Patents

Literature

163results about "Bed hydrotreatment processes apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

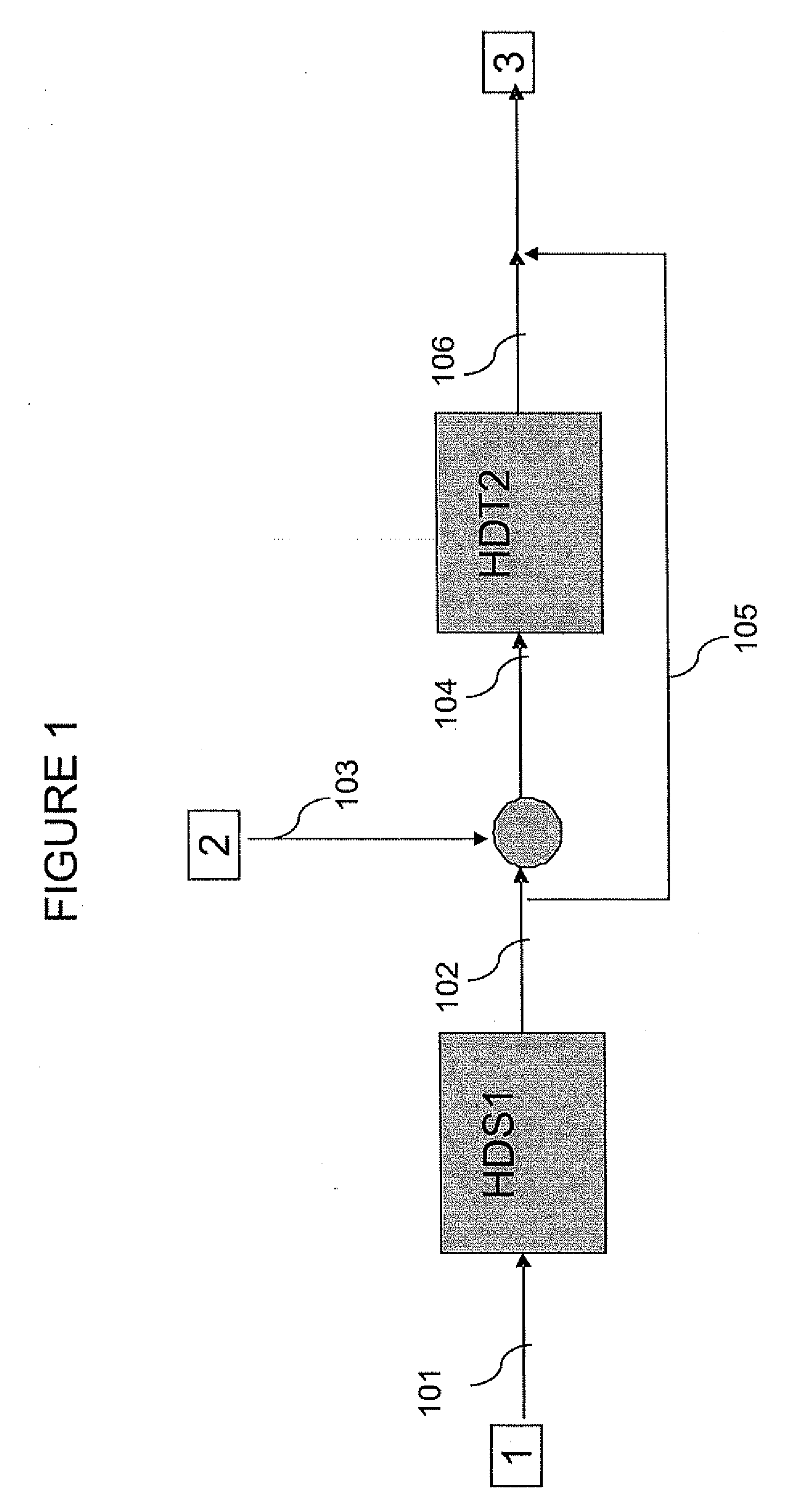

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with quench injection of the oils on the last catalyst bed

ActiveUS20080173570A1Low costReduce use costCatalytic crackingHydrocarbon oil crackingDistillates petroleumVegetable oil

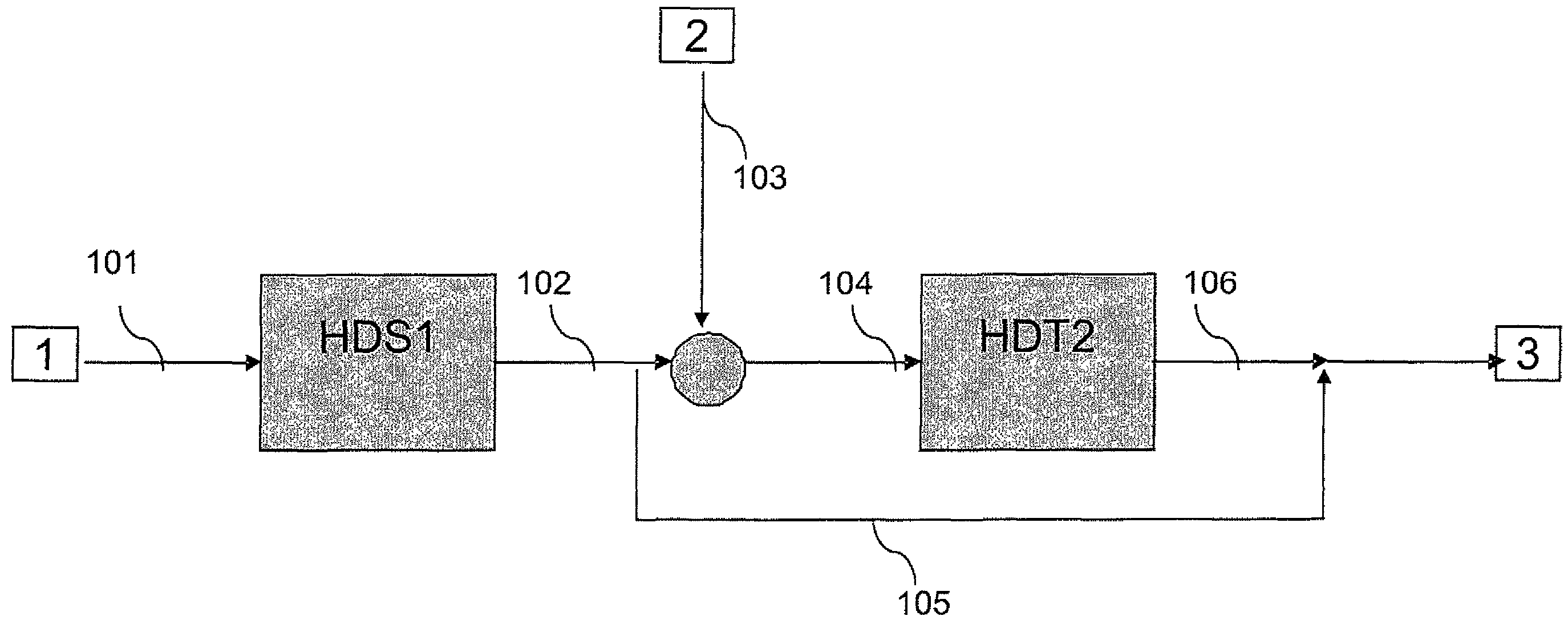

A hydrotreating method uses two catalyst beds with the introduction, on the last catalyst bed, of oils of animal or vegetable origin for co-treating a mixture made up of oils of vegetable or animal origin and of petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil effluents meeting specifications with an improved cetane number. The first catalyst bed is dedicated to only the deep desulfurization reactions (HDS1) of a petroleum type feed. The effluents of the first catalyst bed having an effluent sulfur content below or equal to 50 mg / kg are separated into two streams. The first stream, which is predominant, is sent to the gas oil pool. The second stream is mixed with oils of vegetable or animal origin. The resultant oil-petroleum cut mixture is then subjected to a milder hydrotreatment (HDT2). The effluents obtained at the outlet of the second catalyst bed can optionally be mixed with the predominant stream from the first bed. The process economy, the tolerance to the specifications relative to oils of animal or vegetable origin and the quality of the products obtained are thus greatly improved.

Owner:INST FR DU PETROLE

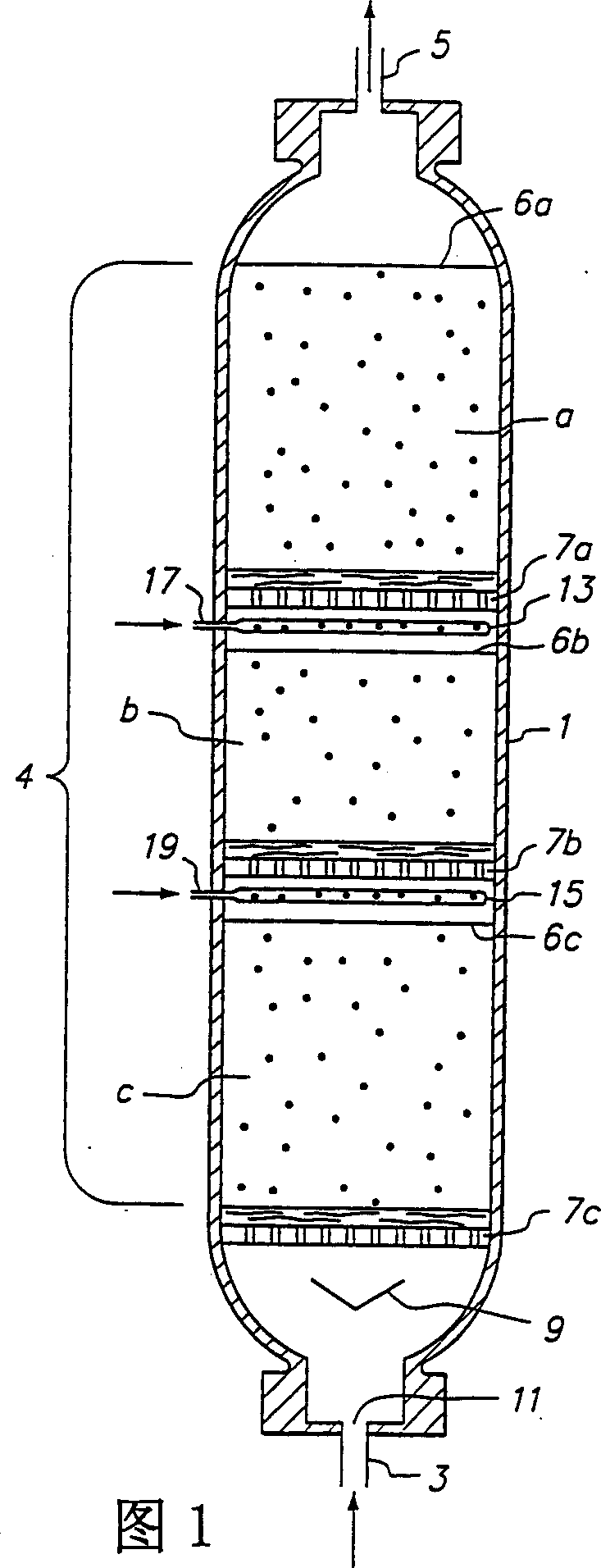

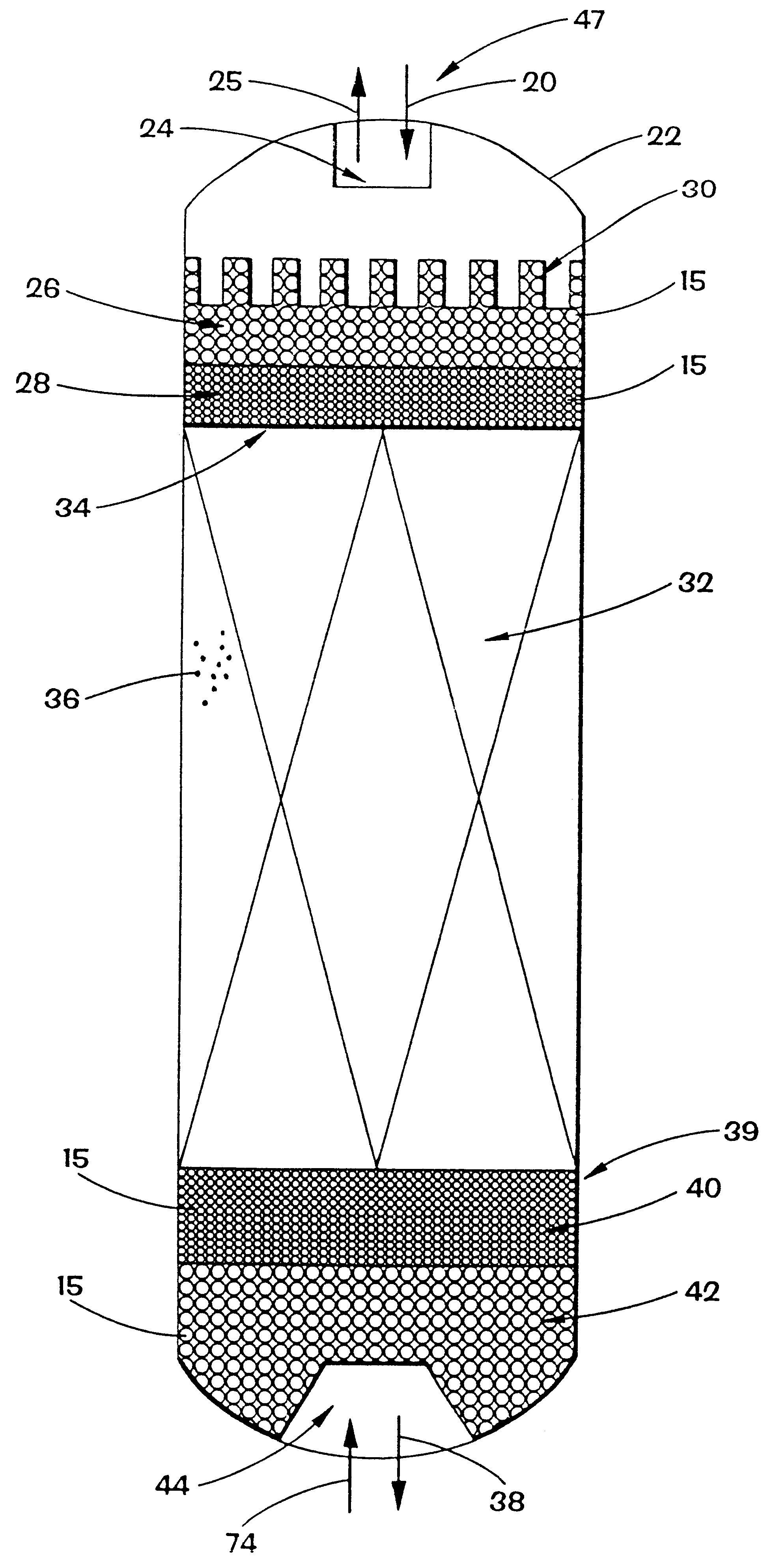

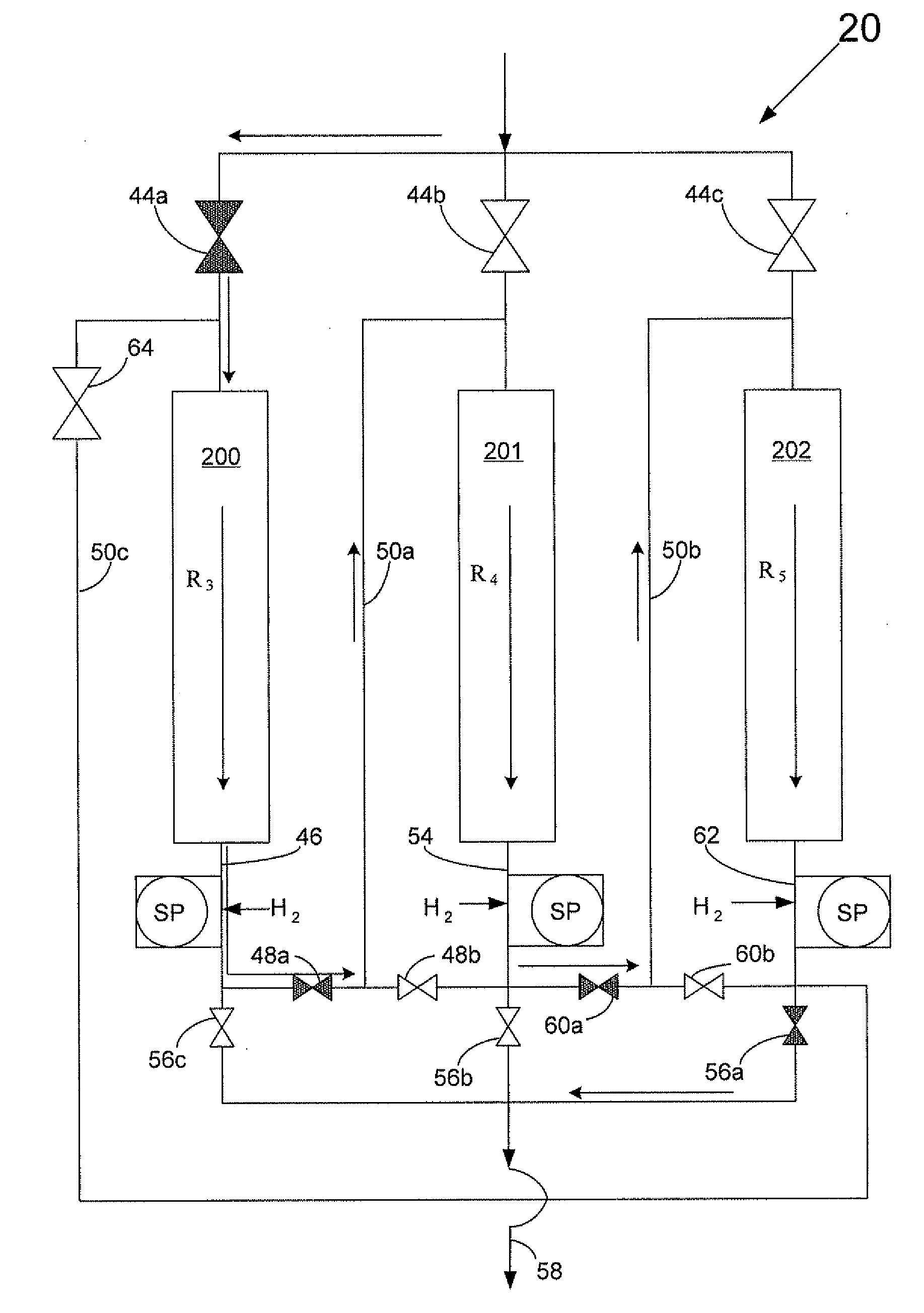

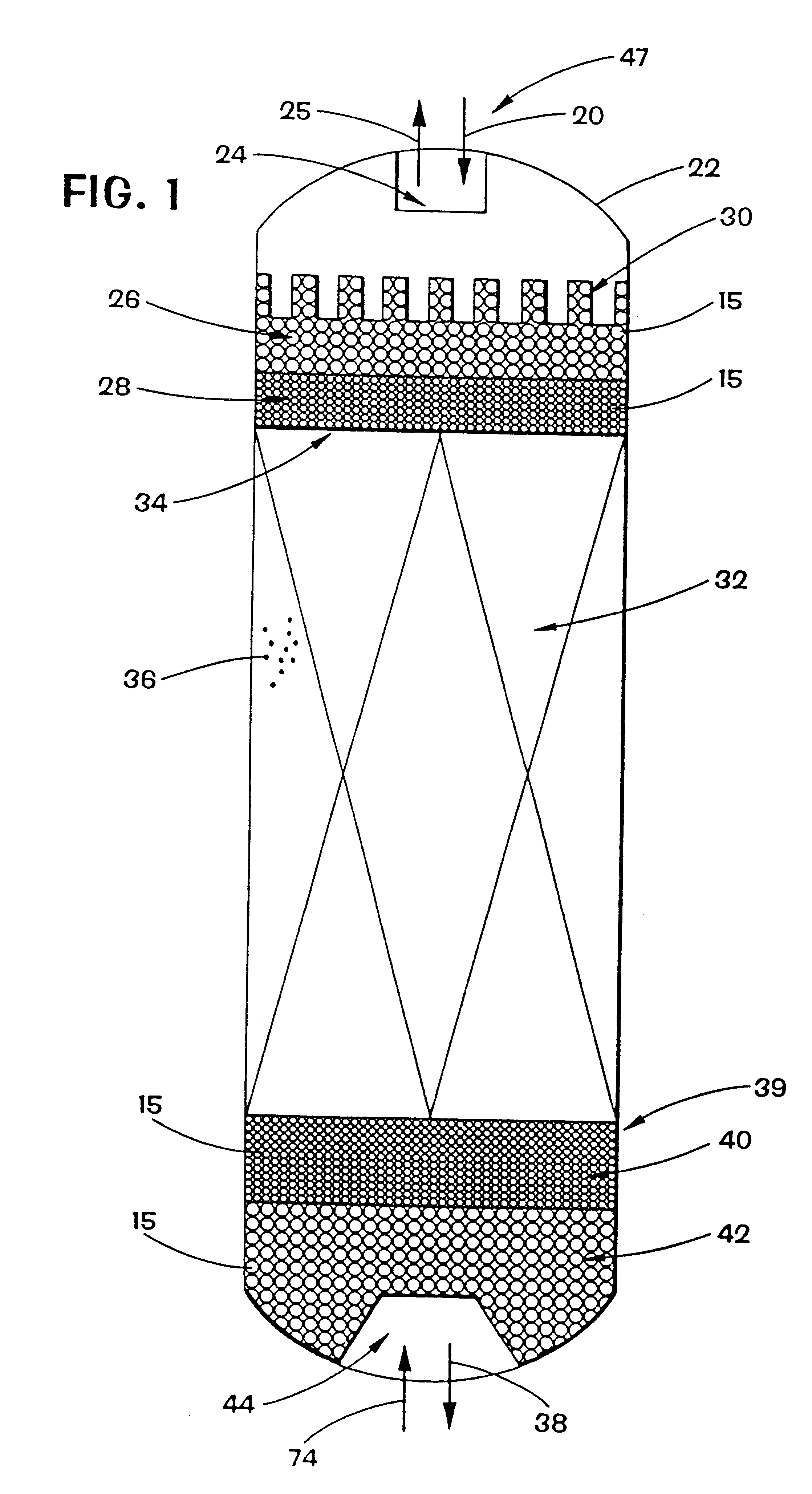

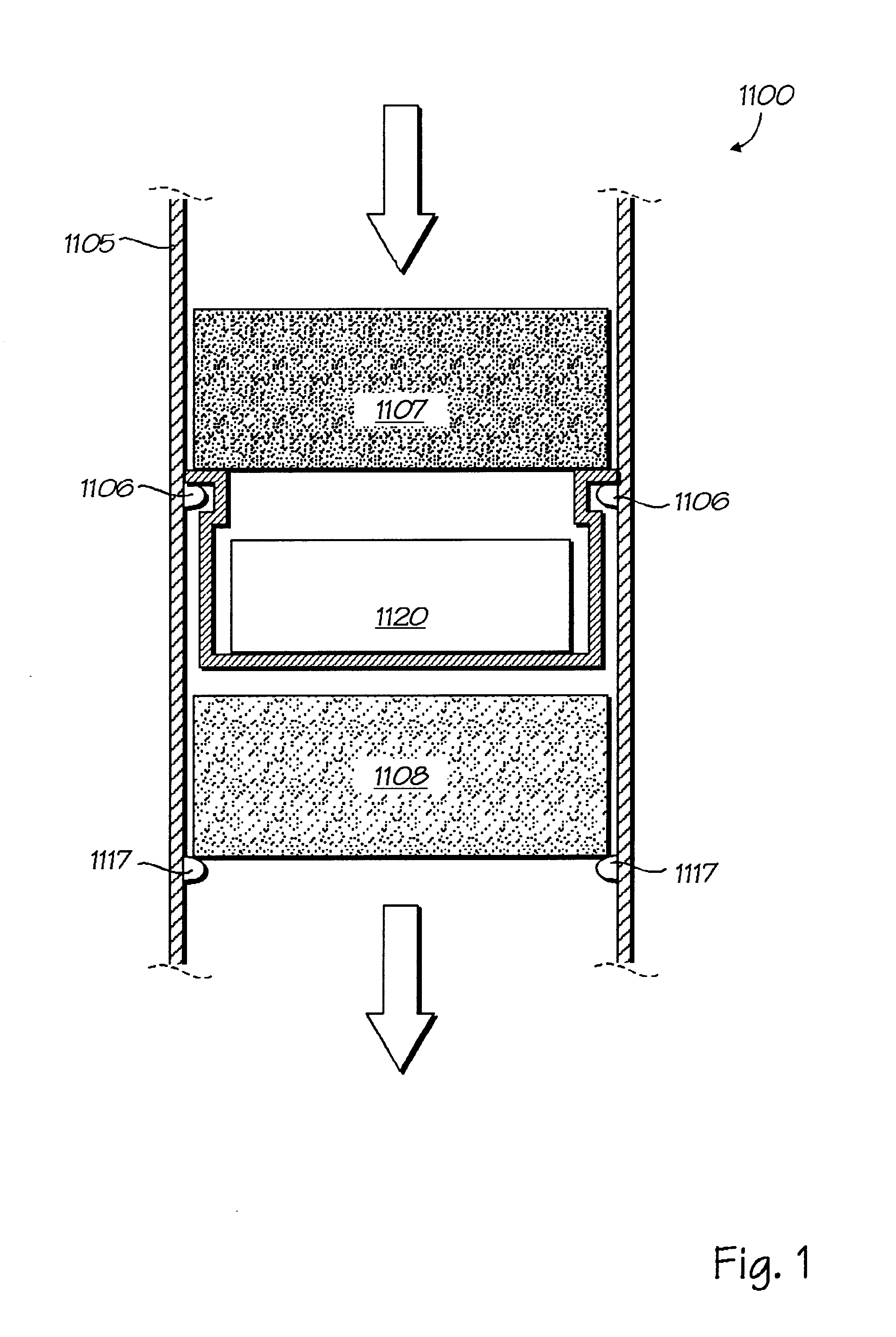

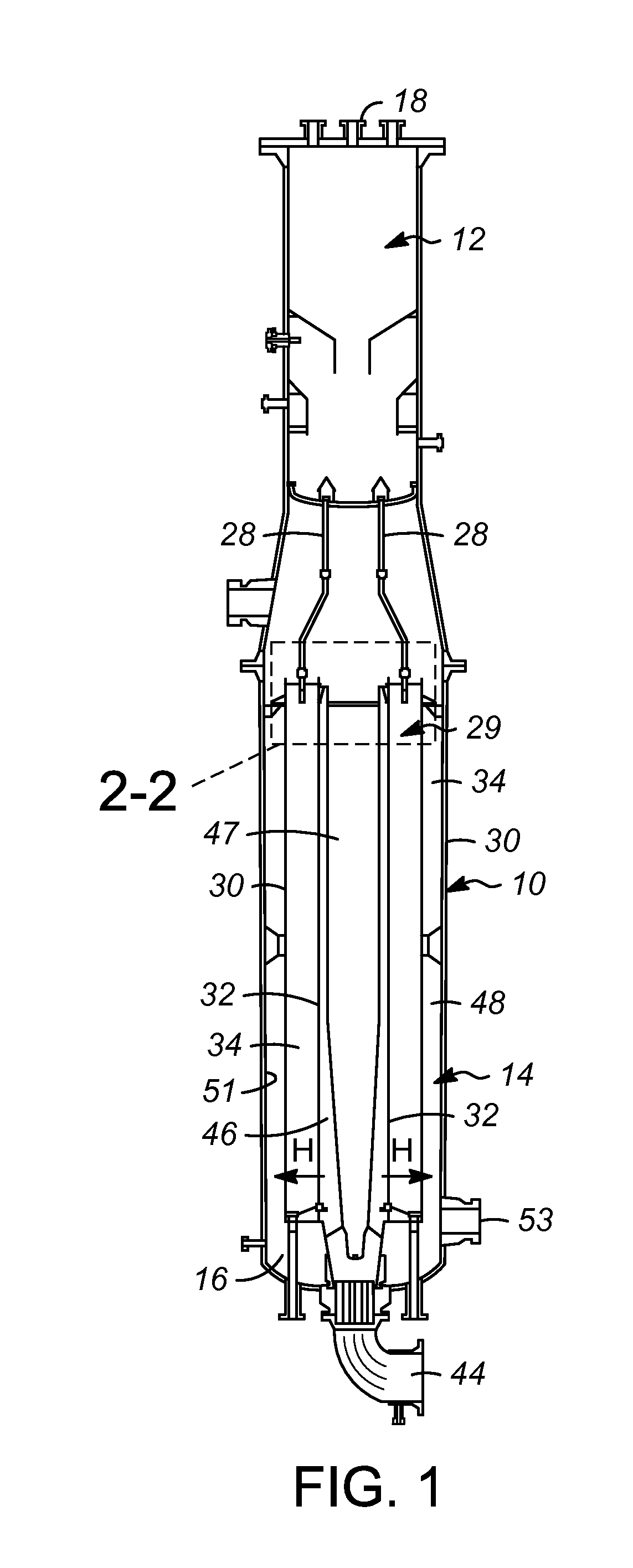

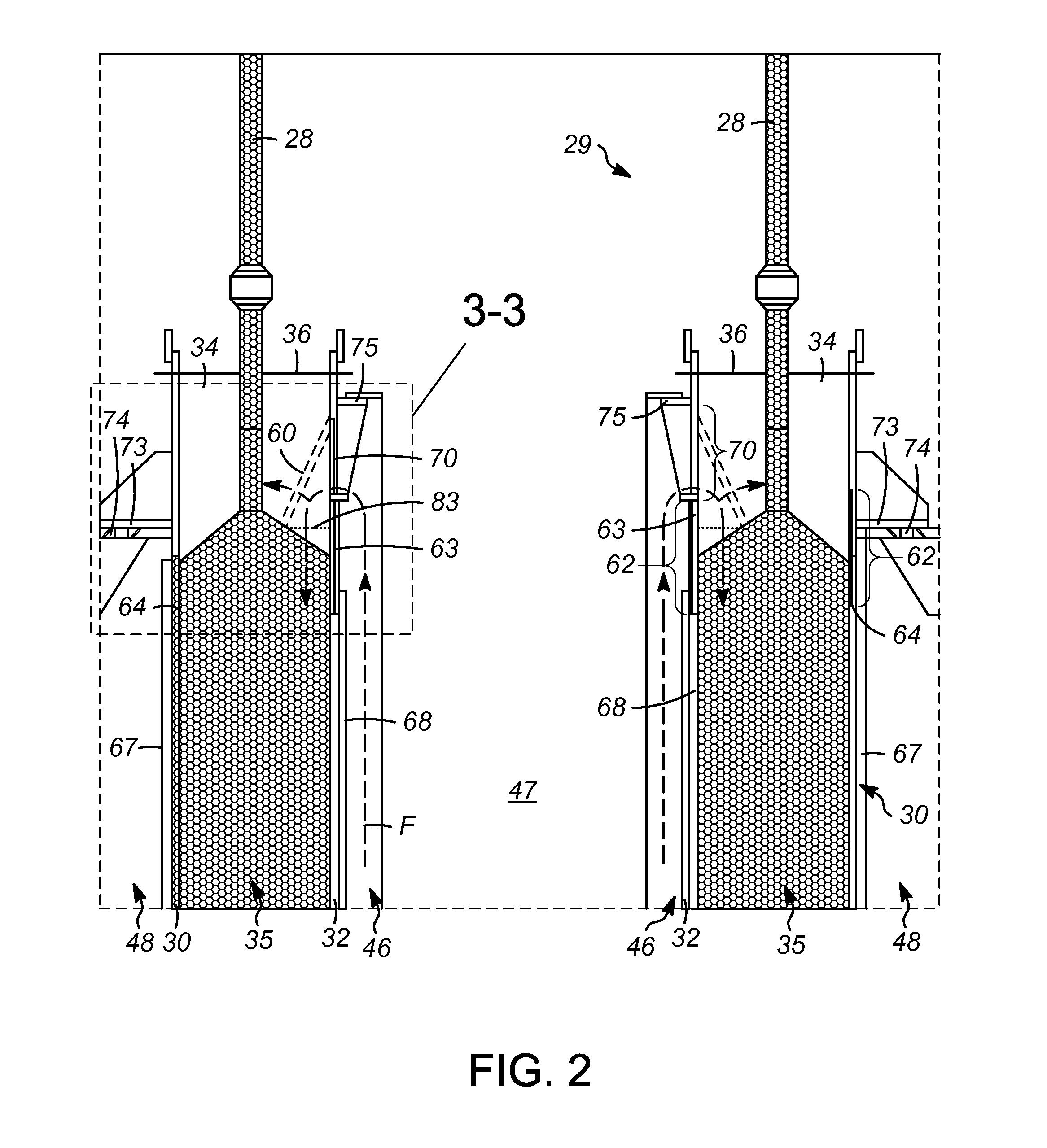

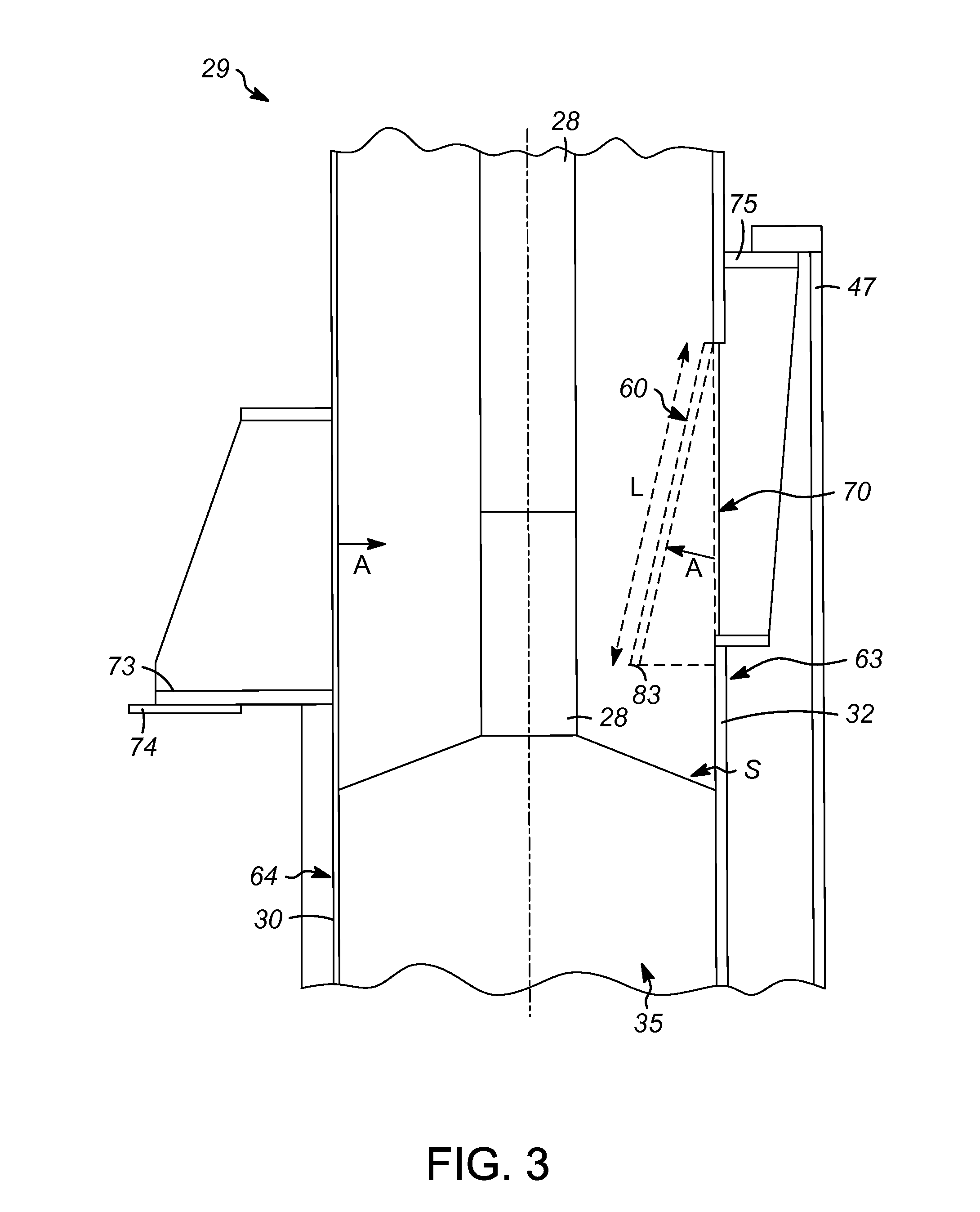

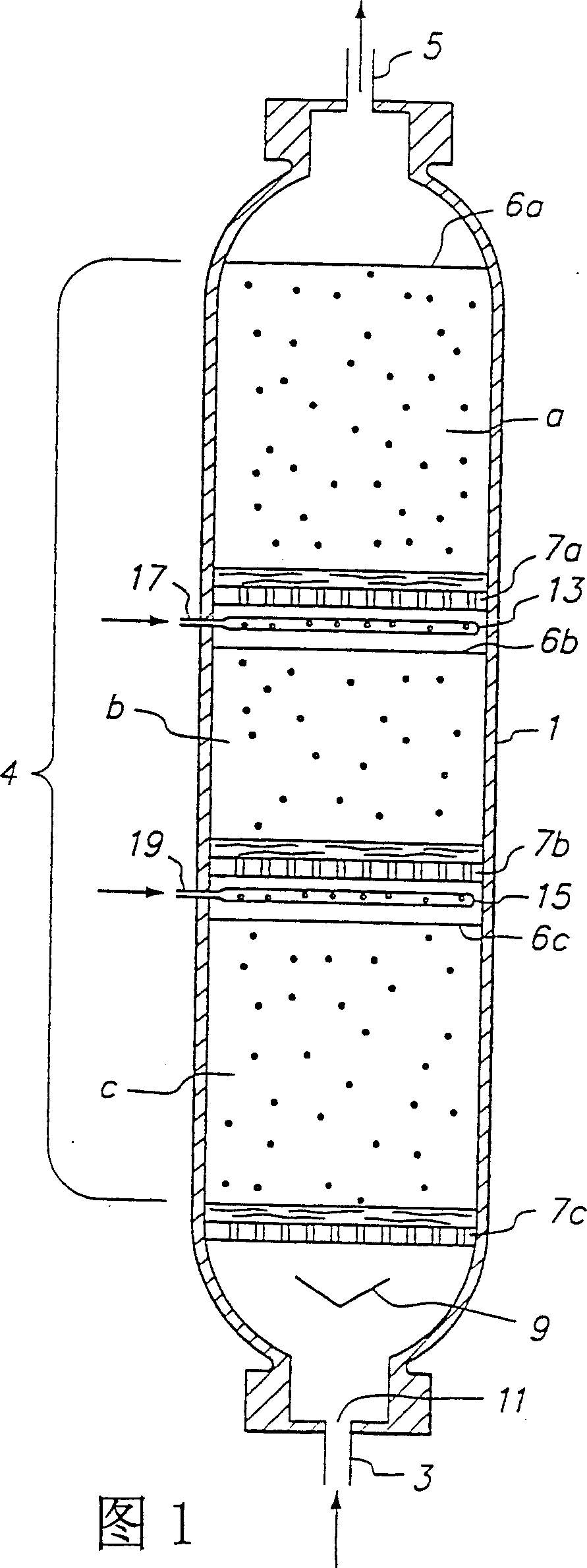

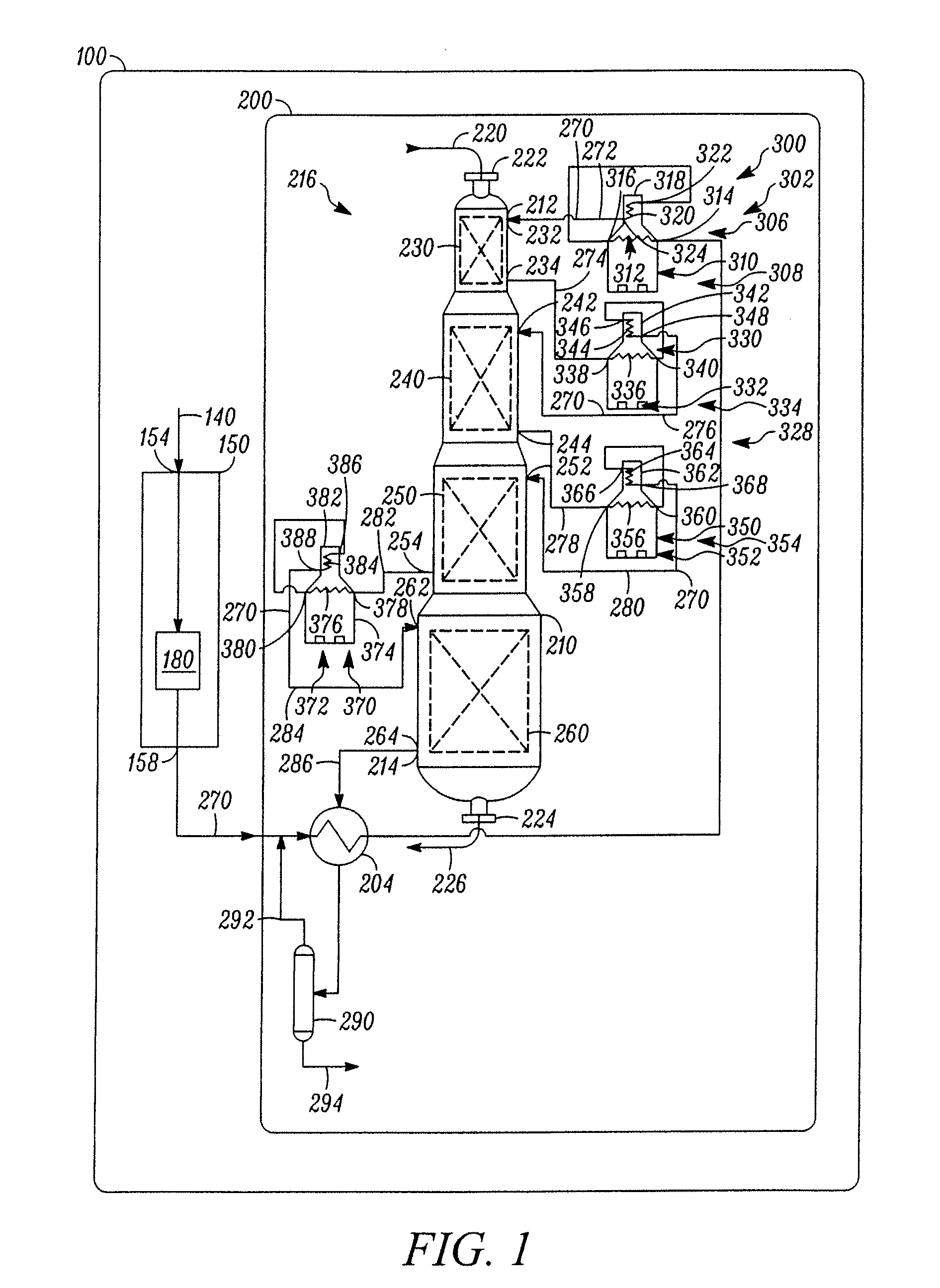

Upflow reactor system with layered catalyst bed for hydrotreating heavy feedstocks

