Patents

Literature

2159 results about "Stainless steel wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

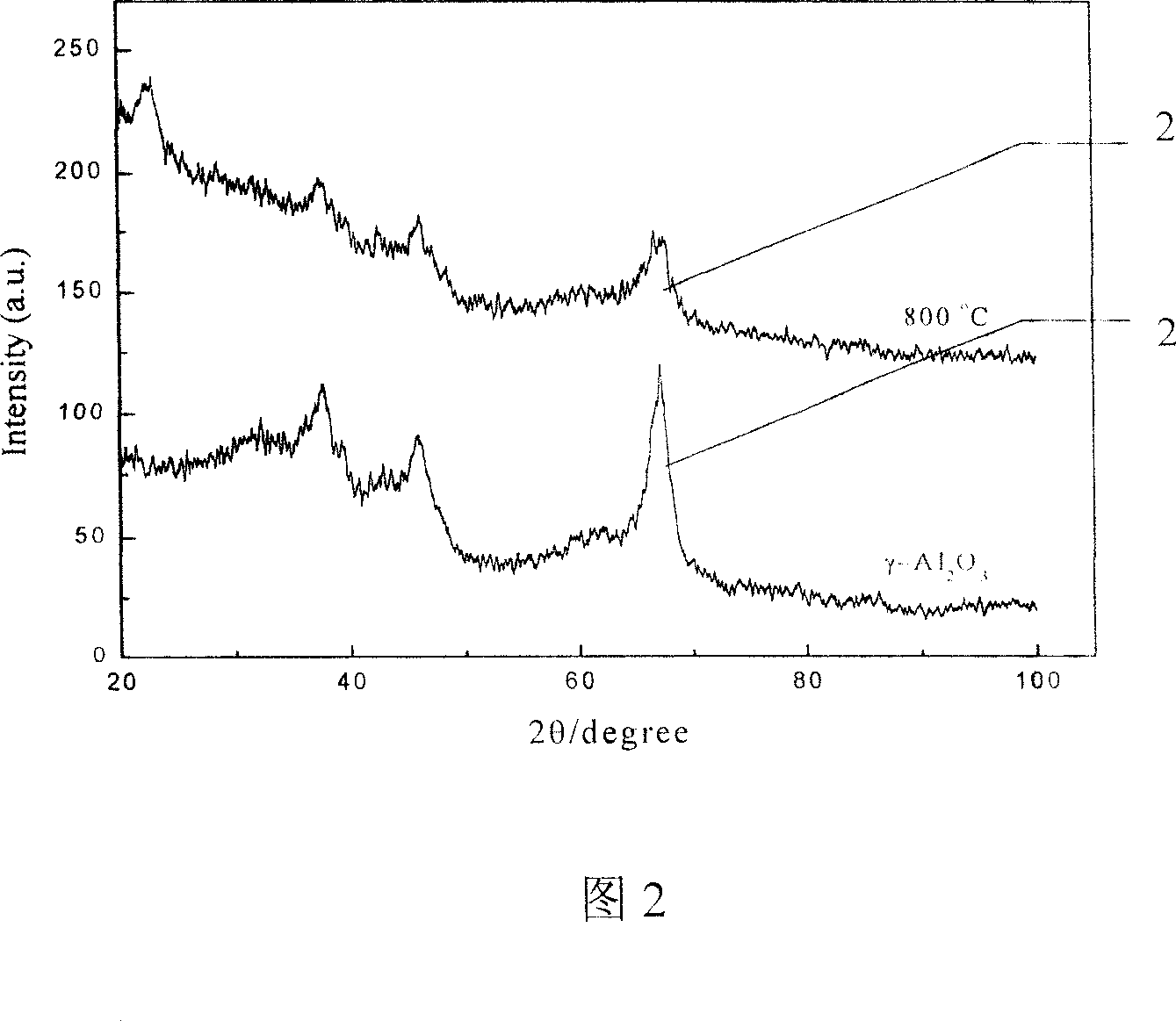

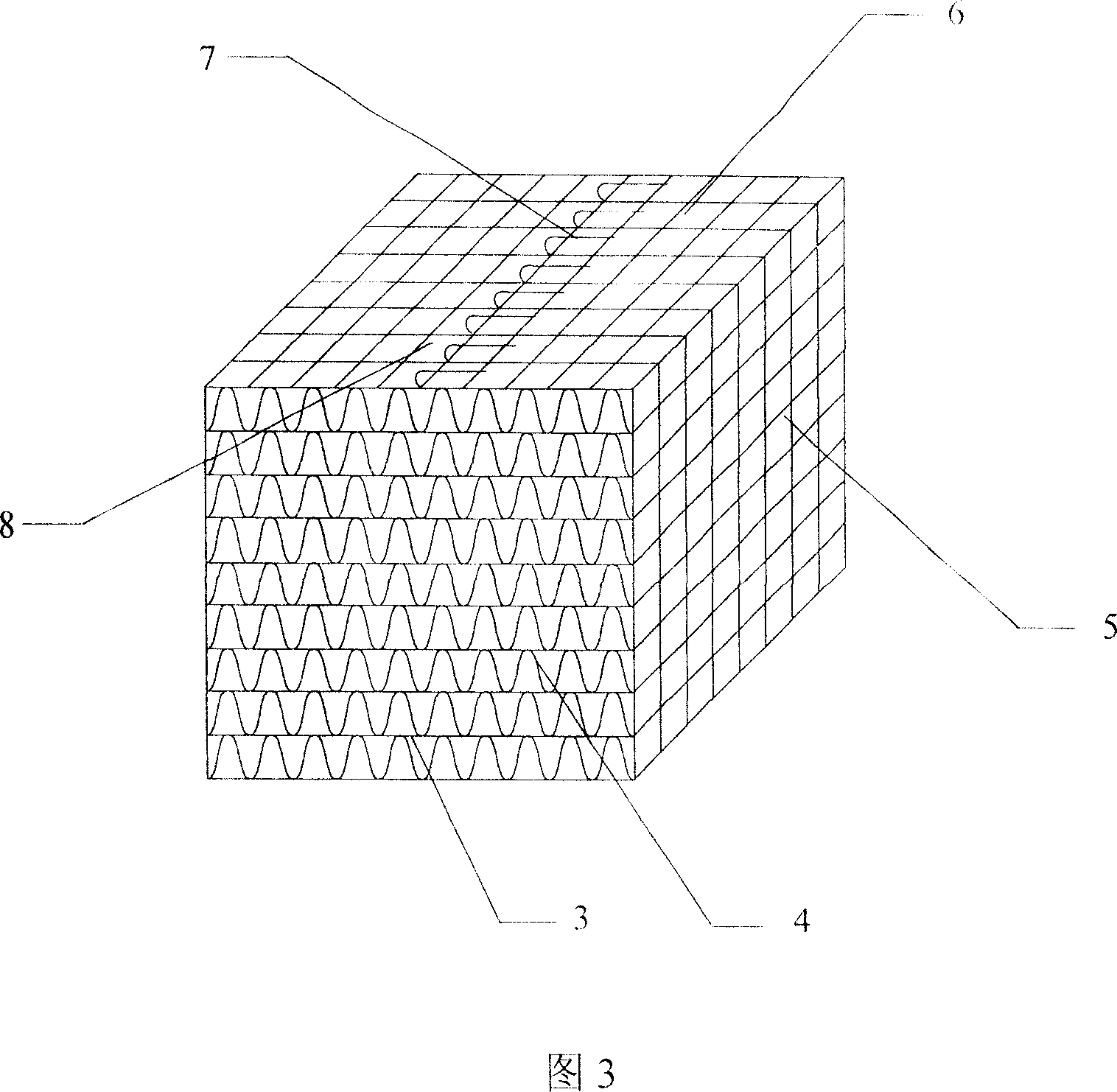

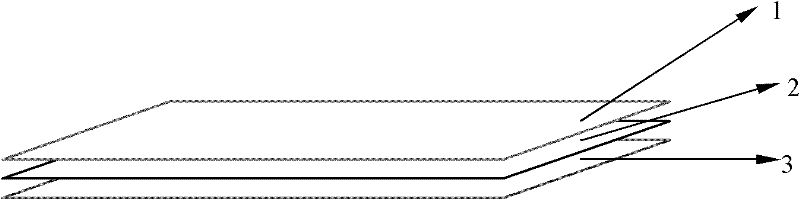

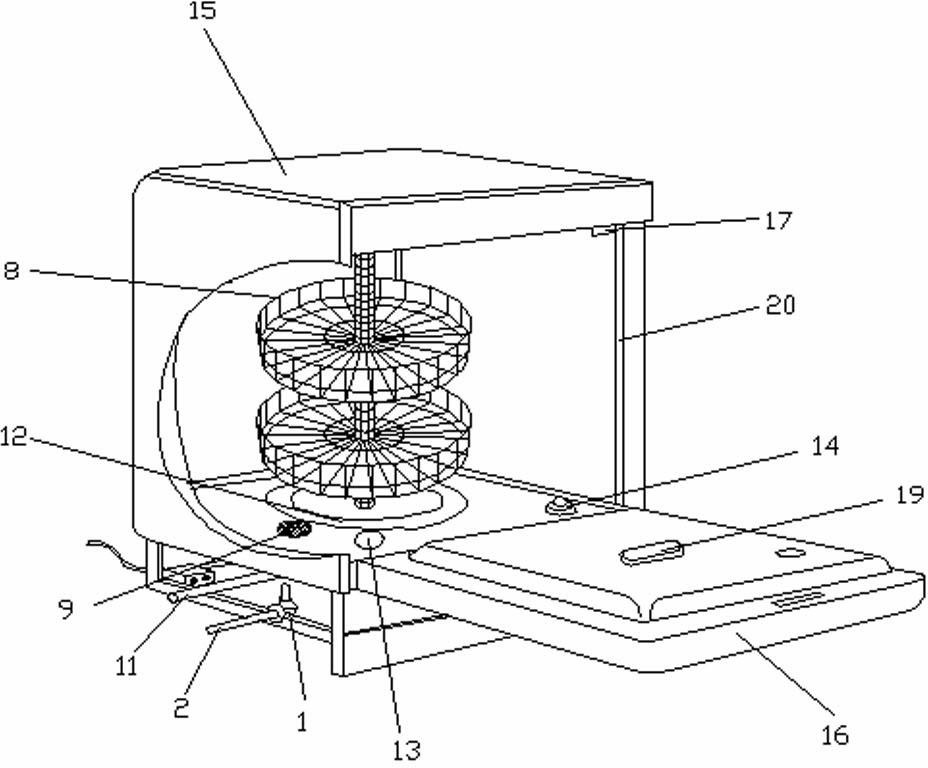

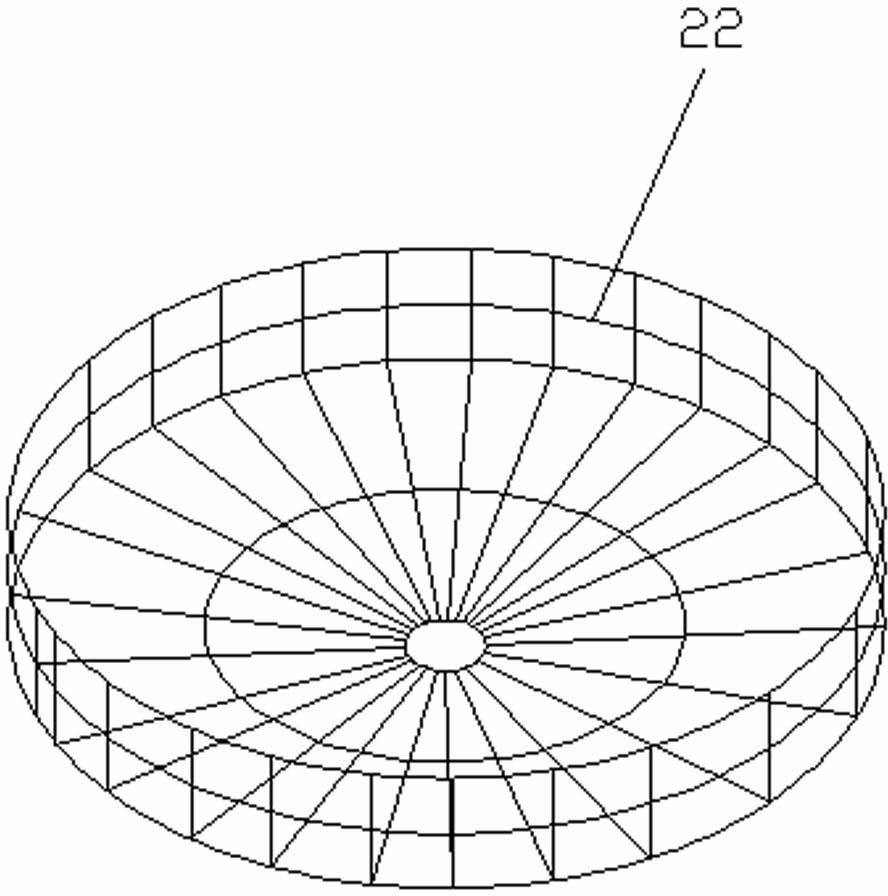

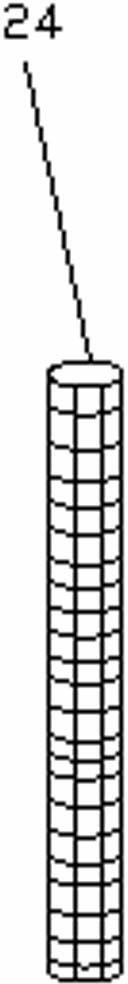

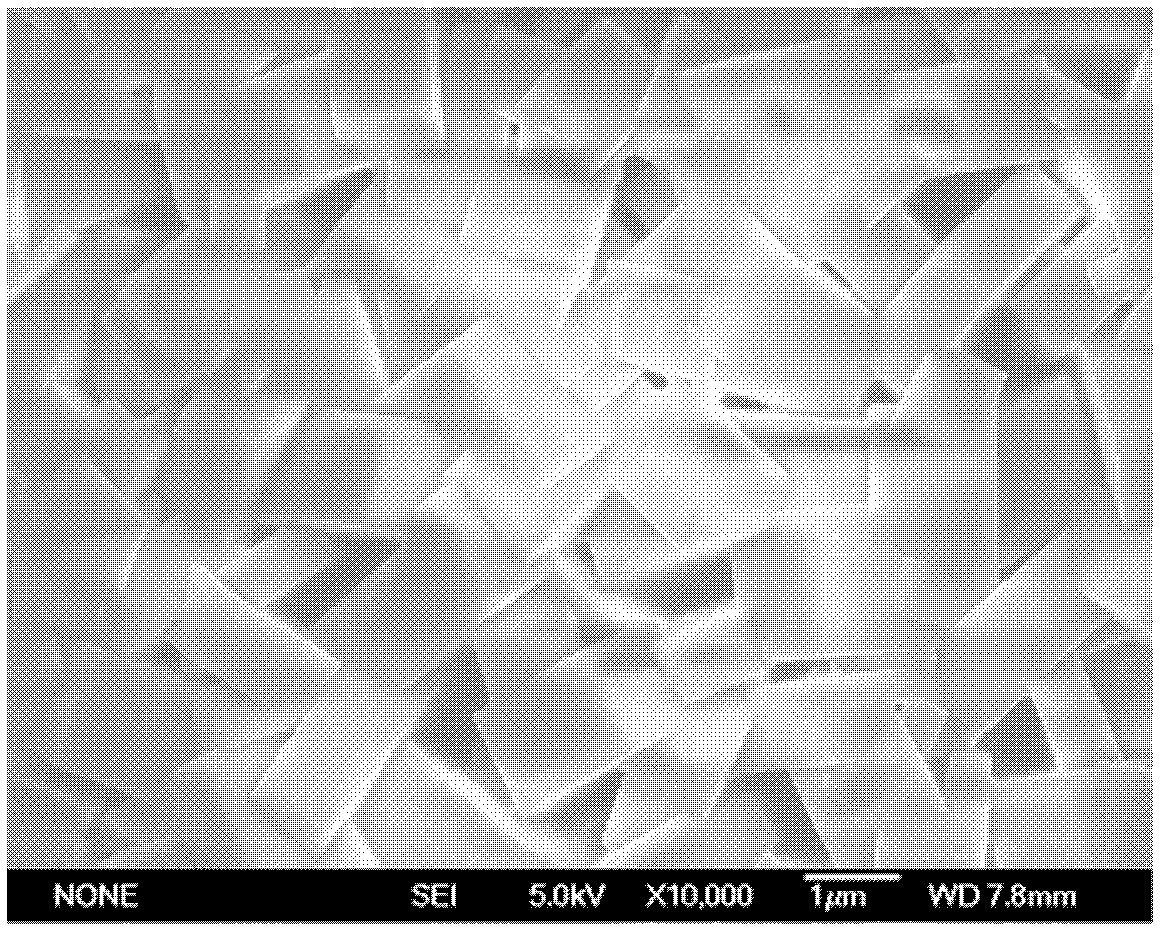

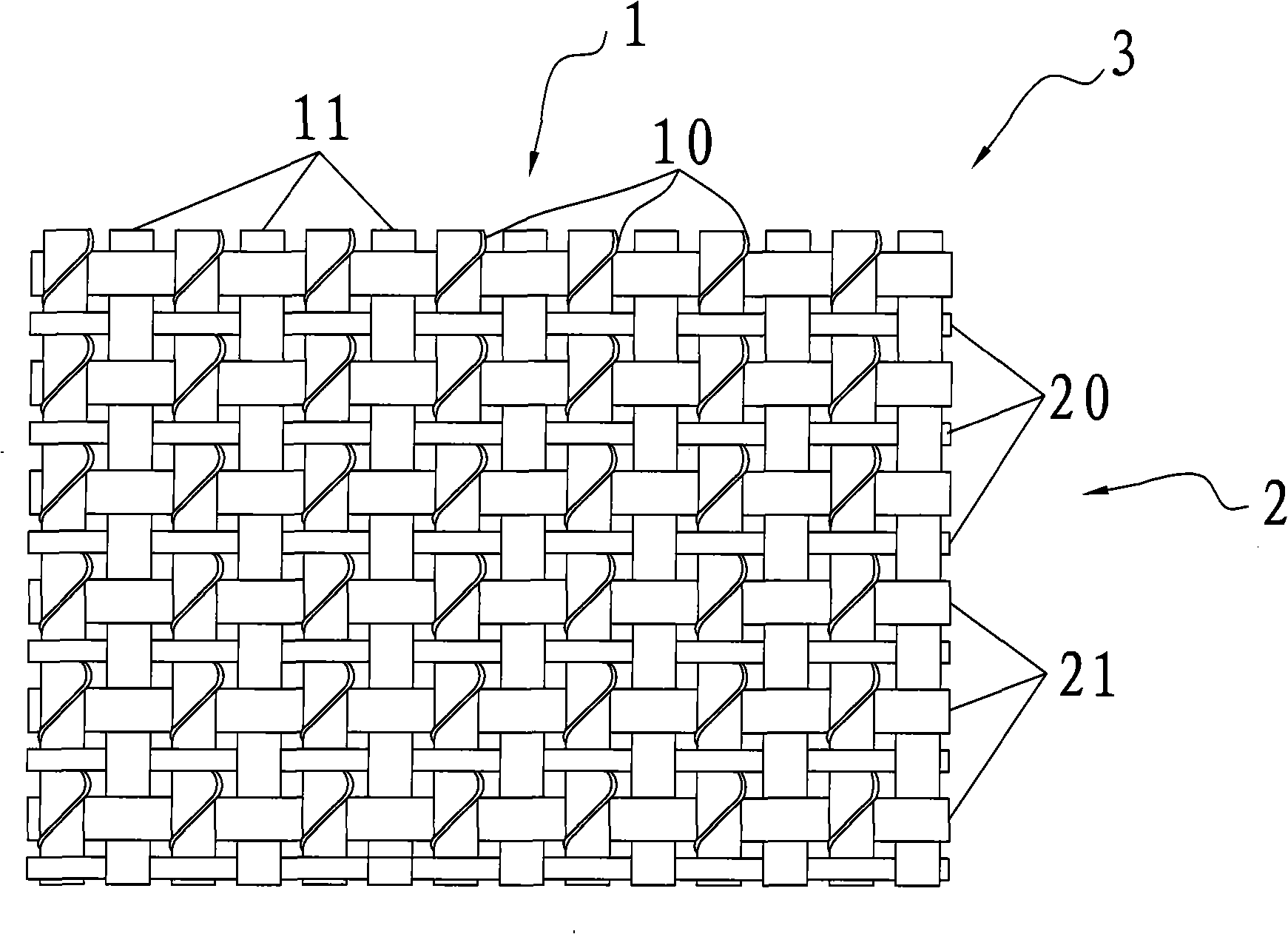

Cellulated wiremesh carrier with alumina coat, and preparation method

InactiveCN101049577AImprove thermal shock resistanceImprove mechanical propertiesCatalyst carriersHoneycomb likeStainless steel wire

A cellular metallic wire net carrier with coated aluminum oxide layer is composed of a metallic carrier and a coated layer and has an internal 3D through structure. Its preparing process includes such steps as preparing the planar metallic wire nets and corrugated metallic wire nets from stainless steel wire, pre-treating, preparing electric depositing liquid from gamma-Al2O3 powder, electric depositing to form a coated aluminum oxide layer on said metallic wire nets, stacking them in stagger mode, and binding them together by the strips of metallic wire net.

