Patents

Literature

189results about How to "Low sulfur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

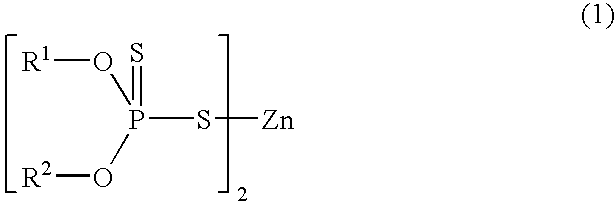

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS6730638B2Reduce friction and wearReduce frictionOrganic chemistryOrganic compound preparationCombustionSulfur

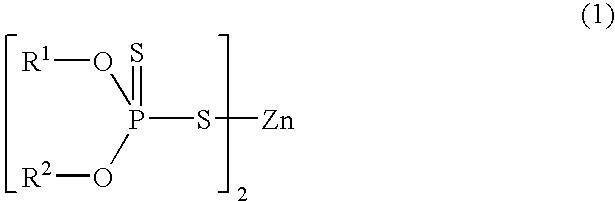

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Low sulfur metal detergent-dispersants

InactiveUS20070027057A1Little to no corrosionLow sulfurOrganic compound preparationDetergent compounding agentsSulfur contentMetal

A process for preparing alkylhydroxybenzoate detergent-dispersant additives having low sulfur content and high TBN is described. The alkali metal alkylhydroxylbenzoate, alkaline earth metal alkylhydroxybenzoate and overbased alkaline earth metal alkylhydroxybenzoate reaction products described have a sulfur content in the range of from about 0.1 to 1.2 wt % are effective anti-corrosive detergent-dispersant additives in lubricating oil compositions.

Owner:CHEVRON ORONITE CO LLC

Method for preparing mesophase asphalt by coal liquefaction residue

ActiveCN101580729AHigh C/H atomic ratioLow ashWorking-up pitch/asphalt/bitumen by chemical meansSolventChemistry

The invention relates to a method for preparing mesophase asphalt by coal liquefaction residue. In the method, the coal liquefaction residue is ground, screened and dried, and is extracted at certain temperature for certain time by using organic solvent as extracting solvent; the extracted mixed liquor is filtered, purified and evaporated; the extracting solvent in the extract liquor is evaporatedto obtain refined coal liquefaction oil asphalt, thus obtaining the mesophase asphalt by charring for 4-10 hours in a high-pressure autoclave under the conditions of 410-460 DEG C, 3-4MPa of constantpressure and stirring. The method has simple process and convenient and safe operation, the mesophase asphalt with high quality is prepared and can be used as raw materials of high power and ultra high power graphite electrode, carbon fiber and the like.

Owner:CHINA COAL RES INST +1

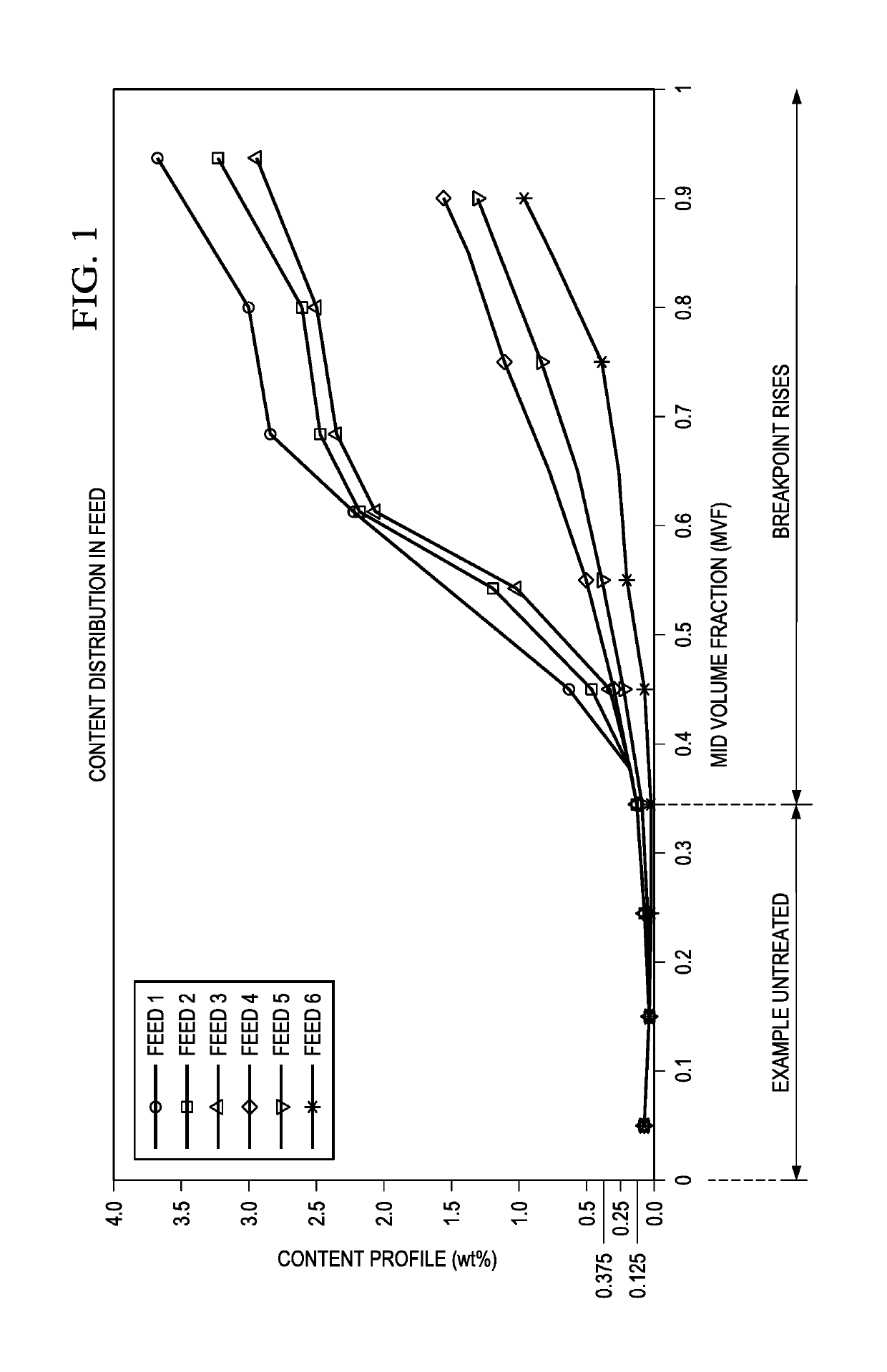

Process for desulfurizing hydrocarbon fuels and fuel components

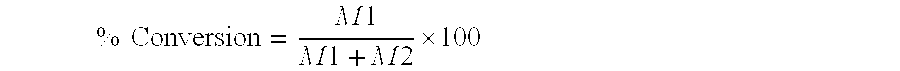

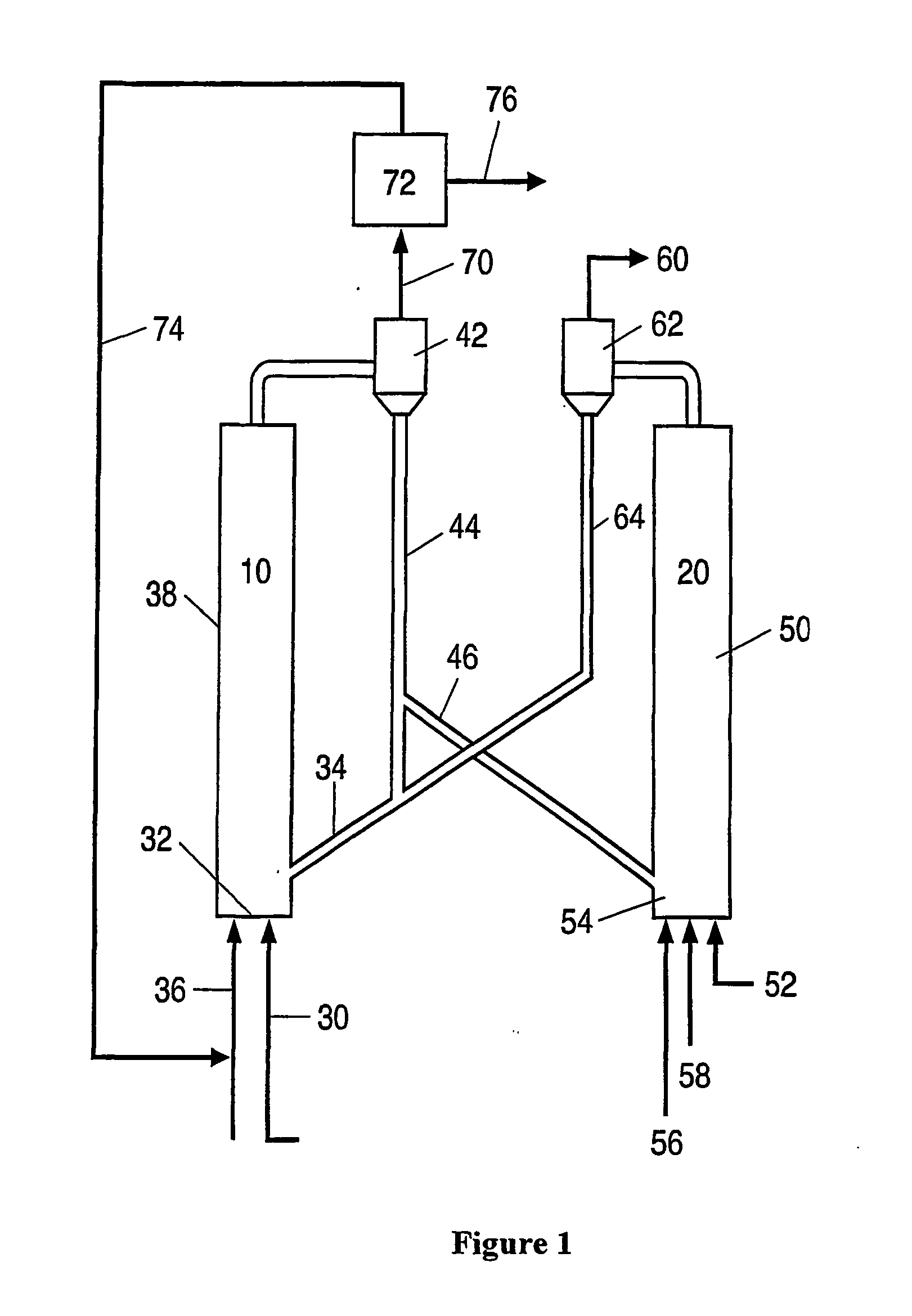

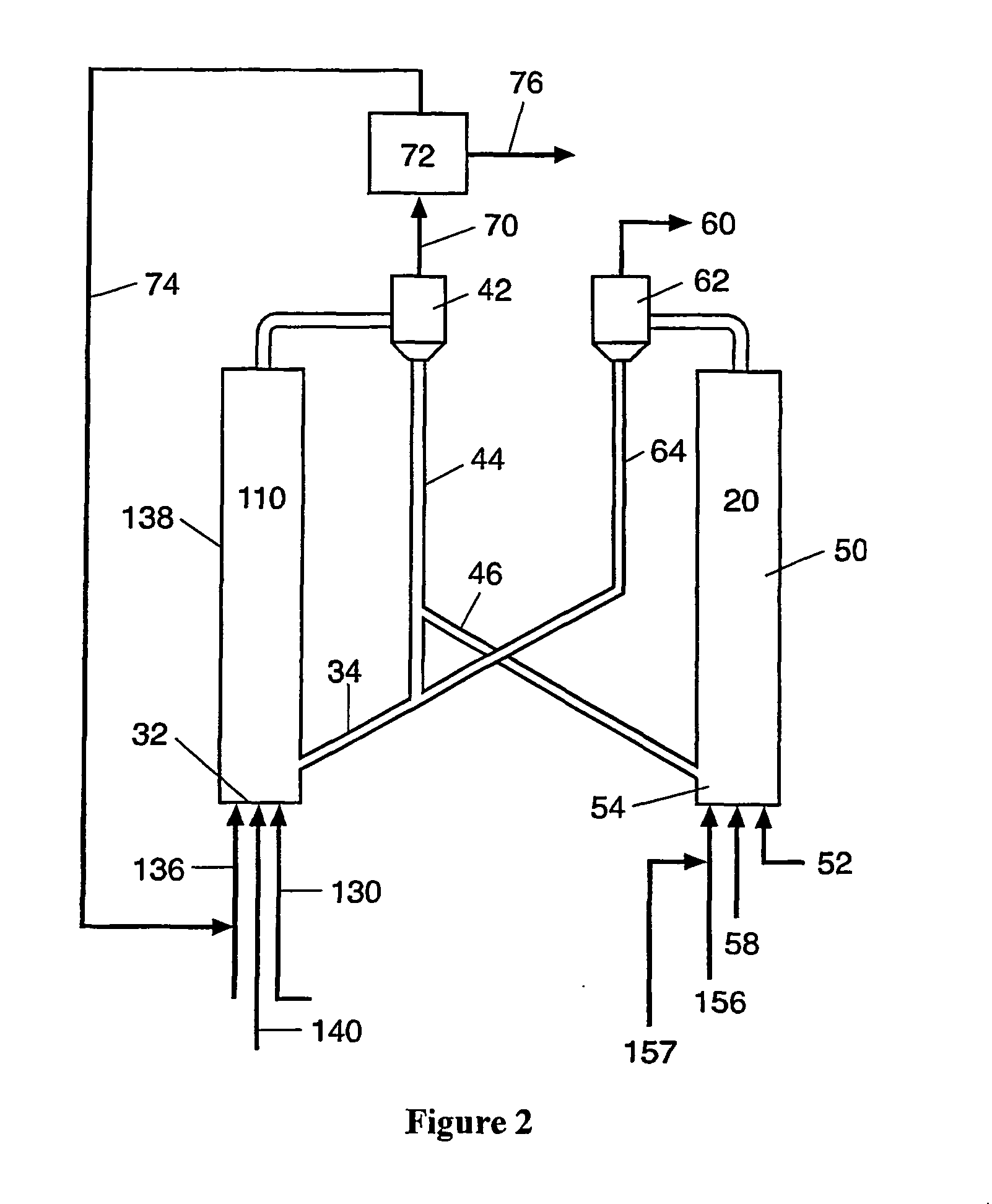

InactiveUS20050098478A1Substantial sulfur removalLow costCatalytic crackingHydrocarbon oils refiningHydrodesulfurizationSorbent

