Patents

Literature

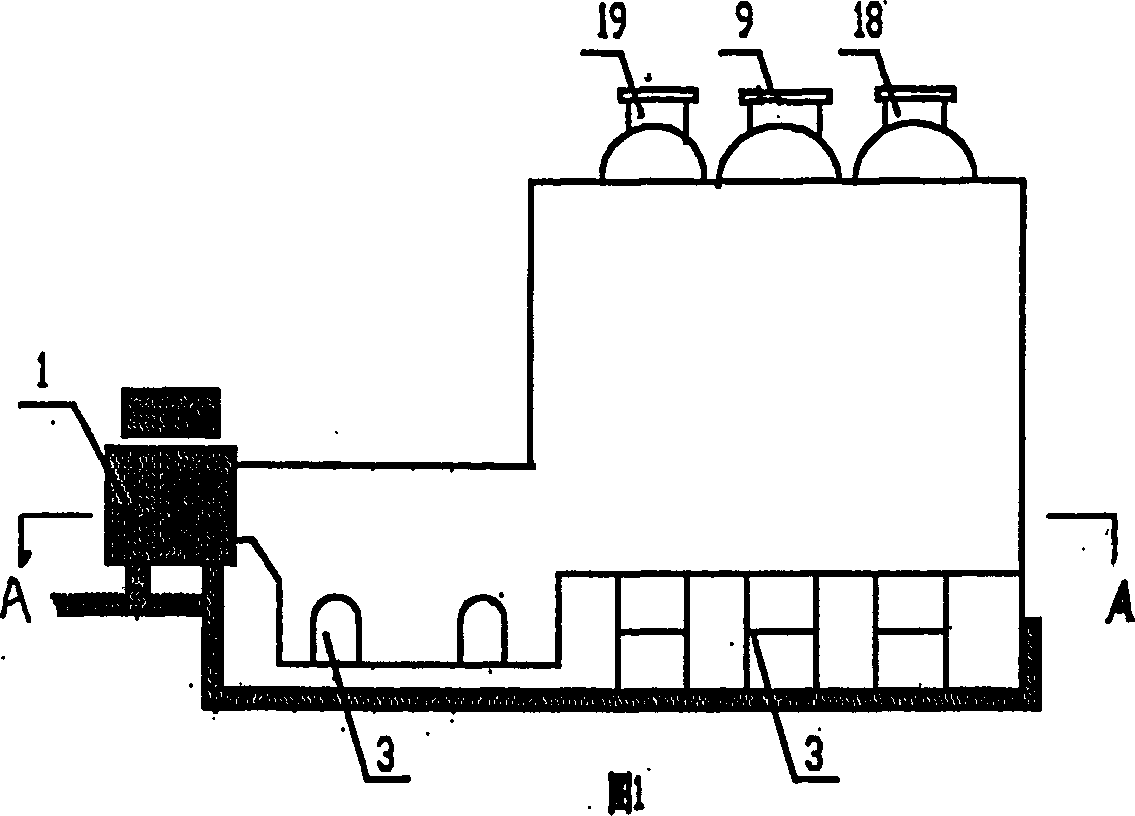

170results about How to "Raise the preheat temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

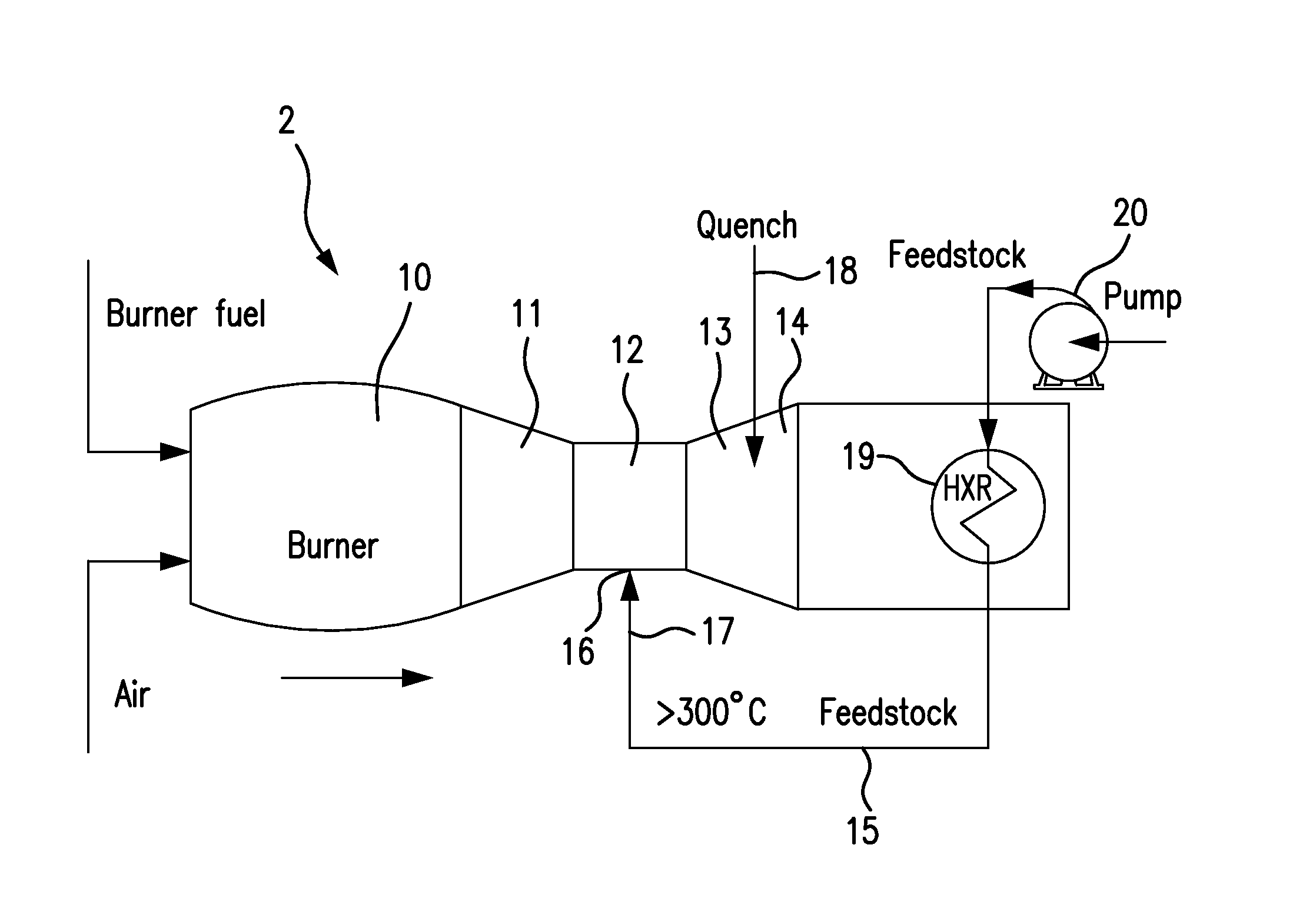

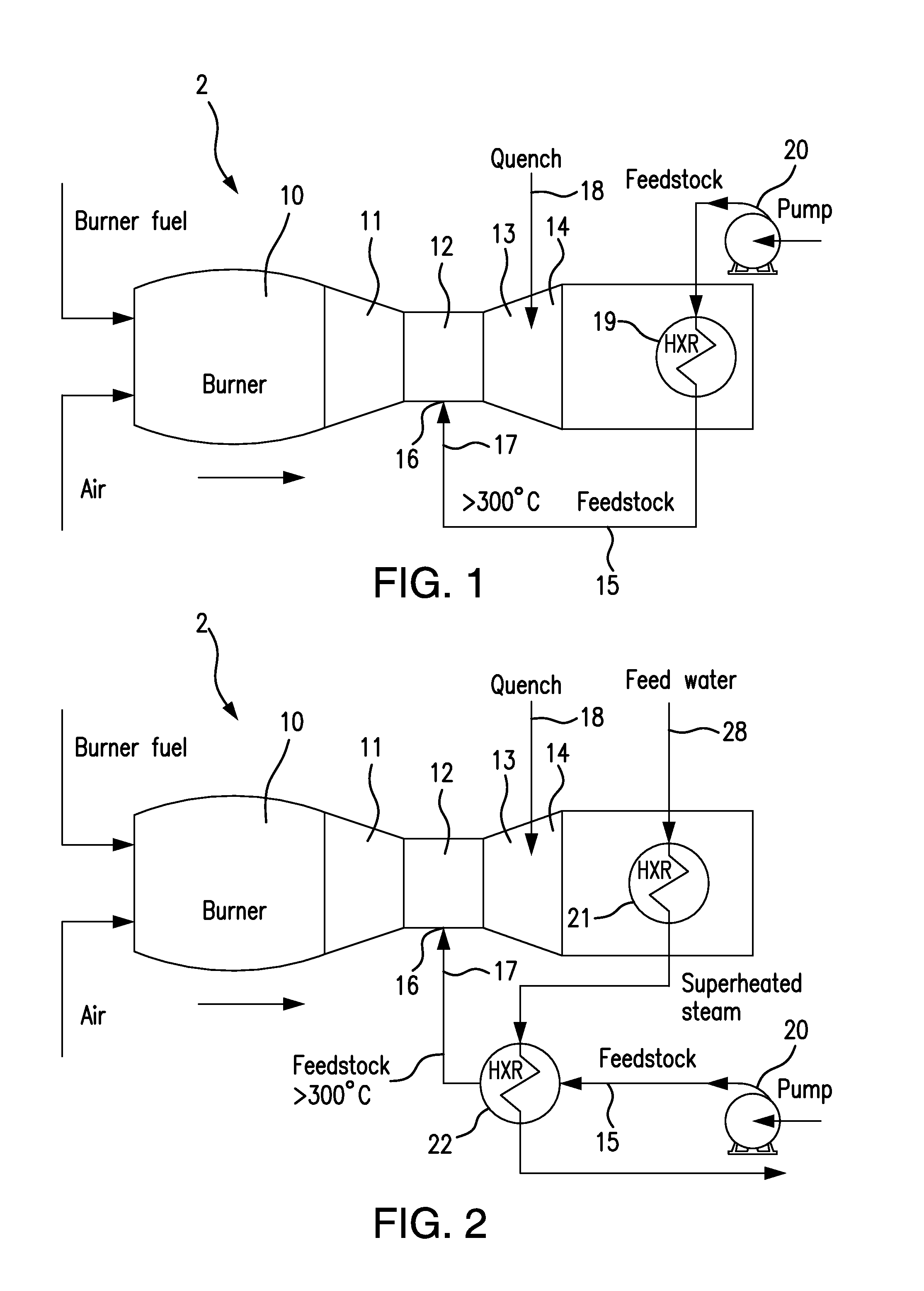

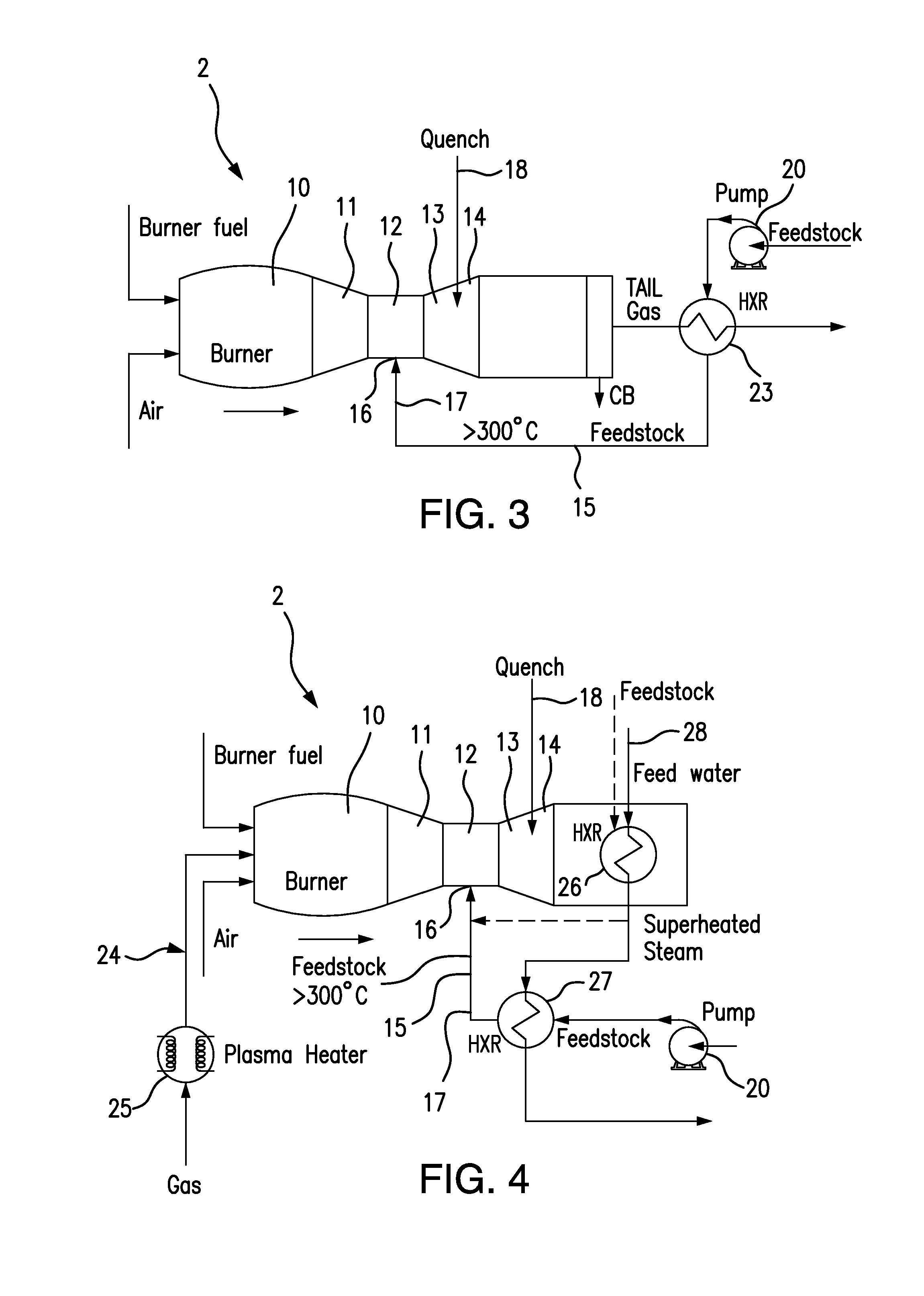

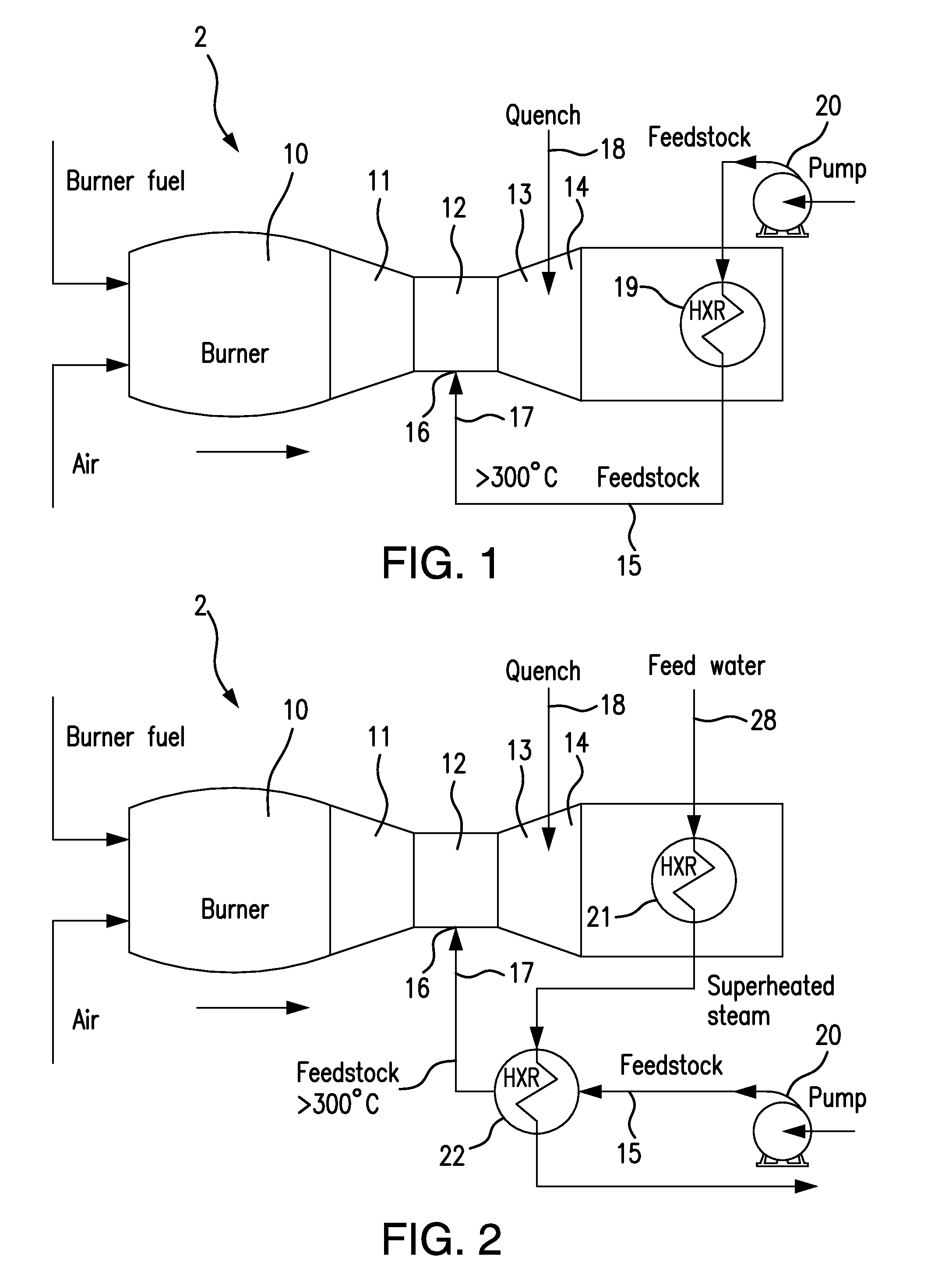

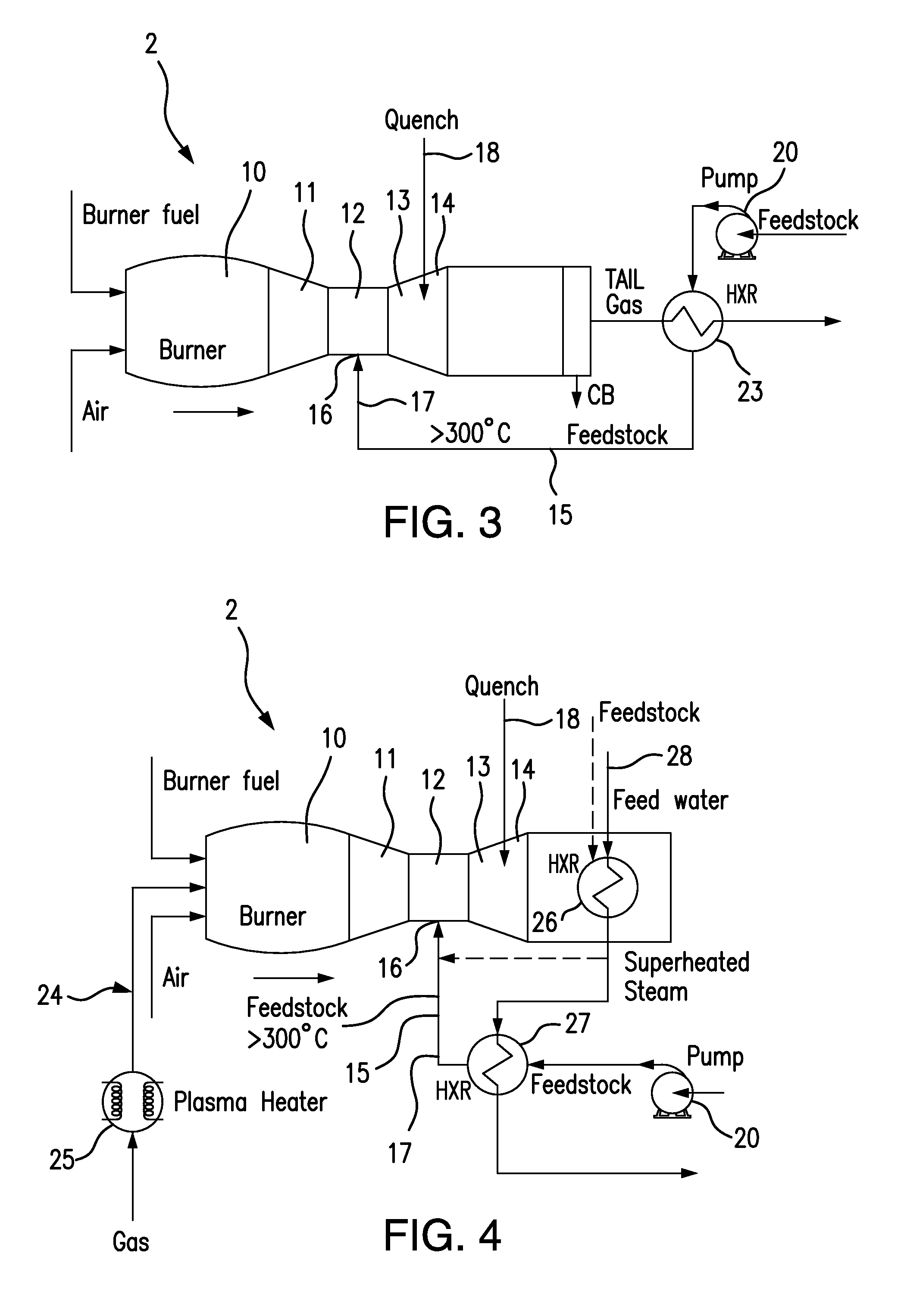

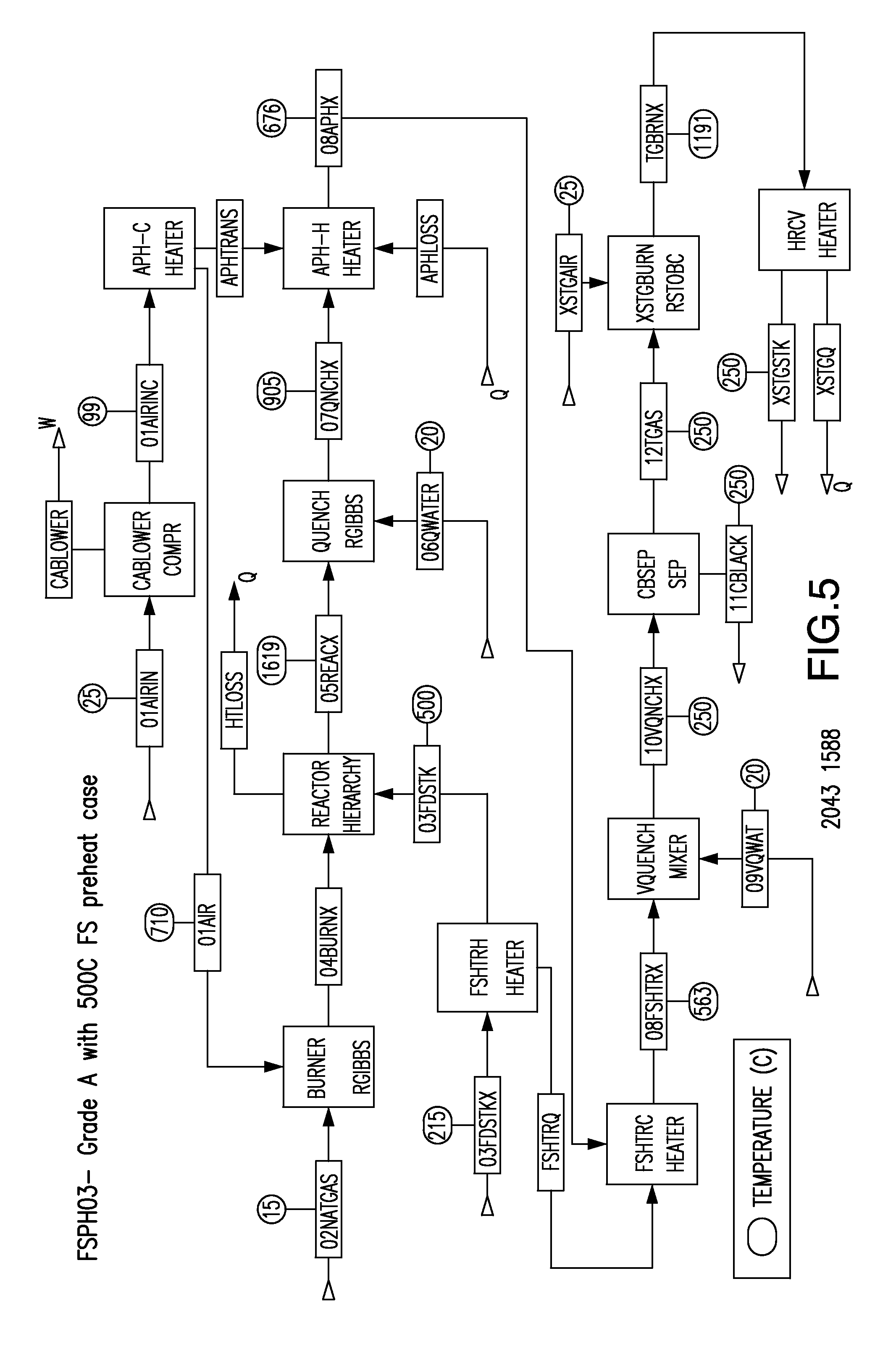

Method For Carbon Black Production Using Preheated Feedstock And Apparatus For Same

ActiveUS20150064099A1Raise the preheat temperatureReduce riskGraphiteInorganic pigment treatmentHot TemperatureMaterials science

