Patents

Literature

789 results about "Work zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

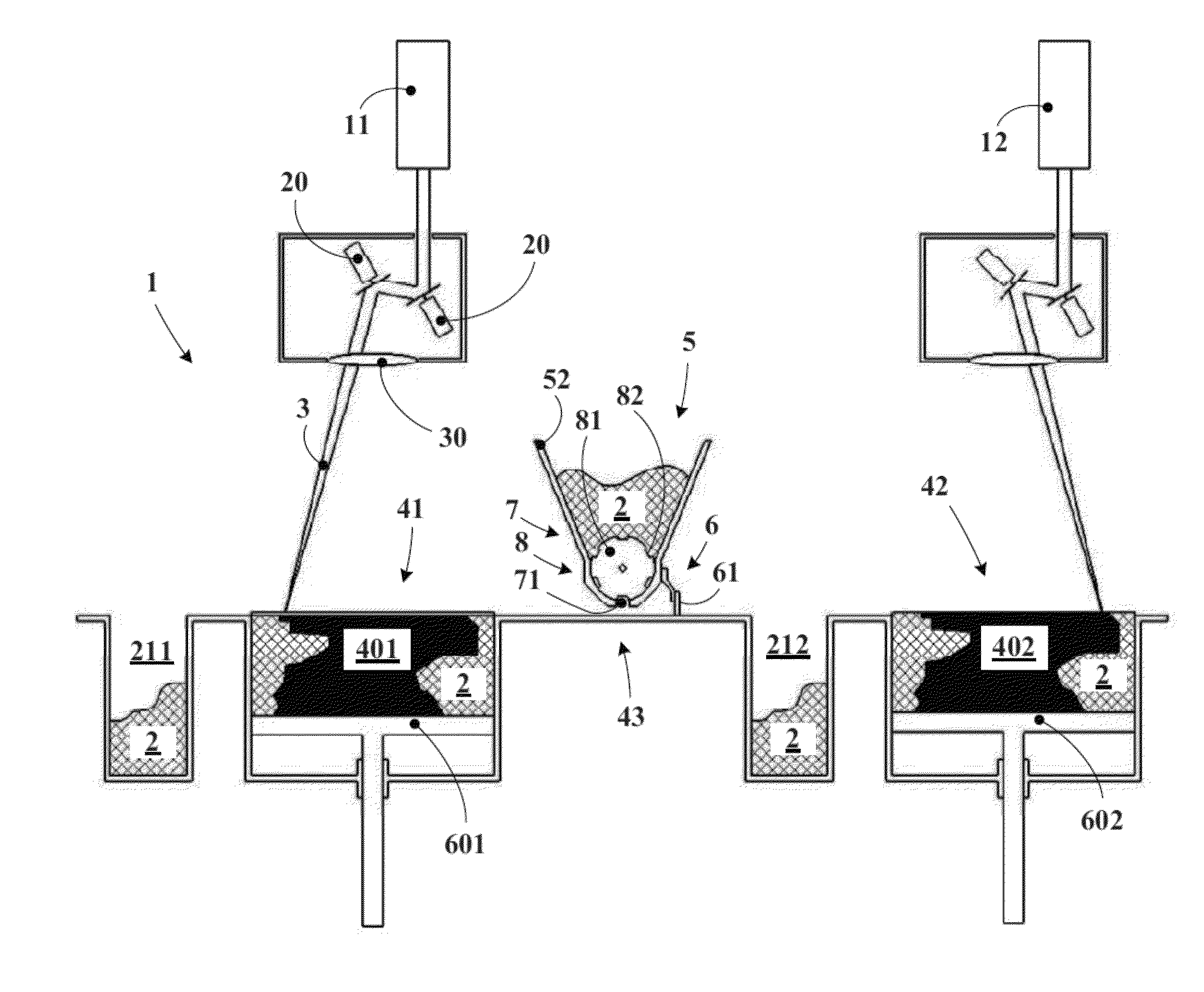

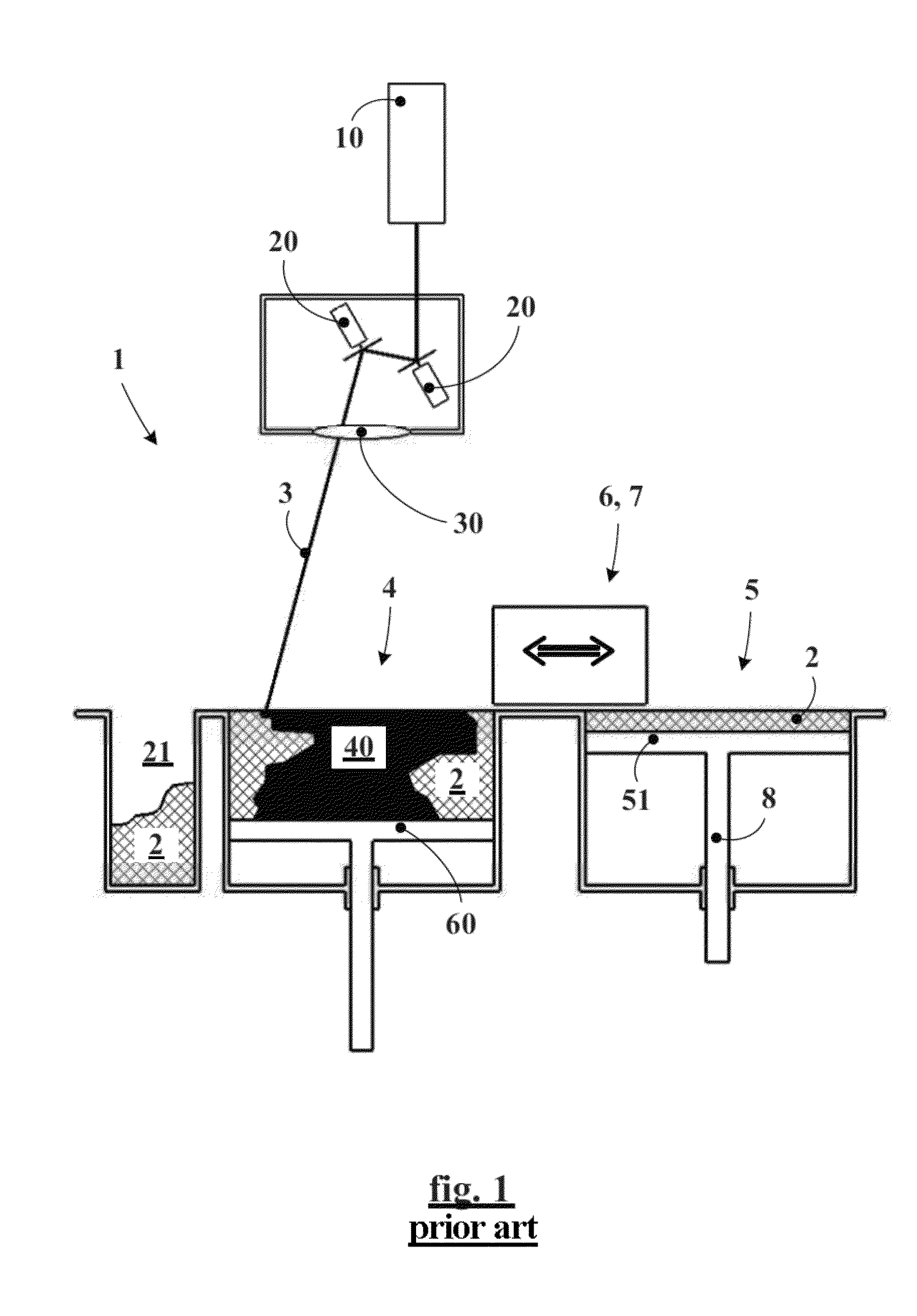

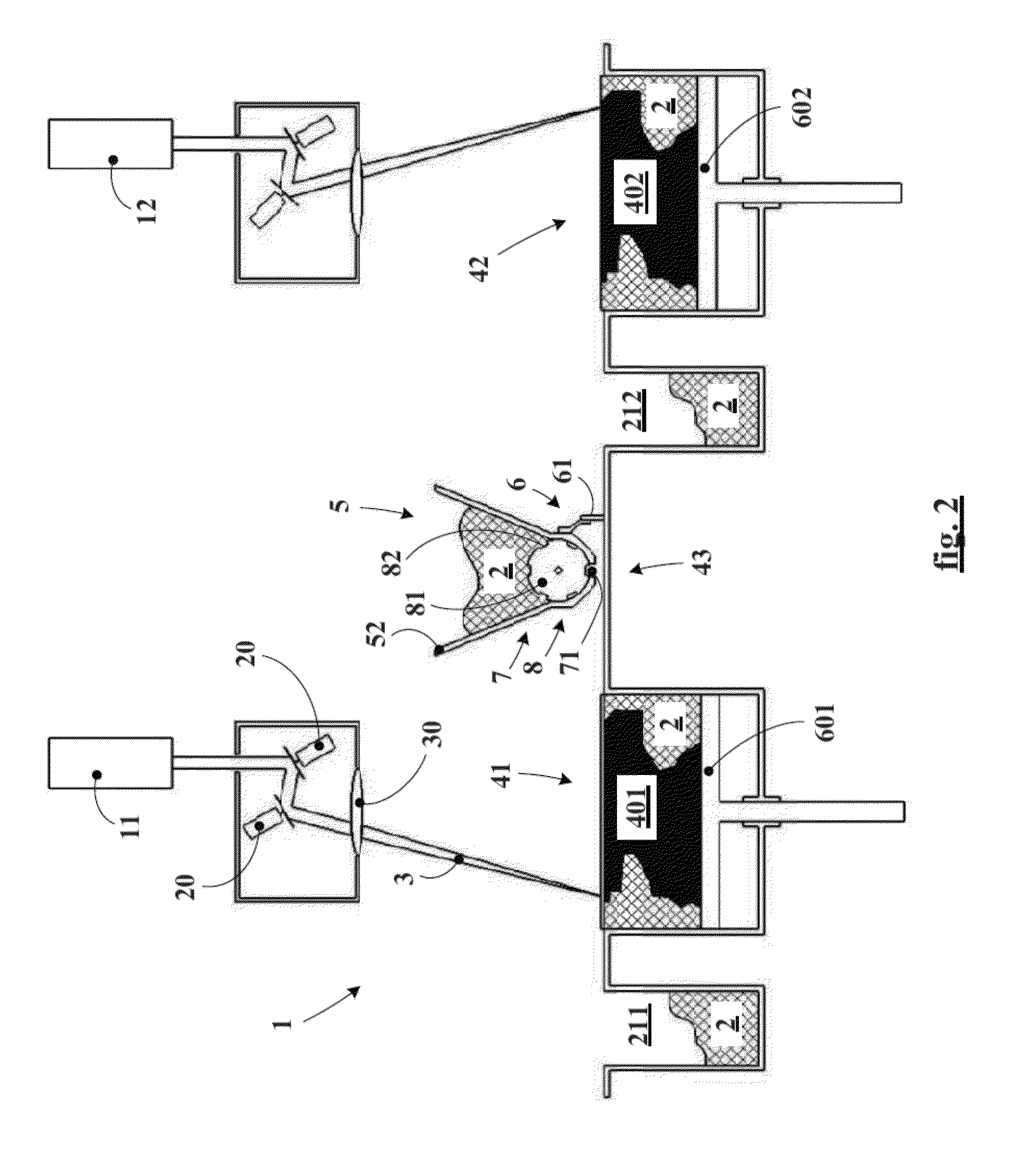

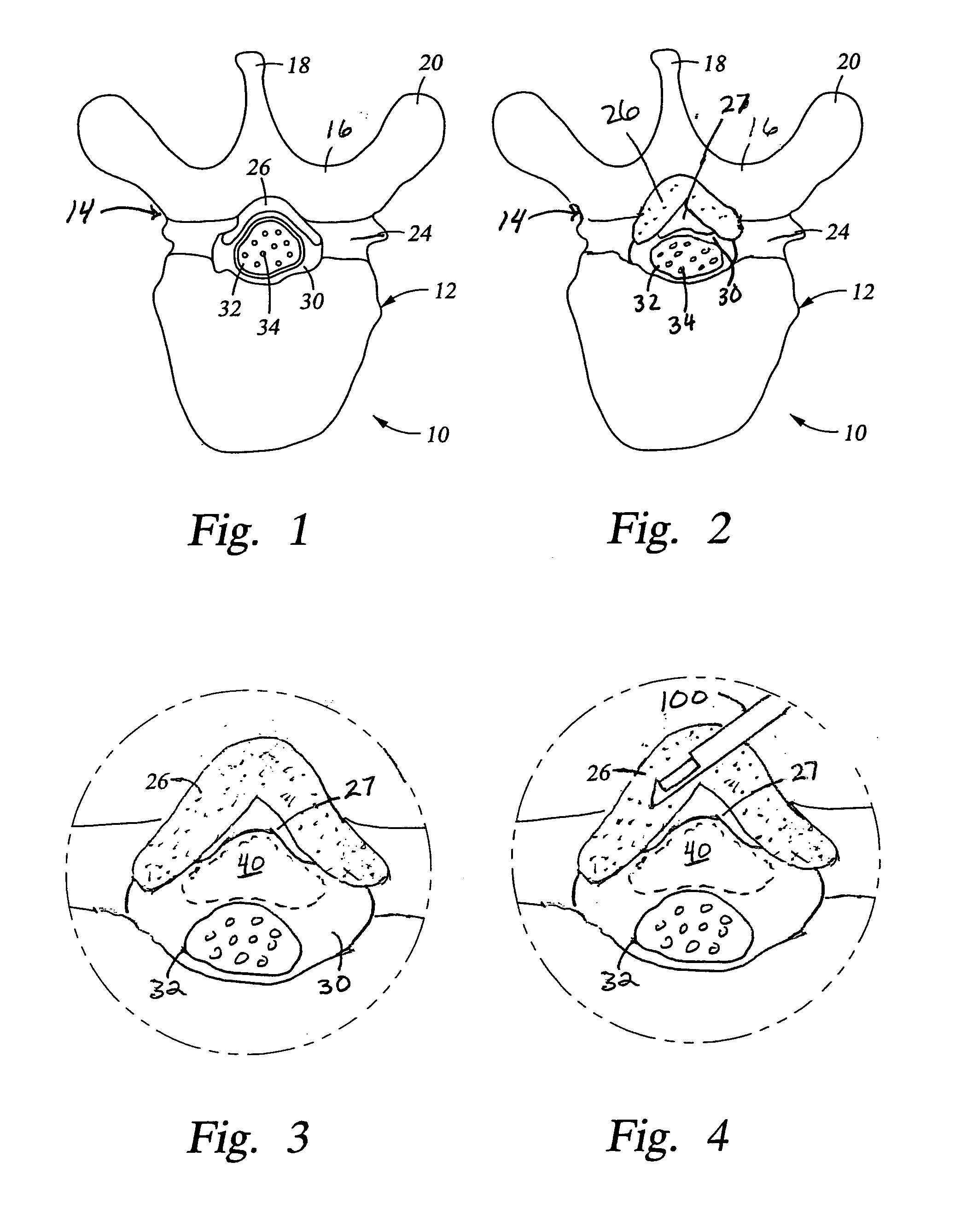

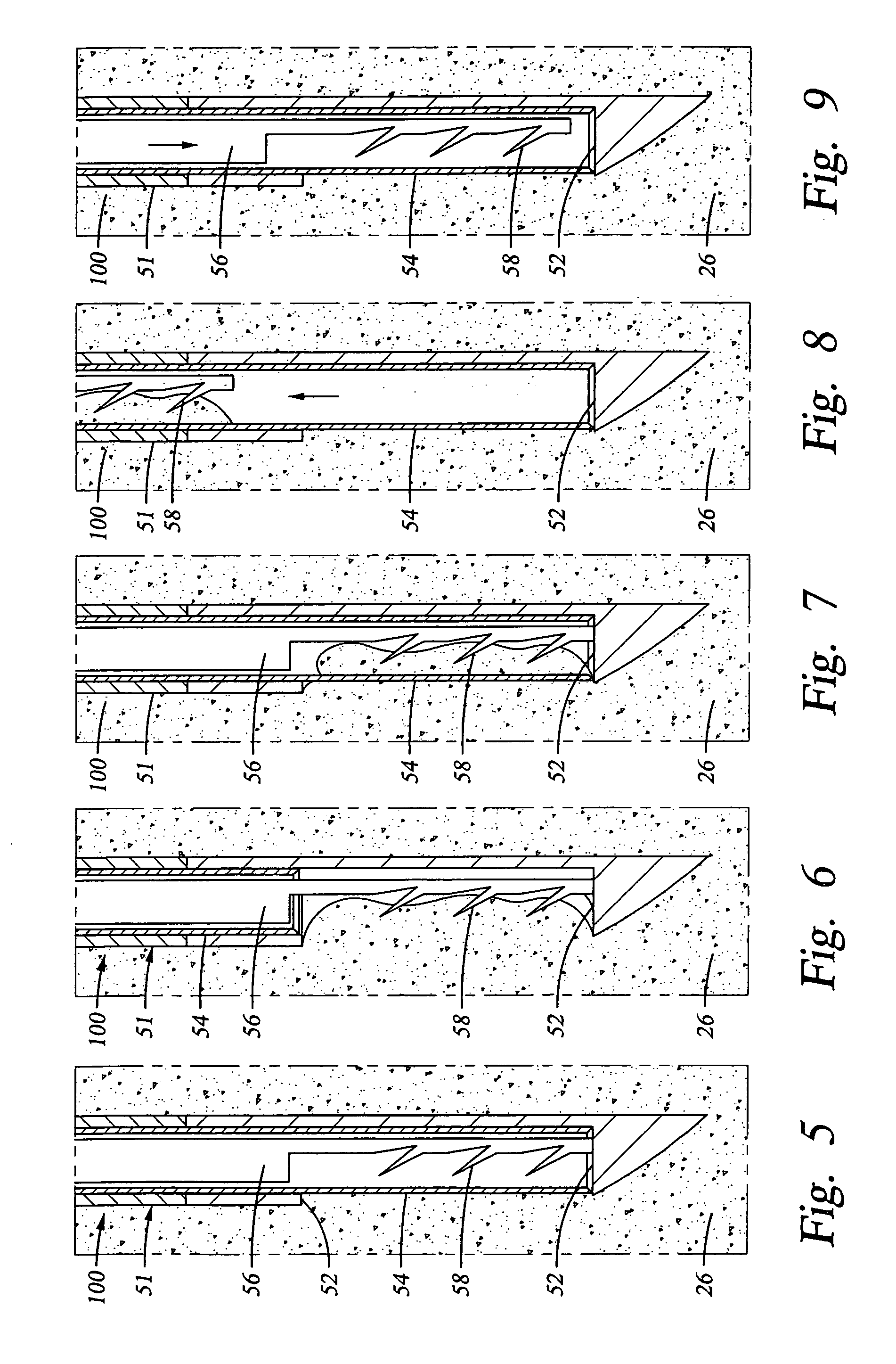

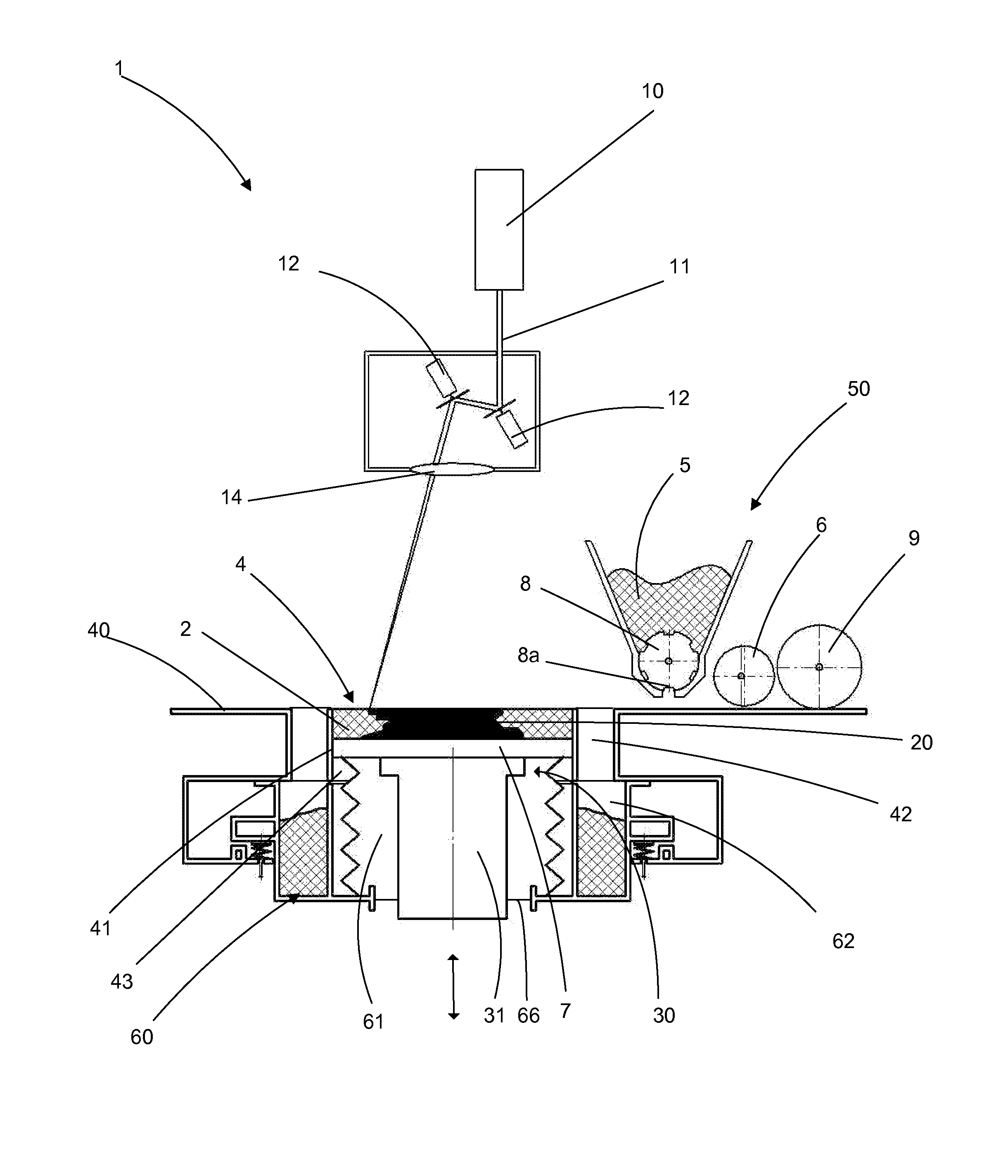

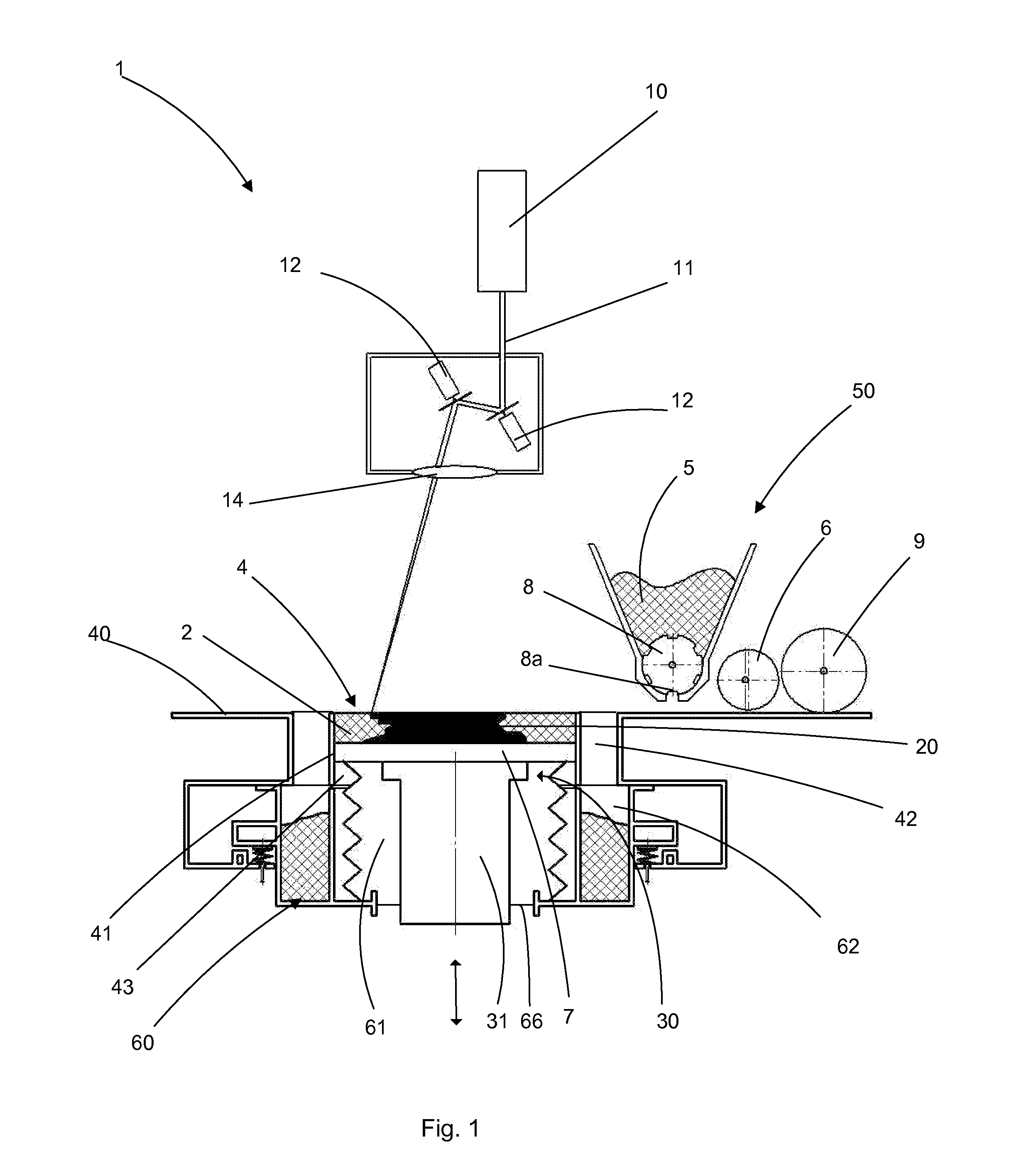

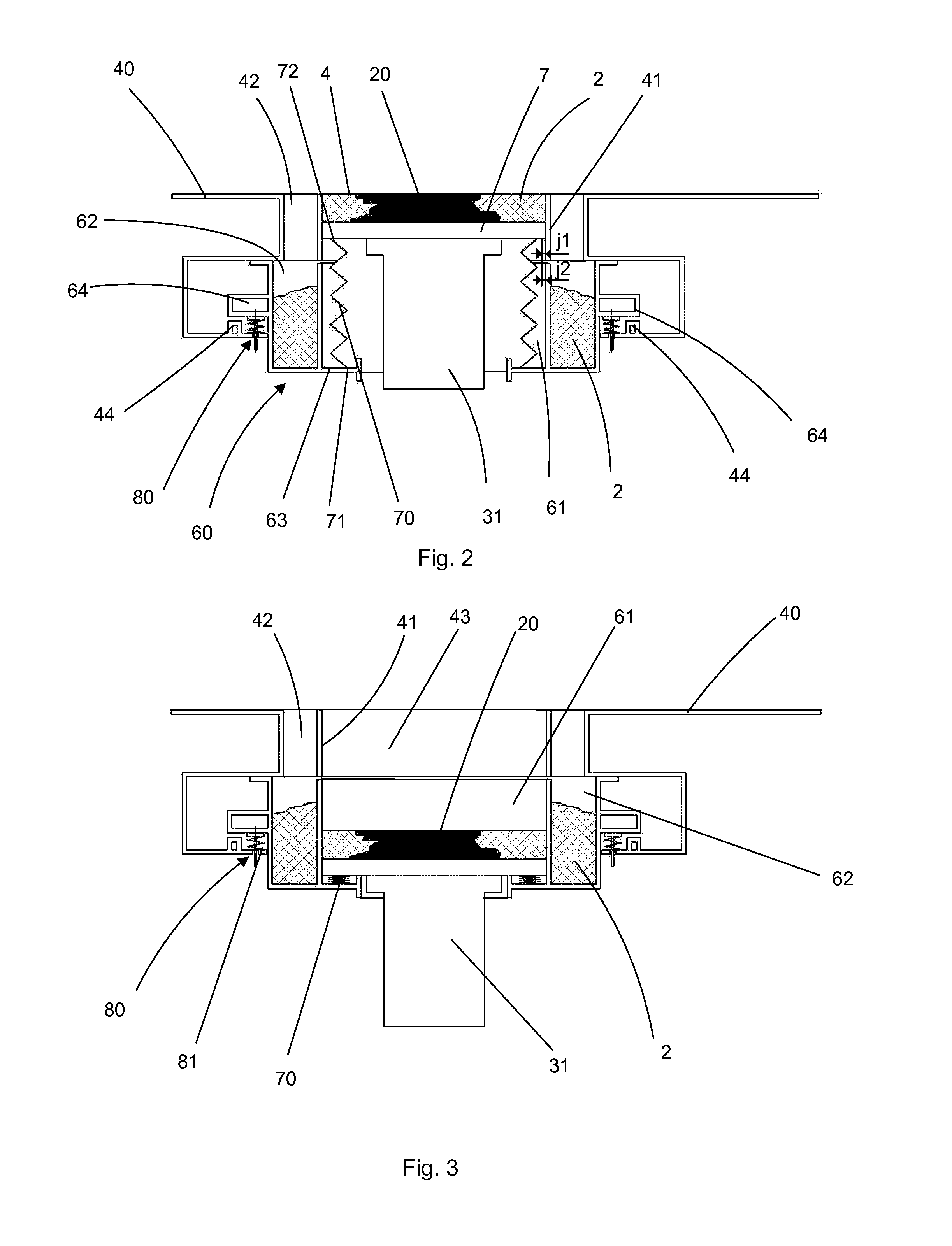

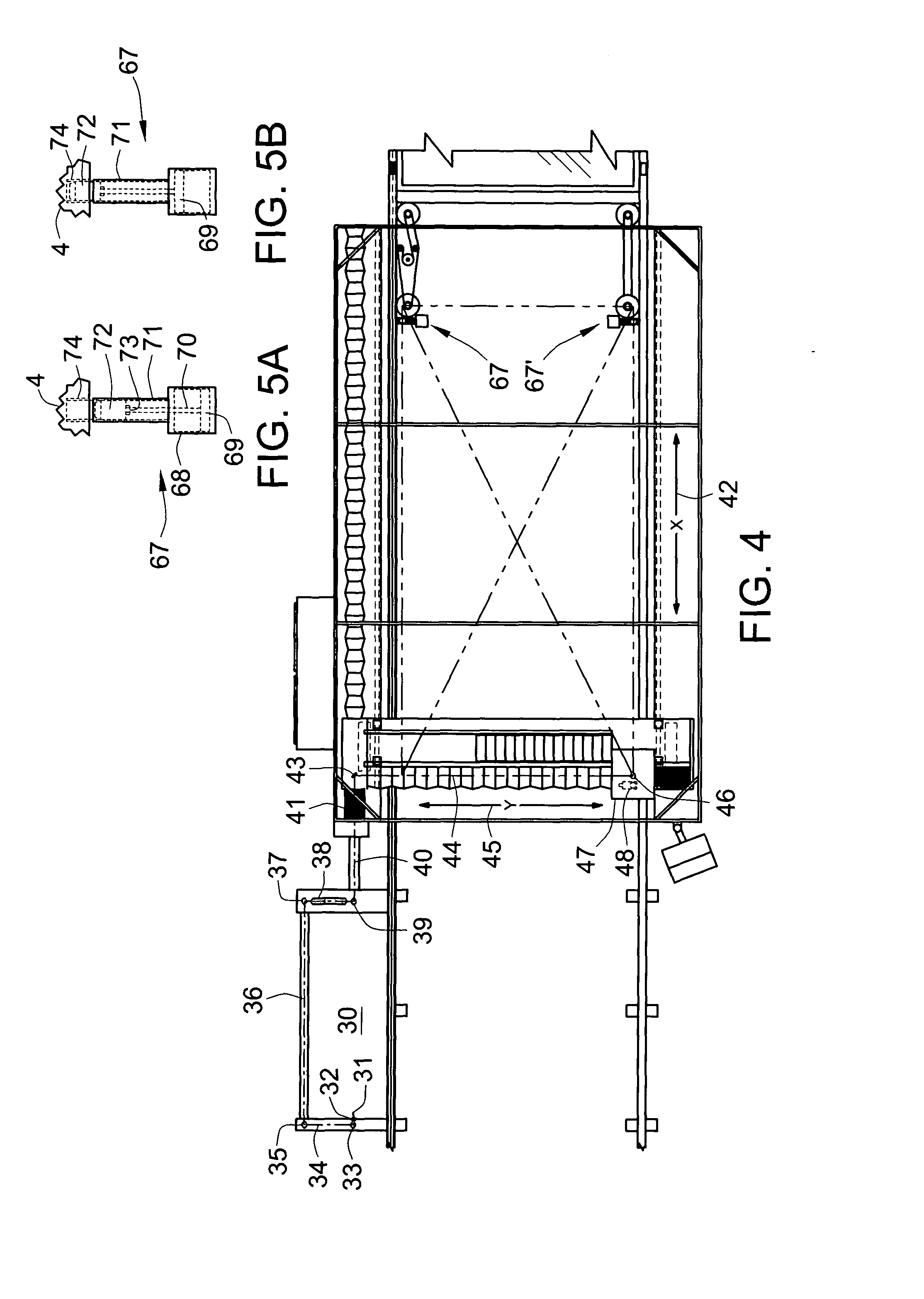

Machine and method for powder-based additive manufacturing

ActiveUS20150139849A1Additive manufacturing apparatusArc welding apparatusWork zoneAdditive layer manufacturing

acting on a powder layer in a working zone, containing a device for layering said powder, said device including:means for storing powder,means for distributing powder that travel over the working zone to distribute powder in a layer having a final thickness for additive manufacturing,feeding means that transfer powder from storage means to distributing means,metering means that control the quantity of powder transferred from storage means to distributing means,said machine being wherein:storage means are positioned higher than the working zone,feeding means utilize gravity,feeding means and the metering means move with the distributing means,the machine has two separate working zones and two separate working trays that move independently of one another,each of the working trays is associated with only one working zone, andthe layering device is common to both working zones.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

