Patents

Literature

3874 results about "Thermal recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

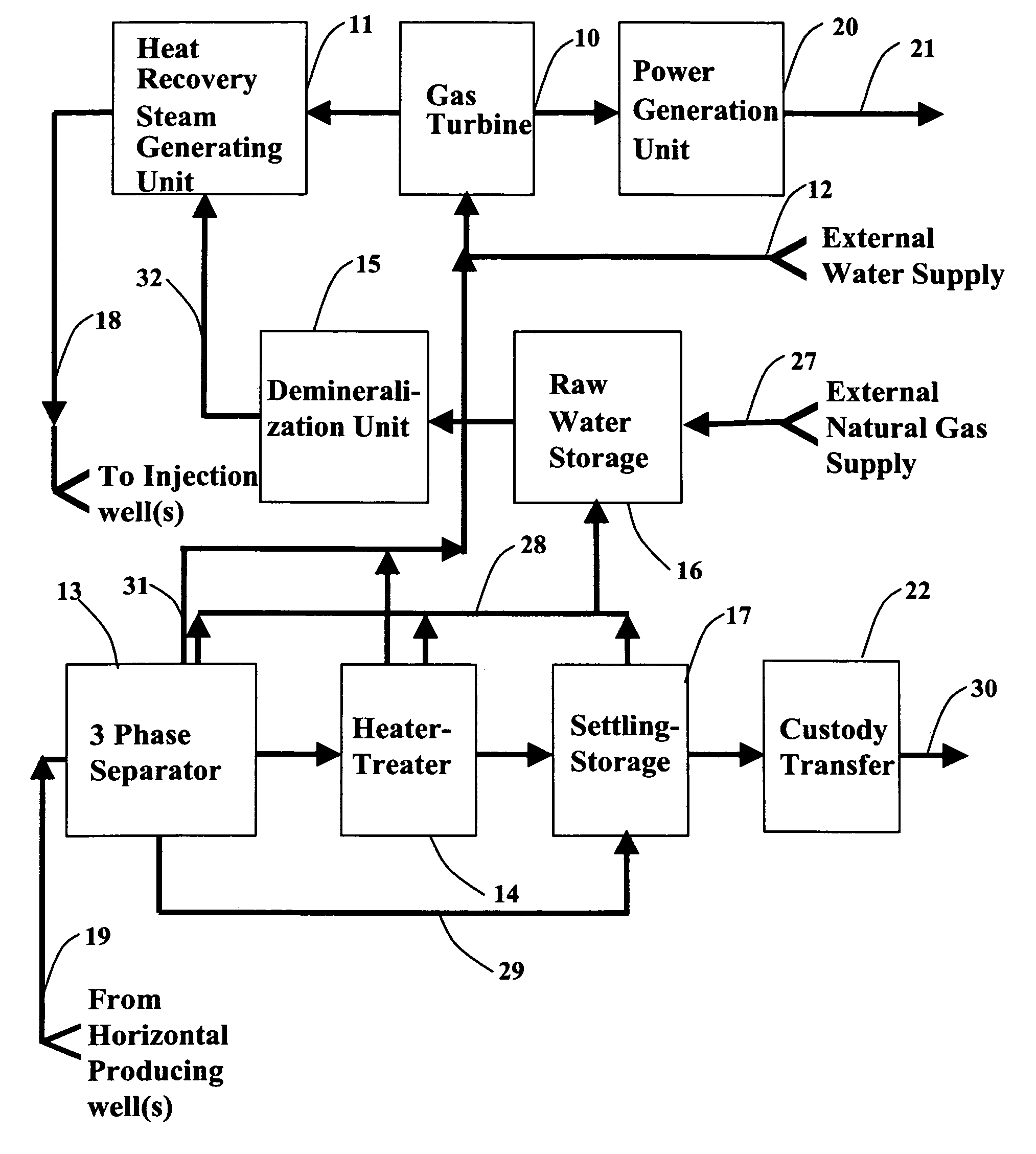

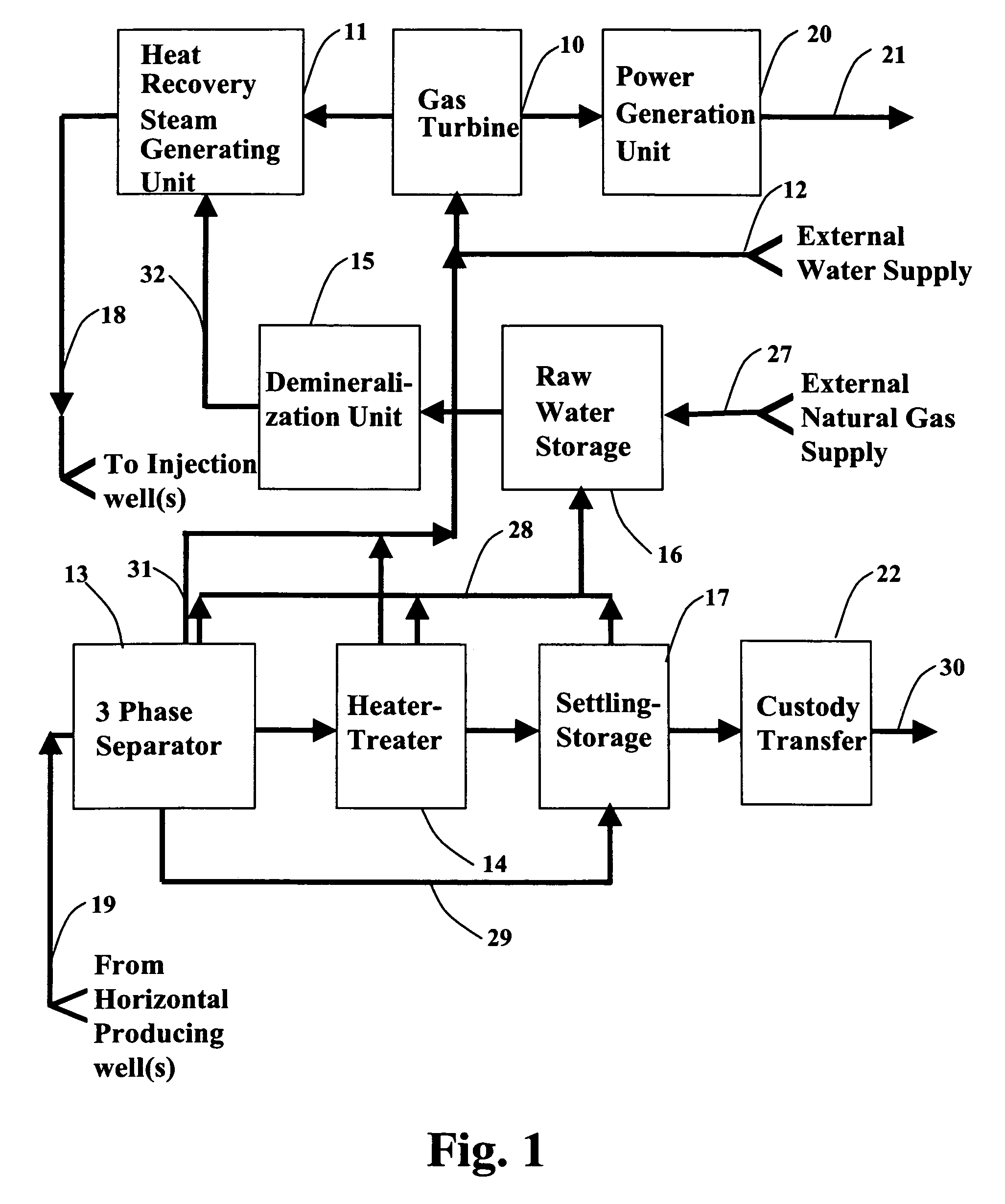

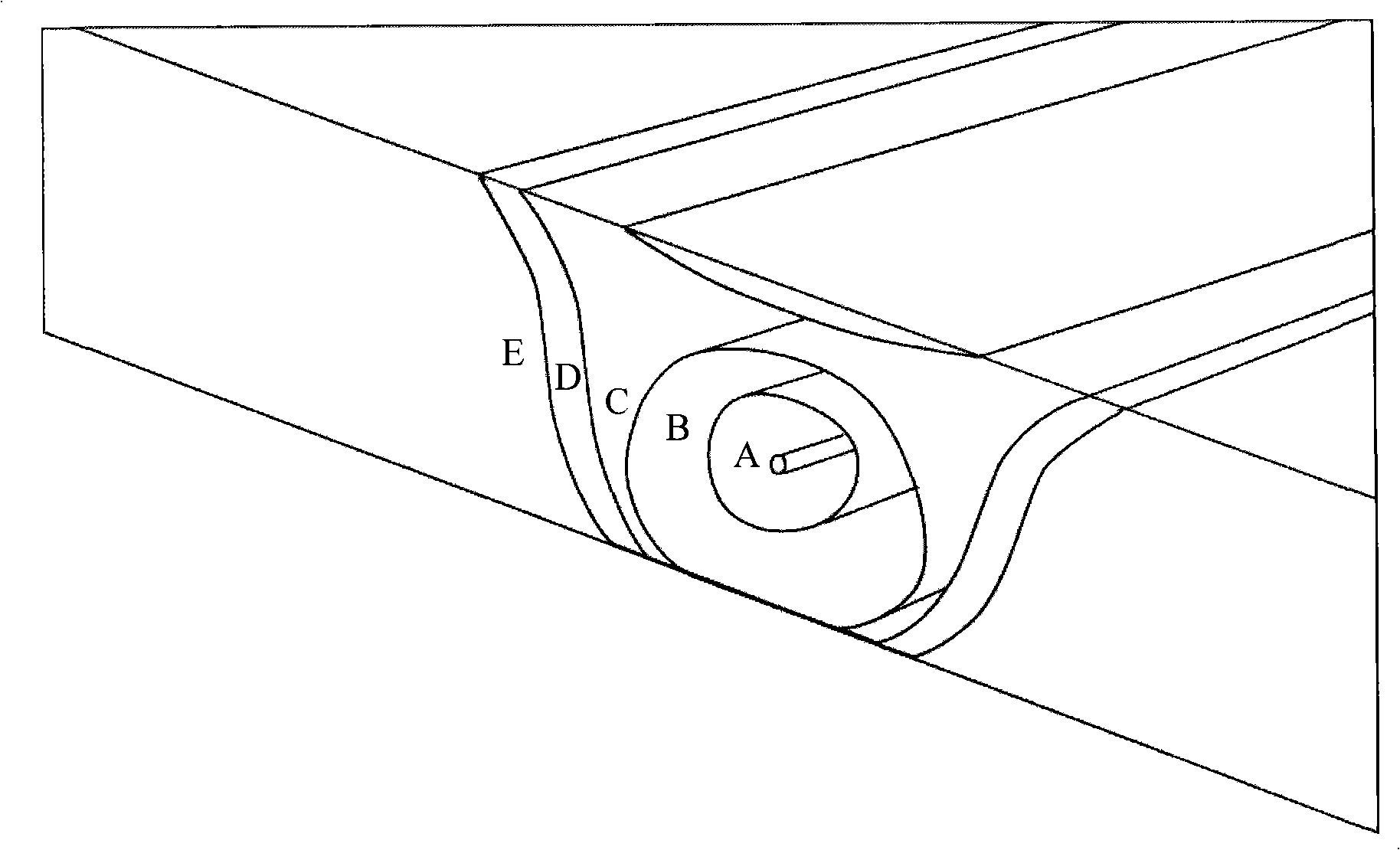

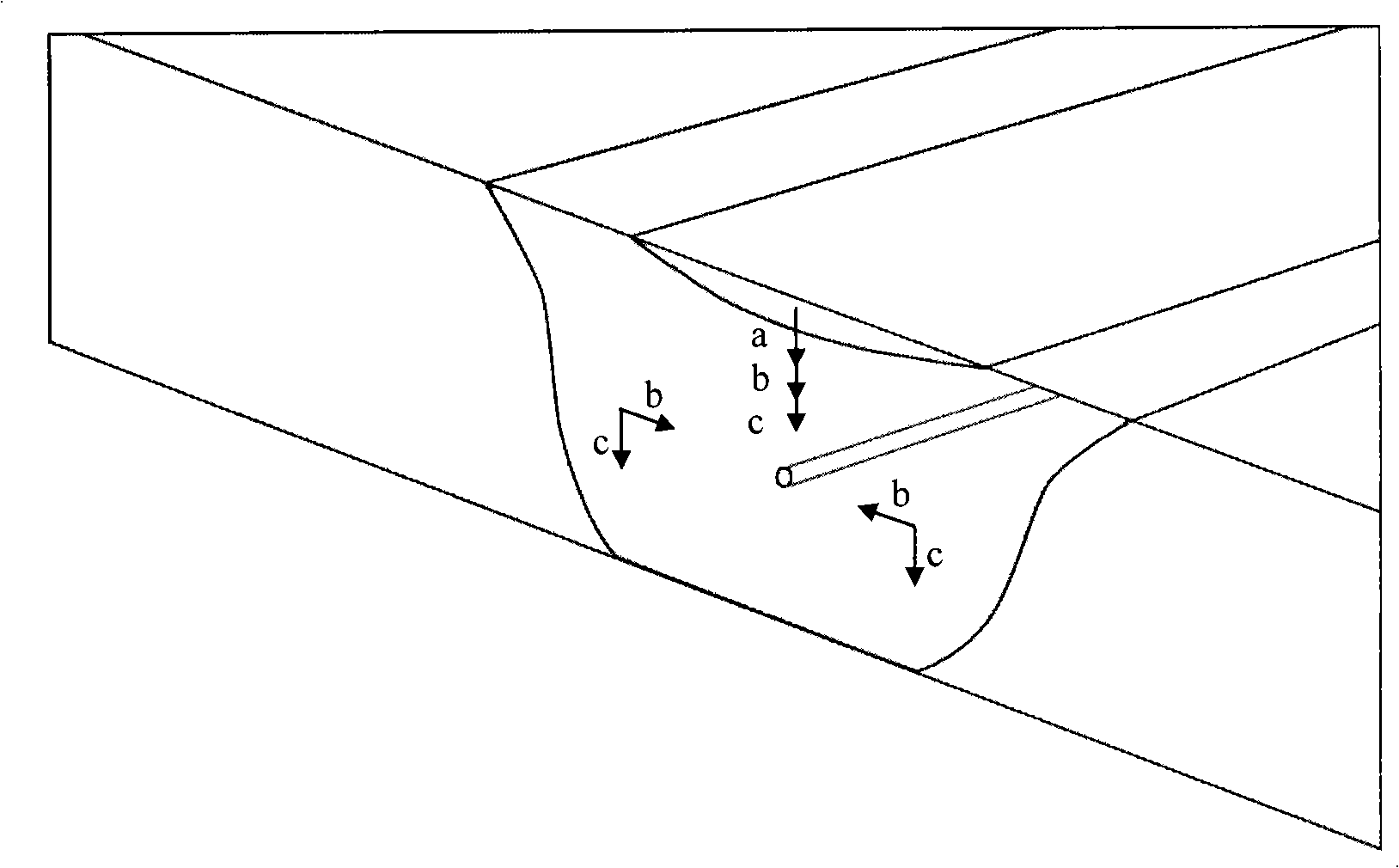

SAGD-plus

A combination of SAGD with cogeneration technology for exploiting shallow heavy oil and bitumen reservoirs under primary, secondary and tertiary thermal recovery. Superheated steam is generated by the heat recovery from the exhaust of an above-ground hydrocarbon powered turbine driven electric generator cogeneration plant and is injected through well bores into the hydrocarbon bearing reservoir that is traversed by at least one horizontal producing well bore and one injection well bore to heat the reservoir formation and to induce gravity drainage of the hydrocarbons and allowing their recovery from the horizontal producing well bore. Electrical power that is generated is sold to the electric grid and can be used to offset the fuel costs for the above ground hydrocarbon turbine-driven elector generators.

Owner:BABCOCK JOHN A

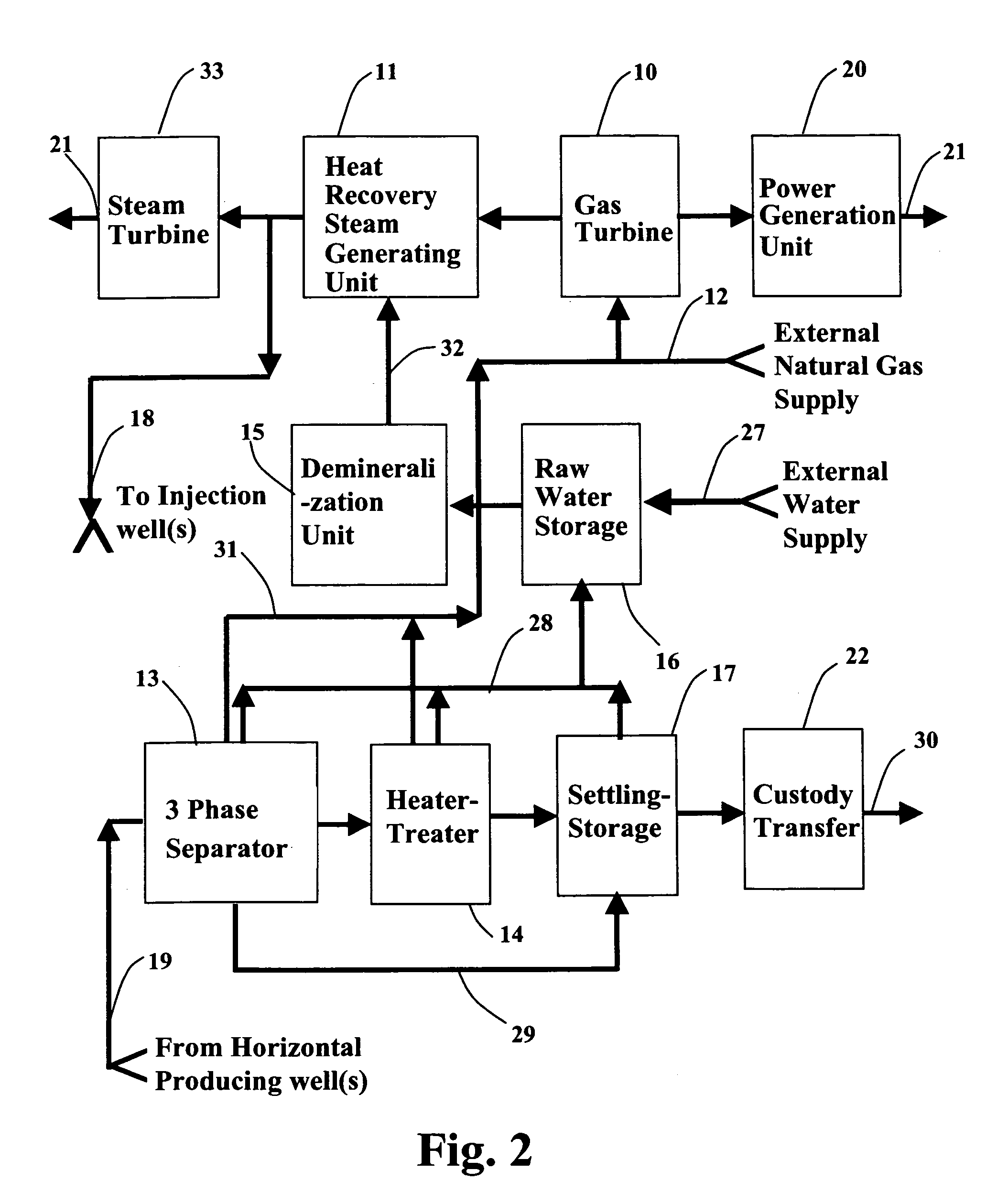

Methods and apparatus for starting up emission-free gas-turbine power stations

InactiveUS6945052B2Large capacityGas turbine plantsIndirect carbon-dioxide mitigationPower stationCombustion chamber

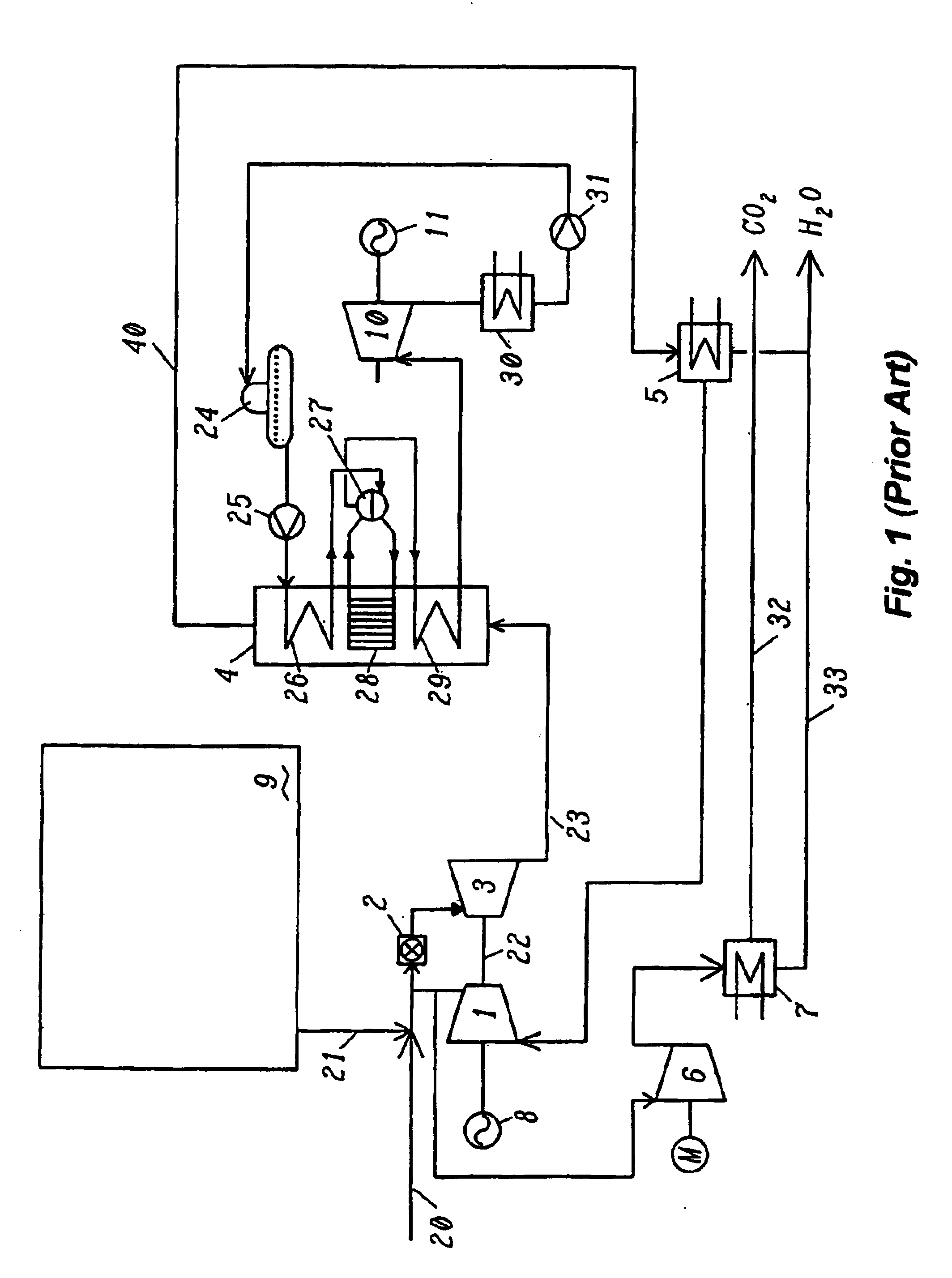

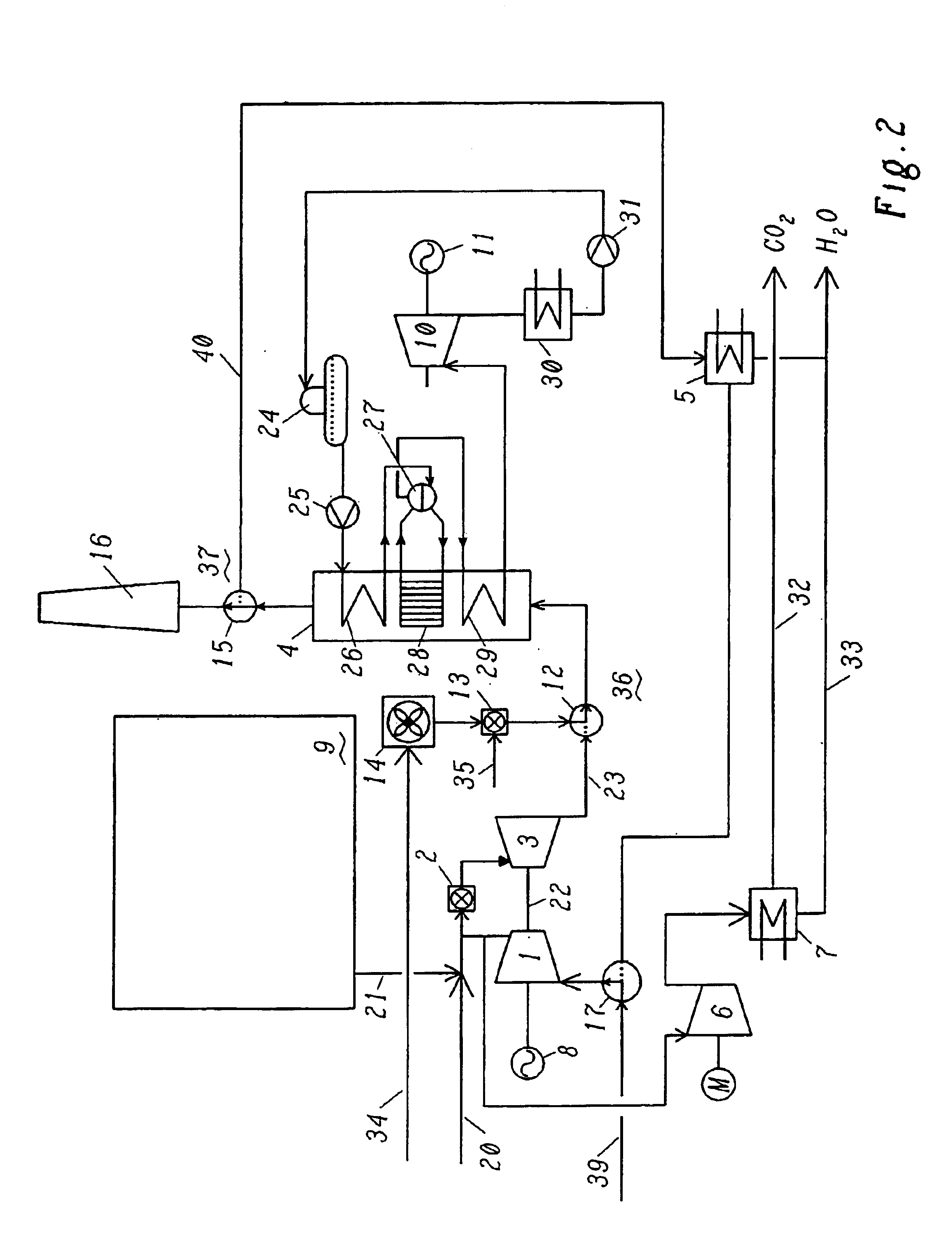

In a power generation plant having at least one gas turbine cycle with heat-recovery boiler (4) and at least one steam turbine cycle operated via the heat-recovery boiler (4), the gas turbine cycle being designed to be semi-closed and essentially free of emissions and essentially comprising a compressor (1), a combustion chamber (2) arranged downstream of the compressor (1), a gas turbine (3) arranged downstream of the combustion chamber (2), a heat-recovery boiler (4) arranged downstream of the gas turbine (3), and at least one generator (8) coupled to the gas turbine (3), modes of operation with the gas turbine cycle stopped and start-up using fresh air are made possible by first means (12) being arranged which alternatively or additionally allow hot gas to be fed into the hot-gas path (23) between gas turbine (3) and heat-recovery boiler (4), and by second means (15) being arranged which alternatively or additionally allow exhaust gas to be expelled from the exhaust-gas path (40) downstream of the heat-recovery boiler (4).

Owner:ANSALDO ENERGIA IP UK LTD

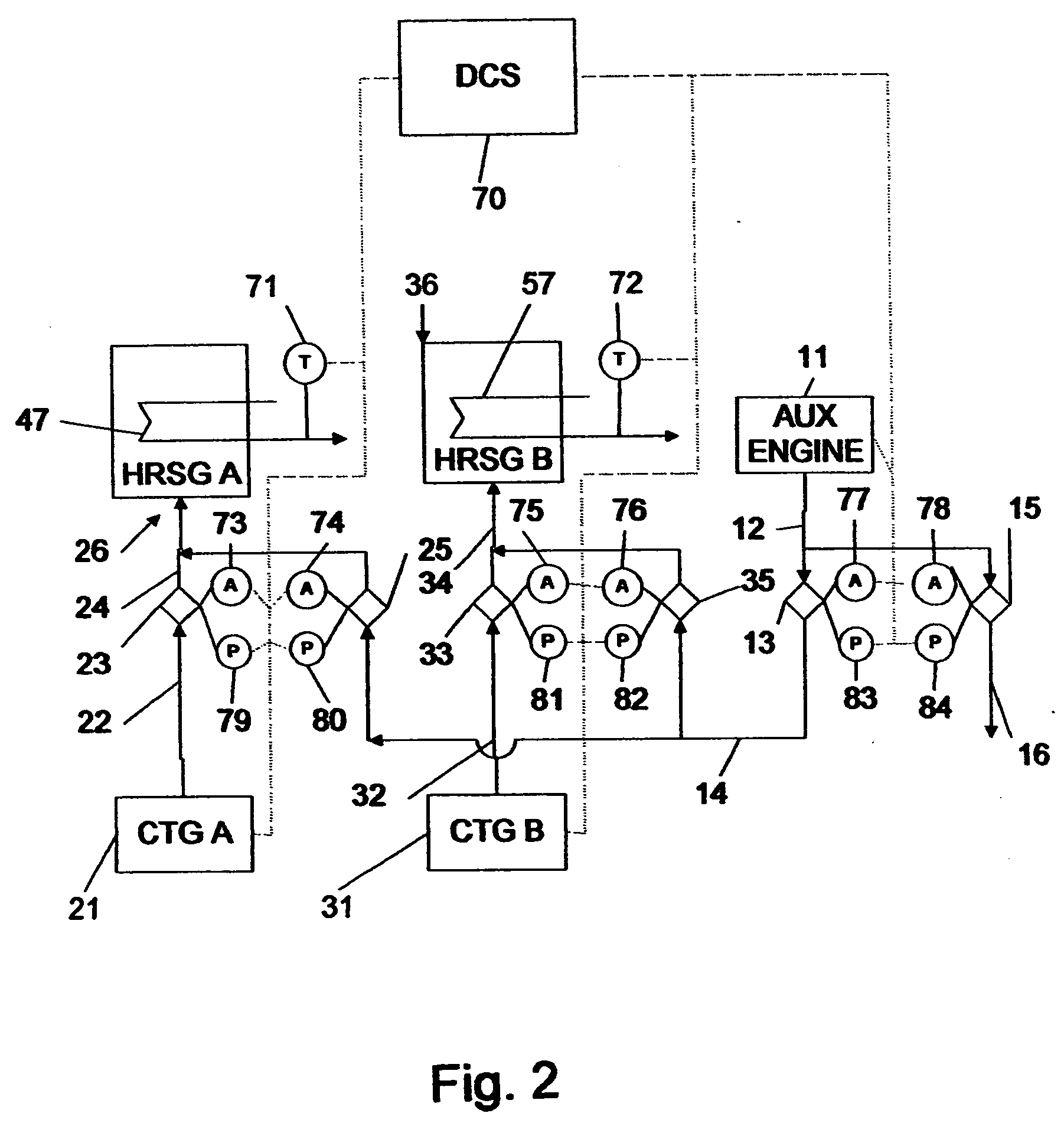

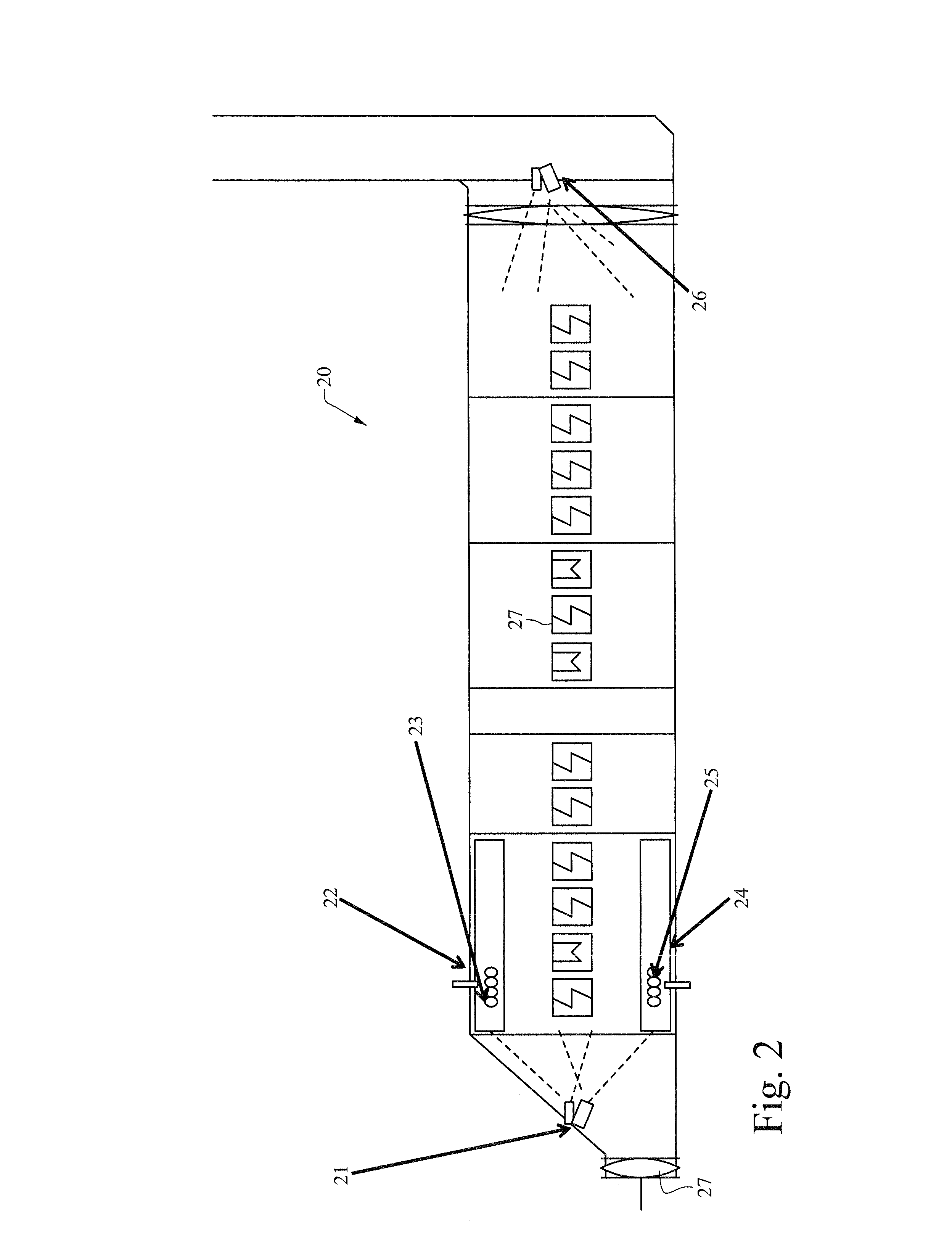

Method and apparatus for combined cycle power plant operation

InactiveUS20050034445A1Stress minimizationEmission reductionTurbine/propulsion fuel supply systemsEngine fuctionsPower stationCombustion