InactiveCN1349554ATreatment with hydrotreatment processesBed hydrotreatment processes apparatusReactor systemSulfur

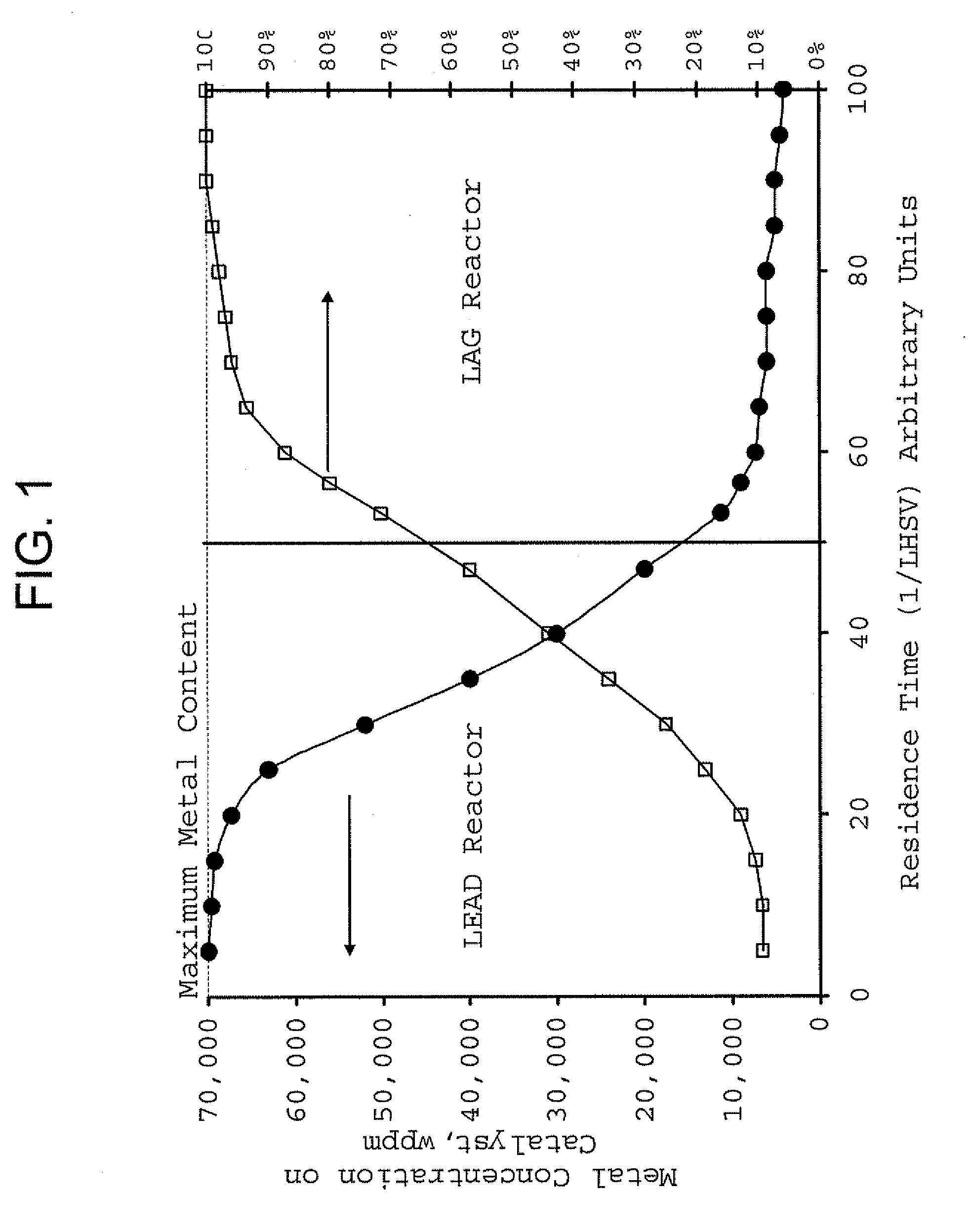

A reactor system and process for hydrotreating a heavy feedstock contaminated with metals sulfur and carbon residue using an upflow fixed bed reactor with at least two catalyst layers having different hydrogenation activity.

Owner:CHEVROU USA INC

Filtration and flow distribution method for chemical reactors

InactiveUS6258900B1Reduce turbulenceHigh trafficCatalytic naphtha reformingMembrane filtersChemical reactorFiltration

Owner:CRYSTAPHASE PRODS

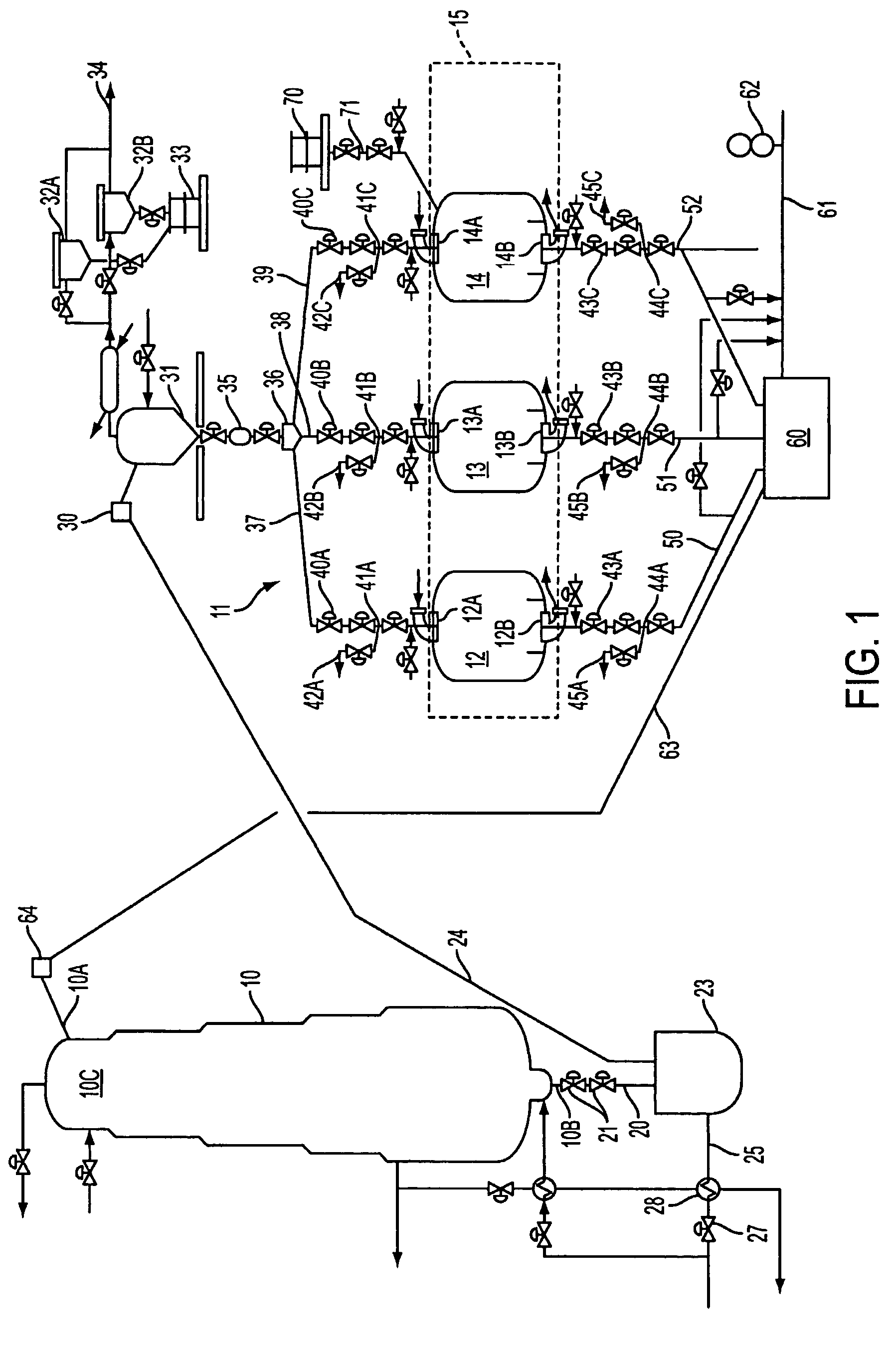

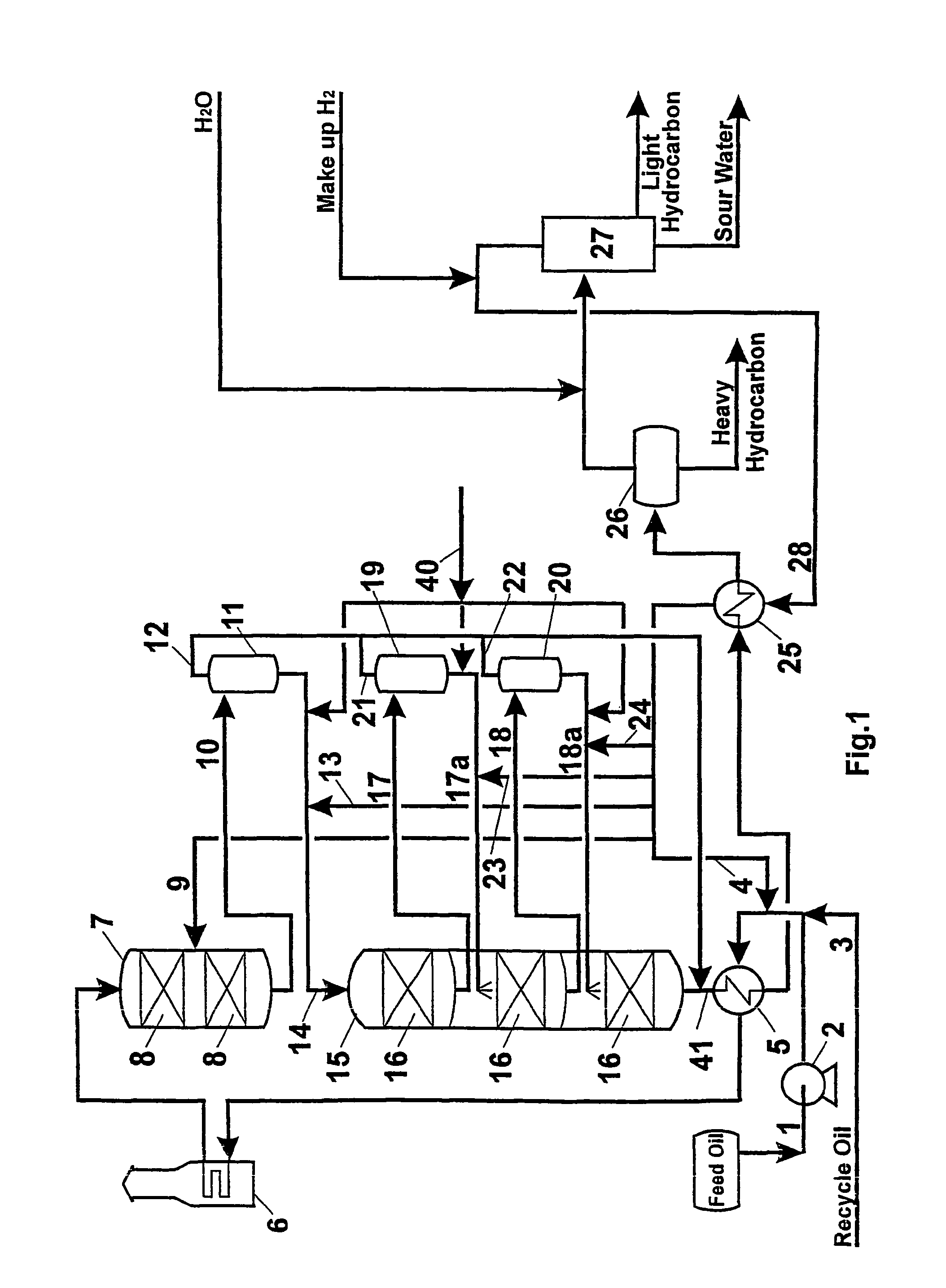

Process for catalytic hydrotreating of sour crude oils

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

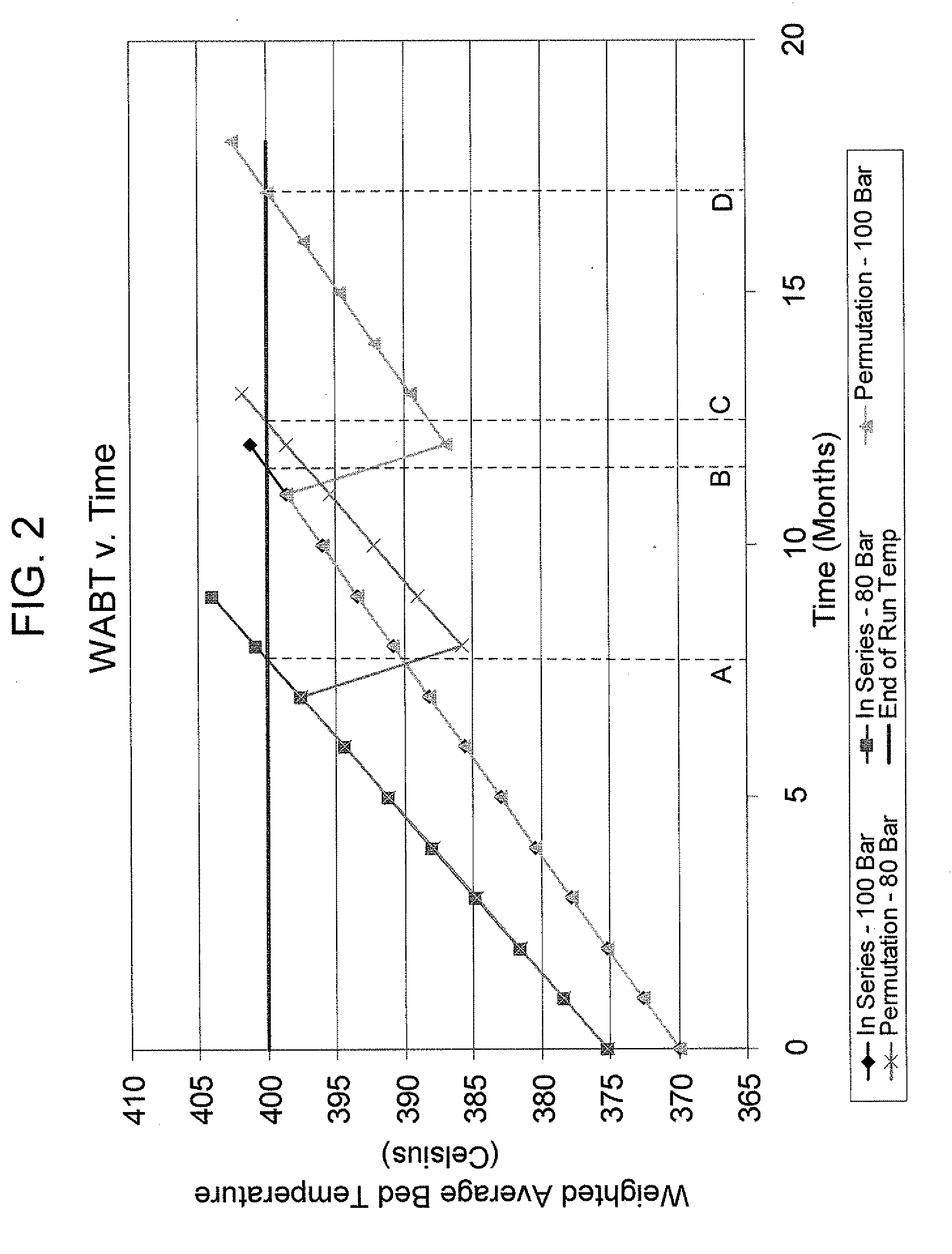

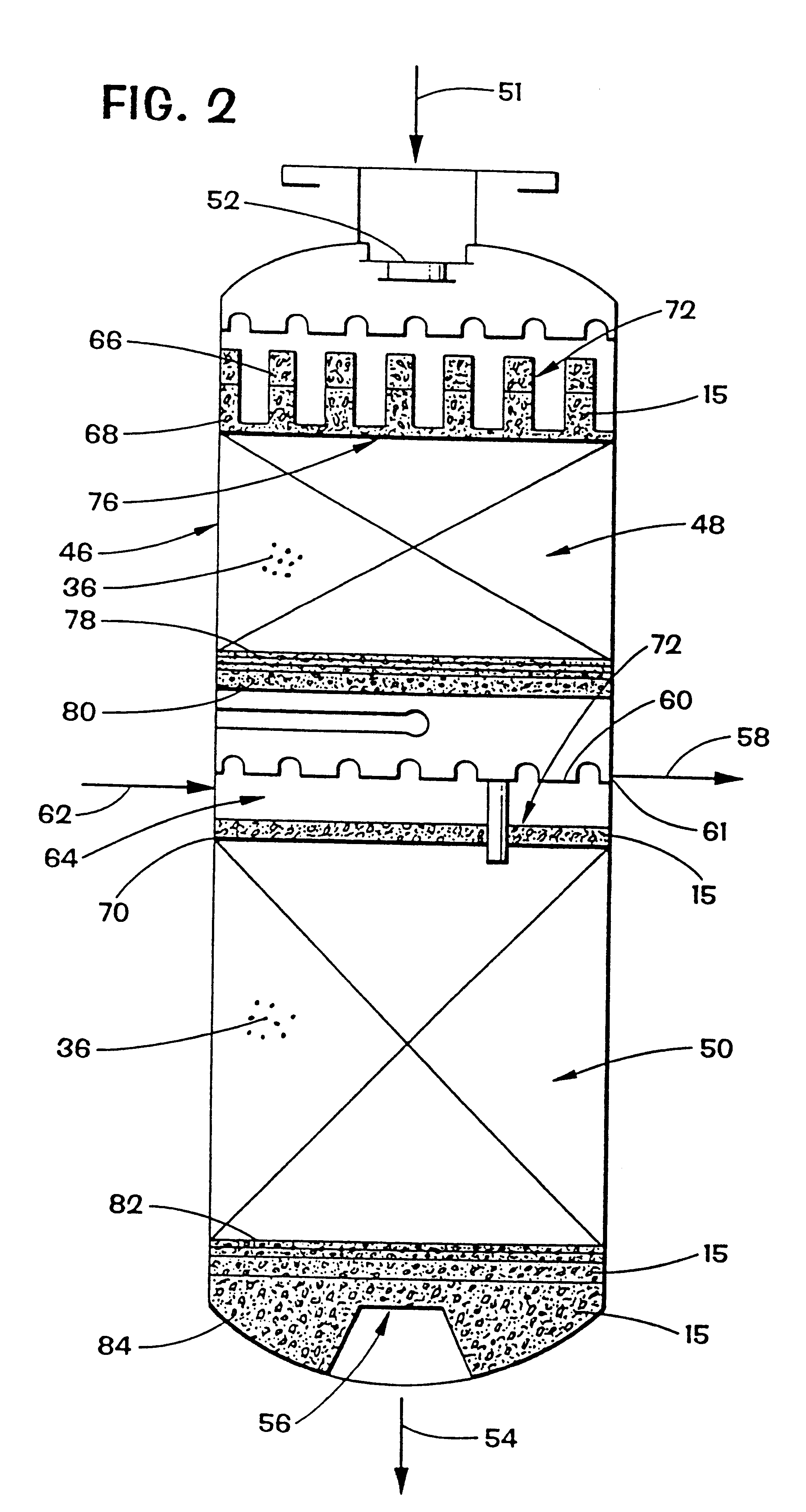

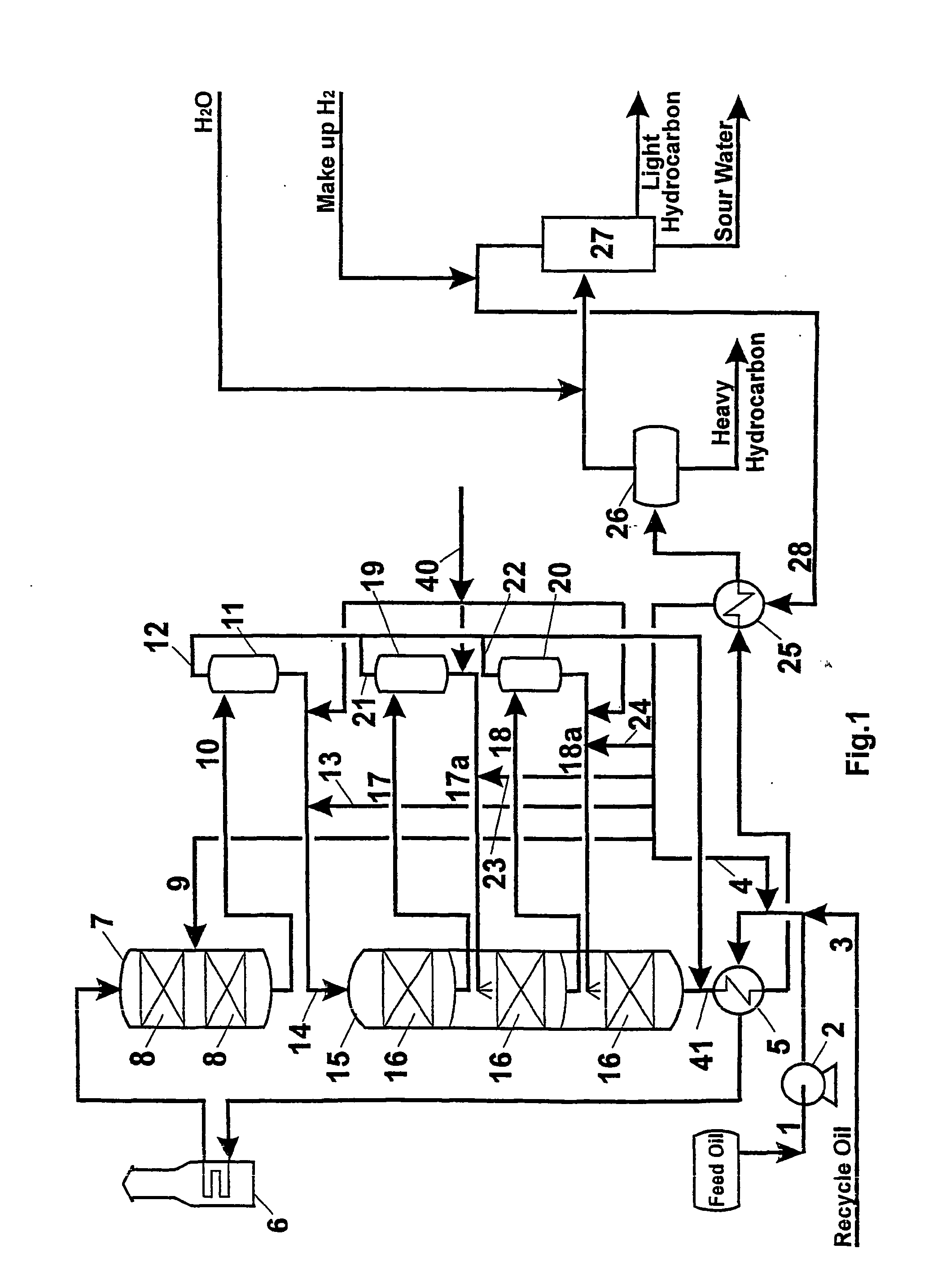

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

Filtration and flow distribution method for chemical reactors using reticulated ceramics with uniform pore distributions

InactiveUS6291603B1Reduce turbulenceEntrance losses may be reducedCatalytic naphtha reformingMembrane filtersPore distributionFiltration

