Patents

Literature

72results about How to "Realize welding automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

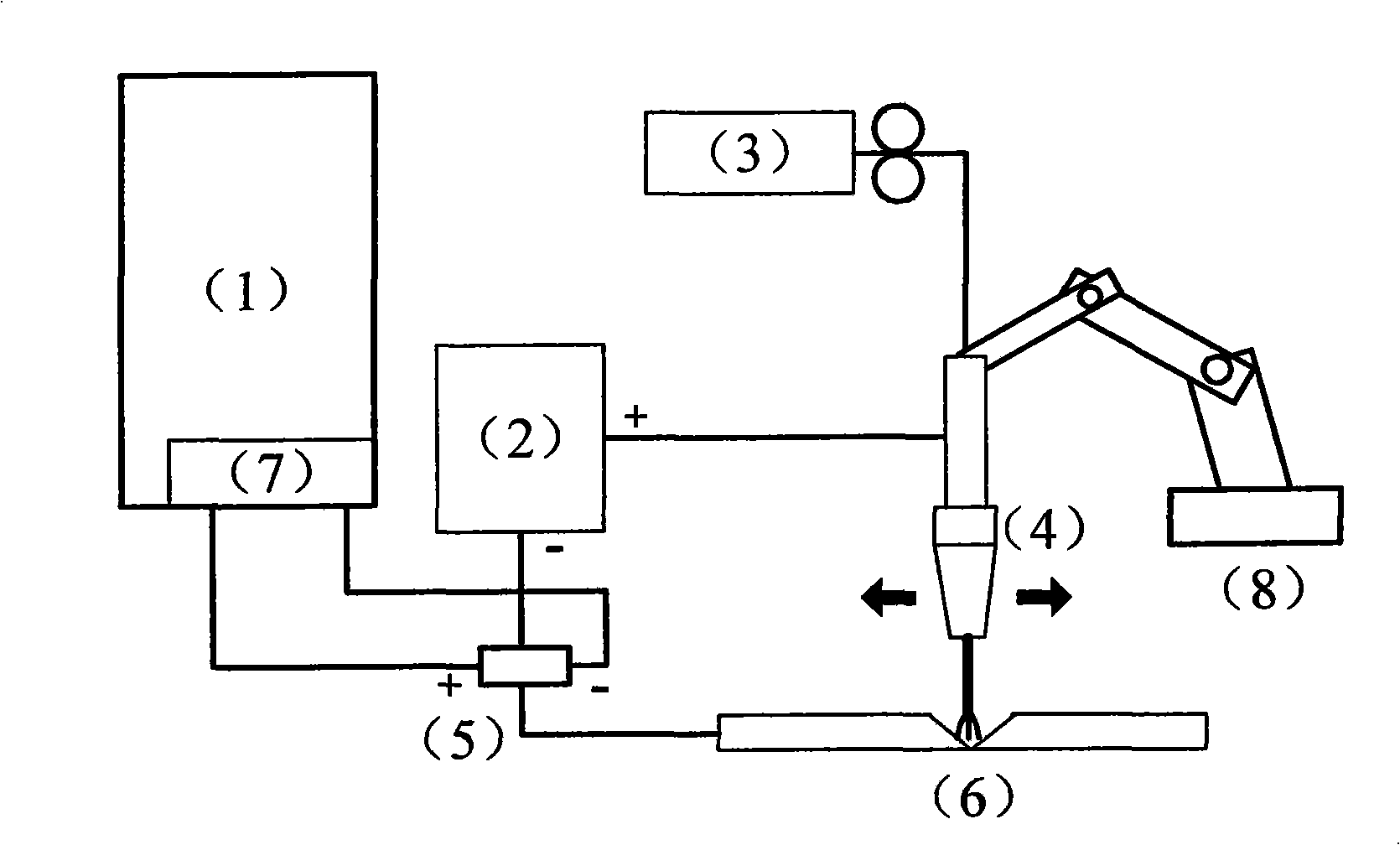

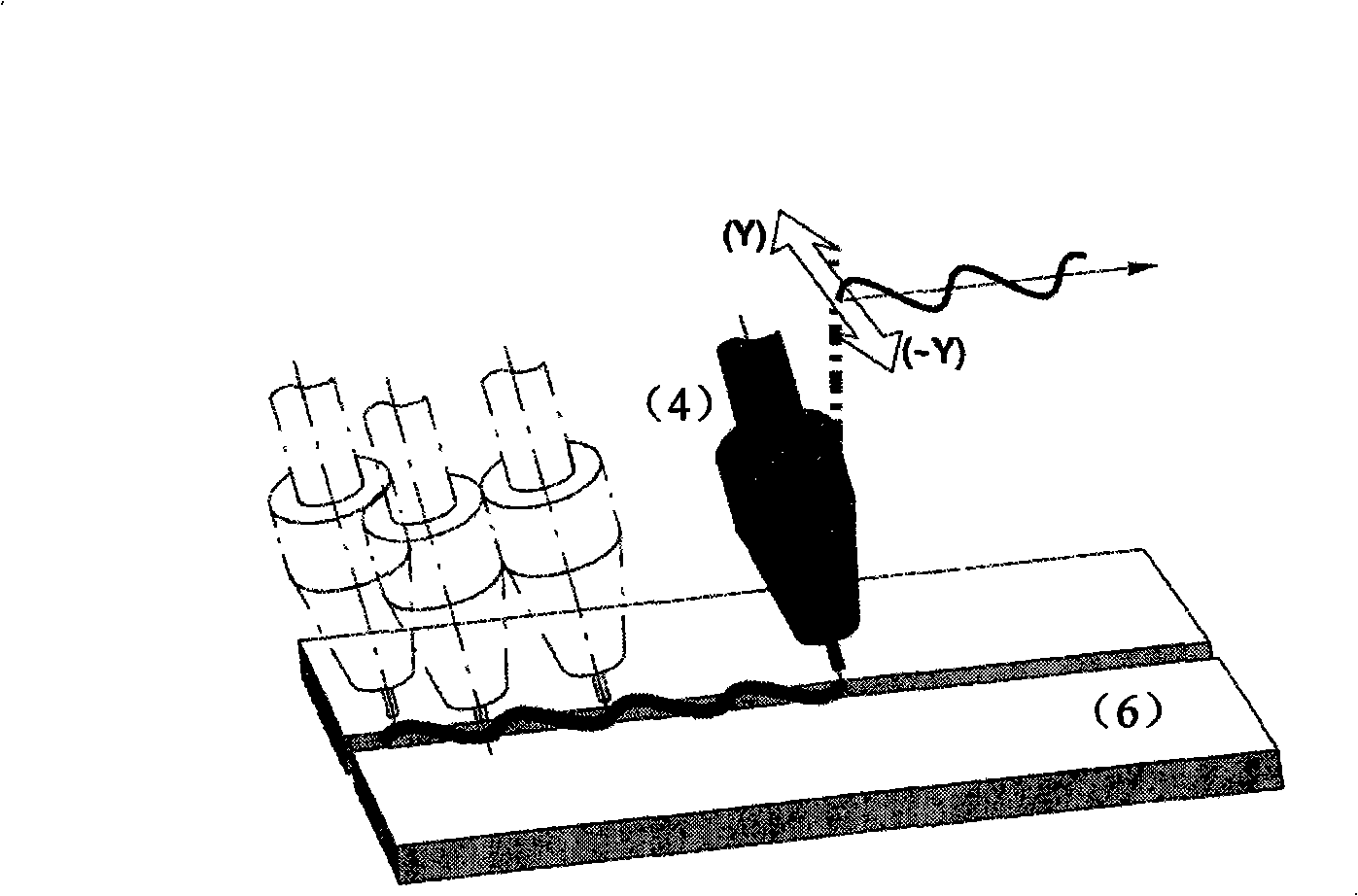

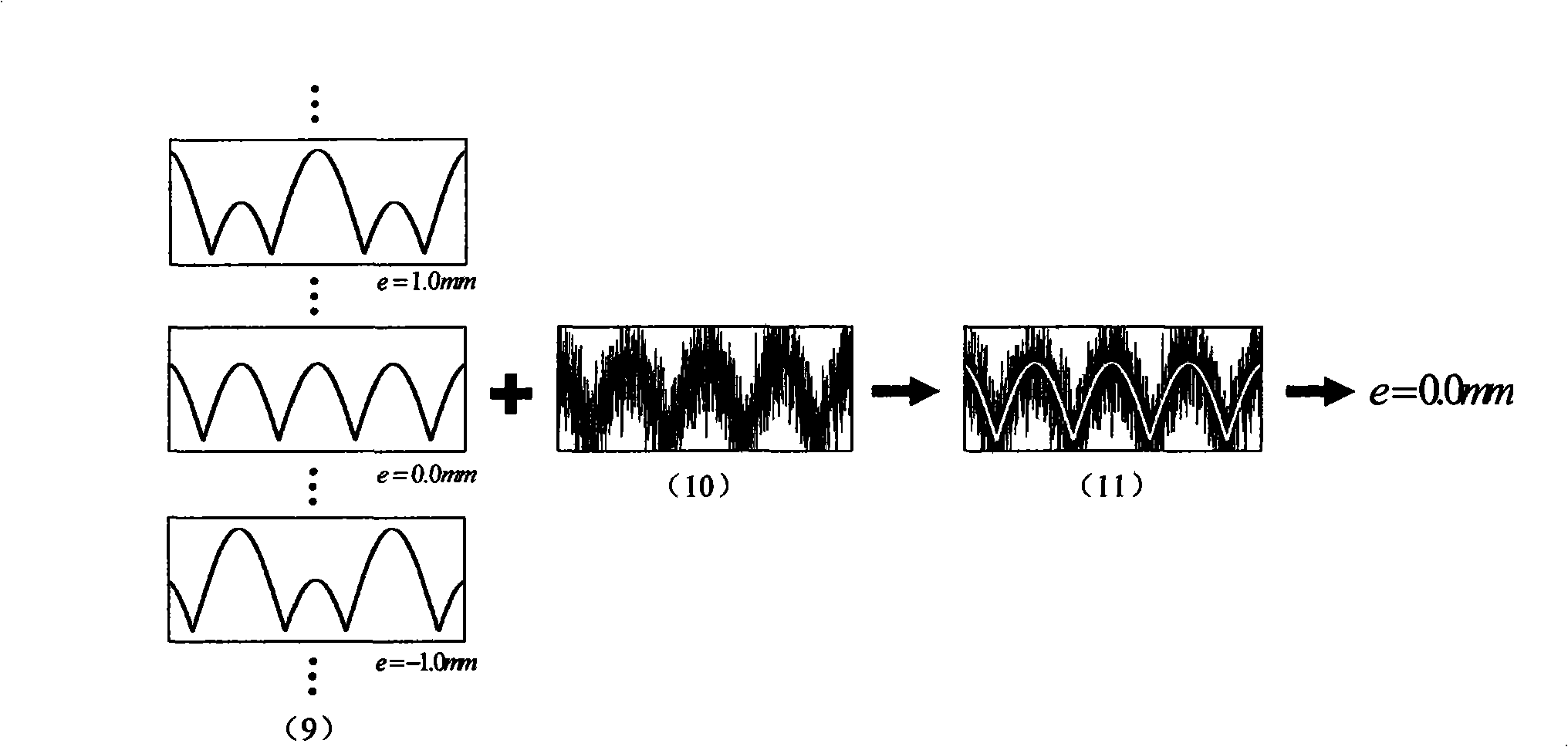

Method for extracting arc sensor welding gun position deviation information

InactiveCN101514886AImprove anti-interference abilityReliable extraction resultsArc welding apparatusUsing electrical meansEngineeringMinimum mean square error

The invention introduces a method for extracting arc sensor welding gun position deviation information. The basic idea of the method is combining a sampling result of a welding current signal with approximation of function to calculate the deviation information of the welding gun position. In the method, the relation of the welding current signal and the welding gun position deviation information under the condition of not considering the interference is derived firstly; then a welding current waveform which is most similar to an actual welding current sampling signal is calculated in minimum mean-square error sense; and the deviation value corresponding with the waveform is the deviation information of the welding gun position to be extracted. The method introduced by the invention can improve the precision of the arc sensor and also considers the integral characteristic of the welding current sampling signal completely to ensure that the deviation extraction result is more reliable.

