Patents

Literature

331 results about "Glass furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeycomb catalyst for denitration of glass furnace fume and preparation method thereof

ActiveCN101791551ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrogen oxides

The invention discloses a honeycomb catalyst for SCR (Selective Catalytic Reduction) denitration of glass furnace fume, which comprises a carrier and active components. The honeycomb catalyst is characterized in that the carrier is a honeycomb titanium-silicon carrier which contains 30-50 wt% of TiO2-SiO2 powder, 10-20 wt% of TiO2 and 20-50 wt% of high-viscosity attapulgite; the active components comprise amorphous MnOx, V2O5 and WO3, wherein the amorphous MnOx accounts for 5-25.0% of the total weight of the catalyst, V2O5 accounts for 0.5-5.0% of the total weight of the catalyst, and WO3 accounts for 0.1-8.0% of the total weight of the catalyst. By adopting the high-viscosity attapulgite, the catalyst has high plasticity, strong binding power and strong water absorption; by selecting the TiO2-SiO2 powder, not only the apparent structures, such as the specific surface, the pore volume and the like, of the carrier can be improved, but also the conversion rate of SO2 to SO3 is inhibited. The selective reducing catalyst can be widely applied to selective reduction of nitrogen oxide in glass furnace fume.

Owner:沈炳龙

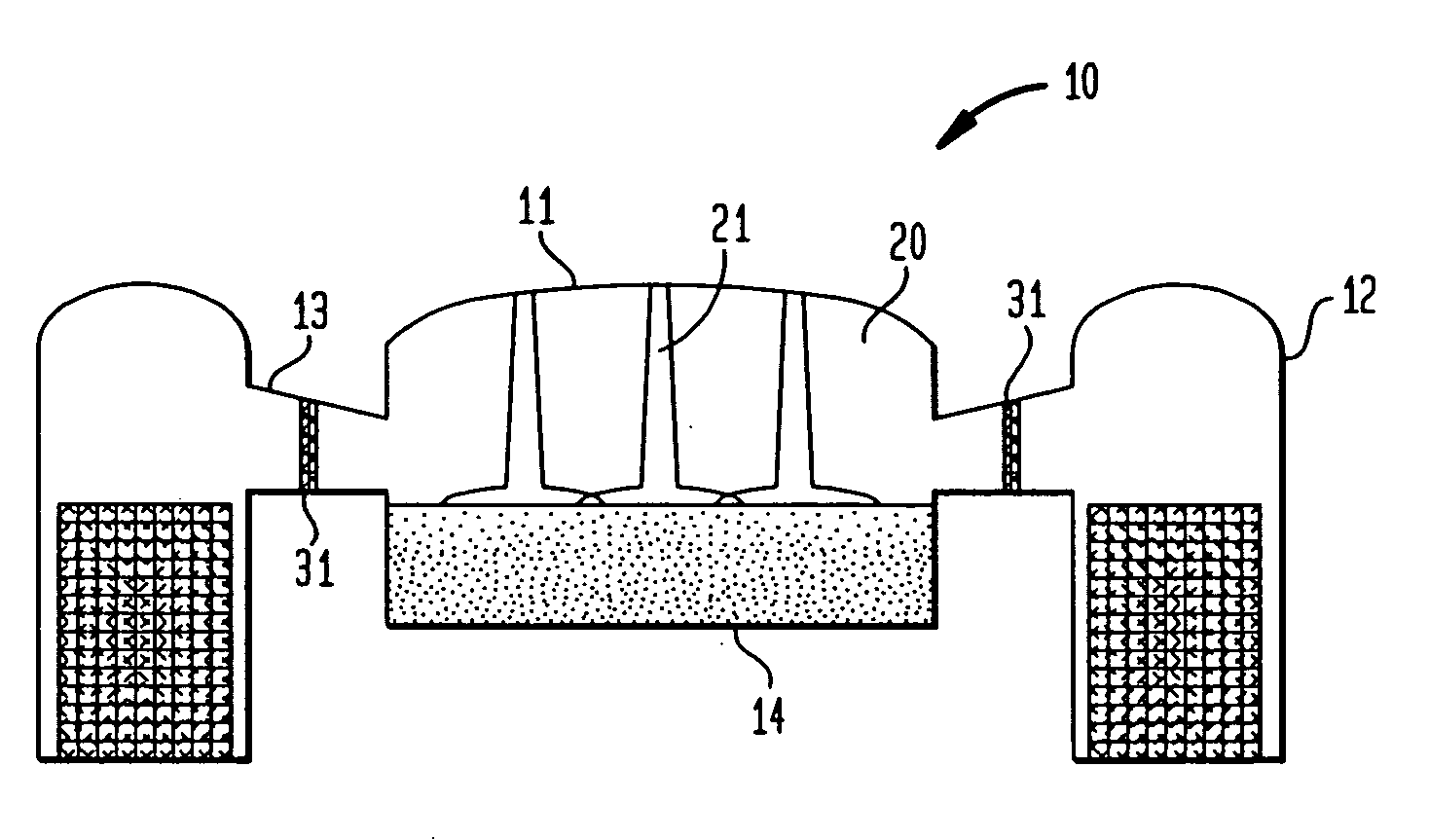

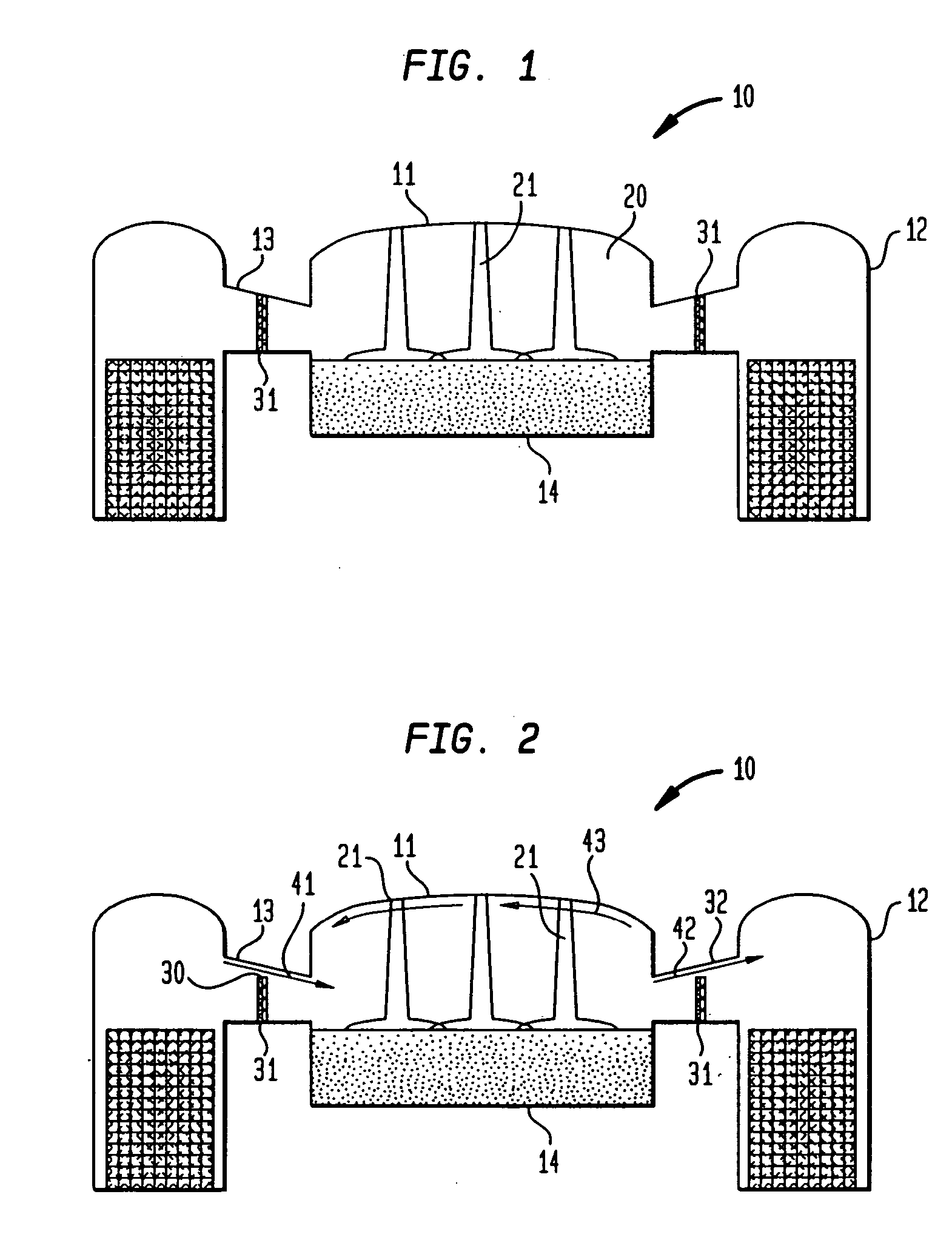

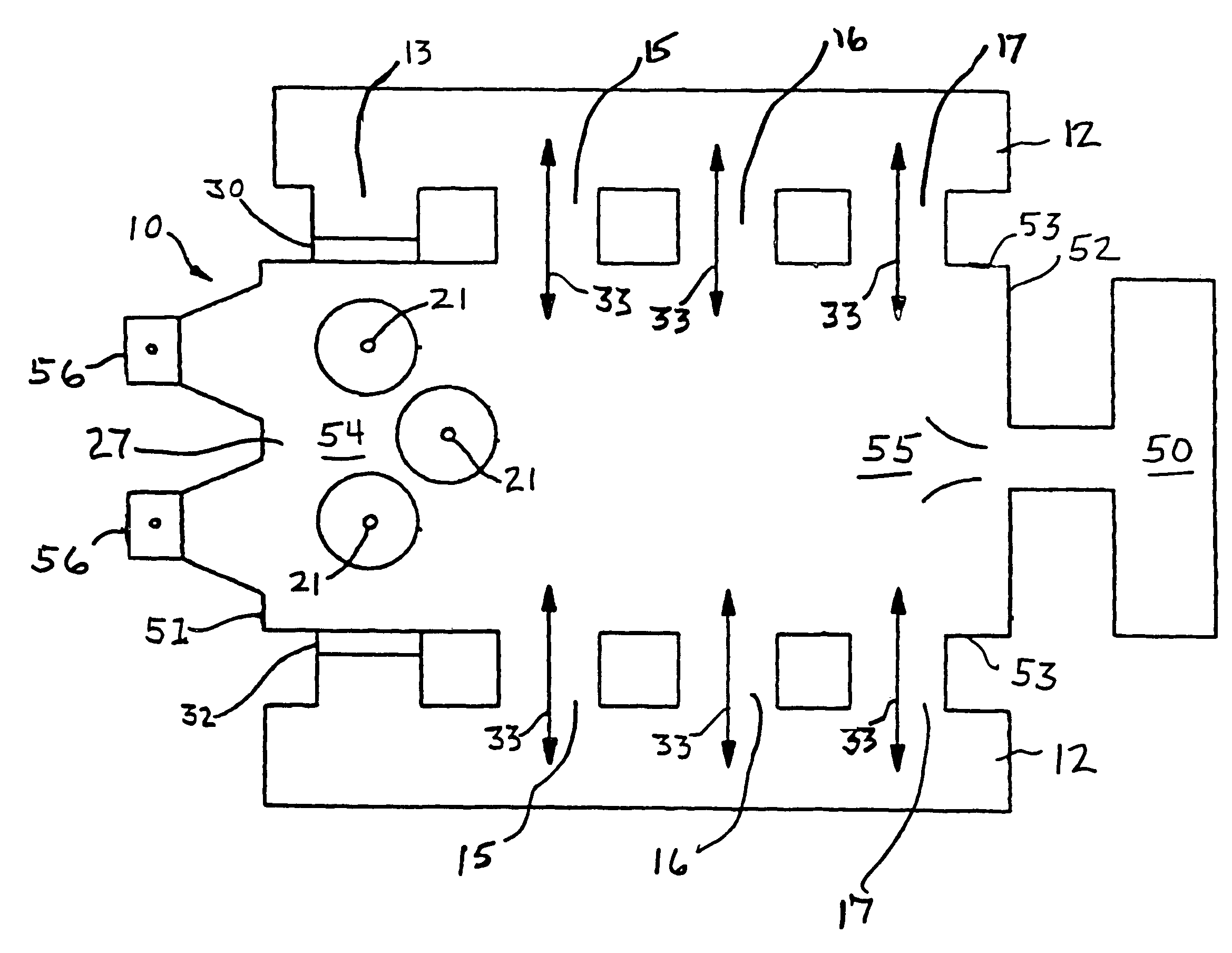

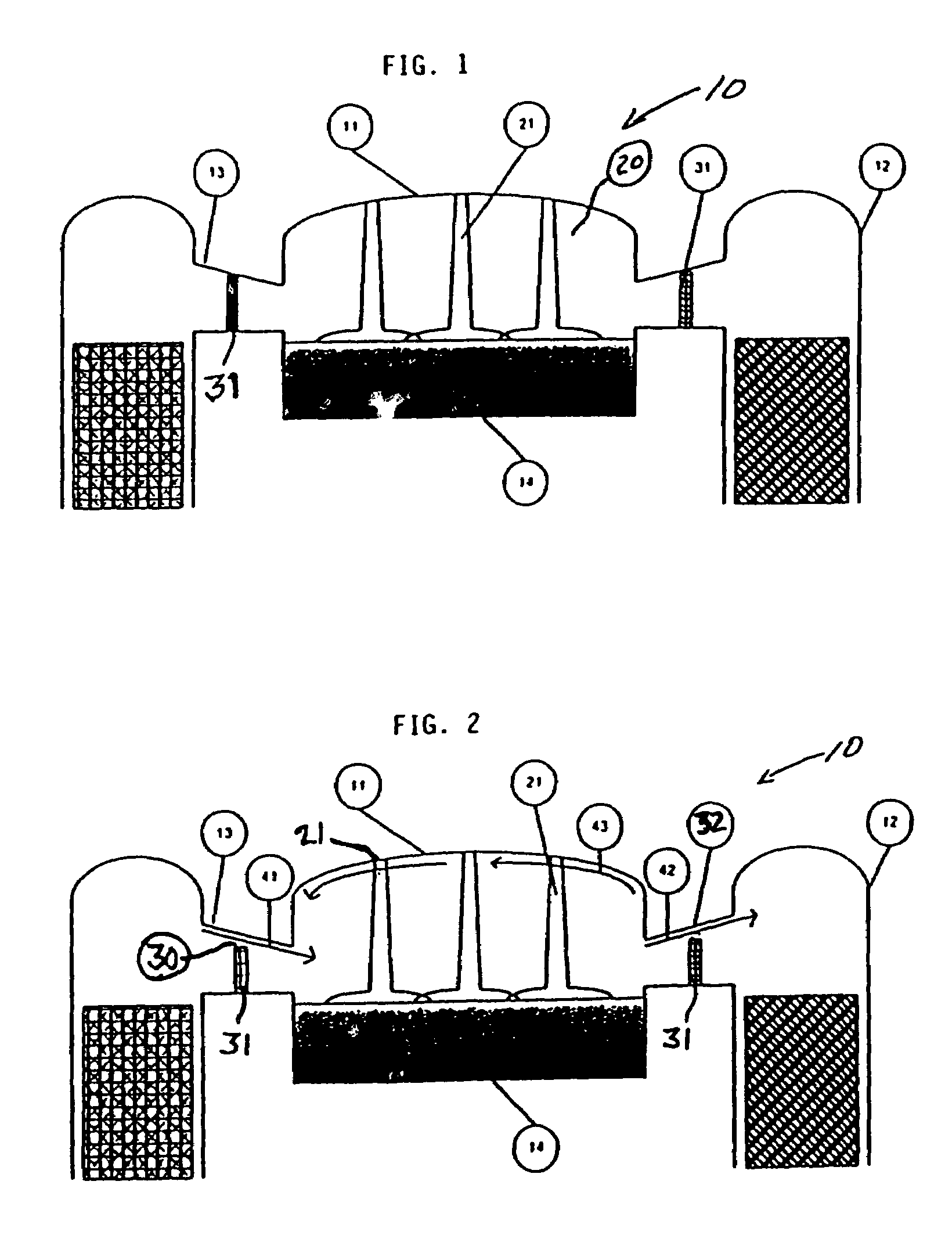

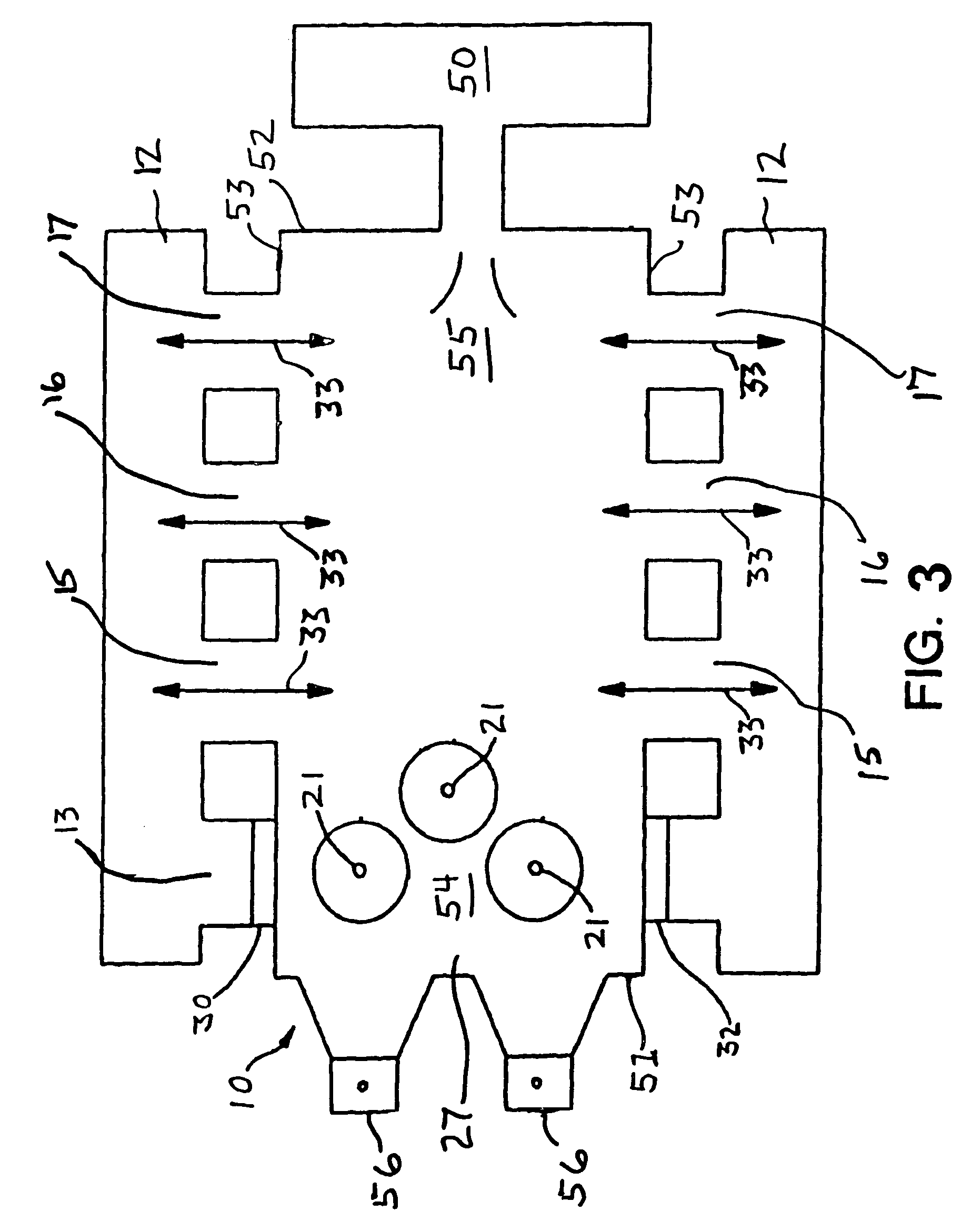

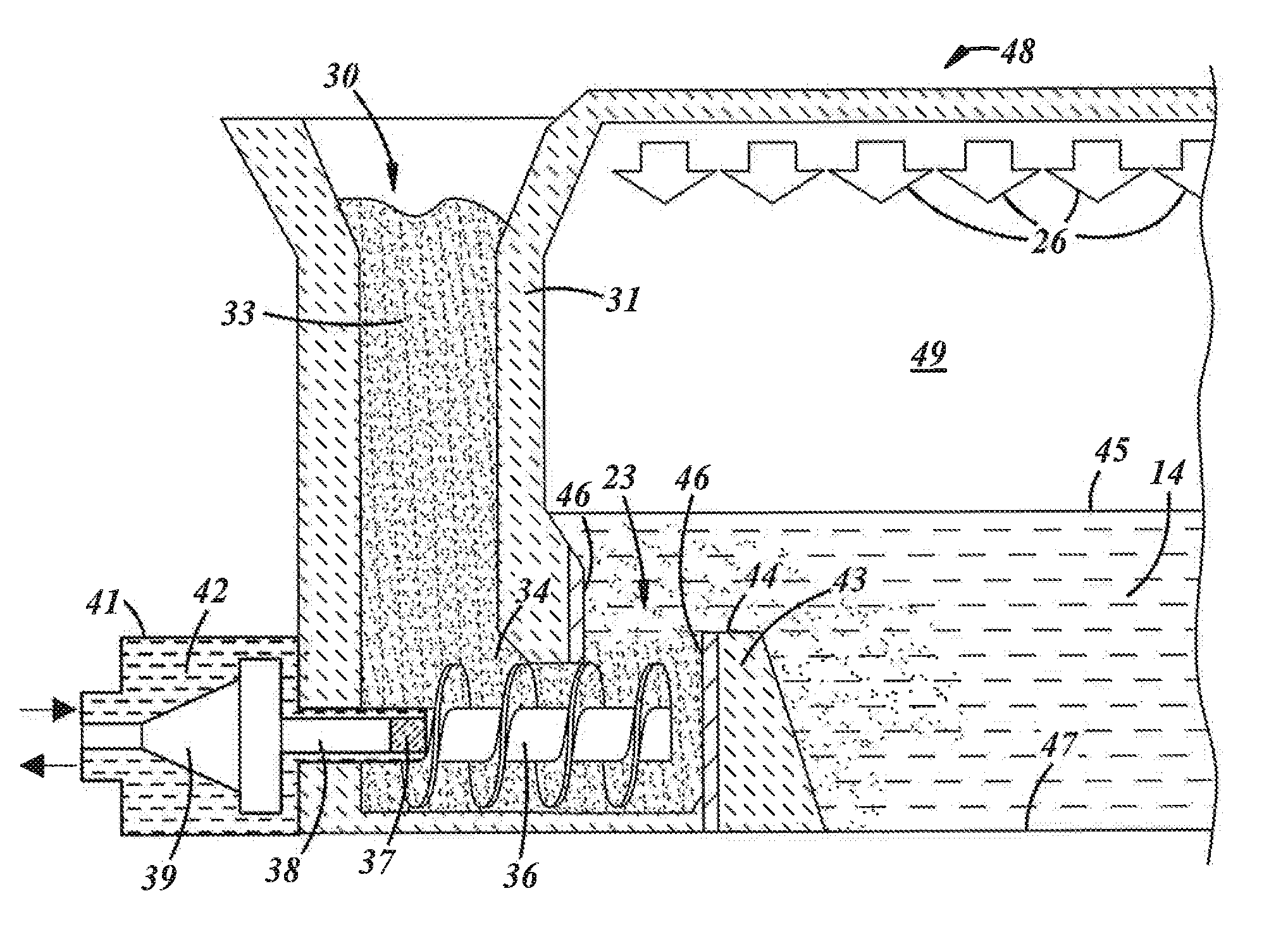

Gas injection for glass melting furnace to reduce refractory degradation

InactiveUS20070119213A1Reduce adverse effectsReduce corrosionGlass transportation apparatusSolid fuel combustionGlass furnaceRefractory

A glass melting furnace has a gas inlet positioned proximate to a charging section oxy-fuel combustion region to introduce gas into the region and to at least partially displace gas having a partial pressure of alkali vapor from the region, and optionally a gas outlet is adapted to provide an exit for a volume of furnace atmosphere. A method for reducing alkali vapor corrosion of glass furnace refractory structures includes providing a gas inlet proximate to the oxy-fuel combustion region; introducing a volume of gas from the inlet into the region, displacing a volume of gas having a partial pressure of alkali vapor from the region; and, optionally providing a gas outlet adapted to provide an exit for a volume of furnace atmosphere.

