Patents

Literature

1228 results about "Clean coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal pollution mitigation, often called clean coal, is a series of systems and technologies that seek to mitigate the pollution and other environmental effects normally associated with the burning (though not the mining or processing) of coal, which is widely regarded as the dirtiest of the common fuels for industrial processes and power generation.

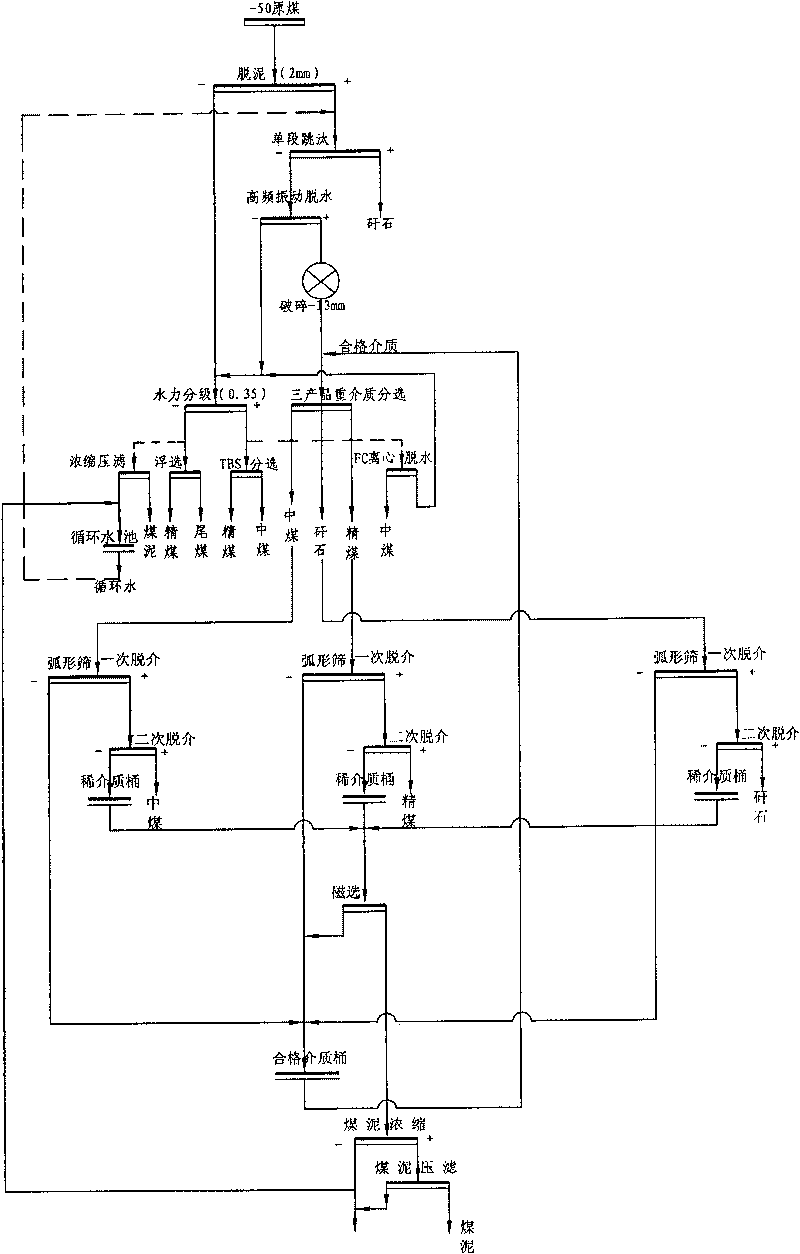

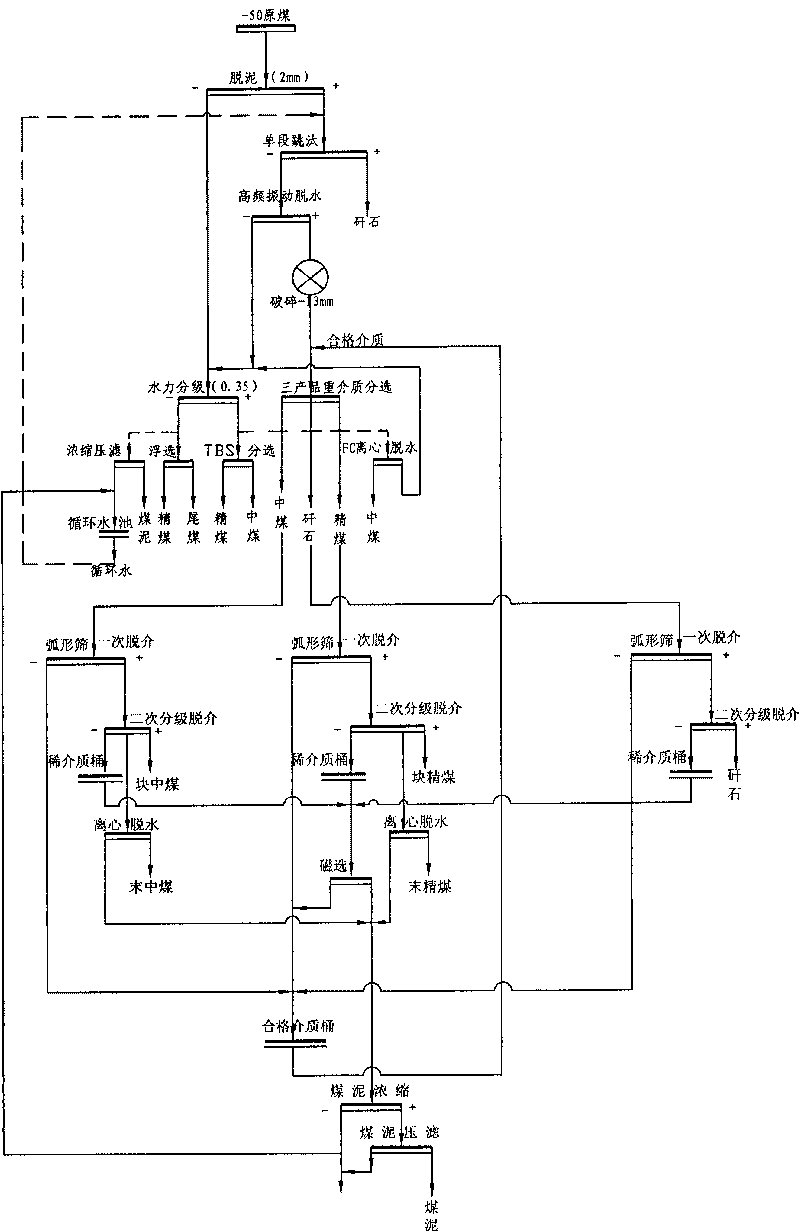

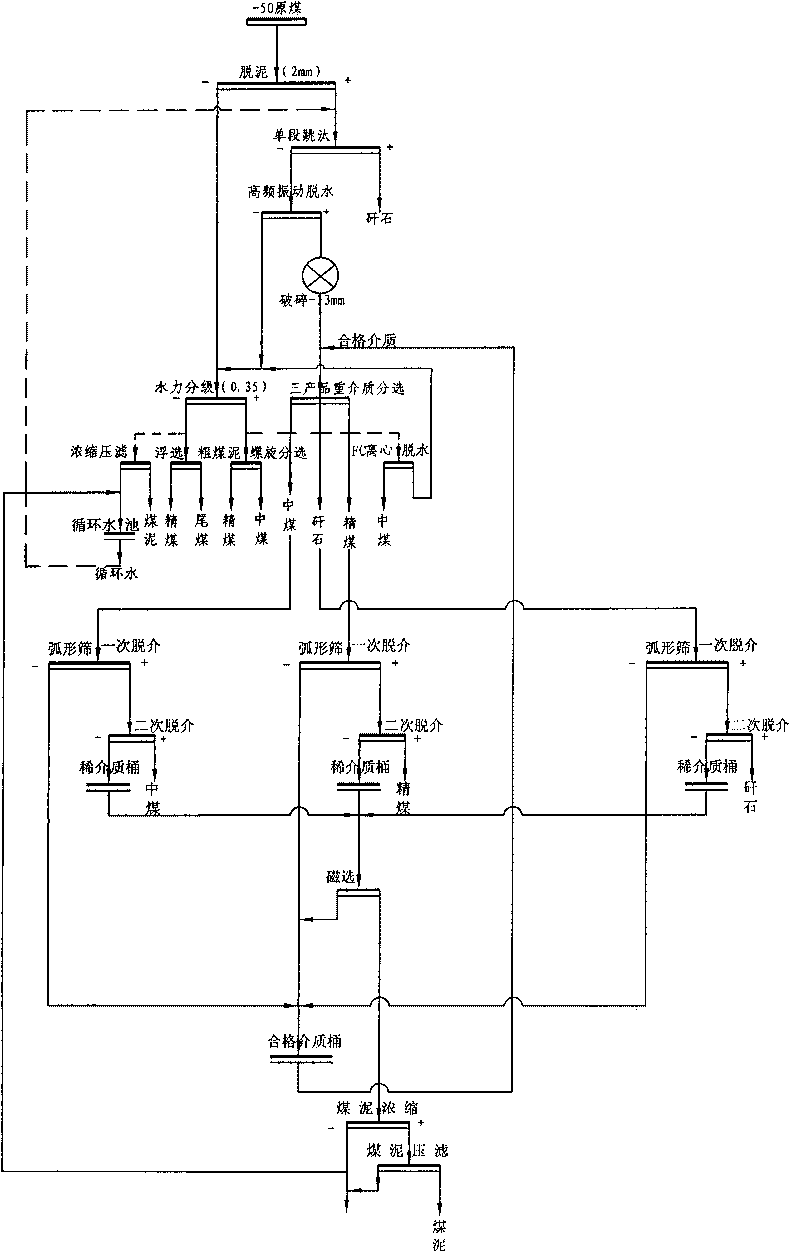

Raw coal washing process capable of realizing non-polar ash conditioning

InactiveCN101716552AReduce the amount of re-insertionReduce manufacturing costWet separationCycloneSingle stage

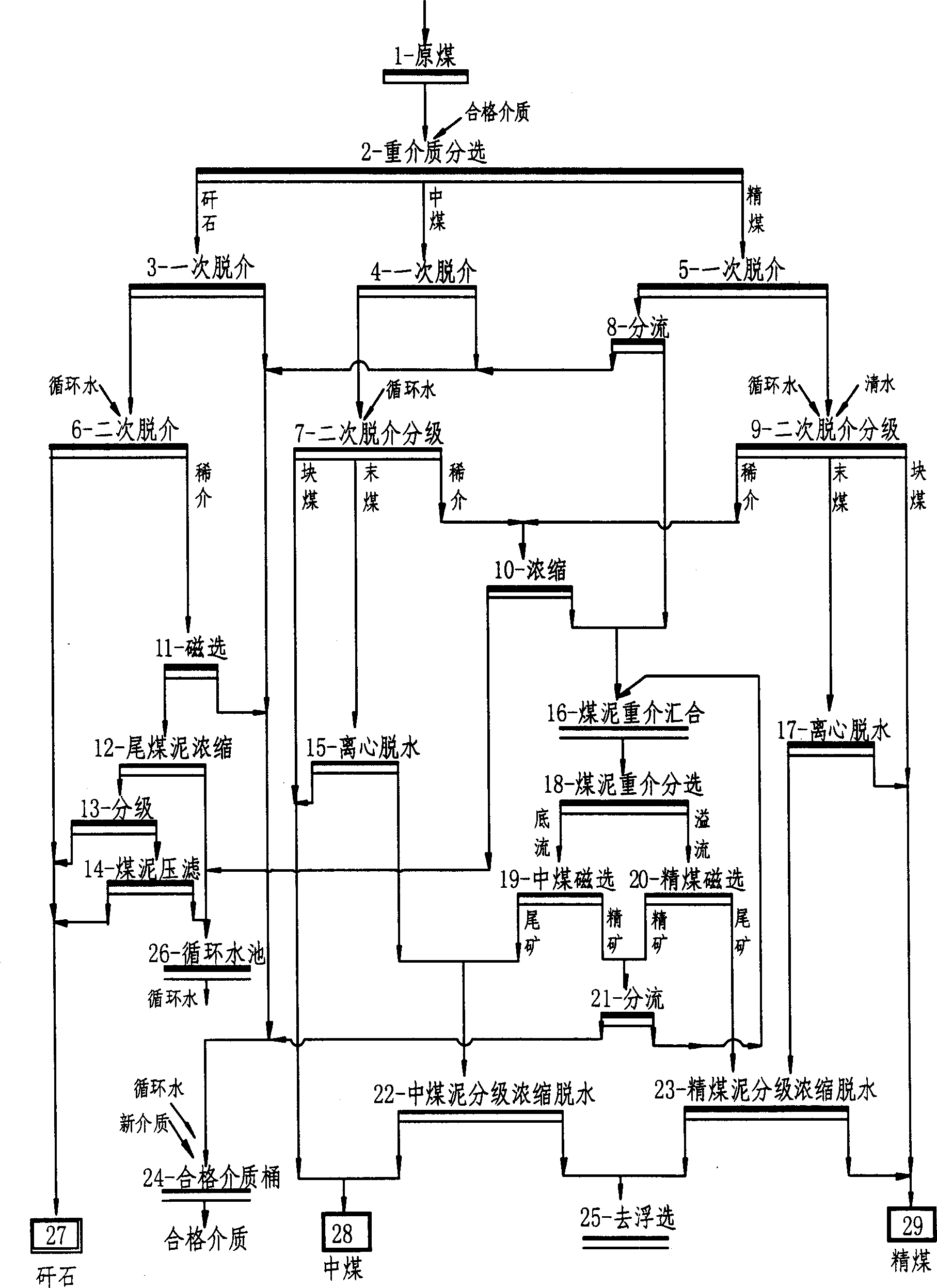

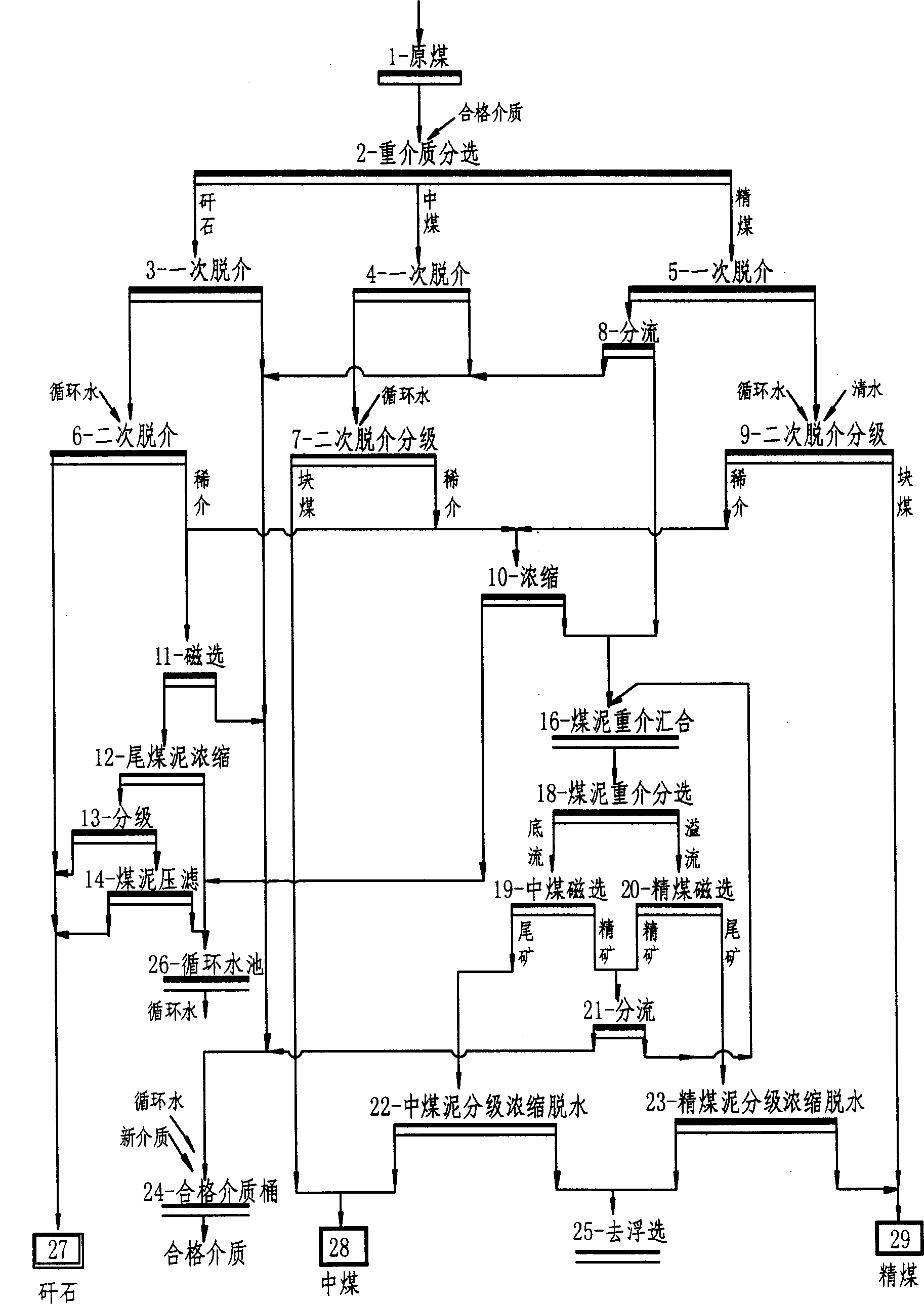

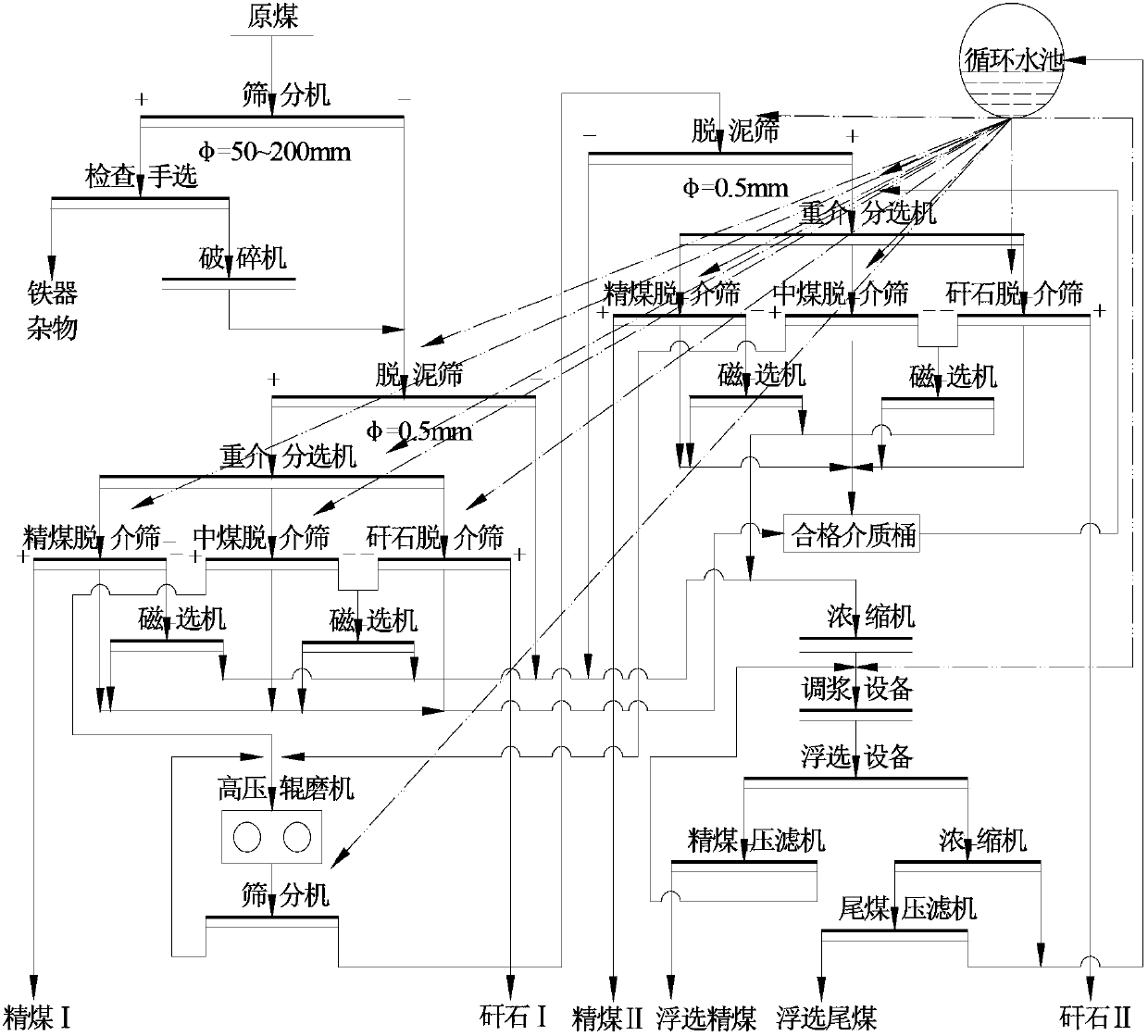

The invention provides a raw coal washing process capable of realizing non-polar ash conditioning. The process comprises the following steps: a, desliming and screening the part of raw coal with granularity less than 50 to 100mm; b, carrying out single stage jigging separation on screen products on a desliming screen; c, crushing lump coal obtained from the step b, namely screen products on an oscillating screen, by a crushing machine; d, feeding the crushed products from the step c into a three-product heavy medium cyclone for separation; e, respectively treating underflows and overflows obtained from a hydroclone in the step c; f, carrying out TBS separation or centrifugal dehydration treatment on the underflows of the hydroclone from the step e; g, respectively carrying out primary medium removal on clean coal, middlings coal and gangue obtained from the step d; h, respectively carrying out secondary medium removal and dehydration on the three products from the step g; and i, carrying out magnetic separation on undersize dilute medium obtained by secondary medium removal on the coal gangue in the clean coal in the step h, feeding the separated magnetite powder into a qualified medium tank, collecting residues, and carrying out coal slurry concentration.

