Patents

Literature

899results about "Extrusion cleaning devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

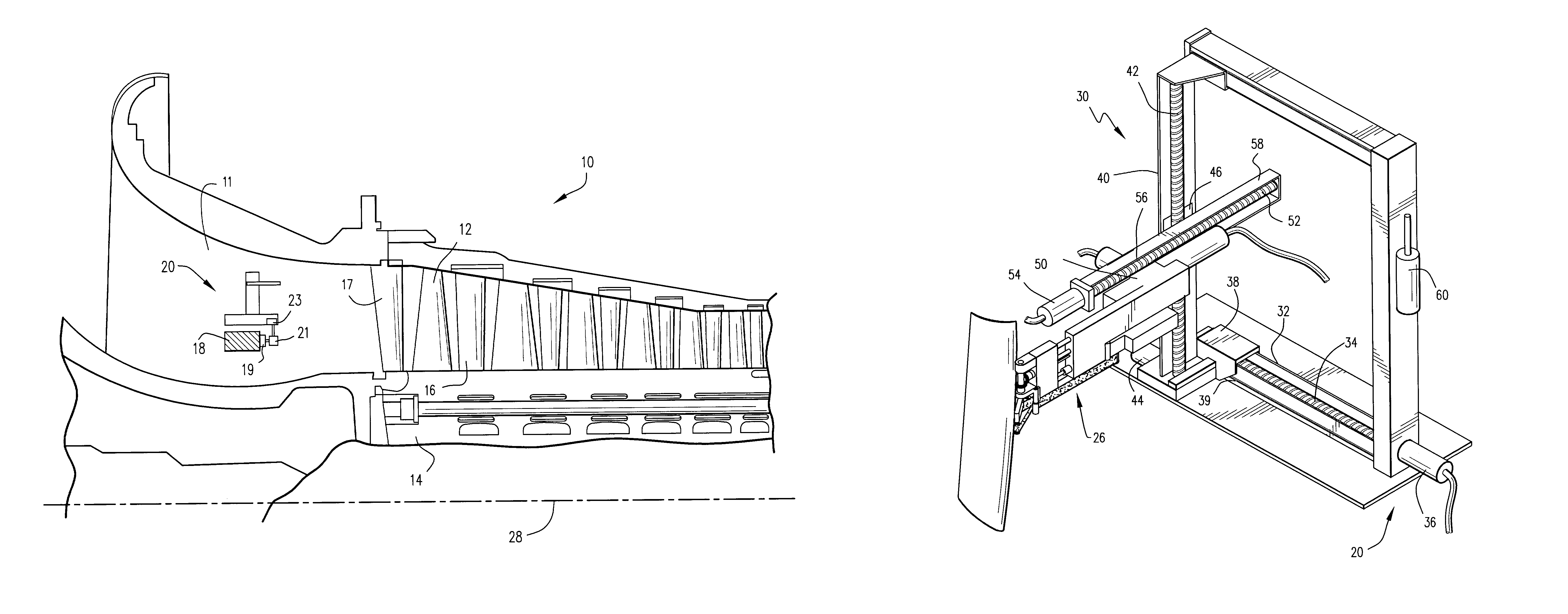

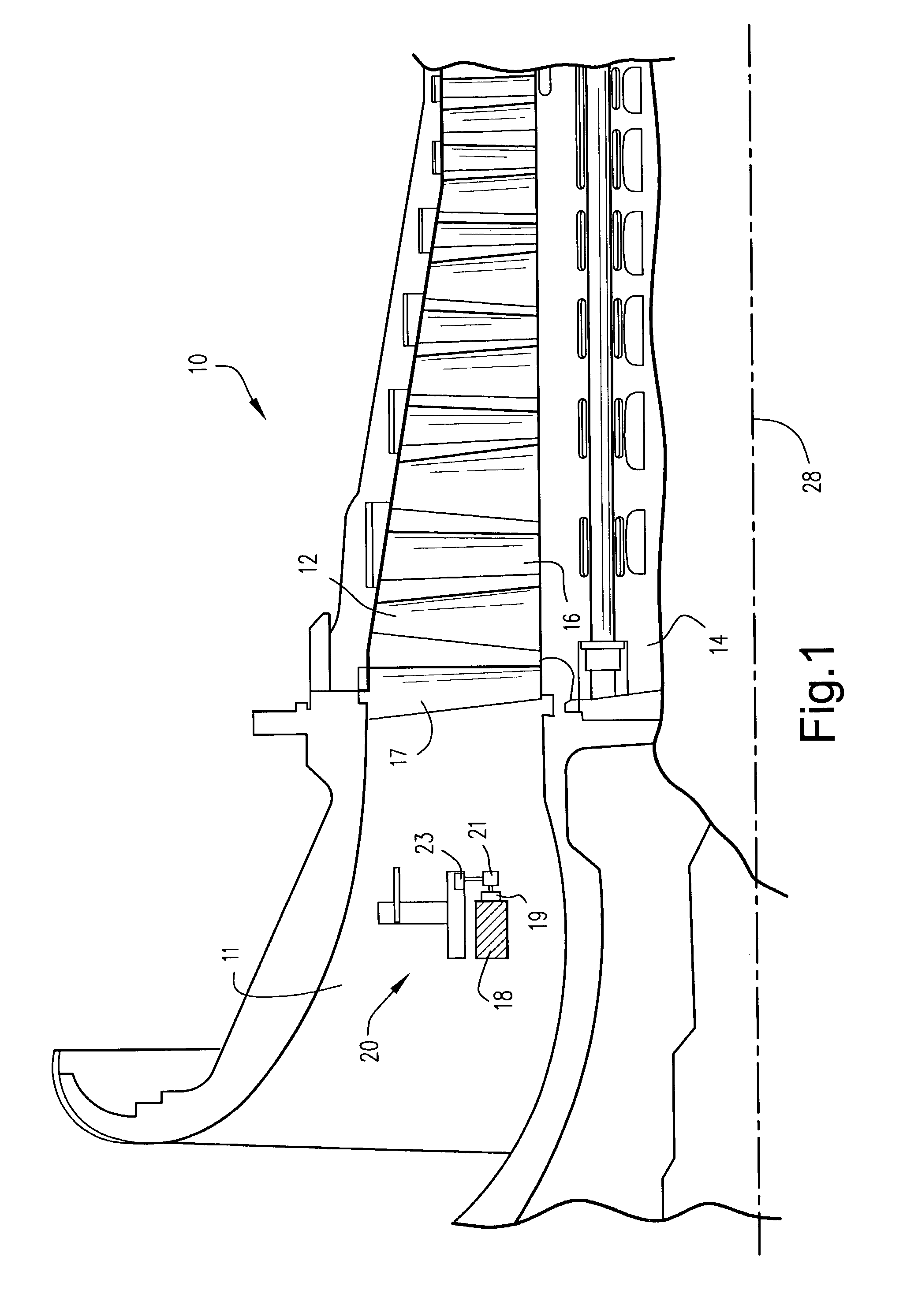

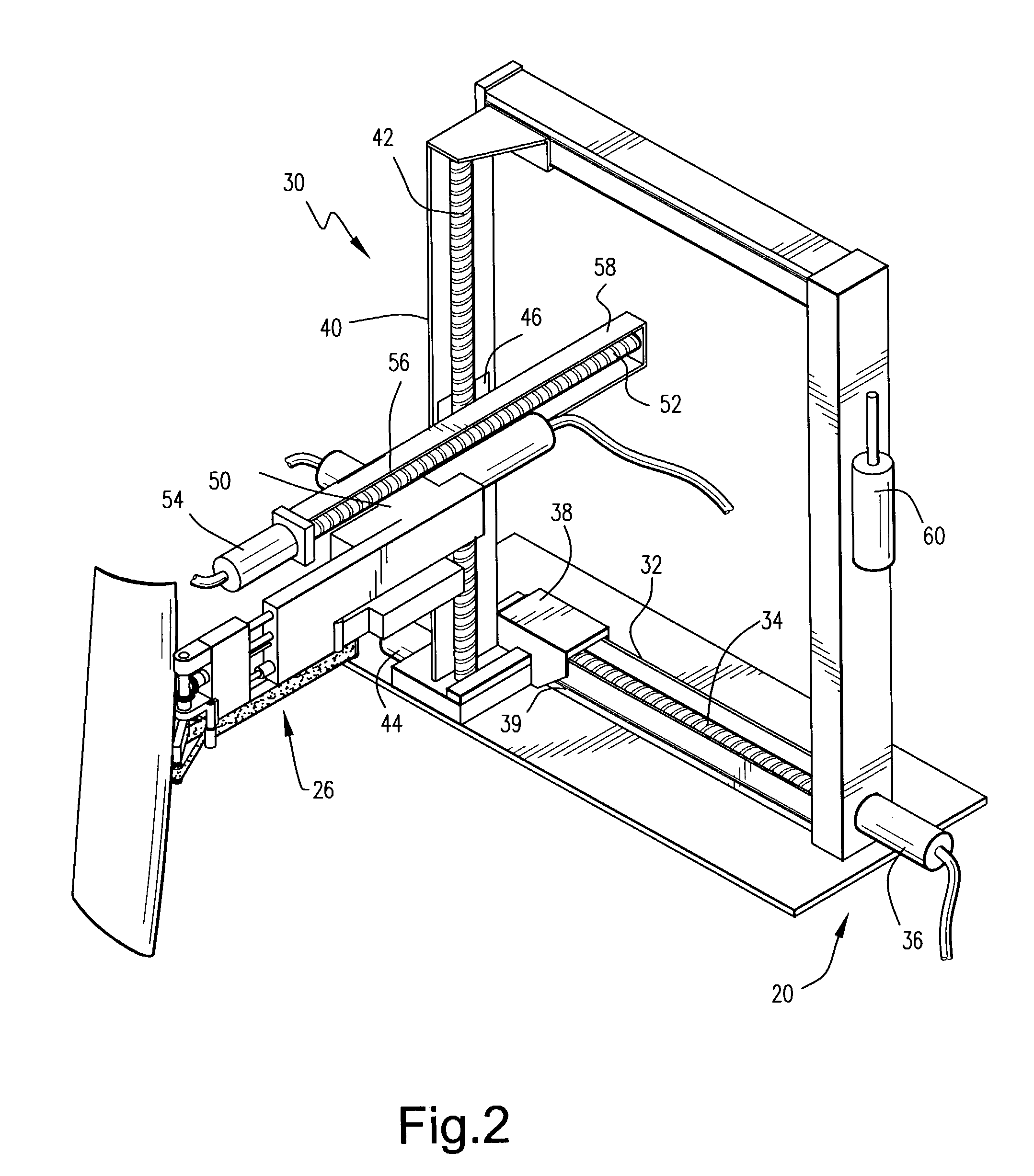

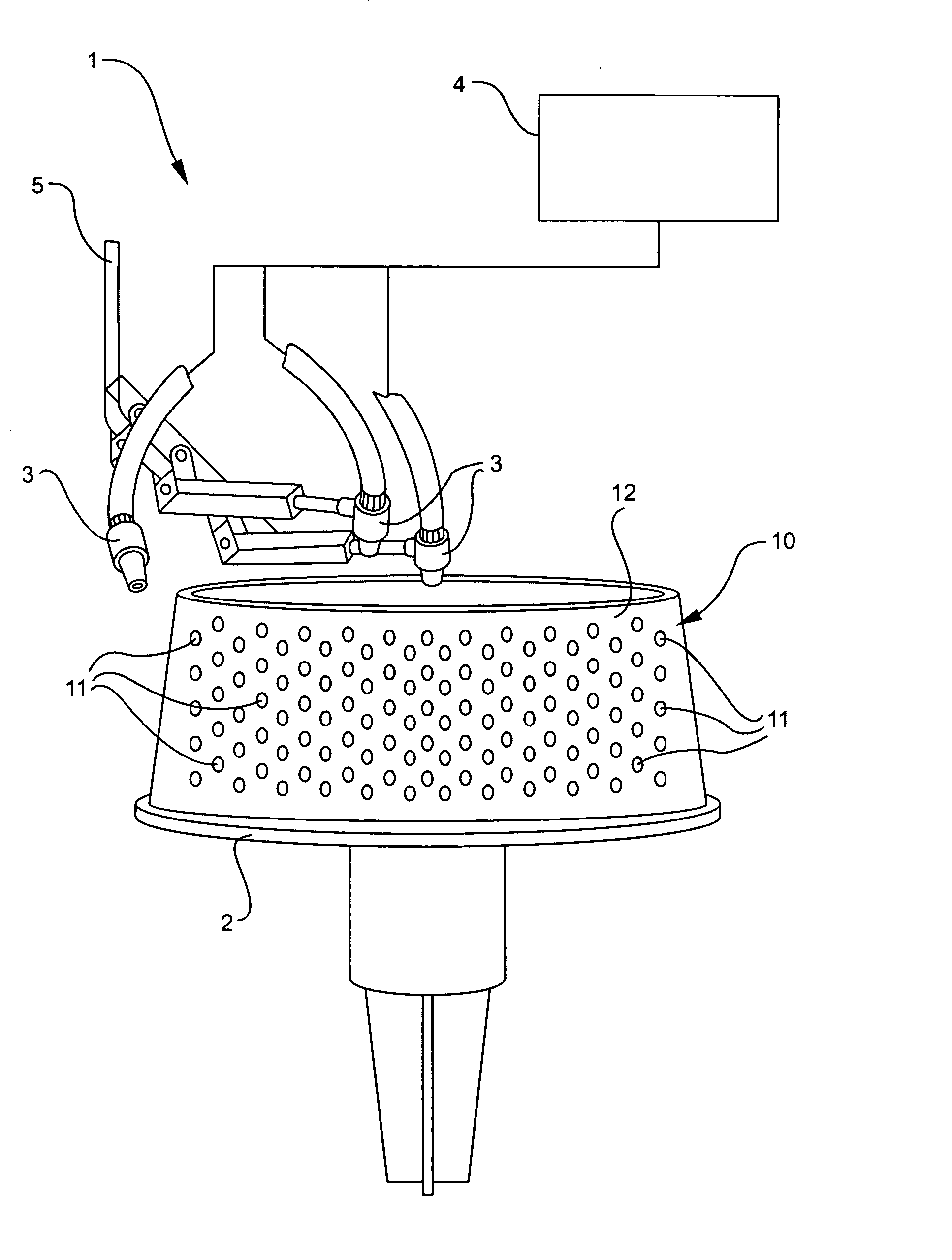

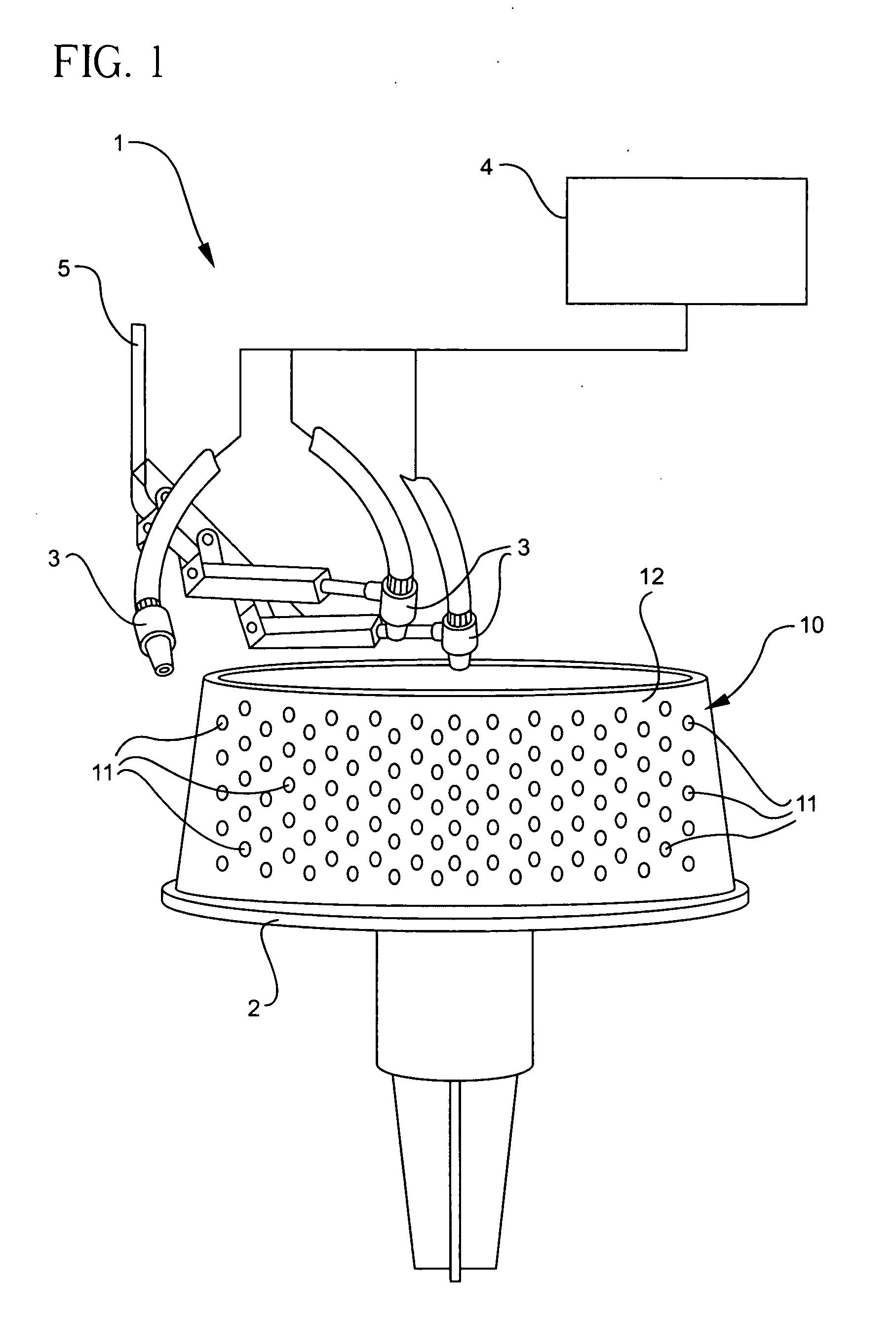

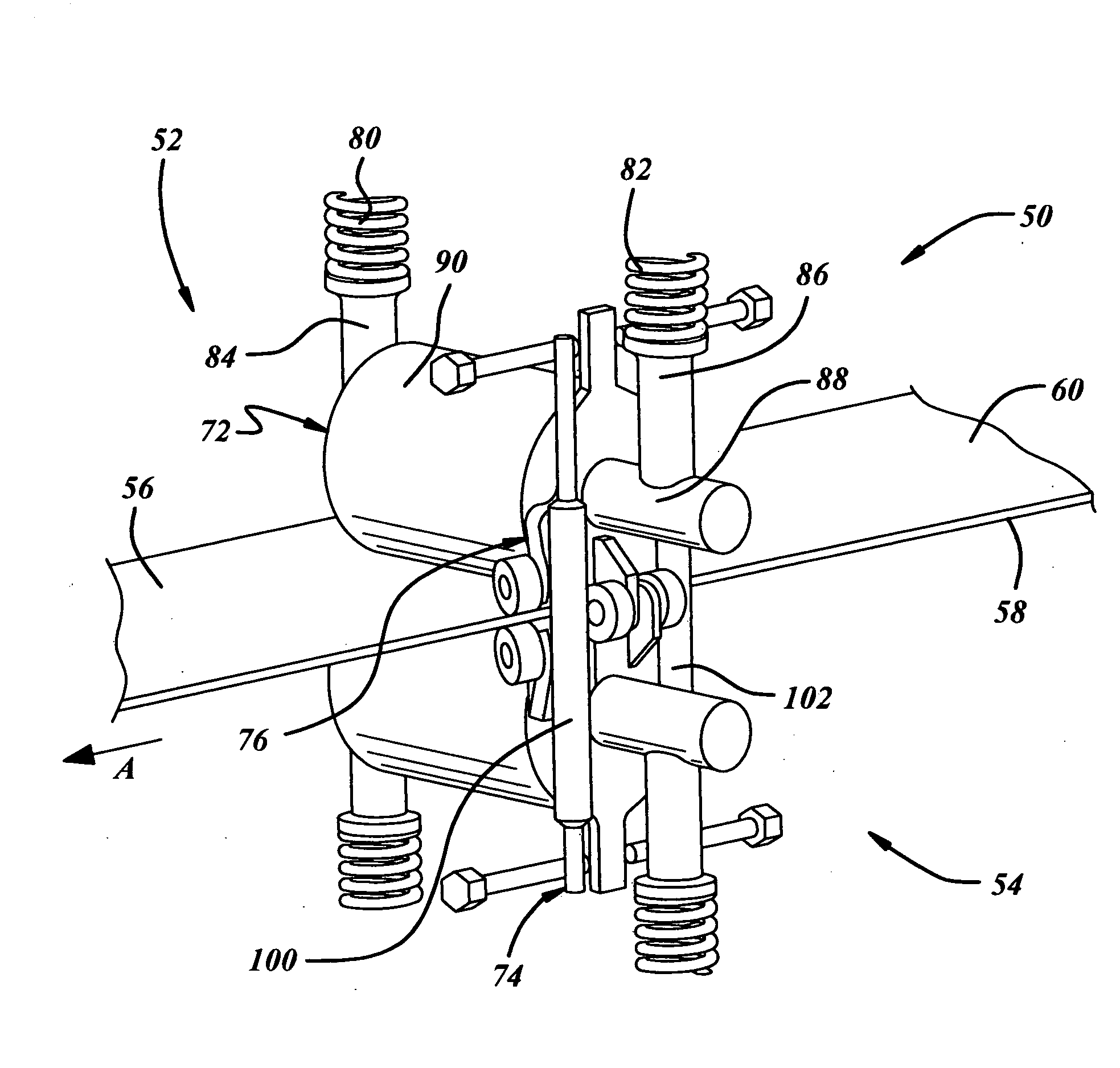

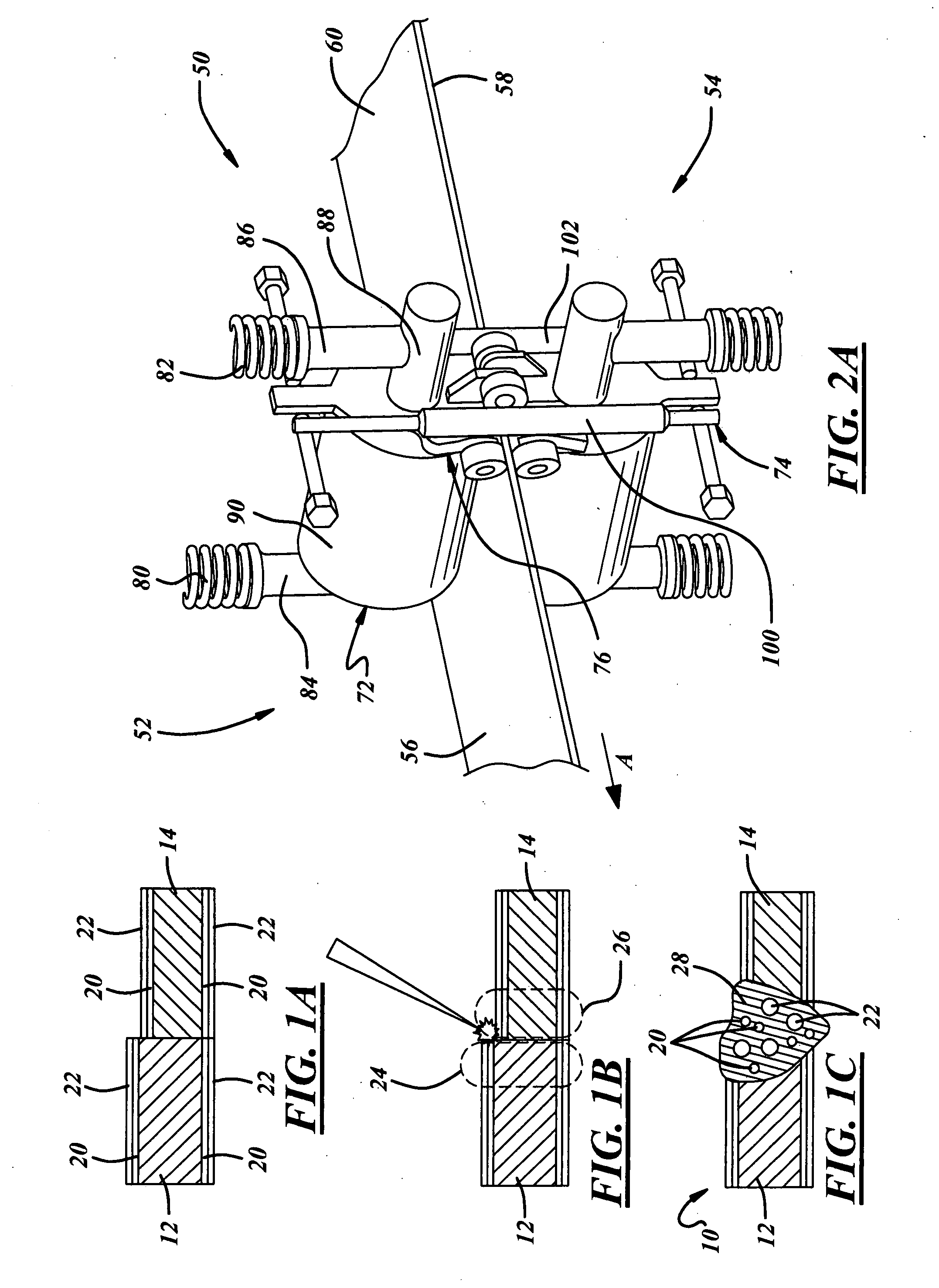

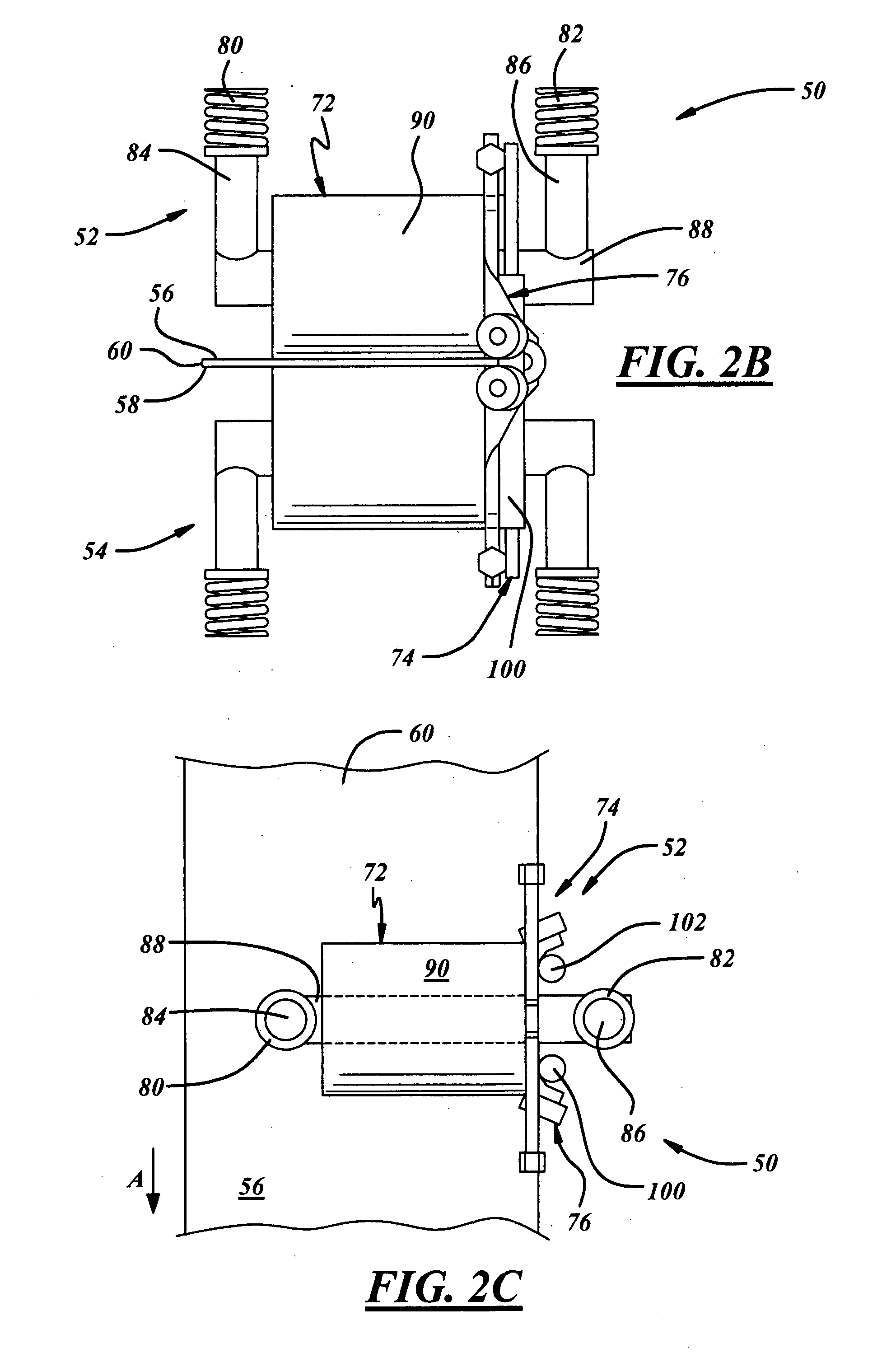

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

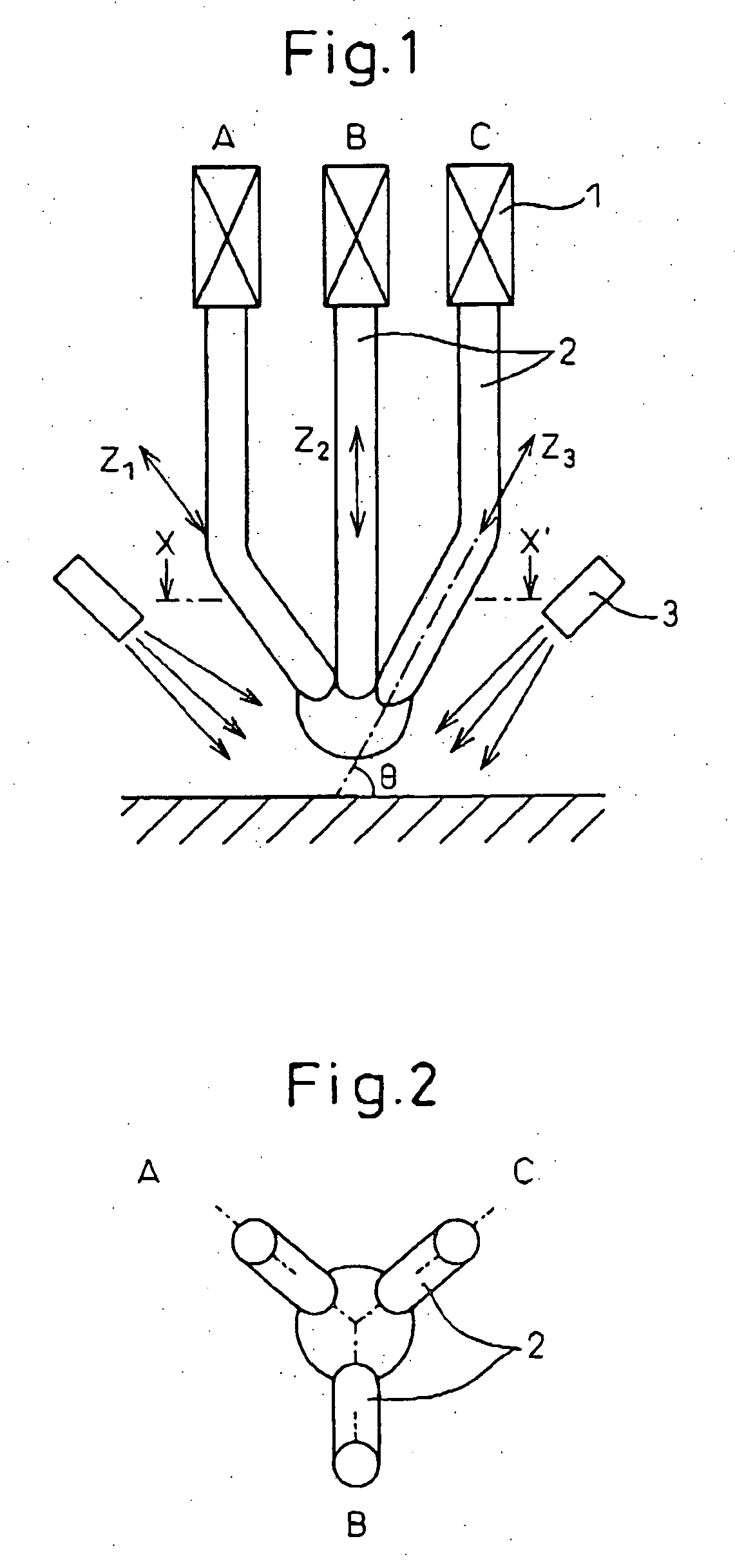

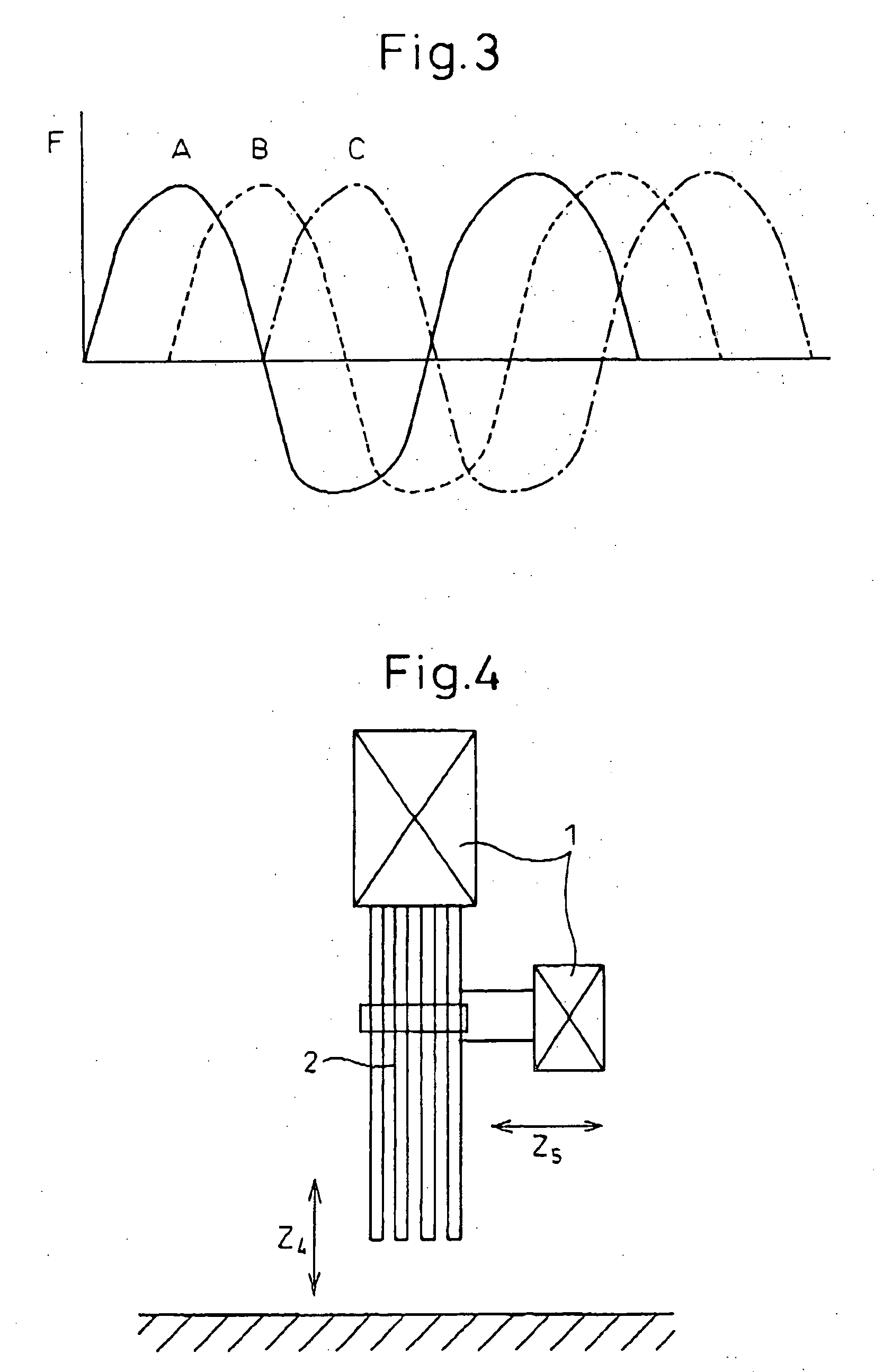

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

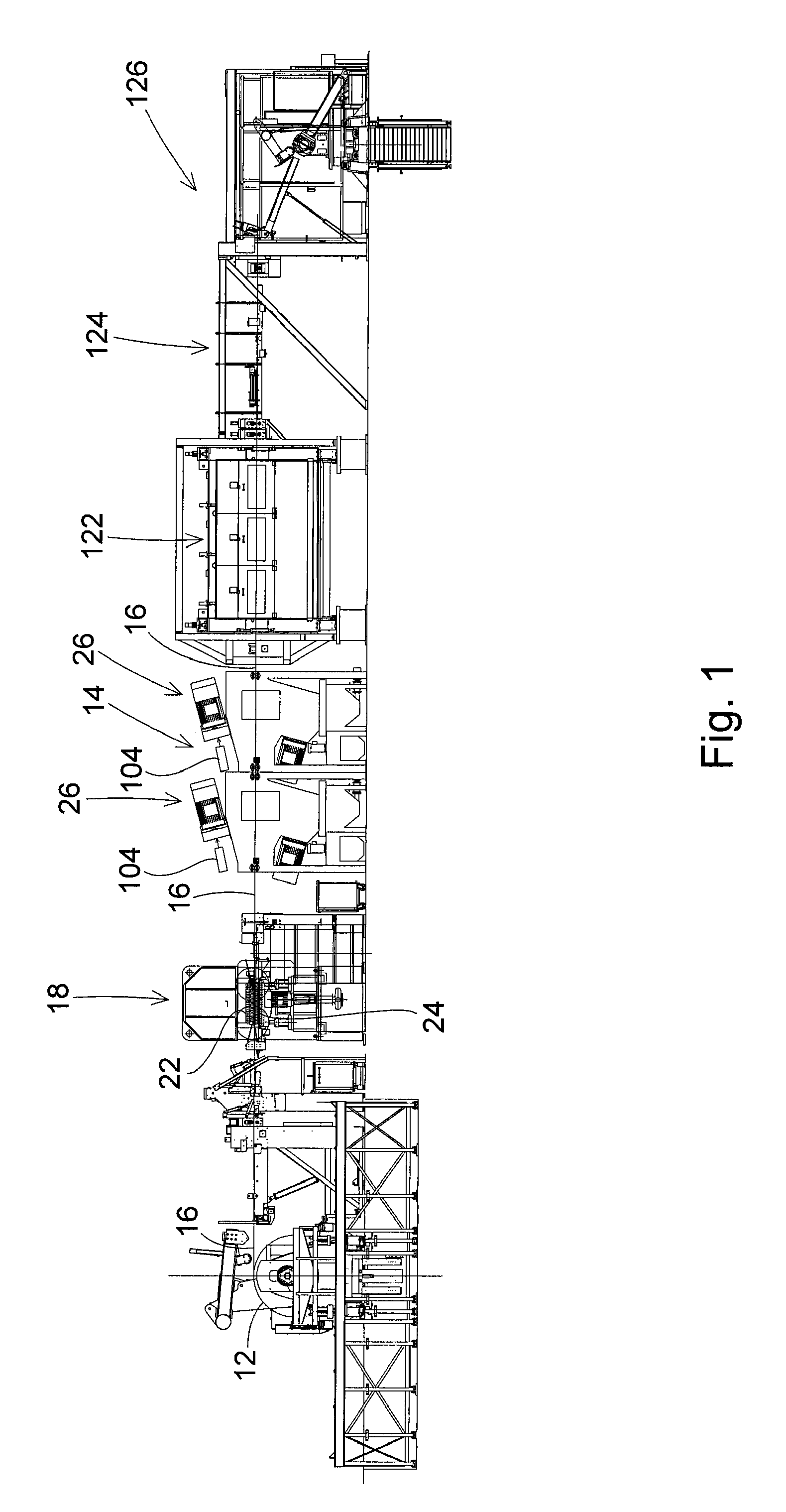

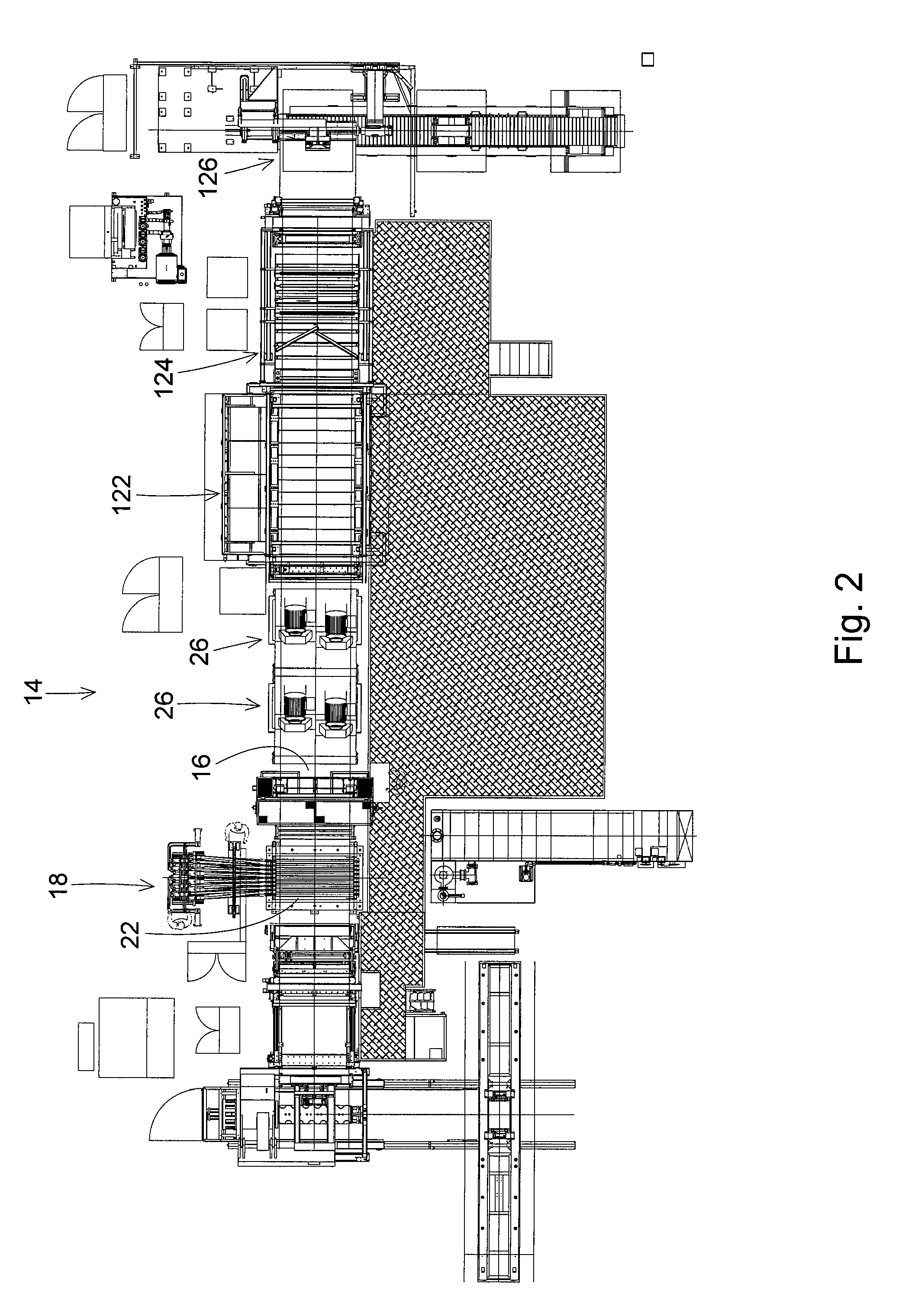

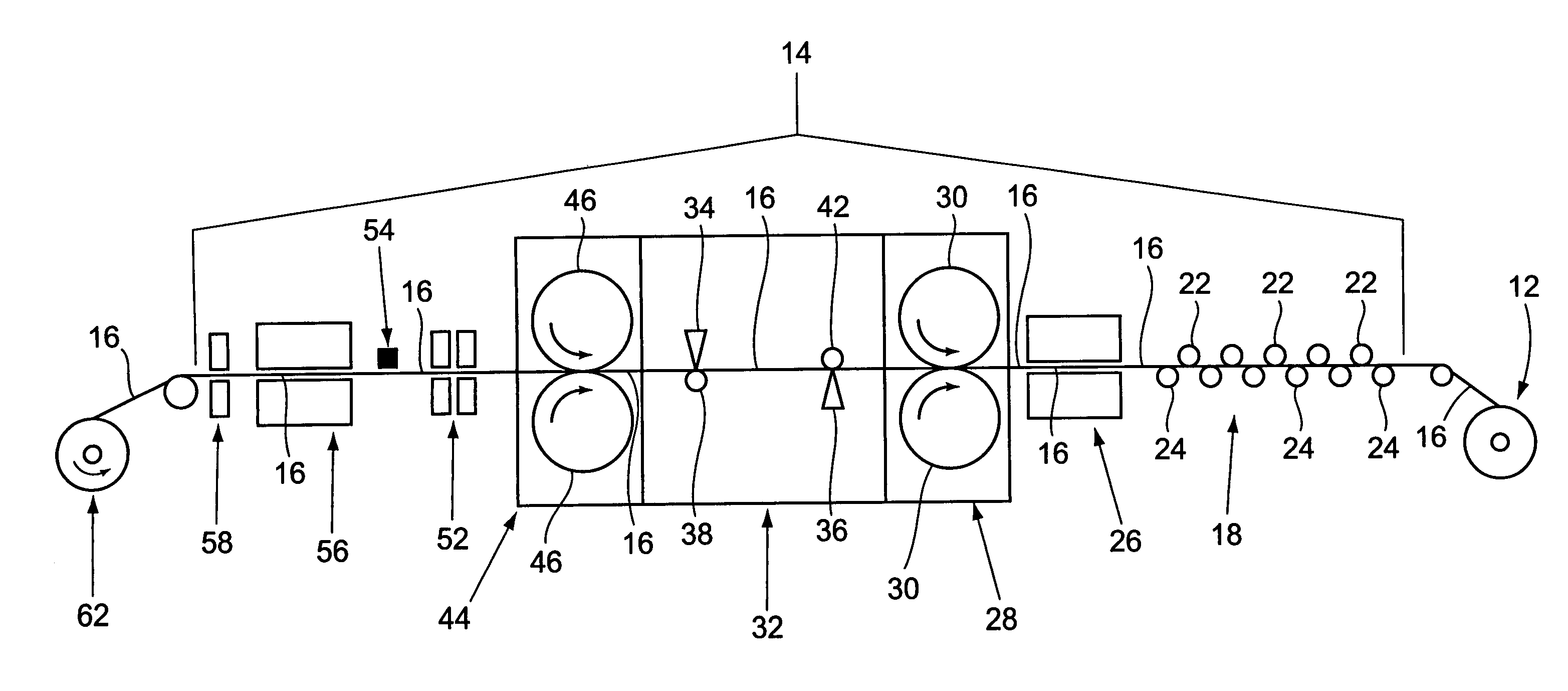

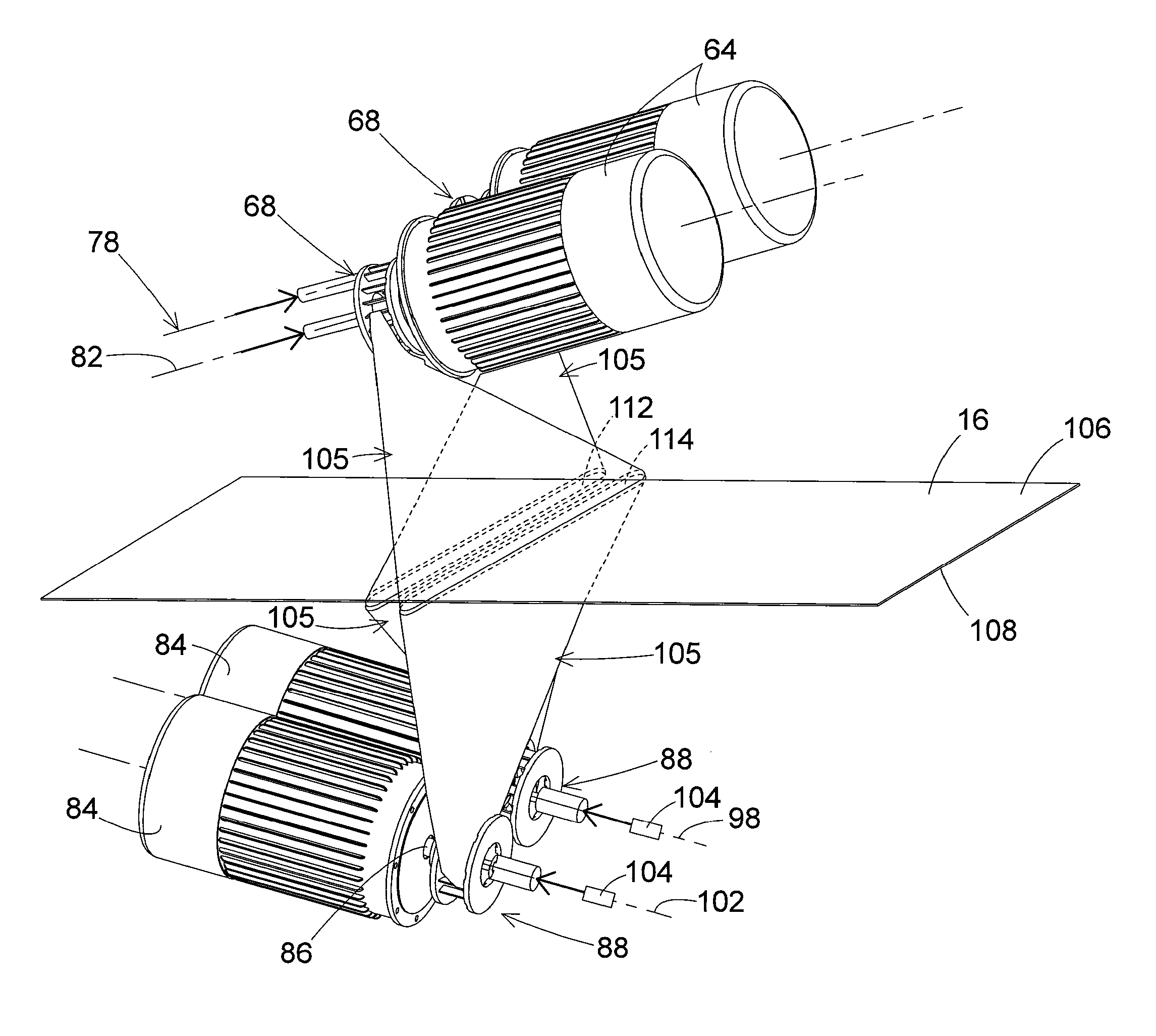

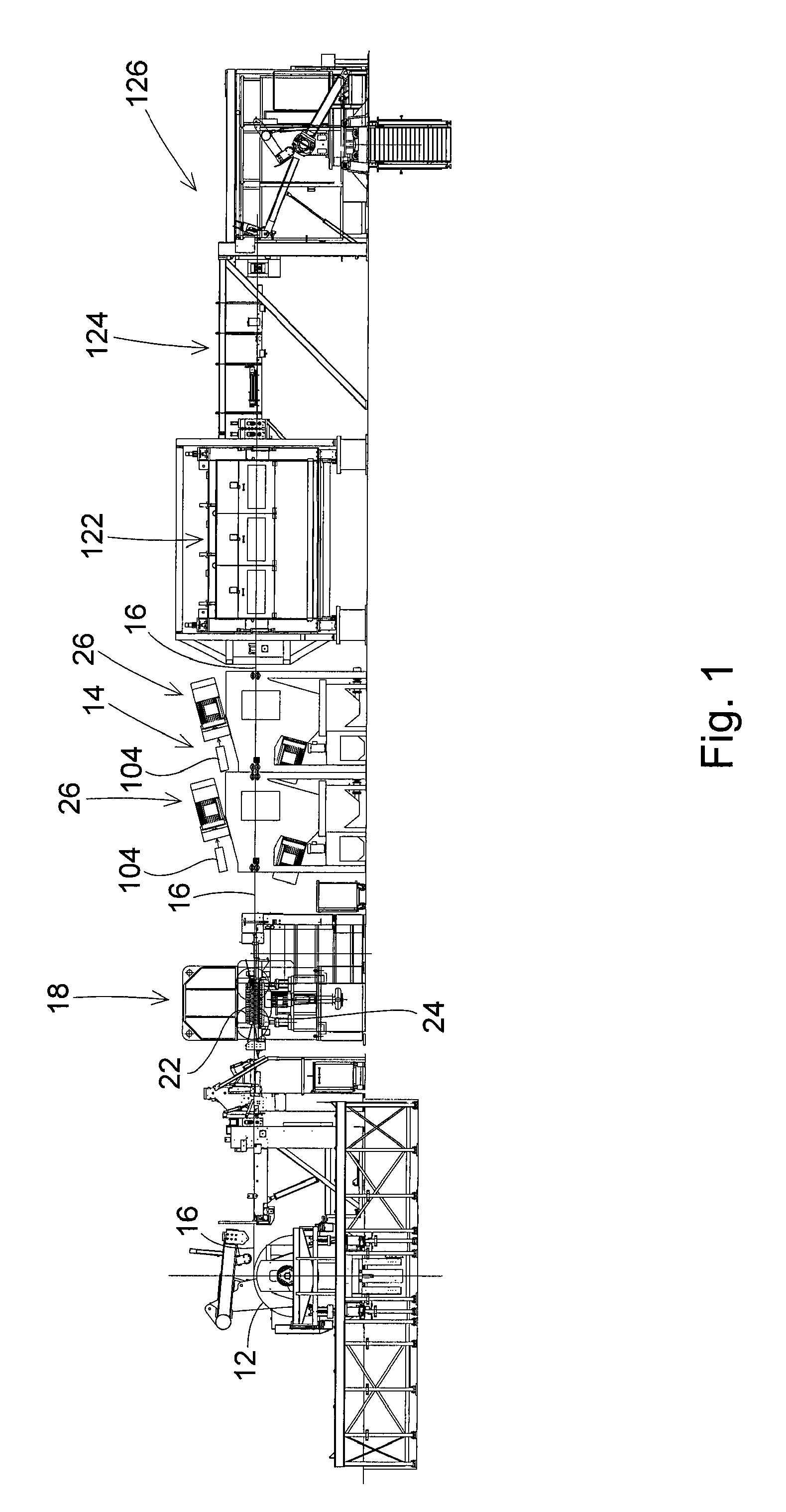

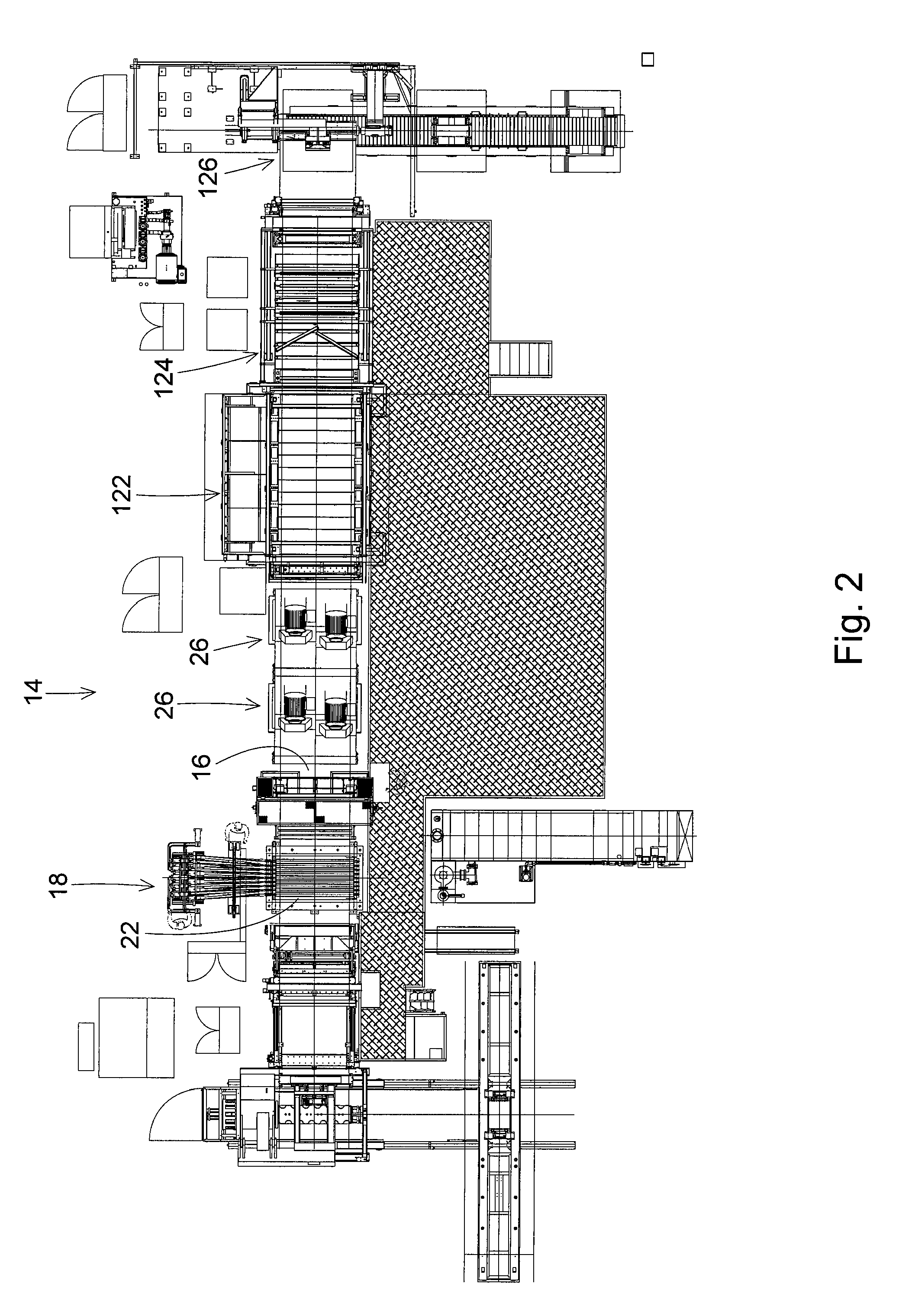

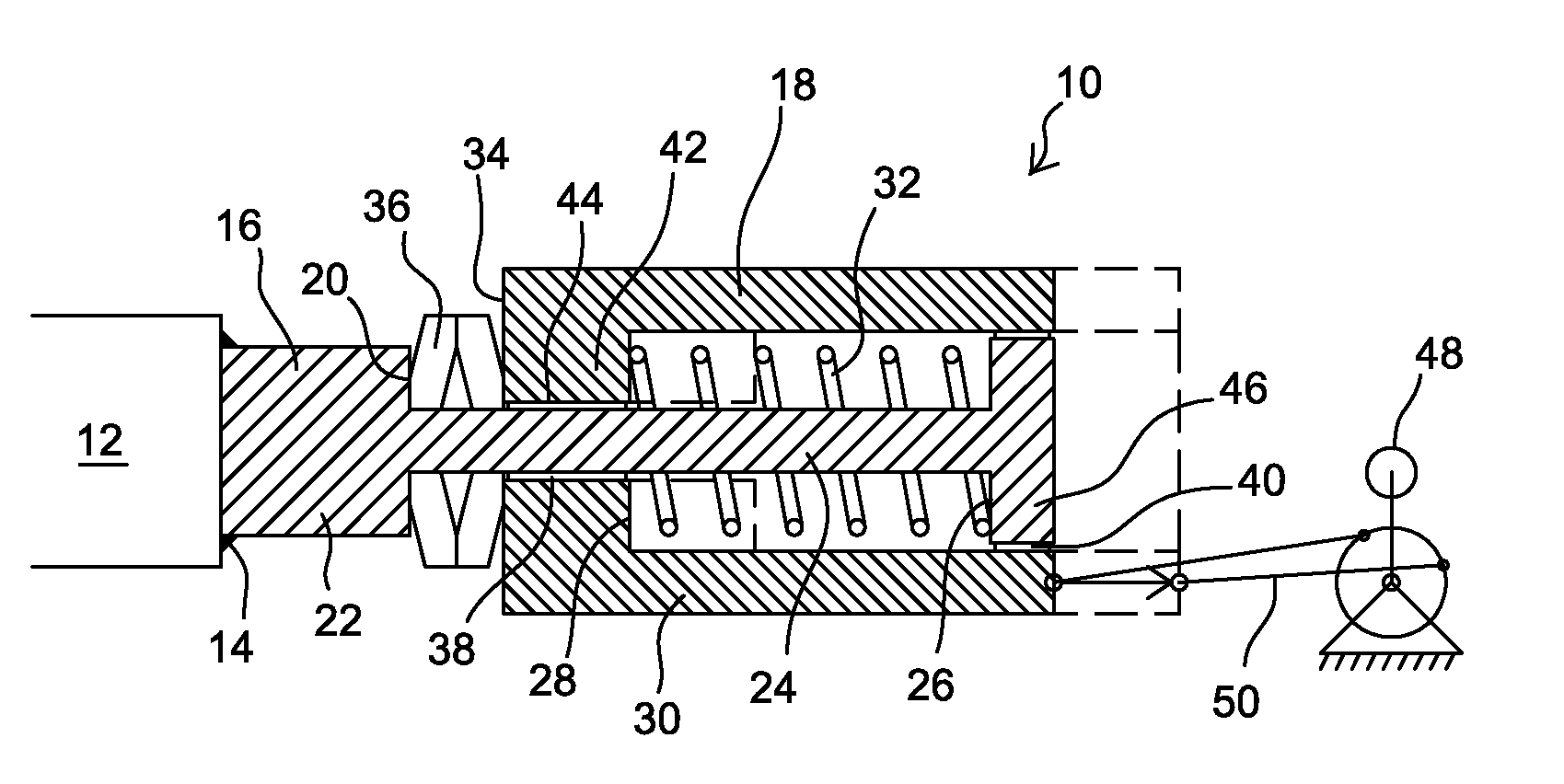

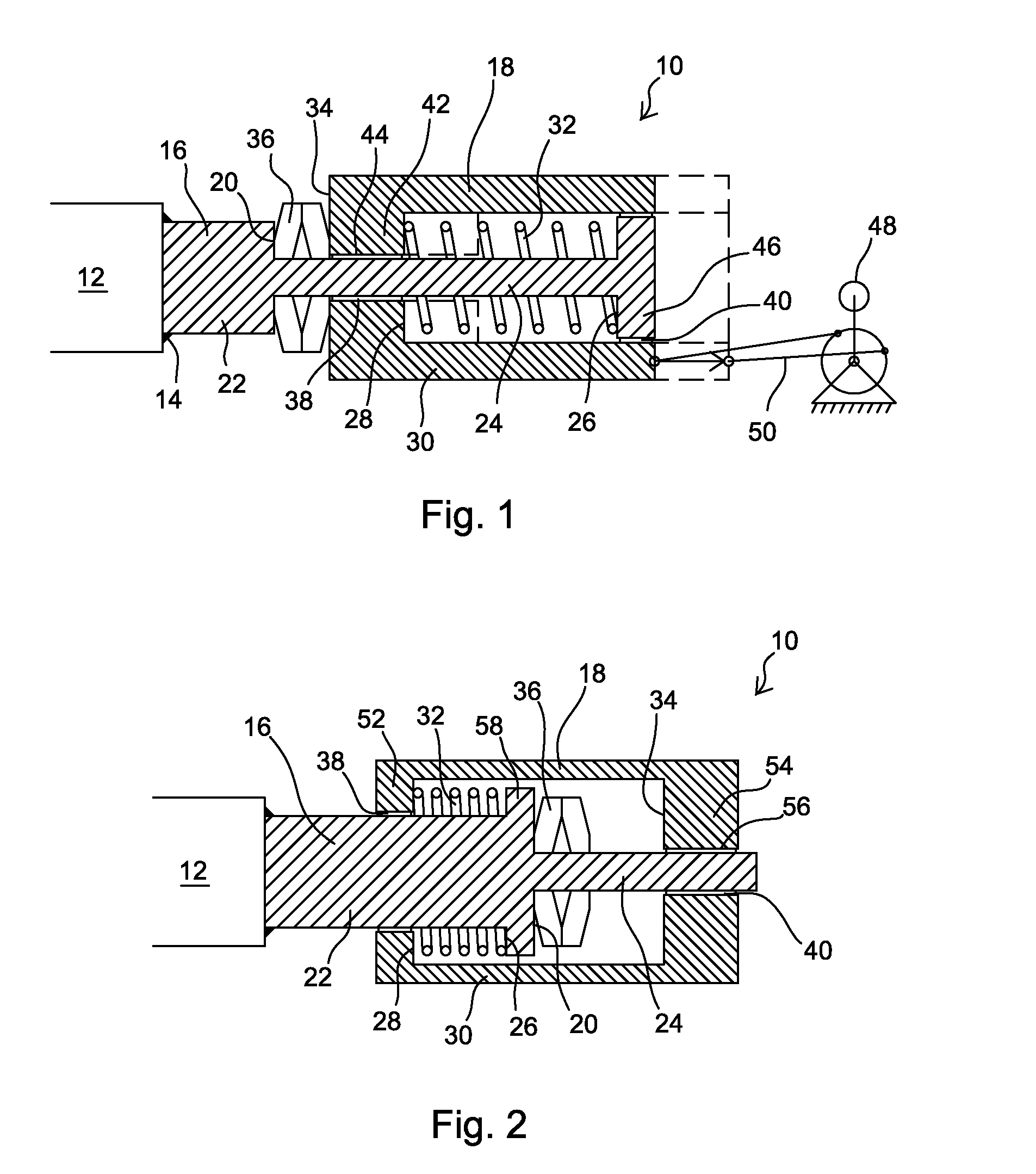

Slurry Blasting Apparatus for Removing Scale From Sheet Metal

ActiveUS20080182486A1Prevent reoxidationAvoid contact damageImpeller wheelsRotor bladesEngineeringMetal

Owner:THE MATERIAL WORKS

Production process of contact net anchorage steel wire rope

InactiveCN102517941AHigh breaking forceGood non-rotationRope making machinesExtrusion cleaning devicesIndustrial engineeringHeat treating

The invention discloses a production process of a contact net anchorage steel wire rope. The production process comprises the following steps: carrying out surface acid cleaning and phosphating; drawing; carrying out lead bath heat treatment; galvanizing; drawing; detecting; entwisting; stranding; forging; and greasing. The production process has the advantages of convenience in operation and time-saving and labor-saving properties; and the produced contact net anchorage steel wire rope has the advantages of high breaking force, long fatigue service life, good abrasion resistance and good corrosion resistance.

Owner:NANTONG GUANGMING STEEL WIRE PROD

Method for removing oilfield mineral scale from pipes and tubing

A method for removing mineral scale from tubing is disclosed. The method may include the steps of making a first longitudinal cut along a length of the tubing, making a second longitudinal cut along a length of tubing, and removing a plurality of sections of tubing, wherein the sections of tubing are defined by the first and second longitudinal cuts.