Owner:LINDE LLC

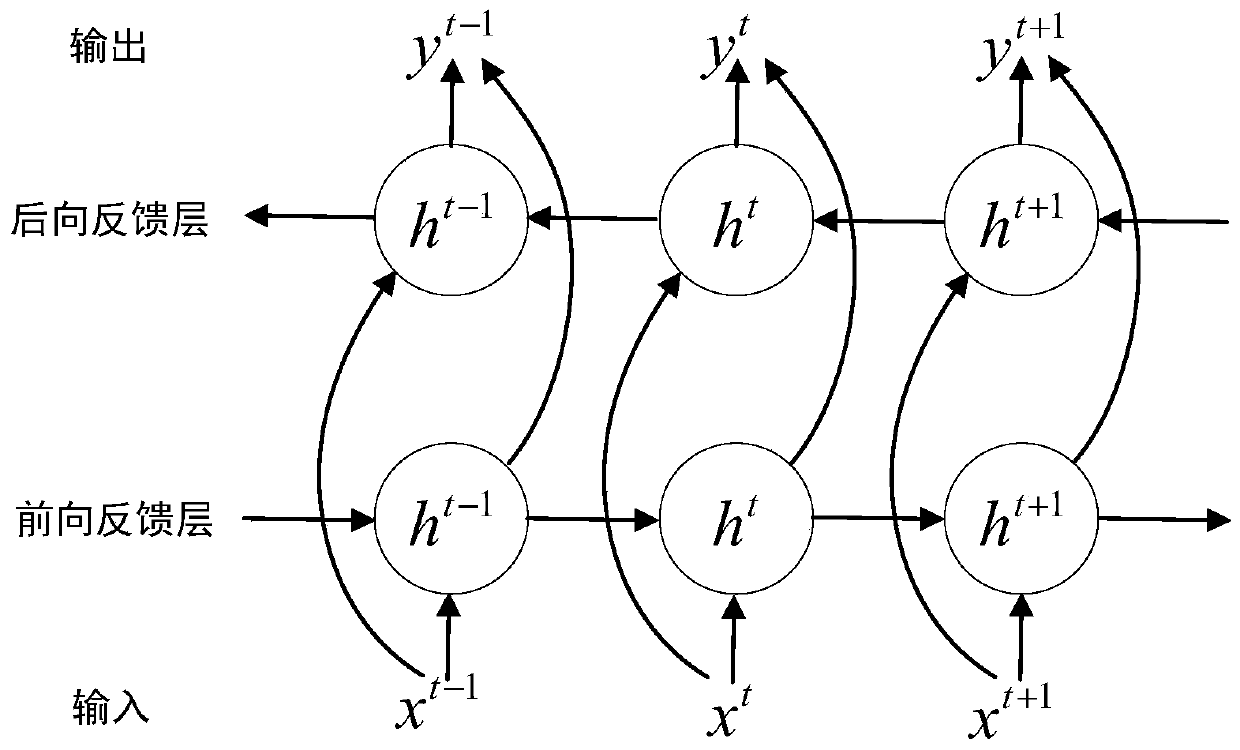

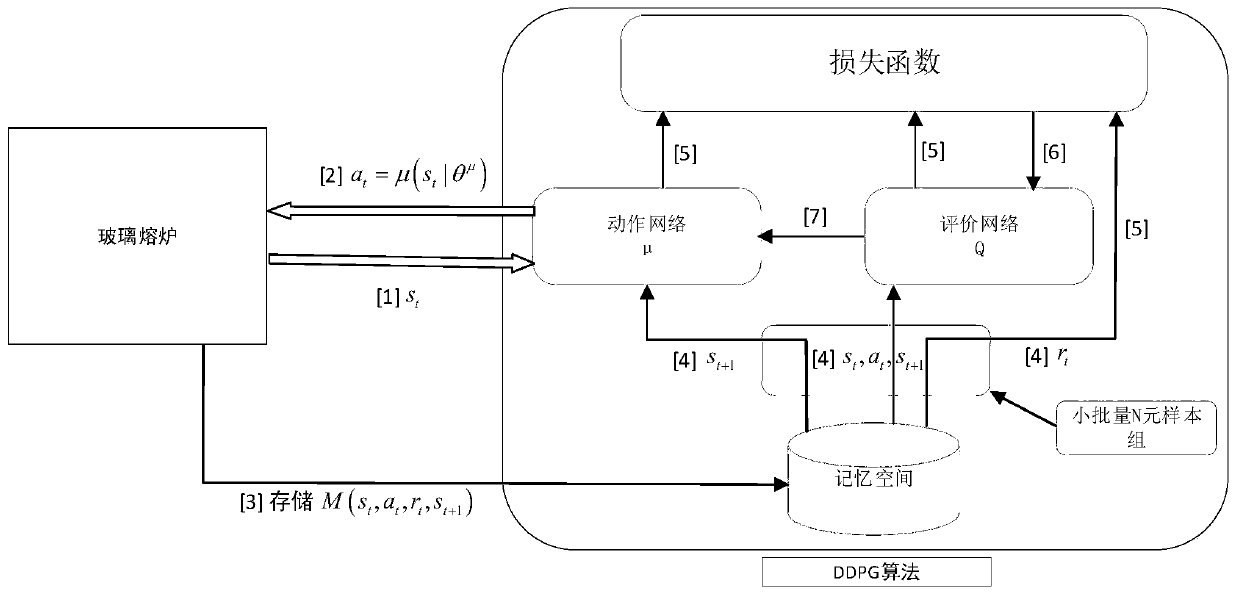

Glass furnace temperature control method based on deep learning and reinforcement learning

ActiveCN110187727AEasy to predictEasy to controlAuxillary controllers with auxillary heating devicesTemperature controlGlass furnace

The invention provides a glass furnace temperature control method based on deep learning and reinforcement learning. The method comprises the following steps: establishing a temperature simulation model and a temperature control model through a total-oxygen glass kiln furnace taking natural gas and oxygen as fuel, and maintaining the stabilization of the kiln temperature by regulating a fuel valve; collecting temperature, oxygen flow, natural gas flow, natural gas valve openness, natural gas valve opening and kiln pressure at each key point of the kiln through a sensor; establishing a kiln temperature simulation model by using a deep neural network, thereby simulating the kiln temperature change environment; establishing a kiln temperature control model based on the deep learning and reinforcement learning, and outputting the offset needing to be adopted by the natural gas and oxygen valves in real time according to the current furnace state by using two established models. By utilizing the historic kiln data, the temperature simulation model and the temperature control model are online or periodically updated, thereby reaching precise temperature control.

Owner:WUHAN UNIV OF TECH

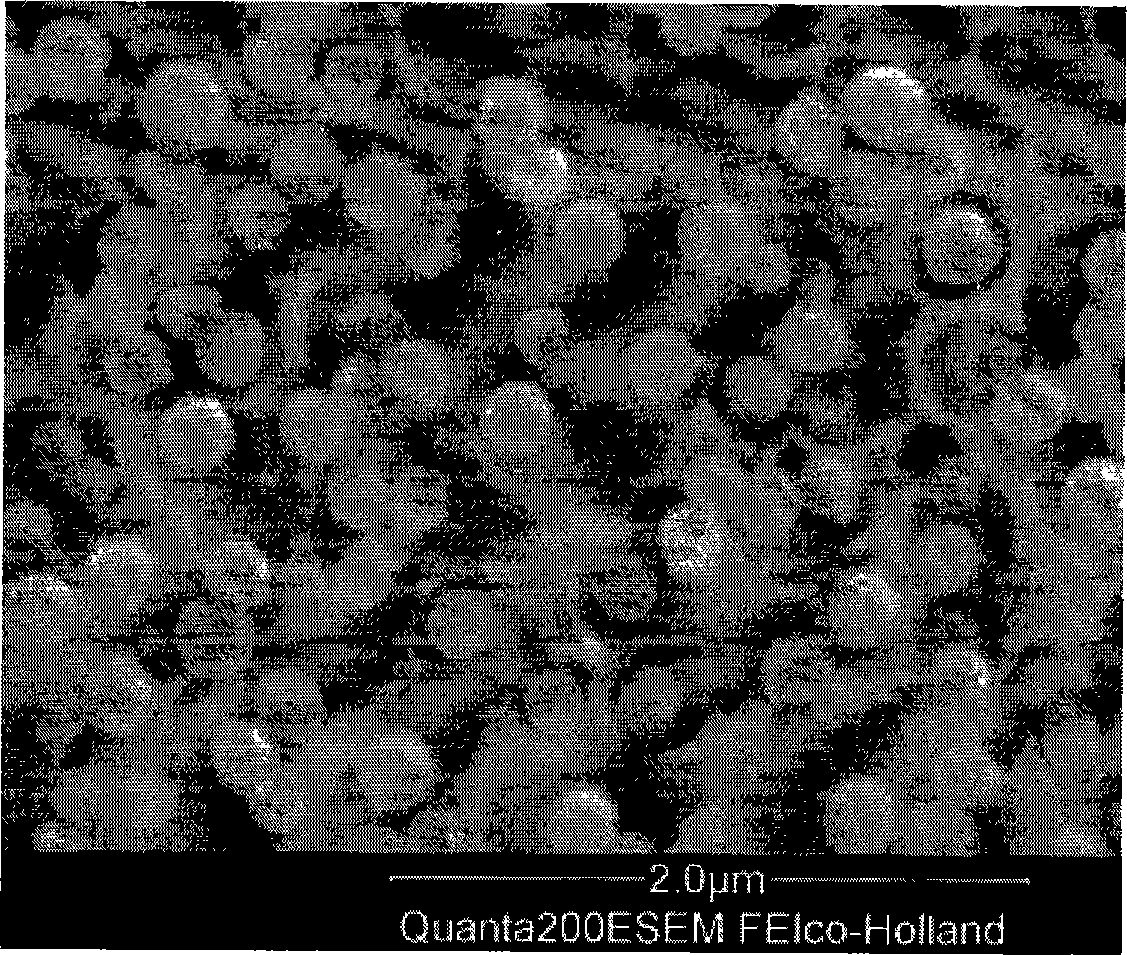

Non-fluorin environment protection opacifiedglass material and method for manufacturing same

InactiveCN101244889AGood opacification effectHigh opacityGlass furnace apparatusGlass furnacePhosphate

The invention relates to a fluorine-free environmental opaque glass material and a preparation method thereof and belongs to the new material field of glass. Composition of the glass material is SiO2-Al2O3-B2O3P2O5-MgO-CaO-SrO-BaO-Li2O-Na2O-K2O. The preparation method comprises that raw materials are mixed to make an even batch, then the batch is put into a corundum crucible, and then the batch is casted and molded after being melted and insulated under 1500 DEG C to 1520 DEG C for 3 hours, and then the batch is insulated and annealed under 550 DEG C to 560 DEG C for 1 hour. The preparation of the invention replaces the fluoride with a small amount of phosphate to generate opaque effect, and no environmental pollution can be caused in the industrial production of the opaque glass, and the short service life of glass furnaces and safety problems caused by fluorine can be avoided, and a compact net structure reconstruction technology is adopted to adjust the relative contents of SiO2 and P2O5, meanwhile, alkali metals or alkaline earth metal oxides are introduced, and the glass produces significant opaque effect under the spontaneous phase separation in the process of cooling, and a small amount of B2O3 is introduced to enhance the opaque effect of the glass, meanwhile, a certain amount of Al2O3 is introduced to endow the glass with excellent chemical stability.

Owner:QILU UNIV OF TECH

Gas injection for glass melting furnace to reduce refractory degradation

InactiveUS7168269B2Reducing alkali vapor corrosionReduce adverse effectsIndirect carbon-dioxide mitigationGaseous fuel burnerGlass furnaceRefractory

A glass melting furnace has a gas inlet positioned proximate to a charging section oxy-fuel combustion region to introduce gas into the region and to at least partially displace gas having a partial pressure of alkali vapor from the region, and optionally a gas outlet is adapted to provide an exit for a volume of furnace atmosphere. A method for reducing alkali vapor corrosion of glass furnace refractory structures includes providing a gas inlet proximate to the oxy-fuel combustion region; introducing a volume of gas from the inlet into the region, displacing a volume of gas having a partial pressure of alkali vapor from the region; and, optionally providing a gas outlet adapted to provide an exit for a volume of furnace atmosphere.

Owner:BOC GRP INC

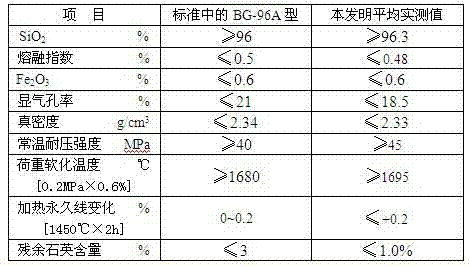

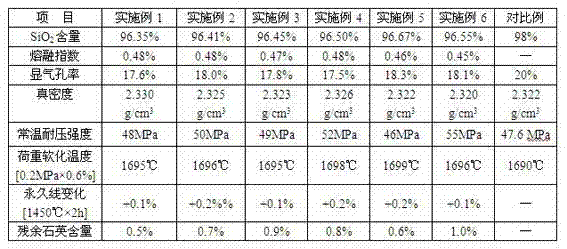

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

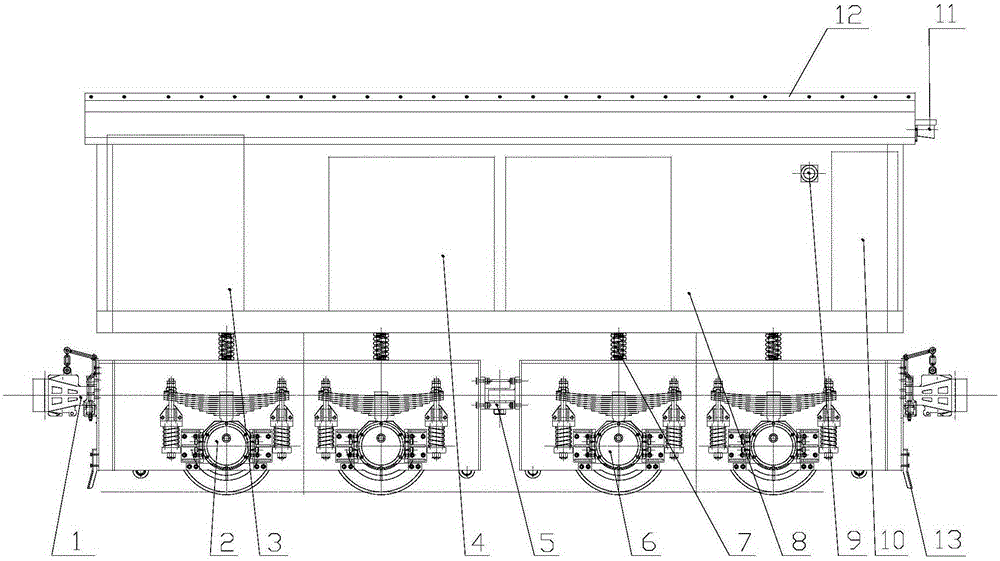

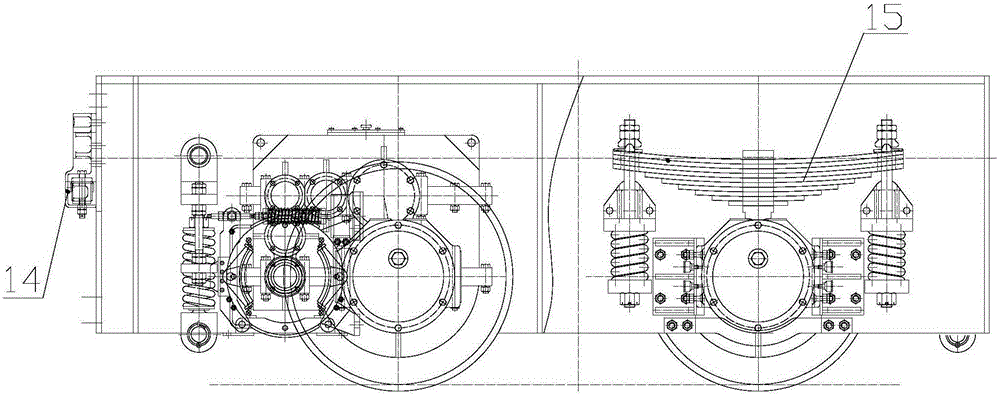

Molten iron tank alignment tractor below blast furnace

ActiveCN105170964APrevent splashImprove work efficiencyMelt-holding vesselsMicrocontrollerGlass furnace

The invention relates to a molten iron tank alignment tractor below a blast furnace. The molten iron tank alignment tractor comprises a tractor body controlled by a tractor master control system. The tractor master control system is provided with a master control module and is in wireless communication connection with an outer remote control unit through a remote control signal receiver. A rotary encoder is installed on an output shaft of a speed reducer of the molten iron tank alignment tractor and connected with a tractor alignment control system. The tractor alignment control system at least comprises a single-chip microcomputer, a key circuit, a display module and a communication module. The communication module is additionally in communication connection with the tractor master control system and a blast furnace casting control system. The molten iron tank alignment tractor can replace an internal combustion locomotive to finish molten iron tank alignment operation, remote alignment is completed through remote control, operation is convenient, alignment is accurate and reliable, efficiency is high, and mis-operation and molten iron splashing can be prevented. Equipment operation and the automatic charging process are both remotely controlled, the man-machine contact frequency is greatly reduced, and the safety accident rate is reduced. A breakthrough is made in blast furnace casting alignment operation.

Owner:鞍钢集团(鞍山)铁路运输设备制造有限公司

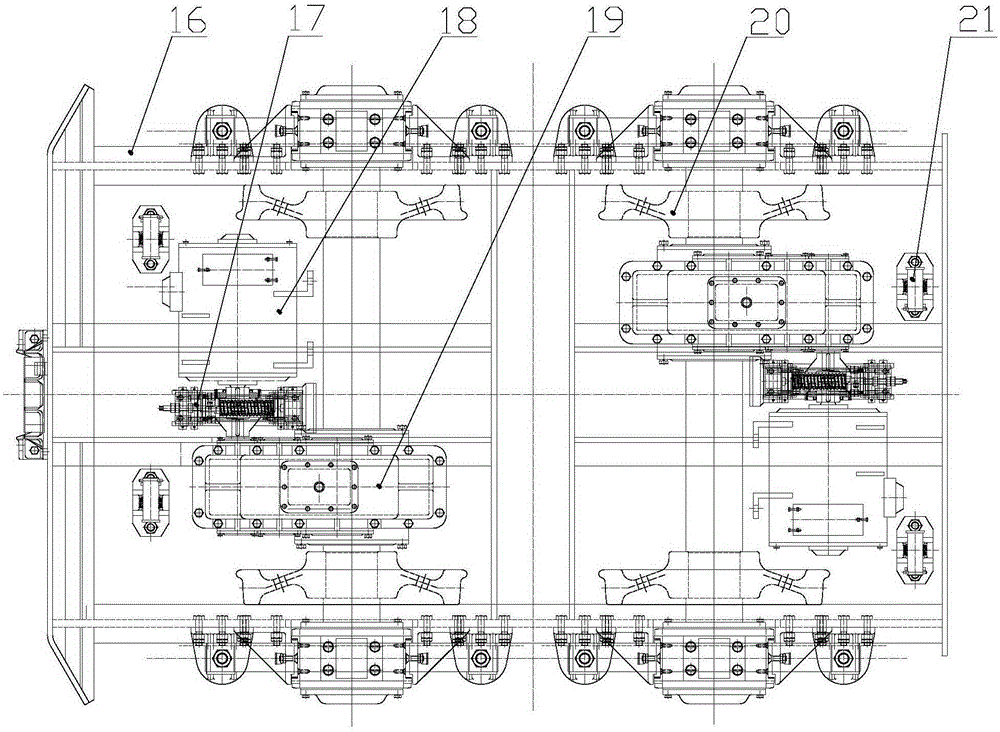

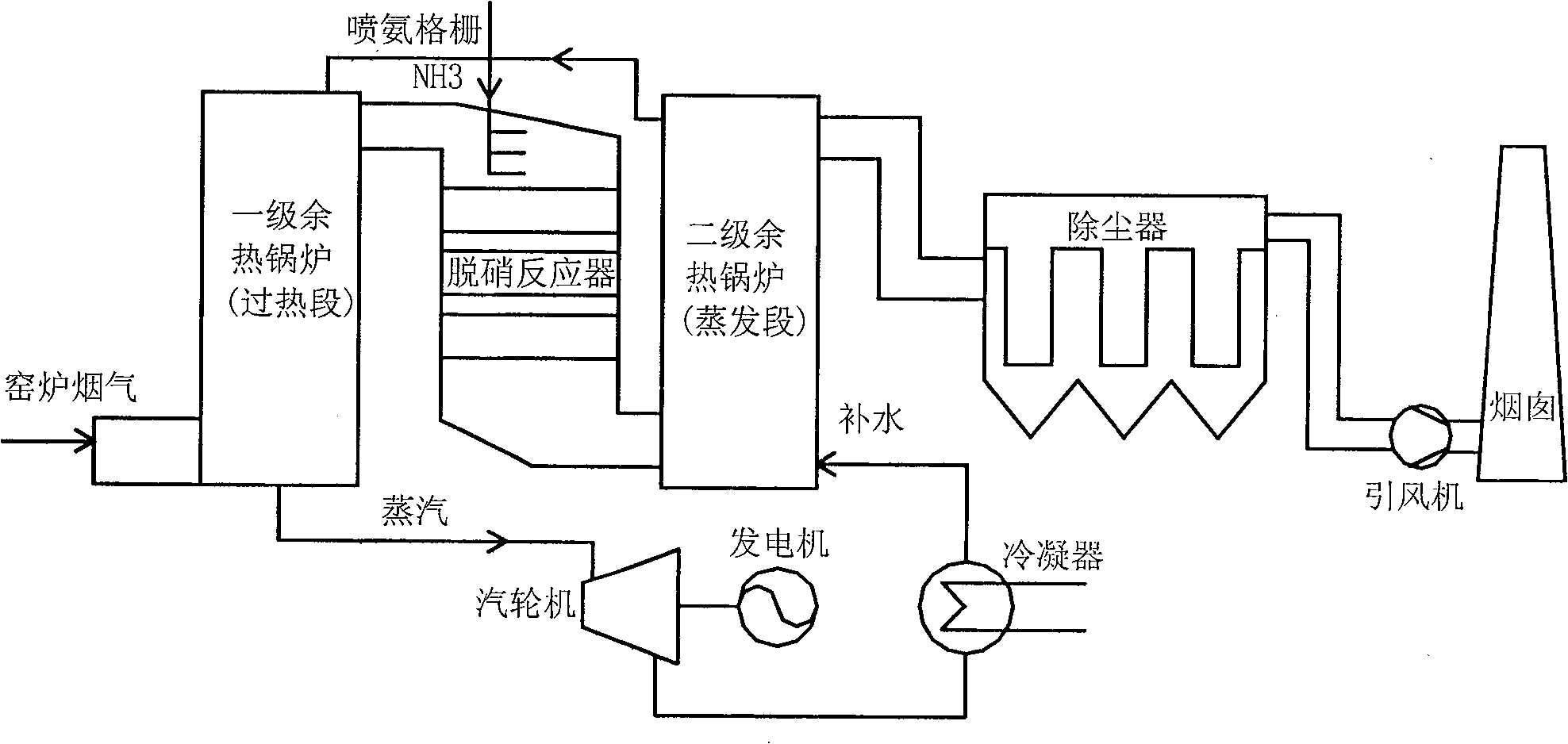

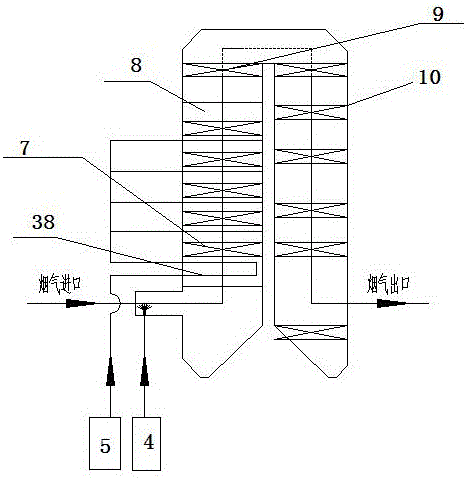

Power-generation and denitrification integrated device by residual heat of glass furnace and method thereof

InactiveCN101898086ASmall side effectsHigh activityDispersed particle filtrationIncreasing energy efficiencyGlass furnaceEvaporation

The invention provides a power-generation and denitrification integrated device by residual heat of a glass furnace and a method thereof, relating to the field of waste gas chemical purification treatment. Regarding NOX in large-output volume continuous flue gas in flat glass industry, SCR and SNCR technologies are adopted currently. SCR has the problems of large equipment investment, high technical difficulty, residual heat waste and the like, while SNCR has a large NH3 usage amount, is hard to ensure reacting temperature and staying time, can easily cause secondary pollution, and has low denitrification efficiency. Aiming at the problems and being different from hot topic studying directions, such as high-performance low-temperature denitrification catalyst, additive and the like, the invention discloses the power-generation and denitrification integrated device by the residual heat of the glass furnace and the method thereof, wherein a denitrification system is arranged between the overheat section and an evaporation section of the residual heat boiler; the temperature of the flue gas is cooled to a medium temperature range by using the overheat section of the primary residual heat boiler; and the flue gas performs a catalytic reduction with a reducing agent NH3 in a reactor under the action of a catalyst V2O5 / TiO2 to generate non-polluted N2 and H2O, and the temperature of denitrification and catalysis is between 300 and 400 DEG C.