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

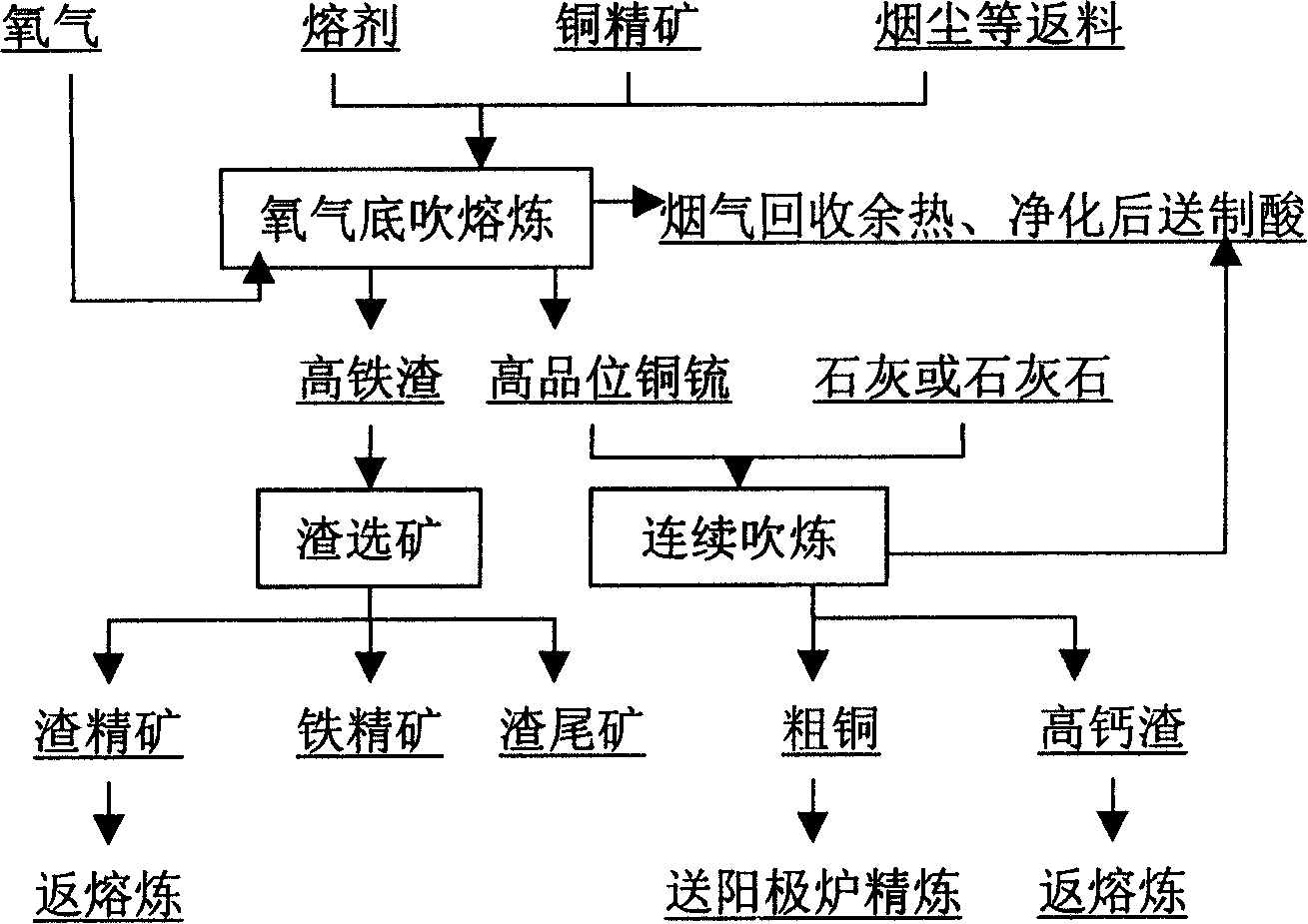

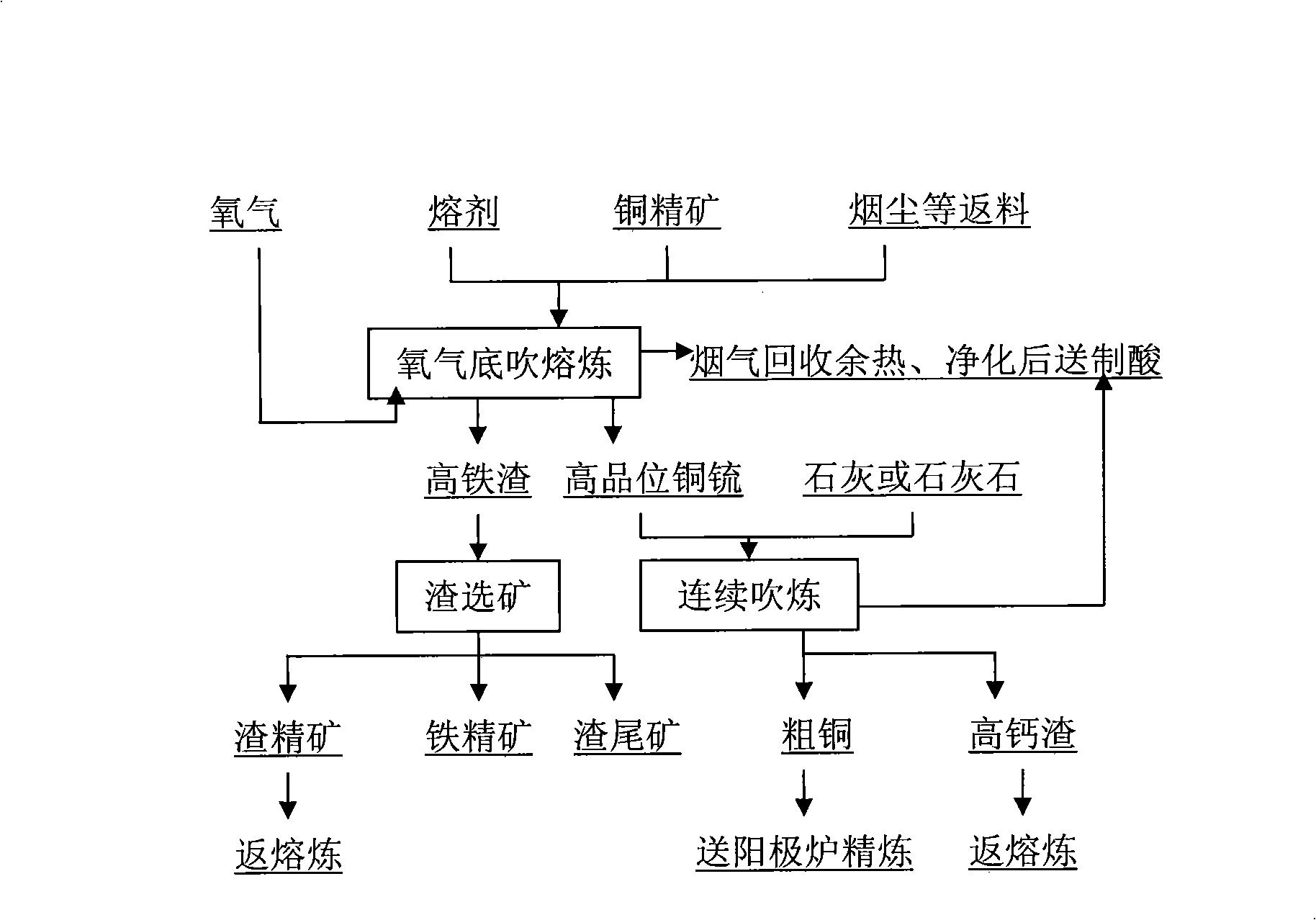

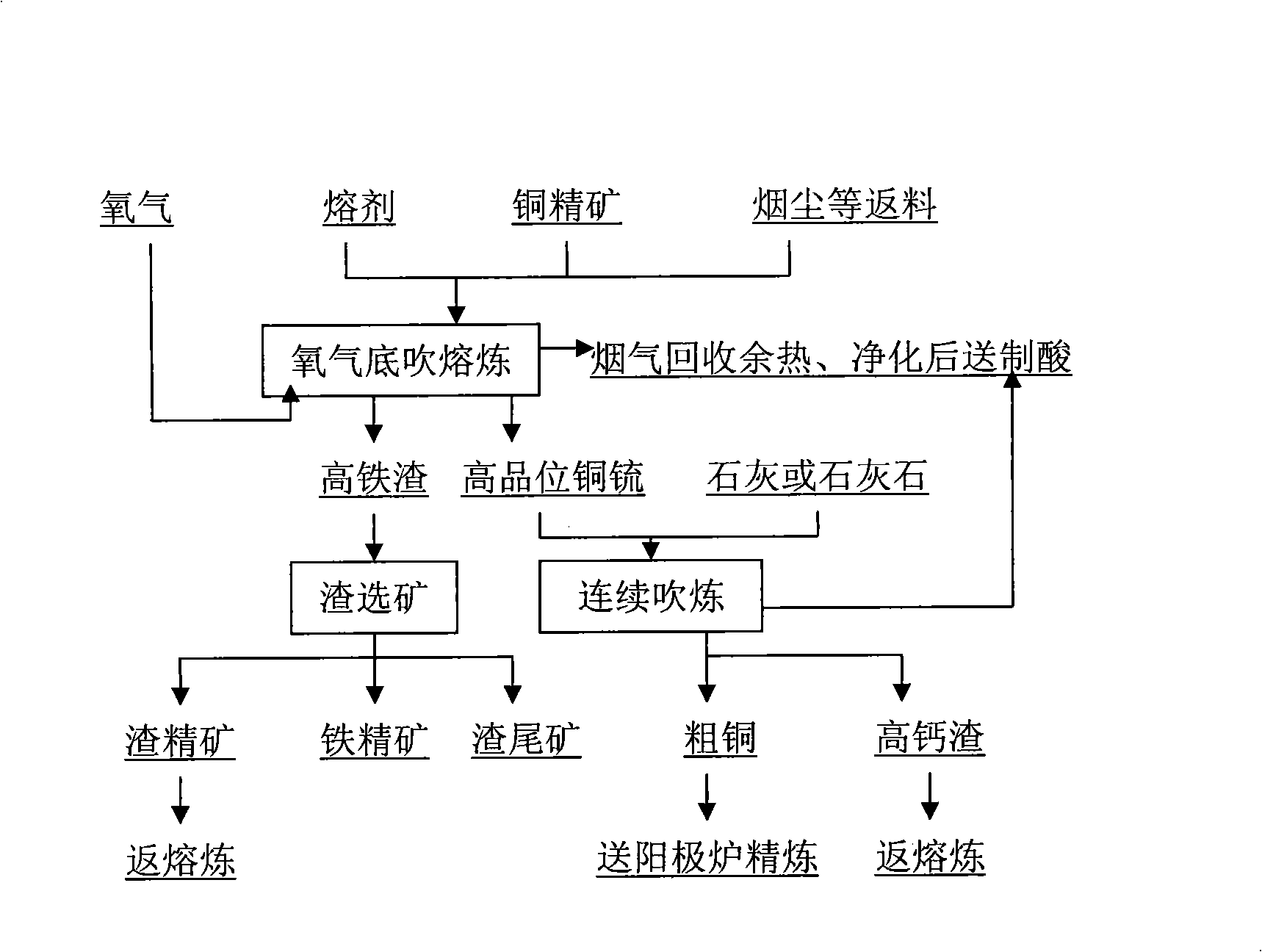

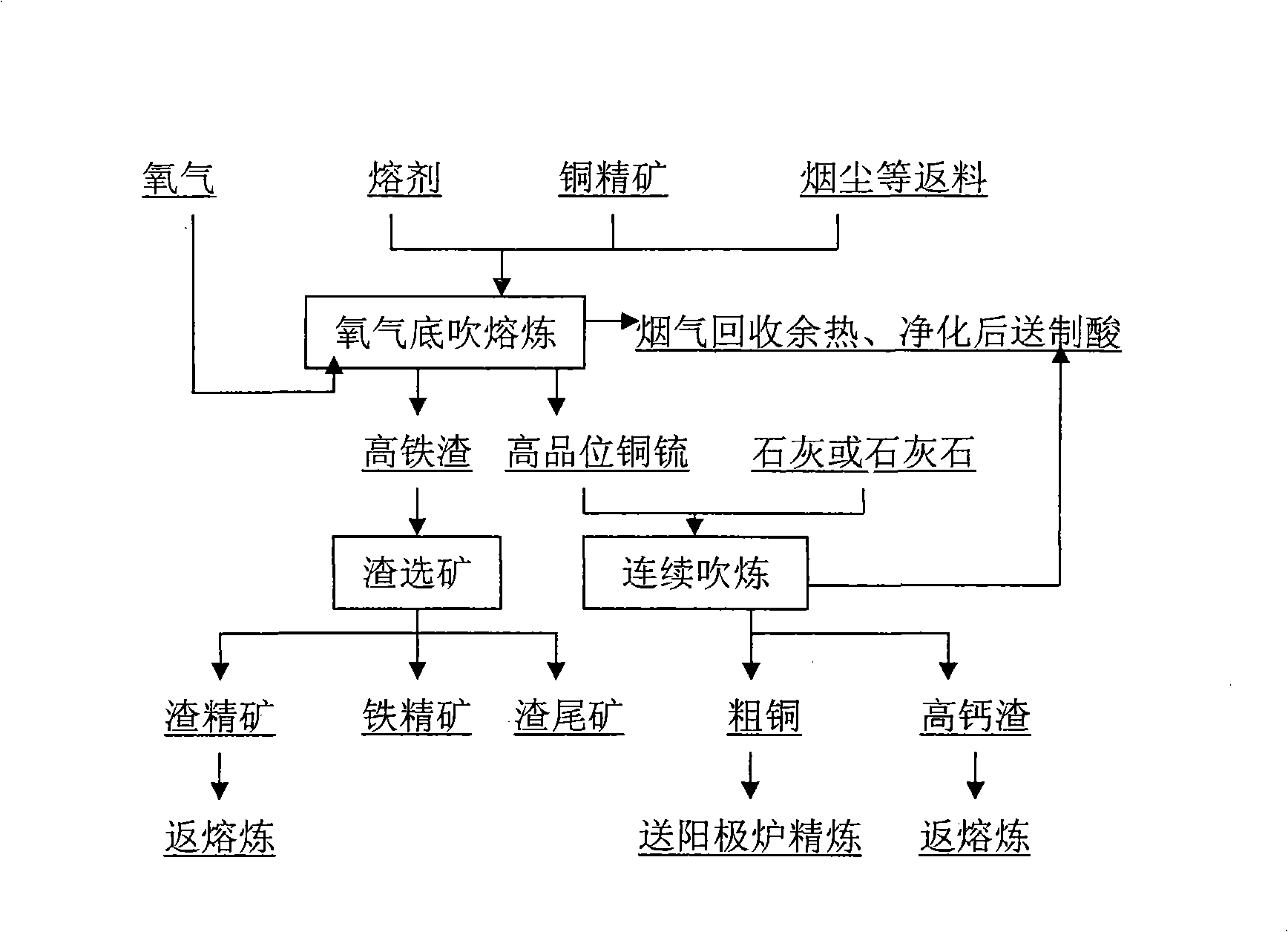

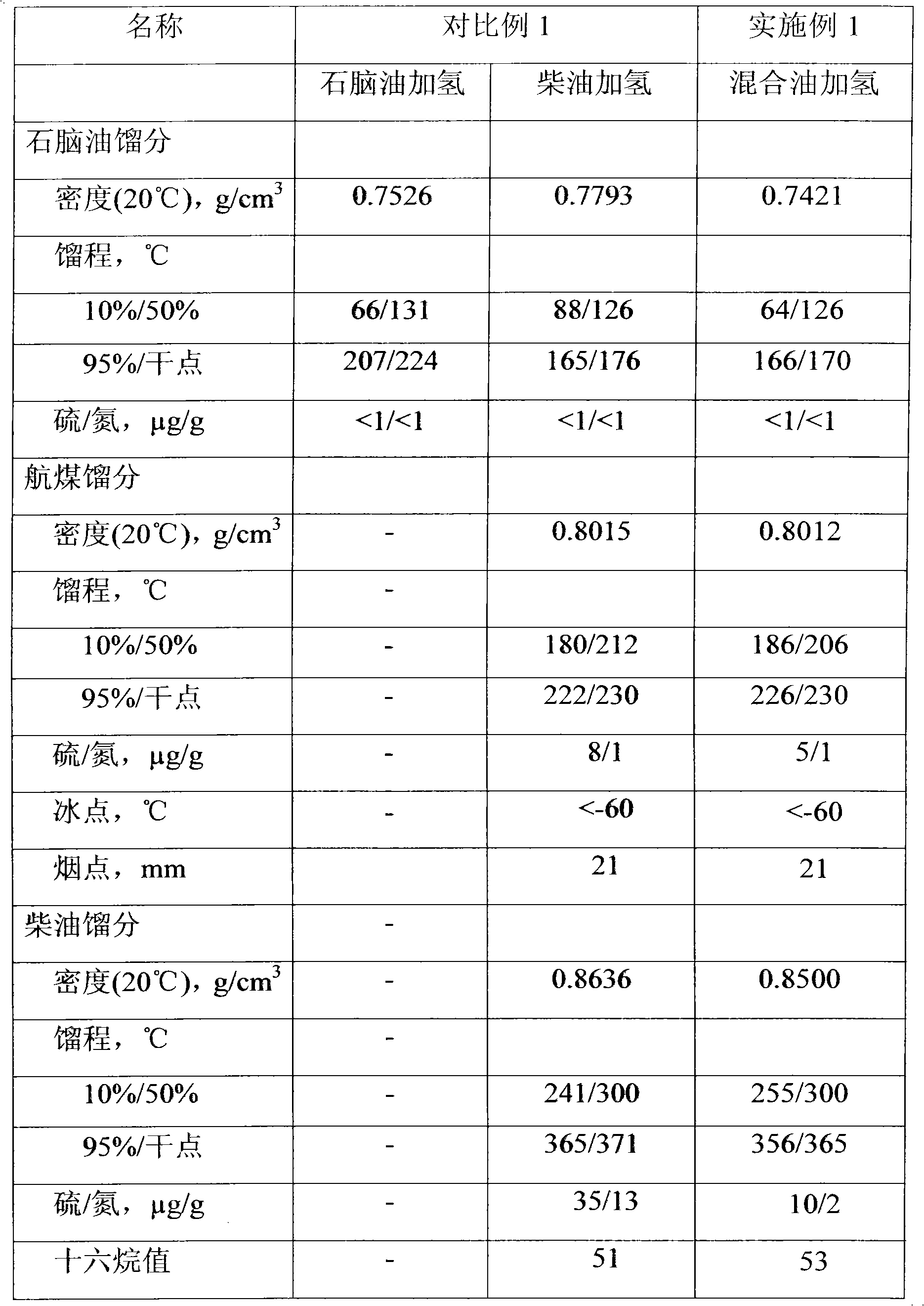

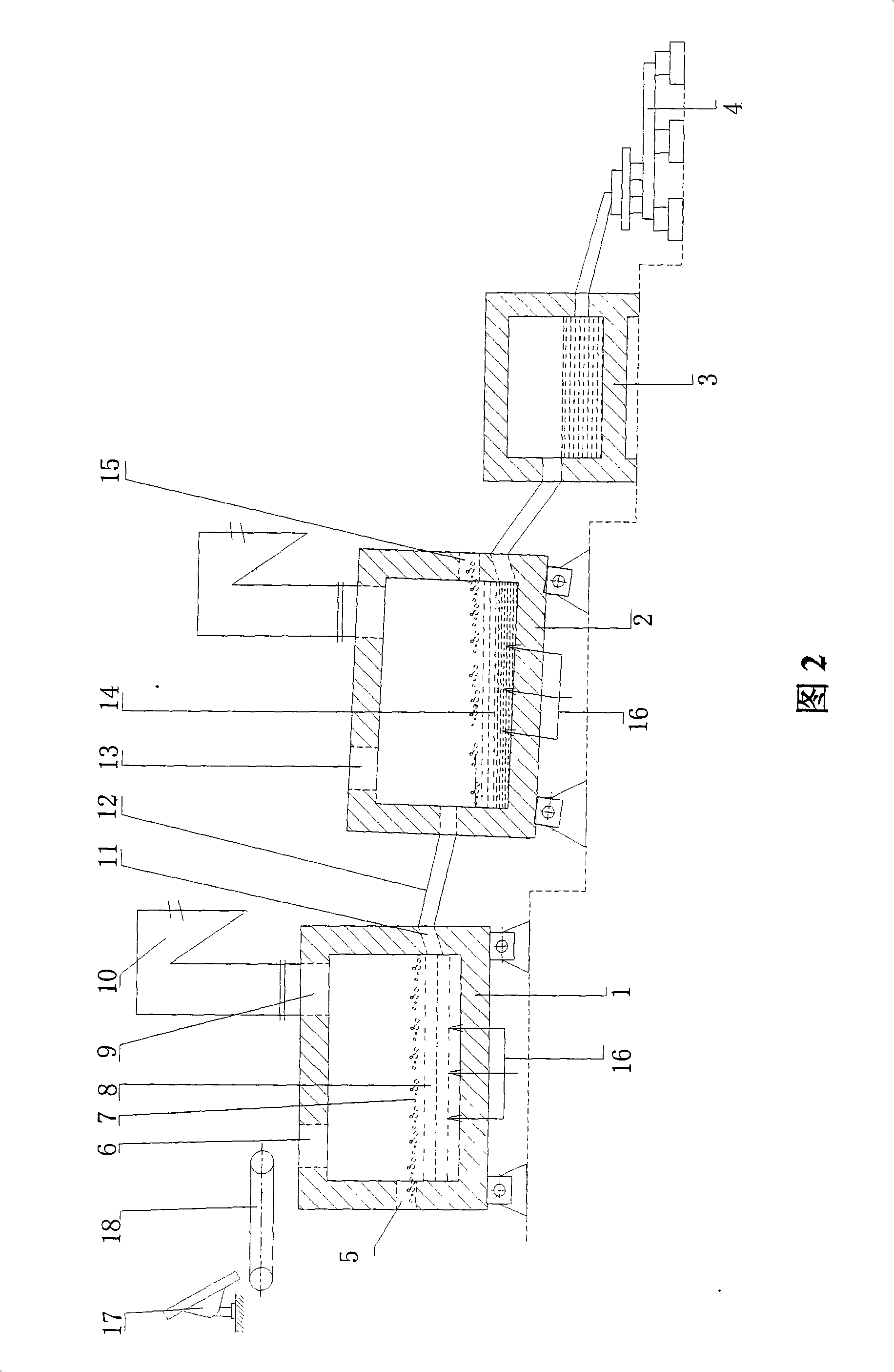

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

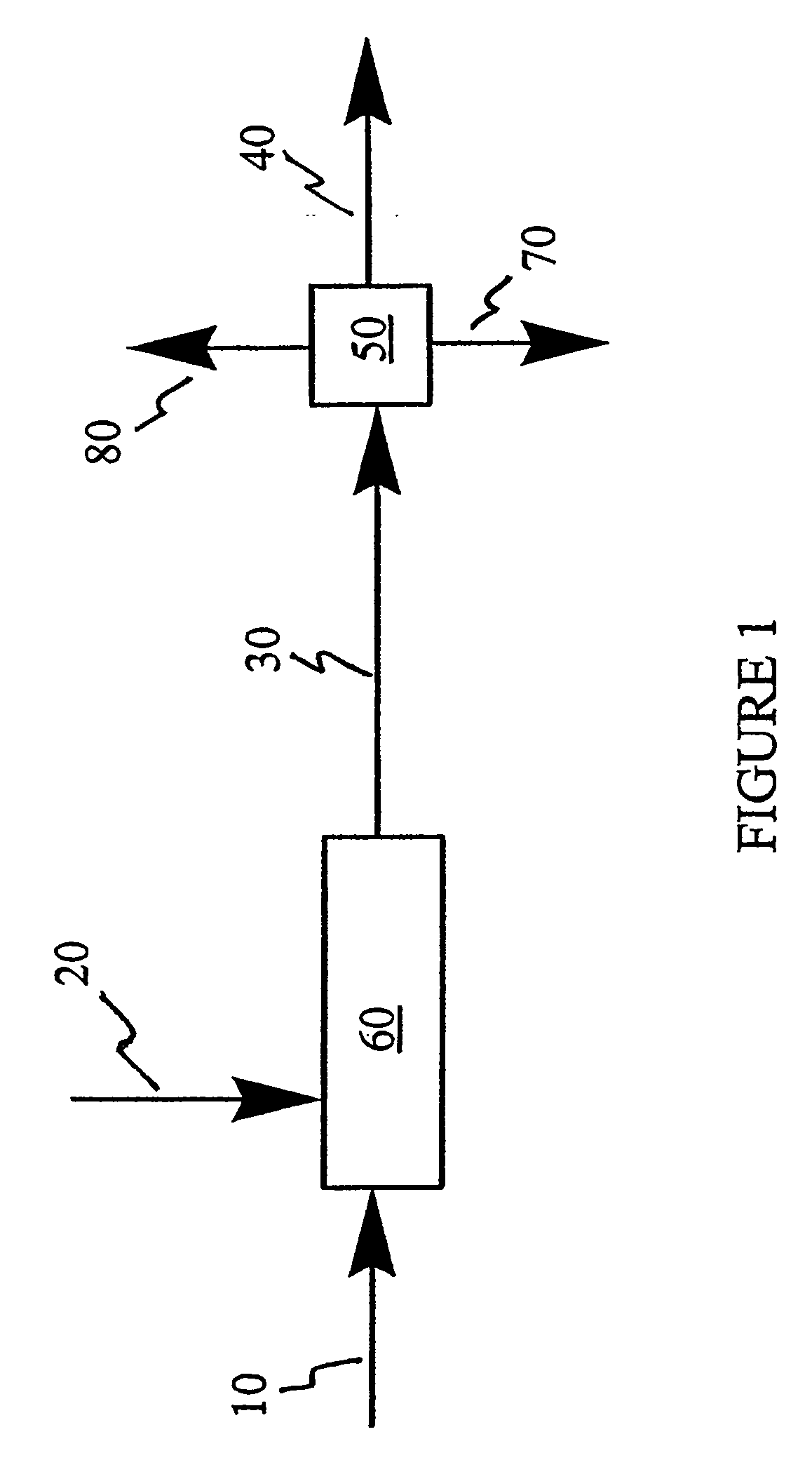

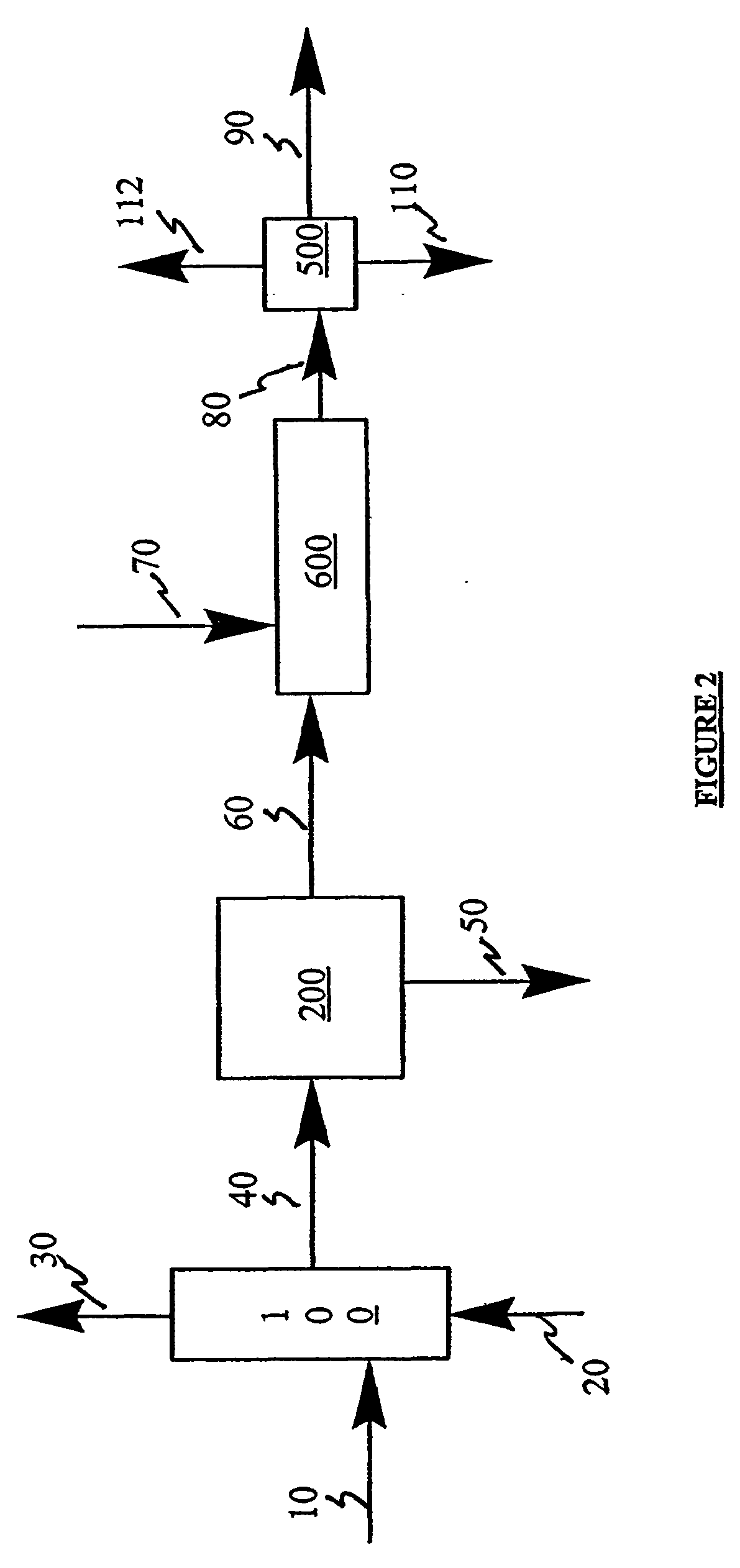

Oxidative desulfurization of sulfur-containing hydrocarbons

InactiveUS20050150819A1Reduce sulfur contentLow sulfurRefining with oxygen compoundsRefining with metal oxidesGas phaseOxygen

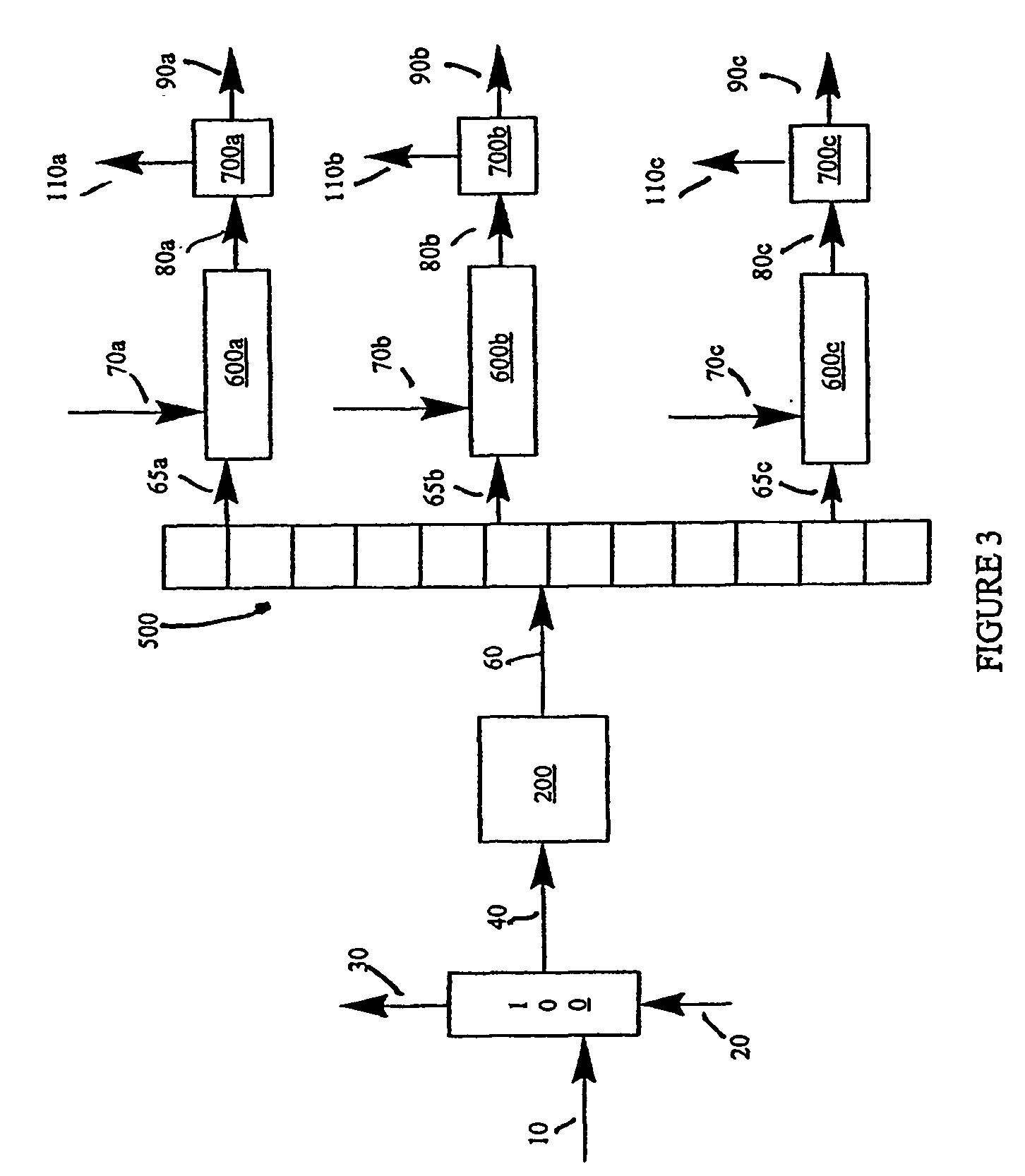

A method for desulfurizing a hydrocarbon stream (10) containing heterocyclic sulfur compounds, which process comprises contacting the heterocyclic sulfur compounds in the gas phase (60) in the presence of oxygen (70) with a supported metal oxide catalyst, or with a bulk metal oxide catalyst (600) to convert at least a portion of the heterocyclic sulfur compounds to oxygenated products as well as sulfur-deficient hydrocarbons and separately recovering the oxygenated products separately from a hydrocarbon stream with substantially reduced sulfur.