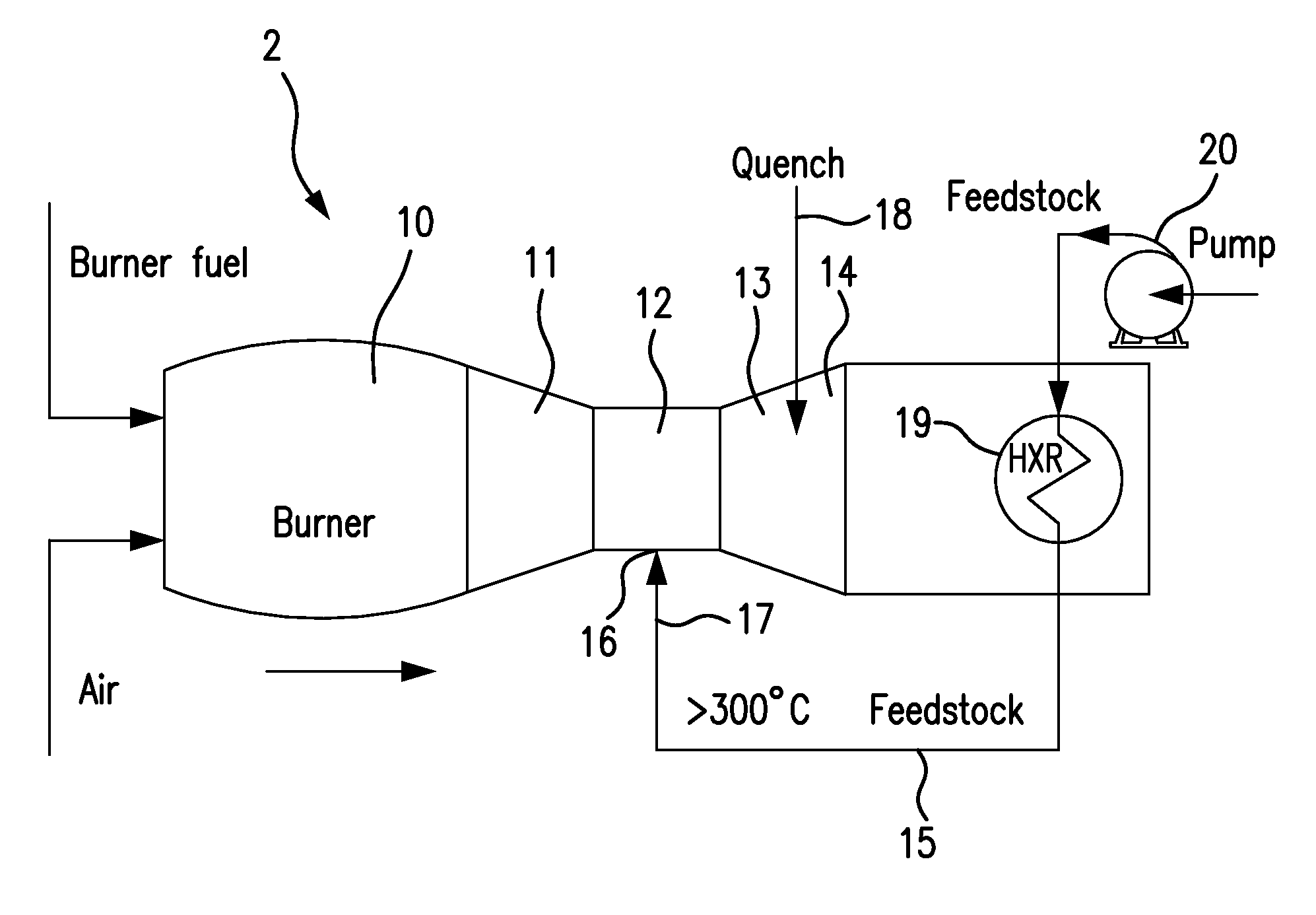

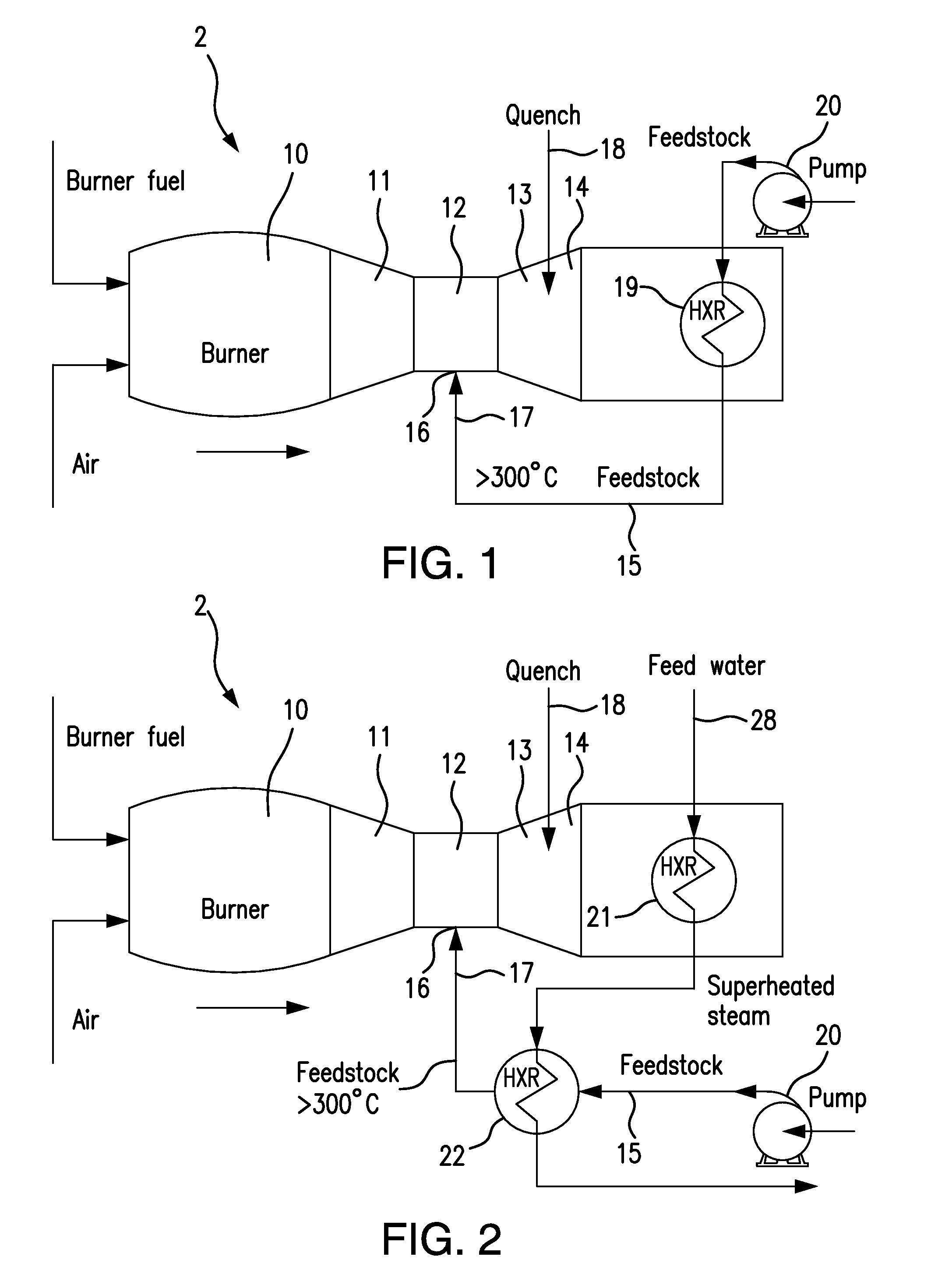

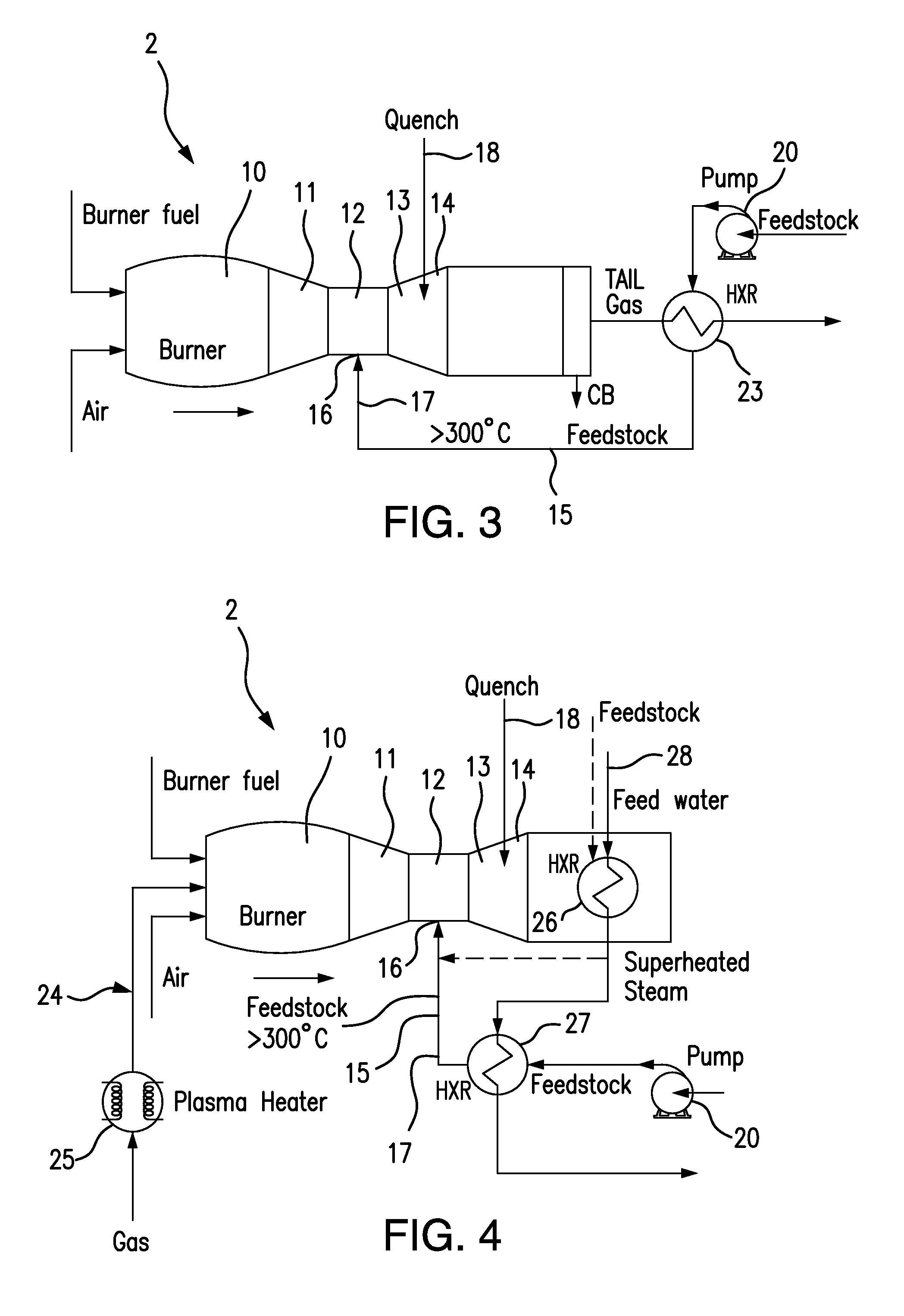

Methods for production of carbon black using high temperature feedstock at temperatures exceeding about 300° C. with fouling control are provided. An apparatus for production of carbon black according to these methods also is provided.

Owner:CABOT CORP

Method for carbon black production using preheated feedstock and apparatus for same

ActiveUS8871173B2Raise the preheat temperatureReduce riskGraphiteInorganic pigment treatmentMaterials scienceCarbon black

Methods for production of carbon black using high temperature feedstock at temperatures exceeding about 300° C. with fouling control are provided. An apparatus for production of carbon black according to these methods also is provided.

Owner:CABOT CORP

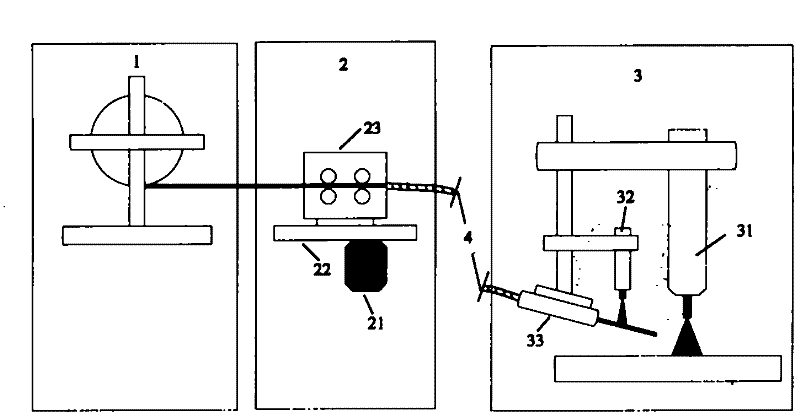

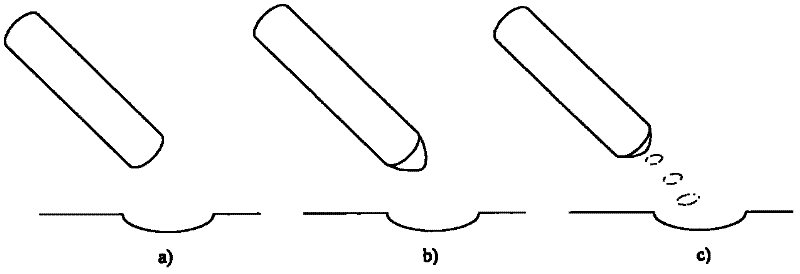

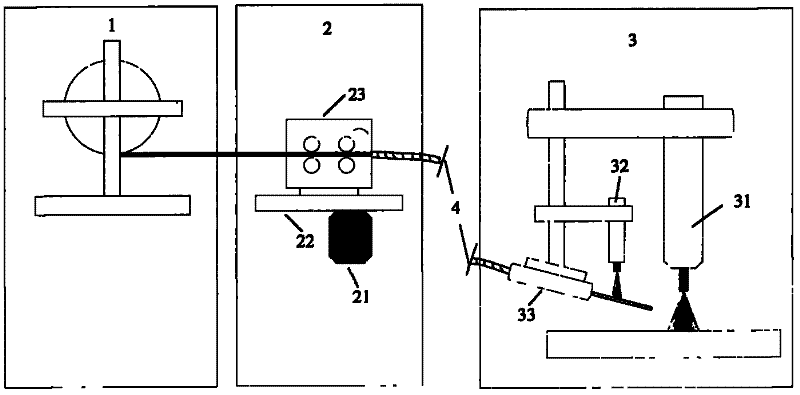

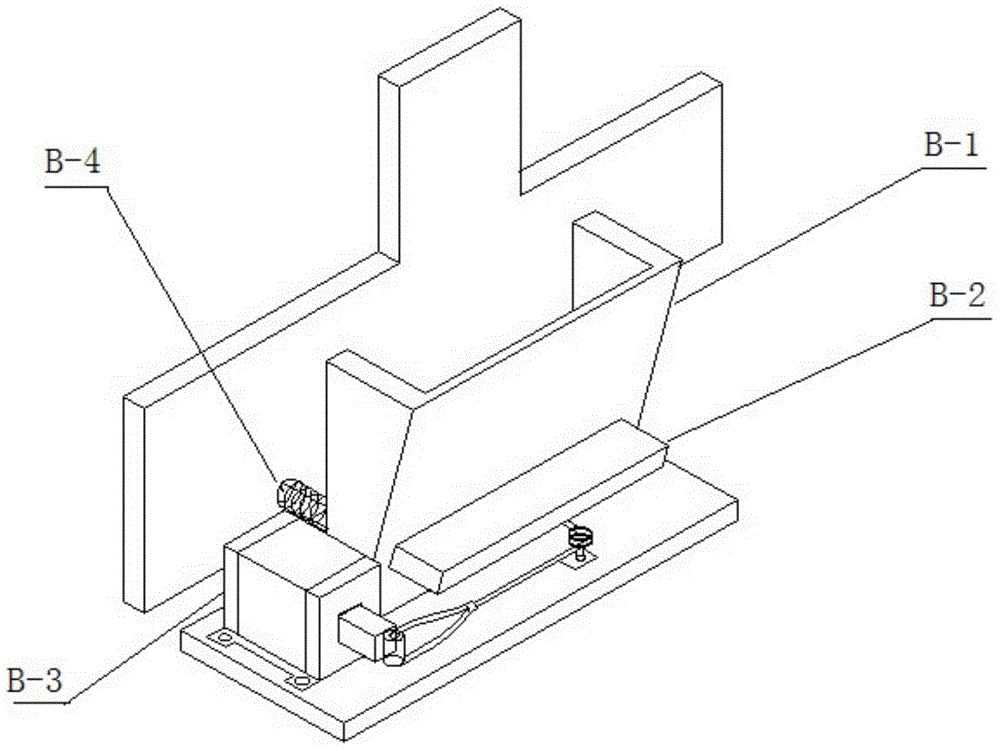

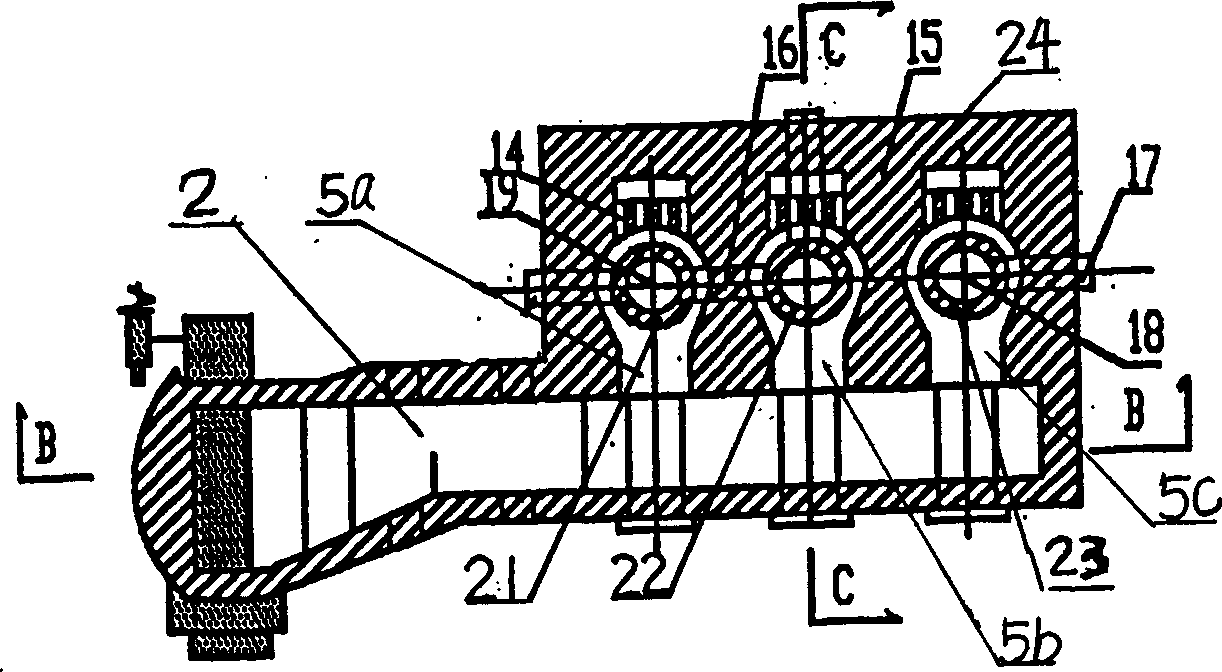

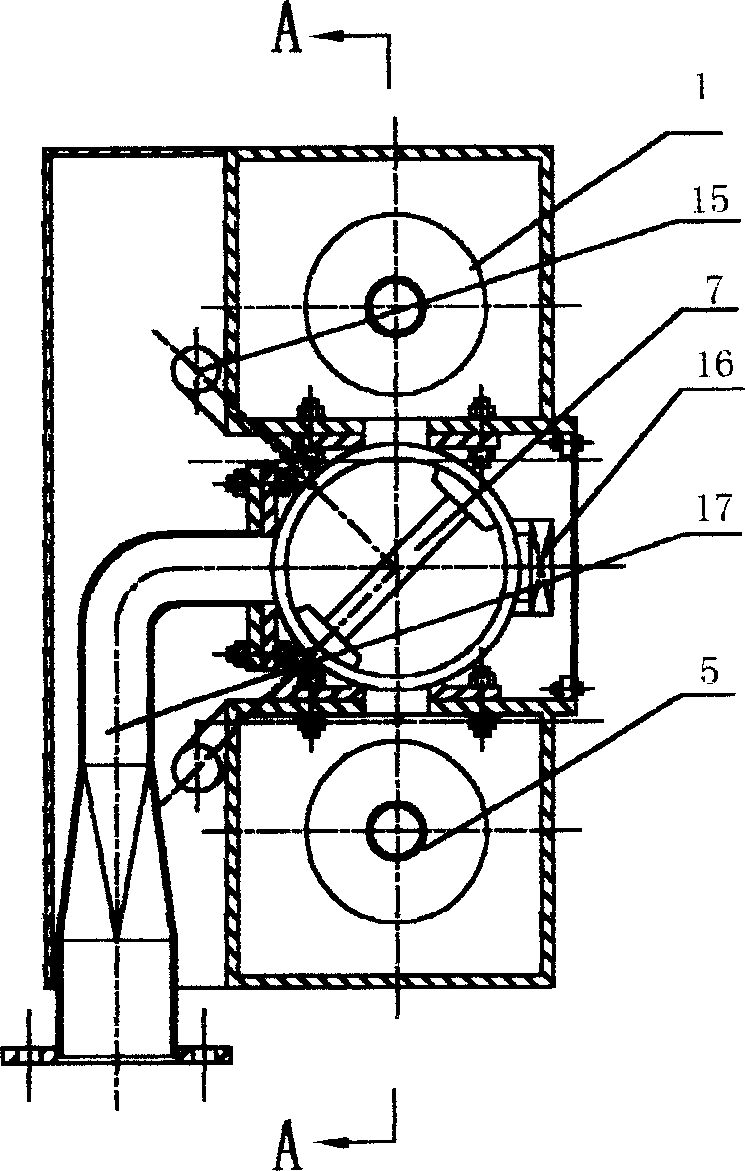

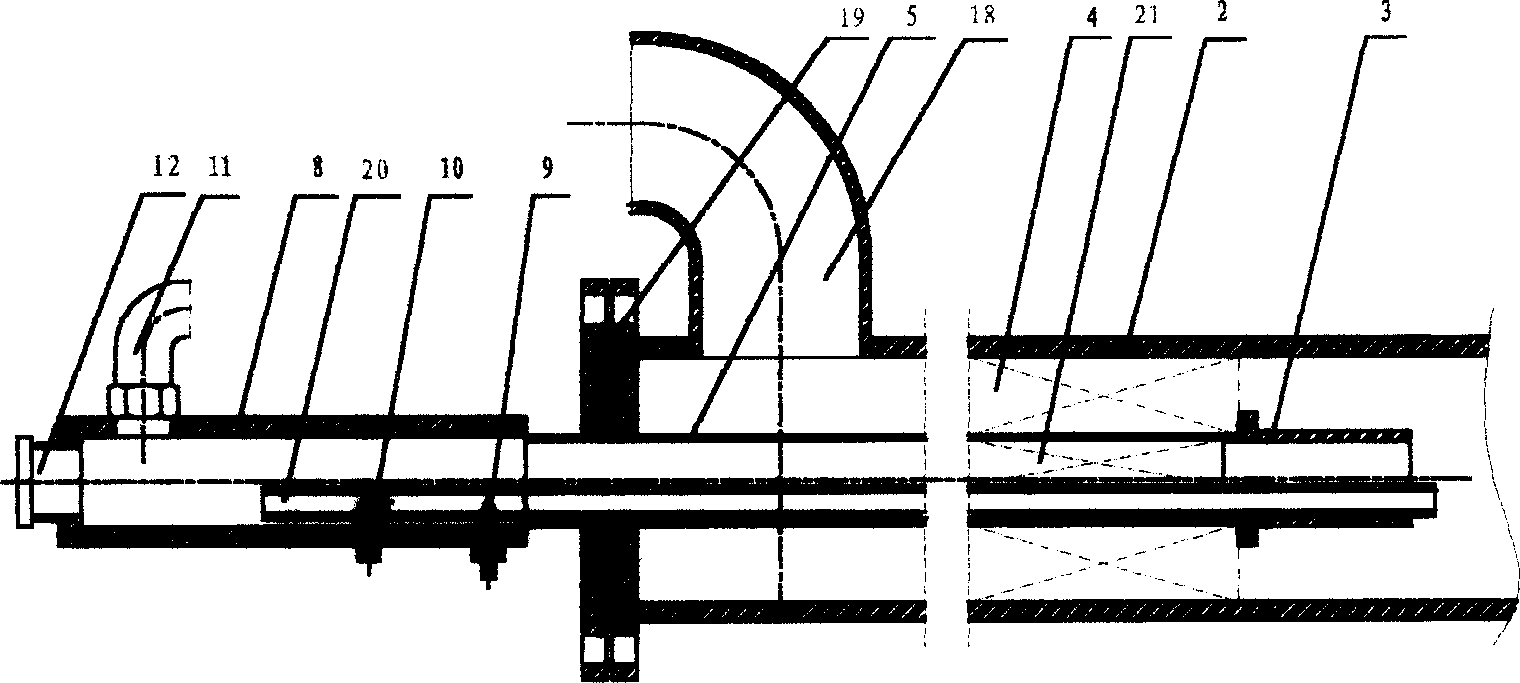

Cold metal transition welding method and device thereof

The invention aims at providing a cold metal transition welding method and a device thereof. The device consists of an MAG (Metal Active Gas) welding wire automatic feeding unit, a vibration wire feeding unit and an argon arc hot wire welding gun unit; the MAG welding wire automatic feeding unit is connected with the vibration wire feeding unit; the vibration wire feeding unit is connected with the argon arc hot wire welding gun unit through a hose; the argon arc hot wire welding gun unit comprises a straightener, an auxiliary arc welding gun and a main TIG (Tungsten Inert Gas) arc welding gun; and the auxiliary arc welding gun and the main TIG arc welding gun compose a heating source of the argon arc hot wire welding gun unit. The welding method comprises the following steps of: switching on a welding main circuit, and initiating a main TIG arc to heat a welding workpiece; and starting the MAG welding wire automatic feeding unit and a vibrating motor after the arcing of an auxiliary arc is stable. According to the cold metal transition welding method and the device thereof, the welding process is stable, the welding quality is even, the wire-feeding speed and the welding current are independently adjusted, the device is simple, and the cost is low. Based on the ordinary MAG welding wire feeding and arc wire-heating equipment, the vibration wire feeding unit is introduced, thewire heating manner is changed, thus, the cold metal transition welding is realized.

Owner:LIAONING SUPOR SHOWER EQUIP

Manufacturing method of magnesian pellets

InactiveCN102766763ALower the temperature of preheating stage IIHigh strengthBlast furnace detailsIron powderRoasting

A manufacturing method of magnesian pellets is particularly used in enterprises adopting a grate-rotary kiln process to manufacture the magnesian pellets. The manufacturing method of the magnesian pellets comprises ingredients by weight: 94-98% of iron powdered ore, 2-4% of high magnesium oxide (MgO) content fusing agent and 1.0-2.5% of bentonite, wherein proportion of the iron powdered ore with grain size smaller than 0.074mm is higher than 80%, and moisture content of the iron powdered ore is lower than 7.5%. The manufacturing method comprises the following steps of: evenly mixing the iron powdered ore and the high MgO content fusing agent, conducting high pressure roller-milling pretreatment, enabling the proportion of the iron powdered ore with grain size smaller than 0.005mm to be 11%-20%, and then mixing, pelletizing and roasting with the bentonite. The manufacturing method can reduce preheating temperature of the pellets, simultaneously, can further improve strength of the pellets to enter a rotary kiln, shortens high-temperature roasting time and solves the technical problems of high preheating temperature, low pellet preheating strength and long high-temperature roasting time when the MgO pellets are manufactured.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method For Carbon Black Production Using Preheated Feedstock And Apparatus For Same

ActiveUS20130039841A1Increase in temperatureRaise the preheat temperatureGraphiteAlkali metal halidesCarbon blackMaterials science

Methods for production of carbon black using high temperature feedstock at temperatures exceeding about 300° C. with fouling control are provided. An apparatus for production of carbon black according to these methods also is provided.