Owner:无锡迅德环保科技有限公司

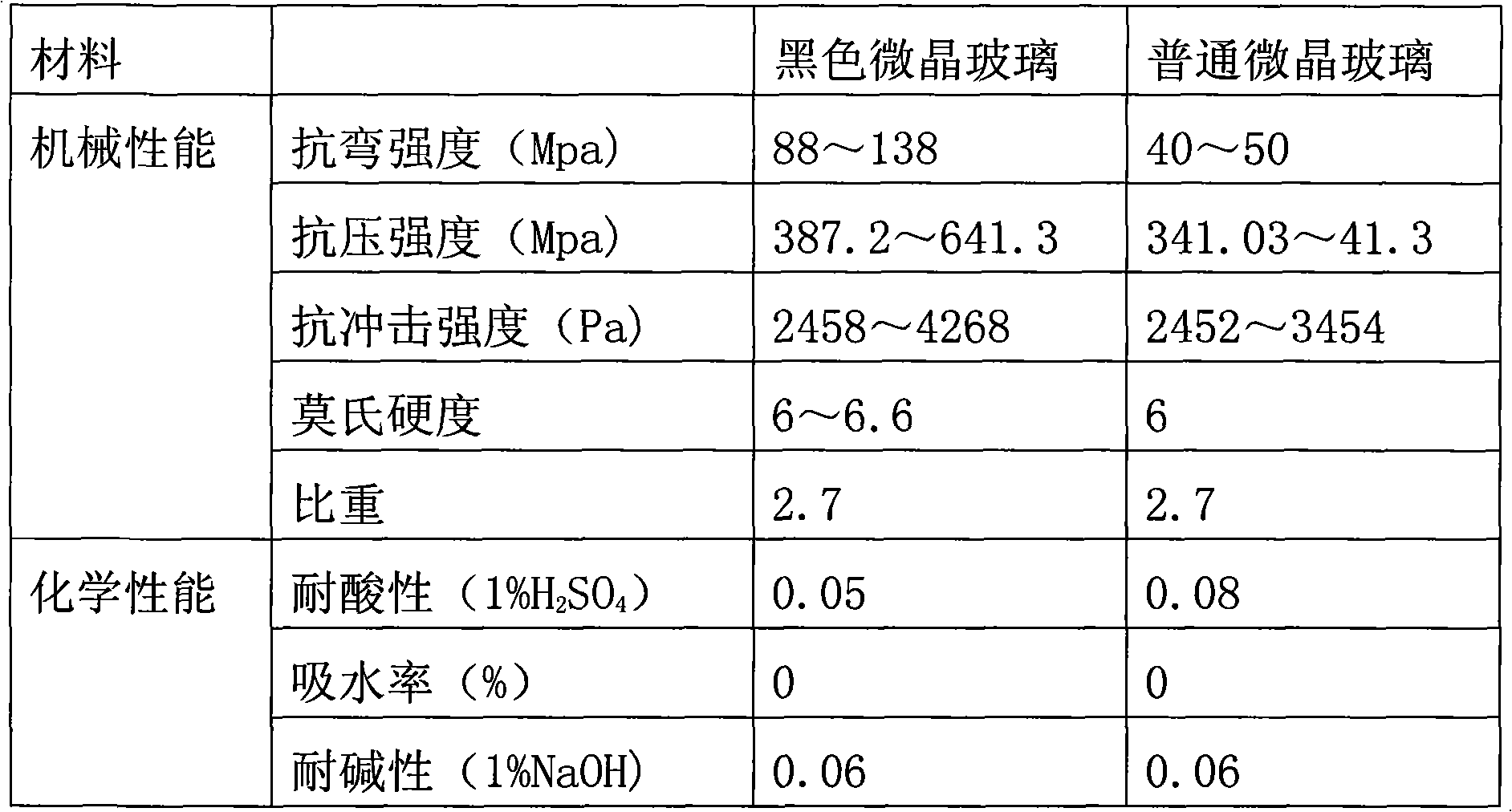

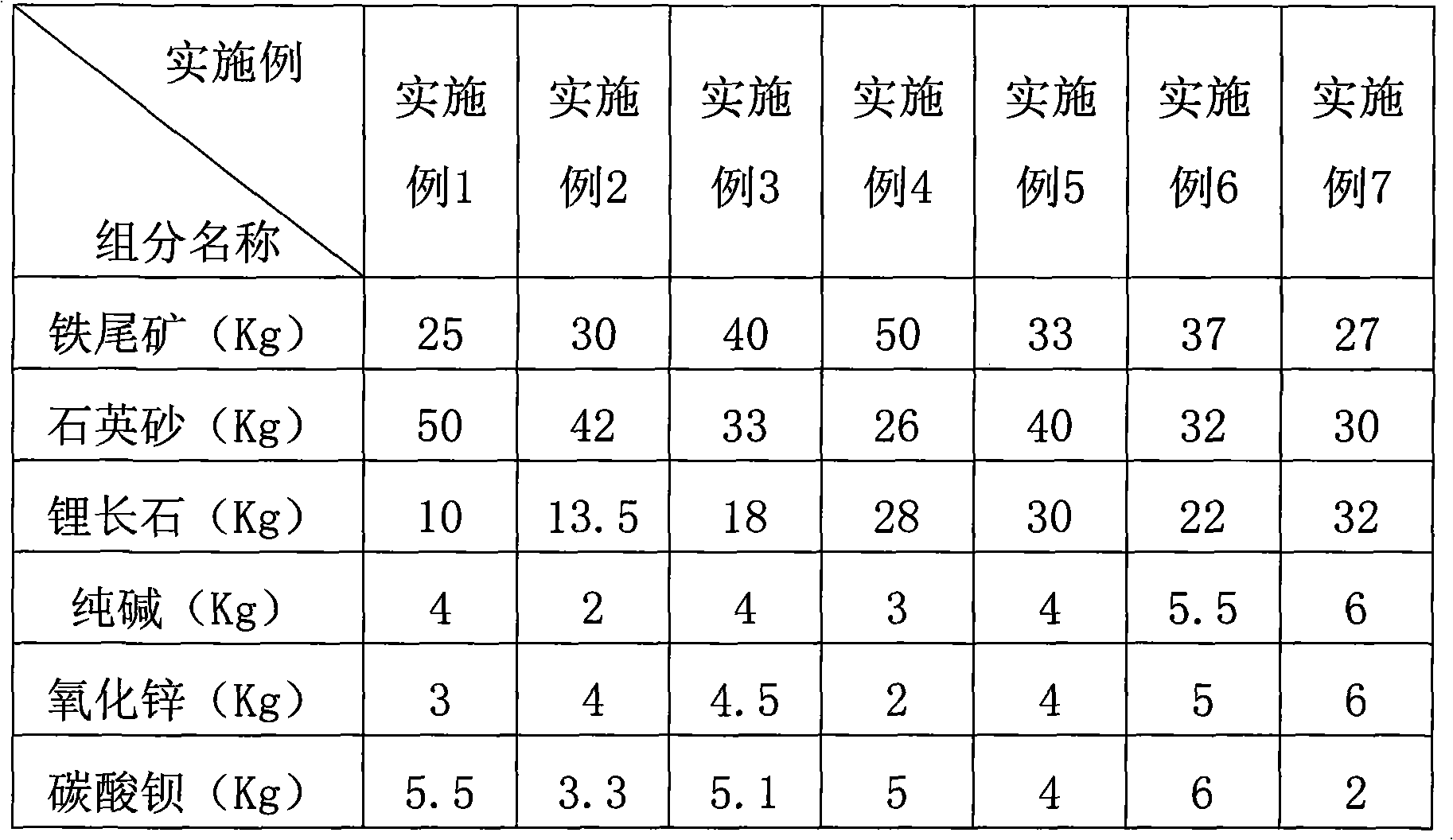

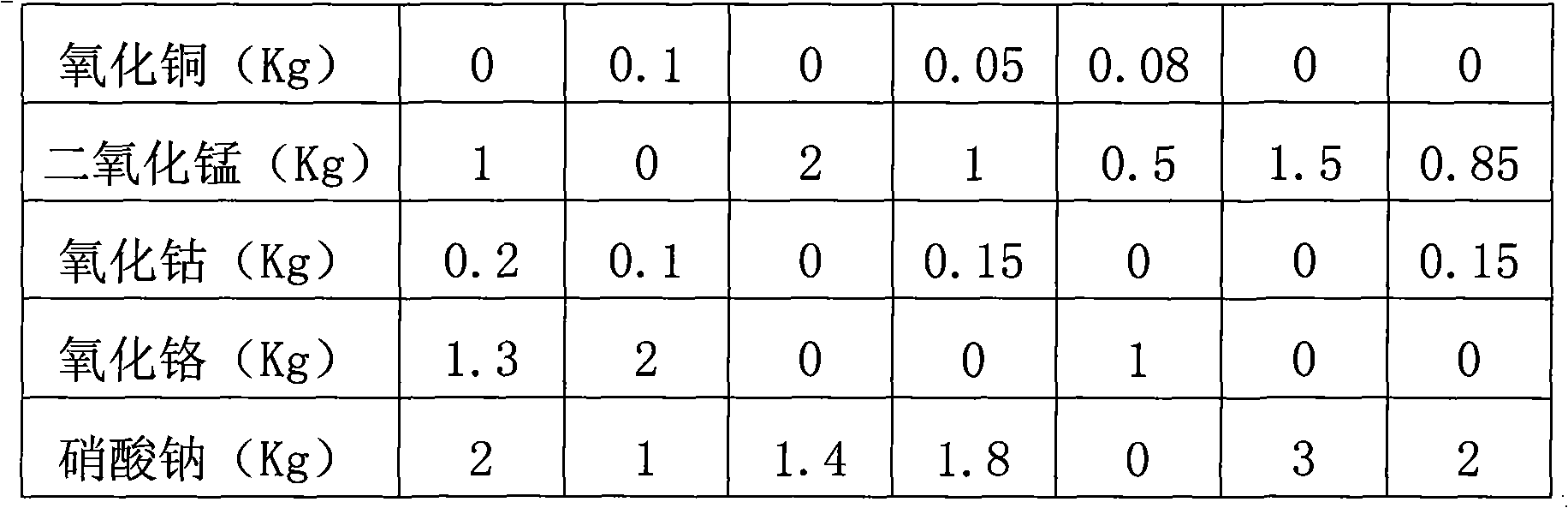

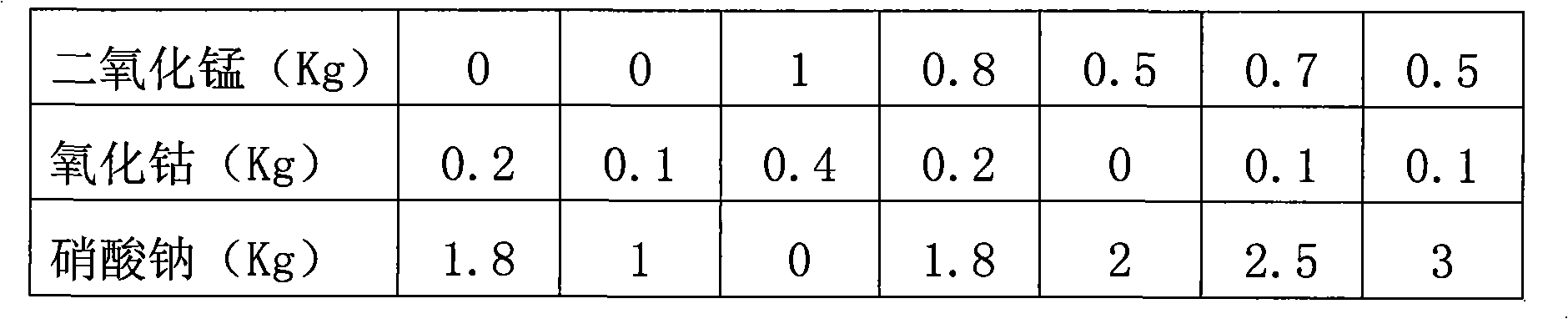

Black glass ceramic and production method thereof

The invention discloses a black glass ceramic and a production method thereof in order to solve the problems of the conventional glass ceramic, i.e. single color and high production technique cost. The black glass ceramic is produced with the following components in part by weight: 25 to 50 parts of iron tailings, 20 to 50 parts of quartz sand, 10 to 32 parts of petalite, 2 to 6 parts of sodium carbonate, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 0.1 part of copper oxide, 0 to 2 parts of manganese dioxide, 0 to 0.2 part of cobalt oxide, 0 to 2 parts of chromic oxide and 0 to 3 parts of sodium nitrate. Since the invention utilizes the discarded iron tailings as the material of the black glass ceramic, the waste is made profitable, pollution is reduced, the environment is protected, moreover, the physicochemical performance of the product can be enhanced, and the single-color problem of the black glass ceramic is solved; the corrosion of the refractory material of a glass furnace by molten glass is reduced, and thereby the service life of the equipment is prolonged; and the application range of the black glass ceramic is wide.

Owner:浮山县晋盛新型建筑材料有限责任公司

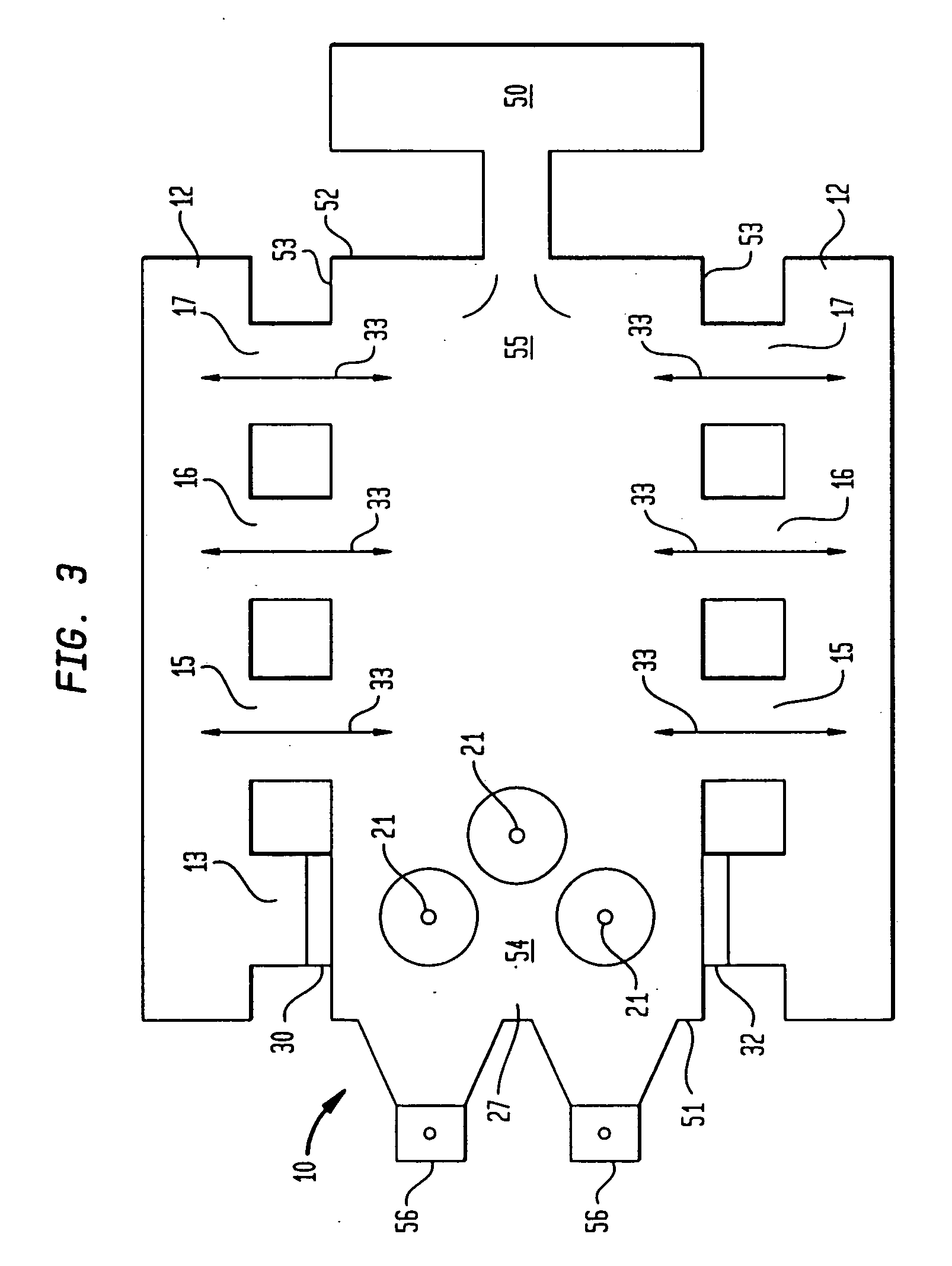

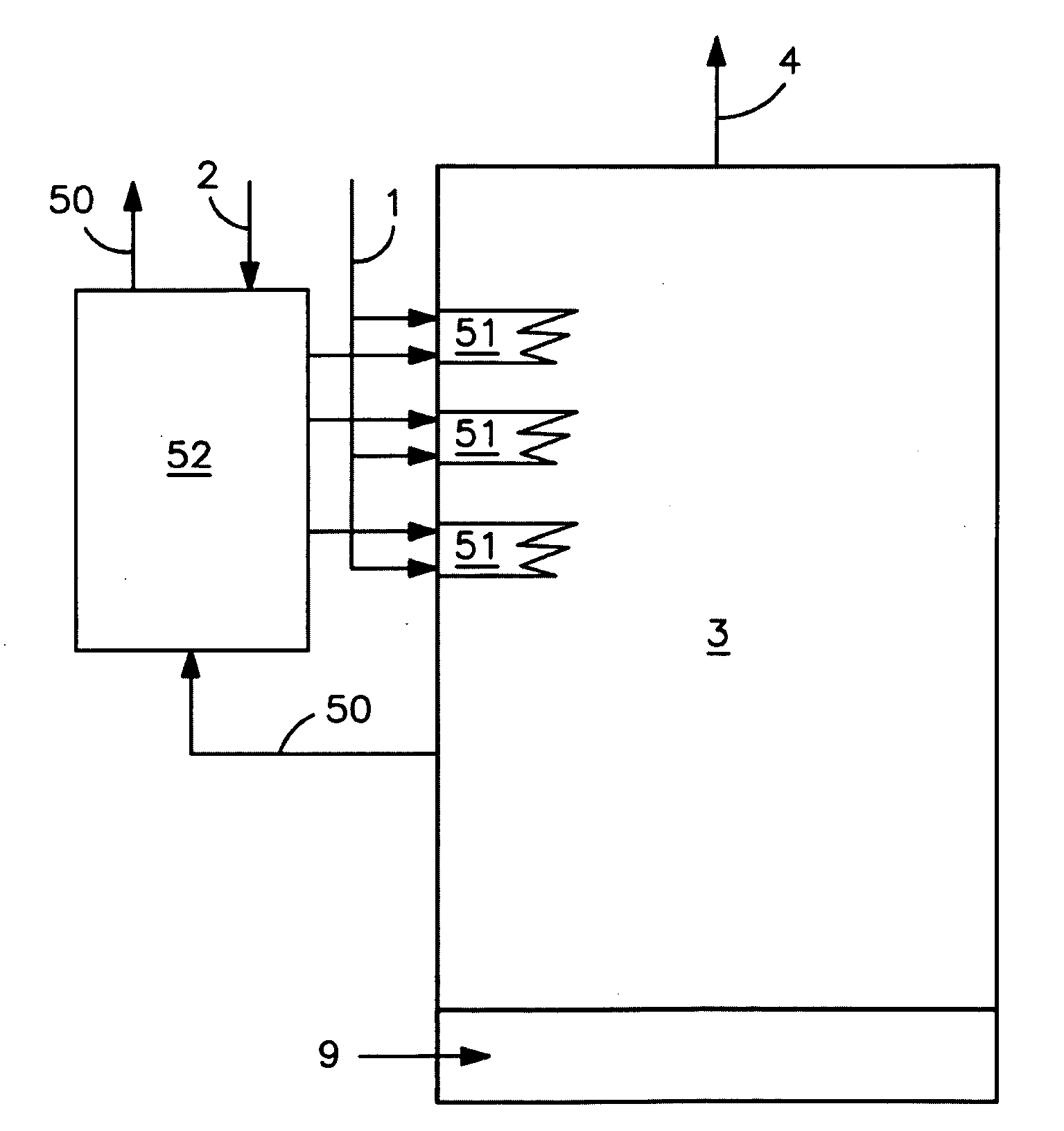

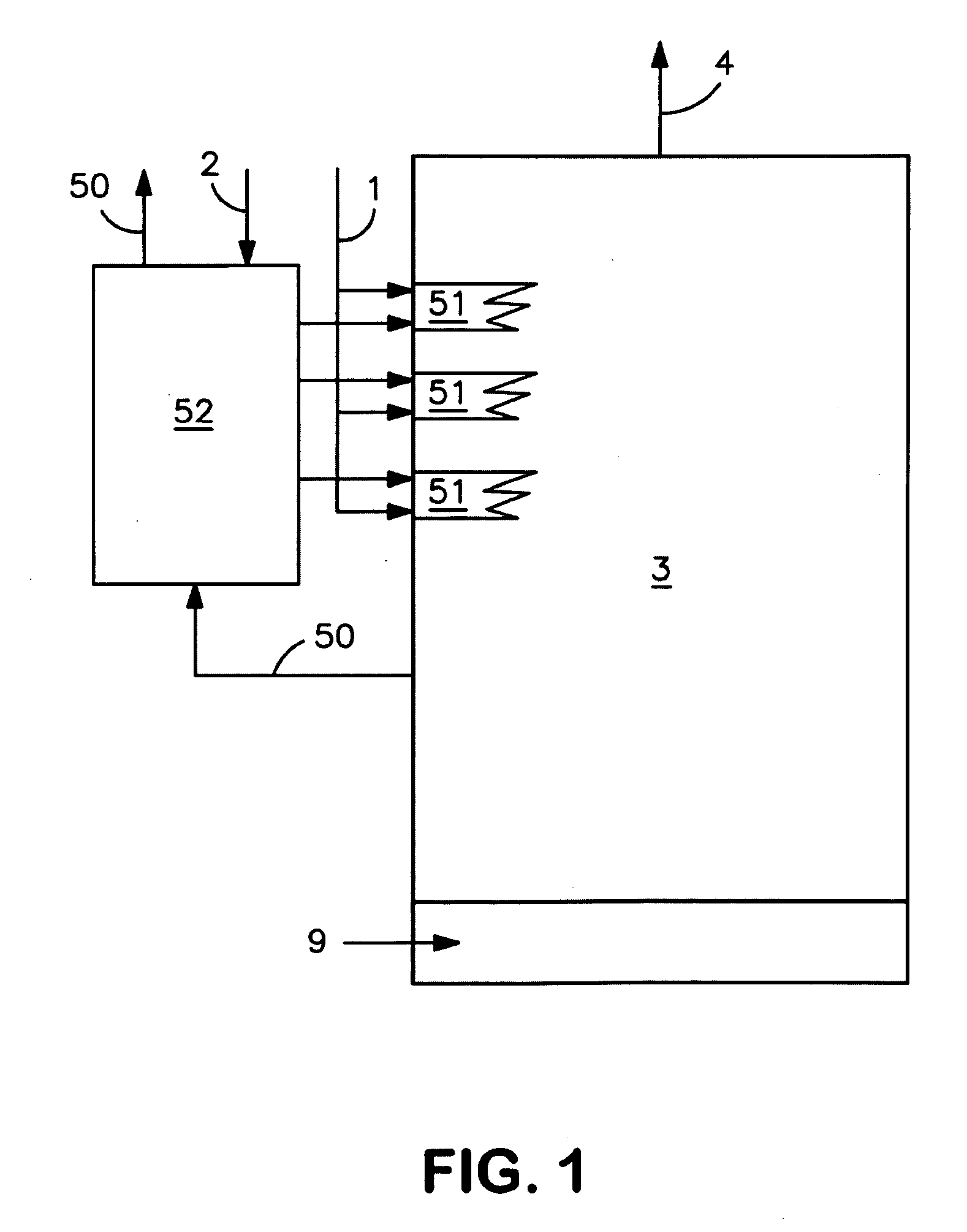

Method for heating glass melting furnace with sectional combustion oxygen fuel burner mounted on the top

InactiveCN1374261AMaintainance of heating chambersIndirect carbon-dioxide mitigationEngineeringLiquid fuel

An industrial glass furnace optionally housing a recuperator, regenerator, electrical heating, or other means for providing heat to the glass batch, having at least one staged combustion oxy-fuel burner in the top of the furnace providing heat to melt the glass batch by providing a flow of fuel to the oxy-fuel burner; providing a flow of gaseous oxidizer associated with the oxy-fuel burner; injecting the fuel and oxidizer into the furnace; and burning the fuel to cause At least a portion of the combustion is achieved in the vicinity of the glass-forming material such that convective and radiative heat transfer to the glass-forming material is enhanced without significantly disturbing the glass-forming material. In one embodiment, the oxy-fuel burner is adapted to inject liquid fuel. In another embodiment, the oxy-fuel burner is adapted for staged combustion of fuel and includes at least one external oxidizer injector and two internal fuel injectors, the innermost fuel injector being adapted for high velocity fuel injection, and the innermost fuel injector Another fuel injector between the injector and the external oxidizer injector is suitable for low speed fuel injection.

