Patents

Literature

566results about "Gas purification by catalytic conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

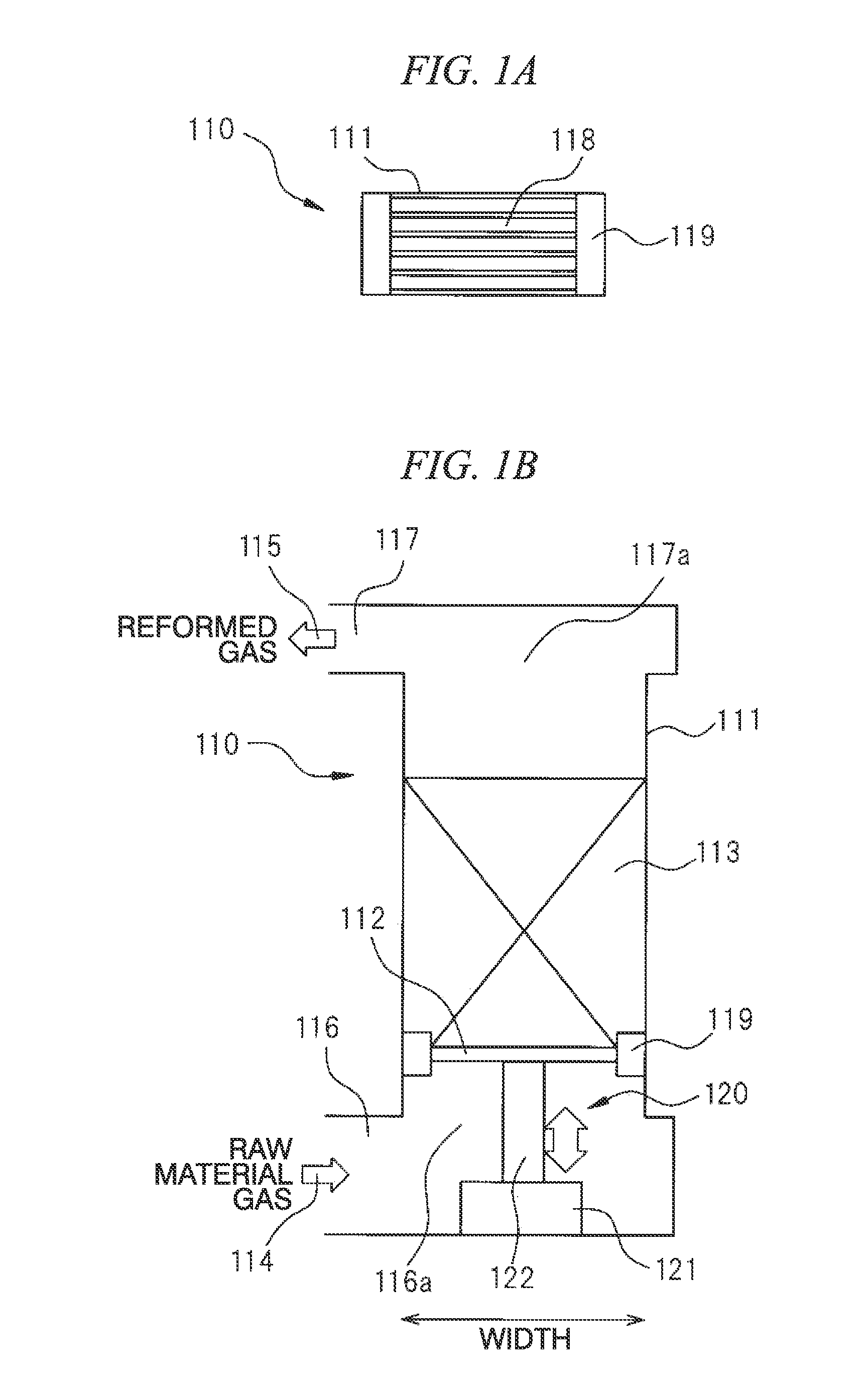

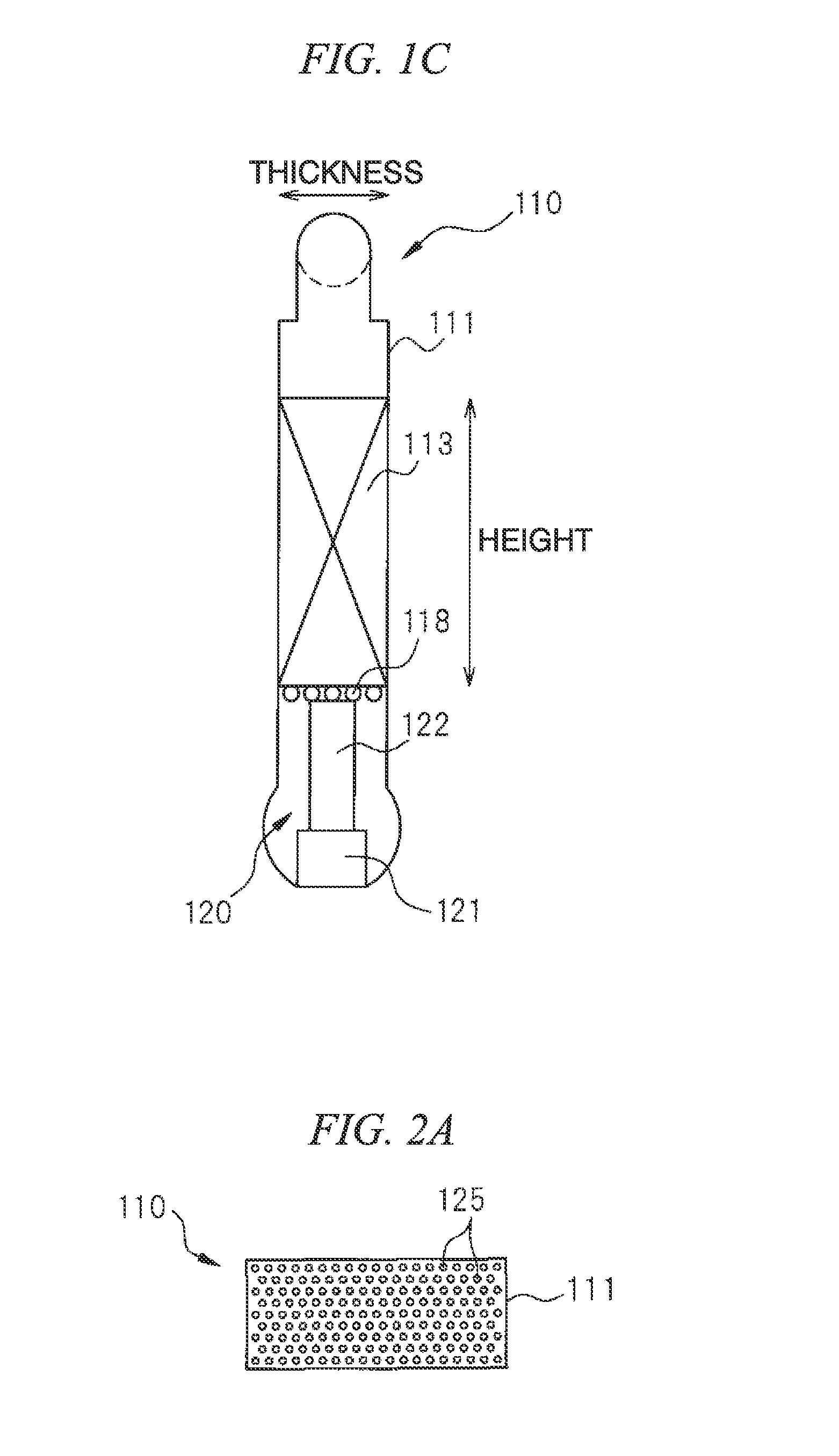

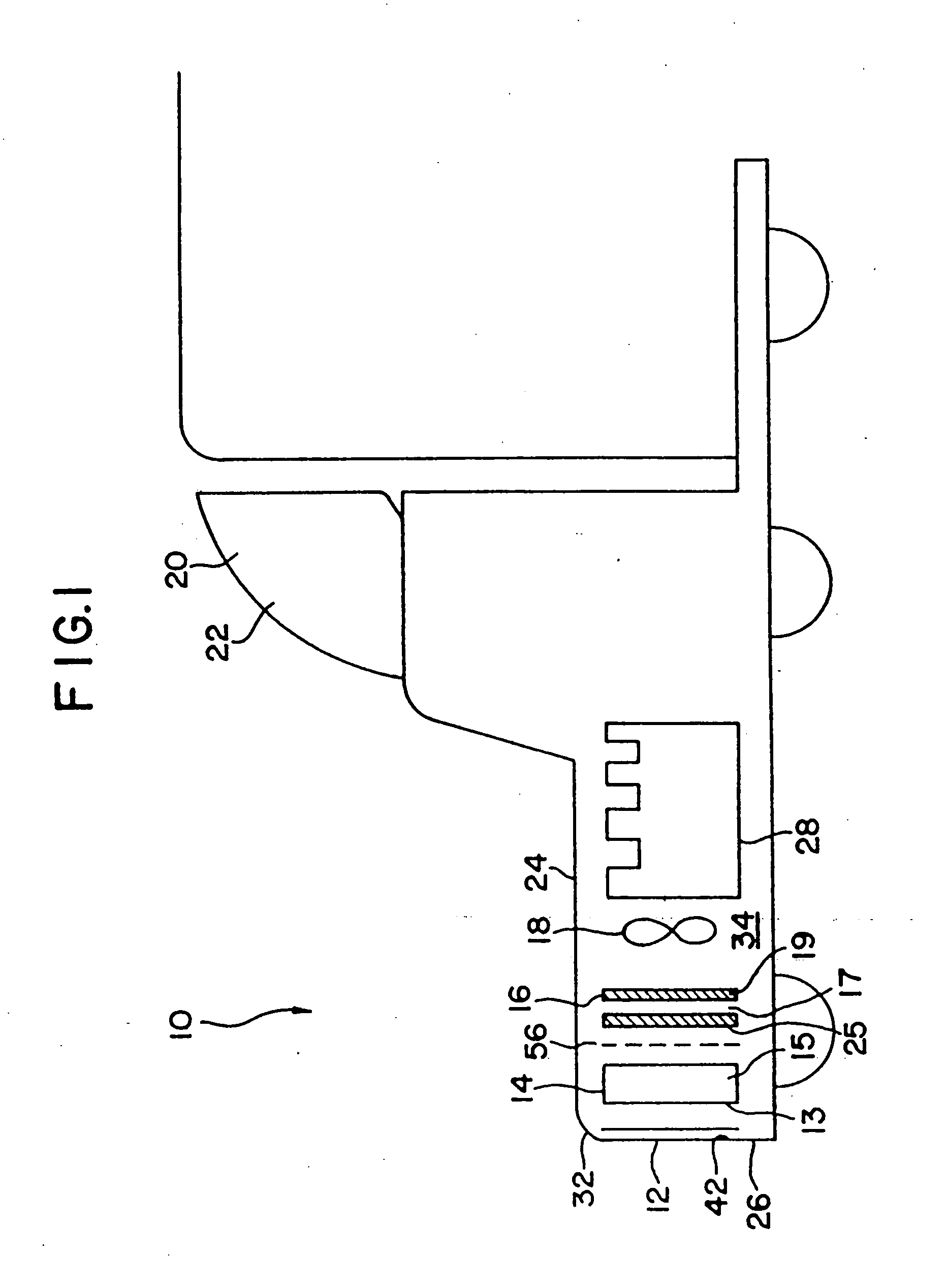

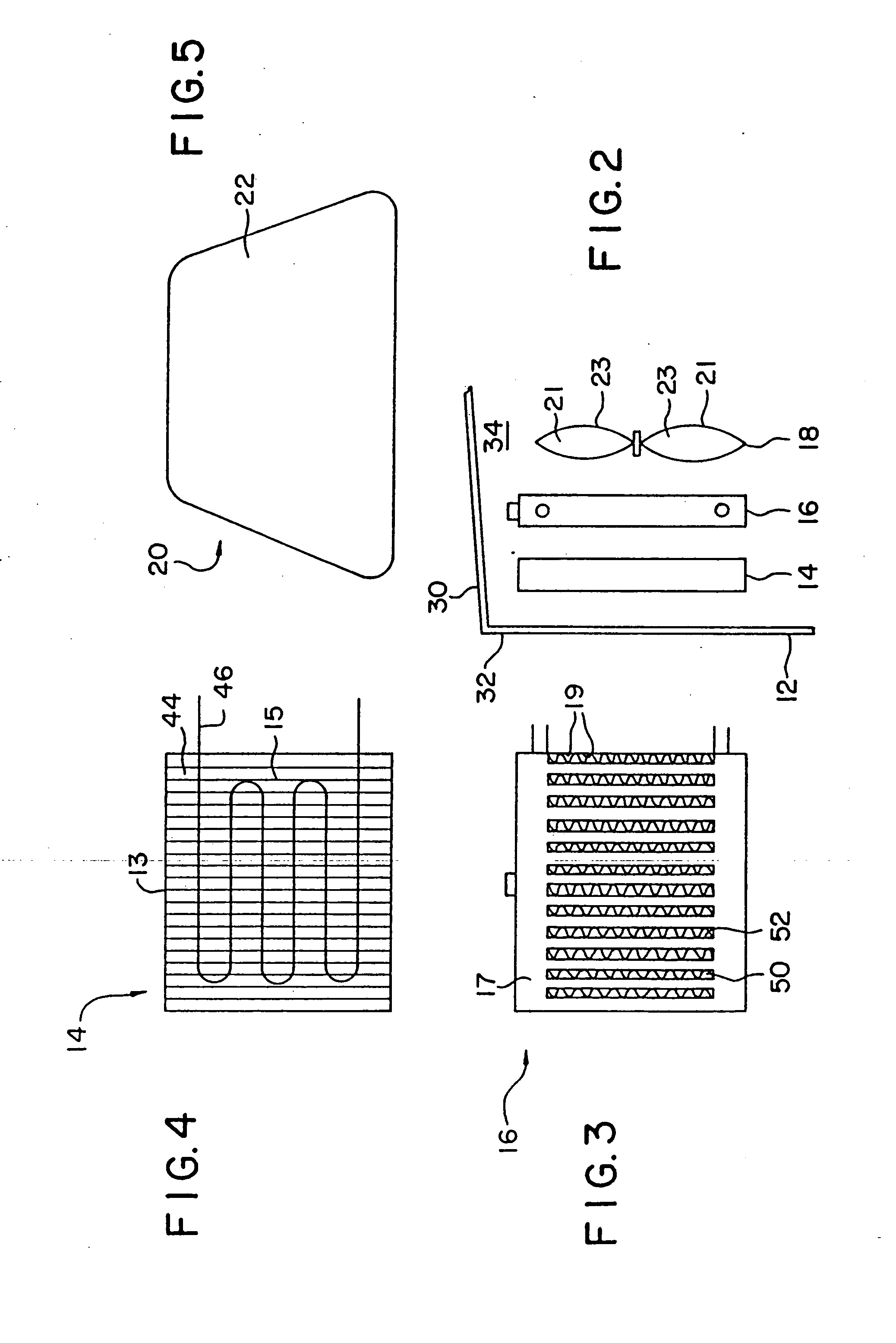

Continuous fixed-bed catalytic reactor and catalytic reaction method using same

ActiveUS20150010467A1Efficient removalImprove efficiencyCatalytic gas-gas reactionGaseous chemical processesFixed bedChemistry

A continuous fixed-bed catalytic reactor includes an inflow path for raw material gas for a catalytic reaction and an outflow path for reformed gas, a catalytic reaction container that is connected to the inflow path and the outflow path and holds a clumpy catalyst, catalyst holders that have a ventilation property and hold the clumpy catalyst, and a driving mechanism that moves the clumpy catalyst up and down by moving the catalyst holders up and down.

Owner:NIPPON STEEL CORP

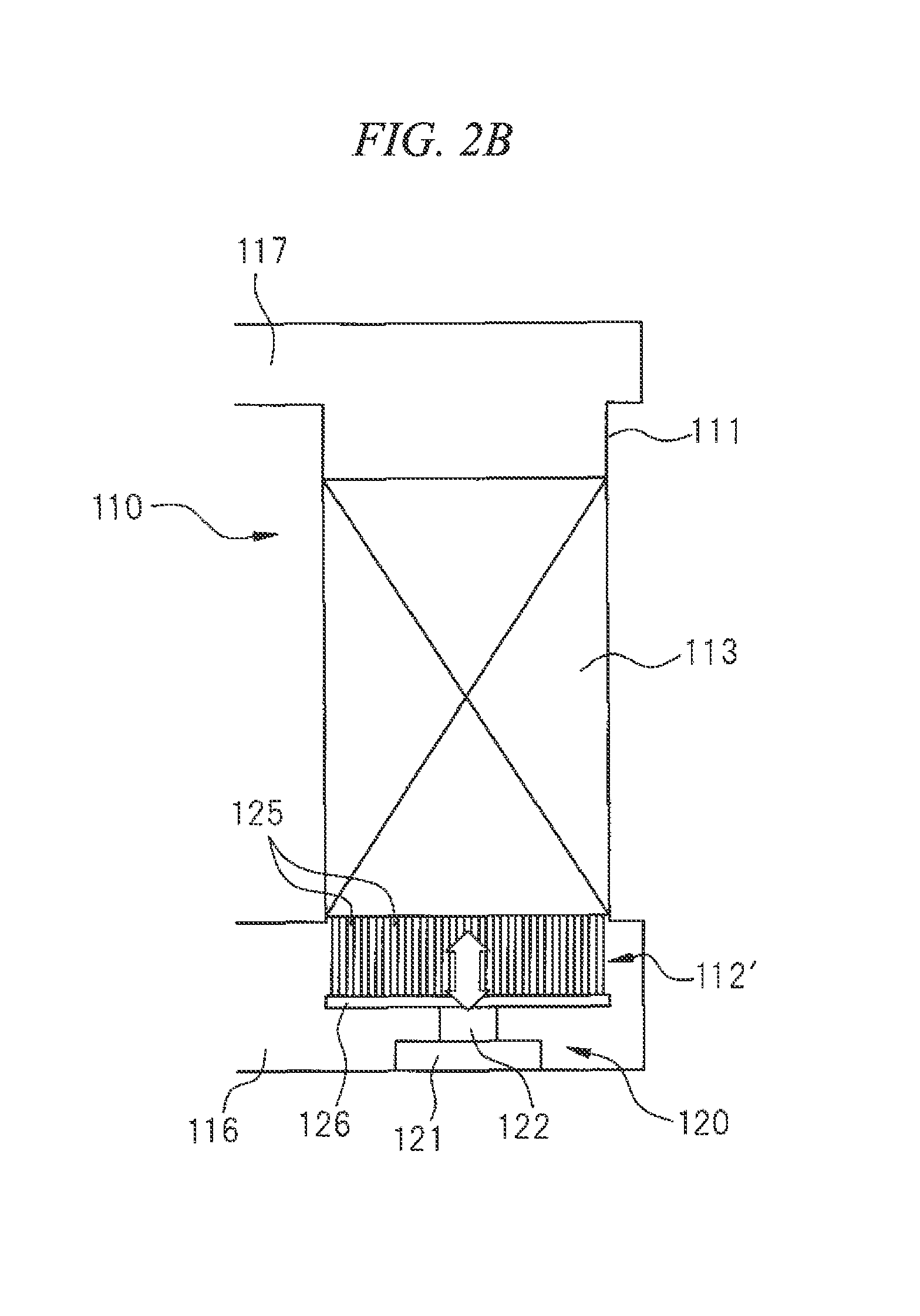

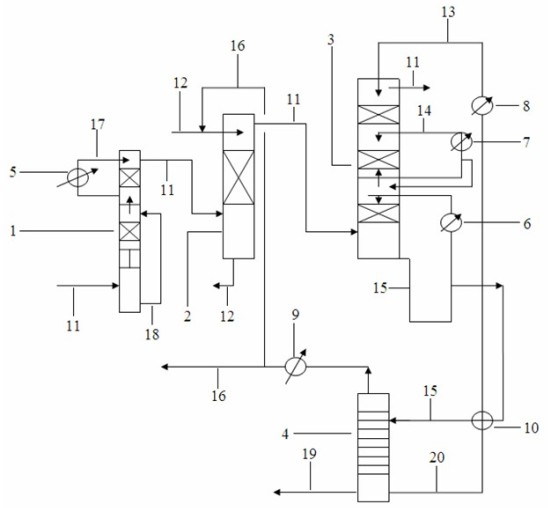

Catalytic deoxidation process of oxygen-contained coal bed gas

InactiveCN101613627AReduced activityHigh activityGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsFixed bedProduct gas

