Patents

Literature

1182results about "Hydrocarbon distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

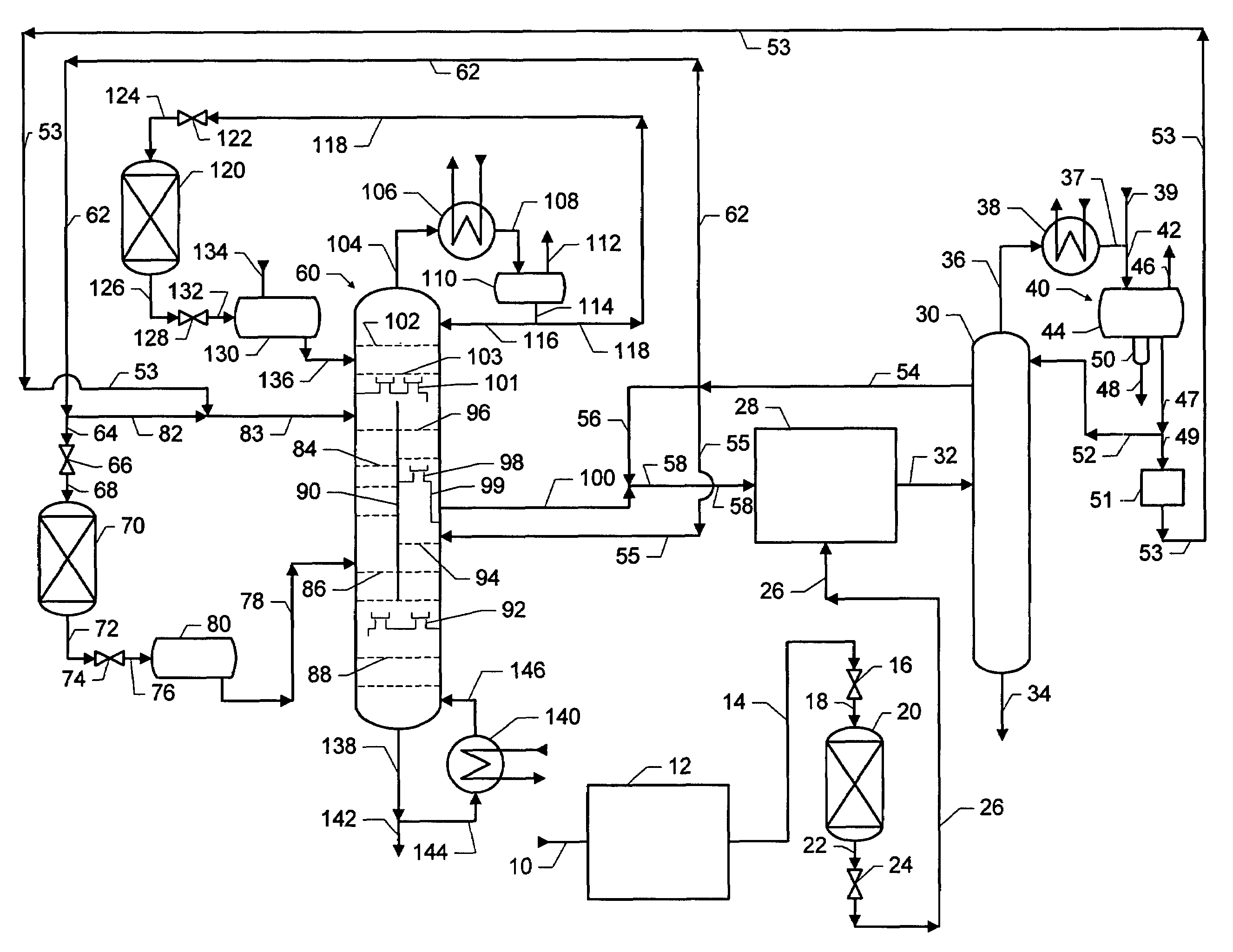

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

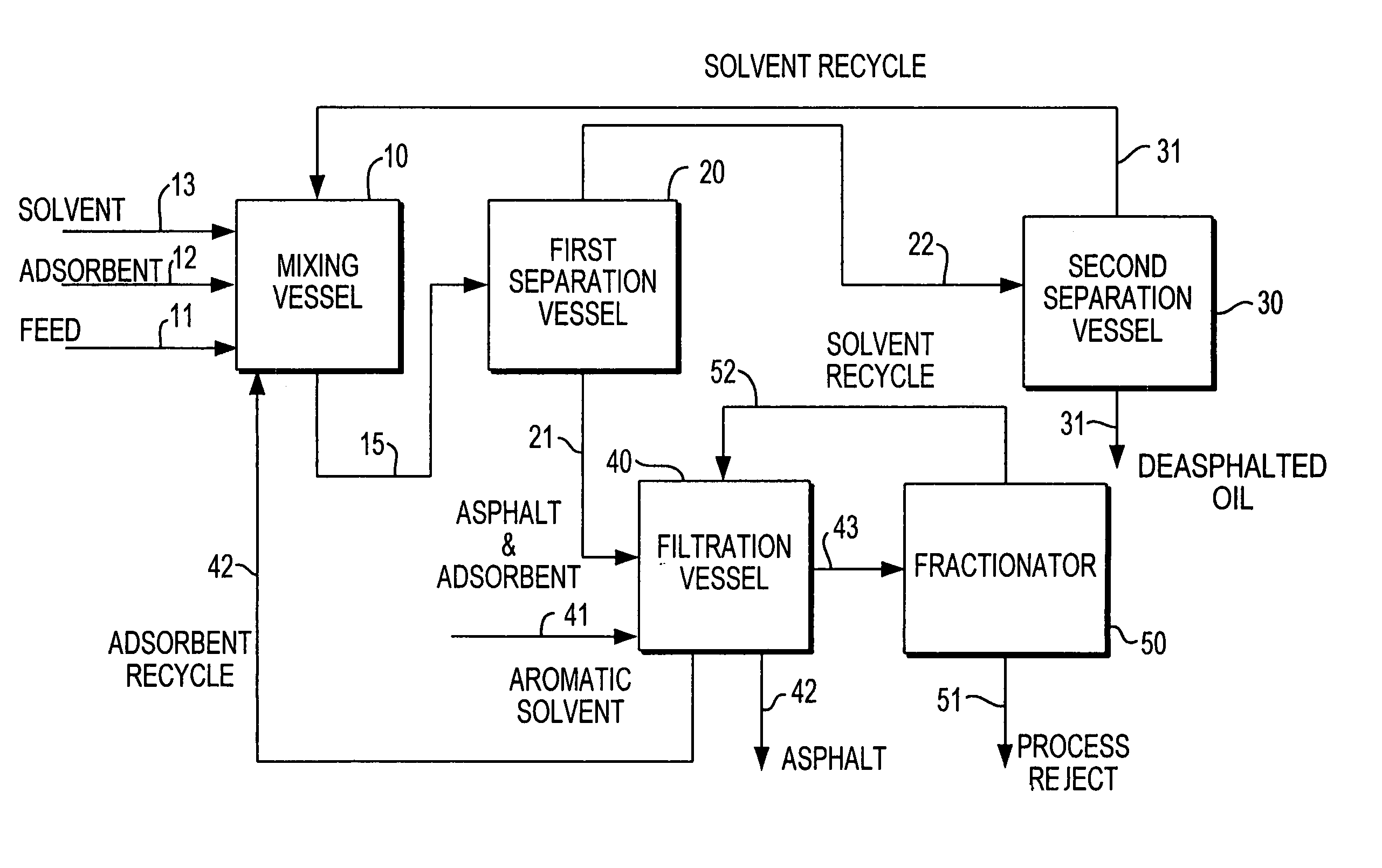

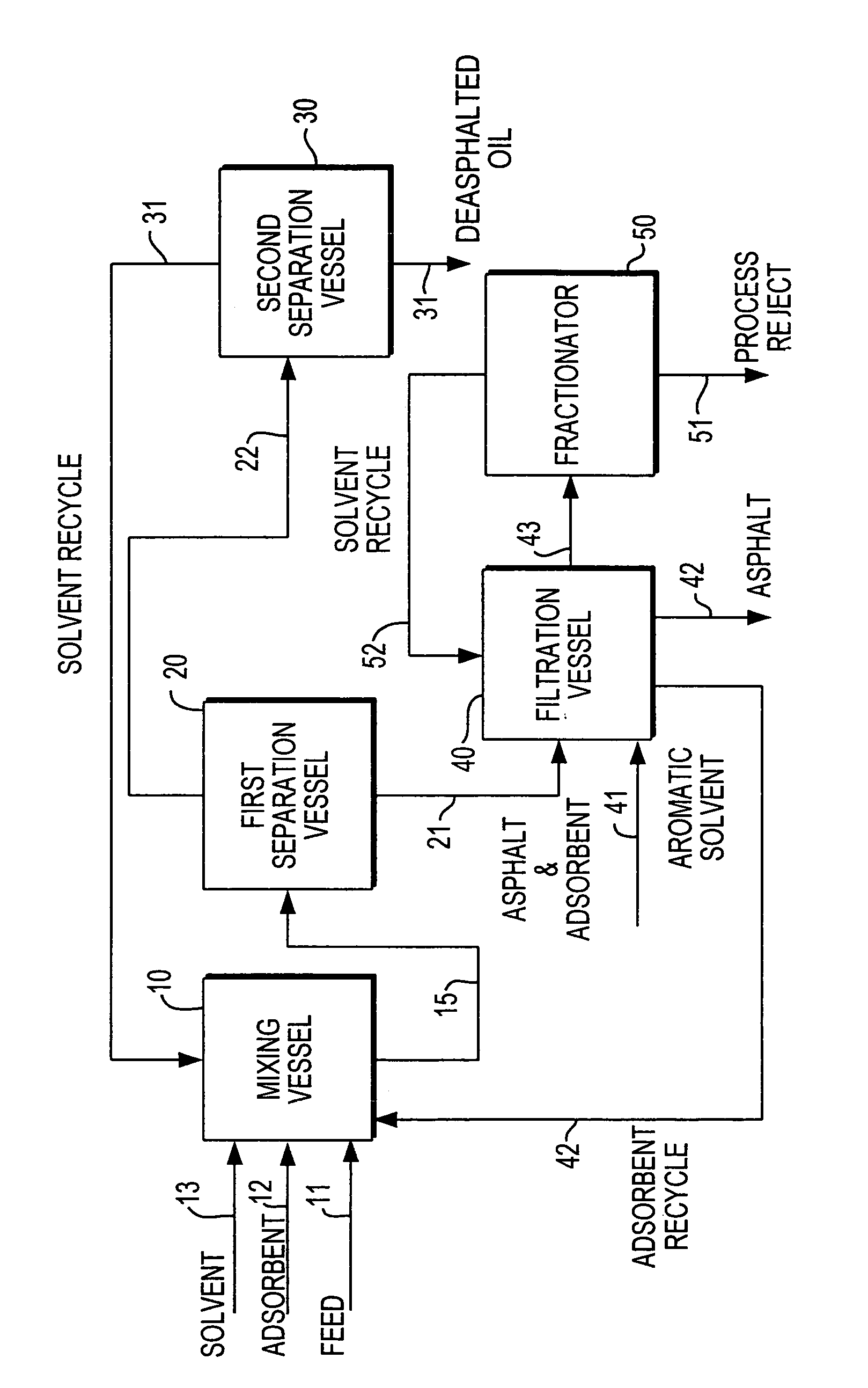

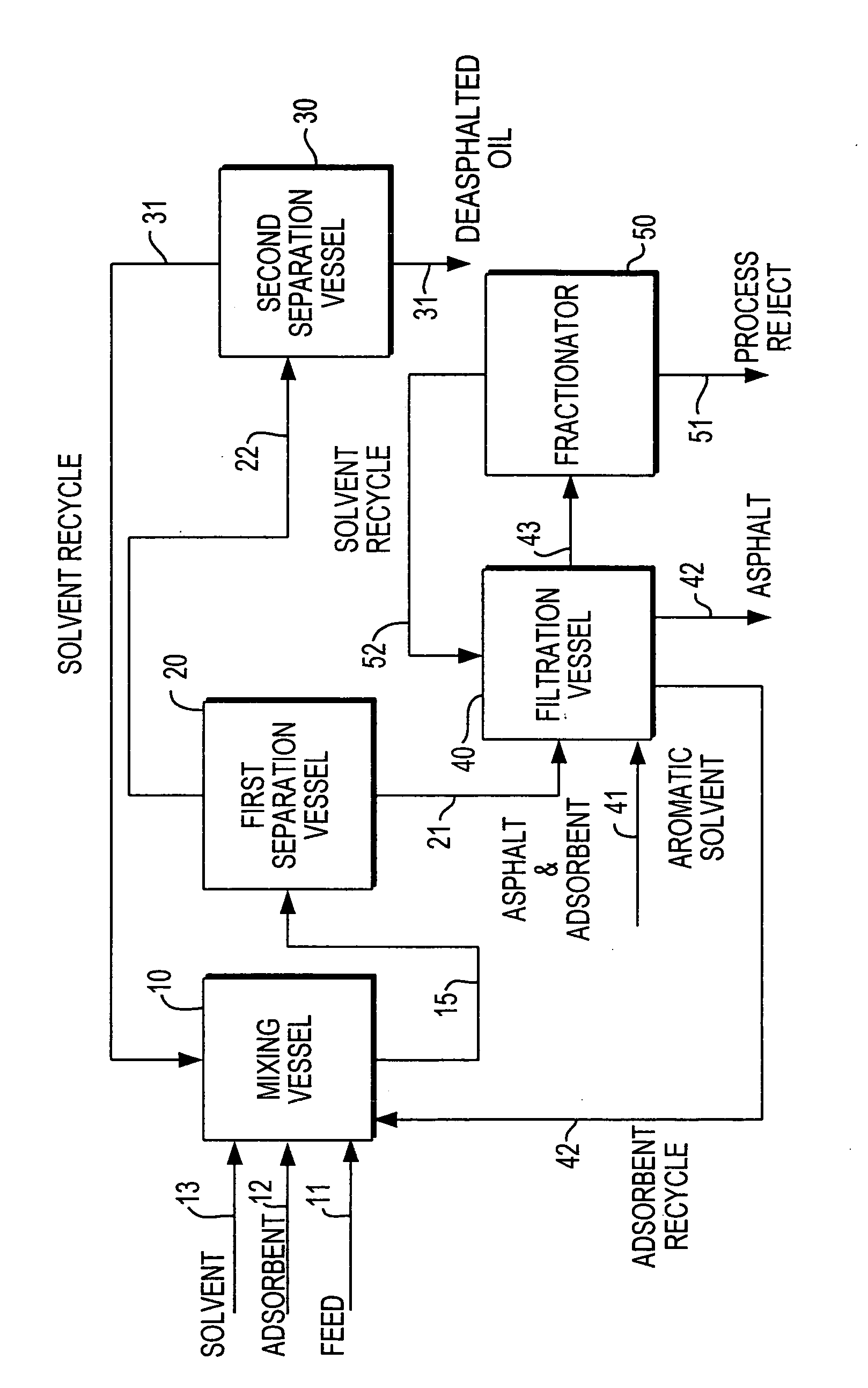

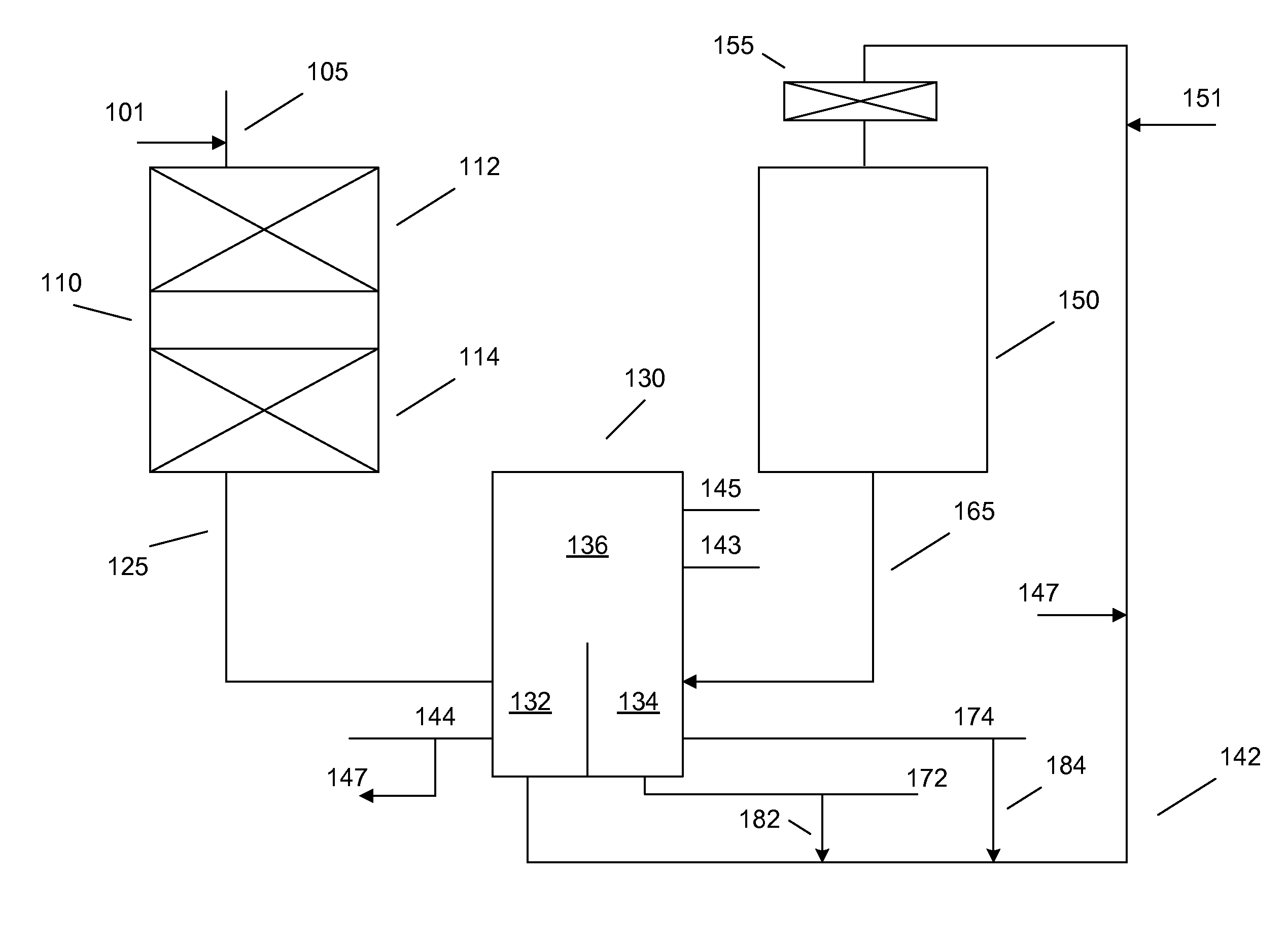

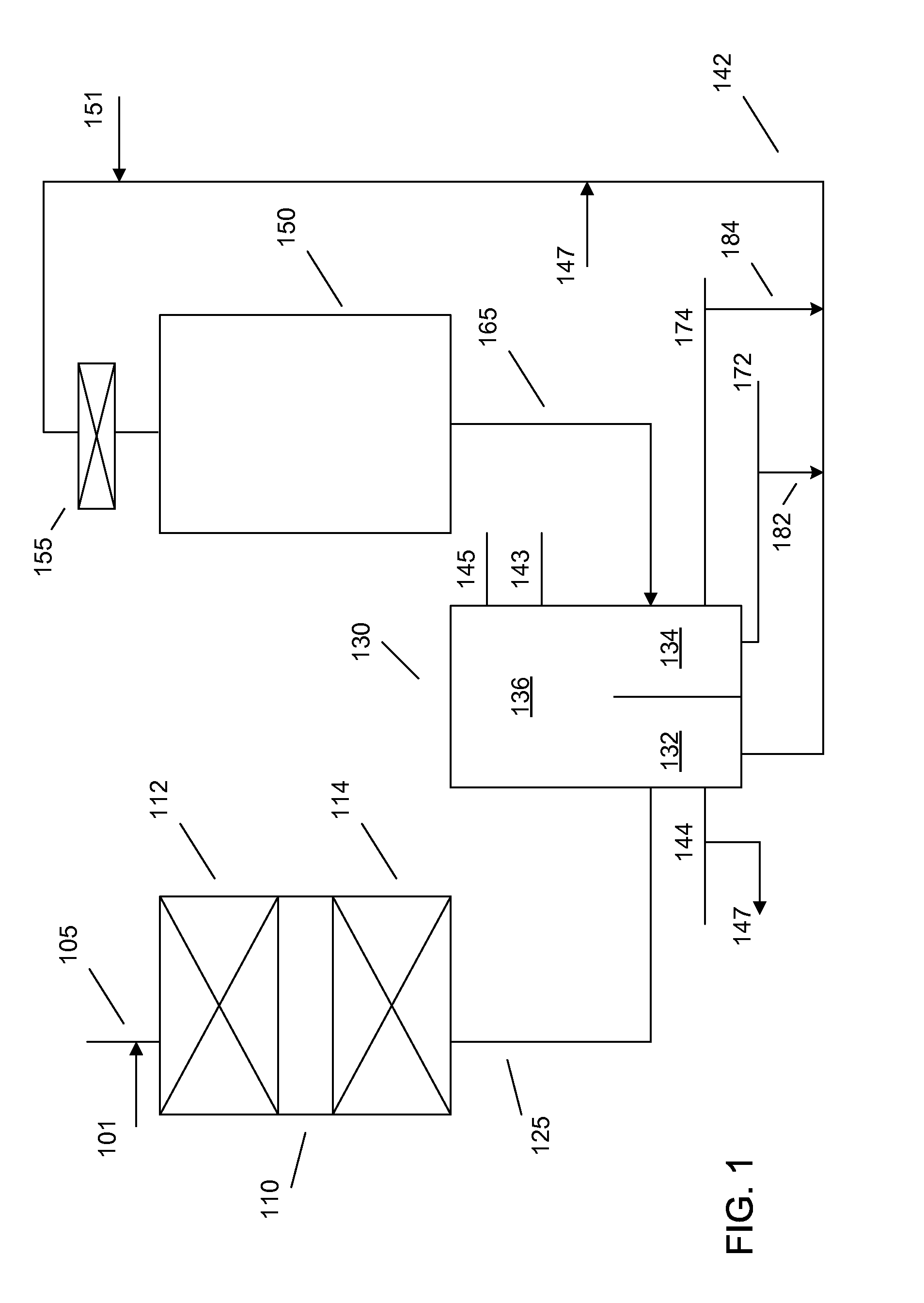

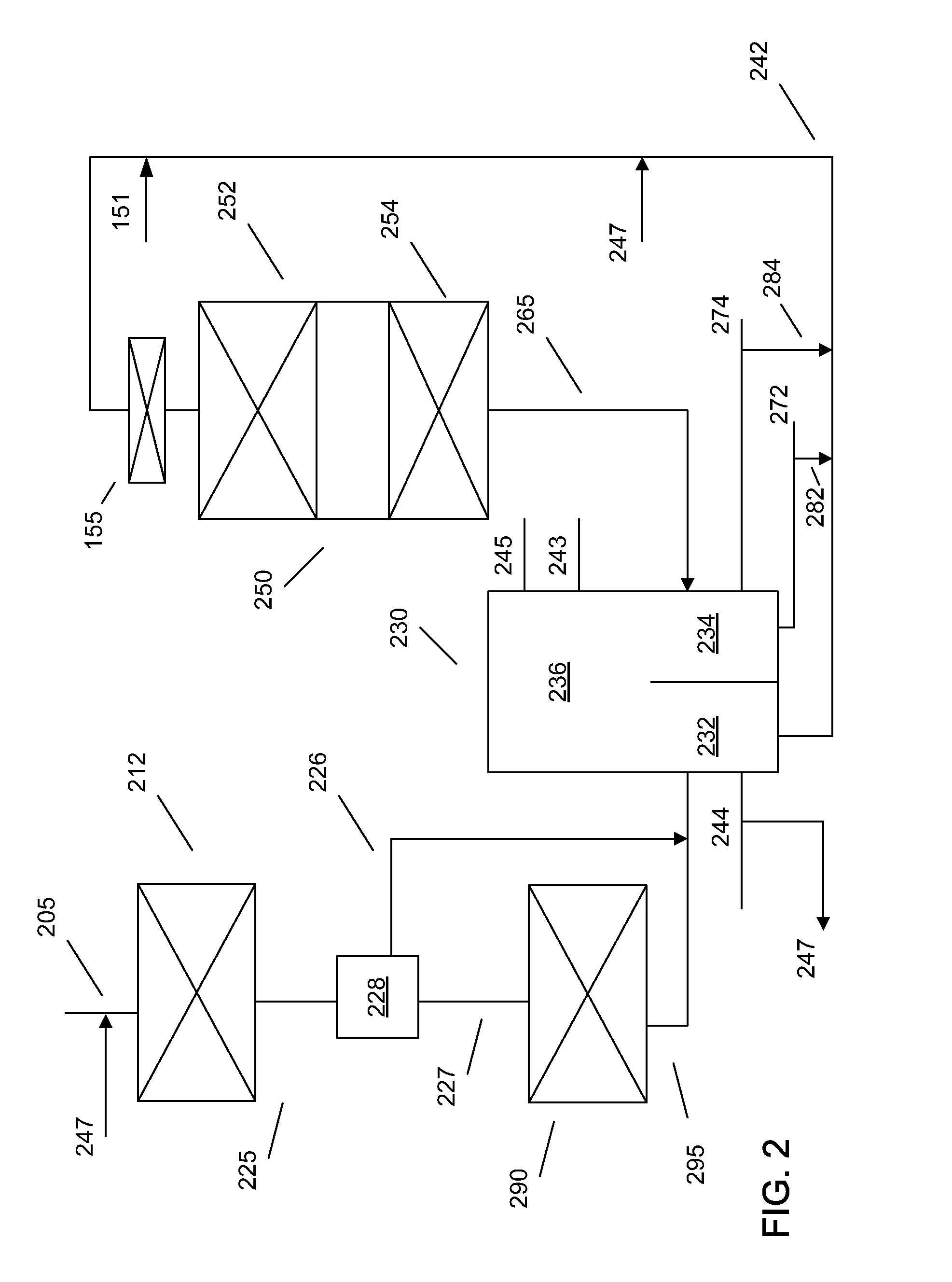

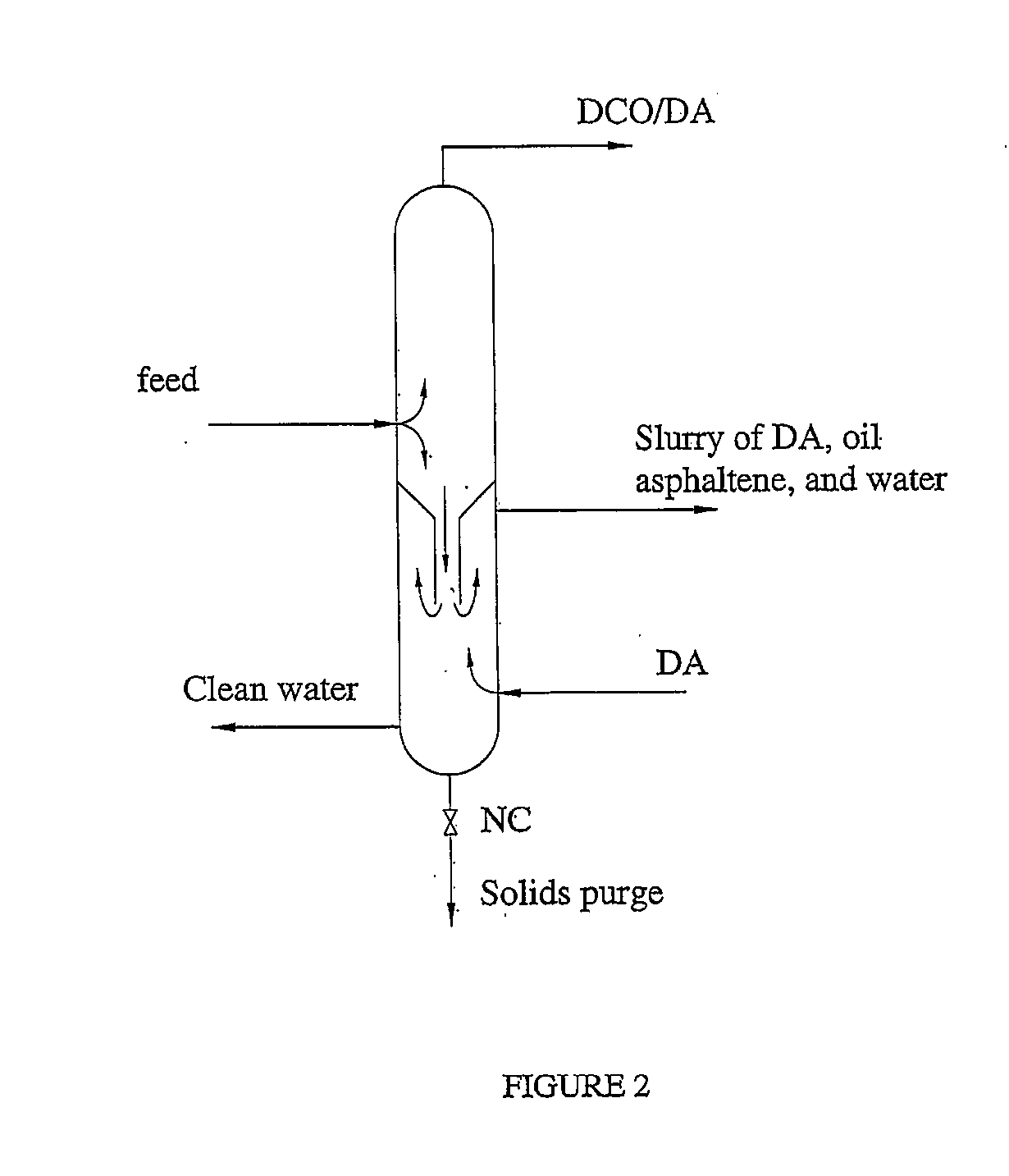

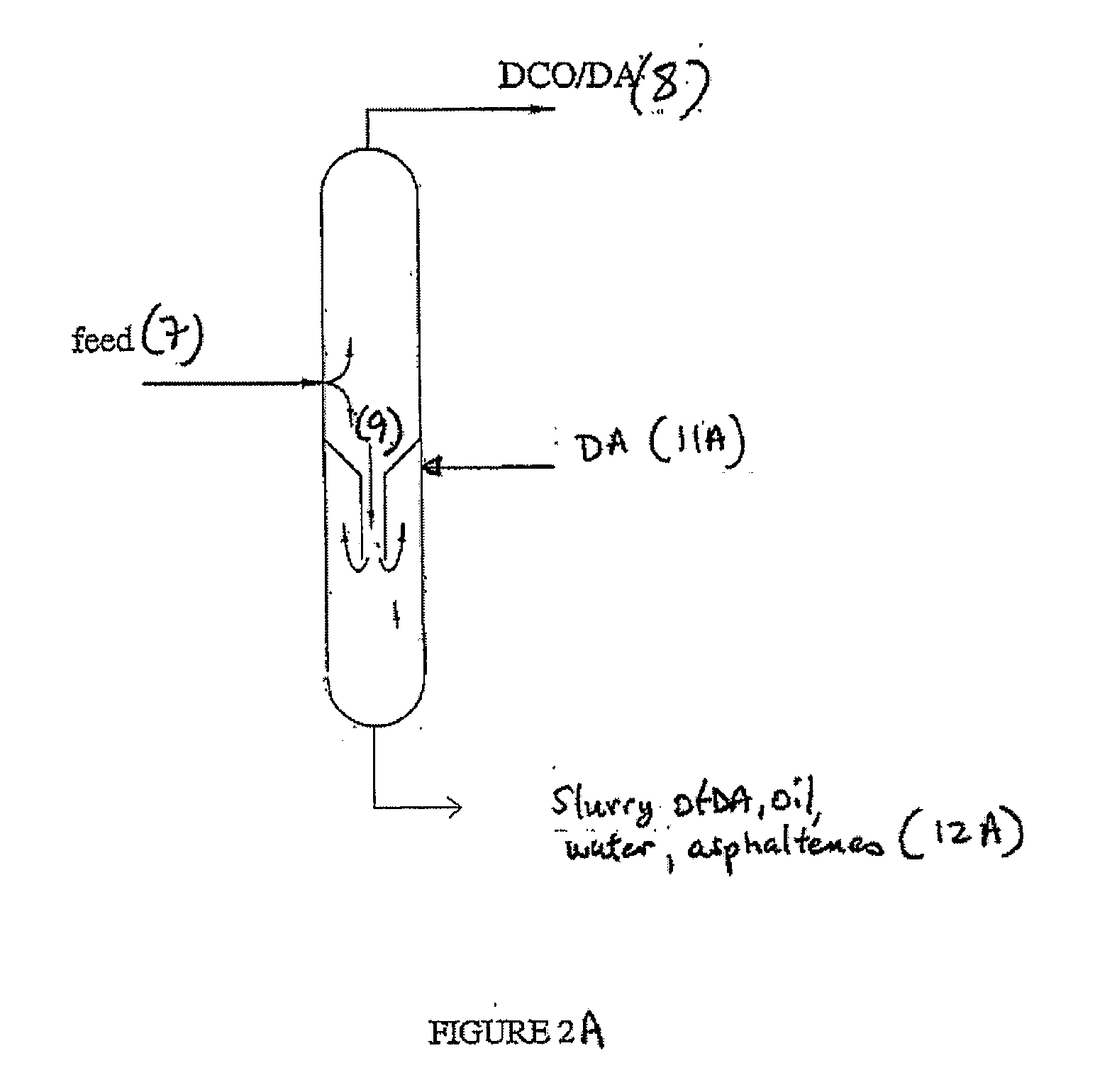

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

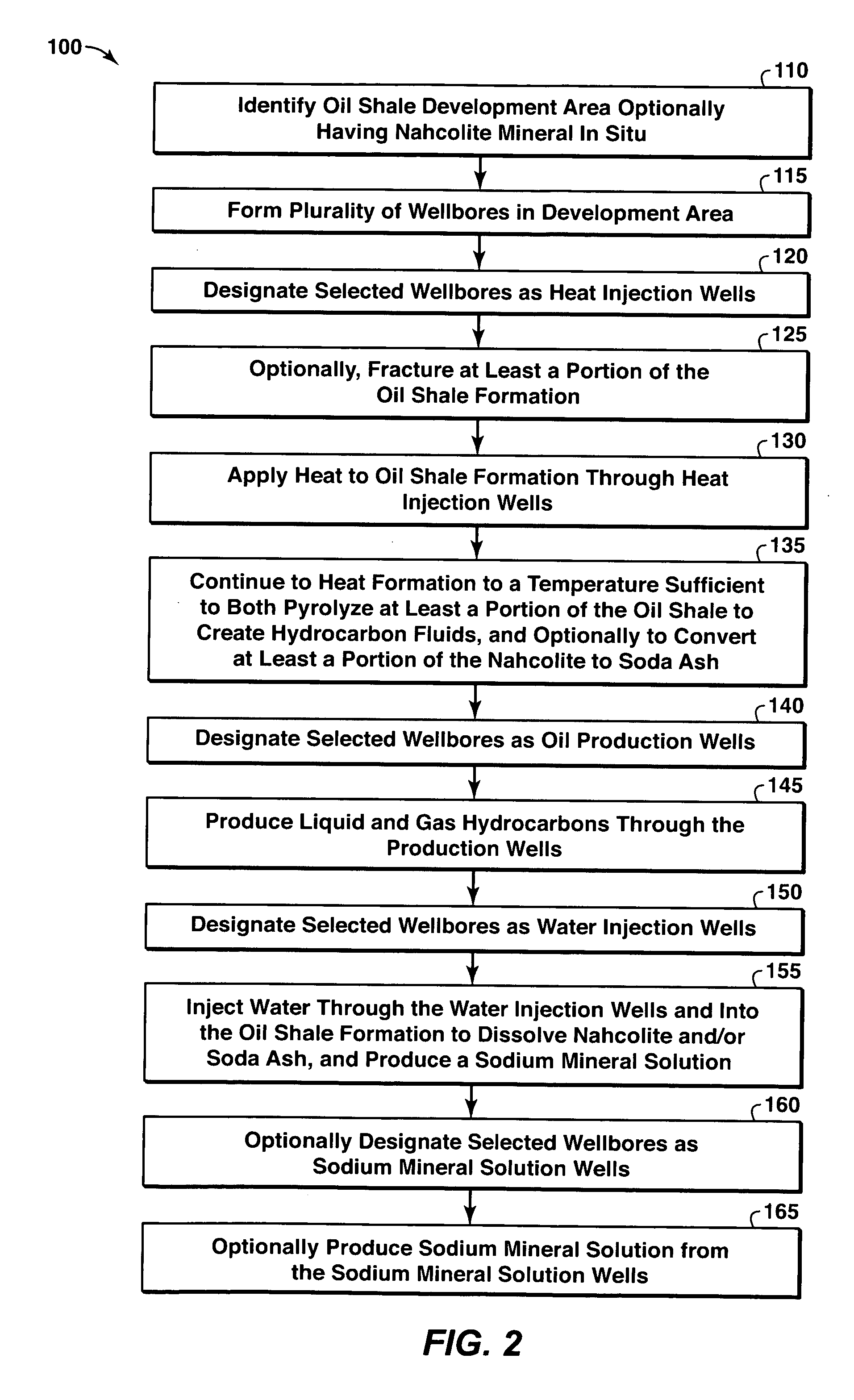

Process for producing Hydrocarbon fluids combining in situ heating, a power plant and a gas plant