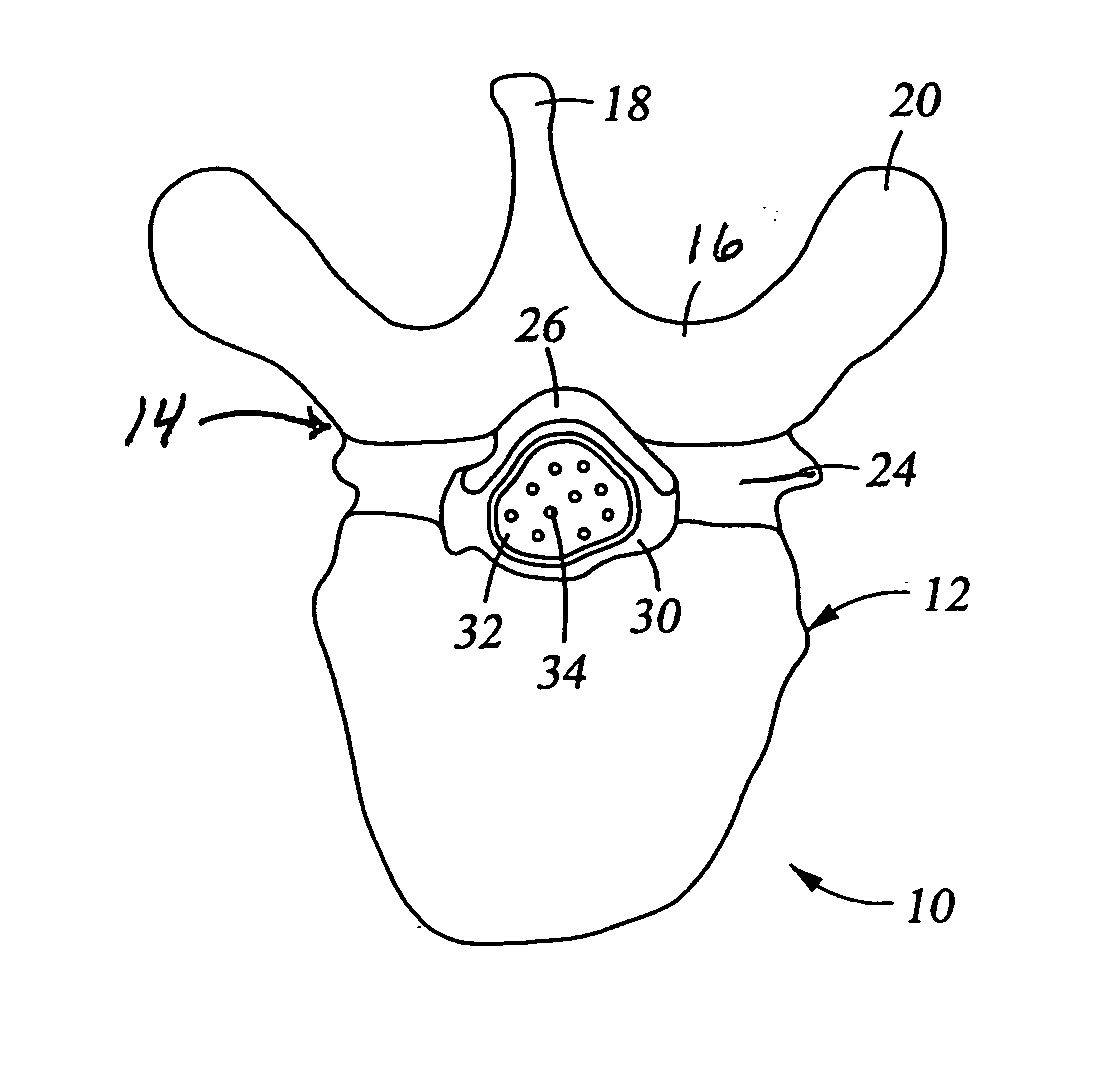

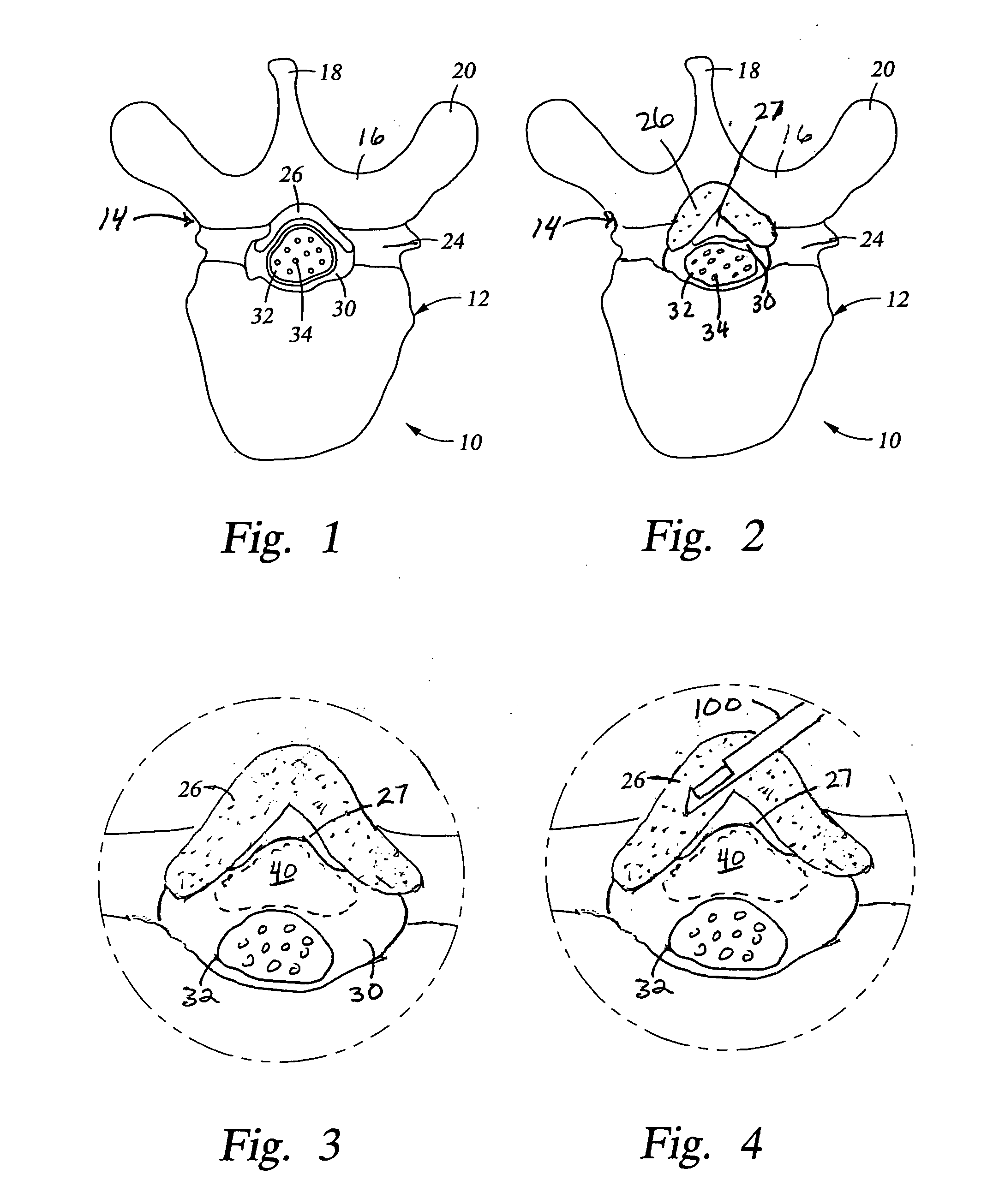

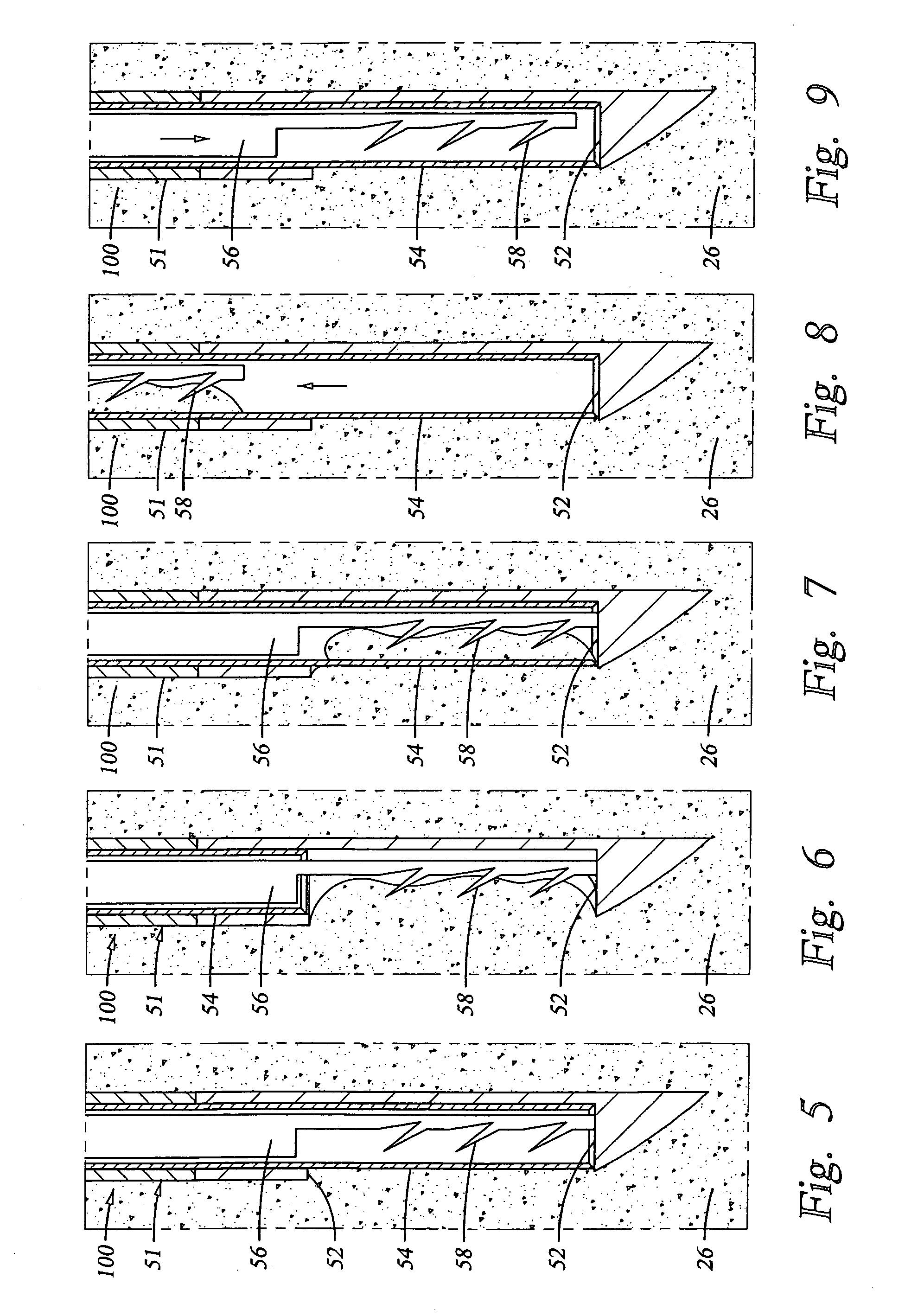

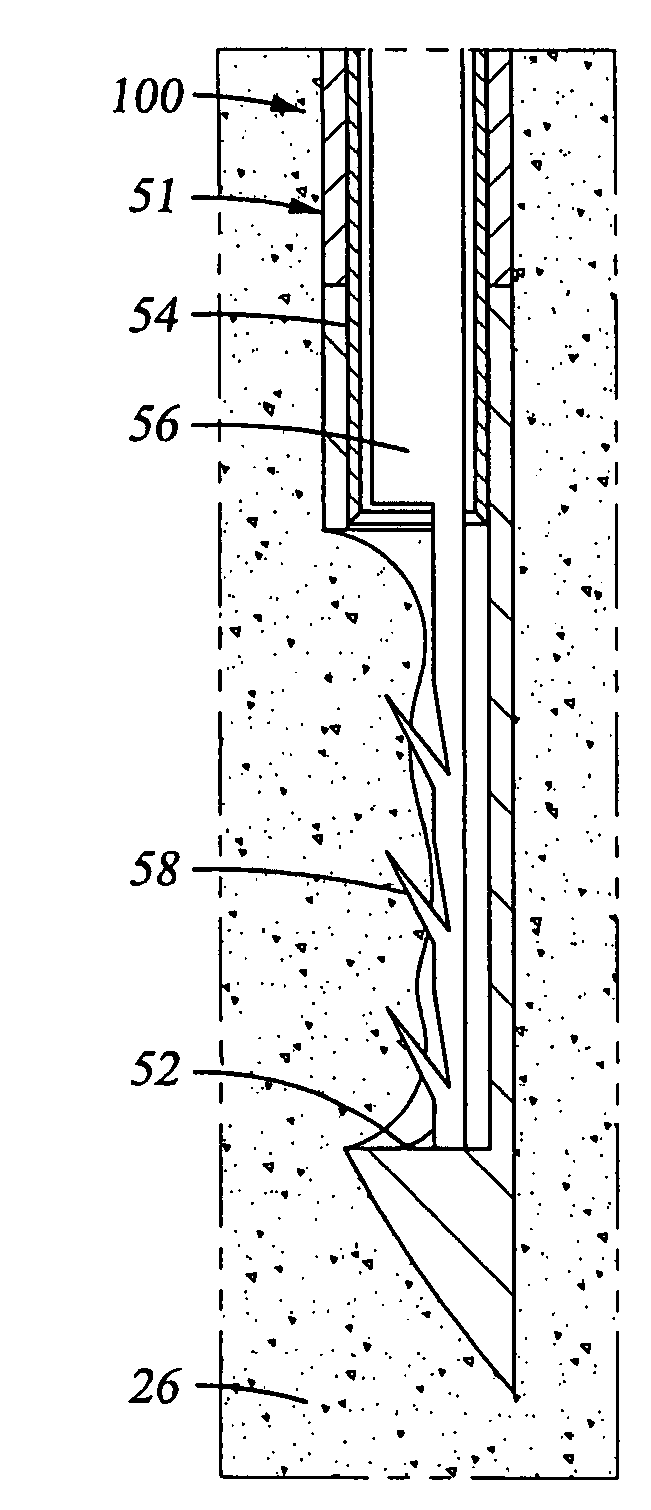

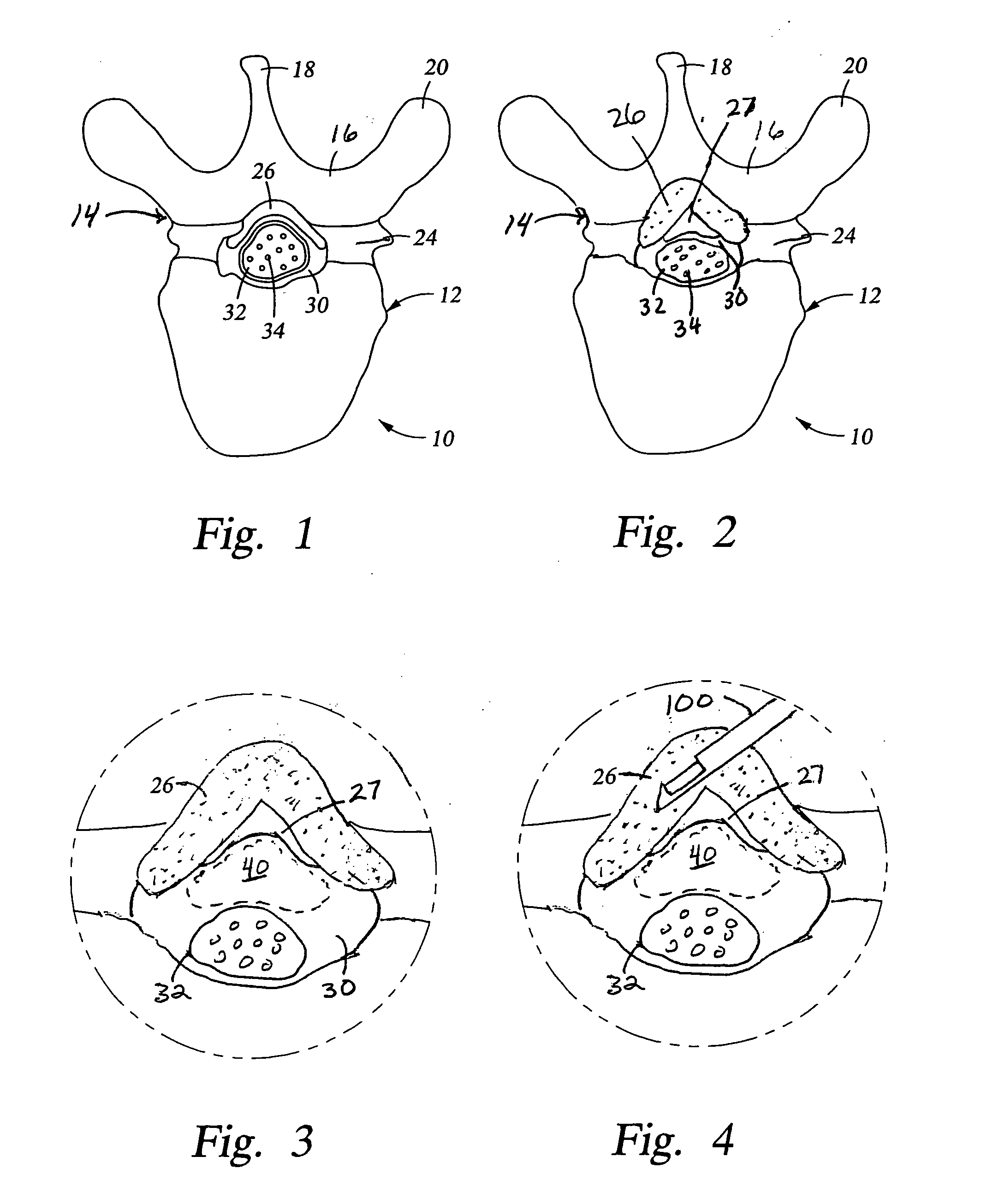

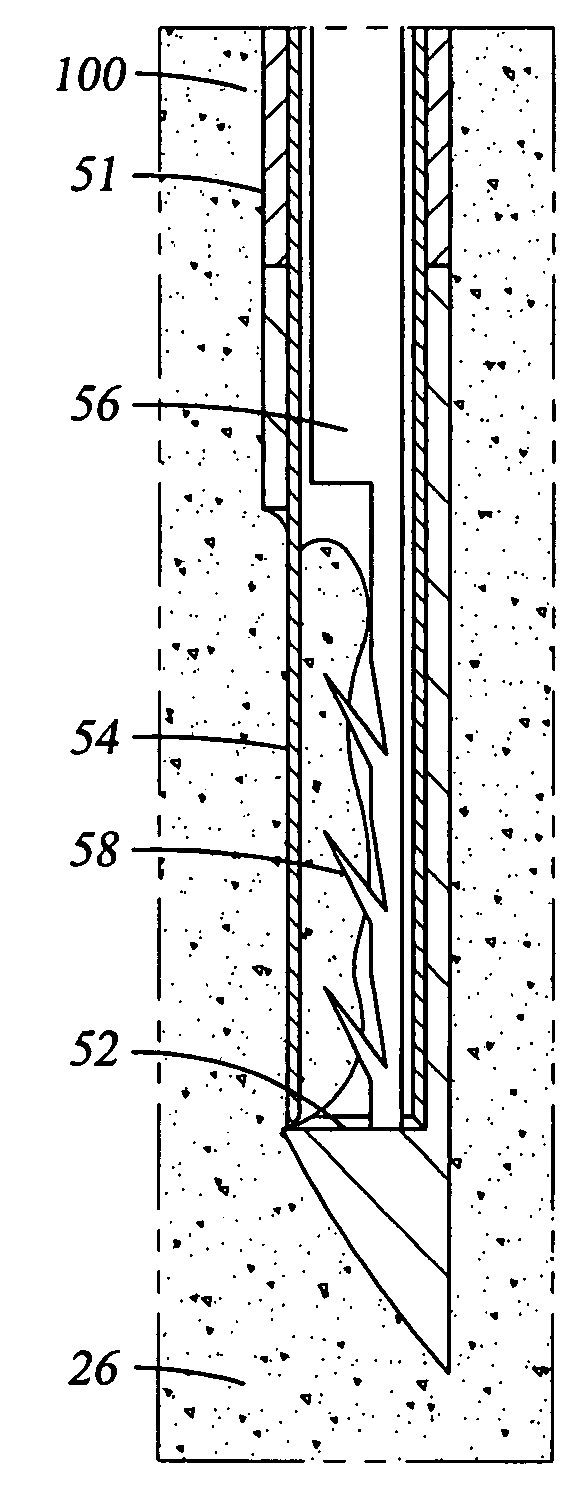

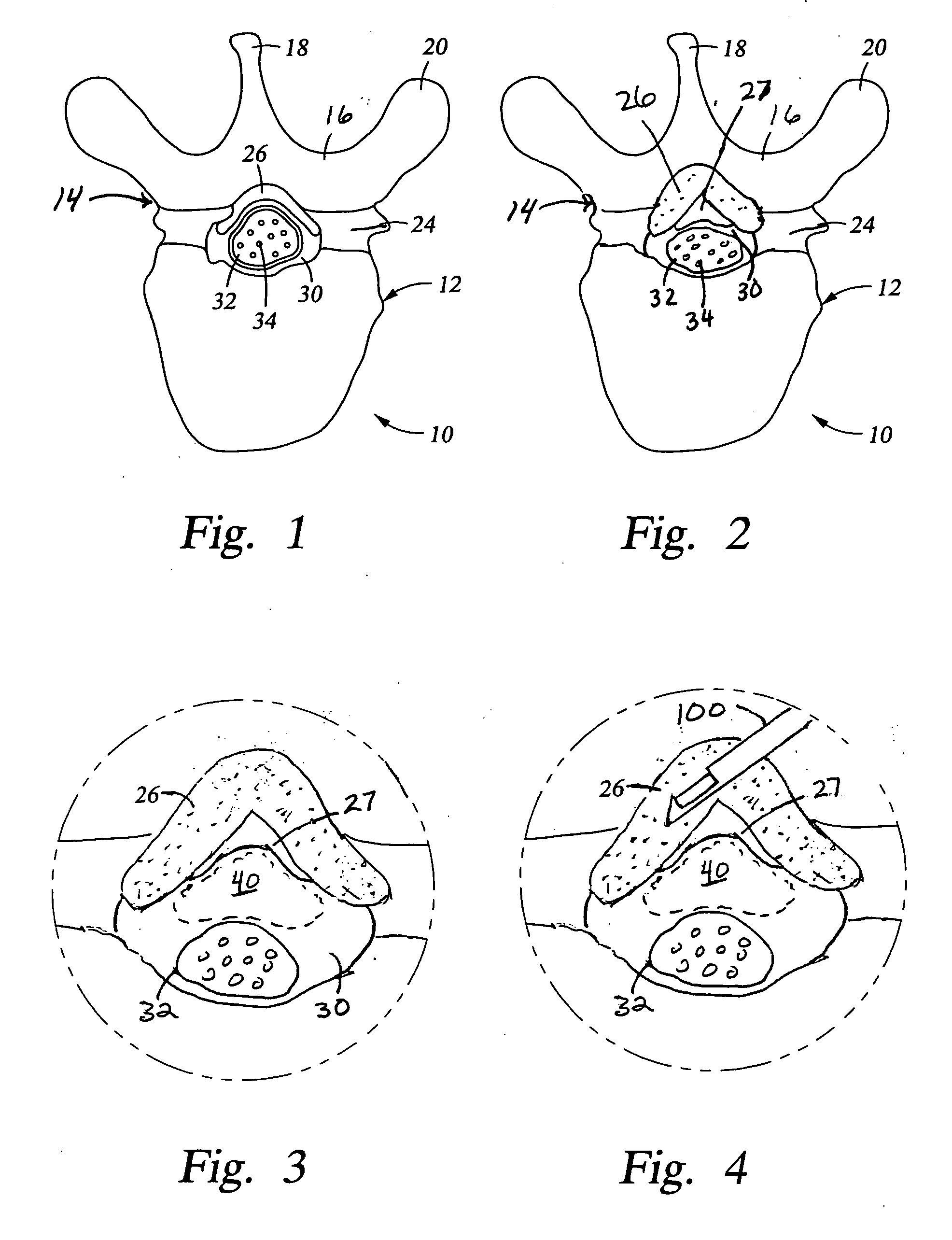

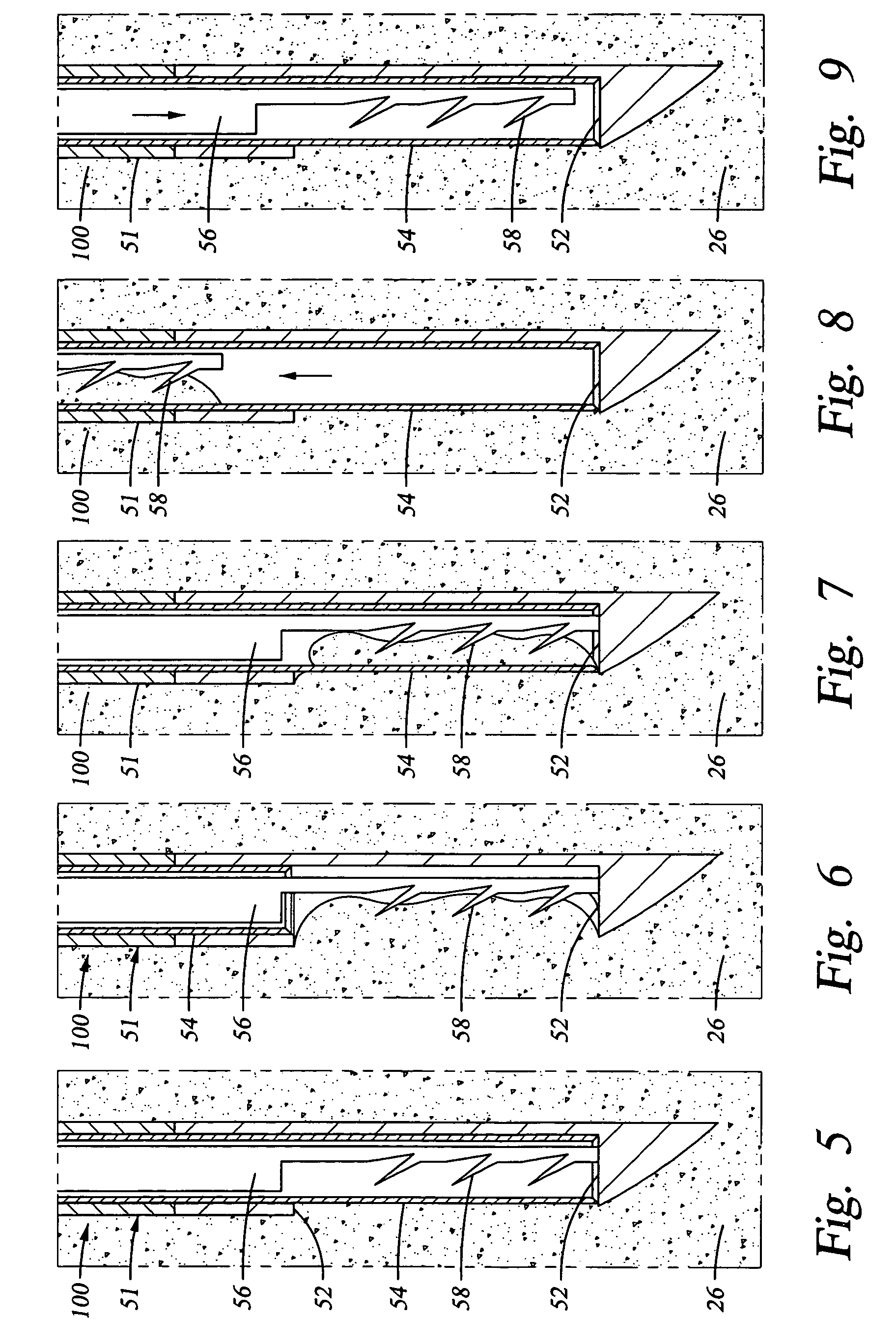

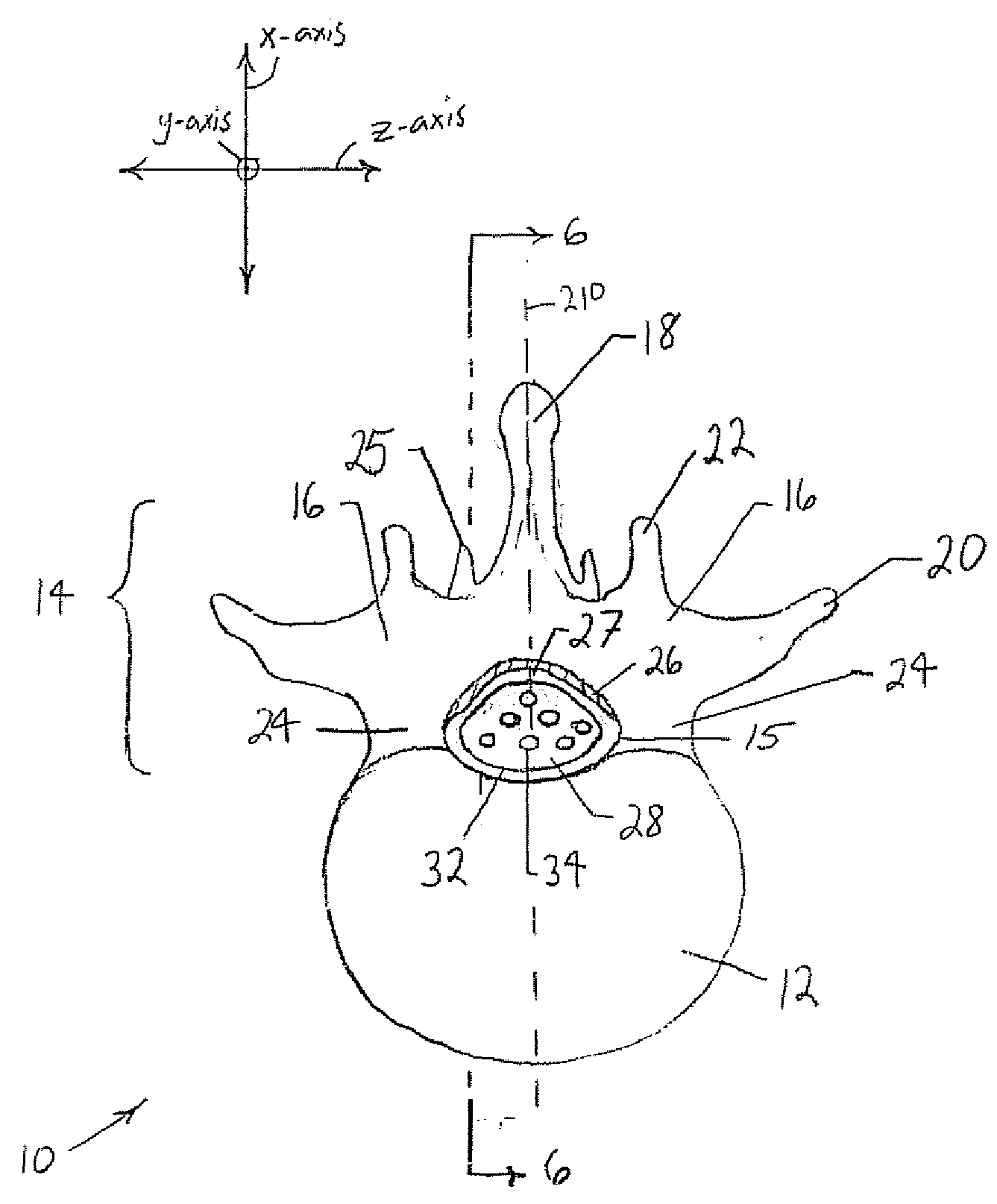

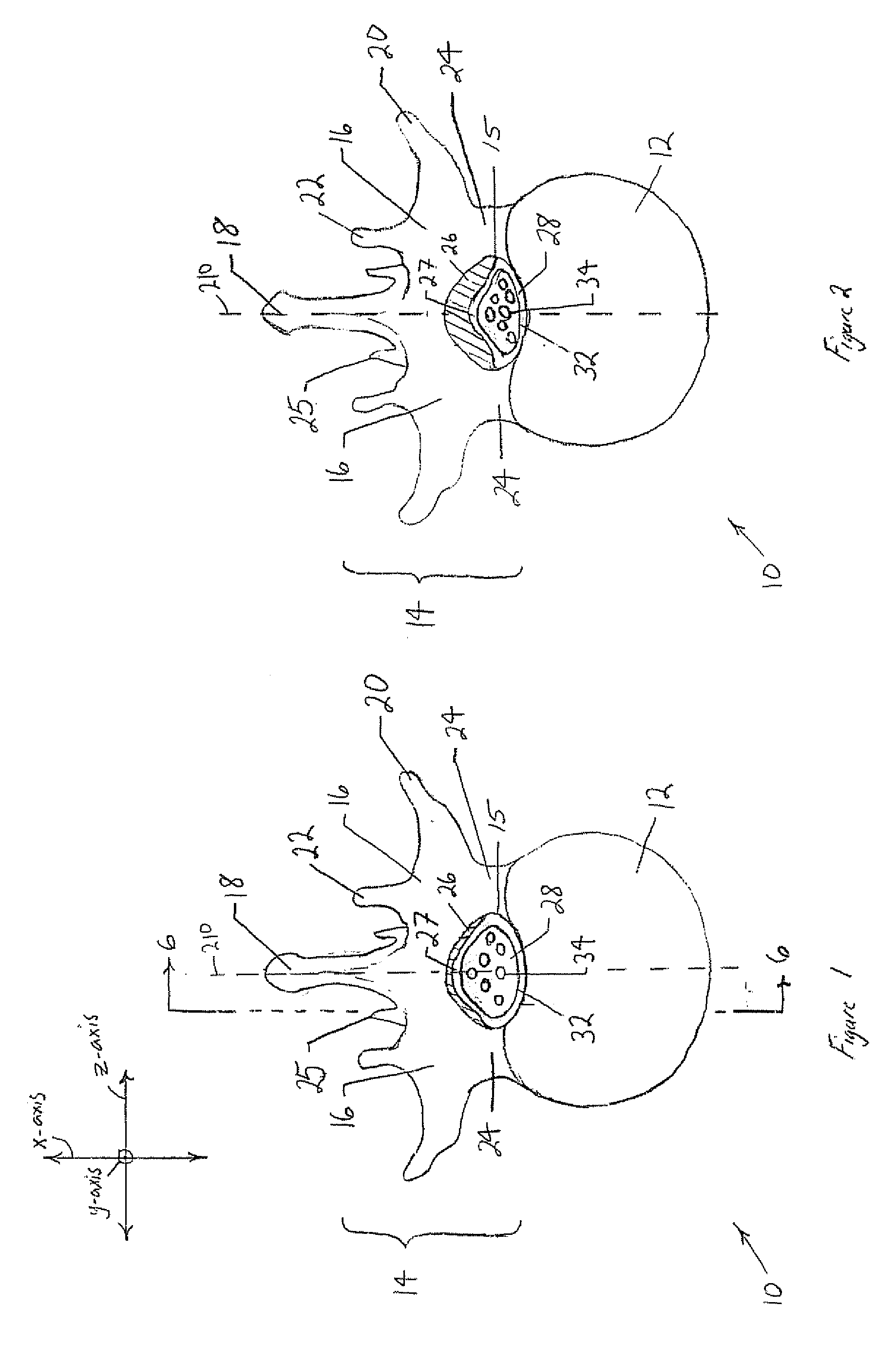