Owner:SOUTHEAST UNIV

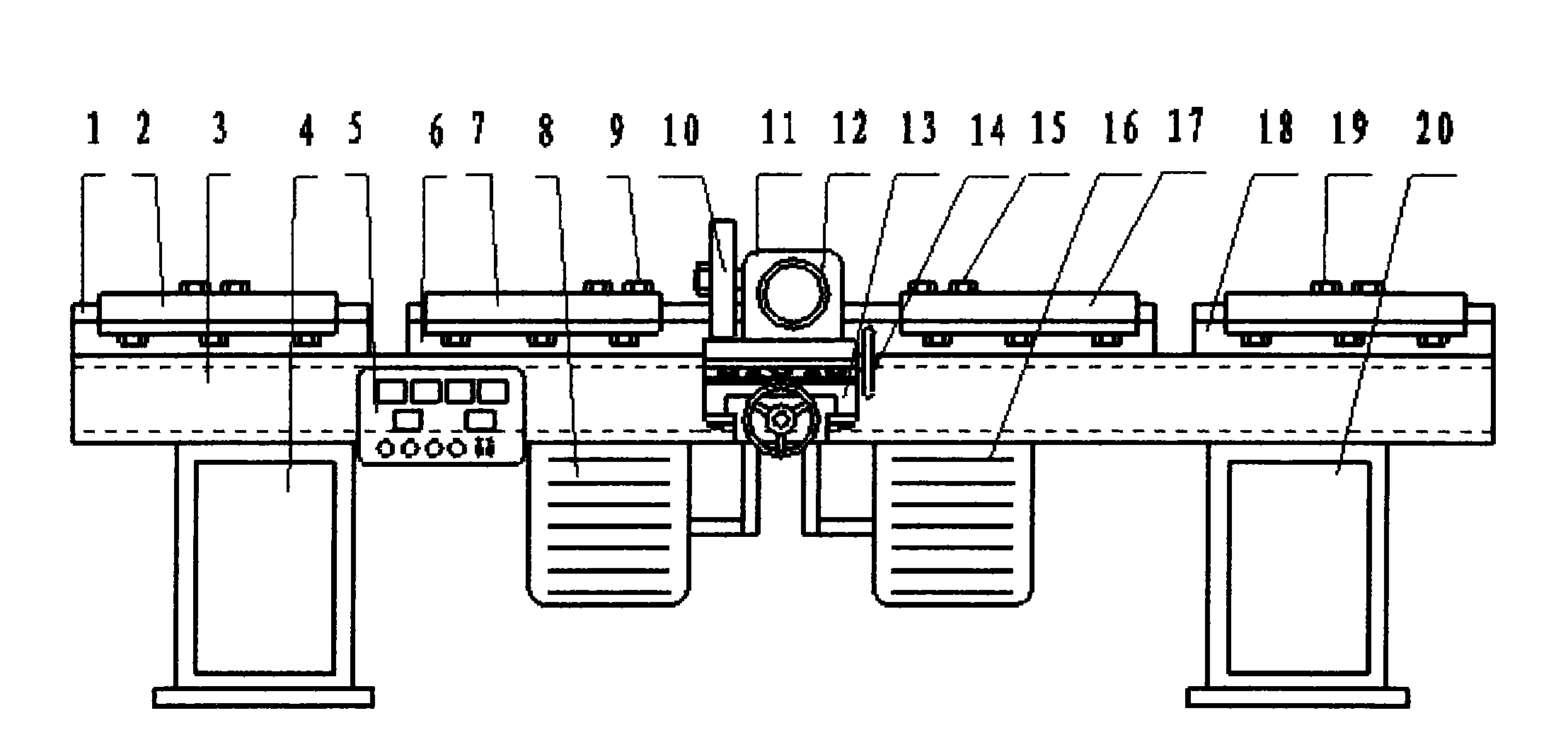

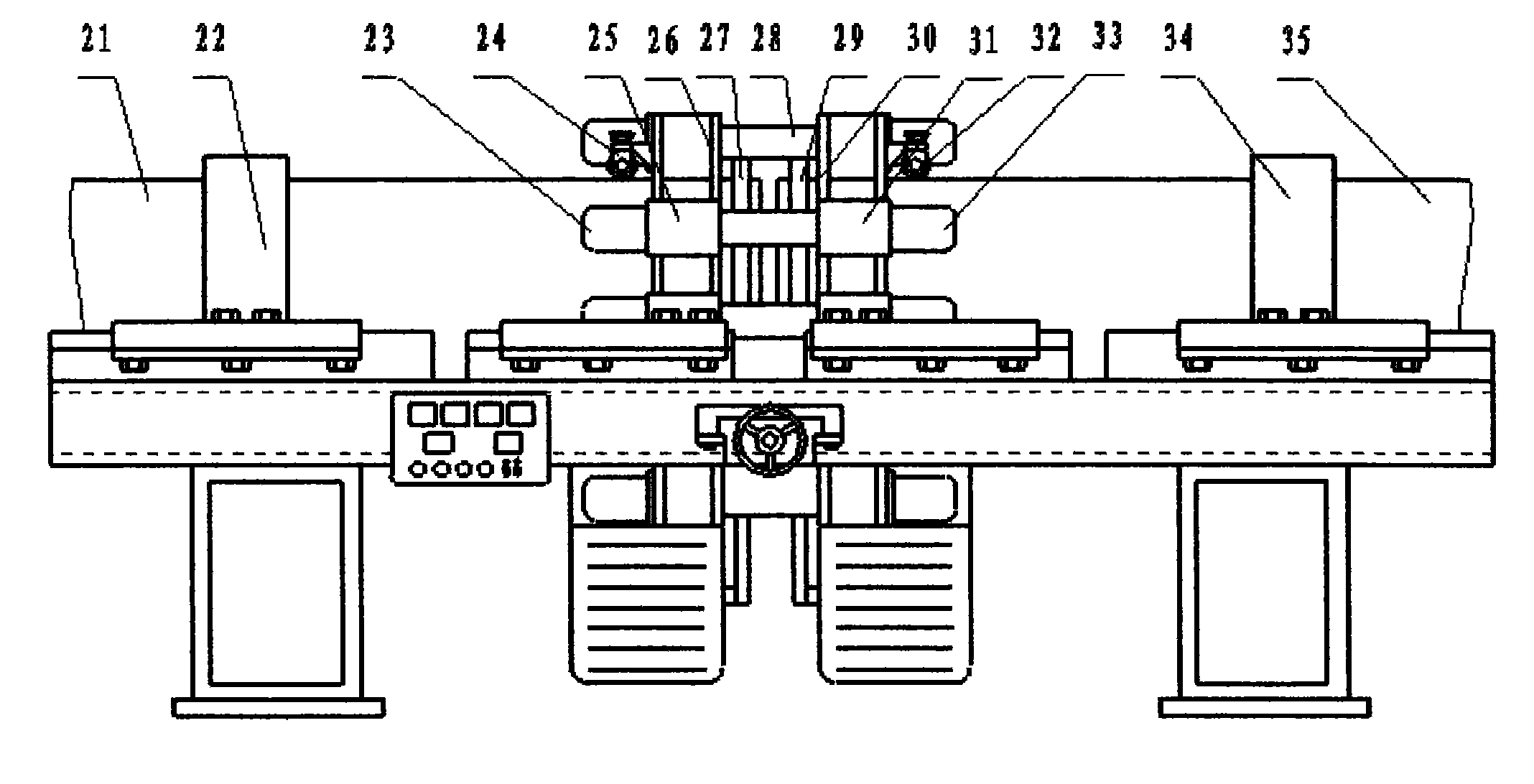

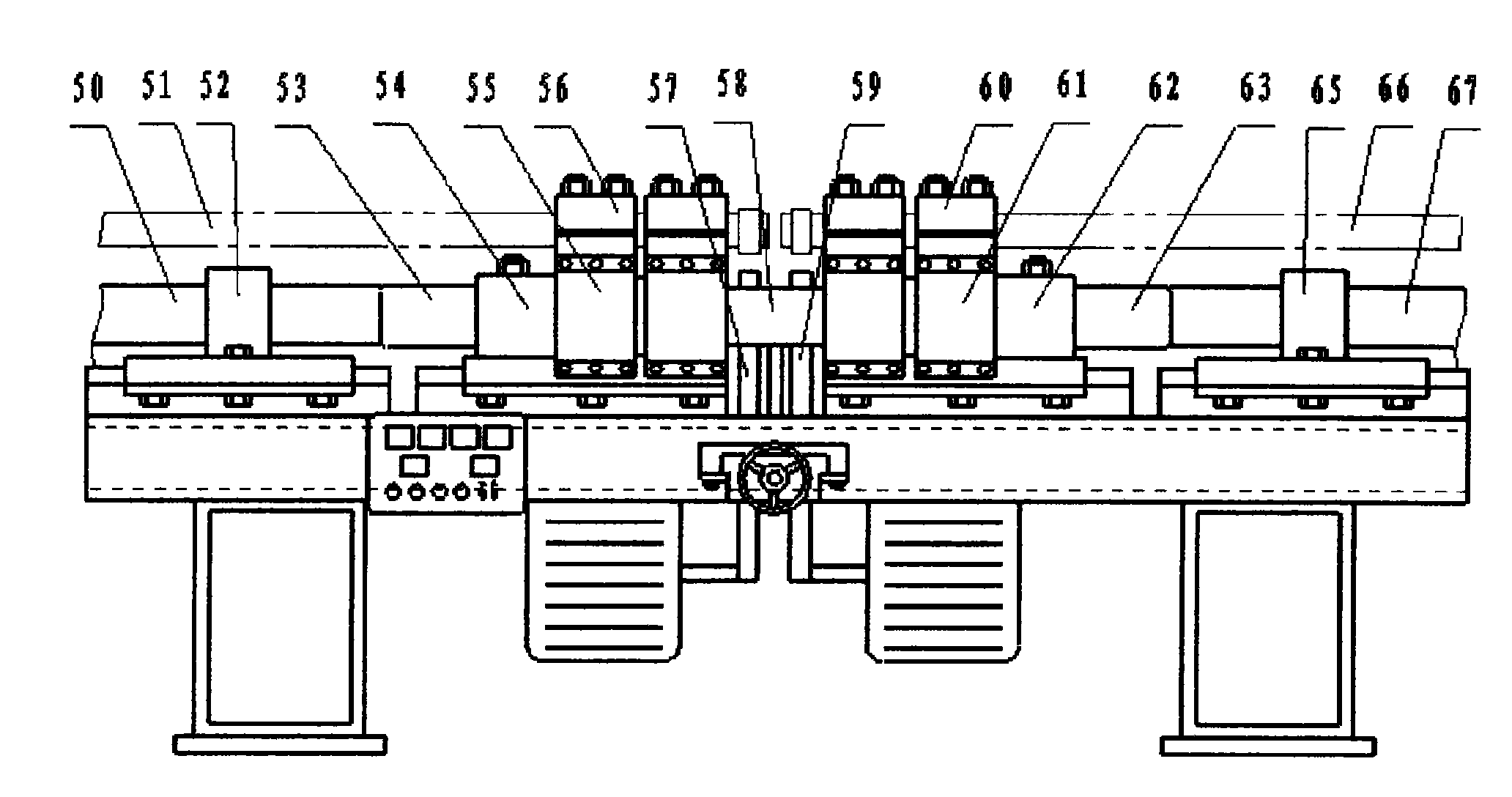

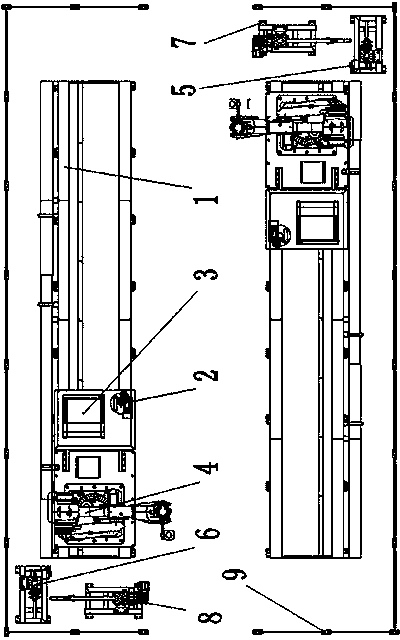

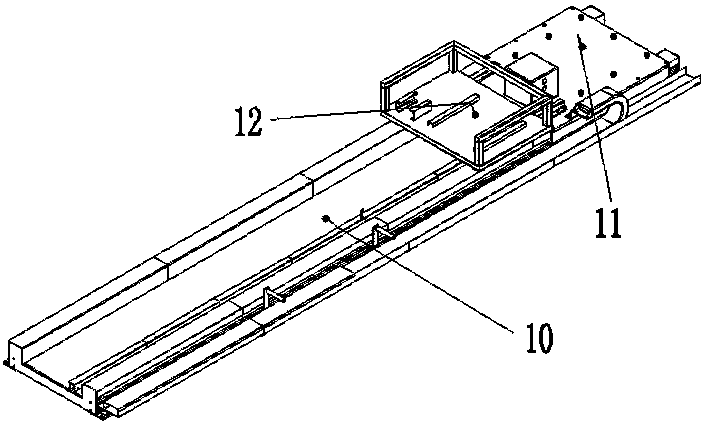

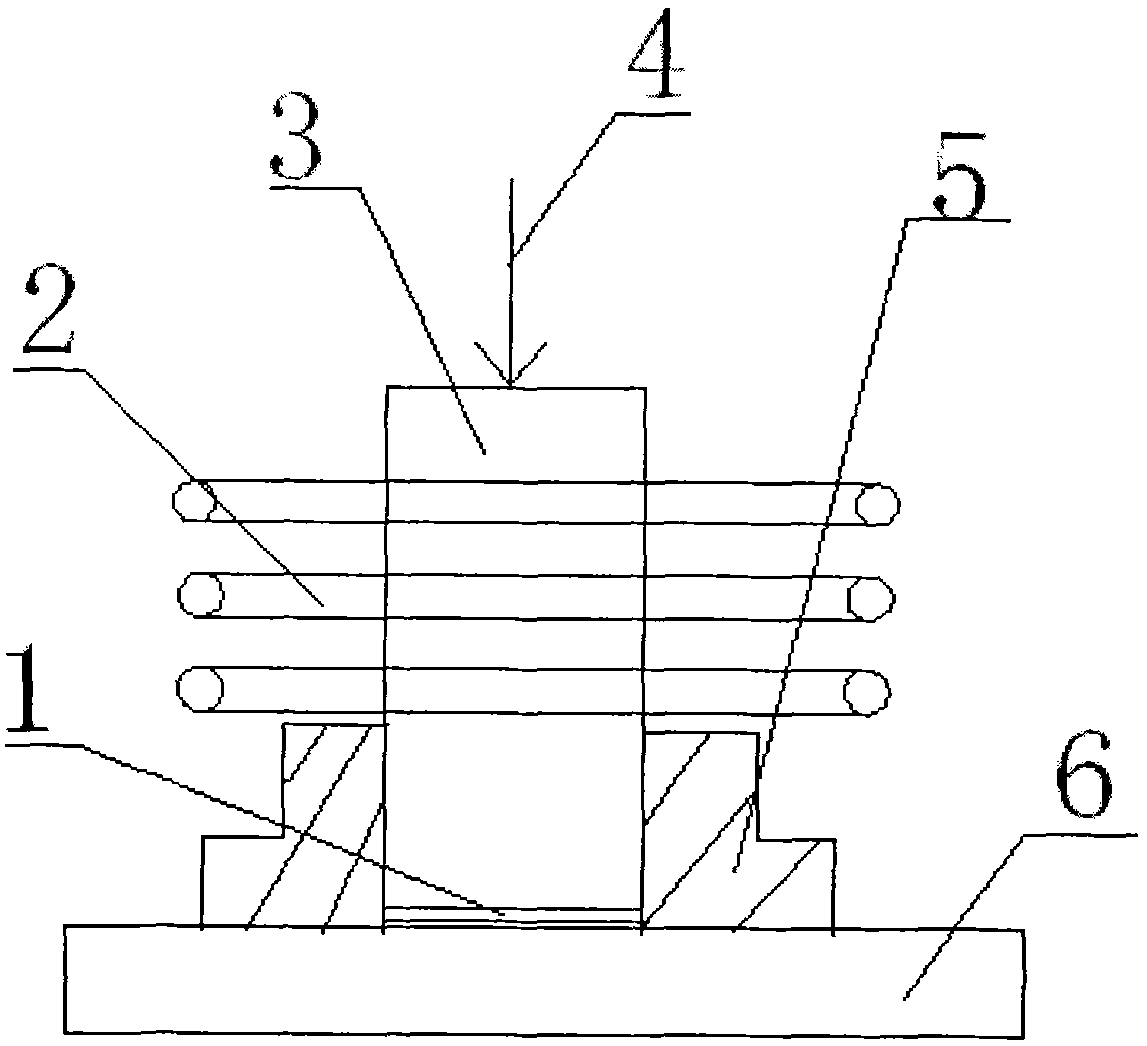

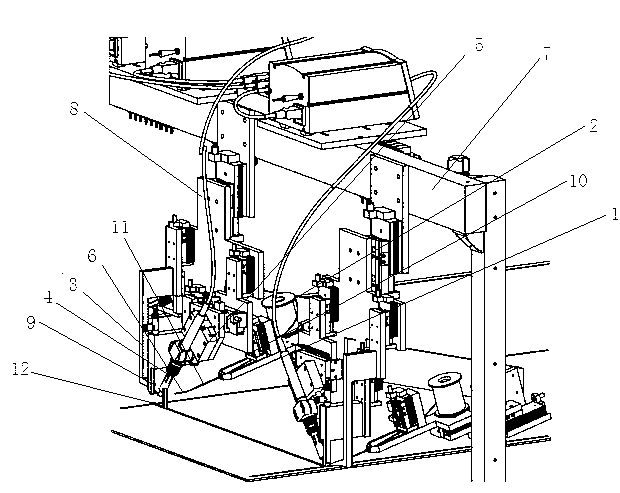

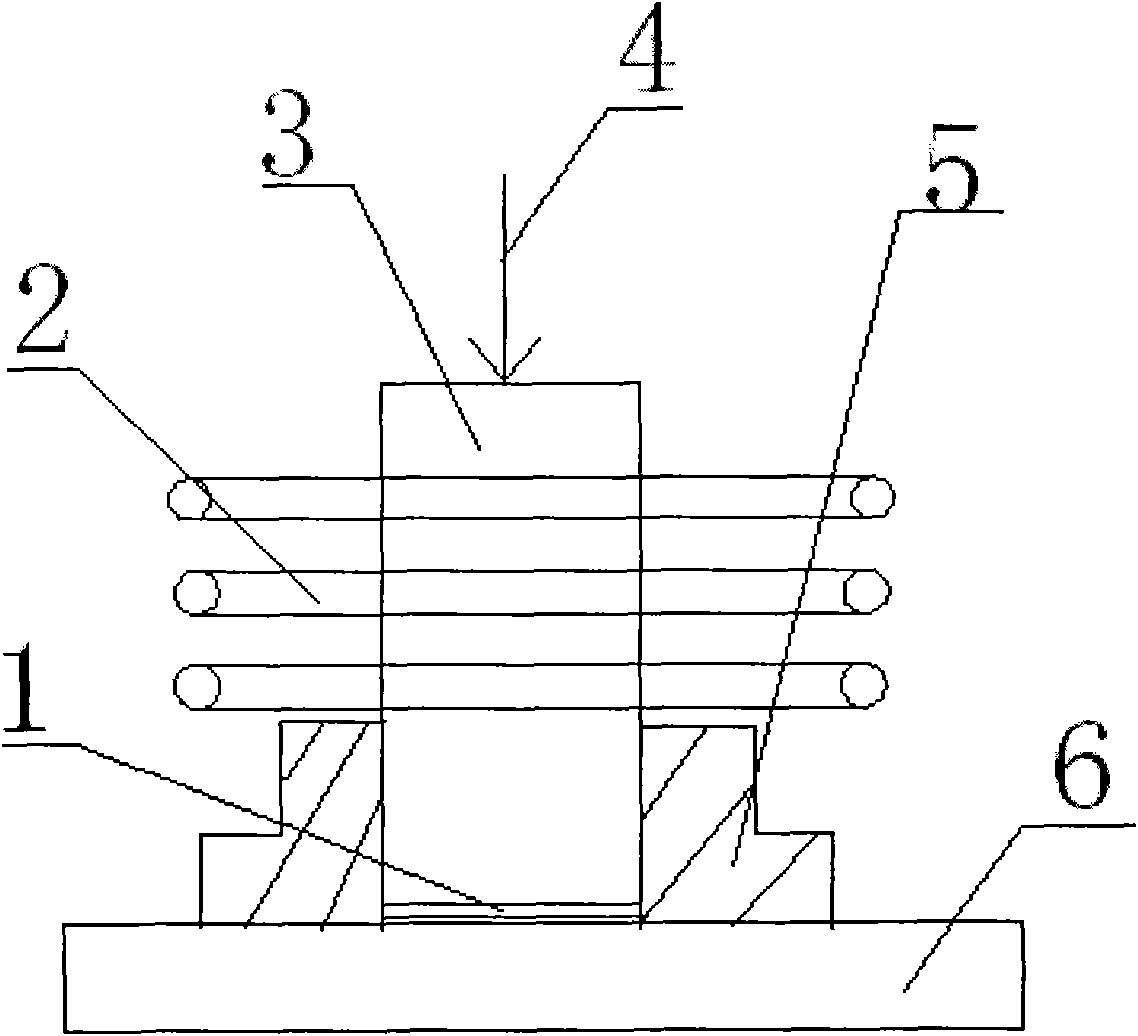

Steel induction heating solid phase welding method and butt welding machine tool

InactiveCN101623794ARealize welding automationLow priceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransformer

The invention relates to a steel induction heating solid phase welding method and a butt welding machine tool. The butt welding machine consists of a machine body and a butt welding clamp, wherein the machine body mainly comprises a machine tool body, an electric cabinet, a welding controller, a left main guide rail, a left main slide rail, a left induction heating transformer, a tool holder, a right induction heating transformer, a right main guide rail, a right main slide rail and a hydraulic cabinet; and the hydraulic steel tube and steel rail butt welding clamp mainly comprise a left hydraulic cylinder, a left hydraulic cylinder fixing seat, a left steel rail fixing clamp, a left induction heating ring, a connecting rod of a piston rod, a right induction heating ring, a right steel rail fixing clamp, a right hydraulic cylinder fixing seat and a right hydraulic cylinder. The butt welding clamp is arranged on the end face to be welded of the steel product; and the induction heating rings are sleeved on the end face to be welded of the steel product respectively; an induction heating power supply is connected with the primary of the induction heating transformer by a cable, and the secondary of the induction heating transformer is connected with the induction heating rings respectively; and the induction heating rings can heat the end faces to be welded of two steel products to a thermoplastic state in a shot time, and the upsetting pull force is generated on the welding clamp, so that the two steel products are welded together.

Owner:陈炯

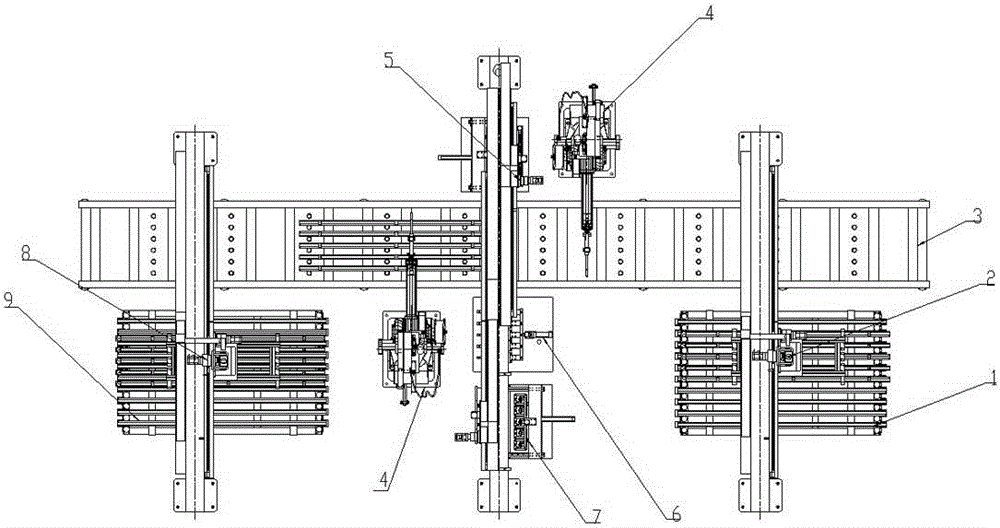

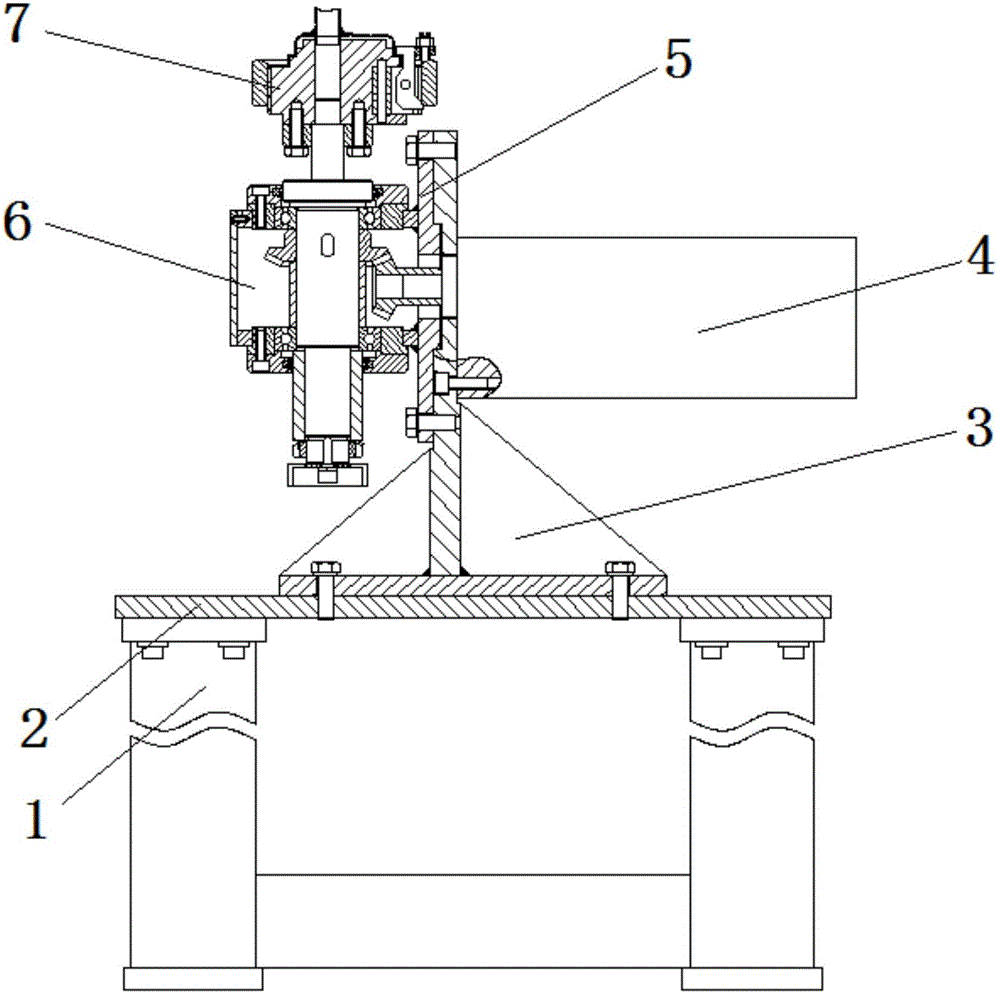

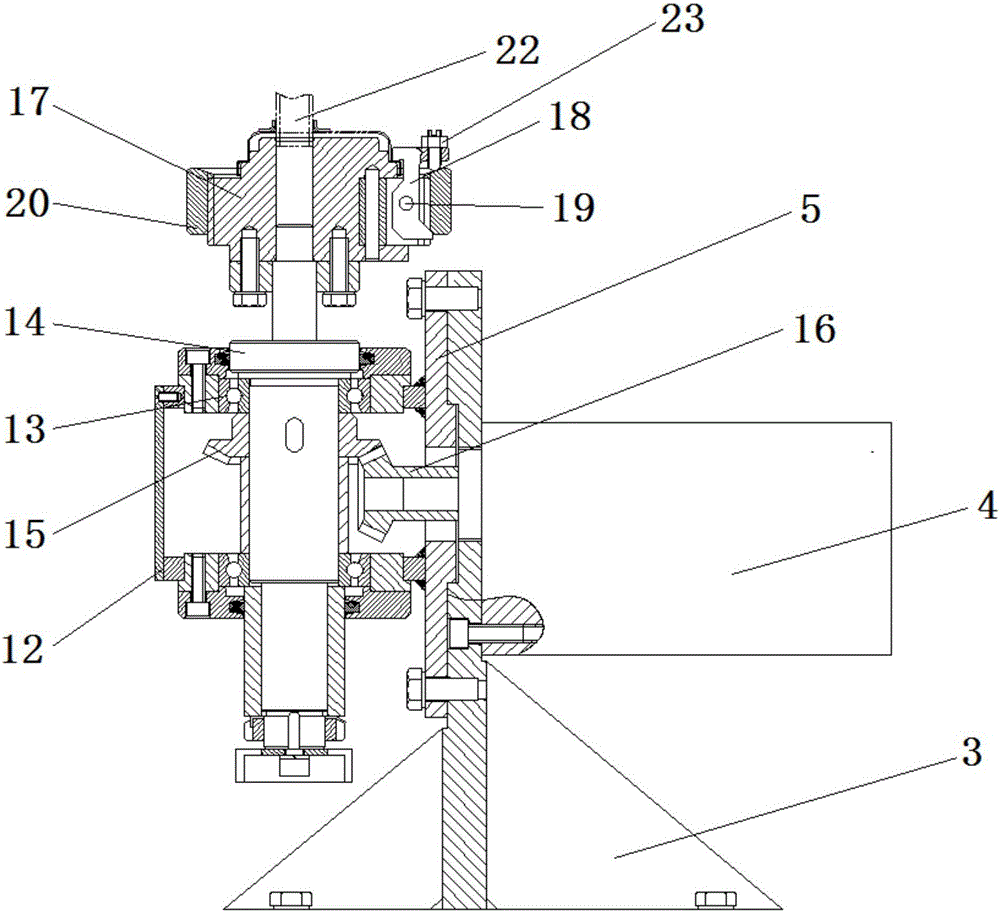

Robot automatic welding system for car body

InactiveCN104384695AHigh degree of automationHigh repeatabilityWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention discloses a robot automatic welding system for a car body and relates to the technical field of robot spot welding automation. The robot automatic welding system for the car body comprises a robot walking mechanism, an electrode dresser, a robot control cabinet, a robot, a C-shaped servo electrode holder placing rack, a C-shaped medium-frequency servo electrode holder, an X-shaped servo electrode holder placing rack, an X-shaped medium-frequency servo electrode holder and a latticed fence, wherein the robot walking mechanism comprises a walking mechanism base assembly, a movable sliding table and a support assembly, the movable sliding table is slideably arranged on the walking mechanism base assembly, the support assembly is installed on one side of the movable sliding table, the robot is fixedly installed on the movable sliding table, the electrode dresser and the robot control cabinet are installed on the support assembly, the robot control cabinet is connected with the robot, and the C-shaped medium-frequency servo electrode holder and the X-shaped medium-frequency servo electrode holder are connected with the robot through tool changers. The robot automatic welding system for the car body has the advantages that the acting stability is reliable, the repetitive accuracy is high, the labor conditions of operating workers are improved and the welding quality and labor productivity are improved.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

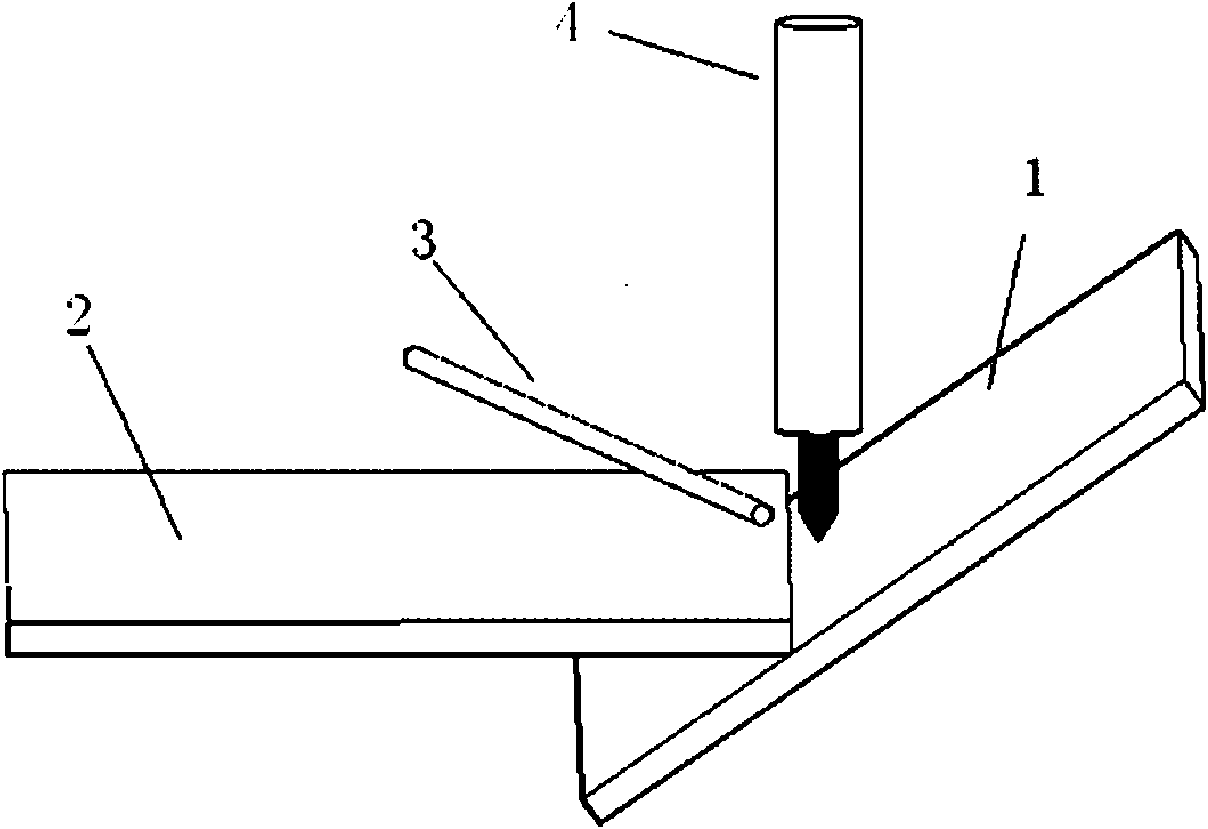

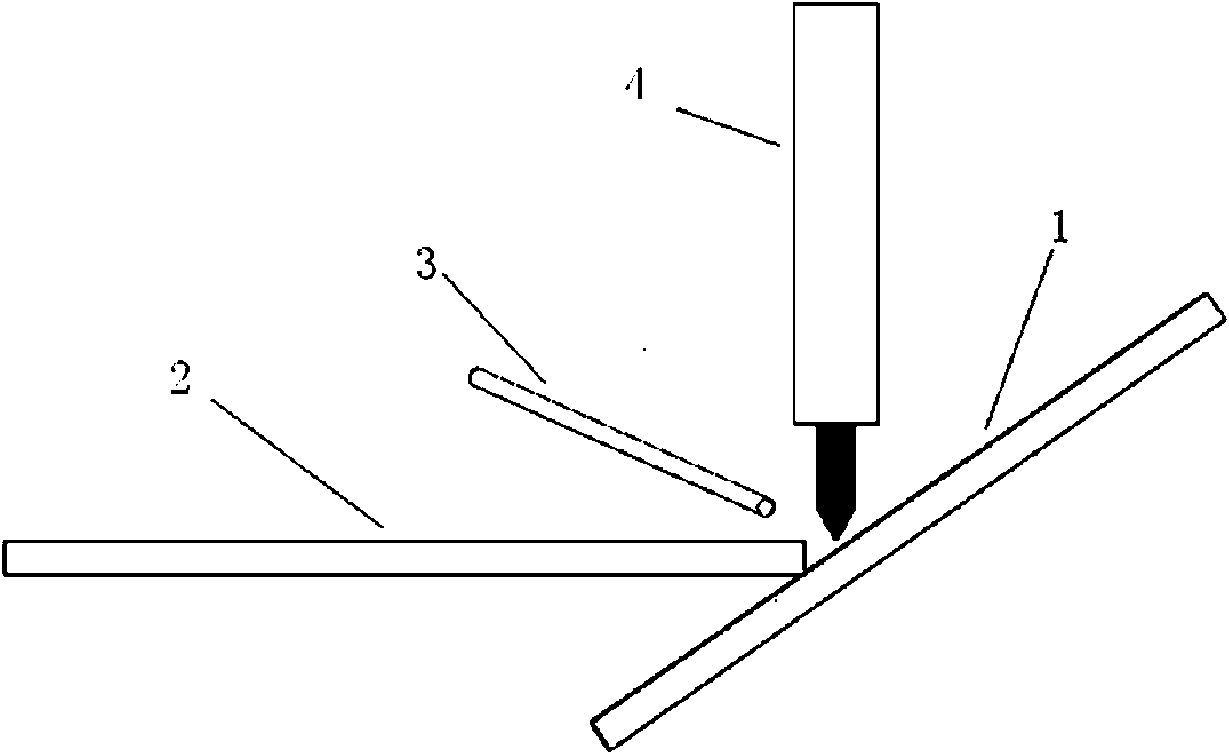

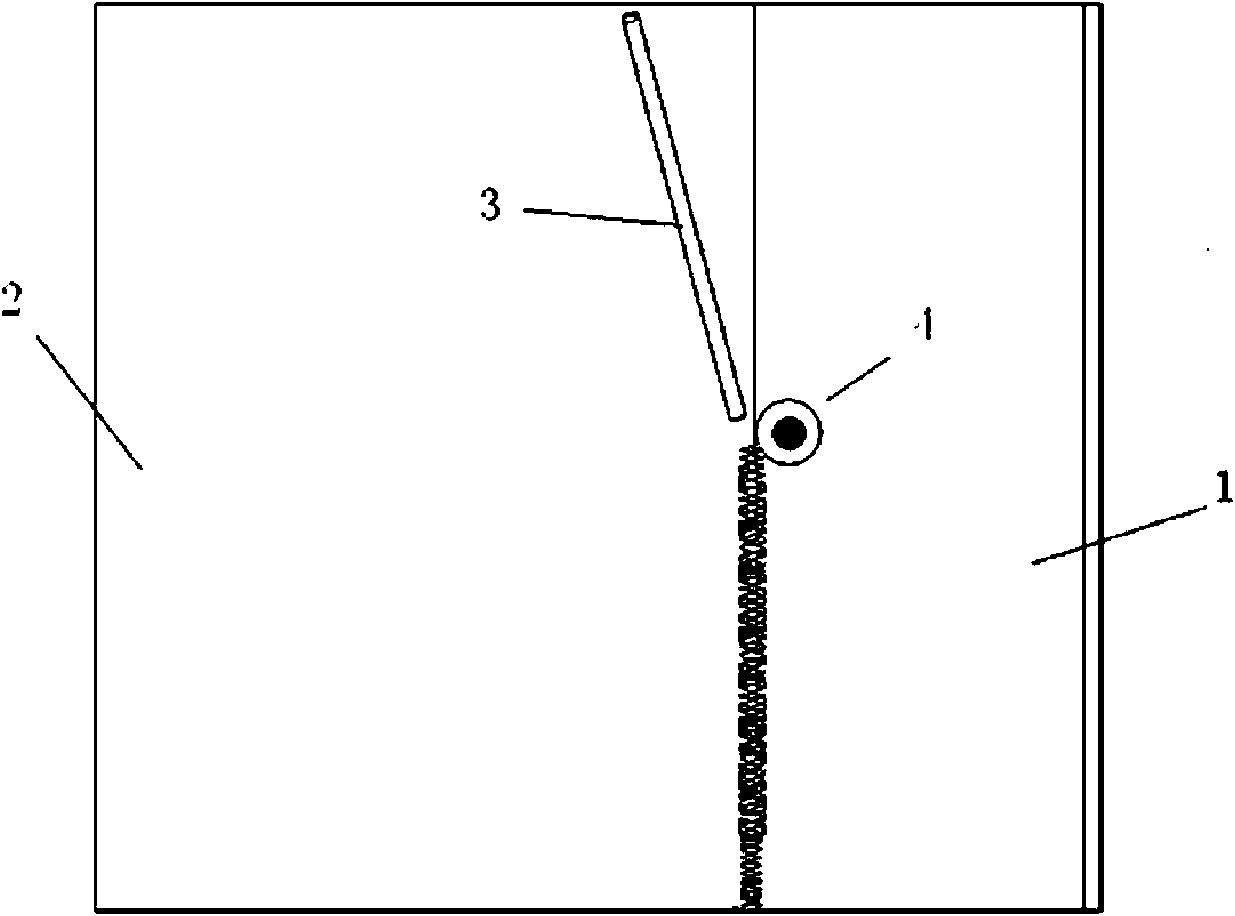

Angle welding method of stainless steel sheet on basis of image processing

InactiveCN101664853AReduce scrap rateRealize welding automationImage analysisArc welding apparatusQuality controlEngineering

The invention relates to an angle welding method of a stainless steel sheet on the basis of image processing, belonging to the technical field of metal welding. A welding quality control method comprises the following steps: image processing results are used for replacing the sensitive technological parameters of welding visual information, adjusting the position of a welding gun in real time andthe like to control welding quality; a welding clamp on which a clamp at one side is positioned at the horizontal position and forms an angle of 90 degrees to 180 degrees with a clamp at the other side is adopted to fix a sheet; a stepping motor controls the mobility of the clamp; an imaging processing algorithm is adopted to detect the position of a tungsten electrode; and the tungsten electrodeis adjusted to optimum parameter in real time according to results. The angle welding method greatly reduces reject rate, improves production efficiency, simultaneously has fast calculating speed andcontrollable calculation precision, is applicable to detection of other cylindrical images and has very wide application prospect in the welding image detection.