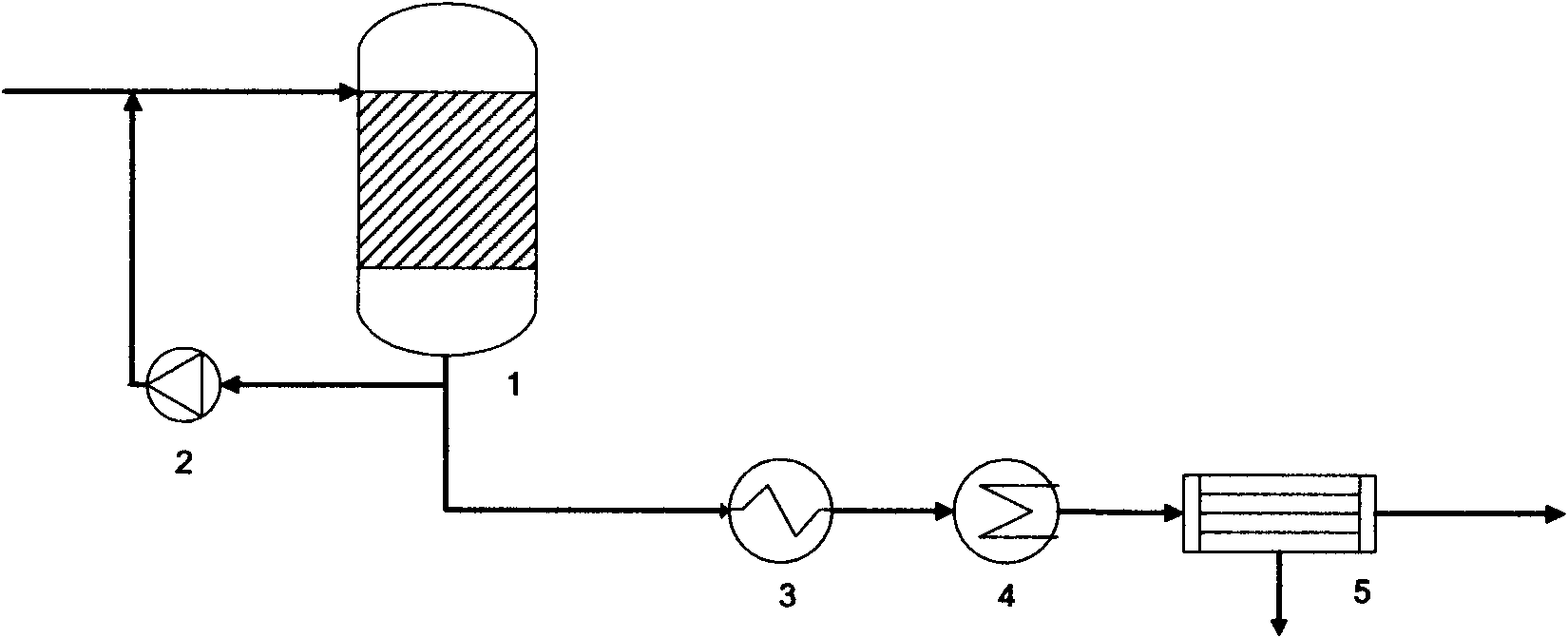

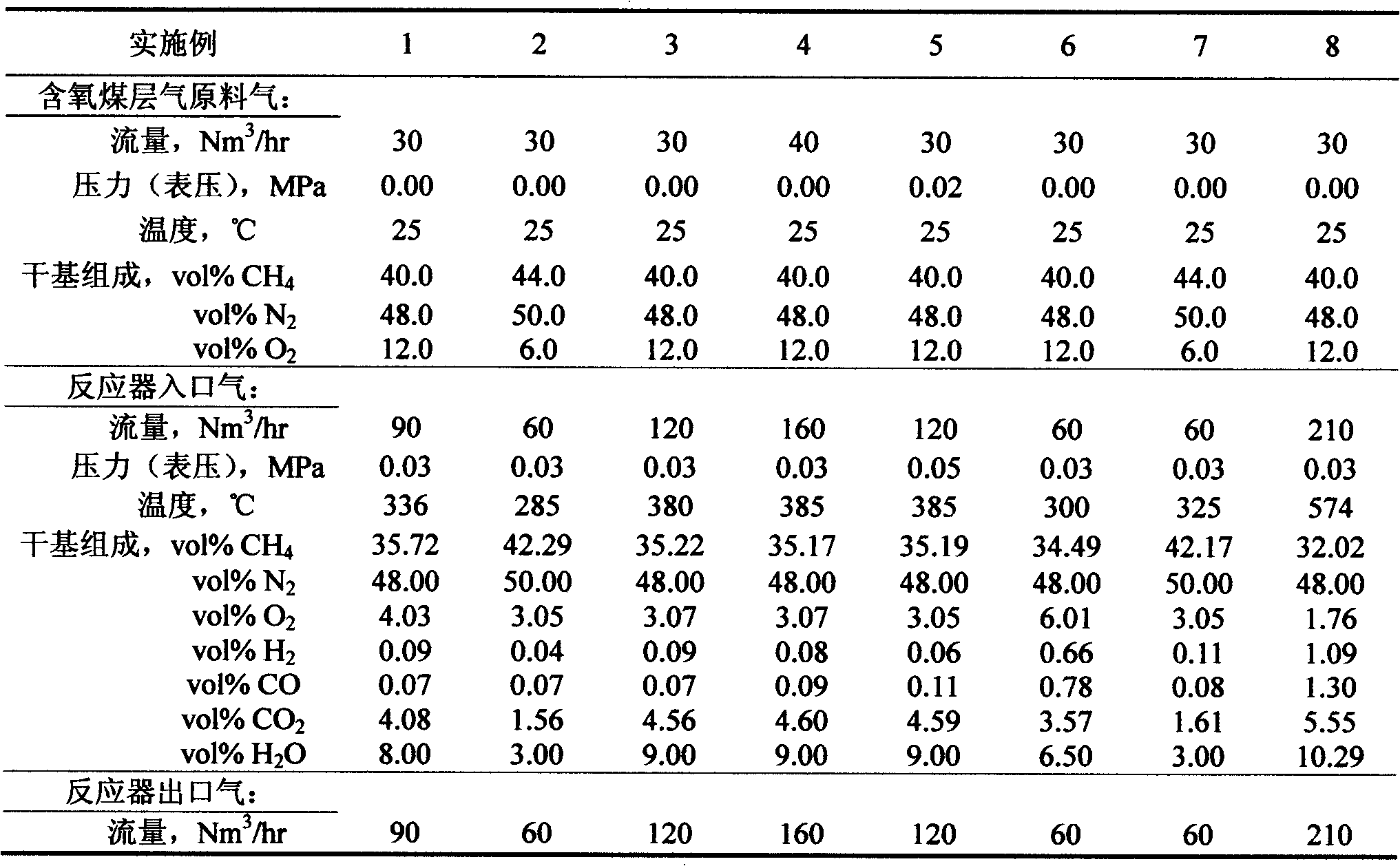

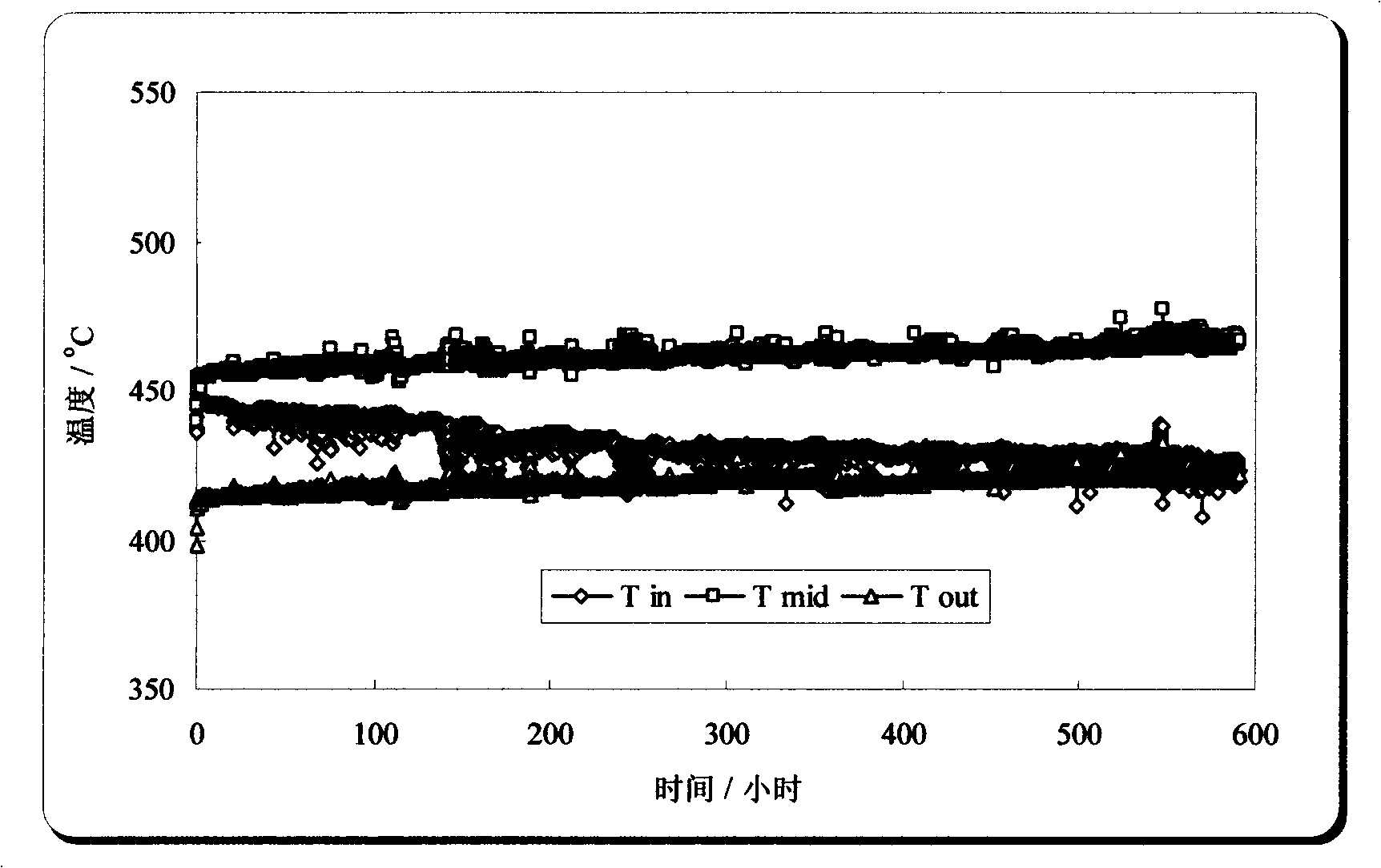

The invention relates to a catalytic deoxidation process of oxygen-contained coal bed gas. The oxygen-contained coal bed gas and coal bed gas product gas returned with a certain recycle ratio are mixed to go to a fixed bed adiabatic catalytic reactor, methane in the coal bed gas is reacted with oxygen to generate carbon dioxide and water, thereby the concentration of the oxygen in the coal bed gas product gas is reduced to be lower than 0.2 percent. The invention can effectively remove the oxygen in the oxygen-contained coal bed gas with the concentration of the oxygen of 1-15 percent, the recovery ratio of the methane is similar to theoretical recovery ratio obtained by calculation according to complete conversion of the methane and the oxygen, and security risk which exists in subsequent coal bed gas separation (liquification, pressure varying adsorption, barrier separation, and the like) technical process can be completely eliminated due to the low-concentration oxygen in the product gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Coal bed gas deoxidation catalyst as well as preparation method and application thereof

InactiveCN101664679AExtend your lifeElimination of active oscillationsGas purification by catalytic conversionCatalyst activation/preparationRare-earth elementAlkaline earth metal

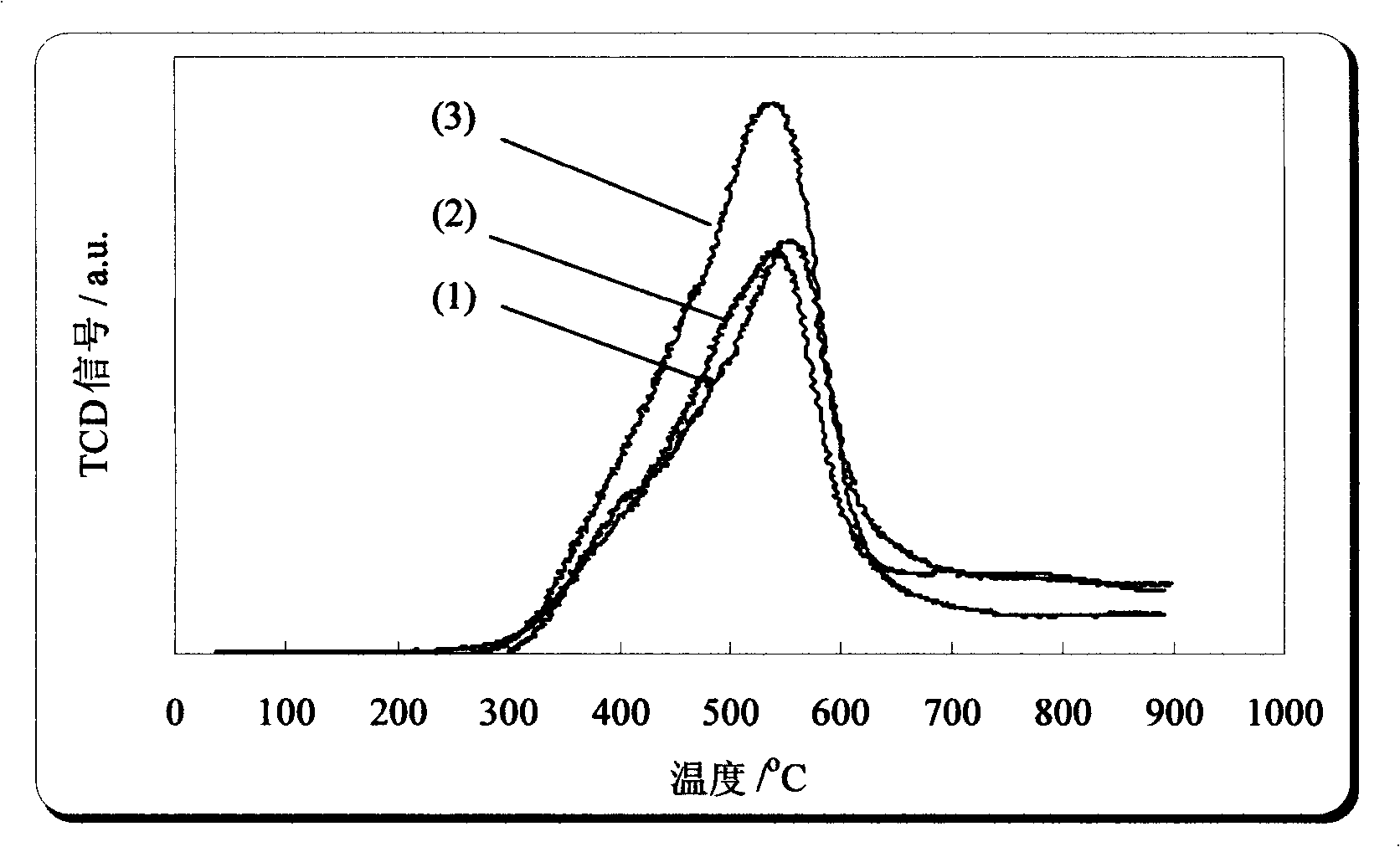

The invention relates to a coal bed gas deoxidation catalyst as well as a preparation method and the application thereof. The coal bed gas deoxidation catalyst takes one or the combination of severalplatinum group noble metals, i.e. Pd, Pt, Ru, Rh and Ir, as main catalyzing active components and takes one or the combination of several alkali metal / alkaline-earth metal oxides, i.e. Na2O, K2O, MgO,CaO, SrO and BaO, and multi-element compound oxides of CeO2, lanthanide series rare earth elements, i.e. Pr, Nd, Sm, Eu, Gd, and the like, or / and transition elements, i.e. Y, Zr, La, and the like, or / and gamma-Al2O3 as auxiliary catalysts, and the catalyzing components are loaded on an inert carrier in a coating way so as to prepare an integral catalyst. The coal bed gas deoxidation catalyst hasthe advantages of low igniting temperature, stable combustion process, high activity, long service life, and the like, is suitable for the methane catalyzing and combustion process taking coal bed gasdeoxidation purification as a purpose and can also be extensively applied to the catalyzing and combustion process of CO and low-carbon hydrocarbon under fuel-rich and oxygen-poor reducing atmosphere.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-temperature gas composite oxide desulfurizer and production thereof

InactiveCN1712500AHigh mechanical strengthHigh wear resistanceGas purification by catalytic conversionActive componentFluidized bed

A high-temperature gas composite oxide desulfurizer and its production are disclosed. The desulfurizer consists of active component zinc oxide 33í½50% and multiple additives 31í½51% which comprises titanium dioxide, active stabilizer, surface modifier, strength reinforcer, regenerative improver and composite binder. The process is carried out by mixing active component with additives, grinding, kneading, forming, laying aside, drying, particle rectifying, calcining at 850í½1060íÒC in high-temperature furnace, and obtaining desulfurizer. It achieves better reactivity and efficiency, good abrasion resistance and regeneration. It can be used for fixed bed, fluidized bed and desulfurizing reactor of flowing bed.

Owner:CHINA COAL RES INST

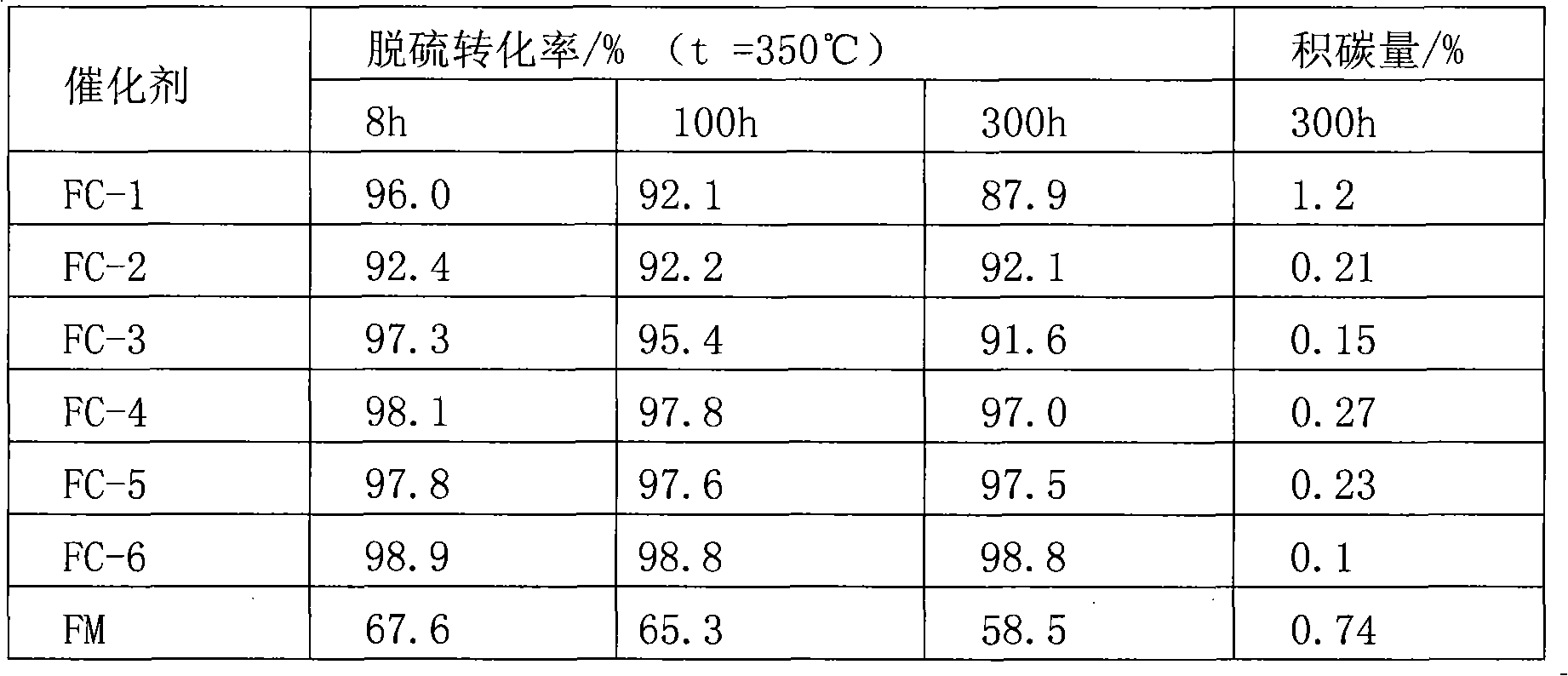

Catalyst for direct oxidation and desulphurization and its prepn. method

ActiveCN1868572AHigh activityGood choiceDispersed particle separationSulfur preparation/purificationSulfurVanadium oxide

A catalyst used directly for oxidative desulfurizing to H2S gas contained acidic gas is proportionally prepared from iron oxide, aluminum oxide, titanium oxide, zinc oxide, and vanadium oxide by co-deposition method. It has high activity, selectivity and H2s conversion rate.

