Patents

Literature

107 results about "Vitrinite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vitrinite is one of the primary components of coals and most sedimentary kerogens. Vitrinite is a type of maceral, where "macerals" are organic components of coal analogous to the "minerals" of rocks. Vitrinite has a shiny appearance resembling glass (vitreous). It is derived from the cell-wall material or woody tissue of the plants from which coal was formed. Chemically, it is composed of polymers, cellulose and lignin.

Coke coal blending ratio and coking method thereof

The present invention is one kind of coke coal blending ratio and coking process. The coke coal consists of fat coal 20-23 weight portions, coking coal 50-55 weight portions, 1 / 3 coking coal 15-20 weight portions, and lean coal 8-12 weight portions. The compounded coal has the quality including ash content 9-10 %, sulfur content 0.65-0.73 %, volatile component 24-26 %, G value 83-88, Ymm of 16-20, and Xmm of 20-30. The quality parameters, vitrinite reflectances and microscopic ingredients of the said four kinds of coal are specifically defined. During the coking process, the mixed coal material is sintered at 1200 deg.c for not less than 16 hr. The present invention can obtain coke with high strength.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

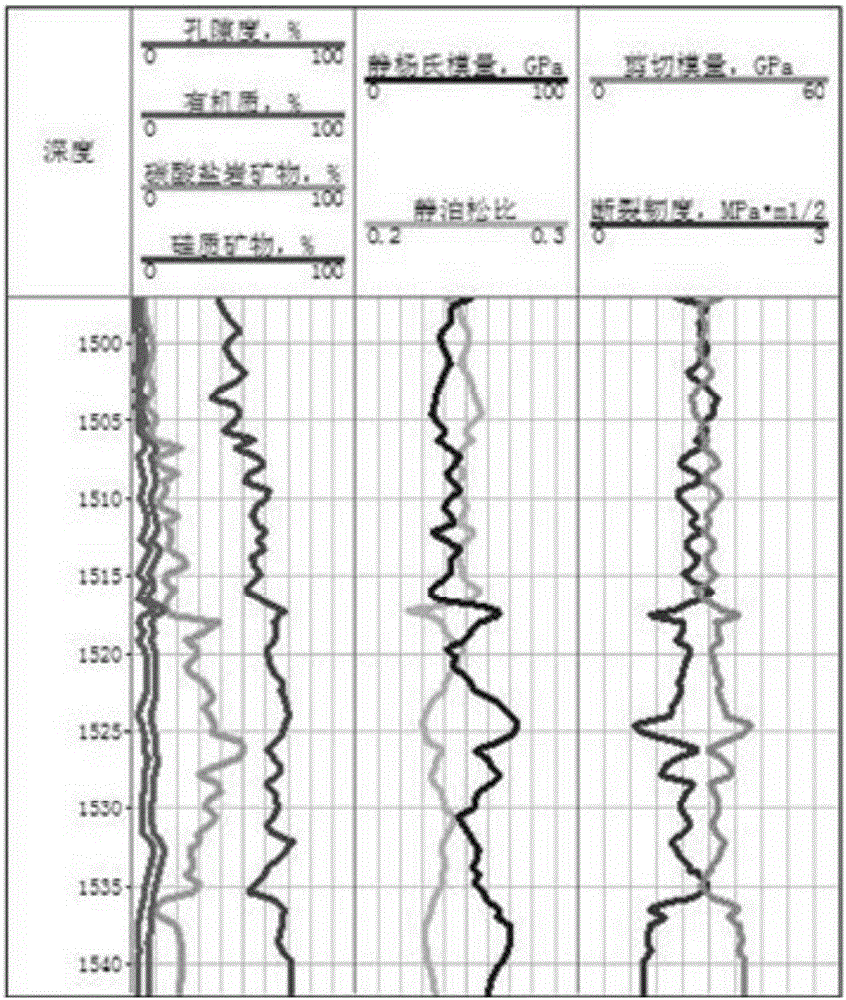

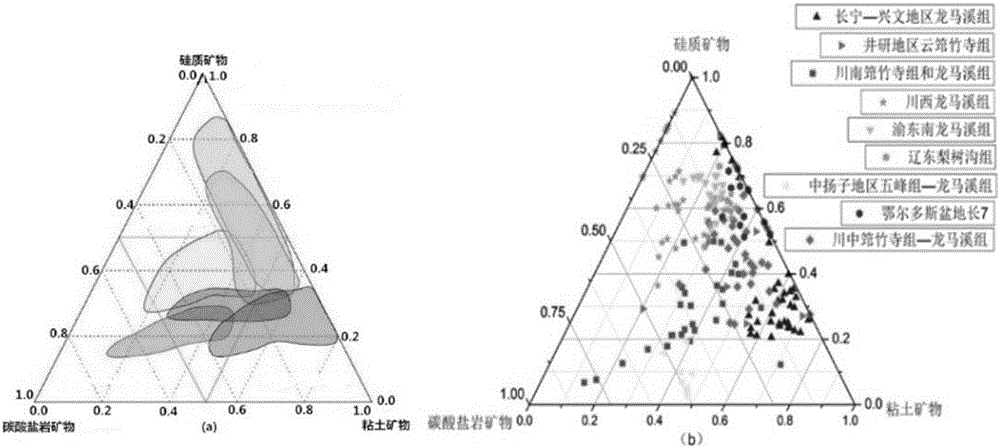

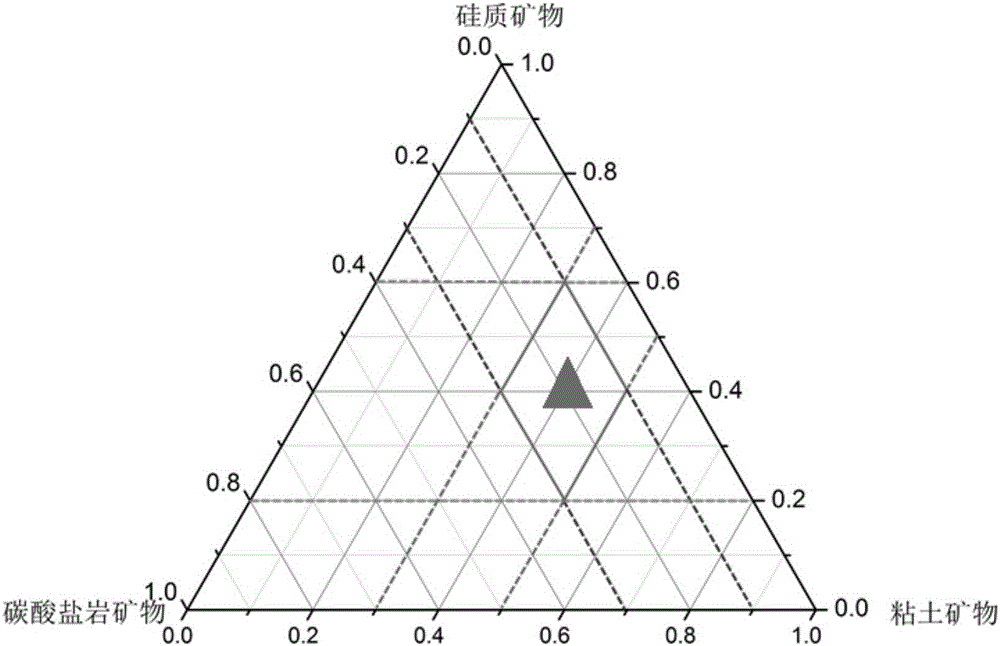

Shale gas reservoir compressibility evaluation method based on weight distribution

InactiveCN106204303AAccurate calculationEasy to calculateData processing applicationsFluid removalAdditive ingredientCompressibility

The invention discloses a shale gas reservoir compressibility evaluation method based on weight distribution. The shale gas reservoir compressibility evaluation method preferably chooses a compressibility evaluation parameter according to factors of a geological sweet heart and an engineering sweet heart. Starting from an angle of evaluating a shale reservoir gas-bearing property and an easy alterationability potential, the shale gas reservoir compressibility evaluation method integrates a mineral ingredient content and mesomechanics parameters to calculate engineering sweet heart parameters through standardizing geological sweet heart parameters, and constructs a compressibility evaluation model which can perform continuous determination on the reservoir; a geological sweet hear compressibility evaluation index, an engineering sweet heart compressibility evaluation index and a comprehensive compressibility evaluation index can be calculated only through obtaining a shale reservoir total organic carbon content, a vitrinite reflectivity and a mineral constituent content, and thus shale gas reservoir compressibility evaluation is realized. The shale gas reservoir compressibility evaluation method can accurately divide an effective fractured layer segment and a shielding layer segment, and guides fracture design and construction.

Owner:XI'AN PETROLEUM UNIVERSITY

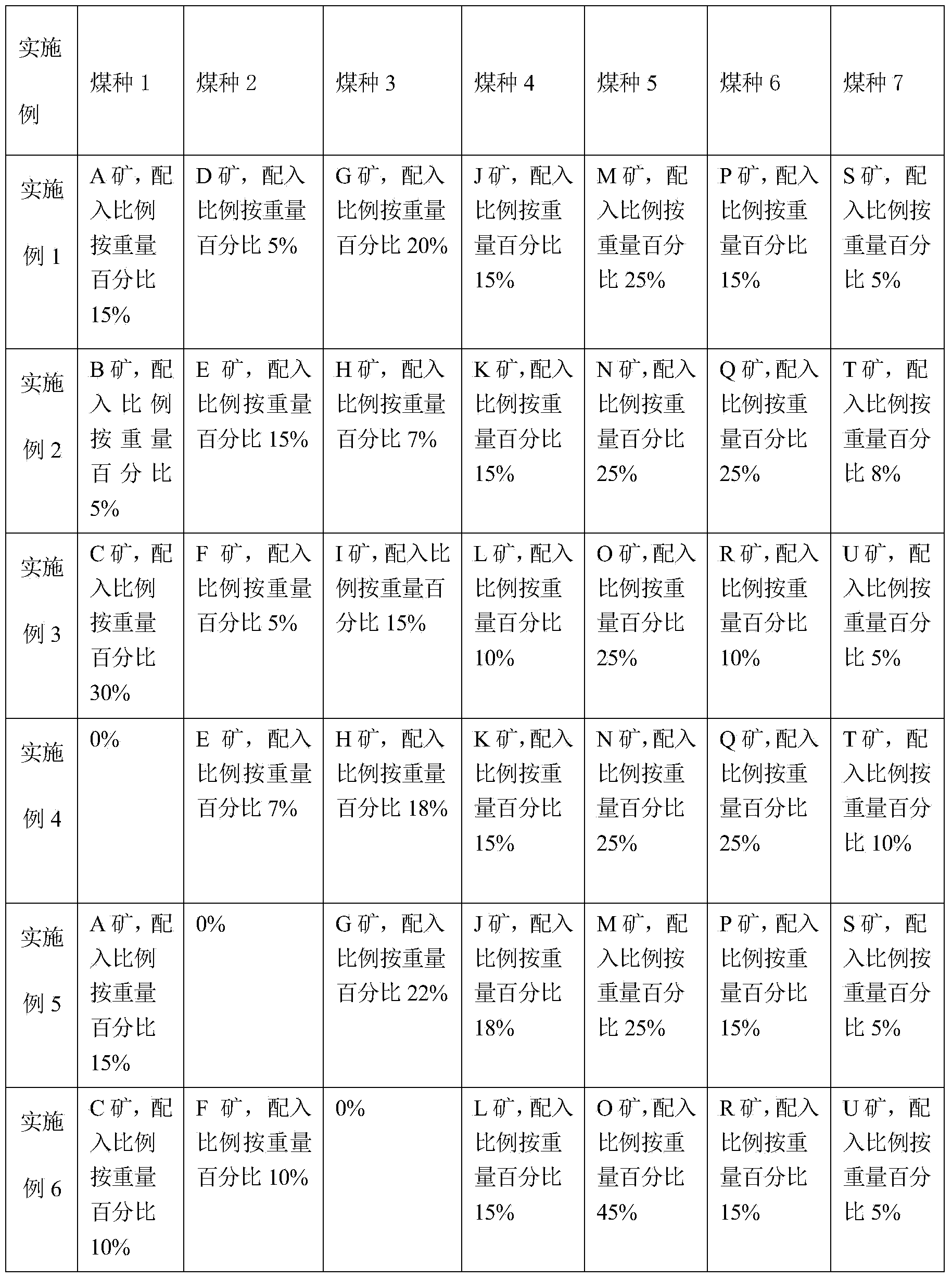

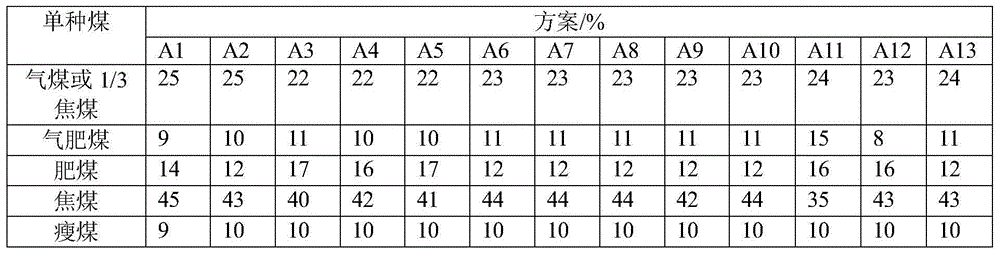

High-proportion coal blending and coking method

ActiveCN101942315ALow ashLow sulfurSpecial form destructive distillationProcess engineeringVitrinite

The invention relates to a high-proportion coal blending and coking method, wherein the coal blending varieties for coking used in the method comprises gas coal, fat coal, coking coal, lean coal and one third of coking coal. The coking method comprises the following steps: A. crushing raw coals separately, wherein crushed particle grade is less than 3mm, and the coal with particle size being lessthan 2mm accounts for more than 60% of the raw coal; and B. carrying out basic coal blending coking on the raw coals obtained in step A, wherein anhydrous ash-free basis volatile matter (Vdaf) of thebasic coal blending quality is 26.0-30.0%, the averagely maximum reflectance (MMR) of vitrinite is 1.0-1.1%, ash content (Ad) is less than 10.1%, total sulfur (St, d) is less than 1.1%, caking index (G) is more than 74, maximum thickness of a gelatine layer is more than 18mm and ratio between active components and inert components is 1.7-1.8. The coal blending coking method of the invention can enlarge coking coal source, lower ash content, sulfur content and phosphorus content in coke, reduce production cost of enterprises, increase economic benefit, improve competitiveness of enterprises, and achieve good comprehensive benefit.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Method of coal blend coking

ActiveCN102021008ANo deterioration in qualityReduce coal blending costsCoke ovensMetallurgySoftening

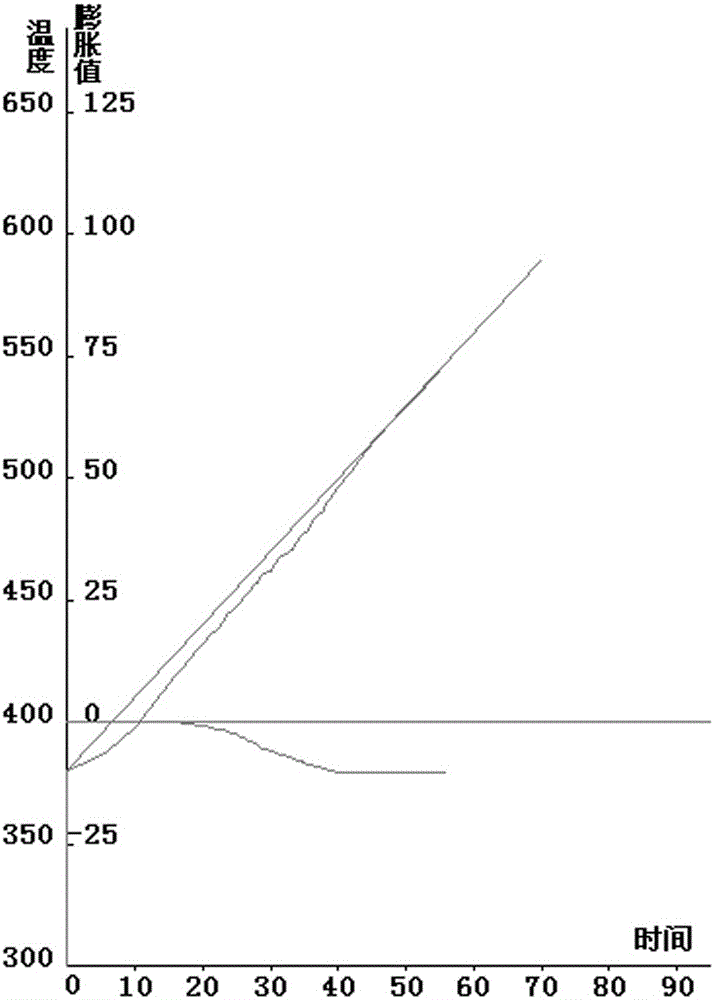

The invention discloses a method of coal blend coking, comprising the steps as follows: blending various single coking coal as follows in percentage by weight: 1-5 percent of gas-fat coal, 5-15 percent of fat coal, 25-35 percent of 1 / 3 coking coal with Vdaf larger than 29 percent, 3-10 percent of Indonesia coal, 25-35 percent of coking coal with the Vdaf smaller than 27 percent and 10-15 percent of lean coal, wherein, to the Indonesia coal, the Vdaf is between 27-29 percent, the Y value is no more than 25mm and the maximum reflectance of vitrinite is 1.0-1.15 percent, the G value is larger than 85, the initial softening temperature is larger than 400 DEG C, the maximum fluidity temperature is between 450-470 DEG C, the Gieseler fluidity maximum value is smaller than 500ddpm, the Audiberts-Arnu dilatation b percent is larger than 100 percent, and the coking coarse mosaic is over 60%; and the G value of mixed coal is 79-82, the Gieseler fluidity of the mixed coal is 400-1000ddpm, and the Audiberts-Arnu dilatation (a+b) percent of the mixed coal is 30-40 percent.

