Patents

Literature

695results about How to "Efficient sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

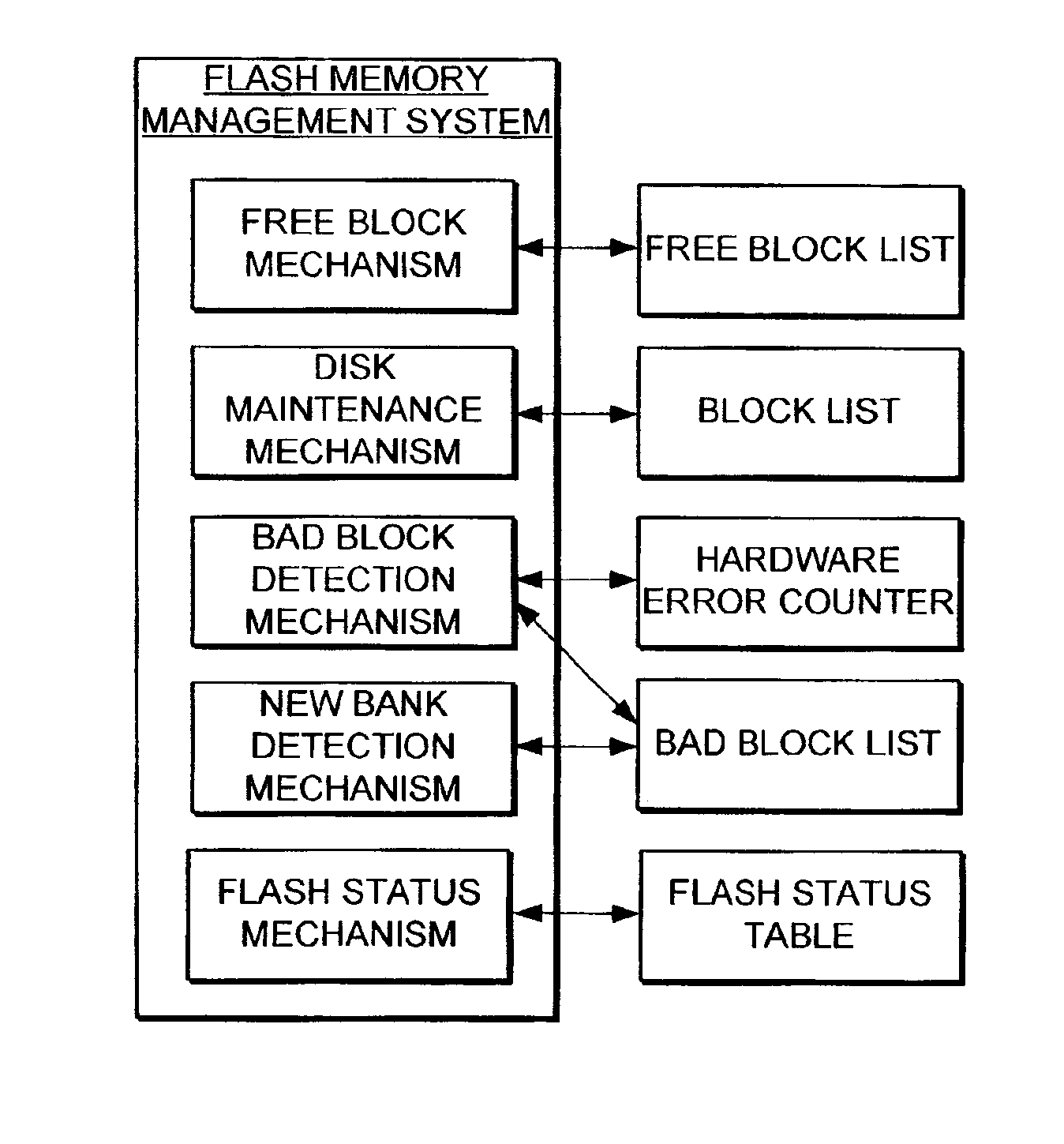

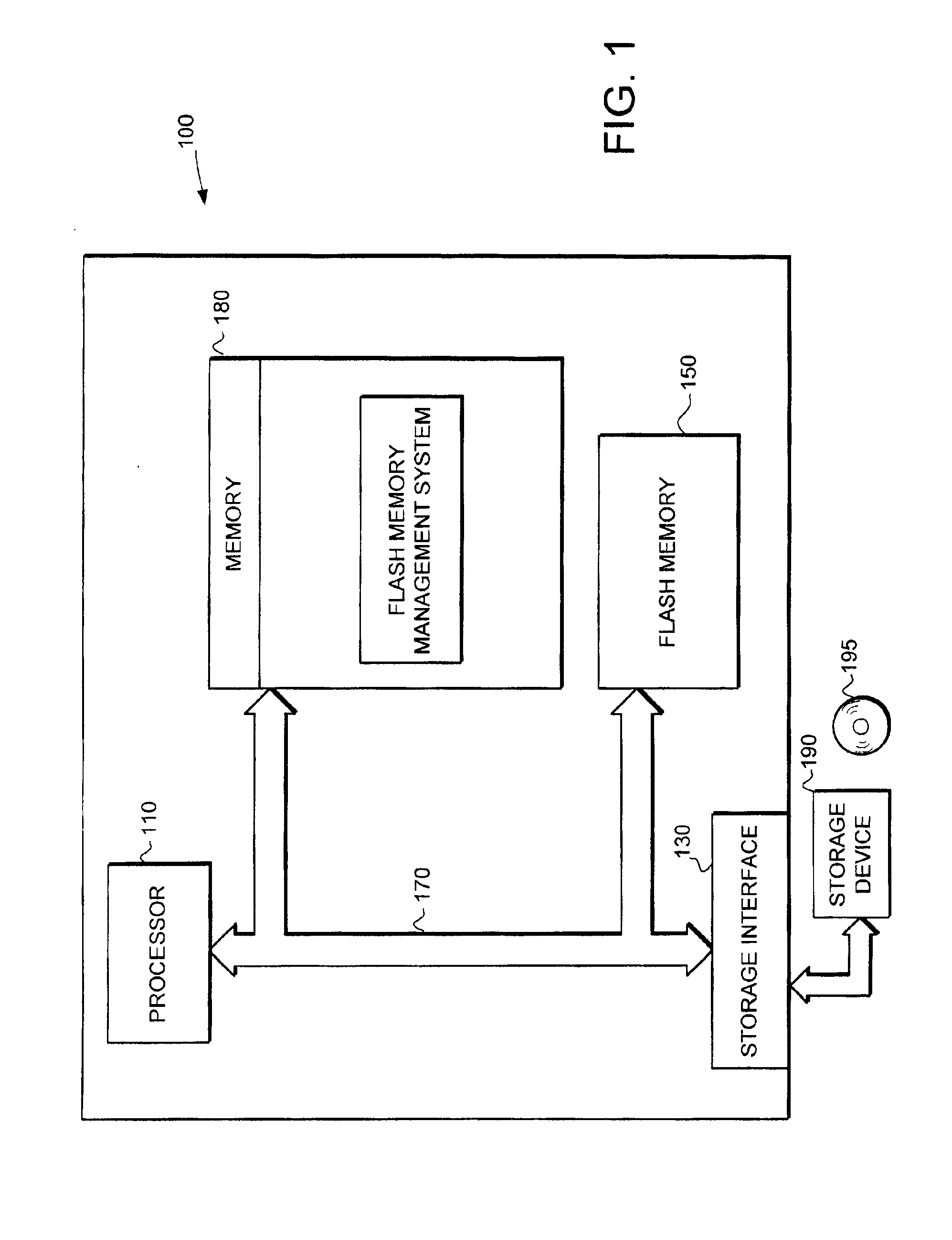

Flash memory management system and method utilizing multiple block list windows

InactiveUS6895464B2Improve performanceImprove reliabilityInput/output to record carriersMemory loss protectionRapid accessBlock detection

The present invention provides a flash memory management system and method with increased performance. The flash memory management system provides the ability to efficiently manage and allocate flash memory use in a way that improves reliability and longevity, while maintaining good performance levels. The flash memory management system includes a free block mechanism, a disk maintenance mechanism, and a bad block detection mechanism. The free block mechanism provides efficient sorting of free blocks to facilitate selecting low use blocks for writing. The disk maintenance mechanism provides for the ability to efficiently clean flash memory blocks during processor idle times. The bad block detection mechanism provides the ability to better detect when a block of flash memory is likely to go bad. The flash status mechanism stores information in fast access memory that describes the content and status of the data in the flash disk. The new bank detection mechanism provides the ability to automatically detect when new banks of flash memory are added to the system. Together, these mechanisms provide a flash memory management system that can improve the operational efficiency of systems that utilize flash memory.

Owner:III HLDG 12 LLC

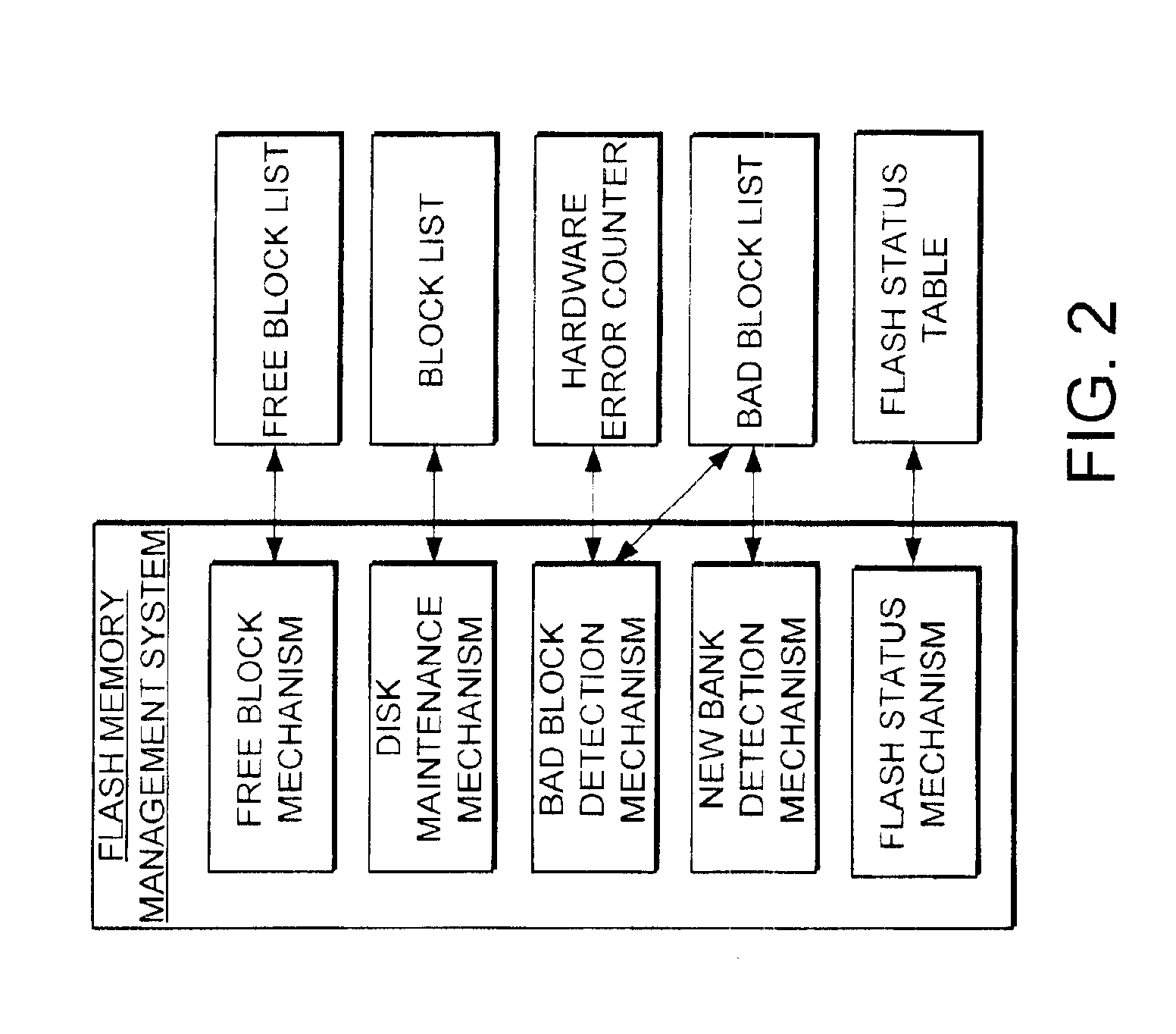

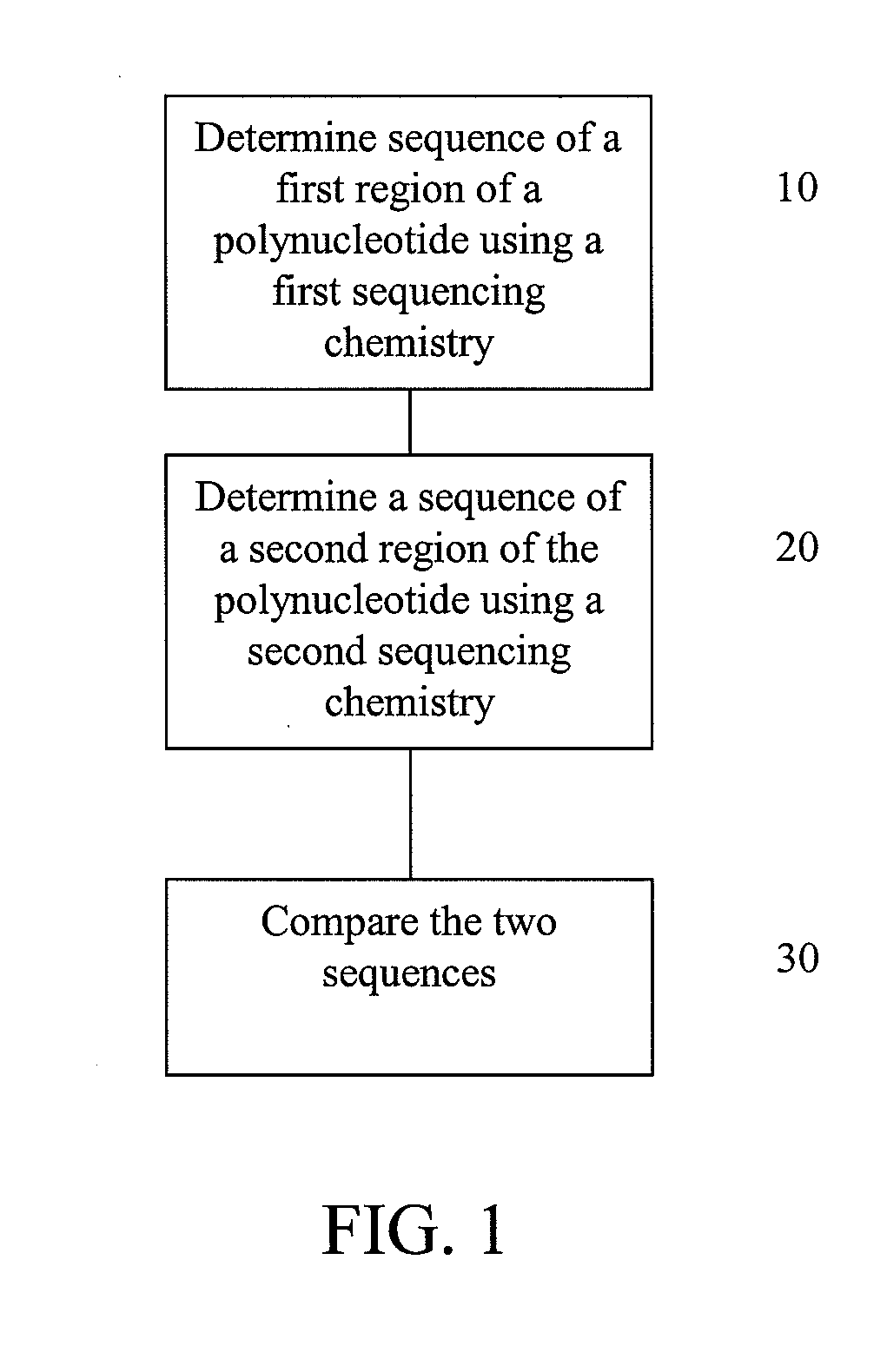

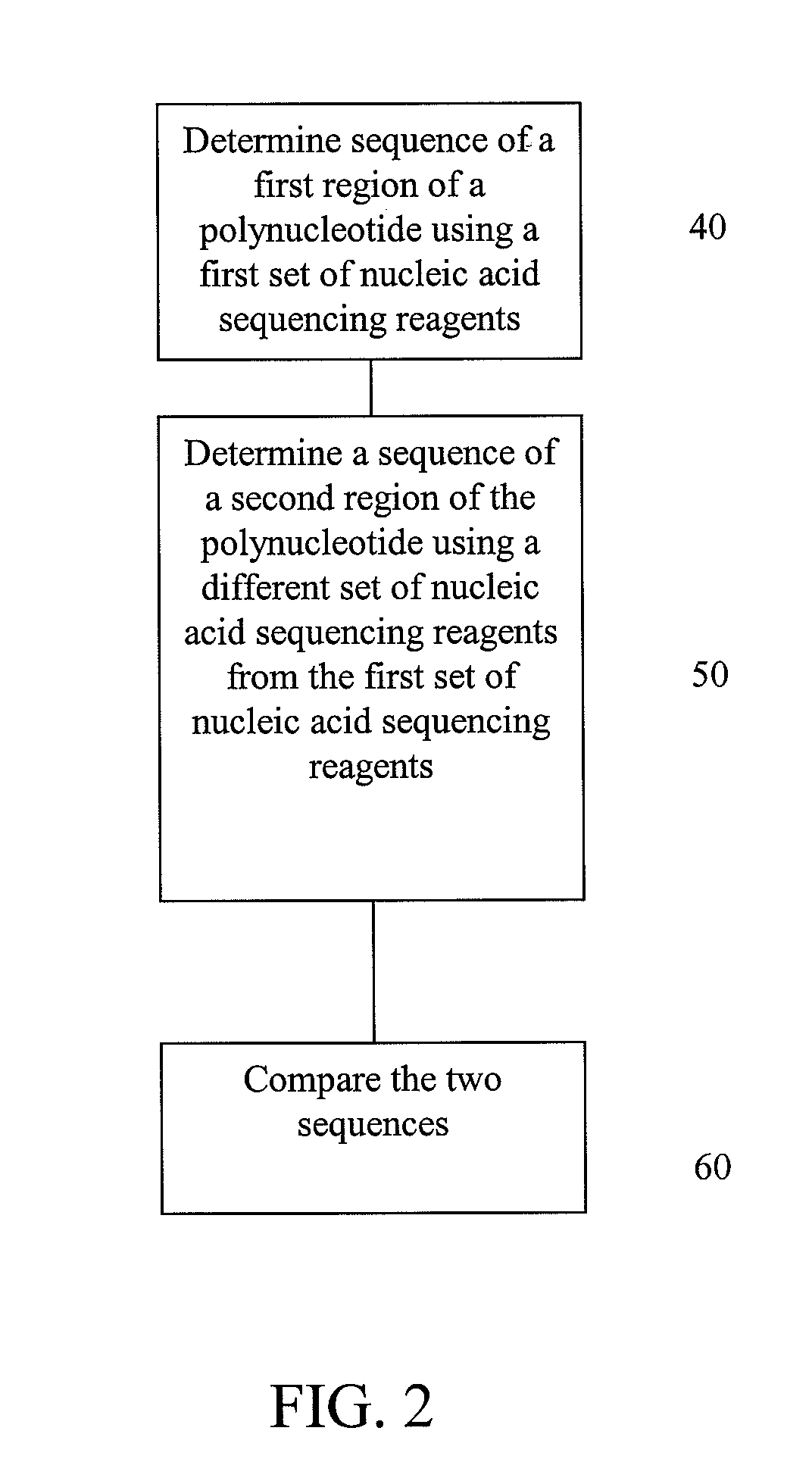

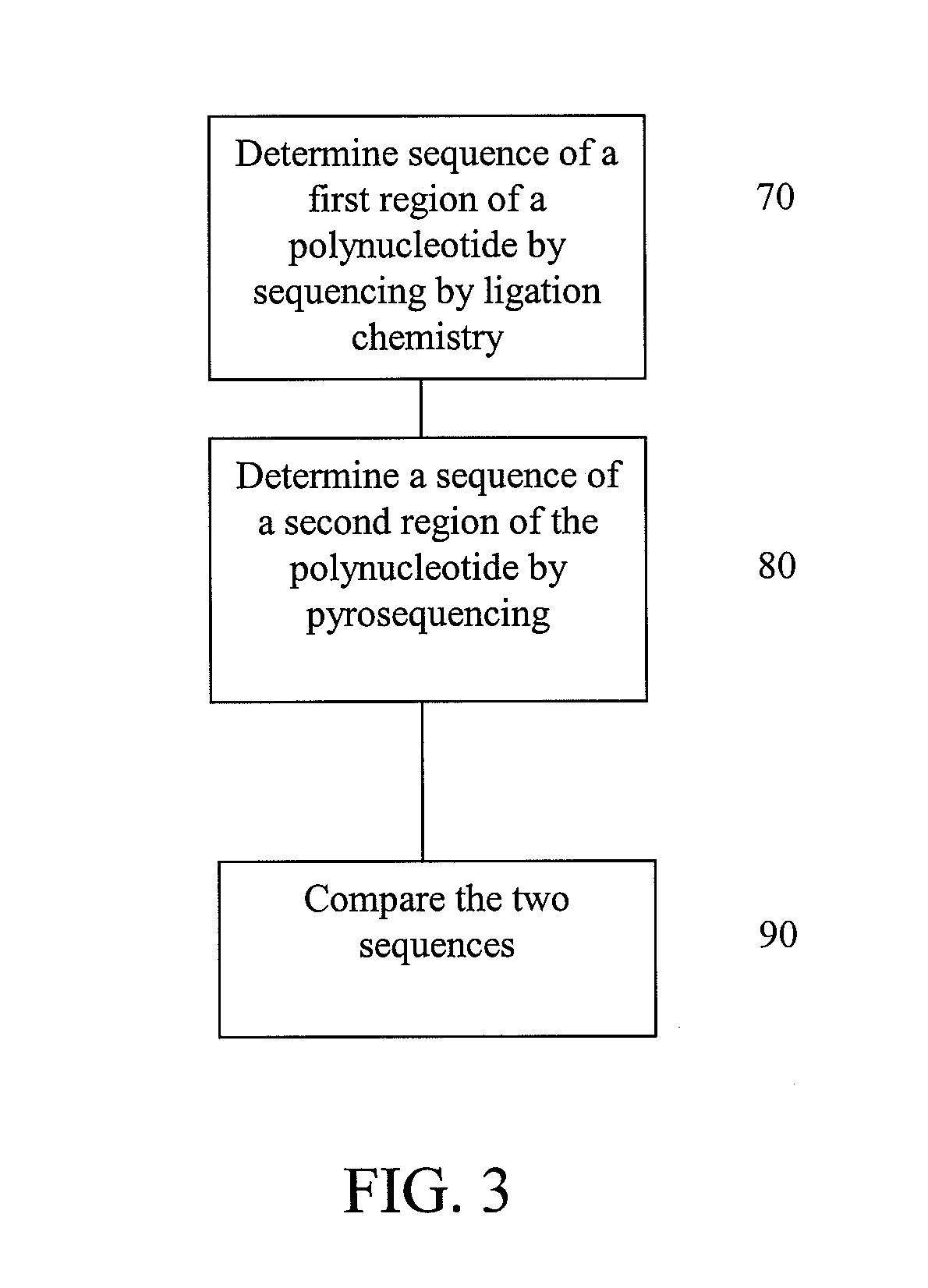

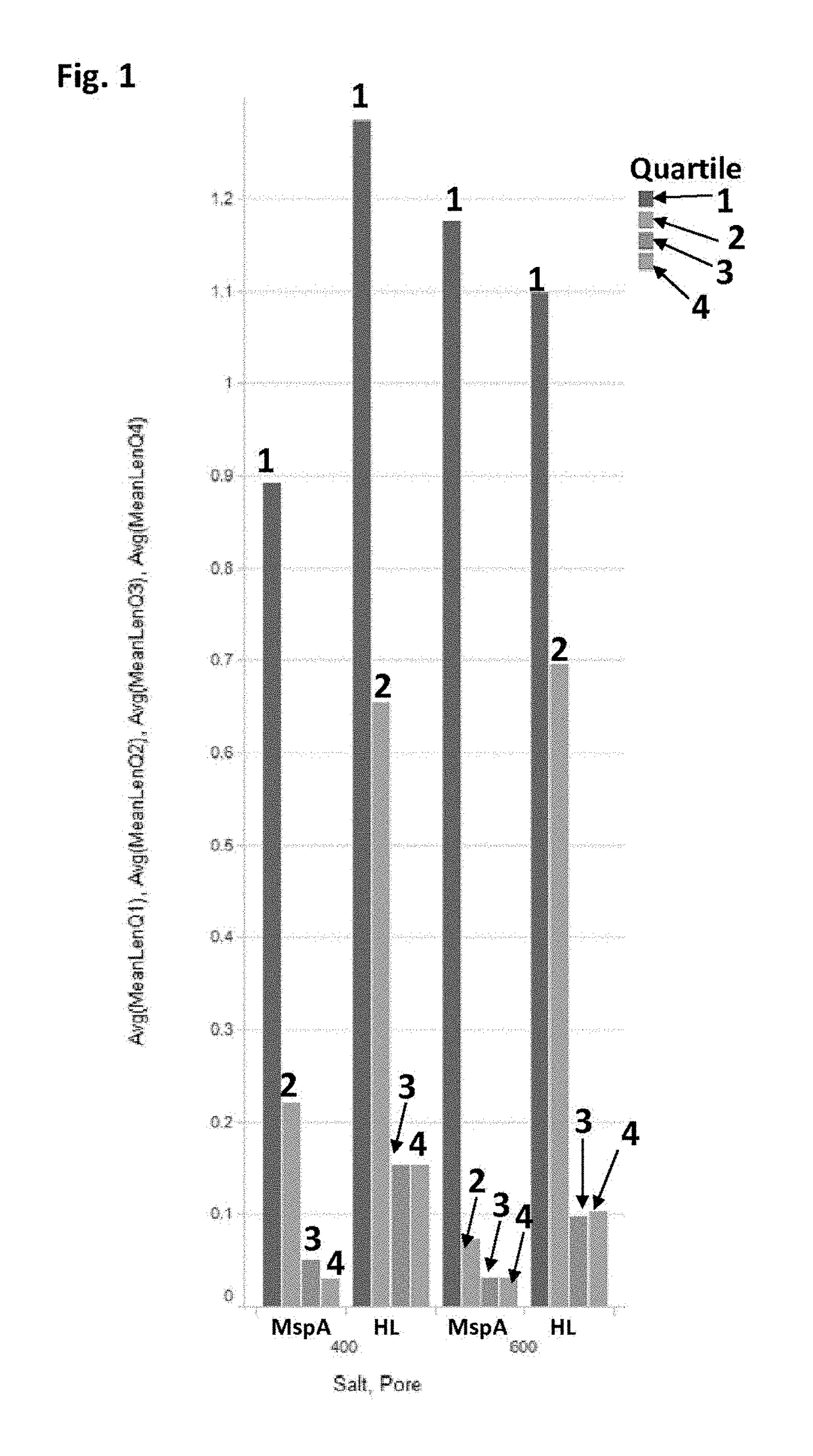

Alternative nucleic acid sequencing methods

InactiveUS20090062132A1Efficient sortingAccurate sortingNucleotide librariesMicrobiological testing/measurementNucleic acid sequencingMassive parallel sequencing

Embodiments are provided that provide for parallel sequencing of nucleic acid segments. In some embodiments, a single sequence is sequenced by at least two different sequencing techniques and the results compared, allowing for deficiencies or strengths of one technique to be complemented by the second technique.