Owner:CRYSTAPHASE PRODS

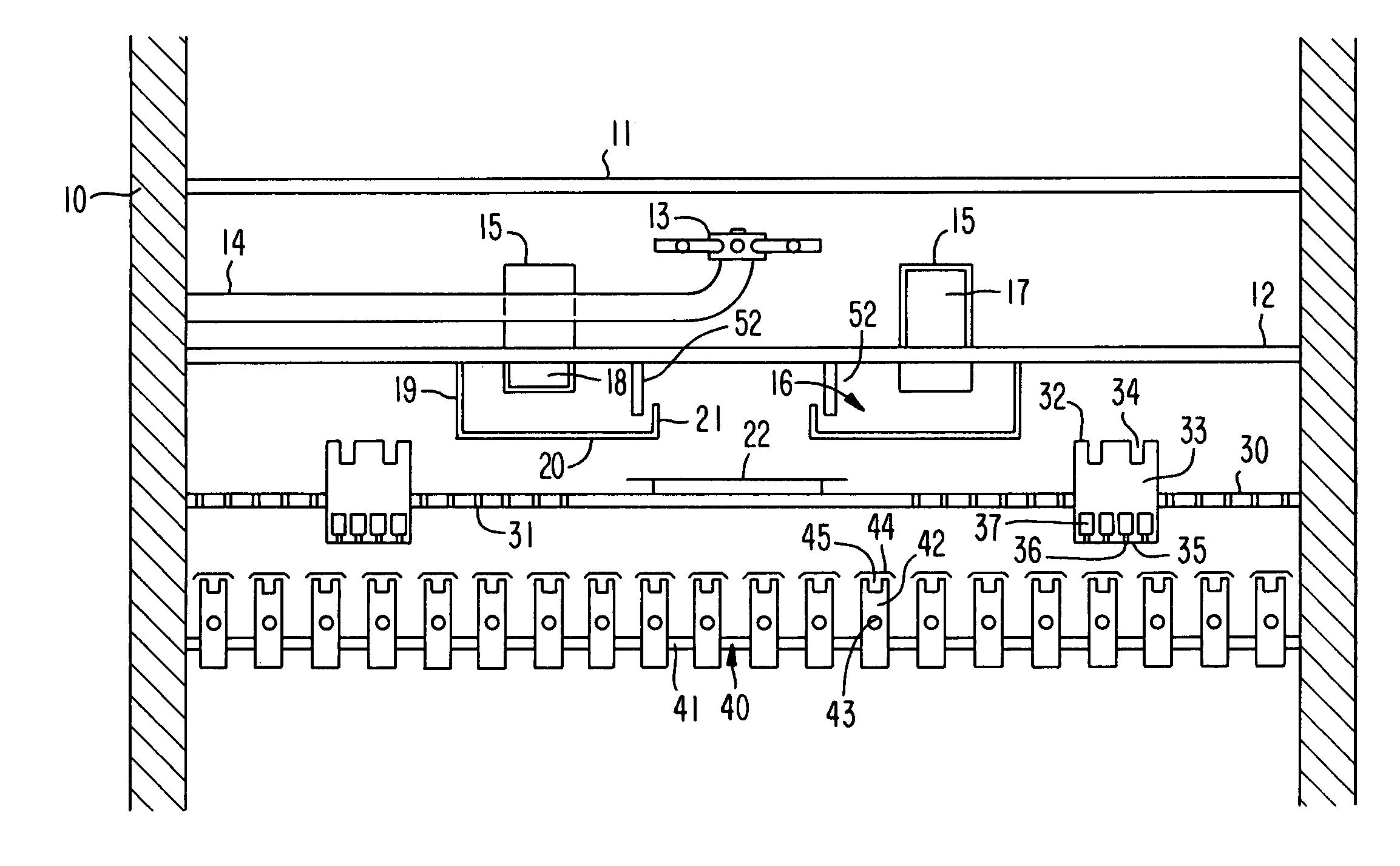

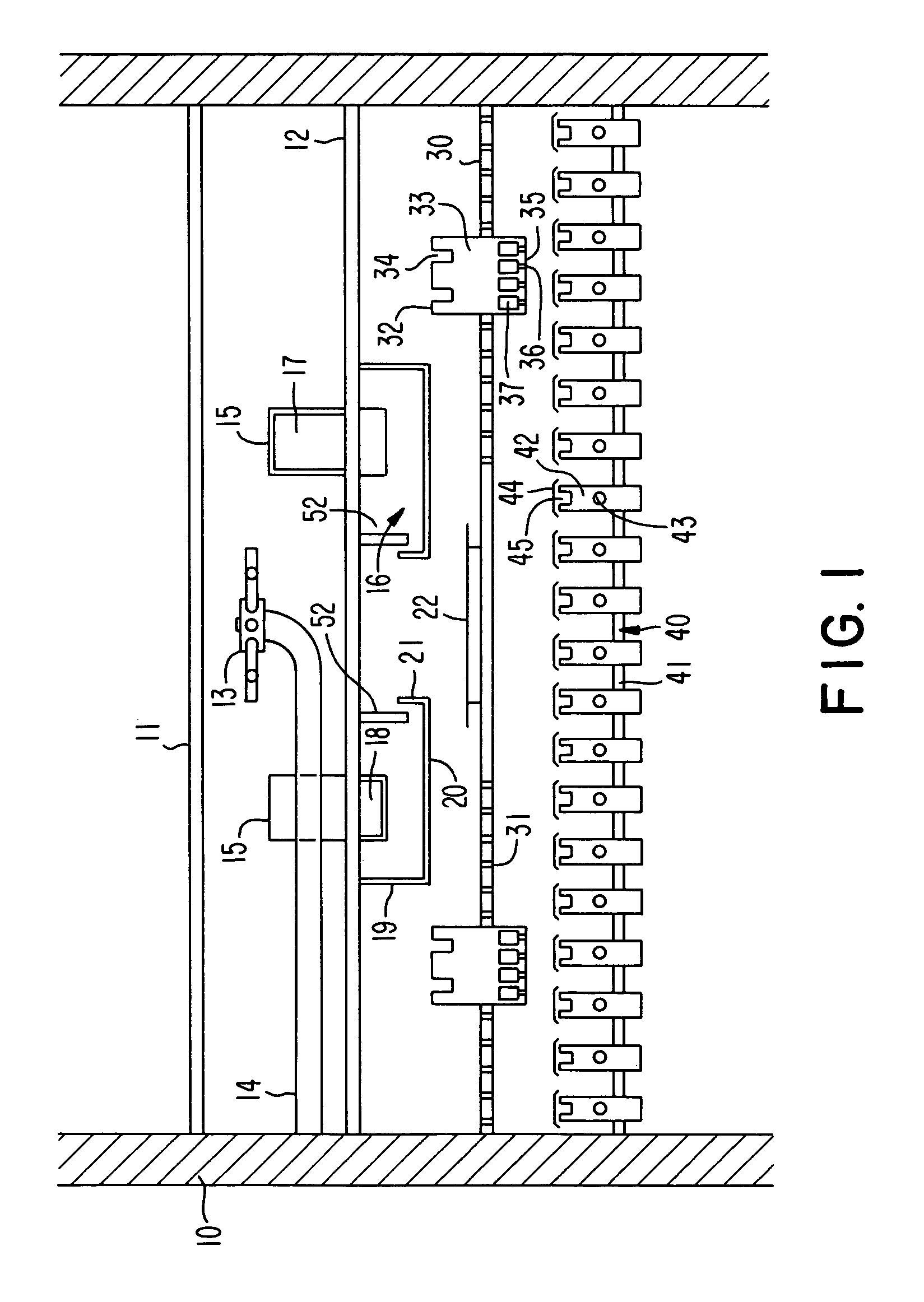

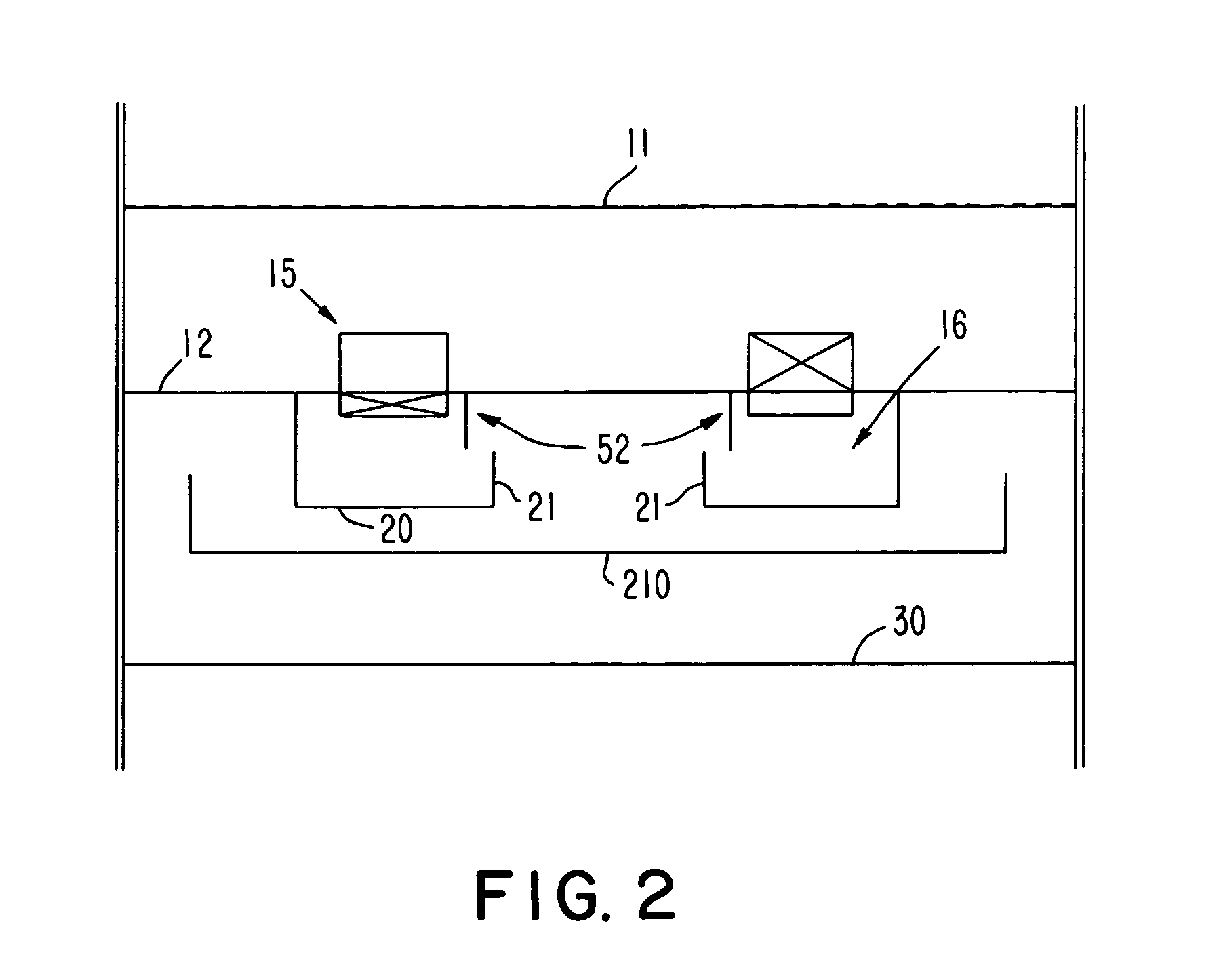

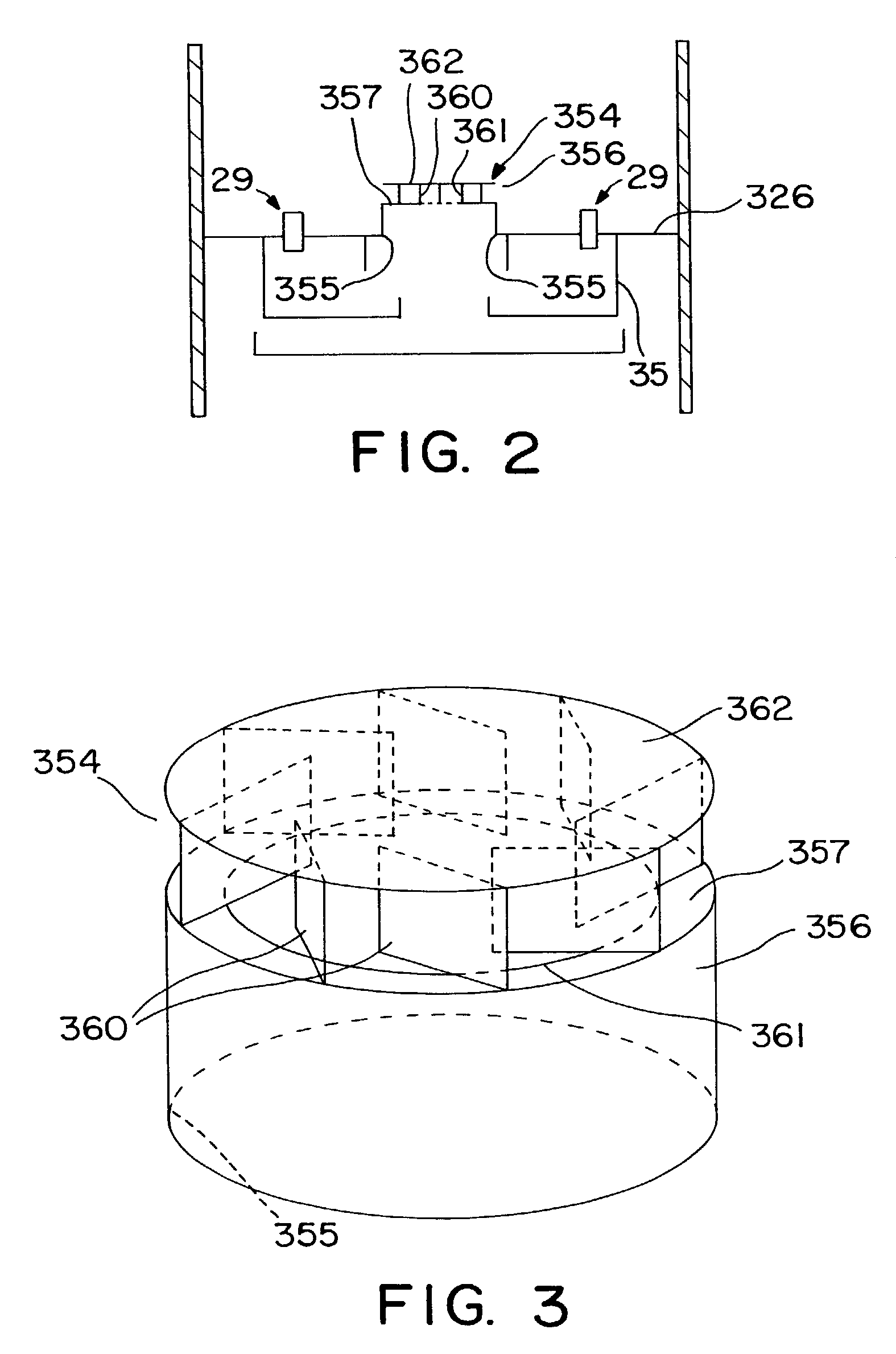

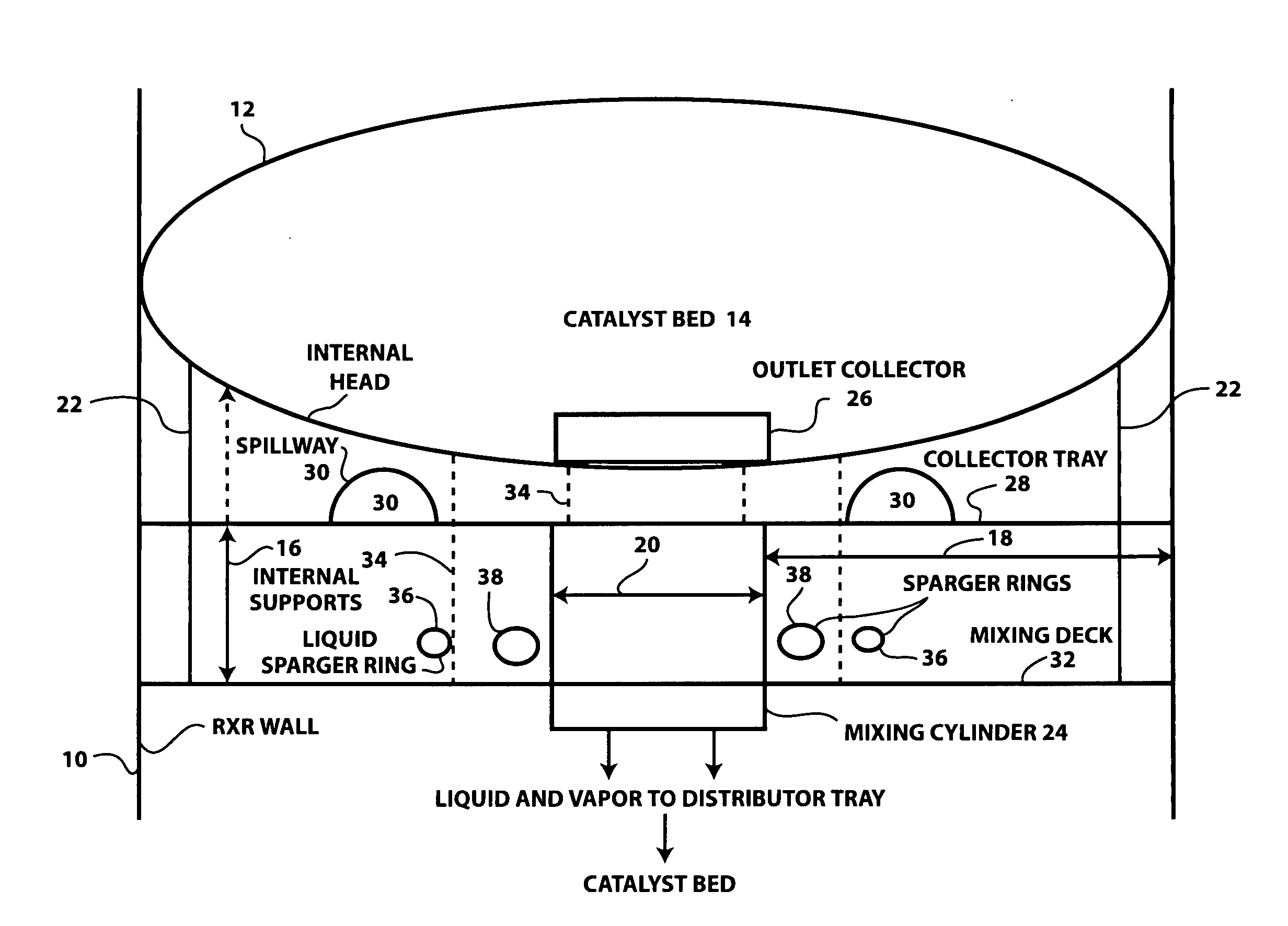

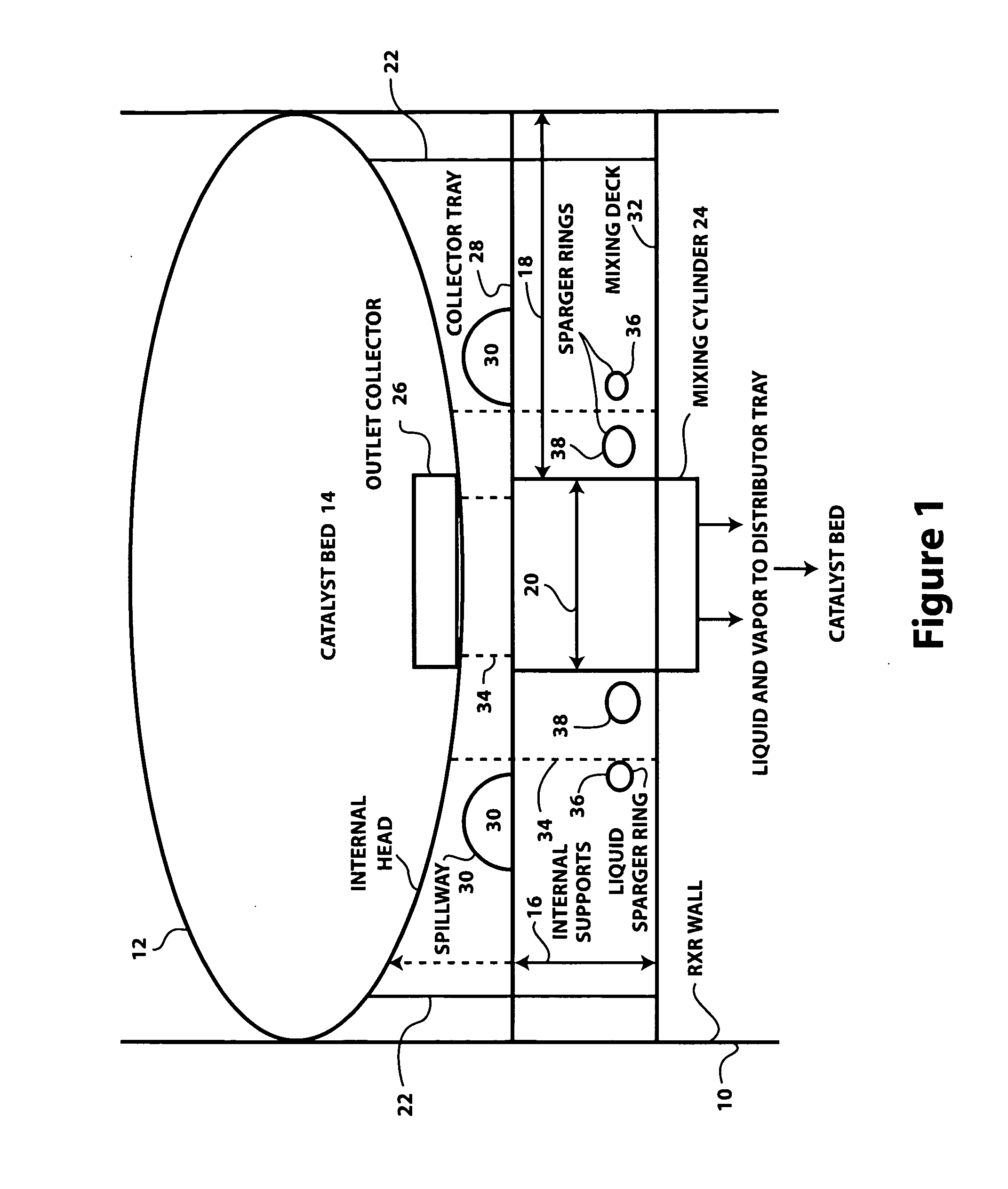

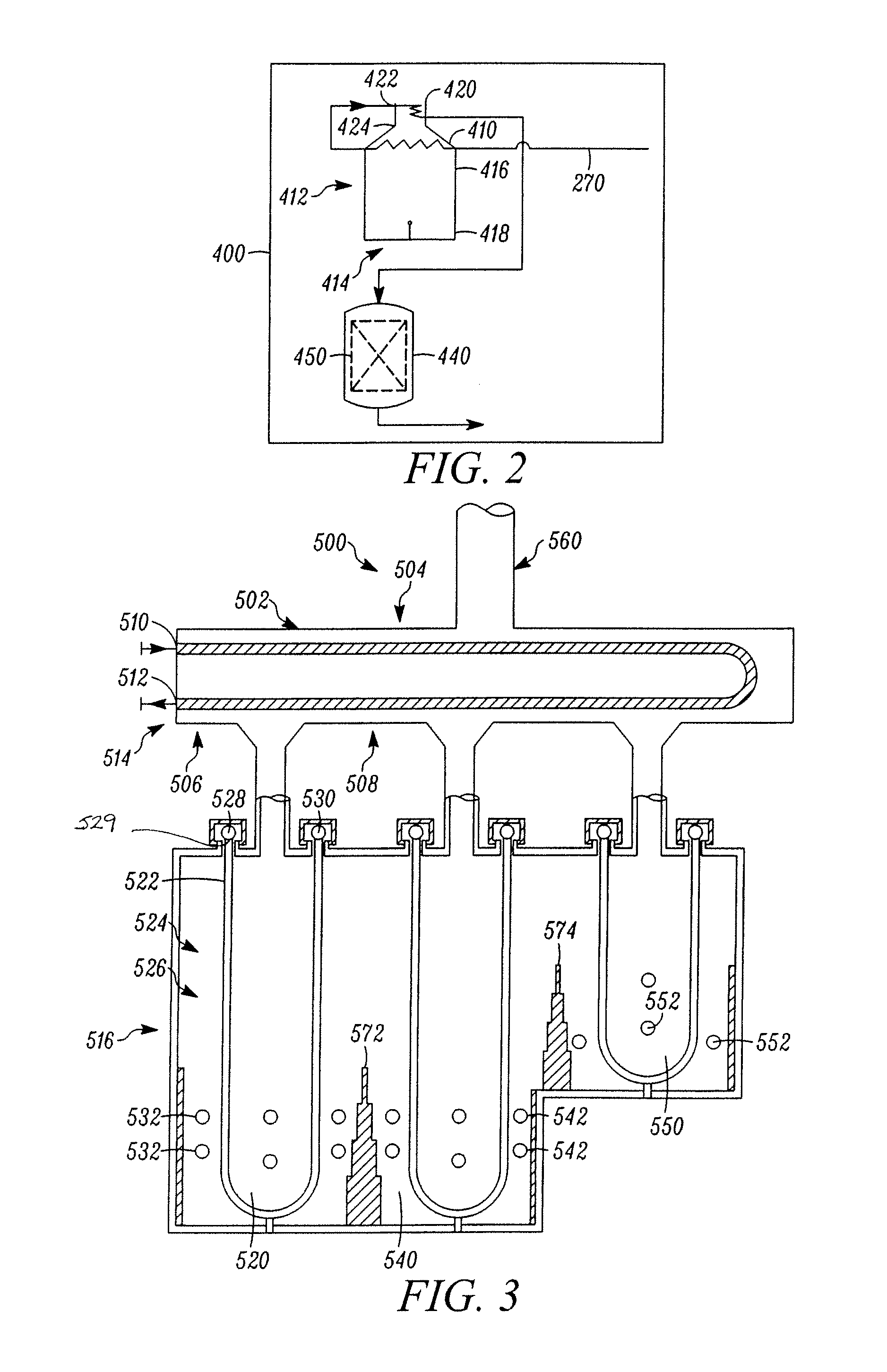

Quench box for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor

InactiveUS7112312B2Reduce in quantitySimple designPhysical/chemical process catalystsFlow mixersFixed bedEngineering

Owner:H2ADVANCE

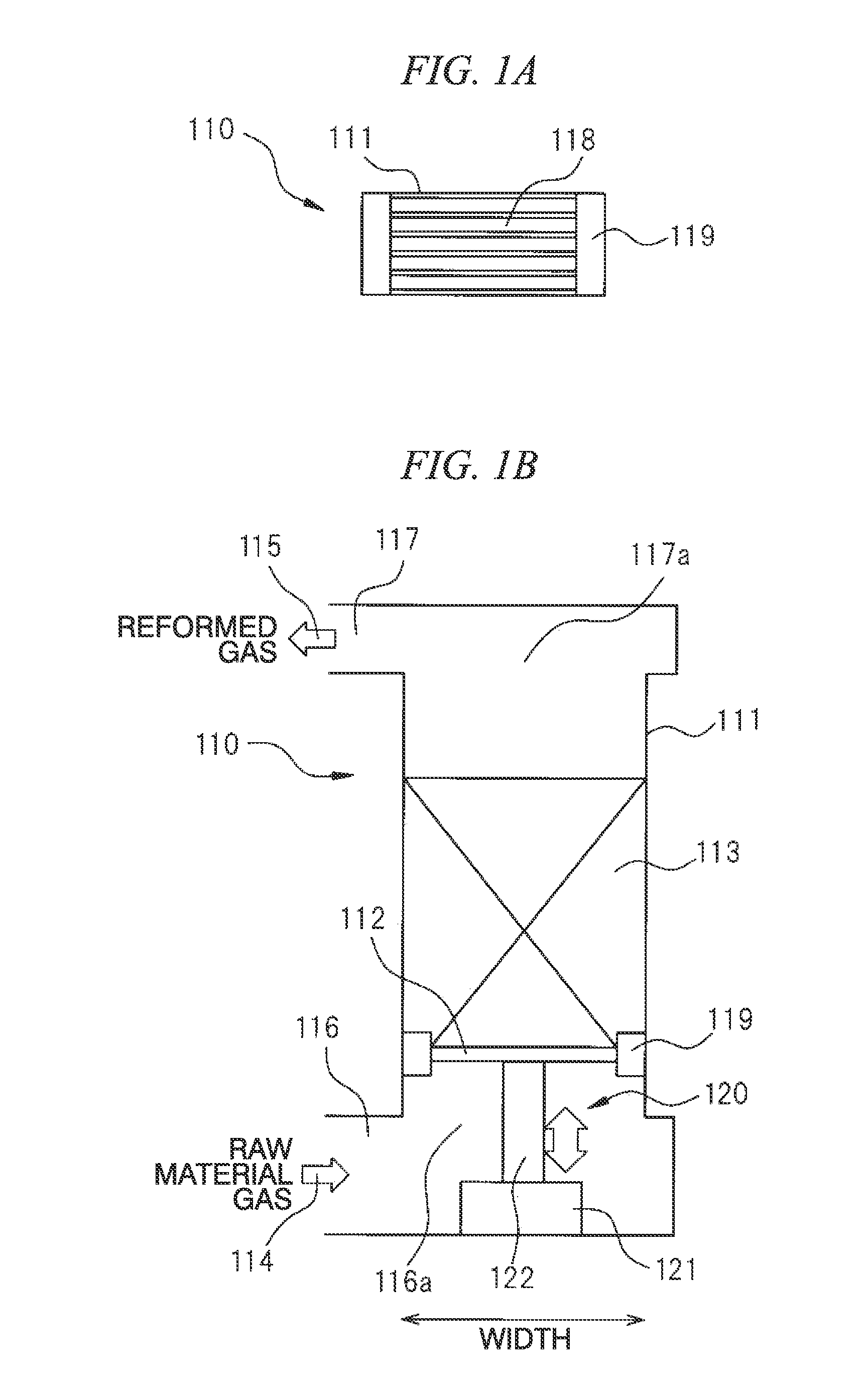

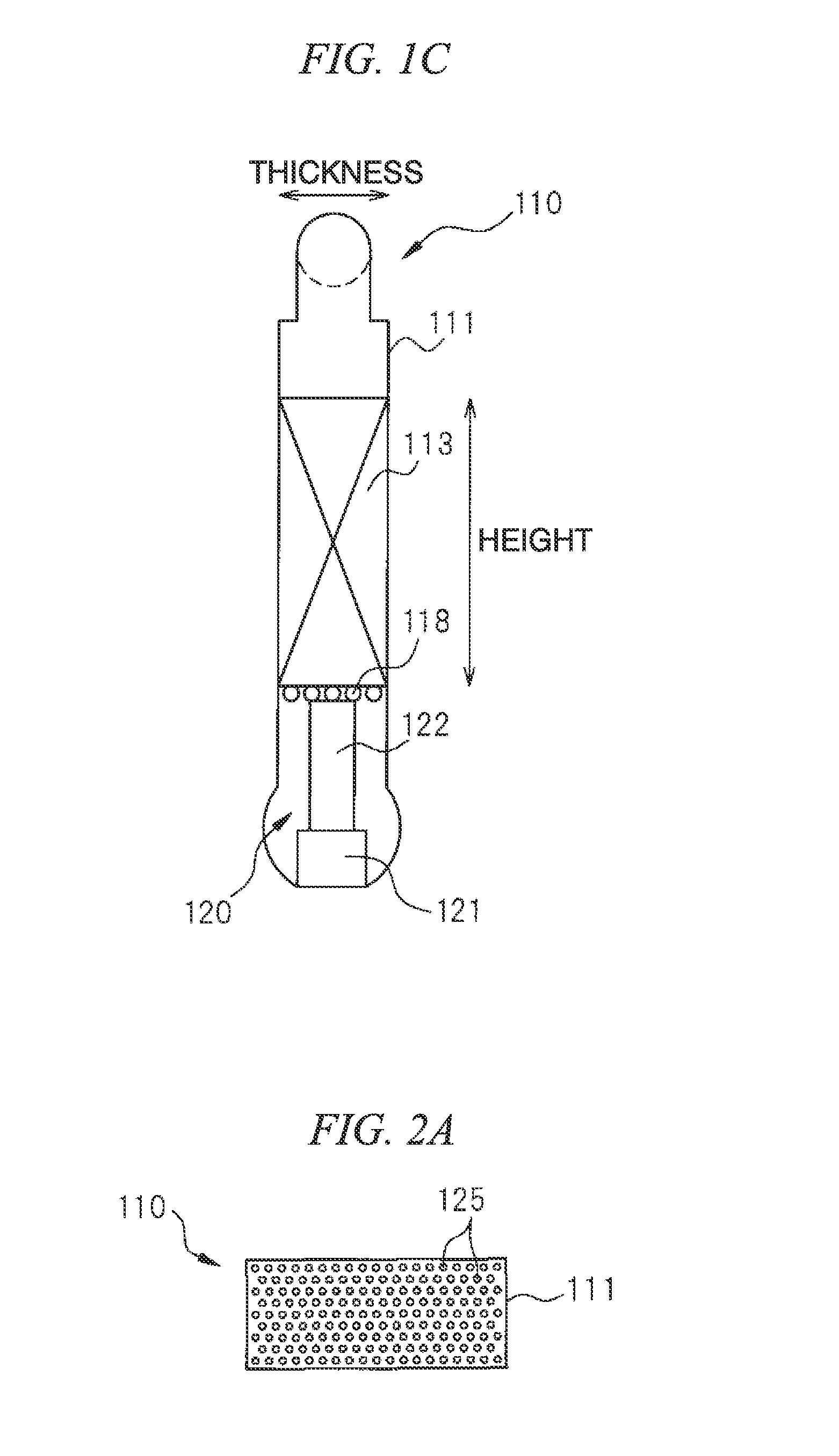

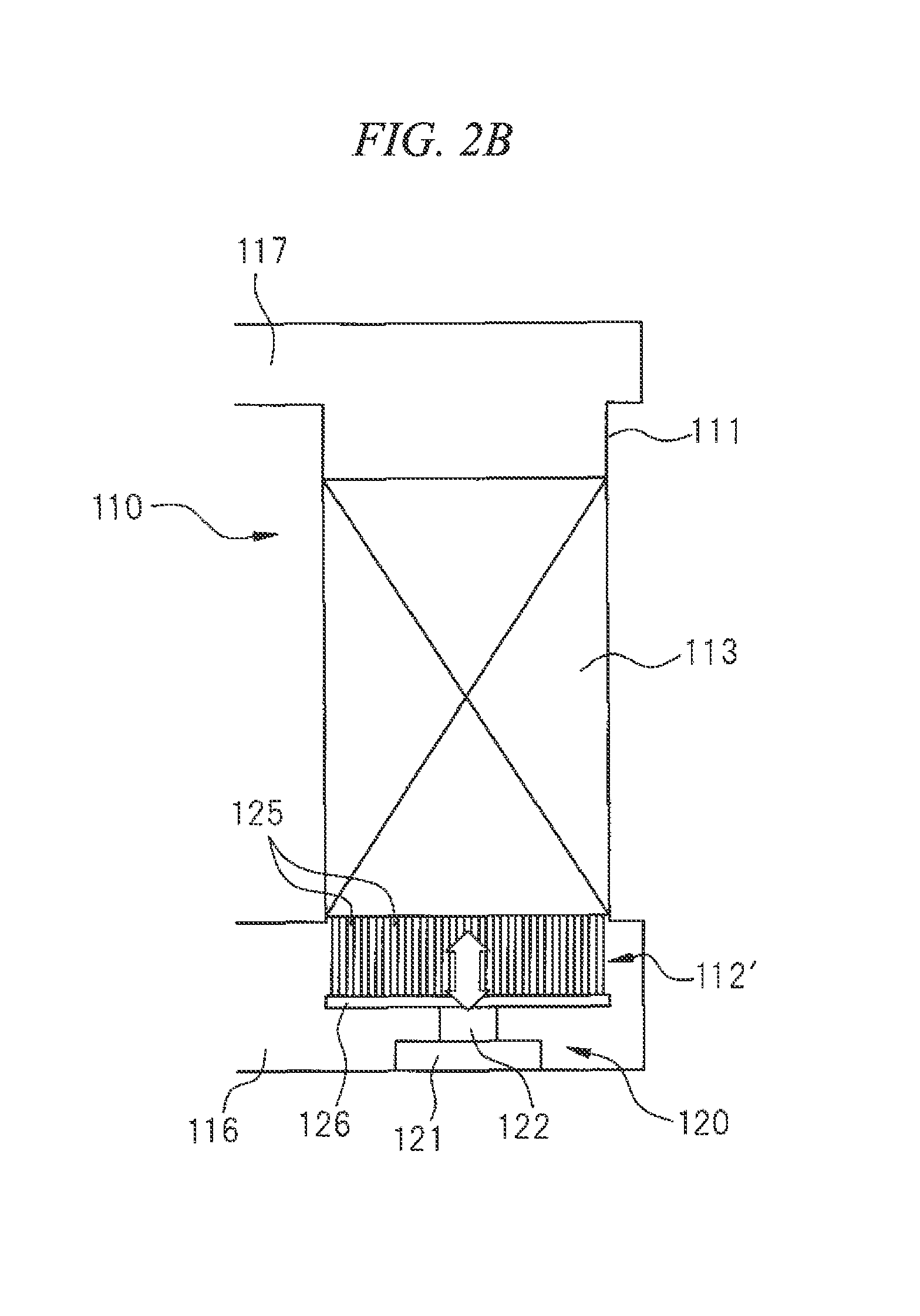

Continuous fixed-bed catalytic reactor and catalytic reaction method using same

ActiveUS20150010467A1Efficient removalImprove efficiencyCatalytic gas-gas reactionGaseous chemical processesFixed bedChemistry

A continuous fixed-bed catalytic reactor includes an inflow path for raw material gas for a catalytic reaction and an outflow path for reformed gas, a catalytic reaction container that is connected to the inflow path and the outflow path and holds a clumpy catalyst, catalyst holders that have a ventilation property and hold the clumpy catalyst, and a driving mechanism that moves the clumpy catalyst up and down by moving the catalyst holders up and down.

