Patents

Literature

322results about How to "Improve welding productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

900MPa high-strength steel preheating-free combined welding method

The invention discloses a 900MPa high-strength steel preheating-free combined welding method. 700-800 MPa low-hydrogen type high-tenacity shielded metal arc welding is adopted for backing welding, then a 900MPa high-tenacity solid wire is matched with Ar+CO2 mixed gas shielded welding for implementing filling welding, and a 800MPa flux-cored wire is matched with CO2 gas shielded welding for cosmetic welding. A crack-free welding joint can be obtained by welding 900MPa high-strength steel through adopting a preheating-free and postweld heat treatment free combined welding process, and a joint region is smooth and clean, and can meet operating requirements on a high-strength steel welding structure for higher bearing capacity because the room temperature tensile strength of weld metal is more than 860MPa and the damping power of a V-shaped notch of the weld metal with the test temperature of 0 DEG C is more than 90J; and meanwhile, the method has welding cost reduced by about 25 percent, simple and convenient operation and easy popularization.

Owner:SHANDONG UNIV

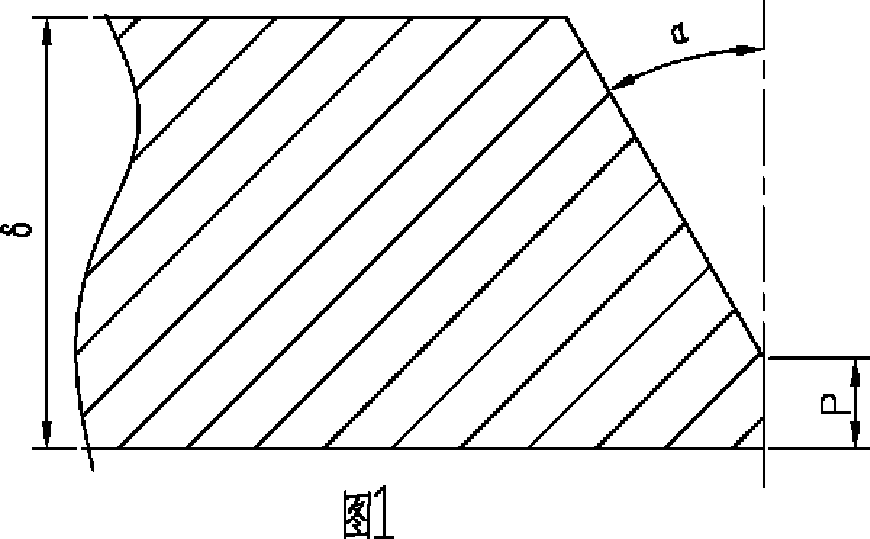

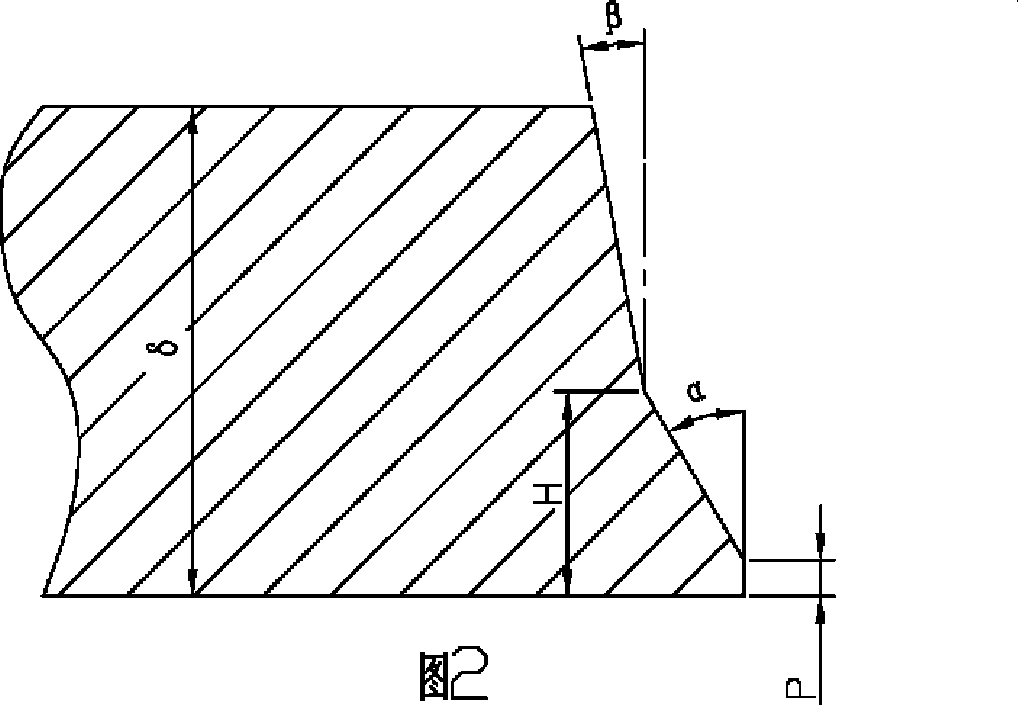

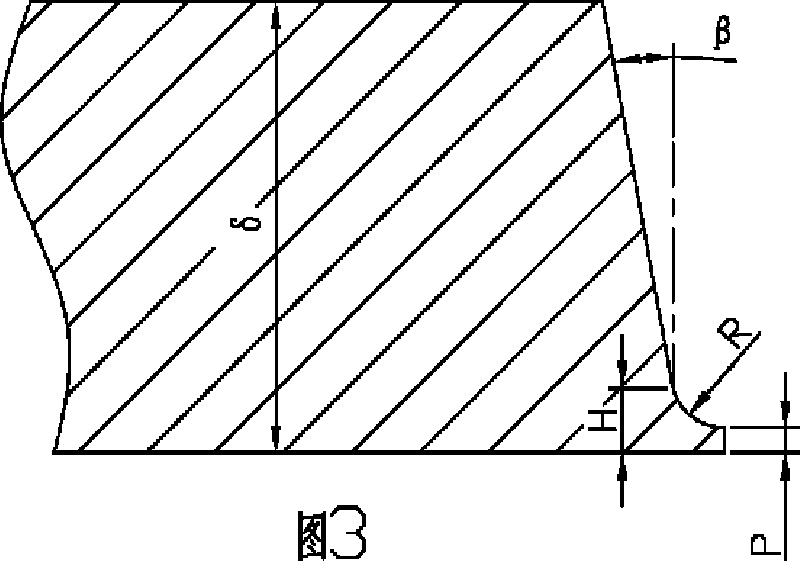

Lower alloy steel laser-electric arc hybrid welding method

InactiveCN103495810AImprove forming qualityImprove welding qualityMetal working apparatusWorkpiece edge portionsHeat-affected zonePetrochemical

The invention relates to a lower alloy steel laser-electric arc hybrid welding method in the technical field of metallurgy, machinery, ships, automobiles, pipelines, petrochemical industry, marine equipment, pressure vessels, war industry and the like. In order to solve the problems existing in a traditional welding method, on the basis of the effect law of laser-electric arc coupling characteristics and laser-electric arc hybrid welding parameters, the welding parameters and the groove sizes of all welding joints of multilayer welding are optimized with the orthogonal design test method, and the researched and developed lower alloy steel laser-electric arc hybrid welding method has the advantages of being small in heat input amount, large in fusion depth, small in deformation and high in welding speed, capable of reducing the area of the welding joints, the width of the heat affected zone and the exhaust amount of harmful gas and smoke and favorable for improving welding quality and welding efficiency, lowering production cost, improving the quality of products and relieving environmental pollution. The method includes the processing steps that welding grooves are machined, the optimized welding parameters are adopted for all the welding joints of the multilayer welding, and lower alloy steel laser-electric arc hybrid welding is performed.