Owner:LEHIGH UNIVERSITY

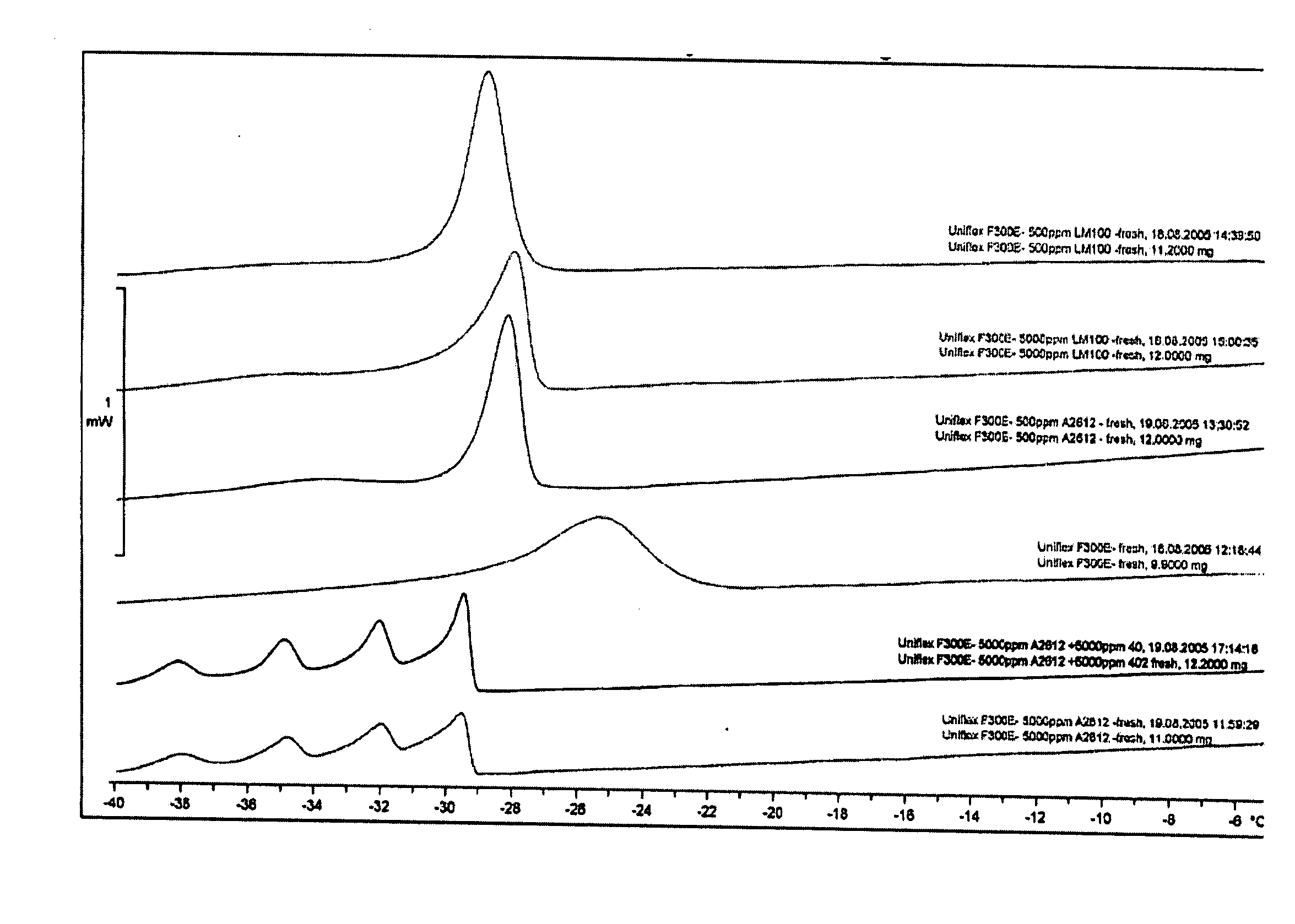

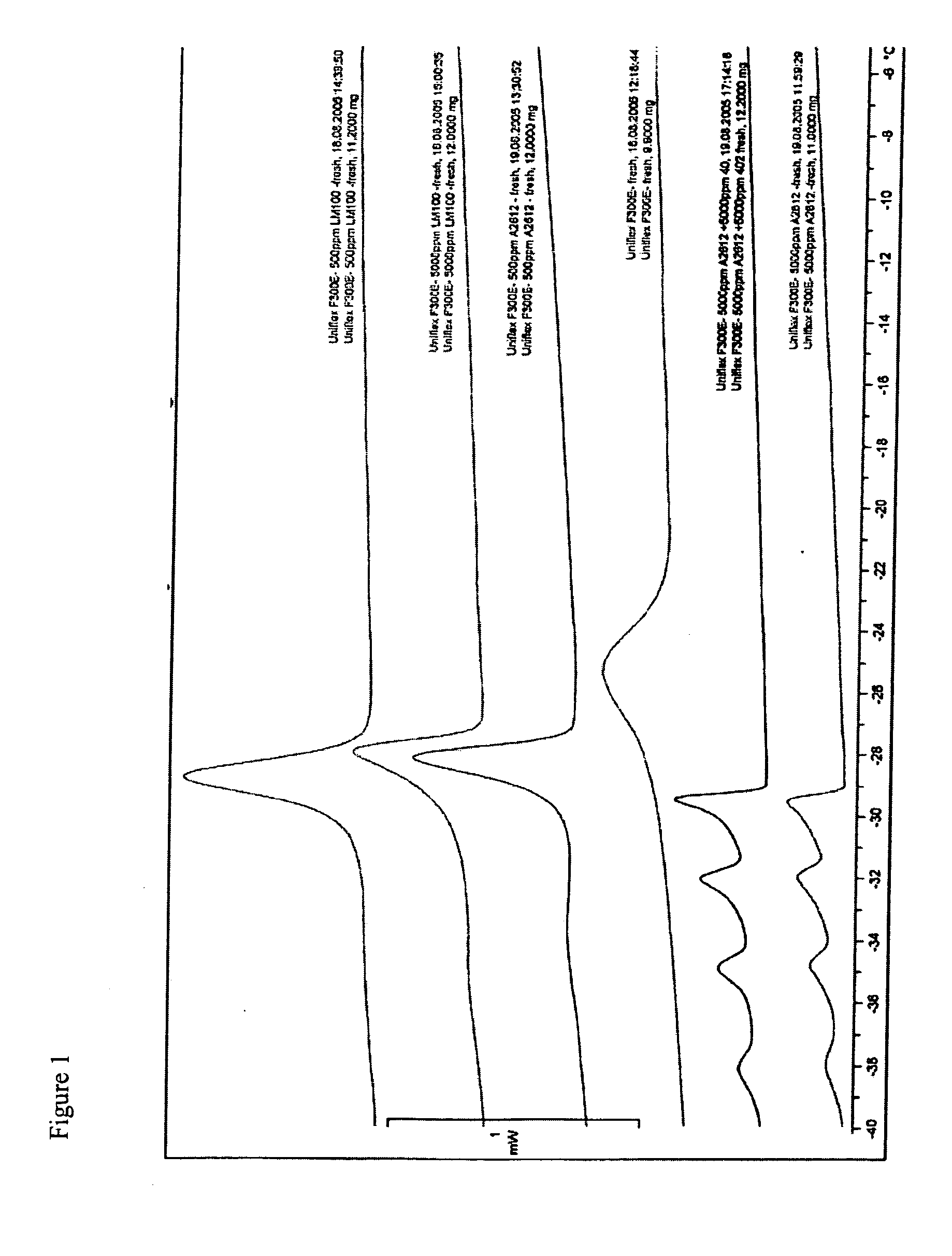

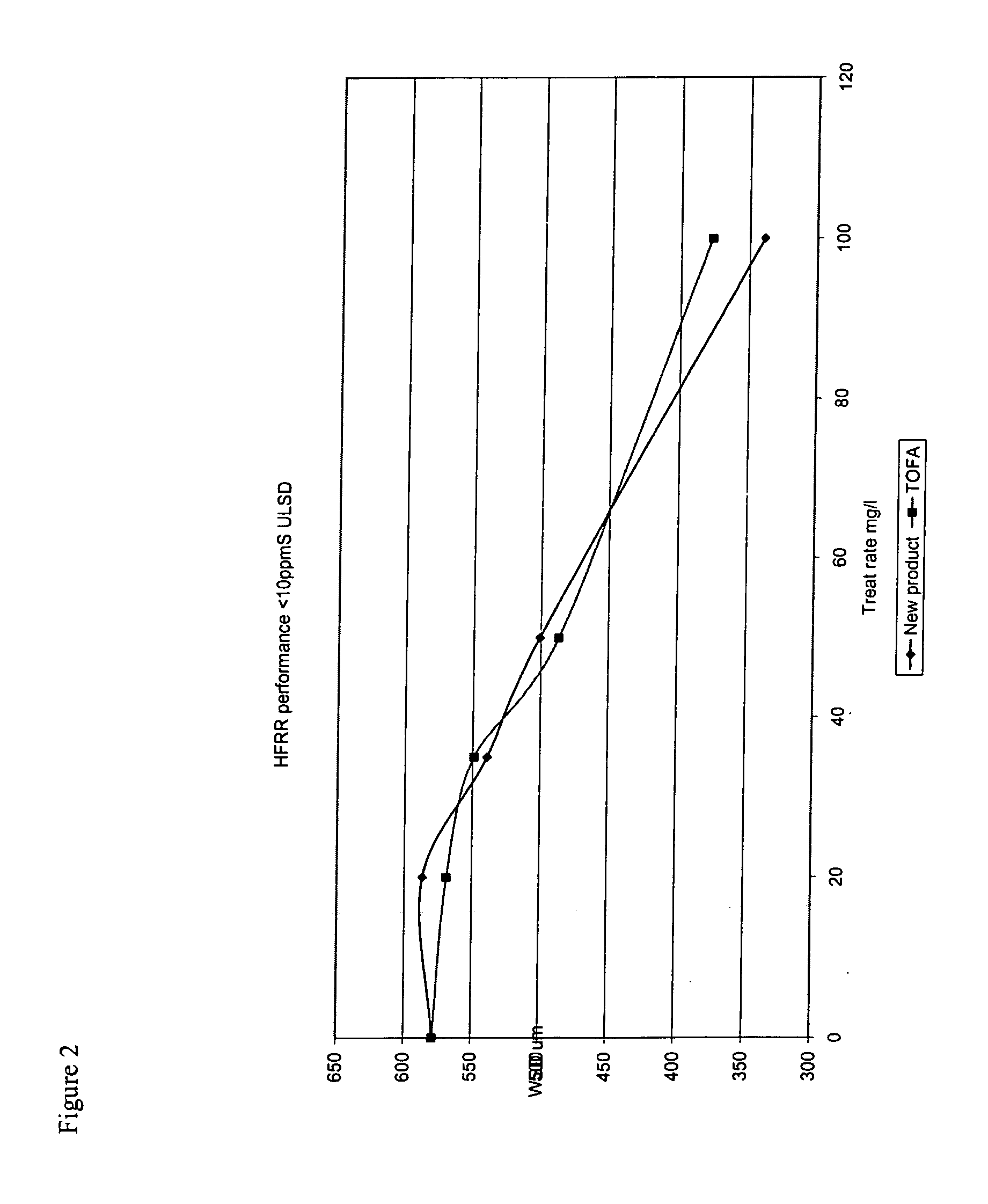

Compositions containing fatty acids and/or derivatives thereof and a low temperature stabilizer

InactiveUS20060229222A1Good low temperature stabilityImprove low temperature performanceCosmetic preparationsFatty acid esterificationFatty acid

Owner:ARIZONA CHEM CO

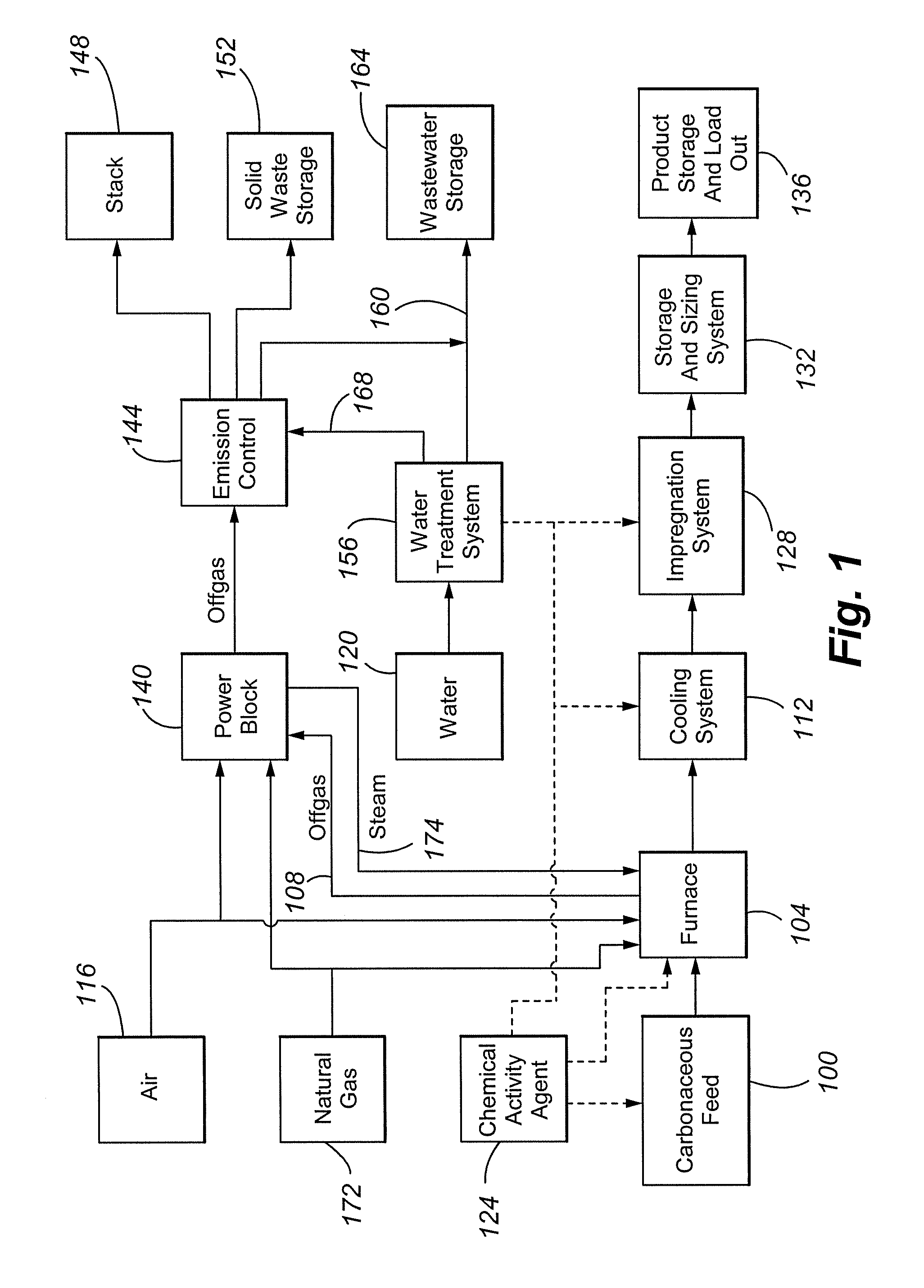

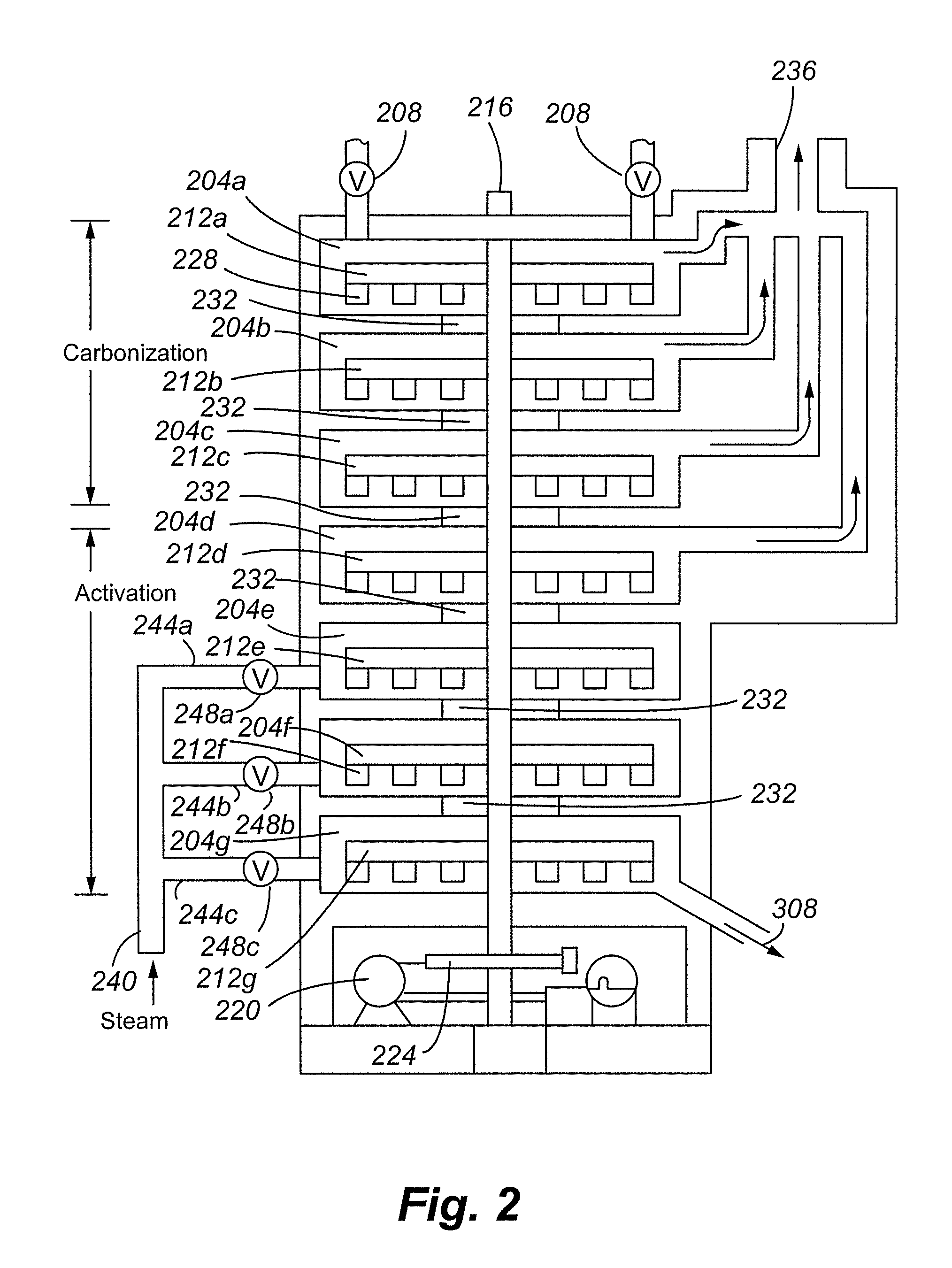

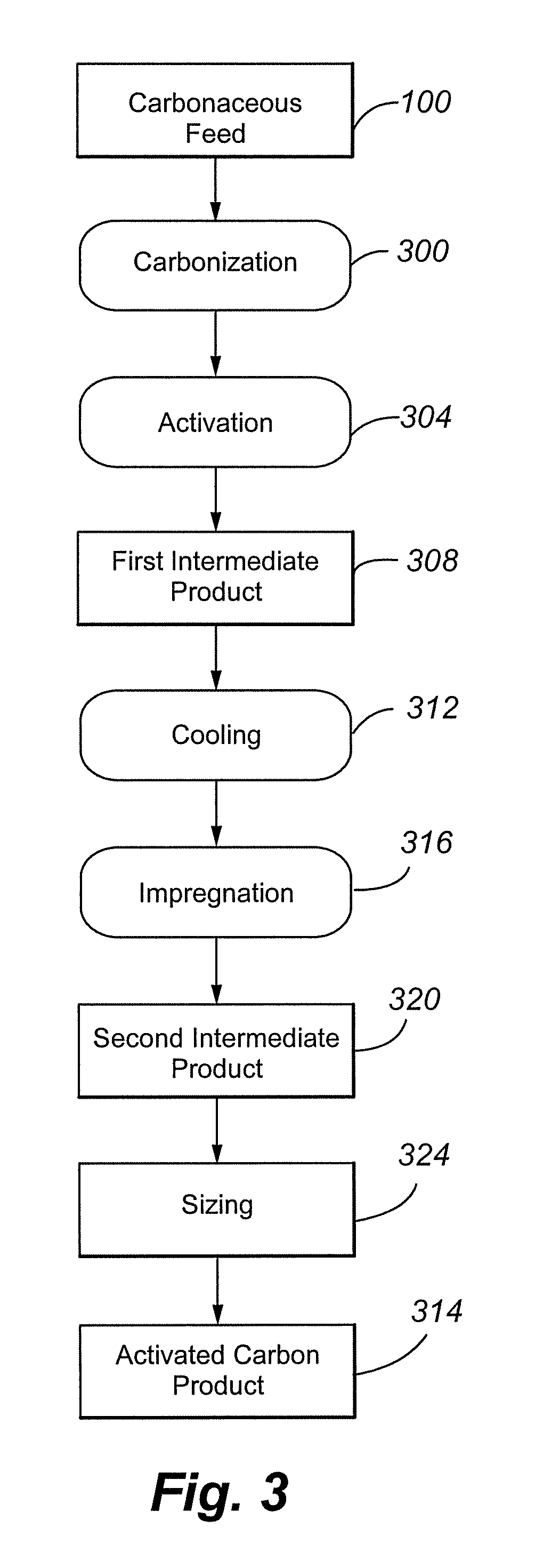

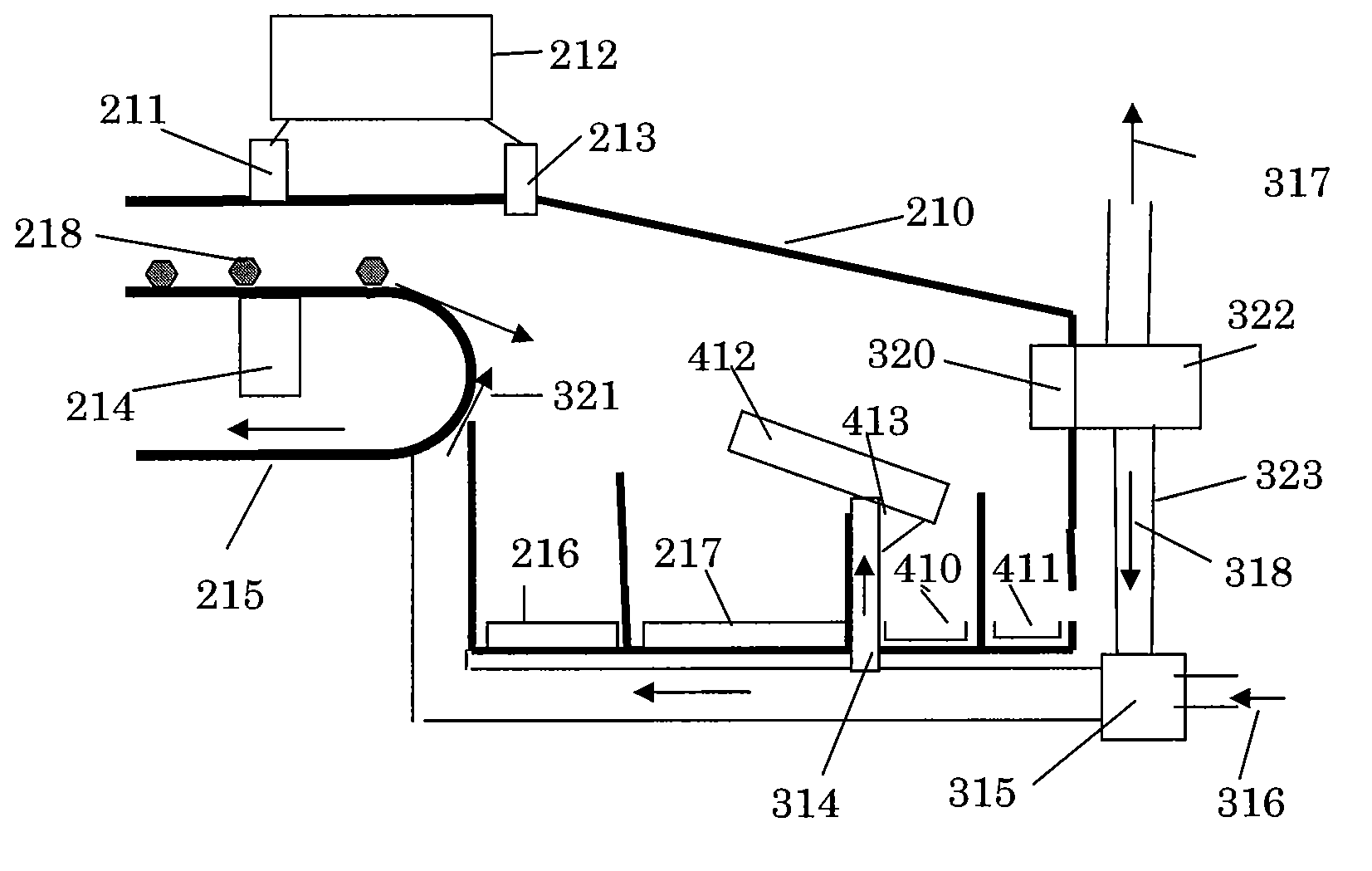

Process for the manufacture of carbonaceous mercury sorbent from coal

InactiveUS20070254807A1Large specific surface areaYield maximizationGas treatmentCarbon compoundsActivated carbonSorbent

The present invention is directed to a process for manufacturing a carbonaceous sorbent, particularly activated carbon, that uses lower average residence times and / or higher operating temperatures to produce activated carbon having favorable properties for mercury collection.