Owner:CABOT CORP

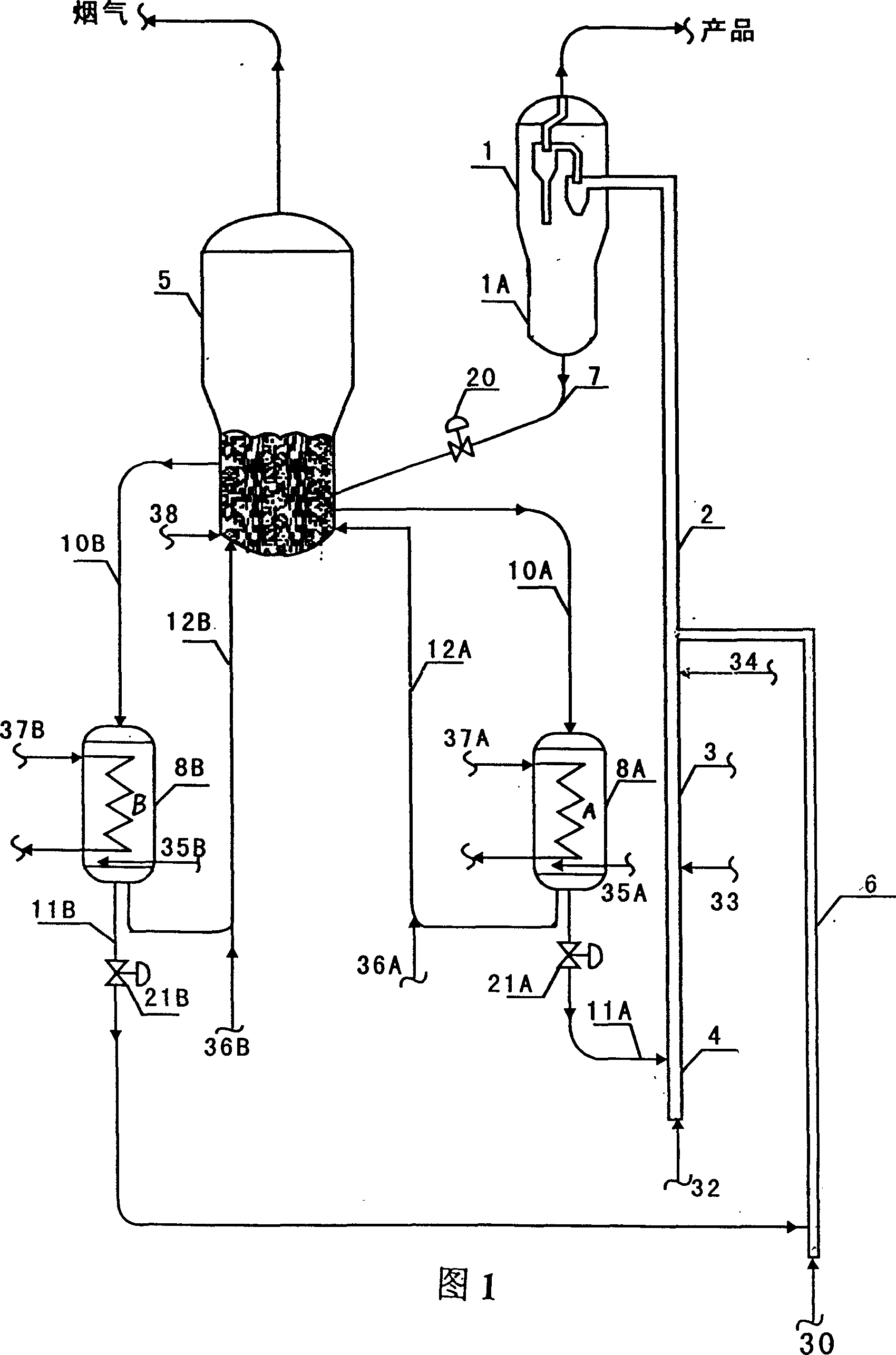

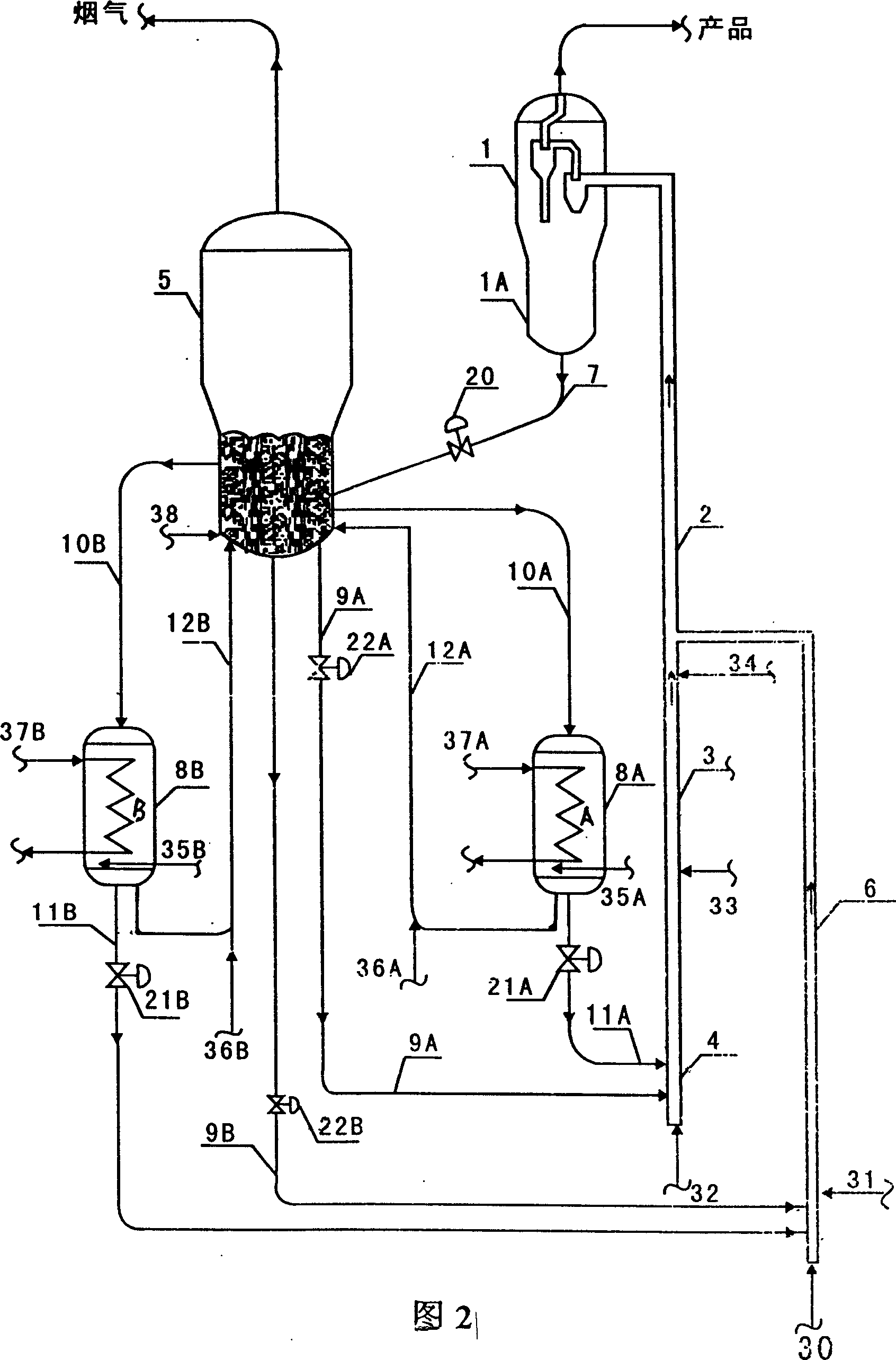

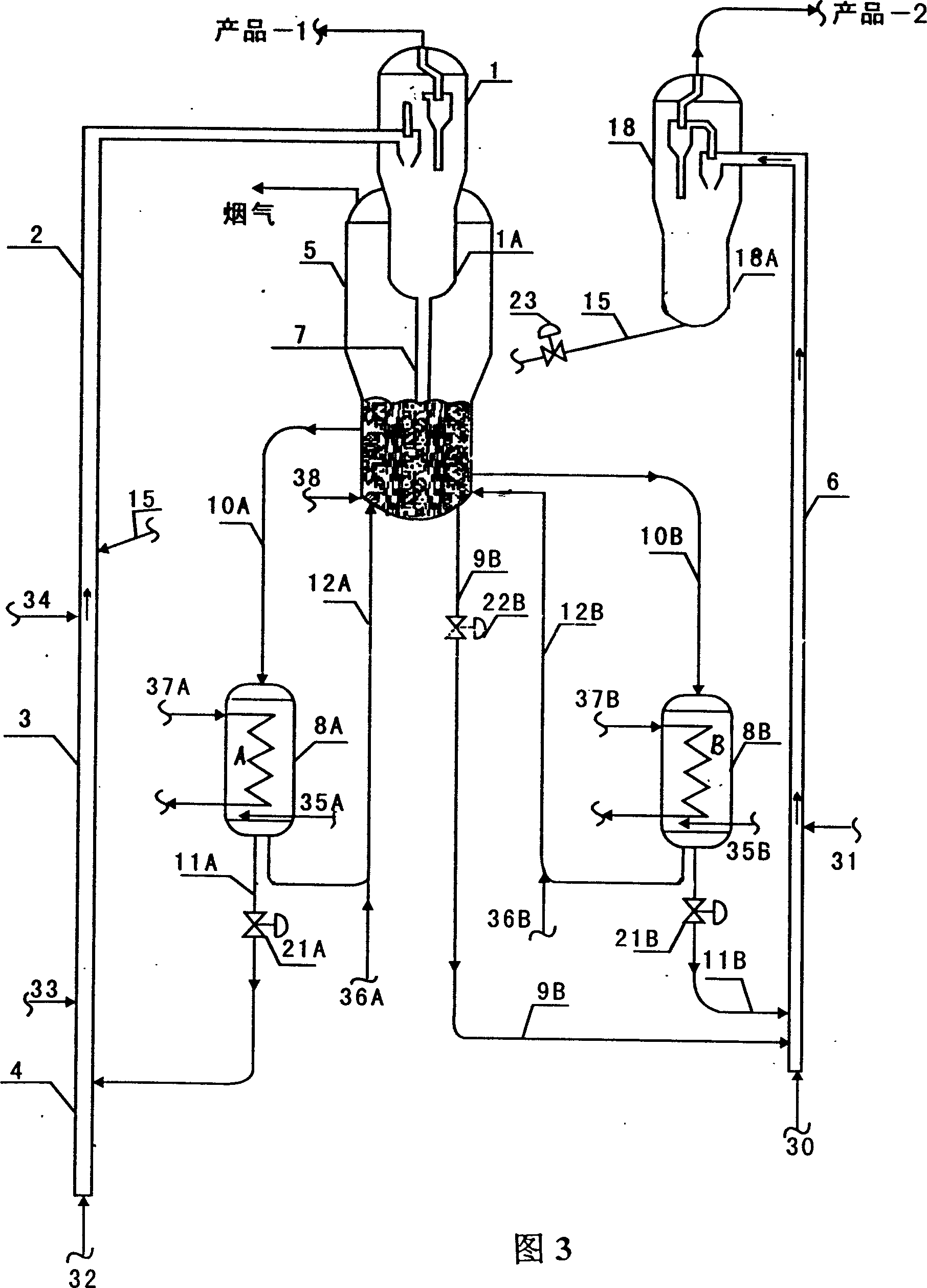

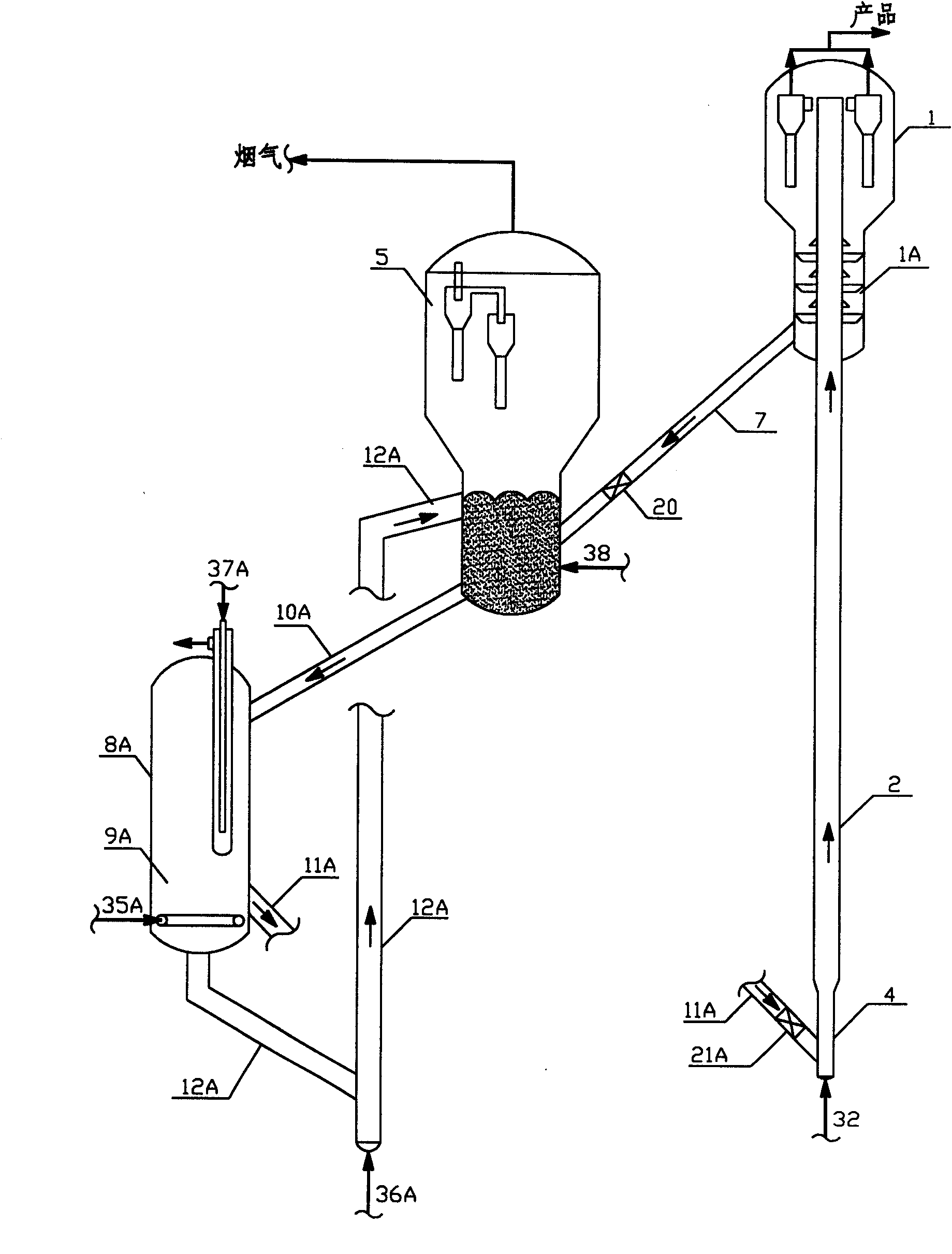

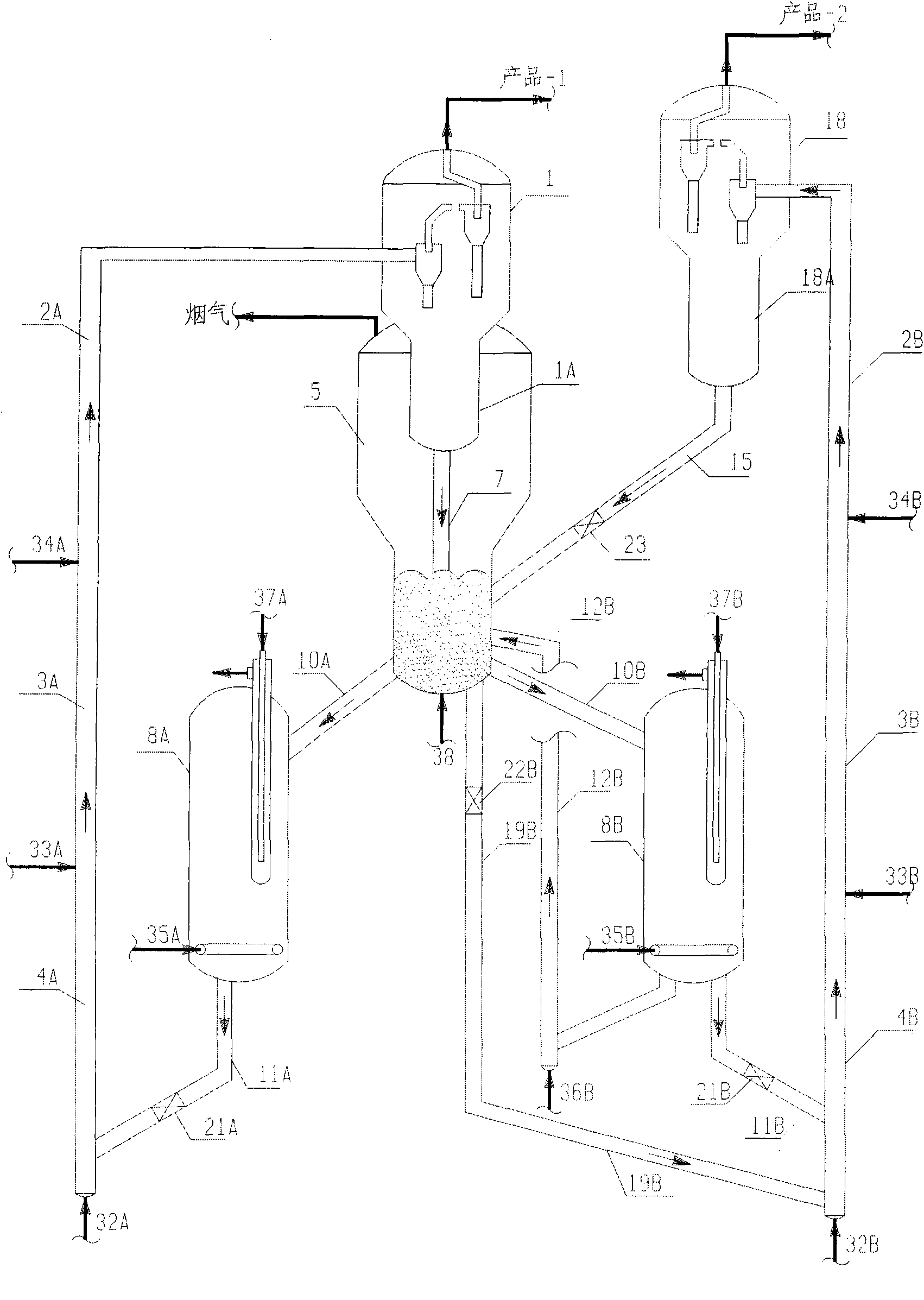

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

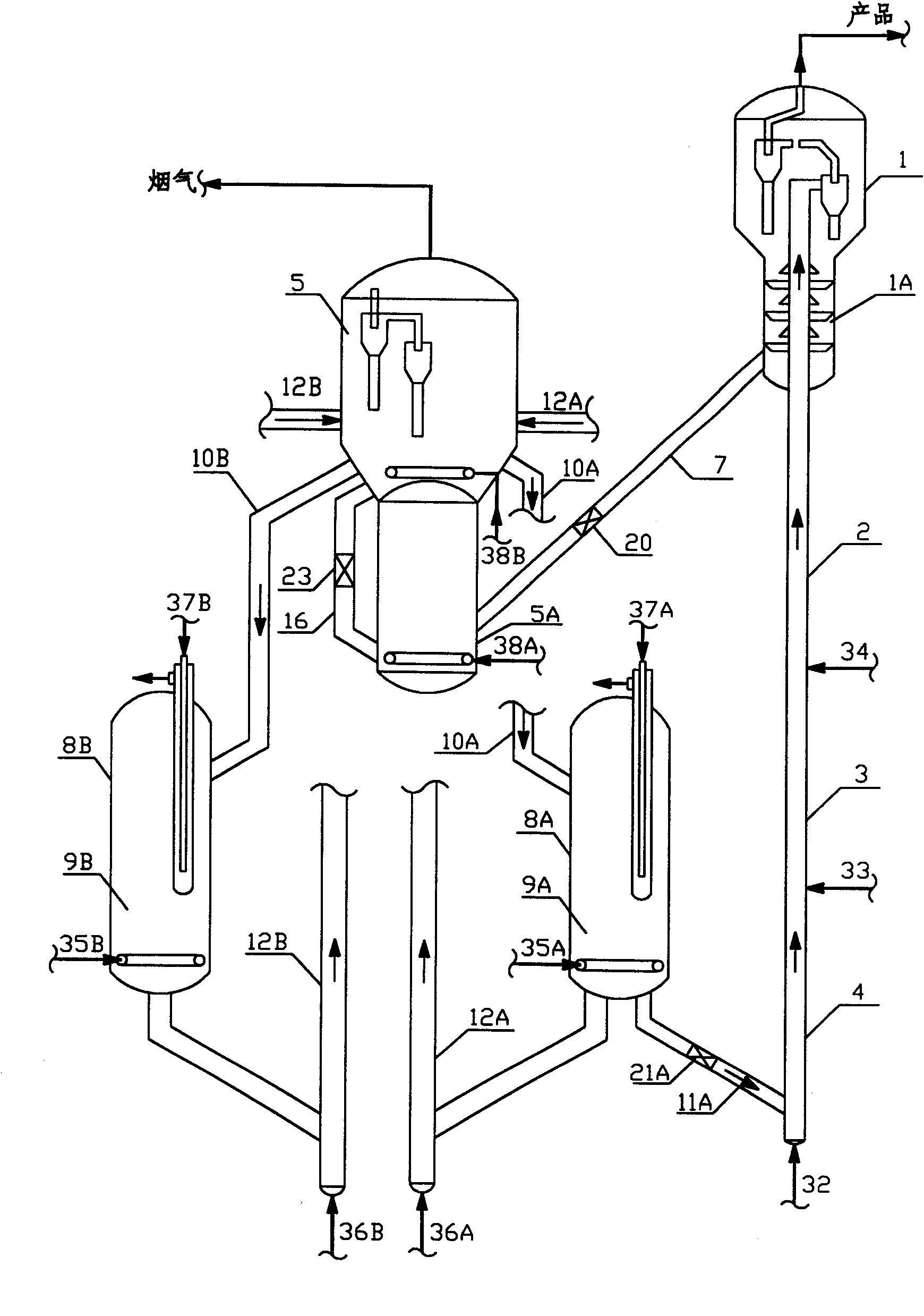

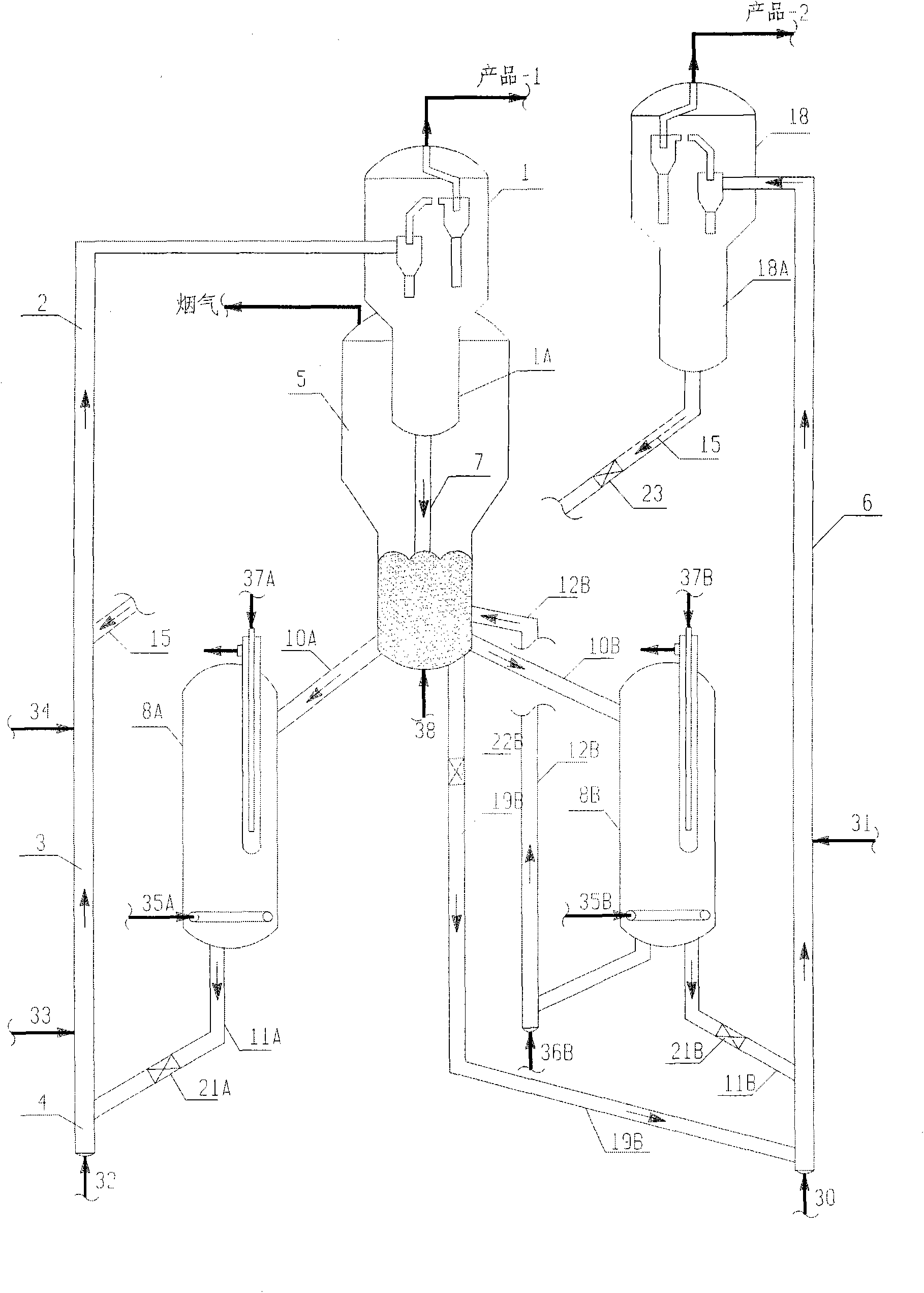

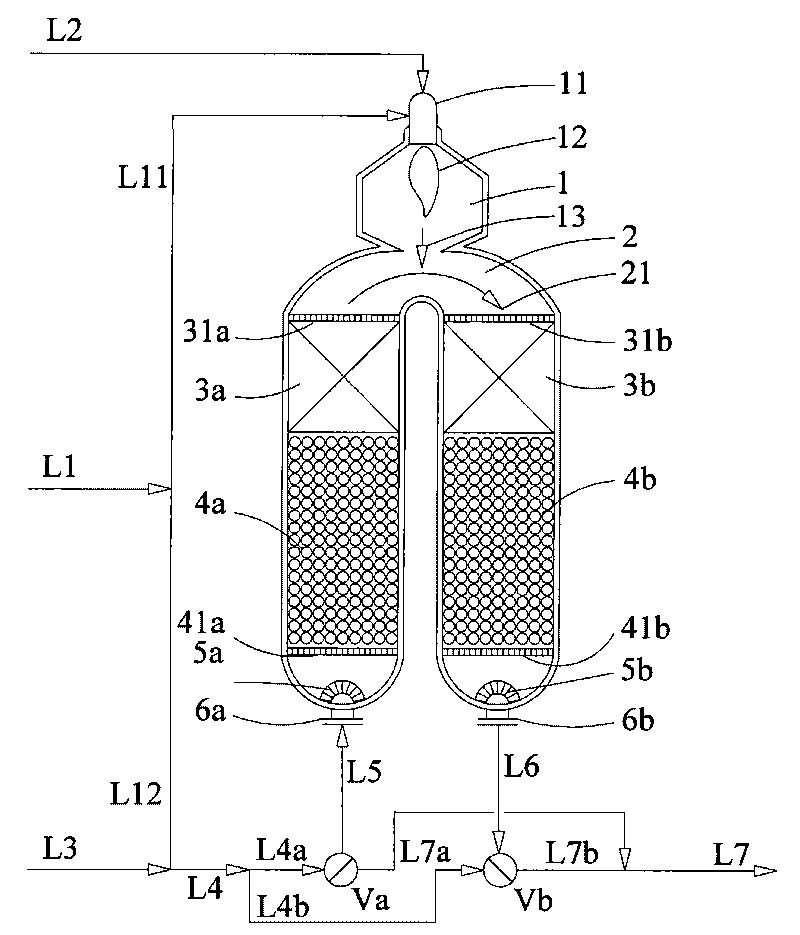

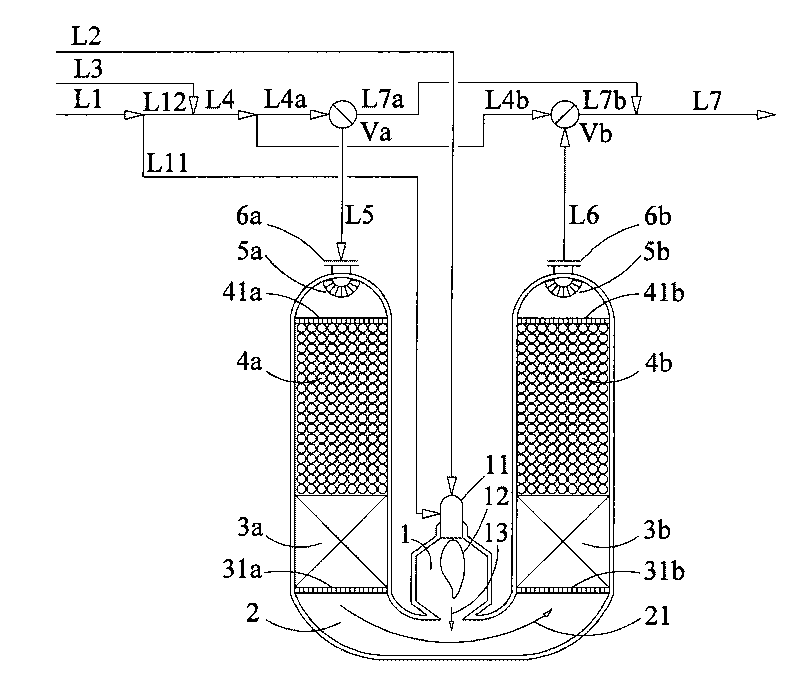

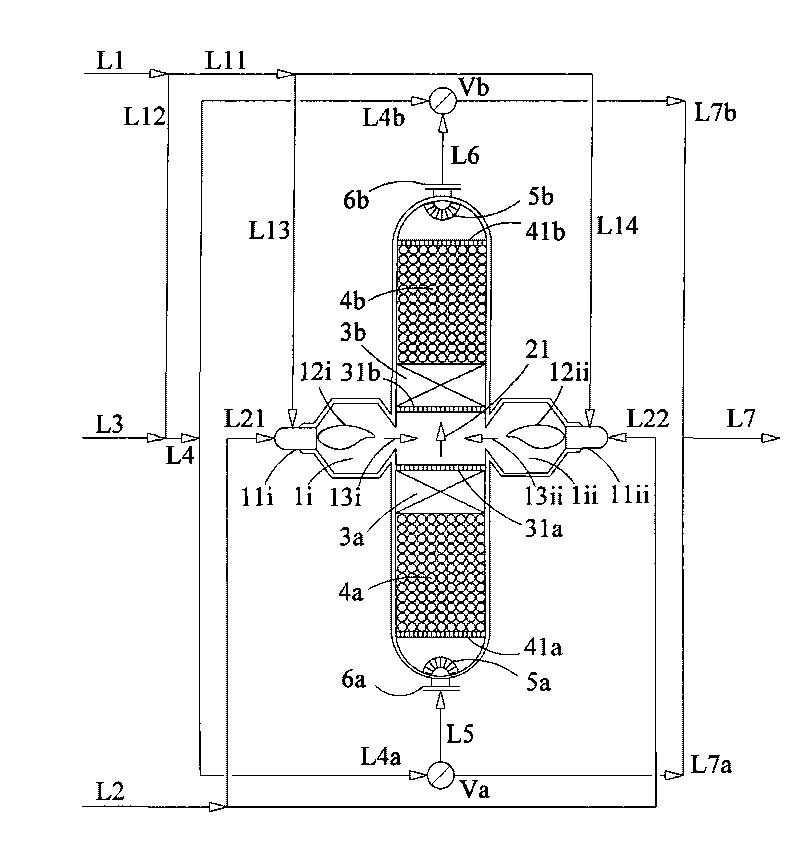

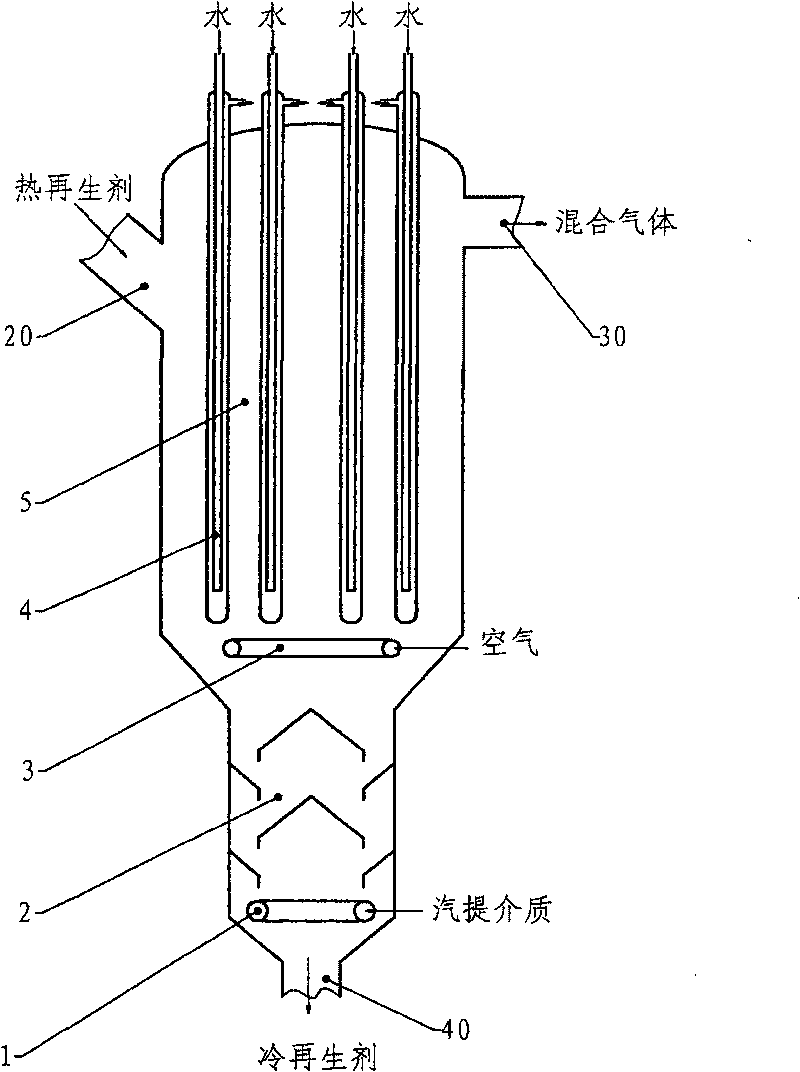

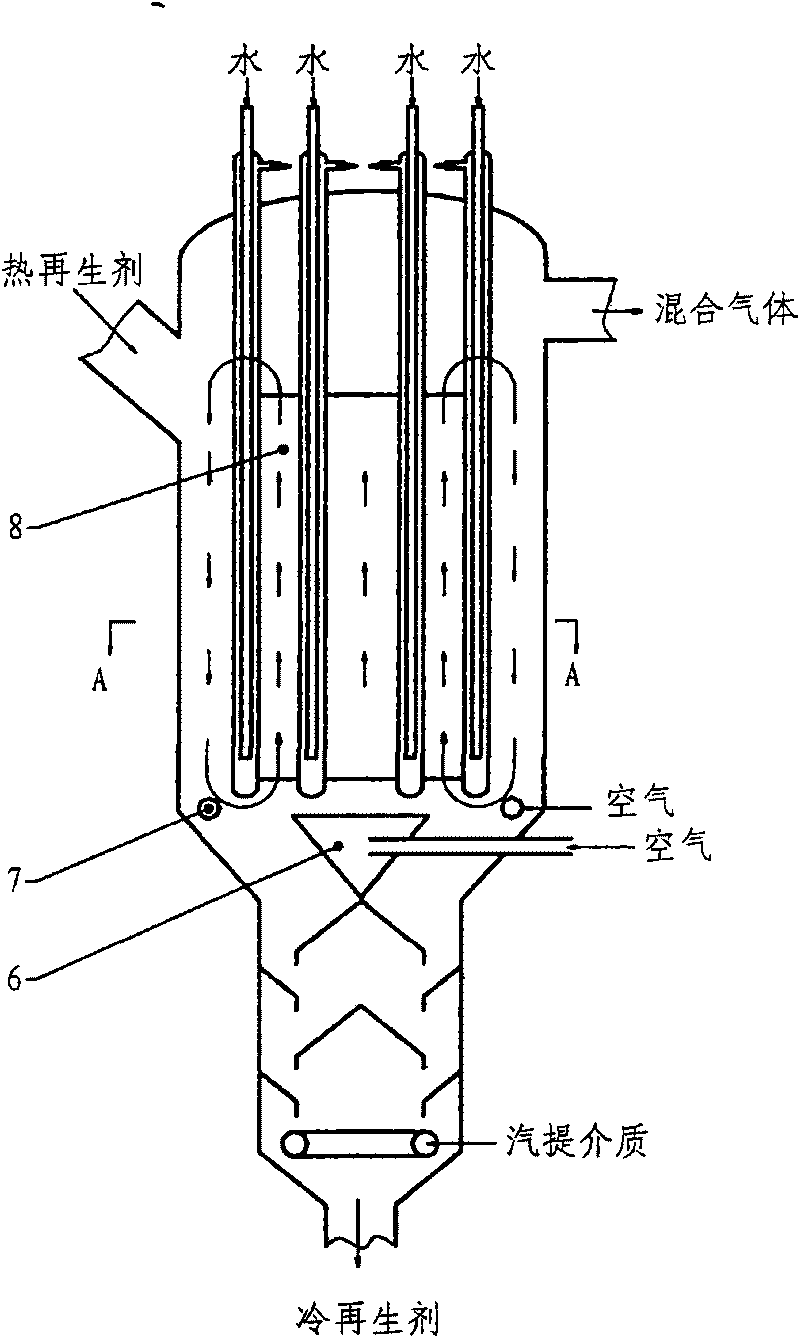

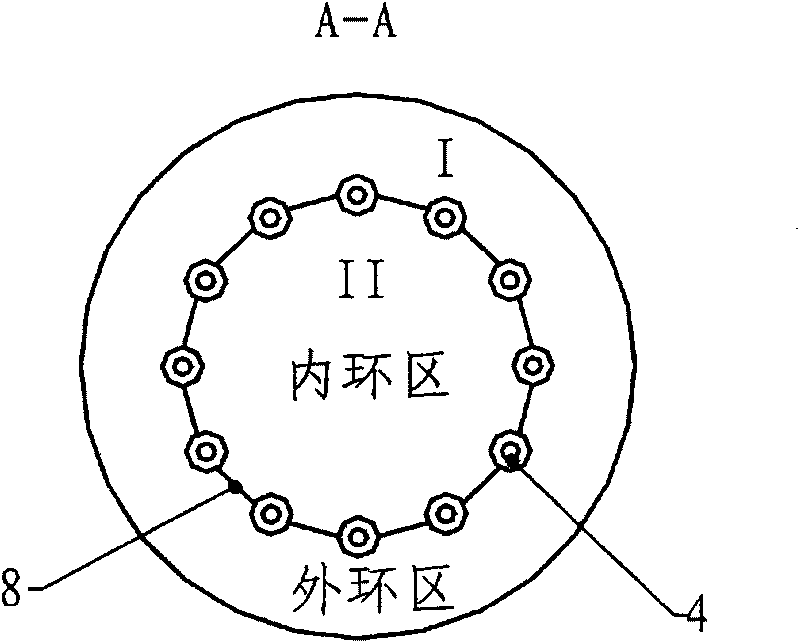

Method and device for circulating cold regenerated catalyst

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

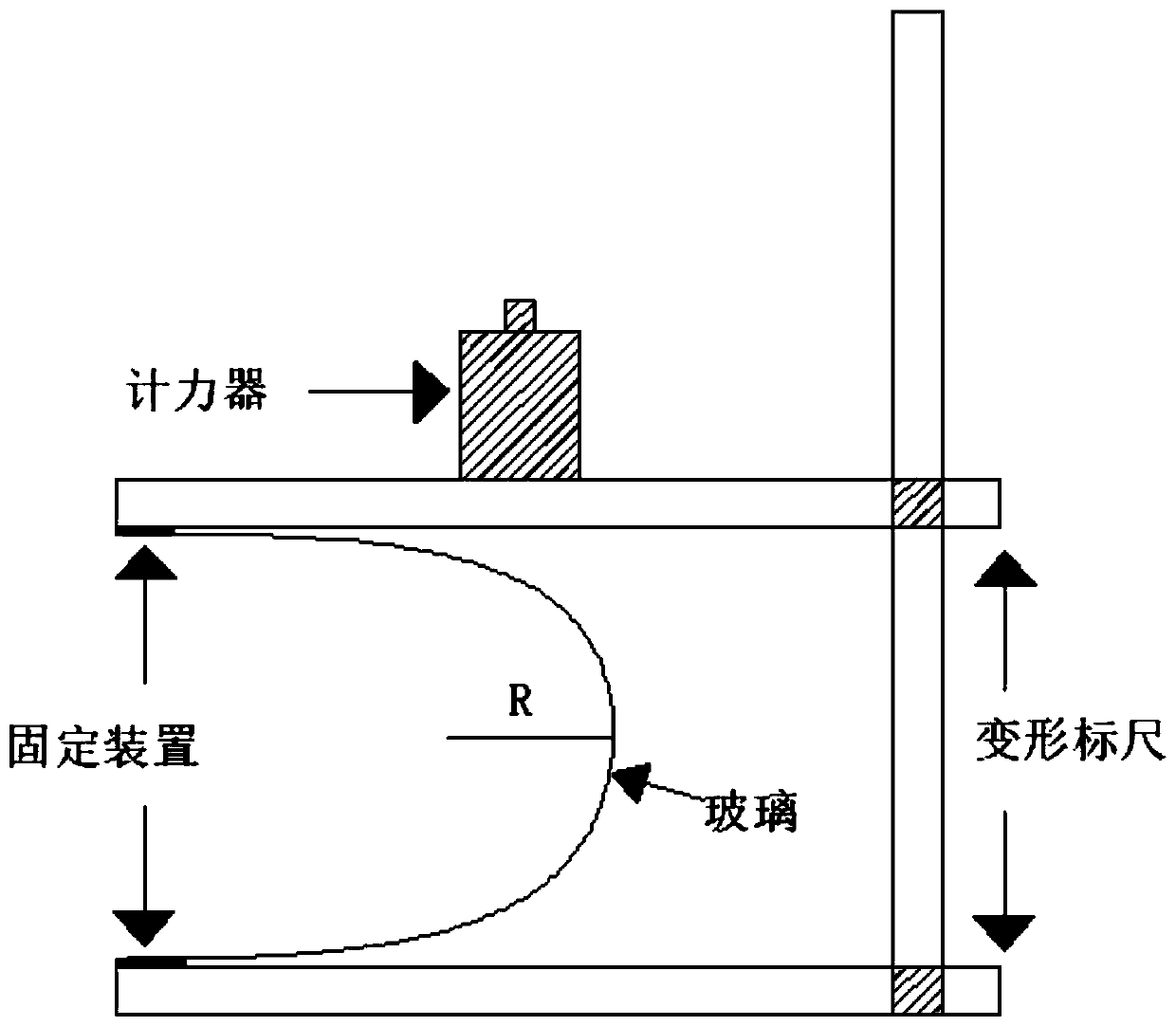

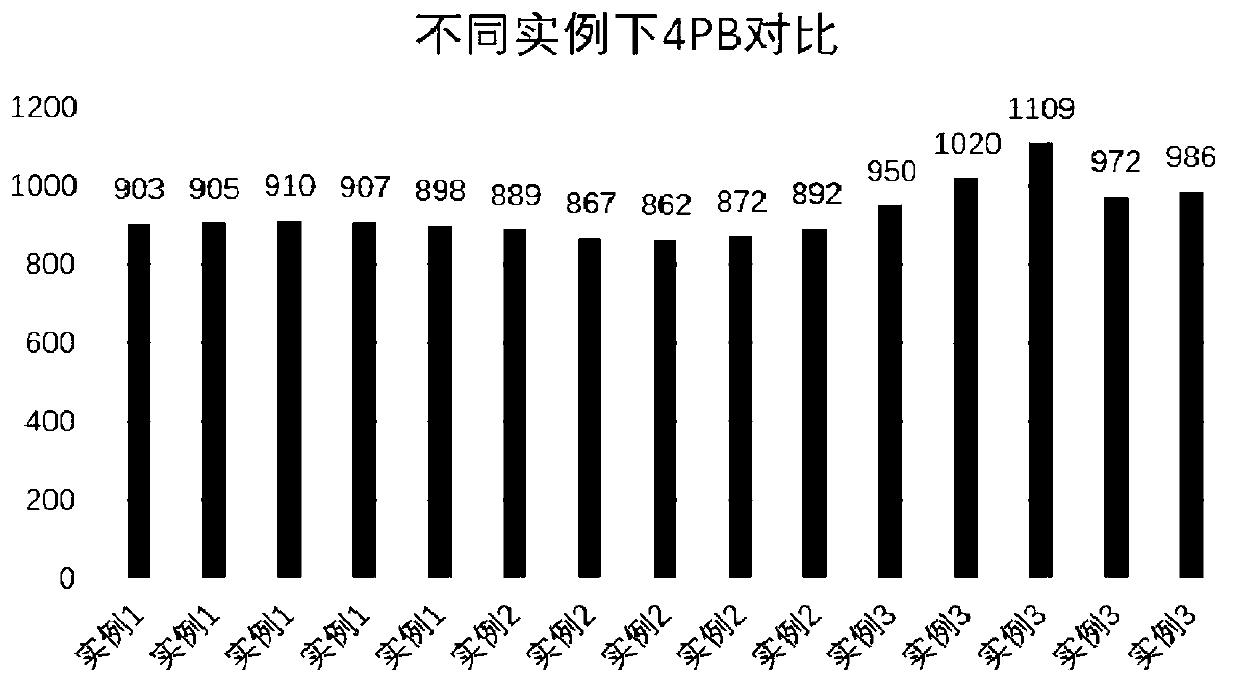

Ultrathin toughened glass with low curvature radius, preparation method thereof, glass device, and mother glass

The invention discloses an ultrathin toughened glass with a low curvature radius, a preparation method thereof, a glass device, and a mother glass. The thickness of the toughened glass is in a range of 30 to 150 [mu]m; the surface pressure stress of any surface of the toughened glass is in a range of 300 to 1200 MPa; in a toughened glass 2PB test, the minimal value of the curvature radius of a formed curved surface is in a range of 2 to 12 mm; in a toughened glass 2PB bending test, the toughened glass can bear a maximal bending pressure of 200 to 800 MPa; the absolute value of the linear density integral of the tensile stress of unit thickness of the toughened glass is 5000 to 160000 MPa / mm; and the Vickers hardness of the toughened glass is in a range of 580 to 780 kgf / mm2. A conventionaltoughening technology is optimized to reduce or eliminate micro-cracks in the glass surface and reduce the internal stress of glass; at the same time, the pressure stress on the glass surface and thedepth of an ion exchange layer are controlled in a certain range to realize high flexibility and strong thermal shock resistant performance, and the toughened glass can be bended in a small curvatureradius or can be repeatedly folded.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

