Condensation electric arc welding gun

A technology of arc welding and electrode holders, which is applied in the field of welding torches and arc welding torches, can solve problems such as difficulty in further increasing energy density, difficulty in improving welding production efficiency, excessive heat input and heat-affected zone, etc., and achieves improved welding production efficiency and good Ability to control weld shape, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

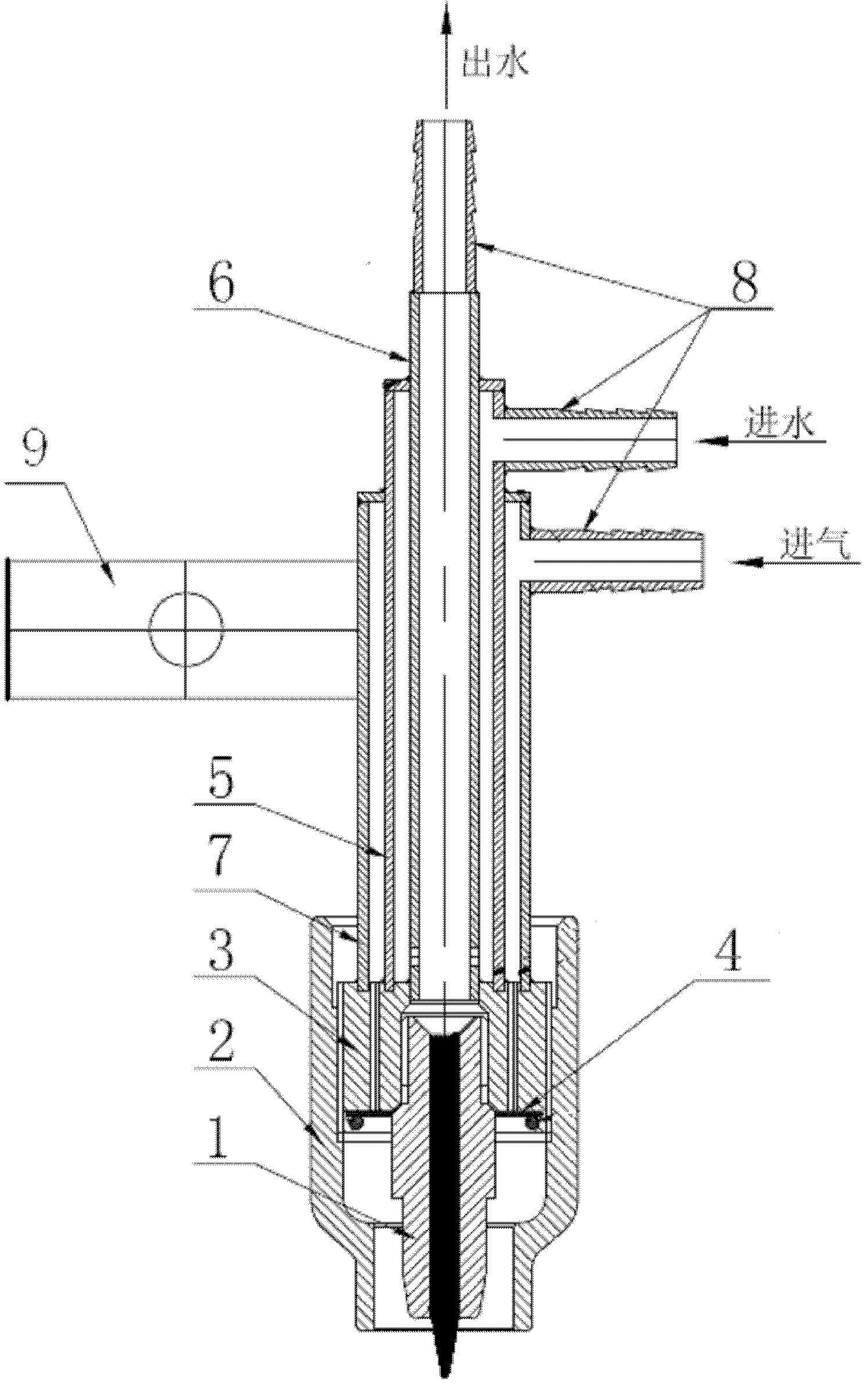

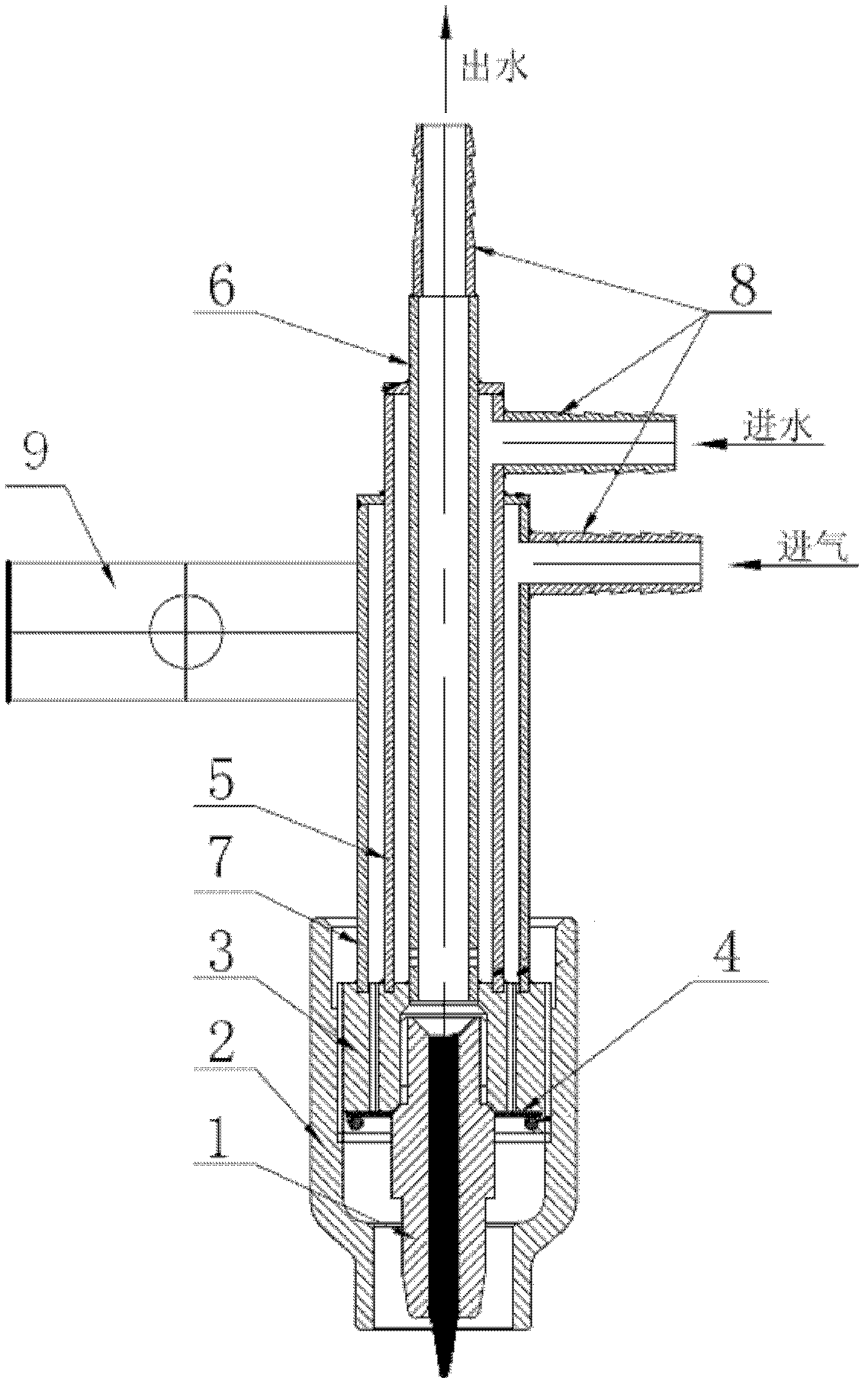

[0015] The structure diagram of the condensation arc welding torch is shown in figure 1 , the main connecting body 3 is a circular cylinder with threads on the inside and outside; one end of the water outlet straight pipe 6 is coaxially welded on one end face of the main connecting body, and has a through hole; the water inlet casing 5 is coaxially sleeved On the outside of the straight water outlet pipe, there is a water inlet channel in the middle. The water inlet channel communicates with the straight water outlet pipe through the hole on the straight water outlet pipe. The water inlet sleeve is also welded on the same end face of the main connector. It is sealed and welded together with the water outlet straight pipe, and is provided with a water inlet; the air inlet sleeve 7 is coaxially sleeved outside the water inlet sleeve, and an air inlet channel is left in the middle, and the air inlet sleeve is also welded on the same part of the main connecting body. The end face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com