Owner:HENAN POLYTECHNIC UNIV

Process for heavy media separation of coarse coal slurry

InactiveCN1424151ALess investmentReduce the lower limit of heavy media sortingReversed direction vortexMagnetic separationCycloneRecovery method

A heavy medium coal-dressing process for recovering all the coarse slime is based on the simplifier JZJ technology and features its additional technological steps such as concentrating the suspension of diluted medium, mixing it with suspension of clean coal, regulating the dressing density, separating by small-diameter cyclone equipment, removing medium and recovering product. Its advnatages are simple system, high outupt rate of clean coal, and low cost.

Owner:天地科技股份有限公司唐山分公司

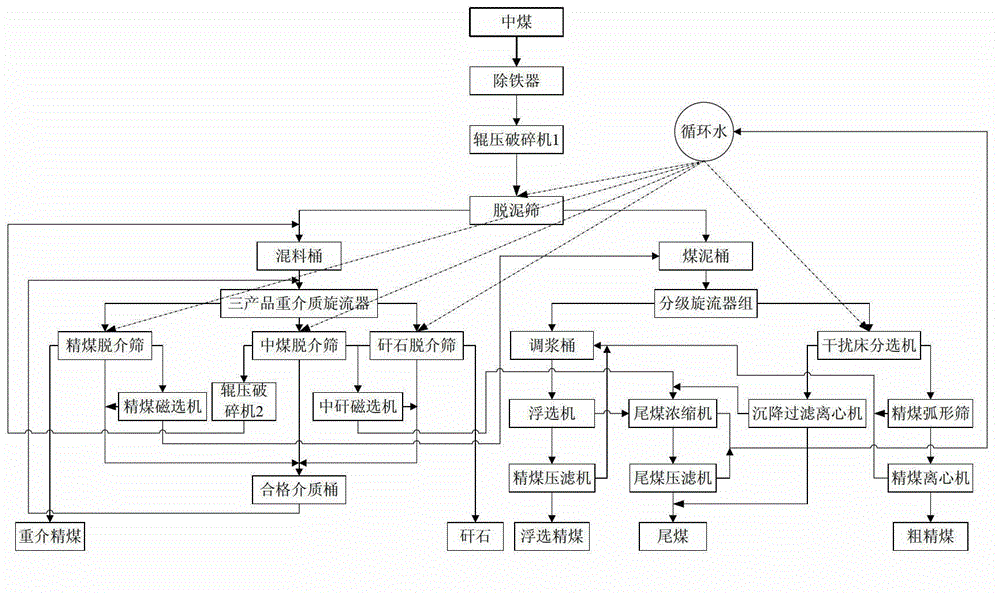

Efficient crushing and three-section type screening method of coking coal gravity middings

An efficient crushing and three-section type screening method of coking coal gravity middings belongs to coal crushing, dissociating and screening processes. Gravity middings in a coking coal preparation plant are taken as a raw material to be crushed through rolling to the fraction being below 6 mm or 3 mm; a desliming screen is used to deslime a material with the fraction being 1 mm, a material with the fraction being 6 to 1 mm or 3 to 1 mm enters into a three-product dense medium cyclone, and clean coal, middings and gangues are respectively obtained after two sections are subjected to medium drainage; the material with the fraction being 1 mm is mixed with tailings in a clean coal magnetic separator, fine coal slimes with the fraction being 0.25 mm are deslimed by a classifying cyclone; coarse coal slimes with the fractions being 1 to 0.25 mm enter into a teetered bed separator for screening, light products are dewatered by a sieve bend and a coal slime centrifuge to obtain coarse clean coal, and heavy products are dewatered by a screen bowl centrifuge to obtain tailings; the fine coal slimes with the fractions being 0.25 mm enter into a flotation machine for flotation, and foamed clean coal and the tailings are sequentially subjected to concentration and pressure filtration dewatering to obtain flotation clean coal and the tailing product; and after the gravity middings are crushed through rolling, the product returns to a mixing barrel. The method has the advantages that the graded screening is carried out on the preselected coal slimes with coarse fraction and fine fraction, and the equipment screening precision is improved.

Owner:CHINA UNIV OF MINING & TECH

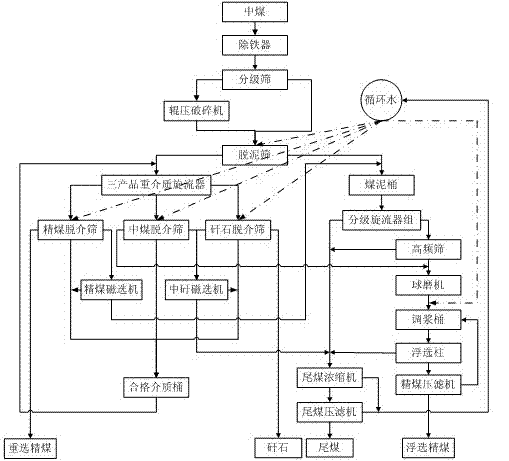

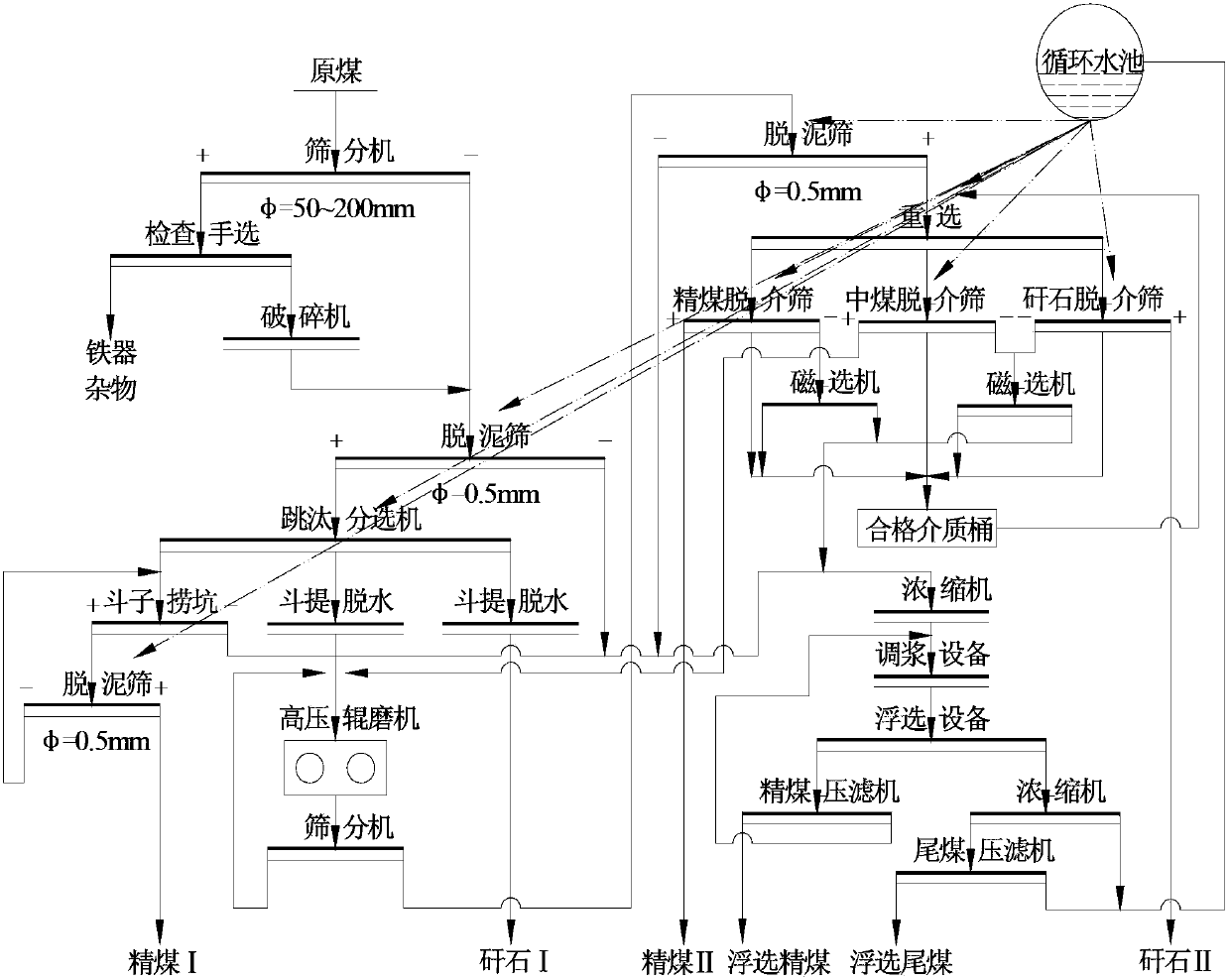

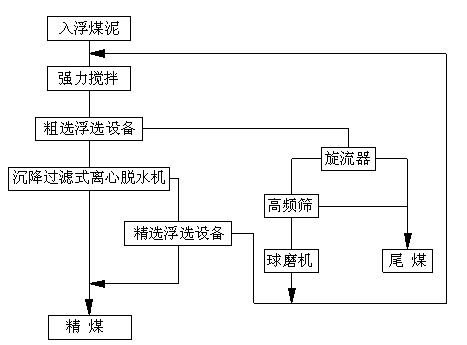

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

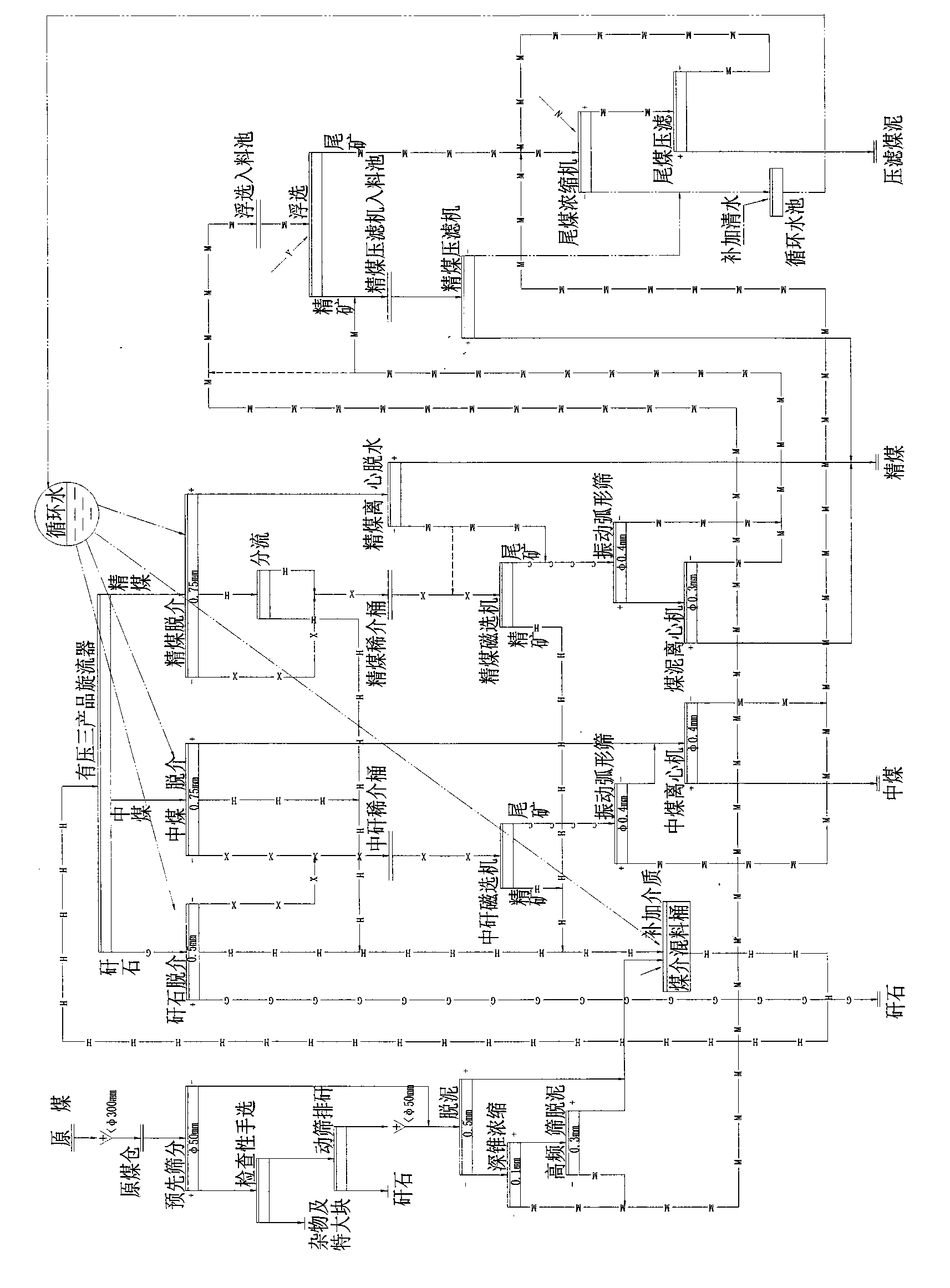

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

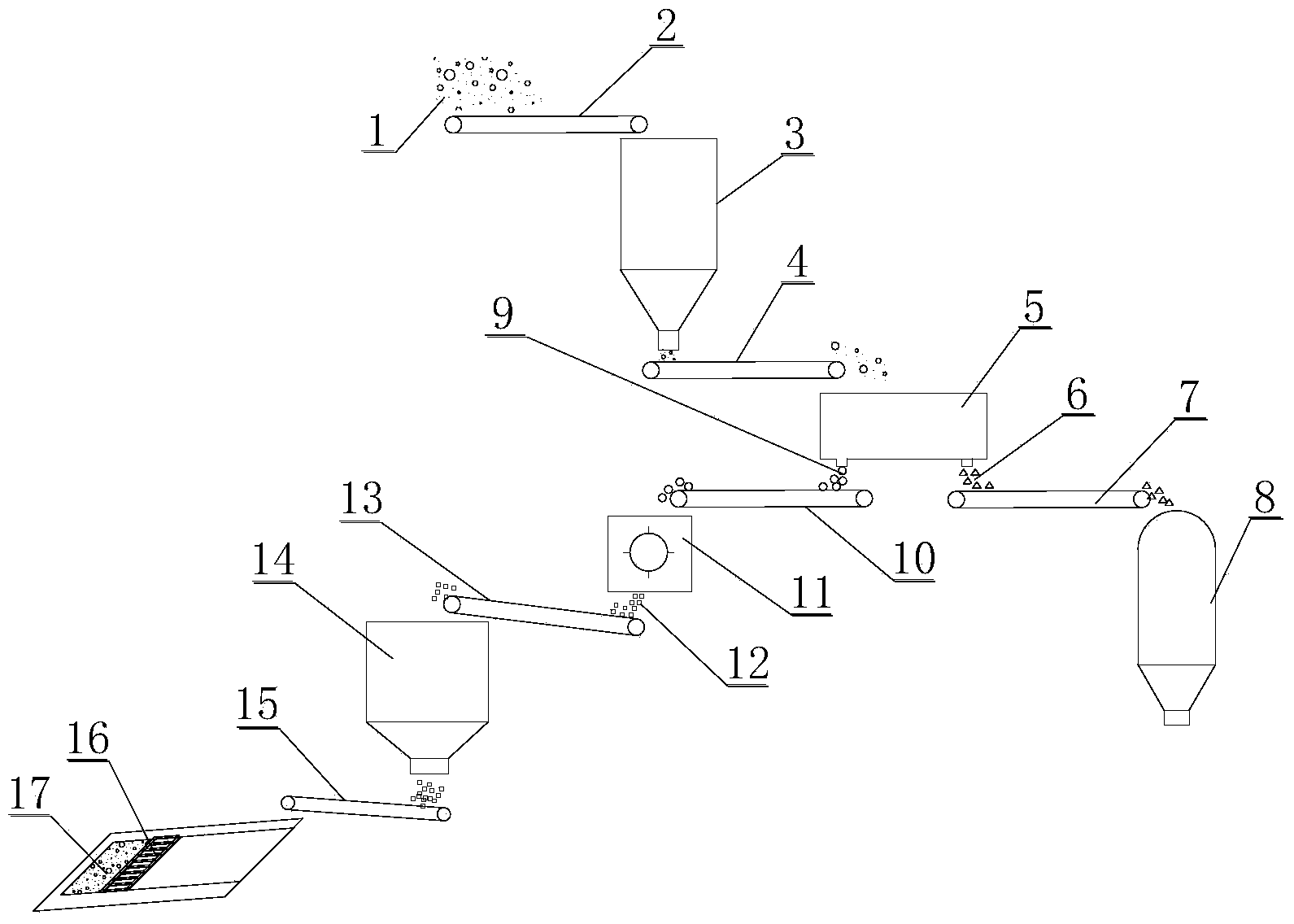

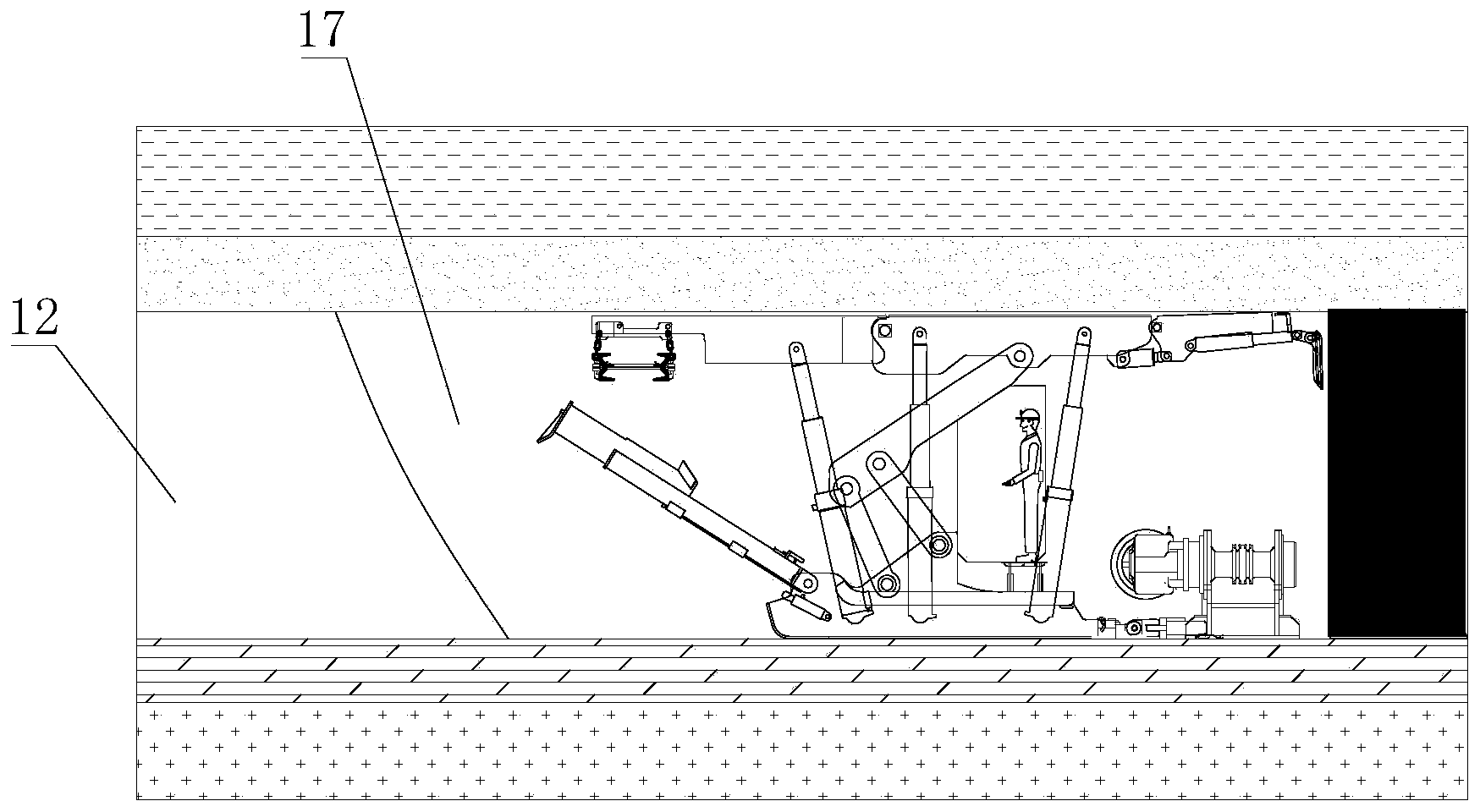

Coal mine underground mining, dress and filling integral method

InactiveCN104033153ASolve lifting problemsRealize no MasuiUnderground miningSurface miningCoal storagePollution

The invention discloses a coal mine underground mining, dress and filling integral method, which comprises the following steps that: a raw coal belt conveyor, a raw coal cabin, a raw coal feeding belt conveyor, a washing system, a cleaned coal belt conveyor, an underground coal storage cabin, a washed coal gangue belt conveyor, a digging coal gangue belt conveyor, a crushing machine, a coal gangue feeding belt conveyor, a coal gangue cabin and a filling coal belt conveyor are adopted; underground mined raw coal is subjected to dressing by washing by the washing system; cleaned coal subjected to dressing by washing is conveyed into the underground coal storage cabin and is hoisted onto the ground; and washed coal gangue obtained after the dressing by washing is crushed by the crushing machine and is then conveyed to a solid filling coal mining work surface for mine goaf filling. The mining, dress and filling integral method has the advantages that the safe and efficient exploitation under a railway, a water body and a building is realized; the mine auxiliary hosting pressure is reduced; the coal quality is improved; and the problems of ground occupation, pollution and the like caused by coal gangue discharge onto the ground are solved.

