A method of manufacturing a stainless steel product

A technology of duplex stainless steel and products, applied in manufacturing tools, cleaning equipment for metal extrusion, metal extrusion, etc., can solve problems such as high tooling, fracture, wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

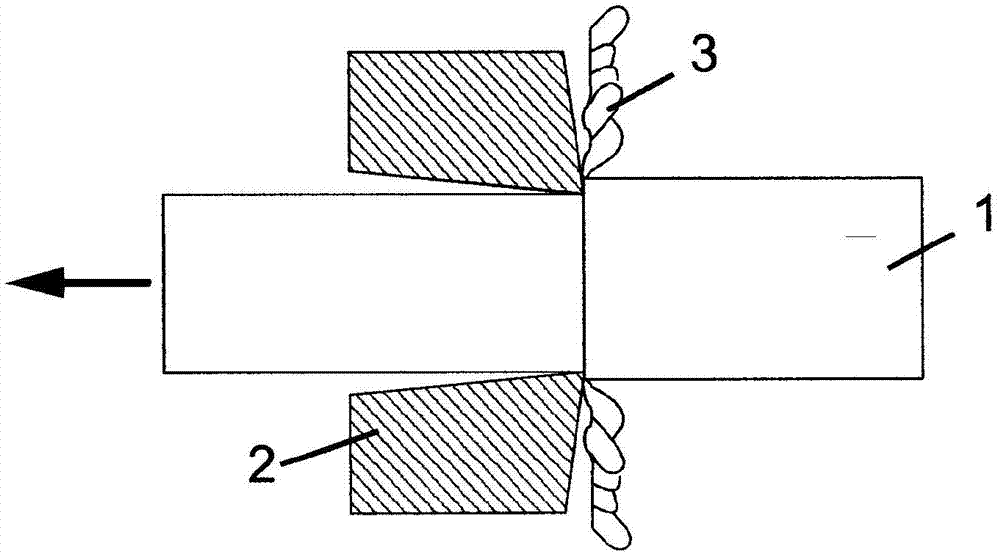

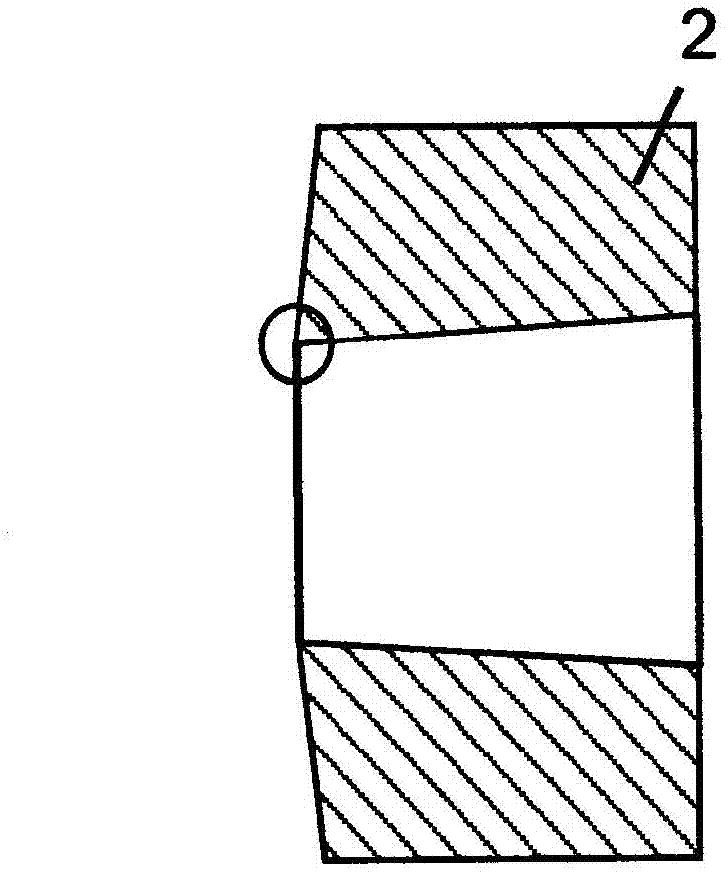

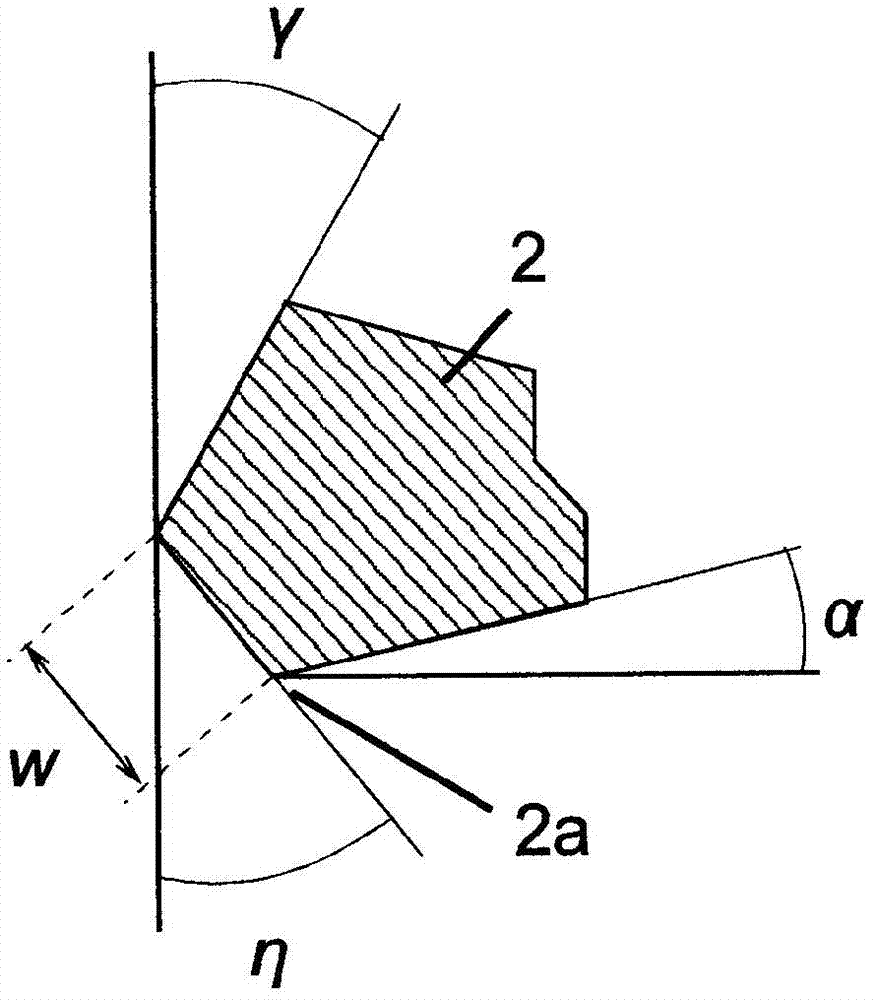

[0010] The raw material for the process of making the inventive peeled duplex stainless steel wire product, hereinafter also referred to as peeled duplex stainless steel wire product, is duplex stainless steel wire with a diameter of 5.5-12 mm, which may be annealed or not. Annealing generally produces larger grain sizes and softer materials. However, the effect is negligible for duplex stainless steel wire and therefore both materials can be used.

[0011] Manufacturing method of the present invention comprises the following steps:

[0012] • The wire surface is preferably roughened by pickling in hydrochloric acid, especially if there is scale on the wire surface resulting from annealing. This can be combined with a stronger pickling using a salt bath furnace and a secondary pickling. However, as an alternative to pickling, mechanical roughening is also possible.

[0013] • Apply a washcoat, preferably sodium borate hydrate, on the wire surface.

[0014] ●Peel off the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com