Owner:武汉钢铁有限公司

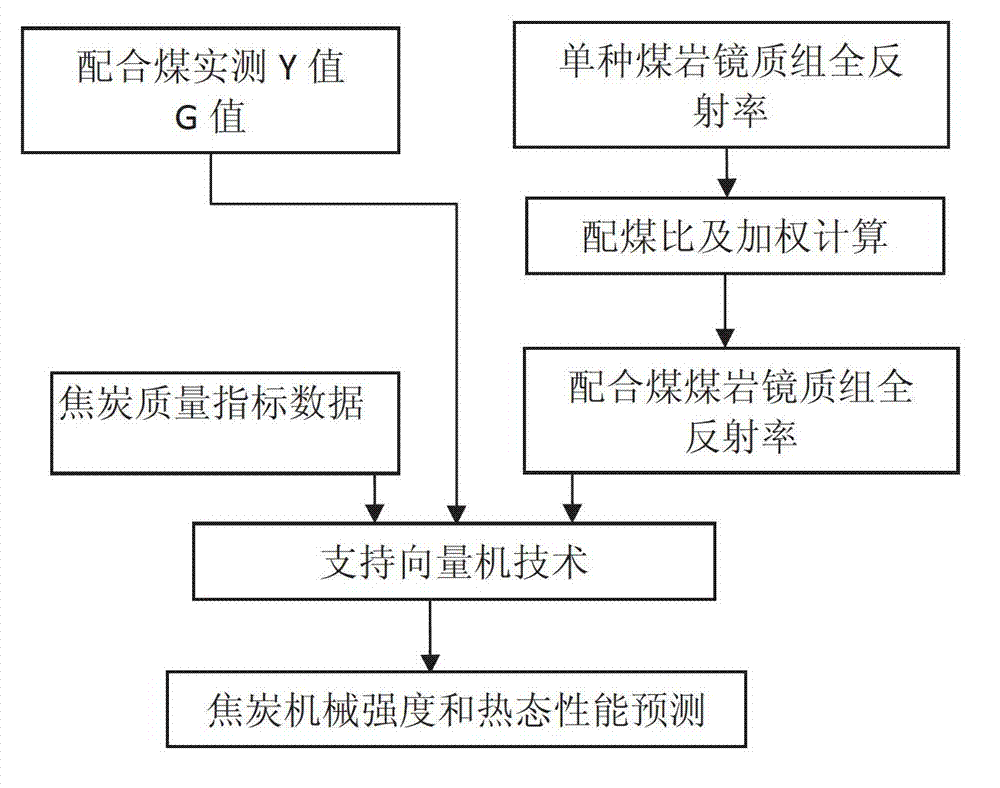

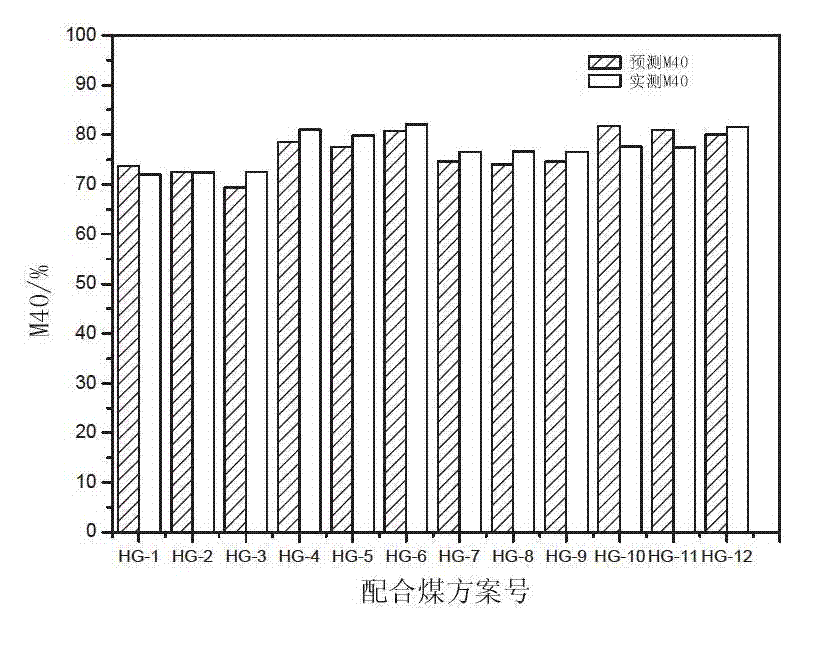

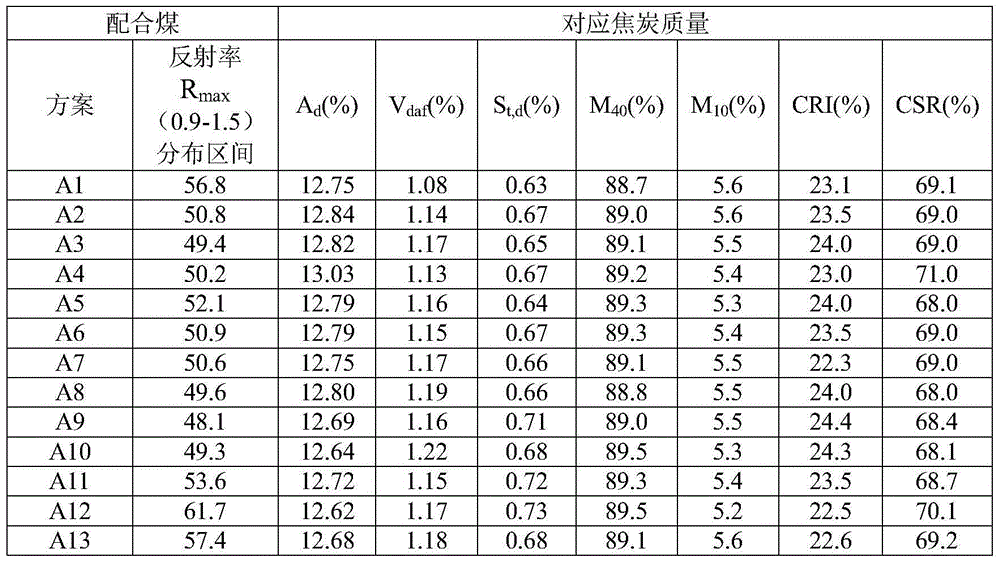

Method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance

ActiveCN102890144AMultiple Intrinsic Indicator ParametersThe prediction method is practicalFuel testingSupport vector machineThermal state

The invention discloses a method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance, thereby providing important technical assurance for the improvement of the stability and quality of coke produced by a coke making enterprise. The method provided by the invention comprises the following steps of: establishing a coking coal resource information database, and inputting the caking property index of coking blended coal and the coal rock index of single coking coal into the coking coal resource information database; and establishing a coke quality prediction model through a support vector machine, and then predicting the quality index of the coke according to the coal-quality caking property index level of the coking blended coal, wherein the coal-quality caking property index level comprises two factors, namely the maximum thickness value Y of a gelatinous layer and a caking index value G, and comprises coal rock vitrinite total-component reflectance and the liver-inert ratio of macerals. The method provided by the invention is capable of characterizing the maximum thickness value Y of the gelatinous layer indicating the quantity of metaplast in the softening process of the coking coal and indicating the caking property quality of the metaplast, thereby realizing the prediction process with the goal of predicting the mechanical strength and thermal state performance of the coke.

Owner:UNIV OF SCI & TECH LIAONING

Coal-rock blending method suitable for tamping coking

InactiveCN102816577AGuaranteed cold performance of tamped cokeGuaranteed Cold PerformanceCoke ovensVolumetric Mass DensityComputer science

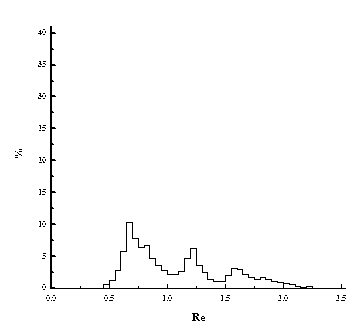

The invention relates to a coal-rock blending method suitable for tamping coking. The technical scheme includes: step one, subjecting single coal for coking to detection of processes and coal-rock properties and calculating an active-idle ratio A / I; step two, matching according to the active-idle ratio A / I, the maximum mean reflectivity of vitrinite and distribution proportion of random reflectivity Re of the vitrinite, and if the A / I of blended coal after blending is 2.0-2.5, 1.00-1.40%, and distribution histogram of the random reflectivity Re of the vitrinite of the blended coal is continuous, then starting step four; step three, repeating the step two if the conditions are not met; step four, taking blended coal samples for detection of the maximum thickness of gelatinous layer Y value, if the Y value ranges from 10mm to 15mm, then completing the coal blending; step five, if the Y value is not between 10mm to 15mm, circulating the step two; and step six, furnacing for coking after tamping, wherein the tamping density is 1.10-1.15g / cm3. The coal-rock blending method suitable for the tamping coking can refine the blended coal after the tamping coking, expand utilization range of coking coal resources and improve coke quality.

Owner:WUHAN UNIV OF SCI & TECH +1

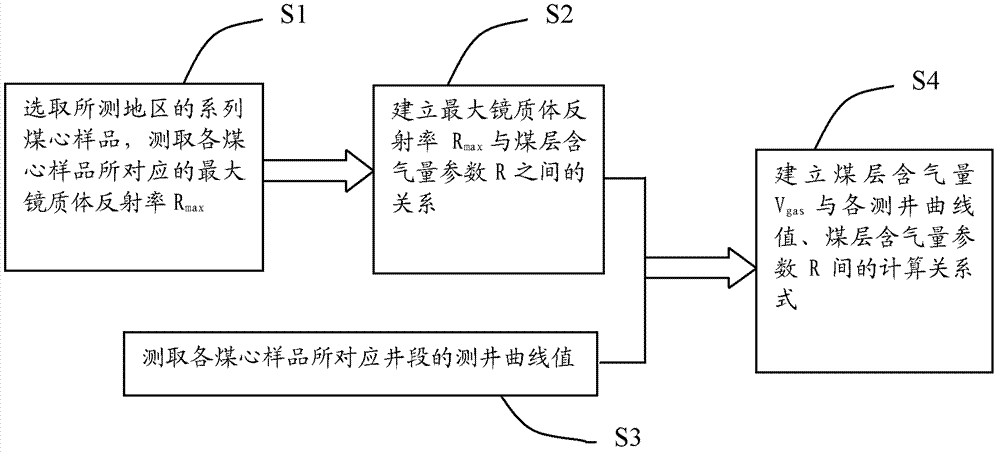

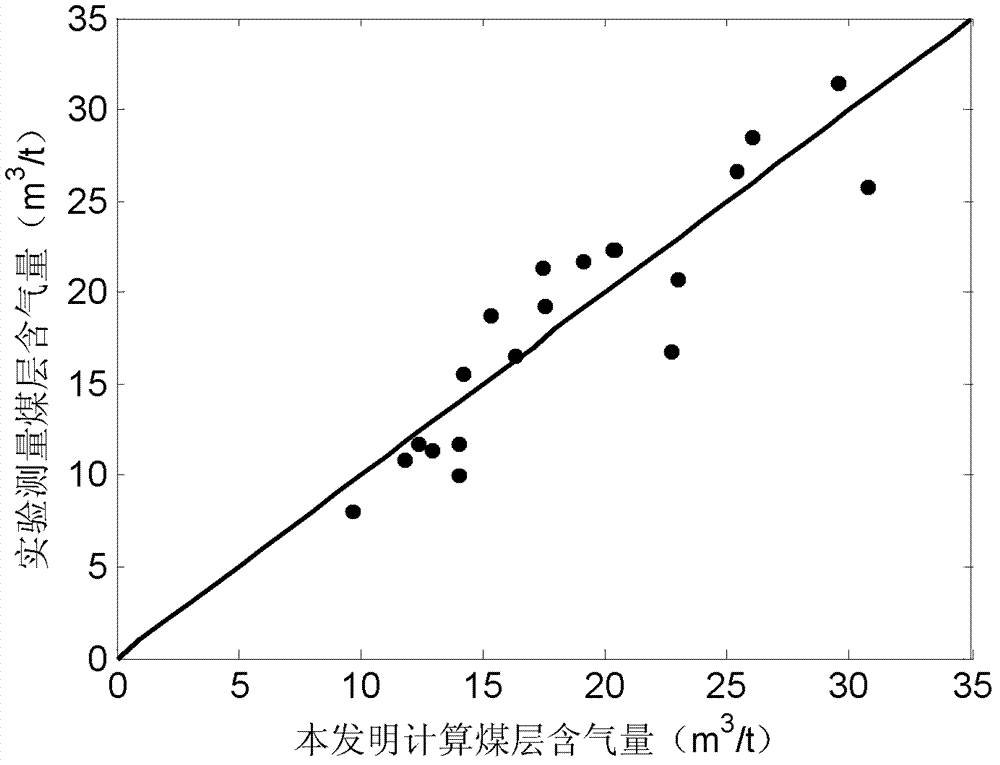

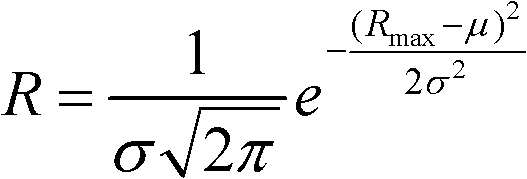

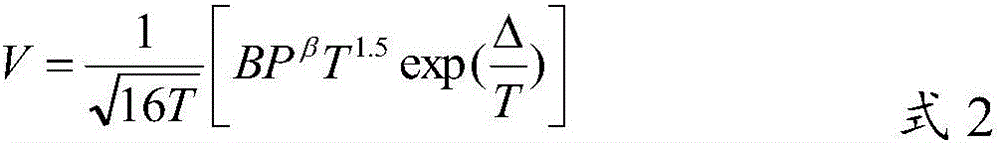

Coal-bed gas-content calculation method

ActiveCN103364844ASignificant impactIn line with the actual geological conditionsGeological measurementsWell loggingCoal rank

The invention discloses a coal-bed gas-content calculation method including: selecting a series of coal-core samples of a tested area; measuring a corresponding maximum vitrinite reflectivity Rmax of each coal-core sample and a well log value of each of corresponding well sections of the coal-core samples; establishing a relationship between the maximum vitrinite reflectivities Rmax and coal-bed gas-content parameters R; and establishing a calculation formula of the coal-bed gas content Vgas according to the well log values and the coal-bed gas-content parameters R. Through introduction of the vitrinite reflectivity, the coal-bed gas-content calculation method takes an effect of coal rank on the coal-bed gas content into full consideration so that the calculated coal-bed gas content complies with an actual geological condition in a better way. And at the same time, the coal-bed gas content is convenient to obtain and low in cost because of being capable of being obtained only based on the well logging information and the vitrinite reflectivity. Moreover, coal-bed gas content of continuous well sections can be obtained so that application effect is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