Owner:DALIAN UNIV OF TECH

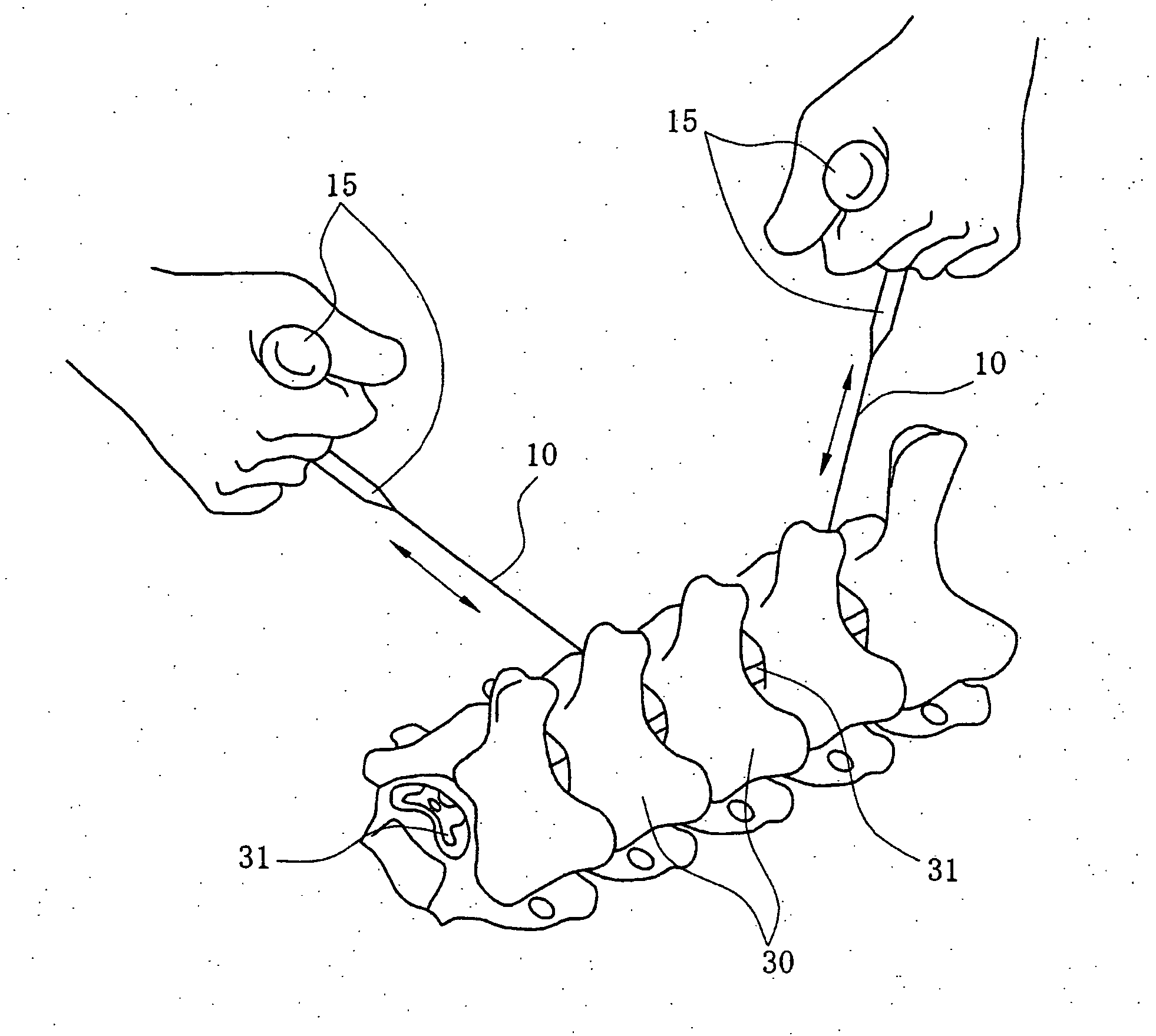

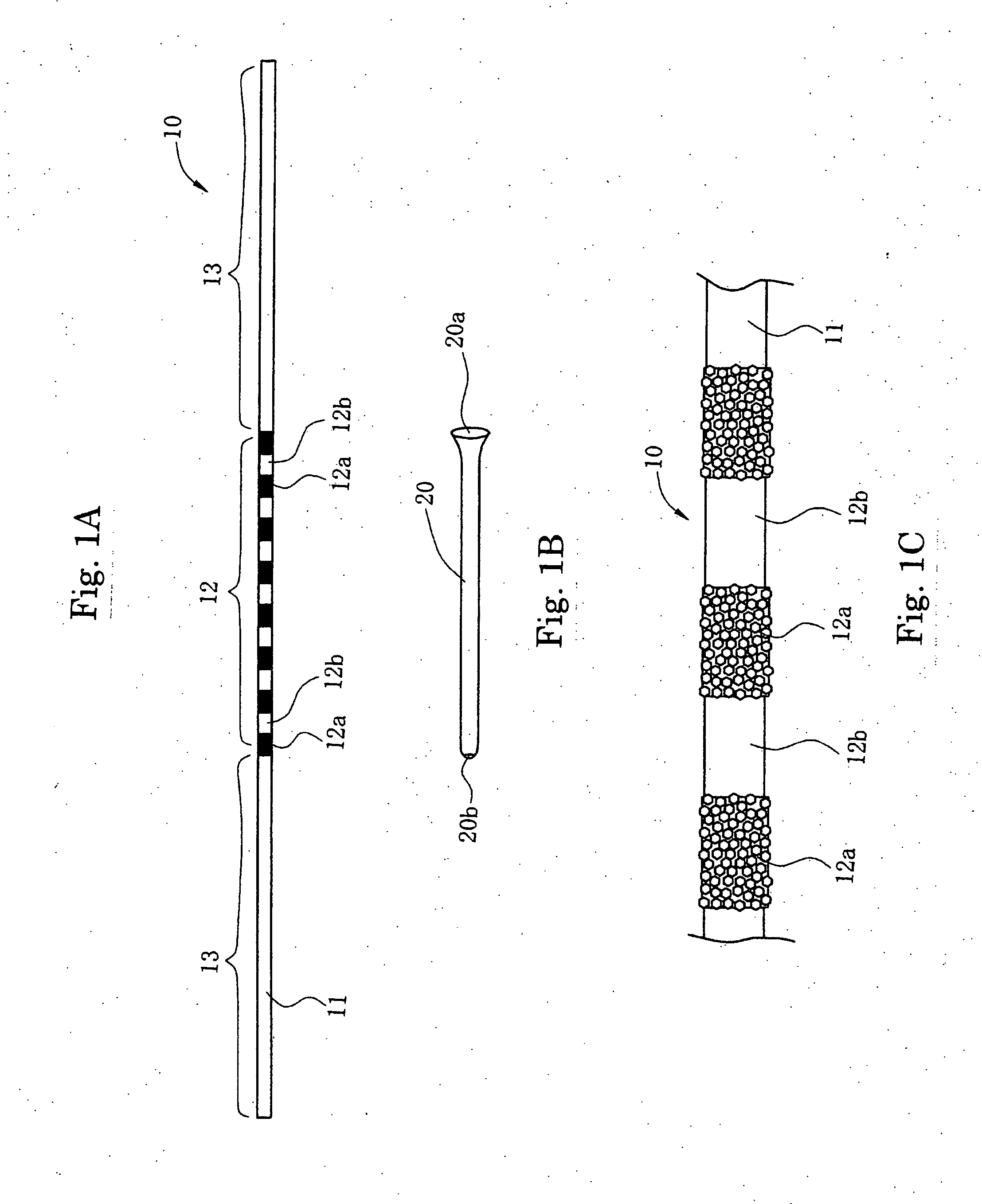

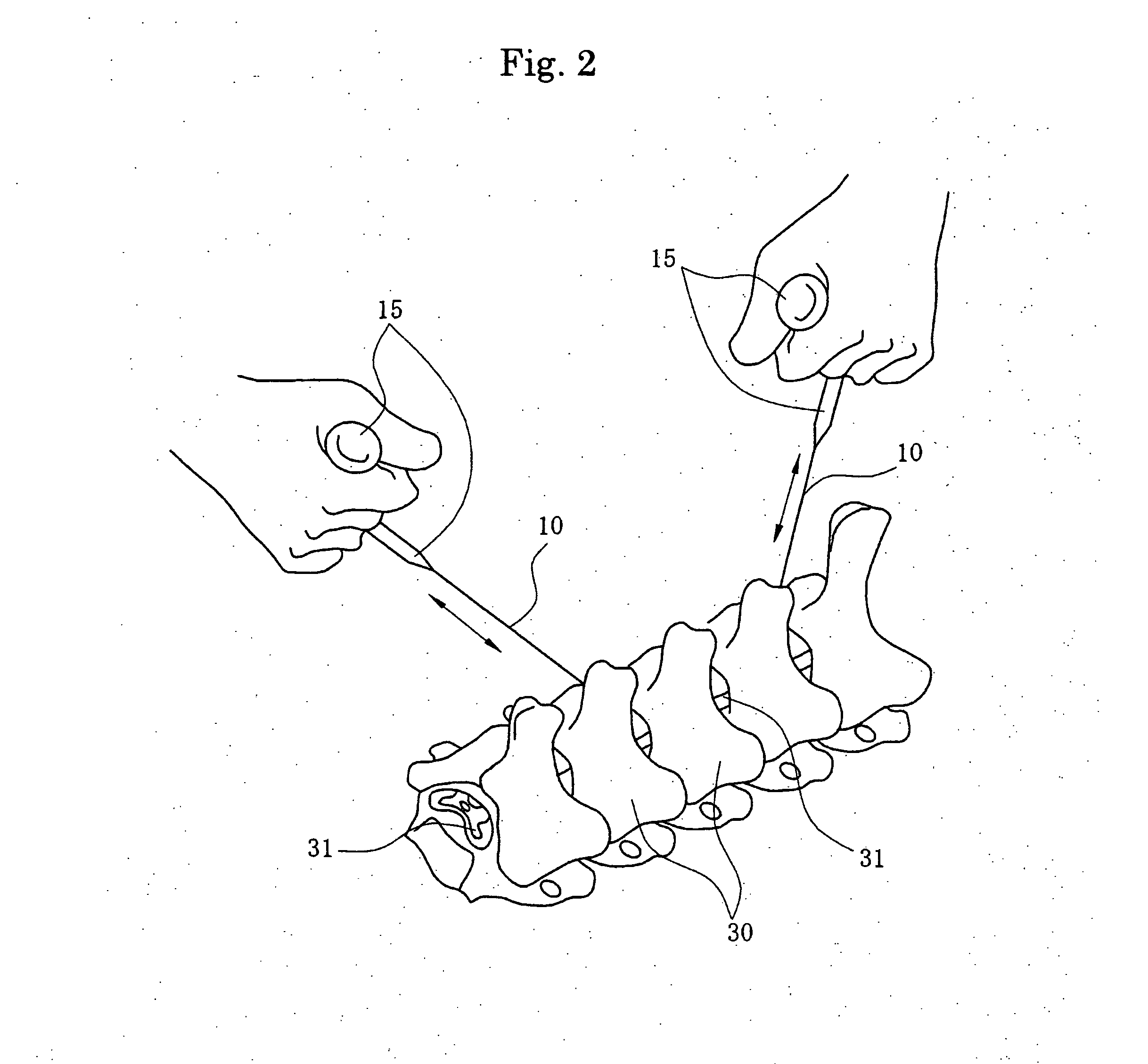

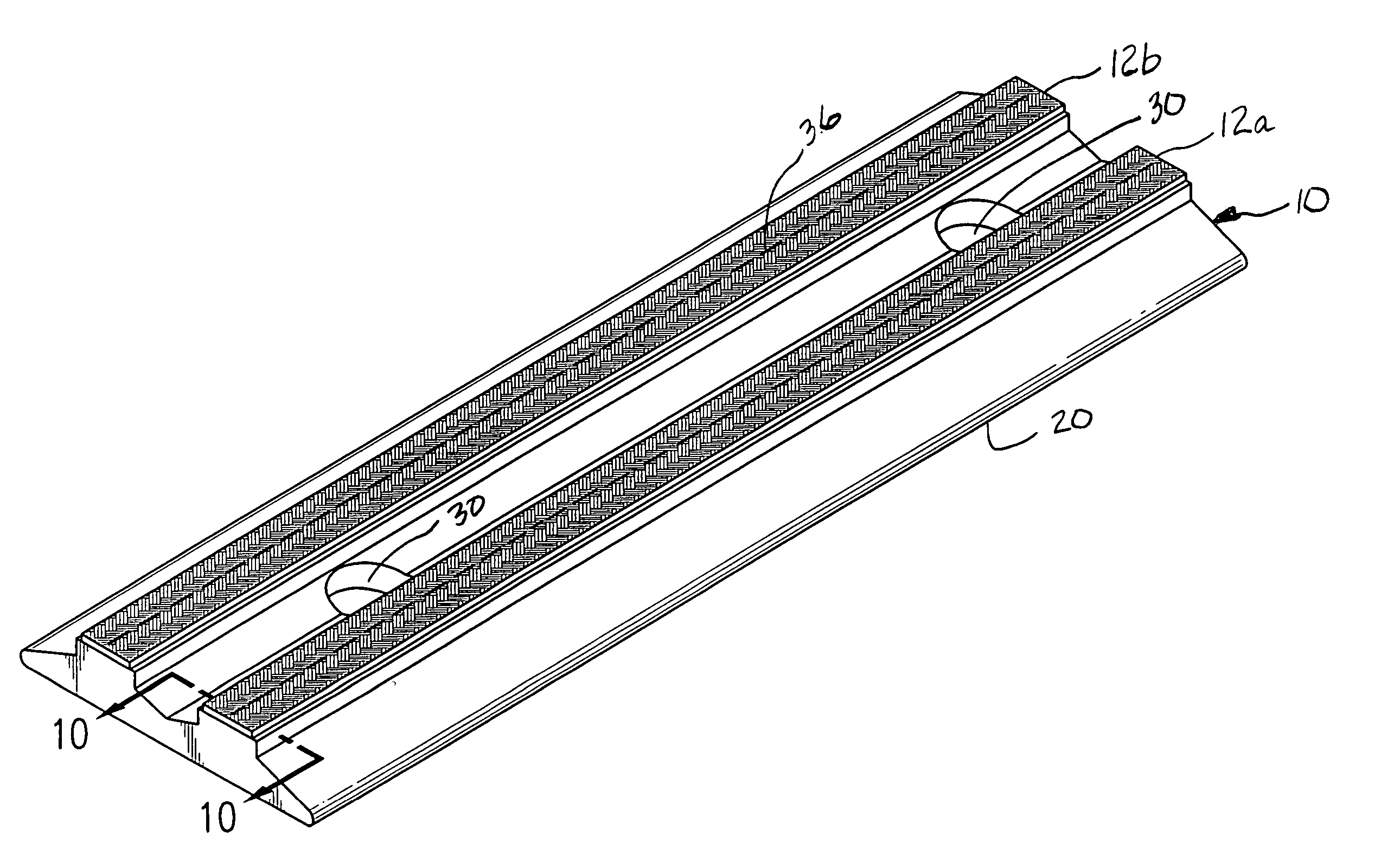

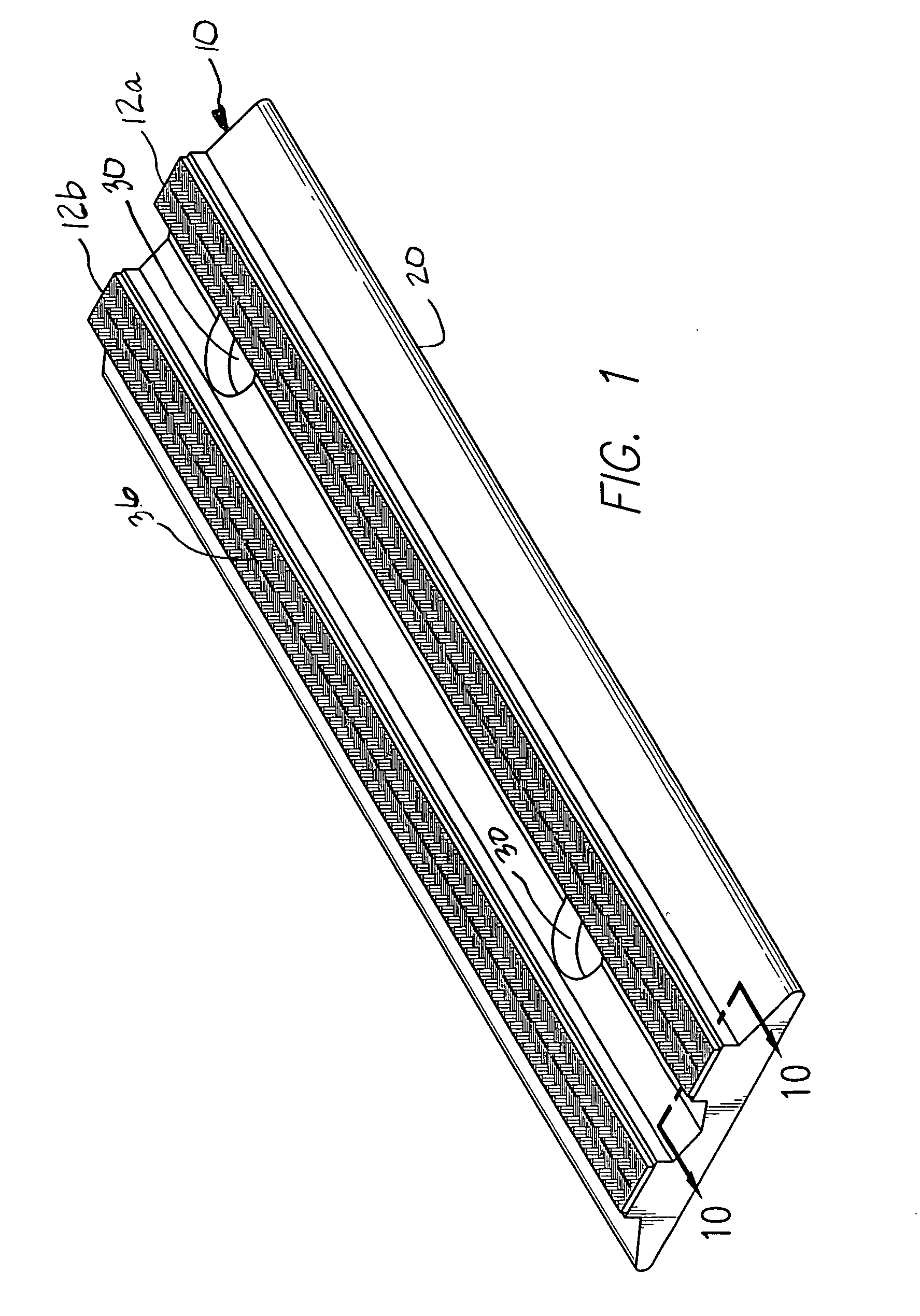

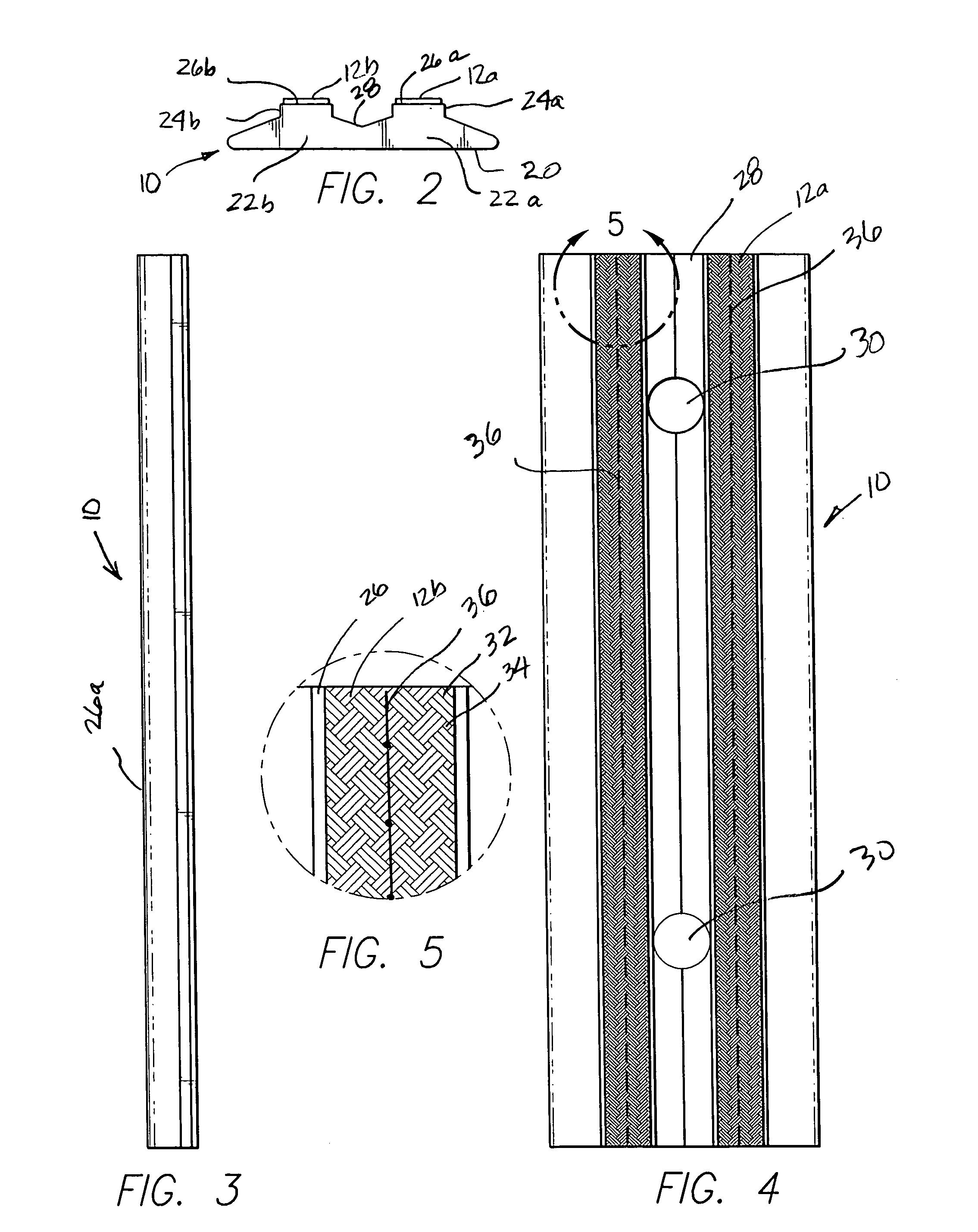

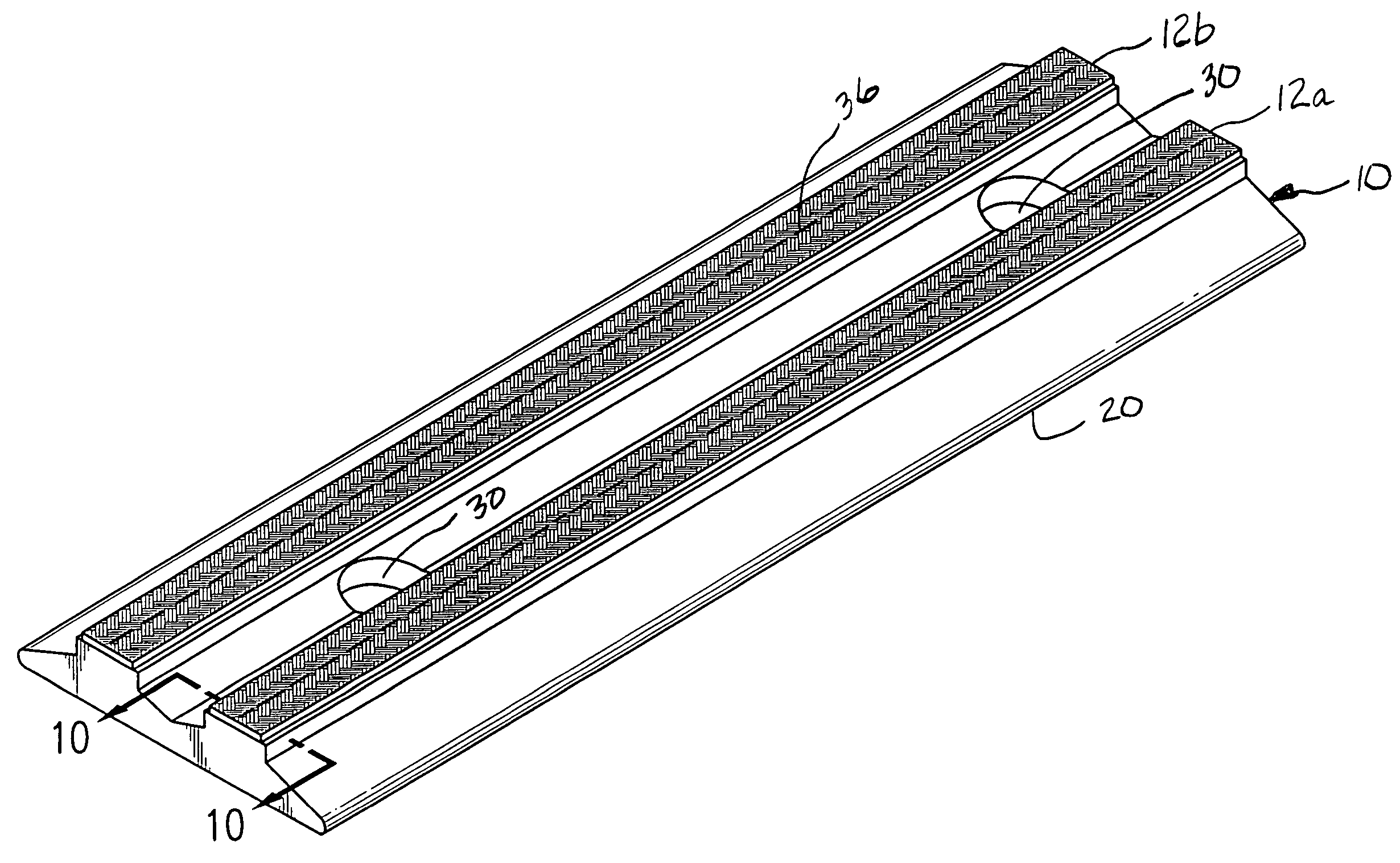

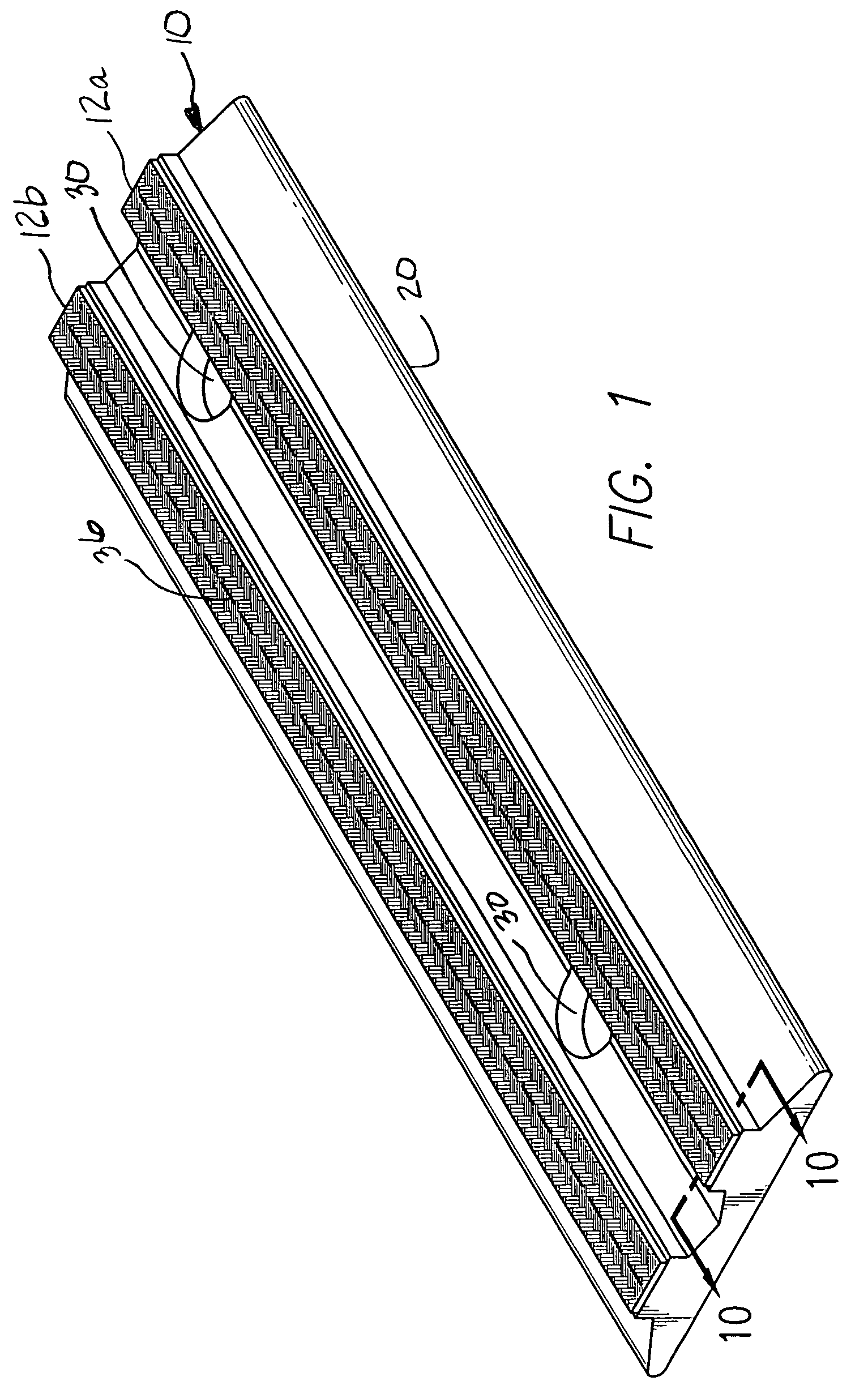

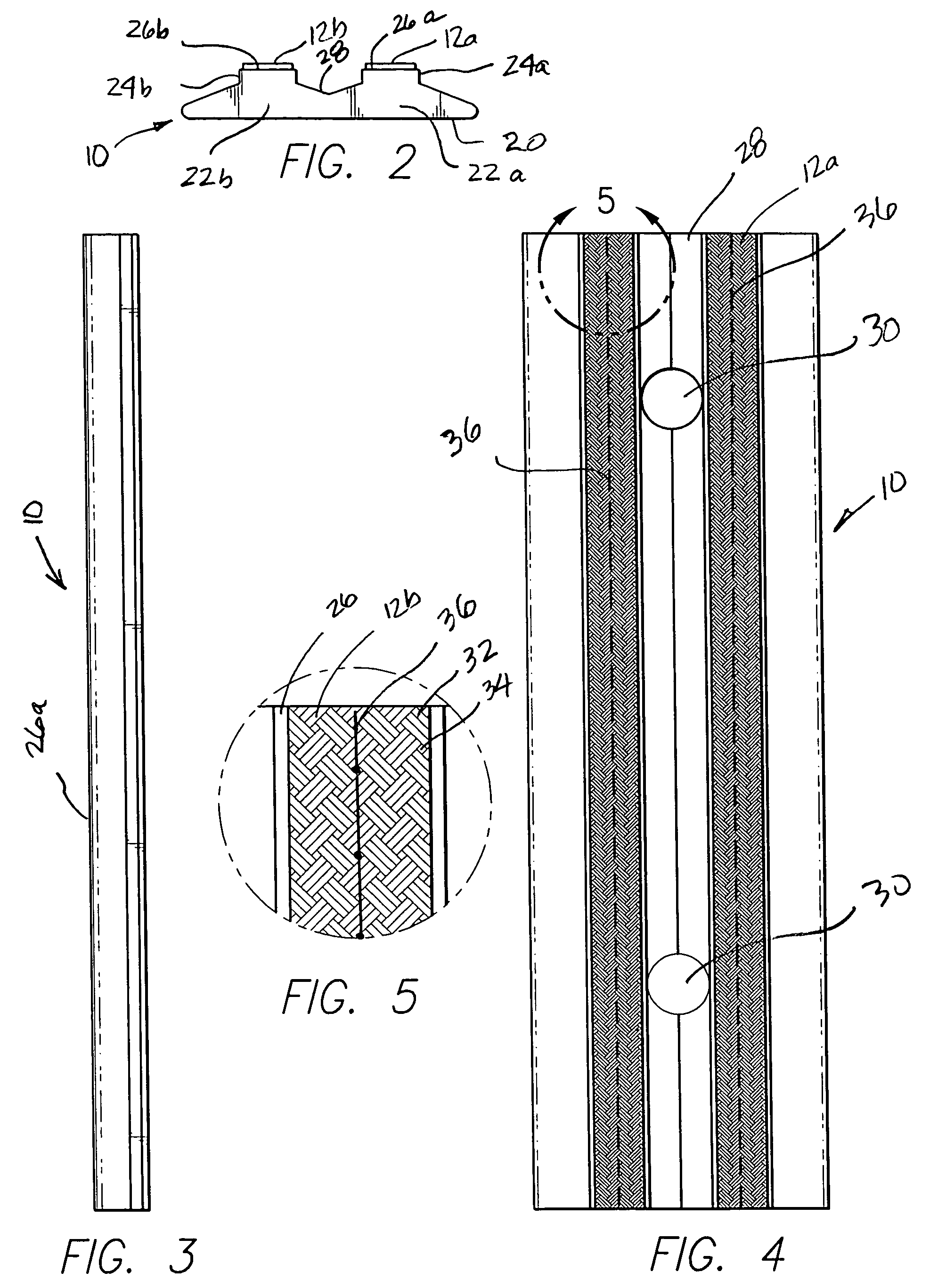

Surgical saw

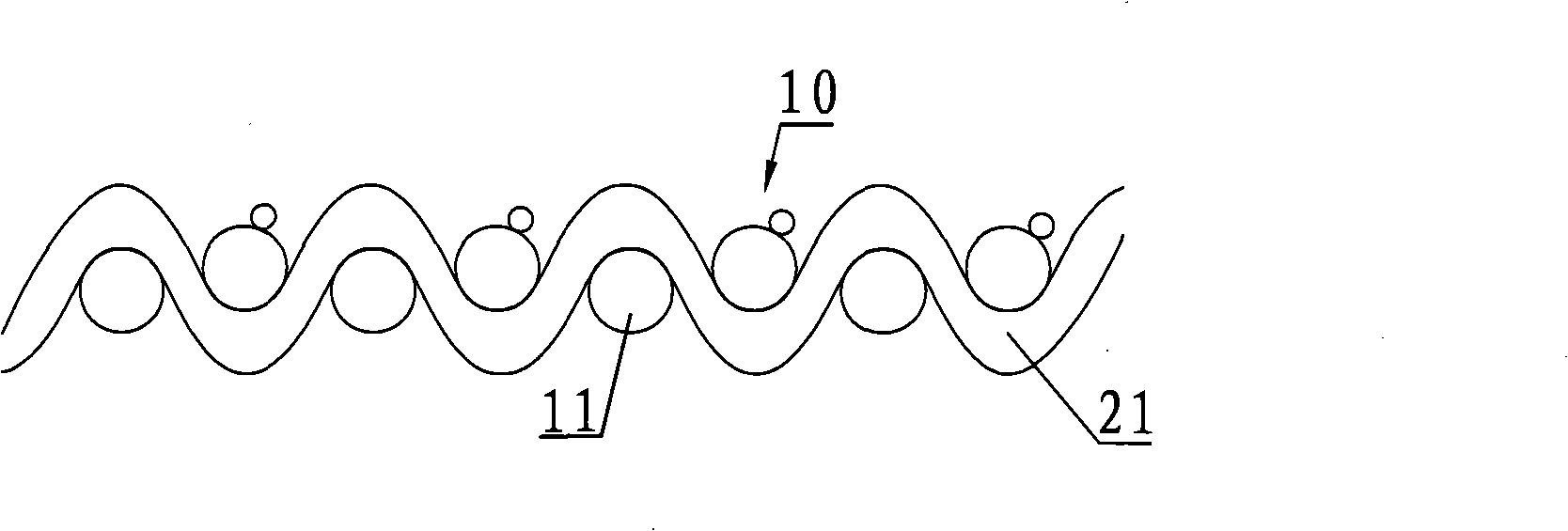

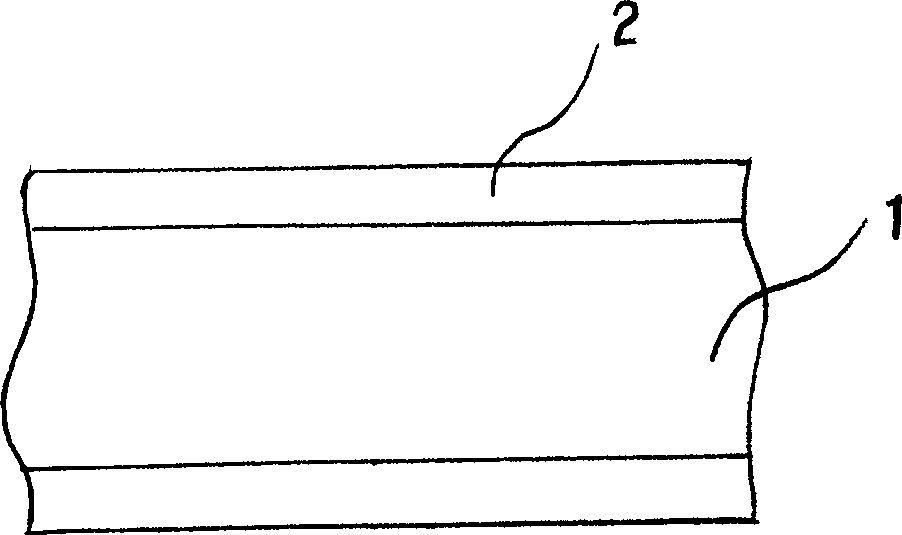

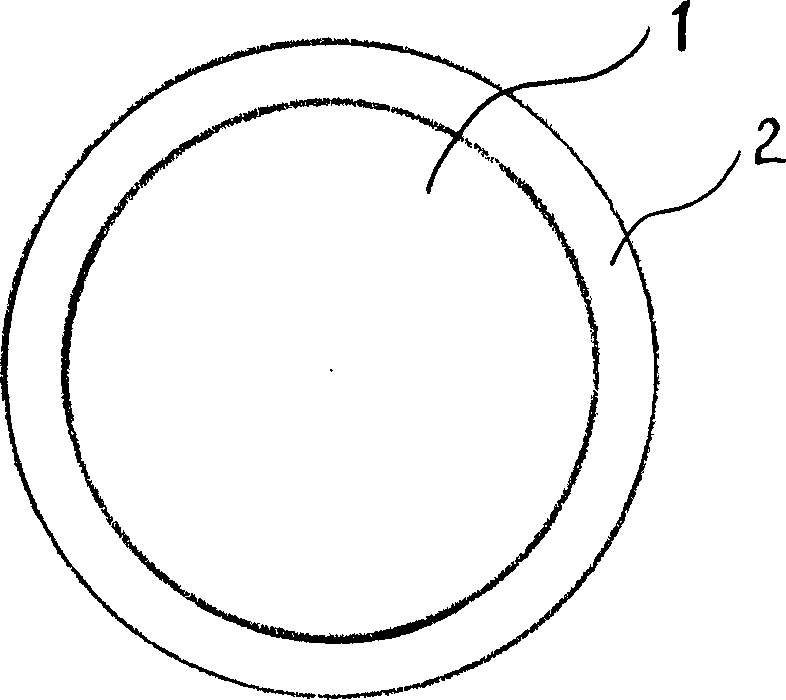

A surgical saw for cutting bone that can be used with ease in tight places yet maintain sufficient cutting power. The surgical saw 10 has a flexible linear body made of twisted stainless steel wire and cutting parts formed on the flexible linear body. The cutting parts are made of abrasive material affixed to the flexible linear body 12a alternating with portions of the flexible linear body with no abrasive particles 12b. Auxiliary cutting parts 13 of lesser cutting power may be provided along both lateral sides of each of the cutting parts 12.

Owner:MANI INC

Electric deterrent device

A deterrent device for delivering an electric shock to an animal, pest or bird to be deterred, having the typical components of a non-conductive base to which the electrically conductive elements are attached. Instead of the typically-used copper wire, however, the braided elements comprise smaller strands of a conductive material, such as copper, aluminum or stainless steel wire, is used and is mechanically attached to the non-conductive base. The braided elements can be mechanically attached using a simple sewing operation in which the braid is sewn to the base. Because of the mechanical attachment and the ability of the braided elements to flex in both contraction and extension, the device of this invention can be used in tight corners and other contorted locations without having the wires of the typical prior art device pull free of the base.

Owner:BIRD BARRIER AMERICA

Electric deterrent device

Owner:BIRD BARRIER AMERICA

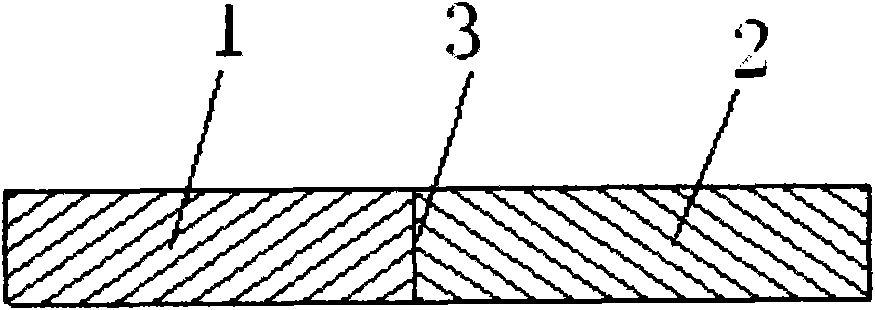

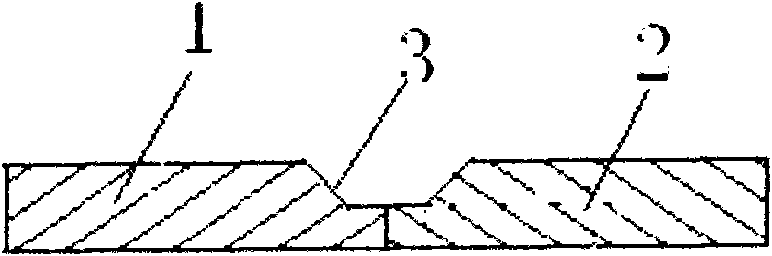

Cold rolling manufacture method of copper and aluminum composite plate strips

InactiveCN102615102ADiffuse fullyFull responseAuxillary arrangementsMetal rolling arrangementsChemical reactionCopper

The invention discloses a cold rolling manufacture method of copper and aluminum composite plate strips. The cold rolling manufacture method comprises the following steps that: 1, a copper plate and an aluminum plate are subjected to homogenization annealing treatment; 2, surface treatment is carried out: firstly, the copper plate and the aluminum plate subjected to the homogenization annealing treatment are subjected to soaking degreasing, then, the copper plate and the aluminum plate subjected to the soaking degreasing are taken out for drying, and next, the composite surfaces to be rolled of the copper plate and the aluminum plate are ground by a stainless steel wire brush; 3, the copper plate and the aluminum plate are subjected to cold rolling compounding by a cold rolling mill, so copper and aluminum composite plate blanks are obtained; and 4, the copper and aluminum composite plate blanks subjected to the cold