Owner:CHINA UNIV OF MINING & TECH

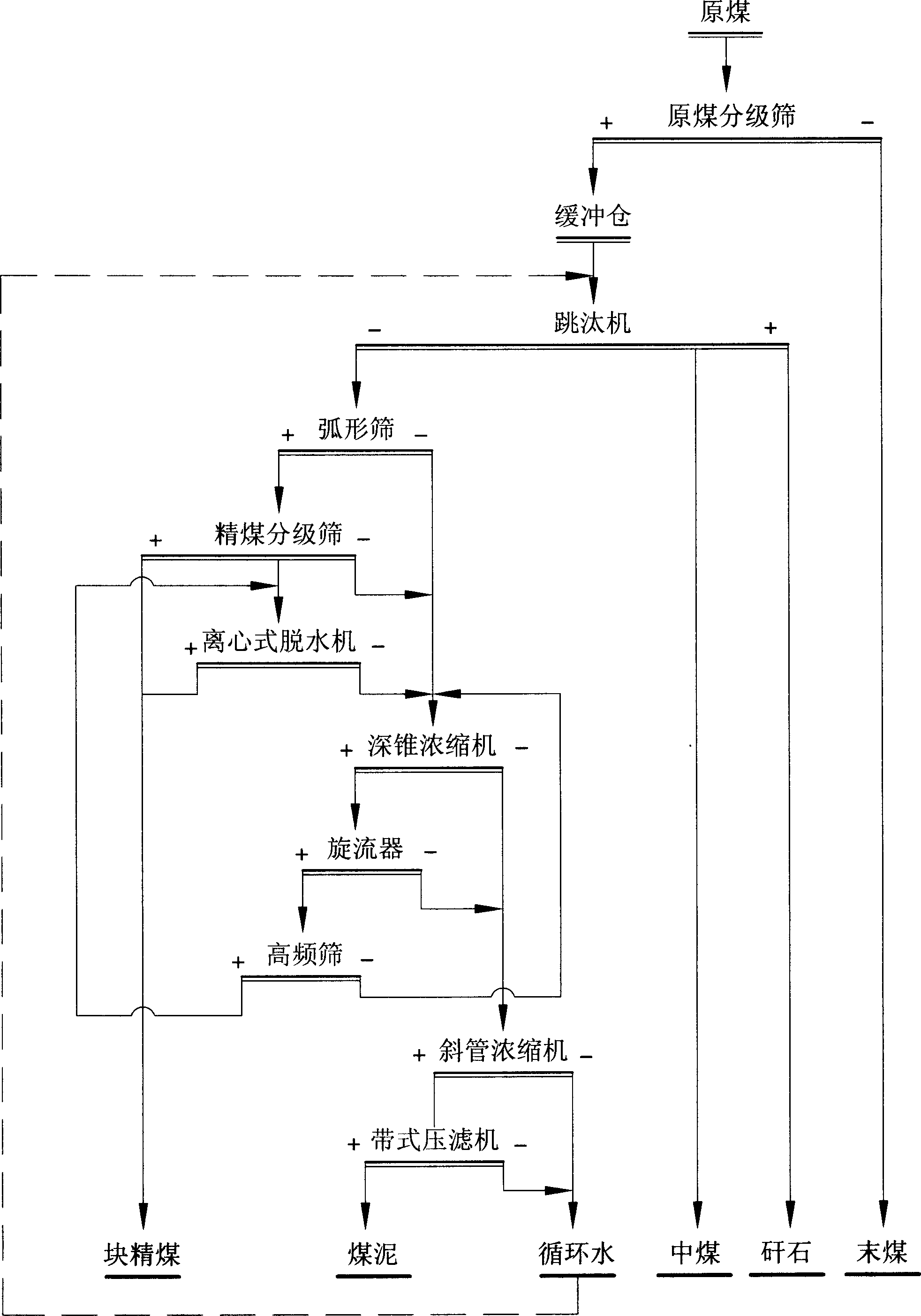

Raw coal sorting process

InactiveCN1883812AReduce generationLow investment costWater/sewage treatmentWet separationEconomic benefitsEngineering

A raw coal separation process with high economic benefit and low cost comprises the steps of : classifying the raw coal by classifying screen; outputting the obtained underscreen materials, and washing and separating overscreen materials in a jigging machine; outputting obtained waste rocks and middlings, inducing the obtained cleaned coal blocks into staged dewatering screen to give underscreen water which is sent into deep cone concentration tank; outputting obtained large-size cleaned coal blocks, inducing the obtained small-size cleaned coal blocks into spin extractor to give underscreen water which is sent into deep cone concentration tank; outputting small-size cleaned coal blocks and inducing the centrifugate into deep cone concentration tank; underflow after condensation by the deep cone concentration tan entering into swirler; underflow in swirler entering into high frequency screen and overflowing liquid entering into slant-tube thickener; overscreen materials of high frequency screen entering into spin extractor and underscreen water entering into deep cone concentration tank; overflowing liquid in deep cone concentration tank entering into slant-tube thickener; overflowing liquid in slant-tube thickener entering into circulating water tank; condensed underflow entering into belt type press filter; outputting obtained coal slime, and the filtrate entering into circulating water tank.

Owner:ZAOZHUANG MINING GRP CO LTD

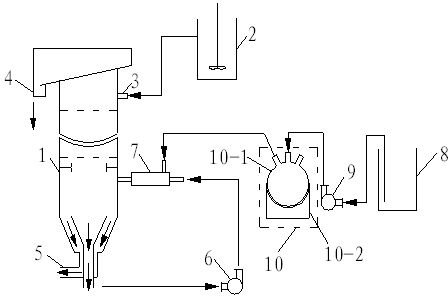

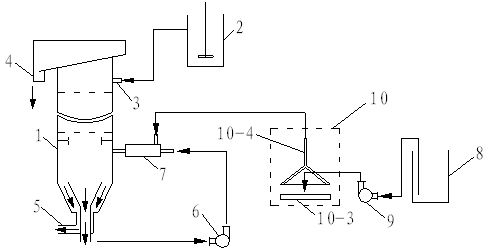

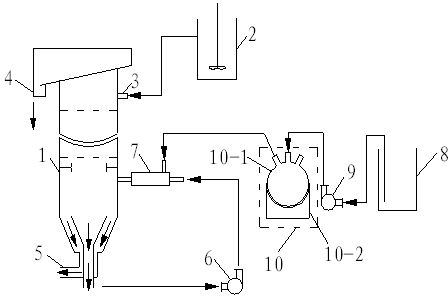

A coal deep purification system and method

The invention relates to a system and a method for deeply purifying coal. The system is composed of a flotation column, a mixing tank, a circulating pump, a bubble generator, an oil storage barrel, a gasoline pump and an oil gas generator. The method comprises the following steps: adding kerosene or diesel oil into the oil gas generator and then heating and evaporating the kerosene or diesel oil,thereby generating kerosene or diesel oil steam; introducing the kerosene or diesel oil steam together with air into a floatation device, thereby generating oil bubbles; and promoting the wetting property of the bubbles under the condition of maintaining the floatation of a mineral main body, thereby achieving the purpose of promoting the floatability of the mineral. The problem of difficulty in flotation of low-rank coals can be solved, the rate of multipurpose utilization of the coal can be increased and the economic value can be promoted. The system and method provided by the invention aresuitable for deeply purifying the low-rank coals with low metamorphic grade, such as brown coal, long flame coal, non-caking coal, weakly caking coal, gas coal, and the like, can be used for greatly promoting the yield of clean coal and can be used for obviously reducing the dosage of the kerosene or diesel oil used as a collecting agent. The system has the advantages that the structure is simple, the operation is convenient, the floatation index of the low-rank coals is excellent and the dosage is small.

Owner:CHINA UNIV OF MINING & TECH

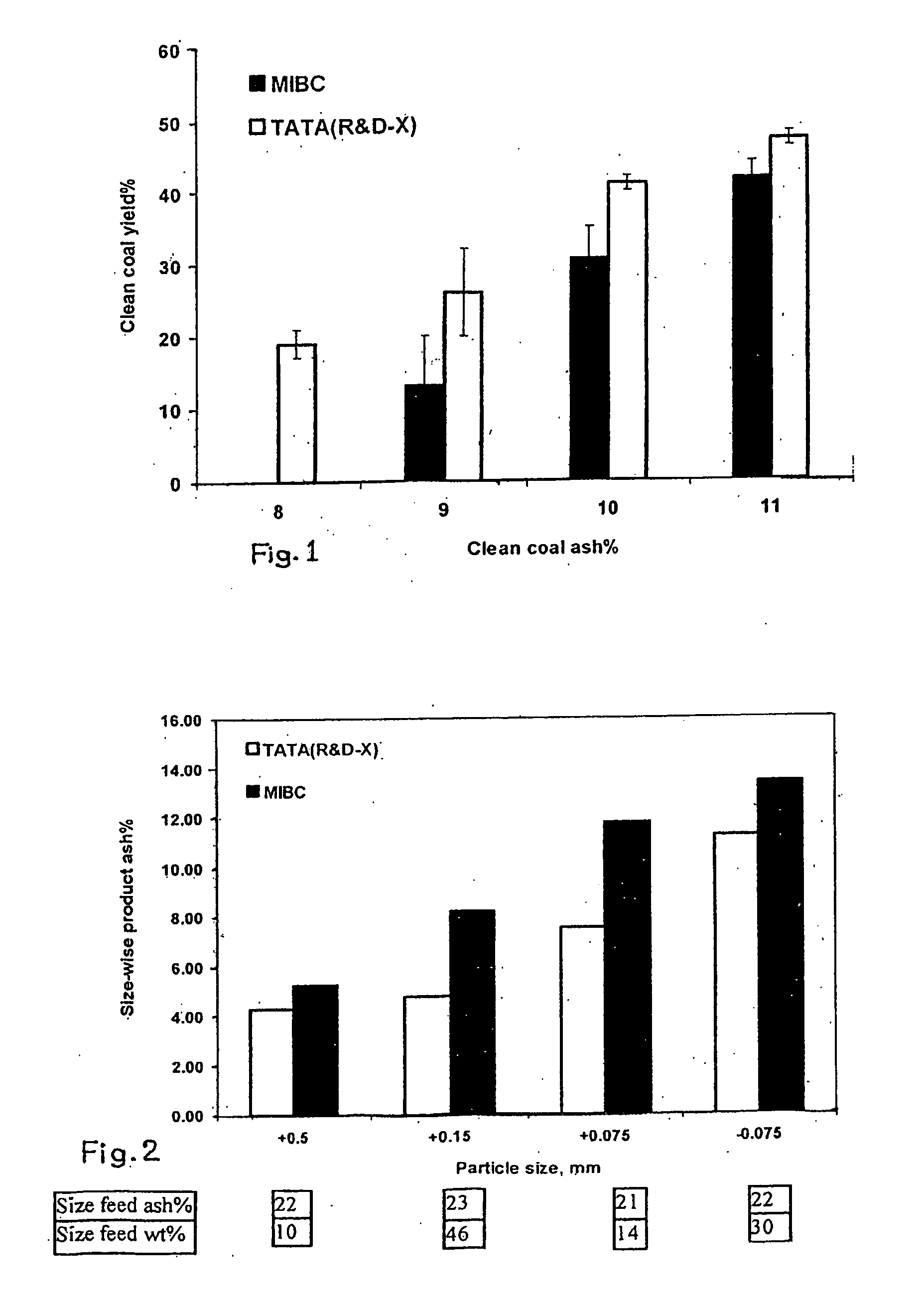

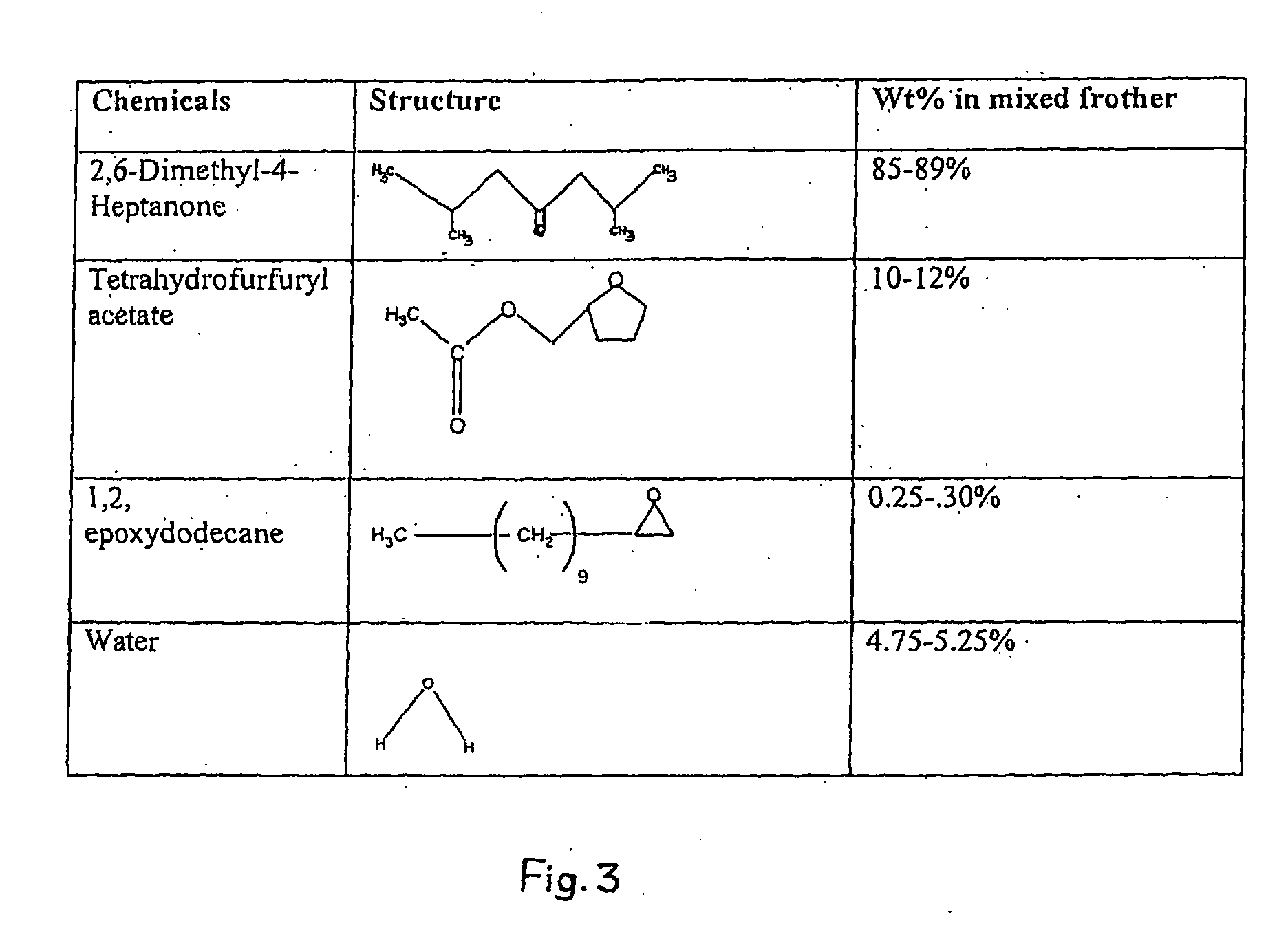

Blended frother for producing low ash content clean coal through flotation

An improved frothing agent adaptable to froth flotation process to enhance coal selectivity for separation and efficiency of the forth flotation process comprises:-A blended mixture ofKetone (2,6 Dimethl-4-Heptanone)85-89%(Wr %)Ester molecule(Tetrahydrofurfuryl acetate)10-12%(Wt %)Epoxide conditioner (1,2-Epoxydodecane)0.25-0.30%(Wt %)Water4.75-5.25%(Wt %)

Owner:TATA STEEL

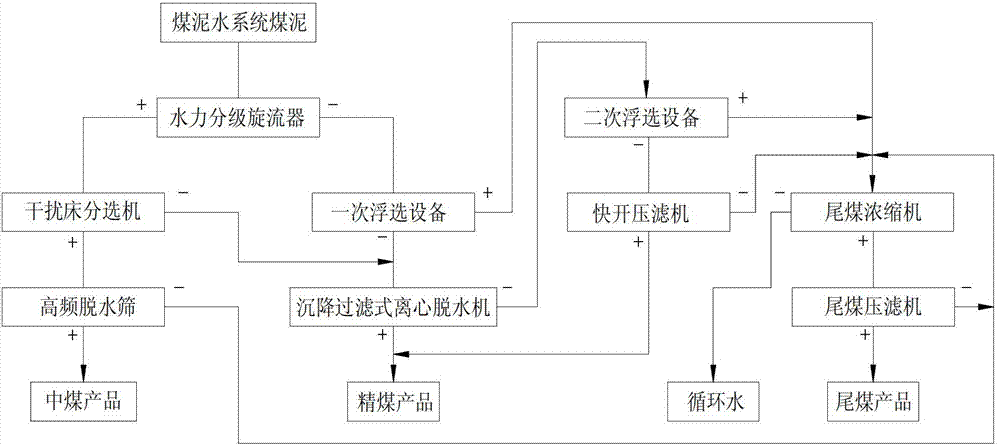

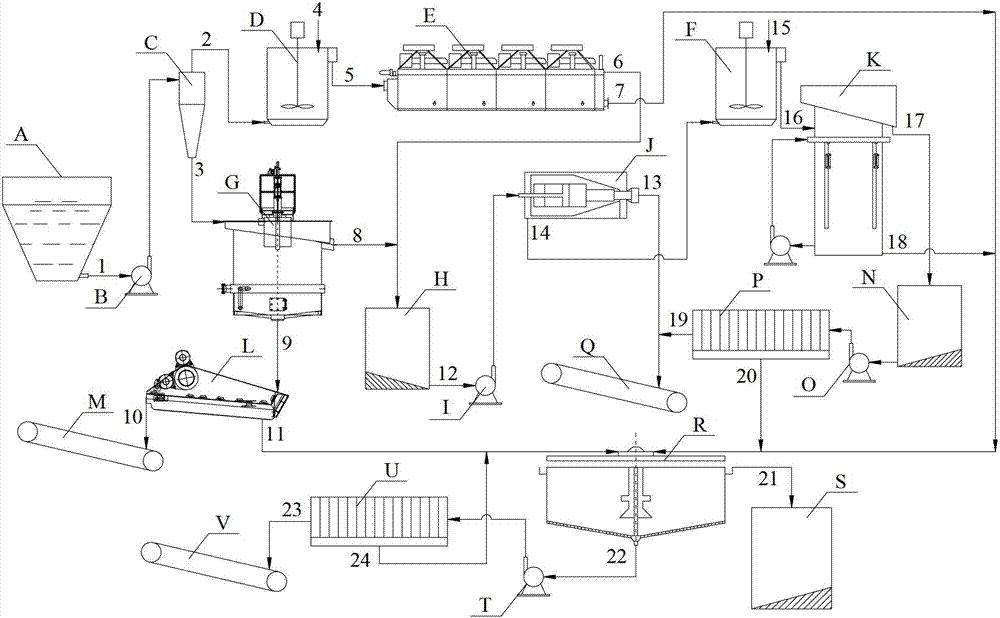

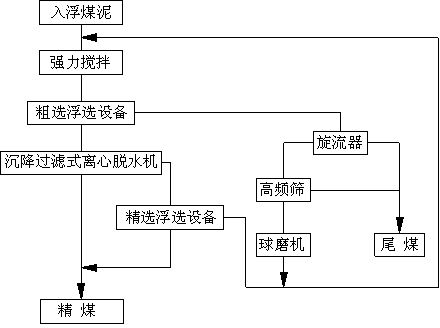

Classifying, separating and dewatering method for high-ash-content difficultly-separated coal slime

ActiveCN103240168AGive full play to the advantages of sortingRealize high-precision sortingFlotationWet separationCycloneFluidized bed

The invention discloses a classifying, separating and dewatering method for high-ash-content difficulty-separated coal slime. The classifying, separating and dewatering method includes: pumping a coal slime water system coal slime to a hydraulic classifying cyclone for classifying, enabling the coal slime to enter primary floatation equipment to separate by overflowing, subjecting bottom flow to entering a separating machine of a liquid-solid fluidized bed to separate, mixing and 'doping' primary floated fine clean coal and coarse-grain clean coal prior to entering a horizontal sedimentation perforated basket centrifuge to dewater and recycle, enabling filtrate and centrifugate of the horizontal sedimentation perforated basket centrifuge to enter secondary floatation equipment to separate, dewatering secondarily-separated clean coal by a quick-opening filter press, doping on-sieve products of coarse-grain tailing coal slime dewatered by a high-frequency sieve into coal products, and mixing backwater of the high-frequency sieve and primarily-separated tailing coal, the secondarily-separated tailing coal and filtrate of a clean coal quick-opening filter press into a tailing coal concentrator and the filter press to dewater and recycle. Therefore, high-quality clean coal low in ash content and water and high in recycling rate is obtained, the problem of 'loss of coarse coal' of floatation of tailing coal is solved, and the technical difficulty of high-precision separation of high-ash-content difficultly-separated coarse and fine coal slime is overcome.