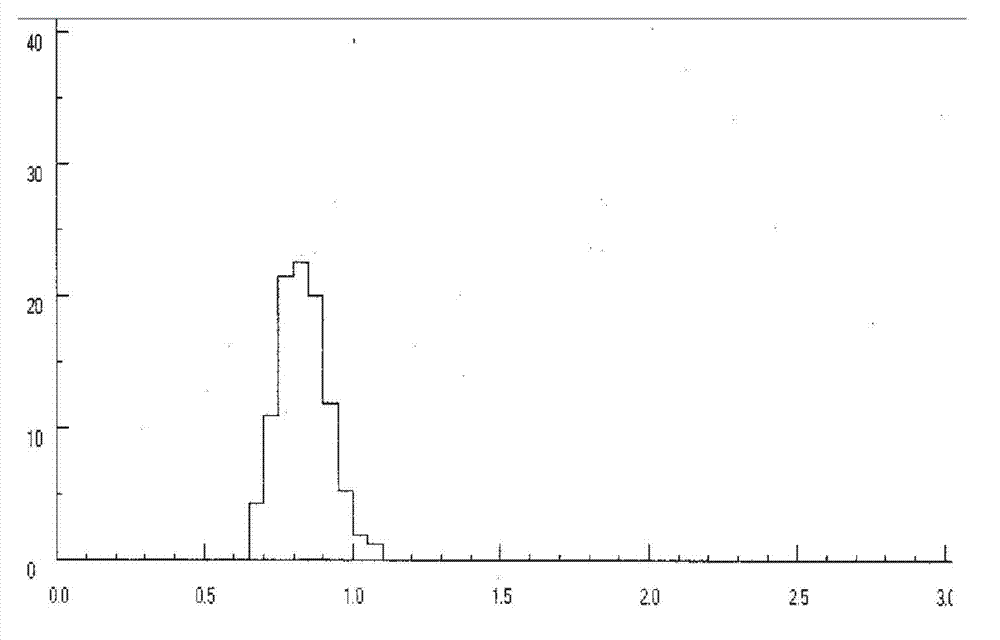

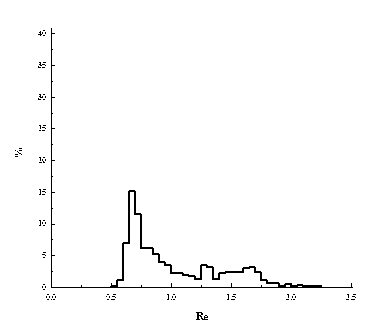

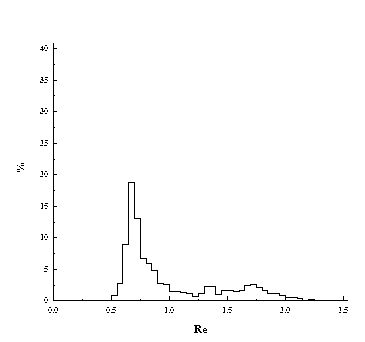

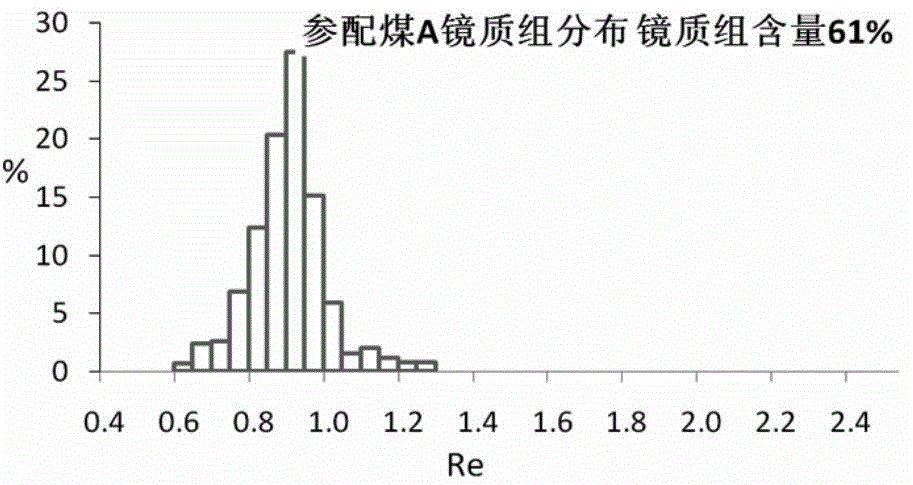

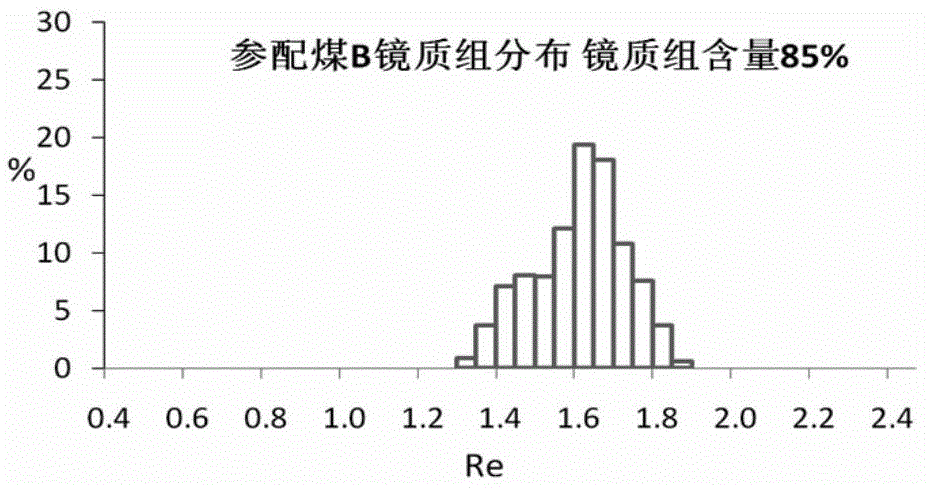

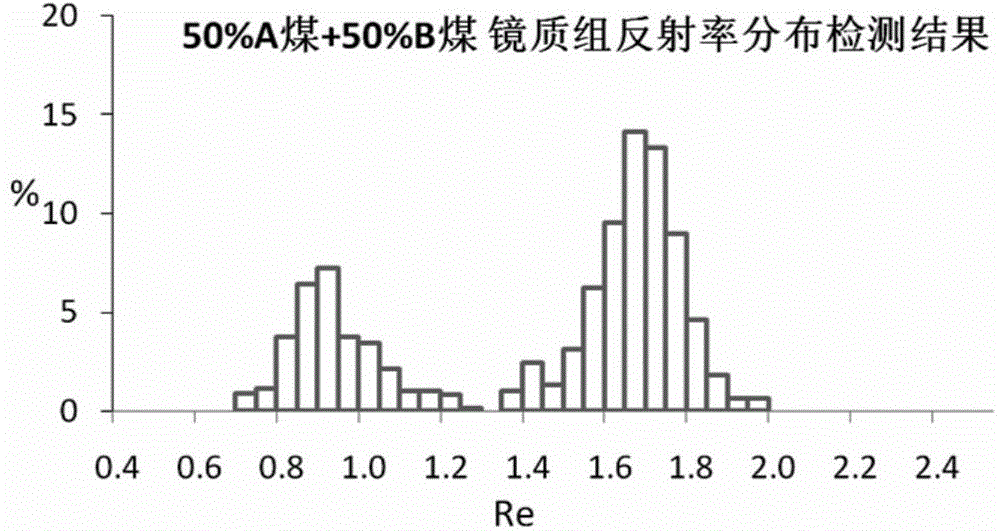

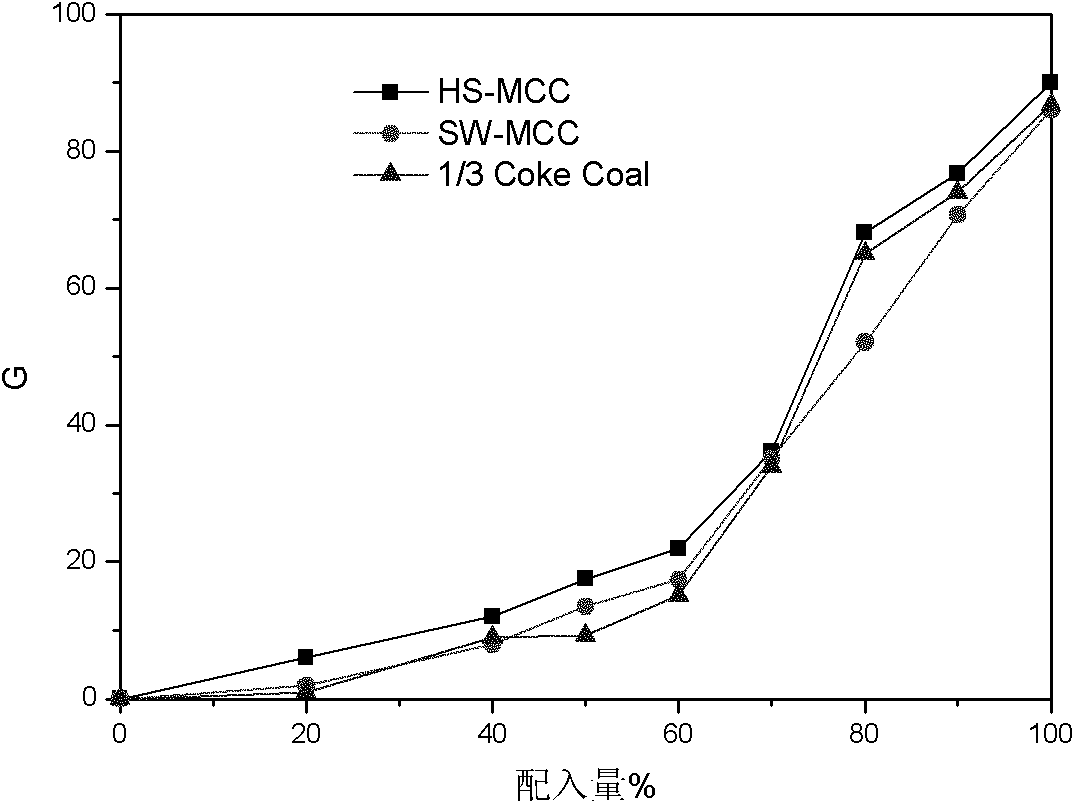

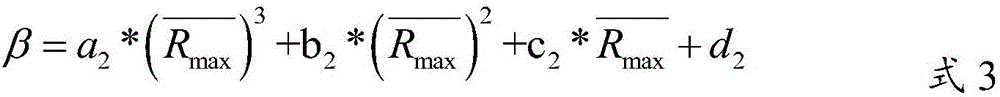

Prediction method matched with coal blend vitrinite reflectance distribution and application of predication method

The invention relates to the field of coking, and particularly relates to a method for predicting the vitrinite reflectance distribution of coal blend according to coal blend ratio, vitrinite content and reflectance distribution, and a method for guiding coal blend by combining a mobility change function and a G value. The method comprises the following steps: by adopting a coal petrography analysis system, detecting the vitrinite reflectance distribution and vitrinite content of coal blend, and calculating the vitrinite reflectance distribution and content of the coal blend according to the vitrinite content, the reflectance distribution and coal blend ratio of the coal blend; and through calculation, controlling the vitrinite reflectance distribution range, the mobility and the G value of the coal blend, thus further controlling the mass of coke. According to the method disclosed by the invention, the errors of simply adding and calculating the vitrinite reflectance distribution of the coal blend according to the coal blend ratio without the consideration of different contents of different single vitrinite in a traditional method are corrected, the vitrinite reflectance distribution of the coal blend can be accurately predicted, high-strength coke under relatively low caking index conditions can be blended by combining the mobility function and G value.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

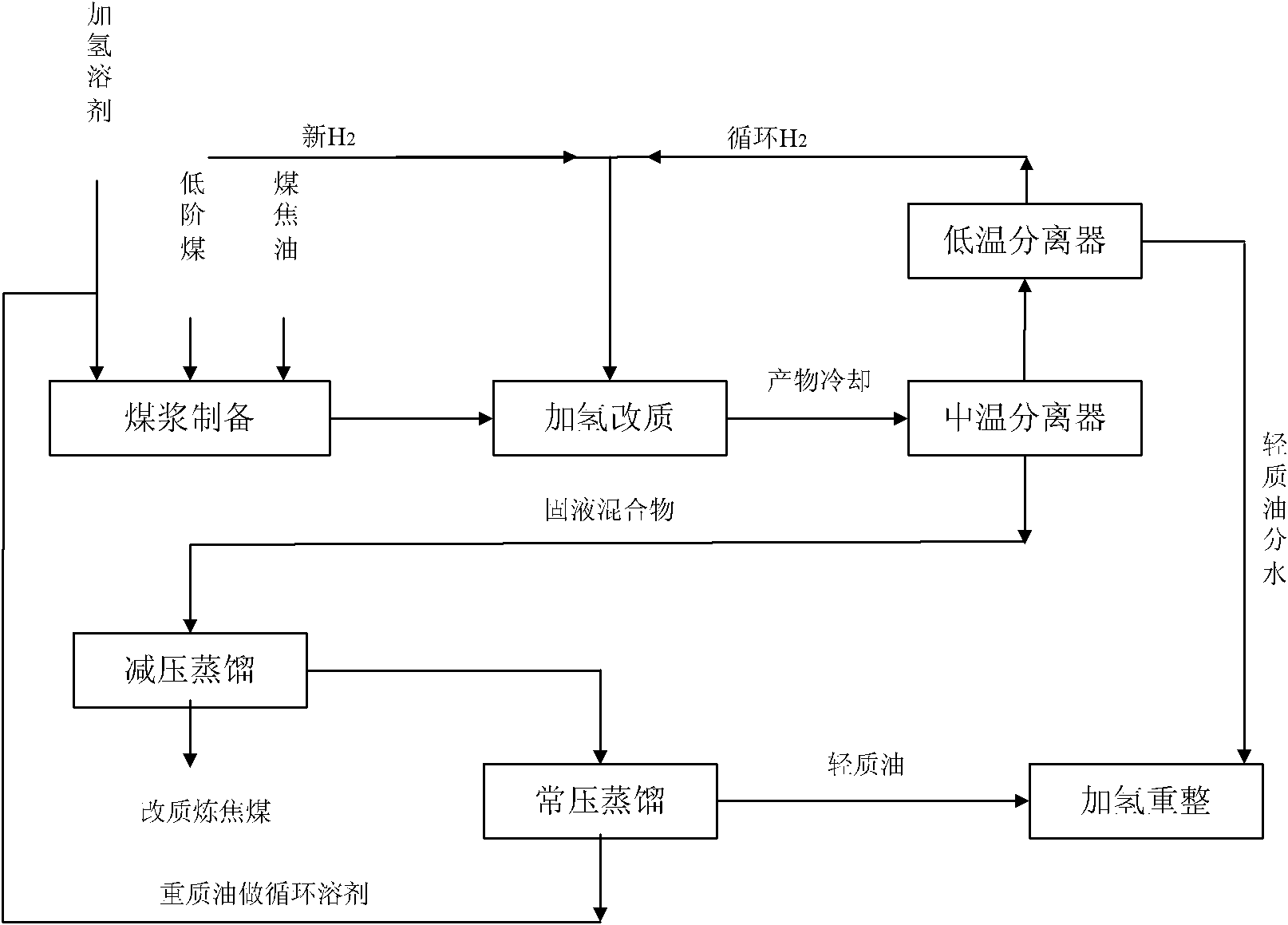

Method for preparing coking coal by modification by low-order nonadhesive coal

ActiveCN102154049AAdhesive hasSimple processCoke ovensSolid fuelsHydrogenation reactionReaction temperature

The invention discloses a method for preparing coking secondary coal by modification by low-order nonadhesive coal, which comprises: drying the low-order nonadhesive coal and roughly grinding the low-order nonadhesive coal till the particle size is smaller than 0.3 millimeter, and mixing the ground low-order nonadhesive coal with treated high-temperature coal tar; mixing the mixture with a hydrogenation solvent and a catalyst, adding the obtained mixture into a give reactor to perform a hydrogenation reaction, wherein the reaction time is 350 to 420 DEG C, the dwelling time is 30 to 60 minutes, and the system pressure is 9 to 16MPa, the weight part ratio of the particle mixture to the hydrogenation solvent is 1:(1-3), and the weight part ratio of the particle mixture to the catalyst is 1:(0.01-0.06); and finally, distilling the reaction product under a reduced pressure to obtain the solid modified coking coal. The caking index G of the solid product (modified coking coal) of the method is more than 75, the average maximum reflectivity of vitrinite is about 0.7 and can partially replace primary coking coal for coking with secondary coal. The method has an obvious industrial application prospect.

Owner:CCTEG CHINA COAL RES INST

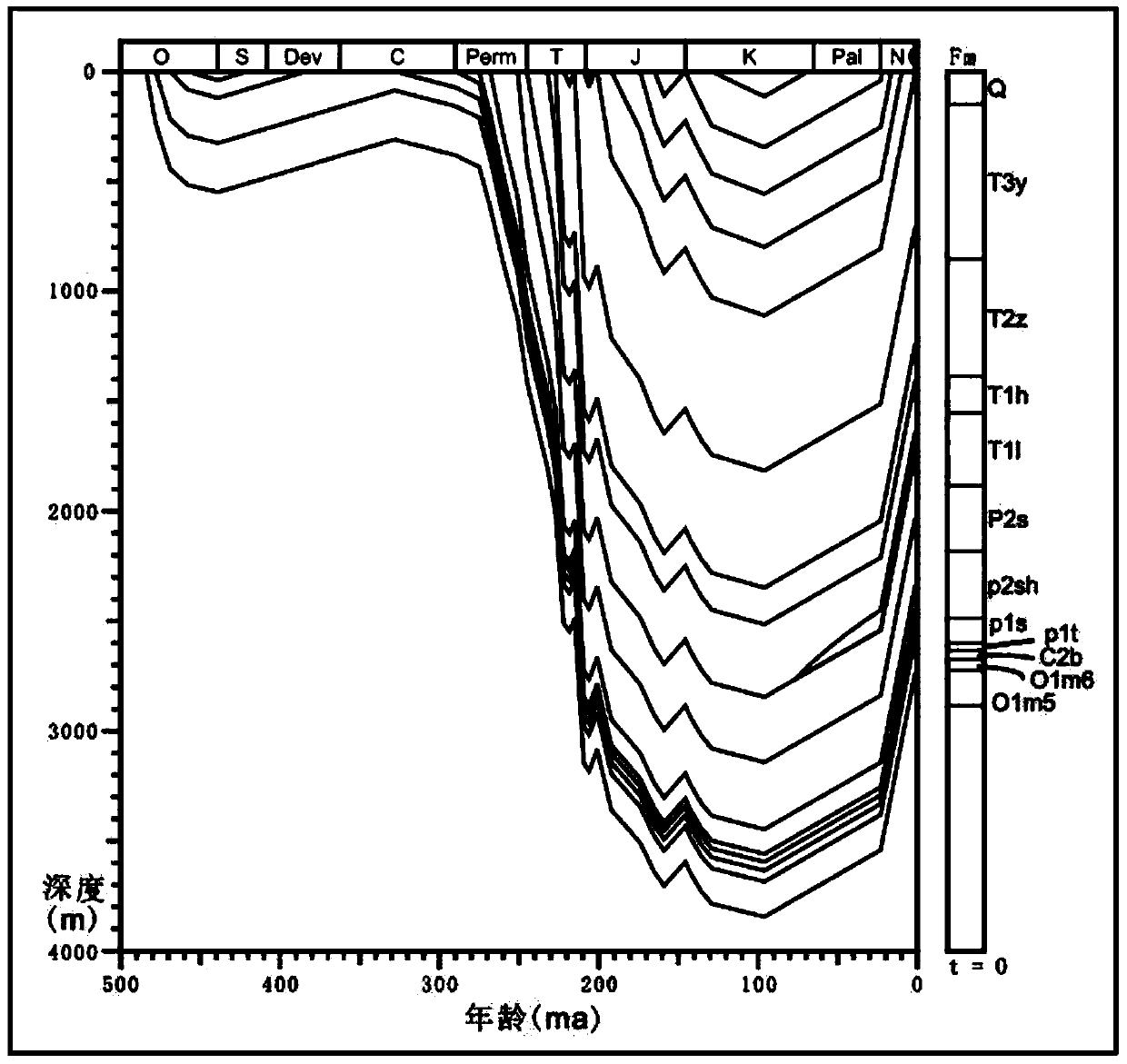

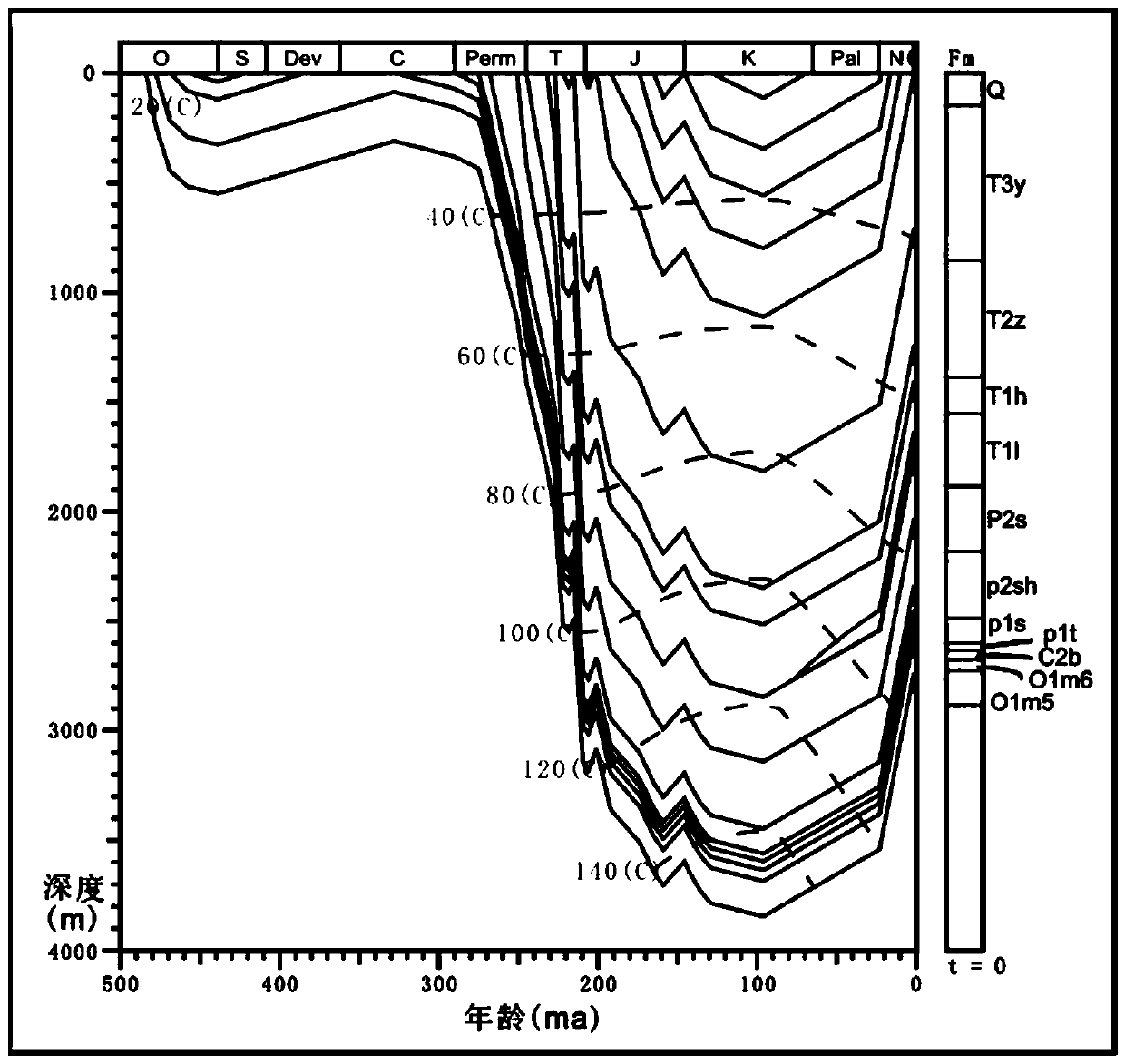

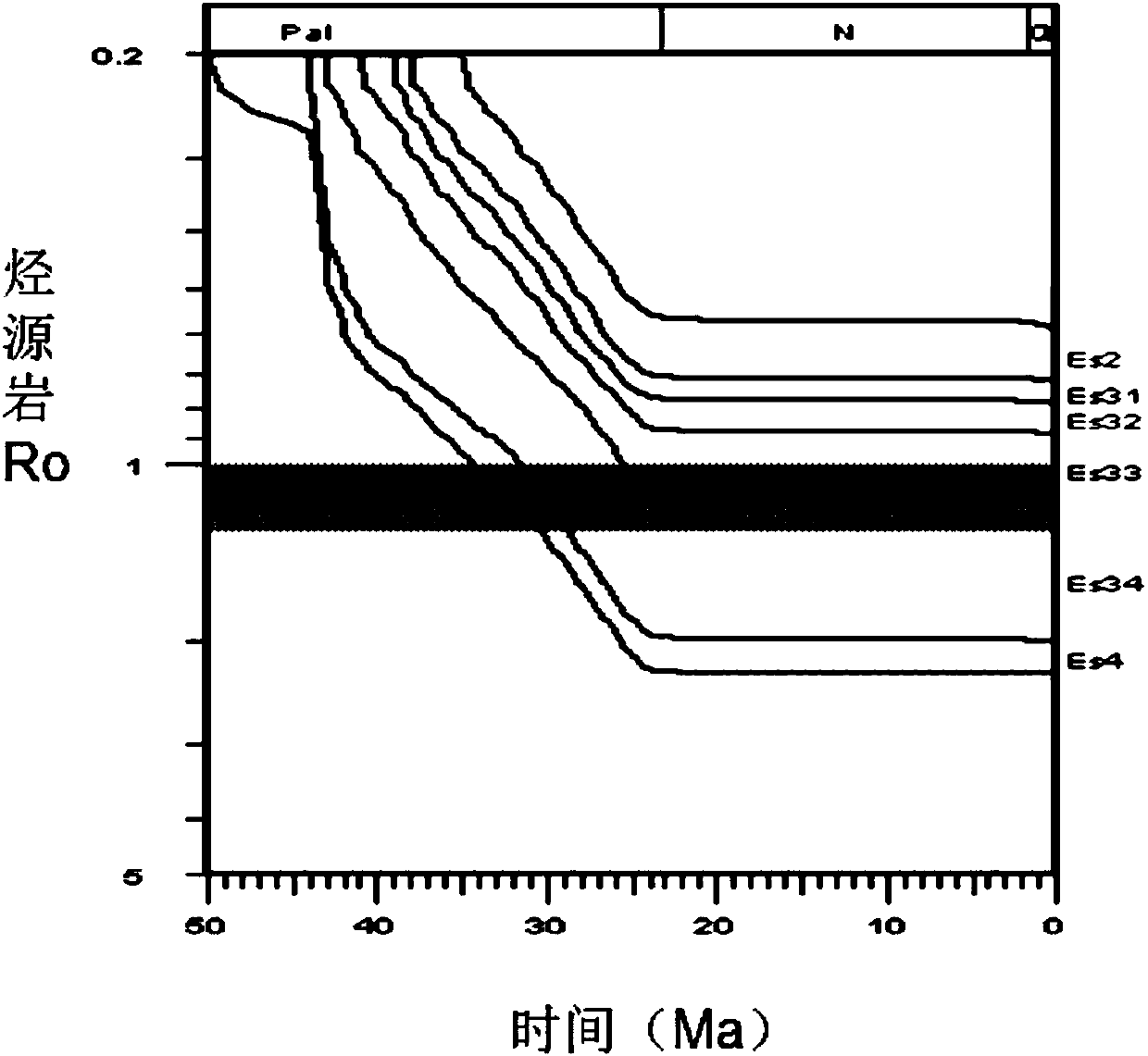

Method for establishing burial-thermal evolution history map of shale gas reservoir