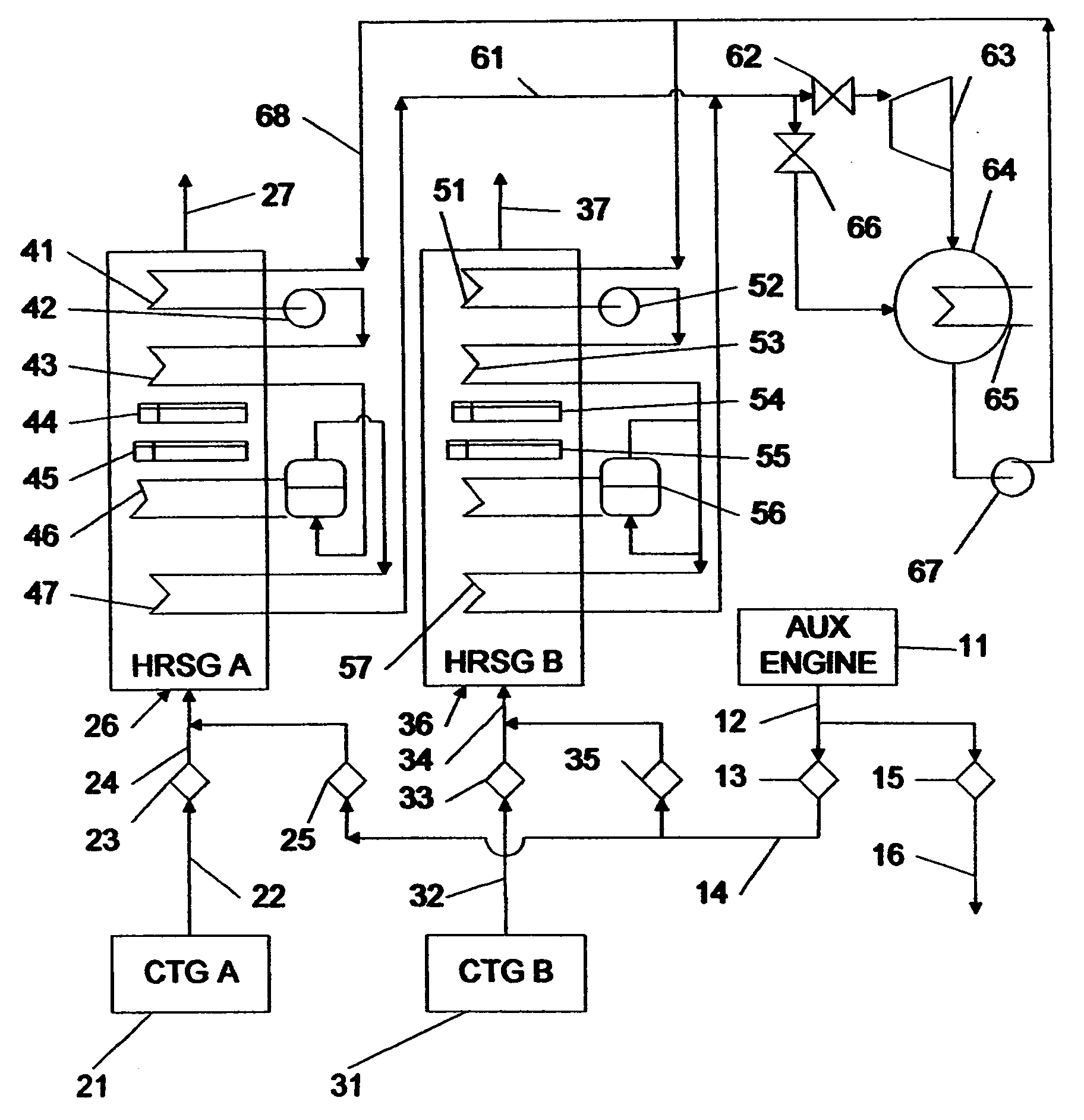

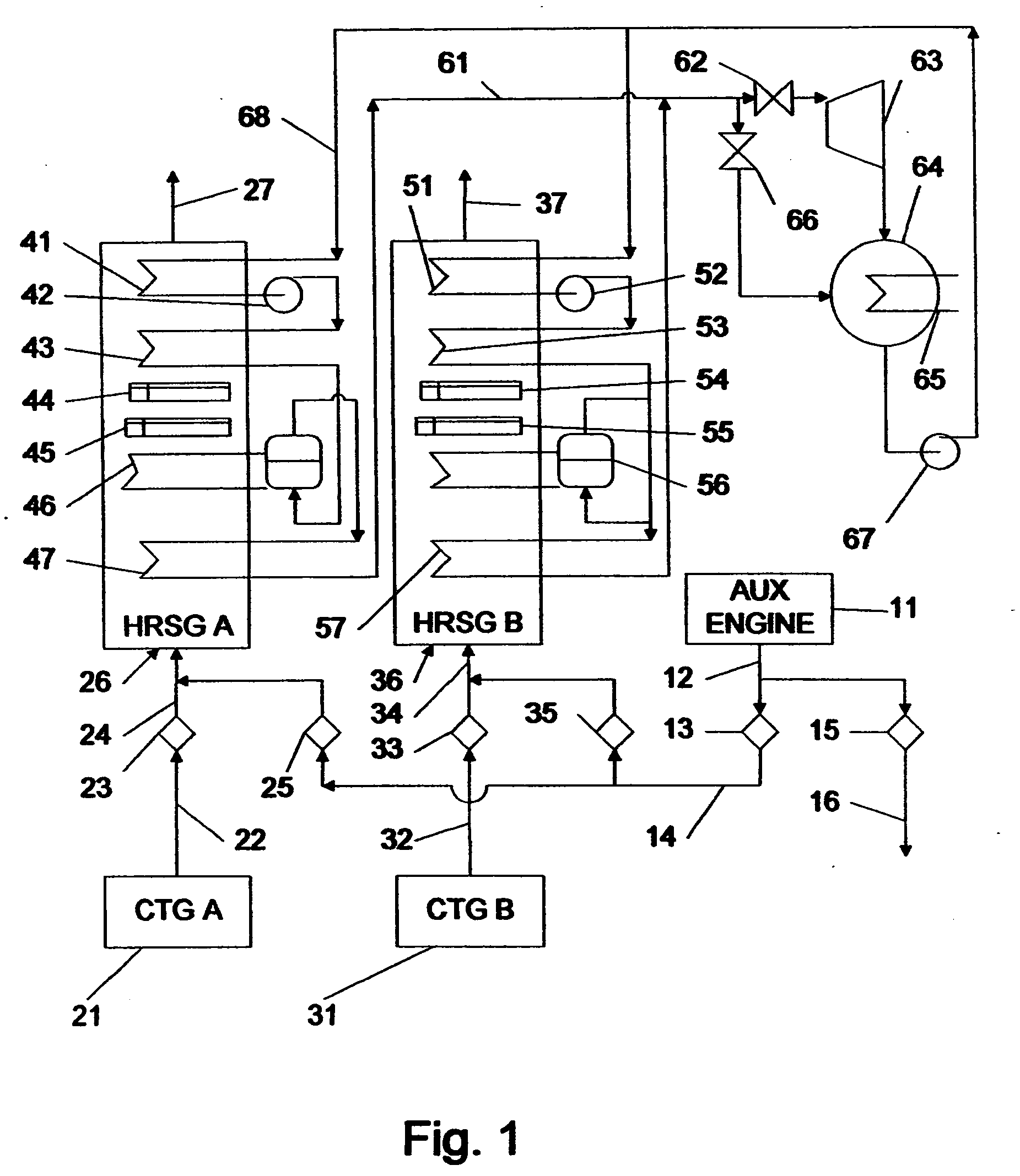

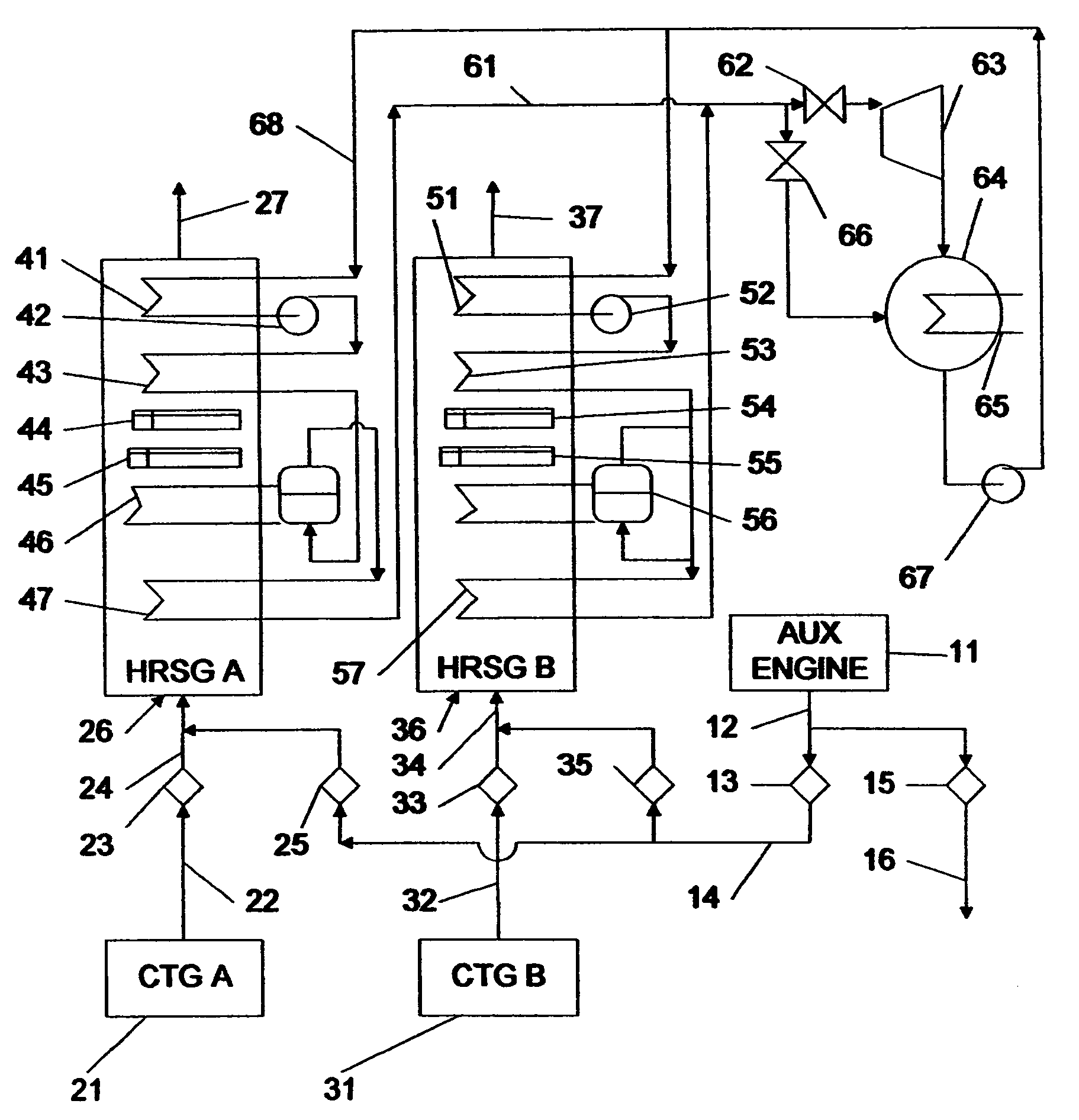

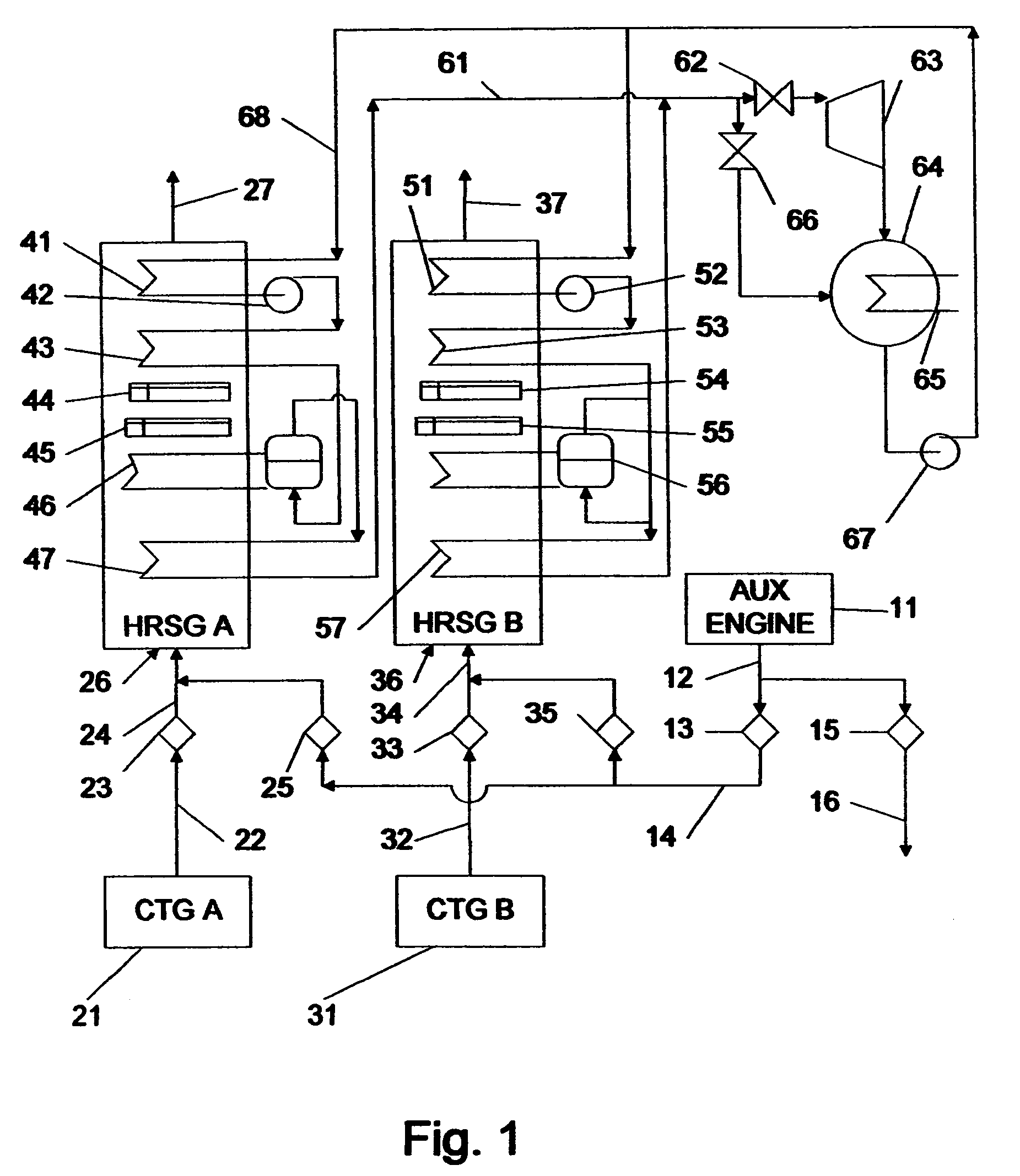

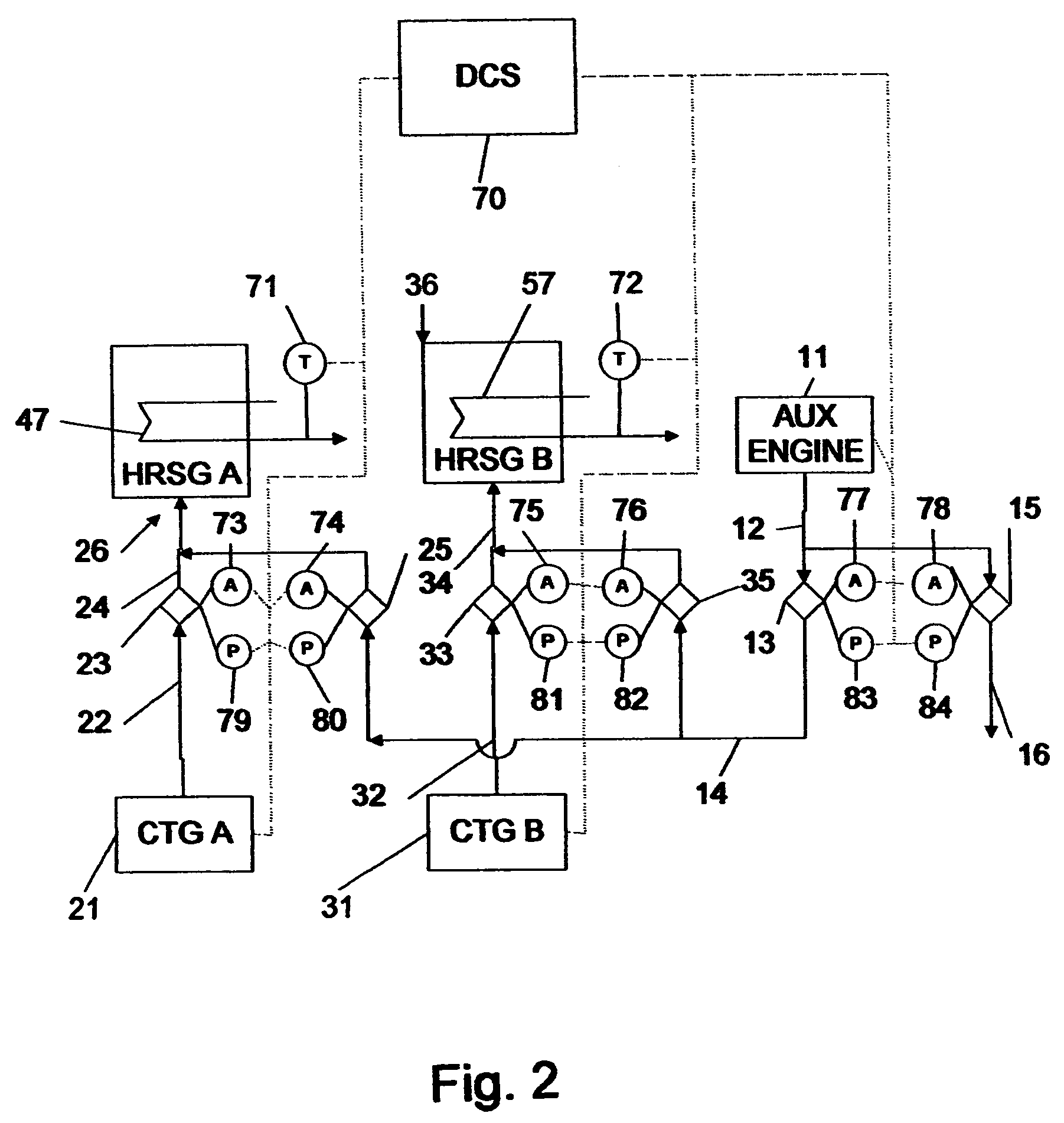

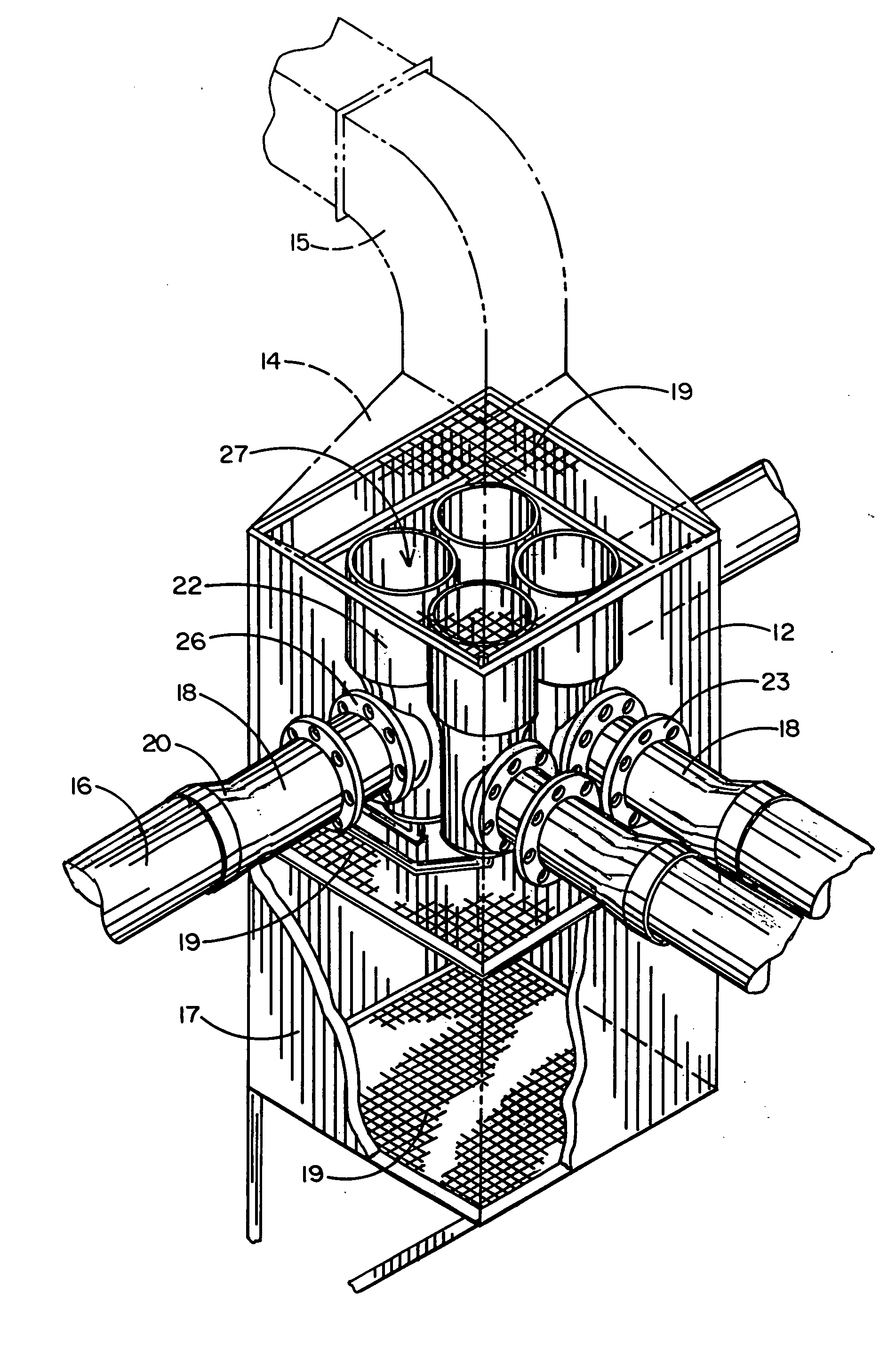

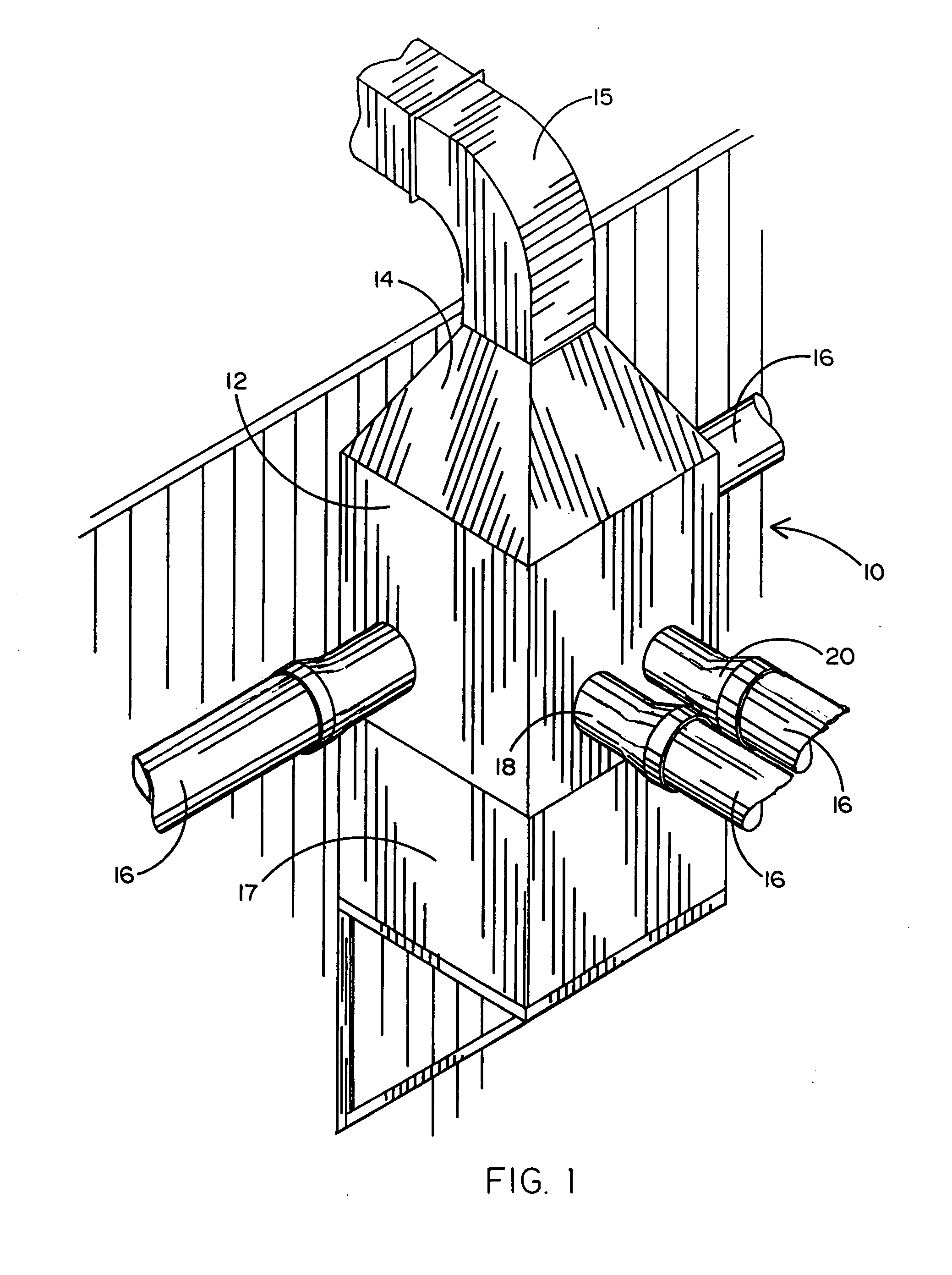

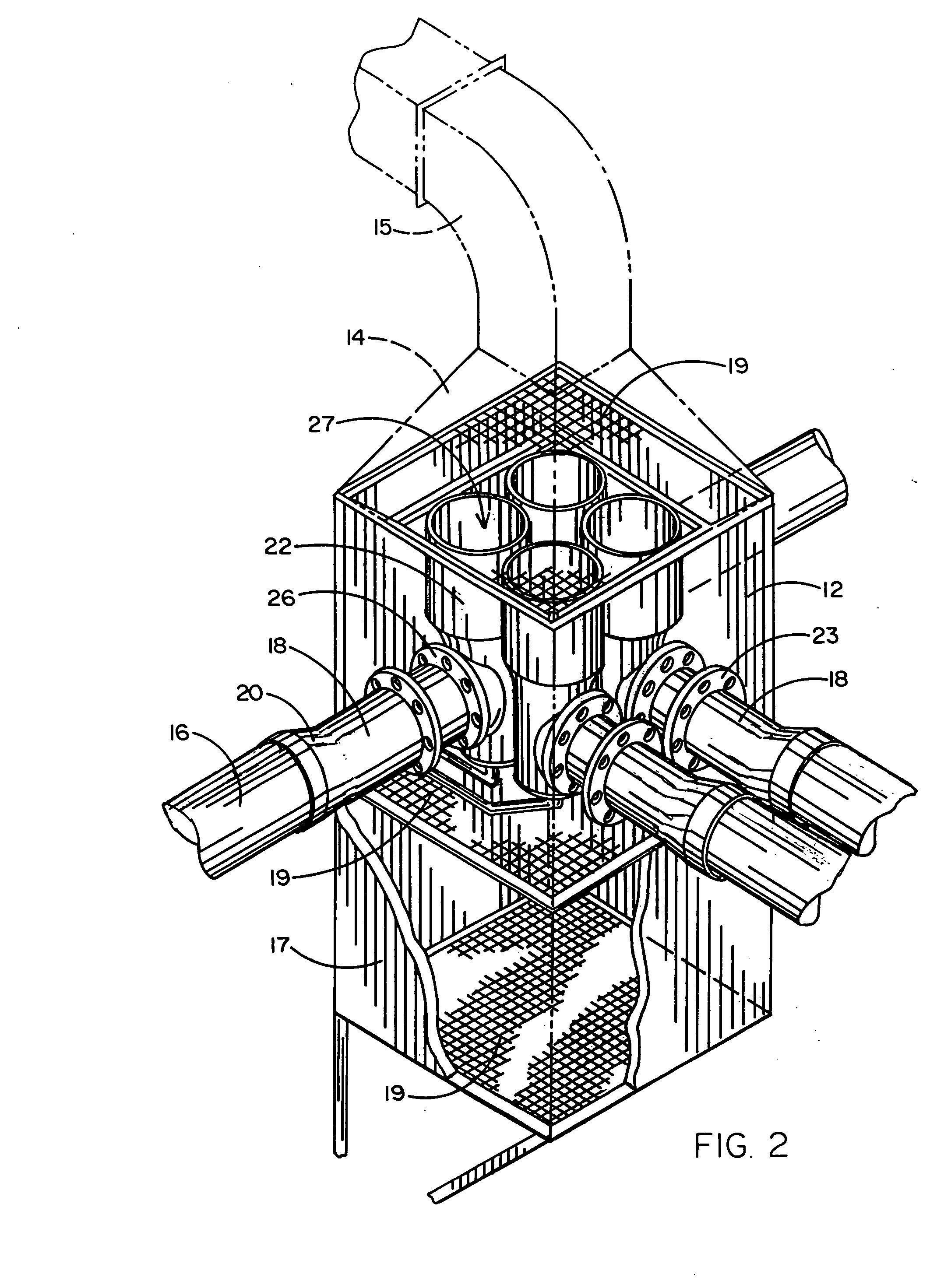

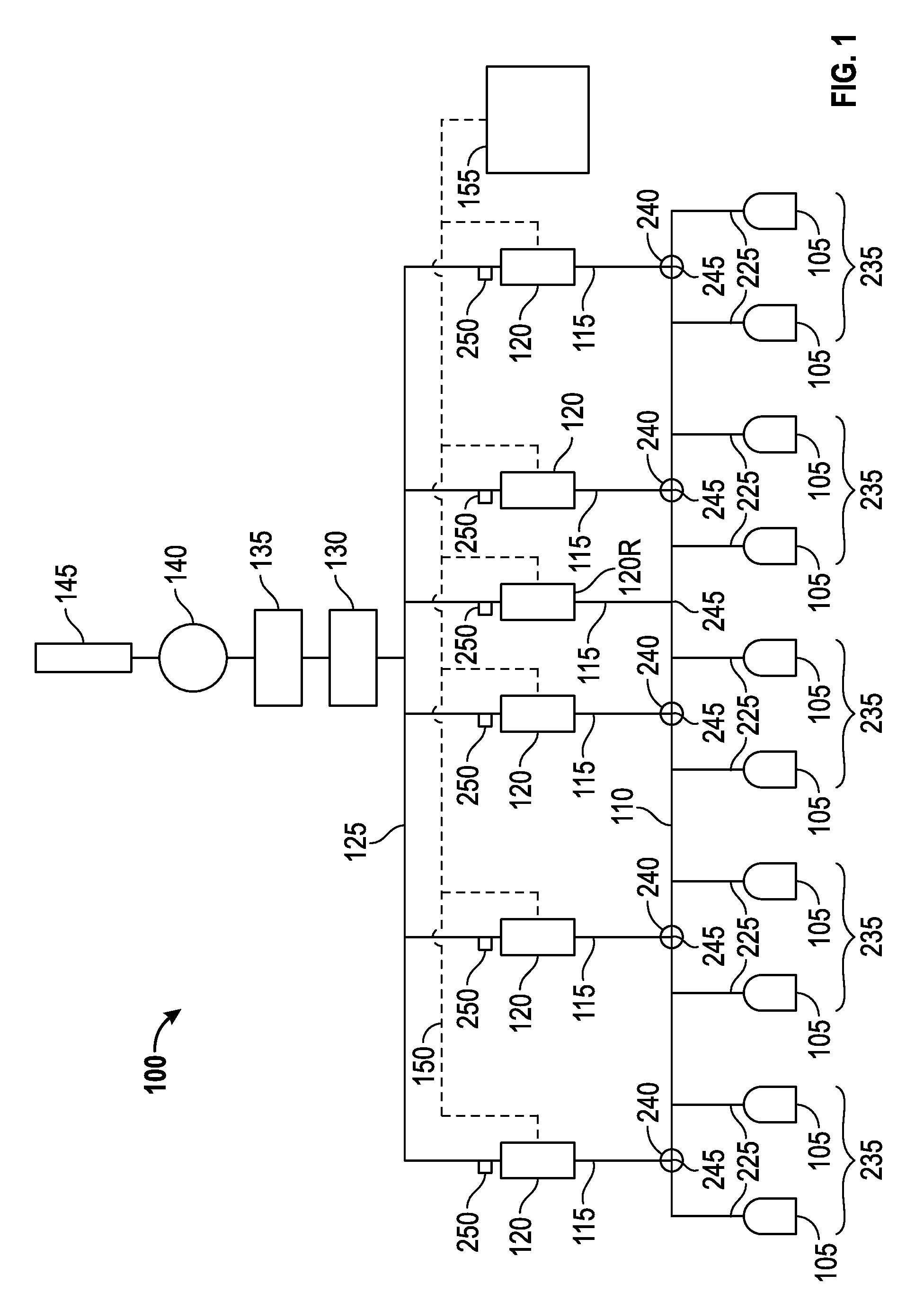

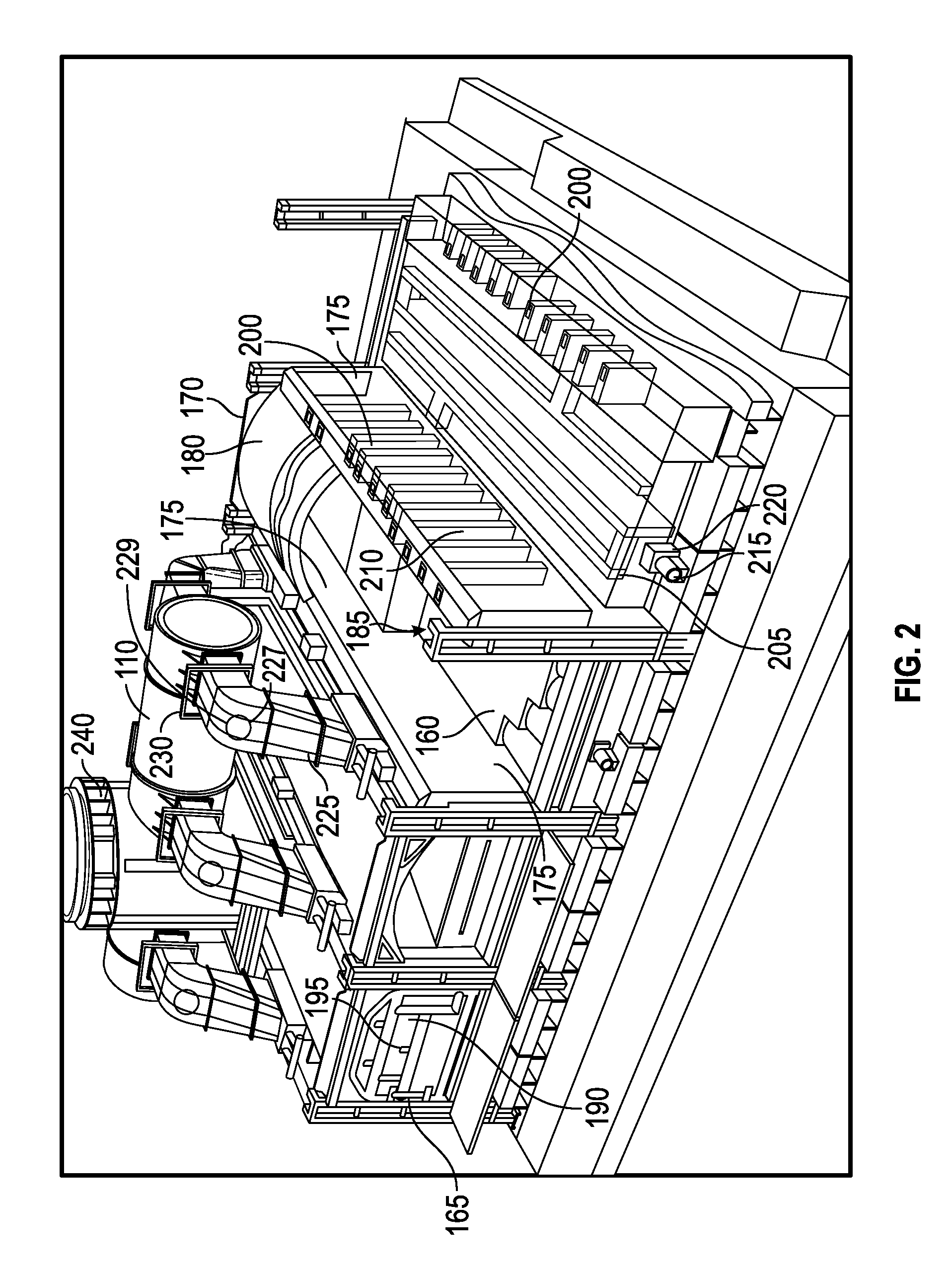

Methods and apparatus are disclosed for starting up a combined cycle plant using a startup duct to connect an auxiliary engine to the inlet of a plurality of HRSGs or other heat recovery systems. Each HRSG is fed by a combustion turbine. Dampers are supplied to isolate each HRSG from the startup duct and its CTG. The auxiliary engine is also ported to a stack allowing simple cycle operation. Dampers are also supplied to isolate the auxiliary engine from the startup duct and from its stack. During startups, the large CTGs will be isolated and the auxiliary engine will be connected to the HRSGs and started, allowing the HRSG to pressurize. As each HRSG pressurizes, it is isolated from the startup duct and connected to its respective CTG. The CTG is then started and loaded. The auxiliary engine is turned off and isolated when the last HRSG pressurizes.