Owner:BOC GRP INC

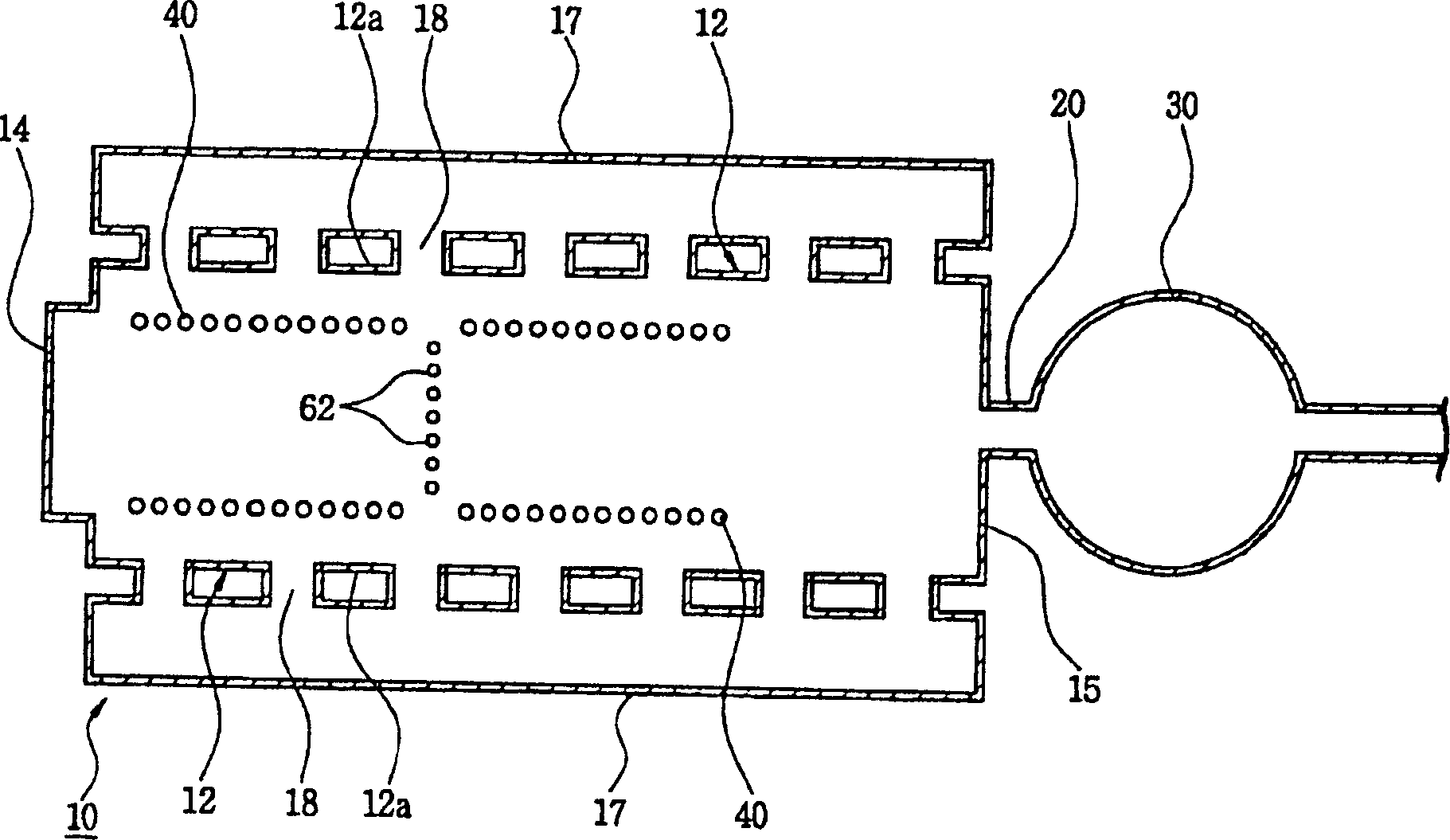

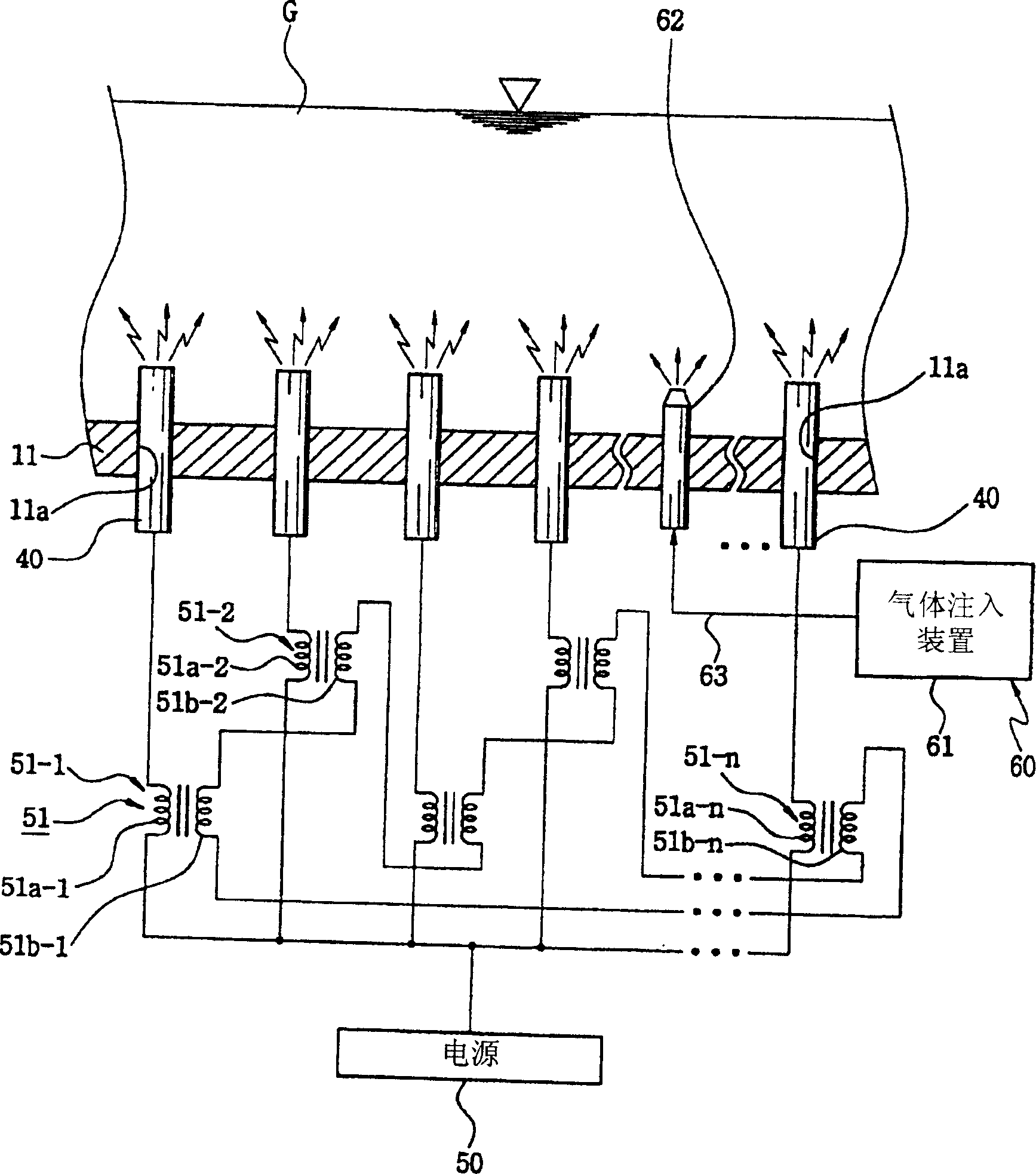

Electric boosting system for of smelting kiln of glass furnace

InactiveCN1762865AImprove efficiencyIncrease productionGlass furnace apparatusElectric furnaceElectrical resistance and conductanceHeat resistance

An electric boosting system comprising a plurality of molybdenum electrode rods for generating resistive heat of molten glass and a power source connected to the molybdenum electrode rods for power required to operate the molybdenum electrode rods Applied to molybdenum electrode rods. The molybdenum electrode rods are arranged in the heating zone and the cooling zone, are arranged on the bottom of the melting furnace and are installed along two opposite side ends of the melting furnace bottom so as to face each other.

Owner:SAMSUNG CORNING CO LTD

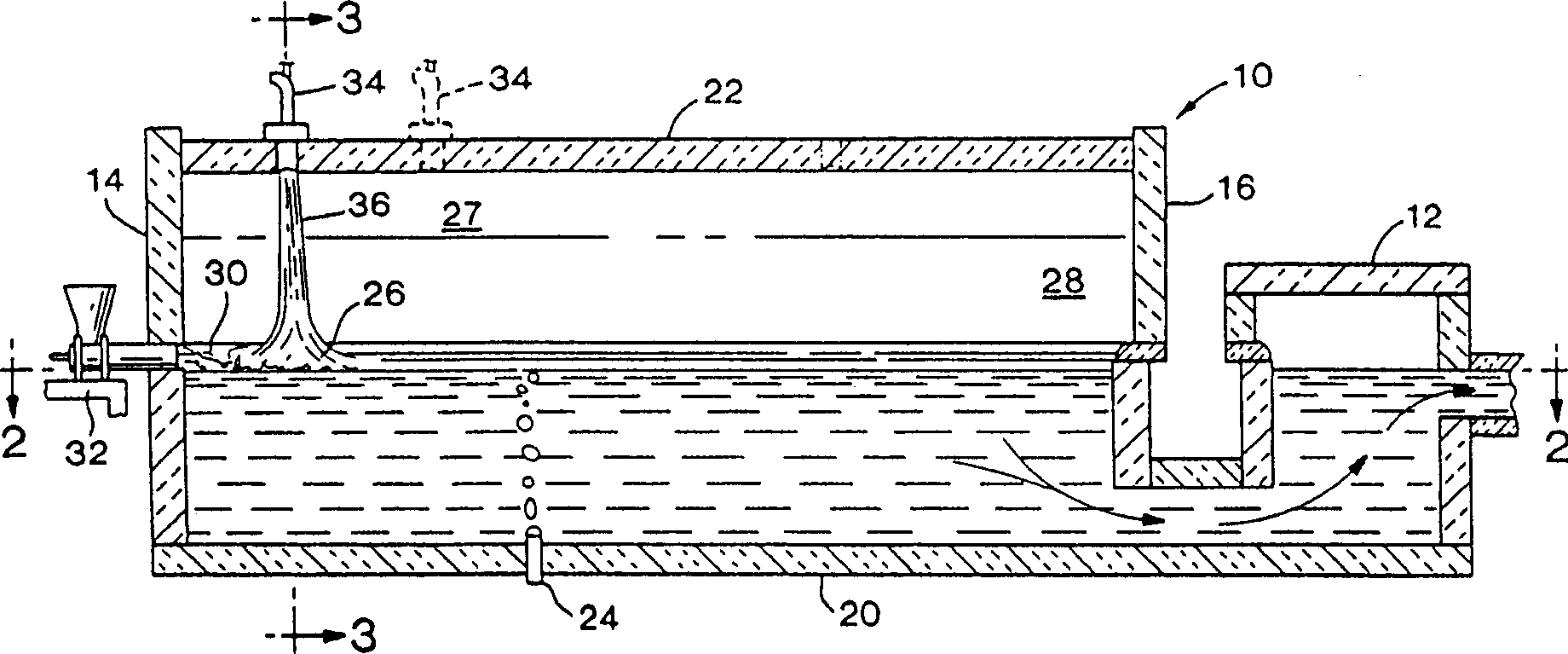

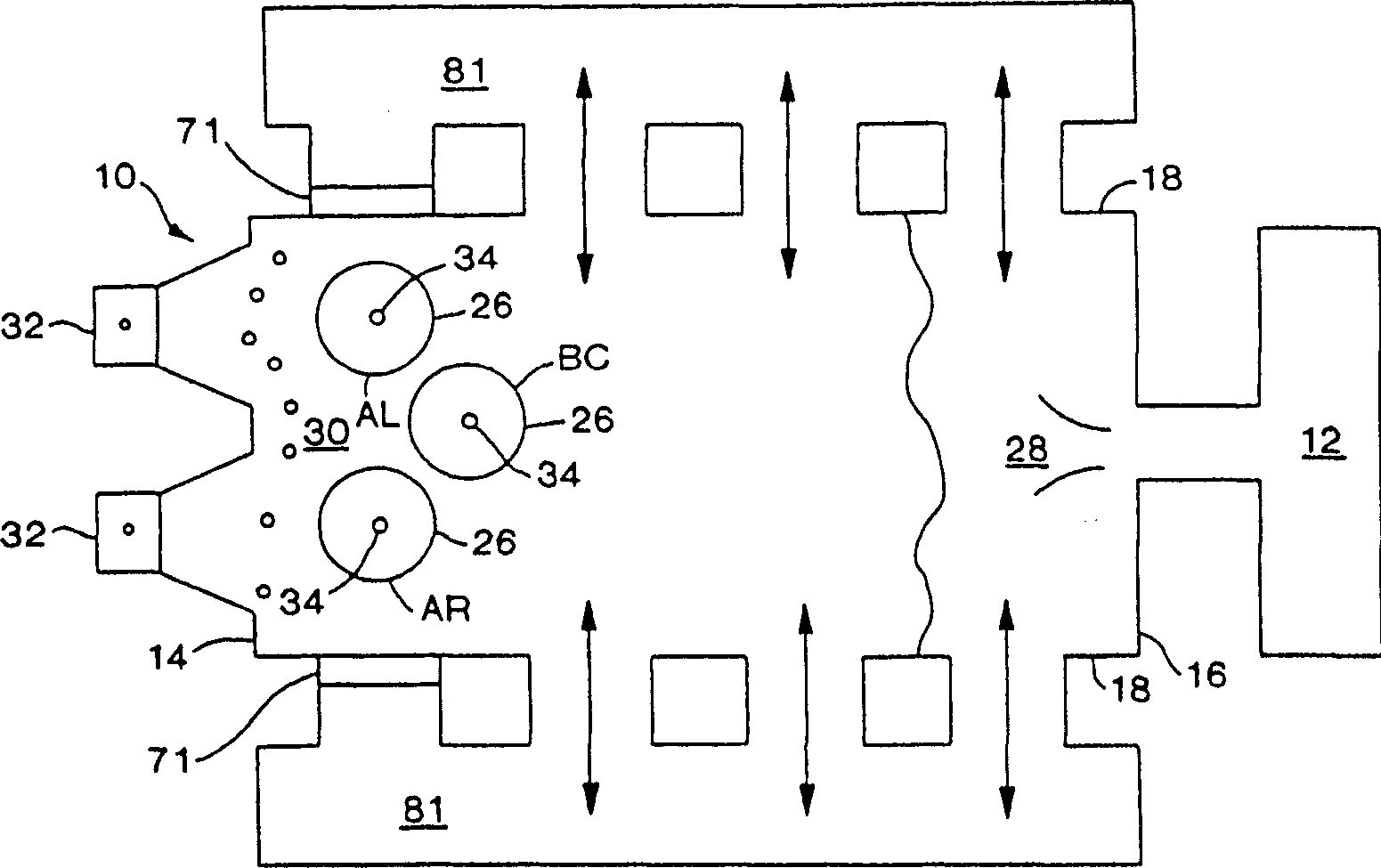

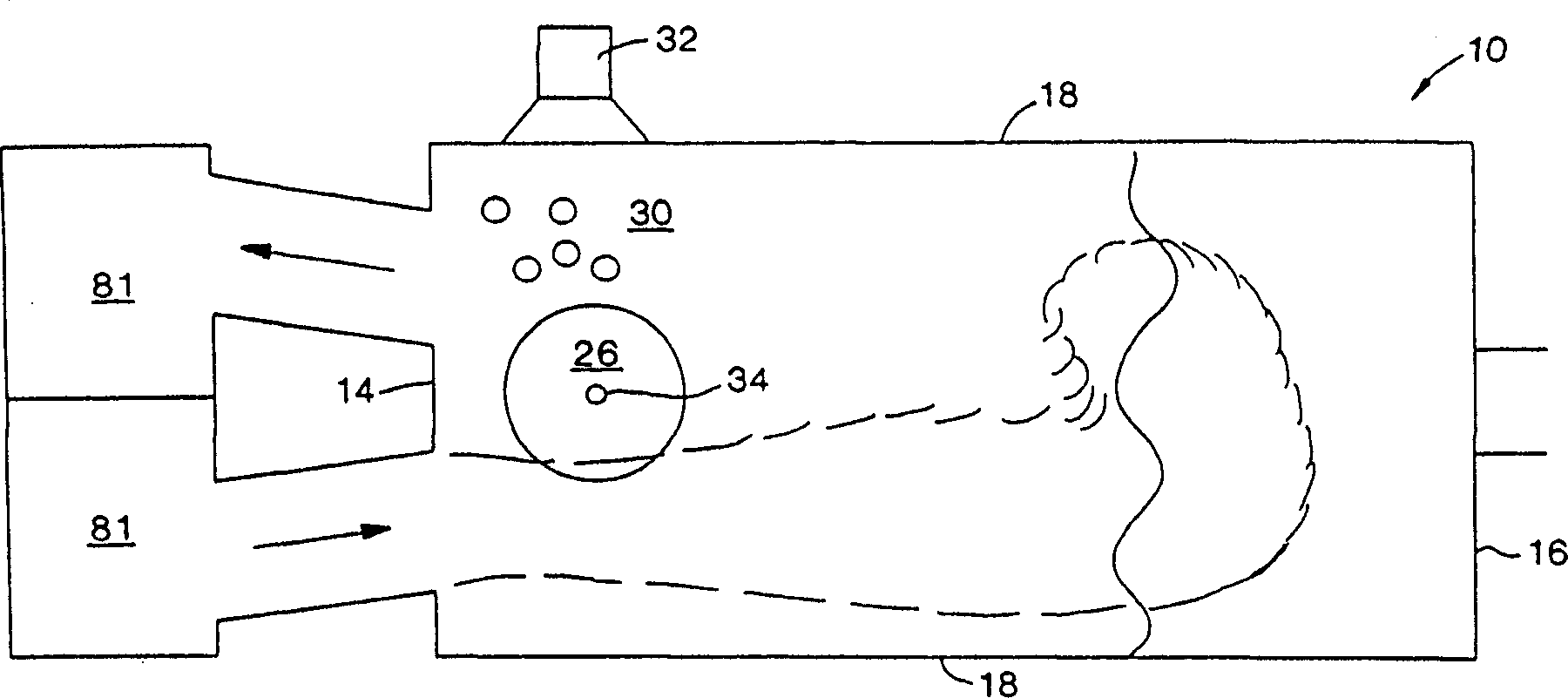

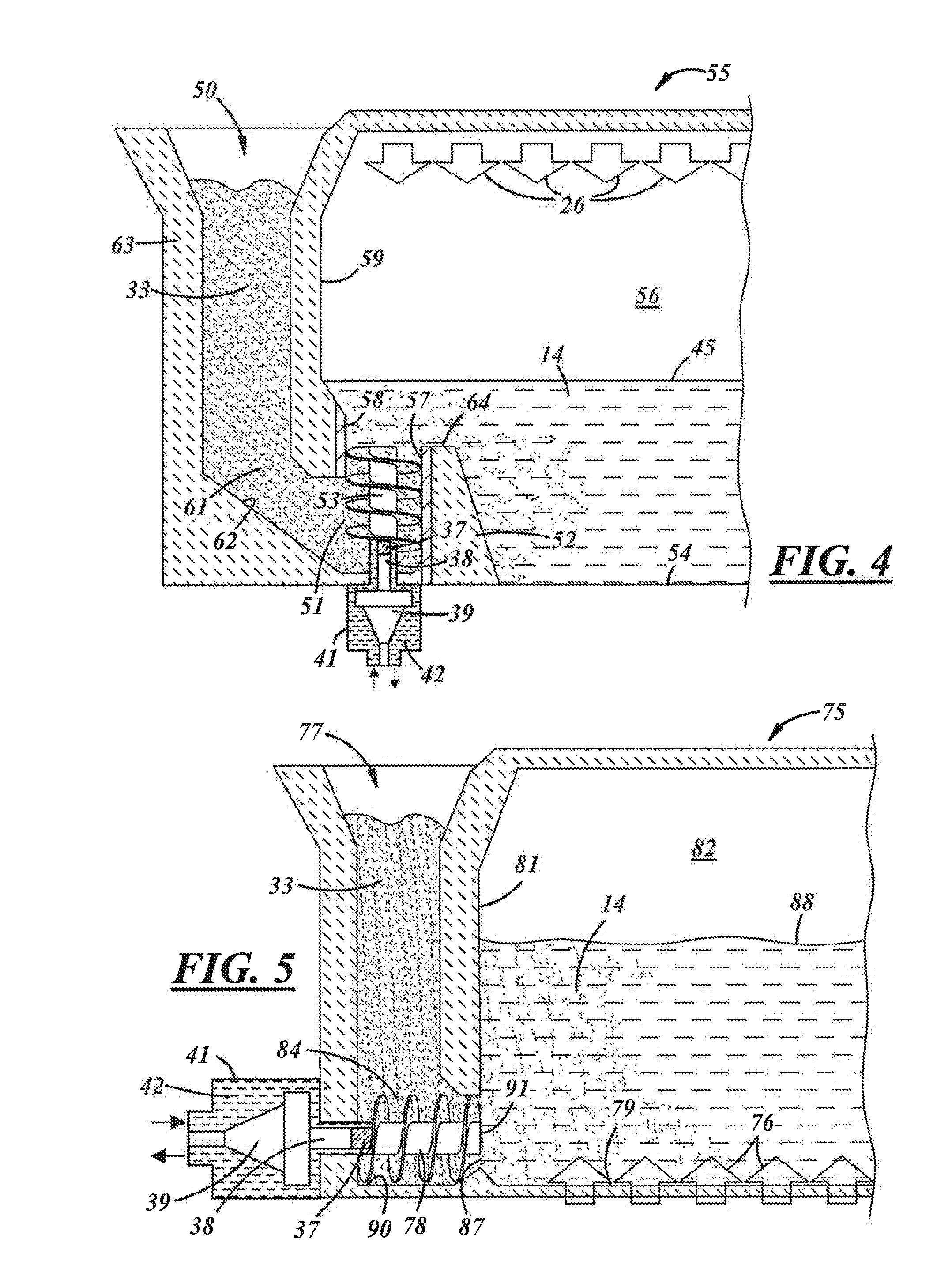

Glass Furnace with Bottom Material Feed

ActiveUS20150307382A1Eliminate the problemCharging furnaceGlass furnace apparatusGlass furnaceScrew conveyor

A glass furnace includes a furnace chamber for containing glass melt and a screw conveyor for receiving glass batch material and feeding the glass batch material to the furnace chamber. A dam wall is disposed with respect to the screw conveyor such that batch material from the screw conveyor must flow upward over the dam wall before entering the furnace chamber. The top of the dam wall may be below the level of the melt pool in the furnace chamber.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Glass furnace flue gas to heat glassmaking material and oxidant

Heat in a stream of combustion products obtained from a glassmelting furnace heated by oxy-fuel combustion is passed to incoming glassmaking materials in a heat exchanger without requiring reduction of the temperature of the stream yet without causing softening of the glassmaking material.