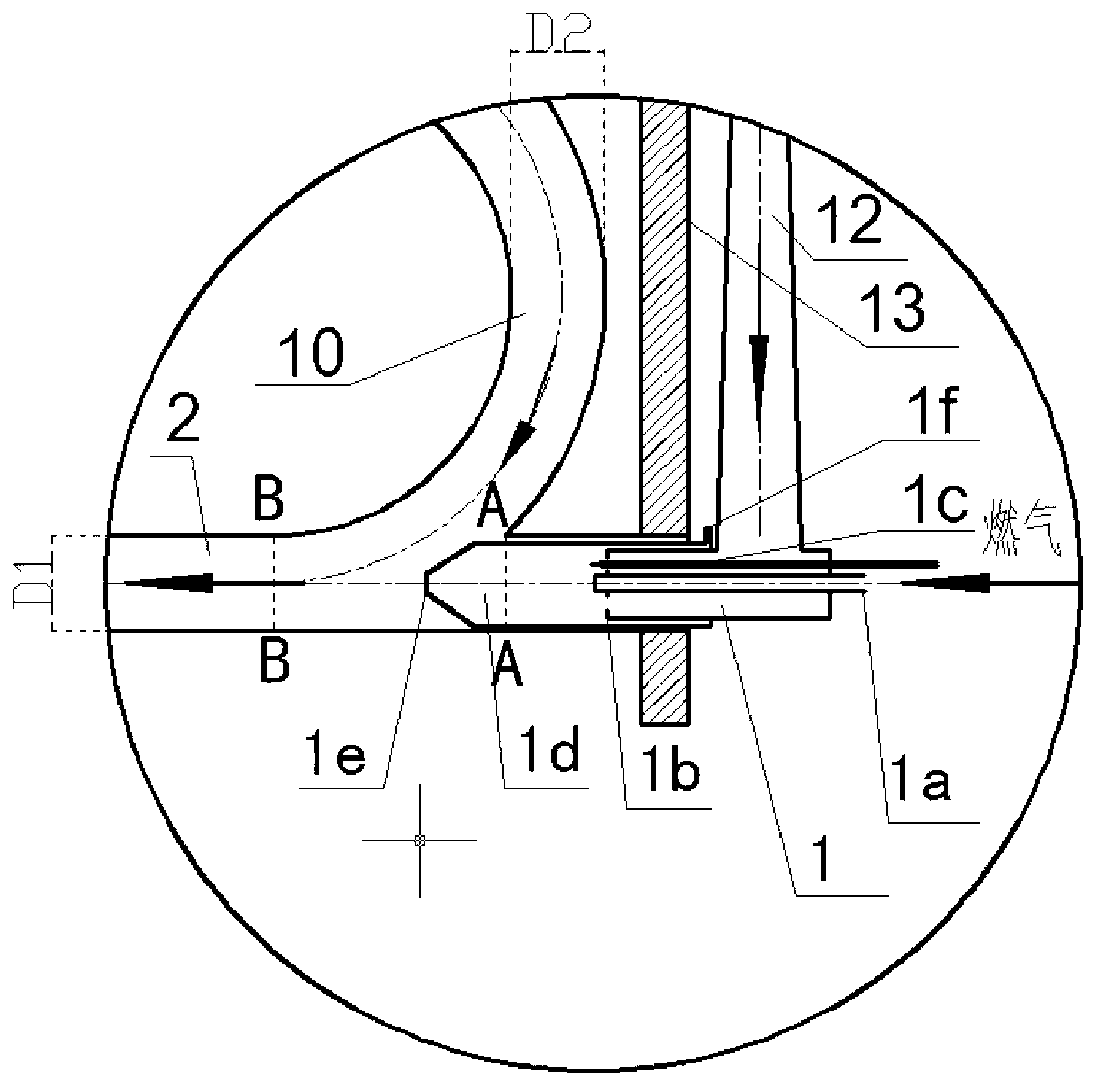

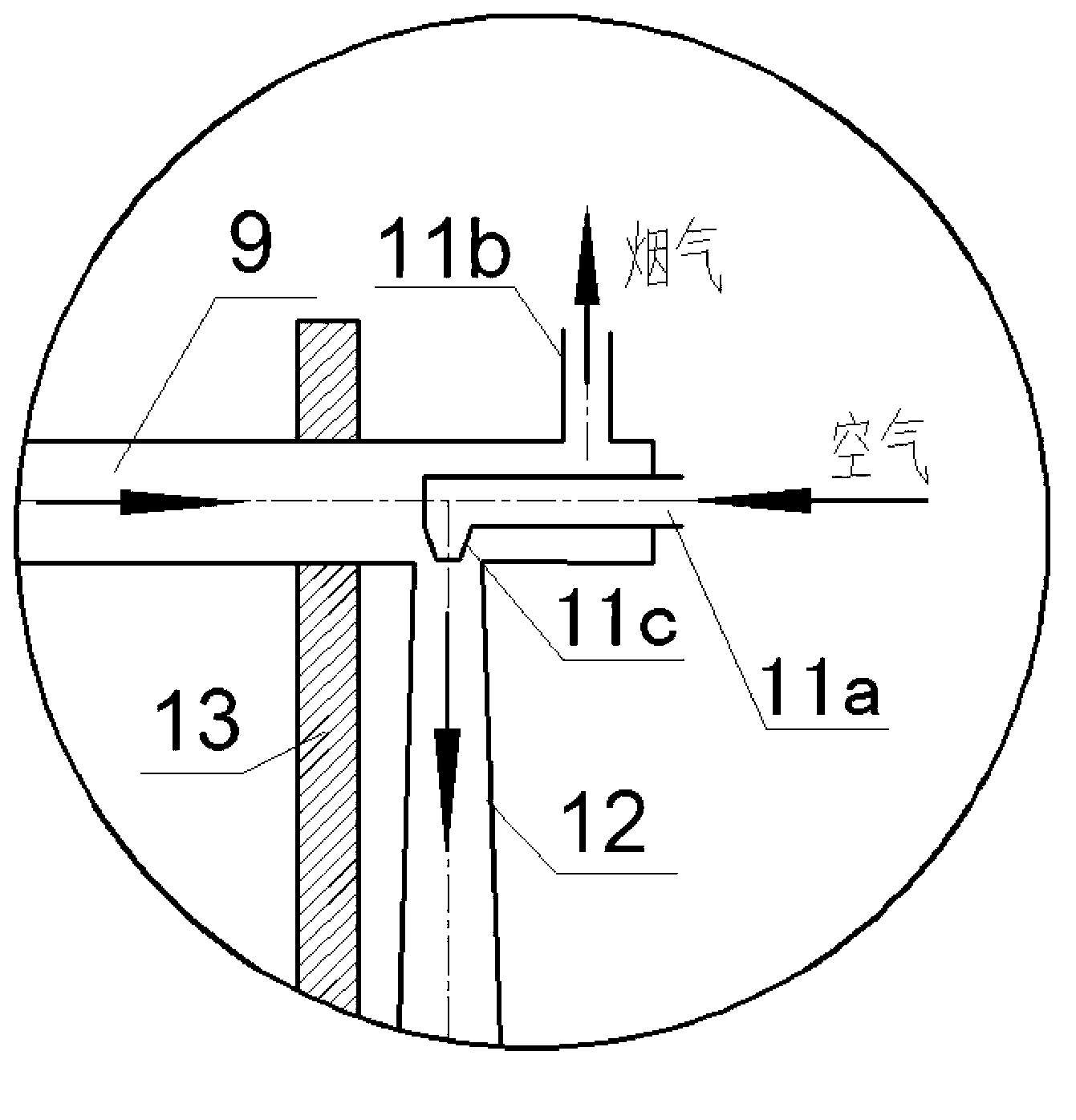

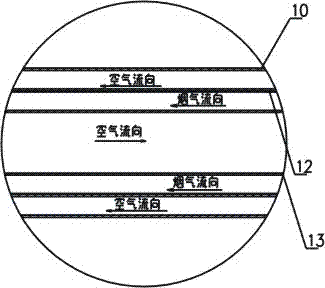

Air injecting and backflow flue gas entraining heat exchanger for radiant tube combustion device

InactiveCN102418936AGuaranteed validityIncrease the heat exchange areaCombustion processIndirect carbon-dioxide mitigationPollutantFlue gas

The invention relates to the technology of a heat exchanger, in particular to an air injecting and backflow flue gas entraining heat exchanger for a radiant tube combustion device. The heat exchanger comprises a heat exchanger shell with a four-way structure, wherein the heat exchanger shell is connected with an inner core tube, a heat exchange tube and a high-temperature air injection tube; the high-temperature air injection tube has a conical reducing tube structure and is used for forming an air injection channel; the air injection nozzle end of the heat exchanger shell is connected with a main combustion nozzle through a corrugated pipe; and the flue gas inlet end of the heat exchanger shell is communicated with a radiant tube. In the heat exchanger, a conical reducing air injection pipe is added, negative pressure zone entrainment flue gas is formed, and the flue gas is mixed with preheated air; on the basis of effective heat exchange of the heat exchange tube, the preheating temperature of air is increased effectively; after the flue gas is mixed with the air, the oxygen concentration in a combustion zone is reduced, the generation amount of NOx is reduced, and the discharge amount of pollutants is reduced; fin structures arranged on the outer and inner sides in a staggered way increase a heat exchange area, and the turbulence scale of the flue gas and the air, improve a heat exchange effect, and utilize the flue gas afterheat efficiently; and the components are easy to assemble and disassemble.