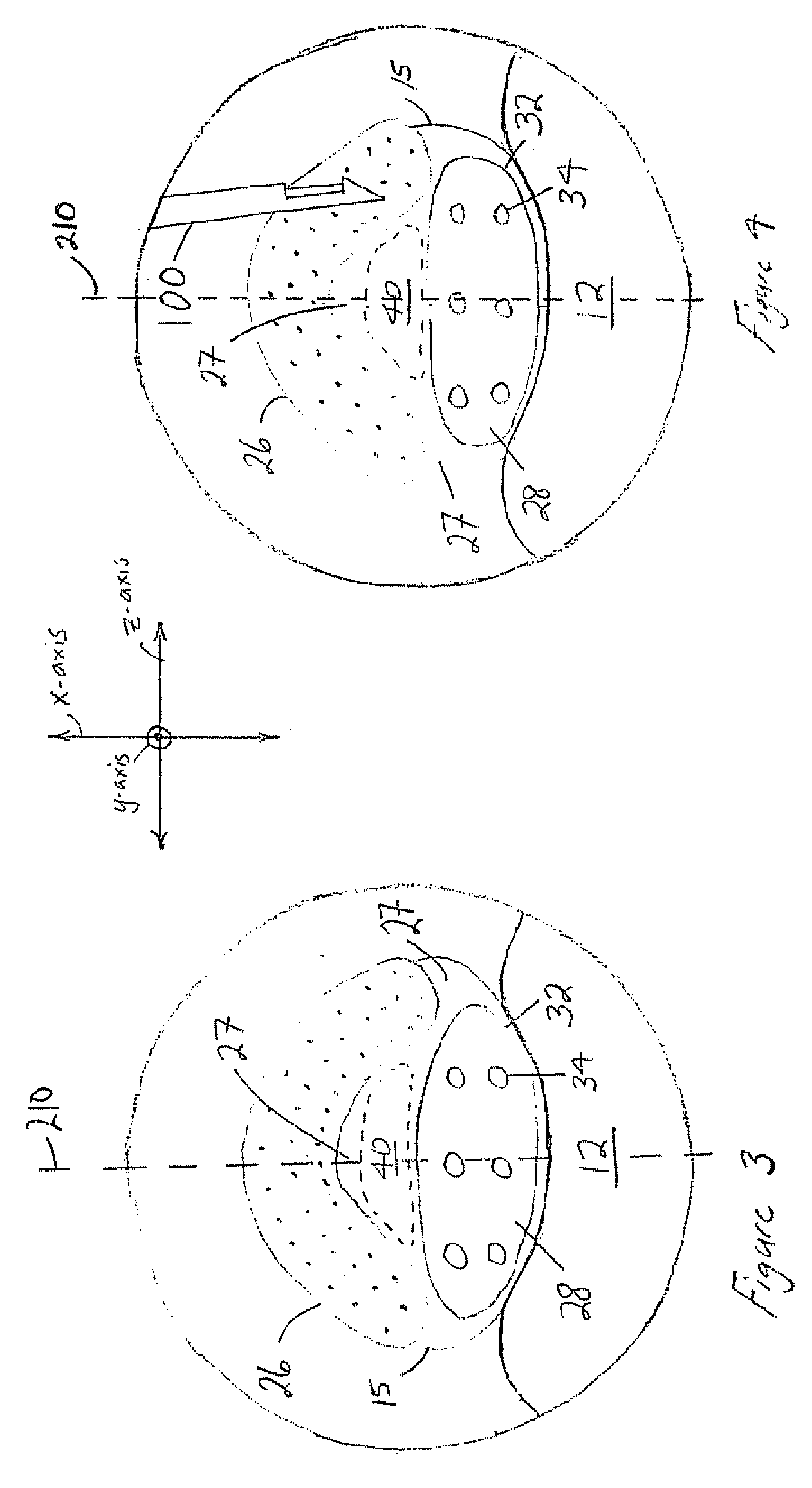

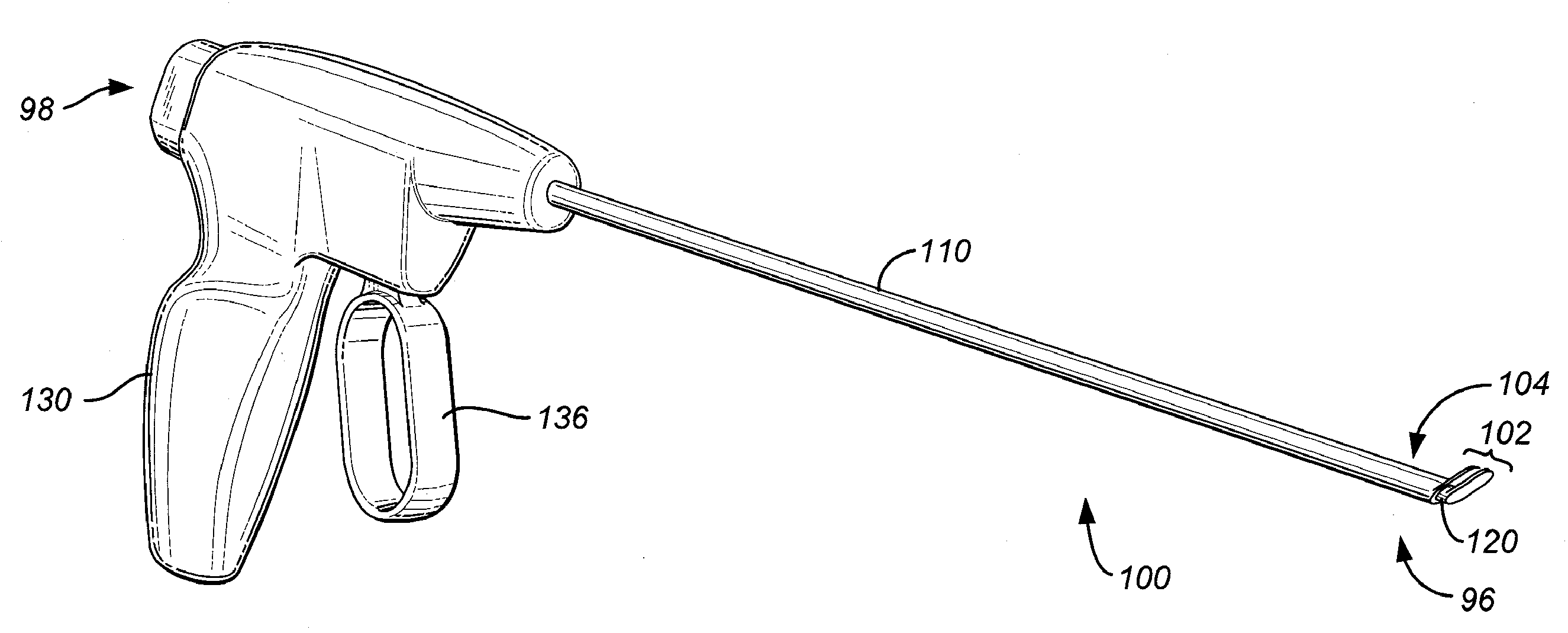

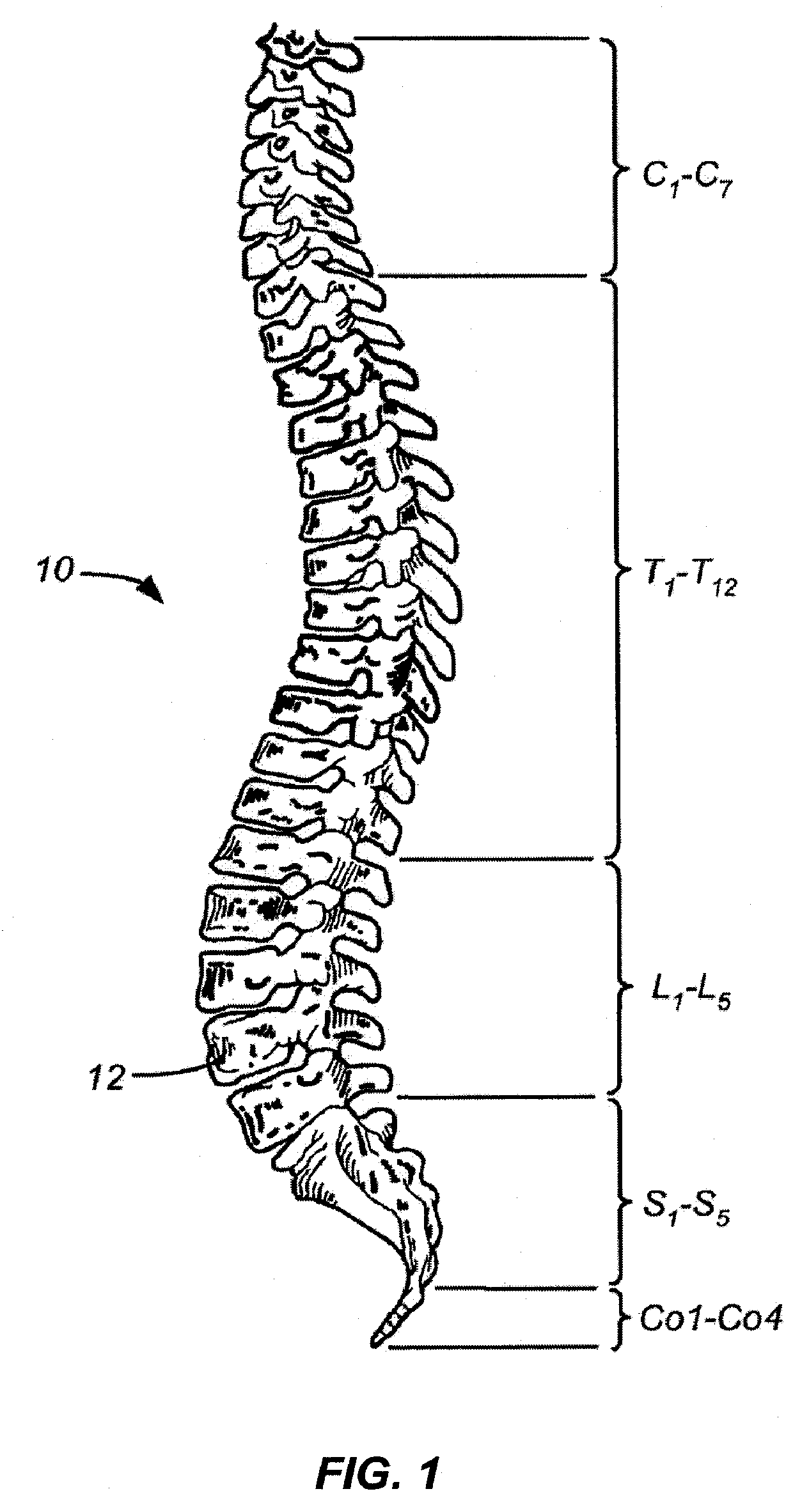

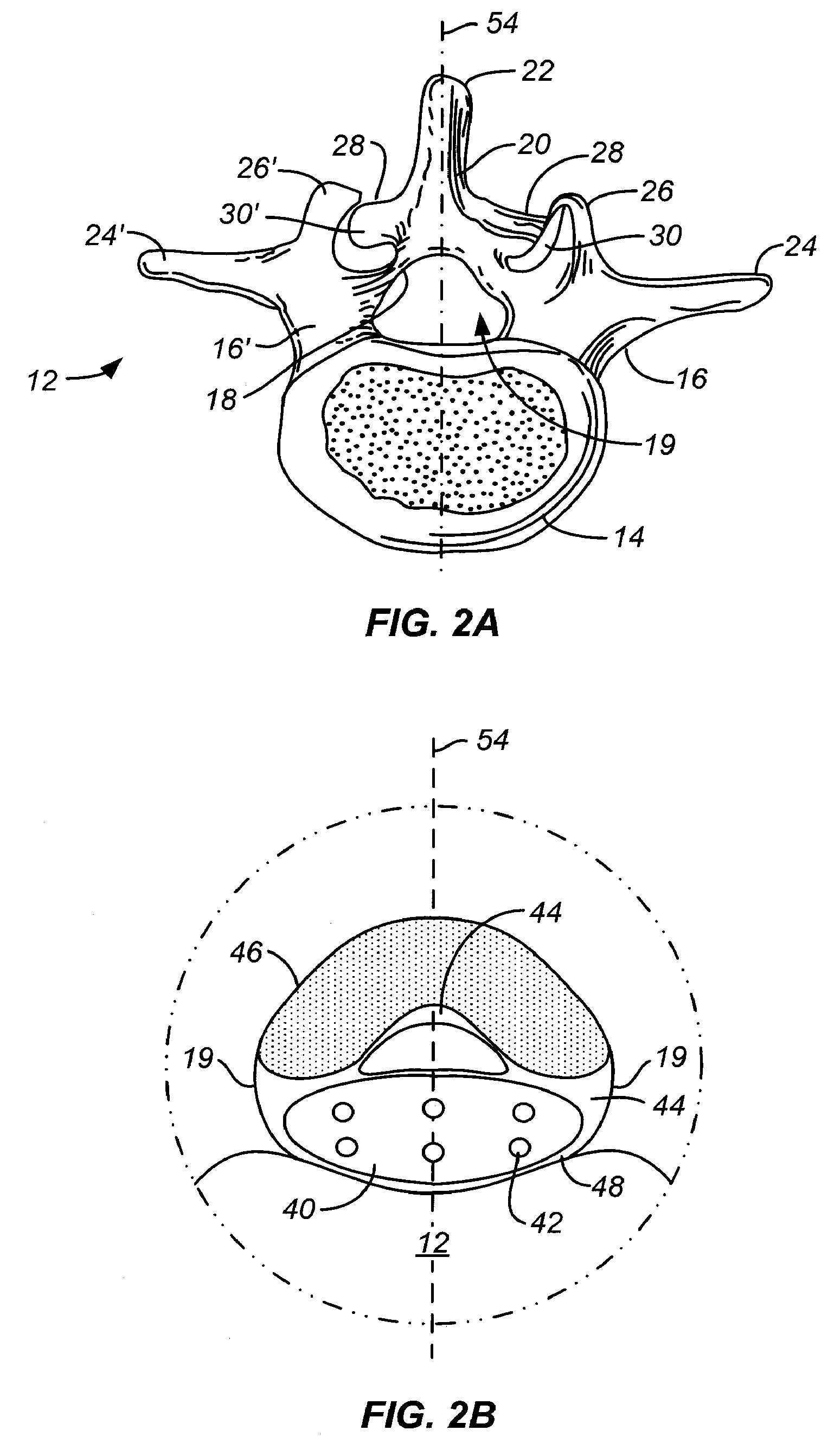

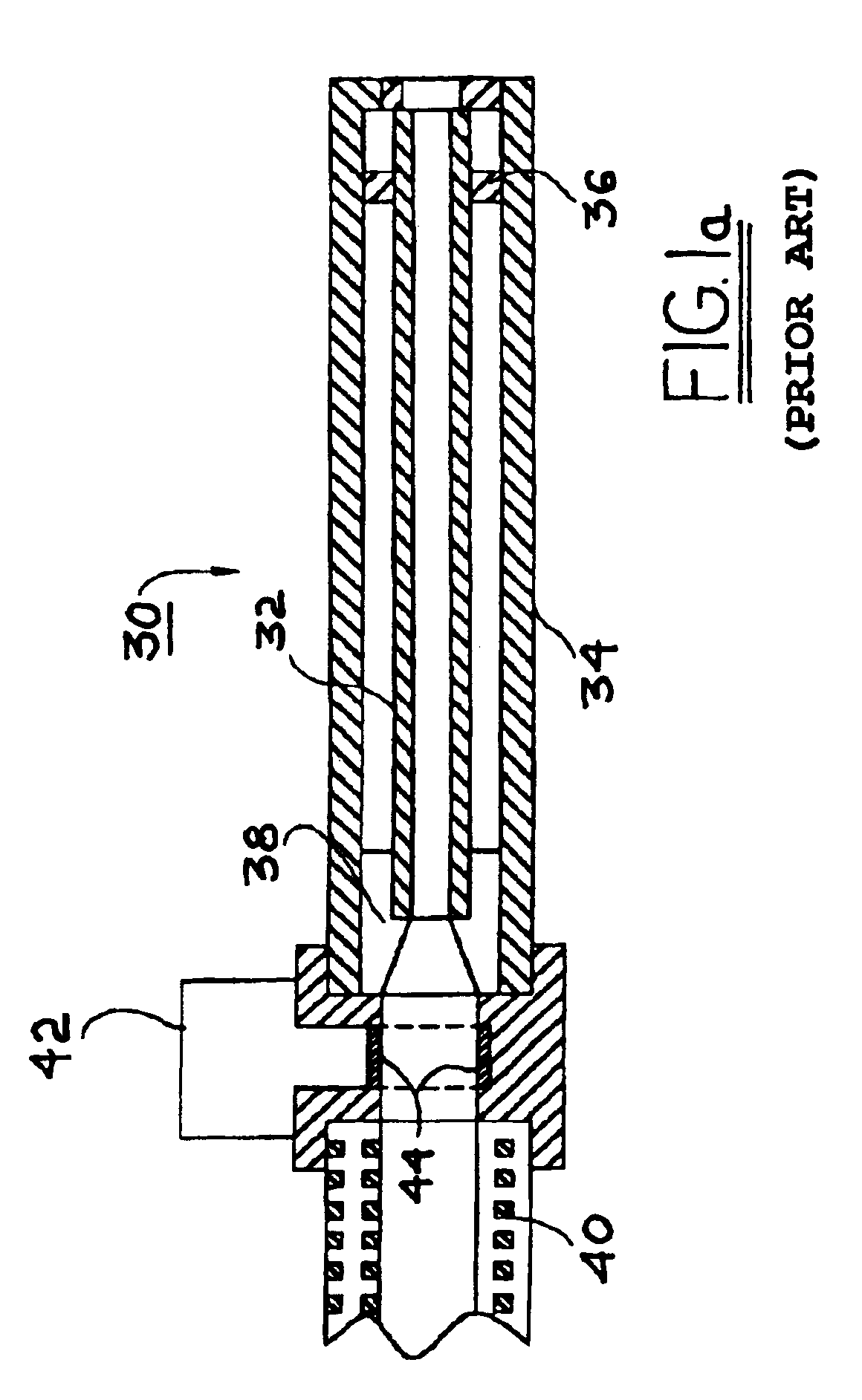

Spinal ligament modification kit

InactiveUS20060036211A1Prevent leakageUse minimizedSuture equipmentsSurgical needlesSpinal ligamentsSpinal column

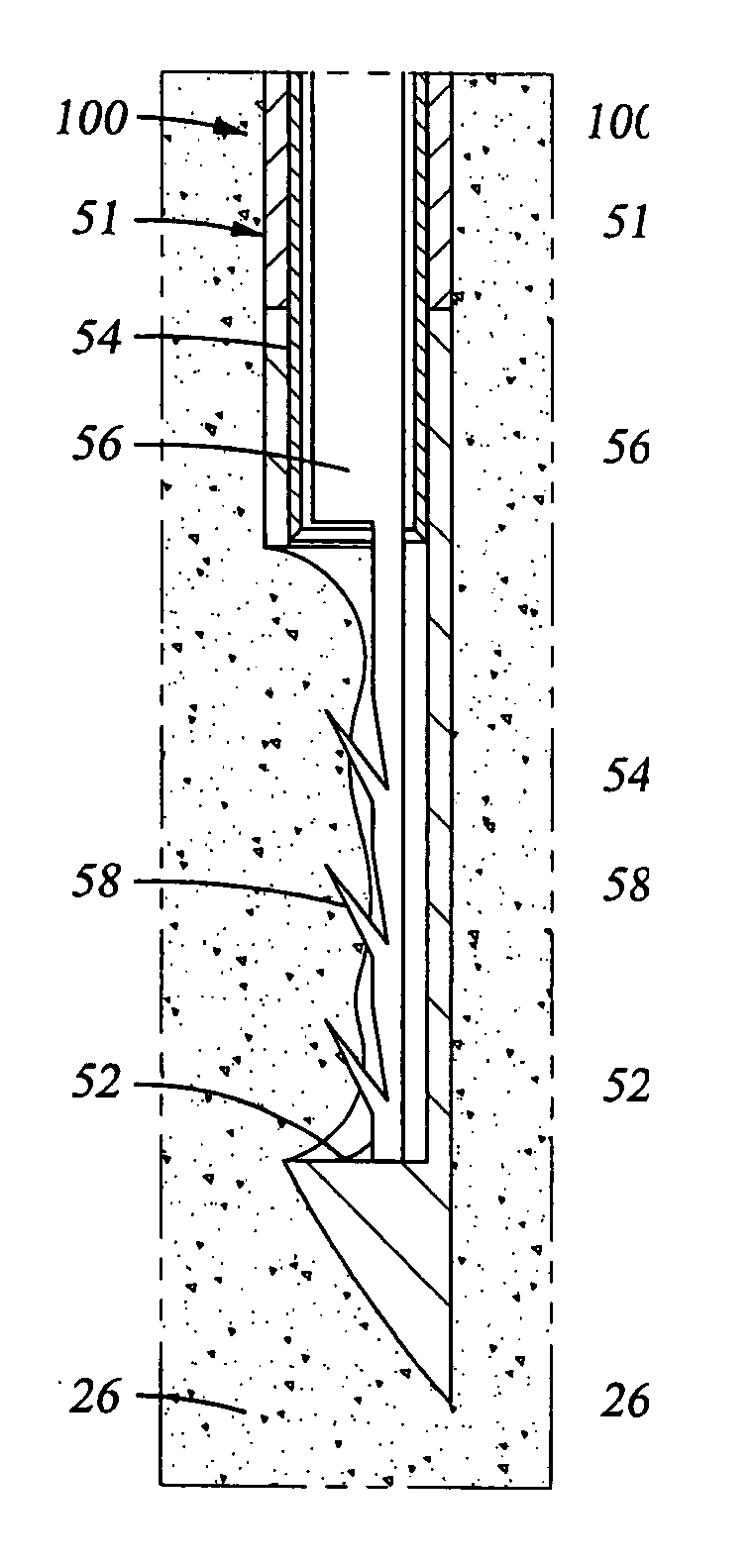

A method for treating stenosis in a spine comprises percutaneously accessing the epidural space in a stenotic region of interest, compressing the thecal sac in the region of interest to form a safety zonem, inserting a tissue removal tool into tissue in the working zone, using the tool to percutaneously reduce the stenosis; and utilizing imaging to visualize the position of the tool during at least a part of the reduction step. A tissue excision system for performing percutaneous surgery, comprises a cannula comprising a tissue-penetrating member having a distal end defining an aperture on one side thereof, an occluding member slidably received on or in the cannula and closing the aperture when the occluding member is adjacent the cannula distal end, means for engaging adjacent tissue via the aperture, and cutting means for resecting a section of the engaged tissue.