InactiveCN110517794AImprove accuracyAccuracy of high thermal evolution historyInformaticsInstrumentsGround temperatureLithology

The invention provides a method for establishing a burial-thermal evolution history map of a shale gas reservoir. The method comprises the steps of acquiring layering data of a current stratum and static temperature measurement data of the current stratum; establishing a stratum lithology model of an interval for research; acquiring various burial history parameters; calculating the paleo-thickness and the buried depth of each stratum in each period; determining the ground temperature gradient, the heat conductivity, the heat generation rate and the ground heat flow value characteristics of the current ground temperature field; analyzing a formation mechanism and an evolution rule of the paleo-geothermal field; determining the maximum paleo-ground temperature experienced by the stratum towhich the sample belongs in the geological evolution process by using vitrinite reflectivity data; moreover, determining the paleo-geothermal gradient at the moment jointly by utilizing the Ro data ofthe multiple samples at different depths; determining a paleo-temperature evolution process of the sample, restoring a paleo-geothermal gradient evolution history, and drawing a burial history map ofthe paleo-geothermal field of the research area; calculating hydrocarbon source rock maturity evolution history; establishing and drawing a burial-thermal evolution history map of a sedimentary basin. According to the invention, high thermal performance history precision can be obtained.

Owner:CHANGAN UNIV

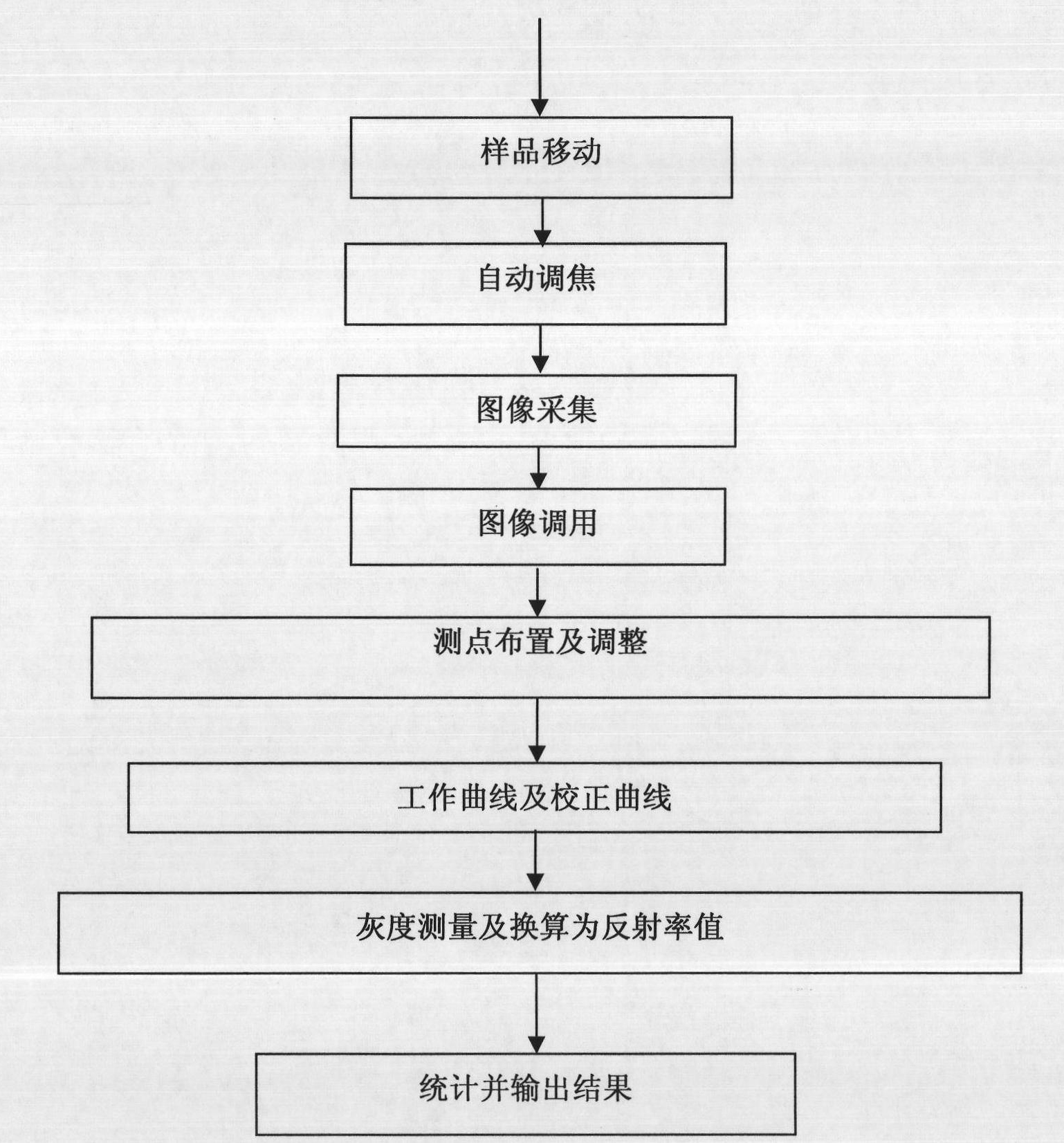

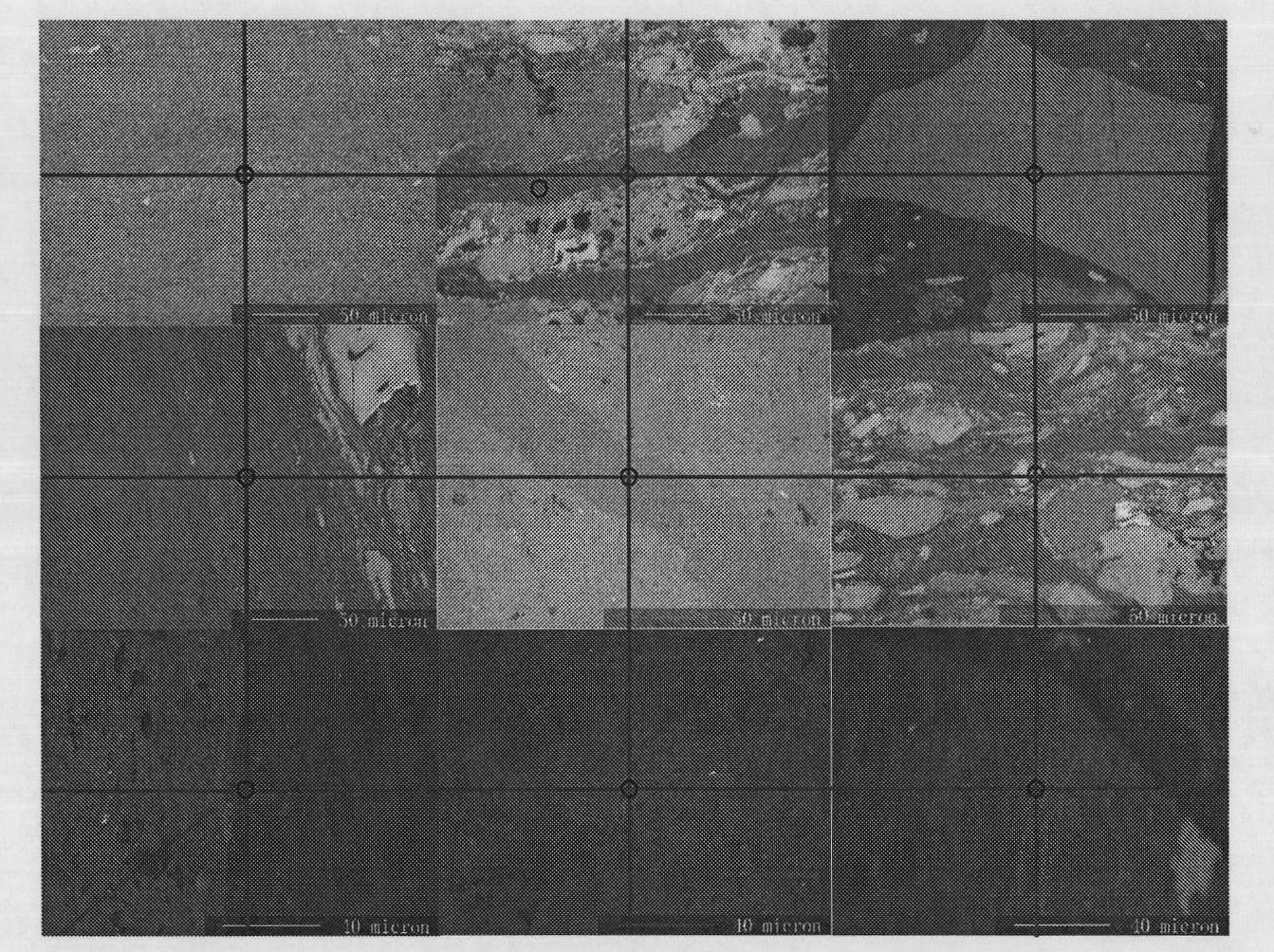

Method for detecting reflectivity of coal or organic rock vitrinite and special equipment thereof

InactiveCN101846623AAchieve traceabilityImprove test accuracyScattering properties measurementsReflectivity measurementNational standard

The invention discloses equipment for detecting the reflectivity of coal or organic rock vitrinite. The equipment comprises a stand, an imaging device and an image collection device, wherein a coal or organic rock vitrinite sample is placed on the stand, the imaging device images the sample, and the image collection device is used for collecting an image formed by the imaging device. The equipment is characterized by also comprising a vitrinite reflectivity measurement device carrying out image invocation, measuring point arrangement, vitrinite reflectivity measurement, linkage, statistics and result output on the image collected by the image collection device; and the magnification of the imaging device is at least 5 times. The equipment is adopted to carry out reflectivity test, which has simple and convenient procedure, is easy to operate, conforms to the national standard requirement of vitrinite reflectivity test and improves the accuracy and the efficiency of the reflectivity test of coal vitrinite greatly.

Owner:CHINA COAL RES INST +1

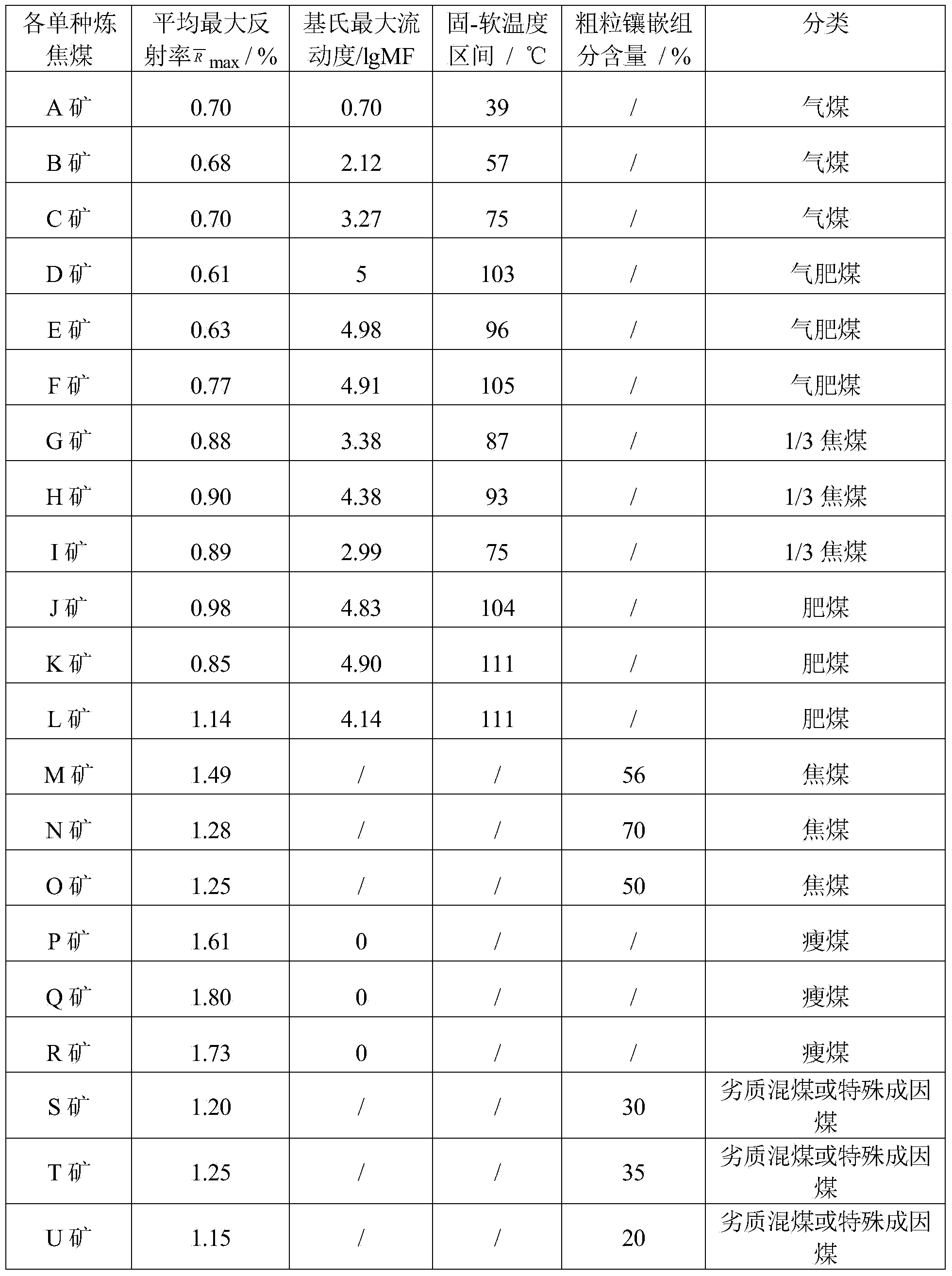

Coal quality sorting and coal distributing method based on cokeability of coking coal

ActiveCN103952166AOvercome apparent limitationsAvoid mutual interferenceCoke ovensClassification methodsComputer science

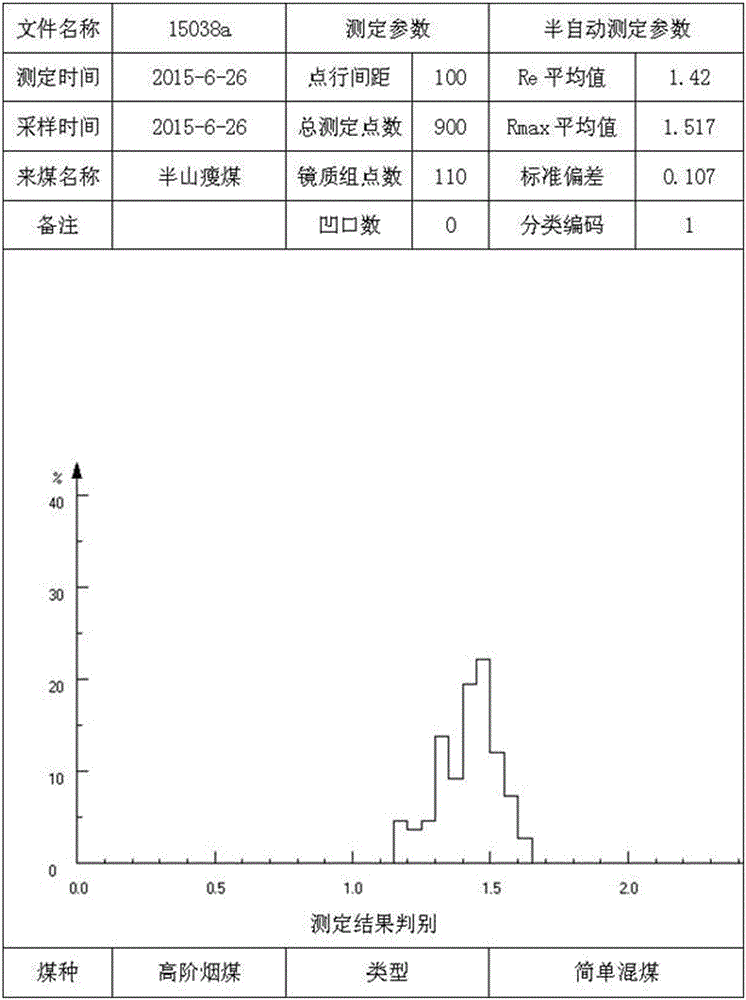

The invention discloses a coal quality sorting method based on cokeability of coking coal. The sorting method comprises the following steps: 1) determining the indexes which affect the cokeability of coking coal: determining the average maximum reflectivity of vitrinite, the Gieseler maximum fluidity, solid-soft temperature interval and optical organizational structure of coke as the indexes of cokeability of coking coal; 2) determining the indexes which affect the cokeability of coking coal; and 3) correspondingly dividing various single coal into determining the indexes which affect the cokeability of coking coal: gas-fat coal, gas coal, fat coal, 1 / 3 coking coal, coking coal, lean coal, inferior mixed coal or special cause coal according to different measuring results in the step 2). The invention further discloses a coal distributing method based on the cokeability of coking coal. By taking the average maximum reflectivity of vitrinite, the Gieseler maximum fluidity, solid-soft temperature interval and optical organizational structure of coke as the sorting indexes, not only are the indexes simple to set, but also the inferior mixed coal or special cause coal can be differentiated, and part of highly degenerative coke is prevented from being misjudged as lean coal, so that resources are scientifically and reasonably configured.