Owner:EXKAL LTD

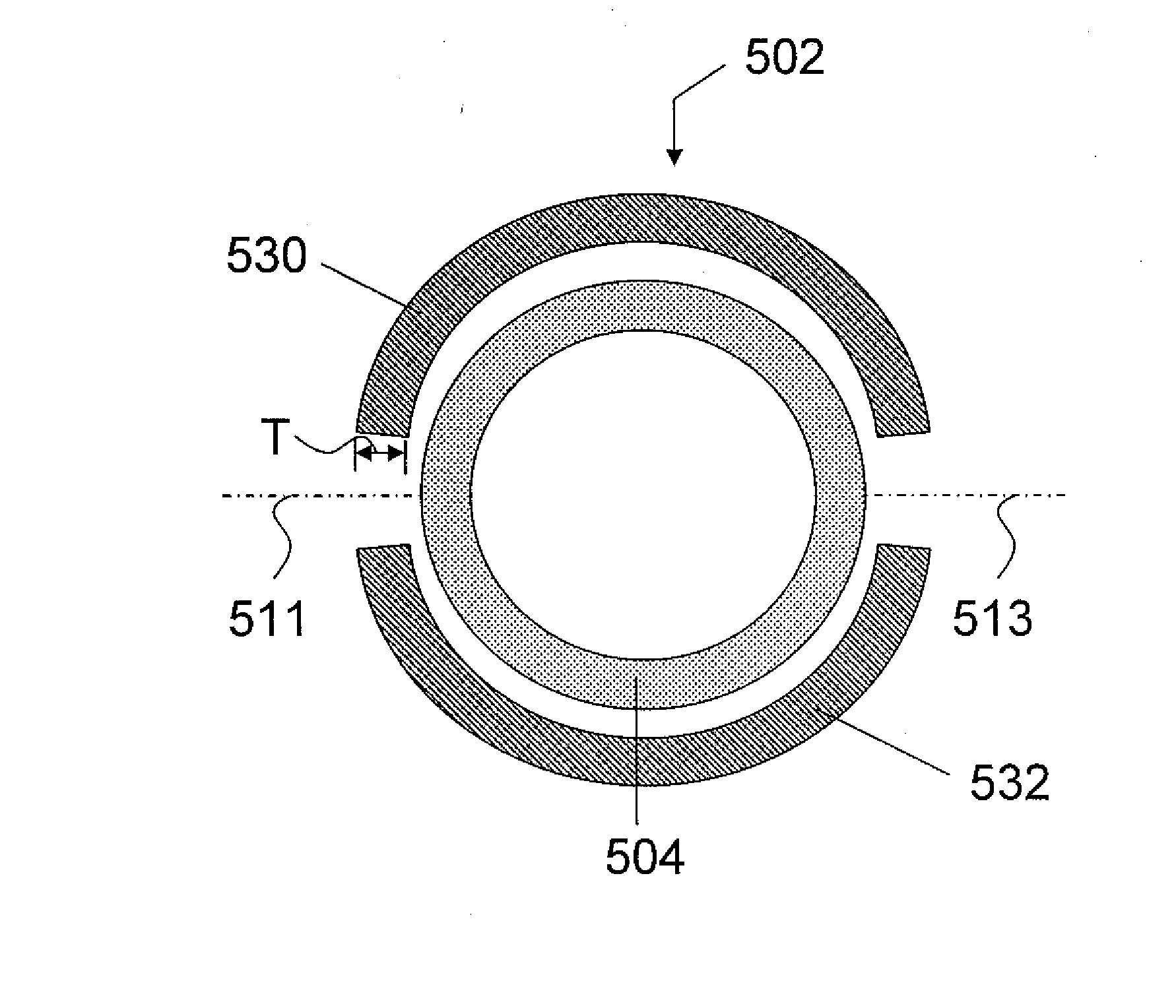

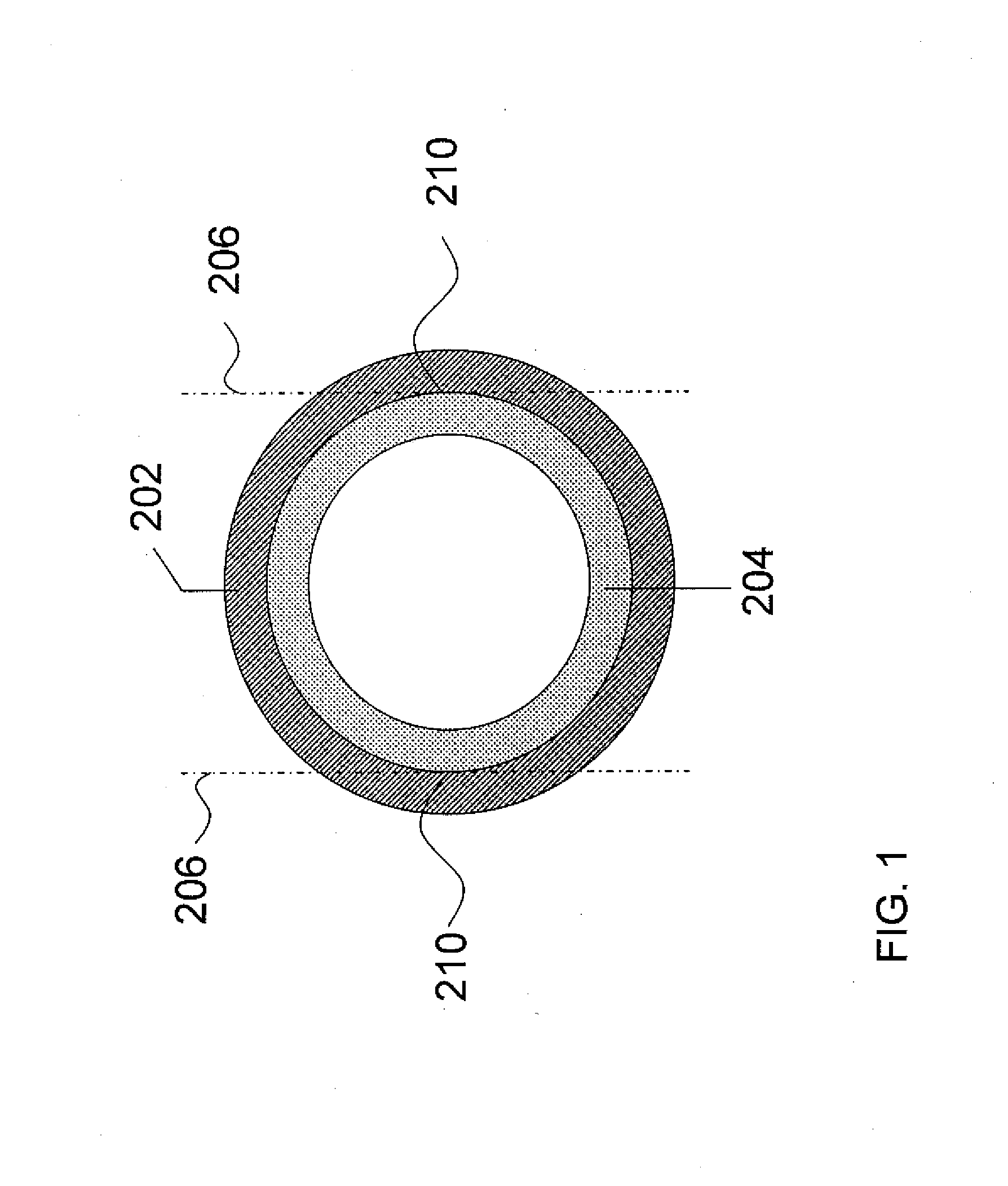

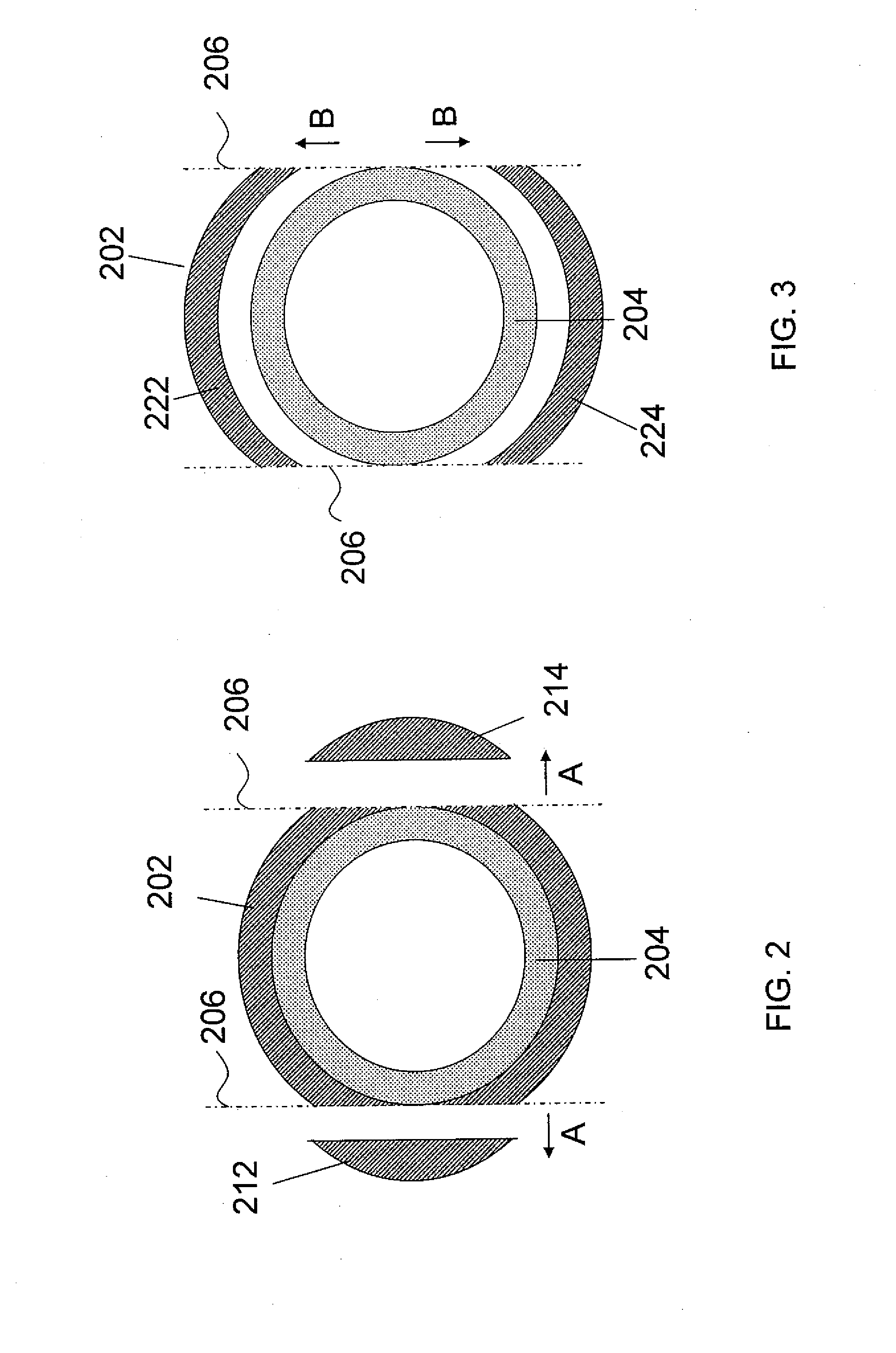

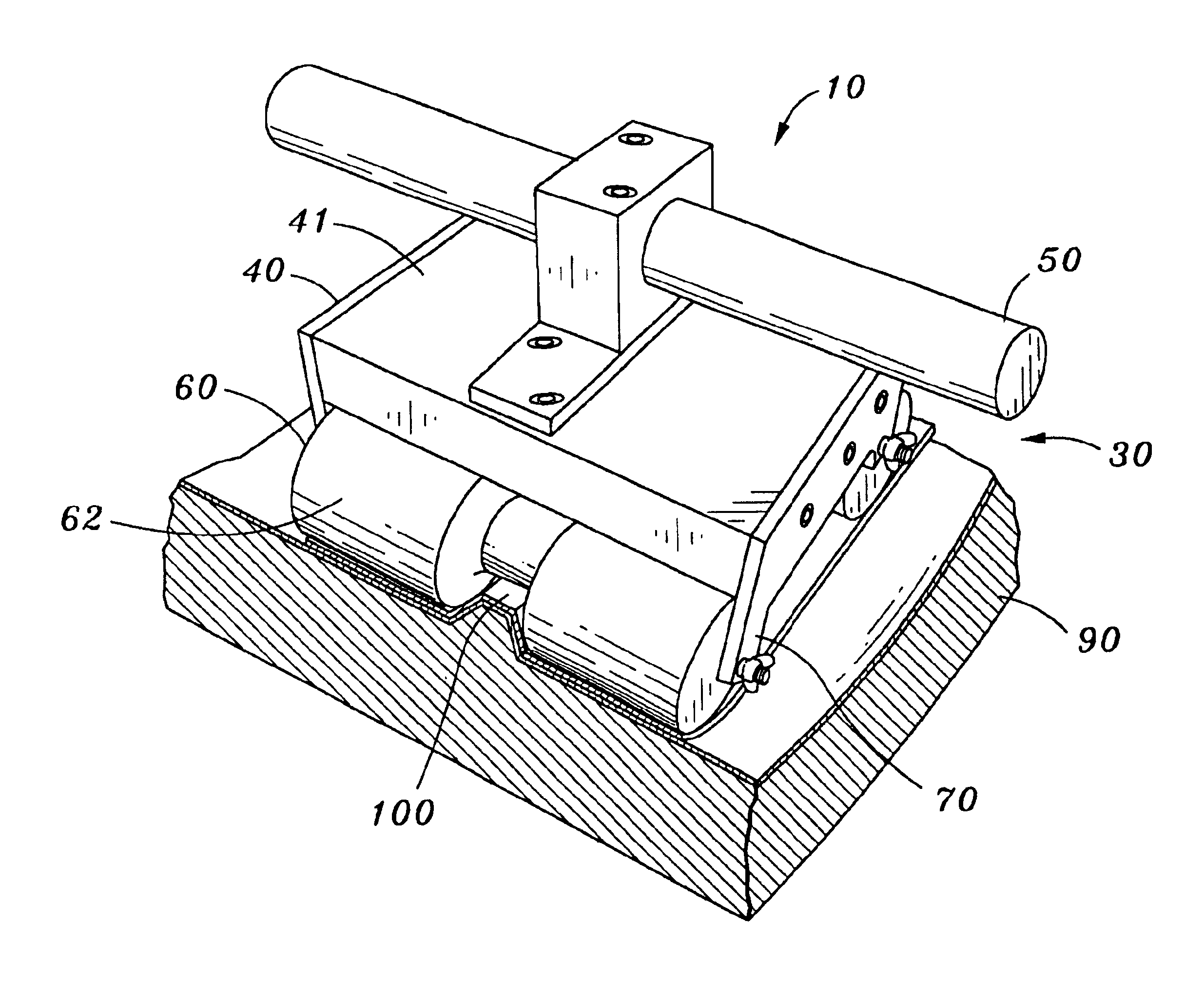

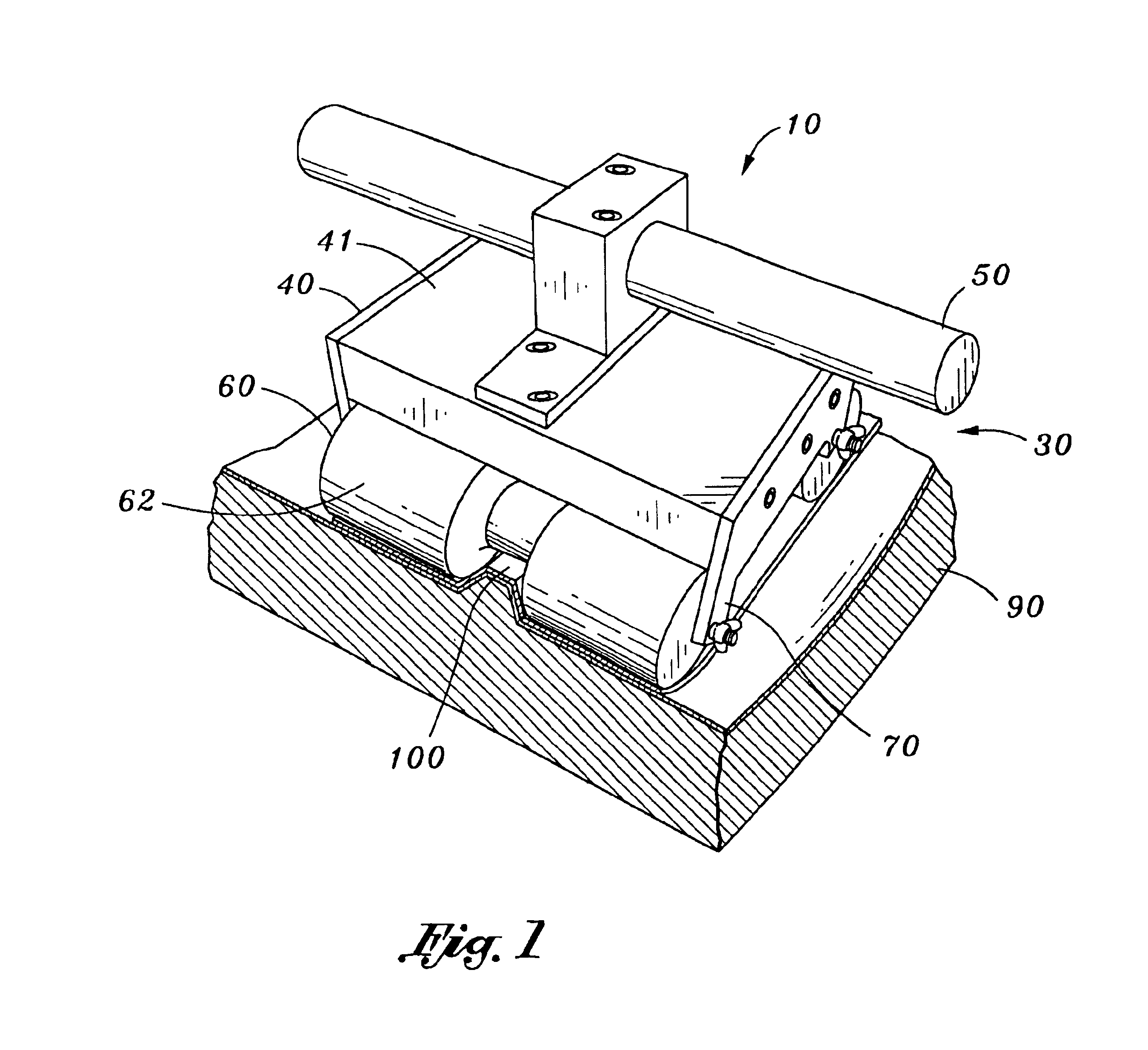

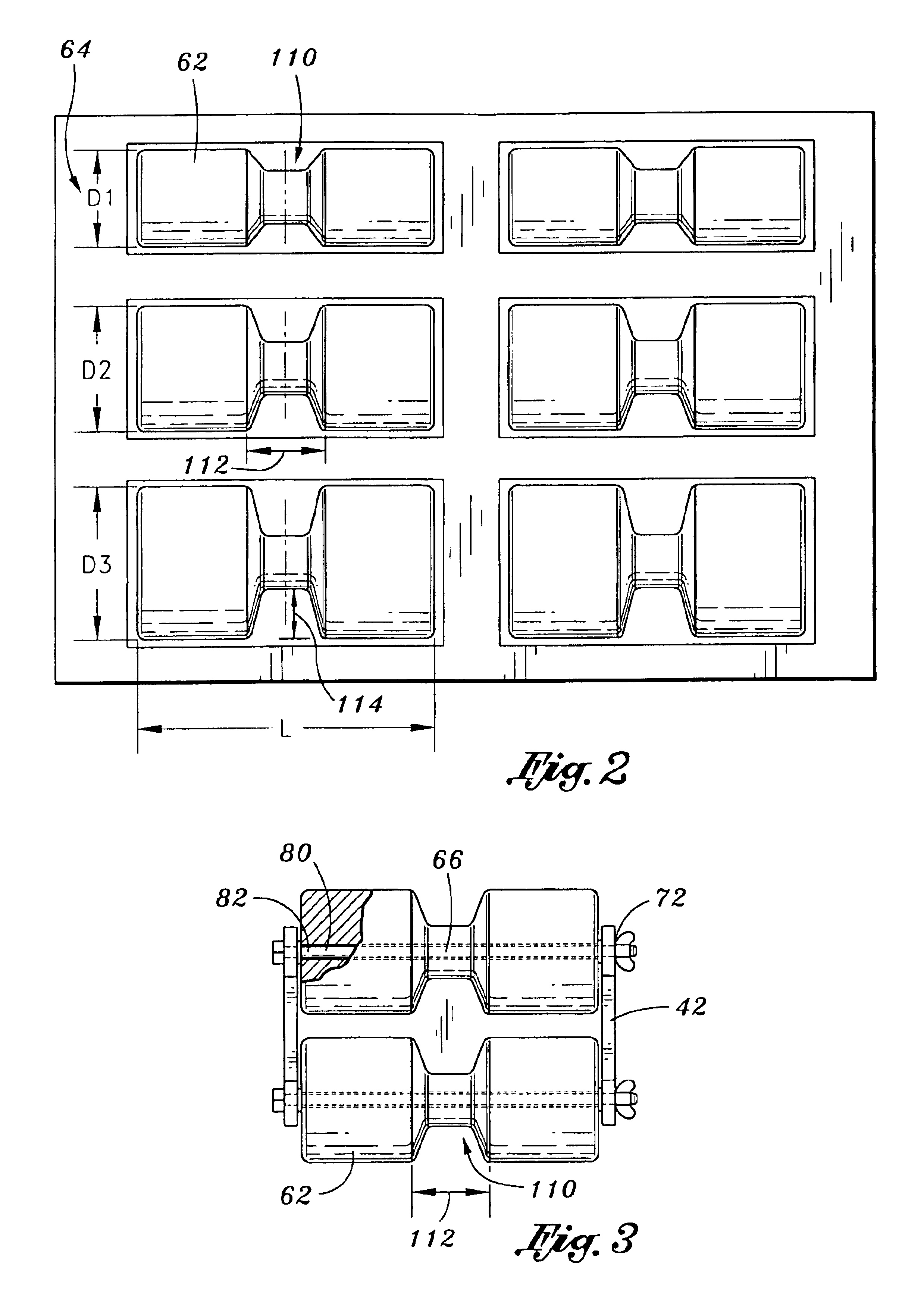

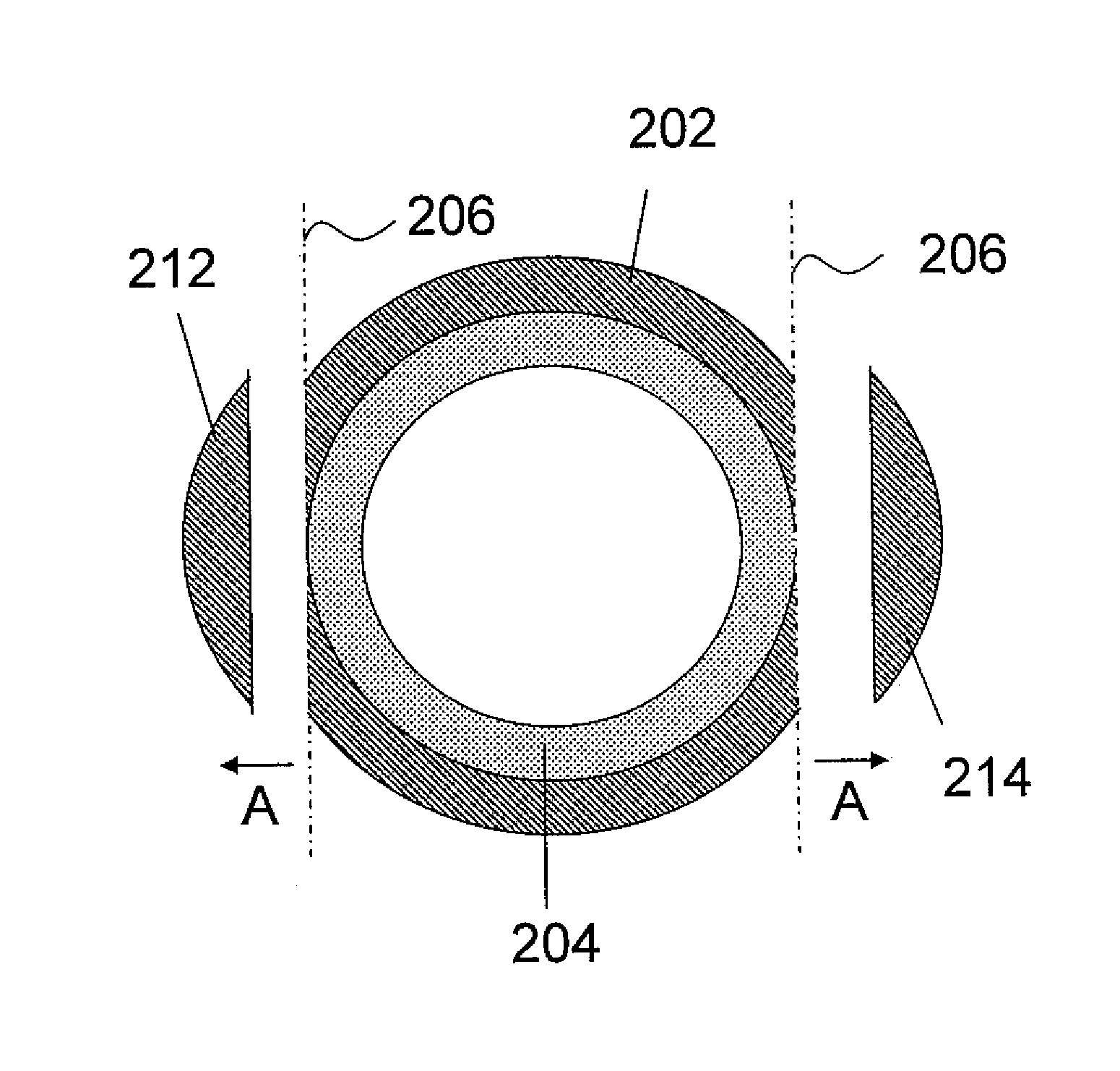

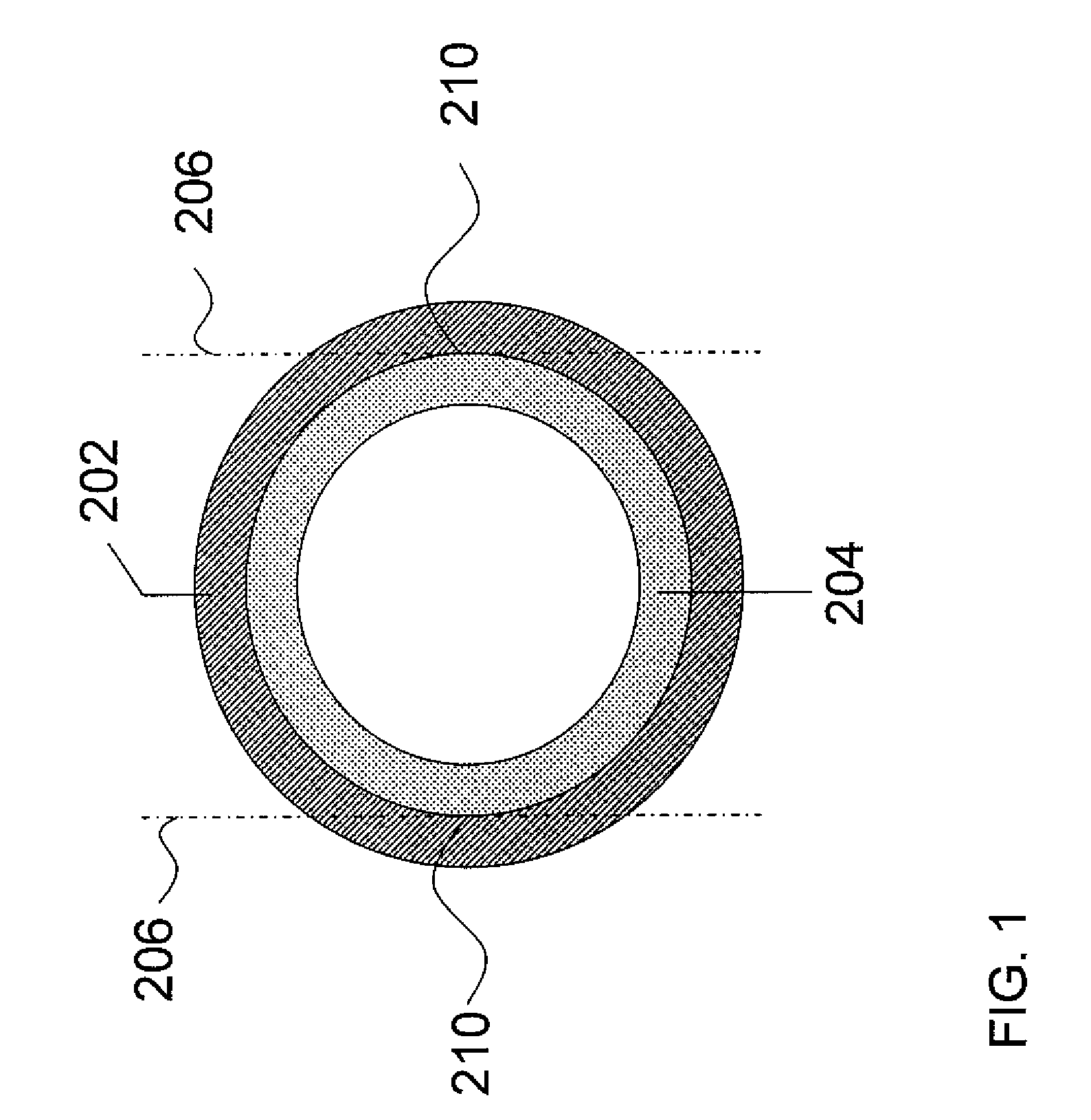

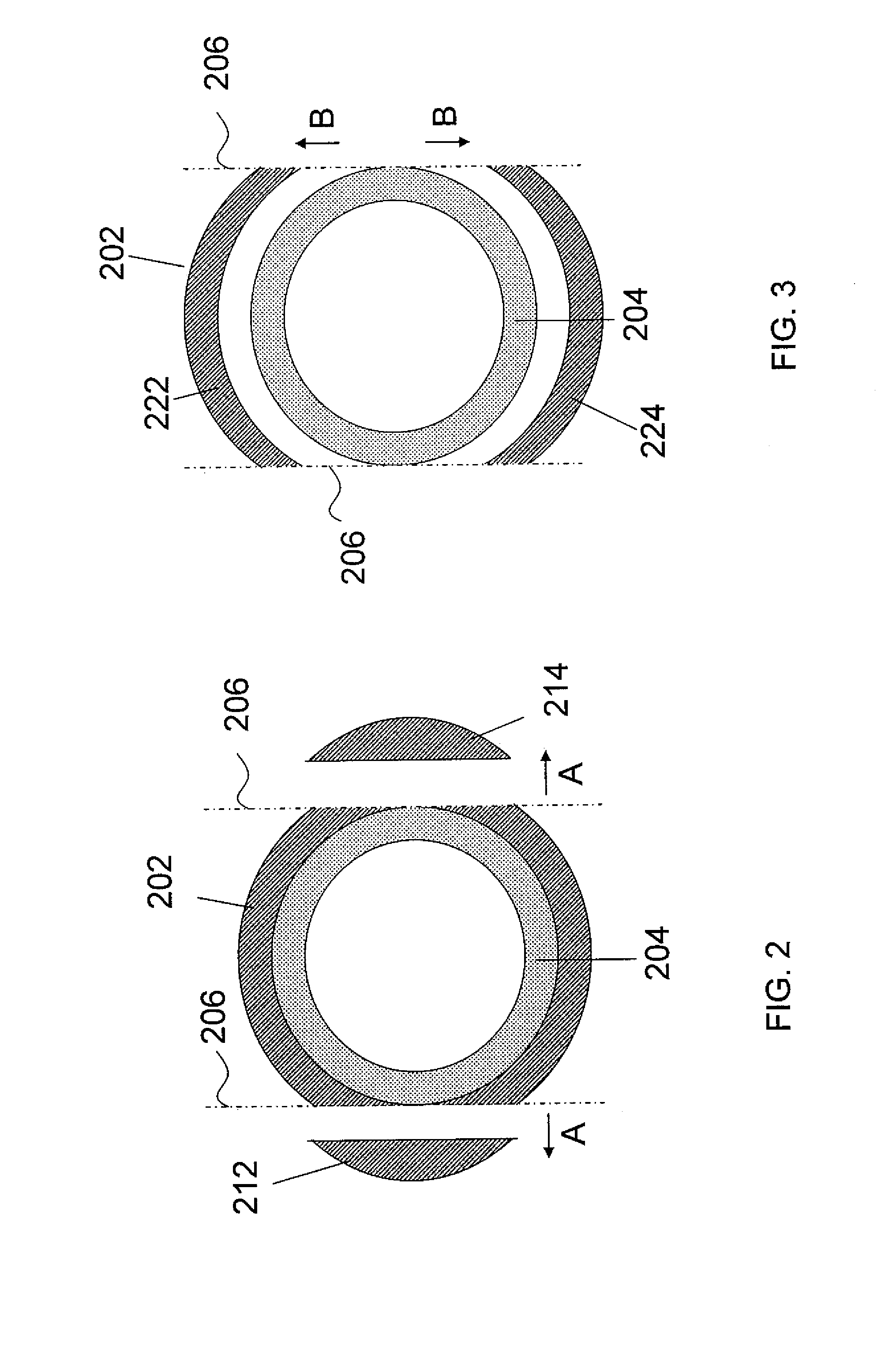

Conformal transverse hat profile roller

There is provided a variable pressure roller system for installing a preform having contact surfaces onto a configuration of a mold surface by applying pressure thereon. The roller system of the present invention comprises a roller carriage. A grasping handle may be mounted to the roller carriage. Moreover, the roller system may further comprise a plurality of rollers, wherein each respective one of the plurality of rollers is defined by a weight to generate a specific pressure corresponding thereto. Furthermore, each respective one of the plurality of rollers may be removably engageable to the roller carriage. Each respective one of the plurality of rollers may be adapted to uniformly distribute the specific pressure corresponding thereto on the contact surfaces for conforming the preform to the configuration of the mold surface when engaged to the roller carriage.

Owner:NORTHROP GRUMMAN SYST CORP

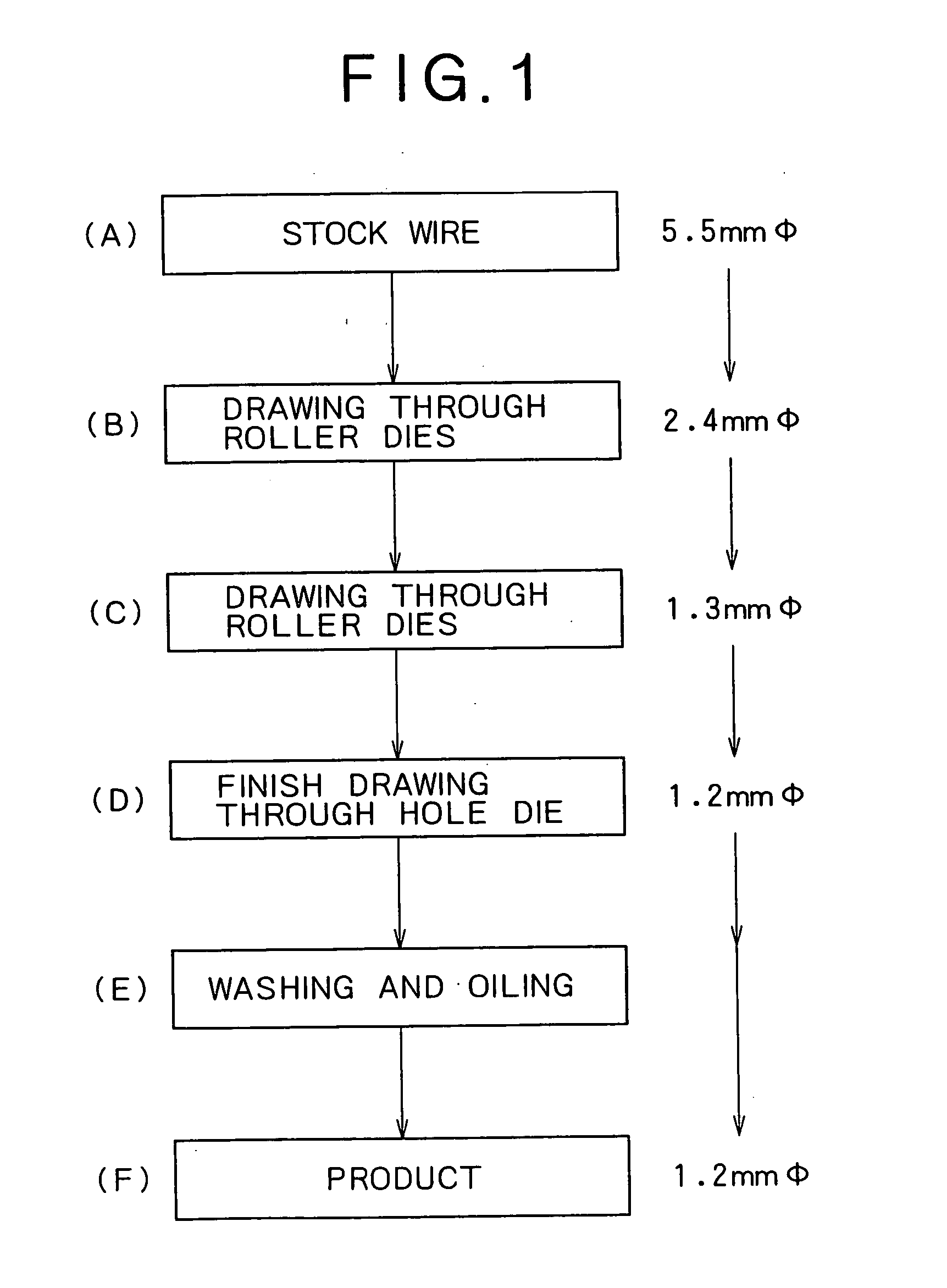

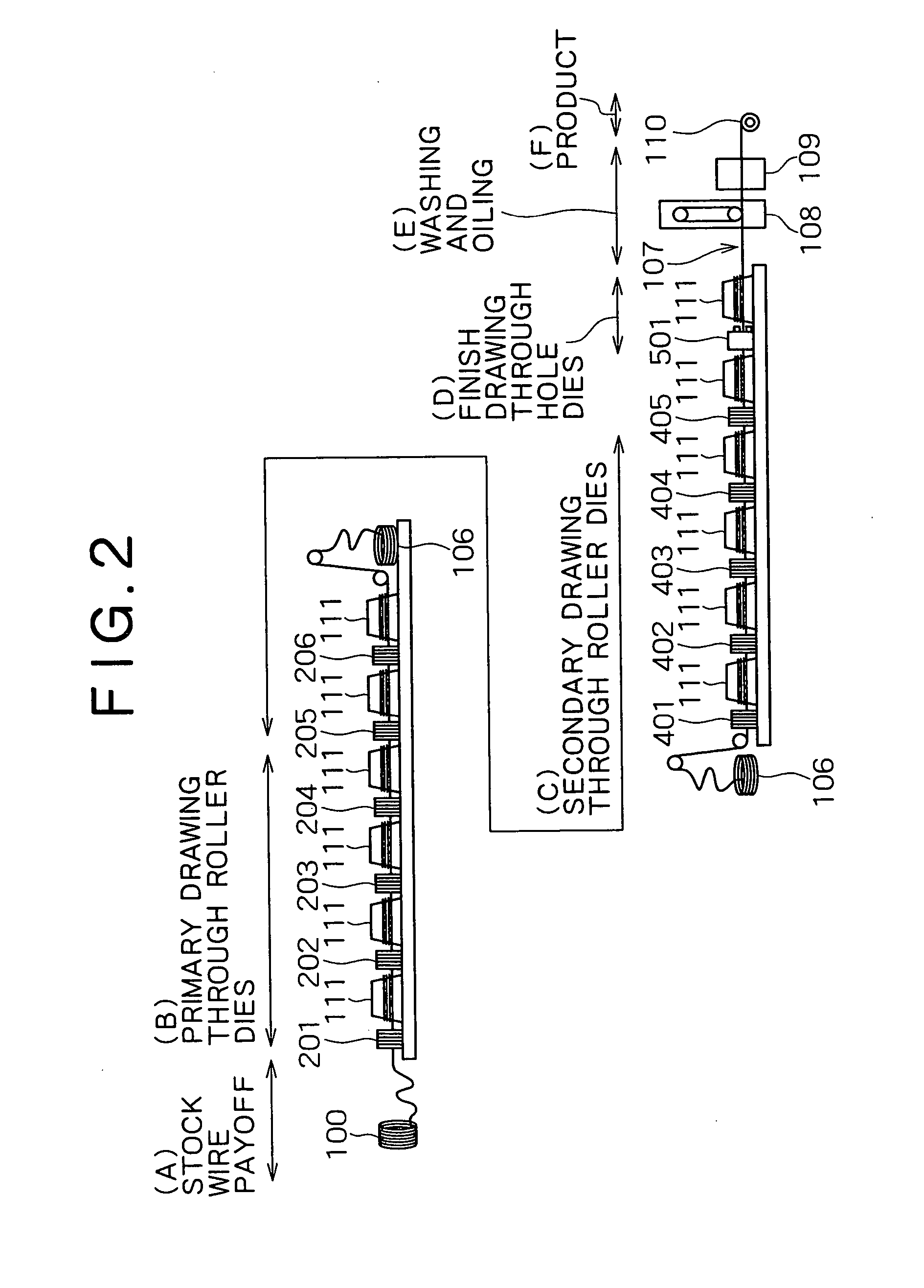

