Patents

Literature

478 results about "Recovery boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery boiler is the part of Kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usually used in the process or in making electricity, much as in a conventional steam power plant. The invention of the recovery boiler by G.H. Tomlinson in the early 1930s was a milestone in the advancement of the kraft process.

Methods and apparatus for starting up emission-free gas-turbine power stations

InactiveUS6945052B2Large capacityGas turbine plantsIndirect carbon-dioxide mitigationPower stationCombustion chamber

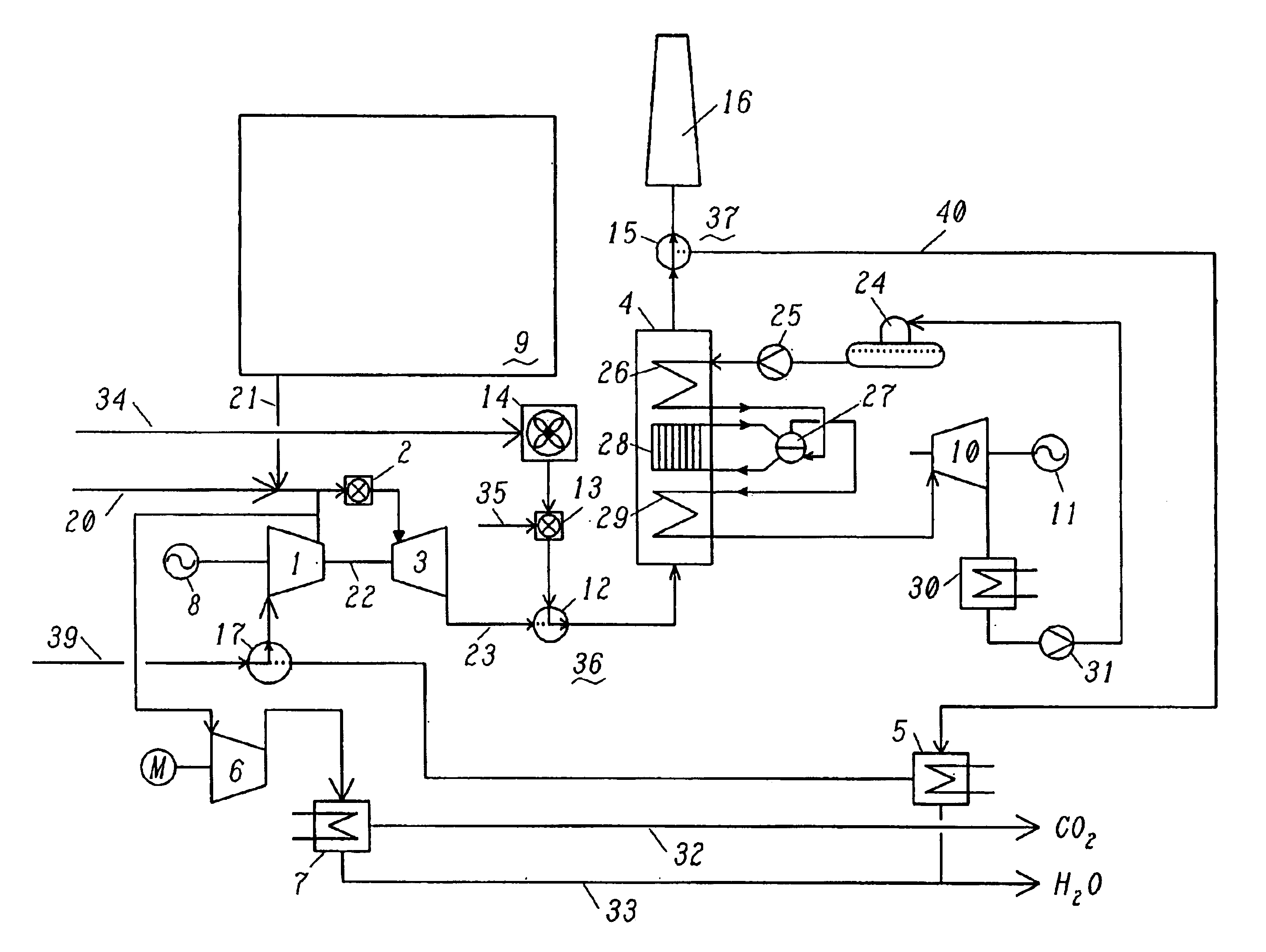

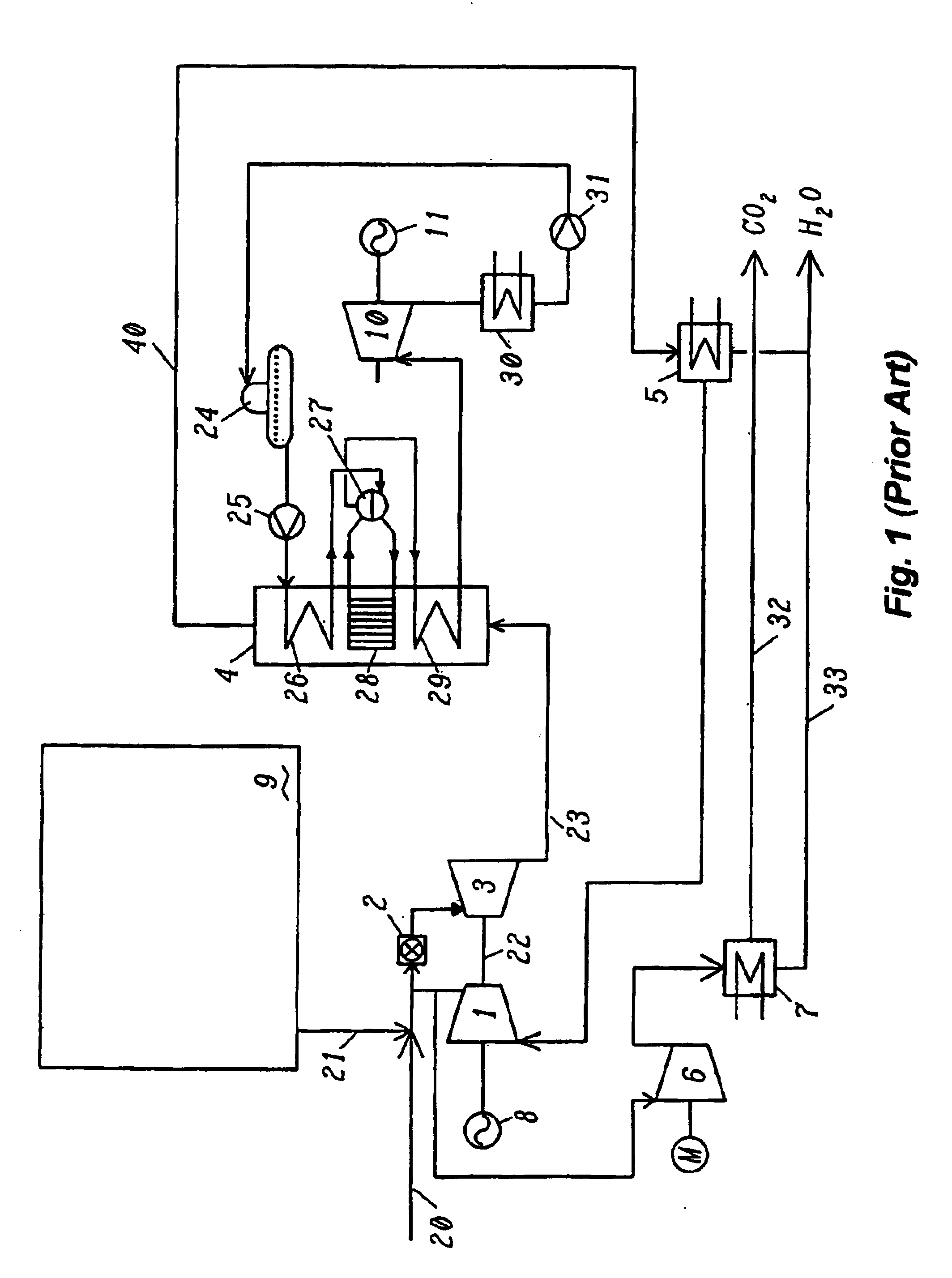

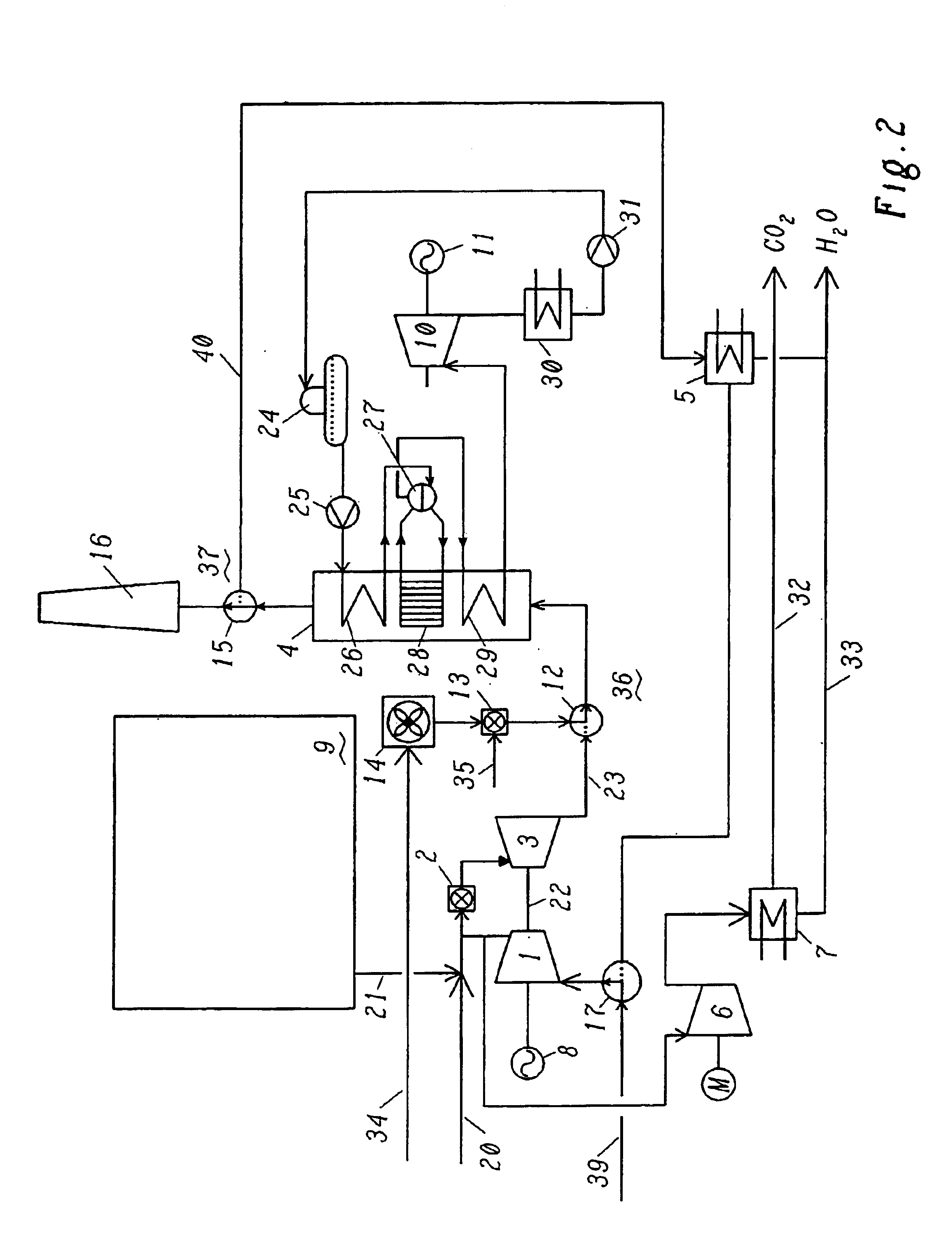

In a power generation plant having at least one gas turbine cycle with heat-recovery boiler (4) and at least one steam turbine cycle operated via the heat-recovery boiler (4), the gas turbine cycle being designed to be semi-closed and essentially free of emissions and essentially comprising a compressor (1), a combustion chamber (2) arranged downstream of the compressor (1), a gas turbine (3) arranged downstream of the combustion chamber (2), a heat-recovery boiler (4) arranged downstream of the gas turbine (3), and at least one generator (8) coupled to the gas turbine (3), modes of operation with the gas turbine cycle stopped and start-up using fresh air are made possible by first means (12) being arranged which alternatively or additionally allow hot gas to be fed into the hot-gas path (23) between gas turbine (3) and heat-recovery boiler (4), and by second means (15) being arranged which alternatively or additionally allow exhaust gas to be expelled from the exhaust-gas path (40) downstream of the heat-recovery boiler (4).

Owner:ANSALDO ENERGIA IP UK LTD

Method for separating lignin from black liquor, a lignin product, and use of a lignin product for the production of fuels or materials

ActiveUS20100325947A1Control balanceLower requirementSolid fuelsPulp by-products recoveryChemistryRecovery boiler

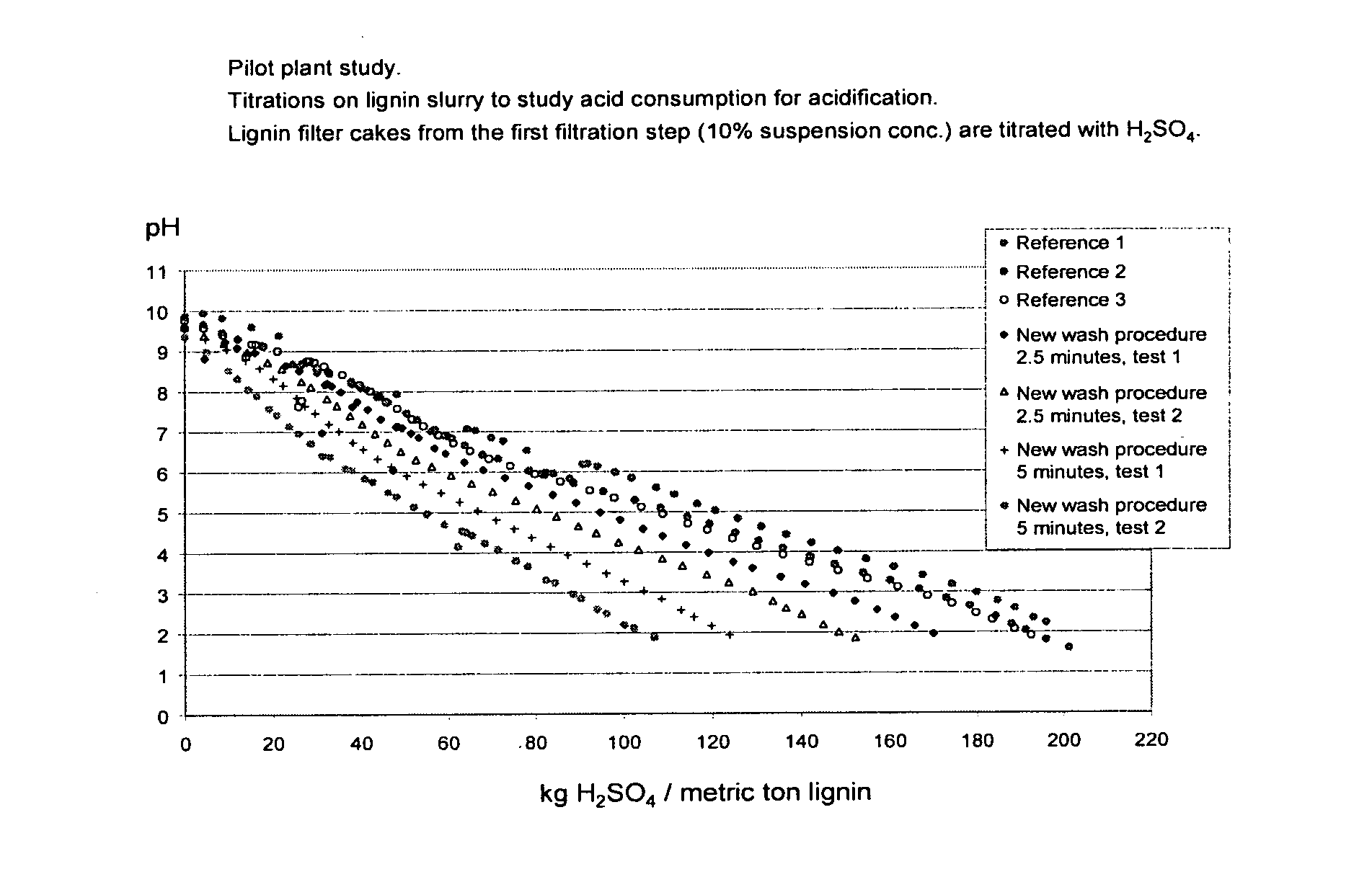

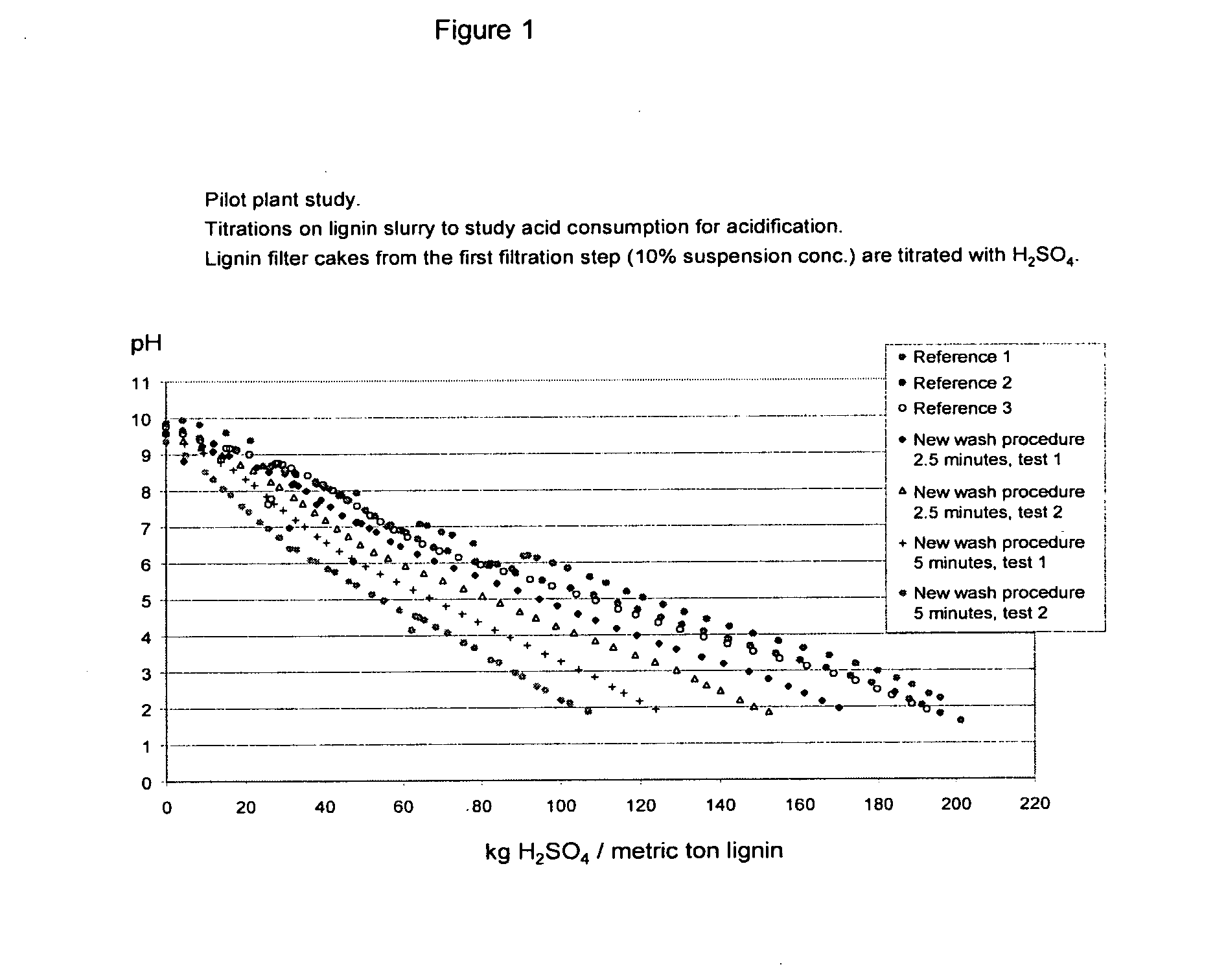

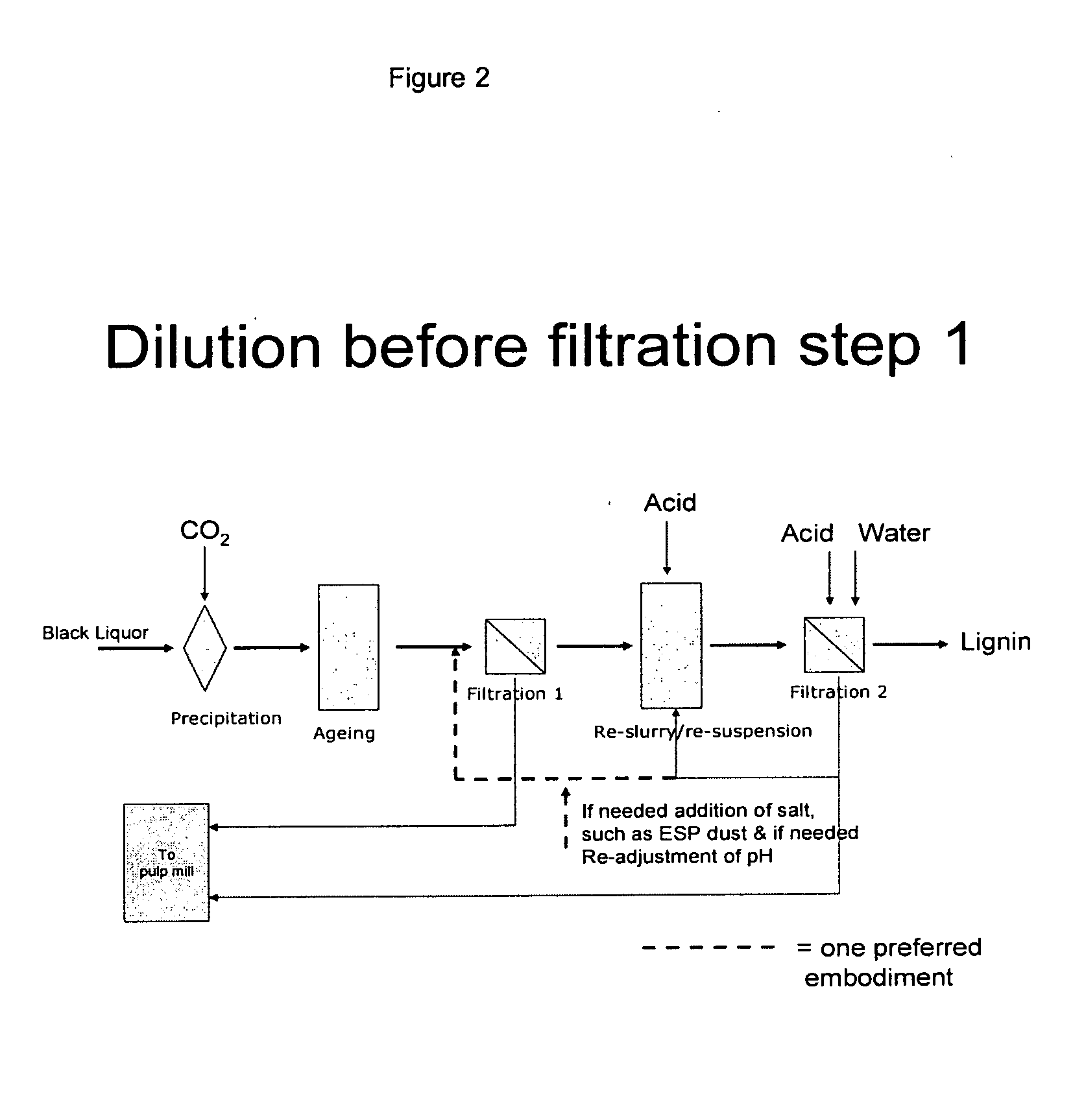

The method is for controlling a sodium and sulphur balance of a pulp mill while separating lignin from black liquor. Lignin is precipitated by using an acid followed by filtration. The lignin filter cake thus obtained is re-suspended in acidic liquid and dewatered to form a second cake. The filtrate obtained after dewatering of the second cake is returned for washing and suspension of the first cake. Sodium sulphate-rich ESP (electrostatic precipitator) dust produced in the recovery boiler is used in the washing of the precipitated lignin cake.