Owner:JILIN UNIV

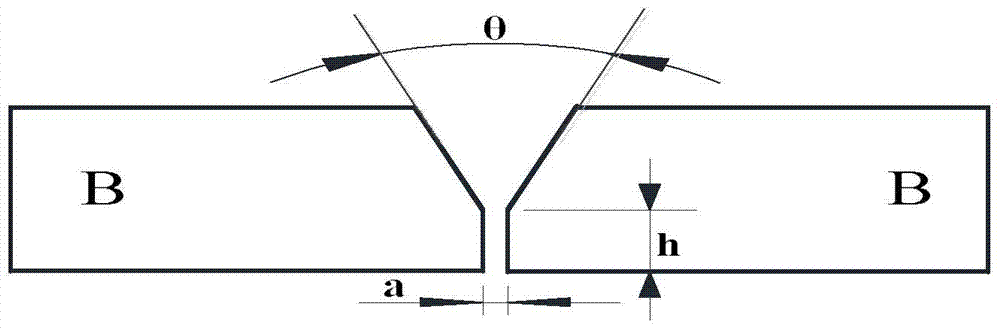

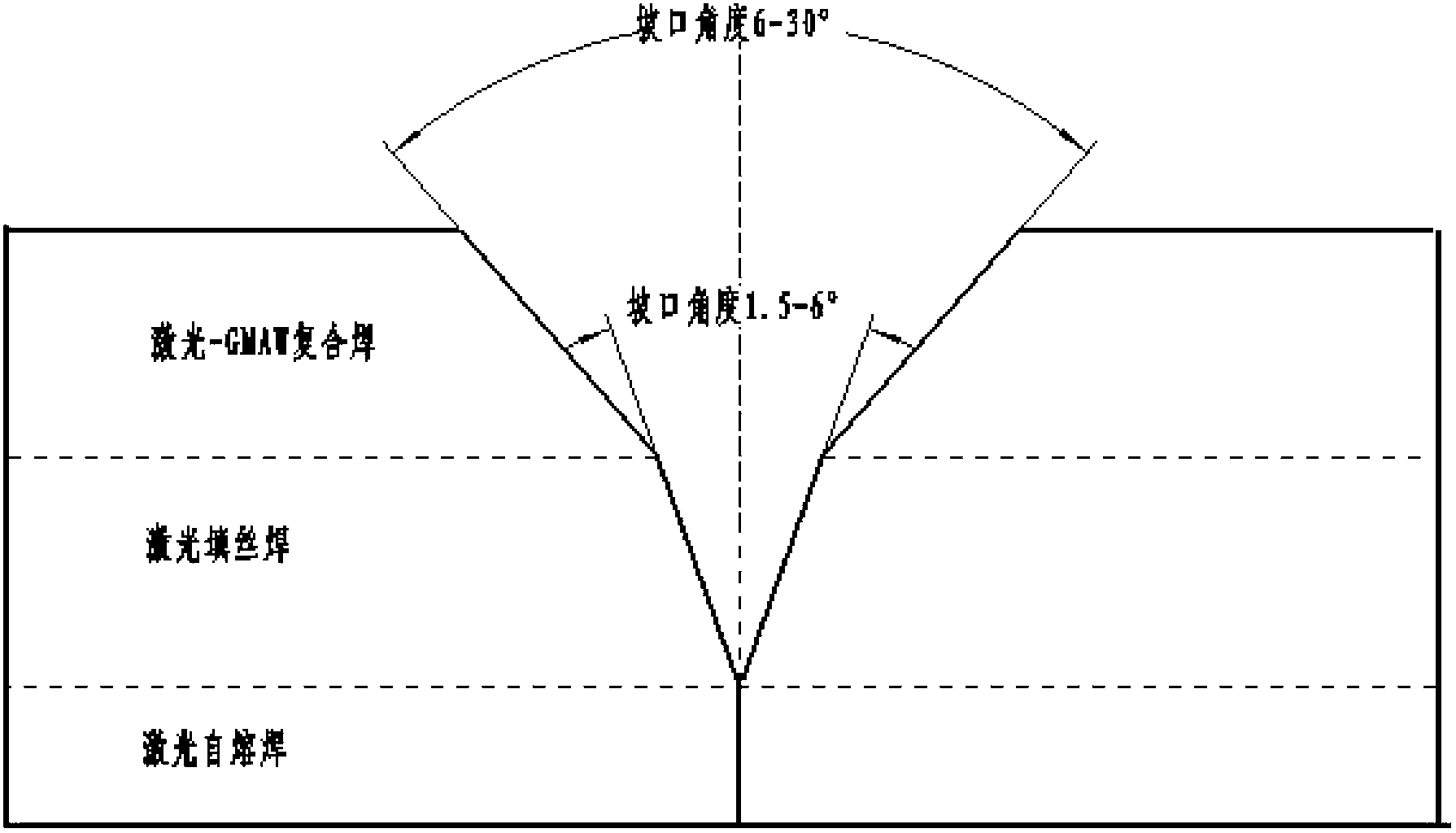

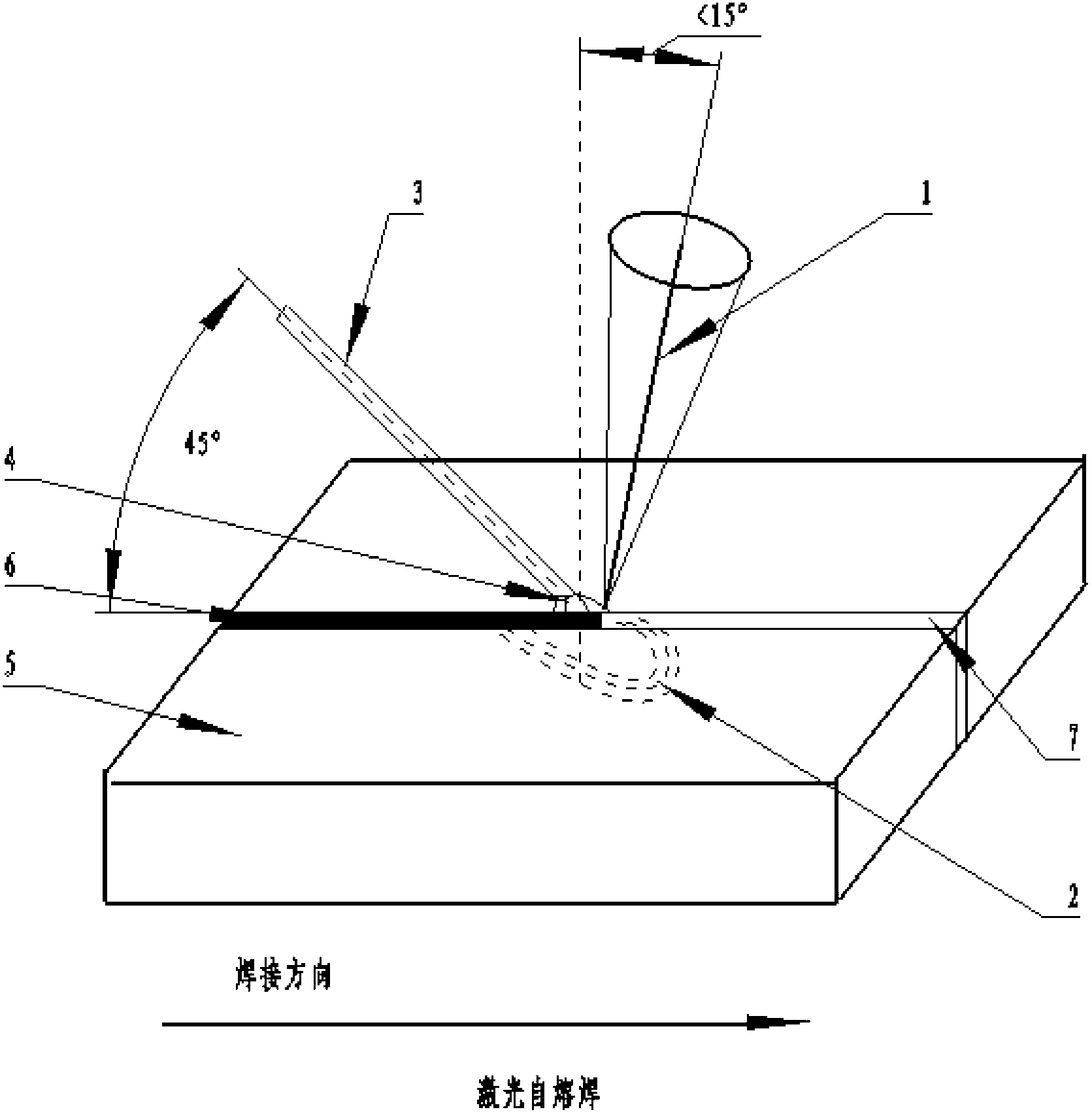

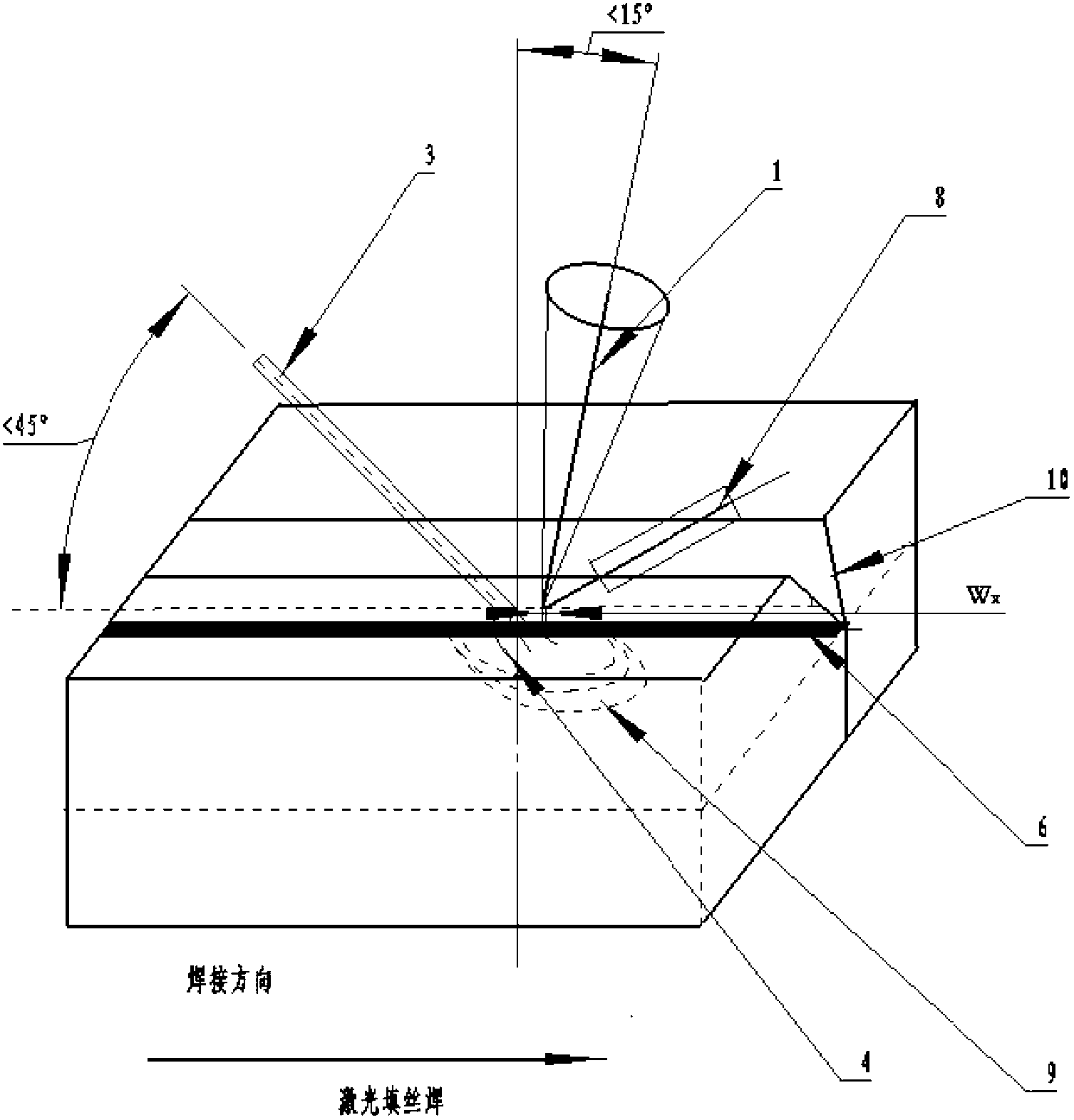

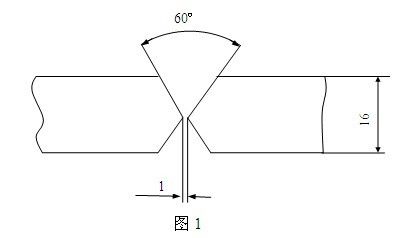

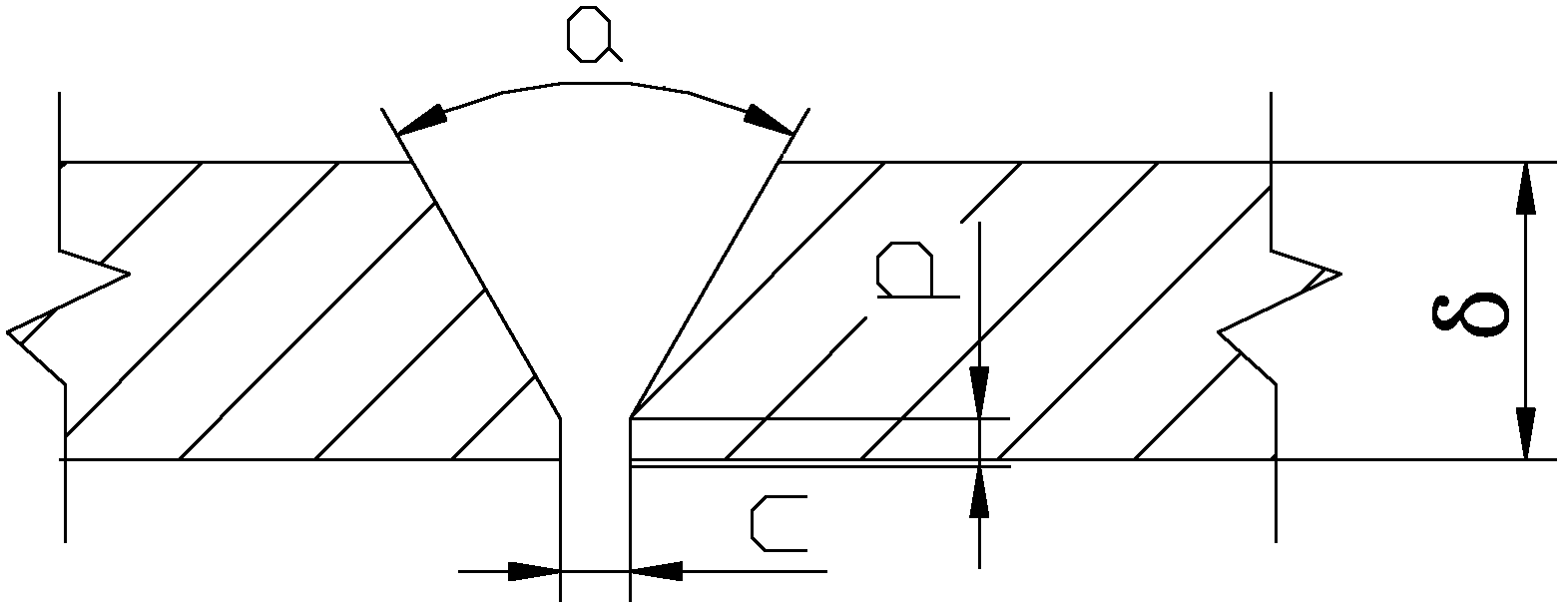

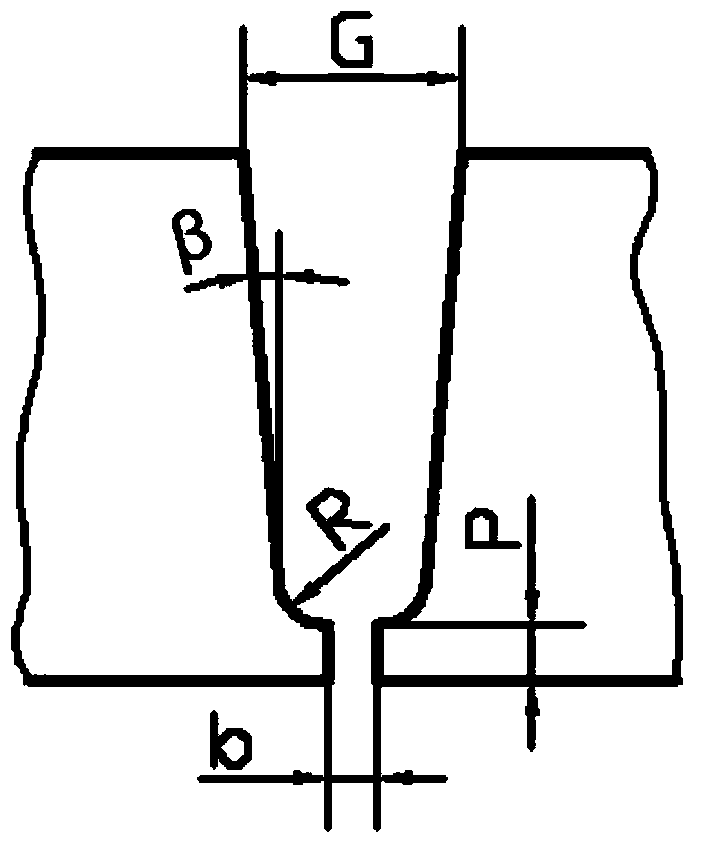

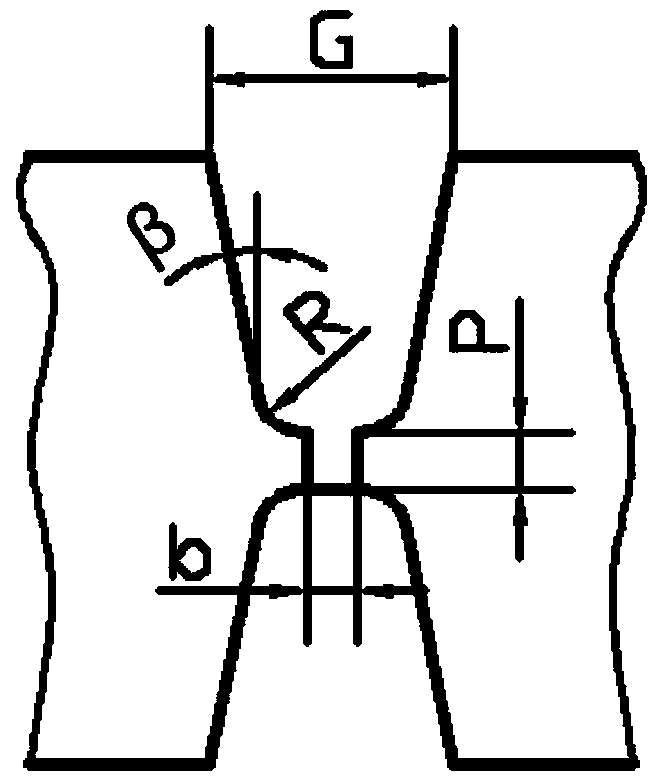

Narrow gap multi-pass laser welding method for thick plate

InactiveCN103008895AReduce consumptionImprove welding productivityLaser beam welding apparatusWorkpiece edge portionsThick plateGas metal arc welding

The invention discloses a laser welding method for a thick plate. A gap is reserved on the thick plate or a divided edge with a blunted edge is performed, a laser autogenous welding is adopted at the welding bead part for welding a pass for bottoming, then, the laser wire filling welding is carried out, a welding wire and a laser beam maintain an included angle being 15 degrees to 75 degrees, the welding wire extends into the divided edge gap from the front of the laser beam, when the filling wire welding cannot fully fill the divided edge gap, the laser-GMAW (gas metal arc welding) composite welding is finally carried out, and the welding of the thick plate is completed. The preserved gap value is respectively smaller than or equal to 0.5mm, the width of the performed welding bead used for the wire filling welding is smaller than or equal to 2.5mm, and the width of the performed welding bead used for the composite welding is smaller than or equal to 10mm. The laser welding method has the advantages that the problem of high-efficiency and high-quality welding of the thick plate is solved, so high-quality and efficient thick plate welding joints with small welding deformation and high gap bridging capability are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

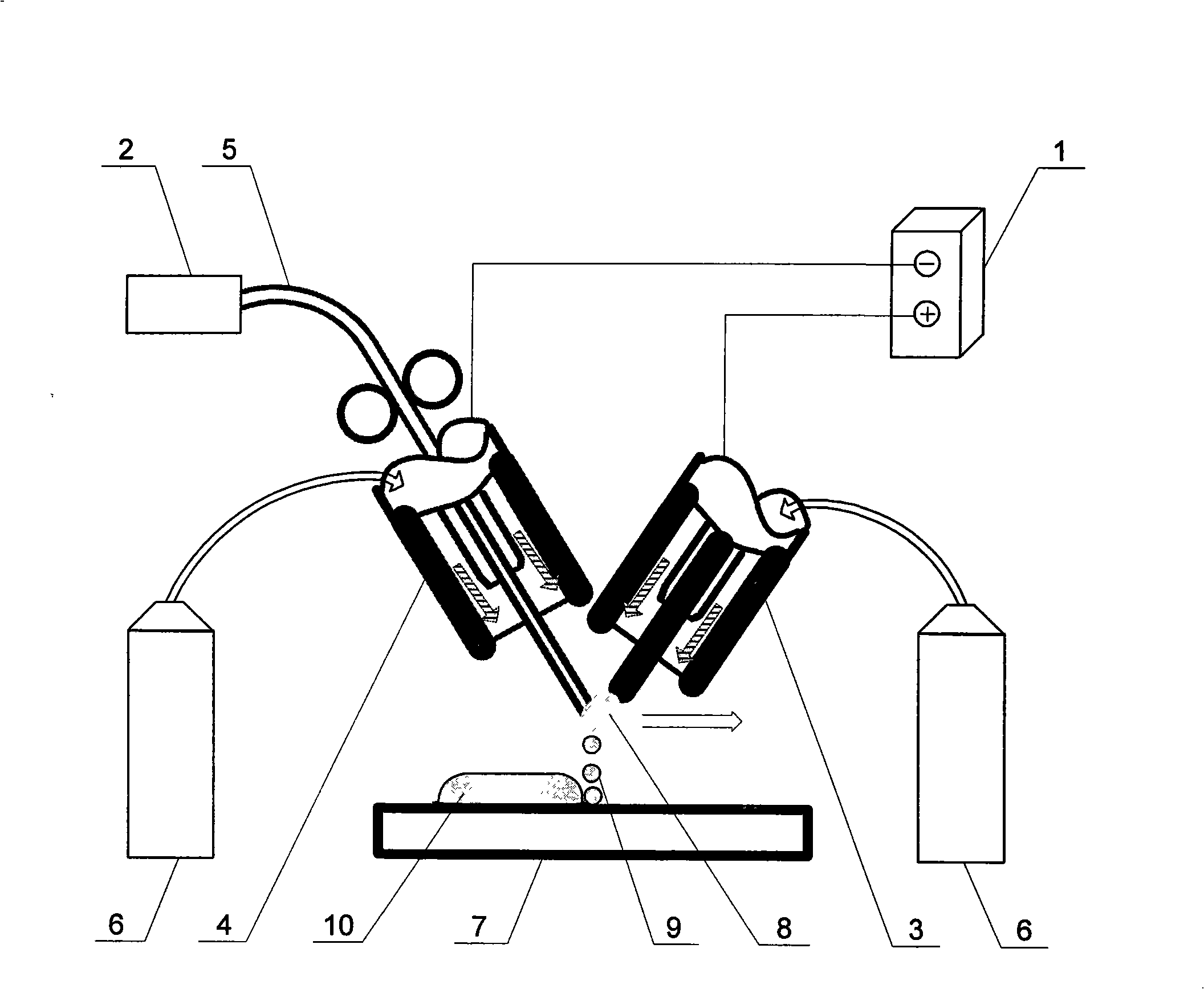

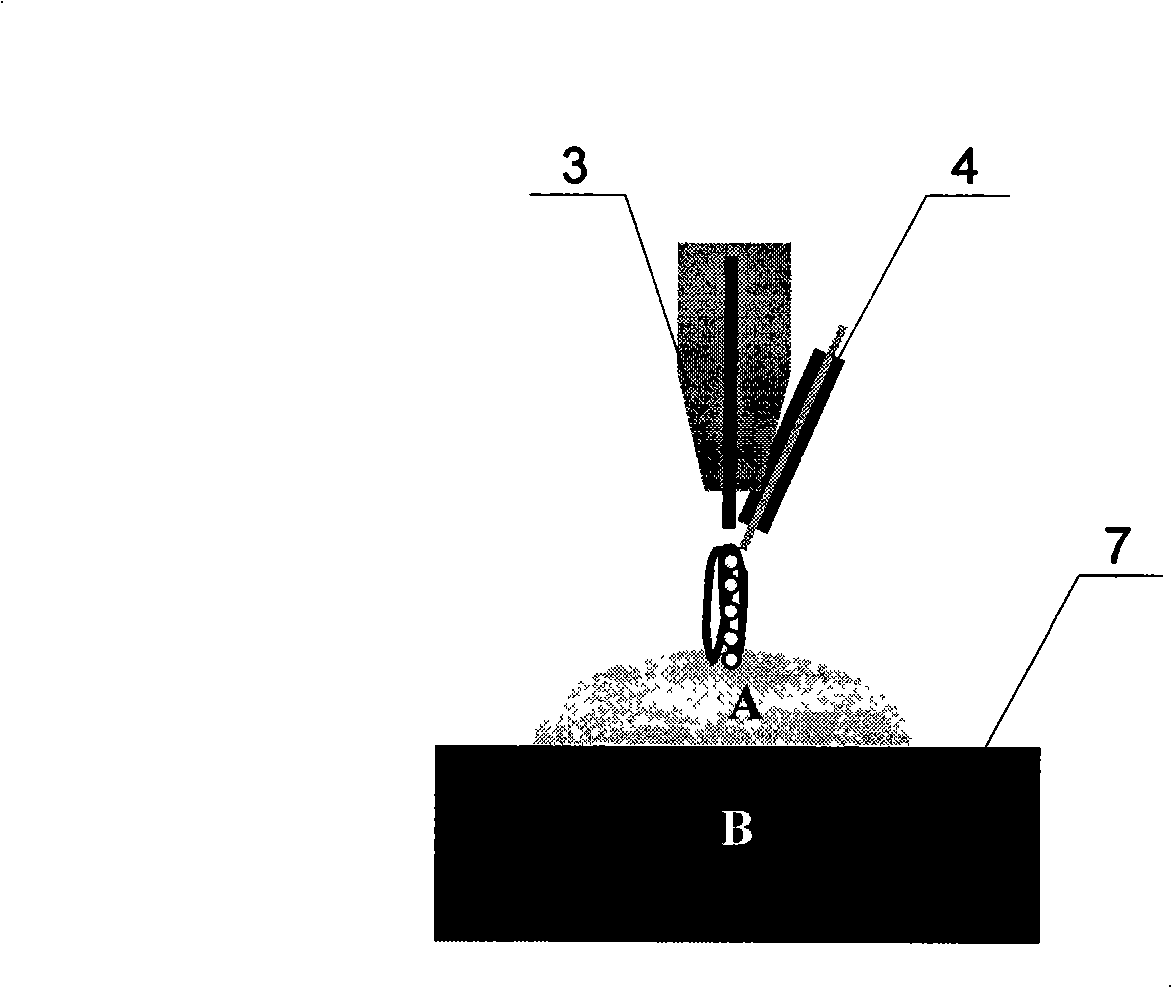

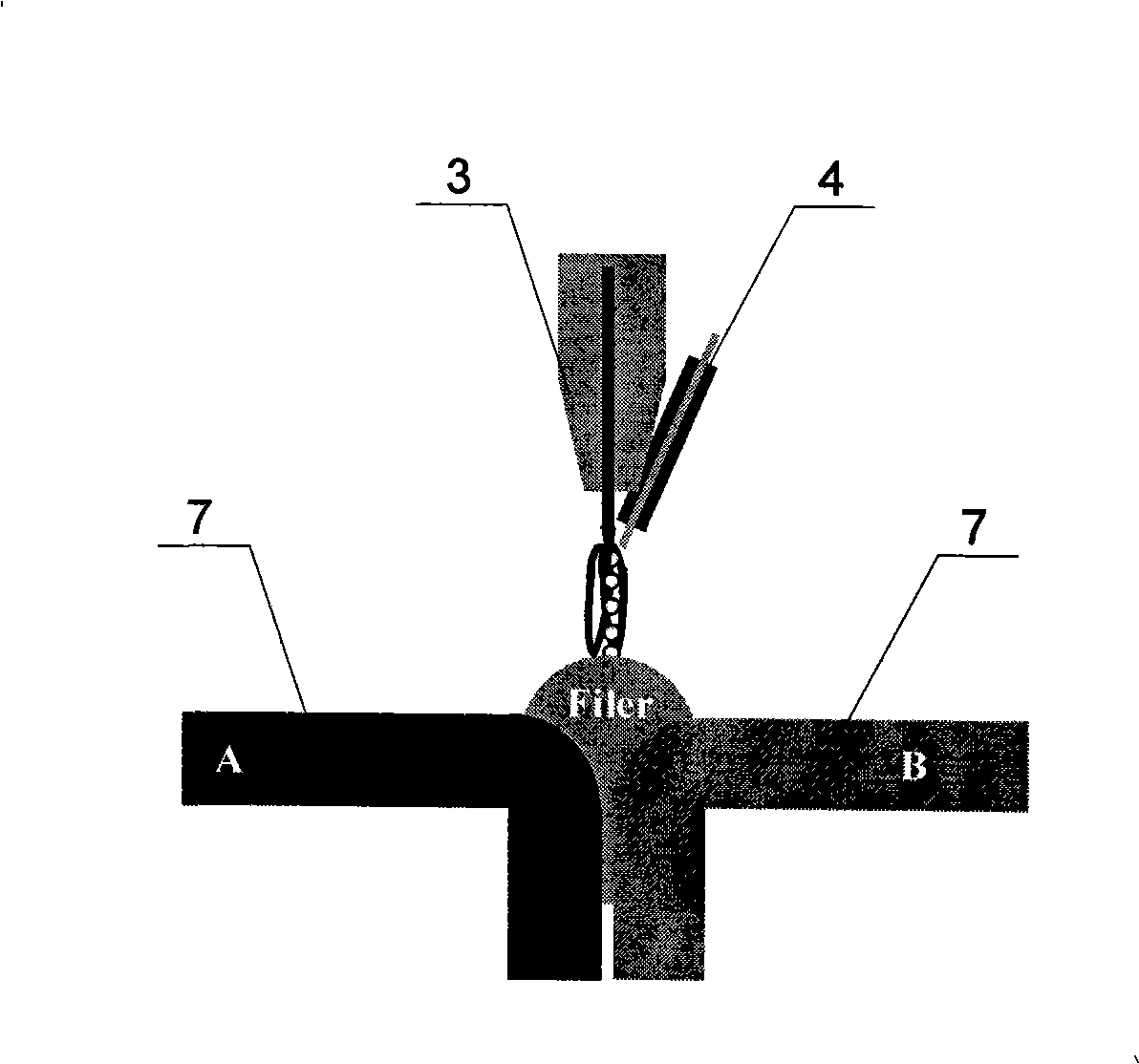

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

Semi-automatic welding method of metal flux cored filler rod conduit root

ActiveCN101417364AQuality improvementReduce cleanup costsArc welding apparatusWorkpiece edge portionsShielding gasMetal powder

The invention relates to the technical field of welding of a long distance pipeline and is a semi-automatic welding method of root welding of a pipeline with metal powder core welding wire; the root welding layer welding is carried out as follows: the metal powder core welding wire and short arc control technology are adopted, protective gases are added to carry out welding of root welding bead of full position; the welding parameters are as follows: welding current is 140A to 200A; the welding voltage is 15V to 18V; the welding speed is 16cm / min to 26cm / min; the wire feed speed is 350cm / min to 500cm / min; the wire extension is 8mm to 12mm; and the pendulum deflection is based on that weld metal is deposited to the edge of a welding pipeline. The method solves the bottleneck problem of restraining the flow construction operation of the semi-automatic welding, effectively solves the problems of undercut, depression and the like of the back surface of welding seams of circular welding joints, reduces the cost of cleaning of the surface of welding pipelines, reduces the labor intensity of workers, increases the thickness of deposited metal, reduces the welding layers, greatly improves welding production efficiency, obtains high-quality welding seams and improves the welding speed, can reduce one third time of welding compared with manual welding and reduces the operation cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

