Patents

Literature

661results about How to "Reduce mechanical damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

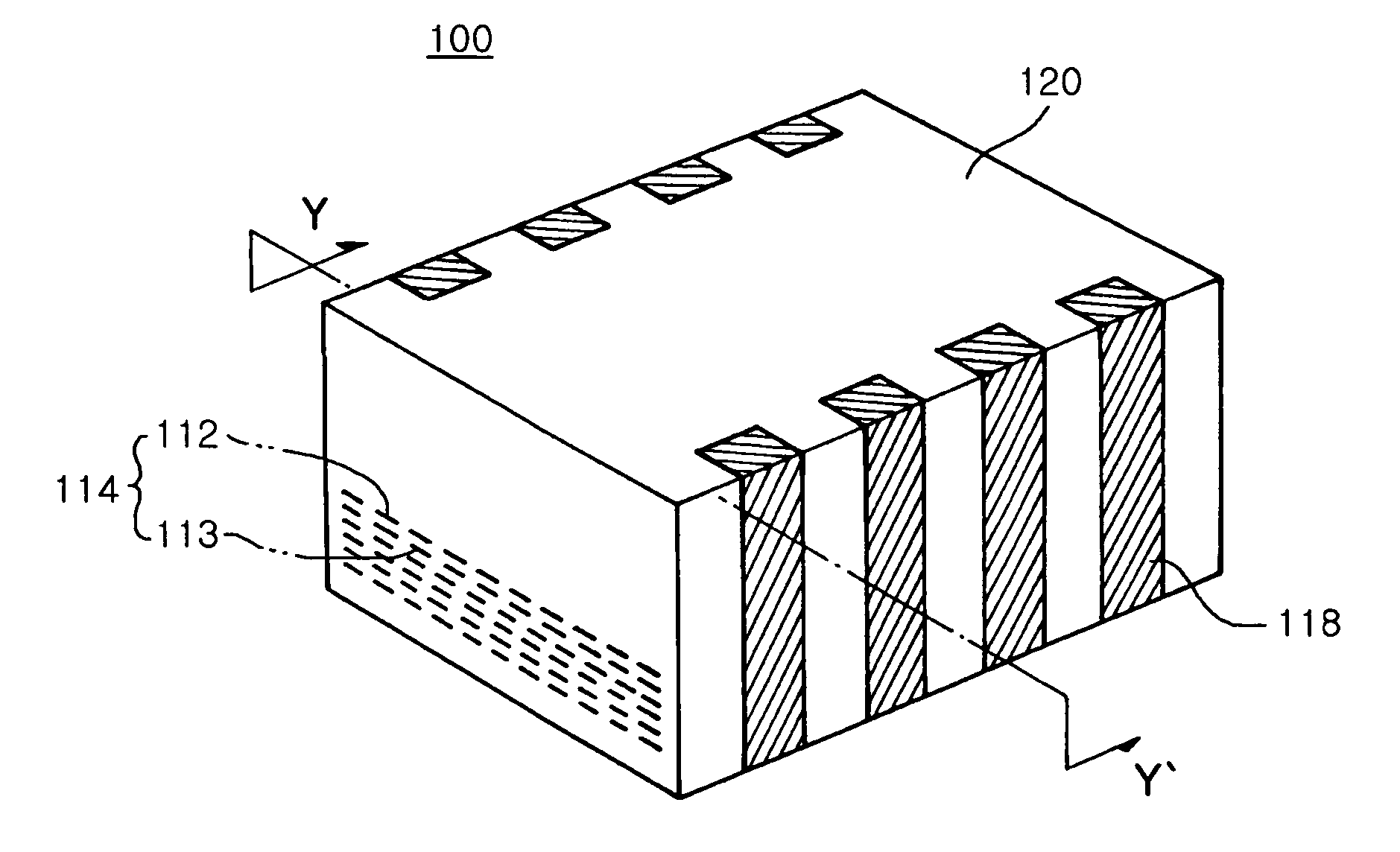

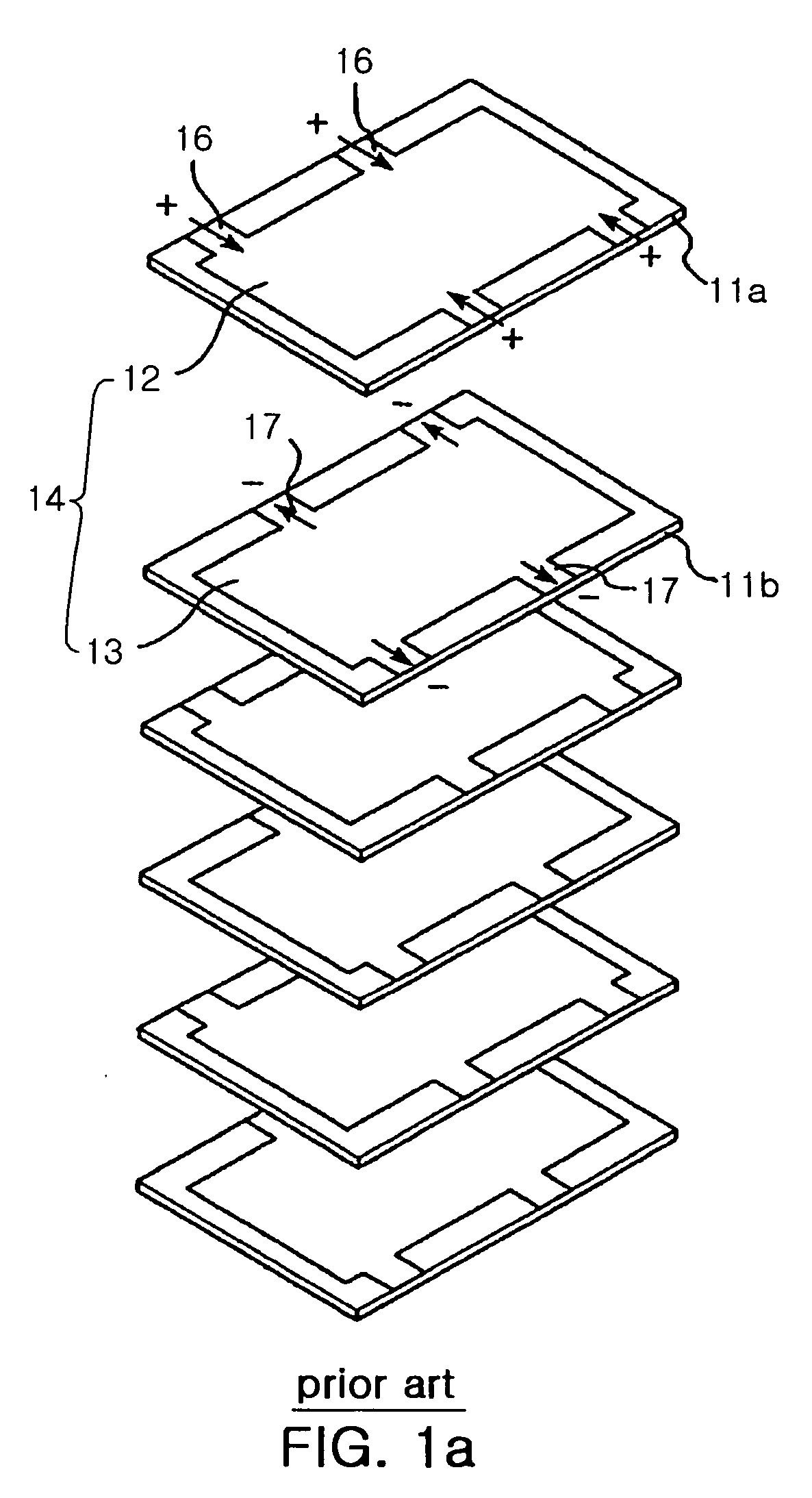

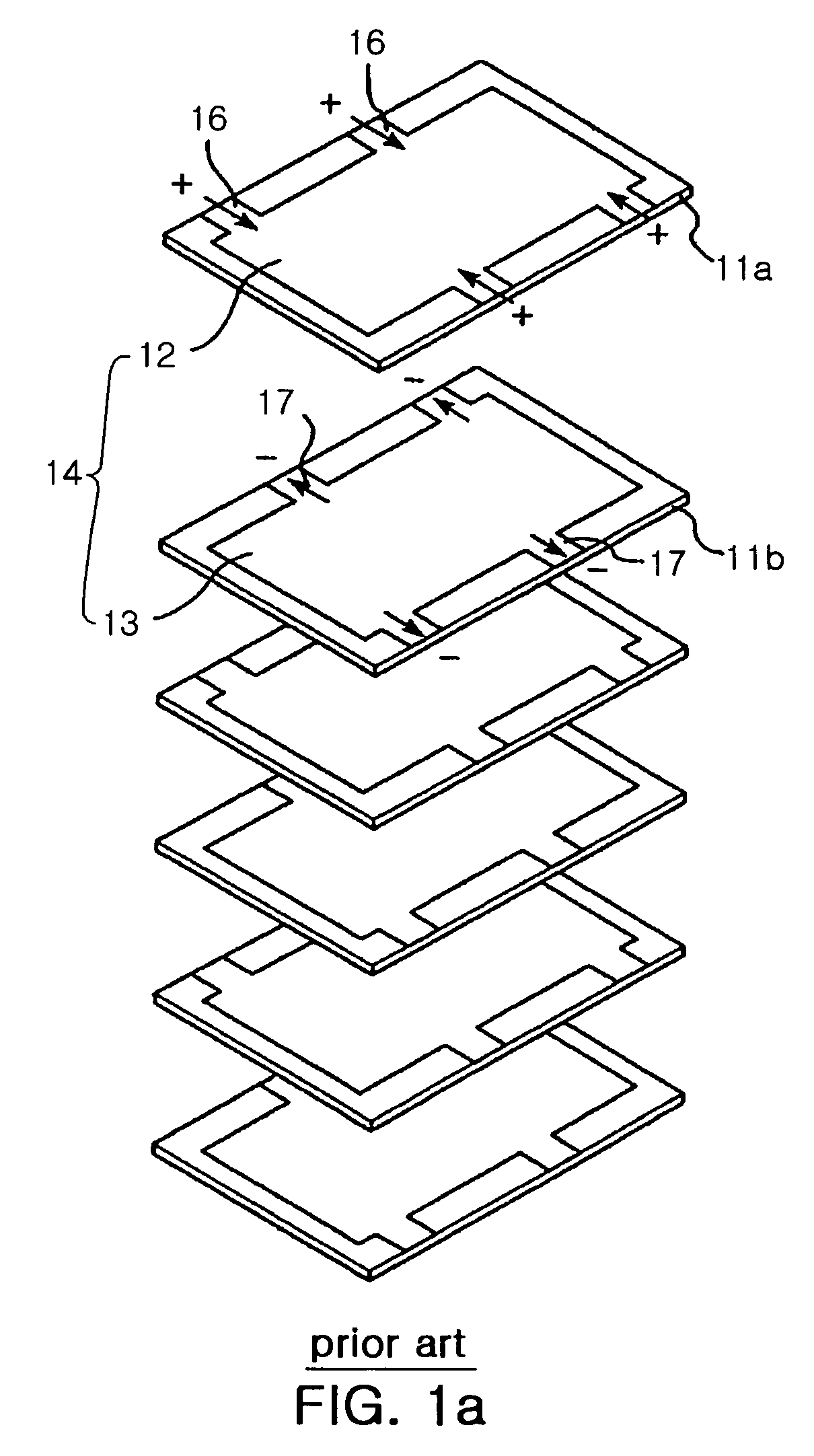

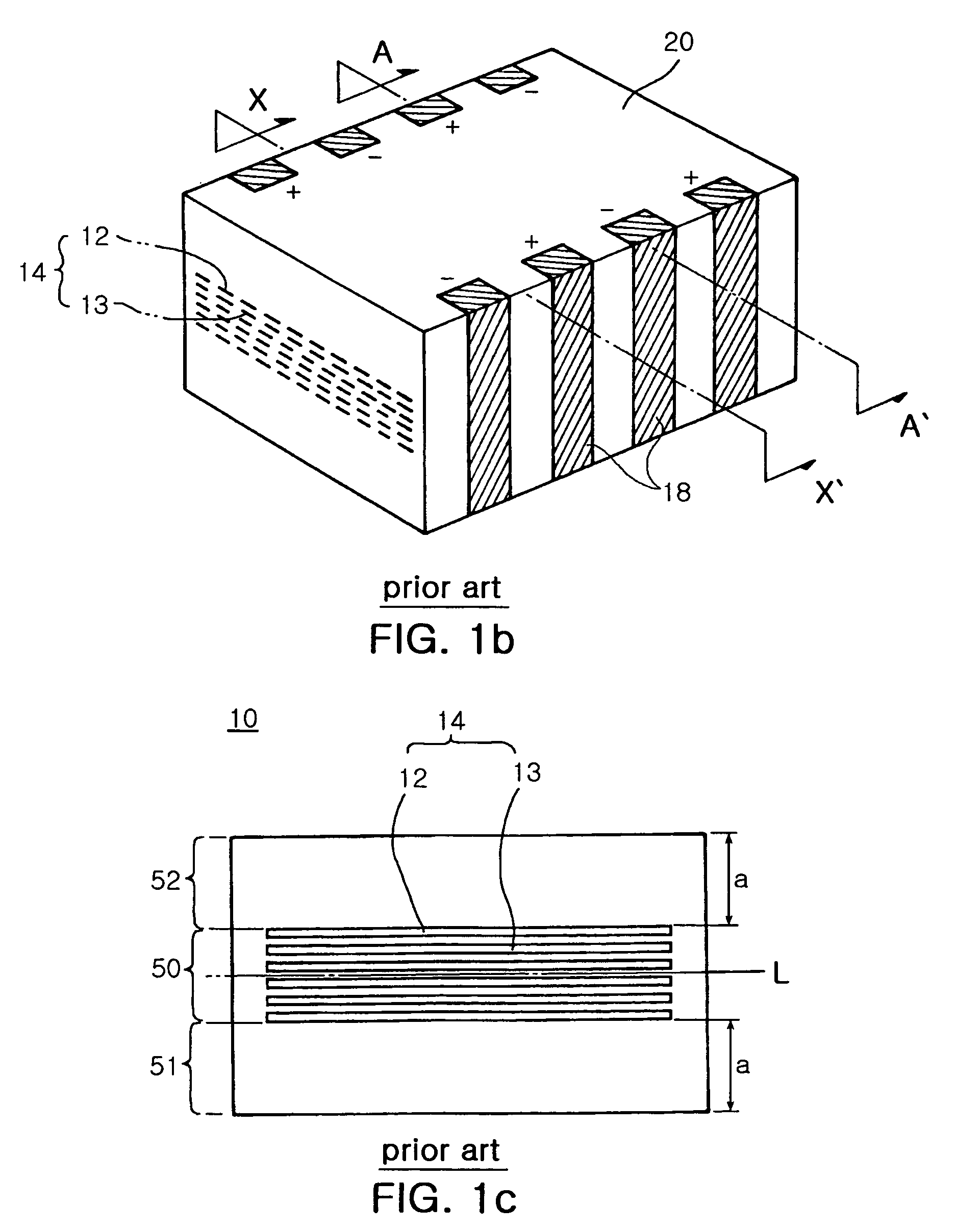

Multilayer chip capacitor

ActiveUS20060158827A1Reduce generationAvoid insufficient thicknessFixed capacitor electrodesFixed capacitor dielectricEngineeringCapacitor

A multilayer chip capacitor, which reduces ESL generated due to current flowing through external electrodes and assures an improved mechanical strength. The multilayer chip capacitor includes an upper dummy layer and a lower dummy layer; a plurality of internal electrodes interposed between the upper and lower dummy layers; and external electrodes connected to the internal electrodes, wherein the thickness of the lower dummy layer is smaller than the thickness of the upper dummy layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