Owner:VALMET AB

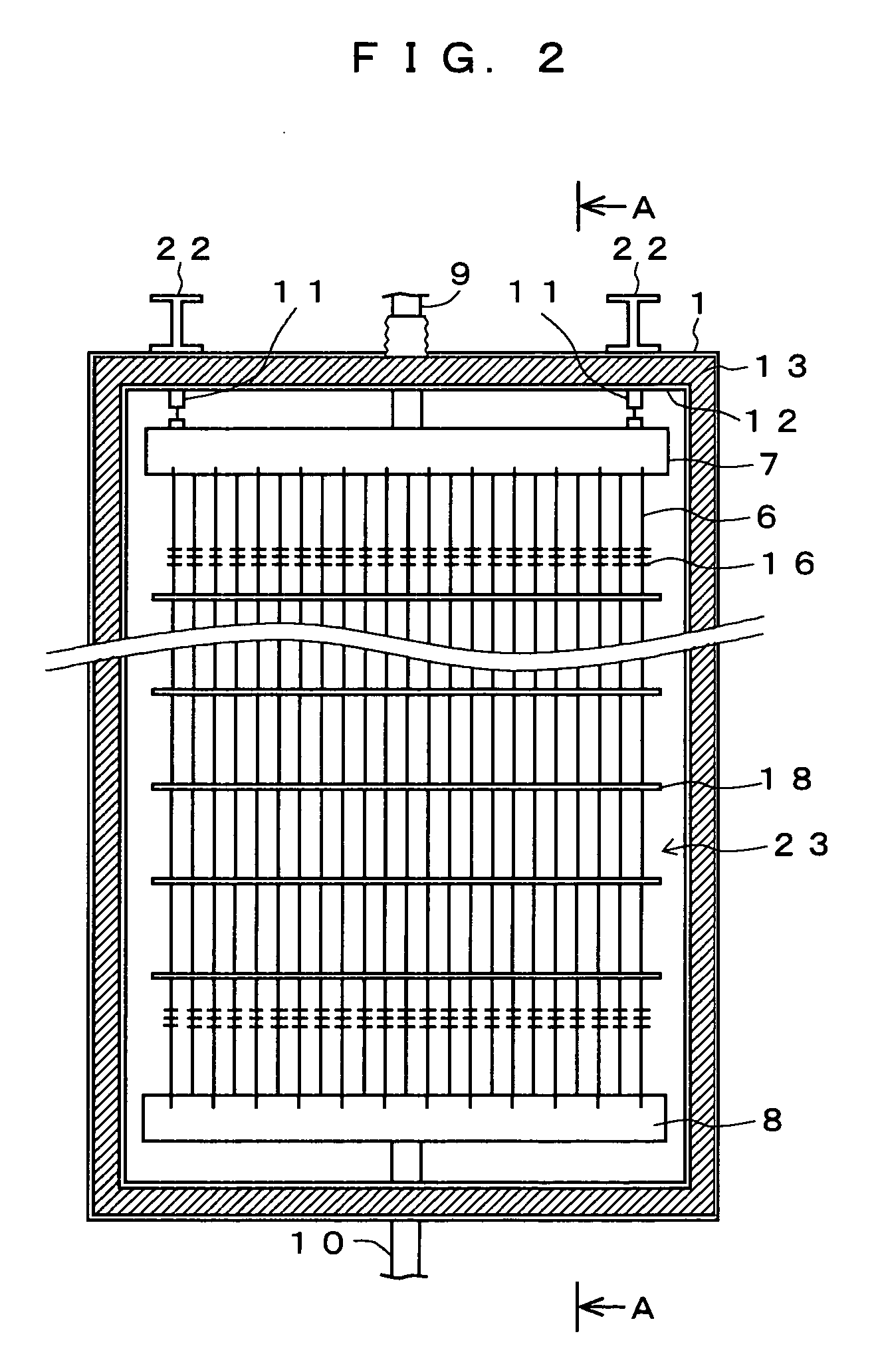

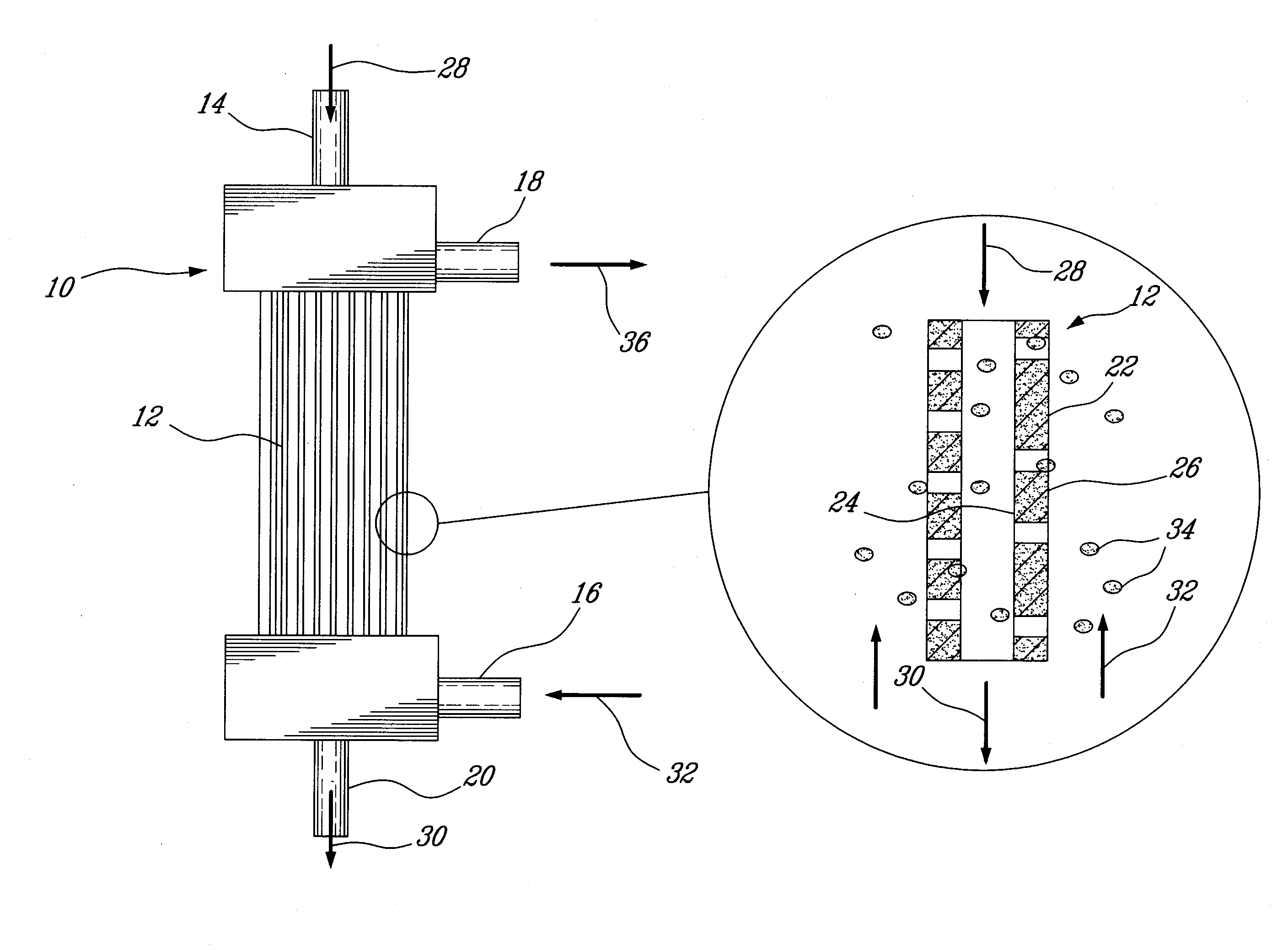

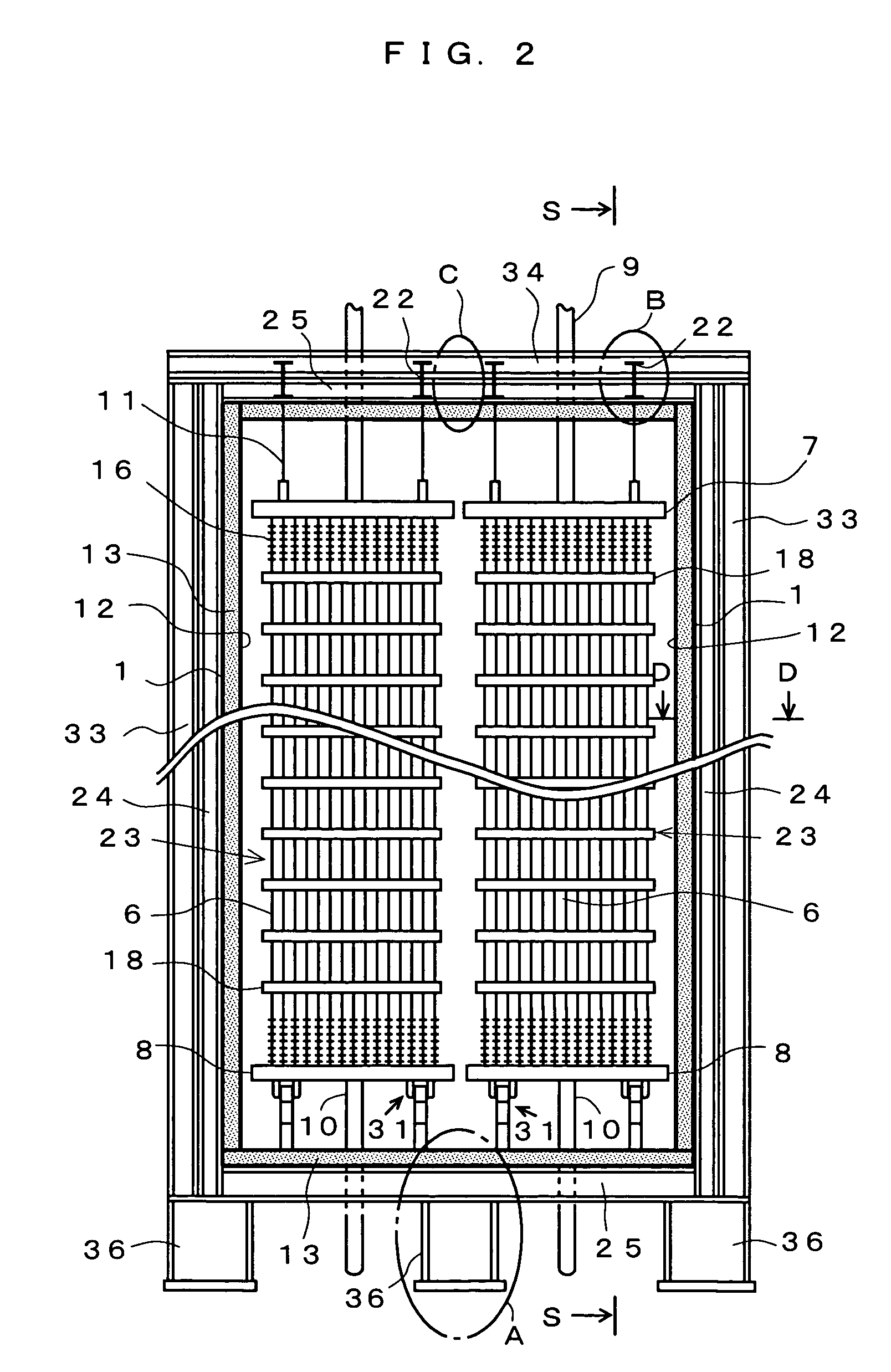

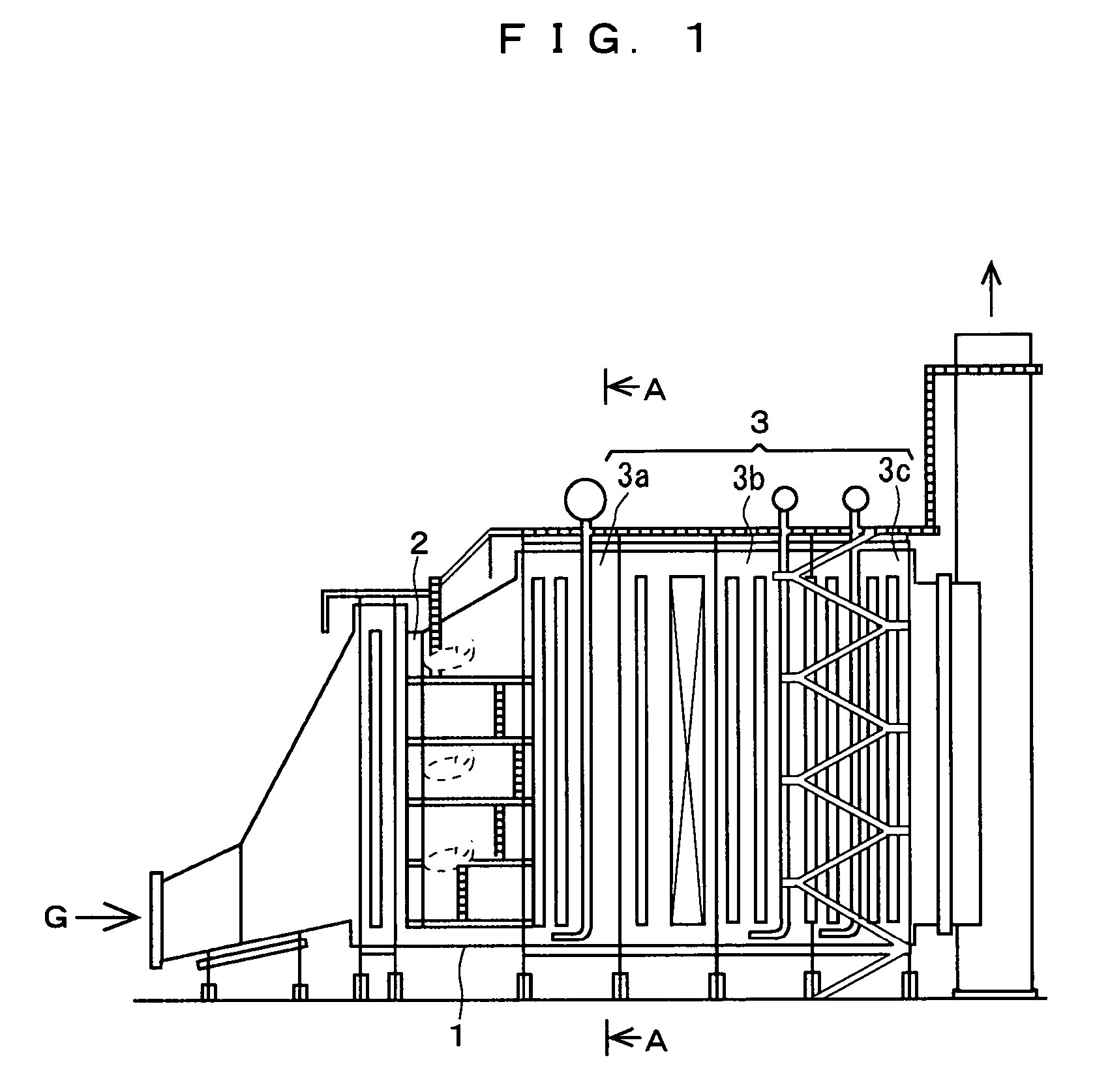

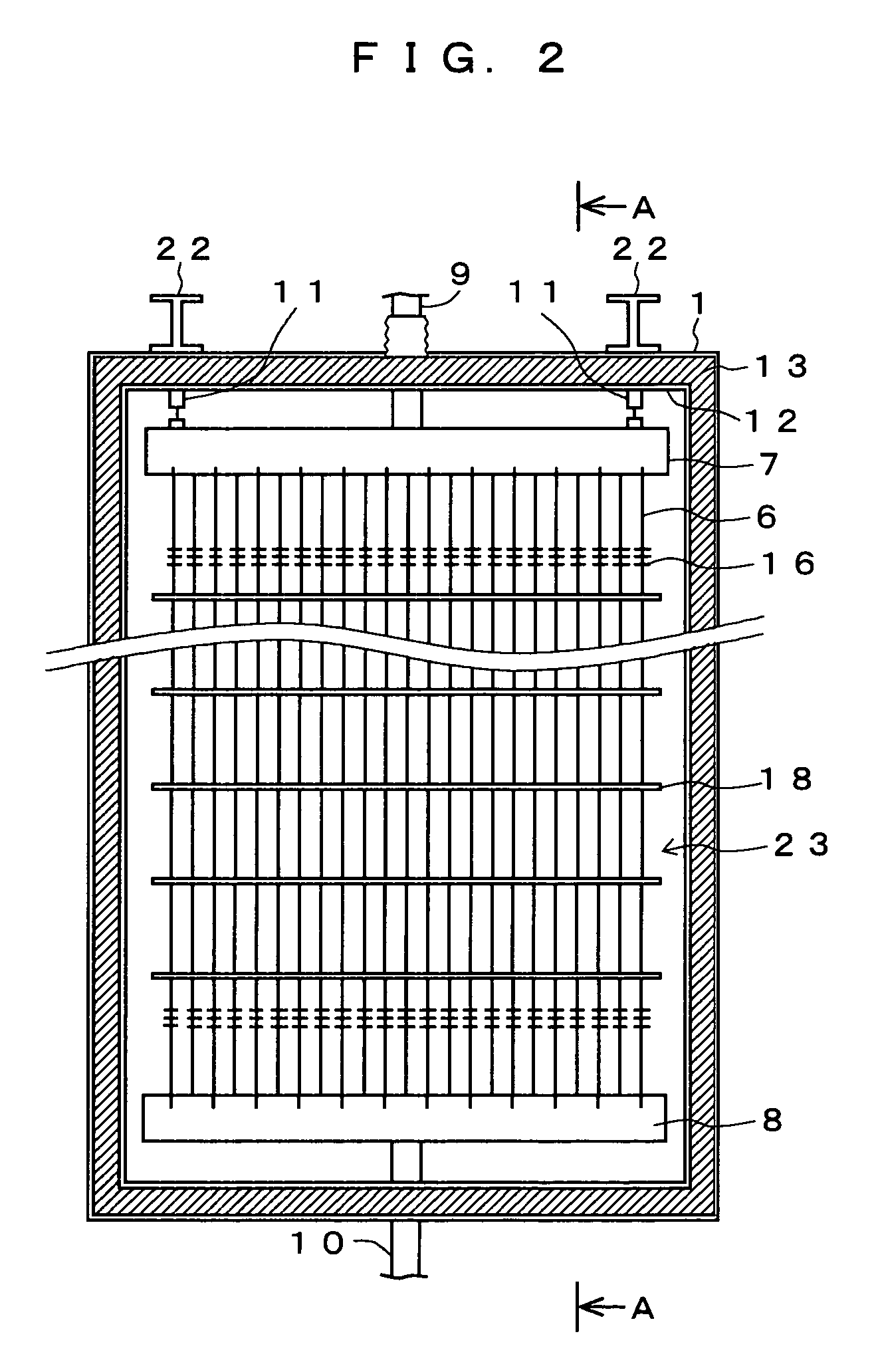

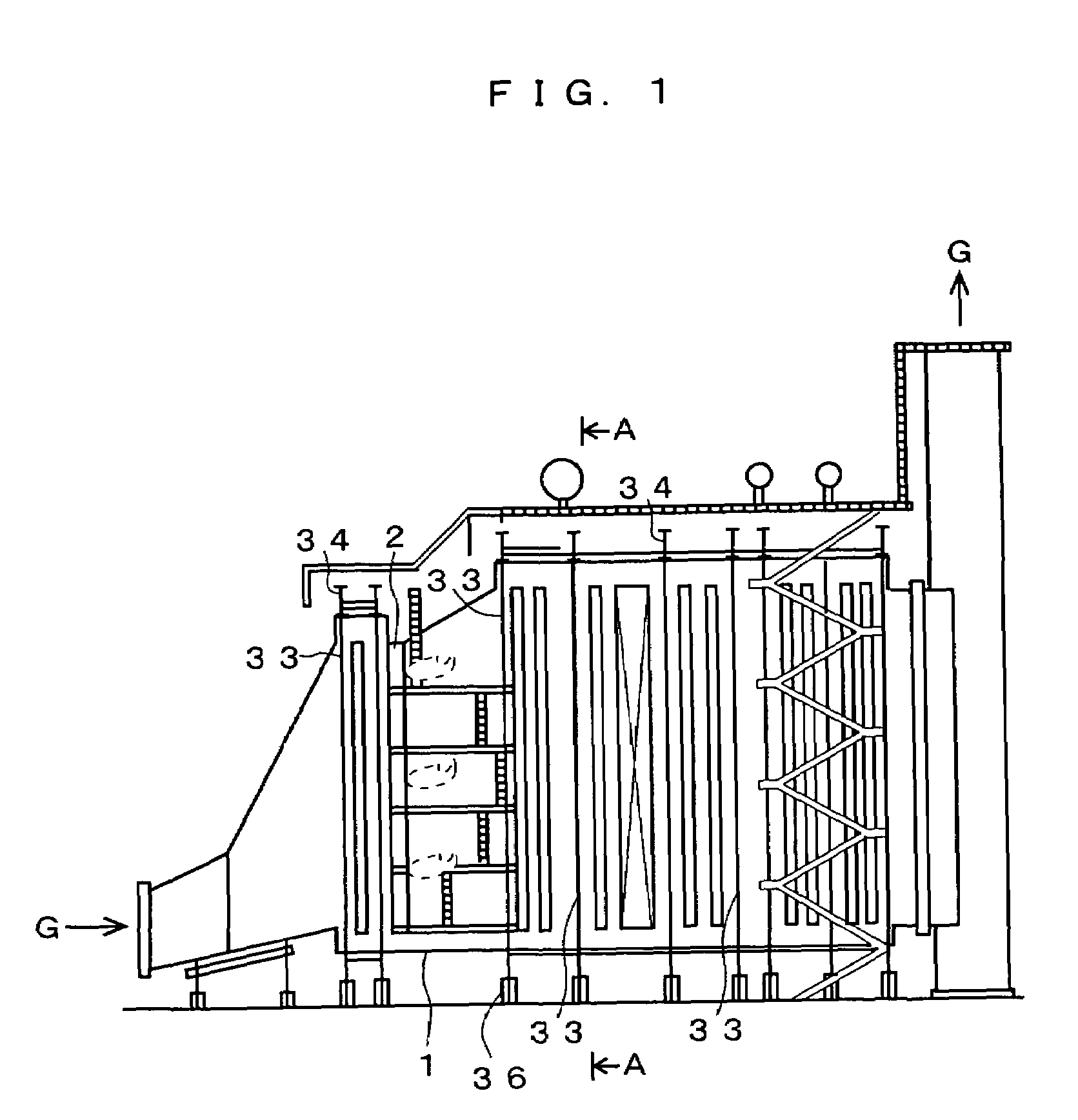

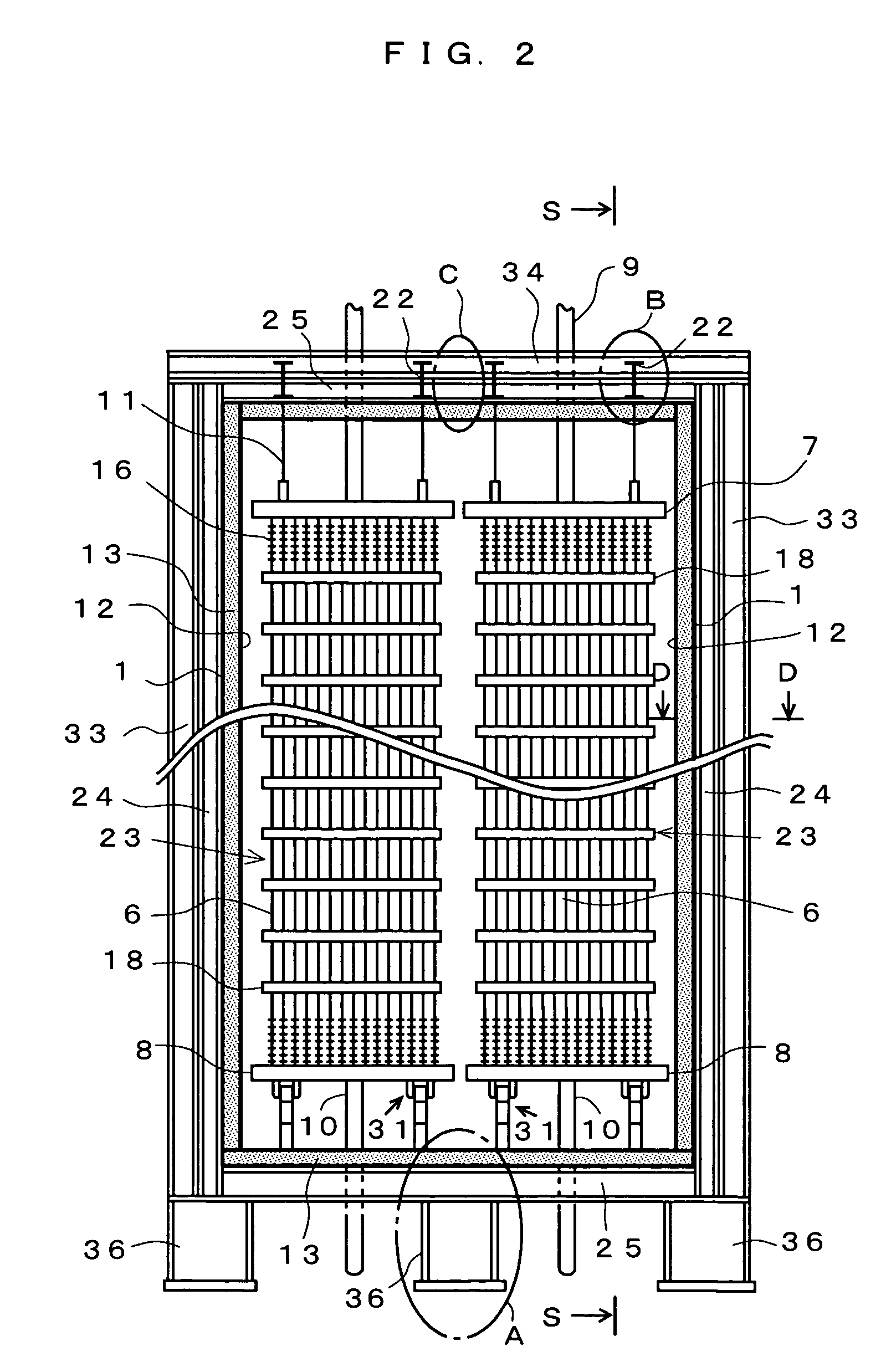

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS20070119388A1Easy to installShort timeBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