Owner:武汉钢铁有限公司

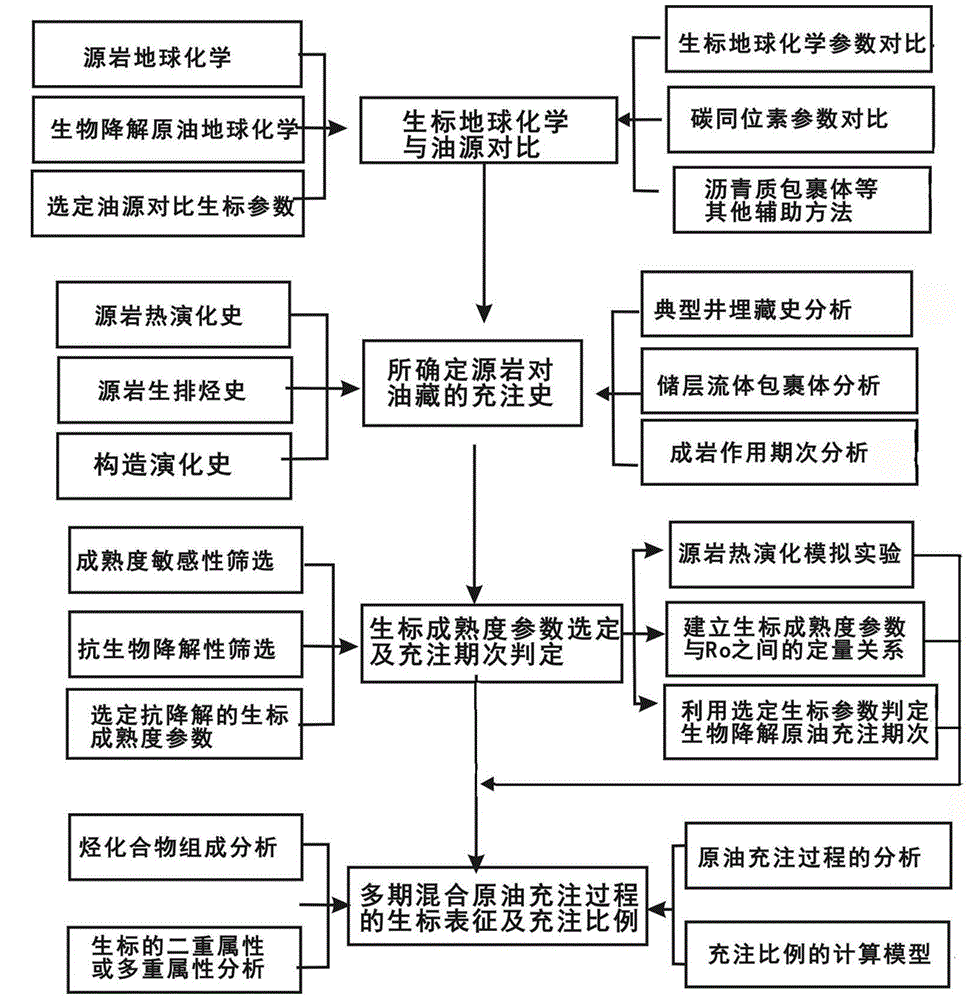

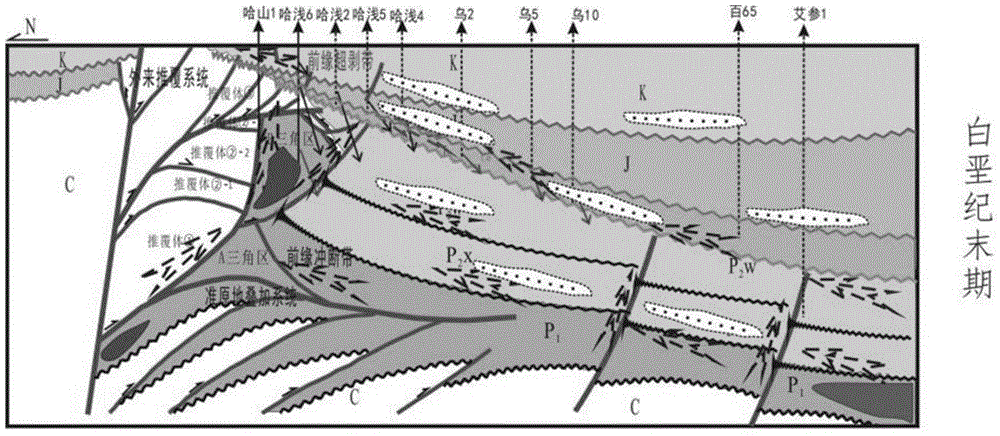

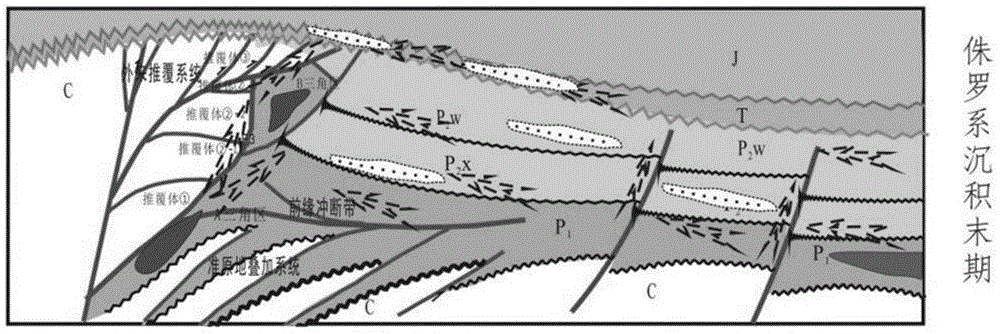

Discrimination method for charging period of underground biodegradation heavy oil reservoir

The invention relates to a discrimination method for the charging period of an underground biodegradation heavy oil reservoir, and belongs to the field of petroleum geological exploration. According to the specific technical scheme, biomarkers with high anti-biodegradation ability and good sensitivity of crude oil charging and related parameters thereof are selected, a molecular biomarker parameter TA (I) / TA (I+II) of the underground biodegradation heavy oil maturity and a quantitative relation of TA (I) / TA (I+II) and the vitrinite reflectivity Ro are calibrated, and the charging period of biodegradation heavy oil is discriminated by employing the parameter. According to the method, based on chromatography mass spectrometry characteristics and molecular biomarker response of biodegradation crude oil, effective discrimination of the charging period of the biodegradation heavy oil can be realized, the reservoir forming process of the biodegradation heavy oil is tracked, and the problem of the calculation of the proportion of crude oil being charged in different periods for multi-period mixed crude oil is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Coal blending method for producing high-quality coke by high-proportion matched use of lean coal and gas coal

The present invention relates to A sort of The coal blending method of producing high-quality coke by using lean coal and gas coal in a large proportion. The specific implementation process is: the following coal types are mixed according to the weight percentage to obtain the blended coal: the maximum reflectance of vitrinite R max >1.4% lean coal 20-21%, No. 45 gas coal 20-21%, fat coal 0%, coking coal 43-48%, 1 / 3 coking coal 12-17%, the sum of the weight percentages of the above coal types is 100%, the sum of the cheapest lean coal and gas coal in the mixed coal is ≥40%, and the most expensive fat coal is zero. On the premise of ensuring the quality of high-quality coke required by the blast furnace, the coal blending structure is optimized, coking coal resources are expanded, the consumption of high-quality coking coal resources is reduced, the cost of coal blending and blast furnace coke is reduced, thereby reducing the cost of iron After the implementation of this achievement, the cost of coking coal blending has been reduced by 12 yuan / ton of coal.

Owner:SGIS SONGSHAN CO LTD

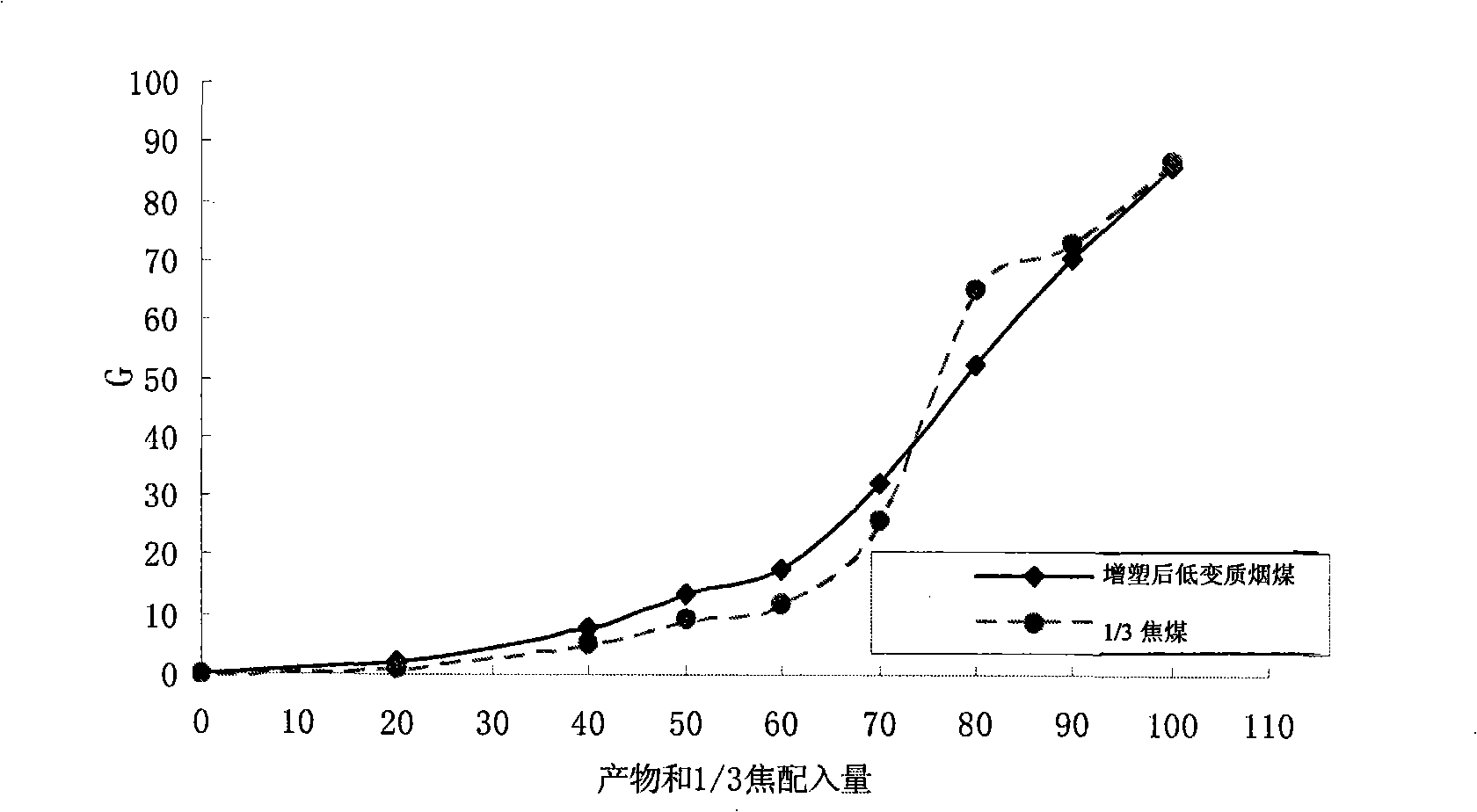

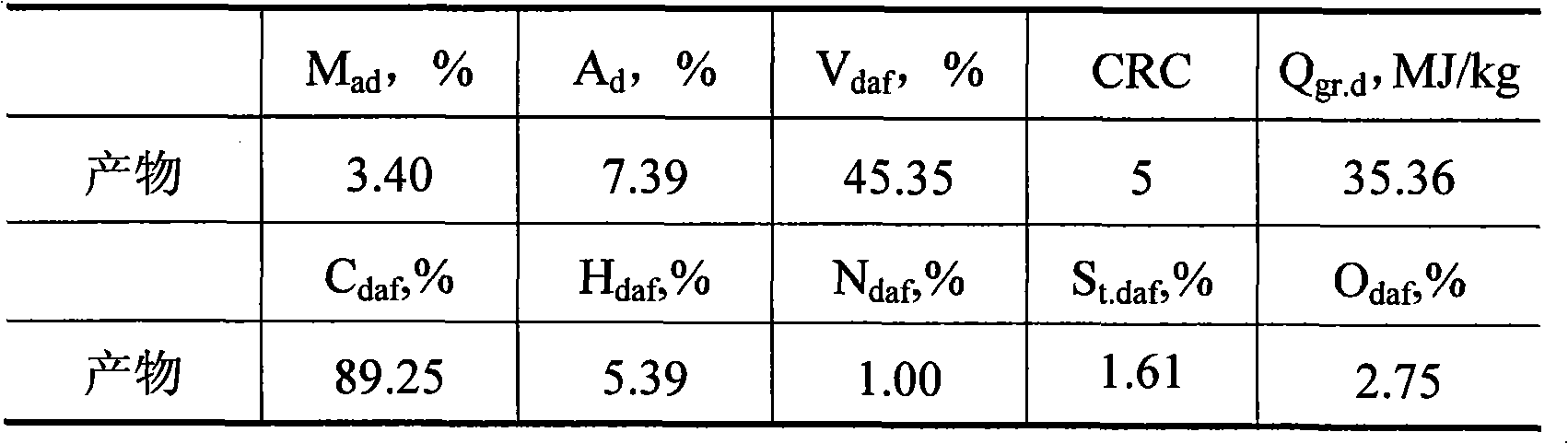

Method for plasticizing lower-grade metamorphic bituminous

The invention discloses a method for plasticized low metamorphic bituminous coal. The method is to uniformly mix the low metamorphic bituminous coal and hydrogenation solvent, to take ferric oxide as catalyst, to infuse hydrogen for reaction, and to obtain a product, wherein, the hydrogenation solvent is tetranap; the amount of the hydrogenation solvent is 2.0 to 2.5 times of the mass of the low metamorphic bituminous coal, and the hydrogen pressure is between 2 and 6 MPa; the amount of the catalyst ferric oxide and the amount of the cocatalyst brenstone are respectively 1 to 6 percent and 1 to 3 percent of the mass of the raw materials, namely the low metamorphic bituminous coal; and the reaction temperature is between 340 and 400 DEG C and the reaction time is between 20 and 60 minutes. The method is simple and convenient in technique and easy to operate; and the conversion rate of the raw material coal can reach over 80 percent, and the reaction hydrogen consumption is 0.45 percent. The technical property of the plasticized product is similar to that of gas coal; the mean maximum reflectivity Rmax of a vitrinite is about 0.76 percent; and the bond property is obviously strengthened and the binding index reaches about 60. The low metamorphic bituminous coal product obtained by utilization of the plasticizing method provided by the invention completely meets the requirements of coal blending and coking and has important industrial application value.