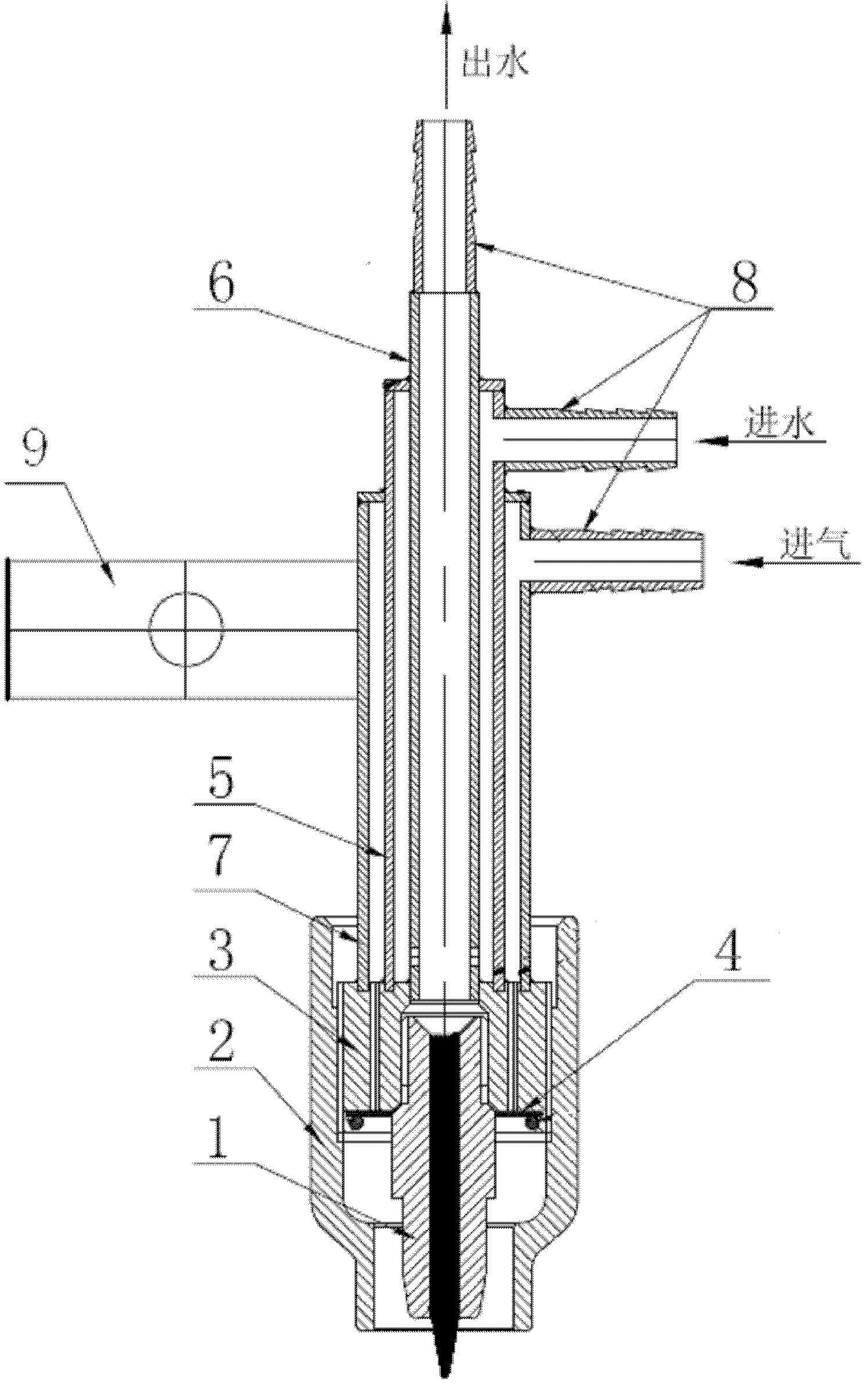

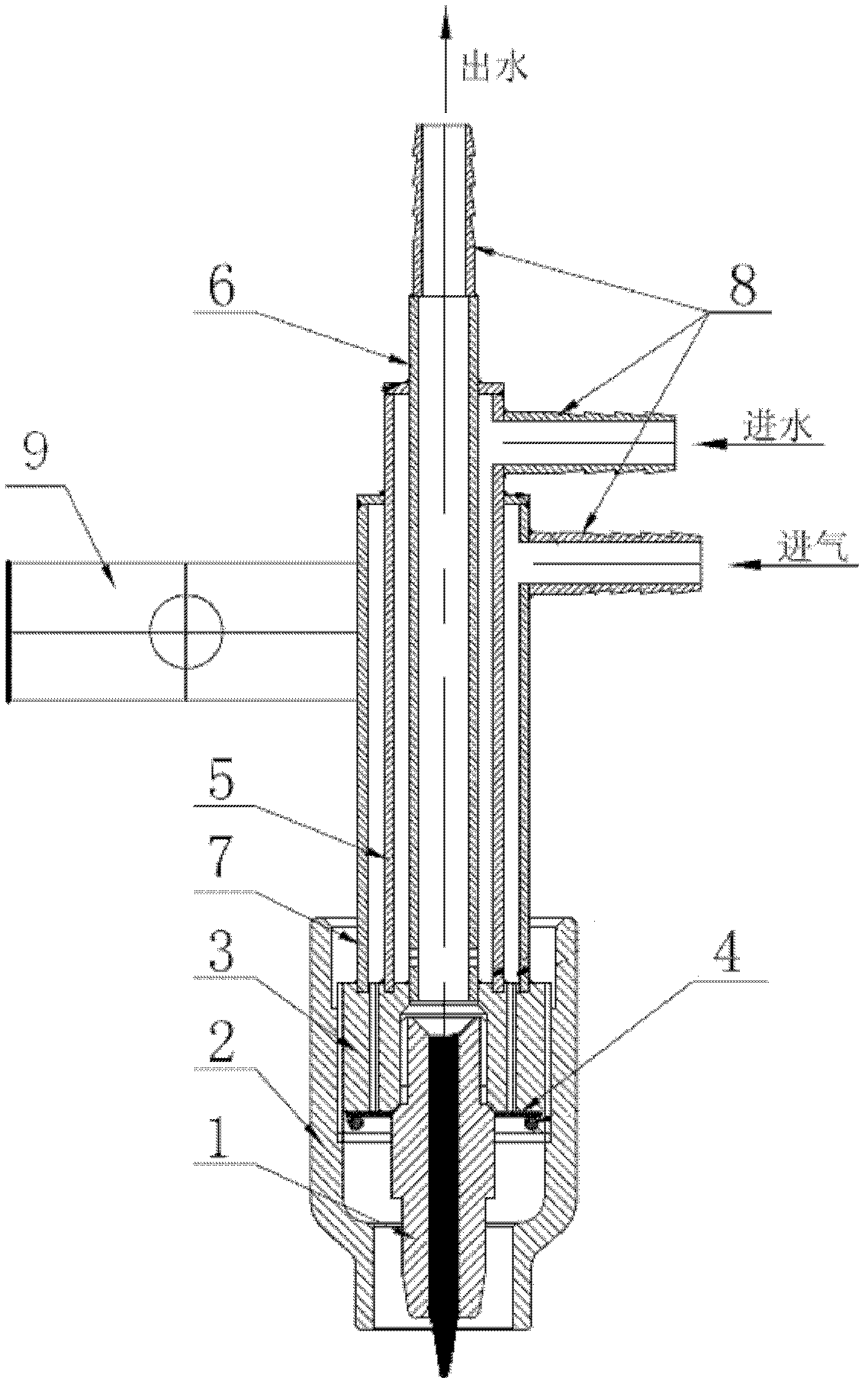

Condensation electric arc welding gun

InactiveCN102528249AIncrease energy densityAbility to control shapingElectrode supporting devicesElectrical conductorShielding gas

The invention discloses a condensation electric arc welding gun, which belongs to the technical field of welding equipment. A tungsten electrode is closely embedded in the center of an electrode holder; the electrode holder is sleeved in the center of a main connector through thread; the root part of the electrode holder is mutually engaged with the main connector by using an inclined surface, so that water cooling effect to the electrode and no leakage are guaranteed; a ceramic nozzle is sleeved on the periphery of the main connector through threaded connection; a protective gas laminar flow screen is a stainless steel wire net which is fixed on the other end face of the main connector through an O-shaped steel wire spring, so that protective gas forms laminar flow; a water outlet pipe, a water inlet bushing or a gas inlet bushing is provided with a cable connecting end; the water inlet bushing is coaxially sleeved outside a water outlet straight pipe; and the gas inlet bushing is sleeved outside the water inlet bushing, a water inlet passage is remained in the middle of the gas inlet bushing and the water inlet bushing, and the gas inlet bushing and the water inlet bushing are welded on the same end face of the main connector to form a water cooling passage and a gas protection passage. Apart from the ceramic nozzle, all the remaining materials are conductors. According to the condensation electric arc welding gun, the free electric arc energy intensity can be improved, and better capacity of controlling welding joint formation is achieved.

Owner:BEIJING UNIV OF TECH

Argon-enriched mixed gas protection welding method for high-strength abrasion-resistant steel

InactiveCN102049597AIncreased sensitivity to cold crackingImprove toughnessArc welding apparatusWelding/cutting media/materialsButt weldingCrack resistance

The invention discloses an argon-enriched mixed gas protection welding method for high-strength abrasion-resistant steel, which comprises the following steps: adopting high-strength abrasion-resistant steel plates the hardness grades of which are the same, and combining and butting the steel plates the thicknesses of which are the same; adopting mixed gas containing 80% of Ar and 20% of CO2 and BHG-3 welding wires; eliminating iron rust and greasy dirt around welding seams before welding; when the fixed point butt welding and backing welding on the steel plate the thickness of which is 32mm or below 32mm is carried out, preheating to 75 DEG C before welding, and continuously welding, wherein the temperature among the welding beads of filing and cap welding seams is not lower than 60 DEG C, and the welding heat input quantity is controlled at 10-15 Kj / cm in the welding process; and when the fixed point butting welding and backing welding on the steel plate the thickness of which is 40mm is carried out, preheating to 100 DEG C before welding, and continuously welding, wherein the temperature among the welding beads of the filing and cap welding seams is not lower than 75 DEG C, and the welding heat input quantity is controlled at 10-15 Kj / cm in the welding process. By the invention, welding joints have higher strength, and the welding seams have excellent crack resistance.

Owner:NANJING IRON & STEEL CO LTD

Deposit welding rod containing rare earth and production method

InactiveCN101190481AReduce segregationReduce subcoolingWelding/cutting media/materialsSoldering mediaRare earthRoom temperature

The invention provides a surfacing electrode containing rare earths with a welding core but without a coating. The composition of the welding core is 3.2% to 6.5% of C, 0.4% to 2.5% of Si, 0.4% to 2.0% of Mn, 0.01% to 1.0% of Re, 10% to 35% of Cr, 0.0% to 2.0% of Mo, 0.0% to 2.8% of Ni, 0.0% to 2.5% of W, 0.0% to 1.5% of V, 0.0% to 1.0% of Ti, 0.0% to 1.5% of Nb, 0.0% to 0.5% of Cu, 0.0% to 0.6% of Al, not more than 0.08% of S, not more than 0.08% of P, not more than 0.08% of , not more than 0.08% of <N>, and 59.64% to 85.99% of Fe. The welding rod is suitable for the build-up welding of burning single-roll crusher hammer; the hardness HRC of the build-up welding layer at room temperature is not less than 50 and crack is allowable for build-up welding layer.

Owner:PANZHIHUA UNIV

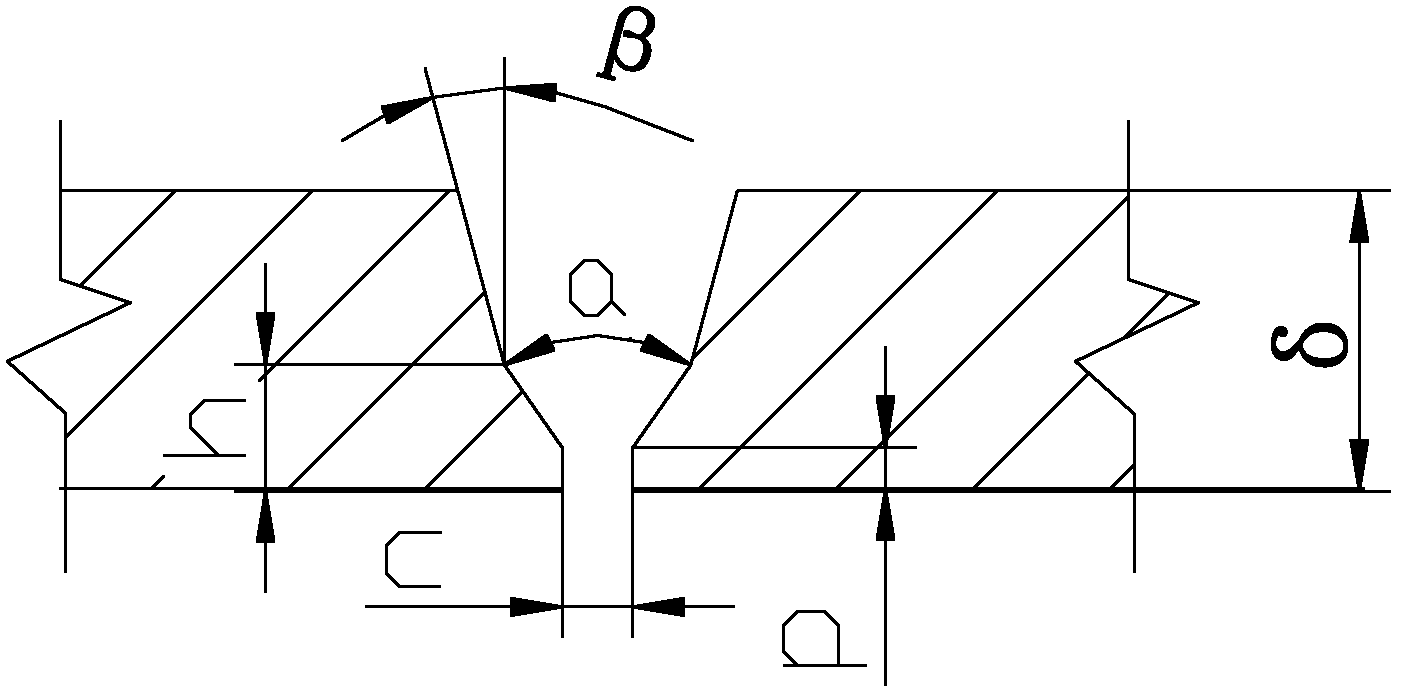

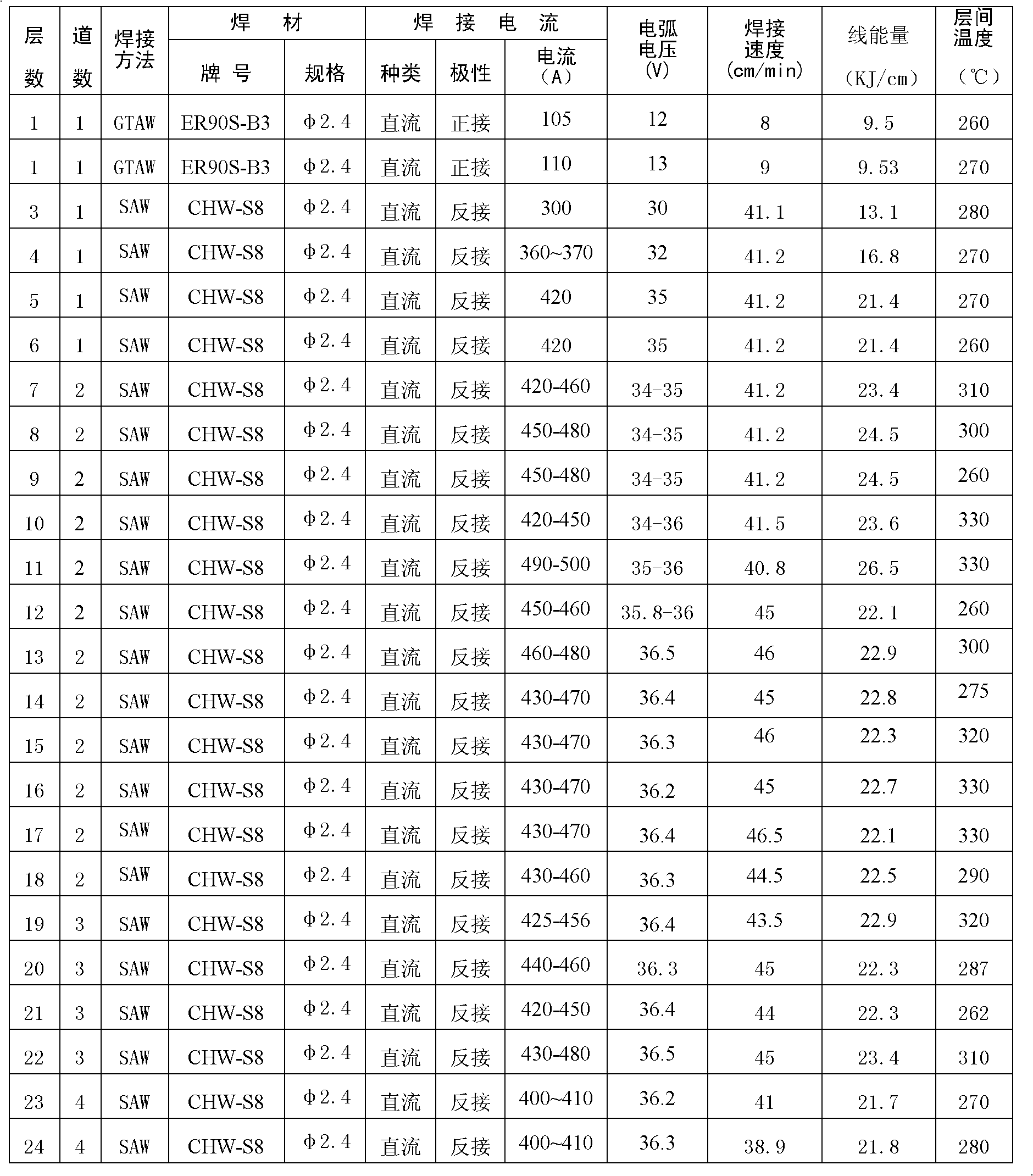

Thick-wall chromium-molybdenum steel pipeline submerged arc welding technology

InactiveCN102248267ABeautiful weld shapeImprove weld seam qualityArc welding apparatusPower flowEngineering

The invention discloses a thick-wall chromium-molybdenum steel pipeline submerged arc welding technology, which is characterized in that an automatic submerged arc welding is used for filling and welding a cover: a pipeline is placed on a rolling tire, an automatic submerged arc welder is used for welding the pipeline, the rolling tire is rotated to drive the pipeline to rotate during welding, and a welding gun is located at a flat welding position and always keeps still; welding parameters are as follows: the welding current is 240-500A, the voltage is 30-36.5V, the welding speed is 36-46.5 cm / min, the extension length of a welding wire is 8-12 mm, and a distance from a tail end of the welding wire to a weld surface is 5-6 mm. The average working efficiency by using the submerged arc welding technology to weld the thick-wall chromium-molybdenum steel pipeline is more than 4-6 times that of the manual welding, the thickness theta of a welding wall is more than the thick-wall pipeline of 30 mm, and the working efficiency is 8-12 times that of the manual welding.