Owner:SHANGHAI JIAO TONG UNIV

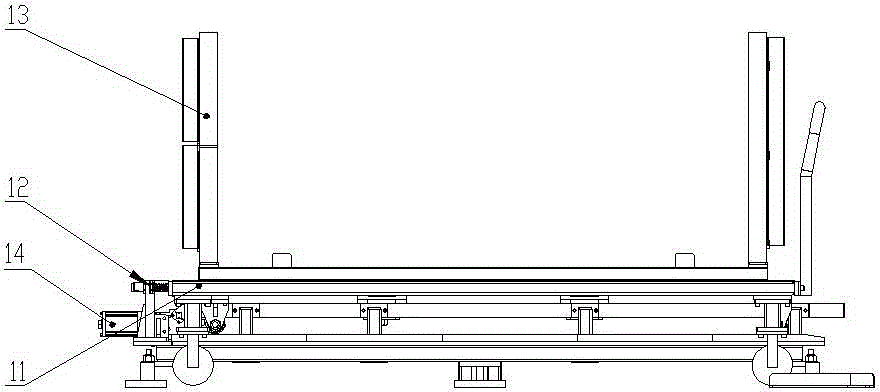

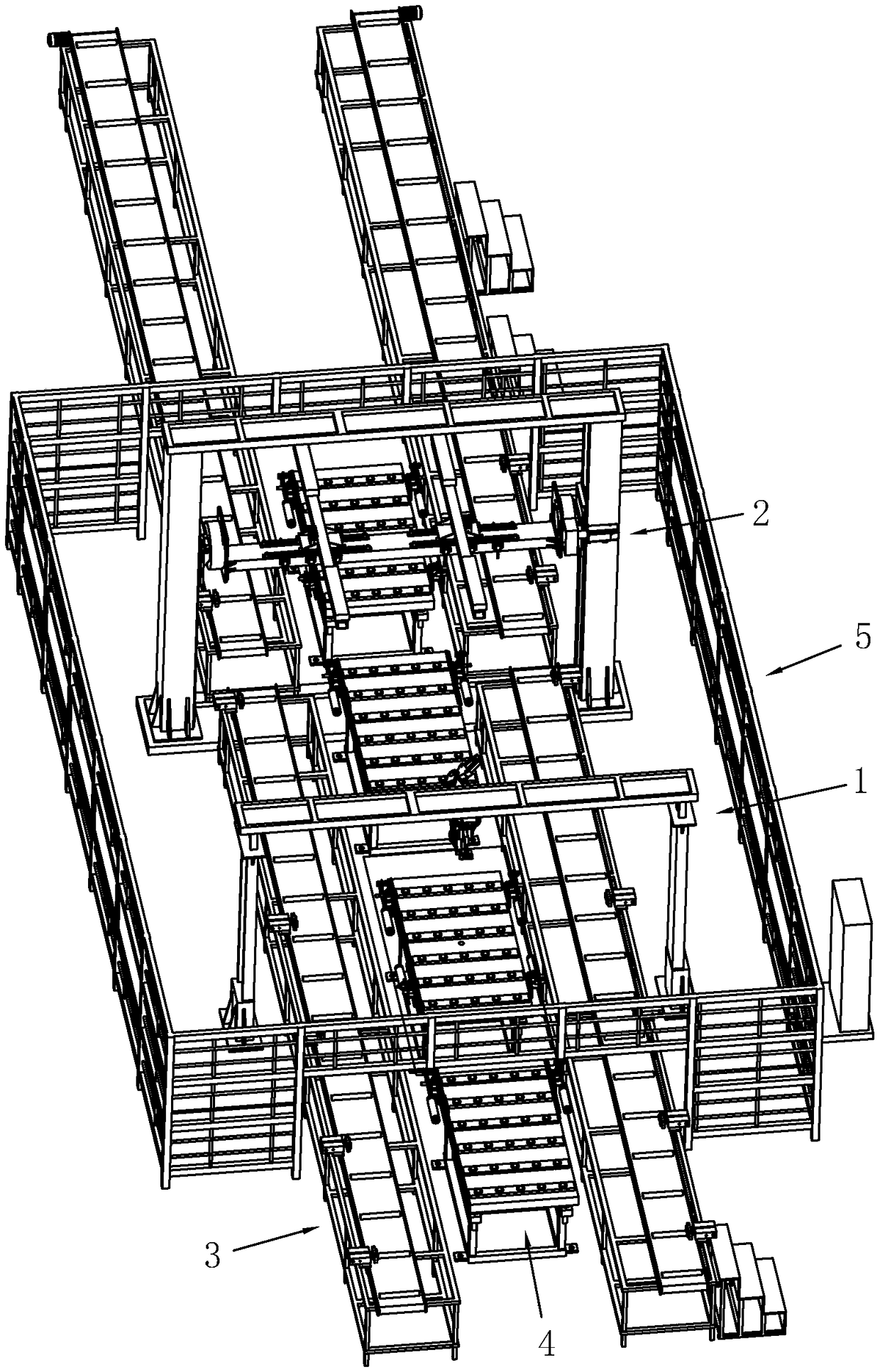

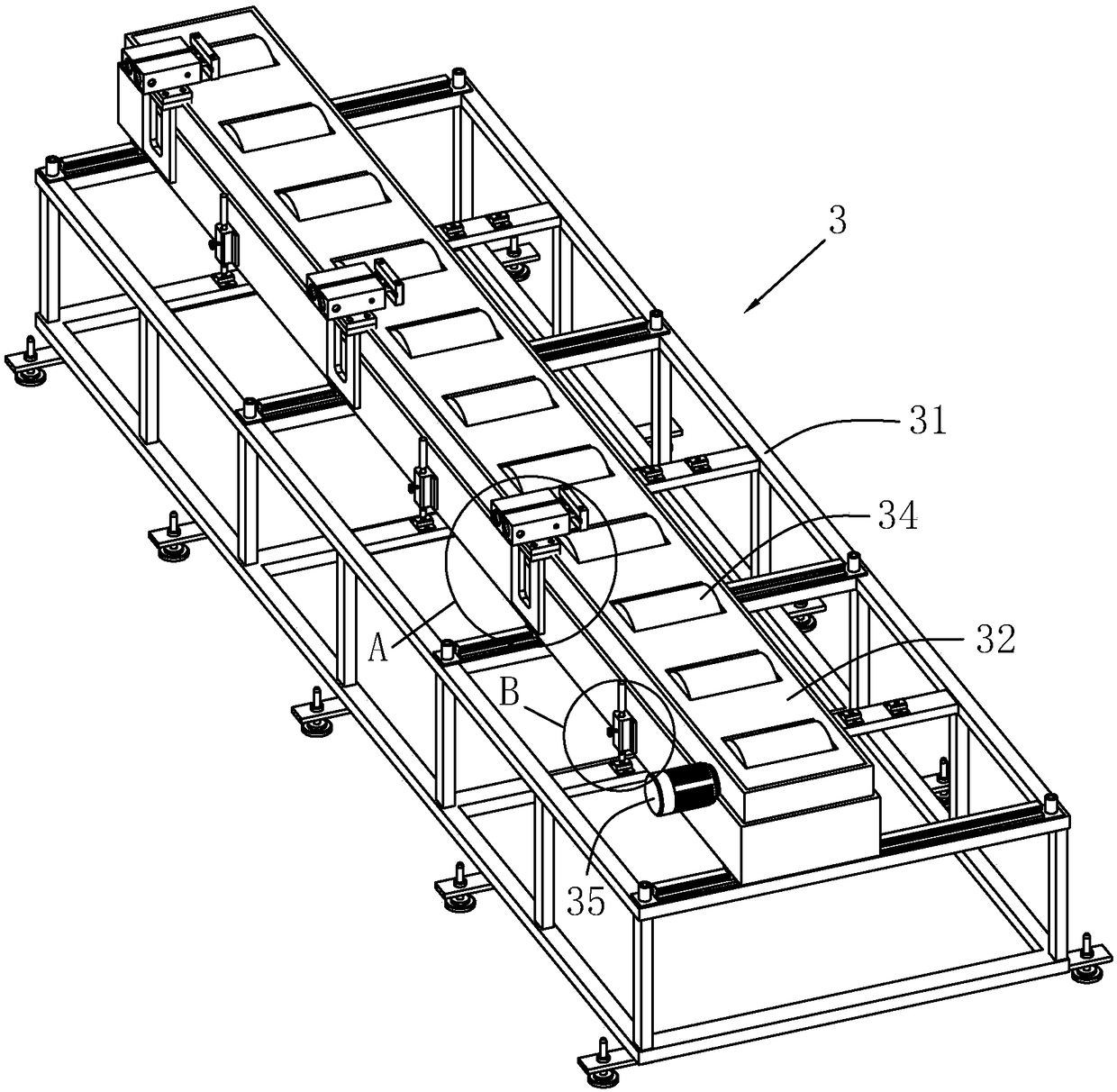

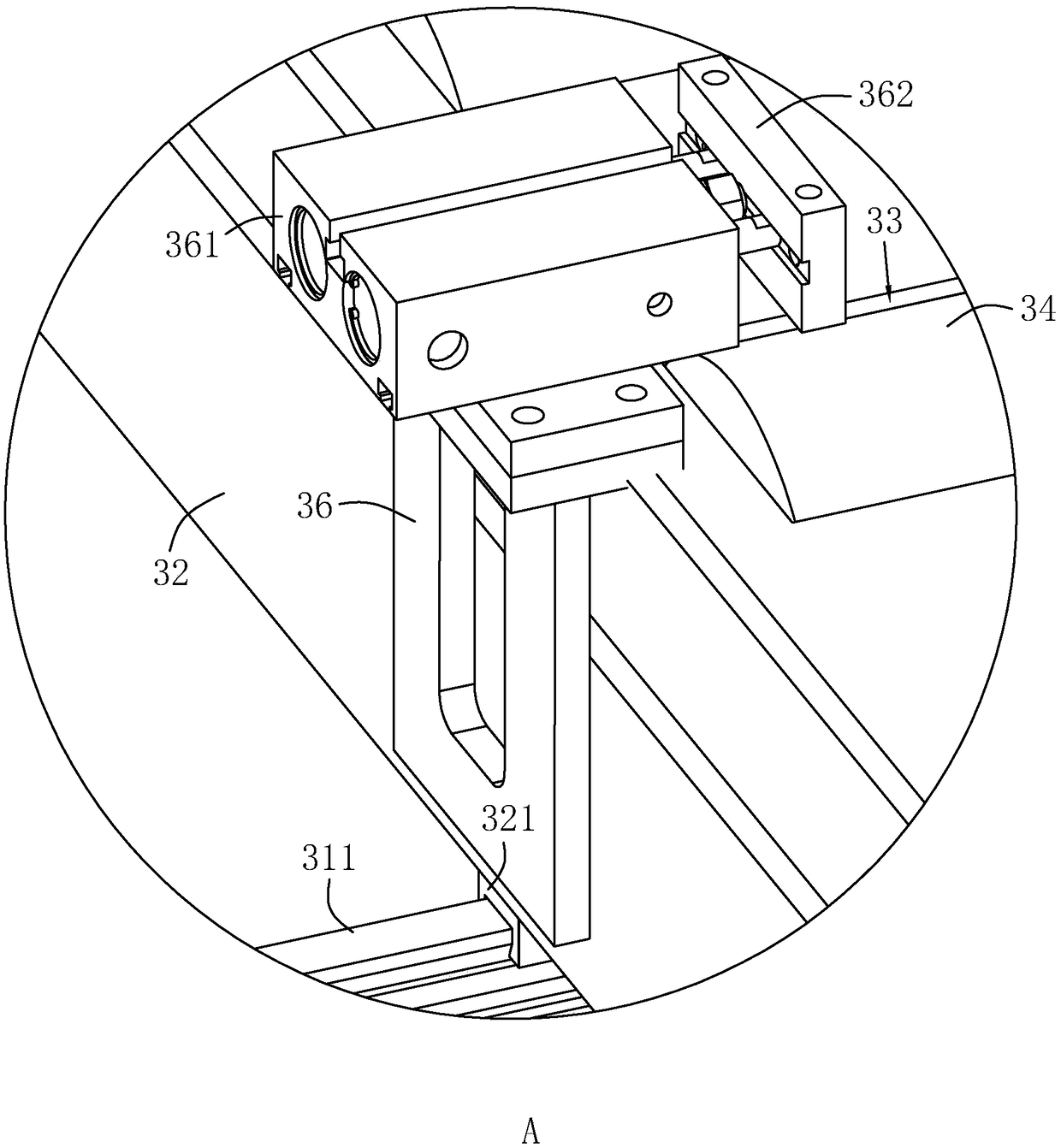

Door pocket welding robot system

ActiveCN105171255AReliable actionHigh repeatabilityWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerControl system

The invention discloses a door pocket welding robot system. The door pocket welding robot system is composed of a feeding cart, a feeding transferring mechanism, a material conveying line, a vertical frame connector feeding mechanism, a small connector feeding mechanism, a small part transferring mechanism, a welding system, a discharging transferring mechanism, a discharging cart and a programmable logic controller (PLC) control system, wherein the feeding cart is arranged on one side of the material conveying line; the feeding transferring mechanism is arranged above the material conveying line; the vertical frame connector feeding mechanism and the small connector feeding mechanism are arranged on one side of the material conveying line; the small part transferring mechanism is located above the material conveying line; the welding system is arranged near the material conveying line; the discharging cart is arranged on one side of the material conveying line; the discharging transferring mechanism is arranged above the material conveying line. The door pocket welding robot system is stable and reliable in motion, high in repeatability precision, high in welding quality, high in labor production efficiency, good in production environment, short in production period and high in automatic plasticity, and the product output is easy to control.

Owner:SHANGHAI SKEQI AUTOMATION ENG CO LTD

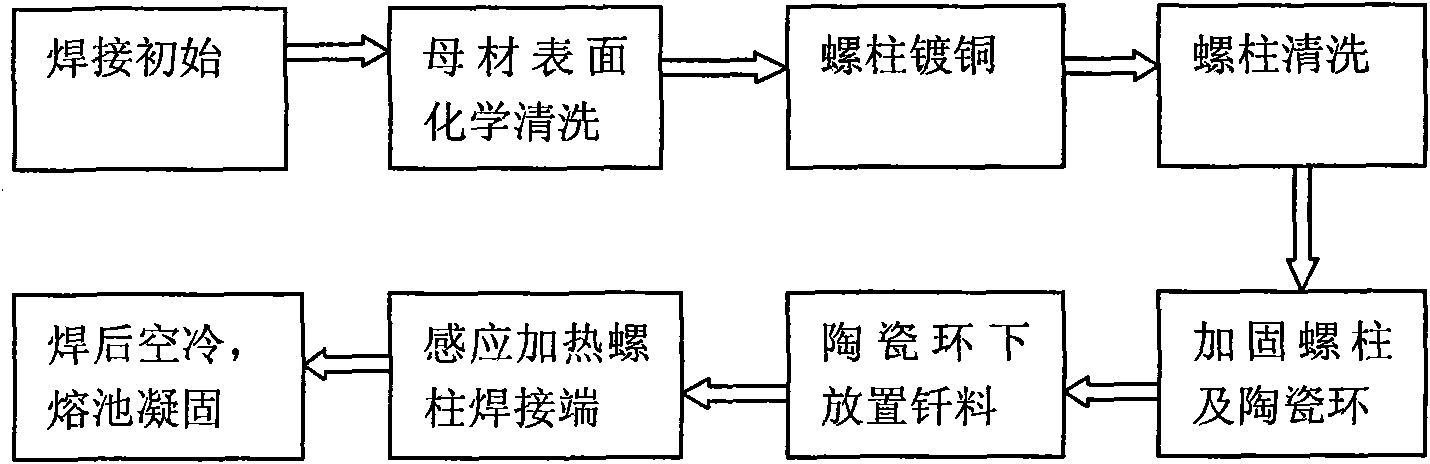

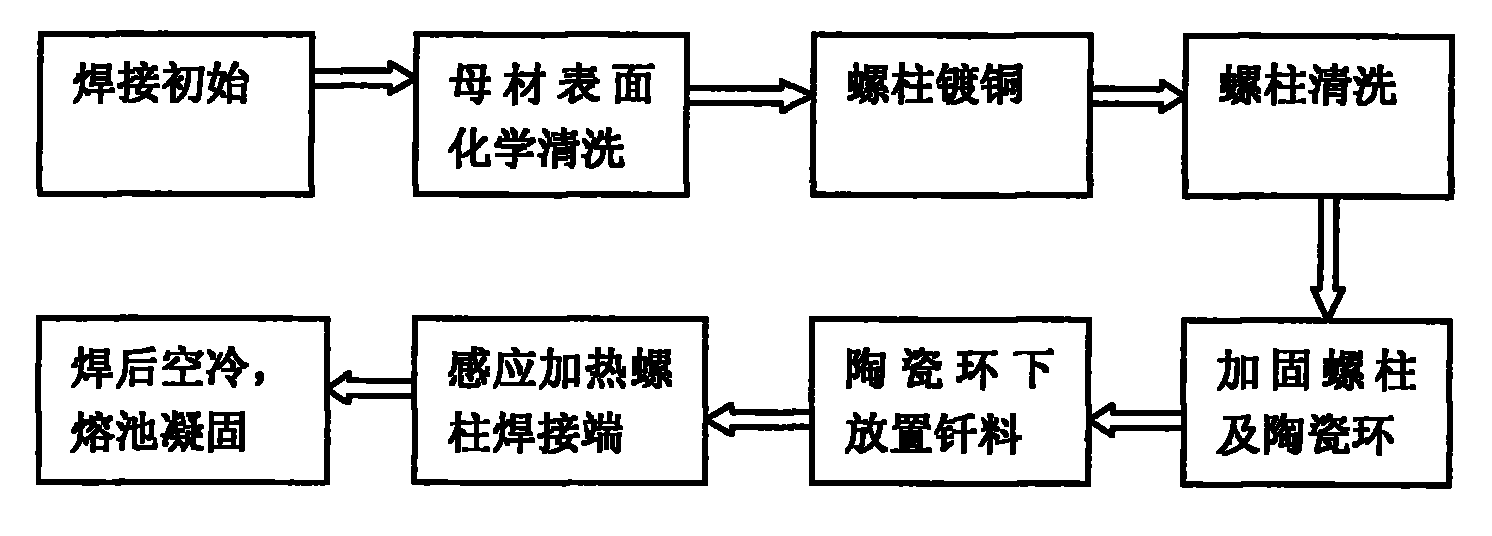

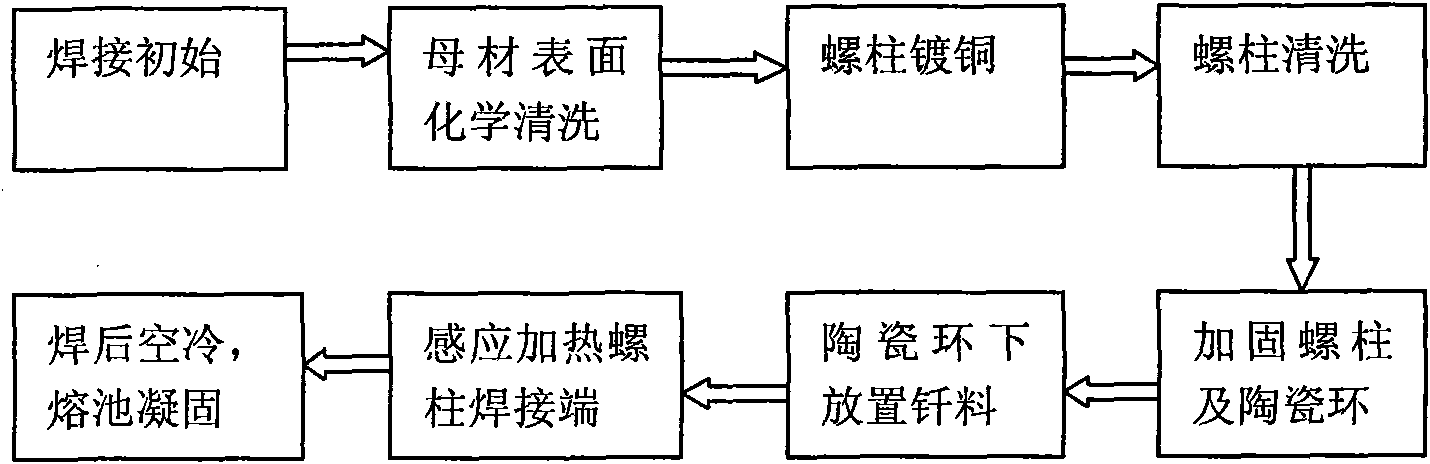

Method of pre-copper-plated induction welding-brazing of aluminum-steel stud bolt

ActiveCN102114561AImprove welding qualityEasy to operateSoldering apparatusWelding/soldering/cutting articlesFriction weldingCopper plating

The invention discloses a method of pre-copper-plated induction welding-brazing of an aluminum-steel stud bolt, which comprises the following steps: processing a steel stud bolt into a flat-bottom no-nut-cap type and conducting copper immersion plating to one end of the steel stud bolt; carrying out chemical cleaning to the surface of an aluminium base material and brazing filler metal; cleaning the surface of an aluminium base material and a brazing filler metal with alcohol, fast drying, and coating a layer of brazing protective agent on the surface of the base material; horizontally placing the aluminum base material, vertically placing the copper-plated end of the steel stud bolt on the aluminum base material, applying vertical downward pressure on the copper-plated end of the steel stud bolt, and filling enough cleaned brazing filler metal on the contact surface of the two; placing a ceramic ring matched with the stud bolt at the contact position of the copper-plated end of the steel stud bolt and the aluminum base material, and filling the brazing filler metal in the ceramic ring; and sheathing an induction heating coil at a welding end of the stud bolt, heating the induction heating coil and completing the welding. The invention can realize the welding of the small-diameter steel stud bolt and the aluminum base material, and has wide range of application to the thickness of plates.