Owner:CCTEG CHINA COAL RES INST

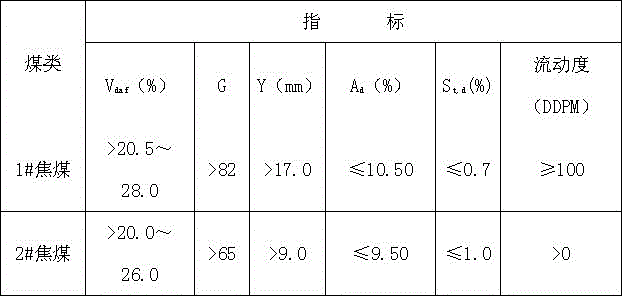

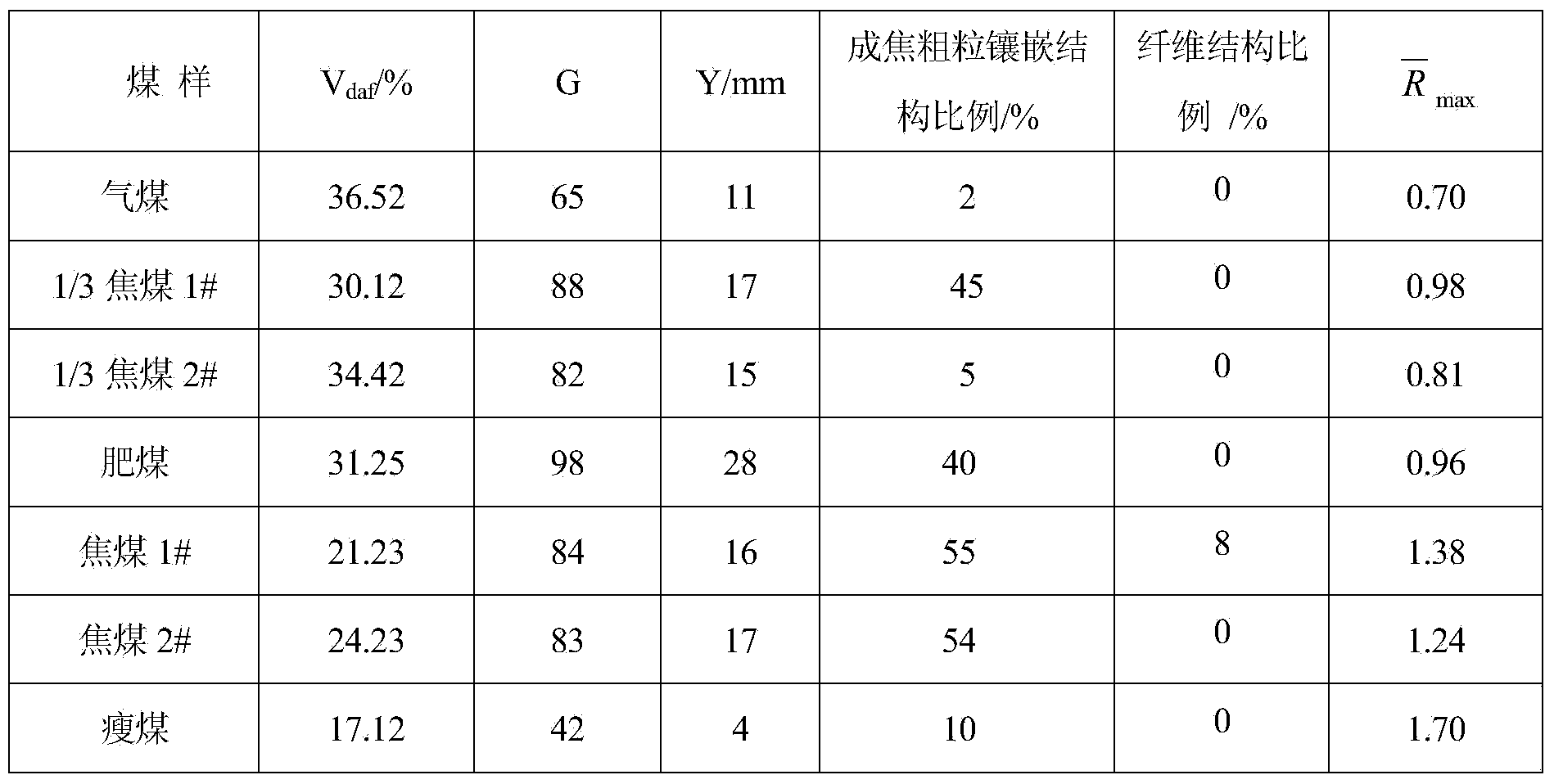

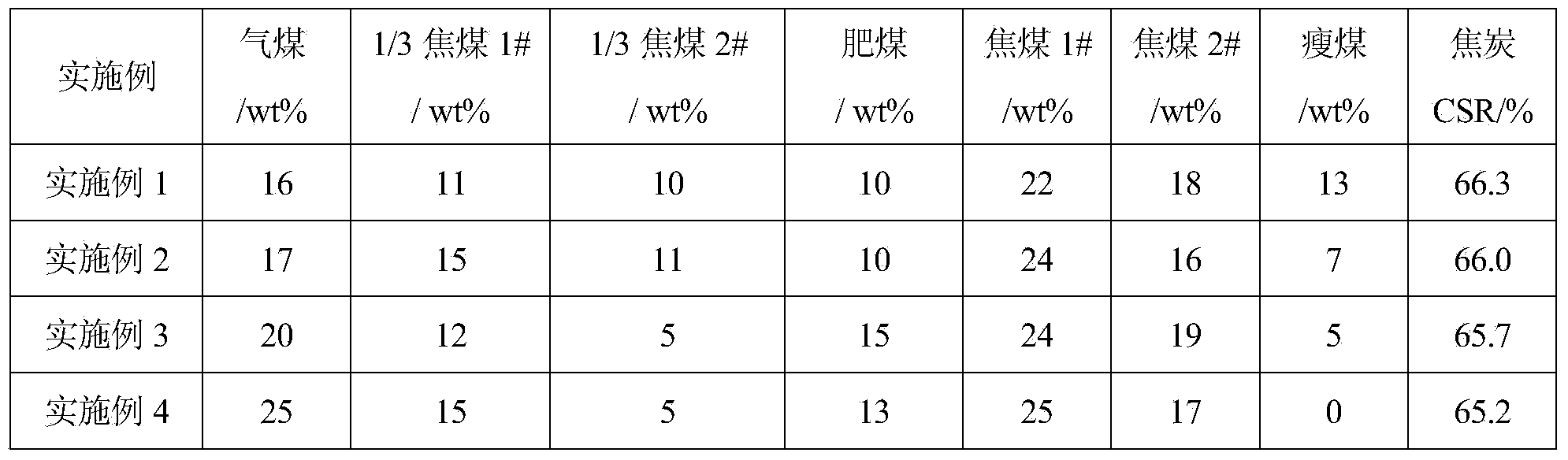

Coal blending method capable of increasing blending amount of gas coal

The invention discloses a coal blending method capable of increasing the blending amount of gas coal. The method comprises the following steps: 1) controlling the reasonable granularity of gas coal; 2) determining and analyzing the volatile compounds, caking index, coarse grain mosaic structure and maximum average vitrinite reflectivity of each coking coal, wherein according to determined values of the above-mentioned indexes, coking coals are respectively recorded as the coking coal No. 1 and the coking coal No. 2, and 1 / 3 coking coals are respectively recorded as the 1 / 3 coking coal No. 1 and the 1 / 3 coking coal No. 2; and 3) determining the blending proportion of each coking coal. According to the invention, through controlling of granularity of gas coal and selection of appropriate coking coal varieties, no or a small amount of high-quality coking coal may be blended, coal properties of different coking coals are given to full play, the blending proportion of gas coal is increased, and coal blending cost is reduced. Dry quenching CSR of a top-mounted coke oven with a height of more than 6 m is no less than 65.0% without coal-free humidifying, coal molding, tamping coking or the like.

Owner:武汉钢铁有限公司

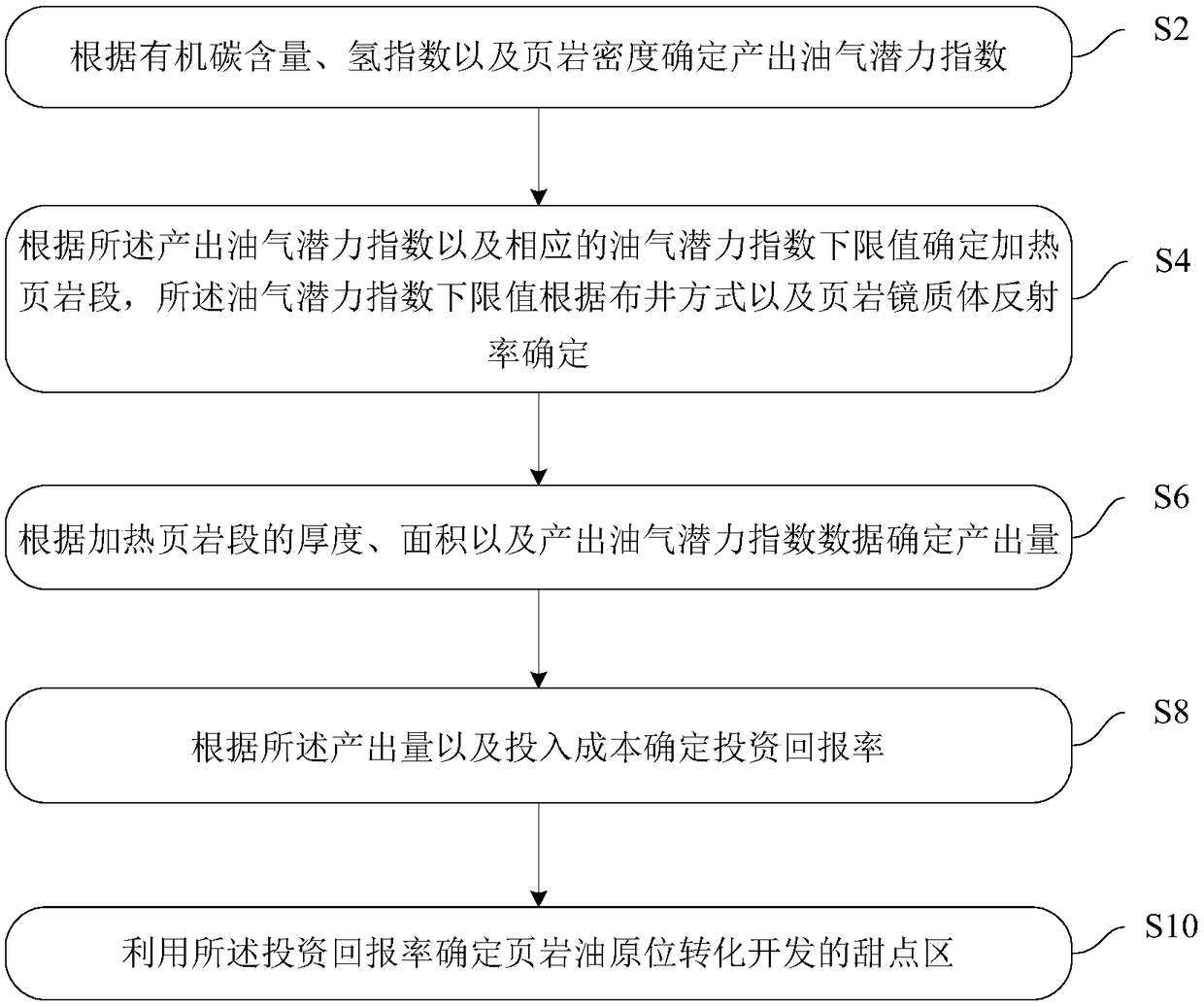

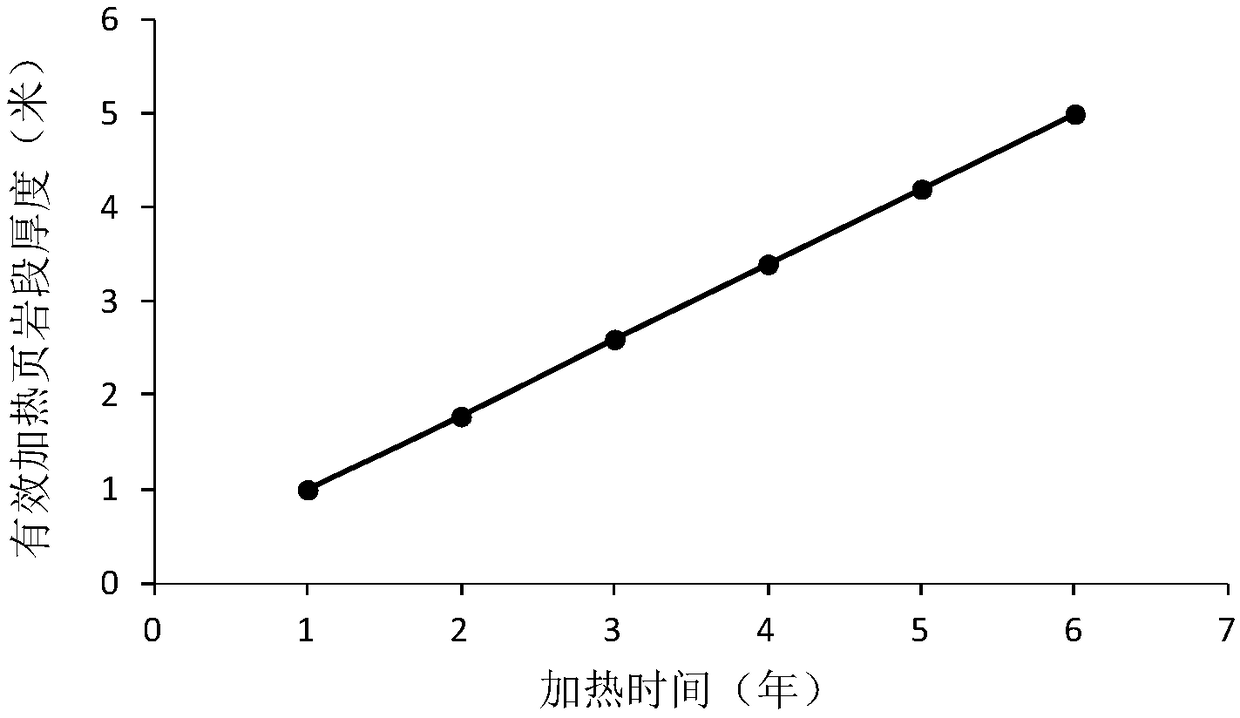

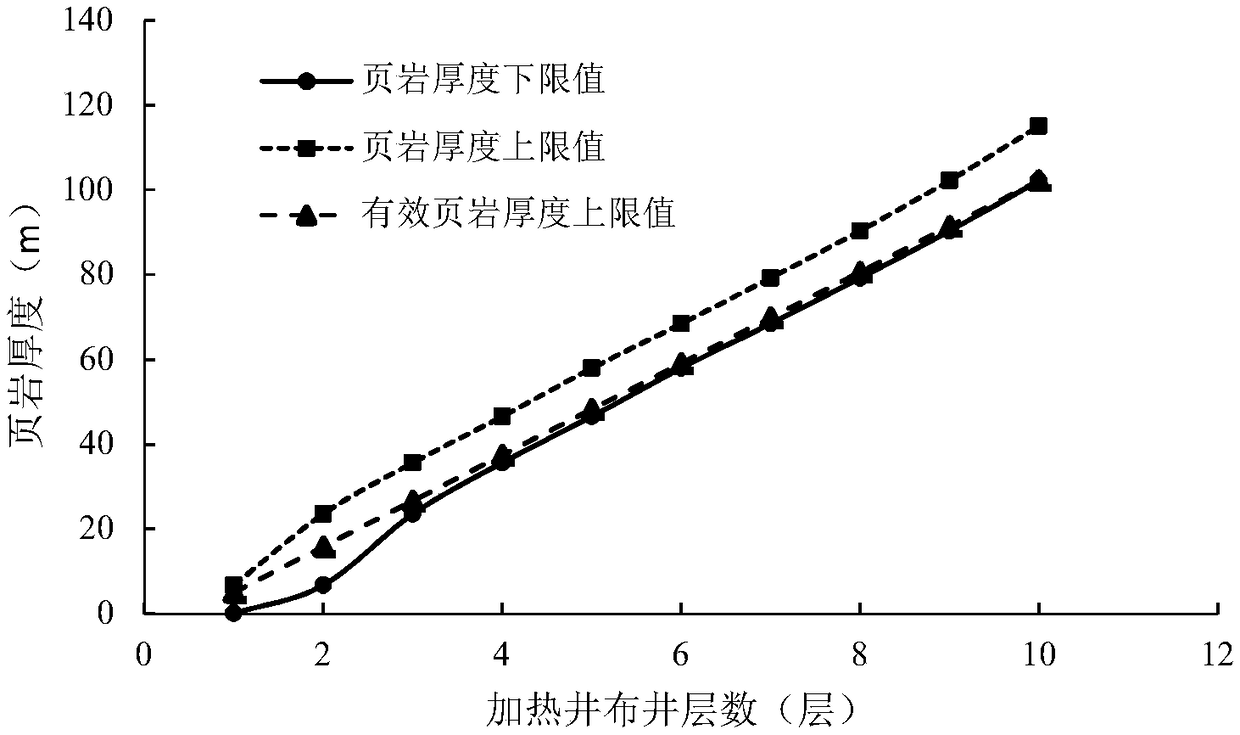

Method, device and system for determining dessert area developed through in-situ transformation of shale oil

The embodiment of the invention discloses a method, device and system for determining a dessert area developed through in-situ transformation of shale oil. The method comprises the steps that an output oil and gas potential index is determined according to the organic carbon content, the hydrogen index and the shale density; a heating shale section is determined according to the output oil and gaspotential index and a corresponding oil and gas potential index lower limit value, and the oil and gas potential index lower limit value is determined according to a well spacing mode and the shale vitrinite reflectivity; the output quantity is determined according to the thickness and the area of the shale section and output oil and gas potential index data; the rate of return on investment is determined according to the output quantity and the investment cost; and the dessert area developed through in-situ transformation of the shale oil is determined by utilizing the rate of return on investment. By utilizing the method, device and system for determining the dessert area developed through in-situ transformation of the shale oil, the accuracy of determining of the dessert area can be improved.

Owner:PETROCHINA CO LTD

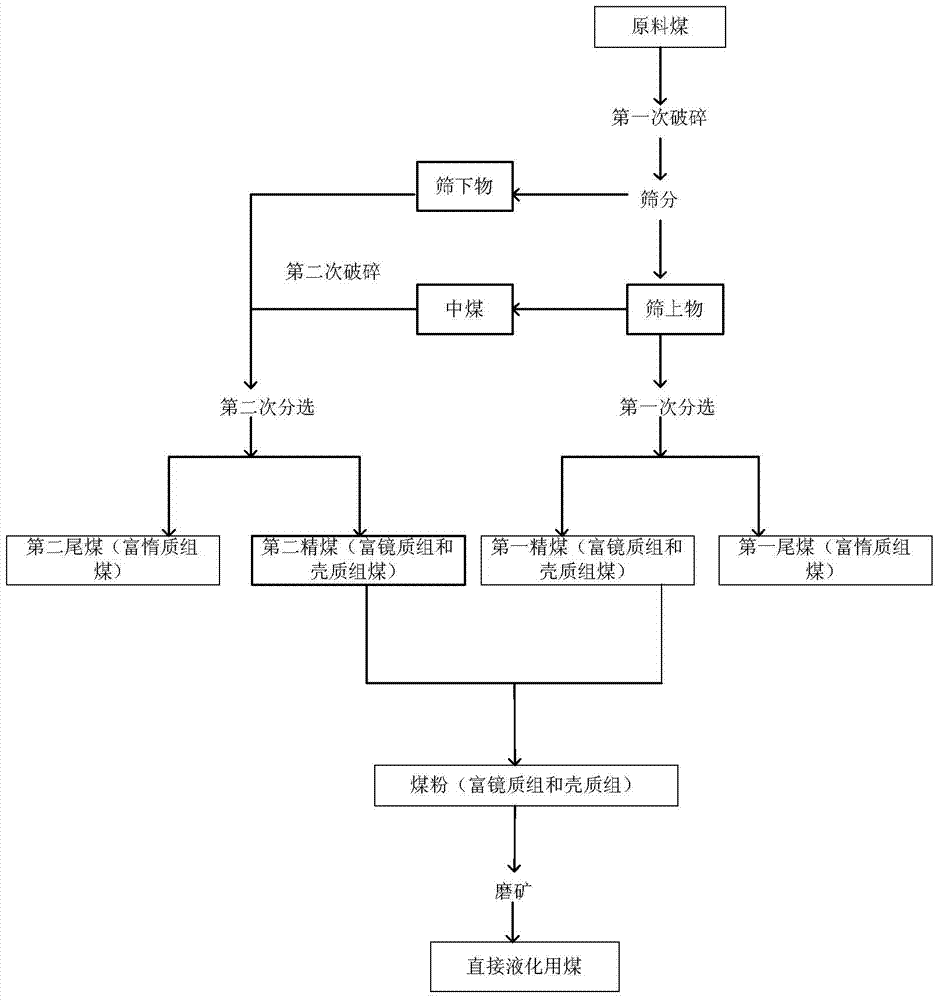

Coal for direct liquefaction and preparation method of coal

ActiveCN103934080AImprove conversion rateHigh yieldSolid fuelsLiquid hydrocarbon mixture productionDensity differenceMaceral

The invention discloses coal for direct liquefaction and a preparation method of the coal. The preparation method comprises the following steps: carrying out first breaking on raw material coal to obtain first broken coal; screening the first broken coal to obtain an oversize material and an undersize material; carrying out first sorting on the oversize material to obtain first clean coal, middling coal and first tail coal; carrying out second breaking on the middling coat to obtain second broken coal; mixing the second broken coal with the undersize material and carrying out second sorting on the mixture to obtain second clean coal and second tail coal; combining the first clean coal with the second clean coal to obtain coal powder containing vitrinite and exinite; grinding the coal powder containing the vitrinite and the exinite to obtain the coal for direct liquefaction. According to the preparation method disclosed by the invention, the raw material coal is broken, preliminarily screened according to the breaking particle size and further sorted twice according to the density difference of different coal macerals, so that the effective separation of high-activity components and high-inertness components in the coal is realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for preparing active carbon with high specific surface area from coal and waste and old plastics by microwave

The invention relates to a novel method for preparing active carbon with high specific surface area from coal and waste and old plastics by microwave, which belongs to the technical field of preparation of active carbon. The method comprises the following steps of: separating different components in coal; carrying out pulverization and oxidization preprocessing on the obtained fusain and vitrinite component; mixing with different waste and old plastics in a certain proportion; adding certain amount of activating agent and uniformly mixing and then placing the mixture into a crucible; embedding the crucible into a ceramic container provided with a heat insulating material and placing the ceramic container into a microwave oven; preheating the ceramic container under the radiation of small microwave power and carrying out carbonized activation by needed power in certain time; cooling and washing by a proper amount of hydrochloric acid; drying and pulverizing to obtain the active carbon with high specific surface area. The preparation process is based on a microwave heating technology and is simple and quick; the active carbon prepared by the synergistic effect of the coal and the plastics has high adsorptive values of methylene blue and iodine and can be used for the treatment of wastewater; meanwhile, the white pollution is eliminated, and the application prospect is wide.