Owner:WISDRI WUHAN WIS IND FURNACE

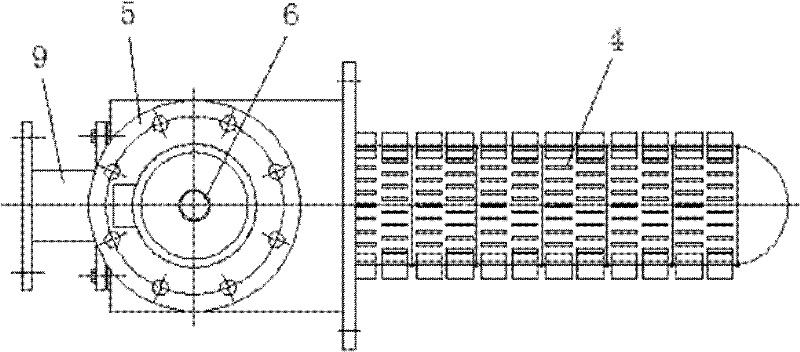

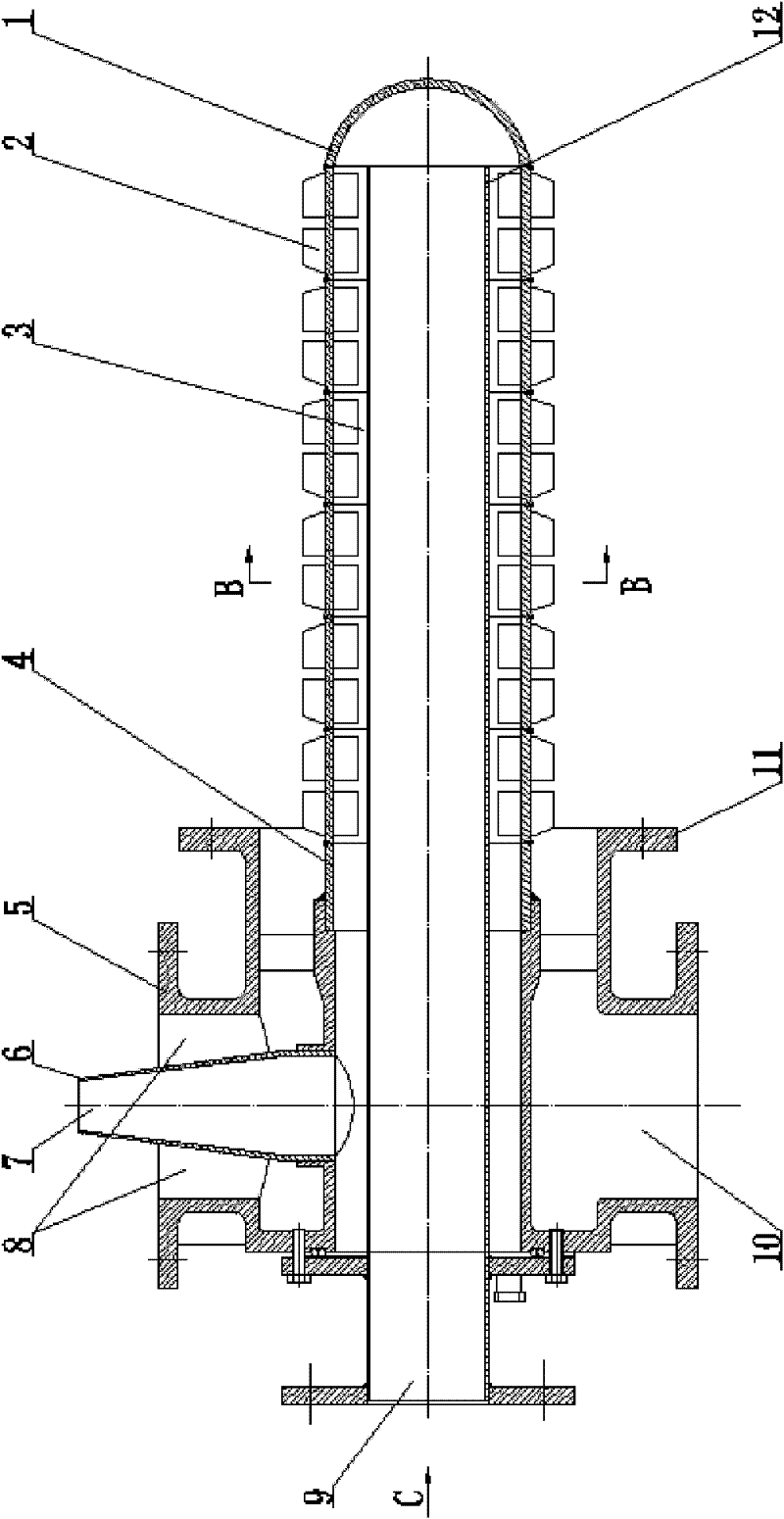

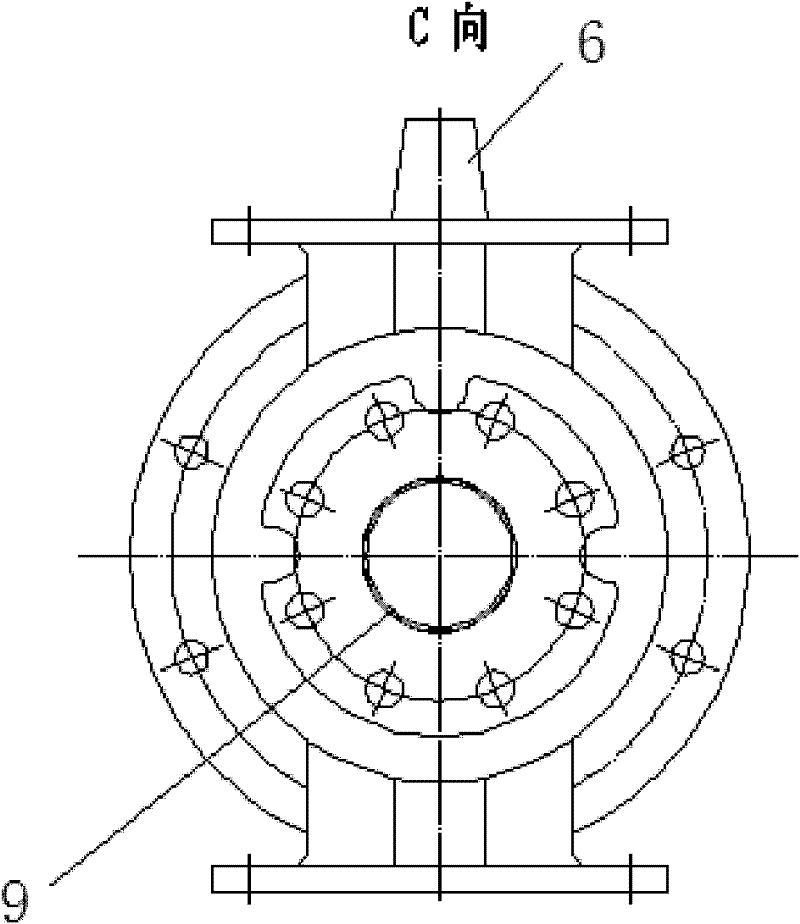

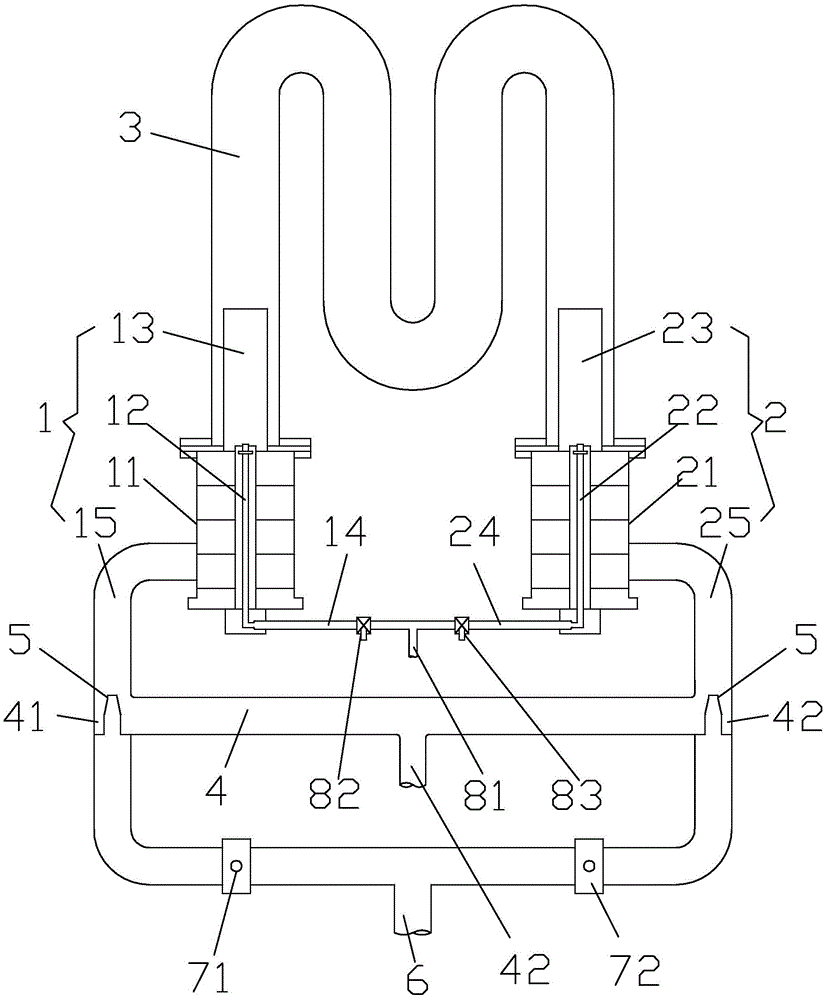

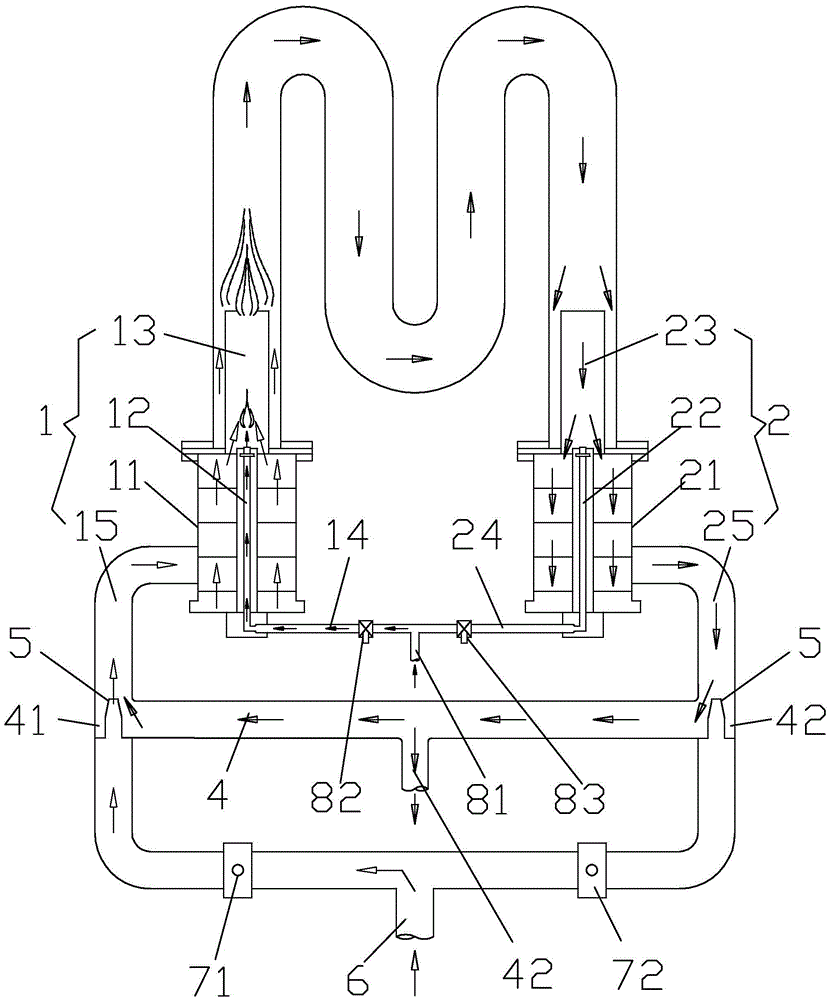

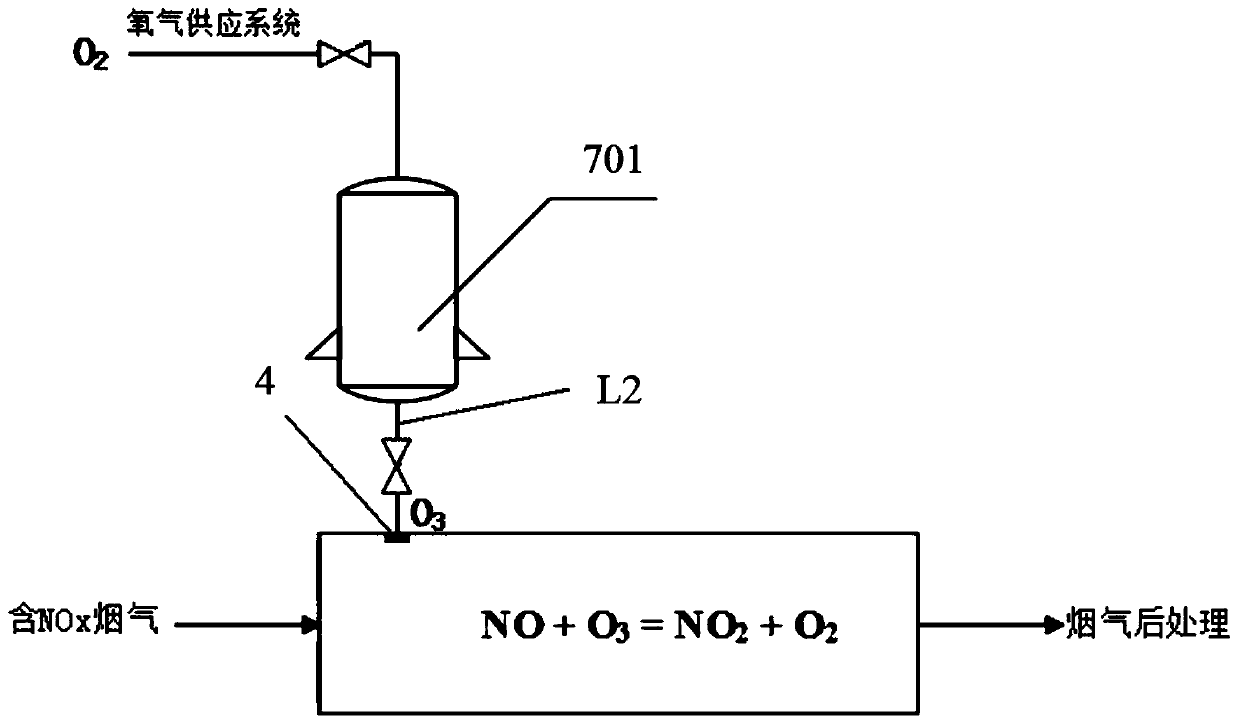

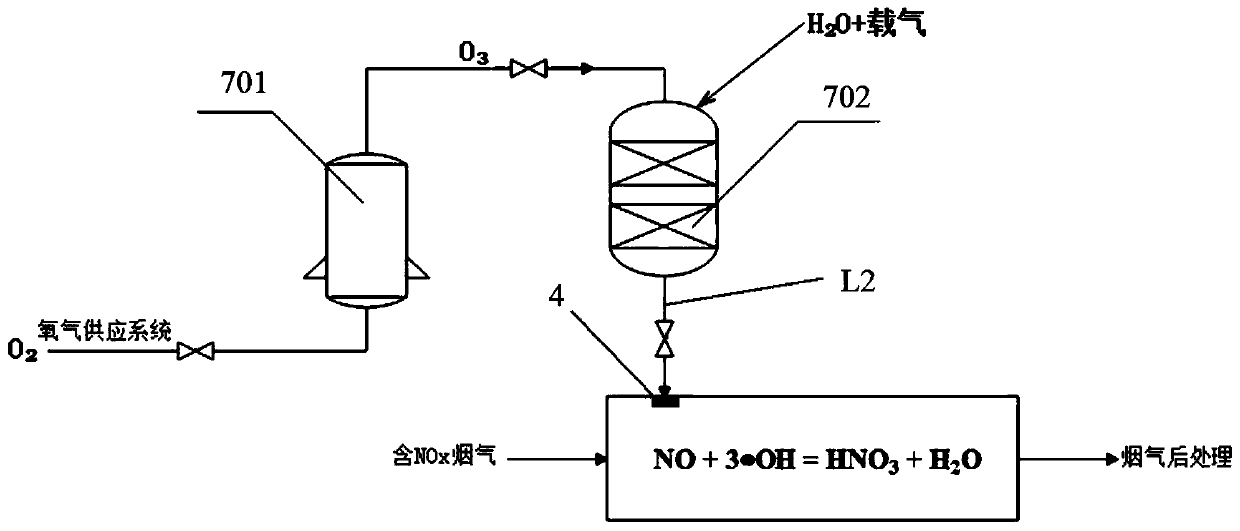

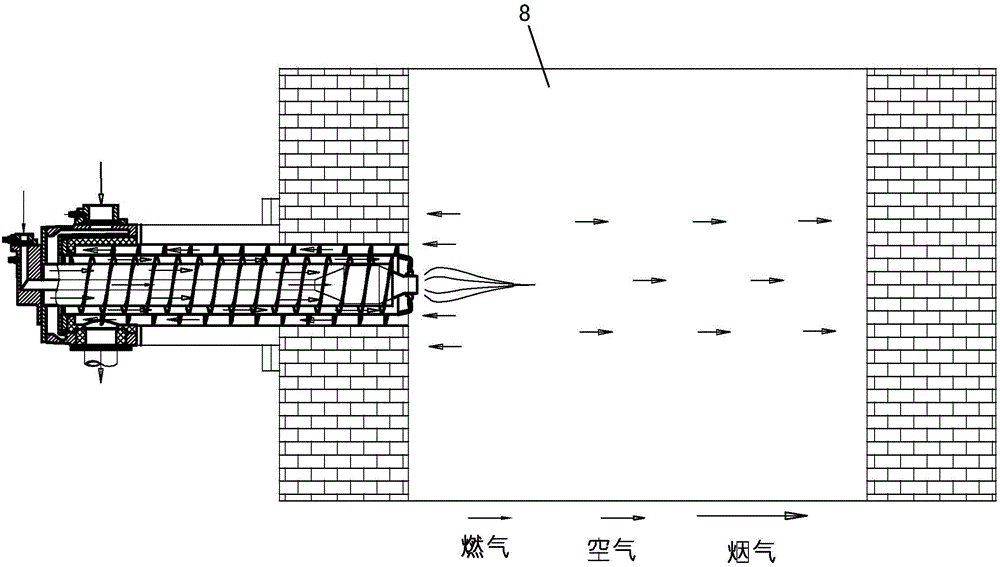

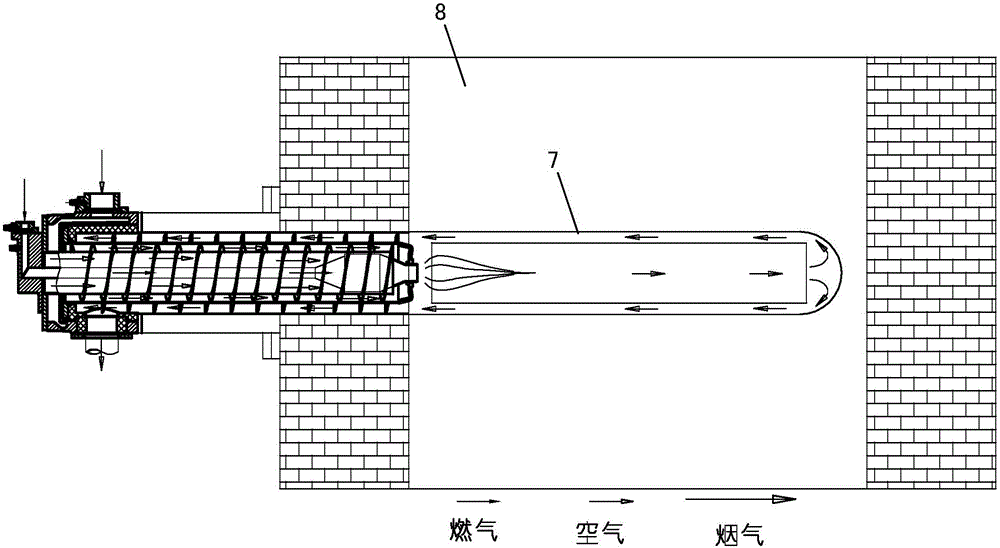

Regenerative radiant tube burner with flue gas recirculation

ActiveCN105465784ARaise the preheat temperatureReduce oxygen contentIndirect carbon-dioxide mitigationGaseous fuel burnerFlue gasEngineering

The invention discloses a regenerative radiant tube burner with flue gas recirculation. The regenerative radiant tube burner comprises a first burner body and a second burner body; the first burner body comprises a first regenerative body, a first burner core penetrating through the first regenerative body and a first air conduit located at the front end of the first burner core, one end of the first burner core is connected with a first gas pipeline, and the first air conduit is connected with a first air pipeline; the second burner body comprises a second regenerative body, a second burner core penetrating through the second regenerative body and a second air conduit located at the front end of the second burner core, one end of the second burner core is connected with a second gas pipeline, and the second air conduit is connected with a second air pipeline; the first air pipeline and the second air pipeline are mutually communicated to form a circulating pipeline which is provided with an air inlet and a flue gas outlet. By means of the regenerative radiant tube burner with flue gas recirculation, the oxygen content of burning supporting air can be decreased, the flame temperature during burning can be decreased, emission of NOx is greatly reduced, and pollution to the atmosphere in the burning process is reduced.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