Owner:APPL BIOSYSTEMS INC

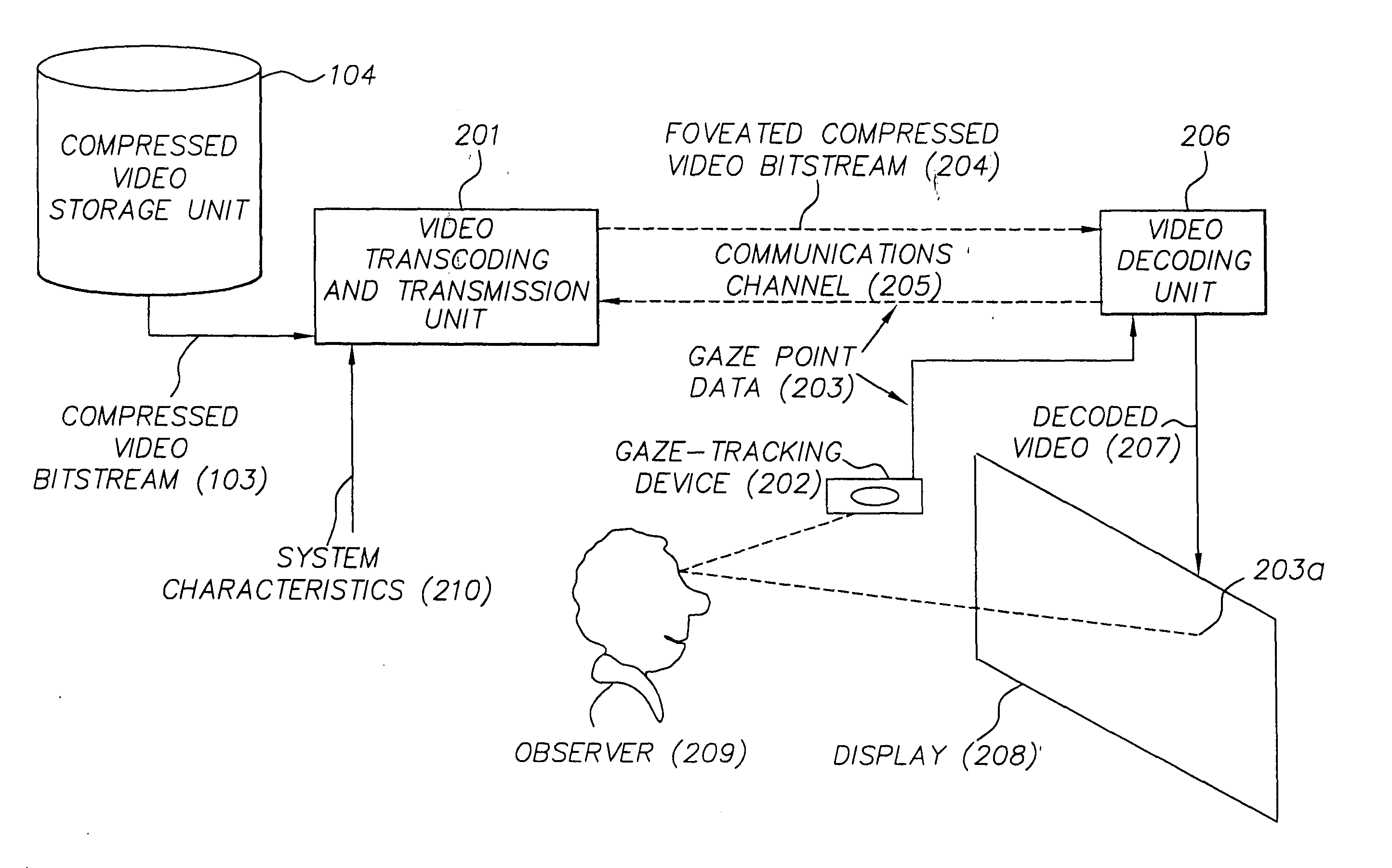

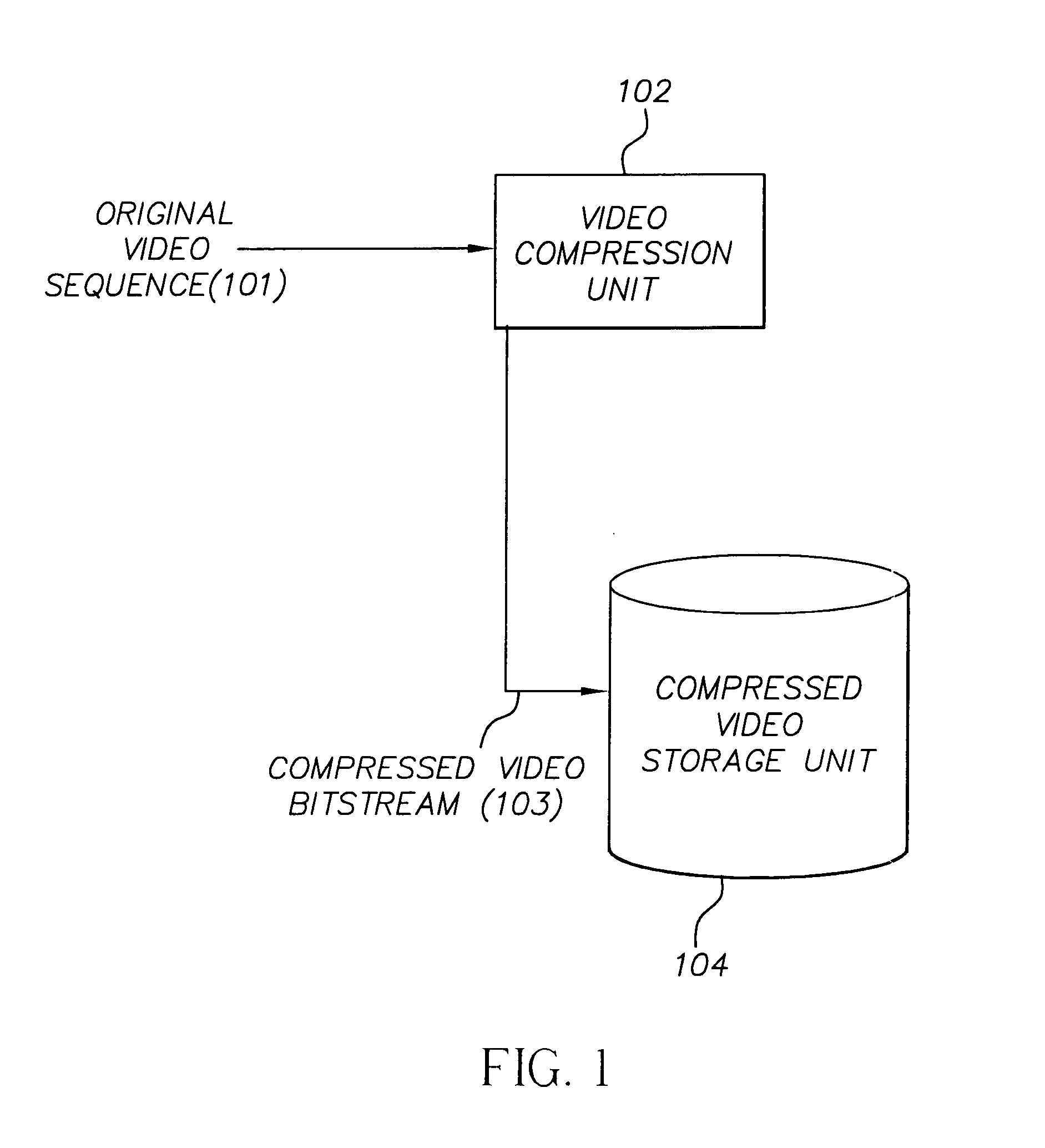

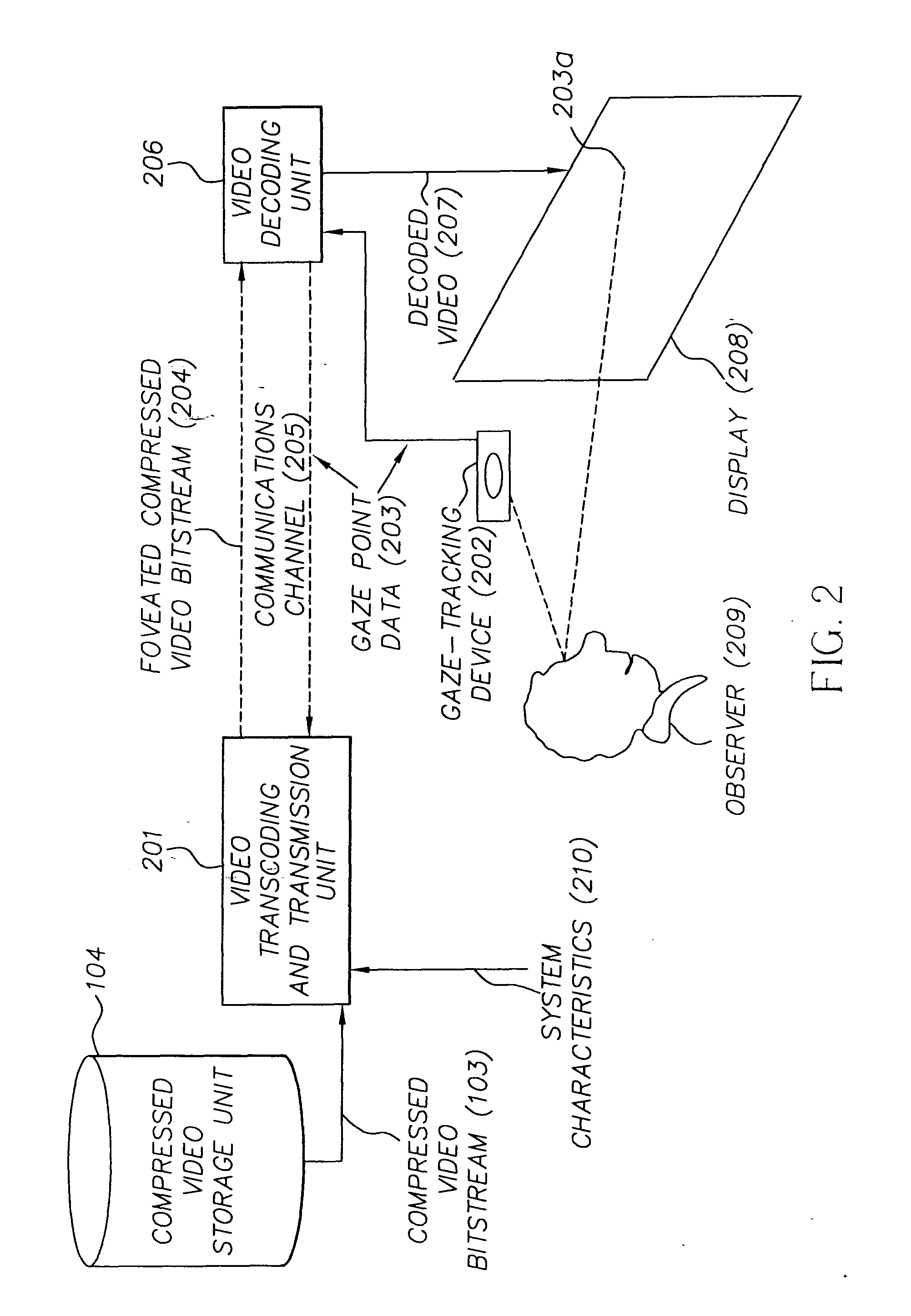

Foveated video coding system and method

InactiveUS20050018911A1Reduce bandwidth requirementsAttenuation bandwidthCharacter and pattern recognitionTelevision systemsDigital videoDisplay device

In transcoding a frequency transform-encoded digital video signal representing a sequence of video frames, a foveated, compressed digital video signal is produced and transmitted over a limited bandwidth communication channel to a display according to the following method: First, a frequency transform-encoded digital video signal having encoded frequency coefficients representing a sequence of video frames is provided, wherein the encoding removes temporal redundancies from the video signal and encodes the frequency coefficients as base layer frequency coefficients in a base layer and as residual frequency coefficients in an enhancement layer. Then, an observer's gaze point is identified on the display. The encoded digital video signal is partially decoded to recover the frequency coefficients, and the residual frequency coefficients are adjusted to reduce the high frequency content of the video signal in regions away from the gaze point. The frequency coefficients, including the adjusted residual frequency coefficients, are then recoded to produce a foveated, transcoded digital video signal, and the foveated, transcoded digital video signal is displayed to the observer.

Owner:EASTMAN KODAK CO

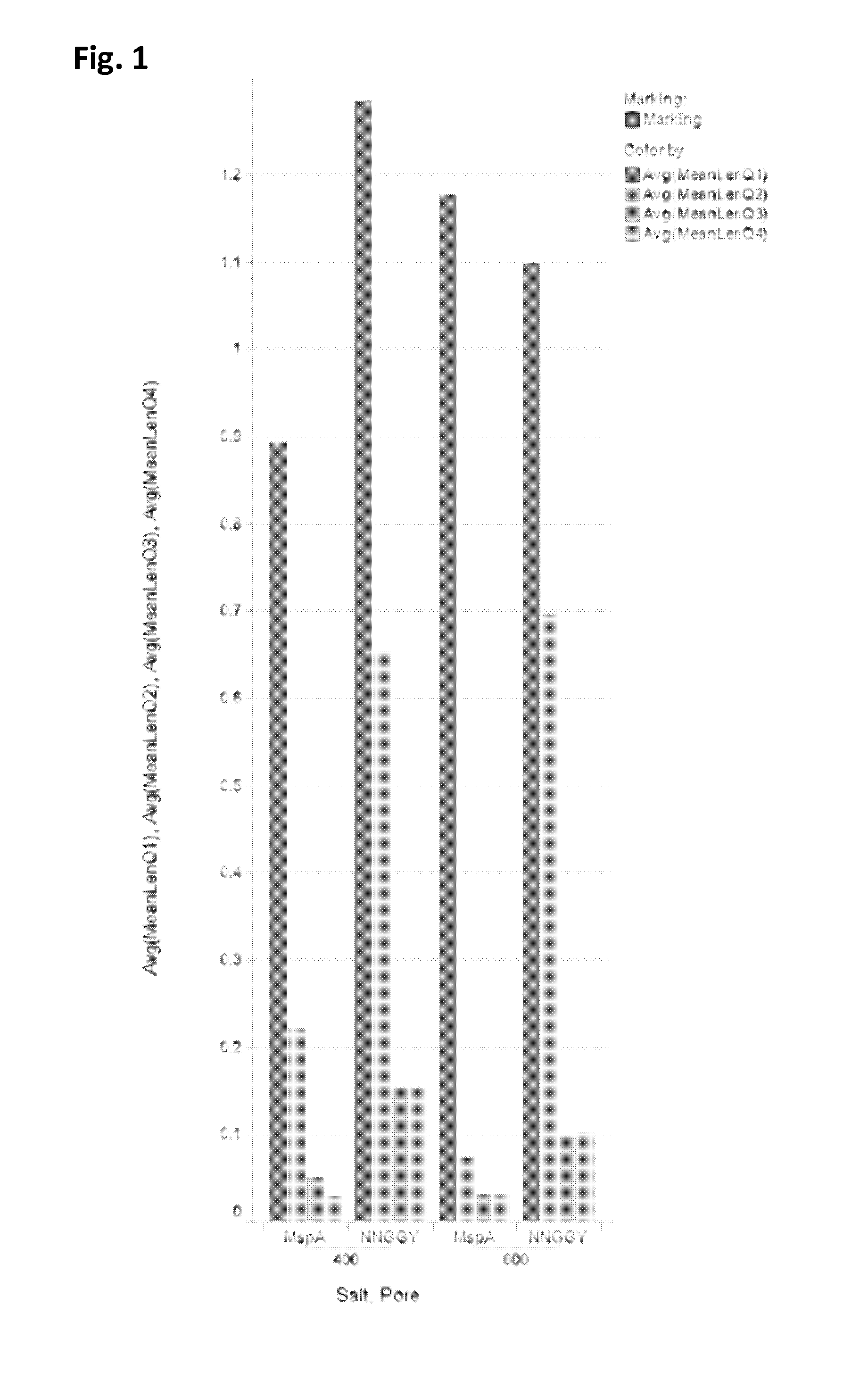

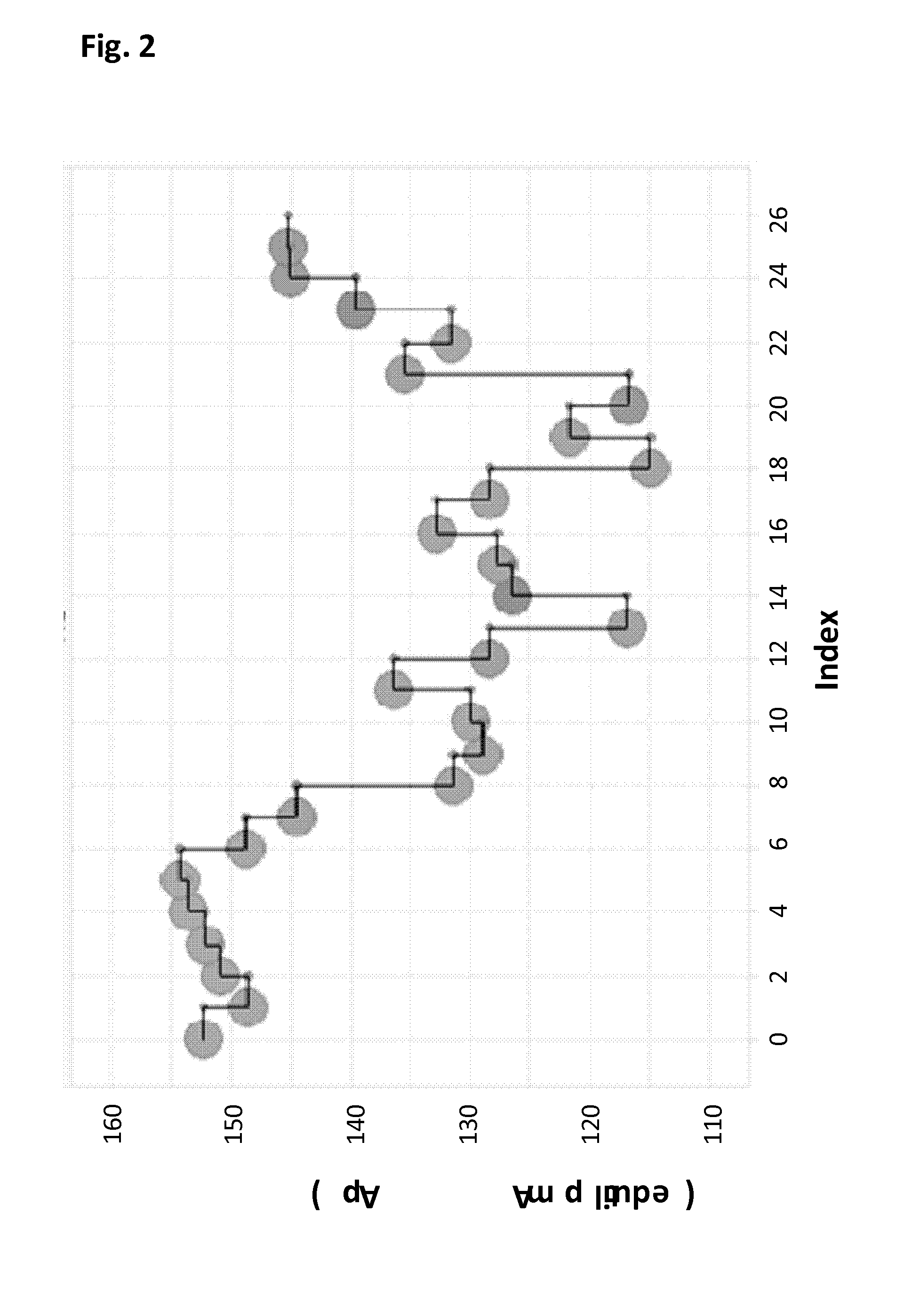

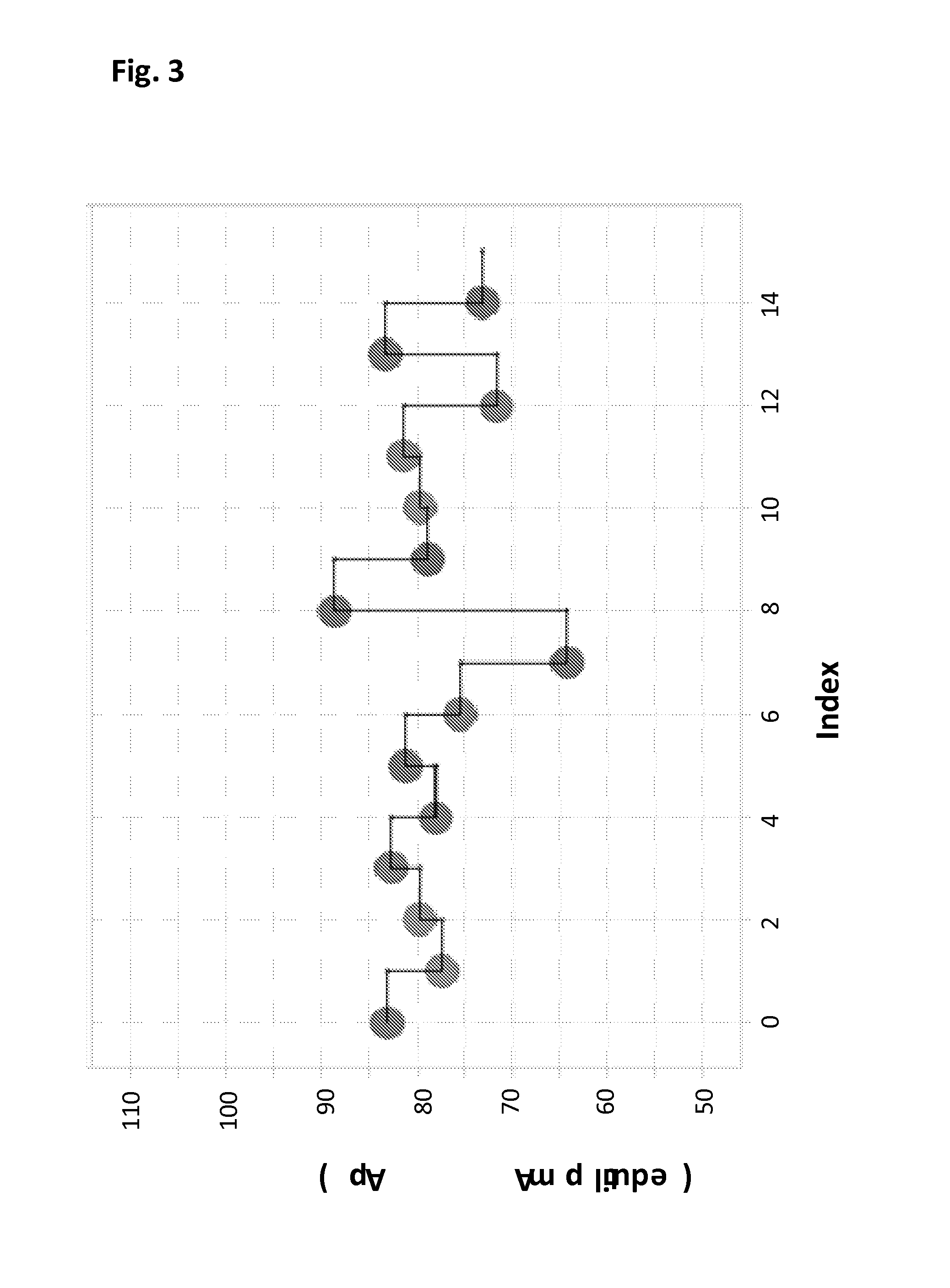

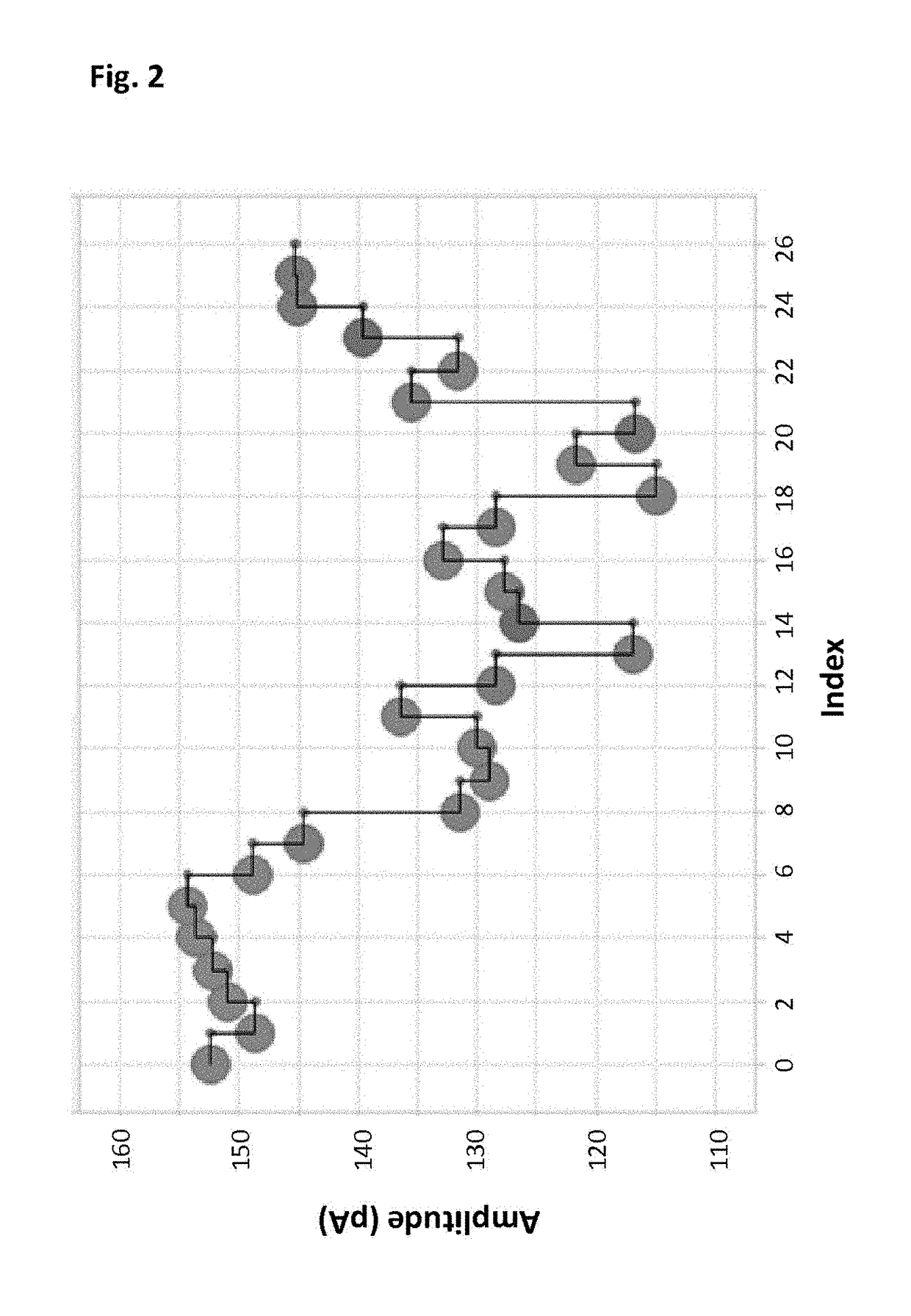

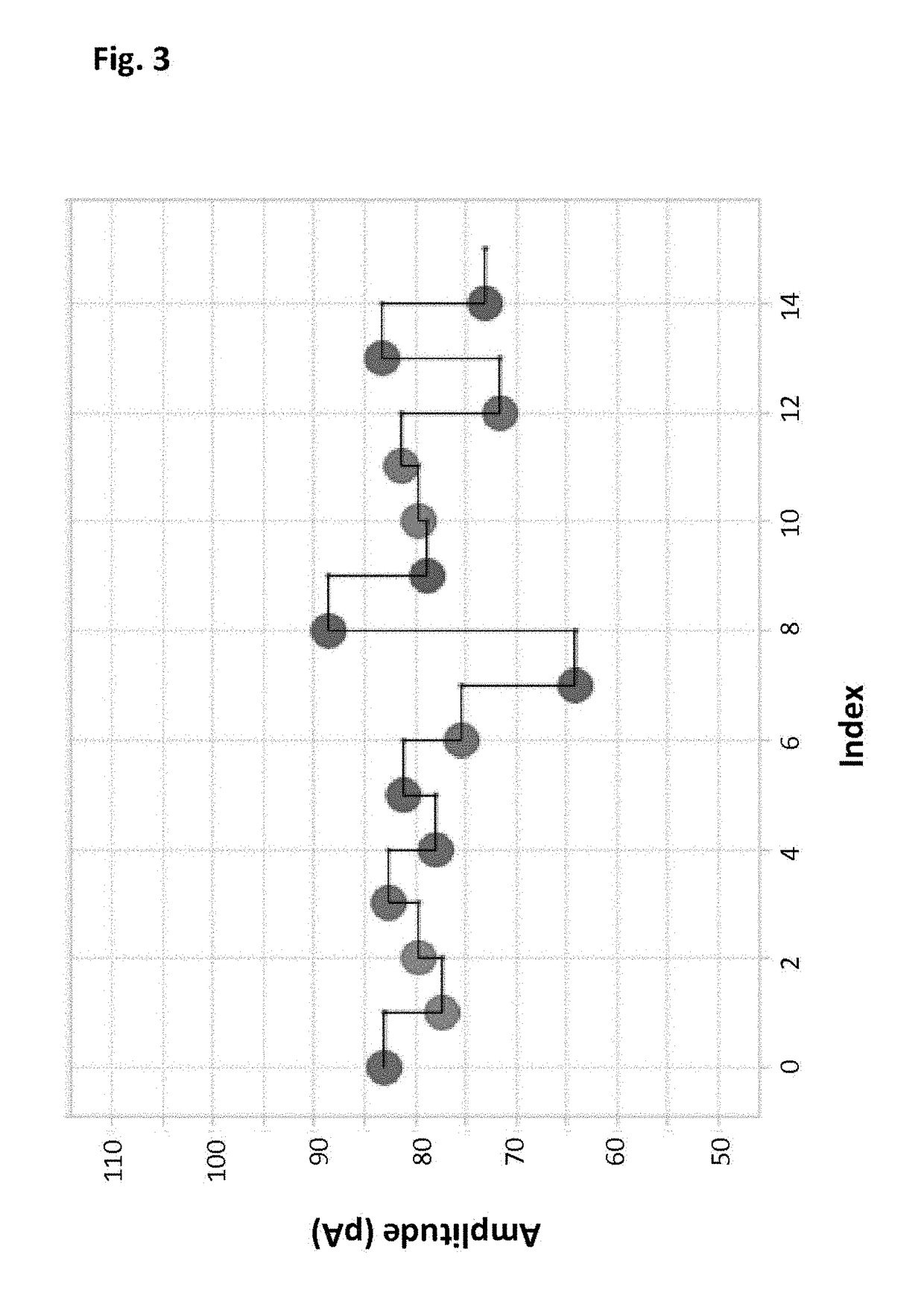

Mutant pores

ActiveUS20140186823A1Easily discriminatedReduce varianceBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acidChemistry

The invention relates to mutant forms of Msp. The invention also relates to nucleic acid characterisation using Msp.