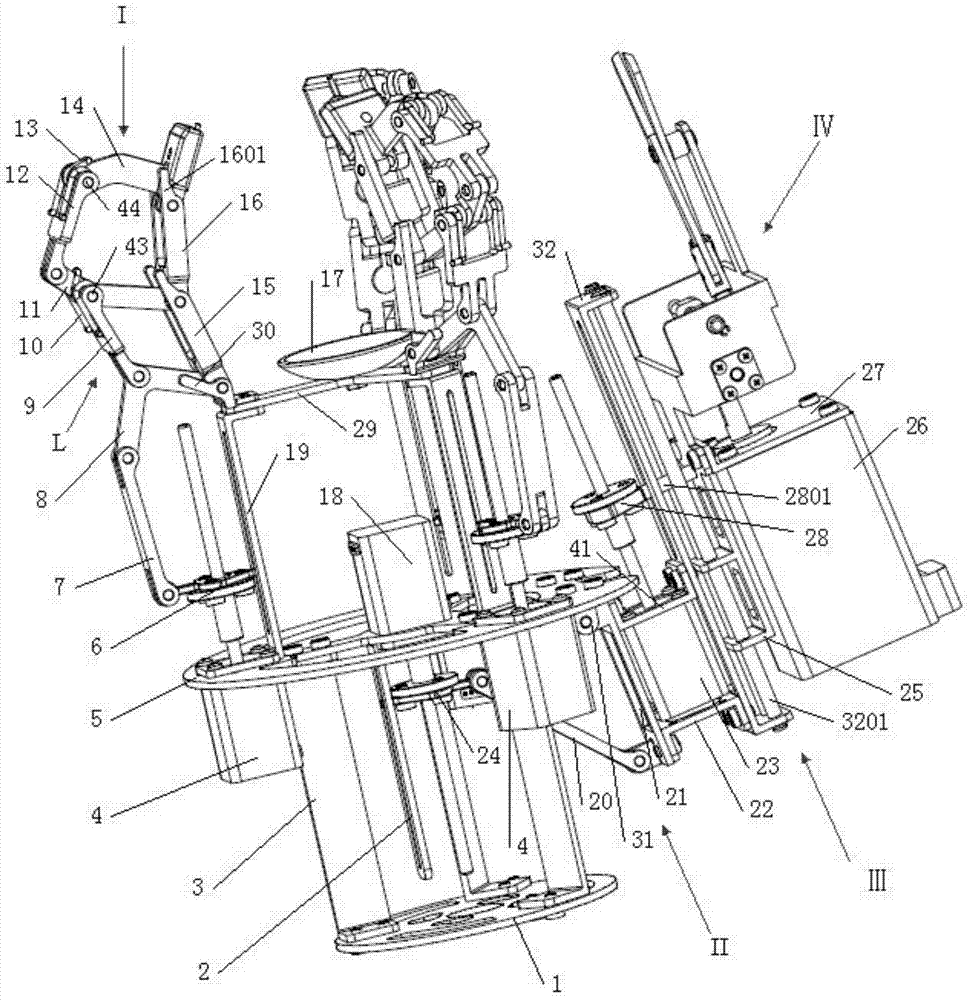

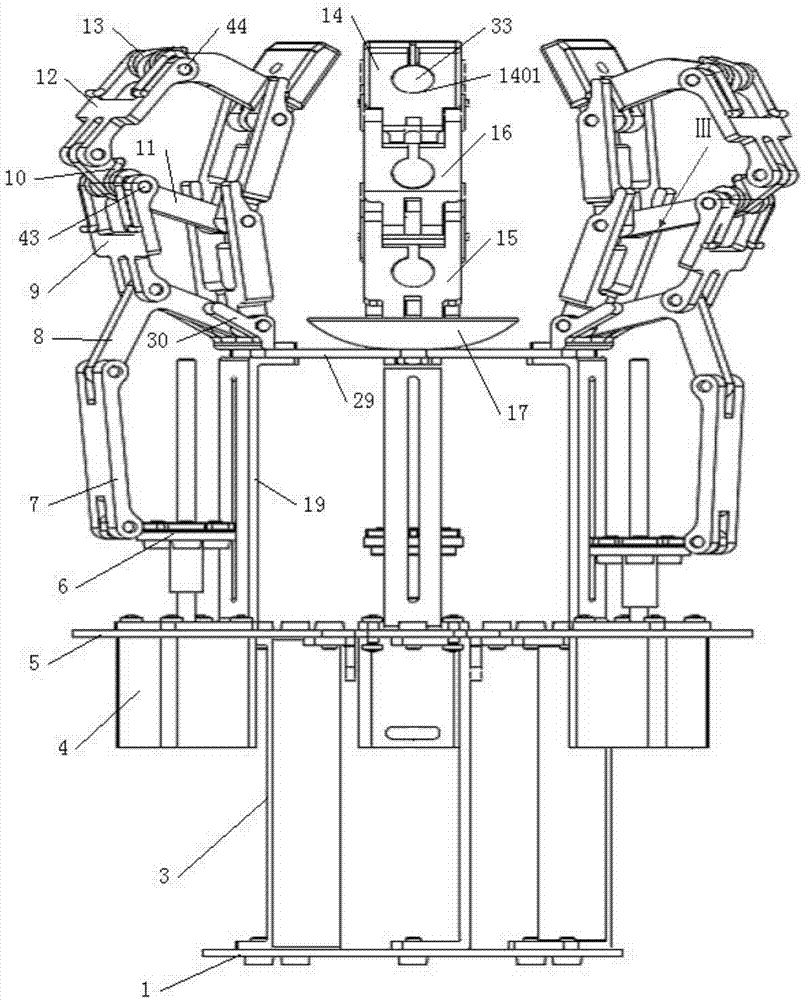

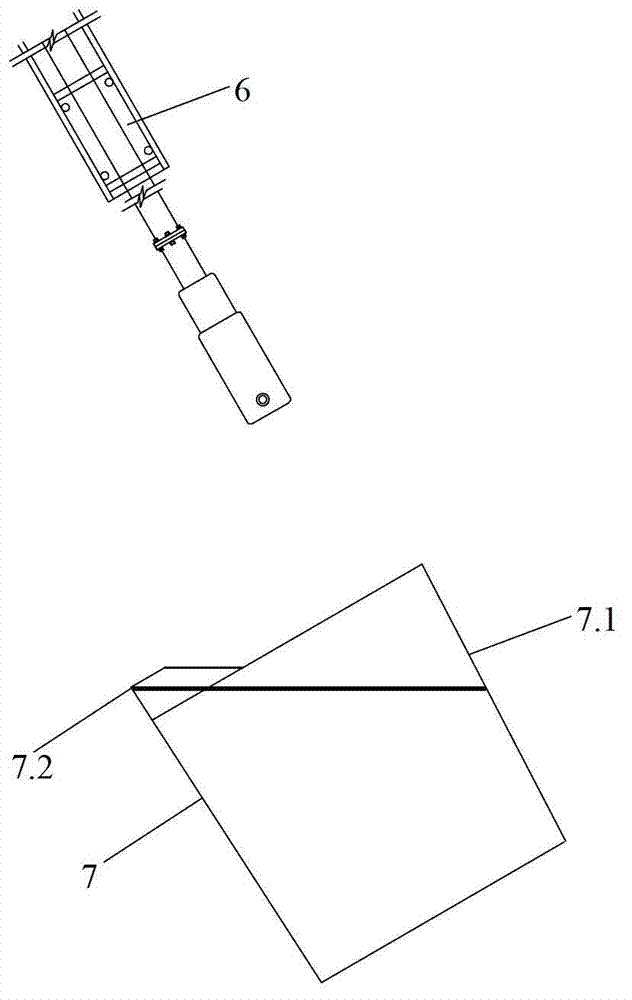

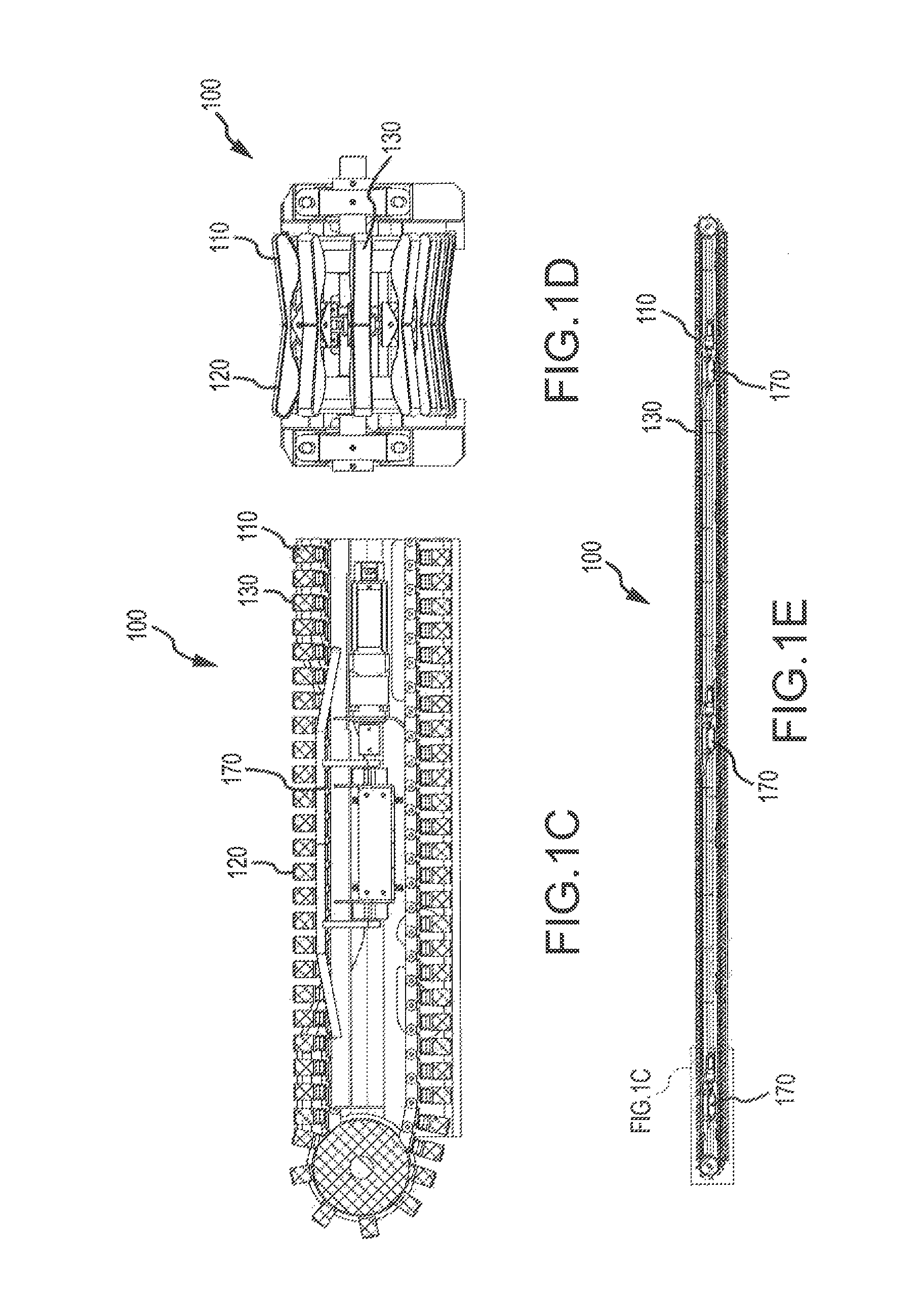

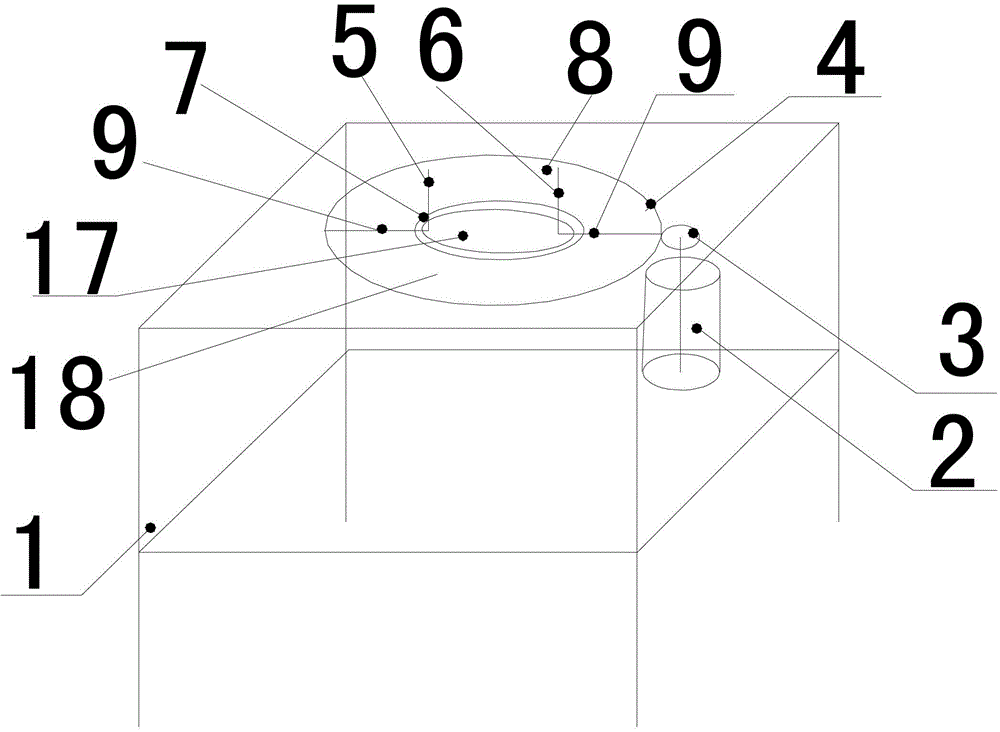

Under-actuated three-finger type fruit-vegetable flexible picking device

InactiveCN104838809AWith envelope grabbing functionImprove stabilityGripping headsPicking devicesRobotic armContact force

The invention belongs to the field of agricultural robots and discloses an under-actuated three-finger type fruit-vegetable flexible picking device which comprises under-actuated finger mechanisms I, a tilting driving mechanism II, a telescopic driving mechanism III, a pruning mechanism IV, a palm supporting disc, a finger driving motor connecting disc and a wrist connecting clamping disc. The three sets of under-actuated finger mechanisms I are evenly distributed on the palm supporting disc which is fixedly connected with the finger driving motor connecting disc. The finger driving motor connecting disc is fixedly connected with the wrist connecting clamping disc which is connected with a wrist of a robotic arm. The tilting driving mechanism II and the telescopic driving mechanism III drive the pruning mechanism IV to tilt and stretch, and the pruning mechanism achieves shear movement. The using range and the using flexibility are expanded, the high picking success rate can be achieved, and mechanical damage on plants and fruits is lowered. Picking of sphere-similar fruits or clustering-growing fruits can be achieved. The device has the advantages that fruit shape self-adaptation capacity is achieved, and contact force is controllable.

Owner:JIANGSU UNIV

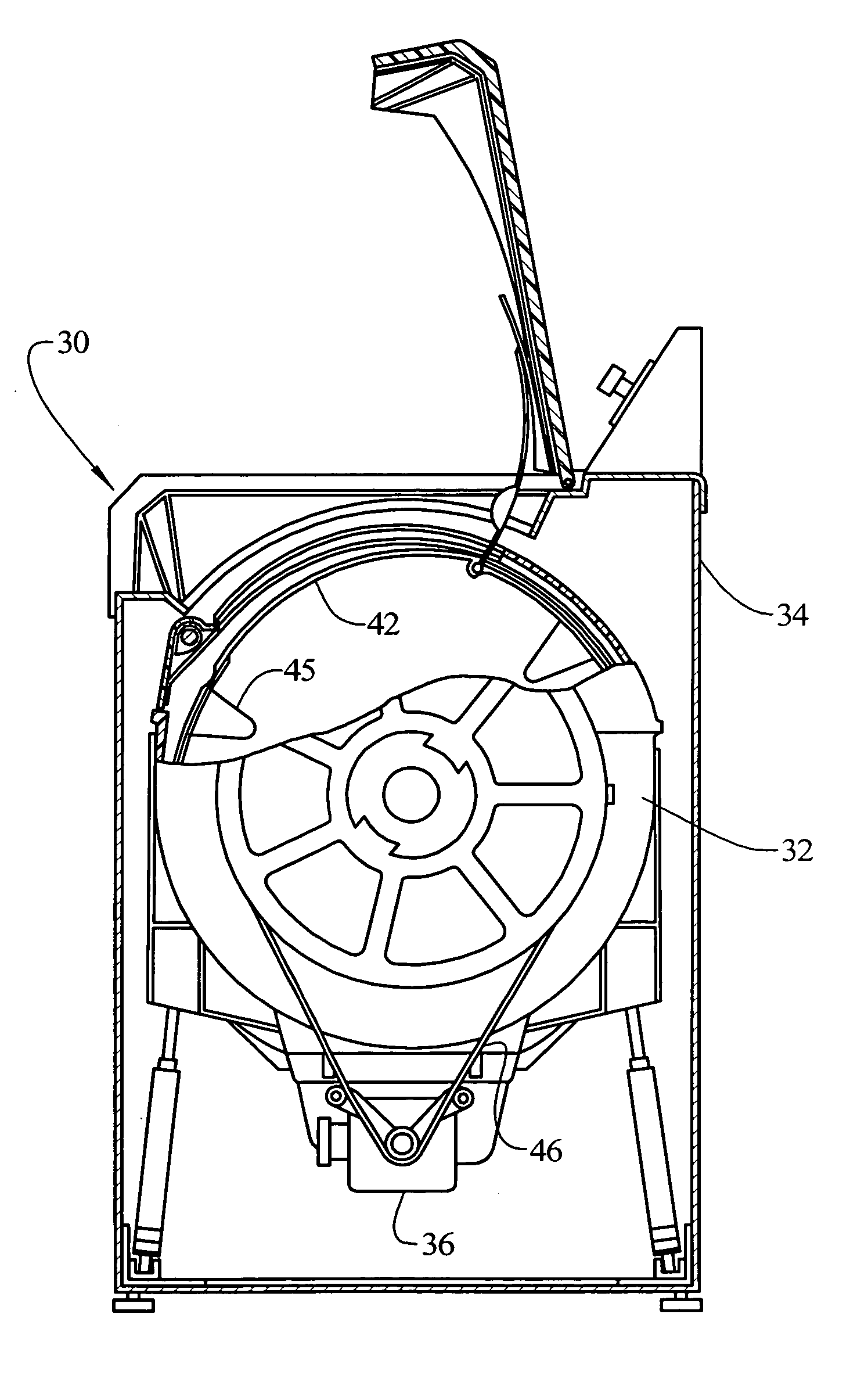

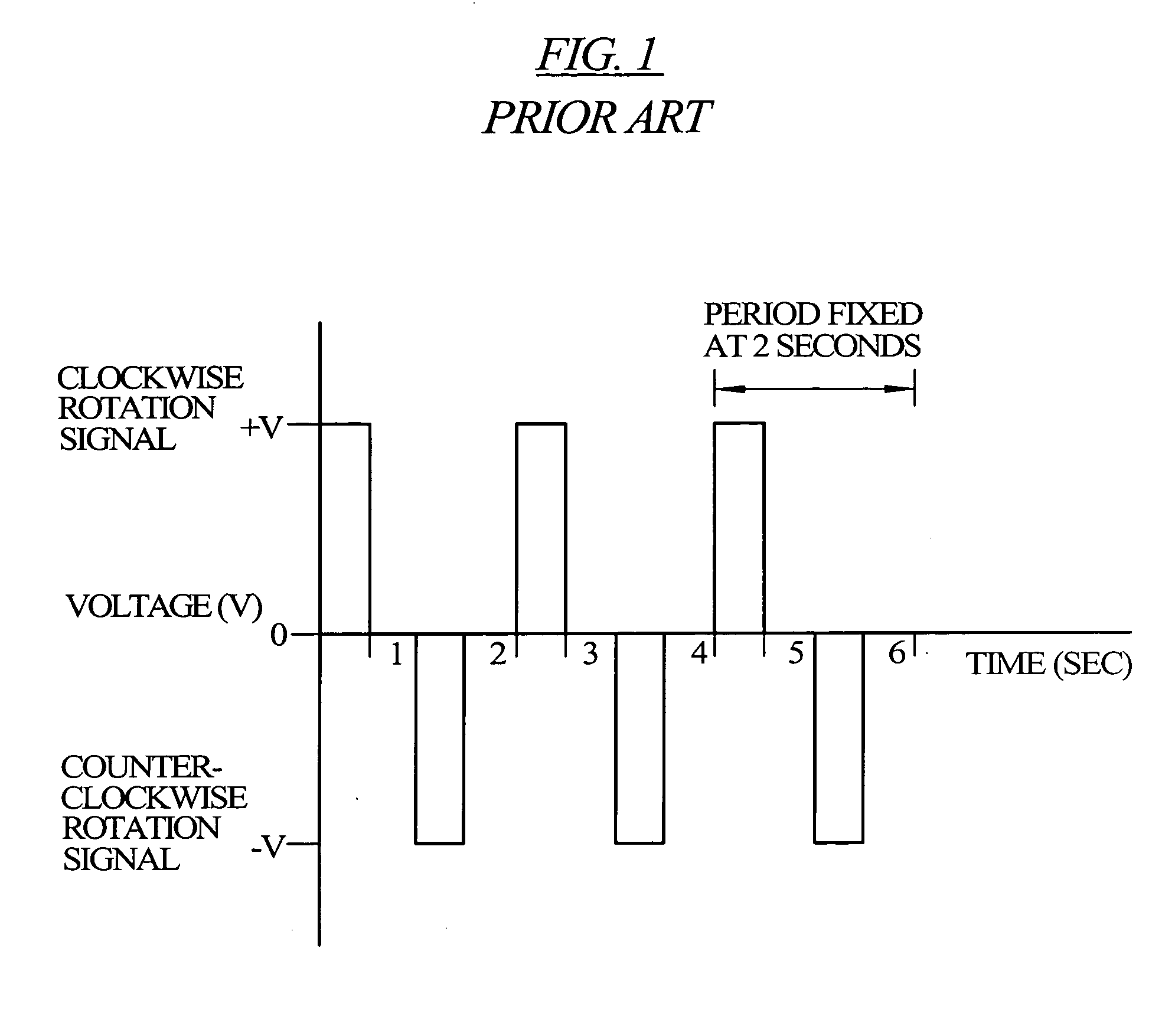

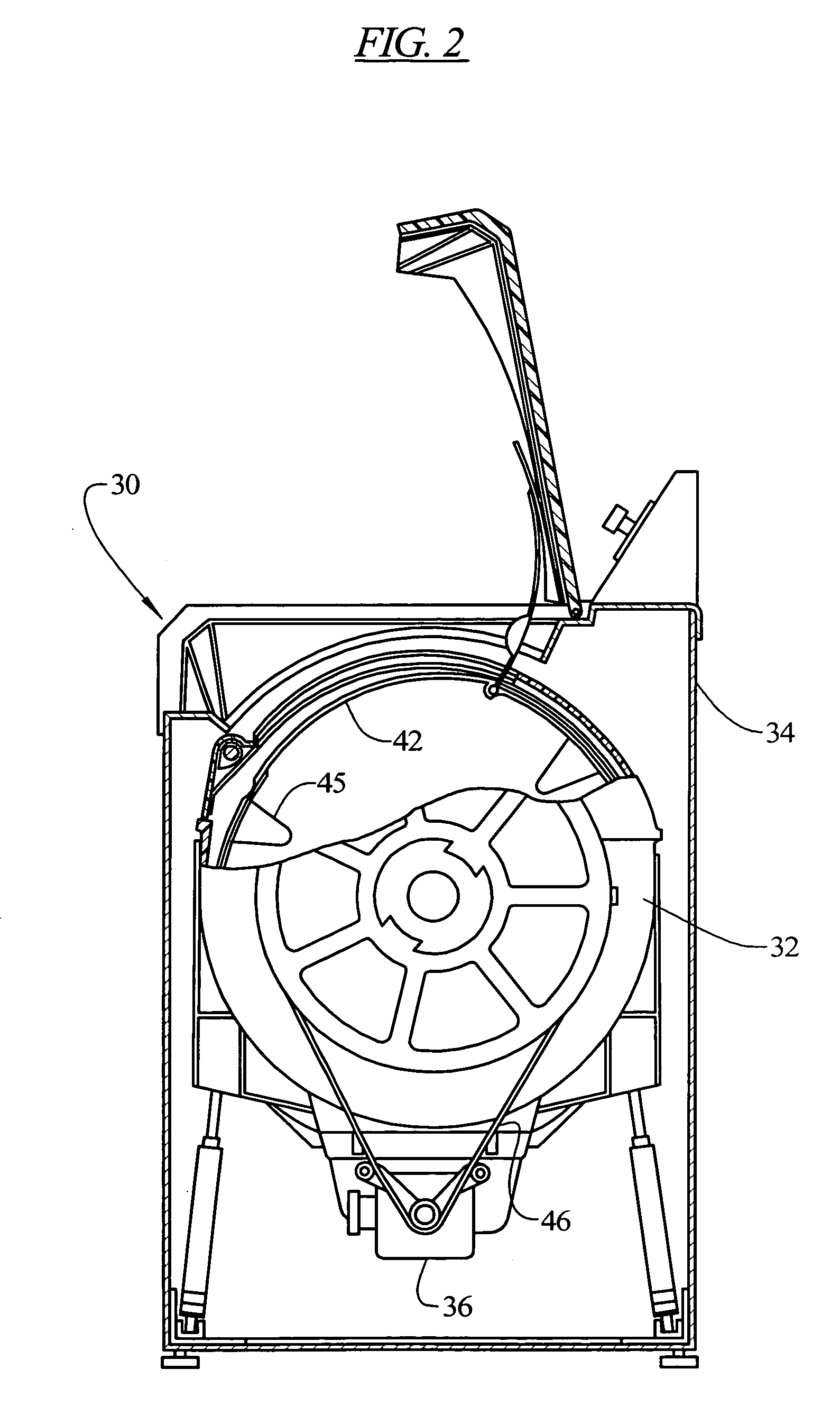

Random tumbling washing machine wash chamber for improving cleaning while minimizing mechanical damage to clothes

InactiveUS20050160536A1Maintaining enhancing removalReduce mechanical damageWashing receptaclesOther washing machinesEngineeringMechanical engineering

Methods and apparatuses consistent with the present invention provide for improved cleaning while minimizing mechanical damage to clothes in automatic washer cycles using time-varying wash chamber oscillations. An automatic washer has a wash chamber with a central axis and is rotatable about the central axis. Items are loaded into the wash chamber. Wash liquid is supplied into the wash chamber. The wash chamber is oscillated about the central axis by time-varying oscillations.

Owner:WHIRLPOOL CORP

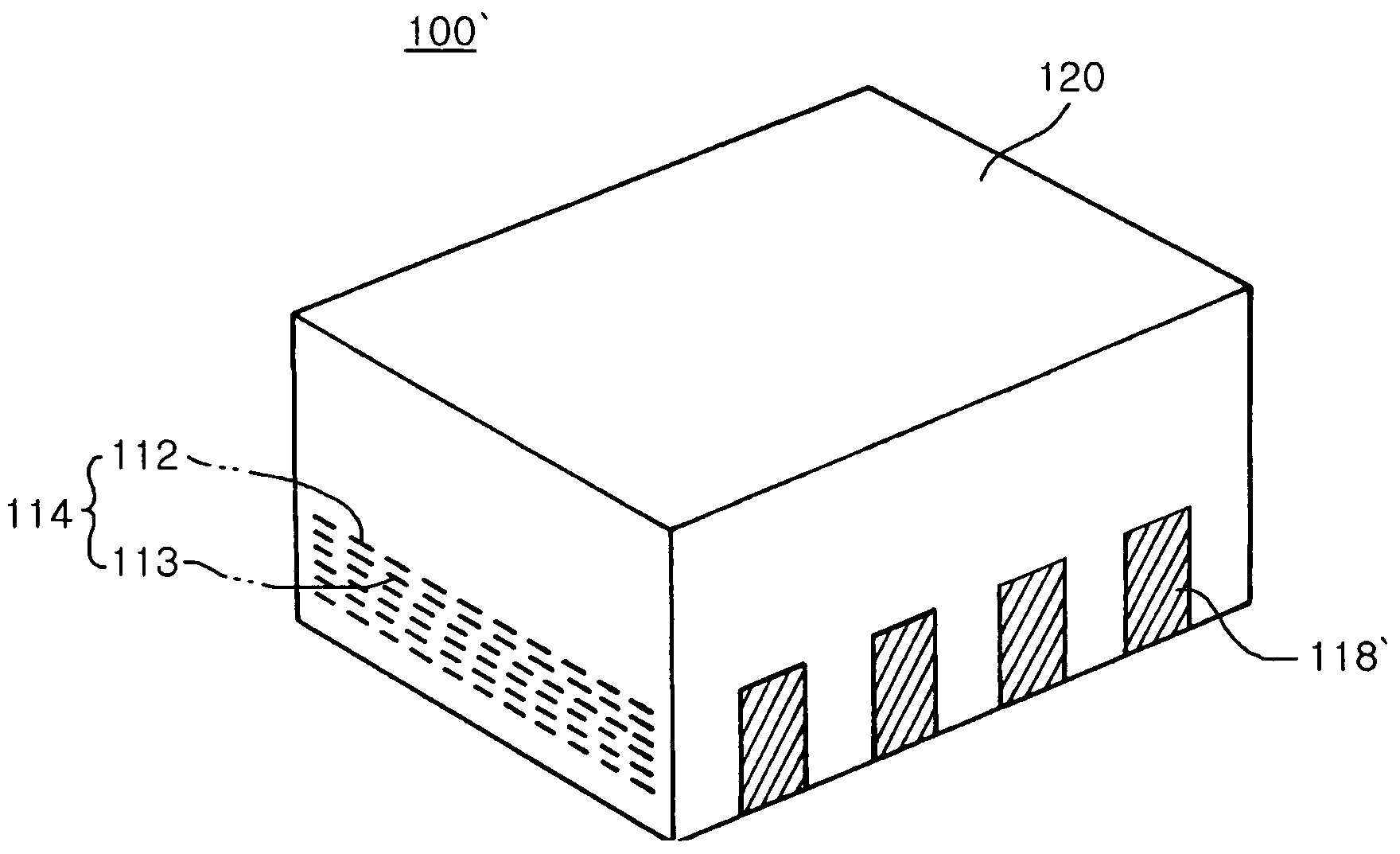

Multilayer chip capacitor

ActiveUS7092236B2Reduce generationAvoid insufficient thicknessFixed capacitor electrodesFixed capacitor dielectricCapacitorElectrical and Electronics engineering

A multilayer chip capacitor, which reduces ESL generated due to current flowing through external electrodes and assures an improved mechanical strength. The multilayer chip capacitor includes an upper dummy layer and a lower dummy layer; a plurality of internal electrodes interposed between the upper and lower dummy layers; and external electrodes connected to the internal electrodes, wherein the thickness of the lower dummy layer is smaller than the thickness of the upper dummy layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