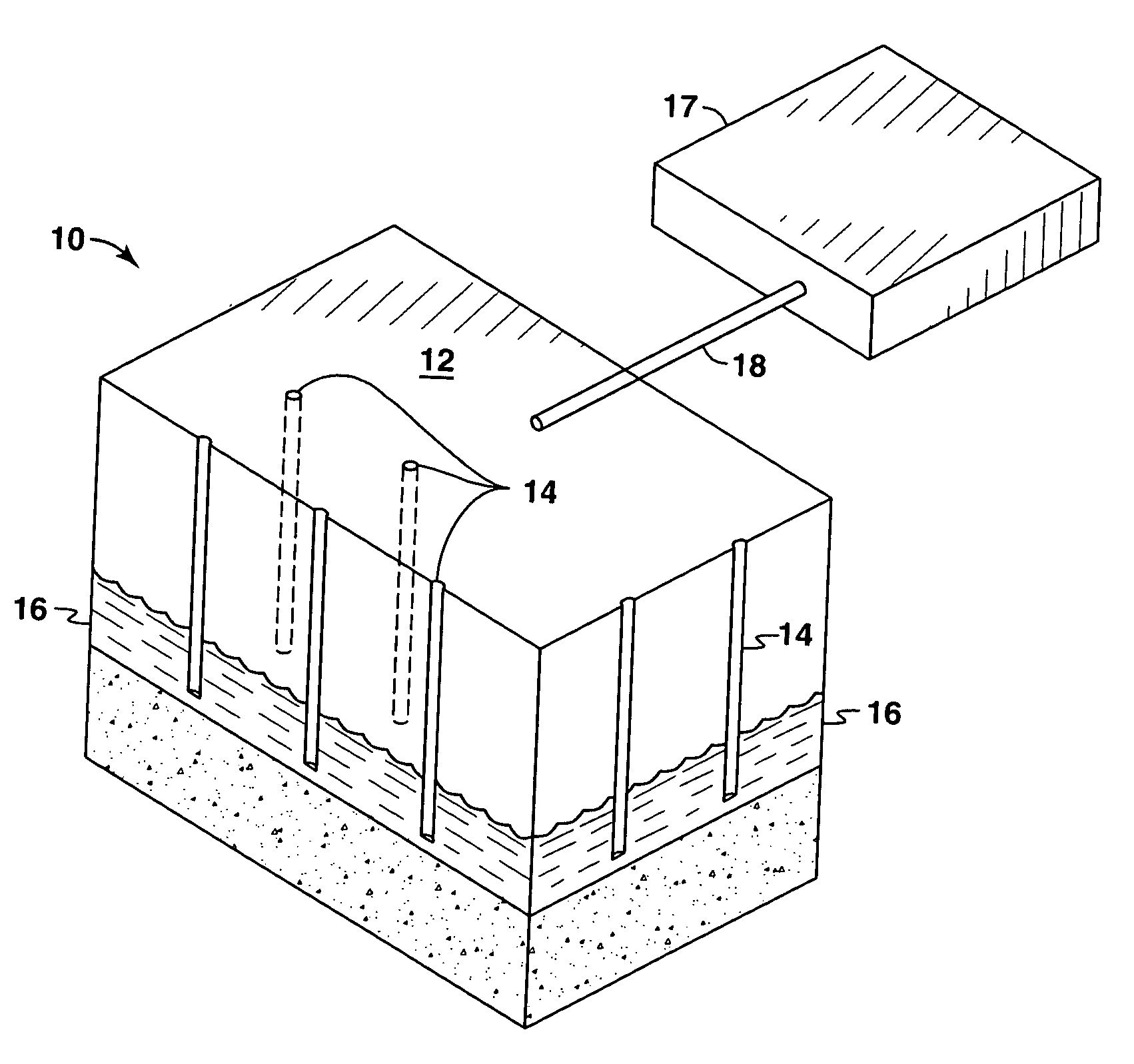

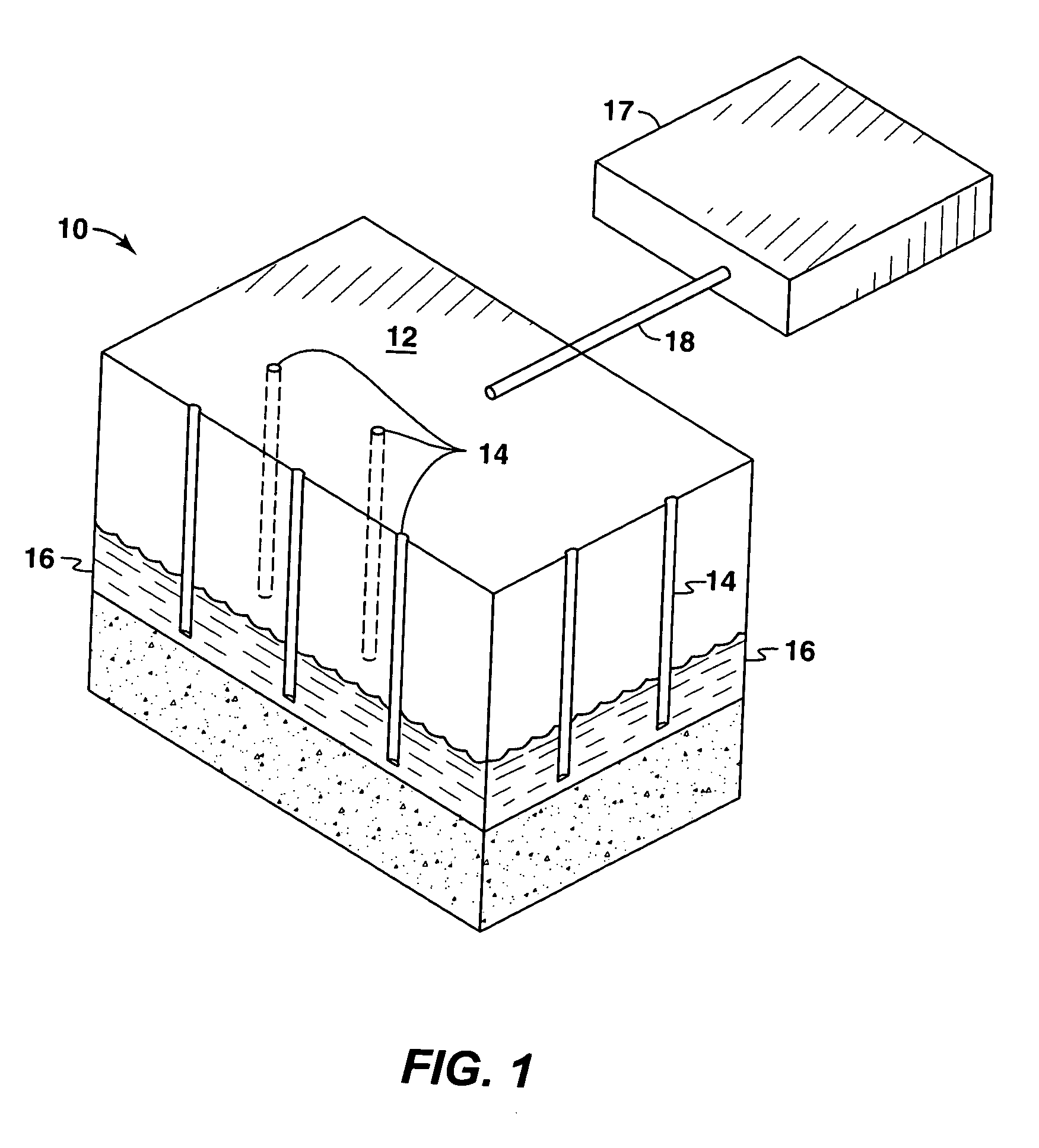

An in situ method of producing hydrocarbon fluids from an organic-rich rock formation is provided. The method may include heating an organic-rich rock formation, for example an oil shale formation, in situ to pyrolyze formation hydrocarbons, for example kerogen, to form a production fluid containing hydrocarbon fluids. The method may include separating the production fluid into at least a gas stream and a liquid stream, where the gas stream is a low BTU gas stream. The low BTU gas stream is then fed to a gas turbine where it is combusted and is used to generate electricity.

Owner:KAMINSKY ROBERT D +4

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

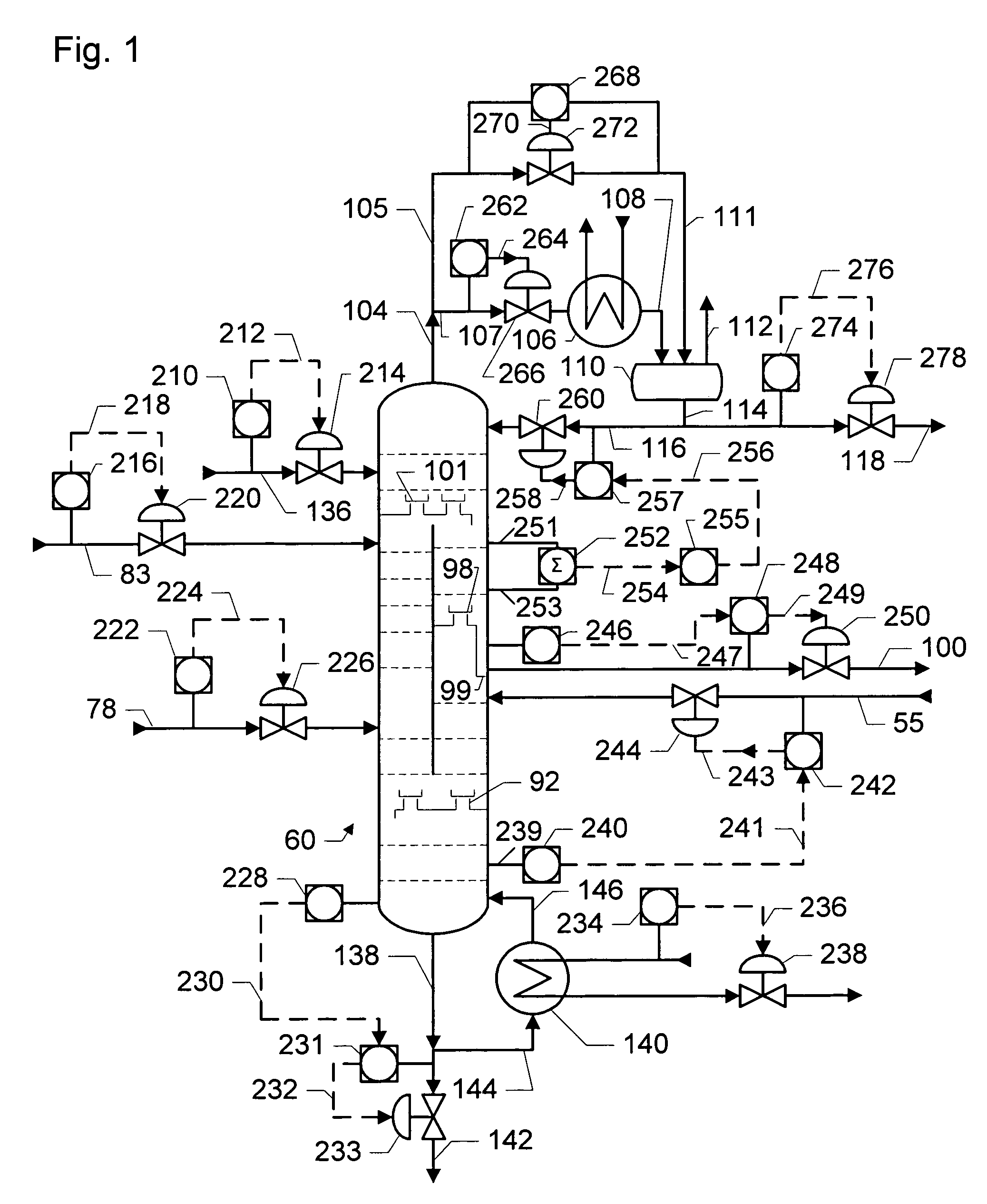

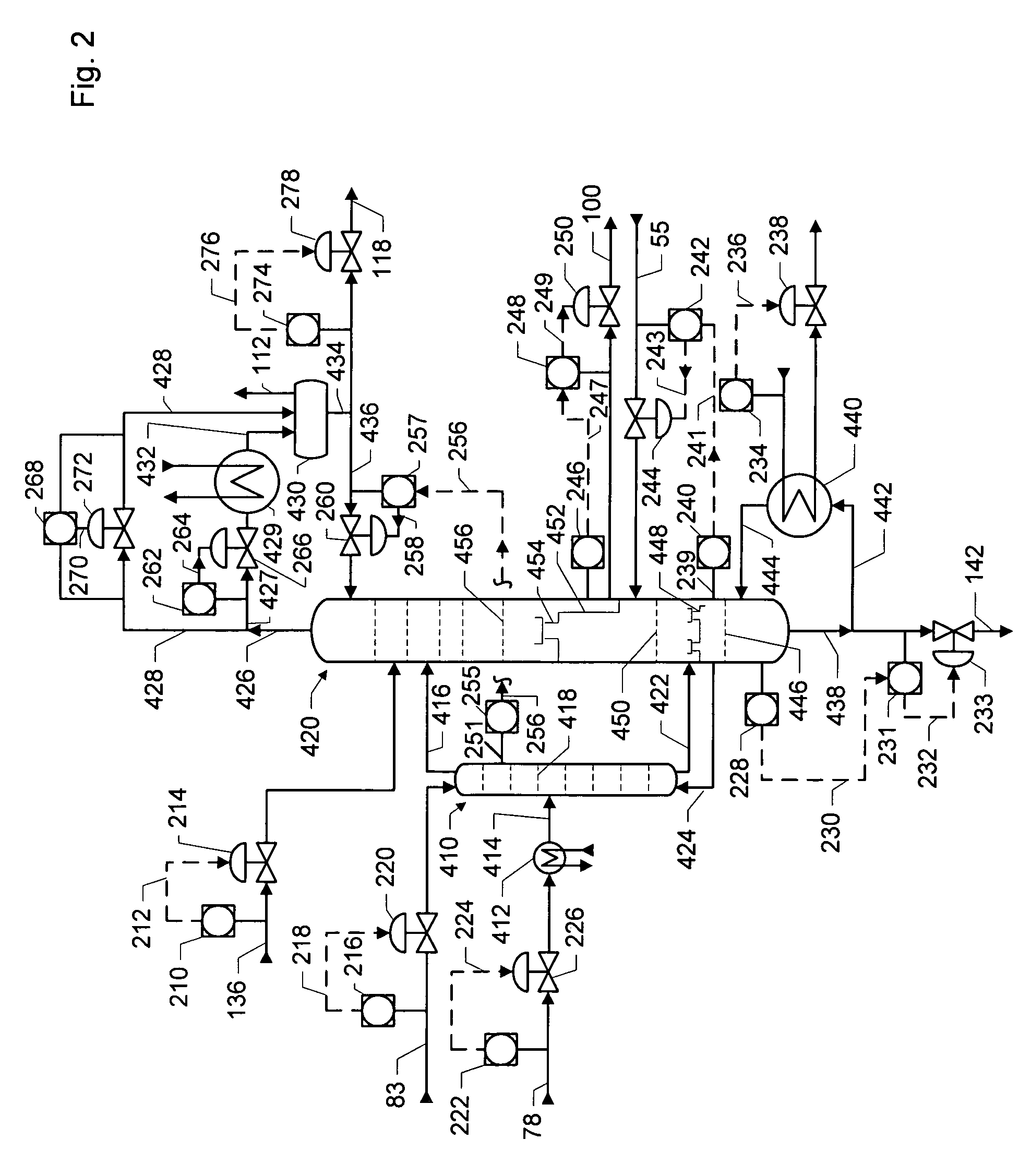

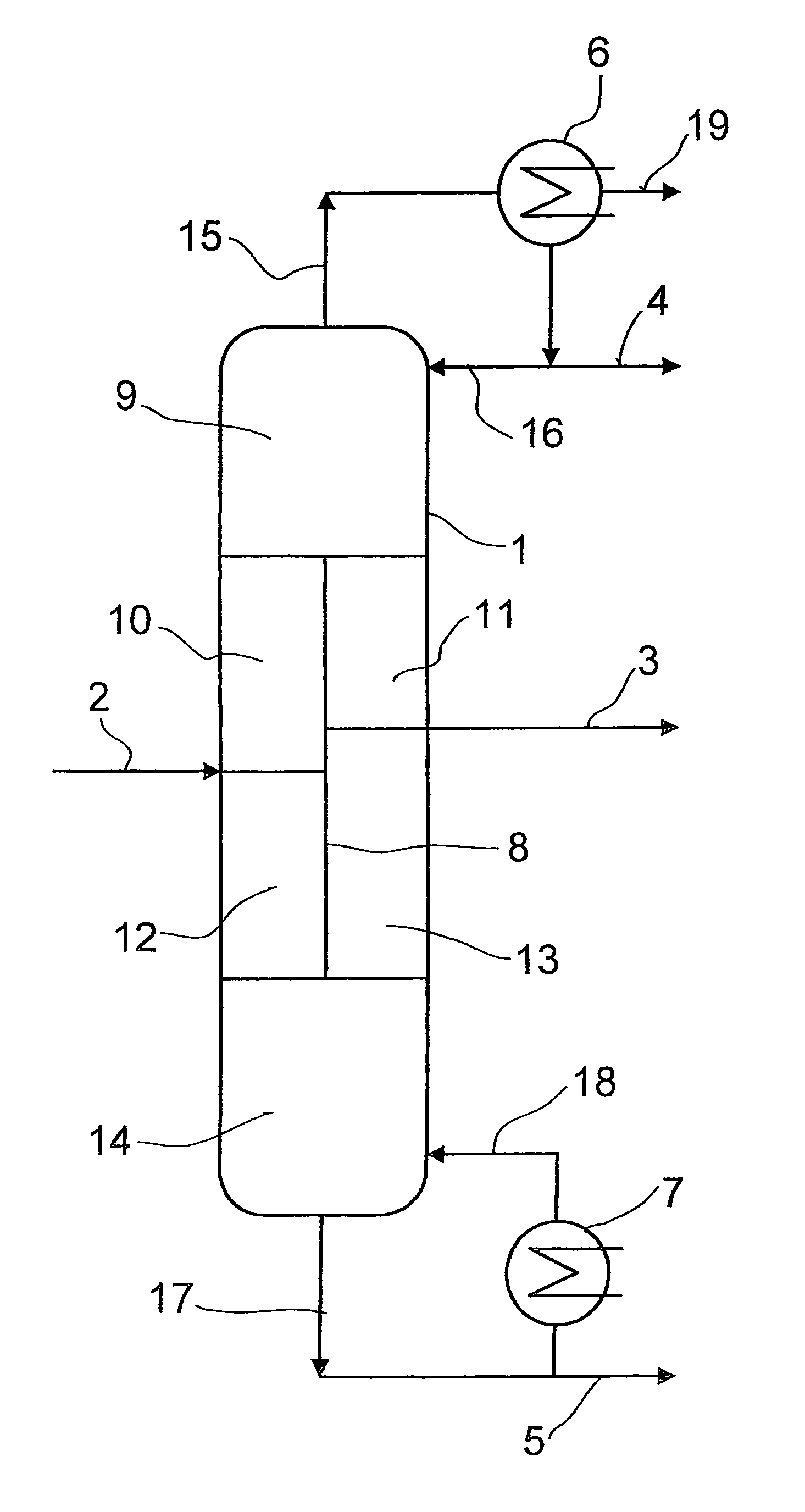

Dividing wall distillation column control apparatus

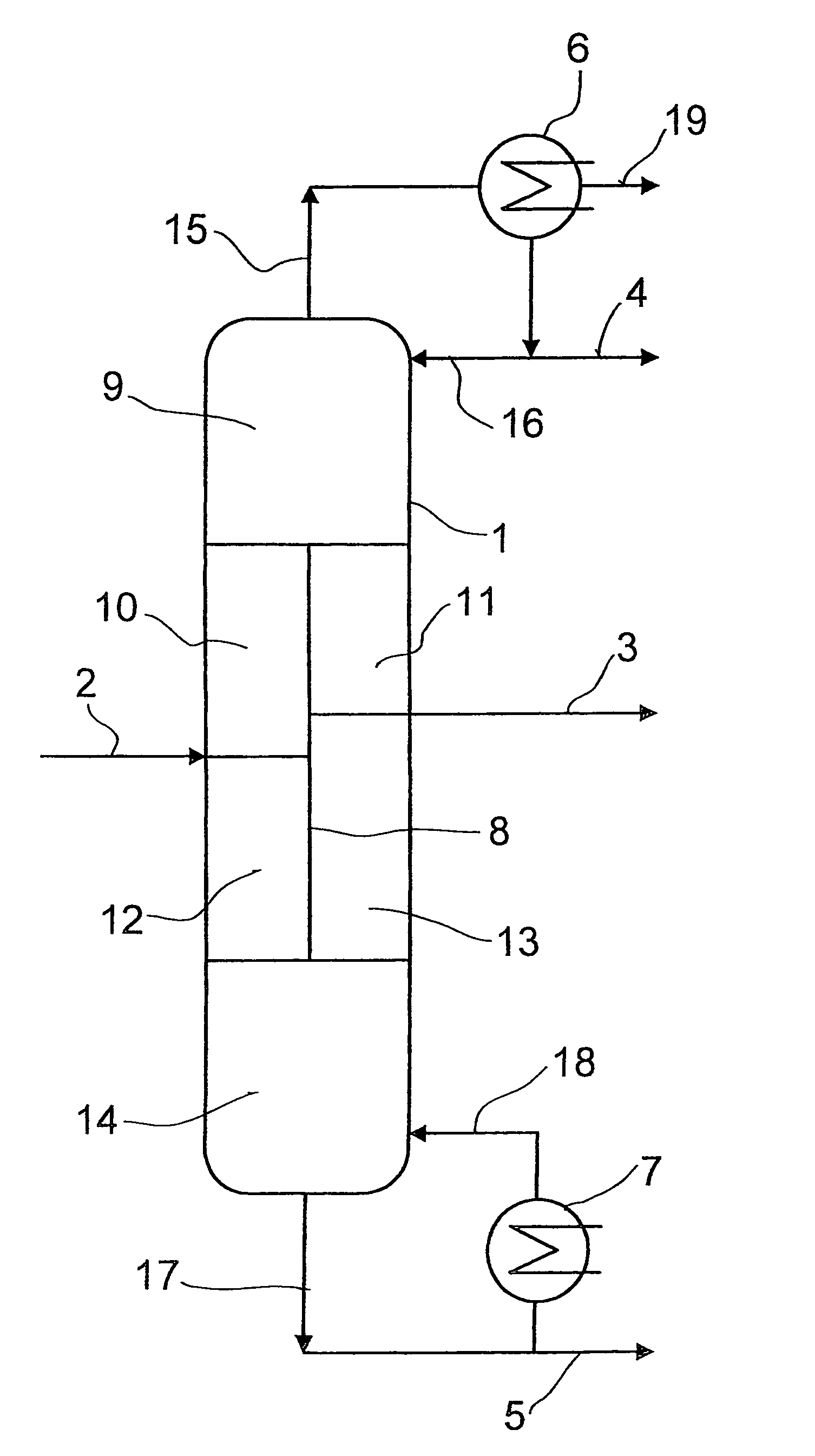

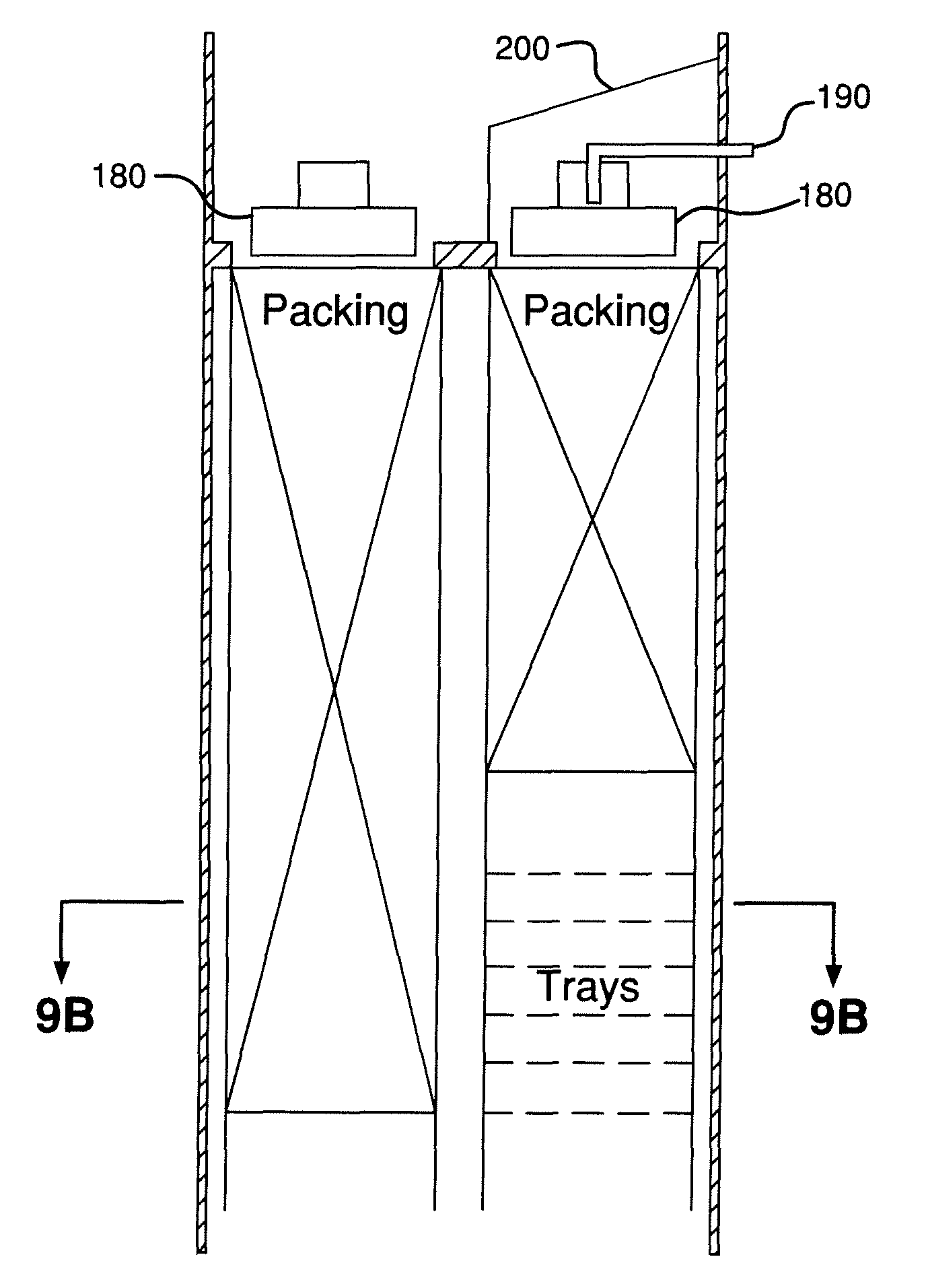

InactiveUS7267746B1Low costThermal non-catalytic crackingDistillation regulation/controlDistillationEngineering

A control apparatus and control method for controlling the separation in a dividing wall distillation column of at least two feeds into at least three products is disclosed. The apparatus uses a temperature measuring device to measure the temperature of fluid in the column, a controller, and a means for adjusting the temperature of fluid in the column. The temperature measuring device may be on either side of the dividing wall or above or below the dividing wall, and more than one such device may be used. The apparatus and method may be used in the production of alkylaromatic hydrocarbons by alkylating aromatic hydrocarbons with olefinic hydrocarbons.