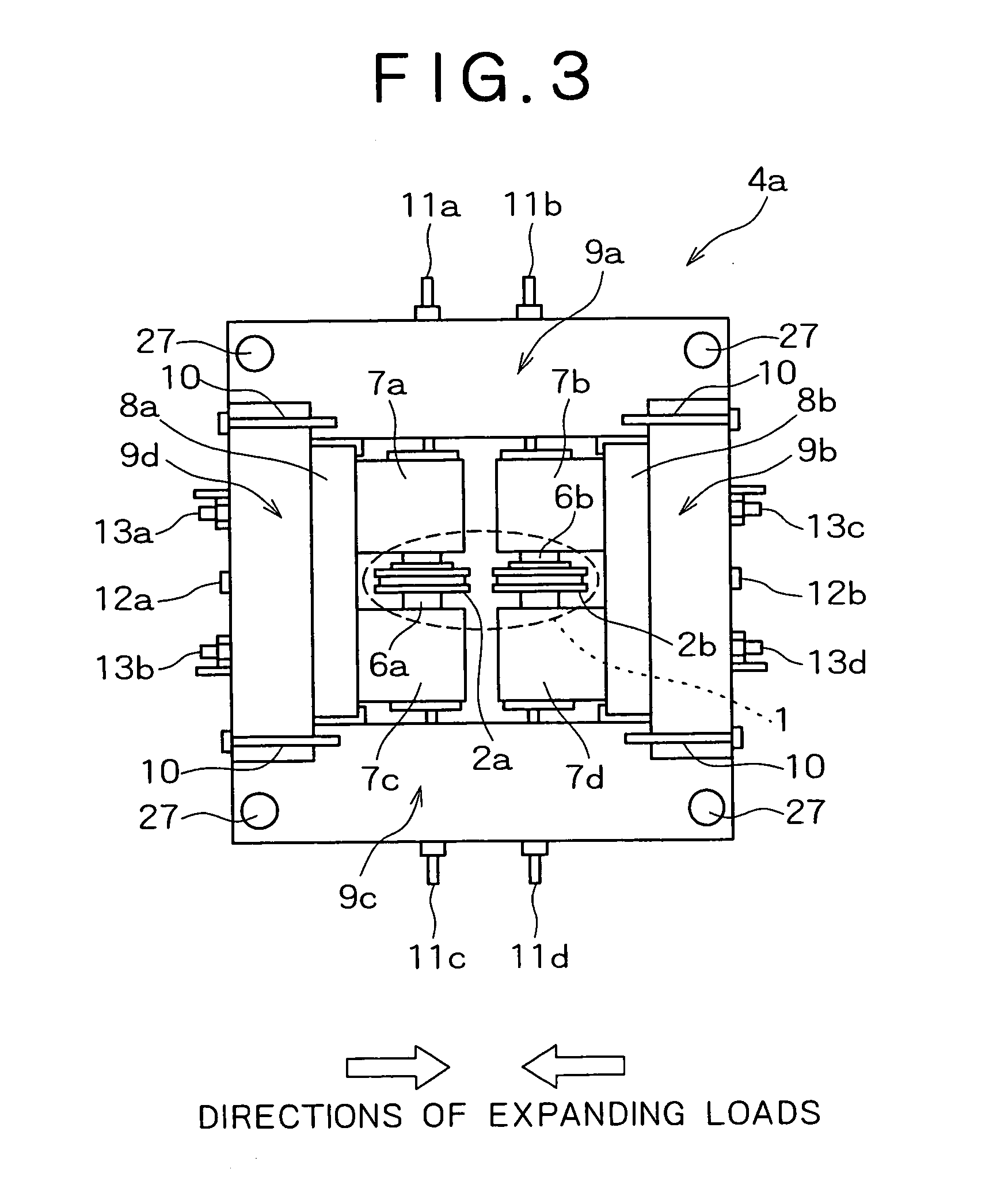

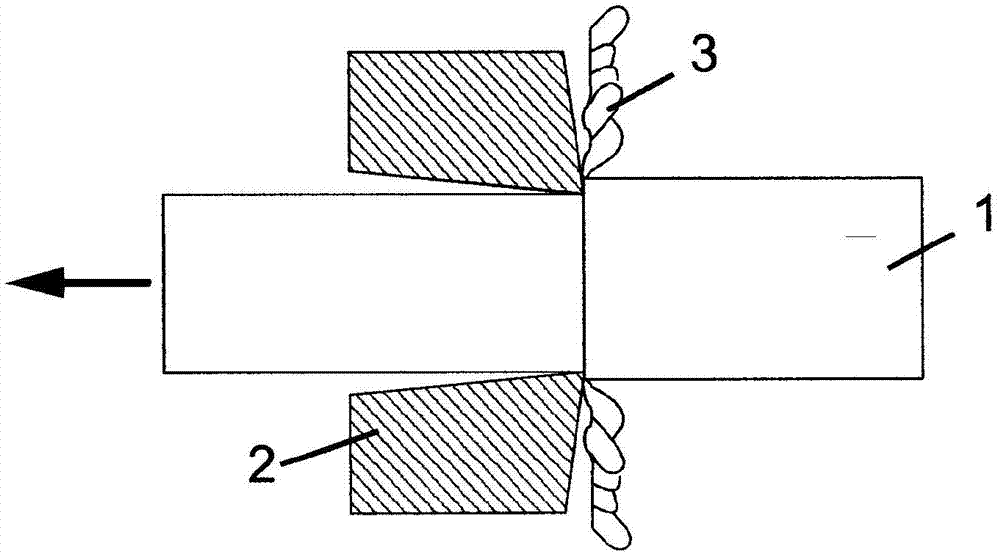

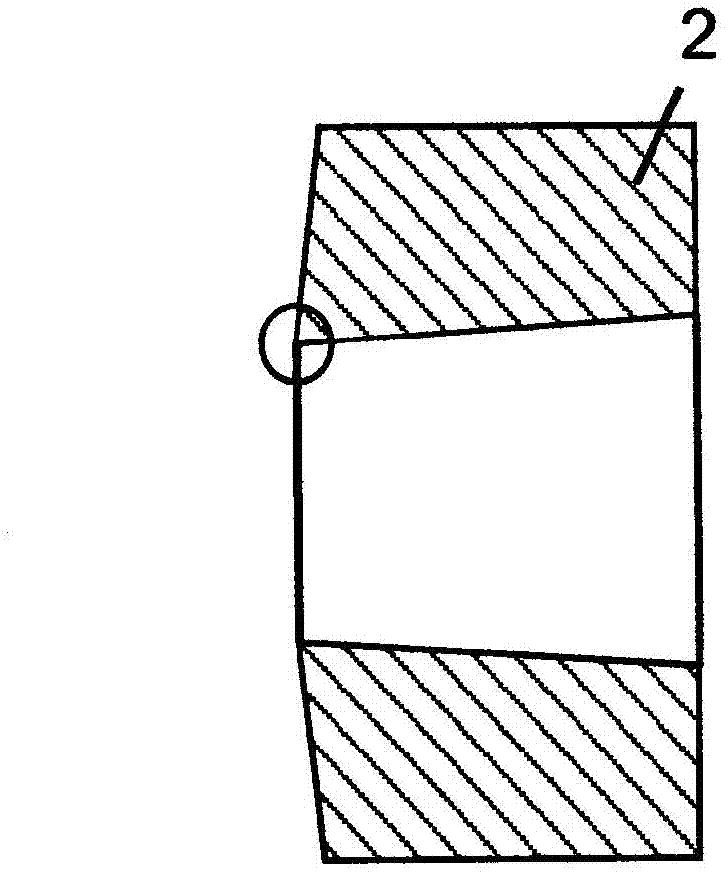

Method of producing solid wire for welding

ActiveUS20050045699A1Uniform applicationEfficient weldingDrawing diesArc welding apparatusCopper platingSodium stearate

A method for efficient production of a welding solid wire free of copper plating. The method consists of drawing by means of roller dies with the help of a dry solid lubricant for drawing which is at least either of sodium stearate or potassium stearate, removing the lubricant from the wire surface by means of a washing device, and applying a lubricant for wire feeding to the surface of the drawn wire by means of an oiling device. High-speed drawing by means of roller dies makes a stock wire into a welding solid wire having the diameter of the finished wire or nearly finished wire. The drawing step is followed by the washing step and the lubricant applying step, which are all accomplished in-line.

Owner:KOBE STEEL LTD

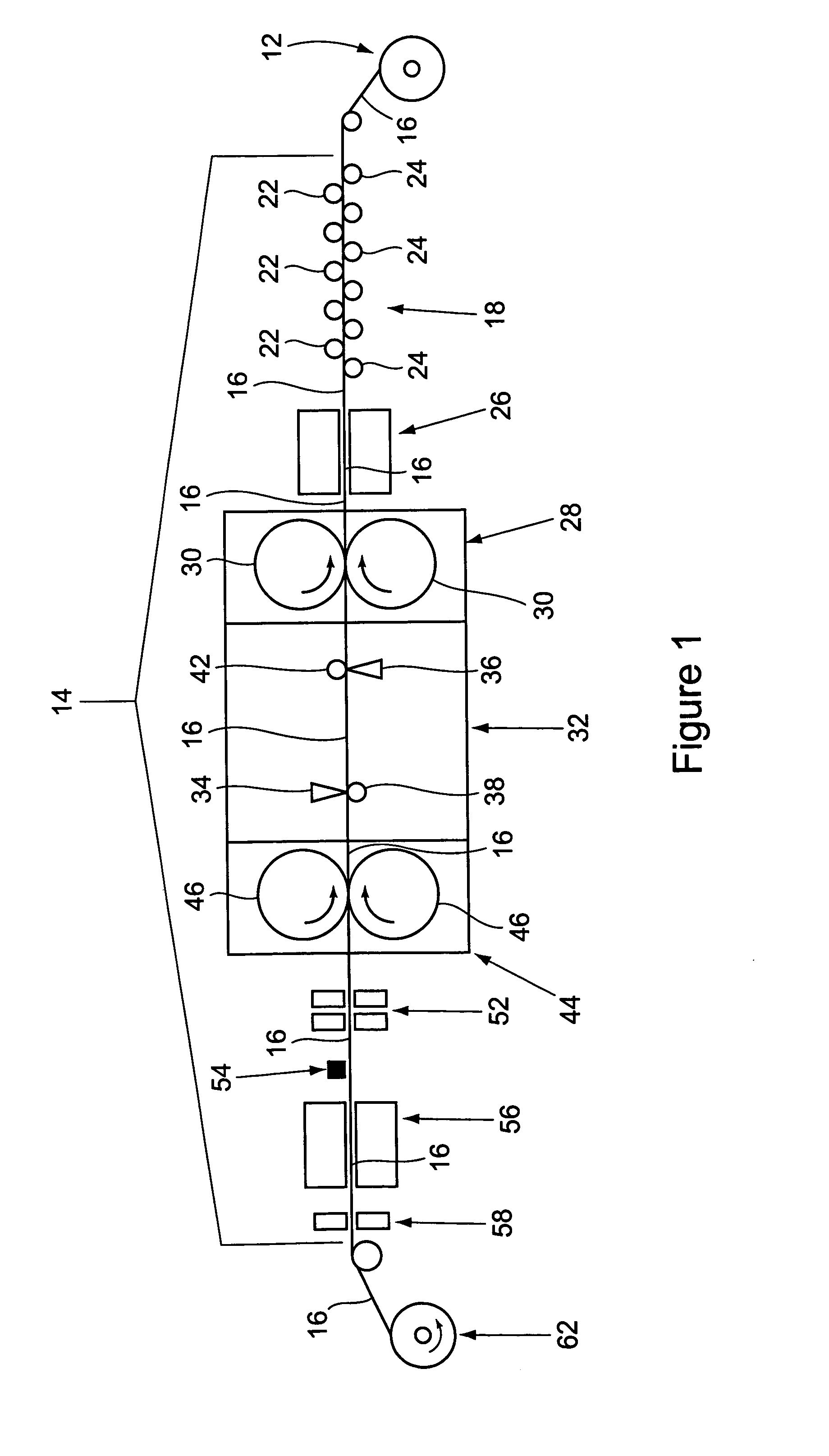

Sheet metal scale removing water jet process

InactiveUS7077724B1Less complexEliminate scalingElectrostatic cleaningWork treatment devicesEngineeringHigh pressure

An apparatus and method of removing scale from the surfaces of processed sheet metal employs high pressure jets of water directed from nozzles positioned in close proximity to the sheet metal surfaces.