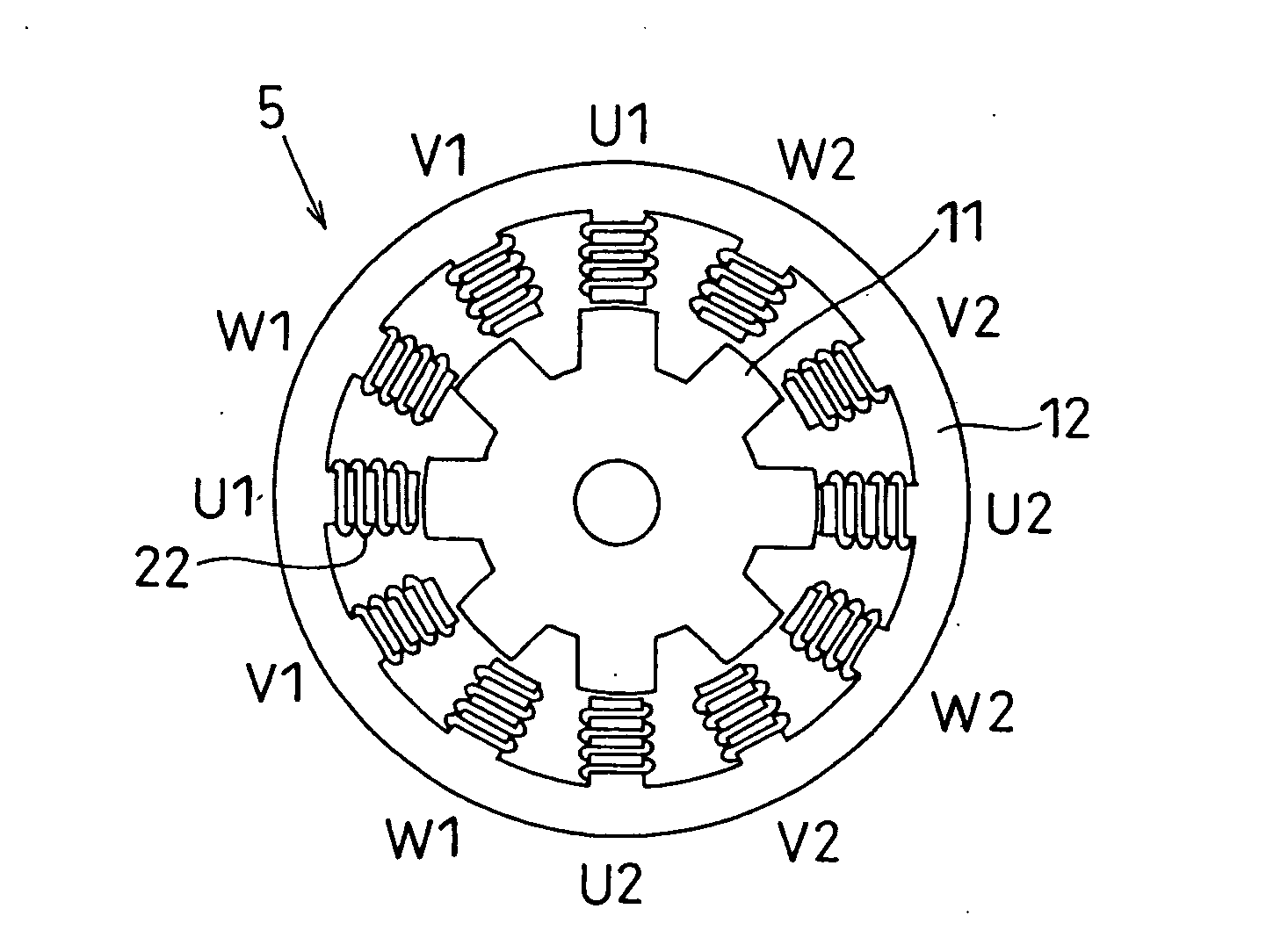

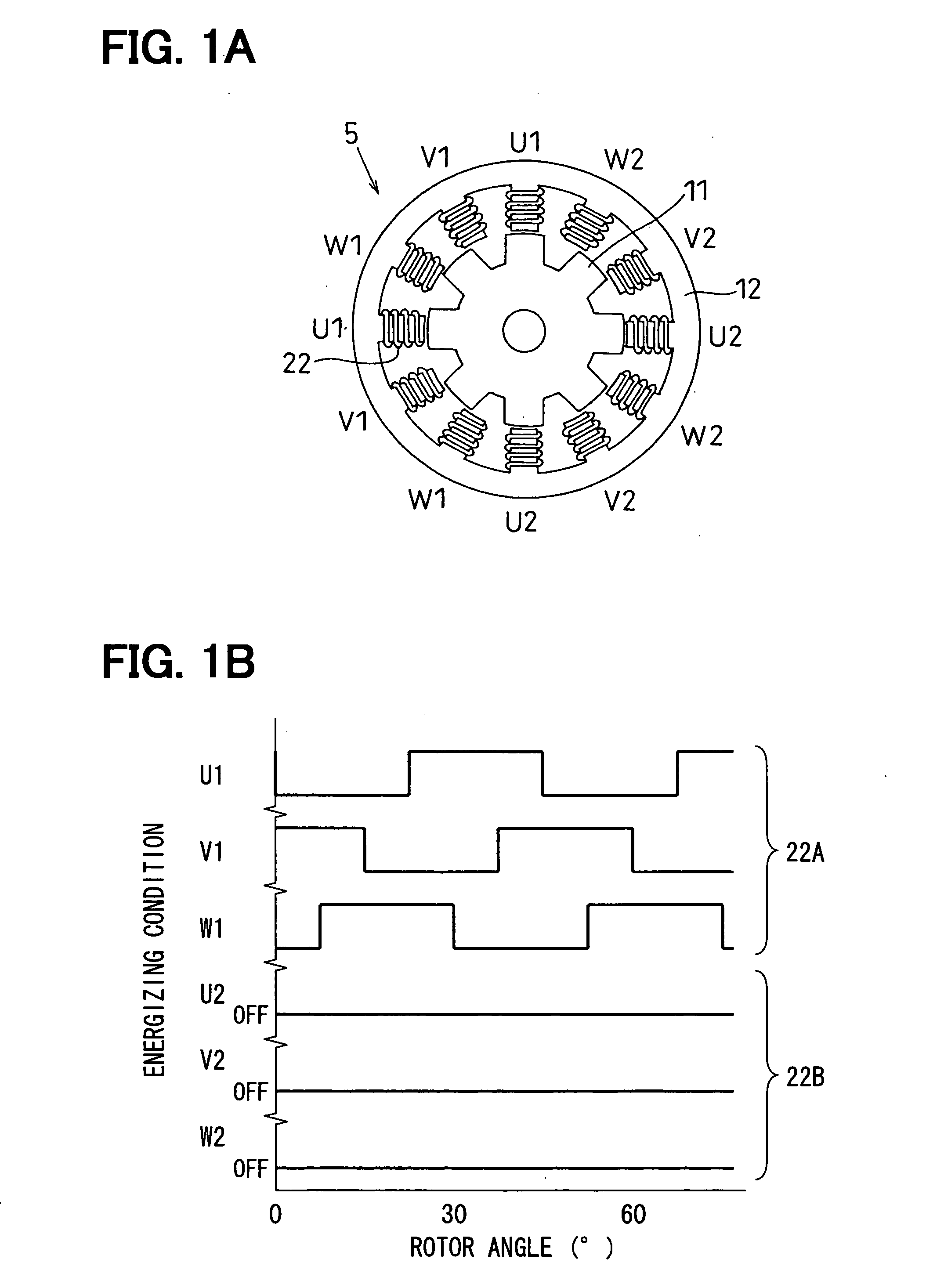

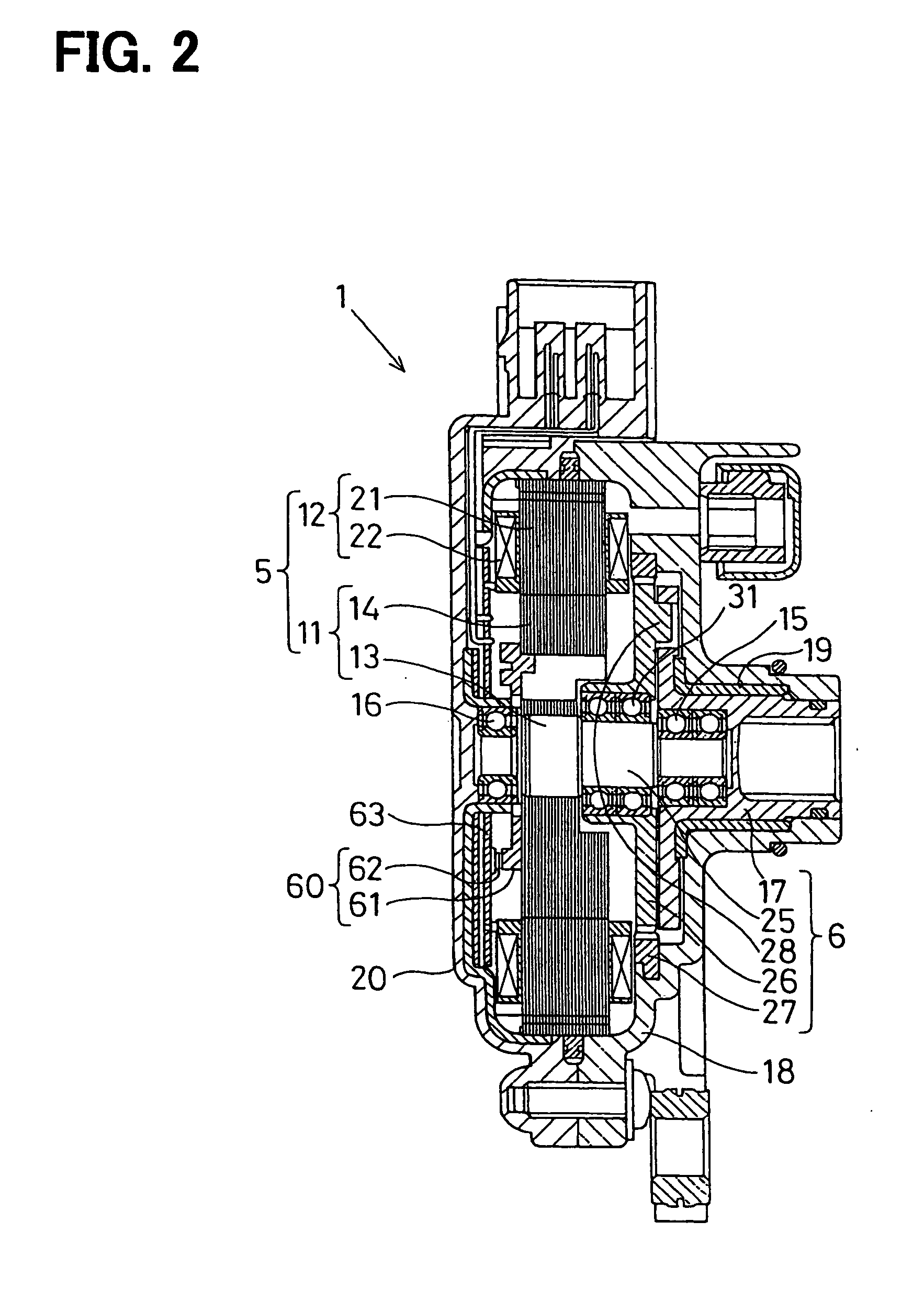

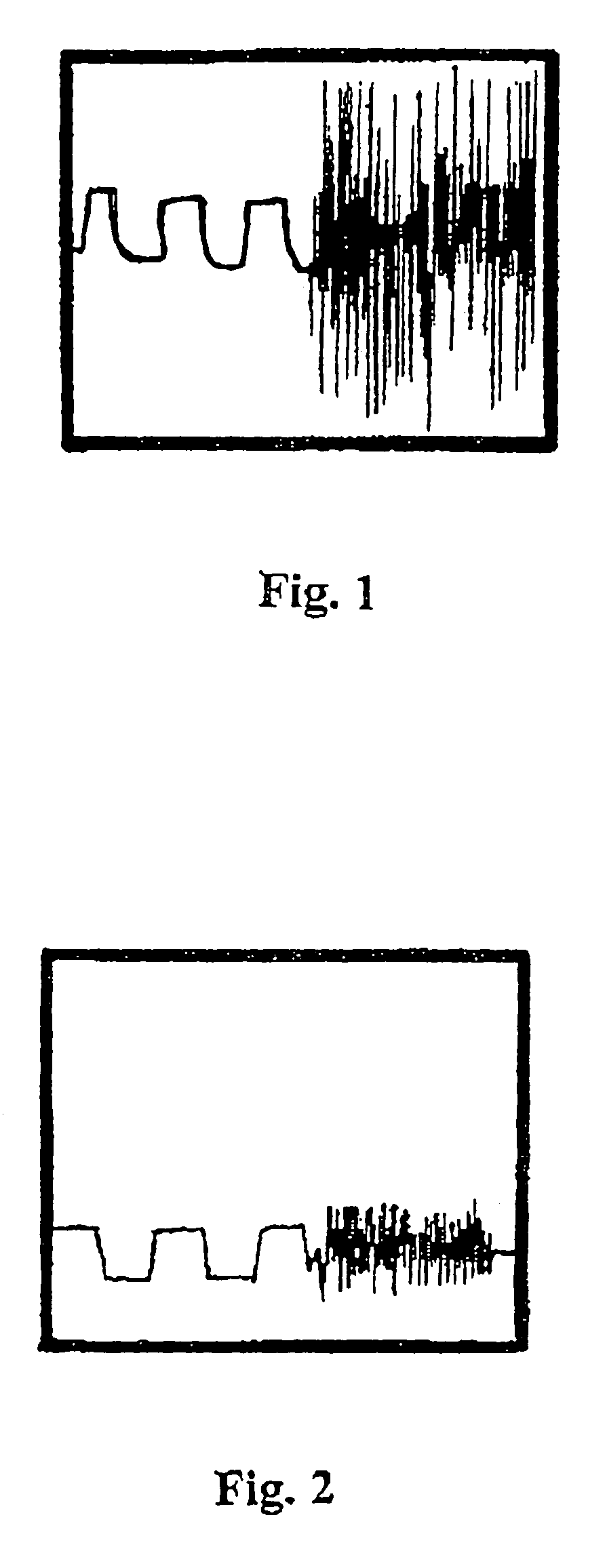

Position detecting apparatus having electric motor and method for detecting position

ActiveUS20060138880A1Reduce harmReduce loadWindingsMagnetic measurementsElectricityLocation detection

A reference position detecting apparatus includes an electric motor and a motor control unit. The electric motor includes a plurality of first coils and a plurality of second coils. The electric motor further includes a rotor that rotates when at least one of the plurality of first coils and the plurality of second coils is supplied with electricity. The motor control unit controls electricity supplied to either one of the plurality of first coils and the plurality of second coils to rotate the rotor to a limit position in a movable range of an object.

Owner:DENSO CORP +1

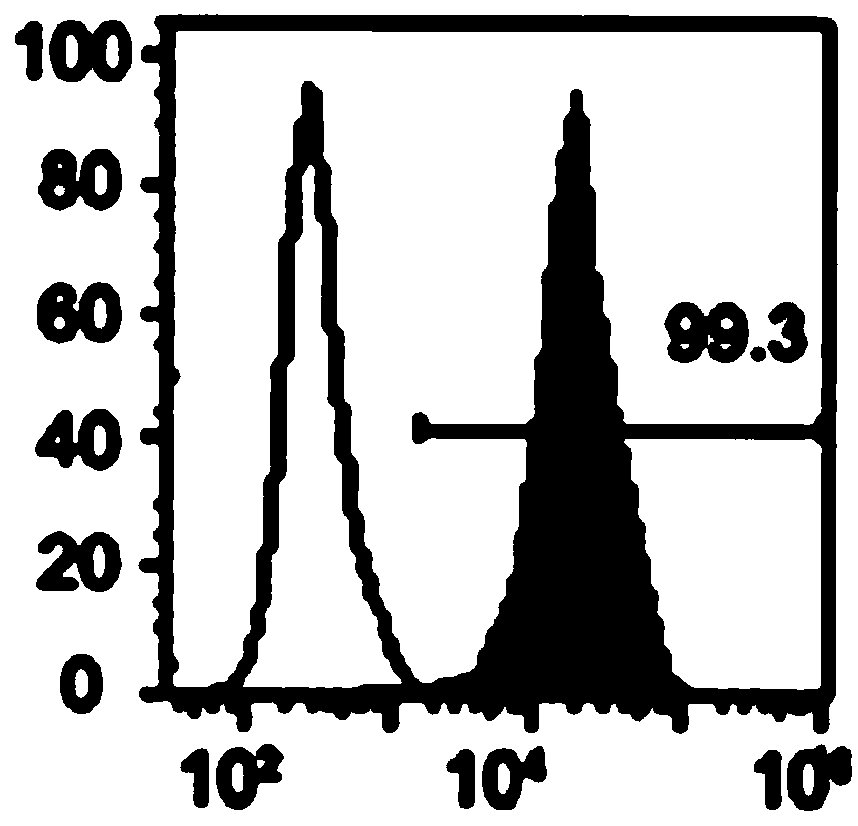

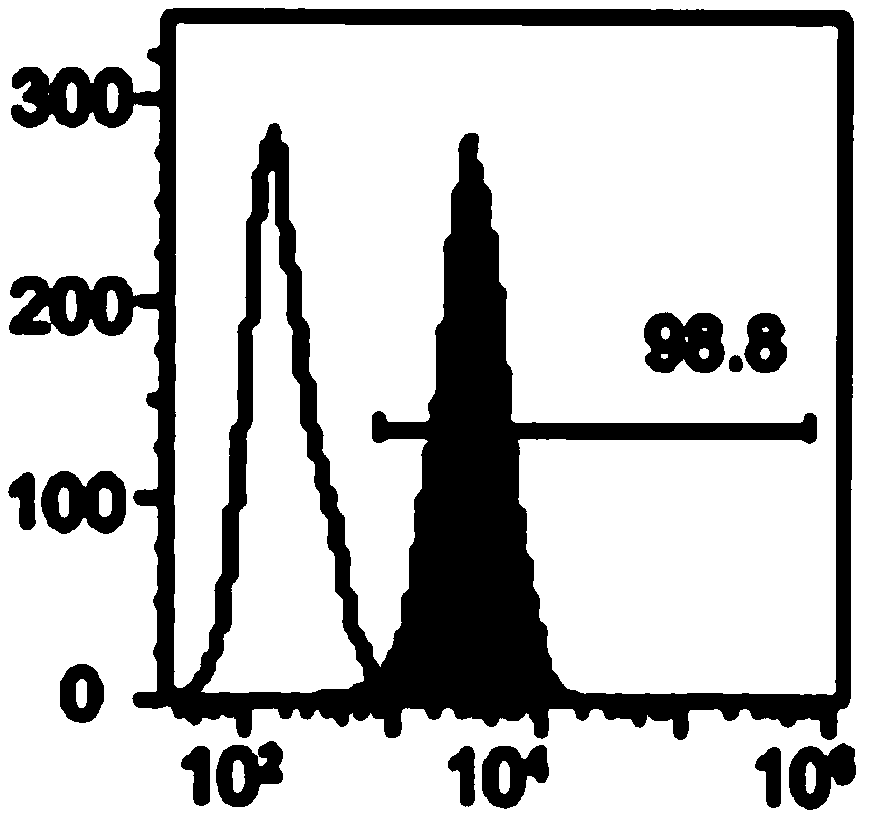

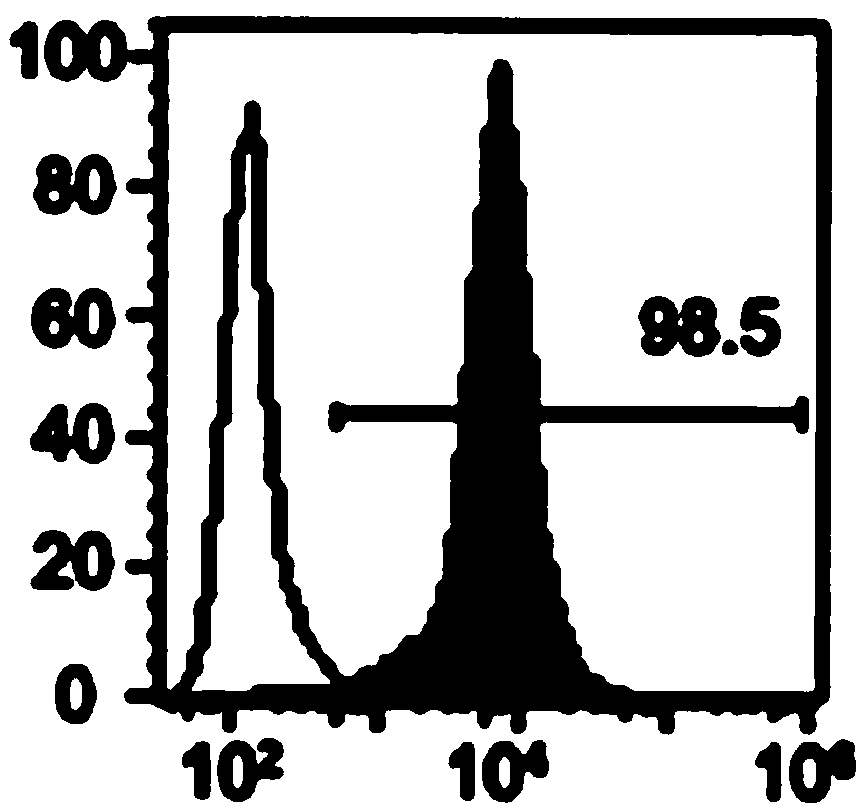

Extraction method of specific mesenchymal stem cell exosome

InactiveCN109097328AReduce mechanical damageImprove separation efficiencyCell dissociation methodsSkeletal/connective tissue cellsSerum freeFiltration

The invention discloses an extraction method of a specific mesenchymal stem cell exosome. The method comprises the following steps: collecting supernatant of serum-free mesenchymal stem cells: firstly, culturing mesenchymal stem cells, changing a culture medium for culturing, centrifuging, and removing cell debrises to obtain initial supernatant; taking the initial supernatant for carrying out further gradient centrifugation, transferring the centrifuged supernatant into a sterile centrifugal tube, centrifuging and collecting supernatant containing micro vesicles; centrifuging the supernatantcontaining the micro vesicles to obtain precipitate containing an exosome, washing and then centrifuging to obtain exosome precipitate; adding the obtained exosome precipitate into sterile PBS and filtering to obtain the specific mesenchymal stem cell exosome. The exosome collected in the extraction method disclosed by the invention adopts a filter membrane for filtration, so the extracted exosomeis enabled to be nanoscale; meanwhile, the rotational speed is reduced and optimized, high-speed mechanical damage is reduced, separation efficiency is high and the cost is low.