rolling are subjected to the diffusion annealing treatment. The cold rolling manufacture method has the advantages that through improving the cold rolling process operation and the process parameters, the copper plate and the aluminum plate are subjected to full diffusion and chemical reaction on the composite surfaces in the manufacture process, so the transition structure with excellent performance is obtained at the composite surfaces, and the bonding intensity of finished products is effectively improved.

Owner:HONGGUANG ELECTRIC GROUP CO LTD

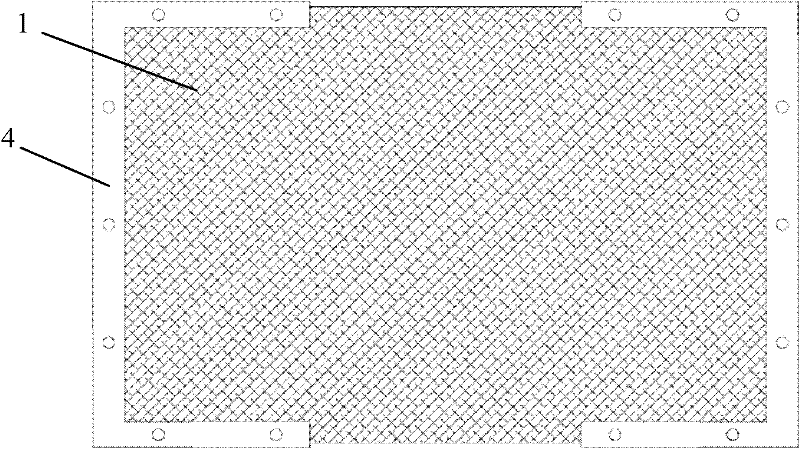

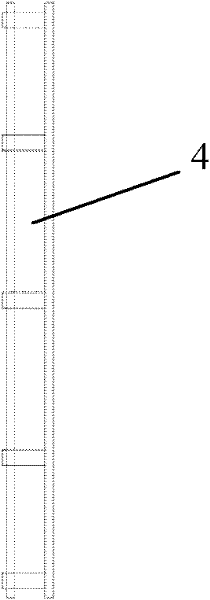

Multifunctional three-layer type air strainer

InactiveCN102225281AEfficacy unchangedReduce resistanceDispersed particle filtrationDeodrantsPolyesterFiber

The invention provides a multifunctional three-layer type air strainer and relates to a strainer. The multifunctional three-layer type air strainer provided by the invention is antimicrobial, self-cleaning and self-nursing, and can be used for increasing a contact area between the strainer and the air, increasing the dust absorbing efficiency, prolonging the service time for filtering, eliminating the planktonic bacteria in air, decomposing harmful matters in air and releasing anion. Three layers of strainers are arranged in the multifunctional three-layer type air strainer, wherein the three layers of strainers are overlapped in turn and then are fixed together with frames by virtue of buckles; the frames and the buckles are arranged on the peripheries of the three layers of strainers; the first layer of strainer is a nonwoven filter cloth layer, a PET (polyester) long fiber filter cloth layer, a glass fiber cloth layer or a stainless steel wire strainer cloth layer; the second layer of strainer is an active carbon strainer cloth layer or a bamboo carbon filter strainer cloth layer; the third layer of strainer is a monofilament filter cloth layer, an apocynum venetum fiber filter cloth layer or a stainless steel wire strainer cloth layer; and the three layers of strainers all contain health functional agents.

Owner:XIAMEN RUNNER IND CORP

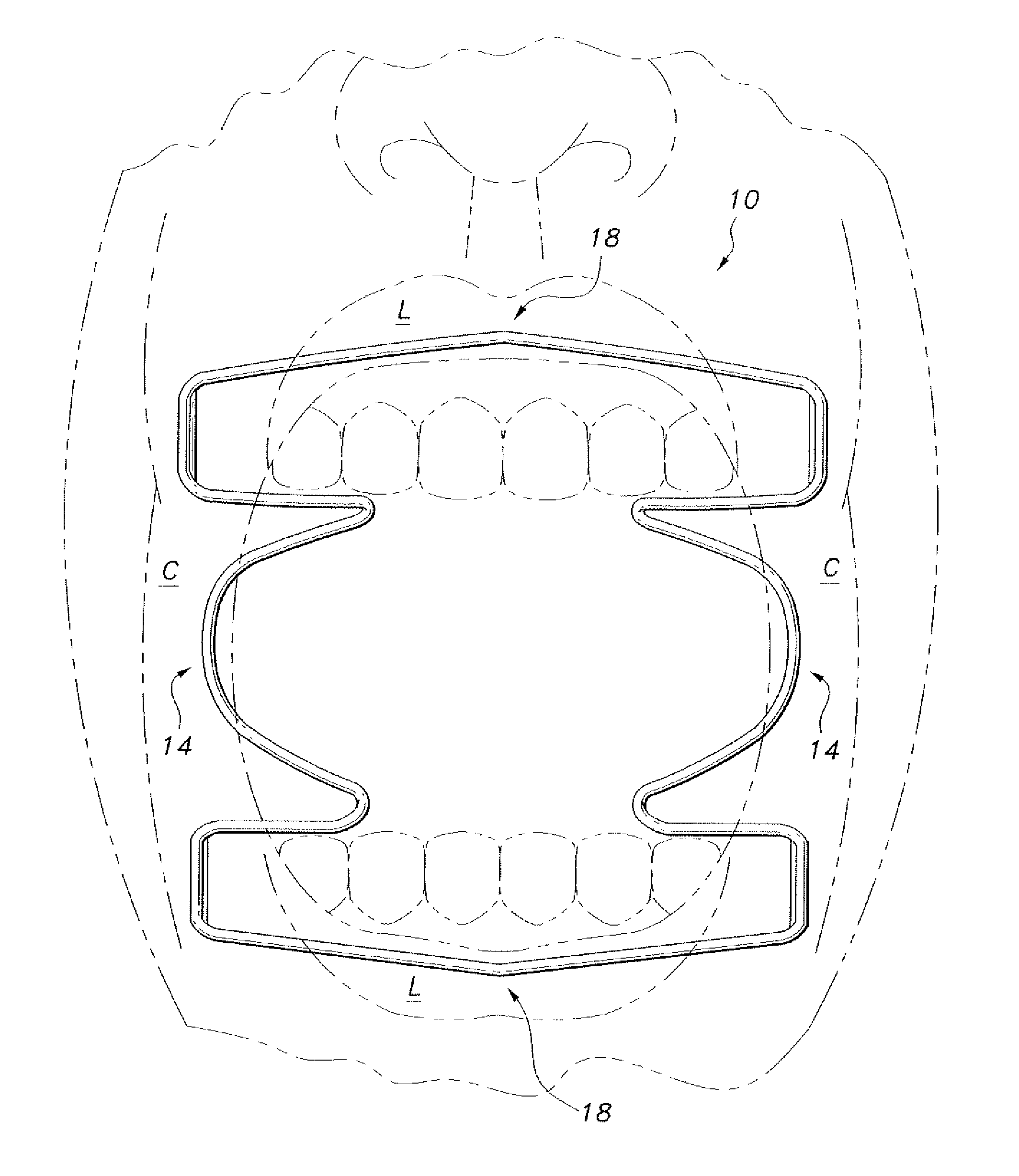

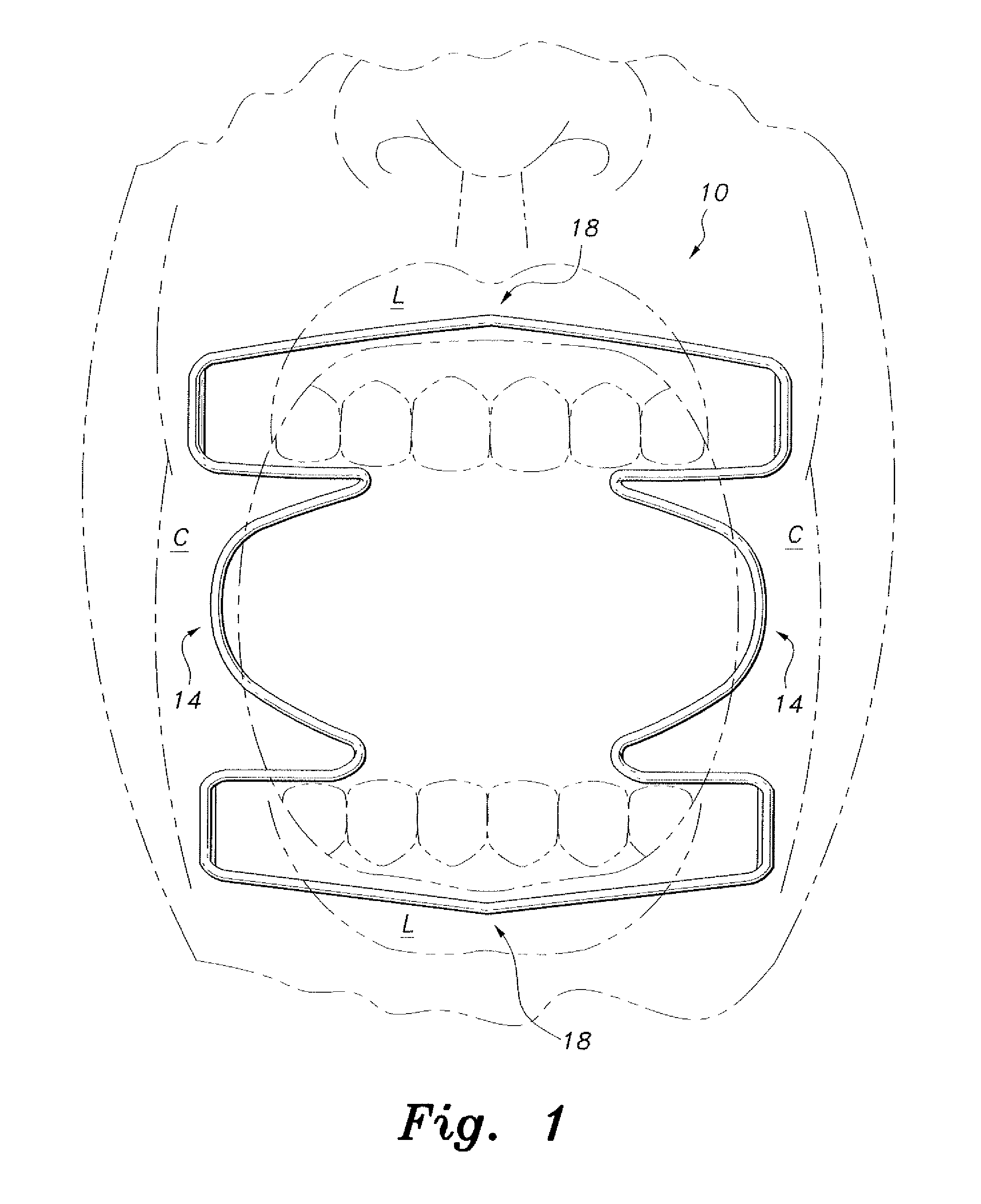

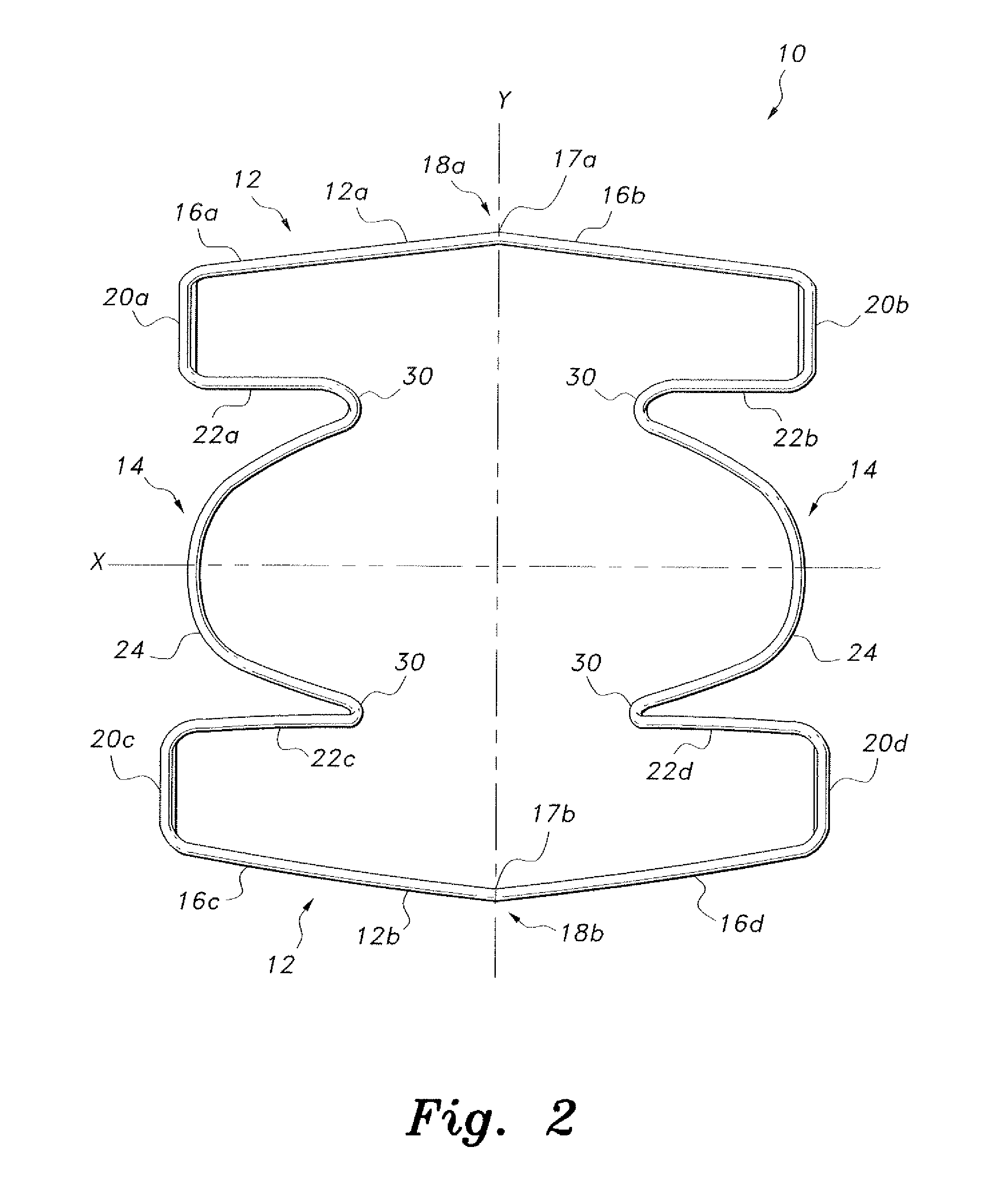

Oral retractor

The oral retractor is provided for retracting at least a portion of a patient's mouth. The oral retractor is formed from single, continuous closed-loop strand of stainless steel wire. The oral retractor includes a superior lip-engaging portion for retracting the patient's upper lip away from the upper teeth and gums, and an inferior lip-engaging portion for retracting the patient's lower lip away from the patient's lower teeth and gums. Bilateral arcuate cheek-engaging portions extend posteriorly from the lip-engaging portions for retracting the patient's cheeks away from the teeth and gums. The lip-engaging portions are formed from linear portions defining tented arches that extend anteriorly, and the superior lip-engaging portion may be canted upward, while the inferior lip-engaging portion may be canted downward. The cheek-engaging portions may be substantially parabolic. The retractor may be substantially symmetrical about planes bisecting the retractor vertically and horizontally.