Owner:WASHINGTON GROUP INTERNATIONAL

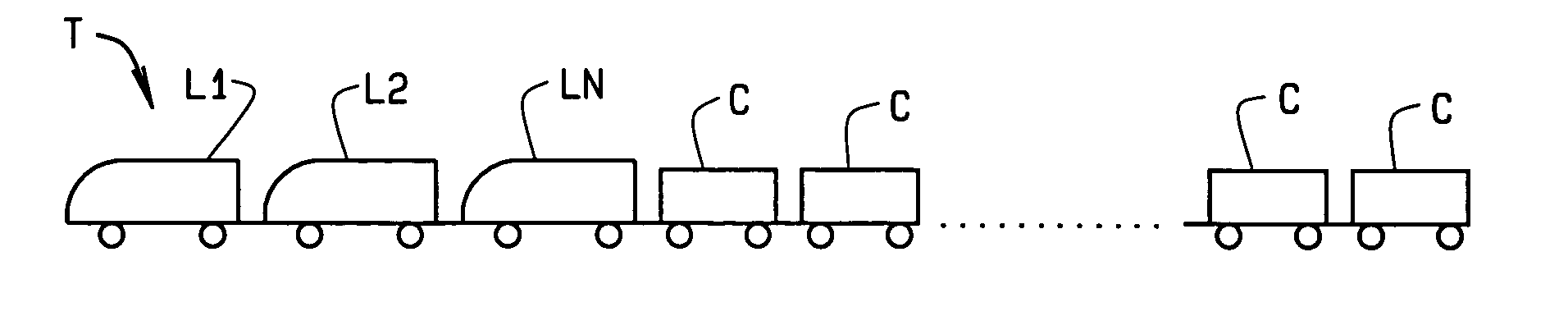

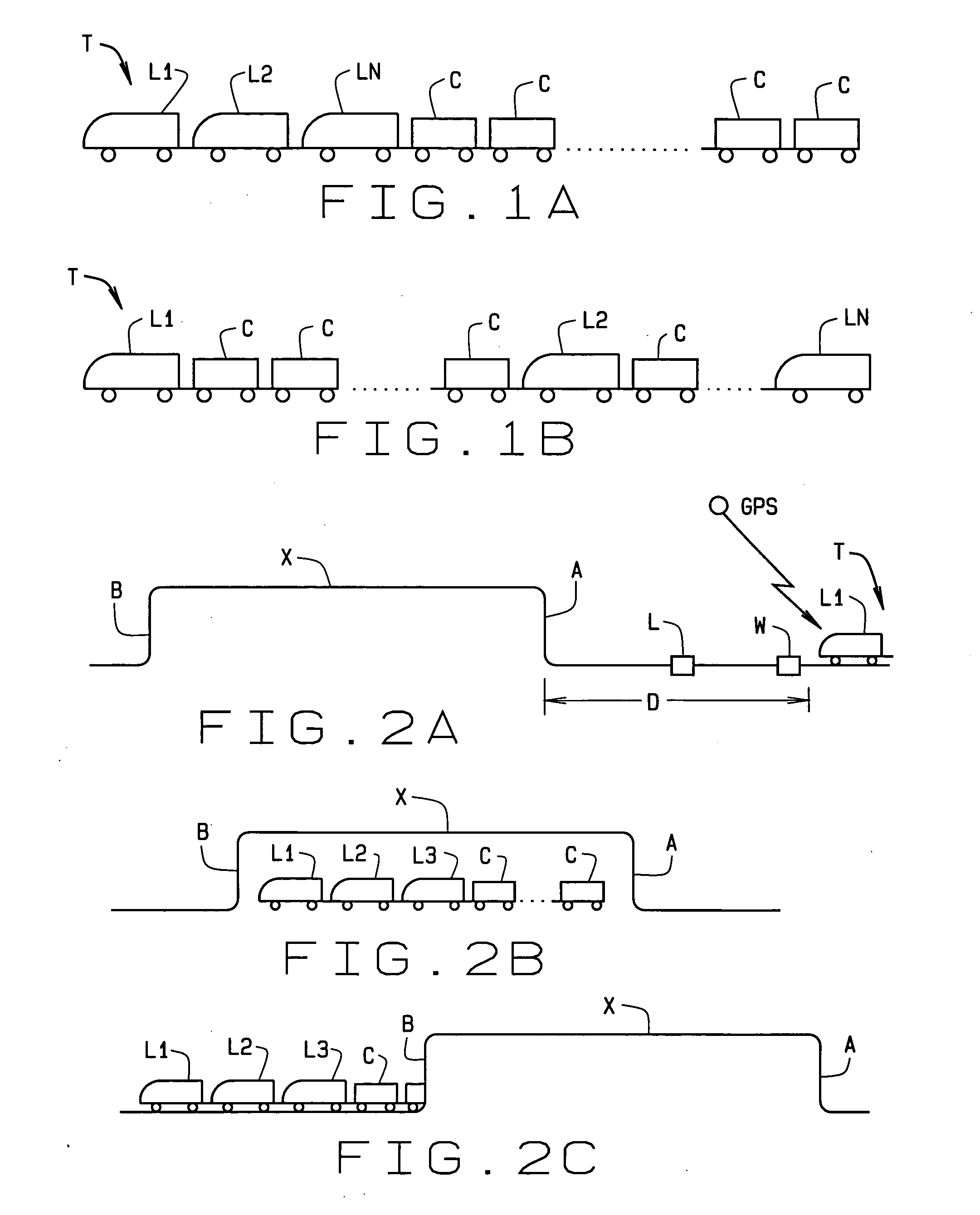

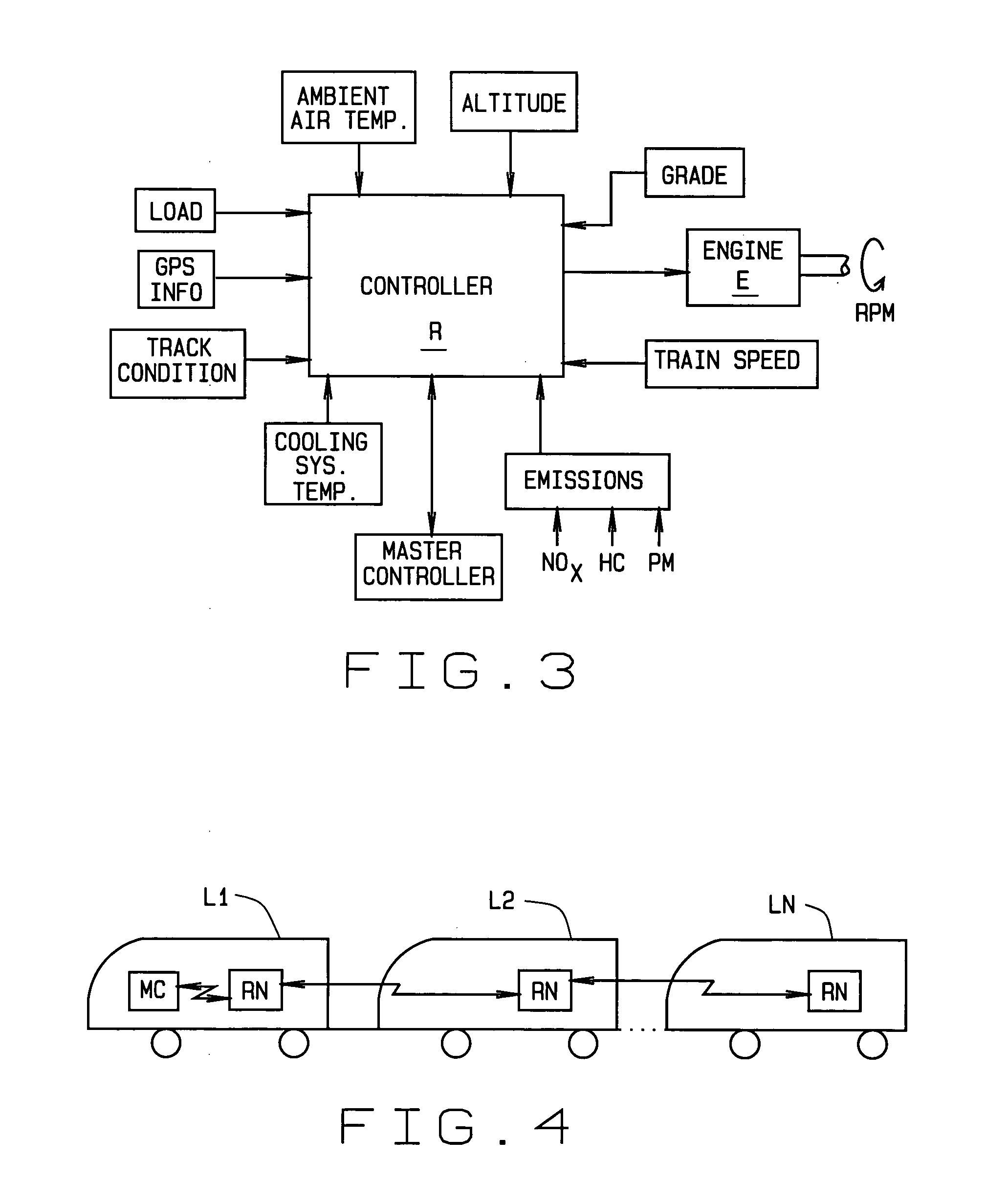

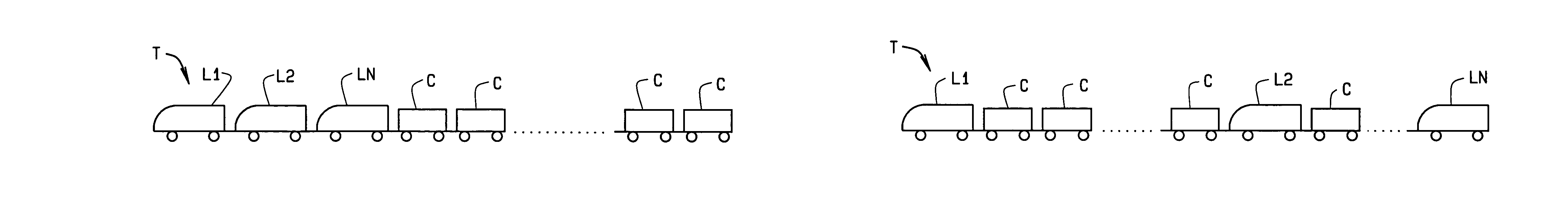

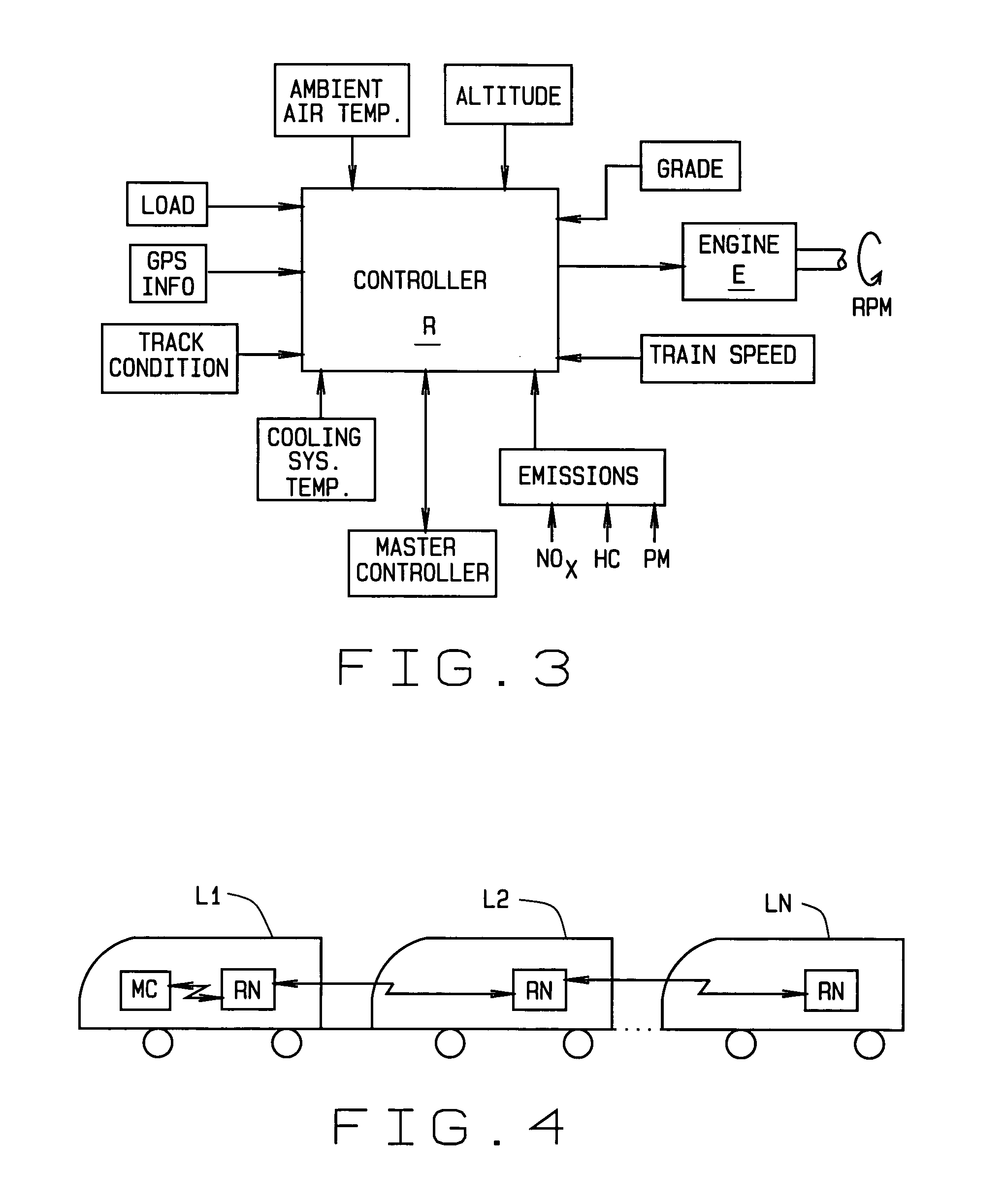

Strategies for locomotive operation in tunnel conditions

ActiveUS20050109882A1Promote recoveryEasy to returnDigital data processing detailsSignalling indicators on vehicleEngineeringThermal recovery

A method of controlling operation of a train (T) for passage of the train through a tunnel. The train has a plurality of locomotives (L1-Ln) pulling the train. The position of the lead locomotive relative to the tunnel entrance is determined, as is the amount of time before the train enters the tunnel. Each locomotive is separately configured for passage through the tunnel as a function of performance characteristics of the locomotive and the locomotive's current operating status, as the train approaches the tunnel. Once the train enters the tunnel, the performance characteristics of each locomotive are continually monitored. The performance requirements for one or more of the locomotives are then dynamically changed as a function of conditions within the tunnel and the current performance characteristics of each locomotive. This is done to maintain a sufficient combined performance capability from the locomotives to move the train through the tunnel. Upon exiting the tunnel, the locomotives' full operating capabilities are quickly restored by enhancing their thermal recoveries.

Owner:GE GLOBAL SOURCING LLC

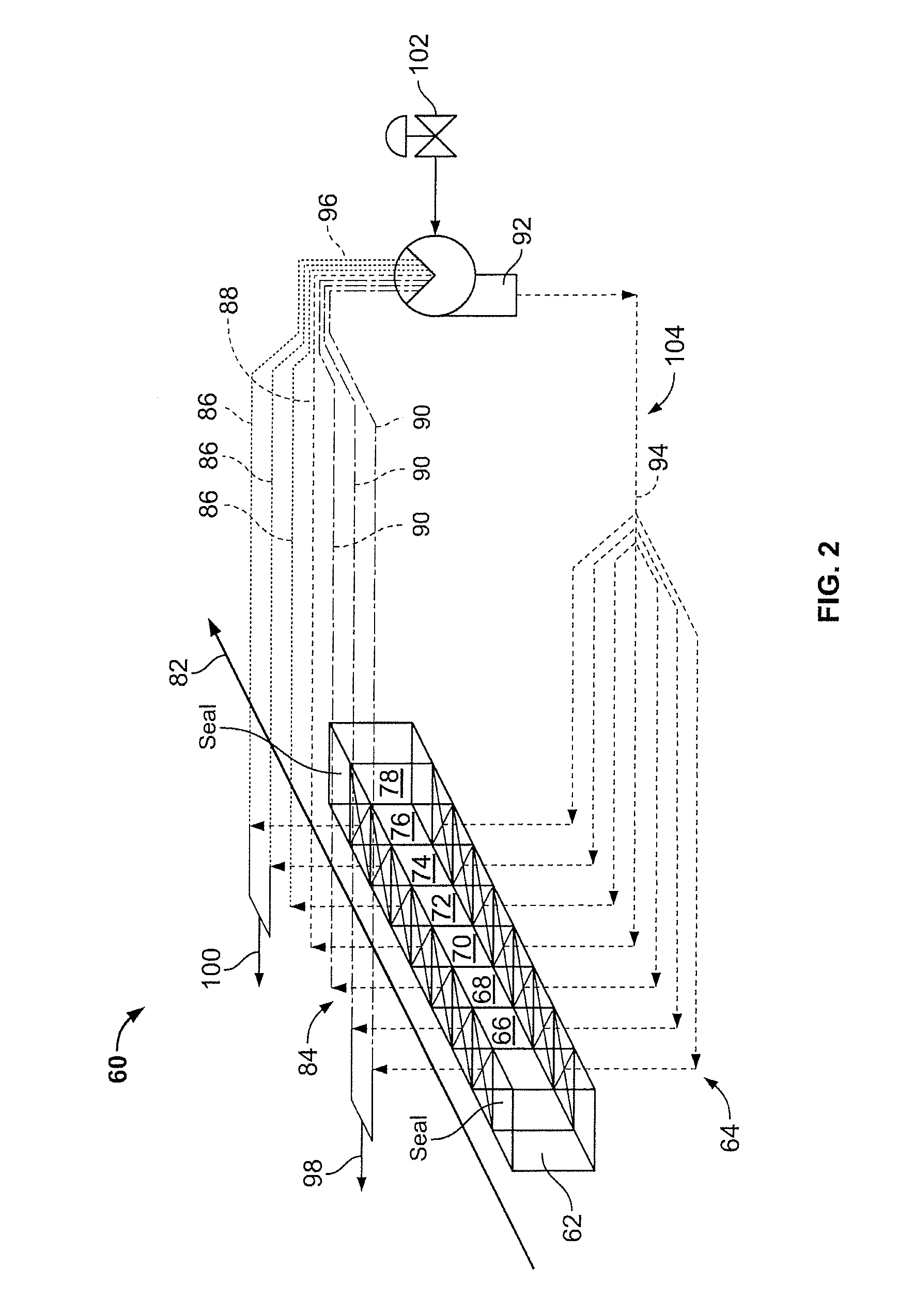

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS20100300866A1Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

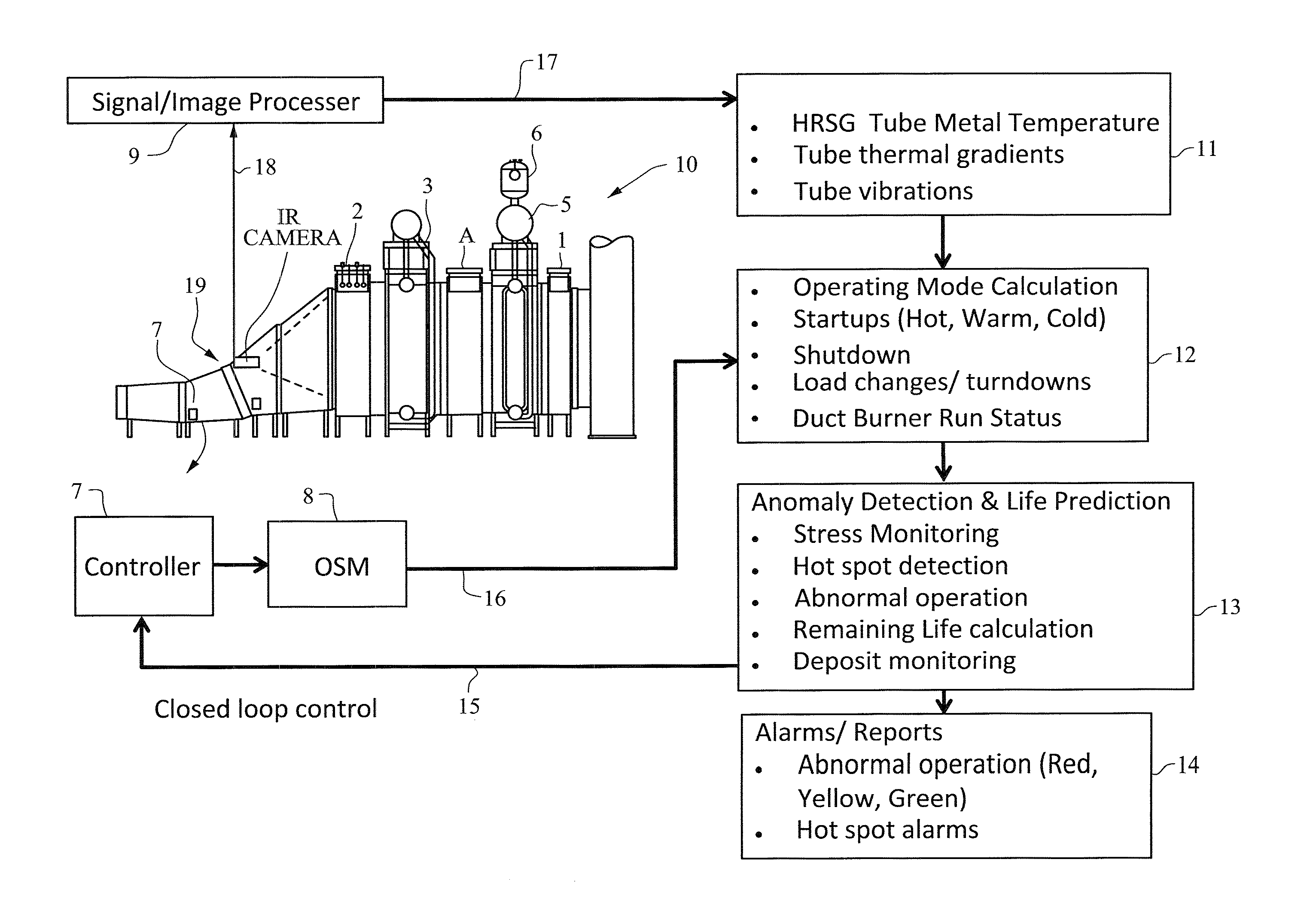

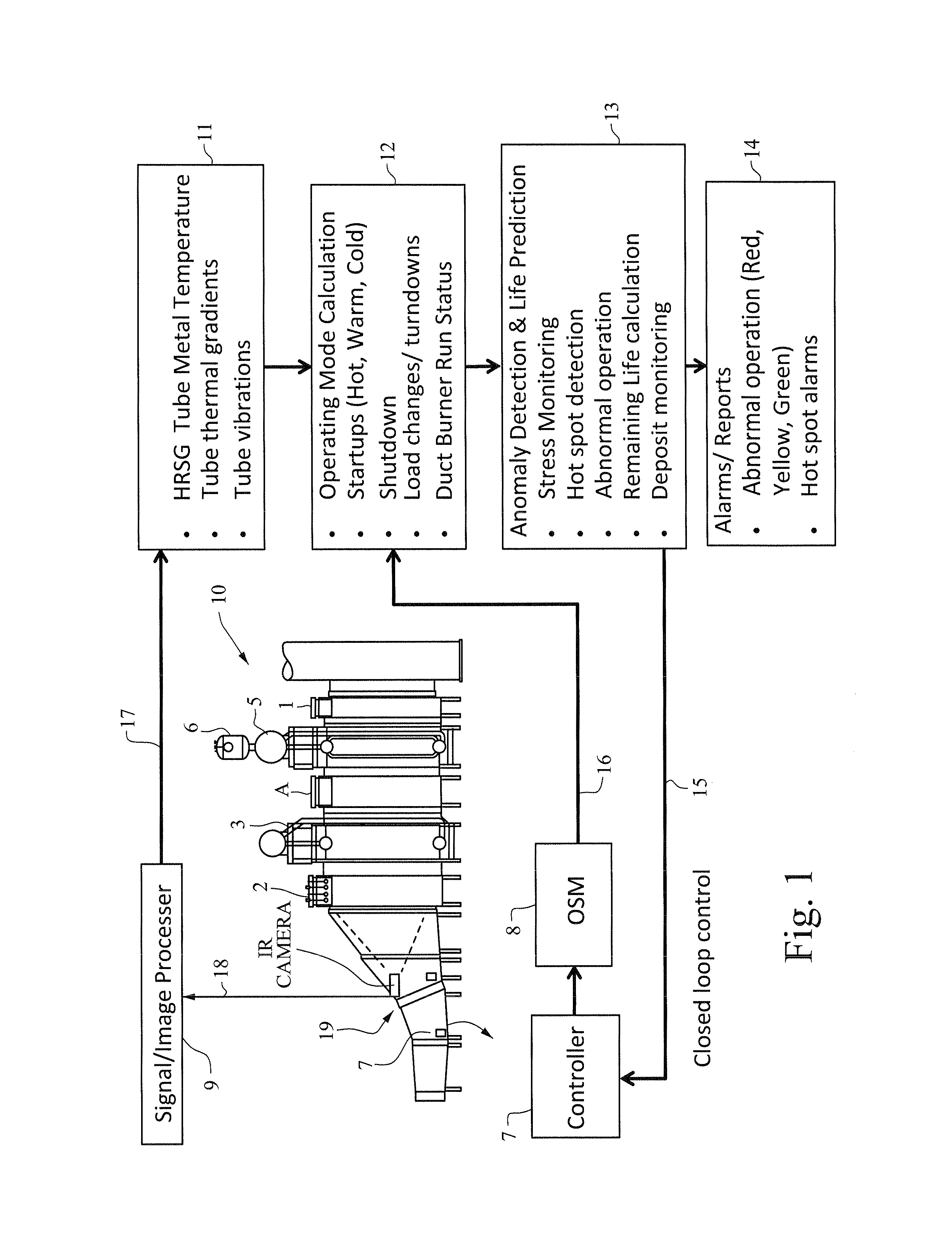

Continuous infrared thermography monitoring and life management system for heat recovery steam generators

ActiveUS20130176418A1Improve reliabilityReduce downtimeTelevision system detailsColor television detailsEngineeringThermography

A method for continuously monitoring the working condition of a heat recovery steam generator (“HRSG”) using infrared thermography, comprising the steps of identifying target locations inside the HRSG, positioning one or more infrared cameras to continuously monitor and record the temperature at each target location, generating continuous thermographic images corresponding to selected components and locations at each target locations, comparing the continuous thermographic images to corresponding, stored base line images and generating a set of comparative data reports in real time for each target location in order to predict the life span or potential failure of HRSG components.

Owner:GENERAL ELECTRIC CO

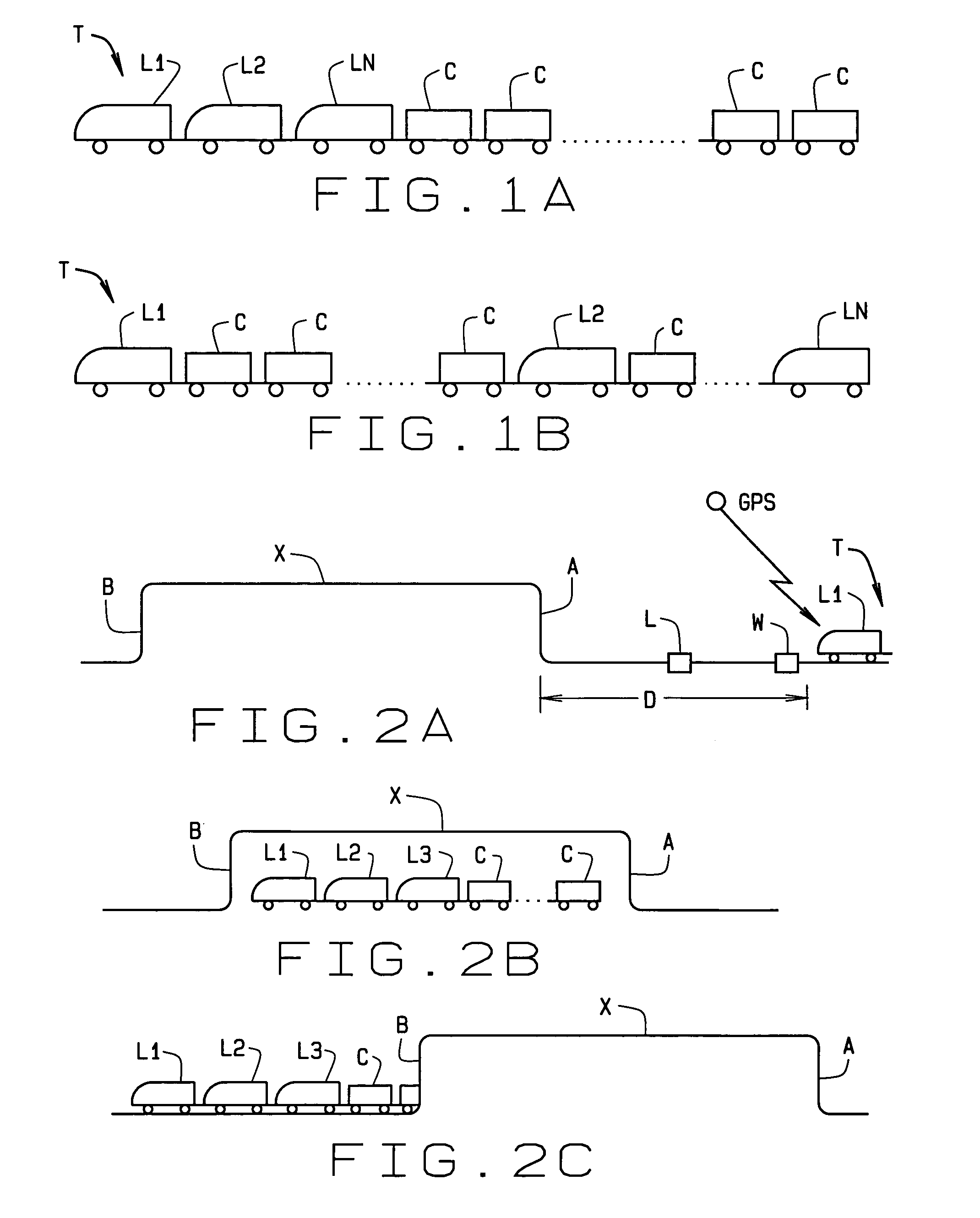

Strategies for locomotive operation in tunnel conditions

ActiveUS7072747B2Easy to returnSufficient effortDigital data processing detailsSignalling indicators on vehicleEngineeringThermal recovery

A method of controlling operation of a train (T) for passage of the train through a tunnel. The train has a plurality of locomotives (L1-Ln) pulling the train. The position of the lead locomotive relative to the tunnel entrance is determined, as is the amount of time before the train enters the tunnel. Each locomotive is separately configured for passage through the tunnel as a function of performance characteristics of the locomotive and the locomotive's current operating status, as the train approaches the tunnel. Once the train enters the tunnel, the performance characteristics of each locomotive are continually monitored. The performance requirements for one or more of the locomotives are then dynamically changed as a function of conditions within the tunnel and the current performance characteristics of each locomotive. This is done to maintain a sufficient combined performance capability from the locomotives to move the train through the tunnel. Upon exiting the tunnel, the locomotives' full operating capabilities are quickly restored by enhancing their thermal recoveries.

Owner:GE GLOBAL SOURCING LLC

Chemically enhanced thermal recovery of heavy oil

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for combined cycle power plant operation

InactiveUS7107774B2Stress minimizationEmission reductionTurbine/propulsion fuel supply systemsEngine fuctionsPower stationProcess engineering

Owner:WASHINGTON GROUP INTERNATIONAL

Barometric thermal trap and collection apparatus and method thereof for combining multiple exhaust streams into one

InactiveUS20090042070A1Controllable and more efficientIncrease contentFuel cell heat exchangeGas turbine plantsScrubberCogeneration

A device that, in any situation where multiple streams of hot or very hot gases or exhaust are generated, can collect gases into one stream and divert the stream efficiently to any manner of reformers, treatment devices, scrubbers, exchangers, etc. The exhaust flow from multiple fuel cell stacks are mixed in a single stream within the invention. This must be done carefully so that the exhaust stack pressure is approximately atmospheric at a variety of operating conditions. The mixing occurs in a device (the invention) called a Barometric Thermal Trap (BaTT). The fuel cell exhaust has a fairly high steam and CO2 content. The steam represents a potentially significant source of latent heat. Typical fuel cell heat recovery units avoid capturing the latent heat due to its relatively low condensing temperature (140 degrees Fahrenheit) and the resultant acidic level of the condensate due to the presence of CO2, which forms carbonic acid. By combining the exhausts into one stream, the BaTT system makes these problems manageable and more cost effective. Design calculations indicate that a Combined Heat and Power (CHP) efficiency of 82% is possible, which is much higher than provided by standard heat recovery designs.