Owner:PETROCHINA CO LTD

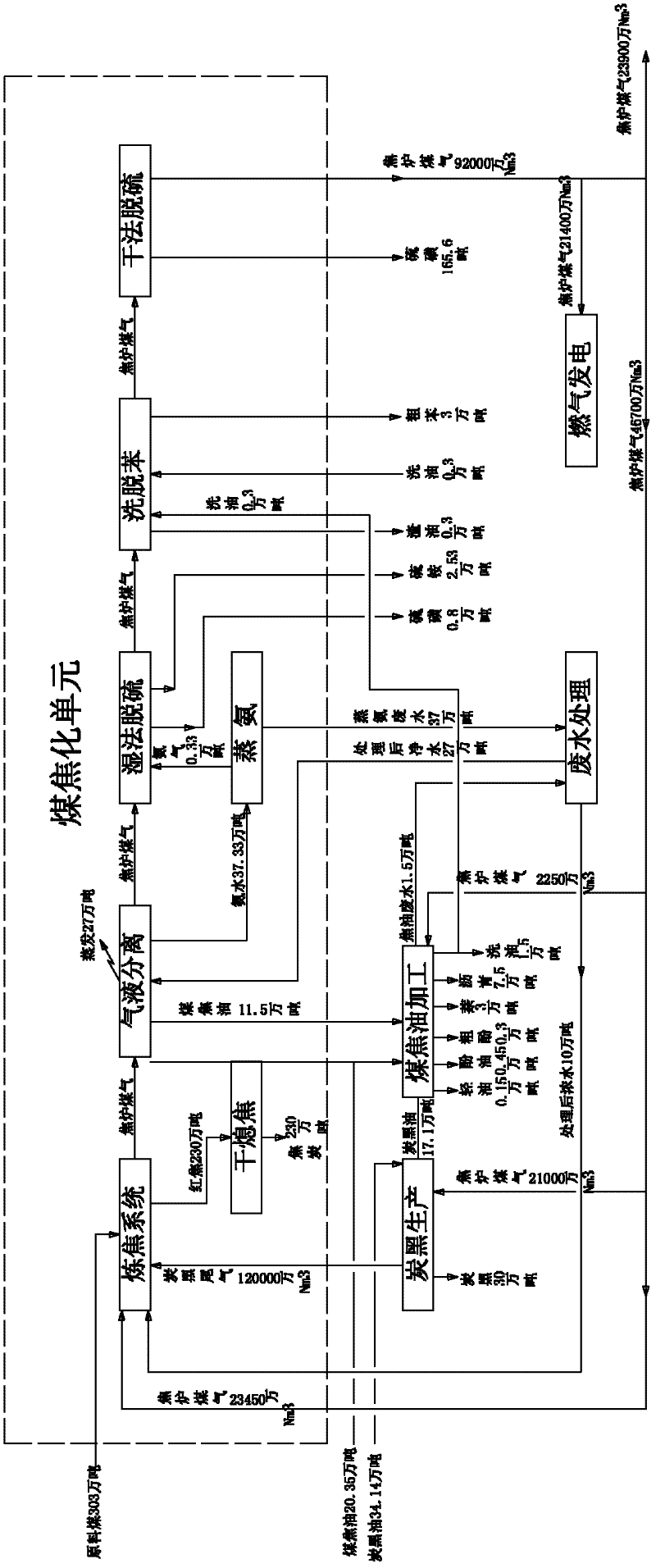

Green circular economy technology with coal coking as the main part

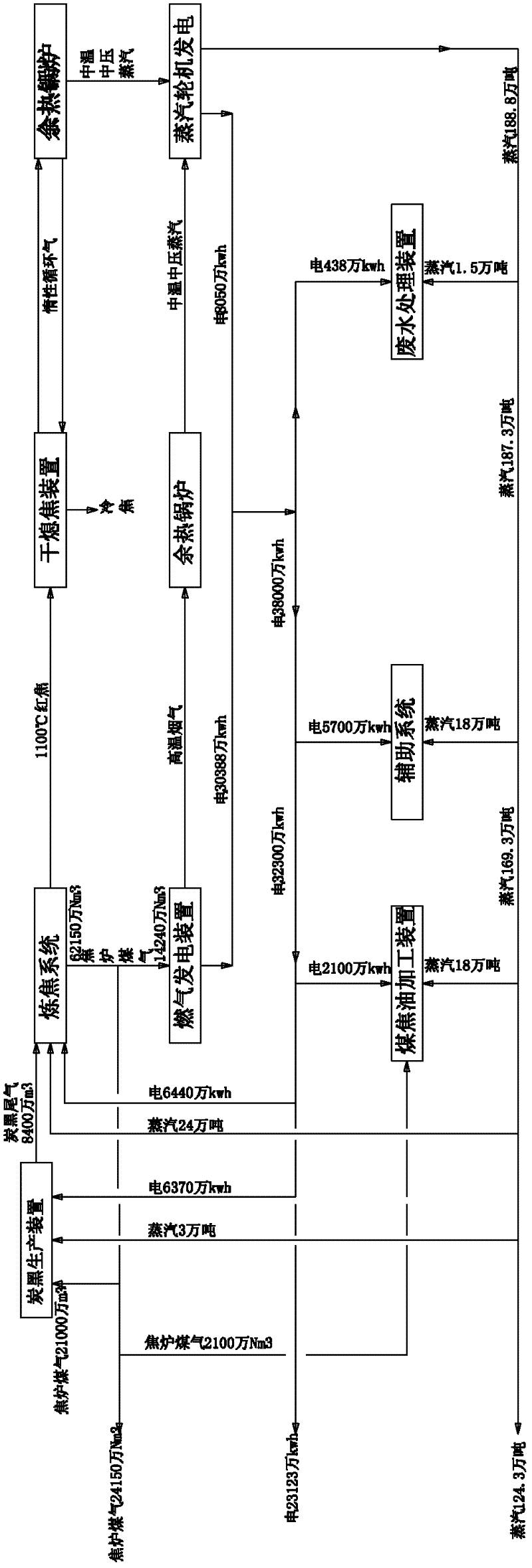

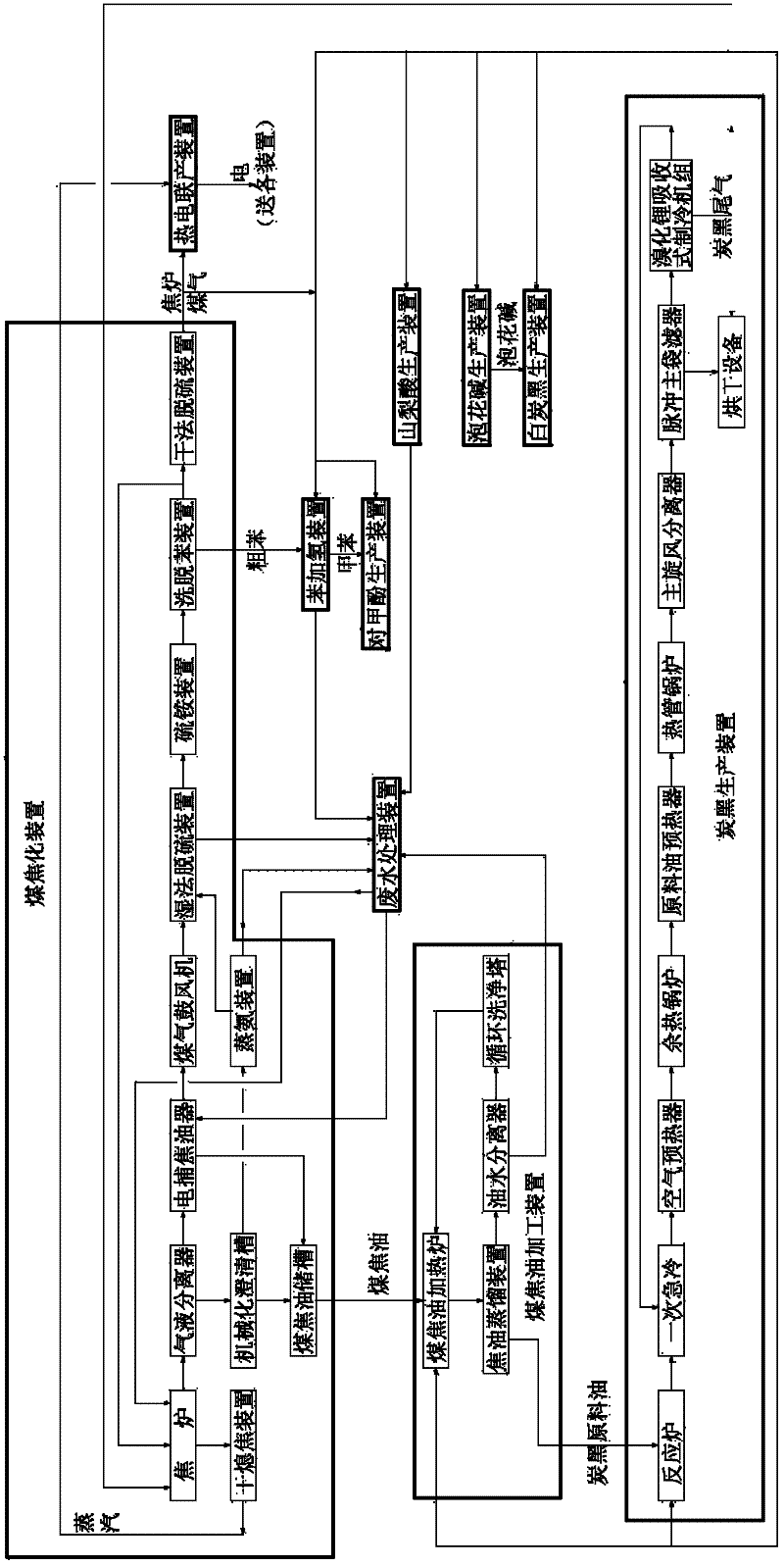

ActiveCN102229806AHigh aromatic contentQuality improvementPigmenting treatmentCoke quenchingCogenerationEngineering

The invention provides a green circular economy technology with coal coking as the main part. The technical scheme of the technology is as follows: a coal coking part, a coal tar processing part, a carbon black part and a part of combined power and thermoelectricity generation by coke oven gas are organically combined to form the relationship of industrial metabolism, symbiosis and coupling; suchmeasures as differentially utilizing tail gas of carbon black, recovering energy of coke drying quenching, reducing, recycling and changing the three wastes into resources, etc., enable resources to be saved, production cost to be reduced and pollution to be lessened; therefore, economic benefits of coal coking enterprises are maximized and the green circular economy technology is realized indeed. The invention also provides an apparatus for realizing the green circular economy technology with coal coking as the main part.

Owner:JINNENG SCI & TECH

Systems and methods for oxidation of synthesis gas tar

Owner:RES USA LLC

Systems and methods for oxidation of synthesis gas tar

InactiveUS20090090053A1Improve propertiesMuffle furnacesGas purification by catalytic conversionTarProduct gas

Owner:RES USA LLC

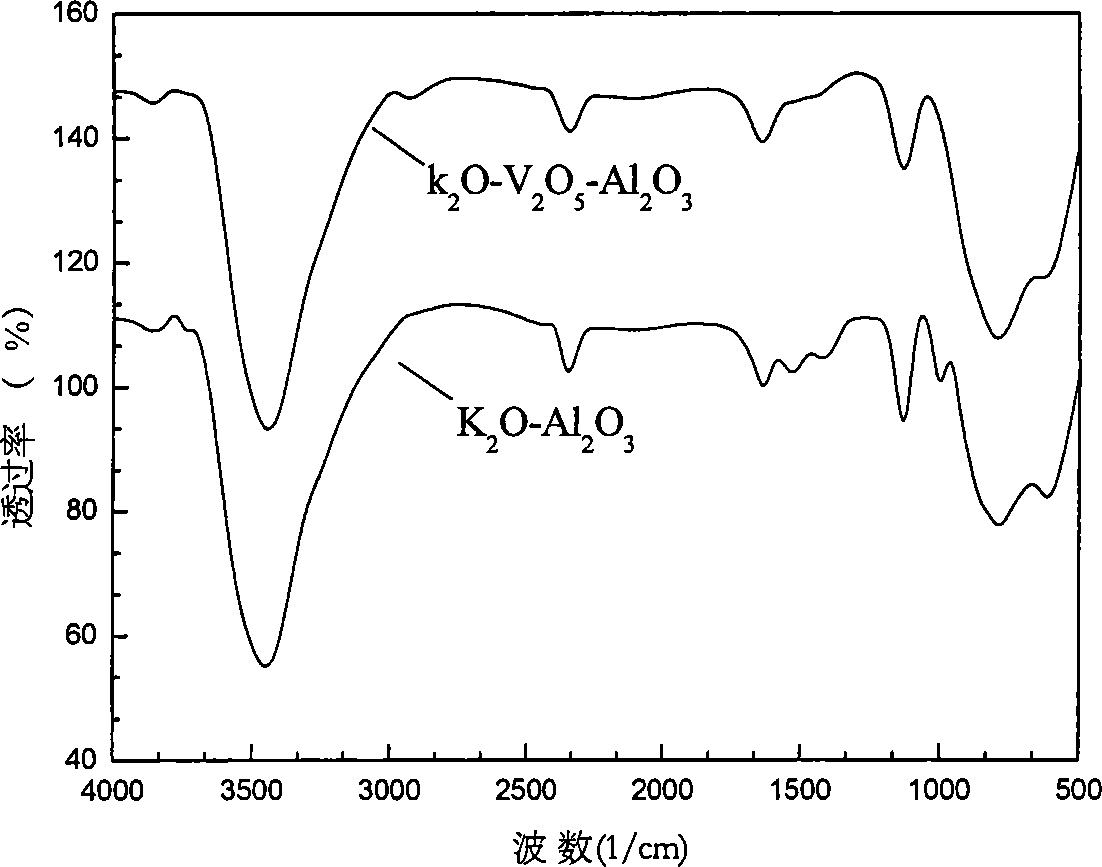

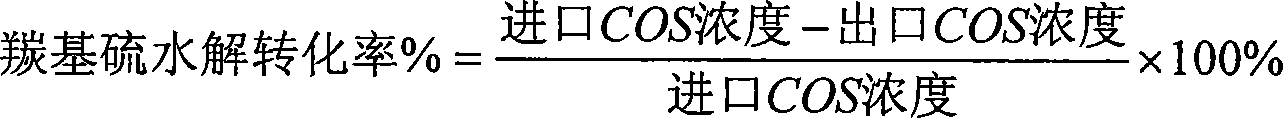

Intermediate temperate carbonyl sulfur hydrolyst and method of preparing the same and use thereof

InactiveCN101108339AOvercome the deficiency of easy sulfation poisoningDispersed particle separationGas purification by catalytic conversionSulfateSulfur

An intermediate temperate carbonyl sulfur hydrolysis catalyst and the preparation method and use is provided, which belongs to the technology field of catalyst and the preparation method and use. The invention is mainly improving the anti-sulfate performance of the catalyst under intermediate temperature by adding modifier V2O5 to change the composite of the catalyst, the preparation method is that: mix the components of catalyst with porous materials components evenly, add water or nitric acid to knead, extrude to forming, then dry and activate. When the catalyst is Phi 3mm multiple 5mm industrial grain, under the normal pressure, the reaction temperature is 200 to 400 DEG C., the airspeed is 4000 to 10000h-1, the concentration of COS is lower than 500mgS / m3. The catalyst in the invention has high COS hydrolysis activity and anti-sulfate performance, the COS hydrolysis conversion rate is more than 99 per cent, which can be used in 200 to 400 DEG C. COS hydrolysis conversion in the feed gas with a 0 to 12 per cent of 02 content.

Owner:TAIYUAN UNIV OF TECH

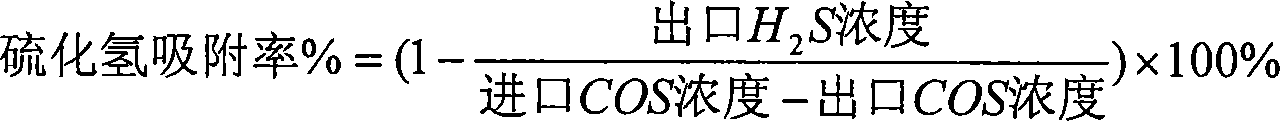

Method for purifying HCN and COS in fuel gas produced from coal

InactiveCN101050389AReduce the use temperatureGas purification by catalytic conversionSteelmakingAlkali metal oxide

This invention discloses a method for purifying HCN and COS in coal-prepared fuel gas. The method relates to hydrolytic conversion of HCN and COS of coal-prepared steelmaking fuel gas, electricity-generation fuel gas, or boiler fuel gas in the presence of the same catalyst. The catalyst is Co-Mo, Fe-Mo or Ni-Mo or Ni-Mo, and alkali metal oxide supported by active aluminum oxide carrier, and used at a temperature of 50-400 deg.C and a space velocity of 500-30000 / h. The method has can effectively remove HCN and COS with the conversion rates both higher than 90%. The method thus can realize environmentally friendly exhaust of gas turbine.

Owner:HAISO TECH +1

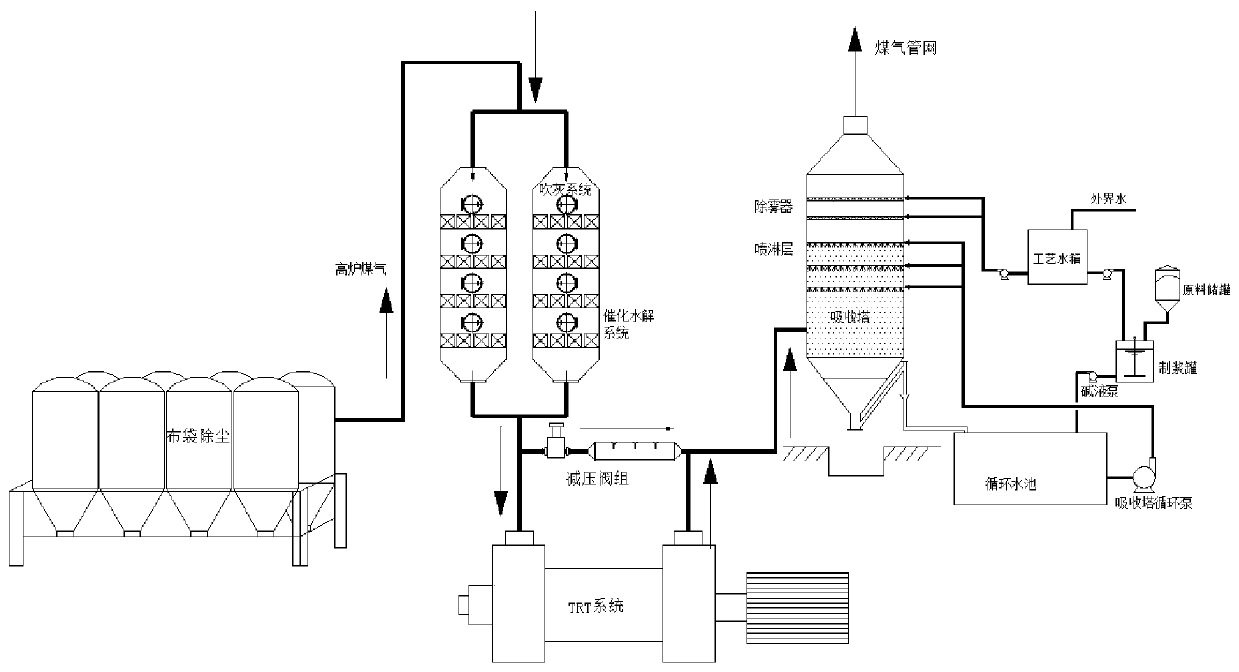

Fine desulfurization process for blast furnace gas

InactiveCN110643395ALow running costLittle resistance lossEnergy inputGas purification by catalytic conversionThermodynamicsDust control

The invention provides a fine desulfurization process for blast furnace gas, and belongs to the technical field of gas desulfurization. The process specifically comprises the following steps that blast furnace gas enters an organic sulfur hydrolysis system after being subjected to bag dust removal; and the hydrolyzed gas enters a top pressure recovery turbine power generation device and then enters a wet alkali washing desulfurization system. The organic sulfur hydrolysis system comprises a hydrolysis reactor and an acoustic wave soot blowing system, and the wet alkali washing desulfurizationsystem comprises an absorption tower, a circulating water tank, a circulating water pump, an alkali liquor storage tank, an alkali liquor pump, a process water tank and a process water pump. The process can effectively reduce resistance loss caused by the hydrolysis system and save large operation cost for enterprises.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

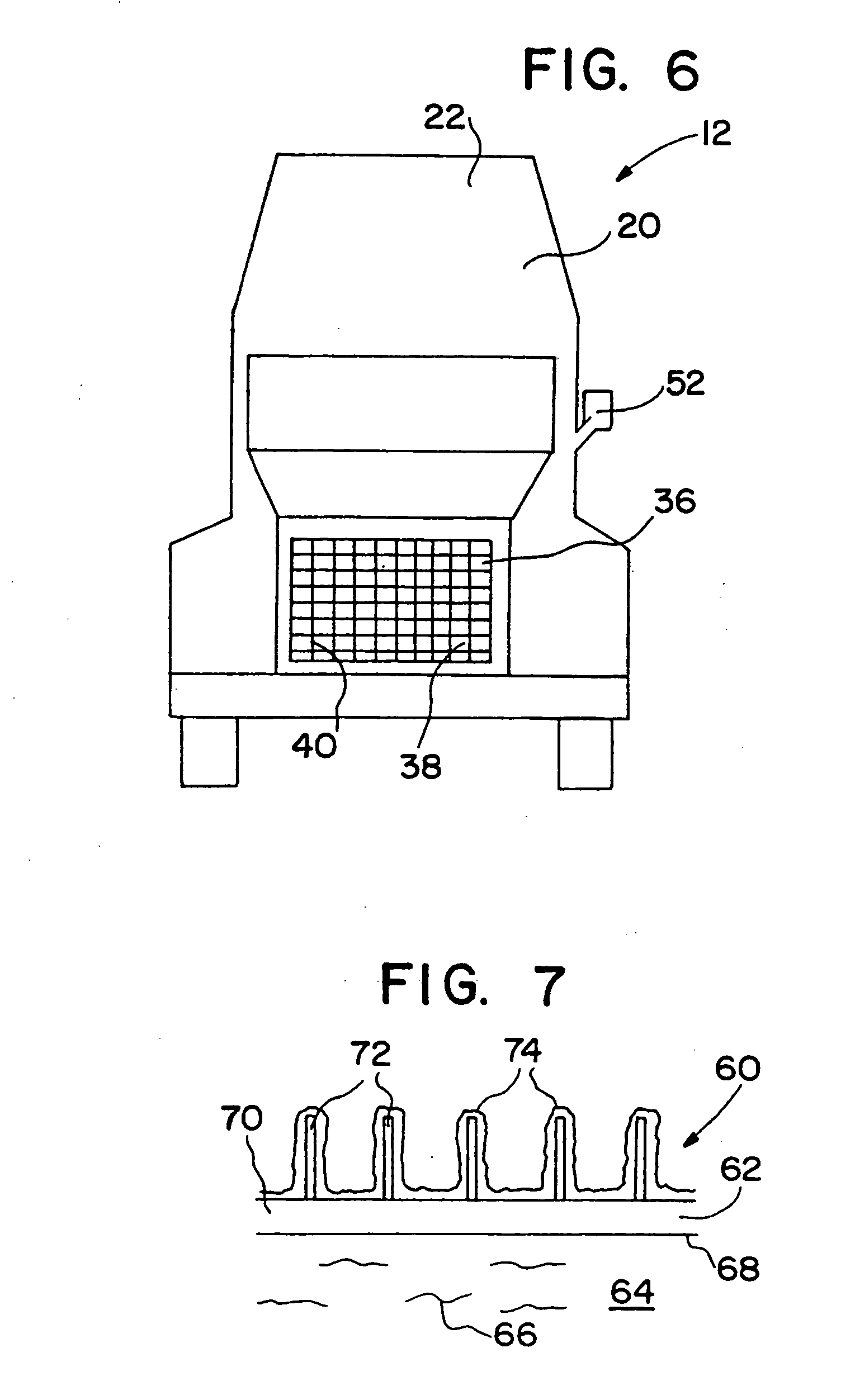

Vehicle having atmosphere pollutant treating surface

InactiveUS20050100492A1Efficiently enableOxygen/ozone/oxide/hydroxideGas treatmentAtmosphereAutomotive engineering

A method and apparatus for treating the atmosphere comprising moving a vehicle through the atmosphere, the vehicle having at least one atmosphere contacting surface and a pollutant treating composition located on said surface. A specific embodiment comprises coating a motor vehicle radiator with pollutant treating catalyst.