Owner:NANJING UNIV OF SCI & TECH

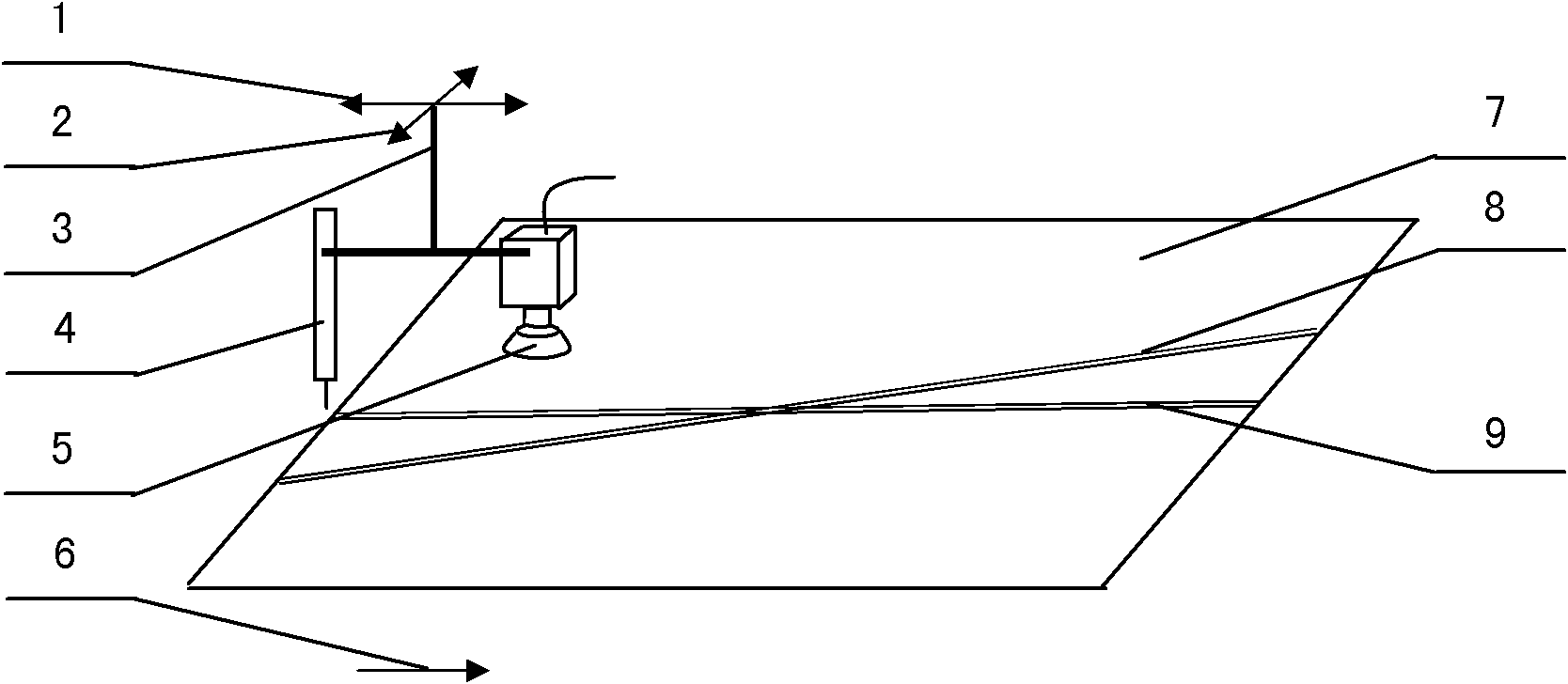

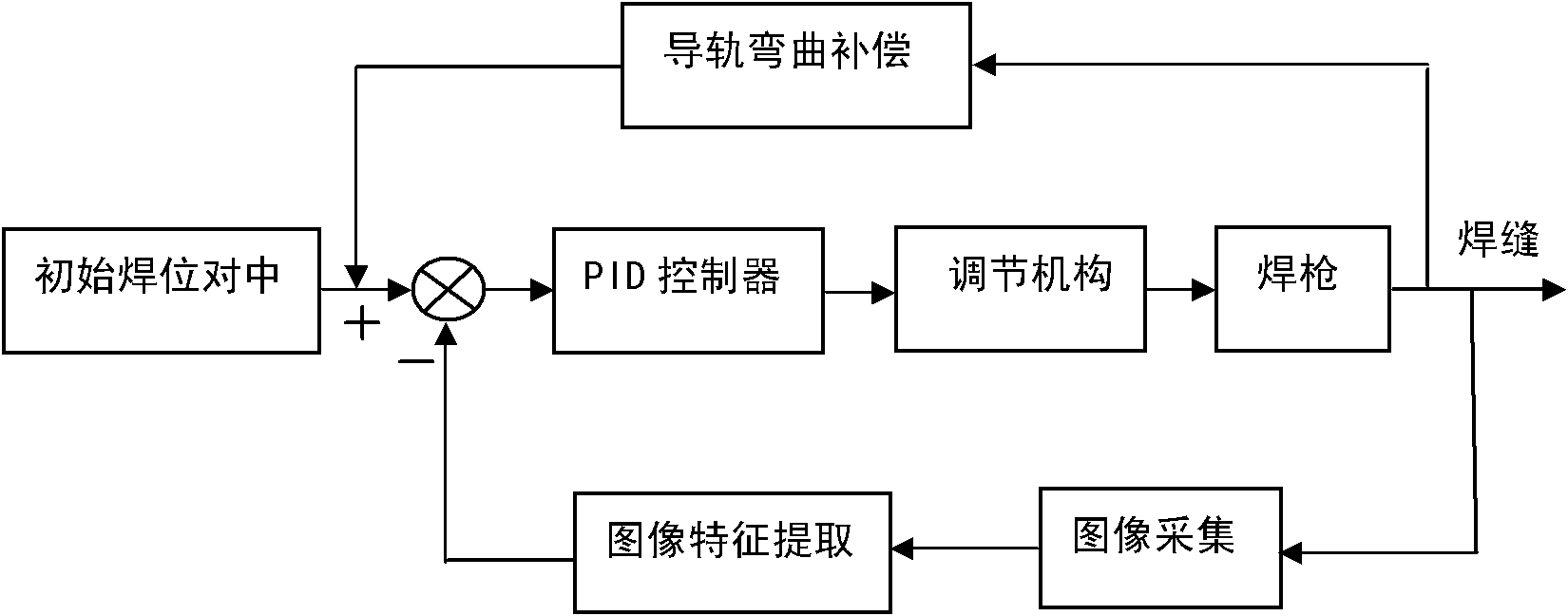

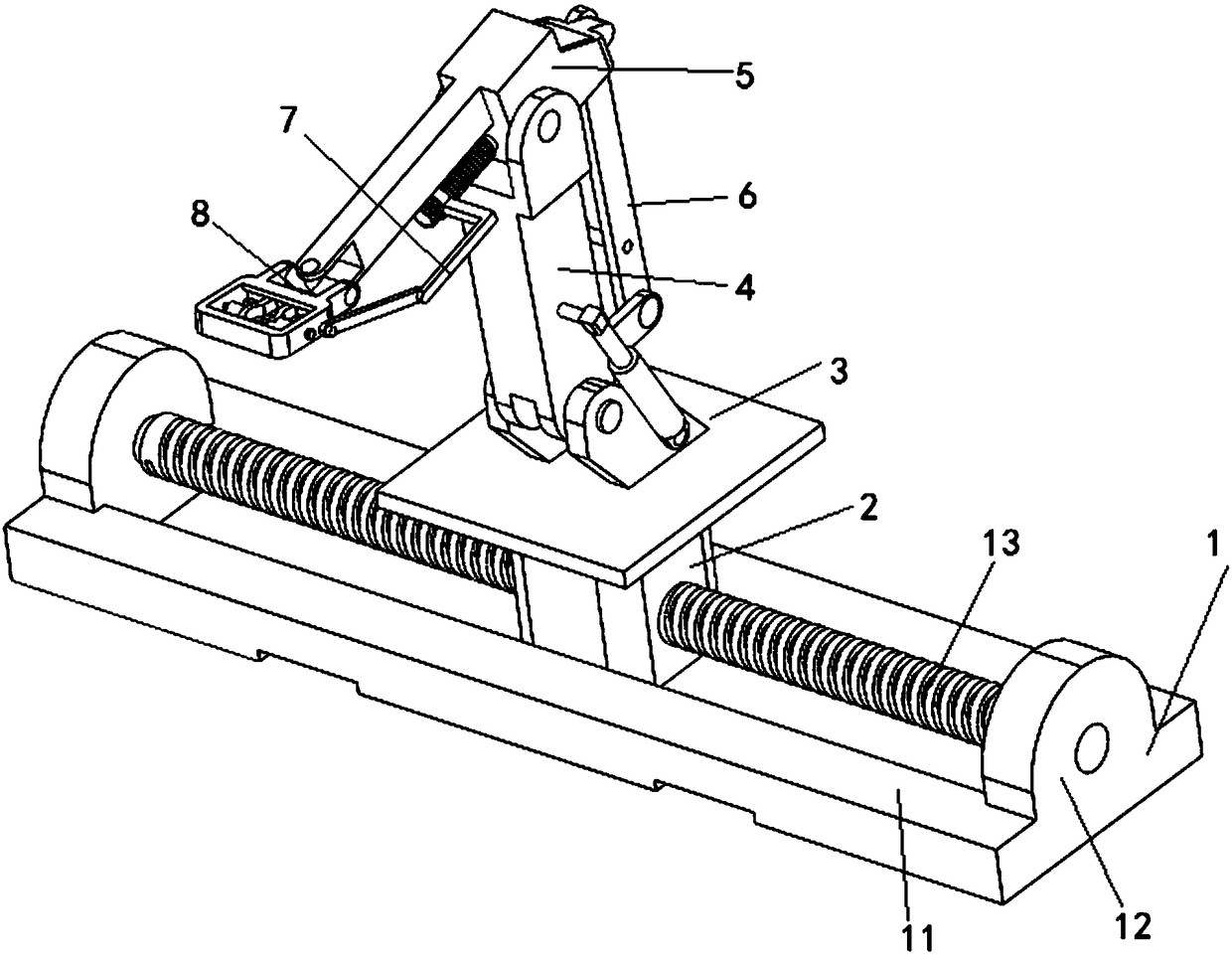

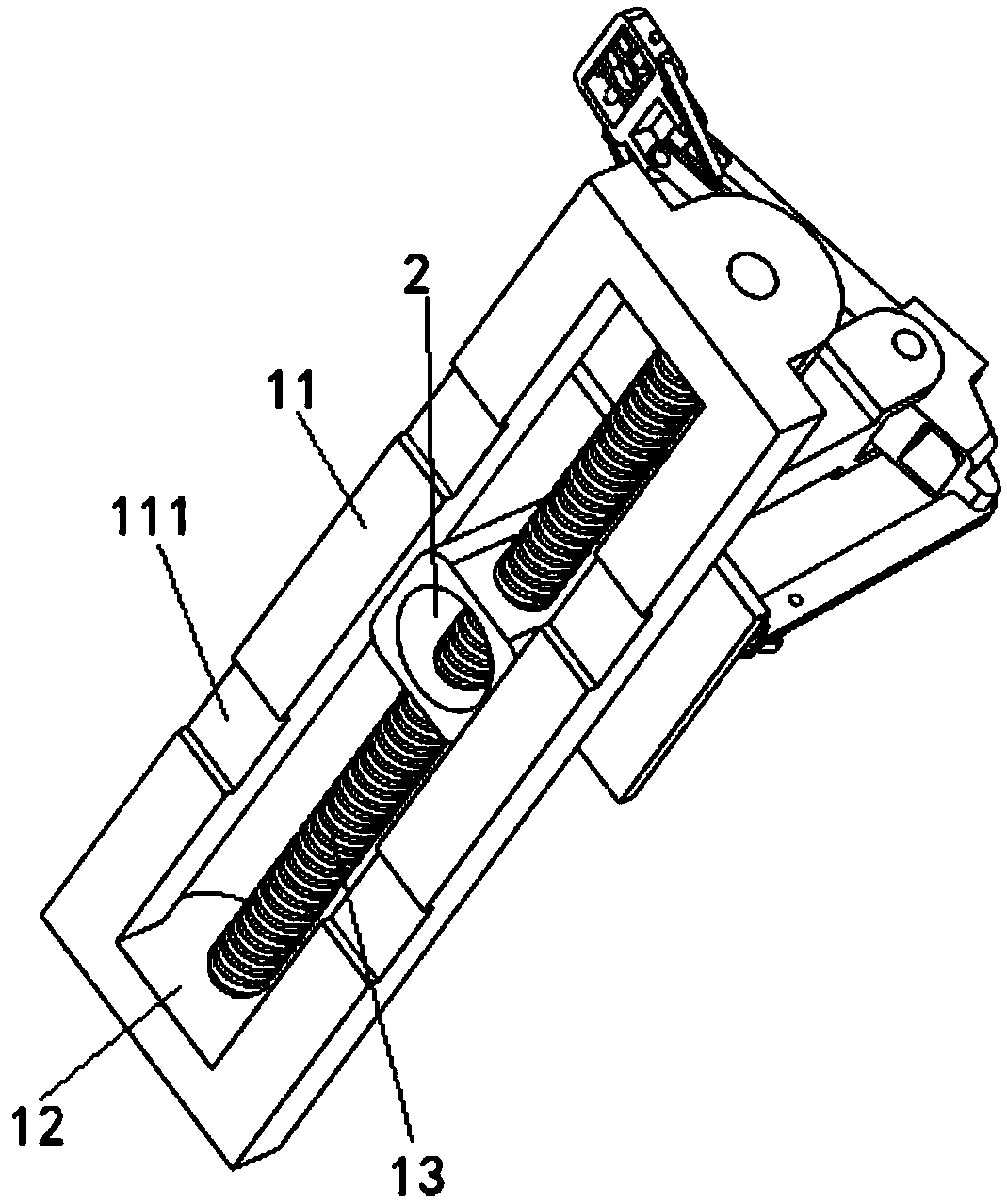

Method and device for centering initial welding positions of flat narrow welding lines and tracking welding lines

InactiveCN102179598AThe method is simple and reliableImprove alignment accuracyArc welding apparatusPosition/direction controlPID controllerEngineering

The invention discloses a method and a device for centering initial welding positions of flat narrow welding lines and tracking welding lines. In the method and the device, a traveling mechanism is connected with an adjusting mechanism in a central symmetry mode; one end of a vertical part of a connecting rod is positioned in the center of the traveling mechanism, and is vertical to the travelingmechanism and fixedly connected with the traveling mechanism; a welding gun and a camera are respectively fixed at two ends of a horizontal part of the connecting part of the connecting rod; the connecting rod fixedly connects the welding gun and the camera into a whole; the traveling mechanism is used for controlling the welding gun and the camera to move along the horizontal direction of a welding line of a weldment; the adjusting mechanism is used for controlling the welding gun and the camera to move in a direction vertical to the welding line of the weldment; position data of the traveling mechanism and characteristic point image data of the welding line are utilized to realize the automatic centering of the initial welding positions, and the current characteristic point image coordinate of the welding line is obtained and is taken as a reference image coordinate FC0i; and a proportional-integral-derivative (PID) controller controls and adjusts the movement of the traveling mechanism according to the deviation of the reference image coordinate FC0i of the welding line and the current image coordinate FCi of the welding line.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

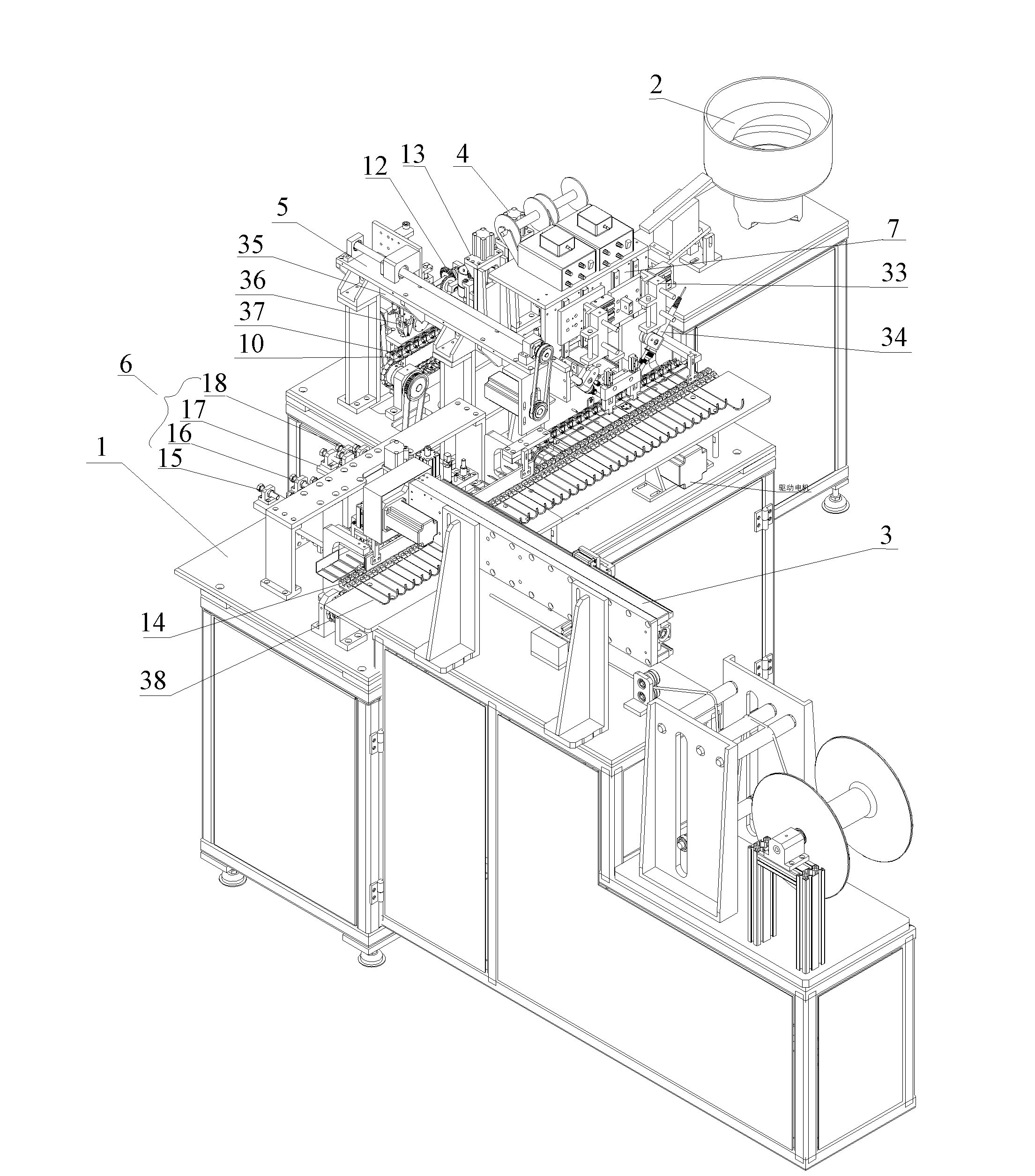

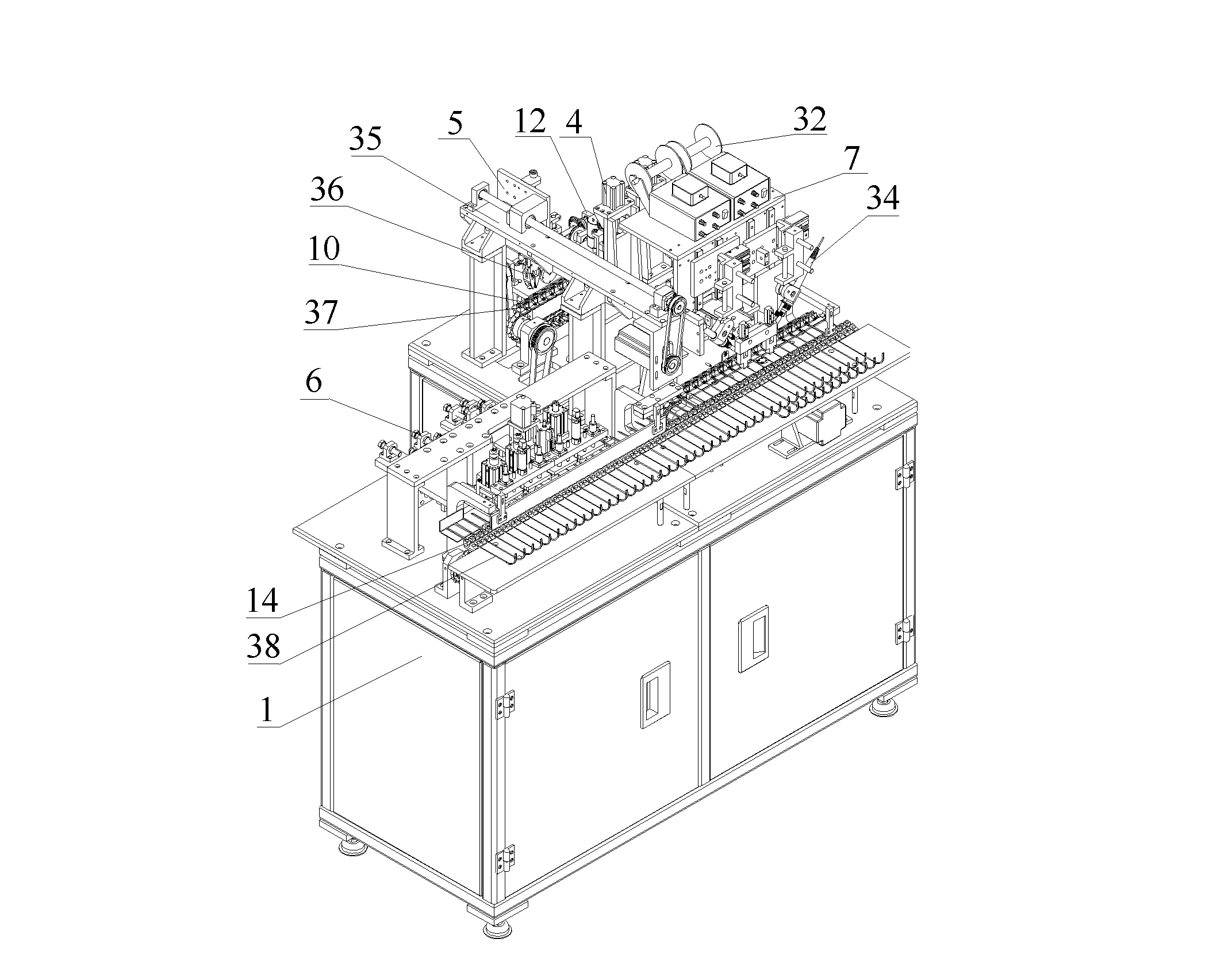

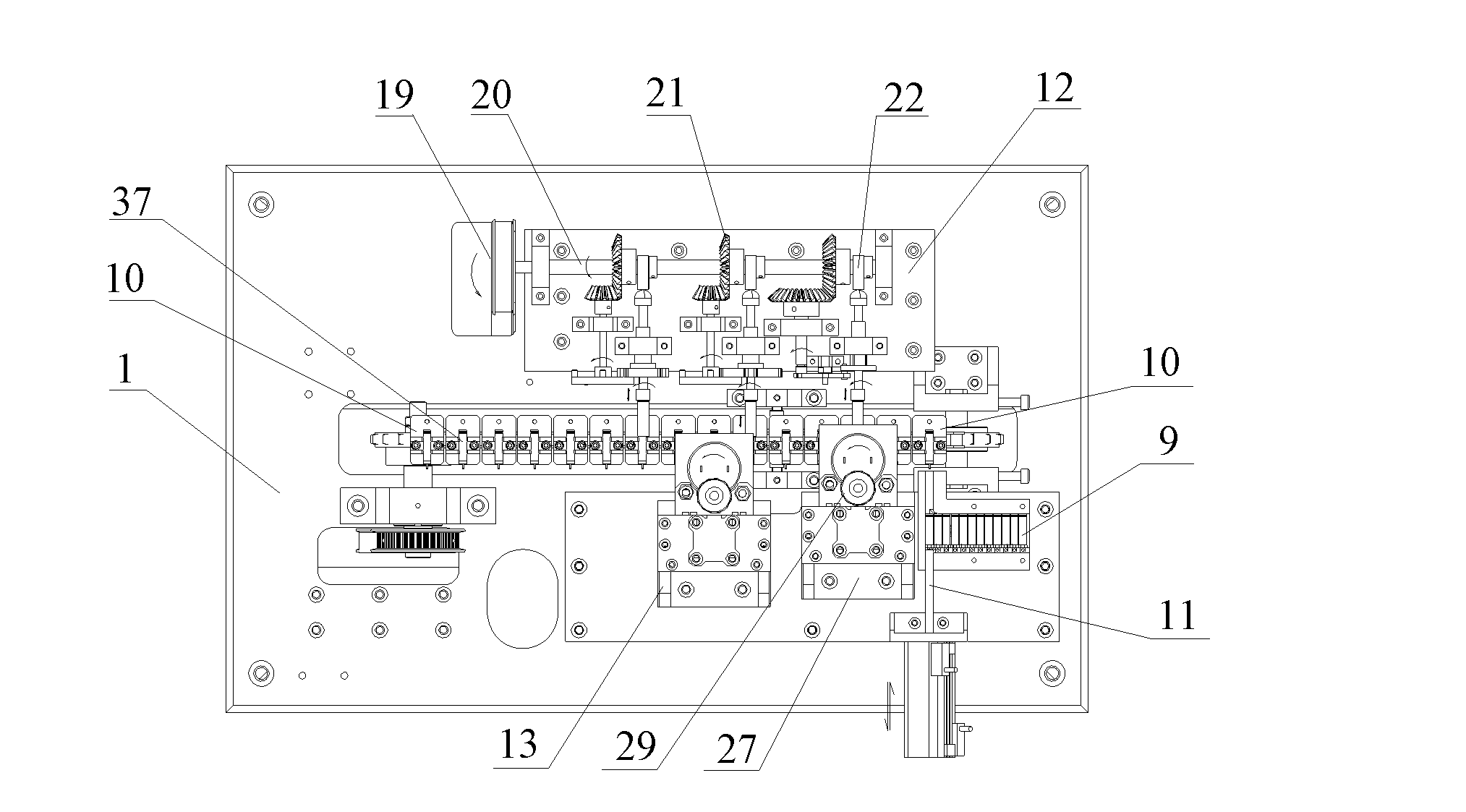

Automatic welding machine for DC (direct-current) power supply connector

InactiveCN102593685ARealize welding automationImprove welding efficiencyLine/current collector detailsEngineeringDirect current

The invention provides an automatic welding machine for a DC (direct-current) power supply connector. The automatic welding machine comprises an operating platform, a connector vibration feeding mechanism, a cable pay-off mechanism and a control mechanism of the cable pay-off mechanism, wherein the connector vibration feeding mechanism, the cable pay-off mechanism and the control mechanism of the cable pay-off mechanism are connected with the operating platform of the automatic welding machine for the DC power supply connector. The automatic welding machine further comprises a connecter grinding and processing mechanism, a connector translation mechanism, a cable separation processing mechanism and a connector welding mechanism which are arranged on the operating platform of the automatic welding machine. According to the automatic welding machine for the DC power supply connector provided by the invention, the DC power supply connector is ground by the connector grinding and processing mechanism on the operating platform of the automatic welding machine, the aligned separation, the stripping, peeling and the uniform cutting are carried out on the cables by the cable separation processing mechanism, and the DC power supply connector and cable bodies are welded by the connector welding mechanism so as to realize the automation of DC power supply connector welding. The automatic welding machine provided by the invention has high welding efficiency, and not only are the operating conditions improved, but also the processing efficiency and the product quality are improved.

Owner:东莞市双力数控设备有限公司

Thin film solar cell bus bar intersection automatic hot welding device

InactiveCN103121135ARealize welding automationAvoid wasting time and effortWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLinear drive

The invention relates to a thin film solar cell bus bar intersection automatic hot welding device and belongs to the field of semiconductor welding equipment. The device comprises a thin film solar cell transmission positioning mechanism, wherein a wire feeding sliding plate driven by a linear driving mechanism is arranged above the transmission positioning mechanism, a welding wire wheel is arranged on the wire feeding sliding plate in a rotary model through a shaft, a welding presser foot is arranged above a thin film solar cell bus bar intersection and is driven by the linear driving mechanism, and a welding gun is arranged on a welding gun sliding plate driven by a welding gun sliding plate linear driving mechanism. In a welding process, the linear driving mechanism of the wire feeding sliding plate drives the wire feeding sliding plate to send a welding wire to the intersection, the linear driving mechanism drives the welding presser foot to be pressed on the welding wire, the linear driving mechanism of the welding gun sliding plate drives the welding gun on the welding gun sliding plate to reach to the intersection, and then hot welding is achieved. The thin film solar cell bus bar intersection automatic hot welding device is good in welding quality, high in welding speed, applicable to large-scale thin film solar cell production, and capable of effectively improving product quality and production efficiency.

Owner:河南新能光伏有限公司

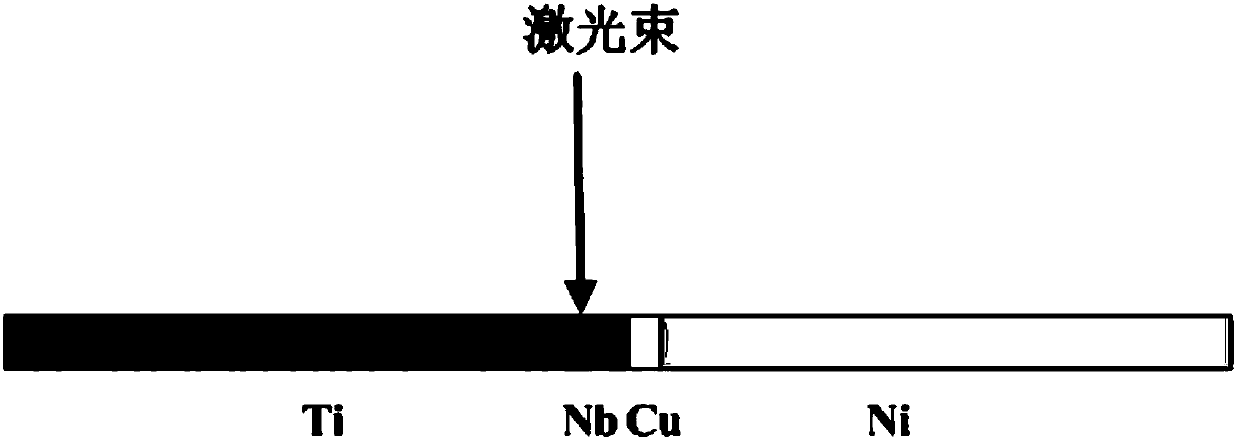

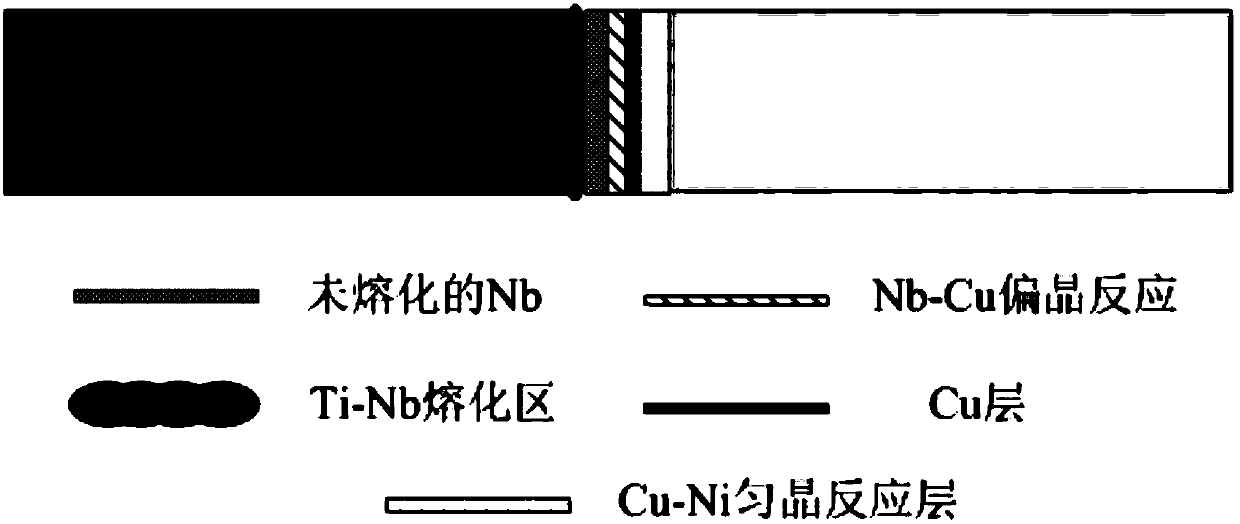

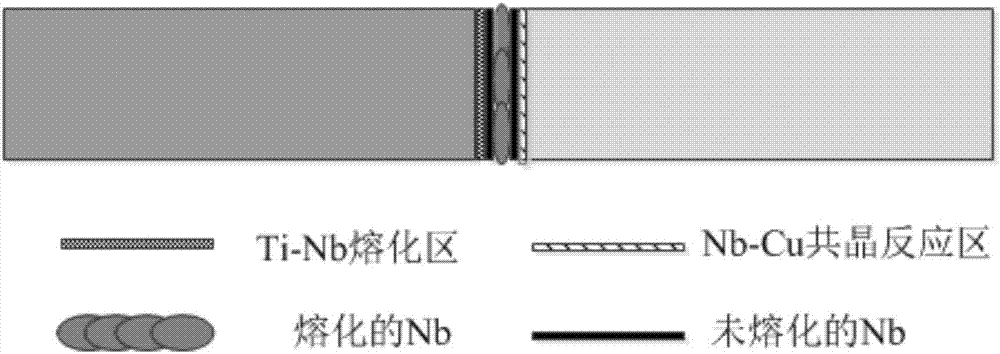

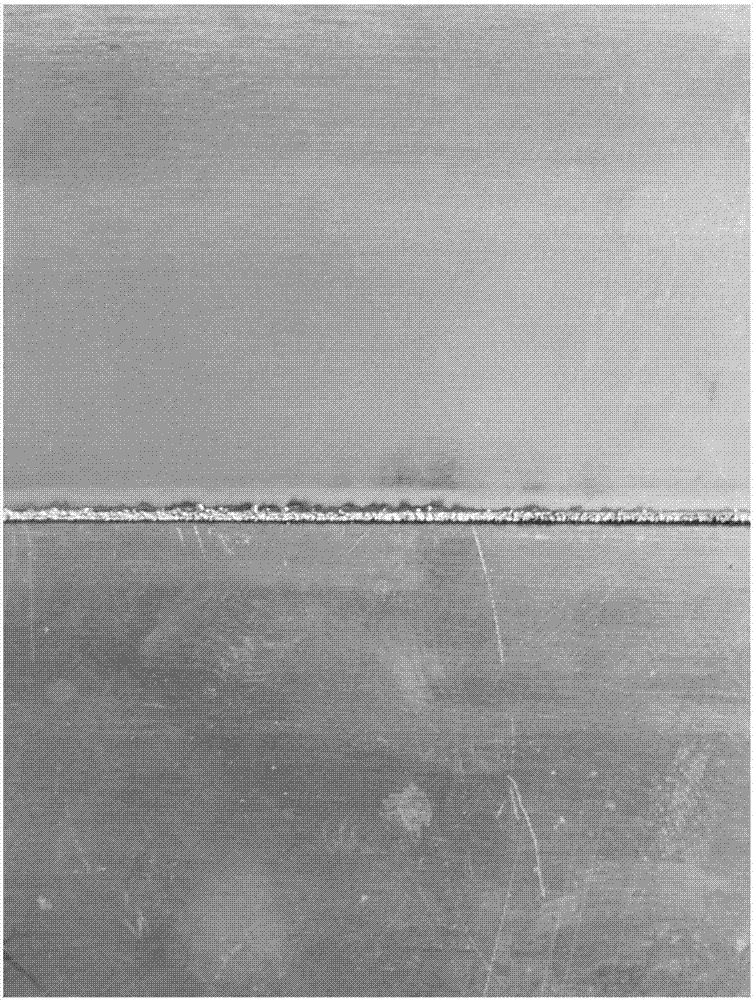

Laser-induced monotectic and isomorphous reaction welding method for titanium-nickel heterogenic joint

ActiveCN107931840AHigh strengthImprove plasticityWelding/soldering/cutting articlesLaser beam welding apparatusBond interfaceNiobium

The invention discloses a laser-induced monotectic and isomorphous reaction welding method for a titanium-nickel heterogenic joint. According to the method, two layers of composite interlayer solder are added between a titanium material and a nickel material, niobium metal serves as the first layer of composite interlayer solder, copper metal serves as the second layer of composite interlayer solder, the bonding interface of the niobium metal and the titanium material is the interface 1, the bonding interface of the niobium metal and the copper metal is the interface 2, the bonding interface of the copper metal and the nickel material is the interface 3, and the focal point of a welding heat source is located near the interface 1; and in the welding process, heat generated by the welding heat source forms a fusion welding mode on the bonding interface of the first layer of composite interlayer solder and the titanium, and the heat is higher than the melting point of the second layer ofcomposite interlayer solder when transmitted to the interface 2 and the interface 3 through the first layer of composite interlayer solder. By means of the welding method, formation of titanium-nickel intermetallic compounds is avoided, a fusion welding seam is formed at the interface 1, soldered seams are formed at the interface 2 and the interface 3 at the same time, and the obtained titanium-nickel heterogenic metal joint achieves the tensile strength of 200-230 MPa and the elongation percentage of 2-4%.