Owner:NIPPON STEEL CORP

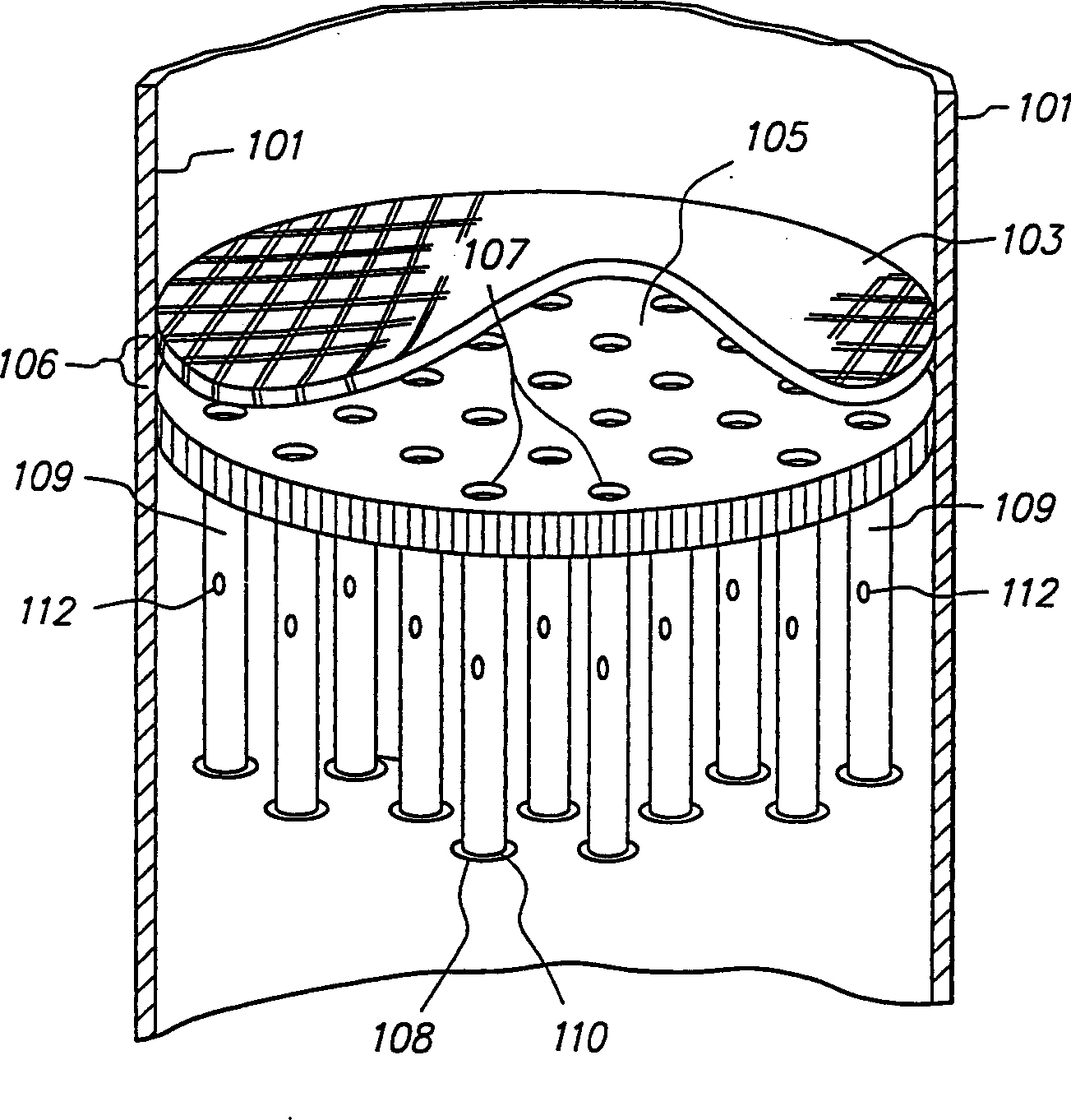

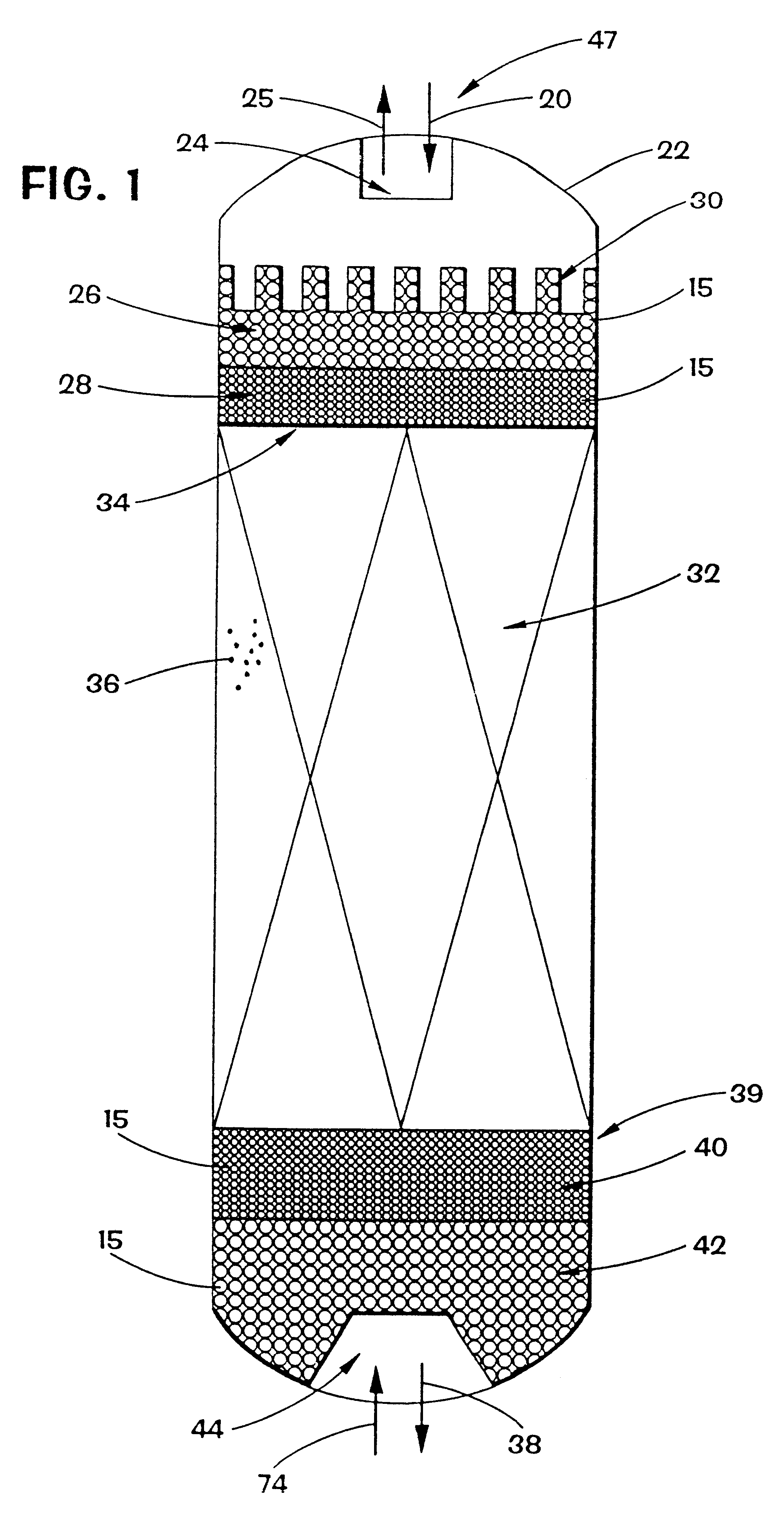

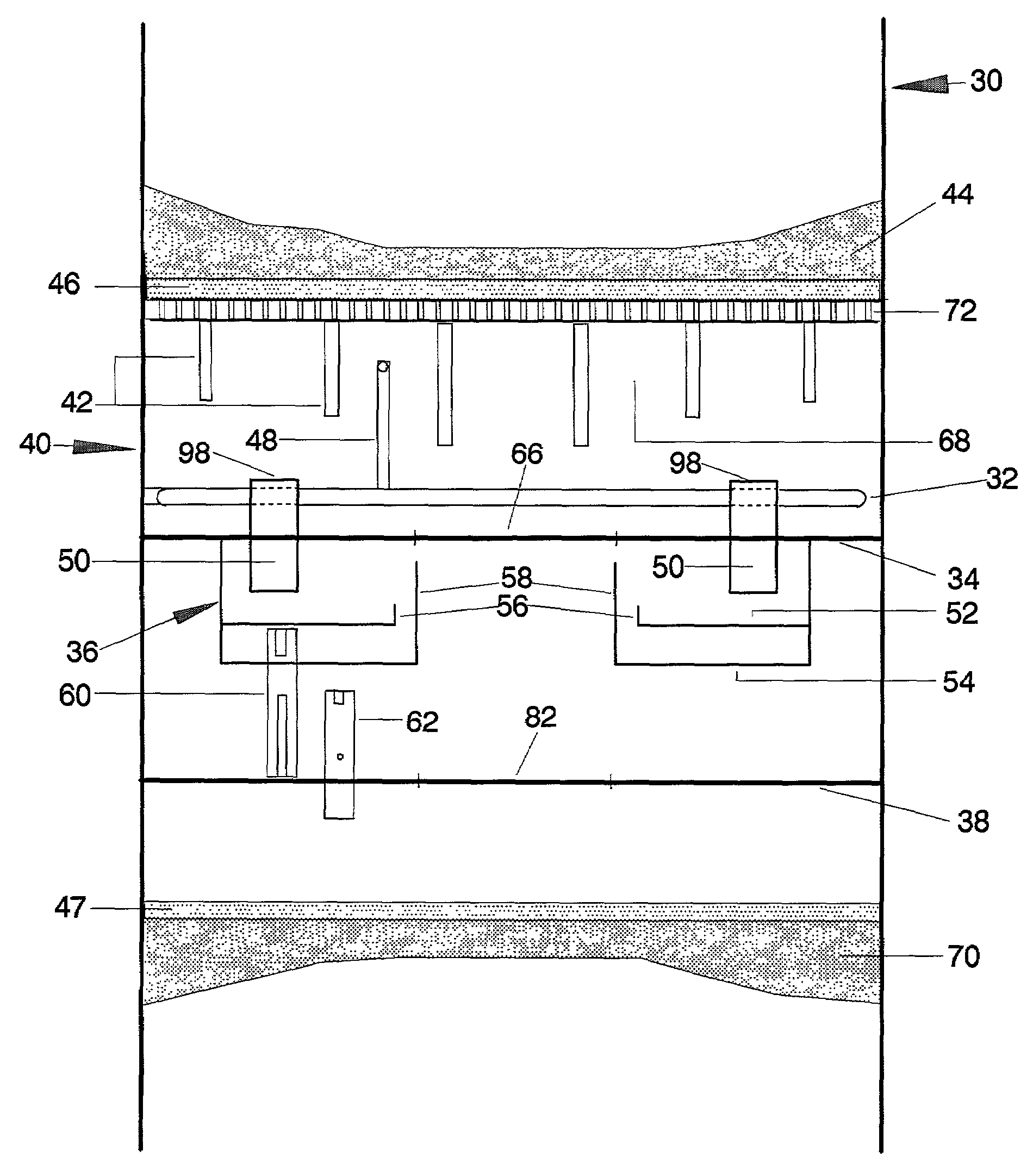

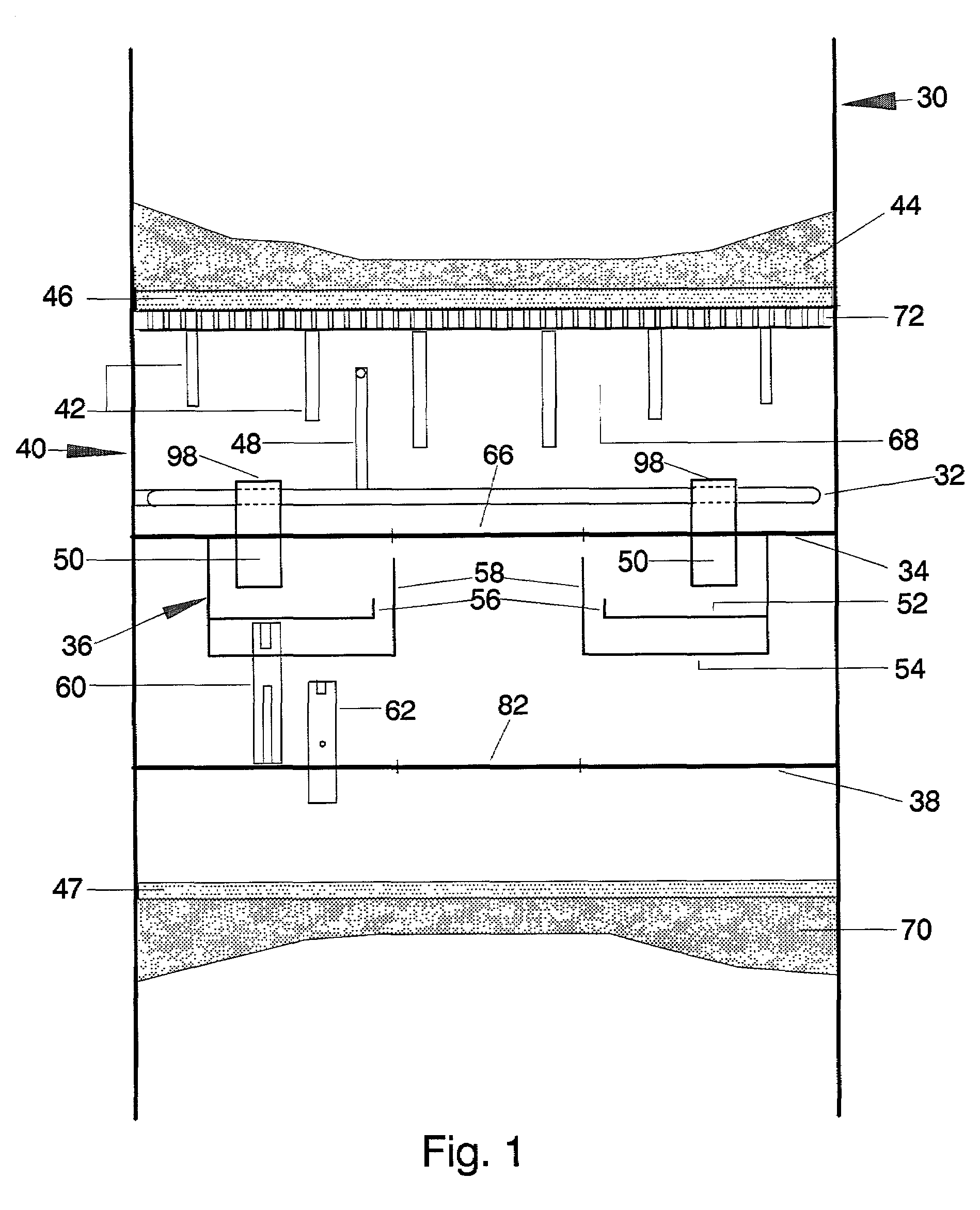

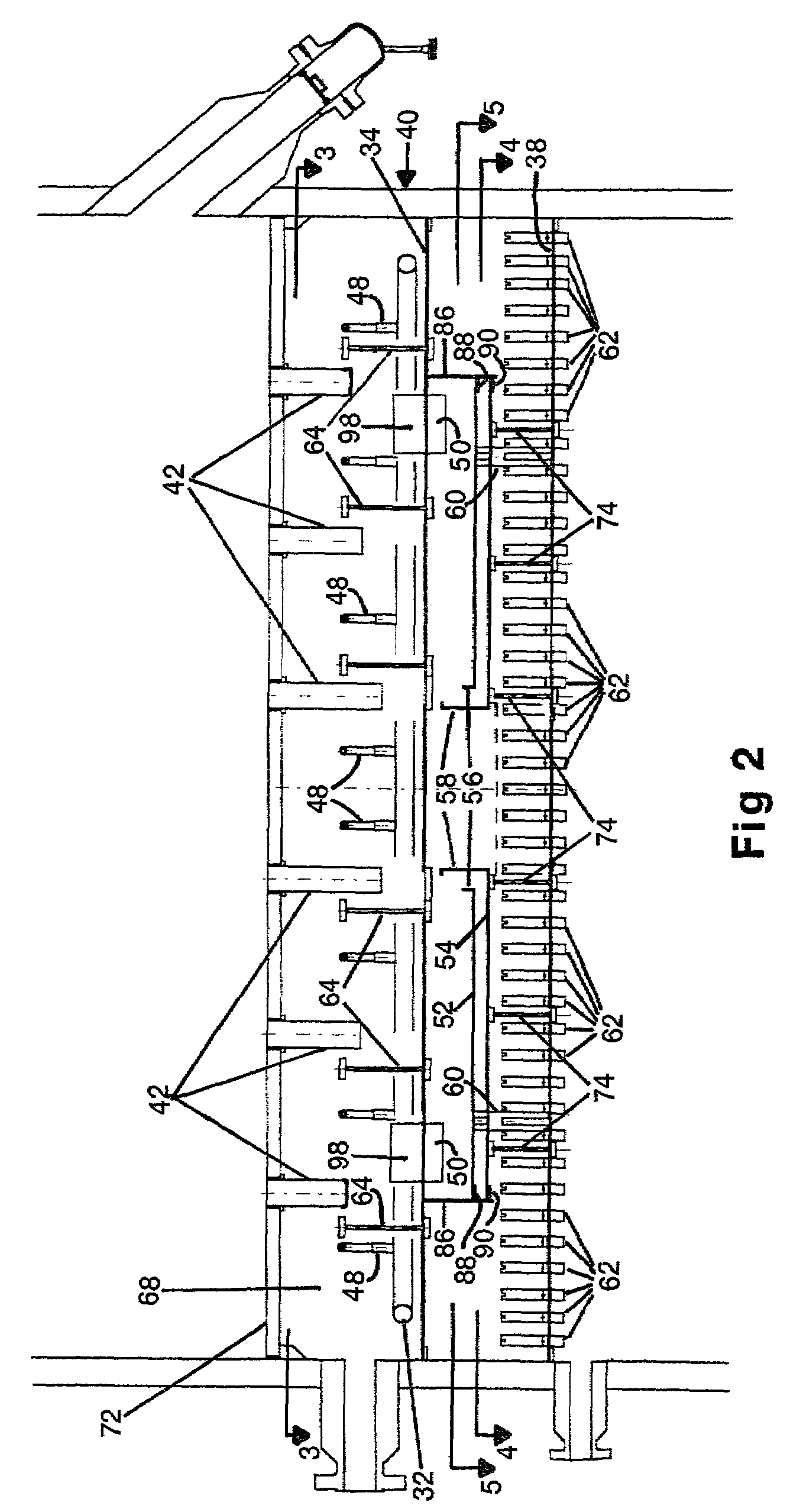

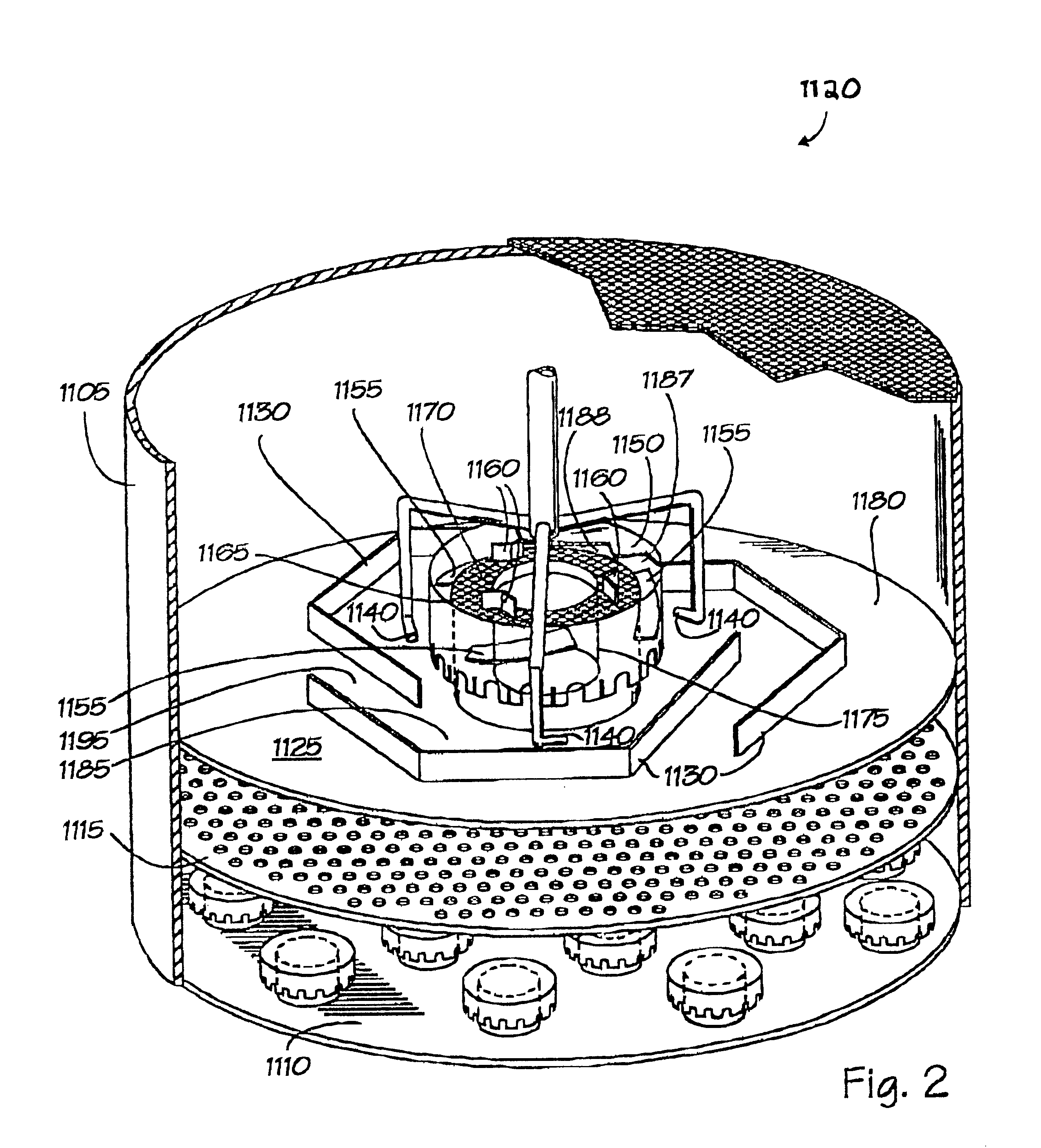

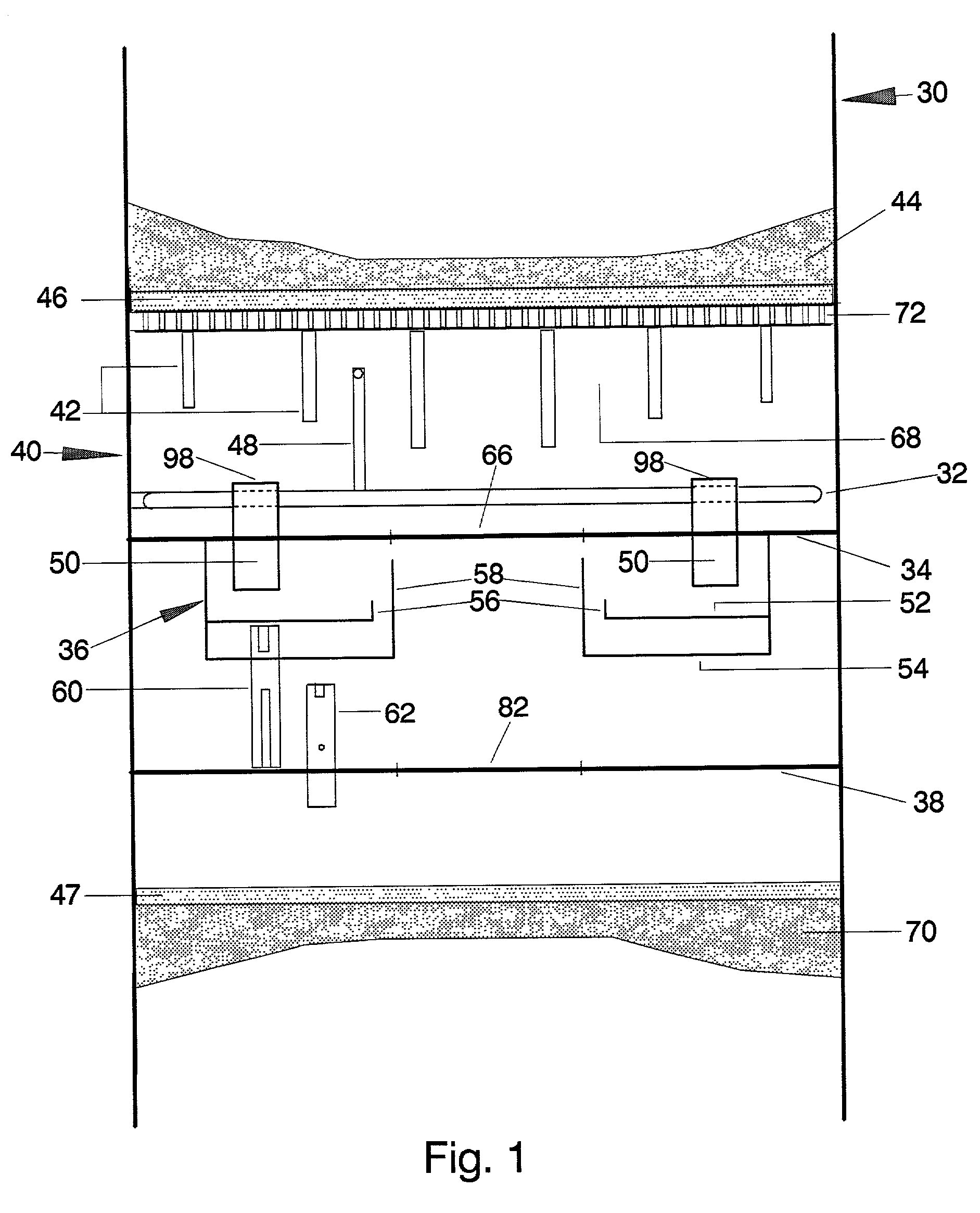

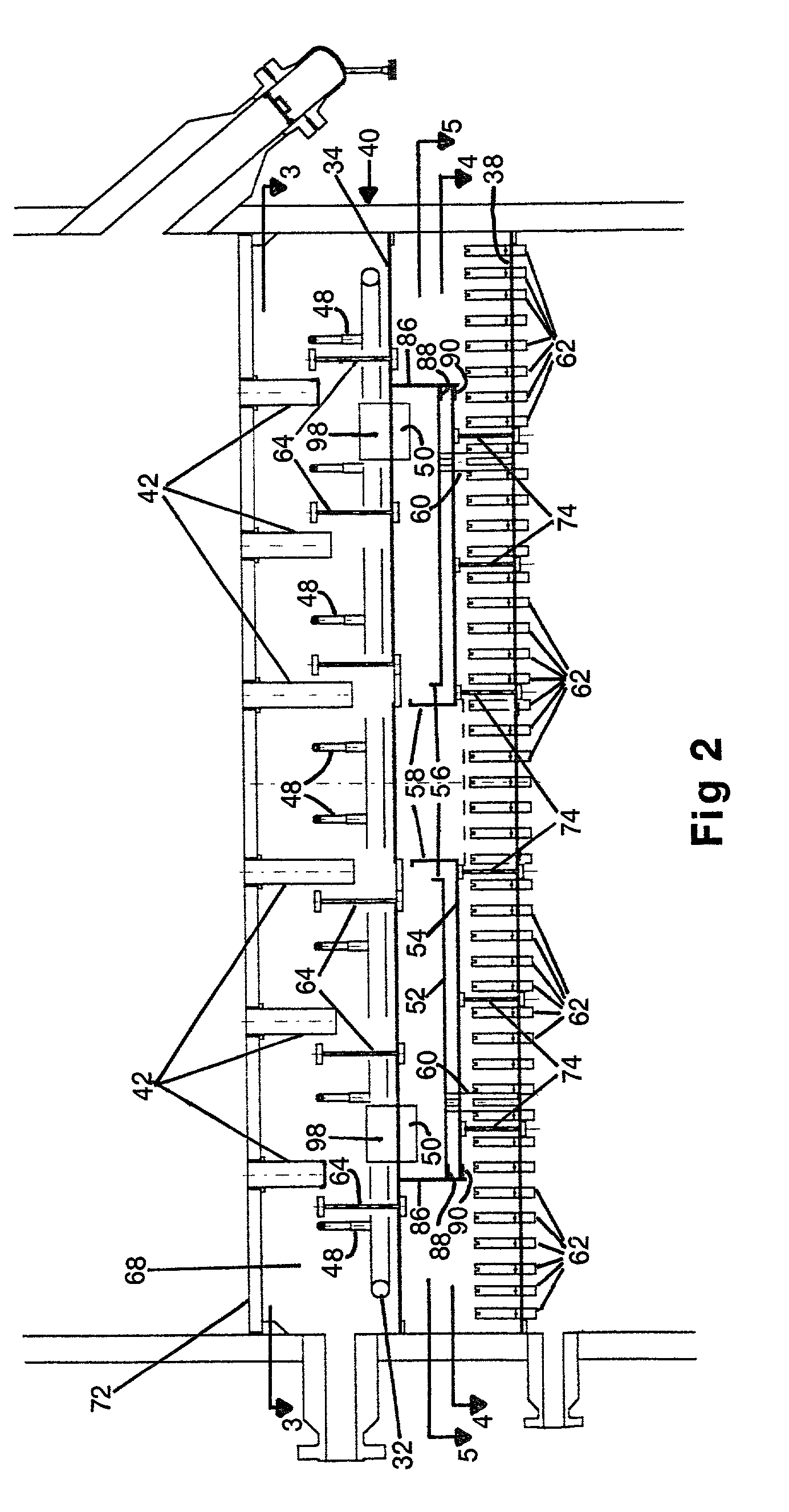

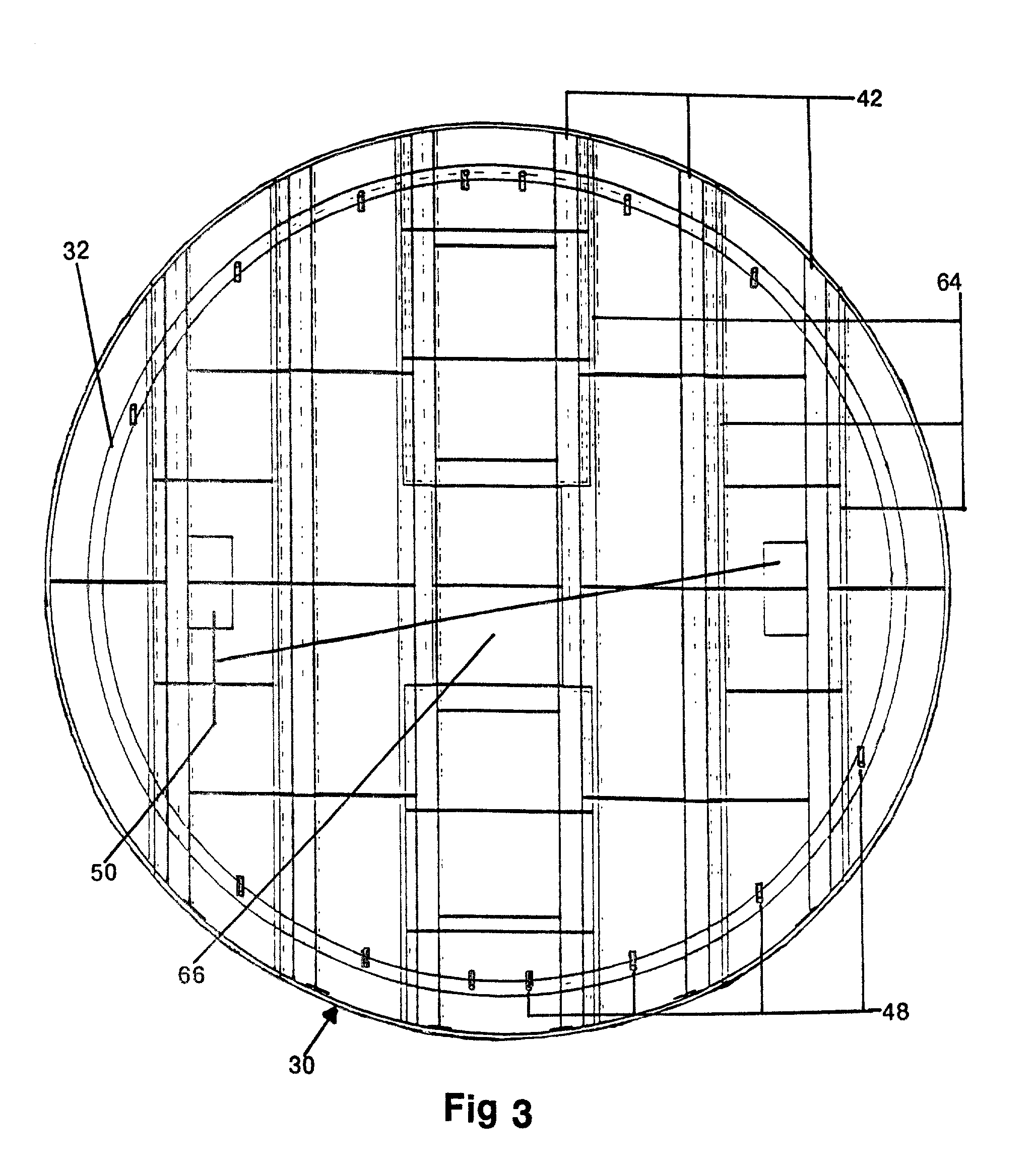

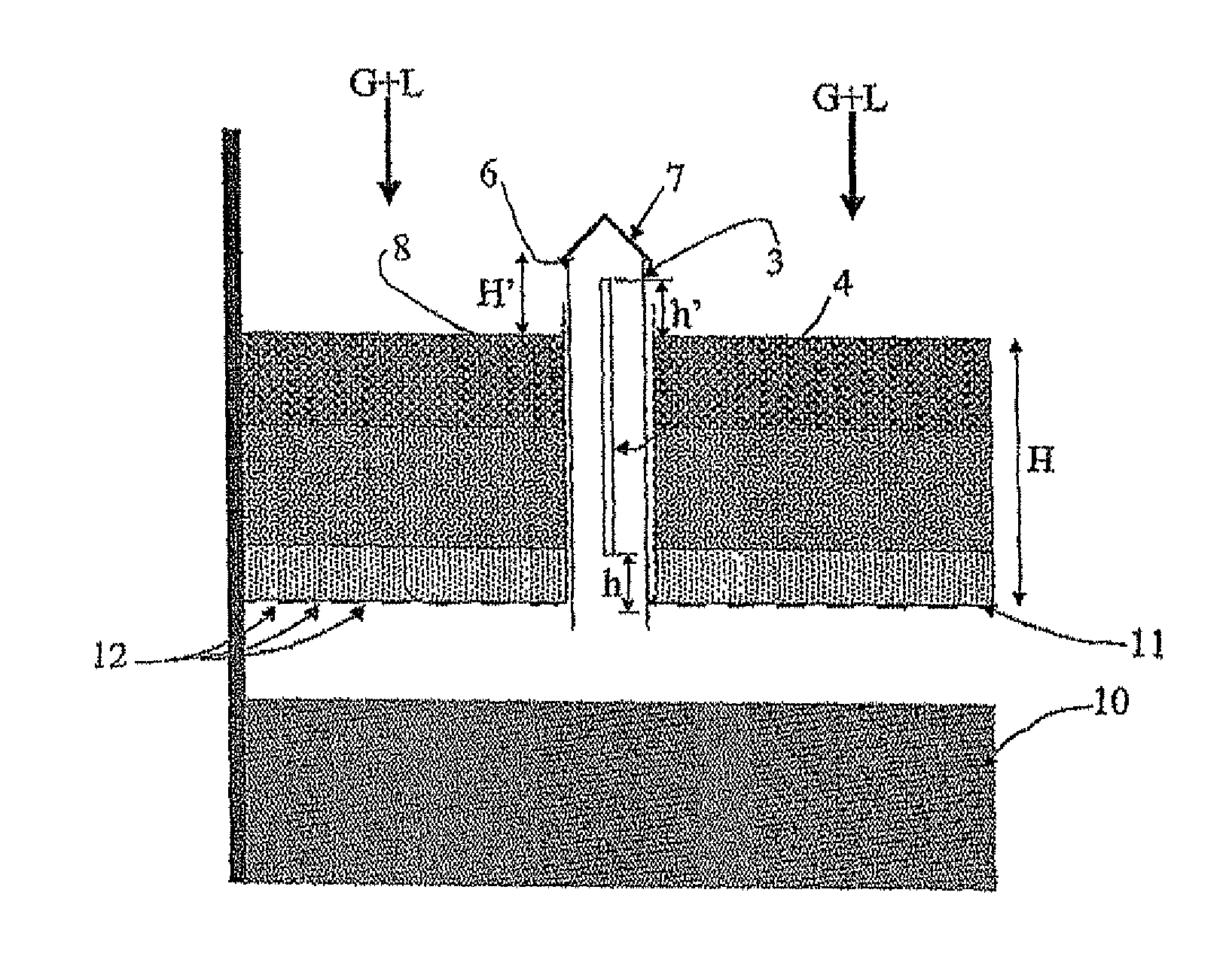

Fluid distributor assembly for a multi-bed, downflow catalytic reactor

InactiveUS6183702B1Low liquid holdupWell mixedPhysical/chemical process catalystsFuel re-atomisation/homogenisationProduct gasEngineering

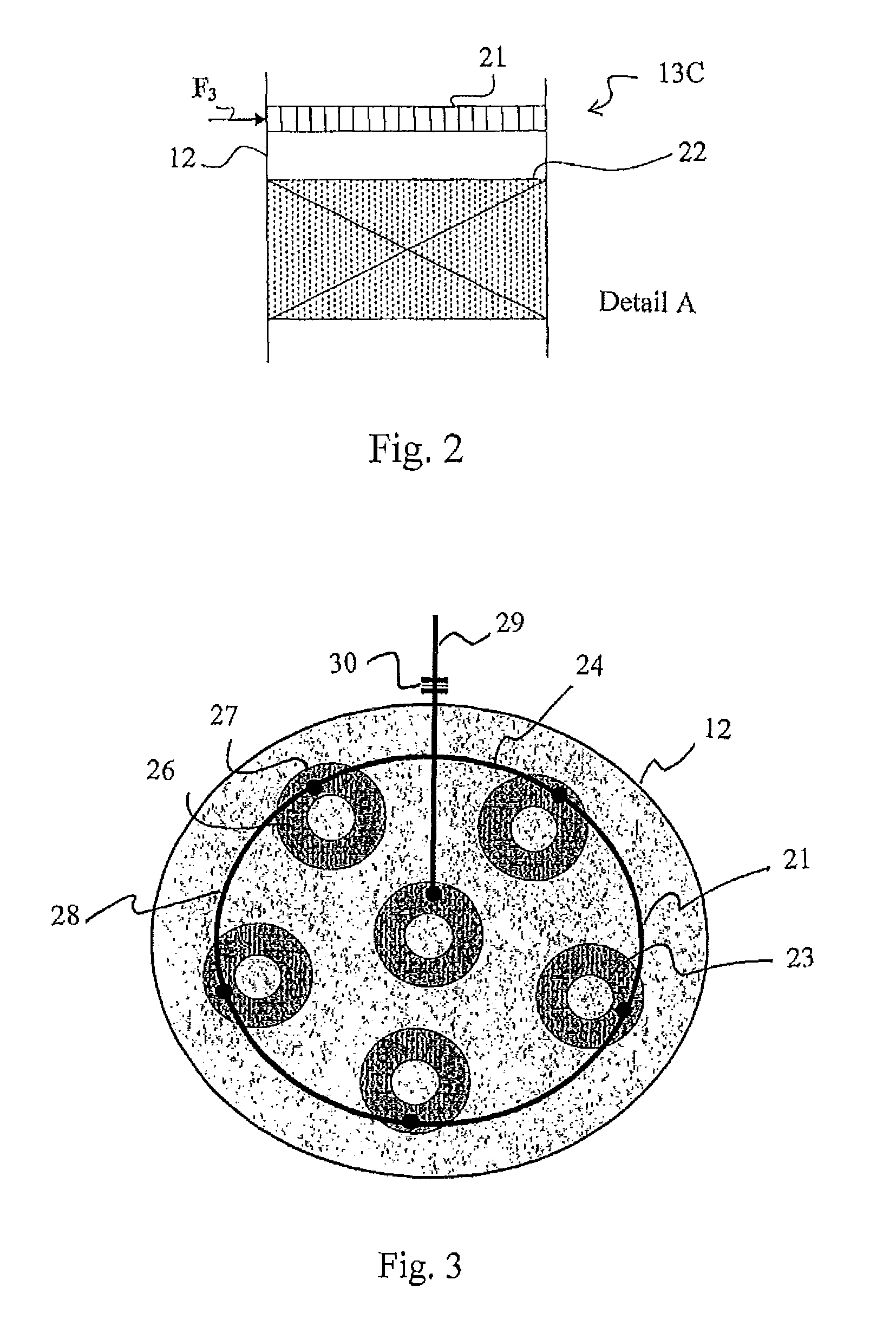

A distributor assembly for a multi-bed, downflow catalytic reactor is disclosed. The distributor assembly is configured for disposal and fixable attachment between the inner surfaces of the walls of a multi-bed downflow cylindrical reactor wall and for disposal between vertically stacked catalyst beds within the reactor. The assembly includes:(a) a collection plate configured for substantially horizontal disposal between the walls of a cylindrical reactor;(b) a plurality of generally arc-shaped elongated baffles disposed in a staggered, substantially symmetrical pattern about the collection plate;(c) a first mixing zone configured to be bounded on the bottom by the collection plate, on one side by a wall of a cylindrical reactor, and on the opposite side by the outer surface of the elongated baffles;(d) a cylindrical weir fixably attached to the collection plate about the outlet;(e) a second mixing zone bounded on the bottom by the collection plate, on one side by the outer surface of the cap and the first cylindrical weir, and on the opposite side by the inner surface of the elongated baffles;(f) a cap disposed over and about the first cylindrical weir, thereby forming a third mixing zone, plurality of semi-spiral-shaped baffles disposed in the third mixing zone, the semi-spiral-shape;(g) baffles having an elongated shape, having one lateral edge fixed to an inner surface of the cap or an opposite lateral edge fixed to an outer surface of the first cylindrical weir;(h) a substantially doughnut-shaped screen member disposed over a top portion of the cylindrical weir;(i) a plurality of fourth-mixing-zone baffles fixably attached to a top surface of the doughnut-shaped screen member; and(j) a plurality of quench gas ports disposed in the second mixing zone.