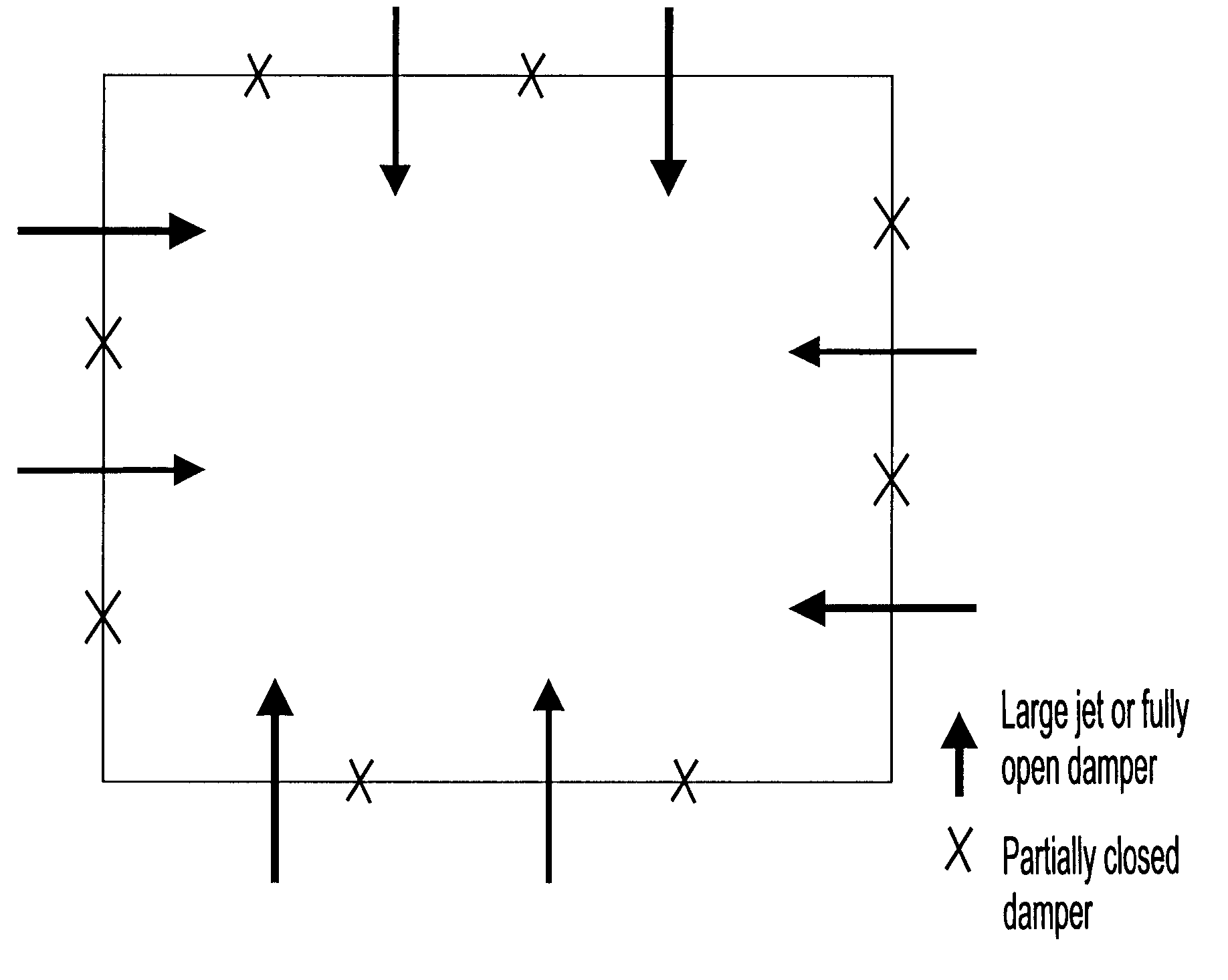

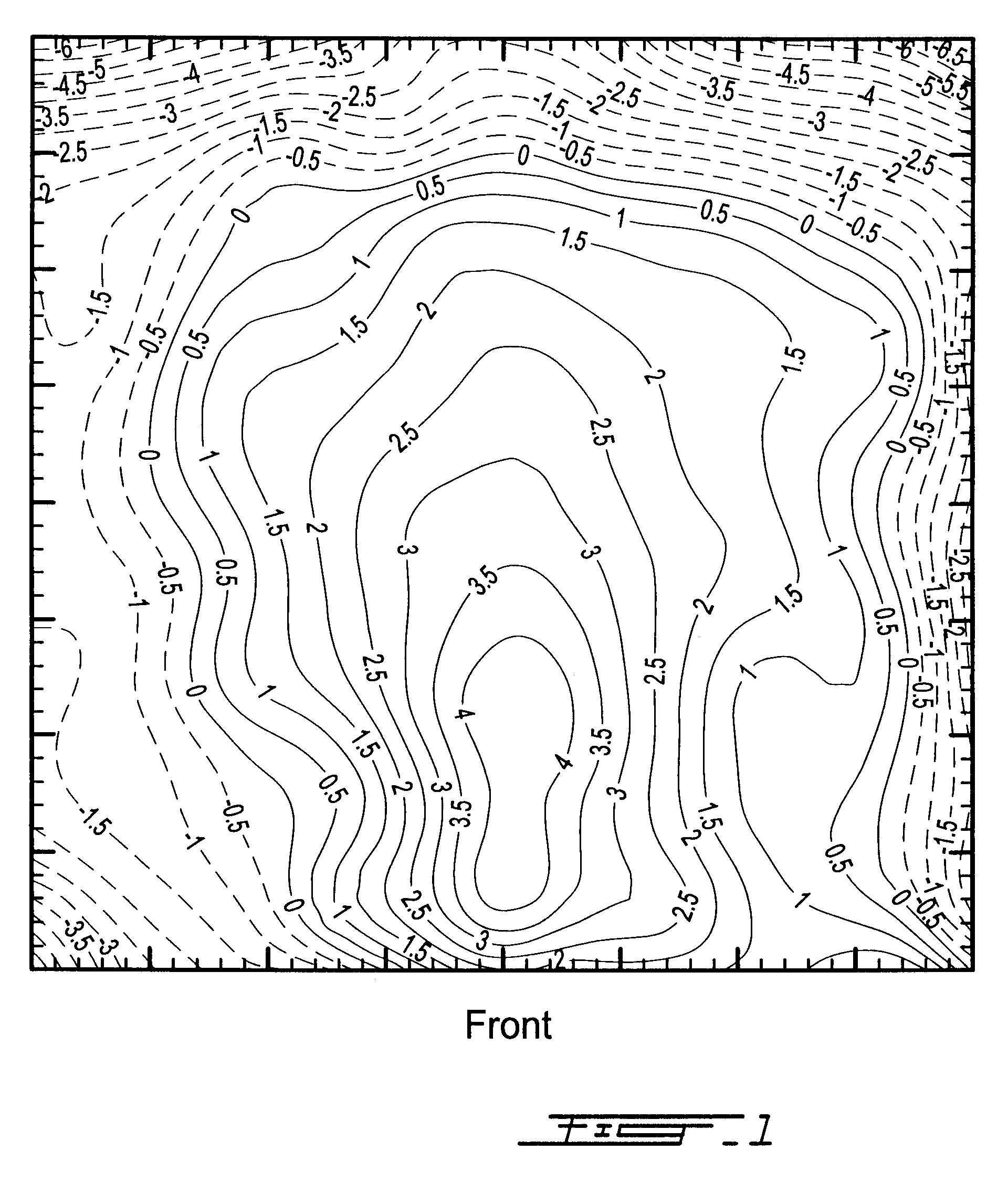

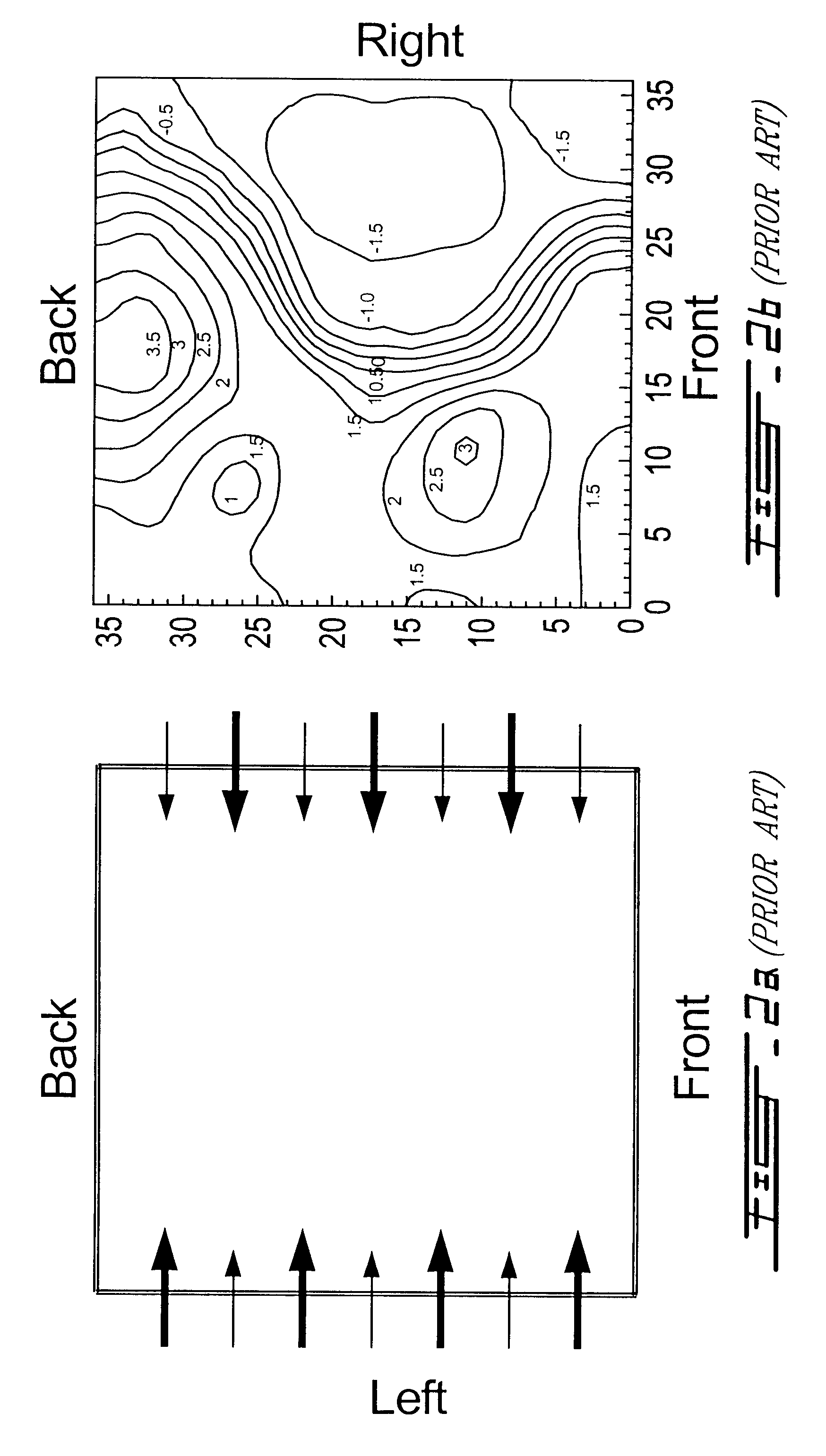

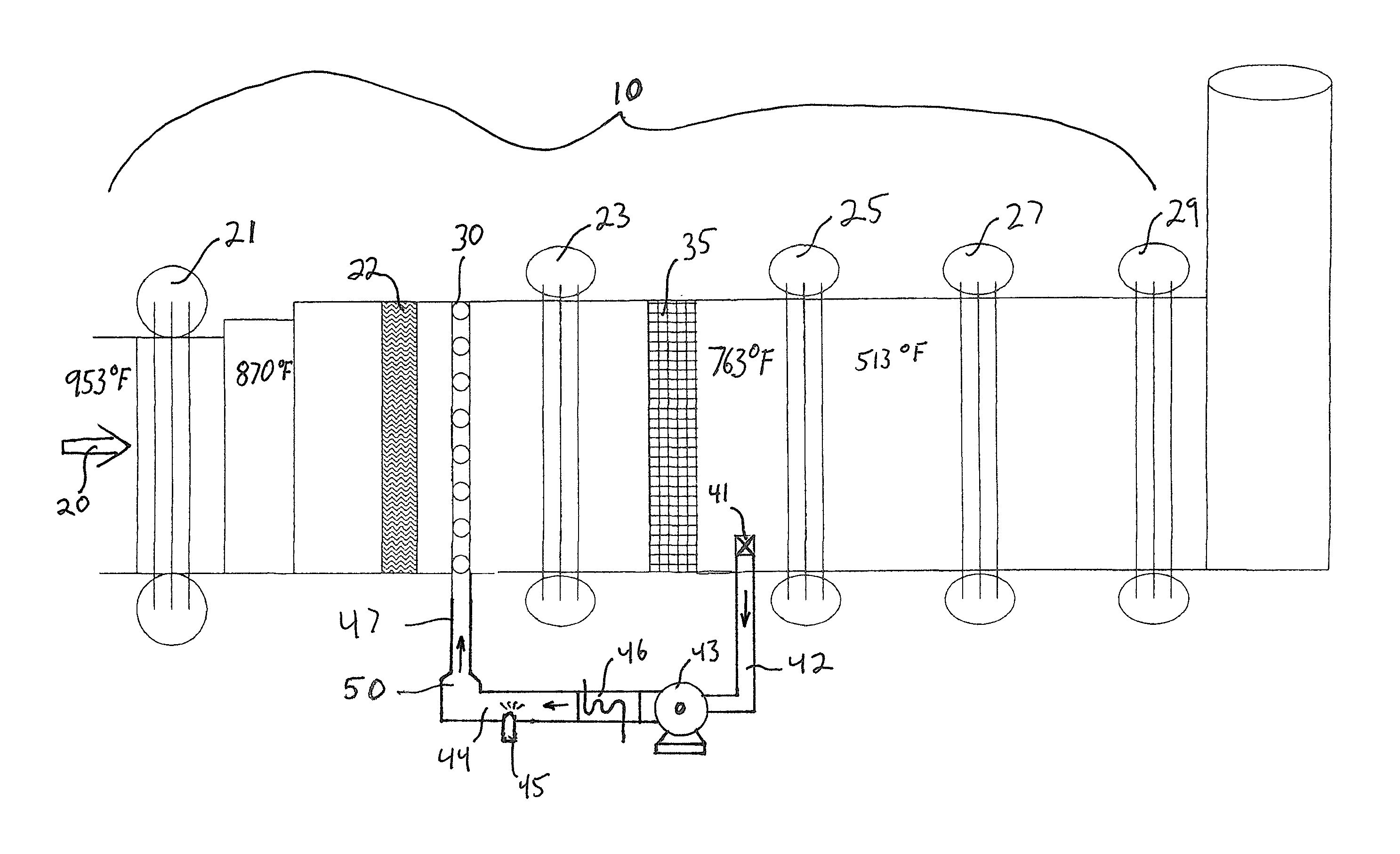

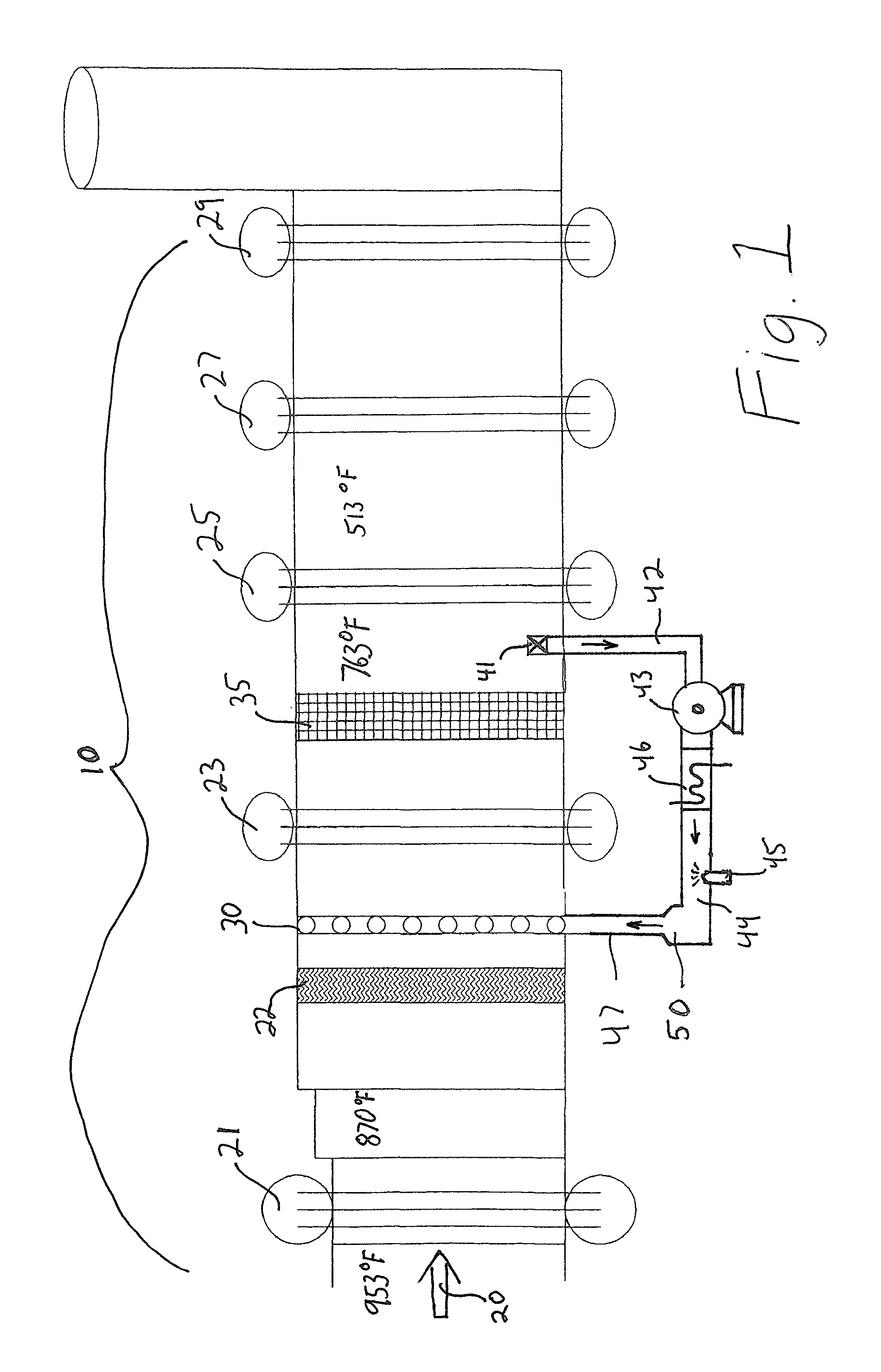

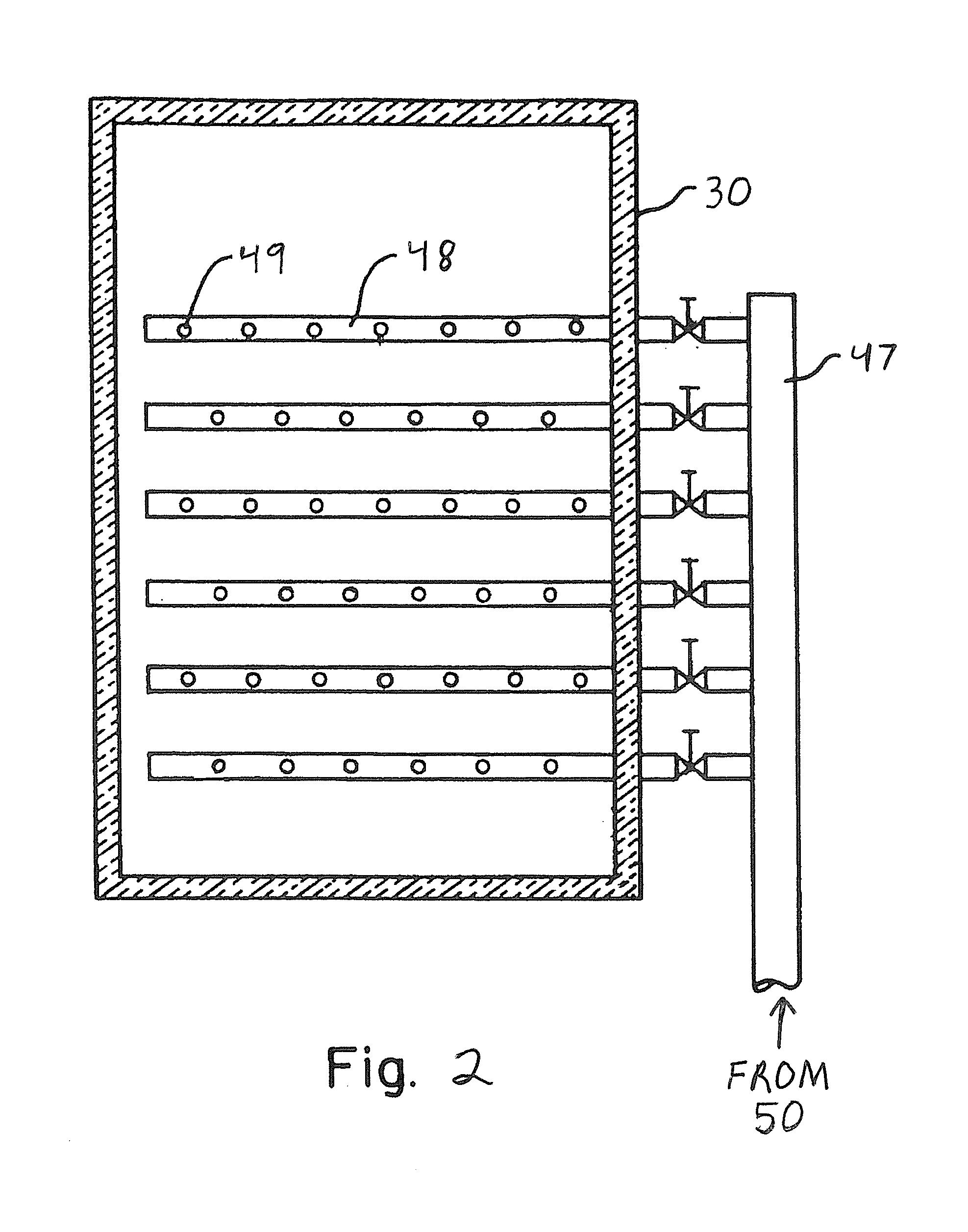

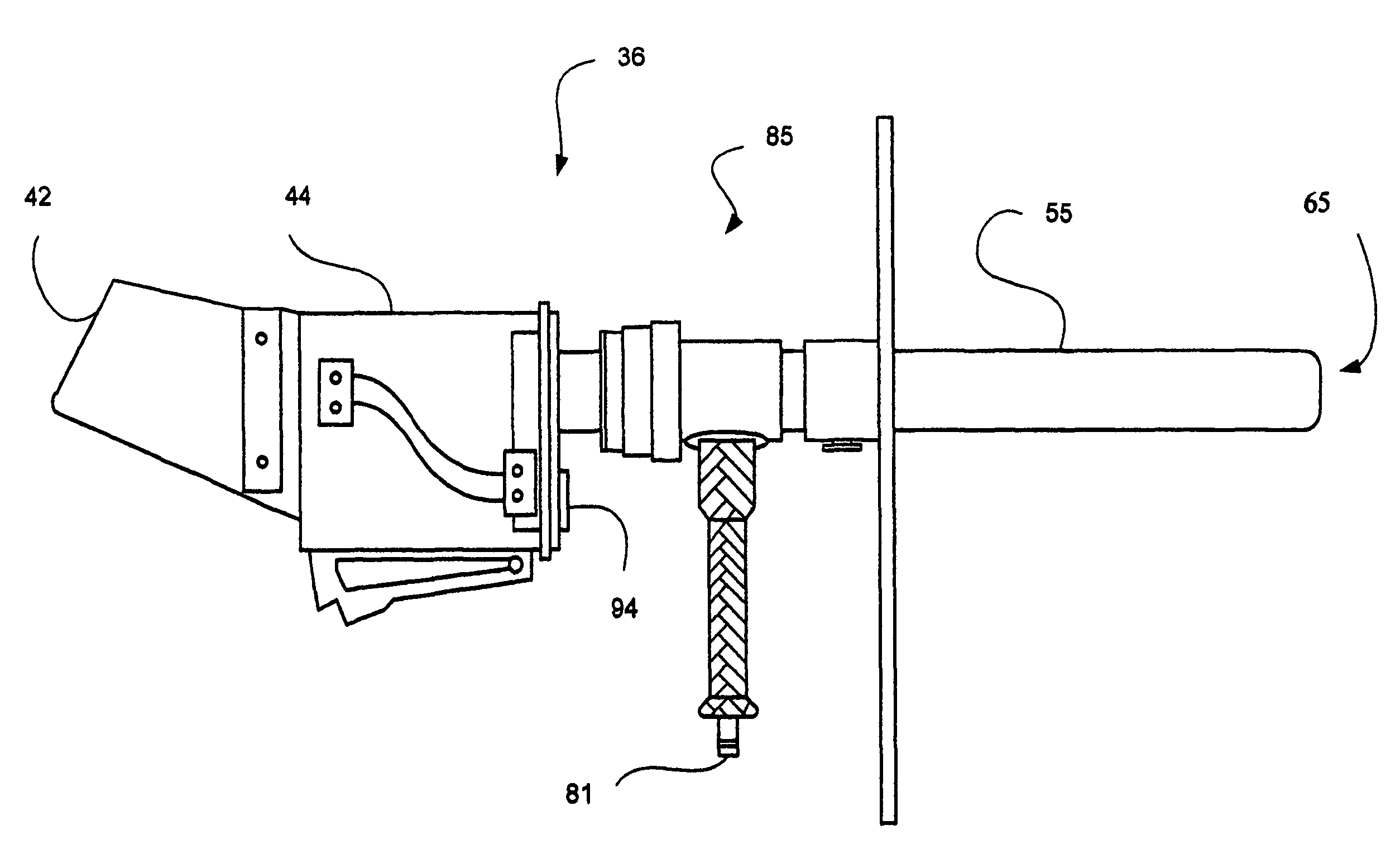

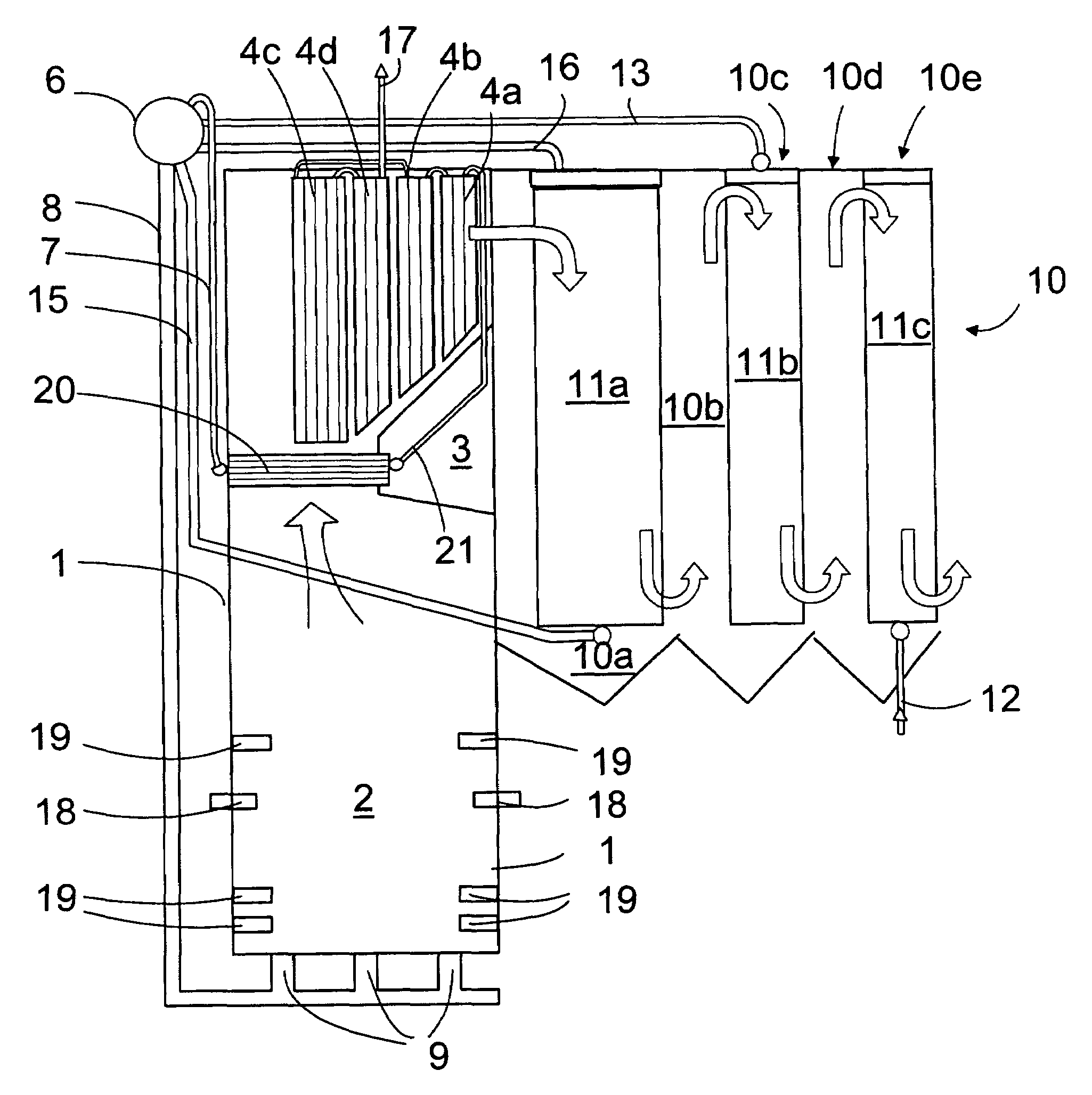

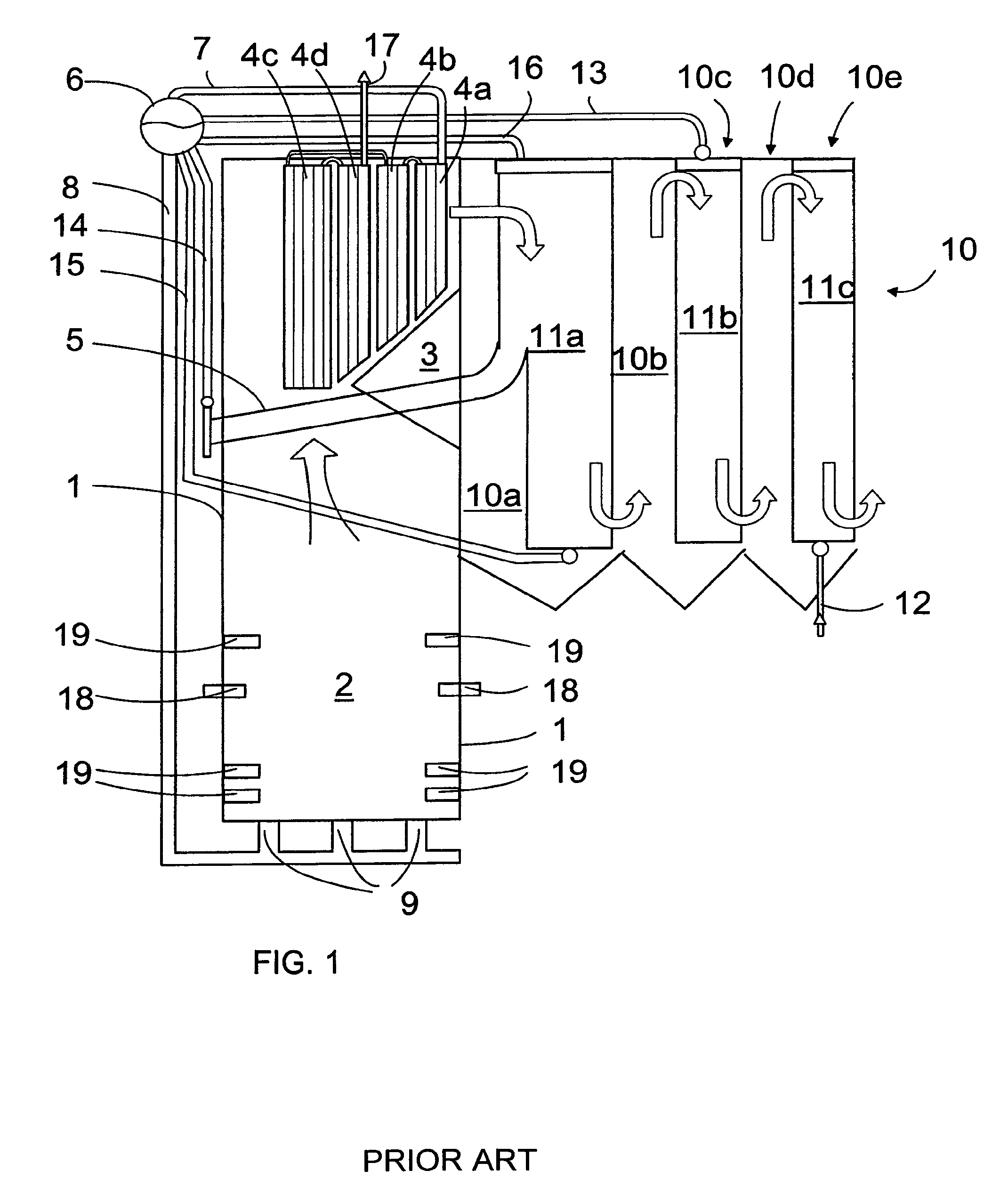

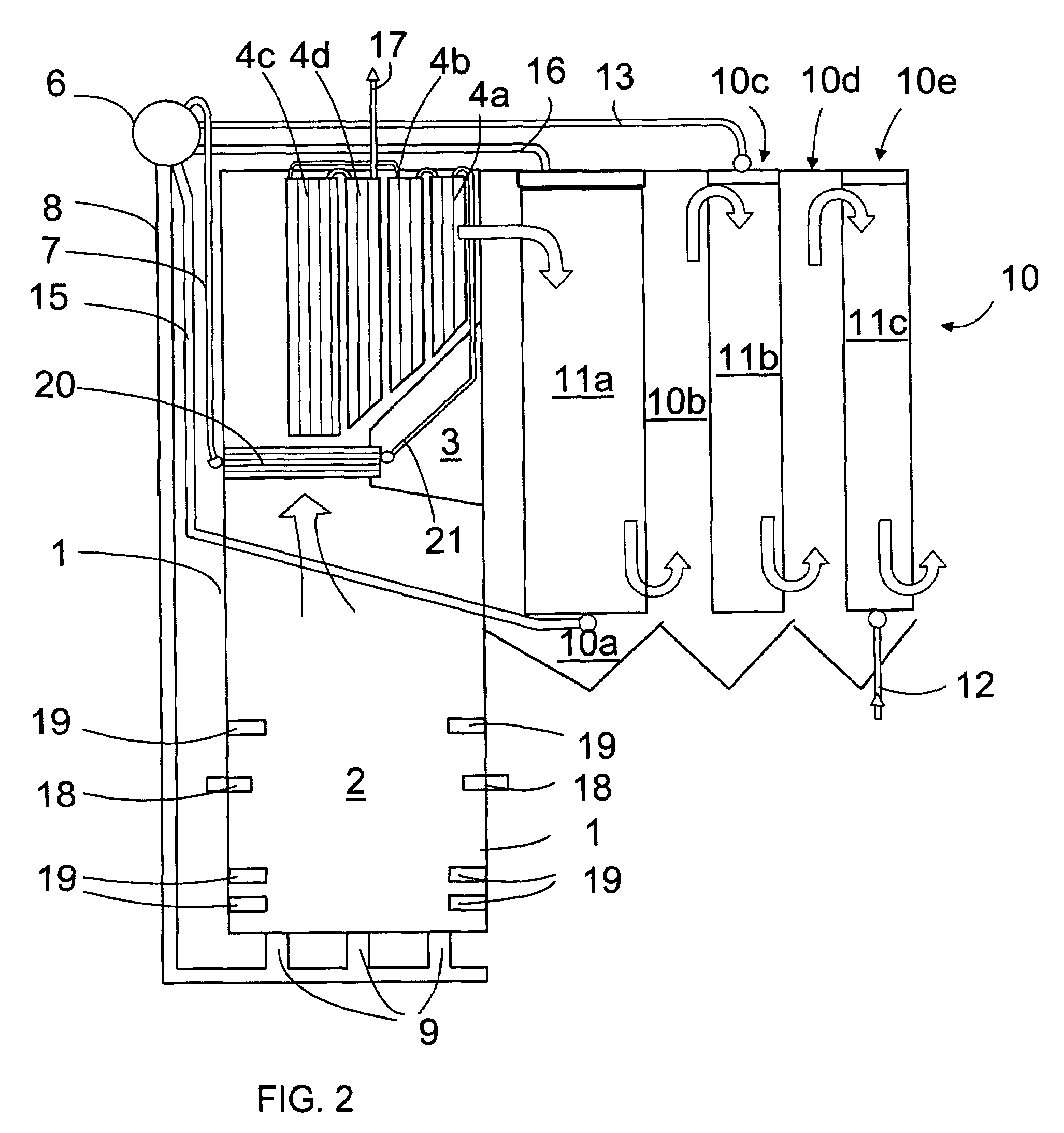

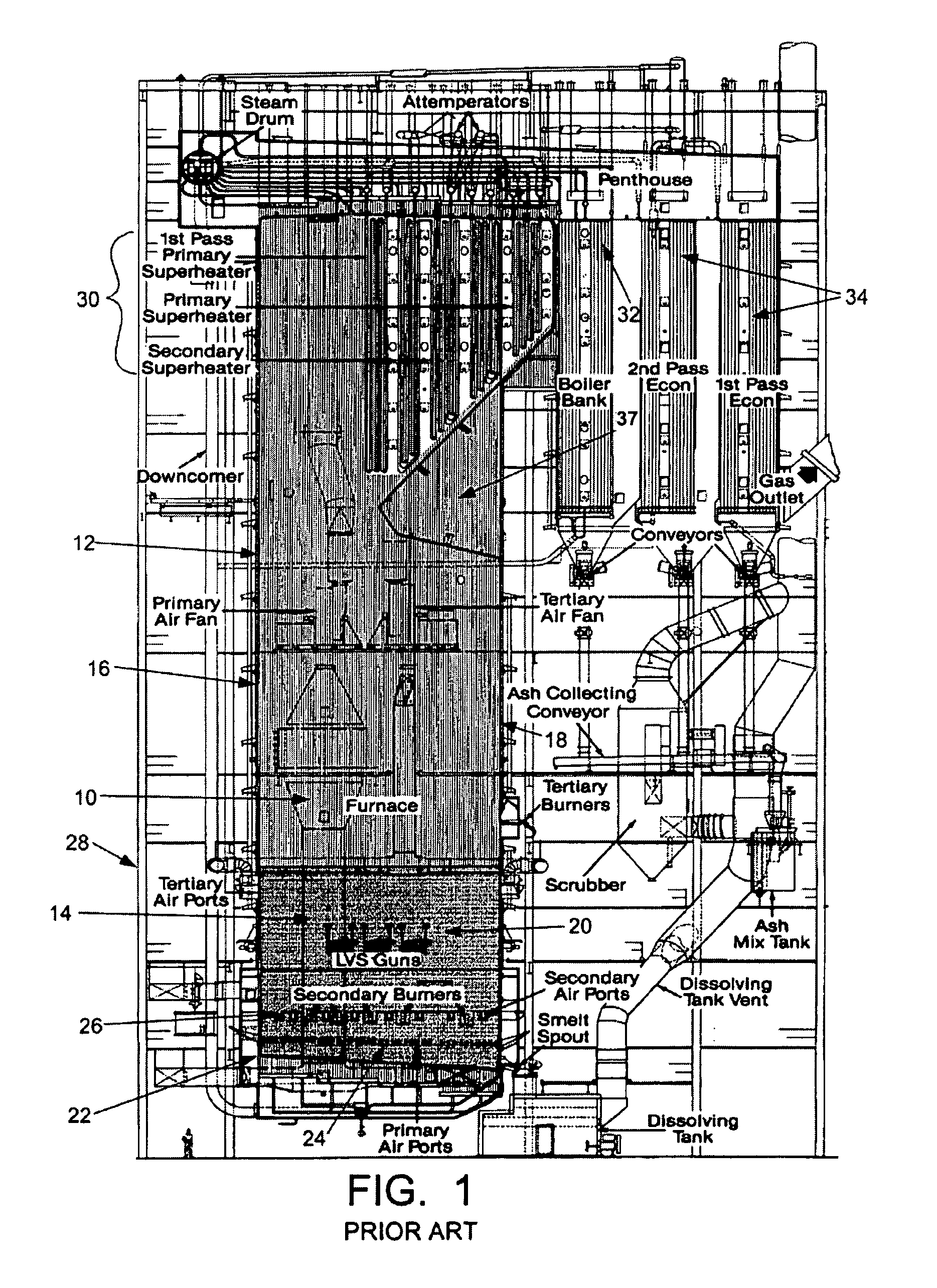

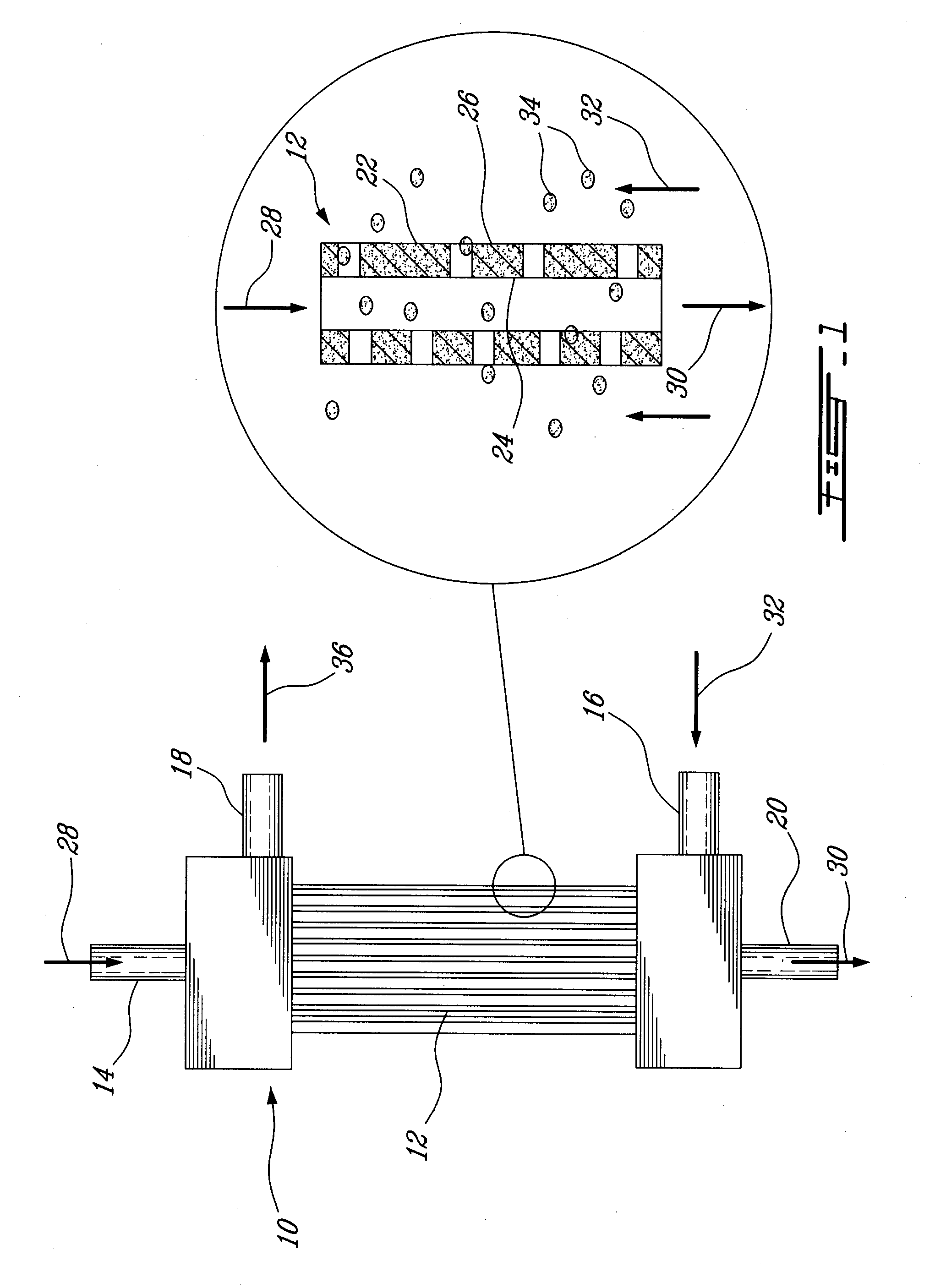

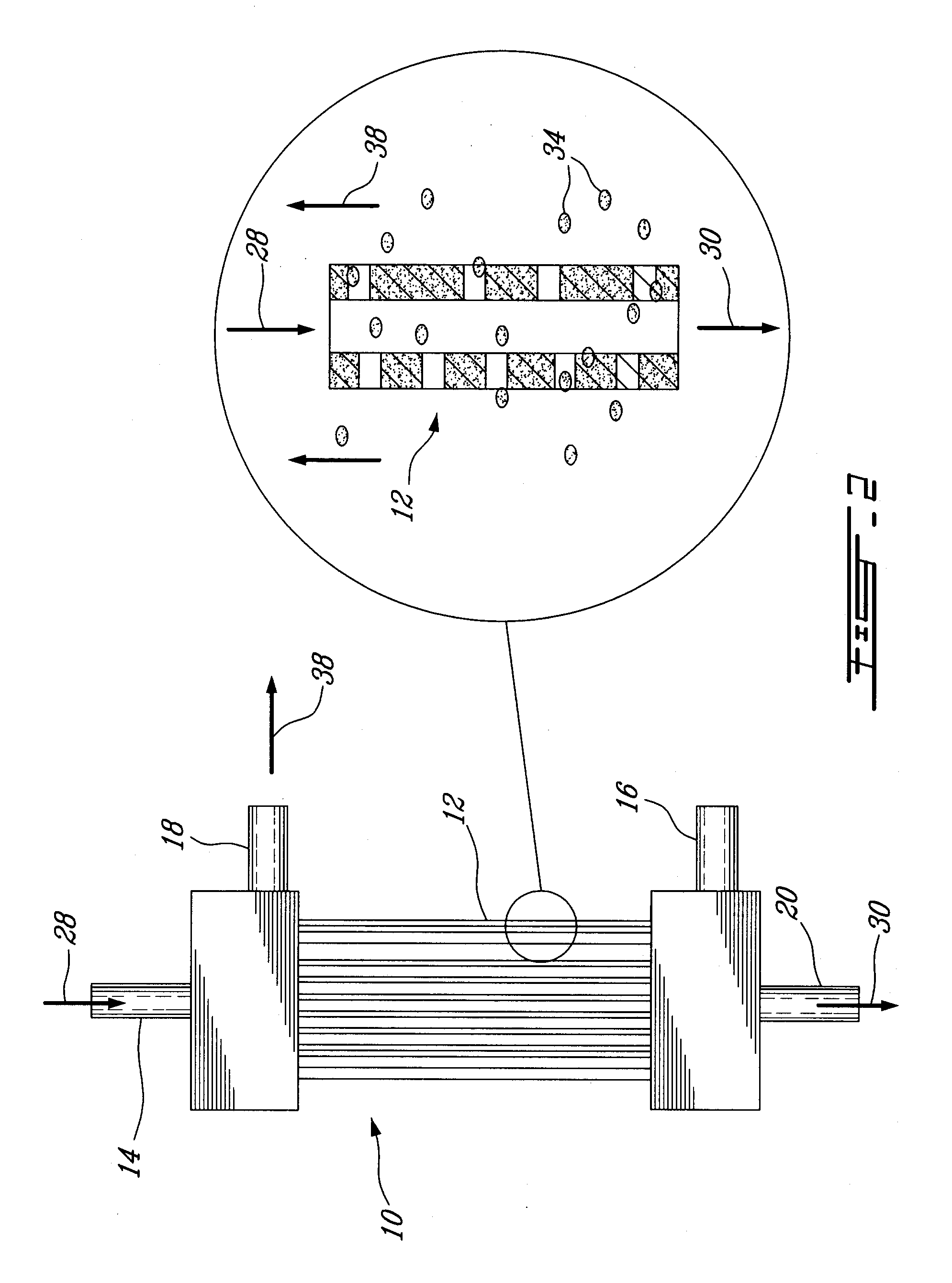

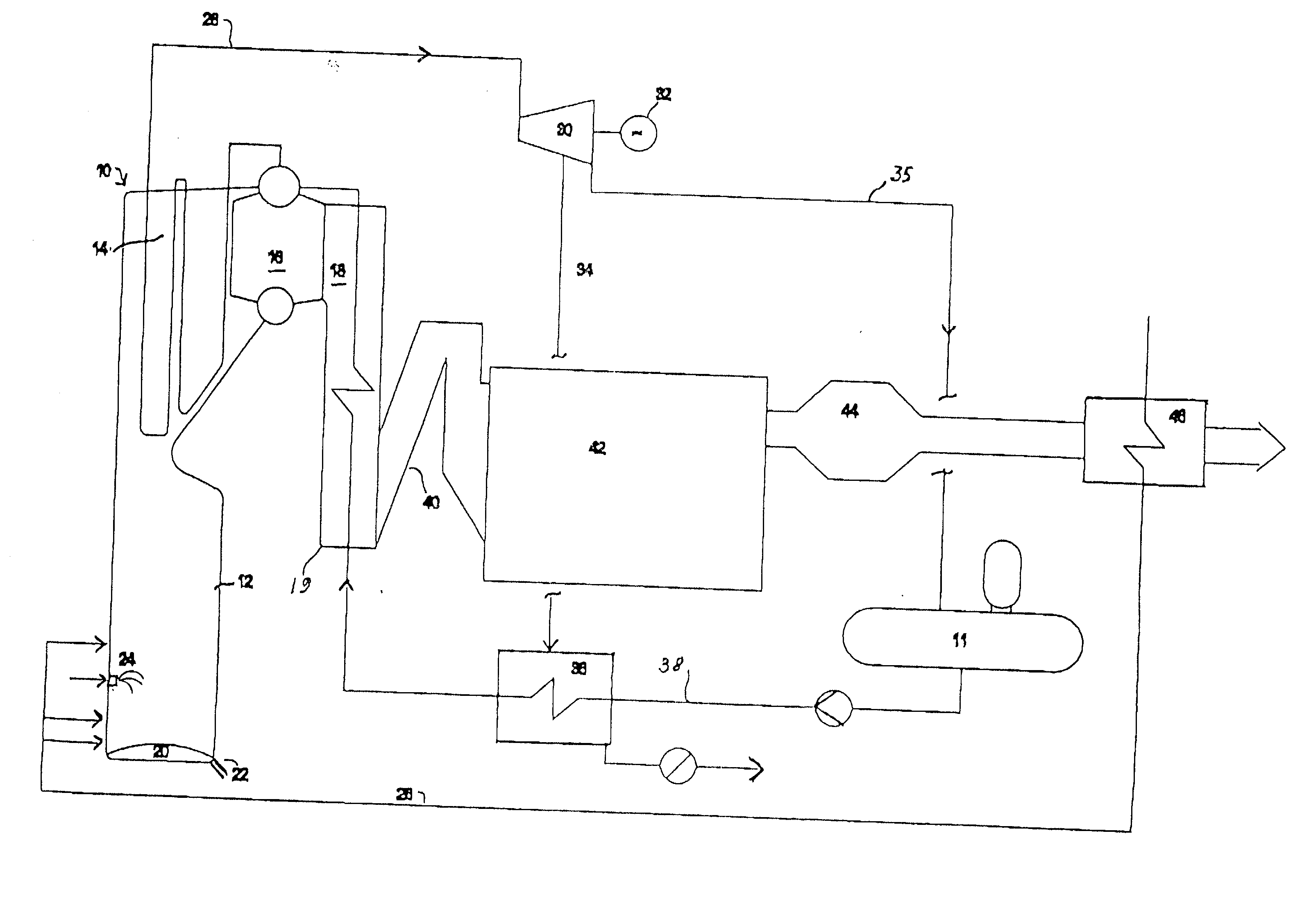

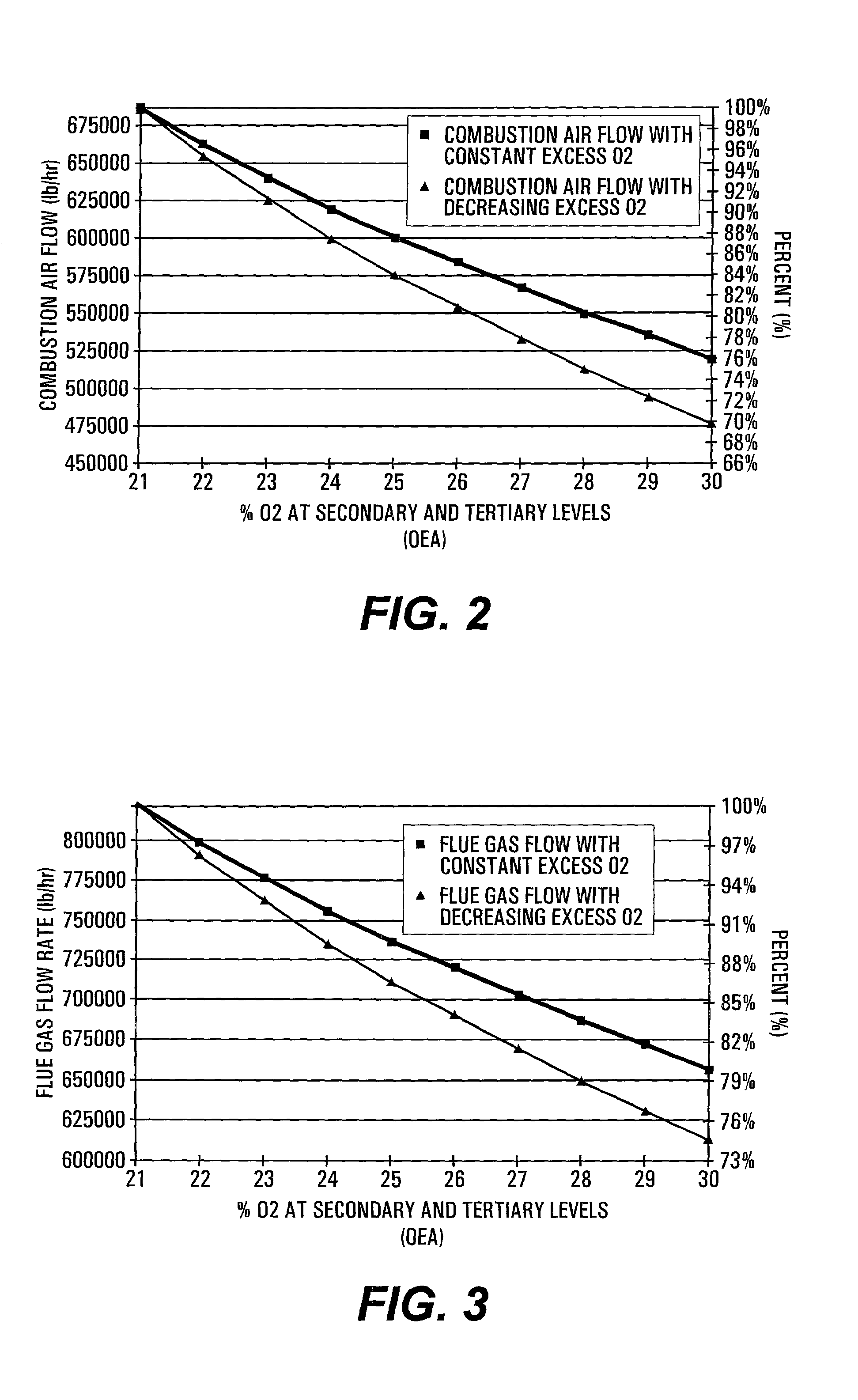

Method and apparatus for optimizing the combustion air system in a recovery boiler

InactiveUS6279495B1Improve boiler efficiencyAvoid costly modificationPulp liquors combustionSolid fuel combustionParticulatesChemical recovery

A method and an apparatus for optimizing the combustion air system in a power boiler or chemical recovery boiler by improving fluid flow and gas mixing are disclosed, whereby one can increase boiler capacity and combustion uniformity and reduce particulate and gaseous emissions. The method involves interlacing of the secondary and, where applicable, the tertiary air supply through opposing air ports on all four walls of the boiler, and is implemented by alternately opening wide or partially closing a port damper on one side, while partially closing or opening wide a port damper on the opposite side, such that a 70-100% open damper on one side opposes a partially closed (10-40% open) damper on the other and vice versa in an alternating fashion, along opposing walls. In a preferred embodiment, the optimization is further enhanced by balancing primary air flow, achieved by adjusting port dampers and windbox pressures so that the primary air flow is evenly distributed between opposite walls, between all four walls of the boiler and between individual airports on each wall. Windbox pressure and other key measurements of boiler operation ensure proper balancing and an adequate interlacing of air flows at the primary, secondary and tertiary elevations, respectively.