Owner:BAOJI UNIV OF ARTS & SCI

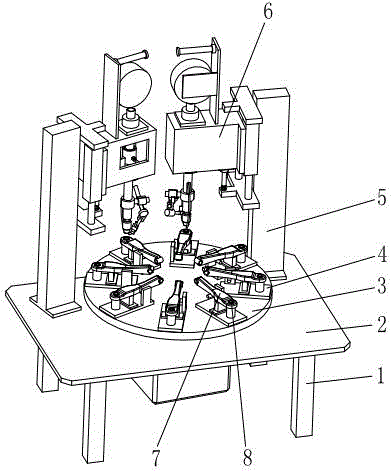

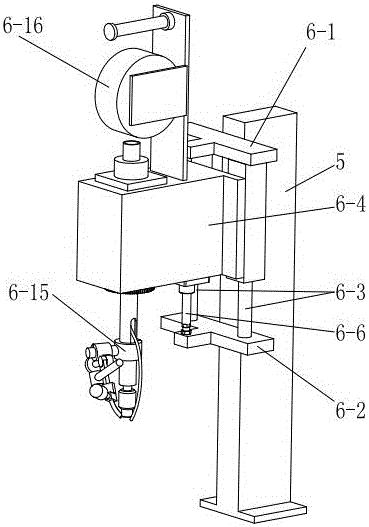

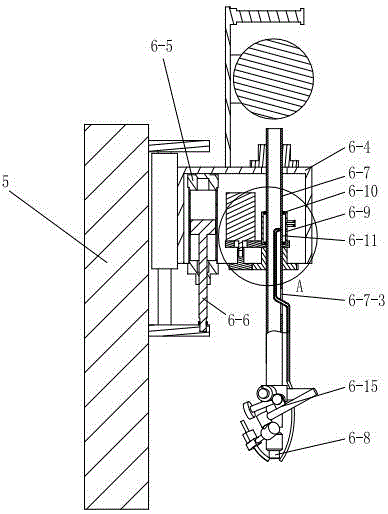

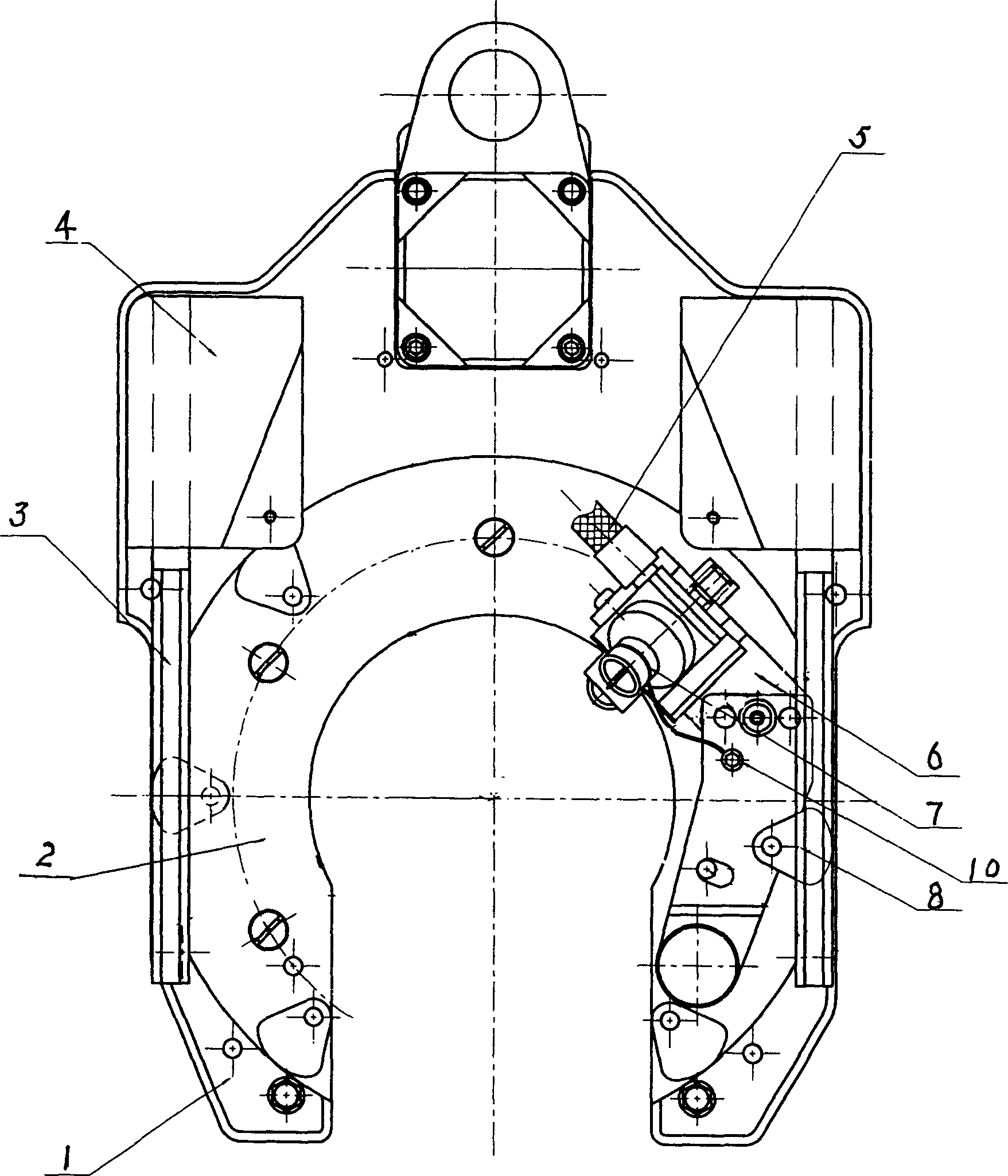

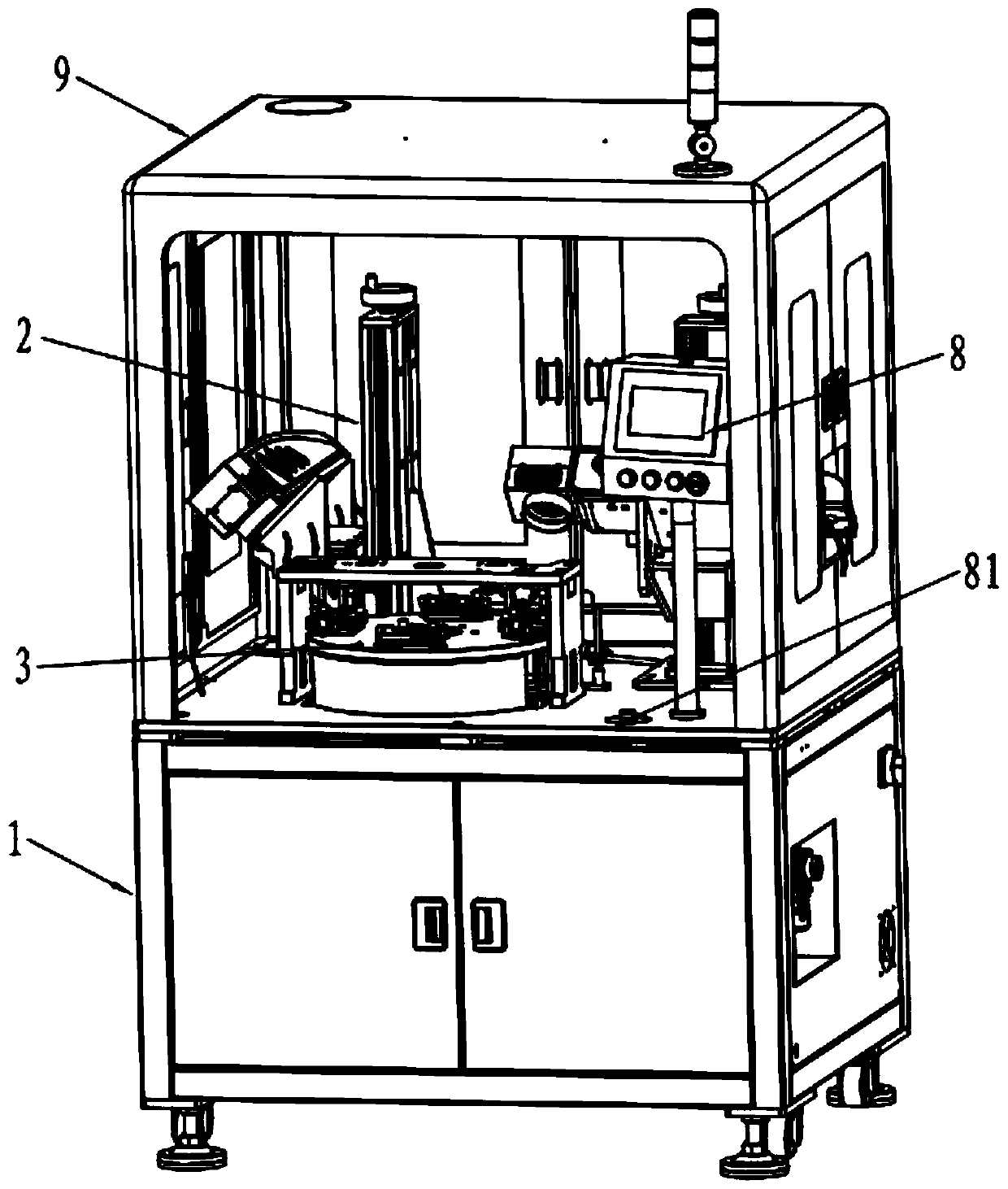

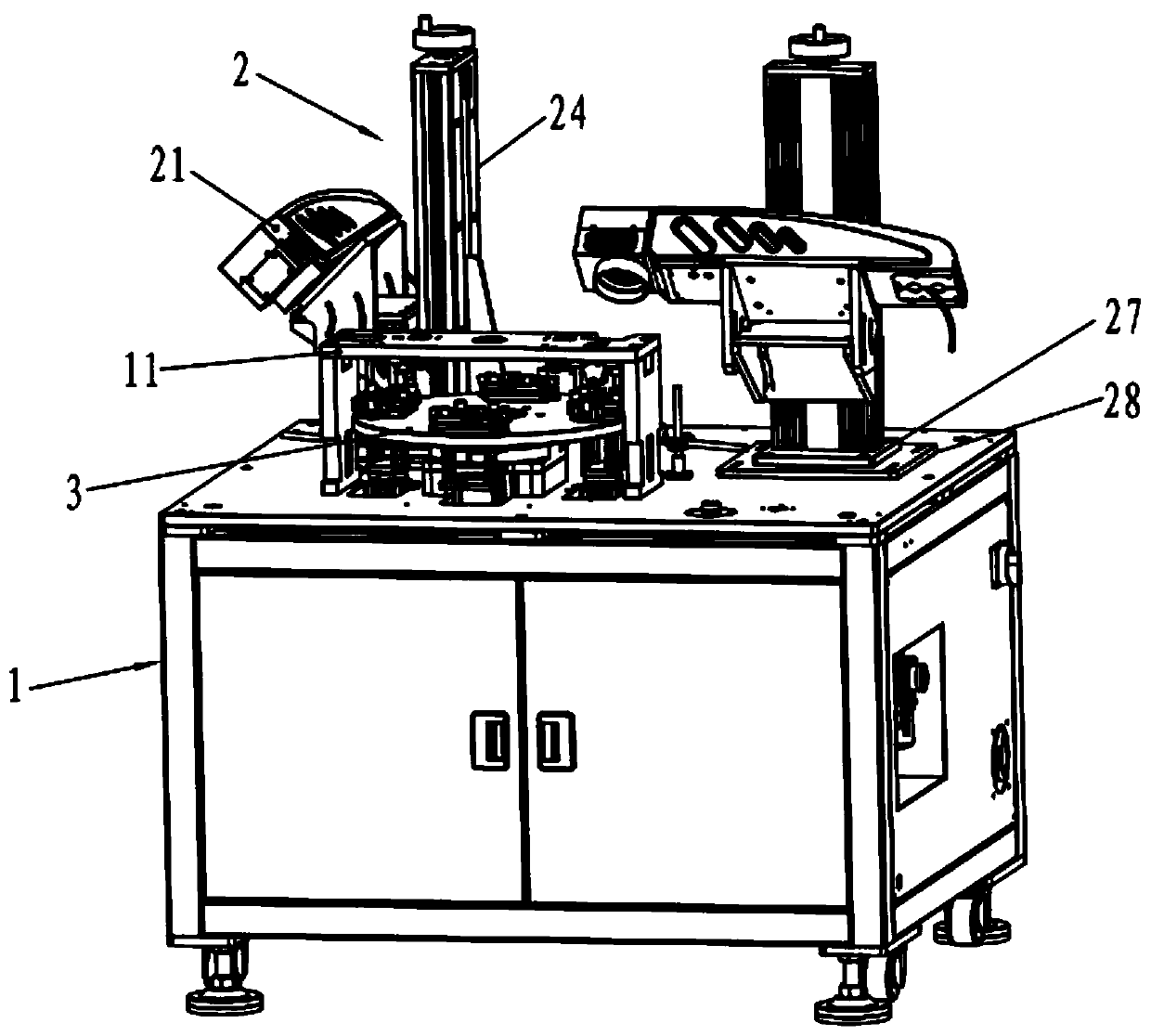

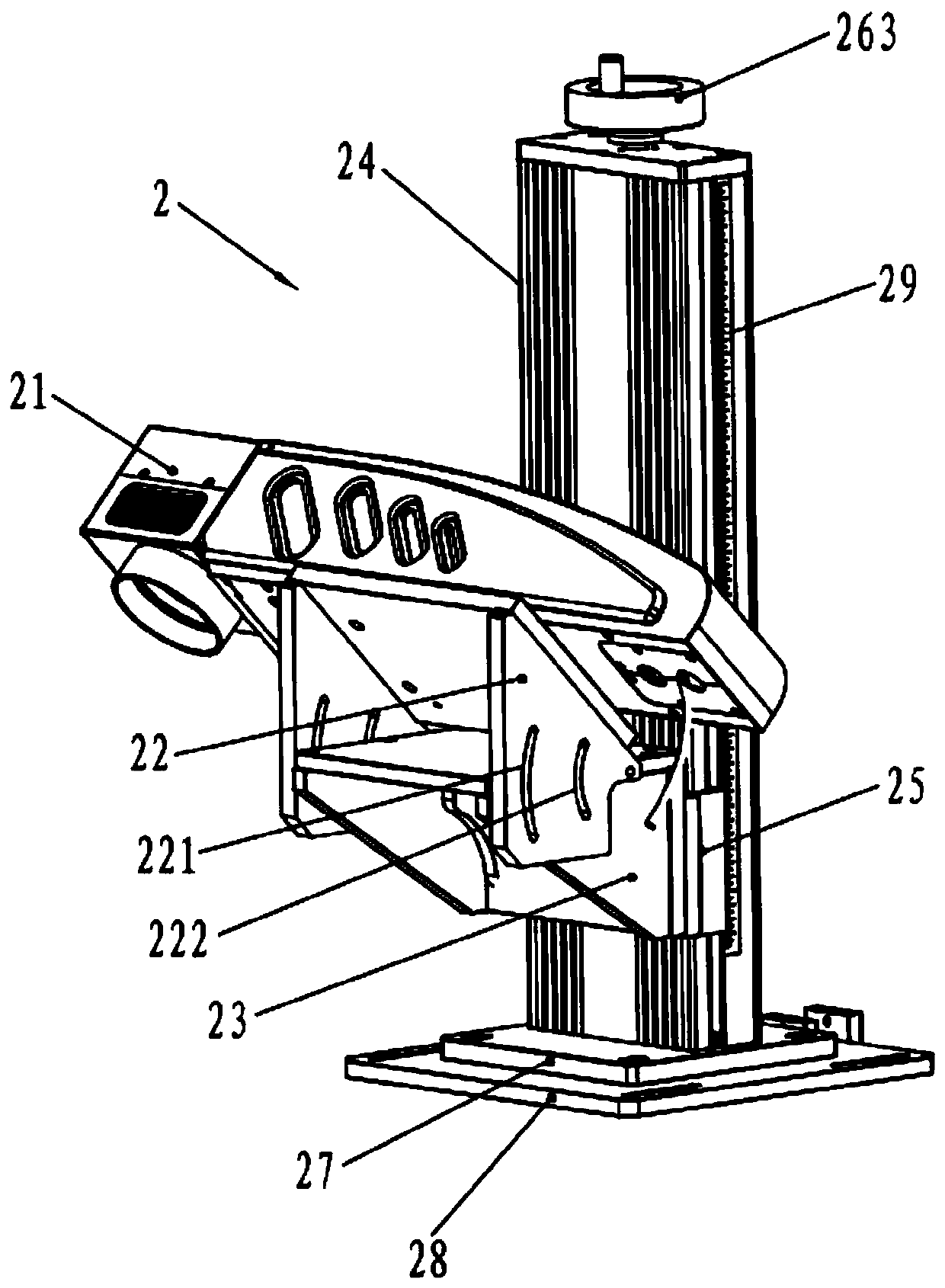

Welding device for automobile swing arm welding assembly and swing arm welding forming method of welding device

ActiveCN106064270ARealize welding automationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention discloses a welding device for an automobile swing arm welding assembly. The welding device comprises a machine body, wherein a working table is arranged on the machine body; a rotating table is arranged on the working table; a plurality of clamp devices distributed along the circumference are fixedly arranged on the rotating table; at least one vertical column is arranged on the working table; welding device bodies are fixedly arranged at the upper ends of the vertical columns, and are positioned above the clamp devices. The welding device for the automobile swing arm welding assembly realizes welding automation, and the multiple welding device bodies can synchronously weld a plurality of workpieces correspondingly, so that the working efficiency is greatly improved. The invention further discloses a swing arm welding forming method of the welding device.

Owner:台州林轩科技有限公司

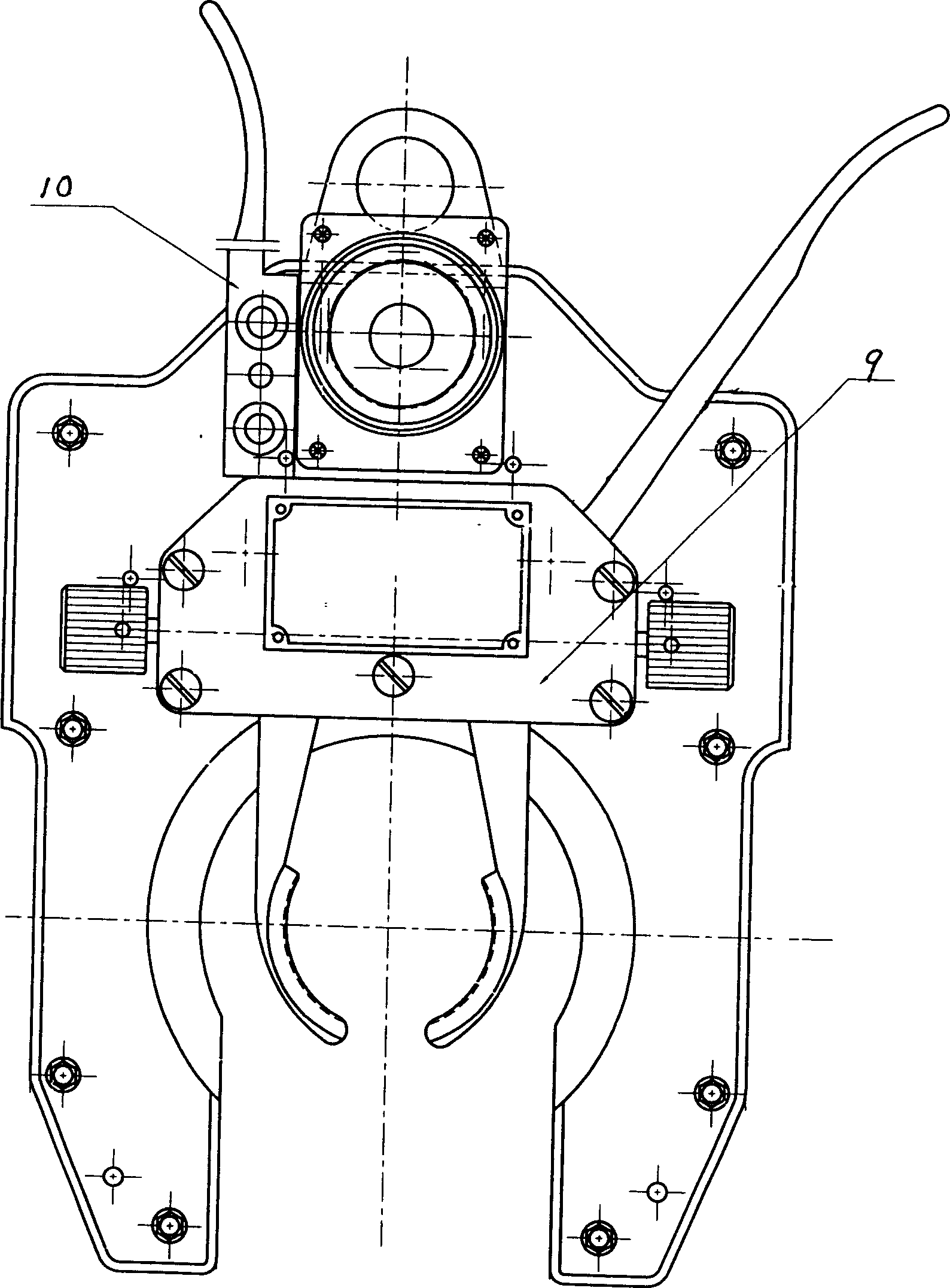

Automatic welding process and device for long pipe joint in boiler pipe header

ActiveCN1714979ASolve the problem of full penetrationImprove automatic welding levelArc welding apparatusEngineeringConductor Coil

The automatic welding process for long pipe joint in boiler pipe header seam features that the welding process includes the first manual argon arc welding for 2 or 3 dots each joint; subsequent fixing the long pipe welding machine head outside the joint with fixture; and automatic rotating welding with welding head aligned obliquely to the seam. The long pipe welding apparatus for the said technological process consists of base plate, rotating mechanism, positioning board, vertical locating unit, cable, welding machine, welding machine head,wire winding pin, fixture and handle. The present invention has the advantages of automatic operation, raised welding quality and high production efficiency.

Owner:SHANGHAI BOILER WORKS

Solder and welding method

ActiveCN103706967ARealize full area weldingReduce labor intensityWelding/cutting media/materialsSoldering mediaSlagMetal alloy

The invention discloses solder and a welding method. The solder comprises, by weight, 5-10% of sulfate, 10-20% of metallic oxide, 5-10% of wetting agents, 30-60% of metal alloy, 5-20% of slag former and the balance diluent. According to a steel claw designed for solving the technical problem of aluminum-steel direct welding by the application of the chemical welding principle, aluminum-steel full-area welding is achieved, specific resistance is reduced, the mechanical strength of the welding surface is improved, the solder is convenient to use, high in welding efficiency and good in welding quality, automation of welding can be achieved, labor intensity of workers is low, and the efficiency is high.