Owner:SINOPEC THE FOURTH CONSTR

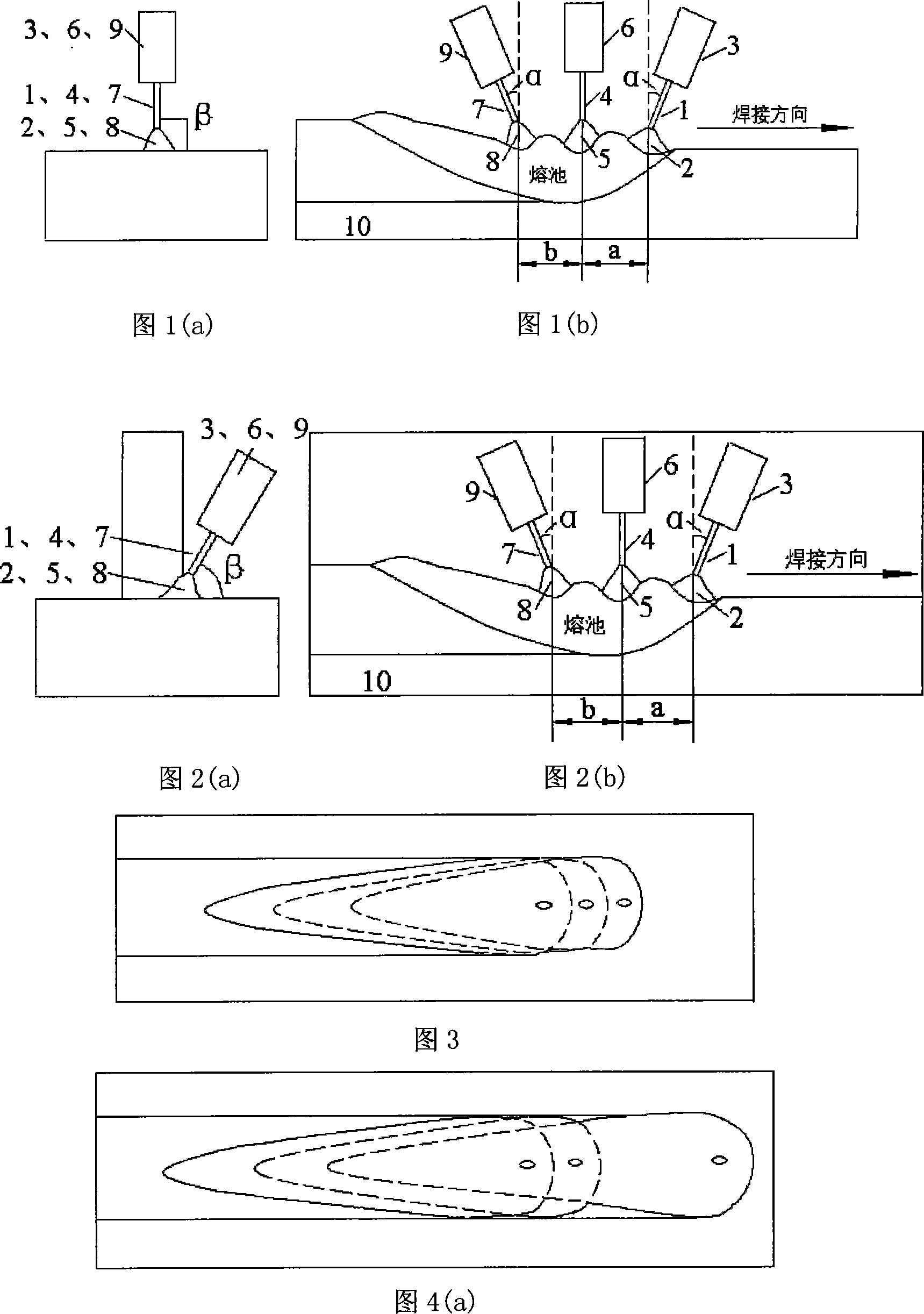

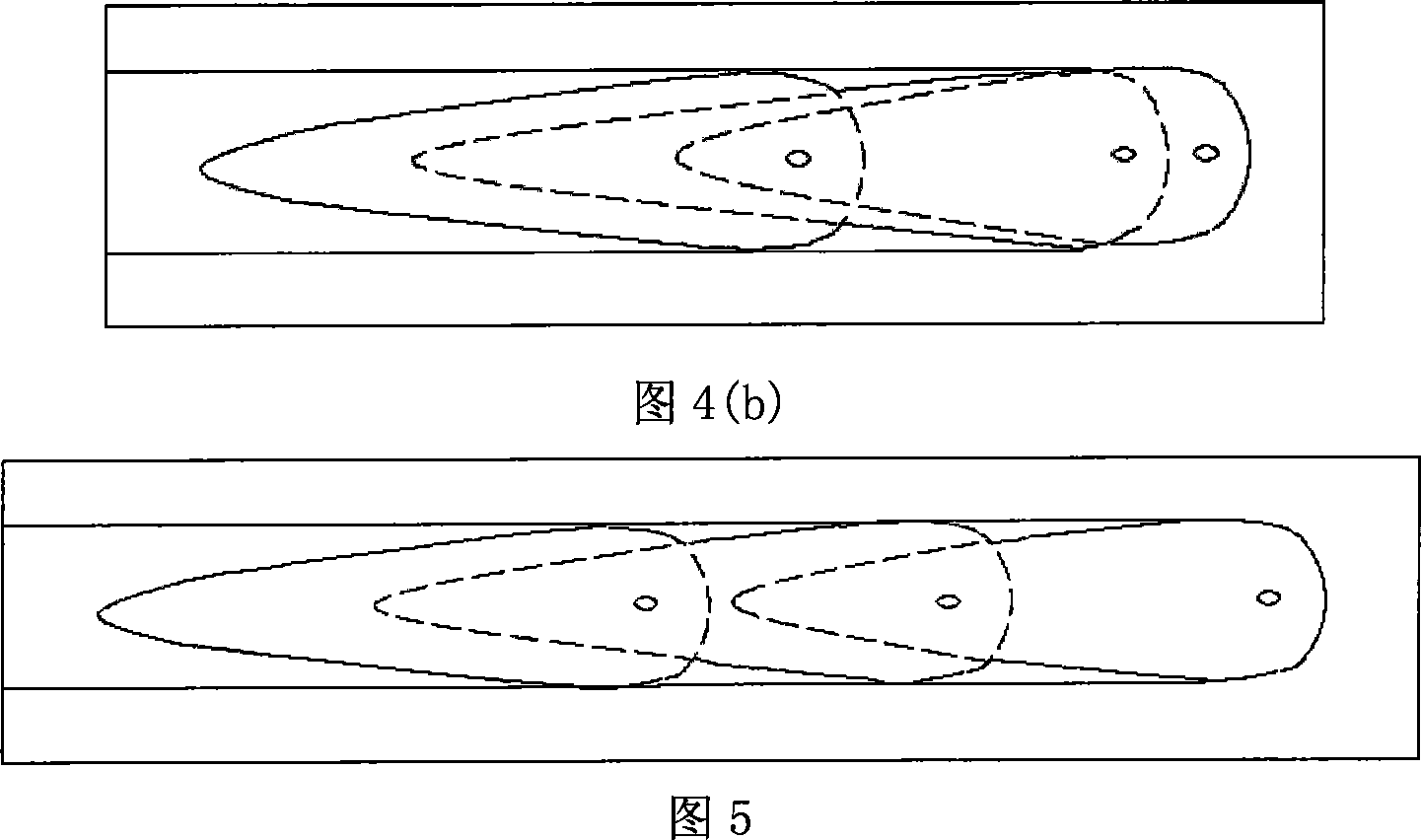

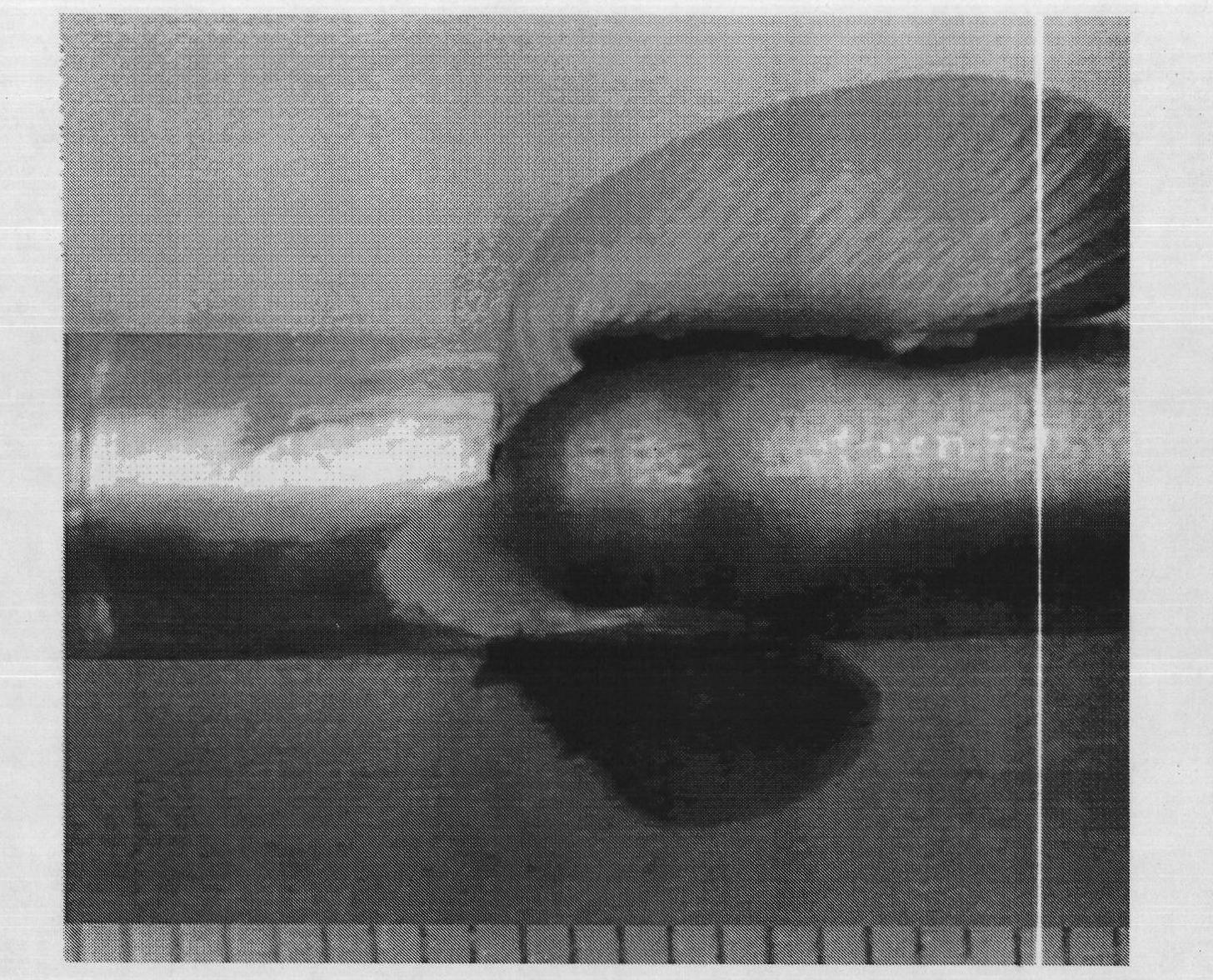

Three-filum open arc welding method

InactiveCN101134260AImprove welding productivityArc welding apparatusWelding power supplyGas metal arc welding

The present invention relates to welding technology, and discloses three wire open arc welding process. Three welding torches with separate welding wires and welding power sources and separate welding parameter adjustments are applied simultaneously in the gas metal-arc welding. These three welding torches are arranged longitudinally in the welding direction for flat welding or corner welding, and their angles and intervals are regulated separately. For high welding speed and welding quality, their electric arc parameters are regulated separately and they may operate in the welding mode of one, two or three molten pools. The present invention has high welding efficiency and is especially suitable for long weld seam welding.