Owner:CHEVROU USA INC

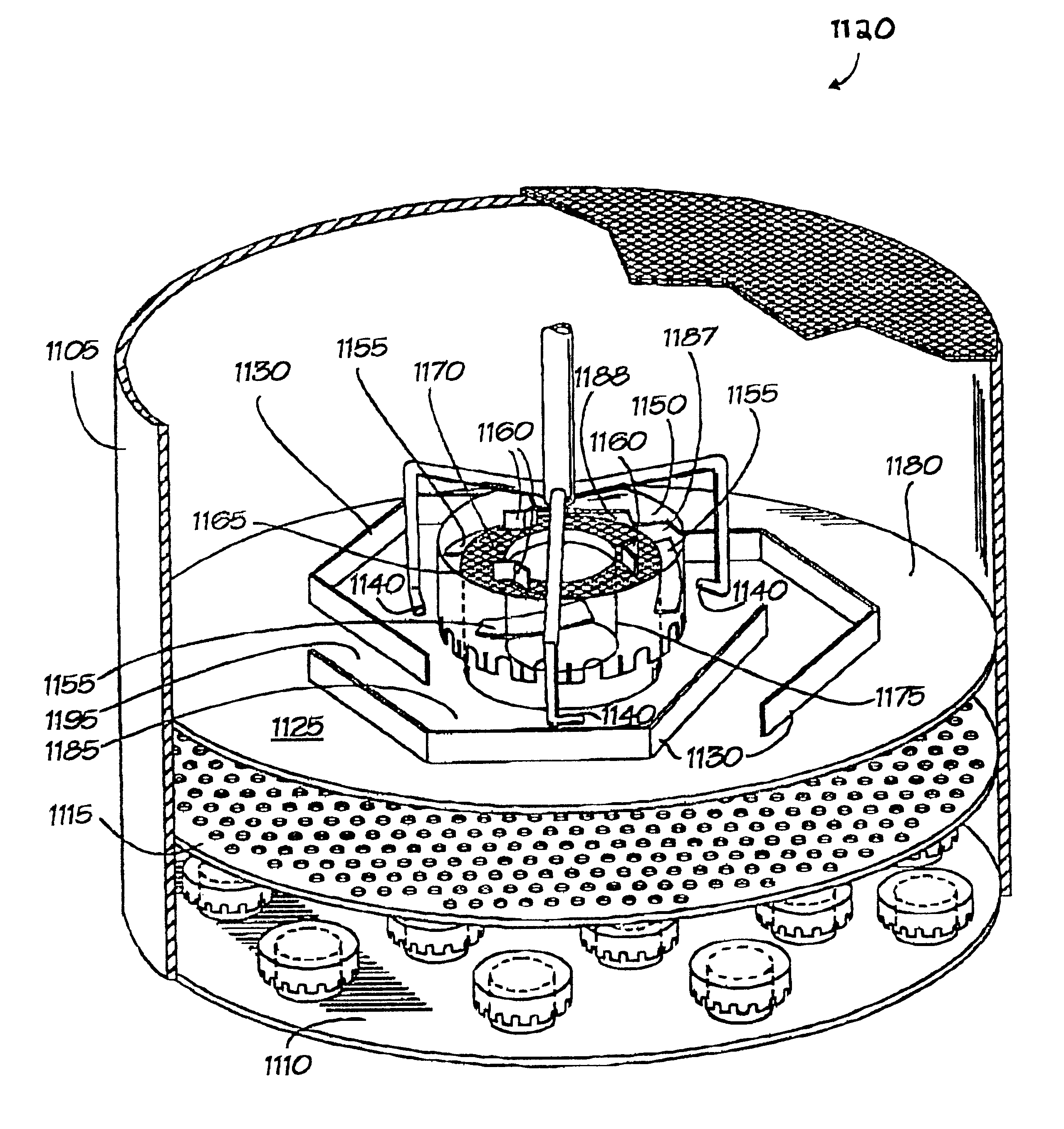

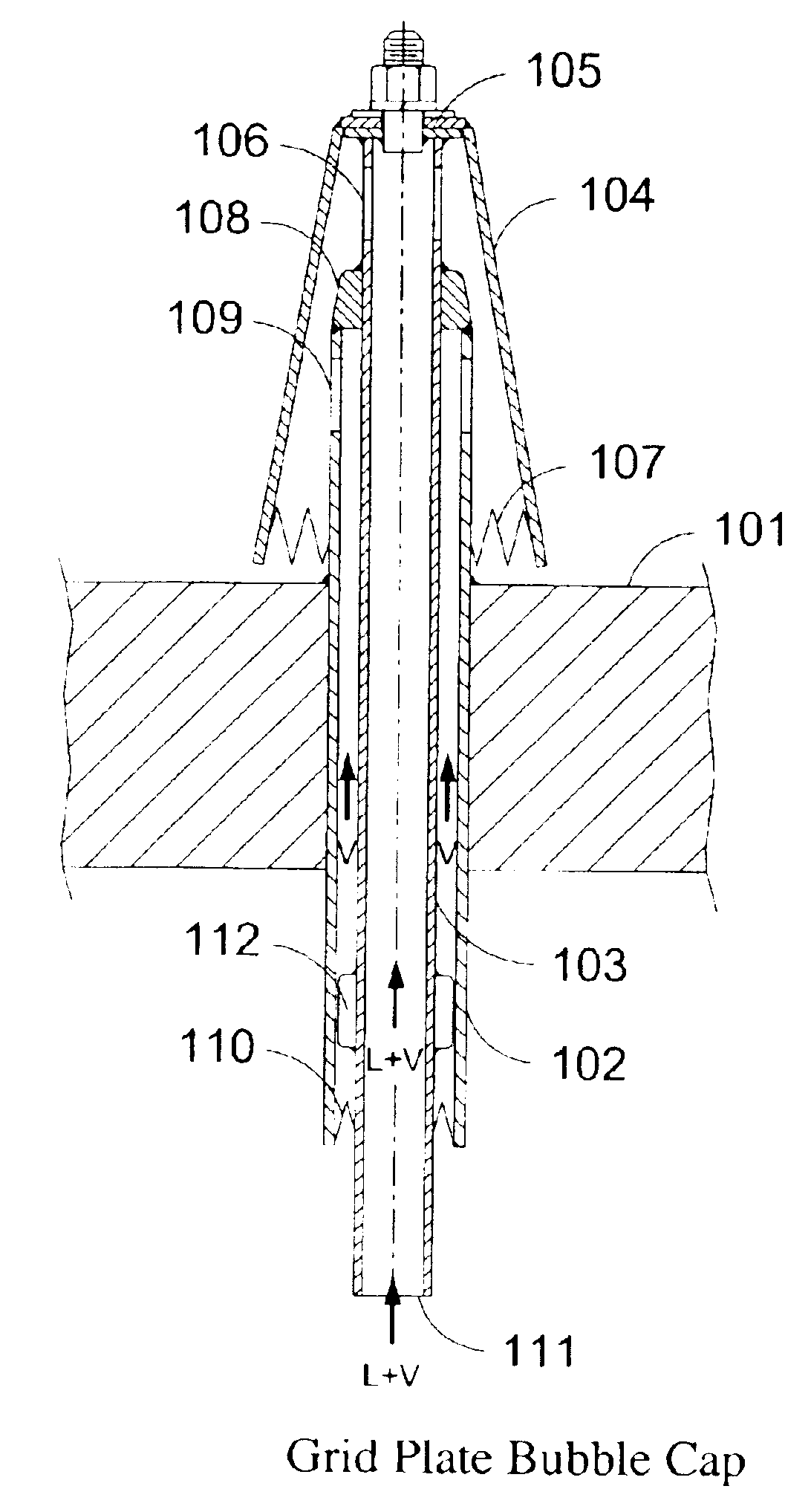

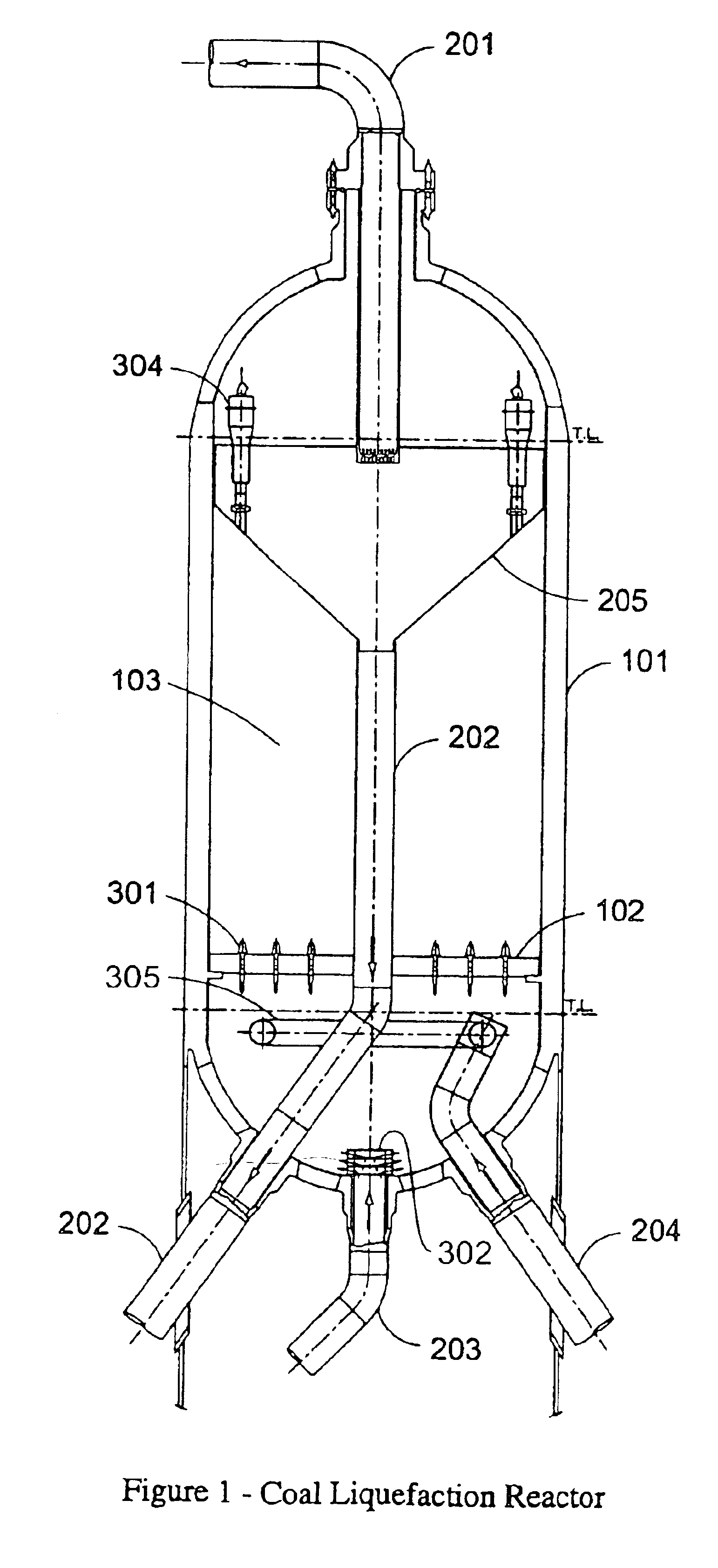

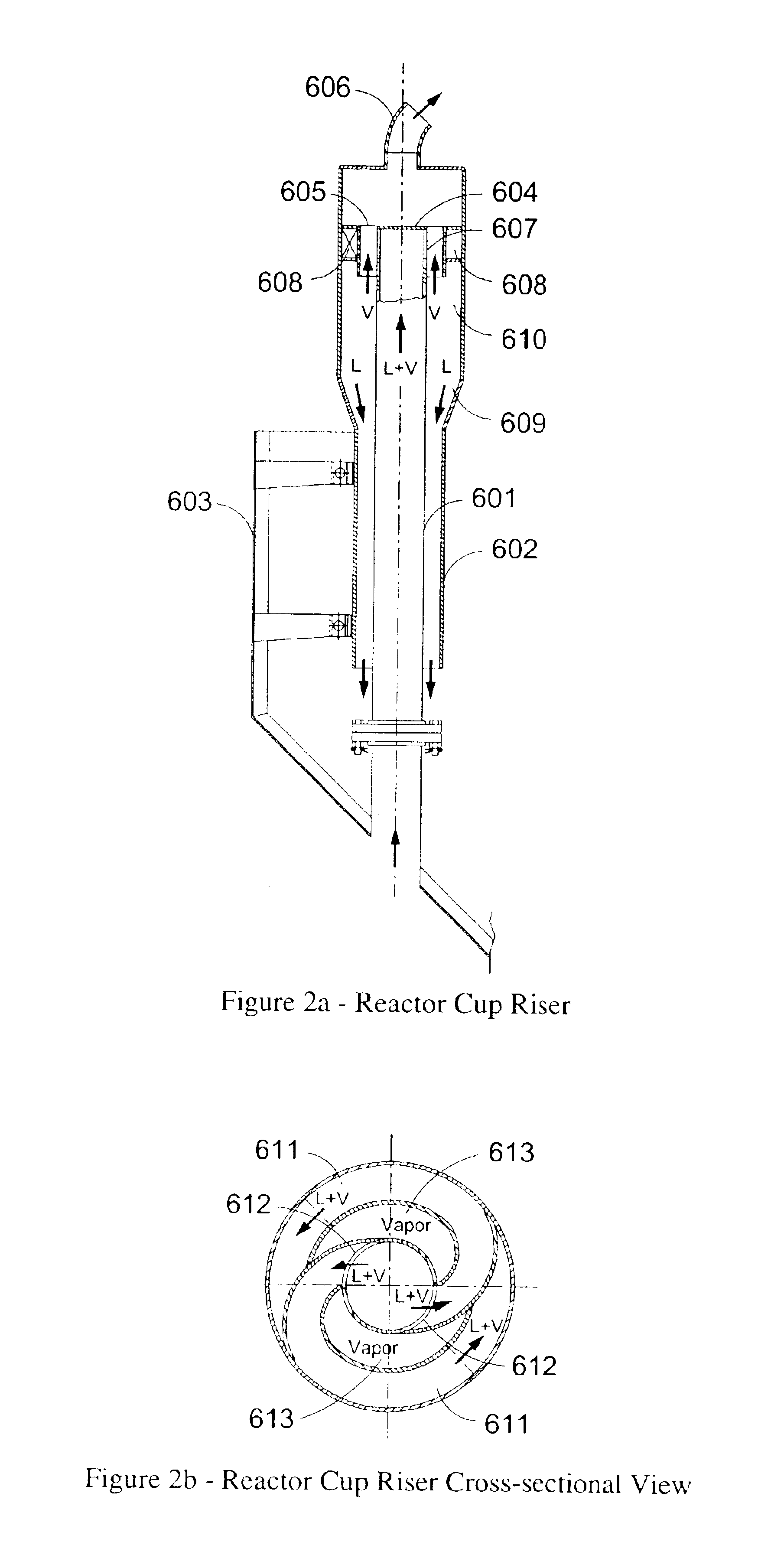

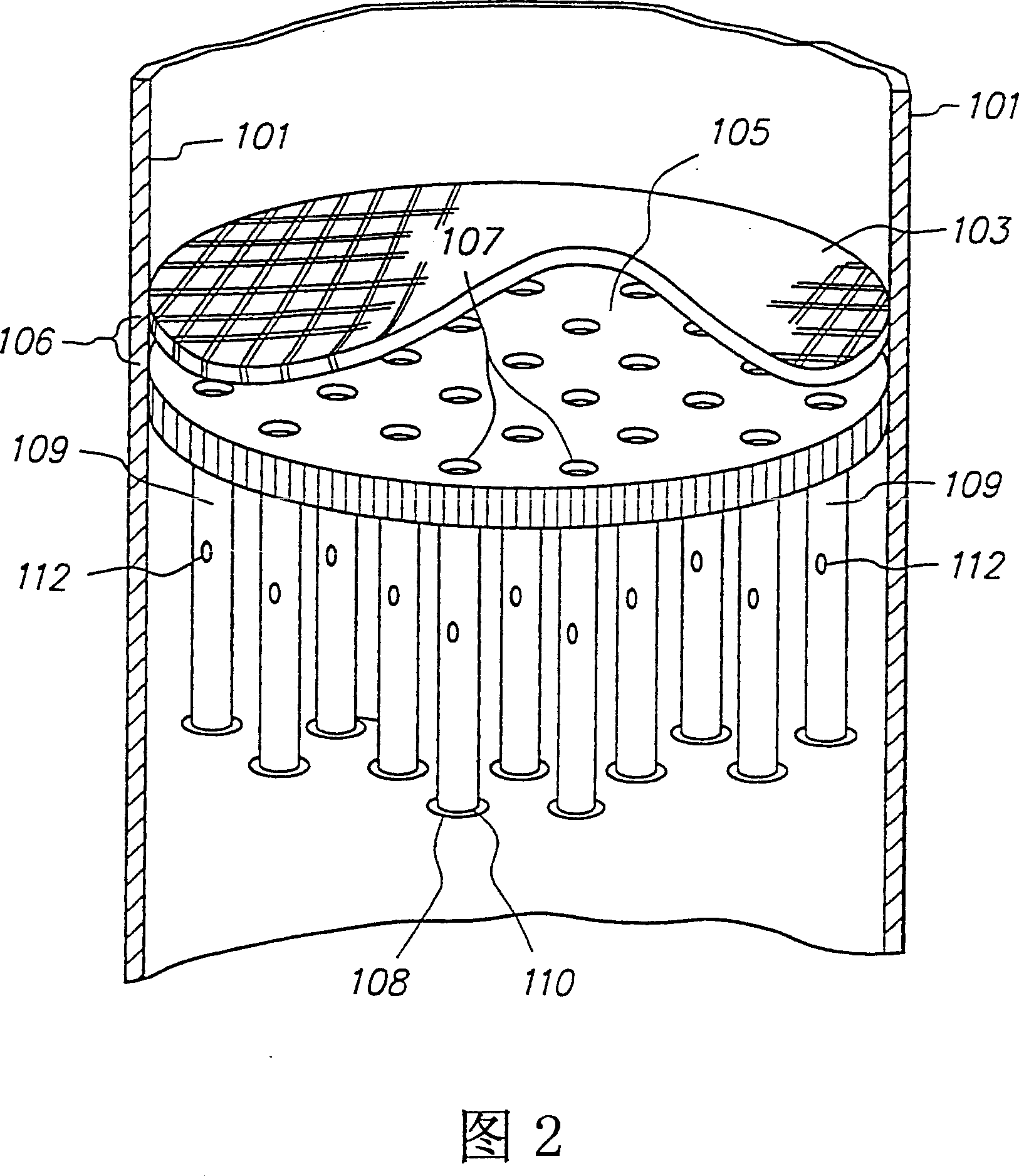

Apparatus for hydrocracking and/or hydrogenating fossil fuels

InactiveUS6960325B2Liquid mixed wellIncrease surface areaCarburetting airUsing liquid separation agentLiquid hydrocarbonsSolid particle

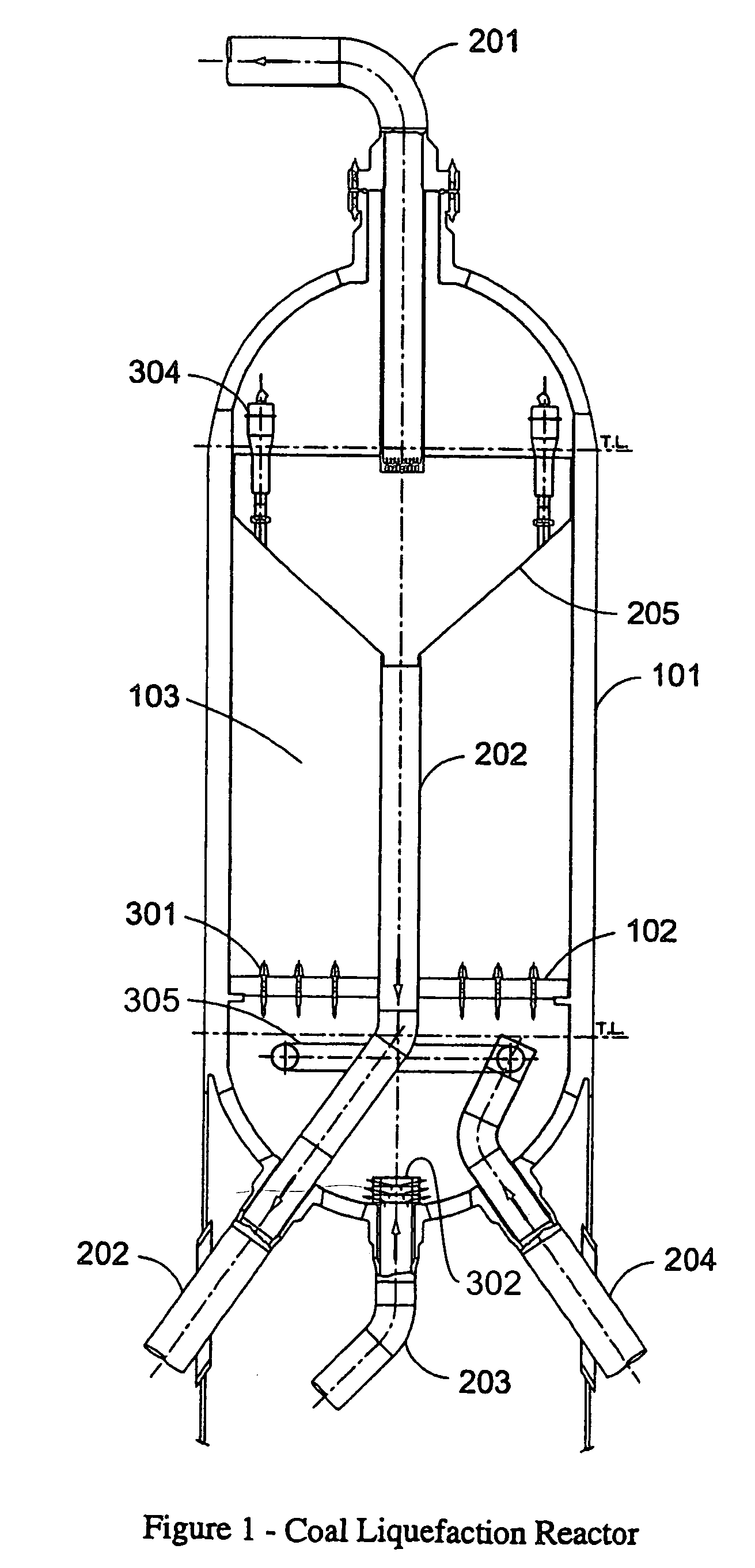

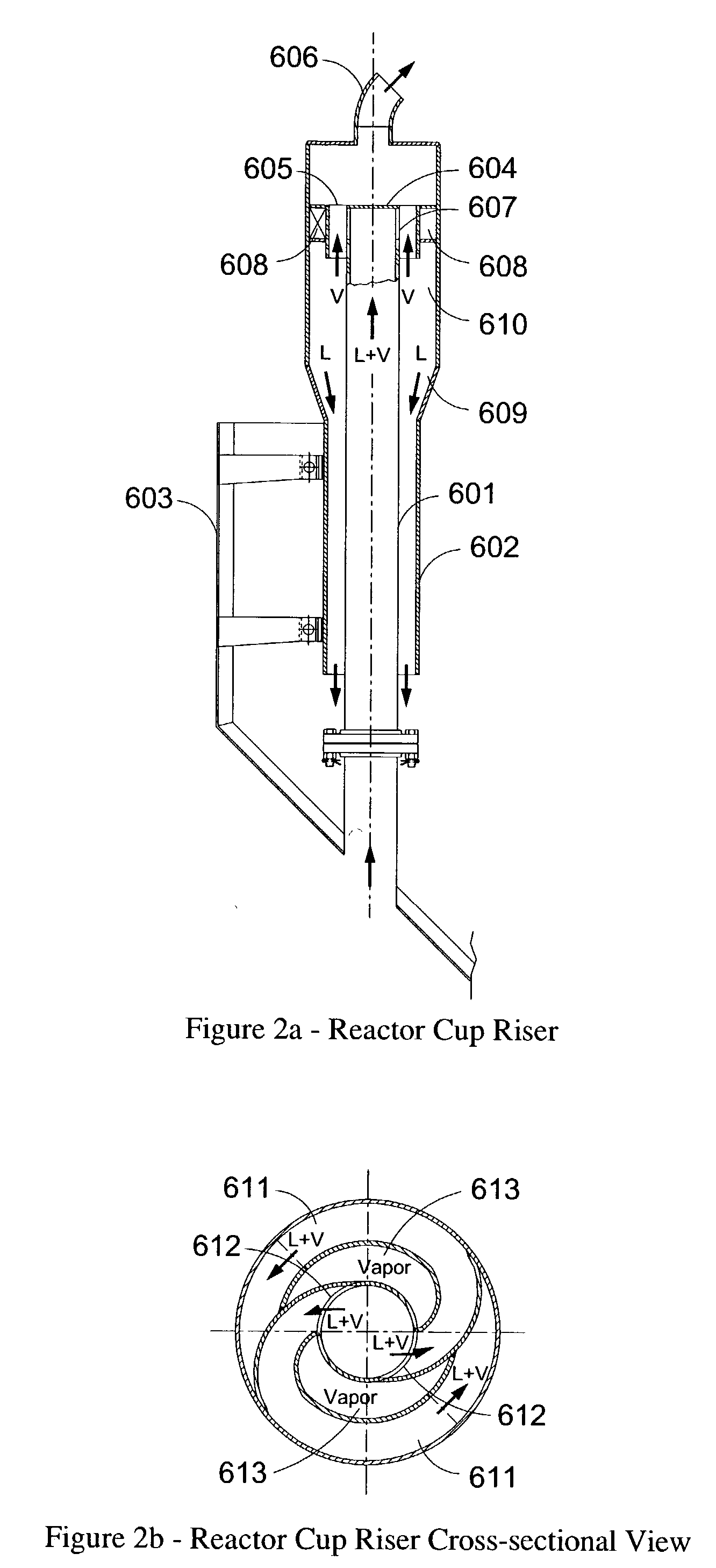

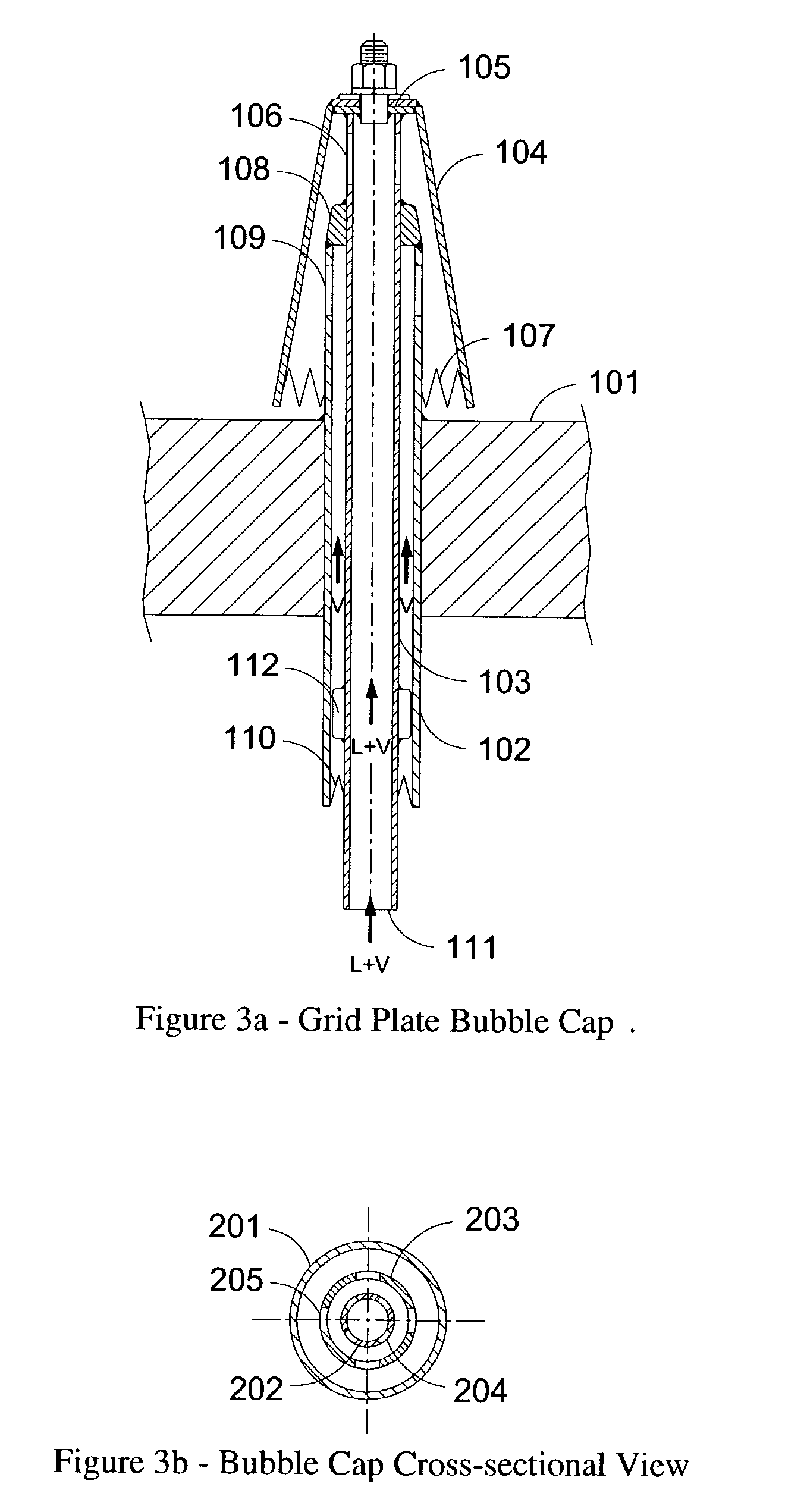

A catalytic hydrocracking reactor vessel for the conversion of a hydrogen gas and fossil fuel feedstream to light liquid hydrocarbons. The reactor vessel comprises reactor cup riser with a helical cyclonic separator conduit for separating a liquid and vapor product stream to provide an essentially vapor-free liquid recycle stream, a grid plate bubble cap with a tapered bell cap wall housing having serrated edges for producing small hydrogen bubbles of increased total surface area of bubbles at lower pressure drop, optionally a feedstream inlet pipe sparger containing rows of downward directed slots for even distribution of the feedstream across the cross-sectional area of the reactor and providing free drain of solid particles from the sparger, and optionally a liquid recycle inlet distributor containing vertically curved plates for creating a whirling motion in the liquid recycle stream for better mixing with the feedstream with minimal solids settling.

Owner:HEADWATERS TECH INNOVATION LLC +1

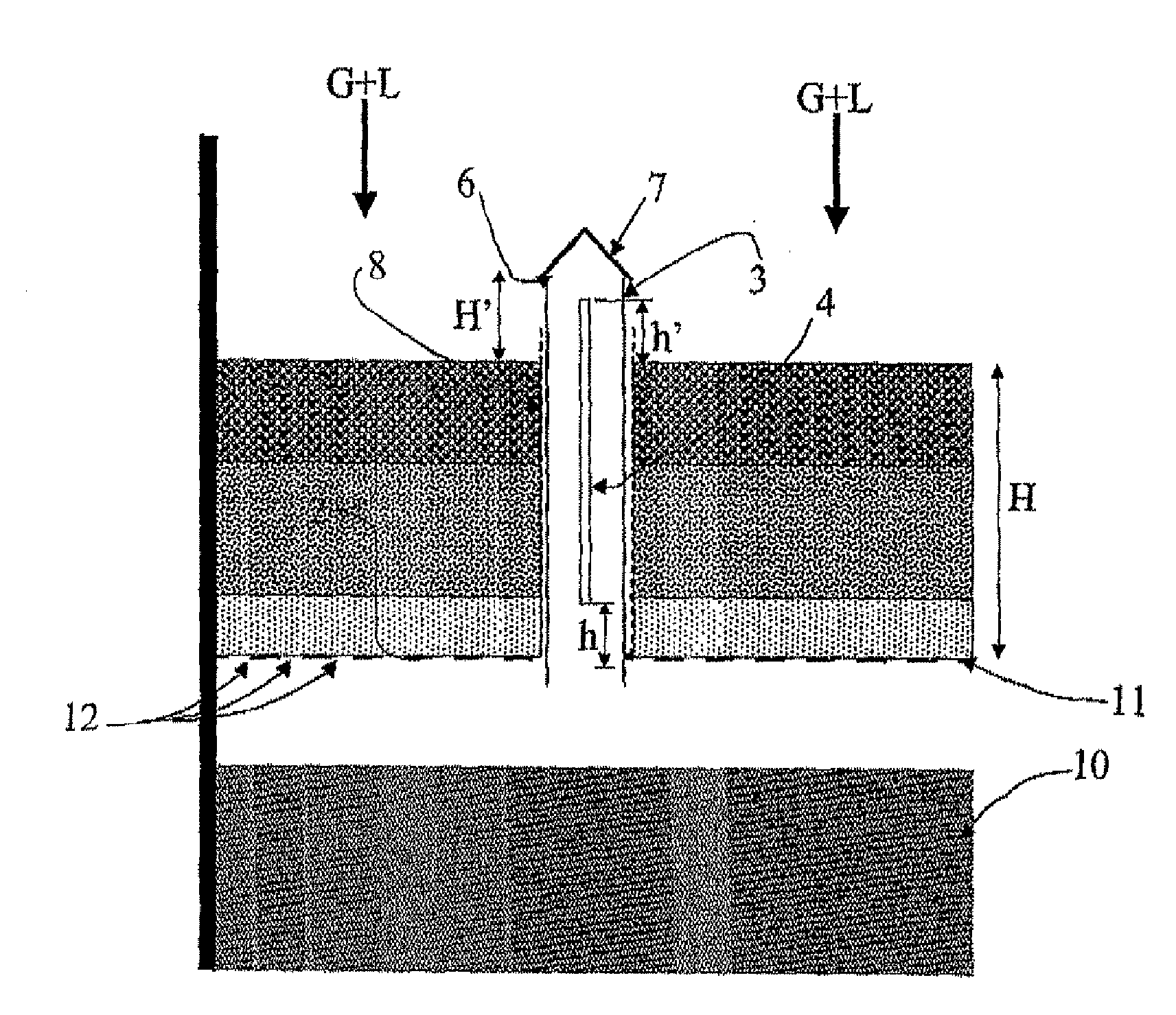

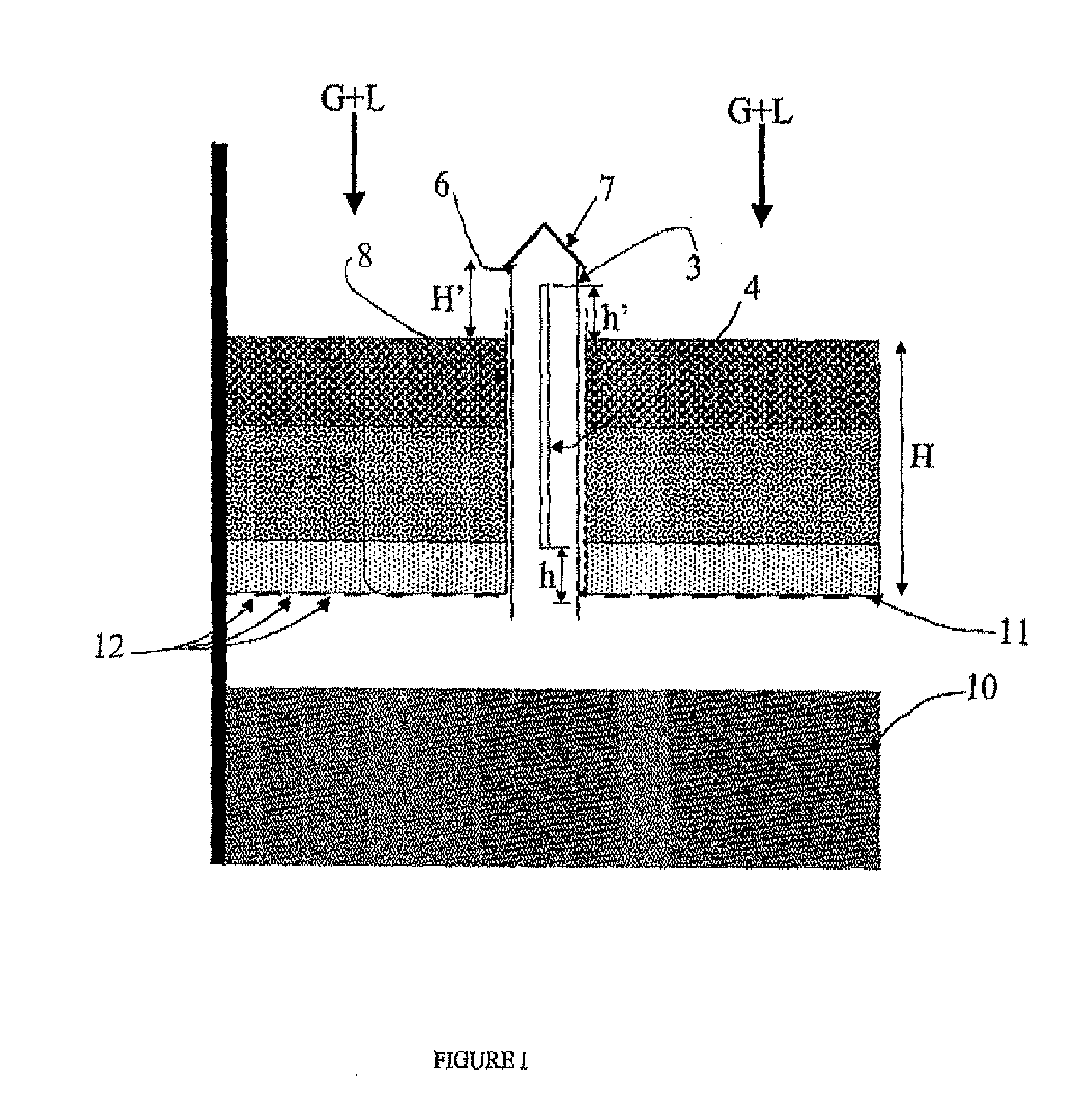

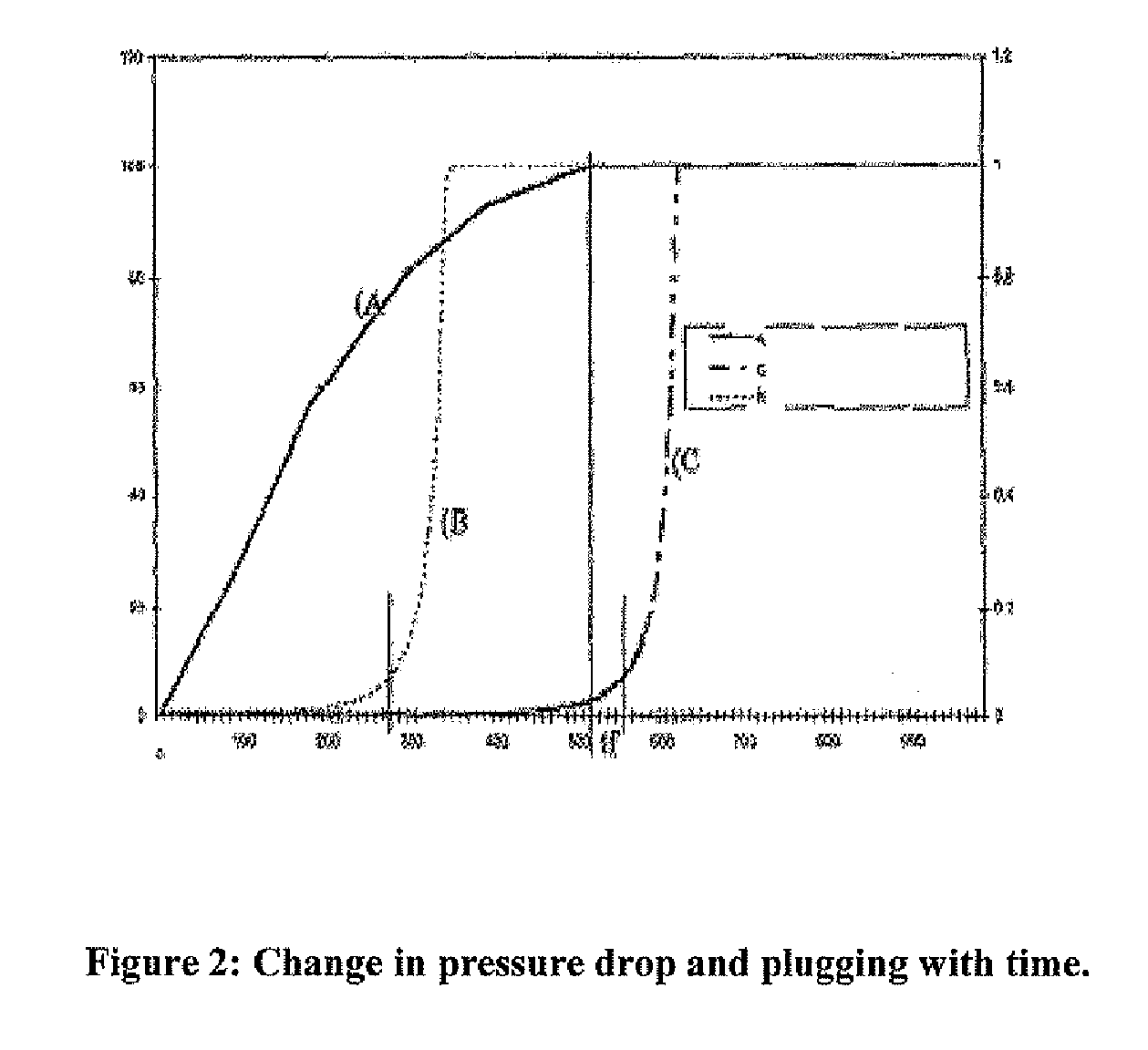

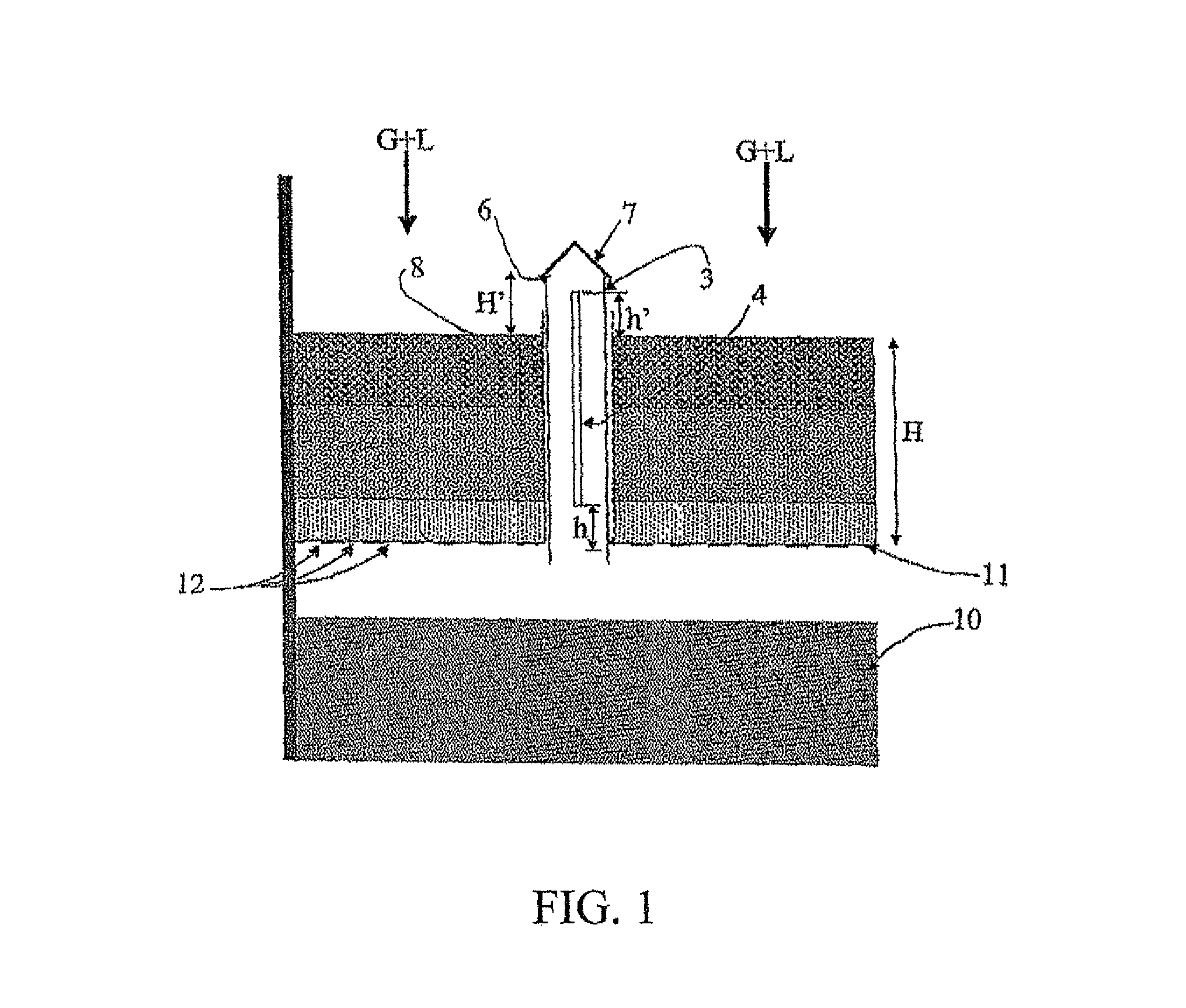

Filtration tray for fixed bed reactor with a co-current down-flow of gas and liquid

The device described in the present invention can trap plugging particles contained in the liquid feed supplying a reactor functioning in gas and liquid co-current down-flow mode using a specific distributor tray comprising a filtration medium.The present device is of particular application to the selective hydrogenation of feeds containing acetylenic and dienic compounds.

Owner:INST FR DU PETROLE

Multiphase mixing device with baffles

ActiveUS7045103B2Smooth connectionIncrease volumePhysical/chemical process catalystsMixing methodsGas phaseEngineering

The present invention provides a novel means to provide more effective mixing of quench gas and process fluids in a height constrained interbed space of a catalytic reactor without increasing pressure drop. In particular, the device improves the effectiveness of an existing mixing volume in mixing the gas phase of two-phase systems. According to the present invention, the quench zone hardware contained within the reactor includes a substantially vertical continuous perimeter solid baffle attached to the underside of the collection tray.

Owner:EXXON RES & ENG CO

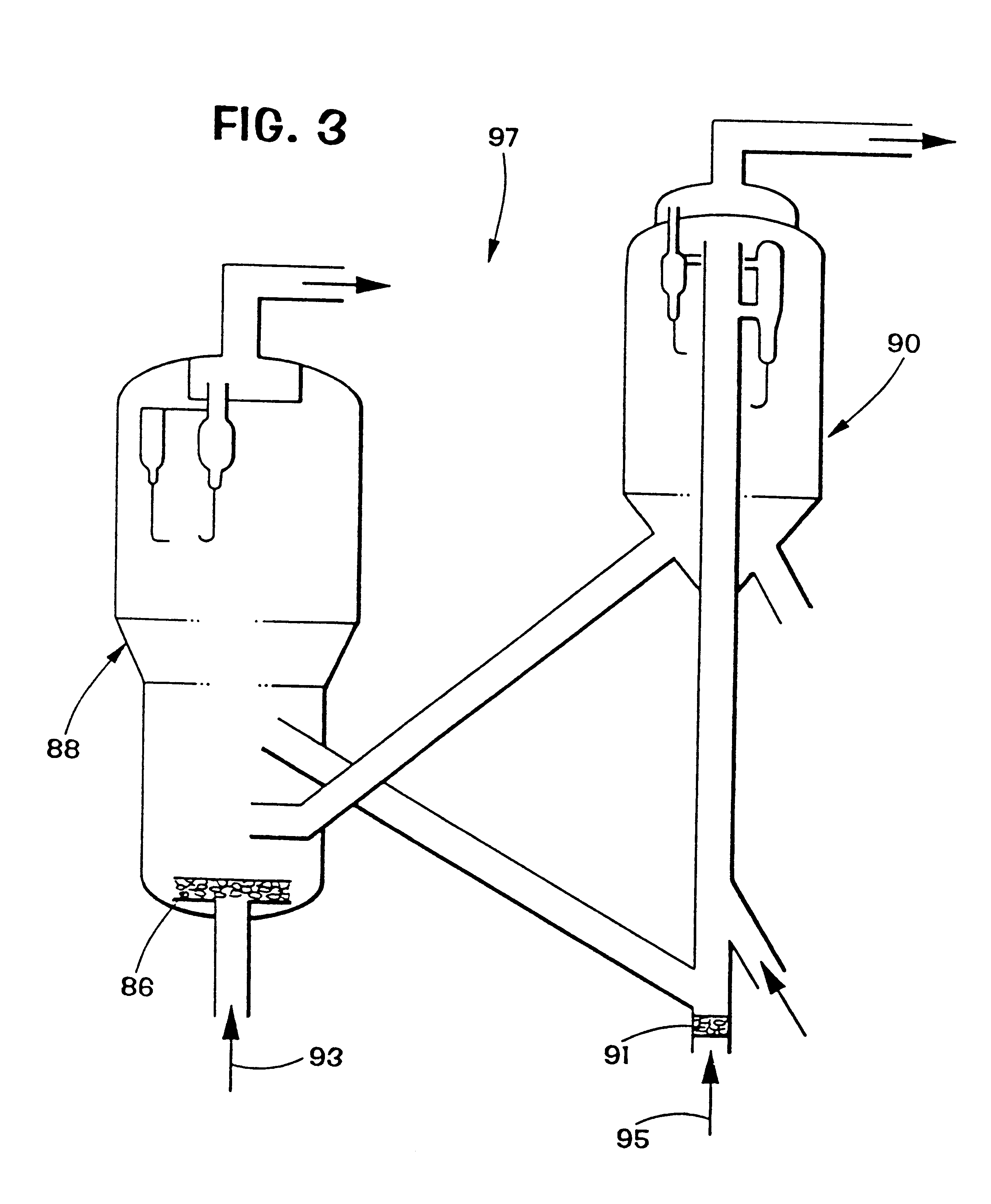

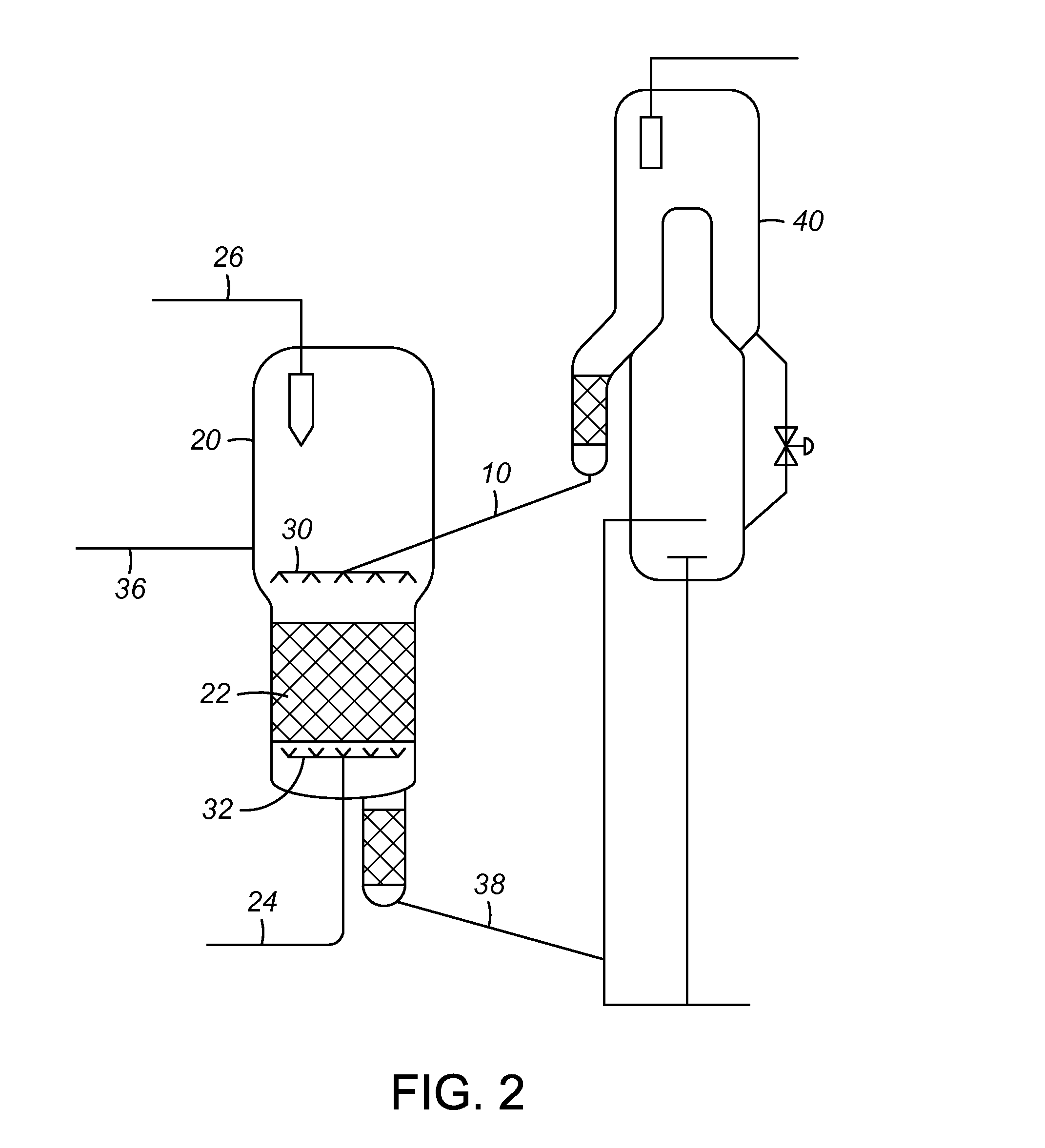

Counter-Current Fluidized Bed Reactor for the Dehydrogenation of Olefins

ActiveUS20140142362A1Large caliberHydrocarbonsBed hydrotreatment processes apparatusFluidized bedDehydrogenation

A process and apparatus for the dehydrogenation of paraffins is presented. The process utilizes a reactor that includes a slower flow of catalyst through the reactor, with a counter current flow of gas through the catalyst bed. The catalyst is regenerated and distributed over the top of the catalyst bed, and travels through the bed with the aid of reactor internals to limit backmixing of the catalyst.