Owner:KING SAUD UNIVERSITY

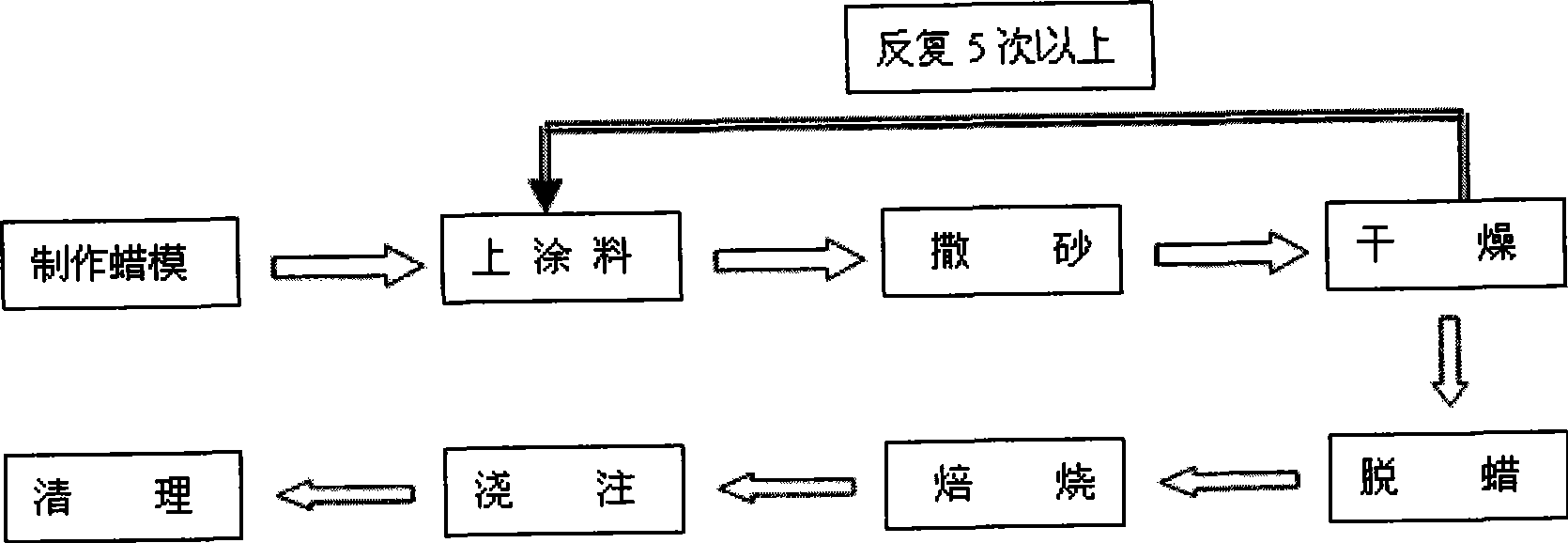

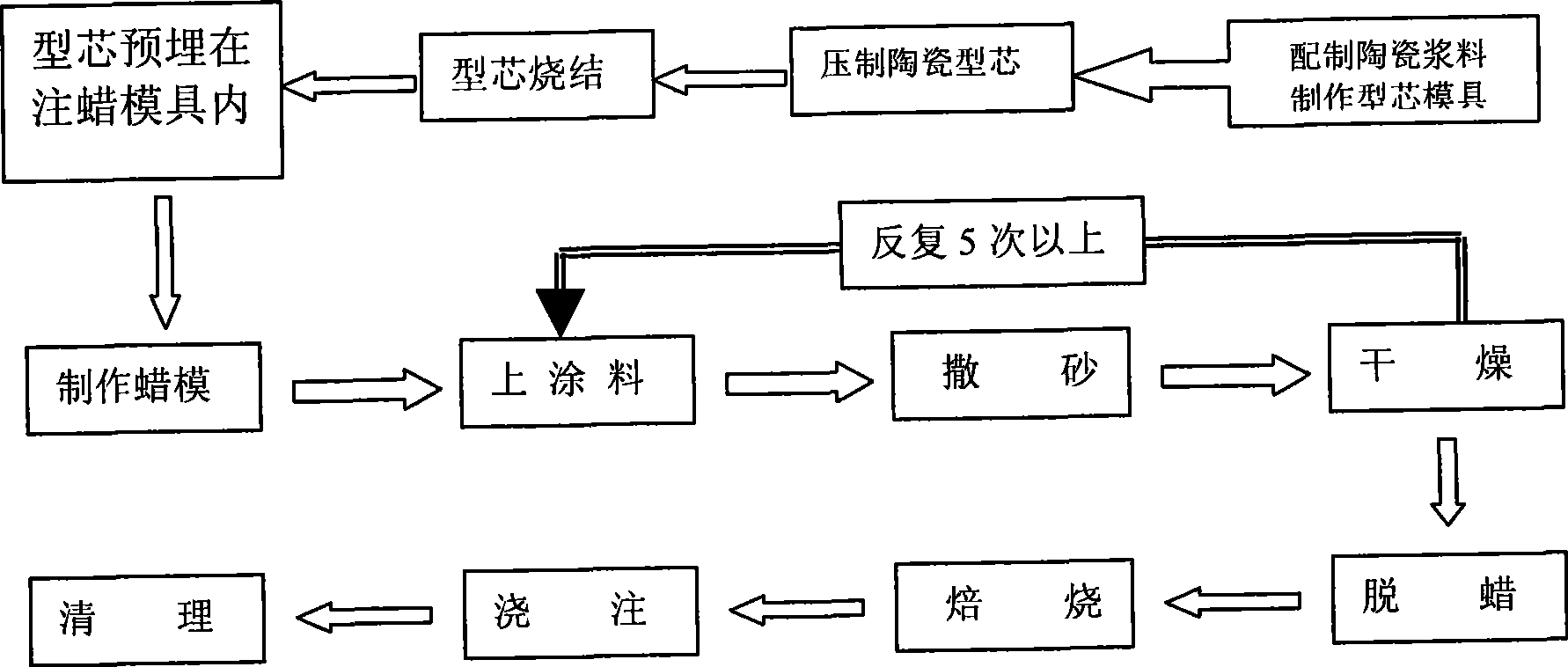

Case-making method of silicasol investment casting with elongated hole structure

ActiveCN101480697AShort cycleLow costFoundry mouldsFoundry coresInvestment castingStainless steel wire

The invention relates to a case making method of a silica sol investment casting with a slender hole structure, and the method is achieved through adopting the following steps of max mould preparation 1, doping 2, sanding 3, drying 4, in-hole grouting 5, continuous case making 6, demaxing 7 as well as roasting and casting 8, wherein the steps between the doping 2 and the drying 4 are adopted for 2-3 times; wherein in the step 5, the in-hole grouting is achieved through the following steps: soft white slime is used for plugging up the lower end and a lateral hole of a part, and a stainless steel wire used for ensuring that a mandril is not fractured at the end part is inserted into the end part of the hole, and the diameter of the stainless steel wire is about 2mm; and sizing agent is injected after the process of plugging up the hole and inserting the wire are ready, and the case making is continued after the sizing agent is solidified. The invention has the advantages that a mold core die is independently manufactured, the period is short, and the cost is low; in addition, the method is not limited by the sorts of the dies and is especially suitable for small amount of products or a single product, and the application is flexible.

Owner:SHANGHAI ZHONGZHOU SPECIAL ALLOY MATERIALS

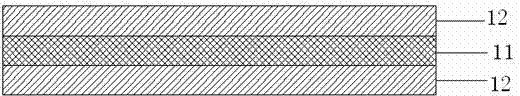

Anti-static polytetrafluoroethylene filter bag and preparation method thereof

InactiveCN103191602AHigh temperature resistantCorrosion resistantDispersed particle filtrationSynthetic resin layered productsChemical industryEngineering

The invention discloses an anti-static polytetrafluoroethylene filter bag and a preparation method thereof. The anti-static polytetrafluoroethylene filter bag comprises a bag head, a bag body and a bag bottom, wherein the bag head is made from a polytetrafluoroethylene filter material; the polytetrafluoroethylene filter material comprises a base cloth; the base cloth is weaved through warps and wefts by twisting polytetrafluoroethylene filament fibers and stainless steel fibers; the upper surface and lower surface of the base cloth are symmetrically covered with non-woven layers; the non-woven layers are prepared by blending polytetrafluoroethylene fibers or one or more of the polytetrafluoroethylene fibers, polyphenylene sulfide fibers, polyamide fibers, polyamide-imide fibers and glass fibers; and the overlapped edge of the bag body is provided with a stainless steel wire mesh layer. The filter material prepared through the method disclosed by the invention has the advantages of good high temperature resistance, corrosion resistance and electric conductivity and persistent static elimination, reduces the fire hazard or explosion generated due to electrostatic sparks and can be widely applied to the high-temperature fire prevention, explosion prevention and dust removal in the fields of iron and steel smelting, refuse burning, a coal-fired power plant, cement, chemical industry, and the like.

Owner:南京际华三五二一环保科技有限公司

Stainless steel wire drawing liquid composition

The invention relates to stainless steel wire drawing liquid, the formula thereof comprises the following components: 10 to 30 percent of base oil, 10 to 30 percent of petroleum sodium sulfonate, 5 to 20 percent of mixed alcohol amine, 15 to 30 percent of turkey red oil and turkey red oil ammonium salt, 1 to 3 percent of bactericide, 0.1 to 1 percent of copper corrosion inhibitor, 10 to 20 percent of ester oil and the balance of water. The stainless steel wire drawing liquid is characterized by having excellent lubricating performance and stainless steel rust-preventing performance. In addition, the stainless steel wire drawing liquid related by the invention has an excellent defoaming function and can greatly improve the environmental hygiene of wire drawing processing enterprises.

Owner:河北九熙新材料科技有限公司

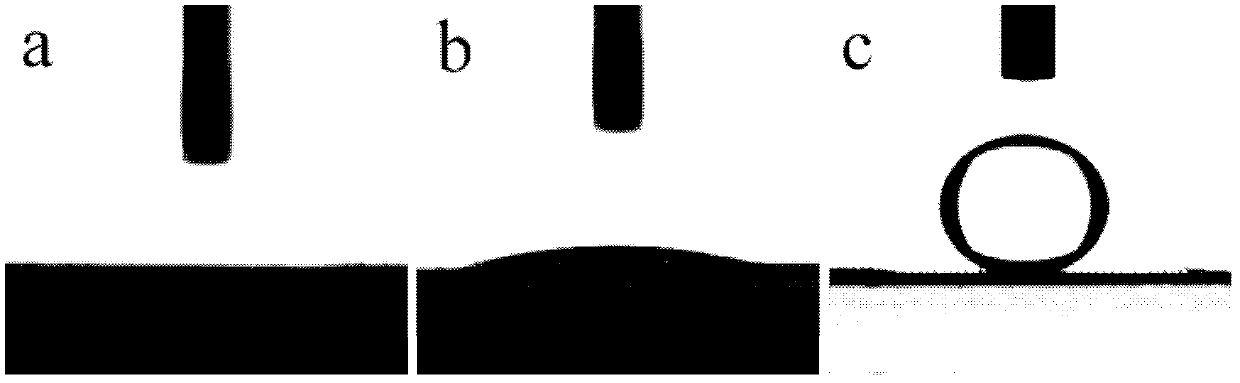

Superhydrophilic underwater-superlipophobic oil-water separation membrane, and preparation method thereof

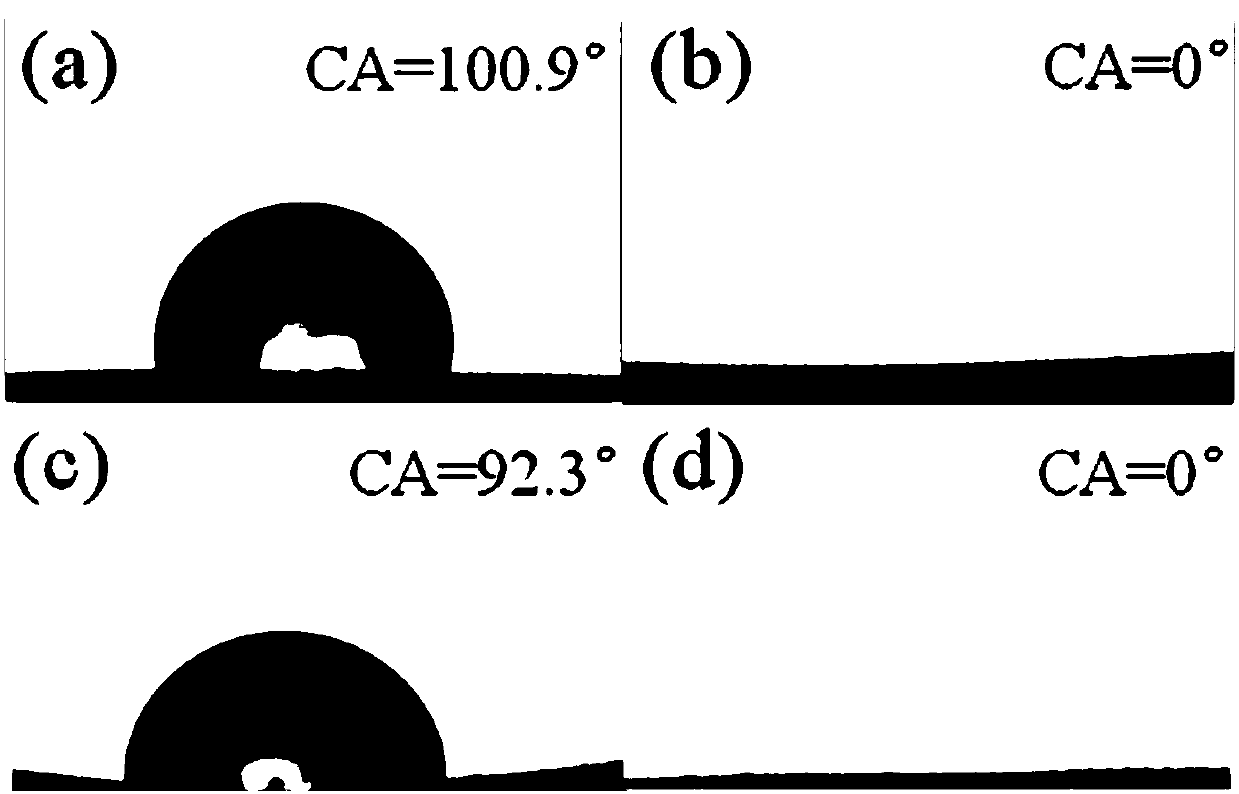

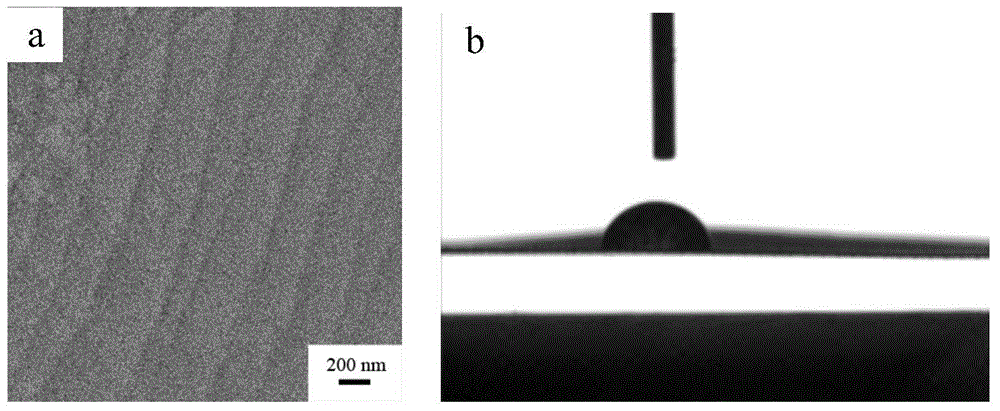

InactiveCN107583470AGood film formingImprove hydrophilicitySemi-permeable membranesCross-linkPolyvinyl alcohol

The invention discloses a superhydrophilic underwater-superlipophobic oil-water separation membrane, and a preparation method thereof. According to the preparation method, stainless steel wire mesh ornylon cloth are modified with a polyvinyl alcohol-silicon dioxide composite coating so as to change the surface properties and provide the stainless steel wire mesh or nylon cloth with super hydrophilicity and underwater super lipophobicity; dip coating process is adopted so as to realize loading of the surface of the stainless steel wire mesh or nylon cloth with polyvinyl alcohol-silicon dioxide, wherein a polyvinyl alcohol aqueous solution and an ethanol dispersion solution of silicon dioxide are prepared firstly, and are mixed via ultrasonic treatment, the pH value is adjusted, and a cross-linking agent is added so as to obtain a coating solution, and dip coating is adopted so as to obtain the superhydrophilic / underwater-superlipophobic oil-water separation membrane. The superhydrophilic underwater-superlipophobic oil-water separation membrane possesses both super hydrophilicity and underwater super lipophobicity, is suitable for treatment of sewage containing n-hexane, cyclohexane, diesel oil, soya-bean oil, lubricating oil, and silicone oil, and possesses excellent oil water separation performance.

Owner:SHANGHAI UNIV

Process for production of radioresistant worsted face fabric

InactiveCN101012591ASolve the difficulty of uneven final surface in shrinking productionSolve the difficulty of unevennessWoven fabricsYarnPolyesterWorsted

The invention relates to a manufacturing method for anti-radiation spinning fabric. At first, wool and polyester are combed in double and spun into the wool yarn; then the wool yarn and fine stainless steel wire are combined into fine stainless steel yarn; finally anti-radiation spinning fabric is generated by the wool yarn and fine stainless steel yarn through weaving and dyeing. The fabric manufacturing method makes that the fabric is not only provided with anti-radiation performance but also high-grade fabric and good wearability by folding and stranding, weaving and dyeing. It can satisfy demands of office white collar class to the fabric of business wear.

Owner:杨毅方

Automatic TIG gasket-free single-side welding and double-side molding process for aluminum alloy

InactiveCN102079003AReduce distortionImprove welding qualityArc welding apparatusWorkpiece edge portionsUltimate tensile strengthStainless steel wire

The invention discloses an automatic tungsten inert gas (TIG) gasket-free single-side welding and double-side molding process for aluminum alloy, which comprises the following steps of: selecting welding equipment and materials, performing assembly and clearing, performing tack welding, clearing grease dirt and oxide films in 50 millimeters of two sides of a groove by using acetone and a stainless steel wire wheel, placing a shell on a welding operation rack, regulating a welding gun to be aligned with the groove, preheating, welding a first layer without adding welding wires, clearing the oxide film on the surface of the seam by using the stainless steel wire wheel after the first layer is welded to expose metal luster, welding a second layer, adding the welding wires for covering the surface, and making the welding direction of the welding gun and a cylinder swing vertically to form a seam. The process has the advantages of high efficiency, low labor intensity, high welding quality, attractive appearance, no undercut or arc crater cracks, workpiece deformation resistance and high seam qualification rate.

Owner:陕西国德电气制造有限公司

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

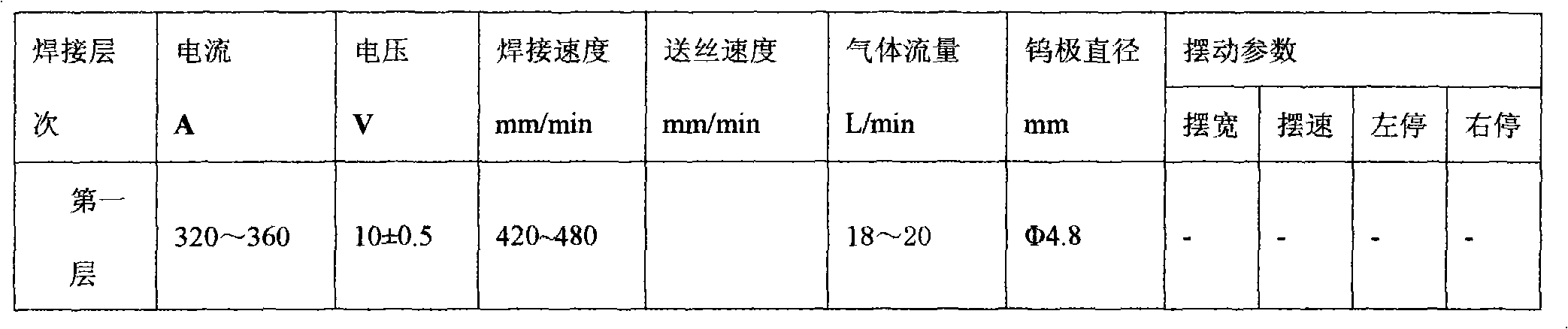

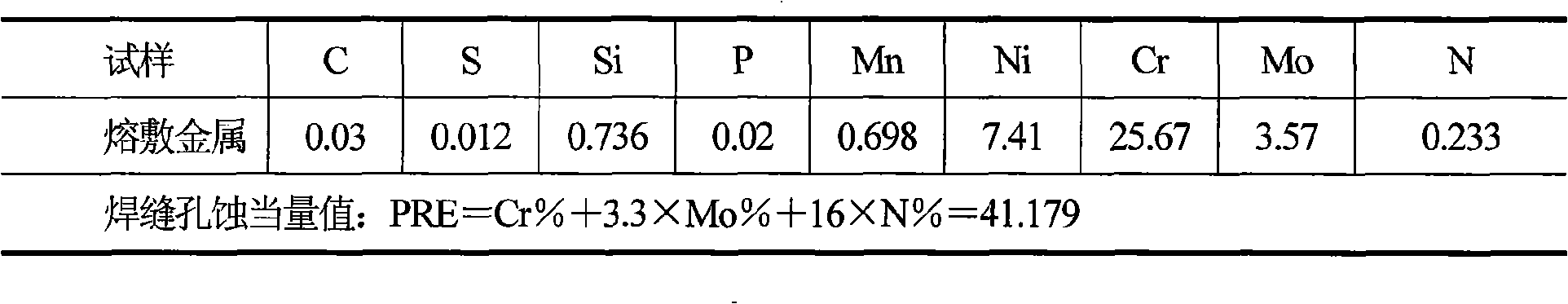

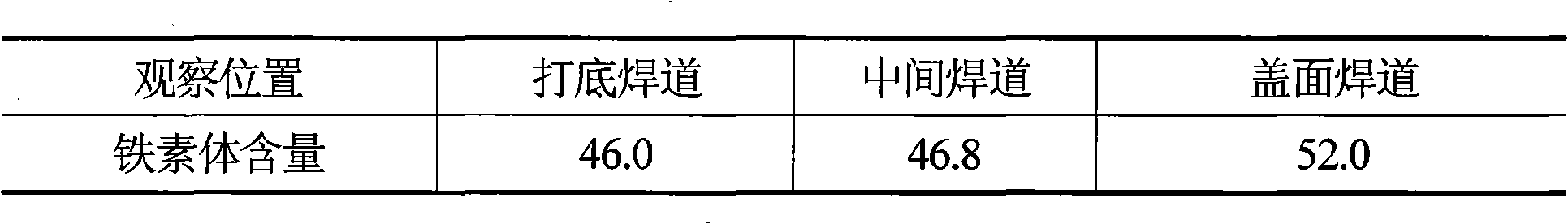

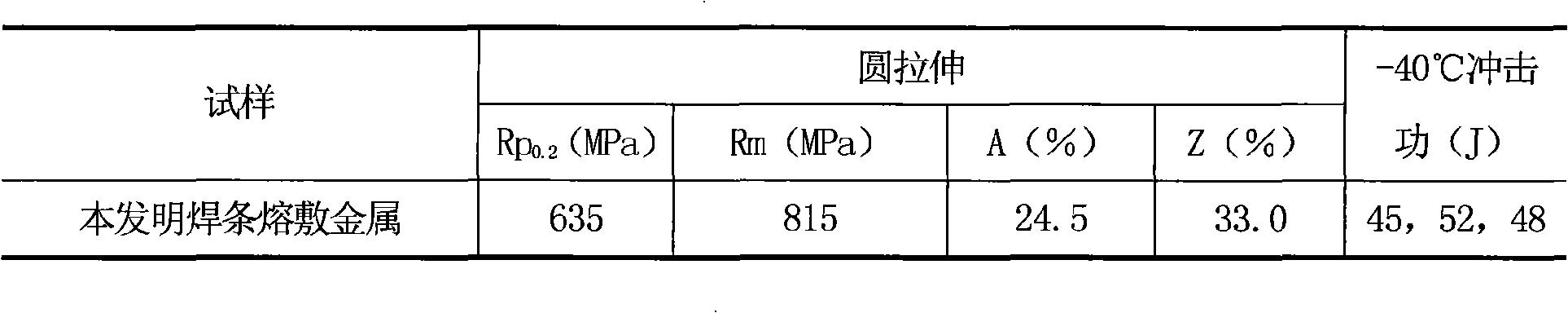

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

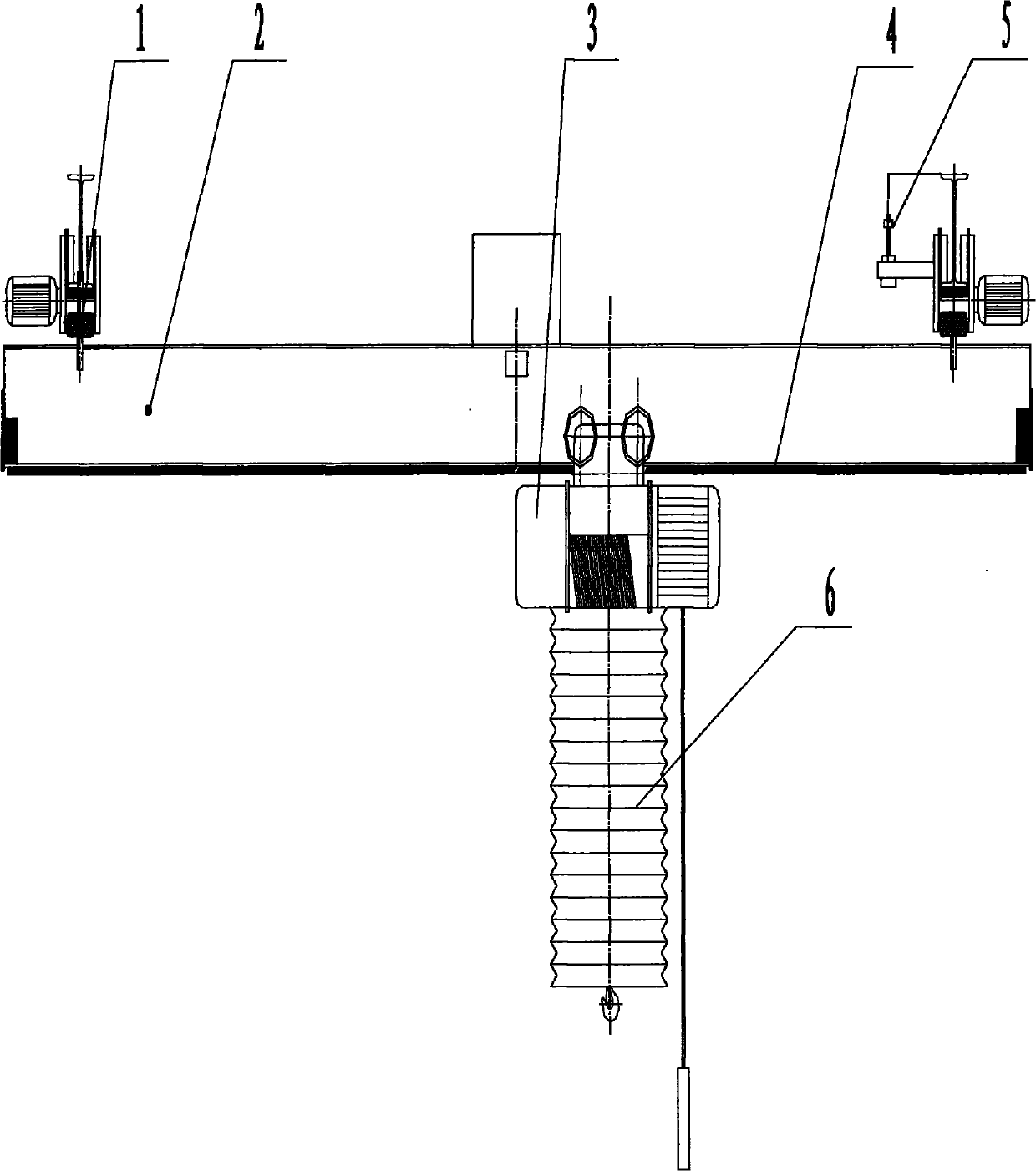

Stainless steel, stainless steel wire for bridge pull sling as well as preparation methods and application thereof