Owner:PRAXAIR TECH INC

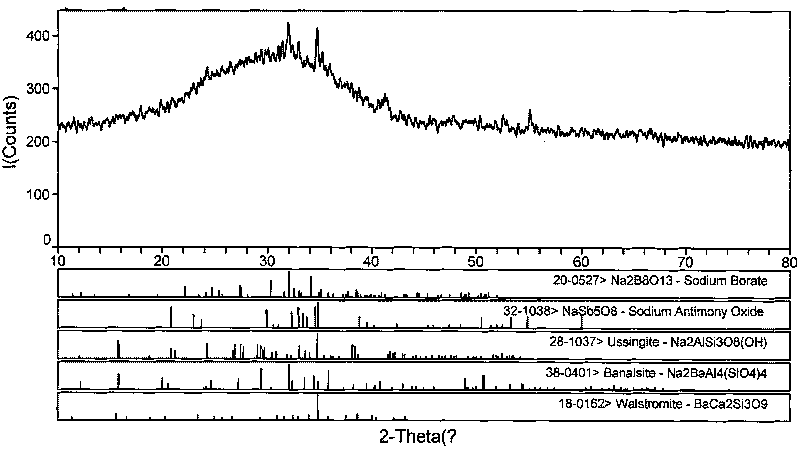

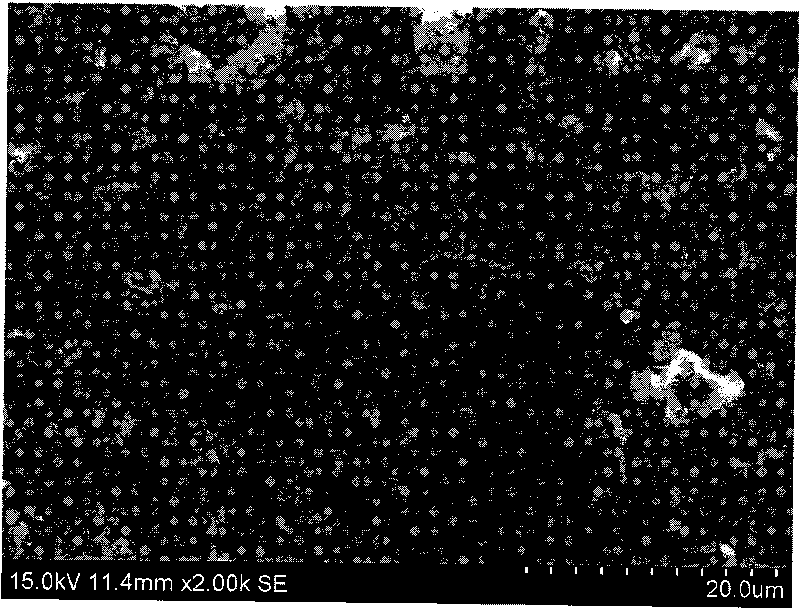

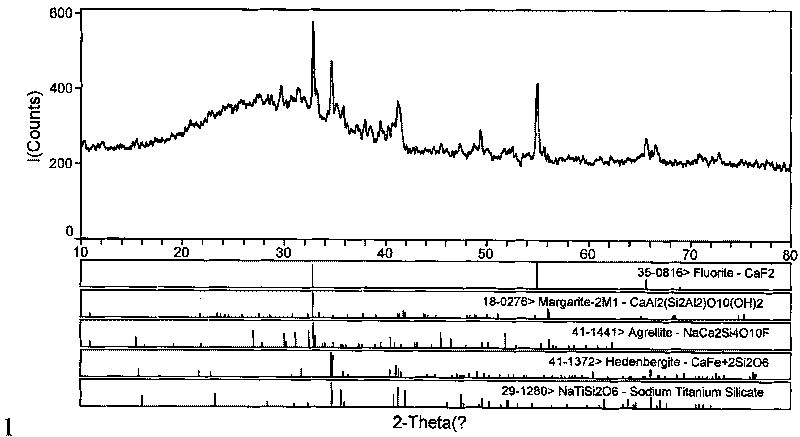

Method for producing microcrystalling foam glass with gold tail ore

The invention discloses a method for producing microcrystalling foam glass with gold tail ore, which comprises the steps of: firstly, putting gold tail ore powder, waste glass powder, fluorite powder, sodium nitrate powder, calcite powder, pure alkali powder, sodium fluosilicate powder and antimonous oxide powder into a mixer to be evenly mixed, and putting into a glass furnace to be melted; draining molten glass liquid into a water pond and water quenching; fishing out water quenched glass, and ball milling and screening with 150 screen mesh to produce the glass powder; and putting the glass powder, foaming agent, ammonium dihydrogen phosphate, iron sesquioxide and manganese dioxide powder into the mixer to be evenly mixed, putting into a foam glass-producing mould, and moving the mould into to a foaming furnace and heating to obtain the microcrystalling foam glass by means of temperature raising, fast cooling and annealing.The method not only is good for recycling waste substance and protecting environment, but also has low producing and foaming temperature and simple production technology, and the produced foaming glass has high structural intensity, low water absorption rate, small density and low heat conduction coefficient.

Owner:承德新通源新型环保材料有限公司

Sintered product produced from a zircon-based charge

ActiveUS20110107796A1Improve the immunityGlass furnace apparatusFurnace liningsChemical compositionGlass furnace

The present invention relates to a sintered product elaborated from a starting charge containing 75-99% of zircon, in mass percentage based on the oxides and having the following average weight chemical composition, in mass percentages based on the oxides60%≦ZrO2≦72.8%,27%≦SiO2≦36%,0.1%≦B2O3+GeO2+P2O5+Sb2O3+Nb2O5+Ta2O5+V2O5,0.1%≦ZnO+PbO+CdO,B2O3+GeO2+P2O5+Sb2O3+Nb2O5+Ta2O5+V2O5+ZnO+PbO+CdO≦5%0% ≦Al2O3+TiO2+MgO+Fe2O3+NiO+MnO2+CoO+CuO≦5%,other oxides: ≦1.5%,for a total of 100%.Notably used in a glass furnace.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Vanishing mould casting technique of blast furnace cooling wall

InactiveCN101185963AFast preparationEliminate fire defectsFoundry mouldsFoundry coresGlass furnaceLight pollution

The invention discloses a lost foam casting process used for a blast furnace cooling wall, aiming to solve the problems of prior casting technique of blast furnace cooling wall that casting cost is high, casting quality is poor, labor intensity is high, working efficiency is low and manufacturing process has heavy pollution, etc. The invention has the advantages that the method is simple, the cost is low, the size of cast pieces is accurate, the surface is smooth, the working efficiency is higher the, labor intensity is lower, the manufacturing process has lighter pollution and is easy for control. The method of the process is as the following: 1) water tubes of the cooling wall are stewed and manufactured; 2) a cooling wall foam plastic model in which the cooling wall water tubes are arranged is manufactured; 3) refractory dope is painted on the surface of the foam plastic model and is dried for 30 to 48 hours at a temperature from 40 to 50 DEG C; 4) a casting system is assembled; 5) boxing-up, forming and vibration for shape are carried out; 6) vacuumizing casting is carried out, with vacuum degree from minus 0.02 to minus 0.08 MPa and casting temperature from 1000 to 1600 DEG C; after the casting, pressing time is 10 to 60 minutes; 7) shaking and cleaning are carried out.

Owner:肖燕鹏

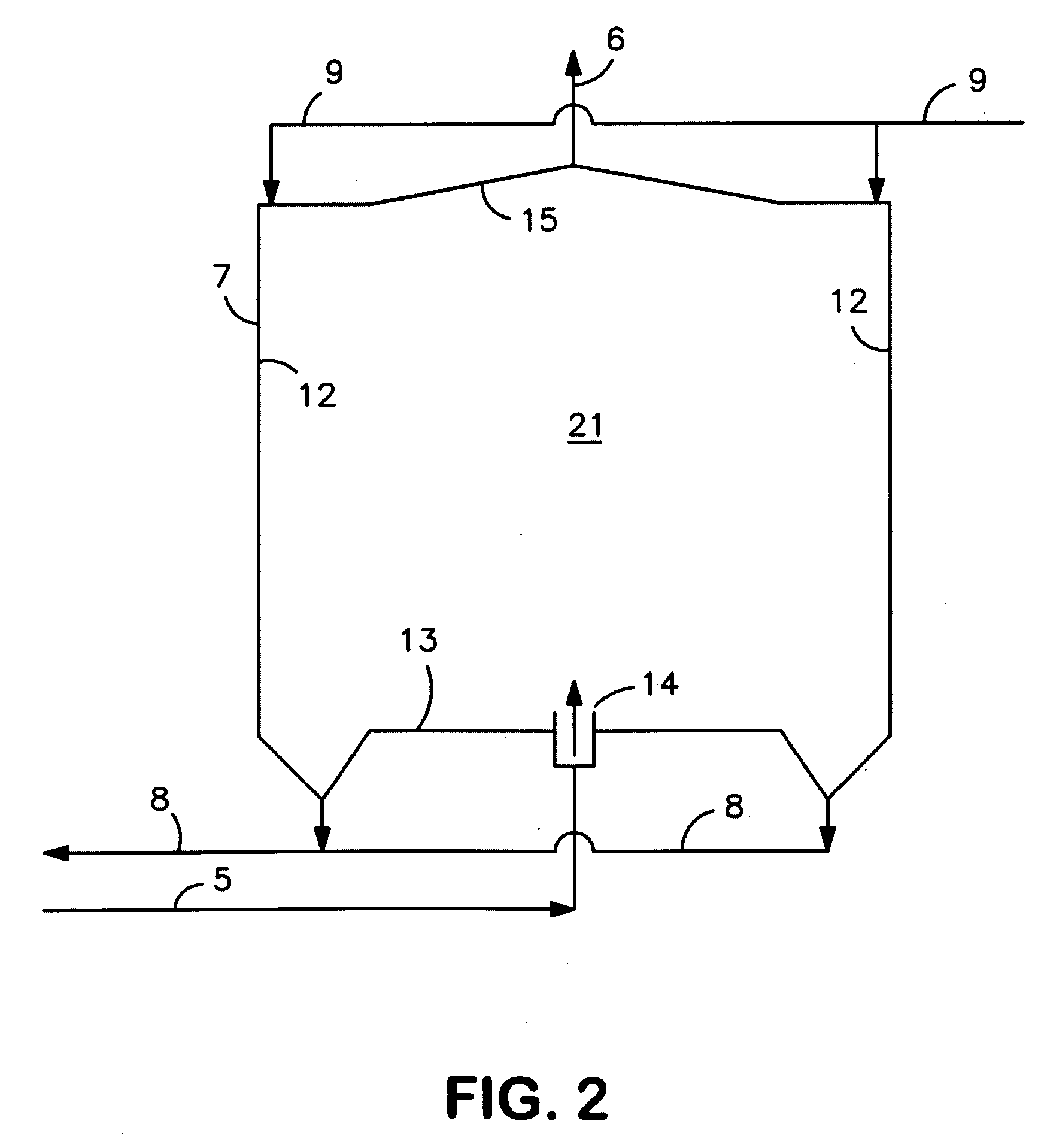

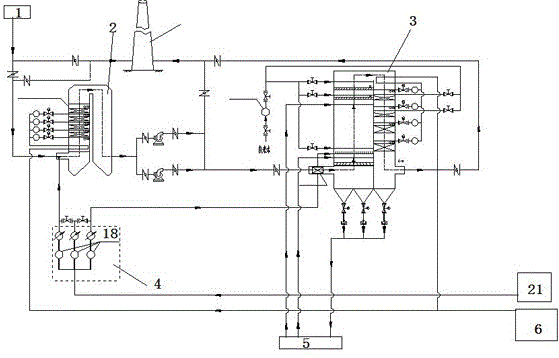

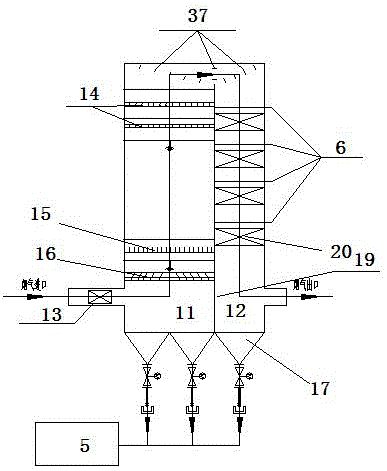

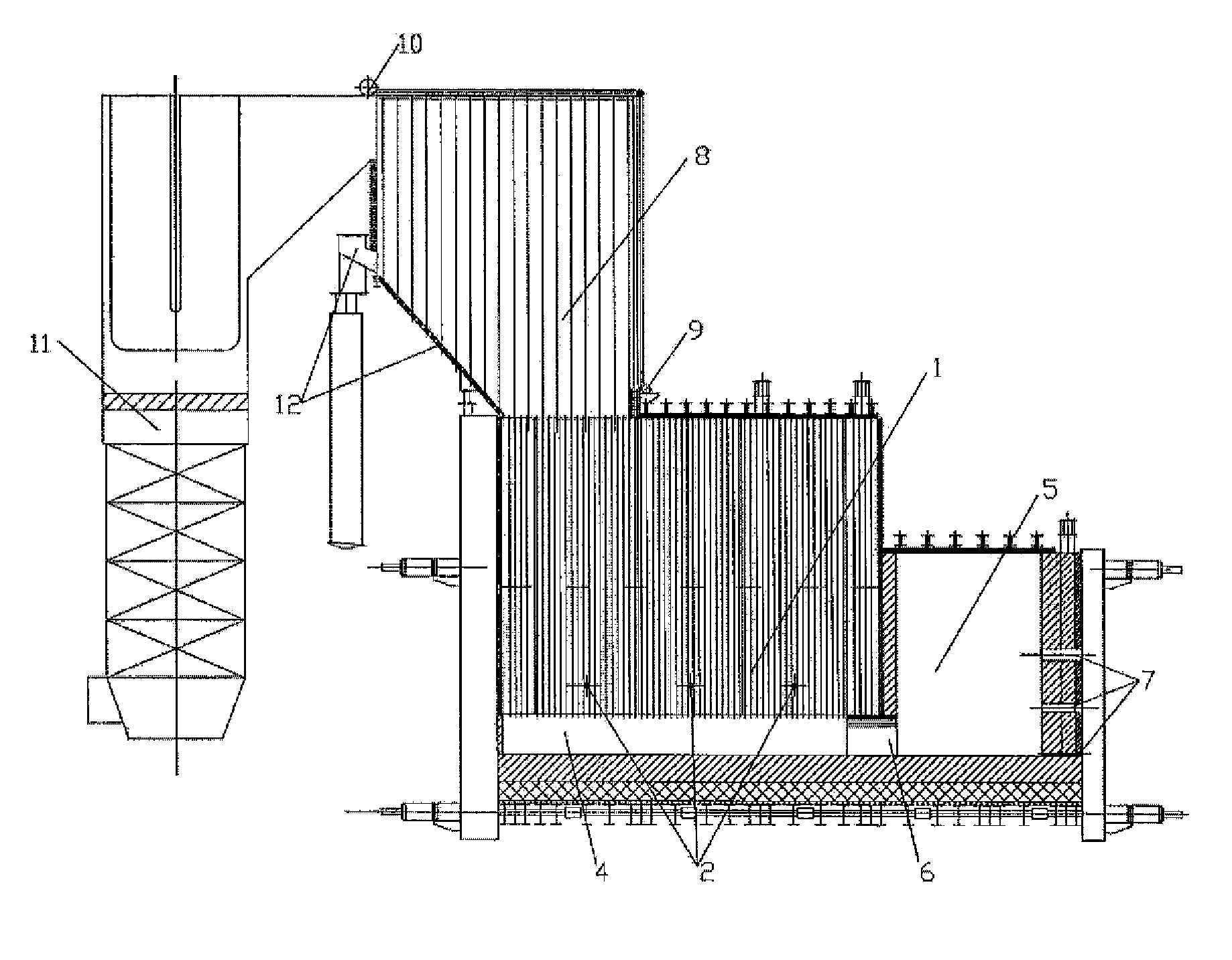

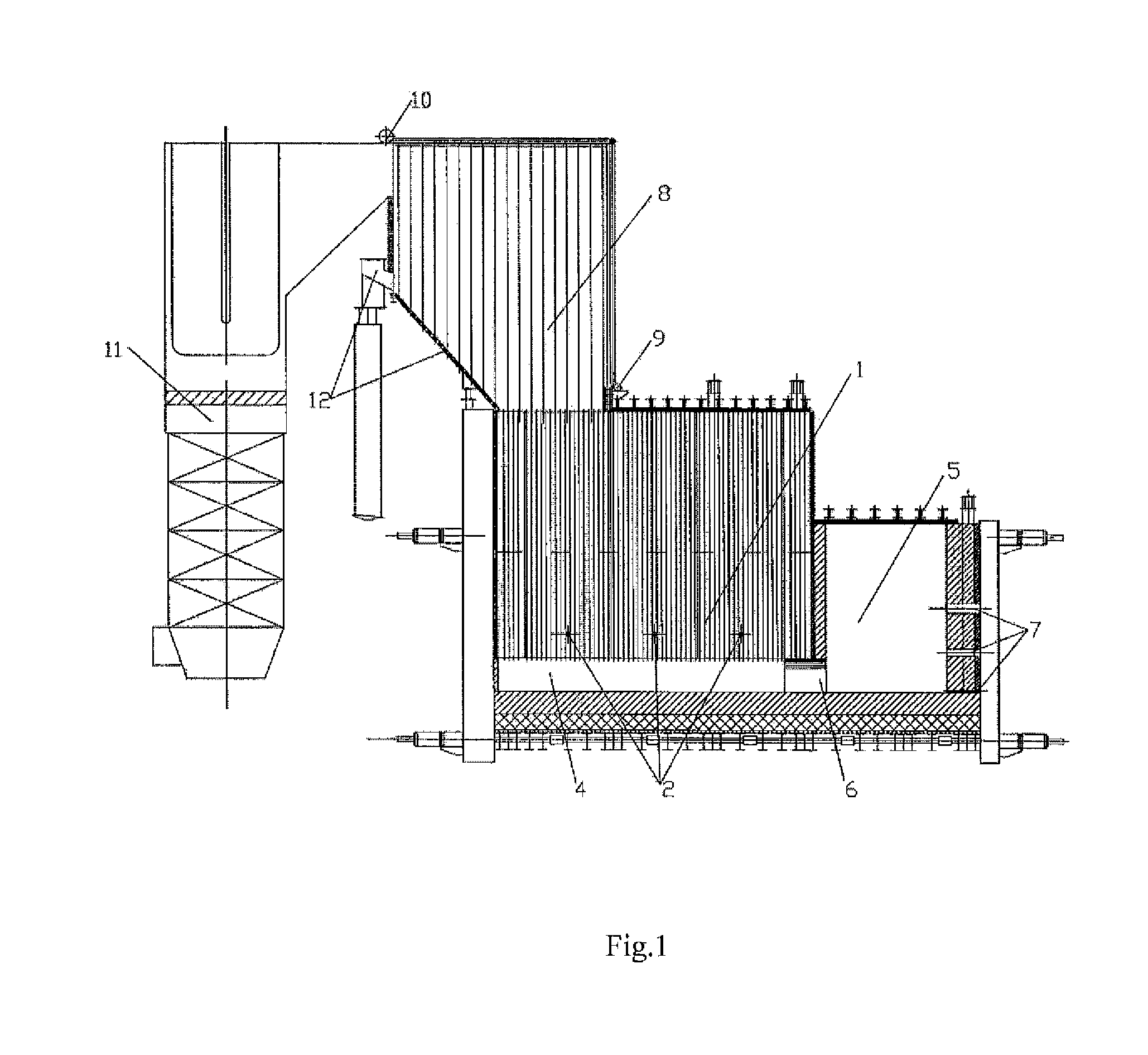

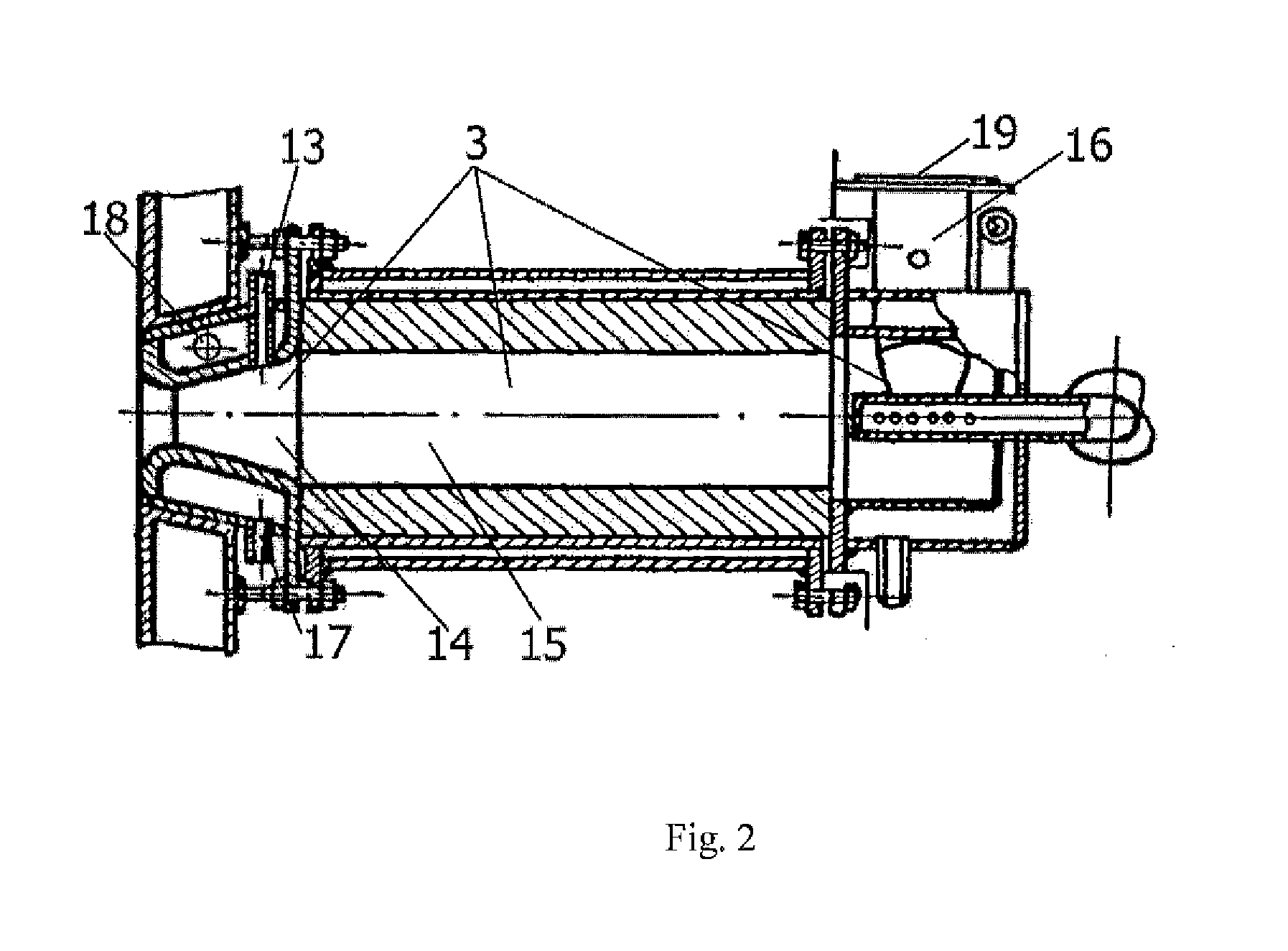

Glass-furnace-smoke integrated-denitration-desulfurization-dedusting technological device and technology

InactiveCN106268318AReduce physical poisoningReduce temperature dropGlass furnace apparatusDispersed particle separationGlass furnaceProcess engineering

The invention belongs to the technical field of smoke purifying, and provides a glass-furnace-smoke integrated-denitration-desulfurization-dedusting technological device and a technology. A waste-heat boiler (2) of the glass-furnace-smoke synchronous denitration-desulfurization-dedusting technological device is internally and sequentially provided with a primary heat exchanger (7), a medium-temperature denitration reactor (8), a secondary heat exchanger (9) and a multistage heat exchanger (10) from front to back in the smoke flow direction; a low-temperature denitration-desulfurization-dedusting reacting tower (3) comprises a tower body divided into a main tower body (11) and an auxiliary tower body (12); a reducing agent evaporator (13) is arranged in a smoke inlet in one side of the main tower body (11); a low-temperature catalysis reacting bed (20) is arranged in the auxiliary tower body (12). By means of the glass-furnace-smoke integrated-denitration-desulfurization-dedusting technological device and the technology, the one-time investment cost and the occupied area are saved, and meanwhile the operating cost is reduced; and the aims of clean governance and zero release are achieved as a whole.