Owner:OXFORD NANOPORE TECH LTD

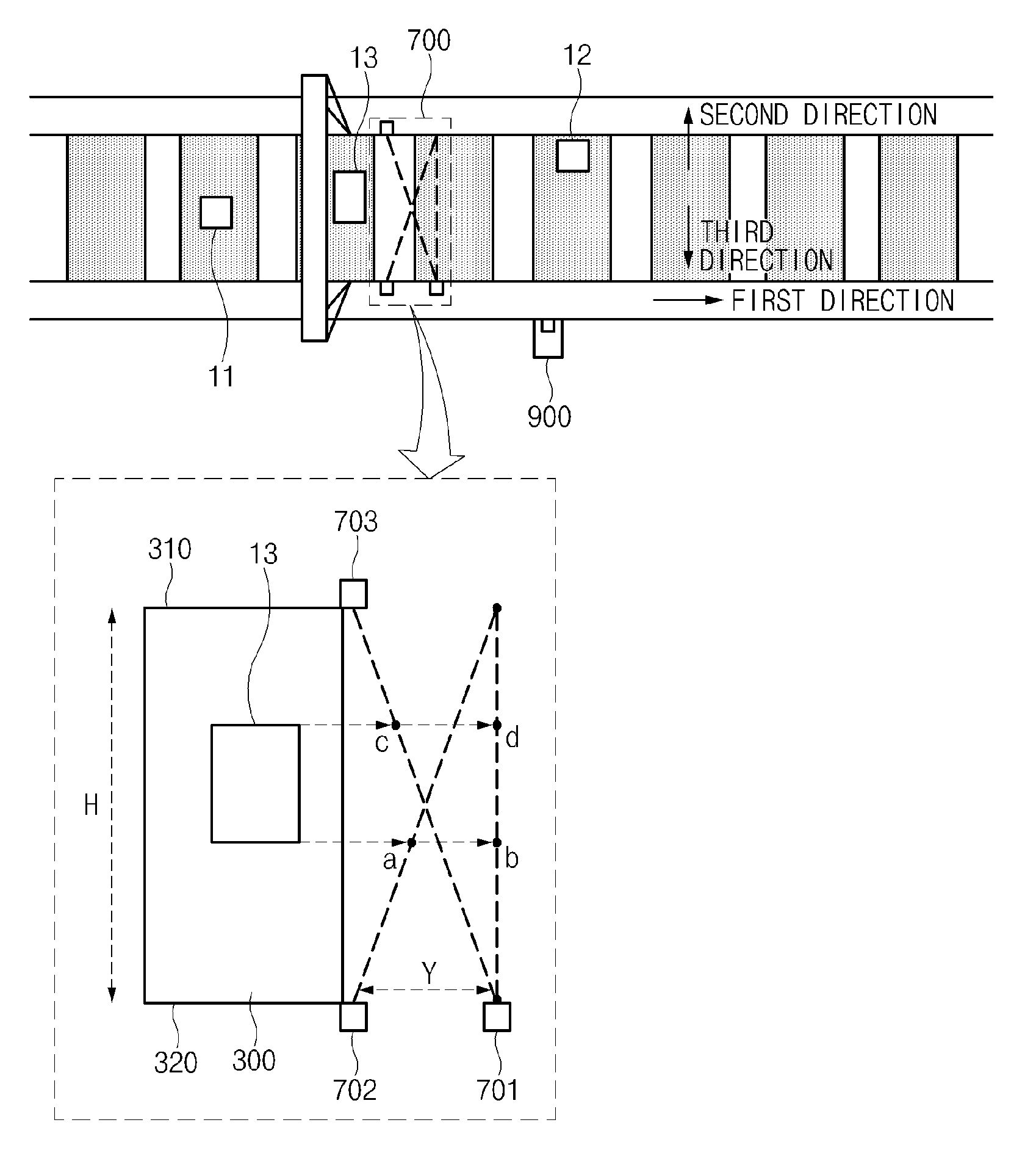

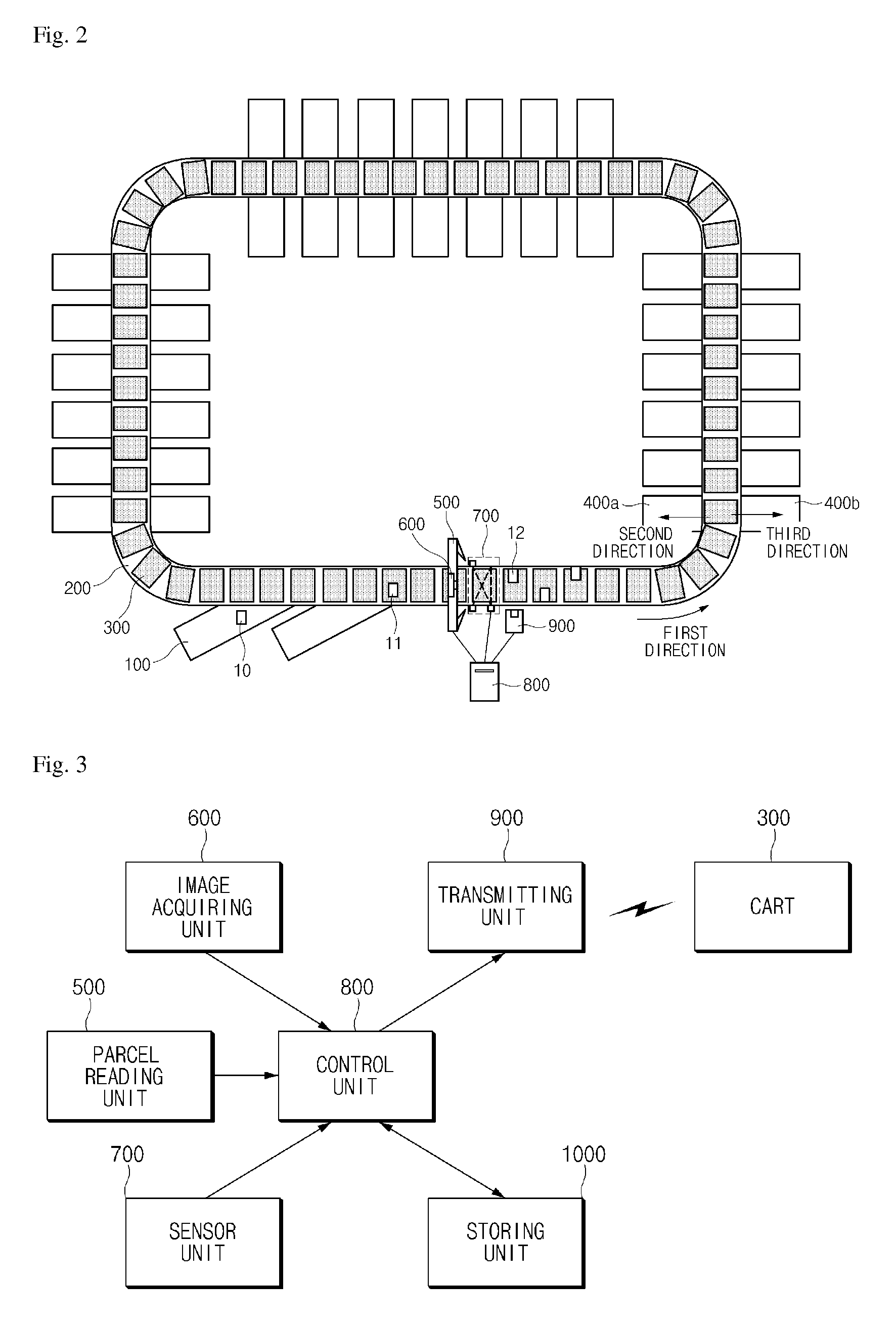

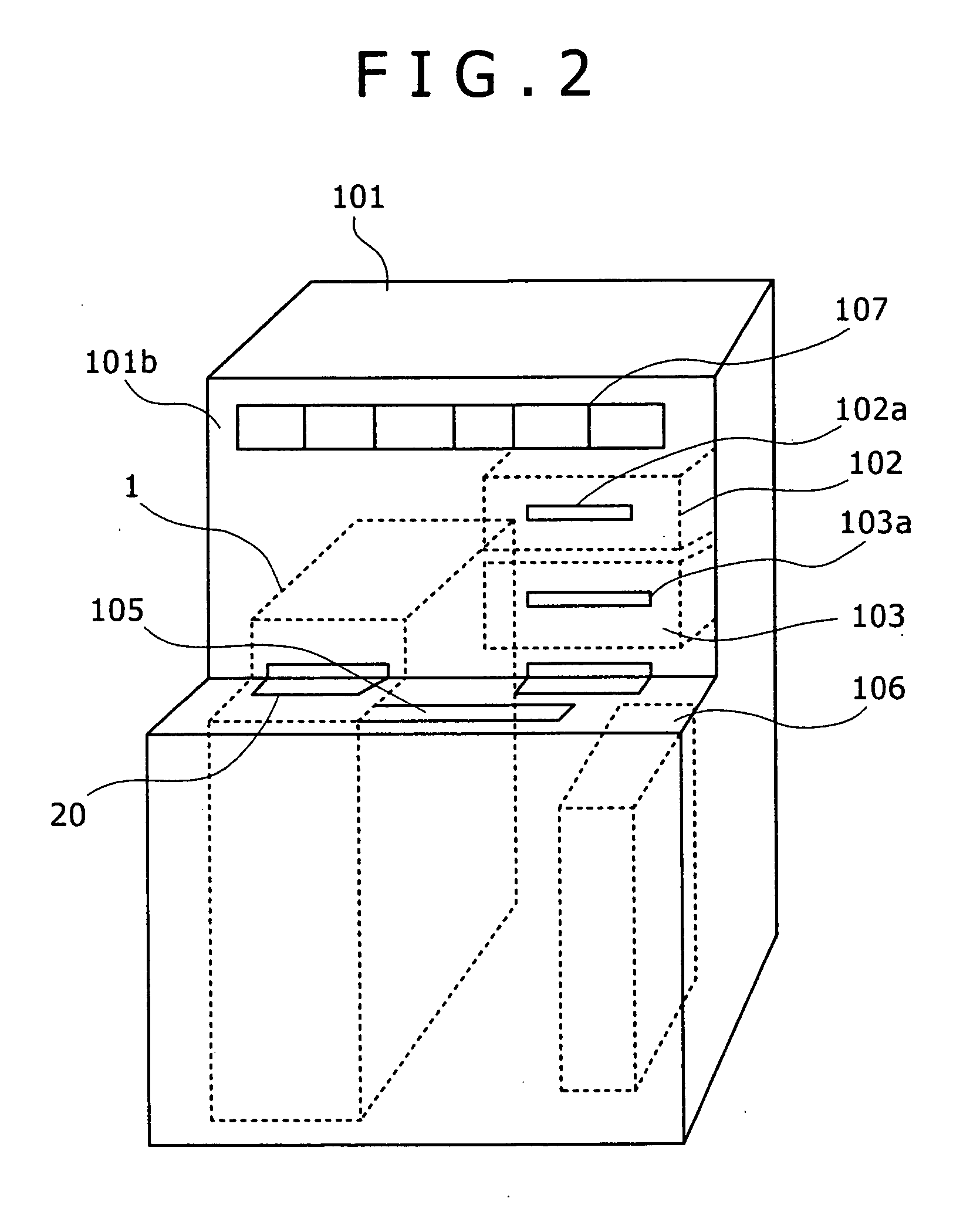

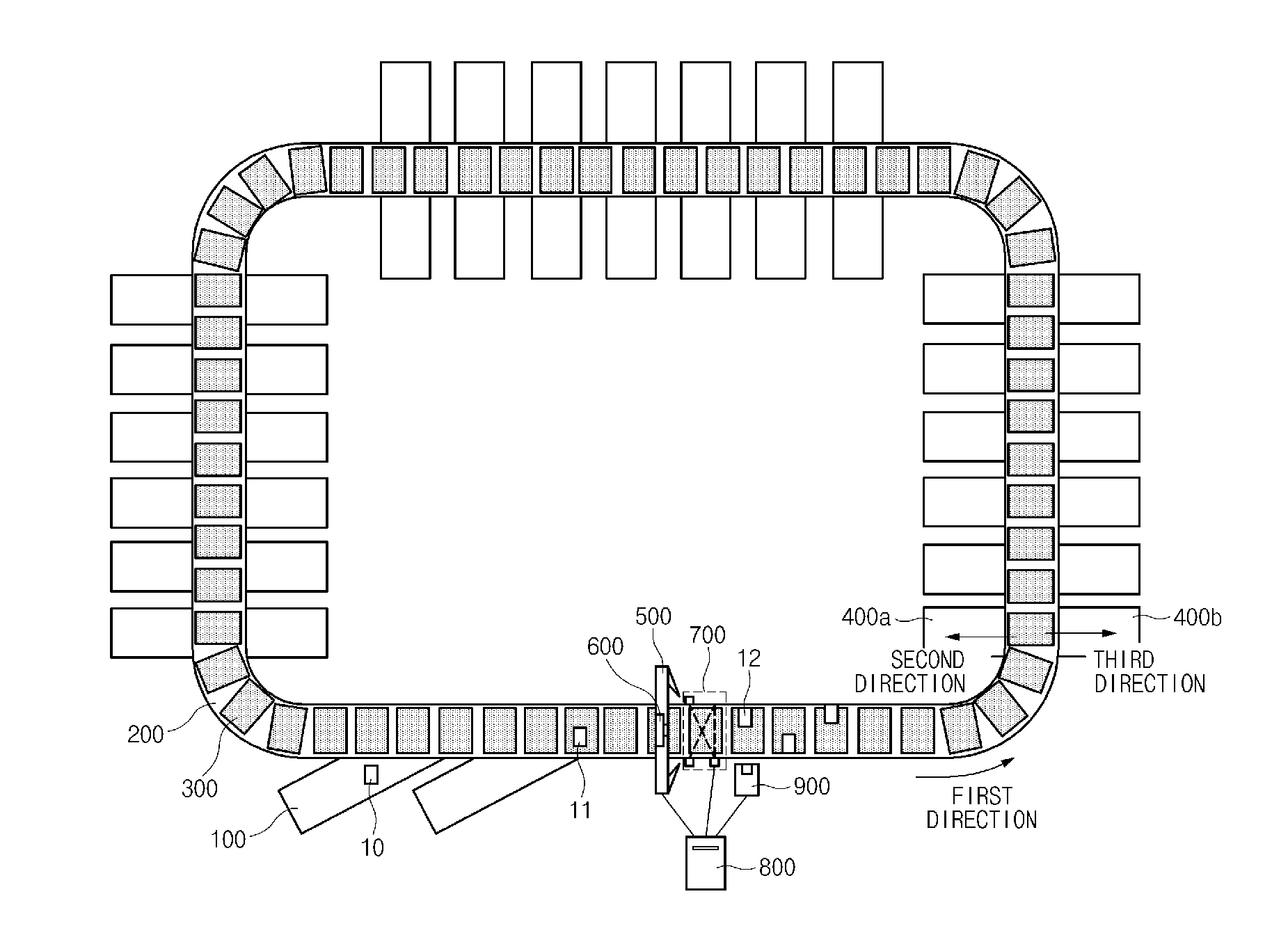

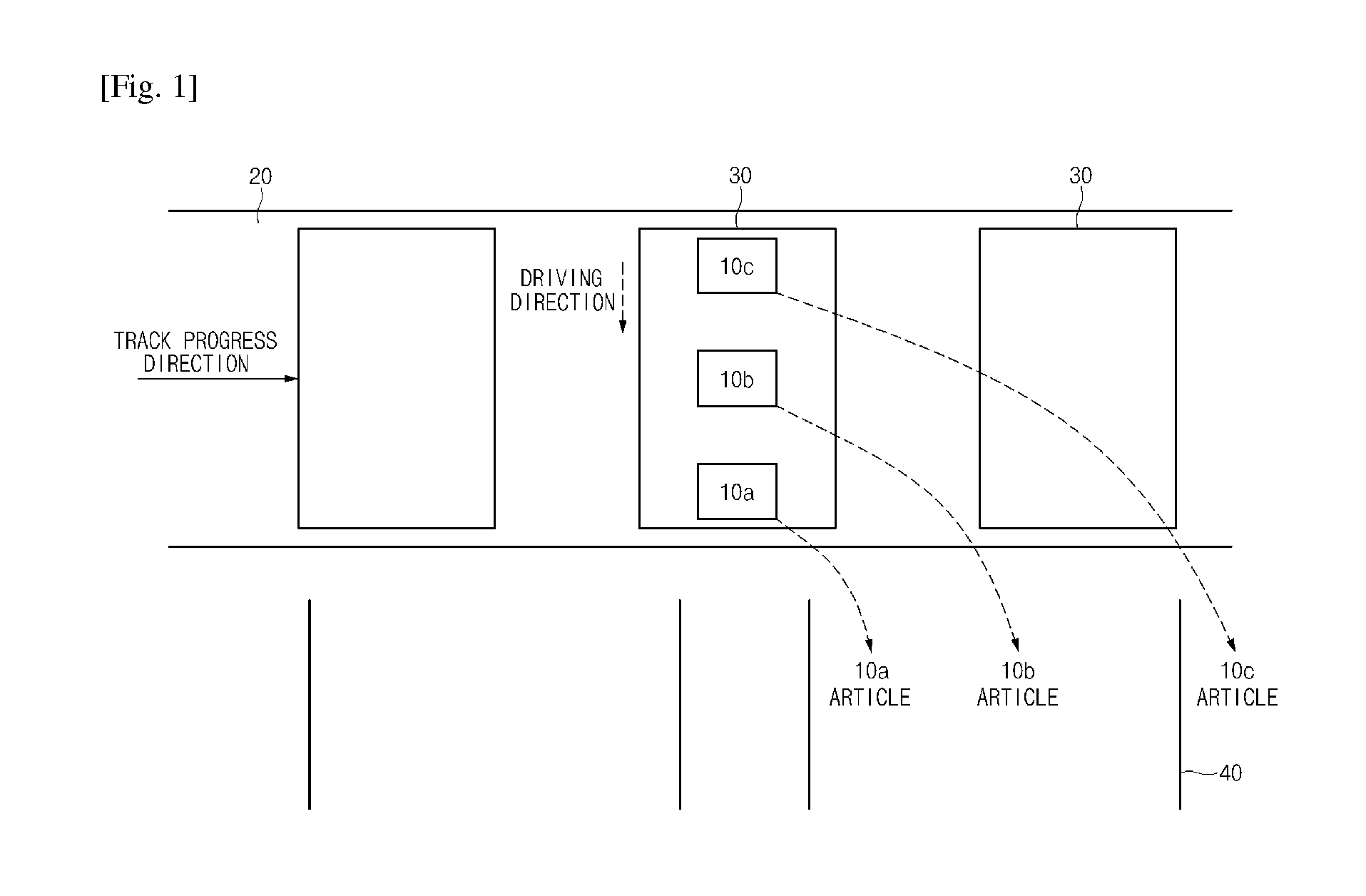

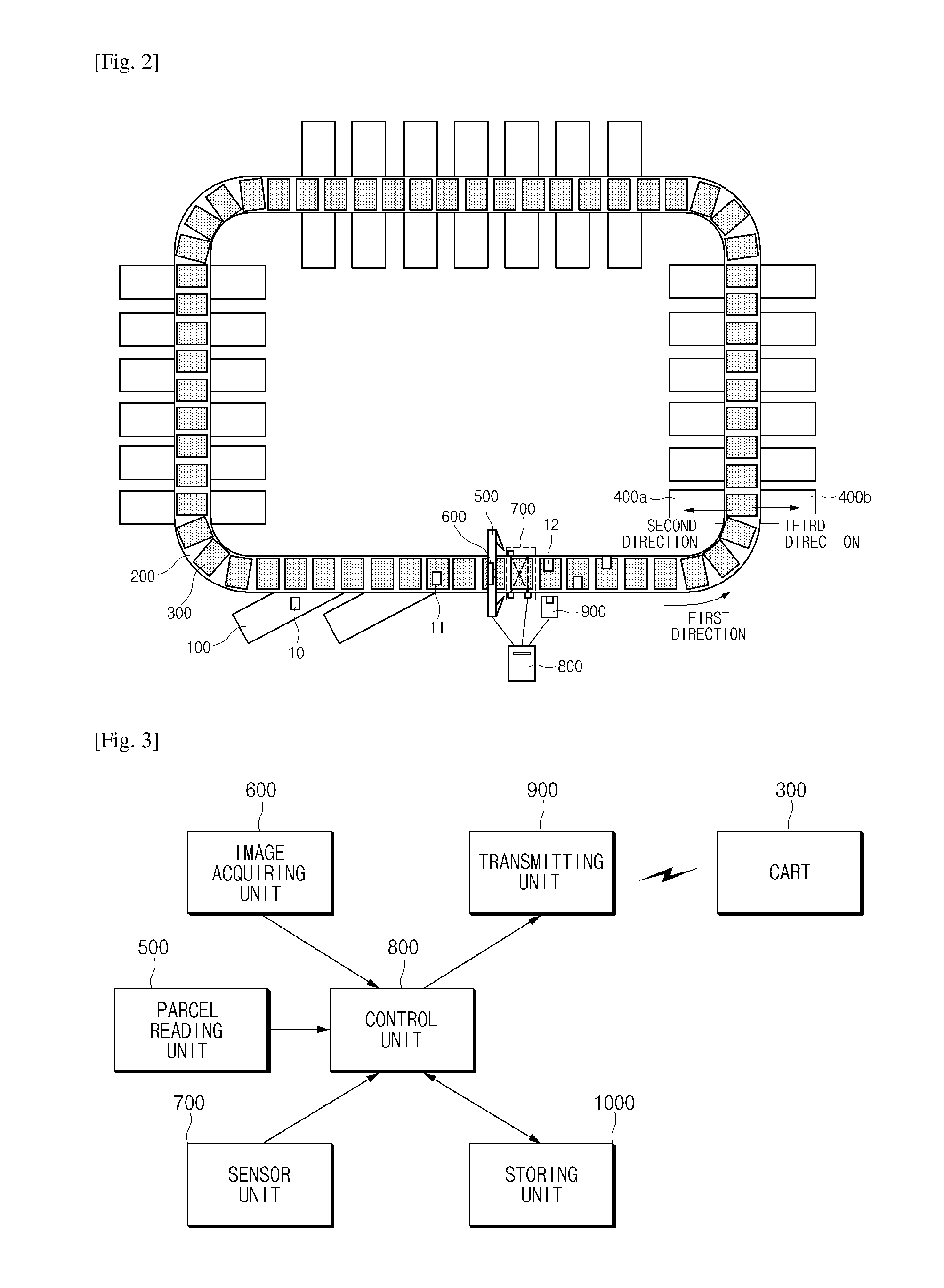

System and method for sorting parcel

A system and method for sorting a parcel moves an article to a cart according to destination information of the article to classify the article to a chute for each destination. An article position detecting unit detects positional information of the article loaded on the cart that moves in a first direction by a track which moves in the first direction. A control unit controls the cart to rotate in a second or third direction according to the detected positional information of the article and destination information of the article.