Owner:UOP LLC

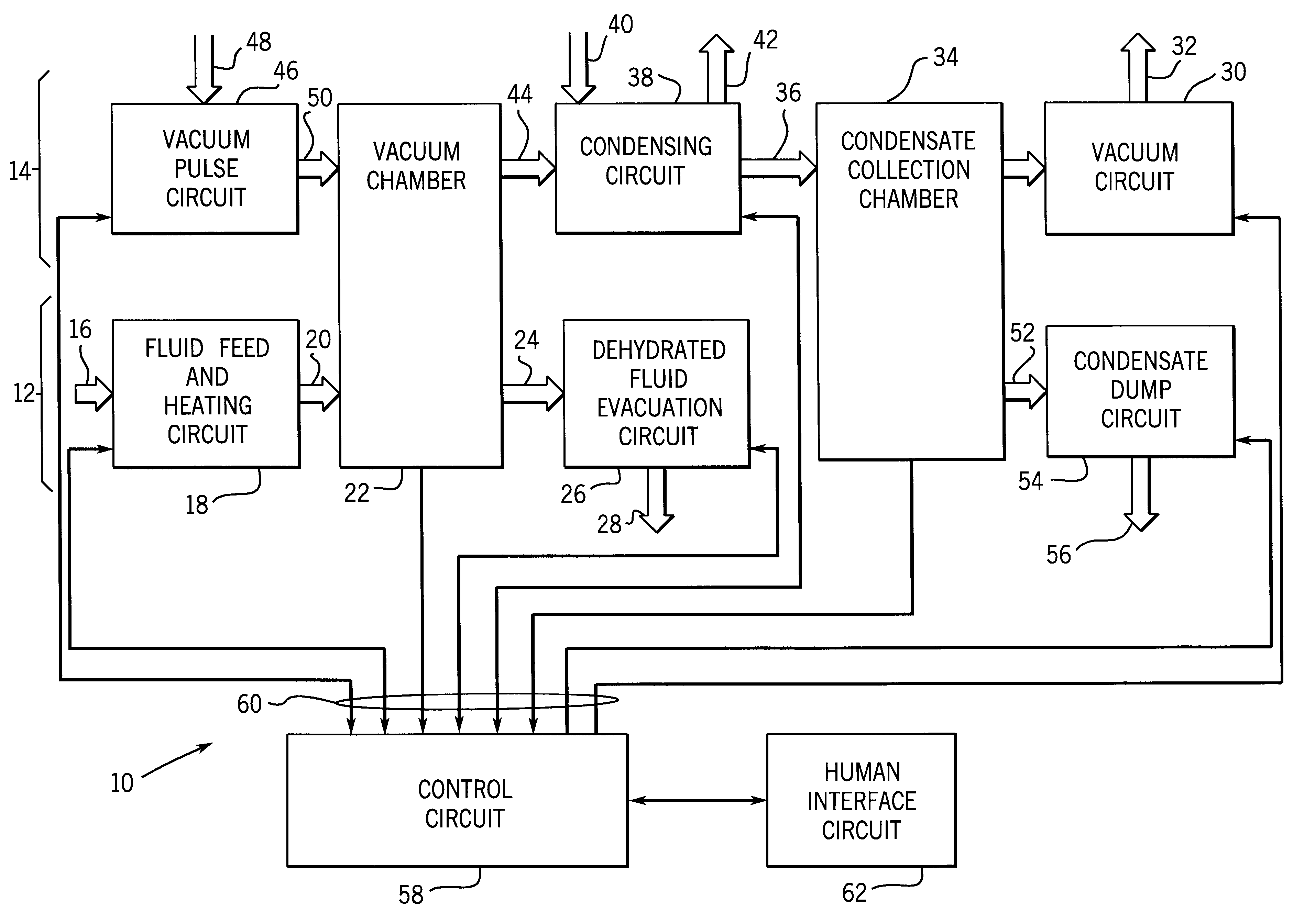

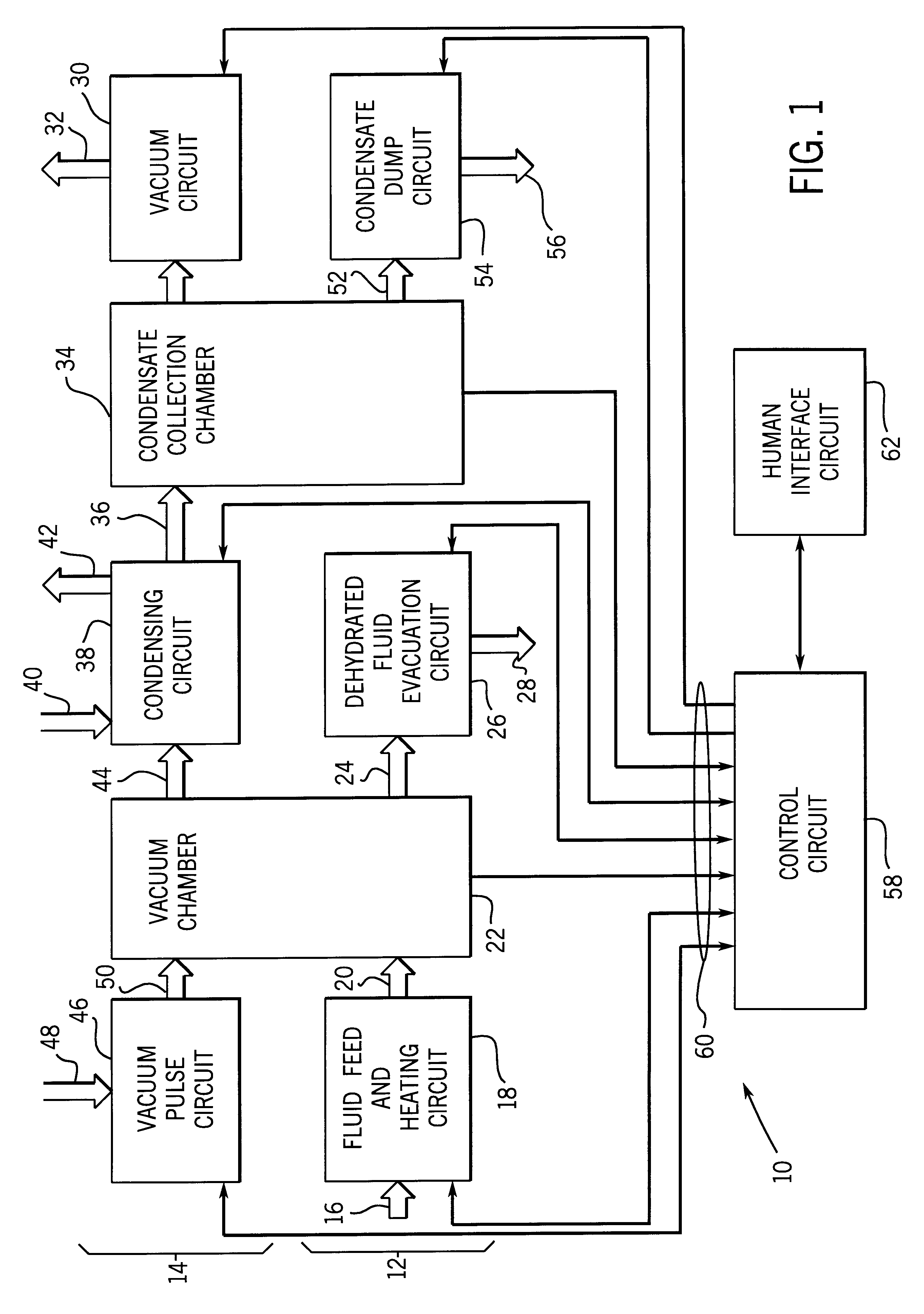

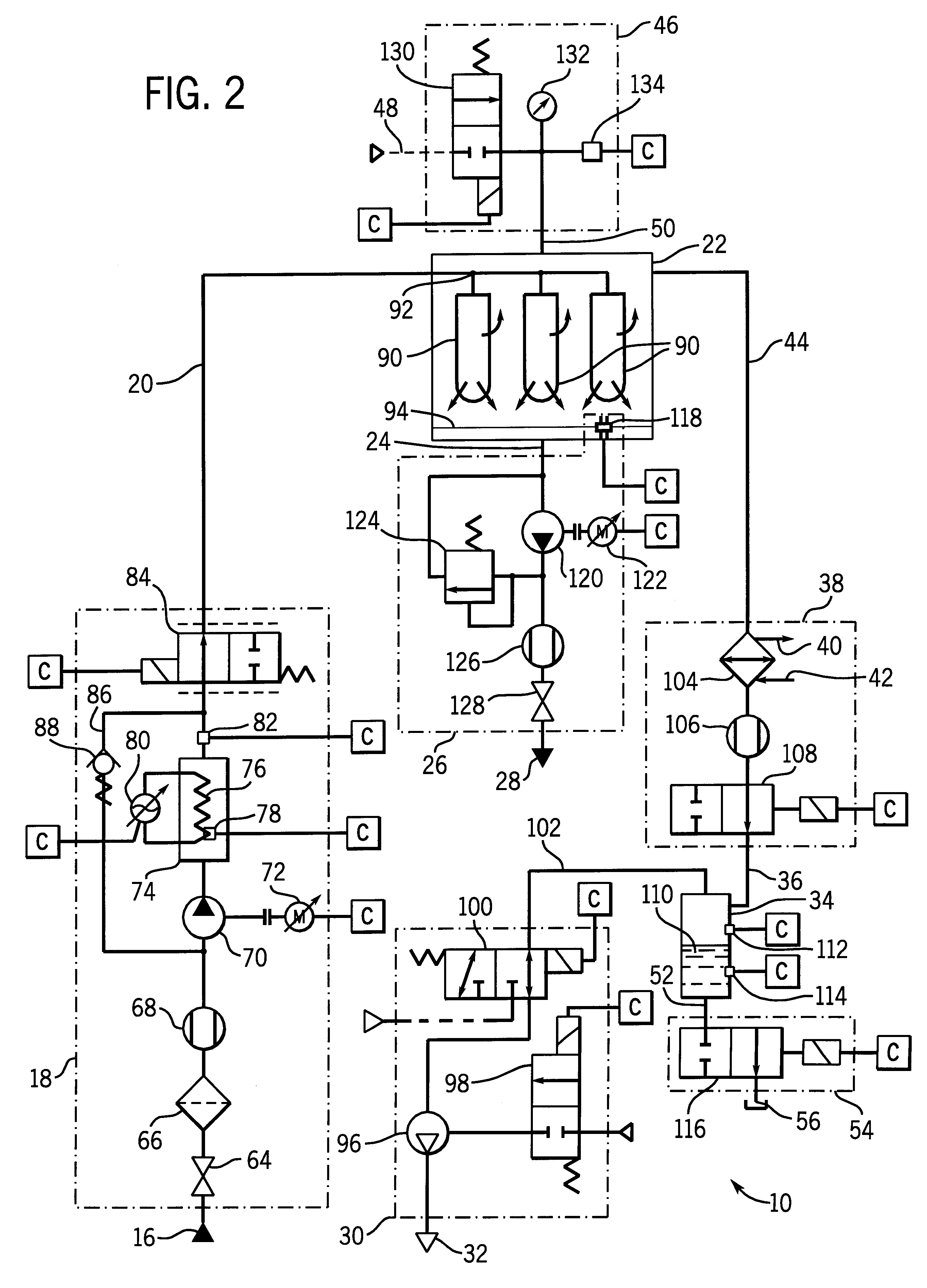

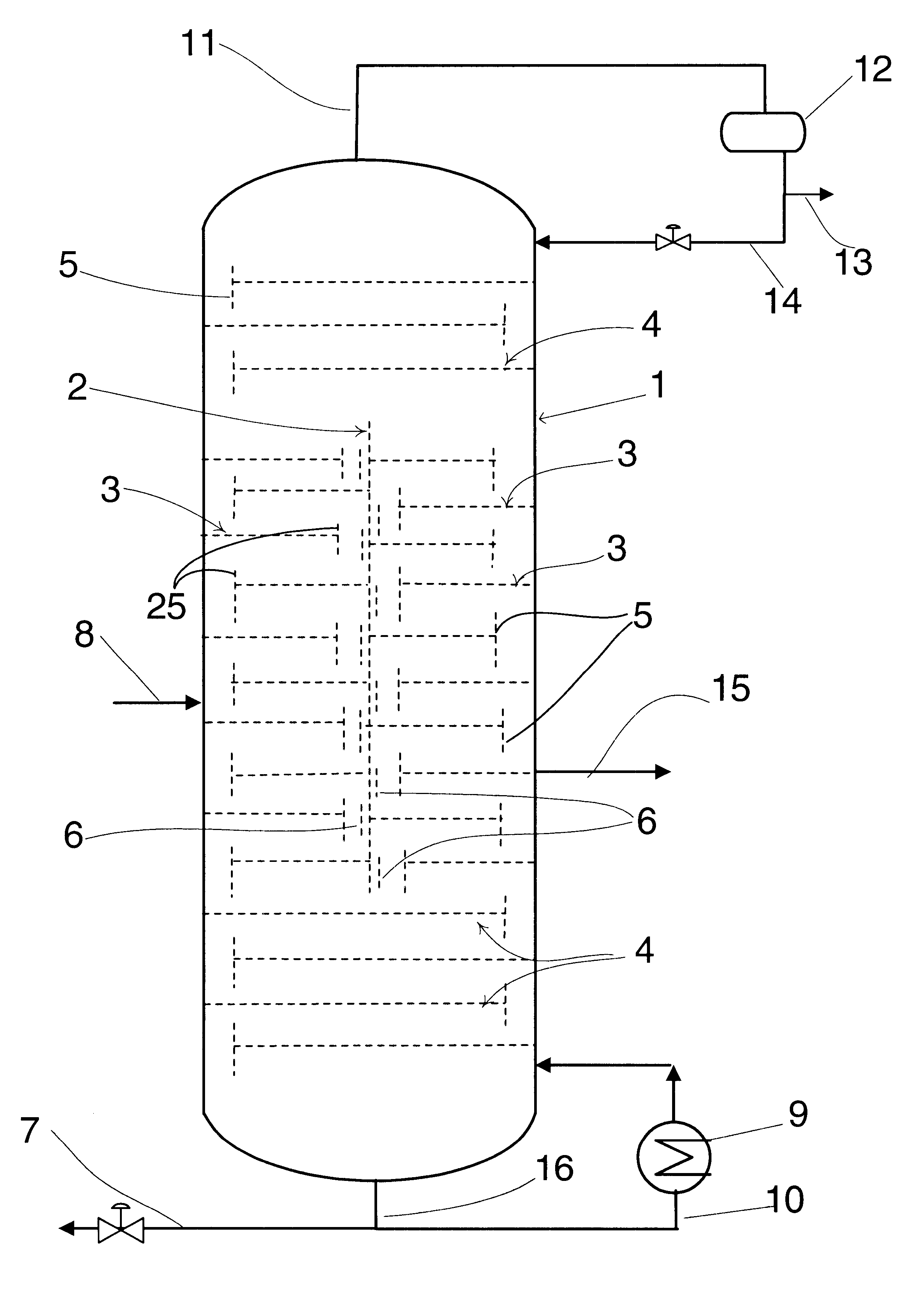

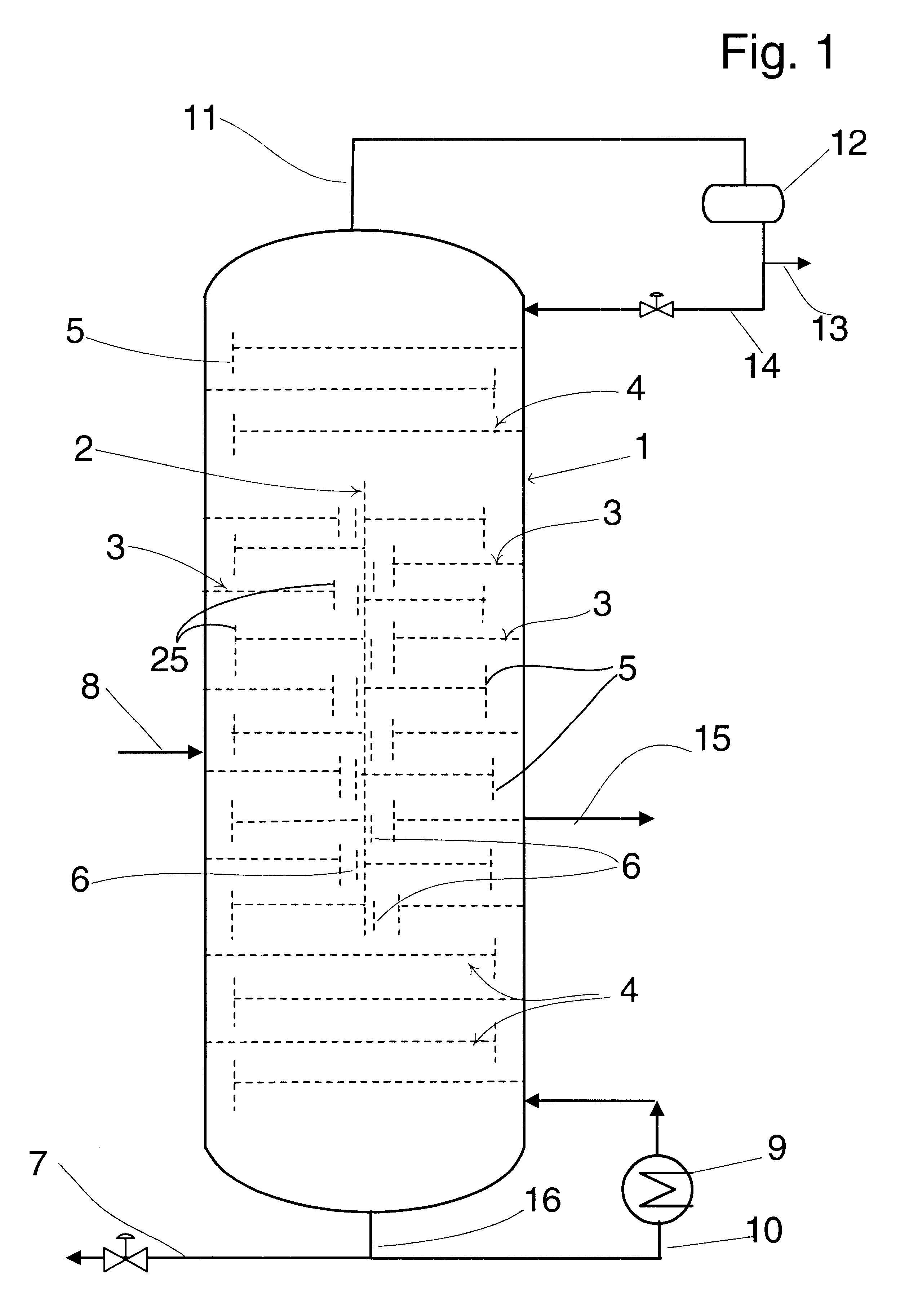

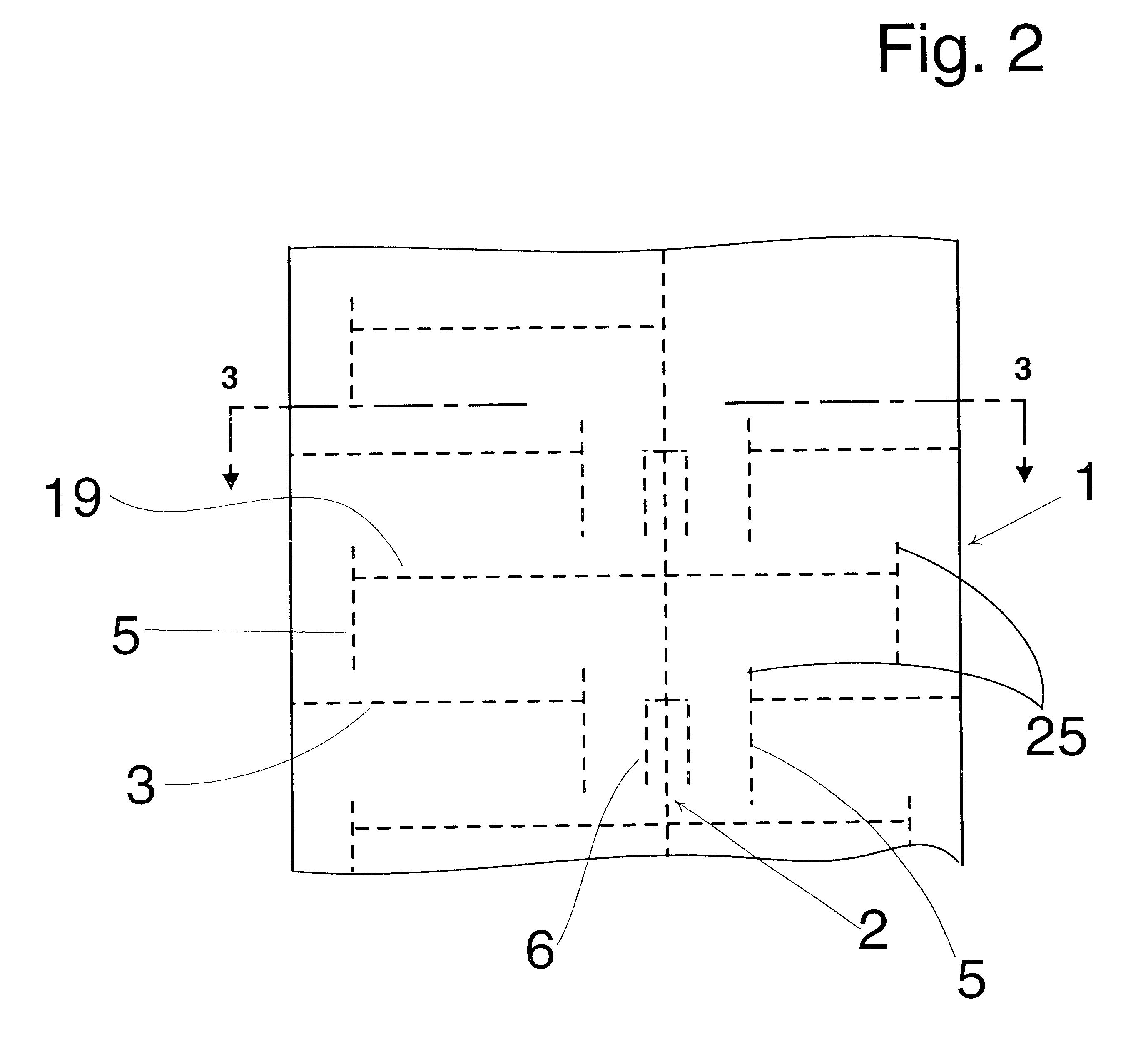

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

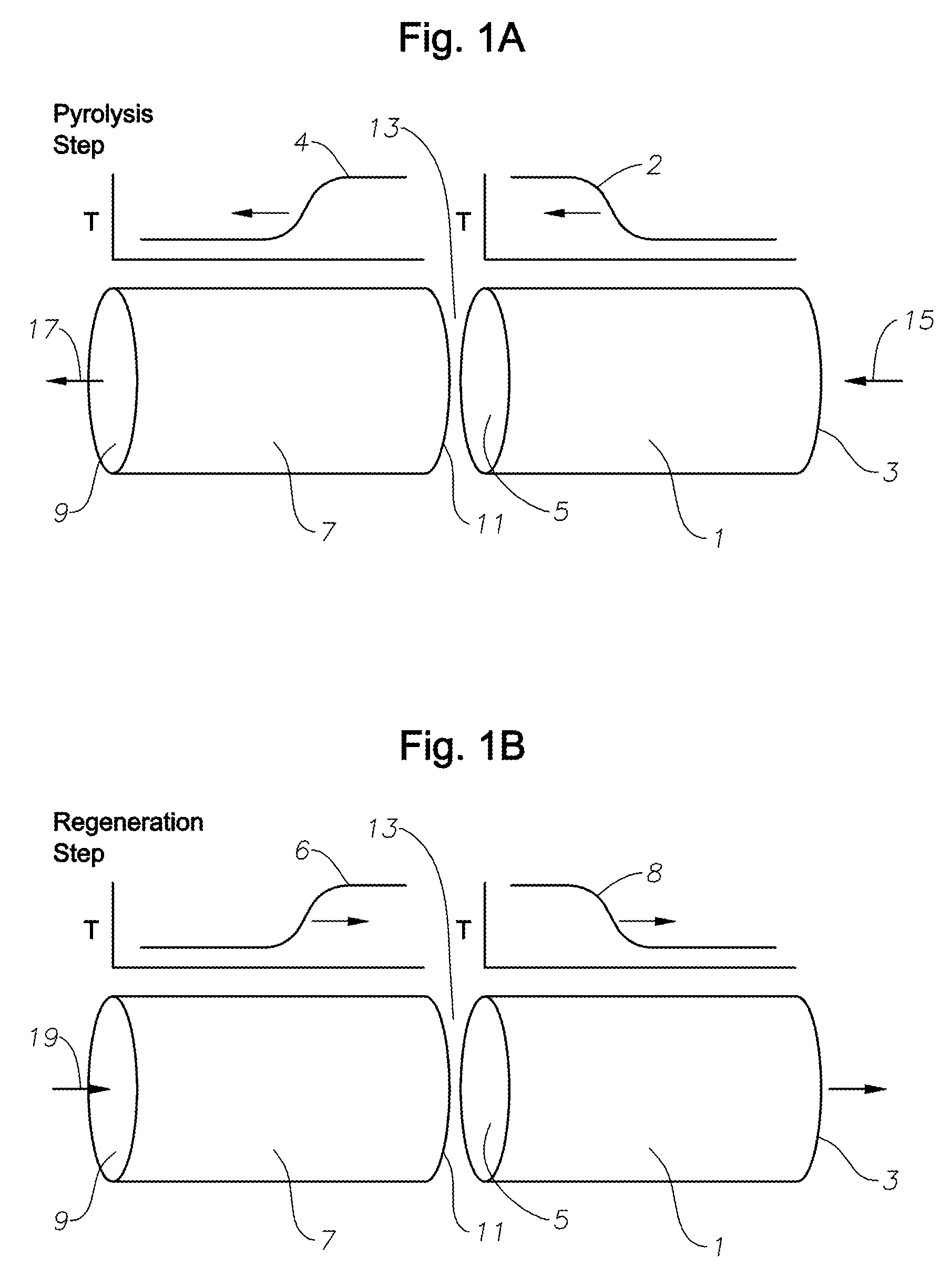

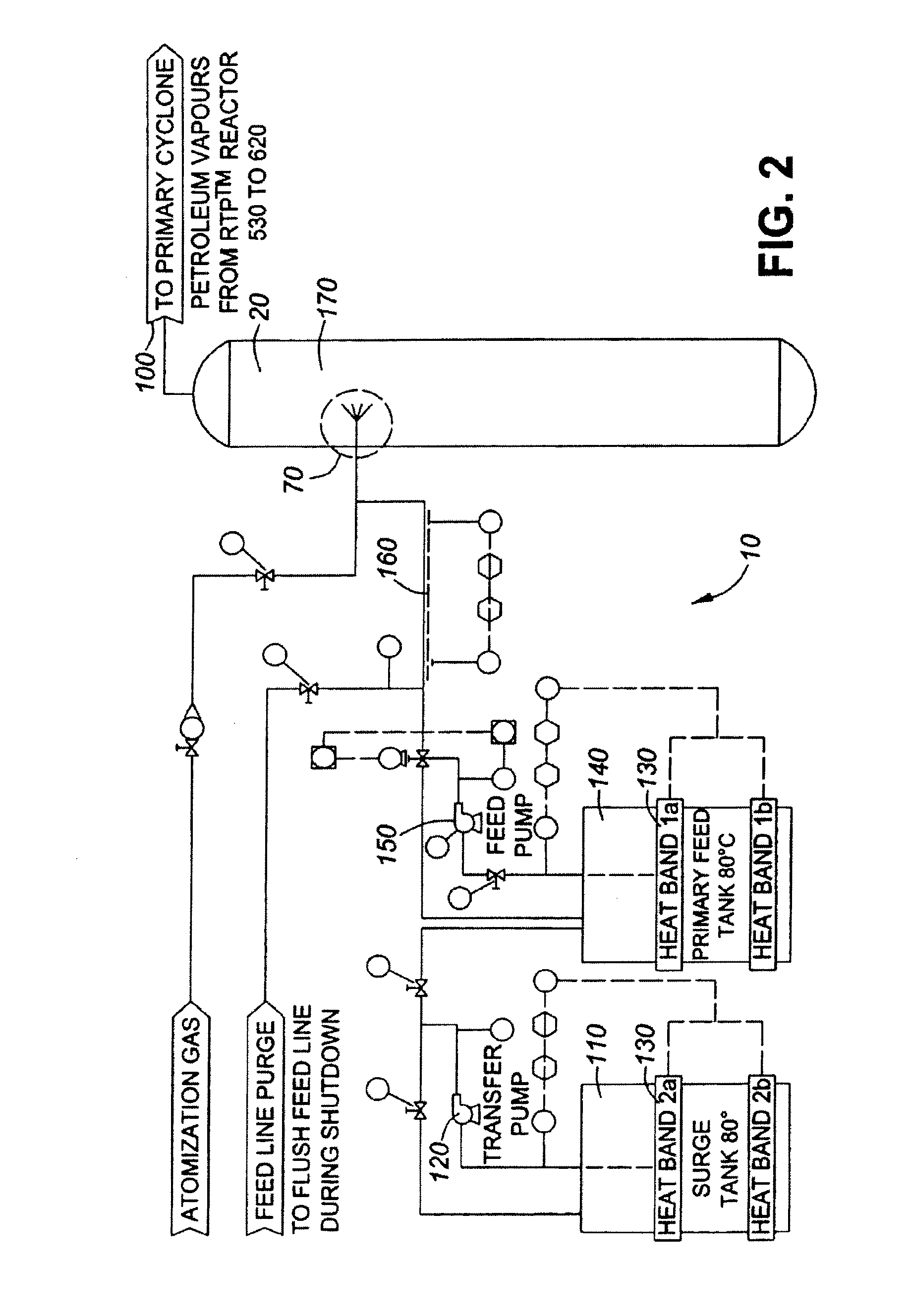

Pyrolysis reactor conversion of hydrocarbon feedstocks into higher value hydrocarbons

ActiveUS20090008292A1Thermal non-catalytic crackingCatalytic crackingReactor systemProcess engineering

In one aspect, the inventive process comprises a process for pyrolyzing a hydrocarbon feedstock containing nonvolatiles in a regenerative pyrolysis reactor system. The inventive process comprises: (a) heating the nonvolatile-containing hydrocarbon feedstock upstream of a regenerative pyrolysis reactor system to a temperature sufficient to form a vapor phase that is essentially free of nonvolatiles and a liquid phase containing the nonvolatiles; (b) separating said vapor phase from said liquid phase; (c) feeding the separated vapor phase to the pyrolysis reactor system; and (d) converting the separated vapor phase in said pyrolysis reactor system to form a pyrolysis product.

Owner:EXXONMOBIL CHEM PAT INC

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS20080093260A1Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