Owner:FPINNOVATIONS INC

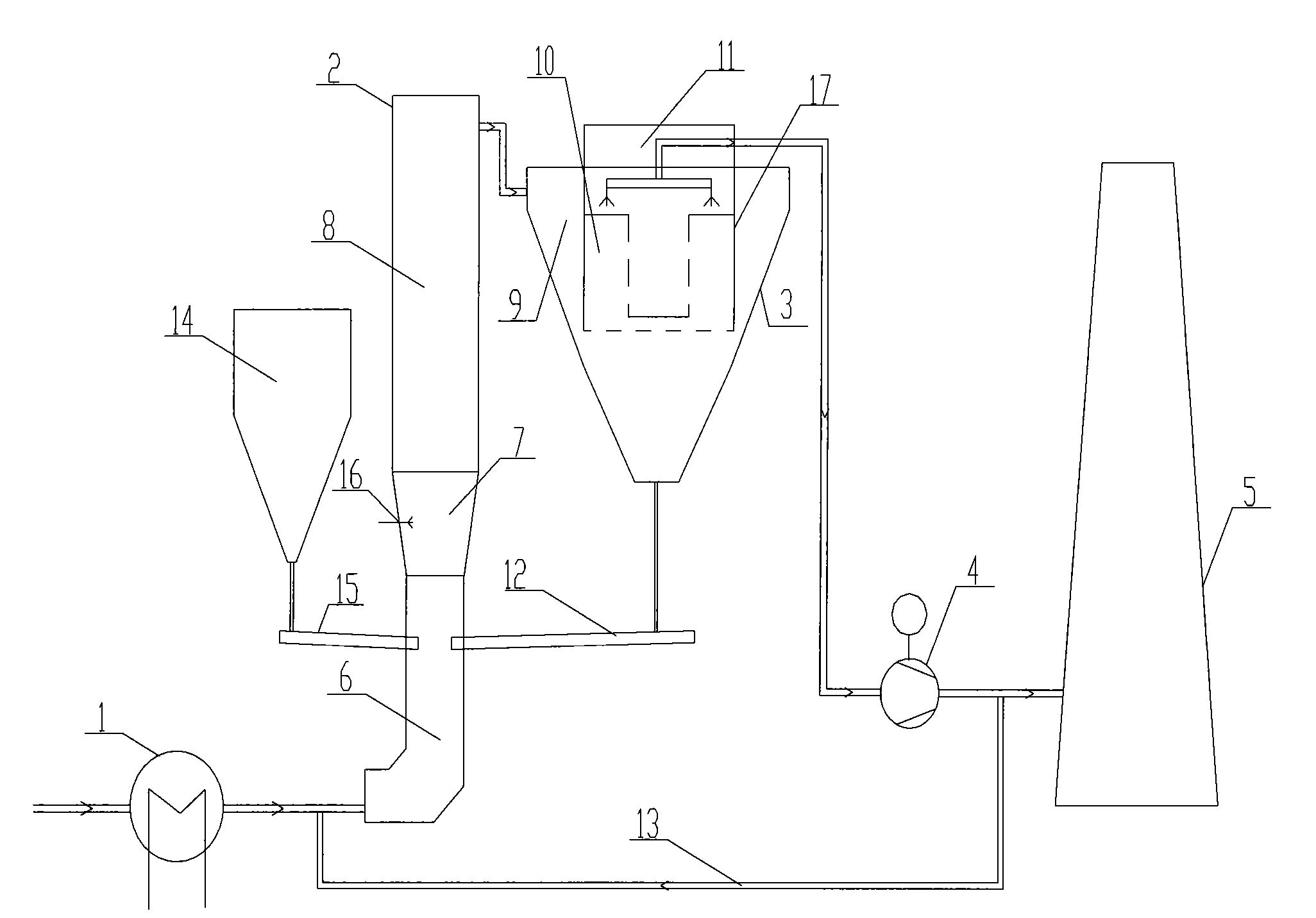

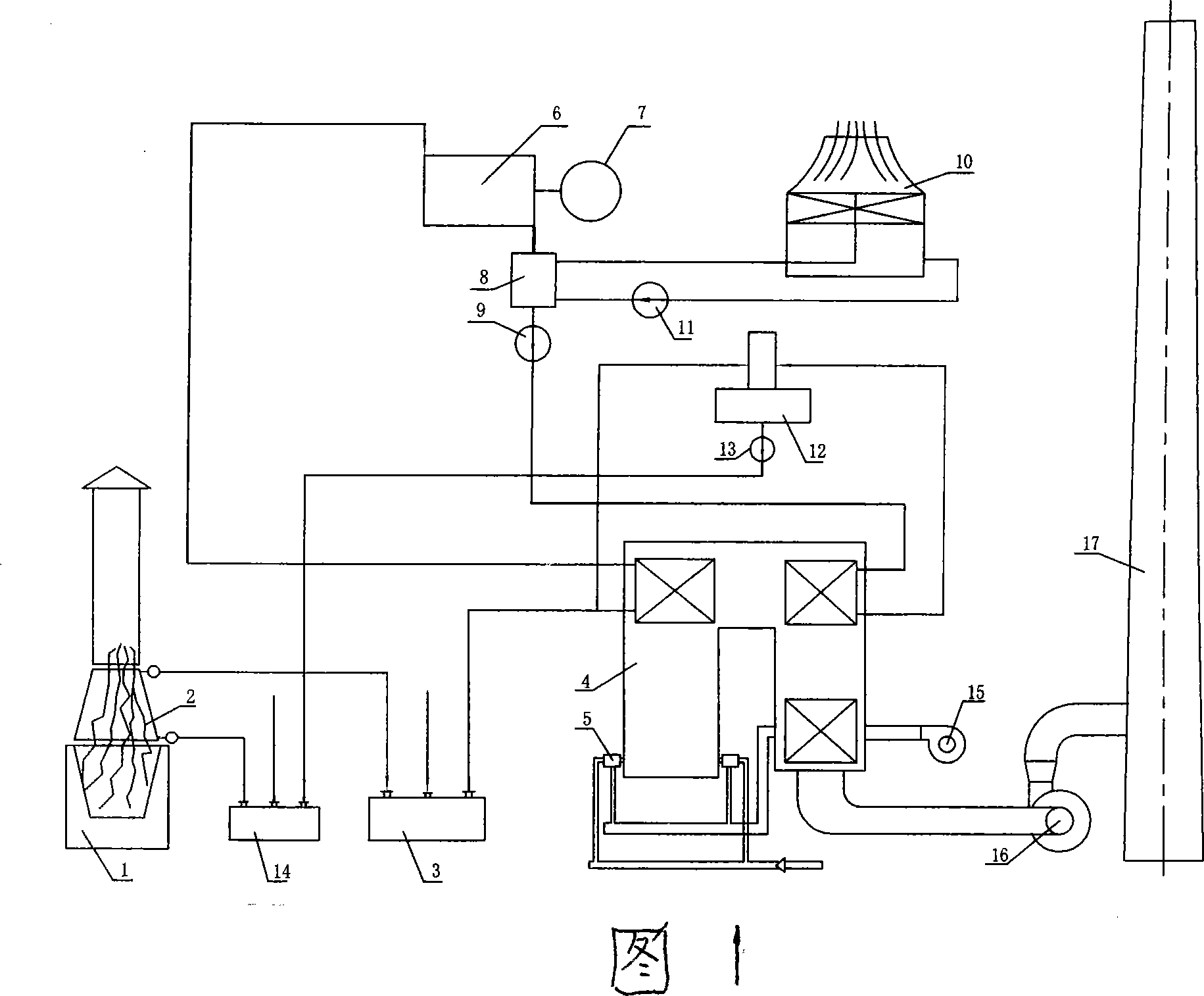

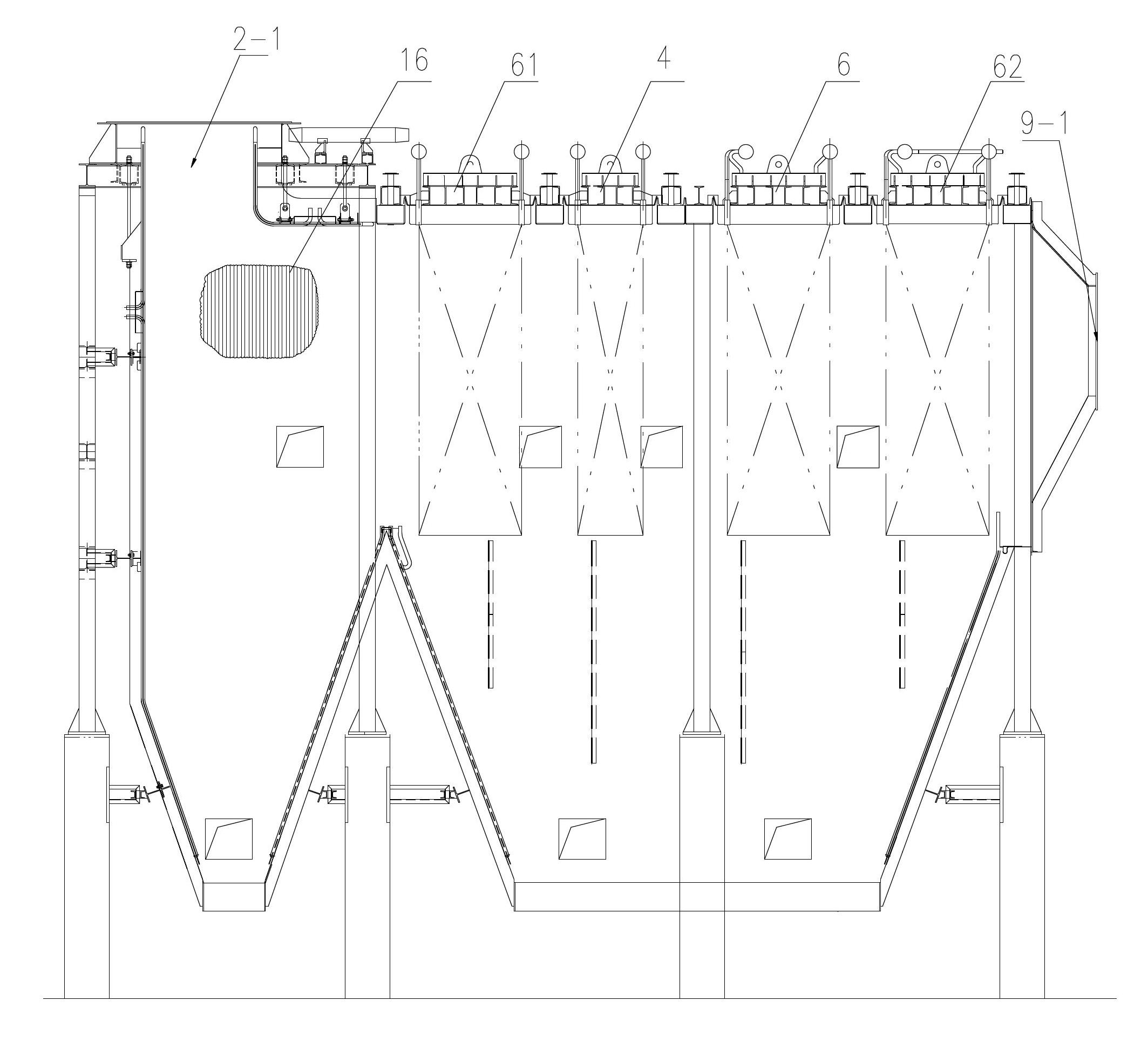

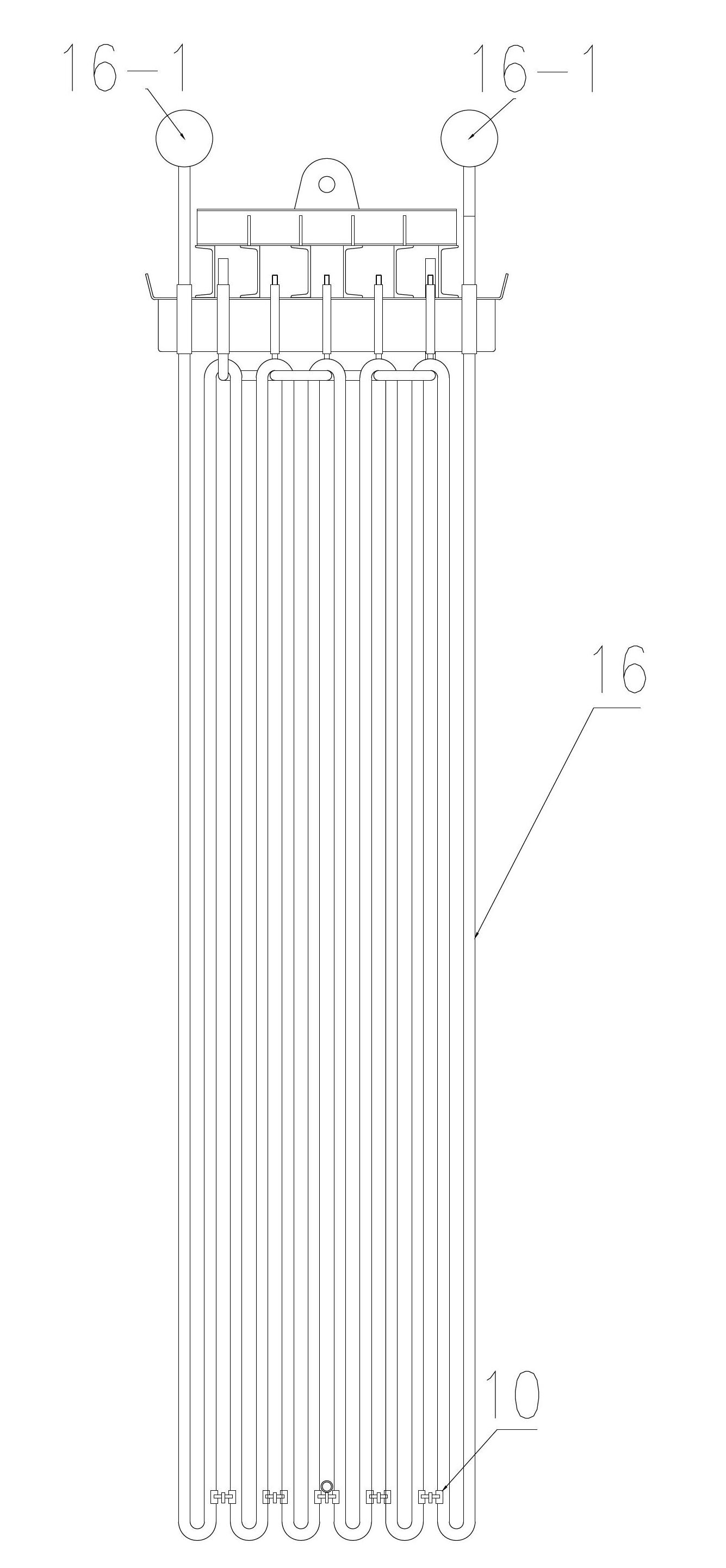

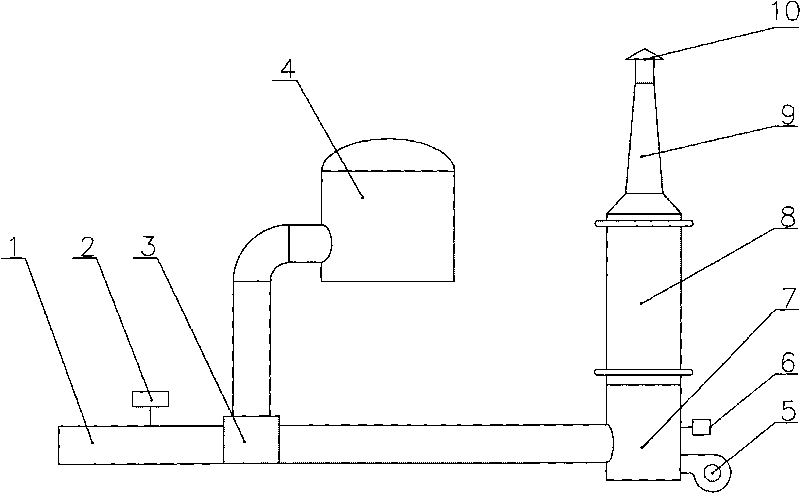

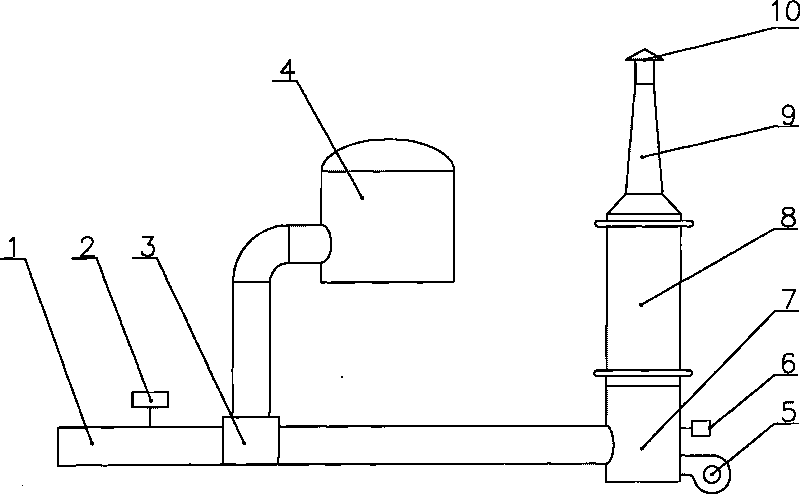

Clearing device for smoke pollutants of glass kiln and clearing method thereof

InactiveCN101628201ASolution to short lifeReduce loadCombination devicesGlass furnace apparatusSmall footprintEngineering

The invention relates to smoke treatment, in particular provides a clearing device for smoke pollutants of a glass kiln and a clearing method thereof. The clearing device is suitable for the glass kiln with high smoke temperature, smaller smoke amount, high clearing efficiency, stable system operation, simple structure and small floor area and is provided with an afterheat recovery boiler, a reaction tower, a bag dust collector, a circulating fluidization flume, a clean smoke recirculating flue, an absorbent bin and a feeding air flume which are sequentially connected. The clearing method comprises the following steps: smoke emitted by the glass kiln enters the afterheat recovery boiler; original smoke emitted by the afterheat recovery boiler enters a high-temperature reaction region of the reaction tower for premixing treatment with an absorbent, is accelerated by a Venturi accelerating region before entering a circulating fluidization reaction region and is cooled and purified before entering the bag dust collector; the purified smoke emitted from the reaction tower firstly enters the bag dust collector to remove particles and is emitted to a chimney by a draft fan in a purification chamber; and reaction dust emitted by the reaction tower is collected by the bag dust collector and is returned to the high-temperature reaction region.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

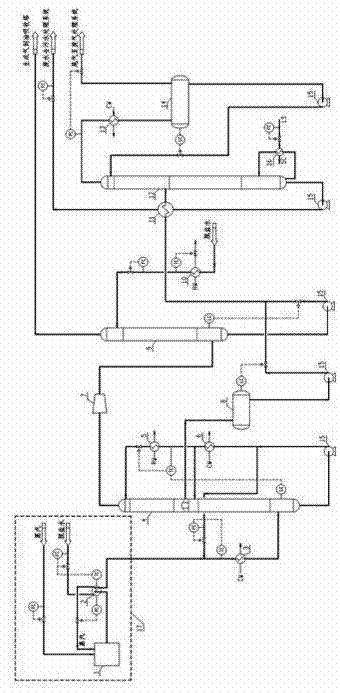

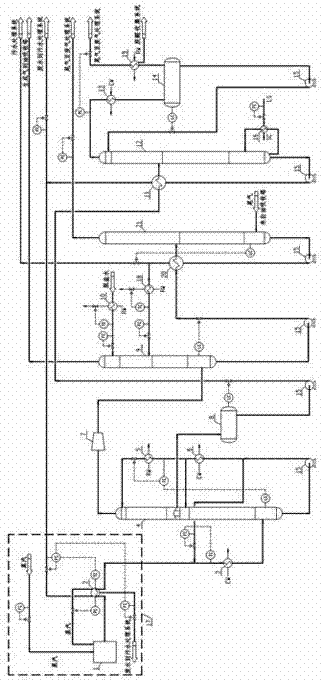

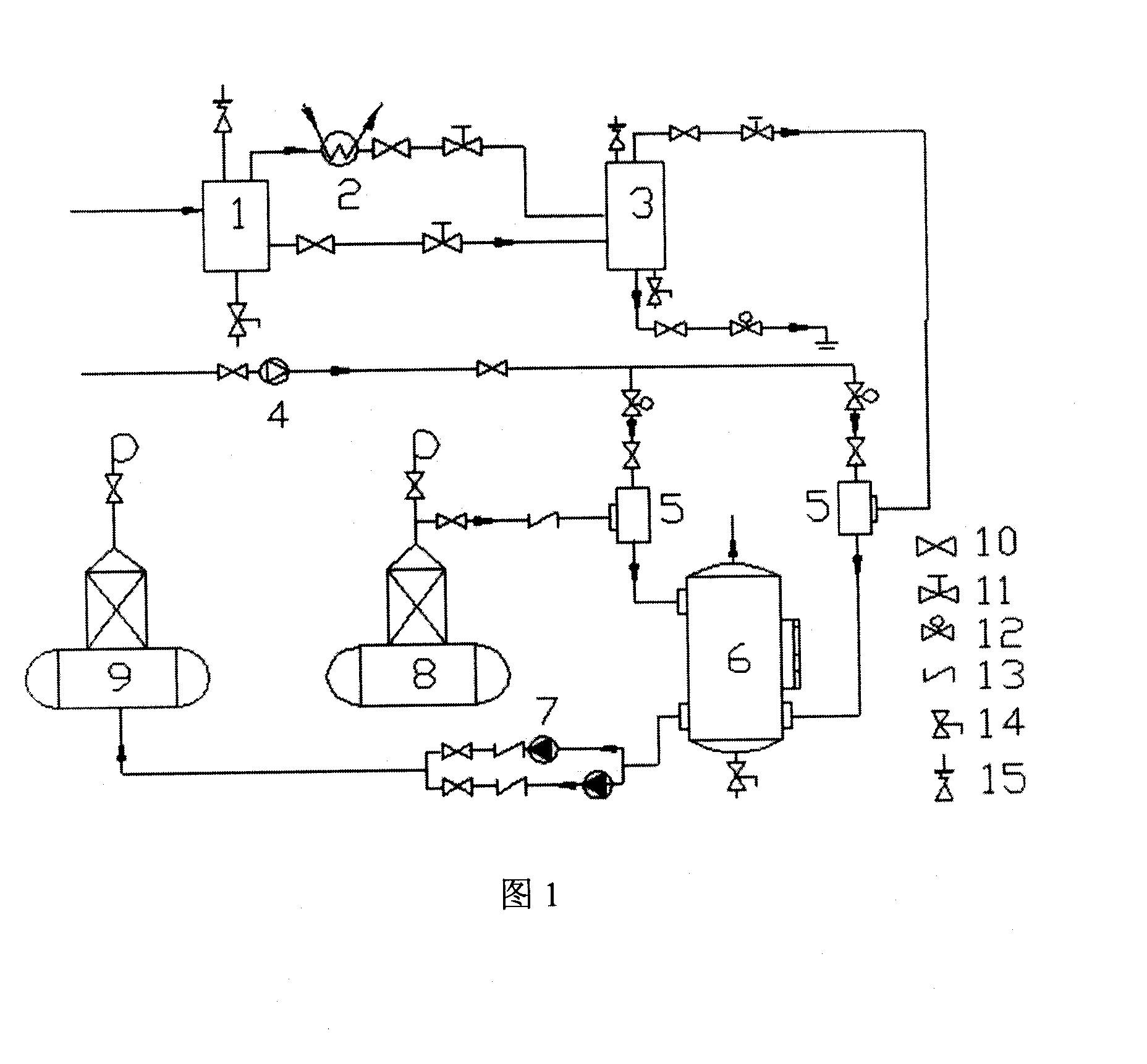

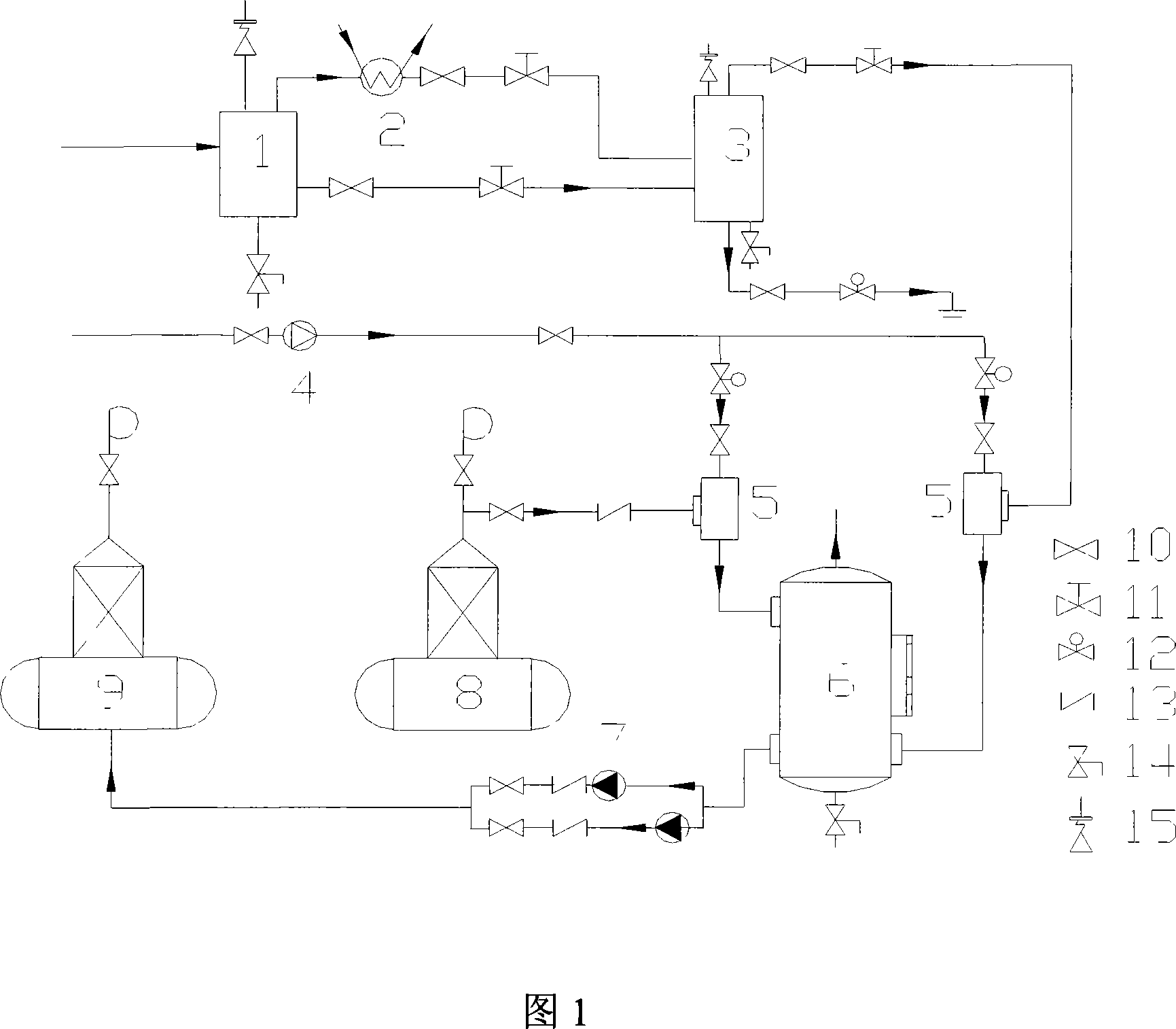

Process method for circularly utilizing waste water produced by butadiene preparation through butene oxidative dehydrogenation

ActiveCN102826950AReduce dosageReduce cloggingChemical industryDispersed particle separationWater useChemical industry

The invention relates to a process method for circularly utilizing waste water produced by butadiene preparation through butene oxidative dehydrogenation and belongs to the technical field of chemical industry. The process method is characterized in that: firstly, most of the waste water is sent to an exhaust-heat recovery boiler for use after most organic matters in the waste water discharged from a water-cooling acid rinsing tower are deprived through a waste water distillation tower, and desalted water replenishing of the exhaust-heat recovery boiler is replaced; secondly, partial waste water returns an aldehyde rinsing tower for reusing after most aldehydes in the waste water discharged from the aldehyde rinsing tower are deprived through a blowdown tower, and desalted water using quantity of the aldehyde rinsing tower is reduced; and thirdly, low temperature condensation is carried out for tail gas containing acid and aldehyde, organic matters condensate liquid in the tail gas is recycled, and loads of a waste gas processing system is lightened. Compared with the prior art, a waste water classifying treatment and cyclic utilization process of the process method effectively reduces water replenishing quantity of a technical process, greatly reduces effluent quantity of the waste water simultaneously, reduces a chemical oxygen demand (COD) concentration of discharged sewage and an organic content in discharged gas, and has advantages of being economic, environment-friendly and the like.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

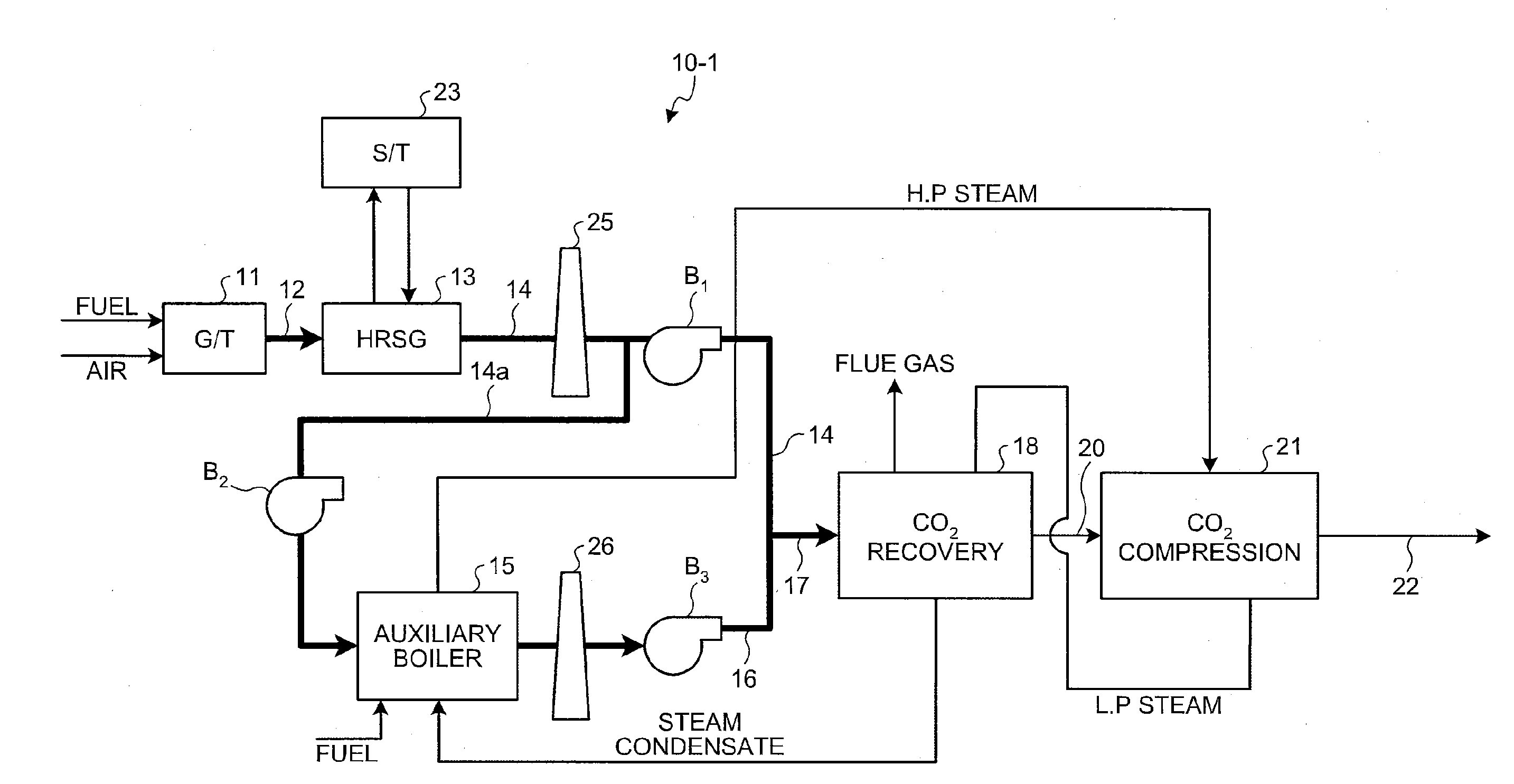

Method and apparatus for flue gas treatment

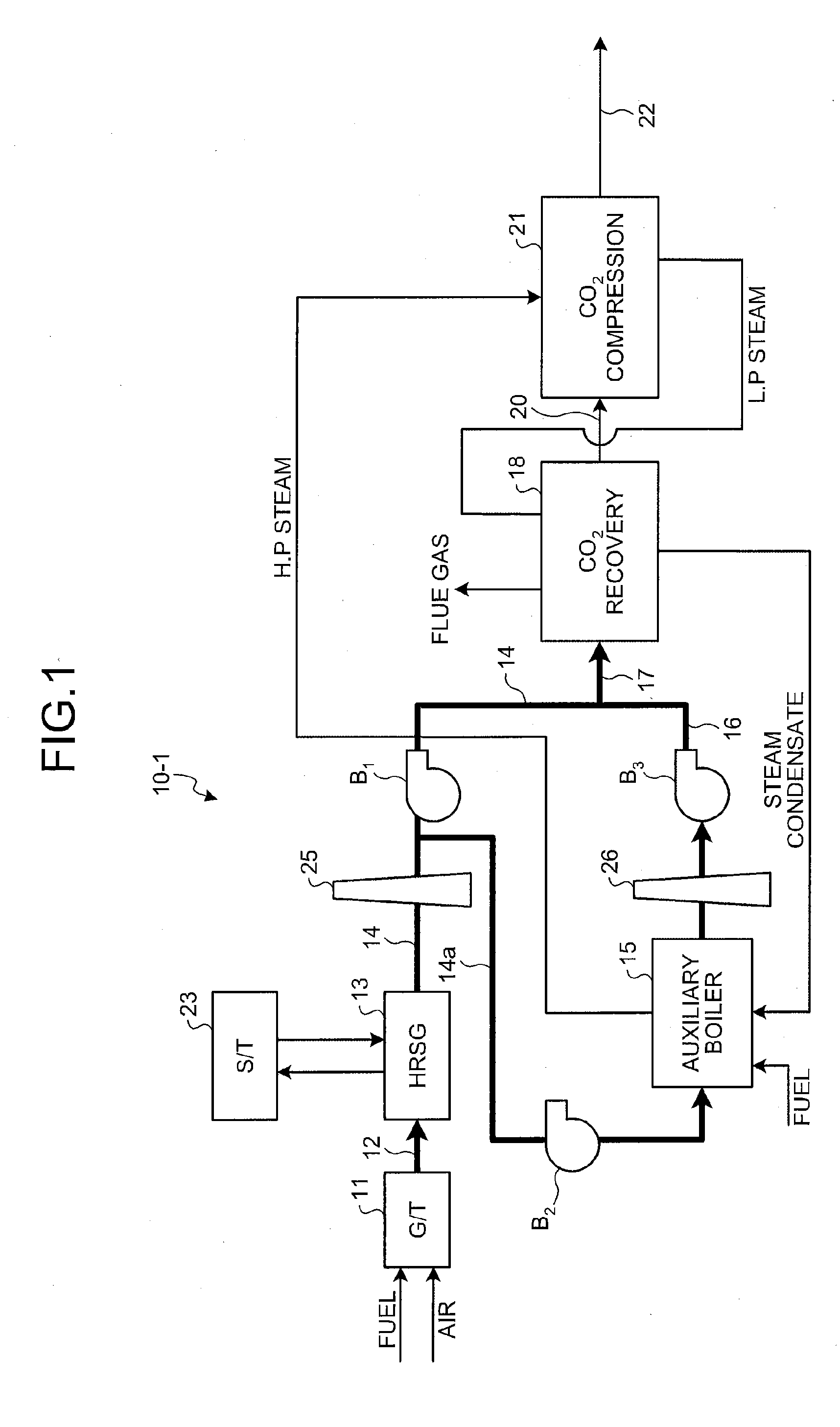

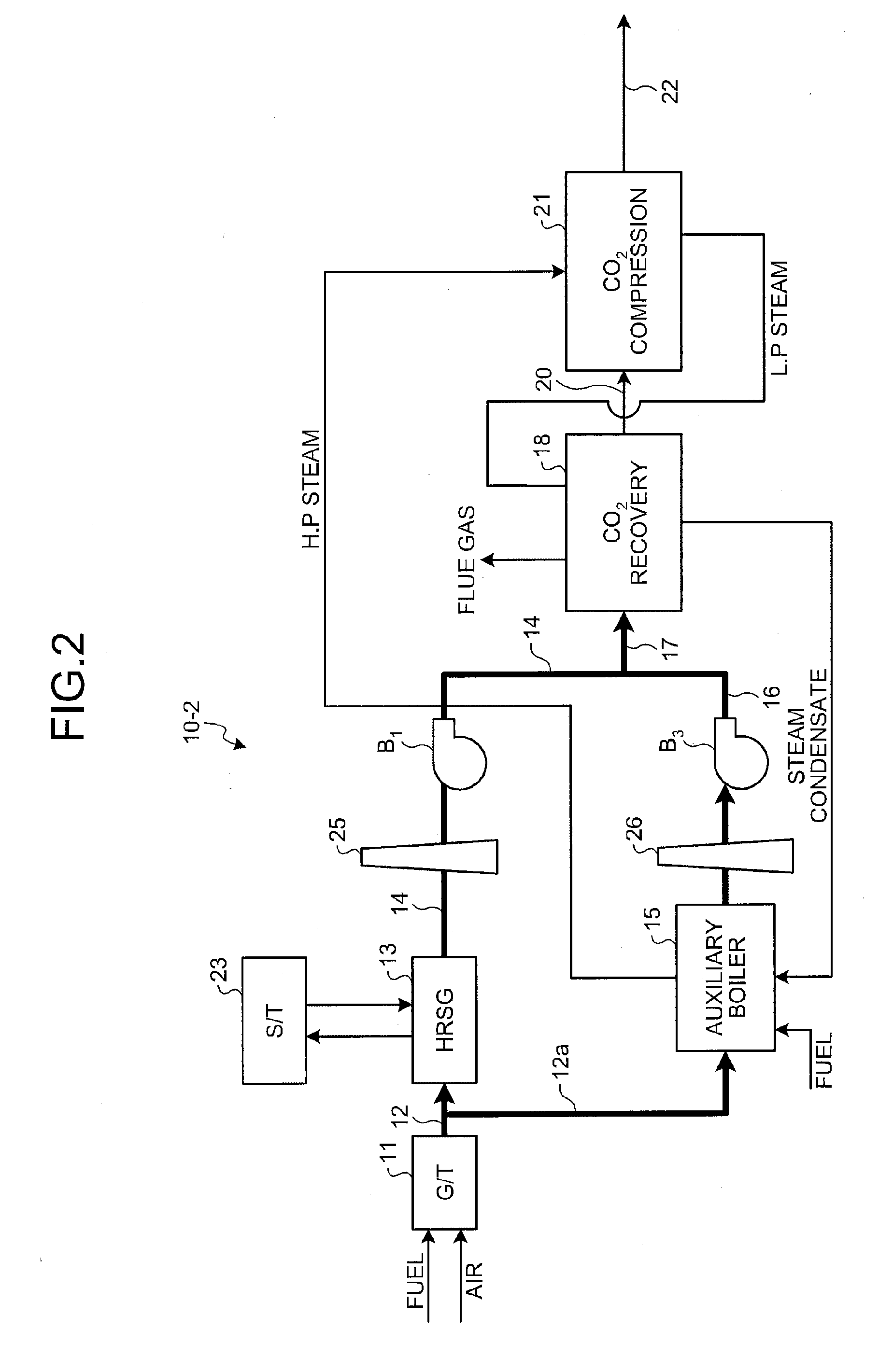

ActiveUS20090252659A1Improve processing efficiencyIncrease carbon dioxide concentrationSteam generation heating methodsInternal combustion piston enginesFlue gasExhaust fumes

A method for flue gas treatment includes causing a combustion in a boiler using at least a part of a flue gas emitted from a gas turbine and introduced from at least one of an upstream side and a downstream side of an exhaust heat recovery boiler, which recovers a high-temperature heat of the flue gas, so as to increase a concentration of carbon dioxide in the flue gas, and recovering carbon dioxide in a carbon dioxide recovery apparatus.

Owner:MITSUBISHI HEAVY IND LTD +1

Method for recycling and regenerating steel plant residual heat boiler saturated steam

InactiveCN101178017AIncrease profitEfficient use ofSteam engine plantsSteam superheatersCooling towerDeaerator

The invention relates to a method to recycle saturated steam from waste heat boiler in steel plant to generate. The method is characterized in that the invention comprises a converter, a converter heat recovery boiler, a steam filtering pressure stabilizer, a saturated steam heating furnace, a heating furnace burner, a low pressure turbine, a motor, a condenser, a condensate pump, a cooling tower, a circulating water pump, a deaerator, a water supply pump, a water supply distributor, a blower, an induced draft fan and a chimney. The invention has the advantages of making full use of the current waste heat boiler of the steel plant, adopting the steam filtering pressure stabilizer and the saturated steam heating furnace, improving efficiency by 140 percent compared with the traditional small-sized medium temperature and medium pressure unit and efficiency being 20 percent up higher than that of the most efficient gas turbine in the world.