Owner:UNIV INC AT CALIFORNIA STATE UNIV NORTHRIDGE THE

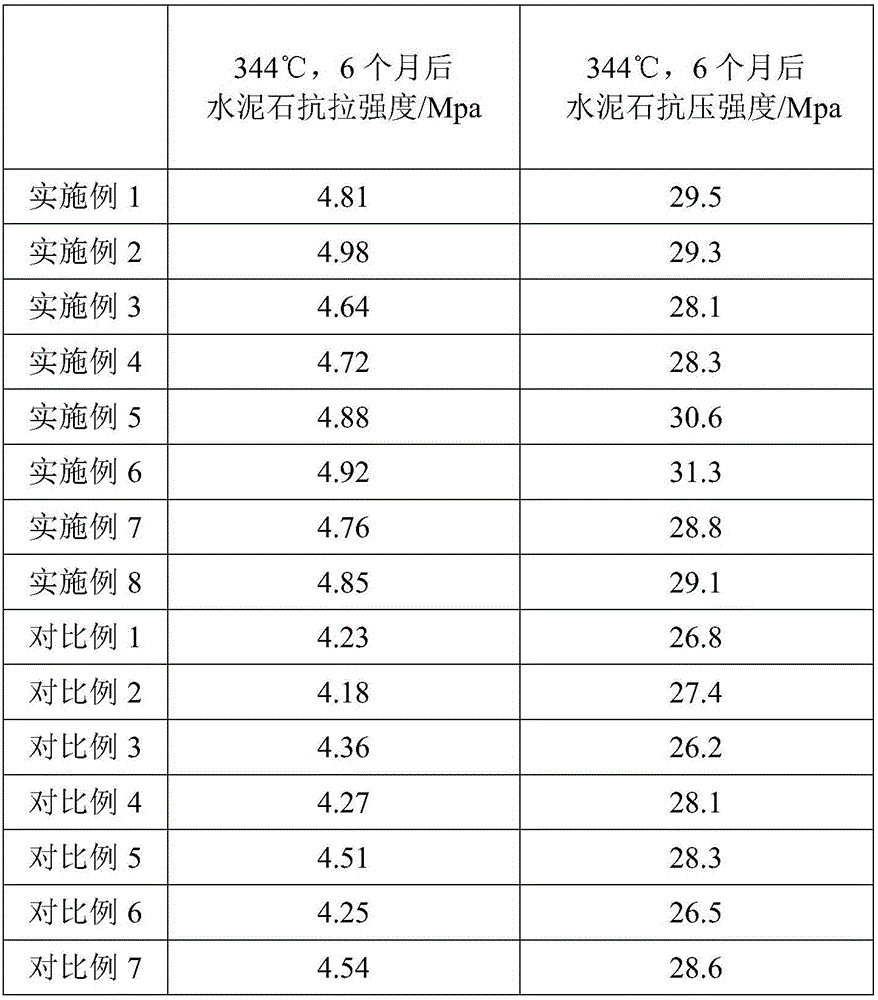

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

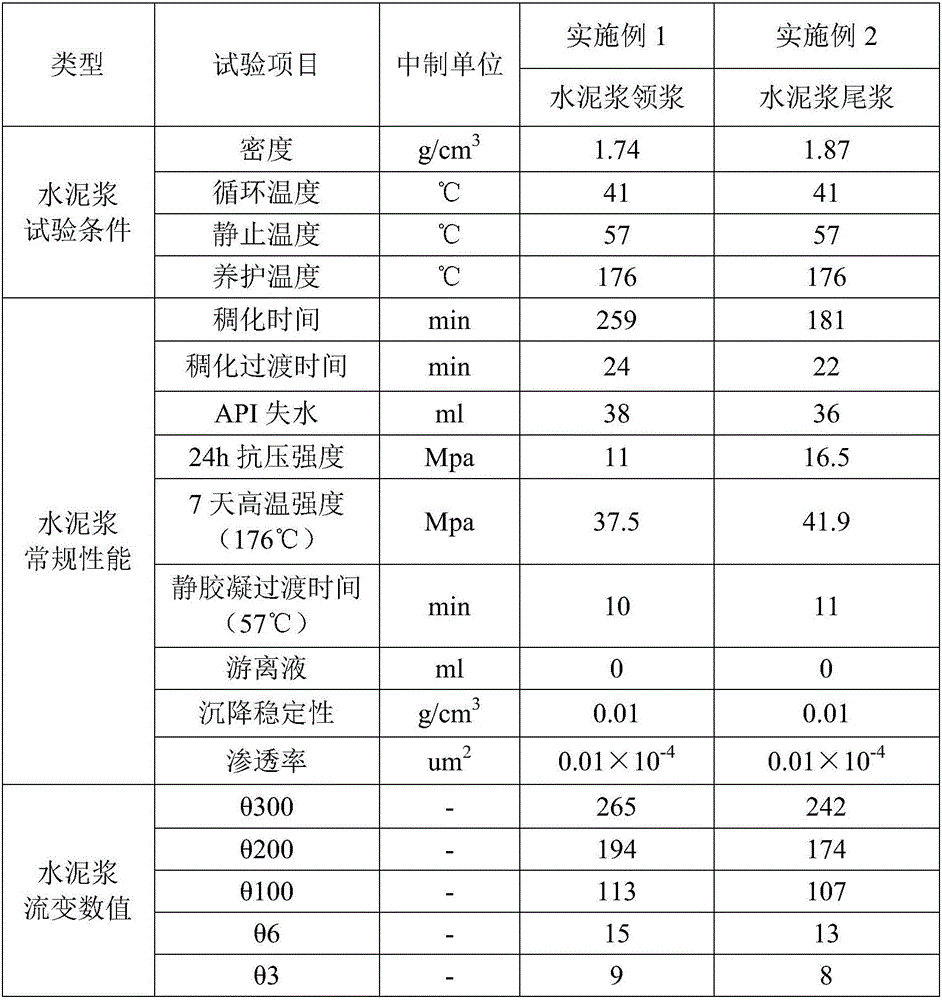

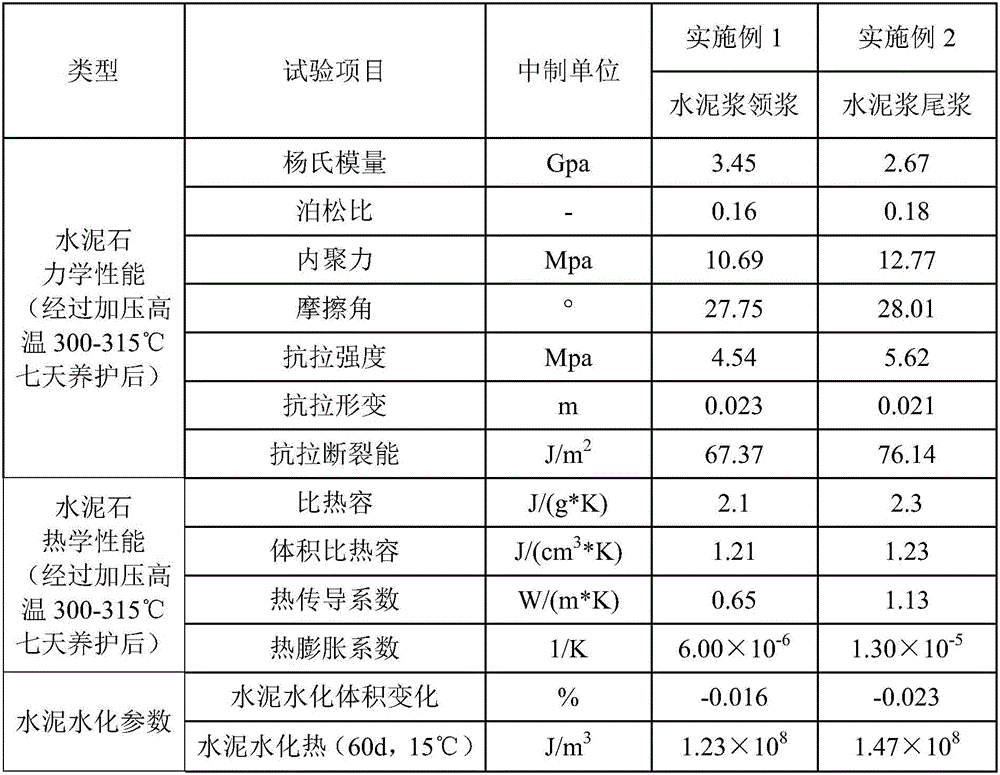

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

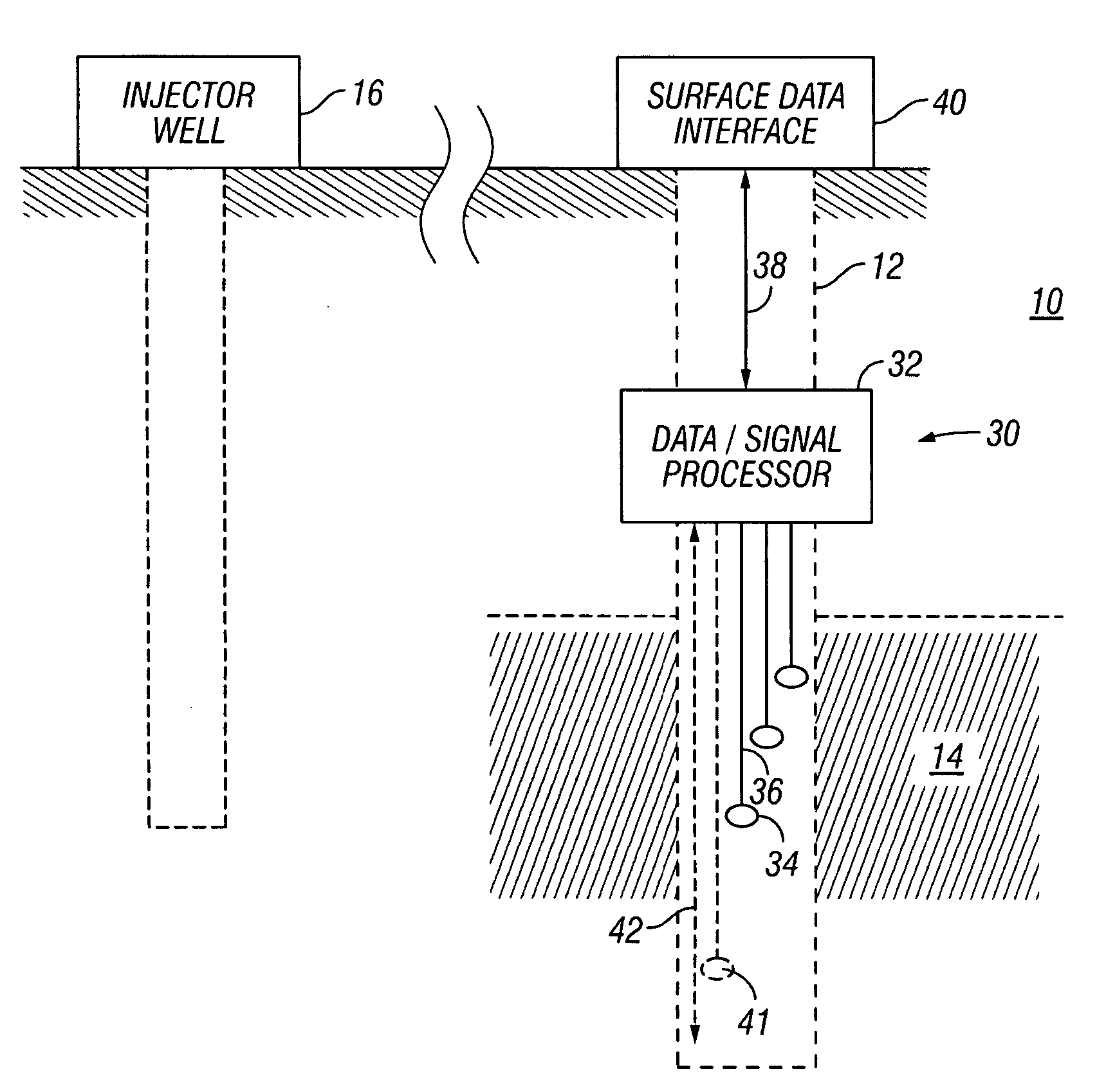

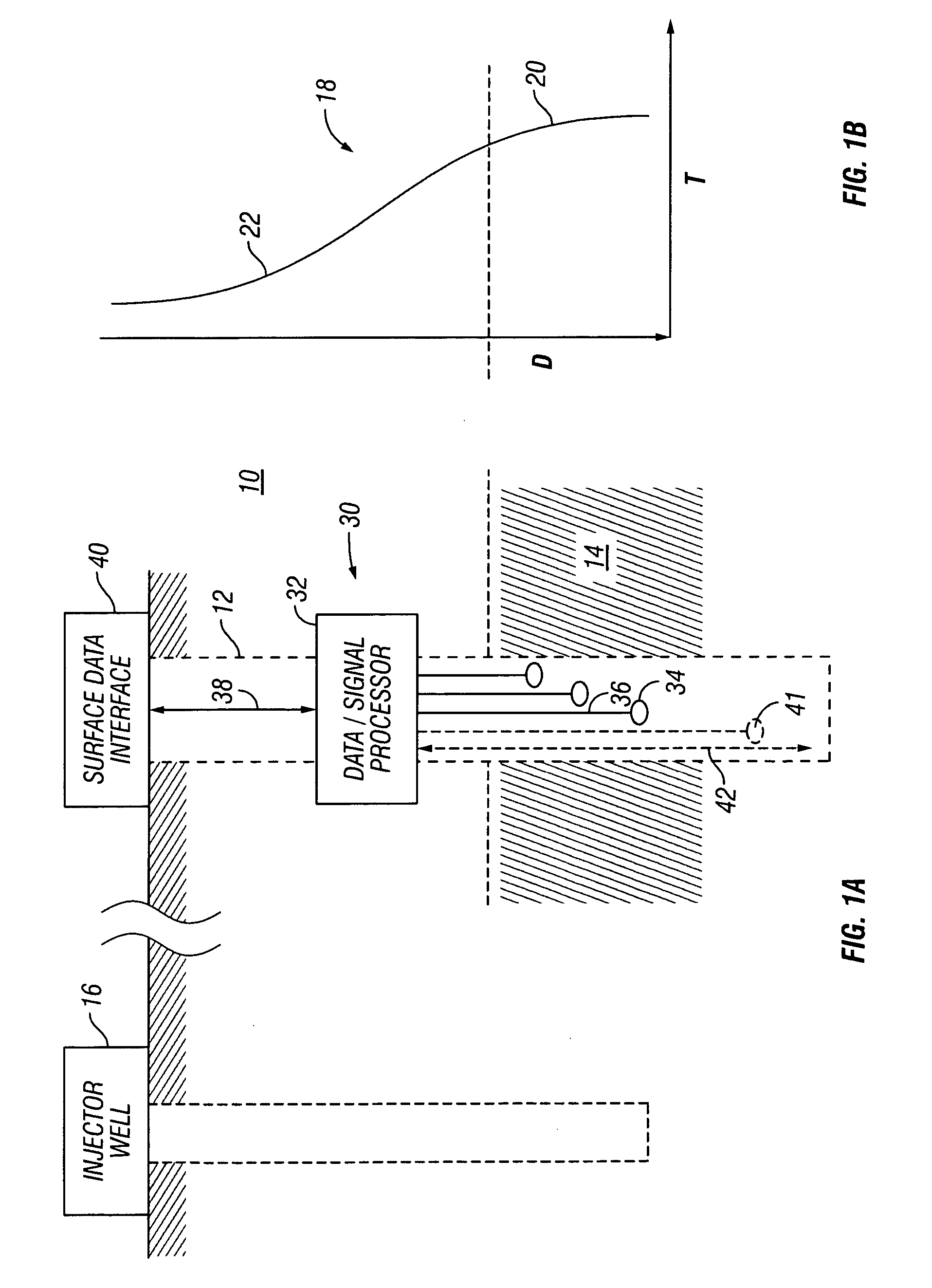

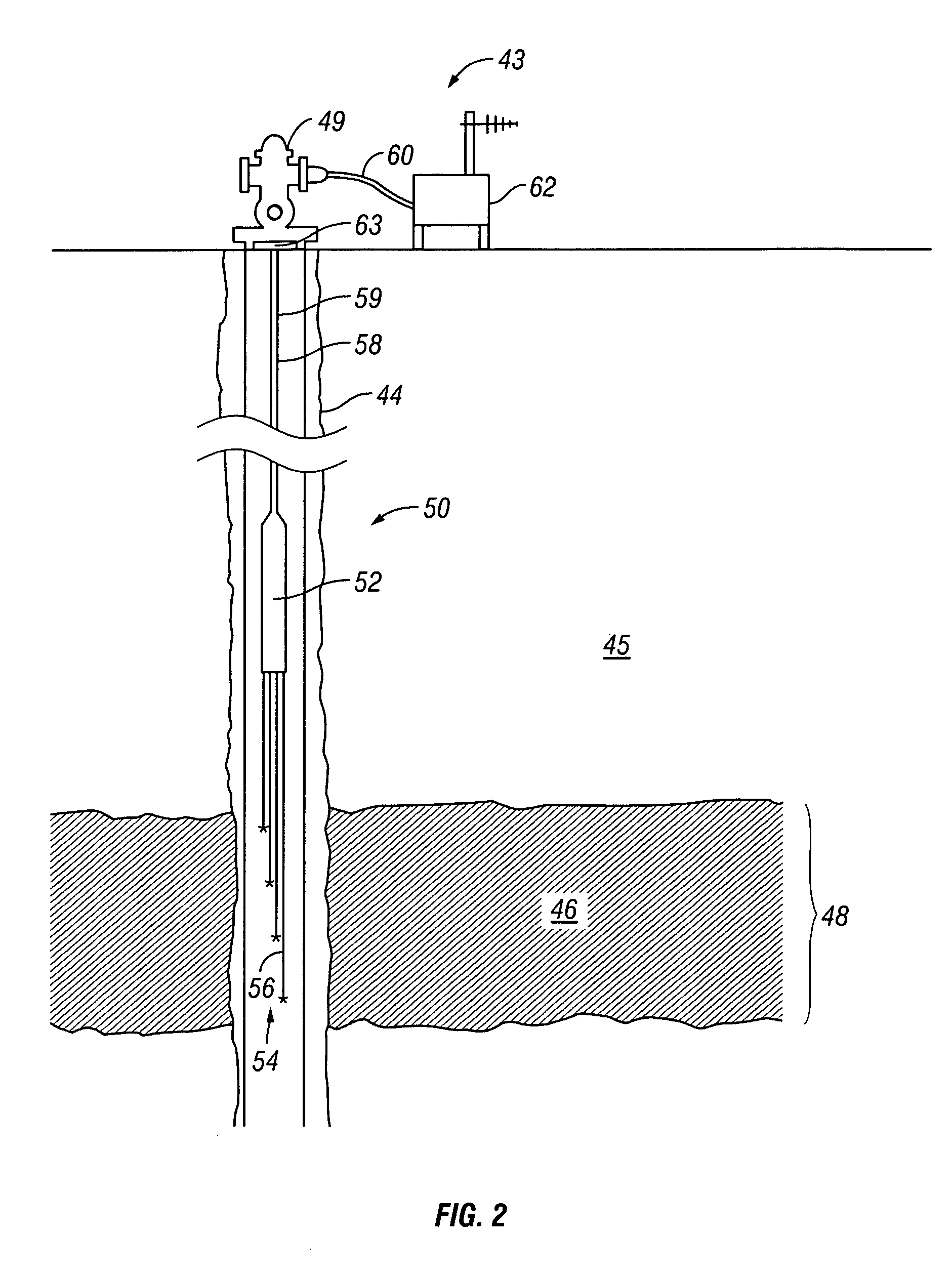

Systems and methods for acquiring data in thermal recovery oil wells

ActiveUS20060250274A1Electric/magnetic detection for well-loggingSurveyHeat-affected zoneThermal impact

In connection with thermal recovery projects, a system determines temperature gradients for a heat affected zone associated with a subterranean hydrocarbon reservoir. An exemplary system includes a plurality of temperature sensors distributed in the wellbore at least partially along the heat affected zone. A downhole processor positioned proximate and substantially outside of the heat affected zone receives and digitizes the temperature measurements. A data link such as a data cable coupled to the downhole processor conveys the temperature measurements to a surface interface.