Owner:SHANGHAI JIAO TONG UNIV +1

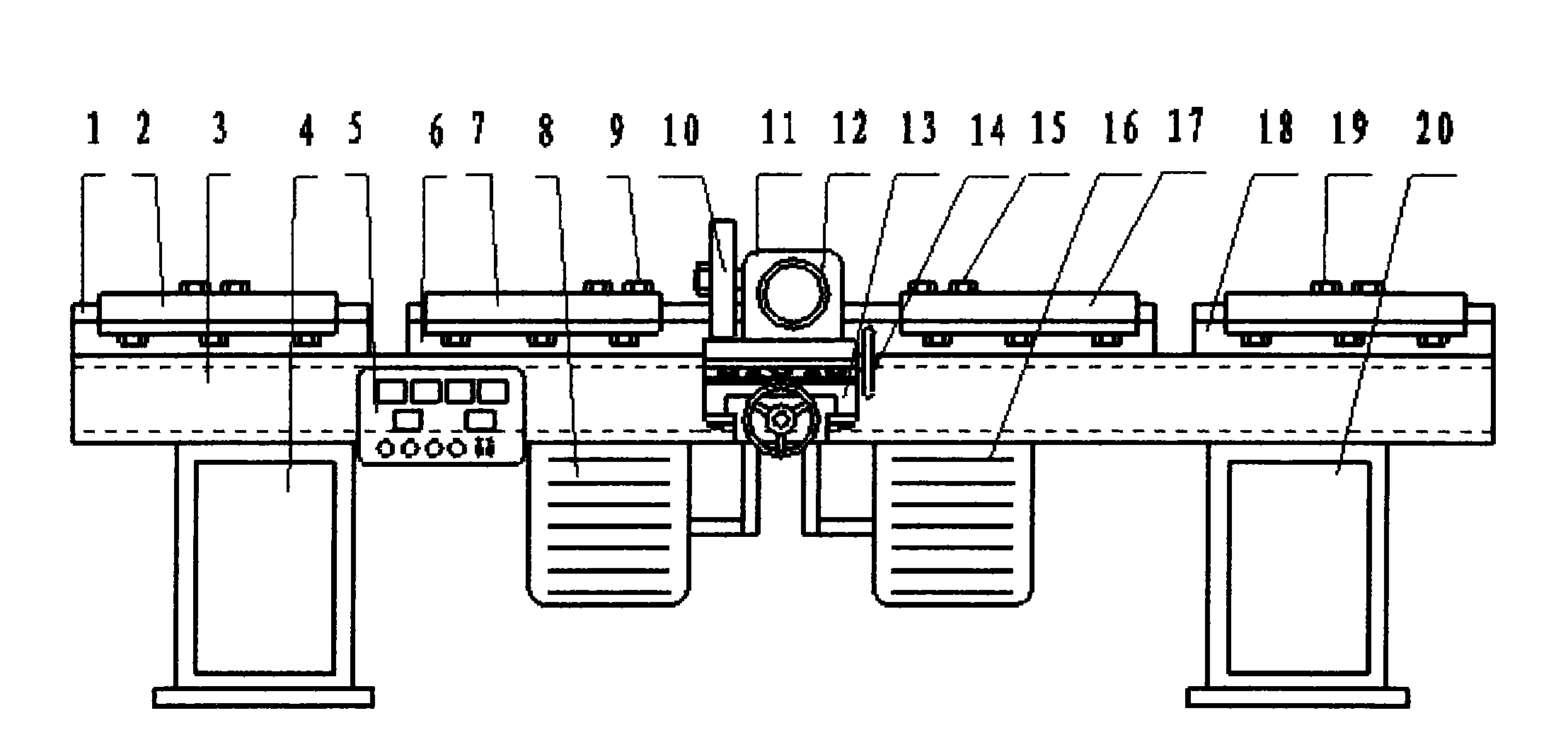

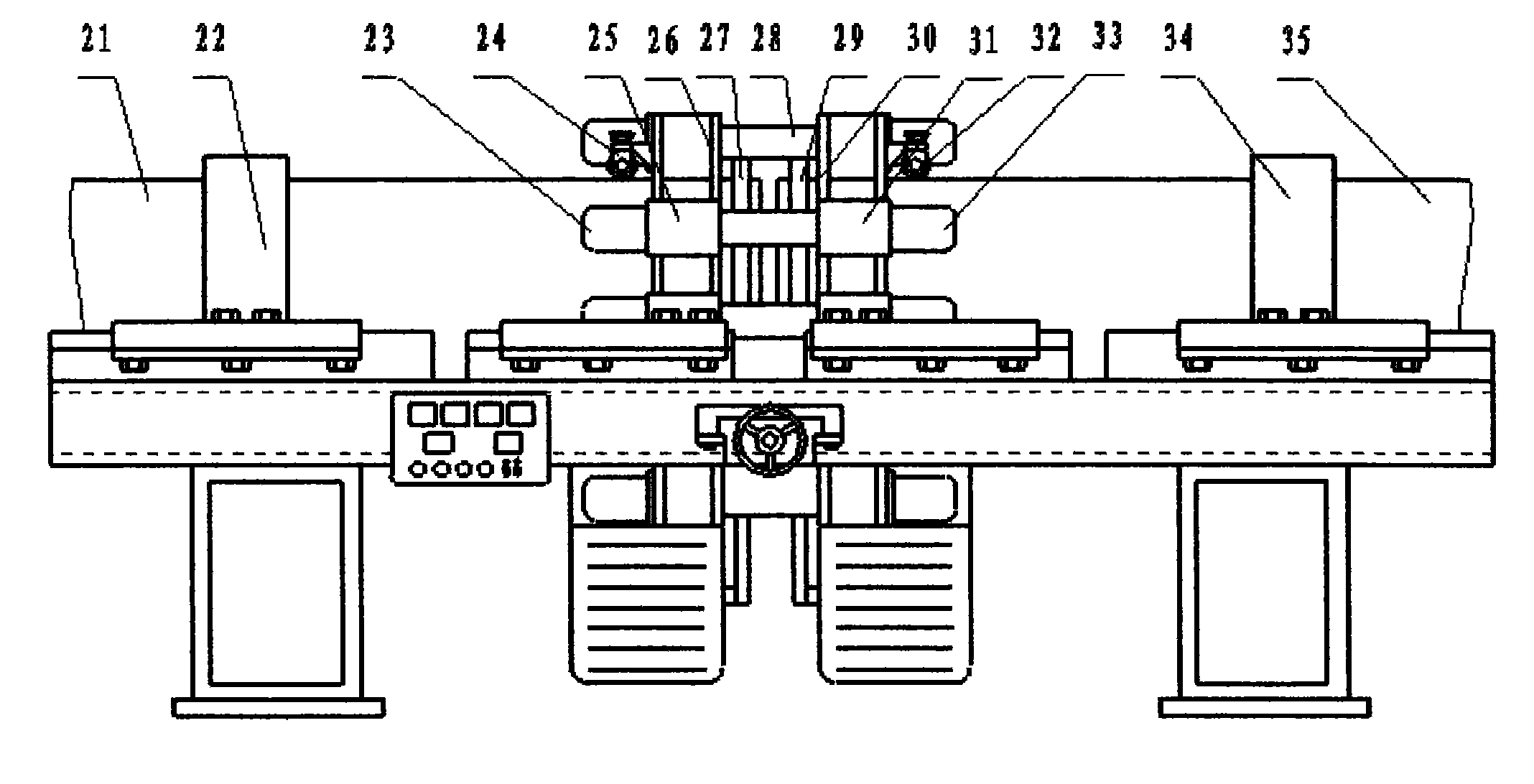

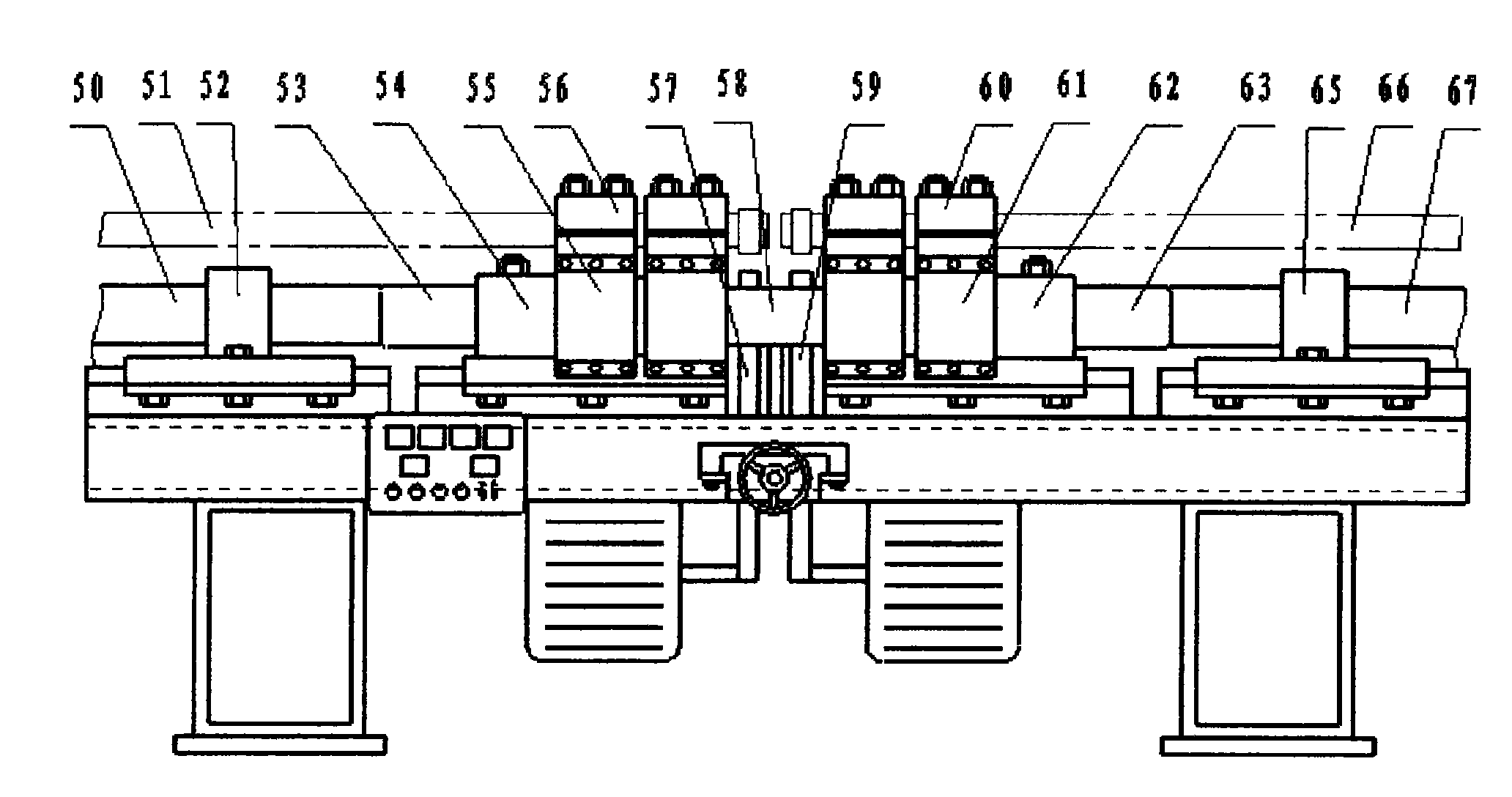

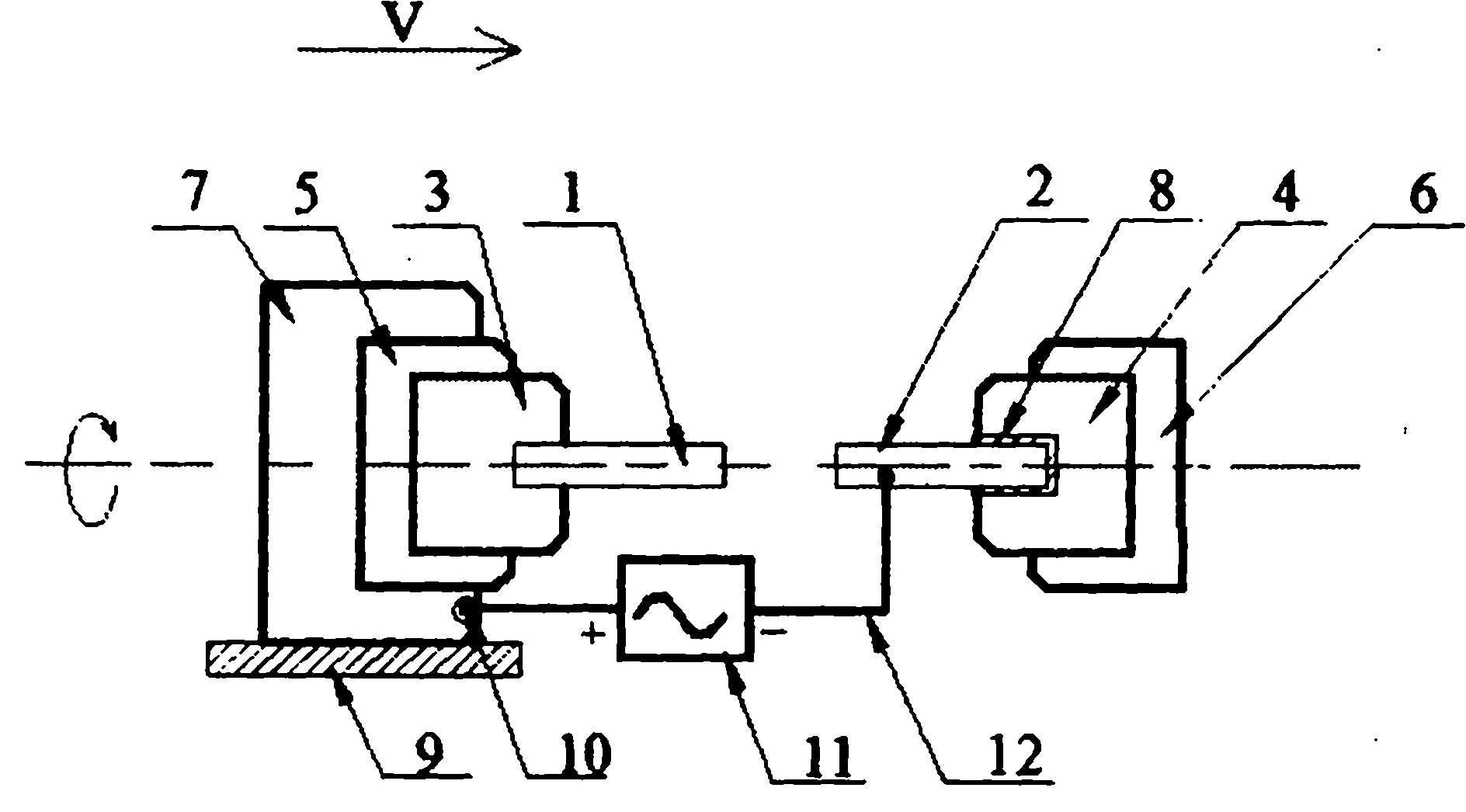

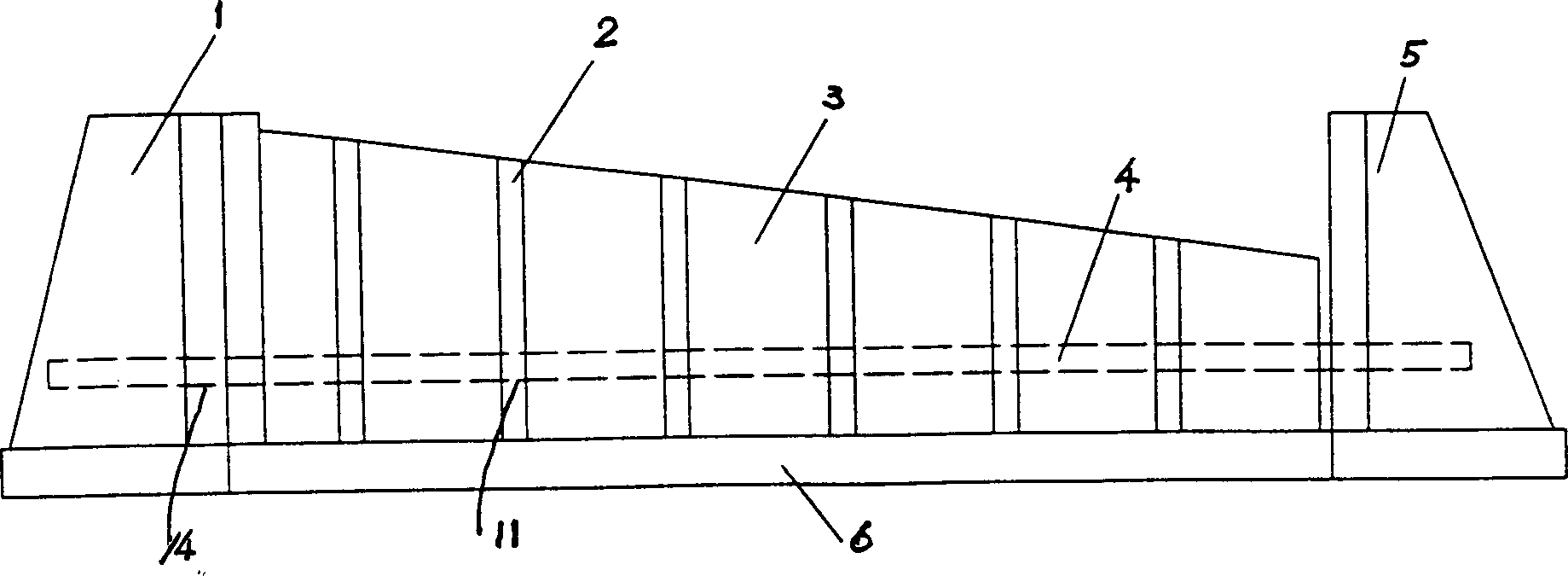

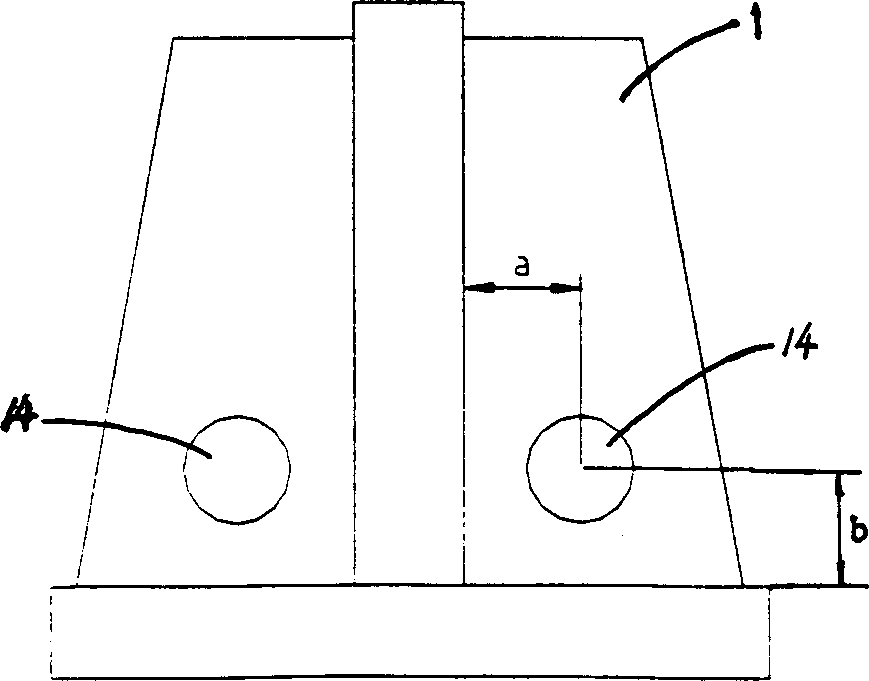

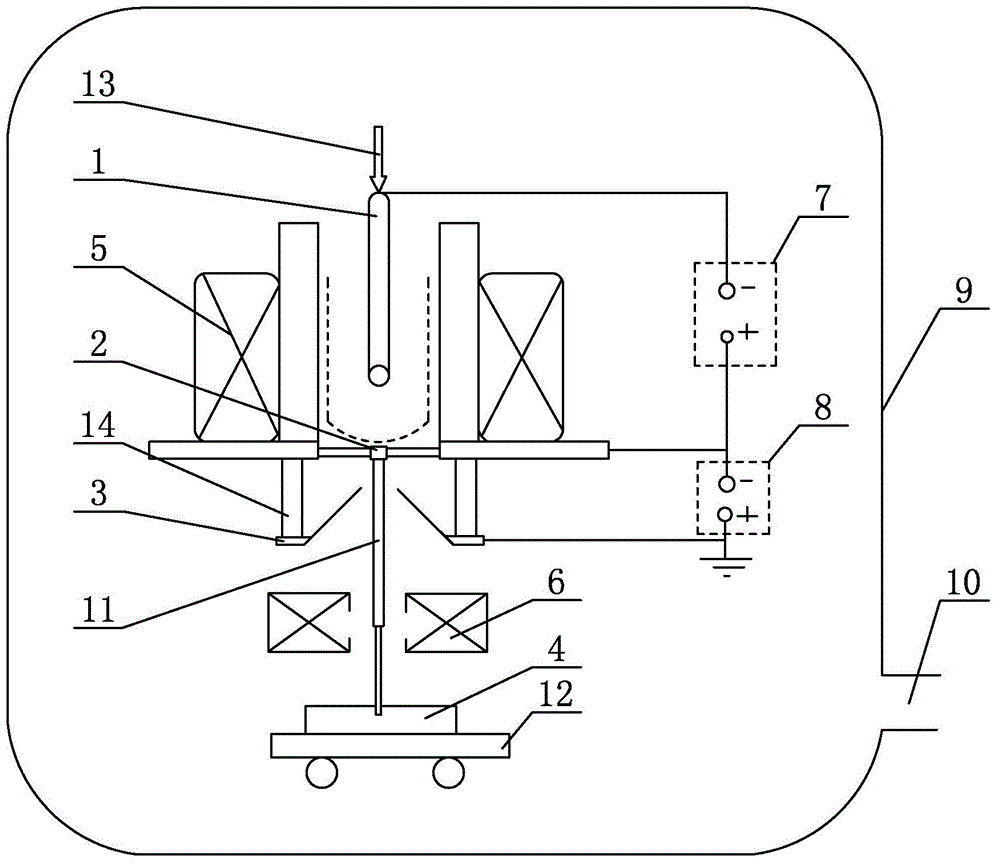

Steel induction heating solid phase welding method and butt welding machine tool

InactiveCN101623794ARealize welding automationLow priceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransformer

The invention relates to a steel induction heating solid phase welding method and a butt welding machine tool. The butt welding machine consists of a machine body and a butt welding clamp, wherein the machine body mainly comprises a machine tool body, an electric cabinet, a welding controller, a left main guide rail, a left main slide rail, a left induction heating transformer, a tool holder, a right induction heating transformer, a right main guide rail, a right main slide rail and a hydraulic cabinet; and the hydraulic steel tube and steel rail butt welding clamp mainly comprise a left hydraulic cylinder, a left hydraulic cylinder fixing seat, a left steel rail fixing clamp, a left induction heating ring, a connecting rod of a piston rod, a right induction heating ring, a right steel rail fixing clamp, a right hydraulic cylinder fixing seat and a right hydraulic cylinder. The butt welding clamp is arranged on the end face to be welded of the steel product; and the induction heating rings are sleeved on the end face to be welded of the steel product respectively; an induction heating power supply is connected with the primary of the induction heating transformer by a cable, and the secondary of the induction heating transformer is connected with the induction heating rings respectively; and the induction heating rings can heat the end faces to be welded of two steel products to a thermoplastic state in a shot time, and the upsetting pull force is generated on the welding clamp, so that the two steel products are welded together.

Owner:陈炯

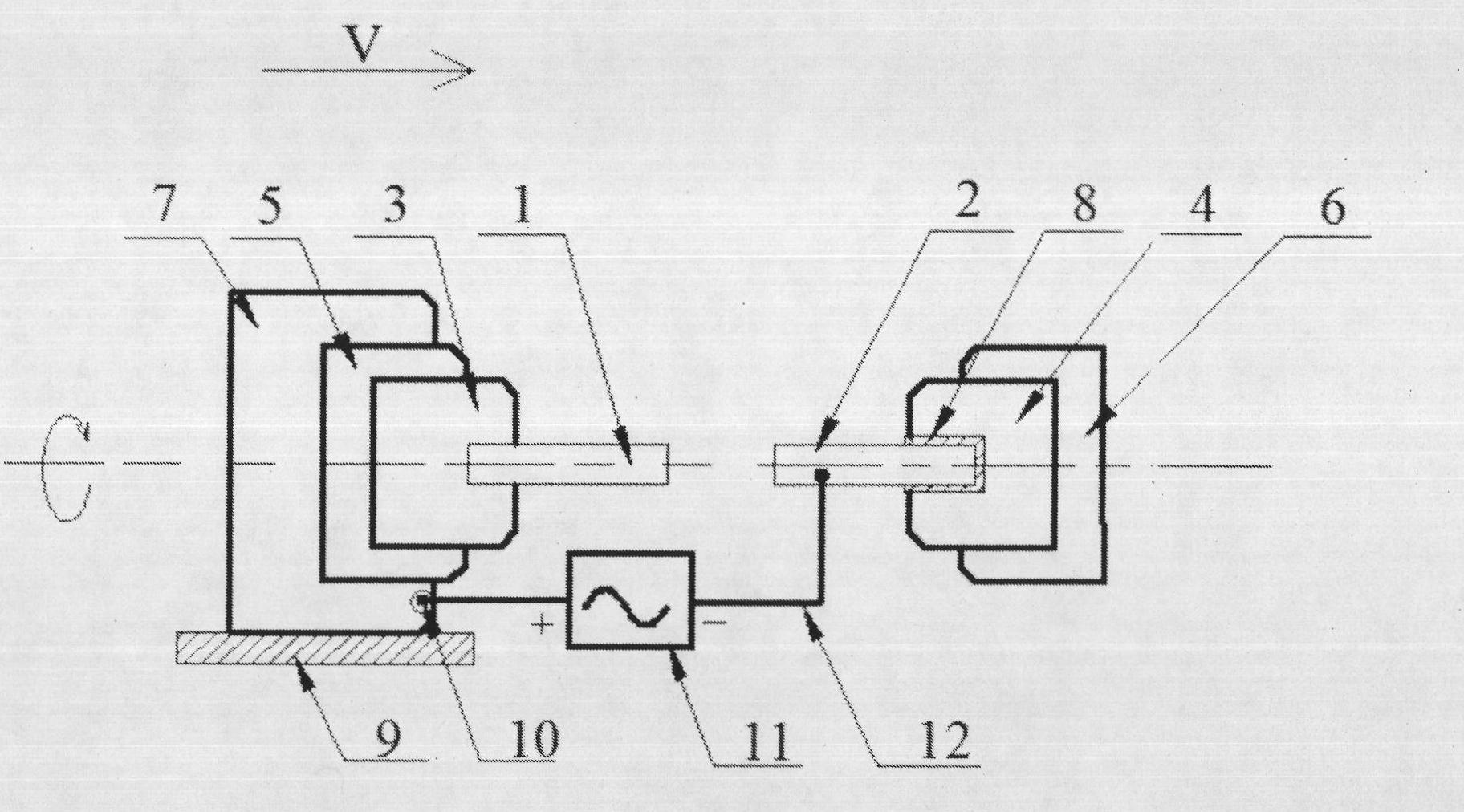

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

Low-speed diesel engine frame welding method

InactiveCN1405482ASolving Concentricity ProblemsSolve the deformationMachine framesWelding apparatusLow speedEngineering

A method for welding the frame of a low speed diesel engine. It includes the following steps: 1) By passing locating iron pipes through the screw holes in small iron plates, a number of small iron paltes are located between two bed-jigs according to the requirements of design, and spot welded on a guide plate and a triangle plate to form guide plate components. 2) The bilateral symmetric and located guide plate components are put symmetrically side by side and located by butt strap welding. 3) The welded and located bilateral guide plate component are welded in symmetry. 4) After welding, butt straps are removed, and the bila-teral guide plate components are separated. 5) with the help of the bed-jig, the bilateral guide plate components and a division plate are located on a cast-iron platform.

Owner:HUDONG HEAVY MACHINERY +1

Q690 and Q980 high-strength dissimilar steel non-preheating welding method

InactiveCN102513662AHigh plasticity reserveImprove applicabilityArc welding apparatusWelding/cutting media/materialsAbsorbed energyMixing ratio

The invention discloses a Q690 and Q980 high-strength dissimilar steel non-preheating welding method. A bottom layer of a to-be-welded workpiece adopts low-match 700-800MPa high-strength high-toughness welding wires, and adopts argon and carbon dioxide (Ar+CO2) mixed gas shield welding. A welding bead of a bottoming layer adopts 700MPa high-strength high-toughness solid wires, and a surface covering layer adopts 800MPa high-strength flux-cored wires. In a welding process, welding heat input is strictly controlled, and diffusible hydrogen content of welding lines is controlled at a super-low hydrogen level. The mixing ratio of argon and carbon dioxide of mixed gas shield welding is 75-95%Ar: 25-15CO2. By adopting the process without pre-heating or post-weld heat treatment to weld Q690 and Q980 high-strength dissimilar steel, welding joints which have no internal cracks can be obtained. An area of joints is flat and smooth, tensile strength at room temperature of weld metal is larger than 760MPa, and V-notch impact absorbing energy of weld metal at test temperature 0 DEG C is larger than 68J, thereby meeting the requirement of a high-strength dissimilar steel welding structure for high carrying capacity.

Owner:SHANDONG UNIV

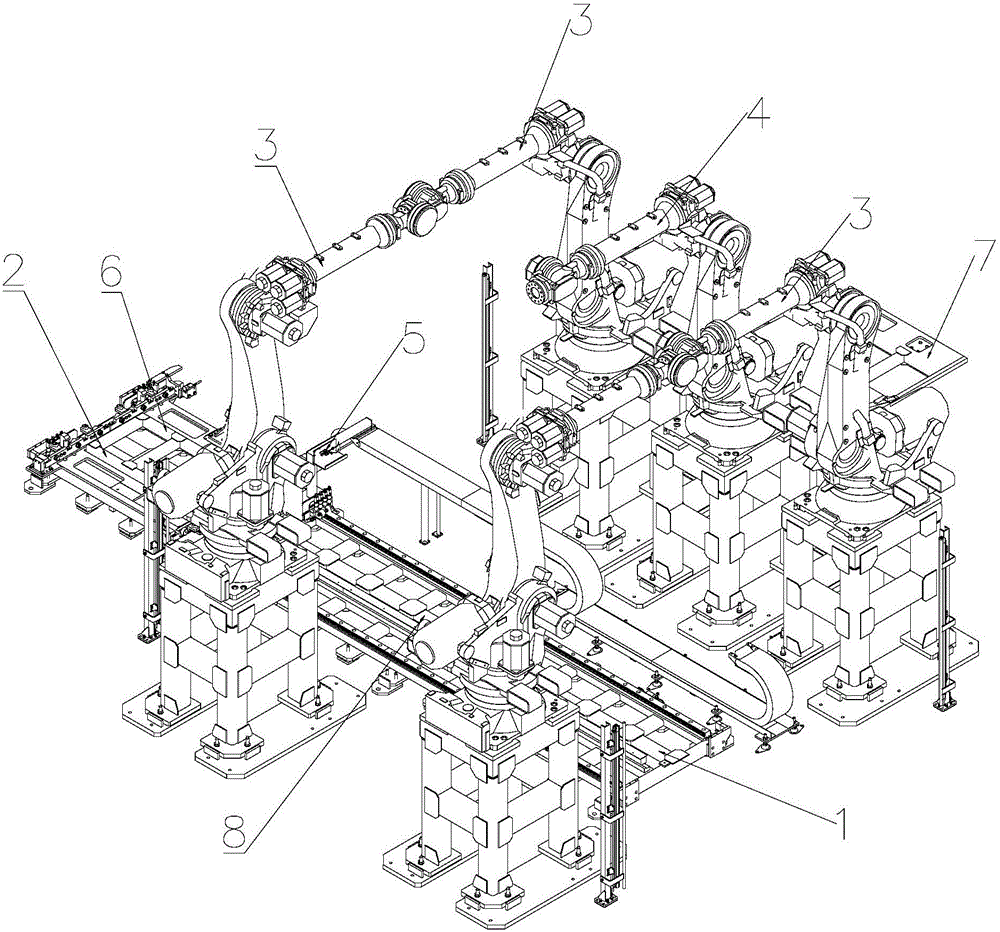

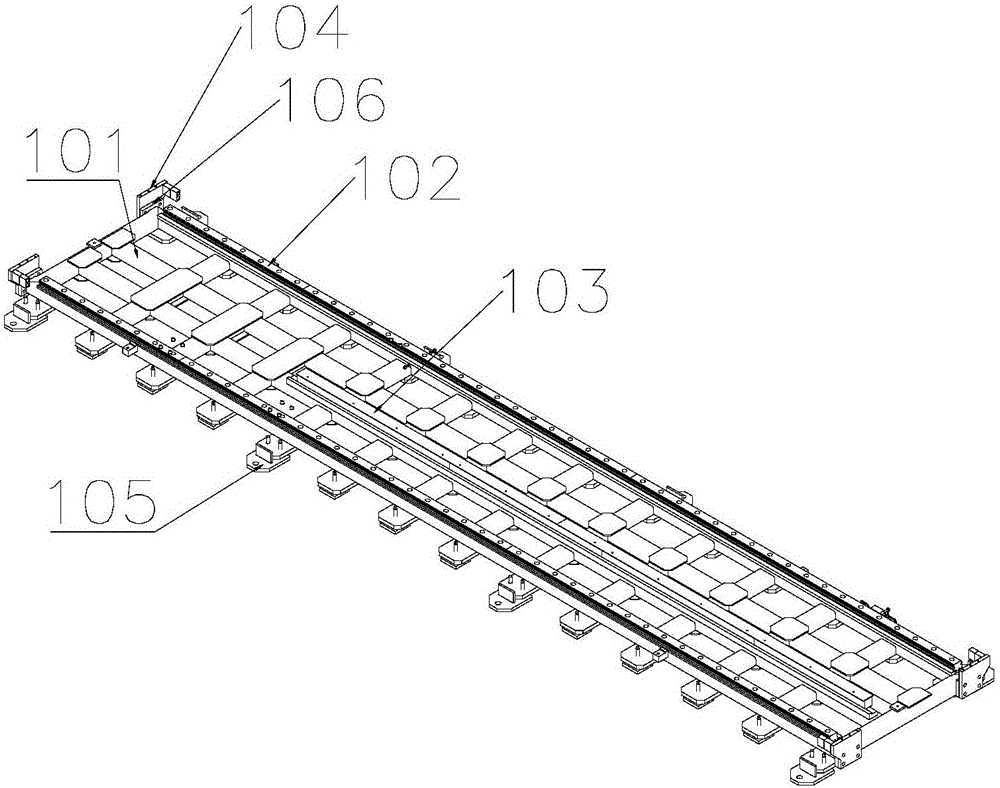

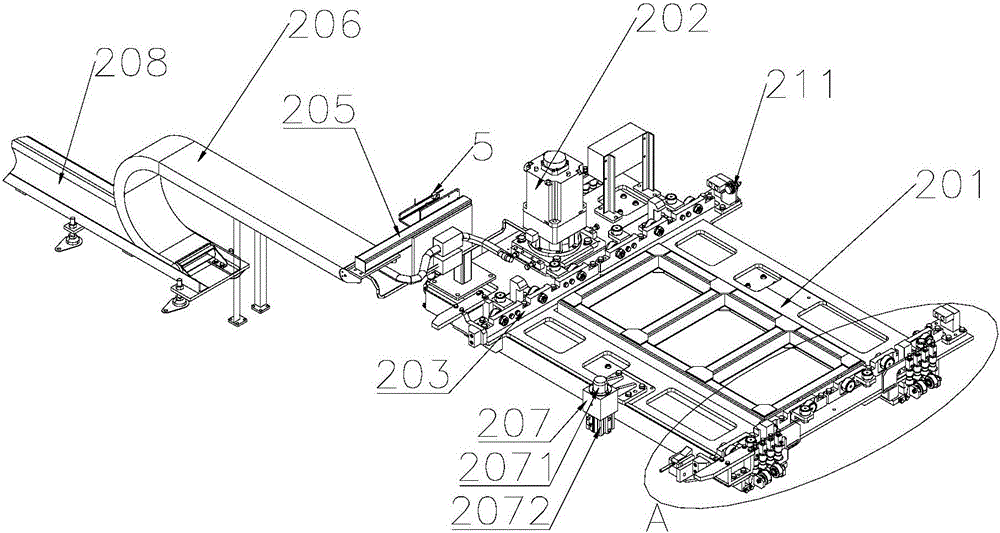

Intelligent flexible welding system

ActiveCN106002011AImprove efficiencyLow investment costWelding/cutting auxillary devicesAuxillary welding devicesTransfer operationIndustrial engineering