Owner:湖北优耐安科技有限公司

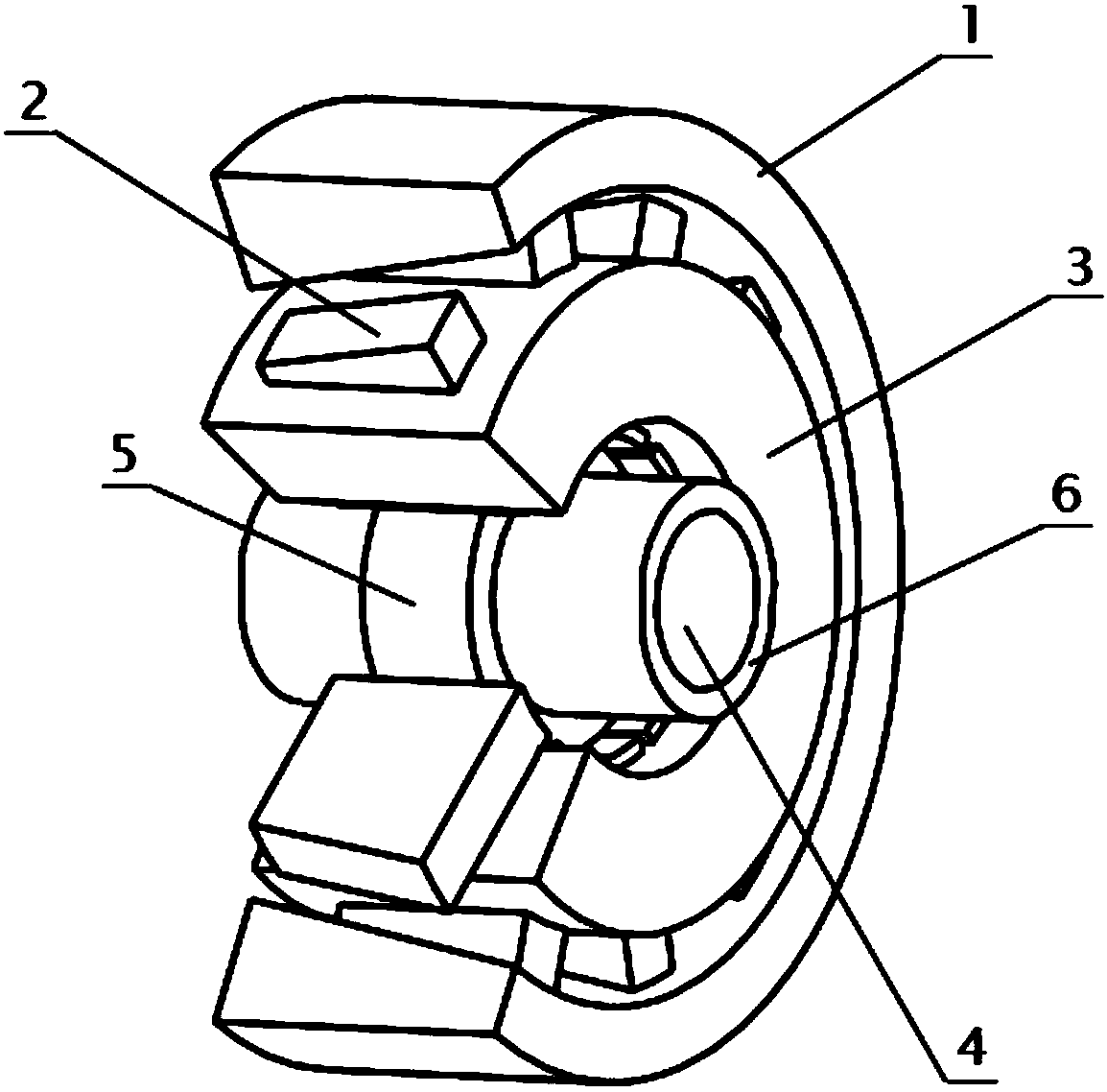

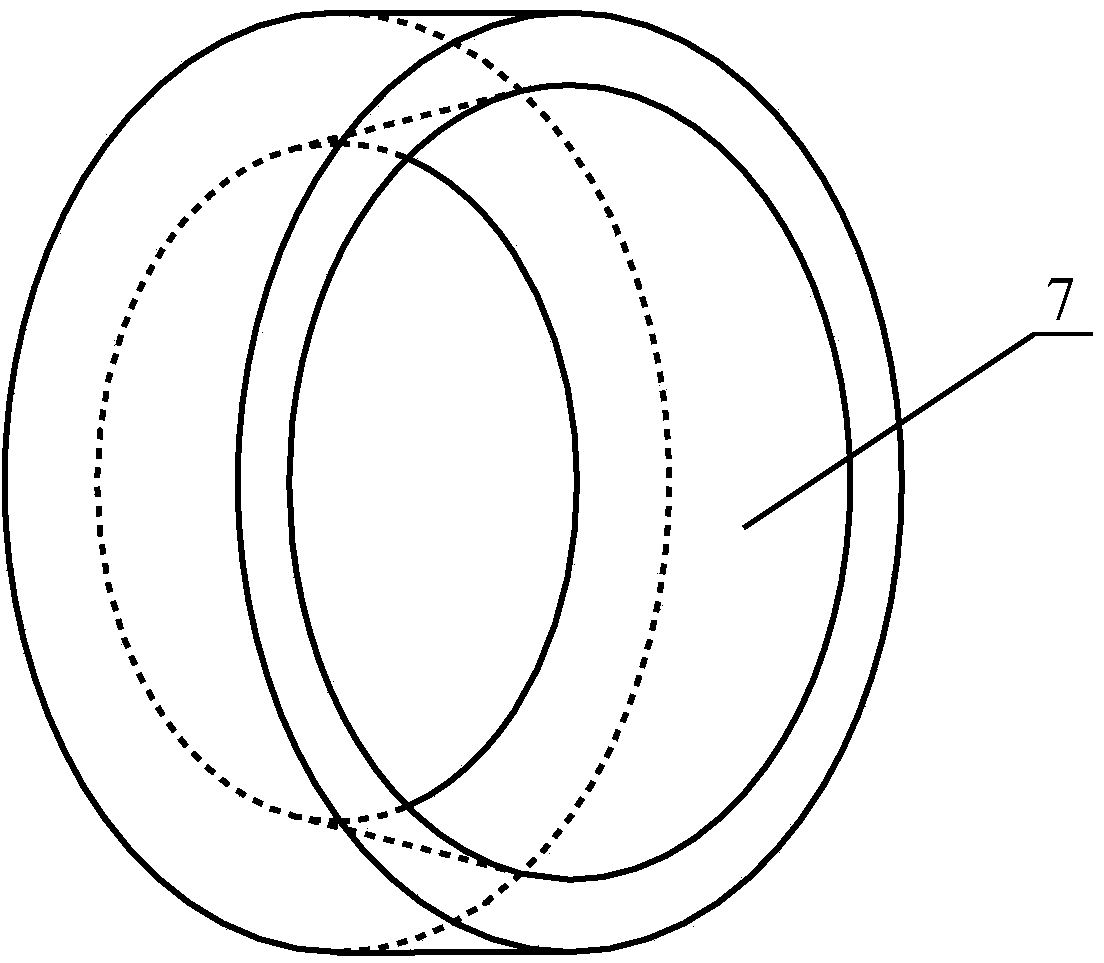

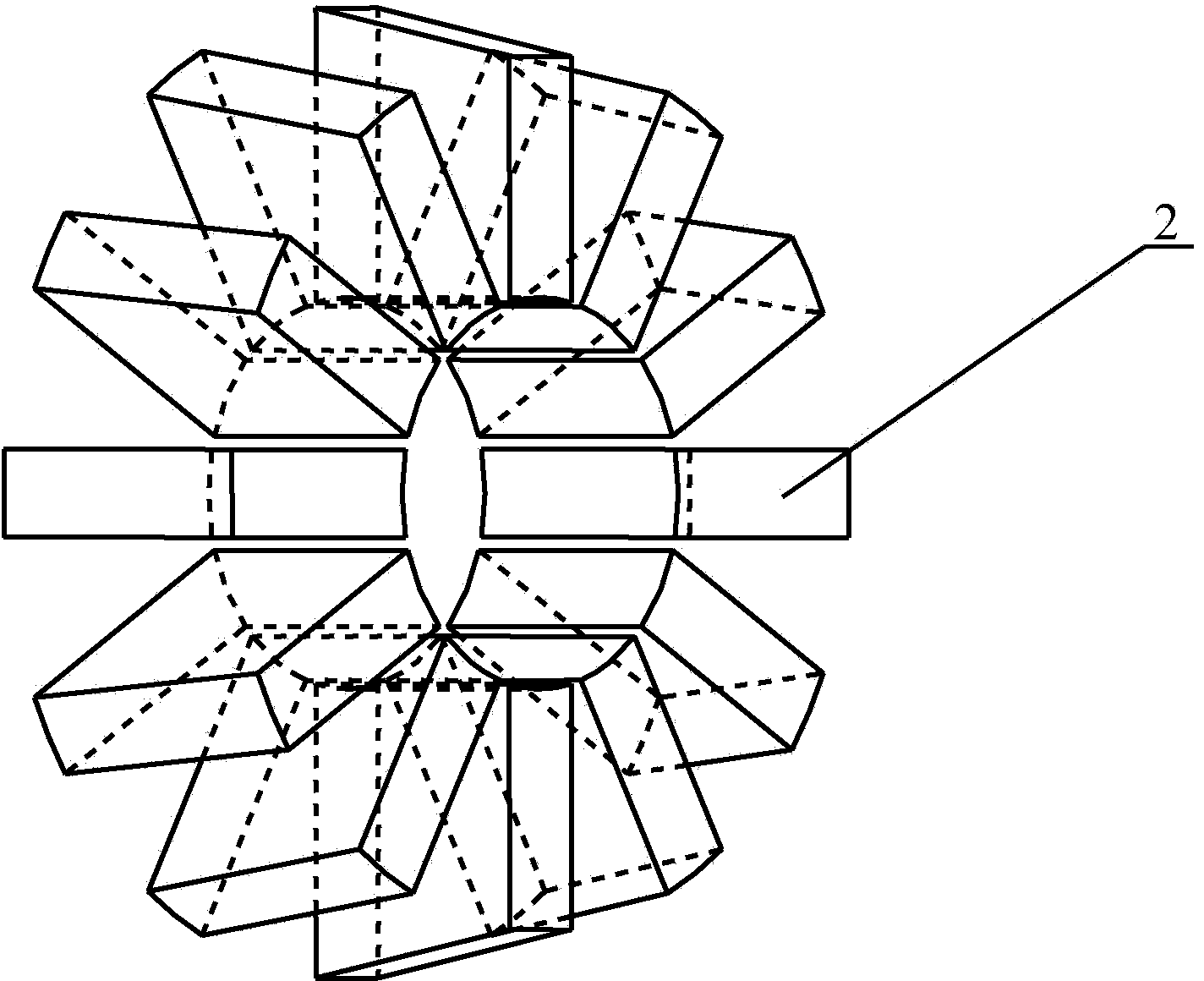

High-frequency vibration radial linear friction welding device and high-frequency vibration radial linear friction welding process for pipelines

InactiveCN103894729AReduce dependenceReduce the human factorNon-electric welding apparatusFriction weldingAxial thrust

The invention discloses a high-frequency vibration radial linear friction welding device for pipelines. The high-frequency vibration radial linear friction welding device comprises a radial ring. The radial ring can sleeve the outer surface of a pipeline, a support cotter is arranged in the pipeline, the outer surface of the radial ring is in contact with an end of each radial convex piece, the multiple radial convex pieces are peripherally and uniformly arranged and are respectively inserted in a plurality of limiting grooves in a limiting groove body, and the other end of each radial convex piece is in contact with the wedge-shaped inner wall of a radial reversing fixture; the reversing fixture is clamped on a vibrating body controlled by a controller, force is applied to the reversing fixture by the vibrating body, the convex pieces which are in contact with the reversing fixture drive the radial ring to vibrate at a high frequency in a reciprocating manner along the axial direction of the pipeline, axial thrust is simultaneously exerted on the reversing fixture and is converted into radial thrust, accordingly, the radial ring and the pipeline are pushed against each other and generate heat by friction, upset forging is stopped at a preset upset forging moment, and the pipeline is completely welded. The invention further discloses a welding process implemented by the aid of the high-frequency vibration radial linear friction welding device.

Owner:SHANDONG UNIV

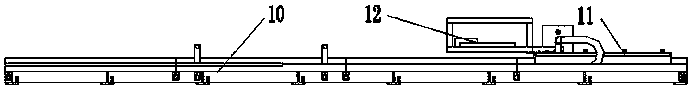

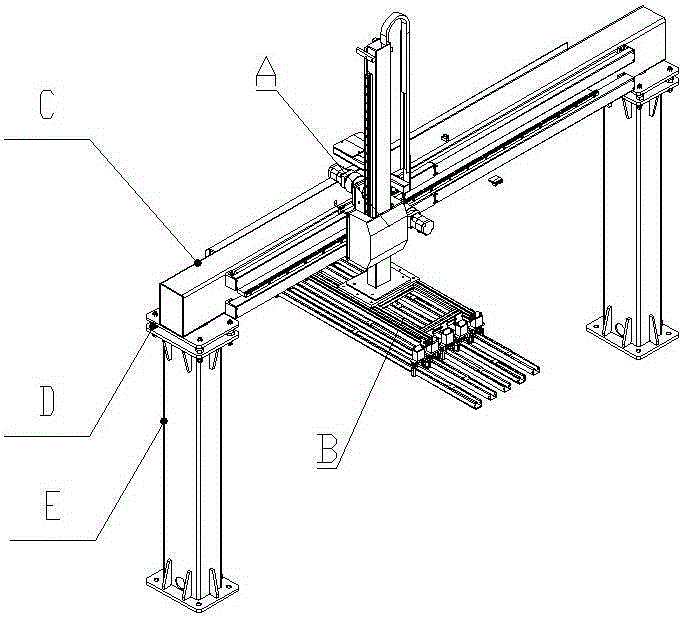

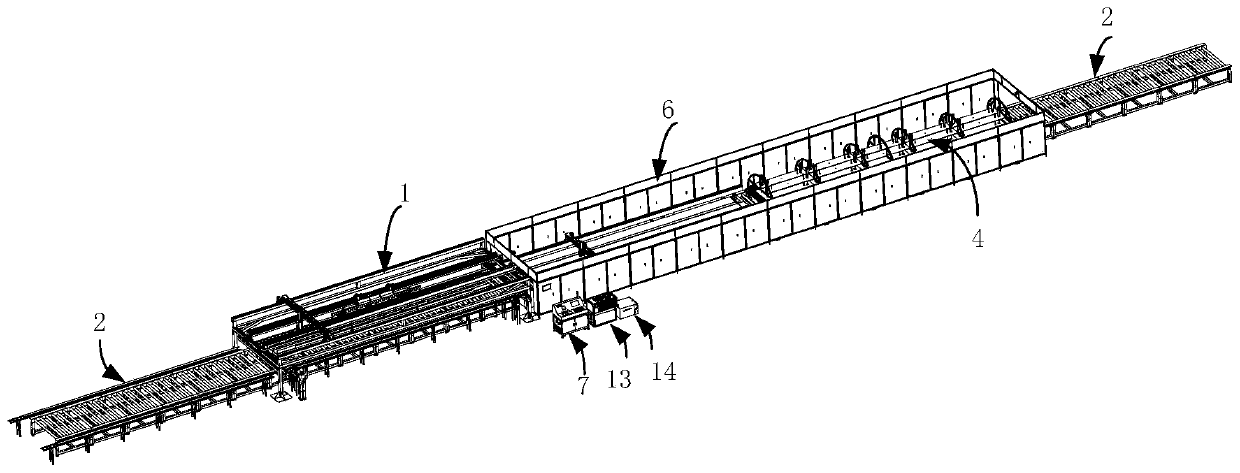

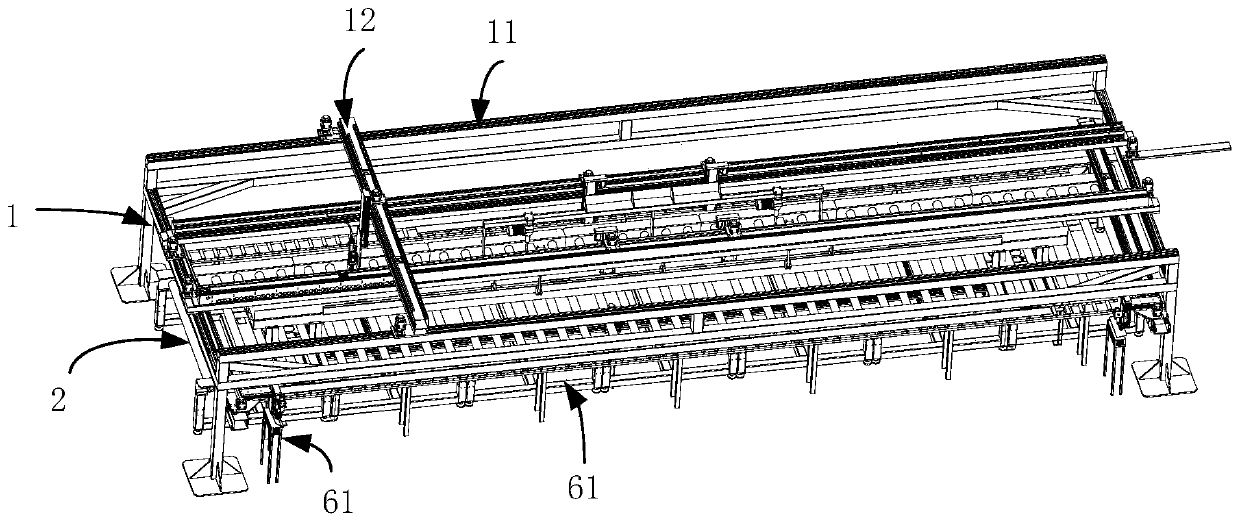

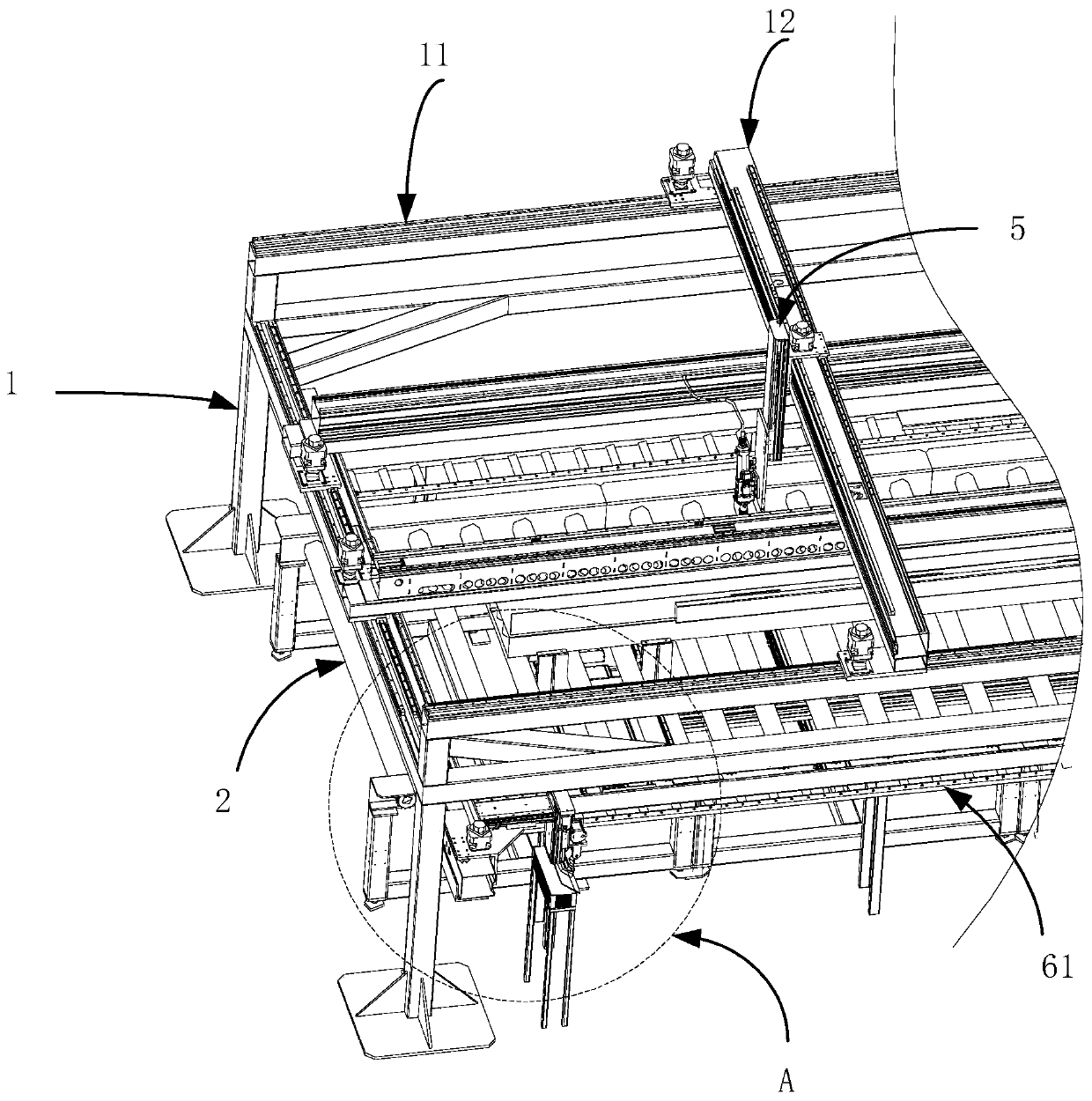

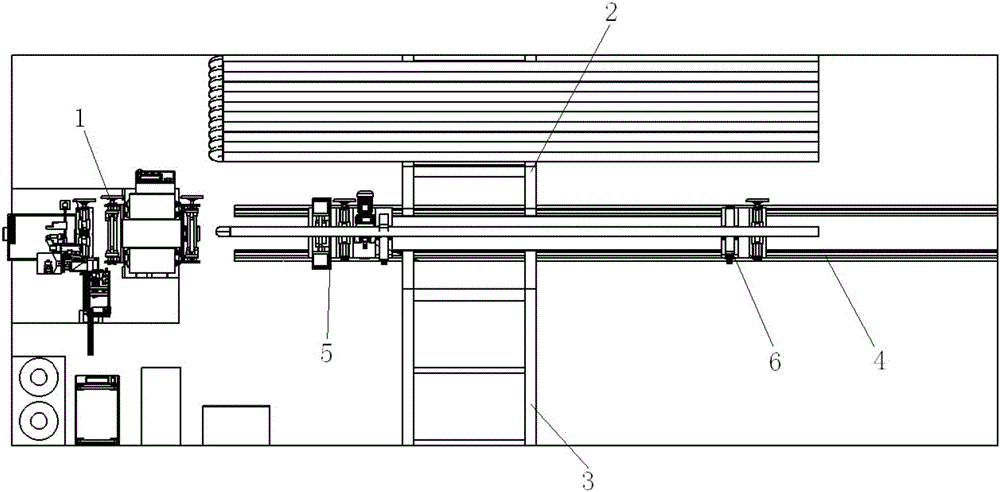

Automatic production line of civil protection gate

PendingCN108788564ARealize welding automationImprove welding effectWelding/cutting auxillary devicesAuxillary welding devicesProduction lineWelding process

The invention relates to an automatic production line of a civil protection gate, and belongs to the field of processing of civil protection facilities. The automatic production line of the civil protection gate comprises a welding device and a turning device, wherein the welding device and the turning device are sequentially arranged; conveying devices for conveying the civil protection gate arearranged on the two sides of the welding device and the turning device; fixing devices for fixing the civil protection gate are arranged between the two-sided conveying devices and positioned under the welding device and the turning device; when the civil protection gate needs to be automatically welded, the civil protection gate is conveyed to the lower part of the welding device through the conveying devices, so that one side of the civil protection gate is welded by the welding device; after the welding is carried out, the civil protection gate is conveyed to the lower part of the turning device through the conveying devices, and the civil protection gate is turned at 180 degrees by adopting the turning device; after being turned, the civil protection gate is conveyed to the lower partof the welding device through the conveying devices again, and is then welded; and after the two sides of the civil protection gate are welded completely, the civil protection gate is conveyed away through the conveying devices, and the next welding process of the civil protection gate is carried out, so that automatic welding of the civil protection gate is realized, and therefore, a great quantity of manpower is reduced.

Owner:上海祈祿机械有限公司

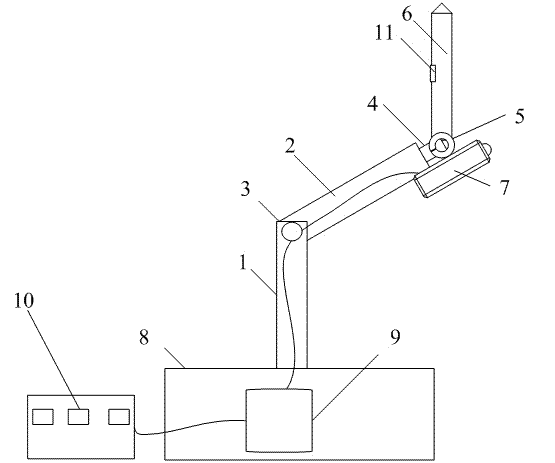

Automatic welding assembly mechanical arm

ActiveCN108705231AReduce volumeEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an automatic welding assembly mechanical arm which comprises a sliding fixing seat and an omni-directional welding tool mounted on and fixed to the sliding fixing seat. The omni-directional welding tool comprises a positioning cylinder, a first joint seat, a second joint seat and a third joint seat which are connected and fixed sequentially from bottom to top. The automaticwelding assembly mechanical arm is provided with the first joint seat, the second joint seat, the third joint seat, a fourth joint seat and the sliding fixing seat, the mechanical arm can achieve omni-directional no-dead-corner welding on the surfaces of workpieces with different shapes through simultaneous action of four movable joints and a position adjusting seat, the problem that an existingwelding mechanical arm cannot achieve welding of arc faces and uneven faces is solved, the automatic welding process is achieved, and the welding efficiency is improved.