Owner:THE MATERIAL WORKS

Method for removing oilfield mineral scale from pipes and tubing

A method for removing mineral scale from tubing is disclosed. The method may include the steps of making a first longitudinal cut along a length of the tubing, making a second longitudinal cut along a length of tubing, and removing a plurality of sections of tubing, wherein the sections of tubing are defined by the first and second longitudinal cuts.

Owner:EXKAL LTD

An acidless descaling process for cold rolled steel strip and manufacturing device thereof

InactiveCN1864880AAvoid harmReduce harmWork treatment devicesExtrusion cleaning devicesScaling skinTeeth scaling

The invention relates to a method for removing scale of cold rolling strip steel without acid. Wherein, the strip steel on the release machine, via the drawing roller, is fed to the cutter to be cut head or cut end; it uses welder to weld the head and end; feeding it to the wide adjustable free sheath to be stored; feeding it to multi-roller tooth scale remover to break the ferric oxide on the surface of strip steel; the steel brusher removes the left scale skin; in the scale removing box, the high-pressure water flows with the wet sand with 5% water content to brush the strip steel; washing it with water after removing scale; the strip steel via two steering rollers torsions the strip steel for 180 degrees; via another scale removing box, it removes the ferric oxide skin left on the back of strip steel; feeding it to another wide adjustable free sheath to be stored; feeding it to passive groove; to passivate the strip steel; the strip steel via another cutter is cut; the cut strip steel is fed to the coiling machine to be coiled. The invention has lower cost and lower metal consumption of strip steel, without fuel consumption.

Owner:刘复麟 +2

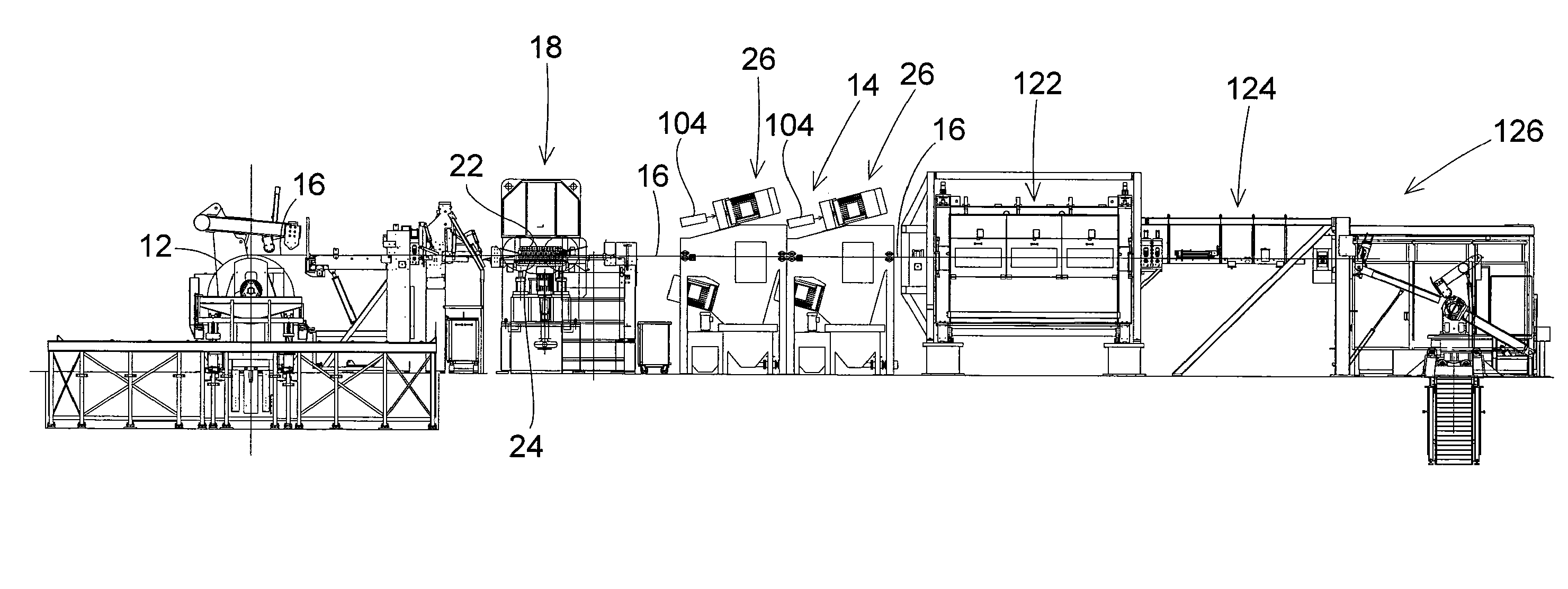

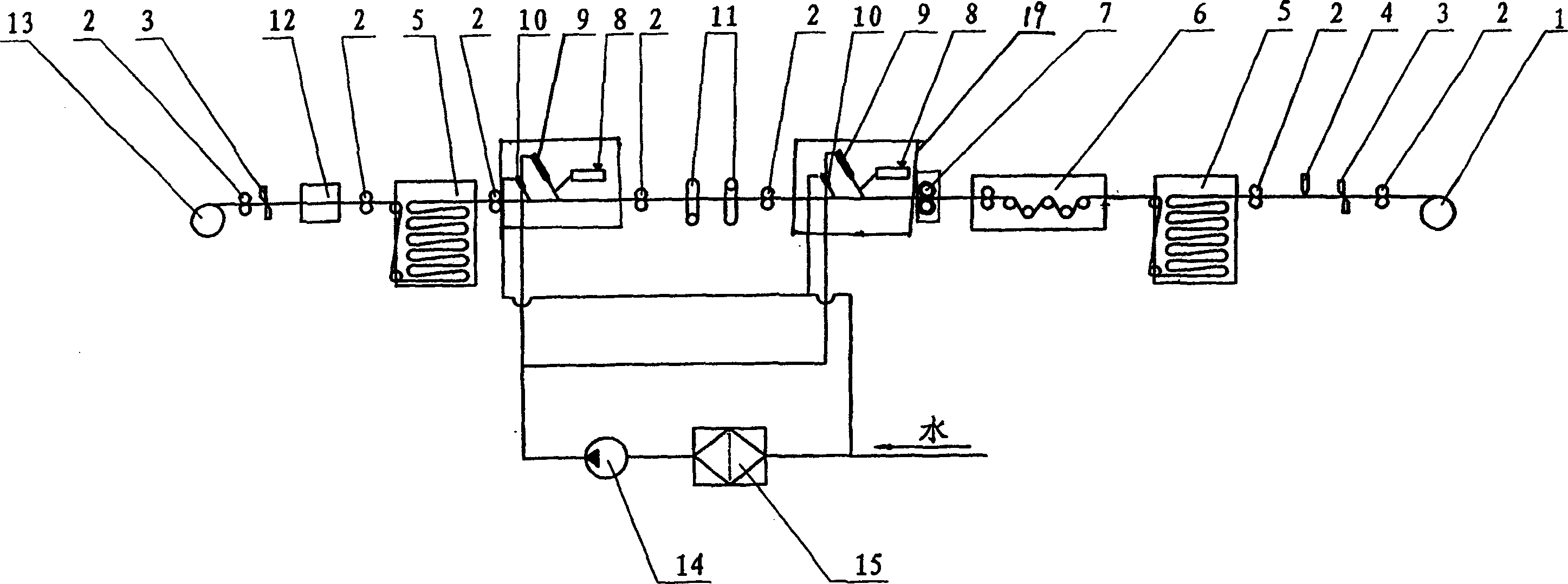

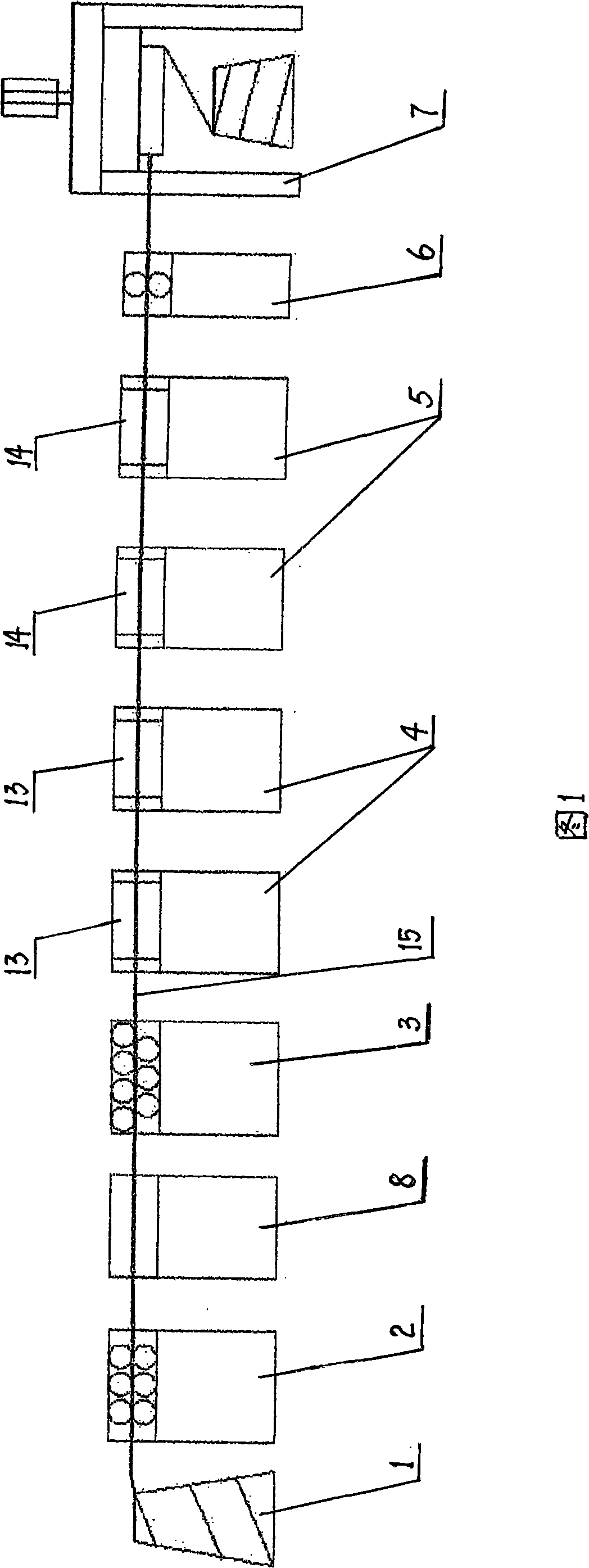

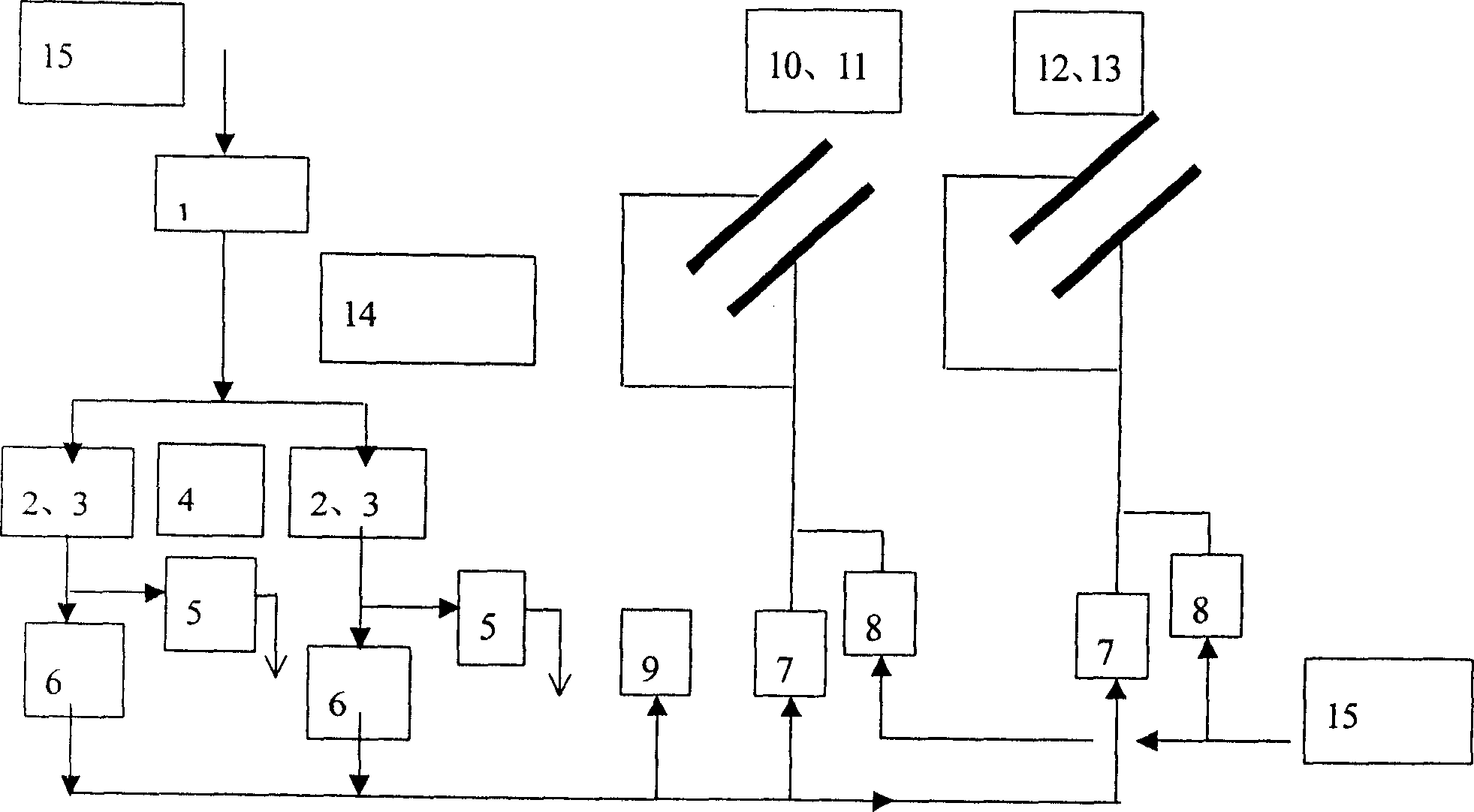

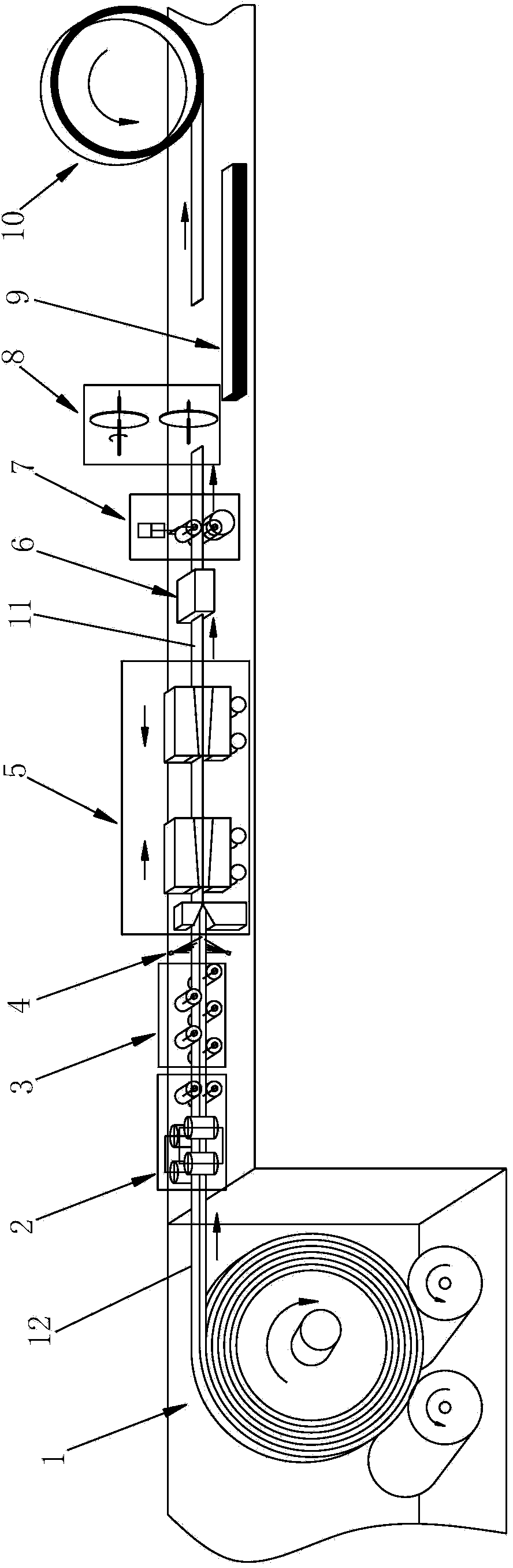

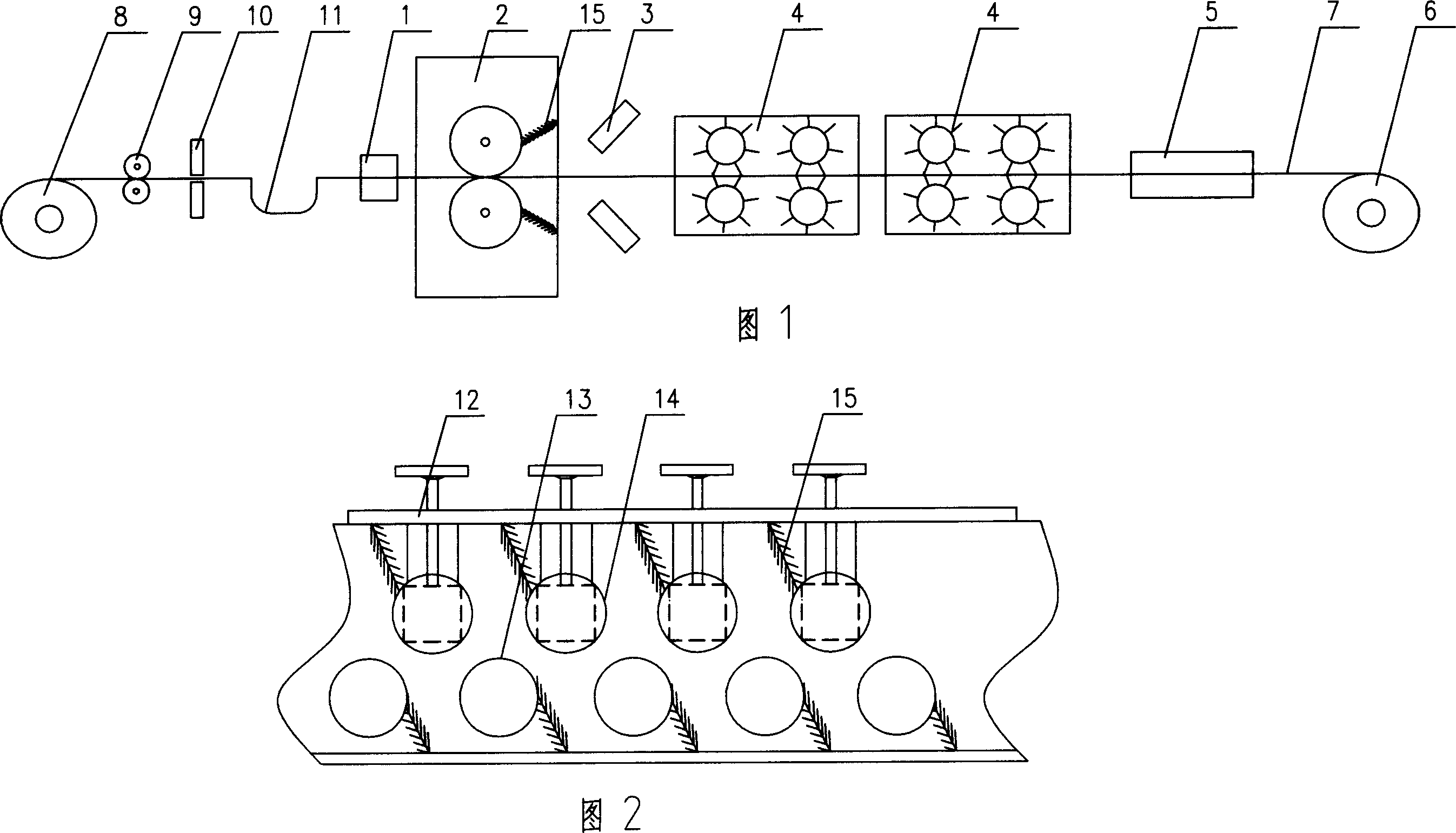

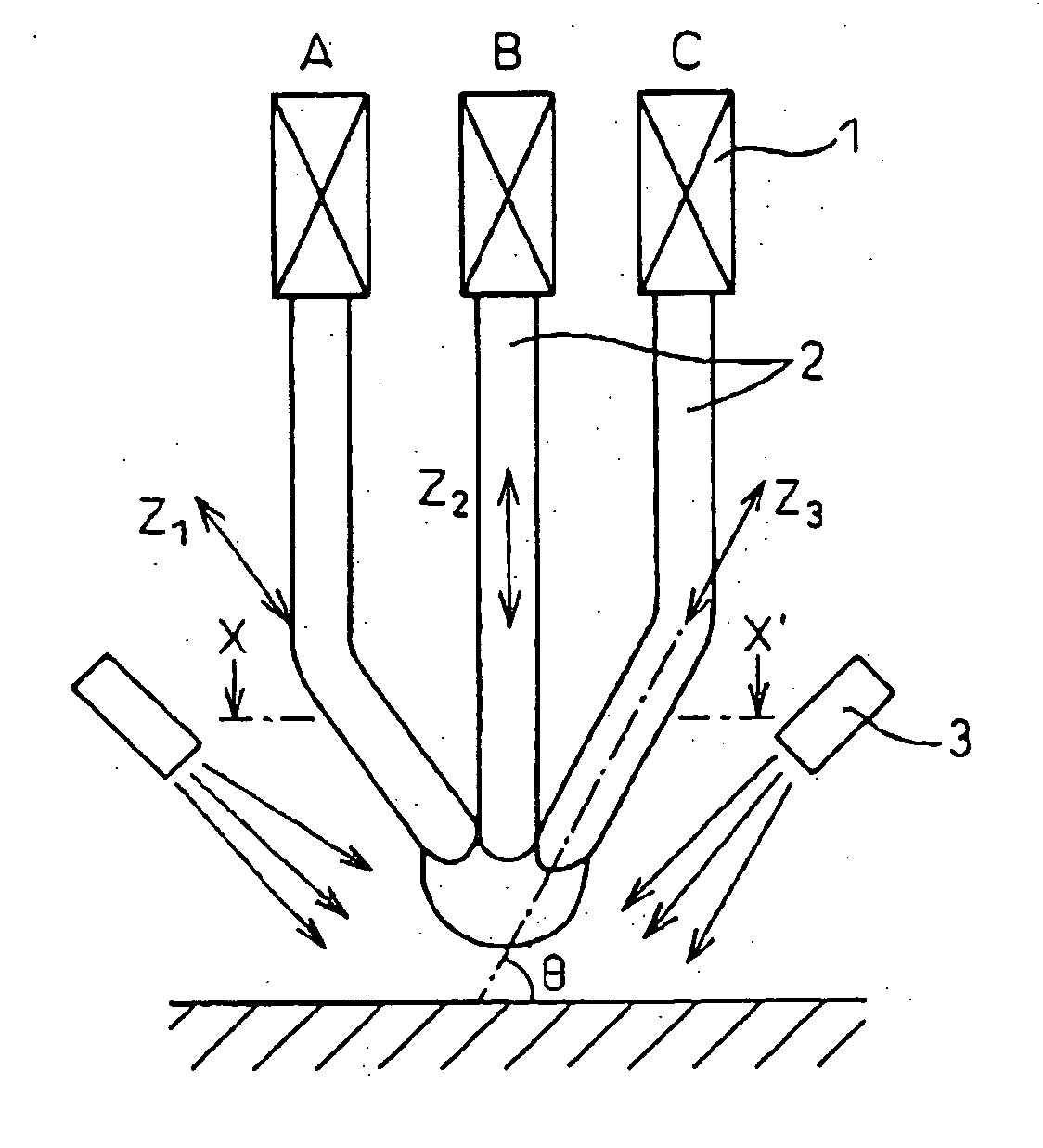

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

Preparation method of copper covered steel woven wire special for communication cable shielding layer

InactiveCN1913046AWill not disconnectGood flexibilitySingle bars/rods/wires/strips conductorsExtrusion cleaning devicesCopper wireThin wire

This invention relates to a preparation method for special steel woven filaments for communication cable shield layers including rough drawing, plating, mid-drawing, fine-drawing and annealing of copper-wrapped steel filaments with the mechanical performance approaching to copper wires, the extension rate of which reaches to 20% and the tensile strength reaches to that of copper wires, so it will not be broken when used in weaving cable shield layers and the product will not be hard and keep fine flexibility.

Owner:仲庆

Process for removing thermal barrier coatings

InactiveUS20050126001A1Molten spray coatingHollow article cleaningThermal barrier coatingMetallic substrate

Briefly, the present invention provides a process which uses an air jet containing non-abrasive particulate media at a low pressure which selectively removes thermal barrier coatings from components without damaging the metallic substrate. This process selectively removes thermal barrier coatings from the cooling holes of components.