Owner:CHINA UNIV OF MINING & TECH

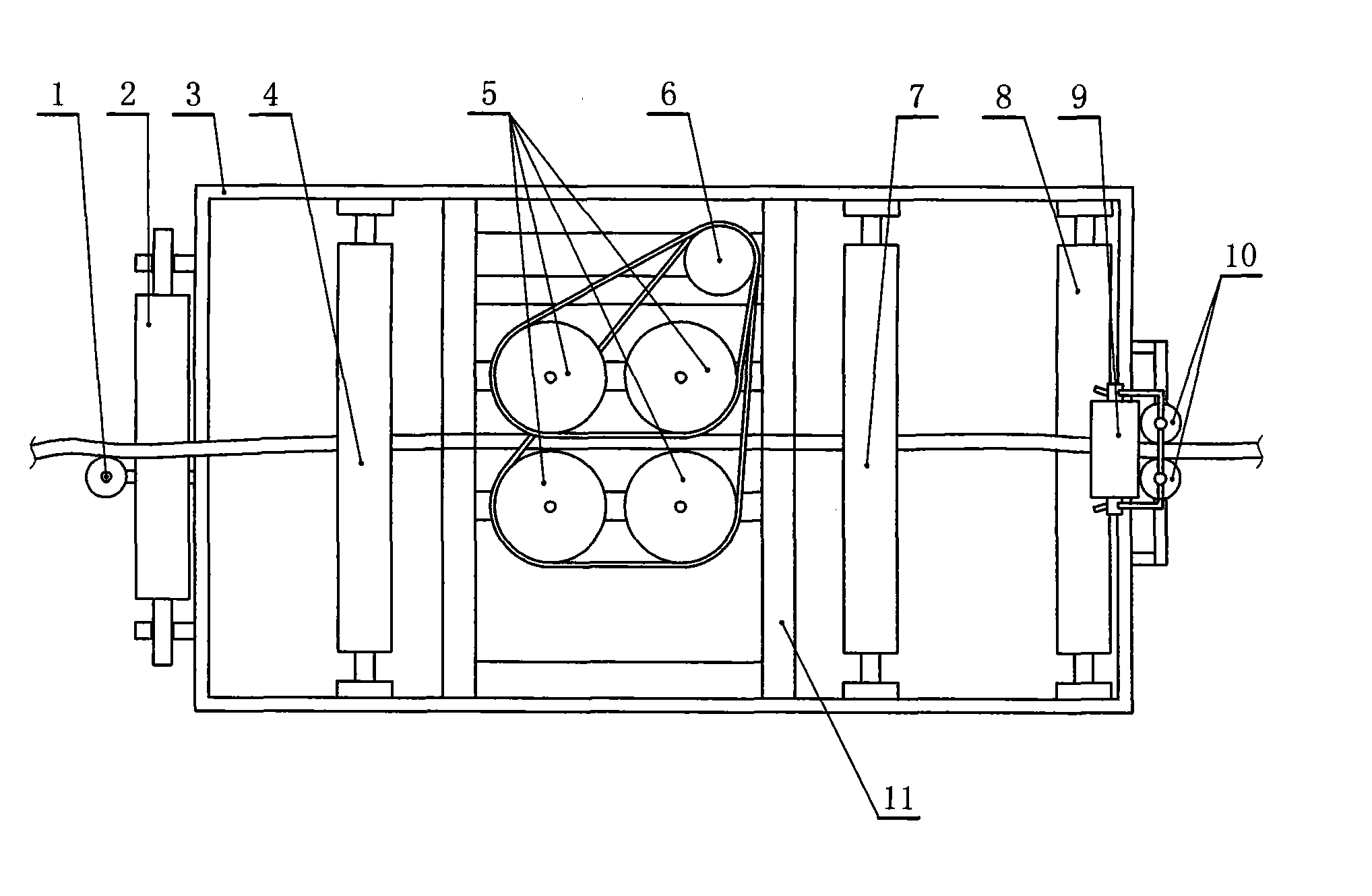

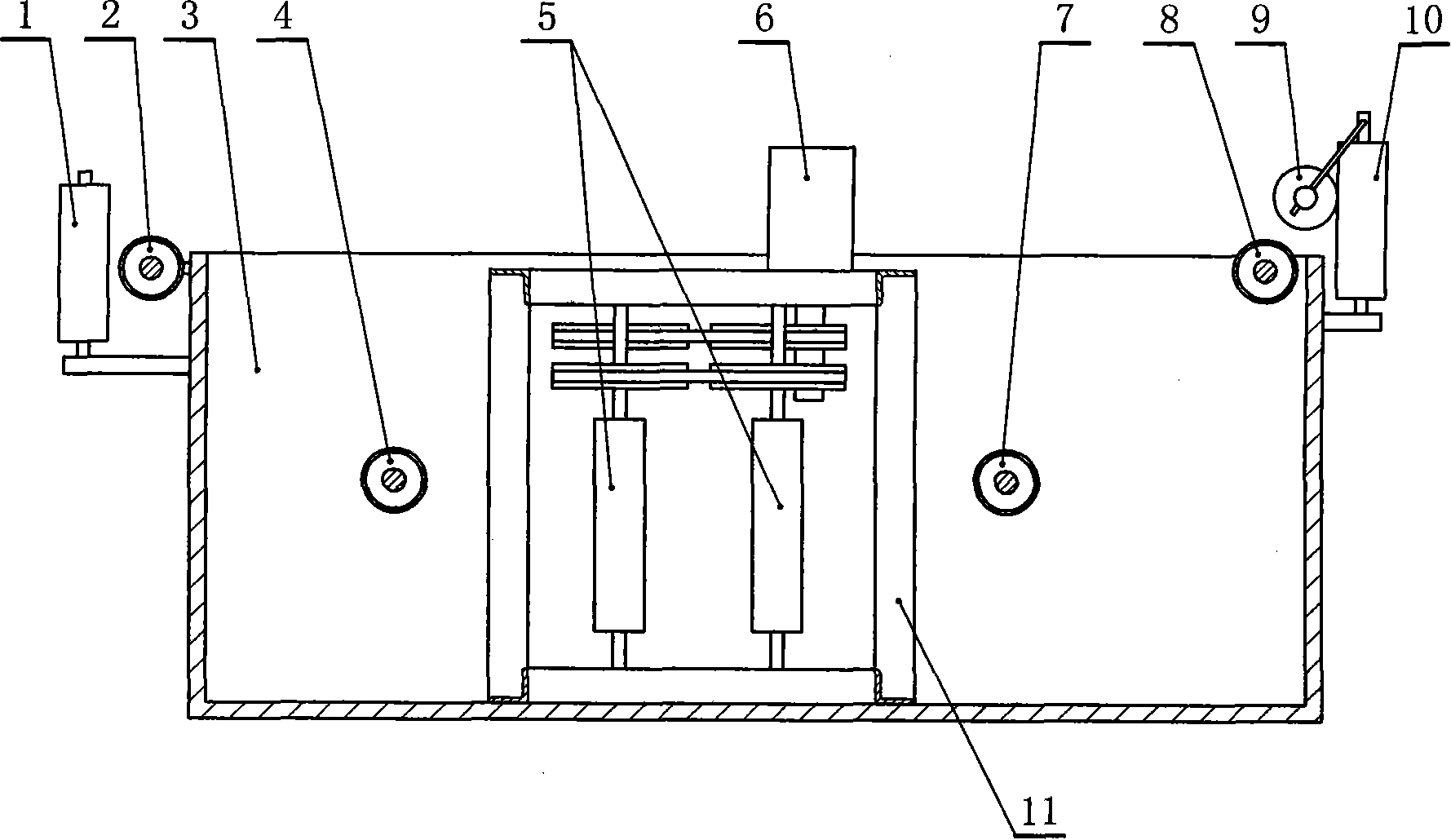

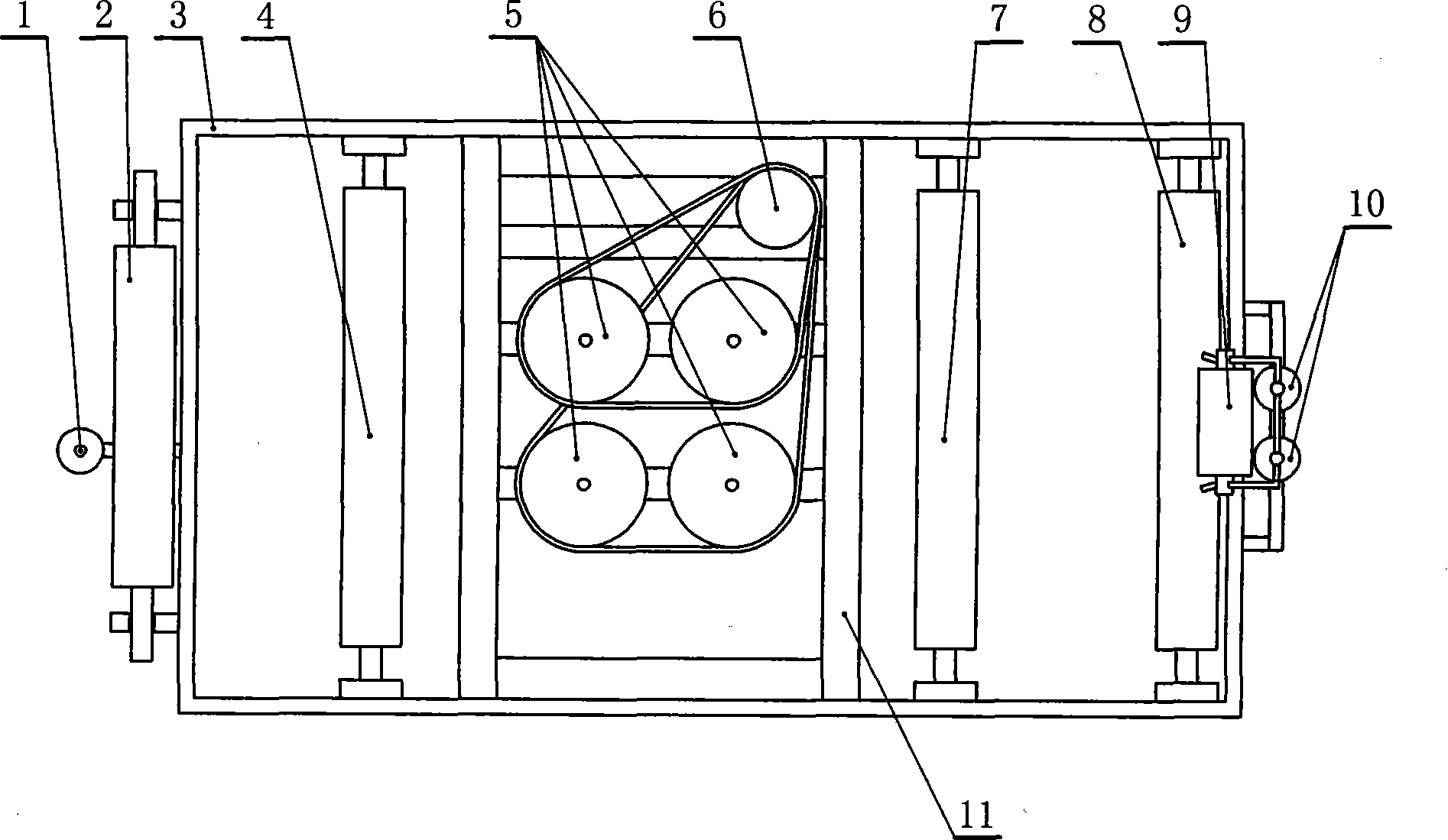

Electrical cable washer

InactiveCN101249496AReduce labor intensityAutomate cleaningFilament handlingCleaning using toolsElectric machineryEngineering

A cable cleaning machine capable of cleaning coal dust and mud as a substitute for manual operation belongs to mine machinery, and comprises a cleaning box, lead-in rollers relatively rotatably arranged on the left upper edge of the cleaning box, a lead-in compression roller and a lead-out compression roller relatively rotatably arranged on the corresponding left and the right sides in the cleaning box, and lead-out rollers relatively rotatably arranged on the right upper edge of the cleaning box, wherein the lowest point of the lead-in compression roller is lower than the highest point of the lead-in compression roller; the highest point of the lead-out roller is higher than the lowest point of the lead-out compression roller; a cleaning support is fixedly arranged in the cleaning box; a motor and a cleaning wheel are fixedly arranged on the cleaning support; brushes are arranged on the cleaning wheel; the motor is transmissively connected with the cleaning wheel; and the orthographic projection of the connection line of the lowest point of the lead-out compression roller and the lowest point of the lead-out compression roller intersects the cleaning wheel. The cable cleaning machine can substitute for manual operation for cleaning mine cables taken back under the well and achieve automatic cleaning with high efficiency and good cleaning effect, thereby lowing labor intensity.

Owner:枣庄矿业(集团)有限责任公司柴里煤矿

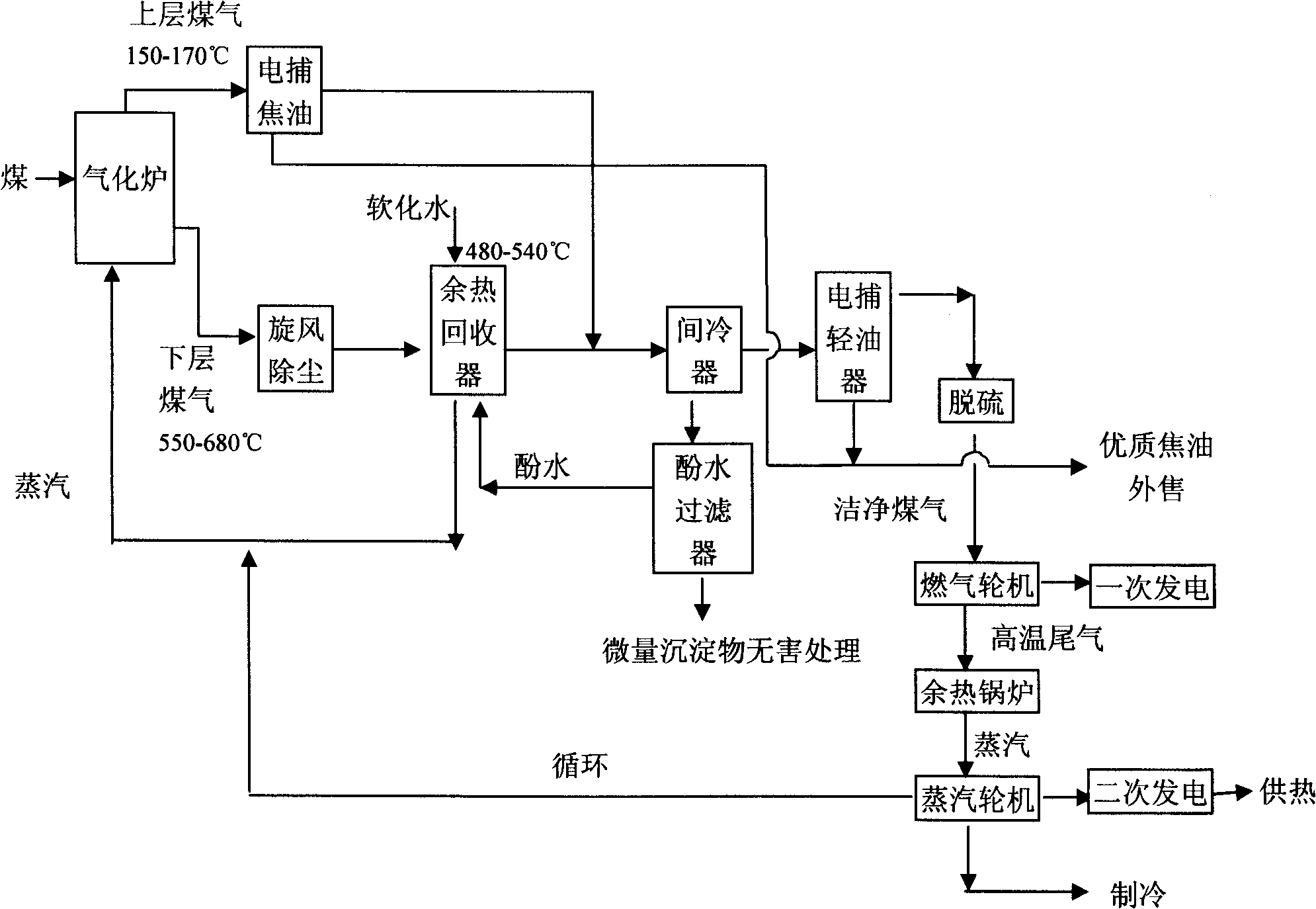

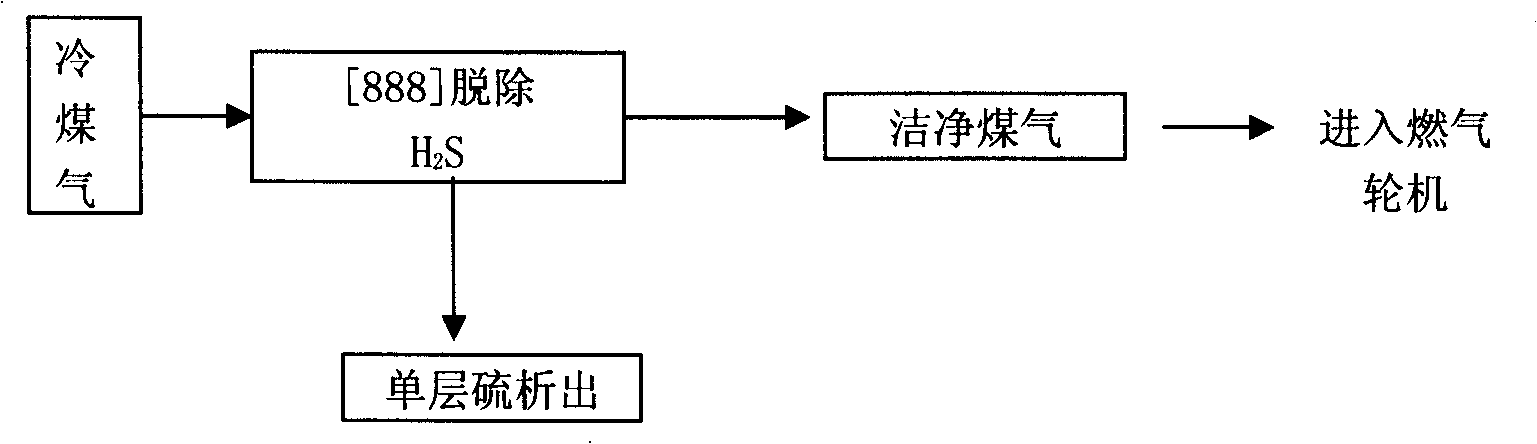

Integrated gasification combined cycle thermoelectric oil gas multi-production process for efficient clean region

InactiveCN101280223ATake advantage ofImprove economyEnergy inputGas turbine plantsHigh pressureIntegrated gasification combined cycle

The invention relates to a combined cycle thermoelectric oil gas multiple co-production process of high efficiency and clean regionally-integrated coal gasification, which includes the steps as follows: (1) the crushed coal is fed into the high pressure high efficiency gasifier for gasification when the air and steam are injected and the temperature and pressure are increased; (2) the coal gas generated through the gasification is divided into an upper layer and the lower layer; the coal gas in the lower layer is processed with dust collection and desulphurization; the coal gas in the upper layer is processed with electrical tar precipitation and desulphurization; (3) clean coal gas and the air are compressed to be fed into a gas turbine; the coal gas and the air are combusted to have expansion to drive the generator to generate electricity for once; (4) the high temperature tail gas is fed into a waste heat boiler to generate steam; the steam enters a steam turbine to drive the steam turbine to generate electricity for the second time; the steam is then used for heat supply or cool supply. The combined cycle thermoelectric oil gas multiple co-production process makes full use of the coal resources and integrates the coal compressed gasification, waste heat boiler supplemental combustion, coal gasification, the tar pyrolysis and the level two to level three pressure technique of the waste heat boiler into a whole to form the multiple co-production process which is applicable to the characteristics of the northern region of China.