Owner:中冶集团华冶资源开发有限责任公司

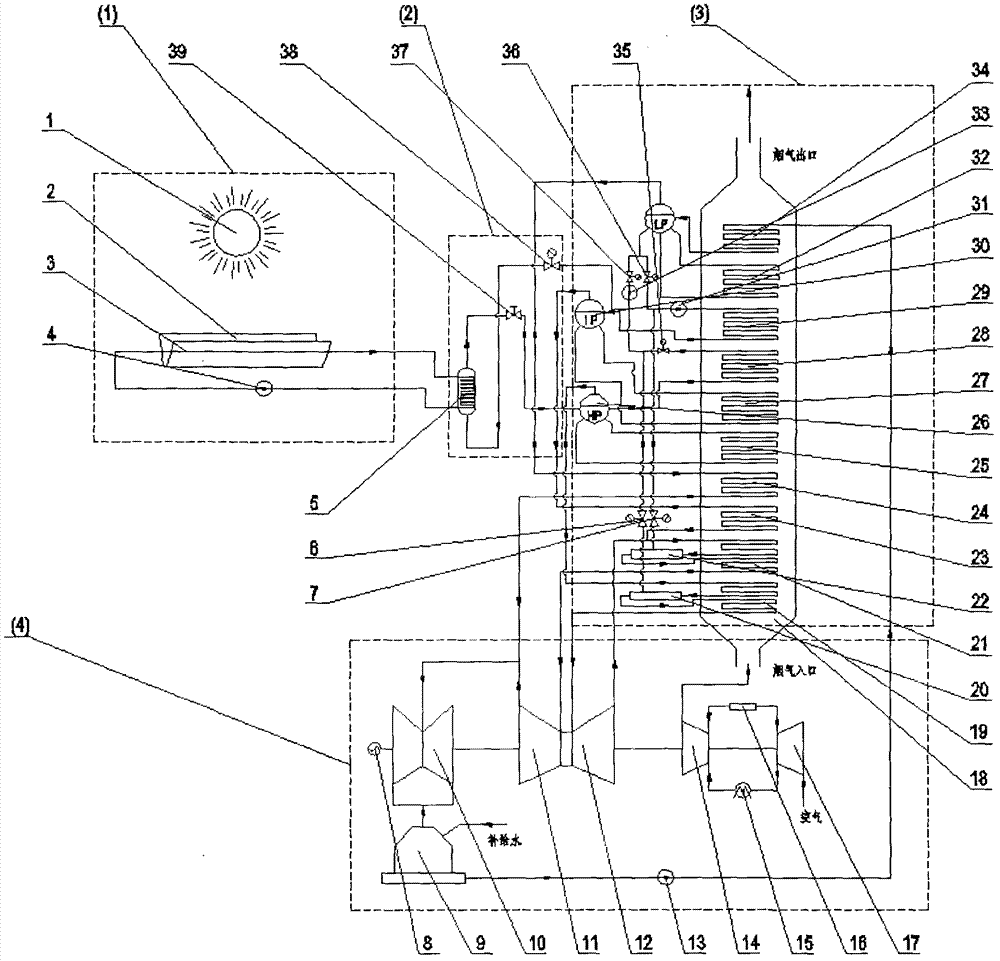

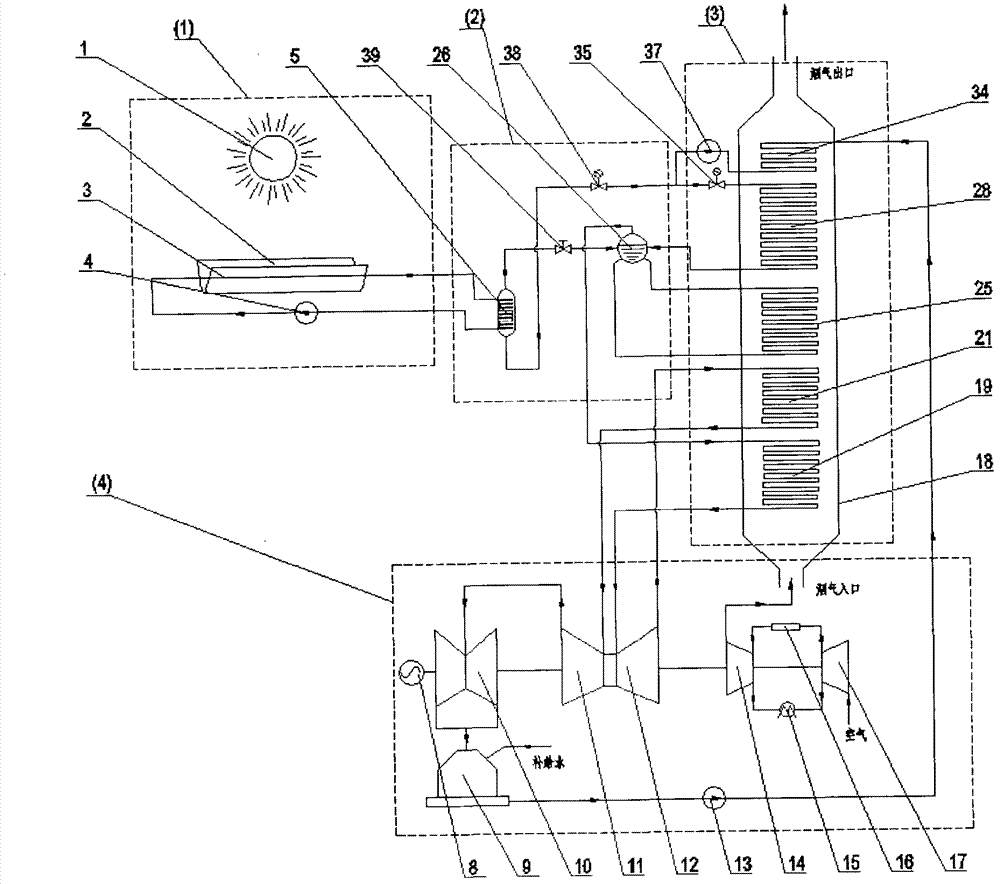

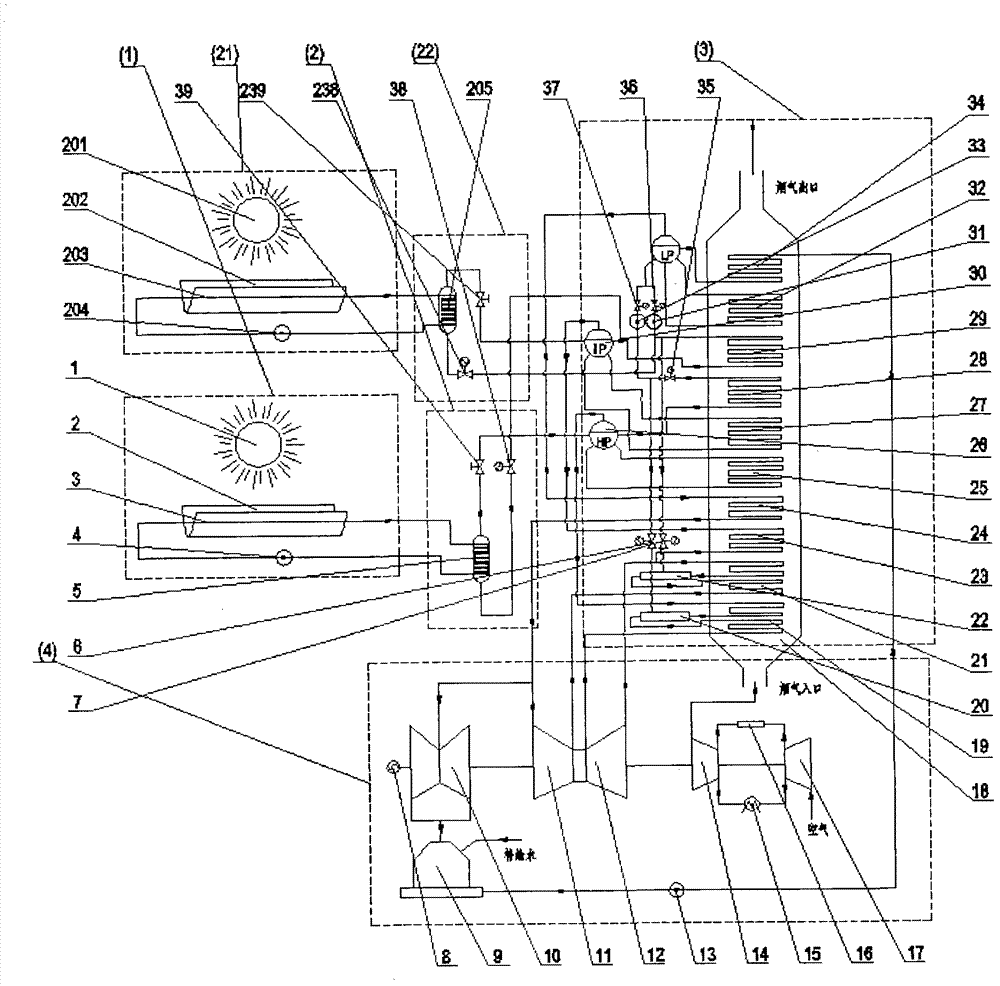

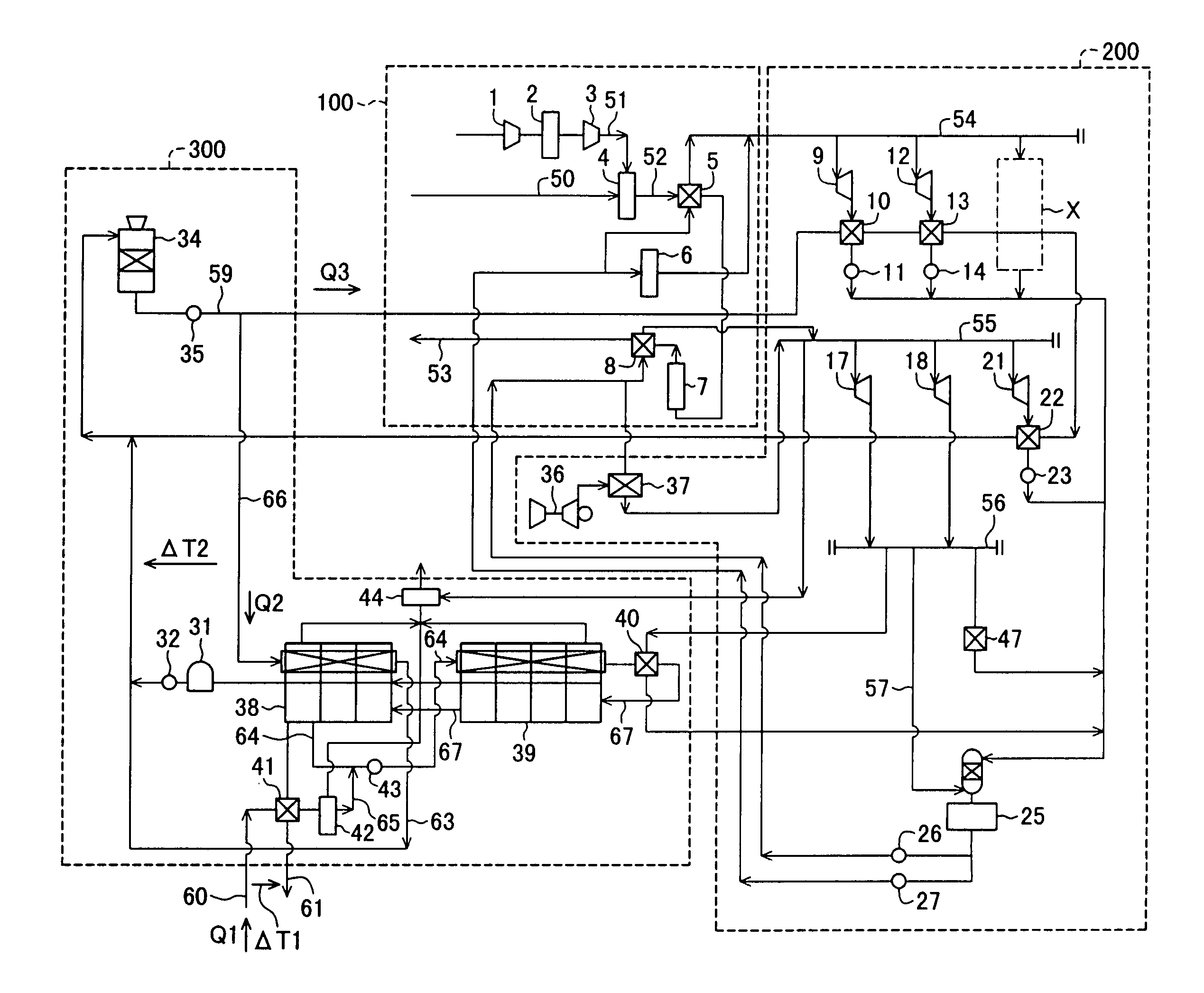

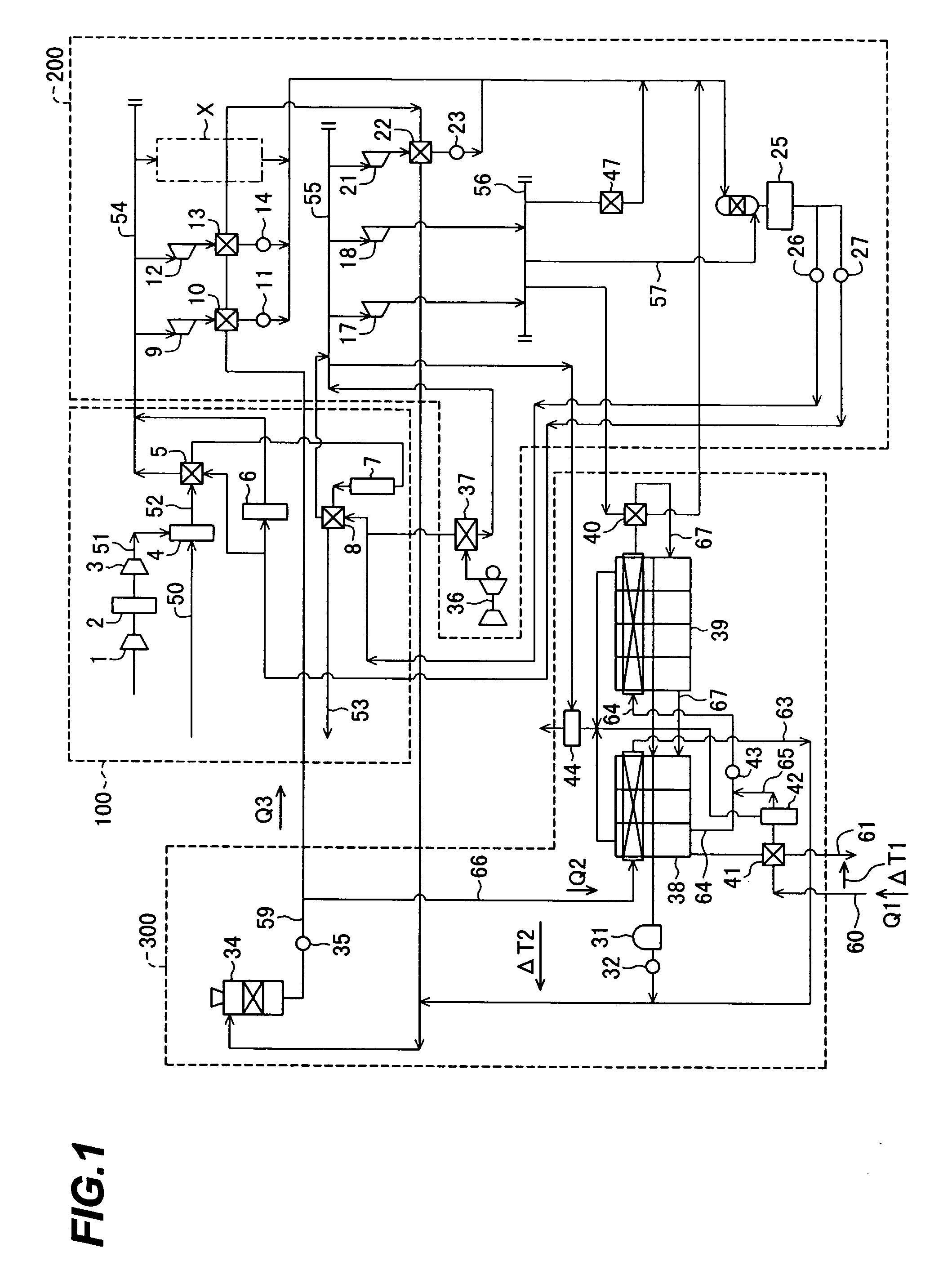

Solar heat collection technology and gas-steam combined cycle device coupling power generation technology

The invention discloses solar heat collection technology and gas-steam combined cycle device coupling power generation technology. The whole technology mainly comprises four parts including (1) solar heat collection technology which enables solar energy to be converted into internal energy of a heat carrying working medium; (2) a solar energy and heat recovery boiler coupling portion which enables heat obtained by using the solar heat collection technology to be input in a heat recovery boiler system through a coupling unit, uses high temperature flue gas in the heat recovery boiler, further improves steam quality and improves generating efficiency of solar energy; (3) the heat recovery boiler which uses the high temperature flue gas discharged from a gas turbine, generates high-temperature steam to push the gas turbine to do work and is an essential device of the gas-steam combined cycle; and (4) equipments such as a gas turbine-steam turbine and a generator, wherein the equipment use the high-temperature gas and steam to push the gas turbine and the steam turbine to do work and generates electricity through the generator.

Owner:雒晓卫

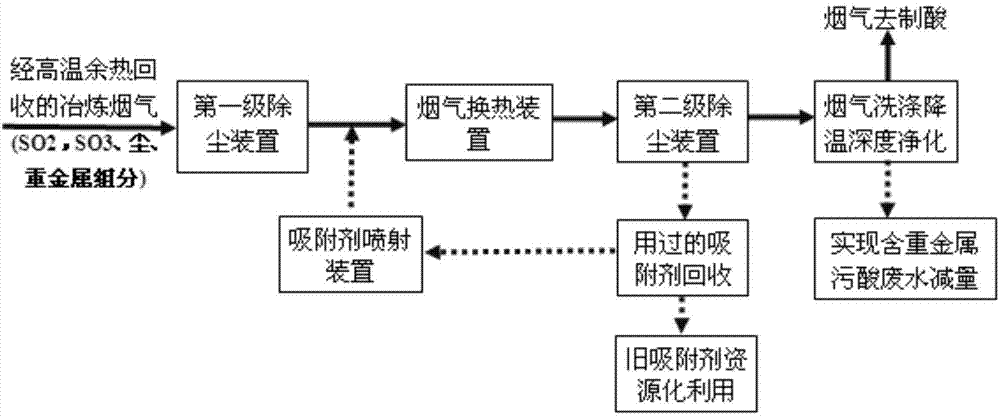

Dry-type removing method for sulfur trioxide and heavy metals in nonferrous smelting acid-making flue gas

ActiveCN104841265AEfficient removalReduce contentCombination devicesSorbentNon-ferrous extractive metallurgy

The invention relates to a dry-type removing method for sulfur trioxide and heavy metals in nonferrous smelting acid-making flue gas. The method comprises the following steps: primarily recovering heat of nonferrous smelting flue gas through a high-temperature heat recovery boiler and carrying out first-stage dust removal through a first-stage dust removal device so as to remove more than 90% of gas dust in the flue gas; then directly jetting, from a flue, the powder of an absorbent capable of adsorbing / absorbing SO3 and heavy-metal components into the flue gas having undergone the first-stage dust removal, and carrying out absorption reaction; then cooling the flue gas containing the absorbent by utilizing a flue gas heat-exchange device so as to allow SO3 and heavy metals to be effectively trapped and collected by the absorbent and part of volatile heavy metals to be condensed through induction; and finally, trapping and collecting the absorbent having absorbed SO3 and the heavy metals and granular heavy metals via a second-stage dust removal device. Compared with the prior art, the dry-type removing method provided by the invention can effectively remove the heavy metal components and SO3 in the flue gas from upstream and reduces the concentration of sulfuric acid and the contents of heavy metals in washing wastewater.

Owner:SHANGHAI JIAO TONG UNIV

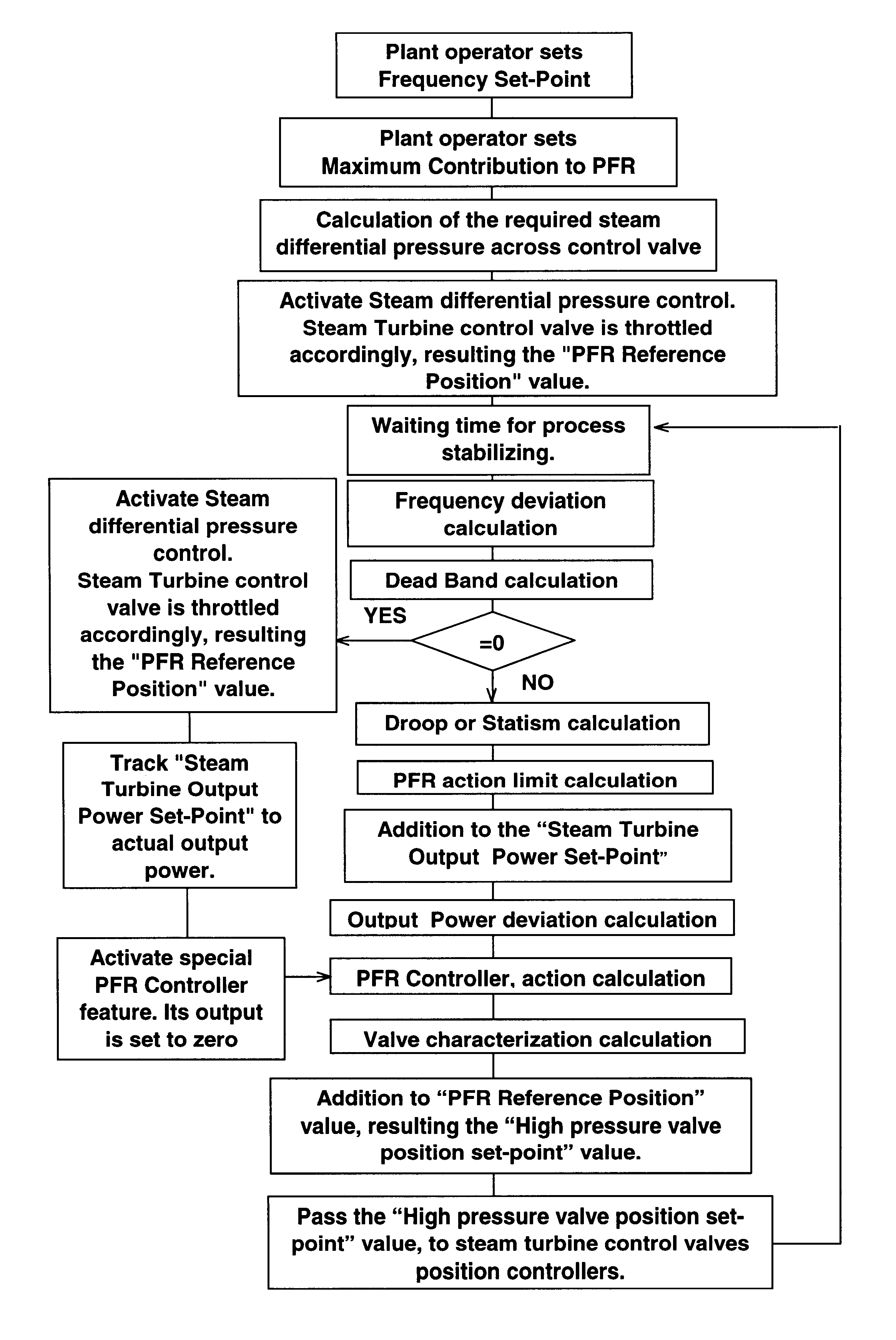

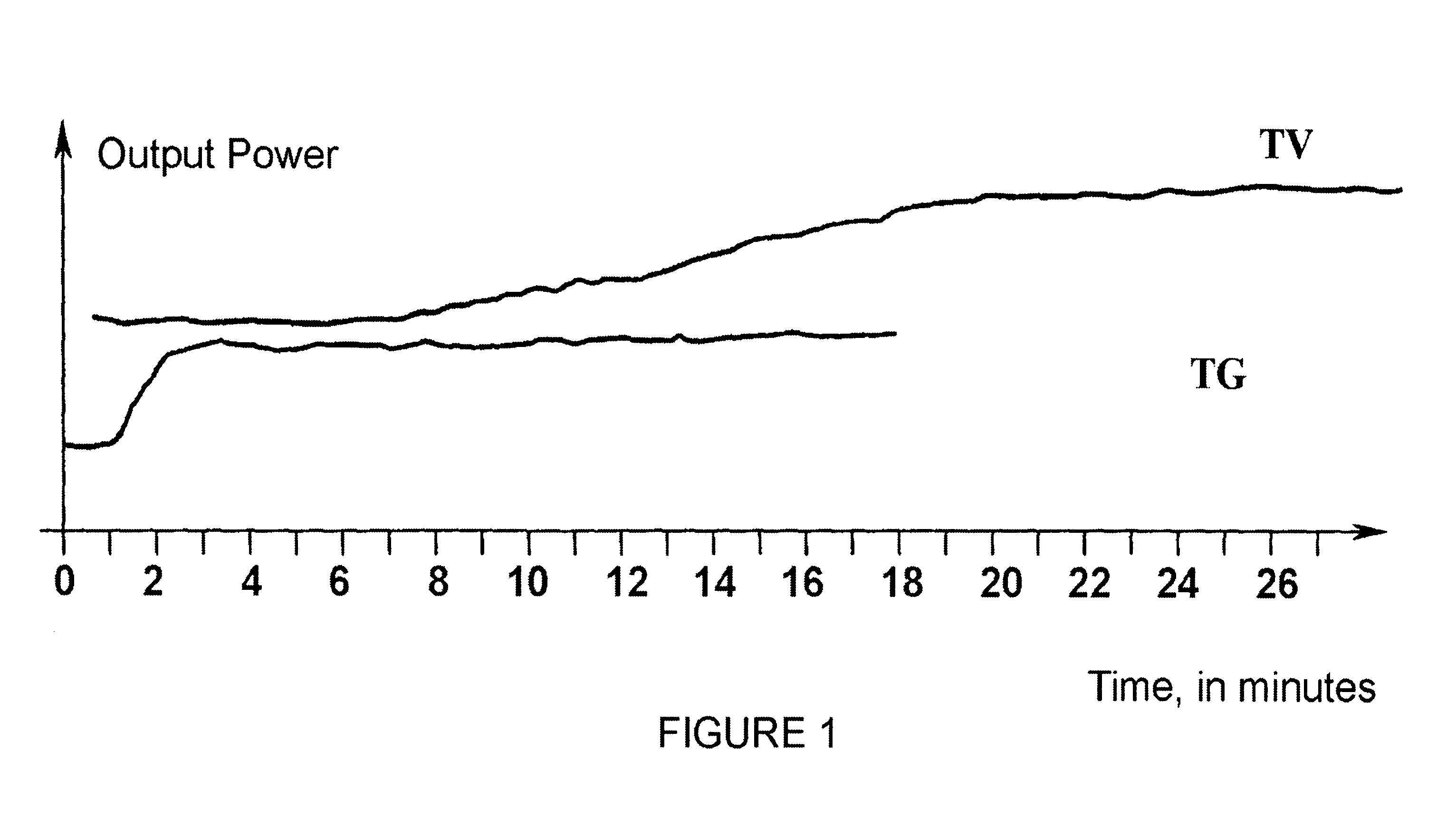

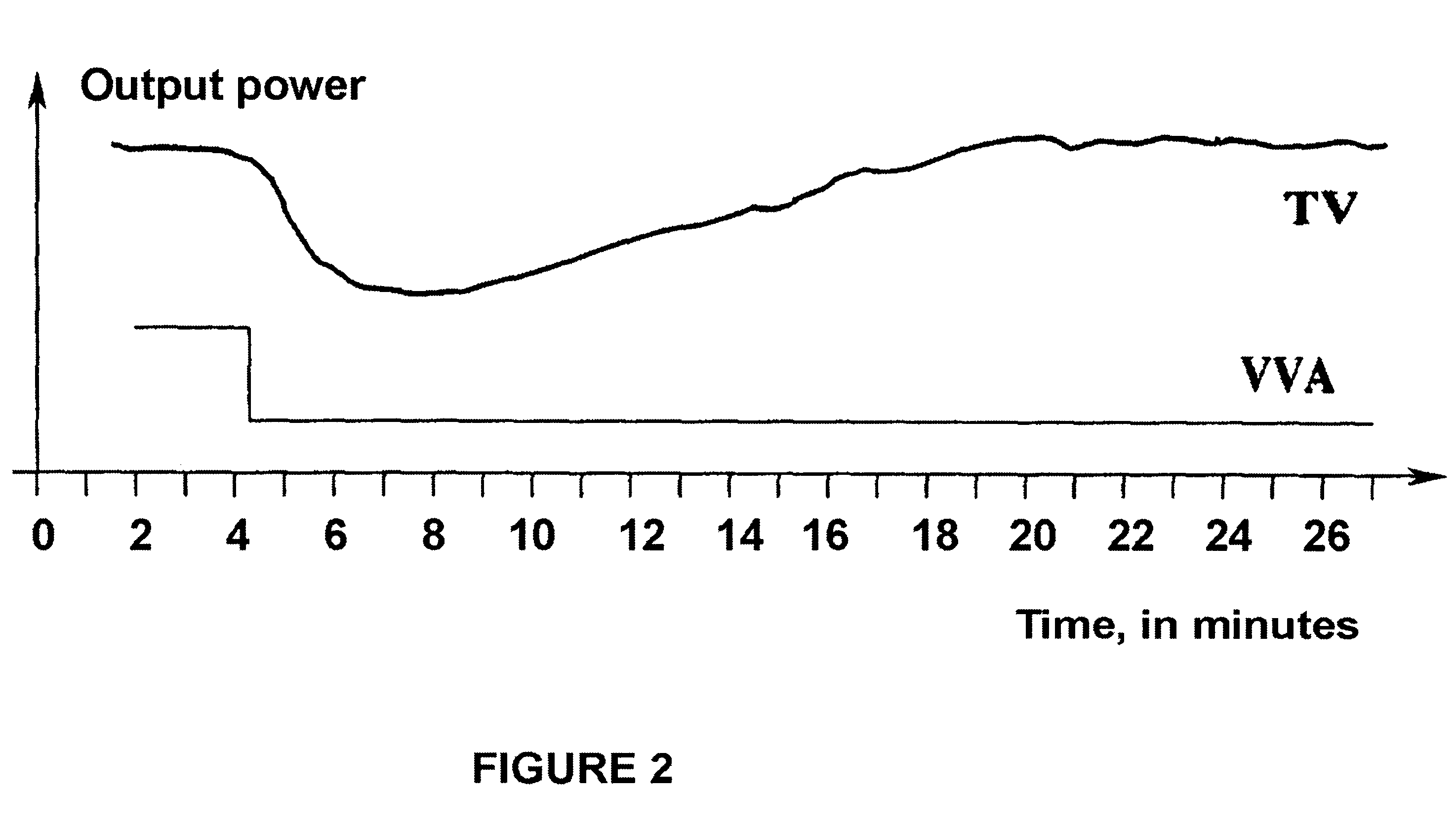

Primary frequency regulation method in combined-cycle steam turbines

Owner:PETROBRAS ENERGIA

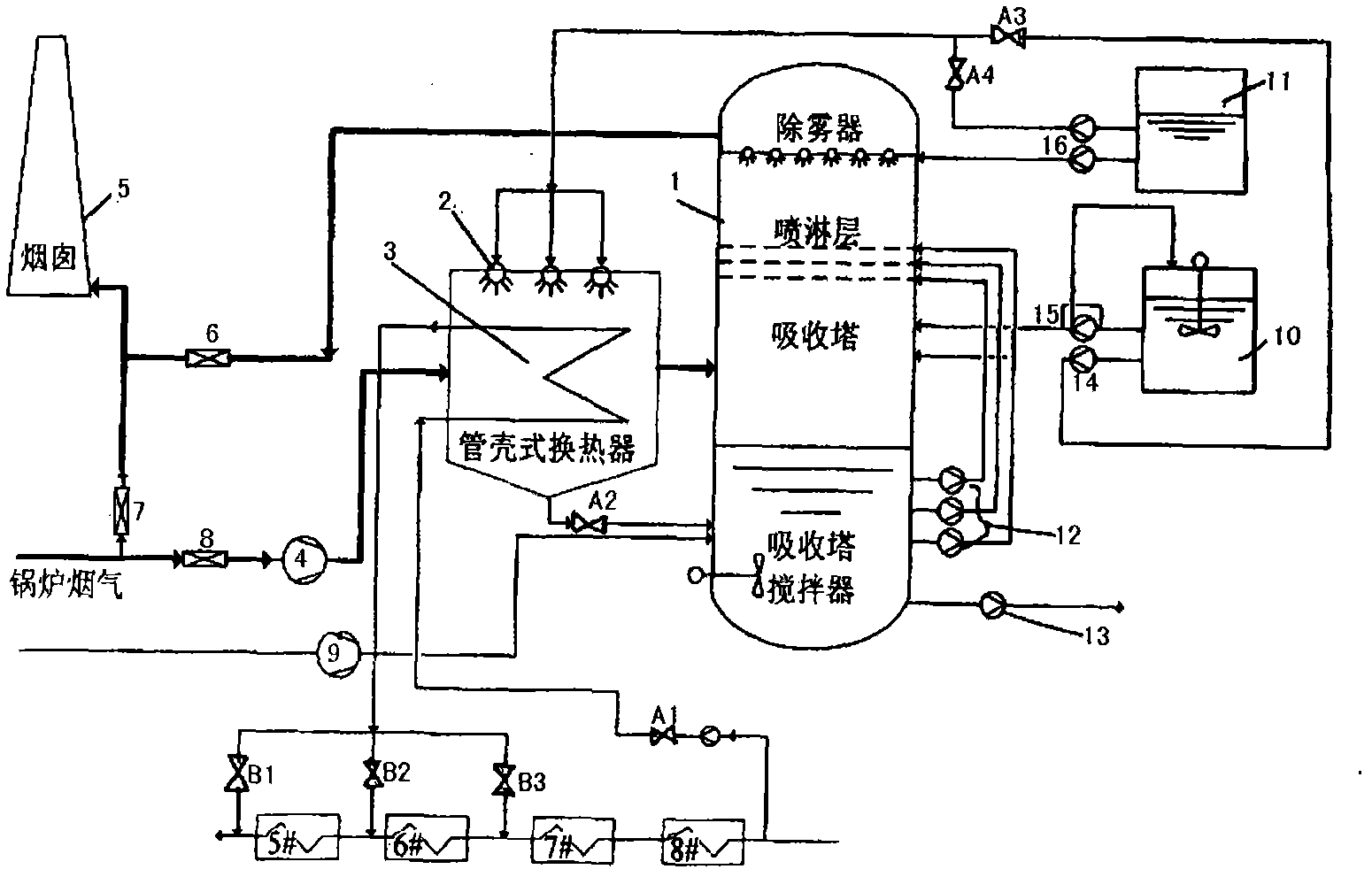

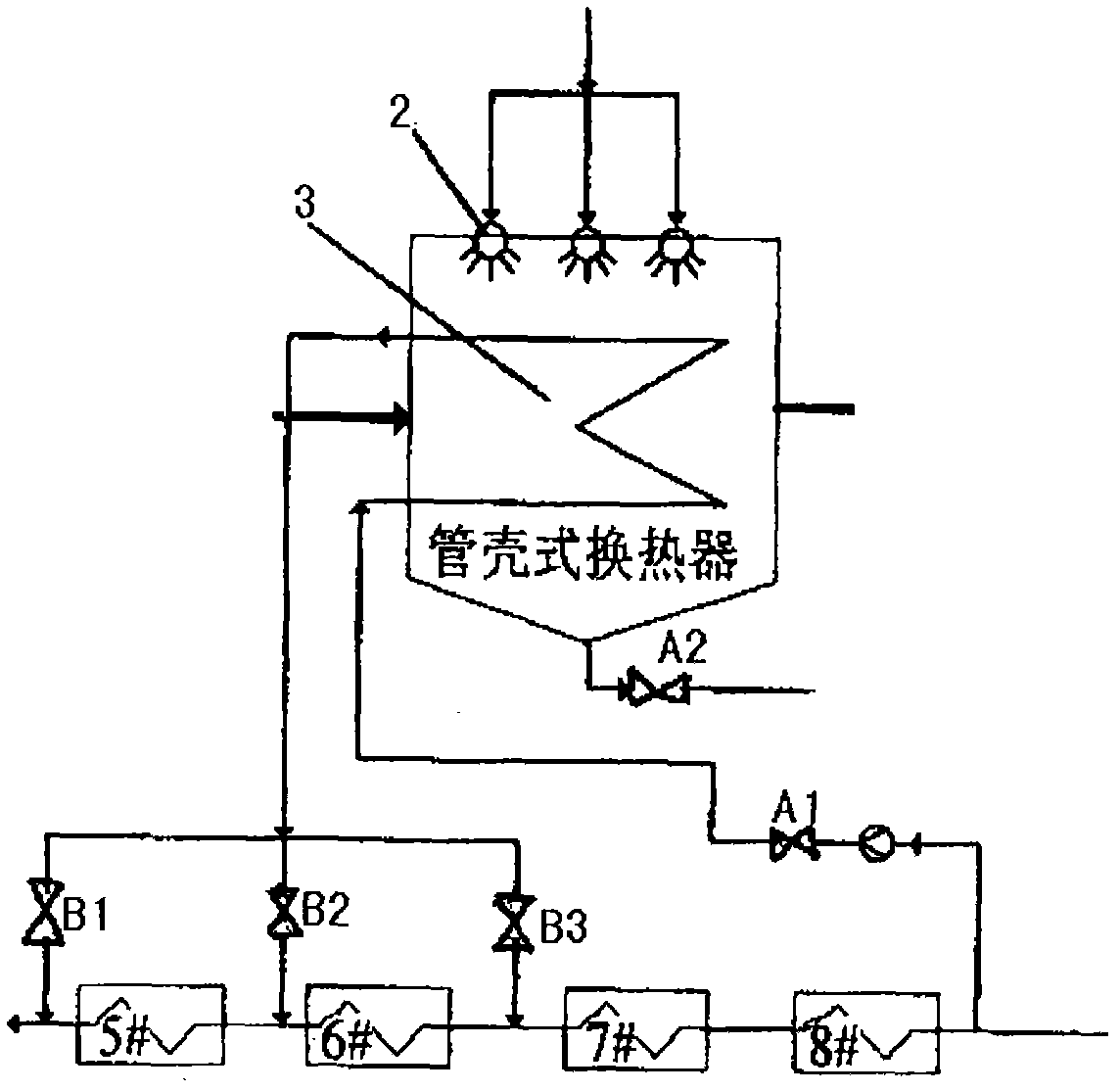

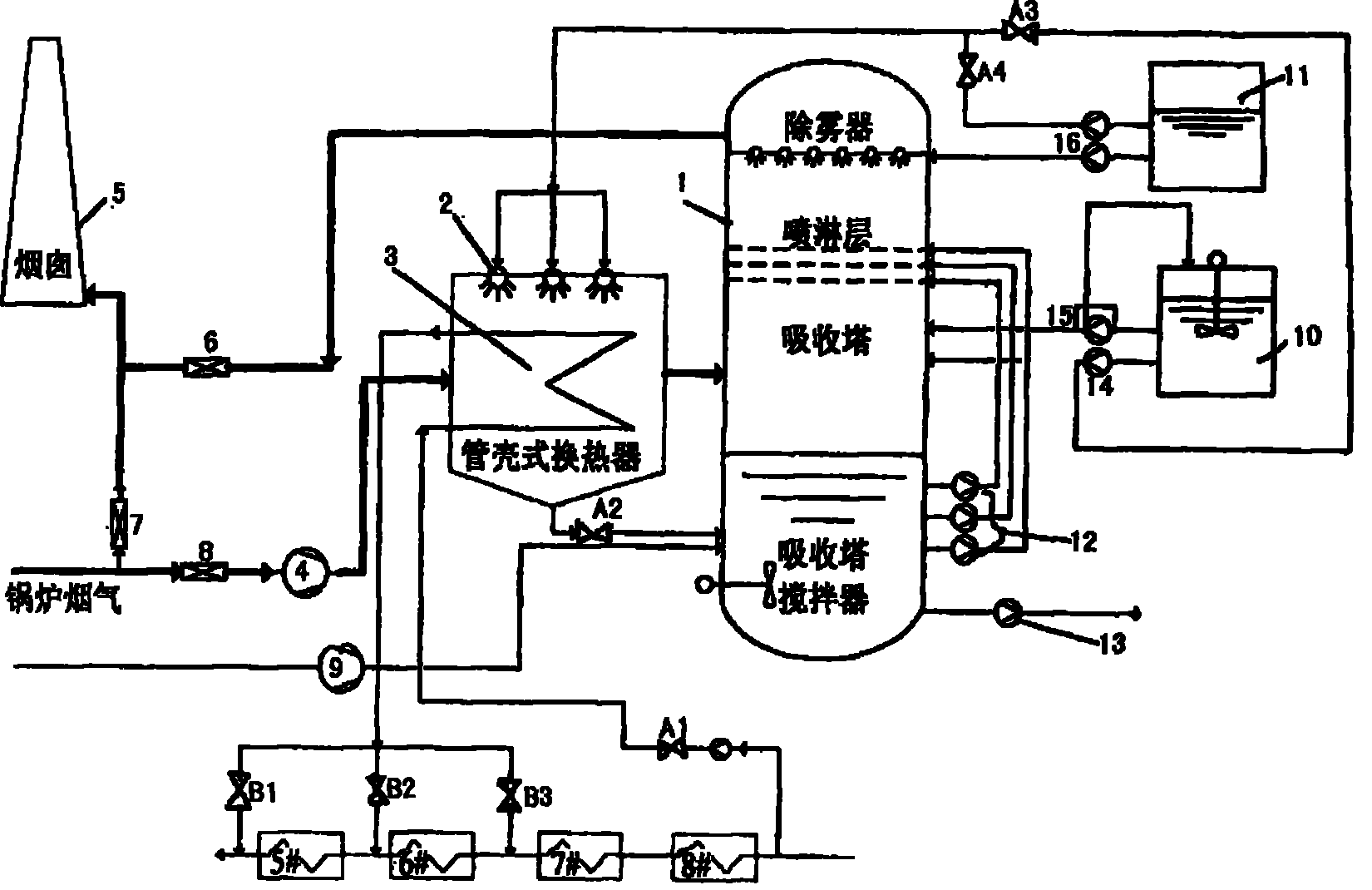

Integrated system for utilizing residual heat of boiler smoke and removing sulfur

