Clearing device for smoke pollutants of glass kiln and clearing method thereof

A technology for glass furnaces and pollutants, applied in glass furnace equipment, combined devices, separation methods, etc., can solve problems such as large water consumption, low efficiency, and easy corrosion of equipment, and achieve low dust load on filter bags and stable system operation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

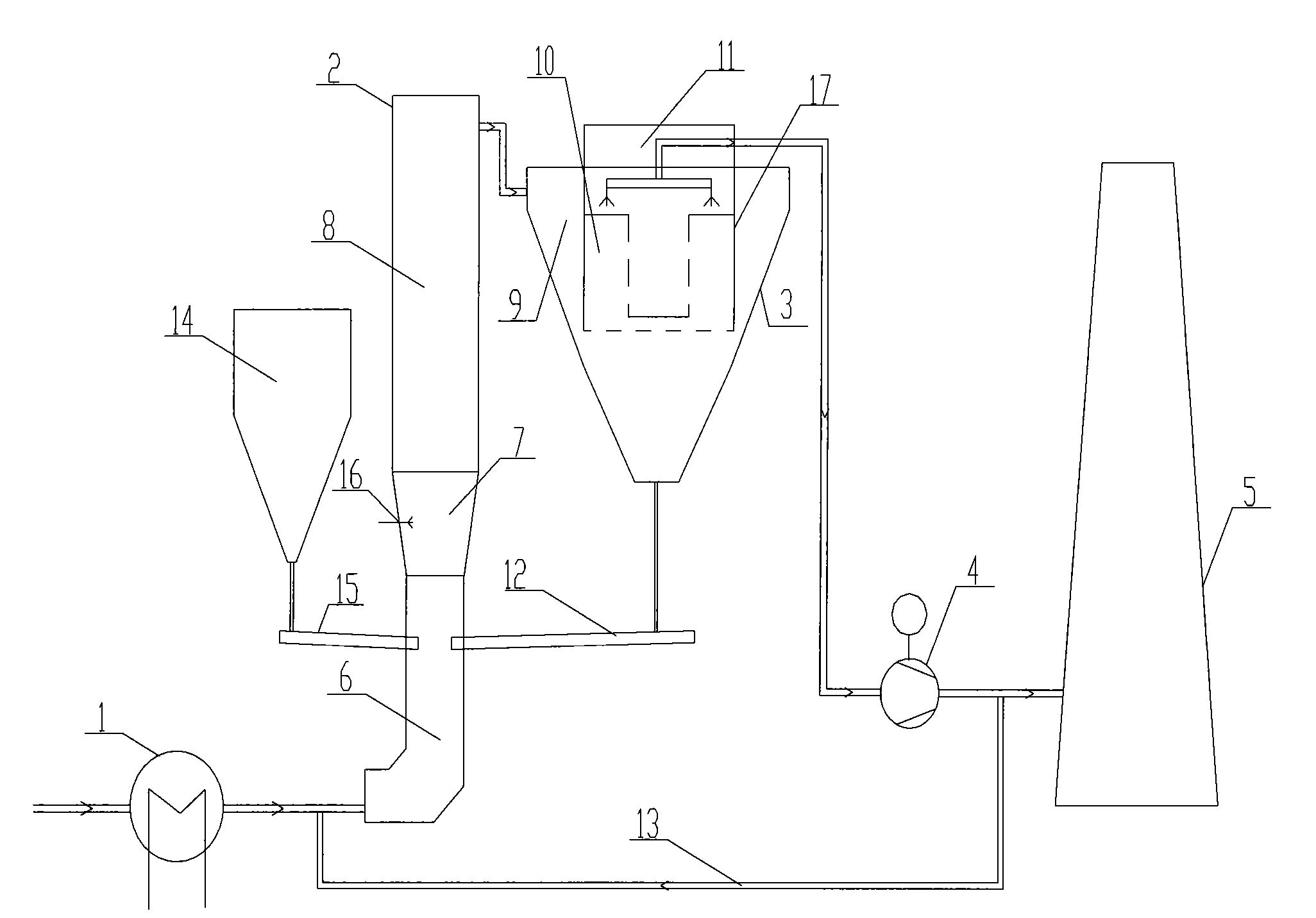

[0024] like figure 1 As shown, the glass kiln flue gas pollutant removal device of the present invention is provided with a waste heat recovery boiler 1, a reaction tower 2, a swirl type multi-stage combined bag filter 3, a circulating fluidization chute 12, a cleaning Flue gas recirculation flue 13 , absorbent bin 14 , feed air chute 15 , induced draft fan 4 and chimney 5 . Among them, the reaction tower 2 is equipped with a high-temperature reaction zone 6, a Venturi acceleration zone 7 and a circulating fluidized reaction zone 8, and the high-temperature reaction zone 6 is set at the bottom of the reaction tower 2, and the flue gas inlet of the high-temperature reaction zone 6 is externally connected to a glass furnace through a flue The exhaust port of the waste heat boiler, the circulating fluidized reaction zone 8 is set on the upper part of the reaction tower 2 , and the Venturi acceleration zone 7 is set between the high temperature reaction zone 6 and the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com