Owner:山东联合能源技术有限公司

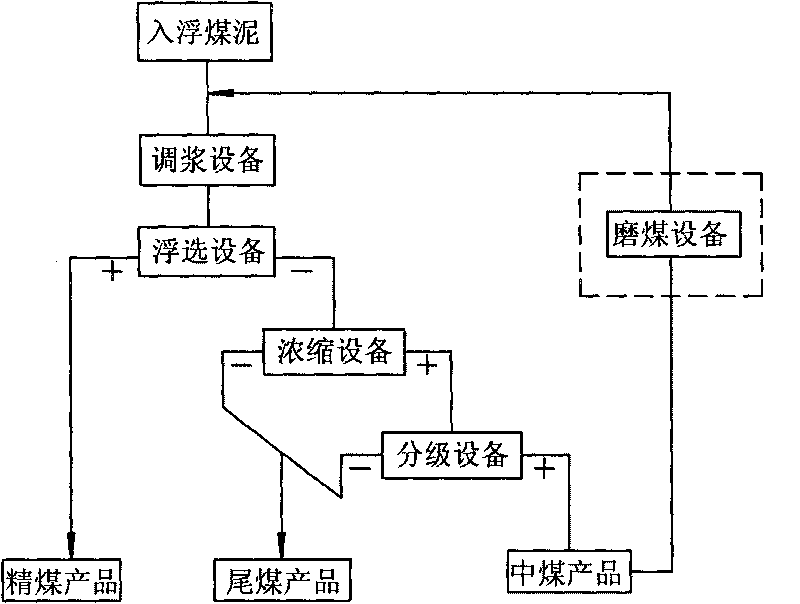

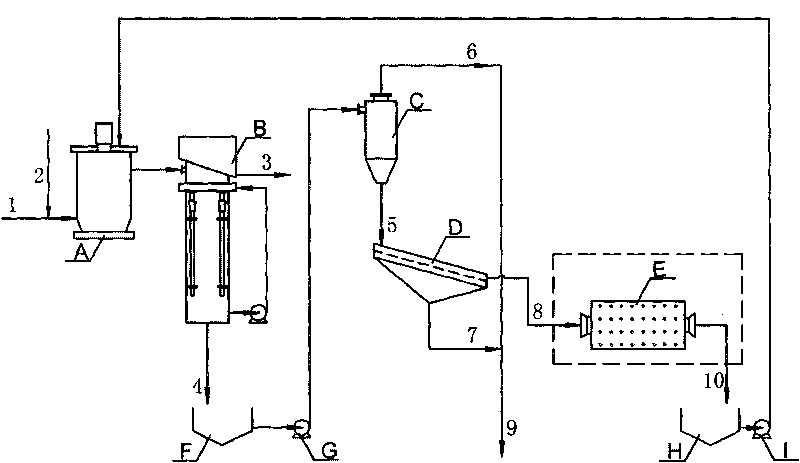

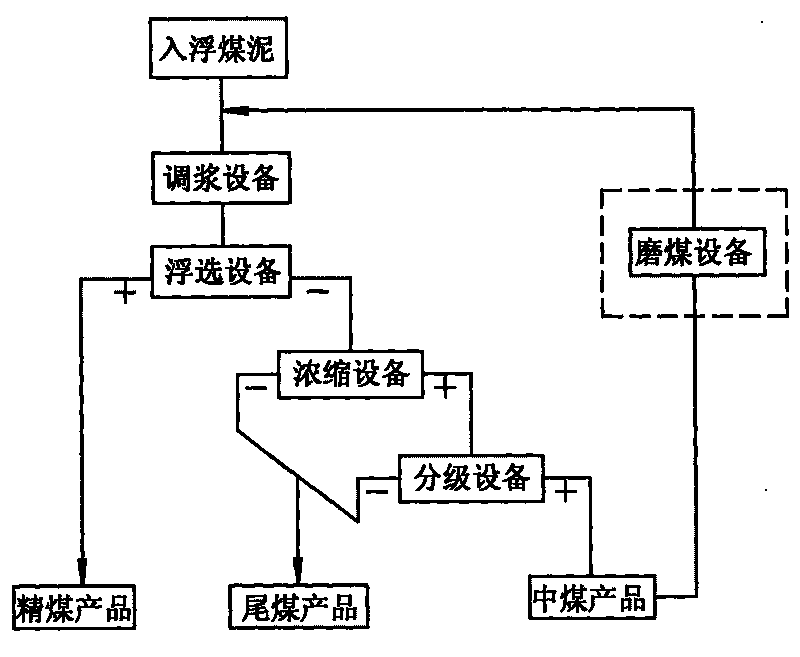

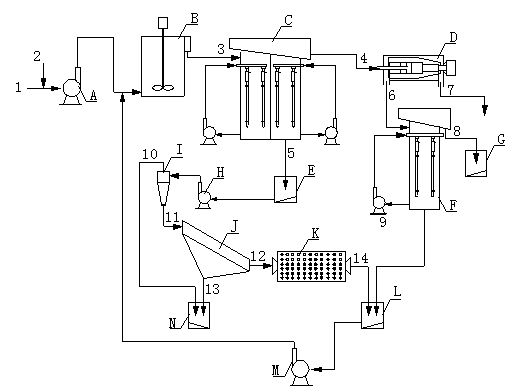

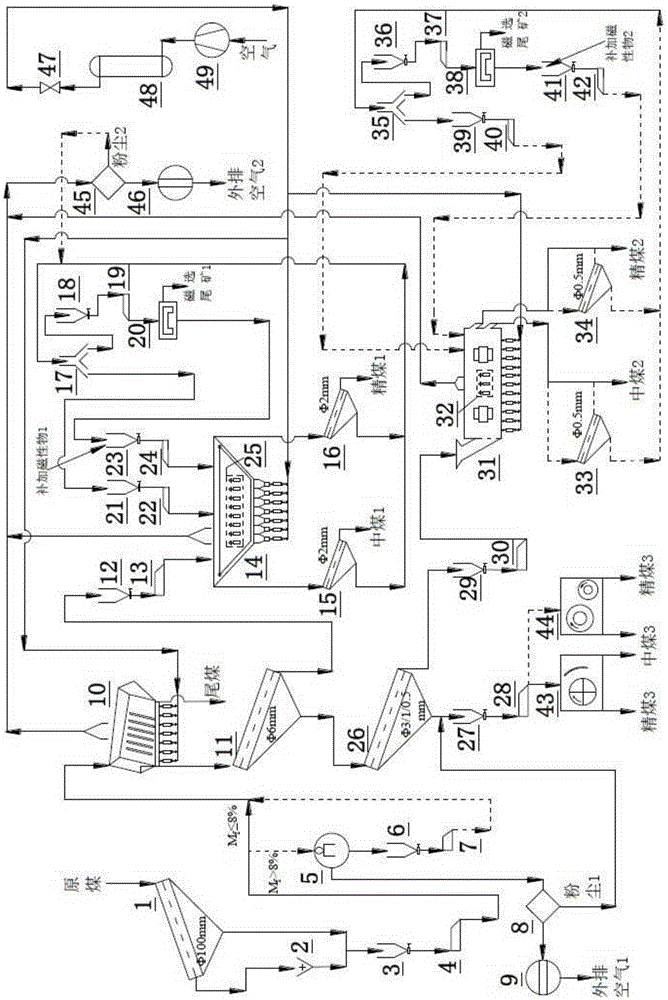

Coal slime floating process

InactiveCN101757982AEfficient sortingSolve the difficult selection problemFlotationProcess engineeringSlurry

The invention discloses a coal slime floating process, which comprises the following operations: adjusting slurry of floatation coal slime; floating the coal slime; concentrating and classifying; and regrinding and refloating middlings. Coal slime floating equipment is adopted and is matched with corresponding slurry adjusting, concentrating and classifying, and coal grinding equipment; the coal slime after slurry adjusting is floated by the floatating equipment; and the floated tailings are sorted by the concentrating and classifying equipment to prepare a middling product and a final tailing product. For the middling product with better monomial dissociation, the middling product is directly returned to the slurry adjusting operation, is subjected to slurry adjusting by the slurry adjusting equipment and then is sorted again so as to form a middling refloating process for high ash and difficult floatable coal slime; and for the middling product with poor monomial dissociation, the middling product is subjected to coal grinding operation by a coal mill, returned to the slurry adjusting operation by the slurry adjusting equipment, and then is sorted again so as to form a middling regrinding and refloating process for the high ash and difficult floatable coal slime; therefore, the conflict between the quality of clean coal and combustible component recovery rate in the floatation of the high ash and difficult floatable coal slime is solved. The coal slime floating process has the advantages of simple process, low investment, low operating cost and high separation efficiency.

Owner:CHINA UNIV OF MINING & TECH

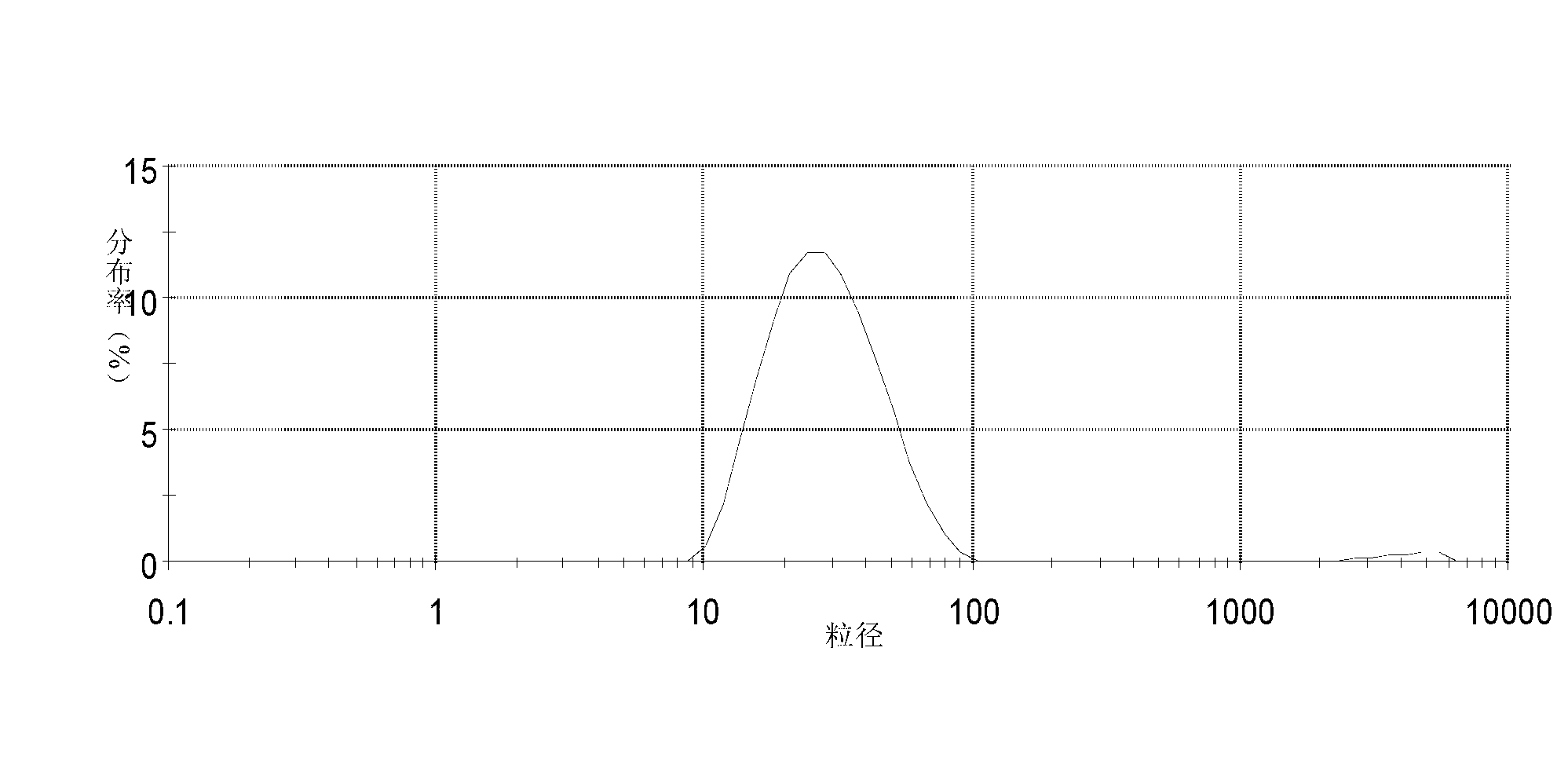

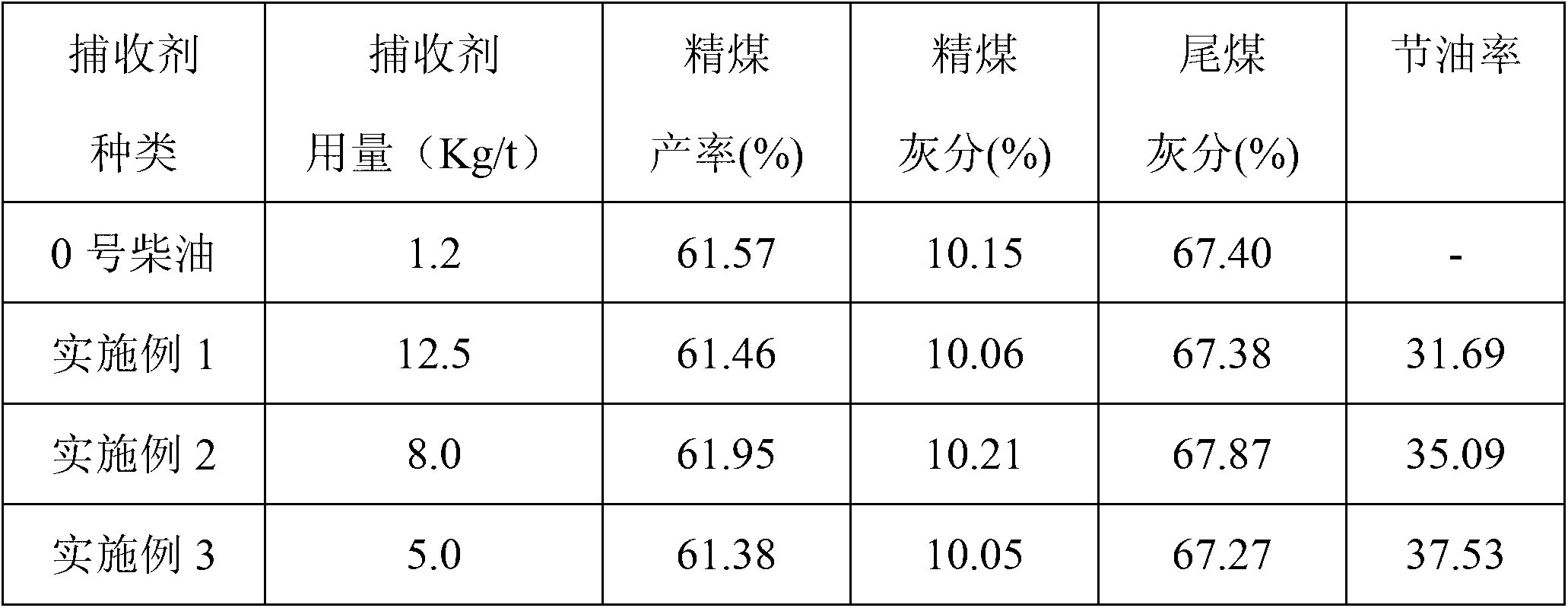

Coal slime microemulsion collecting agent and preparation method thereof

The invention discloses a coal slime microemulsion collecting agent. The coal slime microemulsion collecting agent is composed, by mass percent: 6%-15% of hydrocarbon oil, 2%-6% of main emulsifying agent, 2-4% of cosurfactant, and the balance being water. The hydrocarbon oil is light diesel oil selected from number 10 light diesel oil, number 0 light diesel oil, number -10 light diesel oil, number -20 light diesel oil or number -35 light diesel oil. The main emulsifying agent is alkylphenol polyethenoxy ether surfactant. Cosurfactant is at least selected from one of C4-C8 alcohol. Since collecting agent is applied in coal slime flotation, hydrocarbon oil dosage is saved beneficially, and oil saving ratio can reach more than 30% on the premise that clean coal yield and ash content are almost the same.