Owner:海南海控特玻科技有限公司 +1

Alkali resistant silica refractory

InactiveUS6313057B1Prevent degradationWear is exacerbatedGlass furnace apparatusCrucible furnacesBrickGlass furnace

A fused silica refractory material made from quartz grains and a method of making the material which contains calcium oxide binder in an amount less than one weight percent. The reduction in calcium oxide binder prevents the degradation of fused silica refractory bricks in furnace environments containing alkali vapors, such as in oxygen-fuel fired glass furnaces. The invention also includes a method of preventing the degradation of silica refractory material by alkalis.

Owner:GMIC HLDG

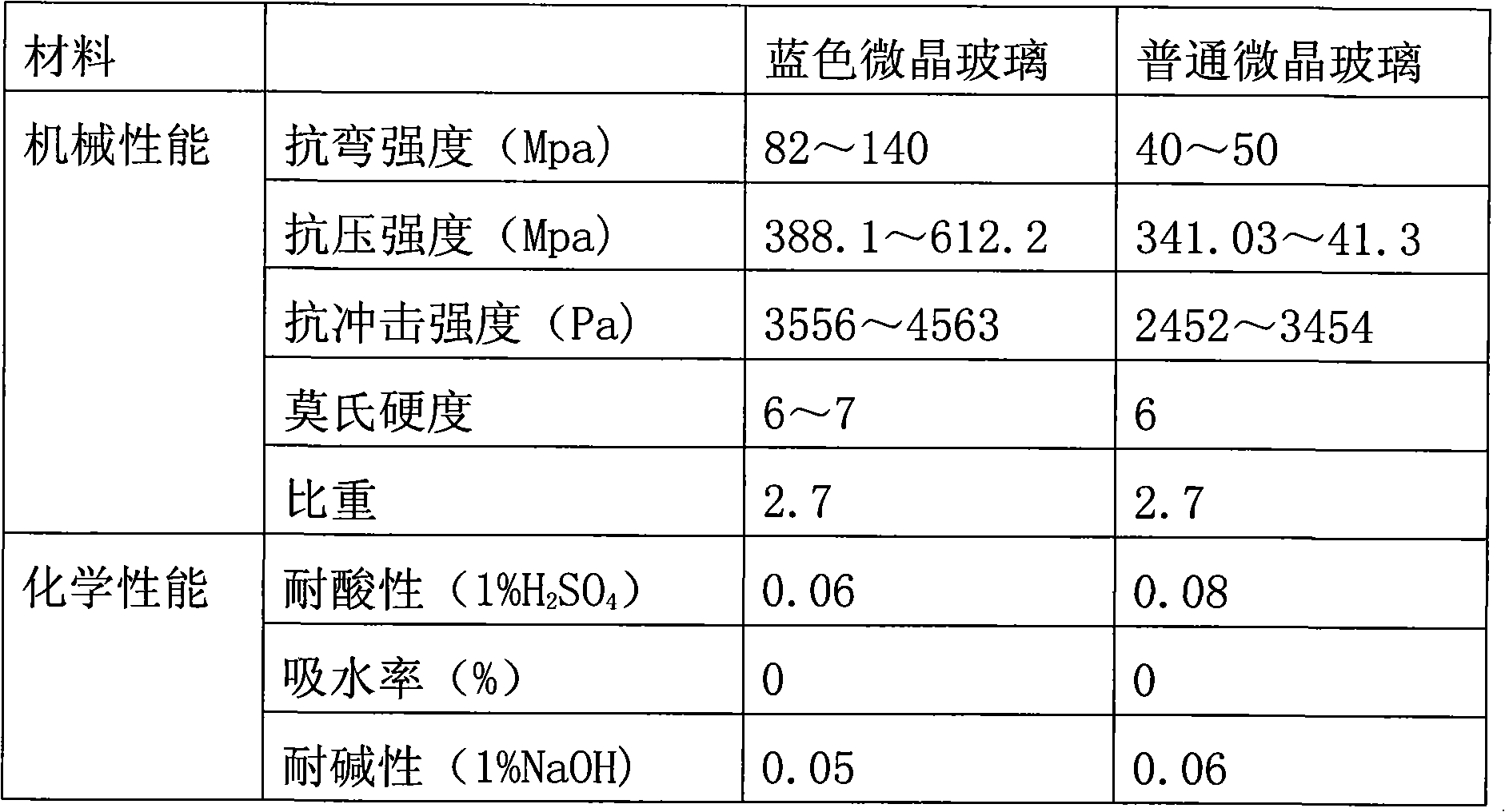

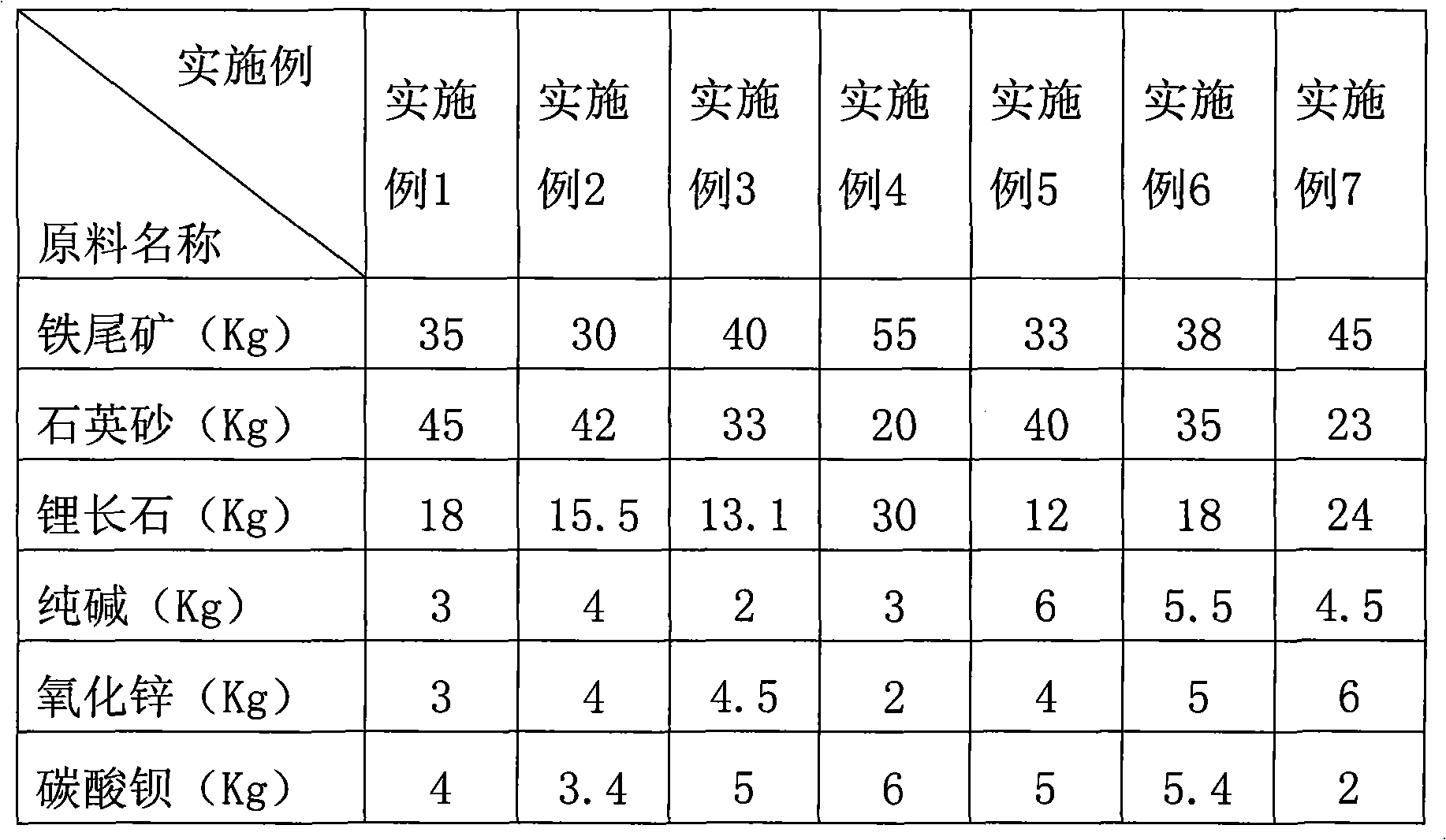

Blue glass ceramics and preparation method thereof

The invention discloses blue glass ceramics and a preparation method thereof, and aims to solve the problems of single color and high production process cost of the conventional glass ceramics. The blue glass ceramics are prepared from the following components in part by weight which serve as raw materials: 30 to 55 parts of iron tailings, 20 to 450 parts of quartz sand, 10 to 30 parts of lithium feldspar, 2 to 6 parts of soda ash, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 1 part of manganese dioxide, 0 to 0.4 part of cobalt oxide and 0 to 3 parts of sodium nitrate. The invention makes waste profitable by using the iron tailings which are wastes as the raw material of the blue glass ceramics, can reduce pollution and protect environment, improve physiochemical performance of the product, solve the problem of single color of the glass ceramics, lighten corrosion of glass metal to a refractory material of a glass furnace and prolong service life of equipment. The blue glass ceramics of the invention have wide application.

Owner:浮山县晋盛新型建筑材料有限责任公司

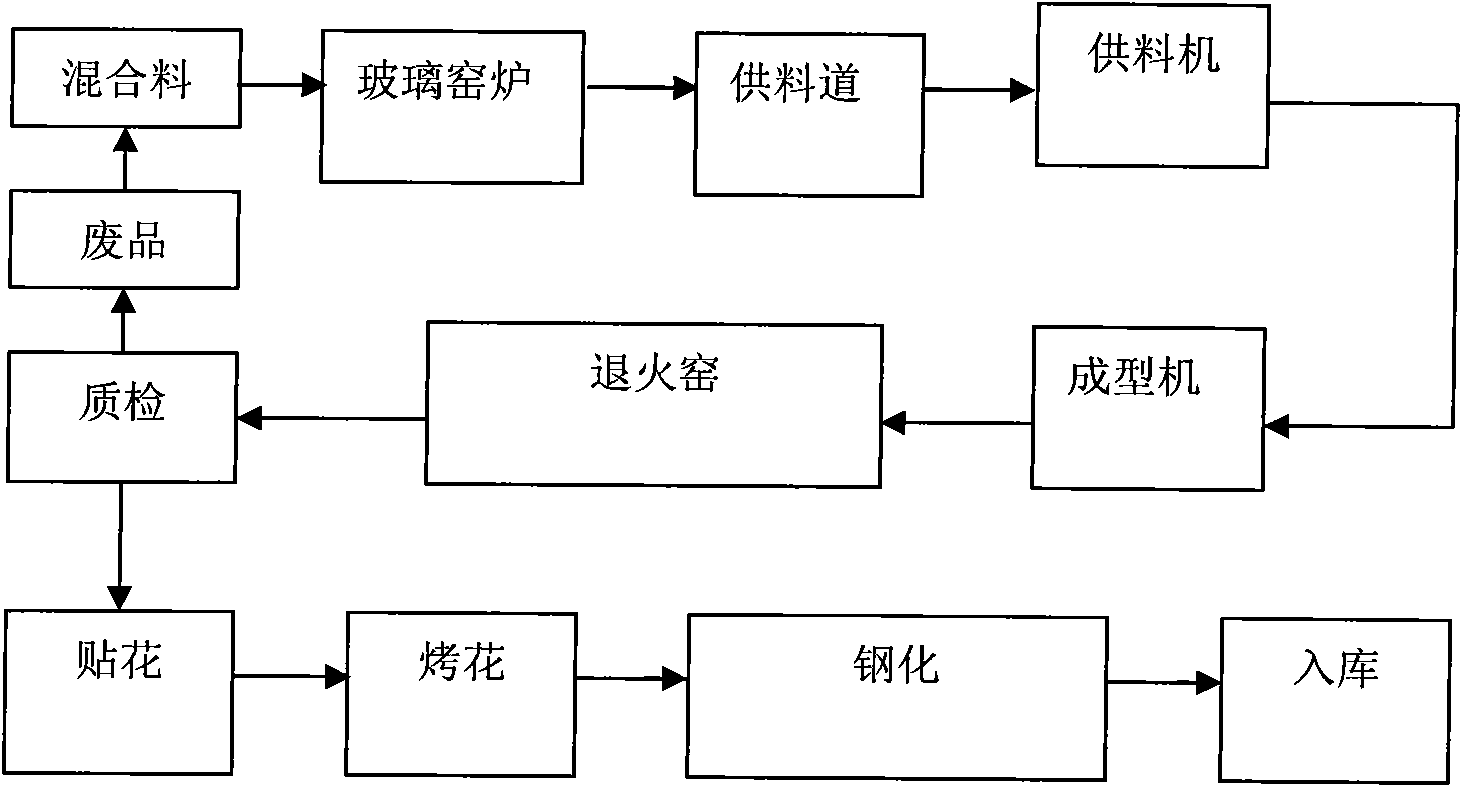

On-line production method of glass plate product

InactiveCN101481202ALess investmentSave roasting costGlass drawing apparatusGlass forming apparatusFlat glassGlass furnace

The invention relates to a method for producing glass board products online, which aims to solve the problems of high equipment investment and high production cost of the prior method. After melting liquid glass flowing out form a glass furnace is shaped by a flat board glass shaper, glass boards are cut at the temperature from 550 DEG C to 900 DEG C, and heat processing or after-shaped heat processing is carried out to the glass boards. The glass boards are cut at the temperature from 550 DEG C to 900 DEG C, and the solid plastic temperature sections of the glass boards are cut by an online synchronous cutter which comprises a transverse cutting knife and a longitudinal cutting knife or a model cutting knife with the same size and shape as a processed glass product. The glass board products are made of plane steel glass, curved-surface steel glass, thin reinforced glass, hot-bent glass or curved-surface doubling glass. The invention can save the investment on preprocessing equipment, simplify production technology and obviously save baking expense, and has the advantages of low investment and low cost.

Owner:梁银生

Surface reinforcing method for tuyere of blast furnace

InactiveCN1974847AInhibit sheddingMake up for high temperature resistanceMolten spray coatingTuyeresGlass furnaceHeat conducting

The present invention is surface reinforcing method for tuyere of blast furnace. The technological scheme of the present invention includes co-permeating alloy elements to reinforce the surface of tuyere and form surface copper alloy layer; and hot spraying to the surface of copper alloy layer to form a surface reinforcing layer. The method of the present invention has no high temperature falling-off of the coating and reinforcement on the co-permeated layer. The tuyere has excellent heat conducting performance, reinforced surface and long service life.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