Owner:深圳市浊安认证生物技术有限公司

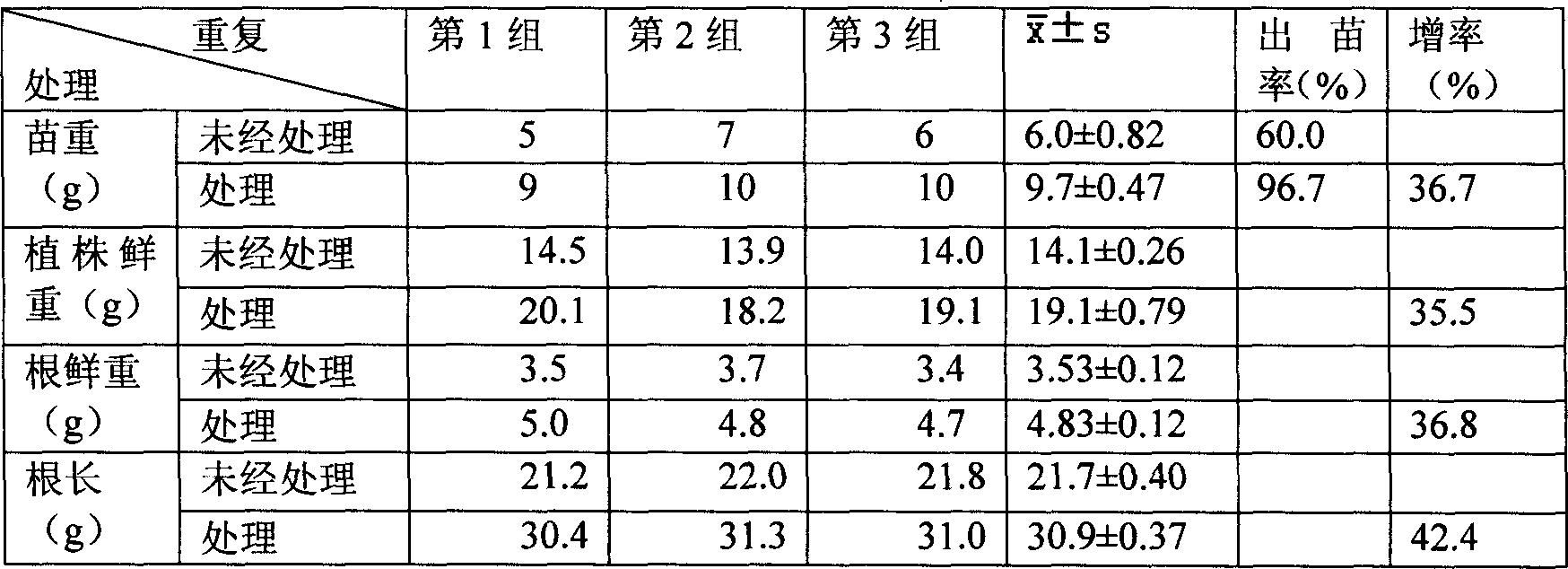

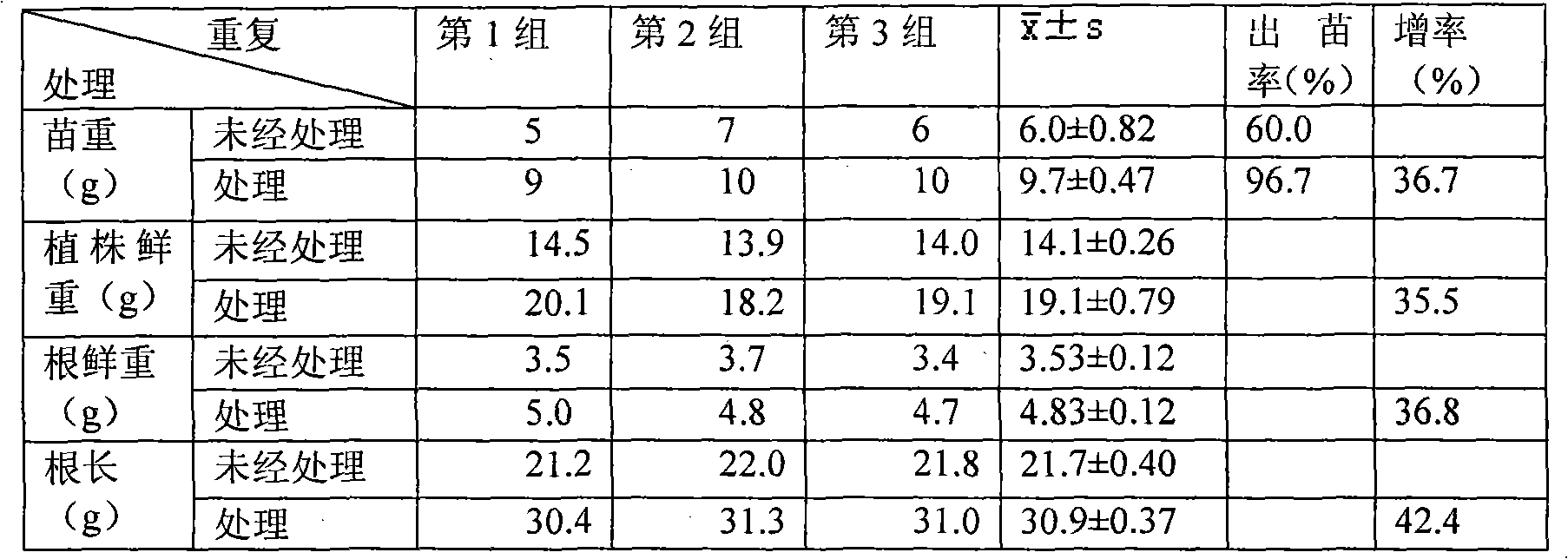

A cold- and draught- resistant seed coating agent and a cold-resistant sprinkling agent

InactiveCN1994090AWith water absorptionWith water retentionBiocideAnimal repellantsGrowth plantSprayer

The invention relates to a cold resistant packing agent, wherein it comprises 5-50% cold resistant nutrient, 10-70% macromolecule water absorber, 0.1-10% disinfector, 0.1-10% antiseptic, 0.01-2% growth adjuster, 0.02-2% cold resistant nutrient, and 0.2-20% oxygen releaser. And the cold resistant sprayer comprises 30-80% cold resistant nutrient, 4-40% cold resistant liquid, 0.02-2. 0% surface activator, 0.001-1. 0% plant growth adjuster and left water. The invention can seed at low temperature. And the cold resistant sprayer can improve the cold resistance of plant / .

Owner:王树禹

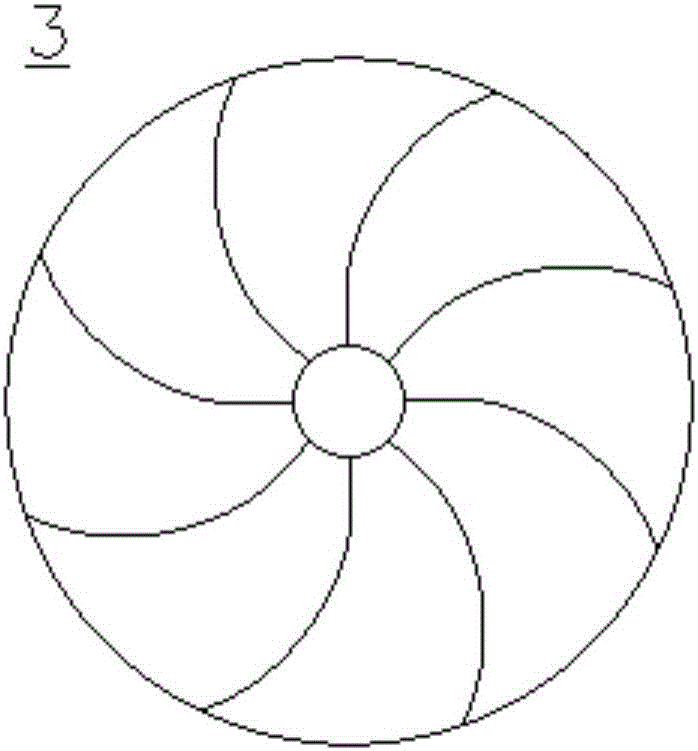

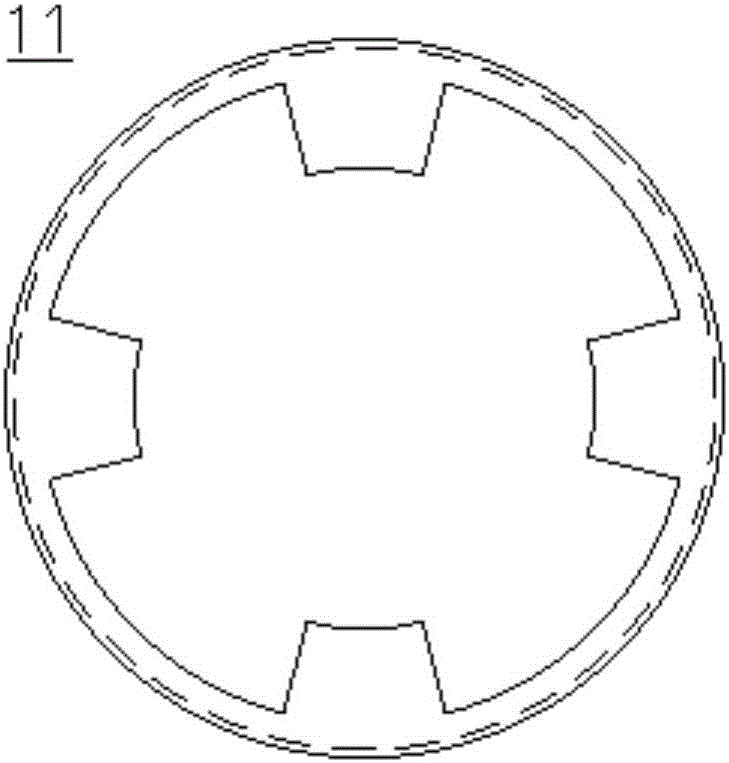

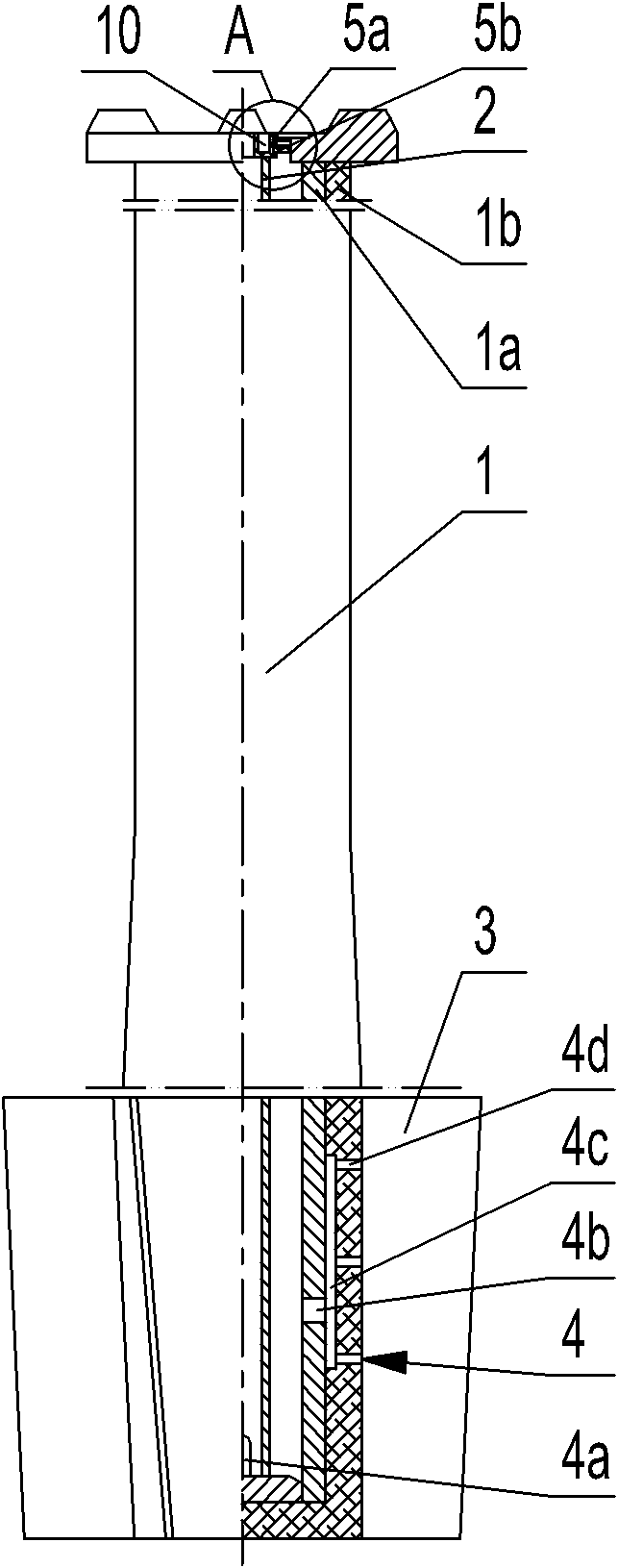

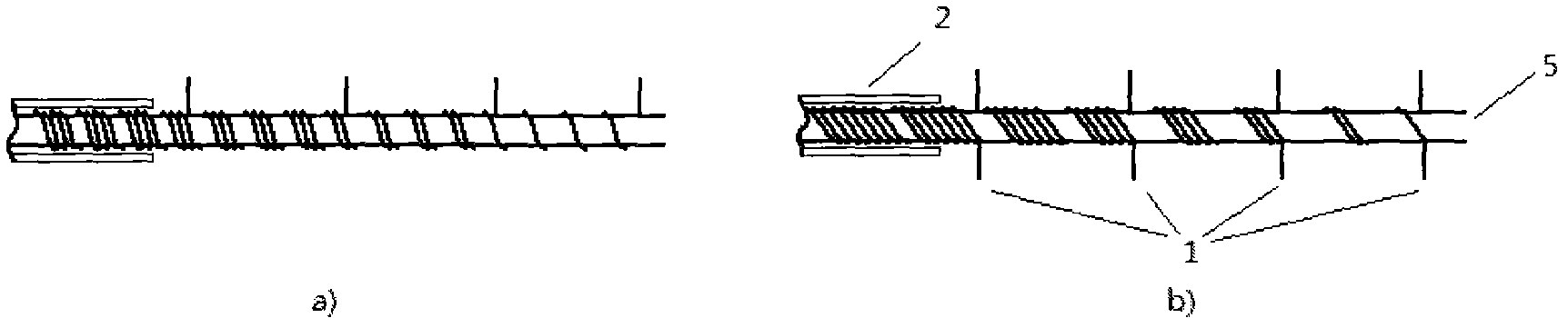

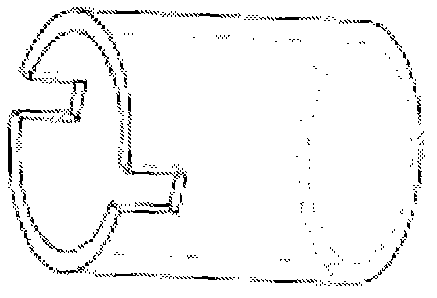

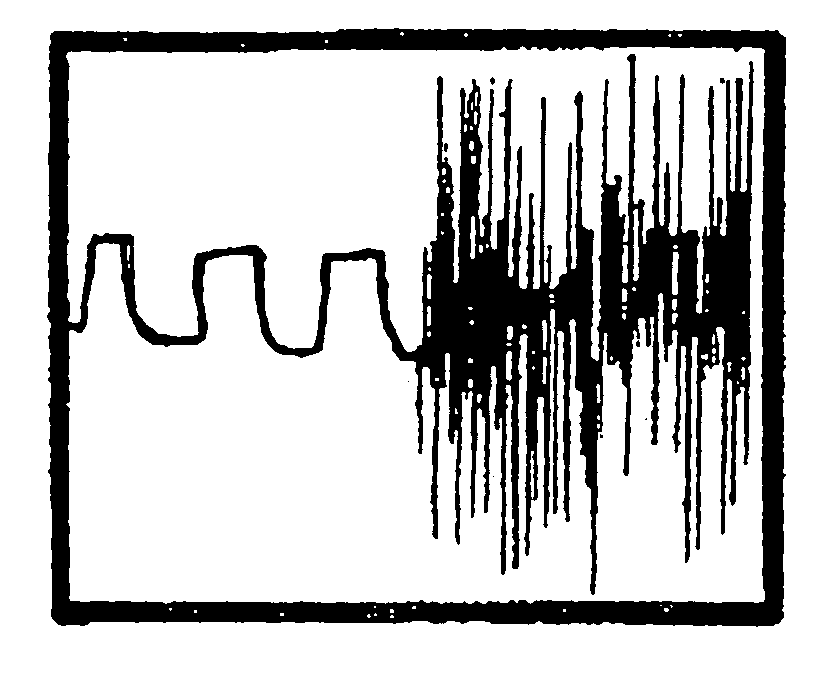

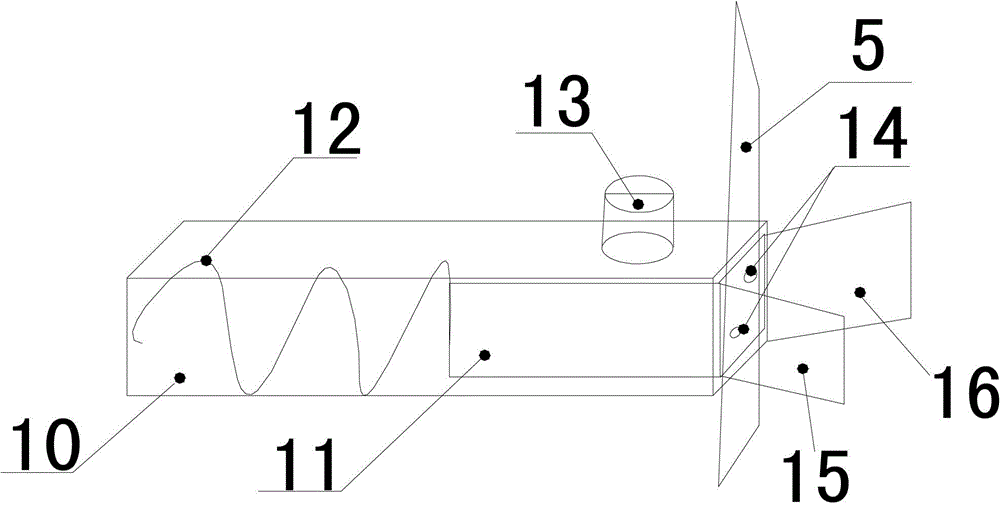

Self-powered ultrasonic scale removal tube cleaner

InactiveCN106269730AReduce mechanical damageGood pigging effectHollow article cleaningImpellerWater quality

The invention discloses a self-powered ultrasonic scale removal tube cleaner. The self-powered ultrasonic scale removal tube cleaner comprises a body, and an ultrasonic generation apparatus, an electromagnetic induction power generation apparatus, a power supply apparatus and a protection apparatus, which are arranged on the body, wherein the body comprises a barrel and a cone; the ultrasonic generation apparatus comprises an ultrasonic generator; the electromagnetic induction power generation apparatus comprises a transmission connecting rod, an induction coil and a converter; the power supply apparatus comprises a packing cup and an impeller with a runner; and the protection apparatus is a metal protection cover, and the metal protection cover is provided with a leak flow hole. The tube cleaner is adopted as a carrier to be combined with the ultrasonic scale removal apparatus, so that the ultrasonic scale removal effect is more remarkable than the scale removal effect by only adopting the tube cleaner; and meanwhile, the self-powered ultrasonic scale removal tube cleaner carries a self-powered power generation apparatus, the automation degree is relatively high, scales are automatically removed, and the tube cleaner is only required to be transmitted and received by a tube cleaner receiving and transmitting barrel. Compared with a chemical tube cleaning way, the problem of changing the water quality is avoided, the phenomenon that a great amount of scales are dropped is avoided, and the tube cleaner plugging phenomenon is avoided.