Owner:CORE LAB CANADA

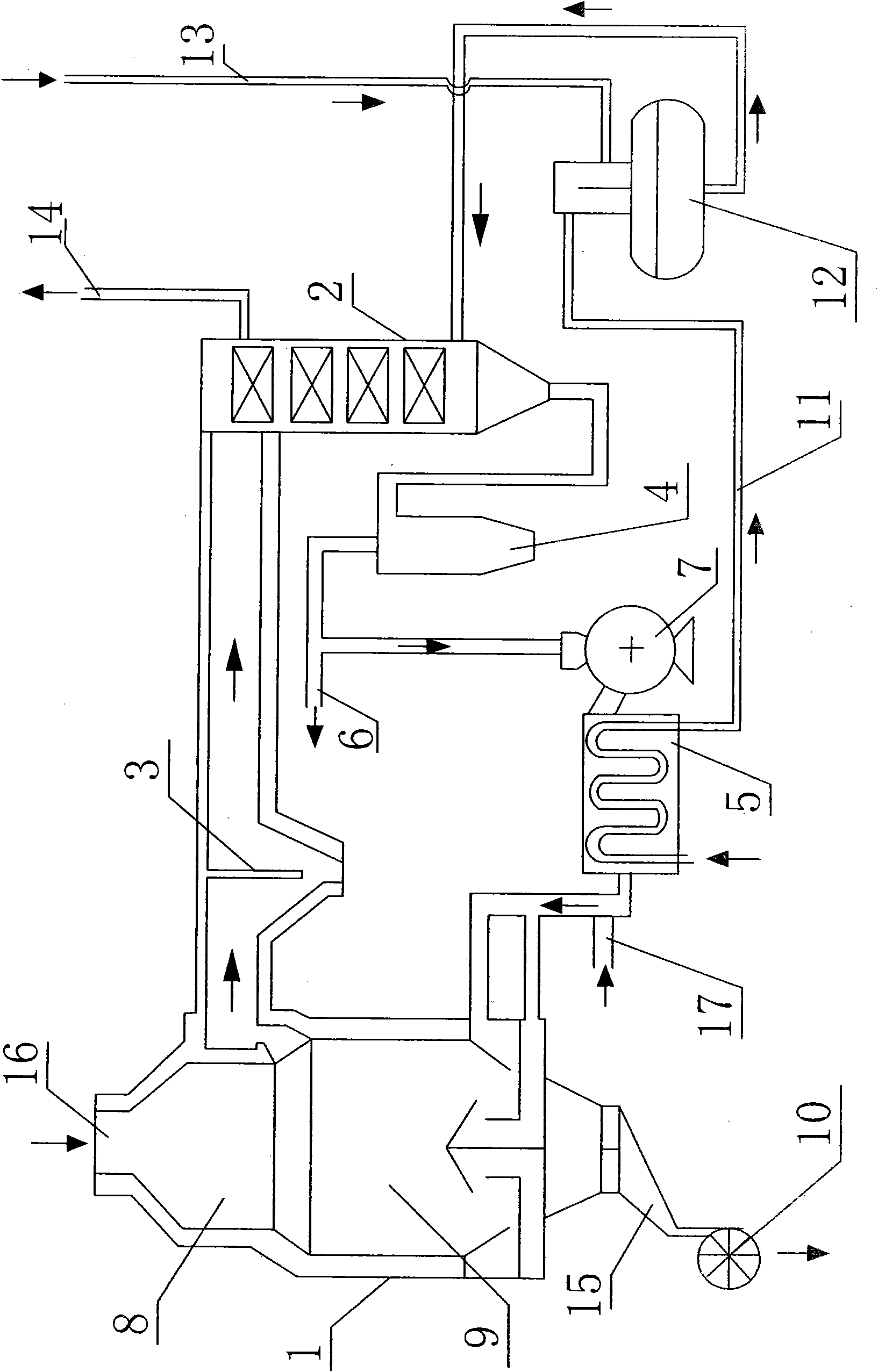

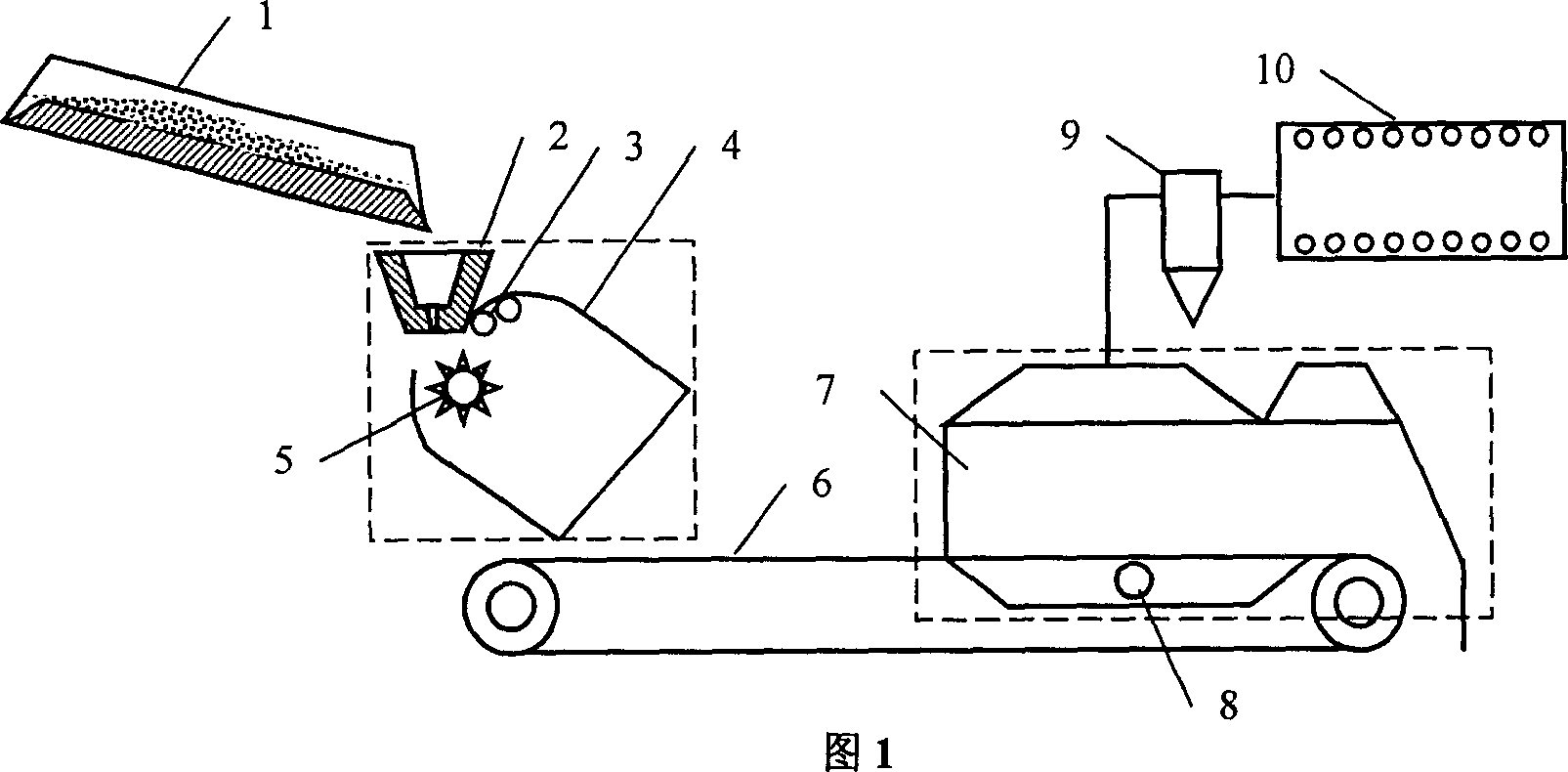

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

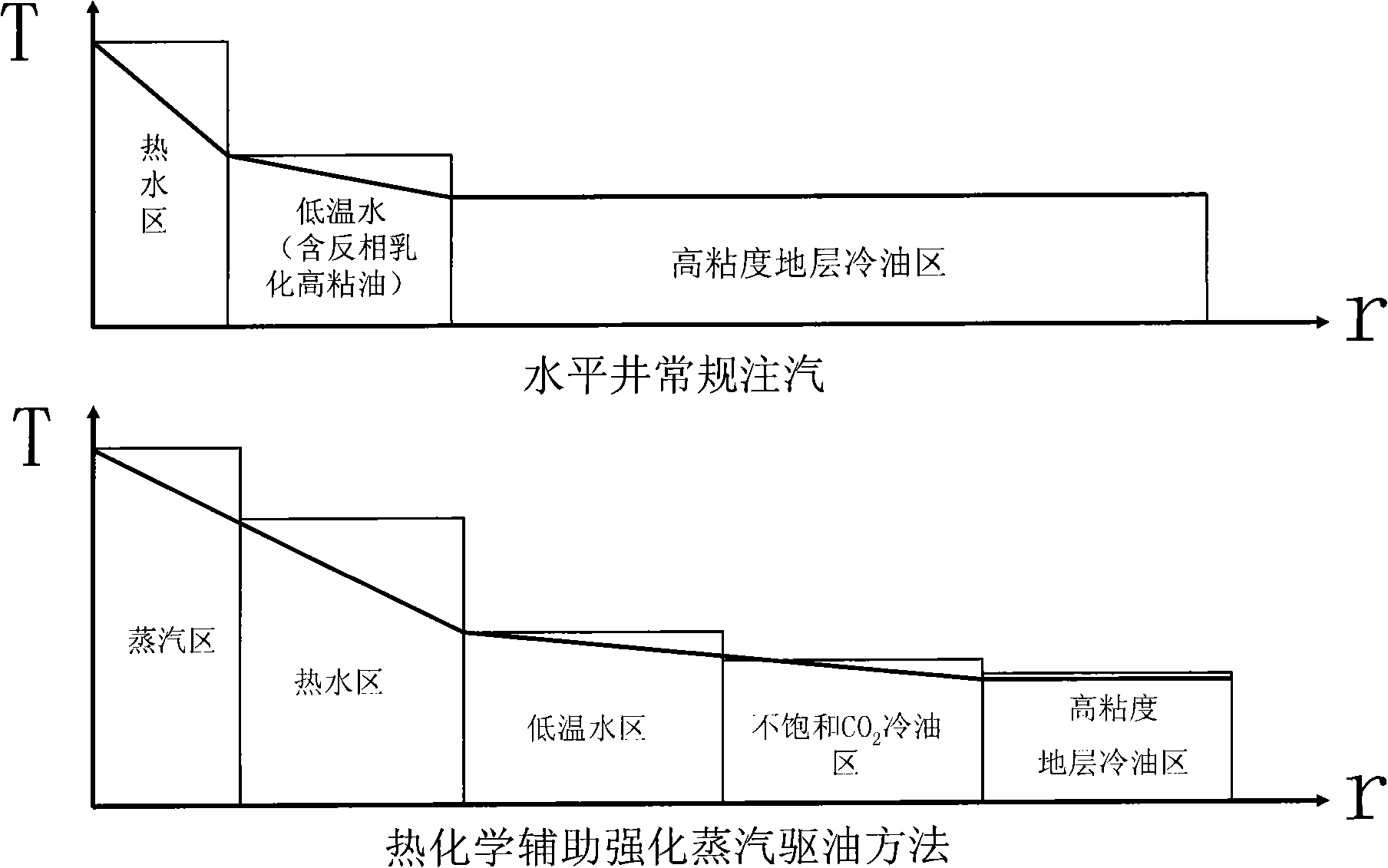

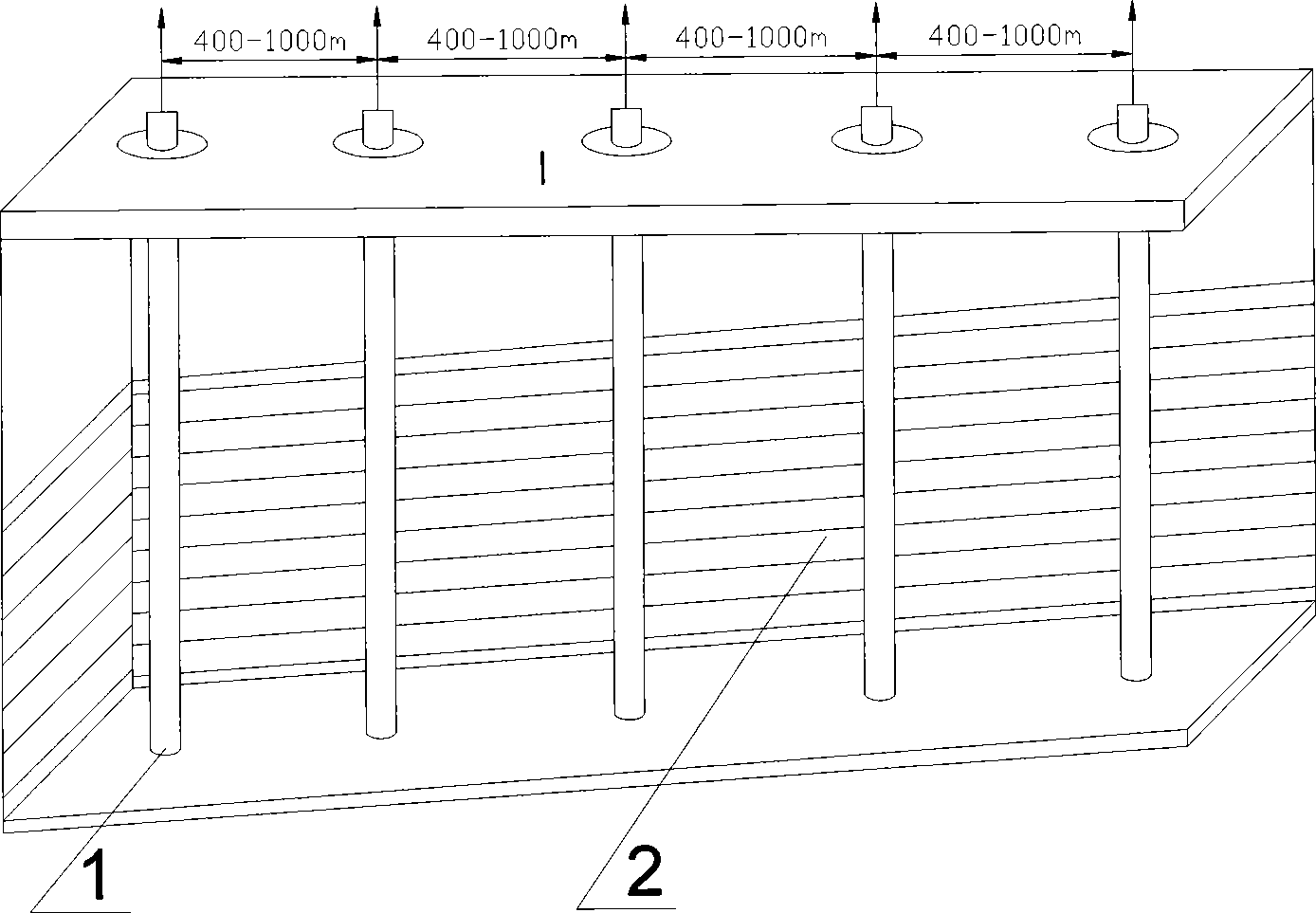

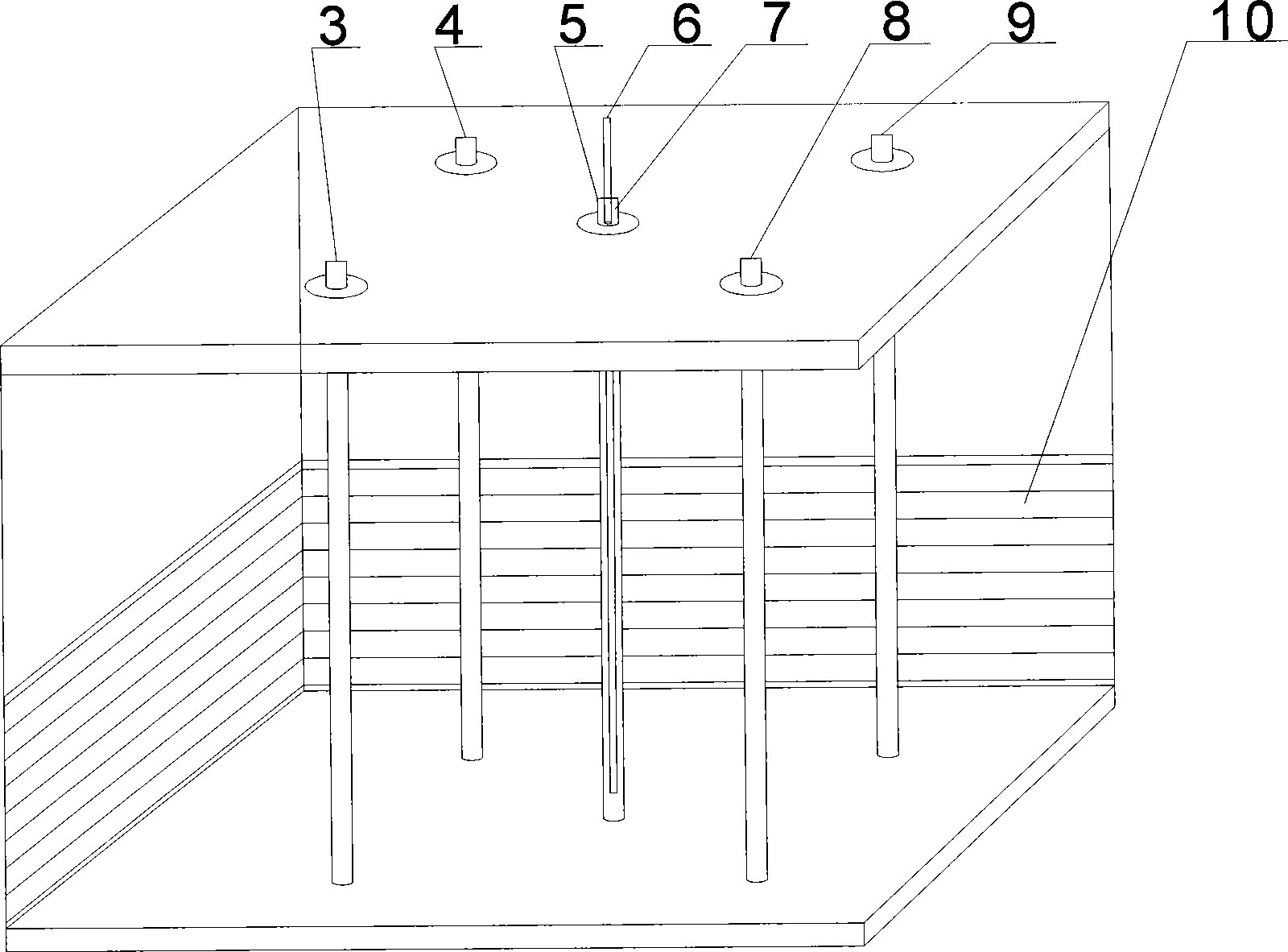

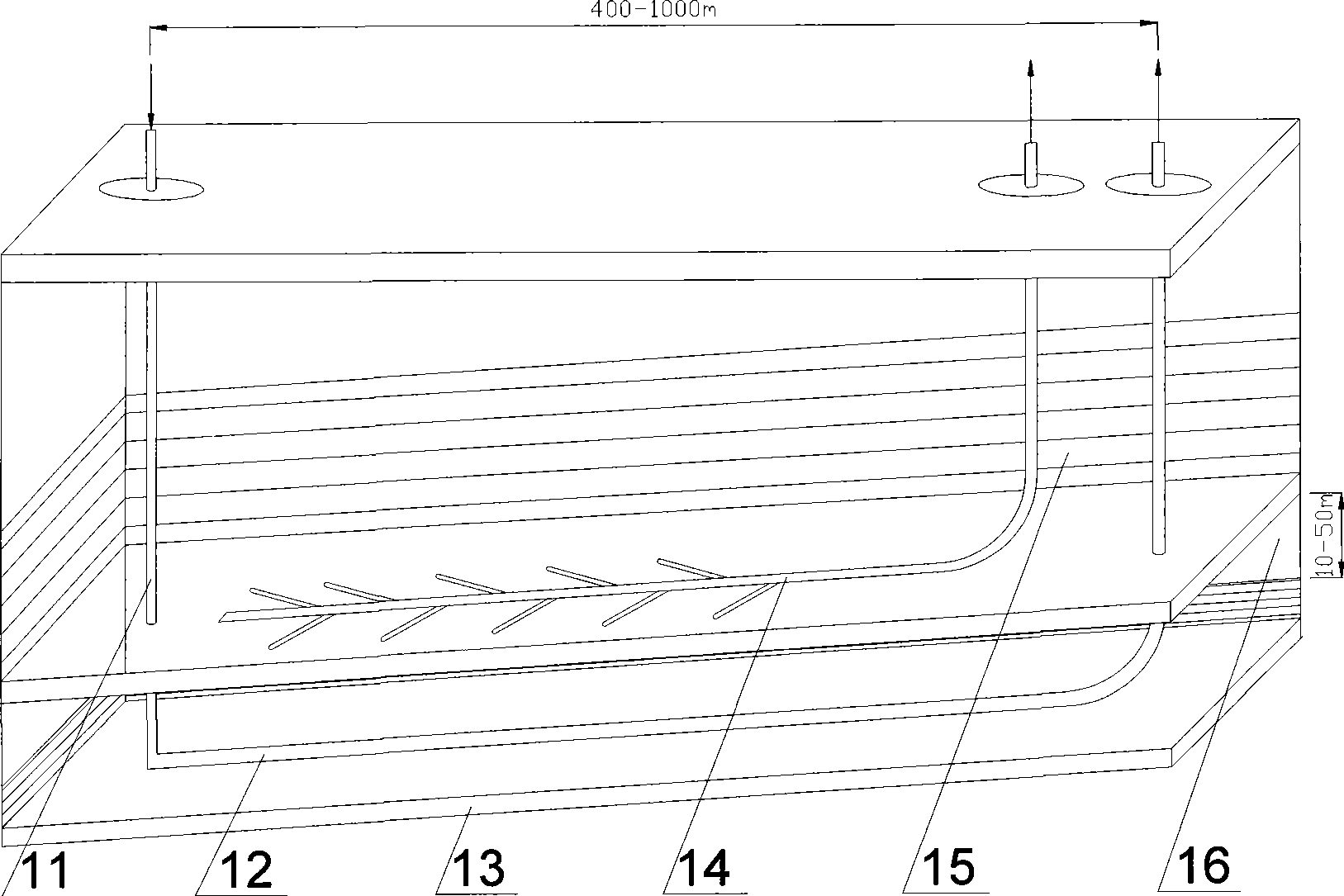

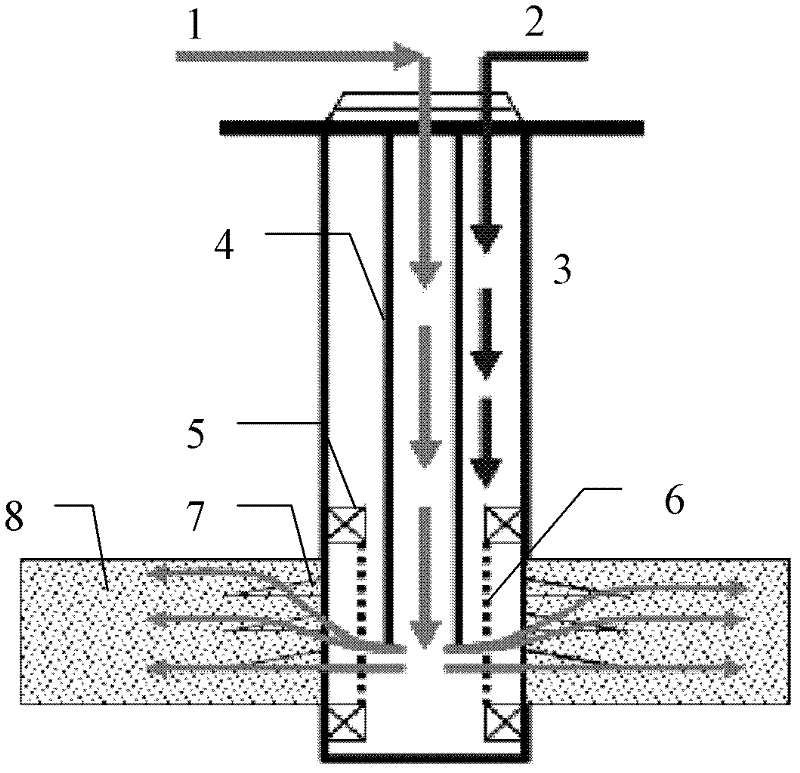

Thermochemistry auxiliary reinforced steam flooding method

The present invention relates to a thermochemistry assistant strengthening steam drive method for thermal recovery of horizontal well using oil-soluble compound viscosity reducer and carbon dioxide. The technique scheme is that: Drilling an horizontal well below the heavy oil reservoir layer, injecting periodically oil-soluble compound viscosity reducer, carbon dioxide liquid and steam in slug injection forms to horizontal well, after shutting in well and opening to blow, continuous oil extraction is operated by the inner lower pump in horizontal well. The present invention can reduce base oil viscosity of super heavy oil reservoir in lower or middle deep layers greatly, reduce steam injection pressure greatly, enhance steam hot wave and range, and enhance period exploitation effect. The scene experiment proves that the average period oil-steam ratio reaches to 0.75, average period oil production is 1800t, the room experiment proves that developing thermochemistry assistant strengthening steam drive in the late period of middle deep layer of super heavy oil reservoir, the final oil reservoir recovery can reach about 40%.

Owner:SHENGLI OILFIELD PETROLEUM DEV CENT

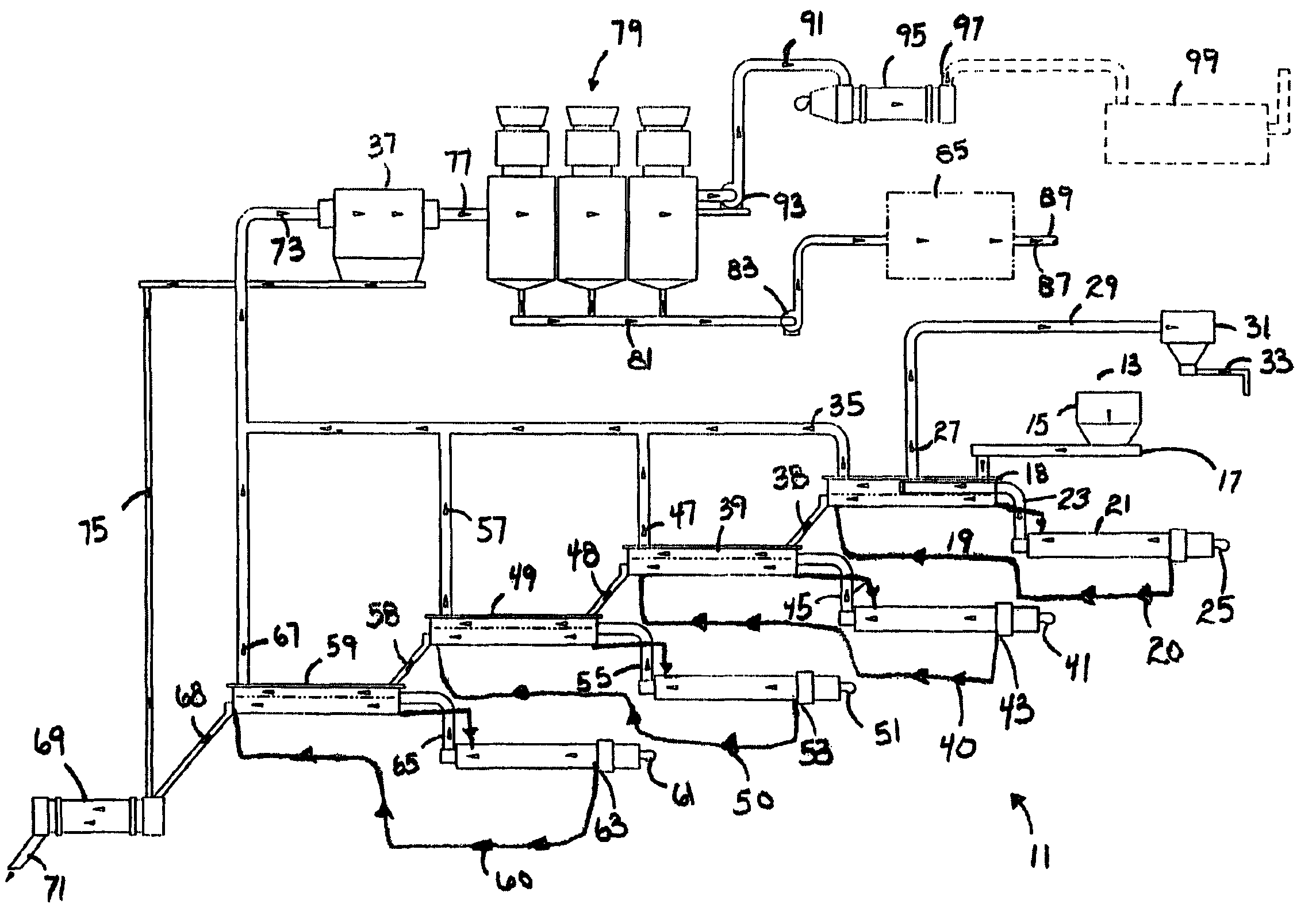

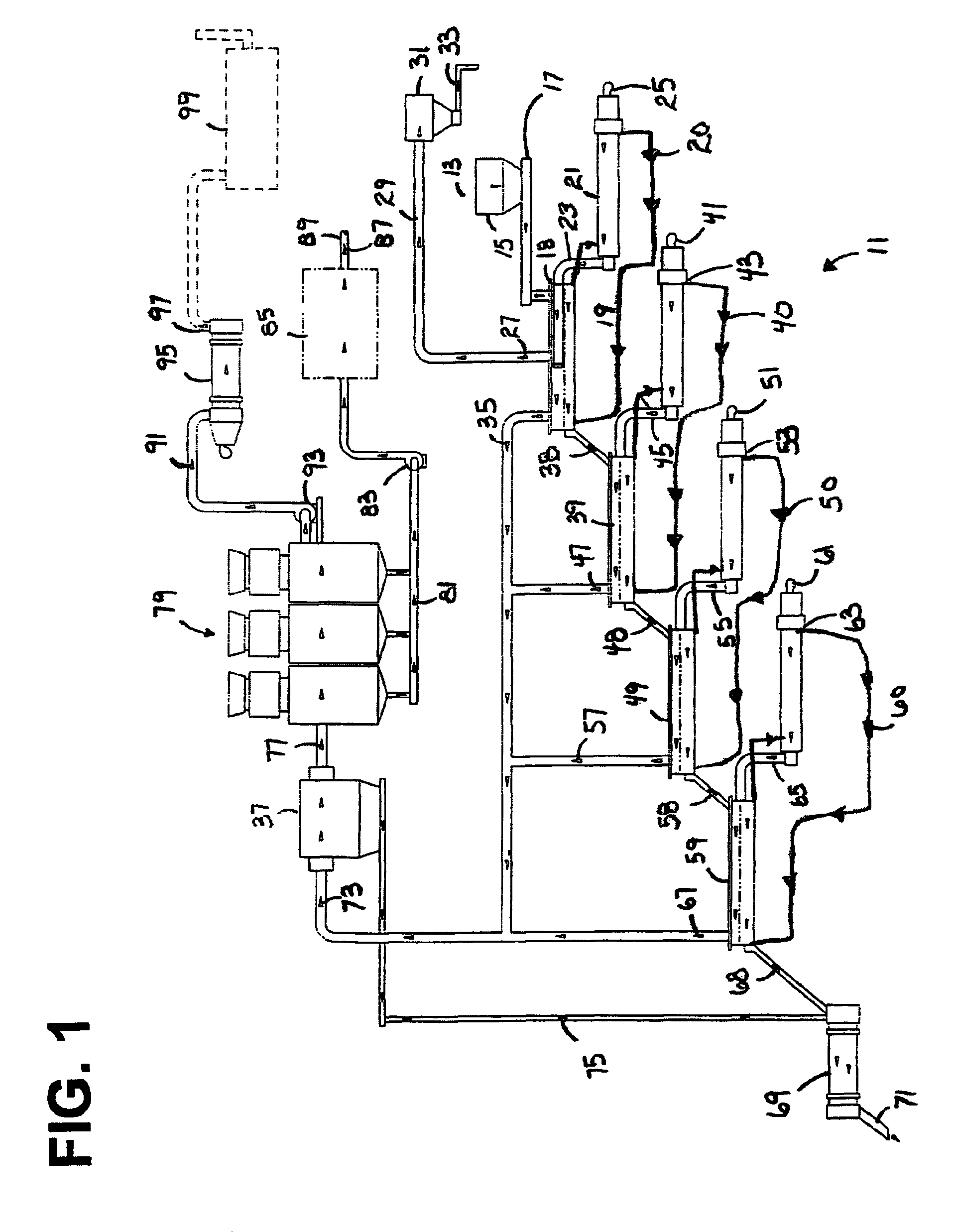

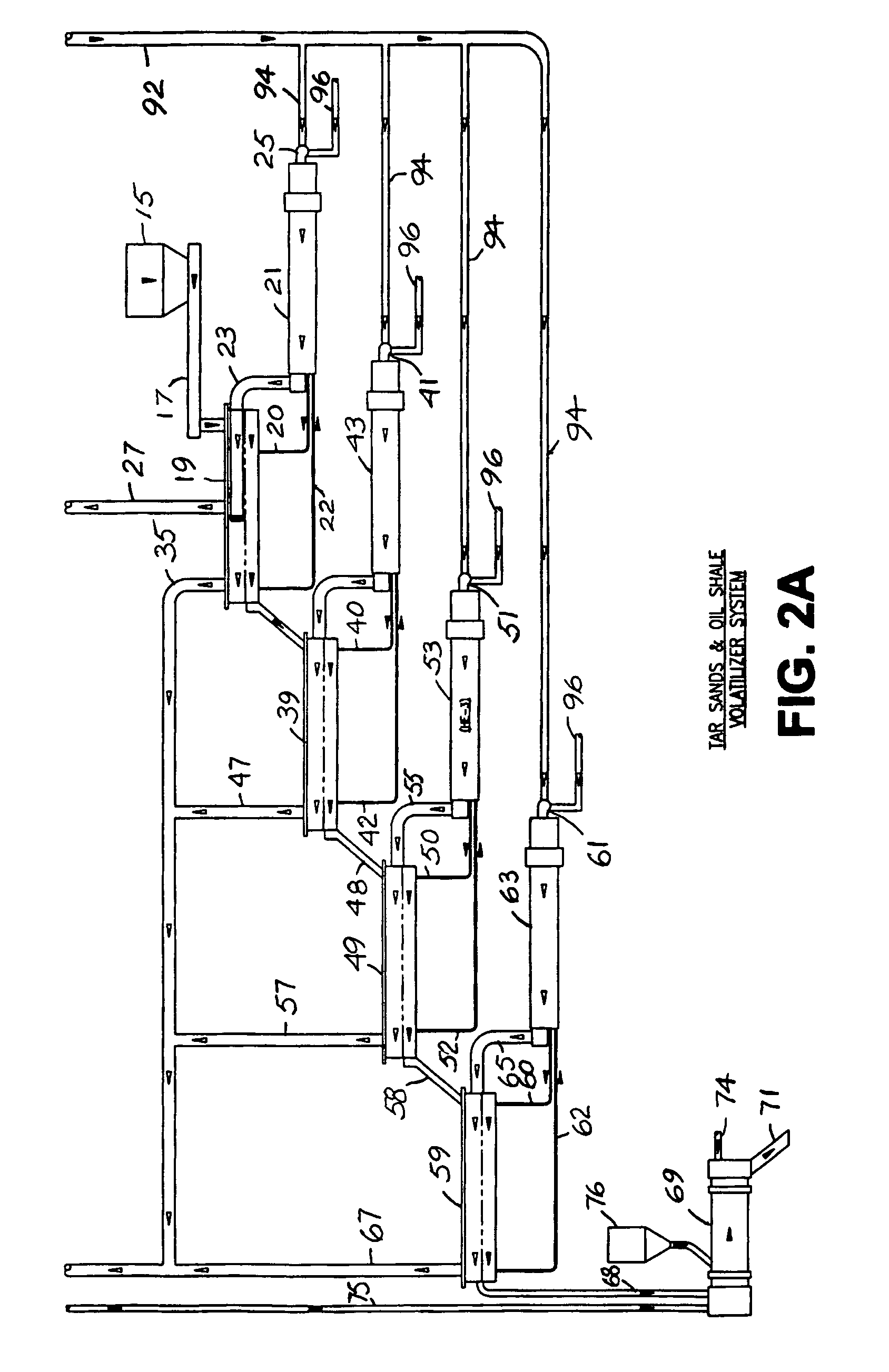

Thermal recovery of petroleum crude oil from tar sands and oil shale deposits

InactiveUS7807048B2Rule out the possibilityEliminate needHydrocarbon oil cracking processIndirect heating destructive distillationParticulatesFuel oil

A tar sand volatilizer system thermally removes petroleum crude oil from tar sands or shale oil. A series of heated augers or thermal screws are used to elevate material temperature gradually using conductive heat transfer. The thermal screws blades and auger case receive a heated fluid. The screws are driven by variable speed drive systems. The unit is sized for any throughput rate desired. Hot clean material discharges into a rotary cooler and re-hydrator unit. The exhaust gases are pulled through a high temperature filter collector for particulate removal. The particulate free petroleum vapor laden hot gas exits the filter house into a multi stage condenser system with water chillers where the vapor temperature is gradually cooled. A microwave upgrader system processes crude oil using catalyst injected microwave technology to produce a diesel like fuel oil in a continuous process stream.