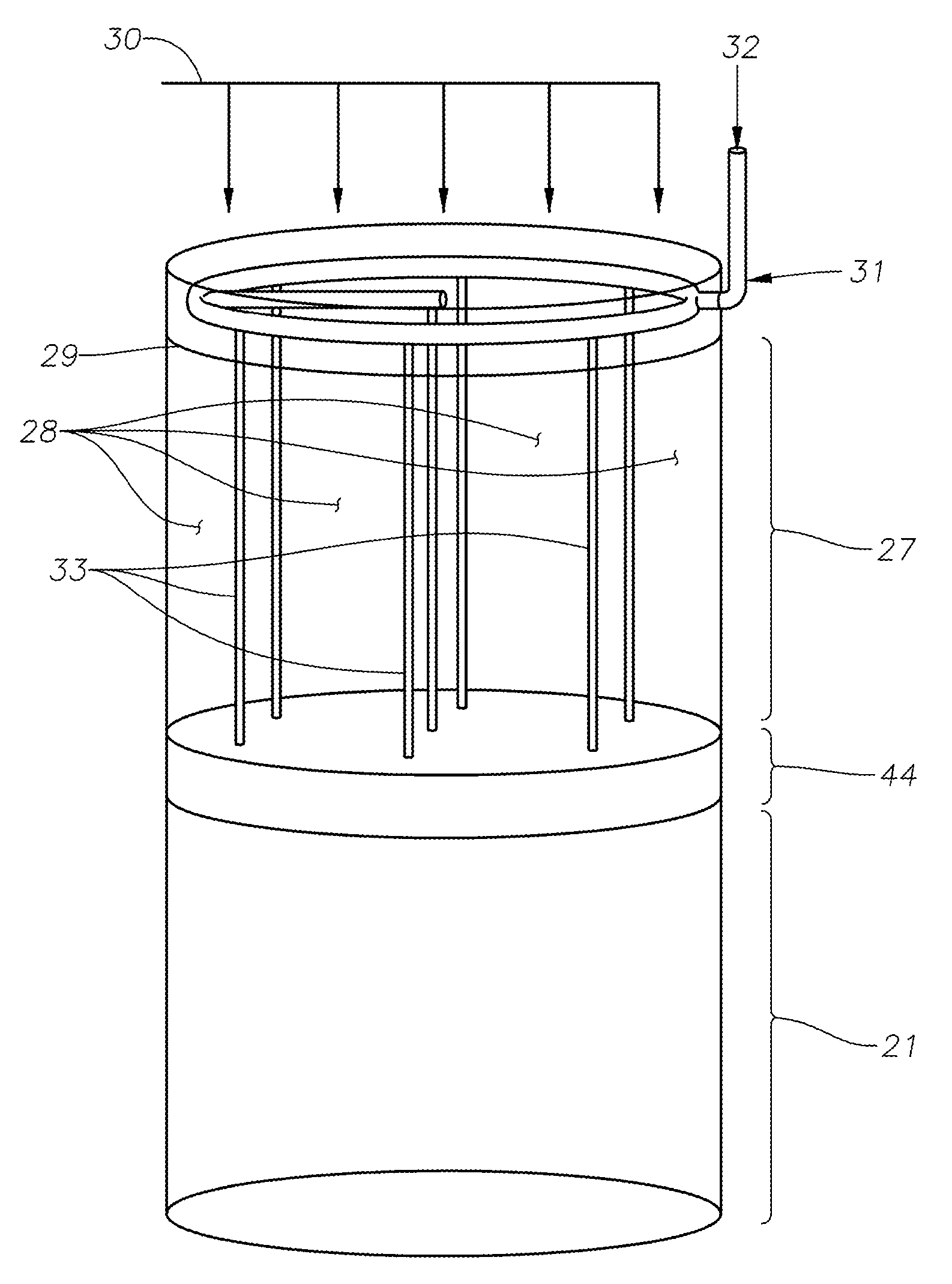

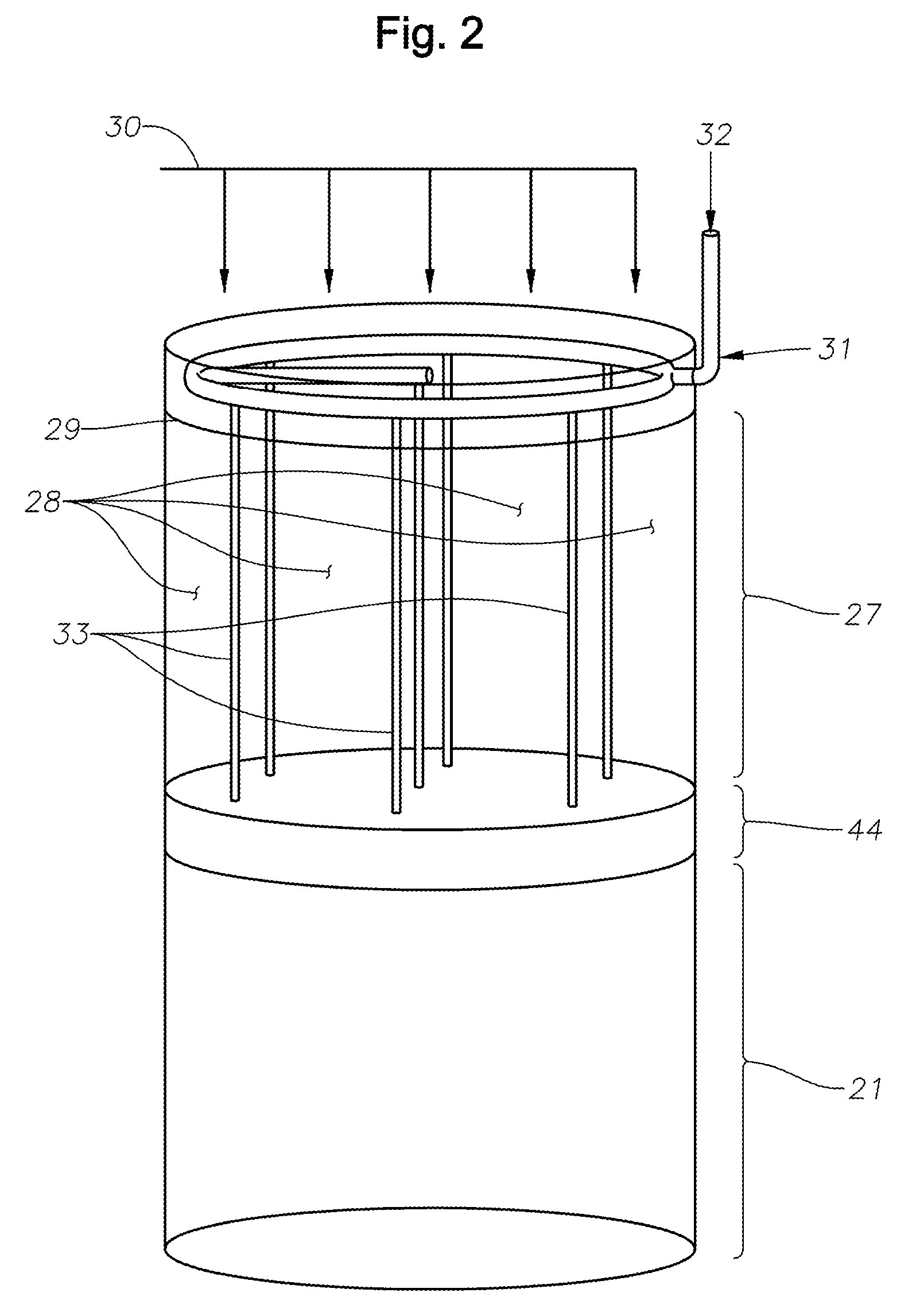

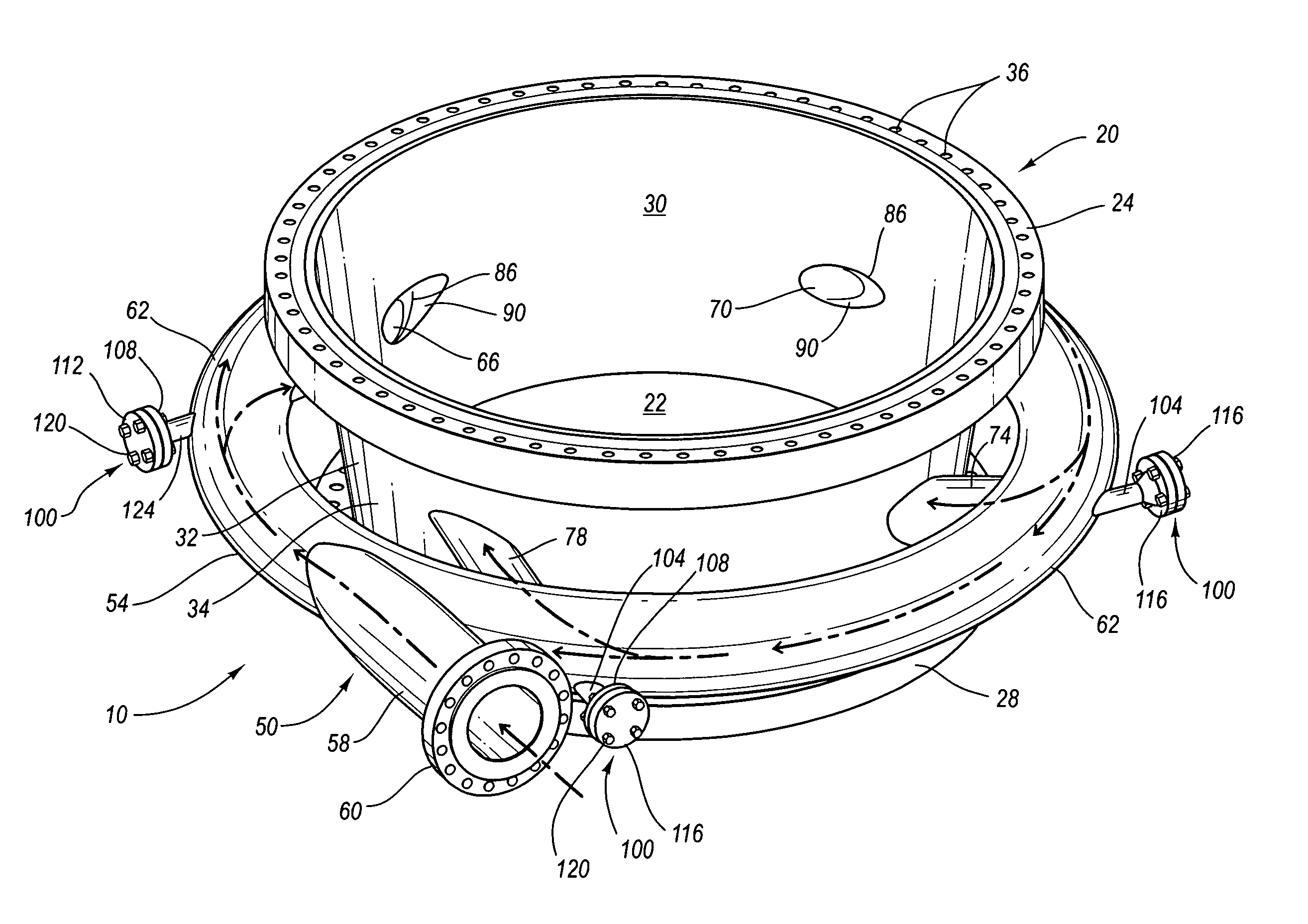

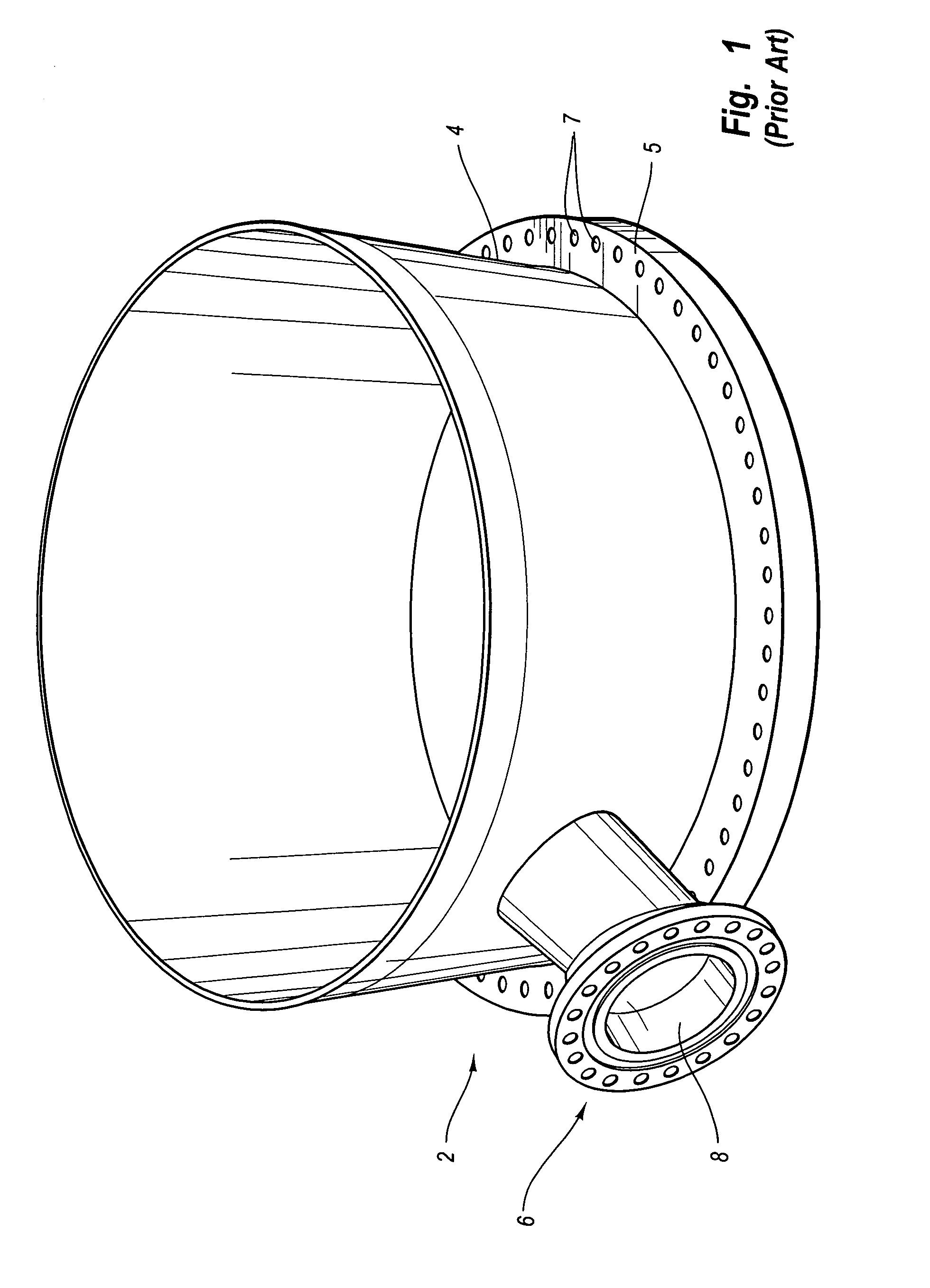

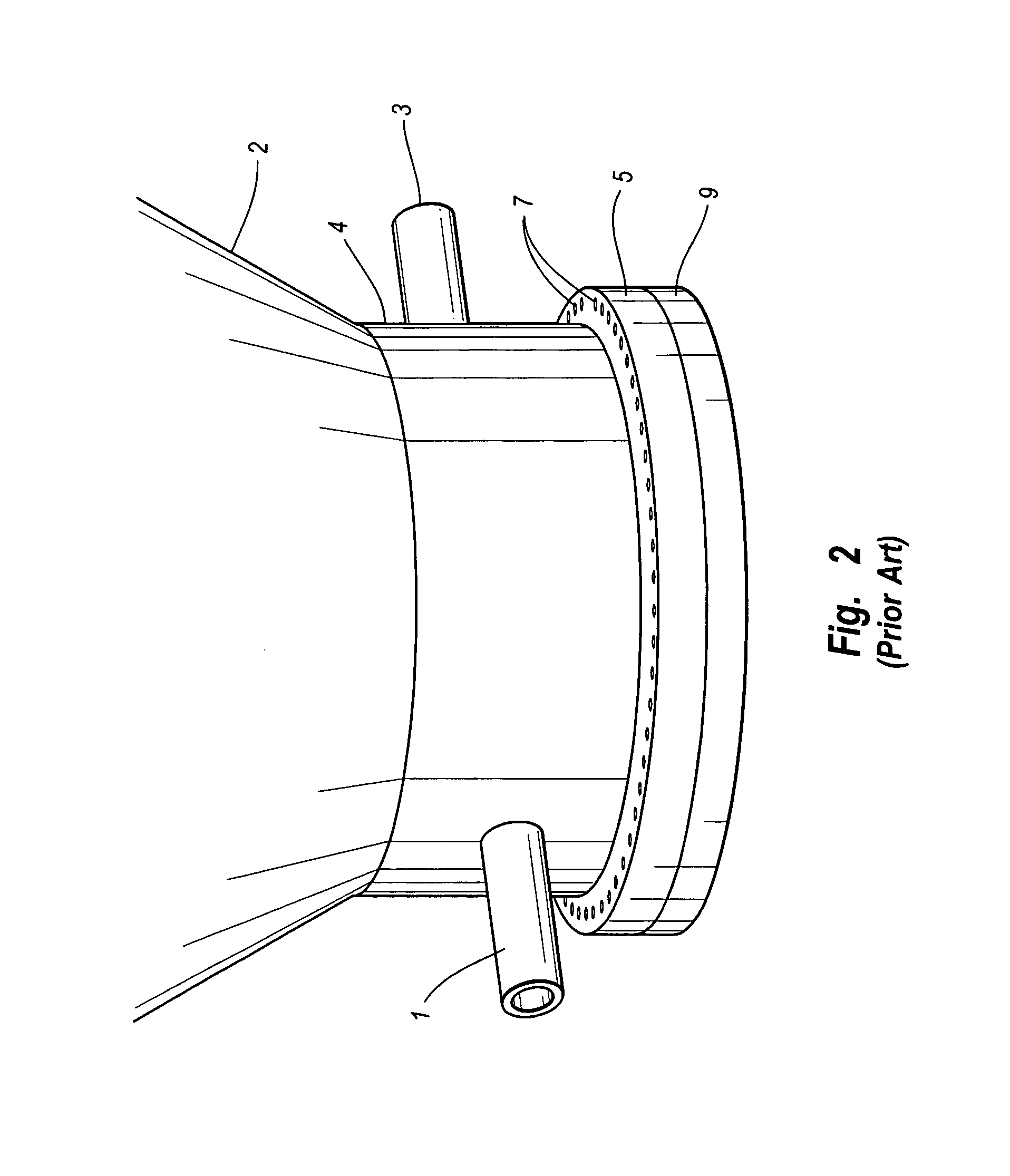

Coker feed method and apparatus

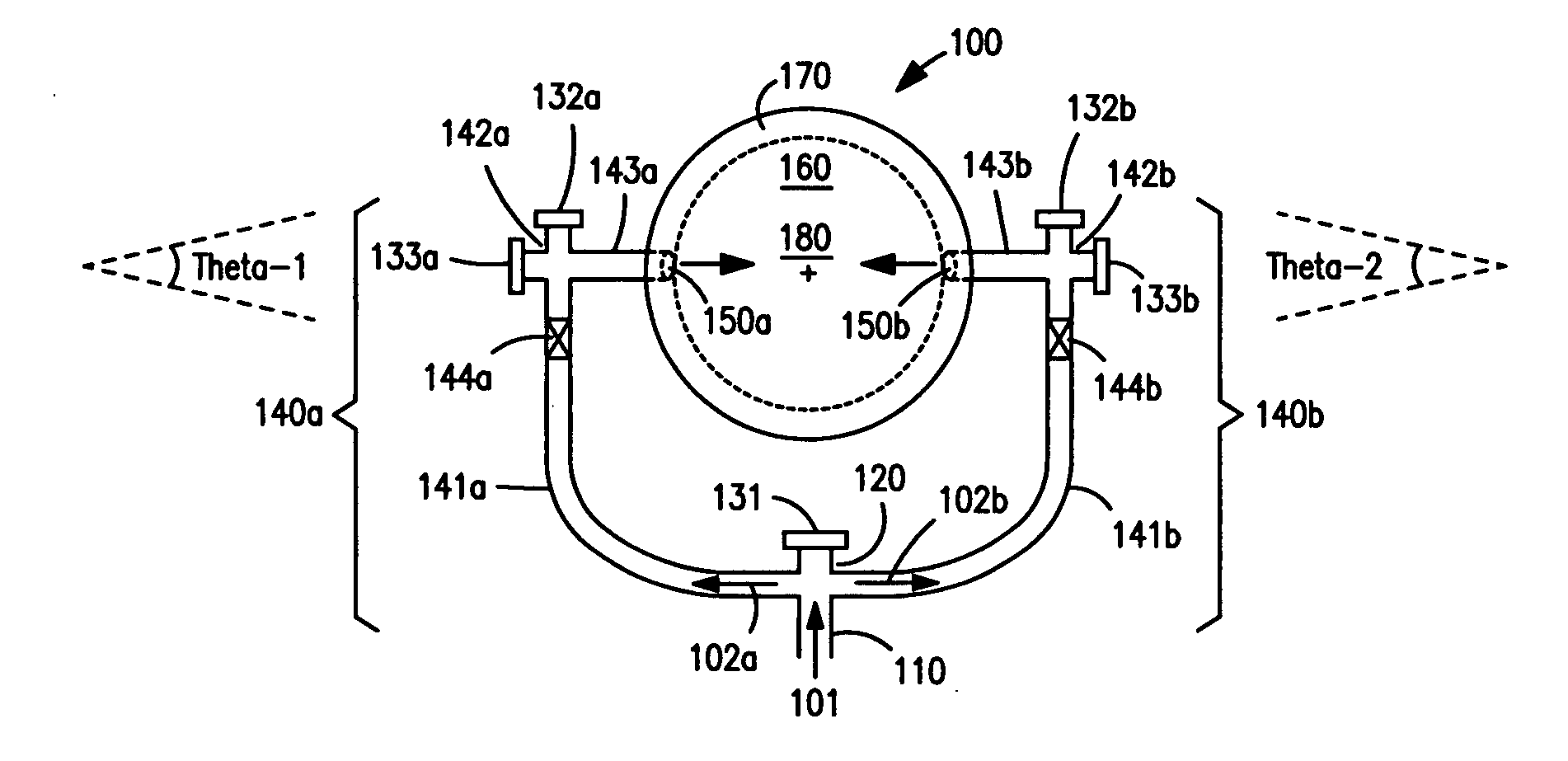

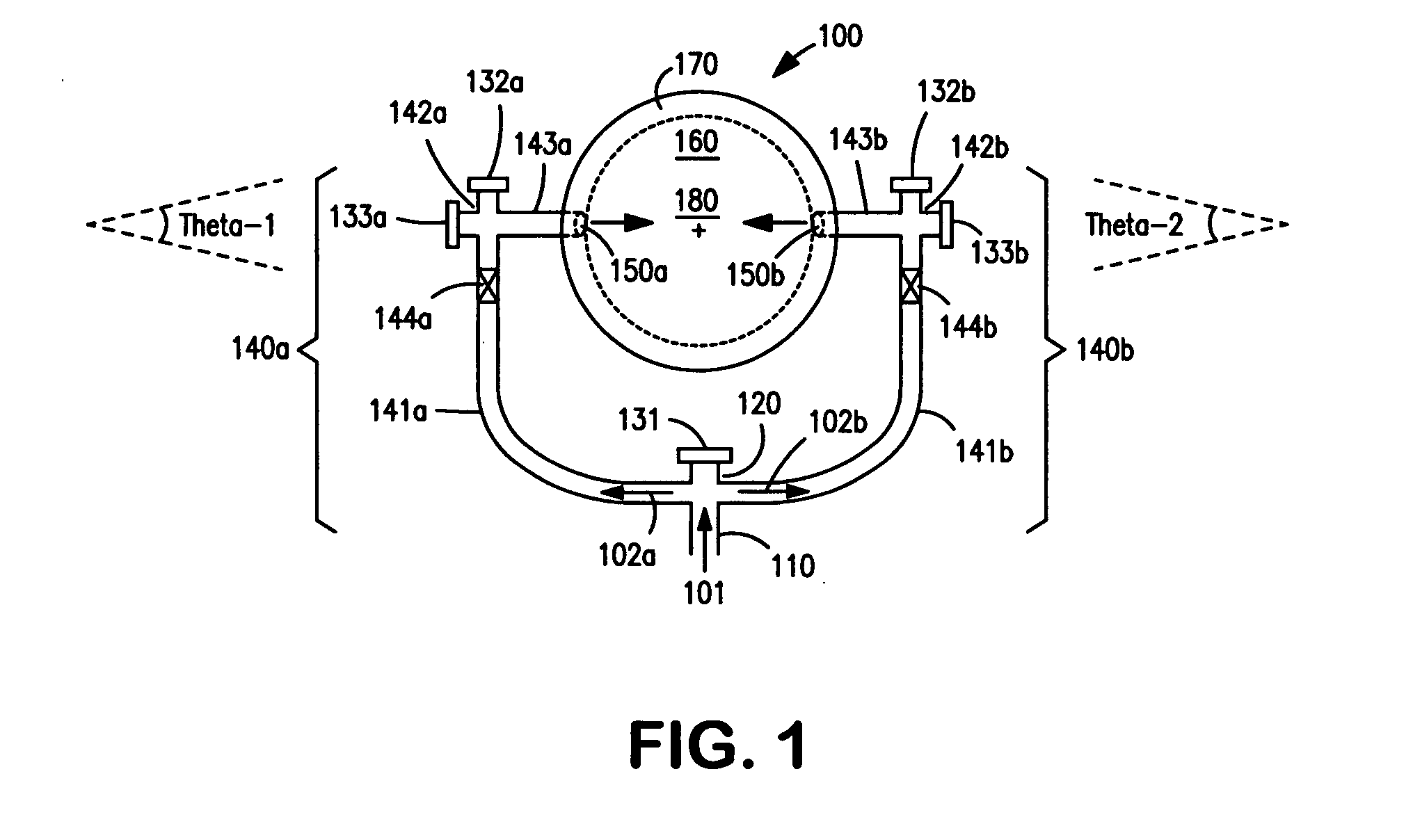

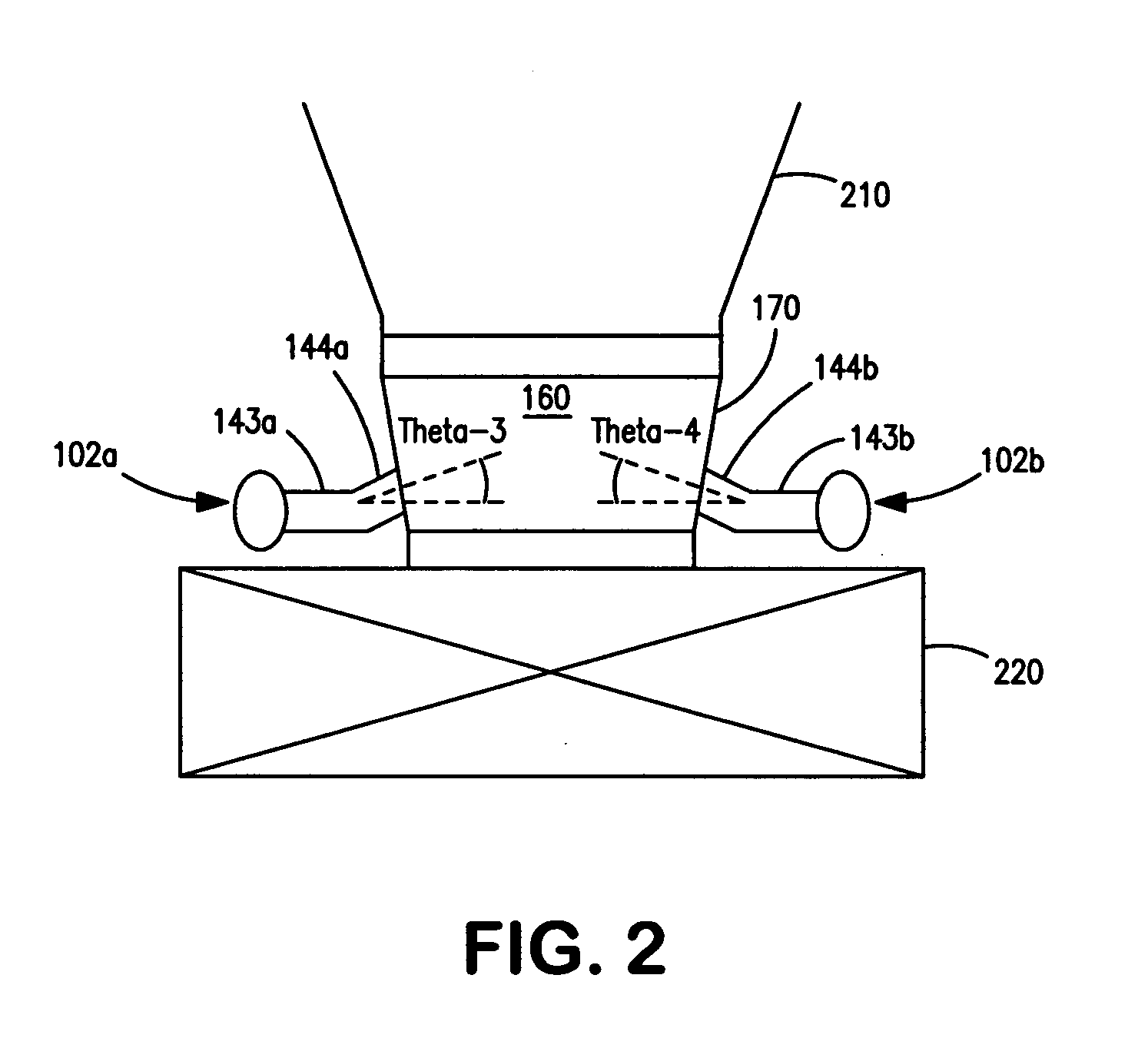

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS20130270157A1Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusEnvironmental engineeringChemical products

The present invention provides a method, an apparatus and chemical products for treating petroleum equipment wherein a fluid is flowing, preferably of the hydrocarbon type, and wherein treating is performed by establishing a closed or semi-closed flow circulation loop, during the normal production operations of the equipment. The treatment can refer to the cleaning of equipment, to yield improvement as compared to normal run conditions and / or to a reduction of coke formation and / or to coke removal on catalysts.

Owner:FERRARA MARCELLO

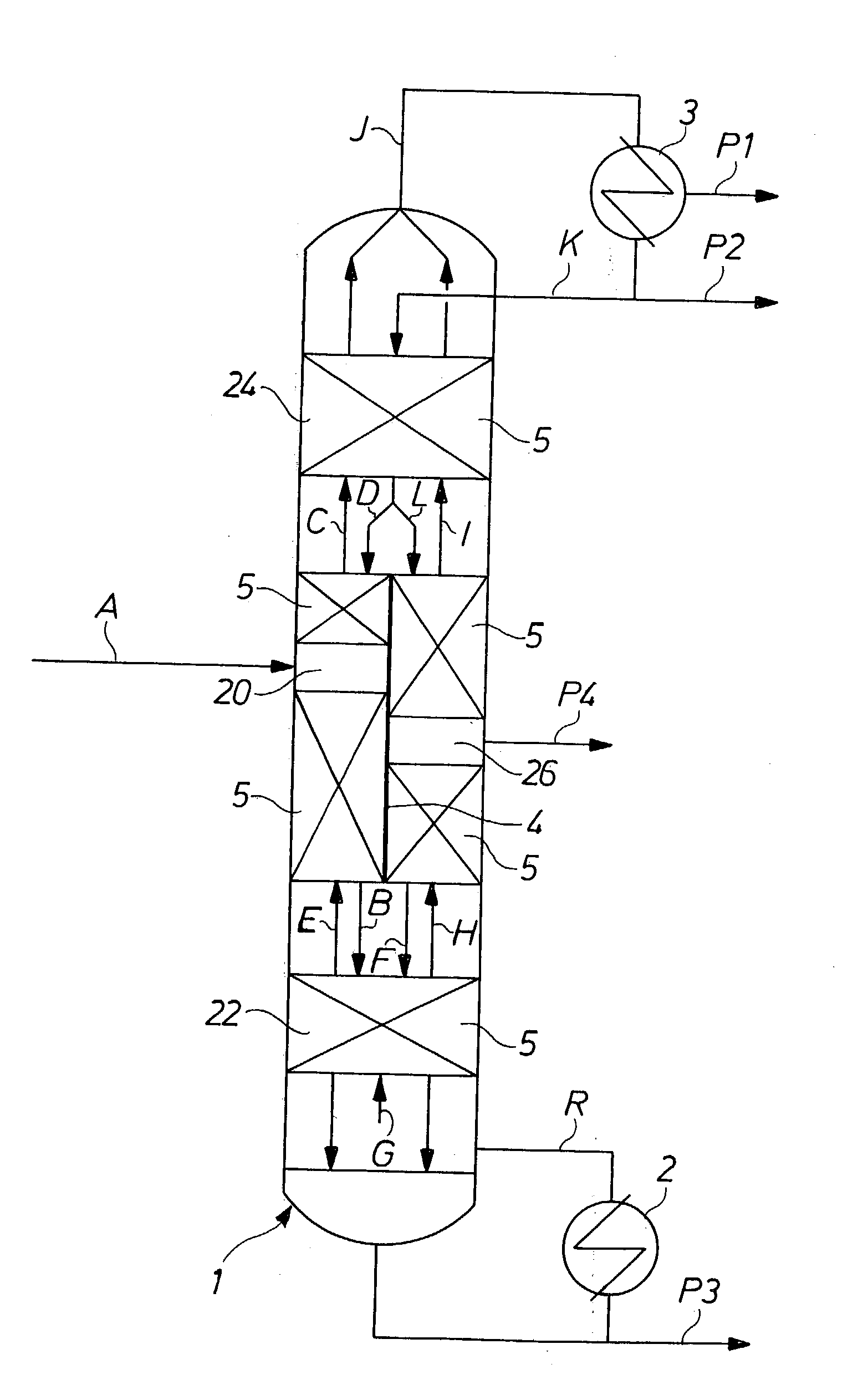

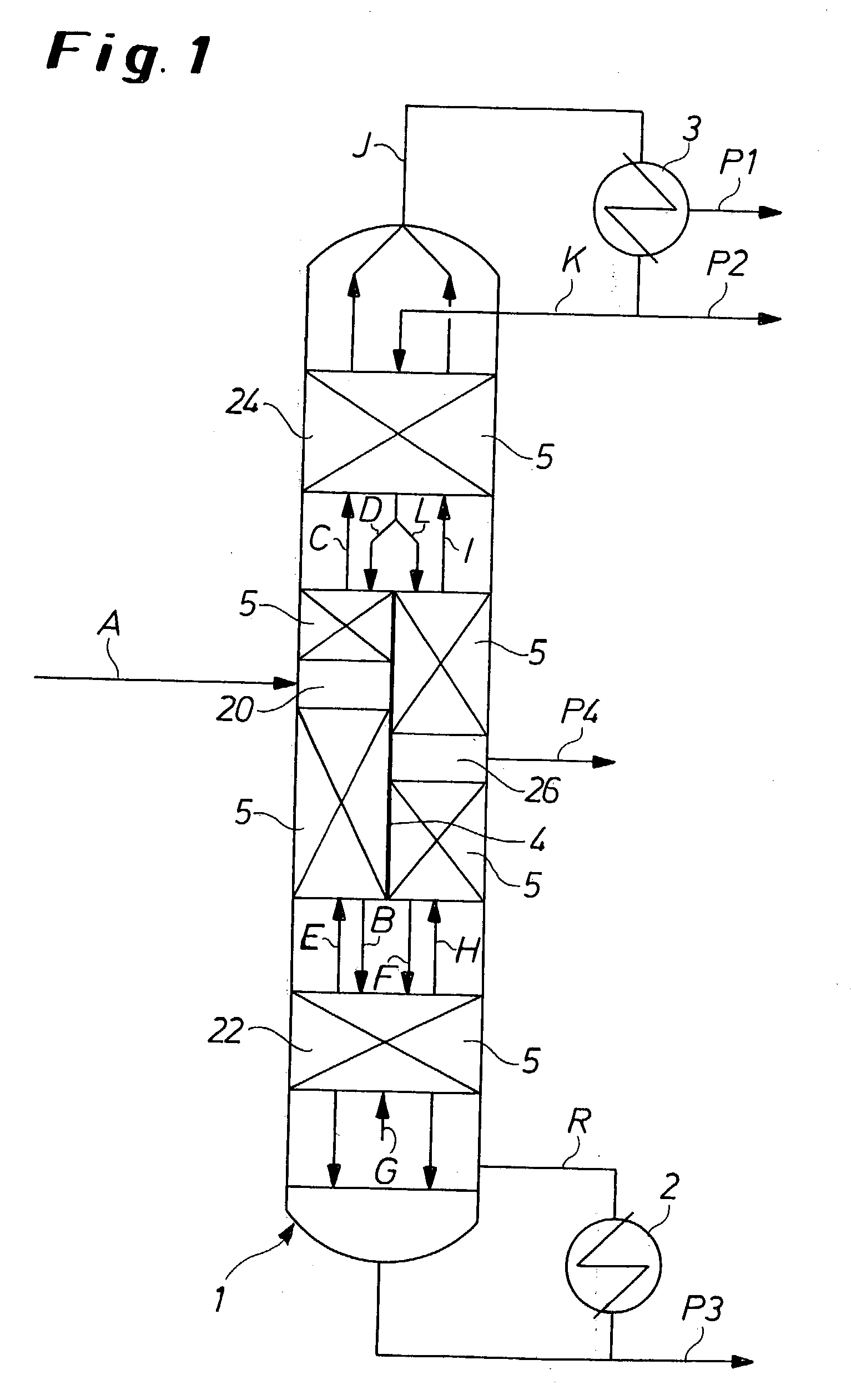

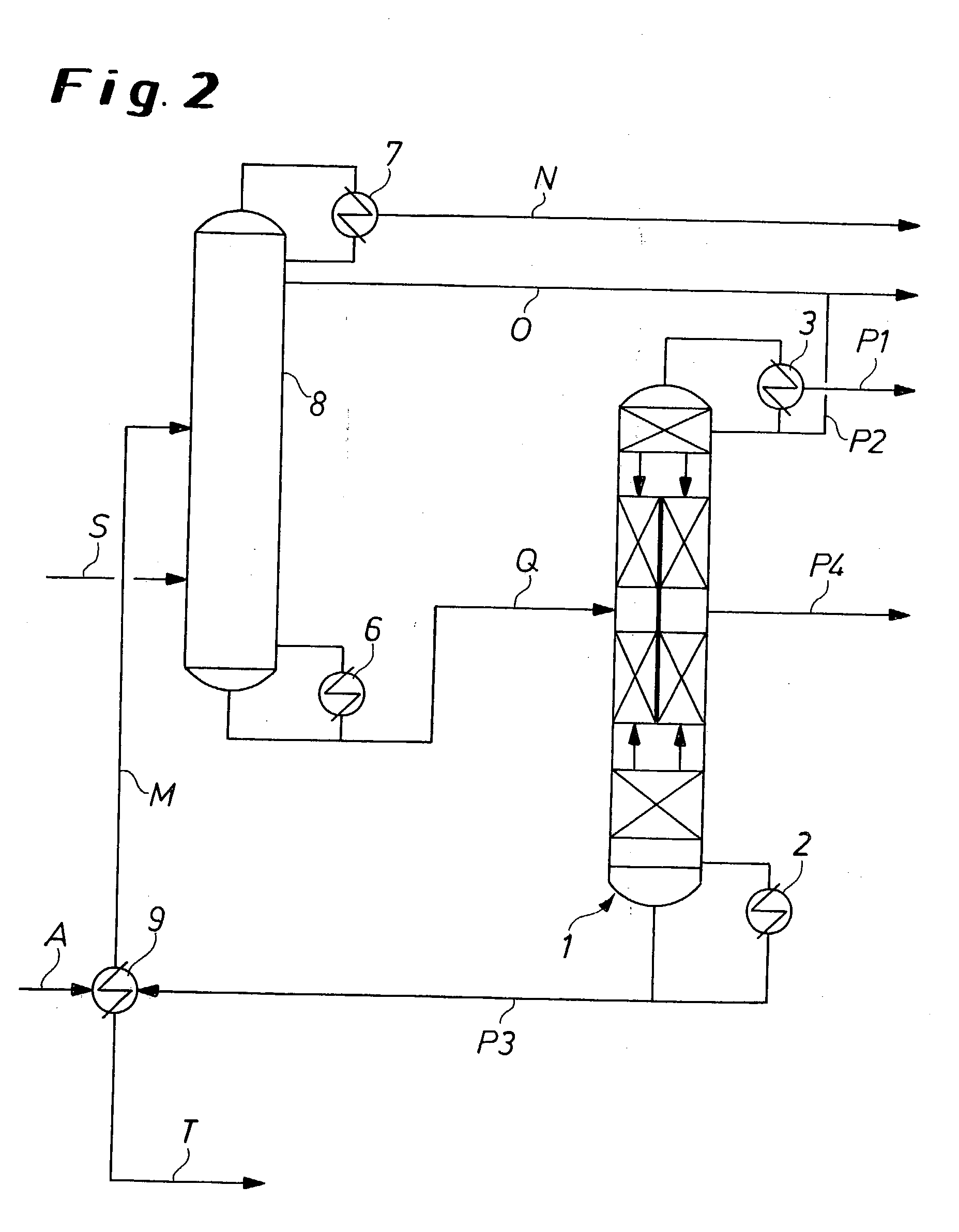

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS20030230476A1Weaken energyLow investment costThermal non-catalytic crackingOrganic compound preparationPurification methodsOrganic solvent

Process for the purification of toluenediisocyanate from a crude distillation feed comprising toluenediisocyanate, an organic solvent and less than 2% by weight phosgene by separating the crude distillation feed in a dividing-wall distillation column into at least four product fractions P1-P4. P1 is a phosgene enriched low-boiler product, P2 is a solvent-enriched product, P3 is a high boiler enriched bottoms and P4 is a toluenediisocyanate product stream.

Owner:COVESTRO DEUTSCHLAND AG

Flexible process for producing base stock and distillates by conversion-hydroisomerisation using a catalyst with low dispersion followed by catalytic dewaxing

InactiveUS6602402B1Facility of preparationImprove hydrogenation activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonPtru catalystEngineering

An improved process for producing very high quality base stock and for simultaneous production of high quality middle distallates, comprising successive hydroisomerisation and catalystic dewaxing steps wherein hydroisomerisation is carried out in the presence of a catalyst containing at least one noble metal deposited on an amorphous acidic support, the dispersion of the metal being less than 20%. The support is preferably an amorphous silica-alumina. Catalytic dewaxing is carried out in the presence of a catalyst containing at least one hydrodehydrogenating element (group VIII) and at least one molecular sieve (preferably zeolite). The sieve is preferable selected from NU-10, EU-1, EU-13, zeolite and ferrierite.

Owner:INST FR DU PETROLE

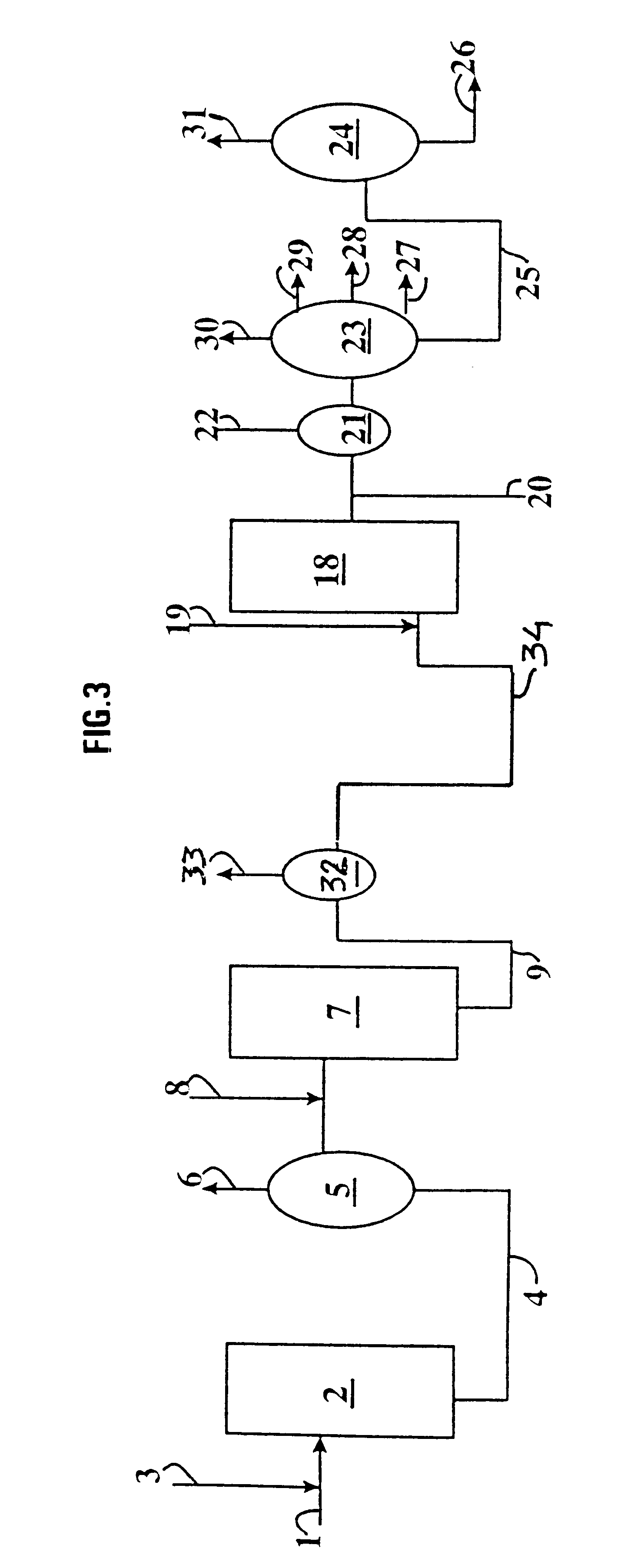

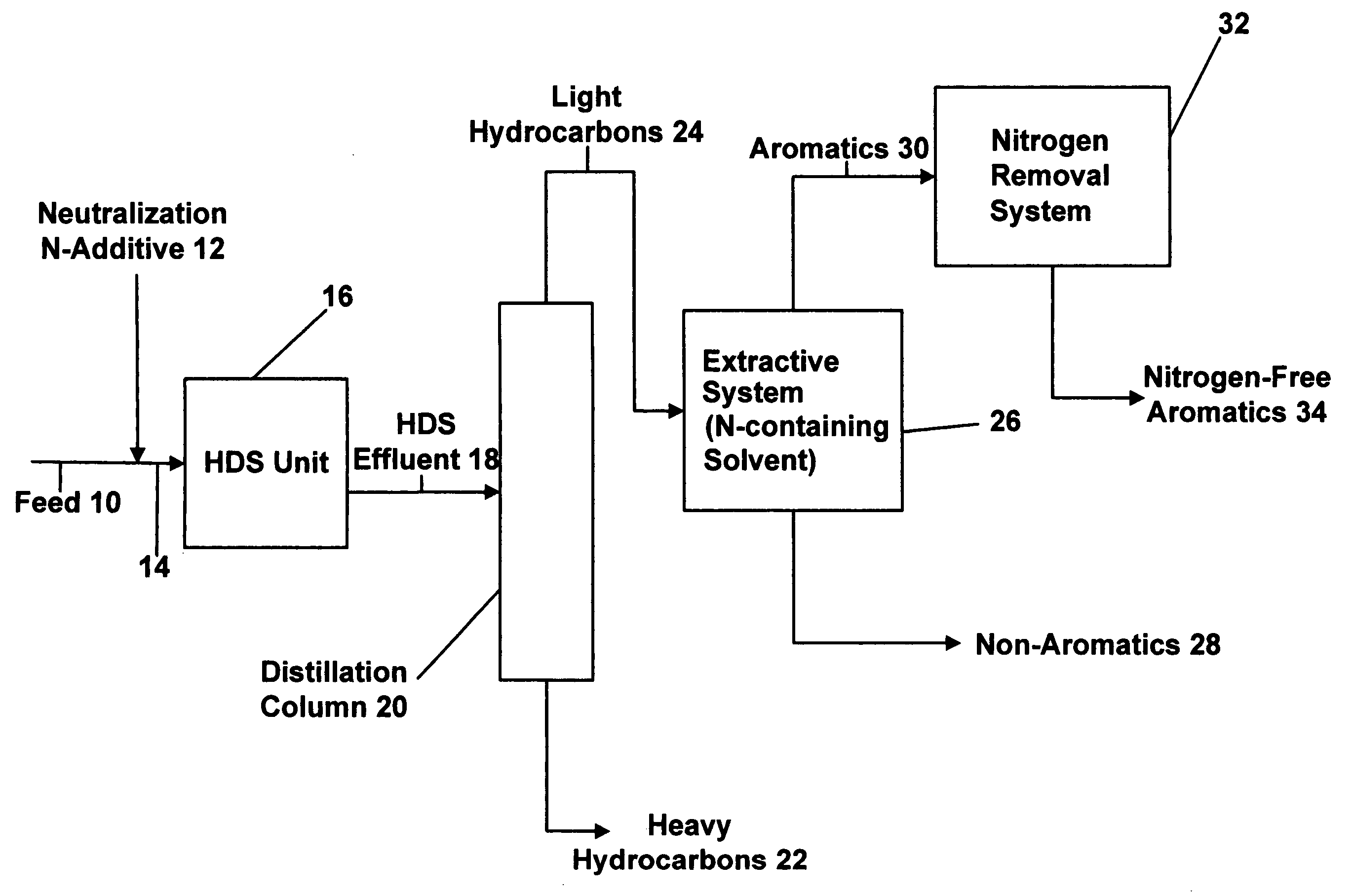

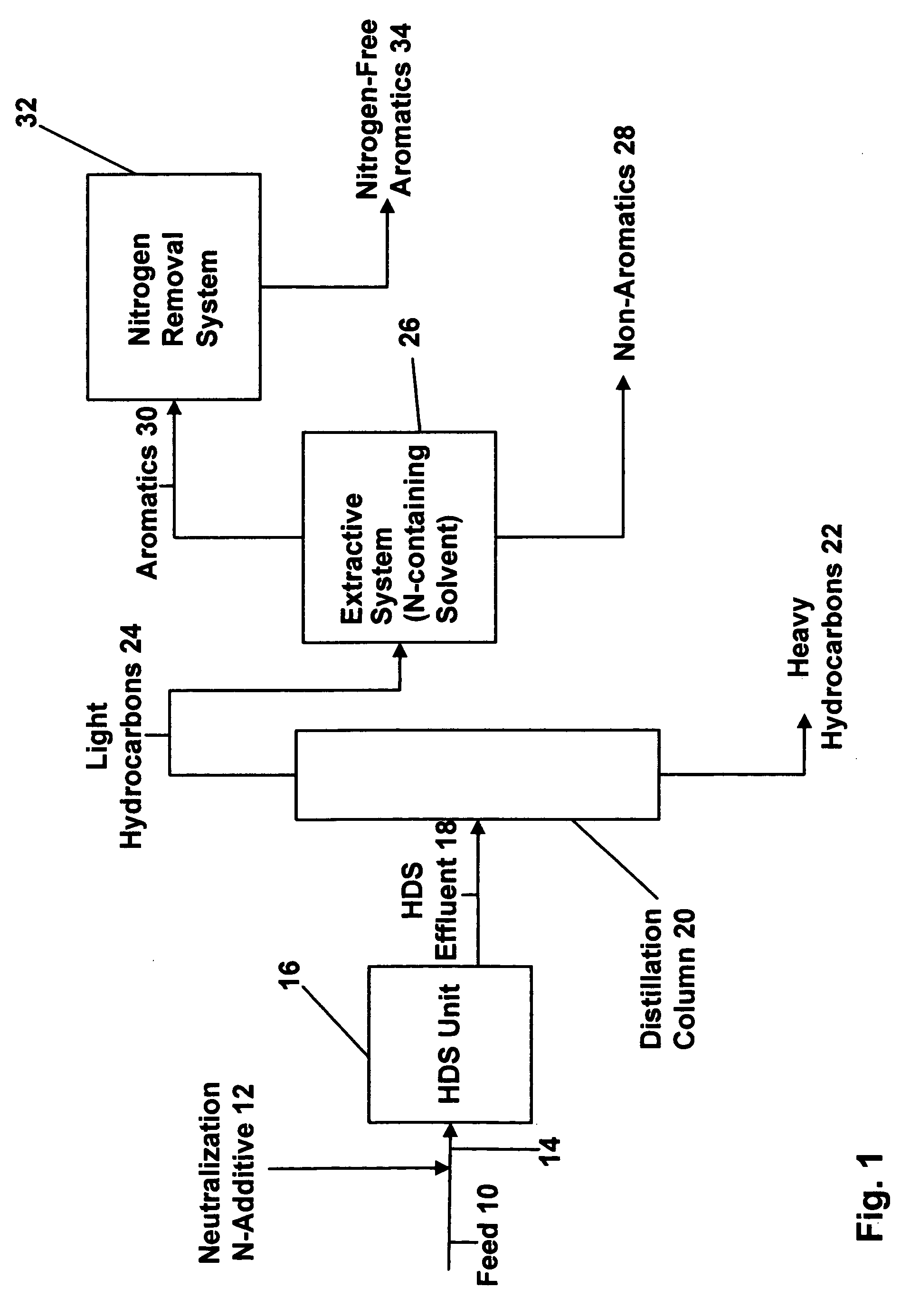

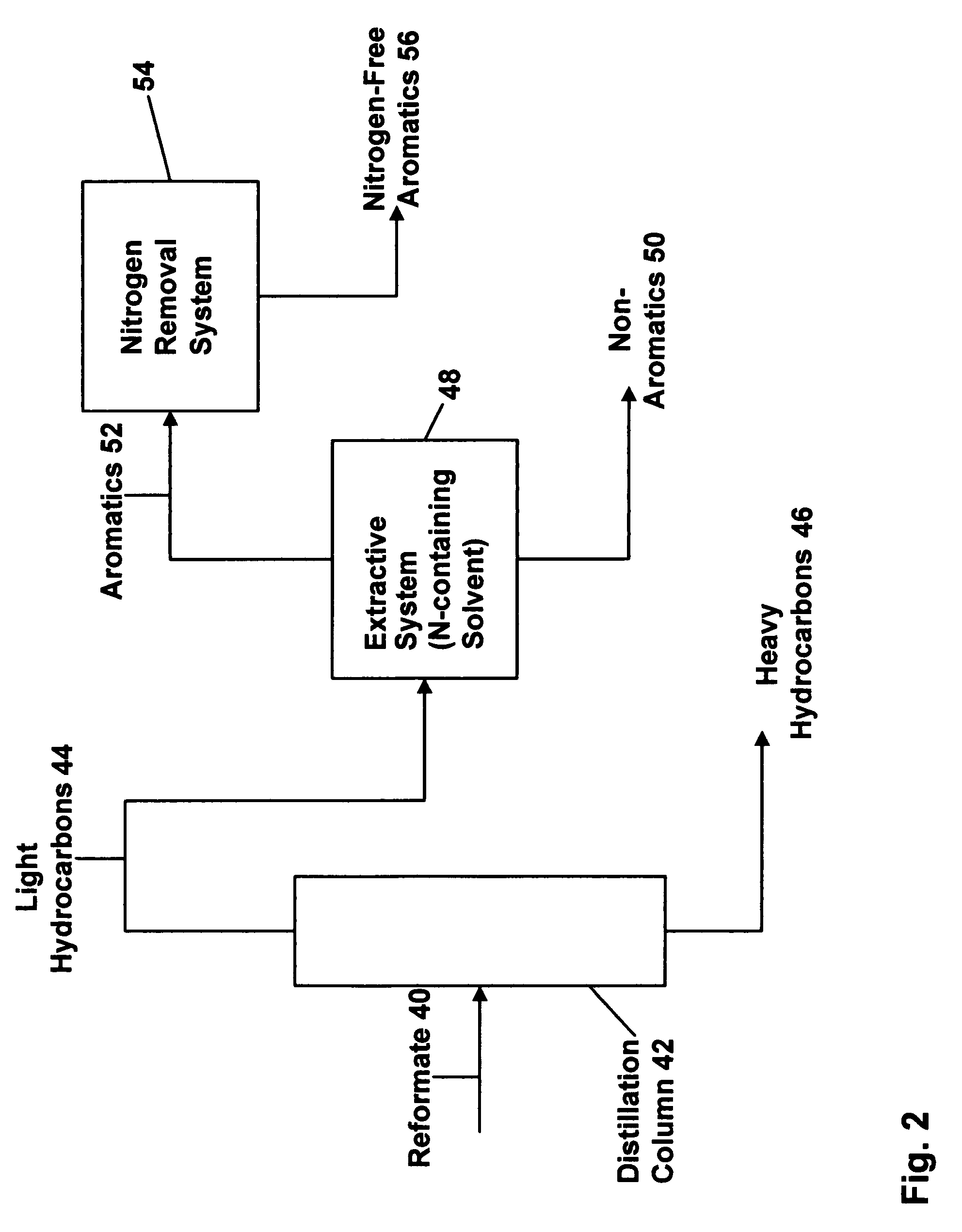

Process for producing petroleum oils with ultra-low nitrogen content

ActiveUS20070000809A1Highly effectiveSpeed up the extraction processHydrocarbon distillationTreatment with plural serial refining stagesLow nitrogenSolvent

A highly effective liquid-liquid extraction process to remove nitrogen compounds and especially basic nitrogen compounds from aromatic light petroleum oils with excellent recovery employs de-ionized water, which can be acidified, as the extractive solvent. The product is an aromatic hydrocarbon with ultra-low amounts of nitrogen poisons that can deactivate acidic catalysts. The extracted oils are suitable feedstock for the subsequent catalytic processes that are promoted with the high performance solid catalysts, which are extremely sensitive to nitrogen poison.