The invention discloses an intelligent flexible welding system. A sliding table mechanism used for carrying workpieces and welding clamps is installed on a base mechanism and slides along the base mechanism. An intelligent detection mechanism is installed on the sliding table mechanism. The base mechanism is provided with a workpiece feed station, a welding station, a welding robot, a gripper robot and a workpiece discharge station. The intelligent detection mechanism recognizes clamp information. The sliding table mechanism slides to the welding station from the workpiece feed station. The welding robot conducts the first stage of welding operation. The gripper robot elevates a workpiece to be subjected to the second stage of welding operation, the sliding table mechanism transfers a next workpiece to the welding station at the same time, the welding operation of the next workpiece is immediately started after the second stage of welding operation of the previous workpiece is completed, and the loading operation, the transferring operation and the welding operation of the workpieces are synchronous. The intelligent flexible welding system is low in cost, products are diverse and flexible, the welding production efficiency is improved, welding programs are automatically switched, unstable factors caused by artificial participation are reduced, and the welding production quality guarantee is improved.

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD

Argon-arc welding for austenitic stainless steel using water cooling welding method

The invention discloses a water-cooling argon-arc welding method for welding austenitic stainless steel, which is characterized in that: after finishing backing welding at the welding seam of a workpiece, the back of the welding seam is cooled with cold water when filling and cover-welding is carrying out for the welding seem. The invention solves the problems that high welding stress and poor corrosion resistance exist in the prior austenitic stainless steel welding and ensures that the welding seam of the austenitic stainless steel has fine metal crystal grains, uniform structure and small residual welding stress. The invention can not only obtain ideal welding joints but also improve the productive efficiency of welding.

Owner:普瑞特机械制造股份有限公司

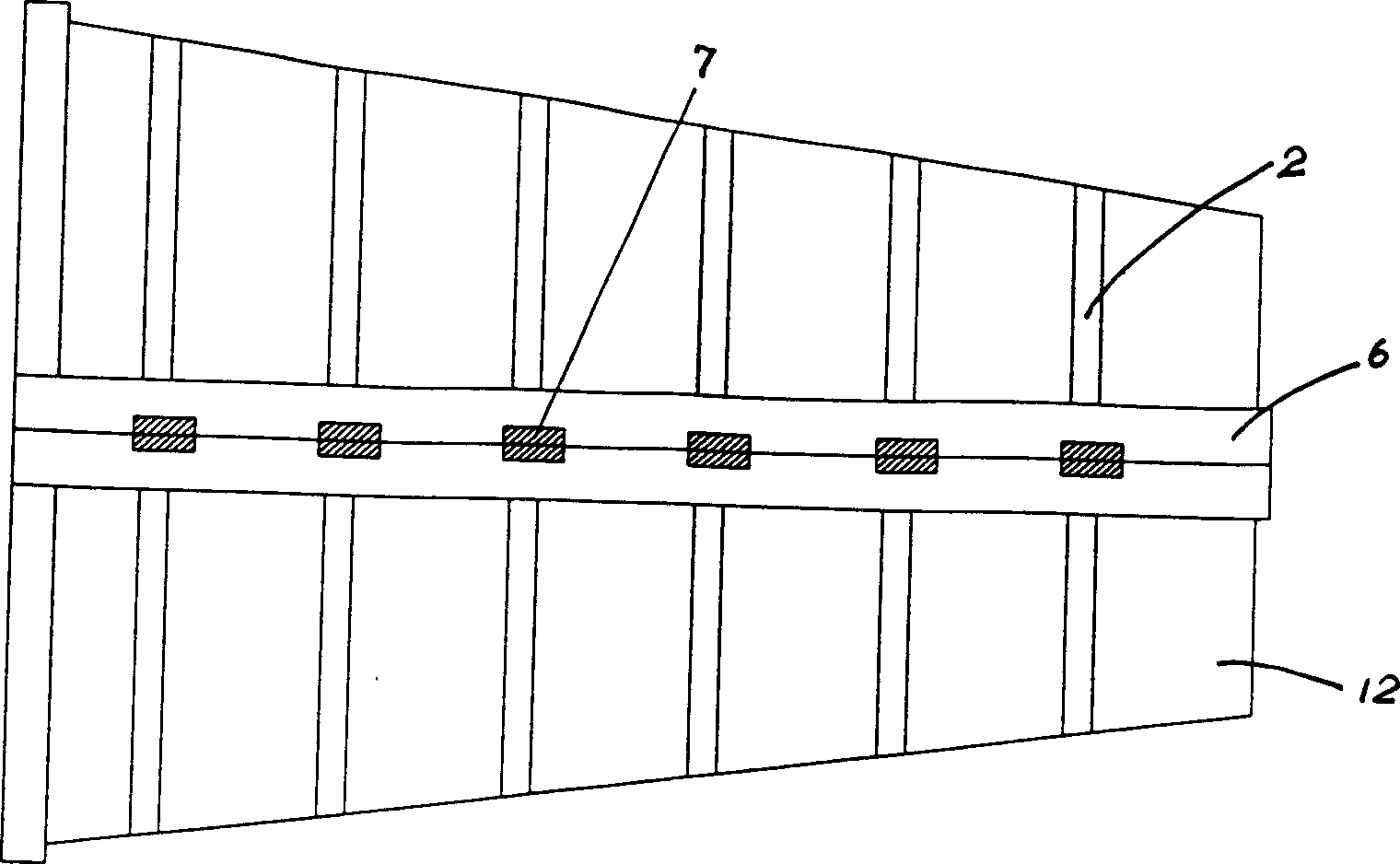

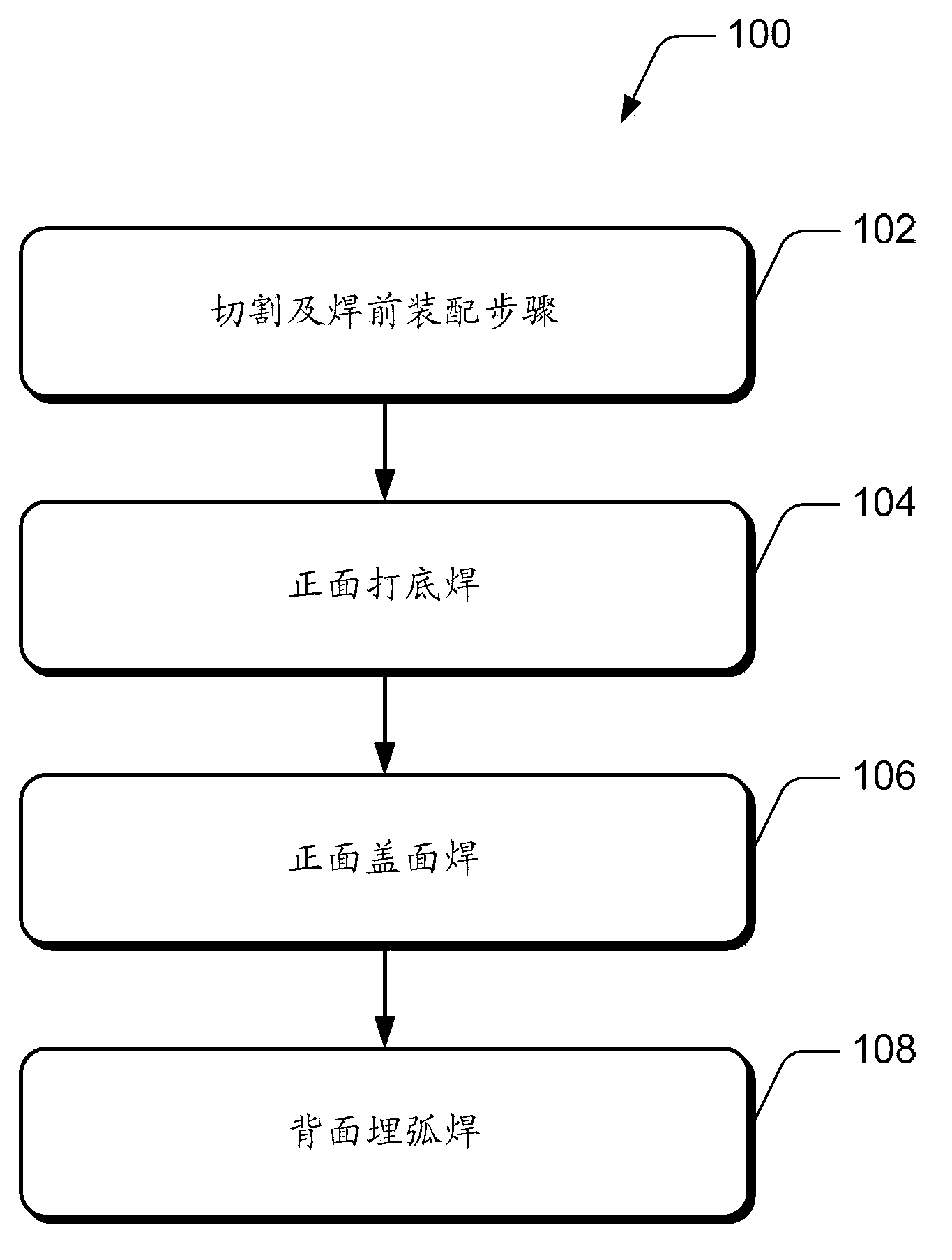

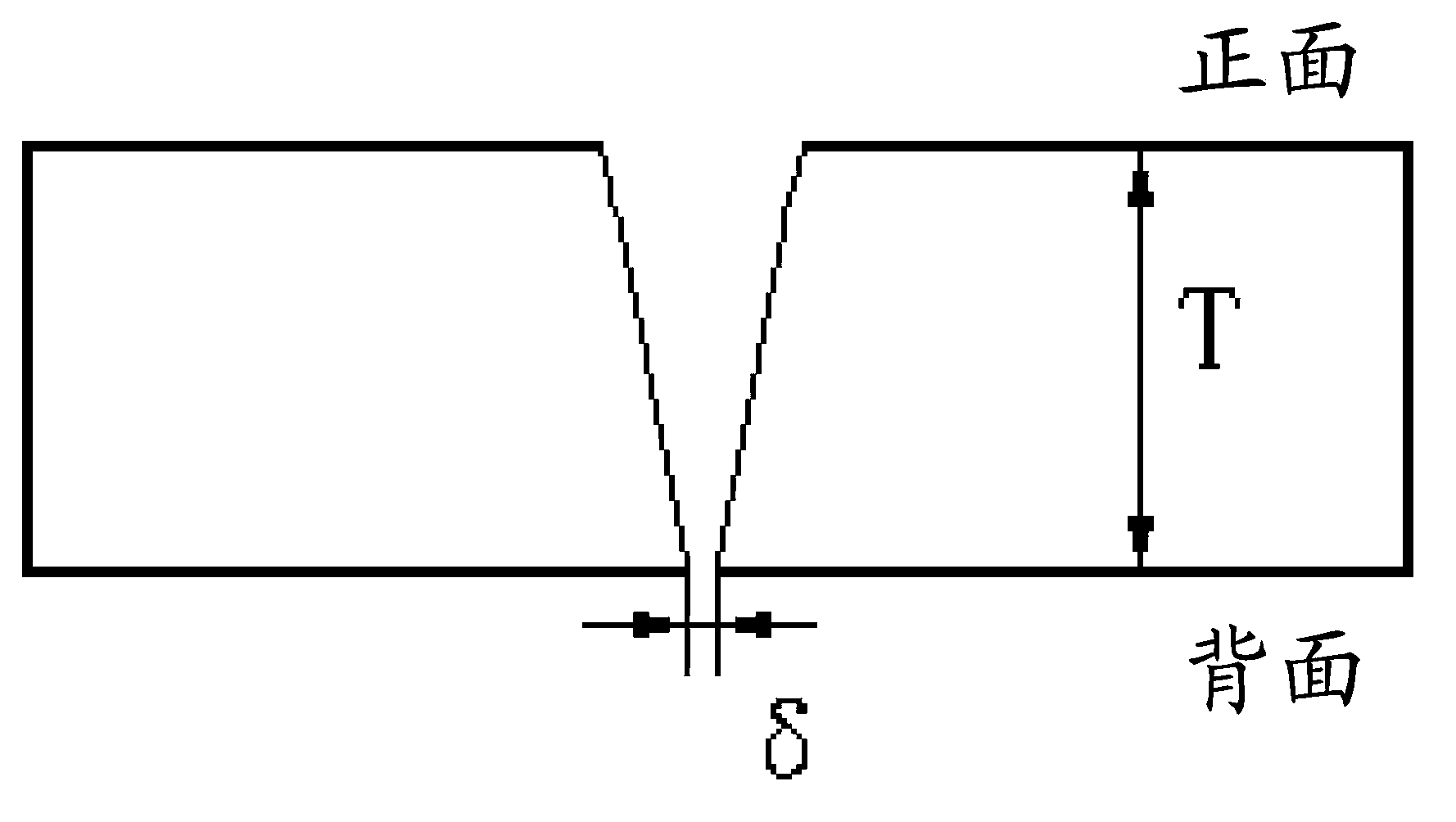

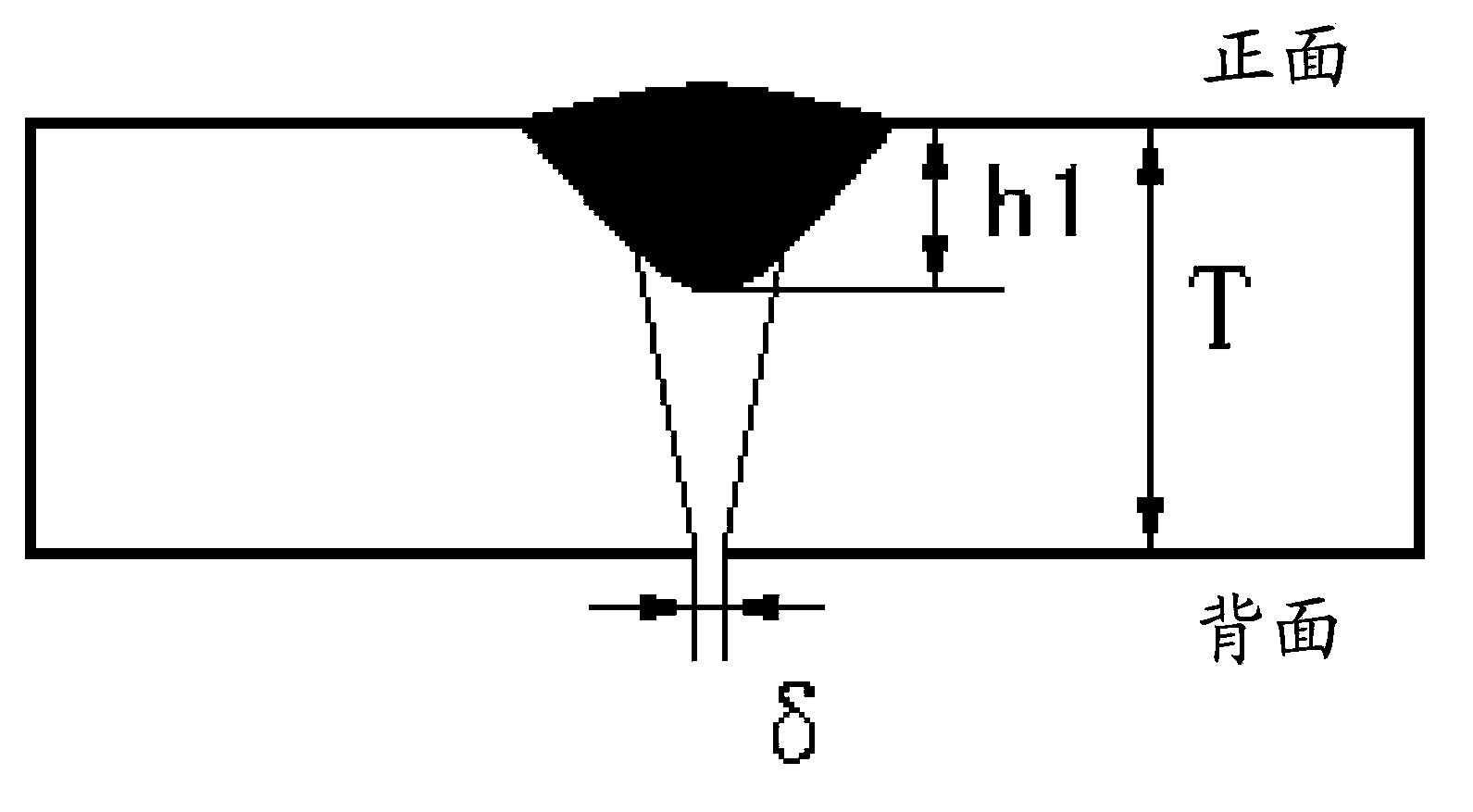

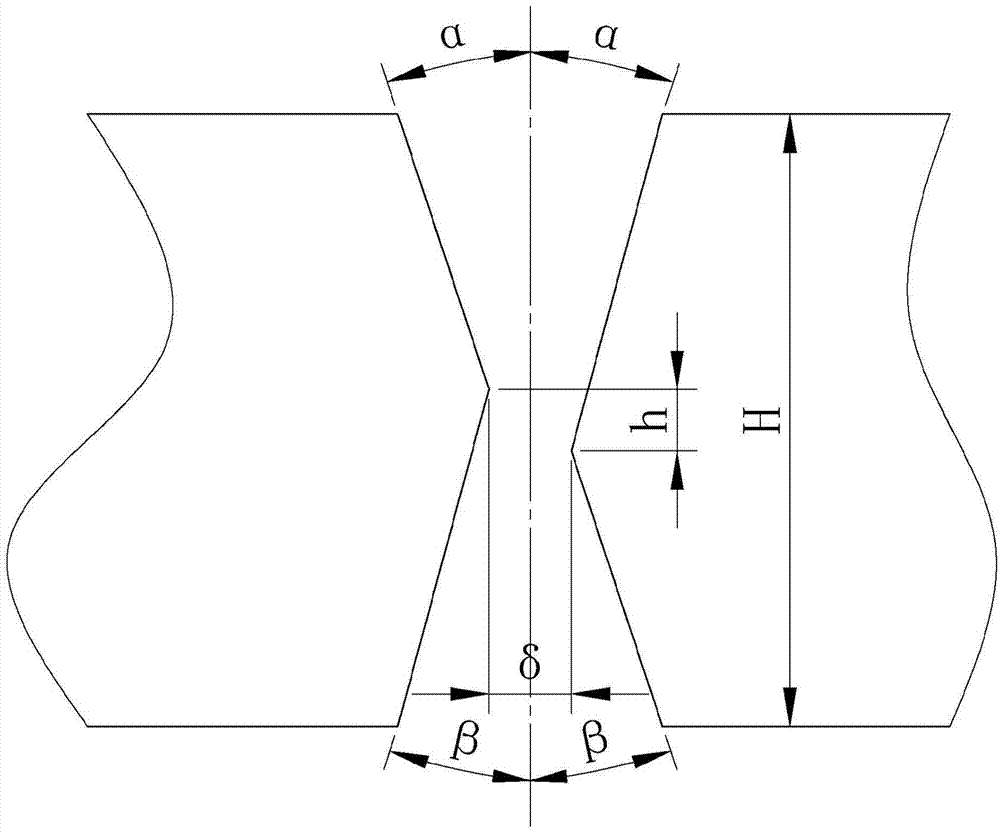

Large-gap back-chipping-free welding process for I-shaped groove of middle thick plate

ActiveCN103785932AImprove applicabilityImprove welding productivityArc welding apparatusPlasma welding apparatusPower flowThick plate

The invention discloses a large-gap back-chipping-free welding process for an I-shaped groove of a middle thick plate. The process includes the following steps: cutting and assembling before welding, namely adopting plasma to cut the middle thick plate and assembling the middle thick plate to form the I-shaped groove, wherein root gap of the groove is smaller than or equal to 3mm, and front gap of the groove is small than or equal to 5mm; performing front back welding, namely performing back welding on the front of the groove by means of small-current oscillation welding to form a welding seam in a large gap without welding penetration; performing front cosmetic welding, namely performing cosmetic welding on the front of the groove in a small-current manner, wherein the welding seam of front back welding is not burnt through in the process of front cosmetic welding; performing back submerged arc welding, namely directly performing submerged arc welding on the back of the groove without through carbon gouging and back chipping, wherein current of back submerged arc welding enables weld penetration depth h3 of back submerged arc welding to be three fourths of thickness of the middle thick plate.