Owner:ADA CARBON SOLUTIONS

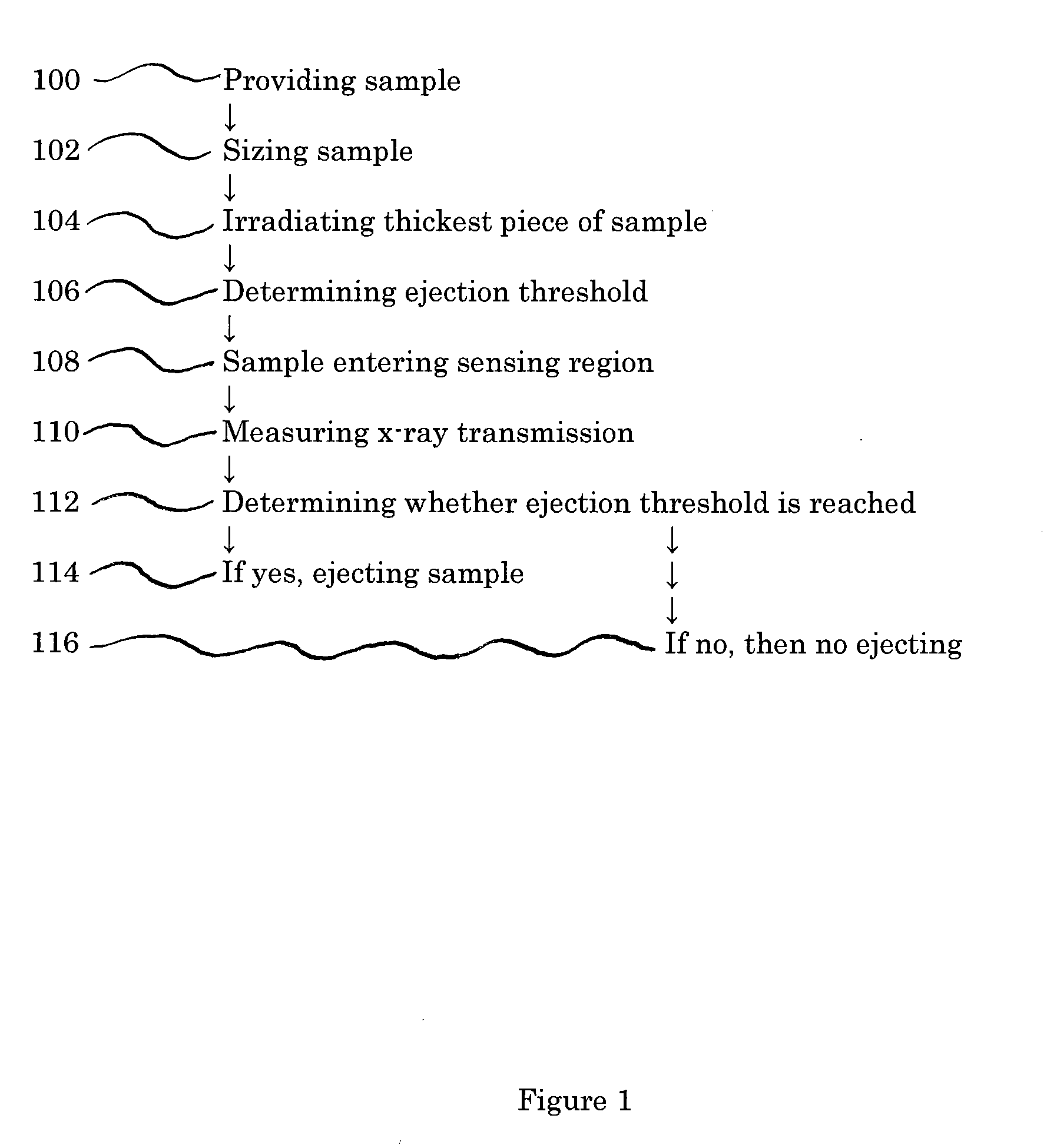

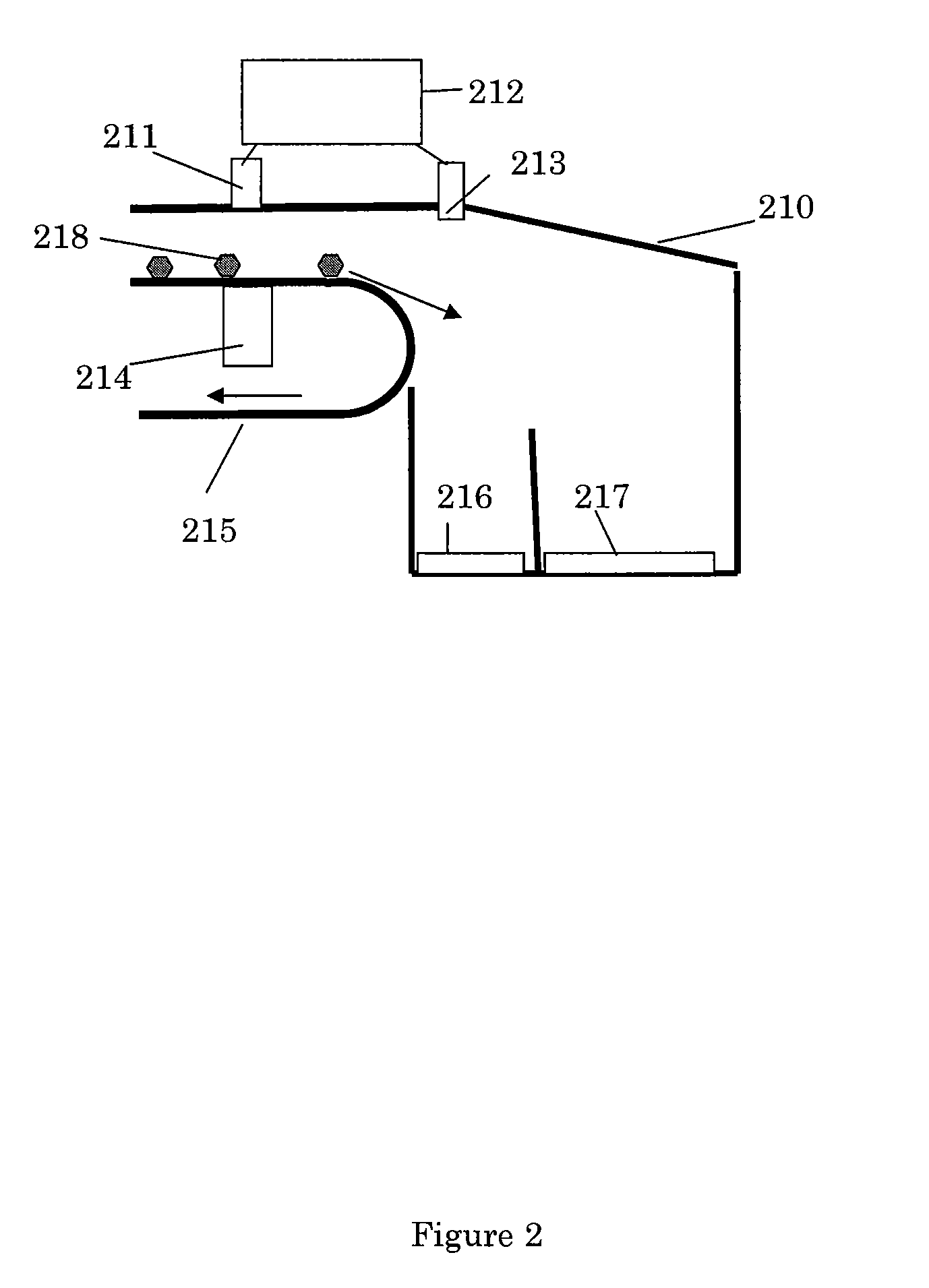

Methods for sorting materials

ActiveUS20100219109A1Low sulfurReduce fire and explosive hazardsDifferential sedimentationSortingCarbon footprintX-ray

Disclosed herein is the use of differences in x-ray linear absorption coefficients to process ore and remove elements with higher atomic number from elements with lower atomic numbers. Use of this dry method at the mine reduces pollution and transportation costs. One example of said invention is the ejection of inclusions with sulfur, silicates, mercury, arsenic and radioactive elements from coal. This reduces the amount and toxicity of coal ash. It also reduces air emissions and the energy required to clean stack gases from coal combustion. Removal of said ejected elements improves thermal efficiency and reduces the pollution and carbon footprint for electrical production.

Owner:MINERAL SEPARATION TECH

High-proportion coal blending and coking method

ActiveCN101942315ALow ashLow sulfurSpecial form destructive distillationProcess engineeringVitrinite

The invention relates to a high-proportion coal blending and coking method, wherein the coal blending varieties for coking used in the method comprises gas coal, fat coal, coking coal, lean coal and one third of coking coal. The coking method comprises the following steps: A. crushing raw coals separately, wherein crushed particle grade is less than 3mm, and the coal with particle size being lessthan 2mm accounts for more than 60% of the raw coal; and B. carrying out basic coal blending coking on the raw coals obtained in step A, wherein anhydrous ash-free basis volatile matter (Vdaf) of thebasic coal blending quality is 26.0-30.0%, the averagely maximum reflectance (MMR) of vitrinite is 1.0-1.1%, ash content (Ad) is less than 10.1%, total sulfur (St, d) is less than 1.1%, caking index (G) is more than 74, maximum thickness of a gelatine layer is more than 18mm and ratio between active components and inert components is 1.7-1.8. The coal blending coking method of the invention can enlarge coking coal source, lower ash content, sulfur content and phosphorus content in coke, reduce production cost of enterprises, increase economic benefit, improve competitiveness of enterprises, and achieve good comprehensive benefit.