Owner:TURBOCOMBUSTOR TECH

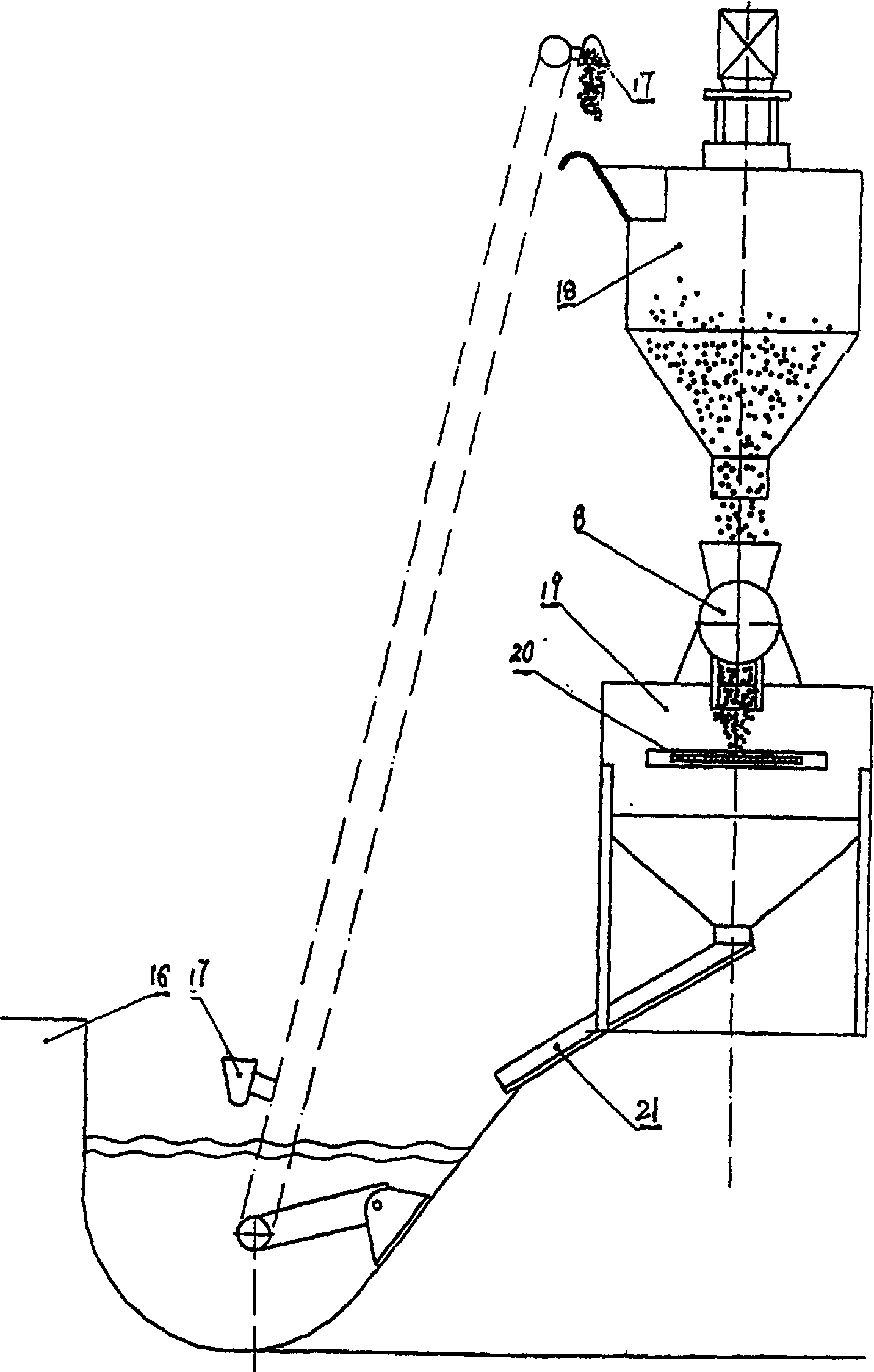

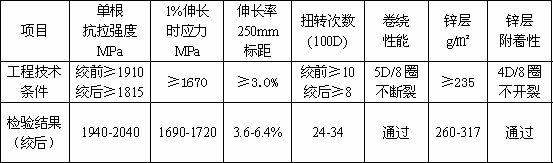

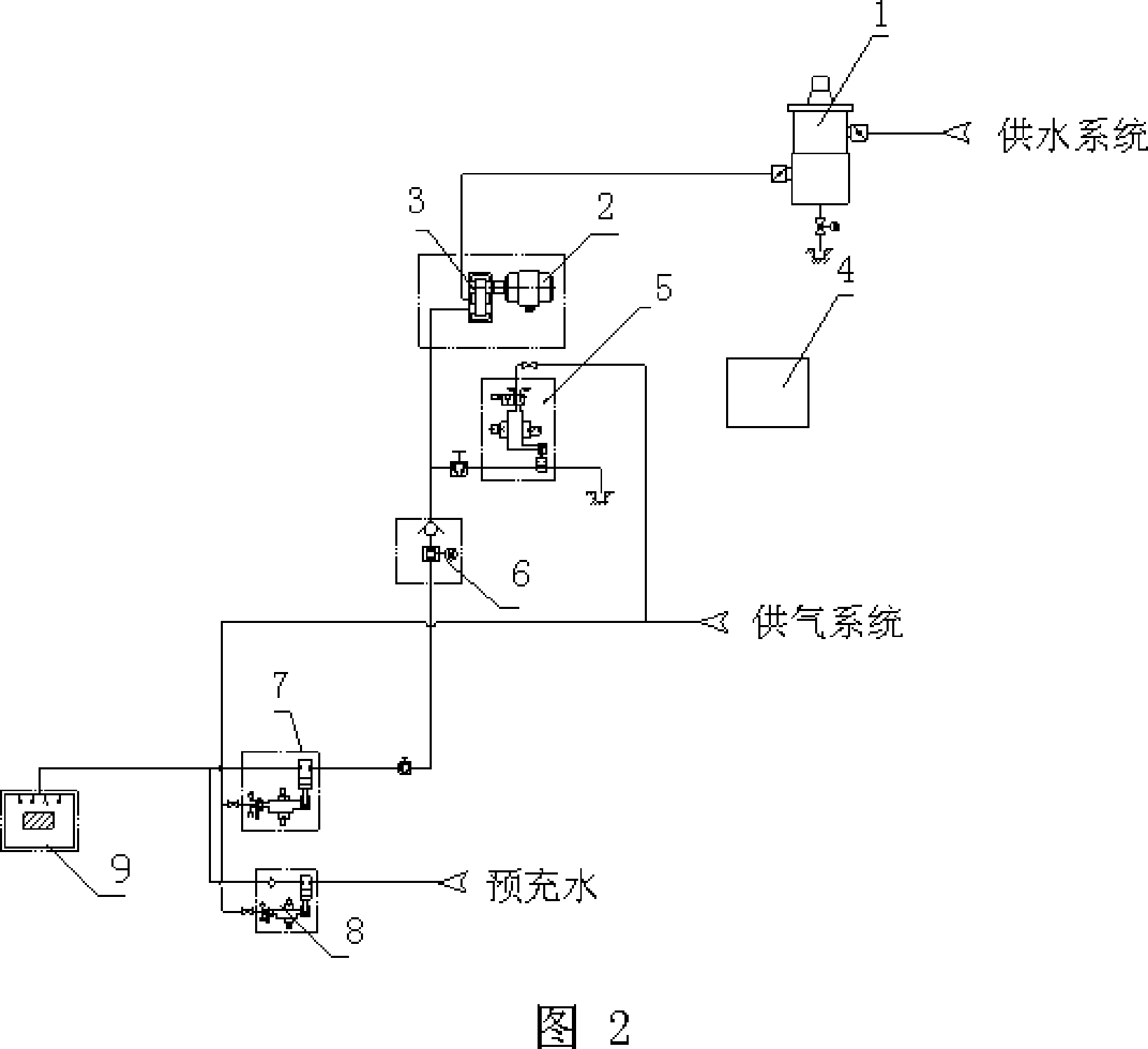

High-pressure water descaling system

ActiveCN1775399AImprove rolling rhythmImprove descaling efficiencyWork treatment devicesExtrusion cleaning devicesWater storage tankSystem pressure

The present invention relates to a high-pressure water scale-removing system. It includes cleaning filter and minimum flow valve group. After the described self-cleaning filter successively are set diaphragm type water storage tank and descaling pump group, and after the described minimum flow valve group successively are set low-pressure precharging valve group, on-machine descaling sprays, on-maching descaling manifold, high-effective descaling nozzle, descaling tank descaling spray valve group, descaling tank descaling manifold and descaling tank high-effective nozzle. Said invention adopts high-pressure variable frequency speed-regulating technique to raise descaling efficiency.

Owner:SGIS SONGSHAN CO LTD

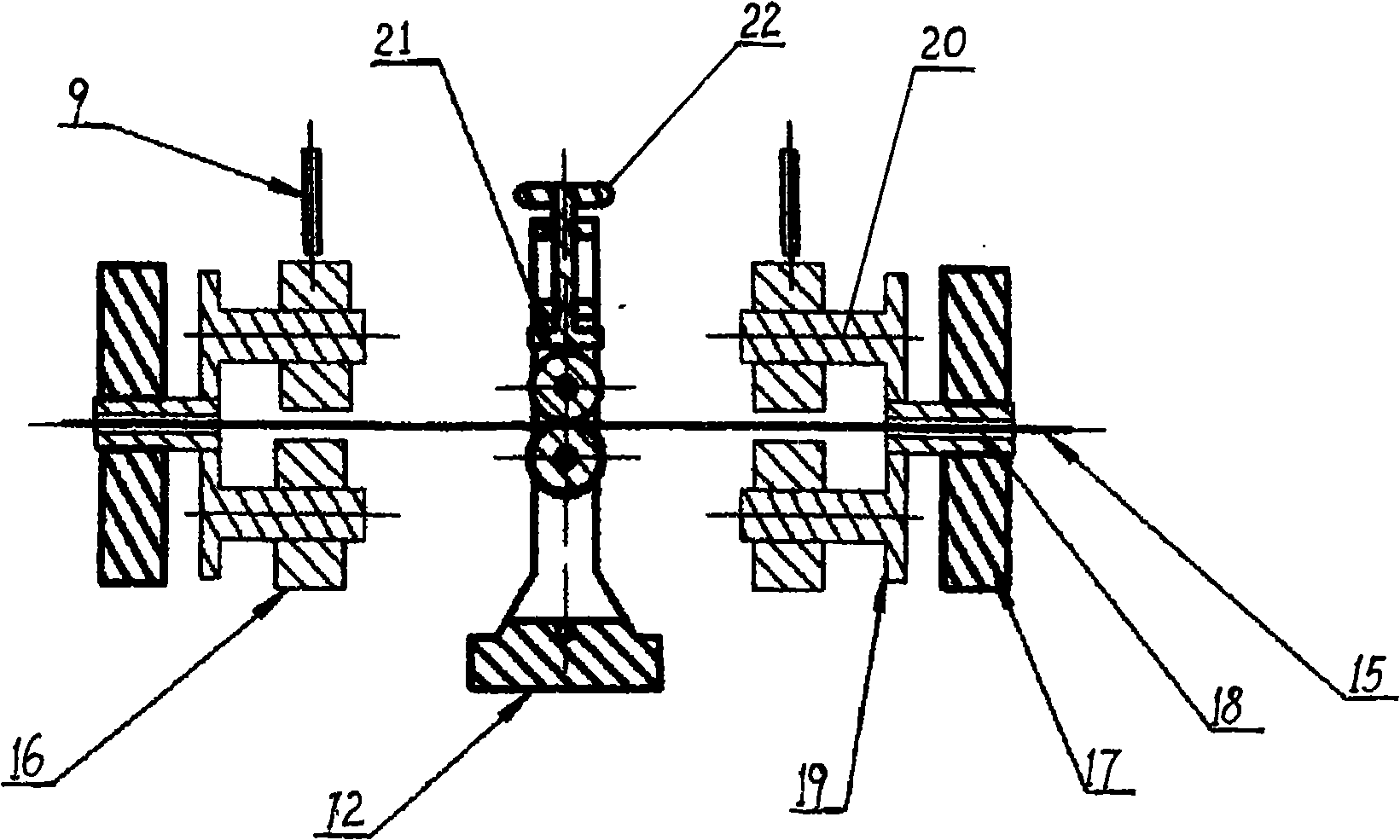

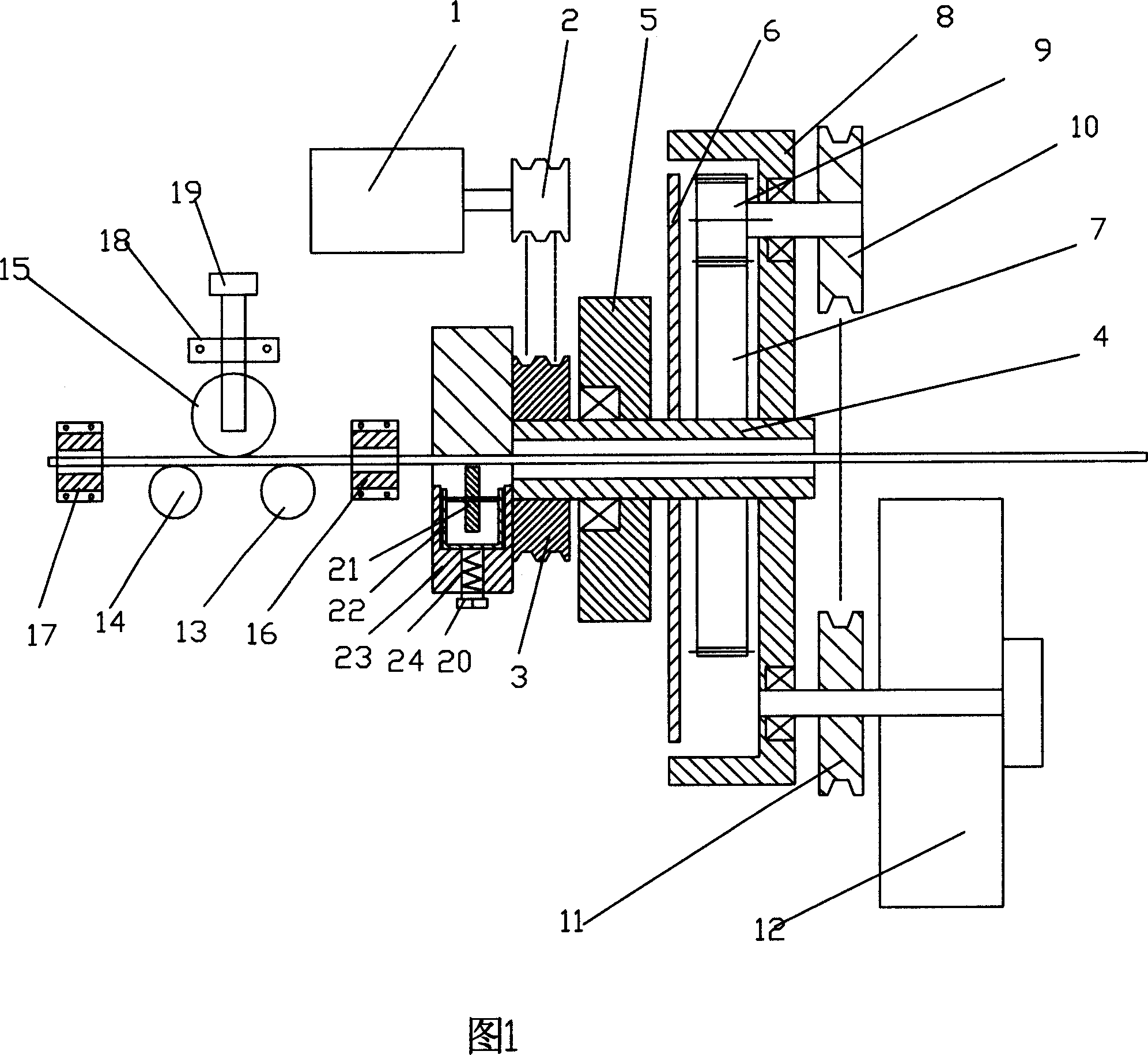

Steel wire rust cleaning method and device

InactiveCN1935396ANo need to deal withNo heating requiredCleaning using toolsExtrusion cleaning devicesIt equipmentMaterials science

The present invention relates to a steel wire rust-removing method and its equipment. Said method mainly includes the following two steps: firstly, mechanically-loosening rusty steel wire by utilizing a group of stripping rollers to make the rust on the steel wire surface be loosened; then brushing the rusty steel wire surface by adopting a steel wire rust-removing device. Said steel wire rust-removing equipment includes the following several portions: a supporting frame, a hollow main shaft, a rotary disk, a rust-removing roller, a pair of front guide sleeves and a pair of rear guide sleeves and a group of stripping rollers.

Owner:王一

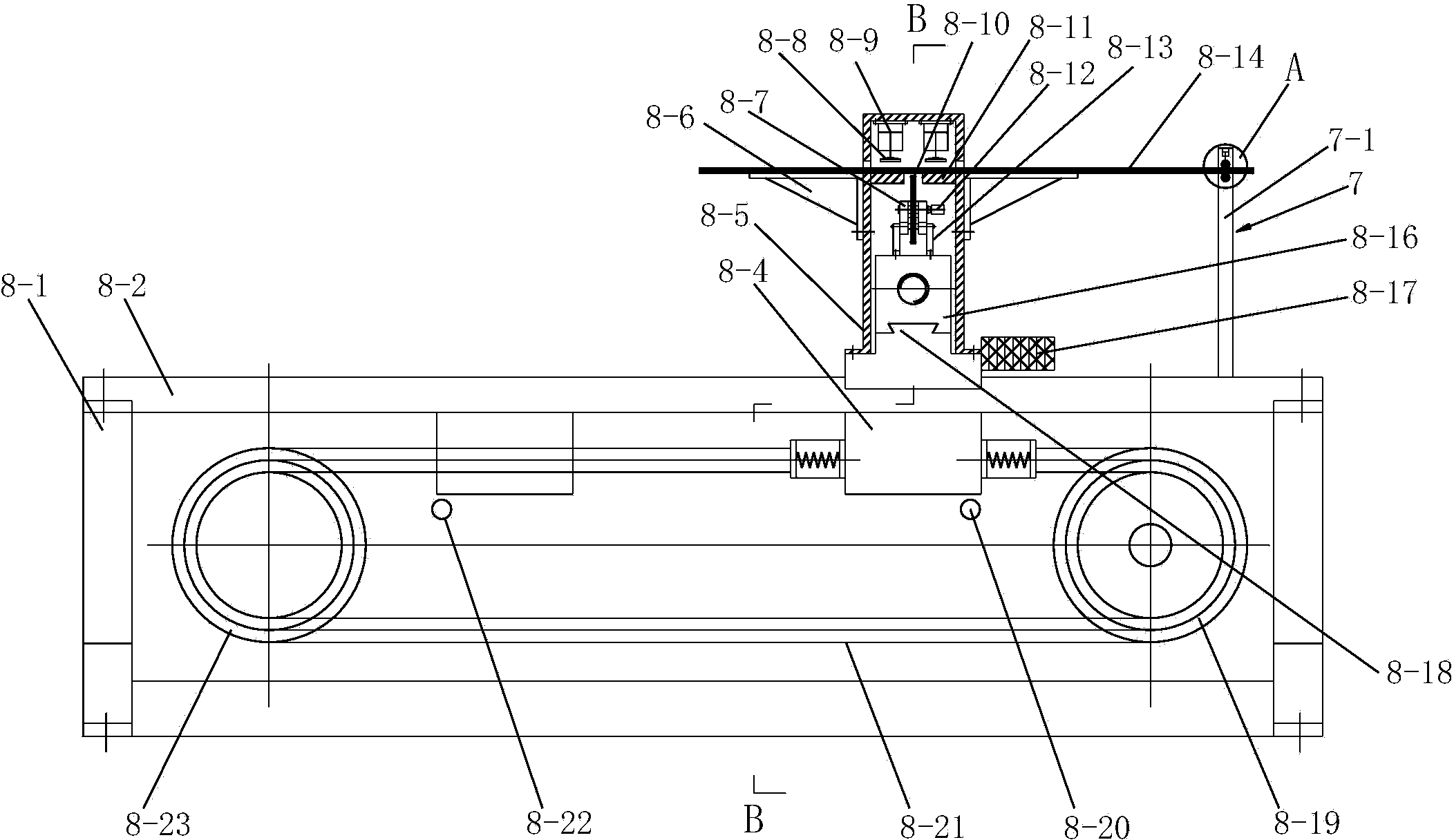

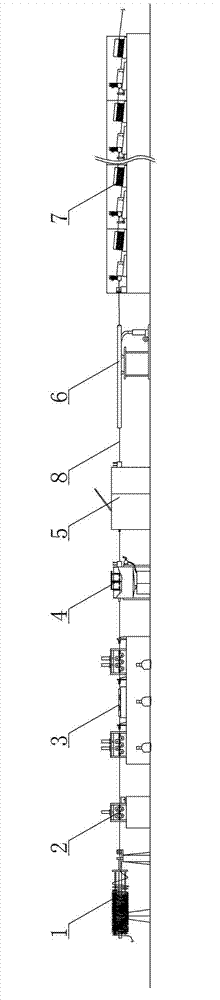

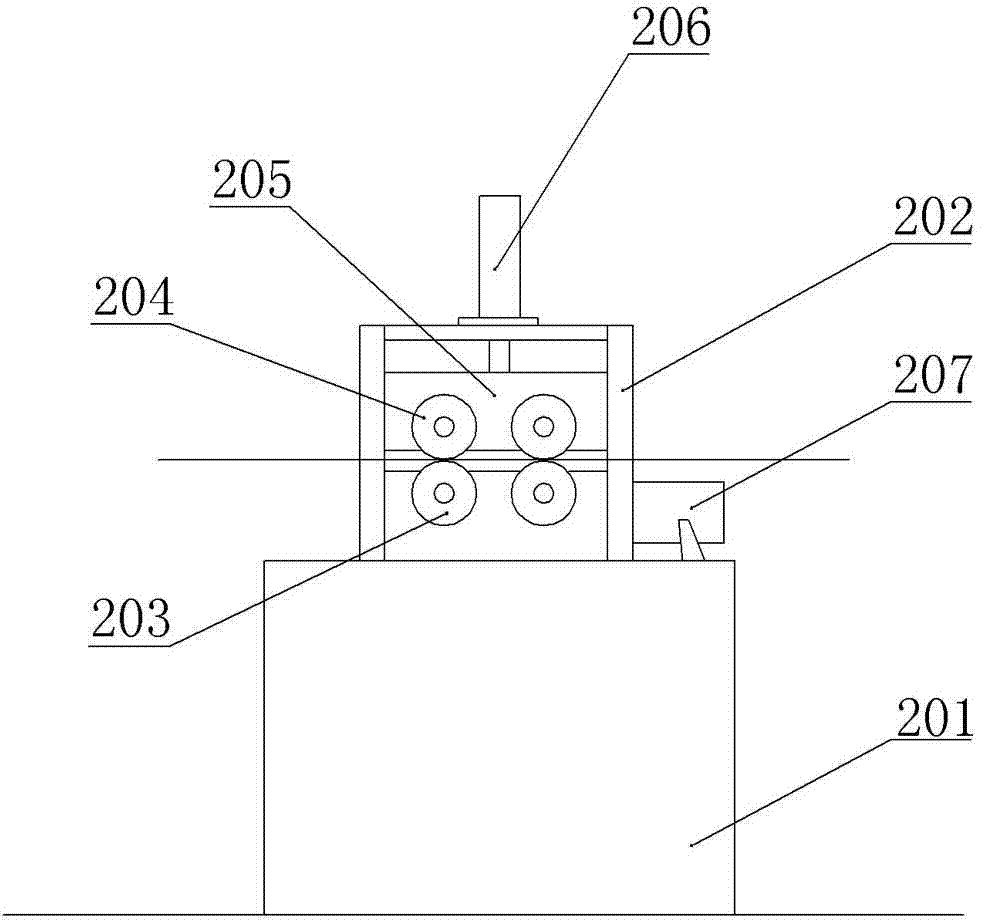

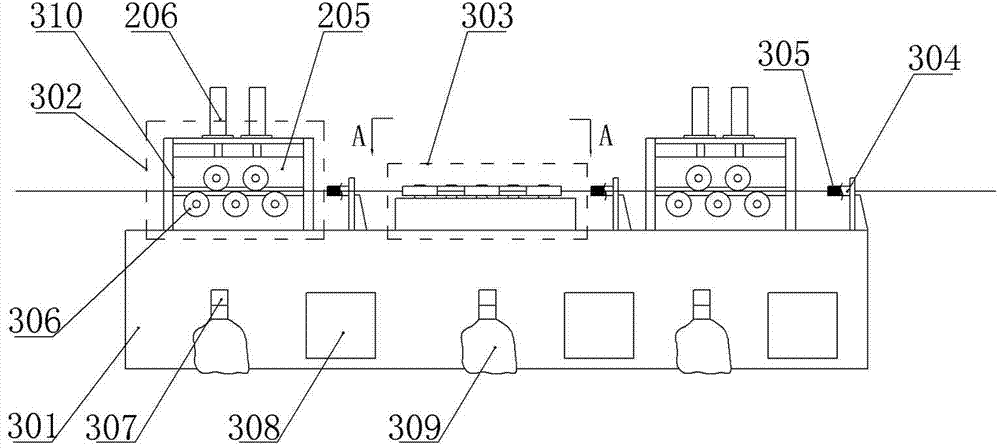

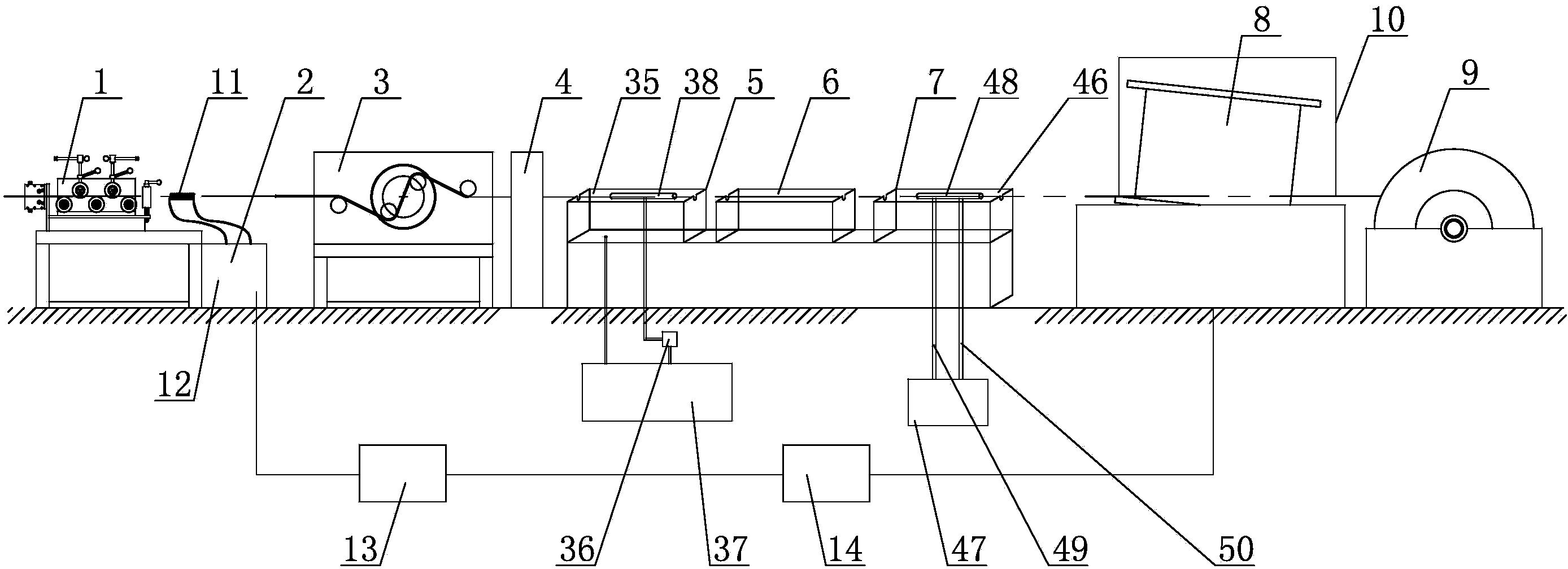

Continuous drawing production line and production method of strip product

ActiveCN103447347ASimple structureNovel and reasonable designMetal sawing devicesMetal sawing accessoriesProduction lineManufacturing engineering

The invention discloses a continuous drawing production line of a strip product. The continuous drawing production line comprises an uncoiler, a straightener, a continuous drawing machine, a length measuring device and a cuttolength saw, as well as a stacking device for stacking the sawn product or a rolling machine for rolling up the sawn product, wherein the uncoiler, the straightener, the continuous drawing machine, the length measuring device and the cuttolength saw as well as the stacking device or the rolling machine are arranged in sequence. The continuous drawing production line provided by the invention has the advantages that the floor space is reduced, the damage and transformation of the products are avoided in hoisting, and the yield is improved. The invention also discloses a production method of the continuous drawing production line of the strip product. The production method comprises the steps of unfolding a pony roll blank to a straight line state, straightening the blank which is unfolded to the straight line state, carrying out continuous drawing processing on the straightened blank to form the product, measuring the length of the product according to the preinstalling length, sawing the product according to the preinstalling length, and stacking the sawn product or rolling up the sawn product. The production method of the continuous drawing production line provided by the invention has the advantages that the production efficiency and the yield are improved.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

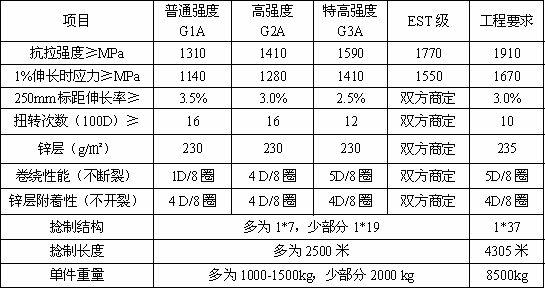

Production process of extra-high strength steel stranded wire for long-span transmission wire

ActiveCN102688906AEasy to implementMeet the technical requirements of large-scale engineeringExtrusion cleaning devicesWire rodHigh carbon

The invention relates to a production process of steel stranded wires, and in particular relates to a production process of an extra-high strength steel stranded wire for a long-span transmission wire. A raw material with a diameter of theta9.0mm and a steel grade of 82B is utilized to produce a 37-strand hot galvanizing steel stranded wire with a total diameter of 20.16mm and a single-wire diameter of 2.88mm for the long-span transmission wire. The production process comprises the following steps of: (1) coiling the raw material, carrying out surface treatment, and drawing a high carbon steel wire rod of theta9.0mm to theta8.5mm; (2) carrying out heat treatment, acid-washing, phosphating, and surface treatment on a wire rod; (3) drawing a finished product: carrying out 13-pass drawing processing by using a high-power and multi-pass LT-11 / 650 type water tank wire-drawing machine, wherein a compression ratio is 12-18.6%; (4) inspecting, putting online, hot galvanizing, and winding by using a spool; and (5) inspecting, and twisting. The production process of the steel stranded wire is simple in realization mode, and all indexes of the produced extra-high strength hot galvanizing steel stranded wire meet the technical requirements of long-span projects.

Owner:巩义市恒星金属制品有限公司

Process for pickling stainless steel in the absence of nitric acid and in the presence of chloride ions

InactiveUS6554908B1Increase speedOptimize allocationLighting and heating apparatusWork treatment devicesRedoxChloride

Process for pickling stainless steel carried out at a temperature of between 20° and 70° C., with the use of a pickling solution containing the following basic ingredients:H2SO4 (free acid): 50 to 200 g / lHF (free acid): 0 to 60 g / lF- anion (total): 5 to 150 g / lSO42- anion (total): 50 to 350 g / lTotal free acidity (H2SO4+HF): between 1 and 7 g. equiv. / l where by "free acid" is meant the acid that does not constitute the anion bound in the form of salts or complexes with the metal cations present in the solution; and, in addition:Fe3+ in a quantity of at least 15 g / lchloride anion in a quantity of between 0.1 and 10 g / l,into which solution is fed, during the pickling process, an oxidant that is able to oxidize Fe2+ to Fe3+ in order to maintain the redox potential of the solution at a value of between +230 and +800 mV.

Owner:HENKEL KGAA +1

High-pressure water descaling system for hot continuous rolling production line

ActiveCN101147923AEasy temperature controlSmall footprintWork treatment devicesExtrusion cleaning devicesProduction lineElectricity

The present invention relates to a high-pressure water descaling system which can be used in the rolling process in the iron and steel metallurgical field. In particular, it relates to a descaling system which can be used in the process of rolling slab and sheet strip. It is characterized by that said invention is aimed at providing an ultrahigh-pressure small-flow high-pressure water descaling system for sheet bar hot continuous rolling production line. The water-out pressure of its descaling pump group is 25MPa-50MPa, and the water flow rate of its descaling nozzle is 20-40L / min..