Owner:SOUTHWEST PETROLEUM UNIV

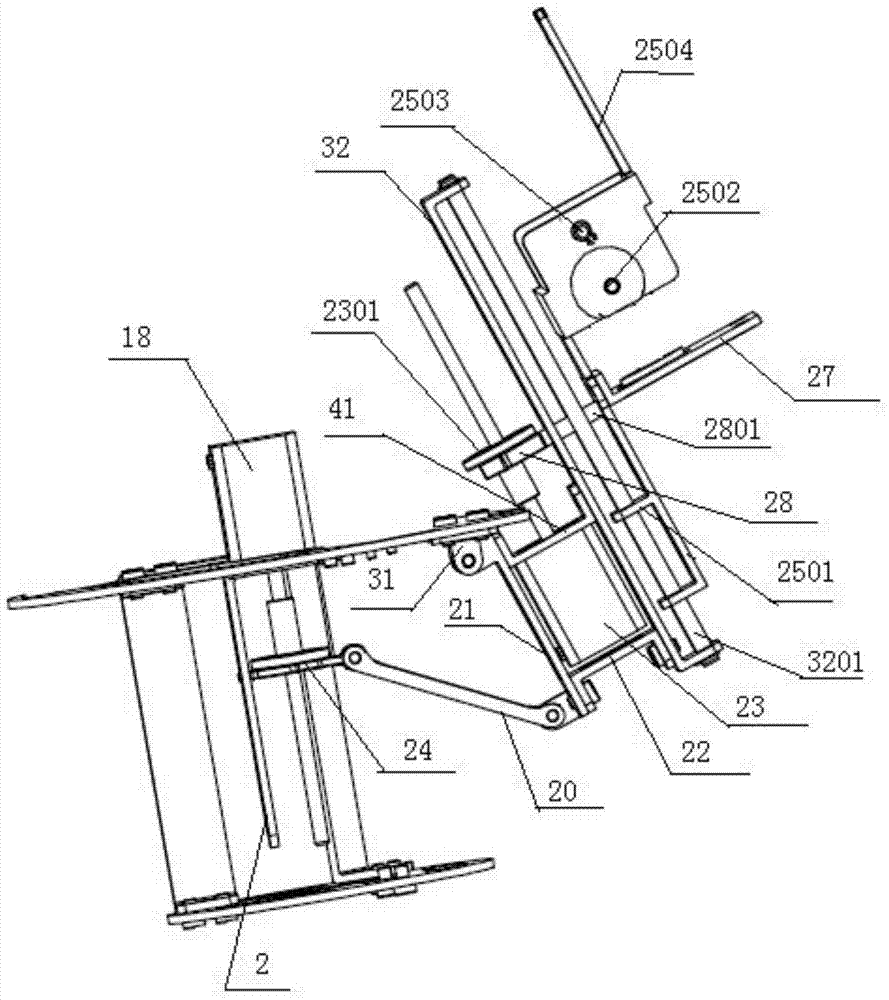

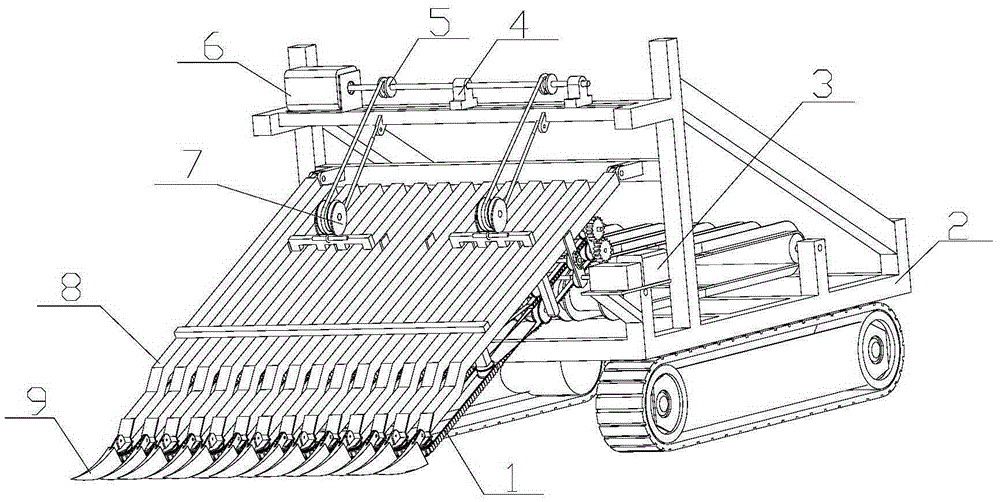

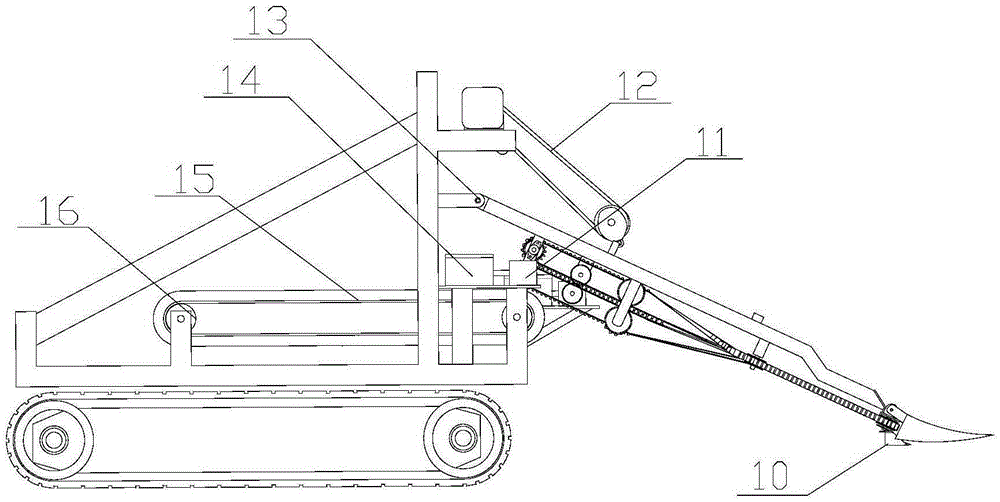

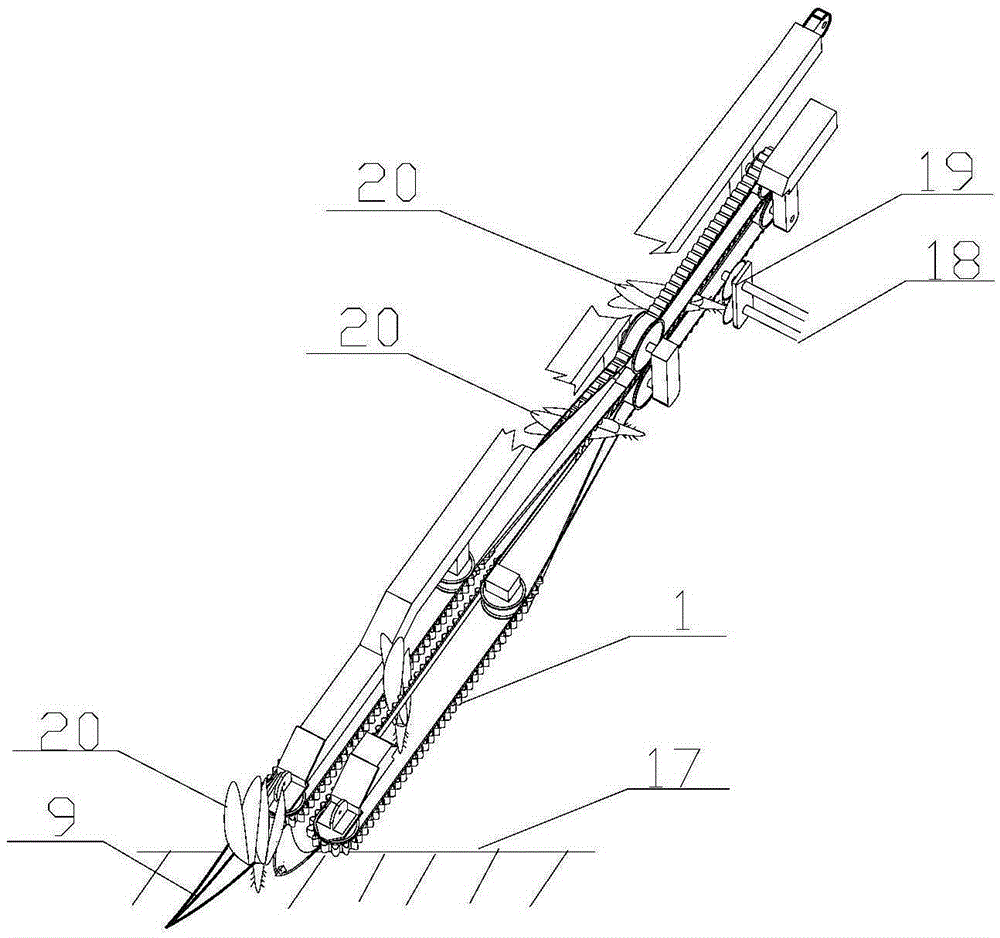

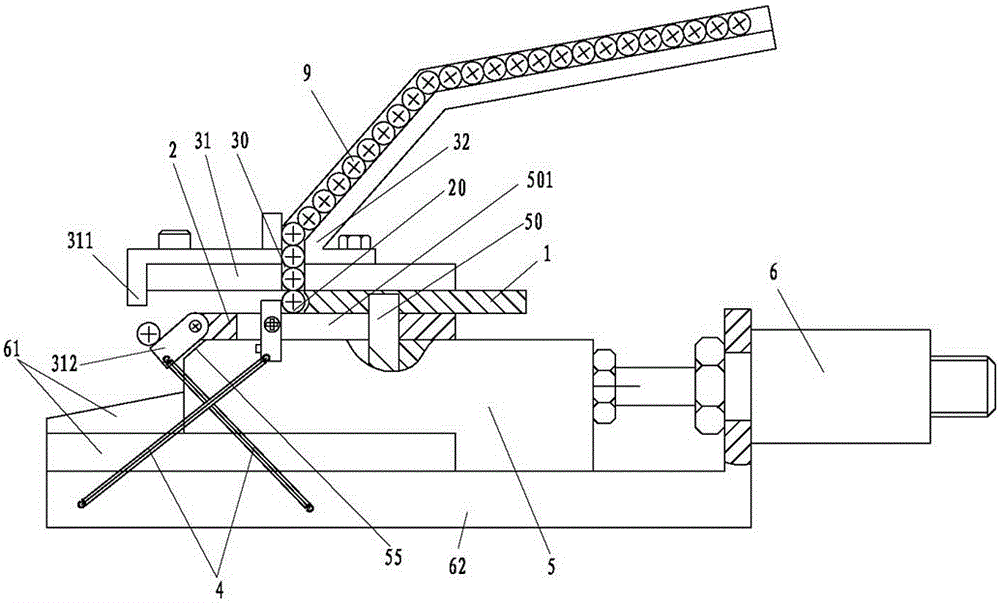

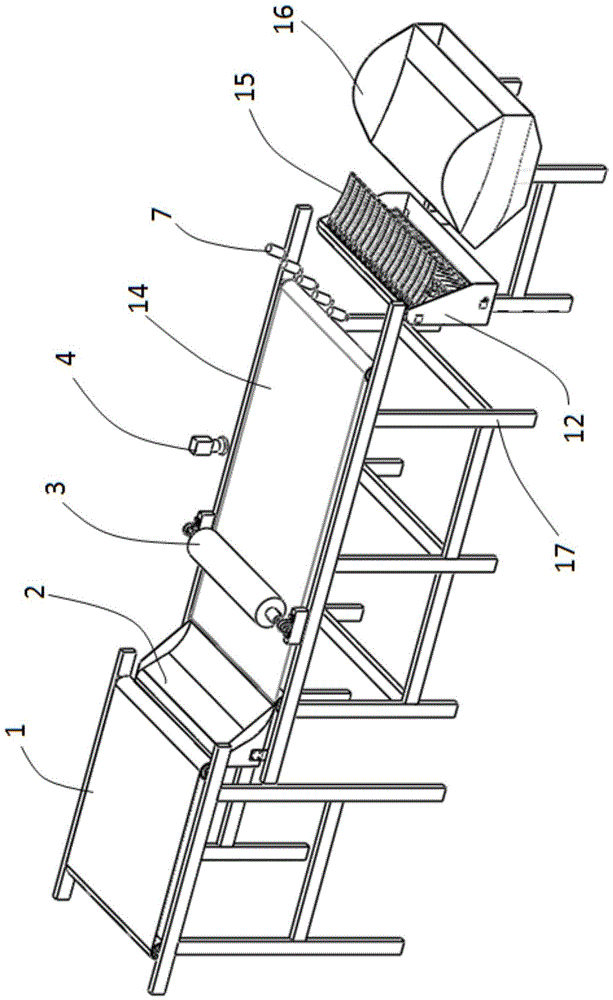

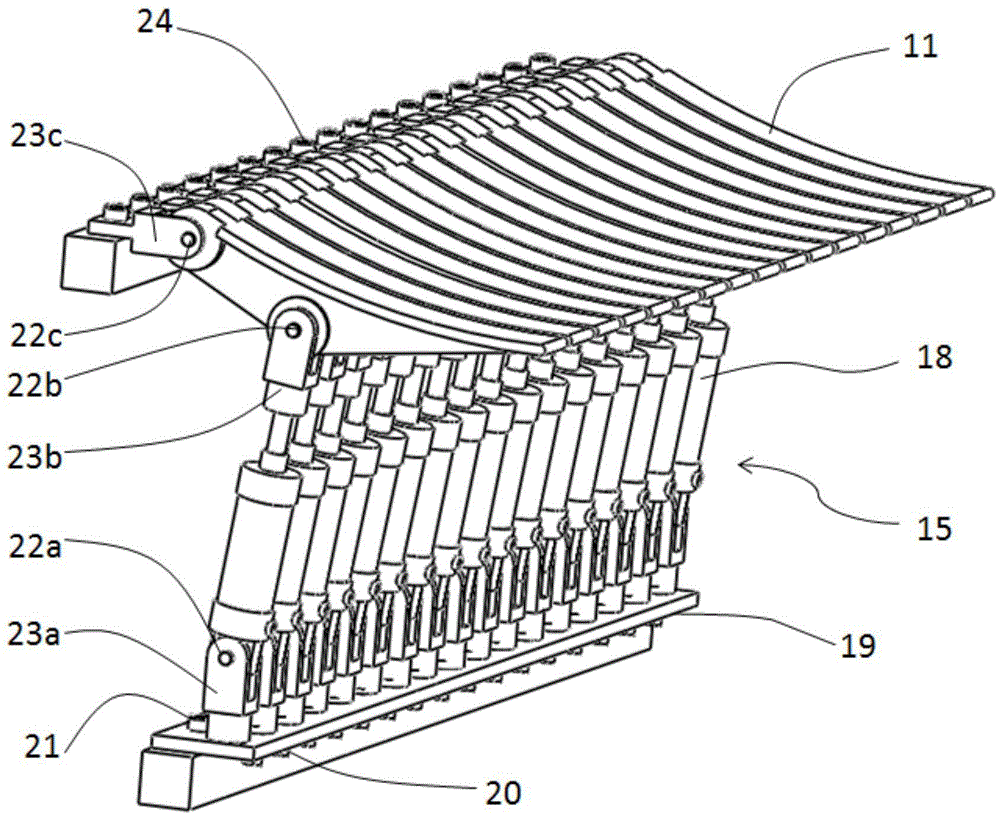

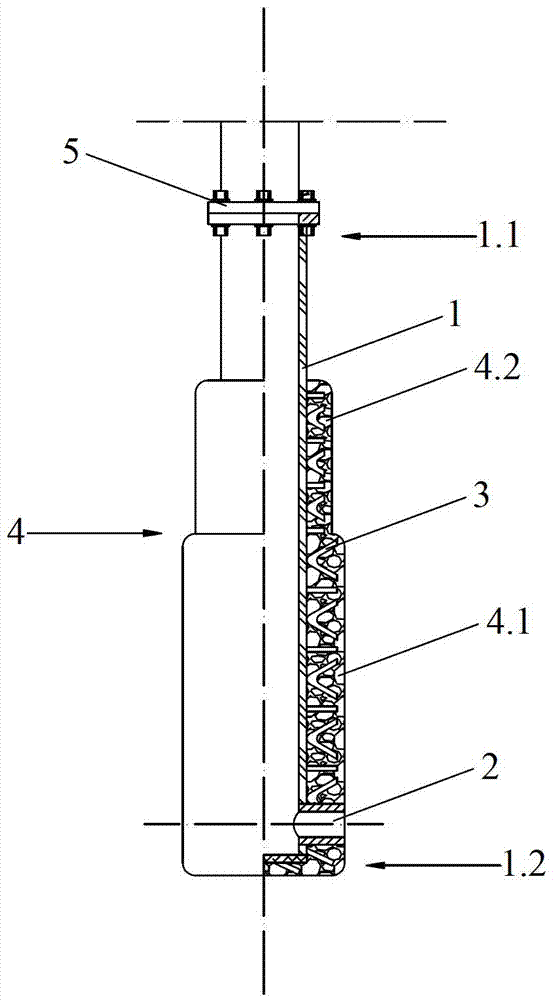

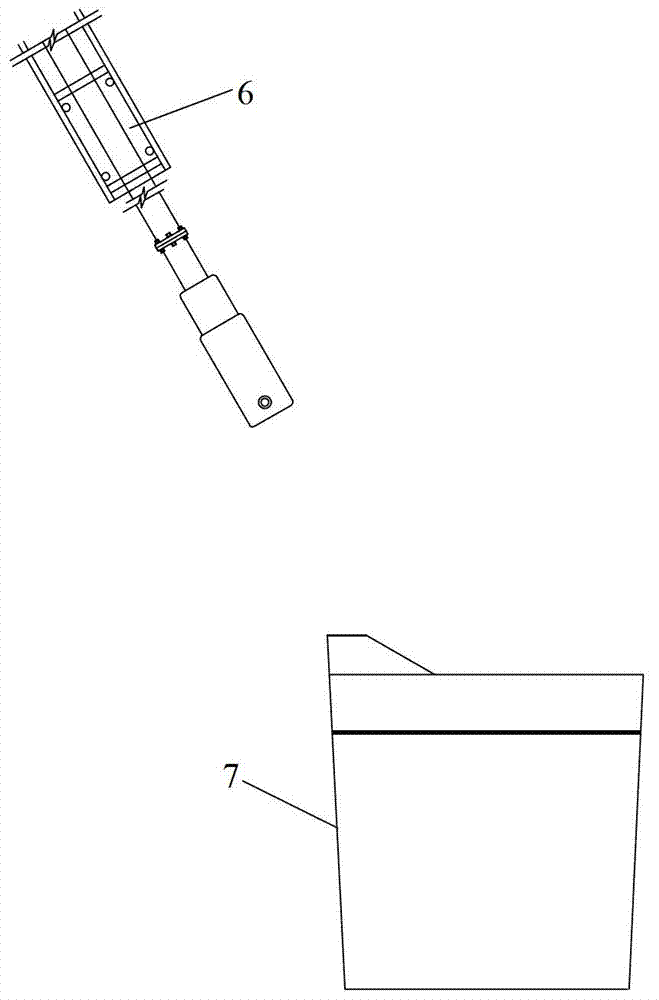

Reaping apparatus and reaping method for continuously reaping whole plants of green vegetables

InactiveCN105409437AIncrease effective yieldReduced Harvest CostsHarvestersParallel processingMechanical engineering

The present invention relates to a reaping apparatus and a reaping method for continuously reaping whole plants of green vegetables. The reaping apparatus comprises a machine frame, a crop divider, a ripper, a clamping, pulling and reversing apparatus, a root cutting apparatus, a transport apparatus, a lifting apparatus, and a walking apparatus. The crop divider is used for dividing and lifting green vegetables in a harvest area; the ripper is used for ripping a soil at roots of the green vegetables that are gathered together by the crop divider; the clamping, pulling and reversing apparatus is used for clamping and pulling the green vegetables that are gathered together, and reversing the green vegetables during a clamping and conveying process; the root cutting apparatus is used for stably and regularly cutting roots of the green vegetables during a clamping and delivering process; the transport apparatus is used for transporting the green vegetables that are pulled out; the lifting apparatus is used for supporting the clamping, pulling and reversing apparatus, and adjusting a height of the clamping, pulling and reversing apparatus from the ground; and the walking apparatus is used for driving the machine frame to walk in the harvest area. According to the reaping apparatus and reaping method provided by the present invention, a pulling method with flexible belts parallel processing is adopted to continuously reap the whole plants of green vegetables; a flexible material is adopted to avoid damage to stems or leaves; and adaptability to vegetable harvest is good.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

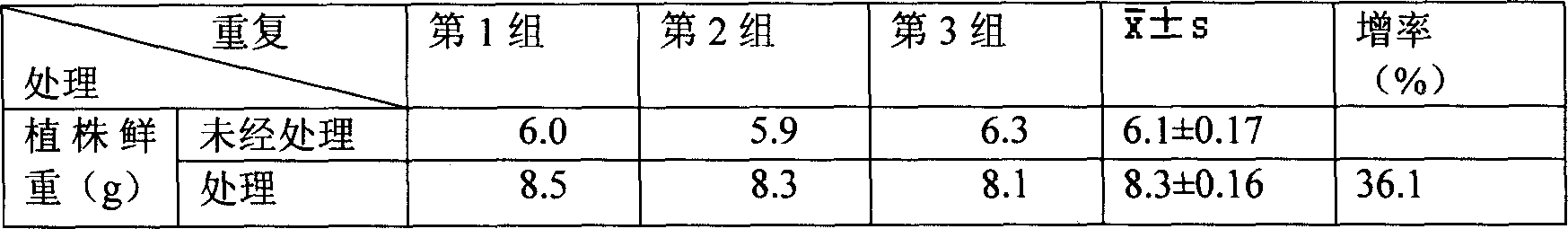

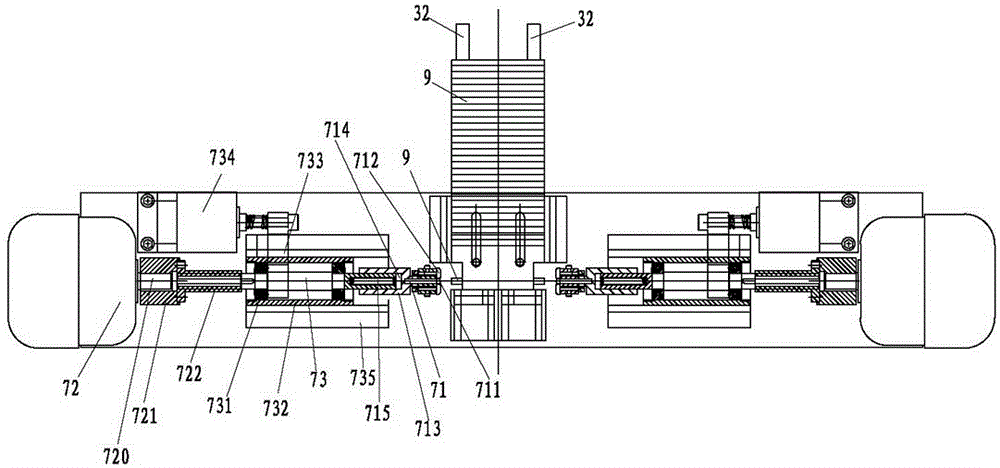

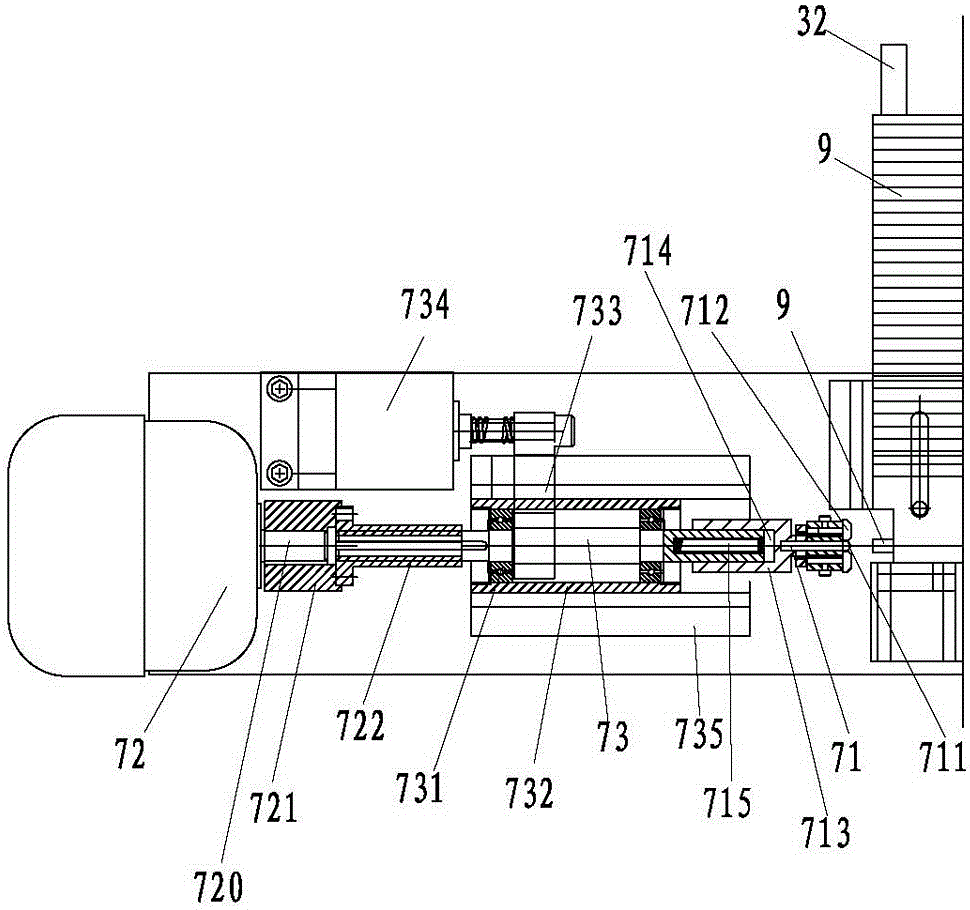

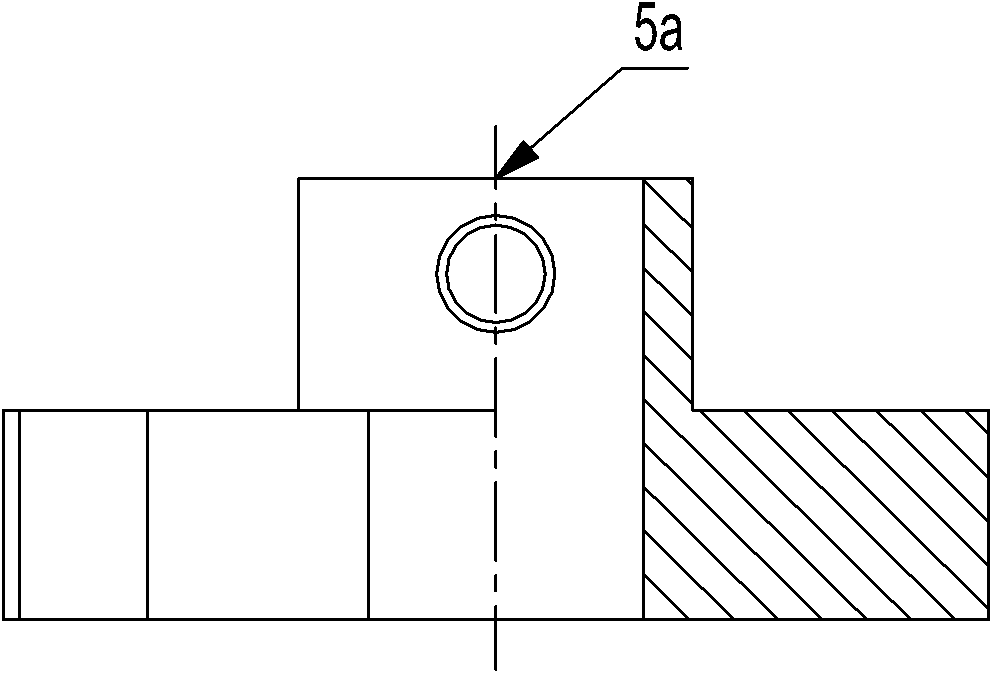

Pipe double-end internal and external chamfering processing apparatus

InactiveCN105108601AImprove mobilityIncrease linkageEdge grinding machinesGrinding feedersElectric machineryEngineering

The invention relates to the technical field of pipe processing equipment, and specifically discloses a pipe double-end internal and external chamfering processing apparatus. The apparatus comprises a feeding mechanism and a pipe double-end internal and external chamfering processing mechanism. The feeding mechanism comprises two feeding devices oppositely arranged on the left and right sides. Each feeding device comprises a feeding plate and a bearing platform, and the bearing platform is provided with an initial falling point from which place the pipe falls. At an initial state, the portion, acting on the pipe, at the front end of each feeding plate is located behind the initial falling point. A front limiting top plate limiting the front part of the pipe is arranged at the position close to the front end of each bearing platform. A discharging plate through which the pipe is supported and discharged is arranged at the front end of each bearing platform. The pipe double-end internal and external chamfering processing mechanism comprises two internal and external chamfering processing devices which are oppositely arranged. Each internal and external chamfering processing device comprises a polishing means including an inner polishing head and an outer polishing head. A motor is arranged on the side, opposite to the pipe, of each polishing means. The pipe double-end internal and external chamfering processing apparatus is safe and stable in operation, high in efficiency and high in fluency, and has good positioning and processing effects.