Owner:CHINA SHENHUA ENERGY CO LTD +2

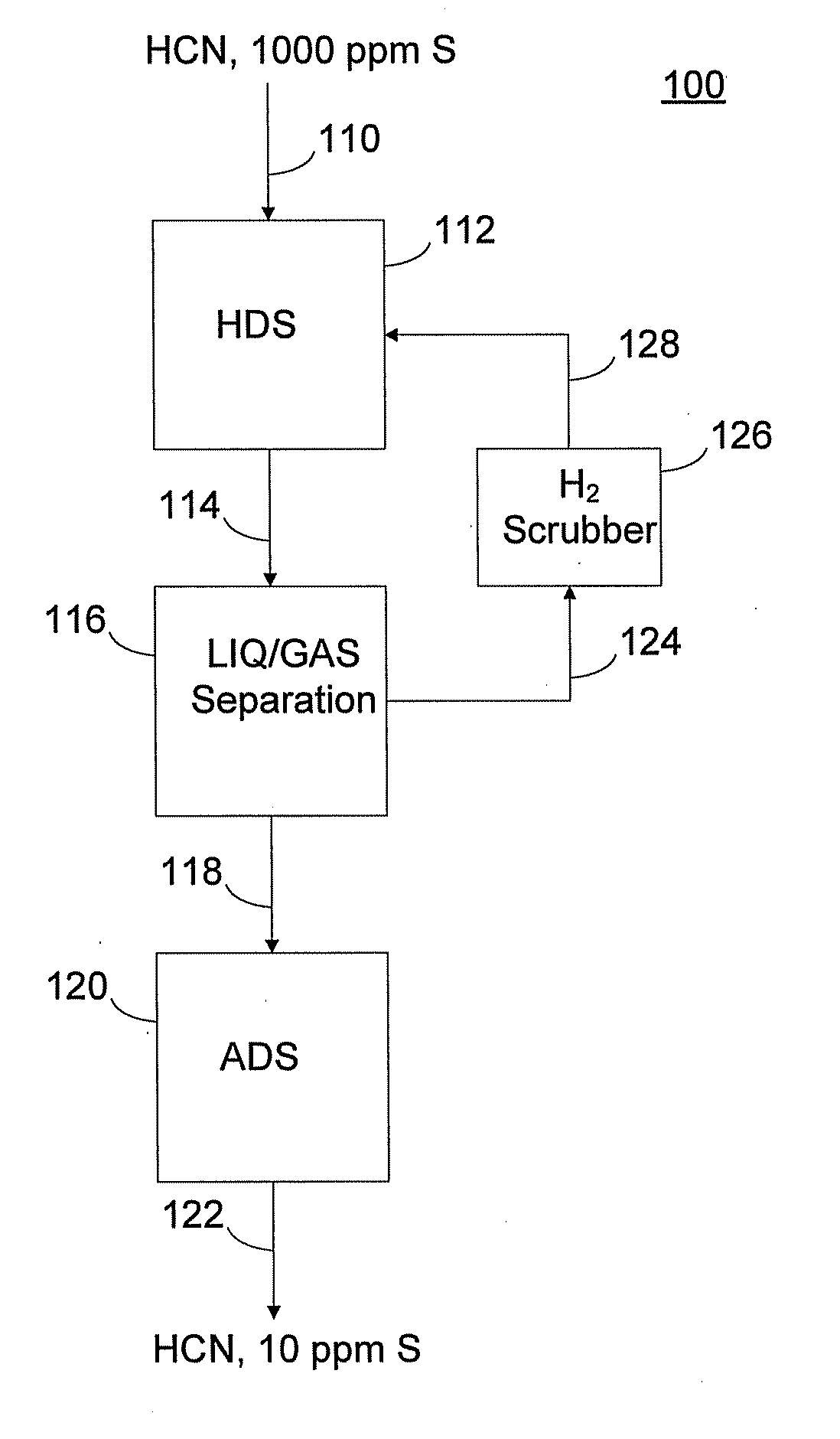

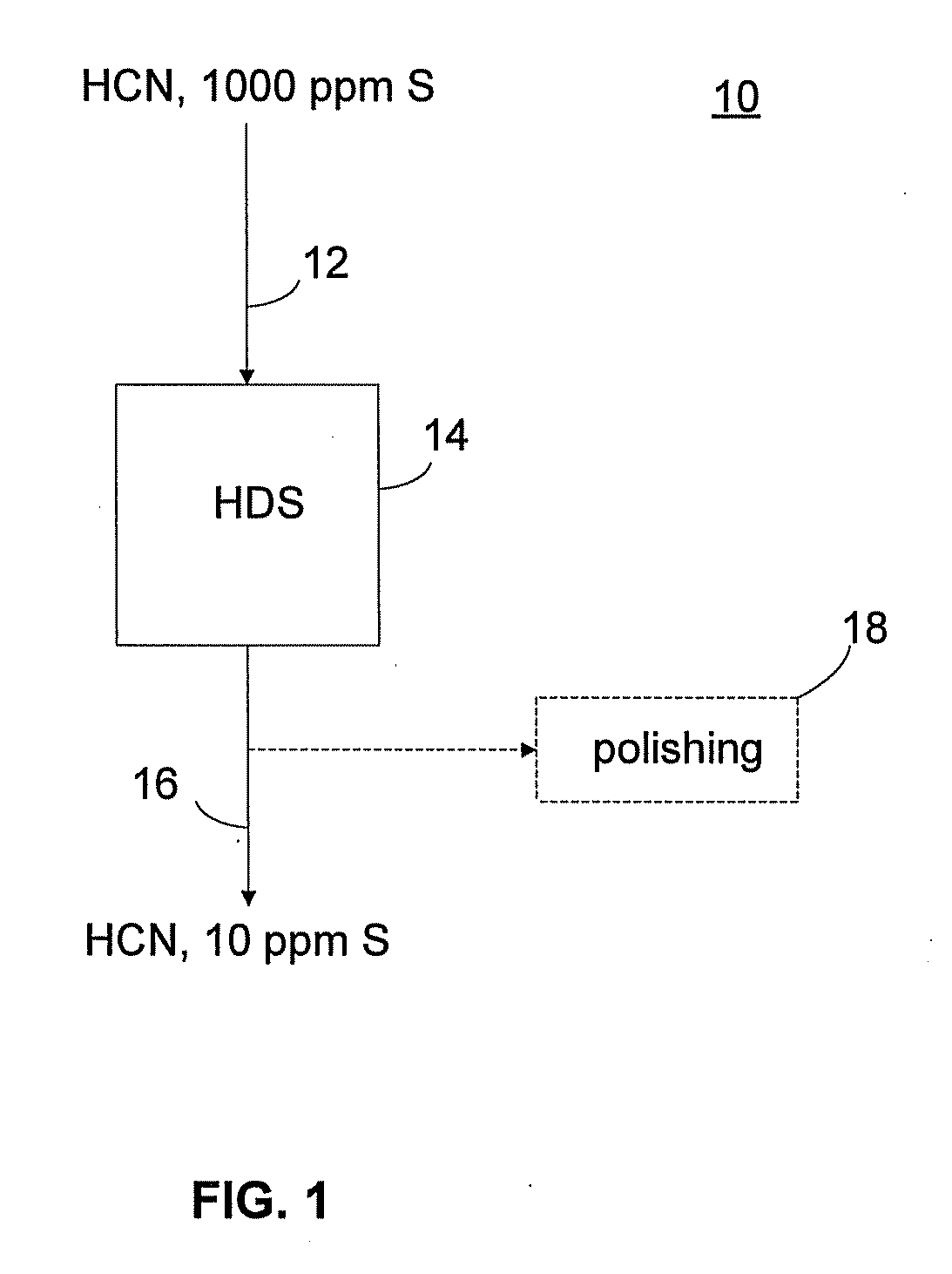

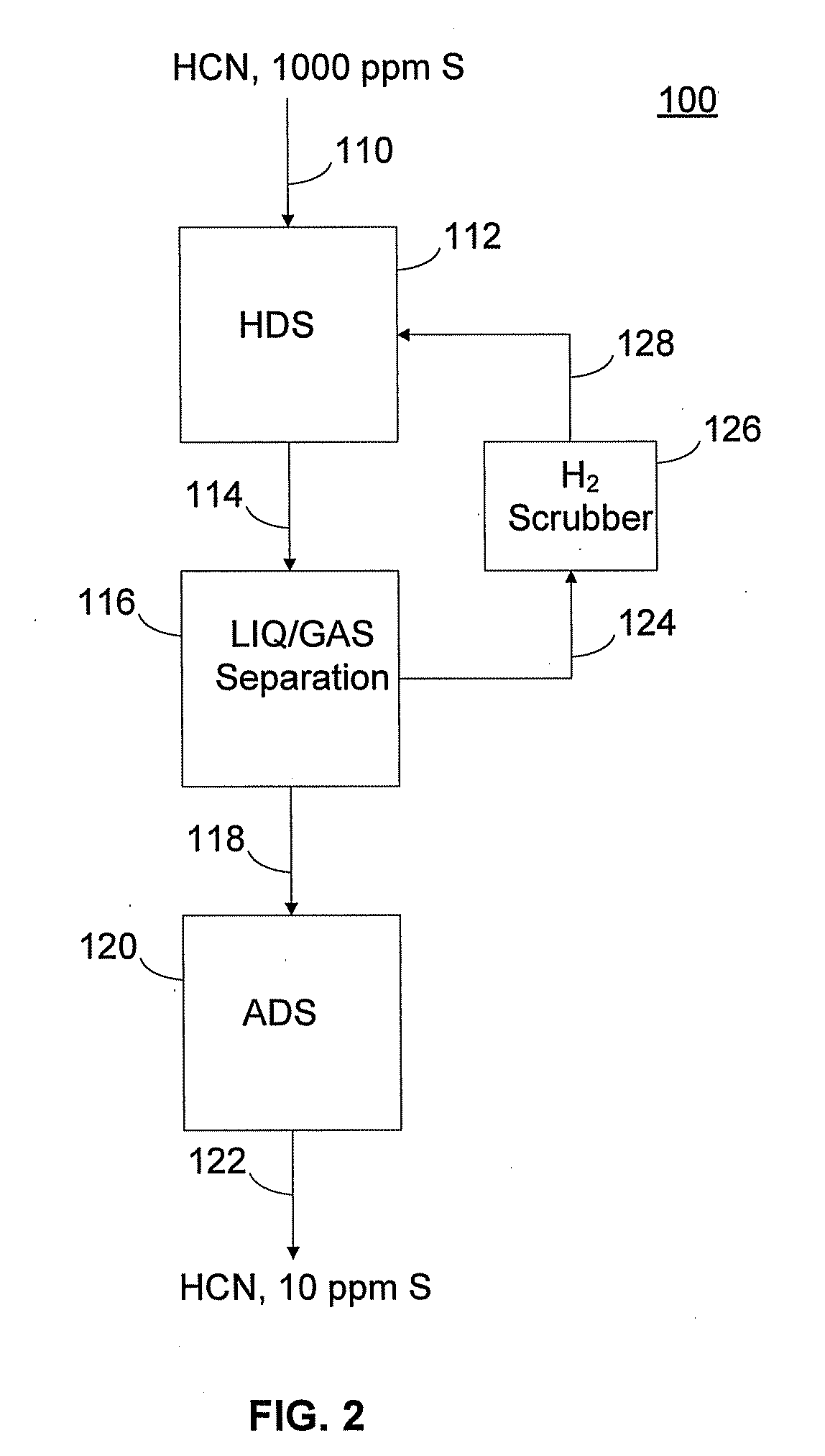

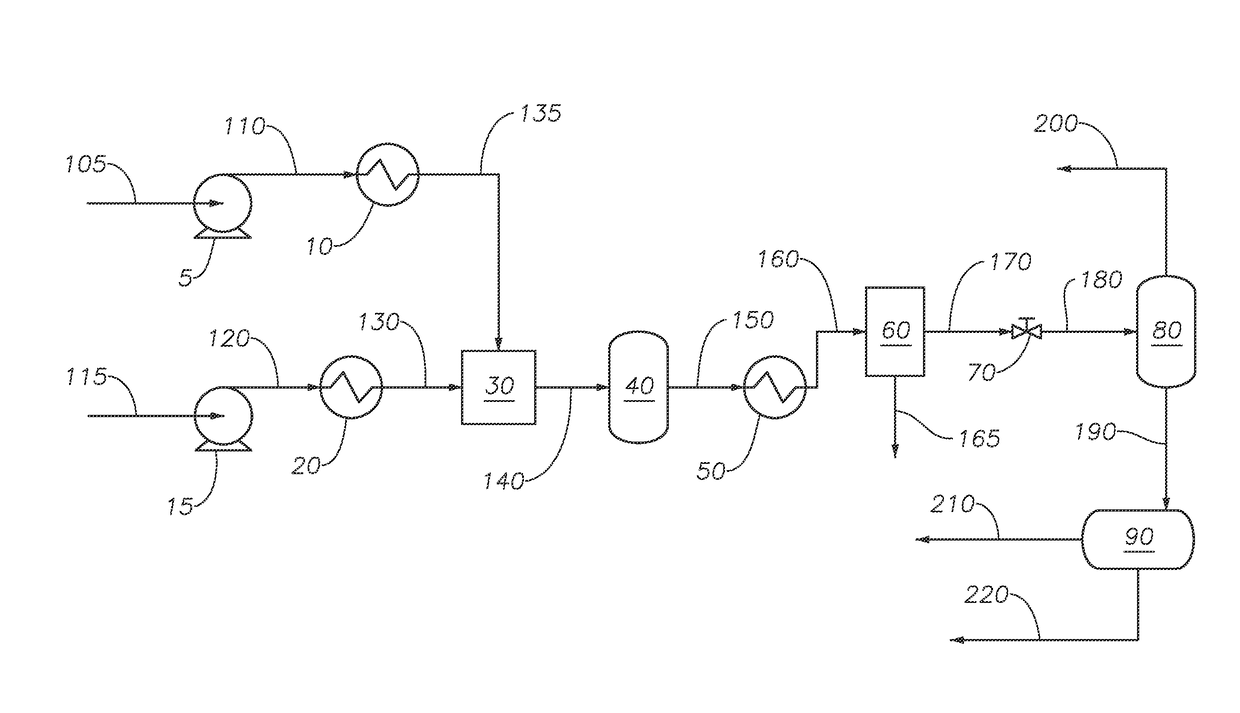

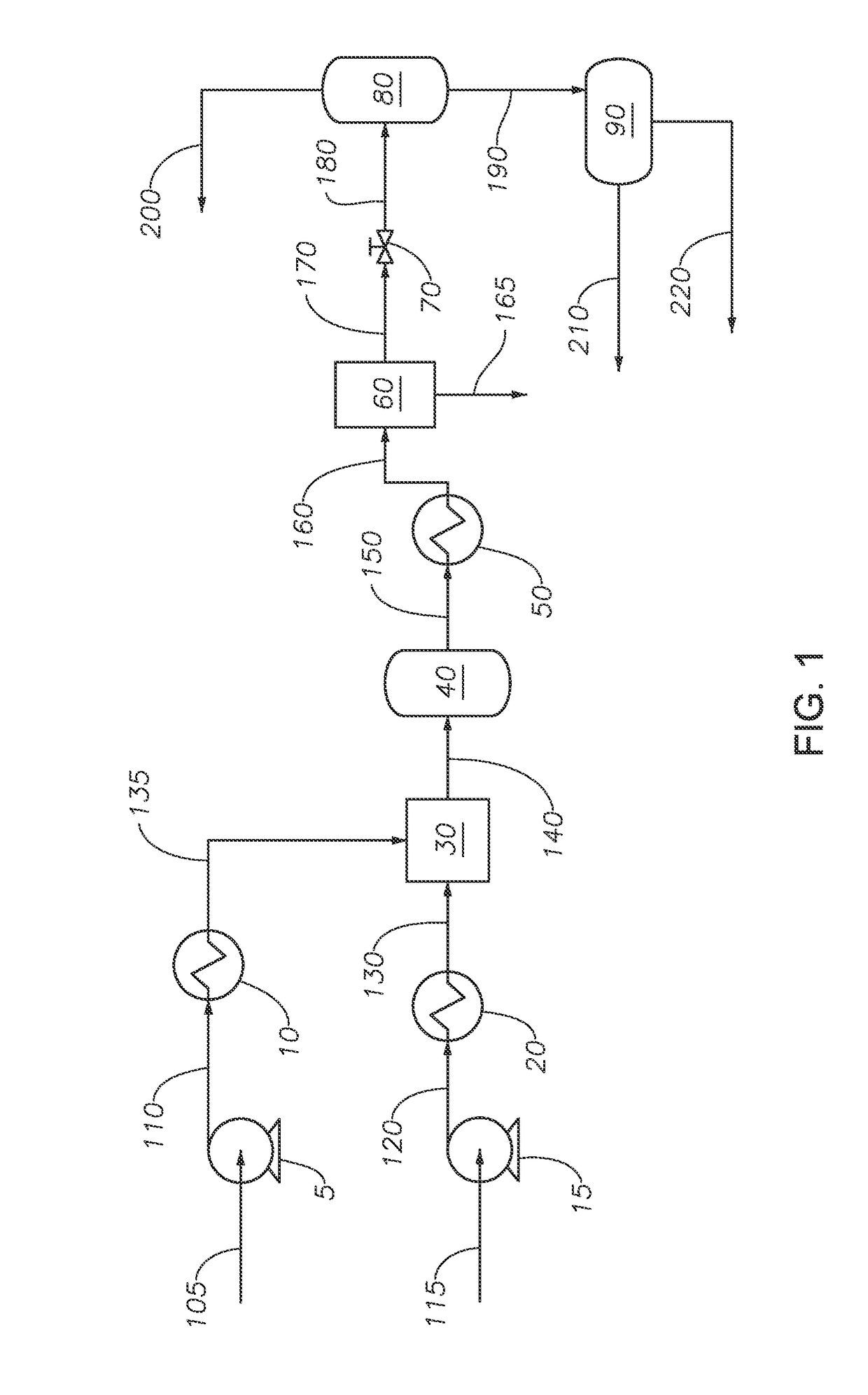

Process to produce low sulfur catalytically cracked gasoline without saturation of olefinic compounds

ActiveUS20090145807A1Reduce sulfur contentLow sulfurTreatment with plural serial stages onlyTreatment with hydrotreatment processesDistillates petroleumHydrogen

The invention relates to a process for the desulfurization of a gasoline fraction with high recovery of olefins and reduced loss of Research Octane Number (RON). A petroleum fraction is contacted with hydrogen and a commercially available hydrodesulfurization catalyst under mild conditions with to remove a first portion of the sulfur present, and is then contacted with an adsorbent for the removal of additional sulfur.

Owner:SAUDI ARABIAN OIL CO

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS20030158048A1Reduce friction and wearLow sulfurOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

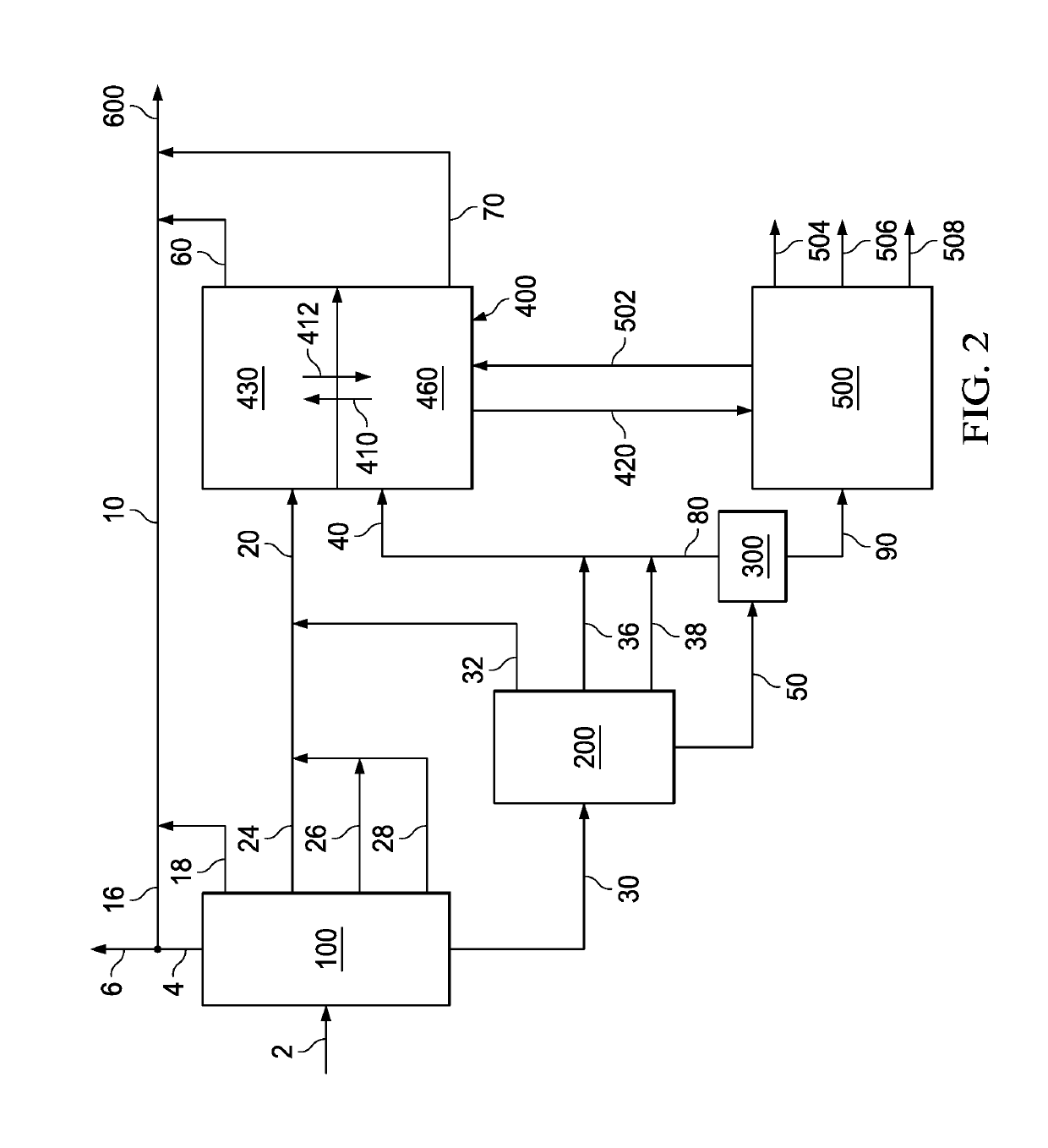

Process for the production of hydrocarbons with low sulfur and mercaptan content

InactiveUS20030217951A1Reduce lossesLow sulfurTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsHydrogenThiol

Process for desulfurization of a cut containing hydrocarbons comprising sulfur compounds and olefinic compounds comprising at least the following successive steps: a first desulfurization in the presence of hydrogen and a hydrodesulfurization catalyst under conditions leading to a desulfurization rate of said cut strictly higher than 90%; separation of most of the hydrogen sulfide from the effluents resulting from the first desulfurization; a second desulfurization of the effluents, with the hydrogen sulfide removed, resulting from the separation step, in the presence of hydrogen and a hydrodesulfurization catalyst, and under conditions leading to a desulfurization rate of said effluents less than that of the first desulfurization.

Owner:INST FR DU PETROLE

Environment-friendly marine fuel

ActiveUS20190093026A1Low costLow sulfurElectrical apparatusLiquid carbonaceous fuelsOpen seaLand based

For the shipping industry, these fuels provide solutions to long outstanding technical problems that heretofore hindered supply of low sulfur marine fuels in quantities needed to meet worldwide sulfur reduction goals. Marine shipping use of high sulfur bunker oils is reported as largest source of world-wide transportation SOx emissions. When ships on the open seas burn cheap low grade heavy bunker oils high in sulfur, nitrogen and metals, the SOx, NOx, and metal oxides go to the environment. This invention converts essentially all of each barrel of crude feed to a single ultraclean fuel versus conventional refining where crude feed is cut into many pieces, and each piece is sent down a separate market path meeting various different product specifications. When in port, ships can use these fuels to generate and sell electricity to land based electrical grids to offset fuel cost in an environment-friendly manner.