Owner:CPC CORPORATION +1

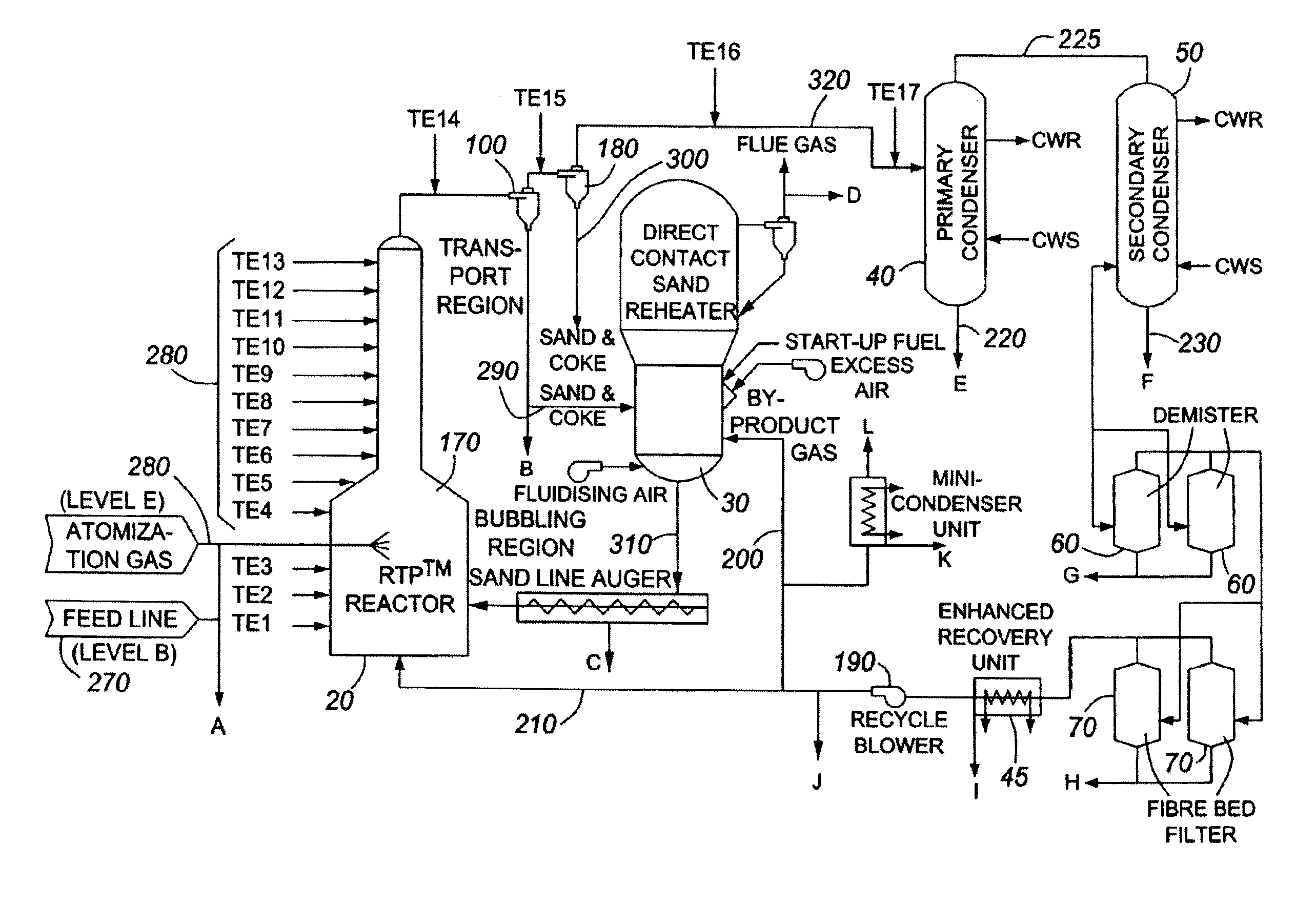

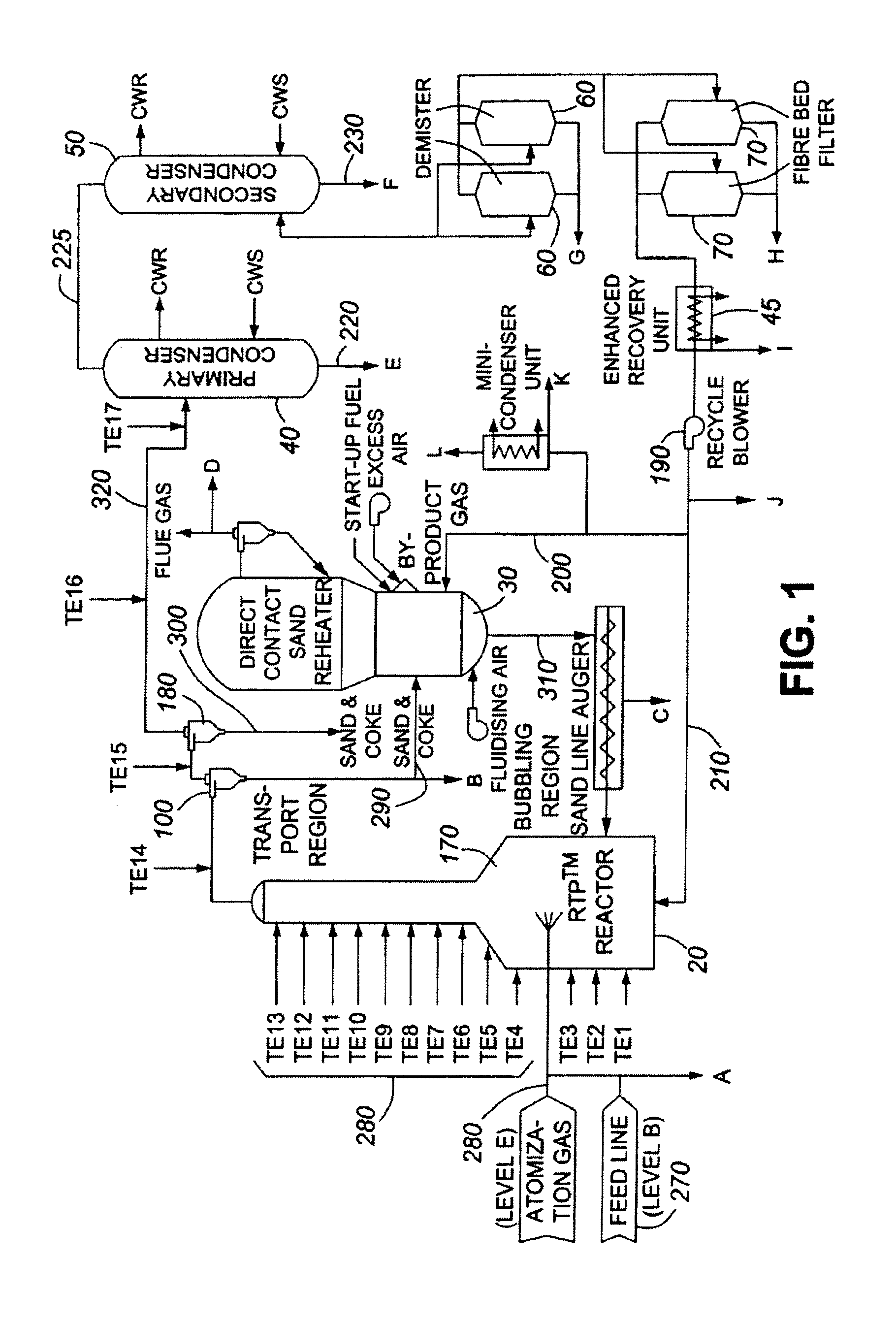

Methods and Systems for Producing Reduced Resid and Bottomless Products from Heavy Hydrocarbon Feedstocks

InactiveUS20080230440A1Cost controlReduce operating costsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesLiquid product

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, collecting a gaseous and liquid product mixture comprising a mixture of a light fraction and a heavy fraction from the product stream, and using a vacuum tower to separate the light fraction as a substantially bottomless product and the heavy fraction from the product mixture.

Owner:IVANHOE HTL GASOLINEEUM

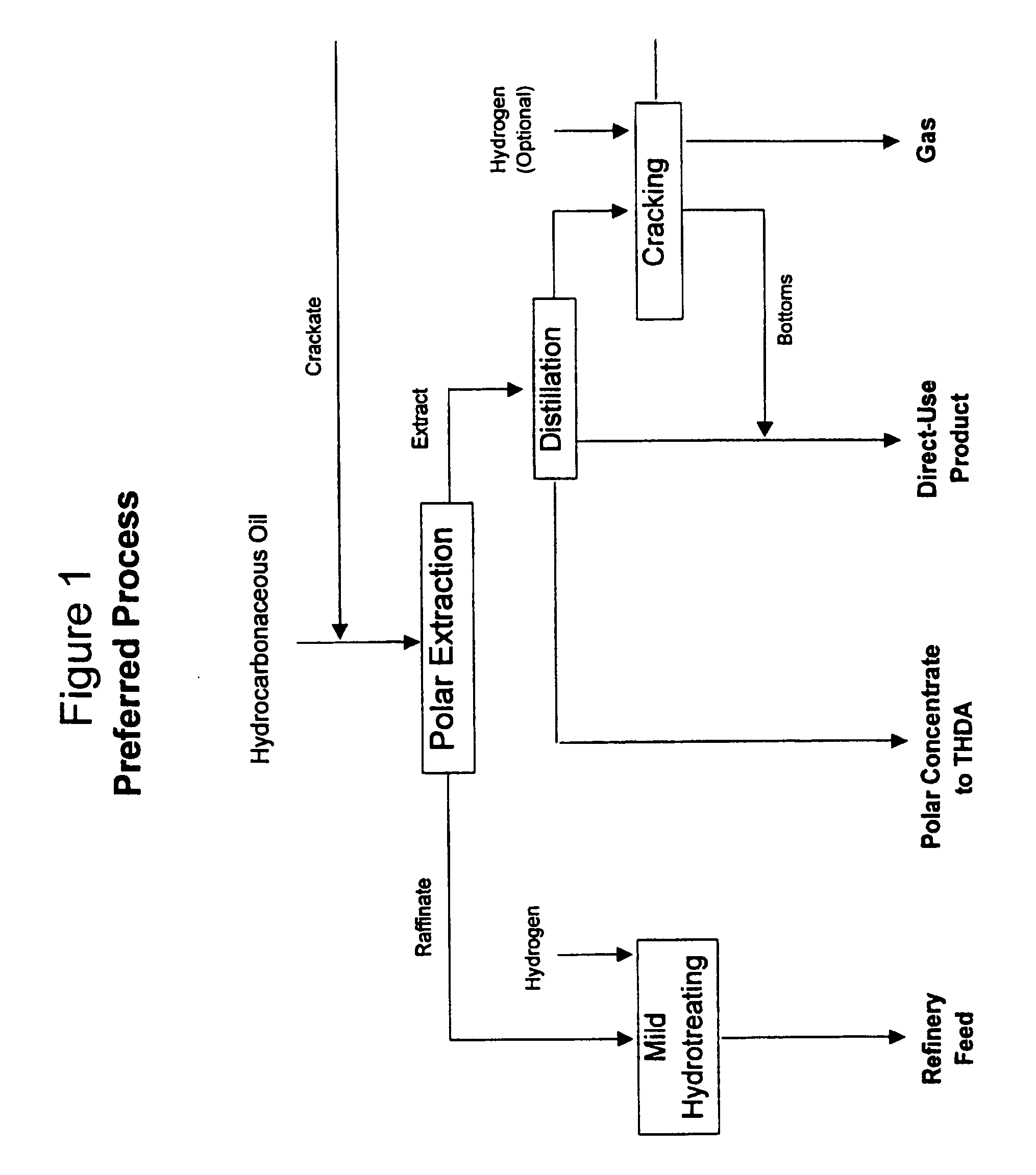

Process for enhancing the value of hydrocarbonaceous natural resources

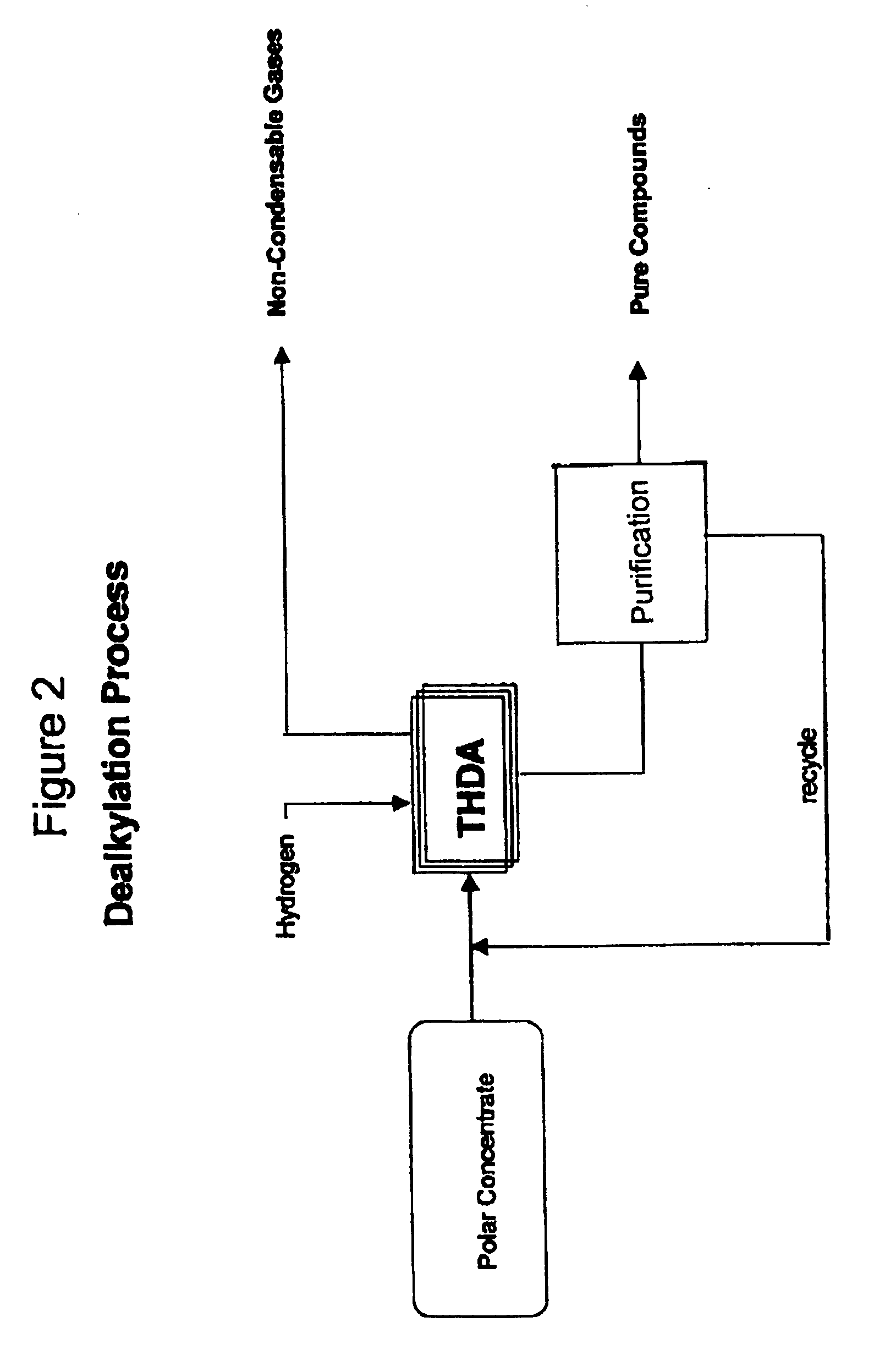

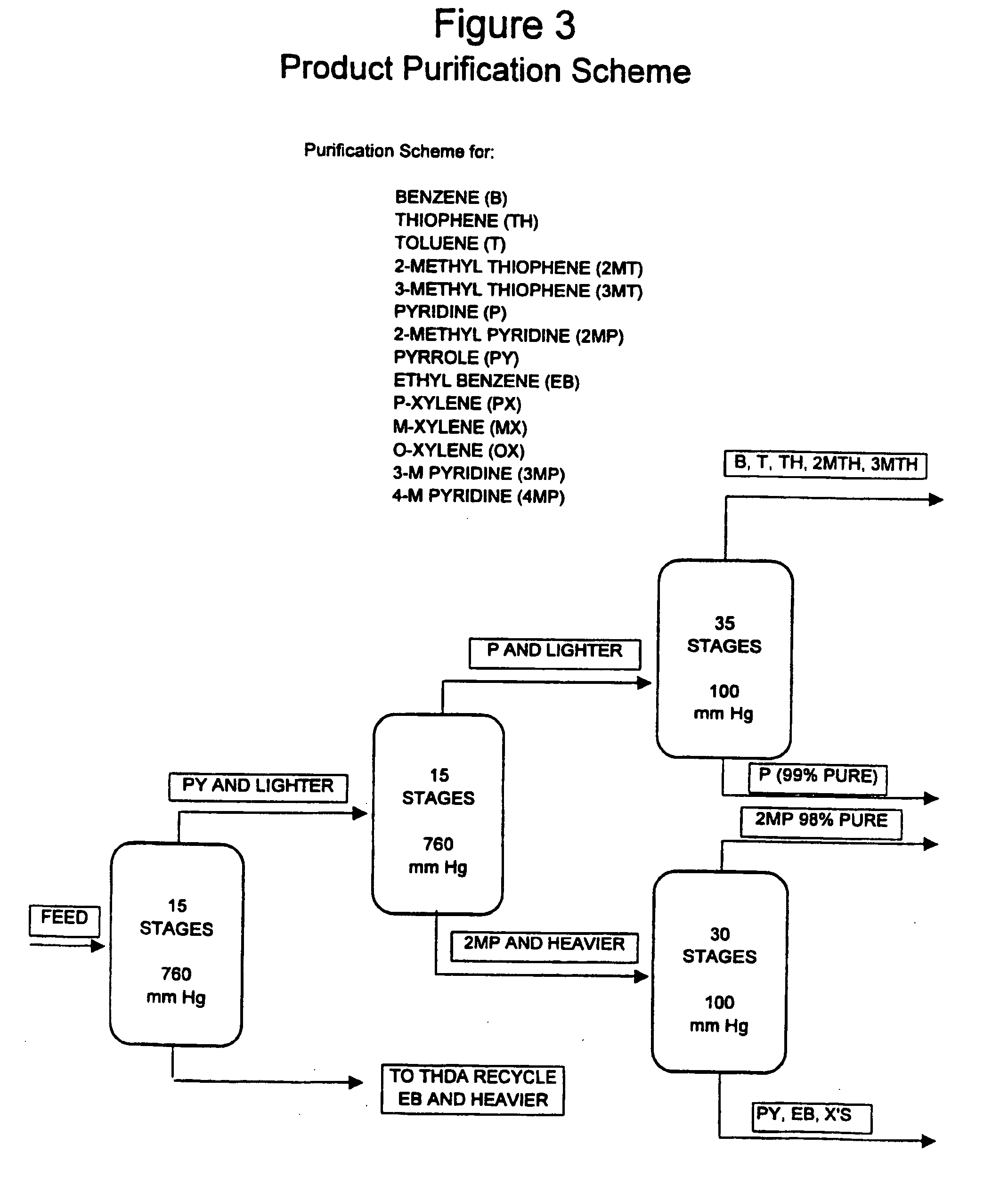

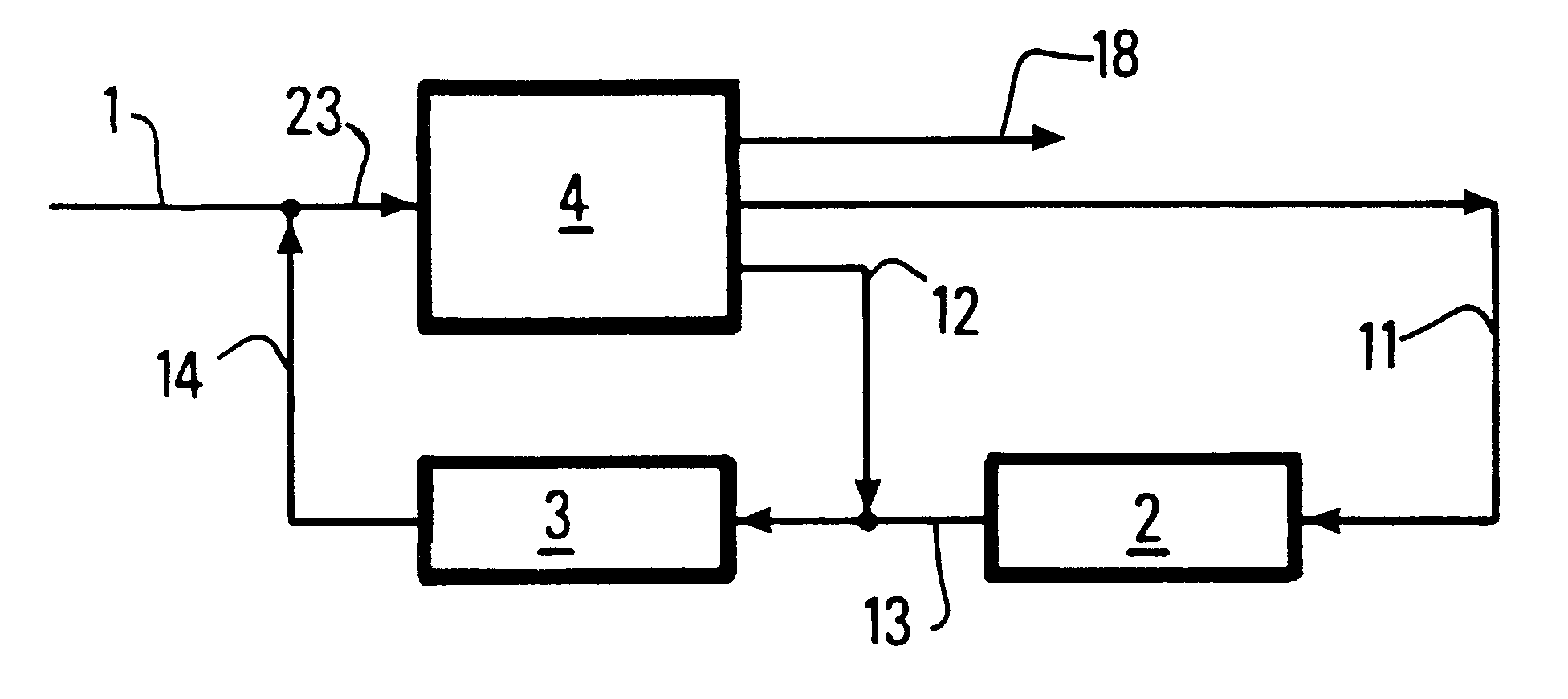

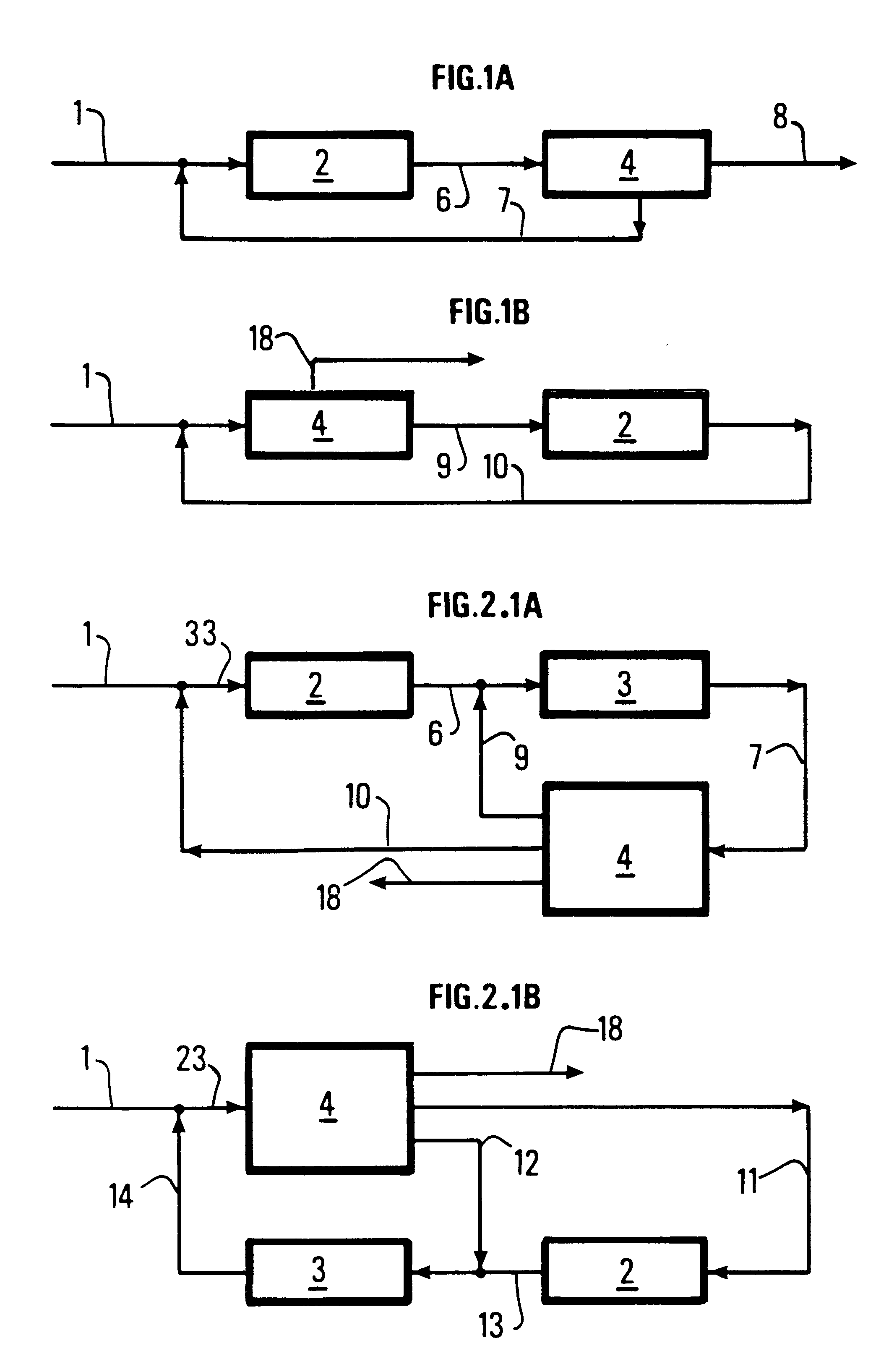

InactiveUS20050167337A1Little and wasteLittle and valueHydrocarbon distillationTreatment with hydrotreatment processesSolubilityNatural resource

A process for upgrading hydrocarbonaceous oil containing heteroatom-containing compounds where the hydrocarbonaceous oil is contacted with a solvent system that is a mixture of a major portion of a polar solvent having a dipole moment greater than about 1 debye and a minor portion of water to selectively separate the constituents of the carbonaceous oil into a heteroatom-depleted raffinate fraction and heteroatom-enriched extract fraction. The polar solvent and the water-in-solvent system are formulated at a ratio where the water is an antisolvent in an amount to inhibit solubility of heteroatom-containing compounds and the polar solvent in the raffinate, and to inhibit solubility of non-heteroatom-containing compounds in the extract. The ratio of the hydrocarbonaceous oil to the solvent system is such that a coefficient of separation is at least 50%. The coefficient of separation is the mole percent of heteroatom-containing compounds from the carbonaceous oil that are recovered in the extract fraction minus the mole percent of non-heteroatom-containing compounds from the carbonaceous oil that are recovered in the extract fraction. The solvent-free extract and the raffinate concentrates may be used directly or processed to make valuable petroleum, chemical or industrial products.

Owner:JAMES W BUNGER & ASSOC

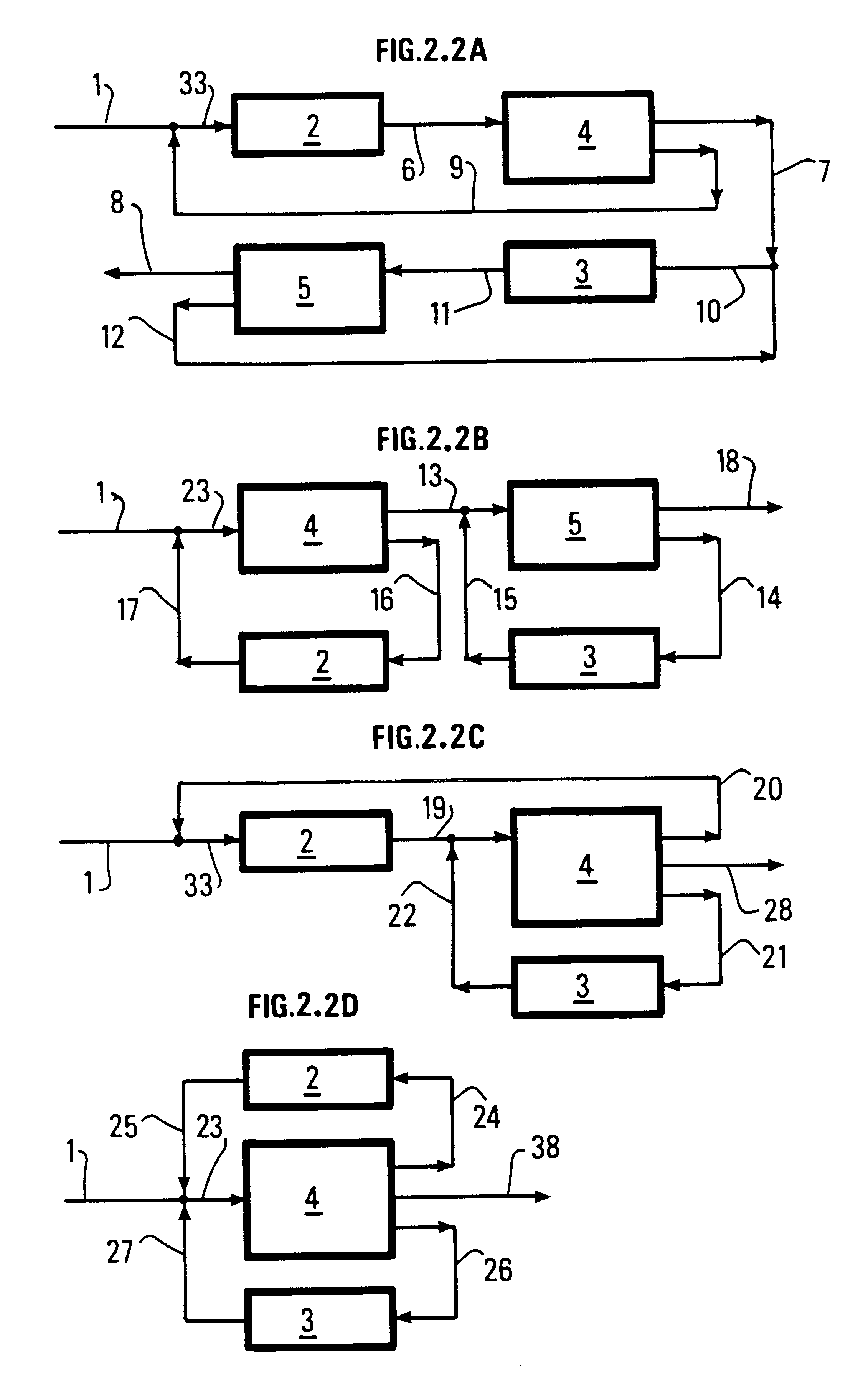

High octane number gasolines and their production using a process associating hydro-isomerization and separation

InactiveUS6338791B1Minimize cracksReduce the amount requiredRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationCyclic alkaneIsomerization

The invention provides a high octane number gasoline pool comprises at least 2% of di-branched paraffins containing 7 carbon atoms, and a process for producing this gasoline pool by hydro-isomerizing a feed constituted by a C5 to C8 cut which comprises at least one hydro-isomerization section and at least one separation section, in which the hydro-isomerization section and at least one separation section, in which the hydro-isomerization section comprises at least one reactor. The separation section comprises at least one unit and produces at least two streams: a first stream which is rich in di- and tri-branched paraffins, and possibly in naphthenes and aromatic compounds which is sent to the gasoline pool; and in a first version of the process, a second stream is produced which is rich in straight-chain and mono-branched paraffins which is recycled to the inlet of the hydro-isomerization section, while in a second version of the process, a second flux is produced which is rich in straight-chain paraffins which is recycled to the inlet of a first hydro-isomerization section and a third stream is produced which is rich in mono-branched paraffins which is recycled to the inlet of a second hydroisomerization section.

Owner:INST FR DU PETROLE

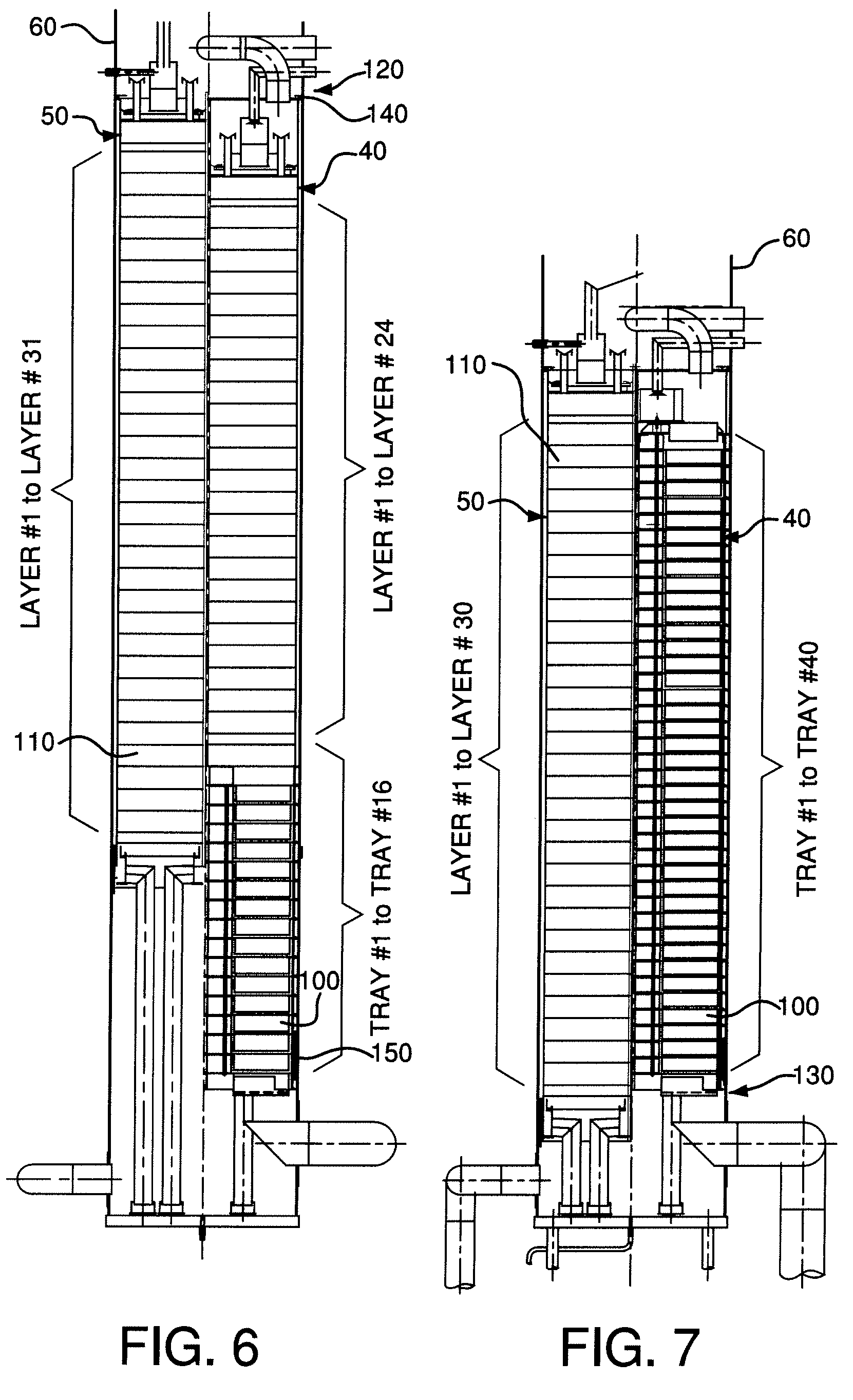

Dividing wall column fractionation tray

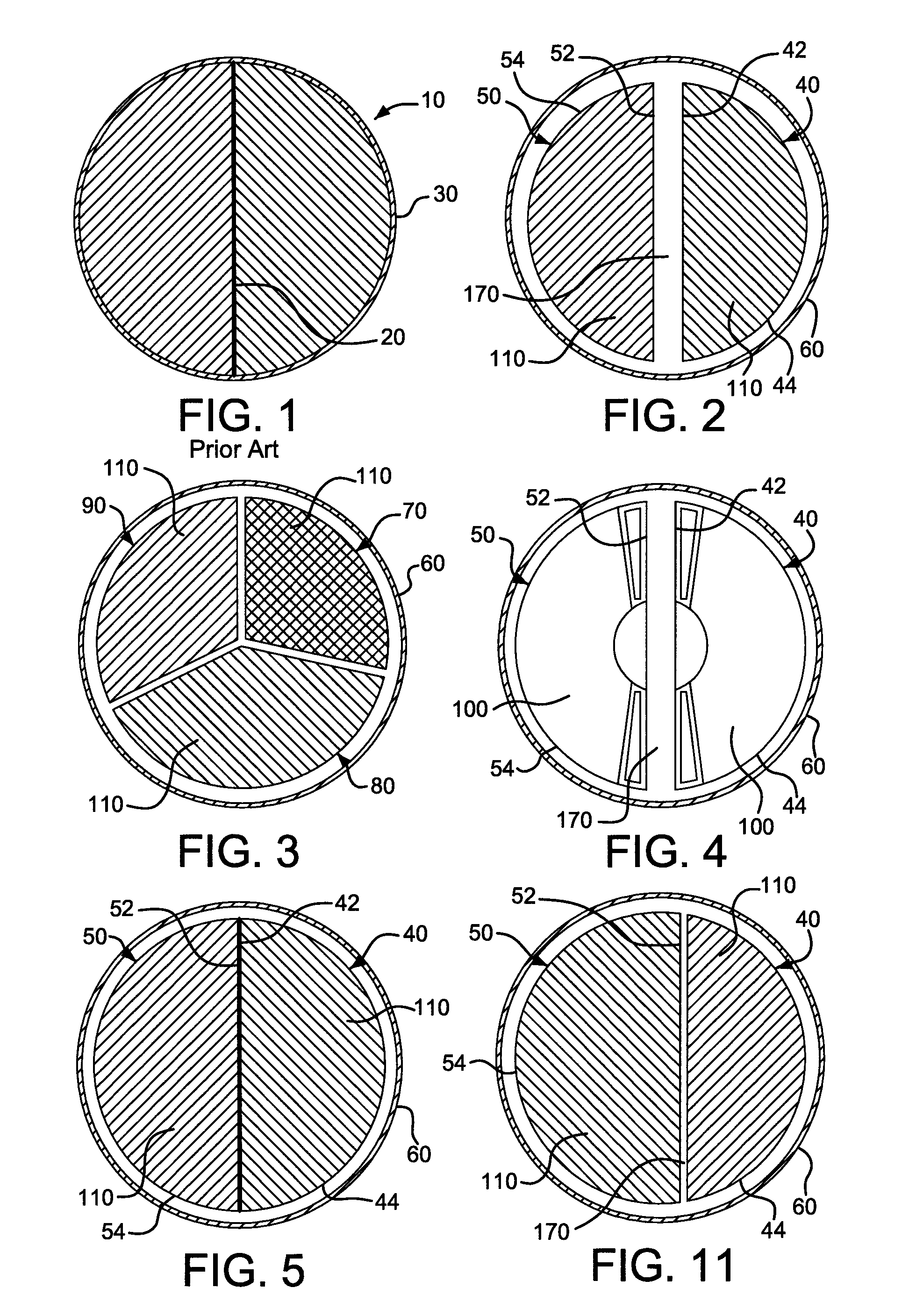

InactiveUS6645350B1Thermal non-catalytic crackingHydrocarbon distillationShortest distanceFractionation

Problems generated by heat transfer through the vertical dividing wall of a trayed "dividing wall column" and into a downcomer of a tray are mitigated by providing a separate vertical isolation wall between the downcomer and dividing wall. The isolation wall forms one side of the downcomer and is spaced a short distance outward from the dividing wall to form an isolation volume which thermally insulates the downcomer from the dividing wall. The added wall is parallel to the dividing wall and supplants the dividing wall as a part of the downcomer. It eliminates a need to insulate the dividing wall.