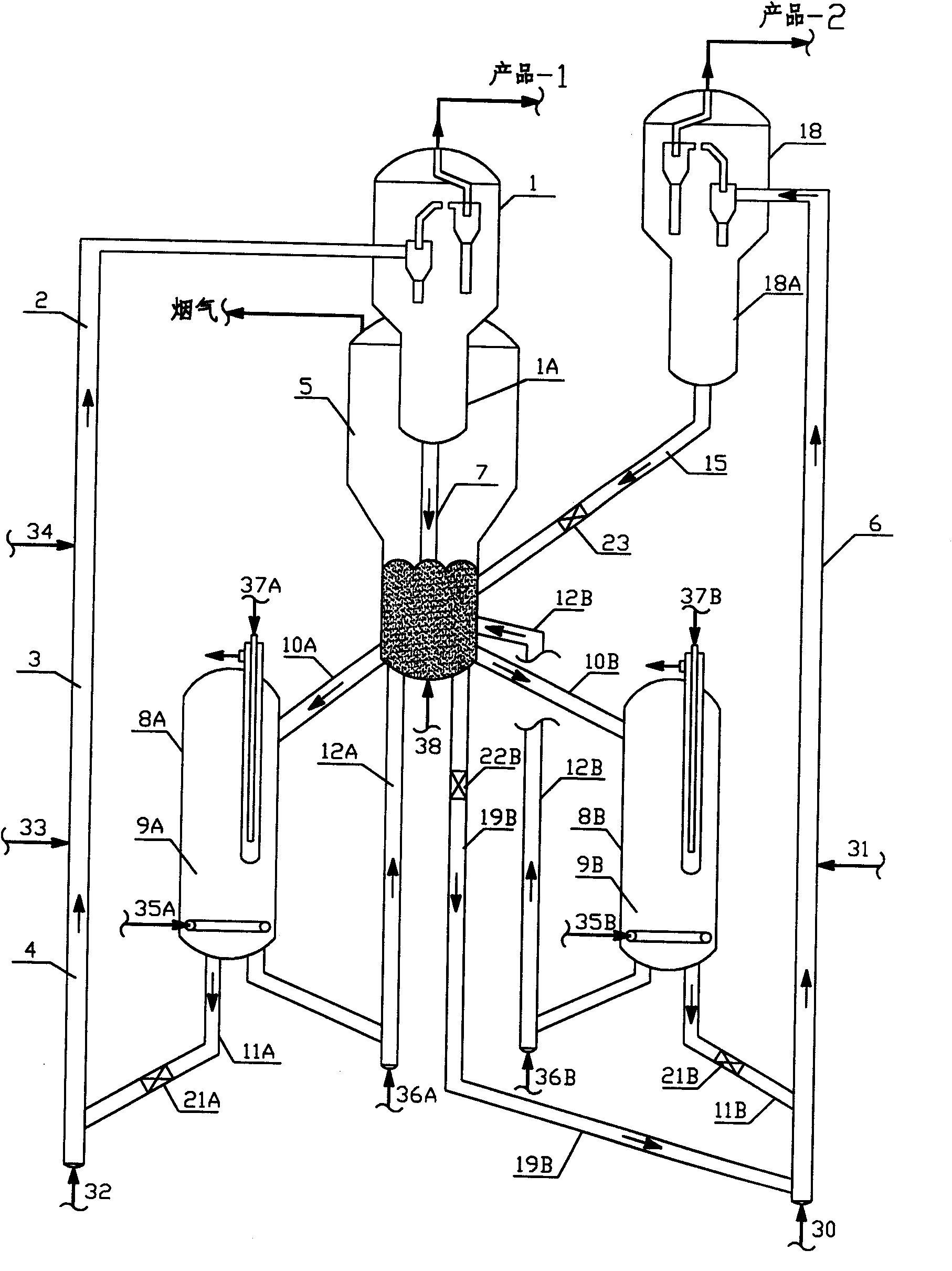

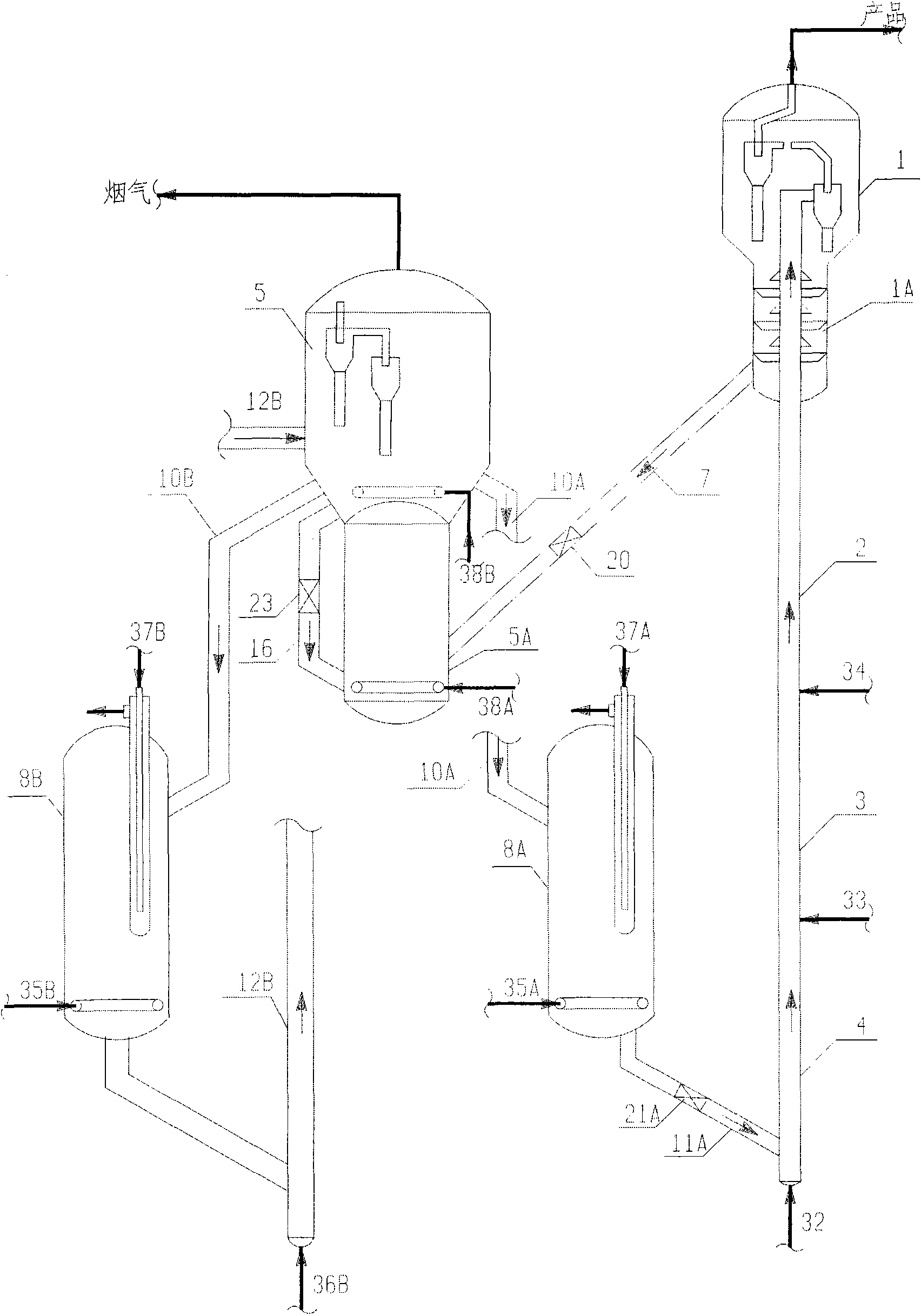

Method and device for fluidized catalytic conversion

ActiveCN101665712AReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationContact time

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

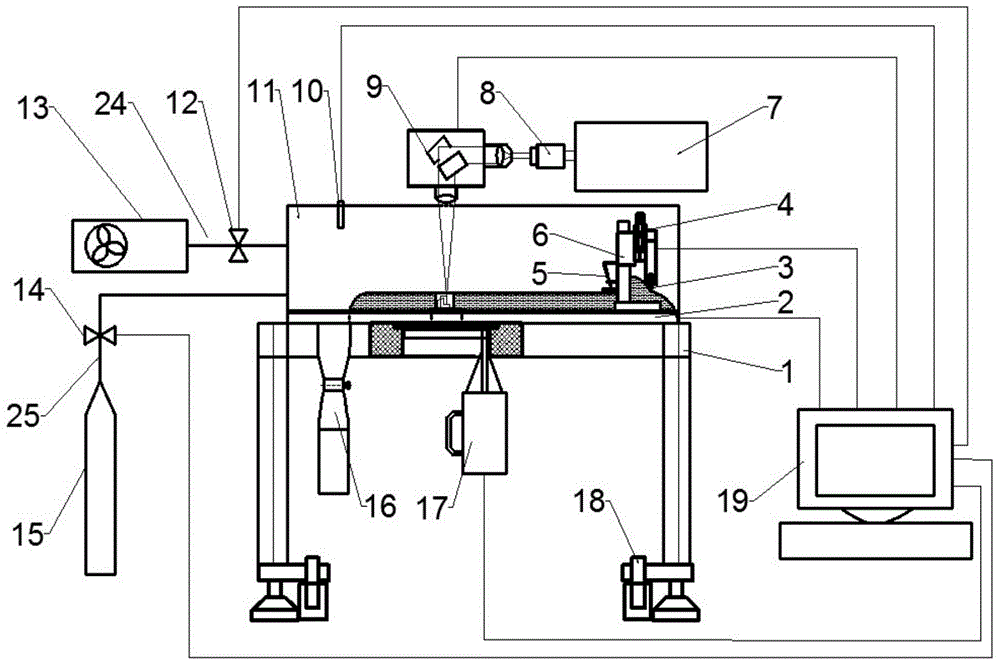

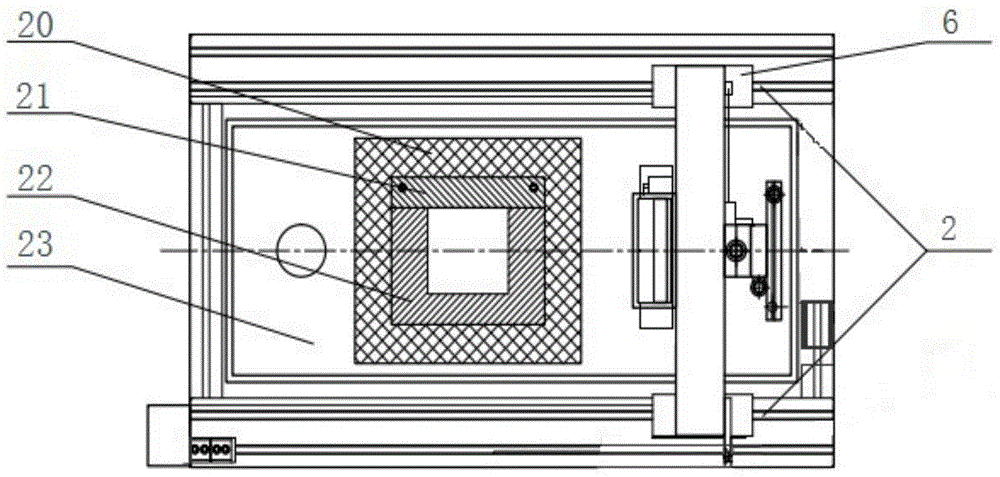

Selective laser fusion molding equipment for ceramic material

The invention discloses selective laser fusion molding equipment for a ceramic material. A closed molding and processing cabin for forming a worktable is arranged in the equipment. According to the equipment, lifting motion of a molding cylinder is replaced by vertical motion of a scraper, a height adjusting device of the scraper is controlled by an industrial personal computer, a vacuum pump and an argon supply device are respectively conducted with the closed cabin through a pipeline; a laser scanning system is arranged on an upper surface of the closed cabin; a dynamic focusing system and a galvanometric scanning system in the laser scanning system are controlled by the industrial personal computer so as to realize real-time focusing; an induction heating system is arranged below the lower surface of the cabin, namely the worktable surface and is similarly controlled by the industrial personal computer, so that constant temperature heating can be realized. Preheating is performed through induction heating, the problem that ceramics are easily cracked due to extremely high temperature gradient in the molding process is solved, the oxygen content is strictly controlled due to atmosphere protection, influence on the performances of the parts of the equipment is avoided, and the whole equipment is simple and is conveniently sealed due to a special powder spreading structure.

Owner:NANJING UNIV OF SCI & TECH

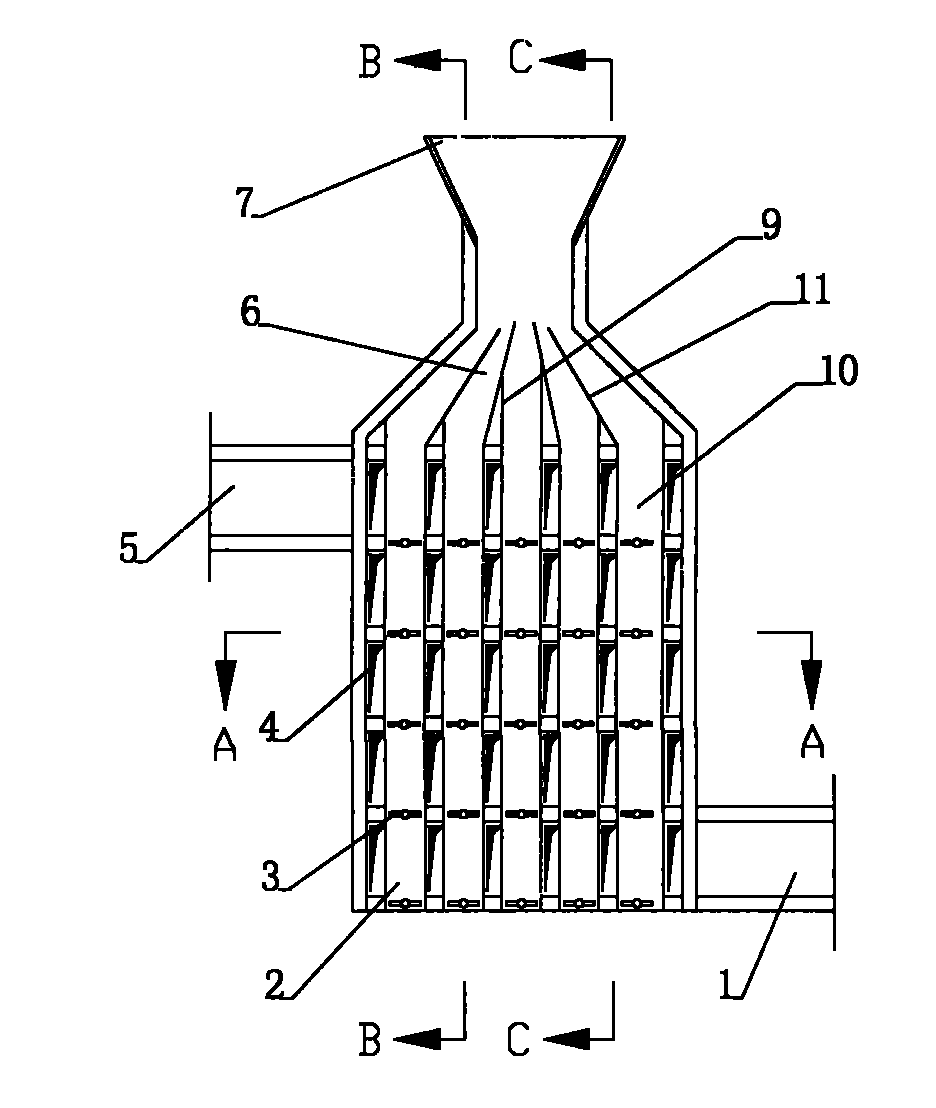

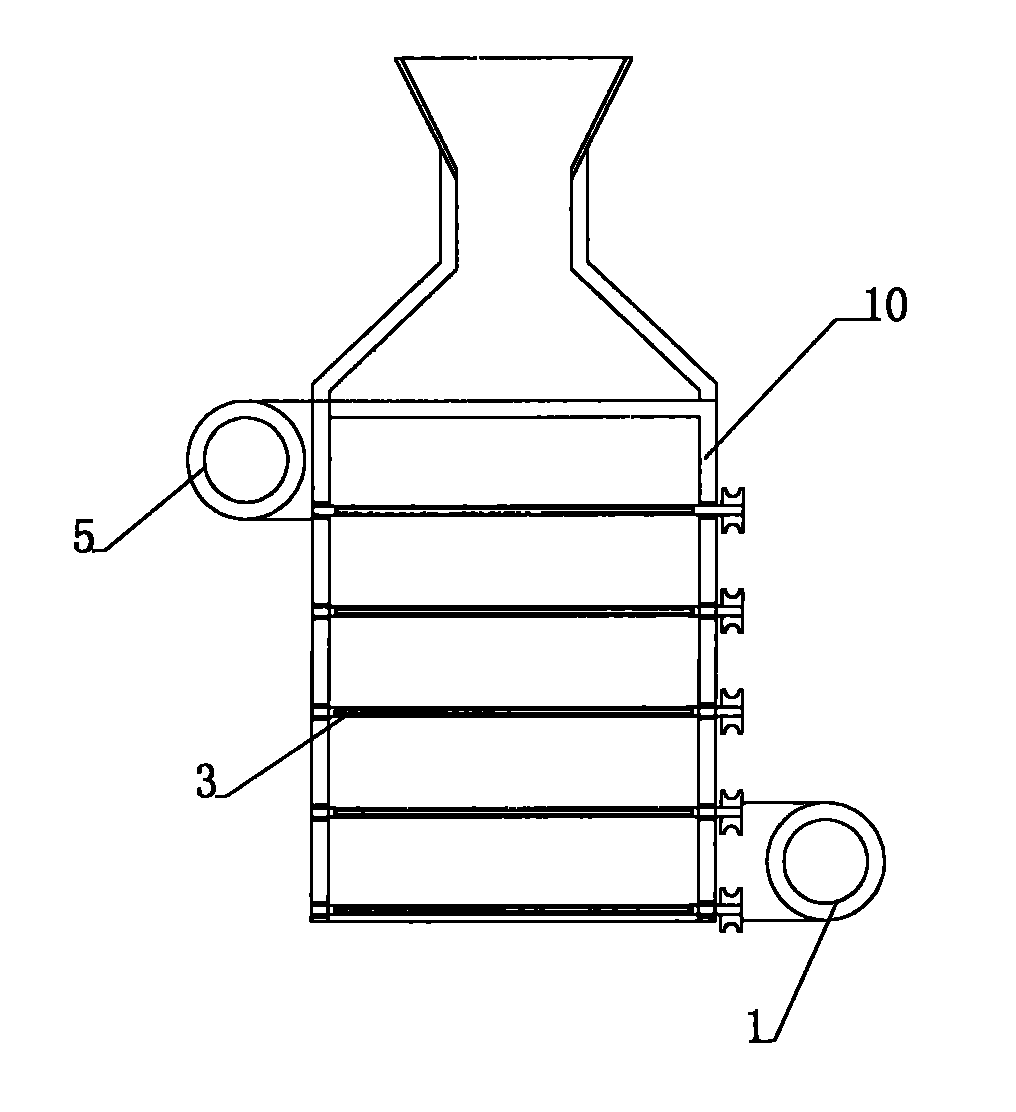

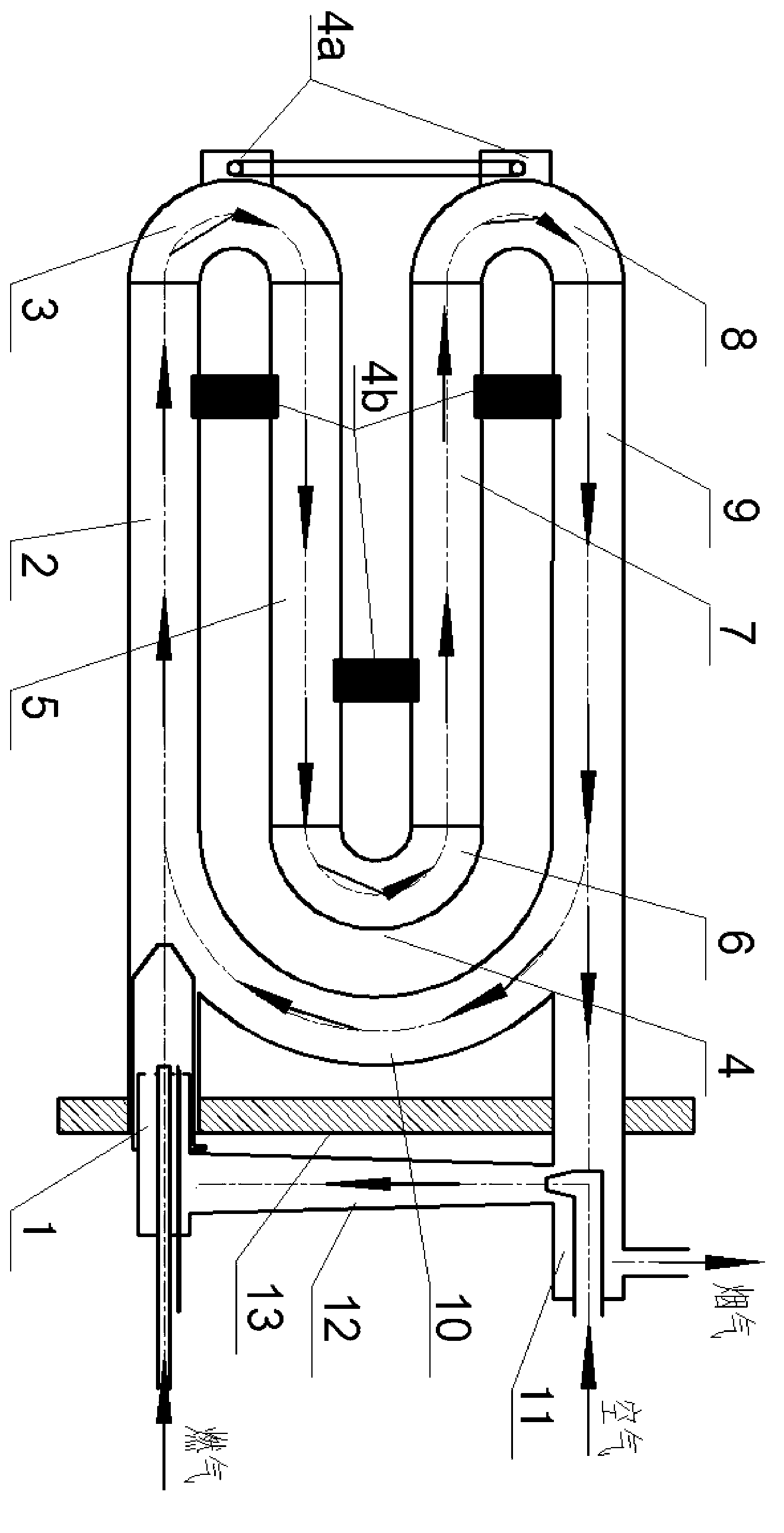

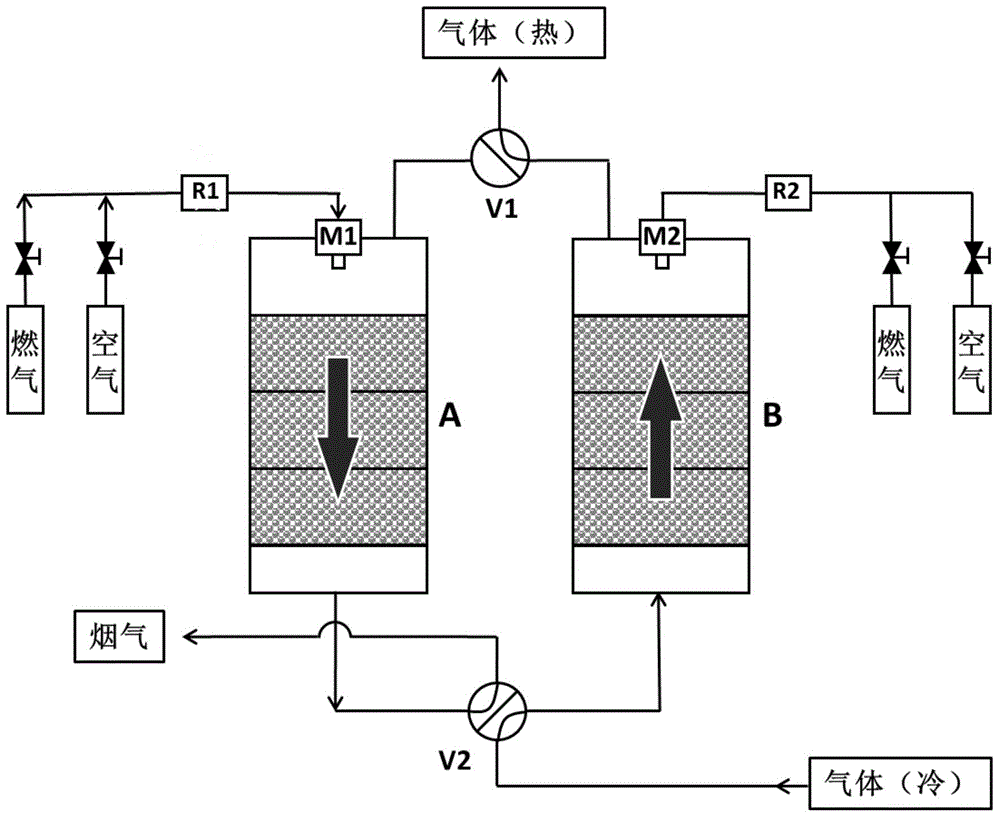

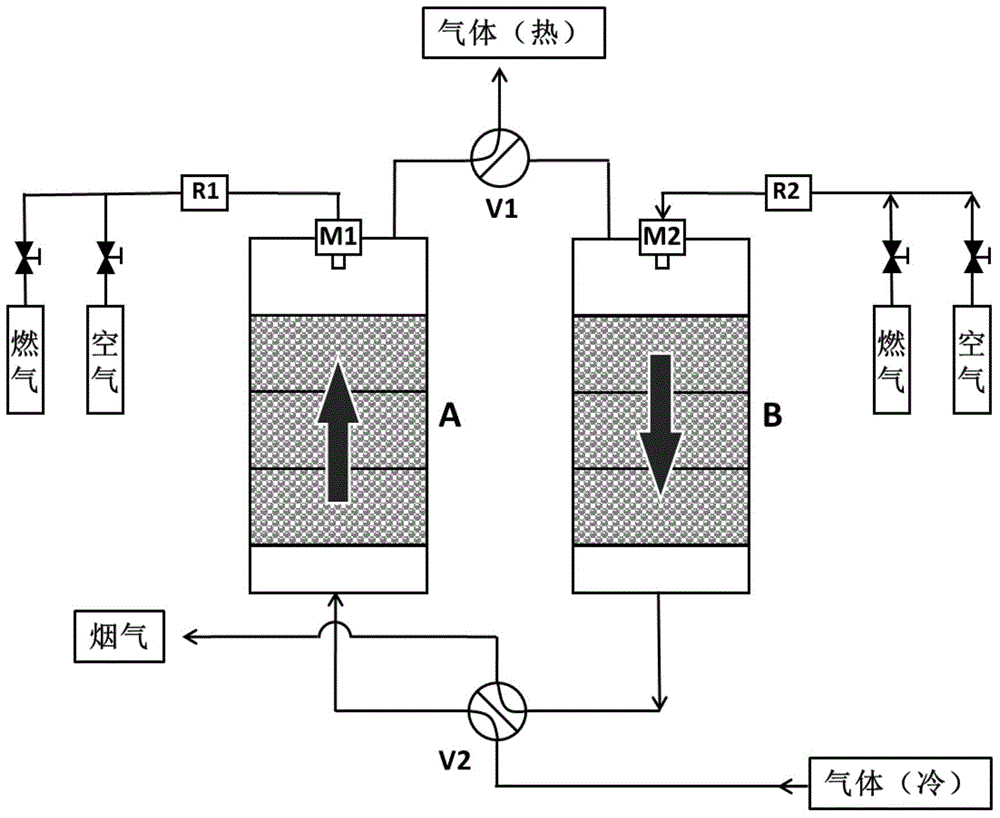

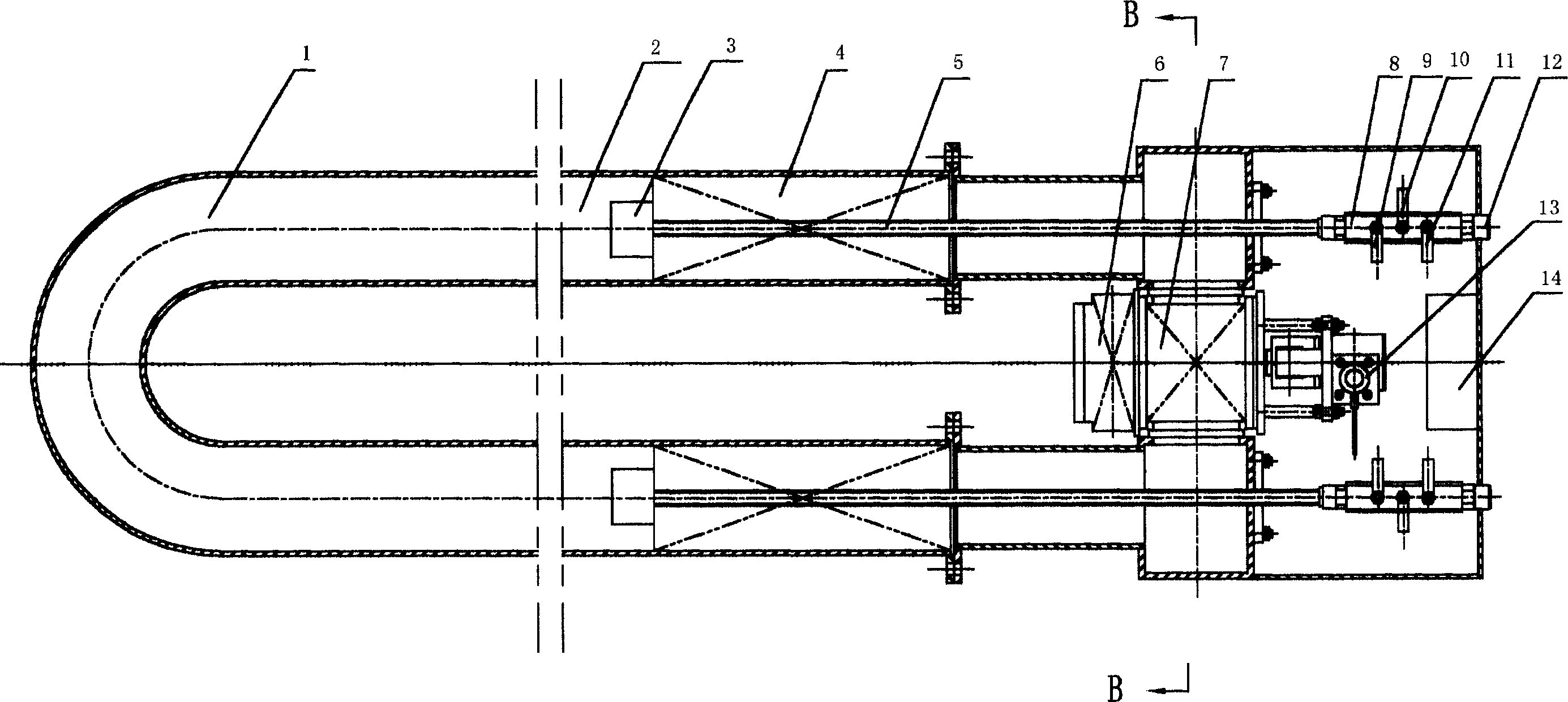

Non-steady state reactor and method for producing synthesis gas

ActiveCN101735872AAvoid the danger of burning out the catalystConvenient temperature controlGaseous fuelsCombustion chamberWater vapor

The invention discloses a reactor device and method for producing synthesis gas by using gaseous hydrocarbon as a raw material for carrying out heat accumulating type self-heating conversion. The reactor mainly comprises a combustion chamber, a mixing chamber, two reforming sections and two heat accumulating sections. The feeding raw gas of the reactor is divided into two paths of gas, wherein one path of raw gas and oxygen gas enter the combustion chamber from a middle combustion nozzle to carry out heat generating reaction; and after the other path of raw gas is mixed with water vapor, the mixed gas laterally enters the reactor through a gas inlet at one end, the mixed gas carries out pre-reforming reaction in one reforming section after being preheated in one heat accumulating section,the gas after reaction is mixed with the high-temperature gas at the outlet of the combustion chamber, then the mixed gas enters the other reforming section to carry out reforming reaction, and products are discharged after being cooled by the other heat accumulating section. The reactor of the invention is matched with a flow direction switching valve capable of periodically changing the flow direction of the gas in the reactor, thus the purposes of preheating feed materials, carrying out reaction and cooling products in one reactor can be realized. The reactor of the invention can reduce the oxygen consumption in the process, improve the yield and the quality of the synthesis gas and improve the heat efficiency of the overall process.