Owner:MAWETAL LLC

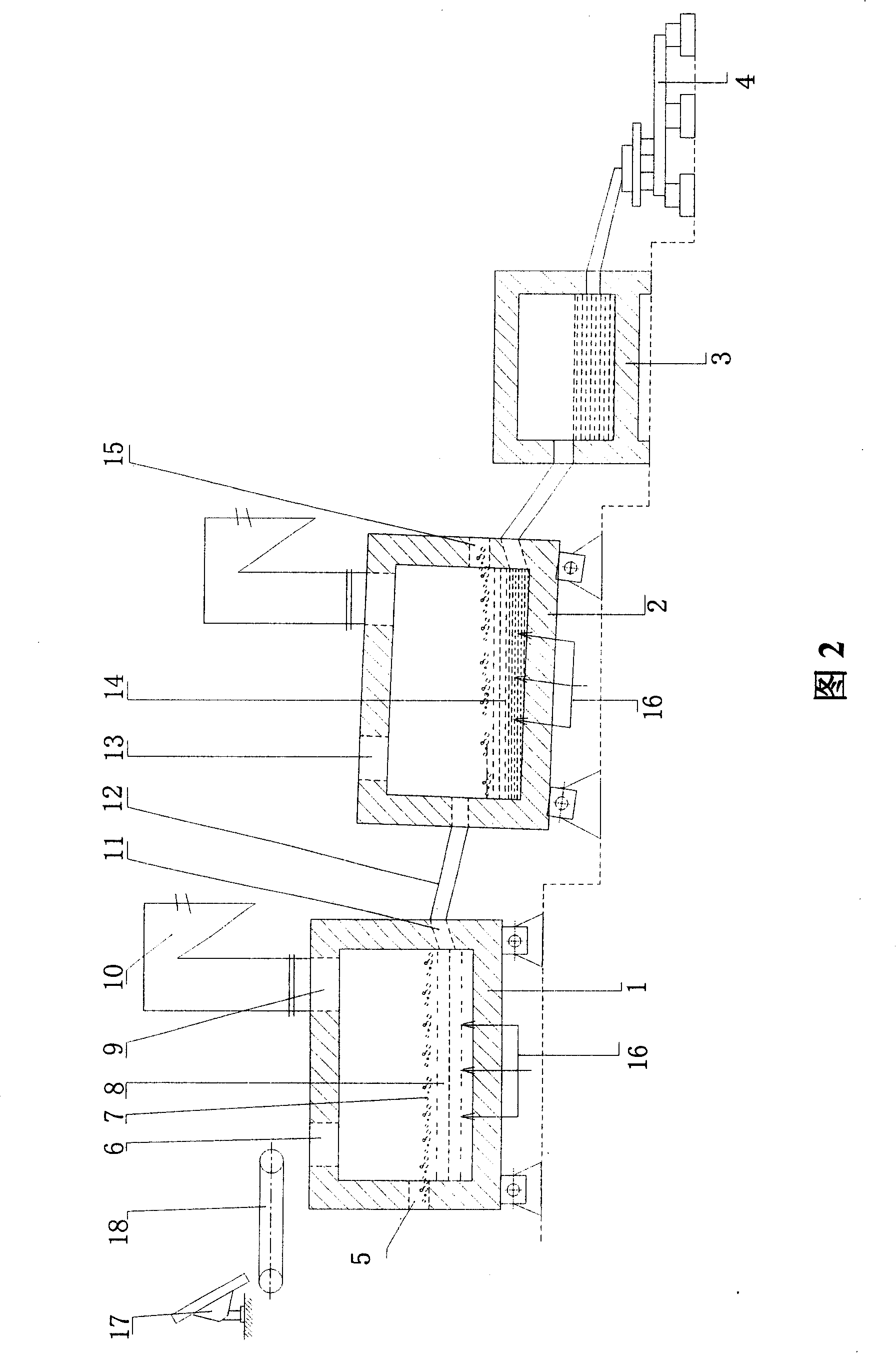

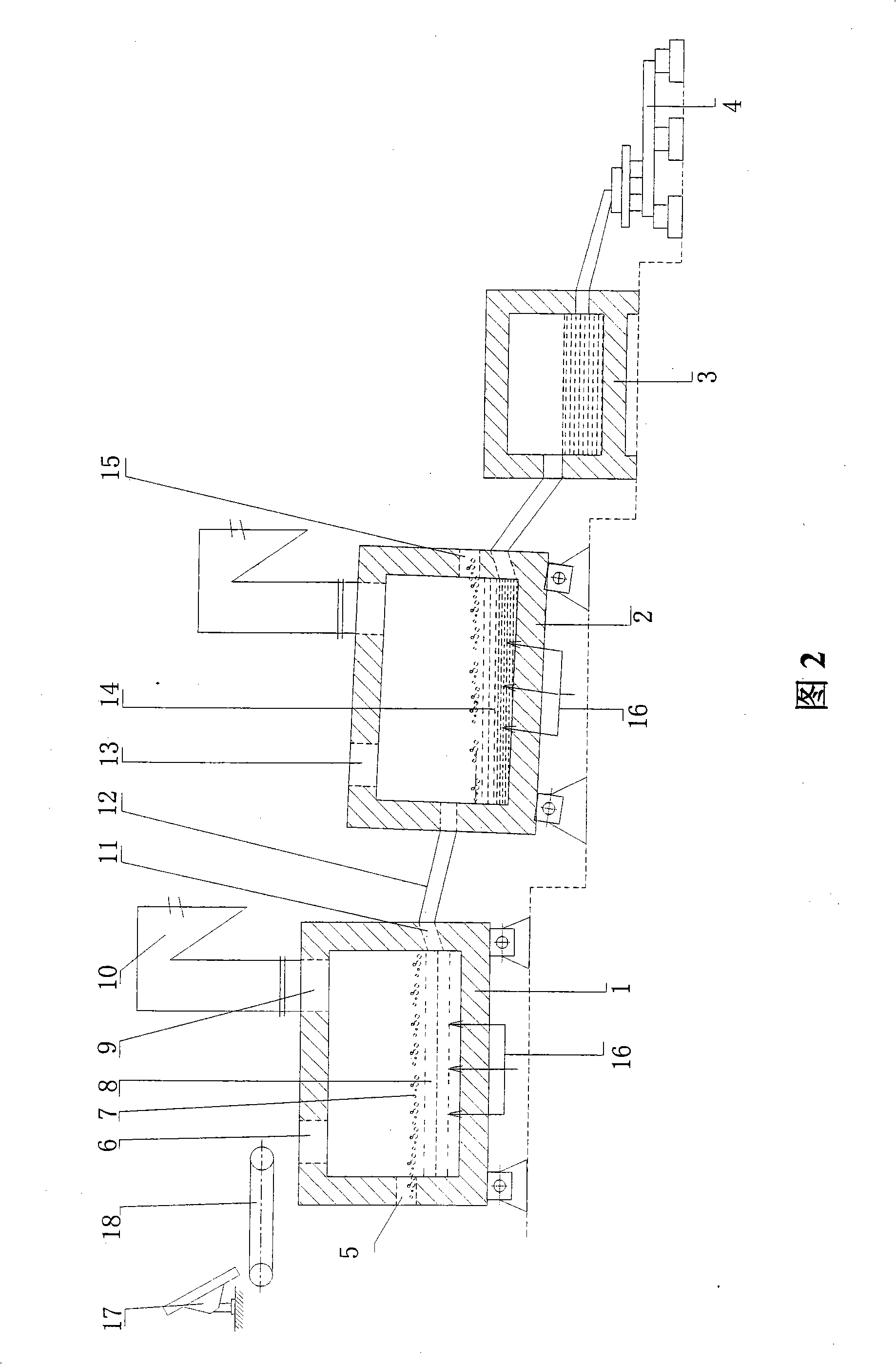

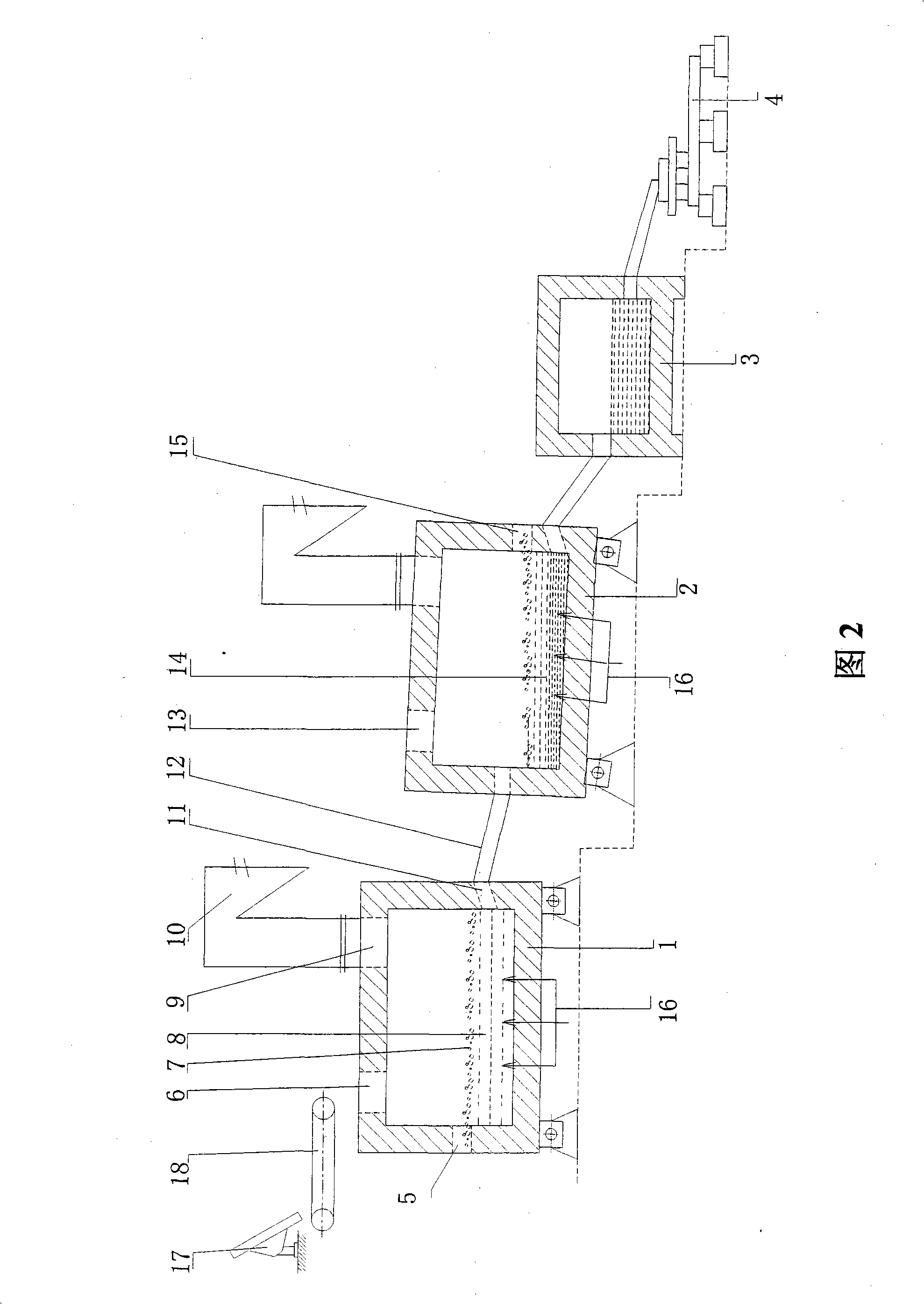

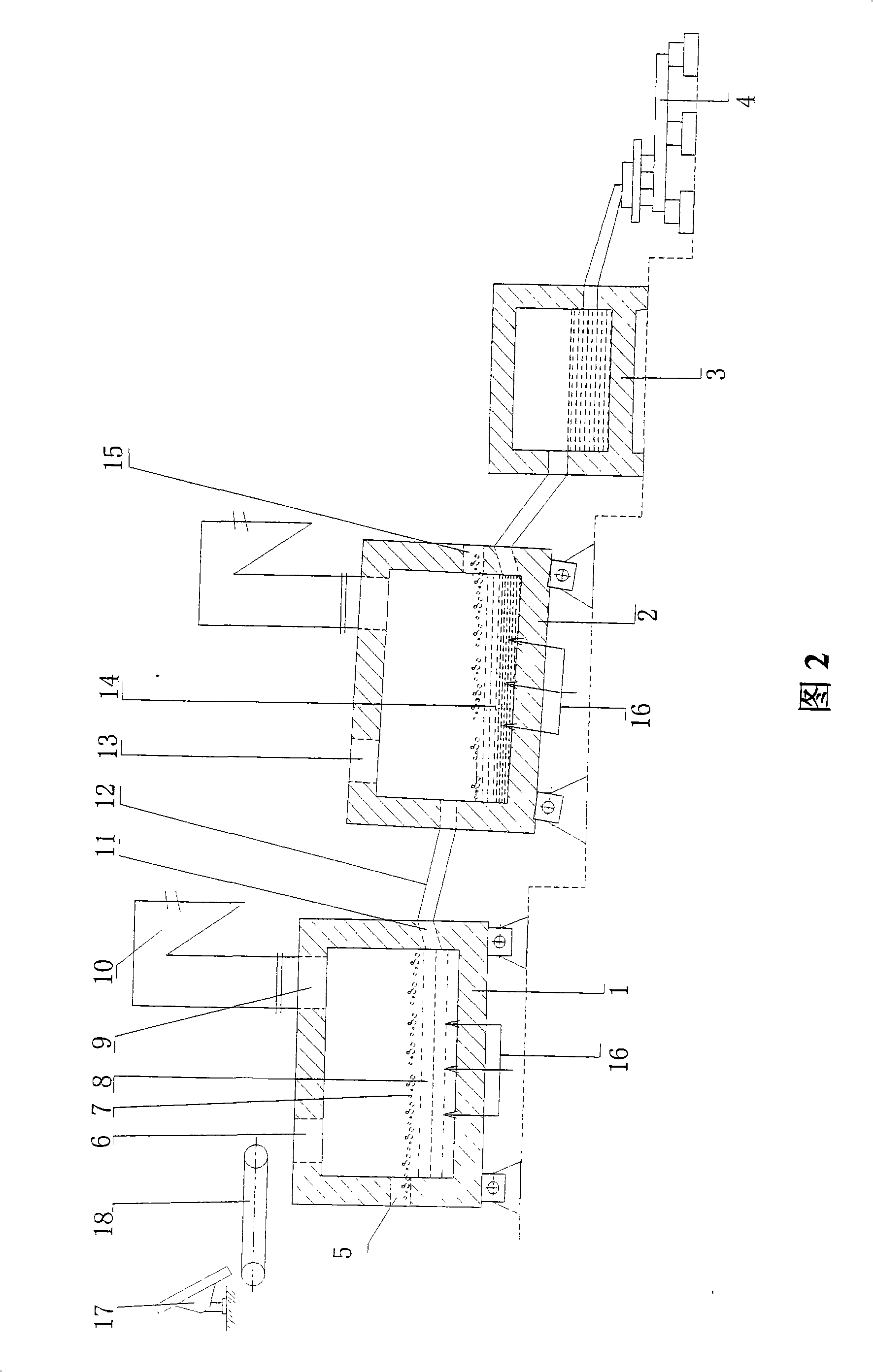

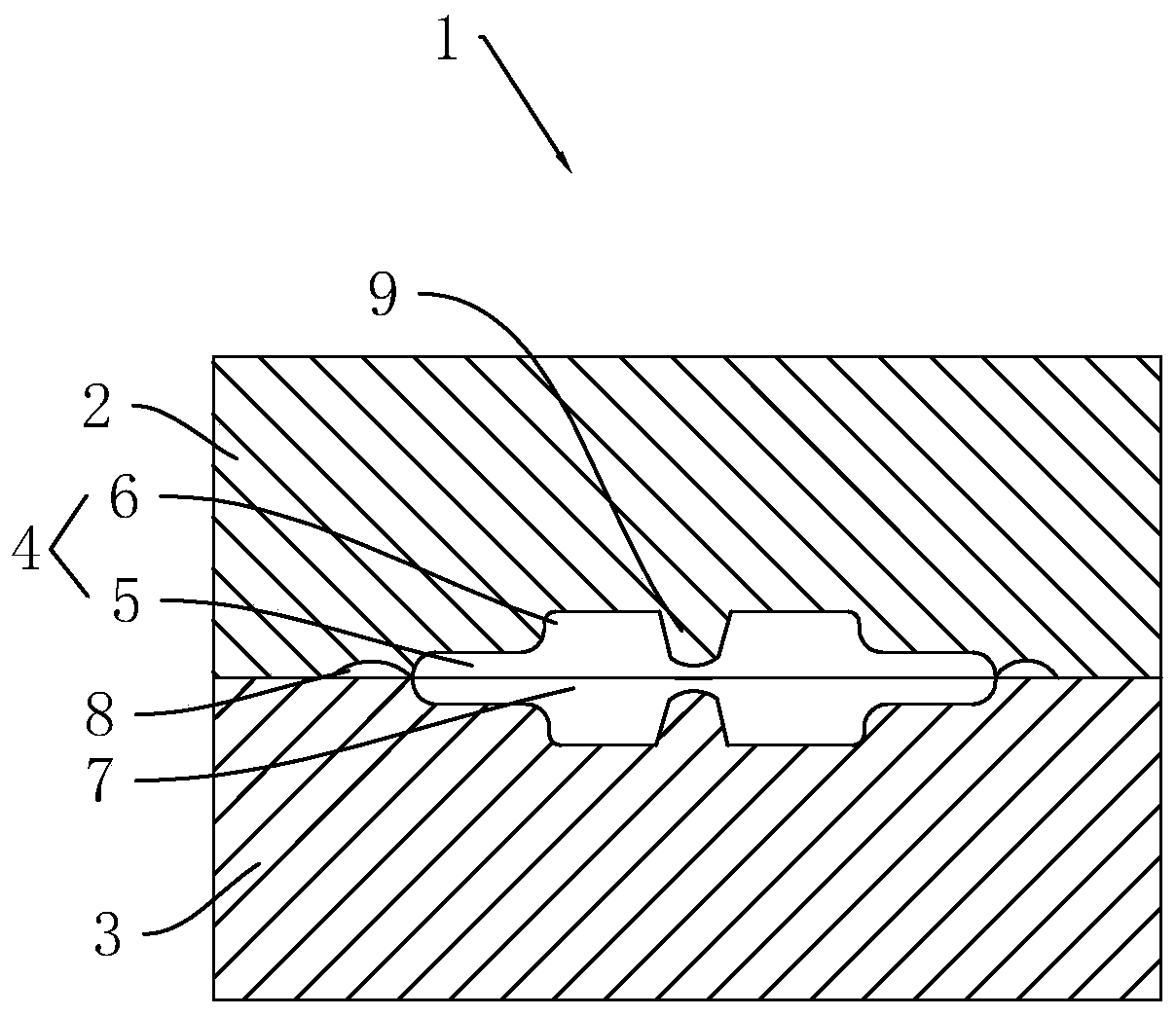

Oxygen bottom blowing continuous copper smelting apparatus

InactiveCN101328543ALess slagHigh yieldRotary drum furnacesCrucible furnacesSmelting processLiquid copper

The invention provides an oxygen bottom blowing continual copper smelting device used in the continual copper smelting process. The device is characterized in that the device comprises an oxygen bottom blowing smelting furnace, an oxygen bottom blowing converting furnace, an anode furnace and an anode plate casting machine, wherein the oxygen bottom blowing smelting furnace and the oxygen bottom blowing converting furnace are connected by a first chute, so that liquid copper matte smelted by the oxygen bottom blowing smelting furnace can be continuously injected into the oxygen bottom blowing converting furnace through the first chute to obtain coarse copper by the continuous converting of the oxygen bottom blowing converting furnace; the oxygen bottom blowing converting furnace and the anode furnace are connected by a second chute, so that the coarse copper can flow in the anode furnace through the second chute and is subjected to refining by the anode furnace to obtain anode copper; and the anode furnace and the anode plate casting machine are connected by a third chute, so that the anode copper can flow into the anode plate casting machine through the third chute and is subjected to casting by the anode plate casting machine to obtain the copper anode plate.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method to remove metals from petroleum

ActiveUS20170107433A1Low sulfurThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productGas phase

A method to remove a metals impurity from a petroleum feedstock for use in a power generating process is provided. The method comprising the steps of mixing a heated feedstock with a heated water stream in a mixing device to produce a mixed stream; introducing the mixed stream to a supercritical water reactor in the absence of externally provided hydrogen and externally provided oxidizing agent to produce a reactor effluent comprising a refined petroleum portion; cooling the reactor effluent to produce a cooled stream; feeding the cooled stream to a rejecter configured to separate a sludge fraction to produce a de-sludged stream; reducing the pressure of the de-sludged stream to produce a depressurized product; separating the depressurized product to produce a gas phase product and a liquid product; separating the liquid product to produce a petroleum product, having a reduced asphaltene content, reduced concentration of metals impurity, and reduced sulfur.

Owner:SAUDI ARABIAN OIL CO

Coal blending and coking method for metallurgical coke

The present invention relates to coal blending and coking method for metallurgical coke, and especially the coal blending and coking method with thermal coal and weakly caking coal. The present invention adopts conventional coking process and the coal consists of weakly caking coal 0-15 wt%, thermal coal 0-10 wt%, gas coal 13-45 wt%, fatty coal 9-20 wt% and coking coal 40-45 wt%. The produced coke has dropping strength M40 of 77-78.5 %, abrasion resistance strength M10 <8.6 %, reactivity of 35-37 %, thermal state strength of 45-55 %, and granularity of 25-40 mm and 40-80 mm, and meets the requirement for iron smelting in blast furnace of 1000 cubic meter or larger. The present invention has expanded coal variety range for coking, and lowered coking cost.

Owner:武钢集团有限公司

Oxidative desulfurization of hydrocarbon fuels

InactiveUS20060226049A1Reduce sulfur contentLow sulfurNon-fuel substance addition to fuelInternal combustion piston enginesSulfurSorbent

A process and apparatus for the desulfurization of hydrocarbon fuels is presented. The apparatus and process use an inorganic metal peroxide and catalyst to oxidize the sulfur compounds. The oxidized sulfur compounds are then adsorbed on an adsorbent.

Owner:UOP LLC

Low sulfur, low ash, and low phosphorus lubricant additive package using an alkylamine salt of dialkylmonothiophosphate

InactiveUS20050026791A1Minimal sulfurLow phosphorus contentOrganic chemistryLiquid carbonaceous fuelsSulfurLubricant

The present invention provides an oil soluble lubricant additive package comprising at least one alkylamine salt of a dialkylmonothiophosphate. Further, the present invention provides lubricating oils based on the lubricant additive package and methods of use.

Owner:AFTON CHEM INTANGIBLES

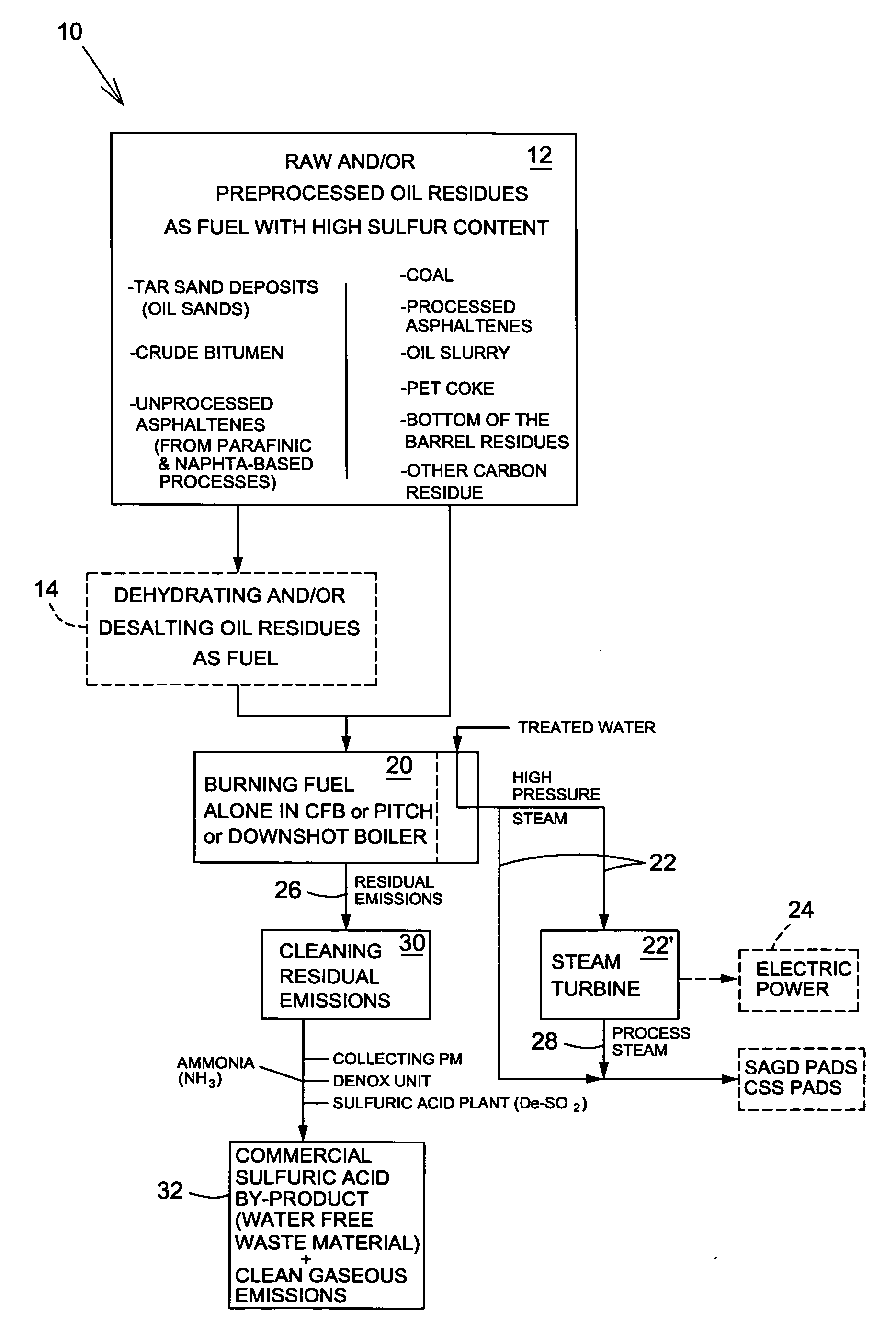

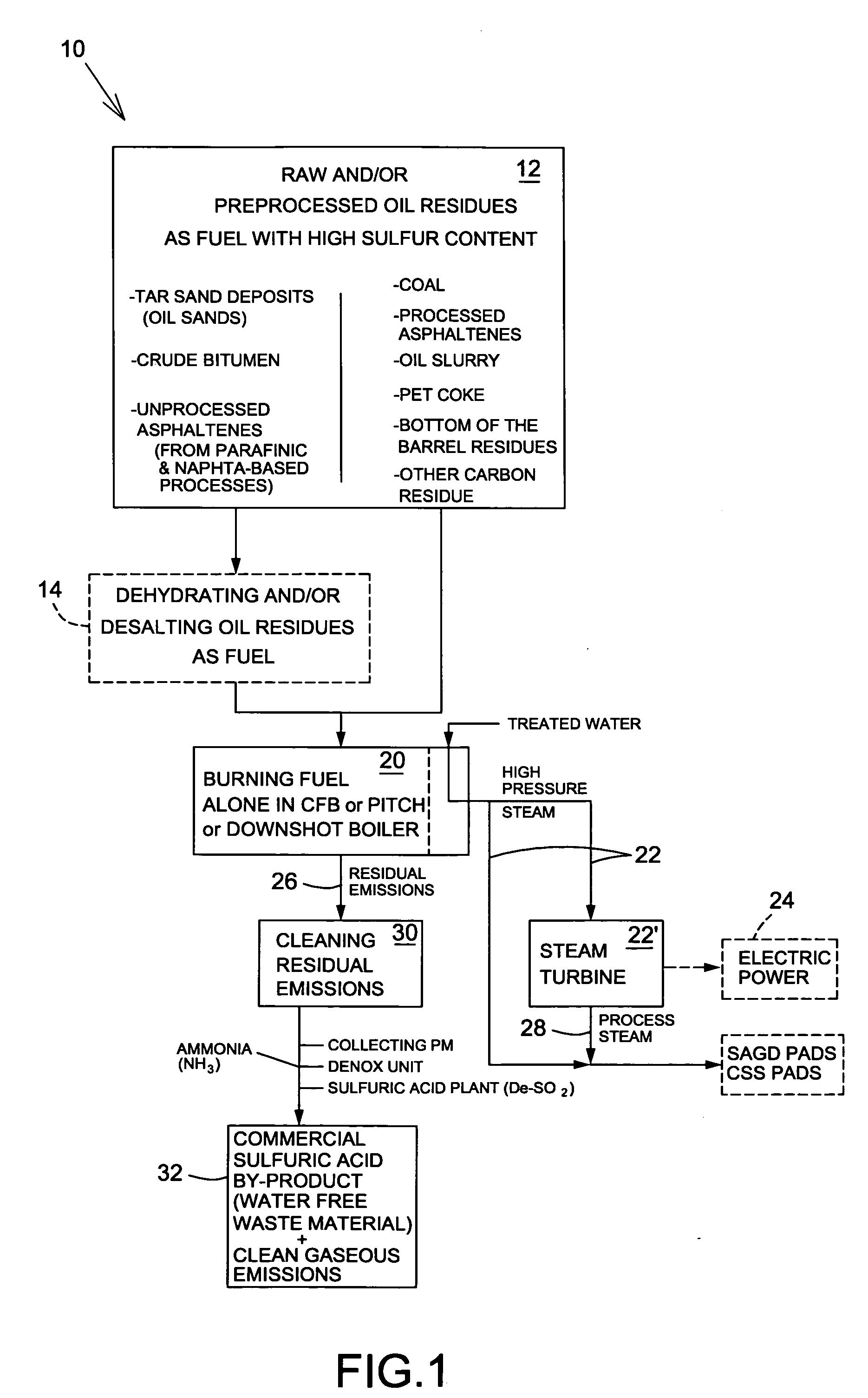

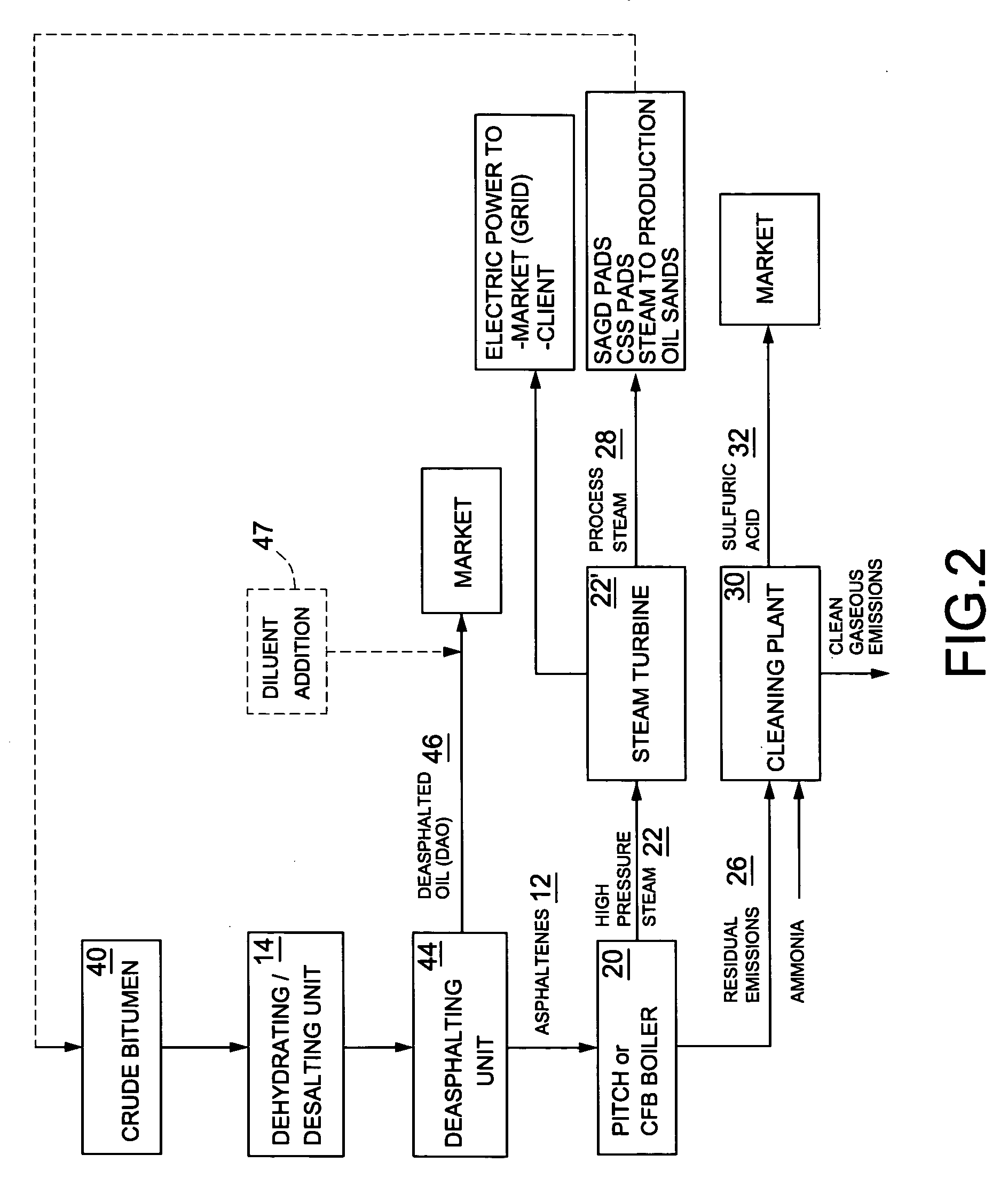

Process for producing steam and/or power from oil residues with high sulfur content

InactiveUS20100126395A1Low costWeaken energyDispersed particle separationSulfur compoundsSorbentDiluent

Power is produced using fuel, preferably with a sulfur content larger than 1% wt, from raw and / or preprocessed oil residues which are burned alone, i.e. without any addition of sorbents, diluents or the like, with a CFB boiler, a pitch boiler or a downshot boiler to generate high pressure steam and / or power and residual emissions. Residual emissions are cleaned to simultaneously remove PM, NOx and SO2 therefrom. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, and / or power and sulfuric acid and meets all emission requirements for PM, NOx and SO2.

Owner:GAUTHIER RICHARD

Converting process of bottom blowing converting furnace continuous copper smelting

The invention provides a converting process for continuous copper smelting by a bottom blowing converting furnace. The process is characterized in that liquid copper matte generated from a bottom blowing smelting furnace passes through a chute to be continuously injected into the oxygen bottom blowing smelting furnace, and oxygenized air is continuously blown in from the bottom part of the converting furnace to continuously convert the copper matte; simultaneously, lime flux or limestone is continuously added from an opening at the top of the converting furnace for slag making by a material bin and a measuring belt feeder according to the required quantity measured, or the top part of the converting furnace is not provided with the opening, the lime flux or the limestone is crushed into powder and fed together with oxygen gas in the furnace for slag making through an oxygen lance by the material bin and the measuring belt feeder; one end of the furnace has an upper part provided with an opening used for discharging smelting slag and a lower part provided with an opening used to be provided with a siphoning installation for discharging coarse copper, thereby realizing continuous addition of the copper matte, continuous converting, continuous addition of the flux, continuous slag making, continuous slag discharge and continuous coarse copper discharge and furthering realizing the continuous converting process.

Owner:CHINA ENFI ENGINEERING CORPORATION

Process of oxygen bottom blowing continuous copper smelting

The invention provides a process adopting the oxygen bottom blowing continual copper smelting. The process is characterized in that an oxygen bottom blowing smelting furnace is utilized to smelt copper-containing materials into liquid copper matte, and the oxygen bottom blowing converting furnace is utilized to continuously convert the liquid copper matte into coarse copper.