Owner:ENGELHARD CORP

Novel organic sulphur hydrogenation catalyst and preparation method thereof

ActiveCN103157481AHigh activityEasy to overflowGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsOrganic sulfide compoundPtru catalyst

The invention relates to an organic sulphur hydrogenation catalyst, comprising specific parts by weight of Al2O3 carrier, ZnO, iron oxide and molybdenum oxide. ZnO added in the hydrogenation catalyst disclosed by the invention is taken as an assistant, and has excellent synergistic effect together with active components of iron oxide and molybdenum oxide. Compared with the sulphur hydrogenation catalyst in the prior art, the organic sulphur hydrogenation catalyst has high thiofuran conversion and removal efficiency when used for removing organic sulfide such as thiophene in gas.

Owner:SHENYANG SANJUKAITE CATALYST

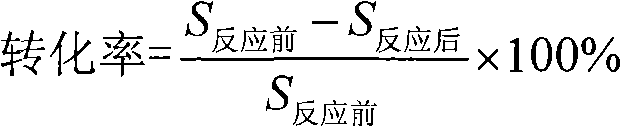

Coking oven gas hydrodesulfurization catalyst and method for preparing same

ActiveCN101797508AEvenly distributedIncrease profitGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationMethanation

The invention discloses coking oven gas hydrodesulfurization catalyst and a method for preparing the same. The coking oven gas hydrodesulfurization catalyst is prepared by loading active components on the carrier of Gamma-Al2O3 with the immersion method. The active components comprises iron oxide, molybdenum oxide and cobalt oxide, wherein the weight of the iron oxide is 2-10 percent of the totalweight of the coking oven gas hydrodesulfurization catalyst, the weight of the molybdenum oxide is 5-20 percent of the total weight of the coking oven gas hydrodesulfurization catalyst, the weight ofthe cobalt oxide is 0.1-5 percent of the total weight of the coking oven gas hydrodesulfurization catalyst, and the balance is Gamma-Al2O3. The coking oven gas hydrodesulfurization catalyst has the characteristic of high hydrodesulfurization activity, less methanation reaction and CO disproportionation reaction and good thermal stability, etc.

Owner:WUHAN KELIN FINE CHEM

Catalyst for improving organic sulfur hydrolysis rate, its carrier and preparation method

ActiveCN1602998AImprove hydrolysis functionHigh low temperature activityGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsAlkali soilHydrolysis

This invention provides one kind of catalyst which can improve organic sulfur hydrolysis rate.First,organic sulfur hydrolysis additive and carrier material is made into alkaline material through the process of kneading drying roasting and grinding.Then,mixing the carrier material alkaline material and alkali soil material,also adding peptizing agent,the catalyst carrier can be made through the process of kneading extruding strip and roasting.The catalyst carrier cab be made into sulfur tolerant shift catalyst by impregnating active component molybdenum and cobalt either alkali metal.The outstanding advantages of this invention is that enhanceding the surface alkaline of carrier by adding alkali promoter in the carrier material, which not only improve the activities of catalyst to the organic sulfur,but also improve the low temperature activities of the catalyst.The catalyst of this invention can be used in pressure range of 1.0-5.0MPa.

Owner:青岛联信催化材料有限公司

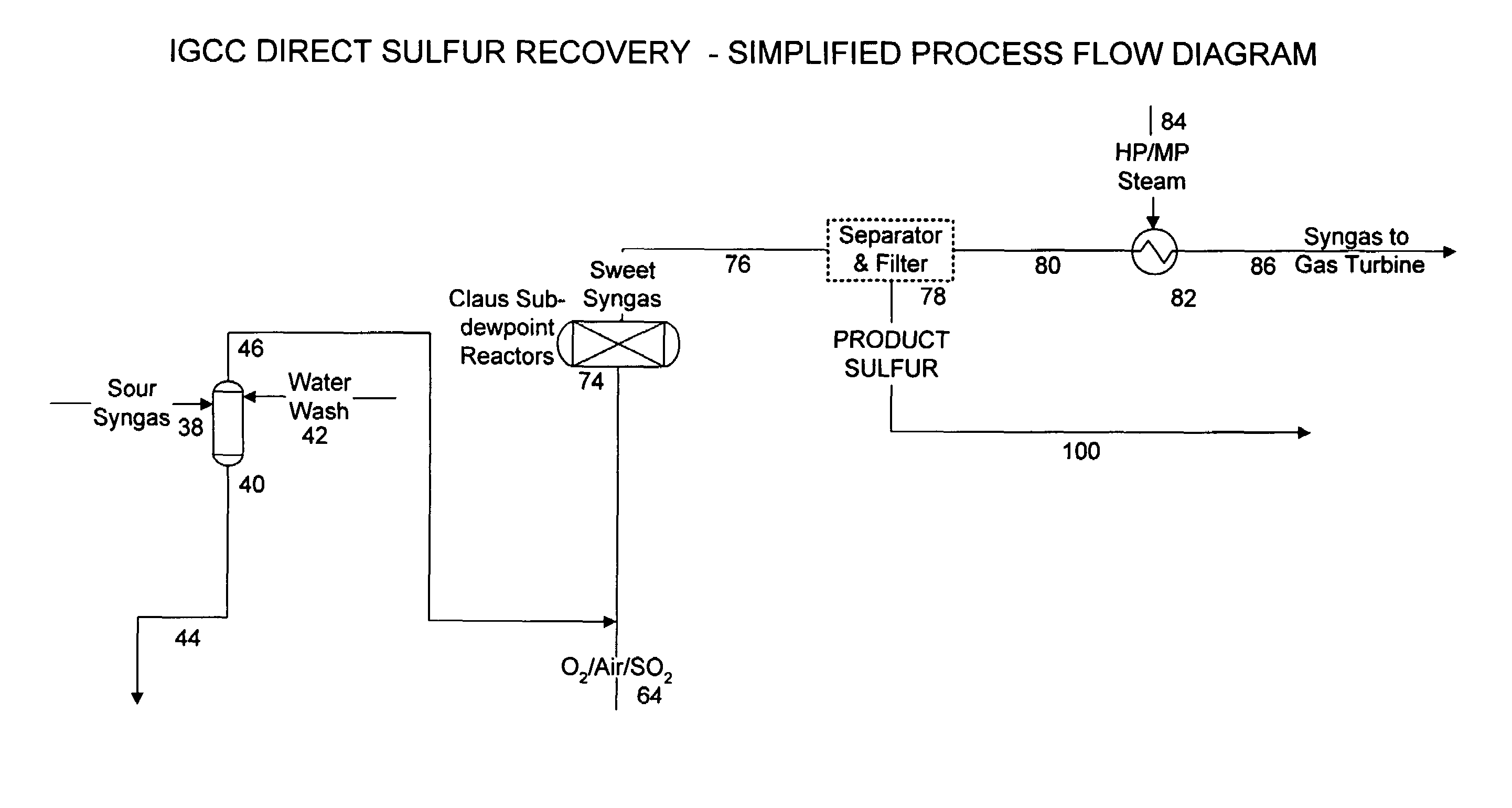

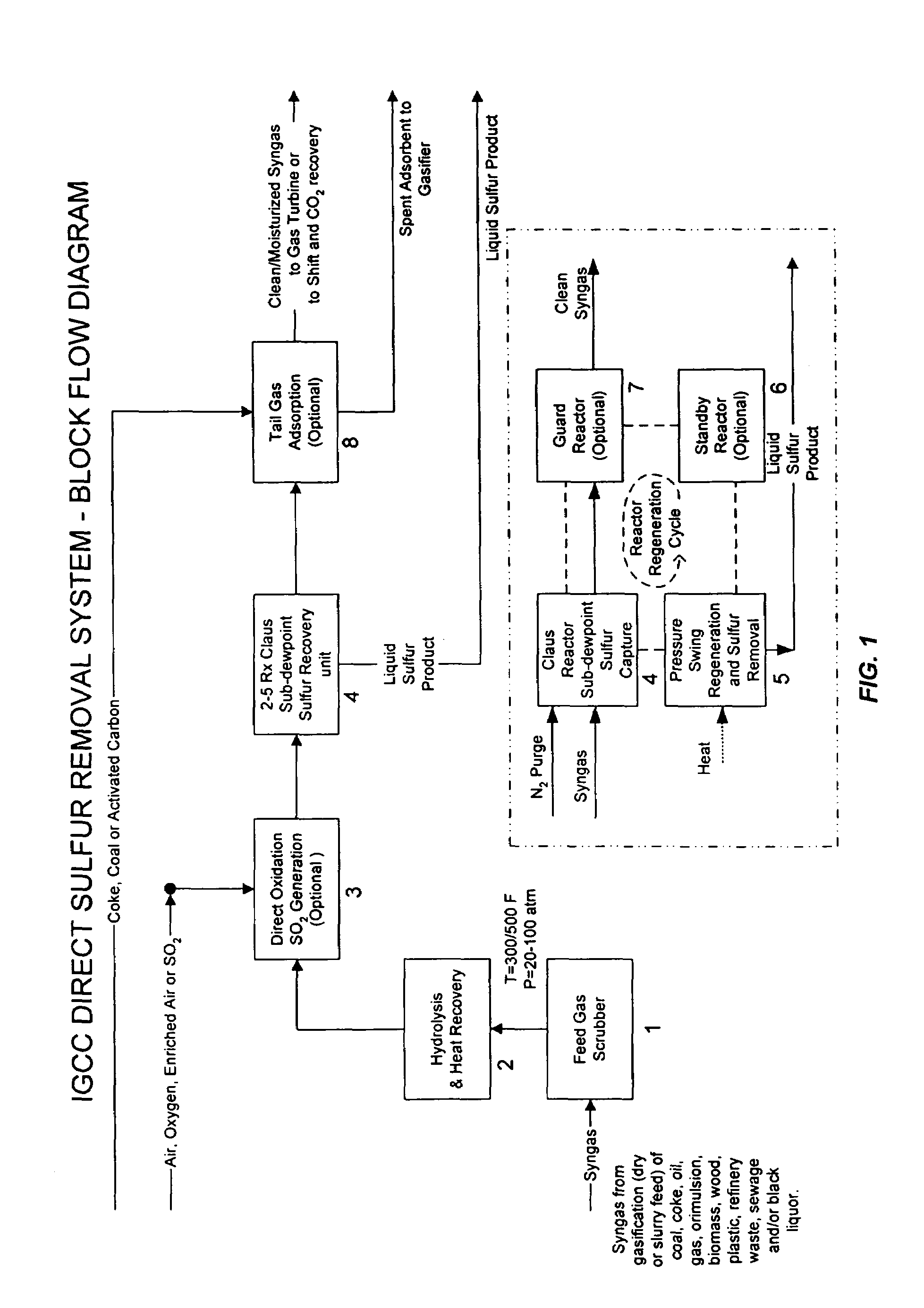

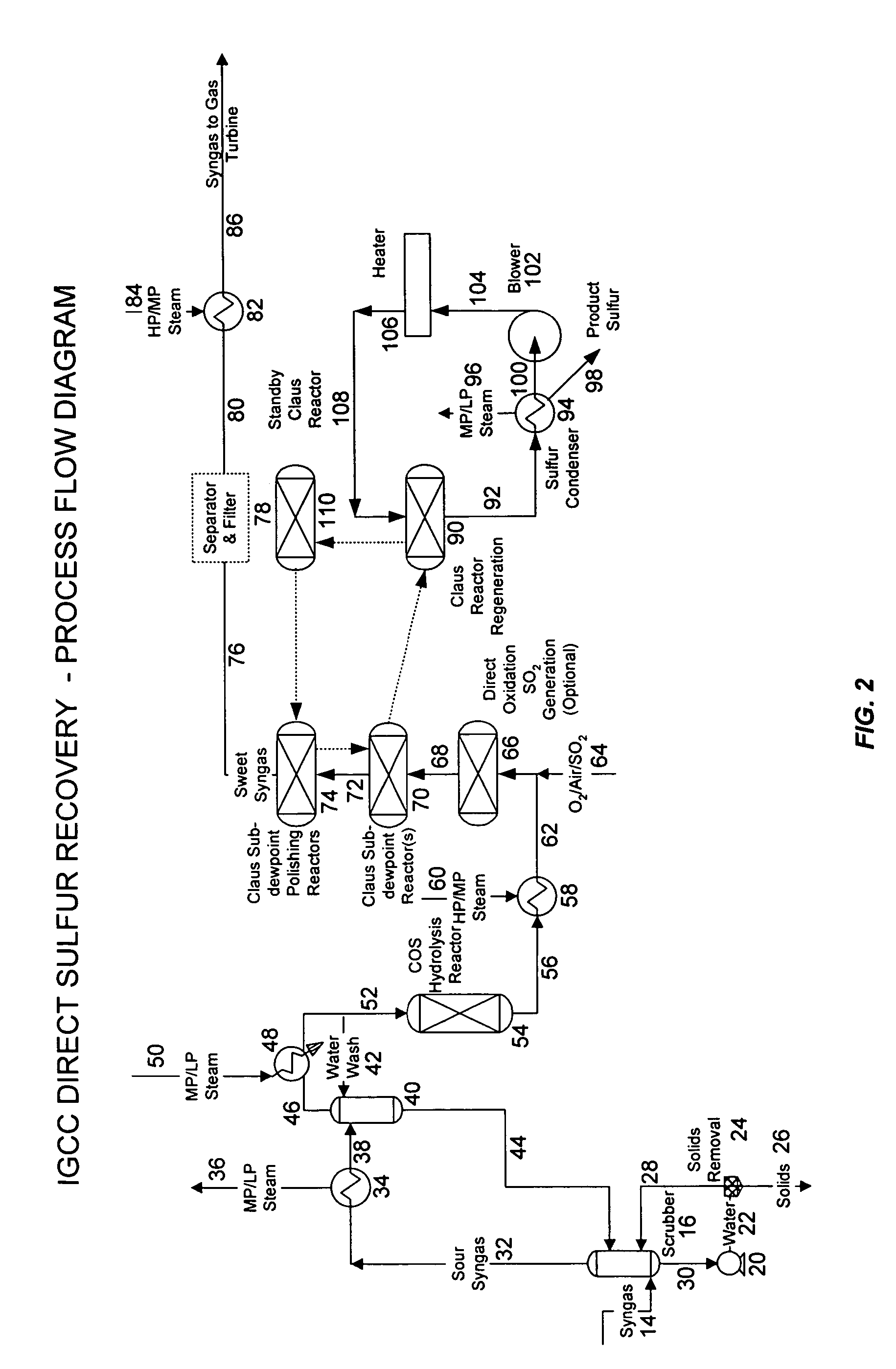

Direct sulfur recovery system

ActiveUS7374742B2Hydrogen separation using liquid contactDispersed particle separationActivated carbonSulfur

Owner:BECHTEL HYDROCARBON TECH SOLUTIONS INC

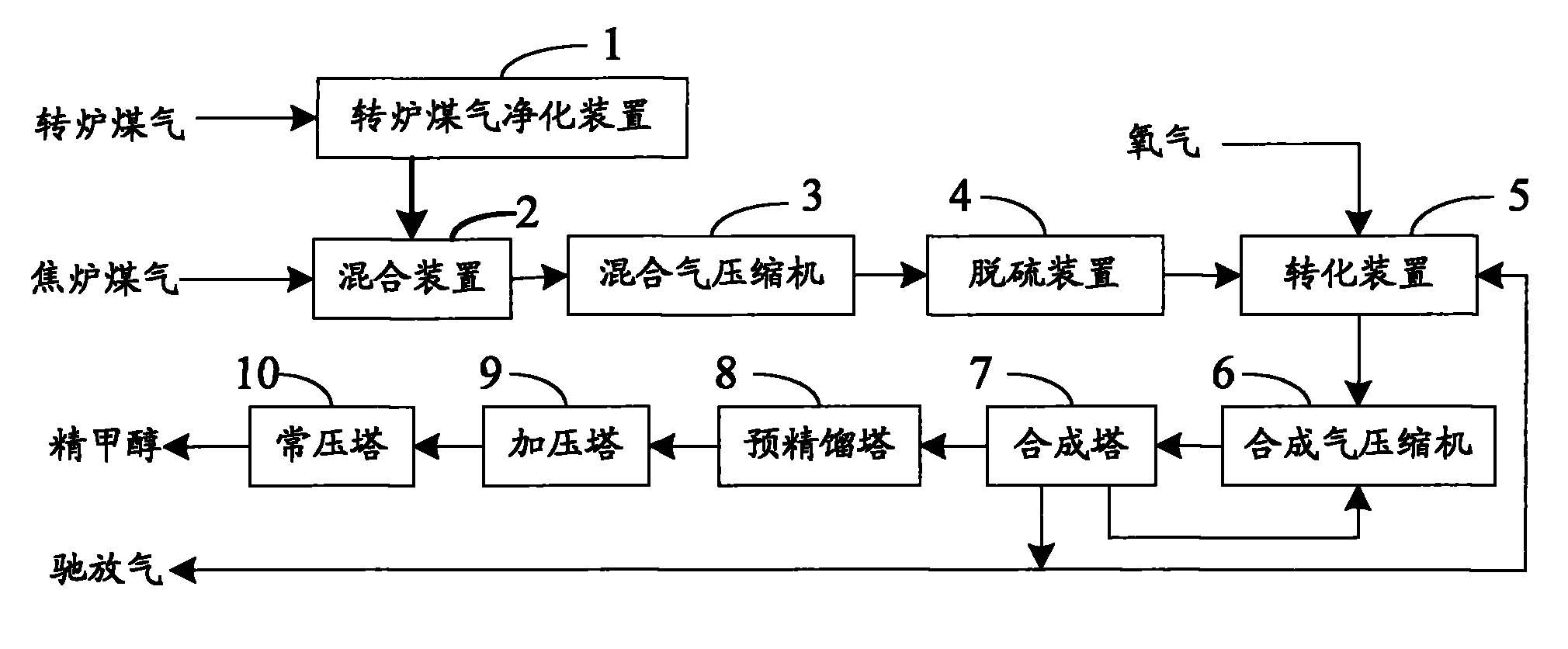

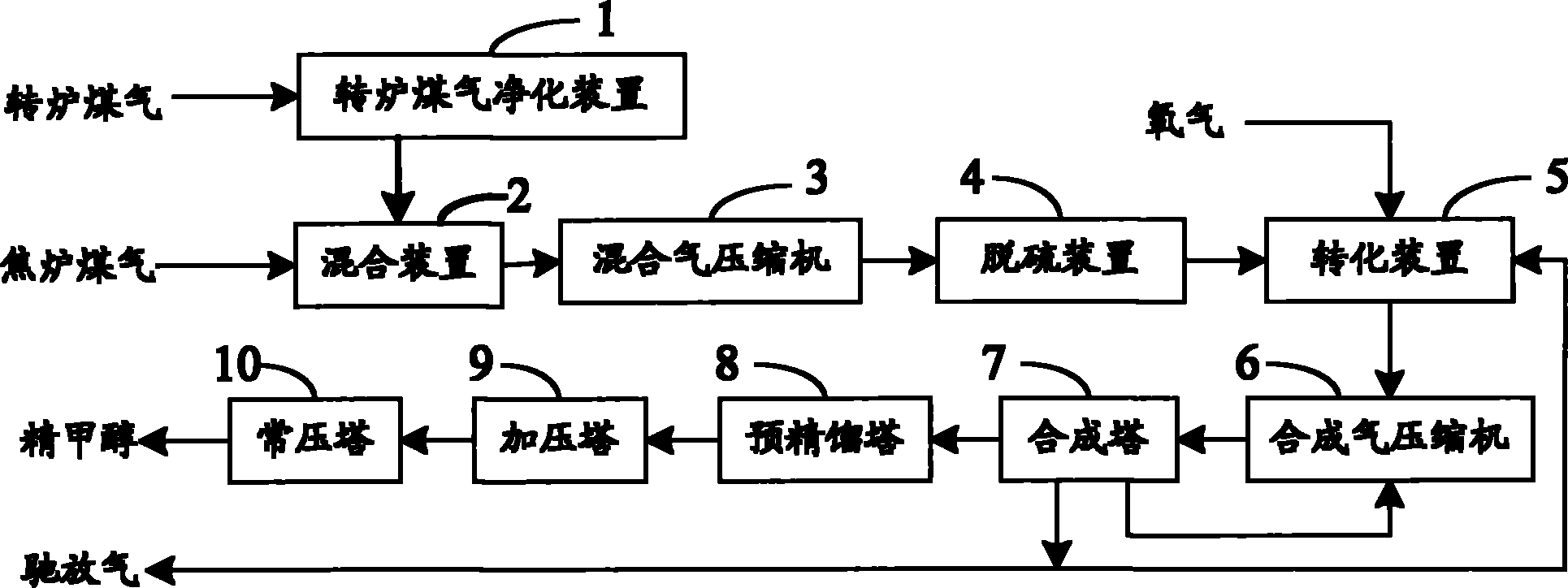

Method and equipment for producing methanol

ActiveCN102079689AIncrease productivityIncrease profitOrganic compound preparationHydroxy compound preparationSteelmakingSyngas

The embodiment of the invention discloses a method for producing methanol, which comprises the following steps of: purifying coal converter gas; mixing the purified converter gas and coke oven gas to obtain mixed gas; and performing reaction on the mixed gas to obtain the methanol. In the method and the equipment for producing the methanol, byproduct gas generated in the steelmaking process, namely the converter gas is purified and mixed with the coke oven gas in the coking process according to a proper ratio, so that a carbon / hydrogen ratio in the synthetic gas generated through desulfurization and conversion of the mixed gas meets the requirement of a theoretical value, the utilization rate of useful elements in the raw materials is improved, the production efficiency is improved, the pollution of waste gas to the environment is reduced, the production cost is reduced and the economic benefit is improved.