Owner:UOP LLC

Multiphase mixing device with staged gas introduction

InactiveUS7052654B2Lower overall pressure dropImprove efficiencyPhysical/chemical process catalystsChemical/physical/physico-chemical stationary reactorsPhase mixingHybrid system

The present invention comprises a mixing system that provides improved mixing of quench gas and process fluids in a height constrained interbed space while not increasing pressure drop. In particular, the device improves the effectiveness of an existing mixing volume in mixing the gas phase of two-phase systems. The mixing system includes a horizontal collection tray, a mixing chamber positioned below the collection tray, at least one passageway extending through the collection tray into the mixing chamber, and a vapor slipstream passageway extending through the collection tray into the mixing chamber for directing a vapor slipstream from above the collection tray into the mixing chamber. The mixing chamber and the collection tray define a two-phase mixing volume. The passageway conducts fluid containing at least some vapor from above the collection tray into the mixing chamber. The mixing chamber preferably includes at least one outlet opening for the downward passage of fluid. The vapor slipstream passageway, optionally, comprises a plurality of inlets arranged to impart rotational movement to the vapor phase at a location within the mixing chamber where the vapor phase has substantially expended the kinetic energy of its initial entry into the mixing chamber. As a result of providing at least one additional passageway for a vapor slipstream, and optionally, including one or more baffles as described above, significant re-acceleration of the vapor phase is achieved in the mixing chamber resulting in improvements in mixing efficiency of both the vapor and liquid phases.

Owner:EXXON RES & ENG CO

Method for revamping fixed-bed catalytic reformers

InactiveUS20050274648A1Avoids major expenseQuality improvementCatalytic naphtha reformingBed hydrotreatment processes apparatusCatalytic reformingThermodynamics

A fixed-bed catalytic reformer unit is converted to moving bed reactor / cyclic regenerator operation by re-using the fixed bed reactors of the original unit as regenerator vessels operated in cyclic regeneration mode in a new catalyst regeneration section. A flow connection, suitably a liftpipe, is provided to convey spent catalyst from the spent catalyst outlet of a new moving bed reactor section to the converted regenerator section, together with a flow connection for regenerated catalyst from the regenerator section to the regenerated catalyst inlet of the new moving bed reactor section. A flow control distributor directs spent catalyst sequentially to each of the regenerator vessels to carry out the regeneration with regeneration gas. Each regenerator vessel is cycled through a fill, regeneration, discharge sequence to maintain a continuous flow of catalyst to and from the reactor section.

Owner:EXXON RES & ENG CO

Filtering distributor plate for supplying a fixed bed reactor having a co-current downflow of gas and liquid for the treatment of heavy clogging feeds

The present invention describes a distributor plate adapted to co-current downflow flows of gas and of liquid, more particularly in the “trickle” mode, said distributor plate integrating a filtration function separate from the distribution function.

Owner:INST FR DU PETROLE

Catalyst retainer for radial flow reactor

InactiveUS20150078970A1Reduce the average velocityAvoid collisionBed hydrotreatment processes apparatusChemical/physical processesEngineering

A catalyst retainer includes an inner particle retention device having apertures and a first non-apertured section; and an outer particle retention device having apertures and a second non-apertured section. The inner and the outer particle retention devices are spaced apart to define a particle retaining space of the retainer. The first non-apertured section and the second non-apertured section define a blanked-off section of the particle retaining space, and the blanked-off section is spaced from an end of the particle retaining space. The catalyst retainer also includes a louver with at least a portion located between the blanked-off section and the end of the particle retaining space. The louver extends into the particle retaining space at an angle with respect to an inner surface of the inner particle retention device. The louver introduces the fluid to the top catalyst free surface in a more uniform manner and hence prevents particle movement and attrition.

Owner:UOP LLC

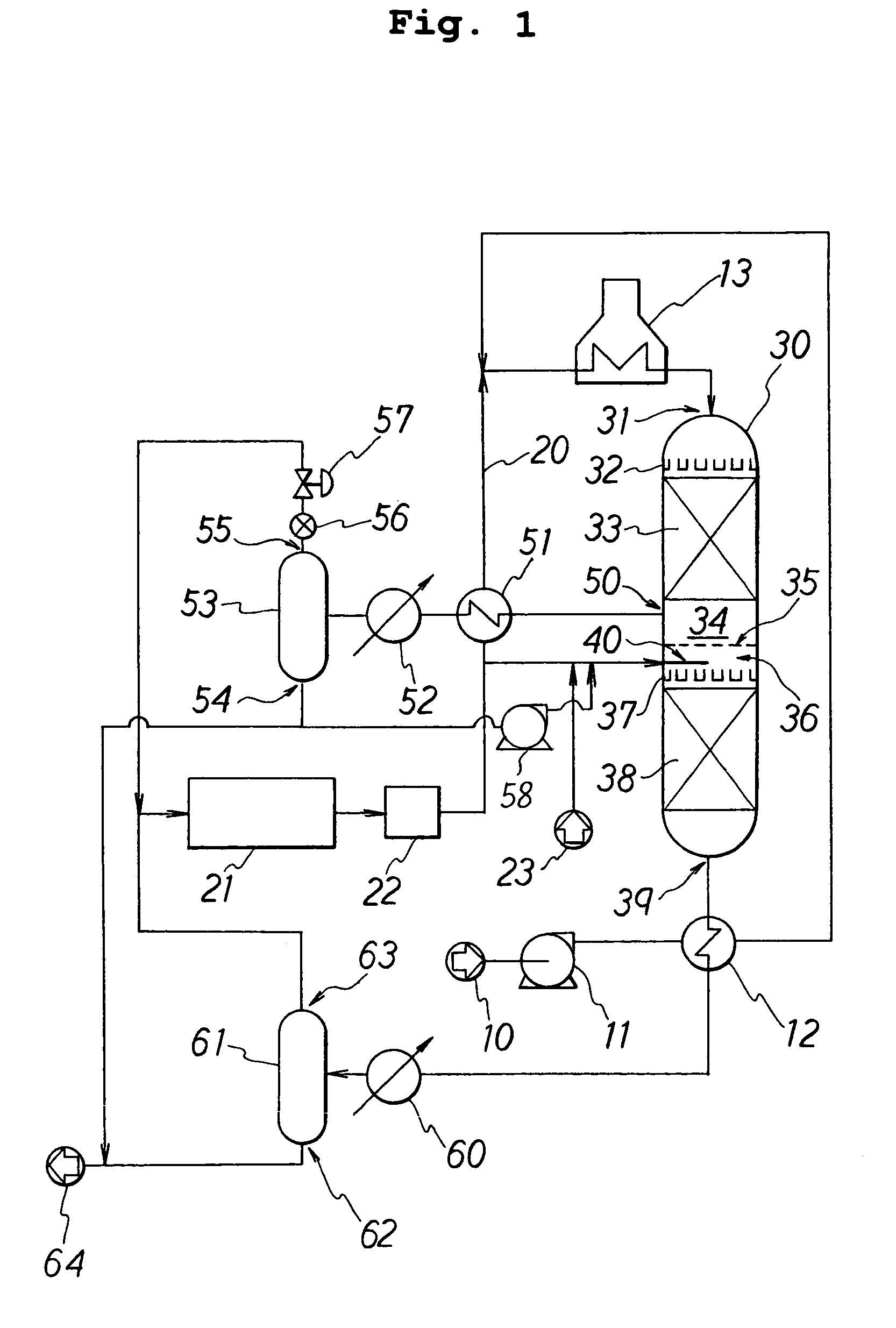

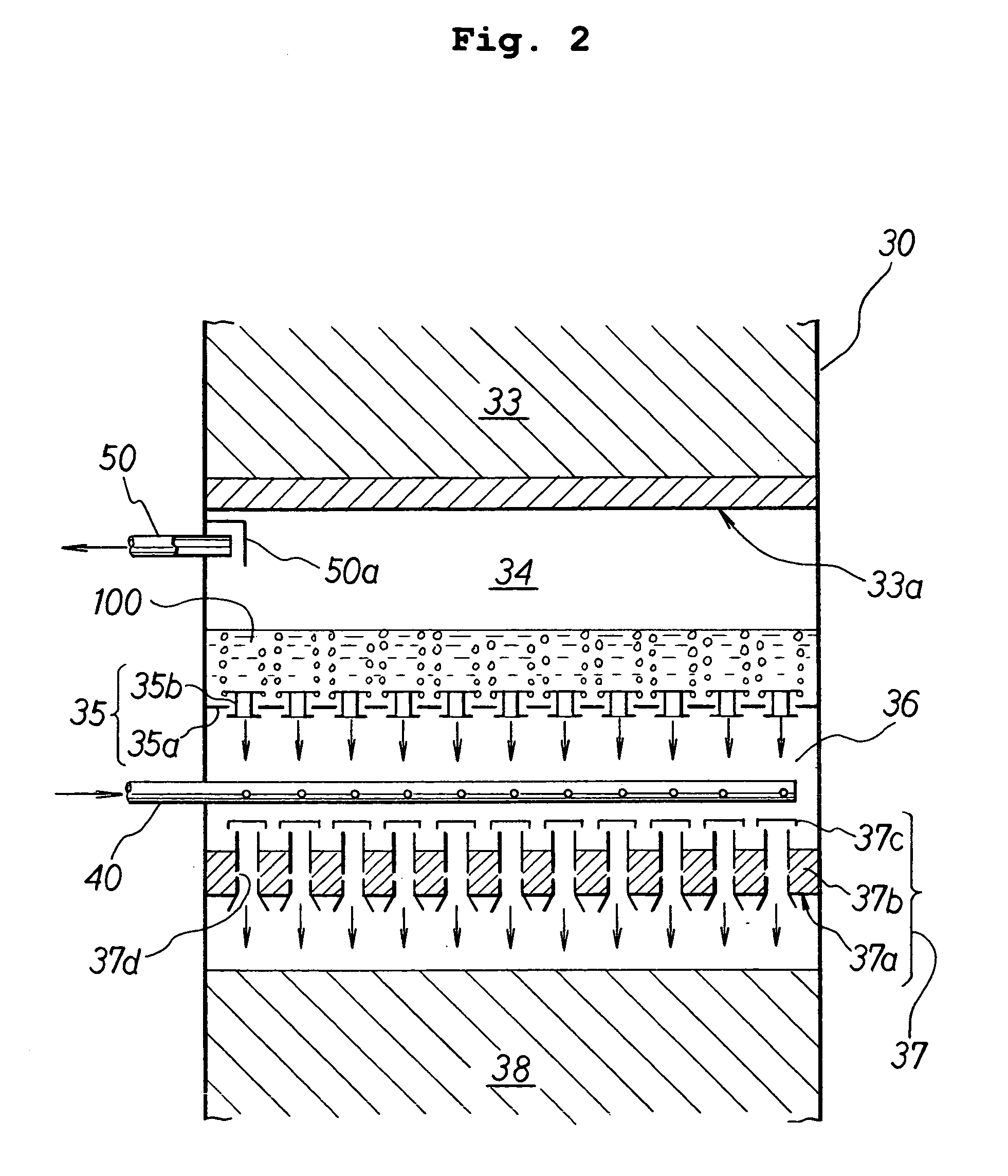

Method and apparatus for stripping sulfur-containing compounds from hydrocarbon feed stock in hydrorefining of petroleum distillates

InactiveUS7001503B1Reduce contentSimple structureHydrocarbon oil crackingTreatment with hydrotreatment processesDistillates petroleumHydrogen

A unit for hydrorefining of hydrocarbon crude oil comprising sulfur-containing compounds comprises first catalyst layer 33 and second catalyst layer 38, top space 34 for separating vapor component and liquid component, bottom space 36, and valve tray 35 that divides top space 34 and bottom space 36. Hydrogen released from hydrogen nozzle 40 placed in the bottom space is passed through liquid component that has accumulated in the valve tray and stripping of liquid components is performed. Hydrogen released from hydrogen nozzle 40 is again introduced, to second catalyst layer 38 as a cocurrent with the stripped liquid component. By stripping, it is possible to reduce the sulfur content, the nitrogen content and reduce the aromatic content of the hydrocarbon crude oil when compared to the conventional method. Since the hydrorefining unit has a simple structure, the unit can be easily made by modifying existing units.

Owner:JAPAN ENERGY CORP +1

Quench box for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor

A compact quench box design for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor has a quench pipe manifold and nozzle assembly, a collection tray, a mixing chamber, and a single final distributor tray. The quench pipe manifold and nozzle assembly is an annular ring pipe having nozzles arising therefrom. The mixing chamber is an annular compartment depending from the collection tray above having a partition pan, forming a partition weir at its inside diameter for liquid to flow, and a bottom section pan, which forms a vapor outlet weir at its inside diameter for vapor flow onto the final distributor tray below. This design reduces the number of manway required for the quench box.

Owner:H2ADVANCE

Upflow reactor system with layered catalyst bed for hydrotreating heavy feedstocks

InactiveCN1315994CTreatment with hydrotreatment processesBed hydrotreatment processes apparatusReactor systemSulfur

Owner:CHEVROU USA INC

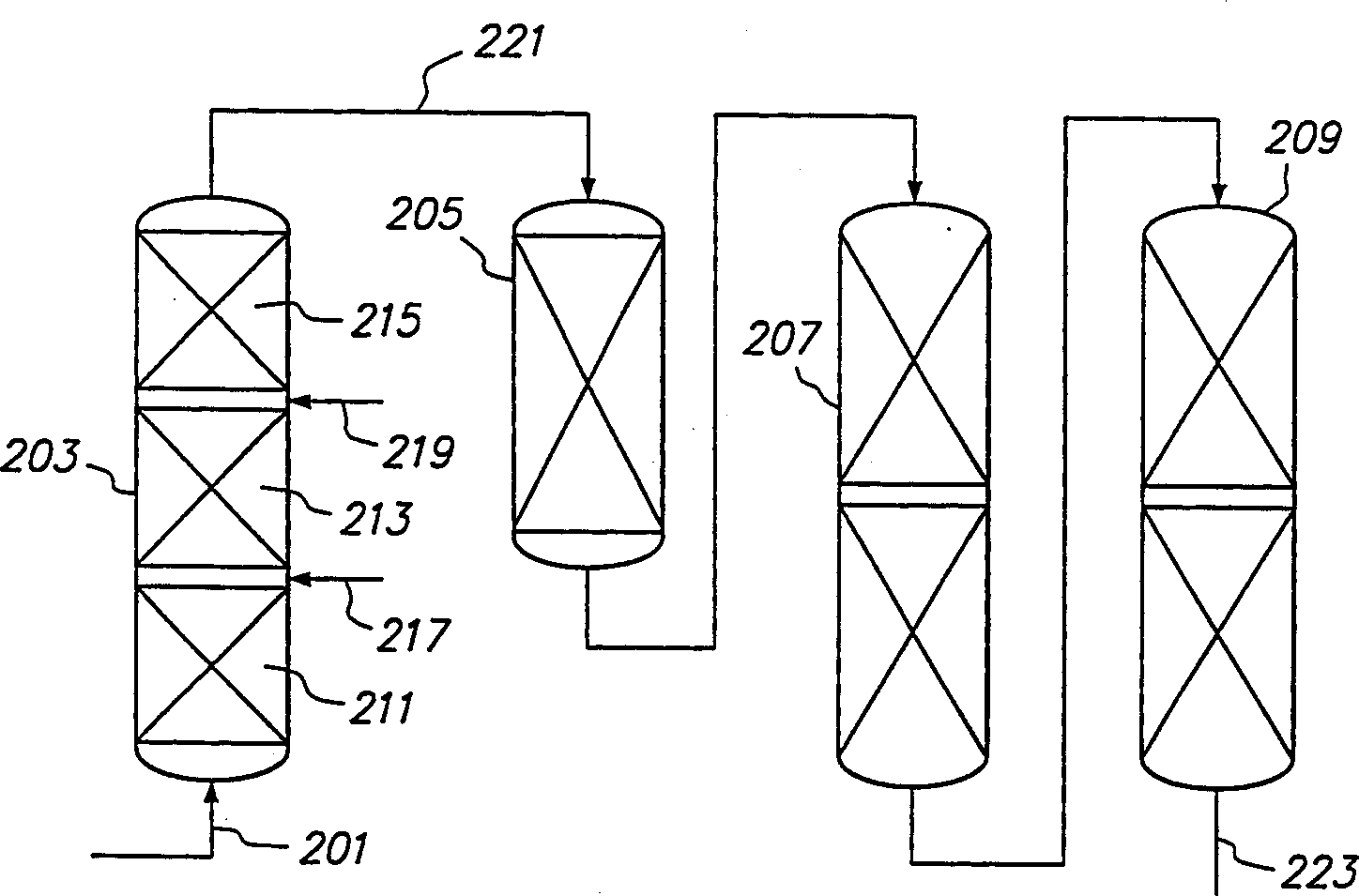

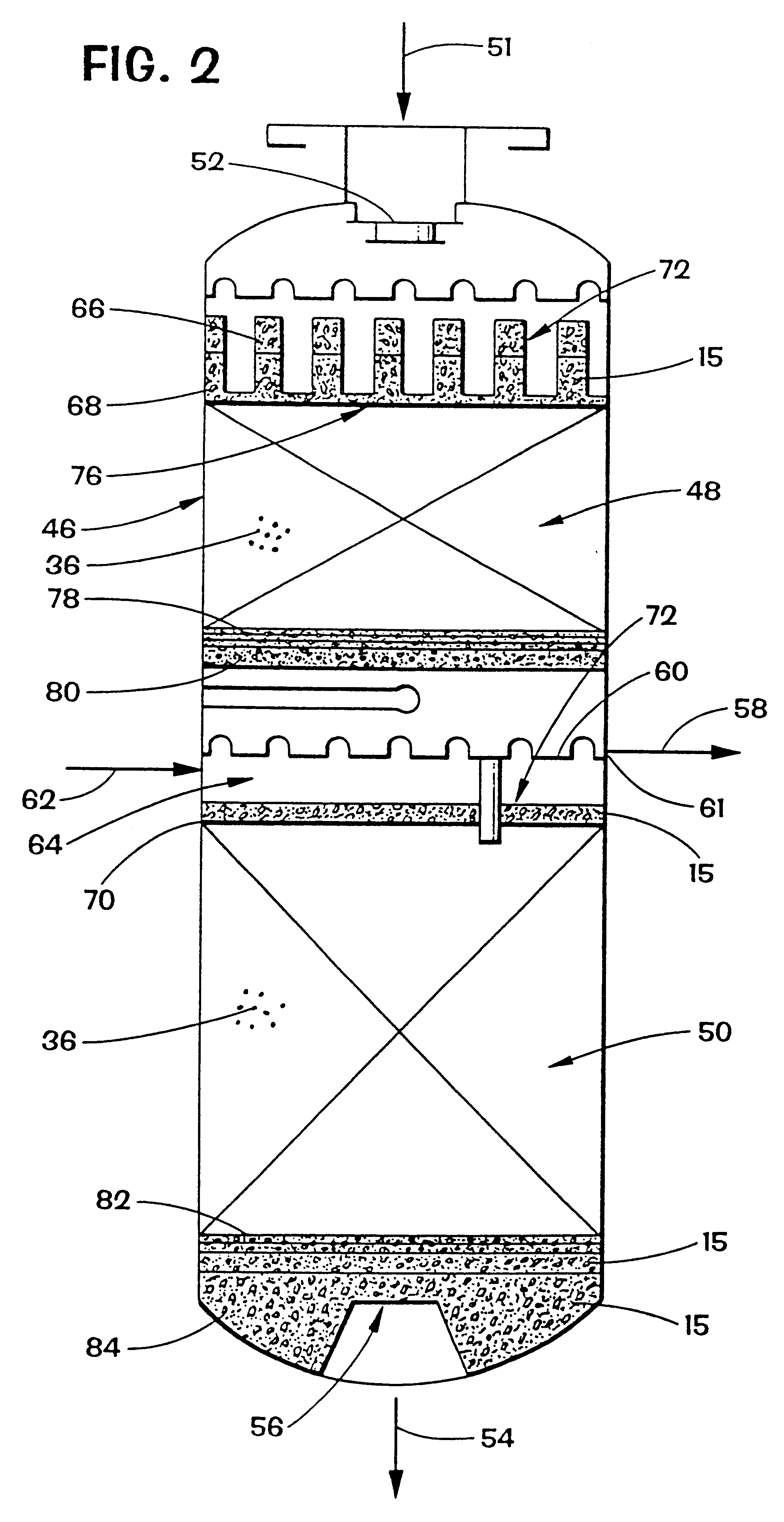

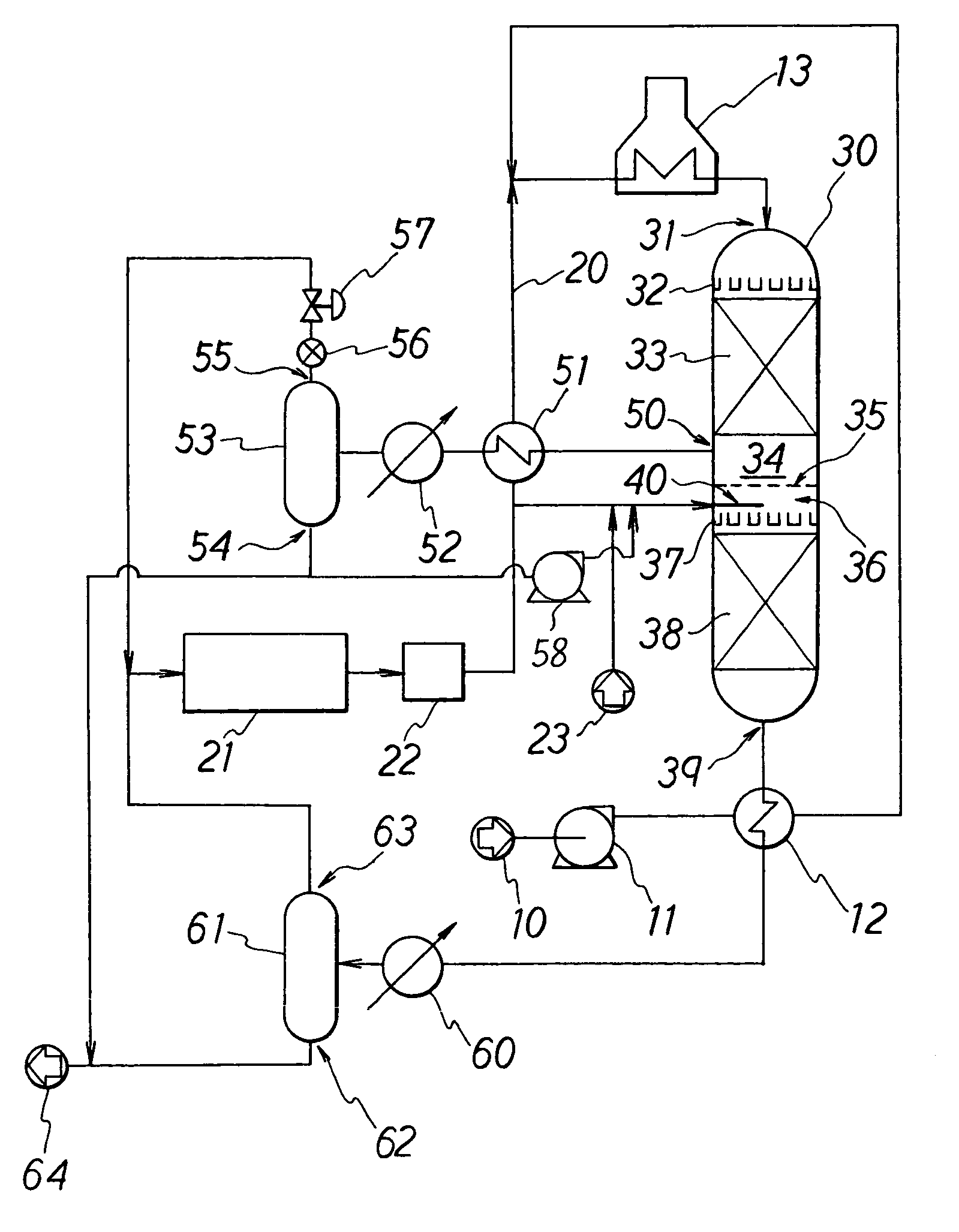

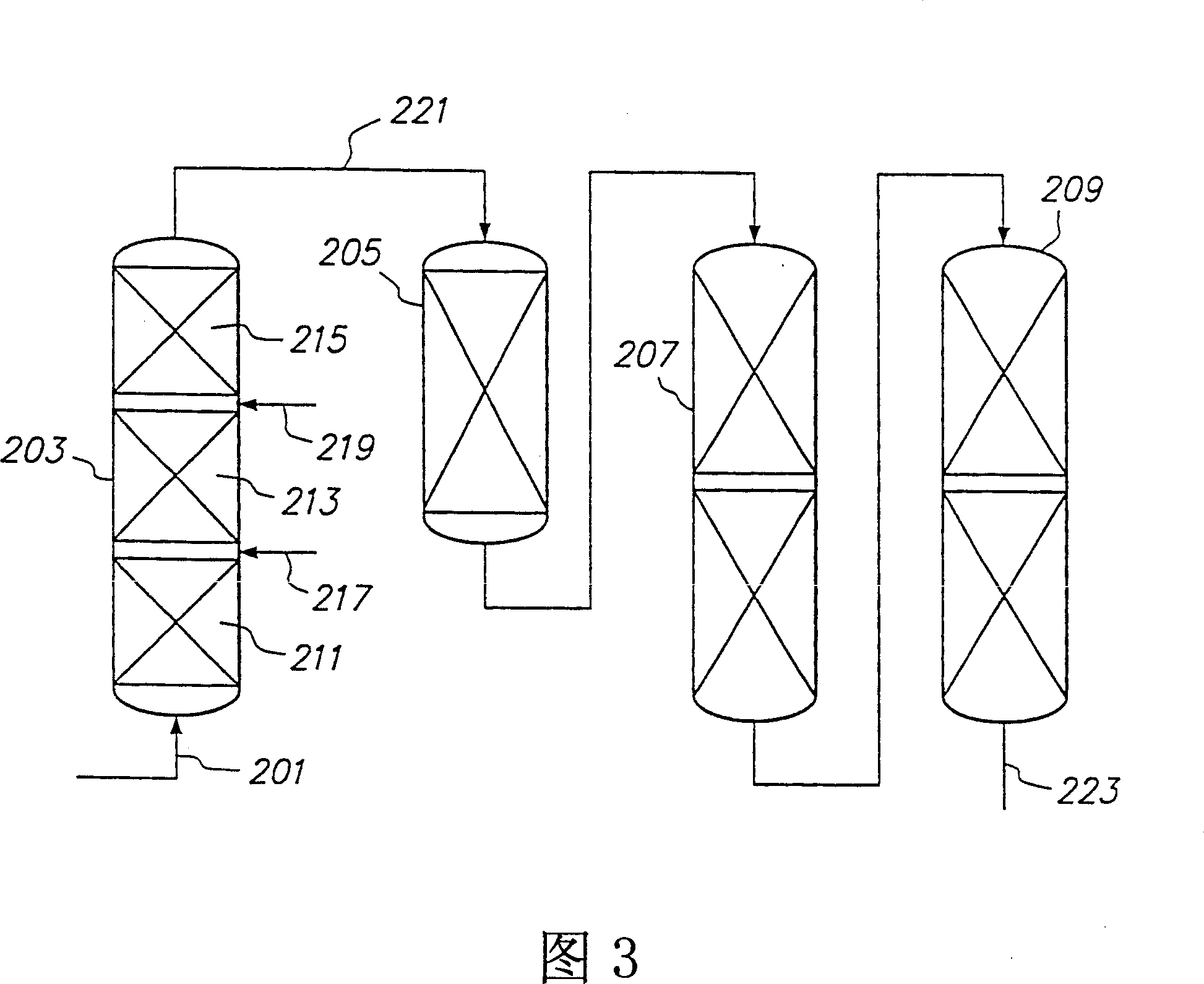

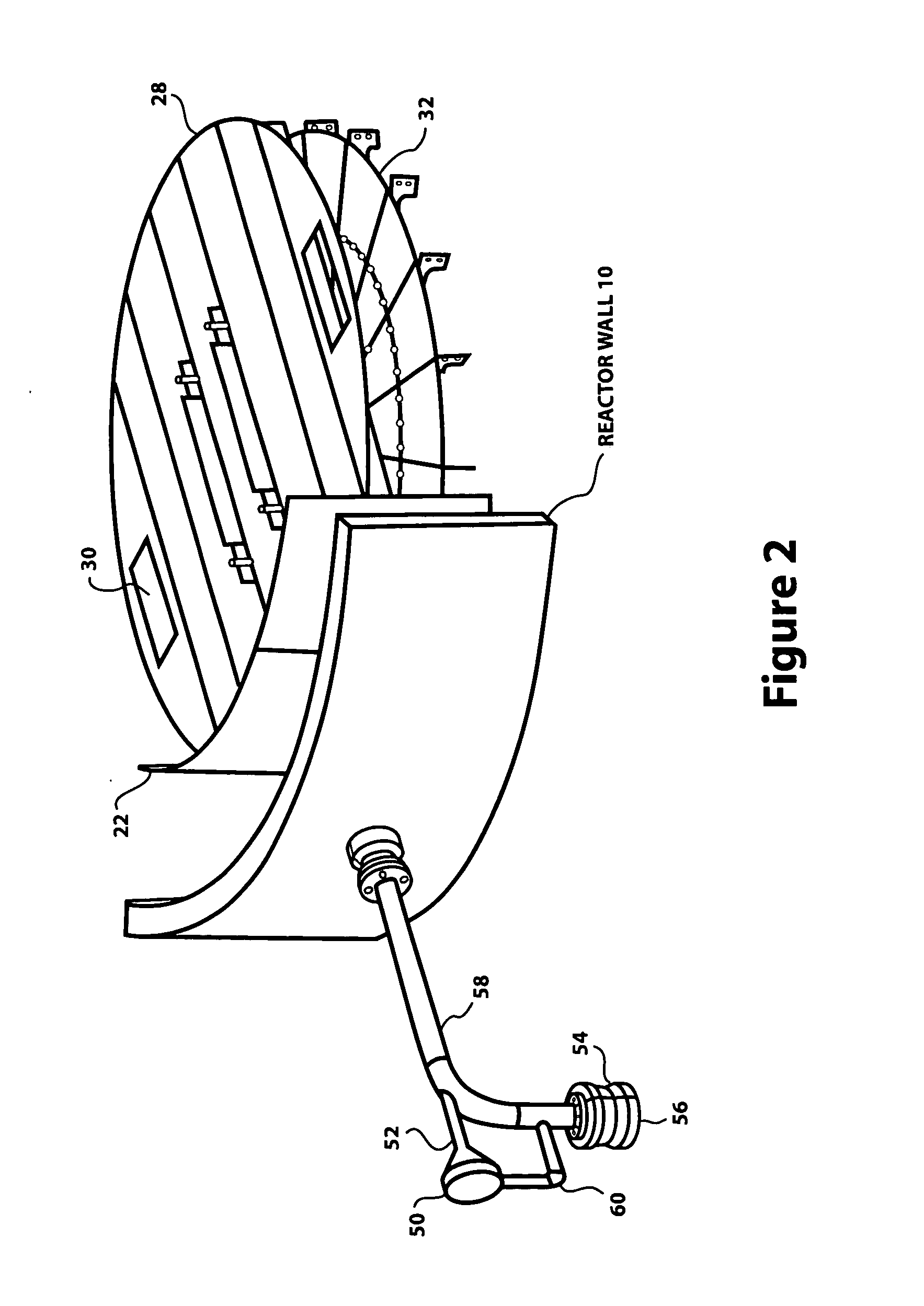

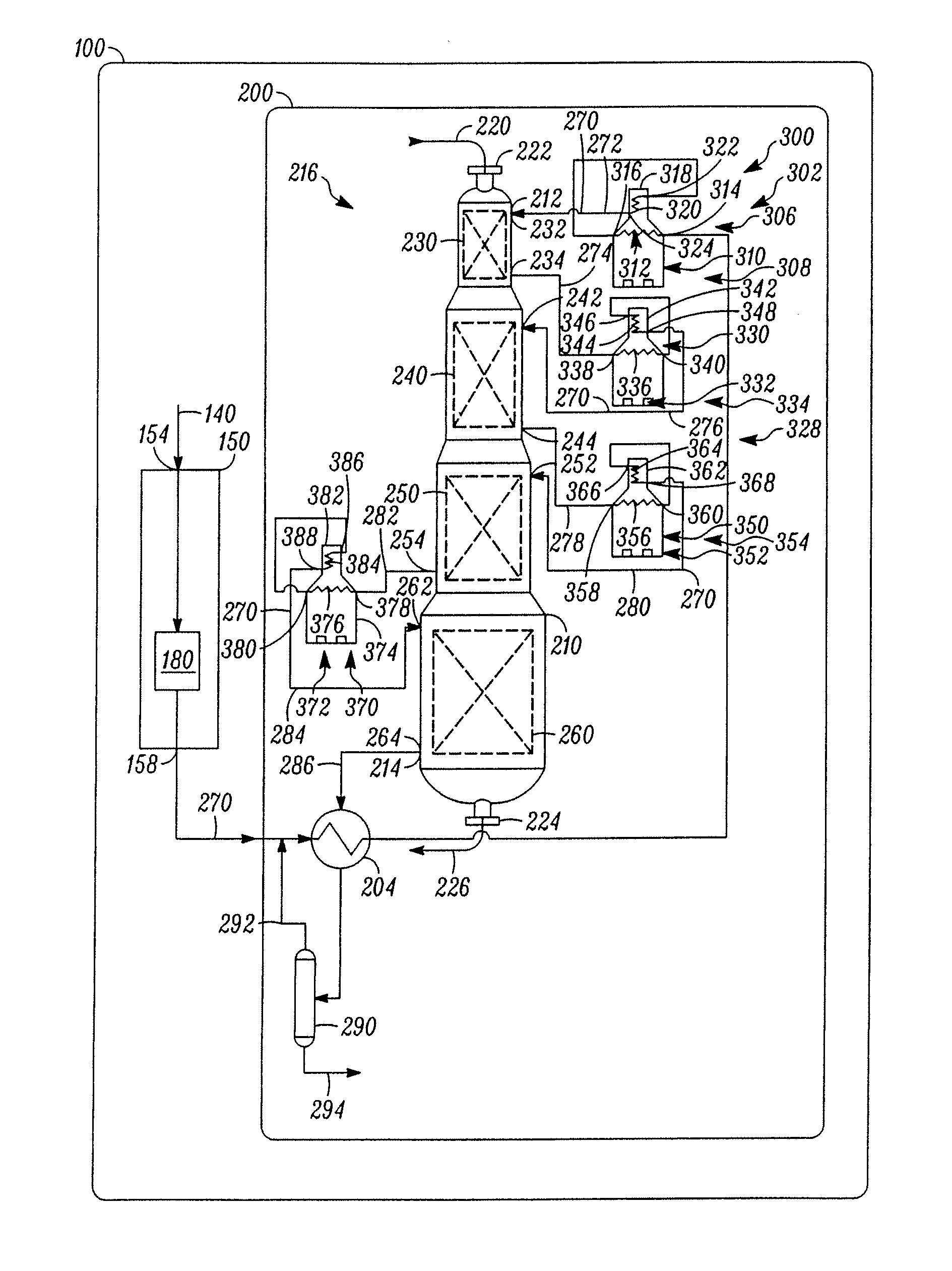

Hydroprocessing process and method of retrofitting existing hydroprocessing reactors

InactiveUS20040045870A1High airspeedExtended service lifeHydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystFluid phase

A process for hydroprocessing a hydrocarbon feed comprising the steps of (a) admixing the feed with a hydrogen rich gas and obtaining a first admixed process stream; (b) contacting the first admixed process stream with a first catalyst being active in hydrocracking of hydrocarbon compounds and obtaining a first catalyst effluent process stream; (c) separating the first catalyst effluent process stream in a gas phase stream and a liquid phase stream, and withdrawing the gas phase stream; (d) admixing the liquid phase stream with a hydrogen rich gas and obtaining a second admixed process stream; (e) contacting the second admixed process gas stream with a second catalyst being active in hydrocracking of hydrocarbon compounds and obtaining a second catalyst effluent process stream; (f) withdrawing and admixing the second catalyst effluent process stream with the gas phase stream obtained in step (c); and (g) withdrawing the admixed process stream provided in step (f).

Owner:HALDOR TOPSOE AS

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with quench injection of the oils on the last catalyst bed

ActiveUS7781629B2Low costLimiting cracking and thermal degradationCatalytic crackingHydrocarbon oil crackingVegetable oilWastewater

Owner:INST FR DU PETROLE

Apparatus for hydrocracking and /or hydrogenating fossil fuels

InactiveUS20050129586A1Efficient separationEliminate failure problemsCarburetting airUsing liquid separation agentLiquid hydrocarbonsEngineering

A catalytic hydrocracking reactor vessel for the conversion of a hydrogen gas and fossil fuel feedstream to light liquid hydrocarbons. The reactor vessel comprises reactor cup riser means with a helical cyclonic separator conduit for separating a liquid and vapor product stream to provide an essentially vapor-free liquid recycle stream, grid plate bubble cap means with tapered bell cap wall housing having serrated edges for producing small hydrogen bubbles of increased total surface area of bubbles at lower pressure drop, optionally feedstream inlet pipe sparger means containing rows of downward directed slots for even distribution of the feedstream across the cross-sectional area of the reactor and providing free drain of solid particles from the sparger, and optionally liquid recycle inlet distributor means containing vertically curved plates for creating a whirling motion in the liquid recycle stream for better mixing with the feedstream with minimal solids settling.

Owner:HEADWATERS TECH INNOVATION LLC +1

Dual gas-liquid spargers for catalytic processing units

InactiveUS20070248510A1Obstruct passageFlow mixersHydrocarbon oils treatment control/regulationTemperature controlChemical physics

This invention relates to a quenching device for temperature control in catalytic processes. More particularly, the quenching device includes gas and liquid spargers for interbed temperature control in an interbed mixing zone in a catalytic reactor. The quenching device includes a first injector for injecting a first quenching fluid into an outer mixing zone and a second injector for injecting a second quenching fluid into an inner mixing zone. The quenching fluids include both gaseous and liquid quenching fluids.