Owner:姜堰经济开发区科创中心

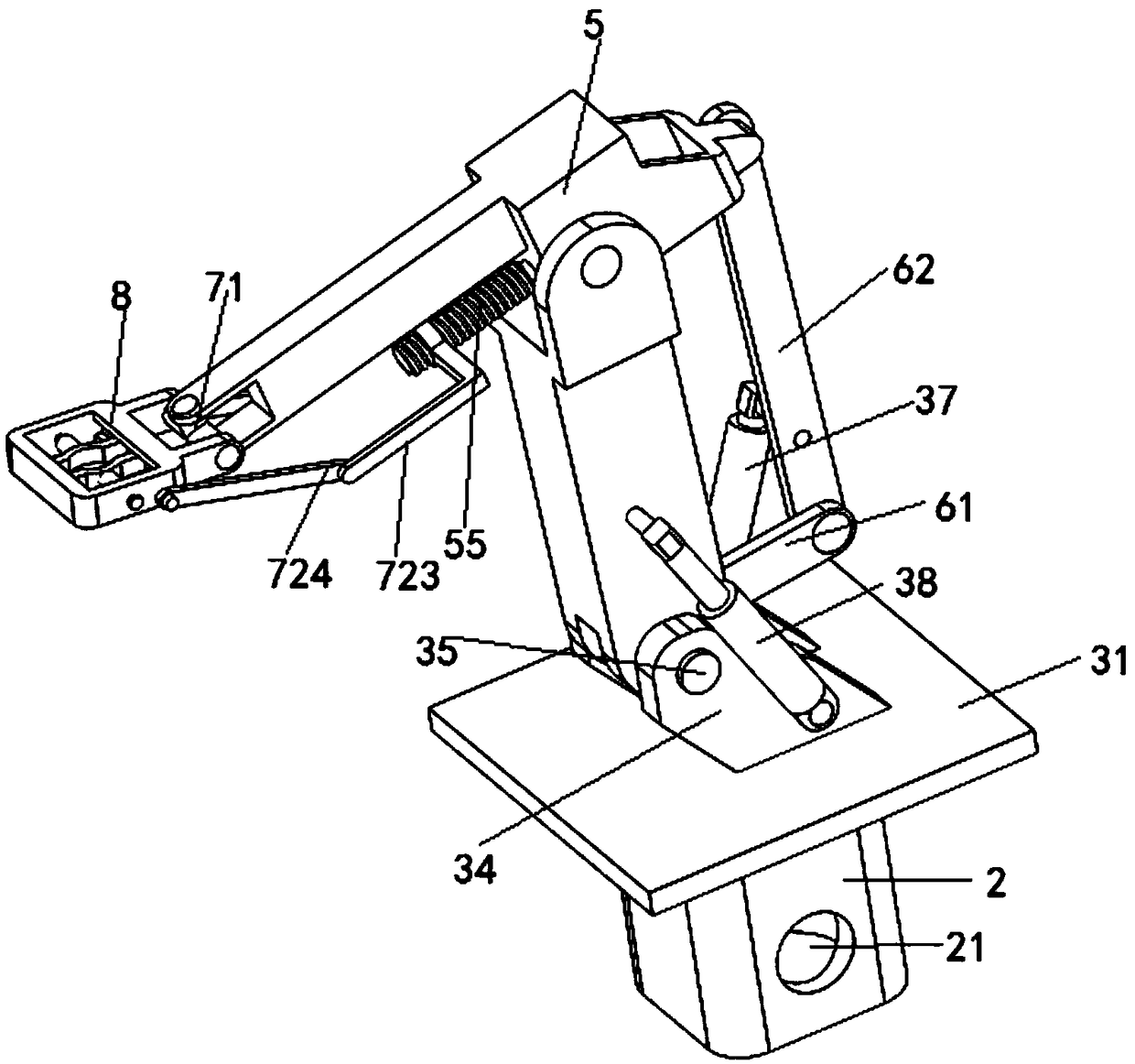

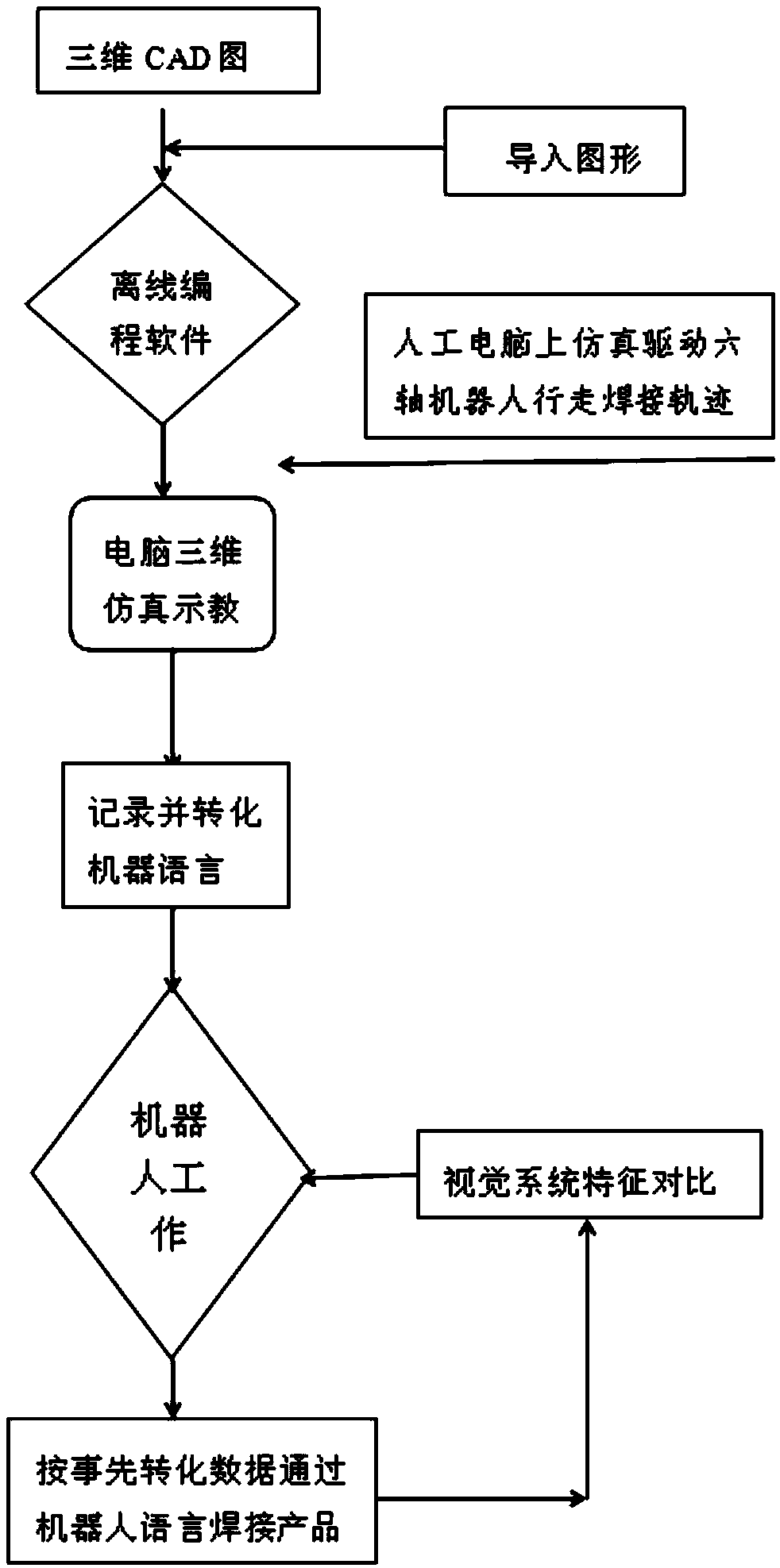

Method for guiding robot to conduct automatic welding through CAD drawing technology

InactiveCN109128439ALow technical requirementsImprove welding qualityArc welding apparatusSimulationRead through

The invention relates to a method for guiding a robot to conduct automatic welding through the CAD drawing technology. The method comprises the steps of conducting simulating demonstration on a 3D CADwelding joint drawing through a 3D diagram and directly marking 3D simulation six-axis robot moving tracks and postures; converting the above tracks and postures into a robot program or a language which the robot can read through coordinate transformation; recognizing feature points of a workpiece through a visual camera after the robot receives a control command and guiding the robot to completewelding. Through the method for guiding the robot to conduct automatic welding through the CAD drawing technology, the stability and the welding quality are improved, and the welding uniformly is ensured; the labor conditions are improved; the labor productivity is improved; the product model changing and updating cycle is shortened, and the corresponding equipment investment is reduced.

Owner:肖依林 +1

Titanium-copper dissimilar metal joint welding method

ActiveCN107297569AImprove bindingPrecise heat controlWelding/soldering/cutting articlesLaser beam welding apparatusNiobiumMetallic materials

The invention discloses a titanium-copper dissimilar metal joint welding method, and belongs to the field of metal material interface welding process. The method includes the steps that middle layer welding flux is added between a titanium material and a copper material, the combining interface between the middle layer welding flux and the titanium material is the interface I, the combining interface between the middle layer welding flux and the copper material is the interface II, and welding heat source focal points are located in the middle layer welding flux; in the welding process, it is ensured that when heat generated by a welding heat source is conducted to the interface I, the temperature generated by the heat is higher than the titanium melting point, when the heat is conducted to the interface II, the temperature generated by the heat is higher that the eutectic temperature of the middle layer welding flux and copper, a non-melting welding flux layer exists between the interface I and the interface II, and the middle layer welding flux is a metal material which generates no intermetallic compound with the titanium material and / or copper material. A titanium-copper intermetallic compound is prevented from being formed by means of the welding method, titanium-niobium and copper-niobium melt-brazed seams can be formed at the same time, the extension strength of the obtained titanium-copper dissimilar metal joint reaches 200-240 MPa, the elongation percentage is 30-40%, and the welding interface does not fracture.

Owner:BAOJI UNIV OF ARTS & SCI

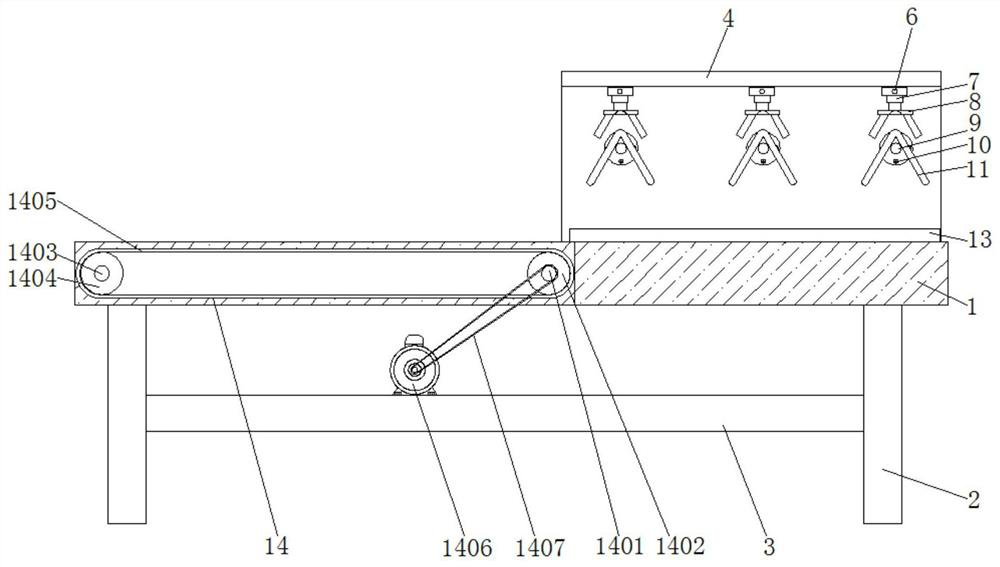

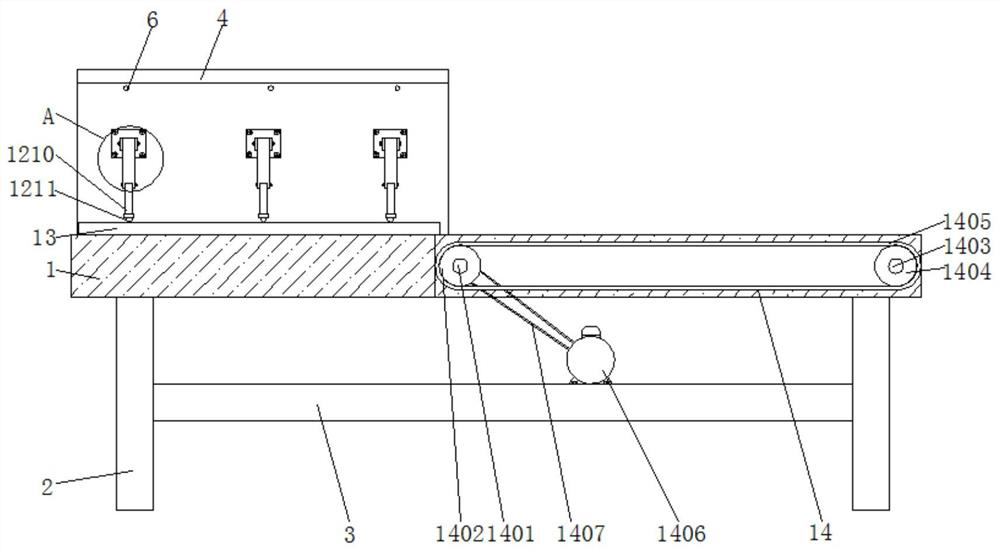

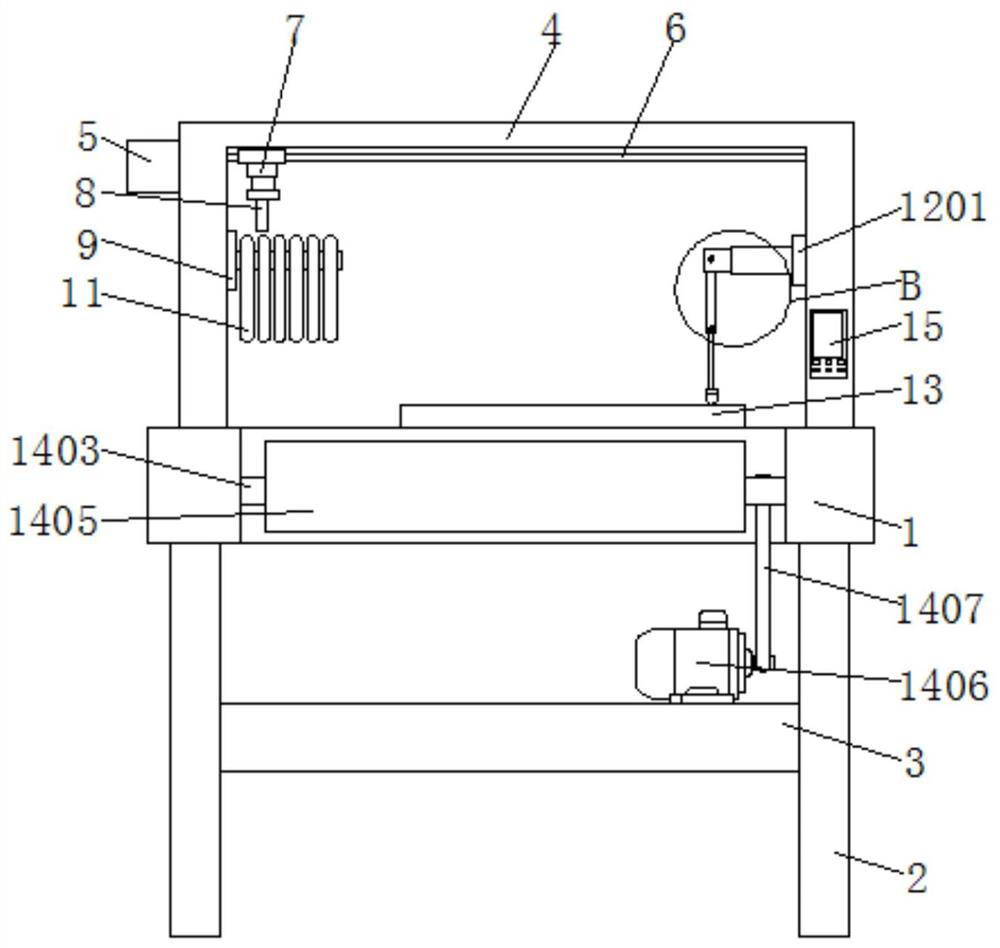

Welding device suitable for batch machining of steel bar truss floor support plates

InactiveCN113146088AEasy to moveImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRebarMachining

The invention discloses a welding device suitable for batch machining of steel bar truss floor support plates. The welding device comprises a workbench, a welding mechanism, a storage table and a conveying mechanism, supporting legs are arranged on the left side and the right side of the bottom of the workbench, a support is installed at the upper end of the right side of the workbench, a lead screw structure is installed at the upper end in the support, a clamping base is installed at the bottom of an electric telescopic rod, a fixing rod is arranged on the inner wall of the rear side of the support, the welding mechanism is installed on the inner wall of the front side of the support, the storage table is arranged at the upper end of the right side of the workbench, and the conveying mechanism is installed on the left side of the workbench. According to the welding device suitable for batch machining of the steel bar truss floor support plates, the welding mechanism is arranged, through matched use of a fixing base, a first supporting arm, a second supporting arm, a welding gun and a welding head, in the welding process of a steel bar truss, the welding gun does not need to be manually held for operation, meanwhile, the production efficiency of the steel bar truss floor support plates is improved, and welding automation is achieved.

Owner:徐州中煤汉泰建筑工业化有限公司

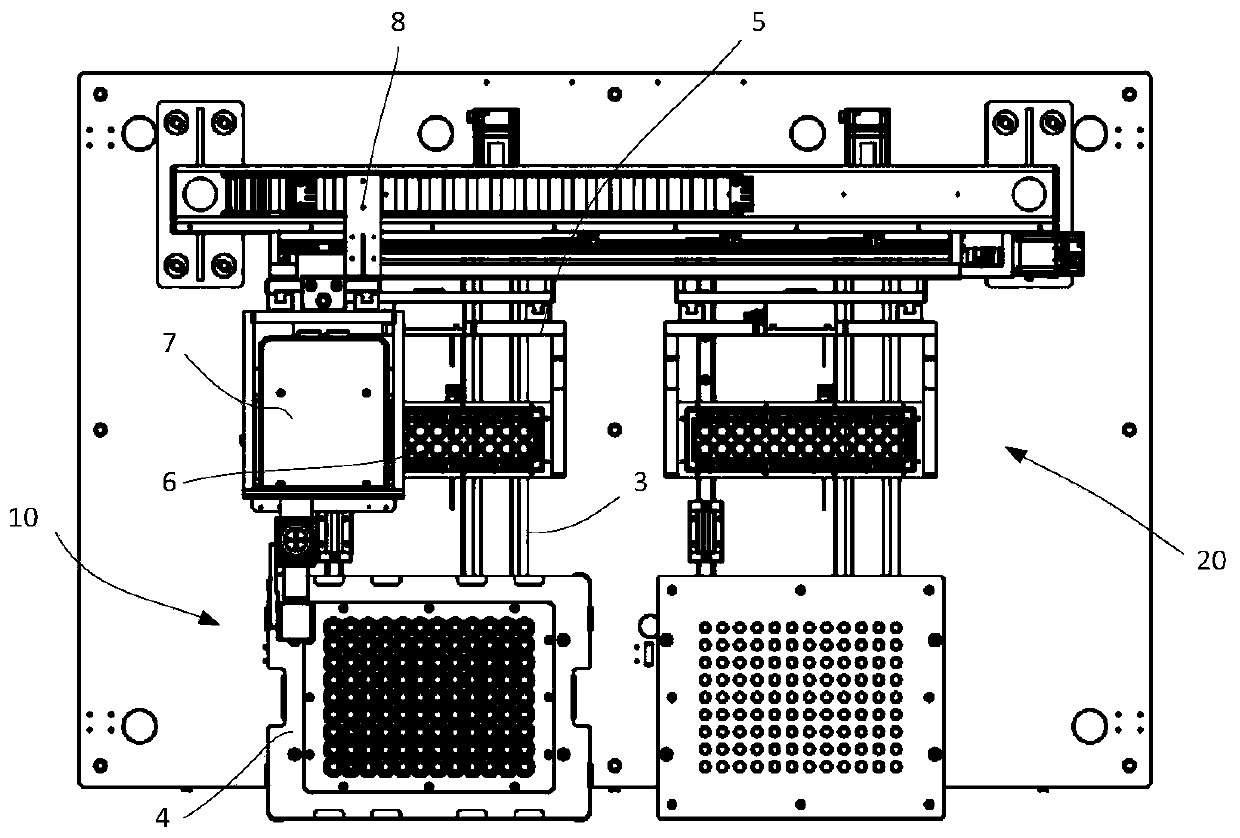

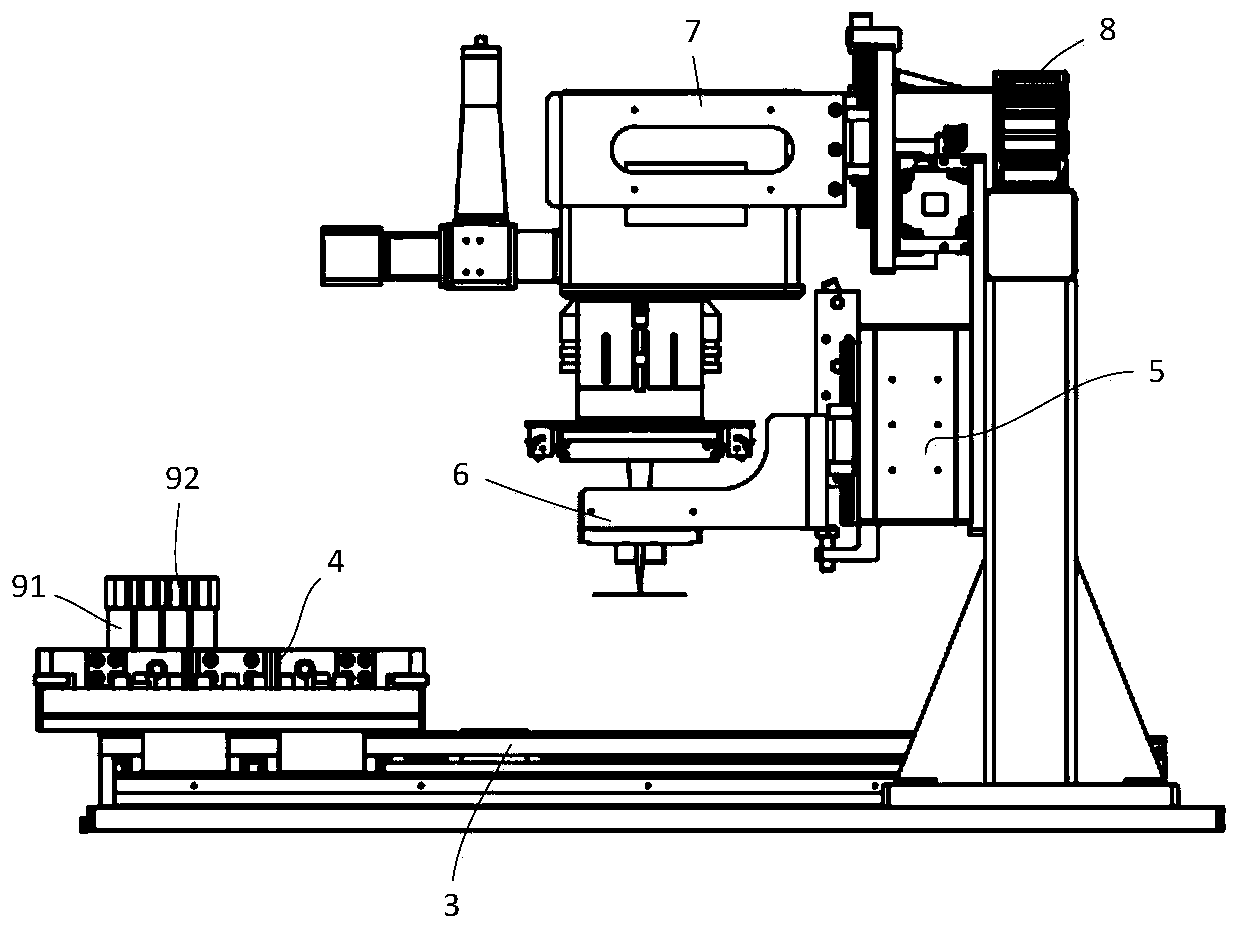

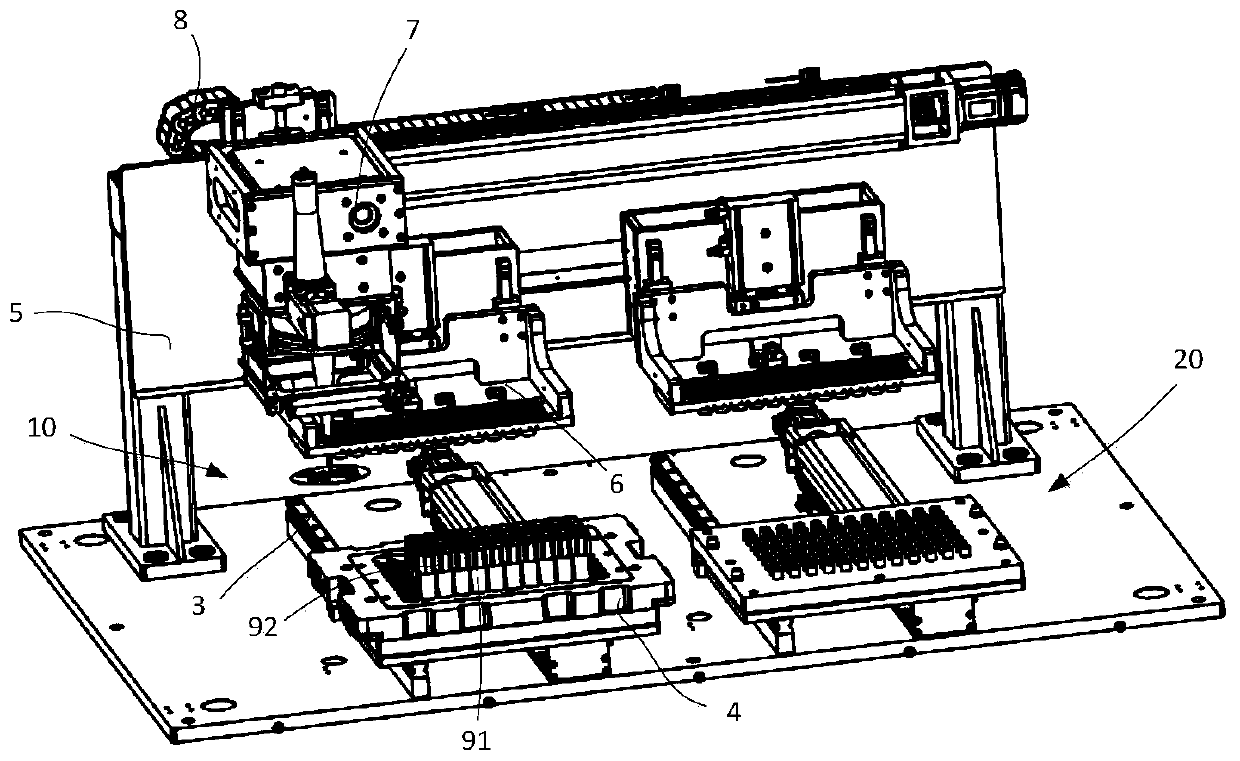

Welding machine

PendingCN109822275ARealize welding automationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention discloses a welding machine. The welding machine comprises at least one welding module. The welding modules comprise bearing frames, bearing tables, welding frames, welding tools and laser machines. The bearing frames are fixedly arranged, the bearing tables are mounted on the bearing frames, elastic jacking structures are arranged on the bearing tables, the welding frames are fixedly arranged, the welding tools and the laser machines are mounted on the welding frames and correspond to the bearing tables, elastic pressure heads are arranged on the welding tools, the elastic pressure heads and the elastic jacking structures cooperate to clamp welded objects, and the laser machines move in place after the welded objects are fixed for welding operation. According to the weldingmachine, the bearing tables and the welding tools are oppositely arranged, the elastic pressure heads and the elastic jacking structures cooperate to clamp the welded objects, the welded objects are welded after being fixed, welding automation is completely achieved, positioning is accurate, the efficiency is high, and the product quality is stable.

Owner:WUXI AOTEWEI INTELLIGENT EQUIP CO LTD

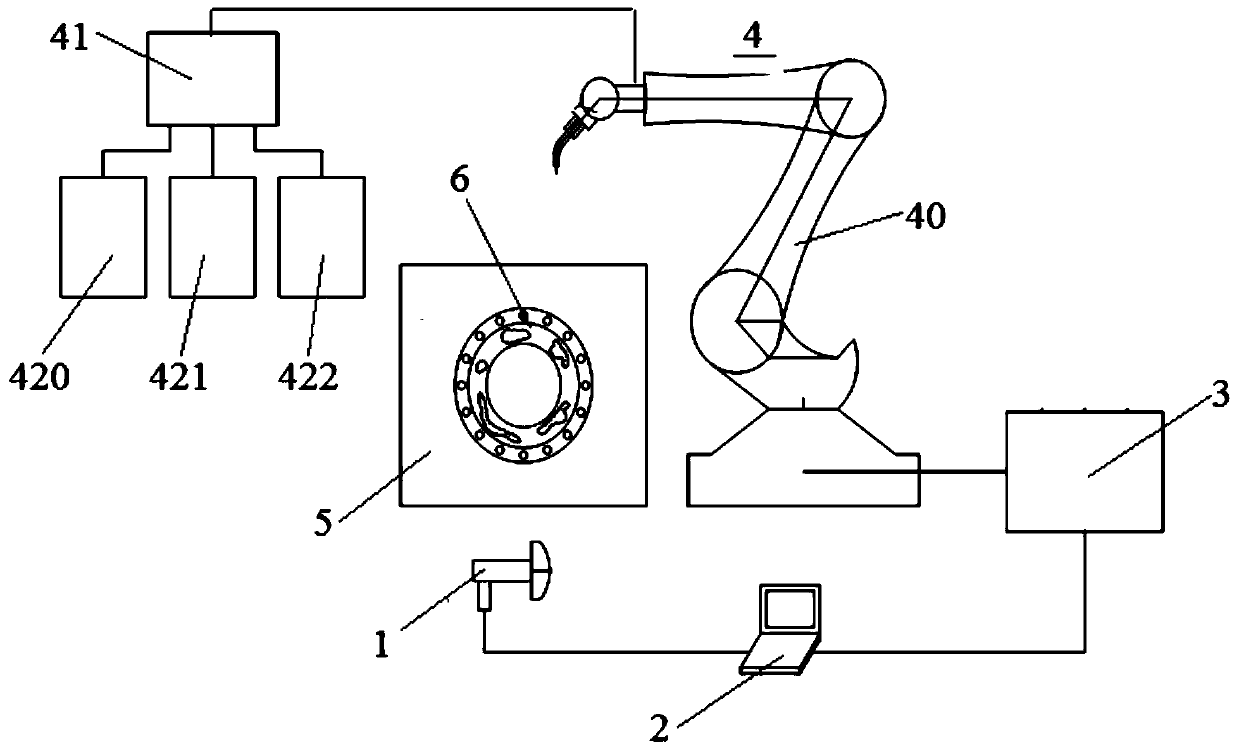

3D printing remanufacturing process and system for nuclear power plant flange

InactiveCN111438449AAchieve relative balanceRealize welding automationProgramme-controlled manipulatorWelding/cutting auxillary devicesHeat-affected zoneManufacturing technology

The invention relates to a 3D printing remanufacturing process and system for a nuclear power plant flange. The method comprises the following steps: removing metal of a flange defect part; scanning the flange and a to-be-repaired area of the flange, establishing a three-dimensional model, planning weld joint configuration of the to-be-repaired area of the flange, generating a robot welding path,guiding the robot welding path into a robot controller, conducting priming coat welding based on plasma arc welding firstly, then filling a cover surface by gas shielded welding, and relieving stresson the weld joints after processing of each layer of weld joints is finished. The system comprises a scanning part, a model analysis part, a robot controller, a robot and a working table. The method is based on robot 3D printing repair, the whole welding sequence and direction are reasonably arranged, welding automation is realized, heavy manual welding work is omitted, relative balance of weldingheat input of the whole component is achieved, the purpose of controlling welding deformation is achieved, the weld joint heat affected zone can be controlled to be smaller than that of a manual welding method, and the residual stress of the weld joints is controlled to be within a relatively small range.