Owner:SICHUAN DAXING ENERGY

Tail gas-recycled sulfur recovery method

ActiveCN101274750BReduce pollutionImprove solubilityDispersed particle separationSulfur preparation/purificationRecovery methodCatalytic oxidation

Owner:江苏晟宜环保科技有限公司

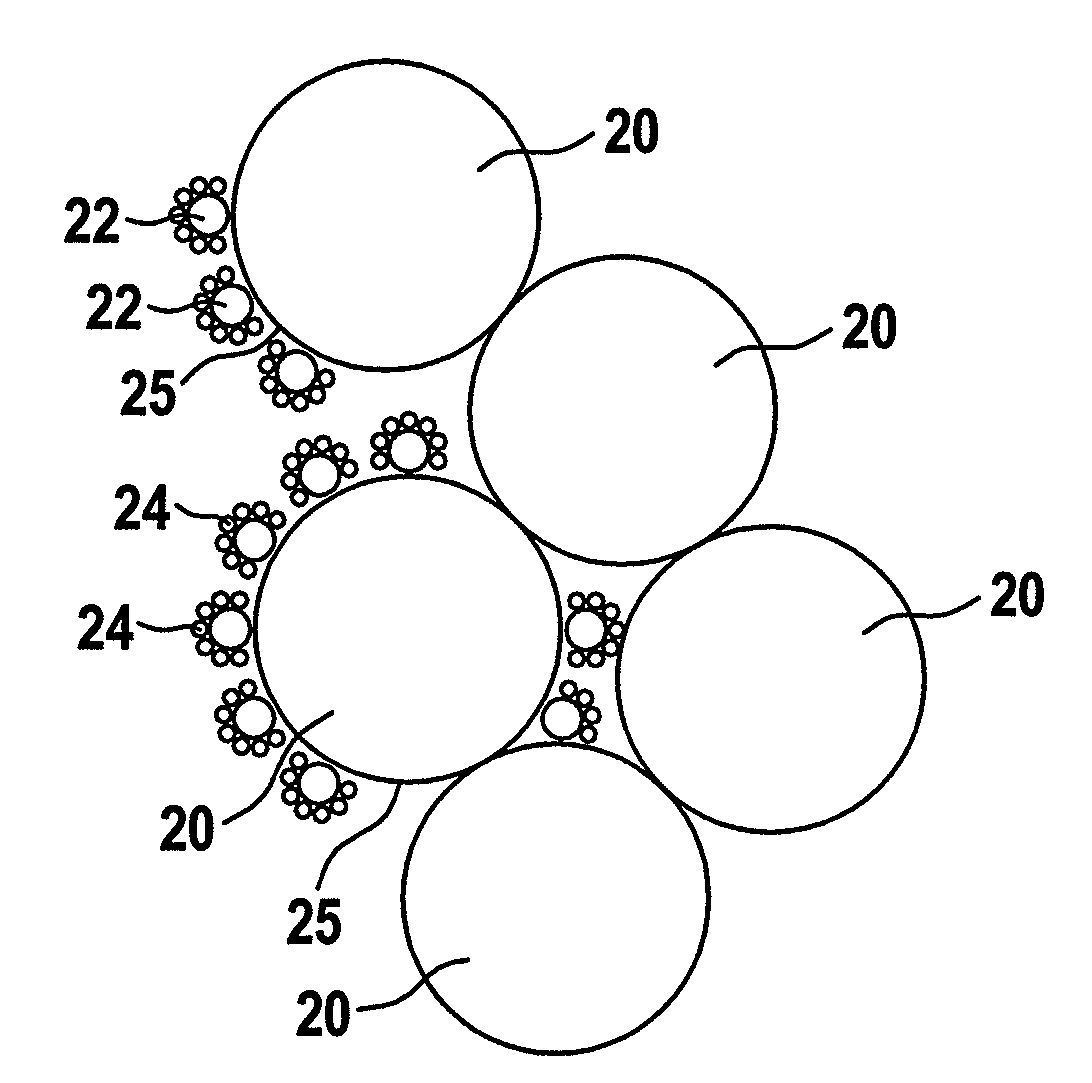

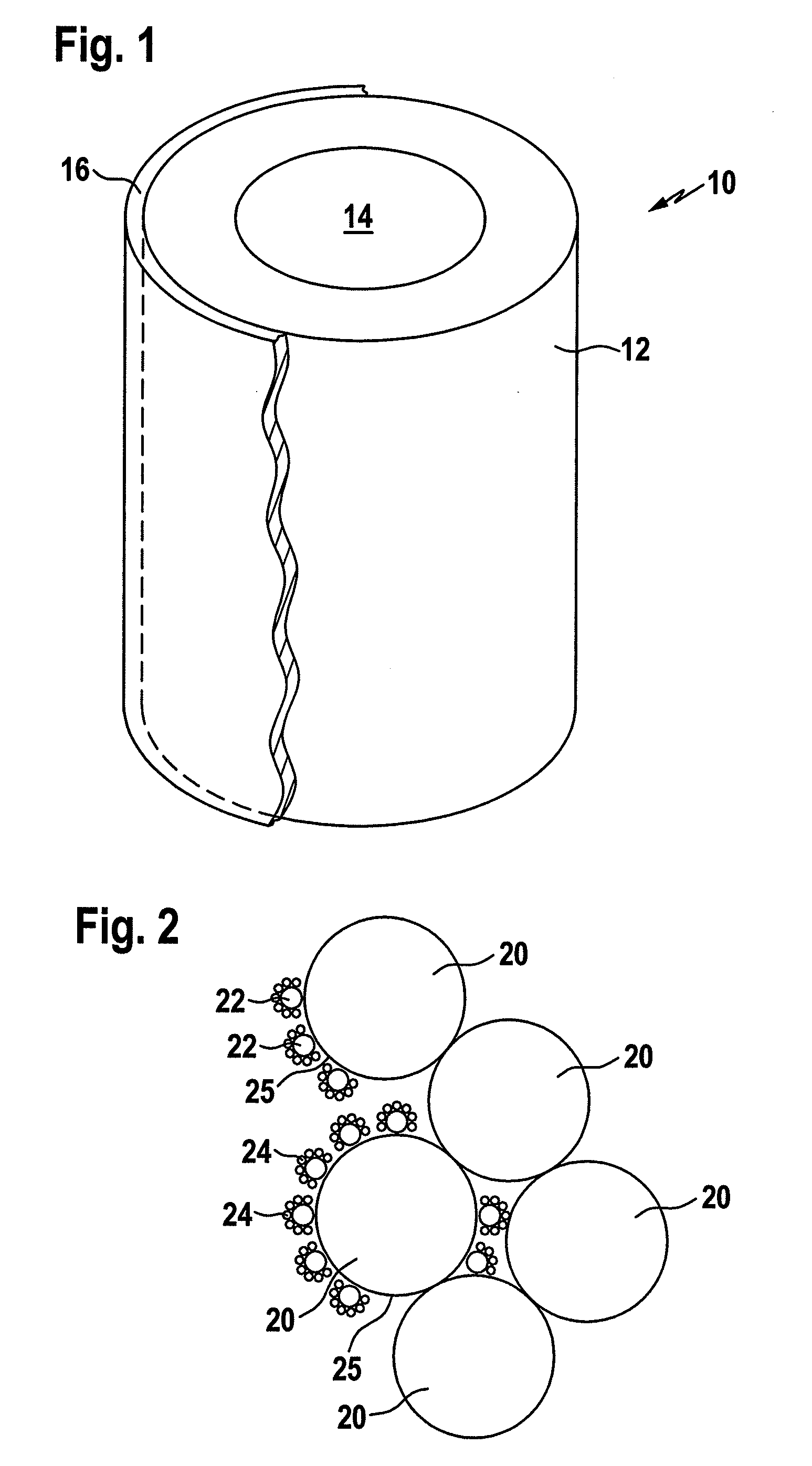

Catalytic element

InactiveUS20090019770A1Improve mechanical stabilityLow flow resistanceCombination devicesCatalytic naphtha reformingGas phaseCompound (substance)

A catalytic element useful for promoting catalytic gas phase reactions is provided, comprising a porous ceramic body comprising a multiplicity of open pores having a coating comprising a basic oxide material and a catalyst material selected from transition metal and noble metal compounds