Owner:ELECTRONICS & TELECOMM RES INST

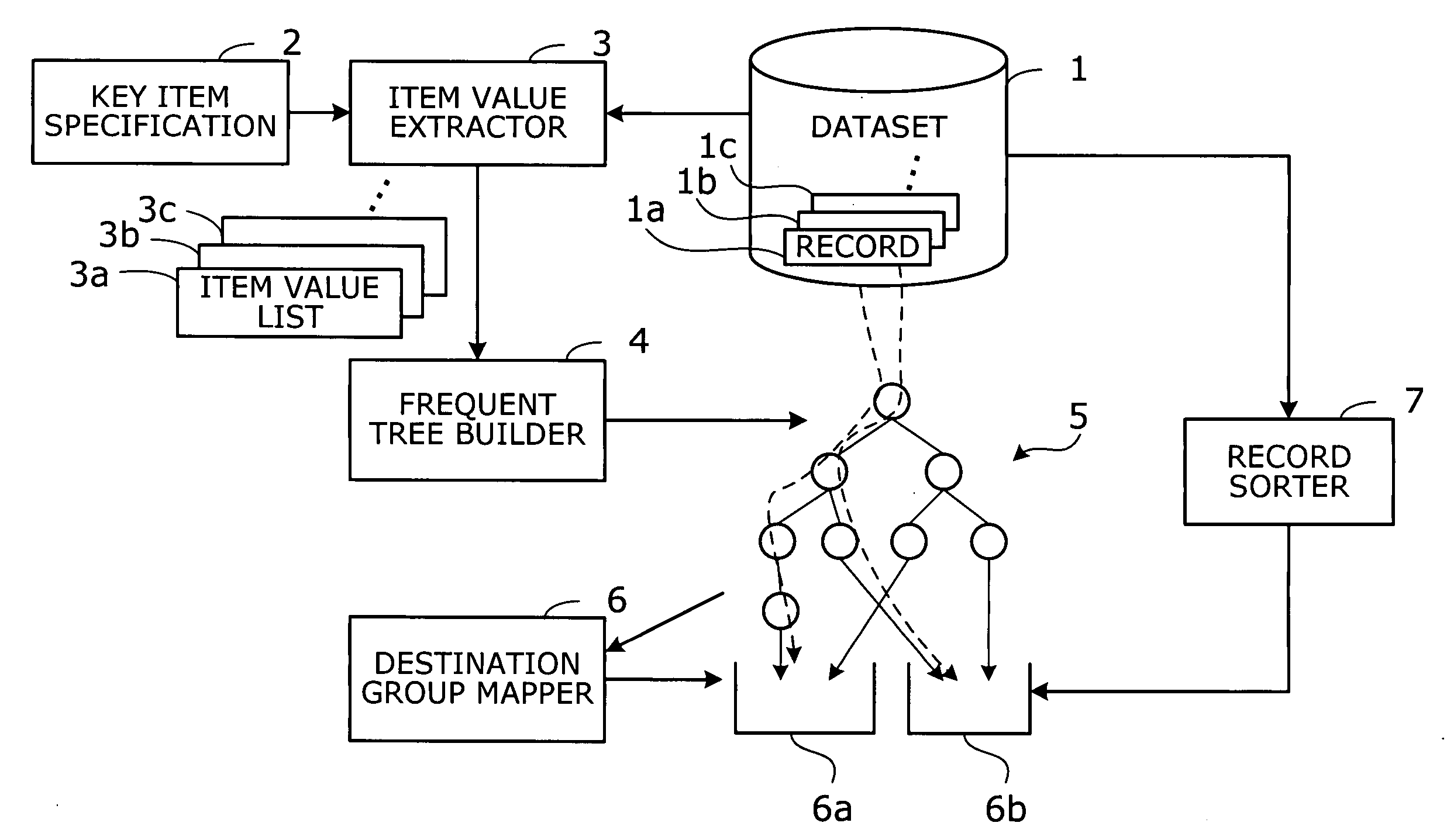

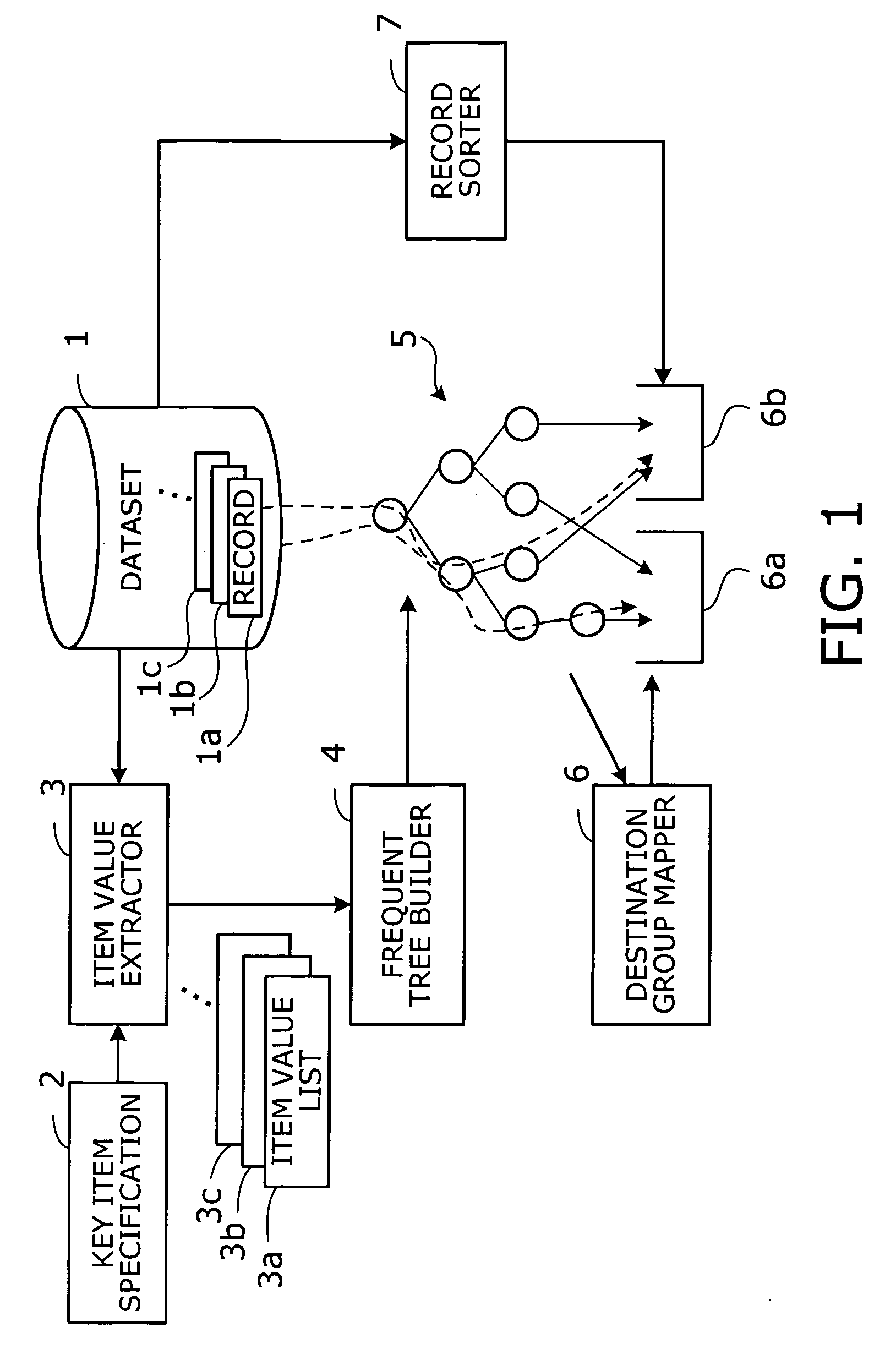

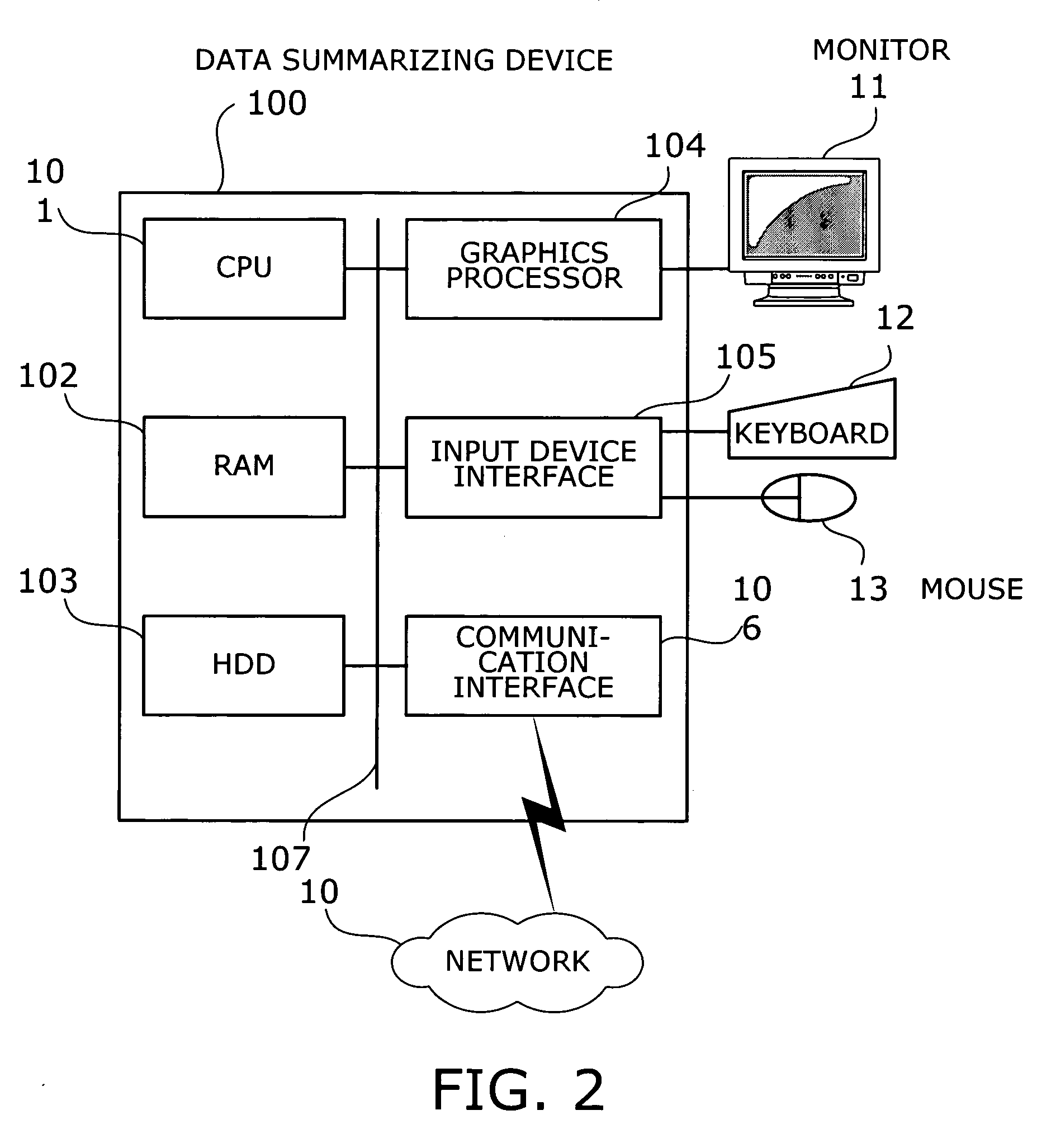

Computer program, device, and method for sorting dataset records into groups according to frequent tree

ActiveUS20070005598A1Efficient sortingDigital data information retrievalOffice automationData setRate parameter

A computer-readable storage medium storing a dataset sorting program is provided to sort records in a dataset into a plurality of destination groups according to a given key item specification. An item value extractor creates an item value list for every record. Then a frequent tree builder builds a frequent tree from the item value lists by finding patterns of item values that appear more often than a threshold specified by a given growth rate parameter. Each item value pattern is a leading part of an item value list with a variable length. A destination group mapper associates each node of the frequent tree with one of the plurality of destination groups. A record sorter traces the frequent tree according to the item value list of each given record, and upon reaching a particular node, puts the record into the destination group associated with that node.

Owner:FUJITSU LTD

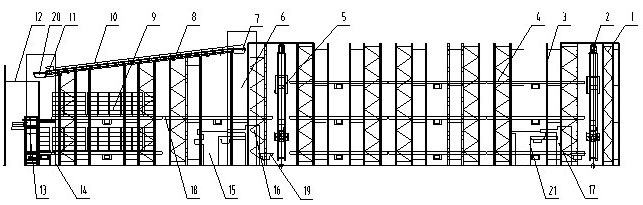

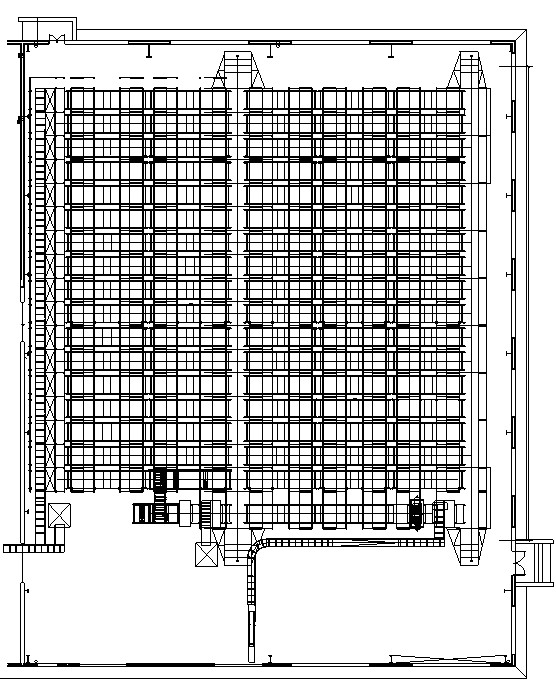

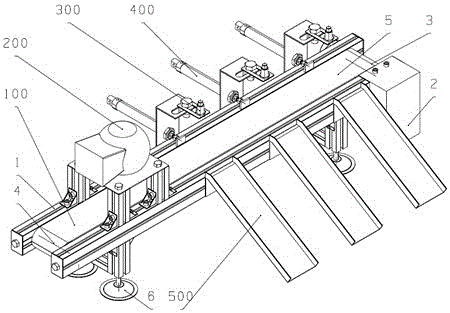

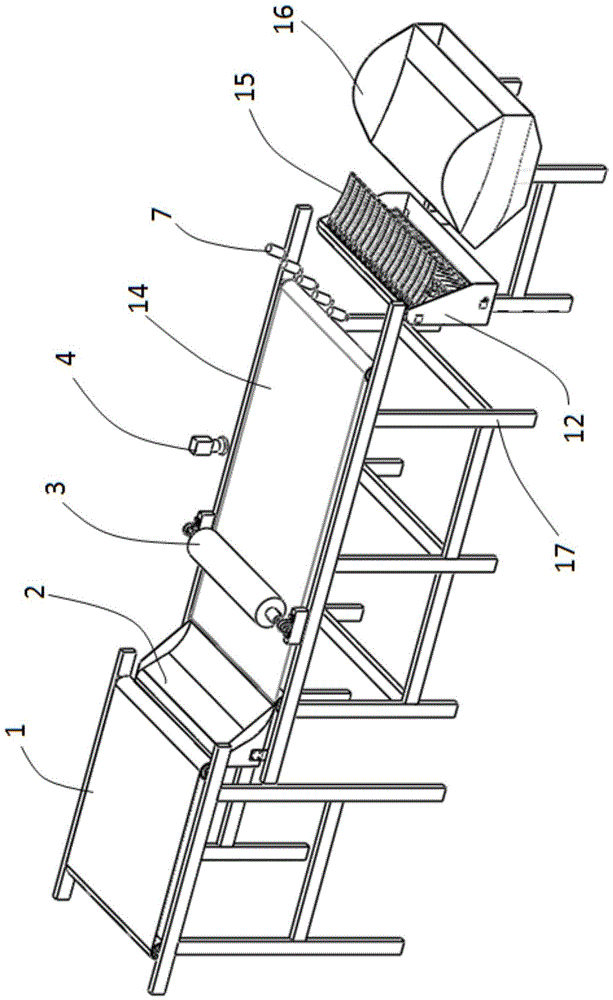

Warehousing method and equipment for intensive logistic warehouses

ActiveCN102092552AEfficient storageReduce storage costsStorage devicesLogistics managementOrder form

The invention discloses a warehousing method and equipment for intensive logistic warehouses. In an adopted technical scheme, the warehousing method for intensive logistics is characterized by comprising the steps of: dividing goods into different types according to the difference in out-going quantity of goods of different brands in a warehouse, storing goods of different types respectively in different positions in a logistic warehouse, and delivering the goods out of the warehouse by adopting different out-going manners. By means of the warehousing method and equipment, the intensive warehouse overcomes the defect that the traditional logistic warehouse is used for storing the goods according to the warehousing time sequence or the varieties of goods, and achieves the functions of classified storage according to the brands of goods and sorted out-going according to requirements of orders, therefore, the intensive storage of goods is effectively realized and the warehouse space is ensured to be fully utilized; meanwhile, the operation sequence is flexible and diverse, the goods storage cost is reduced, and the purposes of efficiently storing and sorting goods of different brands are achieved.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

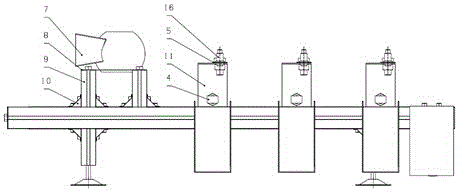

Automatic guide control system

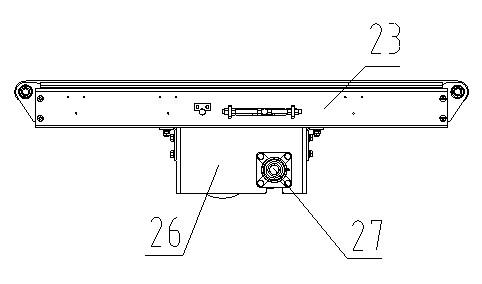

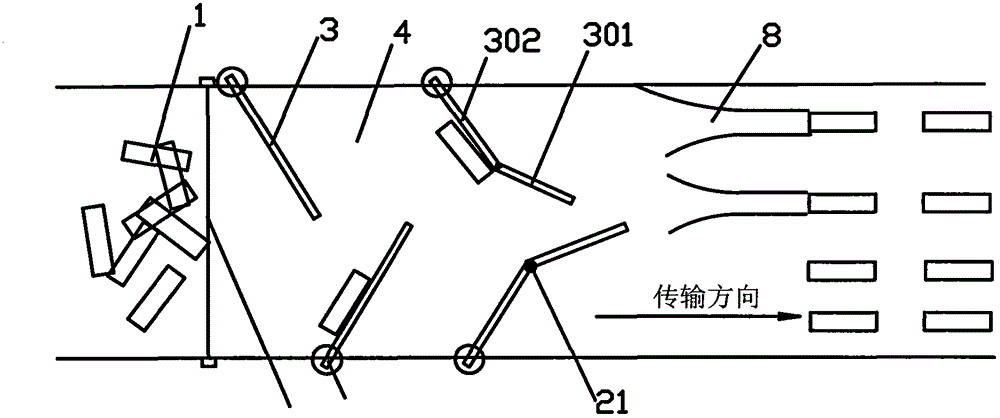

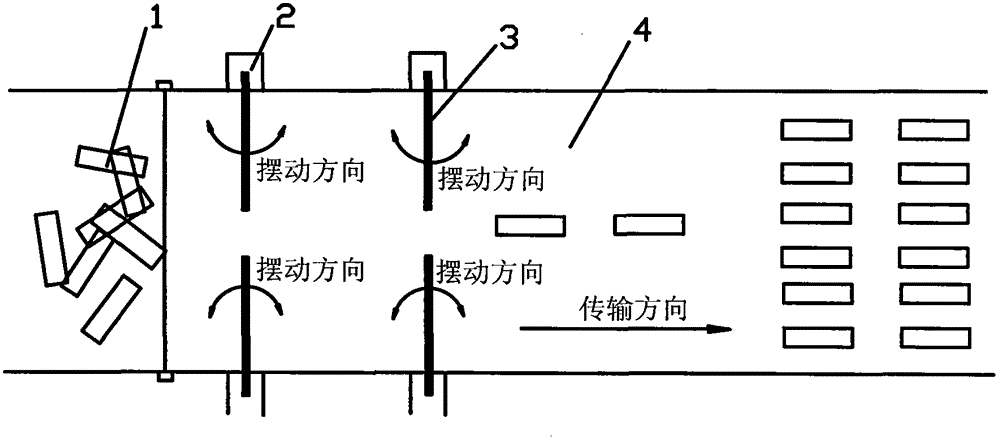

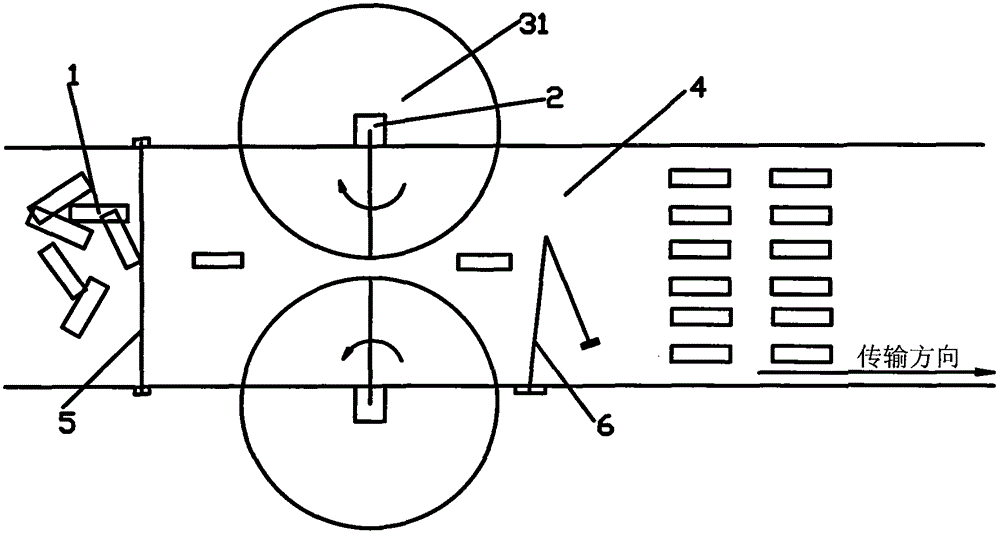

InactiveCN102718053AEfficient sortingSimple structureConveyor partsAutomatic train controlAutomatic control

The invention discloses an automatic guide control system which comprises a transmission belt, guide arms, a control device and a height control arm, wherein the transmission belt is used for transmitting objects along a determined direction; the guide arms are arranged on the two sides of the transmission belt through guide arm installing ends and used for regulating the direction of the objects to be transmitted; the control device can control the movement of the transmission belt; the height of the height control arm can be set, and the height control arm is used for controlling that the objects to be transmitted are not transmitted in an overlapping manner; and the guide arms are arranged to be single or in a large arm-small arm connection manner and can be arranged side by side in multiple groups. The automatic guide control system also comprises guide grooves which are used for guiding the objects passing through the guide arms into specified lines and are arranged side by side in multiple groups. The automatic guide control system has the advantages of simple structure, convenience and effectiveness for sequencing the disordered and scattered materials, strong applicability and high precision.

Owner:ADTECH SHENZHEN TECH

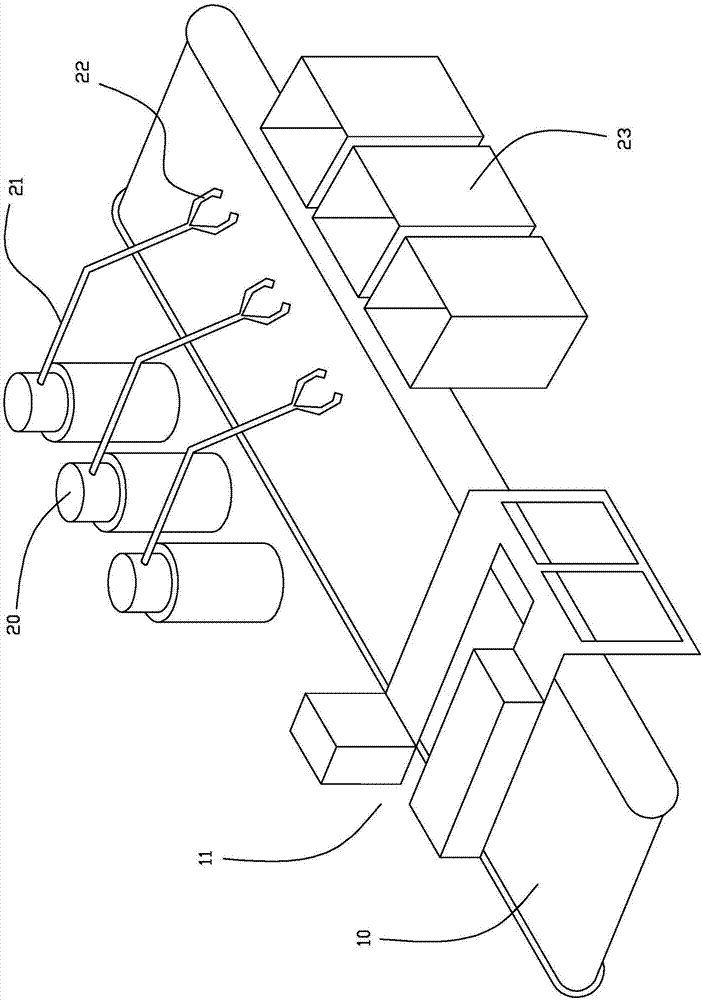

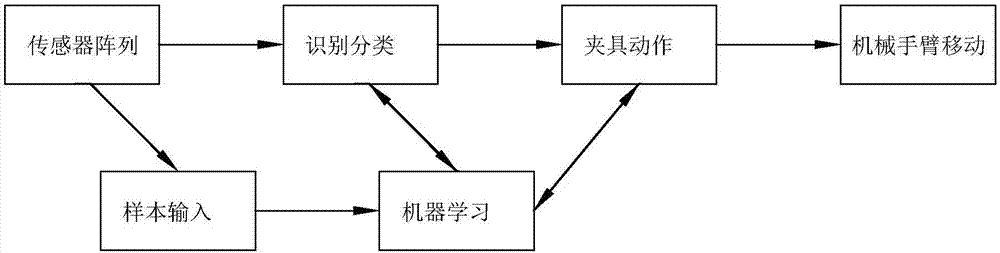

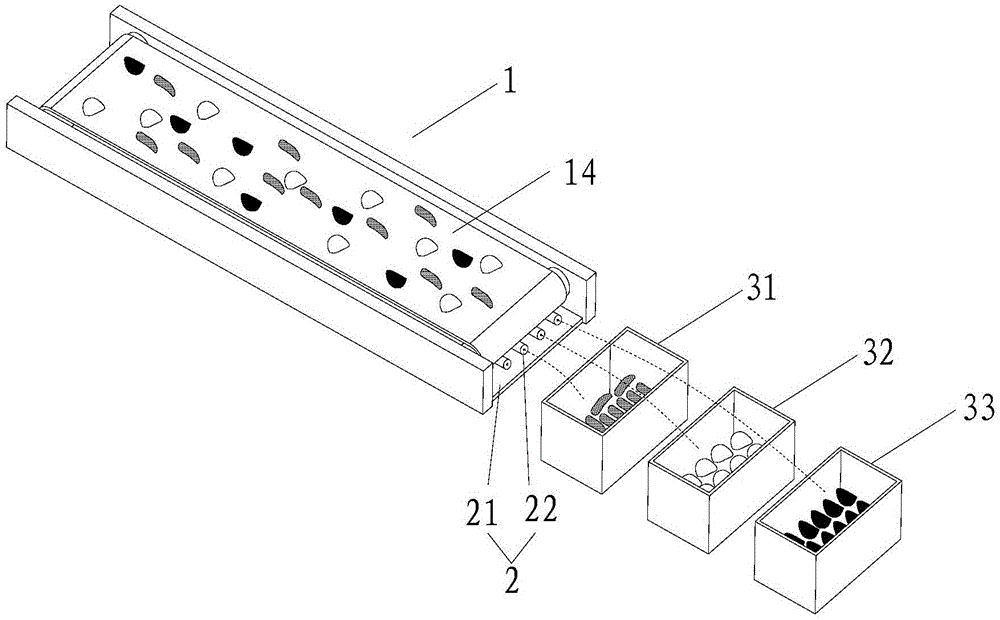

Massive solid building waste sorting system based on multiple detection modes

The invention relates to a massive solid building waste sorting system based on multiple detection modes. A sensor detection and recognition mechanism is composed of a conveyor belt and a sensor array with multiple detection functions; an industrial robot sorting mechanism is composed of a plurality of industrial robots and a plurality of sorting boxes; and a control system is connected with the sensor array and the industrial robots respectively, the sensor array carries out real-time detection, and the control system analyzes information collected by the sensor array and controls the industrial robots to sort massive solid building wastes in different types into corresponding sorting boxes. As for the massive solid building waste sorting system based on multiple detection modes, as a mechanical arm of each industrial robot is provided with a clamp, the massive solid building wastes on the conveyor belt are grabbed by the clamps and moved above the corresponding sorting boxes through movement of the mechanical arms, the clamps release the massive solid building wastes, and the sorted massive solid building wastes fall into the corresponding sorting boxes, so that effective sorting of the massive solid building wastes is realized.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

