Continuous drawing production line and production method of strip product

A production method and production line technology, which are applied in the continuous drawing production line and production field of strip products, can solve problems such as unstable quality, easy bruising and deformation, and difficult production management, so as to reduce the sawing cycle time and avoid collisions. Injury and deformation, easy to promote the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

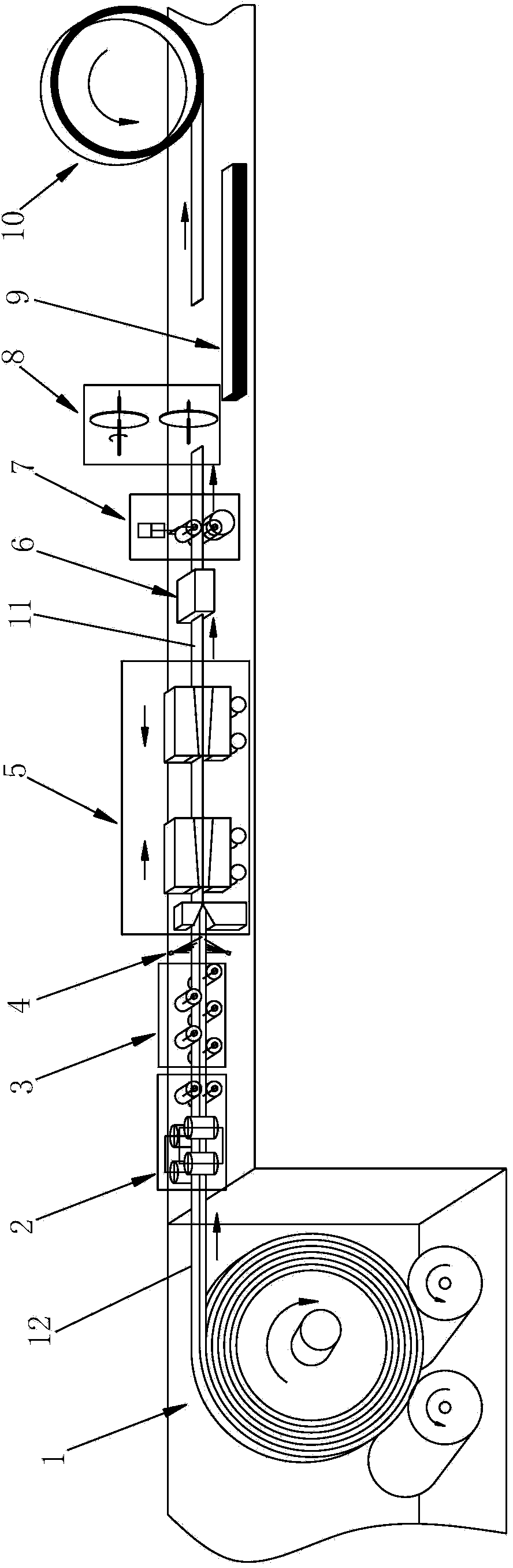

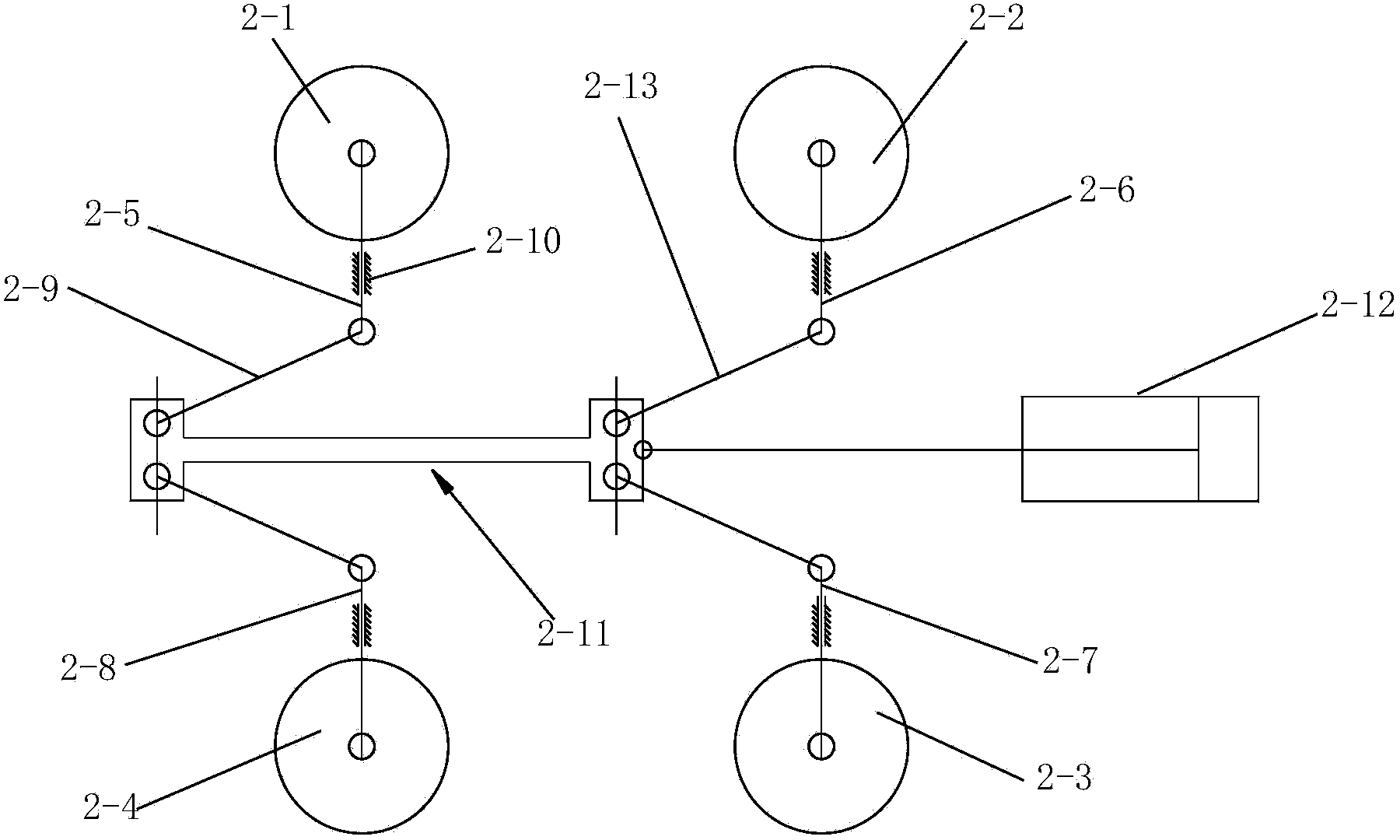

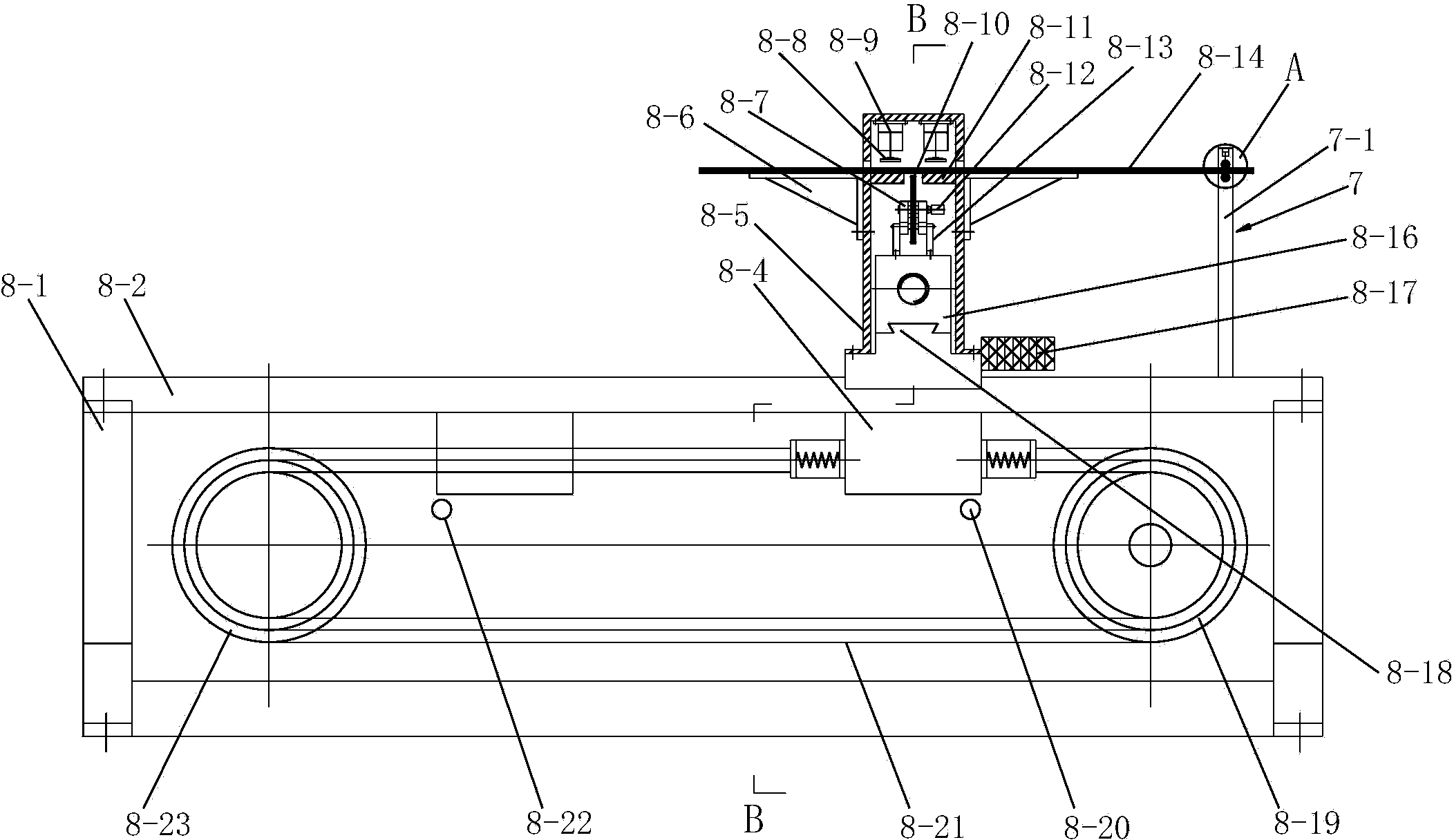

[0073] Such as figure 1 The shown continuous drawing production line for strip products includes an uncoiler 1 arranged in sequence to unroll the coil blank 12 to a straight line state, a straightening machine 3 to straighten the blank 12 unrolled to a straight line state, and a warp The straightened blank 12 is subjected to continuous drawing processing to form the continuous drawing machine 5 of the product 11, the length measuring device 7 for measuring the length of the product 11 according to the preset length, and the length saw 8 for sawing the product 11 according to the preset length , and a stacking device 9 for stacking the sawn products 11 or a winder 10 for winding the sawn products 11 . When the product 11 after sawing is a straight strip, the product 11 is stacked and then lifted, and if the product 11 is a mosquito coil, it is rolled.

[0074] In this embodiment, by uncoiling machine 1, straightening machine 3, continuous drawing machine 5, length measuring de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com