Owner:UOP LLC

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6172271B1Increase productionContinuous operationThermal non-catalytic crackingHydrocarbon distillationForeign matterBoiling point

Owner:MITSUBISHI HEAVY IND LTD

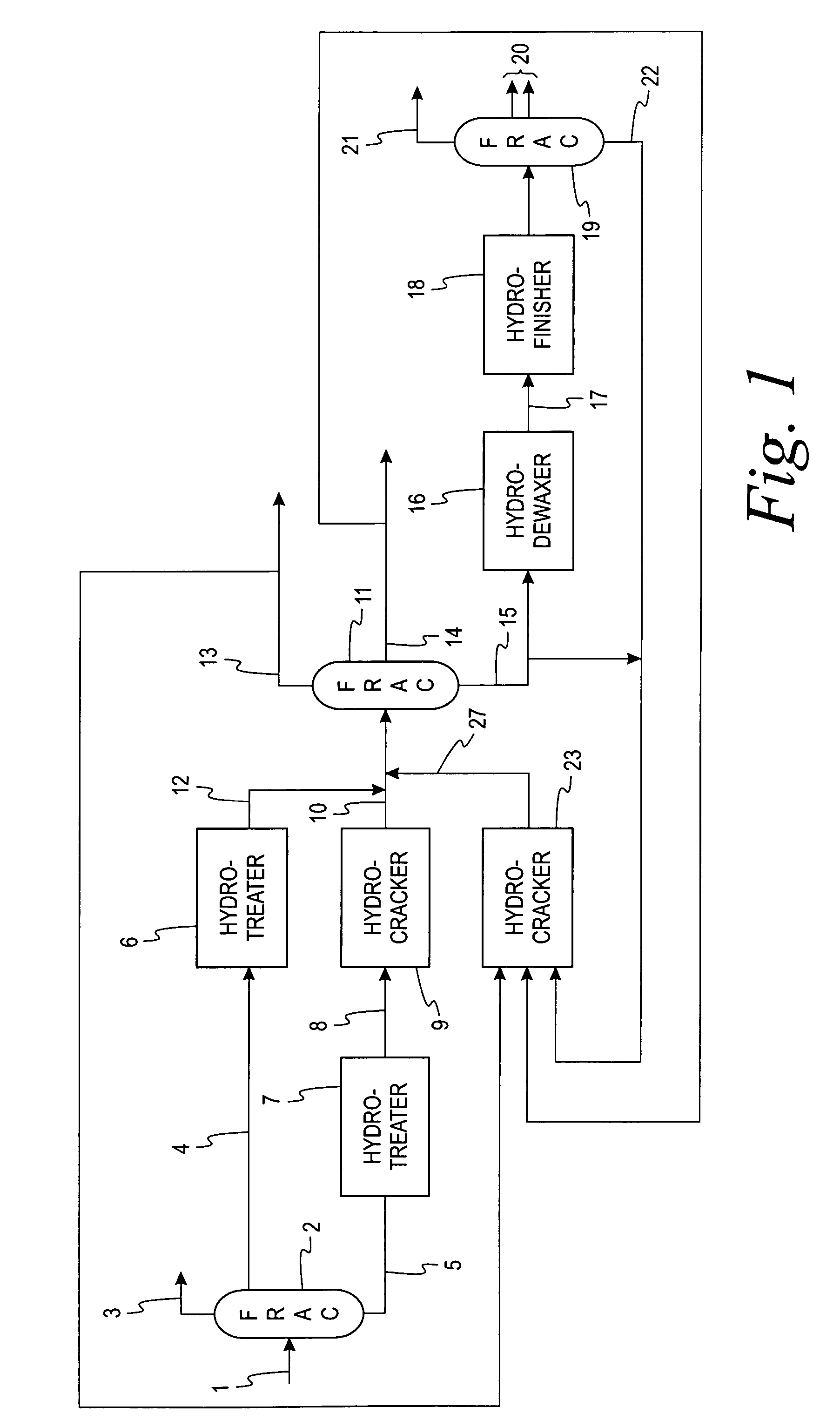

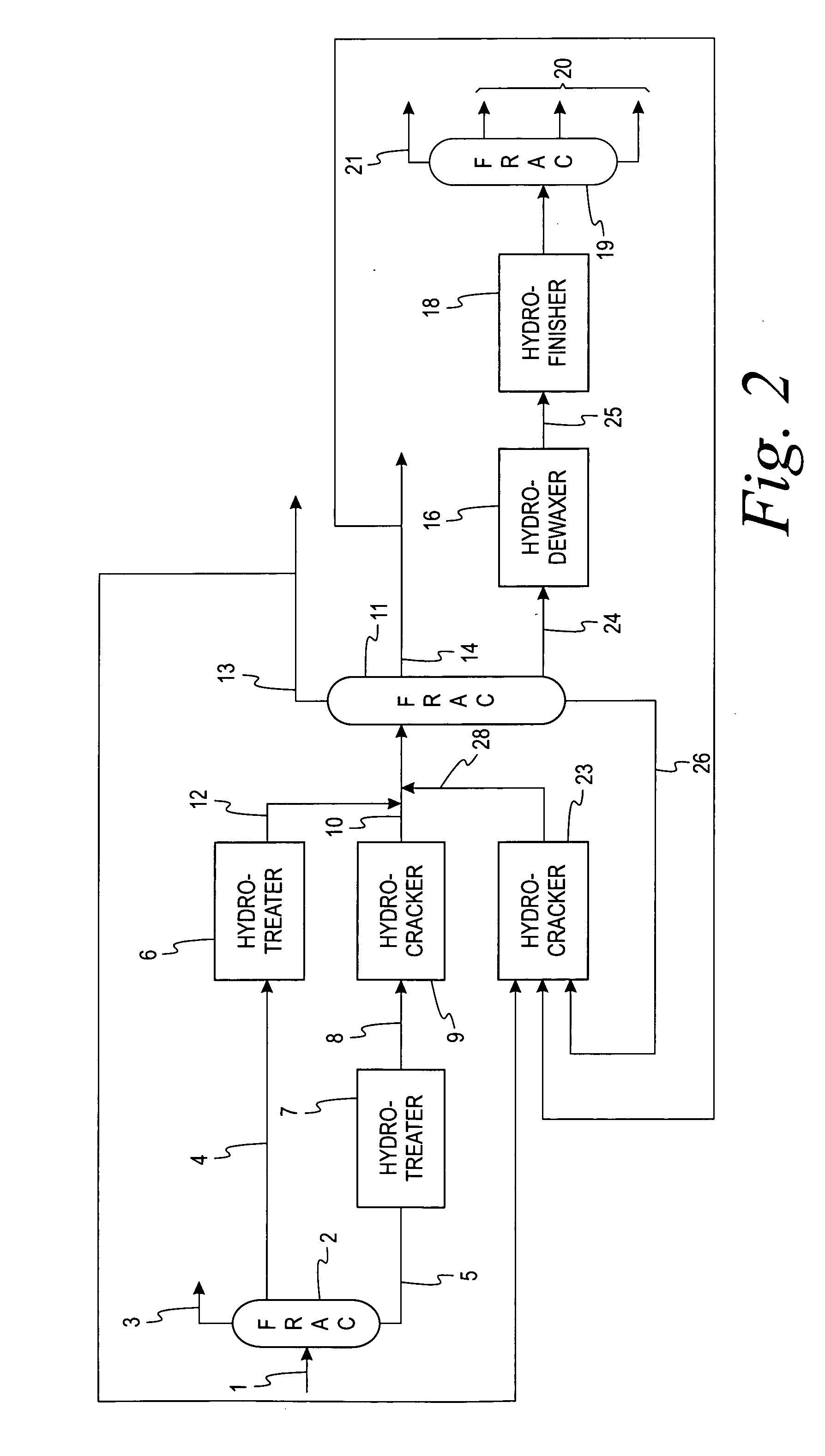

Process to produce synthetic fuels and lubricants

InactiveUS20050183988A1Yield maximizationEquipment cost can be minimizedThermal non-catalytic crackingCatalytic crackingBase oilPetroleum

A process utilizing a low severity hydrocracker prior to a high severity hydrocracker for the processing of petroleum based and synthetic hydrocarbon feedstocks into distillate fuels and high quality lubricant base oils. The process minimizes the size and conditions required by the high severity hydrocracker by closely matching such configuration with the desired product slate.