Owner:COLLETTE JERRY R

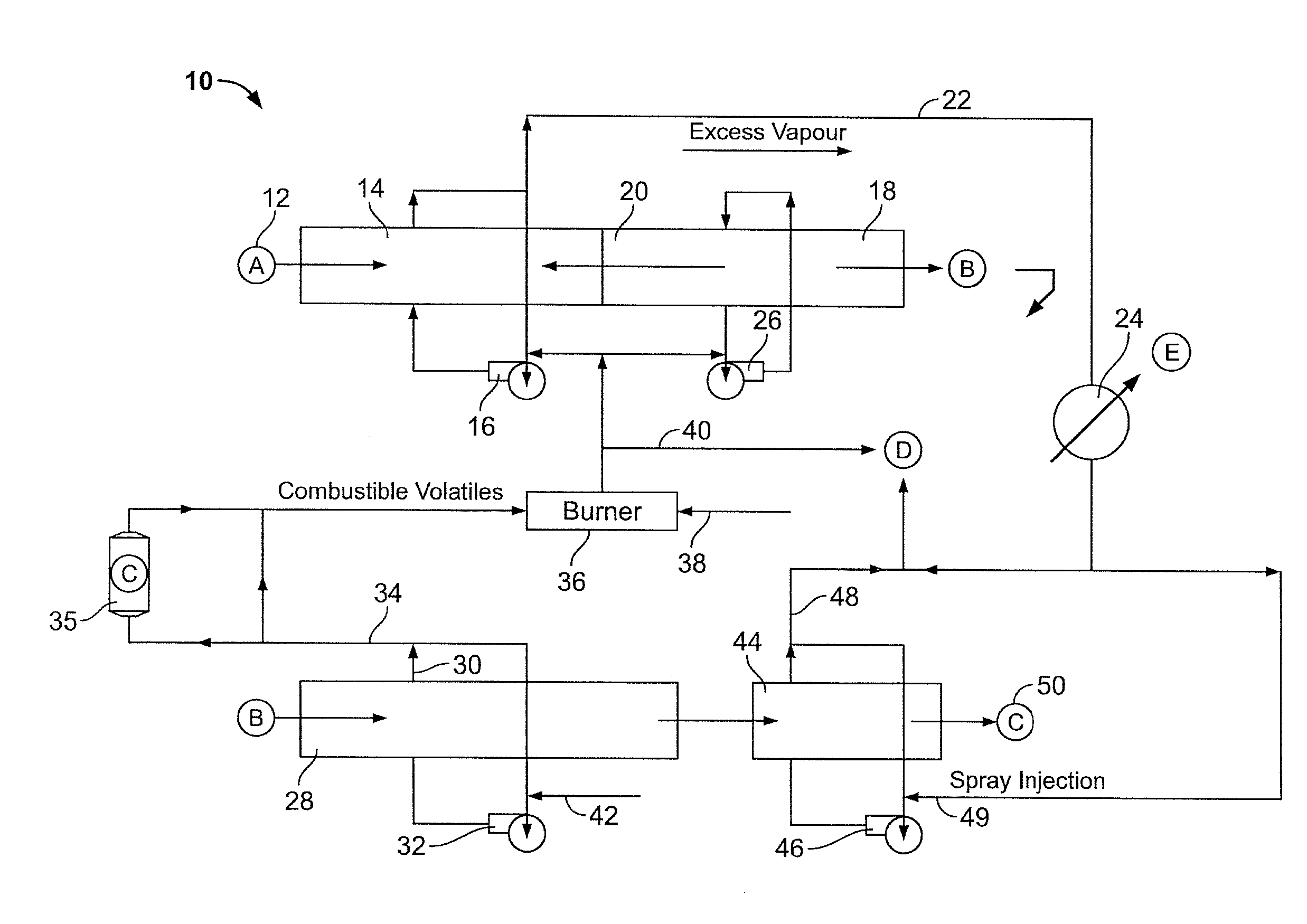

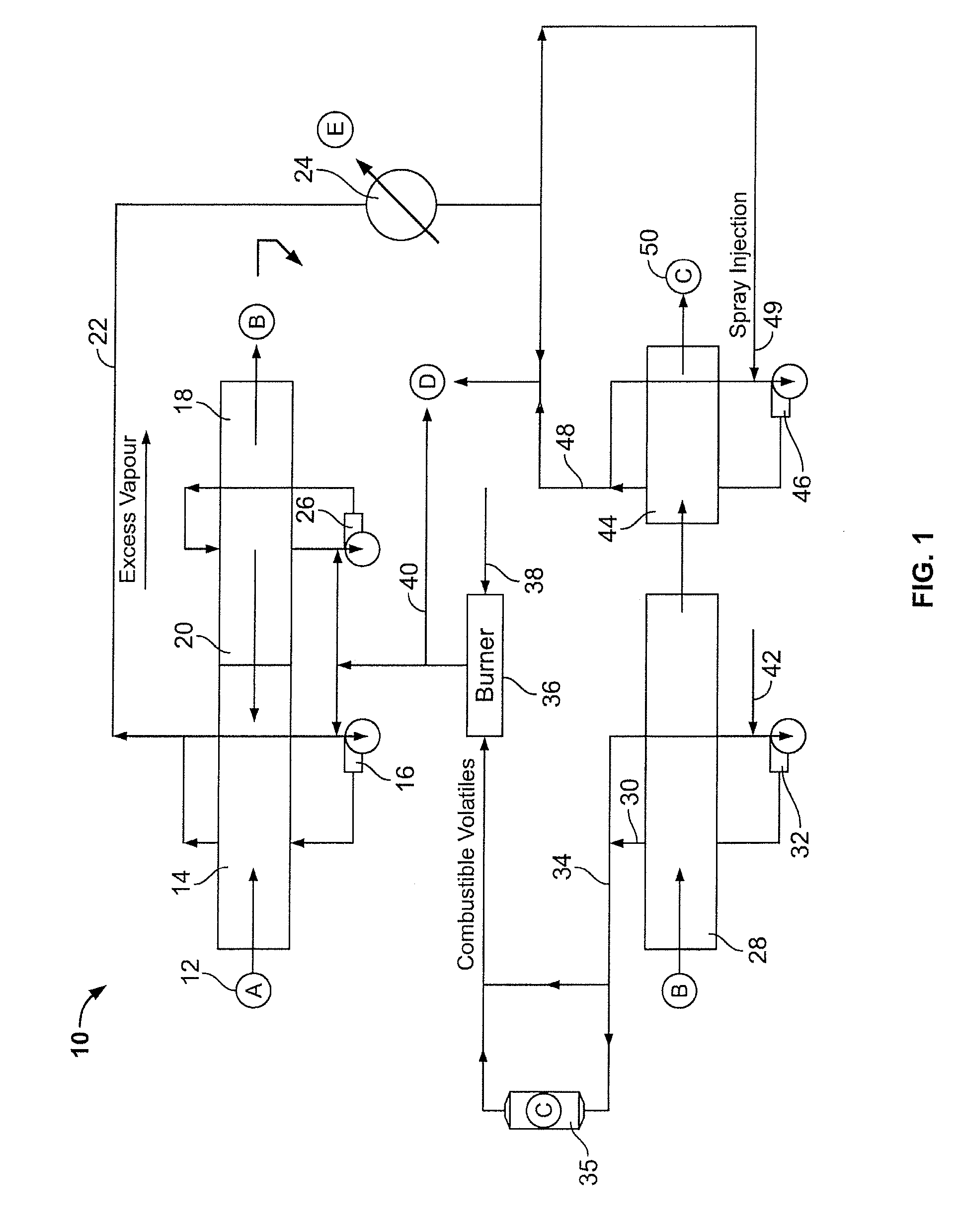

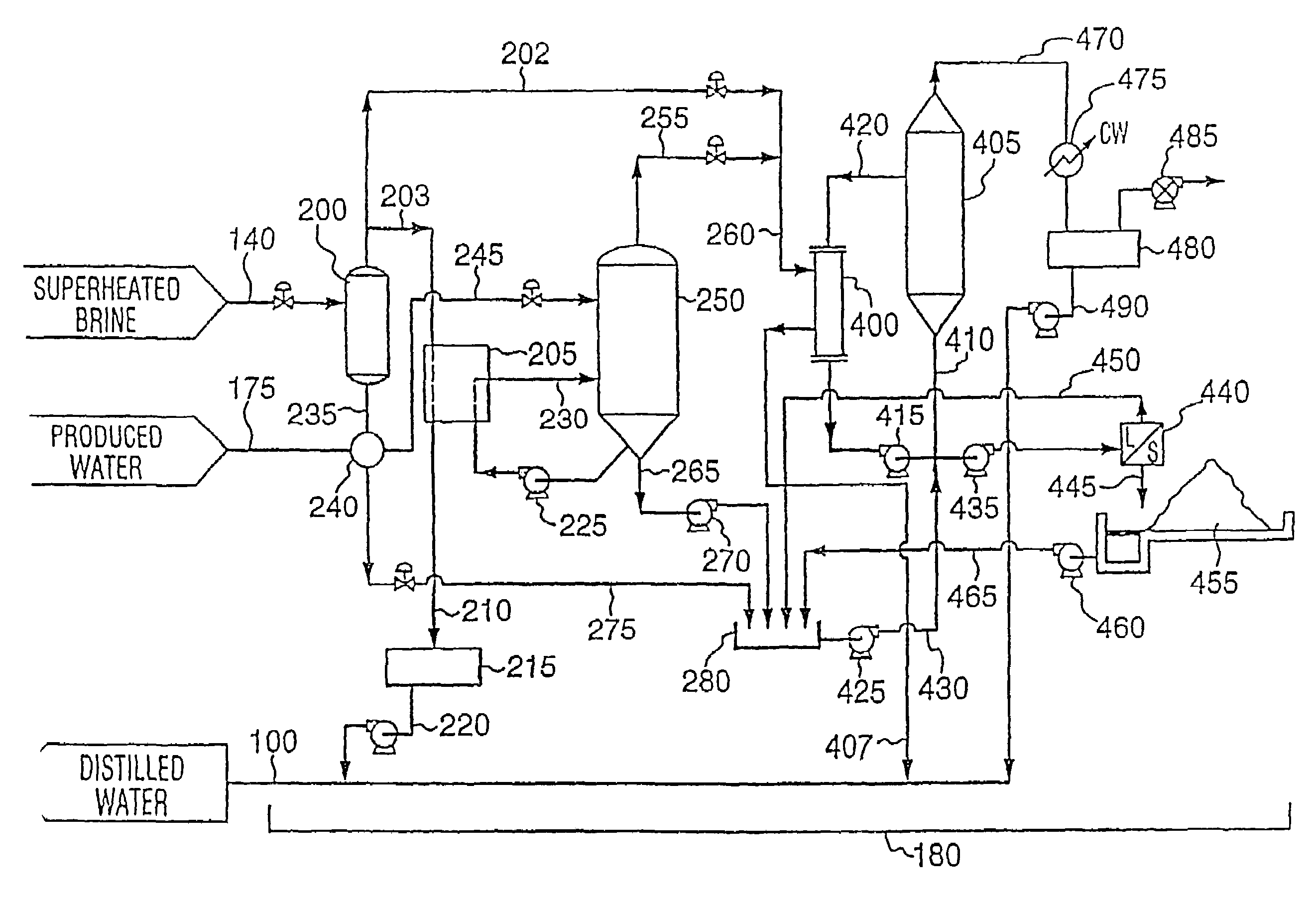

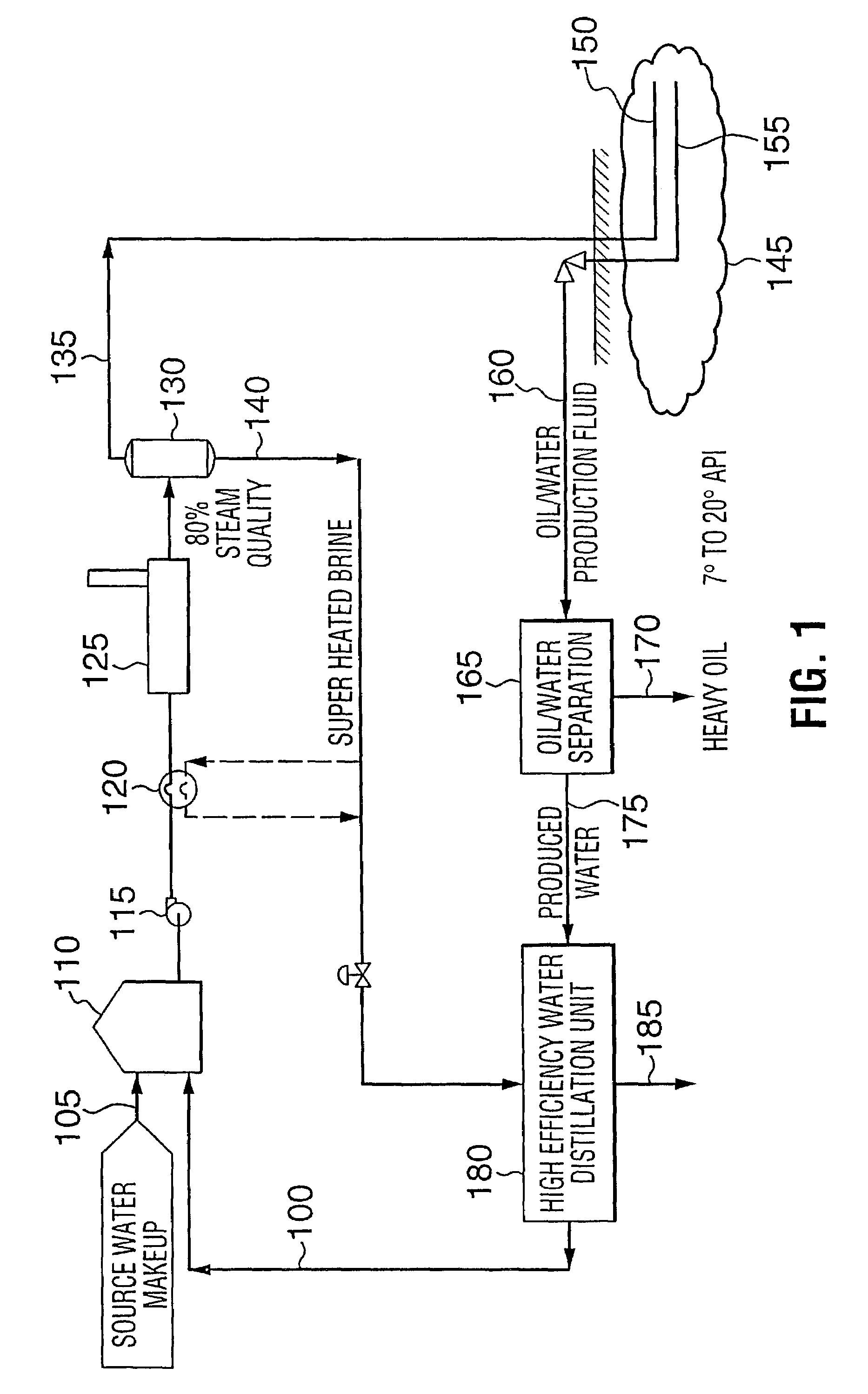

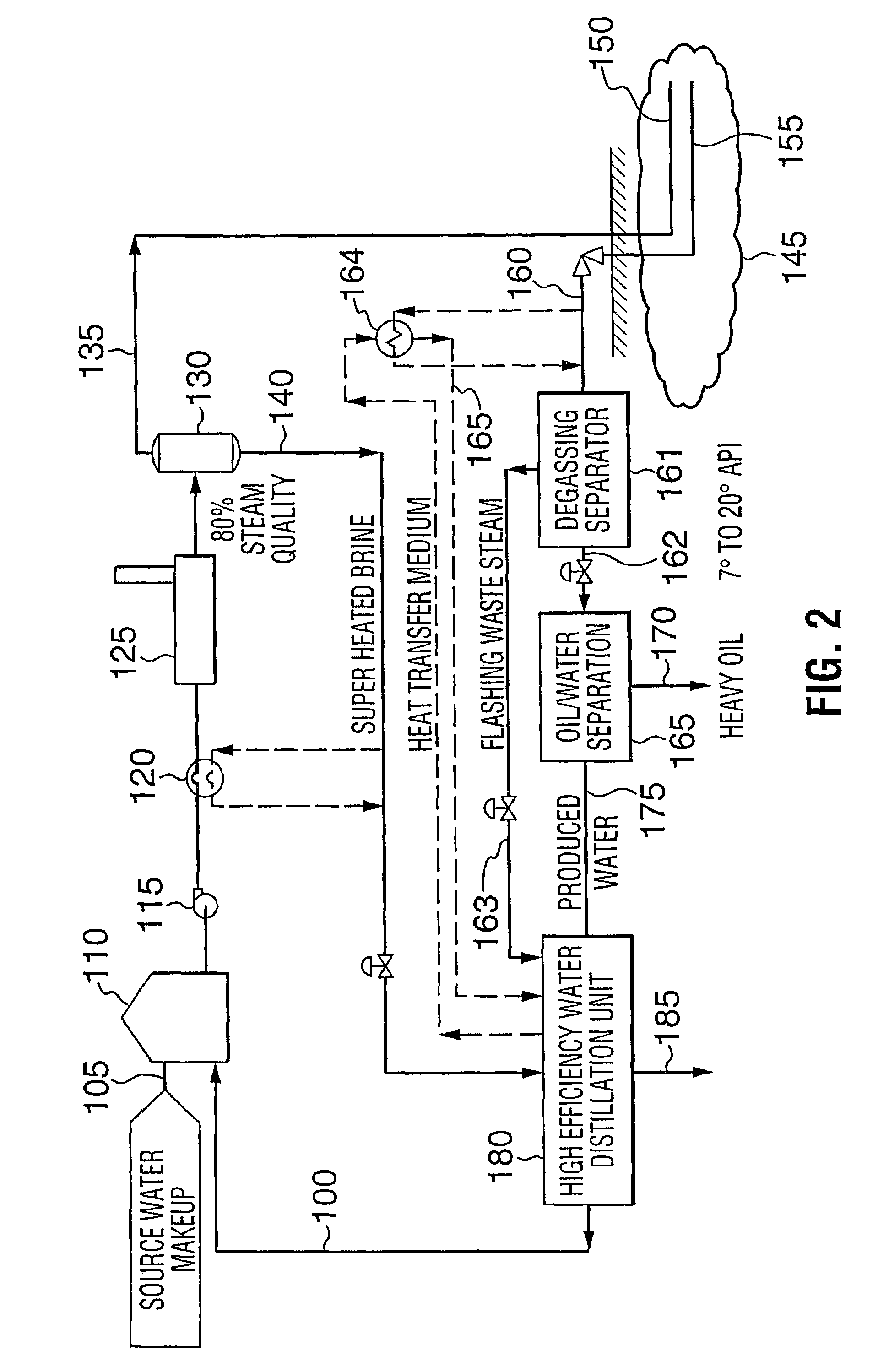

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

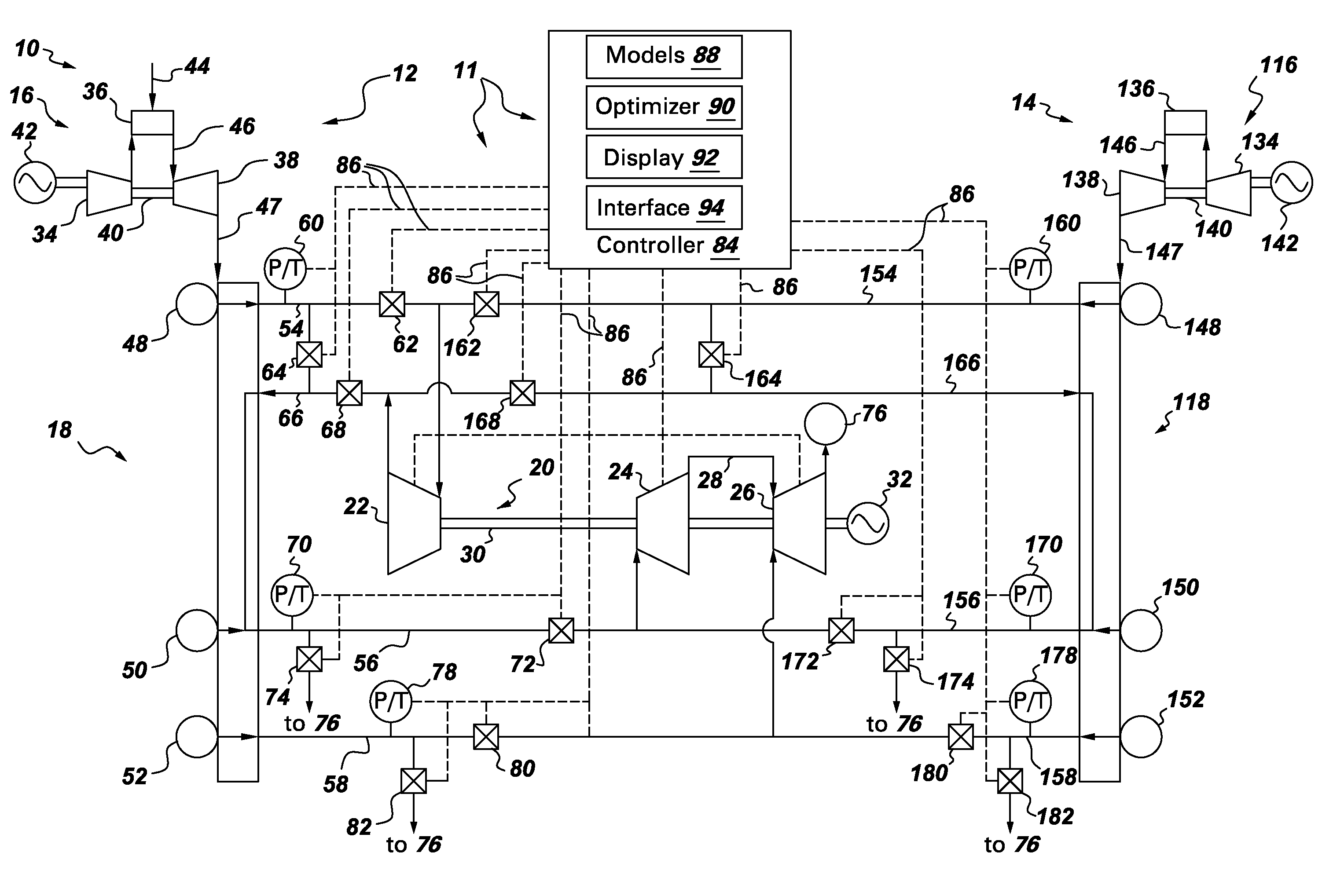

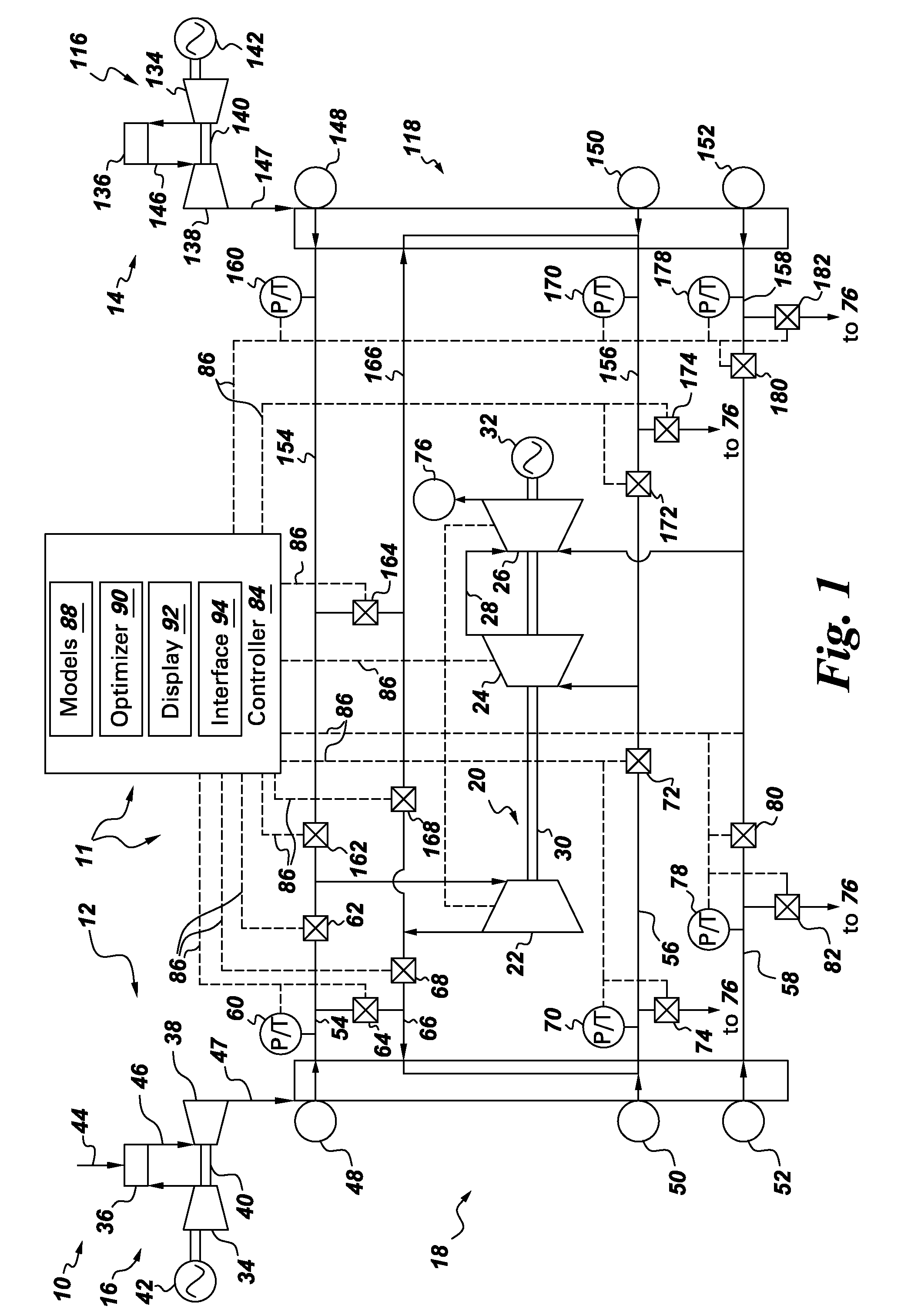

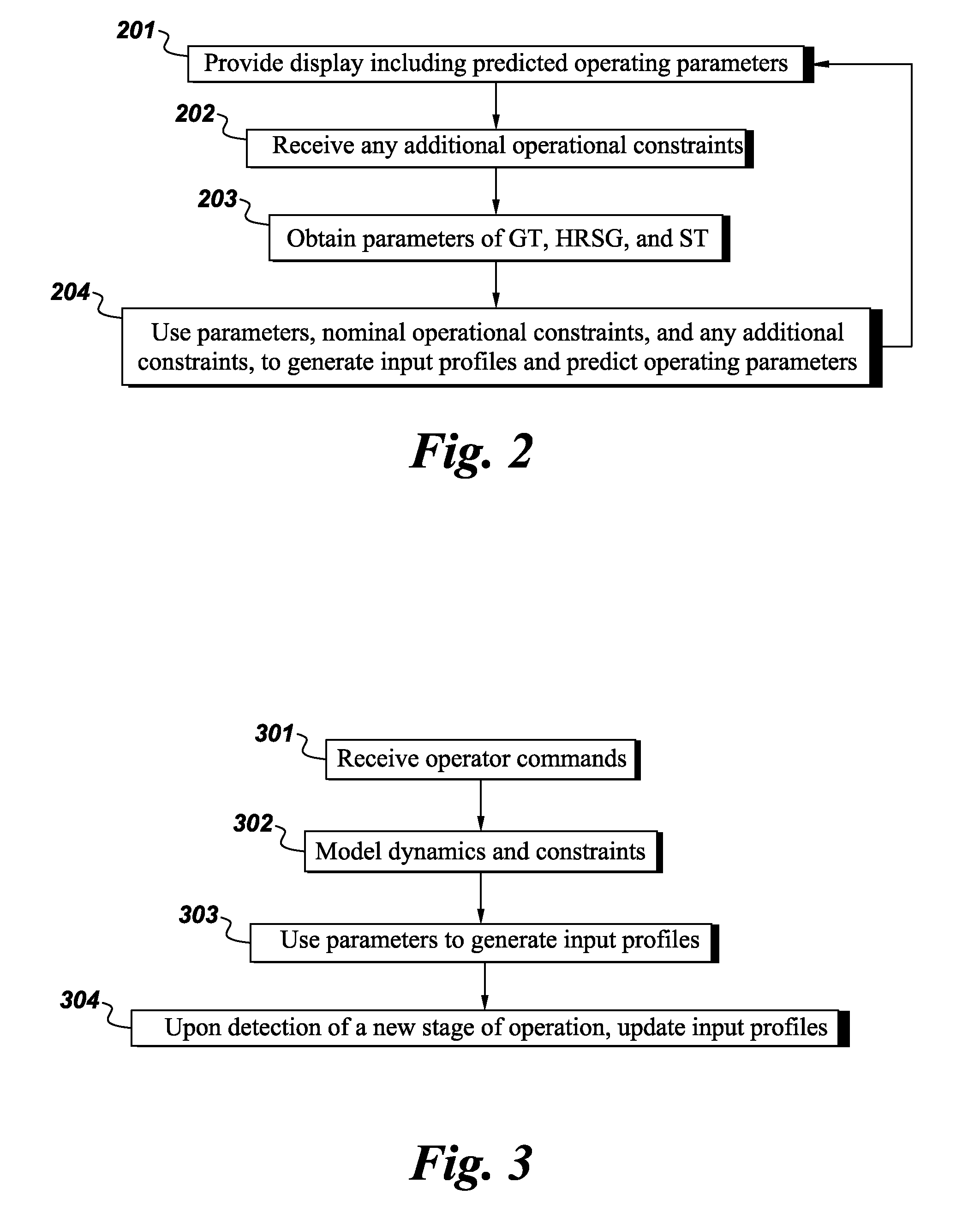

Control of combined cycle power generation system

ActiveUS20090292436A1Easy to operateAnalogue computers for vehiclesLevel controlControl systemAlternative control

A control system for a combined cycle power generation system including a gas turbine engine (GT), a heat recovery steam generator (HRSG), and a steam turbine (ST) includes a display wherein an operator may observe information about predicted operating parameters; a user interface wherein an operator may provide additional operating constraints; and a controller configured to generate input profiles of the GT, the HRSG, and the ST that satisfy the nominal constraints and any additional constraints and to generate the information about the predicted operating parameters. The controller may be configured to detect a stage transition of power generation system operation and update the input profiles. The controller may be configured to generate alternative operating scenarios by mapping alternative control actions to an operating constraint of at least one of the system components.

Owner:GENERAL ELECTRIC CO +1

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

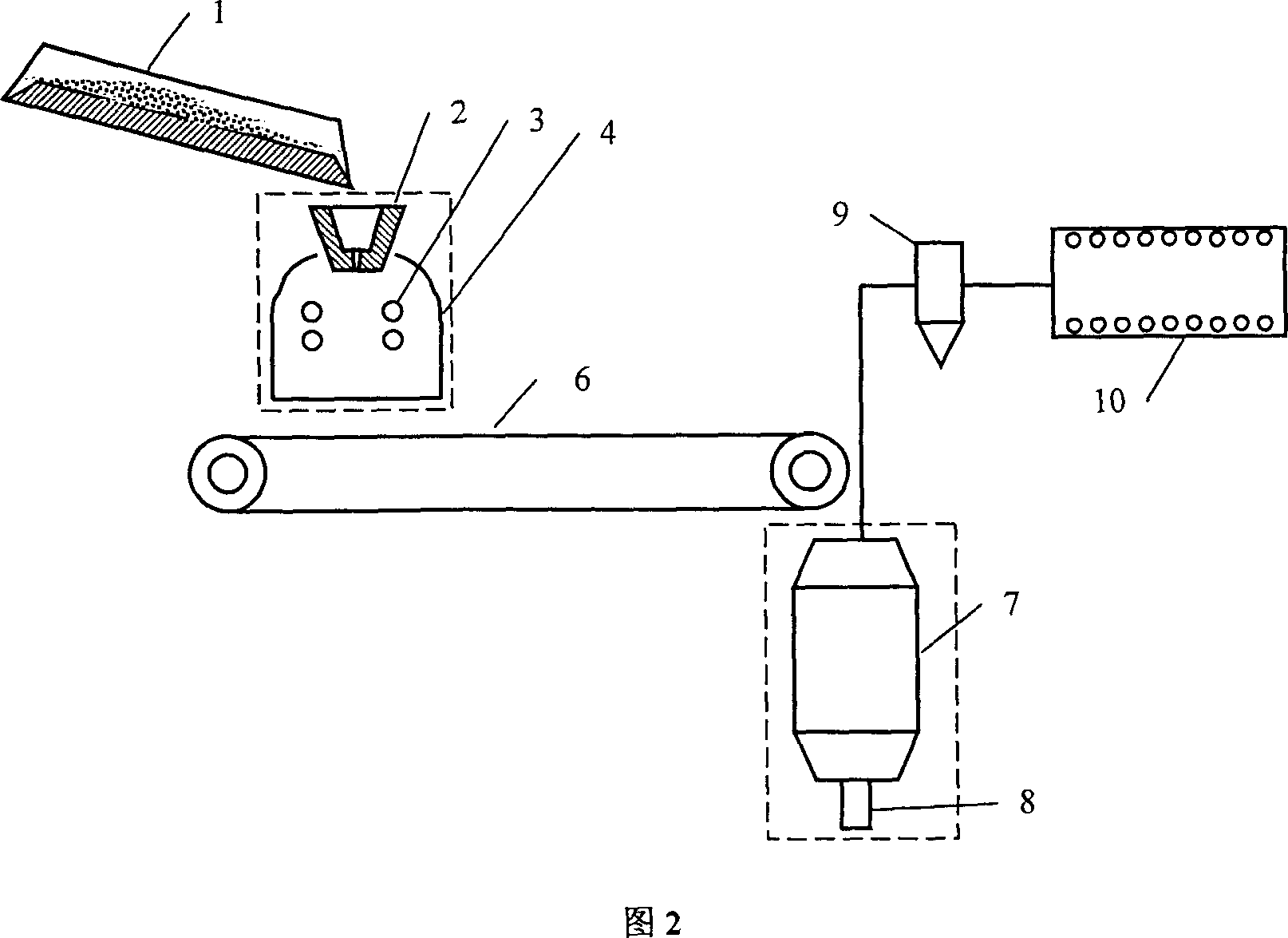

Coke plant including exhaust gas sharing

ActiveUS9243186B2Coke oven safety devicesHorizontal chamber coke ovensExhaust fumesProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

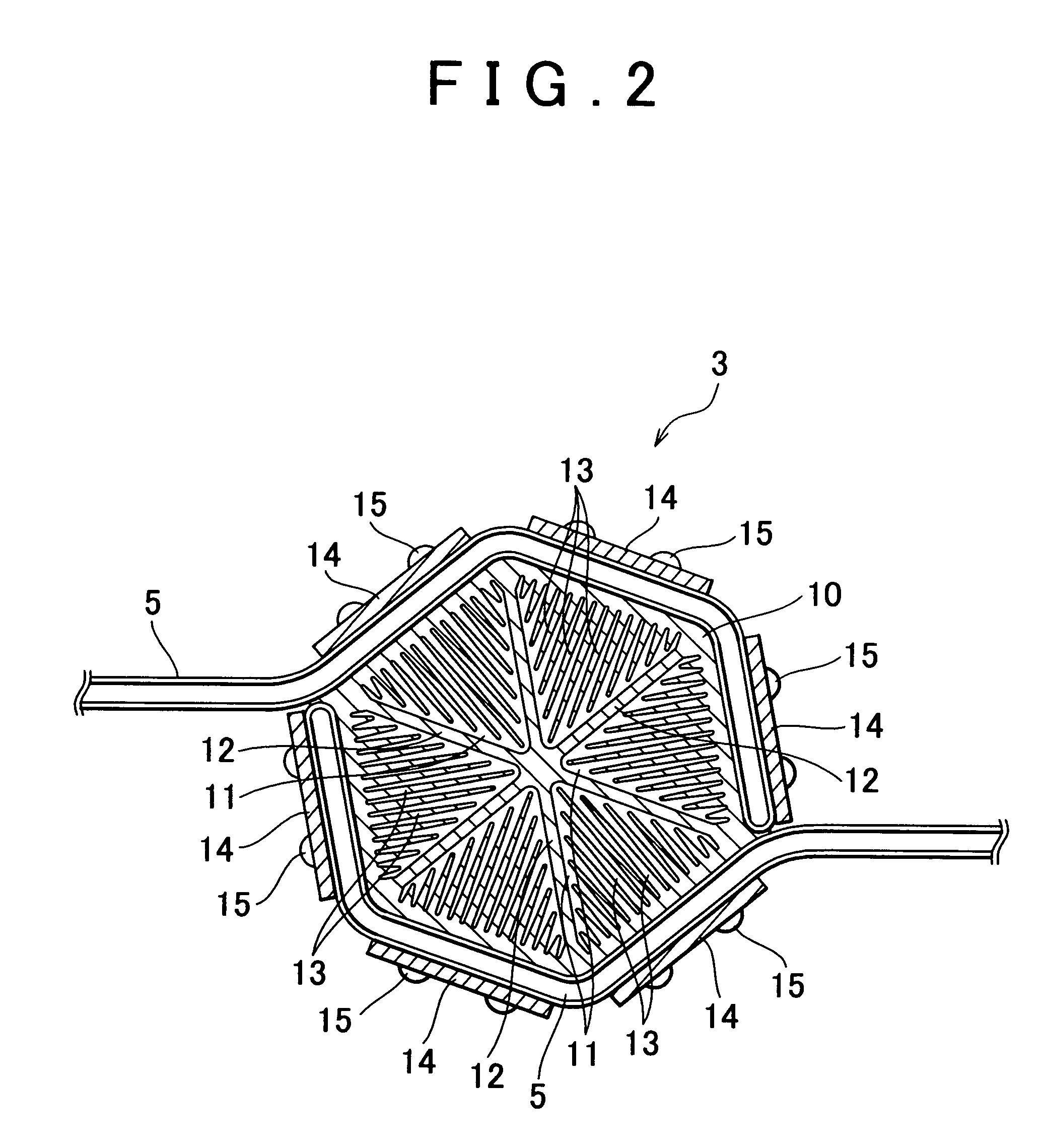

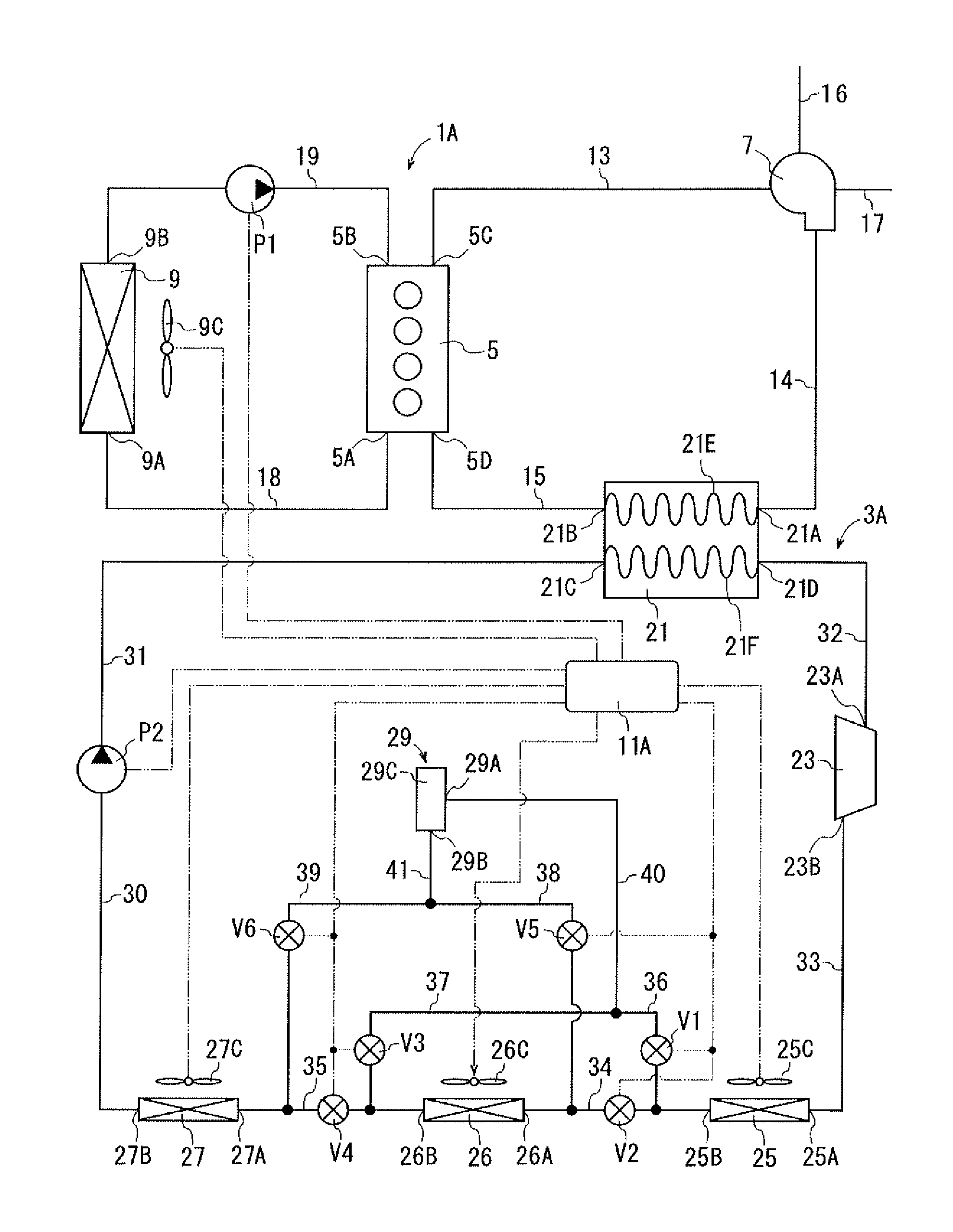

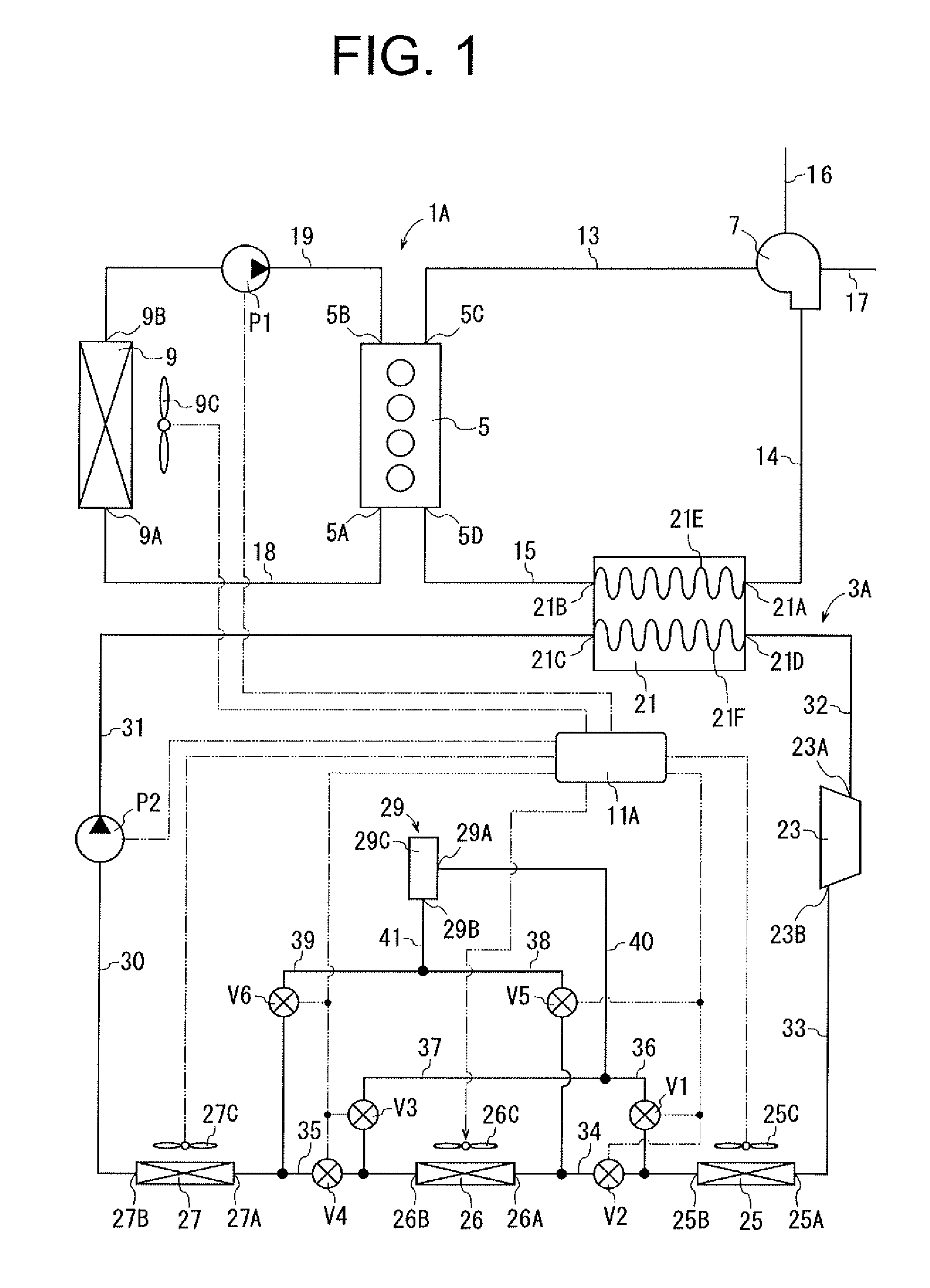

Exhaust heat recovery system

InactiveUS20050204733A1Improve powerSimple configurationInternal combustion piston enginesThermoelectric device with peltier/seeback effectExhaust fumesEngineering

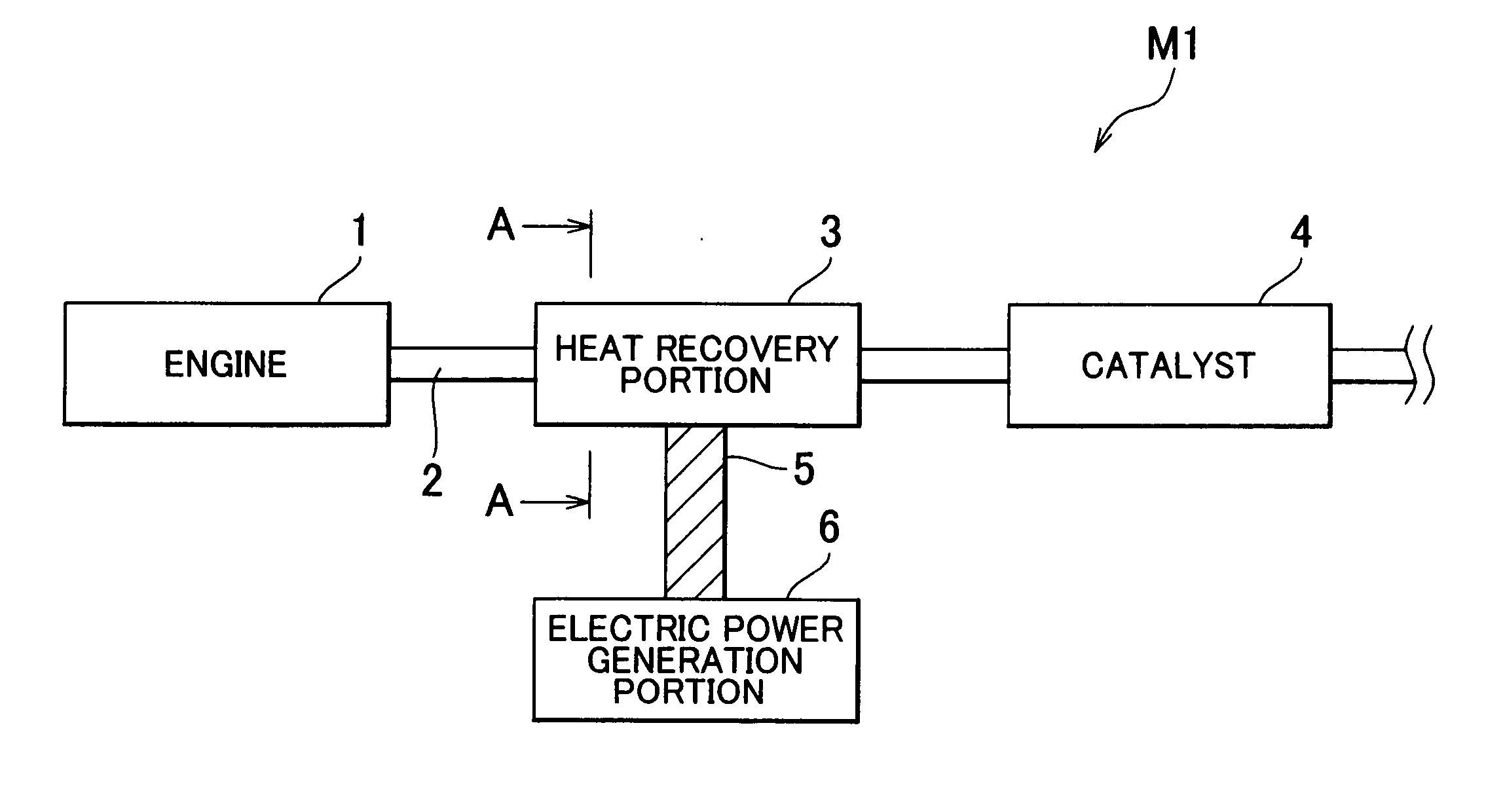

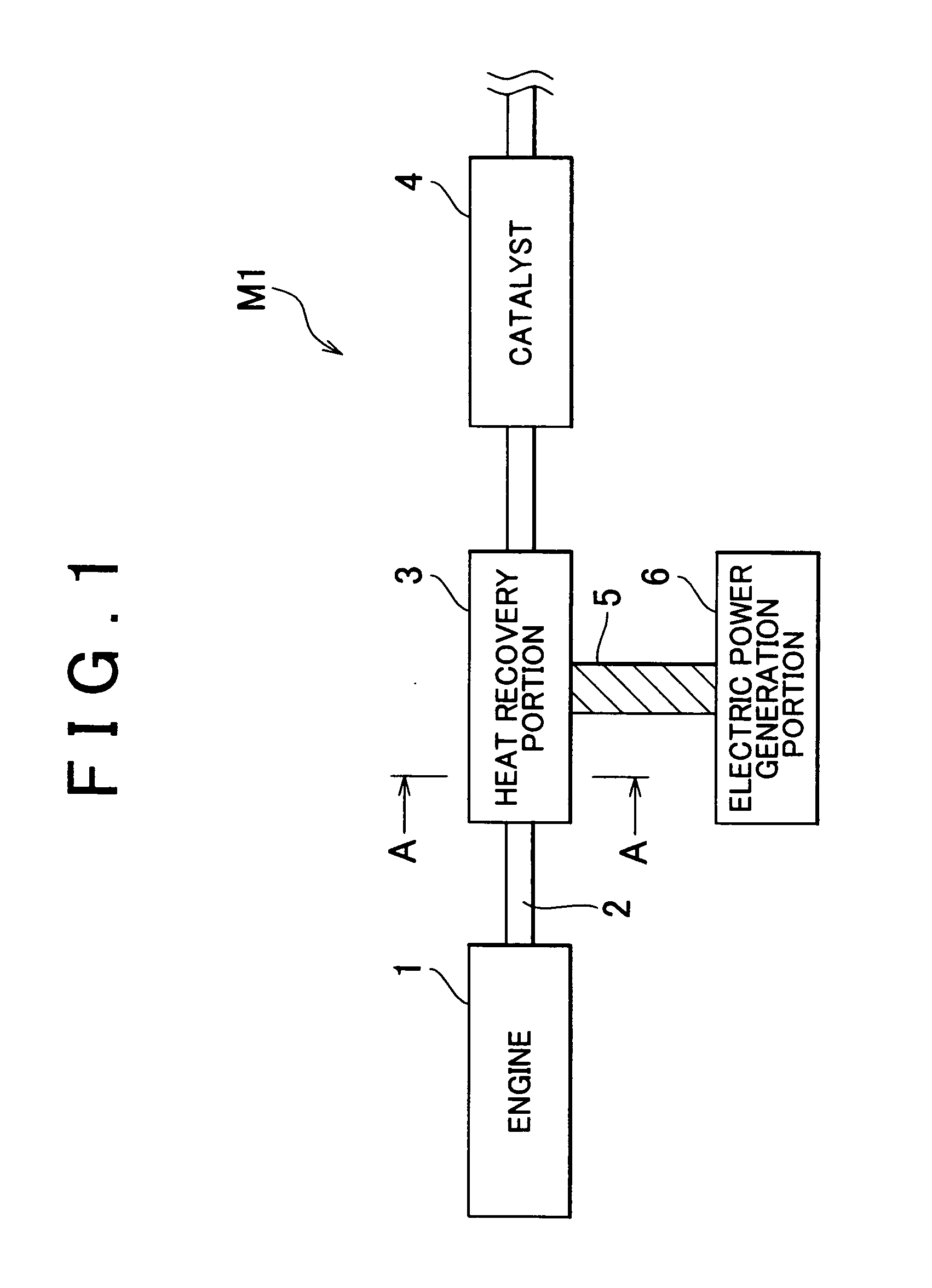

In an exhaust heat recovery system, electric power generation efficiency of a thermoelectric conversion element can be improved, and warming-up of a catalyst can be completed early, without using a complicated device. The exhaust heat recovery system according to the invention includes an exhaust pipe in which exhaust gas discharged from an internal combustion engine flows; a catalyst which purifies the exhaust gas; a heat recovery portion which is fitted to the exhaust pipe, and which recovers heat contained in the exhaust gas; a thermoelectric conversion element which generates electric power using thermoelectric conversion; and a heat pipe which connects the heat recovery portion to the thermoelectric conversion element, and which transfers the heat recovered in the heat recovery portion to the thermoelectric conversion element. An operation starting temperature of the heat pipe is set so as to be higher than an activation temperature of the catalyst.