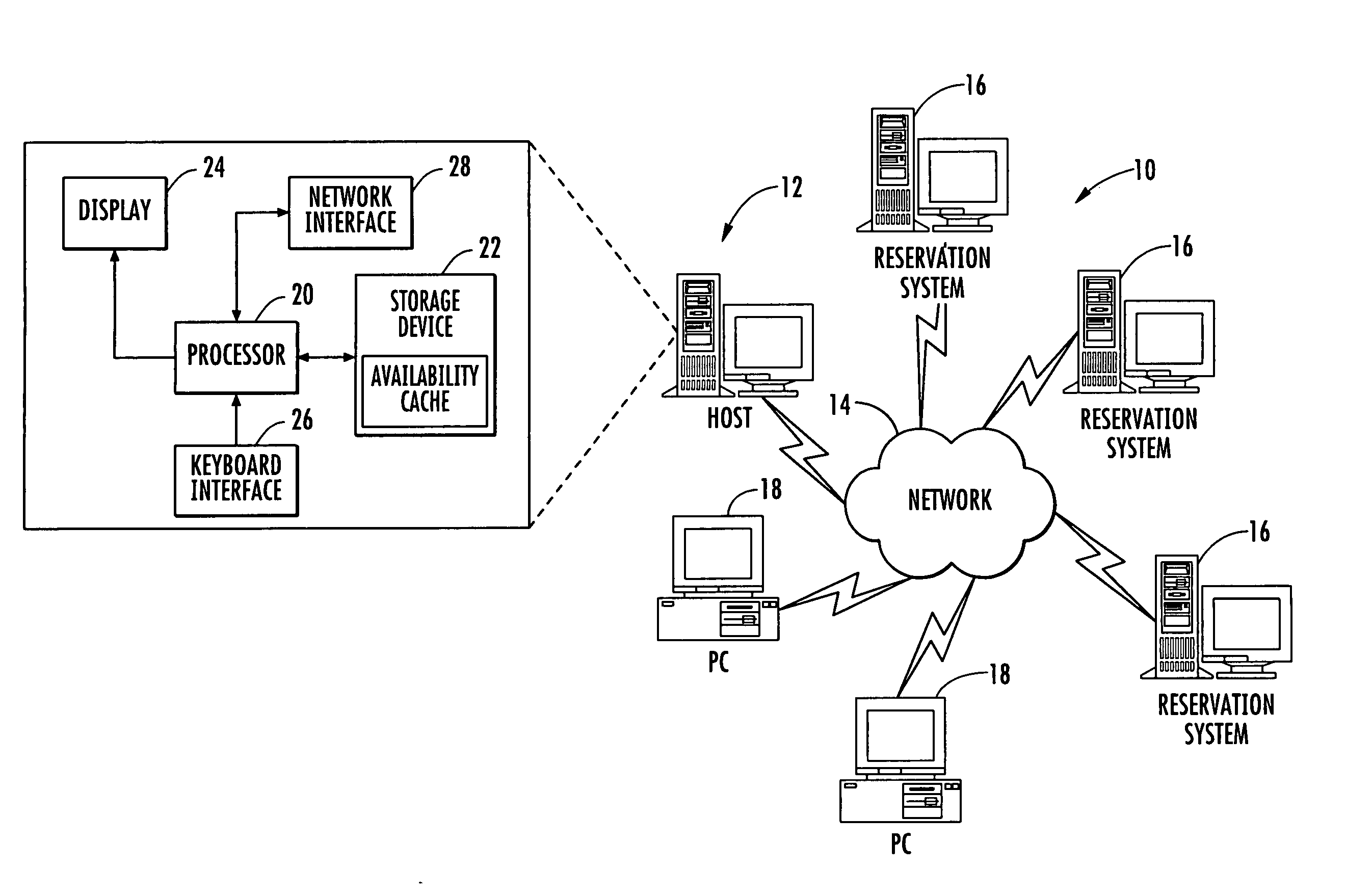

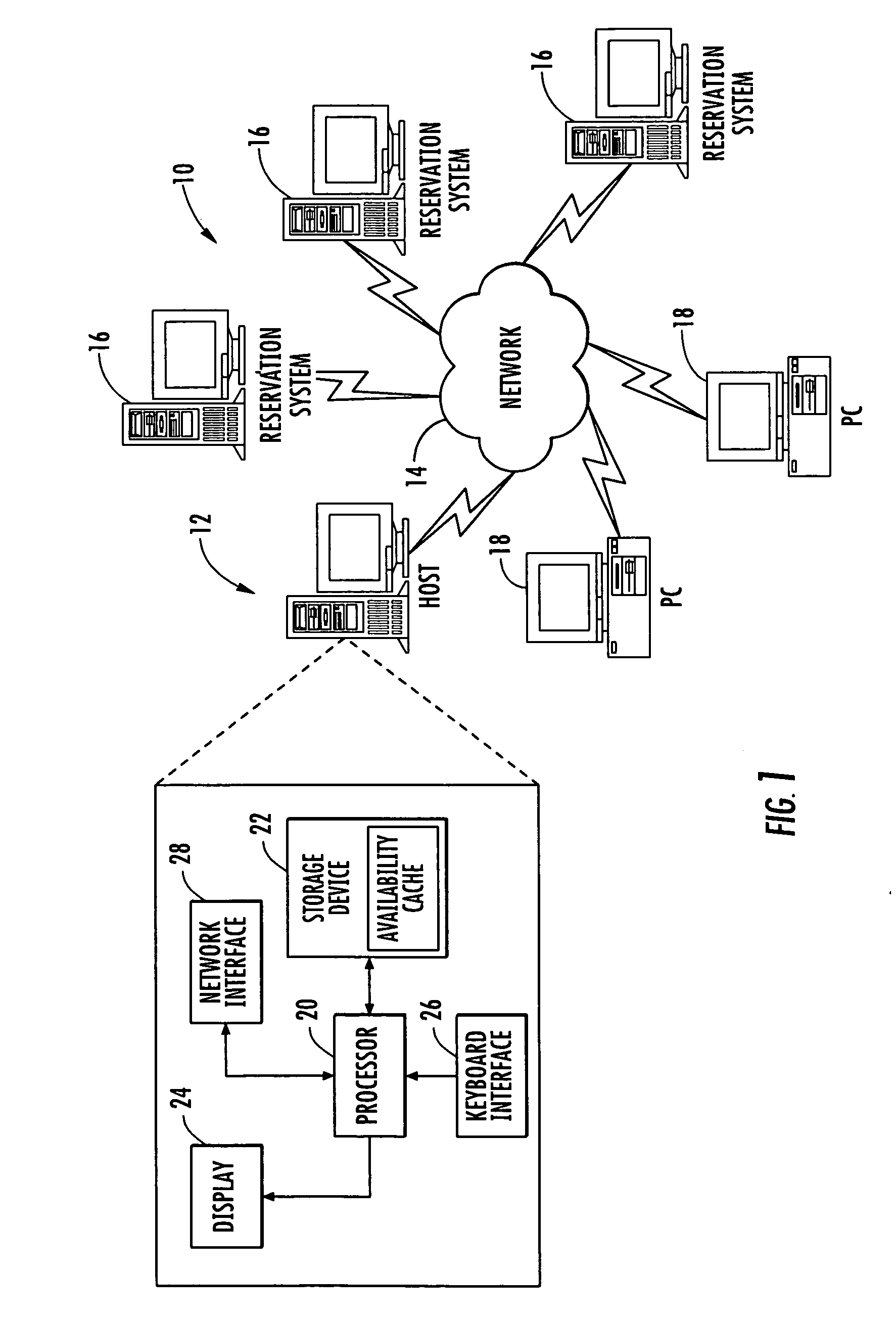

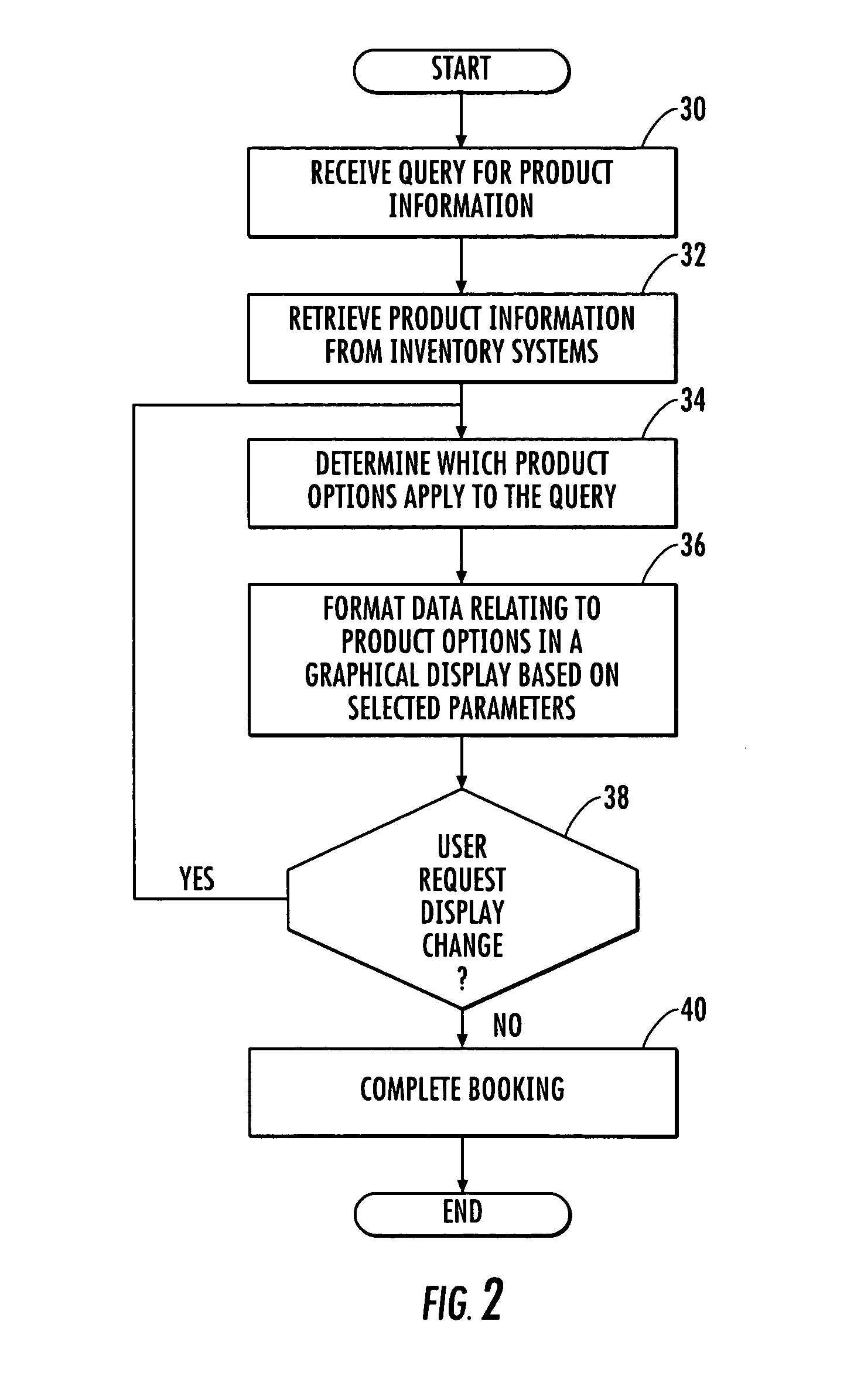

System, method, and computer program product for reducing the burden on inventory system by displaying product availability information for a range of parameters related to a product

A system, method, and computer program product for providing results concerning product option availability via an interactive display. The invention generates data for display that shows product options in a multi-axis display wherein the axes correspond to at least two criteria related to the product options. The disclosed system also includes a user interface in communication with the interactive display capable of receiving a user input, such as a filter command, for selecting a portion of the product options such that the interactive display may generate a modified graphical image in response to the user input such that the user may be more completely informed of available product options and therefore select an optimal product option from the displayed product options.

Owner:SABRE +1

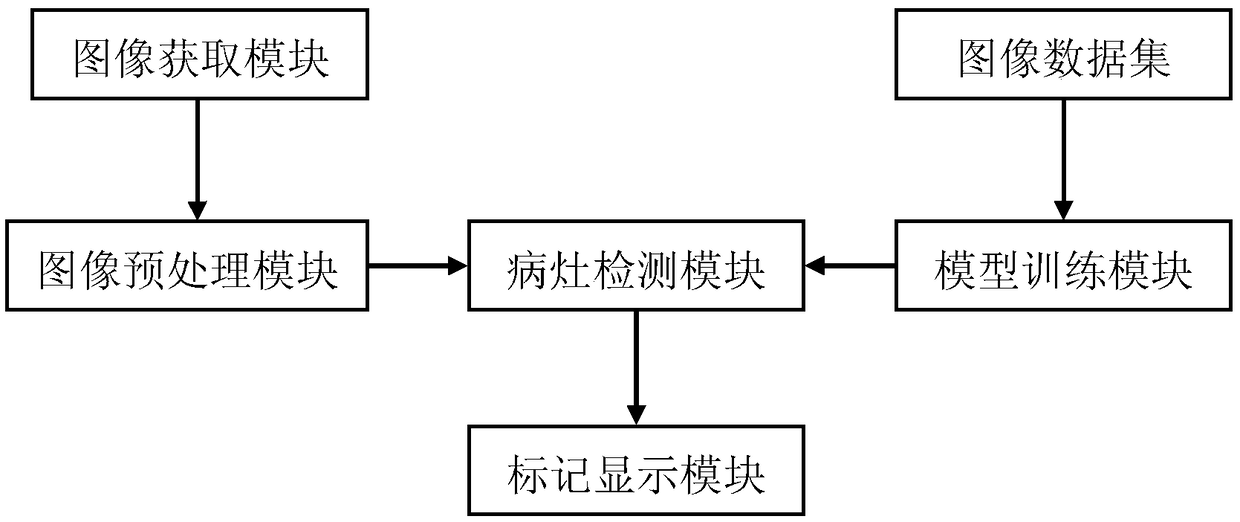

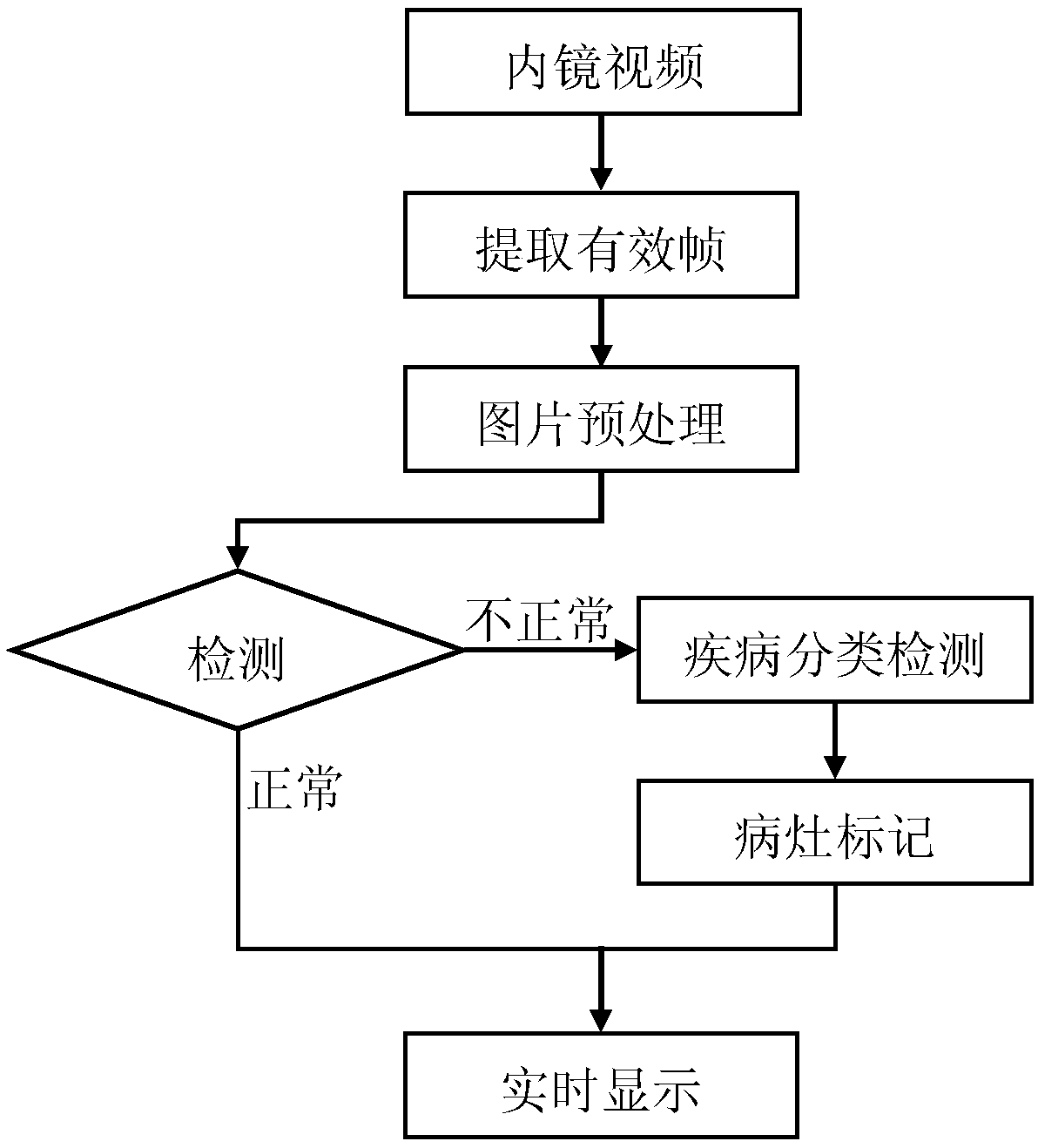

Digestive endoscopy image abnormal feature real-time labeling system and method

InactiveCN108852268AAvoid missingThe effect of feature classification is goodGastroscopesOesophagoscopesDiseaseData set

The invention discloses a digestive endoscopy image abnormal feature real-time labeling system and method. The system comprises an image acquisition module, an image preprocessing module, a model training module, an anomaly detection module and a label display module; the model training module comprises an image data set, a classification model training unit and a detection model training unit. Classification information of suspicious stomach precancerous diseases is acquired through a deep learning CNN classification model, and a target detection model is utilized to quickly and accurately acquire the focus position by means of deep learning CNN and on the basis of a regression method. By using the method, stomach abnormal features are effectively classified and detected under digestive endoscopy, the missed diagnosis rate on the basis of long-time and subjective diagnosis of doctors can be reduced, real-time analysis and real-time suspicious focus display under an endoscope are supported when the doctors conduct endoscopic tests, the working burden of the doctors is reduced, and the efficiency of medical diagnosis work is improved.

Owner:ZHEJIANG UNIV

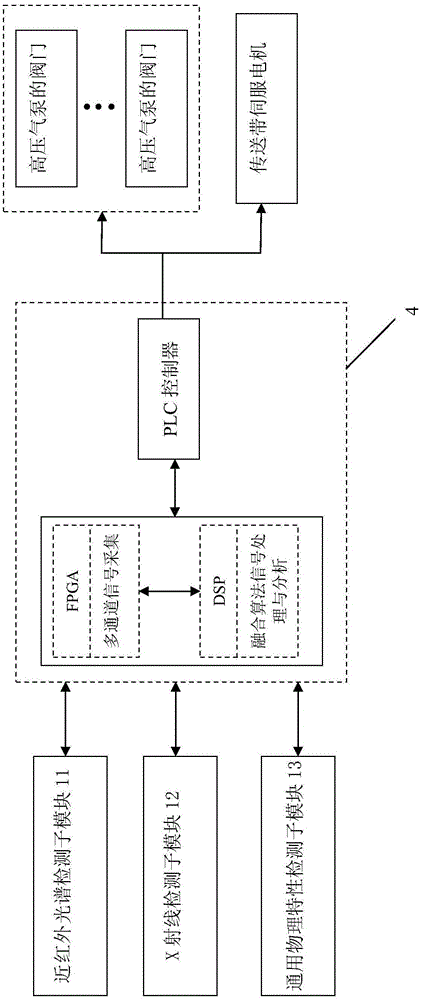

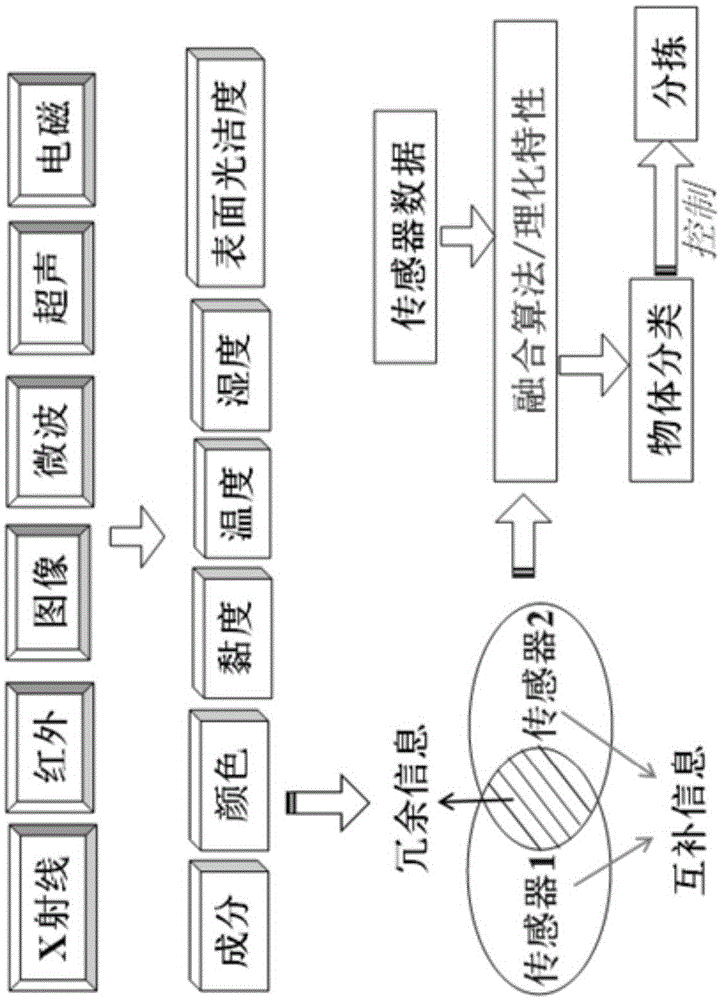

System for sorting blocky solid construction waste on basis of multiple detection modes

The invention discloses a system for sorting blocky solid construction waste on the basis of multiple detection modes. The system is provided with one or more sorting units. Each sorting unit comprises a detection and recognition part, a jet part, a sorting part and a real-time detection and control system. Each detection and recognition part is provided with a sensor array and a conveying belt. Each sensor array comprises various sensor components located above and below the corresponding conveying belt. Each real-time detection and control system is used for achieving signal processing of the corresponding sensor array and controlling the corresponding conveying belt and high-pressure air pumps of the corresponding jet part. By judging object physical and chemical properties obtained after signal processing, the construction waste is selectively jetted into different sorting boxes through high-pressure air guns. The construction waste which is subjected to mechanical sorting (involving primary smashing and screening) and has the similar density is differentiated through spectroscopy and a plurality of other physical and chemical characteristic parameters, in this way, sorting of the solid construction waste is achieved. The system has high analytical precision, cost performance and efficiency and is easy to maintain.

Owner:QUANZHOU INST OF EQUIP MFG

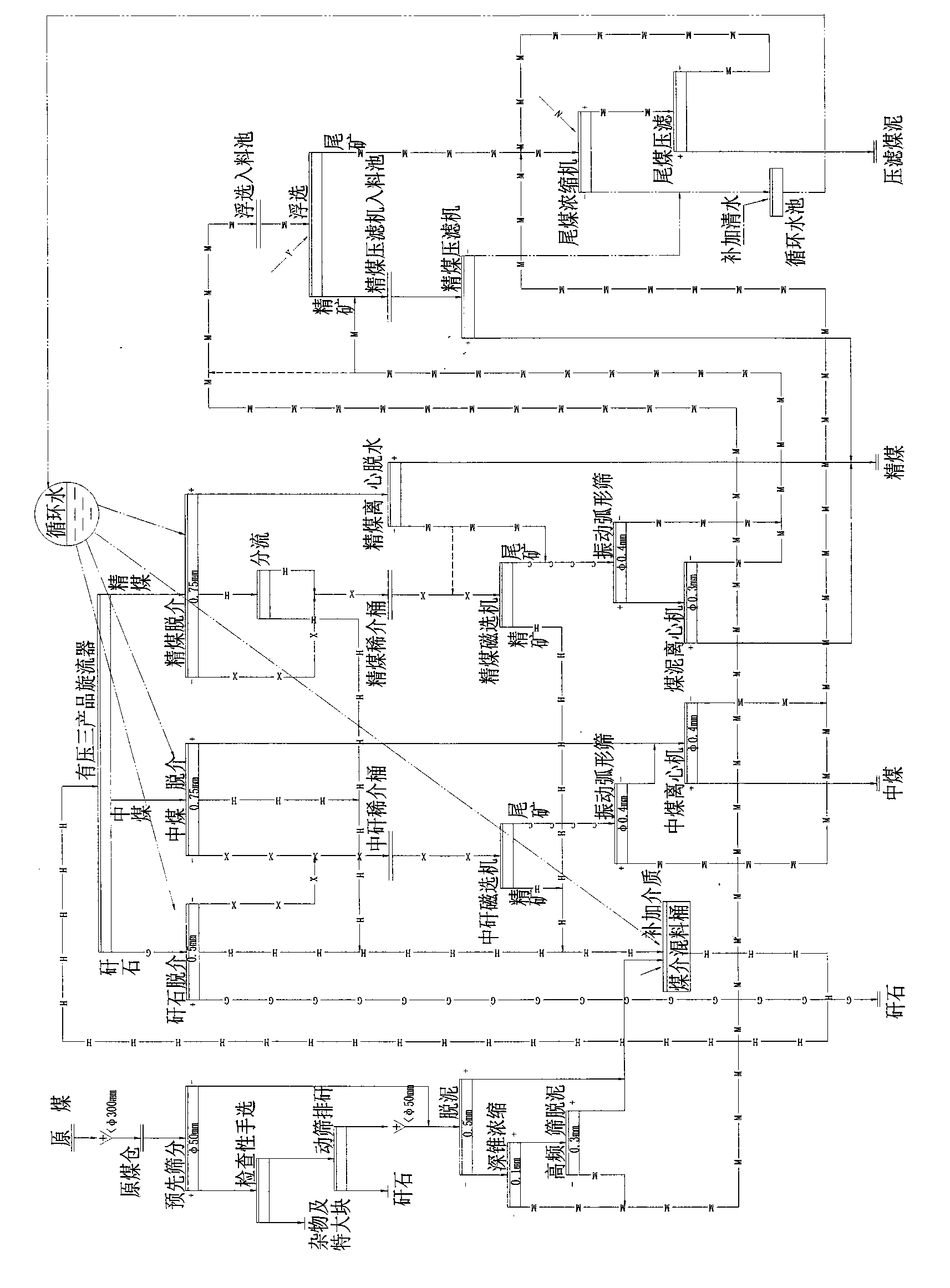

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

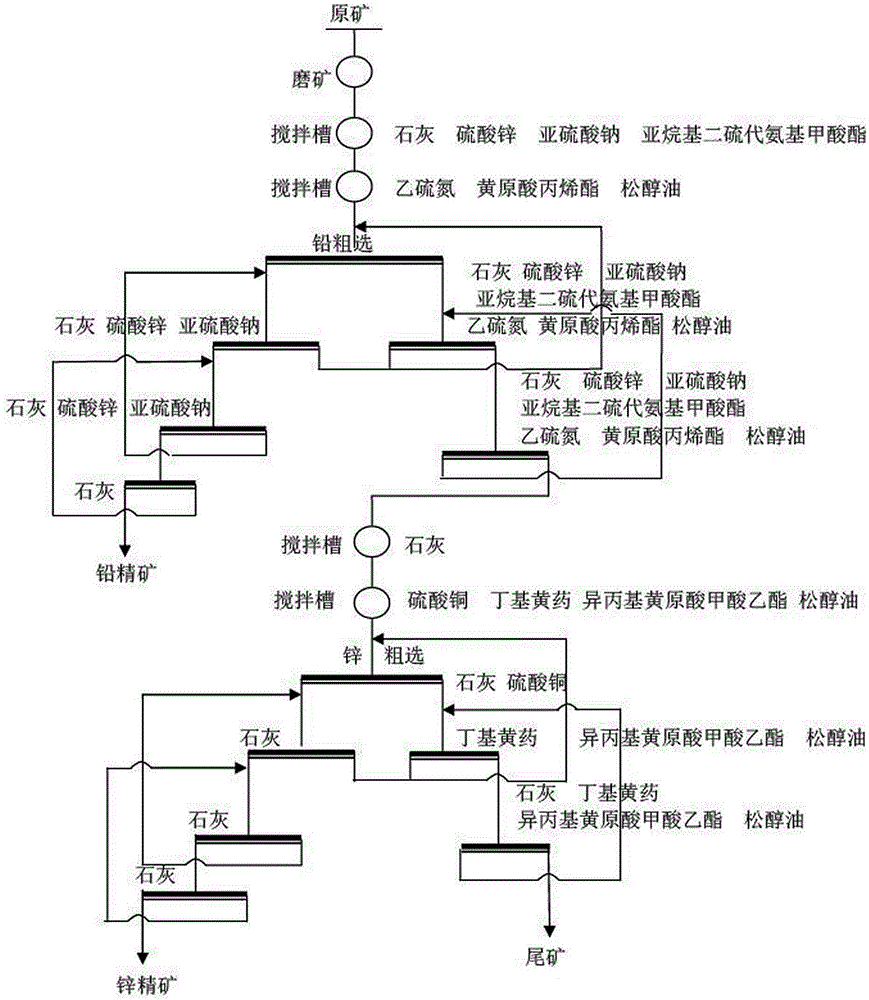

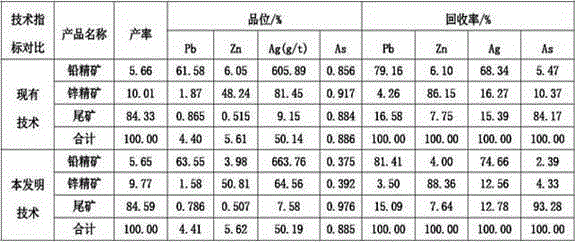

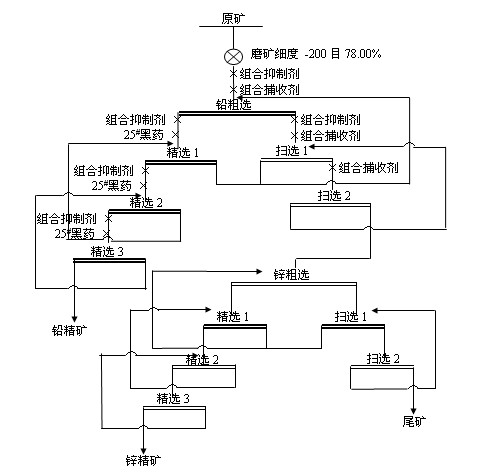

Beneficiation method for complex sulphide lead-zinc ore containing arsenic

The invention discloses a beneficiation method for complex sulphide lead-zinc ore containing arsenic. The beneficiation method is characterized by comprising the steps that raw ore is added into a ball mill to be milled, lime, zinc sulfate, sodium sulfite and p-xylylenebis(n,n- diethyldithiocarbamate) are added after the milled raw ore enters a first stirring tank, and diethyldithiocarbamate, isoamylxanthate and terpenic oil are added into a second stirring tank; a combined inhibitor and a combined collector are added before first-time scavenging and second-time scavenging of lead floatation; the combined inhibitor and the combined collector are added before first-time lead concentration, second-time lead concentration and third-time lead concentration; zinc floatation is conducted on tailings obtained after lead floatation; the combined inhibitor and the combined collector are added before first-time scavenging and second-time scavenging of zinc floatation; and lime is added before each time zinc concentration is conducted. By the adoption of the beneficiation method, lead-zinc concentrate products qualified in arsenic content are obtained, the grade and yield of lead and zinc in lead concentrate can be increased, and the grade and yield of zinc in zinc concentrate can also be increased; highly toxic products such as sodium cyanide or oxidizing agents do not need to be added, serious pollution to the environment is avoided, and clean, environment-friendly and safe production is achieved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

Fluorite mineral flotation method

ActiveCN102921551AConcentrate products are of good qualityGood recovery rate of fluorsparFlotationSodium fluorideMineralogy

The invention discloses a fluorite mineral flotation method. A flotation process of one-segment rough flotation plus scavenging and seven-segment fine flotation is matched with adoption of inhibitors formed by combination of water glass and sodium fluoride, and collecting agents formed by compounding of fatty acid and dimethyl formamide. In the flotation process, fluorites and other minerals in common fluorite minerals, complex fluorite minerals, flotation tailings containing the fluorites, and the like can be effectively separated, and obtained fluorite concentrate products are good in quality and have few impurities. The fluorite mineral flotation method is especially applicable to flotation separation of a large quantity of low-grade fluorite minerals with higher carbonate content, can be used for reducing the content of the impurities in beneficiation products, and has enormous economic benefits and environmental benefits.