Owner:EXXON RES & ENG CO

Hydroprocessing process and method of retrofitting existing hydroprocessing reactors

InactiveUS7156977B2Avoid crackingHigh airspeedTreatment with plural serial cracking stages onlyCoke ovensHydrogenGas phase

Owner:HALDOR TOPSOE AS

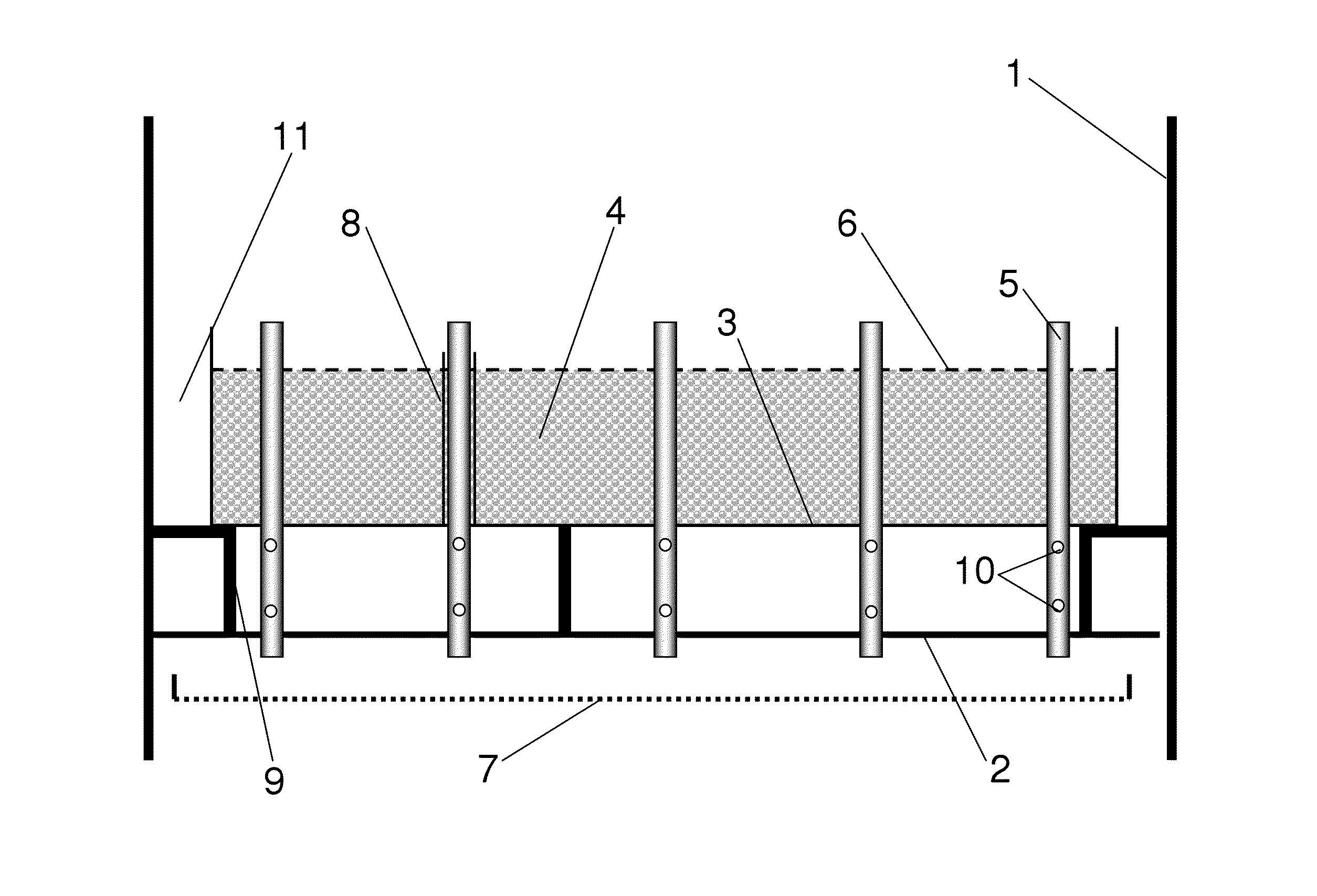

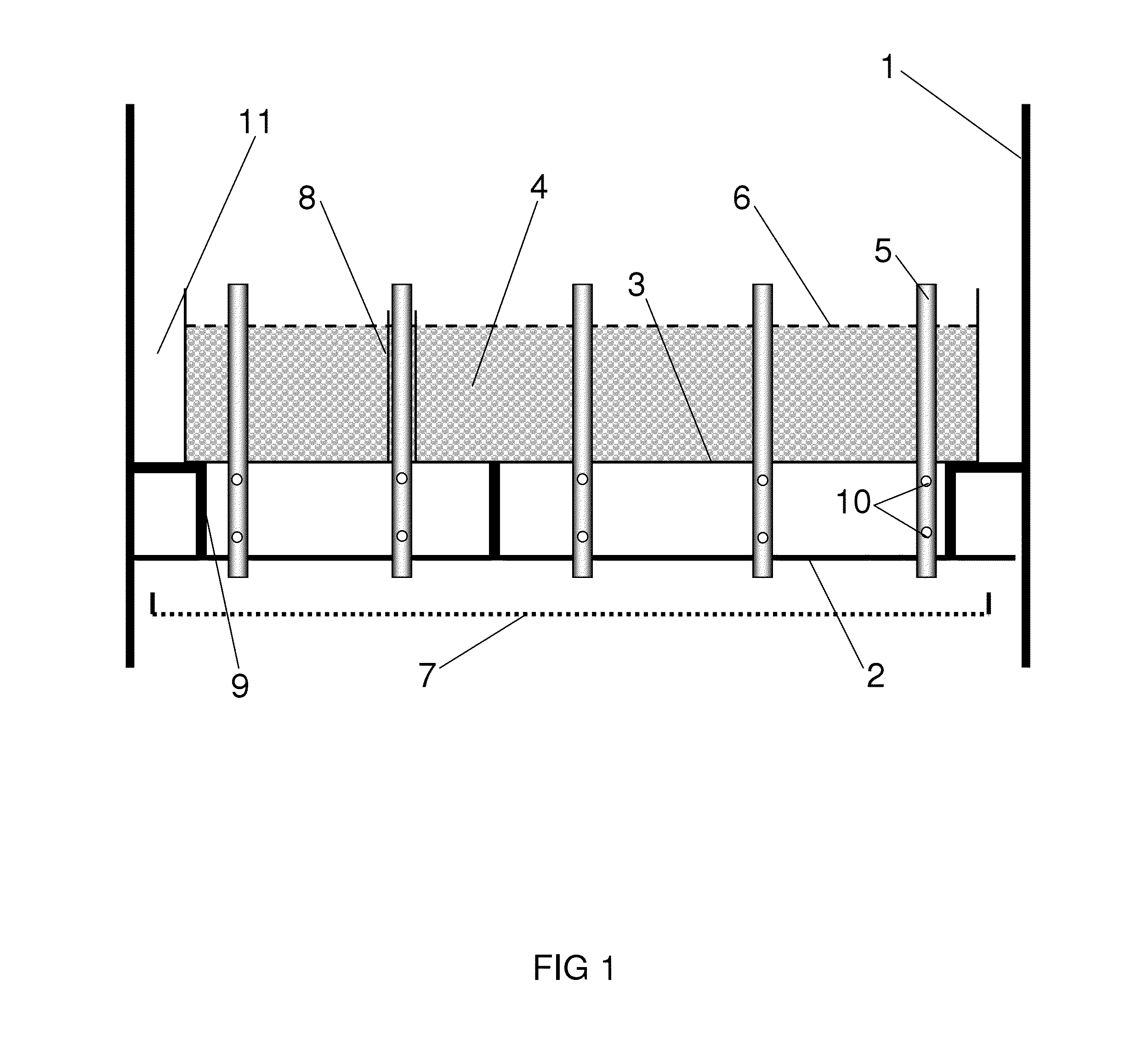

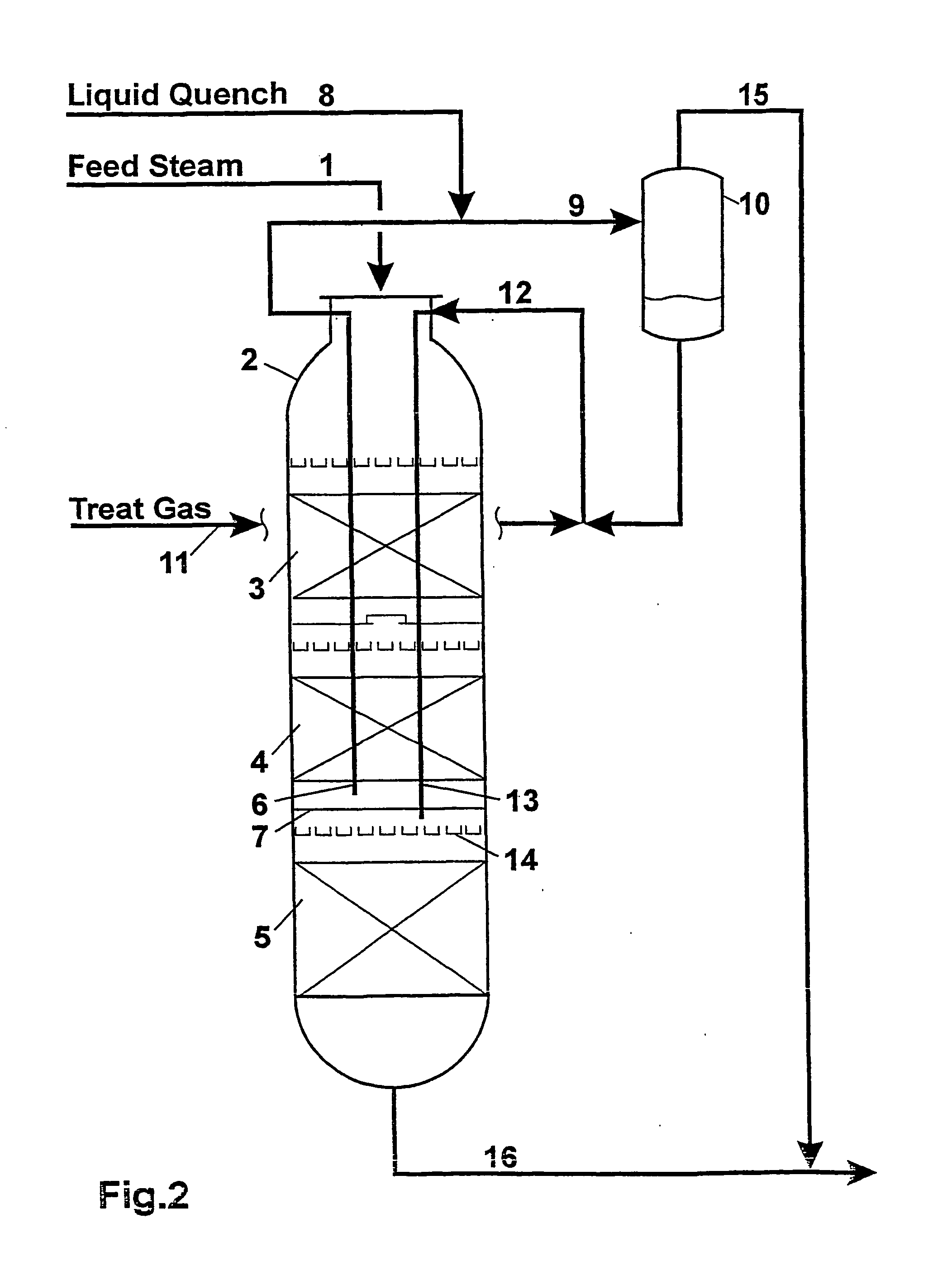

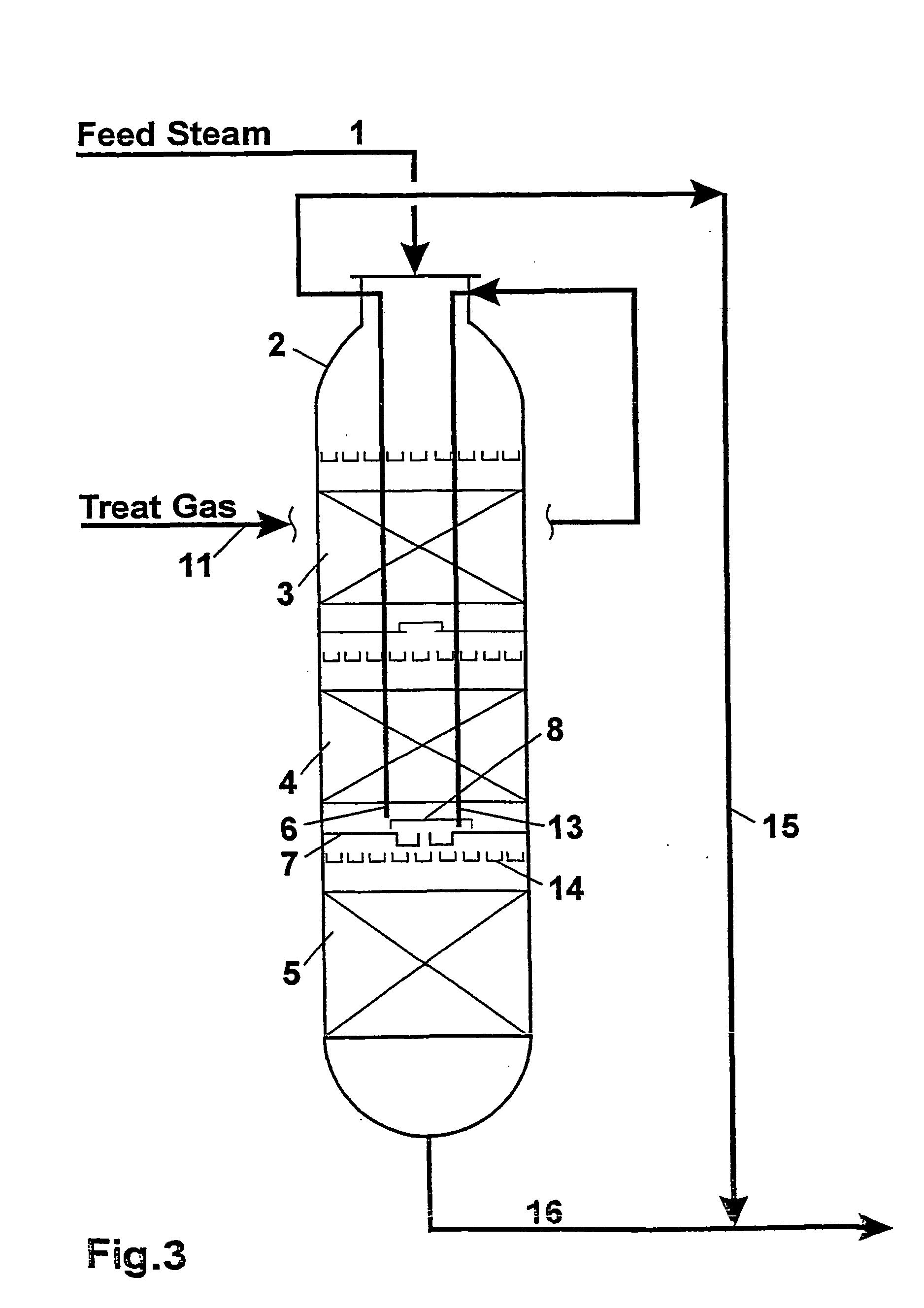

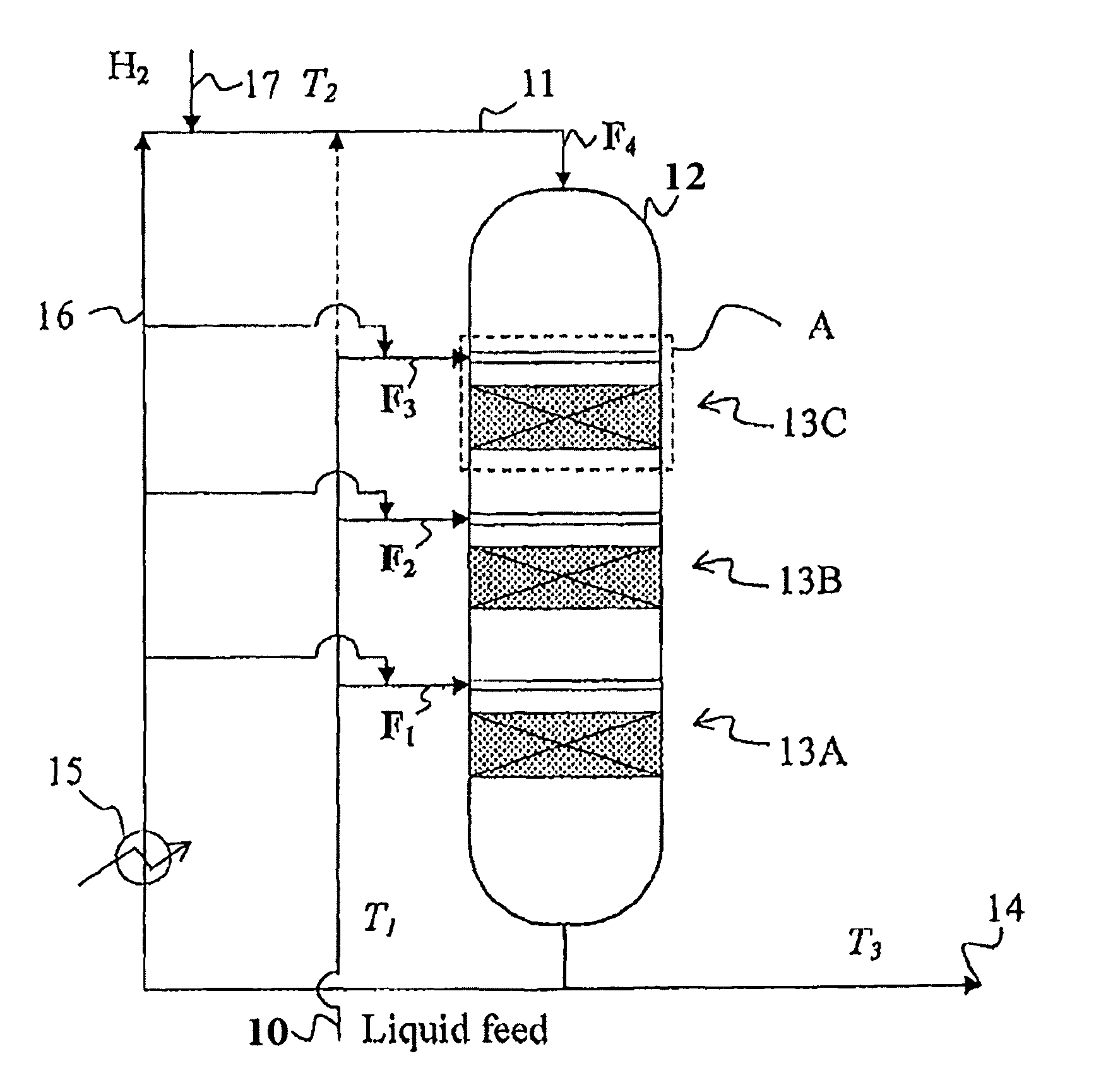

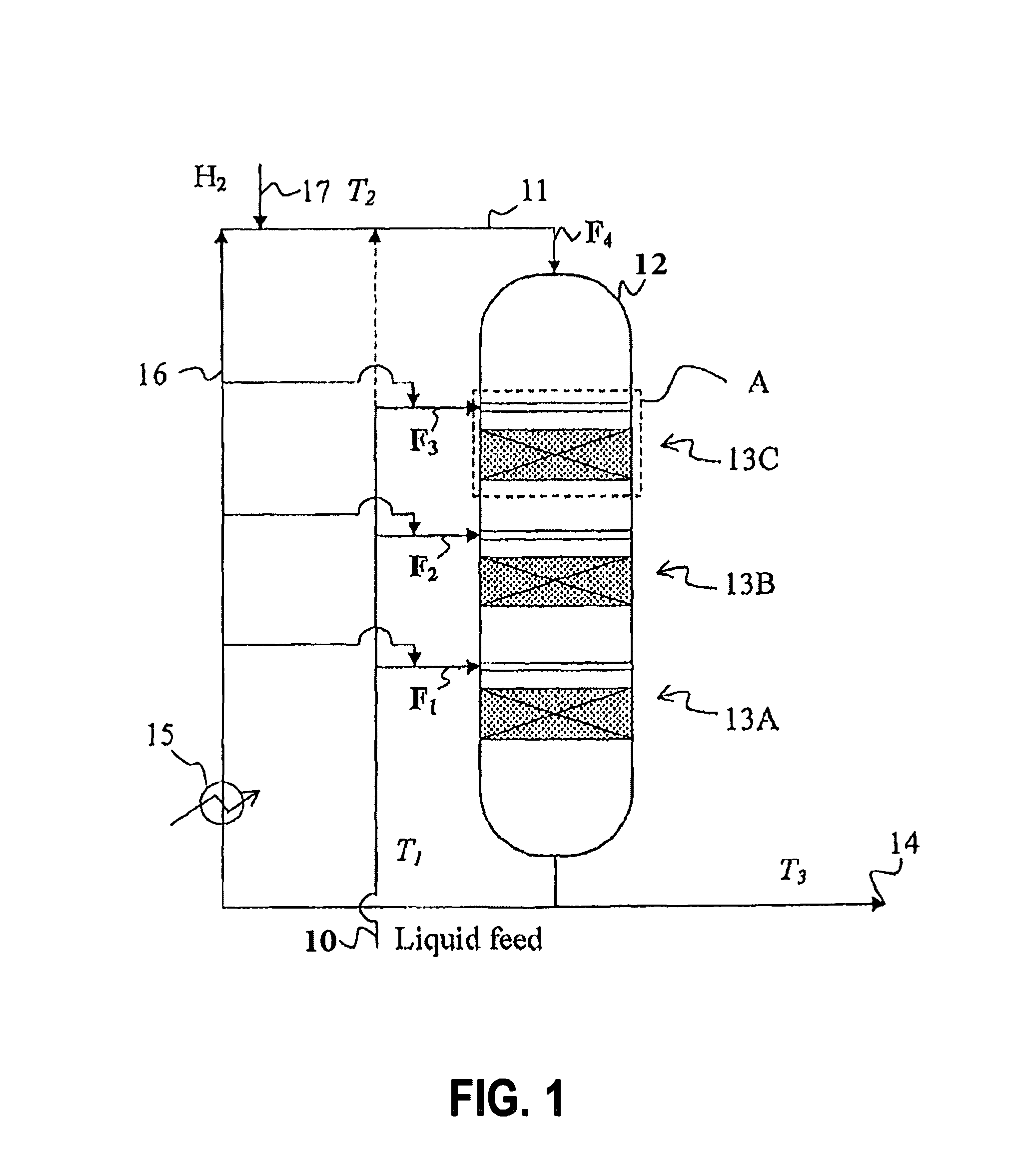

Method and arrangement for feeding heat-sensitive materials to fixed-bed reactors

ActiveUS9352292B2Short stayLower Level RequirementsLiquid hydrocarbon mixture productionHydrocarbonsReactor systemFixed bed

The invention relates to an arrangement for feeding heat-sensitive feedstock to a fixed-bed reactor system comprising means for product recycle and a fixed-bed reactor system comprising a fixed-bed reactor comprising at least one reaction zone having at least one catalyst bed and said reaction zone comprising a cold feed distributor arranged on top of each catalyst bed and a conventional distributor arranged above each cold feed distributor. Also a method is provided for feeding heat-sensitive feedstock to a fixed-bed reactor system wherein said fixed-bed reactor system comprises means for product recycle and a fixed-bed reactor comprising at least one reaction zone having at least one catalyst bed and said reaction zone comprising a cold feed distributor arranged on top of each catalyst bed and a conventional distributor arranged above each cold feed distributor.

Owner:NESTE OIL OY

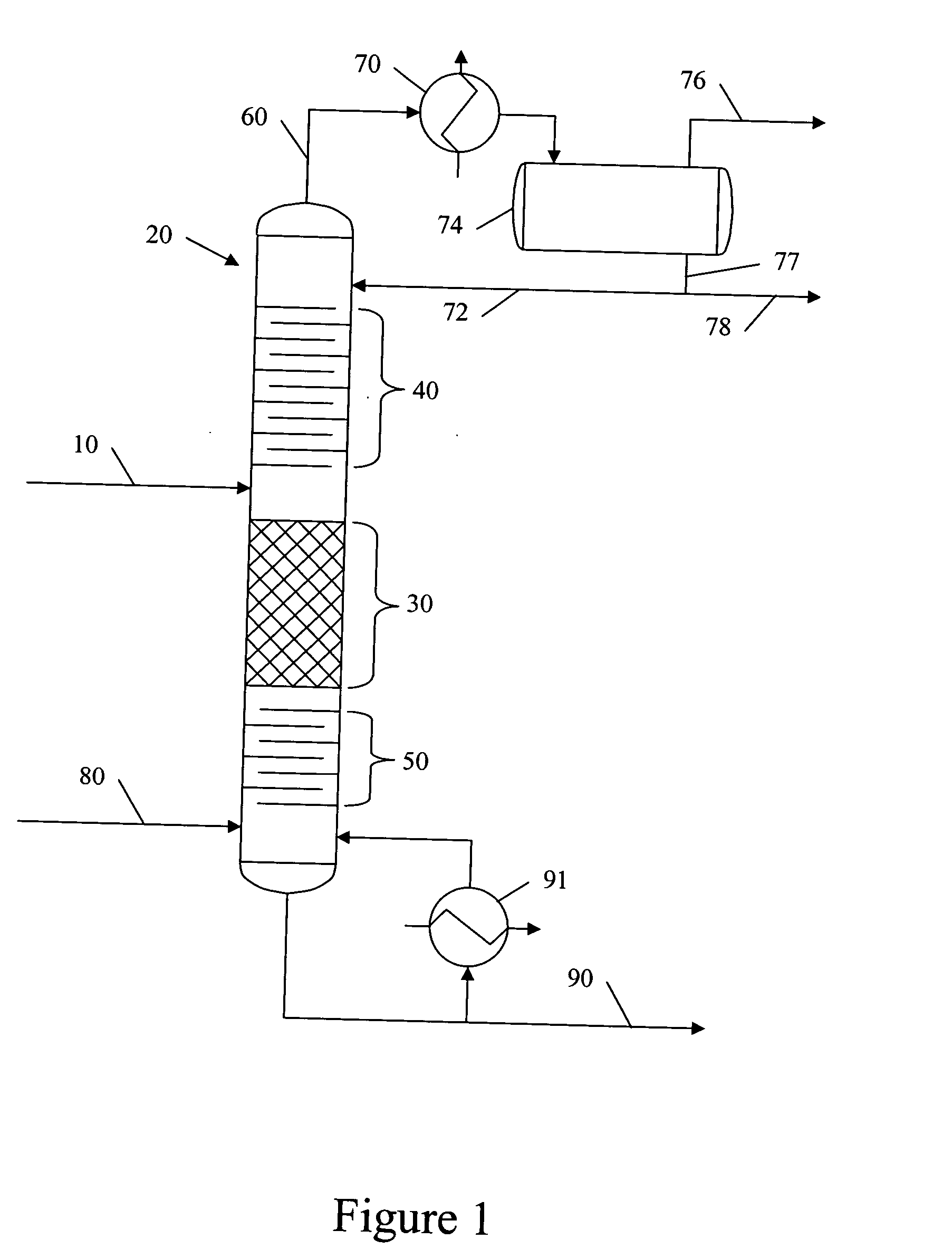

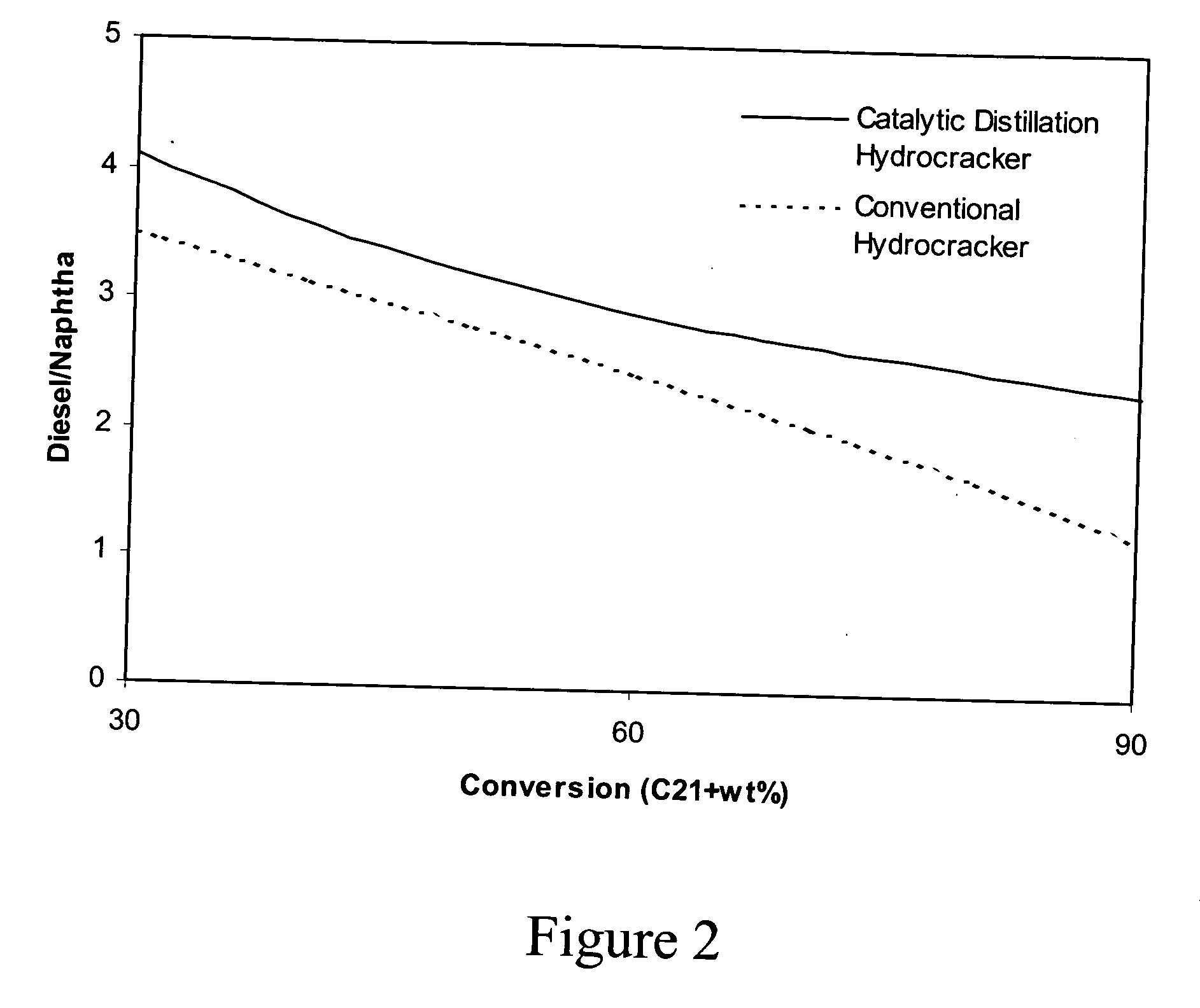

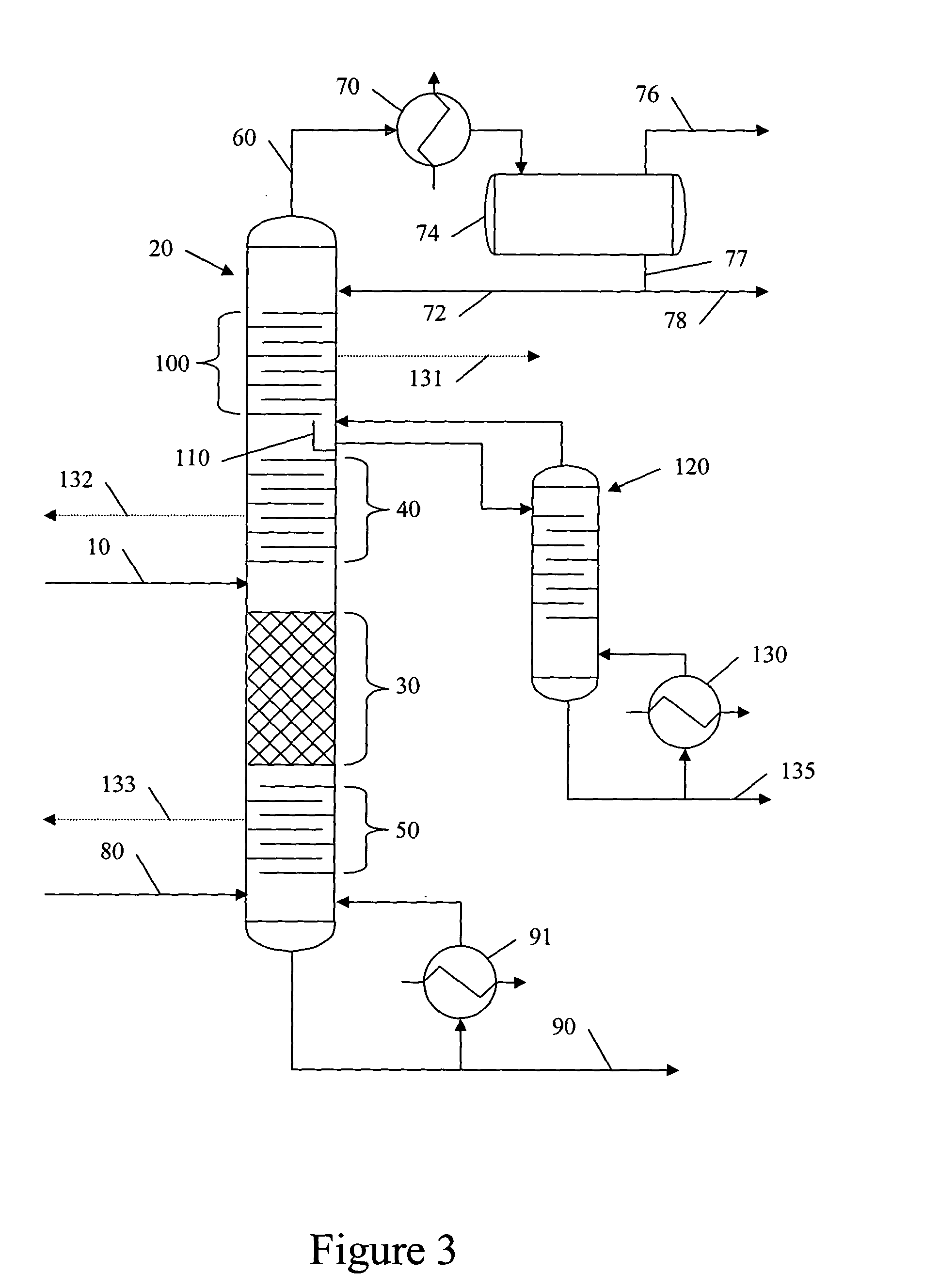

Catalytic distillation hydroprocessing

InactiveUS20050035026A1Improve efficiencyHigh outputRefining to change hydrocarbon structural skeletonHydrocarbon distillationCatalytic distillationHydrocarbon

A method for hydroprocessing a hydrocarbon synthesis product feed to form upgraded fuels and lubricating oils. In a preferred embodiment, the method includes the steps of: (a) contacting a Fischer-Tropsch product with a hydroprocessing catalyst to produce a desired distillate; and (b) counter-currently stripping the desired distillate as it is produced. The method may include distilling the desired distillate or distilling the treated Fischer-Tropsch product.