Owner:SUZHOU NUCLEAR POWER RES INST +3

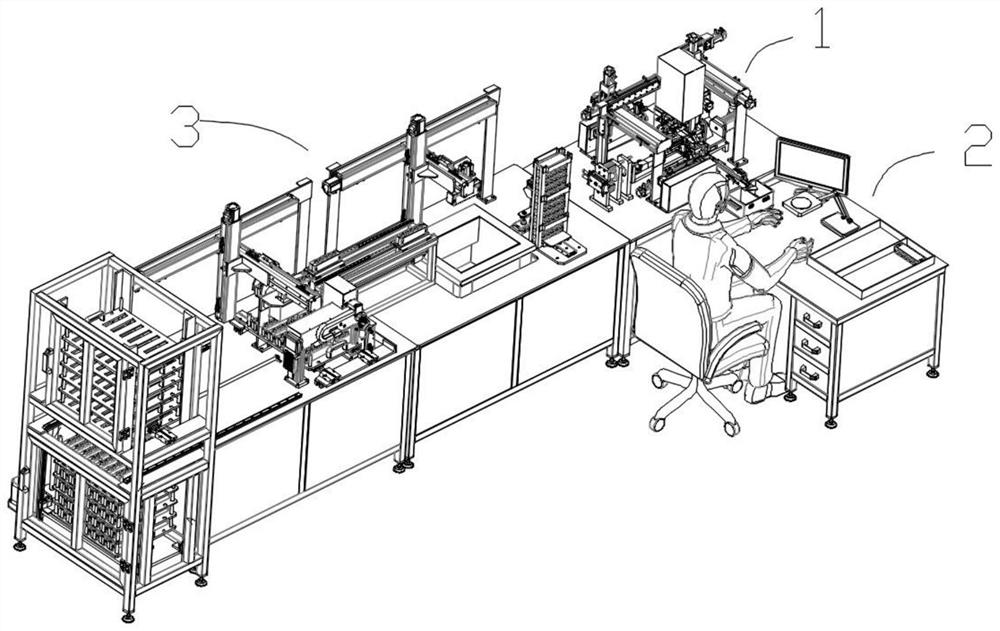

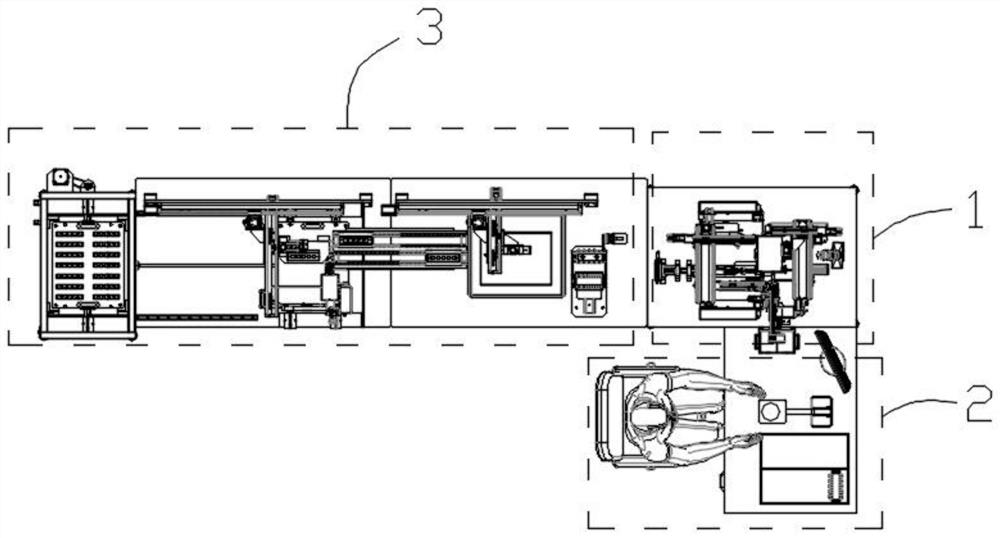

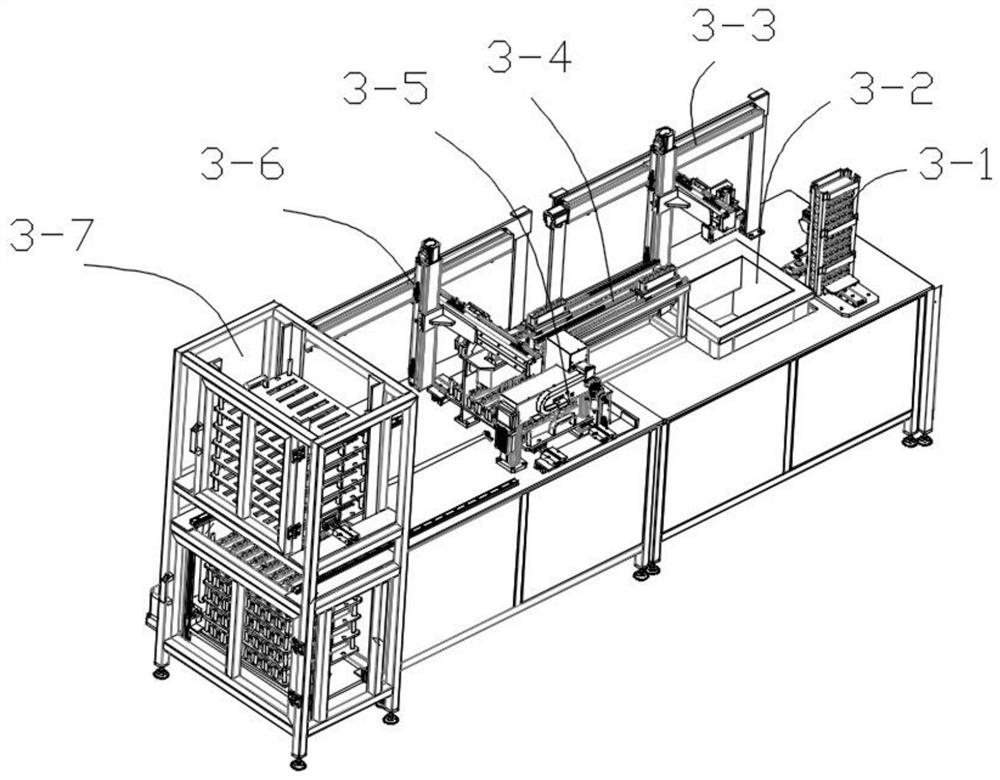

Production line for producing electric igniter support

ActiveCN113513953ARealize welding automationIncrease speedBlasting cartridgesAmmunitionProduction lineControl system

The invention discloses a production line for producing an electric igniter support, and relates to the technical field of electric igniter production. The production line comprises an automatic welding system for welding a leg wire and an igniter wire on a tooth-shaped sheet, a manual auxiliary system for loading the welded tooth-shaped sheet into a tool, an automatic powder dipping and forming system for the electric igniter support formed by dipping the tooth-shaped sheet in the tool with powder, and a control system for controlling the automatic welding system and the automatic powder dipping and forming system, wherein the automatic welding system and the automatic powder dipping and forming system are electrically connected with the control system; and the production line is simple in structure, welding automation and powder dipping automation of the whole electric igniter support are achieved, and the welding speed and quality are remarkably improved.

Owner:四川仲玛智造科技有限公司

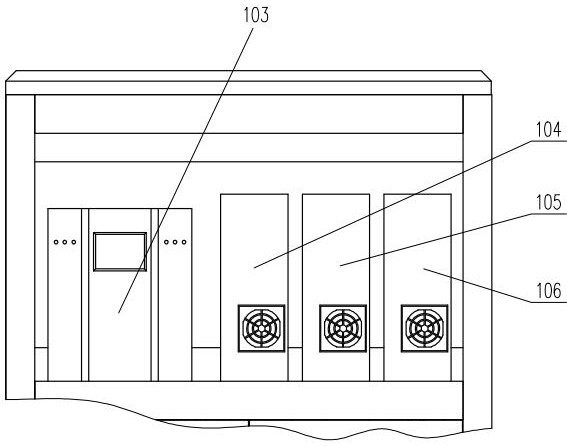

Building core plate welding equipment

PendingCN110883444ARealize the assemblyRealize welding automationWelding/cutting auxillary devicesAuxillary welding devicesControl systemElectrical connection

The invention provides building core plate welding equipment. The building core plate welding equipment comprises a rack, a conveying mechanism, a welding mechanism, an overturning mechanism and a control system, the rack is of a frame structure, the conveying mechanism is mounted in a frame formed by the rack, the welding mechanism is movably arranged on the rack in the mode of corresponding to the conveying mechanism, the overturning mechanism is connected to the conveying mechanism so as to bear to-be-welded core plates from the conveying mechanism and overturn the borne to-be-welded core plates, the control system is electrically connected with the conveying mechanism and the welding mechanism and receives or sends electrical signals to the conveying mechanism and the welding mechanism. According to the building core plate welding equipment provided by the invention, automatic assembling and welding of building core plates are achieved, the welding precision is high, and the welding efficiency is improved.

Owner:SHENZHEN TETELASER TECH CO LTD

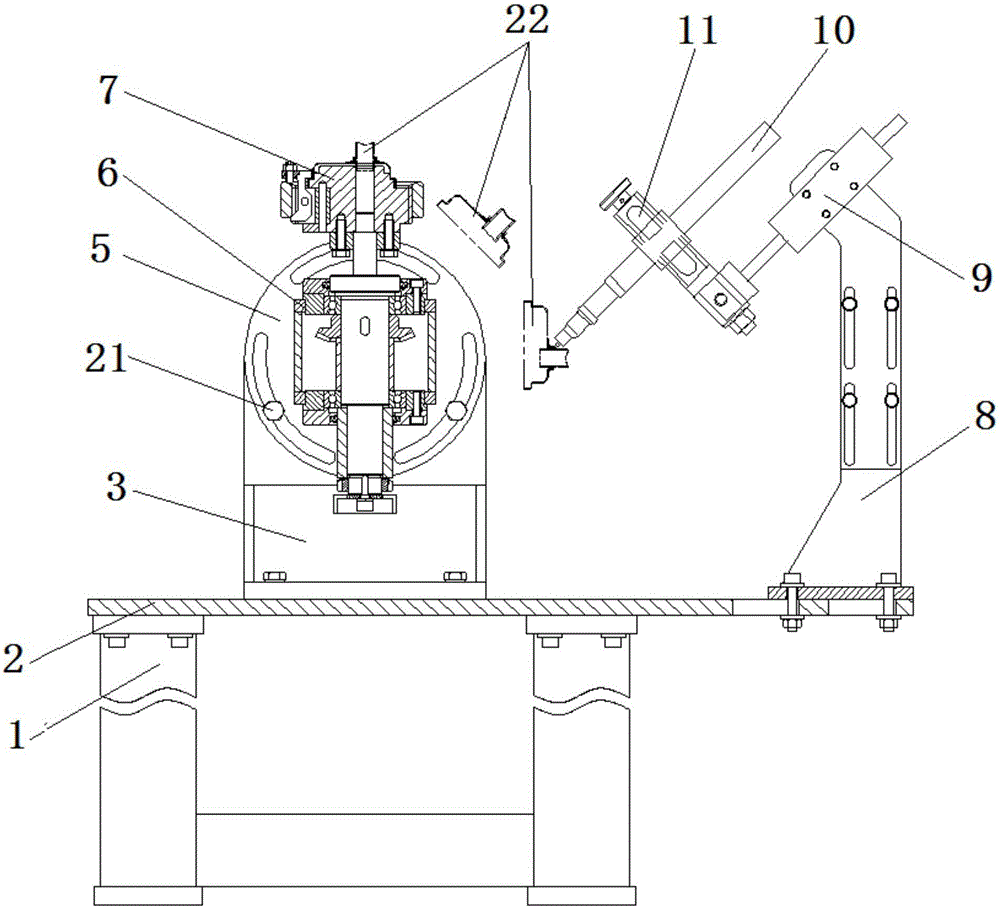

Automatic submerged arc welding system for circumferential welding seam of boiler pipe fitting

InactiveCN106825873ASafe and reliable productionReduce labor costsMetal working apparatusTubular articlesPipe fittingEngineering

The invention relates to the technical field of oil field steam-injection boilers, in particular to an automatic submerged arc welding system for a circumferential welding seam of a boiler pipe fitting. The two sides of a travelling guide rail of the device are separately equipped with a loading rack and an unloading rack; an electric transmission unit and a driven transmission unit are mounted on the travelling guide rail; the pipe fitting on the loading rack can be transmitted onto the electric transmission unit and the driven transmission unit; the pipe fitting on the electric transmission unit and the driven transmission unit can be transmitted to the unloading rack; and an submerged arc welding system for a circular seam filament comprises a pipe fitting clamping rotary main engine and an automatic water-cooling spray gun. The automatic submerged arc welding system realizes welding automation, completely guarantees welding quality, greatly increases welding speed, ensures quick, safe and reliable production of a steam-injection boiler, and effectively reduces labor cost of steam-injection boiler manufacturing. The automatic submerged arc welding system overcomes the defects that manual welding speed for a tube and an elbow of an existing steam-injection boiler, and the tube and a tube circumferential welding seam of the existing steam-injection boiler is low, and manual welding quality cannot be stably controlled.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

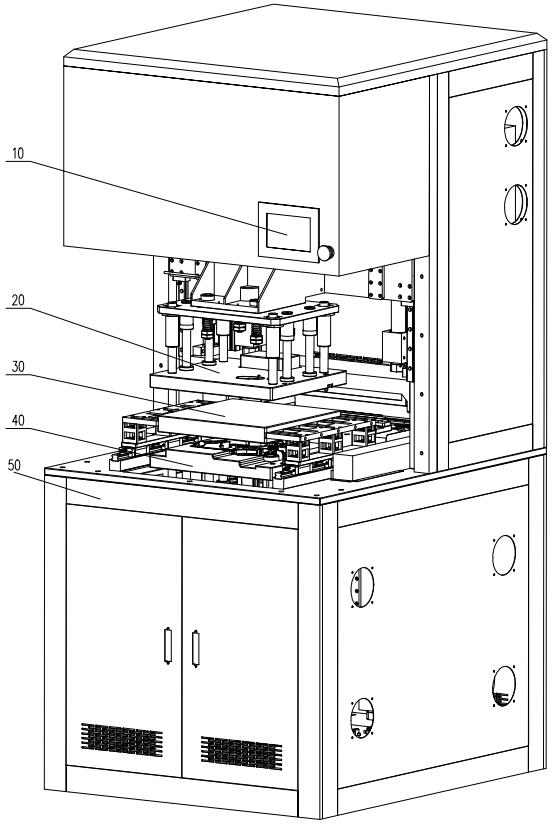

Special precise and quick locating welding machine for disc-shaped parts

ActiveCN107175418AIncreased manipulation of the welding processEasy to realize automatic welding processWelding/cutting auxillary devicesAuxillary welding devicesSlagWeld seam

The invention discloses a special precise and quick locating welding machine for disc-shaped parts and belongs to the technical field of mechanical welding. The special precise and quick fixed-position welding machine aims at solving the problems that when being welded, concentric or non-concentric annular parts are not easy to fix, and good location is not achieved, so that the concentricity is poor, welding seams are not even, and slag inclusion and air holes exist. A machine base upper plate is arranged on a machine base. A support and a welding gun mechanism are mounted on the machine base upper plate side by side, wherein the support is located at the left side, and the welding gun mechanism is located at the right side. A motor and a workpiece adjusting disc are fixedly mounted at the two sides of the support. A transmission mechanism is mounted on the workpiece adjusting disc. The output end of the motor is connected with the input end of the transmission mechanism. The workpiece adjusting disc is fixedly mounted on the output end of the transmission mechanism. The workpiece adjusting disc is a rotary ring flange. By means of the special precise and quick locating welding machine for the disc-shaped parts, quick location and welding automation of the concentric or non-concentric annular parts can be achieved.

Owner:航天科工哈尔滨风华有限公司

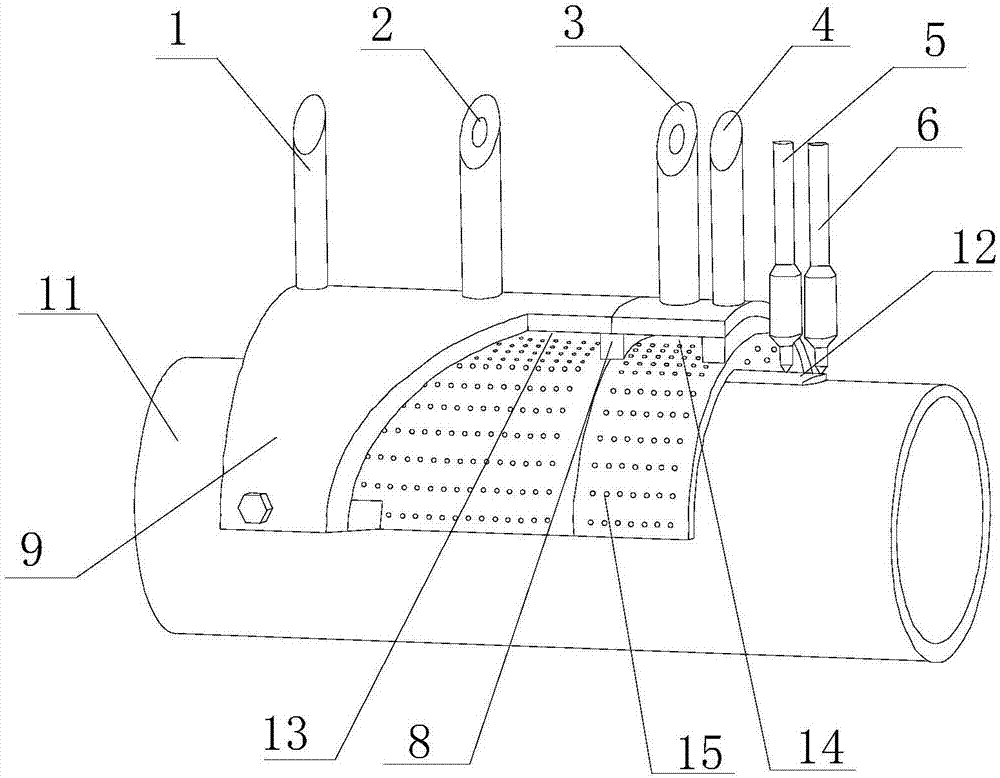

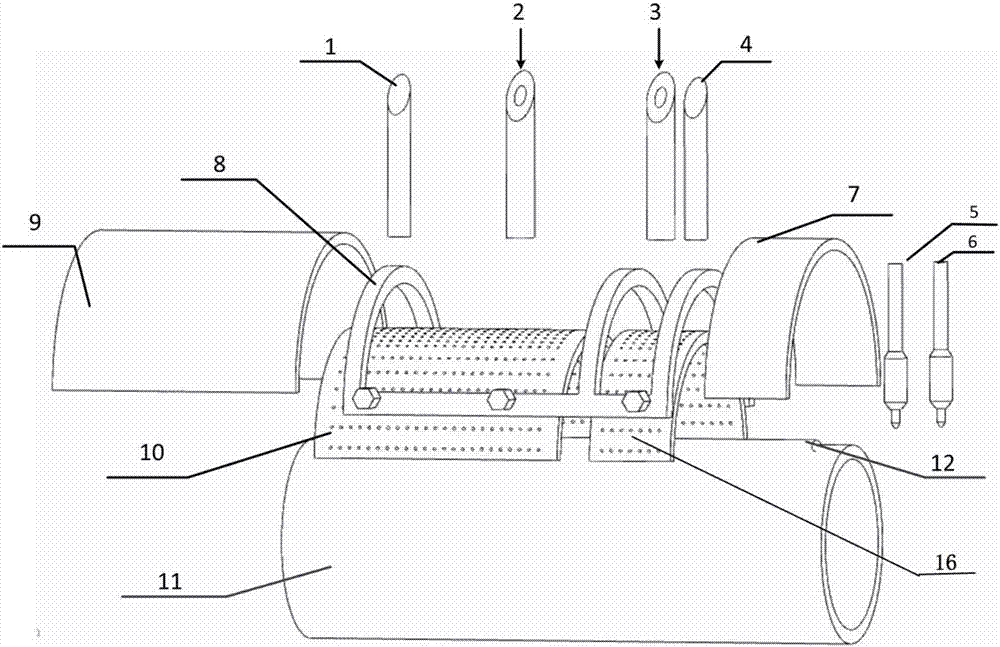

Device and process for removing local overheating effect in pipeline welding process

InactiveCN106975823AProtected weldEliminate overheatingWelding coupling meansWelding protection meansWater storagePipe

The invention discloses a device and process for removing the local overheating effect in the pipeline welding process. According to the device and process, the phenomenon of local overheating of a weld can be removed effectively. According to the technical scheme, the device comprises a mechanical skeleton, a cooling sleeve I, a cooling sleeve II, a cooling sleeve III, a cooling sleeve IV, a suspension rod I, a suspension rod II, a water injecting pipe and an argon injecting pipe; the inner sides of the cooling sleeve III and the cooling sleeve IV make contact with a welding pipeline; the mechanism skeleton is arranged on the outer sides of the cooling sleeve III and the cooling sleeve IV; the cooling sleeve I and the cooling sleeve II are arranged on the outer side of the mechanism skeleton; a cavity formed between the mechanism skeleton and the cooling sleeve III is a water storage cavity; a cavity formed among the cooling sleeve II, the mechanism skeleton and the cooling sleeve IV is an argon cavity; the suspension rod I and the water injecting pipe are arranged on the outer side of the cooling sleeve I; and the suspension II and the argon injecting pipe are arranged on the outer side of the cooling sleeve II.

Owner:山东朝日不锈钢有限公司

Automatic mechanical arm for welding

InactiveCN103612053AImprove stabilityImprove working conditionsWelding/cutting auxillary devicesAuxillary welding devicesProduction rateRobotic arm

The invention relates to an industrial welding robot, in particular to an automatic mechanical arm for welding. The automatic mechanical arm comprises a base, a mechanical arm body and a welding gun. The mechanical arm body is composed of two rigid rod bodies, the first rigid rod body is fixedly connected to the base, the second rigid rod body is in series connection with the first rigid rod body through a rotary joint and can freely move, the tail end of each rigid rod body is connected with a wrist, the wrists are connected with the welding gun, and the inside of the base is provided with a PLC controller. The automatic mechanical arm has the advantages that quality of a welded product is stabilized and improved through mechanical welding, welding uniformity of the product is guaranteed, productivity is improved, 24-hour continuous production can be achieved, work conditions of workers are improved, the automatic mechanical arm can work in a harmful environment for a long time, operations are simple and convenient to carry out, professional staff are needless, requirements for operation techniques of the workers are reduced, and welding automation of small-batch products can be achieved.

Owner:XINGAN ANHUI ELECTRIC LTD BY SHARE LTD

Method of pre-copper-plated induction welding-brazing of aluminum-steel stud bolt

ActiveCN102114561BImprove welding qualityEasy to operateSoldering apparatusWelding/soldering/cutting articlesFriction weldingCopper plating

The invention discloses a method of pre-copper-plated induction welding-brazing of an aluminum-steel stud bolt, which comprises the following steps: processing a steel stud bolt into a flat-bottom no-nut-cap type and conducting copper immersion plating to one end of the steel stud bolt; carrying out chemical cleaning to the surface of an aluminium base material and brazing filler metal; cleaning the surface of an aluminium base material and a brazing filler metal with alcohol, fast drying, and coating a layer of brazing protective agent on the surface of the base material; horizontally placing the aluminum base material, vertically placing the copper-plated end of the steel stud bolt on the aluminum base material, applying vertical downward pressure on the copper-plated end of the steel stud bolt, and filling enough cleaned brazing filler metal on the contact surface of the two; placing a ceramic ring matched with the stud bolt at the contact position of the copper-plated end of the steel stud bolt and the aluminum base material, and filling the brazing filler metal in the ceramic ring; and sheathing an induction heating coil at a welding end of the stud bolt, heating the induction heating coil and completing the welding. The invention can realize the welding of the small-diameter steel stud bolt and the aluminum base material, and has wide range of application to the thickness of plates.

Owner:NANJING UNIV OF SCI & TECH

Laser welding head multi-angle automatic welding machine

PendingCN111001931AThe overall structure is simple and reliableEasy to adjustLaser beam welding apparatusLaser solderingLaser beam welding

The invention discloses a laser welding head multi-angle automatic welding machine. The laser welding head multi-angle automatic welding machine comprises a rack, a welding rotating table and a laserwelding module, wherein the welding rotating table and the laser welding module are both placed on the rack; the welding rotating table is provided with picking and placing stations and welding stations, each station is provided with a lower jig, upper jigs are arranged above the welding stations, and the lower jigs located at the welding stations can move upwards to be combined with the upper jigs; and the laser welding module comprises a laser welding head capable of adjusting the angle and the height, different position angles of different workpieces are welded, automatic multi-station welding is achieved, and the welding efficiency and the welding quality are improved.

Owner:领镒精密五金制造(无锡)有限公司

Manifold welding machine

PendingCN112025131AIncrease productivityImprove pass rateWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention relates to a manifold welding machine. The manifold welding machine comprises a manifold upper portion driving and positioning mechanism, a hot melting plate driving mechanism, a manifold lower portion driving and positioning mechanism and a control system, wherein the control system controls the hot melting plate driving mechanism to move forwards to a working position; the upper driving and positioning mechanism and the lower driving and positioning mechanism move downwards and upwards respectively, welding surfaces of the upper portion and the lower portion of a manifold are attached to a hot melting plate for being heated, and heating melting of the welding surfaces is completed; the upper driving and positioning mechanism and the lower driving and positioning mechanism continue to move downwards and upwards respectively to attach the two hot melting surfaces of the upper portion and the lower portion of the manifold together; when the two hot melting surfaces of theupper portion and the lower portion of the manifold begin to be attached to each other and in contact with each other, an upper pressure sensor and a lower pressure sensor sense pressure increase andtransmit the pressure increase to the control system, and the control system immediately reduces the running speed of the manifold upper portion driving and positioning mechanism and the manifold lower portion driving and positioning mechanism; and when the pressure sensed by the pressure sensors is increased to a set maximum value, the welding surfaces begin to be cooled until the welding surfaces are completely cured.

Owner:NINGBO HENGSHUAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com