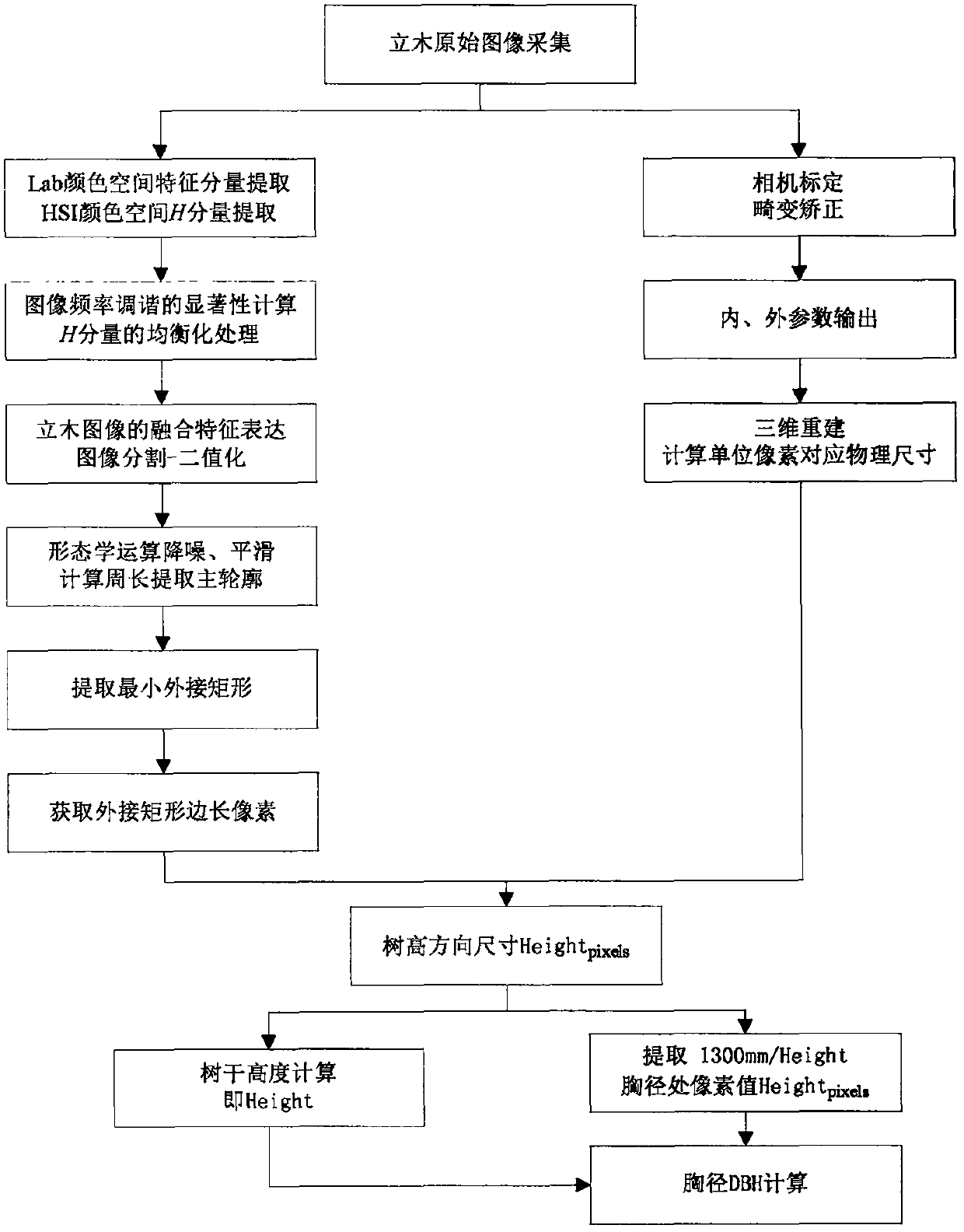

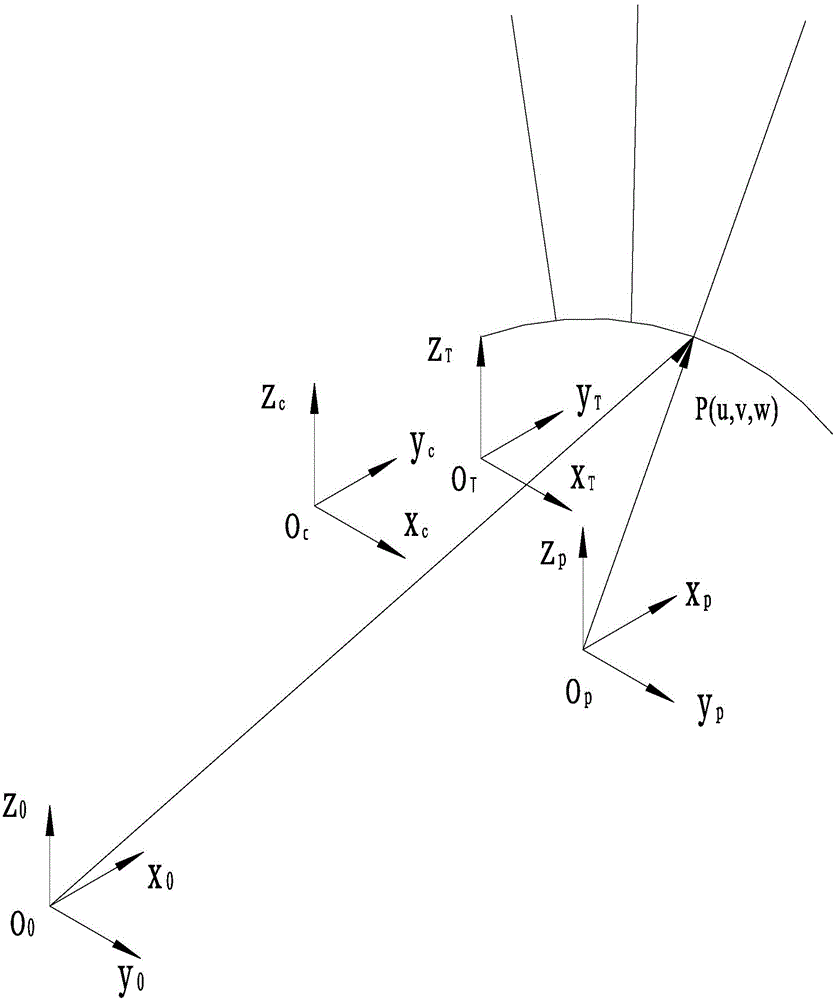

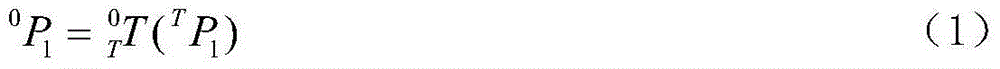

Stem DBH (diameter at breast height) measuring method based on machine visual sense and three dimensional reconstruction technology

ActiveCN107607053ASolving problems with different physical sizes in the real worldSolve different problemsImage analysisUsing optical meansMachine visionDiameter at breast height

The invention discloses a stem DBH (diameter at breast height) measuring method based on machine visual sense and the three dimensional reconstruction technology; the method is realized by the following specific algorithms and models: 1, an intelligent mobile terminal equipment camera calibration model and algorithm, a camera distortion rectification model and algorithm; 2, a two dimensional imagecoordinate system-three dimensional world coordinate system reconstruction model used for solving the problems that unit pixels under different distances are matched with different physical dimensions in the reality world, thus measuring the stem DBH from different distances; 3, a natural environment stem trunk contour detection and extraction algorithm; 4, a stem trunk contour minimum external connection rectangular detection algorithm; 5, a stem trunk height and DBH measuring algorithm used for measuring the DBH of a single stem in a single image. The method can solve the problems in the forest resource investigation works like complex environments, large laboring intensity, and an existing method overly relies on artificial measurements; the method can reduce laboring intensity and labor cost, thus improving working efficiency.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for carrying out automatic powder charging by rapidly positioning blast hole under shaft