Owner:ZHEJIANG TENGYUN REFRIGENRATION TECH

Cold-resistance spraying agent

InactiveCN101253867AImprove cold resistanceReduce mechanical damageBiocidePlant growth regulatorsGrowth plantChilling injury

A cold-resistant sprayer agent relates to a sprayer agent, which solves the problems of maturation period delay, output reduction and grain quality decline resulting from powder seeds under a low temperature condition, chilling injury death, difficult germination and delayed chilling injury in case of encountering the cold current in the seedling stage. The cold resistant sprayer agent is prepared by the weight percent as follows: 30%-80% of cold resistant nutriment, 4%-40% of antifreeze liquid, 0.02%-2.0% of surfactant, 0.001%-1.0% of plant growth regulator and water of the rest. The cold-resistant sprayer improves the cold resistance of the plant at a molecular level and is capable of reducing the mechanical damage formed by the ice crystal in the protoplasm at a low temperature.

Owner:王树禹

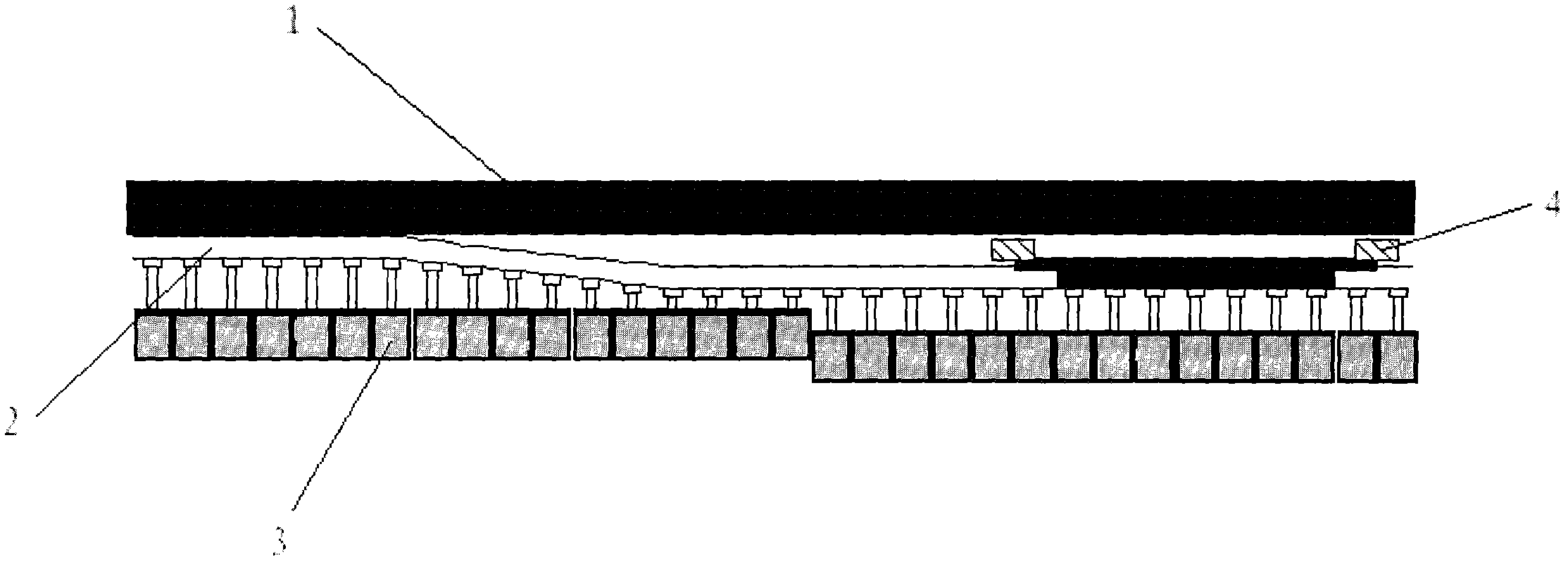

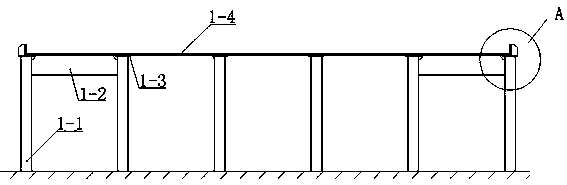

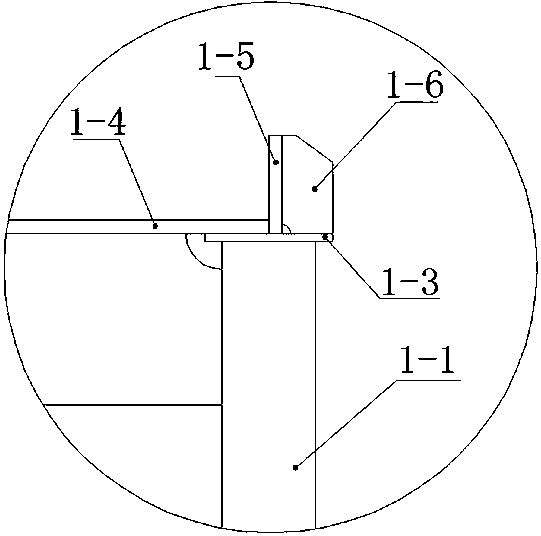

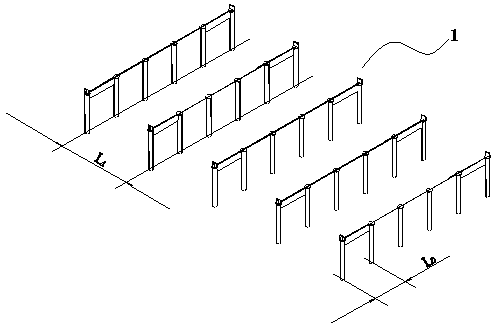

Attitude control system and method based on wireless three-dimensional gyroscope technology for scraper conveyer

ActiveCN102431784ARealize closed-loop controlIdeal curved segmentControl devices for conveyorsGyroscopeControl system

The invention discloses an attitude control system and a method based on a wireless three-dimensional gyroscope technology for a scraper conveyer. The system comprises a wireless three-dimensional gyroscope, hydraulic brackets, a bracket controller and a crossheading monitoring host, wherein the wireless three-dimensional gyroscope is arranged on a sliding chute of the scraper conveyer, and is used for detecting the running attitude of the scraper conveyer; a plurality of hydraulic brackets are connected to one side of the scraper conveyer in sequence; the movement of the scraper conveyer is realized under the pushing actions or pulling actions of the hydraulic brackets; the bracket controller is arranged on the hydraulic brackets, and is used for controlling the pushing or pulling actions of the hydraulic brackets; the crossheading monitoring host is arranged in a crossheading, and is used for concentrically monitoring and controlling the scraper conveyer, the bracket controller and hydraulic brackets; the wireless three-dimensional gyroscope is only communicated with the bracket controller in a wireless way; and the crossheading monitoring host and the bracket controller constitute a communication network system on a work surface through the bracket controller for performing data communication, so that attitude monitoring of the scraper conveyer is realized.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

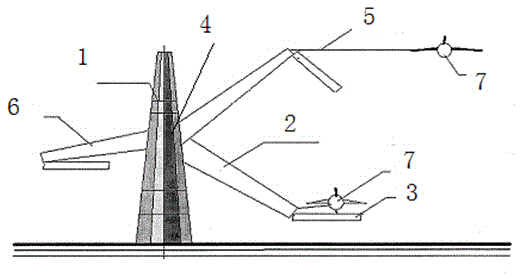

Device for launching and landing aircrafts

InactiveCN104058100AImprove people's livelihoodStrong defenseArresting gearLaunching/towing gearRotational axisFlight vehicle

The invention discloses a device for launching and landing aircrafts. The device comprises a fixedly arranged rotary launching tower, wherein a rotating shaft is arranged at the middle part of the rotary launching tower; a group of rotating arms extending outwards is arranged on the rotating shaft, one end of each rotating arm is hinged to the rotating shaft, and a bearing platform capable of adjusting an angle of inclination is arranged at the extending end of each rotating arm; telescopic flexible elastic ropes matched with the aircrafts are arranged at the extending ends of the rotating arms. The device adopts a brand-new launching and landing manner for the aircrafts, and a large-area runway is not needed, so that a heavy investment is saved; a plurality of aircrafts can be launched at the same during launching, so that the time is reduced compared with the time used during conventionally successive launching; the device is high in controllability and high in reliability, and the requirement for the operant level of navigating mates of the aircrafts is low.

Owner:杨举 +1

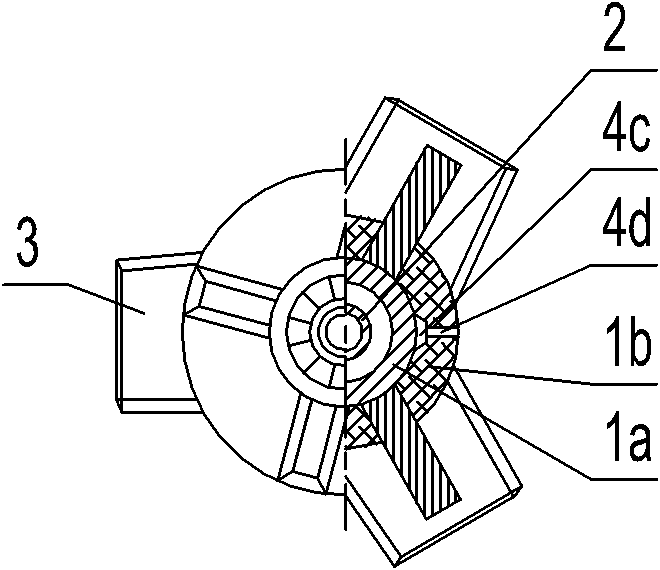

Jet stirrer for mechanical stirring and desulfurizing of molten iron

InactiveCN102154533AContain Adverse Effects of Agitated Desulfurization Kinetic ConditionsReduce volumeRotary stirring mixersTransportation and packagingSlagAir cooling

The invention discloses a jet stirrer for mechanical stirring and desulfurizing of molten iron. The jet stirrer comprises a rotating shaft and stirring blades arranged at the lower end of the rotating shaft and uniformly distributed along the circumferential direction of the rotating shaft, wherein the rotating shaft consists of a metal hollow shaft and a refractory material working lining compounded on the outer side of the metal hollow shaft; an air cooling pipe is arranged in the cavity of the metal hollow shaft; the lower end of the rotating shaft is provided with a jet channel communicated with the air cooling pipe; and the jet channel is positioned between adjacent stirring blades. In the jet stirrer, cooling gas is jetted from a puff port into a stirring center vortex to drive a desulfurizer in a forced vortex area of a stirring center to move relative to molten iron, so that the mixing and dispersing of the desulfurizer in the forced vortex area of the stirring center in the molten iron is realized, and the desulfurizing reaction dynamic condition in the area is improved. Meanwhile, the retention and bonding of desulfuration residues between adjacent blades can be restrained, the effective acting areas of the stirring blades are increased, the dry slag cleaning and maintaining amount of the stirrer is reduced, and the mechanical stirring and desulfurizing production capacity of the molten iron and the utilization ratio of the desulfurizer are increased.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Method for improving ox and sheep freezing sperm fertility rate and its dilute liquid used thereof

InactiveCN1943525AReduce mechanical damageReduced nutritional needsAnimal reproductionPharmaceutical active ingredientsFertilityGlycerol

The invention belongs to technological field of animal reproductive physiology and fertility, more particularly relating to method raising fertilization rate of frozen semen from cow and sheep and dilution used in said method, overcoming present technique problems on frozen semen vitality and low rate of fertilization. Its technical arrangements are, adopting steps for elimination of seminal plasma in preservation of frozen semen, and said steps are twice dilution centrifuging of medium speed & short-term. Inclusions of necessary dilution are, sodium citrate 2H2O:1.8- 2.2g;glucose: 2.8-3.2g; glycerine: 5-7.0ml;yolk: 18- 24ml;double distilled water 100ml;Tris0.01g;penicillin 100 (unit); streptomycin 100 (unit) pH value within 6.8-7.2.

Owner:NORTHWEST A & F UNIV

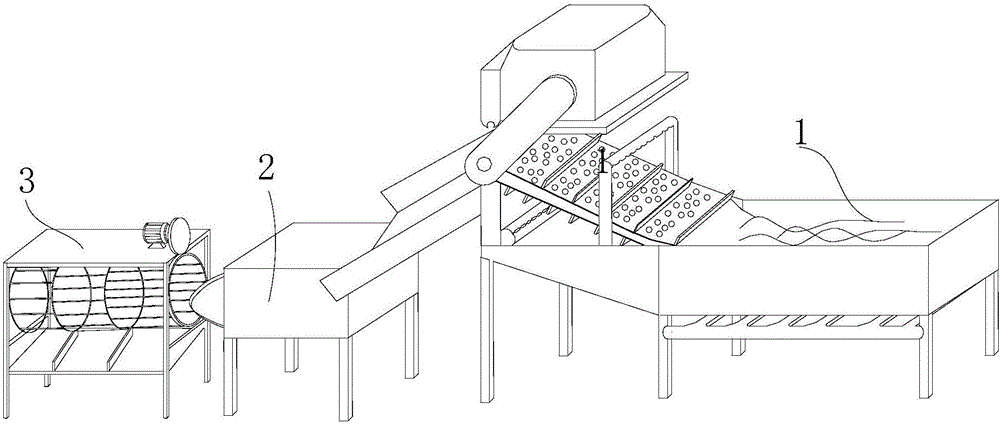

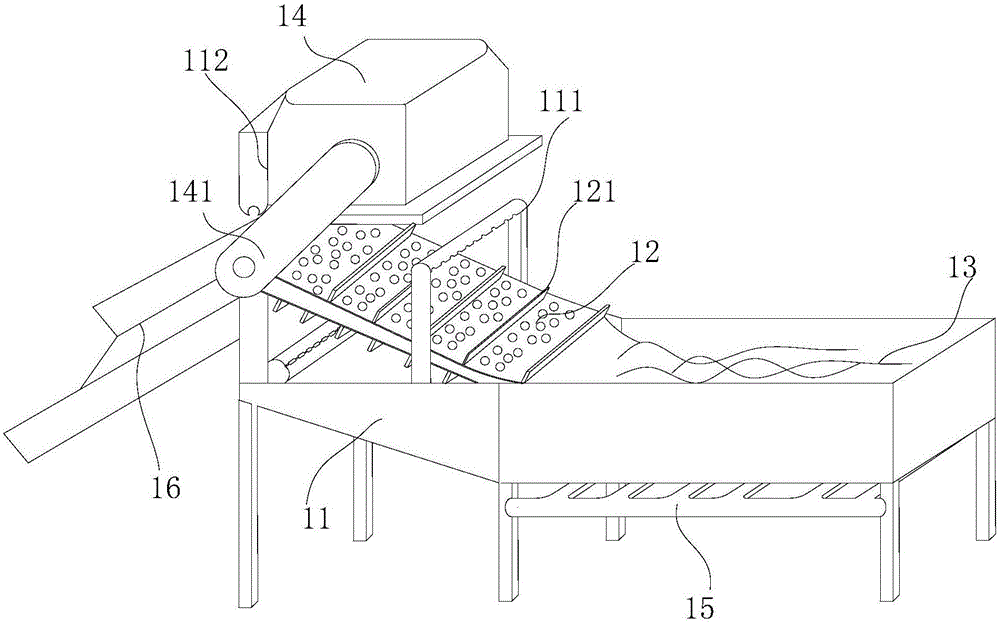

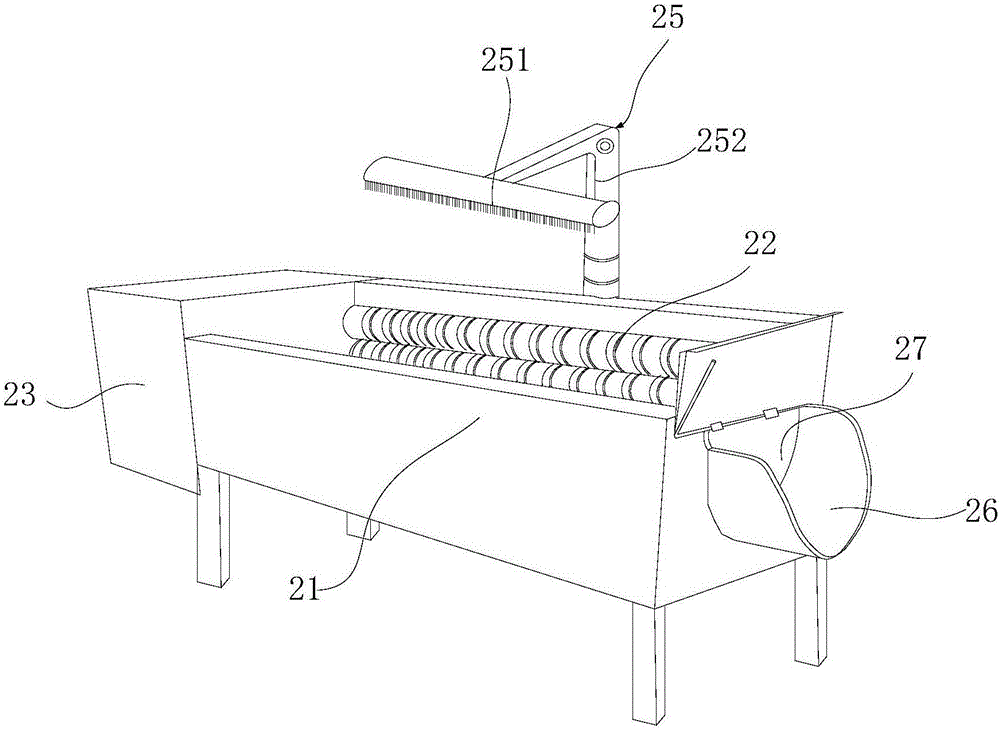

Sweet potato cleaning and sorting equipment

ActiveCN106238309AQuality assuranceClean thoroughlySievingScreeningFood gradeBiochemical engineering

The invention relates to sweet potato cleaning and sorting equipment. The sweet potato cleaning and sorting equipment comprises a soaking machine, a deep cleaning machine and a sorting machine arranged in sequence. The soaking machine comprises a conveying filter screen, a soaking water tank, a bubble cleaning pipe and a plurality of partitions arranged on the conveying filter screen. The deep cleaning machine comprises a cleaning tank and cleaning rollers, and the cleaning rollers are provided with cleaning brushes which are connected in a concave-convex mode. The sorting machine comprises a sorting frame, a cylindrical sorting barrel arranged in the sorting frame, and a third driving device arranged on the sorting frame to drive the sorting barrel to rotate around the central axis of the sorting barrel. According to the sweet potato cleaning and sorting equipment, the soaking machine and the deep cleaning machine are used for double-cleaning of sweet potatoes, the sweet potatoes are cleaned up completely, and the food-grade requirement is met; and the thorough cleaning effect on the sweet potatoes in irregular shapes can be achieved, cleaning efficiency is high, and mechanical damage is little. The sorting machine is used for automatically sorting the sweet potatoes. The structural design is novel, the cost is low, and cleaning and sorting are systematically designed, so that production efficiency is improved; and the sweet potato cleaning and sorting equipment has high market value and broad application prospects.