Owner:SHANDONG UNIV OF SCI & TECH

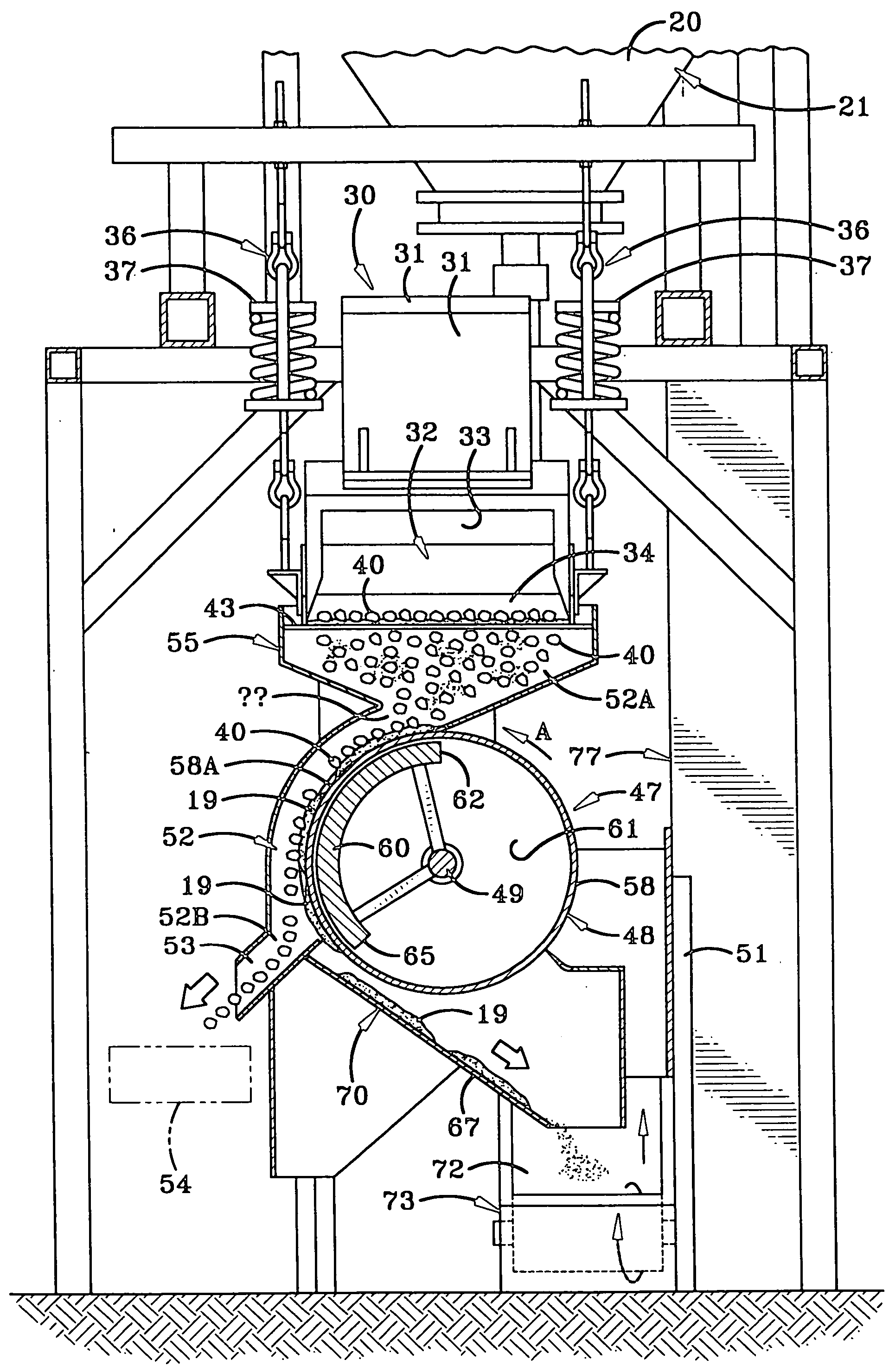

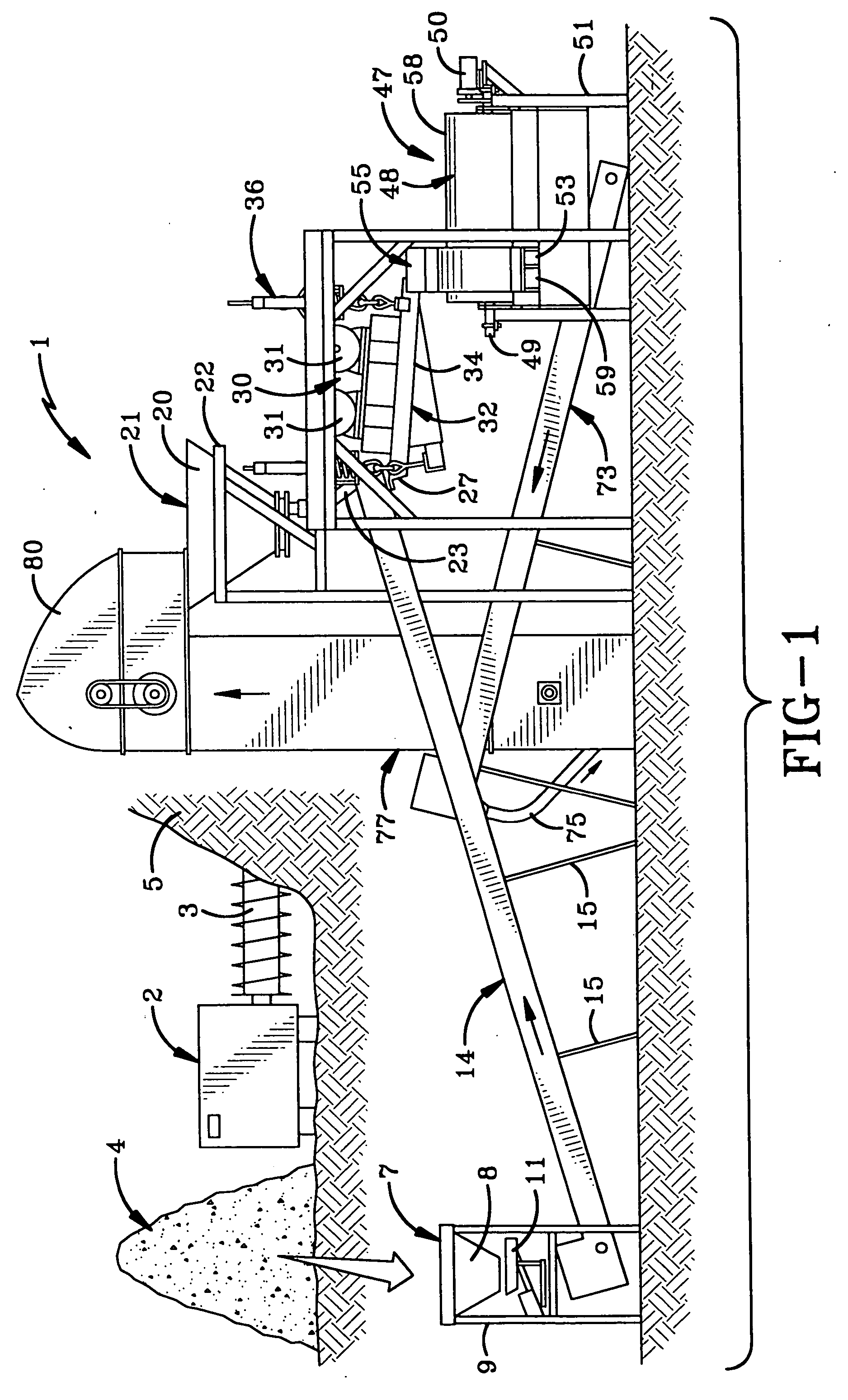

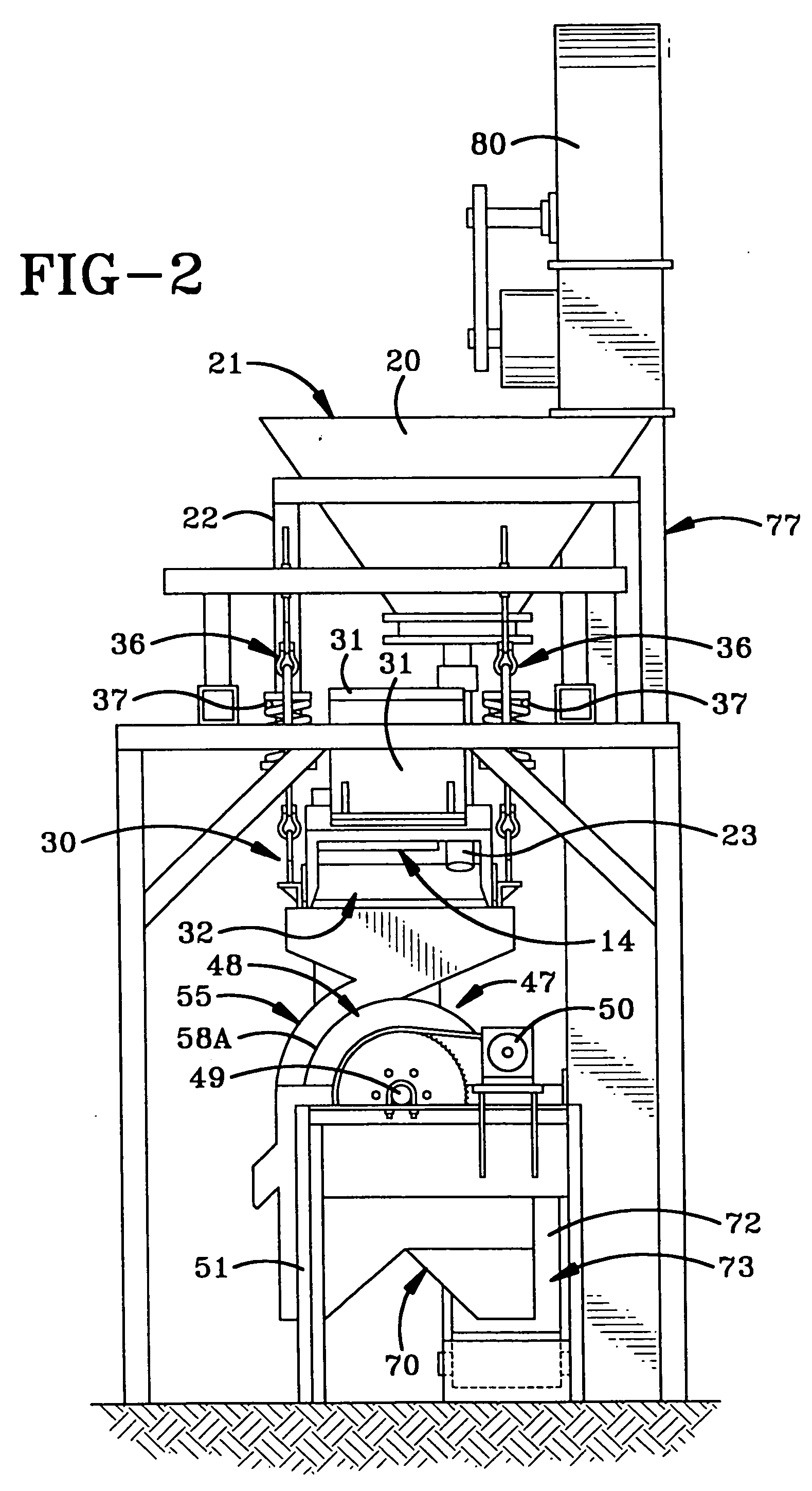

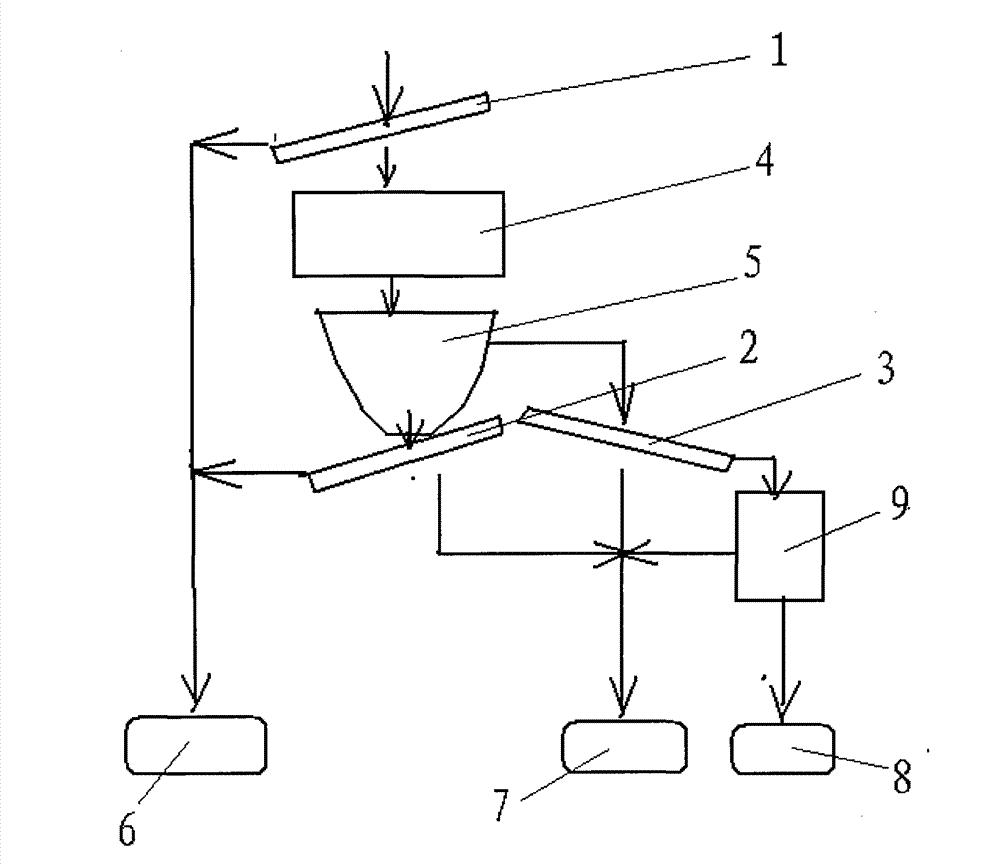

Method and apparatus for cleaning coal

A system for removing clean coal from raw coal without the use of water includes a vibratory separator which receives the raw coal and a supply of magnetic particles. The magnetic particles form a fluidized bed which floats the clean coal from the debris contained in the raw coal and removes the clean coal by a scraper plate. A mixture of debris and magnetic particles which remains after the clean coal is removed is passed by a revolving magnetic separator which removes the magnetic particles from the debris and from the clean coal, and returns the particles for reuse with another batch of raw coal. The magnetic separator includes a rotating drum having a non-magnetic outer surface and an interior magnet which forms a magnetic field adjacent a portion of the drum surface which temporarily attracts the magnetic particles which fall from the drum surface as that portion of the drum surface and collected particles pass beyond the adjacent magnet.

Owner:KELM WARREN E

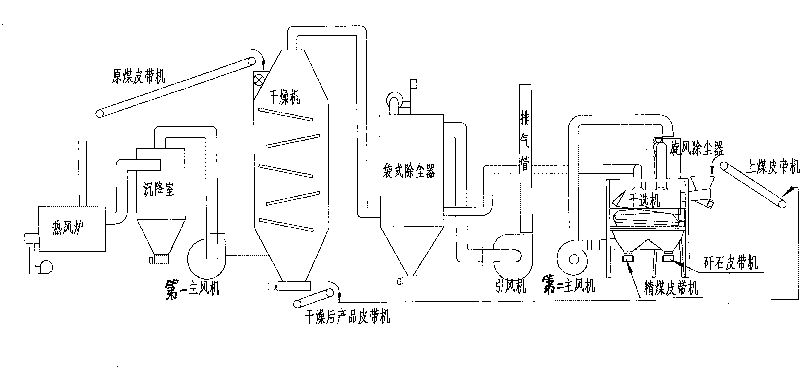

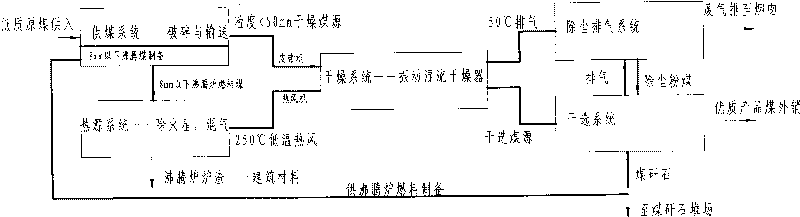

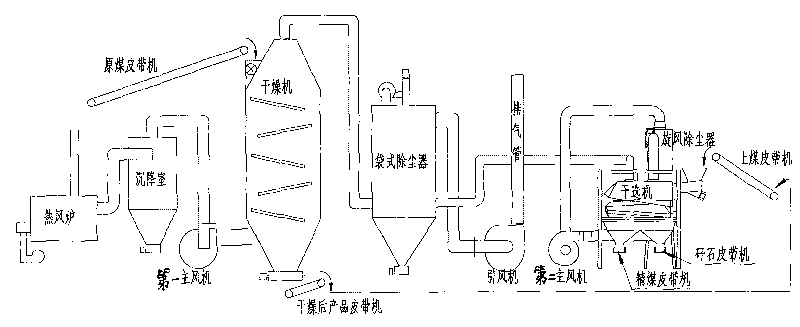

Raw coal upgrading device and method with combination of drying and dry separation

ActiveCN101705131AAvoid wastingLess investmentSolid fuelsDrying solid materialsProcess engineeringCyclonic spray scrubber

Owner:李功民

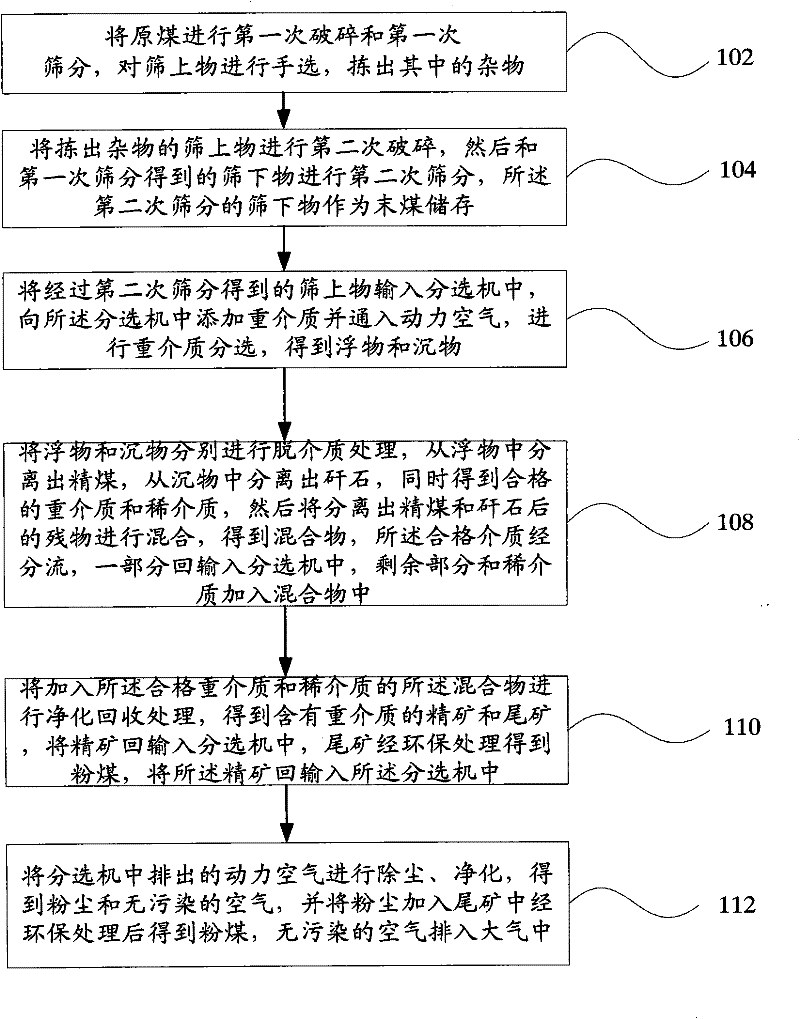

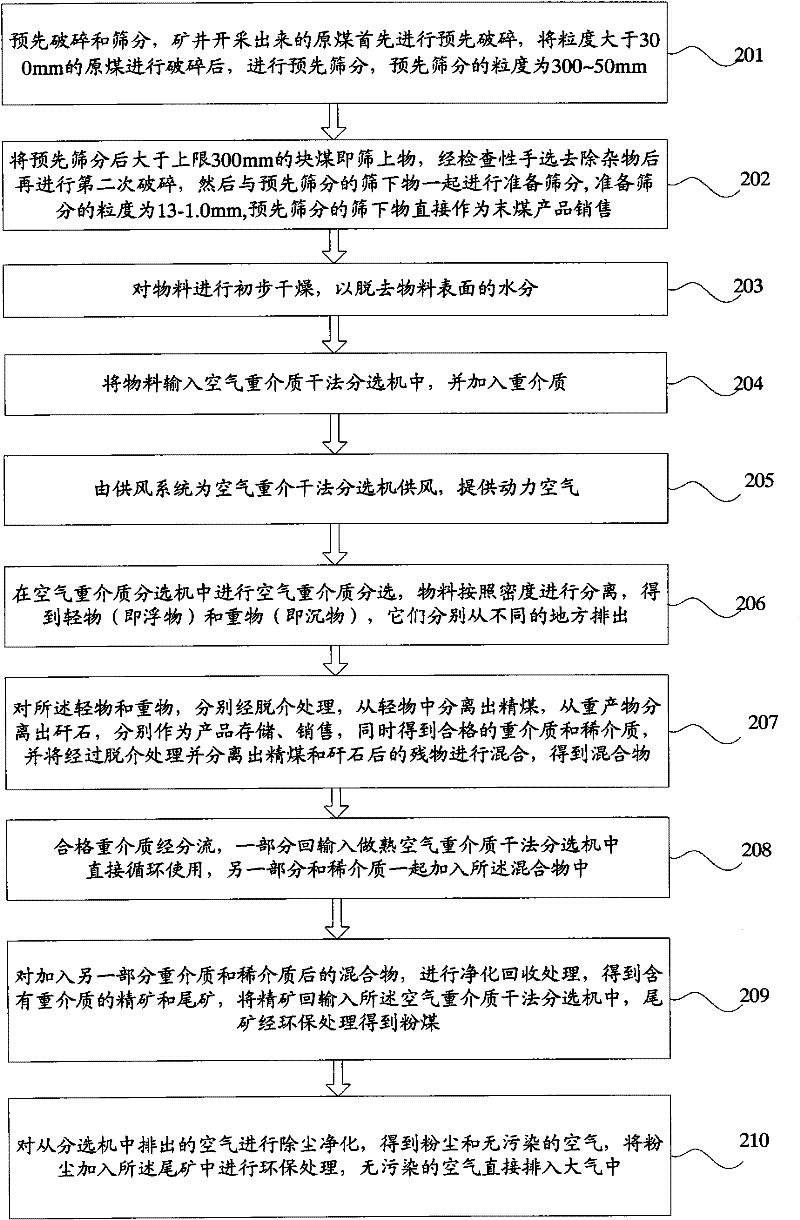

Air and heavy medium dry coal preparation process

InactiveCN102211087AEfficient sortingSolve the problem that coal preparation is difficultGas current separationWater treatment systemWater source

The invention provides an air and heavy medium dry coal preparation process. Gangue is separated from raw coal through dynamic air and a heavy medium, and cleaned coal is prepared. The process comprises the following steps of: crushing and sieving the raw coal twice; conveying the sieved block coal into a separator; introducing the dynamic air and the heavy medium into the separator for separation; and removing the medium to obtain the cleaned coal and the gangue, and performing environment-friendly treatment on tailings and the discharged air. The dry coal preparation process employing the dynamic air and the heavy medium replaces wet coal preparation, can well solve the problem of coal separation in a water-deficient area, and saves water sources; the system is simple, and a complicated coal slime water treatment system in wet coal preparation is saved; meanwhile, coal slime water pollution is avoided, the quantity of equipment is small, power consumption is low, energy is saved, environment is protected, and the efficiency of a coal preparation process flow is effectively improved.

Owner:ZHONGKUANG LVNENG BEIJING ENG TECH

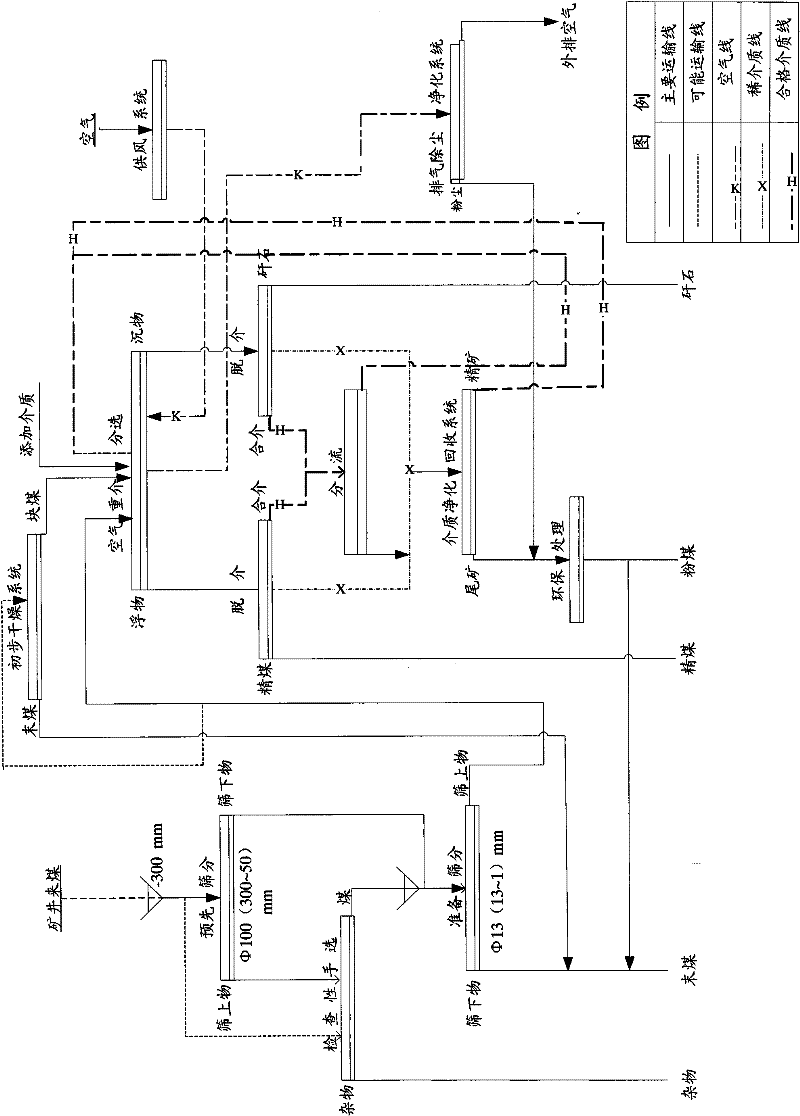

Process for selecting cleaned coals from gangue coals of raw coals and middling coals

The invention relates to a process for selecting cleaned coals from gangue coals of raw coals and middling coals, which adopts a method of desliming before selection and performing separation in a coal-slime separator after crushing. The process can select the cleaned coals from the gangue coals in the raw coals and the middling coals generated from coking coals after being cleaned, has the advantages of simple process, low coal dressing cost and high efficiency, is free from using flotation reagents, recycles water resources and is free from causing pollution to the environment, and the produced cleaned coals are applied to formcoke coal blending or export sales, and the middling coals and coal slimes are used as raw materials for producing moulded coals and biomass moulded coals.

Owner:勃利县森清能源开发有限公司

Method for preparing water coke slurry from lignite char

The invention belongs to the clean coal technical field and provides a method for preparing water coke slurry by using lignite semicoke as a raw material. The method is characterized in that: the lignite is pyrogenated at medium and low temperature to obtain semicoke which is taken as the raw material; sodium lignosulphonate, naphthalenesulfonic acid or composition of the sodium lignosulphonate and naphthalenesulfonic aci is used as a dispersant. Added with small amount of dispersant, the lignite semicoke can produce the water coke slurry with concentration of about 60 percent, excellent fluidity and stability, and being applicable to gasification. The method of the invention has the advantages of reducing the costs of the raw material and the dispersant in the process of slurrying on the premise of meeting the gasification requirements of the water coke slurry.