Owner:SYNFUELS CHINA TECH CO LTD

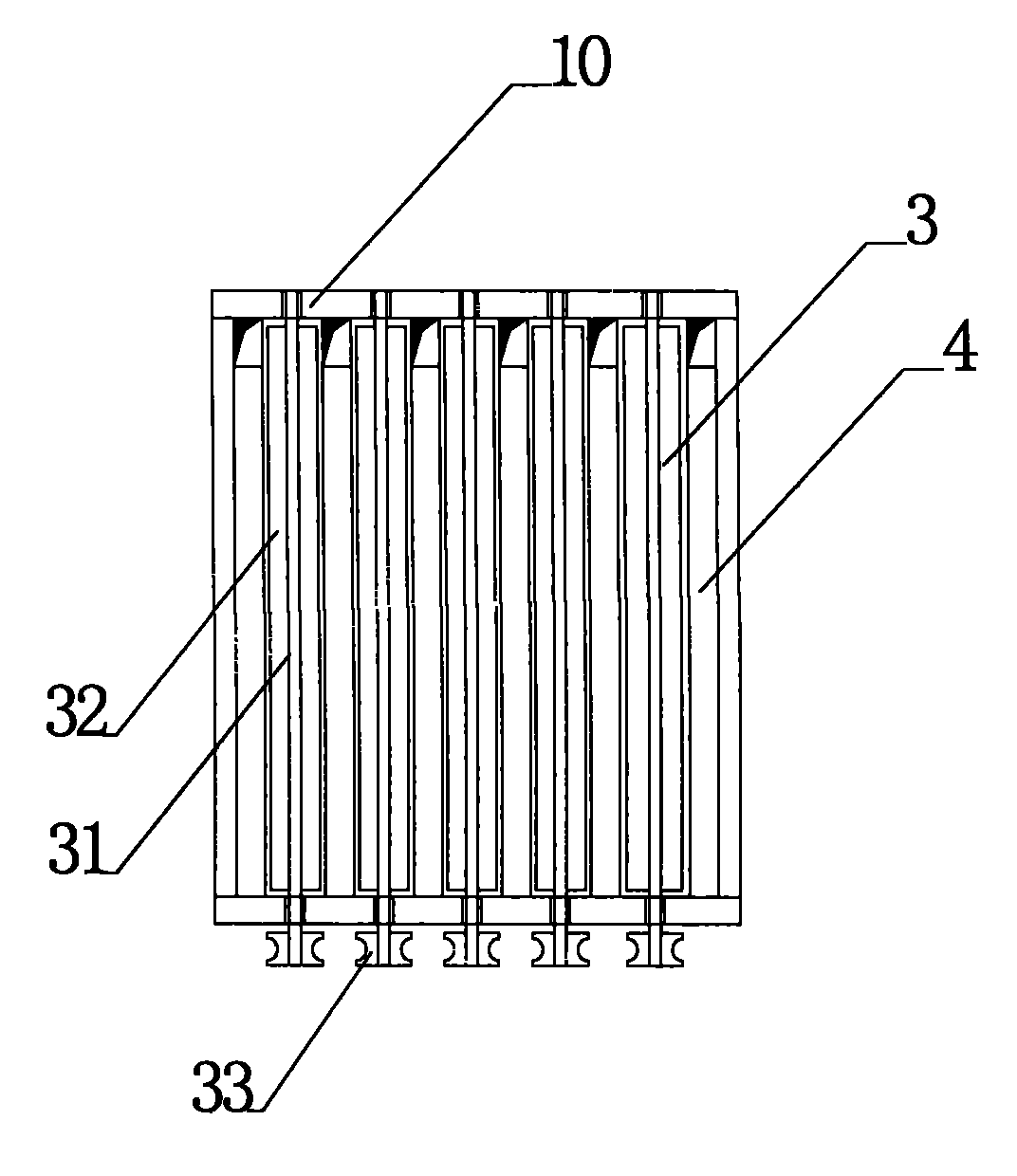

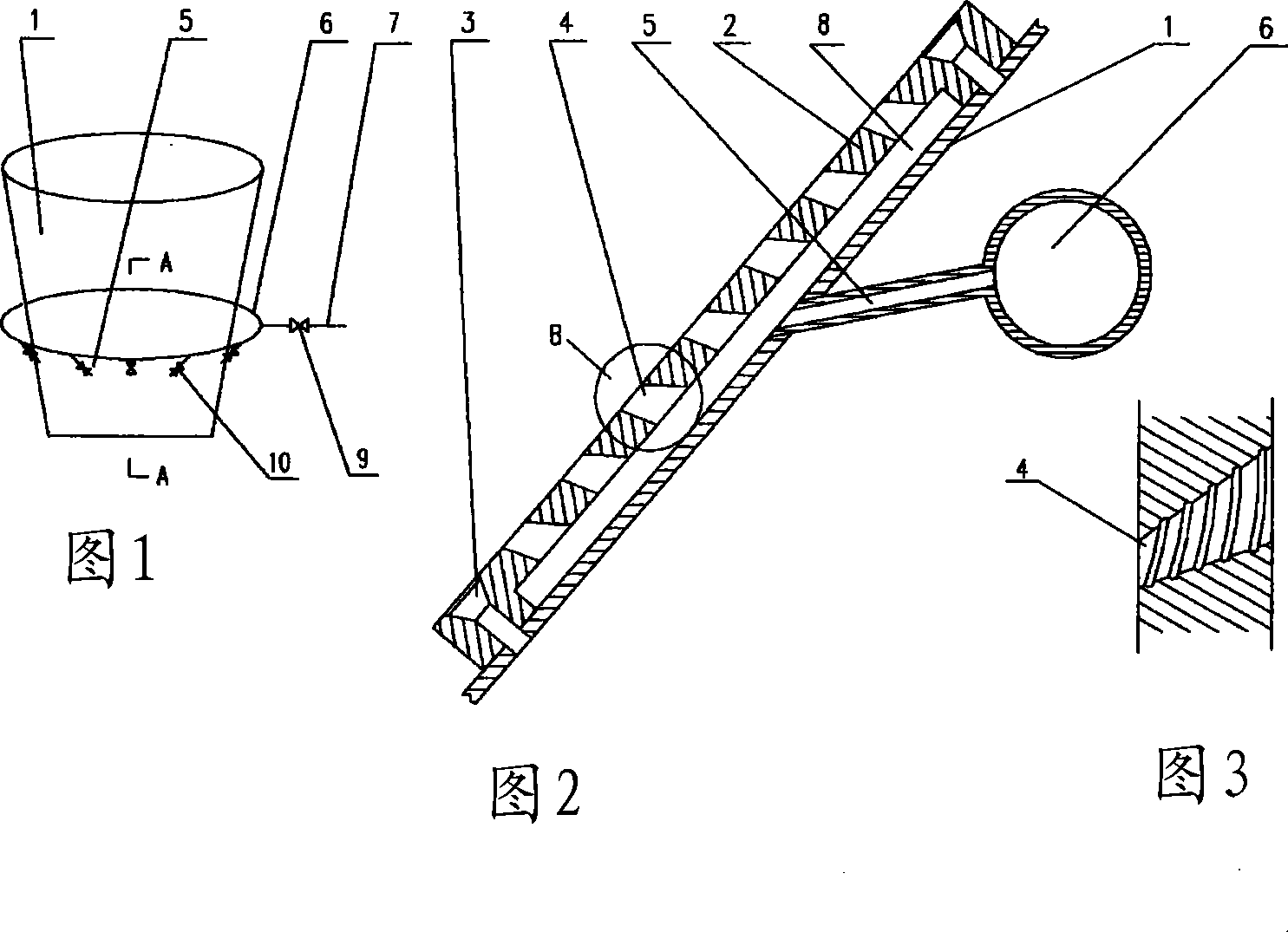

Method and device for preheating batch by using waste heat of fume from pure-oxygen combustion glass furnace

InactiveCN101830628AShorten melting timeRaise the preheat temperatureGlass productionCombustionGlass furnace

The invention relates to a method and a special device for preheating a batch by using the waste heat of fume from a pure-oxygen combustion glass furnace. The method comprises the following steps: granulating the glass batch; dehydrating and drying the grains; and preheating the grains by using a multilayer vertical turning plate preheating mode, wherein the glass batch and the hot fume are contacted indirectly, namely the fume radiates heat to the glass batch by convection, and the glass batch is preheated by a multilayer turning plate preheater to above 400 DEG C and then is delivered to the next process step. Multiple layers of turning plates and multiple flues are arranged in the preheating device, a fume inlet communicated with the flues is positioned on the outer side of the side water on the lower part of the preheater, a fume outlet communicated with the flues is positioned on the outer side of the other side wall on the upper part of the preheater, and the fume inlet and the fume outlet are arranged diagonally; the special preheating device is used to preheat the glass batch, the utilization rate of the waste heat of the high-temperature fume is high, no smoke dust pollution is produced; under self suction, the fume rises along the flues, so no power is consumed; the vertical structure occupies small floor area, so the replacement of space for time is realized; and the promotion and implementation of the device are easy.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

CS2 reactor furnace

The CS2 reactor furnace includes inner furnace body of refractory material, outer furnace body of refractory material, and heating chamber between the inner surface body and the outer furnace body. In the peripheral of the inner surface body, there are sulfur gasifying furnace and carbon material preheating furnace, and the sulfur gasifying, furnace is connected via sulfur vapor duct to the bottom of the inner furnace body. The CS2 reactor furnace of the present invention has no sulfurizing and oxidizing corrosion of inner furnace body and thus long service life. The material preheating speeds the reaction and raise the product yield. Heating the coal-burning gas furnace via the main fire channel communicated with the furnace body can save fuel and stabilize furnace temperature.

Owner:SHANGHAI BAIJIN CHEM GROUP

Rotary kiln lime roasting process

The invention discloses a rotary kiln lime roasting process comprising the following steps: (1), putting a raw material namely lime into a preheater for preheating at first, guiding the flue gas generated by pulverized coal combustion in a rotary kiln into the preheater to preheat the lime by using waste heat, and then discharging the lime, wherein the preheater is communicated with the kiln tail of the rotary kiln; and (2), roasting the preheated lime discharged from the preheater in the rotary kiln which is heated by burner nozzle pulverized coal injection, adding the roasted lime into a cooler from the kiln head to perform cooling, and finally discharging the cooled lime from the bottom of the cooler, wherein in the step (1), a pulverized coal spray gun is arranged at the lower part of the preheater to spray the pulverized coal accounting for 5-30% of the coal spraying quantity of the burner nozzle of the original rotary kiln into the preheater so as to improve the preheating temperature in the preheater, and the pulverized powder sprayed into the preheater is independently measured.

Owner:JIANGSU ZHONGSHENGYUAN TECH CO LTD

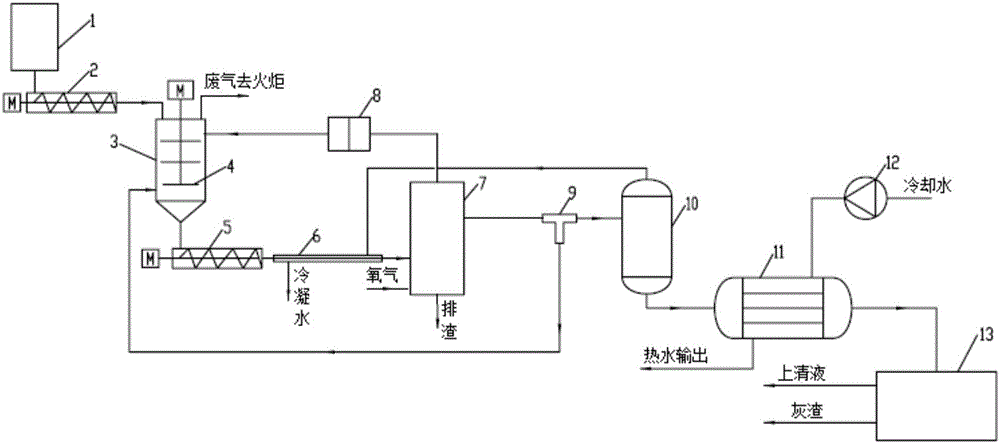

Sludge hydrothermal oxidization reaction system and method with function of product reflux pretreatment

ActiveCN106630526AFully warmed upLow viscositySludge treatment by thermal conditioningSludge treatment by oxidationLiquid productSludge

The invention discloses a sludge hydrothermal oxidization reaction system and method with a function of product reflux pretreatment, and belongs to the field of municipal sludge treatment. A gaseous product generated through hydrothermal oxidation is led out from the top of a reactor, residual oxygen and produced carbon dioxide after the reaction are removed, and then the gaseous product is introduced into a sludge pretreatment tank and directly contacted with sludge for preheating the sludge; a divided flow part of a liquid product flows back to the sludge pretreatment tank; steam and hot water preheat sludge under the stirring action, and the problem that heat recovered by the system is not enough to preheat the sludge to reach the feeding temperature is solved; the residual liquid product is treated with a vacuum flashing method, flash steam is recovered and sent to a pretreatment sludge feeding pipe for tracing heat, and meanwhile, a liquid phase after flash deoxidization enters a downstream heat-exchange device for waste heat recovery. With the adoption of measures, high-temperature material heat of the system can be recovered to preheat sludge, corrosion of dissolved oxygen to a heat exchanger can be relieved, system investment is reduced, and energy utilization rate and economic efficiency of the system are increased.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

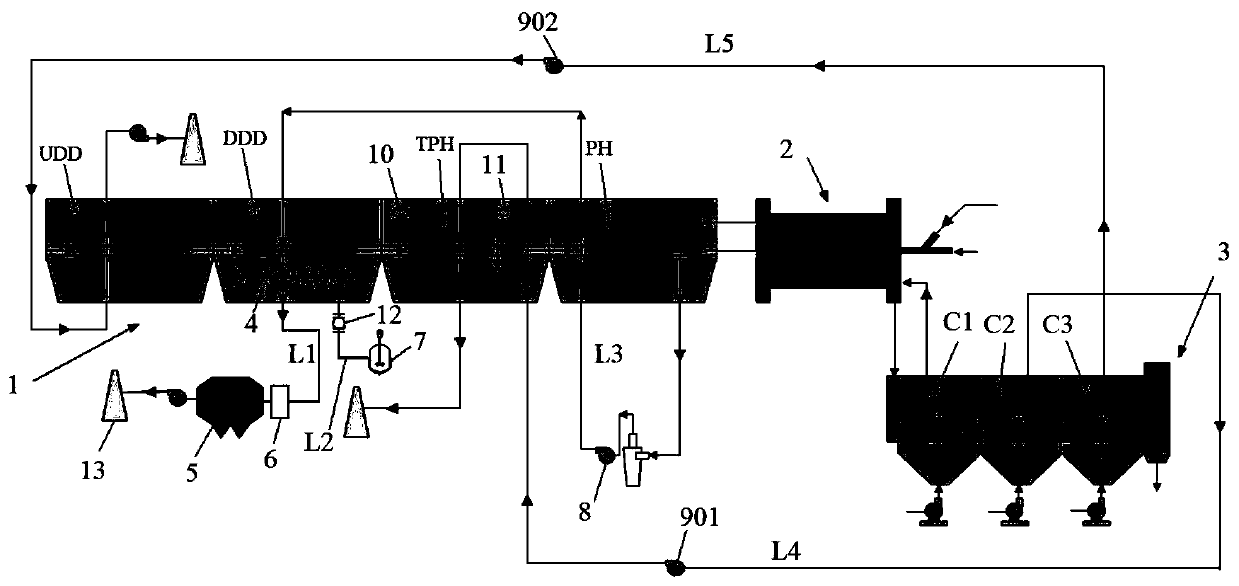

Oxidized pellet production process and system using chain grate-rotary kiln system

ActiveCN110894573AReduce wind temperatureIncrease wind temperatureRotary drum furnacesThermodynamicsProcess engineering

The invention discloses an oxidized pellet production process using a chain grate-rotary kiln system, which comprises the following steps: (1) green pellets are dried, preheated and oxidized through achain grate, then materials passing through the chain grate are conveyed to the rotary kiln to be roasted and then conveyed to an annular cooler to be cooled, and pellet ore is obtained; 2) hot air exhausted from the first circular cooling section is conveyed to the rotary kiln, the hot air exhausted from the rotary kiln is conveyed to a second preheating section, and the hot air exhausted from the second preheating section is conveyed to an air draft drying section in an air draft manner; 3) hot air exhausted from the second annular cooling section is conveyed to the first preheating sectionin an air blowing manner; and 4) the hot air exhausted from the third annular cooling section is conveyed to an air blast drying section in an air blast manner. According to the scheme, hot air is blown into the first preheating section, so that the air pressure in the first preheating section is greater than that of the second preheating section, and gas in the first preheating section does notneed to be denitrified; and meanwhile, a stable hot air area is formed in the first preheating section, and the preheating effect of upper-layer and lower-layer pellets is guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Gas dual-cycle radiant tube heating device

InactiveCN103255271ALower the preheat temperatureRaise the preheat temperatureEngineeringCore temperature

The invention discloses a gas dual-cycle radiant tube heating device. The part in a furnace of the device is a closed inner-ring gas circulating line composed of a first straight tube, a first bend, a second straight tube, a second bend, a third straight tube, a third bend, a fourth straight tube and an added smoke return tube, and the part outside the furnace of the device is an outer-ring gas circulating line composed of an empty smoke switching device, a mixed gas conveying tube and a nozzle. The heating device overcomes the defects that the temperature distribution of a radiant tube along the length direction is non-uniform and the local temperature is high. Returned smoke and combustion flame are mixed through inner-ring gas circulating so as to reduce the core temperature of flame, enhance the uniformity of the surface temperature distribution of the radiant tube, prolong the service life, and reduce the generation of thermal NOx; since the smoke return tube is added, the effective radiation heat exchange area in the furnace is enlarged, and the outer-ring gas circulating is capable of effectively improving the pre-heating temperature of gas, reducing the oxygen content in air and realizing low-temperature combustion, thereby increasing the heat efficiency while alleviating pollution.

Owner:UNIV OF SCI & TECH BEIJING

Preheating method and device for sintering mixture

The utility model discloses a steam preheating method for sinter mixtures and the device thereof, belongs to a sintering process in ferrous metallurgy, and helps to increase the heat exchange efficiency of steam preheating of sinter mixture, save the energy, increase the temperature of preheating the sinter mixture, reduce the energy consumption in sintering process, and increase the yield per machine hour. The technical proposal is that the superheated steam is produced by the waste heat from the sintering process and is introduced to a mixture bin; a steam chamber plate is fixed inside the bin and coupled with the inner wall of the bin, forming a steam chamber; the superheated steam is delivered to the steam chamber by using a branch pipe passing through the bin wall from a link ring pipe; all steam chamber plate are combined and encircled around the bin inner wall to form a ring-shaped preheating zone with heat exchange effect in double heat-conduction mode; and the mixture is pre-heated under the operational conditions (temperature rise up to 55-67 DEG C), thereby increasing the heat exchange efficiency. Compared with the prior art, the invention can increase the retreating temperature of mixture, reduce the solid fuel consumption for ore sintering by 3kg / t, and increase the yield per machine hour by 2 percent.

Owner:ANGANG STEEL CO LTD

Self-pre-heating type nozzle for efficient helical fin

InactiveCN106196073AReduce generationIncrease the heat exchange areaIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorCombustion chamber

A self-pre-heating type nozzle for an efficient helical fin comprises a gas pipe, an air shell, an air opening formed in the outer side of the air shell and an exhaust opening, and further comprises a helical fin air guiding pipe and a helical fin heat exchanger pipe. The air shell is internally provided with an air cavity and communicates with the air opening. The front end of the helical fin air guiding pipe is fixedly arranged in the air shell and communicates with the air cavity. The helical fin heat exchanger pipe is connected to the surface of the helical fin air guiding pipe in a sleeving manner, and the front end of the helical fin heat exchanger pipe is arranged in the air shell and communicates with the air cavity. The surface of the helical fin heat exchanger pipe is connected with a smoke guiding pipe in a sleeved manner, and the smoke guiding pipe communicates with the exhaust opening. One end of the gas pipe is arranged in the helical fin air guiding pipe and is connected with a primary combustor, and the other end of the primary combustor is fixedly arranged at the rear end of the helical fin heat exchanger pipe. By means of the self-pre-heating type nozzle, the temperature of pre-heated air can be effectively improved, the combustion efficiency of fuel can be improved, NOx emission can be reduced, energy sources can be saved, and the cost can be reduced.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

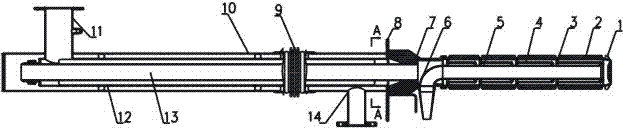

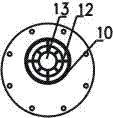

Triple-stroke air-preheating radiant tube burner heat exchanger

InactiveCN102818268ARealize three-stroke preheatingRaise the preheat temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerRecuperatorEngineering

The invention provides a triple-stroke air-preheating radiant tube burner heat exchanger for raising the air-preheating temperature, lowering the exhaust gas temperature, improving the temperature efficiency and thermal efficiency of a heat exchanger. The triple-stroke air-preheating radiant tube burner heat exchanger comprises an end part choke plug, an inner fin tube, a multi-hole jet flow tube, a baffle ring, a middle duct, an air jet tube, a middle heat exchange duct, an exhaust gas stream guidance apparatus, a special-shaped flange, an external air duct, an expansion joint, a central fin heat exchange tube, an external heat exchange tube, an exhaust gas outlet tube and an air inlet tube, wherein the heat exchanger is divided into a build-in heat exchange region and an external heat exchange region by the special-shaped flange and the expansion joint. According to the triple-stroke air-preheating radiant tube burner heat exchanger, the air preheating temperature is improved, the exhaust gas temperature is lowered, and the temperature efficiency and thermal efficiency of the heat exchanger are improved.

Owner:WISDRI WUHAN WIS IND FURNACE

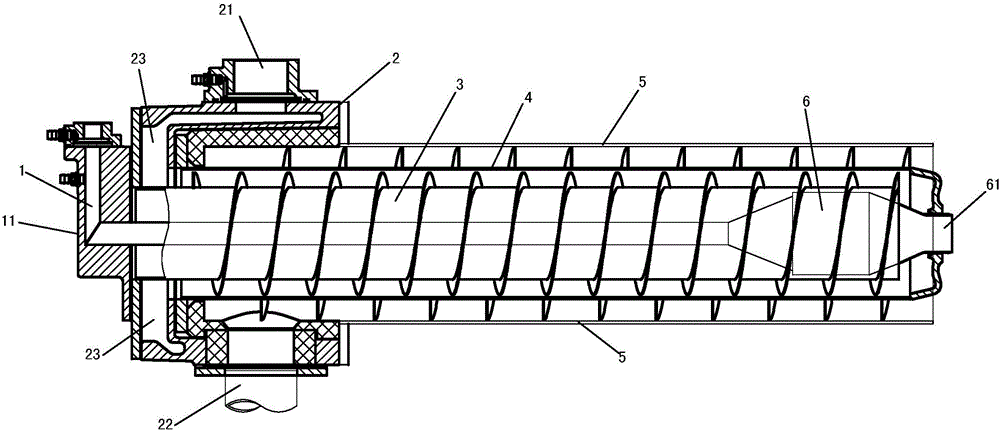

Heat storage gas heating device and heat storage gas heating method

InactiveCN104832922ARaise the preheat temperatureHigh thermal efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerChemical industryPetroleum

The invention belongs to the field of the heat-storage heat exchanging and heating, and relates to a gas heat-storage heating device. The gas heat-storage heating device comprises two partition-type porous ceramic heat storage chambers, a low-temperature four-way reversing valve and a high temperature three-way reversing valve. High-temperature smoke heats a partition-type porous ceramic heat storage body, the heat in the smoke is adequately transferred to the porous ceramic by virtue of the high-efficiency heat exchanging of the smoke and the porous ceramic; low-temperature gas enters the porous ceramic heat storage chambers in a direction opposite to the flowing of the smoke to adequately contact the porous ceramic, and the low-temperature gas is heated to the high temperature. The heat storage gas heating device has the beneficial effects that the gas material is efficiently heated, the structure is simple and compact, flexibility in operation and convenience in overhauling and maintenance can be realized, and the requirement for efficiently heating the gas material at the high temperature in the fields such as petroleum, chemical industry, metallurgy, machinery and the like can be met.