InactiveCN102087021AImprove efficiencyReduce the temperatureDispersed particle separationEnergy industrySlurryIntegrated systems

The invention relates to an integrated system for utilizing residual heat of boiler smoke and removing sulfur. A tubular heat exchanger is used as a heat exchange main body of the system and is arranged on a tail flue between a booster fan and a desulfurization absorber, wherein the tubular heat exchanger is connected to a condensed water heating system; sets of nozzles are arranged in the heat exchanger for intermittently washing the inner tube wall of the heat exchanger and the wall of the flue; the processing water from a desulfurization system or limestone size or the mixture of the processing water and the limestone size are used as washing fluid for washing the walls; and the washing fluid is recovered and reused by returning to the desulfurization absorber after gathering on the bottom of the heat exchanger. By using the integrated system provided by the invention, the temperature of the smoke on the tail part of the boiler can be reduced to 50-70DEG C, thereby recovering the residual heat of boiler smoke and increasing the boiler efficiency. Meanwhile, the smoke within the temperature range which enters into the absorber of the desulfurization system on the tail part still meets the requirement of the temperature for desulfurization reaction, and the water consumption for desulfurization is reduced by 50-80%. Without designing a single size preparation and sewage treatment process, the water-saving and energy-saving properties, the anticorrosion property and reuse of the whole system are finally realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Boiler low grade residual heat combined reclamation method and device

InactiveCN101165399ASelf-utilizationAchieving joint recyclingLiquid degasificationFeed-water heatersRecovery methodWater storage tank

This invention relates to a waste heat combined recovery method of power station boiler and its device composition. It mainly recovers the sewage of boiler, the waste heat and cleaning water of the discharged gas from high pressure deaerator. The device includes flash tank, jet type mixed heater, degas water storage tank, frequency converting pump, softening water pump, pipeline and valve. Softened water is used as working medium. It condenses the flash steam and discharged gas from high pressure deaerator through jet type mixed heater. In the degas water storage tank, the air in the discharged gas from high pressure deaerator is removed. The heat water in the water storage tank is transported into the low pressure deaerator through frequency converting pump. Thus, it fulfills the self-using of recovered heat. This invention only brings in softened water from outside and does not change the original thermal system.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

System and method for urea decomposition to ammonia in a side stream for selective catalytic reduction

ActiveUS20140096532A1Reduce nitrogen oxide emissionsReduce NOxExhaust apparatusEmission preventionRecovery boilerAmmonia gas

A method for reducing NOx emissions in the exhaust of a combined cycle gas turbine equipped with a heat recovery boiler and a catalyst effective for NOx reduction, wherein a slip stream of hot flowing exhaust gases is withdrawn from the primary gas flow after the catalyst at a temperature of 500° F. to 900° F. and directed through a fan to a continuous duct into which an aqueous based reagent is injected for decomposition to ammonia gas and the outlet of the continuous duct is connected to an injection grid positioned in the primary exhaust for injection of ammonia gas into the primary exhaust stream at a location upstream of the catalyst.

Owner:CECO ENVIRONMENTAL IP INC

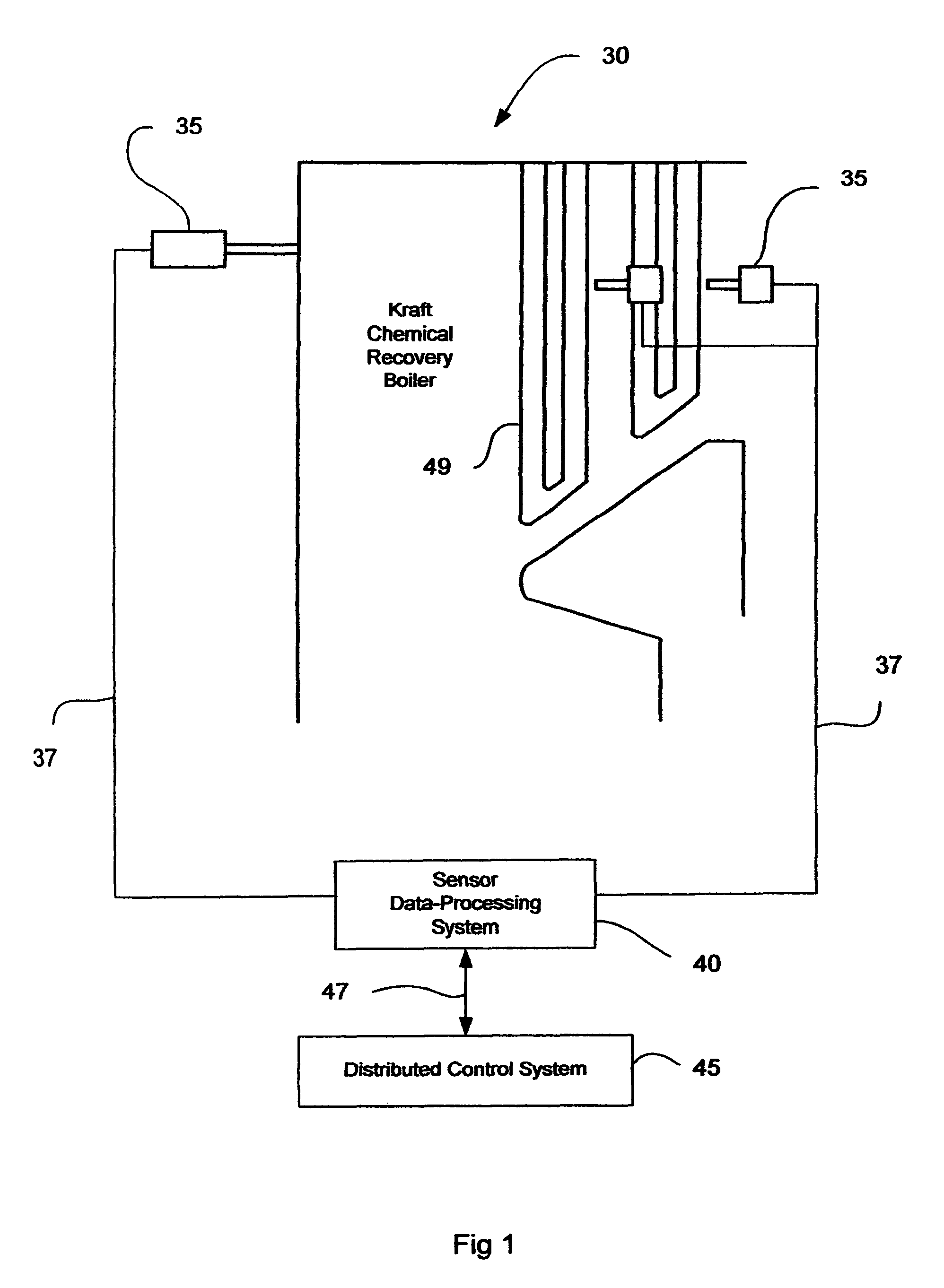

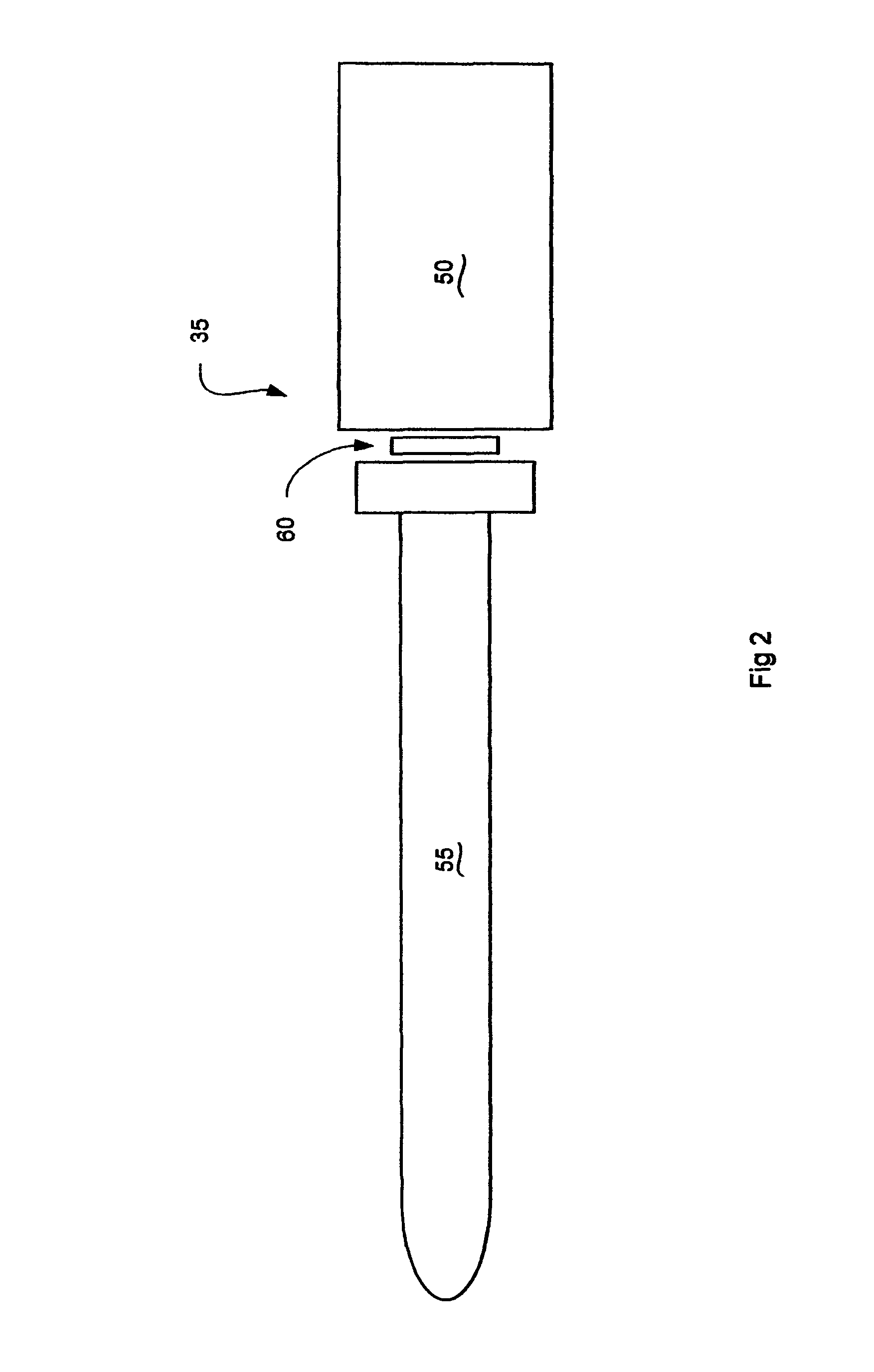

Infrared imaging sensor

InactiveUS7956326B1Low costReduce absorptionRadiation pyrometryWeather/light/corrosion resistanceLow-pass filterImage segmentation

A system for detection and control of deposition on pendant tubes in recovery and power boilers includes one or more deposit monitoring sensors operating in infrared regions of about 4 or 8.7 microns and directly producing images of the interior of the boiler, or producing feeding signals to a data processing system for information to enable a distributed control system by which the boilers are operated to operate said boilers more efficiently. The data processing system includes an image pre-processing circuit in which a 2-D image formed by the video data input is captured, and includes a low pass filter for performing noise filtering of said video input. It also includes an image compensation system for array compensation to correct for pixel variation and dead cells, etc., and for correcting geometric distortion. An image segmentation module receives a cleaned image from the image pre-processing circuit for separating the image of the recovery boiler interior into background, pendant tubes, and deposition. It also accomplishes thresholding / clustering on gray scale / texture and makes morphological transforms to smooth regions, and identifies regions by connected components. An image-understanding unit receives a segmented image sent from the image segmentation module and matches derived regions to a 3-D model of said boiler. It derives a 3-D structure the deposition on pendant tubes in the boiler and provides the information about deposits to the plant distributed control system for more efficient operation of the plant pendant tube cleaning and operating systems.

Owner:VALMET AUTOMATION OY

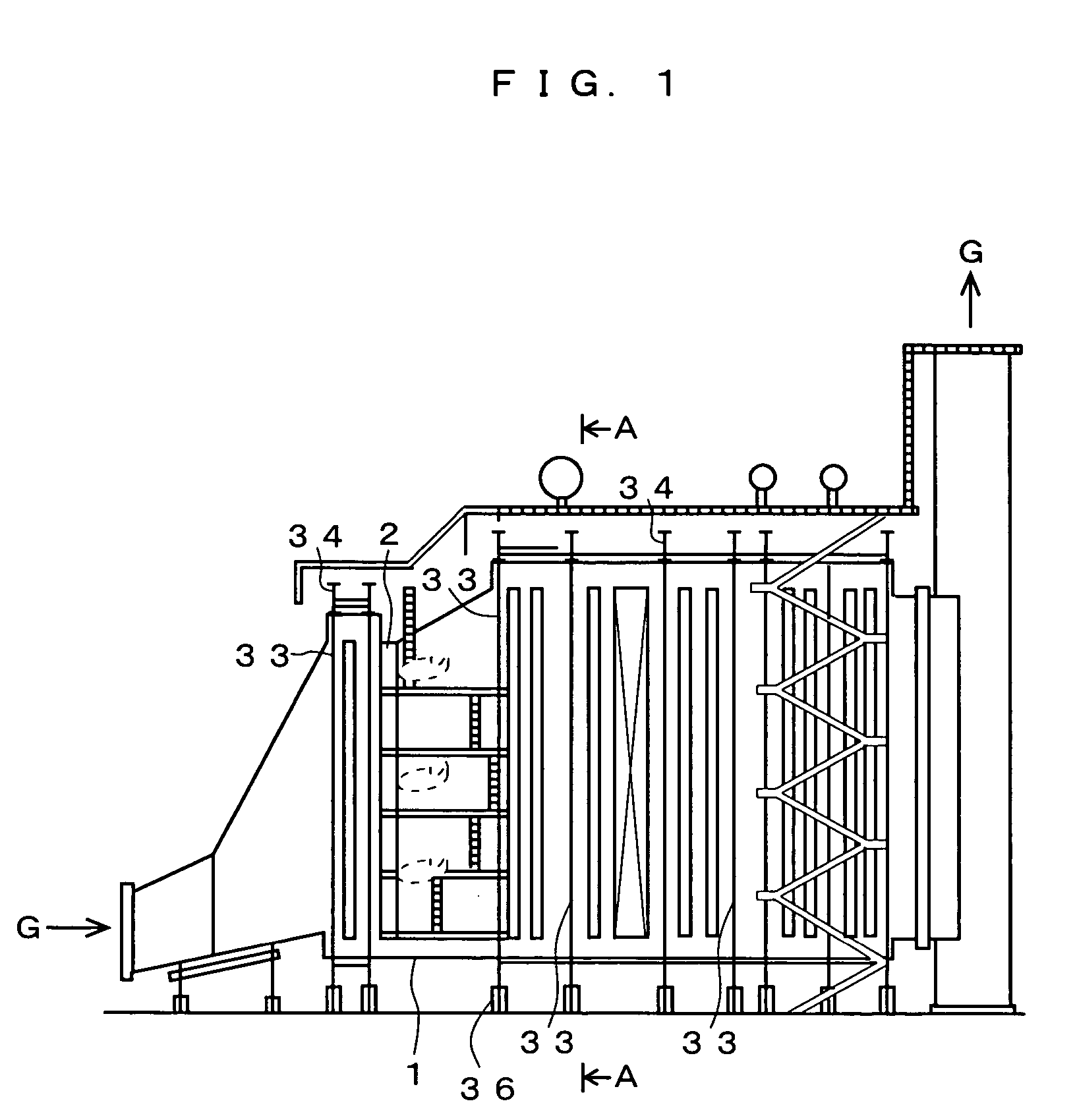

Arrangement in recovery boiler

ActiveUS7434543B2Increase heatFine surfacePulp liquors combustionSteam engine plantsSuperheaterPulp and paper industry

The invention relates to an arrangement in a recovery boiler, into which spent liquor to be combusted and combustion air are fed, the arrangement comprising superheaters in the upper part of the recovery boiler for recovering heat. Instead of screen tubes the invention is provided with a superheater formed of horizontal elements.

Owner:KVAERNER POWER OY

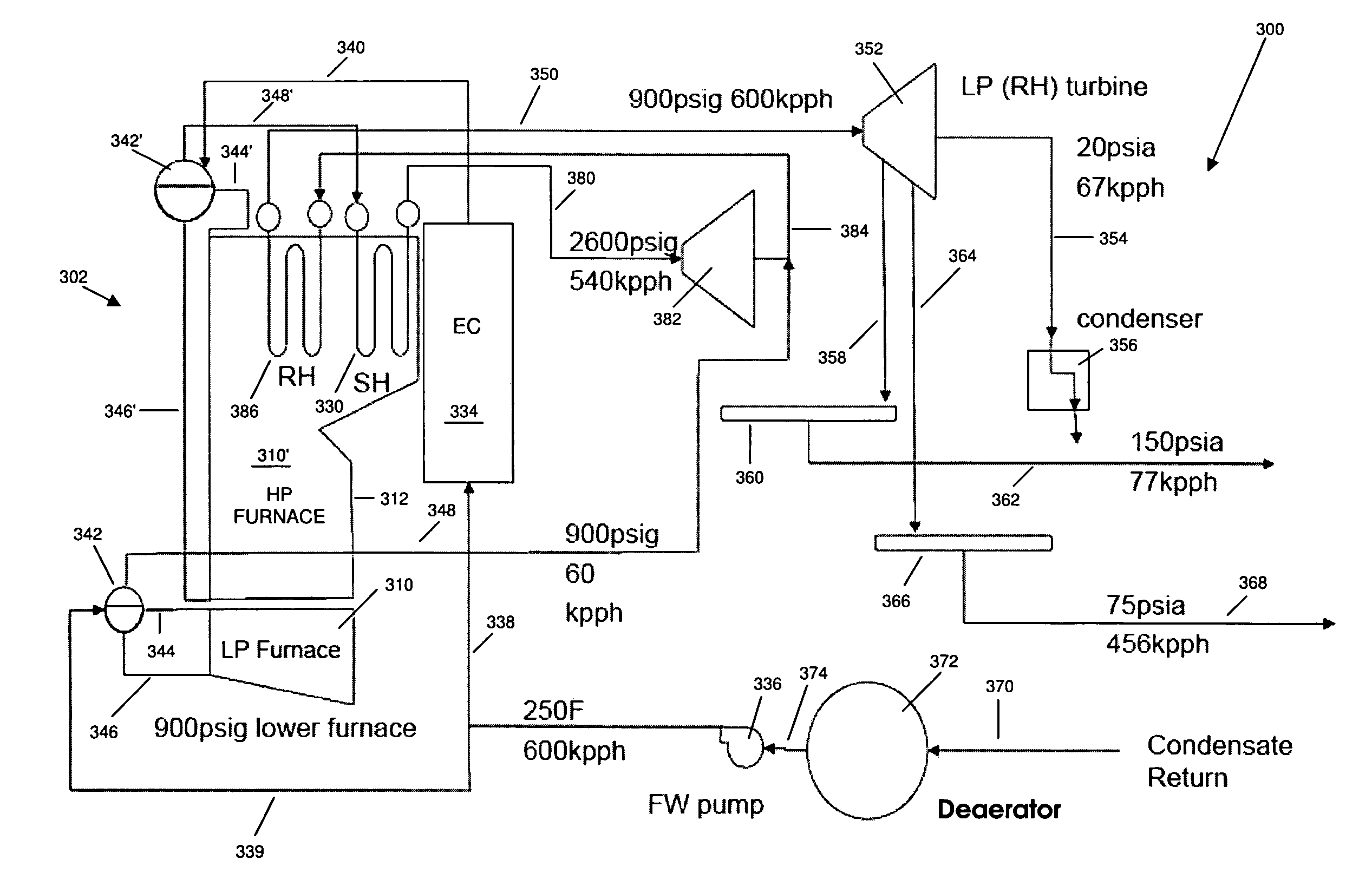

Enhanced steam cycle utilizing a dual pressure recovery boiler with reheat

InactiveUS20090241860A1Increase generationThe material is lowSuperheating controlFood processingBoiler furnaceEngineering

An enhanced steam cycle utilizing a dual pressure recovery boiler with reheat allows a large increase in electrical generation with various turbine cycles while overcoming traditional lower furnace material limitations. A dual pressure designed recovery boiler furnace is provided with a lower furnace and an upper furnace. The lower furnace is operated at a lower temperature to prevent or reduce corrosion of the lower furnace wall tubes caused by the reducing environment. The lower furnace can be either a low pressure natural circulation steam generating (drum) system or economizer. Unlike the lower furnace, the upper furnace is not exposed to a reducing environment and is therefore not as susceptible to severe corrosion rates. The upper furnace is operated at higher temperatures and pressures which permit implementation of higher efficiency reheat steam cycles. The upper furnace thus operates as a high pressure natural circulation steam generating (drum) system, or as a once-through supercritical steam generating system. The dual pressure recovery boiler can thus be coupled to a variety of condensing, non-condensing or a combination of condensing and non-condensing turbine cycles to provide a large increase in electrical generation.

Owner:THE BABCOCK & WILCOX CO

Process for treating pulp mill condenstates using a hollow fiber contactor

A method and apparatus for the treatment of pulp mill condensates is described. A hollow fiber contactor, incorporating a hydrophobic membrane, was used to remove several undesirable compounds from pulp mill condensates. For example, TRS compounds and SO2 were efficiently stripped from kraft and sulphite mill evaporator condensates, respectively. Methanol was also removed from kraft mill condensates but at a lower efficiency than TRS. Furthermore, other undesirable compounds found in condensates of pulp mills that contribute to the BOD and COD loading to effluent treatment systems were also removed. These contactors are cost effective since air, vacuum or a suitable solvent or scrubbing solution can be used as the stripping medium to drive off through the membrane several undesirable compounds from the feed solution. The undesirable compounds removed can thus be burned in the recovery boiler, lime kiln or a dedicated boiler.

Owner:FPINNOVATIONS INC

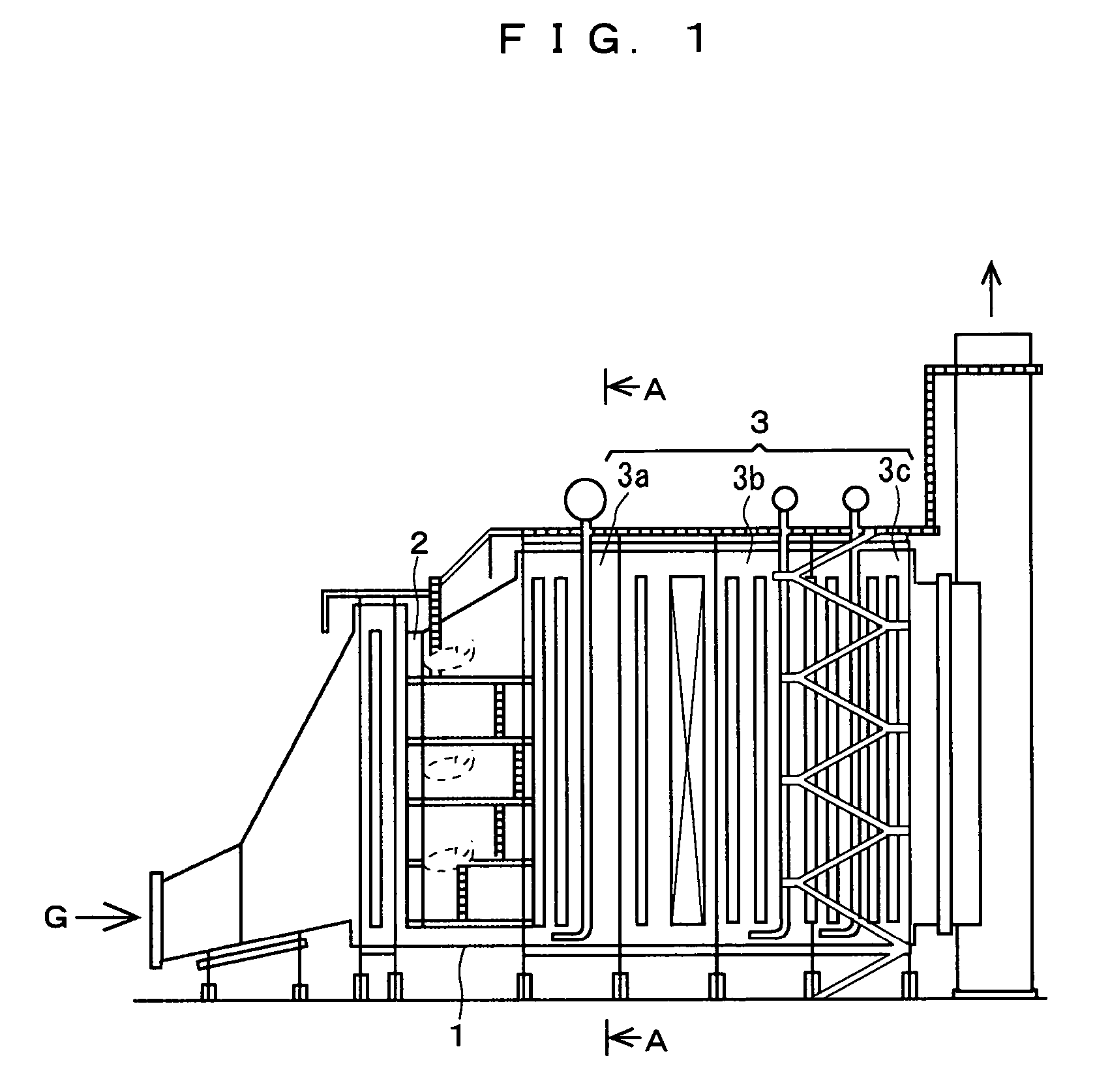

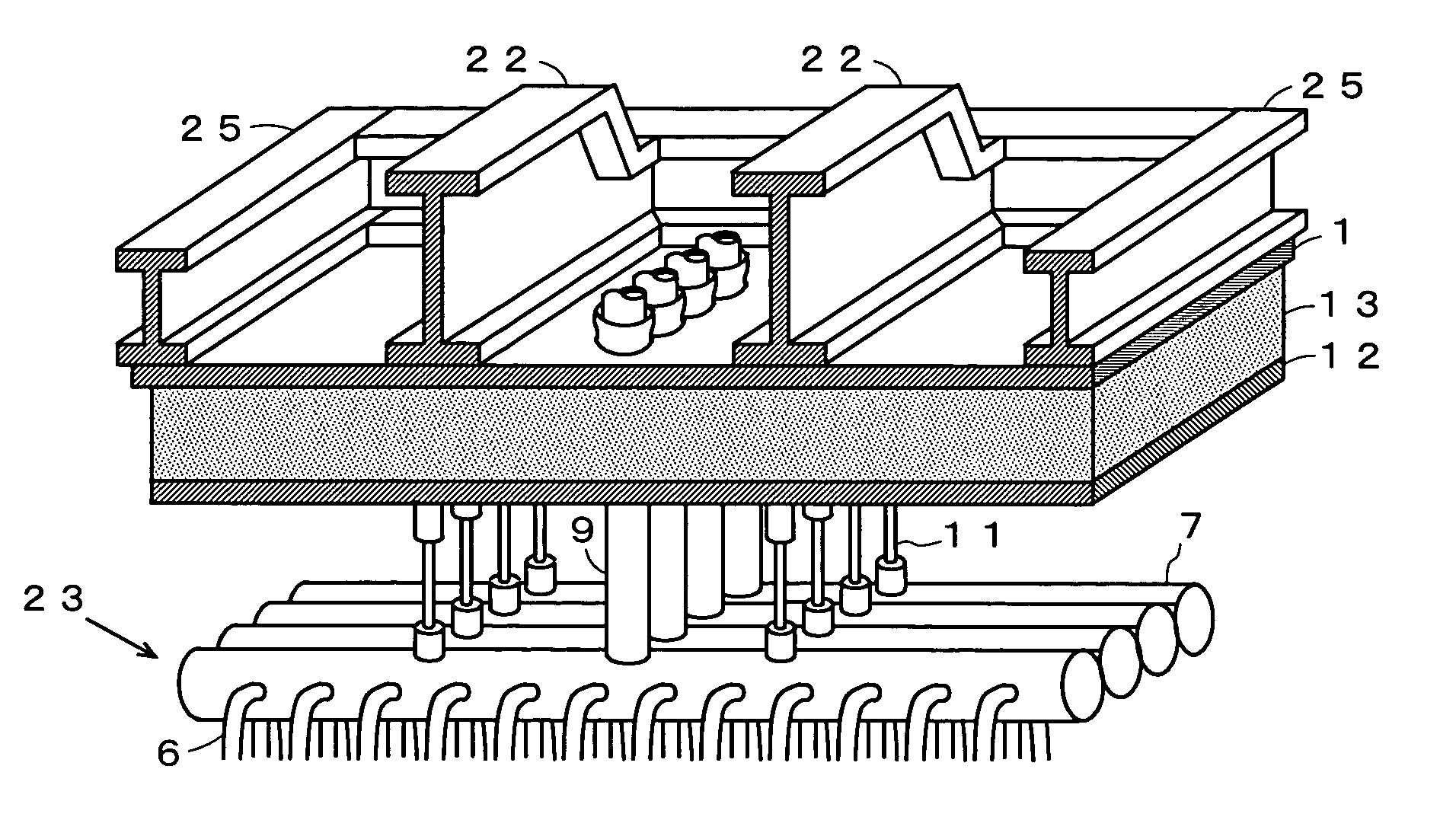

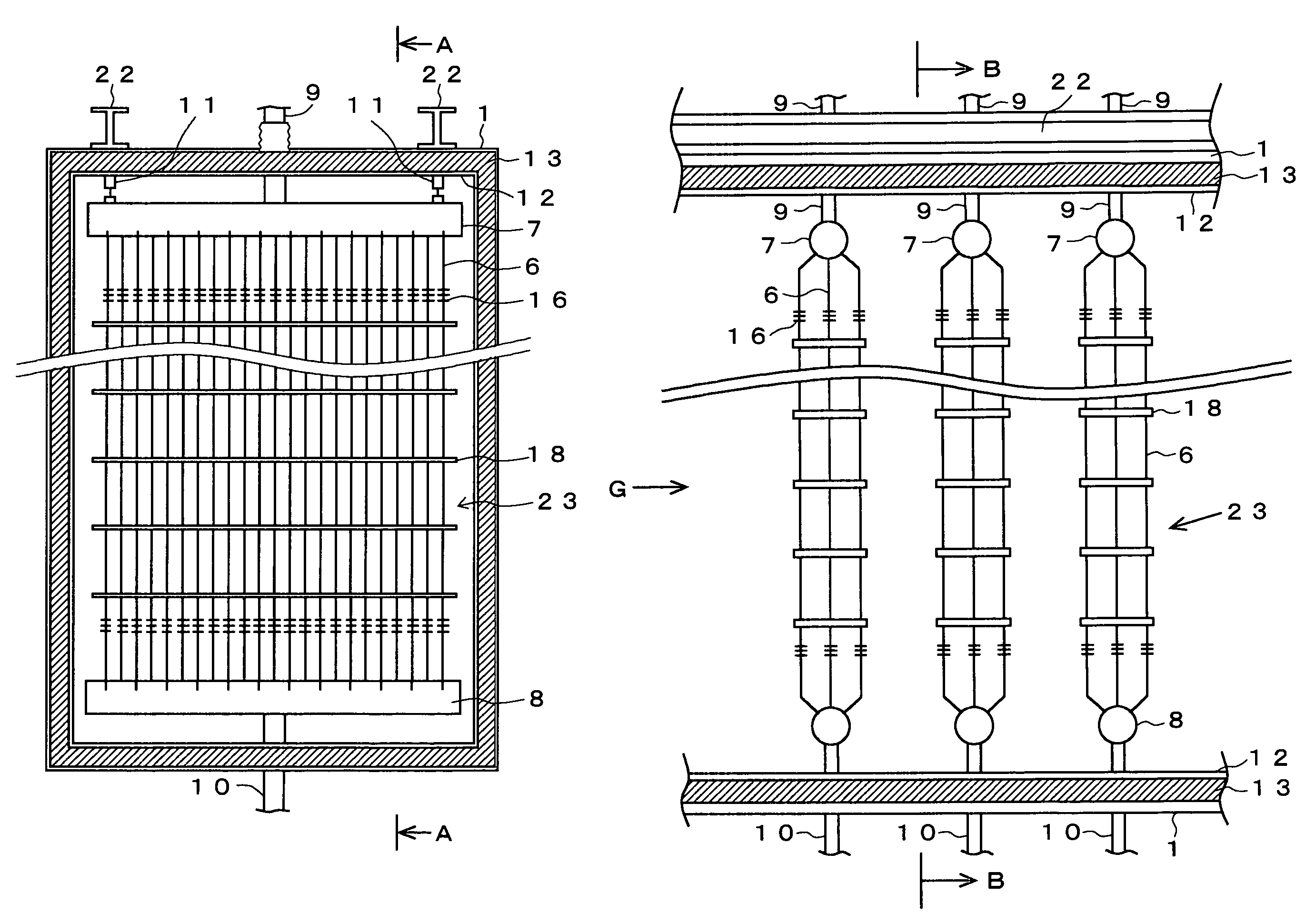

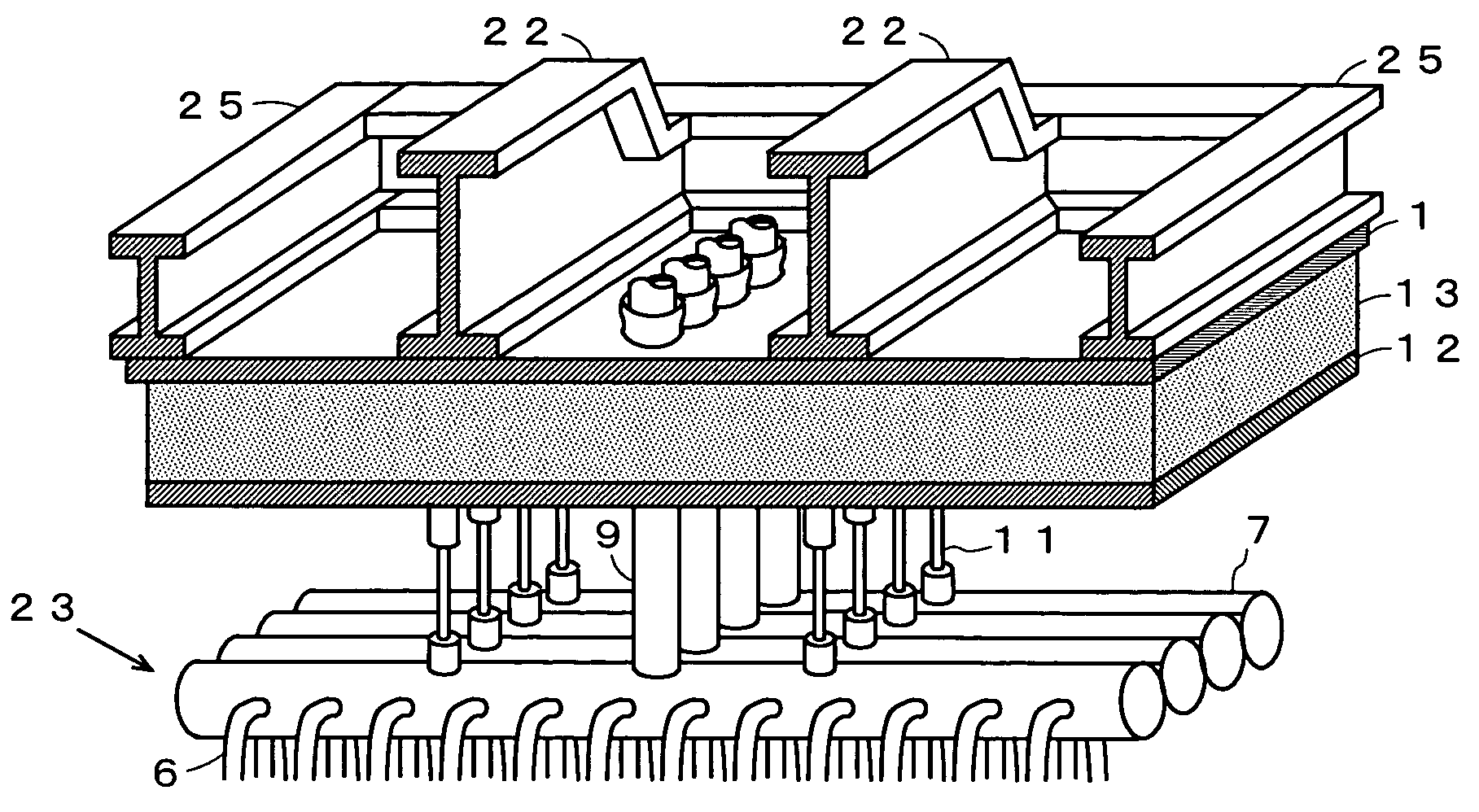

Heat transfer tube panel module and method of constructing exhaust heat recovery boiler using the module