Owner:PALL CORP

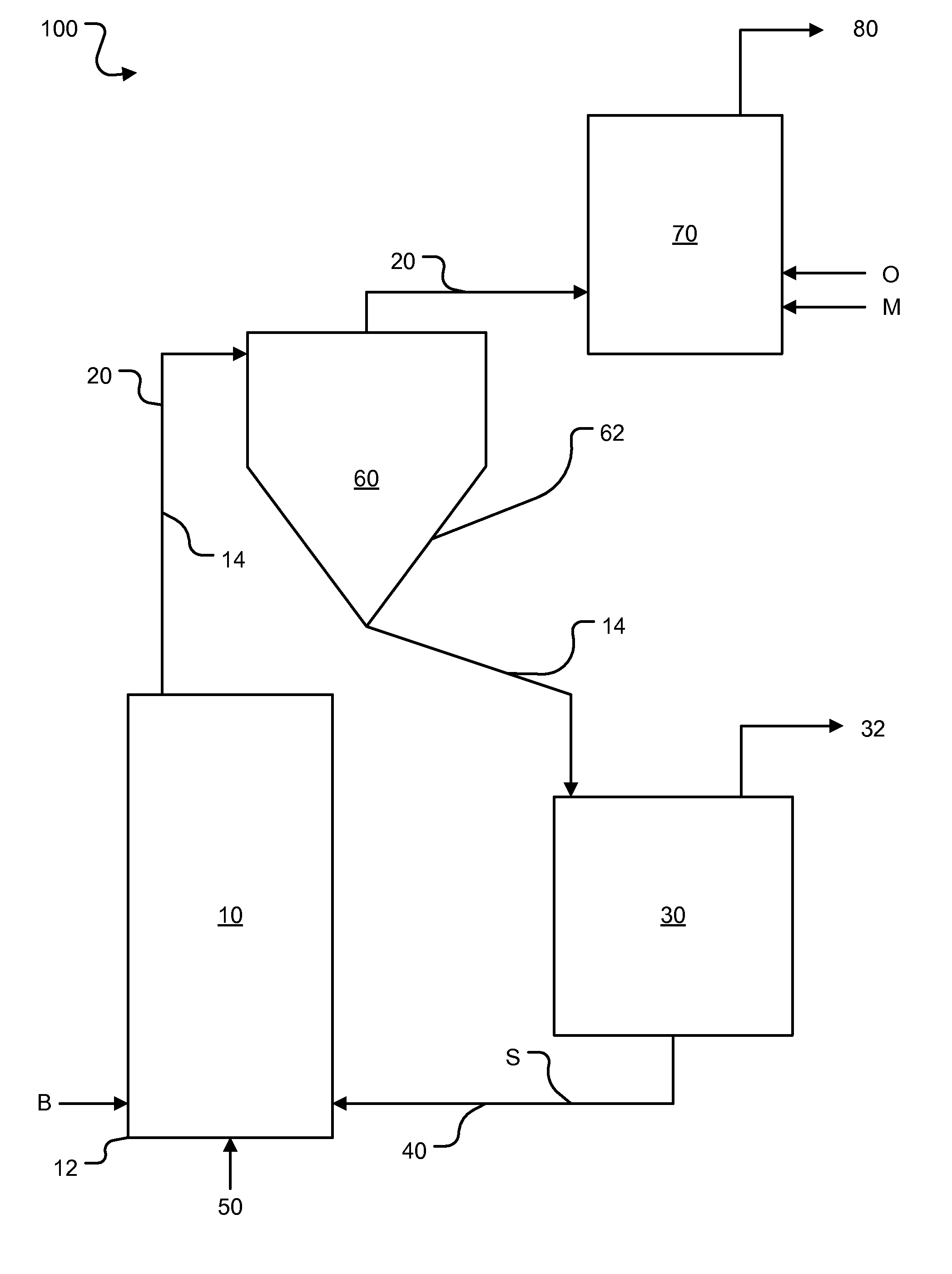

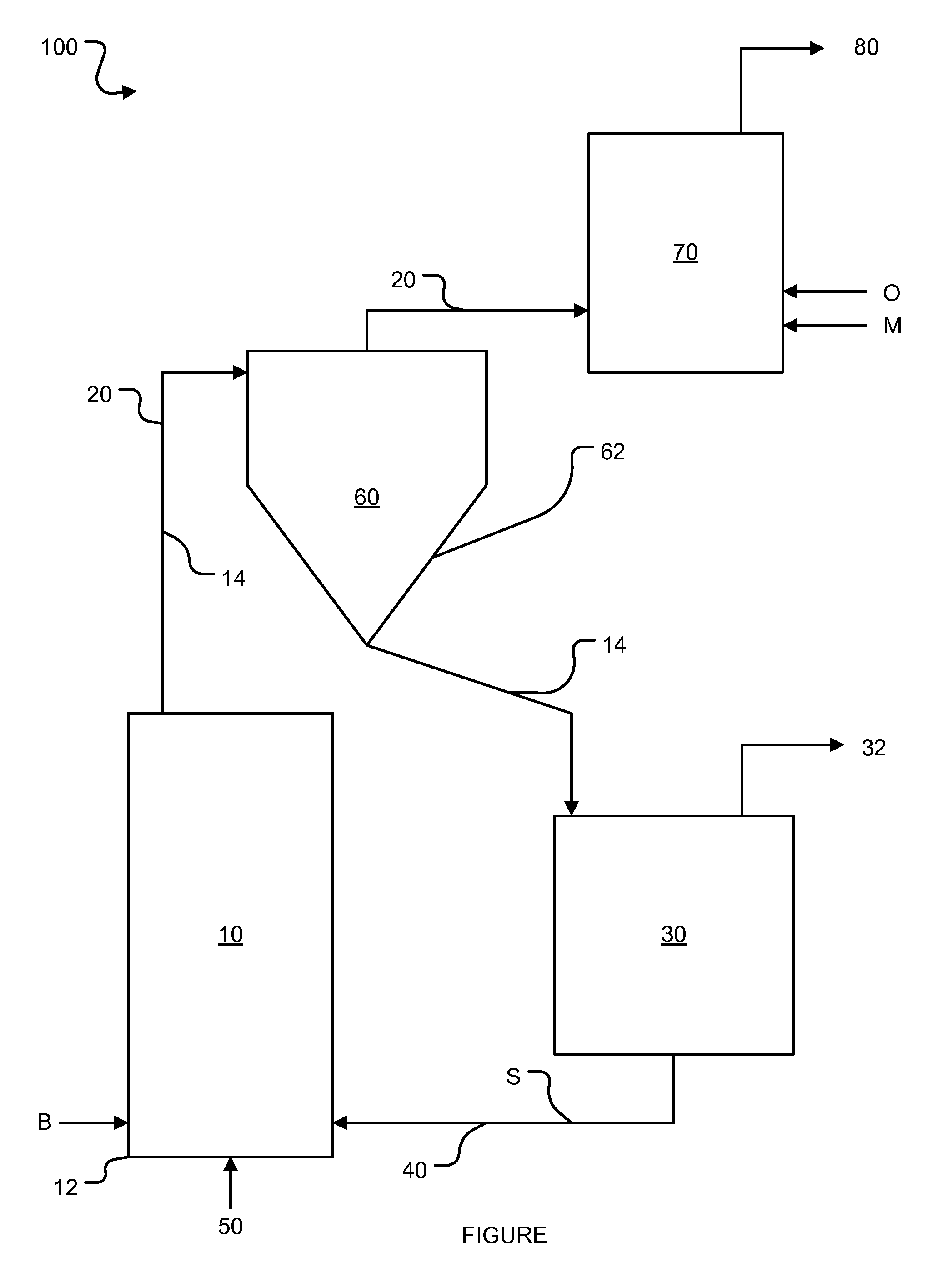

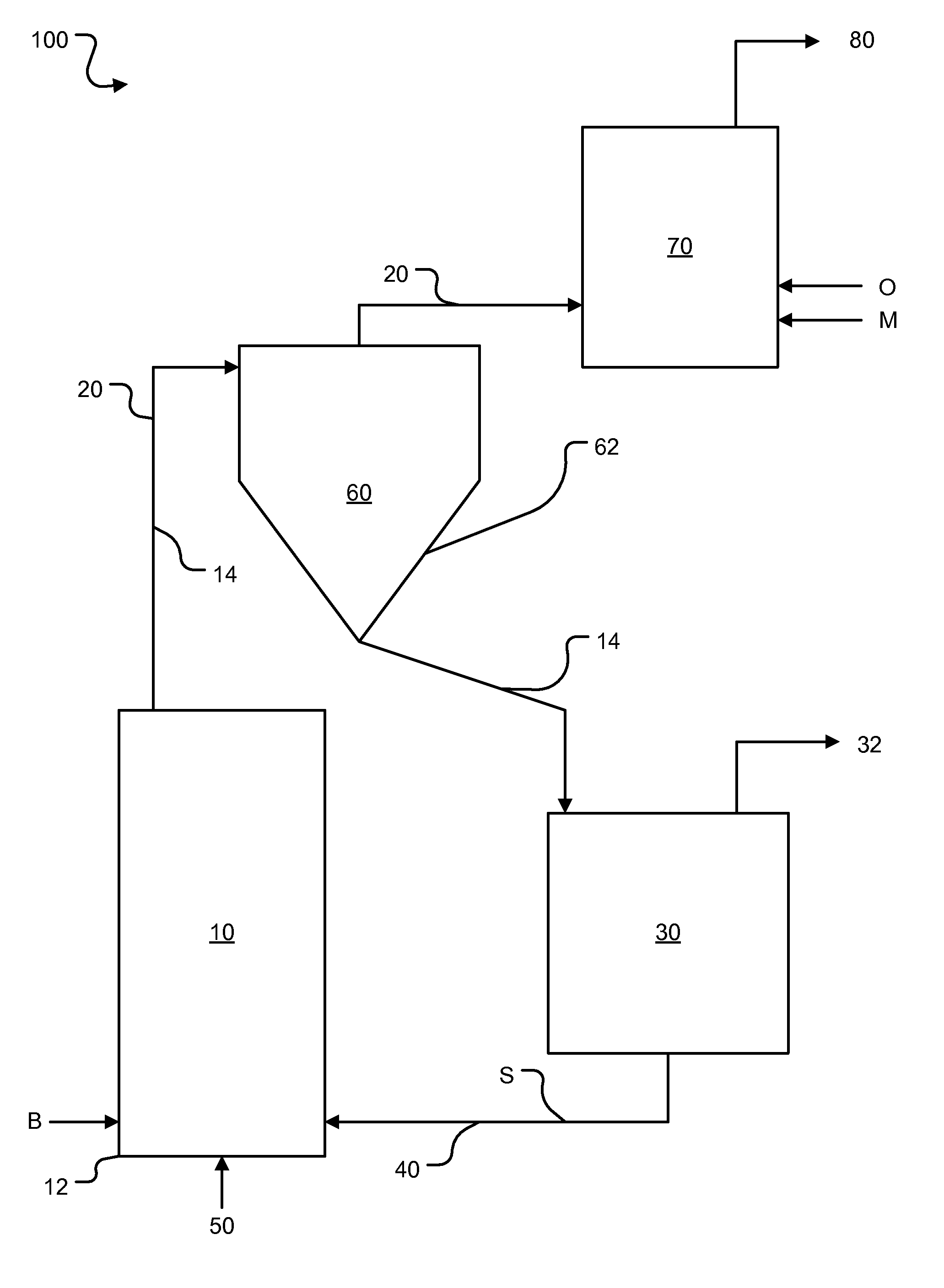

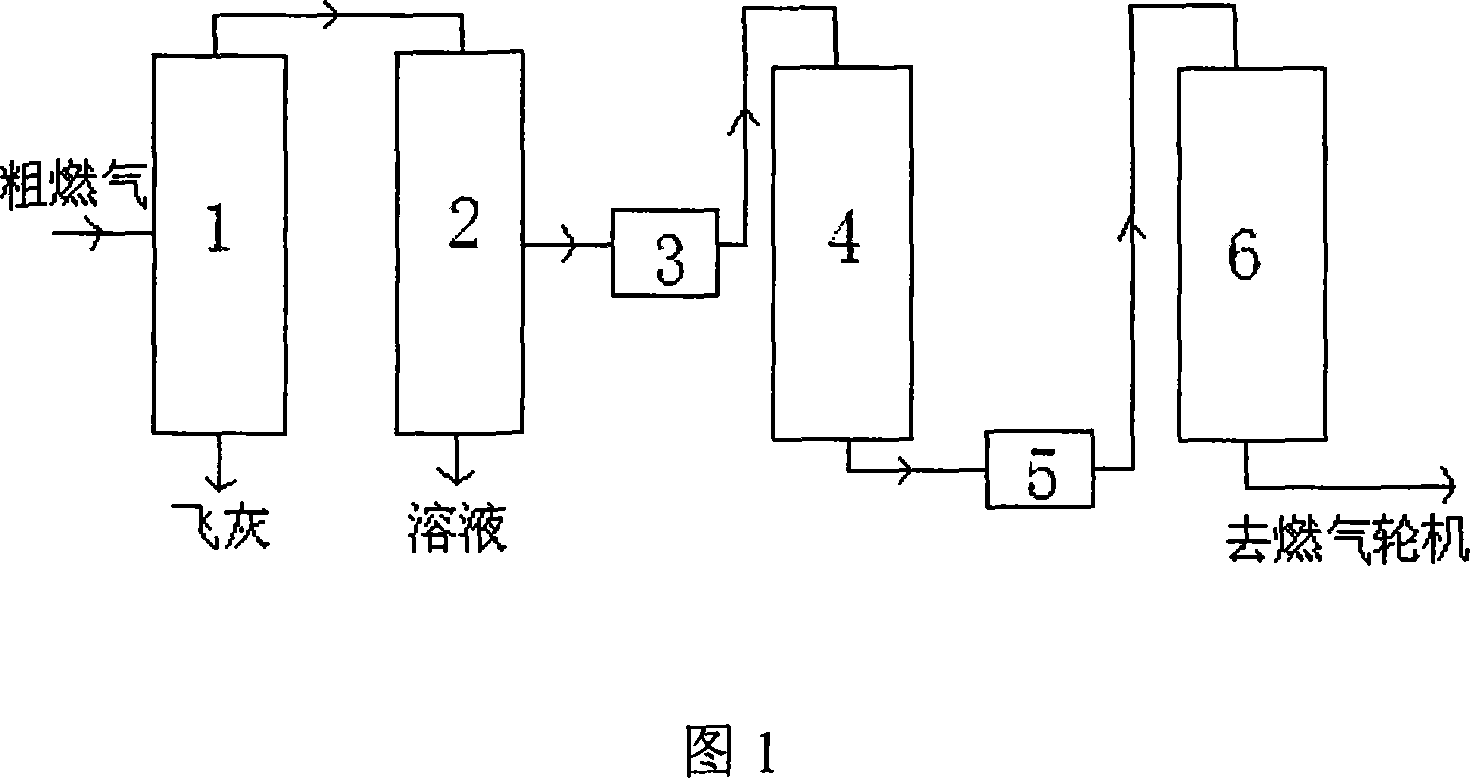

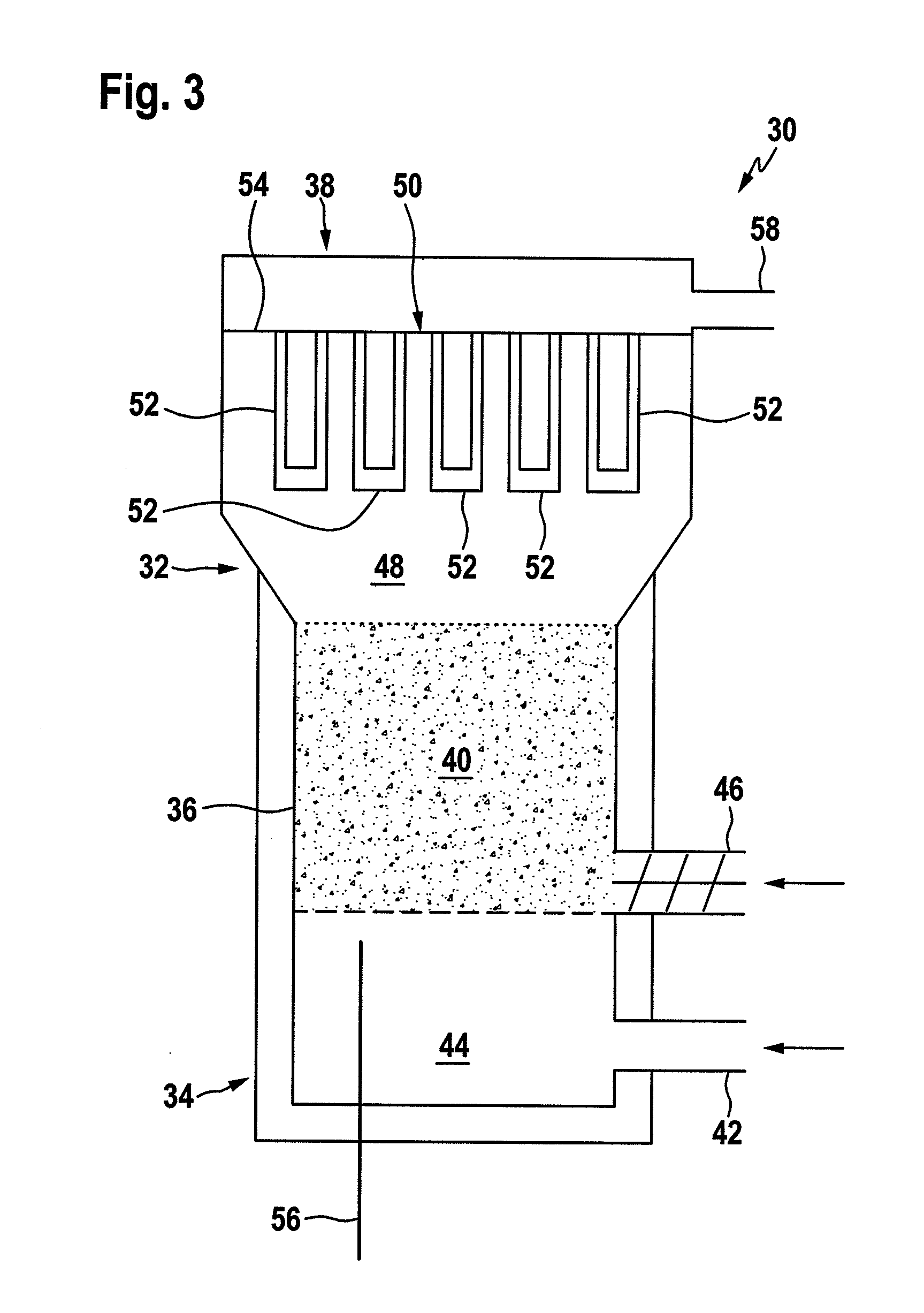

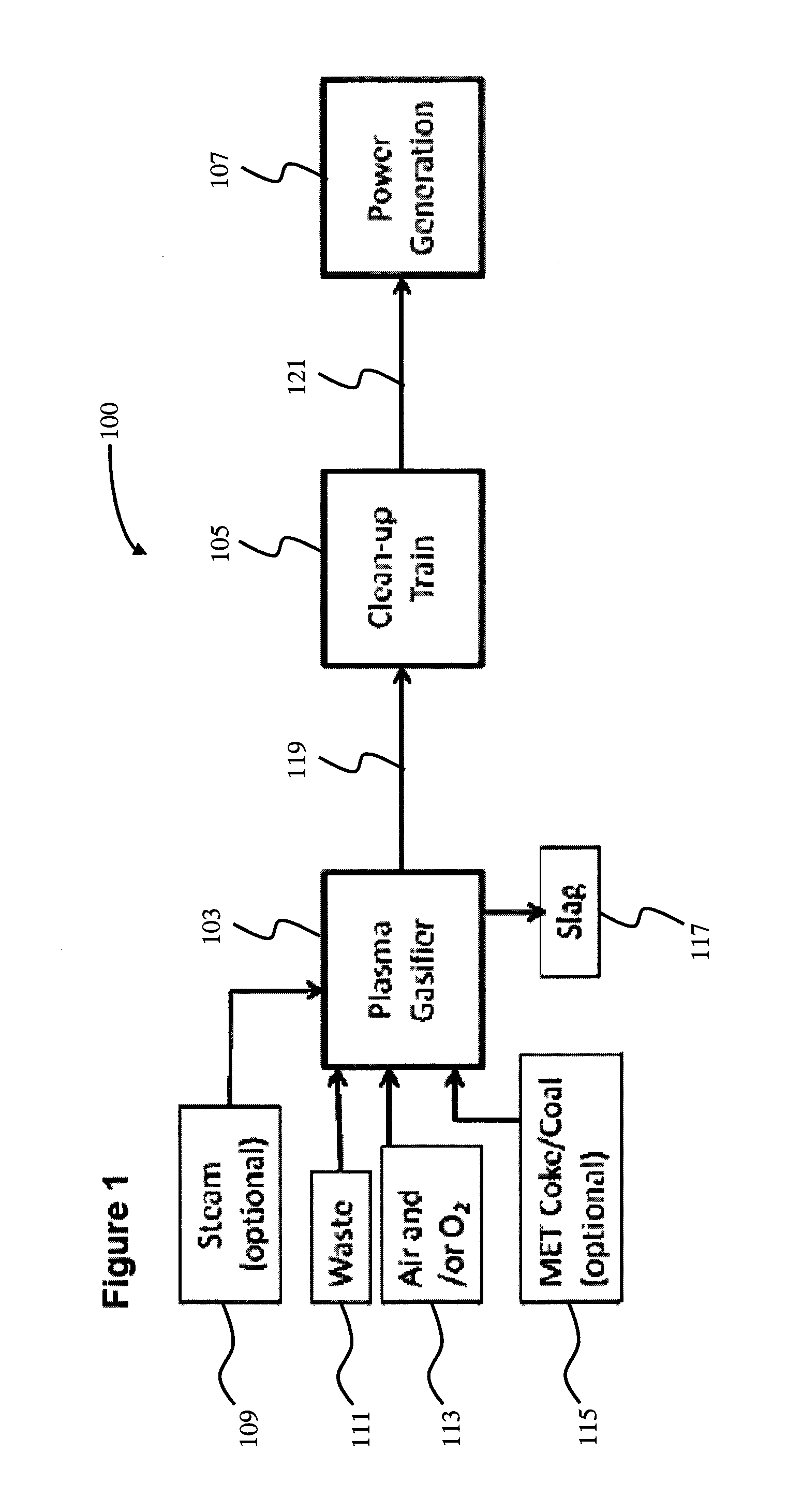

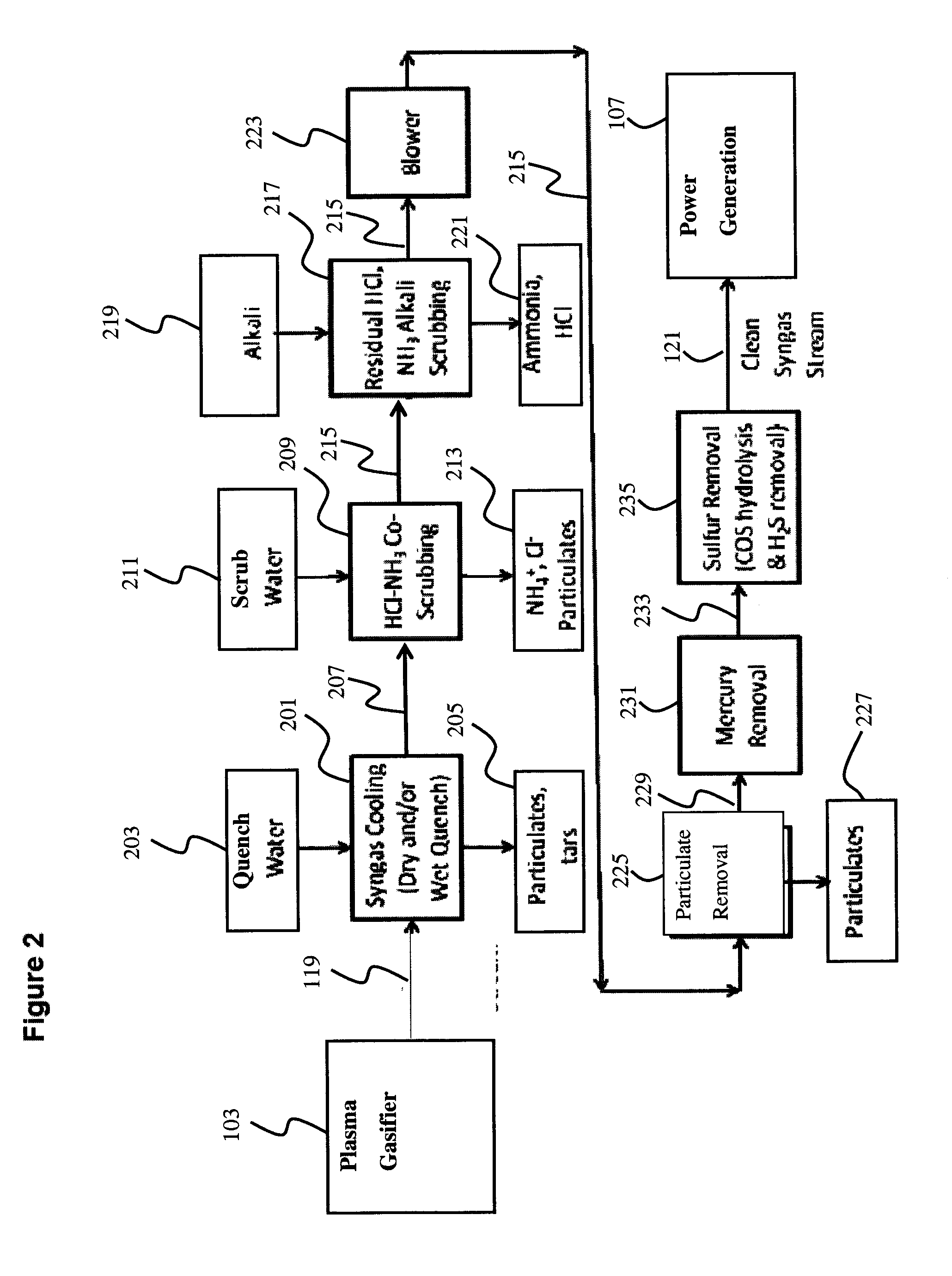

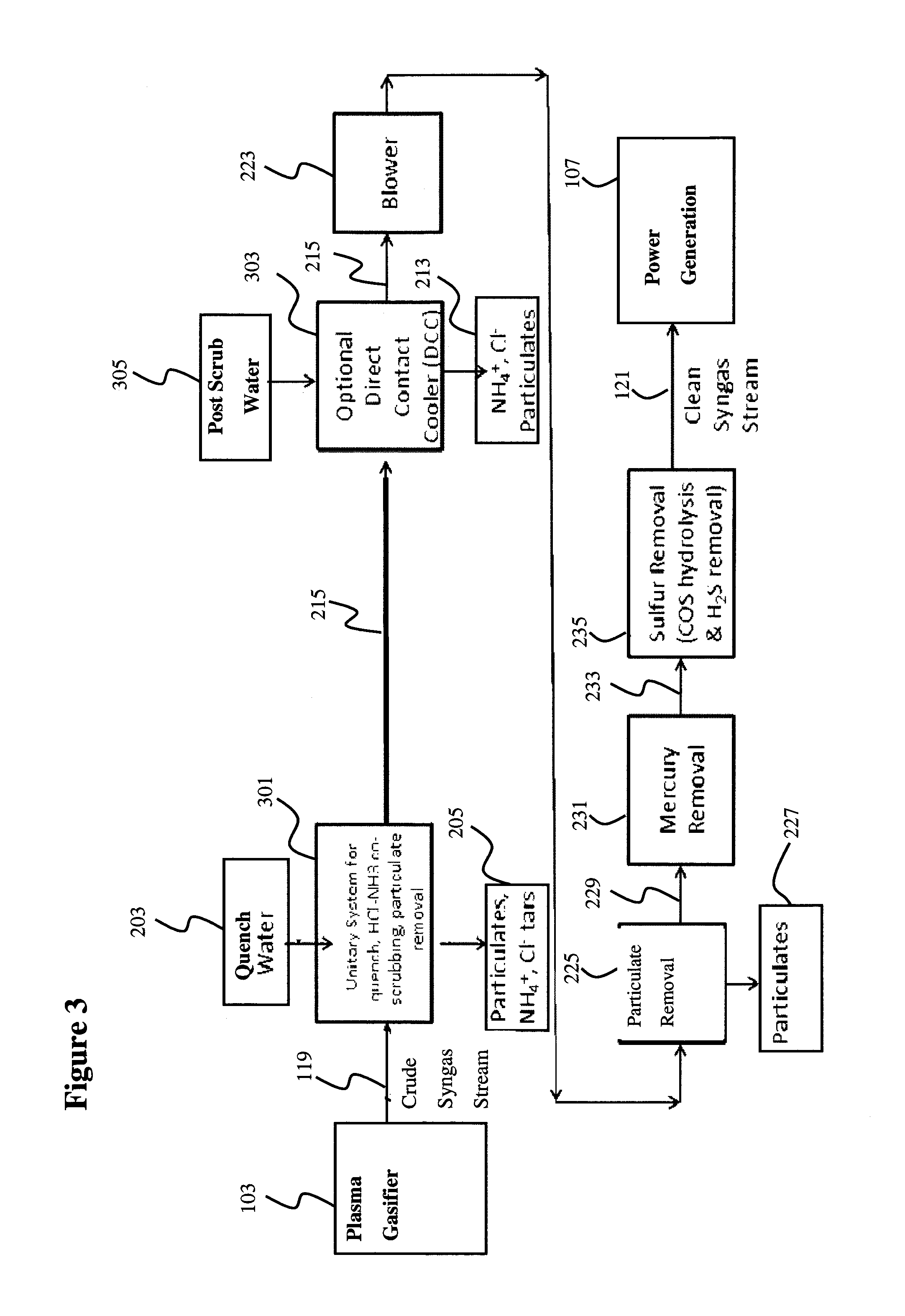

Process and System for Syngas Treatment

A process for the clean-up of a crude syngas stream having widely varying composition and particulate load. The process includes quenching the crude syngas stream with a liquid stream to cool the syngas stream and remove particulates, tars and heavier hydrocarbon compounds. The process further includes co-scrubbing the syngas stream to remove both HCl and NH3 from the syngas stream, removing particulate matter from the syngas stream, and removing sulfur from the syngas stream. A syngas treatment system is also disclosed.

Owner:MILLENNIUM EFW LTD

Method and device for blast furnace coal gas fine desulfurization and purification

InactiveCN110819393AReduce difficultyImprove the efficiency of adsorption and desulfurizationSulfur preparation/purificationGas purification by catalytic conversionThermodynamicsSulfide

The invention provides a blast furnace coal gas fine desulfurization and purification method, which comprises that S1, blast furnace coal gas enters a conversion unit under a positive pressure, and the organic sulfur in the blast furnace coal gas is converted into hydrogen sulfide; S2, the obtained material enters a cooling unit and is cooled; and S3, the cooled stream enters an adsorption unit filled with an adsorption material, and the sulfide in the blast furnace coal gas is adsorbed and removed to form purified coal gas. According to the invention, the low-concentration sulfides in blast furnace coal gas are enriched into sulfur-rich concentrated gas to convert the working condition with large-capacity and low-concentration sulfides into the working condition with small-capacity and high-concentration sulfides, so that the desulfurization effect can be improved, the desulfurization investment cost and the operation cost can be reduced, the sulfur element in the blast furnace coal gas can be recovered, the atom economy is high, and the secondary pollution is reduced.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Novel organic sulfur hydrogenation catalyst carrier and preparation method thereof

ActiveCN102489336AReduce catalysisImprove adsorption capacityCatalyst carriersDispersed particle separationPseudoboehmitePtru catalyst

The invention relates to a novel organic sulfur hydrogenation catalyst carrier. A preparation method of the carrier comprises steps that: a neutralization material, pseudoboehmite (gamma-alumina), an adhesive, a hole expansion agent and a metal additive are mixed; the mixture is subject to knead-molding, drying, and roasting, such that a finished product is obtained. The method is characterized in that the neutralization material is prepared through steps that: pseudoboehmite is soaked by using an alkaline solution, and is neutralized by using an acid solution; and the pseudoboehmite is subject to washing and press-filtrating, such that the neutralization material is obtained. Therefore, impurity content in the pores is greatly reduced, such that the loading of active components is promoted. A catalyst prepared by using the carrier is suitable to be used in hydrogenation catalyzing of organic sulfur in natural gas, coke oven gas, exhaust gas, and the like. Organic sulfur is converted into inorganic sulfides; and the sulfides are removed with the cooperation of an inorganic sulfur desulfurizing agent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

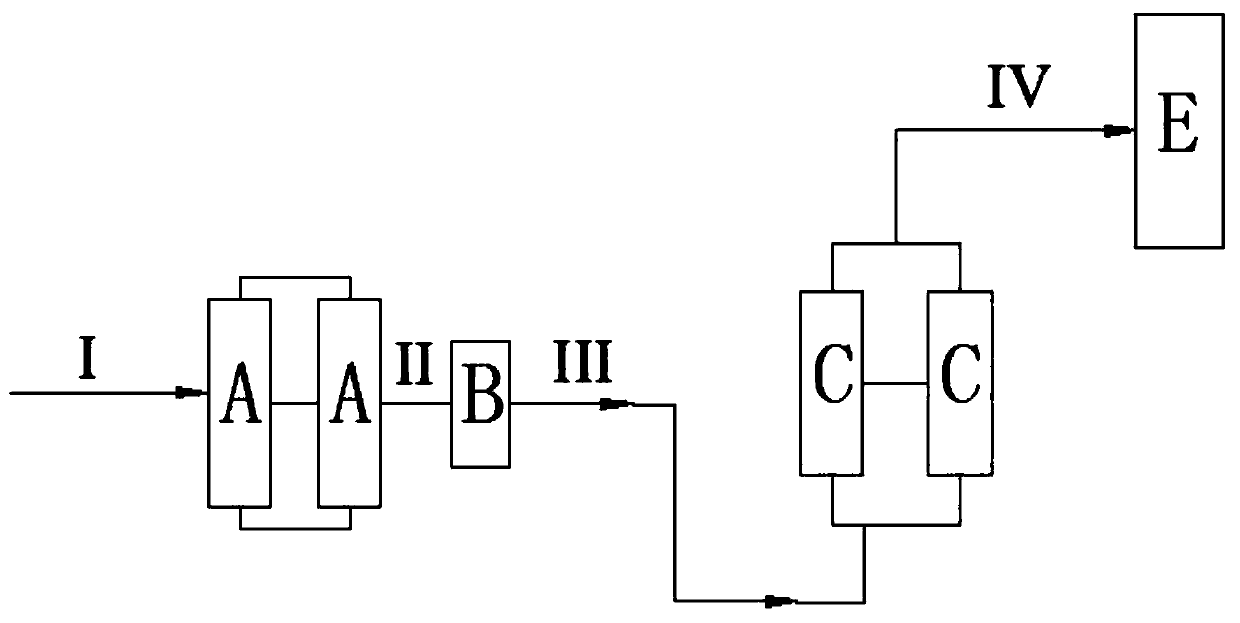

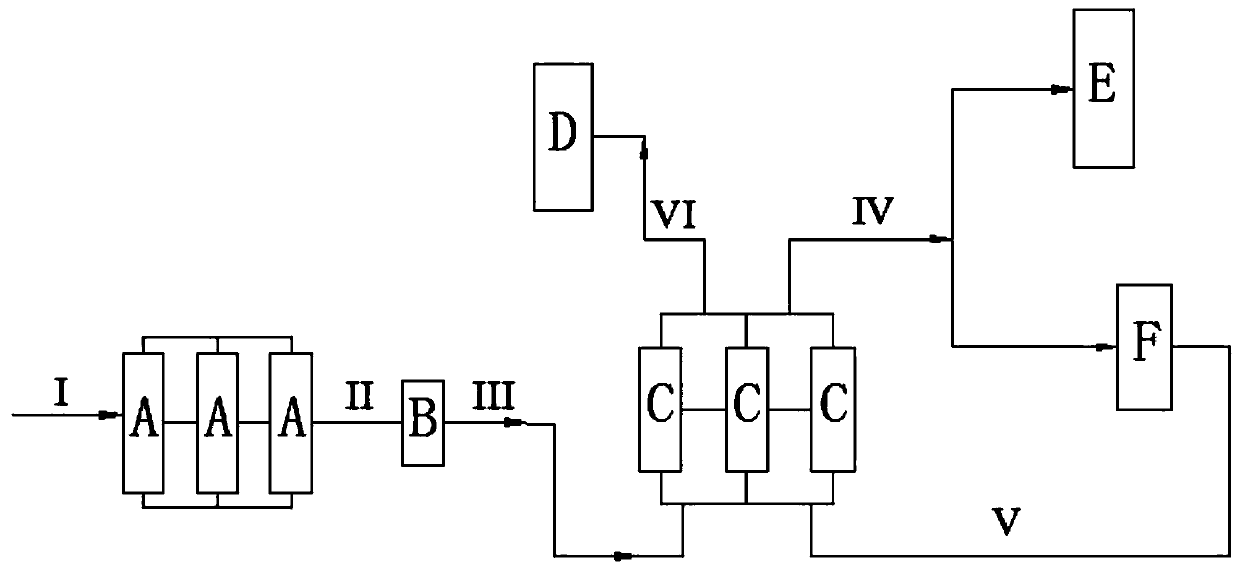

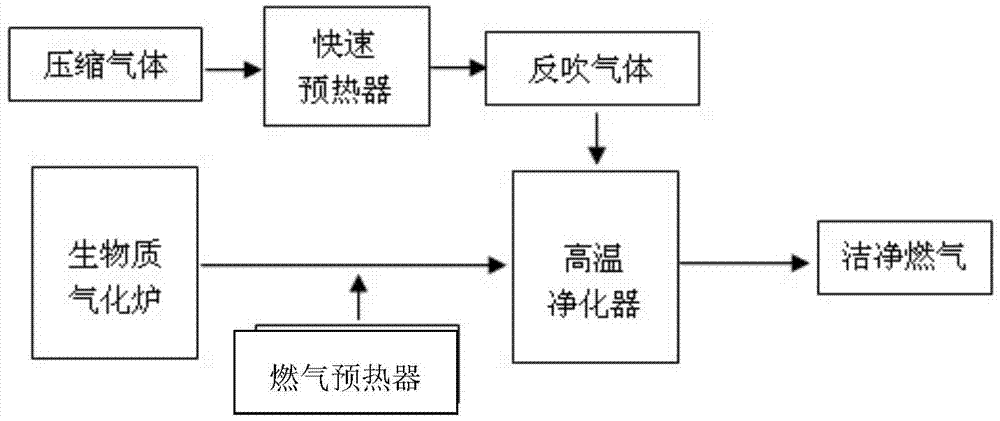

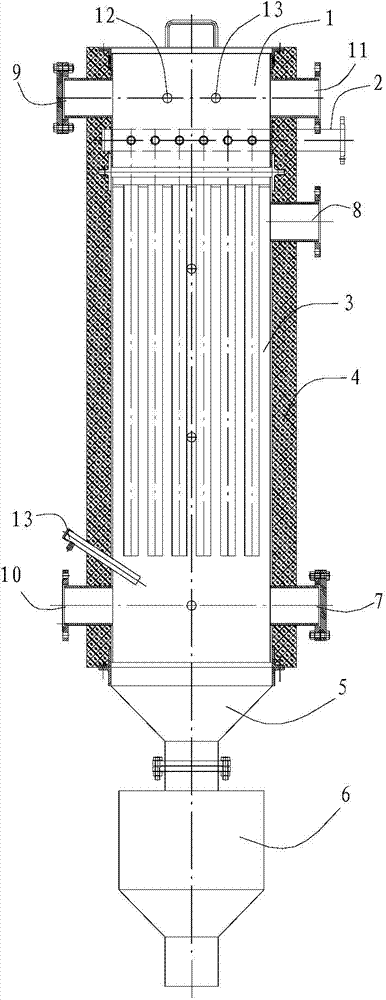

High-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas

ActiveCN103614167AFully purifiedAvoid secondary pollutionGas purification by catalytic conversionGas dust removalInsulation systemIntegrated devices