Owner:REG SYNTHETIC FUELS LLC

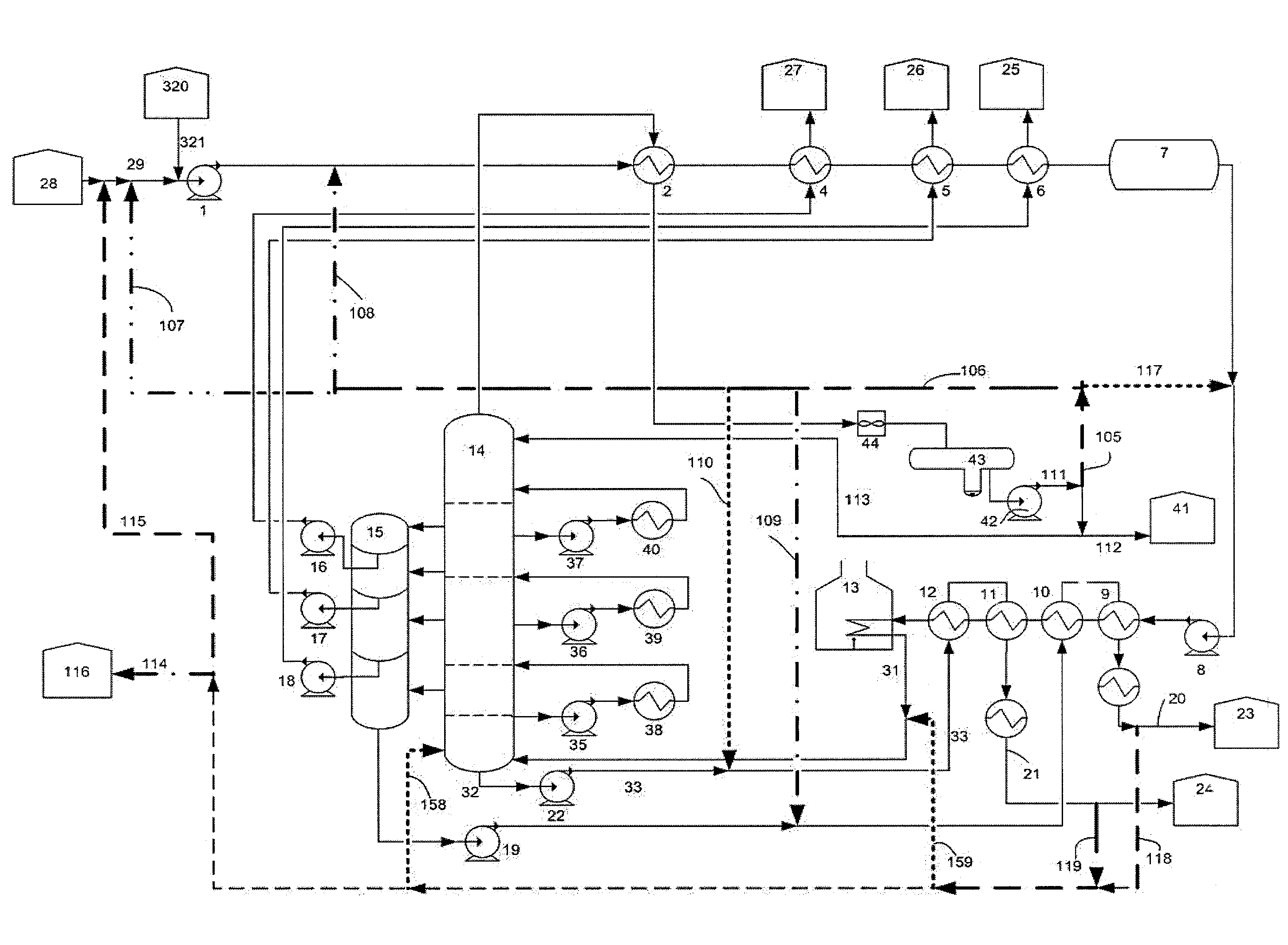

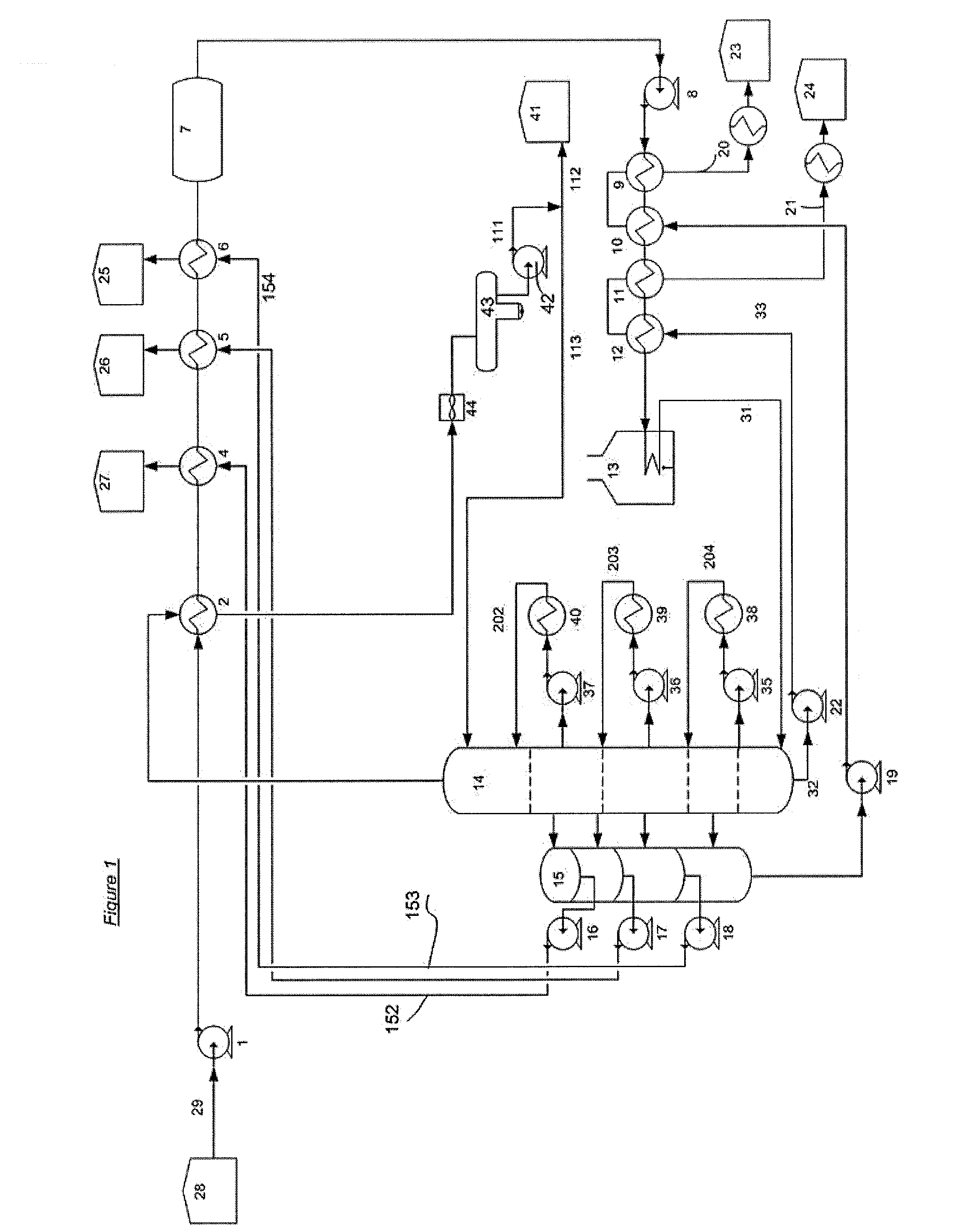

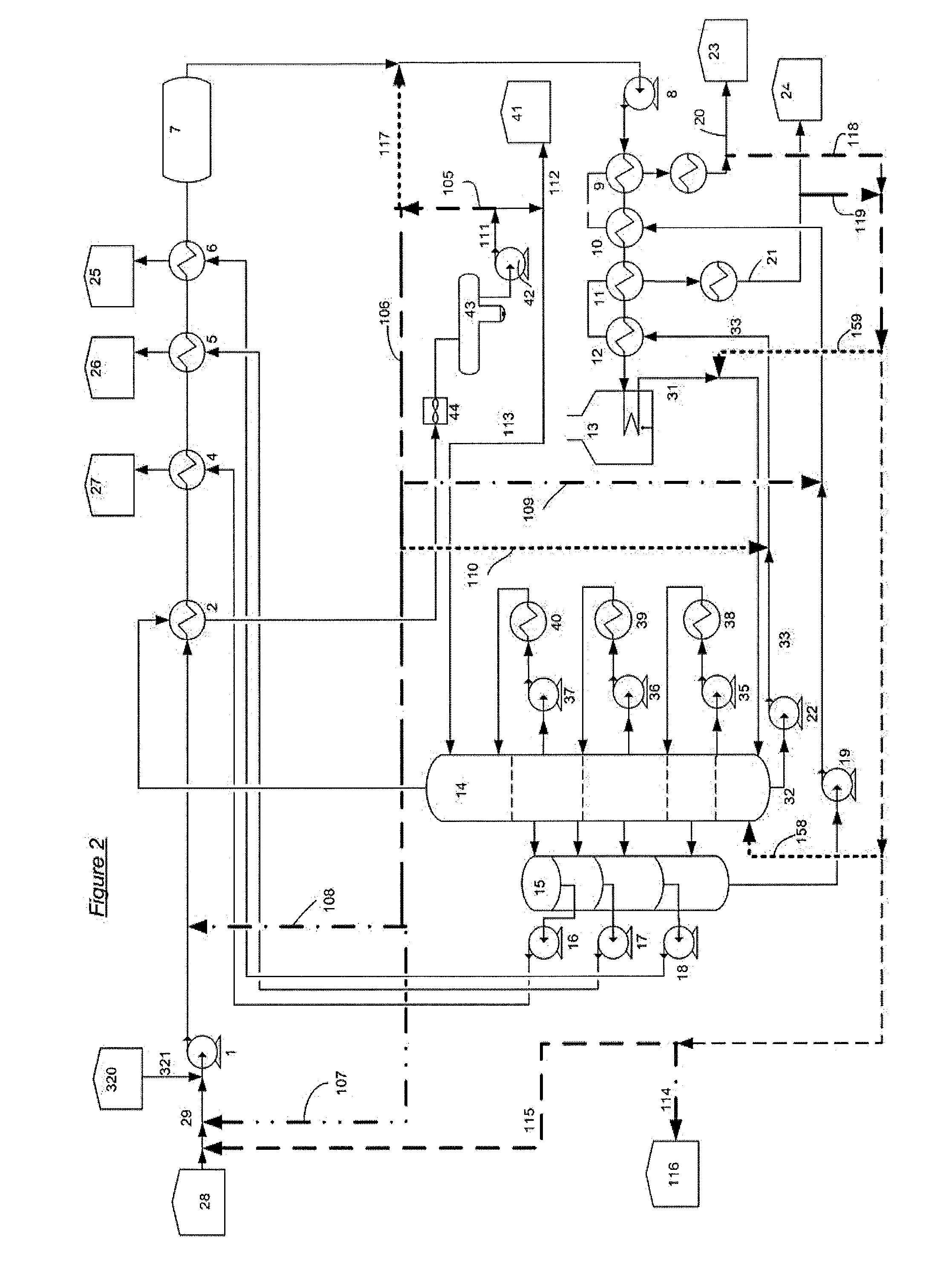

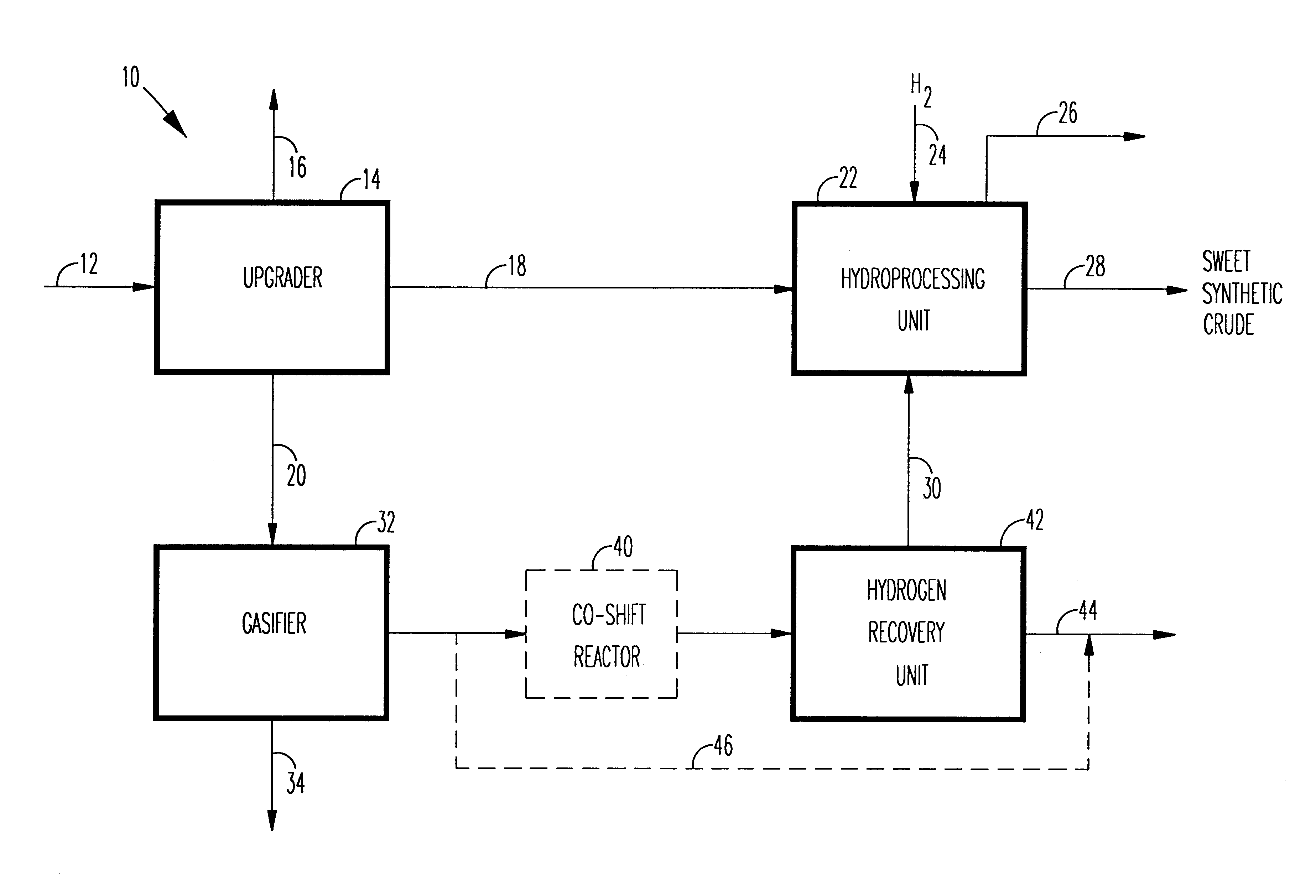

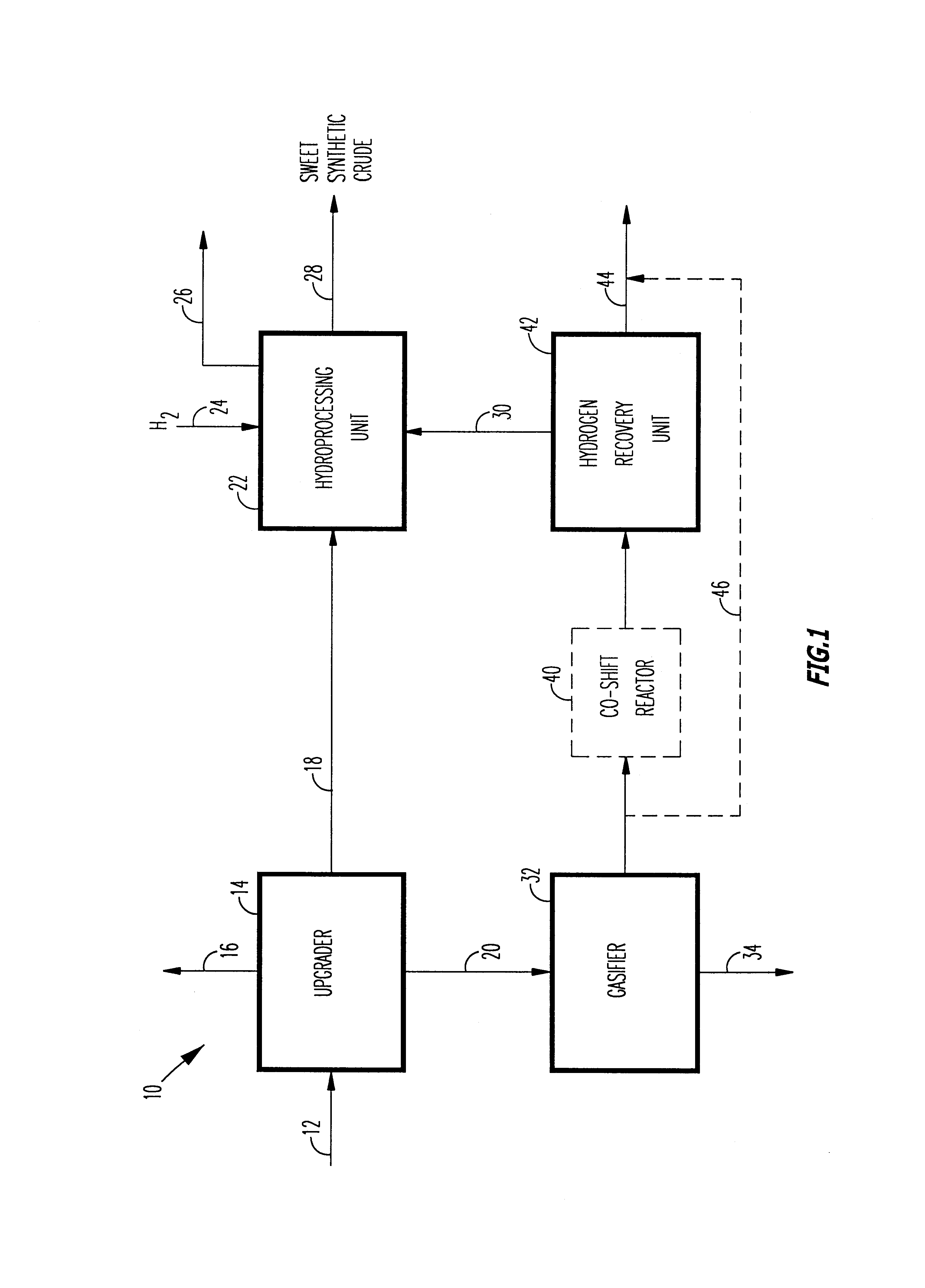

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

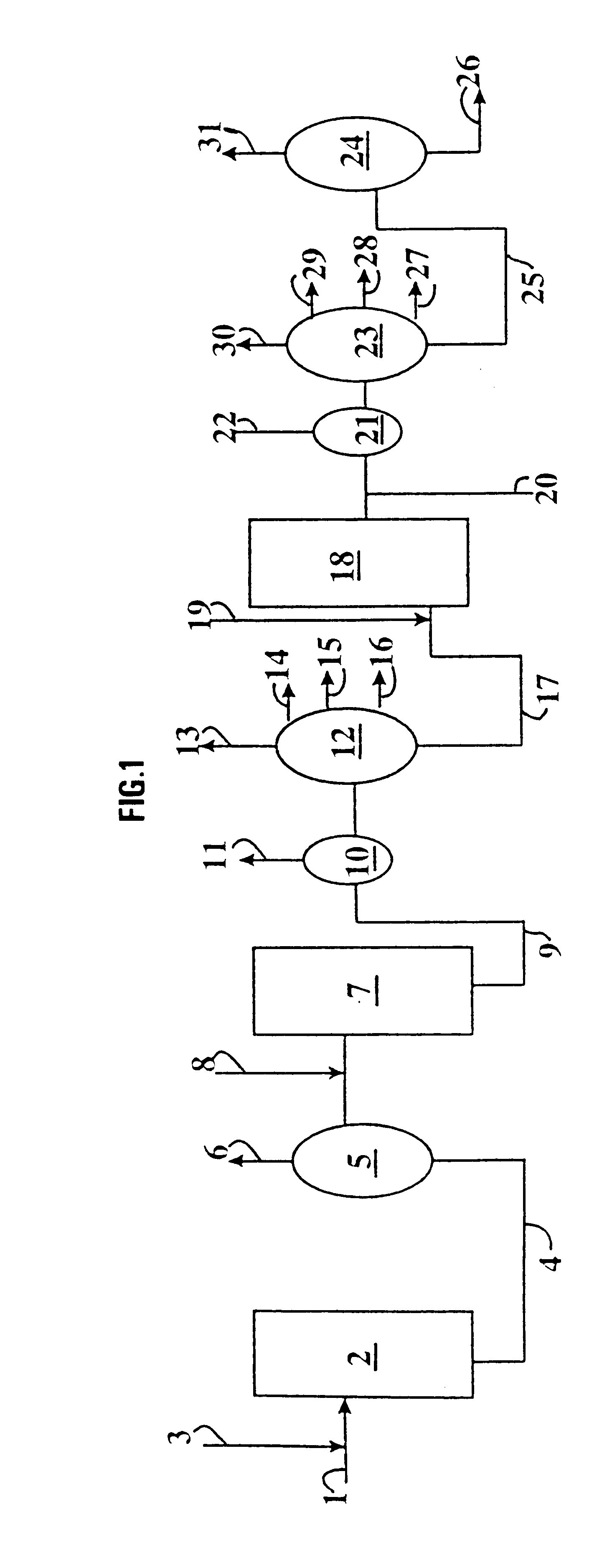

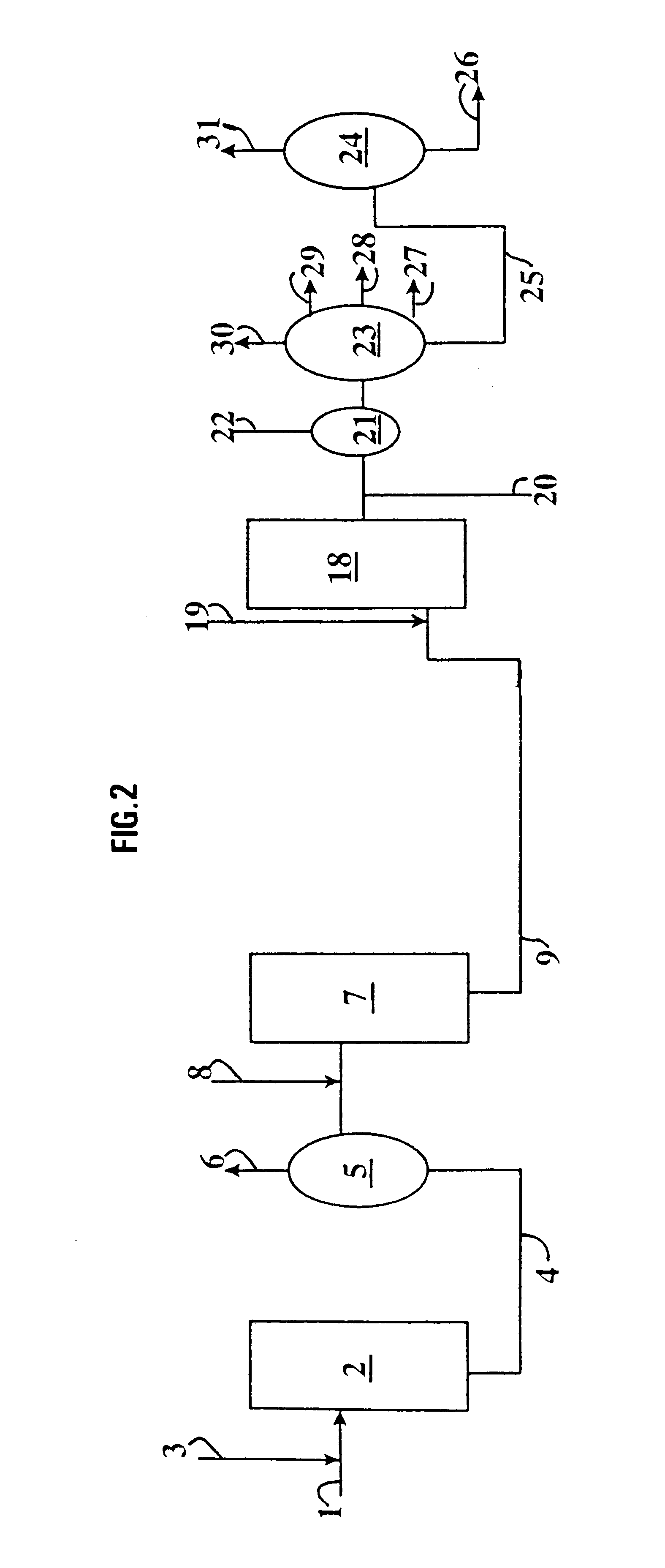

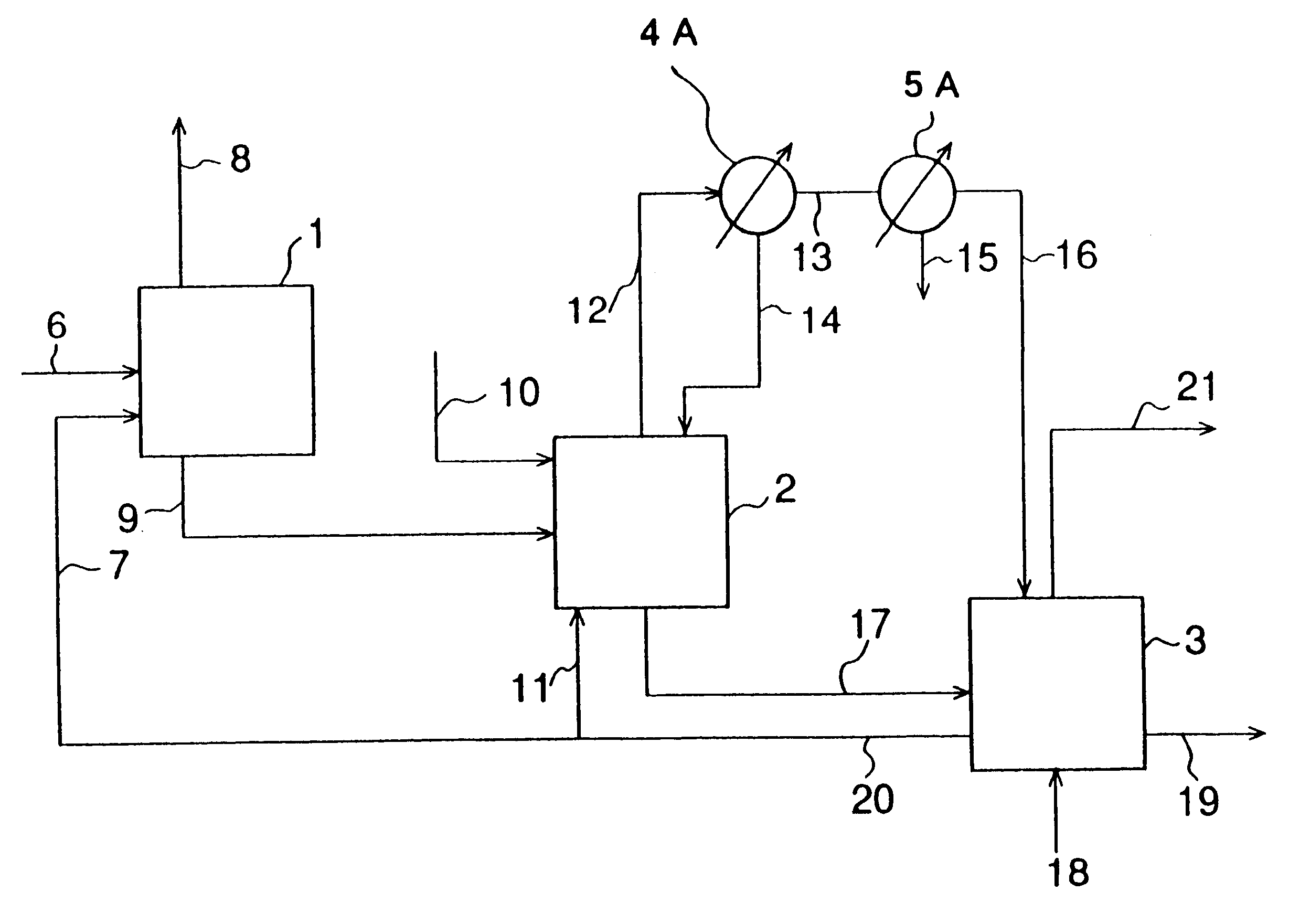

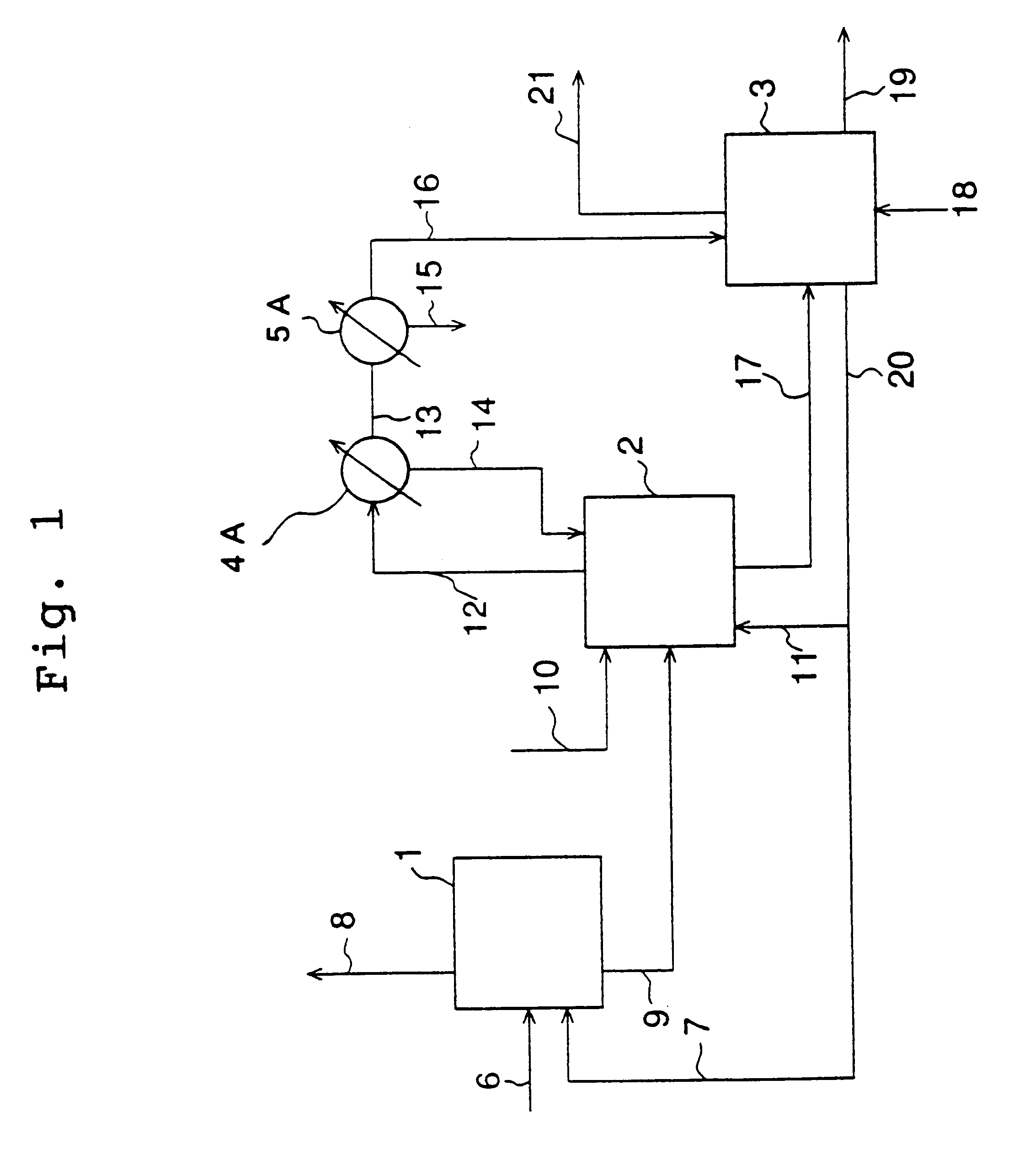

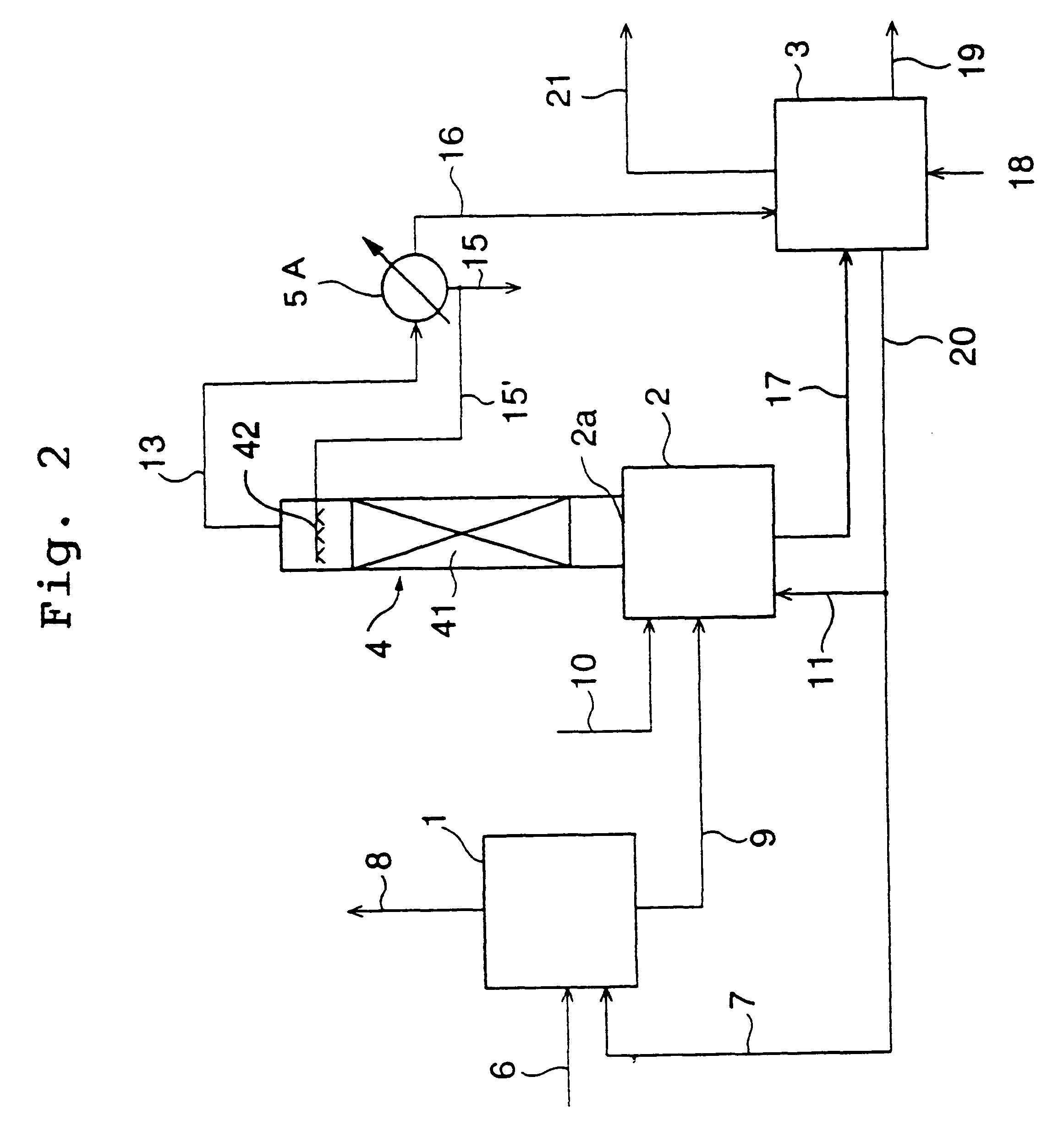

Two stage hydroprocessing with divided wall column fractionator

InactiveUS20120004478A1Low sulfurImprove propertiesCoke ovensHydrocarbon distillationFractionationReaction system

A divided wall column can allow for fractionation of multiple streams while maintaining separate product qualities. Effluents from multiple stages of a reaction system can be processed in a single divided wall column. The divided wall column can produce multiple cuts from each separated area, as well as at least one output from a common area. At least one reaction stage can advantageously have a continuous liquid phase environment.

Owner:EXXON RES & ENG CO

Method and device for obtaining 1,3 pure butadiene from 1,3 raw butadiene by distillation

InactiveUS7132038B2Meet specificationsThermal non-catalytic crackingDistillation regulation/controlDistillationChemistry

A process for obtaining pure 1,3-butadiene from crude 1,3-butadiene by distillation is carried out in a dividing wall column in which a dividing wall is located in the longitudinal direction of the column to form an upper common column region, a lower common column region, a feed section and an offtake section.

Owner:BASF AG

Tangential dispenser and system for use within a delayed coking system

ActiveUS7115190B2Hydrocarbon distillationLiquid hydrocarbon mixture recoveryEngineeringHeat distribution

The present invention features a tangential injection system for use within a delayed coking system, or any other similar system. The tangential injection system comprises a spool, a tangential dispenser, and a hydro blasting system, wherein the tangential dispenser comprises a delivery main surrounding the perimeter of the spool and that functions to deliver a residual byproduct or other material to a plurality of feed lines positioned at a position or at distances around the delivery main for the purpose of providing tangential dispensing of the residual byproduct into the vessel, thus effectuating or inducing even thermal distribution throughout the vessel.

Owner:DELTAVALVE

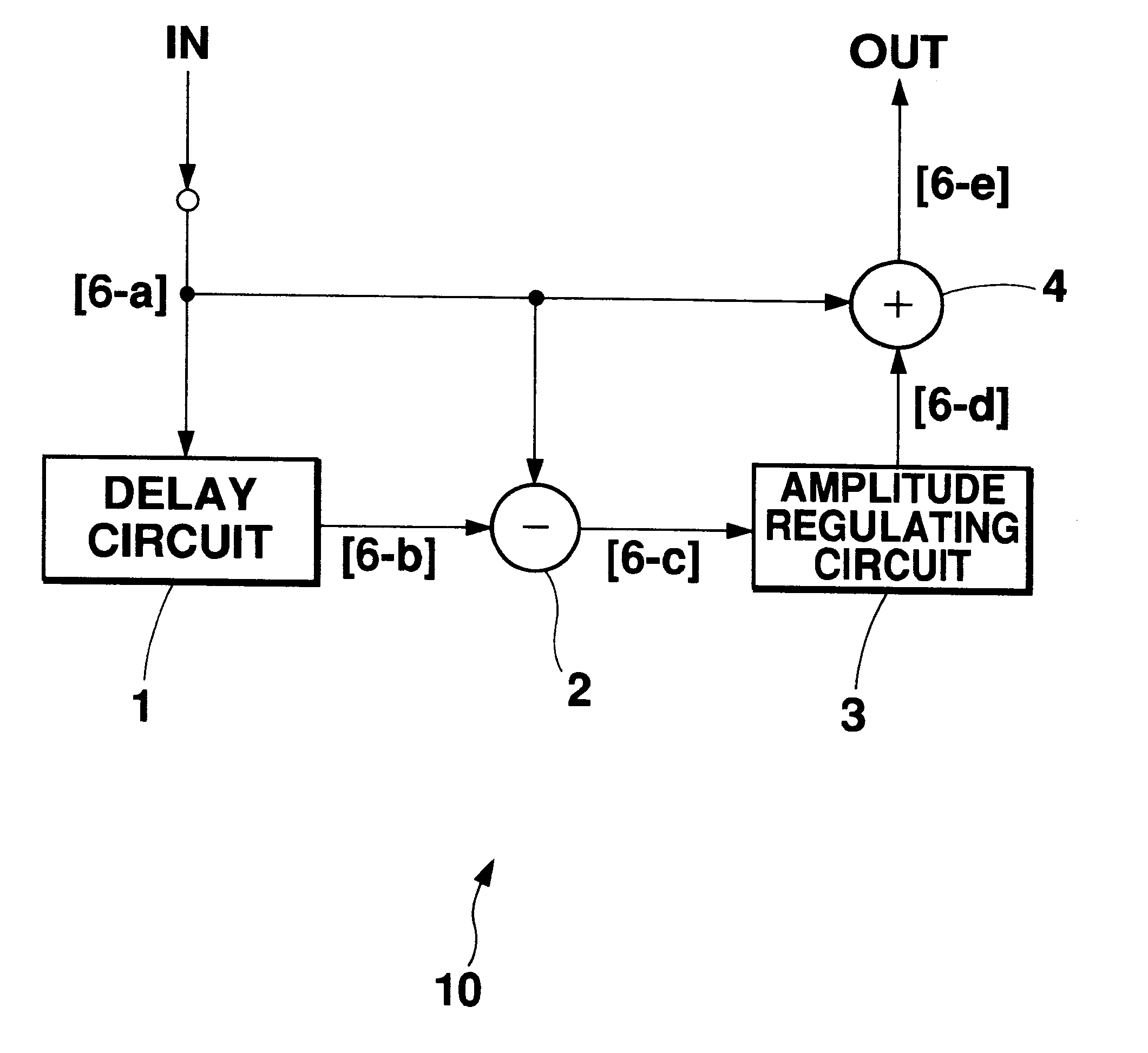

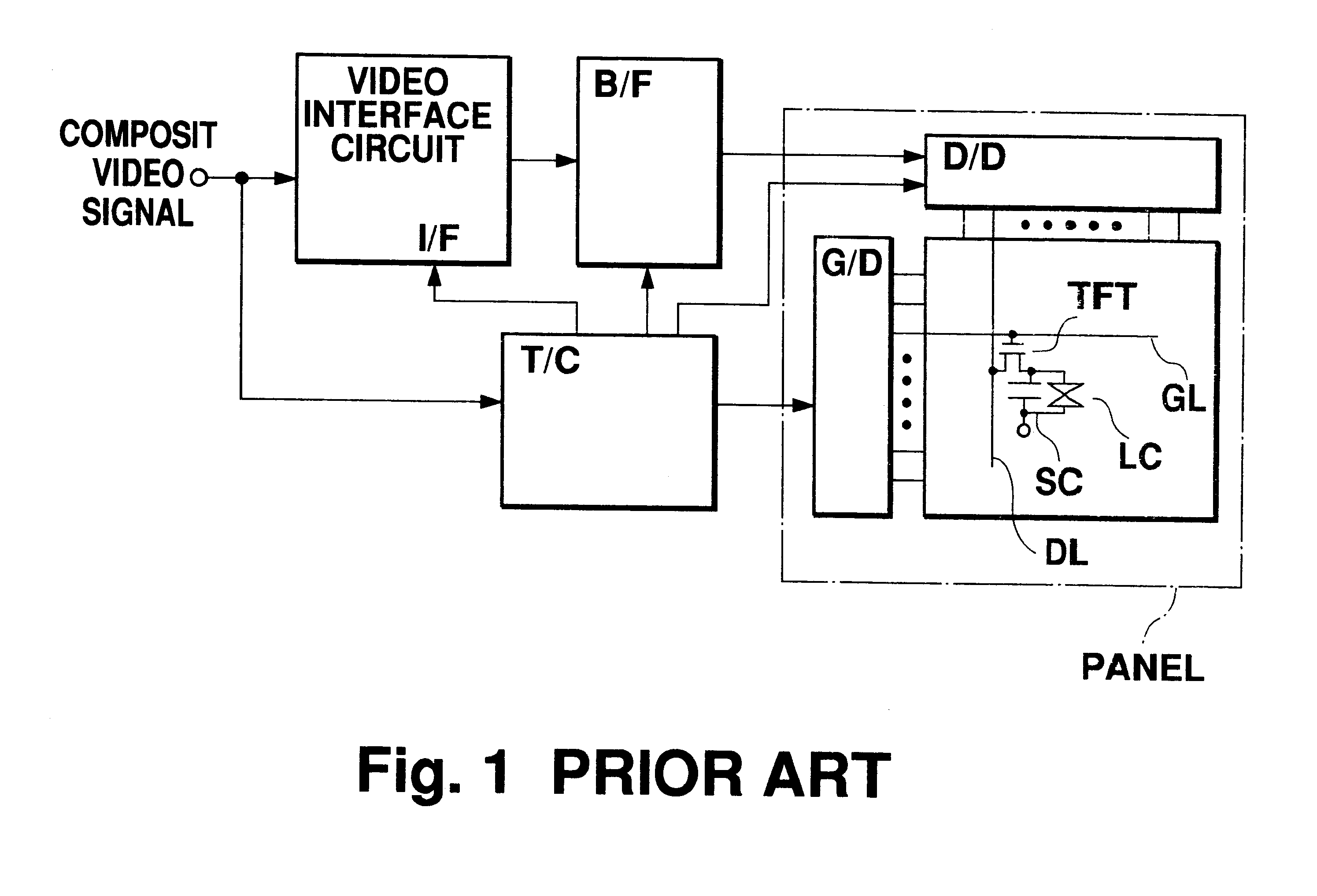

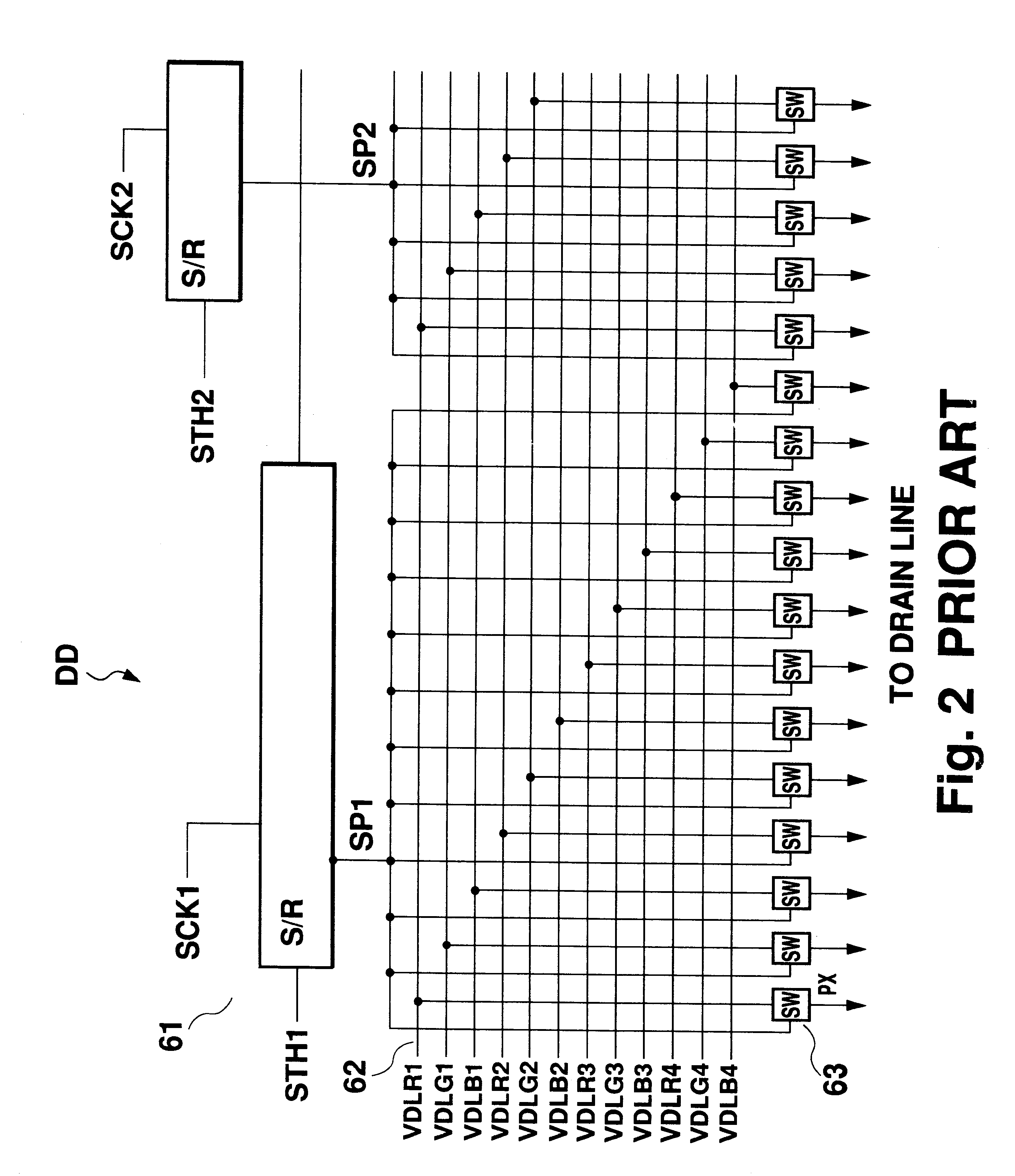

Driving circuit for display device

A signal driving circuit for an active matrix type display device having display pixels arranged in a matrix, comprises a signal waveform correcting circuit receiving an input pixel signal for generating a corrected output pixel signal to the display device, said signal waveform correcting circuit including a delay circuit for generating a delay signal, a difference calculating circuit for calculating a difference signal between the input pixel signal and the delay signal, and a correction circuit for generating the corrected output pixel signal based upon the difference signal and the input pixel signal, wherein a portion of the waveform amplitude of the corrected output pixel signal is formed by adjusting a corresponding portion of the waveform amplitude of the input pixel signal based upon the difference signal.

Owner:SANYO ELECTRIC CO LTD

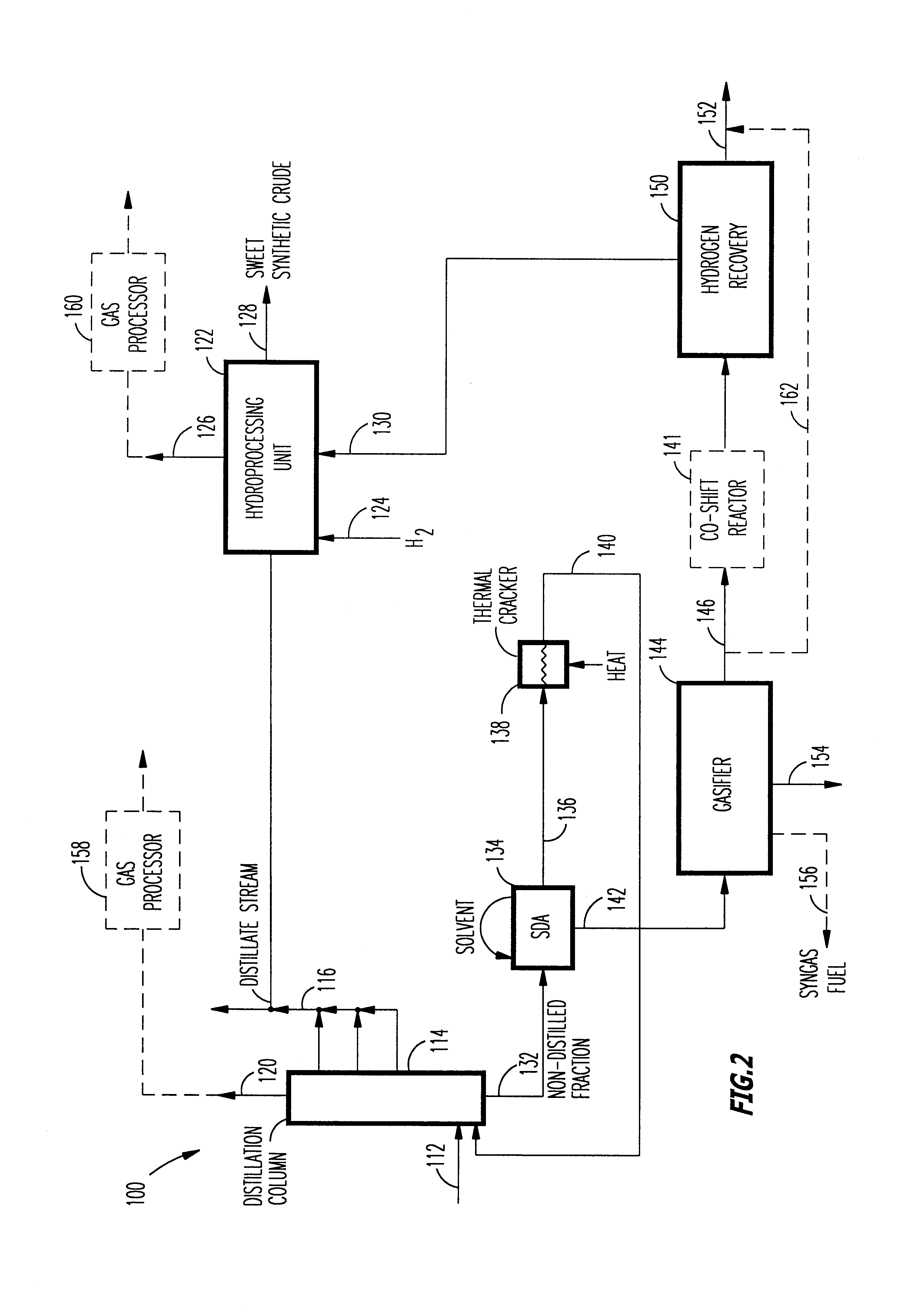

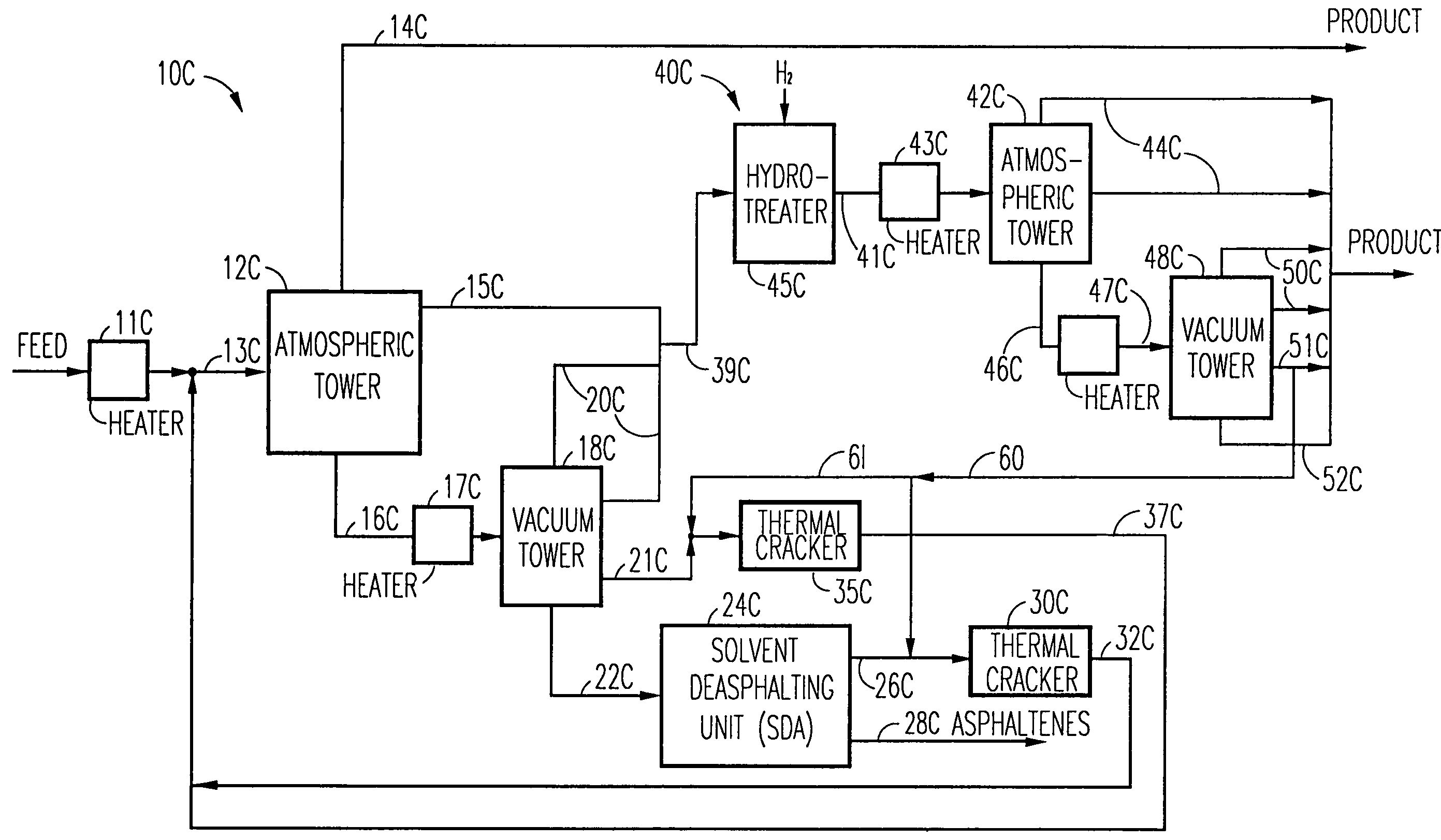

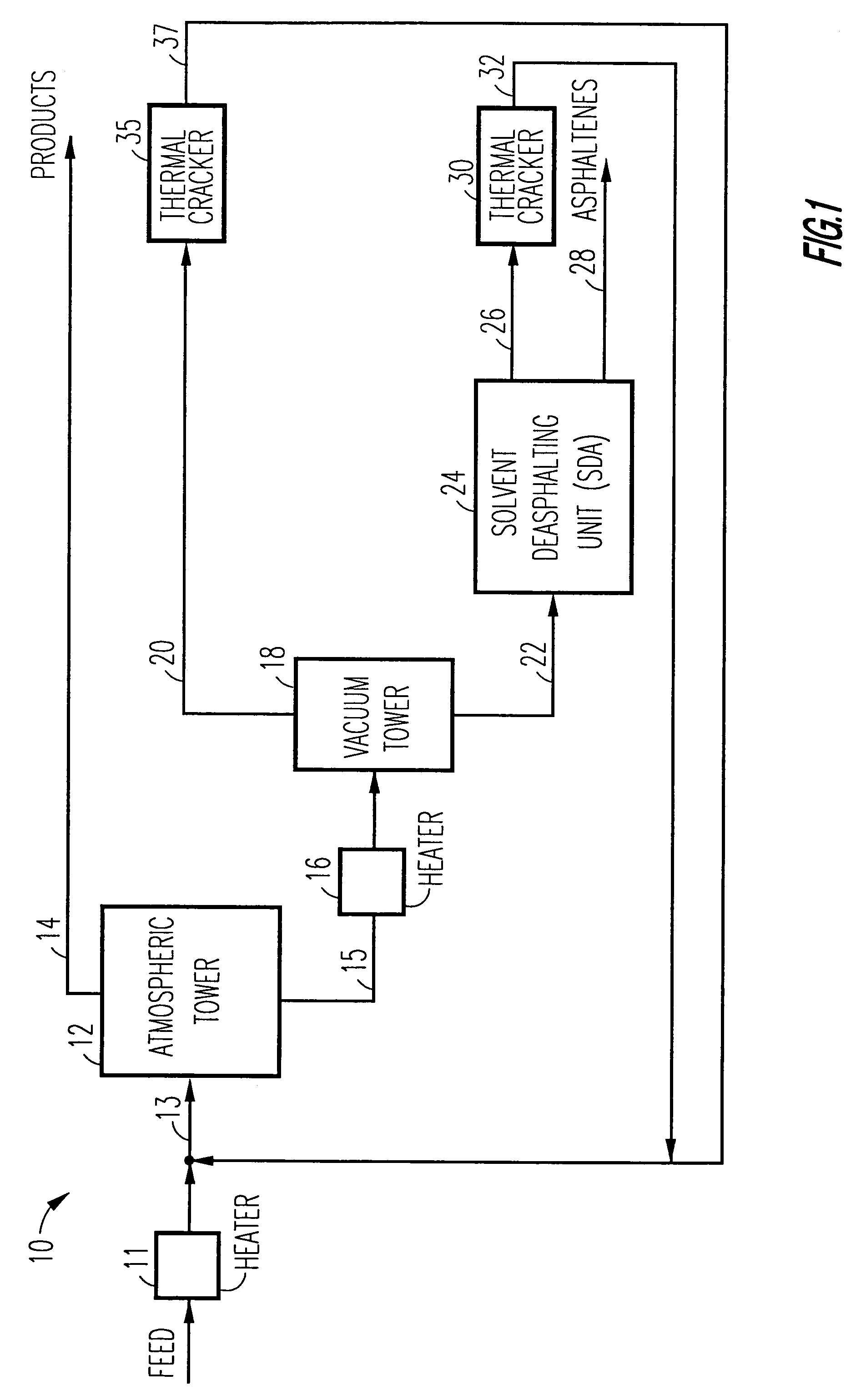

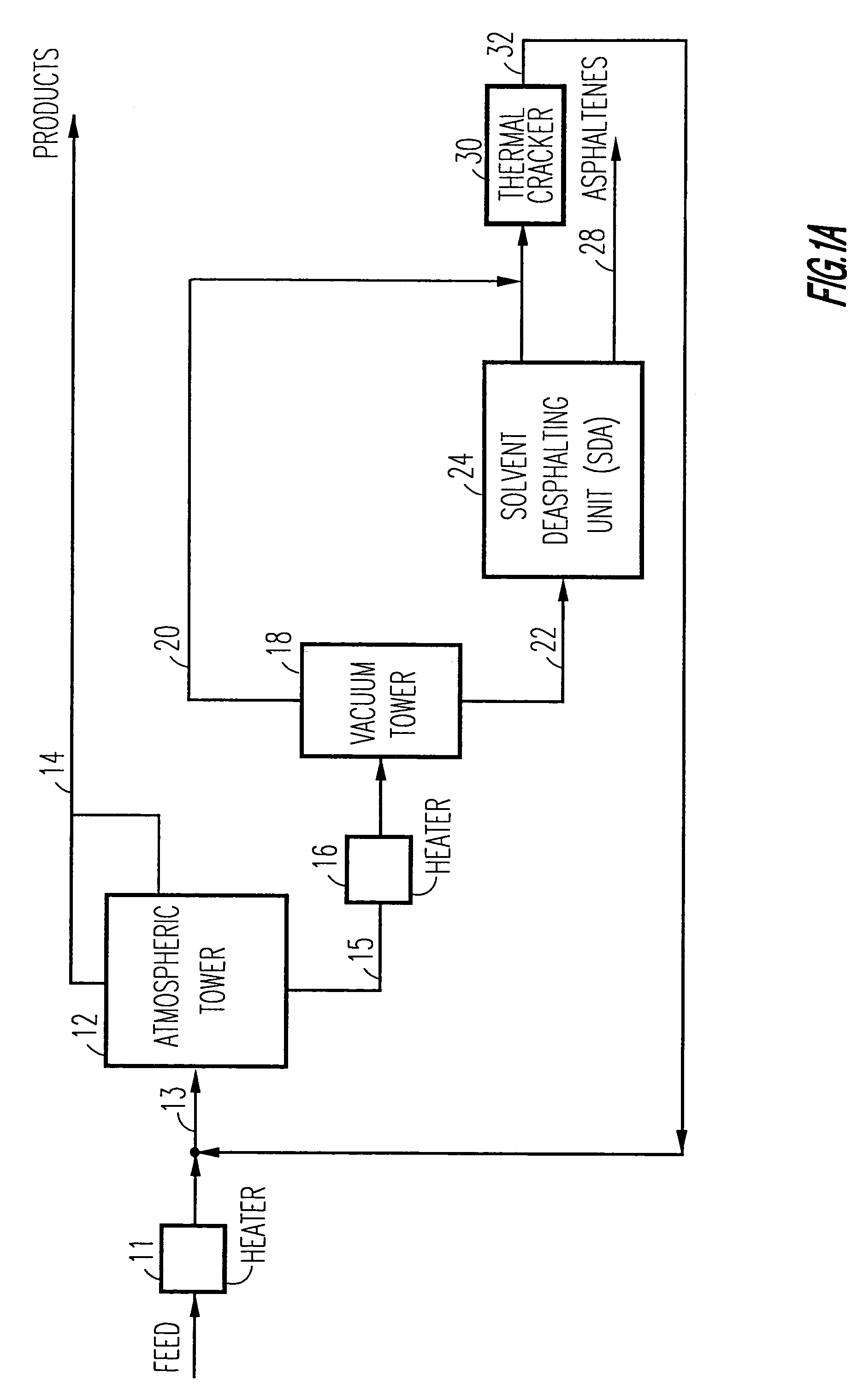

Method of and apparatus for processing heavy hydrocarbon feeds

InactiveUS7297250B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyTowerSolvent

The present invention comprises a method for processing a heavy hydrocarbon feed including: supplying the heavy hydrocarbon feed to a heater for heating the heavy hydrocarbon feed; supplying the heated heavy hydrocarbon feed to an atmospheric fractionating tower for fractionating the heated heavy hydrocarbon feed fed to the inlet of the atmospheric fractionating tower producing light atmospheric fractions and atmospheric bottoms; supplying the atmospheric bottoms to a further heater for heating the atmospheric bottoms and producing heated atmospheric bottoms; supplying the heated atmospheric bottoms to a vacuum fractionating tower for fractionating the heated atmospheric bottoms and producing light vacuum fractions and vacuum residue; supplying the vacuum residue to a solvent deasphalting (SDA) unit for producing deasphalted oil (DAO) and asphaltenes from the vacuum residue; supplying the deasphalted oil to a deasphalted oil thermal cracker for thermally cracking the deasphalted oil and producing a thermally cracked product which is recycled only to the inlet of the atmospheric fractionating tower; and supplying the light vacuum fractions to a light vacuum fraction thermal cracker for thermally cracking the light vacuum fractions for producing a further cracked product which is recycled only to the inlet of the atmospheric fractionating tower.