ActiveUS20060175040A1Small sizeIncrease costBoiler supporting/setting arrangementsRecuperative heat exchangersEngineeringRecovery boiler

The invention provides an exhaust heat recovery boiler construction method in which a necessary number of heat exchanger tube bundle panel modules each having heat exchanger tube bundle panels including a number of heat exchanger tubes and upper and lower headers of the heat exchanger tubes, a casing of the heat exchanger tube bundle panels, heat exchanger tube bundle panel support beams located outside the ceiling wall of the casing, and vertical and horizontal module frames located outside the casing, are prepared so as to have a proper size according to the design specifications of the heat recovery boiler, main frames including main columns, main beams, and bottom wall columns for supporting the modules are constructed in advance at a construction site of the exhaust heat recovery boiler (heat recovery boiler), and the modules are transported and hung down by a crane between the main columns adjacent to each other at the construction site to set the support beams of the modules at the installation height of the main beams, and the horizontal module frames, the main beams, and the bottom wall columns are connected and fixed to each other and the vertical module frames and the main columns are connected and fixed to each other.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

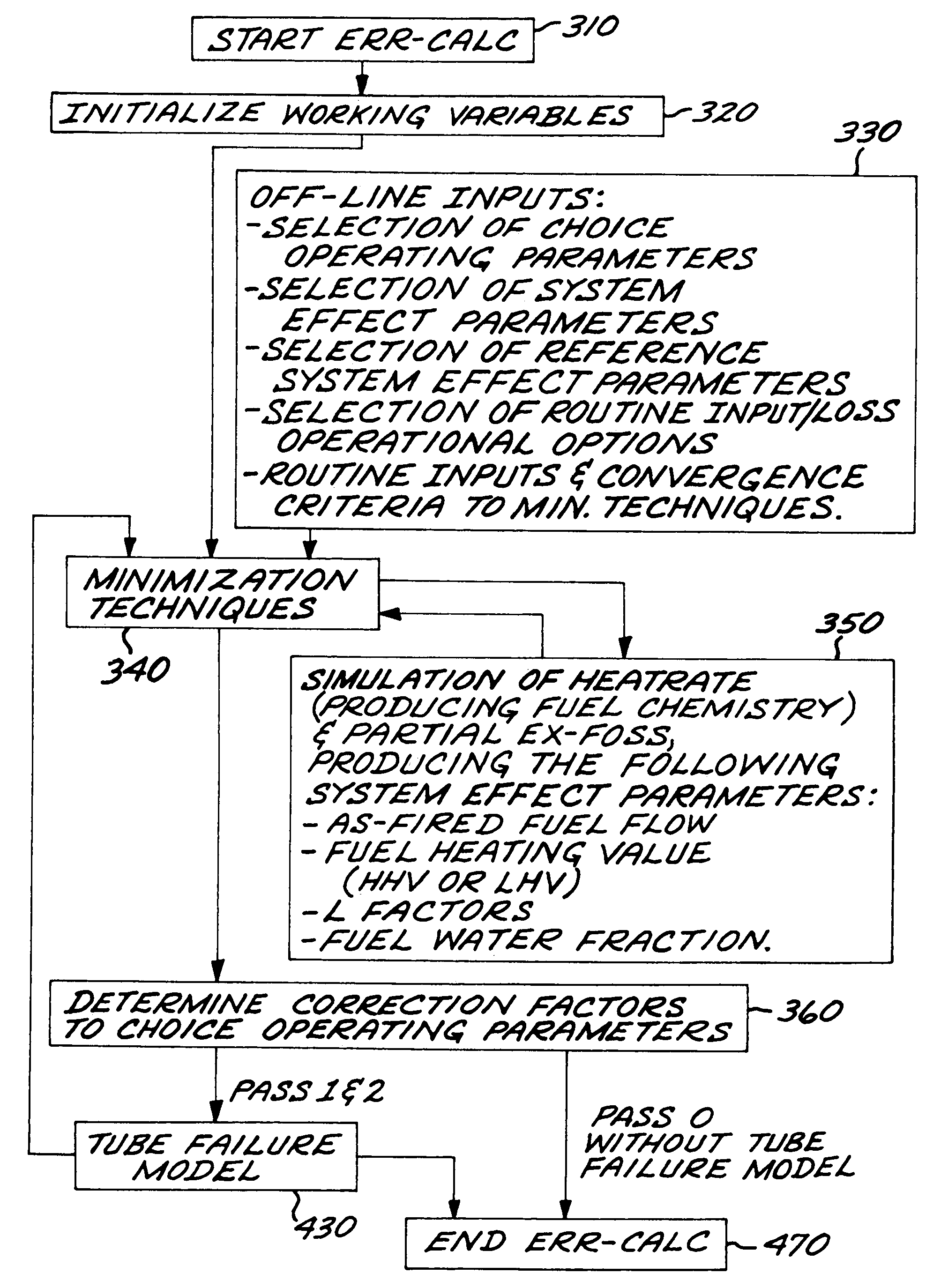

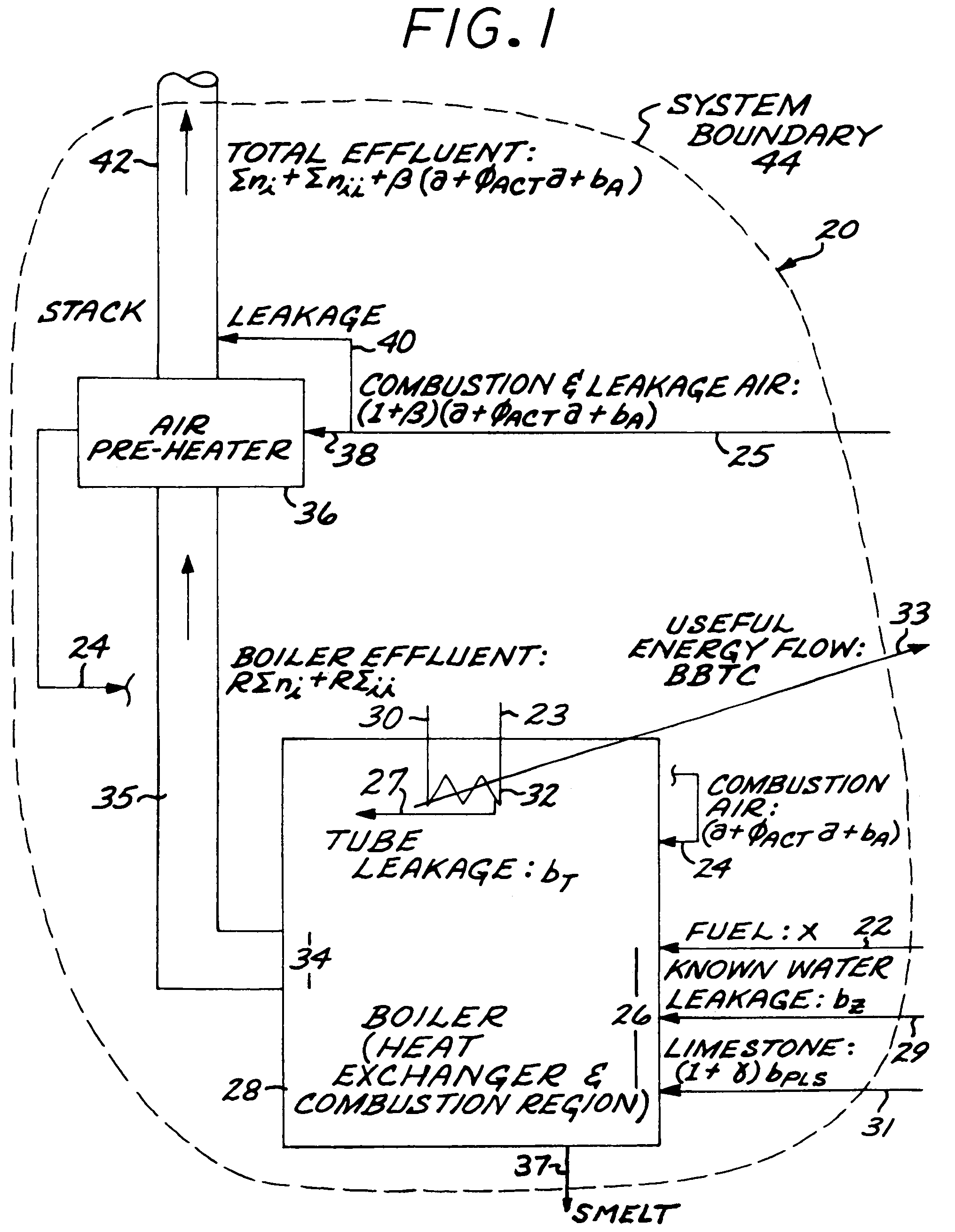

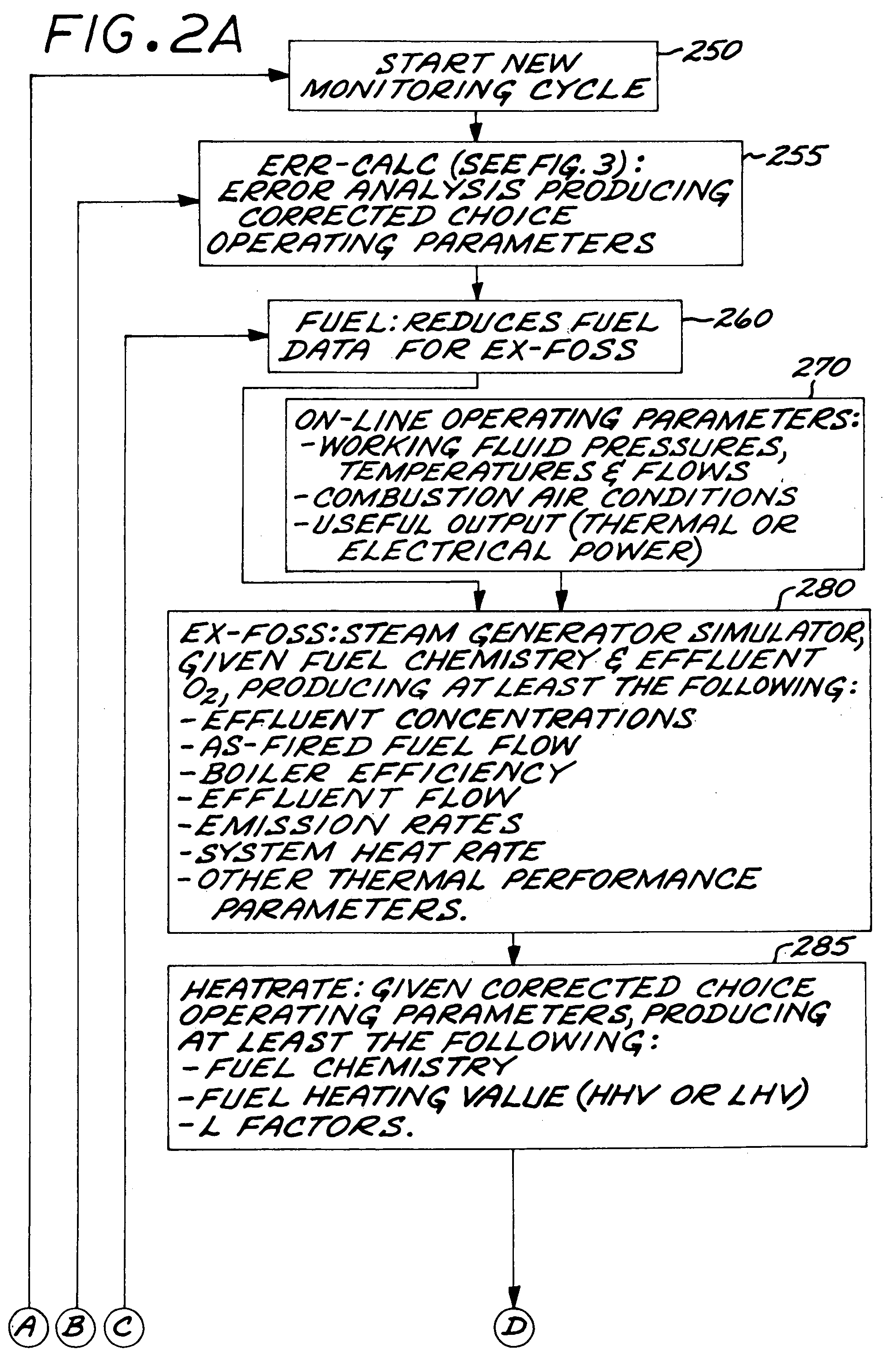

Method for detecting heat exchanger tube failures and their location when using input/loss performance monitoring of a recovery boiler

InactiveUS7039555B2Improve abilitiesReduce outage timeCombustion pretreatment/prehandlingCombustion measurementsRepair timeBlack liquor

This invention relates to a recovery boiler as used by the pulp and paper industry burning black liquor, and, more particularly, to a method for rapid detection of tube failures and the location of the affect heat exchanger within the recovery boiler, without need for direct instrumentation, thereby preventing more serious equipment damage, preventing boiler explosion, preventing injury to operators and minimizing repair time on the affected heat exchanger. This method is applicable to Input / Loss methods of monitoring recovery boilers.

Owner:EXERGETIC SYST

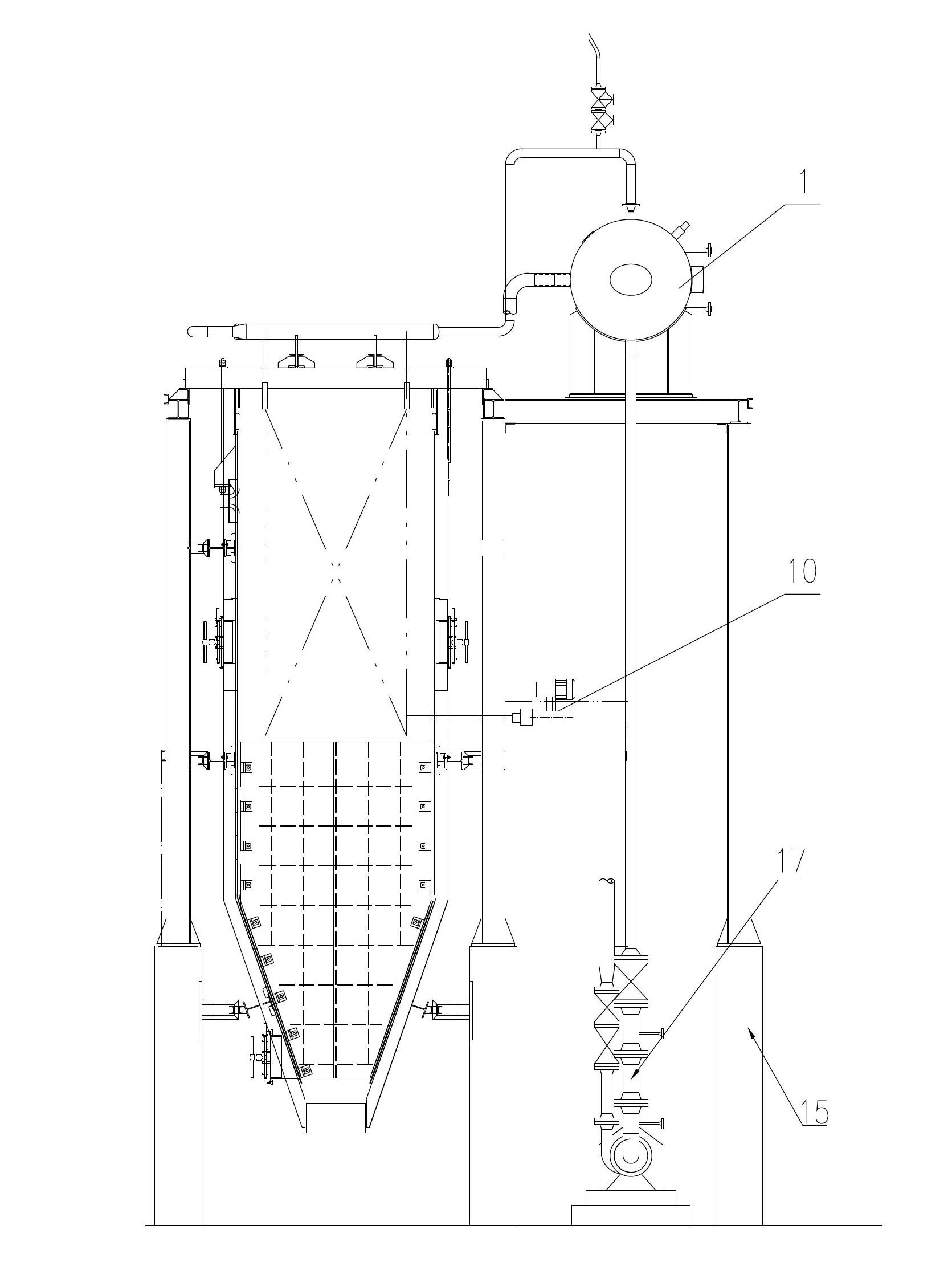

Boiler system using waste heat of flue gas of rotary hearth furnace

InactiveCN102635844ASave floor areaSave electricityIncreasing energy efficiencyCasings/liningsSteel frameHearth

The invention relates to the technical field of waste heat utilization, in particular to a boiler system using waste heat of flue gas of a rotary hearth furnace, which is characterized in that a steam drum is arranged on a steel frame on the flue type heat recovery boiler, and four upper collection boxes with water-cooled walls for a hearth, four upper collection boxes with water-cooled walls for a rear flue and a lower collection box for a roof pipe are suspended under the steel frame; and the flue type heat recovery boiler adopts a vertical structure which consists of the vertical hearth and the vertical rear flue. Compared with the prior art, since the vertical flue structure is adopted by the flue type heat recovery boiler, space is occupied, the area of the occupied plane is reduced, and prospects are created for development of systems of modified or new rotary hearth furnaces which can recycle waste heat of high-temperature flue gas; and the structural layout of boiler pipes is improved, so water in the boiler can circulate naturally depending on the height difference, and the additional power and a large number of maintenance costs required for a boiler water circulating pump can be saved.

Owner:中江能源回收(上海)有限公司

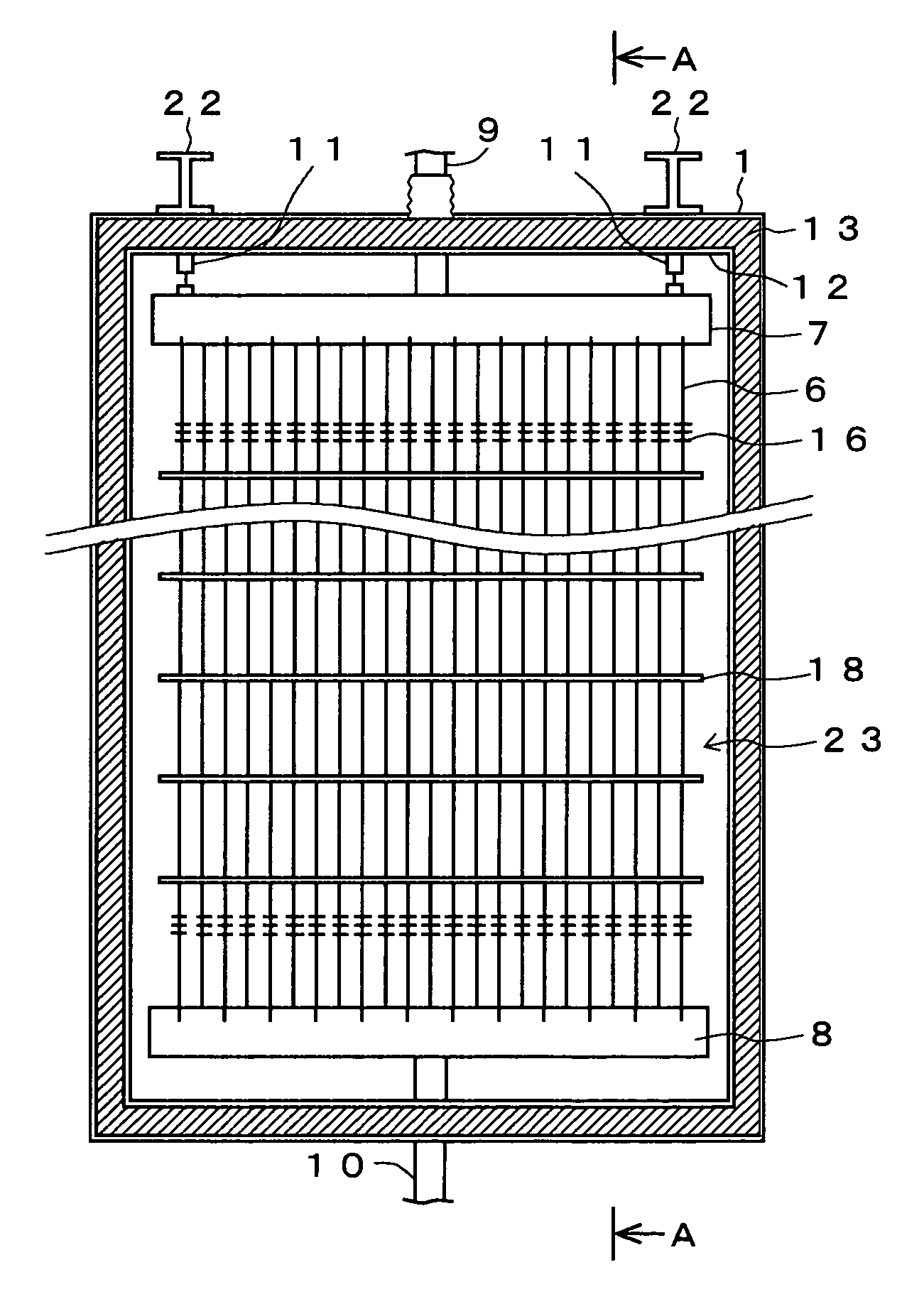

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS7357100B2Avoid damageEffect of preventing damage due to shaking during transportation is increasedBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

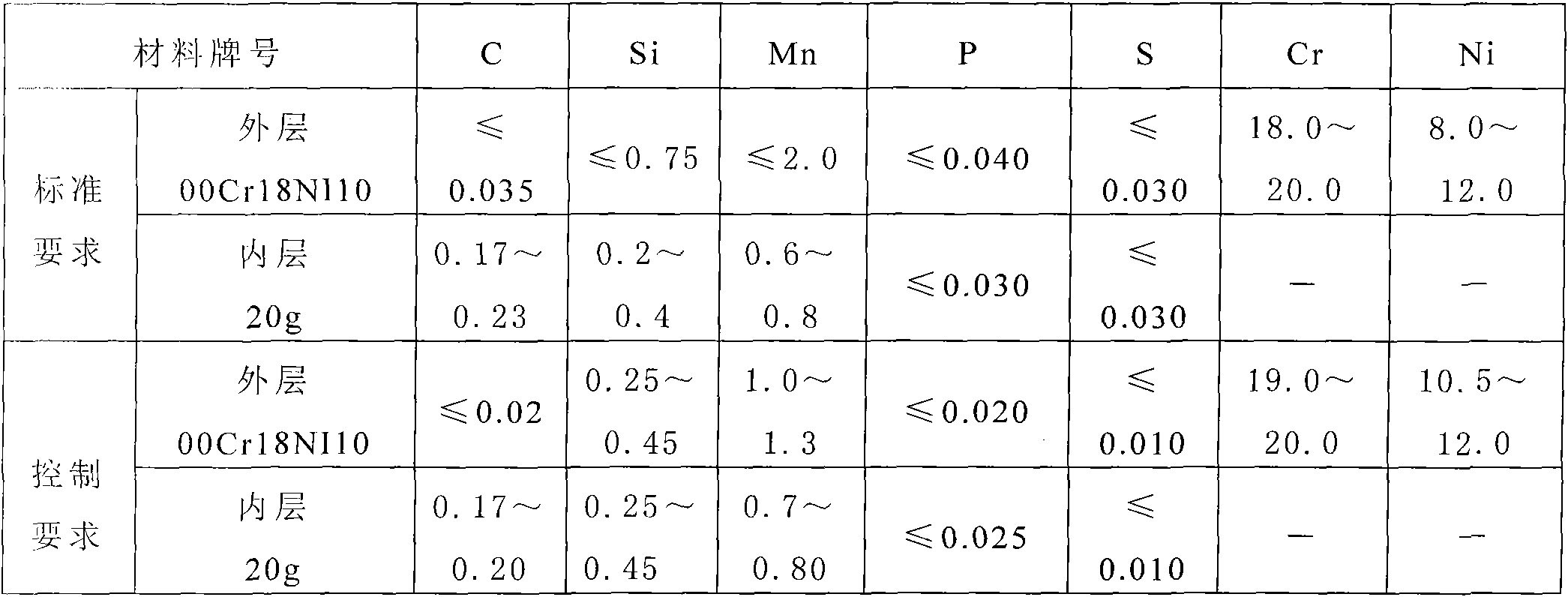

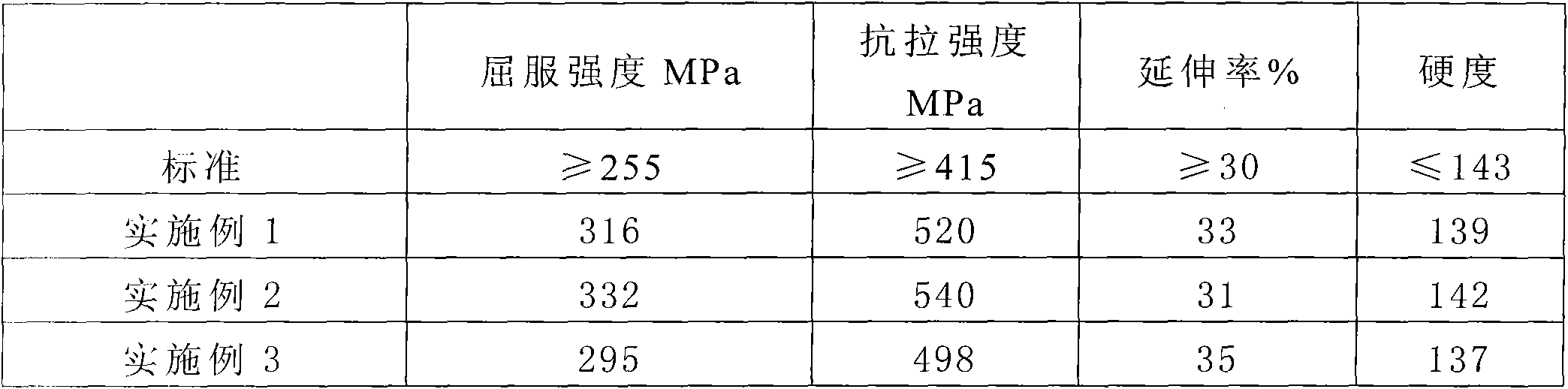

Method for preparing bimetallic seamless steel pipe for alkali recovery boiler

InactiveCN102039326AFine grainNo delaminationRoll force/gap control deviceExtrusion control devicesHigh pressureRecovery boiler

The invention relates to a method for preparing a bimetallic seamless steel pipe for an alkali recovery boiler. The method for preparing the bimetallic seamless steel pipe comprises the following steps of: selecting and treating a pipe blank, namely selecting a bimetallic composite pipe blank which is combined in a metallurgical mode and performing primary annealing; and extruding, namely extruding at an extrusion ratio of more than 10 and performing secondary annealing, wherein the heating temperature of the blank before extrusion is between 1,180 and 1,220 DEG C. The method has the characteristics that: an outer metal layer of the prepared composite pipe is resistant against alkali liquor corrosion, and an inner metal layer of the composite pipe is resistant against high pressure; meanwhile, the composite pipe avoids layering of two metal layers after tests such as flattening, bending and the like.