Owner:LONGQUAN FLUOSPAR +1

Methods for nucleic acid mapping and identification of fine-structural-variations in nucleic acids

ActiveUS20090325239A1Quick buildEfficient sortingSugar derivativesMicrobiological testing/measurementNucleic acid mappingA-DNA

A method of juxtaposing sequence tags (GVTs) that are unique positional markers along the length of a population of target nucleic acid molecules is provided, the method comprising: fragmenting the target nucleic acid molecule to form target DNA insert; ligating the target DNA insert to a DNA vector or backbone to create a circular molecule; digesting the target DNA insert endonuclease to cleave the target DNA insert at a distance from each end of the target DNA insert yielding two GVTs comprising terminal sequences of the target DNA insert attached to an undigested linear backbone; recircularizing the linear backbone with the attached GVTs to obtain a circular DNA containing a GVT-pair having two juxtaposed GVTs; and recovering the GVT-pair DNA by nucleic acid amplification or digestion with endonuclease having sites flanking the GVT-pair. Cosmid vectors are provided for creating GVT-pairs of ˜45- to 50-kb separation sequencable by next-generation DNA sequencers.

Owner:VERSITECH LTD

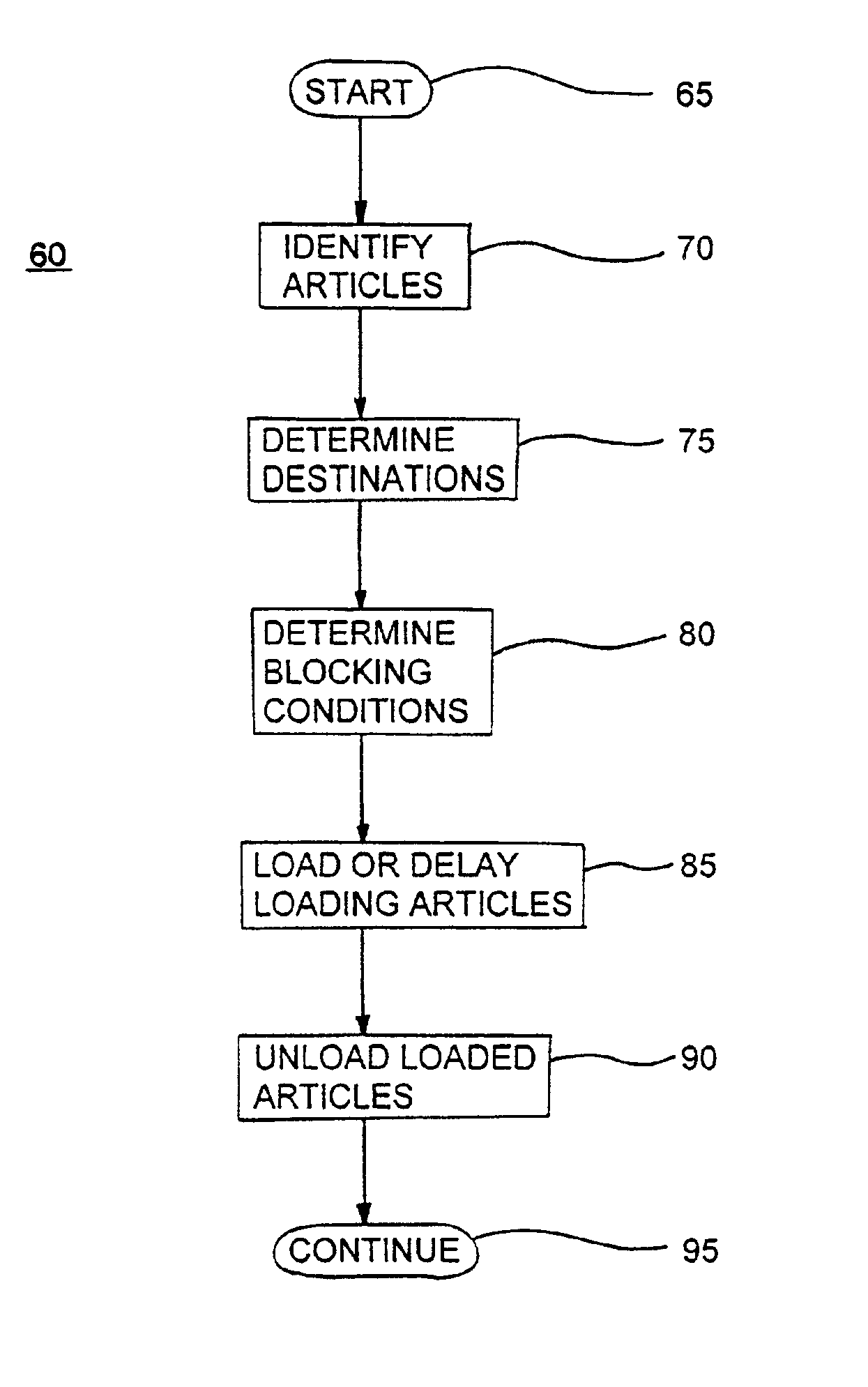

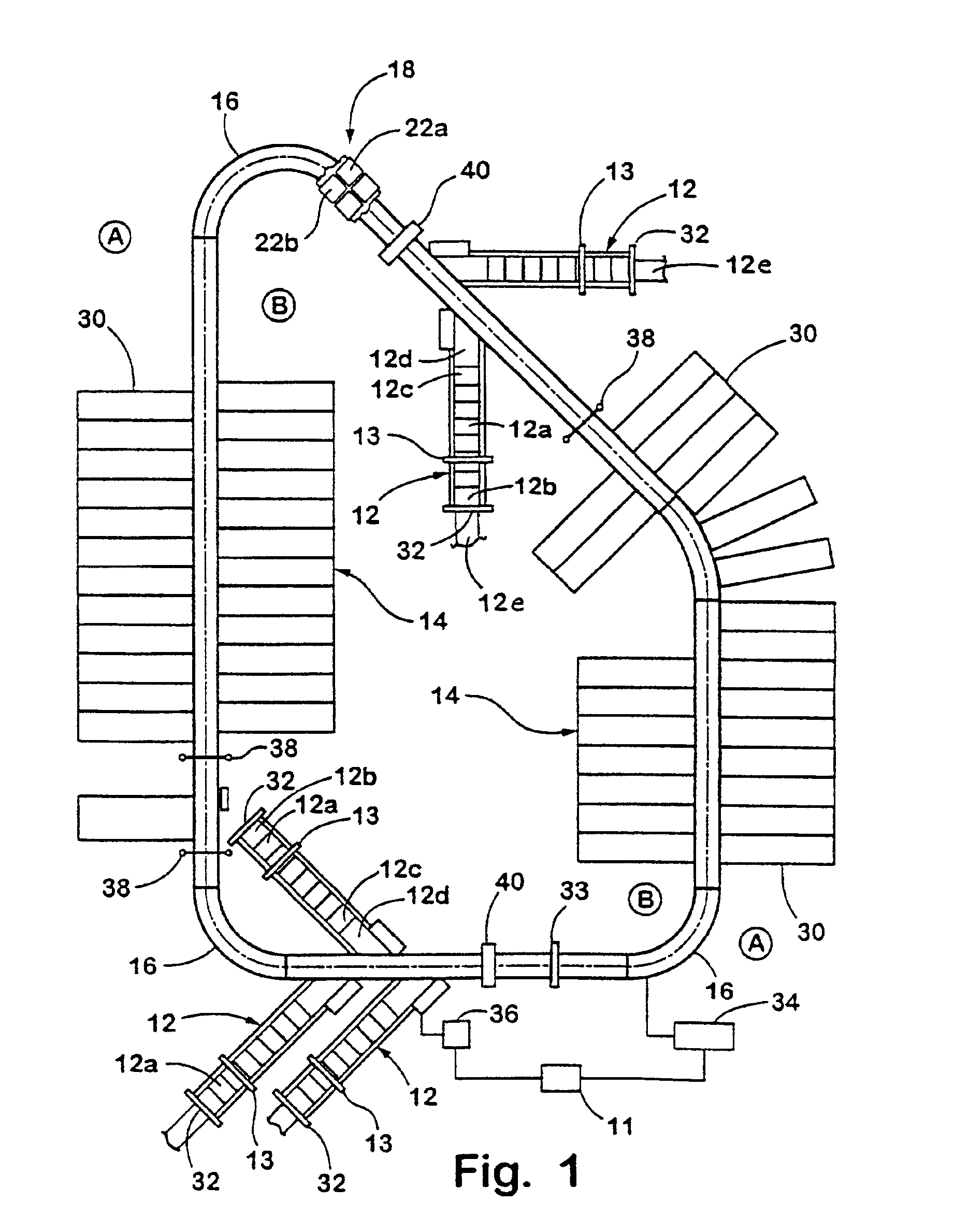

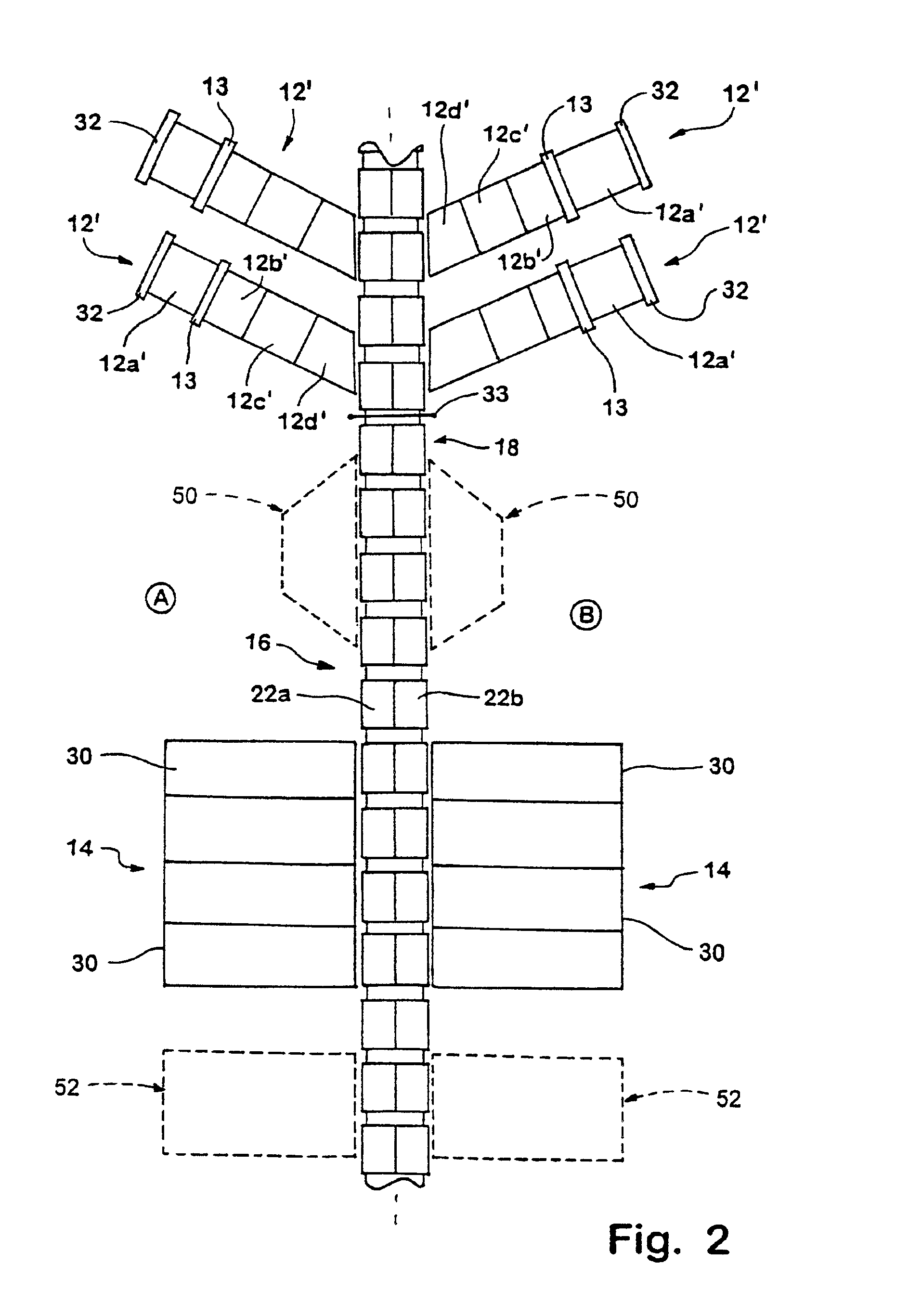

Article sortation system

InactiveUS6889814B2Limit recirculationImprove efficiencyControl devices for conveyorsSeparation devicesEngineeringMechanical engineering

An article sortation system includes a plurality of transport units which are movable along a conveying path between induction stations and discharge stations along each side of the conveying path. Each transport unit has side by side loading and support capability and is operable to receive packages from induction stations and discharge the packages at an appropriate discharge station. The system includes a control which determines the destination of articles and resolves blocking conditions between articles at the induction stations or at the transport units. The system may include a reinduction station for receiving an article from a transport unit and reinducting the article onto a transport unit, in order to resolve a blocking condition between a pair of articles on the respective transport unit.

Owner:DEMATIC

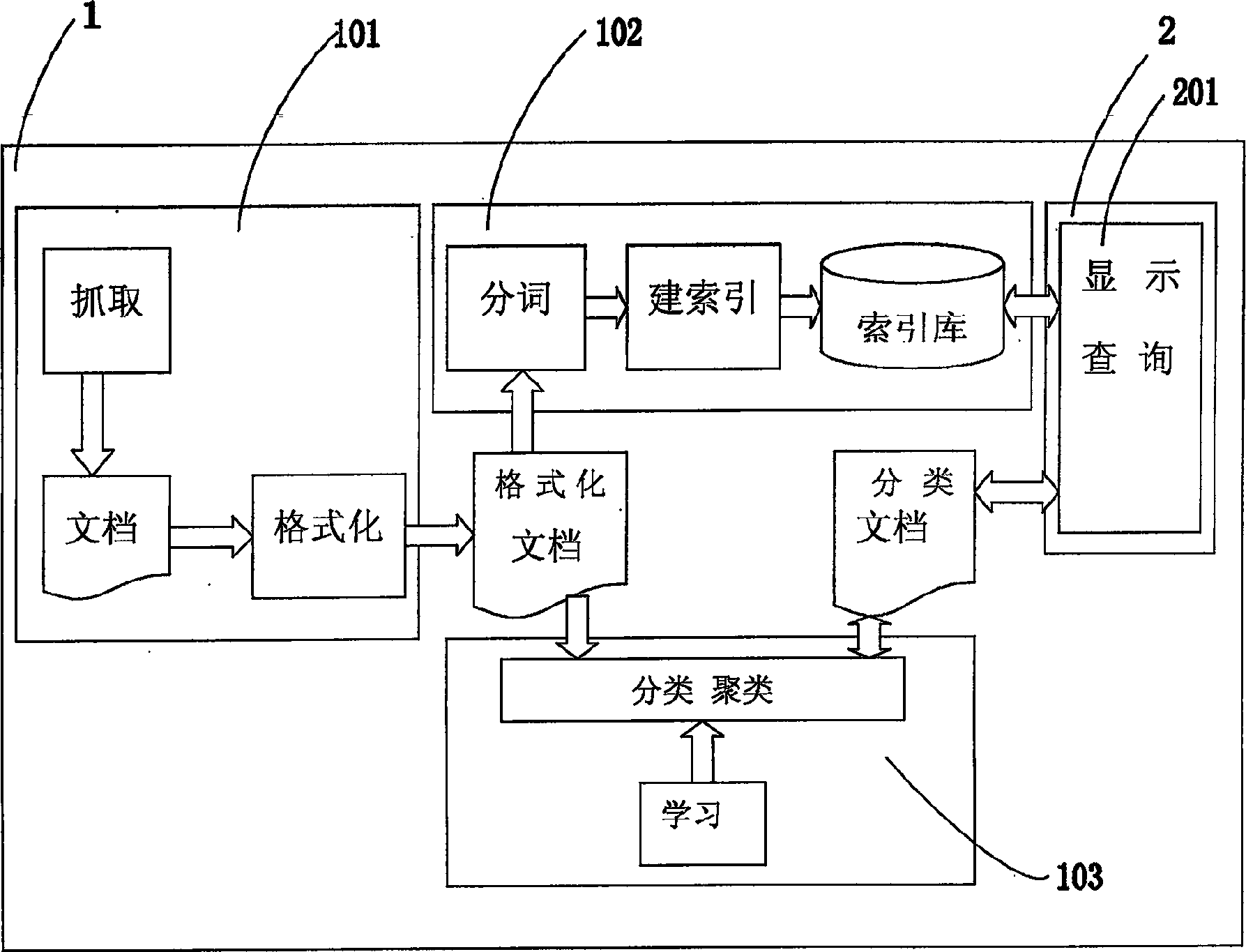

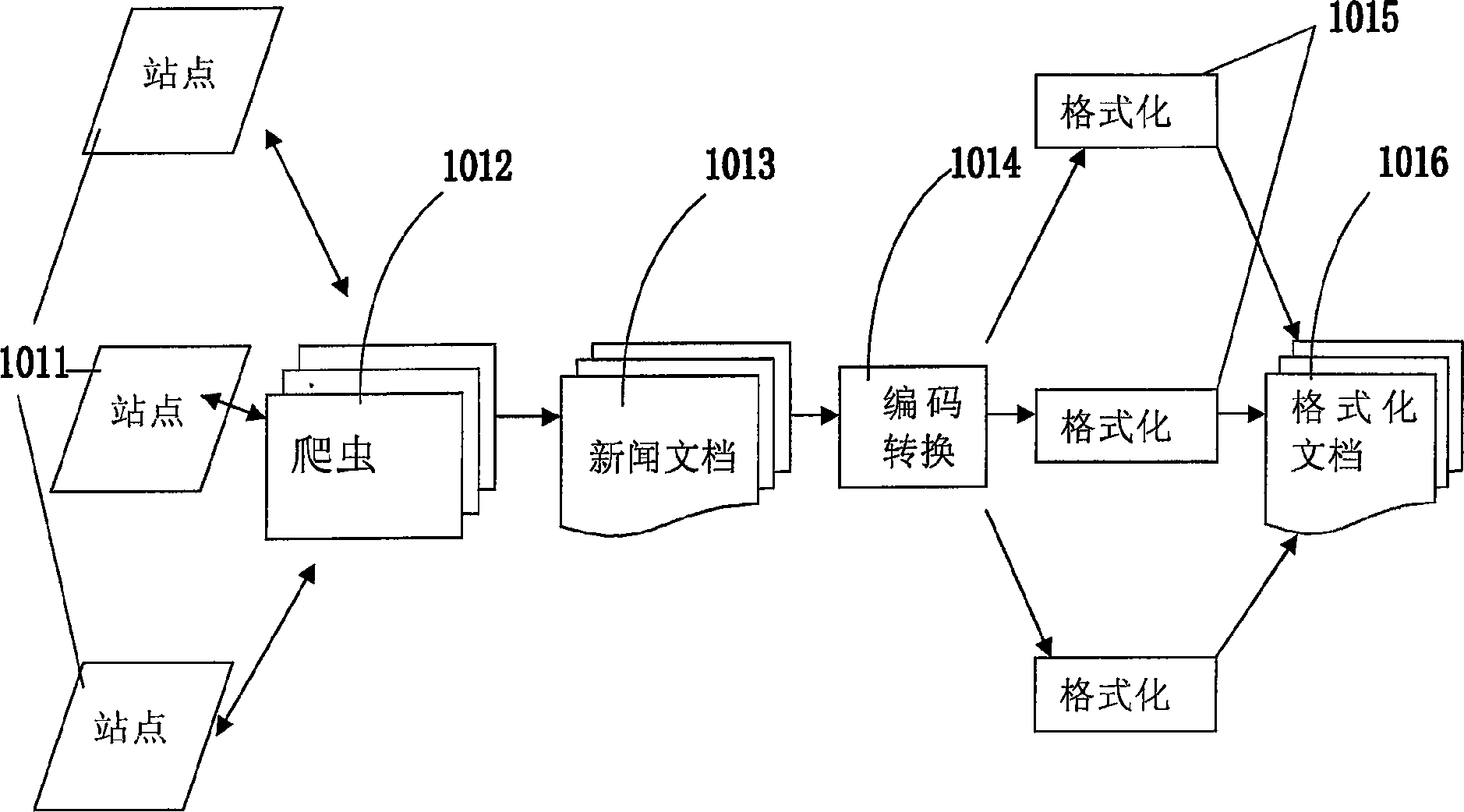

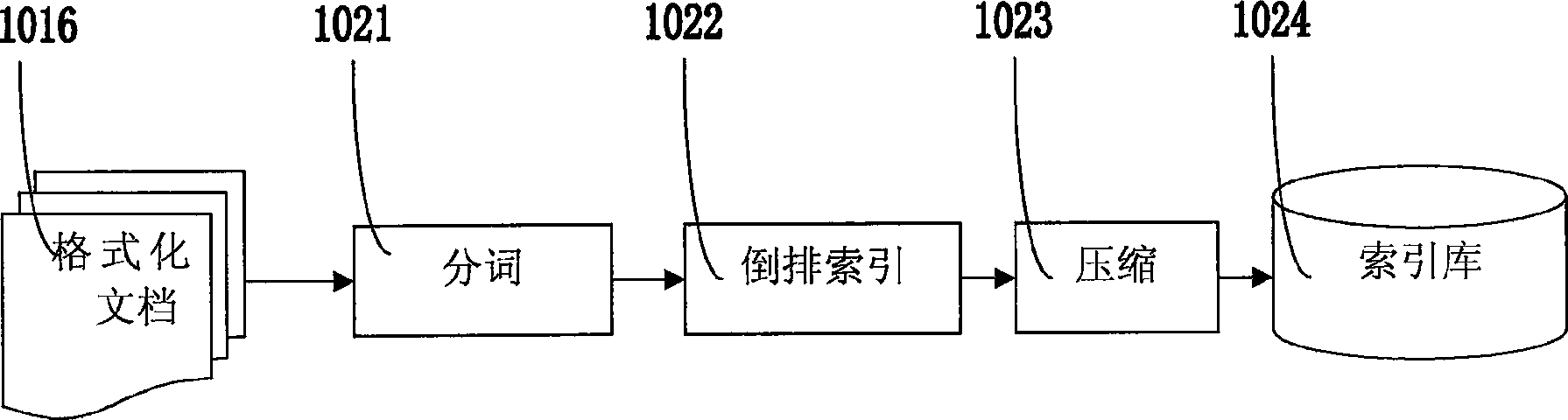

Searching engine with automating sorting function

ActiveCN1873642AImprove accuracyNarrow searchSpecial data processing applicationsUser inputDocument preparation

The invention discloses a search engine with automatic classification function, it includes: the automatic collection and the pretreatment module, which are used to automatically collect the documents from the network, and carry out the pretreatment, and transfer the documents for the computer to read and real-time renews documents; the index module, which is used on the participle after the automatic collection and the pretreatment module processing formatted documents, after and separately gives the participle the word and the documents entrusts with word marking and documents marking, according to word marking and the documents marking, establish index access; the automatic classified module, which can be used in to train and classify automatically the formatted documents that had to deal with; the searches display module, which searches suitable document based keyword appearance in the server, and setups in the client. The invention can classify and search effectually and intellectualized document by Chinese and English.

Owner:上海世纪互联信息系统有限公司

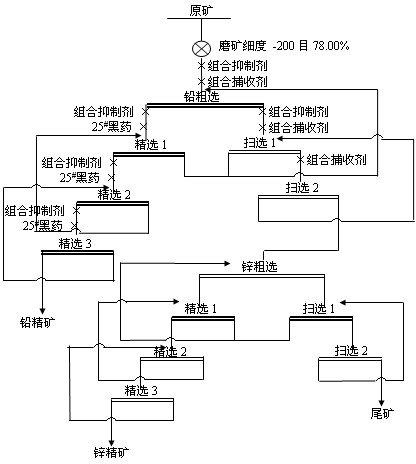

Beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore

The invention relates to a beneficiation method for difficultly selecting lead-zinc ore, in particular to a beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore. The beneficiation method comprises the steps of: (1) ore grinding: grinding raw ore into the ore with the material particle size being smaller than 0.074mm and being 72%-84% of the whole raw ore;(2) differential flotation of lead; and (3) differential flotation of zinc in float lead tailings. Particularly, the method adds a combined inhibitor and a combined collector in the beneficiation process to replace highly-toxic sodium cyanide selecting lead-zinc ore, so that the environmental pollution is reduced. In addition, the method is used for increasing the recovery ratio of lead-zinc concentrate, increasing the recovery ratio of precious metals including gold and silver, and increasing the economic benefit of enterprises.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Mutant pores

ActiveUS9751915B2Easily discriminatedReduce varianceBacterial antigen ingredientsMicrobiological testing/measurementNucleic acid

The invention relates to mutant forms of Msp. The invention also relates to nucleic acid characterization using Msp.