Owner:XIAN UNIV OF SCI & TECH

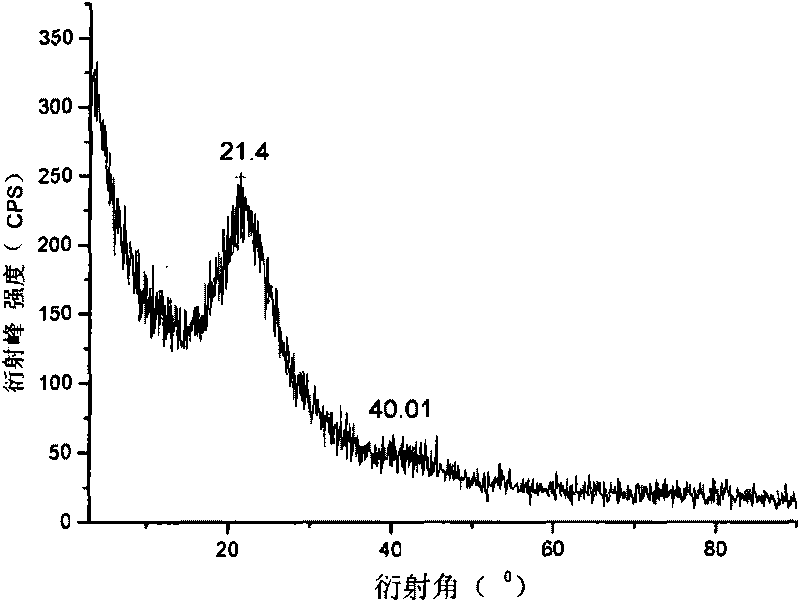

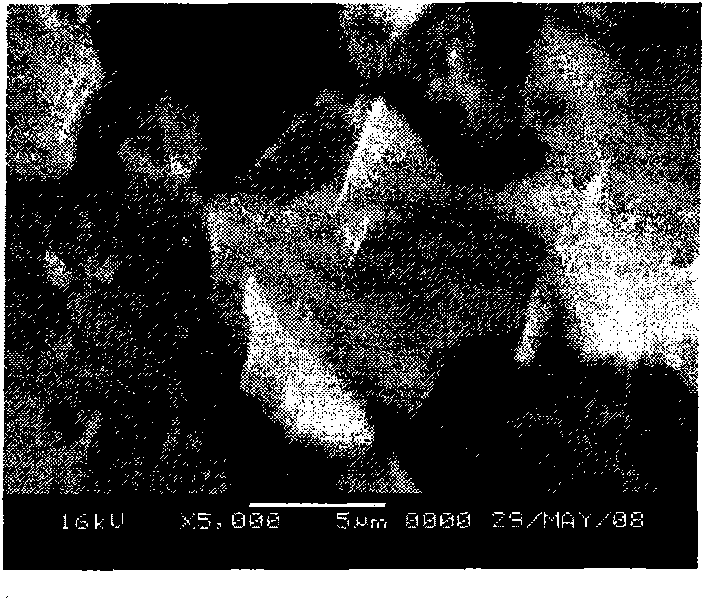

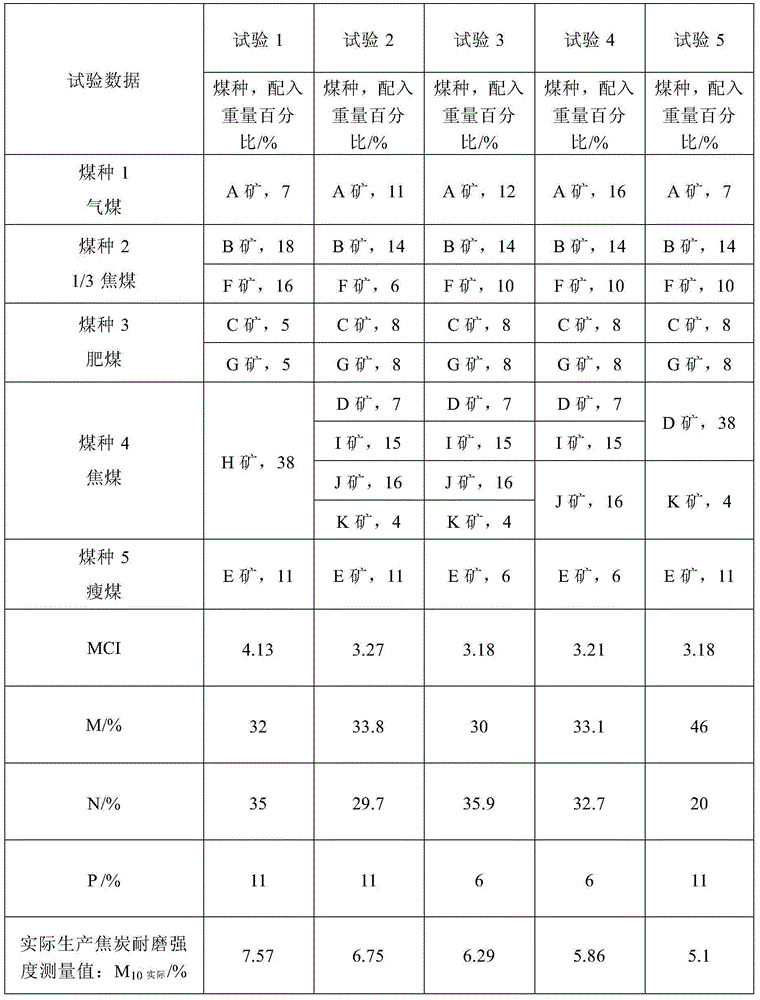

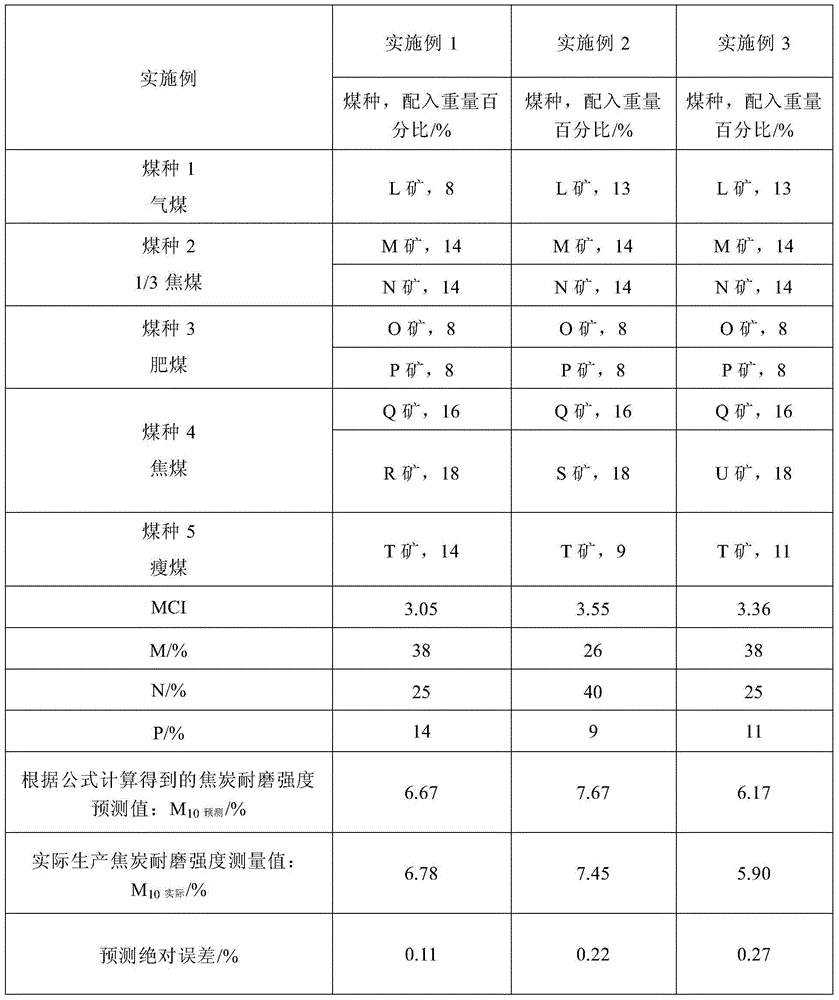

Predicating method for abrasive resistance of coal-blending coking coke

ActiveCN104678075AReduce the binding forceThe prediction formula is simpleFuel testingFiberUltimate tensile strength

The invention discloses a predicating method for abrasive resistance of coal-blending coking coke. The predicating method comprises the following steps: (1) measuring an ash composition, a coke-forming optical tissue structure and a vitrinite mean maximum reflectance of each single coal for coking, calculating or counting the following indexes: a coal-blending mineral substance index MCI, sum N of content of a coarse-grain inlaying component, a medium-grain inlaying component and an incomplete fiber component in the coal blending, sum N of contents of an isotropous component and a fine-grain inlaying component, proportion P of lean coals with reflectance Rmax larger than and equal to 1.65 in themixed coal; (2) setting M10=A+B*MCI+C*M+E*N+F*P, wherein M10 is the abrasive resistance of the coke, unit being %; A, B, C, E and F are constants; and (3) calculating to obtain the predicated abrasive resistance value M10 of the coke. According to the predicating method disclosed by the invention, through few influence factors and simple predicating formulas, the abrasive resistance of the coke can be predicated very well under the condition without coal-blending coking test, so that the predication precision can be within + / -0.3%, and the coke-blending practice can be guided very well.

Owner:武汉钢铁有限公司

Method for blending coking coal by using fat coal with medium and high sulfur content

ActiveCN105713633ASulfur Content GuaranteeMeet the need for focusCoke ovensPerformance indexBlast furnace

The invention provides a method for blending coking coal by using fat coal with medium and high sulfur content. The coking coal comprises the following components in percentages by weight: 8%-18% of 1 / 3 coking coal, 10%-20% of fat coal with medium and high sulfur content, 8%-29% of fat coal, 16%-35% of coking coal with coking index G greater than or equal to 78, 19%-36% of coking coal with coking index G greater than or equal to 75 and smaller than 78, and 8%-22% of lean coal. G value of the coking index of the coking coal is 80-85, Y value is 15-19 mm, and Std is 0.65%-1.15%. The coal properties of the fat coal with medium and high sulfur content are as follows: the mean maximum reflectance of vitrinite is 0.90%-1.10%, and volatiles are 26%-32%. Technological performance indexes are as follows: the G value of the coking index is greater than or equal to 86, the Y value of the thickness of a gel layer is greater than or equal to 20 mm, and Std is 1%-3%. The content of produced coke sulfur is below 1.0%, and reaches the level higher than the level of third-level coke, demands of coke using of a large blast furnace can be met completely, the purposes of fully utilizing the coal with medium and high sulfur and protecting high-quality coking coal resources are achieved, and coking cost can be reduced greatly.

Owner:ANGANG STEEL CO LTD

Method for chemically making cave of open hole of gas well of coal seam

A method for chemically making a cave of an open hole of a gas well of a coal seam includes steps of selecting a coal reservoir with the vitrinite reflectivity lower than 0.6%; forming a channel for reaching the coal seam in a drilling operation mode; preparing aqueous alkali on the ground, pumping the aqueous alkali to a coal seam section along the channel and soaking the coal seam section in the aqueous alkali for a period of time; discharging collapsed slack coal to the ground in a well flushing operation mode; carrying out soaking and well flushing operation repeatedly, computing the collapse diameter of the coal seam according to the weight of the discharged slack coal until the cave with the designed size is formed in the collapsed coal seam section, and organizing follow-up production; and inspecting a chemical cave making application effect by comparing the method to the traditional method for making a cave of an open hole. The method has the advantages that once the coal reservoir with the vitrinite reflectivity lower than 0.6% is reacted with the aqueous alkali, large quantities of organic matters can be extracted, the mechanical strength of coal is sharply reduced, the slack coal is formed, the cave is formed in a collapsed coal wall, and the method for chemically making the cave of the open hole has important significance in aspects of increasing the size of the cave, eliminating pollution zones near the well and reducing construction cost for making the cave of the open hole.

Owner:山西蓝焰煤层气集团有限责任公司 +1

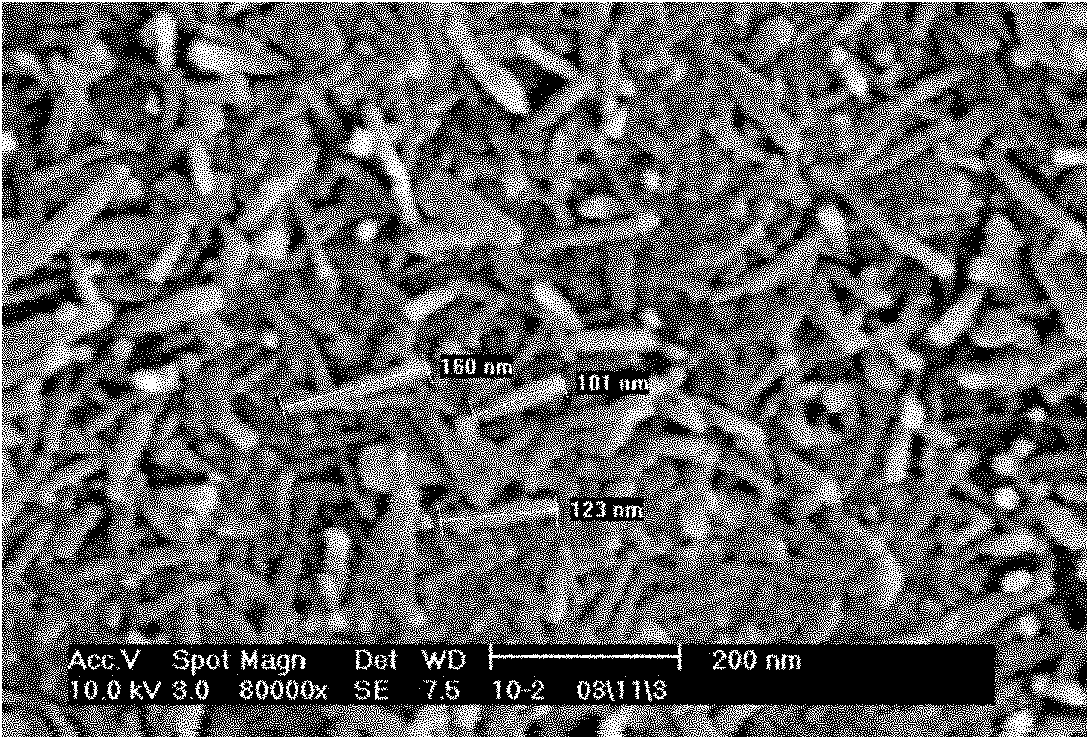

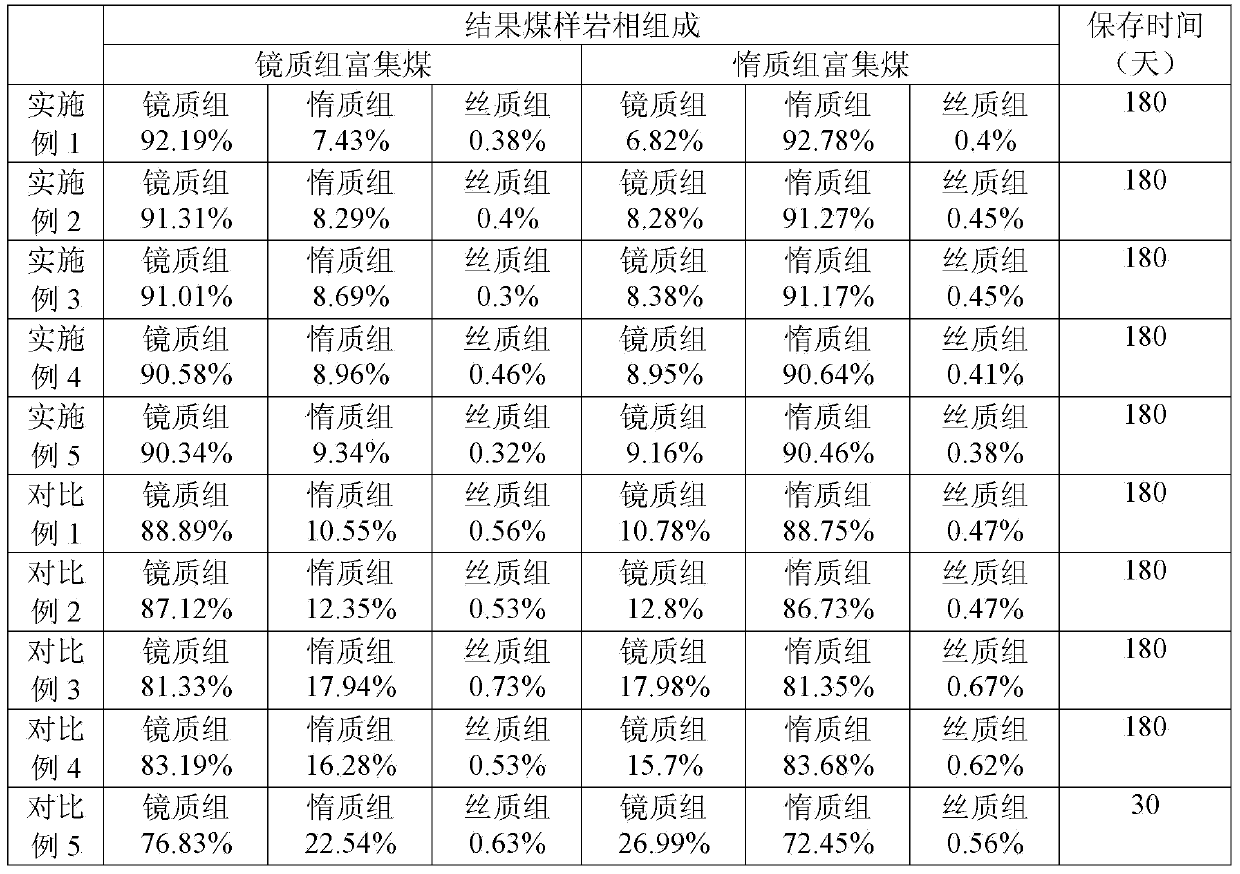

Enrichment method of coal micromaceral

ActiveCN103551238AInfluence composition structureNature of influenceGrain treatmentsEnrichment methodsSolvent

The invention discloses an enrichment method of coal micromaceral. The enrichment method comprises the following steps: a step of crushing and separating, namely, executing crushing and separating treatment for at least two times, crushing a coal sample in the first-time crushing and separating treatment process, and separating out an inert enrichment component of small particle diameter and a vitrinite enrichment component of large particle diameter according to the predetermined particle diameter, wherein the subsequent crushing and separating treatment process for each time is that the vitrinite enrichment component obtained through crushing and separating treatment for the previous time is crushed, and the inert enrichment component of small particle diameter and the vitrinite enrichment component of large particle diameter are separated out according to the predetermined particle diameter corresponding to the subsequent crushing and separating steps; and a step of enriching, namely, collecting the inert enrichment components obtained through crushing and separating treatment for each time to obtain inert enrichment coal, and collecting the vitrinite enrichment component obtained in the last-time crushing and separating treatment process to obtain vitrinite enrichment coal. According to the enrichment method disclosed by the invention, a heavy-medium solvent is not used, so that damage is avoided; the obtained enrichment coal is easy to store; in addition, even through the enrichment coal is ground to be below 200 meshes, the composition structures and the properties of the coal cannot be influenced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Preparation method of coal-based carbon foam from pre-treated bituminous coal

ActiveCN102849723ASatisfy cohesivenessFulfil requirementsCarbon preparation/purificationProcess engineeringBituminous coal

The invention discloses a preparation method of coal-based carbon foam from pre-treated bituminous coal, to overcome the shortcomings of high ash content and unstable caking property of bituminous coal. The method comprises the steps of adding pulverized bituminous coal and surfactant into a flotation solution, stirring to obtain coal slurry, transferring into a horizontal rotor of a centrifugal separator to perform maceral separation, taking upper floating matters, washing with water to remove floatation solution, stirring, filtering, drying filter residue at room temperature to obtain enriched vitrinite, and preparing carbon foam from the enriched vitrinite by high-pressure permeation inert gas method or self pressure boosting method. The preparation method has the advantages of simple process flow and low cost, realizes maceral separation and enrichment of bituminous coal, satisfies requirement of coal-based carbon foam preparation for coal caking property and ash content, and widens coal application range. The prepared coal-based carbon foam has the advantages of uniform pore distribution, high compression strength, and adjustable volume density and compression strength.