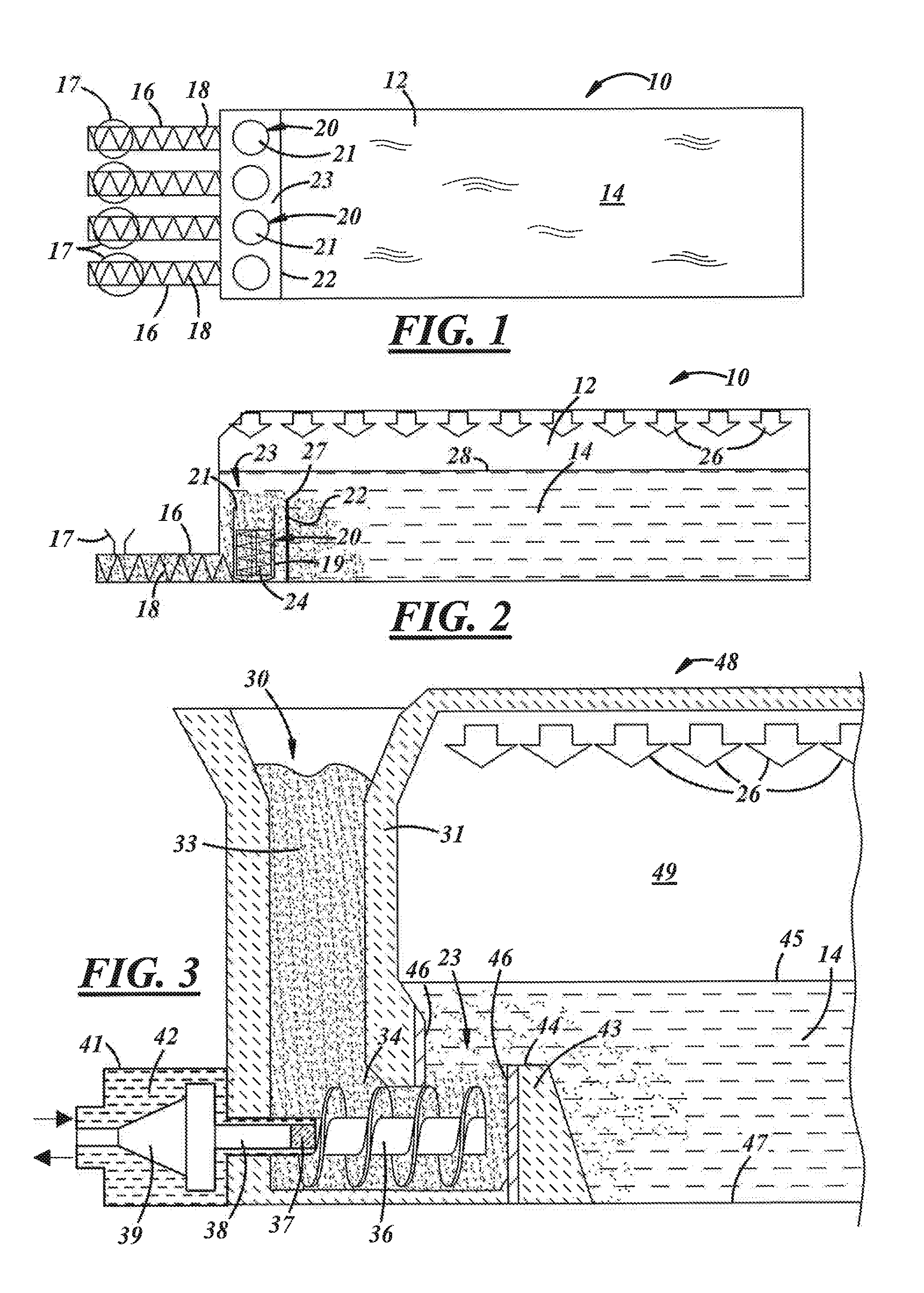

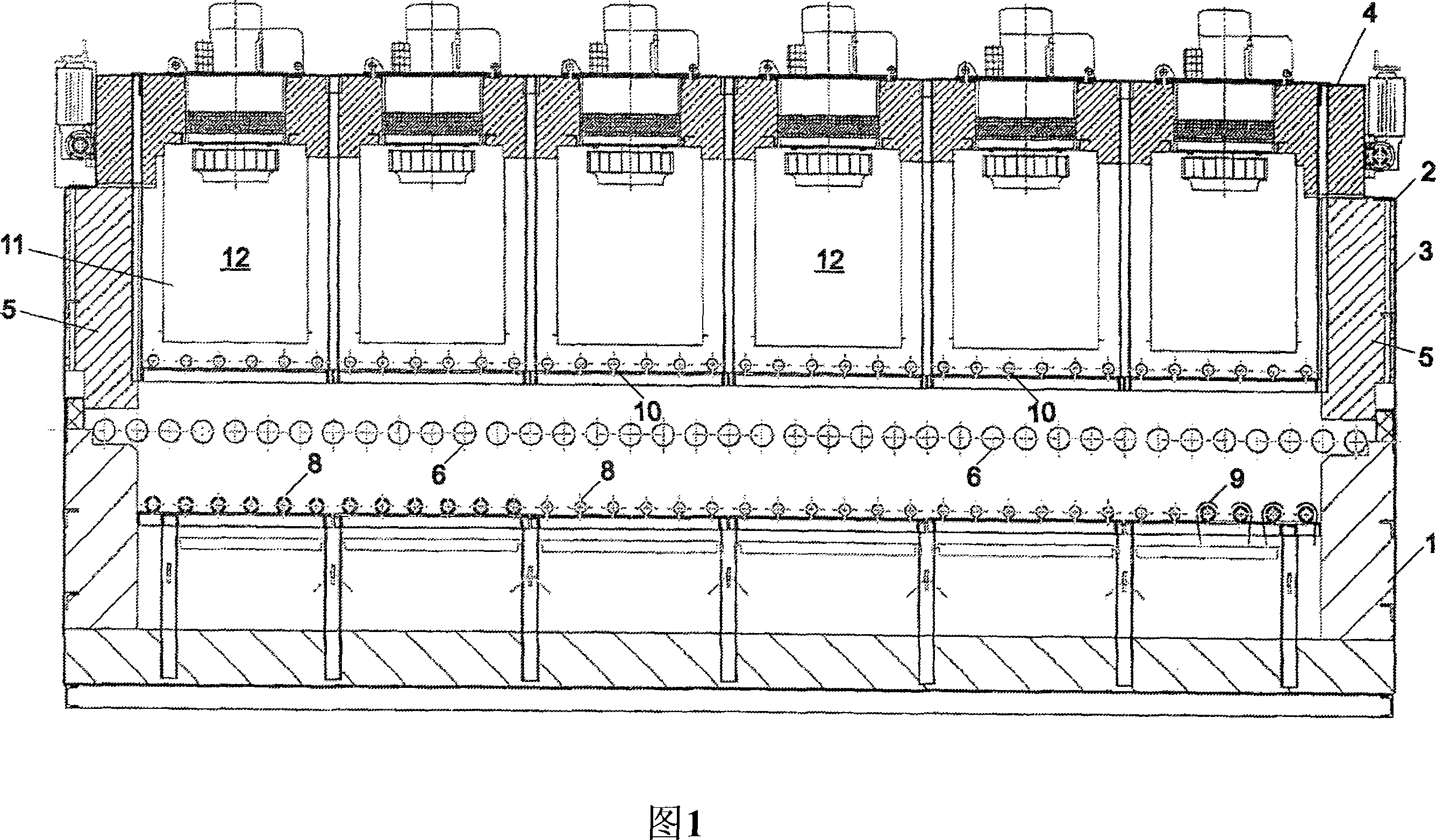

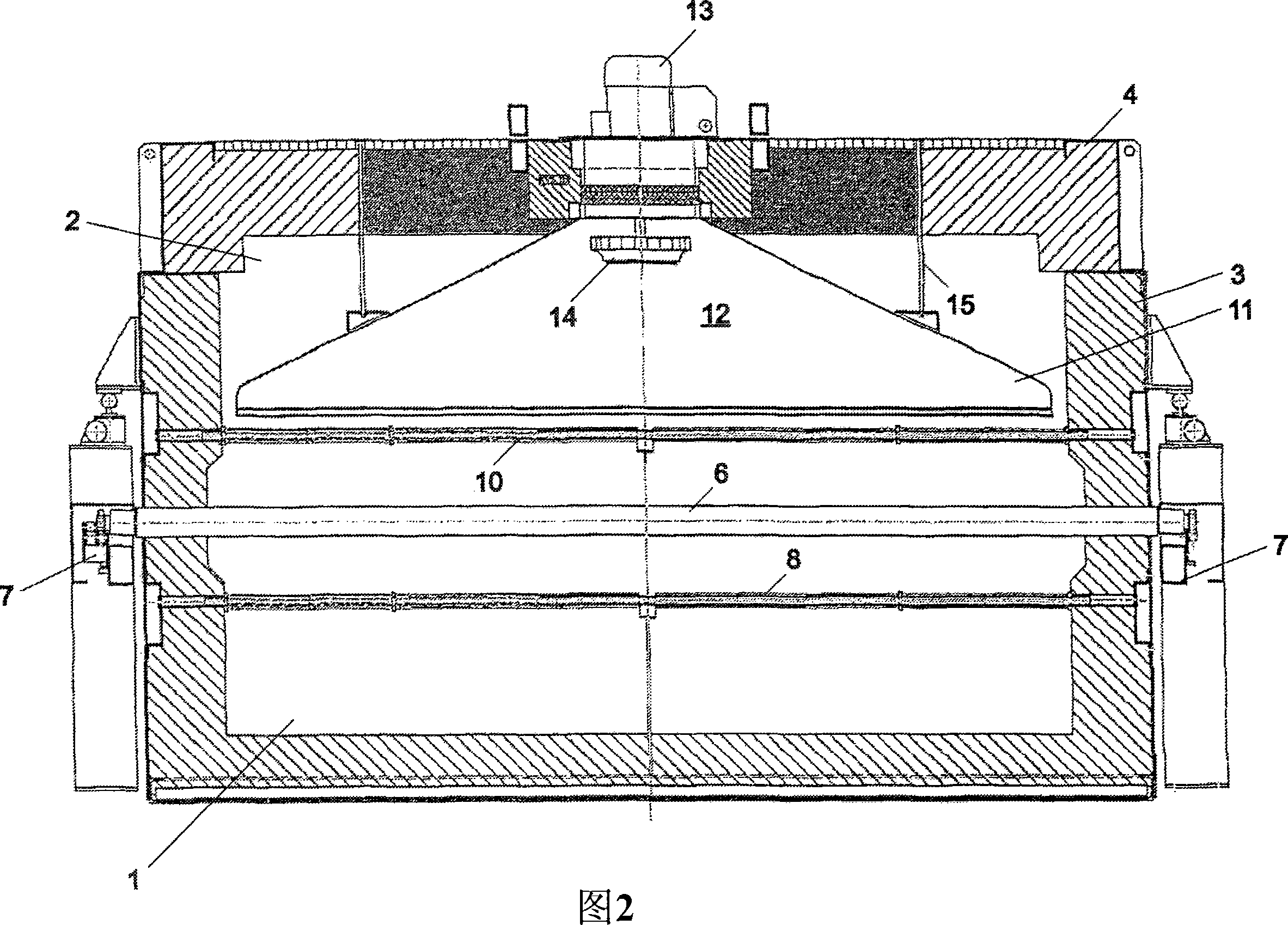

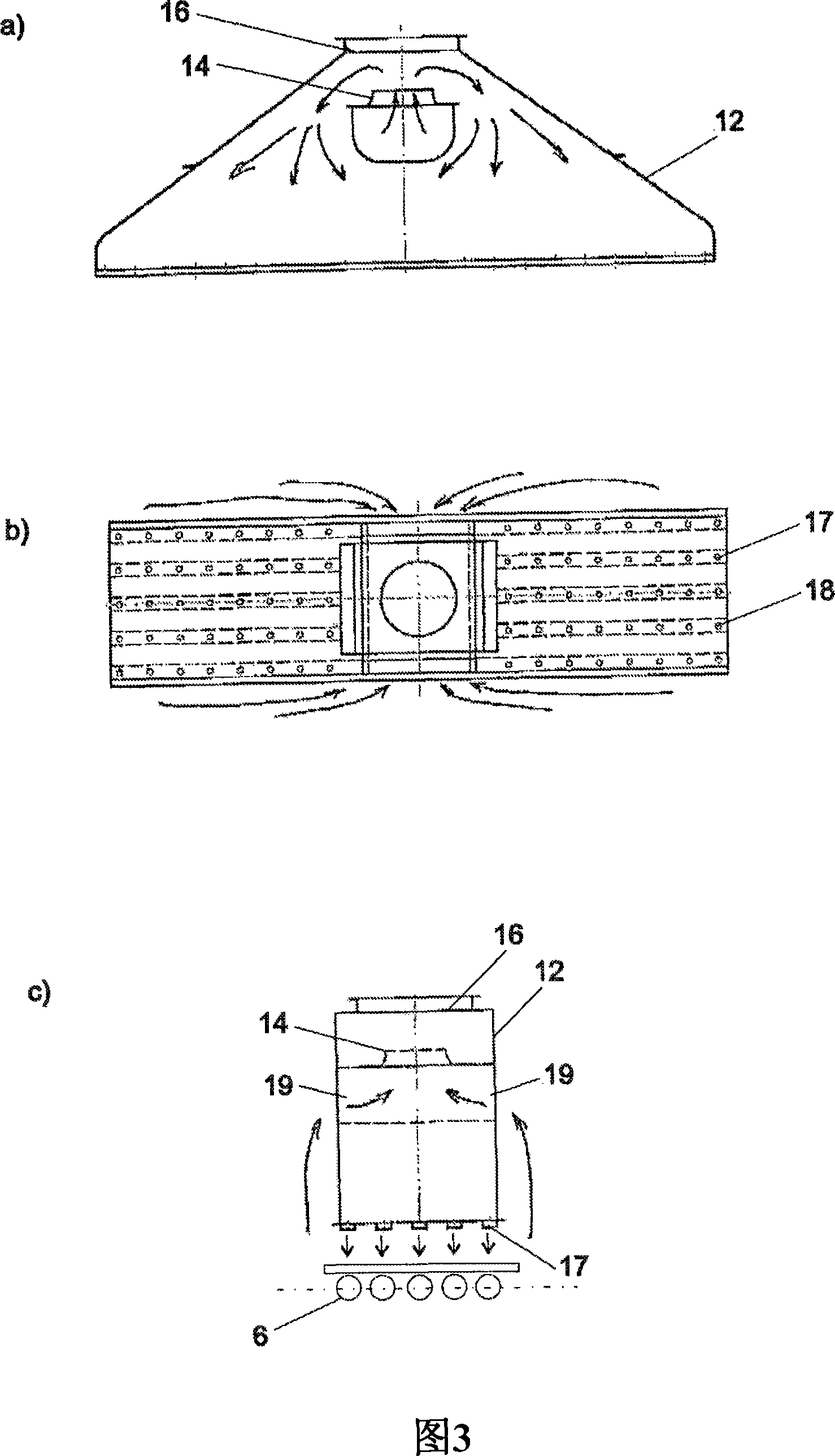

Sheet glass stove

The invention relates to a sheet glass stove, in particular for tempering glass panes comprising a lower stove part (1) provided with stove rollers (6) for transporting the temperable glass panes, wherein the axes of rotation of said stove rollers (6) are arranged substantially in a perpendicular position to the direction of a glass pane extension. The stove also comprises a top stove part (2) consisting of a central section (3) and a lid (4). Said stove also provided with lower heating groups (8) and top heating groups (10), wherein said heating groups (8) are extended under the stove rollers (6) and the top heating groups (10) are extended thereabove and are formed by electric heat resistances. The inventive sheet glass stove comprises several air circulation units (11), which are mounted in the top stove part (2) above the top heating groups (10) and comprise an air circulating hood (12) and an integrated fan wheel (14), respectively, wherein said air circulating hood (12) is provided with exhaust openings (19), which communicate with the stove lower space in the top section of the top stove part (2), and several air nozzles (17) located on the bottom side of the air circulating hood (12) are supplied with compressed air by the fan wheel (14) and lead a coming out air stream in the direction of a heatable glass pane.

Owner:埃里奥克-凯尔维特姆工业制炉有限责任公司

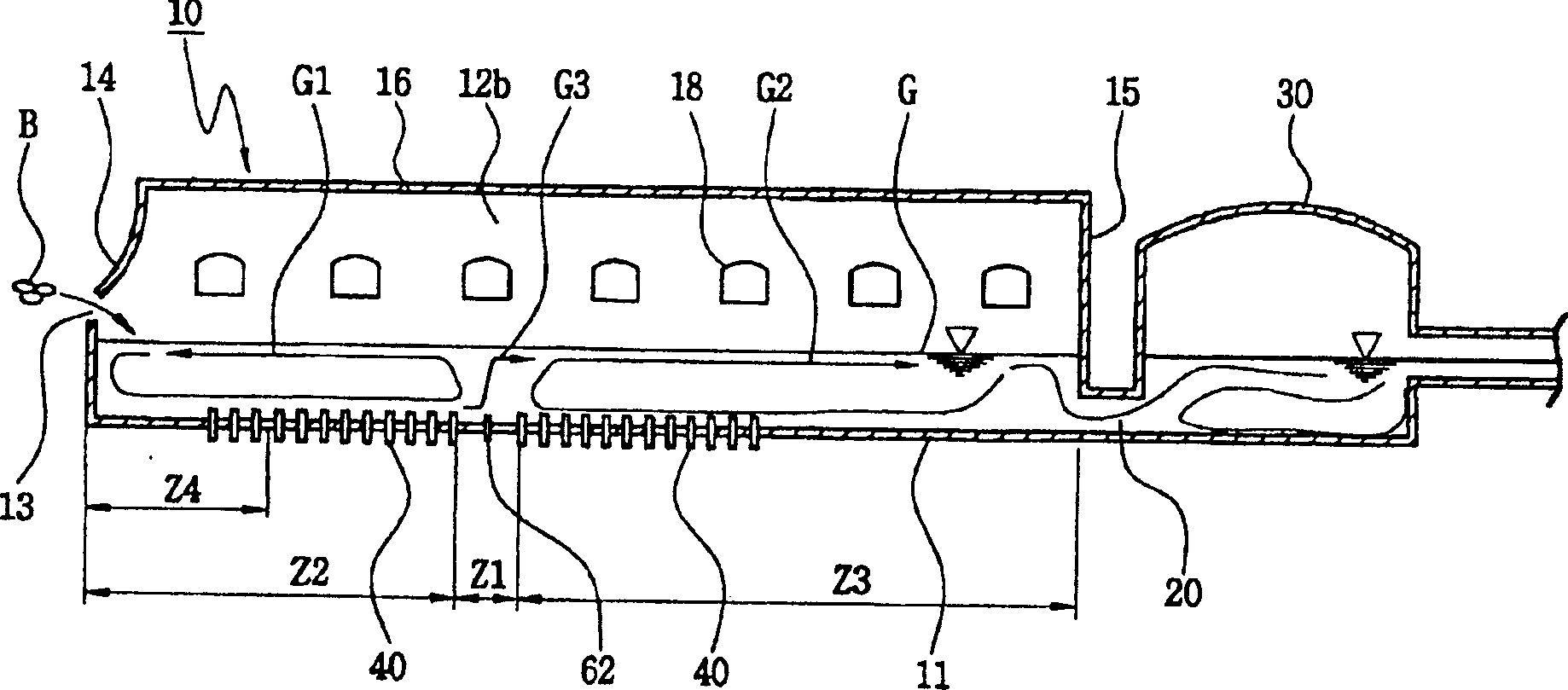

Glass melting method and molten glass layer bubbling glass melting furnace

InactiveUS20140318187A1Stable physical propertiesIncreased phase boundary areaCharging furnaceGlass furnace apparatusMelting tankGlass vessel

This invention relates to the continuous production of molten glass for further production of glassware and can be used for glass melting and obtaining glass semiproduct. The technical objective of this invention is to provide a method and a furnace for producing molten glass with stabilized physical properties due to an increased phase boundary area, higher temperature in the glass furnace bath and intensified mixing as well as due to a higher output of the glass furnace. Molten glass layer bubbling glass melting method comprising melting the glass layer in the first chamber of the furnace to the working level, further uninterrupted loading of large and small charge portions into the molten glass layer with simultaneous intense bubbling of the molten glass layer with high-temperature combustion products aiming at the formation of the maximum possible charge / molten glass phase boundary area and achieving a molten glass temperature of at least 1500° C., which conditions intensify the melting, silicate formation, vitrification and homogenizing processes, delivery of the chemically and thermally homogeneous molten glass produced by bubbling to the degassing and cooling section located under the bubbled molten glass layer, with an intense release from the molten glass layer of process gases that pass through the bubbled layer to the space above the layer where the process gases undergo primary cleaning and cooling, and the degassed molten glass is delivered to the further output section.

Owner:FEDERALNOE GOSUDARSTVENNOE AVTONOMNOE OBRAZOVATELNOE UCHREZHDENIE VYSSHEGO PROFESSIONALNOGO OBRAZOVANIJA NATSIONALNYJ ISSLEDOVATELSKIJ TEKHNOLOGICHESKIJ UNIVT MISIS

Sintered and doped product based on zircon + nb2o5 or ta2o5

Sintered product produced from a starting charge containing 75 to 99% zircon, and having the following average chemical composition by weight, the percentages by weight being based on the oxides: 60% < ZrO2 + HfO2 < 75%; 27%.< SiO2 < 34%; O < TiO2; O < Y2O3 < 3.5%; 0.1 % < Nb2O5 + Ta205 <= 5%; and other oxides: < 1,5 %; for a total of 100%. Use in a glass furnace.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

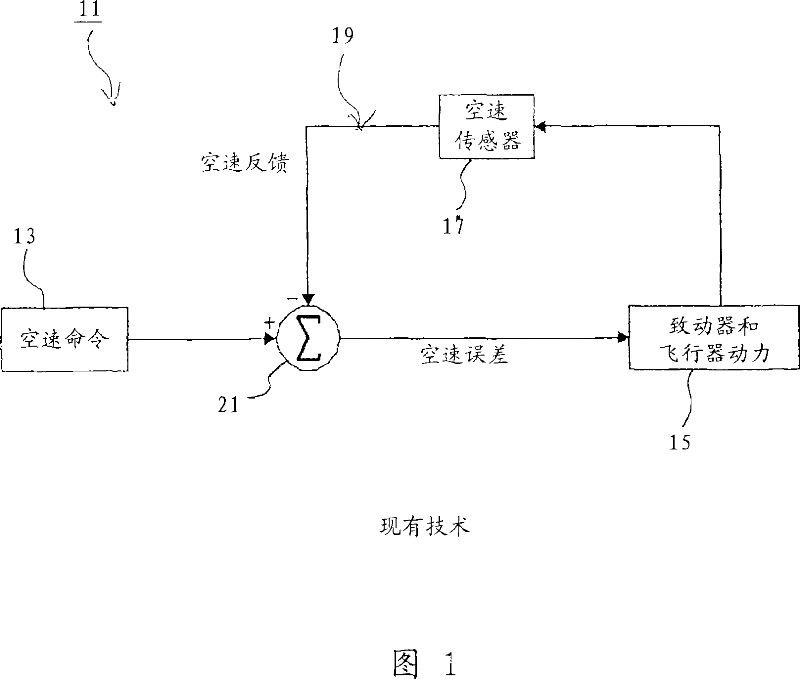

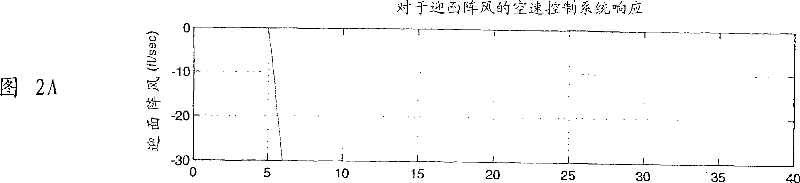

Automatic velocity control system for aircraft

ActiveCN101044055AReduced Power VariationsLittle changeAircraft power plantsAircraft controlGlass furnaceSpeed control system

The invention relates to a molten and cast refractory AZS-type product whose chemical content consists of 15.5 to 22 % by weight ZrO2,10.5 to 15 % by weight SiO2, 1.0 to 2.5 % by weight Na2O+K2O+Li2O and <1 % by weight impurities. Said invention is used for glass furnaces, in particular for the superstructures and roofs thereof.

Owner:BELL HELICOPTER TEXTRON INC

SCR denitration device for flue gas of glass furnace

InactiveCN102000504AReduce consumptionThe reaction temperature range is wide and lowDispersed particle separationSilicon-controlled rectifierGlass furnace

The invention discloses a silicon controlled rectifier (SCR) denitration device for flue gas of a glass furnace, which comprises a flue gas flow controller, an ammonia / flue gas mixed flue, a liquid ammonia bottle, a pressure reducing valve, an ammonia preheater, a flow meter, an ammonia injection controller, an electric heater and a reactor bed. One end of the ammonia / flue gas mixed flue is connected with a flue pipe of the glass furnace; the flue gas flow controller is arranged on the flue; the flue gas flow controller is connected with the ammonia injection controller through a data line and controls the flow meter which is connected to the ammonia injection controller; one end of the flow meter is connected with the ammonia / flue gas mixed flue pipe and the other end of the flow meter is connected with the ammonia preheater, the pressure reducing valve and the liquid ammonia bottle; the ammonia / flue gas mixed flue is connected with the electric heater through the flue; and the reactor bed is arranged inside the electric heater and is connected with a chimney pipe through the flue. The SCR denitration device has the advantages that: the device has higher removal efficiency and lower reaction temperature, needs less energy required by gas heating, saves the production cost, improves the exhaust temperature, and reduces the acid corrosion of the flue.

Owner:UNIV OF SCI & TECH BEIJING

Glass ceramic and preparation method thereof

The invention relates to a glass ceramic and a preparation method thereof, comprising the following raw materials by weight parts: 75-100 weight parts of quartz sands, 10-30 weight parts of lithium feldspar, 30-60 weight parts of feldspar, 25-45 weight parts of sodium carbonate, 2-8 weight parts of sodium nitrate, 2-6 weight parts of barium carbonate, 5-15 weight parts of fluorite powders, 5-10 weight parts of borax, 10-30 weight parts of sodium fluosilicate and 10-20 weight parts of calcite; the method comprises the following steps of: mixing the raw materials and sending the mixture in a glass furnace; melting the mixture as glass melt at the temperature of 1400-1600 DEG C; sending the glass melt into a material supply machine by a material supply passage; sending the glass melt into a forming machine for forming by the material supply machine; sending the formed product into an annealing furnace for annealing; subsequently inspecting the quality of the annealed product; returning the unqualified product to the raw material; and conducting the operations of applique, enamel firing and steeling to the qualified product so as to prepare the finished products. Compared with the prior art, the method has the advantages of low expansion heat-resistance performance, high hardness, being not easy to be scraped or cracked, environmental protection and the like.