Owner:SHANGHAI ZHENHUA HEAVY IND

Welding method achieving medium thick plate backing welding without back gouging

ActiveCN103252557AAutomated welding is easy to implementSimple welding processArc welding apparatusThick plateEngineering

The invention discloses a welding method achieving medium thick plate backing welding without back gouging. The welding method comprises the steps of backing welding and filling welding, wherein double-face double-arc asymmetry welding is adopted in the backing welding, double-face double-arc symmetry welding is adopted in the filling welding, an assembling clearance between root portions of two welding plates is 4-6 millimeters, the angle of a welding gun is 70-85 degrees, standing time of a side wall when the welding gun swings is 0.3-0.6 second, and the amplitude of swinging of the welding gun of the backing welding is more than 5 millimeters. The welding method is suitable for vertical position welding of a medium thick plate with the thickness of more than 20 millimeters, the backing welding without the back gouging can be achieved, and therefore a traditional medium thick plate welding process is simplified, production efficiency is improved, and deformation of workpieces does not exist basically after the welding. In addition, the welding method further achieves automatic welding of a robot of the medium thick plate easily.

Owner:上海交材智能设备有限公司

Micro-plasma arc welding for heat-resistant casting alloy and austenitic stainless steel

InactiveCN101774070AImprove performanceSmooth appearancePlasma welding apparatusProcess equipmentAlloy

The invention discloses a micro-plasma arc welding method for dissimilar metals of a heat-resistant casting alloy and austenitic steel, which realizes rapid welding of the heat-resistant casting alloy and the austenitic steel by adopting micro-plasma arc welding technology and proper process equipment, and strictly controlling welding process parameters, and is particularly suitable for the places where the thickness difference between the heat-resistant casting alloy and the stainless steel is great. Due to the micro-plasma arc welding method for the heat-resistant casting alloy and the austenitic stainless steel, the application range of heterogeneous structural parts of the heat-resistant casting alloy and the austenitic stainless steel is enlarged, and the micro-plasma arc welding method has the advantages of effectively improving the welding production efficiency, along with stable and reliable welding quality. Compared with the argon tungsten-arc process, the production efficiency of the micro-plasma arc welding is improved by more than 2 times.

Owner:SHANDONG UNIV

Active agent for titanium alloy tungsten electrode argon arc welding

InactiveCN102626839AEffective contractionStrong penetrating powerArc welding apparatusWelding/cutting media/materialsPorosityMetallurgy

The invention discloses an active agent for titanium alloy tungsten electrode argon arc welding, which aims to increase the weld penetration, reduce the input of welding heat, thin a weld structure and reduce the weld porosity. In percent by weight, the active agent comprises the following components: 20-30% of CaF2, 10-20% of CrCl3, 10-20% of KF and 40-50% of Te.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

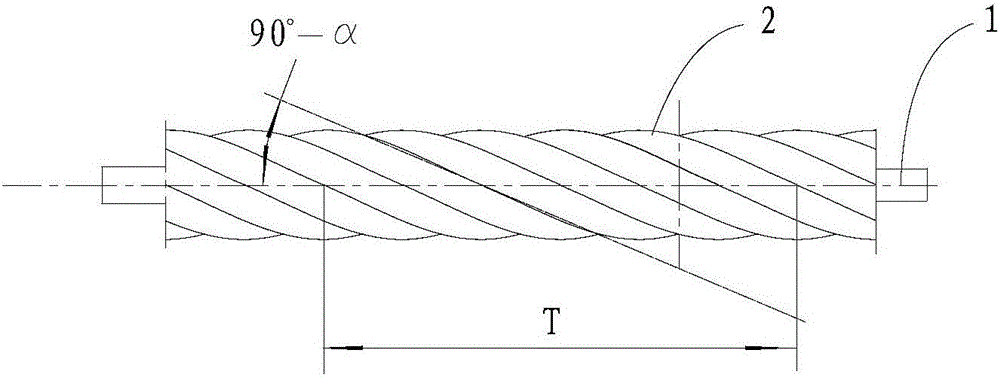

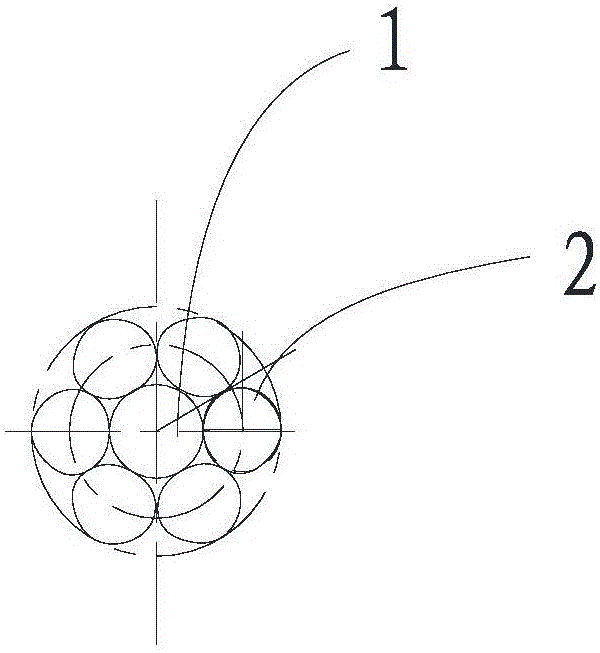

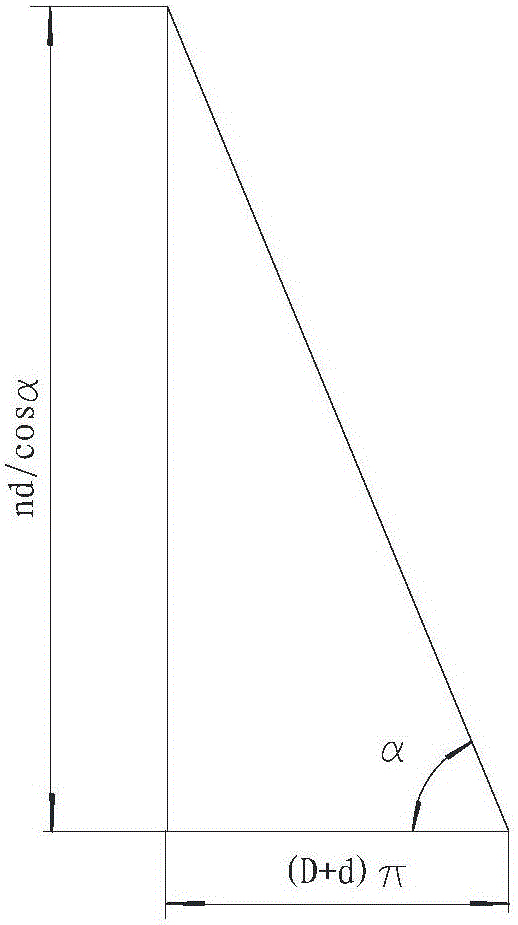

Cable type welding wire

ActiveCN105665955AStable weldabilityImprove the pass rate of twistingWelding/cutting media/materialsSoldering mediaStructure factorWire breakage

The invention provides a cable type welding wire. The cable type welding wire comprises a center welding wire and n peripheral welding wires arranged around the center welding wire in a spiral rotating manner, wherein the diameter of each of the peripheral welding wires is d, and the neighboring peripheral welding wires are separately arranged in an intersecting manner. The cable type welding wire is characterized in that the lay length T of each of the peripheral welding wires is equal to K*m*d, wherein K is the structure factor of the peripheral welding wires, m is the lay length multiple, and d is the diameter of each of the peripheral welding wires; K is larger than or equal to 1, and less than or equal to 1.5; m is larger than or equal to 20, and less than or equal to 25. According to the cable type welding wire provided by the invention, wire breakage is not liable to generate in the manufacturing process; during welding, the peripheral welding wires are arranged compactly, so that the wire feeding process is more stable, and the welding performance of the cable type welding wire is improved.

Owner:SUZHOU YINLI WELDING IND TECH CO LTD

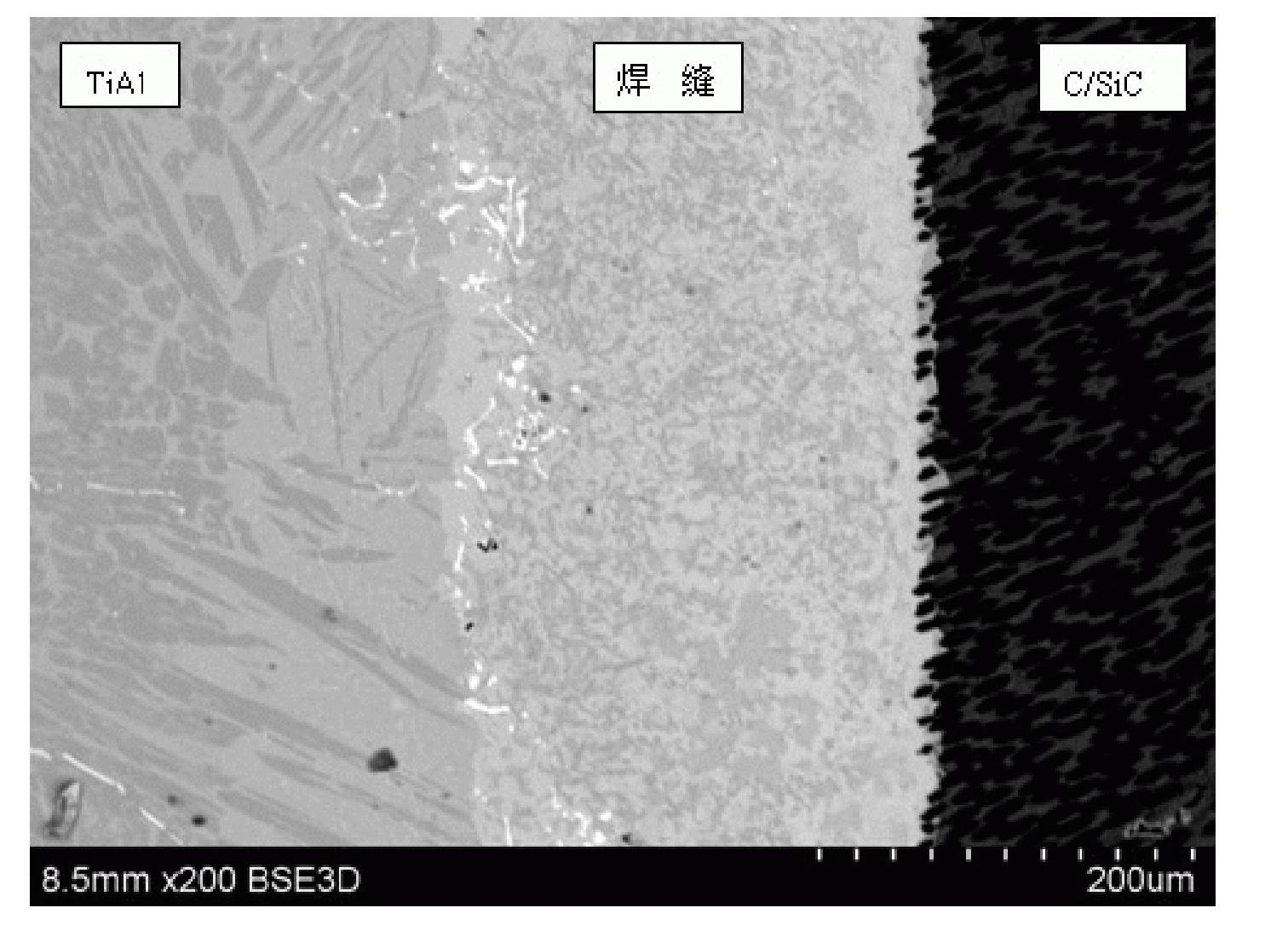

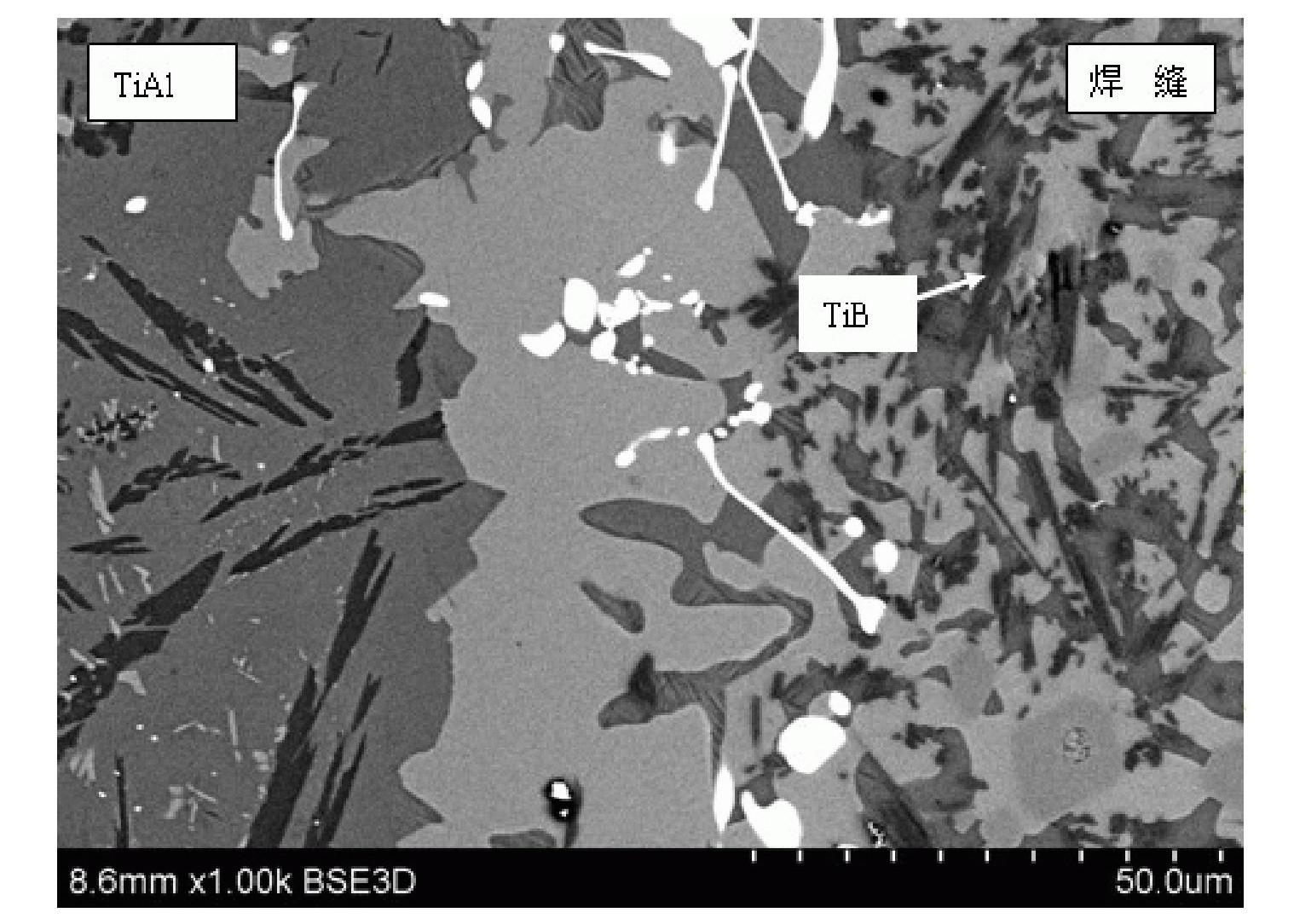

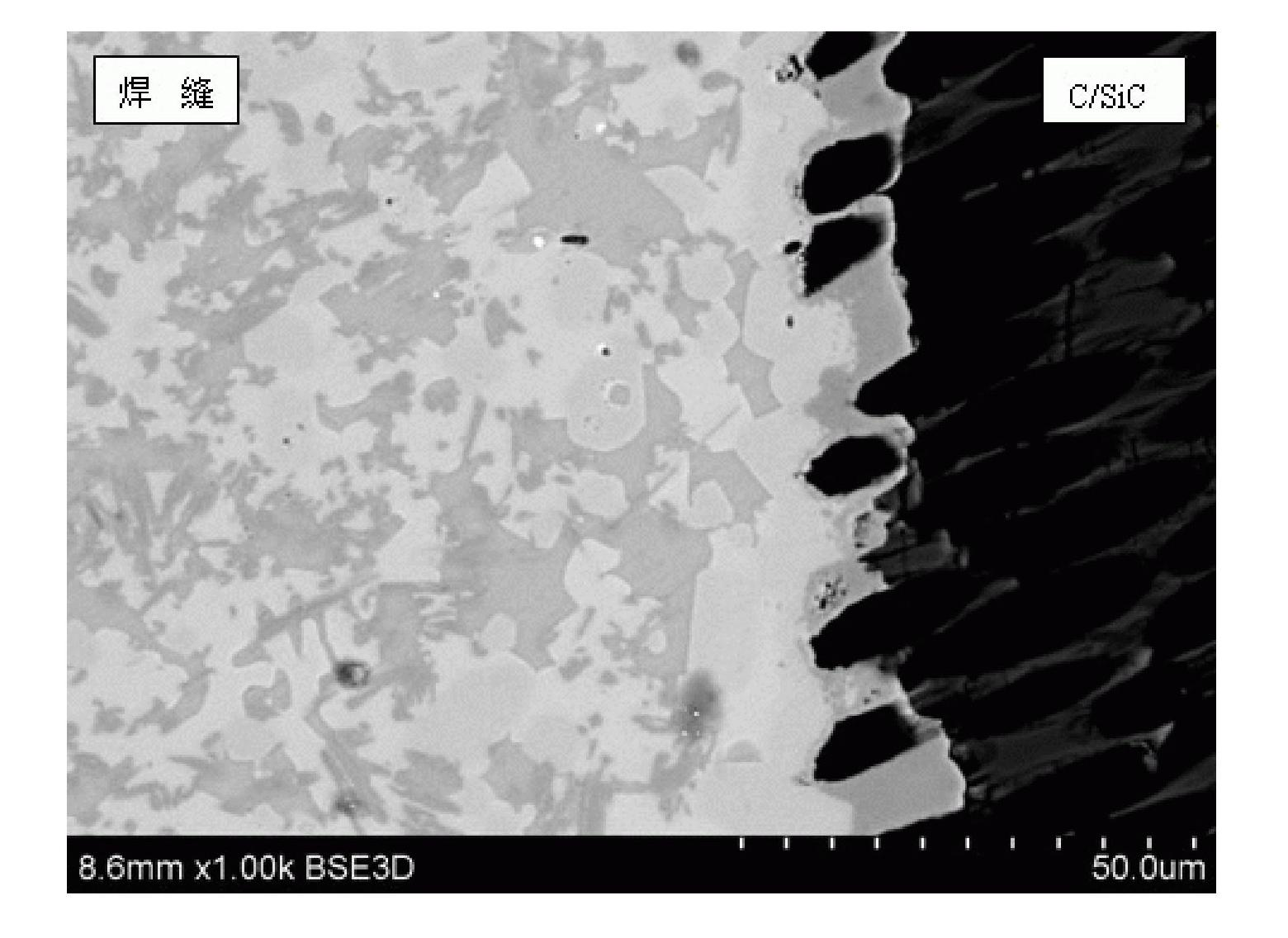

Solder for welding carbon/silicon carbide ceramic matrix composite material and titanium-aluminum-based alloy and soldering method

The invention discloses a solder for welding a carbon / silicon carbide ceramic matrix composite material and a titanium-aluminum-based alloy and a soldering method, relating to solders and soldering methods thereof. By the invention, the problems that the using temperature of the welding joint of the conventional silver-based solder for welding composite materials and titanium alloys is low and the process of a traditional method for indirectly soldering the carbon / silicon carbide ceramic matrix composite materials and metals is complex. The solder comprises titanium material powder, nickel powder and boron powder. The method comprises the following steps of: performing ball milling on the solder, preparing the solder into paste, coating the paste on a joint face to be welded of the carbon / silicon carbide ceramic matrix composite material and the titanium-aluminum-based alloy, putting a piece to be welded into a vacuum heating furnace, heating and preserving heat to complete the welding. The joint welded by the invention has a shearing strength of 40-105MPa at the room temperature, a shearing strength of 30-70MPa at 600 DEG C and the using temperature of not less than 600 DEG C, the soldering process is simple, and the welding efficiency is high. The solder can be used for the welding the carbon / silicon carbide ceramic matrix composite material and the titanium-aluminum-based alloy or a titanium-aluminum-based alloy piece.