Owner:OXFORD NANOPORE TECH LTD

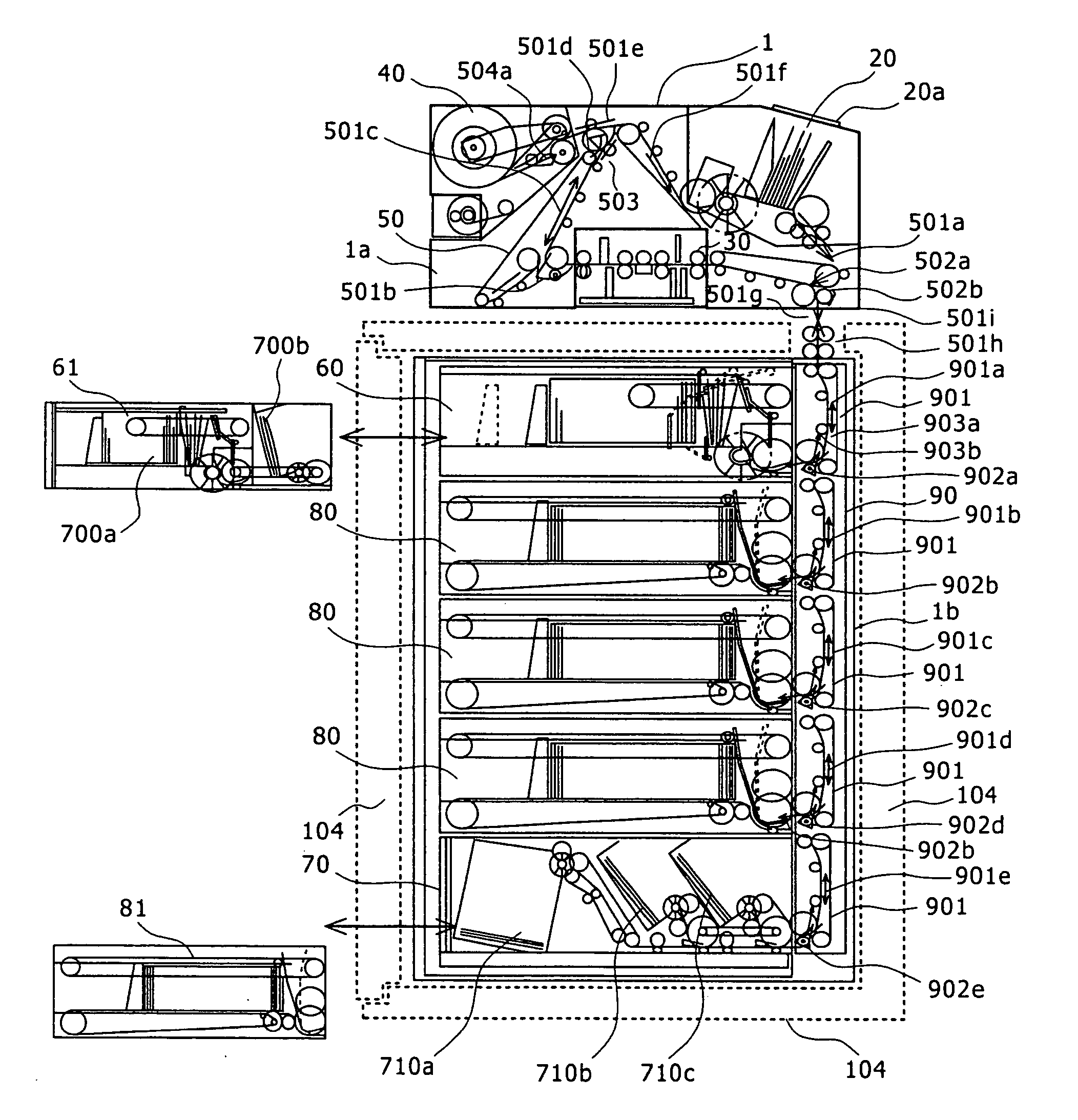

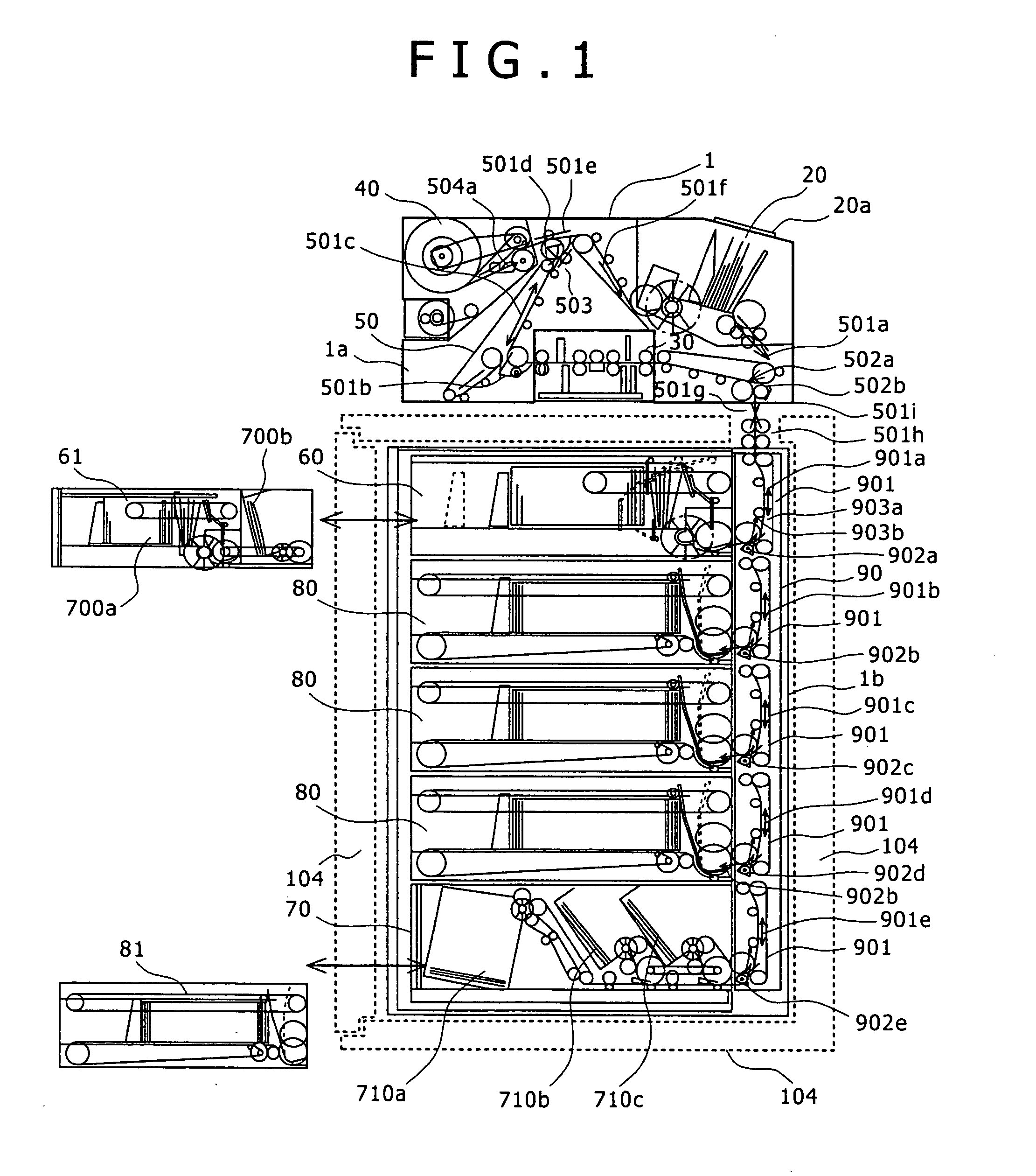

Bill depositing/dispensing apparatus

ActiveUS20050263582A1Flexible configurationFlexible installationComplete banking machinesFinanceEngineering

A bill depositing / dispensing apparatus convenient to use and capable of readily adapting itself to operations to handle many denominations and / or a large number of bills or operations to sort and handle a small number of bills is to be provided. Storing boxes differing in the purpose of use including a deposit box, a first acceptance box with multi-compartments, a second acceptance box with multi-compartments, recycle boxes and a loading / recovering box are configured to have a common external shape, inlet / outlet and driving unit, and a storing box selected according to the purpose of use is fitted to the bill depositing / dispensing apparatus.

Owner:TDK CORPARATION +1

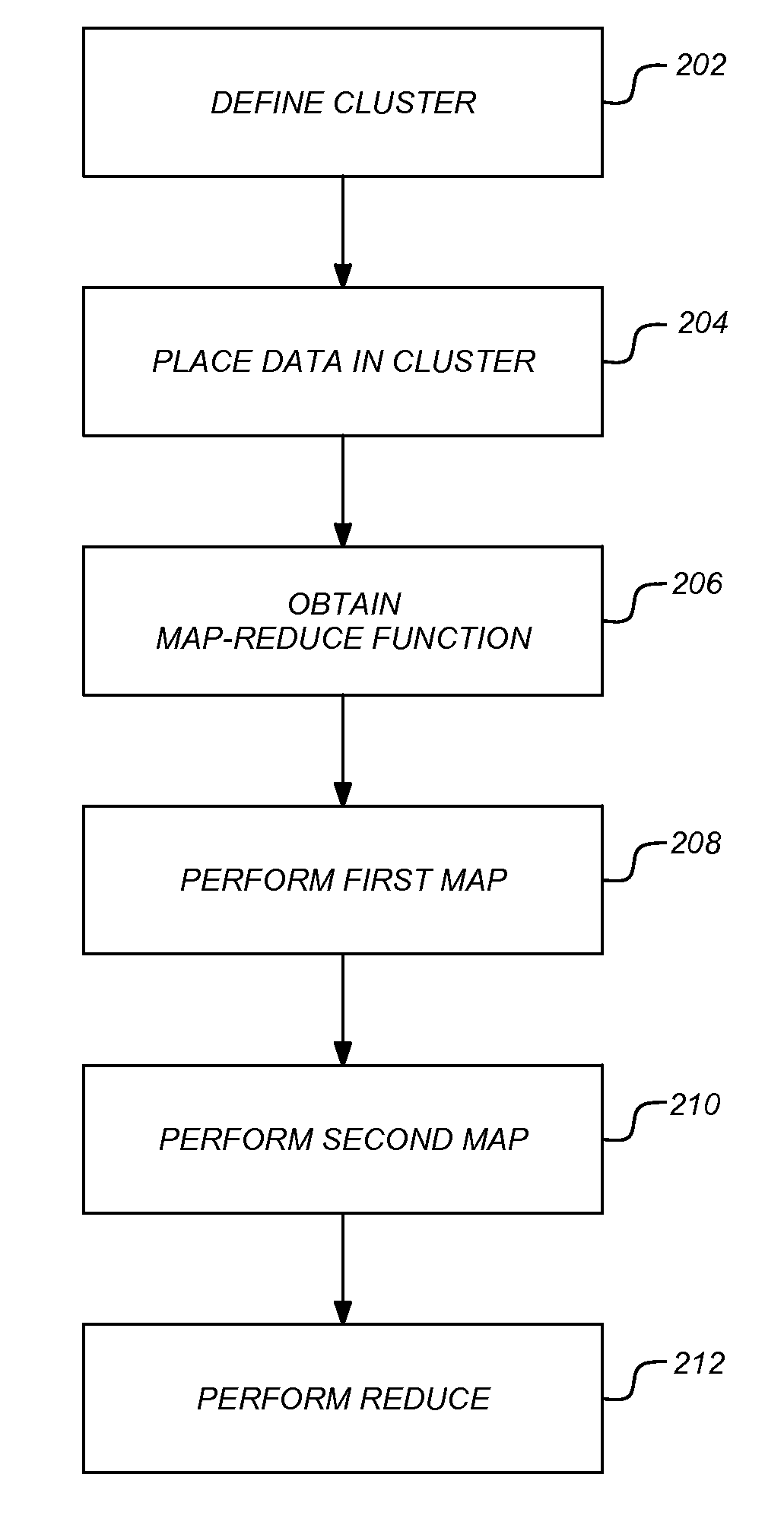

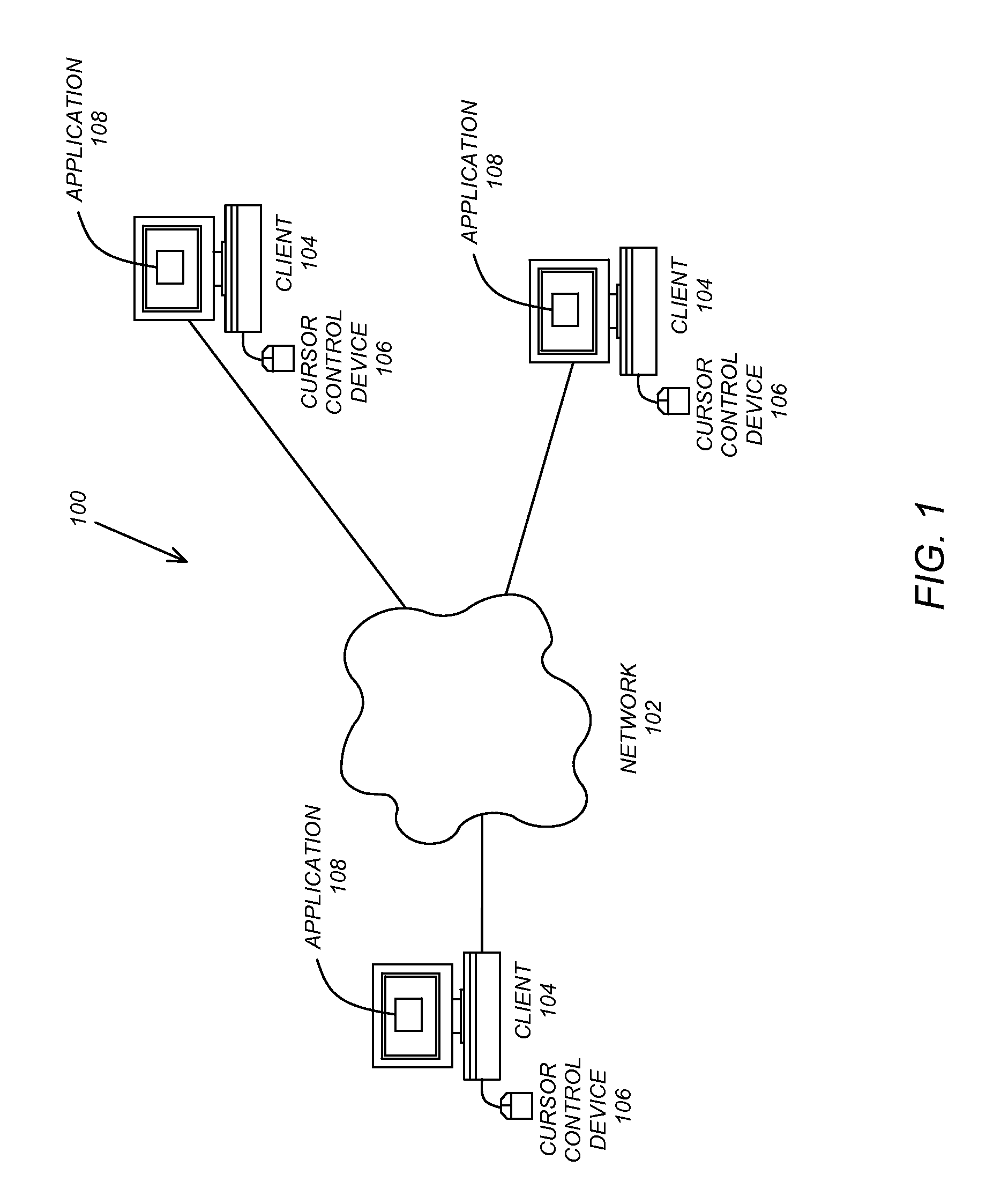

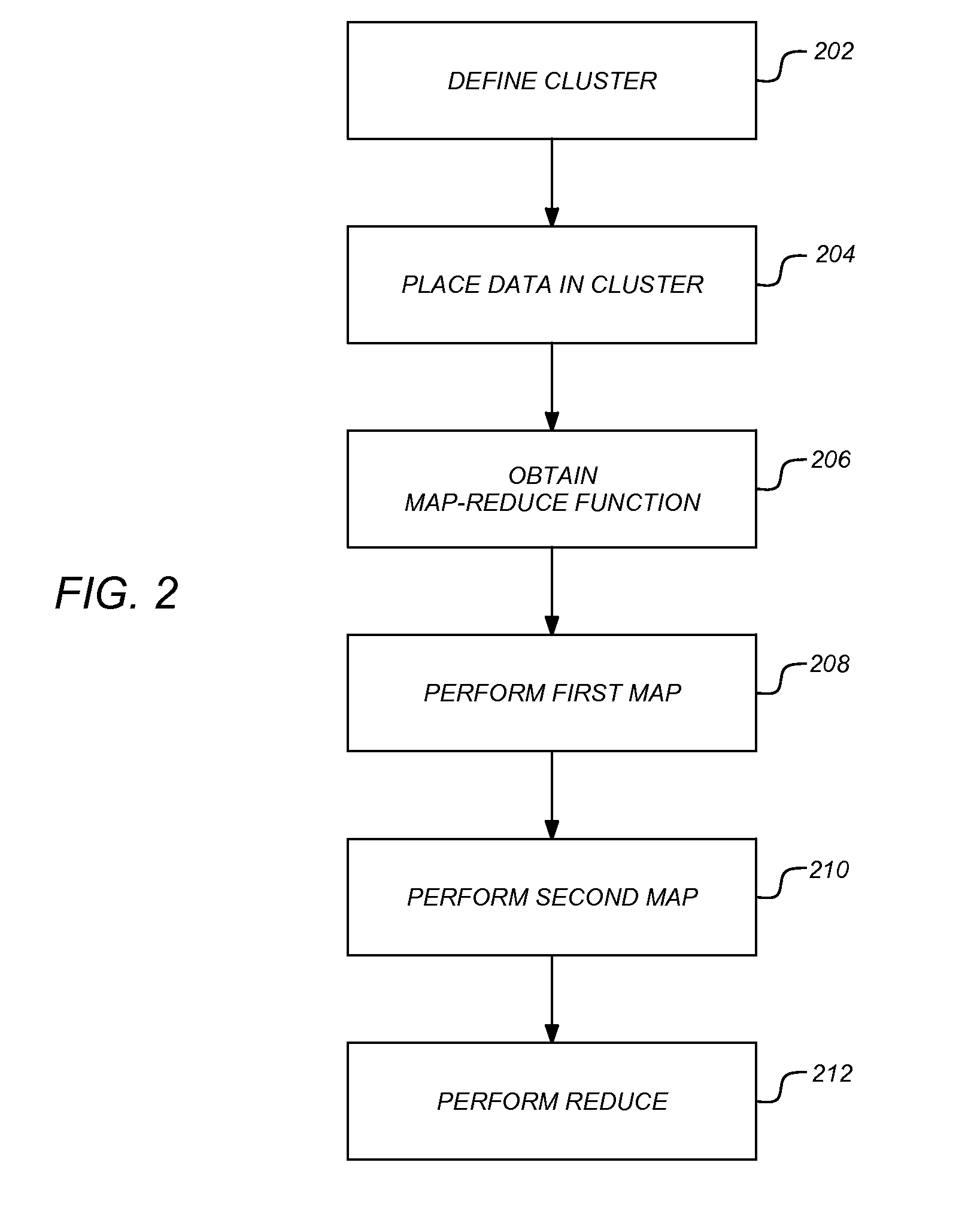

Double map reduce distributed computing framework

ActiveUS8321454B2Create quicklyEfficient sortingDigital data processing detailsProgram controlMap reduceTheoretical computer science

A method, apparatus, system, article of manufacture, and data structure provide the ability to perform a sorted map-reduce job on a cluster. A cluster of two or more computers is defined by installing a map-reduce framework onto each computer and formatting the cluster by identifying the cluster computers, establishing communication between them, and enabling the cluster to function as a unit. Data is placed into the cluster where it is distributed so that each computer contains a portion of the data. A first map function is performed where each computer sorts their respective data and creates an abstraction that is a representation of the data. The abstractions are exchanged and merged to create complete abstraction. A second map function searches the complete abstraction to redistribute and exchange the data across the computers in the cluster. A reduce function is performed in parallel to produce a result.

Owner:MYSPACE LLC

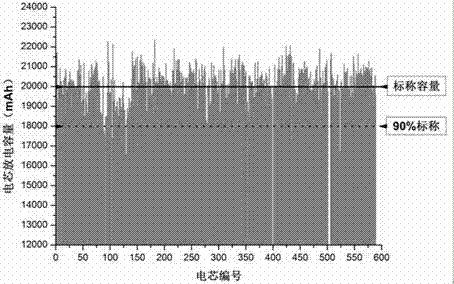

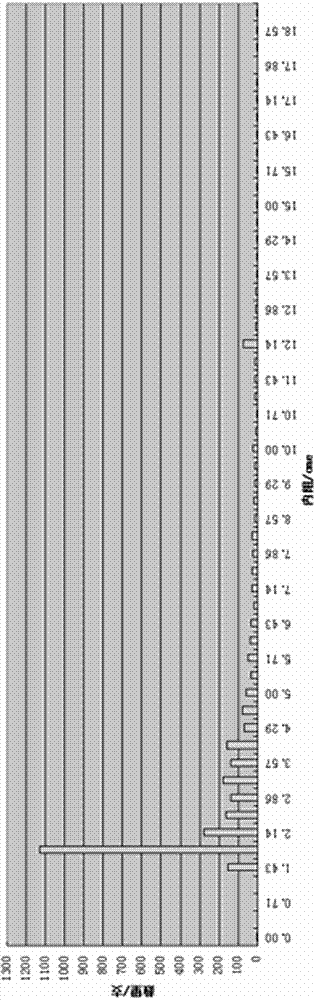

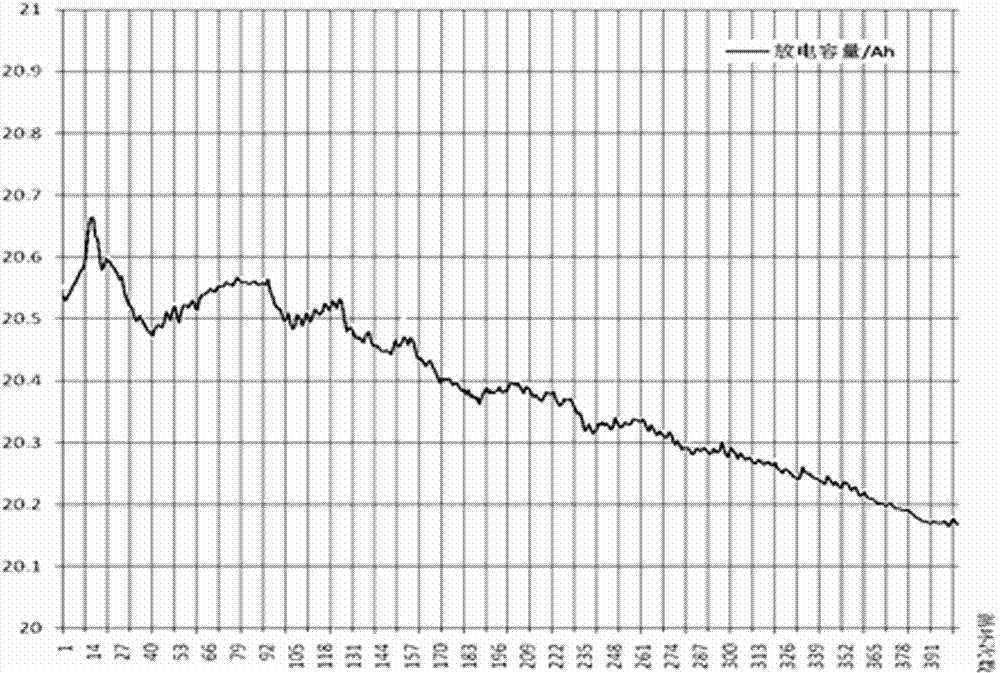

Availability evaluation method on retired dynamic lithium battery

ActiveCN104332666AFew measurement parametersSimple and efficient measurement methodElectrical testingSecondary cells servicing/maintenancePhysicsChemistry

The invention relates to an availability evaluation method on retired dynamic lithium battery. The method comprises the following steps: establishing core parameters for judging the availability of a retired dynamic single lithium battery; establishing the core parameter criteria of the retired dynamic single lithium battery; and establishing the proportion of the core parameter criteria of the retired dynamic single lithium battery; wherein the core parameters comprise residual battery capacity, safety, and cycle performance, the core parameter criteria comprise battery state of health (SOH), battery internal resistance, diaphragm penetration strength decreasing rate, diaphragm porosity, and secondary cycle life, and the diaphragm penetration strength decreasing rate and diaphragm porosity can be used to measure the diaphragm performance. The evaluation method has the advantages of less measurement parameters, simple and high efficient measuring method, and scientific and reliable evaluation result, and is capable of greatly improving the efficiency of screening on retired dynamic lithium batteries.