Owner:CHINA ENFI ENGINEERING CORPORATION

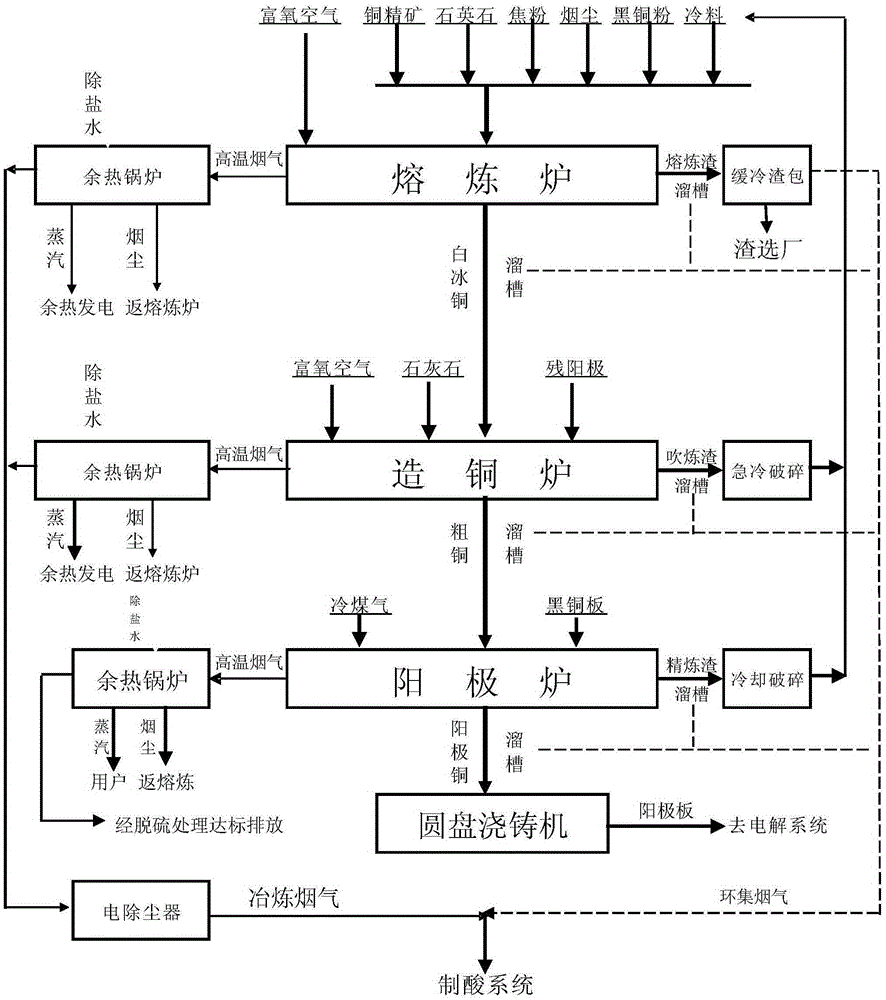

Three continuous furnace technology for continuous production of anode copper with copper concentrate

InactiveCN105238938AReduce metallurgical equipment and plant investmentAvoid sensible heat lossRotary drum furnacesCrucible furnacesSlagContinuous operation

The invention provides a three continuous furnace technology for continuous production of anode copper with copper concentrate. The technology is particularly characterized in that a smelting furnace, a copper making furnace and an anode furnace are in tandem arrangement successively, and kilns are connected by chutes. The technology comprises the steps that the copper concentrate and flux enter the smelting furnace and react with oxygen-enriched air to generate white matte, smelting slag and high-temperature smoke; the smelting slag overflows continuously; a slow cooling slag ladle is put through the chutes for floatation and depletion; the white matte continuously flows into the copper making furnace via siphon through the chute and reacts with the flux and the oxygen-enriched air to generate raw copper, copper converting slag and high-temperature smoke; the raw copper continuously or intermittently flows into the anode furnace via siphon through the chute; the anode furnace alternately operates and produces the anode copper via oxygenation and reduction; and the converting slag is regularly discharged, chilled, broken and returned to the smelting furnace. The technology achieves continuous operation of smelting production of the raw copper with the copper concentrate.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

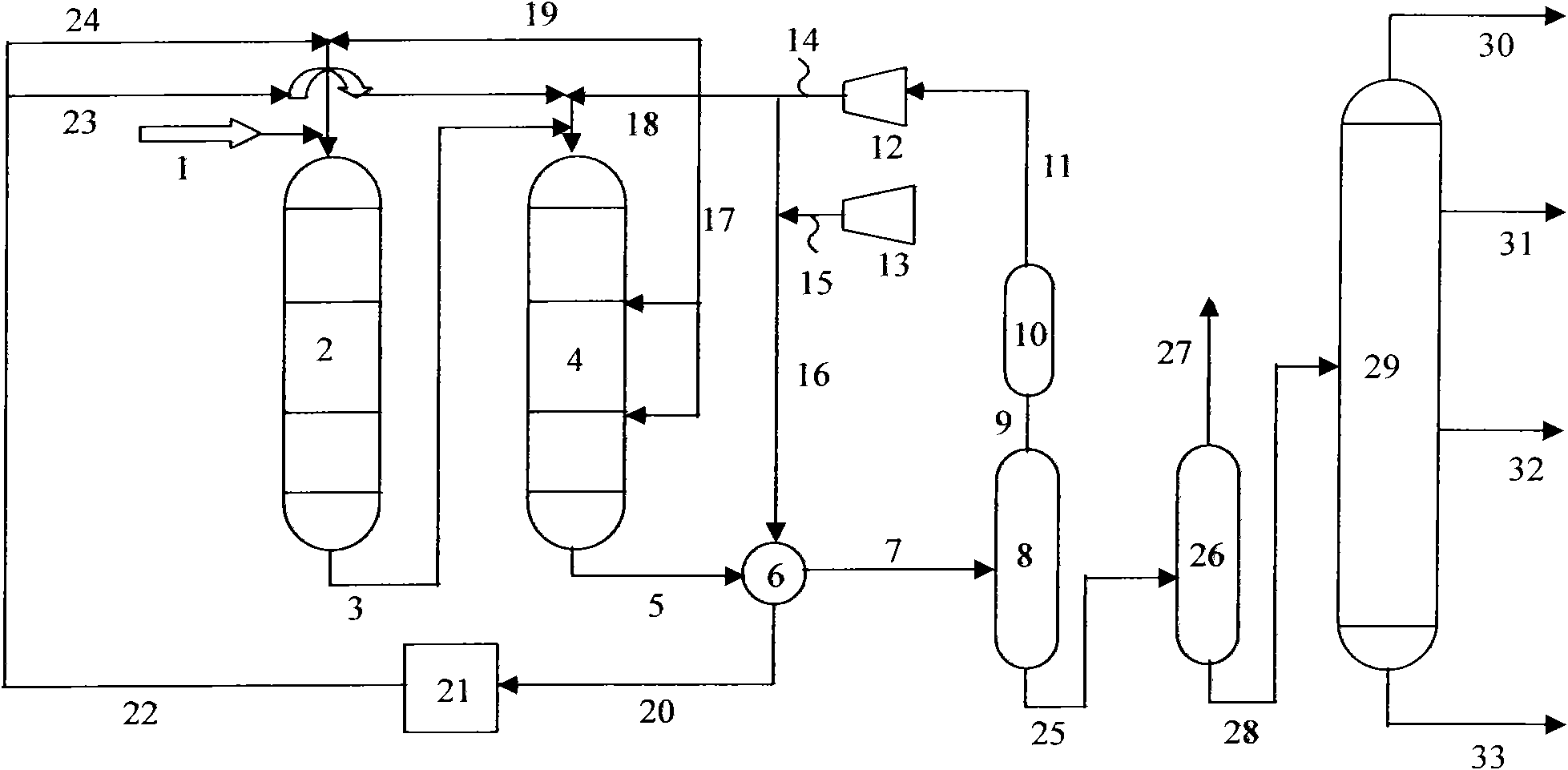

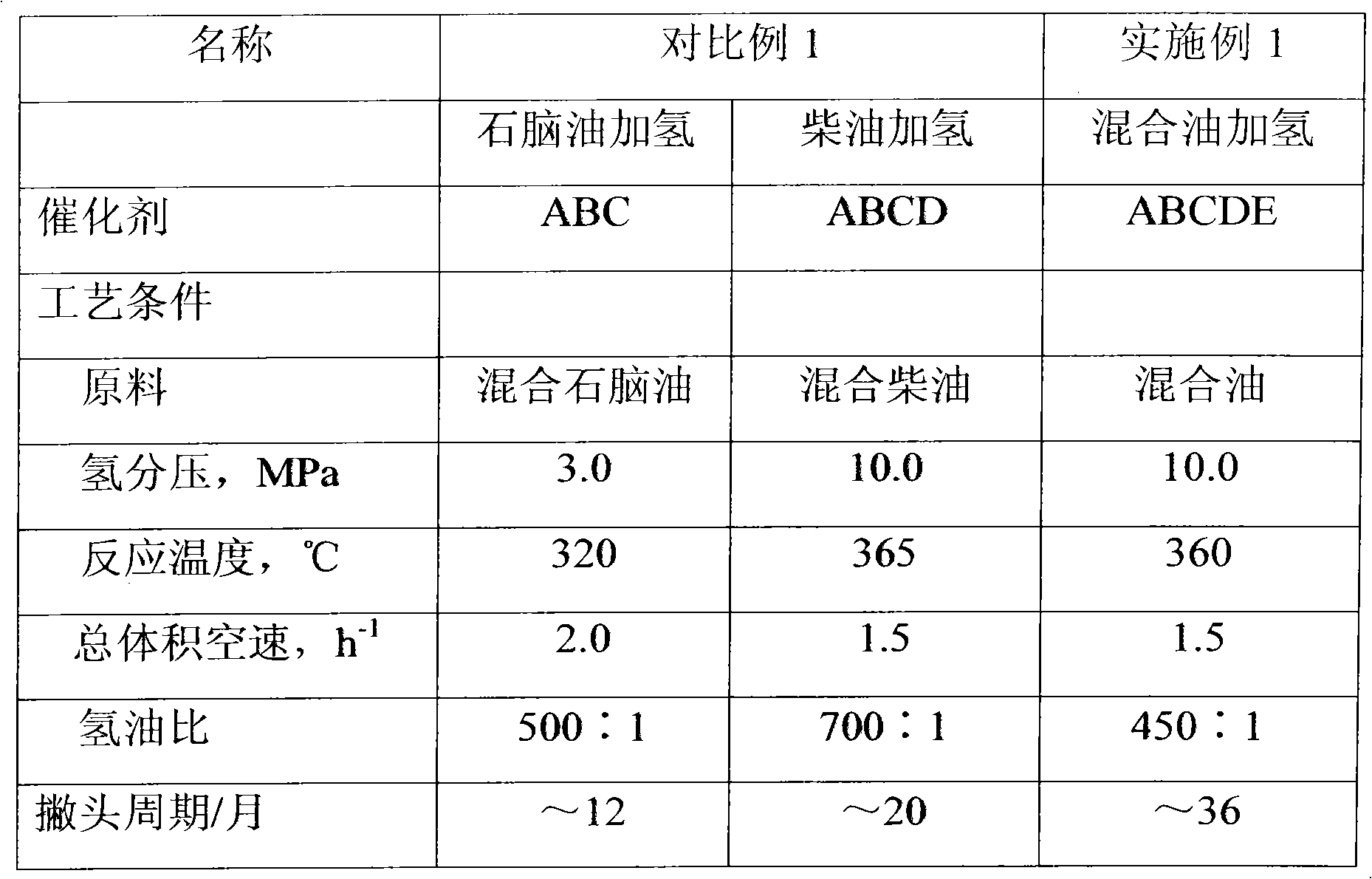

Hydrogenation modification method for coking gasoline and diesel distillates

ActiveCN102465023AAvoid Coking ProblemsFlexible production operationsTreatment with hydrotreatment processesChemistryKerosene

The invention discloses a hydrogenation modification method for coking gasoline and diesel distillates. A coking gasoline and diesel raw material is mixed with heated hydrogen and then introduced to pass through a low-temperature hydrorefining reactor and a hydrogenation modification reactor in sequence; a reaction effluent is separated and modified, and obtained liquid is distilled to obtain gas, gasoline, kerosene and diesel. In the method disclosed by the invention, a process flow of mixing hydrogen behind a furnace is adopted, the heating furnace is only used for heating the hydrogen, the mixed raw material does not pass through the heating furnace, and the temperature of the reactor is controlled based on the quantities of hot hydrogen and cold hydrogen. Compared with the prior art, the hydrogenation modification method disclosed by the invention has the advantage of saving equipment investment and being flexible in production scheme, can be used for flexible production by adjusting process conditions and production distribution according to the differences of raw material properties and product schemes; by implementation of hydrogen mixing behind the furnace, the coking raw material can be effectively prevented from being coked at a furnace tube; and by arrangement of a low-temperature protective agent reactor, olefin saturation is performed at lower temperature so as to reduce coking, meanwhile, coke powder is distributed at a protective agent bed as uniform as possible, so that the long-term operation of a hydrogenation device is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bottom blowing converting furnace for bottom blowing continuous copper smelting

The invention provides a bottom blowing converting furnace used for bottom blowing continual copper smelting. The furnace is characterized in that a furnace body has one end face provided with a copper matte inlet connected with a first chute, the other end face provided with a coarse copper outlet connected with a second chute and a bottom part provided with a bottom blowing spraygun used to blow oxygen gases in.

Owner:CHINA ENFI ENGINEERING CORPORATION

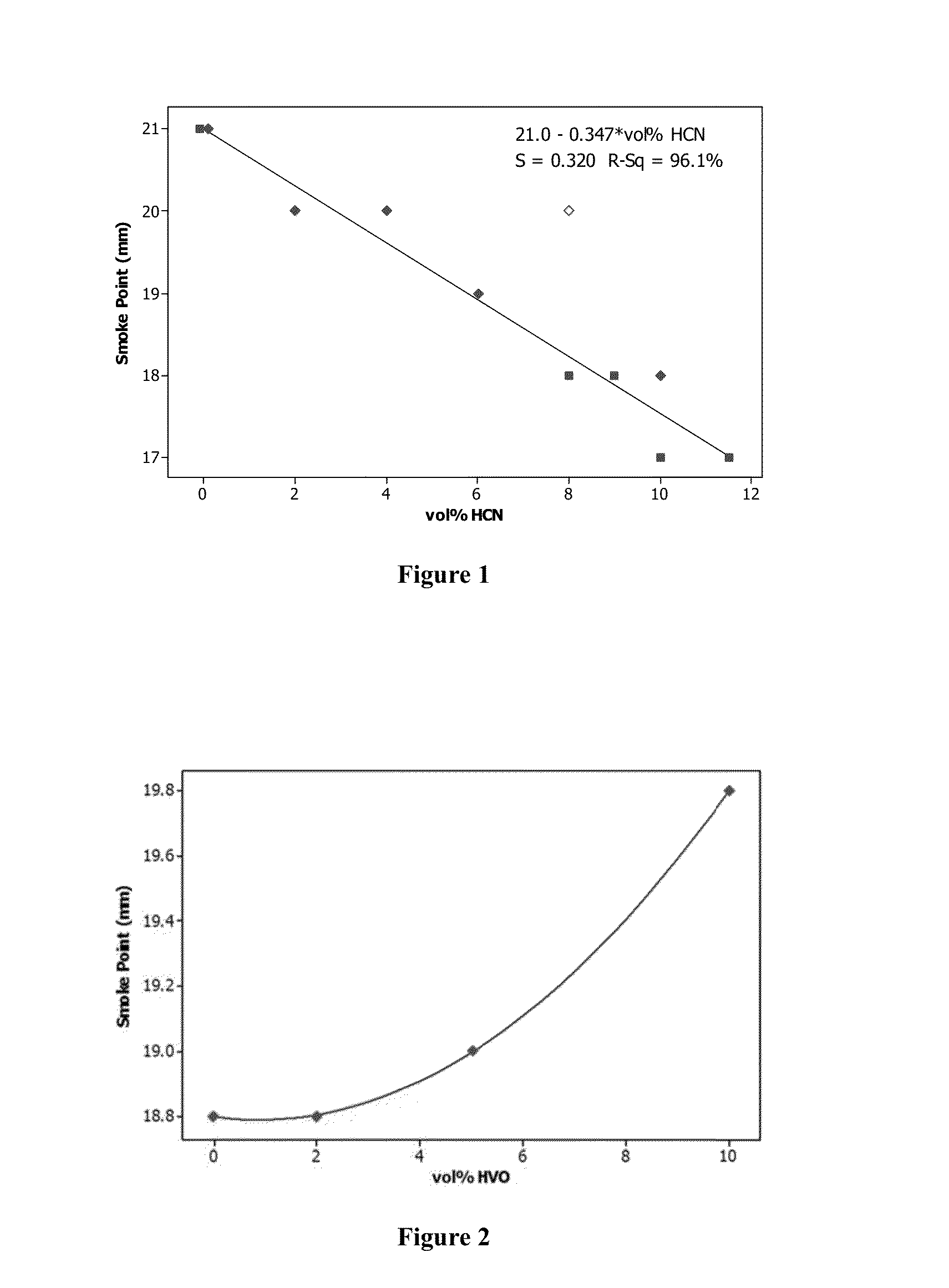

Blending of dewaxed biofuels and synthesized paraffinic kerosines with mineral-based kero(JET) distillate cuts to provide on-spec jet fuels

InactiveUS20150112106A1Improve other propertyLowering naphthaleneBiofuelsSolid fuelsParaffin waxKerosene

The present invention describes a method of making a jet fuel composition comprising: blending from about 3 vol % to about 30 vol % of a catalytically and / or thermally cracked blendstock into a non-cracked jet-boiling-range distillate to produce a jet-type blend with a smoke point less than 18 mm; and thereafter, blending from about 2 vol % to about 50 vol % of synthesized paraffinic kerosine (SPK) into the jet-type blend to produce a jet fuel with a smoke point of at least 18 mm.