Owner:青岛新汉邦食品有限公司

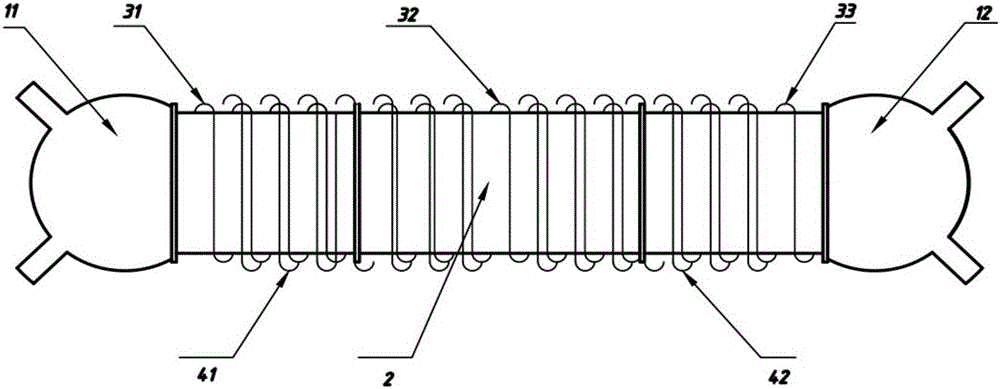

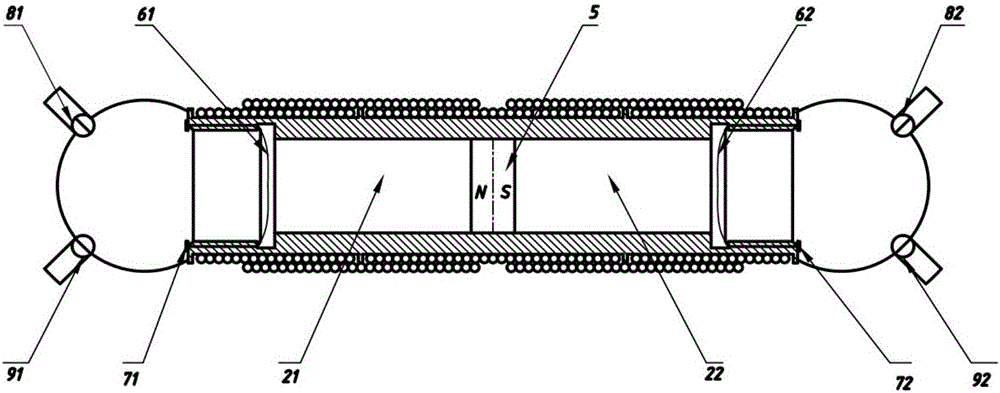

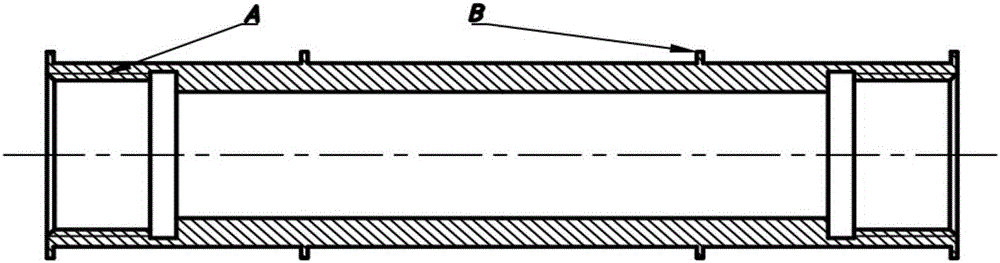

Electromagnetic coil driving type blood pump system

InactiveCN105709287AReduce mechanical damageIncrease travel distanceControl devicesIntravenous devicesBlood pumpEngineering

The invention relates to an electromagnetic coil driving type blood pump system. Two ends of a pump body are respectively connected with a blood flowing cavity; an electromagnetic coil driving cavity is arranged in the pump body; three bottom coils and two top coils are wound outside the electromagnetic coil driving cavity in an overlapping manner; a permanent magnetic rotor is closely fit in the electromagnetic coil driving cavity, and can move under control of the external coil group; the inside of the electromagnetic coil driving cavity is separated into a first work zone and a second work zone by virtue of the permanent magnetic rotor; a sealing elastic film is arranged on the joint of the blood flowing cavity and the electromagnetic coil driving cavity; the edge of the sealing elastic film is tightly clamped by internal and external pipe threads on the joint of the blood flowing cavity and the electromagnetic coil driving cavity to form a seal state together with a seal ring; and a flow-in mechanical valve and a flow-out mechanical valve are arranged on the blood flowing cavity. According to the electromagnetic coil driving type blood pump system, cardiac impulse can be simulated by controlling the electromagnetic coils, and mechanical injury for blood is minimized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

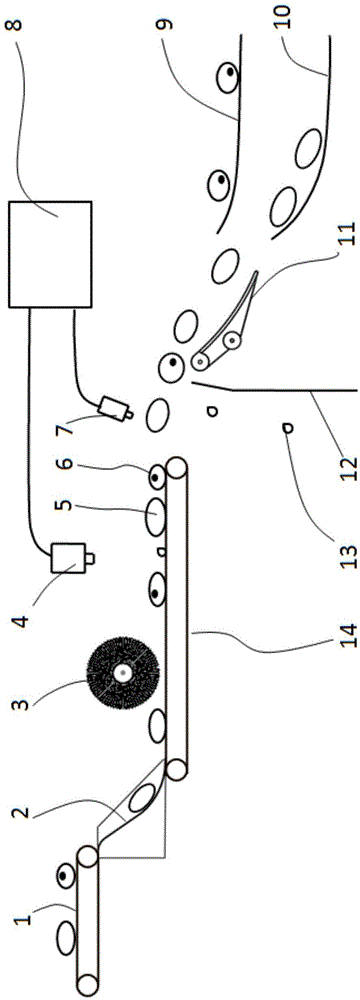

Potato grading control method and device based on machine vision technology

ActiveCN104941922AReduce mechanical damageAccurate sortingGas current separationSortingMachine visionImage detection

The invention discloses a potato grading control method and device based on machine vision technology. The method is characterized in that during image detection, a camera field-of-view is divided into virtual passages with the number corresponding to that of guiding lifting levers according to the number of the guiding lifting levers; a logic value is used for indicating whether to-be-graded potatoes exist on each virtual passage or not; a control and processing unit controls the guiding lifting levers to act according to the detected logic value, and when the logic value is equal to 1, a guiding mechanism corresponding to the guiding lifting levers is upward pushed out by an air cylinder, and potatoes are in contact with the guiding lifting levers, so that the running track of the potatoes is changed, and the potatoes are separated to be thrown into corresponding discharging chutes; and after a camera is used for acquiring images of the potatoes, a virtual circle is drawn by taking the transverse diameters of the potatoes as the diameter according to the image detection result, and whether one or more guide lifting levers are adopted for separating the potatoes is determined according to the areas, occupied by the virtual circle, of the virtual passages. The fast detection of potatoes with various and different quality can be realized, damage to the potatoes can be reduced, and the sorting of the potatoes can be precisely realized.

Owner:ZHEJIANG UNIV

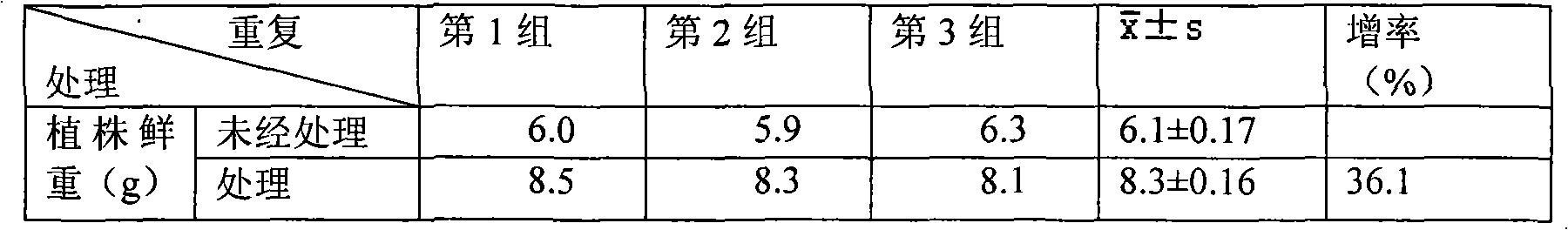

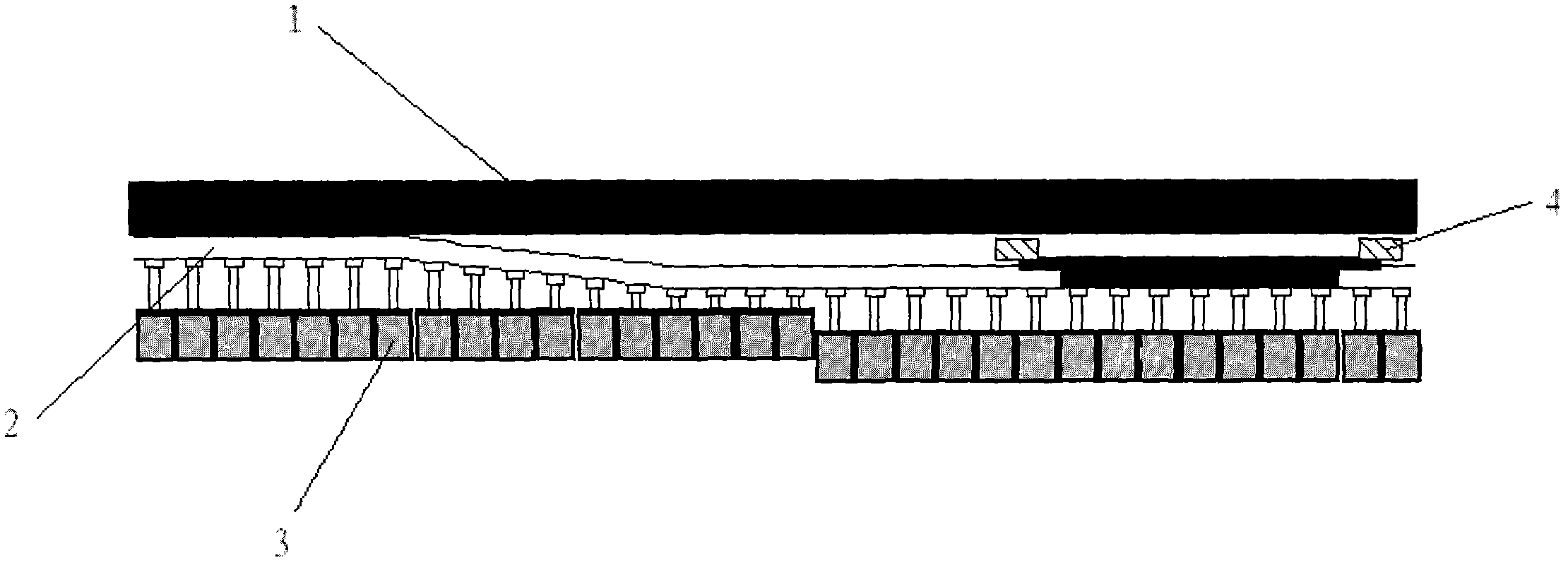

Seedling raising substrate for machine-transplanted seedling tray for hybrid rice

InactiveCN104322311AHigh degree of fitReduce mechanical damageGrowth substratesCulture mediaPhosphoric acidFacultative anaerobic organism

The invention provides a seedling raising substrate for a machine-transplanted seedling tray for hybrid rice. The seedling raising substrate is prepared from the following raw materials in part by weight: 50 to 60 parts of crop stalk with lower than 10 percent of water content, 21 to 30 parts of animal waste with lower than 10 percent of water content, 13 to 20 parts of substrate carrier and 1 to 2 parts of substrate synergist, wherein the substrate synergist consists of the following components in percentage by mass: 65 to 75 percent of calcium cyanamide, 15 to 25 percent of calcium superphosphate, 7 to 9 percent of sodium silicate, 0.5 to 1.5 percent of boron and zinc and 0.5 to 1.5 percent of bioactive fungicide; the bioactive fungicide is one or several of bacillus subtilis, facultative anaerobe and agricultural photosynthetic bacteria; the raw materials are composted and fermented for three times to form the seedling raising substrate for the machine-transplanted seedling tray for hybrid rice. The seedling raising substrate is comprehensive in nutrition, is suitable for mechanized seedling raising for the hybrid rice, and ensures that germination and rooting of rice seeds are quick, the planting percent is high and seedlings are robust.

Owner:HUNAN HYBRID RICE RES CENT

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

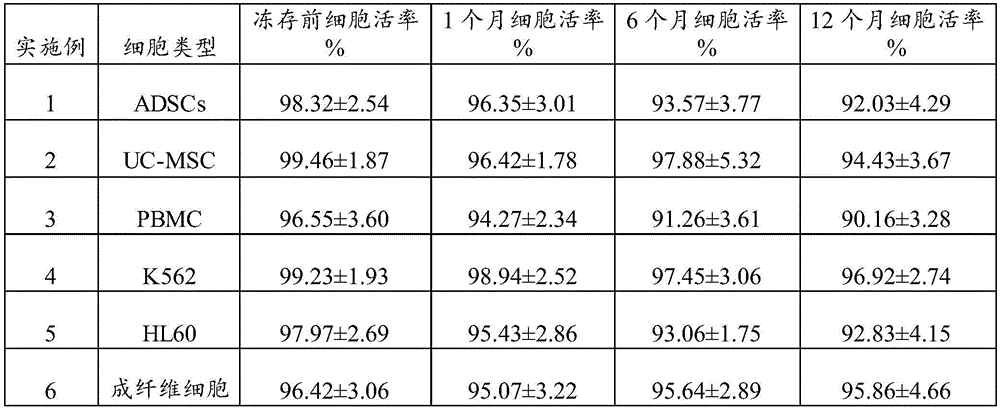

Cell cryopreservation fluid

The invention provides cell cryopreservation fluid.The cell cryopreservation fluid is prepared from, by volume, 9-13% of dimethyl sulfoxide, 2-7% of human serum albumin, 1-3% of dextran, 1-5% of glucose and the balance solvent.Human serum albumin replaces animal serum to serve as a cell nutrient source, the pollution of animal source viruses is avoided, and nutrient substances of multiple components are effectively provided and can be directly absorbed and used by cells; in addition, a large amount of high-polymer protein is contained in human serum albumin and can form a hydration film, the number of crystals formed in the east village process is decreased, and mechanical loss and death of cells are reduced; by means of dextran, permeation pressure can be well maintained, the good permeation pressure environment can still be kept in the temperature decreasing process, and the cell death caused by temperature decreasing and permeation pressure changing is avoided, and the survival rate of cells recovering after being cryopreserved for a long time is increased.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

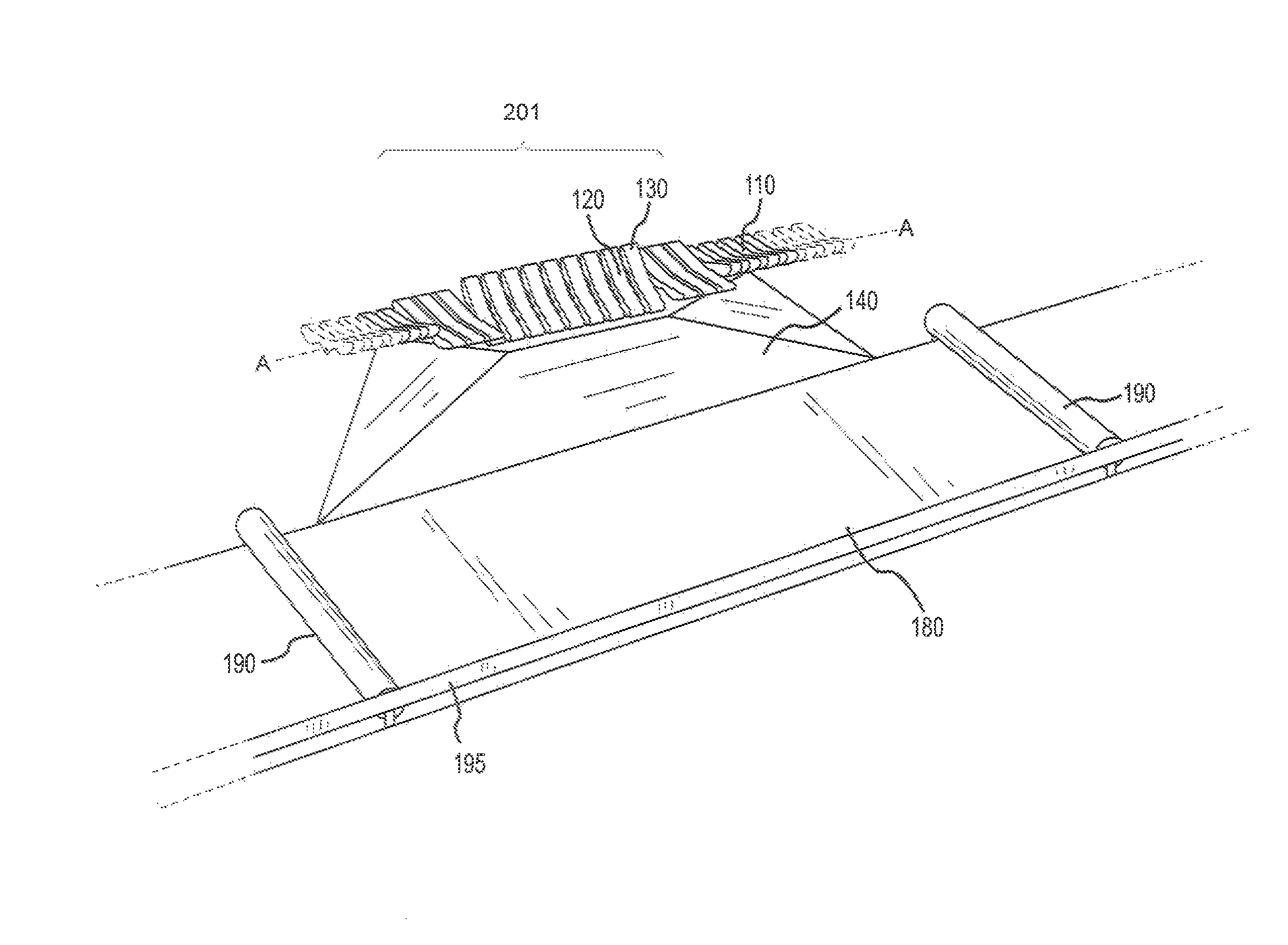

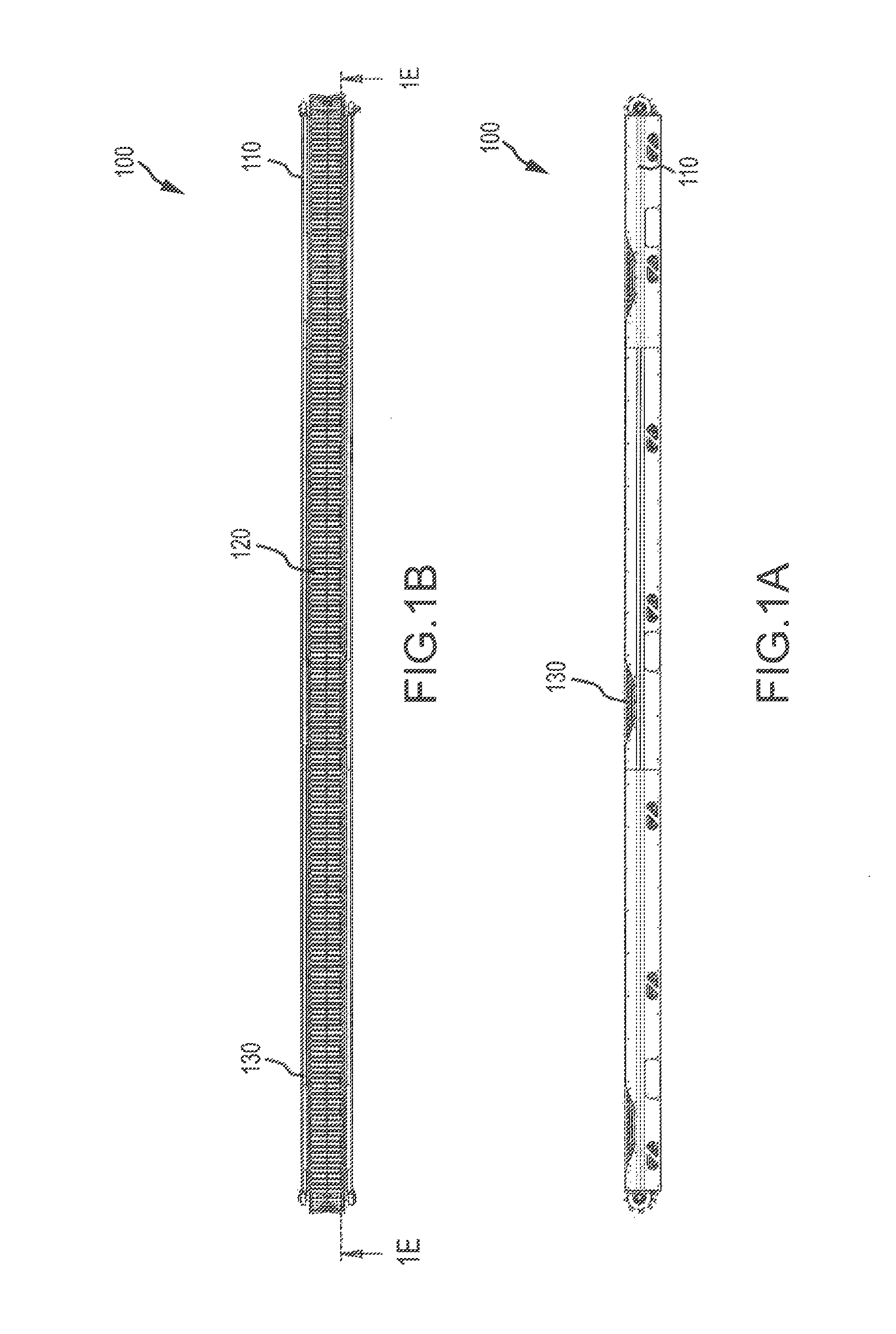

Weighing and sorting system and method

ActiveUS8857625B1Improve portabilityMaximizes its footprintConveyorsSortingSystem configurationSmall footprint

A sorting system configured to sort materials by size, and / or weight is disclosed herein. The sorting system is configured to operate in a smaller footprint as compared with conventional sorting systems. For instance, a main sorting track of sorting system is configured to deliver sorted material to either side of the main sorting track. Additionally, the sorting system is configured to reduce mechanical damage imparted on the material to be sorted by sorting system by a sliding and / or rolled delivery. Aspects of the sorting system may be mounted on a mobile platform.

Owner:OROPEZA JESUS R

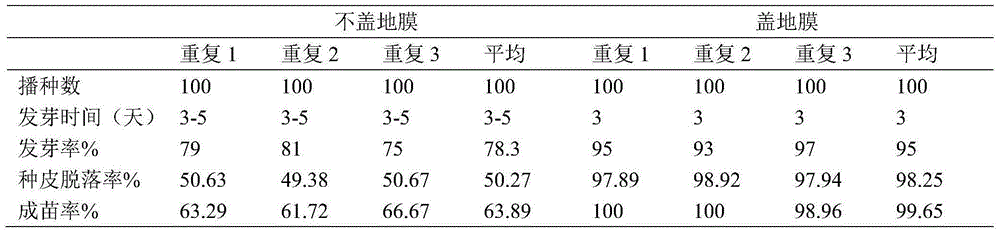

Method of rapid seedling growing of true seeds of sweet potatoes

ActiveCN104969764AAny breeding locationReasonable ratioSeed and root treatmentGrowth substratesGeneration ratePharbitis nil

The invention provides a method of rapid seedling growing of true seeds of sweet potatoes. The true seeds are processed for 30 minutes by concentrated sulfuric acid, rinsed by clean water, directly sown in a base material, then covered by a mulching film for 3 days so that all seedlings can sprout, and then irrigated in a micro-jet manner so that seed coats can shed naturally. The micro-jet watering is performed in daily management so as to control the temperature and the humidity. According to the invention, seedling growing procedures are saved; large labor is reduced; and emergence time of the seedlings of sweet potatoes is increased. In addition, via the combination of the mulching film and the micro-jet irrigation, a problem of manual removing of seed coats after the true seedlings of sweet potatoes sprout is solved, labor is saved and percentage of seedling emergency of the true seedlings of sweet potatoes is greatly increased. Tests and statistics show that the average generation rate of the true seedlings of hybridized combination of sweet potatoes is more than 85%, survival rate of seedlings is more than 90% and requirements on planting, inserting and breeding of new varieties of the true seedlings of sweet potatoes can be completely satisfied.