Owner:UNIV OF SCI & TECH LIAONING

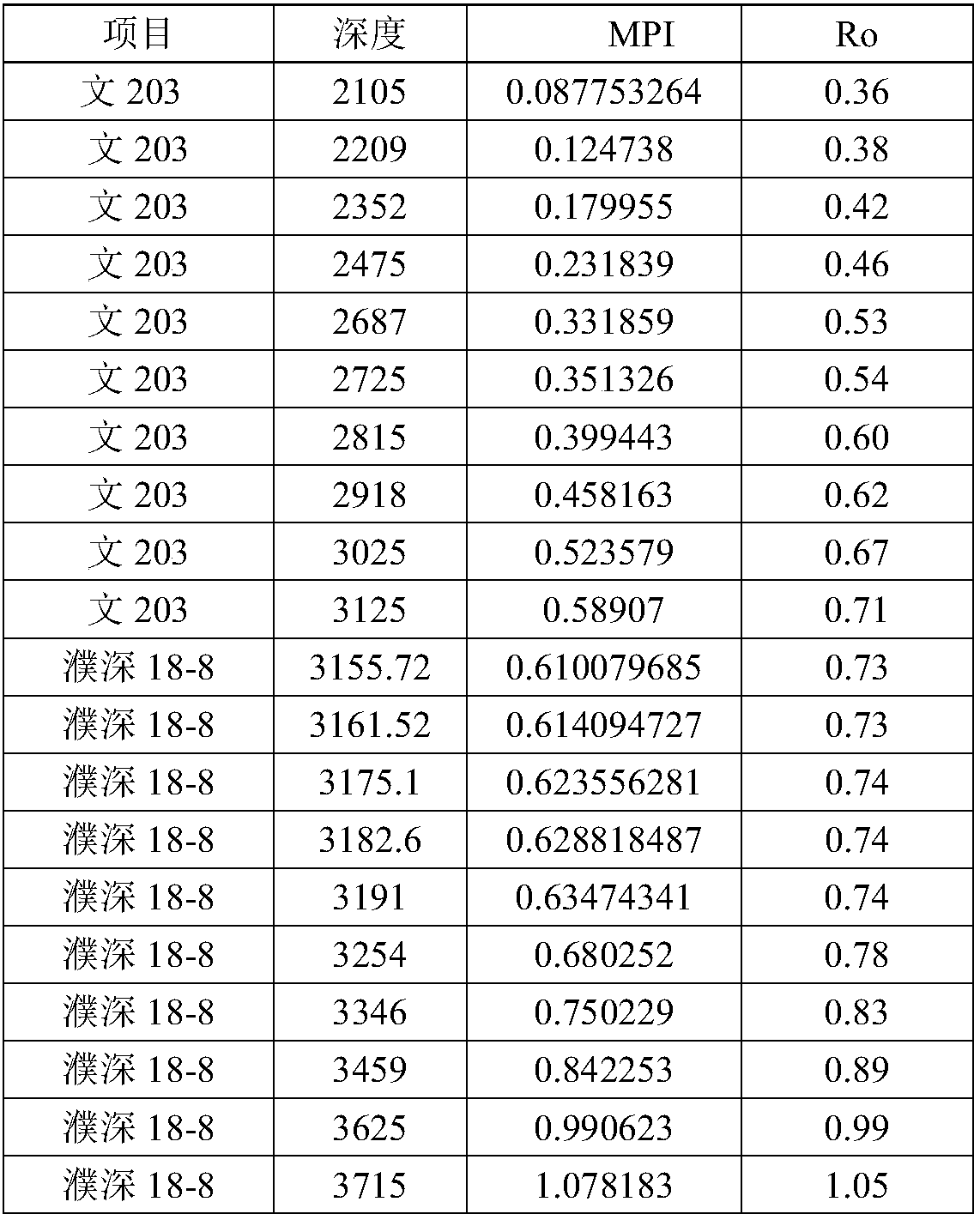

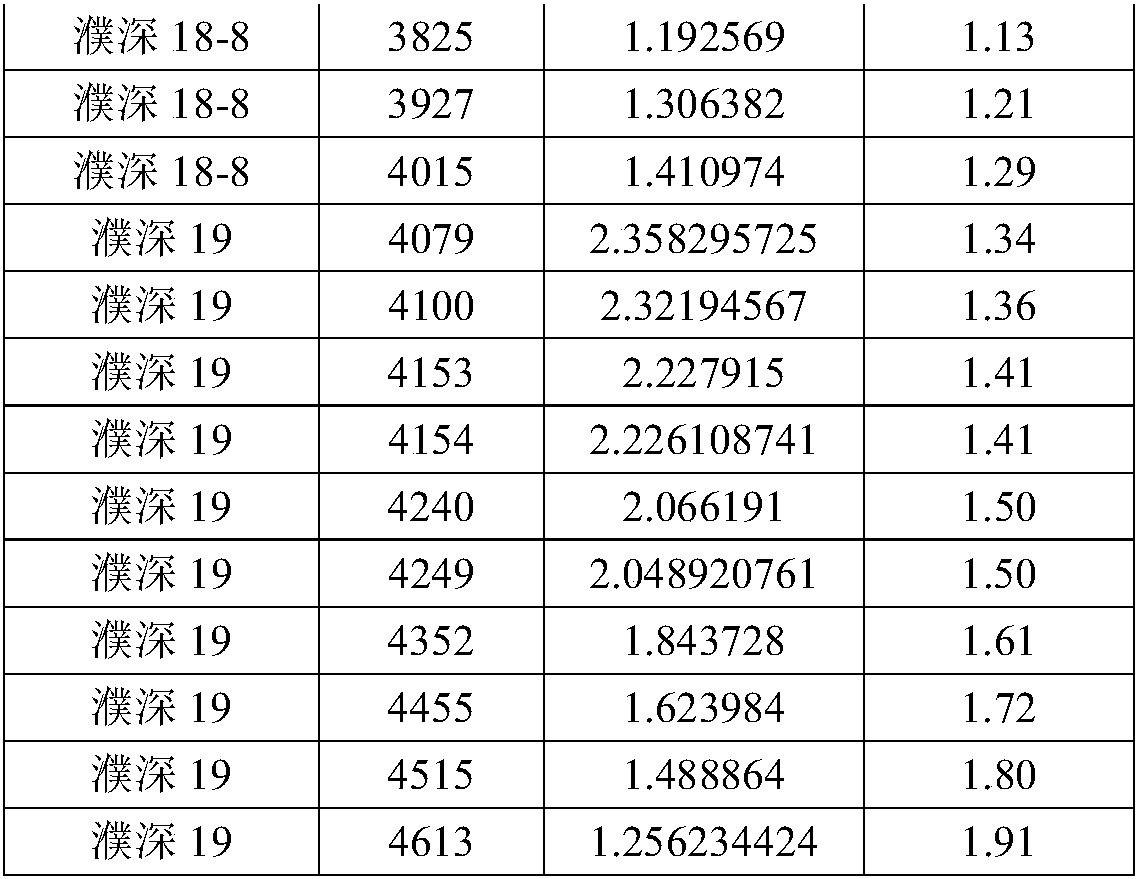

Method for discriminating affinity of high-maturity crude oil

InactiveCN109557191AEfficient ExplorationOvercome the oil source comparison relationshipComponent separationPhenanthreneHorizon

The invention relates to a method for discriminating affinity of a high-maturity crude oil, and belongs to the technical field of oil and gas exploration and development. The method for discriminatingaffinity of the high-maturity crude oil provided by the invention comprises the following steps: 1) calculating the relationship between the methylphenanthrene index MPI and the vitrinite reflectanceRo of the phenanthrene series compound in the source rock extract to obtain the values of A, B, C, and D; 2) calculating the relationship between the methylphenanthrene index MPI of the phenanthreneseries compound in the crude oil and the maturity Rc of the crude oil to obtain Rc; 3) establishing a change relationship between the vitrinite reflectance and the geological history of the source rocks of different horizons; and 4) assuming the source horizon and accumulation time of crude oil by using the Rc in the step 2) and the change relationship between the vitrinite reflectance and the geological history determined in the step 3). The method for discriminating affinity of the high-maturity crude oil provided by the invention can finely determine the source of deep oil and gas, therebyguiding the efficient exploration of deep oil and gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

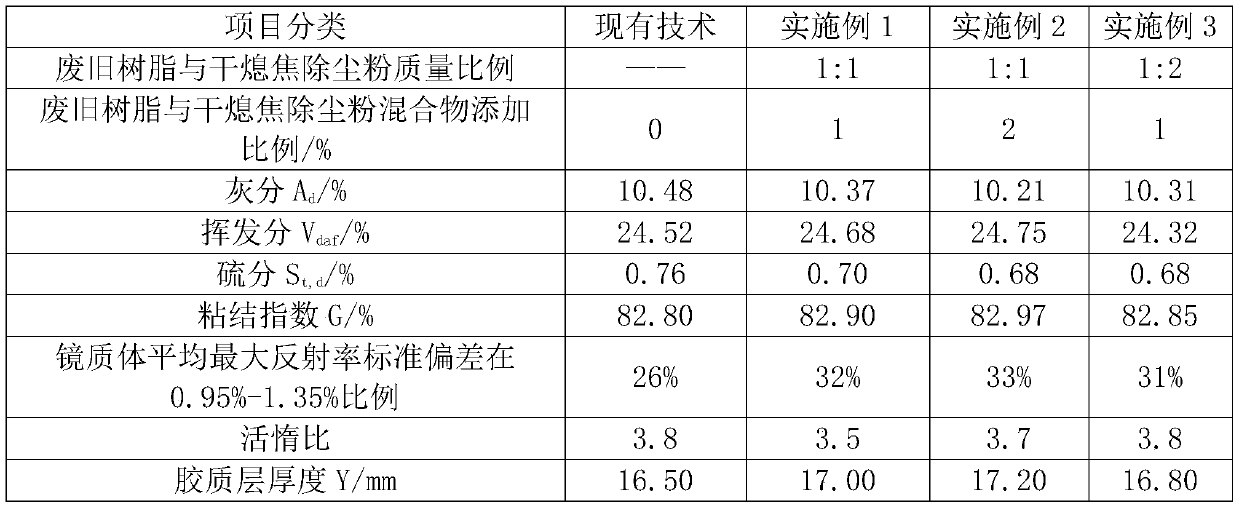

Method for preparing metallurgical coke

ActiveCN110819364AImprove quality indicatorsMeeting ever-increasing demandsProductsReagentsDusting powdersCoke oven

The invention relates to a method for preparing metallurgical coke. The method comprises the following steps: 1) taking blended coal, waste resin and dry quenching dedusting powder as raw materials; 2) intensively recovering the waste resin, and grinding the waste resin to make the particle size less than 3 mm; 3) fully mixing the waste resin with the dry quenching dedusting powder according to amass ratio of 1:1 to 1:5, and carrying out matching pelletizing to make the ball diameter be 1-3 cm; 4) respectively crushing and mixing various coal types in the blended coal, wherein the mass proportion of the average maximum reflectivity, in the interval range of 1.05-1.35%, of vitrinite in the blended coal is not lower than 45%; and 5) mixing the mixed balls of the waste resin and the dry quenching powder with the blended coal, and coking the obtained mixture in a coke oven, wherein the bending mass percentage of the mixed balls is 1-3%. The method achieves recycling of carbon-containing solid wastes of iron and steel enterprises, realizes complete recycling of the waste resin according to the characteristics of low dust, low sulfur and high iron of the waste resin, and achieves the effect of effectively improving the quality index of the coke through reasonable blending of the waste resin in a coal blending coking scheme.

Owner:ANGANG STEEL CO LTD

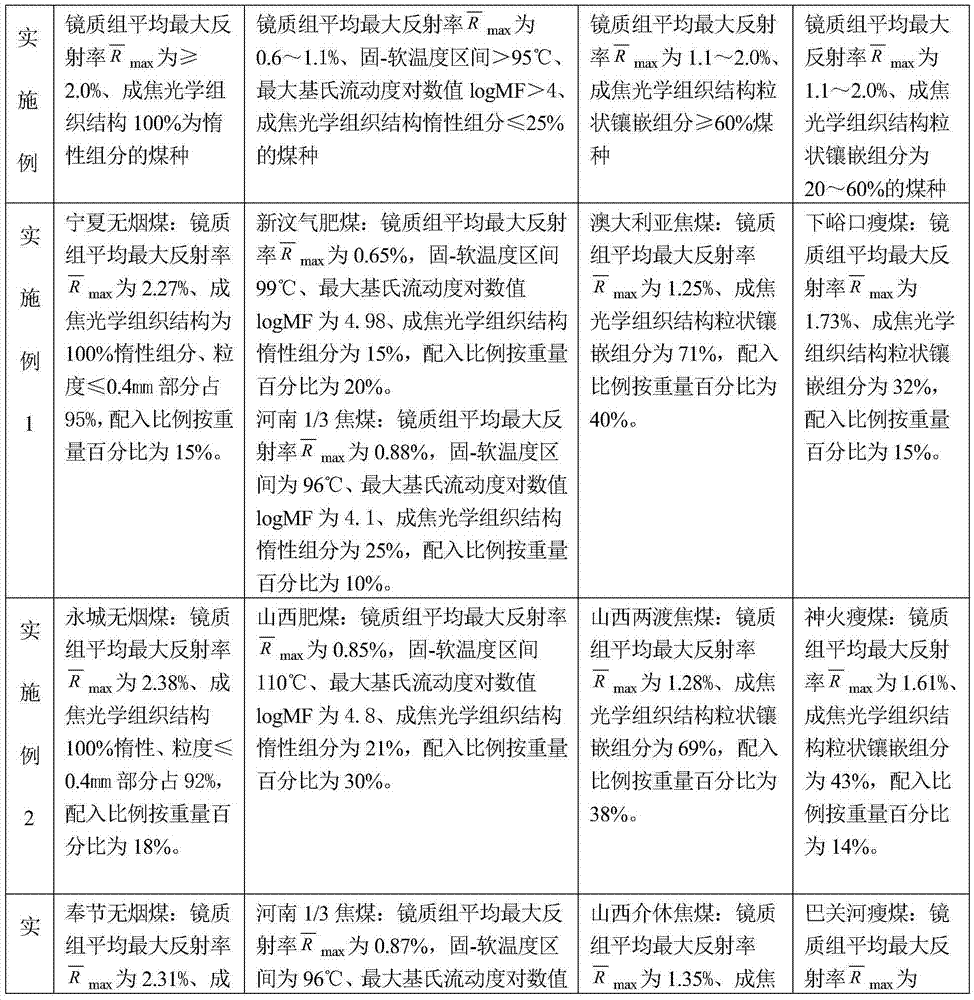

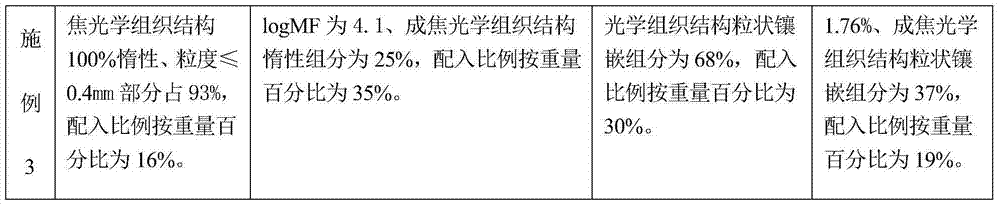

Coking coal blending method of improving homogeneity coefficient of coke size

ActiveCN103923678BUniform particle sizeGood spreadabilityCoke ovensGranularityUltimate tensile strength

The invention discloses a coking coal blending method of improving homogeneity coefficient of coke size. The method comprises the following steps: determining the average maximum reflectivity, the solid-soft temperature interval region, the Gieseler fluidity and the coking optical organization structure of a single coal vitrinite; according to a test result, selecting the type of coal in percentage by weight of 15-18%, wherein formula is greater than or equal to 2.0% and the coking optical organization structure is 100% an inertial component; smashing till the part with particle size less than or equal to 0.4mm is over 90%; 2) selecting the type of coal in percentage by weight of 30-40%, wherein formula is 0.6-1.1%, the solid-soft temperature interval region is greater than 95 DEG C, the maximum Gieseler fluidity log value logMF is greater than 4 and the inertial component of the coking optical organization structure is less than or equal to 25%; 3) selecting the type of coal in percentage by weight of 20-40%, wherein formula is 1.1-2.0% and the granular inlay component of the coking optical organization structure is greater than or equal to 60%; and 4) selecting the type of coal in percentage by weight of 20-60%, wherein formula is 1.1-2.0% and the granular inlay component of the coking optical organization structure is greater 20-60%, and blending coal according to a certain proportional range. According to the coal blending method disclosed by the invention, the coke is uniform in grain size, high in cold and heat state strengths and low in coal blending cost.

Owner:武汉钢铁有限公司

Method for producing high-quality metallurgical coke by using coal and rock indexes

InactiveCN104593028ASimple processOvercoming the problem of a sharp drop in strengthCoke ovensHigh intensityLayer thickness

The invention discloses a method for producing high-quality metallurgical coke by using coal and rock indexes, and belongs to the technical field of blended coal for coking. According to the method, the target of producing high-strength metallurgical coke is achieved by controlling the distribution ranges of volatile index Vdaf, the caking index G, the maximal gelatinous layer thickness Y and the vitrinite mean maximum reflectance Rmax (0.9%-1.5%). According to the method, the feeding ratios of fat coal and coking coal can be reduced to about 50%; the heat intensity CSR of the coke is over 65%; and the requirements of over 2500m<3> blast furnace ironmaking are met.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for improving fineness and particle size composition of stamped coke blended coal

ActiveCN111592901APre-shredding TargetedParticle size analysisSpecial form destructive distillationThermodynamicsCoke

The invention relates to a method for improving fineness and particle size composition of stamped coke blended coal. According to the method, the Hardgrove grindability index and the original finenessare combined, coal difficult to grind or coal with coarse original particles is pre-ground, and pre-grinding is more targeted; through coal petrography analysis on coal having a size of greater than3mm in blended coal, which kind of coal causes unqualified granularity can be judged according to the distribution proportion of each reflectivity interval of vitrinite, the reason why the particle size of the blended coal does not reach the standard can be quickly found and adjusted in a targeted mode, and the situation that in order to improve the fineness of the blended coal, the smashing levelof all pre-smashed coal or blended coal is improved, part of coal is smashed too finely, and energy consumption is increased is avoided. The optimal particle size composition of the coal as fired isachieved by specifically crushing and controlling the ratio of the part with the particle size of more than 5mm to the part with the particle size of less than 0.5 mm. By adopting the method, the cokeobtained by coking achieves high strength and large lumpiness, and the quality level is improved.

Owner:河北中煤旭阳能源有限公司 +1

Method for calculating coal-bed gas absorption amount of gas well

InactiveCN105930667AHigh precisionSpecial data processing applicationsInformaticsCoalbed methaneVitrinite

A method for calculating a coal-bed gas absorption amount of a gas well comprises the following steps: step one: testing and analyzing a coal bed that a gas well passes through, so as to acquiring a coal quality industrial analysis result, and collecting gas well coal bed data; step two: calculating a maximum reflectance of vitrinite according to a dry ash-free volatile; step three: calculating a coal-bed gas absorption amount of each coal bed according to a coal-bed gas dynamic absorption equation; and step four: calculating an absorption amount of each coal bed under different pressures according to a formation temperature of each coal bed, and summing all absorption amount values to obtain a total absorption amount when the gas well passes through all coal beds. The method is capable of greatly improving precision of calculation of coal-bed gas absorption amount of the gas well and has important practical significance for instructing coal-bed gas exploration and development.

Owner:CHINA UNIV OF MINING & TECH YINCHUAN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com