Owner:BEIJING CHANGXING KAIDA COMPOSITE MATERIAL TECH DEV

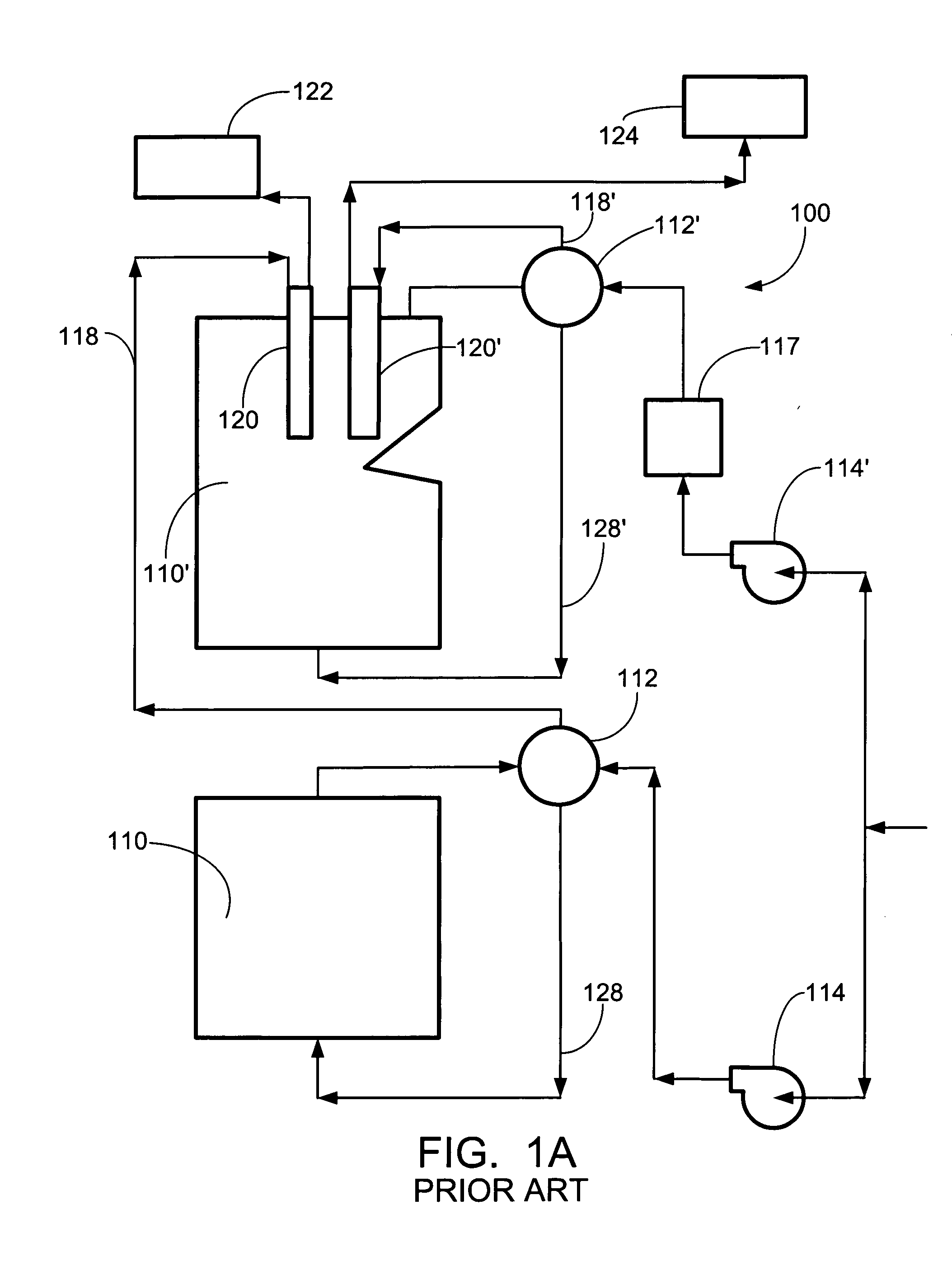

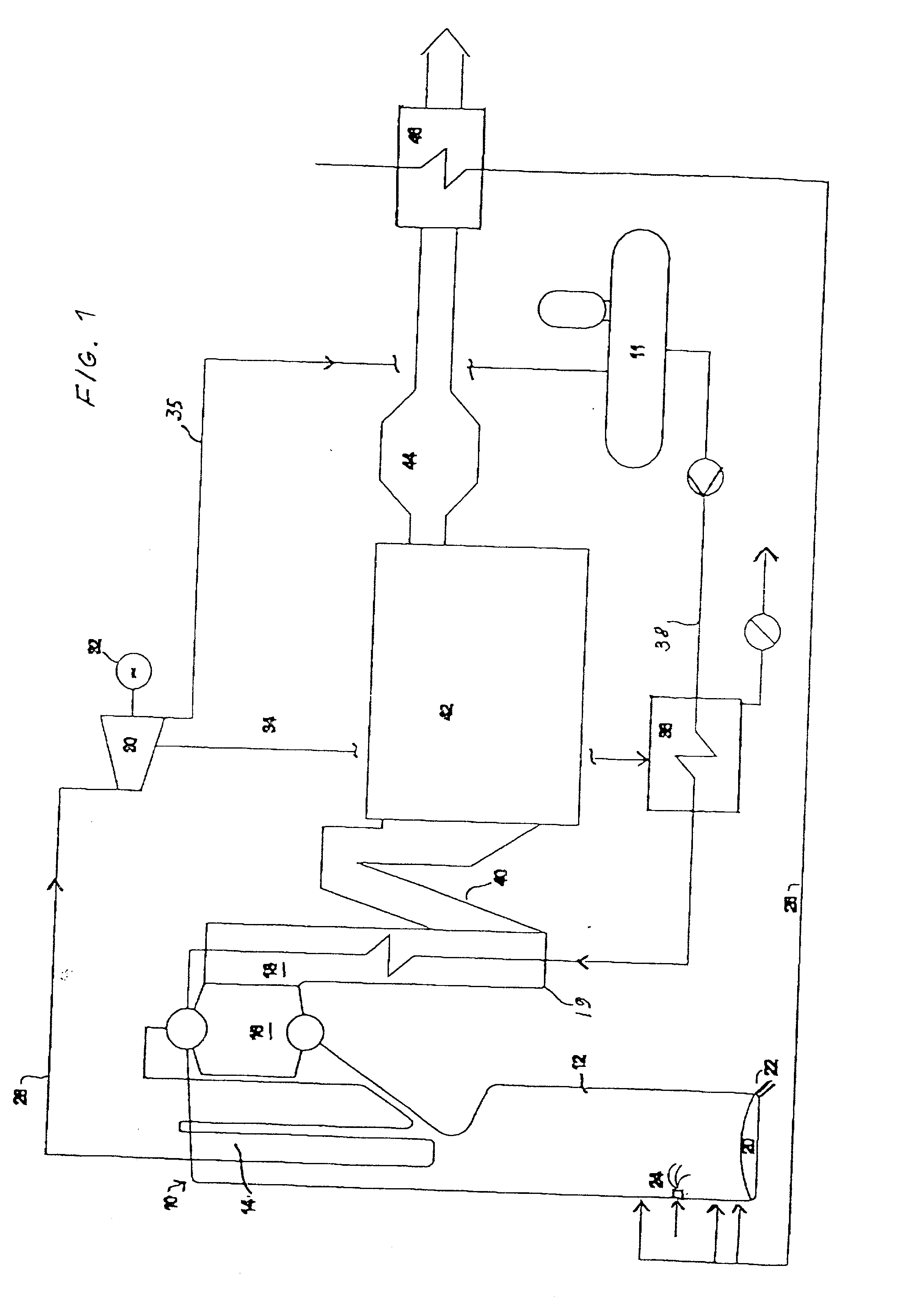

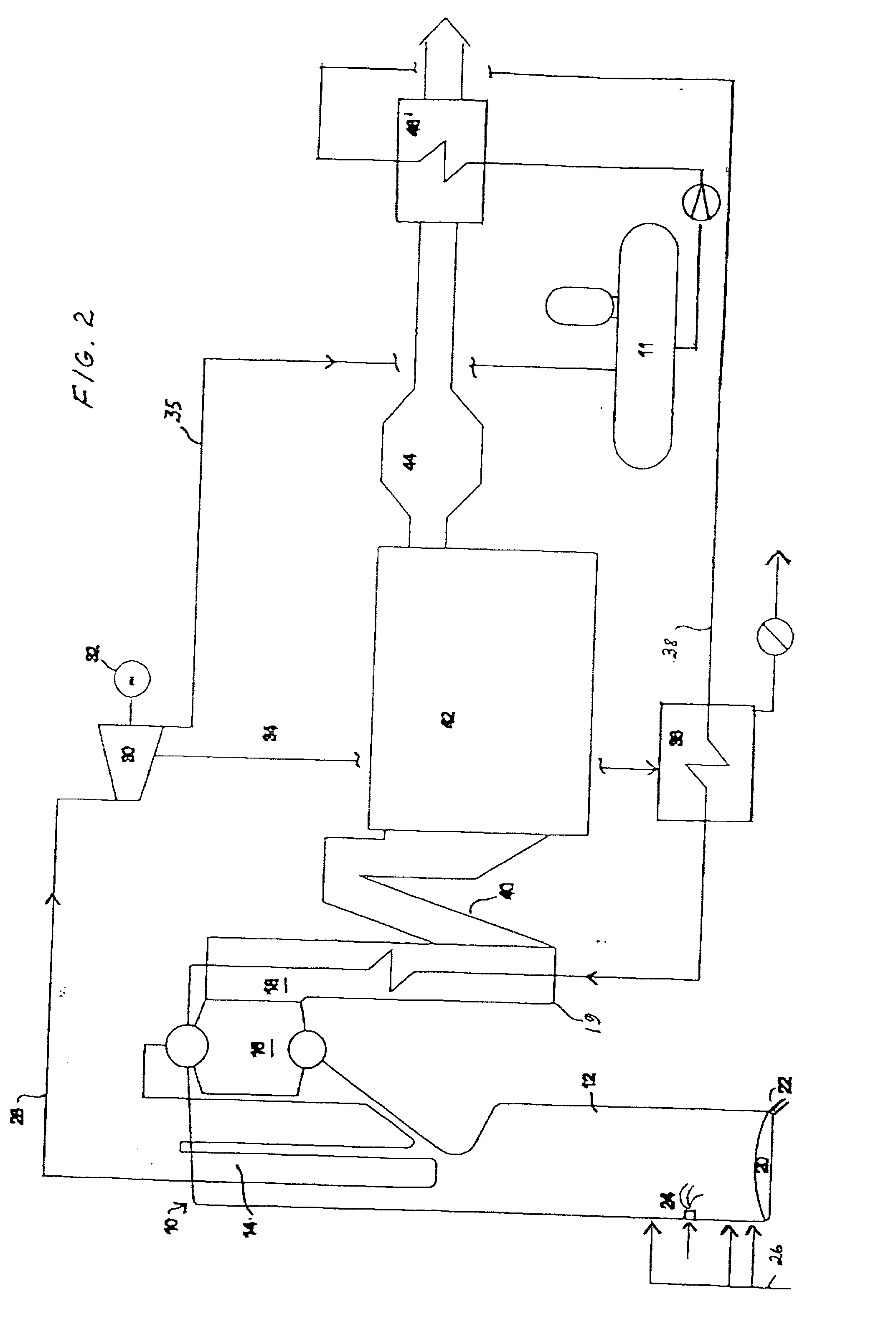

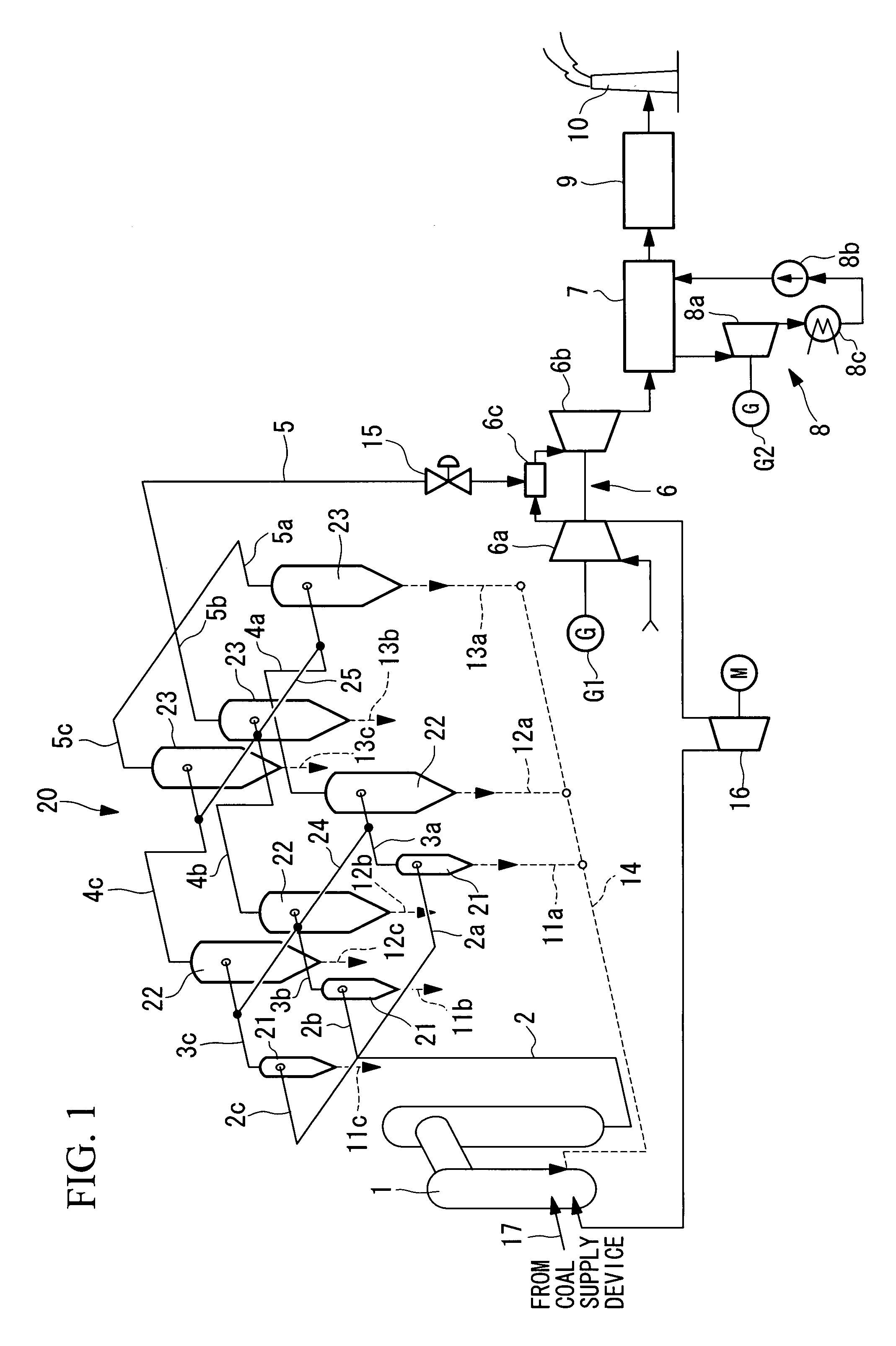

Method and arrangement for producing electrical energy at a pulp mill

InactiveUS20020194849A1Improve power production efficiencyElectrical efficiencyPulp liquors combustionSteam generation using steam absorptionSuperheaterEconomizer

The invention relates to a method and an arrangement in the production of electric energy in a boiler plant of a pulp mill. Black liquor having a dry solids content of more than 80% and combustion air are fed into a furnace of a recovery boiler for combusting black liquor and recovering chemicals contained therein. The flue gases generated in the combustion are led into an economizer of the recovery boiler, in which economizer the feed water for the boiler is heated, and after the economizer to gas cleaning. The feed water is led from the economizer onto the steam-generating bank at a temperature below the saturation temperature and further into a superheater to produce steam having a pressure of more than 80 bar. The steam is led from the recovery boiler to a steam turbine to produce electricity. The temperature of the feed water being led into the economizer is regulated by means of bleed steam of the turbine so that the flue gases exit the economizer at a temperature of more than 250° C. and that after the economizer the flue gases are cleaned in at least a hot electrostatic precipitator and the cleaned flue gases are cooled by the combustion air or the feed water.

Owner:ANDRIZ OY

Heat transfer tube panel module and method of constructing exhaust heat recovery boiler using the module

ActiveUS7275503B2Small sizeReduce shipping costsBoiler supporting/setting arrangementsRecuperative heat exchangersComputer moduleEngineering

Owner:MITSUBISHI HITACHIPOWER SYST LTD

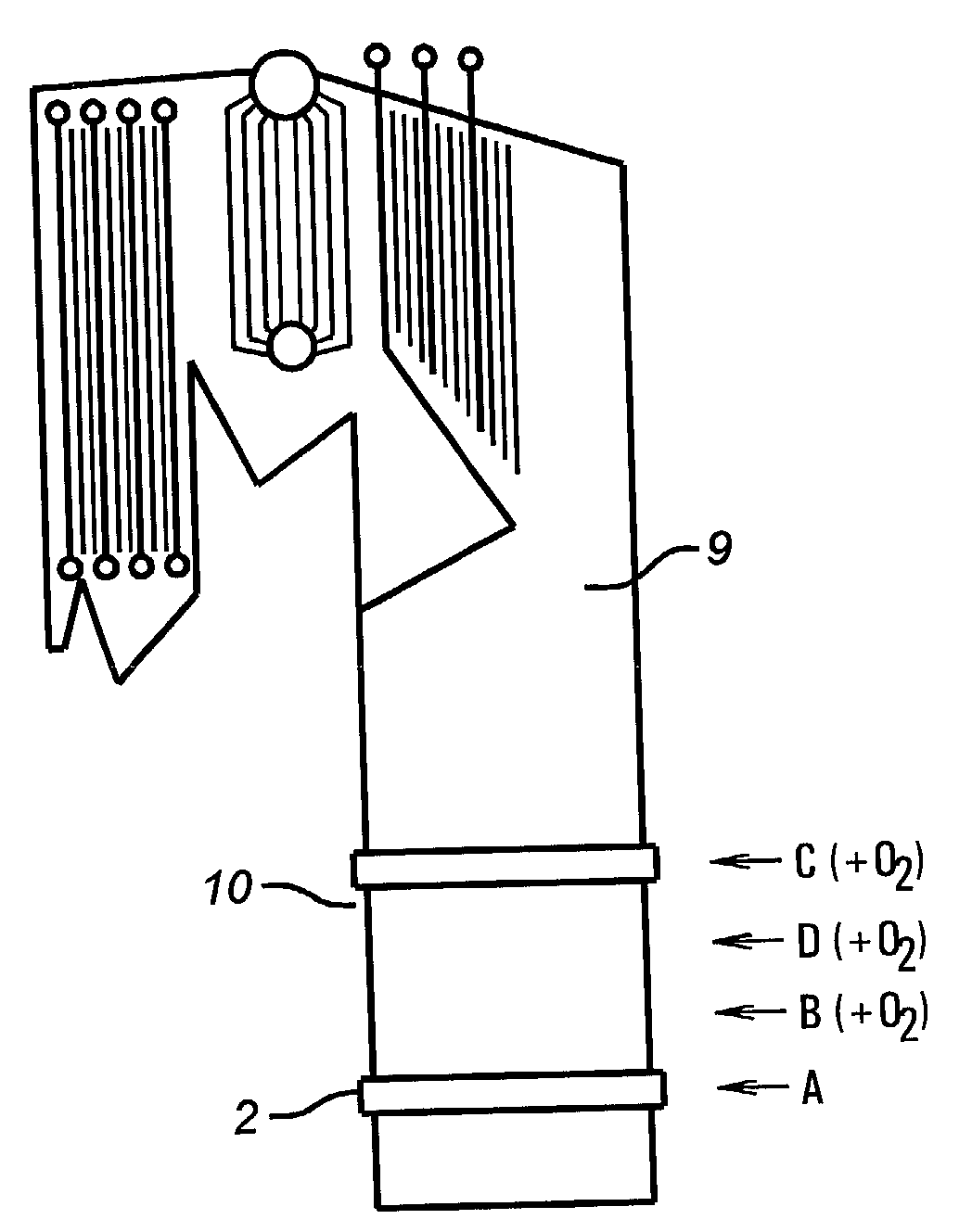

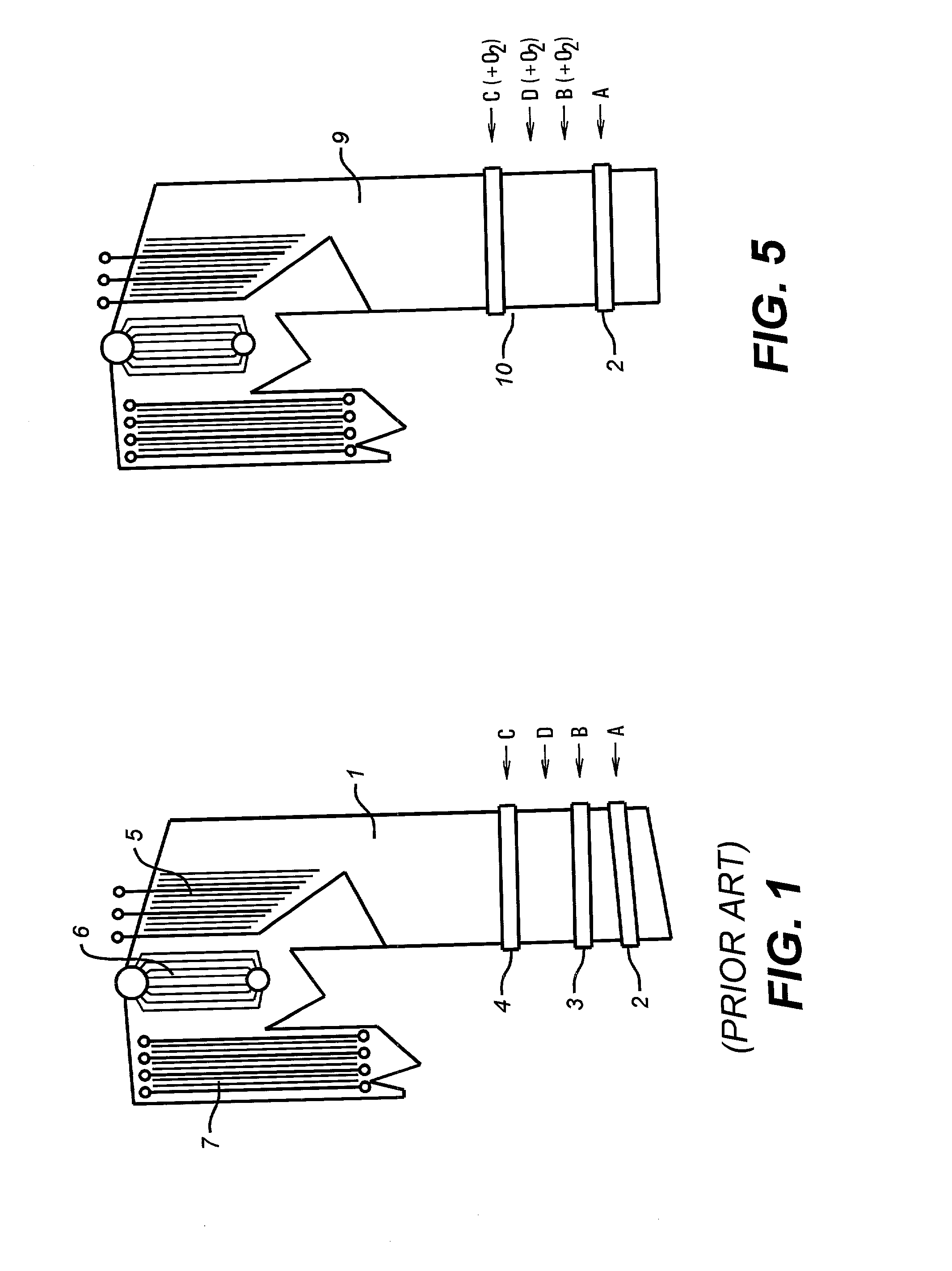

Methods of improving productivity of black liquor recovery boilers

InactiveUS20020043192A1Improve throughputImprove boiler efficiencyPulp liquors combustionSolid fuel combustionProduction rateBlack liquor

Methods of increasing the throughput of recovery boilers equipped with at least two levels of injection of air are presented, the methods improving the thermal efficiency of the boiler with oxygen enrichment of the air in at least one level of the combustion air system, at or above the secondary air level. One embodiment is a method to retrofit black liquor recovery boilers having a two level air injection system with a third level of oxidant injection below or at the same level as the original secondary air, and oxygen enrichment applied to at least the original secondary air stream and said third level. A preferred method is for the third level to be placed at or close to the same level as black liquor injector ports.

Owner:AIR LIQUIDE IND US LP

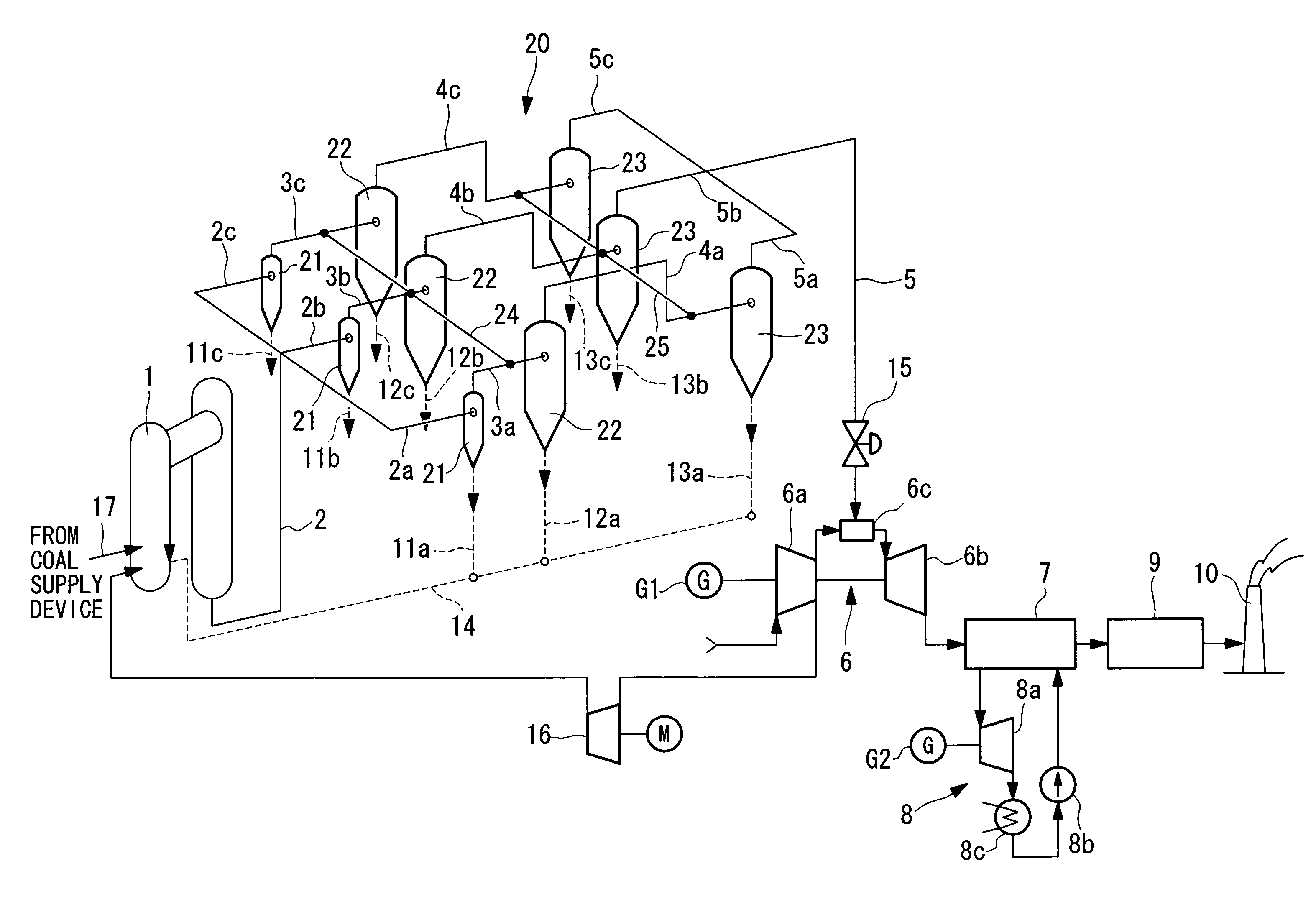

Integrated coal gasification combined cycle plant

InactiveUS20070137169A1High operating requirementsAvoid it happening againCombustion enginesGas turbine plantsCycloneIntegrated gasification combined cycle

A highly efficient integrated coal gasification combined cycle plant is provided having a dust removing system which can reliably exhibit a desired dust removing performance and which can maintain high operational reliability such that the occurrence of dust leaks is prevented. The integrated coal gasification combined cycle plant has a coal gasification furnace configured to yield a coal gas by gasification of coal, a gas turbine generator driven with a gas turbine which is operated using the coal gas as fuel and which discharges a high-temperature combustion exhaust gas, an exhaust heat recovery boiler configured to recover heat from the high-temperature combustion exhaust gas and to produce steam, and a steam turbine generator driven with a steam turbine operated using the steam produced by the exhaust heat recovery boiler. In the above plant, a flue gas desulfurization device configured to desulfurize the coal gas is provided downstream of the gas turbine and the exhaust heat recovery boiler, and the dust removing system which is configured to recover char and to remove dust from the coal gas has at least one line containing a cyclone, a front-stage filter, and a rear-stage filter.

Owner:MITSUBISHI HEAVY IND LTD

Waste heat recovery system of exhaust gas of metallurgical converter

InactiveCN101694352ASmooth circulationRaise the discharge heightManufacturing convertersIncreasing energy efficiencyWaste heat recovery unitCombustion chamber

The invention discloses a waste heat recovery system of exhaust gas of a metallurgical converter, which comprises a CO detector, a three-way valve, a burning chamber, a burner and an exhaust smokestack and is characterized in that a waste heat recovery boiler is arranged between the exhaust smokestack and the burning chamber. In the system, when the gas concentration of the converter is lower than 30% and the gas cannot enter a gas cabinet, exhaust energy is recovered; by arranging the waste heat recovery boiler on the bottom of an exhaust chimney as well as heating softened water by heat generated by burning the gas, the heat valve of the gas of the converter is fully recovered, and the generated saturated steam can be used for production and life.

Owner:无锡市东方环境工程设计研究所有限公司

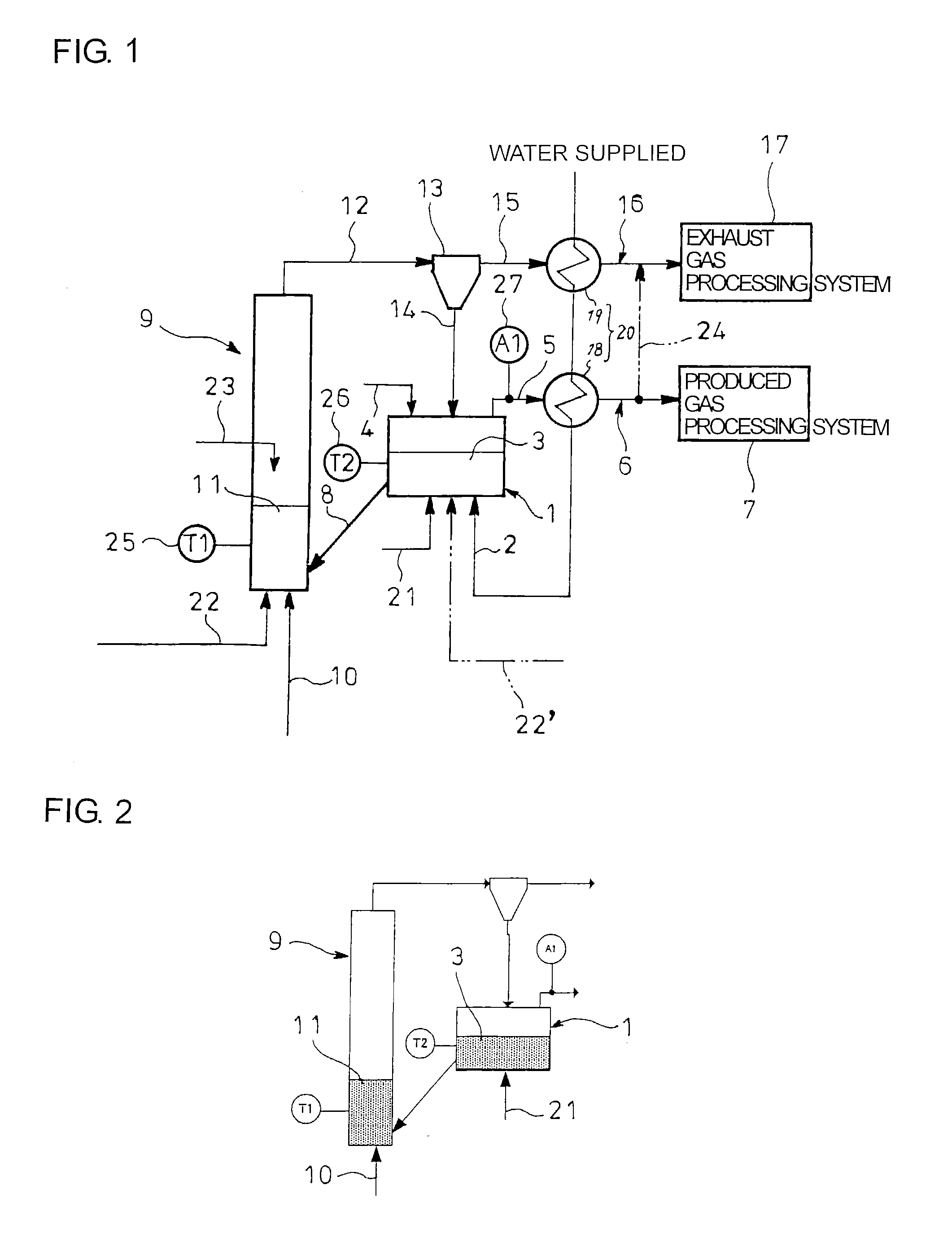

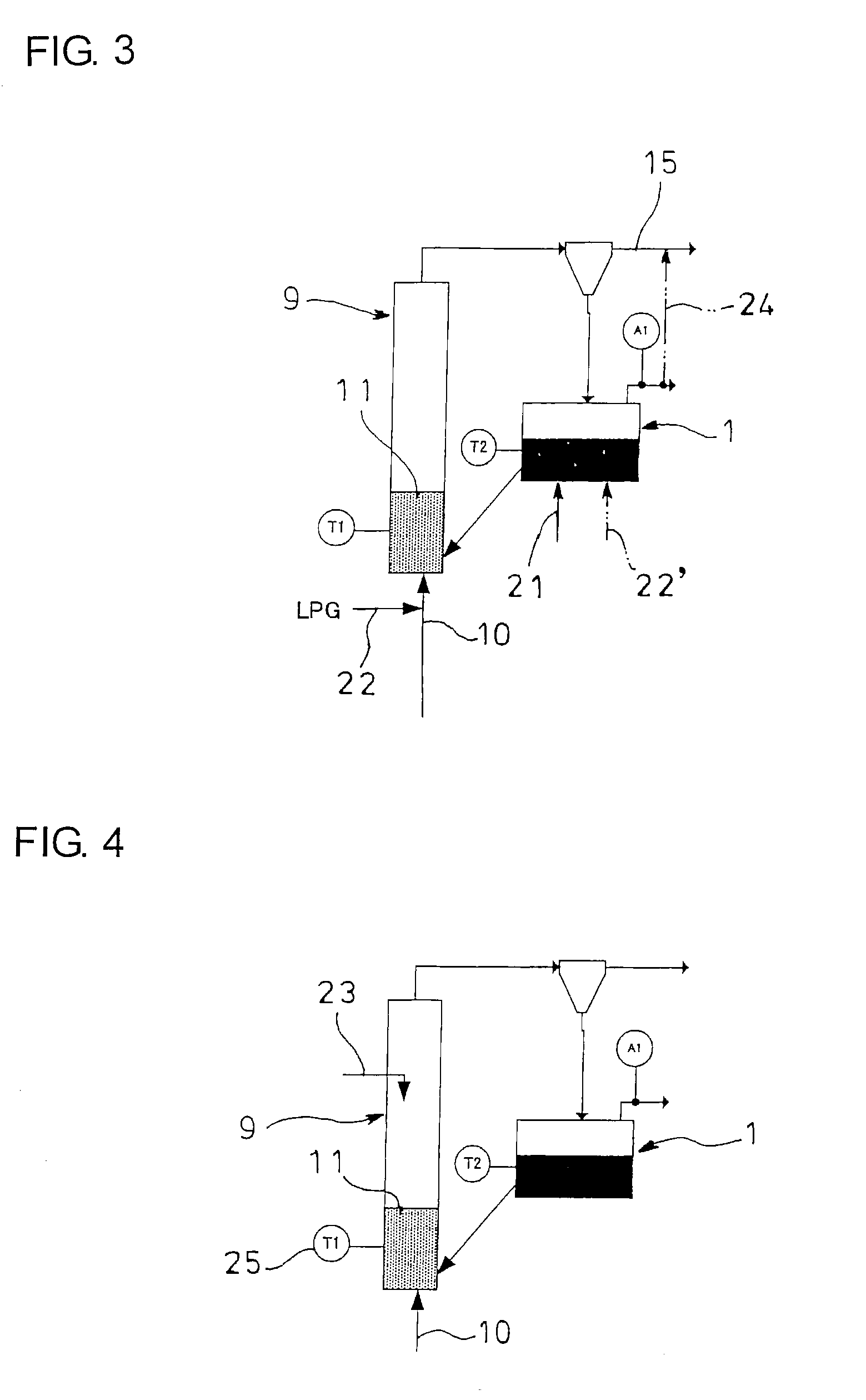

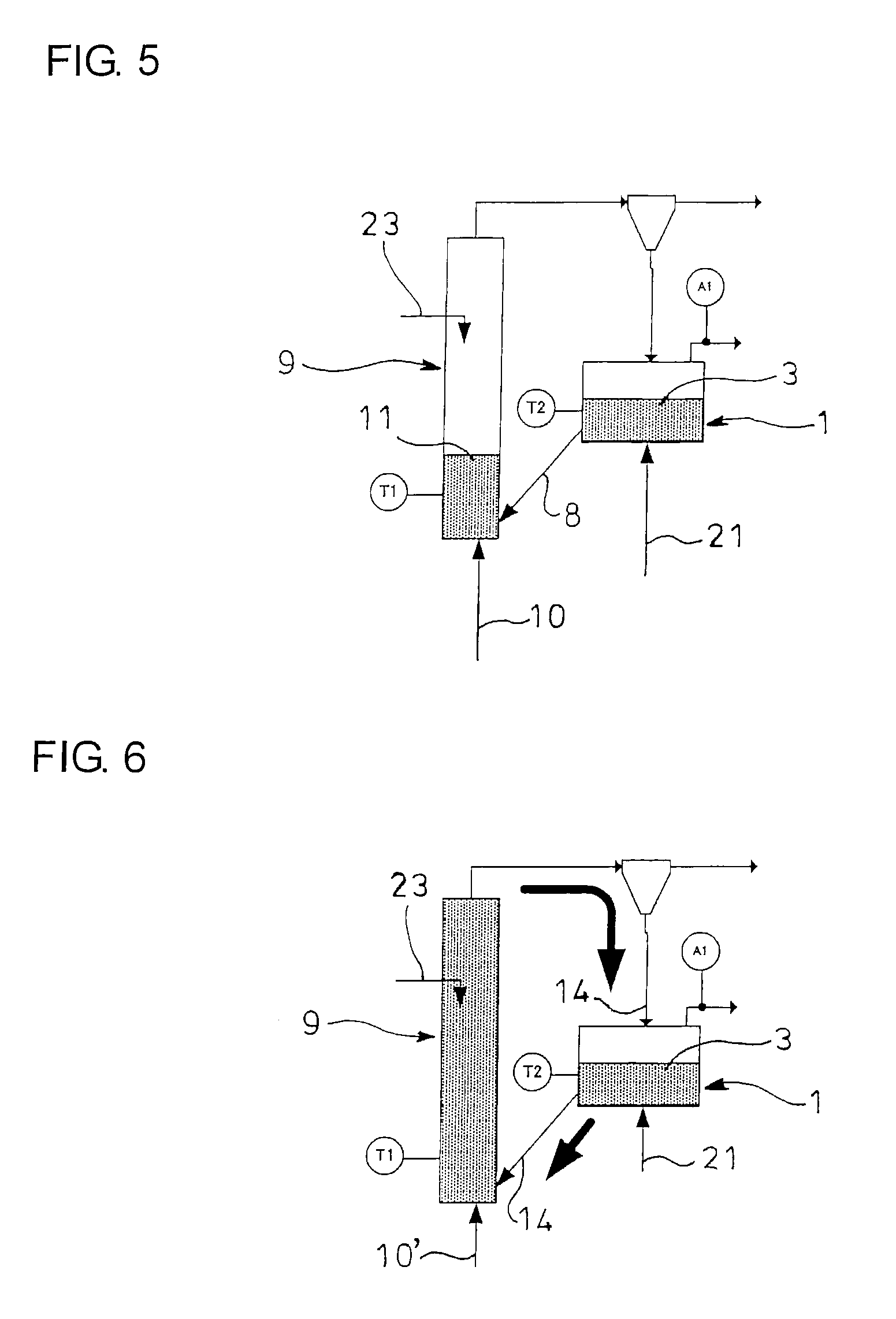

Method of operating gasification facility

ActiveUS20110016789A1Low costEffectively and inexpensively purgedMultiple metal hydridesEnergy inputFluidized bedProcess engineering

Upon cold startup of a gasification facility, a fluidized air 10 is supplied to a combustion furnace 9 to fluidize a combustion-furnace fluidized bed 11 while a preheating fuel 22 is supplied to the combustion furnace to preheat the fluidized bed 11 up to an autoignition temperature of coal. Then, a coal 23 is charged to the combustion furnace 9 to heat the fluidized bed 11 and bed material is circulated between the combustion and gasification furnaces 9 and 1 for heating. Upon startup and shutdown of the gasification facility, steam 2 from an exhaust heat recovery boiler 20 in heat exchange with an exhaust gas 15 from the combustion furnace 9 is supplied to the gasification furnace 1 to purge the gasification furnace 1 and a lead-out passage 6 with the steam 2 utilizing the exhaust heat.

Owner:IHI CORP

Novel fuel production plant and seawater desalination system for use therein

InactiveUS20070039324A1Quantity minimizationCooling water is reducedGeneral water supply conservationSeawater treatmentEvaporationProcess engineering

A novel fuel producing section produces synthesized gas from a feedstock and synthesizes novel fuel from the synthesized gas thus produced, and has exhaust heat recovery boilers for generating steam by recovering excess heat generated from the synthesizing processes. An exhaust heat utilizing section includes steam turbines driven with the steam generated from the exhaust heat recovery boilers. An open circulation cooling water supply section supplies cooling water for a plant, including water for cooling exhausts of the steam turbines, and includes a seawater desalination system for desalinating seawater by the evaporation method and supplying desalinated water to replenish the cooling water. The cooling water supplied from the open circulation cooling water supply section is used in condensing of the desalinated water produced by the seawater desalination system.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com