Owner:TOYOTA JIDOSHA KK

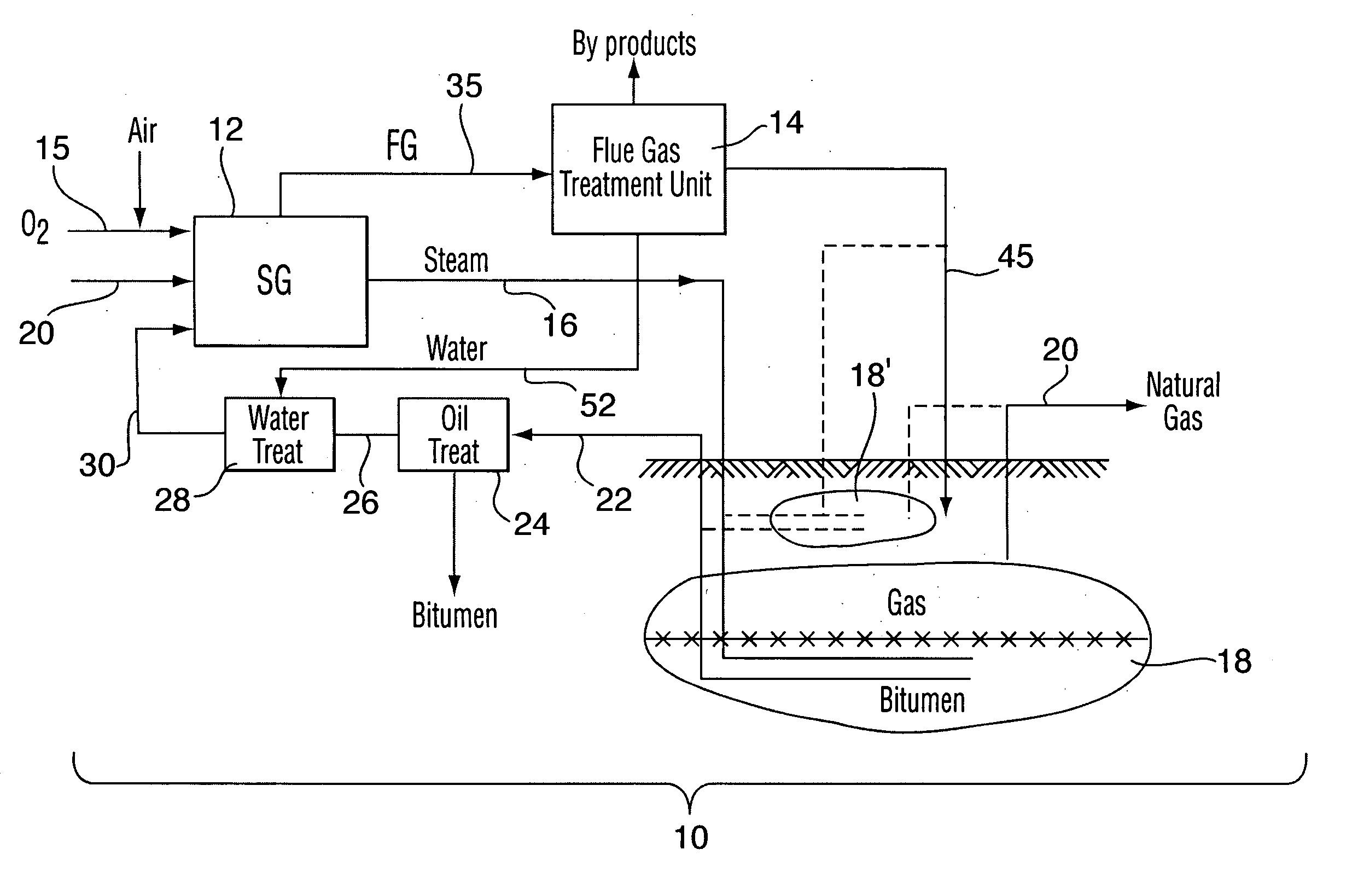

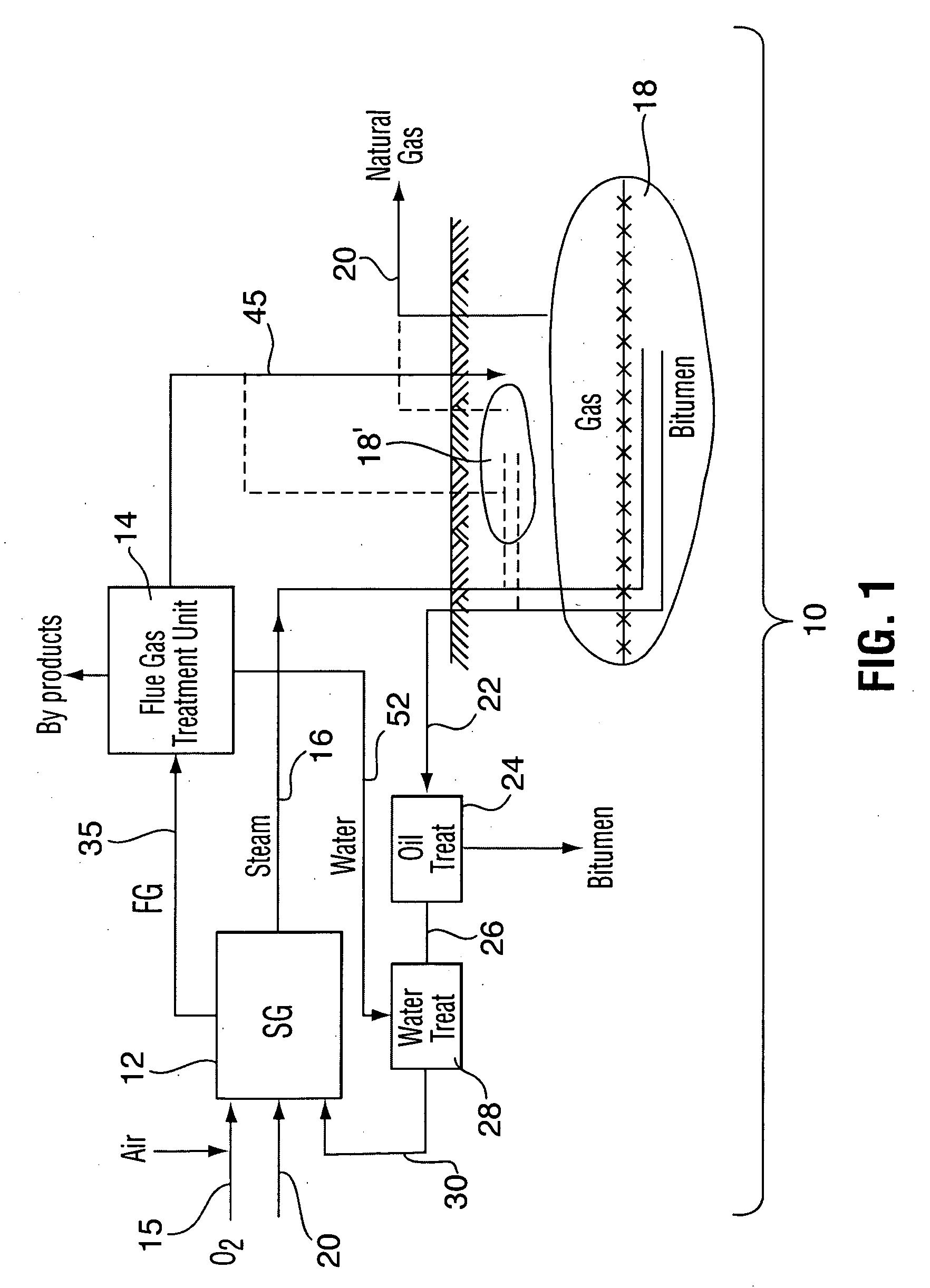

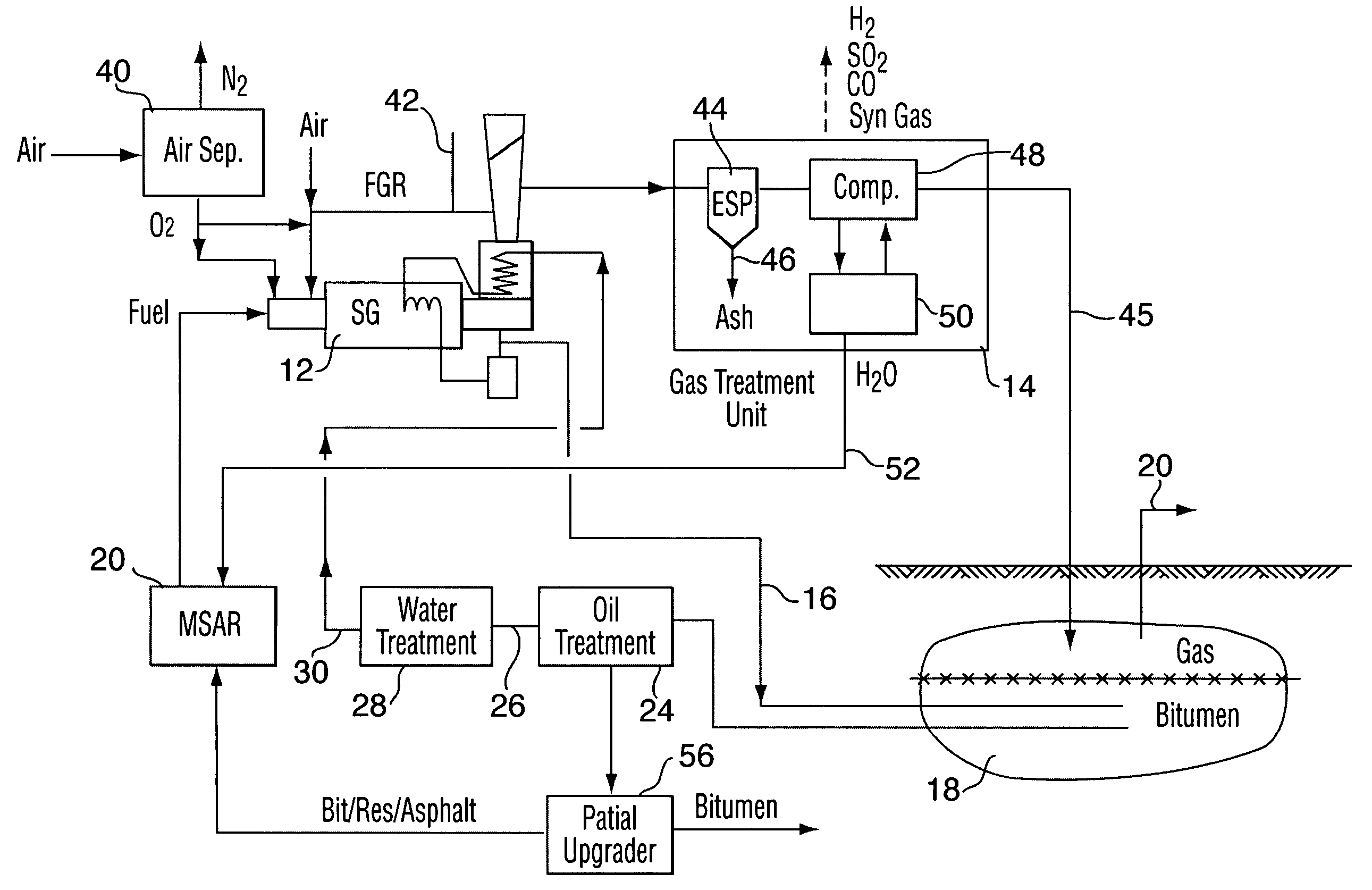

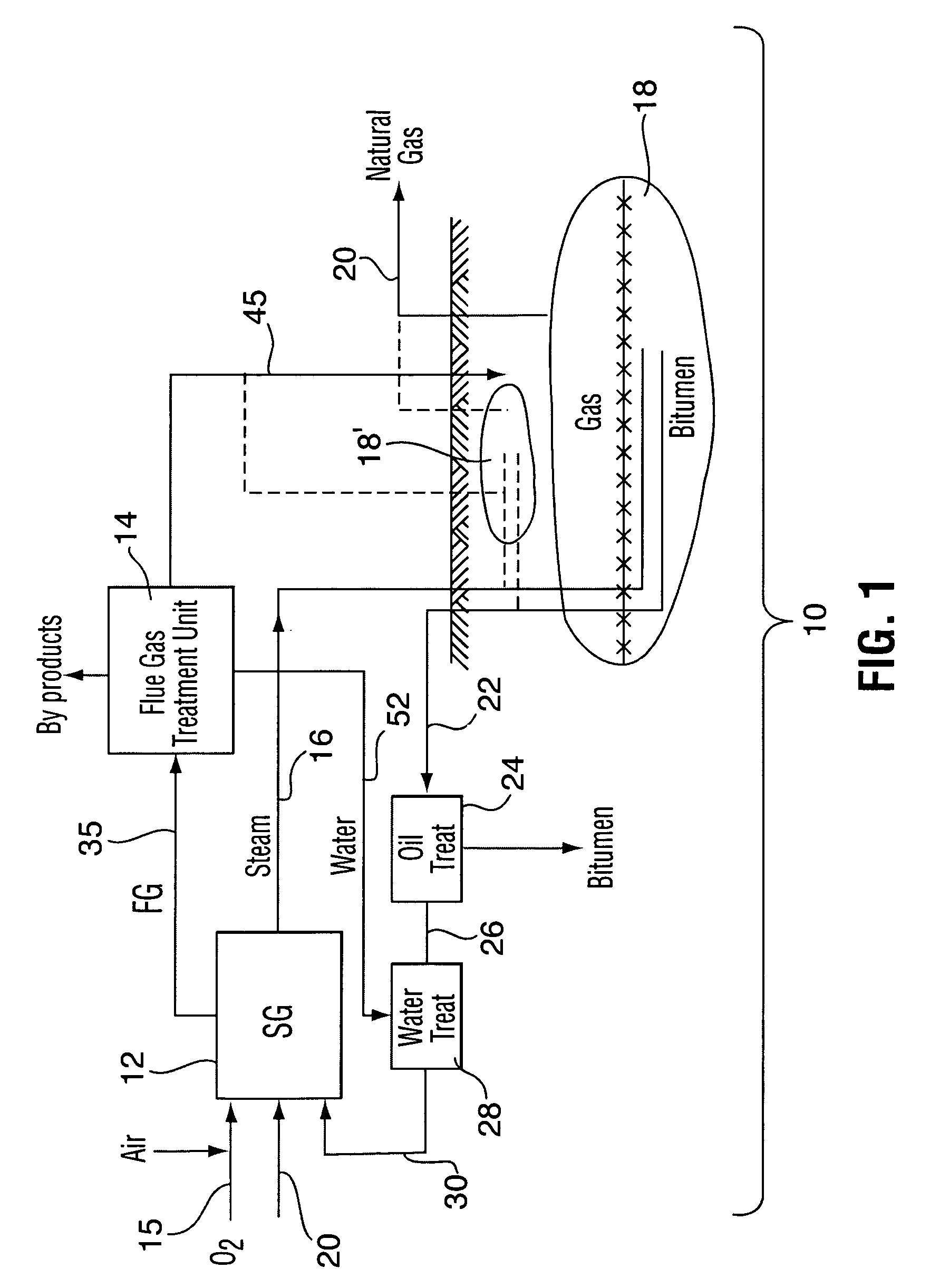

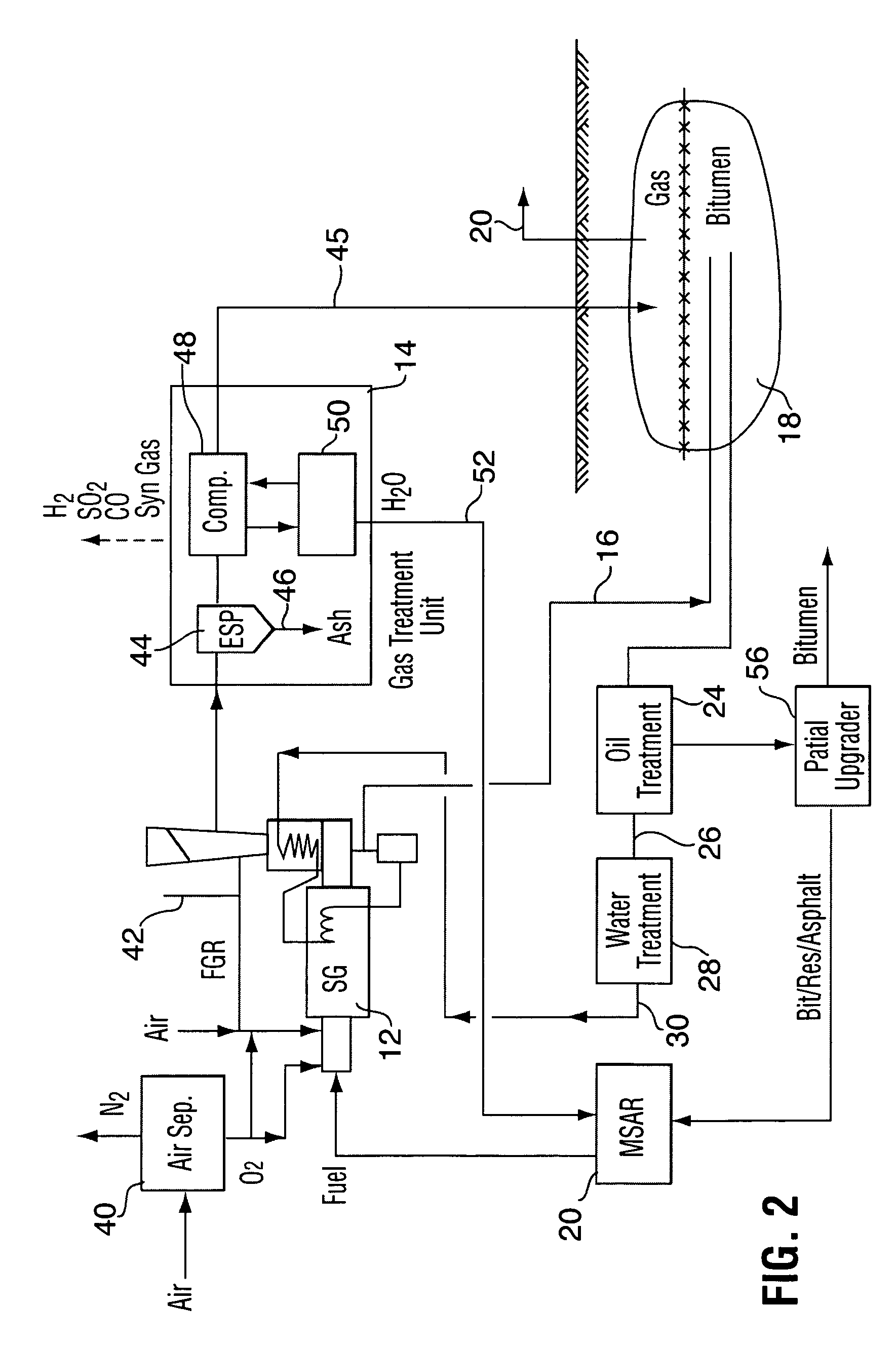

Flue gas injection for heavy oil recovery

InactiveUS20060243448A1Facilitates heat recoveryImprove efficiencyOther gas emission reduction technologiesInsulationFlue gasFuel oil

A variety of methods for thermal recovery of natural gas and bitumen from a formation containing the latter. In general, the methods incorporate a series of existing, but previously uncombined technologies. A modified flue gas from the steam generators conventionally used in a SAGD recovery operation is injected into the formation to enhance recovery with the produced fluids, natural gas, bitumen, inter alia are further processed. The injection of the flue gas conveniently is disposed of and further acts to repressurize the formation which otherwise becomes depressurized when depleted of natural gas. Accordingly, environmental and economic advantages are realized with the methodology.

Owner:COLT ENG CORP +1

Novel coalbed gas thermal recovery process

The invention relates to a new coalbed gas thermal production process which is characterized in that full hot coke is arranged on the lower part of a coalbed gas production well or a gasification well, a gasification agent is pressed in so as to ignite a hole bottom coalbed; and the heat released from the combustion of part of the coalbed can heat up the adjacent coalbed, and improve the analysis capability, permeability coefficient and osmotic pressure of the coalbed, thereby improving the gas yield of the coalbed.

Owner:ENN SCI & TECH DEV

Flue gas injection for heavy oil recovery

InactiveUS7341102B2Speed up recoveryImprove efficiencyOther gas emission reduction technologiesInsulationFlue gasFuel oil

A variety of methods for thermal recovery of natural gas and bitumen from a formation containing the latter. In general, the methods incorporate a series of existing, but previously uncombined technologies. A modified flue gas from the steam generators conventionally used in a SAGD recovery operation is injected into the formation to enhance recovery with the produced fluids, natural gas, bitumen, inter alia are further processed. The injection of the flue gas conveniently is disposed of and further acts to repressurize the formation which otherwise becomes depressurized when depleted of natural gas. Accordingly, environmental and economic advantages are realized with the methodology.

Owner:COLT ENG CORP +1

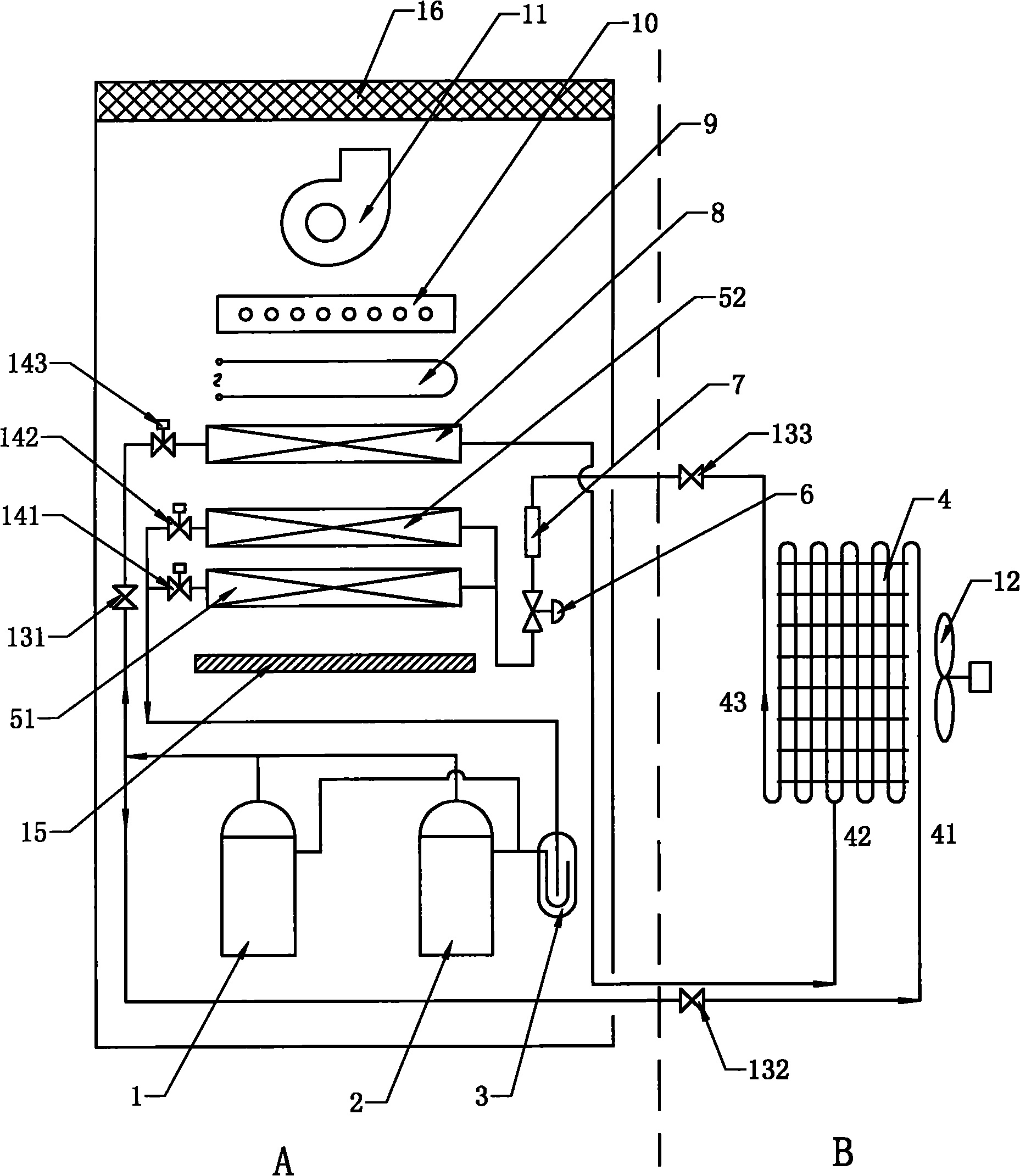

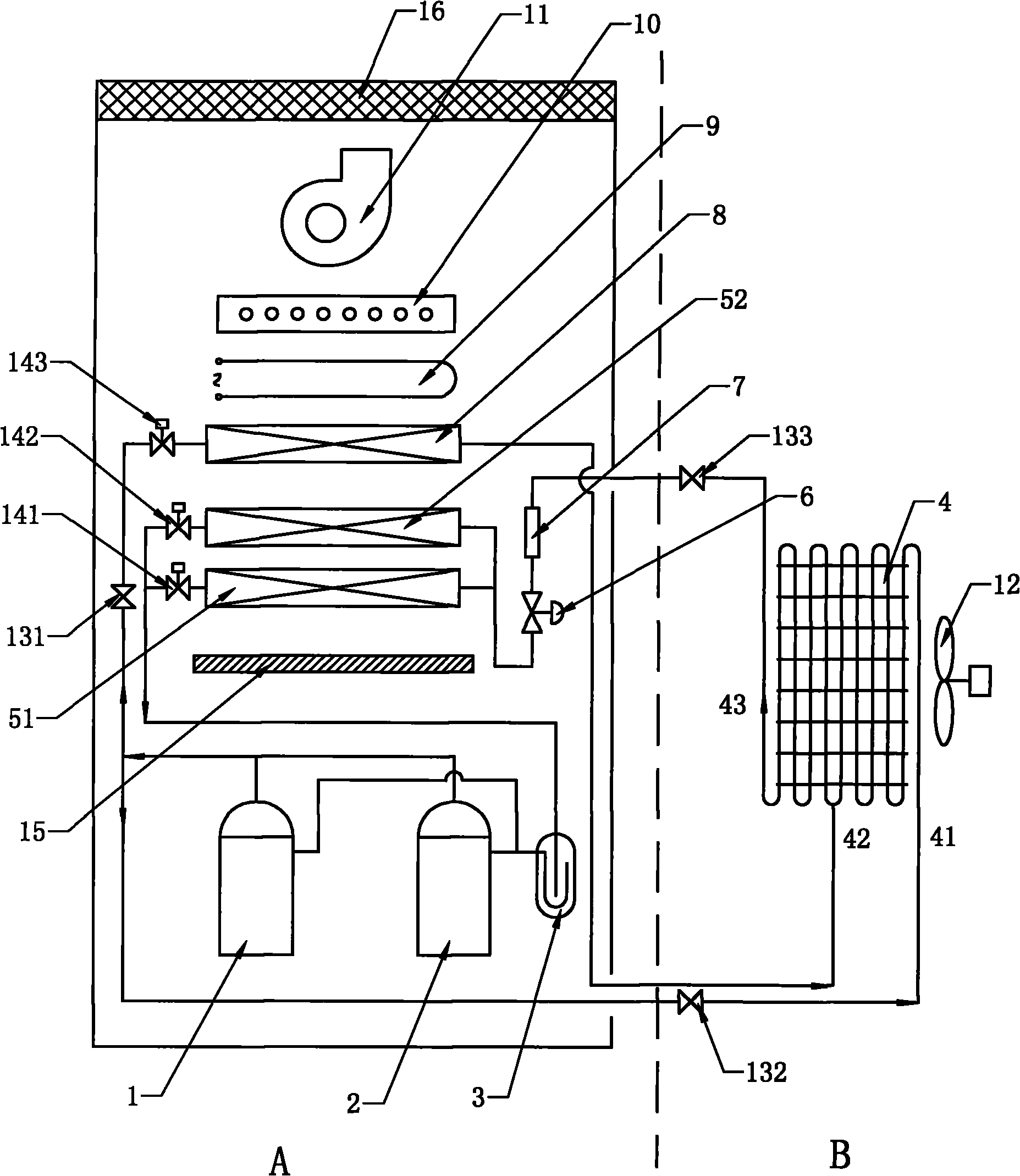

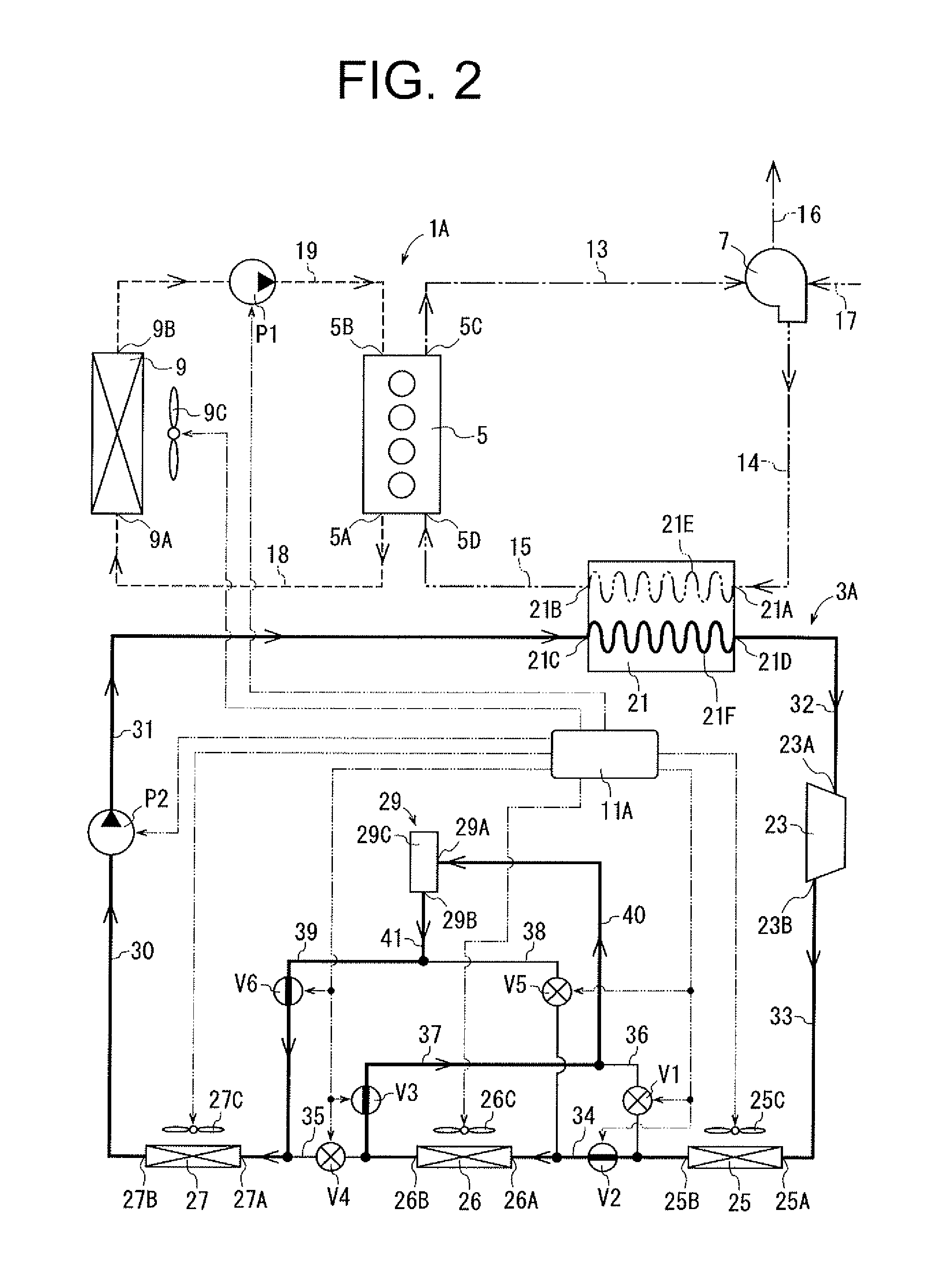

High-precision constant-temperature and humidity air conditioner operated in wide temperature range

InactiveCN101813343AAvoid energy wasteResolve delayCompressorEnergy recovery in ventilation and heatingConstant frequencyElectronic expansion valve

The invention relates to a high-precision constant-temperature and humidity air conditioner operated in a wide temperature range. The air conditioner comprises an outdoor machine and an indoor machine, wherein the outdoor machine is provided with a condenser and a condensing fan; the indoor machine comprises an evaporator, a thermal recovery exchanger, an electric heater, a humidifier and a blower; and a compressor is formed by connecting in parallel a constant-frequency compressor and a variable-frequency compressor (or a digital scroll compressor) and is arranged in the indoor machine. As the system adopts frequency conversion technology or digital vortex technology and electronic expansion valve technology and unique classified evaporator control, condenser fan frequency-conversion control technology and evaporator frostless structural design, the air condition broadens the use environment range, indoor temperature control environment (between 7 and 30 DEG C) and relative humidity control environment (between 35 and 70 percent RH), can be reliably operated in the outdoor high-temperature environment of 45 DEG C, also improves the controlling precision of indoor temperature and humidity, and is applicable to places with severe requirements on temperature and humidity and large environmental temperature change.