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

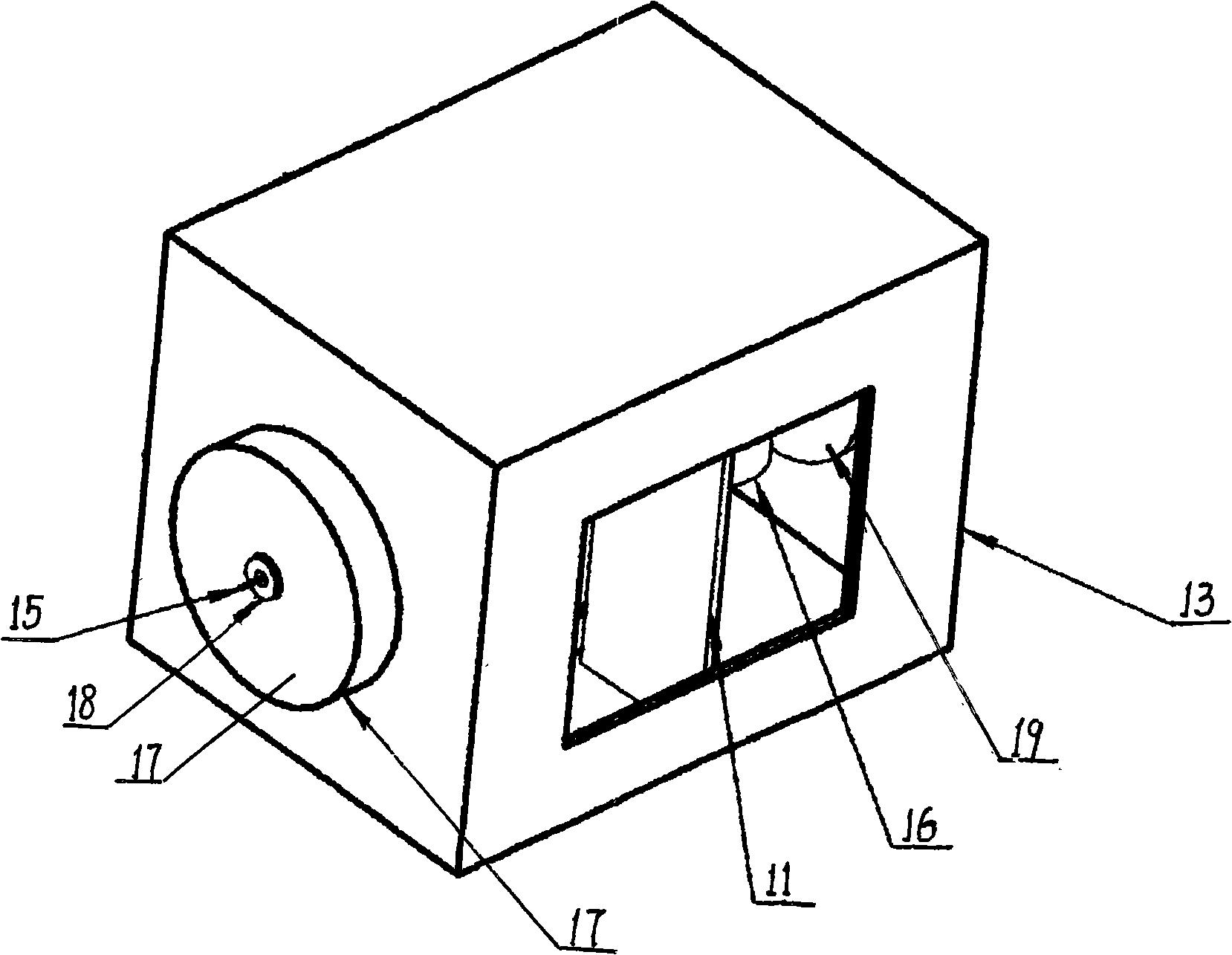

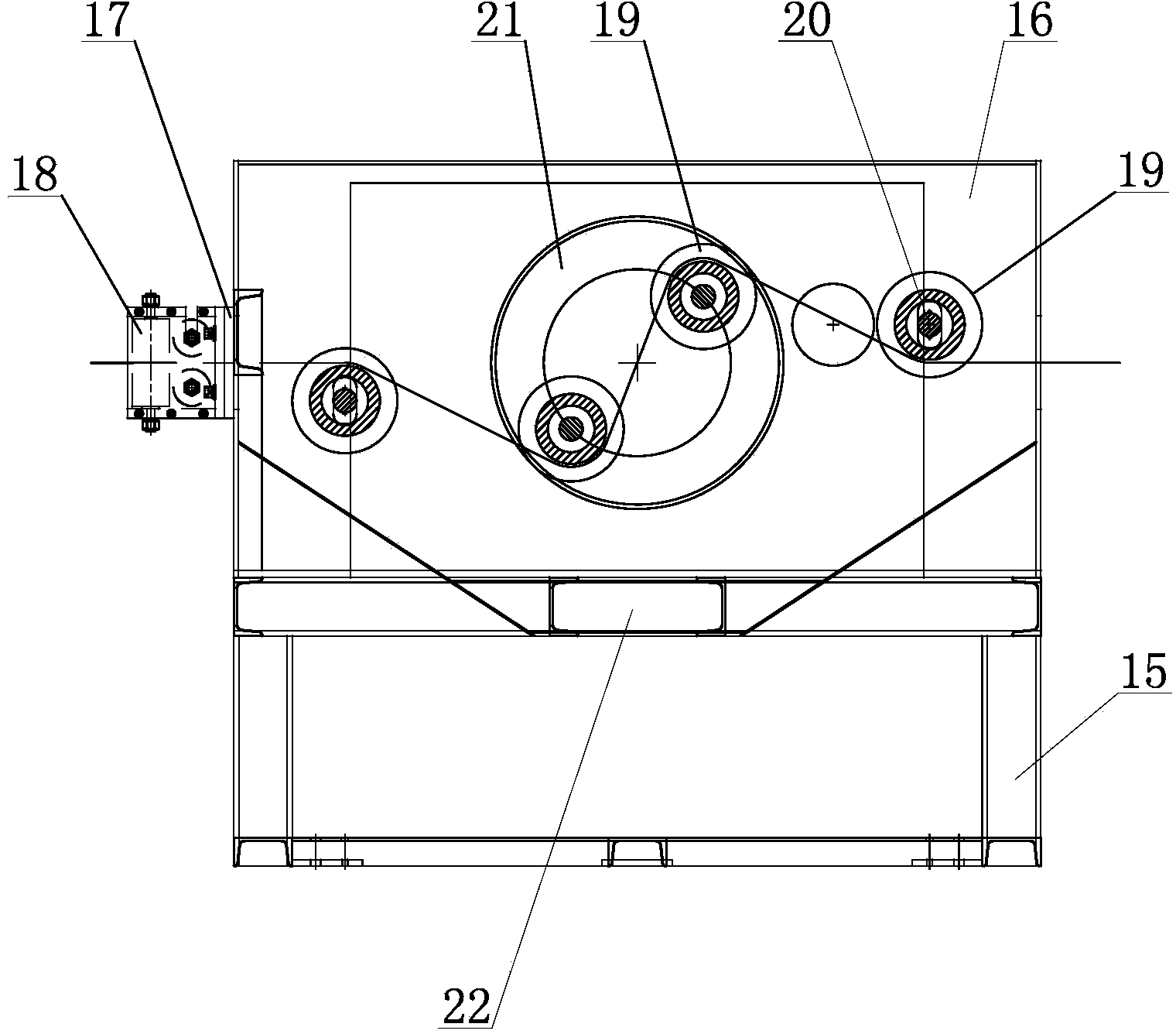

Leveling machine, black strip acid-free derusting device using the same and method thereof

InactiveCN1962105ARust removal achievedEliminate corrosionRoll mill control devicesWork treatment devicesEmulsionEngineering

The invention relates to a flattener, relative thermal rolling band steel non-acid scaling device and method, wherein said flattener comprises a roller cleaner (15) whose end contacts the lower roller and compression lower roller (14); the cleaner (15) can clean the ferric oxide in each rotation of roller, to improve work efficiency. And the scaling device comprises emulsion feeder (1), flattener (2), high-pressure water injector (3), iron brush (4), washing drier (5), and coiling machine (6). The invention can improve the service life and effect of iron brush. And the method comprises that adjusting the injected amount of emulsion to adjust the scaling quality and save cost.

Owner:武钢集团有限公司

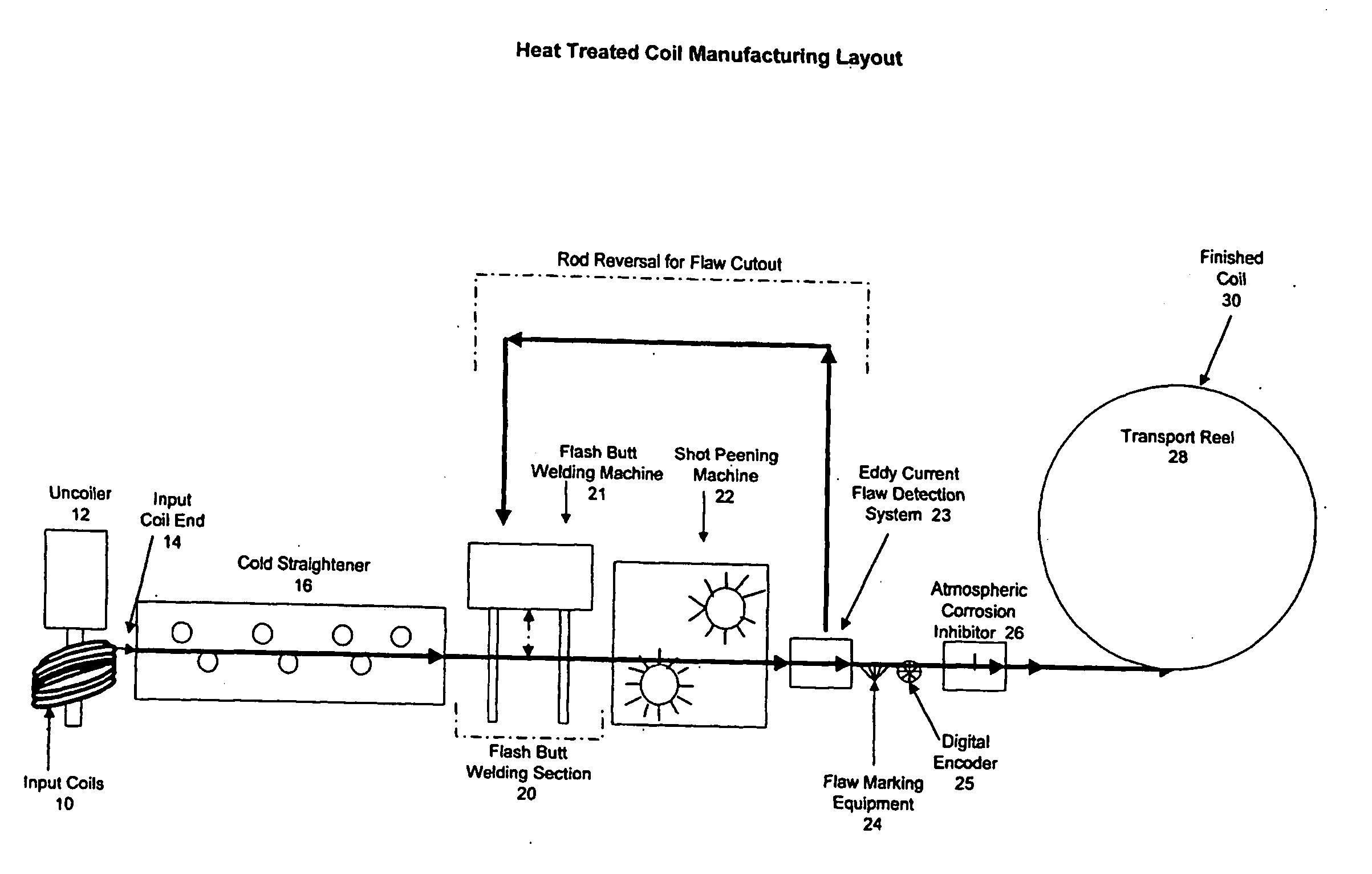

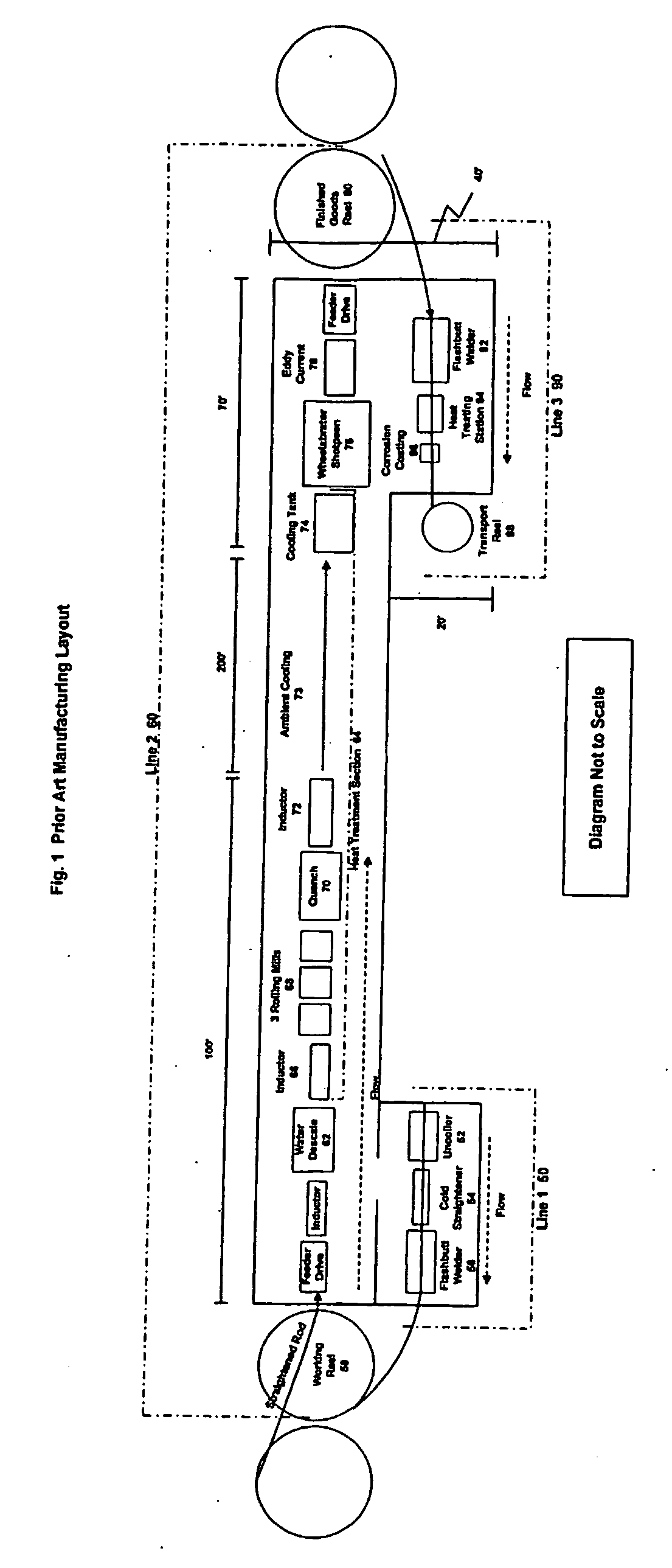

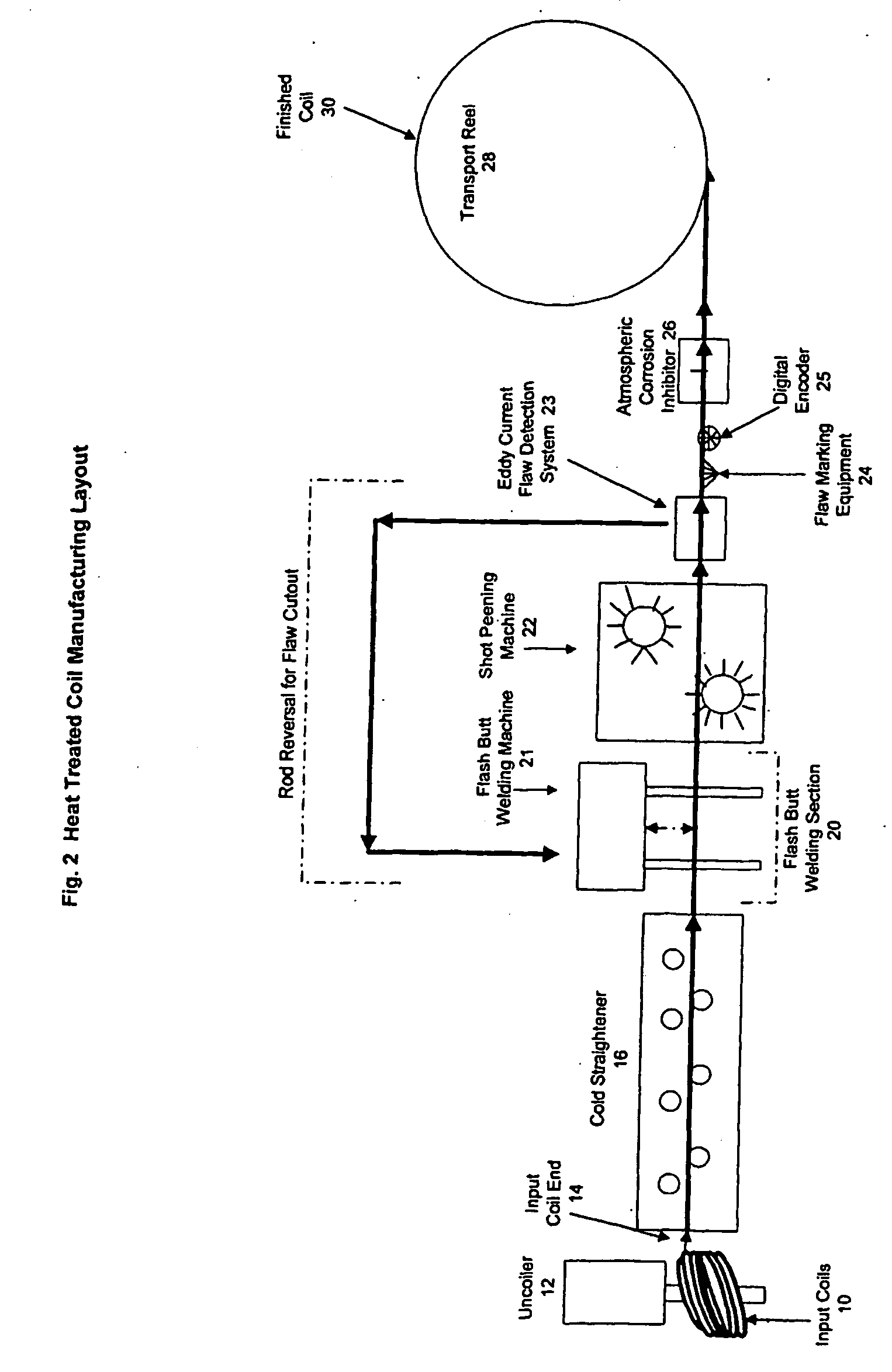

Method of manufacturing continuous sucker rod

InactiveUS20060150384A1Heavy equipmentReduce spacingDrilling rodsWelding/cutting auxillary devicesHardnessMaterials science

An improved process for making continuous sucker rod specifies uniform hardness along and among the input coils which reduces the number of steps required to manufacture the rod, thereby advantageously reducing capital and production costs.

Owner:WEATHERFORD CANADA PARTNERSHIP

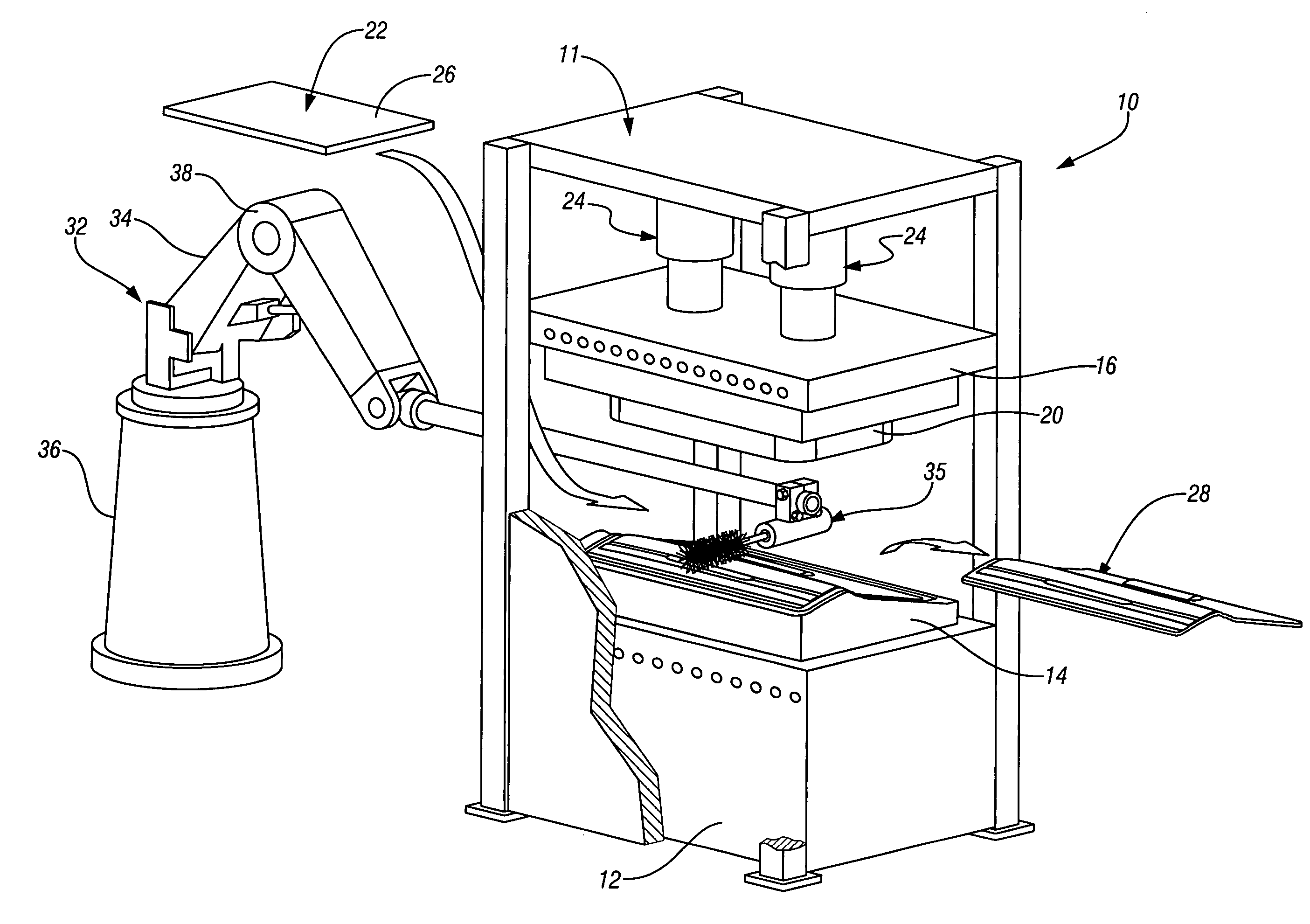

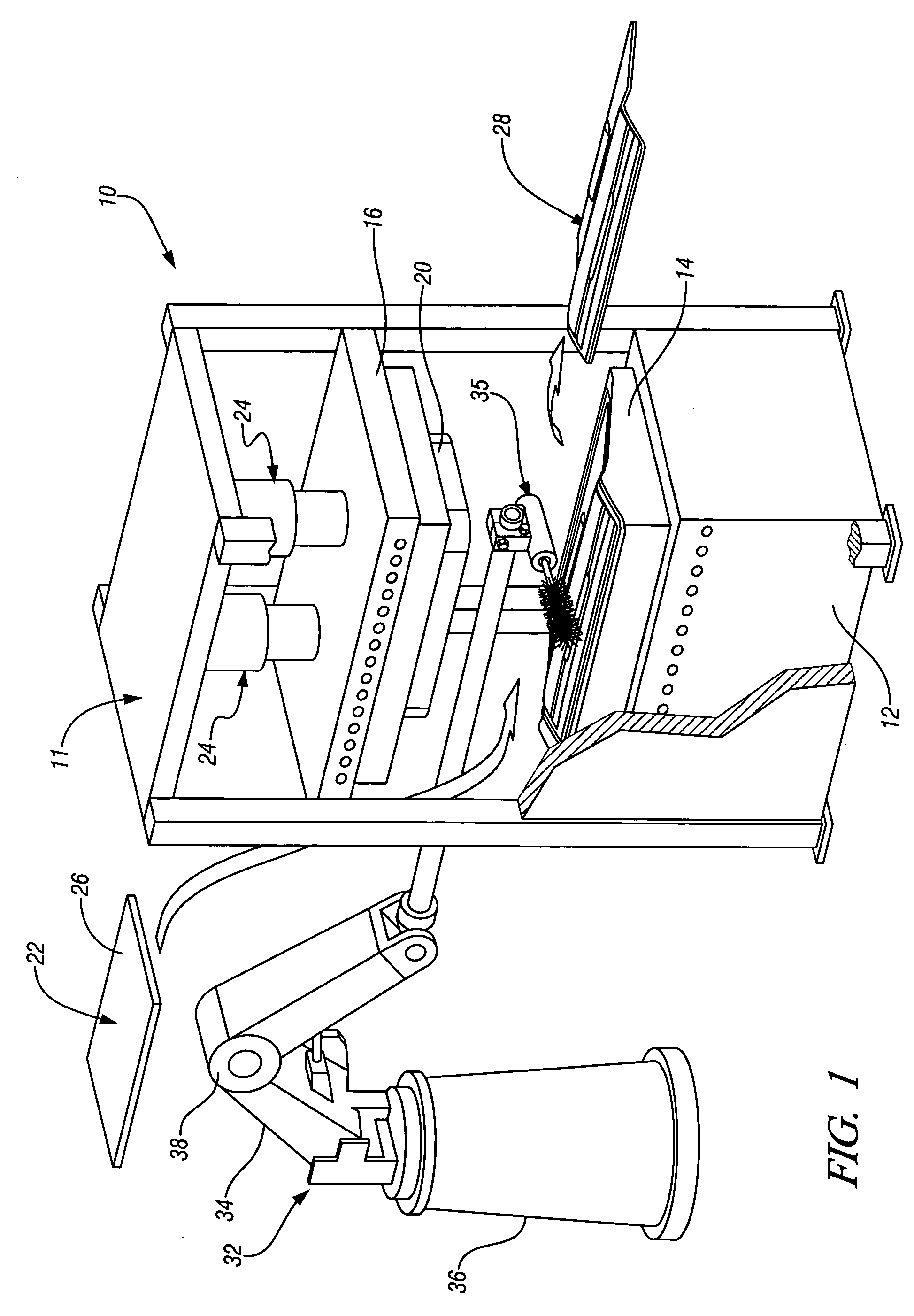

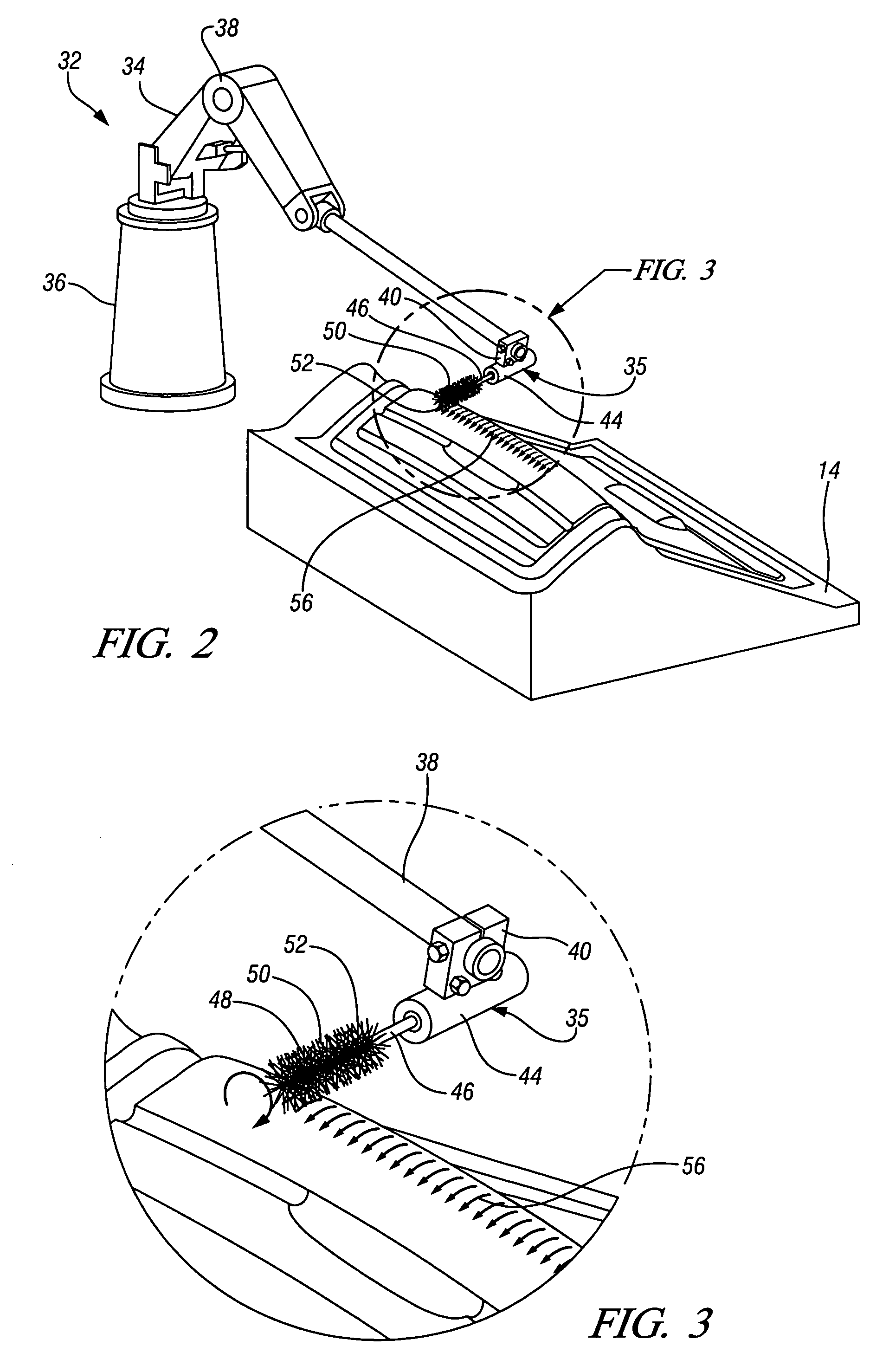

Hot die cleaning system for quick plastic forming cell

ActiveUS20060021408A1Minimize production downtimeMaximizing abilityWork treatment devicesCleaning using toolsBristleMetal forming

A cleaning apparatus for removing metallic buildup from forming surfaces of metal forming dies while the dies are in a press and operating at elevated temperatures. The cleaning apparatus includes a programmable positioner having a robotic arm with an end effector carrying a brush assembly. The brush assembly includes a rotary drive motor rotatably carrying a metallic wire brush. The brush has a plurality of radially extending plain carbon steel bristles having tips adapted for removing metallic buildup from the forming surfaces of dies. The positioner operates to move the rotatable wire brush in a predetermined path that engages the brush with the forming surfaces of the dies for sweeping and cleaning metallic buildup from the forming surfaces.