Owner:JIANGSU XUZHOU SWEET POTATO RES CENT +1

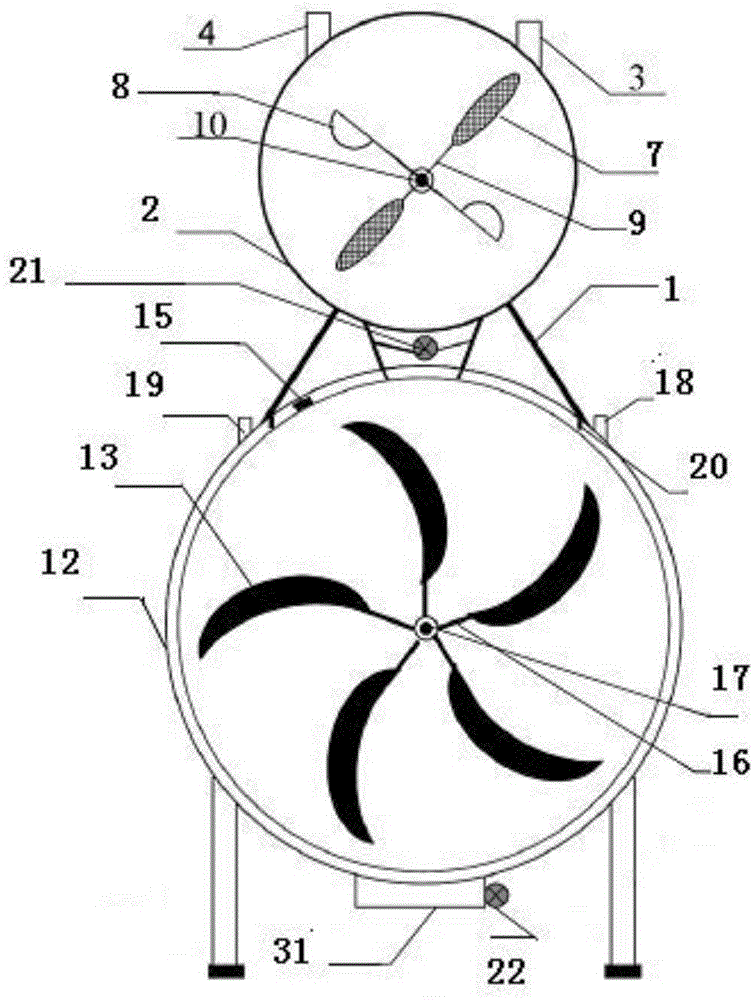

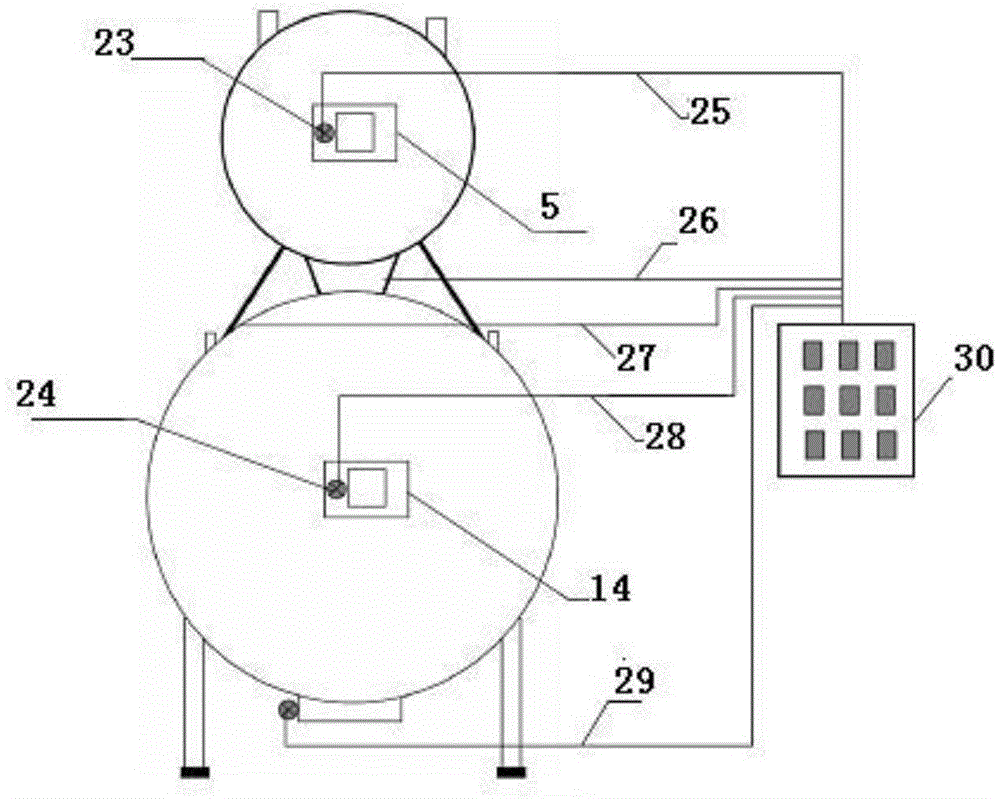

Automatic mixing device for mixed feed additive

ActiveCN105536586AImprove the tightnessQuality improvementFeeding-stuffTransportation and packagingHybrid typeAutomatic control

The invention discloses an automatic mixing device for a mixed feed additive. The automatic mixing device comprises four parts, namely a premixing system, a mixing system, a temperature control system and an automatic control system, wherein the premixing system comprises a premixing bin body, a main and auxiliary material feeding hole, a mixing blade, an adjustable motor and a fixed sealing flange; the mixing system comprises a mixing bin body, a mixing blade, an adjustable motor and a vibrator; the temperature control system comprises an internally inlet / outlet, a seal sheet and an interlayer; and the automatic control system comprises a relay switch gear, a connecting circuit and an automatic control board. The automatic mixing device has the characteristics of high automation, convenience in use, high main / auxiliary material mixing strength and obviously improved mixing degree, is high in device sealing degree, is capable of lowering the pollution rate and the material loss rate, reducing damage to human bodies, decreasing heat produced by machine operation and improving the activity and heat-labile component quality of the mixed feed additive, and is beneficial to quality stability of products in different batches.

Owner:FUJIAN BRADY PHARMA CO LTD

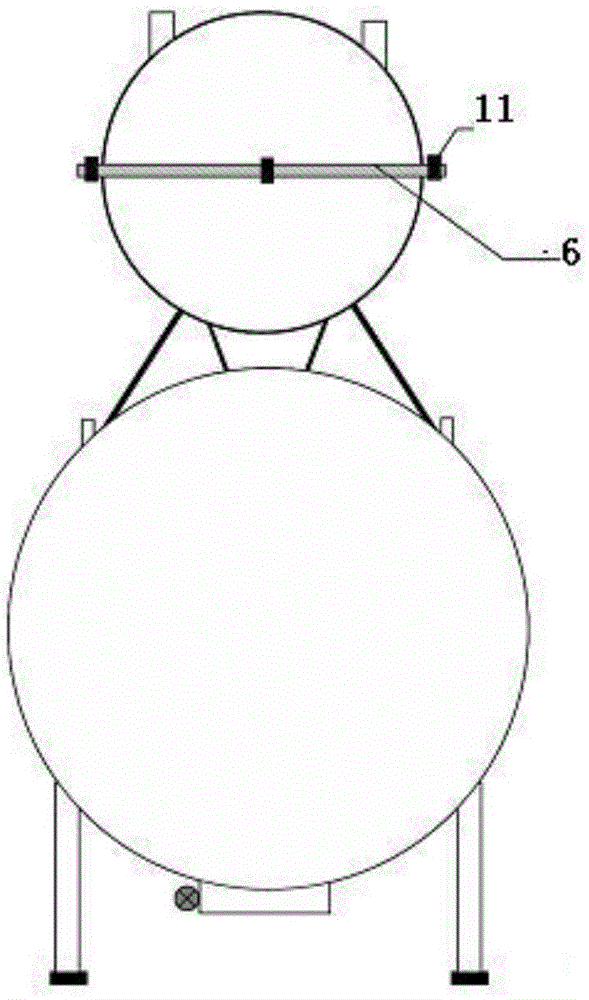

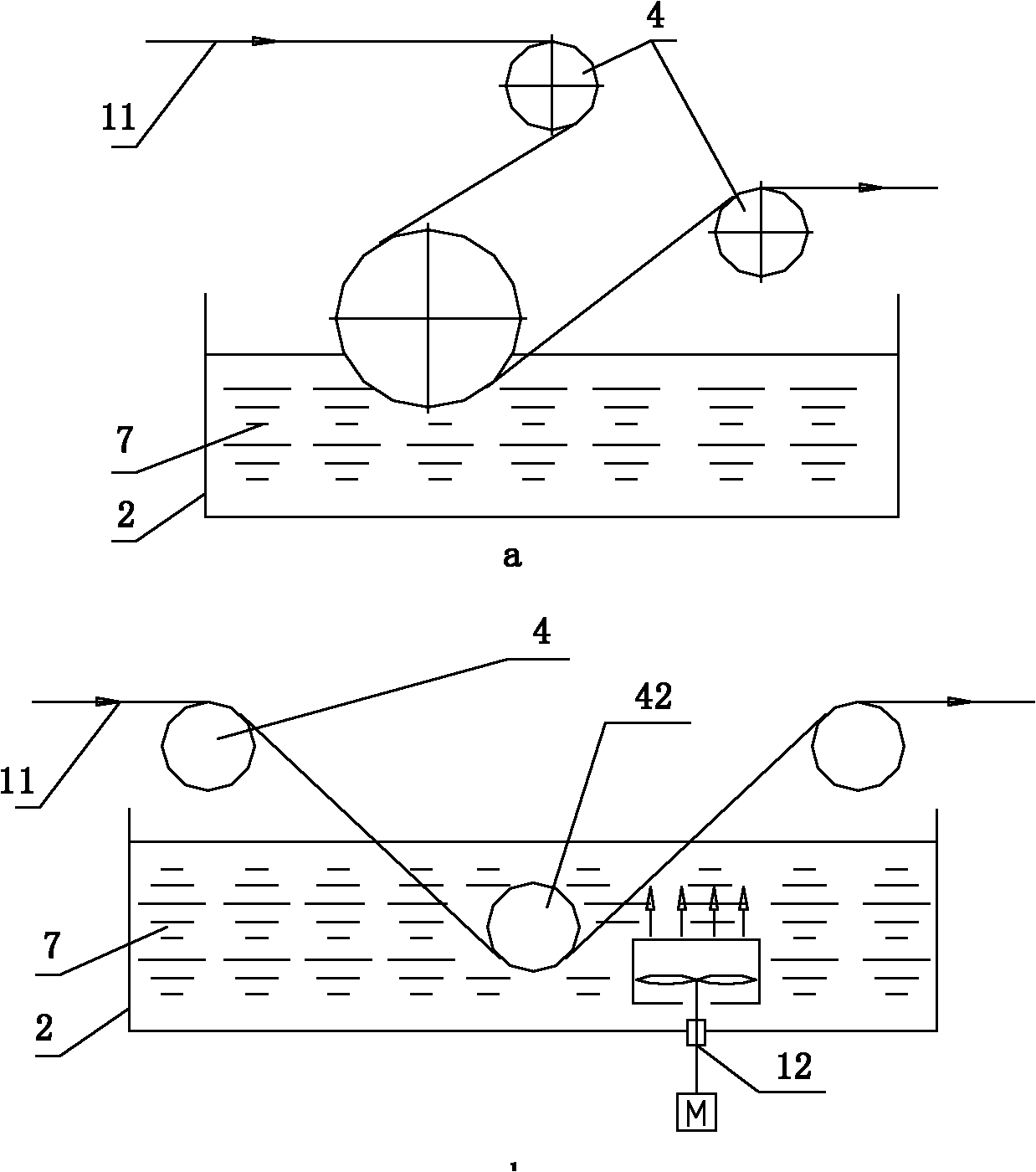

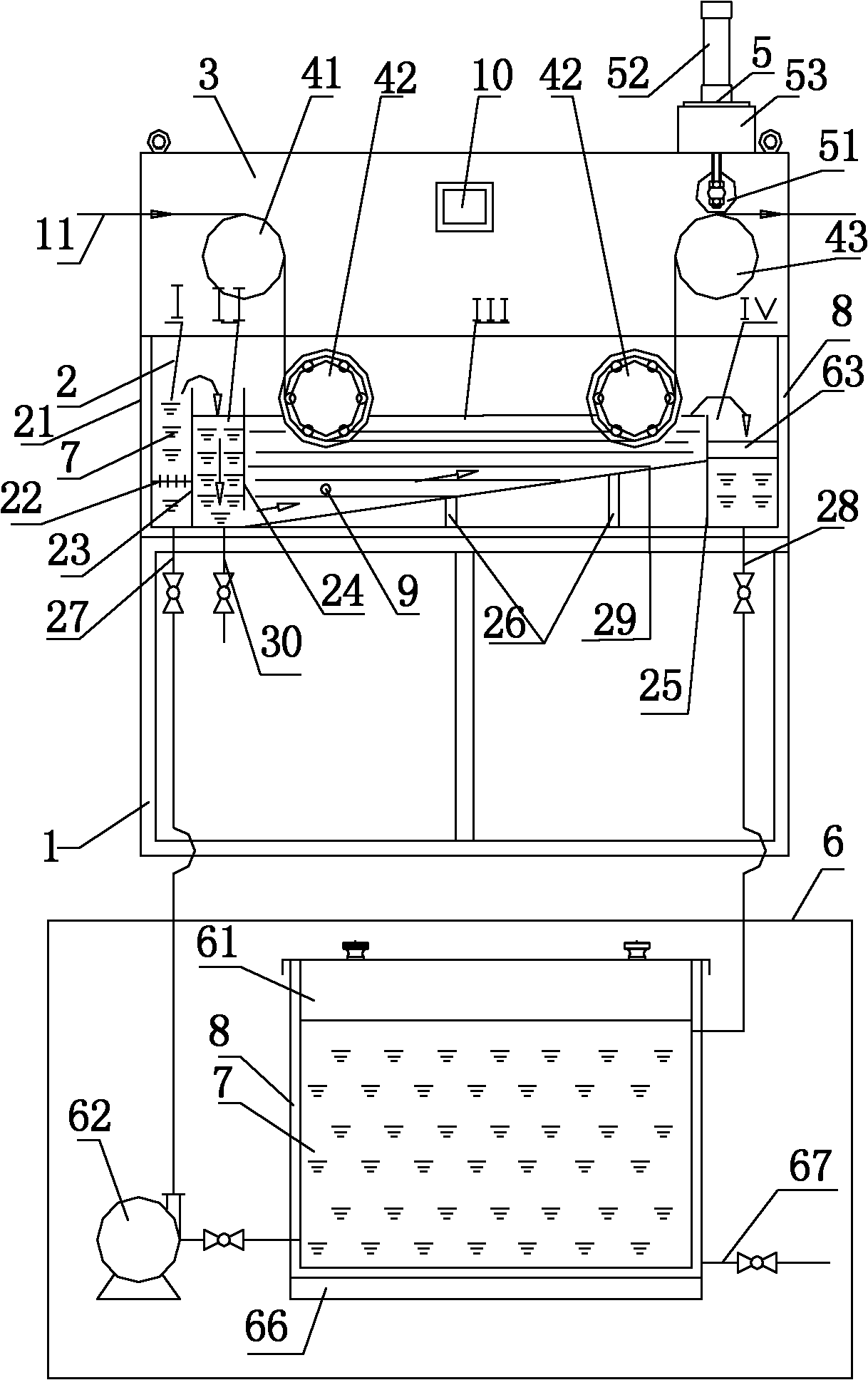

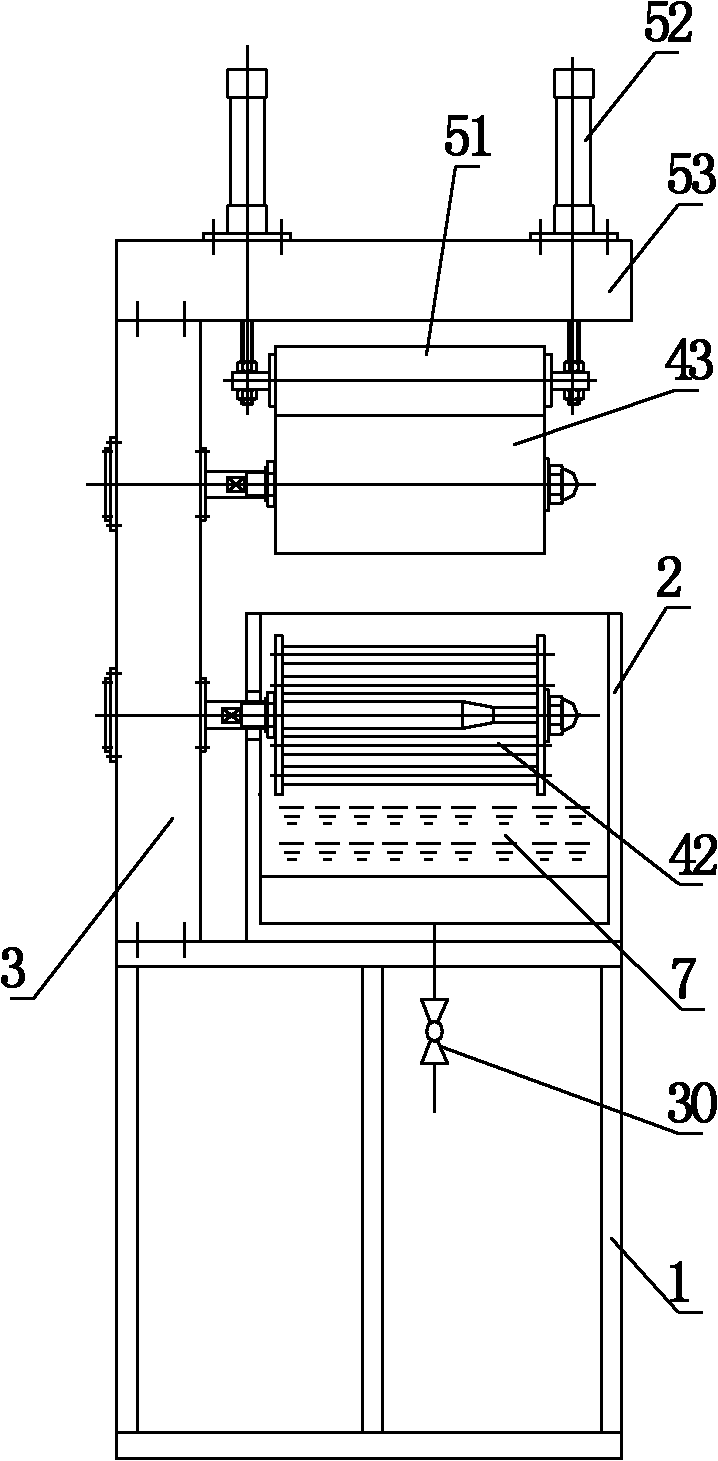

Sizing machine for producing continuous carbon fibers

InactiveCN102031654AAvoid Shaft Sealing ProblemsFlexible rotationTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentFiberCarbon fibers

The invention belongs to a sizing machine for producing continuous carbon fibers, comprising a box body, a sizing groove arranged in the box body and a driving device fixed on the box body, wherein the sizing groove comprises a groove body and a partition board, a liquid distribution plate and an overflow plate which are arranged in the groove body from left to right and are vertical to the bottom of the groove body; the driving device comprises an inlet driving roller arranged at the upper-left part of the sizing groove, two sizing driving rollers positioned in a sizing area and an outlet driving roller arranged at the upper-right part of the sizing groove; the two sizing driving rollers are horizontally arranged and positioned between the inlet driving roller and the outlet driving roller; and driving shafts of the two sizing driving rollers are higher than the liquid level of a sizing agent of the sizing area. The invention solves the problems of long stay time of the carbon fibers in the sizing agent, poor sizing effect, complex structure, high manufacturing cost and inconvenience for daily cleaning and maintenance caused by the traditional sizing machine. By using the invention, the processing and manufacturing cost of the equipment can be reduced, the time of the carbon fibers in the sizing agent can be prolonged and the favorable sizing effect can be obtained.

Owner:西安航科等离子体科技有限公司

Fruit and vegetable preserving backing

InactiveCN1505935AReduce mechanical damageSuppresses aging symptomsFruit and vegetables preservationChlorine dioxidePotassium

The fruit and vegetable preserving backing consists of preferably: preservative 4-40 weight portions, physiological regulator 0-30 weight portions and gas regulator 0-30 weight portions. The preservative is one or two of 2-aminobutane, hydrochloride of 2-aminobutane, sulfate of 2-aminobutane, sodium pyrosulfite, potassium pyrosulfite, sodium bisulfite, potassium bisulfite, stable chlorine dioxide, propyl isothiocyanate, cinamic aldehyde and acetyldehyde; the physiological regulator is potassium permanganate and / or potassium bromate; and the gas regulator one or several of soda lime, sodium hydroxide, lime and active carbon. The present invention has the functions of reducing mechanical damage of fruits and vegetables, suppressing softening, yellowing and other senility symptoms of fruits and vegetables during storage and transportation, reducing rot of fruits and vegetables during transportation caused by vibration and pressure and regulating humidity inside the package.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Implantable biological electrode and manufacturing method thereof

ActiveCN102068760AReduce mechanical damageImprove reliabilityElectrotherapySurgeryElectricityElectrical resistance and conductance

The invention discloses an implantable biological electrode and a manufacturing method thereof. By arranging a backup conducting wire, the reliability of an electrode is improved and the conducting resistance of the electrode is reduced. Each electric path of the electrode is provided with at least one backup channel to ensure that the electrical communication of the path still can be maintained under the condition of the failure of one channel, so that the reliability of the connection of the electrode is improved; moreover, the parallel connection relationship is formed by two or more channels, so that the resistance of the electrode can be reduced.

Owner:BEIJING PINS MEDICAL +1

Plastically deformable implant

InactiveUS6984394B2Long-term useReduce mechanical damageMammary implantsImpression capsJaw bonePlastic implant

The invention relates to a plastically deformable implant for inserting into bodily orifices of the human or animal body. Implants of this type are used, for example, in ophthalmology, in particular, as vitreous body or lens replacements and in dentistry, for example, for filling extraction cavities in jaw-bones. Known implants, however, are not suitable for long-term use. The invention aims to provide a deformable plastic implant which also has a long-term application. This is achieved by the fact that the implant consists of a gel which is not sealed, containing fluorocarbon and which is directly introduced into the natural, or artificially created bodily orifice.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

Method for manufacturing duplex stainless steel middle assembly plate frame of chemical tanker

ActiveCN109552552ANo damageGuaranteed accuracyVessel designingLoad accommodationMetallurgyCompound (substance)

The invention discloses a method for manufacturing a duplex stainless steel middle assembly plate frame of a chemical tanker. The method comprises the following steps: S1, the fabrication of a specialtire frame for duplex stainless steel spliced plates, S2, the splicing of the duplex stainless steel plates; S3, the fabrication of the duplex stainless steel middle assembly tire frame; and S4, thefabrication of the duplex stainless steel middle assembly. The method uses a special duplex stainless steel spliced plate tire frame, ensures the precision of the spliced plates, reduces the consumption of the tire frame material, and reduces the mechanical damage to the surface of the duplex stainless steel plate. In the process of splicing the duplex stainless steel plate, a forced weight restrained deformation method is provided so as to reduce the welding deformation during the splicing process. The method utilizes a dummy compartment to control the assembly precision of flat-bulb steel, and provides a flat-bulb steel and duplex stainless steel welding sequence method so as to avoid a large workload in a subsequent precision correction process and shorten a product construction period.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Rotary type banana combing machine

ActiveCN103141321AAvoid damageImprove postpartum handling efficiencyHorticulture methodsMotor drivePhysical hard work

The invention discloses a rotary type banana combing machine, which comprises a rack, a motor, a first gear, a second gear, a bearing, a shaft sleeve, a cutter head, a cutter rest, a first combing cutter and a second combing cutter, wherein the shaft sleeve is fixedly connected onto the upper surface of the rack, the bearing is fixed on the inner ring of the shaft sleeve, a clamping hole is arranged in the inner ring of the bearing, the second gear is fixed on the outer ring of the bearing, the cutter head is fixed on the upper end surface of the second gear, the cutter rest is fixed on the cutter head, the first combing cutter and the second combing cutter are fixed on the cutter rest, the motor drives the first gear to rotate, and the first gear drives the second gear to make rotational motion. Compared with the prior art, the rotary type banana combing machine effectively solves the problems that the treatment efficiency of bananas after production is lower, the processing period is long, the manual labor is intensive, the labor intensity is greater, the mechanical damage to the banana surfaces is serious, the integral aesthetic property of bananas is affected and the morbidity of microbe diseases is increased, and has the characteristics of simple structure, simplicity and convenience in operation, reduced physical labor, shortened processing period, improved treatment efficiency after banana production, reduced damage to the banana surfaces and the like.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com