Owner:CONOCOPHILLIPS CO

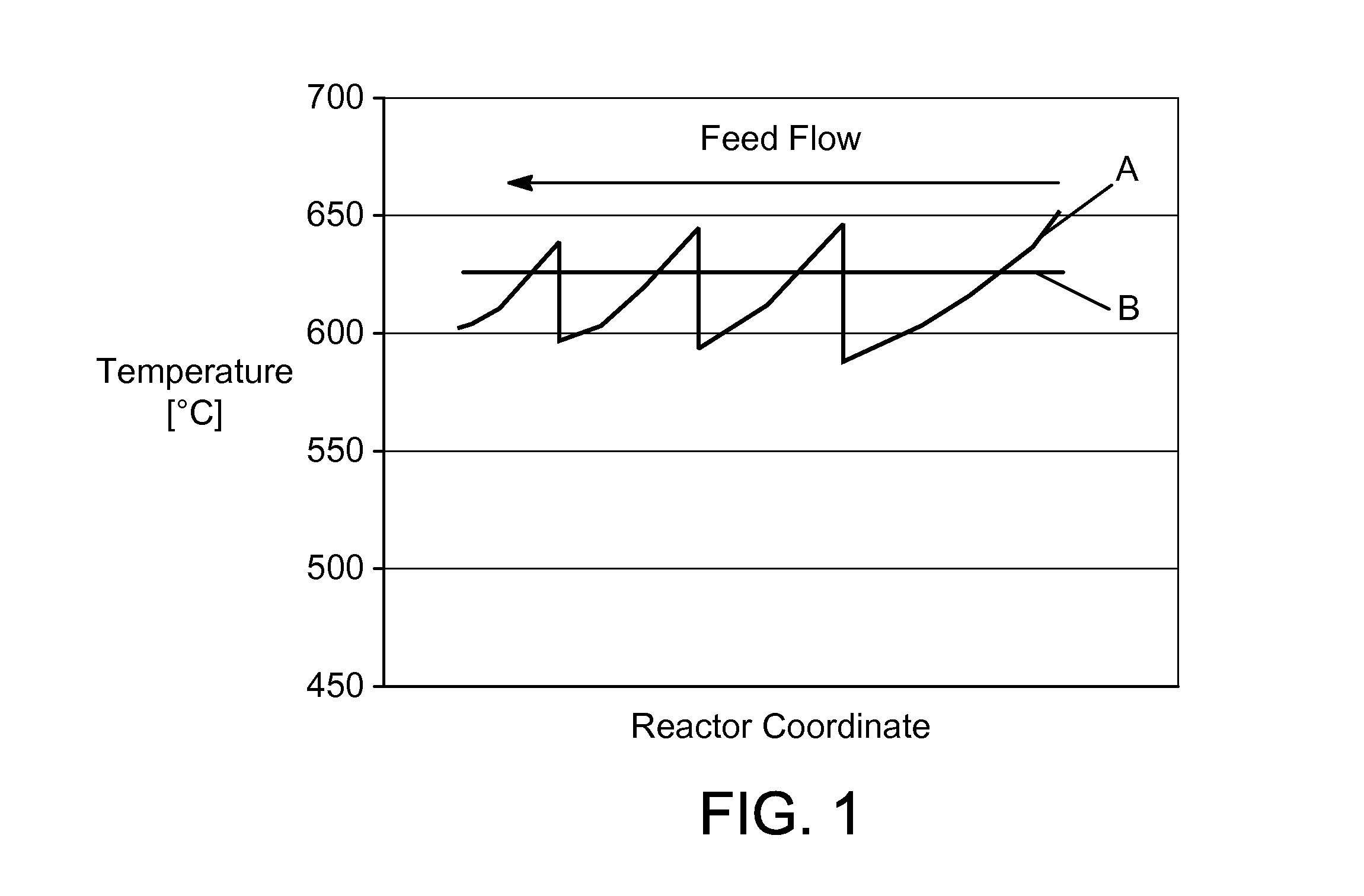

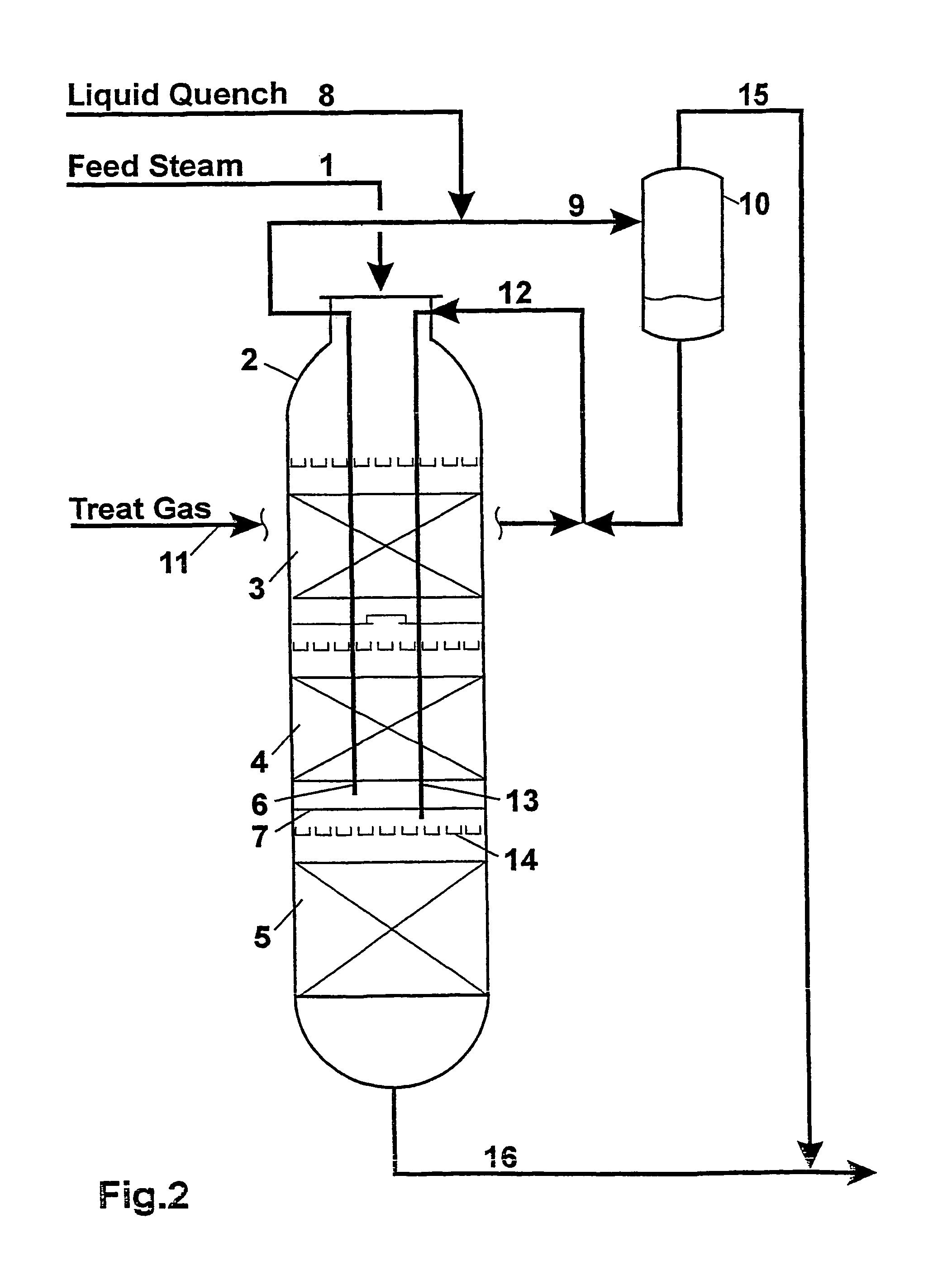

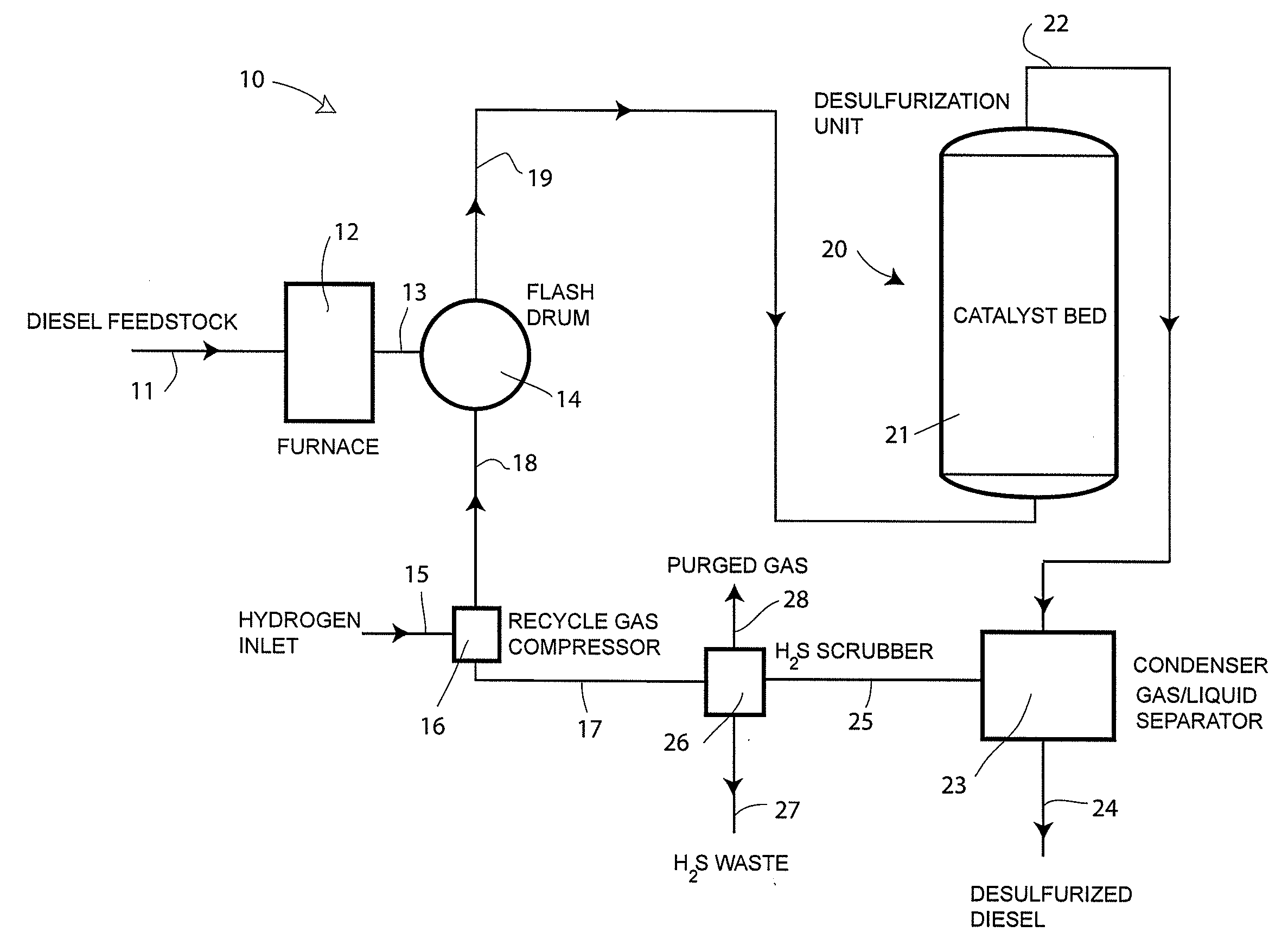

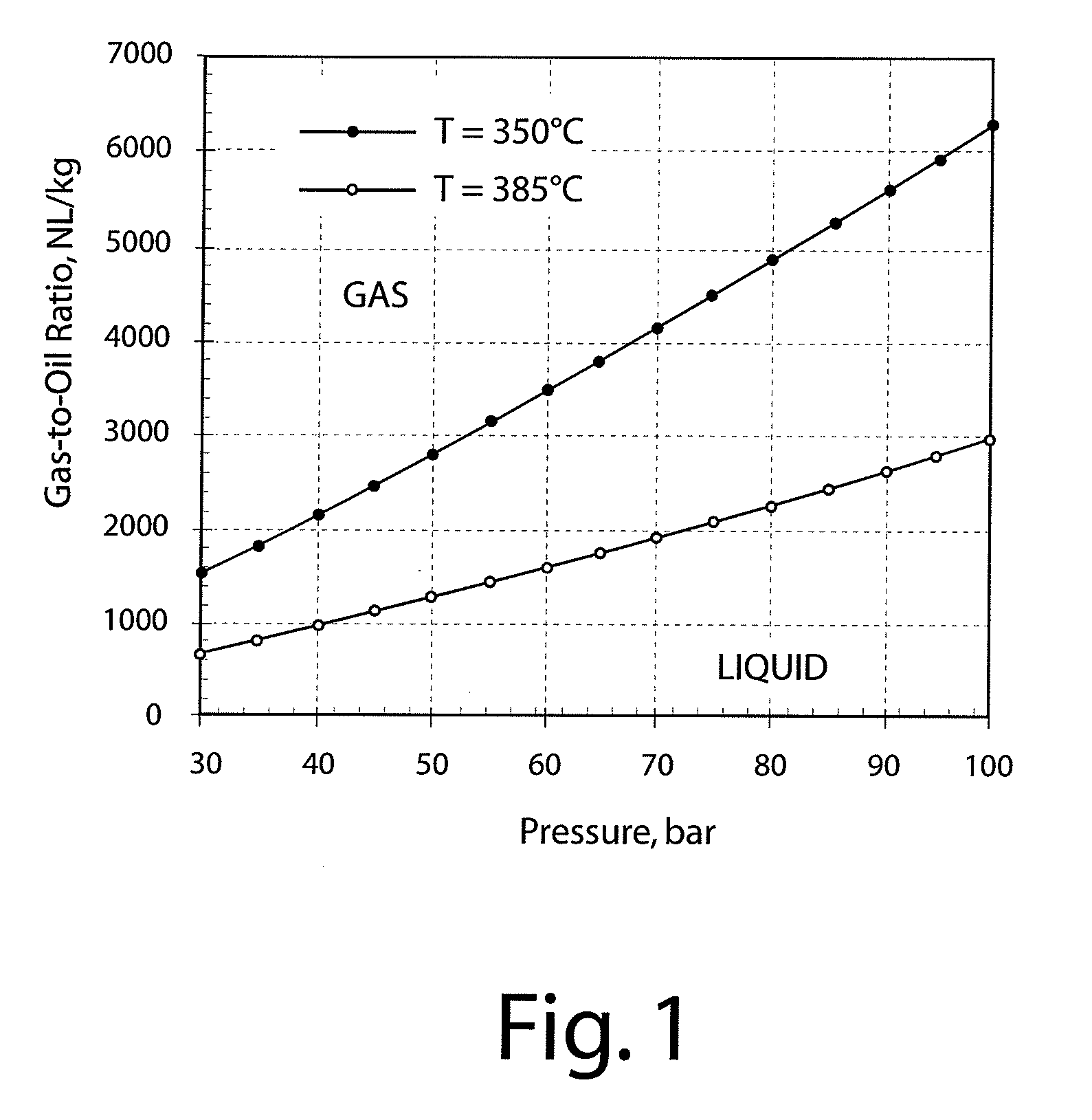

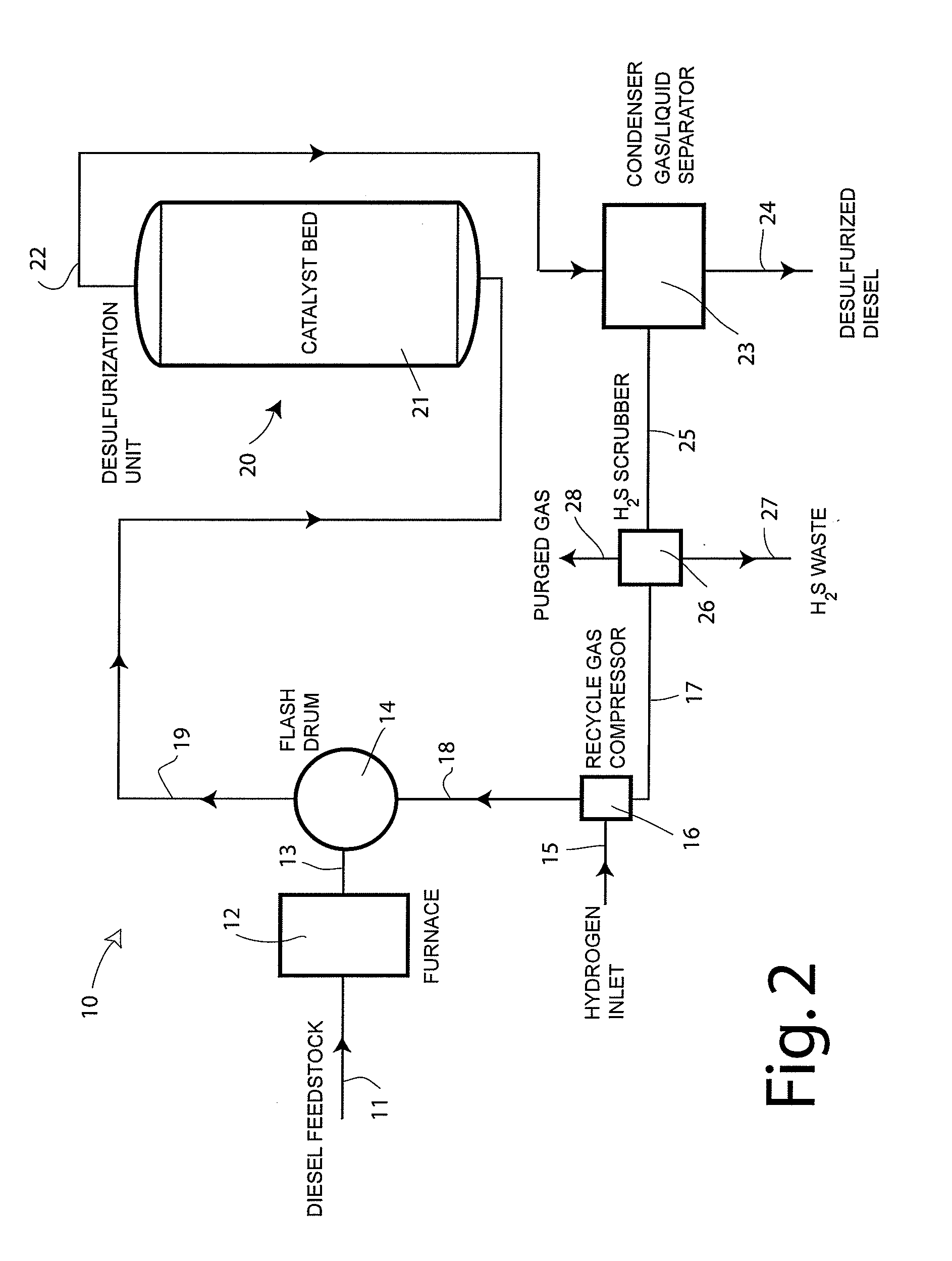

Gas-phase hydrotreating of middle-distillates hydrocarbon feedstocks

InactiveUS20100032347A1Enhancement to hydrotreating reactionMaximization of overall densityGas treatmentDispersed particle separationHydrogenGas phase

A method of subjecting a middle-distillate hydrocarbon feedstock to a hydrotreating reactions to remove heteroatoms and / or hydrogenate aromatics, and apparatus therefor. The method comprising heating a liquid middle distillates hydrocarbon feedstock to produce a heated feedstock, mixing the heated feedstock with a hydrogen-containing treating gas to produce a mixture, and bringing the mixture into contact with a hydrotreating catalyst at an elevated temperature and an elevated pressure effective for hydrotreating the feedstock. The hydrogen-containing gas is mixed with the heated feedstock in a ratio effective to fully vaporize the liquid feedstock at the elevated temperature and pressure before the feedstock is contacted with said hydrotreating catalyst. Ideally, the mixture is passed through a catalyst bed creating a pressure drop in the gas mixture equal to or less than 0.3 bar / m. Such a catalyst bed may be made of structured catalysts, such as monolithic catalysts.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Fired heater for a hydrocarbon conversion process

ActiveUS8282814B2Low costShorten the timeThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonEngineeringInlet manifold

One exemplary embodiment of the present invention can be a fired heater for a hydrocarbon conversion process. The fired heater includes inlet and outlet headers or manifolds, a set of heater tubes with each heater tube having an inlet and an outlet, at least one restriction orifice adjacent the inlet of at least one heater tube. The restriction orifice may be within the inlet manifold and adjacent the inlet of a heater tube, or between the inlet manifold and the inlet to the heater tube. A process may include passing a hydrocarbon stream through the fired heater described herein during the course of operating a hydrocarbon conversion process.

Owner:UOP LLC

Filtration tray for fixed bed reactor with a co-current down-flow of gas and liquid

The device described in the present invention can trap plugging particles contained in the liquid feed supplying a reactor functioning in gas and liquid co-current down-flow mode using a specific distributor tray comprising a filtration medium.The present device is of particular application to the selective hydrogenation of feeds containing acetylenic and dienic compounds.

Owner:INST FR DU PETROLE

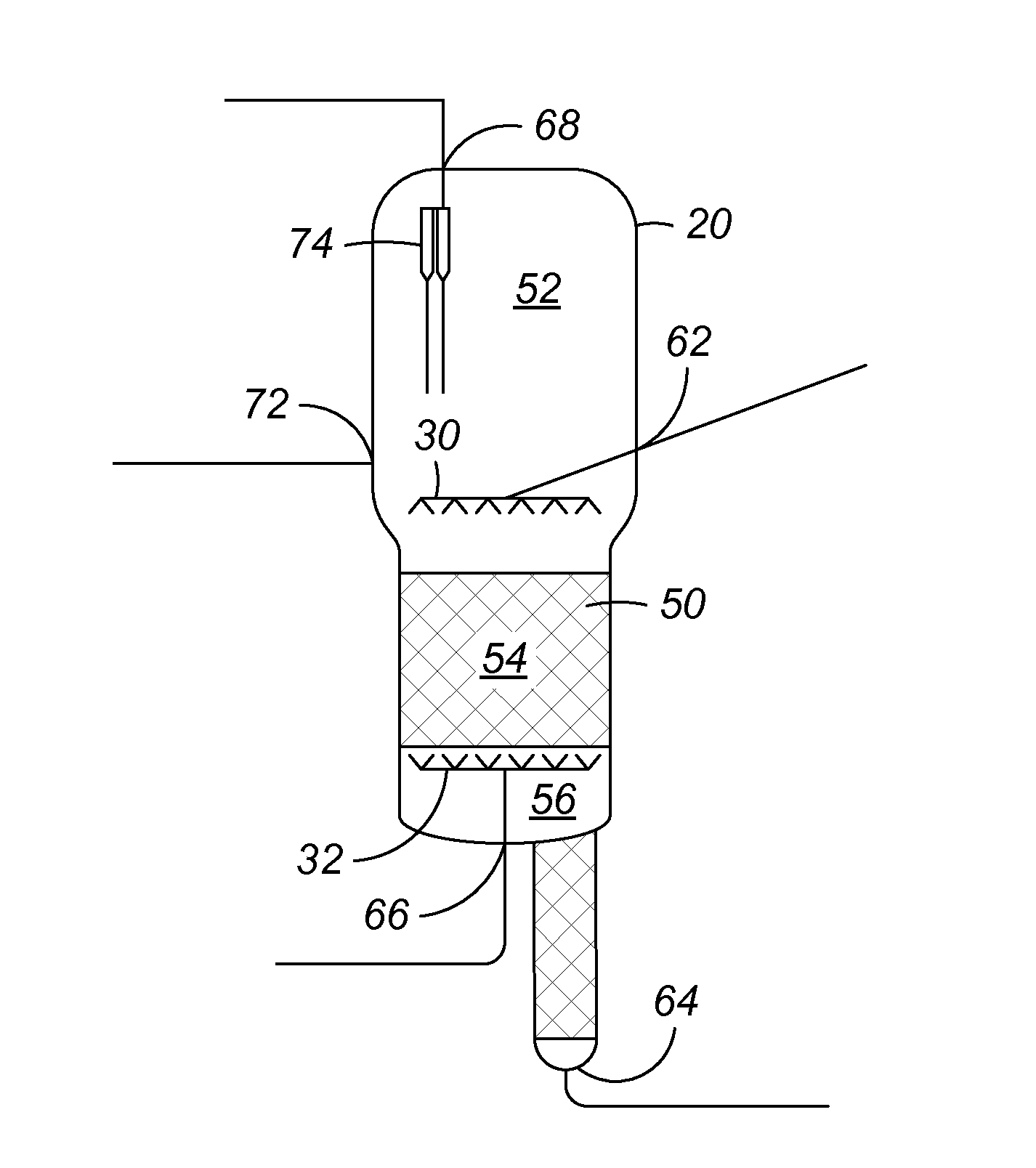

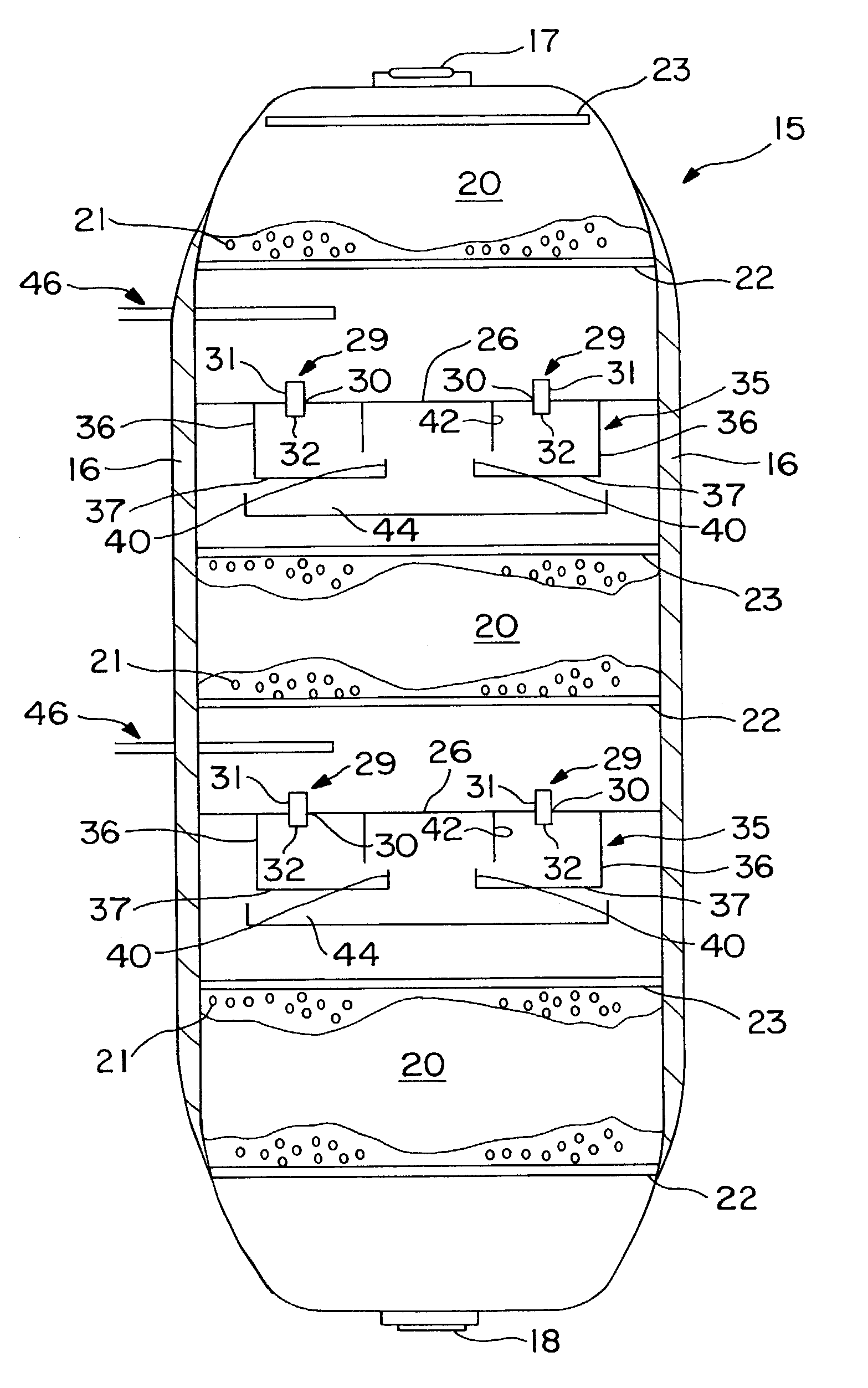

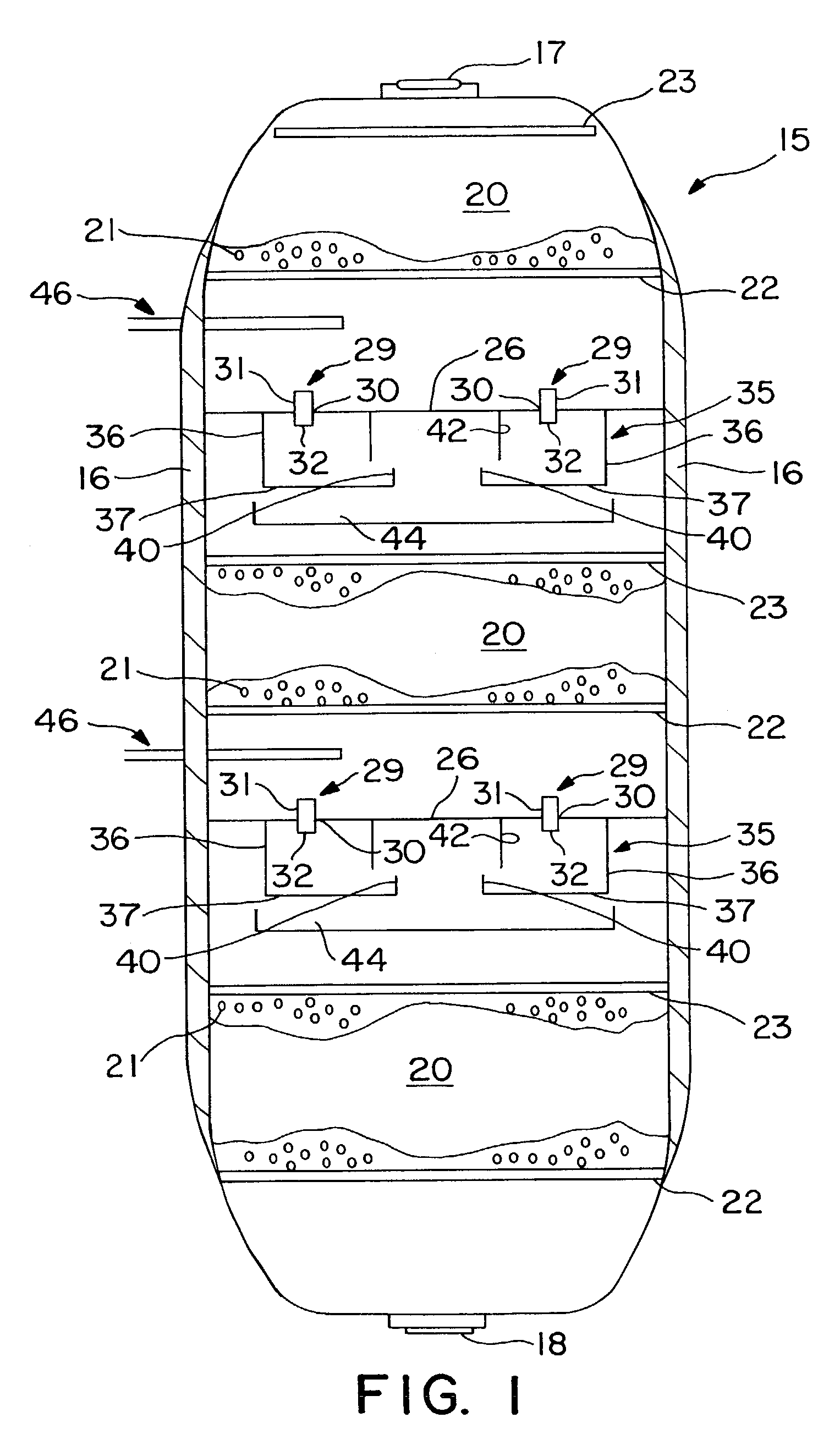

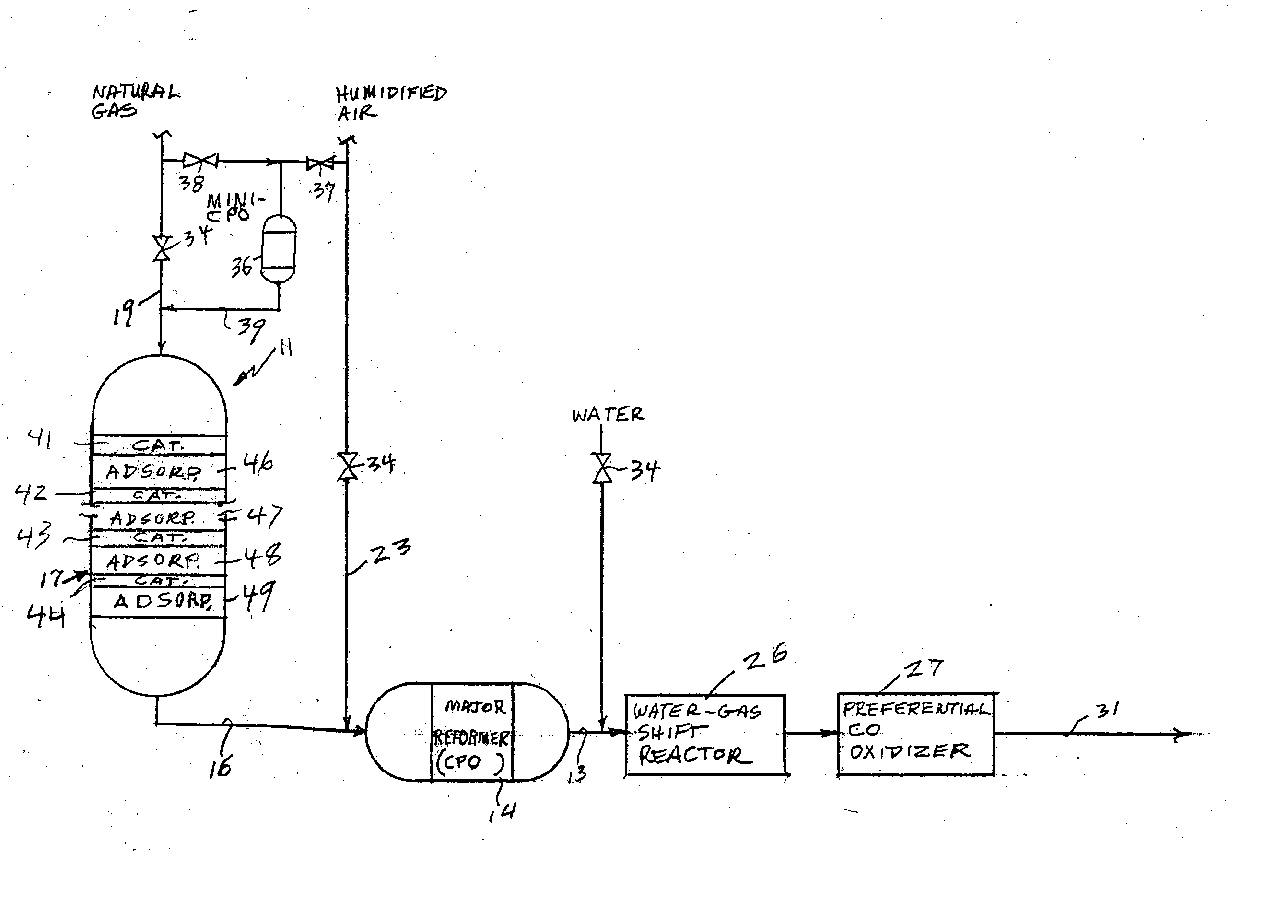

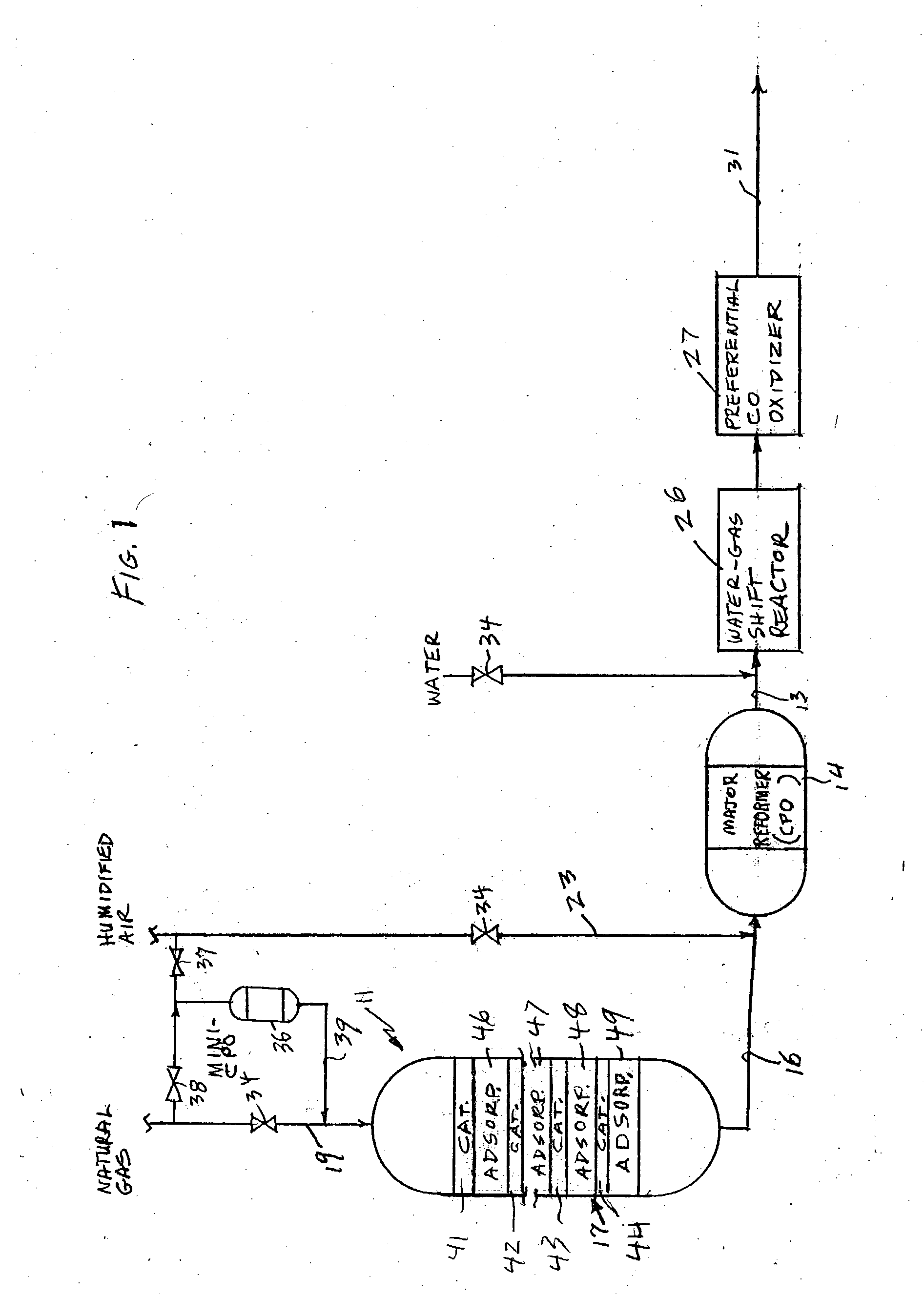

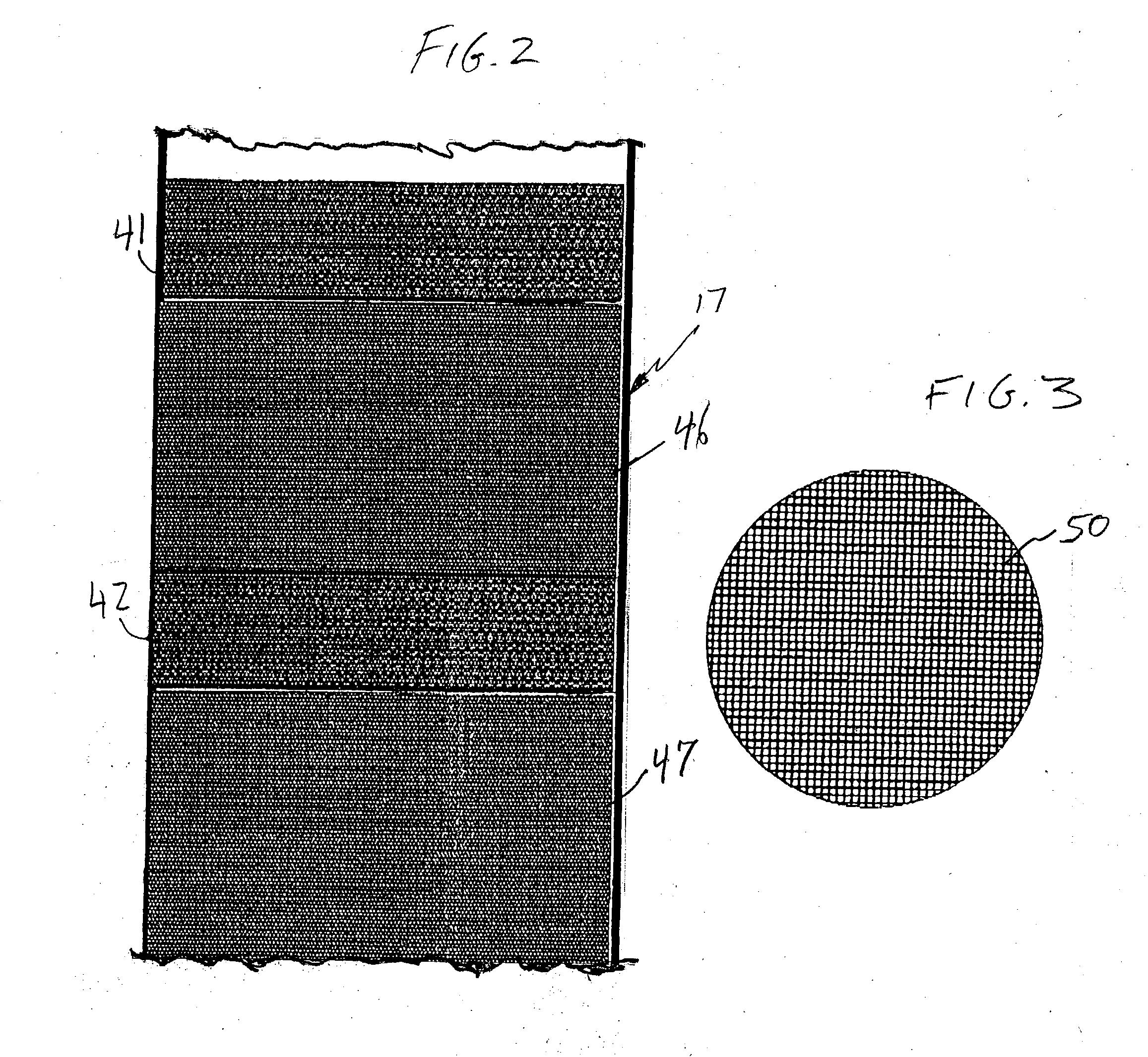

Hydrogen desulfurizer for hydrocarbon feeds with separated adsorption and catalyst material

InactiveUS20040178124A1Intuitive effectEasy to changeTreatment with hydrotreatment processesHydrogen/synthetic gas productionHydrogenSorbent

A hydrogen desulfurizer (11) includes a tank (17) designed for downflow of hydrocarbon feedstock containing a plurality of layers (41-44) of catalyst interspersed with layers (46-49) of adsorbent. The layers may all comprise baskets, the adsorbent comprising pellets, such as zinc oxide pellets; the catalysts may be wash-coated on catalyst support such as monolith or foams, or may be wash-coated on netted wire mesh instead of being contained in a basket. The catalyst is heated to between about 442° F. (250° C.) and about 932° F. (500° C.). A mini-CPO (36) supplies hydrogen to the desulfurizer (11). Heaters (53, 55), which may either be electric or circulating heated fluid may also be used.

Owner:HYDROGENSOURCE

Popular searches

Bio-feedstock Hydrocarbon preparation Refining to eliminate hetero atoms Filtration separation Incinerator apparatus Metal/metal-oxides/metal-hydroxide catalysts Molecular sieve catalysts Other chemical processes Organic-compounds/hydrides/coordination-complexes catalysts Catalyst regeneration/reactivation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com