The invention relates to a stainless steel, a stainless steel wire for a bridge pull sling as well as preparation methods and application of the stainless steel and the stainless steel wire. The stainless steel comprises the components of less than or equal to 0.12% of C, less than or equal to 1.00% of Si, 14.0-19.0% of Mn, less than or equal to 0.06% of P, less than or equal to 0.01% of S, 18.0-22.0% of Cr, 1.0-2.0% of Ni, 0.45-0.65% of N, the balance of Fe and unavoidable impurities; and the method for producing the stainless steel comprises the steps of: the smelting process in an electric furnace: adding scrap steel and corresponding iron alloy or metal into the electric furnace, chemically cleaning, and controlling the chemical composition of crude molten steel in the electric furnace for tapping; the refining process of an argon oxygen decarburizing furnace: firstly, carrying out oxidation-period smelting and then reduction-period smelting, adding slag making material for making slag in the reduction period, and carrying out fine adjustment on the target composition by adding fine-adjustment composition alloy, and then tapping; the process of casting a billet; and the rolling process. The preparation method of the stainless steel wire for the bridge pull sling comprises the steps of: carrying out spinning, cooling, heat treatment, acid washing and cold drawing on the obtained stainless steel. The high-nitrogen stainless steel wire is adopted by the invention, so that the corrosion resistance is better when the strength is improved, and the service life of a bridge is prolonged after the bridge pull sling is made from the high-nitrogen stainless steel wire.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD +2

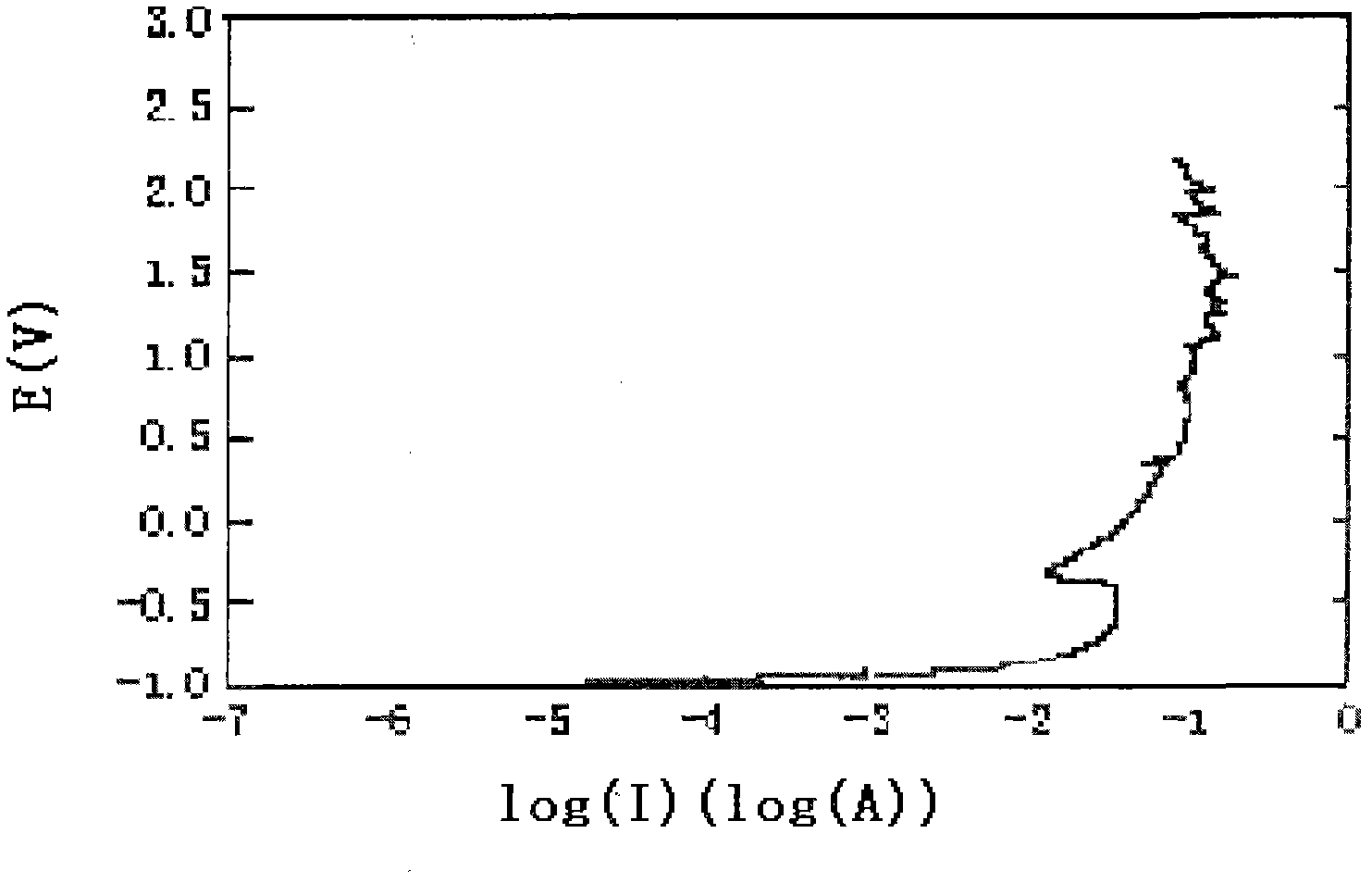

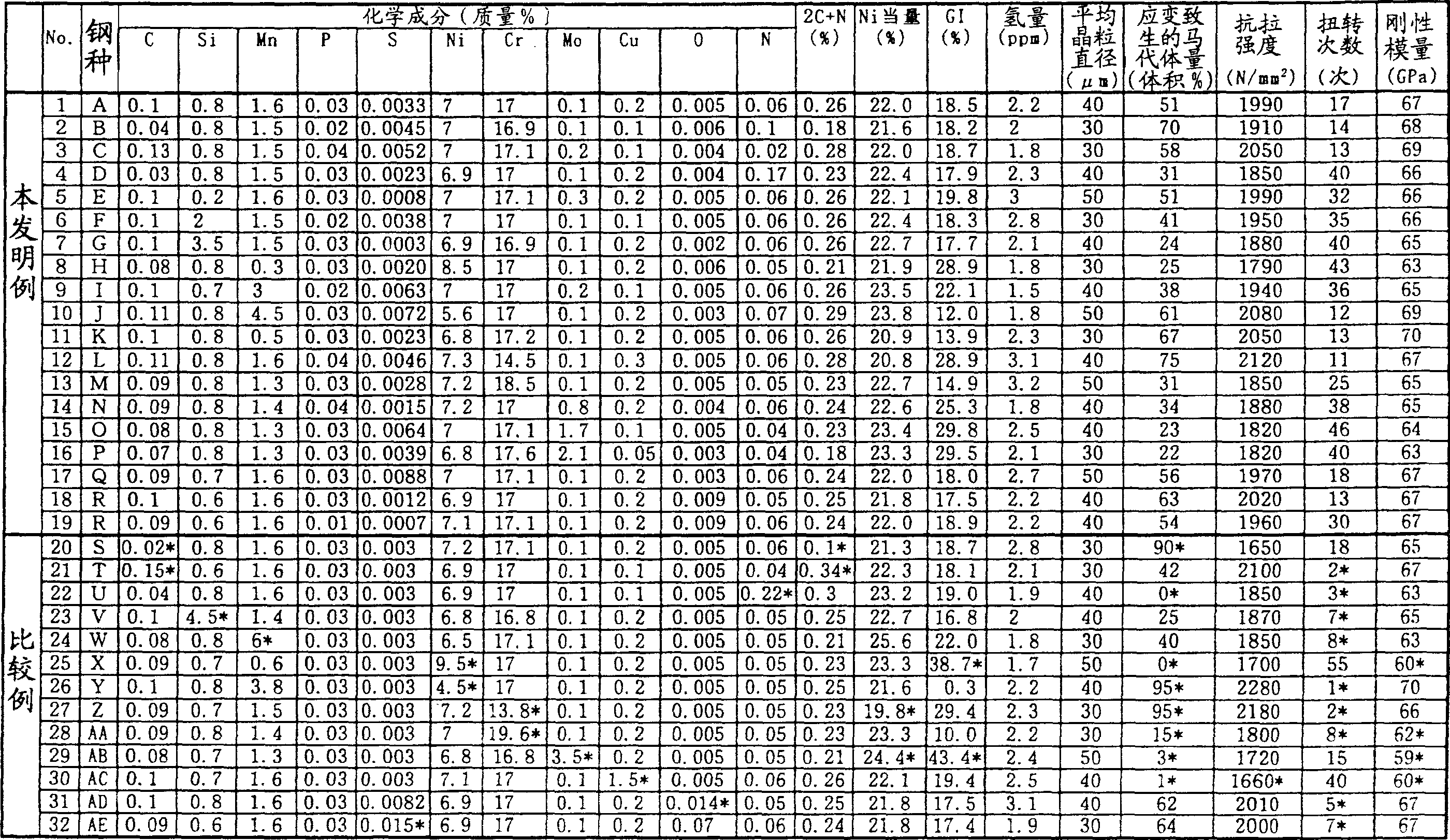

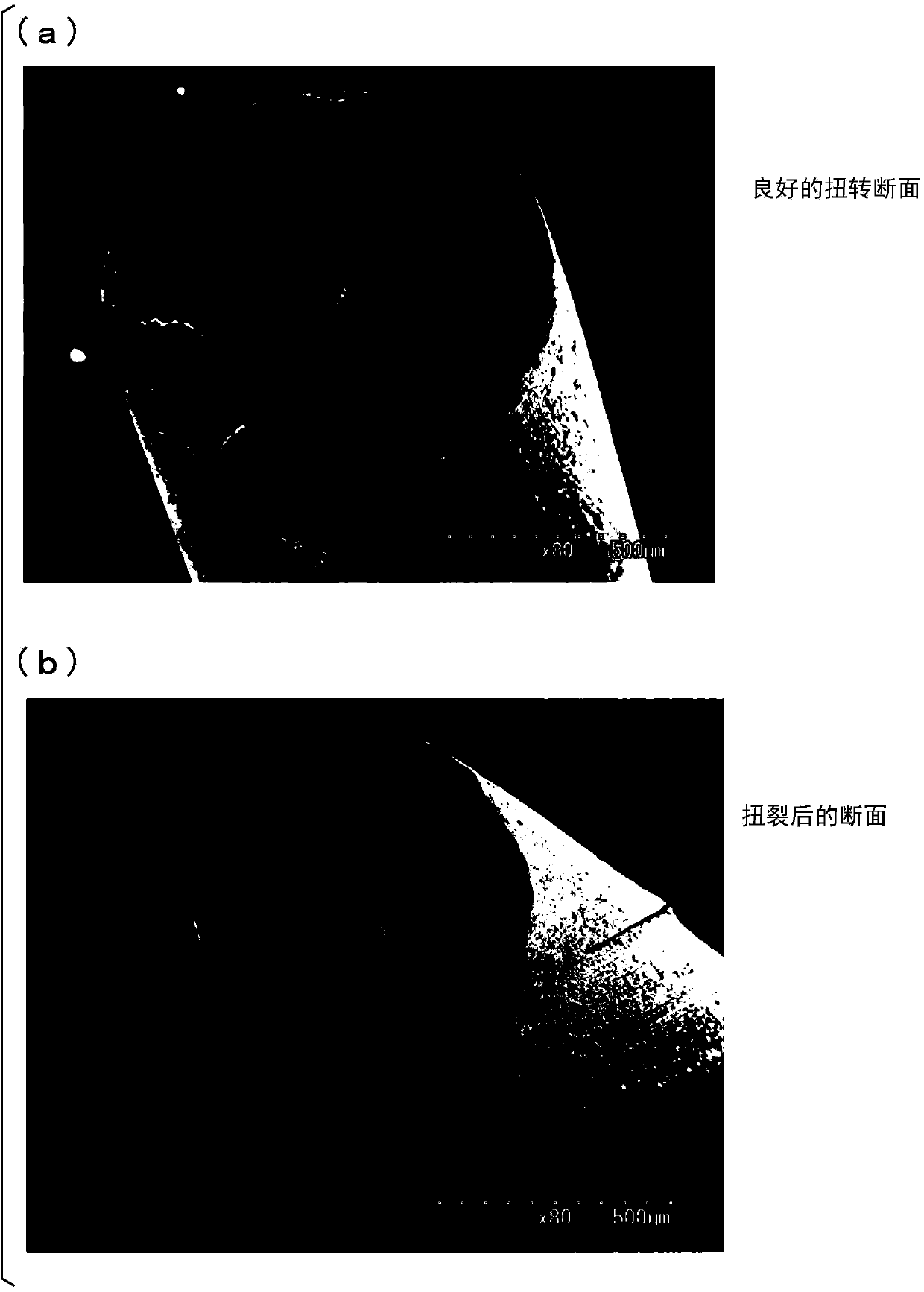

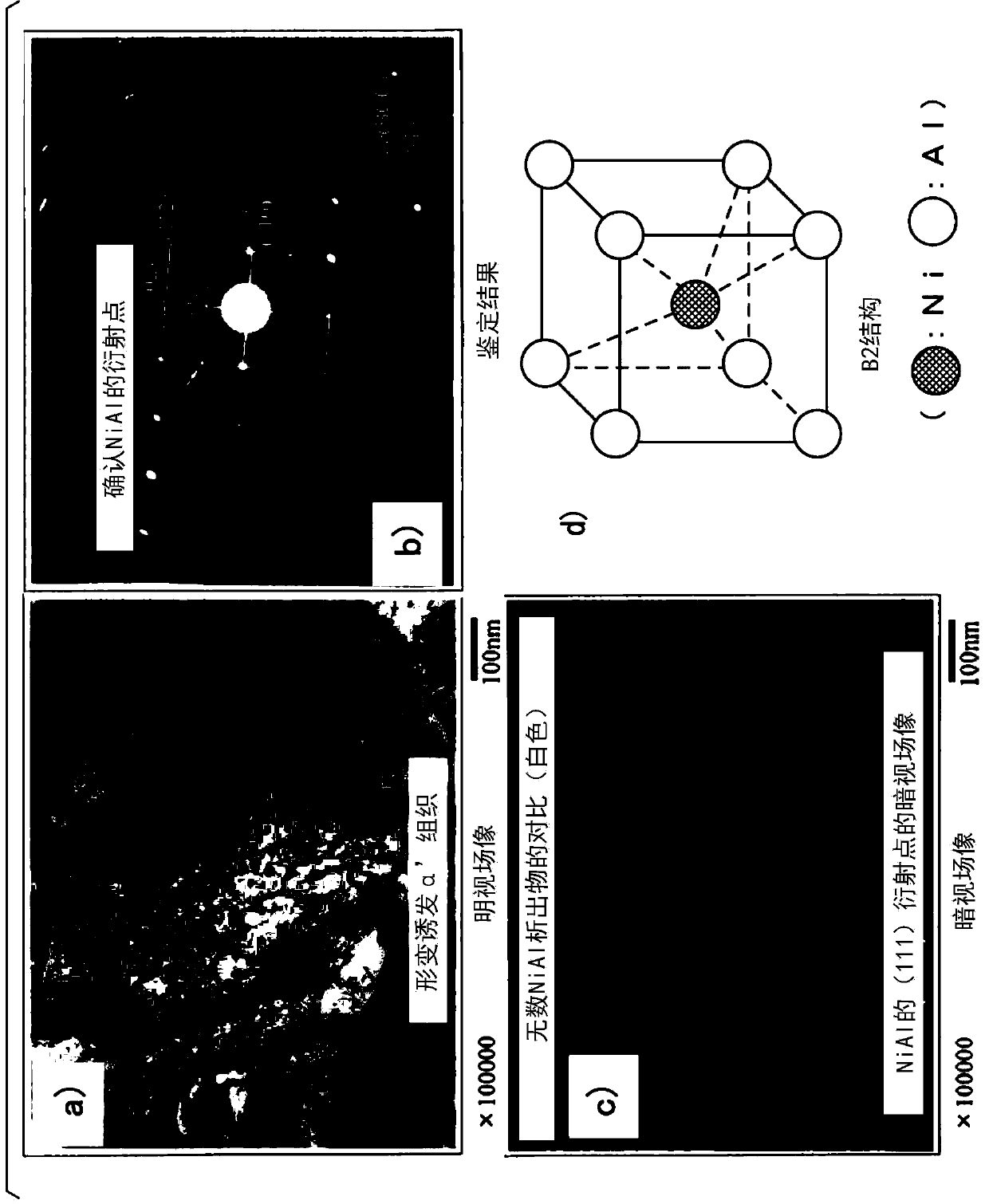

High strength stainless steel wire excellent in ductility-toughness and modulus of rigidity and method for production thereof

A high strength stainless steel wire excellent in ductility-toughness and modulus of rigidity, which has a chemical composition, in mass %, C: 0.03 to 0.14 %, Si: 0.1 to 4.0 %, Mn: 0.1 to 5.0 %, Ni: 5.0 to 9.0 %, Cr: 14.0 to 19.0 %, N: 0.005 to 0.20 %, O: 0.001 to 0.01 %, S: 0.0001 to 0.012 % and balance: Fe and inevitable impurities, provided that the value of (2C + N) is 0.17 to 0.32 %, that the value of Ni equivalent of the following formula (1): Ni equivalent (%) = Ni + 0.65Cr + 0.98Mo + 1.06Mn + 0.35Si + 12.6(C + N) (1) is 20 to 24, and that H <= 4 ppm. The production of the high strength stainless steel wire is achieved through the control of the amounts of basic components, oxygen, hydrogen and sulfur as mentioned above, the formation of finer crystal grains, and the toughness improving effect of ausforming by cold wire drawing.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP +1

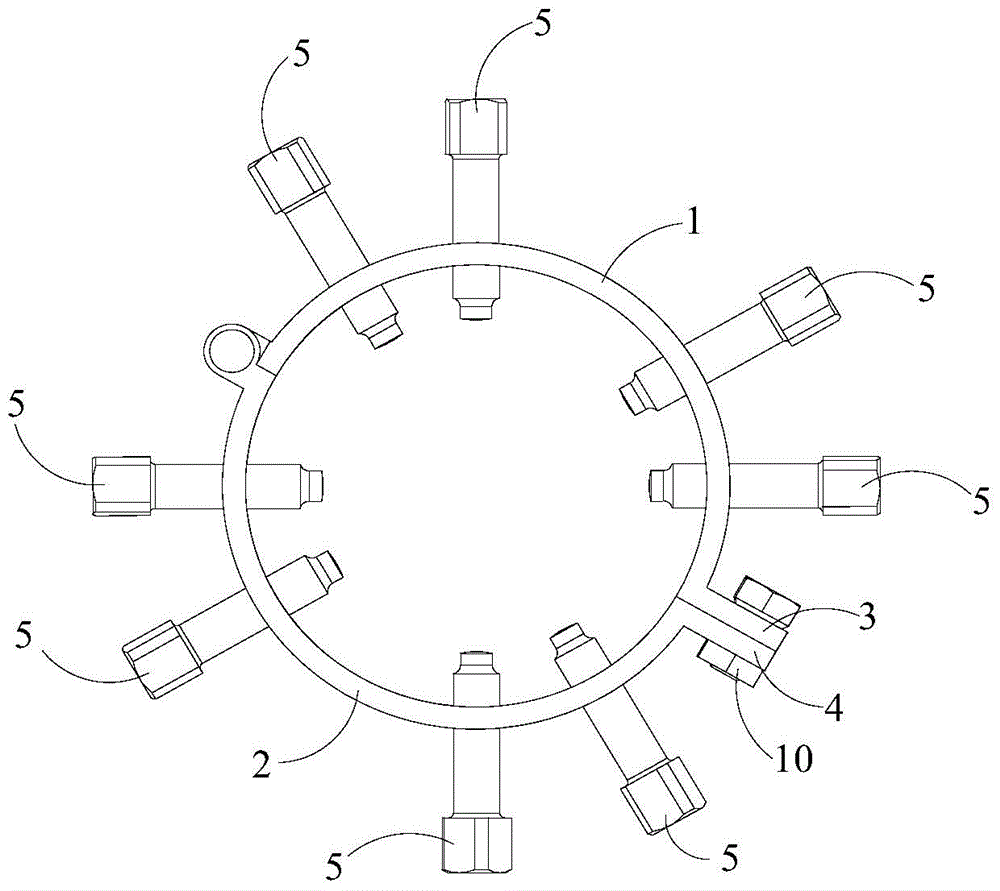

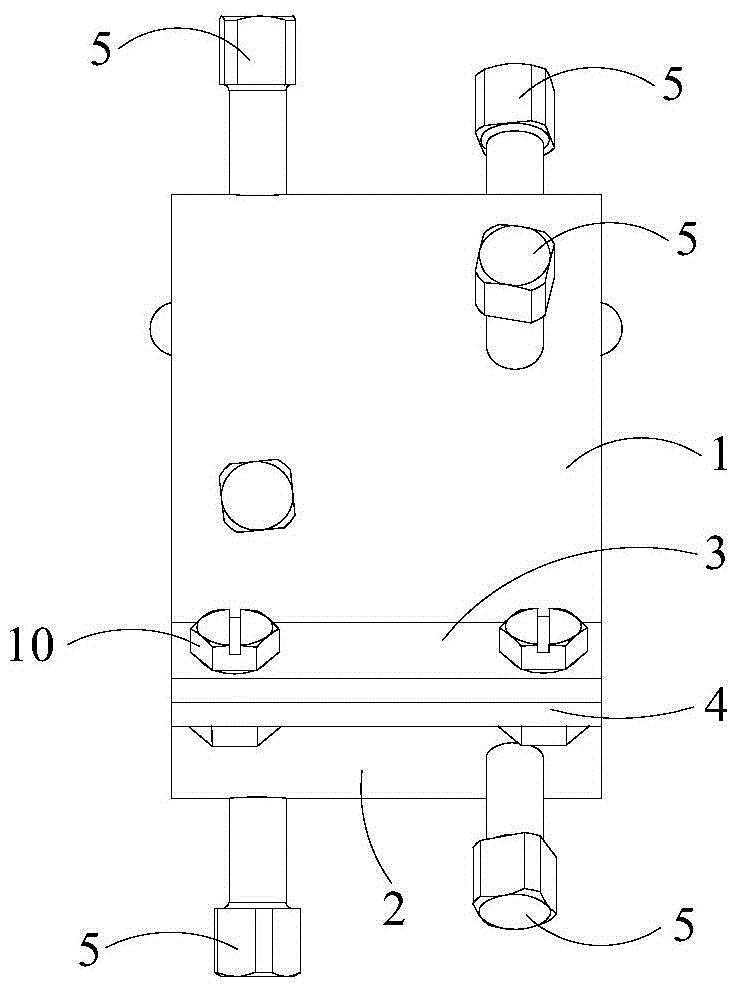

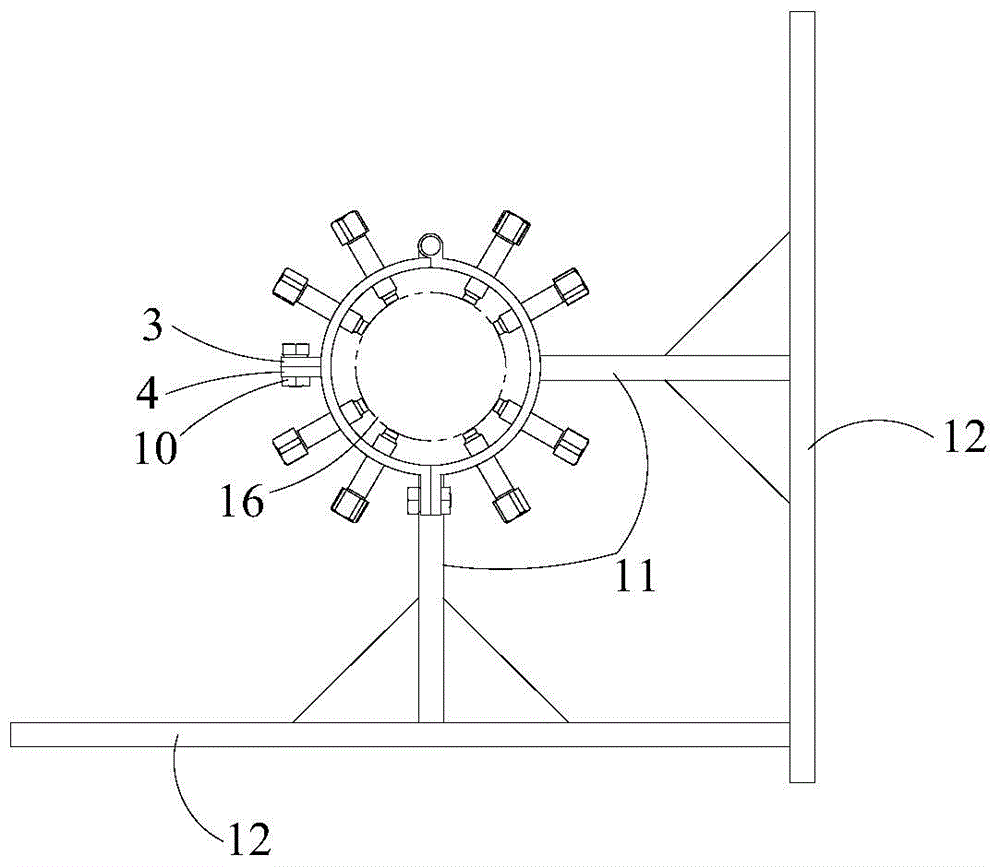

Dishwasher with rotary cage

InactiveCN102113872AFast cleaningShort timeTableware washing/rinsing machine detailsElectricityWater flow

The invention relates to a dishwasher with a rotary cage, which comprises a case body and a rotary cage mounted inside a cleaning chamber of the case body, wherein the rotary cage is mounted on a central shaft that is rotated under the action of a jet water flow or under the drive of a motor, a dish holder is arranged on the rotary cage and used for holding bowls and dishes, and the rotary cage is made by weaving and welding stainless steel wires. With the technical design of the rotary cage, the dishwasher is suitable for both domestic and commercial use. The dishwasher can perform complete cleaning without needing to rotate the water jet pipe. The dishwasher achieves the effect of multi-angle all-direction washing of tableware, is very suitable for cleaning bowls, pots, cups and other deep-edge tableware and utensils in Chinese cuisines, and is more suitable for cleaning western tableware. The dishwasher increases the cleaning speed, reduces the cleaning time and saves water and electricity. The water jet pipe of the dishwasher can supply water to wash the tableware in different angles and all directions, so as to well clean the tableware within a short time, reduce the cleaning time and save water and electricity.