Owner:GM GLOBAL TECH OPERATIONS LLC

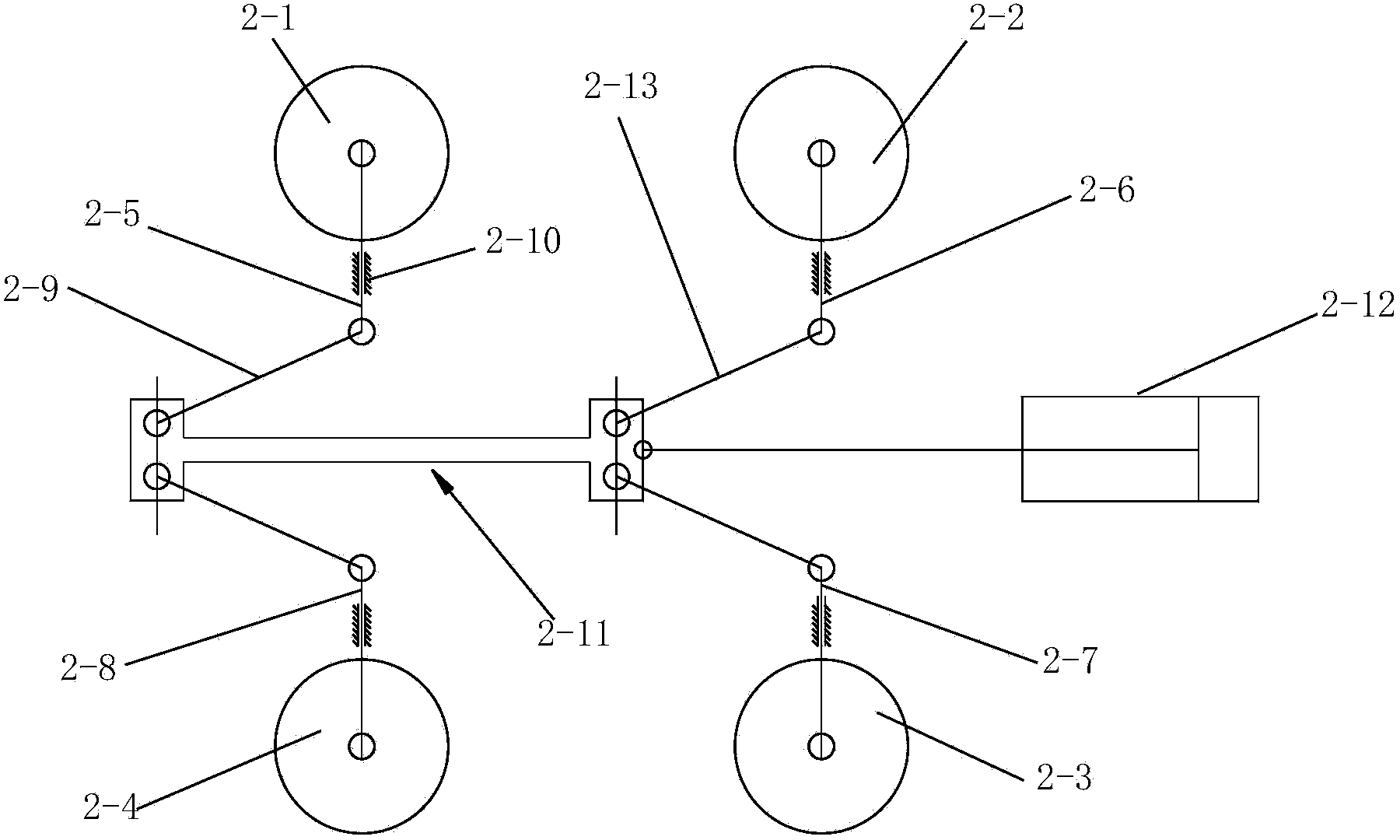

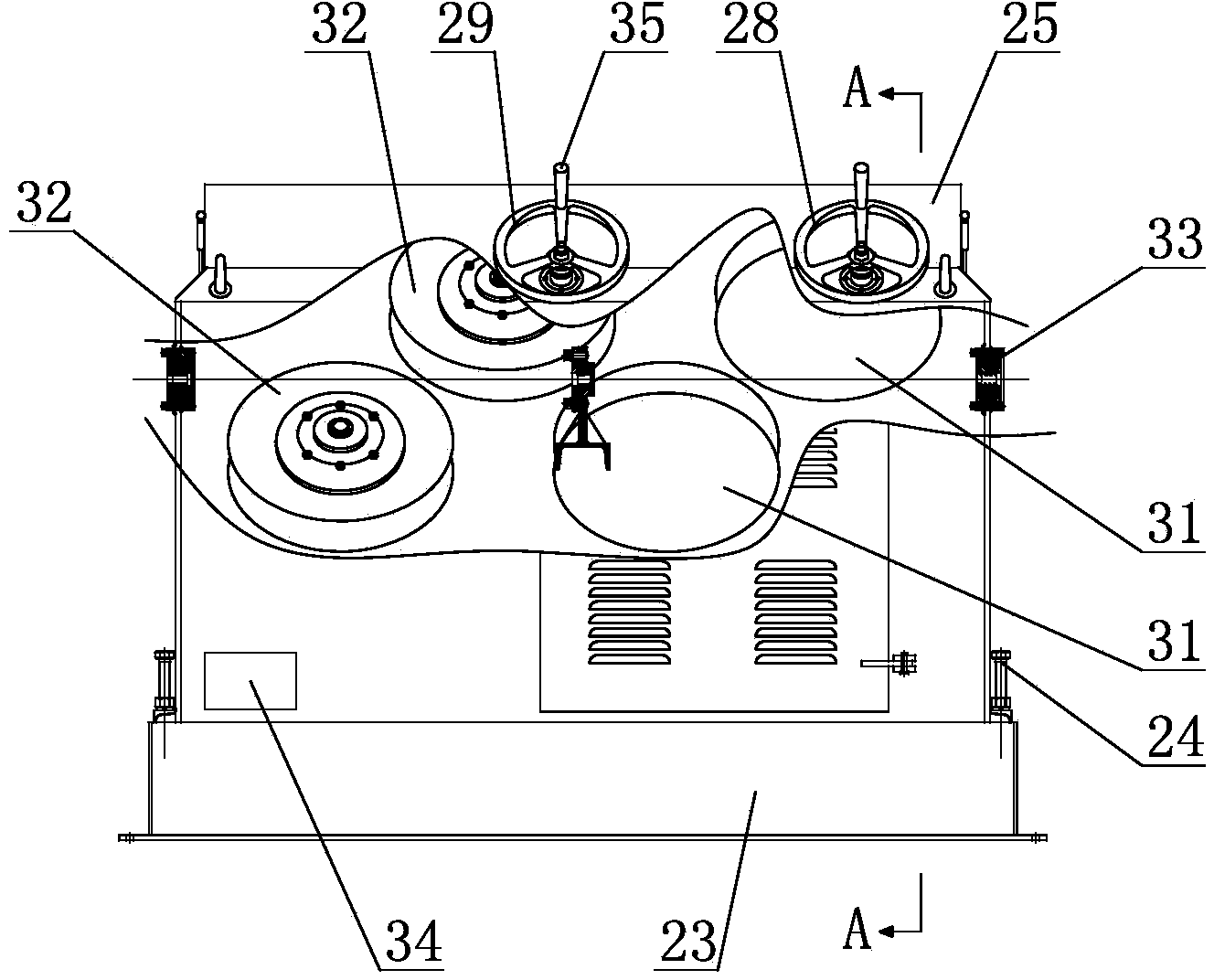

Prestressed steel strand pickling-free and phosphating-free drawing equipment and production process

ActiveCN104841706AGood effectReasonable structural designExtrusion cleaning devicesPre stressPre stressing

The invention belongs to the technical field of prestressed steel strand drawing and discloses pre-stressed steel strand pickling-free and phosphating-free drawing equipment and a production process. The equipment comprises a pay-off rack, a straightening traction device, a shelling device, a high-pressure washing device, a boronizing device, a drying device, a steel strand drawing device and a take-up rack which are sequentially arranged. The pre-stressed steel strand pickling-free and phosphating-free drawing equipment provided by the invention is reasonable in structural design, through the design of multiple shelling wheel sets, the drawing equipment can be matched with a pre-stressed steel strand for physical shelling, and then through the design of a rust removal casing and steel wire balls, rust attached to the pre-stressed steel strand after shelling can be further cleared, so that the overall effect of the pre-stressed steel strand after shelling is good, compared with a conventional acid method, the shelling efficiency is greatly improved, and the degree of automation is high. The adjustment of the corresponding shelling wheels can also be carried out for pre-stressed steel strands with different diameters and pre-stressed steel strands with different degrees of oxidation, so that the application range is wide.

Owner:河南恒星钢缆股份有限公司

Phi 0.03m special titanium filament processing process

InactiveCN101844158AImprove the lubrication effectImprove adhesionDrawing diesFurnace typesTitaniumFriction force

The invention discloses a 0.03m special titanium filament processing process, belonging to the field of metal fine machining. The processing process mainly comprises wire drawing, heat treatment and oxidizing scale treatment; a method for fixing a framework and two ends of a wiredrawing shaft is adopted in two times of wire drawing; by adopting a special lubricating agent, the friction force of the surface of a titanium wire and a calibrating strap part of a wiredrawing film can be reduced; different heat treatment temperatures or annealing points are adopted in two heat treatment processes and the uniform line velocity can be kept; the problems of low tensile strength and poor elongation percentage can be solved; and by adopting a single-line multi-head continuous cleaning method in the treatment process of oxidation scale, the resistance for the titanium wire to pass through a wire release rack, a rinsing tank and leaching pond and to be subjected to drying, taking up and other links can be reduced. The invention has the advantages of simple process and high processing efficiency; the processed titanium wire has high tensile strength and favorable elongation percentage; and the processing of a 0.03mm titanium wire can be realized.

Owner:SHANGHAI GIORAY METAL MATERIAL

Method of manufacturing metal product having nano-crystallized surface layer

A method of production of a metallic product with a nanocrystallized surface layer comprising subjecting a surface layer of a metallic product to ultrasonic impact treatment by one or more ultrasonic indenters vibrating in a plurality of directions, then subjecting the surface layer subjected to the ultrasonic impact treatment to heat treatment at a low temperature to cause precipitation of nanocrystals.

Owner:NIPPON STEEL CORP

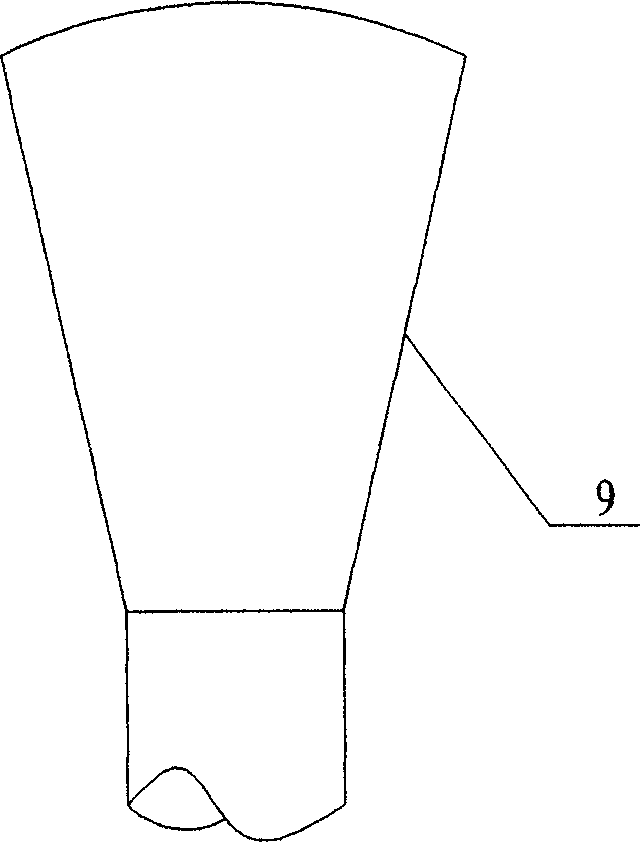

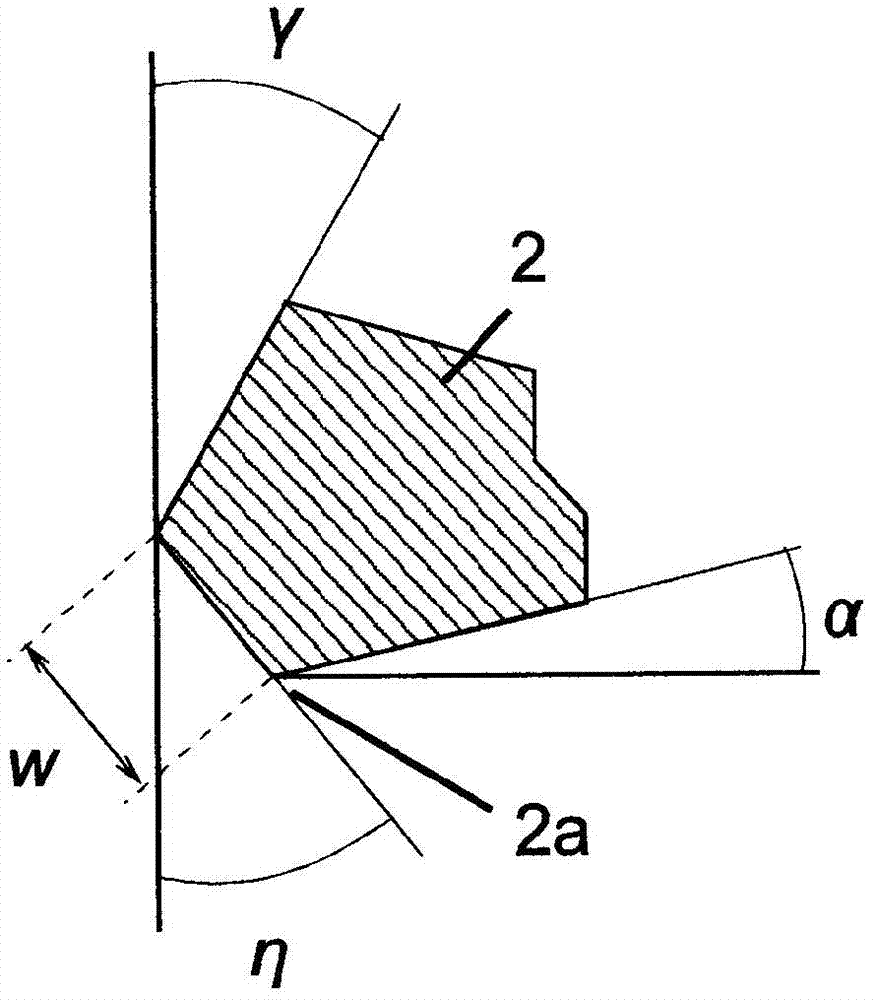

A method of manufacturing a stainless steel product

InactiveCN102781614AReduce the amount of surface defectsLess quantityExtrusion cleaning devicesWire rodMetallurgy

The present invention relates to a method of manufacturing a duplex stainless steel wire product starting from wire rod, the method comprising the following steps: roughening the wire rod surface; applying a carrier coating on the wire rod surface; peeling the wire rod using a shaving die comprising cemented carbide; roughening the wire rod surface; applying a carrier coating on the wire rod surface; and drawing to final wire dimension. In the peeling step, the shaving die used has a rake face land angle eta which is 10-30 DEG , a rake angle gamma which is 10-25 DEG , a clearance angle alpha which is 3-10 DEG , a rake face land width w which is 0.1-0.5 mm, and an edge radius which is 0.02-0.08 mm. The duplex stainless steel wire product manufactured according to the method exhibits excellent fatigue resistance.

Owner:SANDVIK INTPROP AB

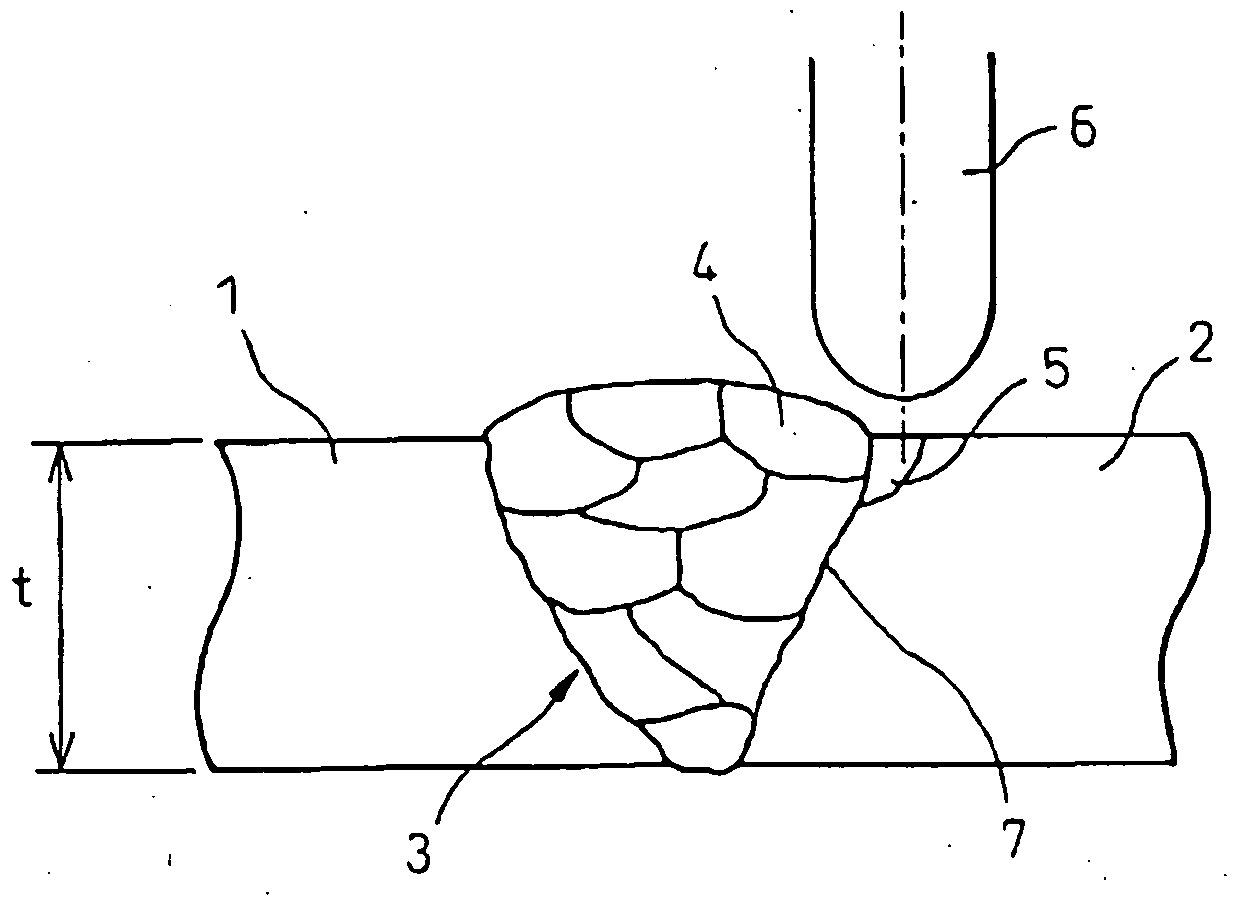

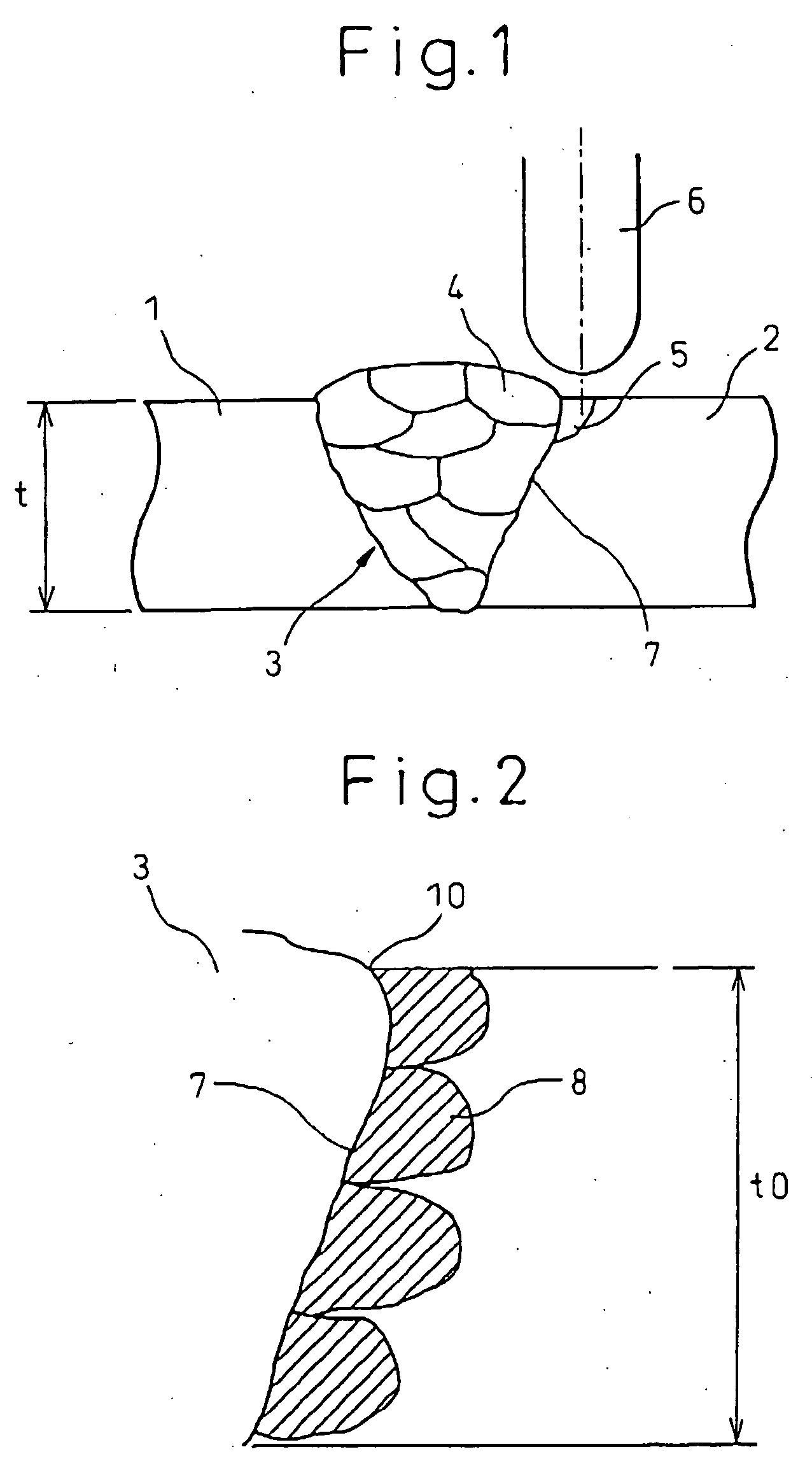

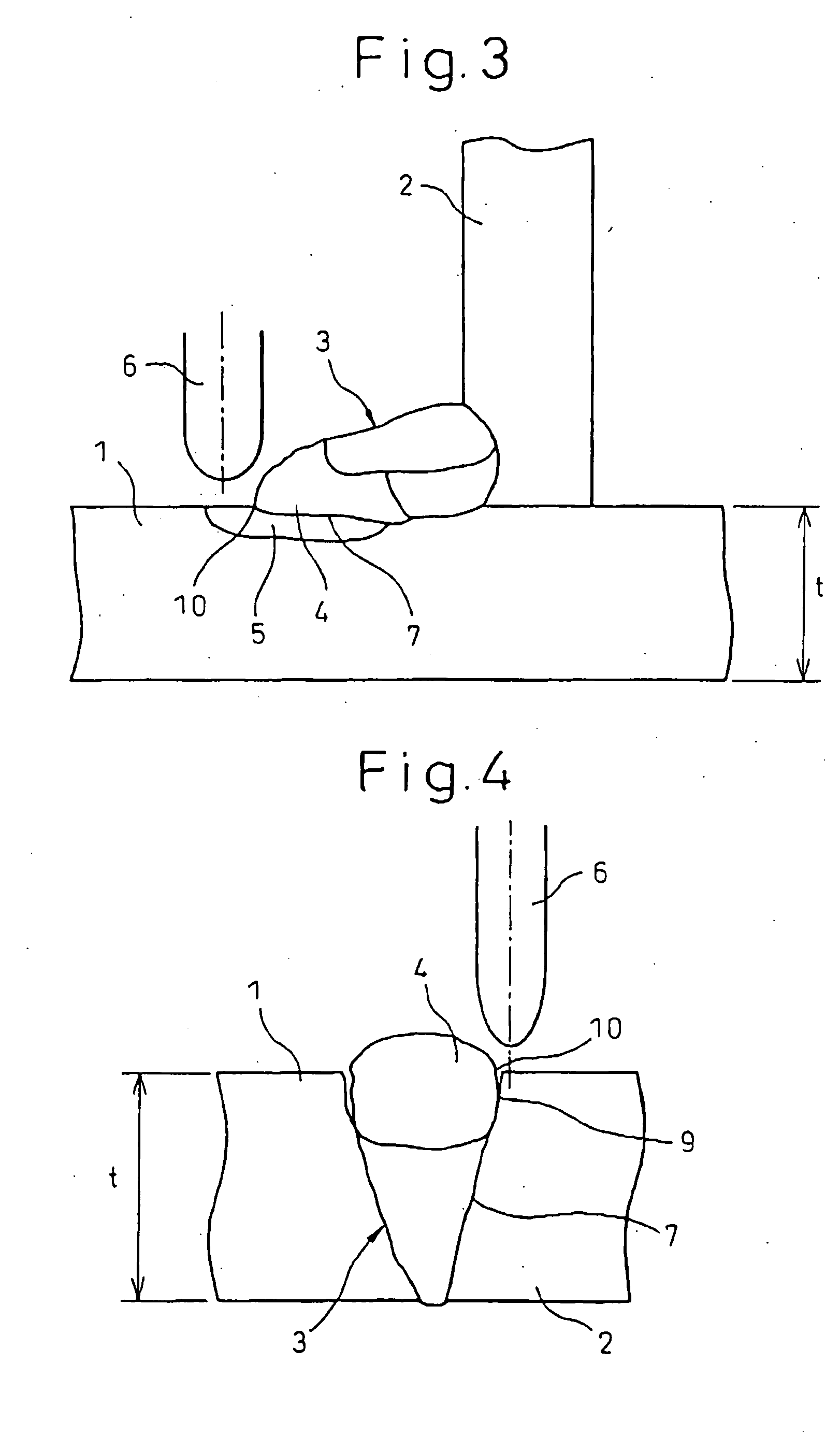

Method of increasing toughness of heat-affected part of steel product welded joint

A method of improvement of toughness of a heat affected zone in a multi-layer welded joint, a fillet welded joint, and a one-pass or several-pass large heat input welded joint of a steel plate is provided, that is, a method of improvement of toughness of a heat affected zone in a welded joint of a steel plate characterized subjecting a surface of a heat affected zone formed by a last pass of a multi-layer welded joint of a steel plate to impacts by an ultrasonic vibration tool or shot peening by ultrasonic vibration steel balls to thereby make an average of longitudinal axis of crystal grains up to a depth of 2 mm or more from the surface of the steel plate in the microstructure adjacent to a fusion line (FL) of a weld metal and a steel plate matrix in said heat affected zone formed by the last pass the equivalent of the crystal grain size of the steel plate matrix before the welding at a depth of ¼ of a thickness t from the surface of the steel plate.

Owner:NIPPON STEEL CORP

Steel strand production device and electrolysis phosphating technology

ActiveCN103769432ANot brittleGuaranteed to peel completelyPhosphatisationDrying gas arrangementsElectrolysisMetallurgy

The invention provides a steel strand production device and an electrolysis phosphating technology. The steel strand production device and the electrolysis phosphating technology are used for solving the technical problems of complicated maintenance, low production efficiency and relatively high cost in a conventional steel strand production technology and poor phosphating effect, low efficiency and high cost in a phosphating process in a production technology. The steel strand production device is provided with a steel bar straightening press, a peeling machine, a dust removal machine, an online phosphating saponification device, a wiredrawing device and a wire take-up device, wherein the online phosphating saponification device is provided with an electrolysis phosphating tank. The steel strand production device is also provided with a heating device, a surface conditioning device, a drying device and a wiredrawing protective device. The electrolysis phosphating technology provided by the invention can be widely applied to production of steel strands.

Owner:威海银兴预应力线材有限公司

Impact Rapping Device

ActiveUS20100108340A1Prevent movementSimple structureReciprocating drilling machinesConstructionsPhysicsRapping

An impact rapping device includes a stationary anvil integrated with a surface to be rapped, the anvil having a hammering axis perpendicular to the surface to rapped, a hammer arranged to move coaxially with the hammering axis, to hit an impact surface of the anvil, and a device for moving the hammer. The anvil and the hammer form a compact unit, which can be assembled in any position. The hammer is supported to lean on the anvil in such a way that the position of the hammer automatically follows changes of place or position of the anvil, and so that the hammer can move only parallel to the hammering axis.

Owner:FOSTER WHEELER ENERGIA OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com