Owner:JINGDEZHEN COKING IND GRP CO LTD

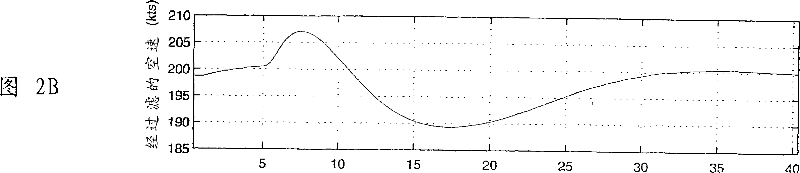

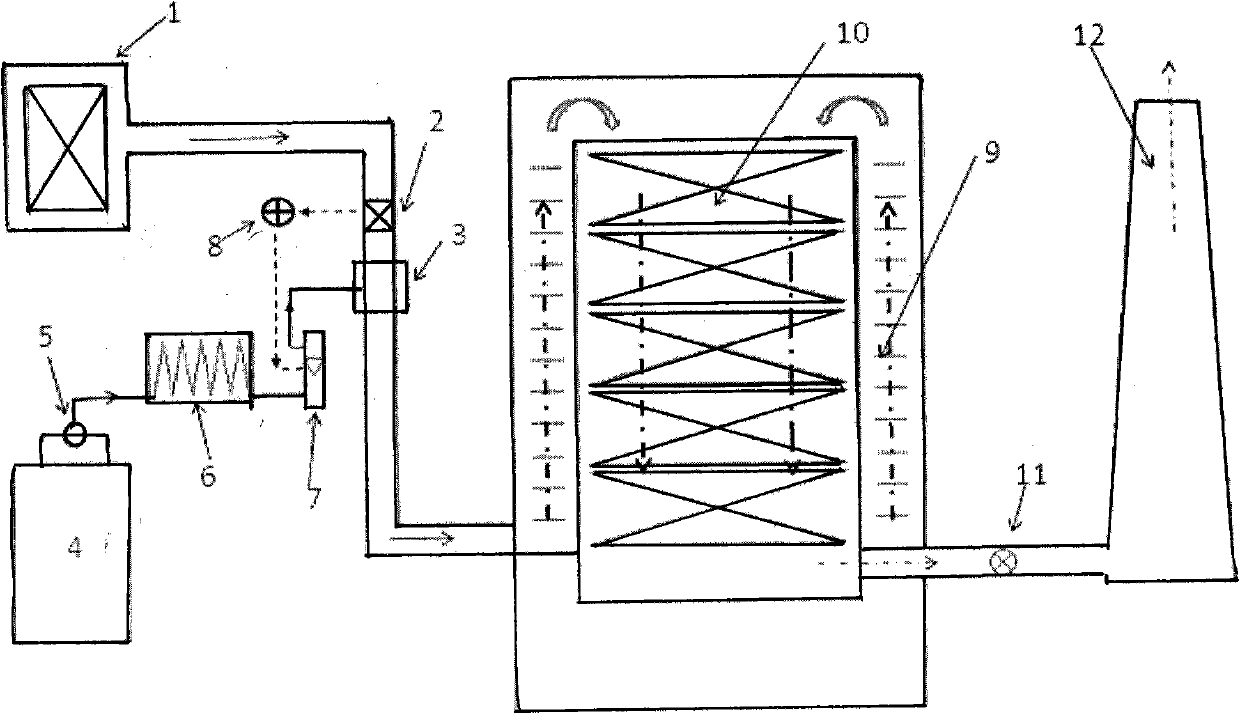

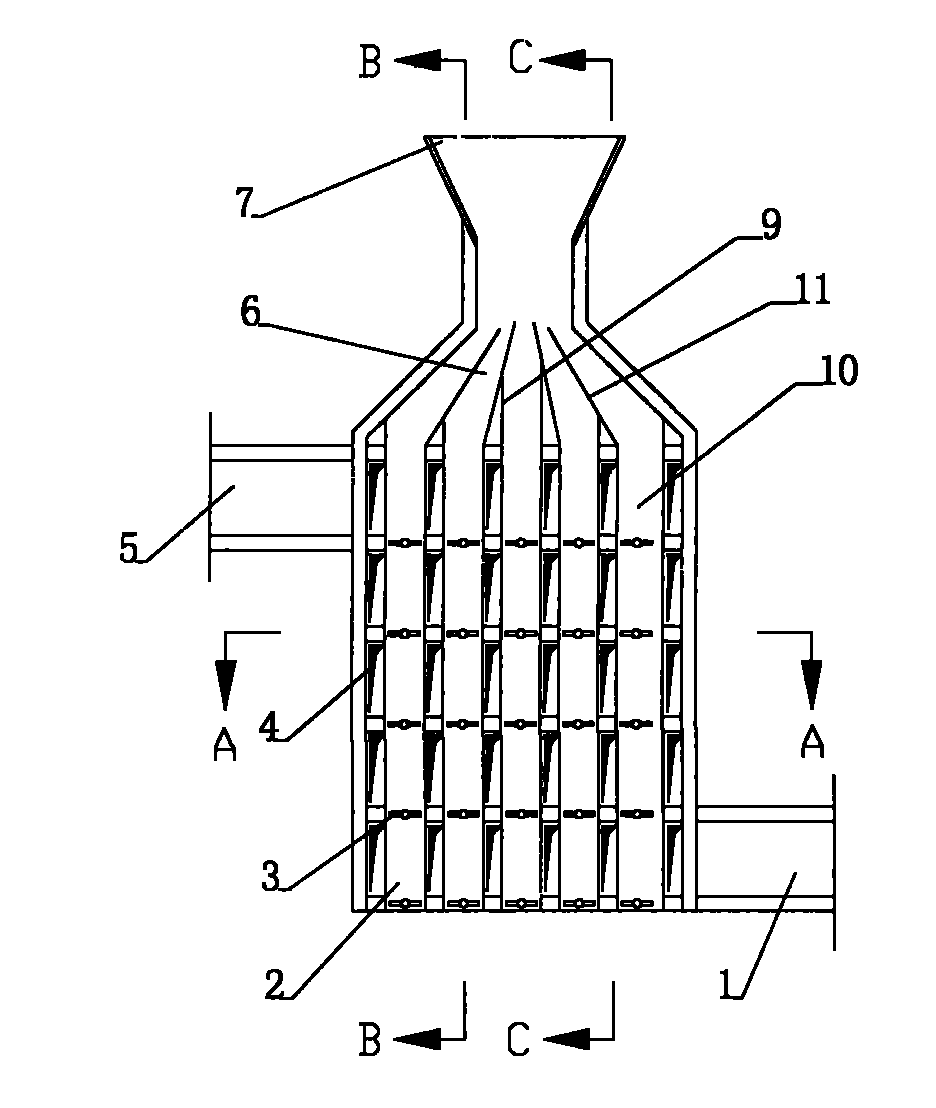

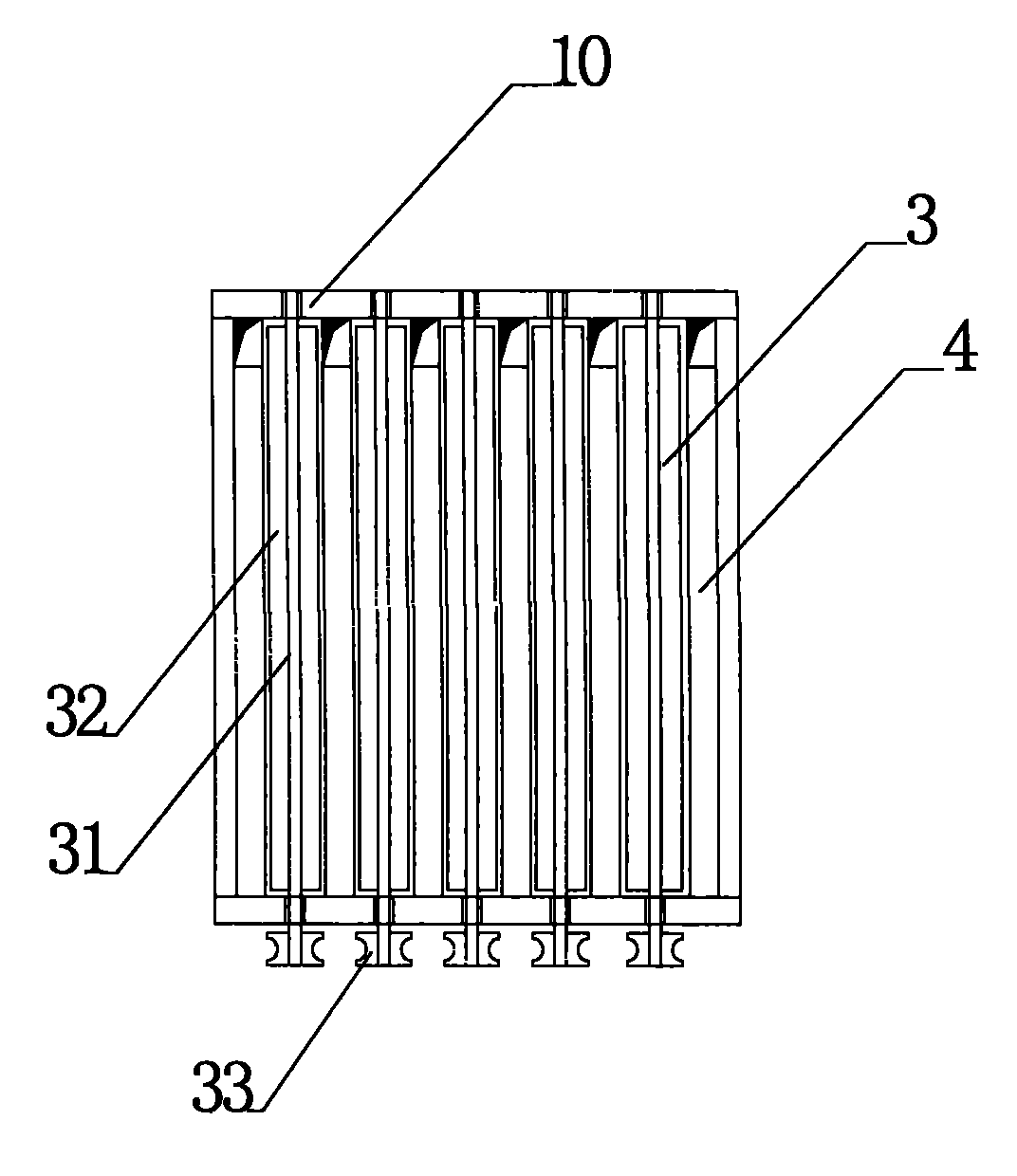

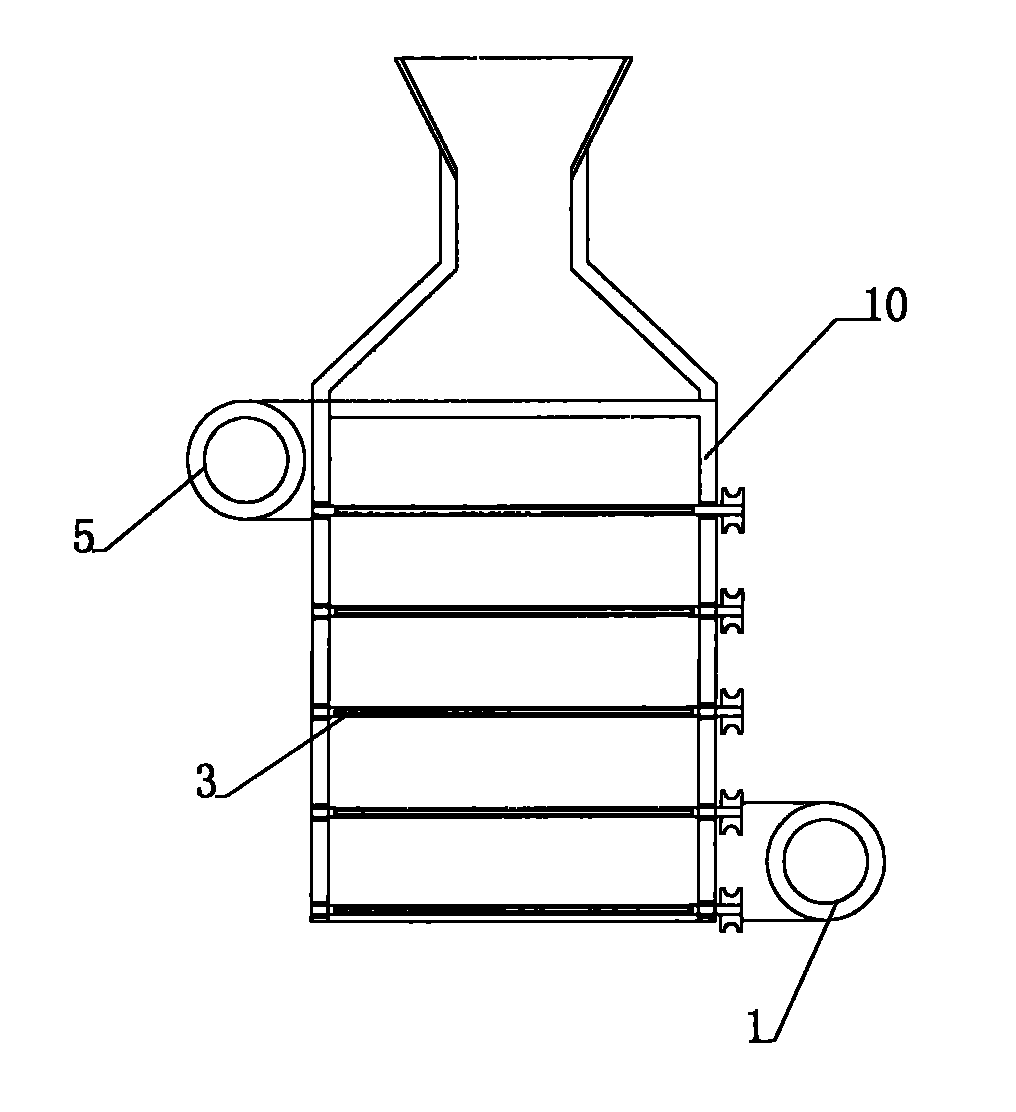

Method and device for preheating batch by using waste heat of fume from pure-oxygen combustion glass furnace

InactiveCN101830628AShorten melting timeRaise the preheat temperatureGlass productionCombustionGlass furnace

The invention relates to a method and a special device for preheating a batch by using the waste heat of fume from a pure-oxygen combustion glass furnace. The method comprises the following steps: granulating the glass batch; dehydrating and drying the grains; and preheating the grains by using a multilayer vertical turning plate preheating mode, wherein the glass batch and the hot fume are contacted indirectly, namely the fume radiates heat to the glass batch by convection, and the glass batch is preheated by a multilayer turning plate preheater to above 400 DEG C and then is delivered to the next process step. Multiple layers of turning plates and multiple flues are arranged in the preheating device, a fume inlet communicated with the flues is positioned on the outer side of the side water on the lower part of the preheater, a fume outlet communicated with the flues is positioned on the outer side of the other side wall on the upper part of the preheater, and the fume inlet and the fume outlet are arranged diagonally; the special preheating device is used to preheat the glass batch, the utilization rate of the waste heat of the high-temperature fume is high, no smoke dust pollution is produced; under self suction, the fume rises along the flues, so no power is consumed; the vertical structure occupies small floor area, so the replacement of space for time is realized; and the promotion and implementation of the device are easy.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

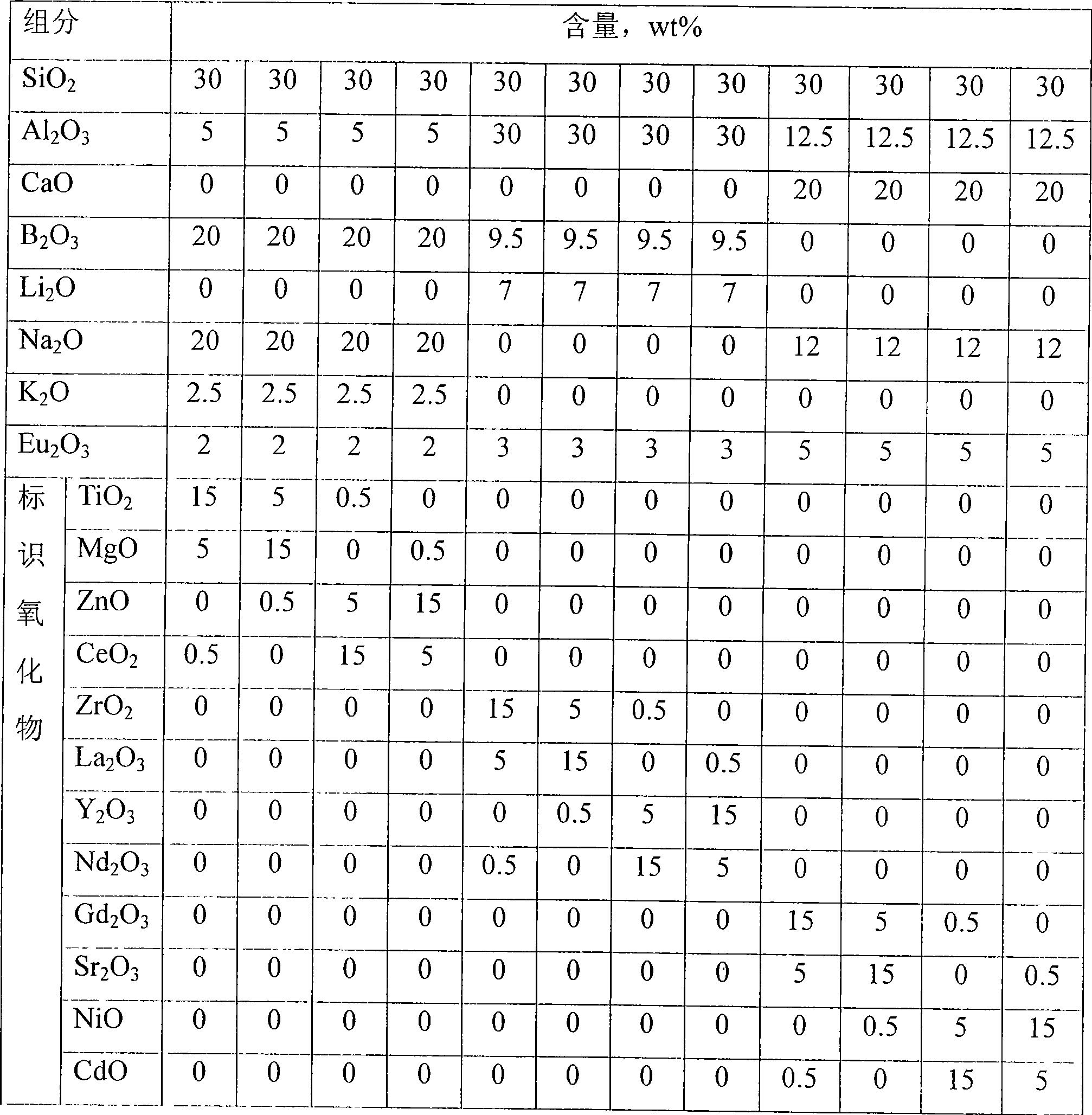

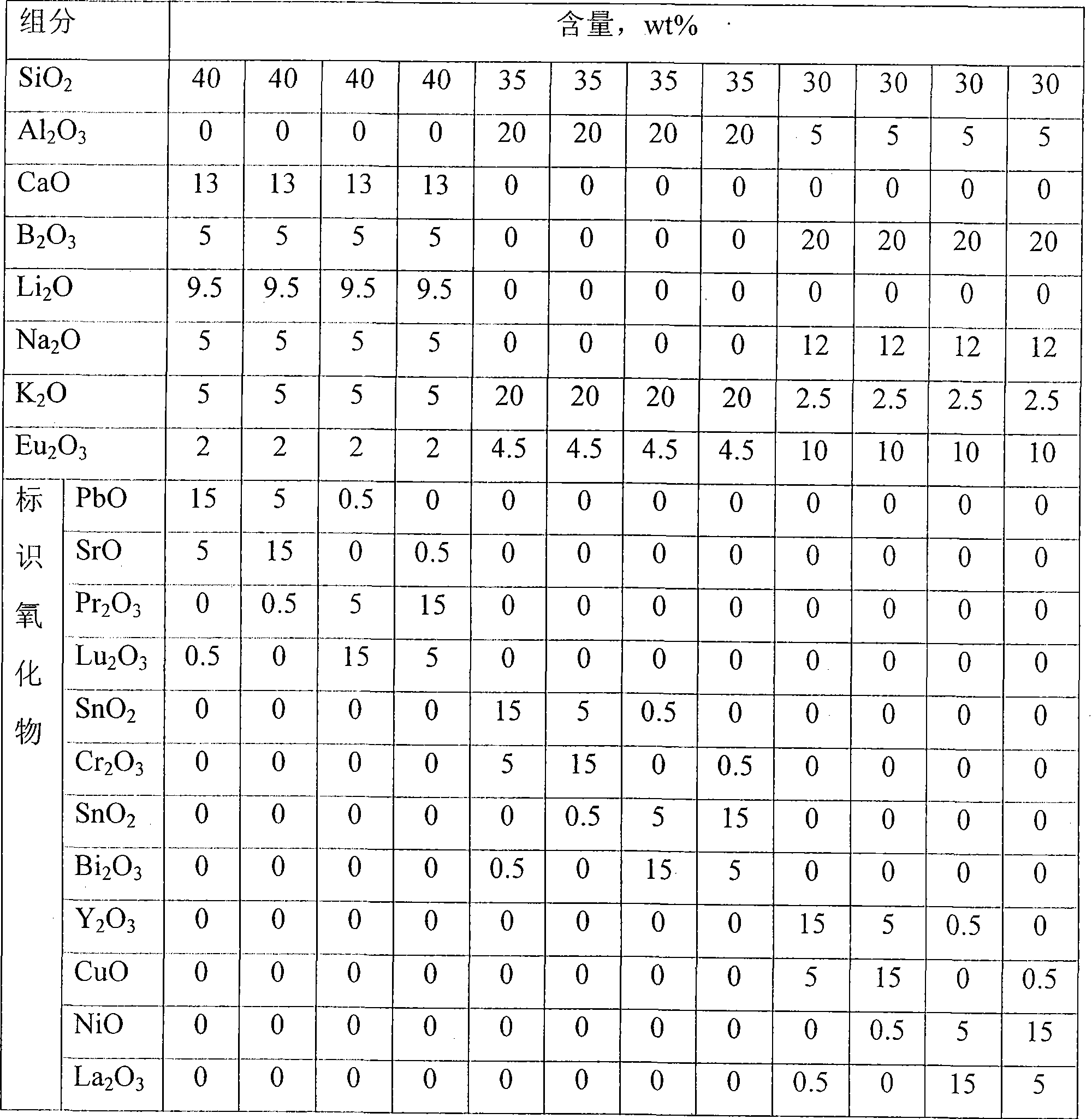

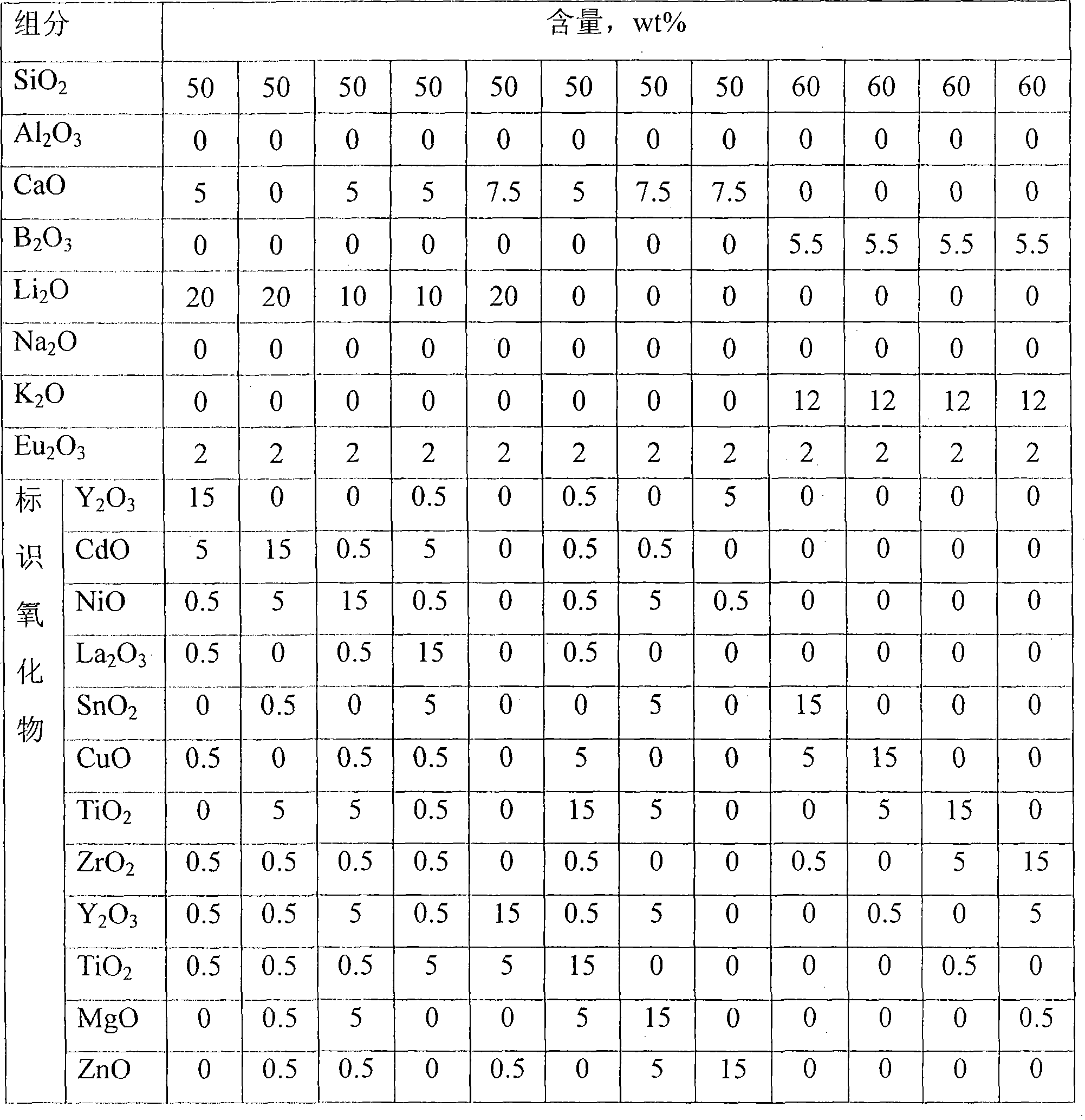

Solid glass micro-bead for explosive identification and manufacture method thereof

InactiveCN101497498AIncrease mark capacityTo achieve the purpose of marking explosivesGlass shaping apparatusNon-explosive/non-thermic compositionsGlass furnaceFluorescence

The invention relates to a solid glass microballoon for explosive marking and a method for preparing the same. The solid glass microballoon comprises basic glass oxide, marking oxide and fluorescence oxide, and is prepared by the following steps: blending and mixing the oxides; filling the mixture into a glass furnace to perform melting at a temperature of between 1,200 and 1,550 DEG C and keeping the temperature for 2 to 10 hours; pouring the mixture into cold water quickly to perform quenching; breaking the cracked glass obtained after the quenching, and screening the broken glass to obtain glass particles of which the particle diameter is between 10 and 2,000 mu m; and melting the glass particles in high-temperature fire of which the temperature is higher than the melting temperature of the glass, and breaking away from the fire to obtain the glass microballoon. By adding the oxides with different types and contents into the glass as a marking characteristic, the marking capacity of explosives is improved, and through extracting markers in the explosives before explosion or on site after the explosion, the correlative information on explosive production, circulation, and the like can be found out so as to achieve the aim of marking the explosives.

Owner:朱冬梅 +3

Crystal liquid substrate glass material and preparation method thereof

ActiveCN101544467AImprove melting abilityGood clarificationStatic indicating devicesGlass furnaceCarbonate

The invention discloses a crystal liquid substrate glass material and a preparation method thereof. 50-61 percent of monox by weight percent, 8.15-11.35 percnet of boric oxide by weight percent and 10-14.5 percent of alumina by weight percent are mixed uniformly, melted at 800-over 1000 DEG C, preserved for 6-10 hours at the temperature and cooled; the cooled mixture is pulverized and screened to obtain premix; the premix of monox, boric oxide and alumina is mixed with other components according to the following weight percentage: 1-4.5 percent of strontium caronate, 2.8-8.0 percent of barium carbonate, 4-9.48 percent of calcium carbonate, 0-0.5 percent of magnesium carbonate, 0-0.5 percent of zinc oxide and 4-6.0 percent of barium nitrate; and the above materials are thrown into a glass furnace after being mixed uniformly and stirred, and the crystal liquid substrate glass is finally obtained by drawing after melting at 1500-1650 DEG C and clarification. The invention can enhance the melting capacity of glass and improve the clarification effect of glass.

Owner:IRICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com