Owner:袁哲

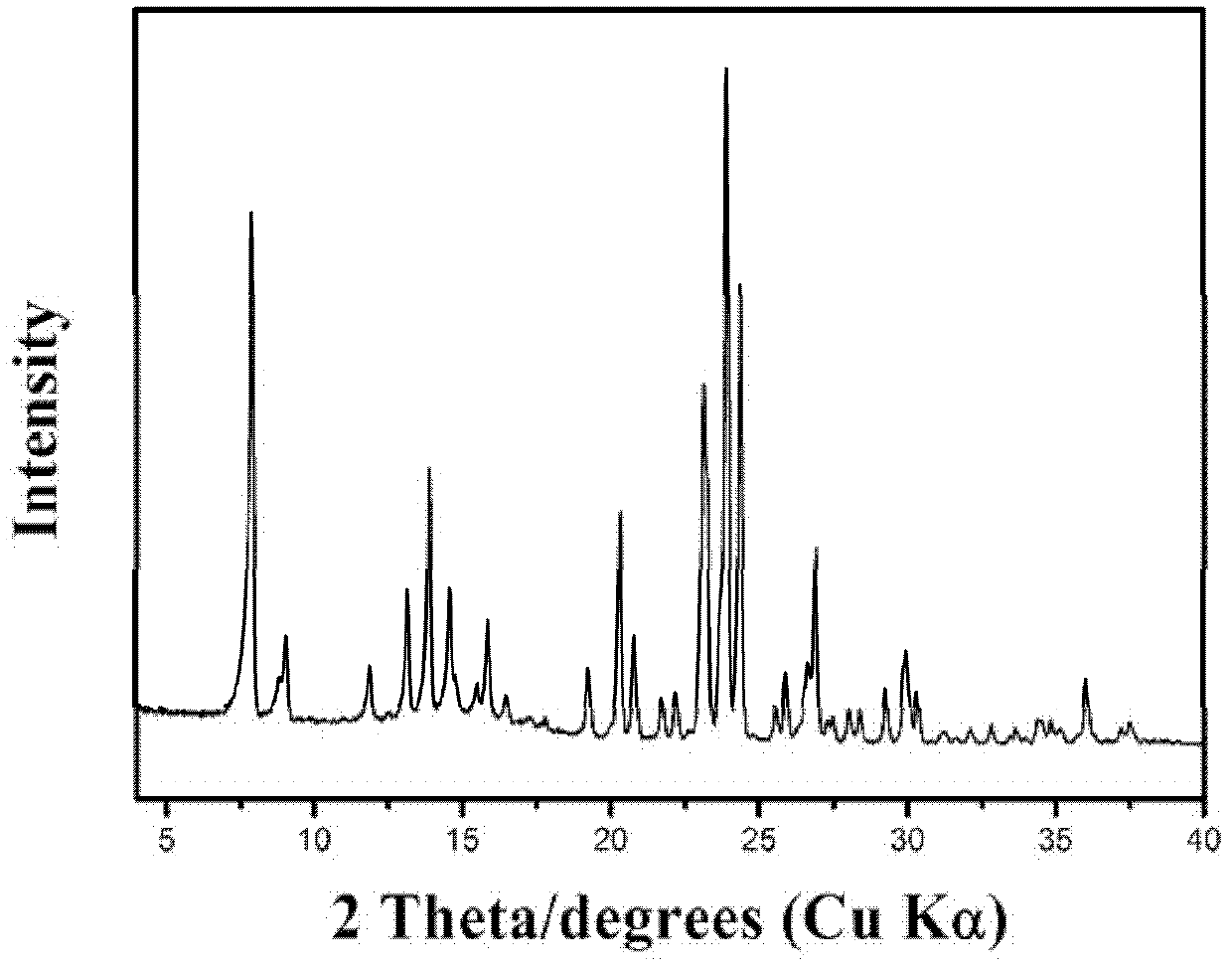

Inorganic phase separation membrane and application of thereof to oil-water separation

The invention discloses an inorganic phase separation membrane and application of thereof to oil-water separation, belongs to a functional material technology and relates to the superhydrophilic and underwater super hydrophobic oil inorganic phase separation membrane which grows a molecular sieve coating on a porous base, and thus micro and nanometer scale, a composite surface and a mesh structure are formed. The membrane material can be used for separating various greases at high efficiency and high speed and low energy consumption under various serious water body environments; and the membrane can be used for a long time and is easy to regenerate. The inorganic phase separation membrane consists of the porous base and the molecular sieve coating grown on the porous base; the aperture size of the porous base is 20-200 micrometers; the thickness range of the molecular sieve coating is 3-50 micrometers; the mass ratio of the porous base to the molecular sieve coating is (100:1)-(5:1); the porous base is made of a stainless steel wire mesh, a copper mesh, an aluminum mesh or porous ceramic; and framework types of the molecular sieve are LTA, SOD, FAU, MEL, CHA, MFI , DDR, AFI, BEA or PHI.

Owner:JILIN UNIV

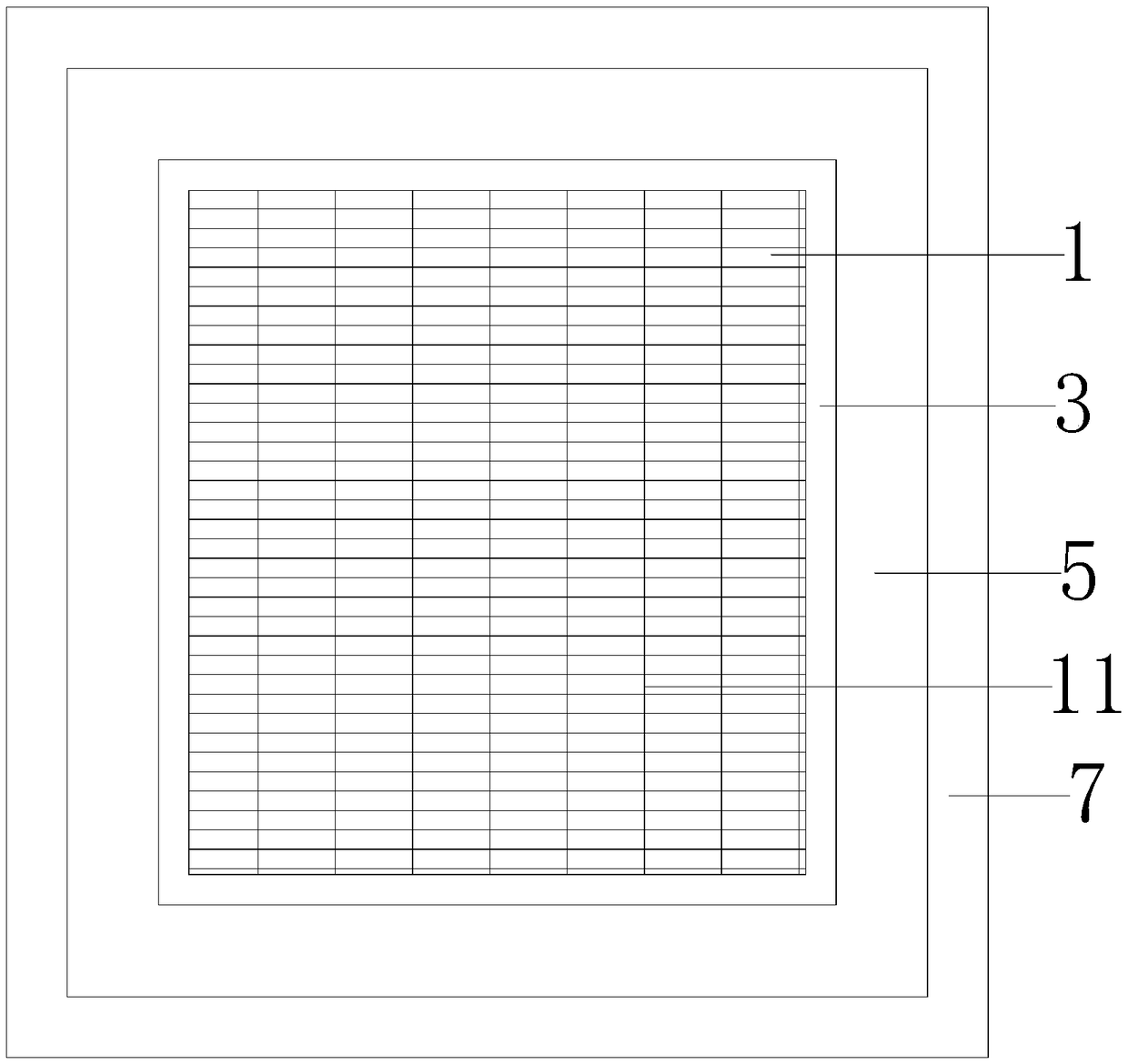

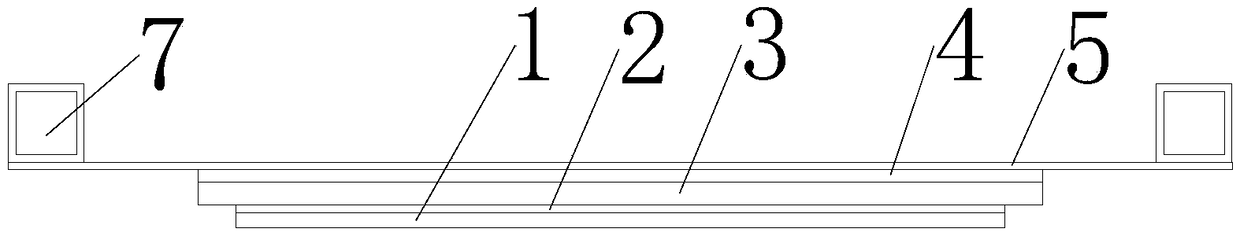

Polyimide solar net plate and manufacturing method

PendingCN108749276ADowngradeReduce manufacturing costScreen printersSynthetic resin layered productsWire gauzeScreen printing

The invention relates to a solar net plate, in particular to a polyimide solar net plate. The polyimide solar net plate comprises a net frame and a polyester wire net. The polyester wire net is tied to the bottom of the net frame. A silk screen printing hole is formed in the center of the polyester wire net, and the polyester wire net is in a concentric square shape. A stainless steel wire net anda polyimide film are further included. The polyimide film is fixed to the bottom face of the stainless steel wire net. A high-temperature glue layer is arranged between the polyimide film and the stainless steel wire net. The polyimide film is provided with a plurality of wire grooves, and a printing pattern is composed of the wire grooves. The top face of the stainless steel wire net is fixed tothe polyester wire net. The stainless steel wire net is larger than the silk screen printing hole and covers the silk screen printing hole, and a hot melt glue layer is arranged between the stainlesssteel wire net and the polyester wire net. The net plate manufacturing technology is simple, the manufacturing cost is low, the yield is high, the service life of the net plate is long, and frictionresistance and cross section sharpness are obviously improved; and the service life reaches 100,000 times or more, and the purchasing cost of printing net plates is reduced for battery piece manufacturers.

Owner:昆山良品丝印器材有限公司

Wastewater treatment method based on electro-Fenton reaction

InactiveCN101798130AImprove conductivityLarge specific surface areaWater/sewage treatment by oxidationElectrochemical responseChemical reaction

The invention discloses a wastewater treatment method based on electro-Fenton reaction, comprising the following steps of: applying a power supply to an electrode containing ferrum in wastewater so that the ferrum of the electrode loses electrons to form ferrous ions, reducing dissolved oxygen in the wastewater on the surface of a stainless steel cathode to generate hydrogen peroxide, and then reacting the hydrogen peroxide with the ferrous ions in the water to generate hydroxyl radicals for oxidizing and degrading organic matters in the wastewater. The invention is characterized in that the wastewater treatment method adopts stainless steel wires as an anode and the cathode for electrochemical reaction, and the power supply applied to the anode and the cathode is a power supply the directions of the anode and the cathode of which can be switched. The invention can reduce by-products of the electrochemical reaction and subsequent wastewater treatment cost and improve reaction efficiency through adopting the stainless steel wires sold in the market as the anode for the electro-Fenton reaction; and meanwhile, due to the adoption of a programmable power supply to switch the directions of the anode and the cathode regularly, the invention effectively prolongs the service life of the electrode and can be widely applied to the treatment of the wastewater with various pH values.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

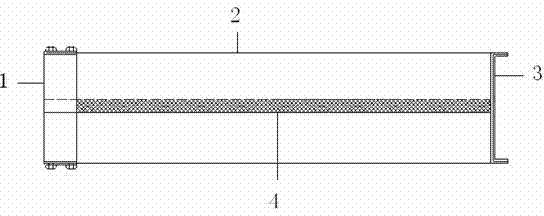

Soil column simulation experiment device aiming at reclaimed soil and coal ash matrix in mining area

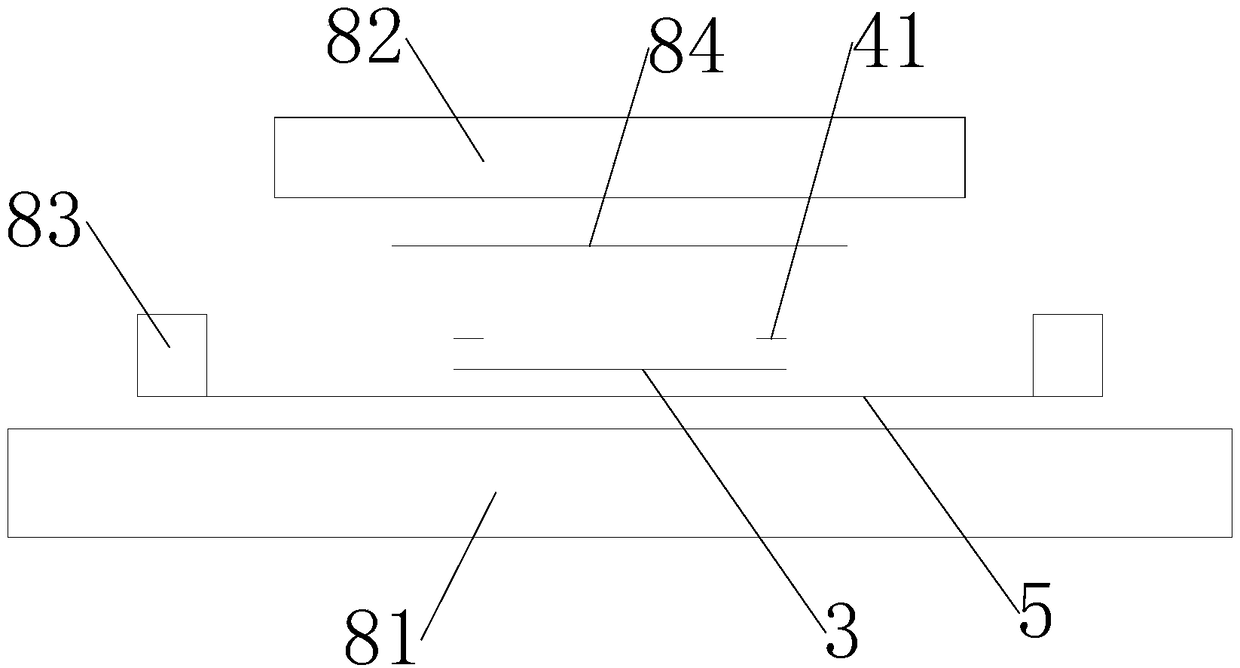

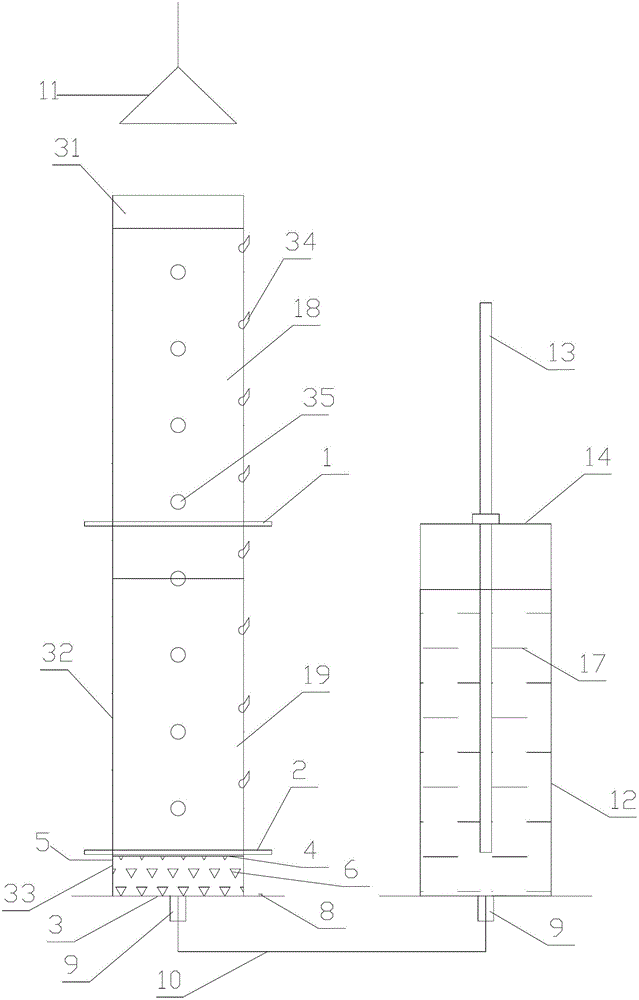

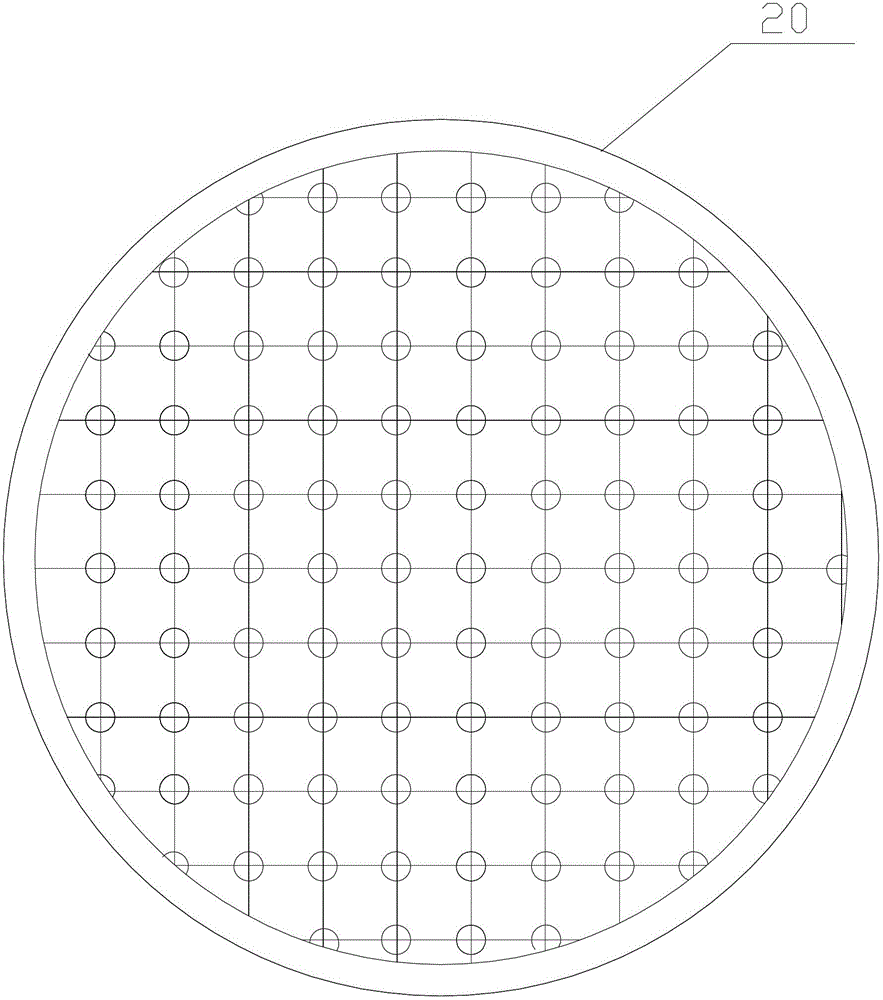

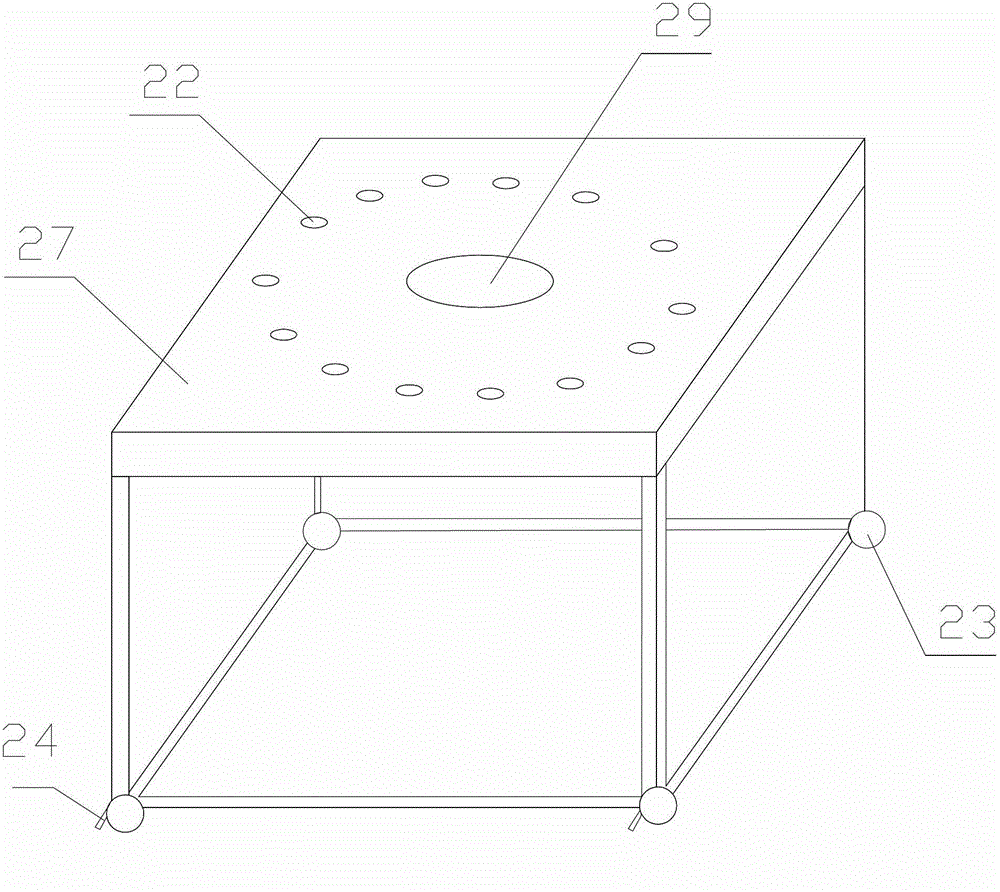

ActiveCN102721799ARealize dynamic observationThe result is accurateEarth material testingEvaporationCapillary water

The invention discloses a soil column simulation experiment device aiming at reclaimed soil and coal ash matrix in a mining area. The soil column simulation experiment device comprises a transparent column body, a plurality of flange disks, a movable plate, a stainless steel wire gauze, a base disk, a bracket and an underground water level simulation component, wherein the base disk is fixed at one end of the column body; the bracket is connected with the base disk; the column body has a multi-section structure and consists of a plurality of sub column bodies; two adjacent sub column bodies are fixedly connected by one of the flange disks; the movable plate and the stainless steel wire gauze are accommodated in a groove of the flange disk close to the bottom; and the underground water level simulation component is connected to the bottom of the base disk. The soil column simulation experiment device has the advantages that when capillary water rises, experiments such as soil water and salt movement under an atmosphere rainfall condition, soil water and salt movement under an evaporation condition and soil water and salt movement under an underground water level change control condition can be simulated; and the water and salt movement in the coal ash matrix of the reclaimed soil filled by the mining area coal ash can be dynamically observed through the device, so that a reclaiming mode suitable for crop growth can be found out.