The invention discloses a high-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas and provides a new process for high-efficiency purification of biomass high-temperature gas at low cost. The process comprises a high-temperature gas heat exchanger (A), a high-temperature gas purifier (B), a Venturi pulse back-blowing system (C), a gas preheater (D) and an electric-heating insulation system (E), wherein the five sets of equipment operate cooperatively to form a set of complete high-temperature gas purifying integrated device; a filtering medium in the high-temperature gas purifier is a modified ceramic membrane dust-removing pipe. When filtering cakes on the outer surface of the modified dust-removing pipe are deposited to certain thickness, deposited ash can be back-blown into an ash discharging hopper box for collection by the Venturi pulse back-blowing system. The high-temperature dust-removing and coke-removing integrated purifying process disclosed by the invention has the advantages that high-efficiency separation and integrated treatment of ash and coke components in biomass gas are realized; the dust-removing temperature is low so as to be beneficial to reducing the manufacturing cost of the equipment and prolonging the service life; biomass ash side products with commercial value are produced while the high-efficiency purification of the biomass crude gas is realized; the process flow is simple and flexible, the operation is simple, the purification cost is low and the suitability for industrial production is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

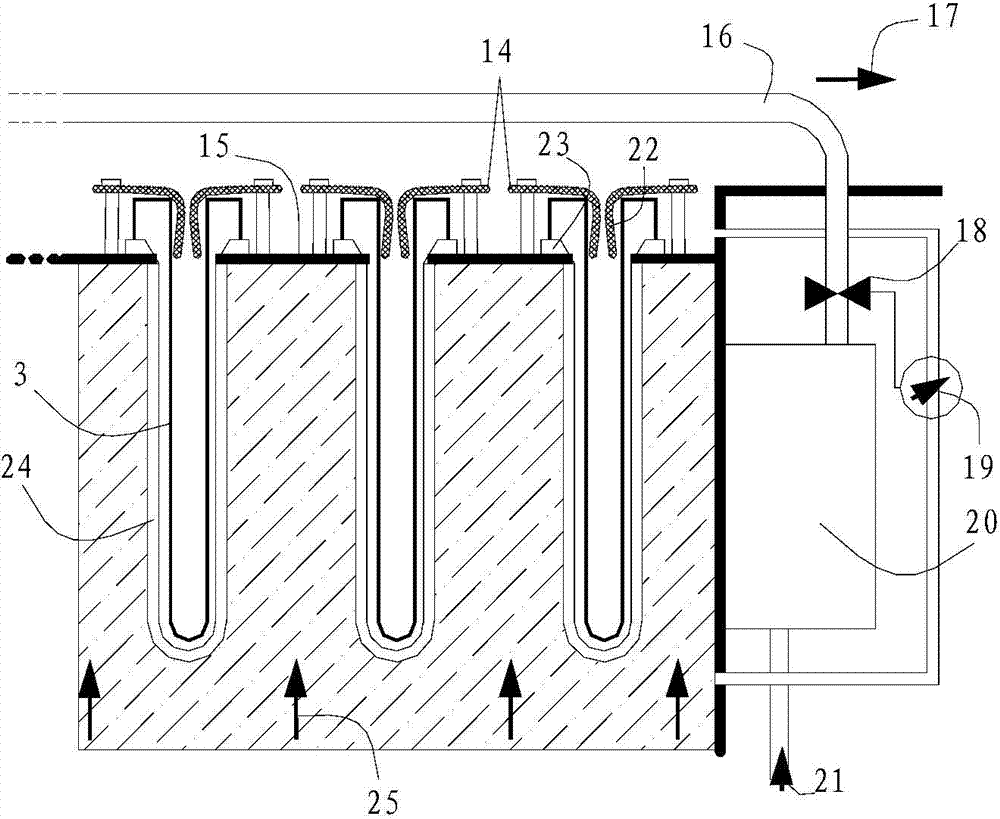

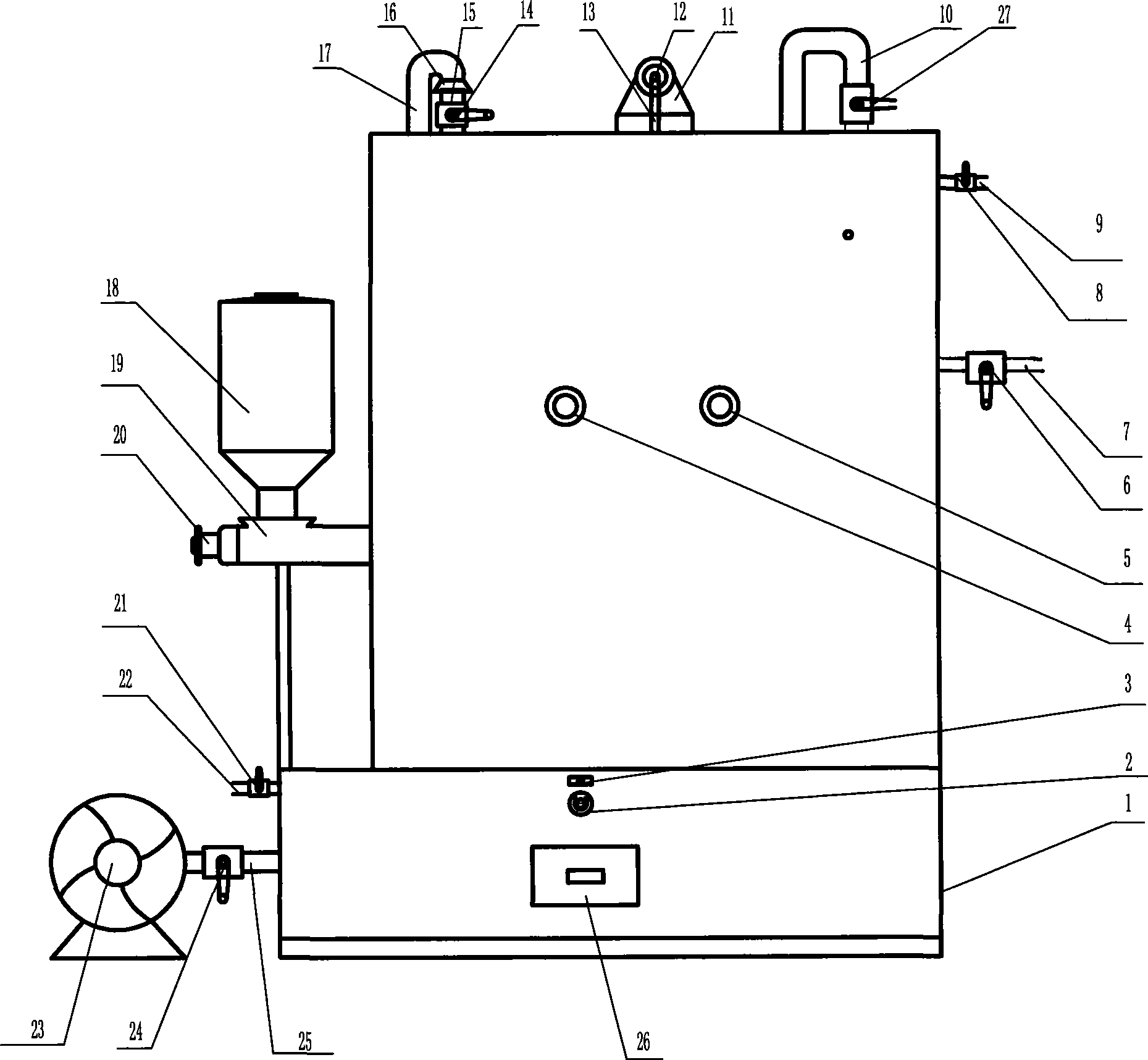

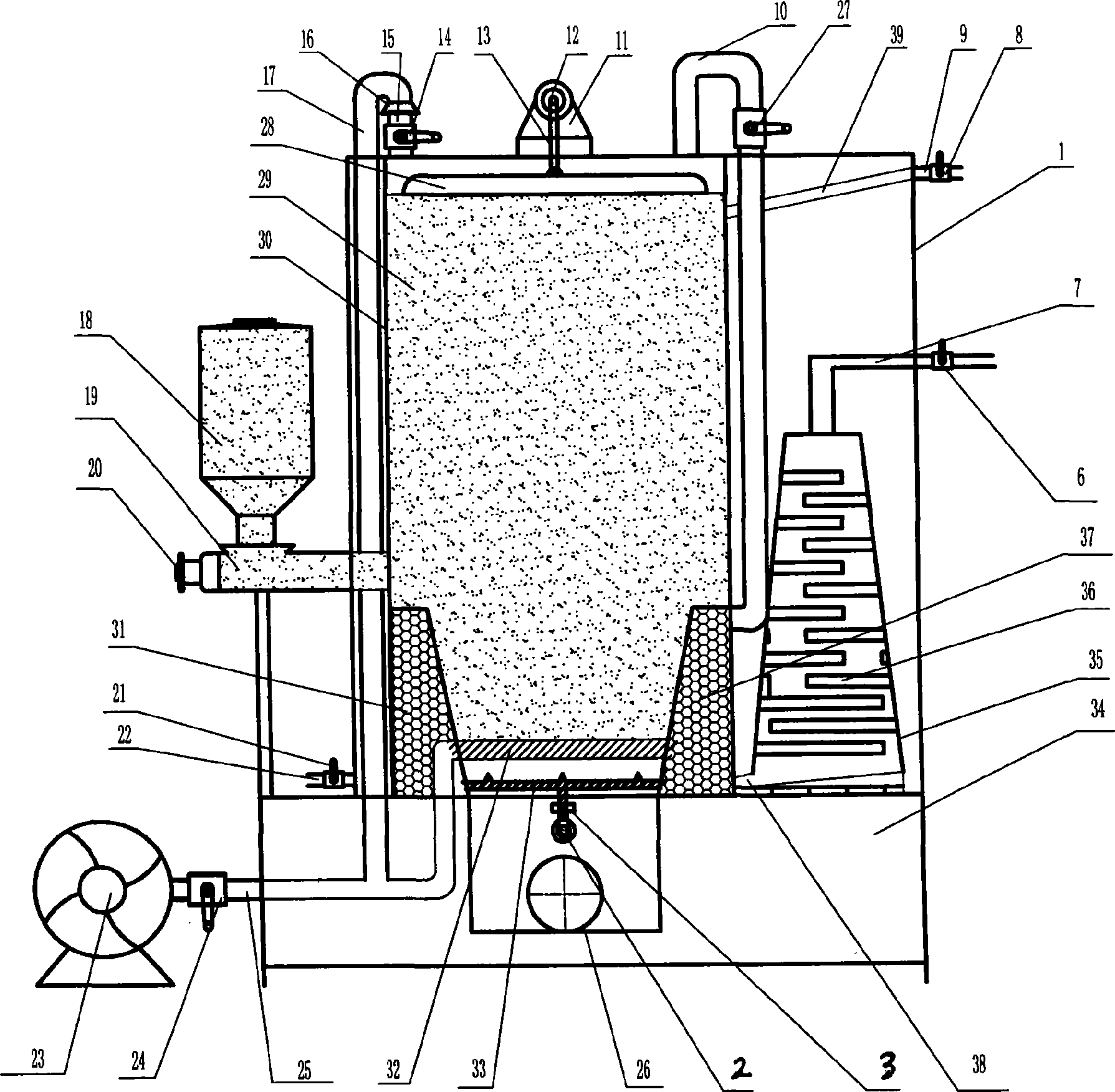

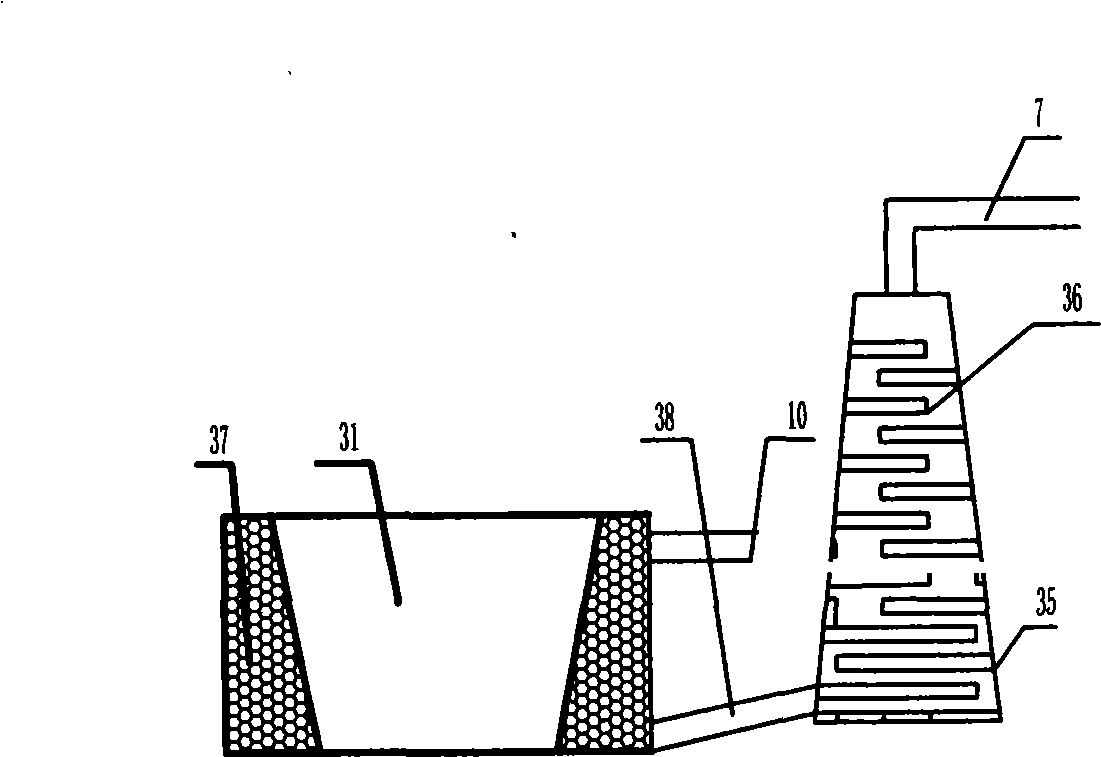

Biomass non-pressure gas making machine

InactiveCN101486929AImprove gasification efficiencyRealization of secondary crackingCatalytic crackingGas purification by catalytic conversionChemical reactionDecomposition

The invention discloses a biomass stress-free gas producing machine which comprises a machine, an air inlet oxygen-feeding device, a rotary dedusting device and a circulating hot water supply device; the biomass stress-free gas producing machine is characterized in that the machine is internally provided with a gas producing collision reaction device and more than one set of parallel-connected or serially-connected gas producing reaction device; each set of gas producing reaction device comprises a gasification furnace, a wastewater and tar high-temperature pyrolysis reaction device and a swaging actuating device; the wastewater and tar high-temperature pyrolysis reaction device is filled with dolomite; the secondary pure gas output tubes arranged at the bottom of each set of the wastewater and tar high-temperature pyrolysis reaction device are connected with the bottom of the collision reaction device after serially connected or parallel connected subsequently. The biomass stress-free gas producing machine is a novel gasification device to carry out second decomposition on the wastewater and tar by using the high-temperature chemical reaction of the wastewater and tar and the dolomite, which takes the dolomite as medium to carry out decomposition on the wastewater and tar by high temperature, so as to actually achieve the goals of zero emission, no secondary pollution, green environmental protection and large-scale gas production in the biomass gas producing technology.

Owner:熊天东

Preparation method of nano zinc oxide mesopore desulfurizer

InactiveCN101337150ADispersed particle separationCatalyst activation/preparationSulfurZno nanoparticles

The invention relates to a preparation method for nano-zinc oxide mesoporous desulfurizer, which uses mesoporous material as desulfurizer carrier, uses nanoscale zinc oxide particles as desulfurization catalyst and carrys the nanoscale zinc oxide particles on the mesoporous material to obtain a mesoporous desulfurizer containing zinc oxide. The zinc oxide nanoparticles have good dispersion and are mainly deposited in mesopores and micropores based on the detection of physical representation and desulfurization performance of synthetic desulfurizer, and the desulfurizer shows excellent H2S removal capacity at room temperature. Additionally, the penetrating sulfur capacity of the mesoporous desulfurizer is also constantly increased along with the increase of the carried nanoscale zinc oxide content.