Owner:HARBIN INST OF TECH

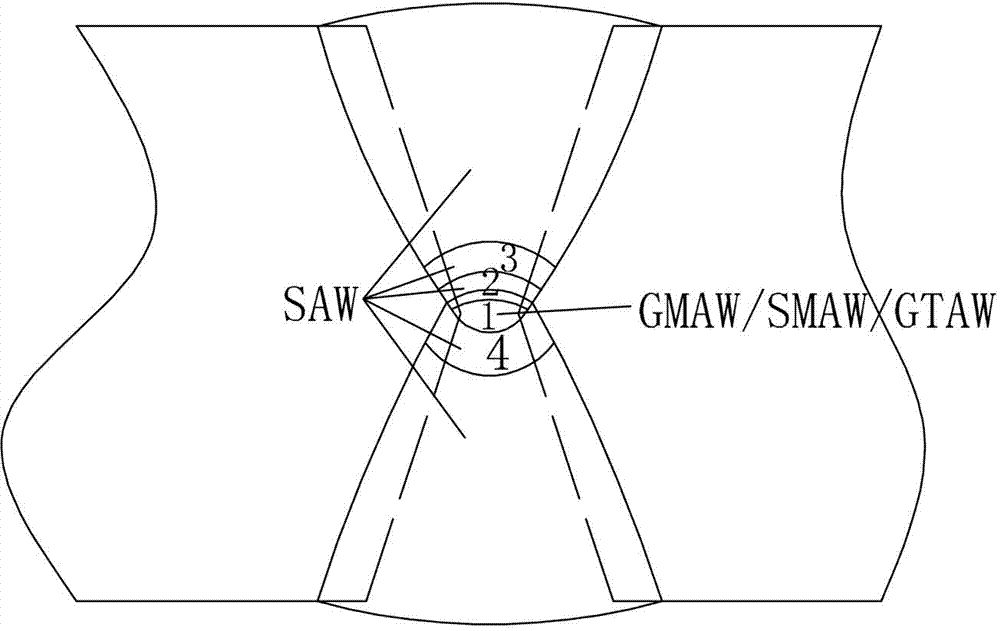

Medium thickness plate X-shaped bevel welding technology without back chipping

ActiveCN104493342AButt welding problem solvingReduce manufacturing costArc welding apparatusWelding/soldering/cutting articlesElectricityThick plate

A medium thickness plate X-shaped bevel welding technology without back chipping belongs to the technical field of welding, especially to the technical field of carbon steel, stainless steel medium thickness plate submerged arc welding. The submerged arc welding is used to weld without back chipping. The technology comprises the following steps: A pre-welding cutting and assembling; B front backing welding; C front low-current submerged arc welding; D back welding; E residue filling and cover welding. The technology method is suitable for welding weld seams of more than 10 mm, and is not sensitive to the differentiation change in the quality of bevels, the assembly clearance, the misalignment value and the surface roughness and suitable for the actual production. A lot of welding materials and electricity are saved, the back chipping and the welding time is shortened, the production cost is obviously saved, and the welding production efficiency is increased.

Owner:RUIDONG GRP

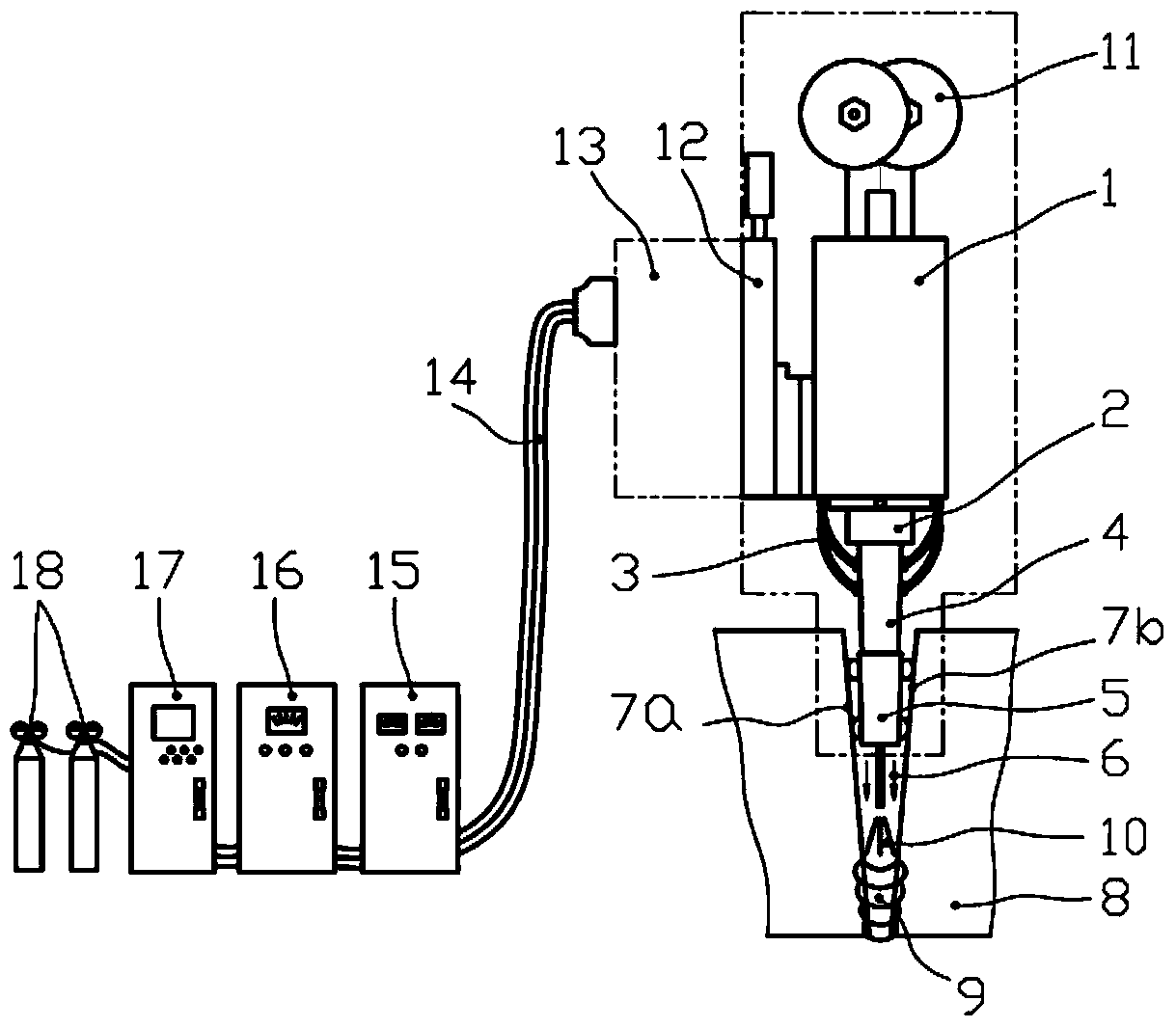

MAG/MIG automatic welding device and method

InactiveCN104289795AImprove reliabilityImprove protectionElectrode supporting devicesWelding coupling meansEngineeringWeld seam

The invention relates to an MAG / MIG automatic welding device and method. The device comprises a wire feeding mechanism, a wire plate is installed at the upper portion of the wire feeding mechanism, and a three-dimensional self-adaptation centering device is installed at the lower portion of the wire feeding mechanism. A plate type welding gun is fixed to the lower portion of the centering device, and a self-adaptation centering sensor is installed at the lower portion of the plate type welding gun. A gas splitting device is arranged in the middle of the lower portion of the welding gun, and the lower portion of the splitting device is connected with a protection nozzle. A welding gun height adjusting mechanism is further included. The welding method includes the steps that welding groove types and sizes, welding wire slip angles and deposition manners are determined, and root gaps, the input power of all welding layers and welding parameters are determined. The MAG / MIG automatic welding device and method have the advantages that self-adaptation intelligent tracking of welding seam tracks under various MAG / MIG welding groove conditions can be achieved, the ultra low welding spattering rate is achieved, welding high-temperature areas under various welding technology conditions can be effectively and reliably protected, the device is durable, high in welding quality, stable, reliable and high in working efficiency, and the welding production cost is greatly lowered.

Owner:武汉纳瑞格智能设备有限公司

Stainless steel electrode

InactiveCN102554510AStable physical and chemical propertiesImprove pass rateWelding/cutting media/materialsSoldering mediaElectrolysisManganese

A stainless steel electrode belongs to the field of welding materials, and is characterized in that chemical components of the electrode (in weight percent) include 40% of rutile, 8% of potassium feldspar, 3% of iron ores, 1.8% of potassium titanate, 1.8% of titanium white powder, 1.8% of metal chromium, 2.4% of fluorite (dried), 2.4% of cryolite, 8% of electrolytic manganese, 0.18% of bismuth oxide, 12% of micro-carbon ferrochromium, 7% of mica (dried), 1.5% of alginate calcium, 0.4% of ferroaluminium and 9.72% of marble. Compared with the prior art, the stainless steel electrode can generate arc, can also be melted to form filler metal for a welding line, and is high in corrosion resistance, and physical and chemical performances of deposited metal are stable.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Low-voltage high-current-beam electron beam vacuum welding device and method

InactiveCN104827177AHigh dielectric strengthHigh emission beam densityElectron beam welding apparatusWelding/soldering/cutting articlesLow voltageHollow core

The invention relates to a vacuum welding device and method, in particular to a low-voltage high-current-beam electron beam vacuum welding device and method. The low-voltage high-current-beam electron beam vacuum welding device and method are used for solving the problems that in the prior art, preparation before electron beam welding is complex and the operating cost is high. The low-voltage high-current-beam electron beam vacuum welding device comprises a hollow cathode, an anode, an accelerating electrode, an axial constraint magnetic field, a focusing mechanism, a discharging power supply, an accelerating power supply, a vacuum chamber, a welding platform and an insulating sleeve, wherein the axial constraint magnetic field, the insulating sleeve, the accelerating electrode, the focusing mechanism and the welding platform are arranged in the vacuum chamber in sequence from top to bottom, the hollow cathode is inserted into the axial constraint magnetic field, the anode is arranged between the hollow cathode and the accelerating electrode and located under the hollow cathode, a workpiece is placed on the working platform, the negative electrode of the discharging power supply is connected with the hollow cathode, the positive electrode of the discharging power supply and the negative electrode of the accelerating power supply are connected with the anode, and the accelerating power supply is connected with the accelerating electrode. The low-voltage high-current-beam electron beam vacuum welding device and method are used in the welding field.

Owner:HARBIN INST OF TECH

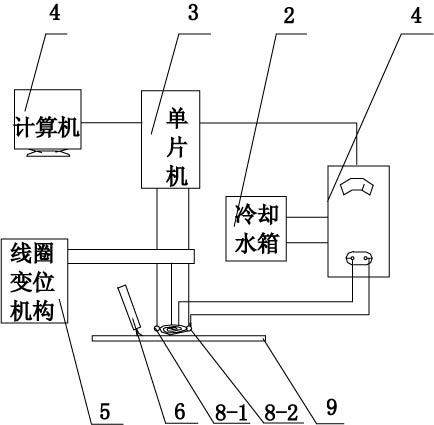

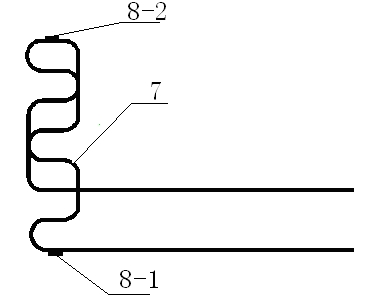

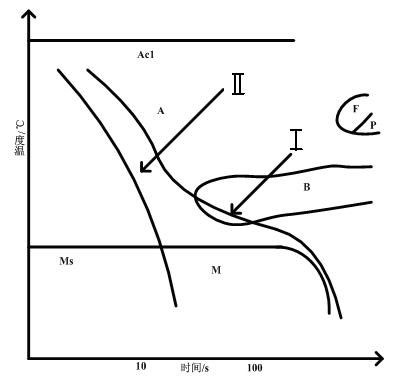

Method for controlling generation of cold crack in welding process based on electromagnetic induction heating

InactiveCN101786213AEvenly heatedImprove toughnessWelding/cutting auxillary devicesIncreasing energy efficiencyHeat-affected zoneEngineering

The invention provides a method for controlling generation of a cold crack in the welding process based on electromagnetic induction heating, relating to a method for controlling generation of the cold crack in the welding process. The invention aims to solve the problems that a welding seam and crystal grains in a heat influence region become coarse and the metal toughness is lowered due to using a pre-welding pre-heating method for preventing generation of the cold crack and the problems of difficult control of flame power, easy surface overburning, welding seam surface state change and welding production procedure increase in a post-welding heat treatment method in the traditional welding process. The method comprises the following steps of searching a welding continuous cooling transformation curve corresponding to special welding materials; determining a workpiece to be welded; welding a temperature field on the surface; determining induction heating process parameters; welding frock; and implementing welding until welding finish. The invention is used for welding.

Owner:HARBIN INST OF TECH

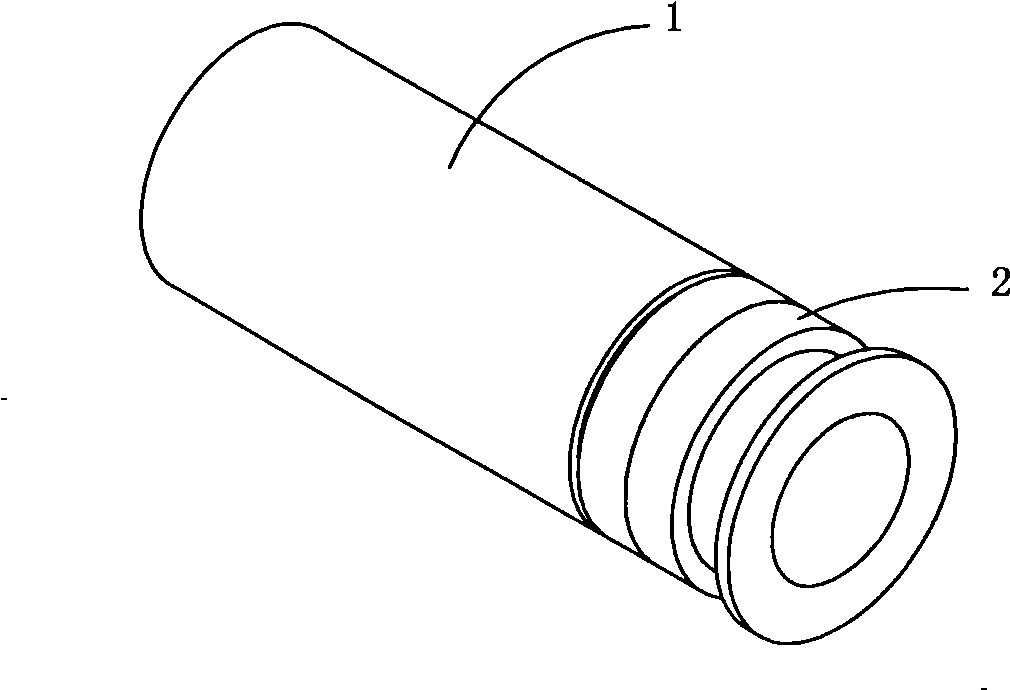

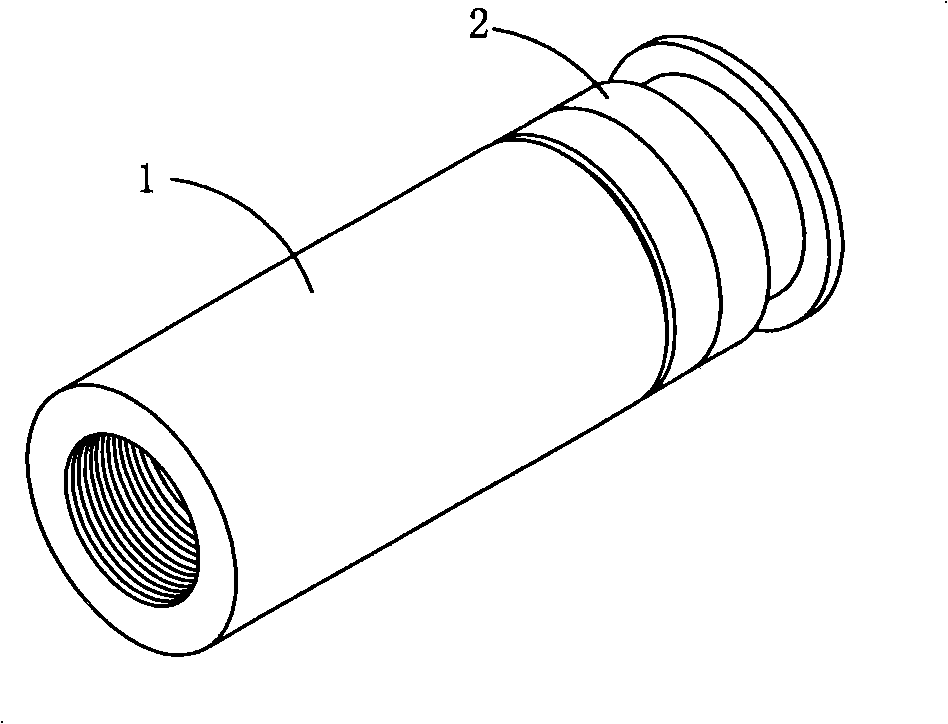

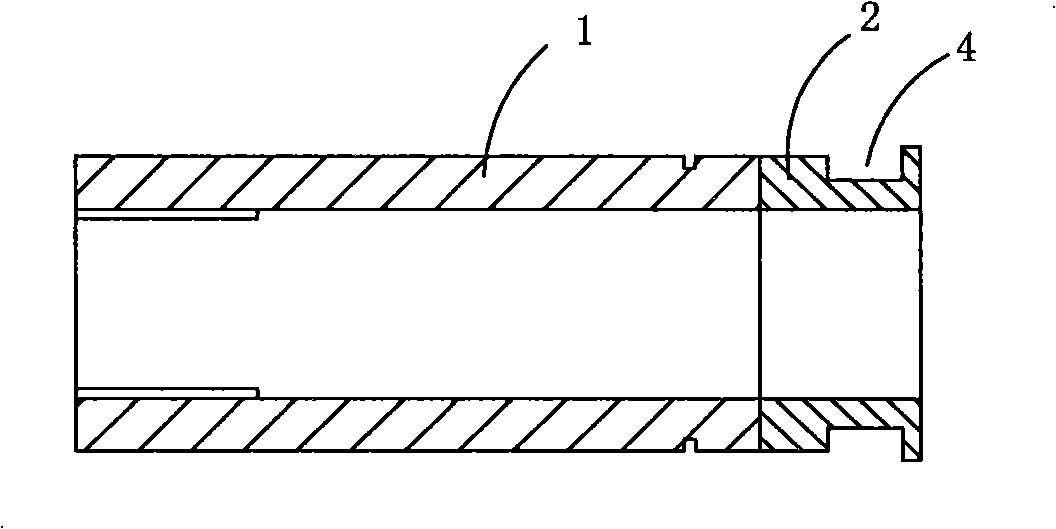

Cuprum aluminum socket connector for conductivity as well as manufacturing method and use thereof

InactiveCN101330174AHigh strengthImprove wear resistanceContact materialsContact member manufacturingElectrical resistance and conductanceLow voltage

The invention discloses a copper-aluminum socket connector for the electric conduction, the preparation method thereof and the application thereof. The socket connector comprises an aluminum body and a copper plug integrated into a whole by welding. The preparation method comprises the following steps: (1) manufacturing the molded aluminum body and the copper plug, and cleaning the welding surfaces of both the aluminum body and the copper plug; and (2) welding the aluminum body and the copper plug into an integrated part by adopting a flash welder or a spin friction welder to obtain the copper-aluminum socket connector semi-product for the electric conduction. The socket connector is mainly applied to a moving contact, a static contact or a conductive contact arm in a high and low voltage switch cabinet or a vacuum circuit breaker. The socket connector has the advantages of non-contact resistance, no galvanic corrosion, smaller resistance, less current conveyance loss, improved current transmission efficiency and reduced power transmission and transformation loss.

Owner:梁楚欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com