Owner:ANHUI UNIV OF SCI & TECH

Super-hydrophobic coating layer used for oil-water separation and having hierarchical structure, super-hydrophobic material thereof, and preparation method of material

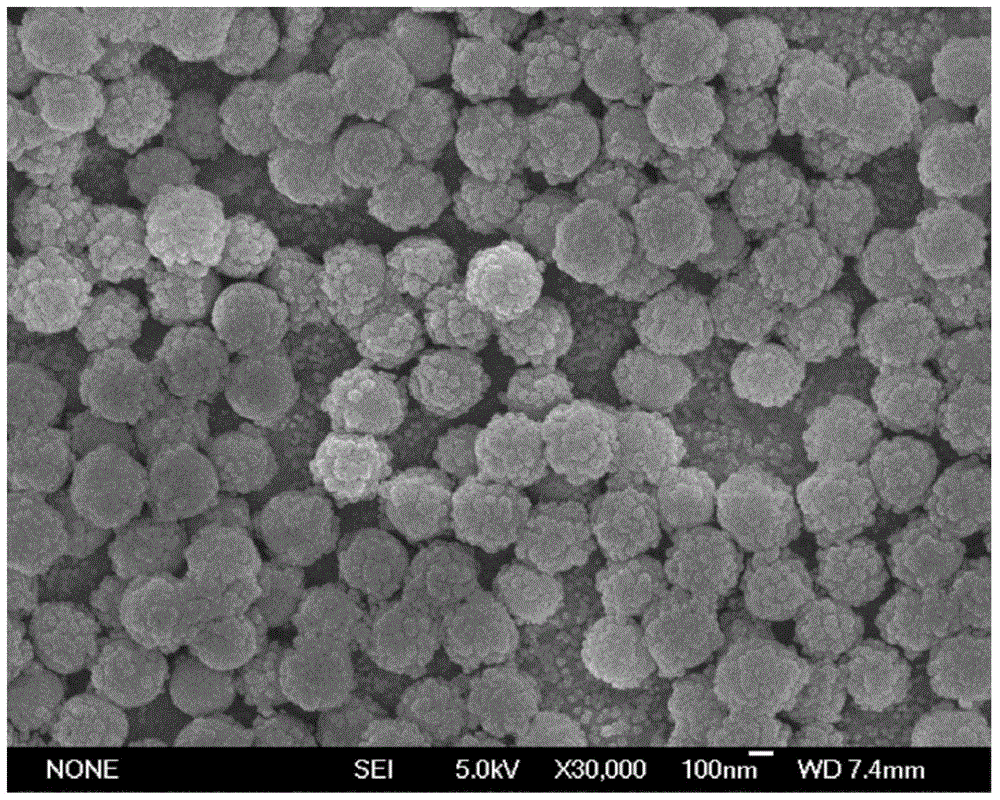

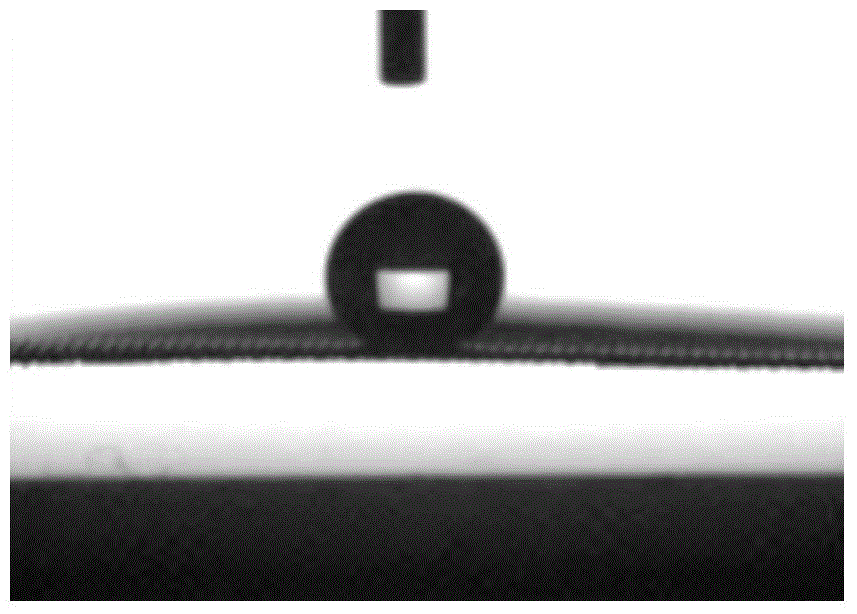

ActiveCN104802488AEasy to separateSimple processLayered productsCoatingsChemical industryOil water emulsion

The invention belongs to the technical field of preparation of nano-materials, and relates to a super-hydrophobic oil-water separation material containing a hierarchical structure coating layer. The hierarchical structure coating layer is formed by a layer of solid spherical SiO2 nano-particles with the particle size of 10-50nm and the particle size of 70-500nm, and the surface of the coating layer is provided with a layer of a low surface energy substance. The coating layer is obtained through layer-by-layer electrostatic in situ self-assembling, and can be used on stainless steel wire nets, stainless steel fiber sintered felts and other metal net products. The water contact angle of the stainless steel sintered nets coated with the hierarchical structure coating layer can exceed 150DEG. The material is simple to prepare, can be used to process filter core materials in coalescence separators, can be repeatedly used in oil-water separation, especially has a good separation effect on an oil-water emulsion, and can be widely used in oil-containing sewage treatment in the petroleum chemical industry, the metallurgy industry, the chemical engineering industry, the beverage industry, the food industry and the pharmacy industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

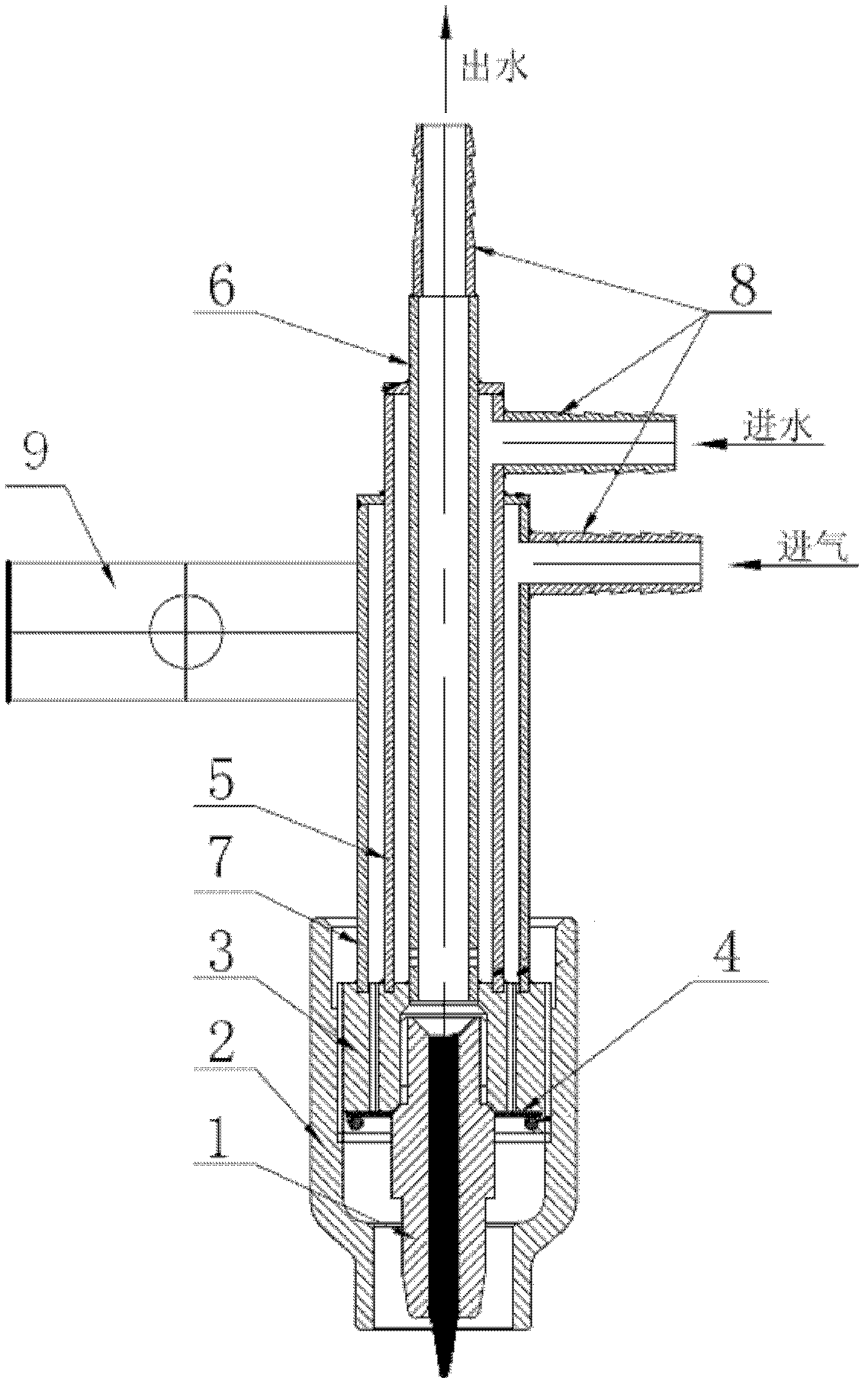

Condensation electric arc welding gun

InactiveCN102528249AIncrease energy densityAbility to control shapingElectrode supporting devicesElectrical conductorShielding gas

The invention discloses a condensation electric arc welding gun, which belongs to the technical field of welding equipment. A tungsten electrode is closely embedded in the center of an electrode holder; the electrode holder is sleeved in the center of a main connector through thread; the root part of the electrode holder is mutually engaged with the main connector by using an inclined surface, so that water cooling effect to the electrode and no leakage are guaranteed; a ceramic nozzle is sleeved on the periphery of the main connector through threaded connection; a protective gas laminar flow screen is a stainless steel wire net which is fixed on the other end face of the main connector through an O-shaped steel wire spring, so that protective gas forms laminar flow; a water outlet pipe, a water inlet bushing or a gas inlet bushing is provided with a cable connecting end; the water inlet bushing is coaxially sleeved outside a water outlet straight pipe; and the gas inlet bushing is sleeved outside the water inlet bushing, a water inlet passage is remained in the middle of the gas inlet bushing and the water inlet bushing, and the gas inlet bushing and the water inlet bushing are welded on the same end face of the main connector to form a water cooling passage and a gas protection passage. Apart from the ceramic nozzle, all the remaining materials are conductors. According to the condensation electric arc welding gun, the free electric arc energy intensity can be improved, and better capacity of controlling welding joint formation is achieved.

Owner:BEIJING UNIV OF TECH

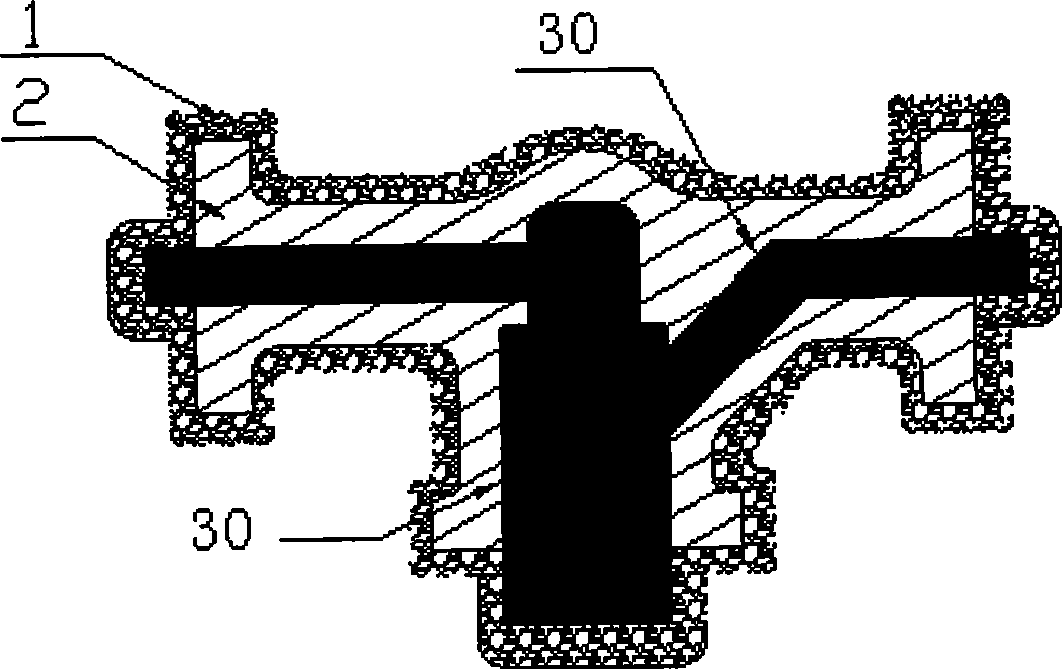

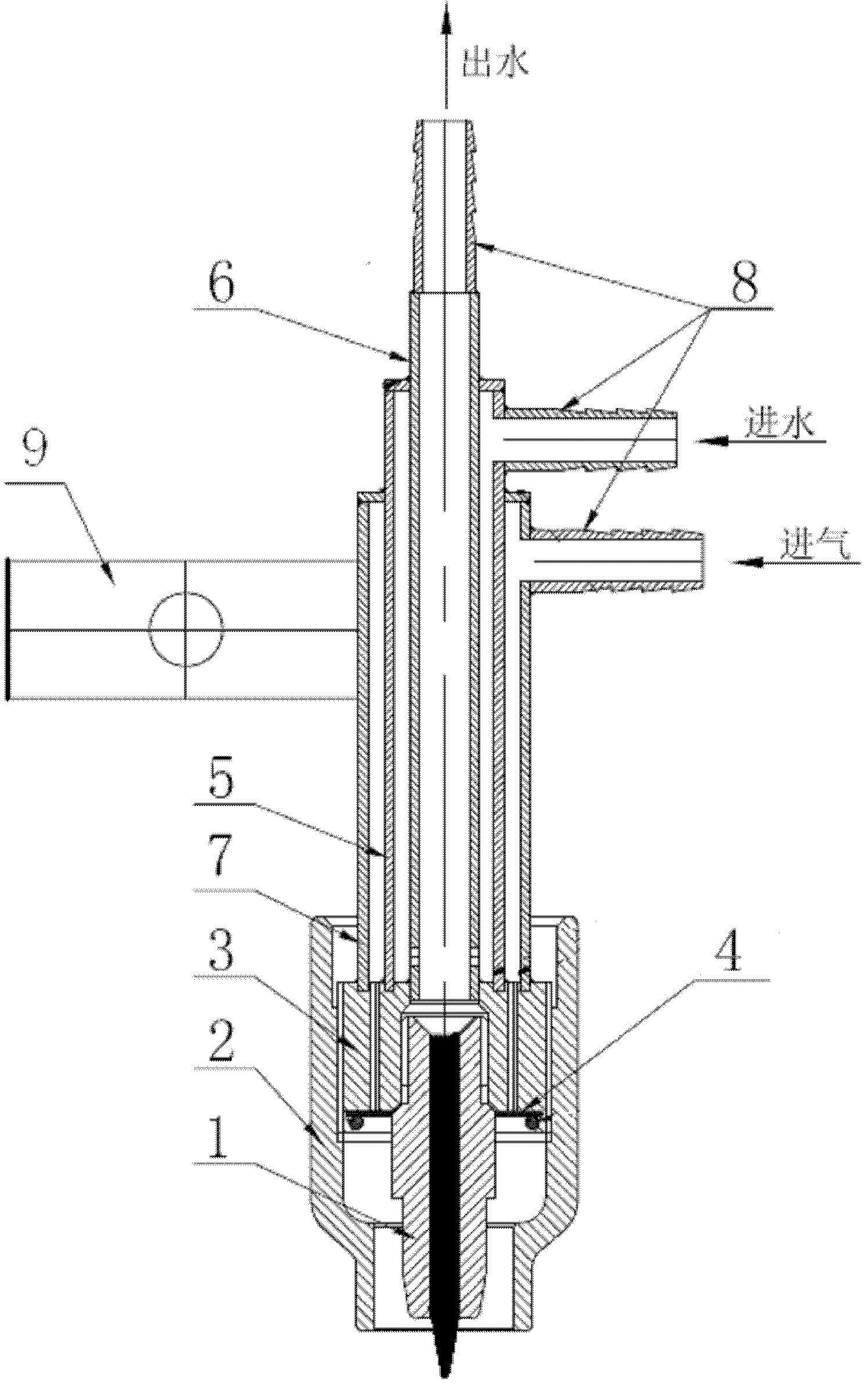

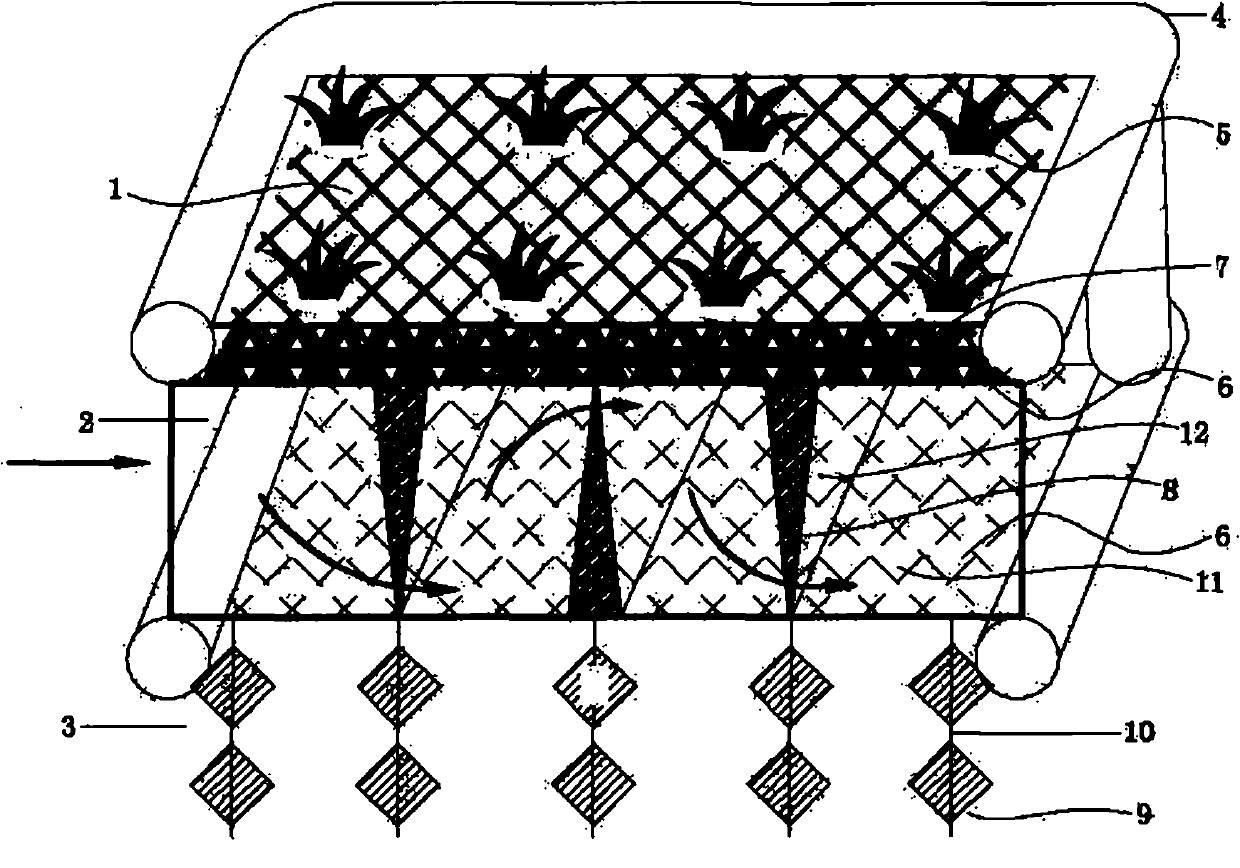

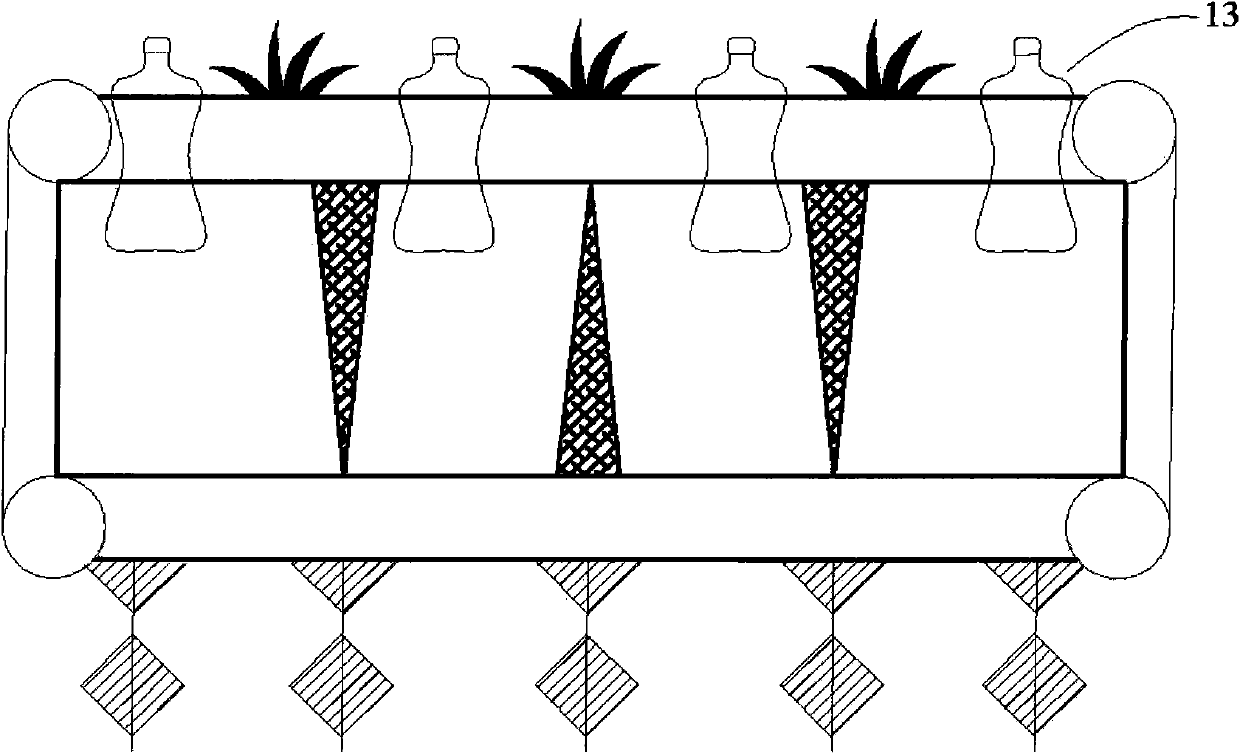

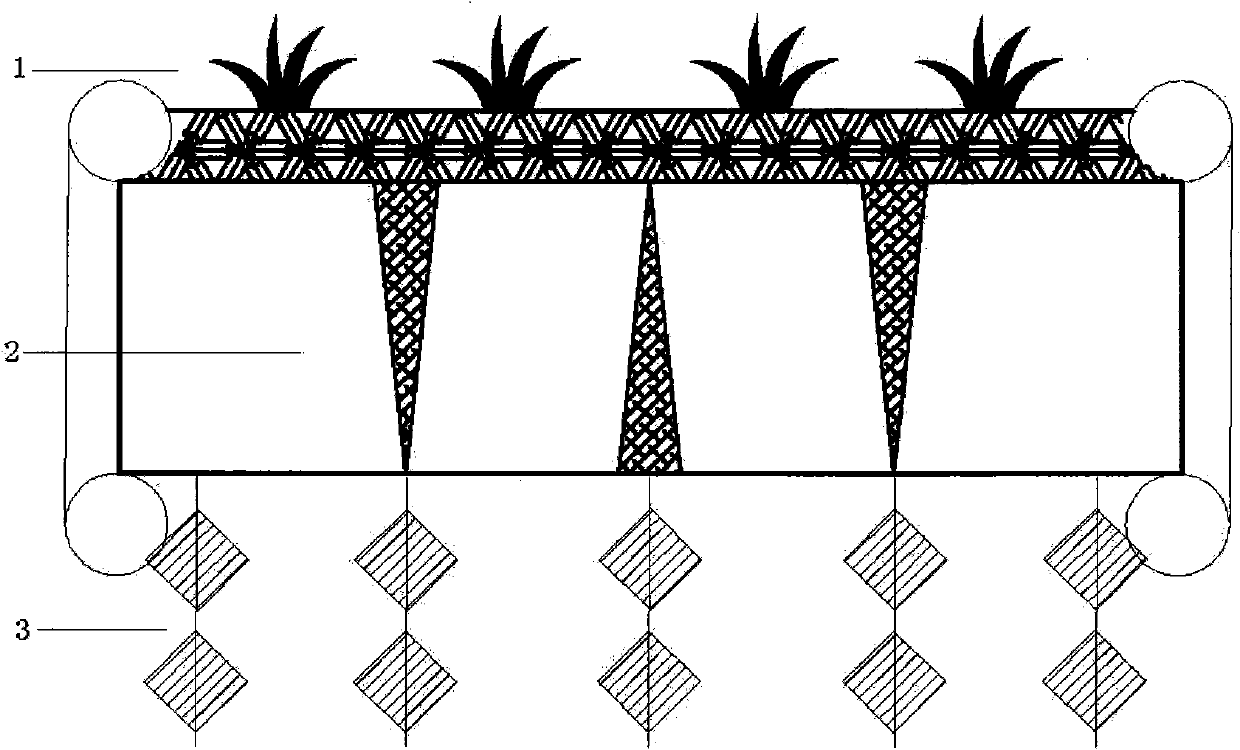

Automatic water oxygen-rich composite floating bed for strengthening biological carbon and phosphorous removal effect

InactiveCN101817591AOxygen enrichment achievedImprove self-cleaning functionTreatment with aerobic and anaerobic processesSupport matrixNitrogen

The invention relates to a method or a process for treating polluted water purification. An automatic water oxygen-rich composite floating bed for strengthening biological carbon and phosphorous removal effect is characterized by comprising a plant absorption and utilization unit (1), an automatic water oxygen-rich multistage aerobic-anaerobic reaction unit (2), a microbial film-forming reinforcement unit (3) and a framework (4); stainless steel wire gauzes (6) are fixed on the top, the bottom and the four sides of the framework (4); the plant absorption and utilization unit (1) consists of a support matrix (7) arranged on the top of the framework and a floating bed plant (5); and the floating bed converts the horizontal water flow passing through the automatic water oxygen-rich multistage aerobic-anaerobic reaction unit into N-shaped water flow so as to realize oxygen enrichment of water in an aerobic area on the middle layer of the floating bed and promote the self-cleaning function of the water of the middle layer.

