Automatic submerged arc welding system for circumferential welding seam of boiler pipe fitting

A submerged arc welding and girth welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of slow manual welding speed and unsteady control of manual welding quality, so as to reduce labor costs and ensure fast and safe. Reliable production, increased welding speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

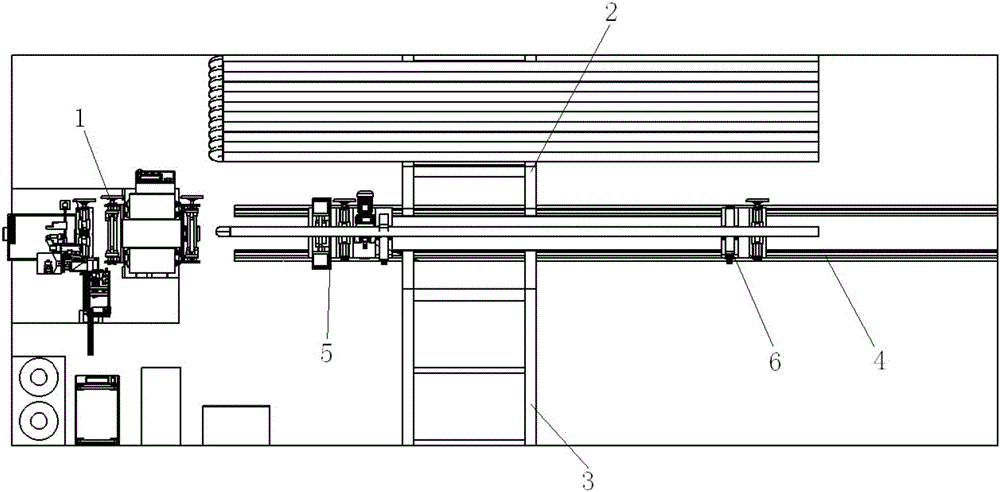

[0015] Such as figure 1 As shown, an automatic submerged arc welding system for the circumferential weld of boiler pipe fittings, including a circumferential seam filament submerged arc welding system 1, a loading frame 2, a blanking frame 3, a walking guide rail 4, an electric transmission unit 5 and a driven transmission unit 6. The two sides of the walking guide rail 4 are respectively provided with a feeding rack 2 and a lowering rack 3. An electric transmission unit 5 and a driven transmission unit 6 are installed on the walking guide rail 4. The pipe fittings on the feeding rack 2 can be transferred to the electric transmission unit. 5 and the driven transmission unit 6, the electric transmission unit 5 and the pipe fittings on the driven transmission unit 6 can be transferred to the blanking frame 3, the circular seam filament submerged arc welding system 1 includes a pipe clamping rotary host and an automatic water-cooled welding torch, The pipe fittings on the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com