Owner:STATE GRID CORP OF CHINA +2

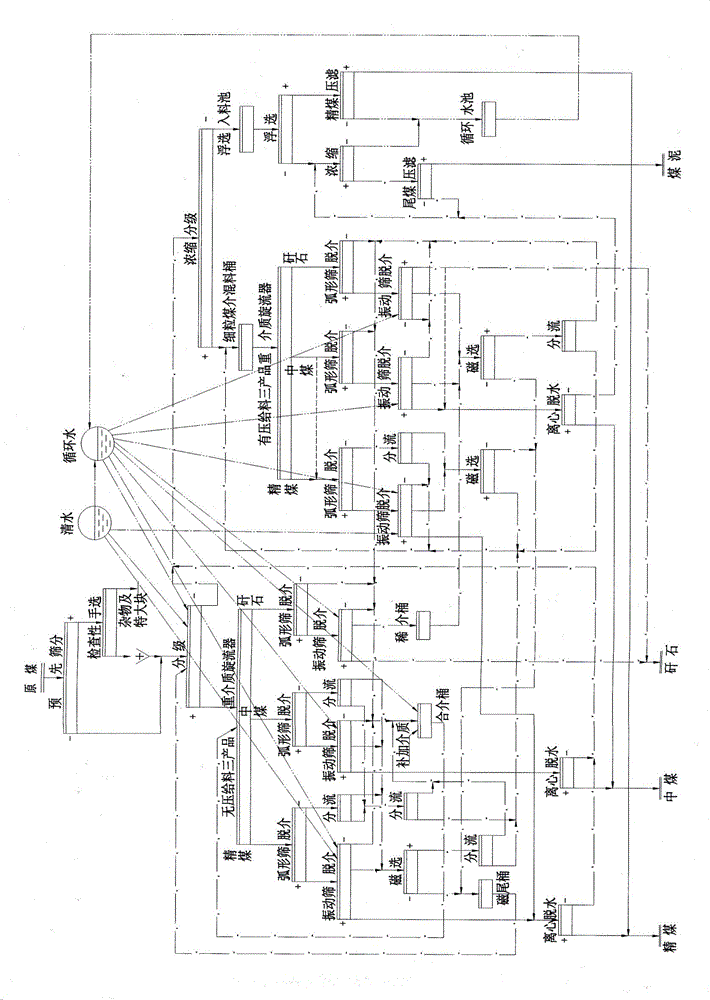

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

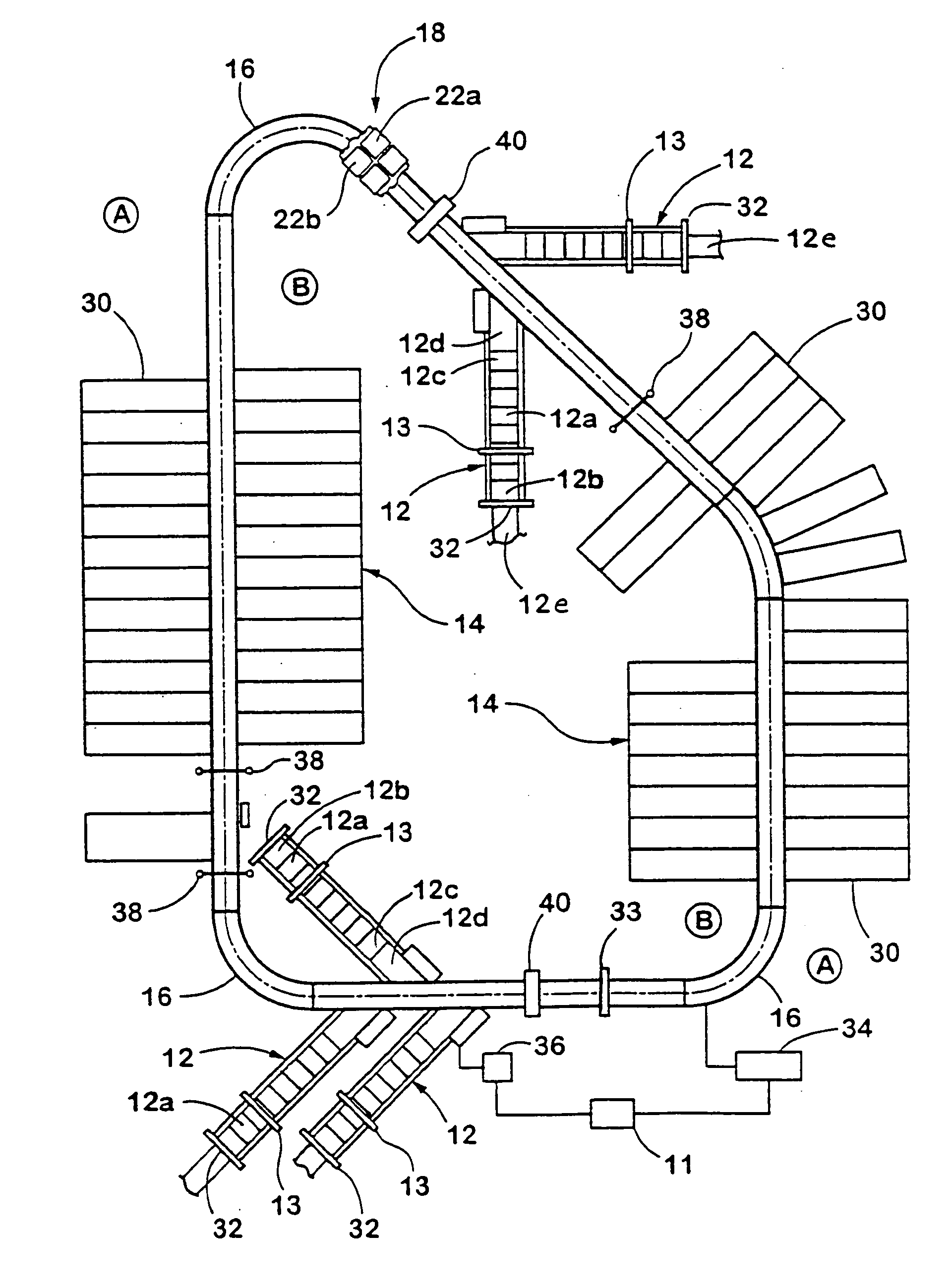

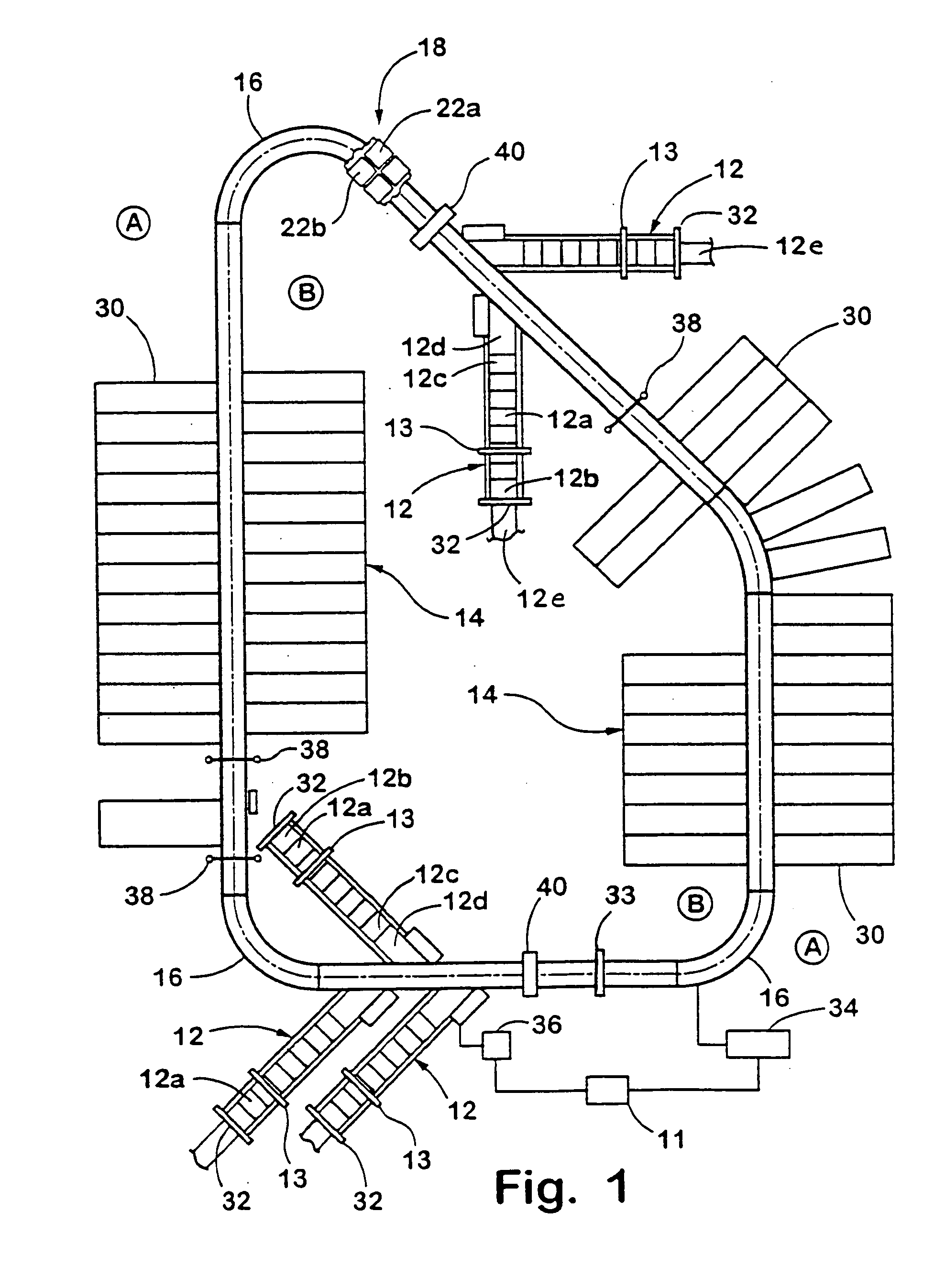

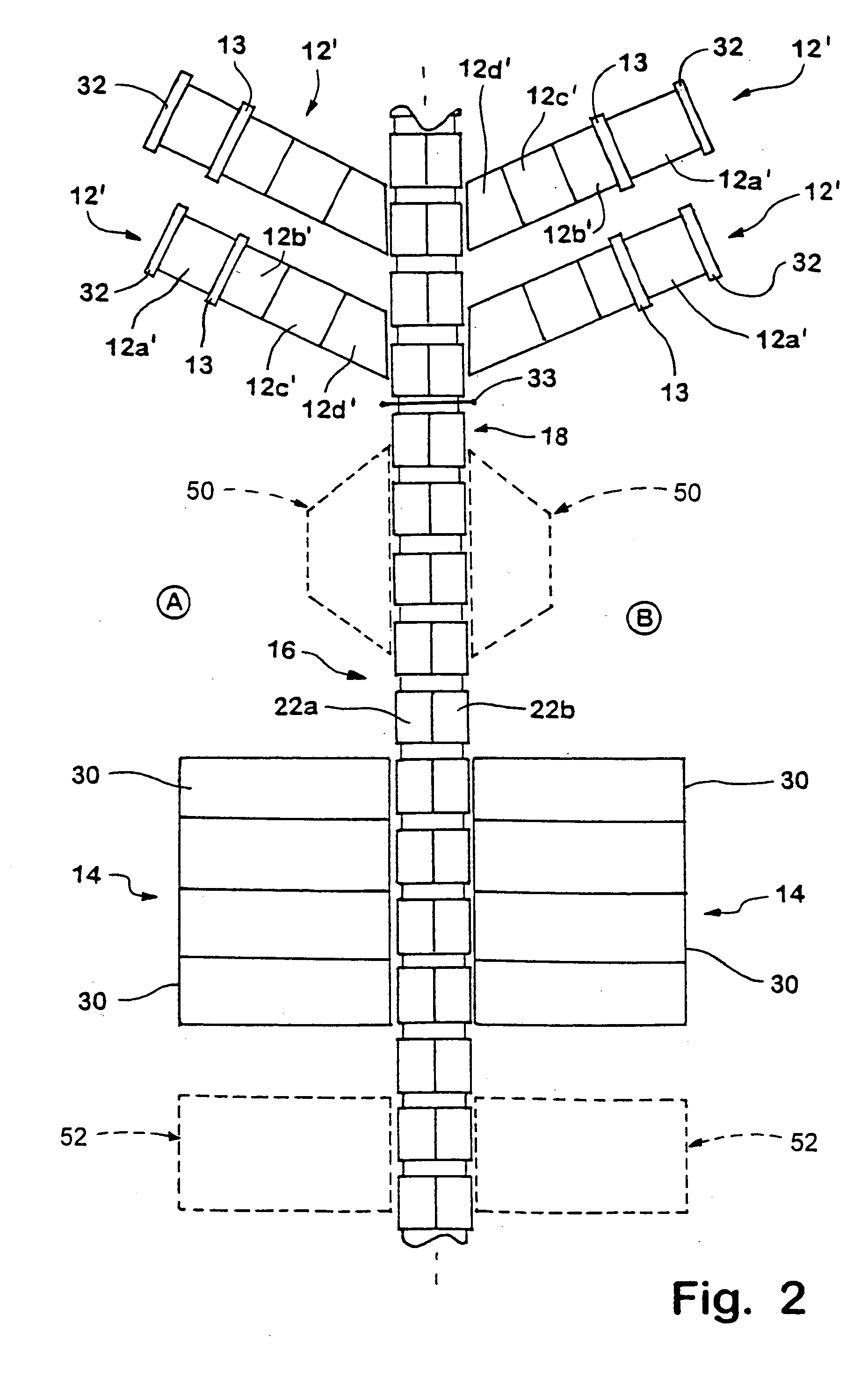

Article sortation system

InactiveUS20050189271A1Limit recirculationImprove throughput and efficiencyConveyorsControl devices for conveyorsEngineeringMechanical engineering

An article sortation system includes a plurality of transport units which are movable along a conveying path between induction stations and discharge stations along each side of the conveying path. Each transport unit has side by side loading and support capability and is operable to receive packages from induction stations and discharge the packages at an appropriate discharge station. The system includes a control which determines the destination of articles and resolves blocking conditions between articles at the induction stations or at the transport units. The system may include a reinduction station for receiving an article from a transport unit and reinducting the article onto a transport unit, in order to resolve a blocking condition between a pair of articles on the respective transport unit.

Owner:DEMATIC

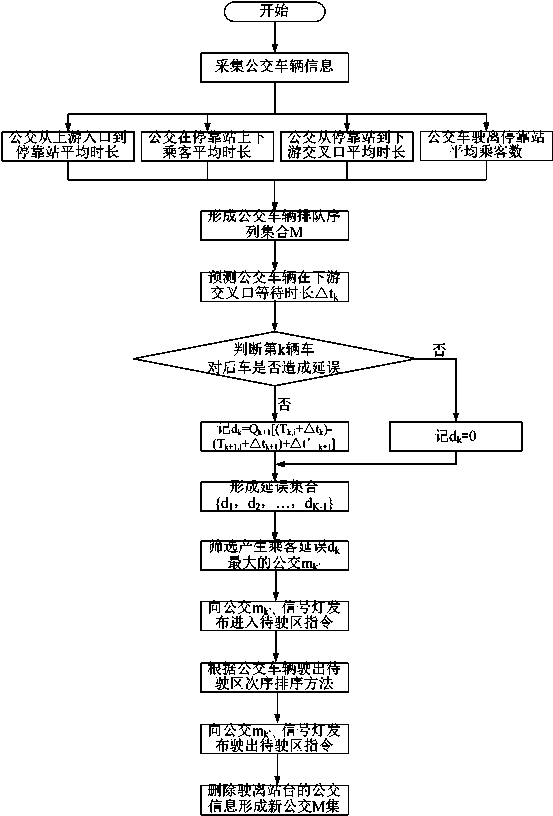

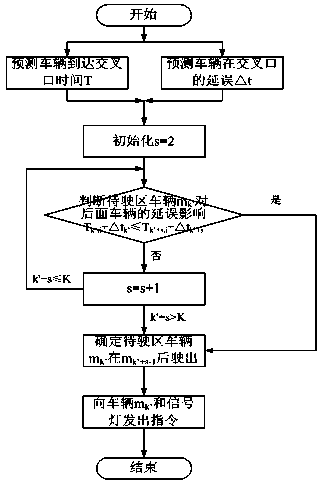

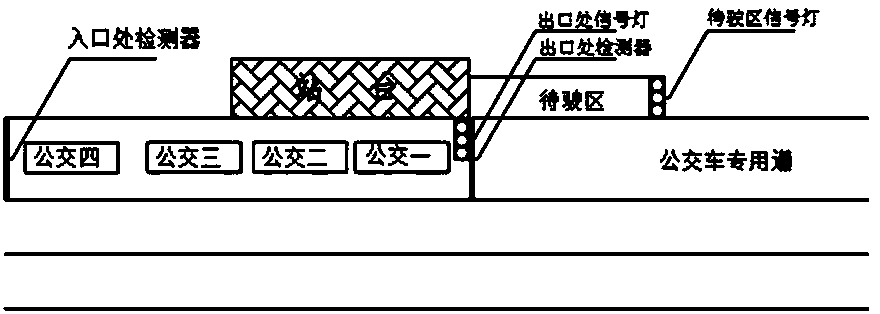

Method for arranging steering buses in sequence in bus stop at inner side of road

InactiveCN103593988AImprove operational efficiencyEfficient sortingRoad vehicles traffic controlTime informationTotal delay

The invention discloses a method for arranging steering buses in sequence in a bus stop at the inner side of a road. The method comprises the steps that according to collected bus real-time information, time when one bus reaches a downstream intersection is predicted, passenger delay caused by steering and a signal phase sequence of the bus is analyzed, so that an optimal scheme of the bus sequence is generated, a driving waiting zone and a signal control light are arranged at the bus stop at the inner side of the road, and therefore the bus operation sequence is effectively adjusted. According to the method for arranging the steering buses in sequence in the bus stop at the inner side of the road, from the perspective of bus operation time and with the combination of bus operation experience data and real-time collected data, the time when one bus reaches the downstream intersection is accurately predicted, passenger delay caused by the driving sequence of the steering buses is accurately judged according to an original green light interval time table, and the reliable steering bus sequence is formed; the driving waiting zone is arranged at the bus stop, so that under the condition of linkage control of an outlet portion and the signal light of the driving waiting zone, the buses are rapidly and effectively lined, total delay of the steering buses in the intersection is reduced, prior passage of the buses at the signal intersection of the downstream is guaranteed, and the operation efficiency of the buses is effectively improved.

Owner:SOUTHEAST UNIV

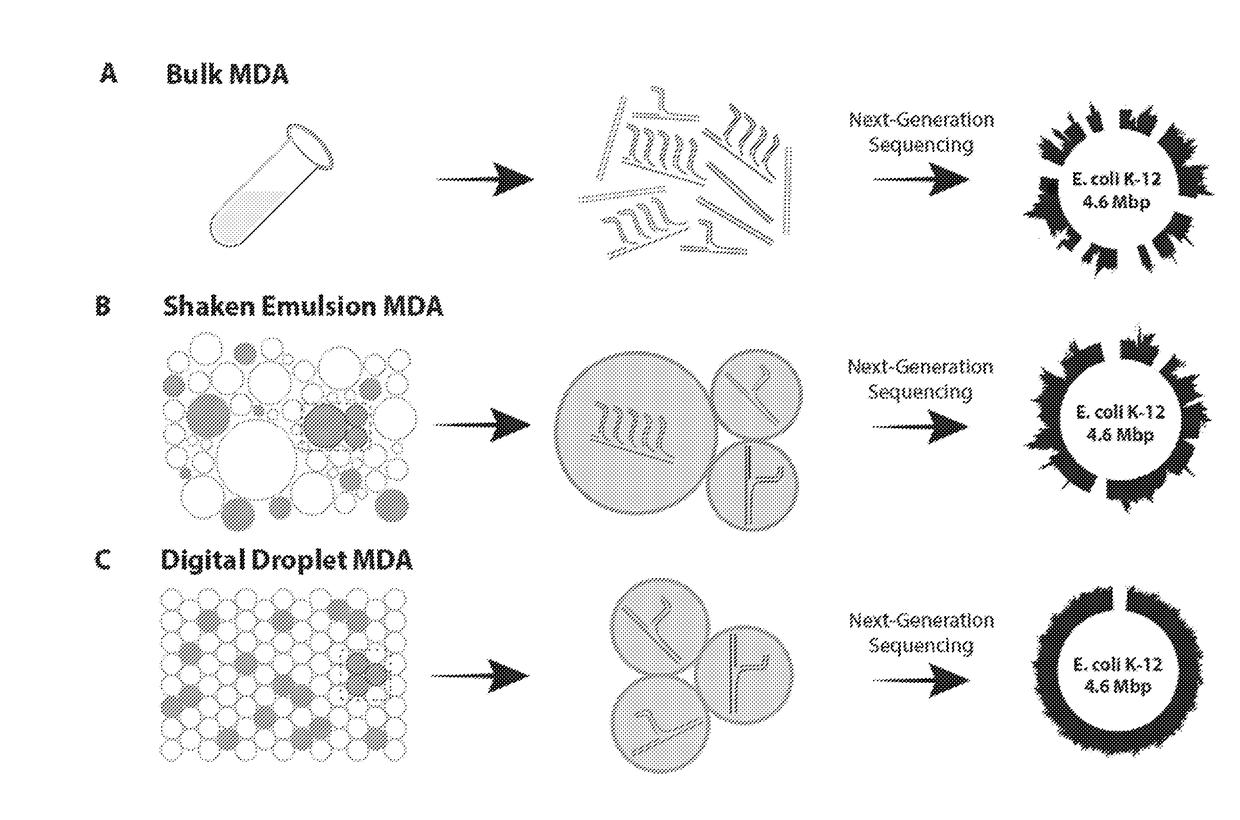

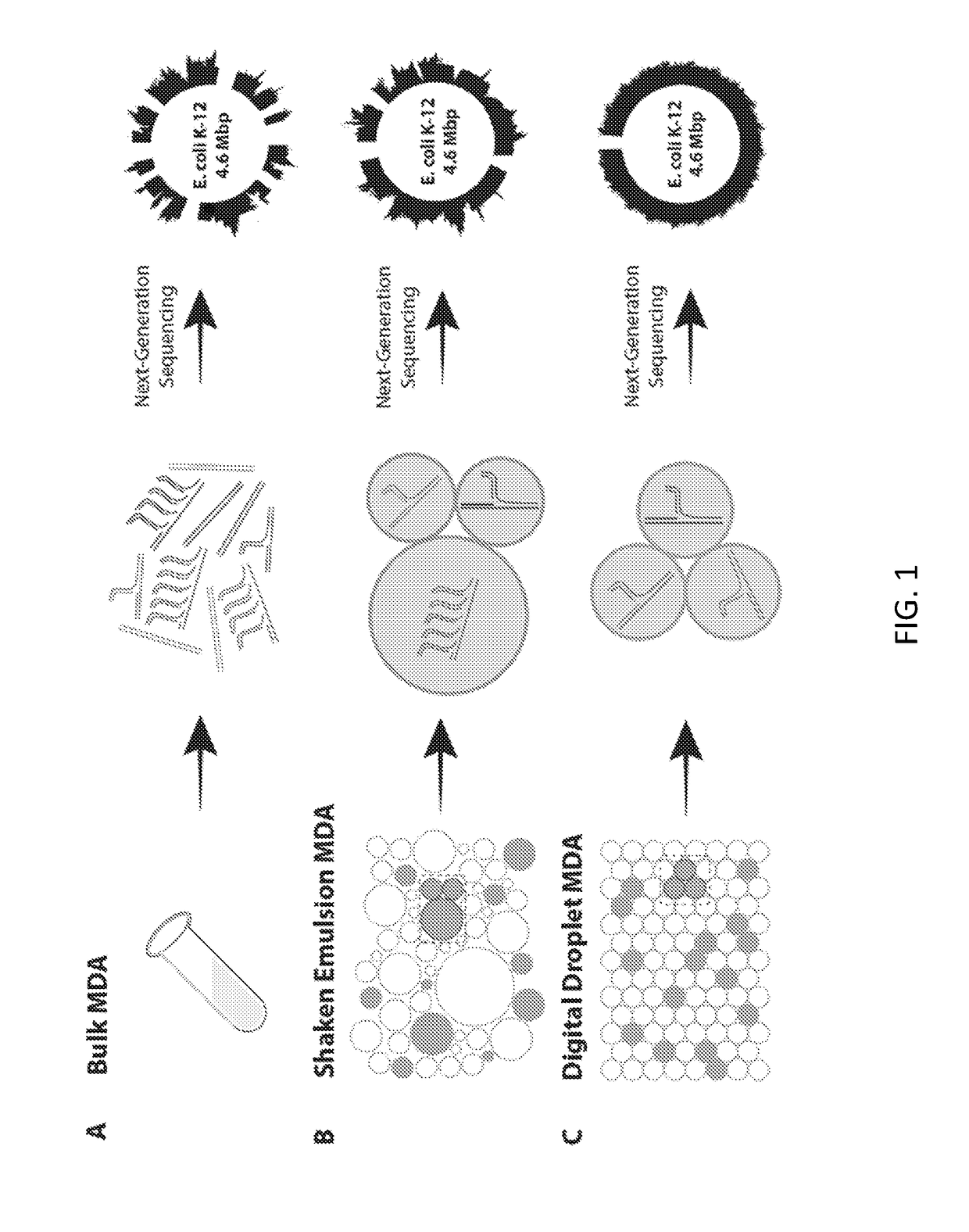

Microdroplet-Based Multiple Displacement Amplification (MDA) Methods and Related Compositions

PendingUS20180237836A1Uniform coverageImprove accuracyMicrobiological testing/measurementLibrary screeningCancer cellGenome

Methods for non-specifically amplifying a nucleic acid template molecule are provided. The methods may be used to amplify nucleic acid template molecule(s) for sequencing, e.g., for sequencing the genomes of uncultivable microbes or sequencing to identify copy number variation in cancer cells. Aspects of the disclosed methods may include non-specifically amplifying a nucleic acid template molecule, including encapsulating in a microdroplet a nucleic acid template molecule obtained from a biological sample, introducing multiple displacement amplification (MDA) reagents and a plurality of MDA primers into the microdroplet, and incubating the microdroplet under conditions effective for the production of MDA amplification products, wherein the incubating is effective to produce MDA amplification products from the nucleic acid template molecule.

Owner:RGT UNIV OF CALIFORNIA

System and method for sorting parcel

InactiveUS20150217334A1Accurate sortingEfficient sortingSortingConveyor partsEngineeringControl unit

Disclosed are a system and a method for sorting a parcel, and more particularly, a system for sorting a parcel that arranges articles to an outlet edge for each corresponding destination.The system for sorting a parcel, which moves an article to a cart according to destination information of the article to classify the article to a chute for each destination, includes: an article position detecting unit which detects positional information of the article loaded on the cart that moves in a first direction by a track which moves in the first direction; and a control unit which controls the cart to rotate in a second or third direction according to the detected positional information of the article and destination information of the article.

Owner:ELECTRONICS & TELECOMM RES INST

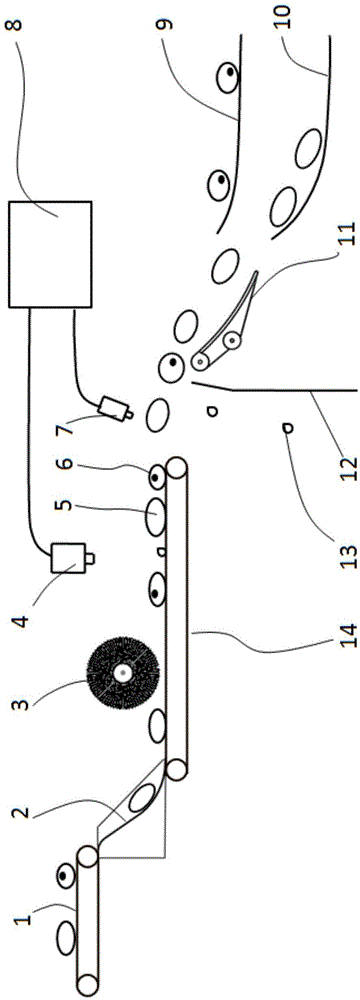

Logistic commodity sorting device and system

InactiveCN106513330AImprove sorting efficiencyEfficient sortingSortingLogistics managementPower component

The invention discloses a logistic commodity sorting device and system. The logistic commodity sorting device comprises an upper computer processing center, a conveying belt device, an automatic scanner device, a signal detection device, a sorting power component device and separating channels. When logistic commodities are placed on the conveying belt device, the automatic scanner device reads information of the logistic commodities and transmits the information to the upper computer processing center, the signal detection device transmits the information to the upper computer processing center when detecting the information of the logistic commodities, the upper computer processing center sends action commands according to the obtained information, the sorting power component device executes the action commands and pushes the corresponding commodities into the corresponding separating channels, and therefore the logistic sorting process can be realized. According to the technical scheme, the logistic commodities can be effectively, quickly and accurately sorted. The logistic commodity sorting device and system are suitable for the sorting work of medium-small logistic sorting stations and can improve the logistic sorting efficiency, lower the labor intensity and lower the labor cost.

Owner:GUILIN UNIV OF AEROSPACE TECH

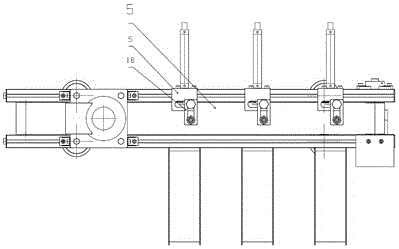

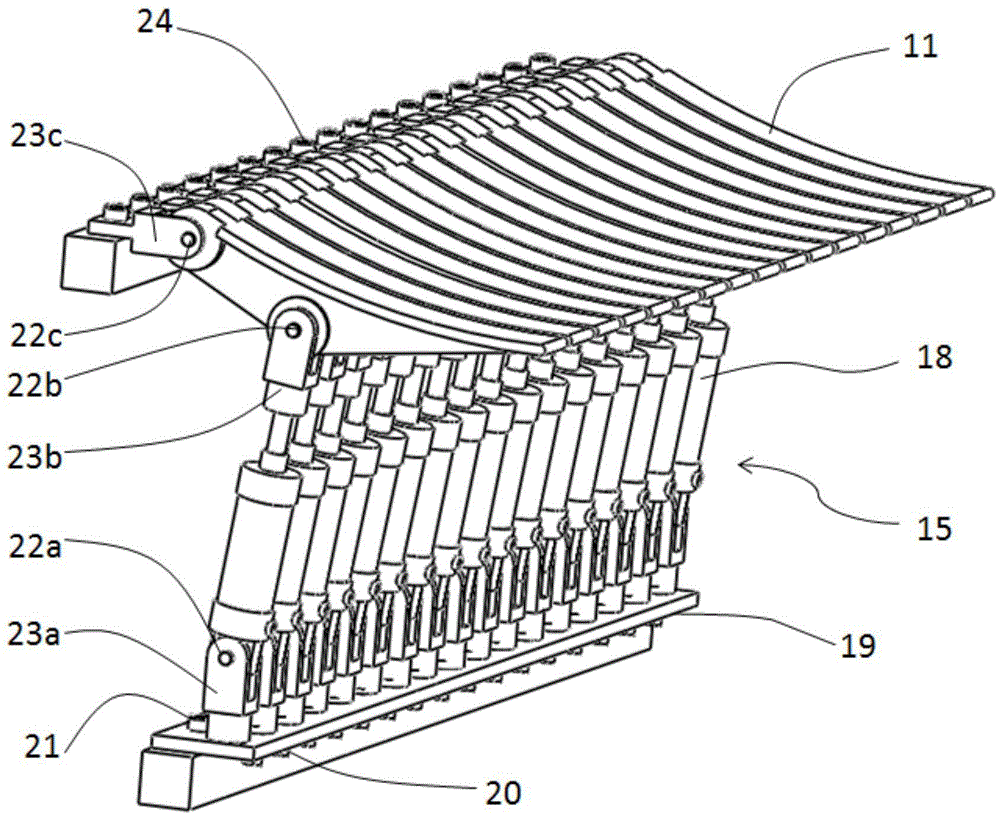

Potato grading control method and device based on machine vision technology

ActiveCN104941922AReduce mechanical damageAccurate sortingGas current separationSortingMachine visionImage detection

The invention discloses a potato grading control method and device based on machine vision technology. The method is characterized in that during image detection, a camera field-of-view is divided into virtual passages with the number corresponding to that of guiding lifting levers according to the number of the guiding lifting levers; a logic value is used for indicating whether to-be-graded potatoes exist on each virtual passage or not; a control and processing unit controls the guiding lifting levers to act according to the detected logic value, and when the logic value is equal to 1, a guiding mechanism corresponding to the guiding lifting levers is upward pushed out by an air cylinder, and potatoes are in contact with the guiding lifting levers, so that the running track of the potatoes is changed, and the potatoes are separated to be thrown into corresponding discharging chutes; and after a camera is used for acquiring images of the potatoes, a virtual circle is drawn by taking the transverse diameters of the potatoes as the diameter according to the image detection result, and whether one or more guide lifting levers are adopted for separating the potatoes is determined according to the areas, occupied by the virtual circle, of the virtual passages. The fast detection of potatoes with various and different quality can be realized, damage to the potatoes can be reduced, and the sorting of the potatoes can be precisely realized.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com