Owner:HOHAI UNIV

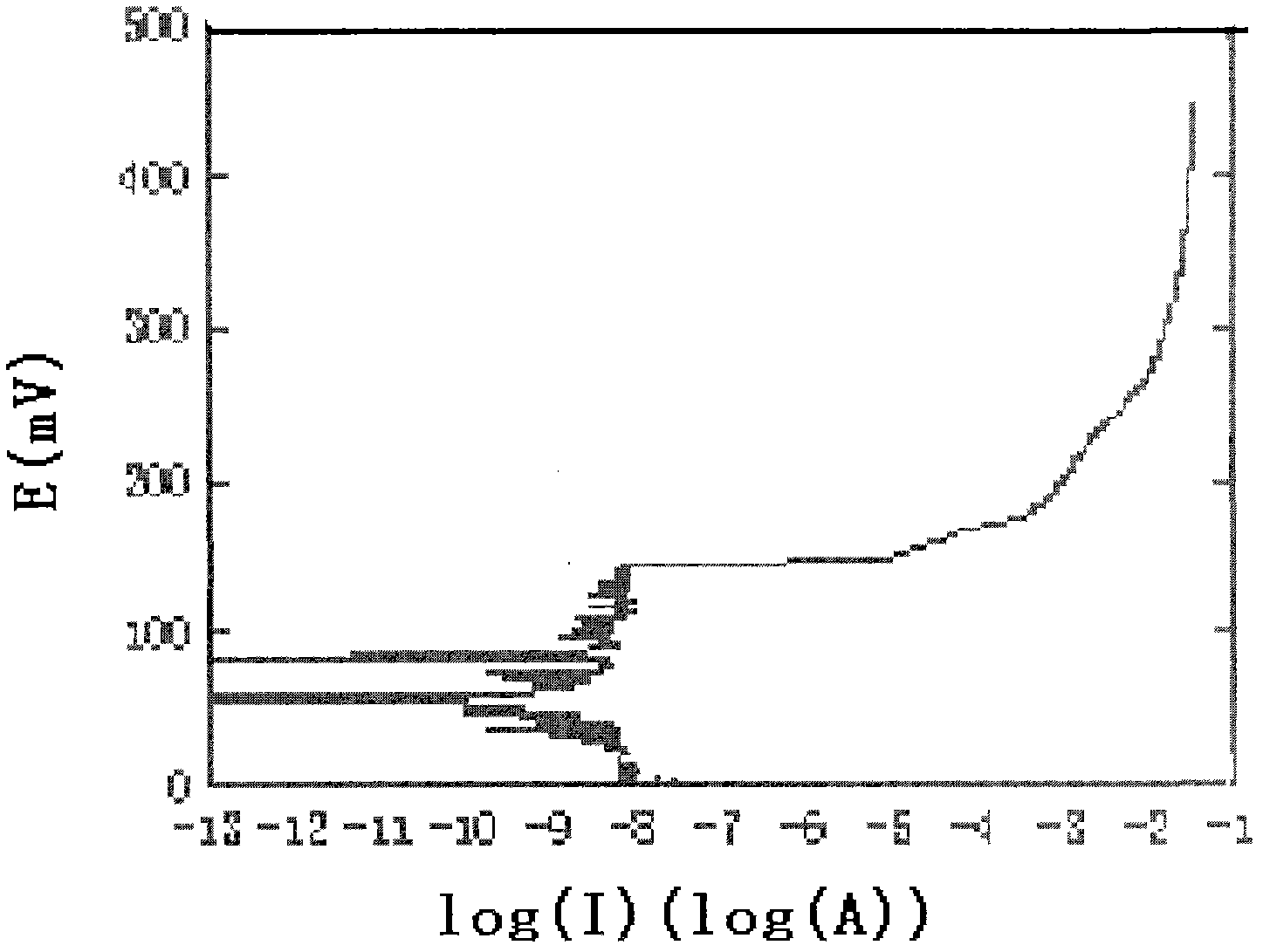

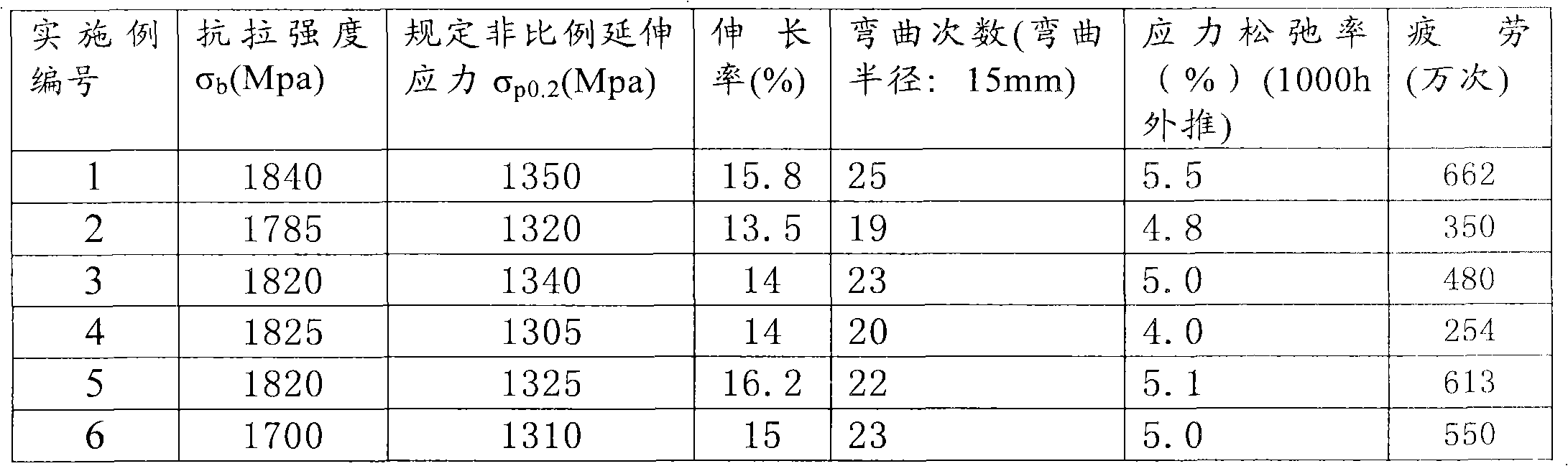

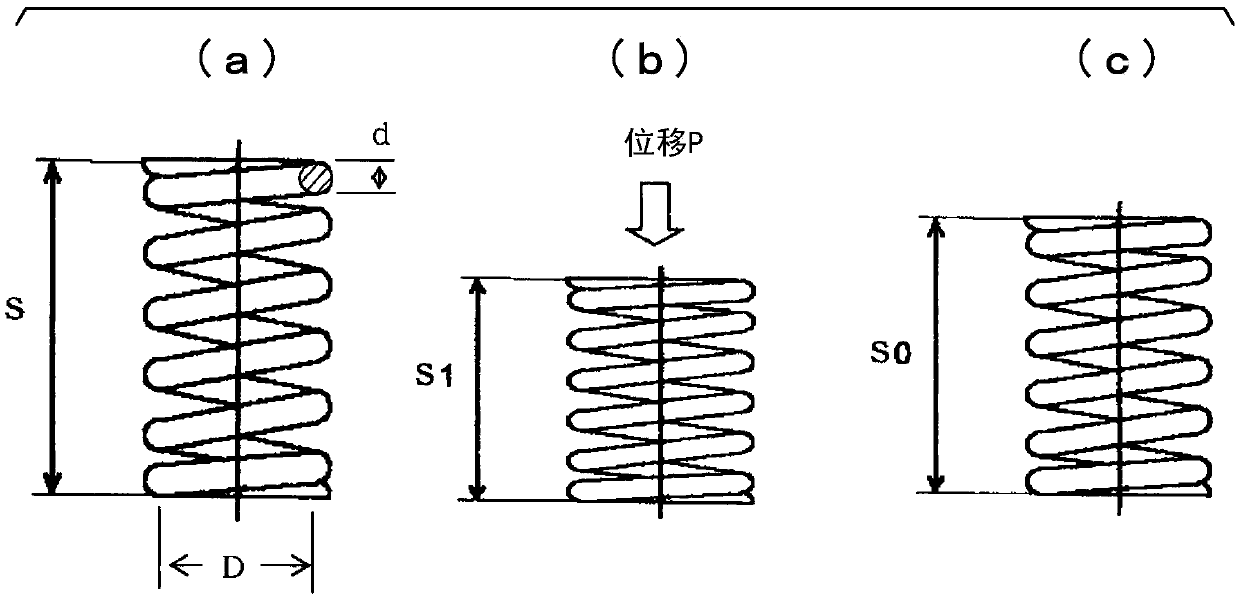

High-strength stainless steel wire having excellent heat deformation resistance, high-strength spring, and method for manufacturing same

ActiveCN104136645APromote precipitationExcellent heat deformation resistanceFurnace typesHeat treatment furnacesUltimate tensile strengthMartensite

This high-strength stainless steel wire contains, by mass percent, C (0.02-0.12%), N (0.005-0.03%), where 0.05% <= (C + N) <= 0.13%, Si (0.1-2.0%), Mn (0.1-2.0%), Ni (6.8-9.0%), Cr (12.0-14.4%), Mo (1.0-3.0%), and Al (0.5-2.0%), the remainder being Fe and unavoidable impurities; the generated index MdS value for deformation-induced martensite being 15-60, the amount of deformation-induced martensite being 80-99 vol%, and tensile strength being 1800-2200 MPa. MdS = 551 - 462 (C + N) - 9.2 Si - 8.1 Mn - 29 (Ni + Cu) - 13.7 Cr - 18.5 Mo

Owner:NIPPON STEEL STAINLESS STEEL CORP +1

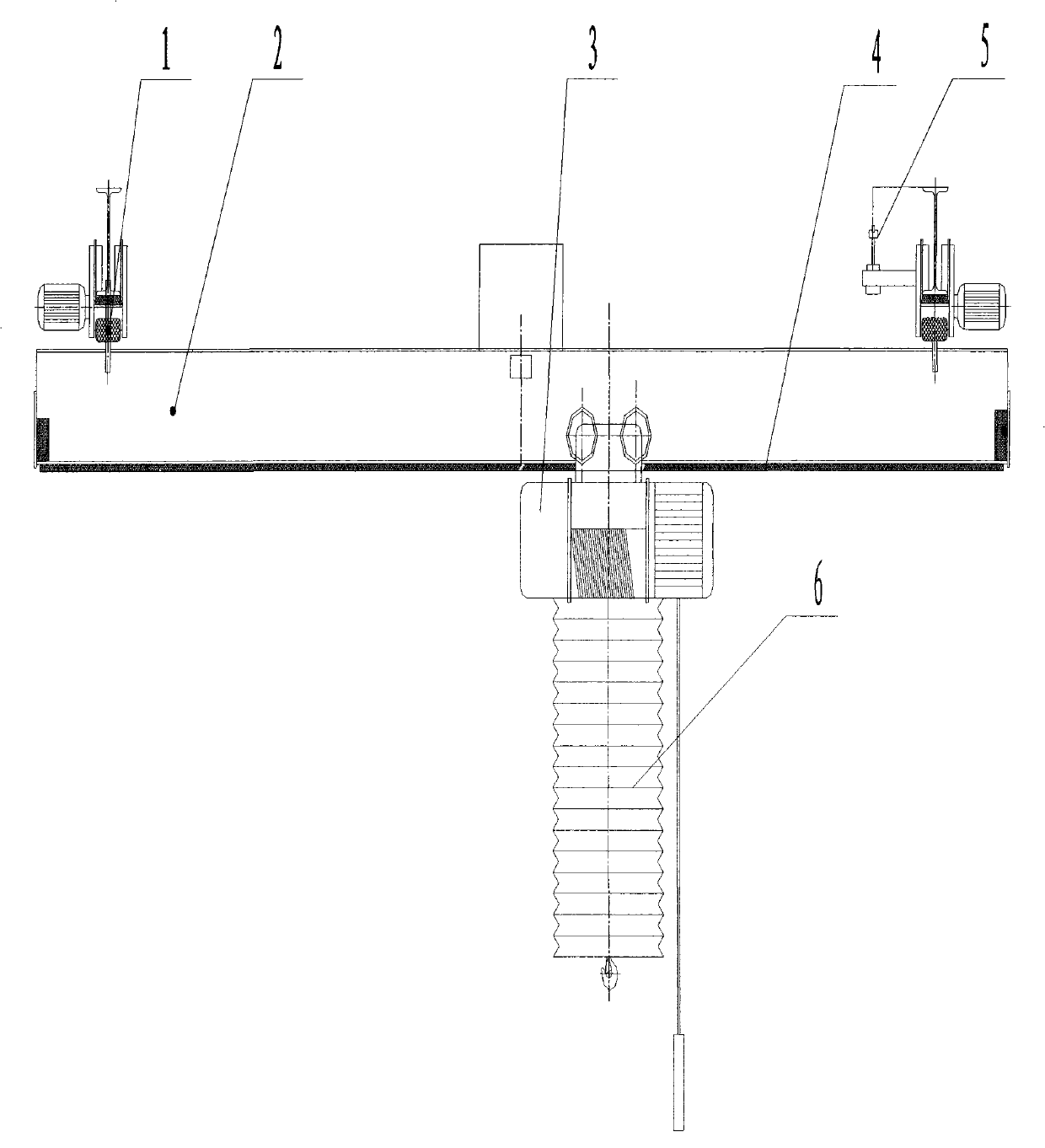

Clean and dust-proof crane

InactiveCN102020205AImprove dustproof effectImprove efficiencyCombination devicesTravelling cranesCycloneSlip line

The invention discloses a clean and dust-proof crane which comprises a crane and a dust remover. The crane comprises a crane cart end beam structure, a main beam, and a trolley; exsertion gears and wheels are both made of dust-free materials such as nylon or hard plastic; the cart end beam structure and the main beam are both made of stainless steel material; wheels of the cart and wheels of the trolley respectively have a dust-proof difference; the lifting steel wire rope is formed of stainless steel wires and the lifting steel wire rope and the pulley are all sealed in a dust-proof cover; a dust-proof safety slip line with a dust-proof device disposed at the lower part is adopted; the turbine fan of the wind-guiding wheel of the dust remover is fixed on the shaft of a motor, and the motor is fixed on a rectangular body by mounting feet; a dust collecting filter is disposed at the lower part of the turbine fan; the whirlwind dust collector includes a multi cyclone unit having a first cyclone and a secondary cyclone disposed outside the first cyclone. The crane has the advantages of excellent dust-proof effect and high efficiency, and is convenient to use.

Owner:CHENGDU WEST TAILI INTELLIGENT EQUIP CO LTD

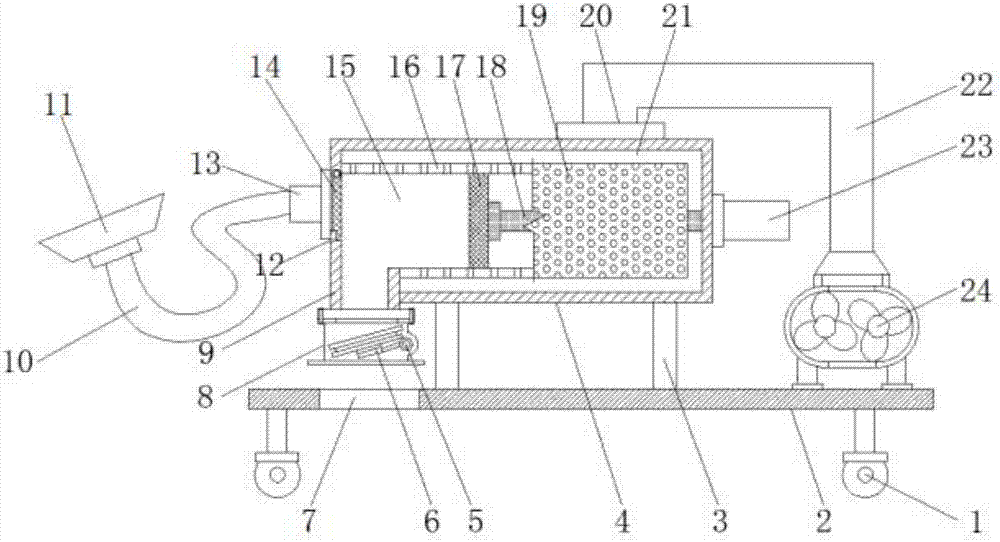

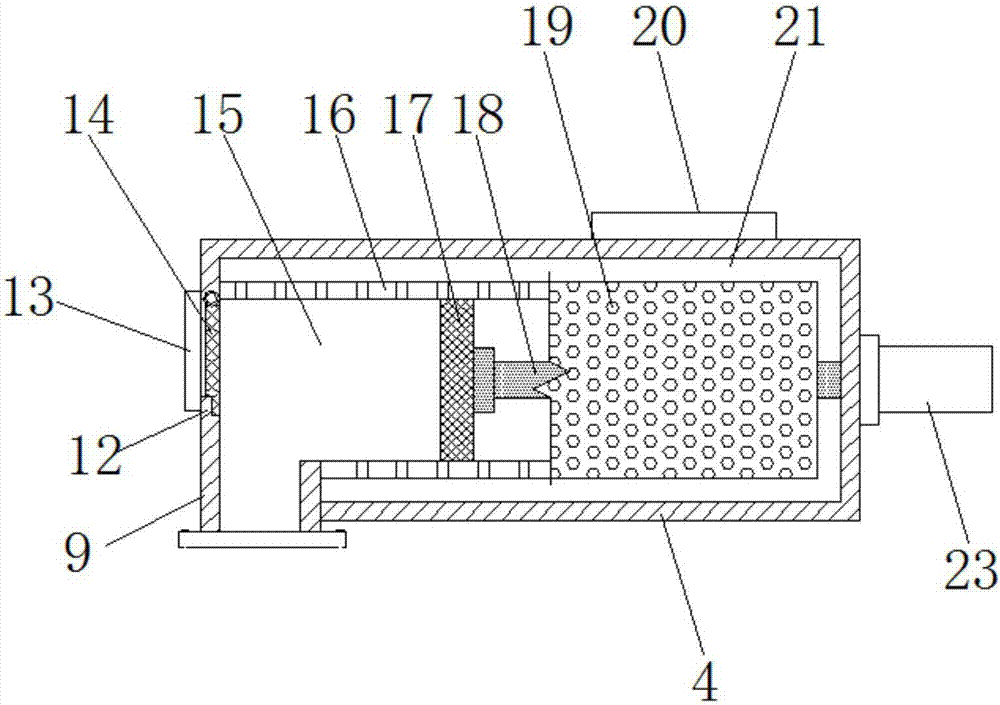

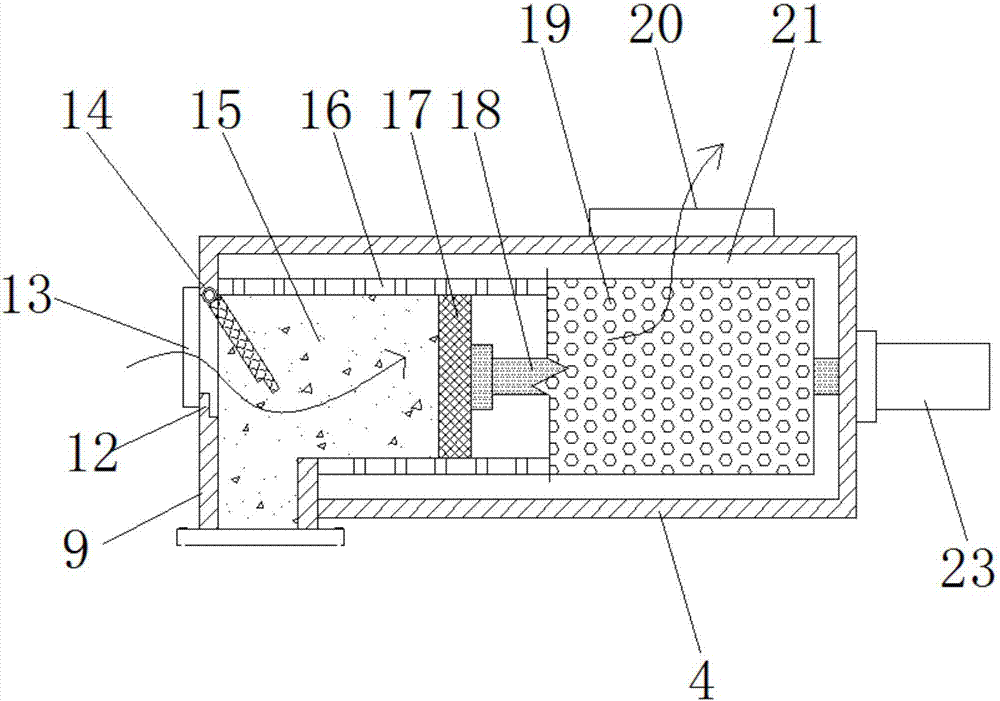

Park fallen leaf suction away and compression device

InactiveCN107139525AImprove structural strengthAvoid deformationRoad cleaningPressesCompression deviceEngineering

The invention discloses a garden leaf suction and compression device, which comprises a fallen leaf collection cylinder, a falling flap valve, a fallen leaf filter cylinder and a stainless steel wire mesh pressing plate. A fallen leaf filter cartridge is welded inside the fallen leaf collection cylinder; the fallen leaf filter cartridge is set as a fallen leaf collection compression chamber, and the front end of the fallen leaf collection cylinder is provided with a fallen leaf input port, and the fallen leaf input port is connected to the fallen leaf collection compression chamber; the fallen leaf filter cartridge The inner slide is equipped with a stainless steel wire mesh pressure plate; the structure is high in strength, convenient and quick to move, saving time and effort, and it is convenient to suck the fallen leaves into the leaf filter cartridge and filter out the fallen leaves, so as to realize the suction of the fallen leaves in the garden, under the compression of the stainless steel wire mesh pressure plate , The fallen leaves filtered in the fallen leaf filter cartridge are pressed into cakes and discharged from the falling flap valve to realize the compression of fallen leaves, improve the efficiency and convenience of compressed and discharged fallen leaves, and facilitate the continuous and uninterrupted absorption of fallen leaves in the garden.

Owner:惠安县灿鑫新材料科技有限公司

Stainless steel pipeline welding connection method and center-adjustable connection clamp

InactiveCN104551356ASave operating timeAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesStainless steel wireSteel pipeline

The invention discloses a stainless steel pipeline welding connection method and a center-adjustable connection clamp. The stainless steel pipeline welding connection method comprises the following steps: A, performing slope holes in the end parts of two or more stainless steel pipelines; B, coaxially arranging the stainless steel pipelines with the preformed slope holes, and filling the space between the preformed slope holes of the every two adjacent stainless steel pipelines with stainless steel sheets and stainless steel wires; C, coating the section, near the slope hole, of each stainless steel pipeline with a layer of anti-splashing agent for welding and the like before welding to wrap and cover the section, near the slope hole, of the stainless steel pipeline; D, mounting an argon protection device filled with argon in the stainless steel pipeline at the to-be-welded part; E, finishing the welding process, cooling the stainless steel pipeline to lower than 50 DEG C, and dismounting the center-adjustable connection clamp. According to the method, the position welding operation which has to be carried out in a conventional method can be avoided, the damage to base metal due to position welding can be completely avoided, the operation time for pipeline assembly and welding is shortened, and the overall precision of a pipeline product is guaranteed.

Owner:LONGKOU CIMC RAFFLES OFFSHORE +2

Radiation-proof fabric and production process thereof

The invention relates to a radiation prevention facing material and manufacturing technique thereof. The radiation protection facing material is principally formed by mutually interlacing a set of warp thread and a set of weft thread, a set of warp thread includes a plurality of warp thread stainless steel wires, a set of weft thread includes a plurality of stainless steel cladding threads which are composed by cladding and winding stainless steel wire on the terylene silk thread or real silk silk thread, and a shielding meshwork with radiation protection function by mutually interlacing the cladding thread and the weft thread stainless steel wire. The manufacturing technique of the radiation protection facing material includes in sequence a single filament twisting process, a fiber strand process, a coating process, a warping process and a weaving process, the tensile force of the silk thread is strictly controlled in these processes. The inventive radiation prevention facing material has good electro-magnetic screen effect, permanent radiation protection function and low production cost.

Owner:SUZHOU XINMIN SILK CO LTD

Wire coated with diamond powder on surface for wire cutting machine

InactiveCN1721113AExpand the range of cutting applicationsAchieve reductionMetal sawing toolsWire cuttingConductive materials

The present invention relates to metal wire (1) with surface plated diamond power (2) used to wire cut machine tool. The thickness of diamond power is 1-4 thread; the metal wire can be steel wire, stainless steel wire, tungsten-molybdenum wire, molybdenum wire and brass wire. It plates diamond power on wire surface for its high hardness (HRC92-95Deg), needs not galvanize impulse current, just through the wire cycle straight line motion on wire cut machine matched with proper sumping amount to realize the cutting for non-conductive material particular to high hardness ( more than HRC 87Deg) material. It enlarges application range for wire cut machine tool.

Owner:上海中晶企业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com