Owner:DALIAN UNIV OF TECH

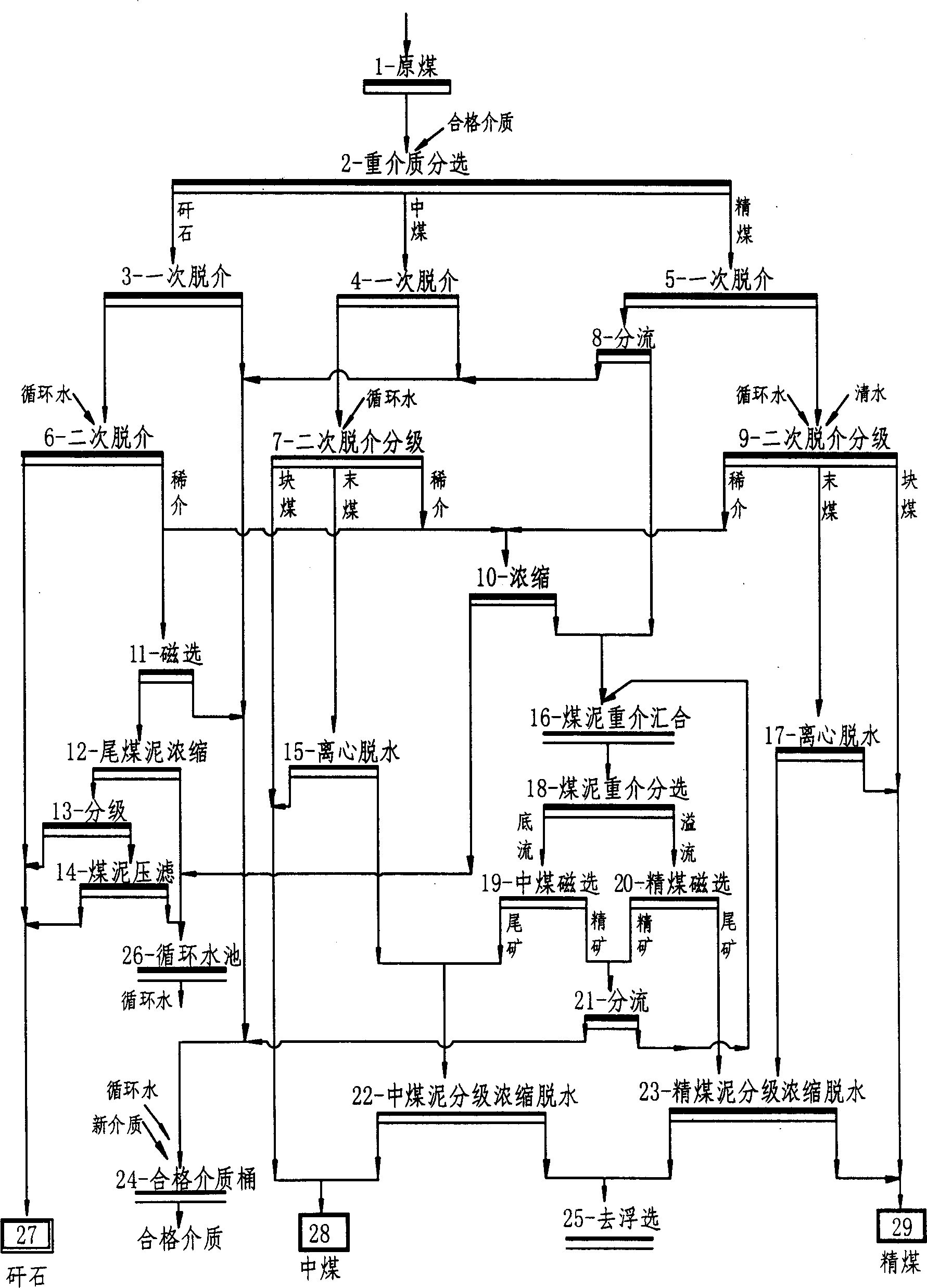

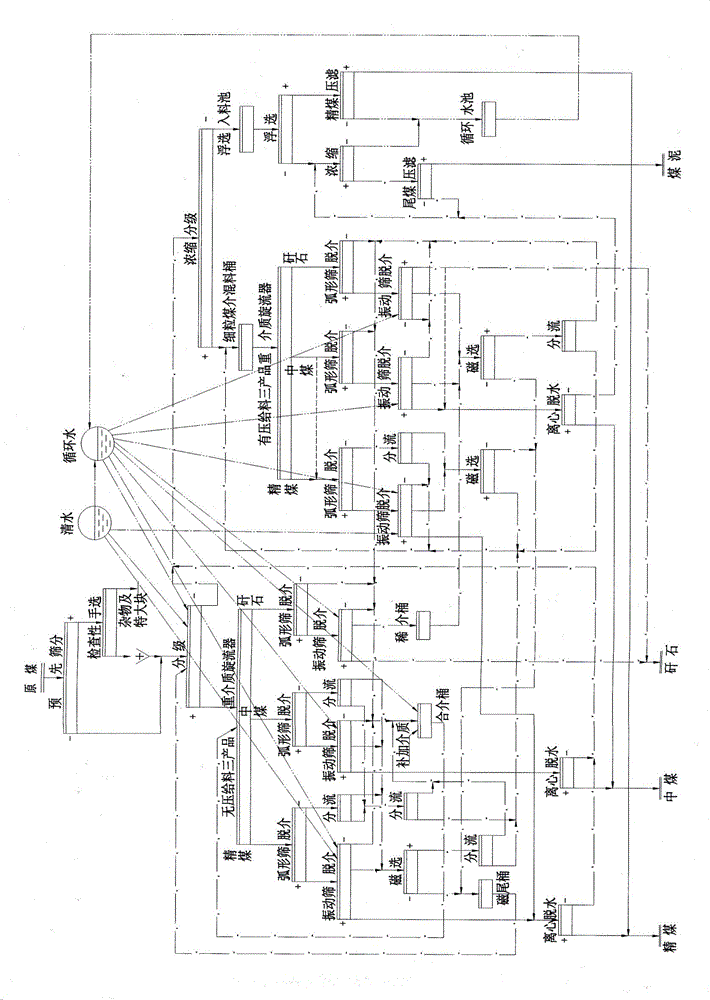

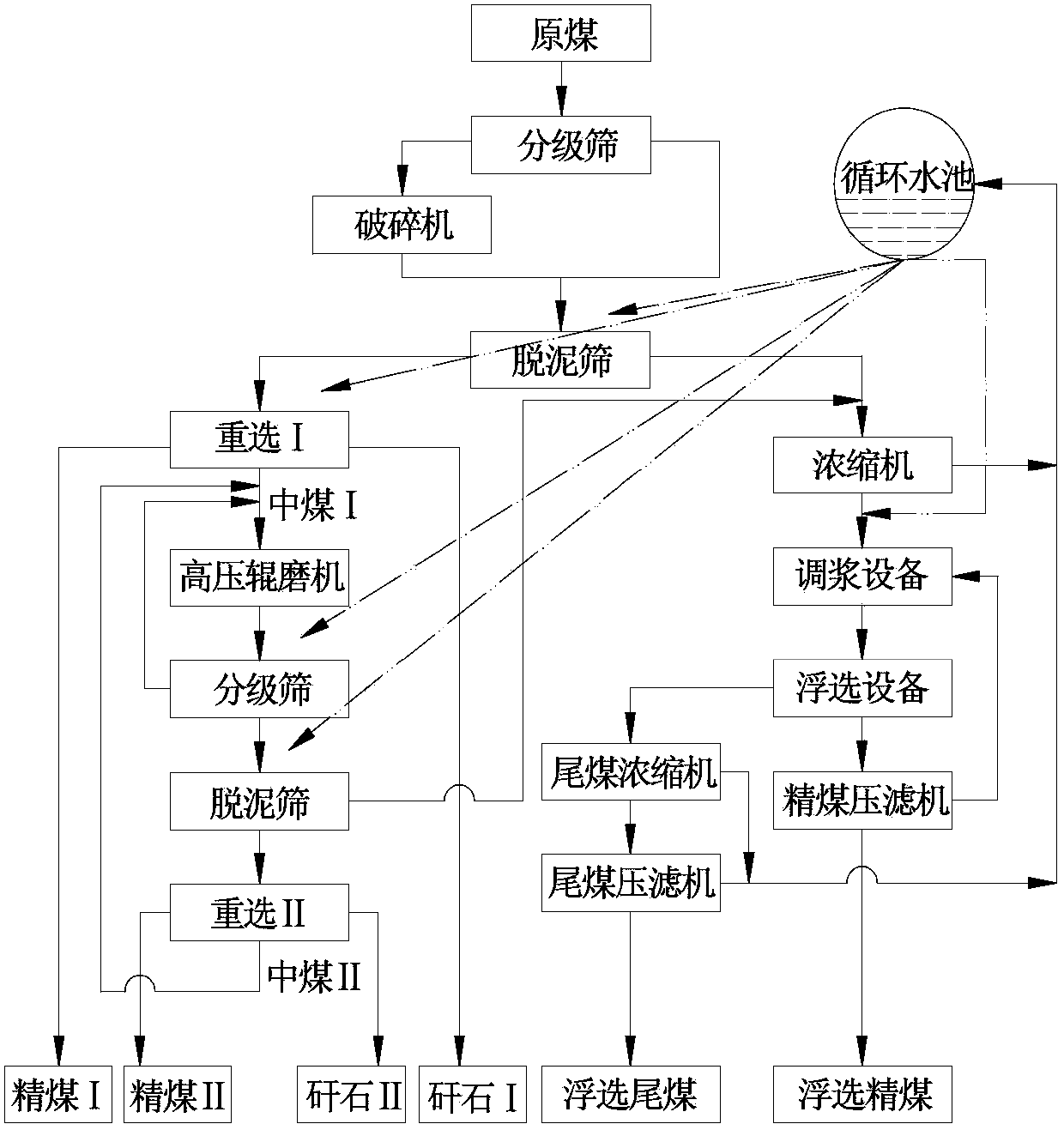

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

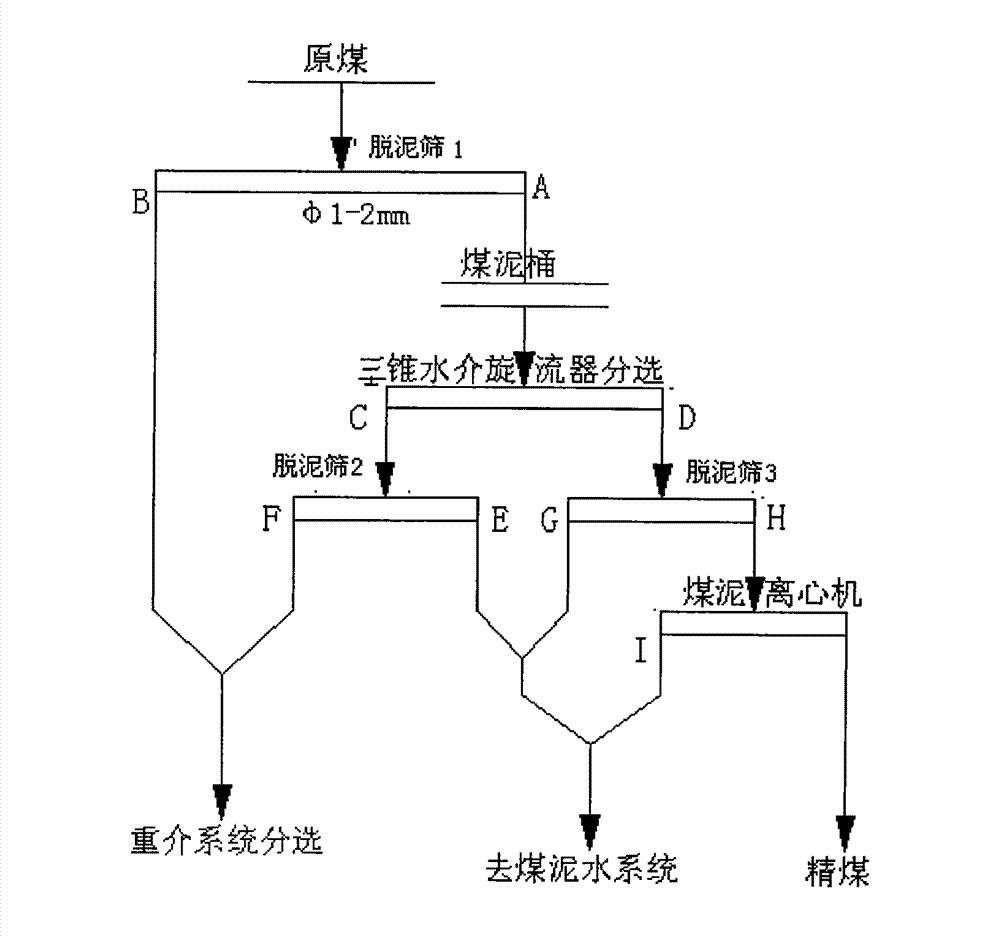

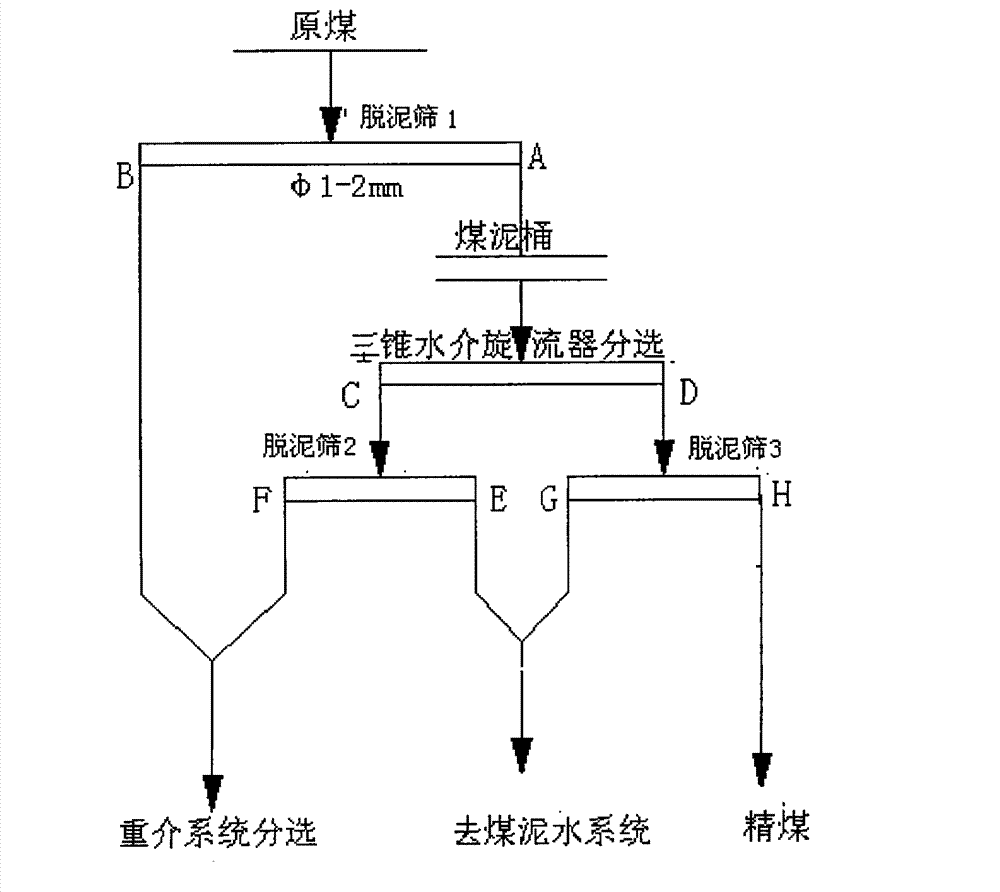

Coarse slime separation process

The invention discloses a coarse slime separation process. Raw coal enters a first desliming screen, siftage enters a three cone angle hydrocyclone for separation, the obtained base flow substance enters a second desliming screen for desliming, and the overflow substance enters a third desliming screen for desliming; second oversize is mixed with first oversize to enter a heavy medium system for separation; third oversize enters a slime centrifugal machine or a sedimentation filter centrifugal machine for centrifugal separation to obtain centrifugal liquid and clean coal; and second oversize, third oversize and the centrifugal liquid are mixed to enter a slime water system for processing, slime water of the slime water system goes to floatation directly or goes to concentration directly for recycling. The three cone angle hydrocyclone is combined with the heavy medium system, and accordingly clean coal ash content of the three cone angle hydrocyclone is guaranteed, and run-off large granular clean coal in the base flow can be recycled. By the combination of the three cone angle hydrocyclone and the heavy medium system, a coarse slime system is perfected and comprehensive efficiency of the coarse slime system is increased by 4-5 percent.

Owner:SHANDONG UNIV OF SCI & TECH

Chemical deashing method for coal

ActiveCN102041128AGood deashing effectImproved deashing efficiencyCalcium/strontium/barium fluoridesDispersed particle separationHydrofluoric acidReaction temperature

The invention discloses a chemical deashing method for coal, belonging to the technical field of clean coal. A novel deashing acid solution is adopted for deashing coal and is a mixed acid of hydrofluoric acid and at least one other inorganic acid, wherein the mass percentage content of the hydrofluoric acid is 5-30%, the mass percentage content of other inorganic acids is 10-40%, and total acid concentration is 10-40%; during acid leaching, the mass ratio of the deashing acid solution to the raw material coal is (1-6):1, reaction temperature is 10-80DEG C, and the process of acid leaching lasts for 4-24 hours; and meanwhile, after exhaust gas and scouring water, generated in a defluorination processing, are graded and reused and a waste mixed acid solution is repeatedly reused, a lime solution is adopted for absorption. The method provided by the invention is suitable for deashing larger coal particles of which the diameter is 1-5mm, and can achieve a better deashing effect. A moderate reaction condition is adopted to ensure that the deashing mixed acid containing hydrofluoric acid is difficult to volatilize, so that energy consumption and cost are lowered and environmental pollution is lightened at the same time.

Owner:YIBIN TIANYUAN GRP CO LTD

Deep preparation technology of coal for direct coal liquefacation

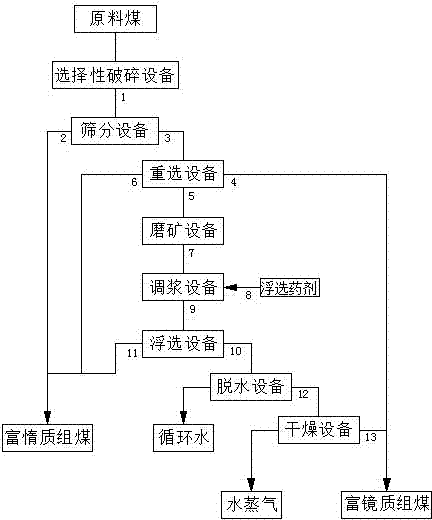

The invention discloses a deep preparation technology of coal for direct coal liquefacation. Feed coal is selectively crushed and then is sieved with a 0.5 mm particle size to grade; products passing through the sieving are separated through gravity concentration equipment, so as to obtain gravity treated cleaned coal, gravity treated middlings and gravity treated tailings; the gravity treated middlings is ground and fed into size mixing equipment; flotation reagent is added to the size mixing equipment, size mixing is performed, and then products are pumped into flotation equipment to perform separation, so as to obtain flotation cleaned coal and flotation tailings; the flotation cleaned coal is filtered and dried and then mixed with the gravity treated cleaned coal to form rich-vitrinite coal which is served as coal for direct coal liquefacation; and the products of the feed coal not passing through the sieving after crushing and sieving, the gravity treated tailings and the flotation tailings are mixed into rich-inertinite coal which can be served as high-quality steam coal, coal for gasification and the like. The technology is based on coal petrography maceral, adopts the differences in terms of densities and surface natures of different coal petrography maceral, and adopts the method of the combination of gravity concentration and flotation, so as to realize the large-scale separation and enrichment of coal maceral, increase the hydrogen-to-carbon ratio of coal for liquefacation, greatly improve the oil yield of direct liquefacation of coal, and obviously increase the economic benefit of direct liquefacation of coal.

Owner:CHINA UNIV OF MINING & TECH

High-pressure roll selective smashing and sorting method for middlings

InactiveCN103386355AHigh yieldQuality assuranceGrain treatmentsWet separationProcess engineeringMineral processing

The invention relates to a high-pressure roll selective smashing and sorting method for middlings, and belongs to the technical field of mineral processing. The method comprises the following steps of: (1) smashing raw coal until the granularity is less than the upper limit of selected granularity suitable for a follow-up cleaning unit, desliming, and enabling the deslimed raw coal to enter resorting equipment to obtain clean coal I, middlings I and gangue I; (2) smashing the middlings I until the granularity is less than the upper limit of smashing granularity suitable for a high-pressure roller mill, carrying out high-pressure roller milling ultrafine smashing, desliming products subjected to ultrafine smashing, enabling the deslimed products to enter the resorting equipment to obtain clean coal II, middlings II and gangue II, wherein the middlings II return to the high pressure roller mill to be mixed with the middlings I so as to be smashed and sorted; (3) carrying out flotation on the coal slime after concentration and size mixing so as to obtain flotation clean coal and flotation tailing. Compared with conventional middlings smashing processes, the method disclosed by the invention is high in product dissociation degree and good in subsequent resorting effect, can be used for improving the clean coal yield, enabling coal resources to be sufficiently and reasonably recycled and utilized, and reducing resource waste.