Owner:广东吉荣空调有限公司

Waste heat recovery system

InactiveUS20130067910A1Non-fuel substance addition to fuelInternal combustion piston enginesWaste heat recovery unitWorking fluid

The waste heat recovery system includes a Rankine cycle device in which working fluid circulates through a pump, a boiler, an expander and then through a heat exchanging device, heat exchange occurs in the boiler between the working fluid and intake fluid that is introduced into an internal combustion engine while being cooled. The heat exchanging device includes a condenser condensing the working fluid, a receiver connected downstream of the condenser and storing liquid-phase working fluid, a subcooler connected downstream of the receiver and subcooling the liquid-phase working fluid, and a selector device serving to change the ratio of the condenser to the subcooler. The waste heat recovery system further includes a determination device for determining required cooling load for the intake fluid, and a controller for controlling the selector device depending on the required cooling load determined by the determination device.

Owner:TOYOTA IND CORP

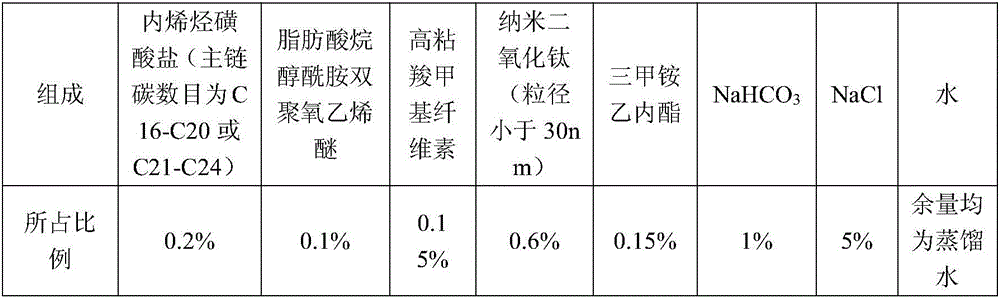

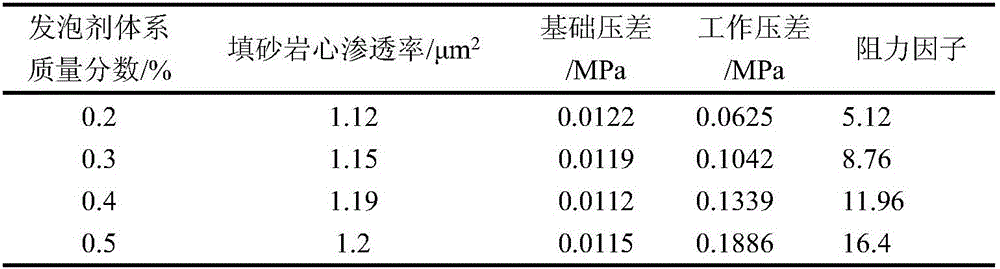

Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

InactiveCN106753307AImprove solubilityImprove performanceDrilling compositionInorganic saltsSolubility

The invention relates to the technical field of heavy oil recovery, in particular to a foam agent system used for switching water drive into steam drive of a heavy oil reservoir or steam huff and puff to improve the oil recovery efficiency. According to the technical scheme, the temperature-resistant and salt-tolerant foaming agent system for thermal recovery of the heavy oil reservoir is characterized by comprising a foaming agent base, a foam stabilizer, a foam fixing agent, a foam promoter, an alkali substance, inorganic salt and a solvent. The foaming agent system can resist the temperature of 350 DEG C and has good thermal stability and better foamability; the foaming agent base in the system is lower than the critical micelle concentration and can produce more foam, the apparent viscosity is substantially increased, and the cost is saved; the foaming agent system has better solubility, causes little damage to formation and is environment-friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

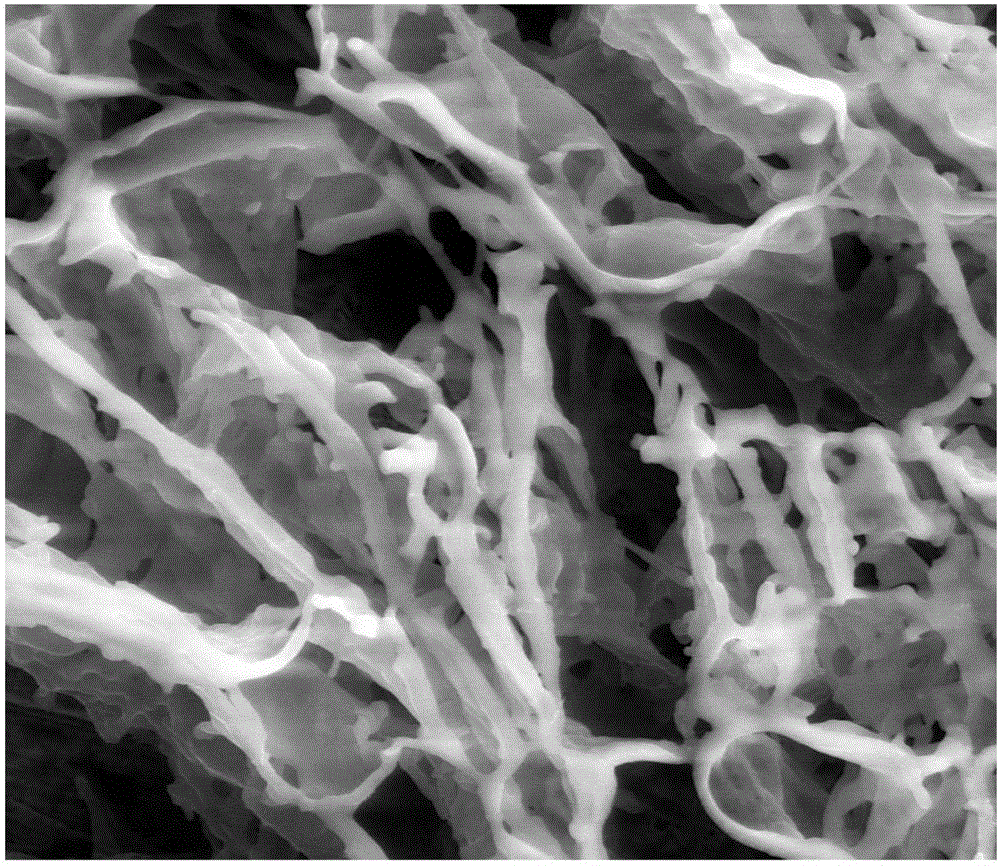

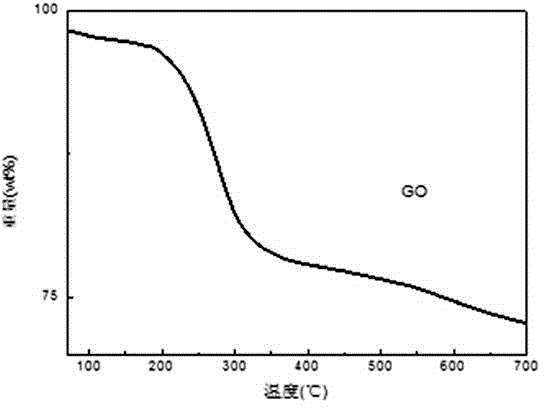

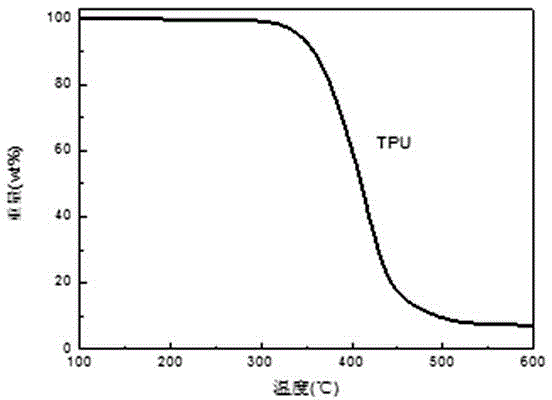

Graphene/thermoplastic polyurethane composite and preparation method thereof

The invention discloses a graphene / thermoplastic polyurethane composite and a preparation method and application thereof. The improved Hummers method is adopted to prepare graphene oxide which is dispersed in DMF to be subjected to ultrasonic treatment, TPU (Thermoplastic polyurethanes) swollen in DMF is poured in, and the solution coating film-forming process is adopted to prepare a GO (Graphene Oxide) / TPU composite film which is subjected to in-situ thermal recovery treatment for 2 h at 200 DEG C to prepare the graphene / thermoplastic polyurethane composite. The prepared graphene / thermoplastic polyurethane composite has the excellent electrical property, is uniform in filler dispersion, can be used for preparing TPU medical cushions, TPU biogas storage bags, TPU wading products and TPU water and oil storage bags, and can also be used in the field demanding relatively much on the obstructing and antistatic performance of materials.

Owner:FUZHOU UNIV

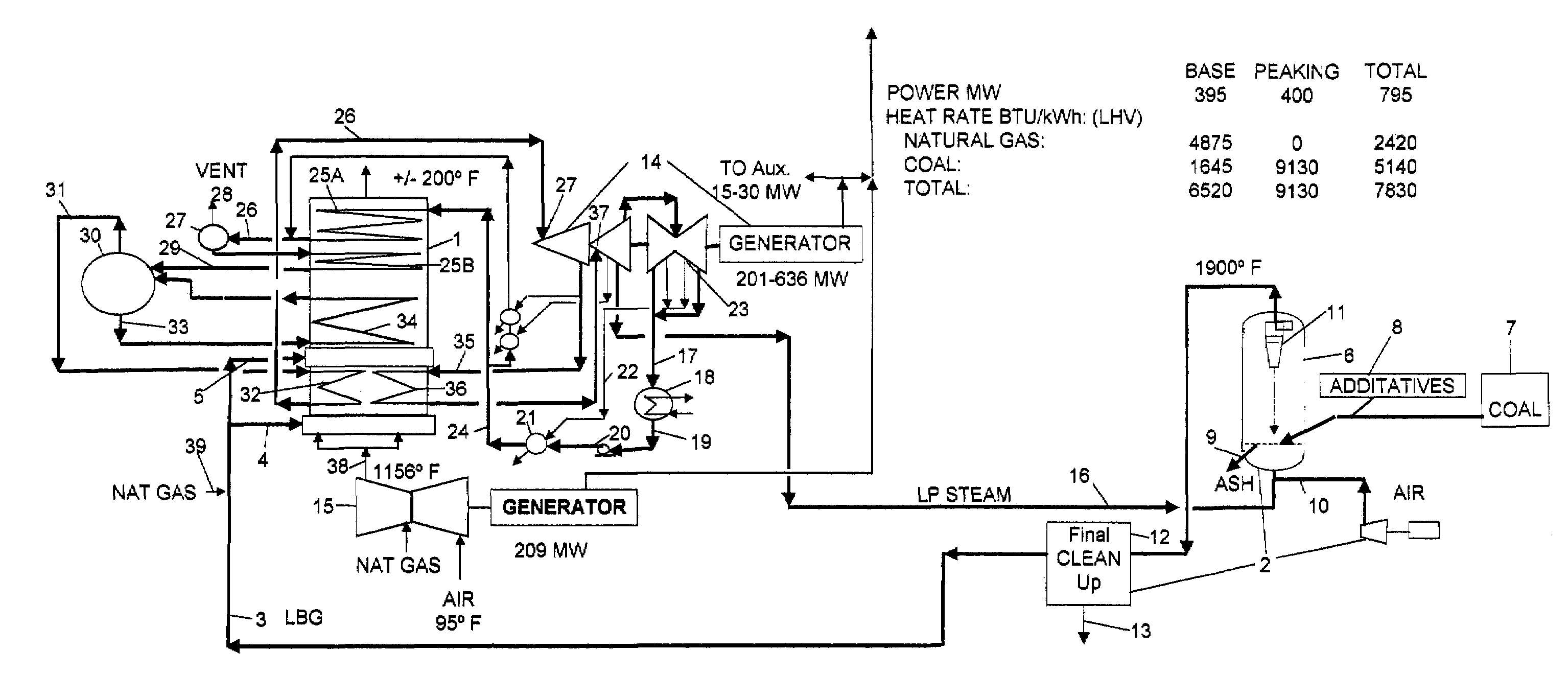

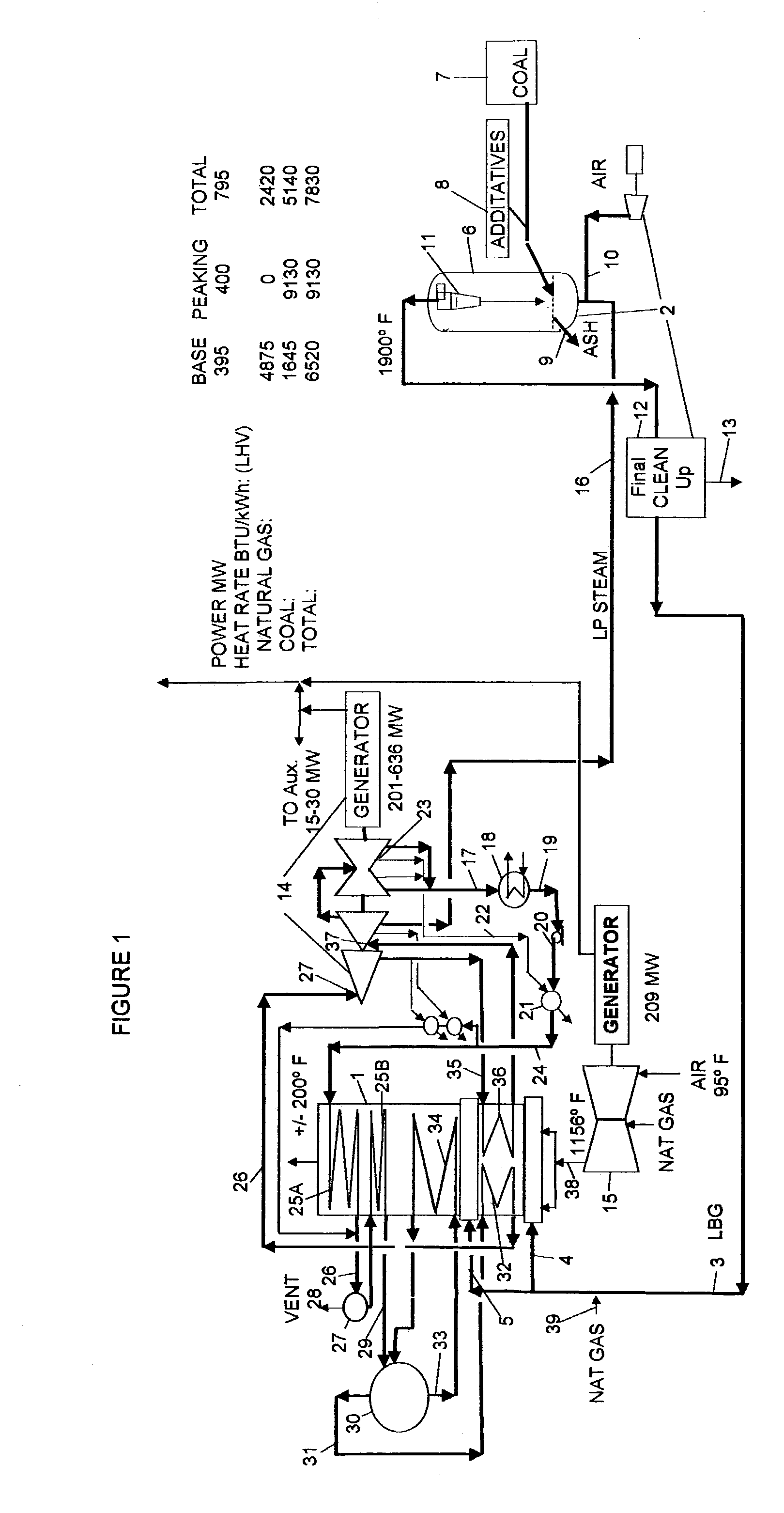

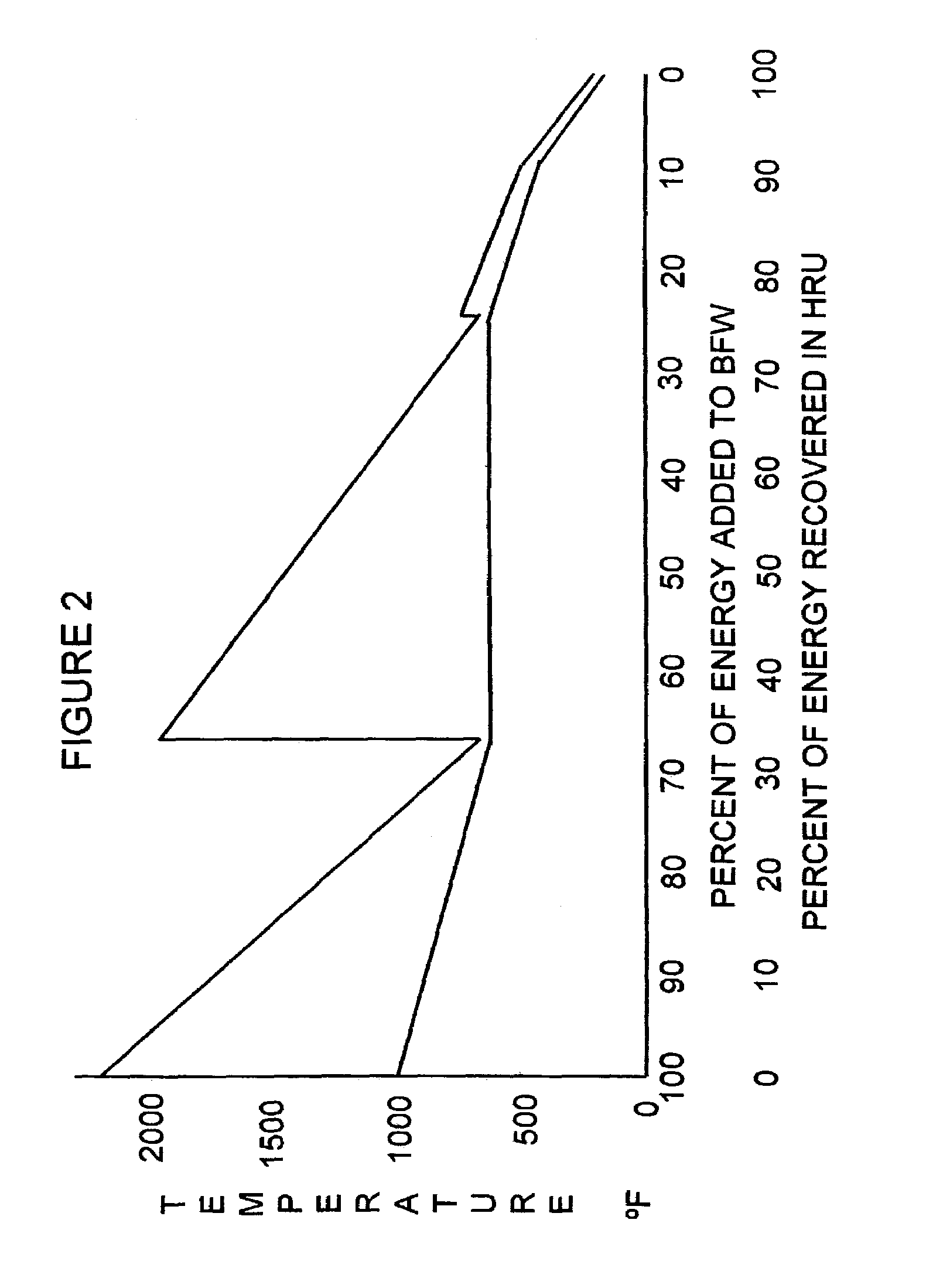

Combined cycle for generating electric power

InactiveUS6966190B2Low costImprove fuel efficiencyBiofuelsCombustion enginesBrown coalHydrocotyle bowlesioides

A combined cycle process that includes gas turbines, a steam turbine train, a heat recovery unit, and a gasification unit that produces low or mid BTU fuel gas from coal, lignite, coke, biomass, or other suitable hydrocarbon containing material wherein the fuel gas is burned in the heat recovery unit at one or more points to increase steam rate to the steam turbine train.The fuel gas injection flow rates into the heat recovery unit are controlled to avoid exceeding peak temperatures in the heat recovery unit of about 2500 F.Optionally, the fuel gas from the gasification unit is cooled by transferring sensible heat to condensate from the steam turbine train to convert the condensate to high pressure steam for driving the steam turbine train.Optionally, a steam boiler unit is integrated into the combined cycle process to raise additional high pressure steam for the steam turbine train. The steam boiler feed water is condensate from the steam turbine train. The steam boiler produces saturated high pressure steam that is superheated in the heat recovery unit.

Owner:WYLIE INVENTIONS

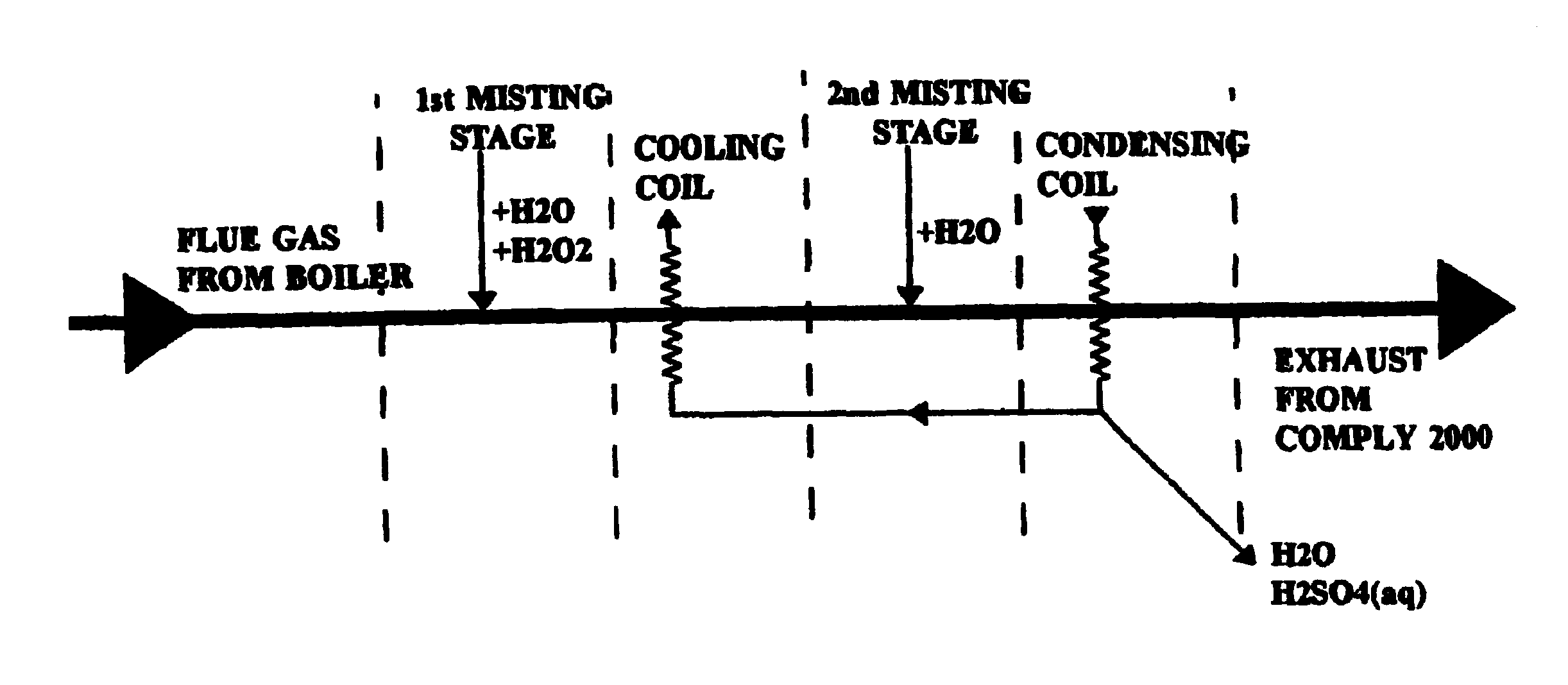

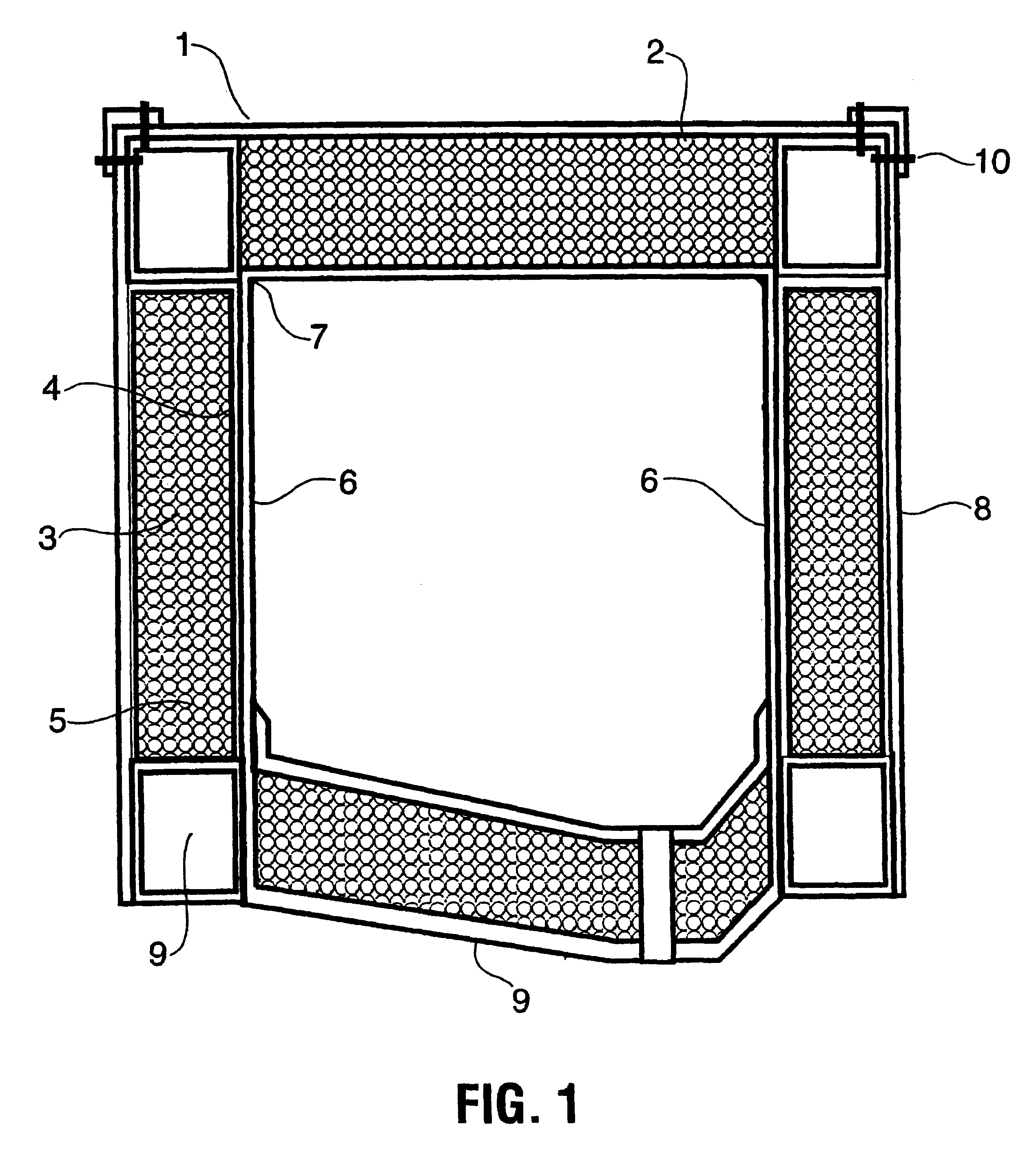

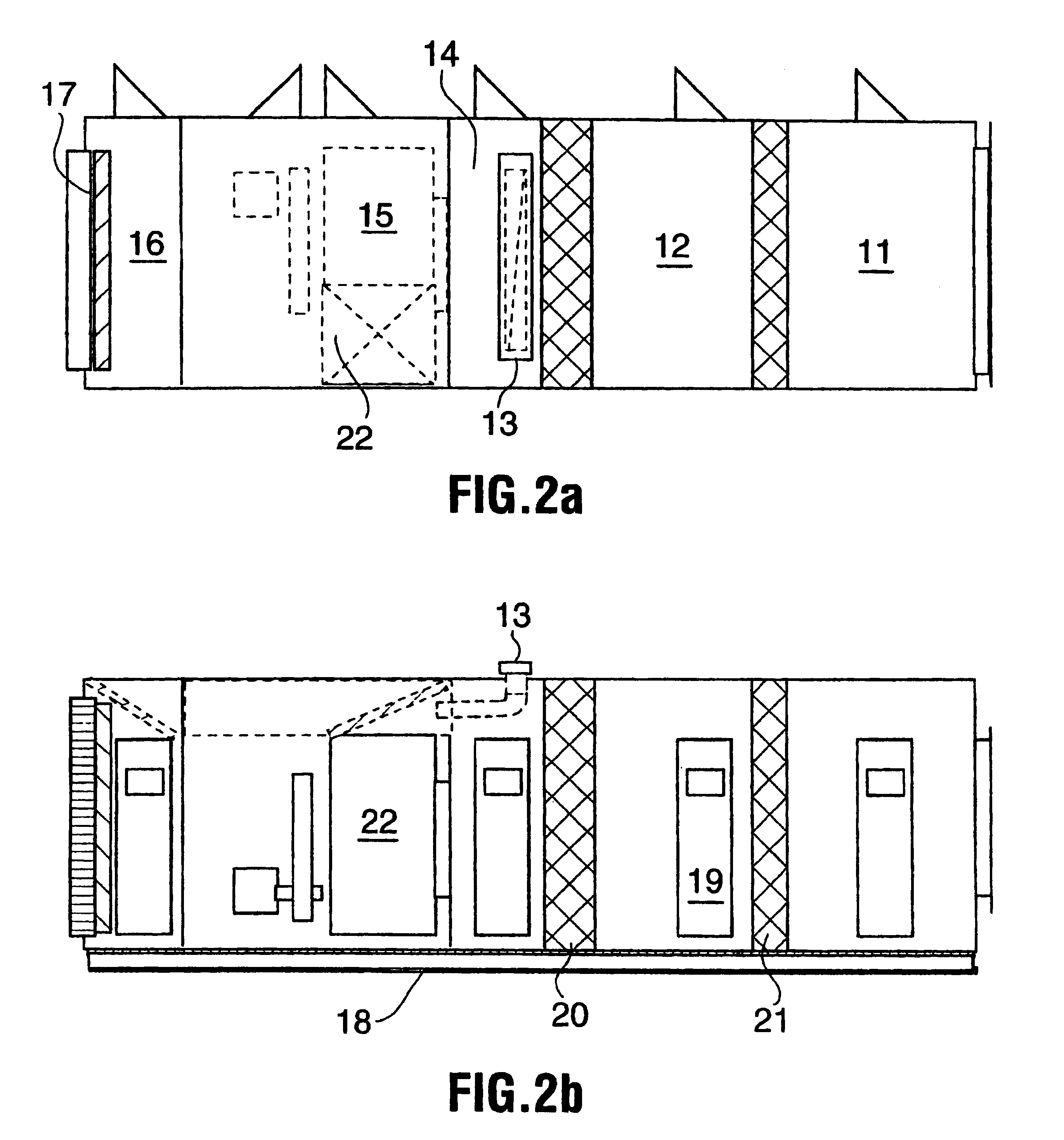

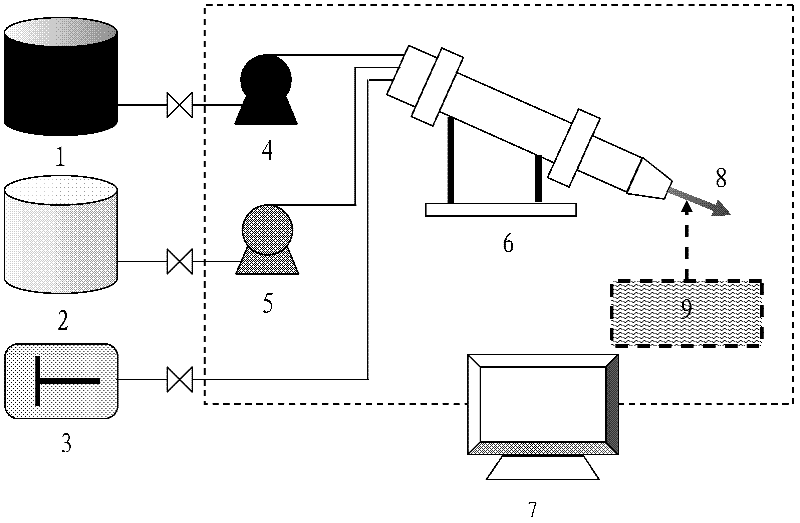

Heat recovery and pollution abatement device

A heat recovery and pollution abatement process with stackless operation for removing the products of combustion from hot boiler flue gas (45) comprising the steps of passing said hot boiler flue gas through a cloud of steam or mist (46), cooling the hot moist flue gas and recovering the heat therefrom (47), passing the partly cooled hot moist flue gas through a second cloud of mist comprised of cold water to total saturation (48), collecting the resulting stream of acid water, forcing the treated flue gas, mixing the treated flue gas with outside air, directing the forced treated air to atmosphere, shutting off the process in the absence of boiler flue gas.

Owner:ALTIRA TECH FUND V

Thermal recovery technology of multielement thermal fluid of thickened oil well

The invention relates to a thermal recovery technology of a multielement thermal fluid of a thickened oil well, comprising the step of injecting a multielement thermal fluid and annular injection nitrogen into an oil layer together. The invention relates to a thermal recovery technology of a multielement thermal fluid of an offshore thickened oil well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com