Owner:ORMAT IND LTD

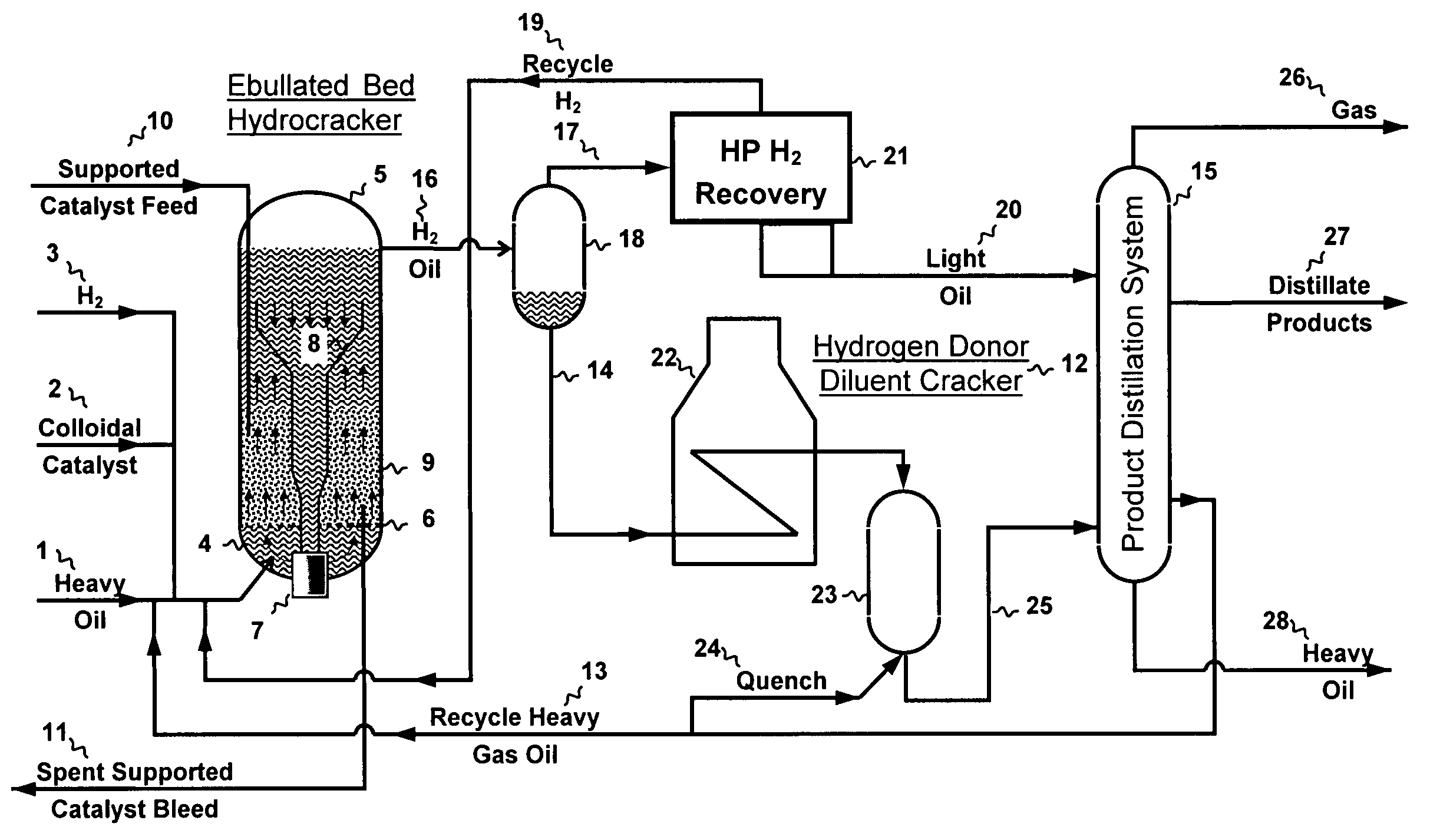

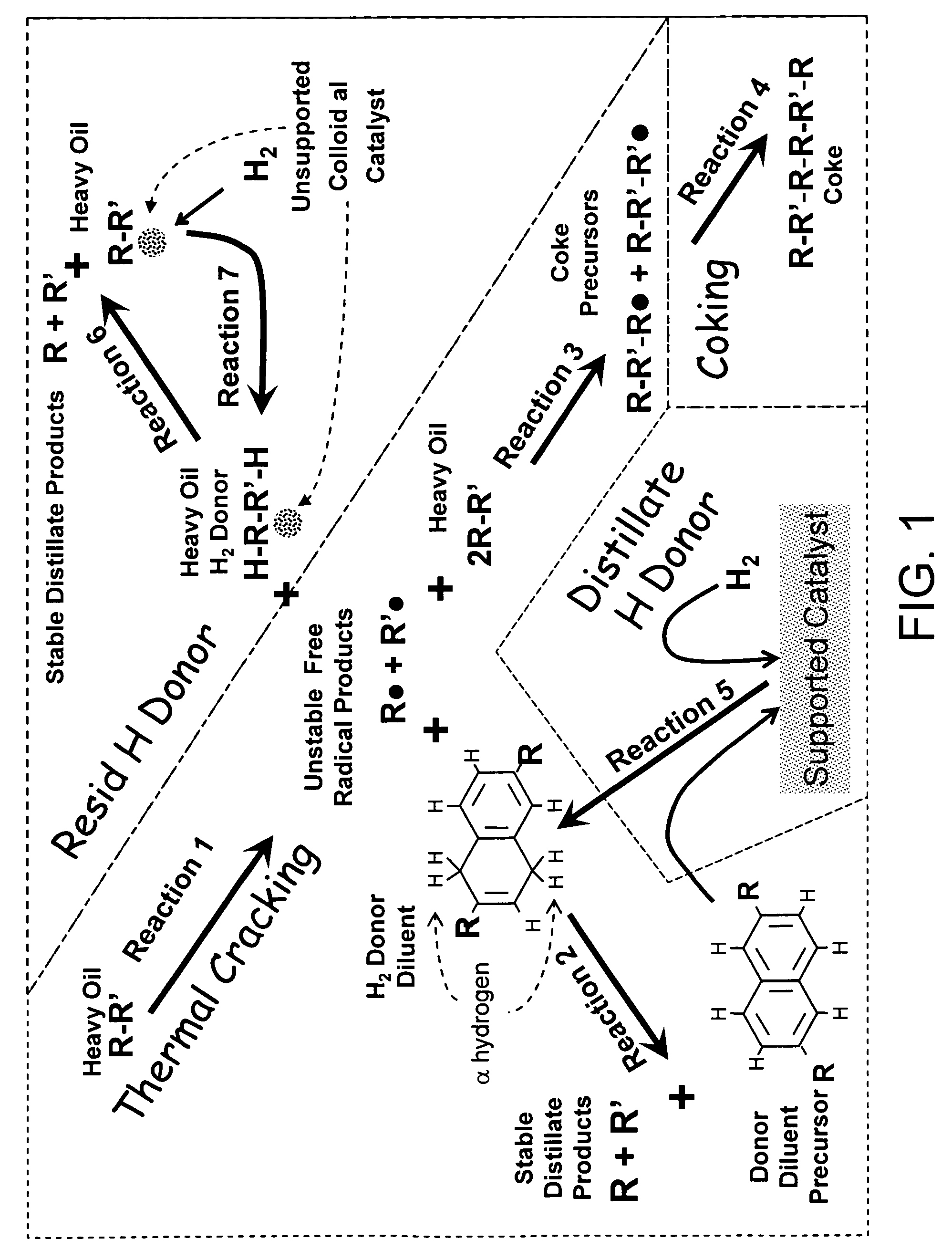

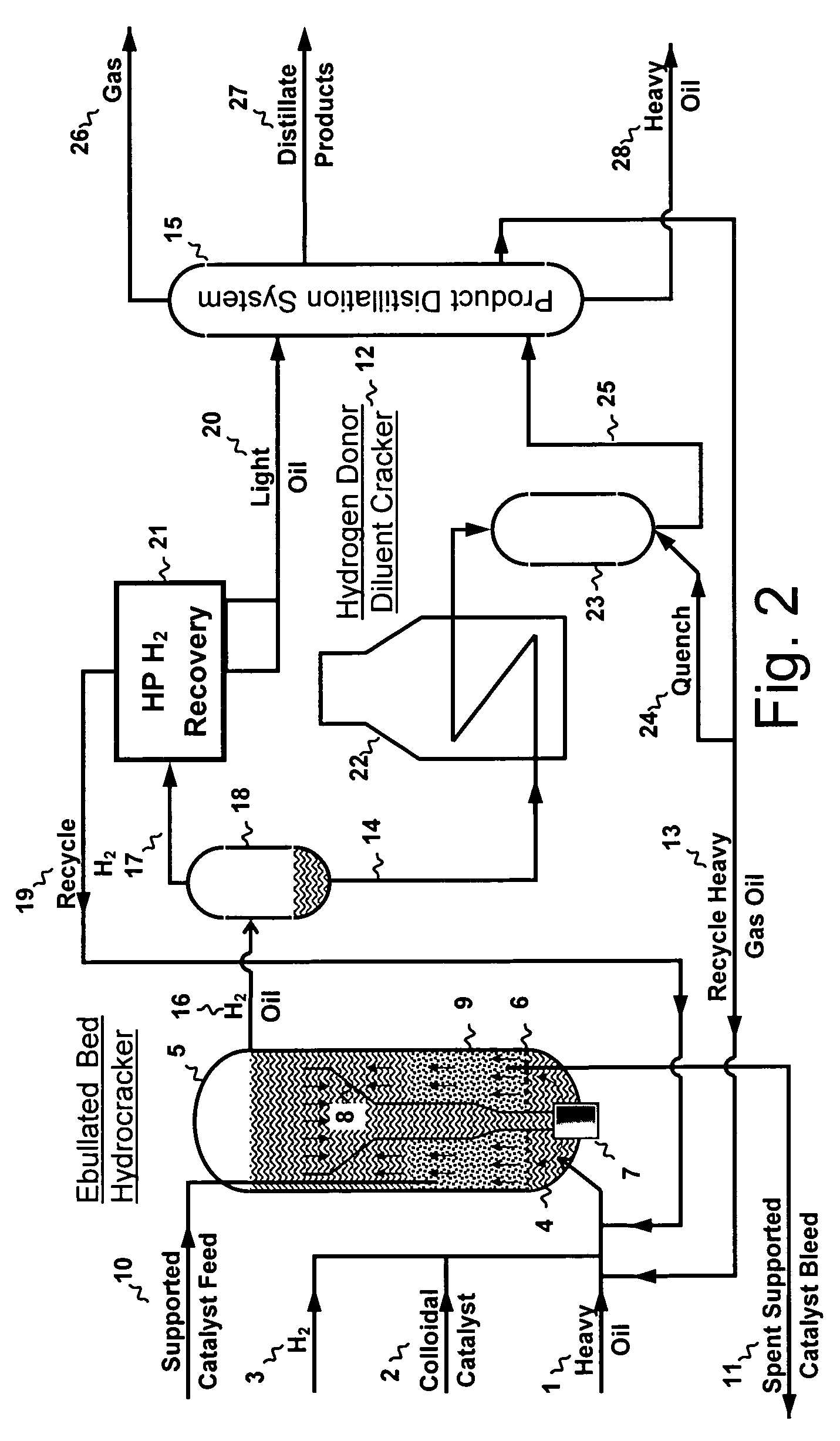

Heavy oil hydroconversion process

InactiveUS20070158239A1Easy transferReduce pressureThermal non-catalytic crackingCatalytic crackingHydrogenDiluent

A method for the efficient conversion of heavy oil to distillates using sequential hydrocracking in the presence of both supported and colloidal catalyst immediately followed by a high temperature-short residence time thermal treatment. The hydrocracker reaction products or a heavy oil and hydrogen donor diluent may be advantageously heated by direct contact with high velocity combustion products.

Owner:BOC GRP INC

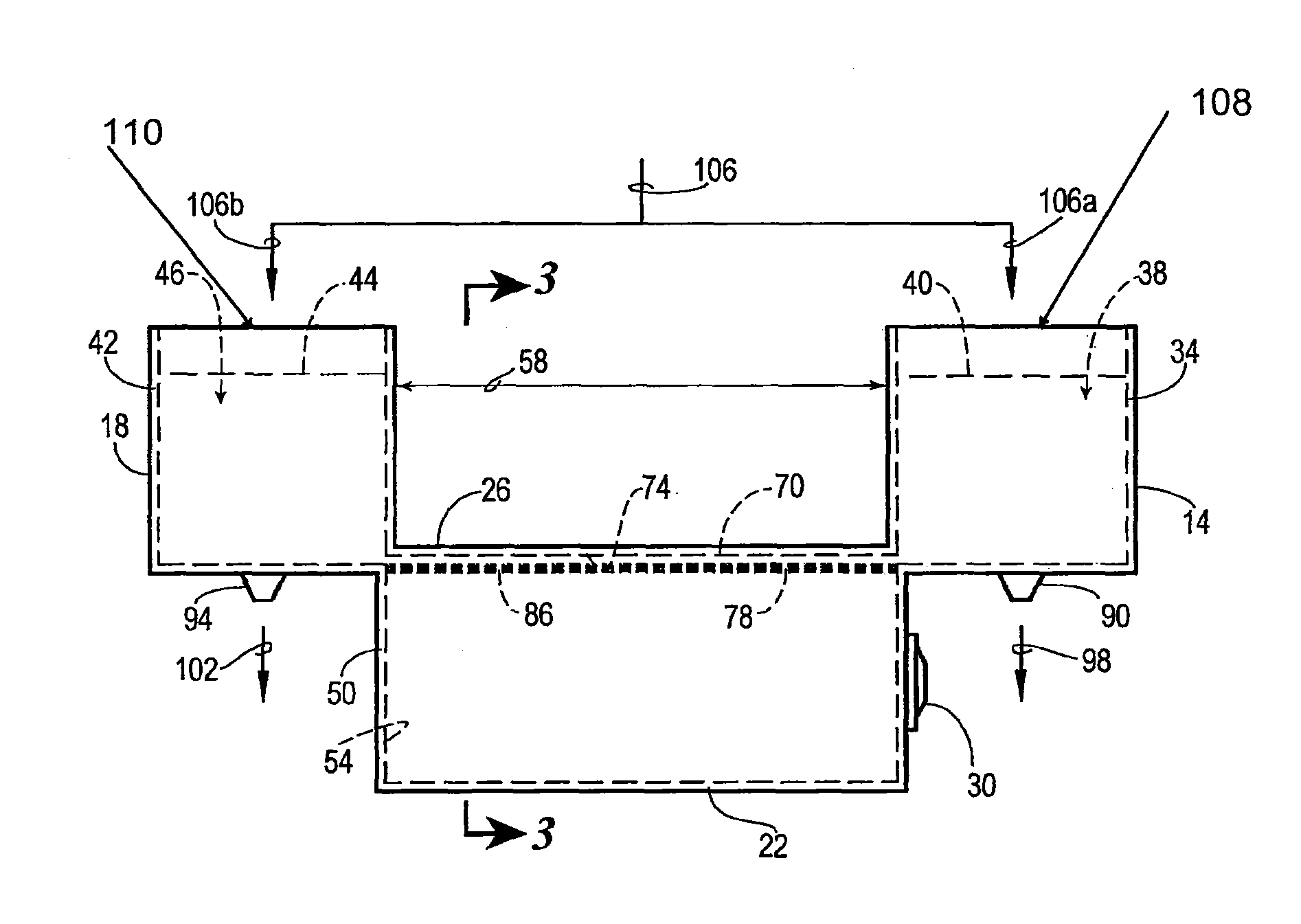

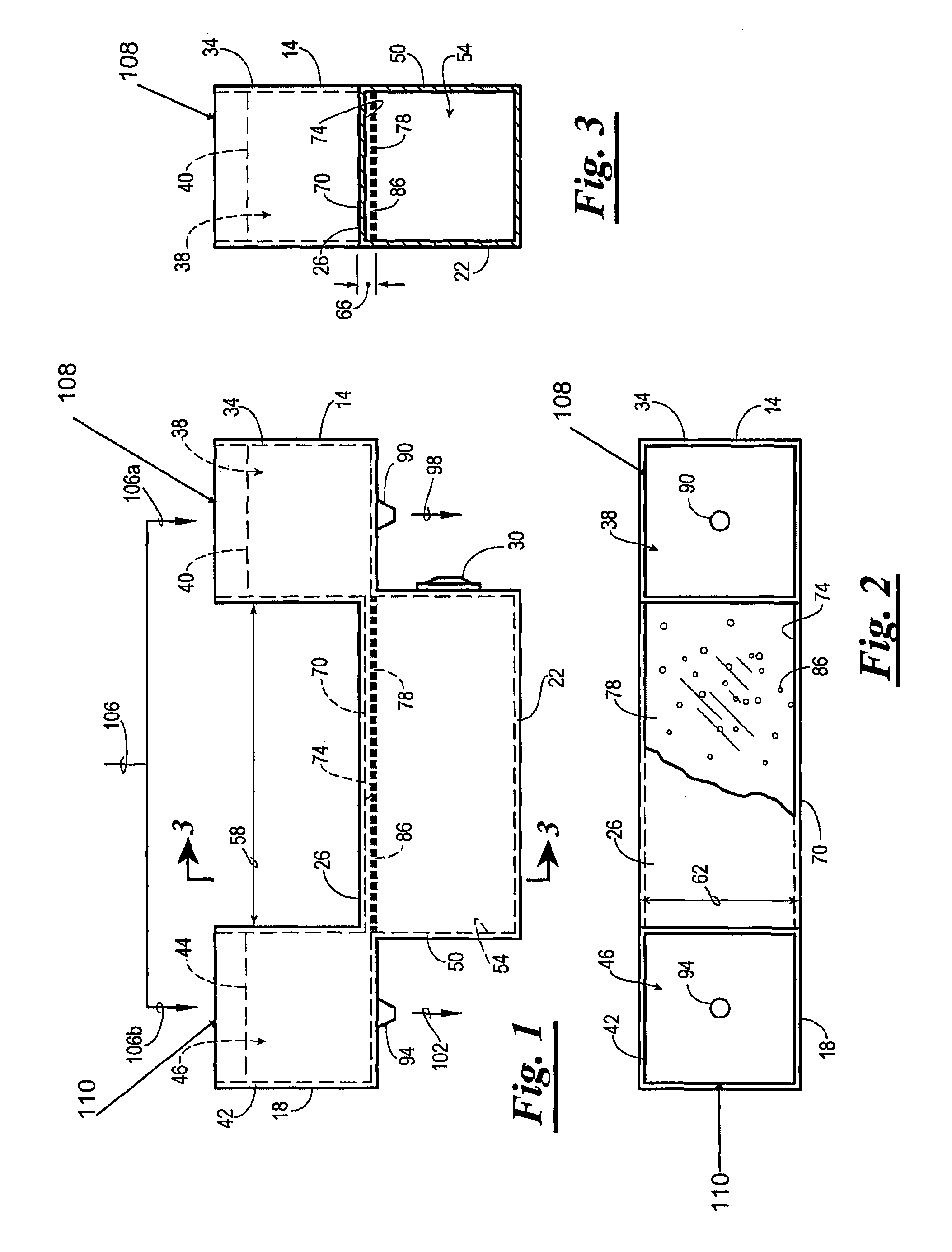

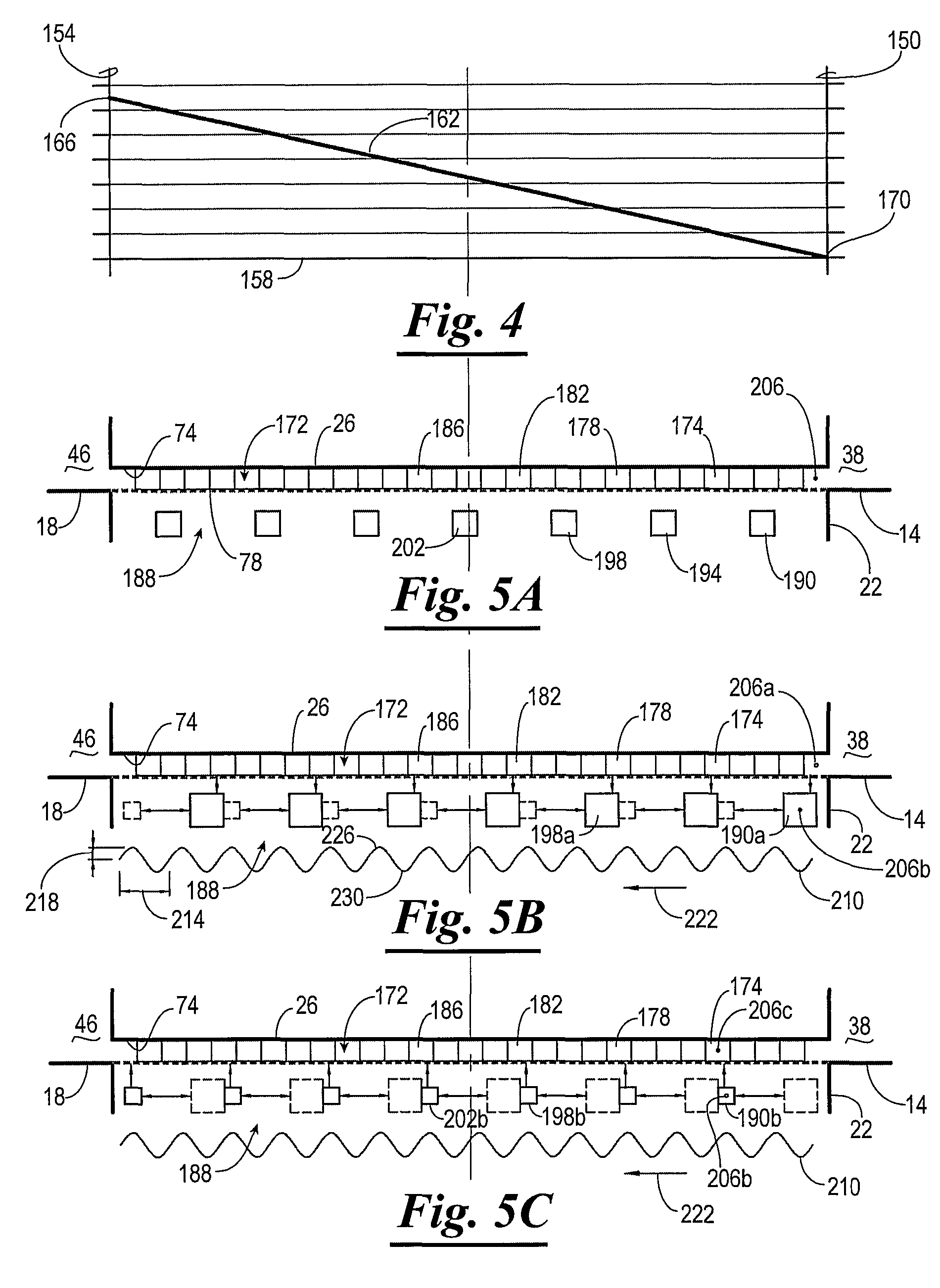

Acoustic/pressure wave-driven separation device

InactiveUS8075786B2Thermal non-catalytic crackingGeneral water supply conservationConcentration gradientAcoustic wave

An acoustic / pressure wave-driven device for separating a first component from a mixture of the first component and a second fluid component. The device comprises a rich reservoir, a lean reservoir, a pump reservoir, a bridge structure, and an acoustic / pressure wave source. The rich reservoir is for containing a fluid mixture having an elevated concentration of the first component. The lean reservoir is for containing a fluid mixture having a lesser concentration of the first component that is leaner than the concentration of the first component in fluid mixture of the rich reservoir. The pump reservoir contains a fluid mixture of the first component and the second fluid component. The bridge structure has a sidewall defining a gradient channel in fluid communication with the rich reservoir and the lean reservoir and a length extending there between. The gradient channel is for containing a fluid having a concentration gradient of the first component along its length. A diffusion portion of the sidewall disposed between the gradient channel and the pump reservoir is adapted to permit diffusion of at least the first component between the gradient channel and the pump reservoir while preventing fluid flow there between. The acoustic / pressure wave source provides acoustic waves into the pump reservoir to cause pressure oscillations in the fluid mixture therein adjacent to the diffusion portion to move molecules of the target component against the concentration gradient from the lean reservoir into the rich reservoir.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

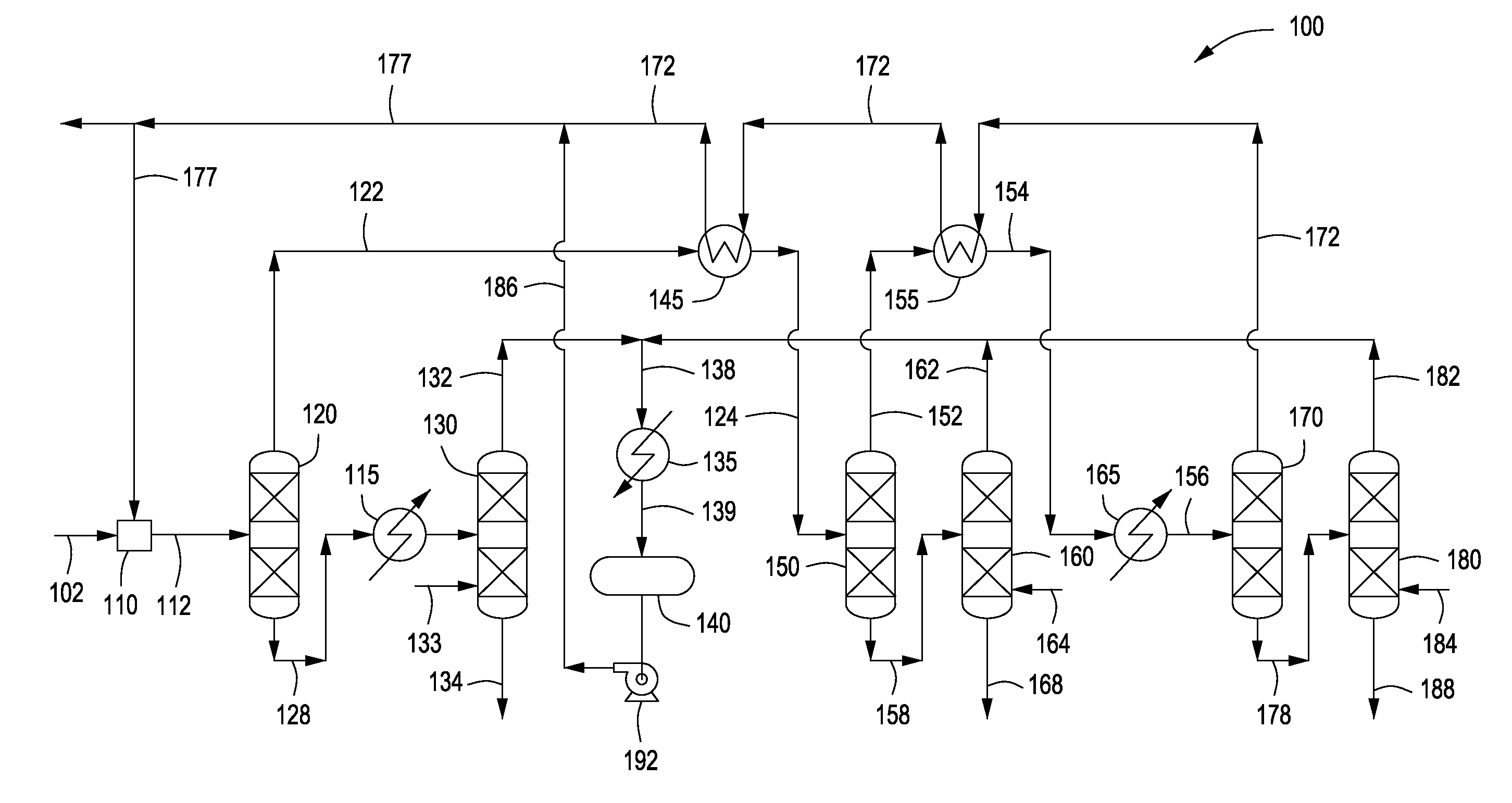

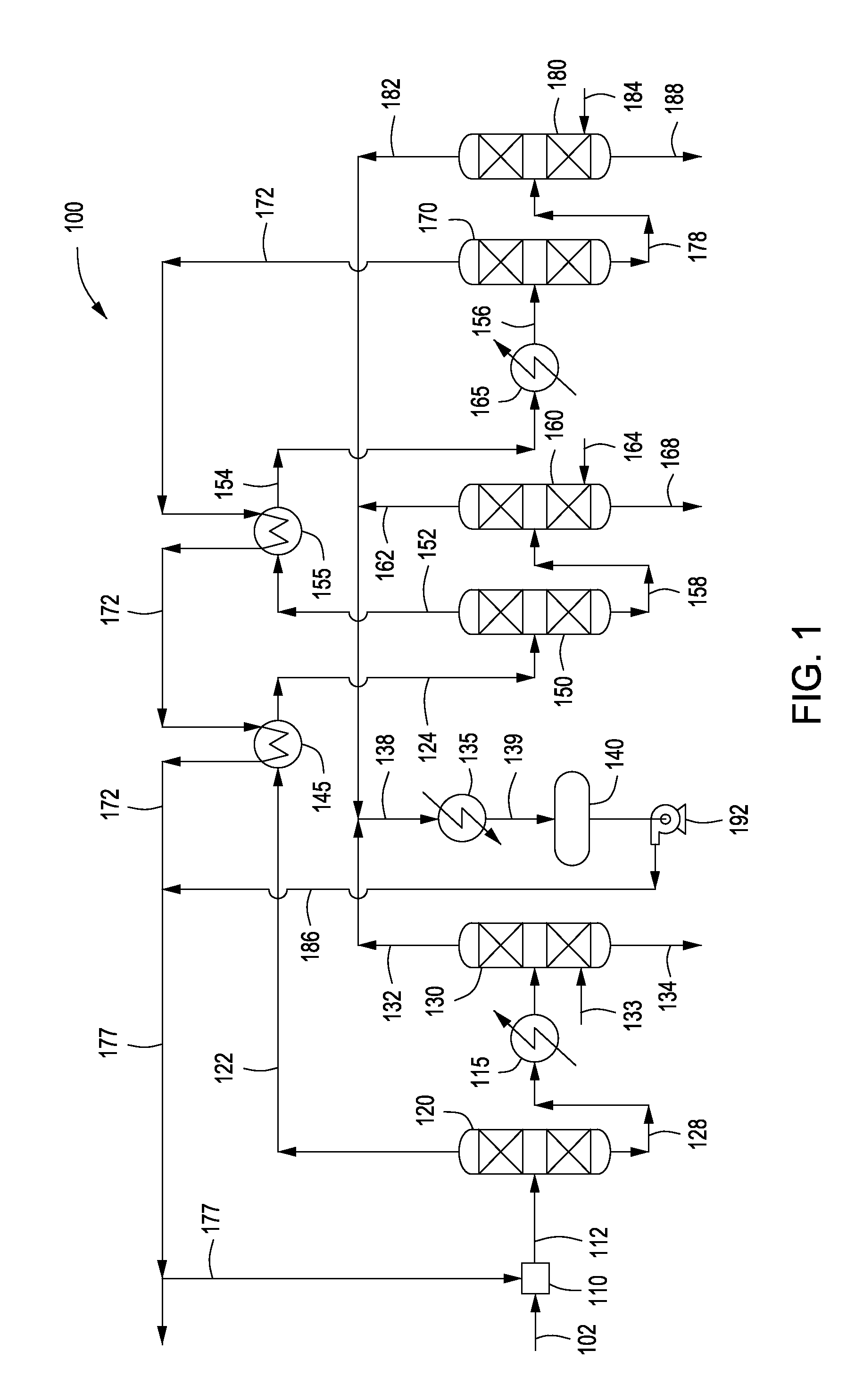

System for upgrading of heavy hydrocarbons

Systems and methods for processing one or more hydrocarbons are provided. One or more hydrocarbons can be selectively separated to provide one or more heavy deasphalted oils. At least a portion of the heavy deasphalted oil can be cracked using a fluidized catalytic cracker to provide one or more lighter hydrocarbon products.

Owner:KELLOGG BROWN & ROOT LLC

Process of hydrotreating heavy hydrocarbon oil

ActiveUS7651605B2Increase deactivation rateImprove throughputCoke ovensHydrocarbon distillationReaction temperatureHeavy crude oil

When a heavy fuel oil with a sulfur content of 1 percent by mass or lower is produced from a feedstock consisting of a heavy hydrocarbon oil derived from a heavy crude oil having an API degree of 30 or less and containing sulfur and metal components in amounts larger than those of ordinary crude oil, the conventional processes requires higher reaction temperature and was accompanied with a remarkably enhanced deactivation rate of the catalyst which results in a remarkable shortened lifetime thereof. Therefore, it is regarded as substantially impossible to treat the feedstock. However, the present invention makes it possible to produce a low sulfur heavy fuel oil with a sulfur content of 1 percent by mass or less by hydrotreating a mix oil of 100 parts by volume of a heavy hydrocarbon oil derived from a heavy crude oil with an API degree of 30 or less and 30 to 1000 parts by volume of a heavy hydrocarbon oil derived from a light crude oil with an API degree of 35 or greater, without lowering the degree of demetallization while retarding the deactivation rate of the catalyst.

Owner:NIPPON OIL CORP

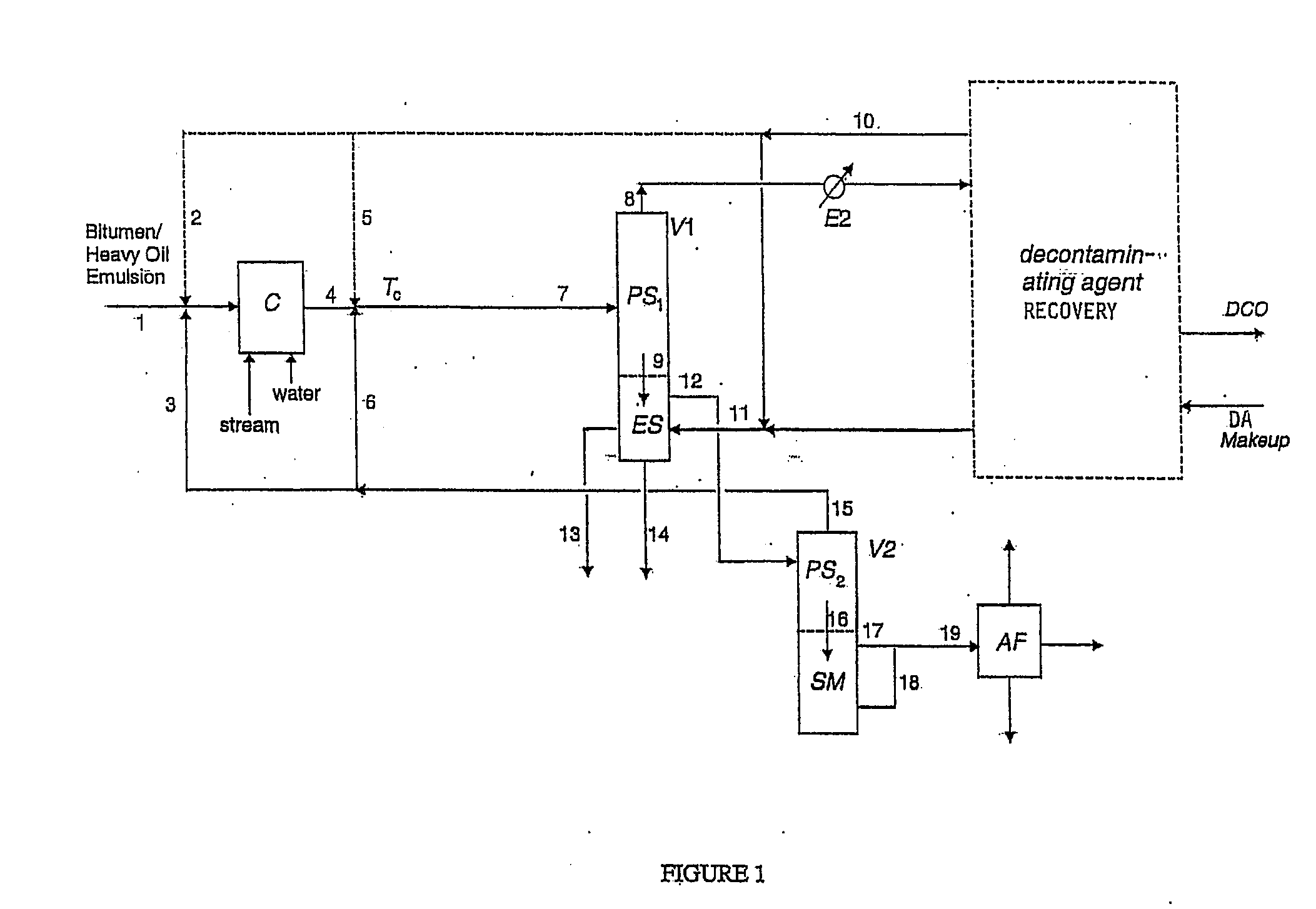

Decontamination of asphaltic heavy oil and bitumen

ActiveUS20060260980A1Distillation regulation/controlHydrocarbon distillationPetroleum productFuel oil

Owner:VALUE CREATION +1

Divided wall columns for smaller sized plants

ActiveUS8480860B2Small diameterEasy to useThermal non-catalytic crackingSolidificationInterior spaceStructural engineering

A divided exchange column includes a shell column having a first longitudinal axis, a cylindrical wall spaced apart from and surrounding the first longitudinal axis and defining a first interior space, a first divided wall column having a second longitudinal axis substantially parallel to the first longitudinal axis, and a second divided wall column having a third longitudinal axis substantially parallel to the first and the second longitudinal axes, where the first divided wall column and the second divided wall column are positioned in the first interior space of the shell column.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com