Owner:UNIV OF SCI & TECH LIAONING

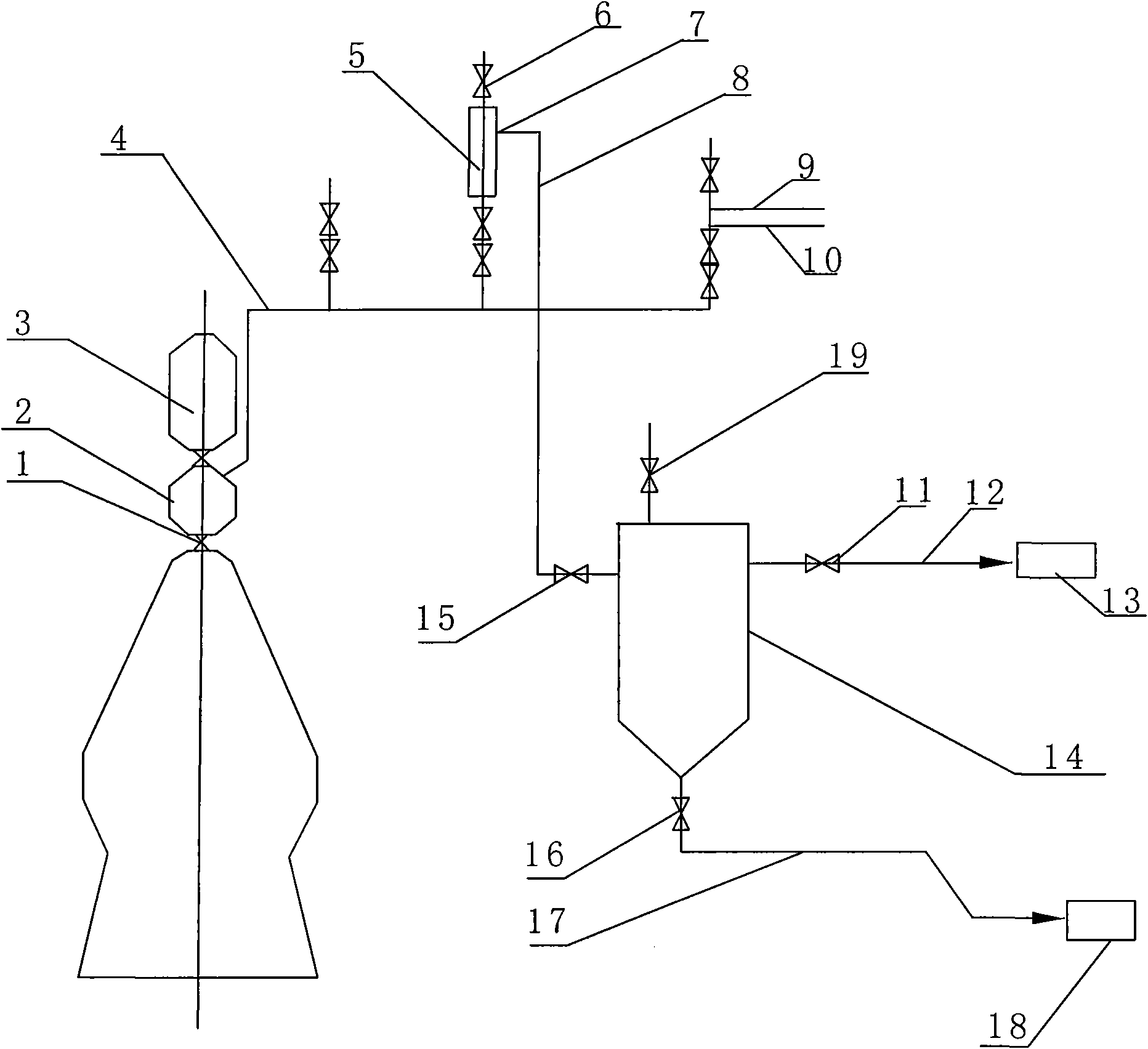

Coal-gas recovering process and device of charging, equalizing and bleeding of blast furnace

InactiveCN101892336AEfficient recyclingEmission reductionBlast furnace componentsBlast furnace detailsCycloneSocial benefits

The invention relates to coal-gas recovering process and device of charging, equalizing and bleeding of a blast furnace. The coal-gas recovering process comprises the following steps that: crude gas equalized and bled from a discharge tank of a blast furnace charging system enters into a furnace top coal gas noise reduction cyclone dust remover via a bleeding pipe; a cut off valve arranged at the furnace top coal noise reduction cyclone dust remover is closed, and a half-cleaned coal gas cut off valve is opened; half-cleaned coal gas formed by the primary dust removal of the crude coal gas via the furnace top coal gas noise reduction cyclone dust remover enters into a bag dust remover via a pipeline and the half-cleaned coal cut off valve; cleaned coal gas dedusted by the bag dust remover enters into a coal gas pipe network, and dust collected by the bag dust remover is conveyed to a dust recovering system for reutilization via a dust discharge outlet, a dust discharge valve and a dust delivery pipeline. The invention has the advantages of simple recovering process and device and easy operation; with the process, not only harmful gas during charging, equalizing and bleeding can be effectively recovered, but also emission of greenhouse gases is reduced; and the invention has significant economic benefits and social benefits.

Owner:ANSHAN HENGTONG BLAST FURNACE EQUIP ENG TECH CO LTD

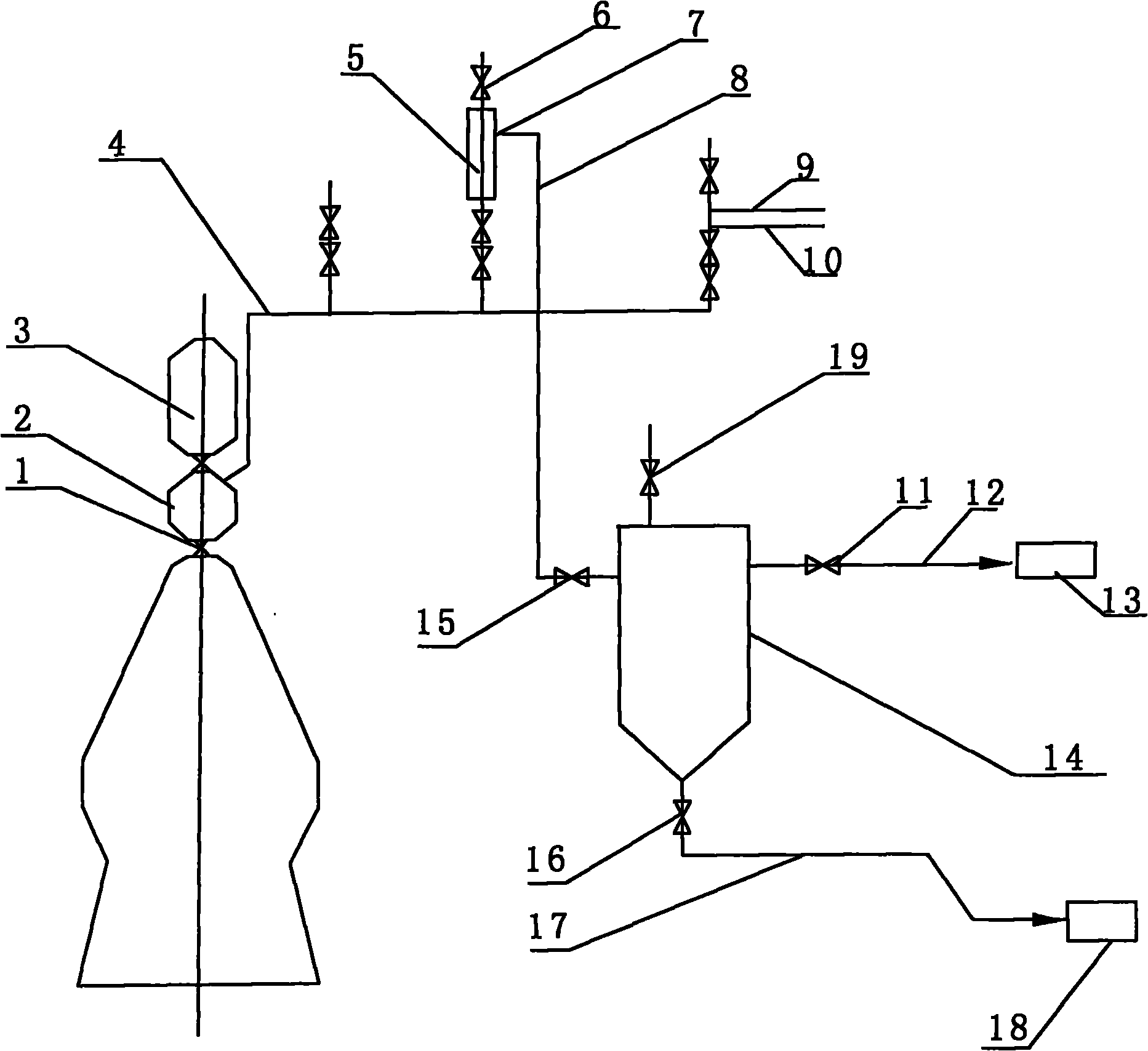

Sorting process for high-ash and difficult-separation coal slime

Disclosed is sorting process for high-ash and difficult-separation coal slime. Floatation coal slime is fed into a stirring barrel to be prepared into ore pulp with percentage concentration of 80g / L-120g / L, the ore pulp automatically flows to roughing and floatation equipment to be sorted, roughing tail coal enters a cyclone to be concentrated in a classified manner, concentrated bottom flow products enter a high-frequency screen to be dewatered, dewatered substances on the high-frequency screen return to roughing pulp mixing operation to be sorted again after being finely ground via a ball mill, floatation rough and fine ores are fed to a precipitation perforated basket centrifuge to be dewatered, after being dewatered via the precipitation perforated basket centrifuge, fine ore filter liquor is fed into concentration flotation equipment to be concentrated, and concentration tail coal and overflow of the ball mill return to roughing pulp mixing operation together via a pipeline to besorted again. Accordingly, low-ash and high-recovery-rate flotation clean coal is obtained. The sorting process not only avoids influence of high-ash content and fine particle slime and integrated ore to a floatation process, but also avoids contradiction between the quality and the recovery rate of a high-ash difficult-separation coal slime sorted product.

Owner:CHINA UNIV OF MINING & TECH

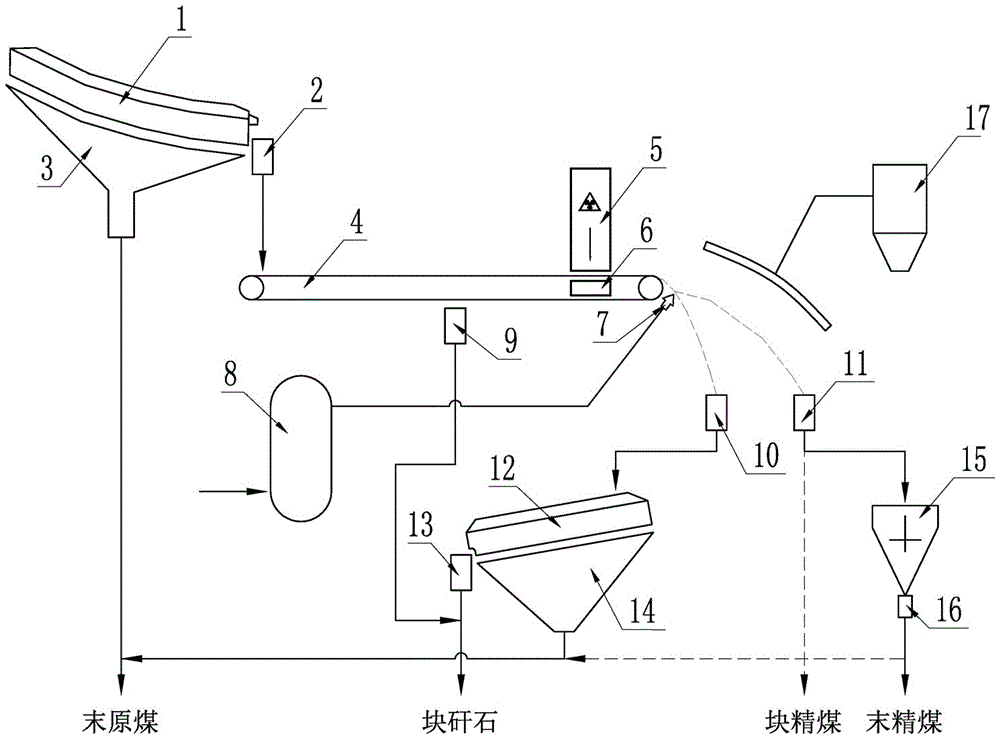

Intelligent lump coal dry method inverted separation system

InactiveCN105537145AAvoid the problem that the force surface is small and it is difficult to blow through the high-frequency solenoid valveAvoid the problem that it is difficult to blow through the high-frequency solenoid valveSortingSolenoid valveSpray nozzle

The invention aims to provide an intelligent lump coal dry method inverted separation system. After supplied raw coal materials are screened through a raw coal classifying screen, raw lump coal enters an intelligent dry separation machine, and are identified by X-rays as clean coal, gangue and other things. The intelligent lump coal dry method inverted separation system is characterized in that conventional gangue blowing operation of intelligent dry separation is turned into coal blowing operation, and the intelligent dry separation machine enables an air spray nozzle which corresponds to the clean coal and is controlled by a high-frequency solenoid valve to be opened according to identifying information of the X-rays, so that the clean coal deviates from the raw coal movement trail, and the clean coal is separated from the gangue and the other things. The intelligent dry separation machine is a dry method separation device which utilizes the rays to conduct intelligent identifying separation on minerals, the clean coal and the gangue are identified according to the difference of the capacities of the clean coal and the gangue for absorbing the rays, and the air spray nozzle serves as an execution mechanism. According to the invention, the intelligent lump coal dry method inverted separation system can be applied to coal preparation plants with a large amount of gangue and a plurality of overlarge blocks and other things so that the problem that an existing conventional intelligent dry method gangue removal system is difficult to handle with overlarge blocks and other things can be solved, and the air consumption and the energy consumption can be reduced.

Owner:TIANJIN MEITENG TECH CO LTD

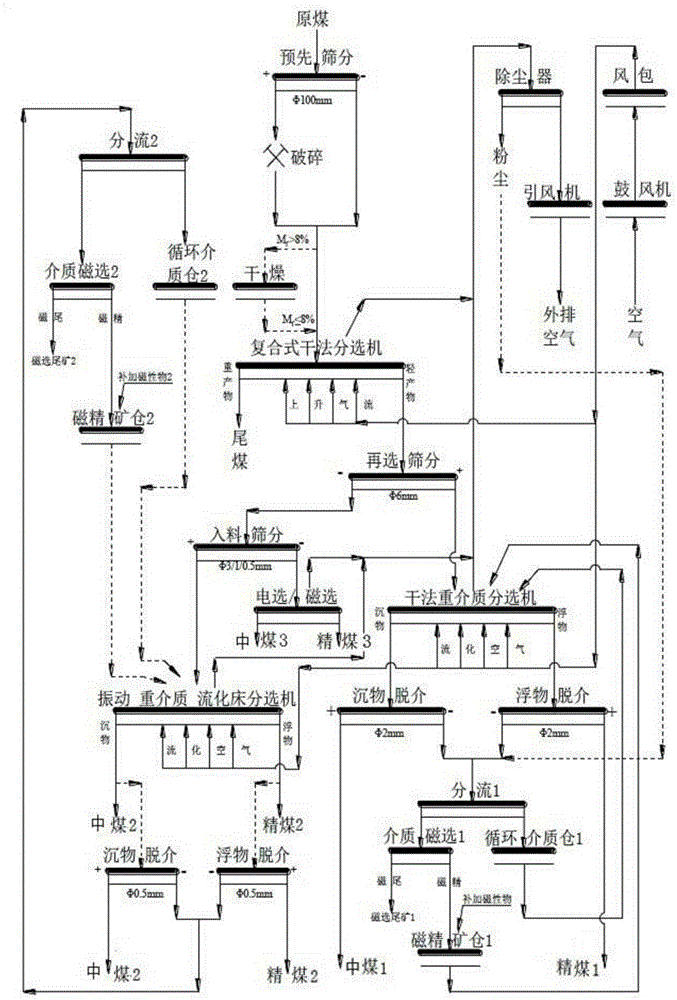

Full-fraction dry method separation clean technology and method for coal

ActiveCN105289985AOvercome limitationsSolve the problem of few selected productsGas current separationGranularityFluidized bed

The invention discloses a full-fraction dry method separation clean technology and method for coal. The technology includes the steps that raw coal to be sorted is screened, crushed and dried and then enters a compound dry method separation machine to obtain rough clean coal and tailings; the rough clean coal is screened through classification screens to obtain products of three fractions; the products of three fractions enter a dry method dense medium separation machine, a vibration dense medium fluidized bed separation machine and a dry method electric separation machine / dry magnetic separator respectively for separation of clean coal and middlings; and after medium solids brought out by the products are removed through a sculping screen, part of the medium solids enter the magnetic separator for removing of non-magnetic substances, then obtained magnetic concentrate flows back to the separator, and the other part of the medium solids are directly and cyclically used. The system comprises a raw coal preparing and drying part, a separating part and a medium purifying circulation and dense control part. According to the full-fraction dry method separation clean technology and method for coal, synchronous efficient separation on coal with large, medium and small granularities can be achieved, and the problems that in a current dry method coal separation field, graded products are fewer, the quality of clean coal is poor, the medium utilization rate is low, and dust is excessively discharged are solved.

Owner:CHINA UNIV OF MINING & TECH

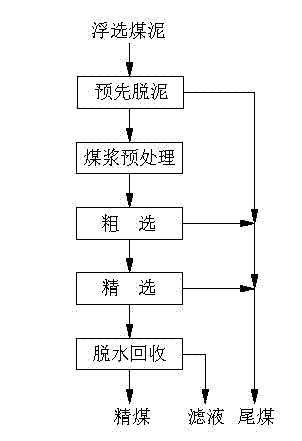

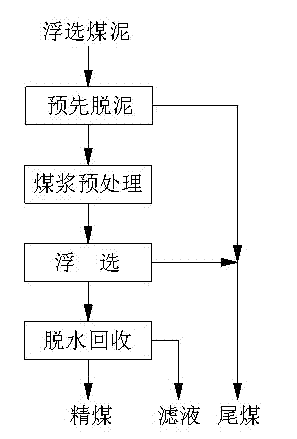

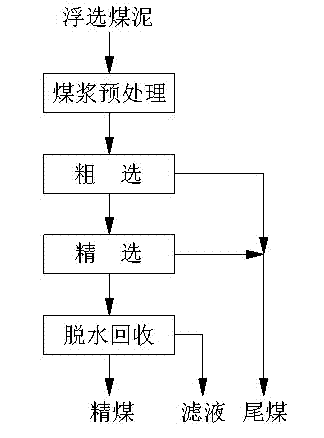

Flotation process method of high-ash-content fine coal slime

The invention relates to a flotation process method of high-ash-content fine coal slime. According to the method, pre-desliming is carried out by using a flotation coal slime flotation feeding desliming pond invented by Tangshan Guohua Technology International Engineering Co., Ltd., preprocessing is carried out by using a pulverization drop-type coal slurry preprocessor, and rough flotation and fine flotation are carried out by using an air jet flotation machine. The method comprises the following steps of: pre-desliming; preprocessing of the coal slurry; controlling of the feeding concentration of the flotation machine; and dehydration and recycling. According to the flotation process method of the high-ash-content fine coal slime, coking clean coal is sorted from inferior coal slime, the flotation process method is scientific and optimized, perfect indexes of sorting are substantially improved, the outward discharging of slime water is thoroughly avoided, the closed cycle of washing water of a coal cleaning plant is realized, and the method is scientific and environment-friendly.

Owner:唐山国华科技国际工程有限公司

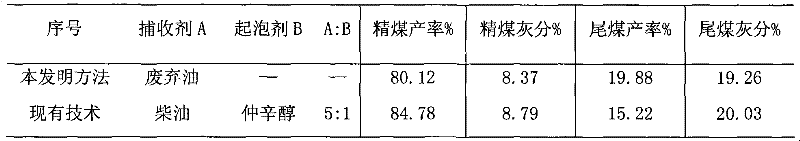

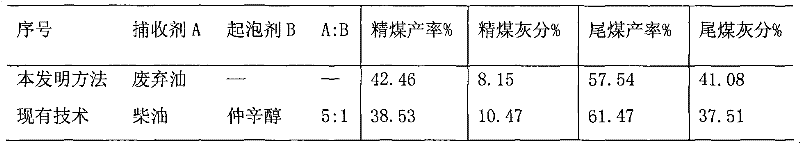

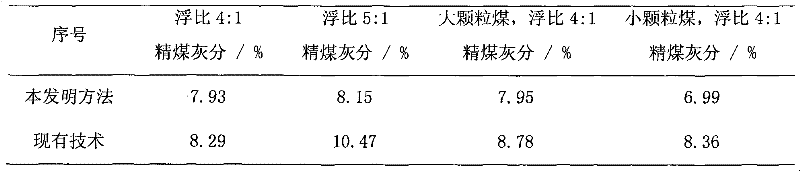

Method for floating coal by using modified waste oil as flotation agent

The invention discloses a method for floating coal by using modified waste oil as a flotation agent, which comprises: determining the modification conditions of waste oil by using clean coal yield as an index; mixing ethanol and waste oil according to a molar ratio of 3:1 to 10:1; adding 0.4 to 1.0 mass percent of alkaline earth and 0.01 to 0.05 mass percent of aluminum oxide serving as a catalyst under the pressure of 3 to 5 kg; heating to 40 to 80 DEG C, and stirring and reacting for 0.5 to 4.5 hours to obtain modified waste oil; directly using the modified waste oil in coal flotation, preparing 75 grams of coal sample, pre-stirring for 2 minutes, mixing slurry for 3 minutes, and floating for 3 minutes; and finally, floating coal varieties with different ash content and particle sizes by using the yields of clean coal, waste coal and ash content after flotation as indexes and using modified waste oil in a flotation amount of 0.72 kilograms per ton of coal and 0.91 kg per ton of coalaccording to a flotation ratio of 4:1 and 5:1. The method of the invention is simple, can change waste materials into valuable materials, is low in cost and environment-friendly, and provides a new approach for utilizing waste oil.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com