Owner:EXXON RES & ENG CO

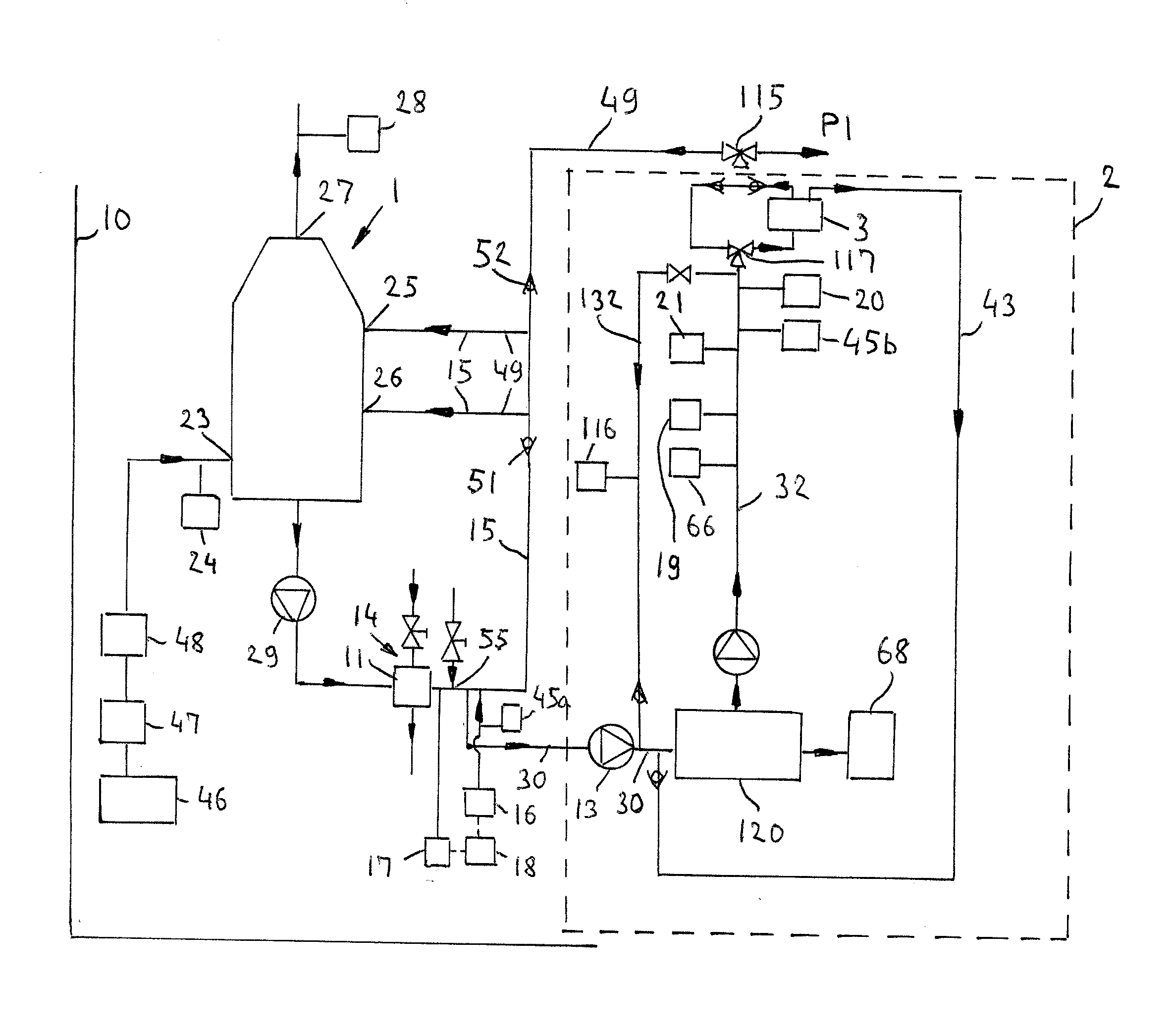

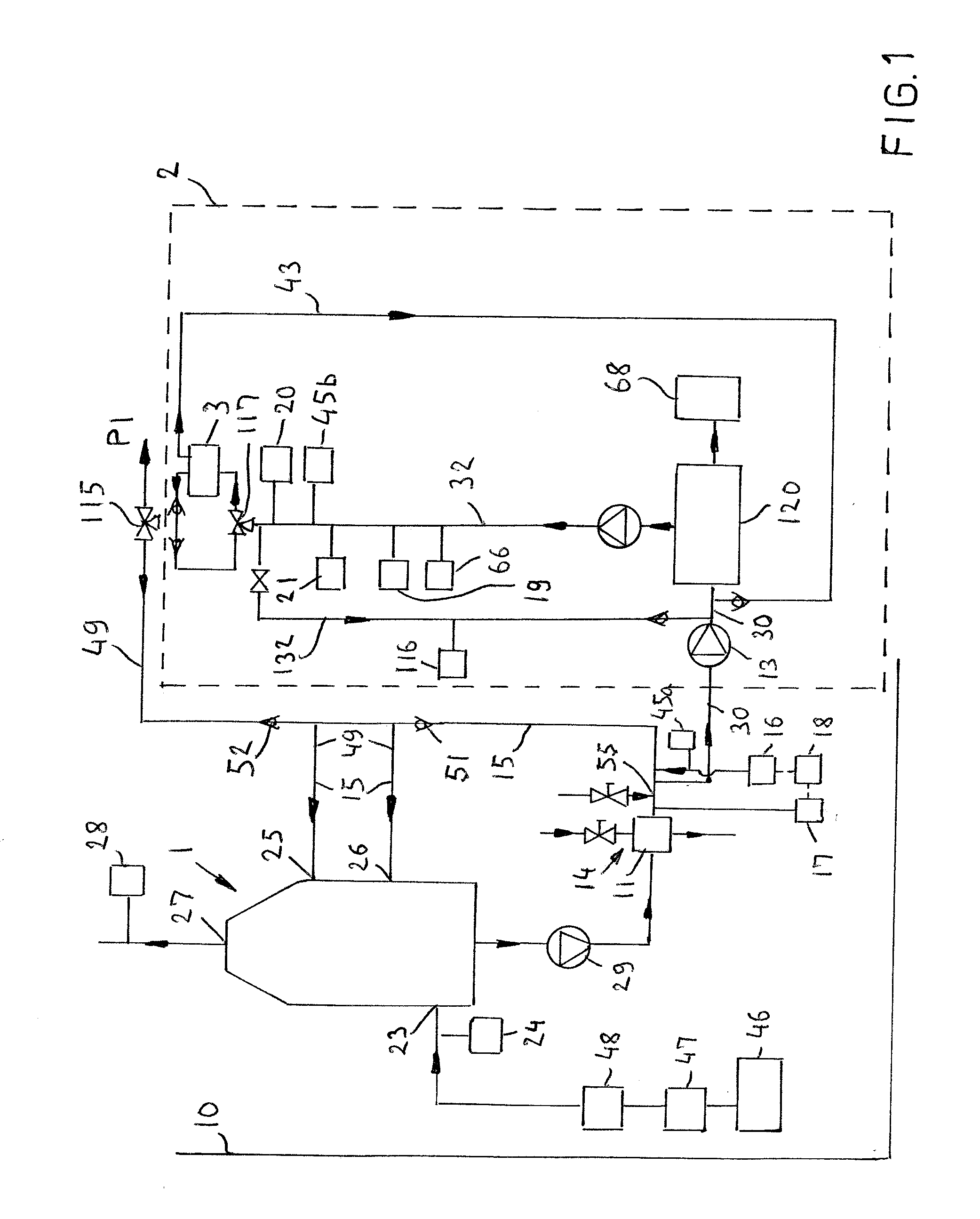

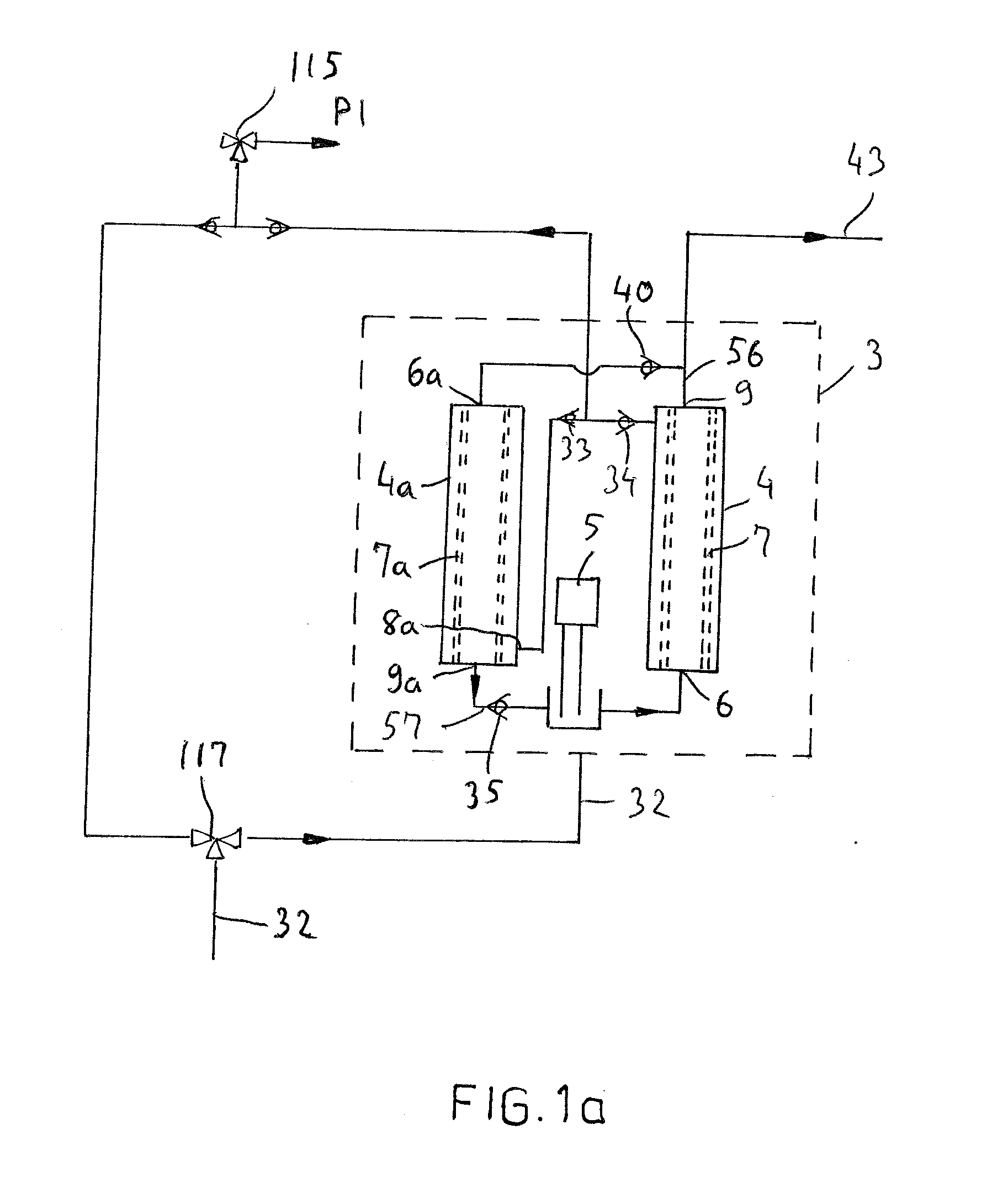

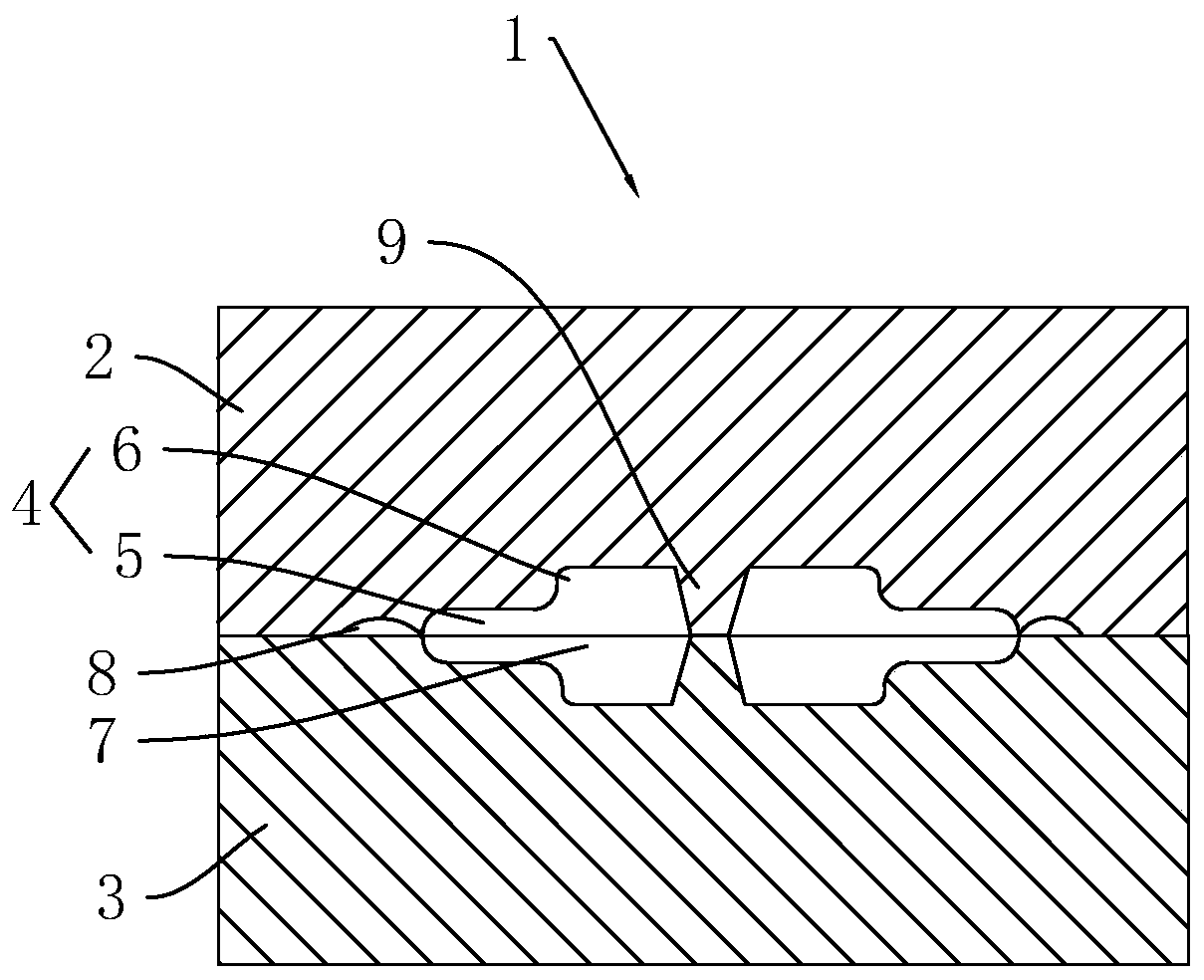

Method for treating impurities contained in exhaust gases of ships, ship with a scrubber, and purification unit

ActiveUS20150182905A1Small volumeEasy transferInternal combustion piston enginesUsing liquid separation agentWash waterBelt filter

A method for treating impurities contained in exhaust gases of ships to reduce sulphur oxide and other emissions, includes scrubbing the exhaust gases in an exhaust gas scrubber and supplying wash water effluent exiting from the scrubber and containing impurities to a purification unit onboard a ship. In order for the method to purify wash water exiting the scrubber sufficiently enough to be discharged directly to sea, the purification unit includes a moving filter band, whereby an aqueous fluid containing impurities originating from the effluent is together with a precipitating agent fed to a surface of the inclined filter band and filtered there through to concentrate impurities onto the surface of the band filter as a precipitate. When necessary, the pH of the purified effluent is adjusted so that it is at least 6.5 before discharging the purified effluent into the sea or returning it to the exhaust gas scrubber.

Owner:OY LANGH SHIP AB

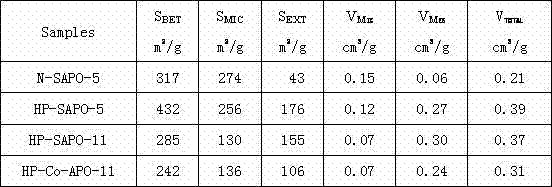

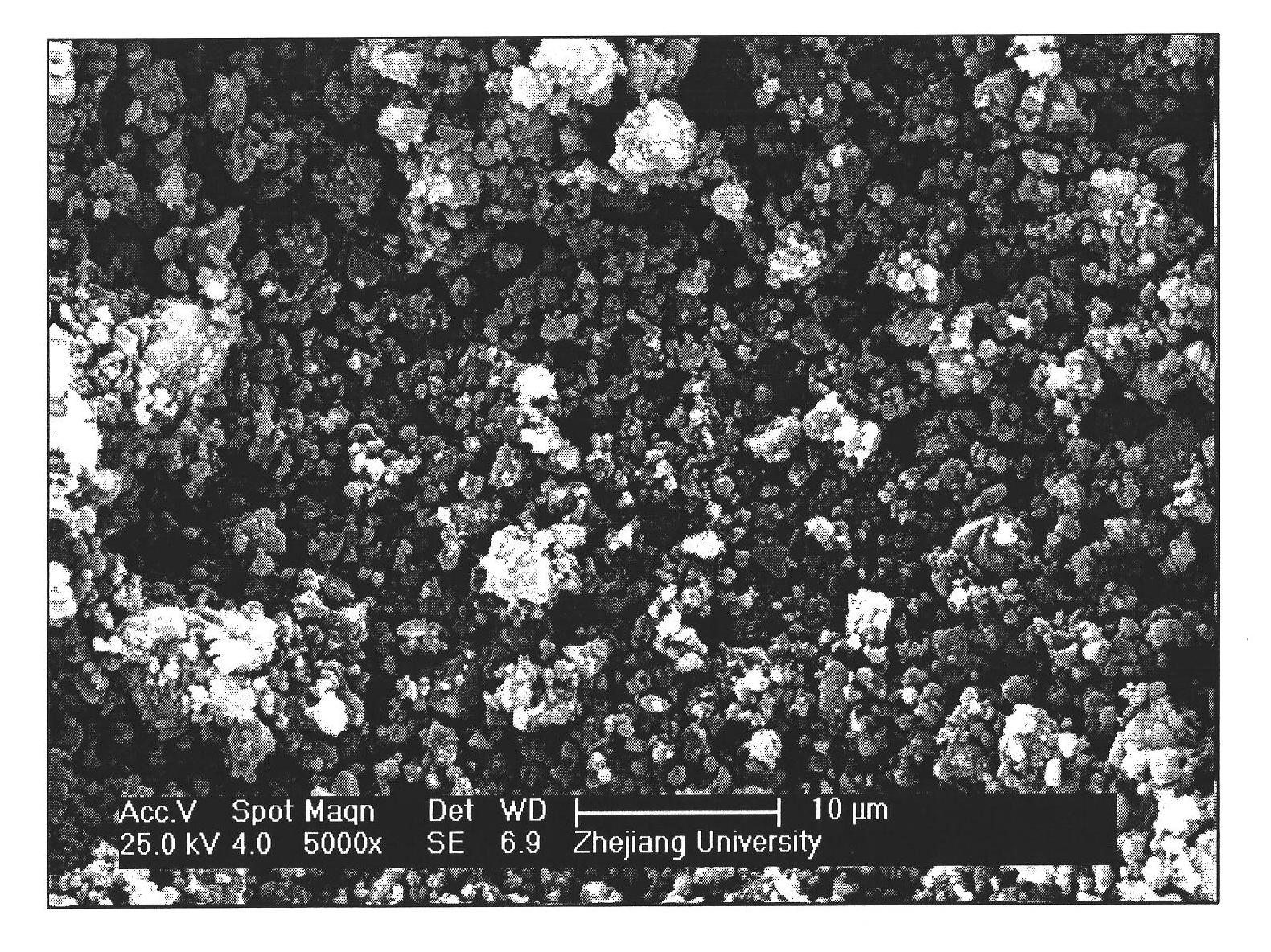

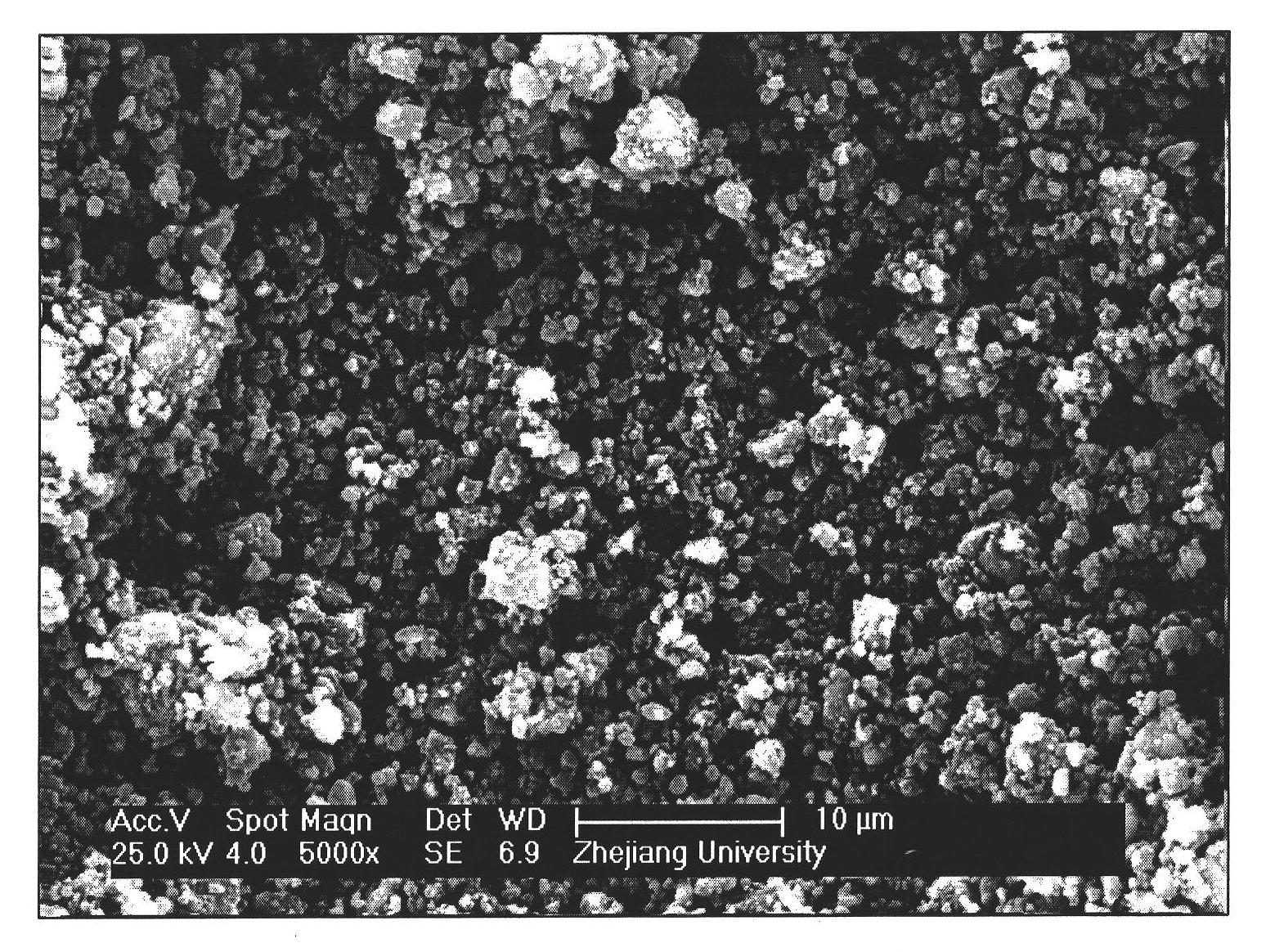

Preparation method for low-quality diesel hydrofining catalyst

ActiveCN102872908ALow sulfurLow nitrogenMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveActive component

The invention discloses a preparation method for a low-quality diesel hydrofining catalyst, which is characterized in that the low-quality diesel hydrofining catalyst comprises an active component, a carrier and an additive; the active component is composed of one or more than one metal of both VIB group and VIII group; the carrier is composed of a multi-orifice AFI, an AEL molecular sieve and a Gamma-Al2O3; the additive is one or more than one of SiO2, TiO2, F and P; and the weight contents of the components are respectively as follows: 5-30 wt percent of the multi-orifice AFI and the AEL molecular sieve, 12-25 wt percent of metals of the VIB group, 3-15 wt percent of metals of the VIII group, 0-15 wt percent of additive, and the balance Gamma-Al2o3. According to the method, the specific surface area is 200-300 m<2> / g, the pore size is 0.30-0.80 cm<3> / g, the average pore diameter is 6-15 nm, and the mechanical strength is not lower than 15 N / mm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

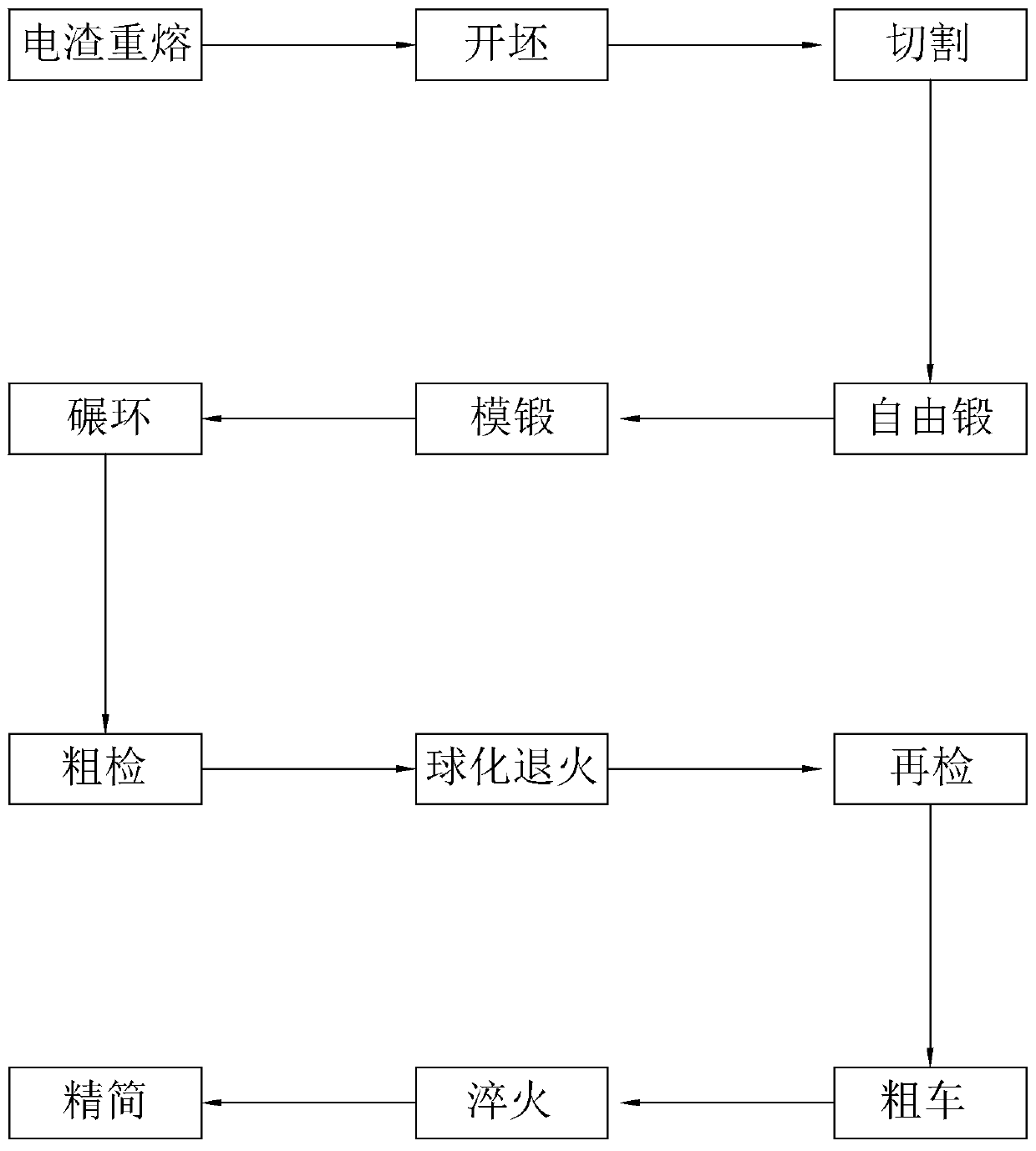

Strength-increasing shield tunneling machine cutter ring machining process

The invention discloses a strength-increasing shield tunneling machine cutter ring machining process, and belongs to the field of shield tunneling machine cutters. According to the technical scheme, the machining process comprises the following steps of S1 electro-slag remelting, S2 cogging, S3 cutting, S4 free forging, S5 die forging, S6 ring grinding, S7 rough inspecting, S8 spheroidizing annealing, S9 secondary inspecting, S10 rough turning, S11 quenching and S12 fine inspecting, wherein in the first step, an electro-slag furnace is utilized for remelting steel ingots into ESR ingots; in the second step, an electro hydraulic hammer is utilized for forging the ESR ingots into raw rod materials; in the fourth step, rod material blanks are subjected to free forging to upsetting; and in thetwelfth step, a cutter ring is cooled, and then the outer diameter, the inner diameter, the inner ring thickness and the outer ring thickness of the cutter ring are inspected. The strength-increasingshield tunneling machine cutter ring machining process has the effect of strengthening the cutter structure.

Owner:JIASHAN XINQIANG STEEL IND CO LTD

Coking composite leaning agent and preparation method thereof

The invention discloses a coking composite leaning agent and a preparation method thereof. The coking composite leaning agent comprises the following raw materials in percentage by mass: 5 to 15 percent of anthracite, 10 to 30 percent of coke powder, 3 to 10 percent of coal tar pitch and the balance of magnesite. The preparation method of the coking composite leaning agent mainly comprises the following steps of: mixing the magnesite, the anthracite and the coke powder in the atmosphere of hydrogen, performing ball milling on the mixture, adding the coal tar pitch into the mixture, and then performing ball milling on the mixture. The coking composite leaning agent of the invention has the advantages of reducing coke sulphur content, improving the mechanical strength of cokes and increasing CO content and CO2 content of the gas, along with low cost of the raw materials, simple preparation method and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com