Owner:SHANGHAI JIAO TONG UNIV

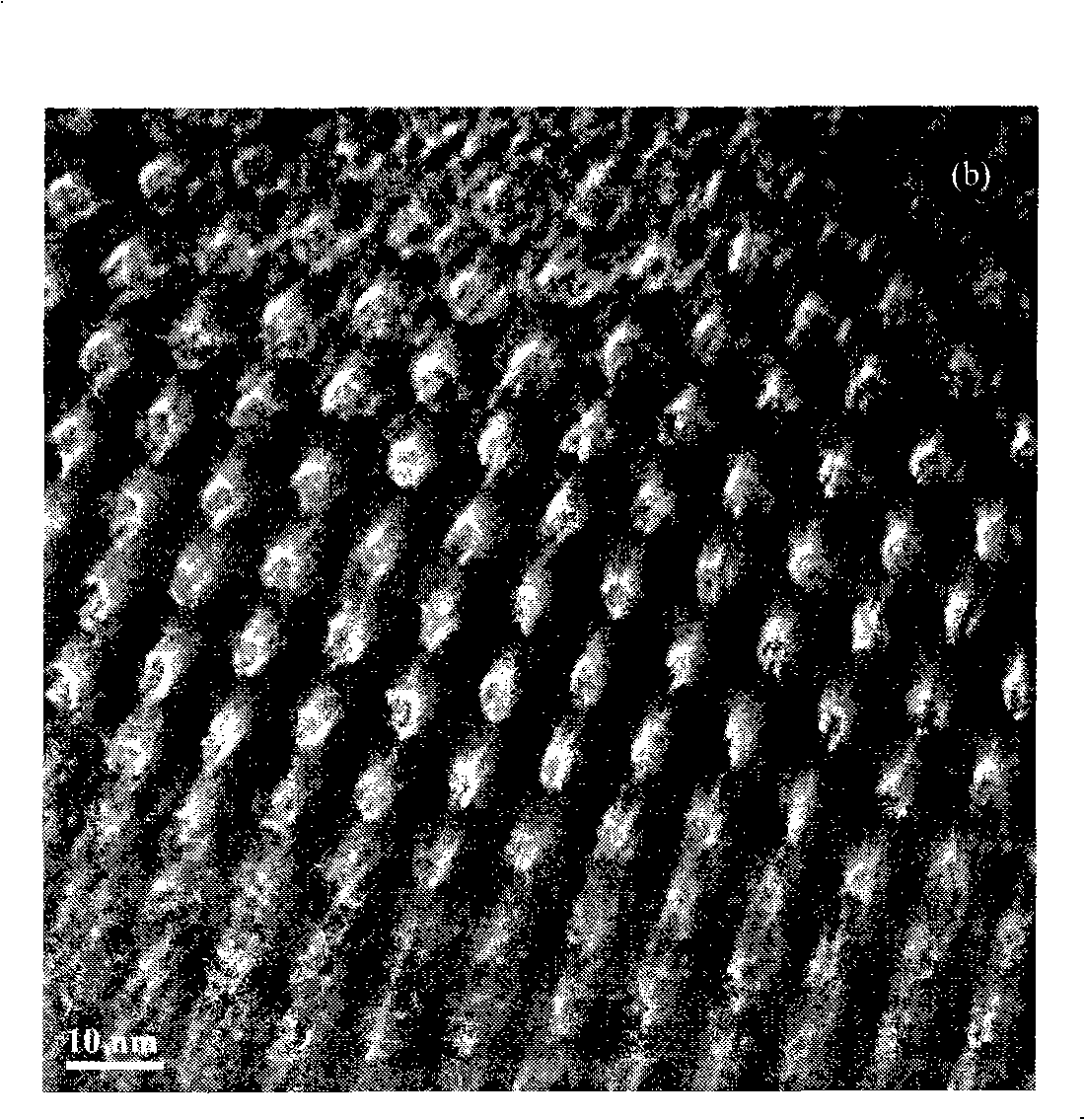

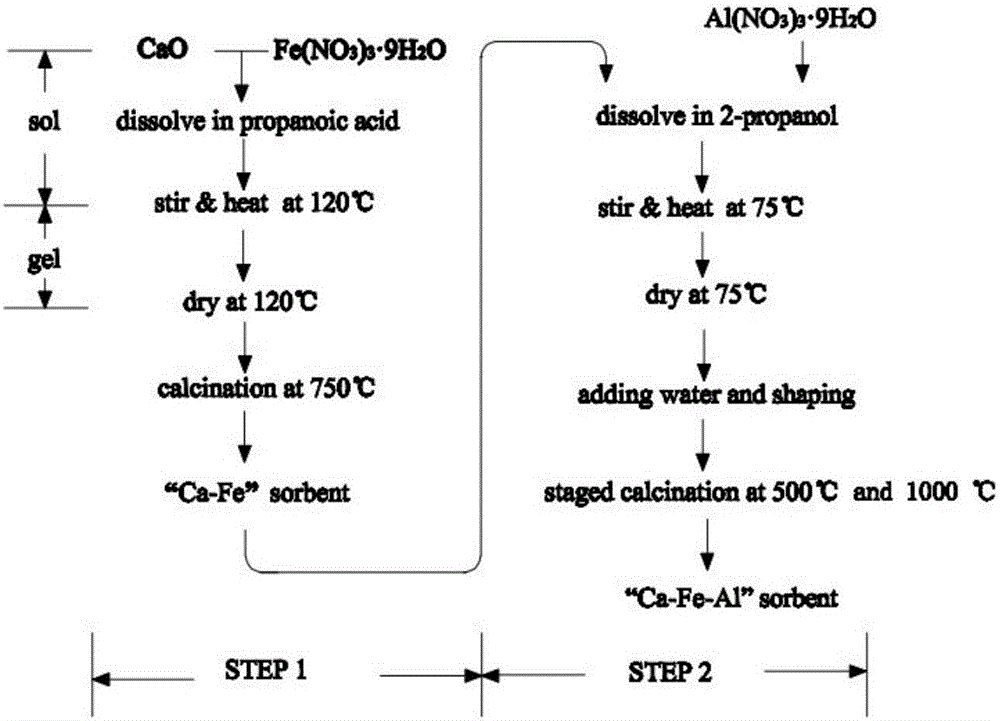

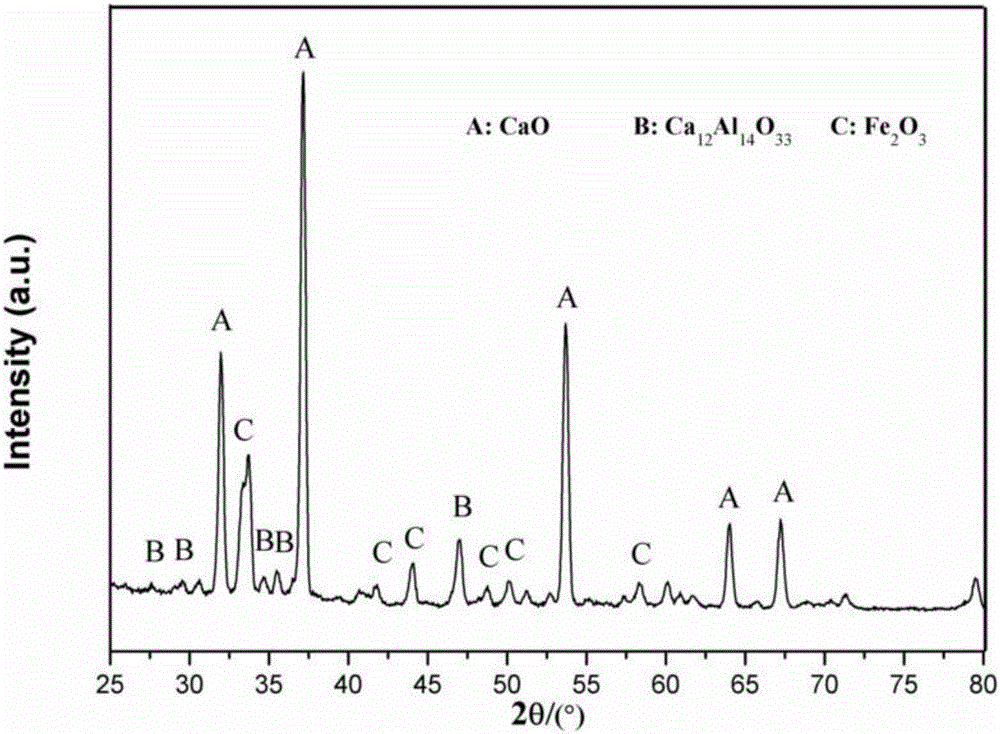

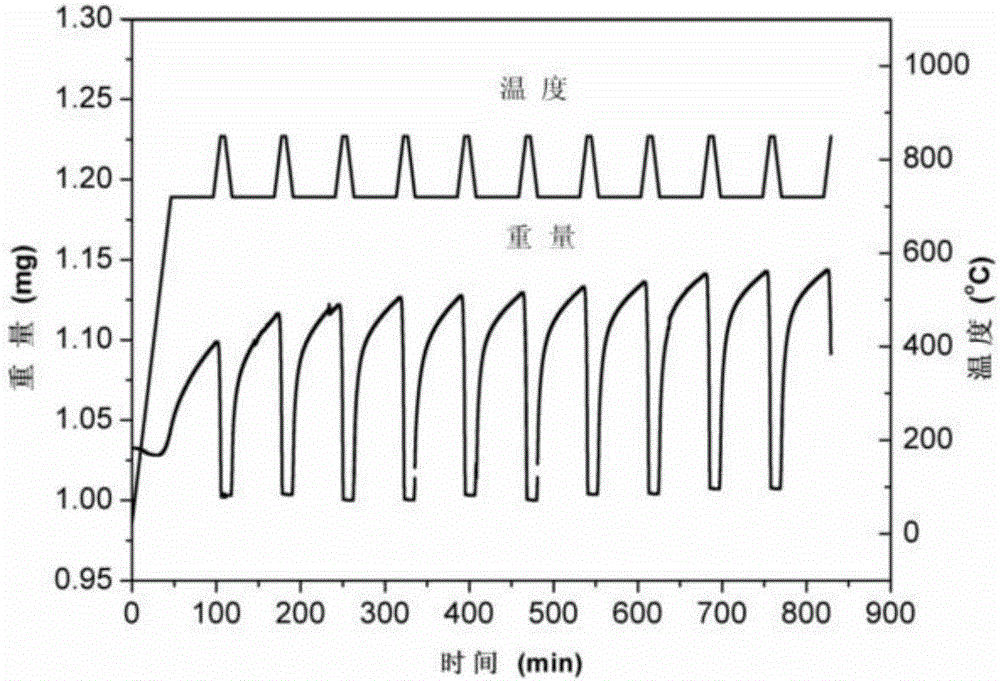

Biomass coke tar catalyst with mayenite loaded with calcium and iron compounds as well as preparation and application

InactiveCN106824206AHigh activityReduce carbon depositionHeterogenous catalyst chemical elementsGas purification by catalytic conversionHigh concentrationActive component

The invention relates to a biomass coke tar catalyst with mayenite loaded with calcium and iron compounds as well as a preparation method and an application of the biomass coke tar catalyst. The catalyst takes the mayenite (Ca12Al14O33) as a carrier and is also loaded with the calcium and iron compounds at the same time; and main chemical components comprise CaO, the mayenite and iron compounds with coke tar catalyzing activity. Compared with a traditional biomass coke tar catalyst, the novel catalyst provided by the invention has the following beneficial effects that (1) compared with a Ni-based catalyst, an iron active component of the coke tar catalyst has the advantages of environmental friendliness and low price; (2) the catalyst contains the CaO and biomass gasified synthetic gas with high-concentration H2 is easy to prepare; (3) the Ca12Al14O33 carrier can be used for easily reducing deposited carbon of the catalyst, the strength of the catalyst can be improved and the activity of absorbing CO2 can be improved; and (4) the catalyst is prepared by adopting a sol-gel method and various active components of the catalyst are uniformly distributed.

Owner:ZHEJIANG UNIV OF TECH

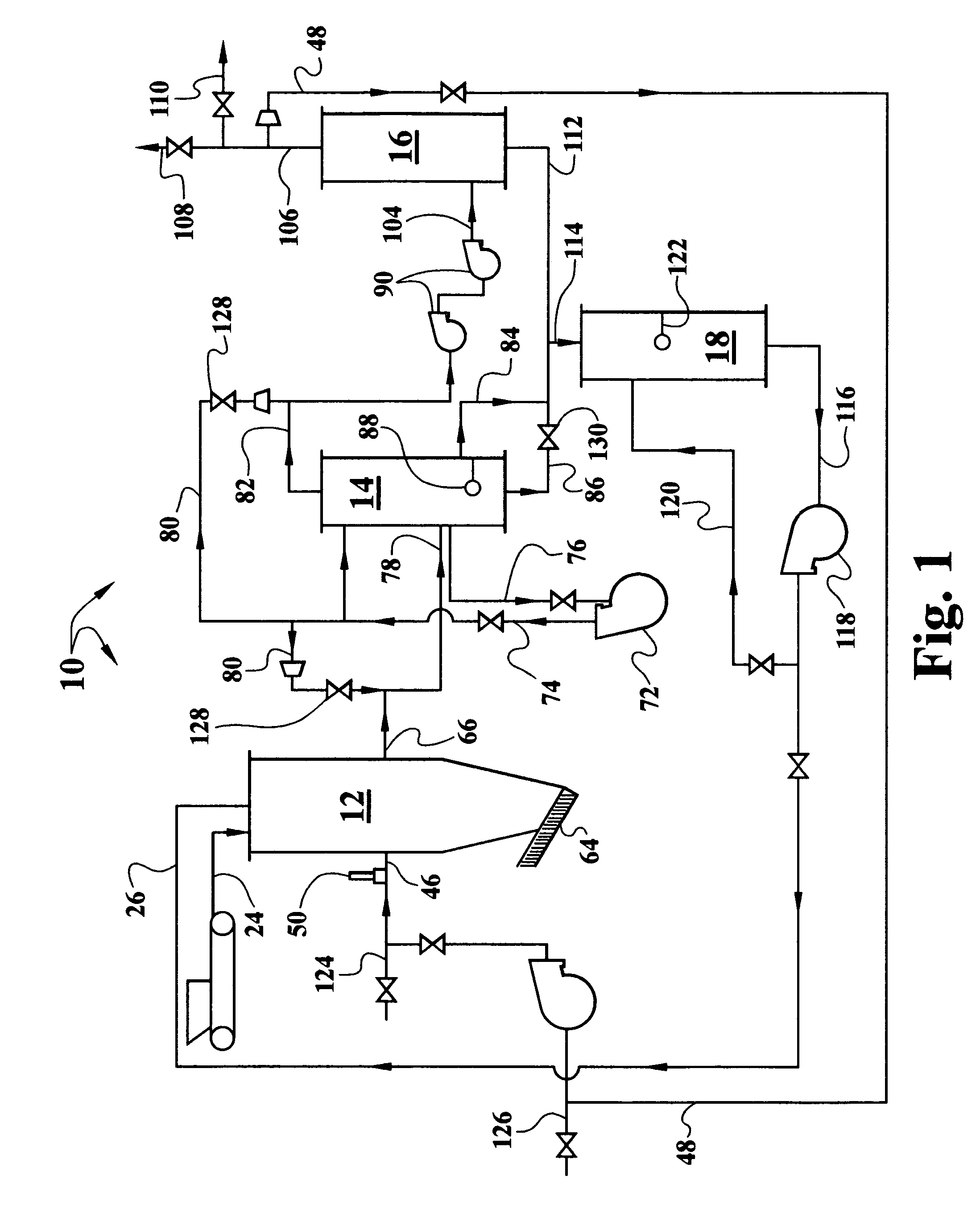

Coke oven gas desulfuration and deamination combined purifying method and special device thereof

InactiveCN102061197AReduce the amount of fixed ammoniumReduce alkali consumptionChemical industryGas purification by catalytic conversionCatalytic oxidationEvaporation

The invention discloses a coke oven gas desulfuration and deamination combined purifying method and a special device thereof. The method comprises a desulfuration method and a deamination method; coke oven gas desulfuration adopts a wet type catalytic oxidation method, and deamination adopts a water washing method; coke oven gas is subjected to cooling naphthalene scrubbing before being desulfurized and then desulfurized; the coke oven gas is subjected to the water washing method deamination and ammonia evaporation after being desulfurized; and ammonia consumed by desulfuration is derived from ammonia generated by gas and ammonia evaporation. The special device comprises an oil naphthalene scrubbing precooling tower, a desulfurizing tower, an ammonia water washing tower and an ammonia evaporating tower which are connected in sequence. The combined process disclosed in the invention has the characteristics of high efficiency, energy saving, lower investment and lower operating cost. The concentrated ammonia water circulating process has the function of adsorbing and removing hydrogen sulfide. The desulfuration and deamination combined process has the effect of desulfuration twice. In addition, a gas naphthalene scrubbing precooling tower adopted by the process of the invention has the functions of scrubbing naphthalene and cooling gas, and the naphthalene scrubbing adopts a wayof combining spraying absorption, liquid film absorption and cooling, thereby improving the naphthalene scrubbing and precooling effect.

Owner:江苏中显集团有限公司

Active carbon desulfurizer and preparation method thereof

ActiveCN101664689AStrong water resistanceReduce manufacturing costOther chemical processesGas purification by catalytic conversionBASIC CUPRIC CARBONATEBasic copper carbonate

The invention relates to an active carbon desulfurizer prepared by a kneading method and a preparation method thereof. The preparation method comprises the following steps: evenly mixing copper oxideor basic cupric carbonate and pulverized coal or charcoal powder with a certain quantity of water, then adding tar and rolling evenly, and then extruding bands to mold, drying and activating to prepare the active carbon desulfurizer for loading the copper oxide. Holes of the active carbon desulfurizer prepared by the kneading method are more than that of the active carbon desulfurizer prepared bya dipping method; the specific surface area of the active carbon desulfurizer is larger than 1,000<2> / g; the active carbon desulfurizer loading CuO and prepared by a kneading method is not only suitable for desulfuration in petrochemical industry, but also suitable for desulfuration of water gas; and when used for desulfuration of water gas, the active carbon desulfurizer not only has high activity, but also achieves over 30 percent of working sulfur capacity and has the advantages of regeneration, strong water resisting property, no argillization, low production cost and simple process.

Owner:一重集团大连工程建设有限公司

Catalyst for removing H2S from gas by catalytic oxidation, preparation method and application

InactiveCN102500362AEasy to prepareHigh desulfurization activityGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonSulfur

A catalyst for removing H2S from gas by catalytic oxidation contains a metal oxide as active component, and active carbon as carrier, wherein the weight percentages of the two components are as follows: active carbon 95.0% to 99.9%, and metal oxide 0.1% to 5%; active carbon has a specific surface area of 850 to 900 m<2> / g, total pore volume of 0.45 cm<3> / g, and micro-pore volume of 0.154 cm<3> / g; and the metal oxide is oxide of Fe, V, Mn, Cu, Ce or Co. The catalyst provided by the invention has a simple preparation method, and can remarkably improve the desulfurization activity and selectivity of active carbon and greatly improve breakthrough sulfur capacity of desulfurizer.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

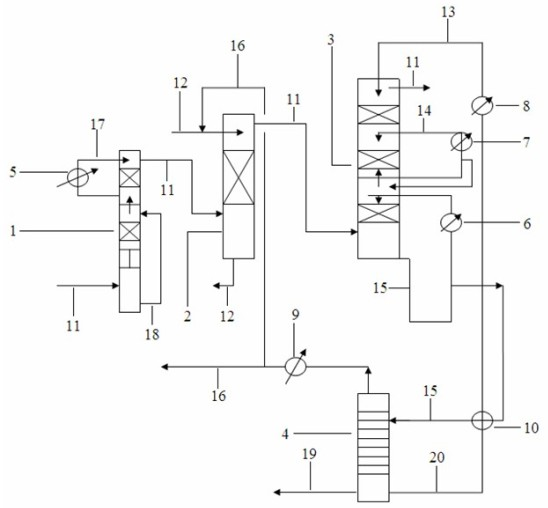

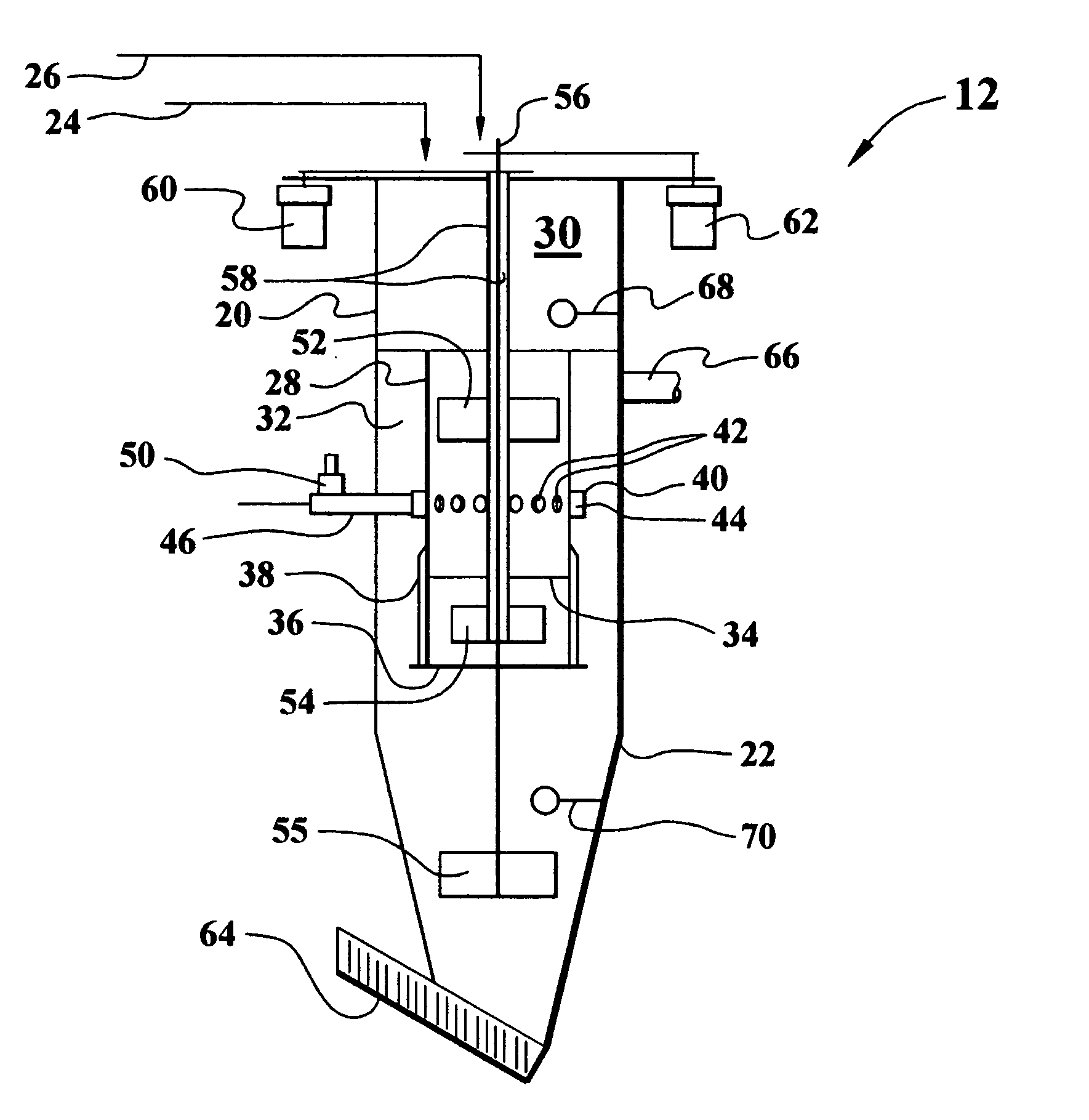

Gasification apparatus and method

InactiveUS20050268556A1High calorific valueAvoid pitfallGaseous fuelsDispersed particle separationCombustorChemical reaction

A gasification system is disclosed having a combustor, a scrubber, a finisher, and optionally a recycler. A carbonaceous fuel is partially combusted in the combustor to generate a combustible gas. An improved ash support and removal system reduces clogging and other problems in the combustor. The combustible gas passes through the scrubber to remove matter such as tar and oil and to undergo preliminary catalytic chemical reactions. The scrubbed gas passes through a hybrid blower to the finisher. Final catalytic chemical reactions occur in the finisher, and wood chips or other filters may also be used in the finisher to provide a relatively clean, dry, combustible gas. Wastewater and other waste products from the scrubber and finisher are captured in the recycler and returned to the combustor.

Owner:POWER RECLAMATION

Popular searches

Combustible gas catalytic treatment Hydrogen production Bed hydrotreatment processes apparatus Chemical/physical/physico-chemical processes Silica Hydrocarbon purification/separation Gas purification by non-gaseous materials condensation Gas purification by liquid washing Multistage water/sewage treatment Hydrocarbons

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com