Owner:DALIAN UNIV OF TECH

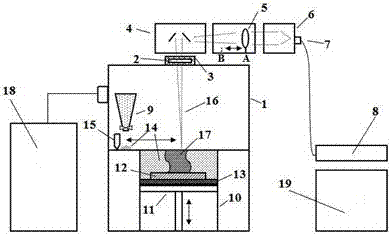

Preheating and insulation device for laser selective melting forming

InactiveCN107983955ARaise the preheat temperatureNot easy to loseAdditive manufacturing apparatusCeramic shaping apparatusWorking environmentOptoelectronics

The invention discloses a preheating and insulation device for laser selective melting forming. Compared with existing laser selective melting equipment, the working environment of the preheating andinsulation device is the vacuum environment with the pressure being 10-1 Pa or above, convection in the vacuum environment is weak, heat is not liable to be dissipated, the preheating and insulation effects can be greatly improved, due to the good heat insulation performance, equipment sensitive elements are not damaged due to obvious temperature increase even though the preheating temperature ishigh, and the preheating temperature of the laser selective melting equipment can be greatly increased; a single laser is used as a light source, conversion of preheating scanning and forming scanningis achieved through moving of a focus lens, and the better economical efficiency is achieved compared with the mode that two lasers are used (one of the two lasers is used for preheating scanning, and the other laser is used for forming scanning); and compared with electron beam selective melting equipment, the laser selective melting equipment is especially suitable for forming magnetic or non-conducting materials, finer powder can be used, the part forming precision is higher, and the market prospects are broad.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

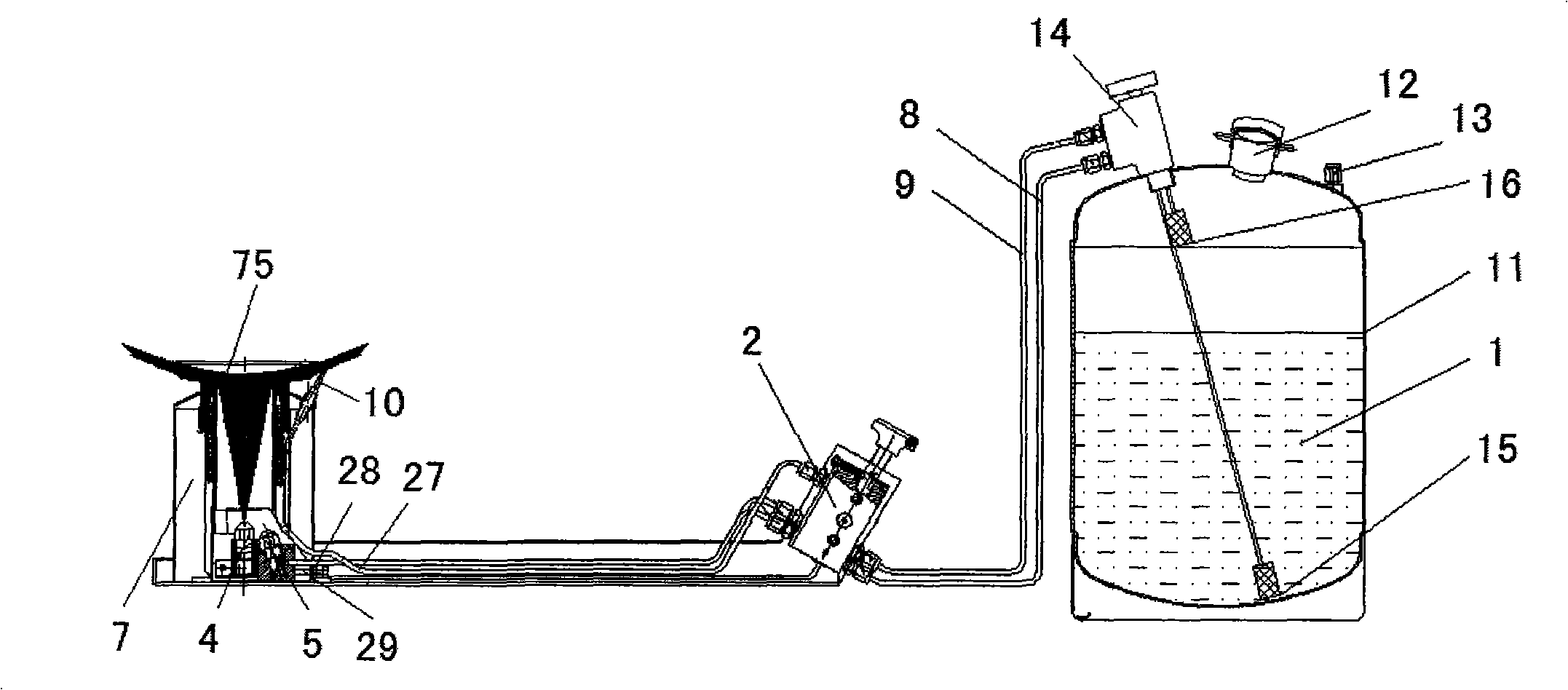

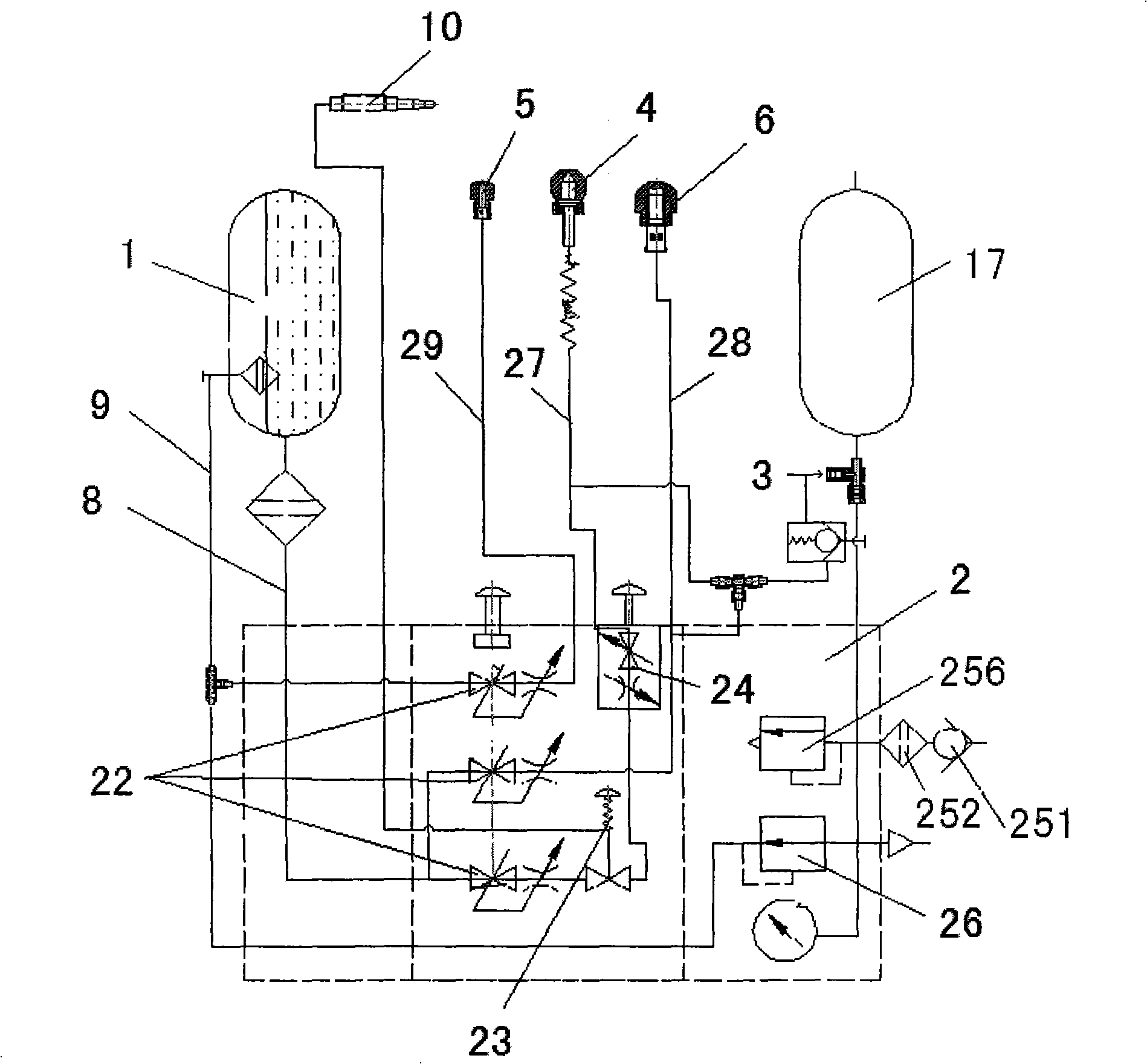

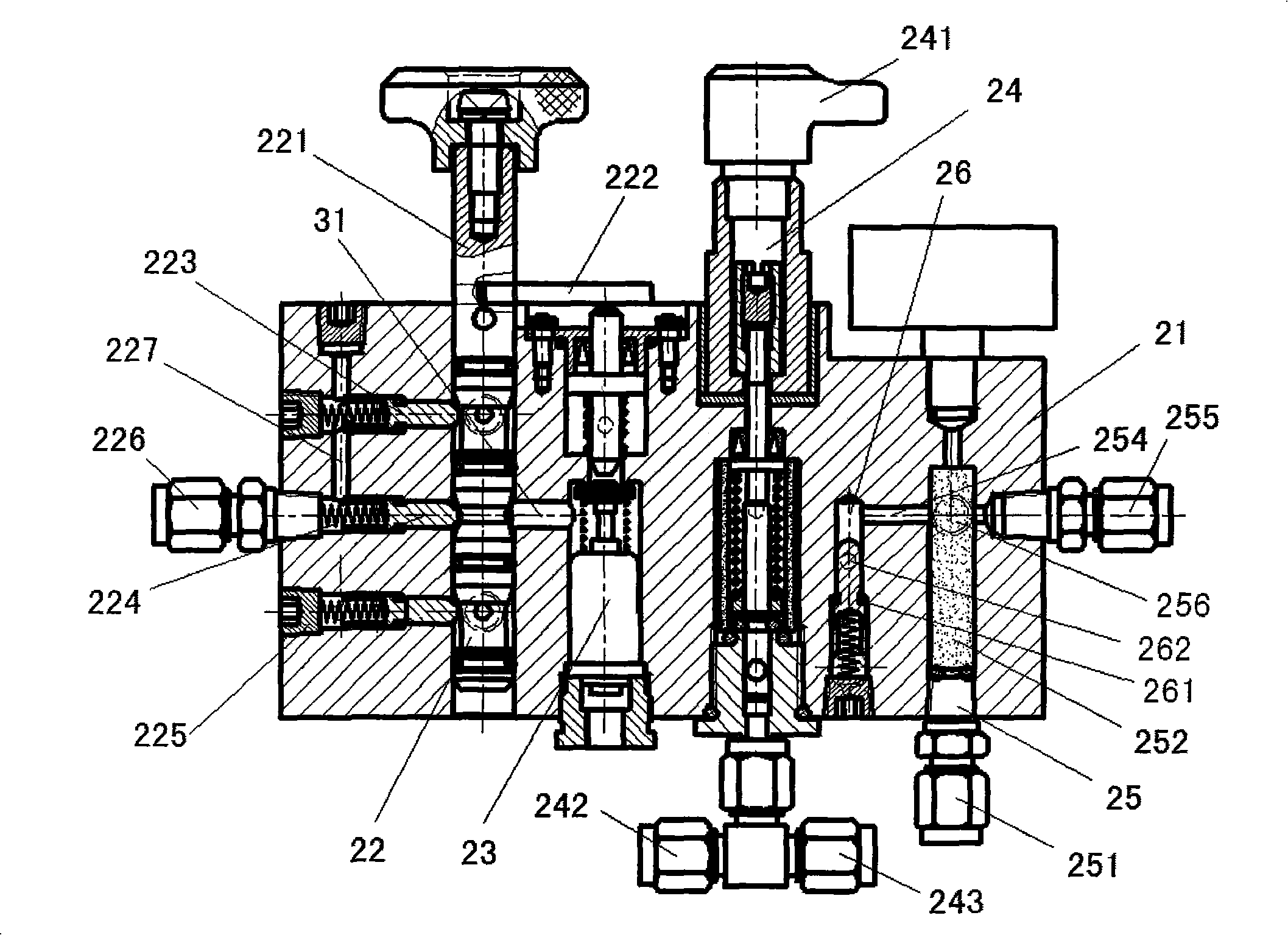

Mixed-oxygen preheating oil burning system

InactiveCN101539291AImprove combustion efficiencyBurn fullyCombustion using gaseous and pulverulent fuelBurnersCombustionEngineering

The invention relates to a mixed-oxygen preheating oil burning system. The system comprises an oil storage tank, a control valve, a combustion apparatus and corresponding connecting pipelines. The oil storage tank comprises a tank body. The top of the tank body is provided with an oil filling opening, a gas filling opening and an oil-gas switch. The inner end of the oil-gas switch is connected with an oil suction pipe extending to the bottom of the tank body and a gas transfer pipe at the upper part in the tank body. The outer end of the oil-gas tank is connected with an oil transfer pipeline and a gas transfer pipeline. The control valve comprises a valve body provided with a switch valve, an electromagnetic valve, an adjusting valve and a pressure maintaining valve thereon. The combustion apparatus comprises a grate, a heat-insulation cylinder, a preheating pipe, a fire cylinder, a fire distributing cylinder, a main oil burner, a preheating oil burner and a compressed air burner. The invention has the advantages of high preheating temperature, adequate combustion and safety. The invention can be widely used in the occasions needing oil burning stoves.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Heat storage type gas radiation pipe burning machine

InactiveCN1570467ARaise the preheat temperatureImprove combustion efficiencyCombustion processFurnace typesCombustion chamberStraight tube

The invention discloses a heat storage coal gas pipe radiator combustion engine. Belonging to indirect calefaction device, it is adopted on steel, mechanism works' protection atmosphere heat treatment stove and porcelain enamels' heating furnace. The lumen in the front of pipe eradiator in U / W shape is combustion chamber. The secondary gas jet and heat retaining mass are set in two rear straight tube lumens. Gas pipe is set in the center of each straight pipe. Passing through the heat retaining mass, the gas pipe's front end connects with the secondary gas jet. Ignition passage which transfers remote ignition kindling to the secondary gas jet is also set in the center of straight tube. The front end of ignition passage directly reaches to the secondary gas jet and rear end connects with remote igniter. The remote igniter is an airtight cavity in long canister shape. Along ignition kindling progress direction in ignition cavity, ignition gas tube, ignition wind tube and high-pressure ignition head are set in turn. Technical scheme of the invention is novelty, reasonable, simple and effective.

Owner:赵升智

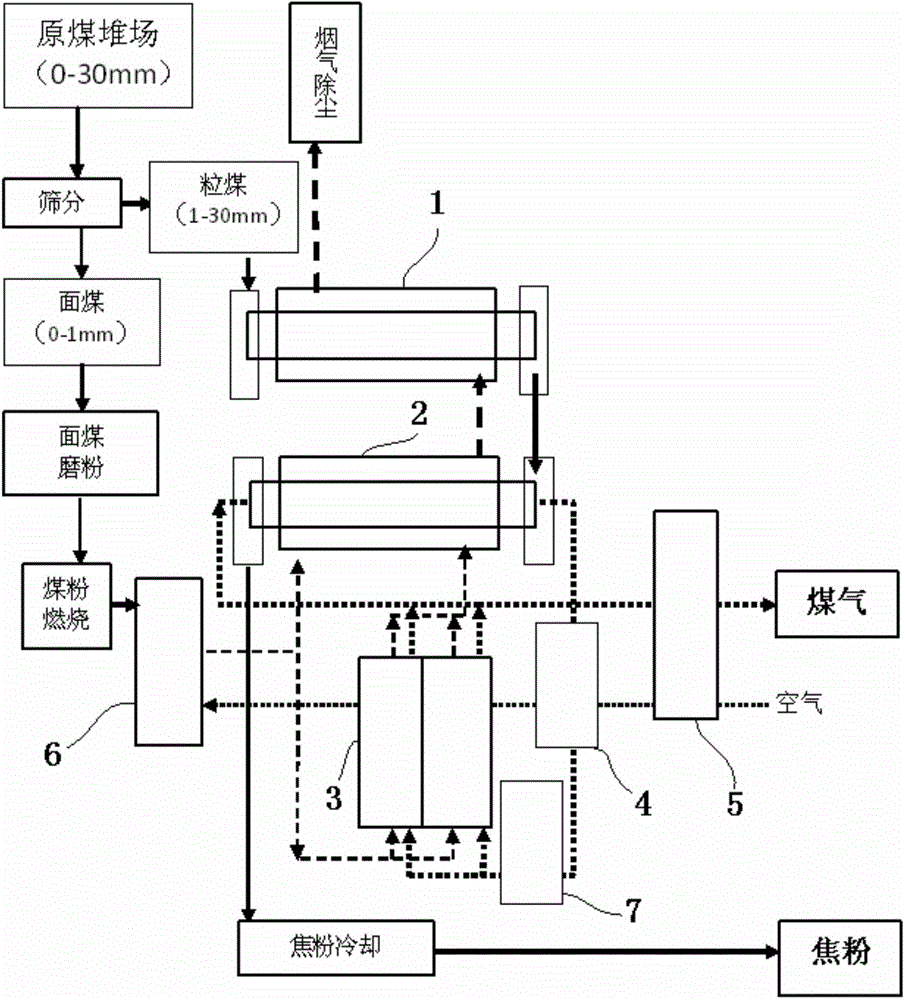

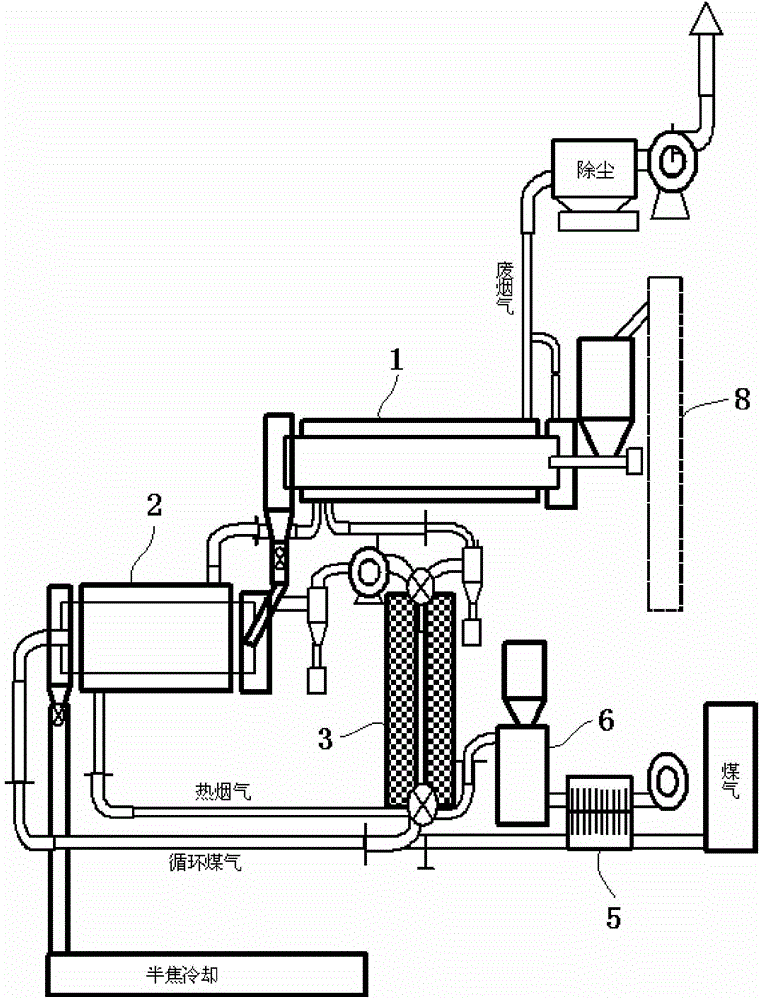

Method and device for producing coal gas by pulverized coal pyrolysis

InactiveCN103980951APlay a filtering roleEasy to transportIndirect and direct heating destructive distillationGas purification by catalytic conversionWater vaporProcess engineering

The invention relates to a method and device for producing a coal gas by pulverized coal pyrolysis. The coal gas production method disclosed by the invention comprises the following step: with an unpurified raw gas which is obtained from raw coal by dry distillation pyrolysis as a raw material, producing the high-quality coal gas inside a regenerative chamber in a pyrolysis manner. The device disclosed by the invention comprises a raw coal drying oven, a dry distillation furnace, a regenerative chamber for pyrolyzing the raw gas, and a hot blast heater for supplying heat. The raw gas is pyrolyzed to produce the coal gas, water vapor in the raw gas reacts with coke powder to produce a water gas, and meanwhile tar is cracked into the coal gas, so as to serve multiple purposes. The method and device disclosed by the invention have the advantages of low energy consumption, low investment, high calorific value of the gas, low semicoke ash and low coal quality transformation cost.

Owner:CHANGAN UNIV

Catalytic conversion method for selective preparation of micromolecular olefin

ActiveCN1721505AGood Small Molecule OlefinGood choiceOrganic chemistryCatalytic crackingReaction temperatureRare earth

The selectively small molecular weight olefin preparing process includes contacting hydrocarbon oil material with rich C4-C8 olefin with catalyst inside the catalytic cracking reactor and reaction at the conditions of temperature 550-700 deg.c, pressure 0.01-0.2 MPa, weight hourly space velocity 1-20 / hr and catalyst / oil ratio 5-30. The catalyst consists of clay 10-70 wt%, inorganic oxide 5-75 wt%, and zeolite 10-70 wt%, the zeolite is high silicon zeolite in five-element cyclic structure containing P and RE and modified with one or several of Fe, Zn, Mg and Ag, and the clay contains rectorite in 10-50 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

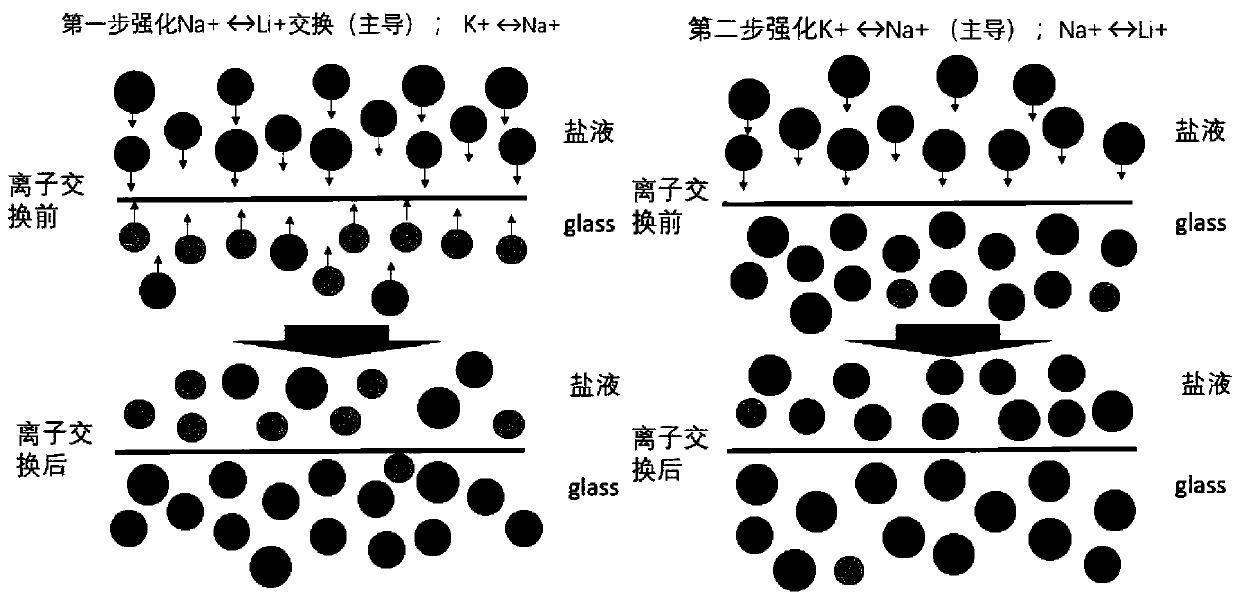

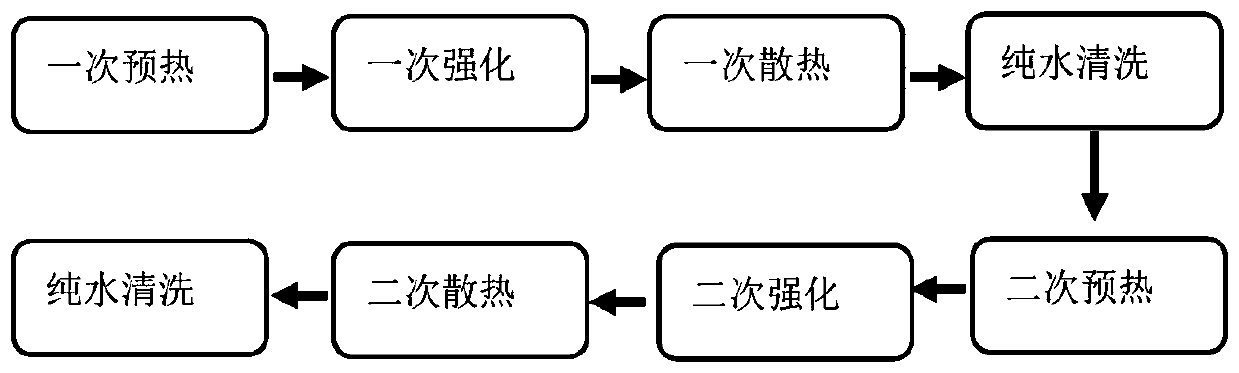

Method for chemically strengthening lithium-aluminum-silicon glass

ActiveCN111087178AIncrease concentrationShorten the strengthening timeCleaning using liquidsPotassium nitrateSalt solution

The invention discloses a method for chemically strengthening lithium-aluminum-silicon glass. The method comprises the following steps: 1) preheating the lithium-aluminum-silicon glass for the first time, and carrying out strengthening for the first time by adopting a mixed molten liquid of potassium nitrate and sodium nitrate as a strengthening salt solution, wherein the temperature of strengthening for the first time is 380-395 DEG C, and the time of strengthening for the first time is 4-6 hours; 2) performing heat dissipation on the glass subjected to strengthening treatment for the first time, and carrying out cleaning by adopting purified water; 3) preheating the glass obtained in the step (2) for the second time, and carrying out strengthening for the second time by adopting the mixed molten liquid of potassium nitrate and sodium nitrate as the strengthening salt liquid, wherein the temperature of strengthening for the second time is 395-410 DEG C, and the time of strengthening for the second time is 2-4 hours; and 4) performing heat dissipation on a product subjected to strengthening for the second time, and carrying out cleaning with the purified water so as to obtain strengthened lithium-aluminum-silicon glass. The method provided by the invention can improve CS and DOL of the product and better monitor the influence of a salt solution on strengthening performance, sothe product has good impact resistance and bending resistance.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD +1

Coupling equipment for realizing temperature adjustment and stripping of catalytic cracking regenerant

InactiveCN101760229AImprove heat extraction and heat exchange efficiencyInhibitory inactivation effectCatalytic crackingFlue gasEngineering

The invention provides coupling equipment for realizing the temperature adjustment and the stripping of catalytic cracking regenerant, which comprises a temperature adjustment section arranged at the upper part and a stripping section arranged at the lower part; the temperature adjustment section is provided with a built-in heat exchange component and at least an air distributor; and the temperature adjustment section extends downwards and reduces the circulation area to form the stripping section. By coupling the stripping area with quite small circulation area at the lower part of the temperature adjustment section, the invention can realize the function of flue gas removal without or only with a small amount of stripping steam, and can best inhibit the inactivation of the regenerant under the steam atmosphere. The coupling equipment of the invention can be arranged in a regenerant circulating pipeline of a catalytic cracker, so that the regenerant directly enters a rise reactor after the temperature is adjusted and the flue gas is removed, thereby not only significantly improving the oil ratio, the regeneration temperature and the raw material pre-heating temperature of the catalytic cracker and facilitating the improvement of product distribution, but also having the function of glue gas removal and reducing the load of a rich gas compressor and the energy consumption of the device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com