ActiveCN103606171ASolve labor intensityFix security issuesImage analysisBlastingMaterials scienceStructured light

The invention provides a method for carrying out automatic powder charging by rapidly positioning a blast hole under a shaft and belongs to the technical field of mine blasting. According to the method, the movement of a powder charging mechanical arm is controlled by a structured light visual system and holes can be aligned automatically; the hole alignment precision is high and automatic positioning from one blast hole to another blast hole can be finished. The method comprises the following steps: determining a working field coordinate system; selecting a blast hole P1 needing to be positioned to finish hole alignment and powder charging work of the blast hole P1; automatically positioning a second blast hole P2 to finish the hole alignment and powder charging work of the blast hole P2; finishing the hole alignment and powder charging work of a third blast hole P3 and a fourth blast hole P4 by referring the hole alignment and powder charging step of the second blast hole P2; calculating a transformational matrix from a blast hole coordinate system to a mechanical arm base coordinate system according to a corresponding relation of position vectors of the four blast holes by the structured light visual system; revising the transformational matrix and utilizing the revised transformational matrix to position subsequent blast holes.

Owner:XIAN UNIV OF SCI & TECH +1

Production jig of optical fiber rapid connector and production method of optical fiber rapid connector

InactiveCN103185929AAvoid processing failureSolve labor intensityCoupling light guidesEngineeringFailure causes

The invention discloses a production jig of an optical fiber rapid connector and a production method of the optical fiber rapid connector. Inserting cores are fixed on an inserting core positioner, glue water is filled into the inserting cores, and the optical fibers are successively inserted into the inserting cores, then an optical fiber length fixing appliance fixes the length of each optical fiber which is inserted into the inserting core and enables the length of each optical fiber which is inserted into the inserting core to be the same, then the optical fibers which are inserted into the inserting cores are solidified to coagulate in the inserting core through the glue water, finally the inserting core positioner is installed on a protective cover fixture, protective covers are prefixed through a protective cover fixator, the number of the protective covers is the same as the number of the inserting cores, the positions of the protective covers correspond to the positions of the inserting cores, a handle is controlled to rotate to enable the protective cover fixator to correspond to and to be close to the inserting core positioner, finally corresponding inserting of the inserting cores into the protective covers are achieved, and production and manufacturing of the optical fiber rapid connector are completed. Compared with the prior art, the production jig of the optical fiber rapid connector and the production method of the optical fiber rapid connector can achieve manufacturing of a plurality of inserting cores, avoid problems of processing failure caused by excessively small inserting cores and optical fibers in manufacturing, solve the problems that labor intensity is high and production efficiency is low in manual manufacturing, and improve production efficiency by five time compared due to the adoption of the manufacturing method.

Owner:SHENZHEN HPN COMM TECH

Cutting device for intersecting line of intersecting pipelines of different dimensions and machining method thereof

InactiveCN107030355ASolve diseconomySolve manual cuttingPlasma welding apparatusComputer engineering

Owner:JIANGSU UNIV OF SCI & TECH

Multifunctional suspension insulator string cross arm side hardware fitting replacement fixture

ActiveCN102231492AGuaranteed safe operationReduce wasteApparatus for overhead lines/cablesEngineeringTower

The invention discloses a suspension insulator string cross arm side hardware fitting replacement fixture, which comprises a cross arm side fixture, a lead side fixture and a frapping device. The cross arm side fixture comprises a first fixture and a second fixture. When the fixture is used, the first and second fixtures can be freely selectively arranged in a required way according to the form of a cross arm end. When fixing holes on the upright sides of T-shaped structures of the first and second fixtures connect the first and second fixtures by utilizing connecting parts, a relative distance between the two fixtures can be regulated according to the needs of the cross arm end. Simultaneously, a position at which the arrangement of the frapping device is required can be regulated by utilizing through holes on one transverse side of each of the T-shaped structures of the first and second fixtures to enable cross arms with different widths to enter the frapping device for fit with an insulator socket fixture. The lower part of each of the first and second fixtures has a ladder-like structure so as to be adaptively arranged on a planar tower material and clamped to angle iron and the like.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com