Owner:VERTOS MEDICAL

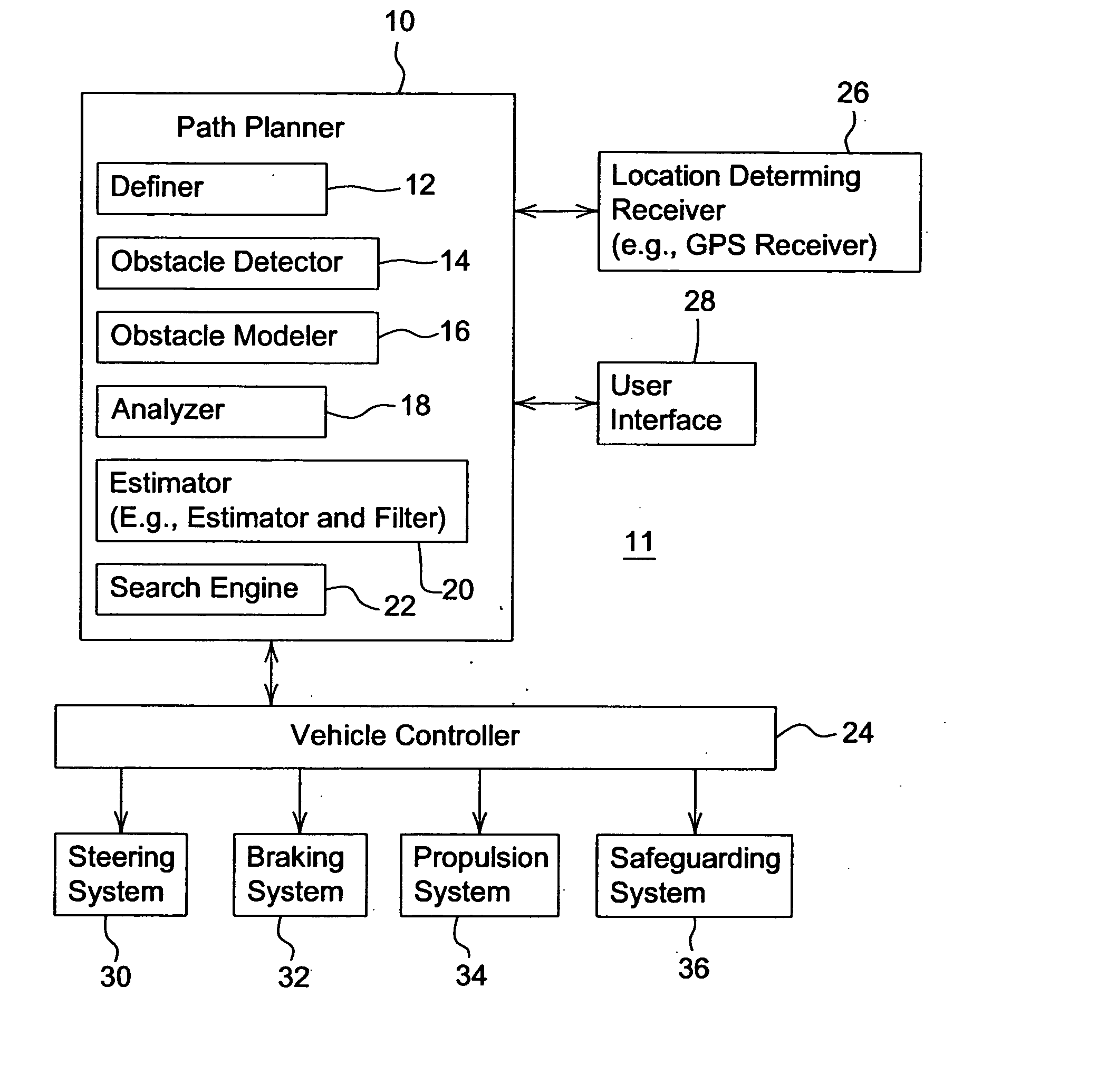

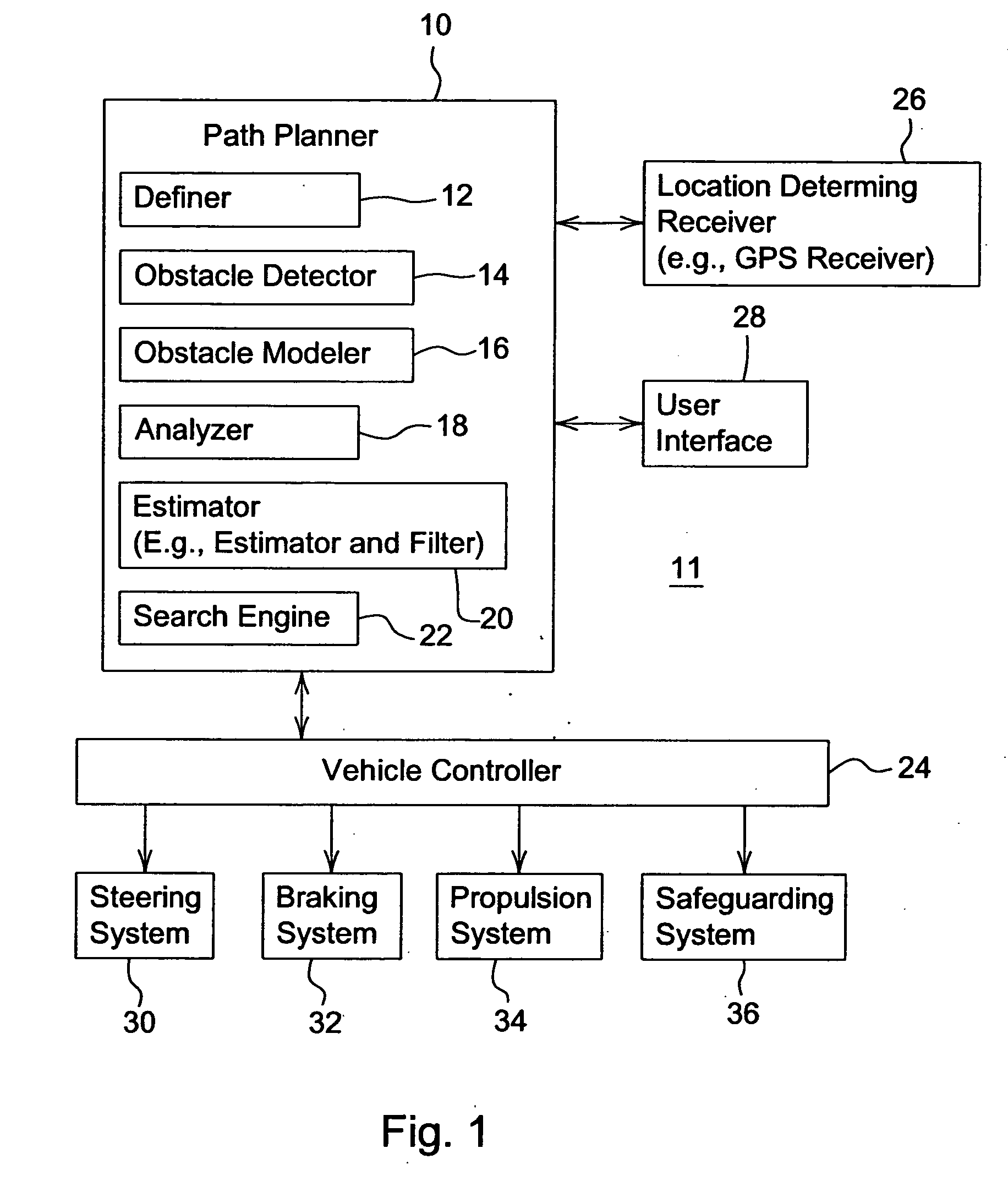

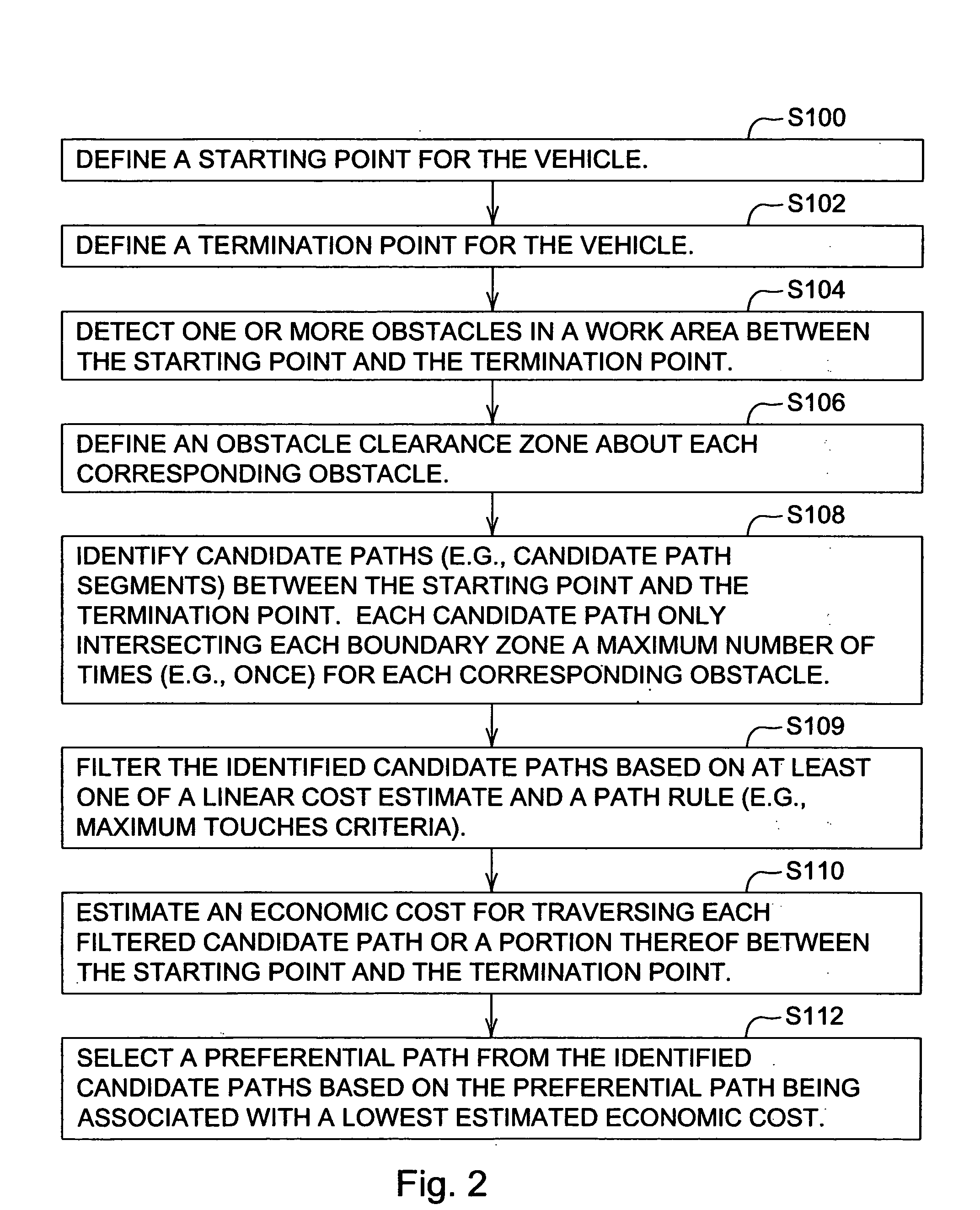

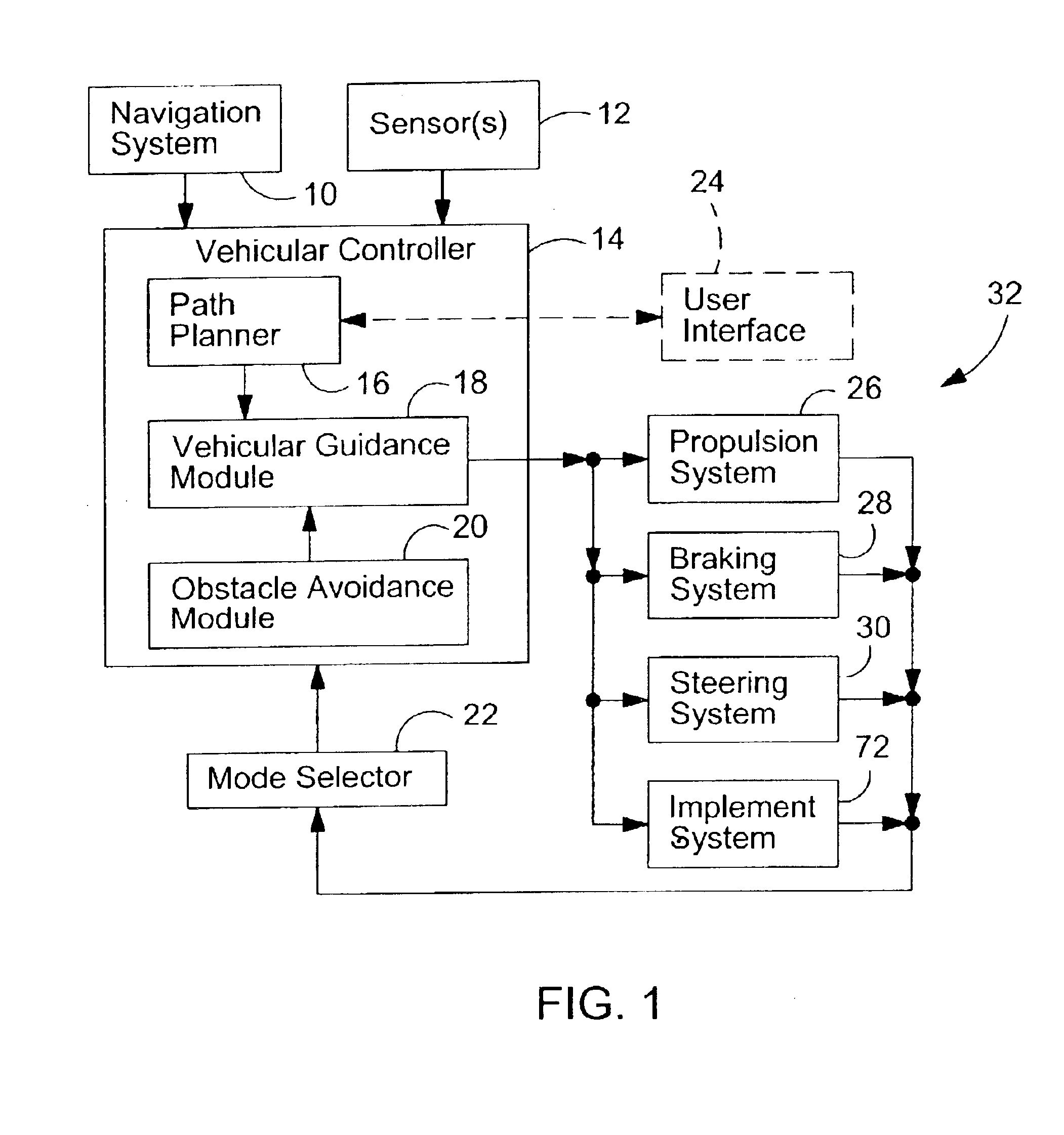

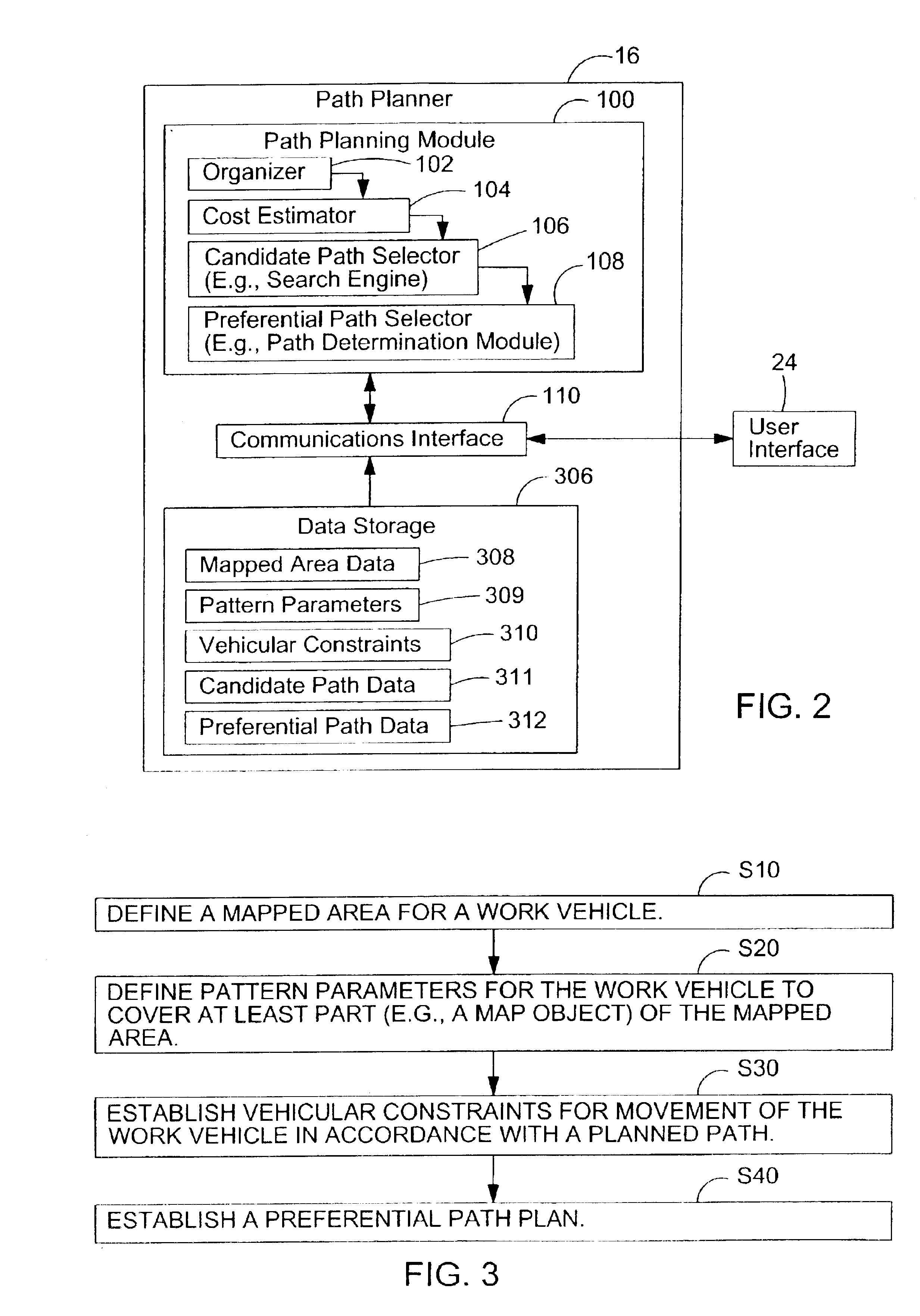

Point -to-point path planning

InactiveUS20050192749A1Instruments for road network navigationNavigational calculation instrumentsComputer scienceCost (economic)

A path planner and a method for determining a path for a vehicle comprises defining a starting point for the vehicle. A termination point is defined. An obstacle detector detects one or more obstacles in a work area between the starting point and the termination point. A boundary zone is defined about each corresponding obstacle. Candidate paths are identified between the starting point and the termination point. Each candidate path only intersects each boundary zone once for each corresponding obstacle. An economic cost is estimated for traversing each candidate path or a portion thereof between the starting point and the termination point. A preferential path is selected from the identified candidate paths based on the preferential path being associated with a lowest estimated economic cost.

Owner:DEERE & CO

Spinal ligament modification

ActiveUS20060036272A1Prevent leakageUse minimizedSuture equipmentsSurgical needlesSpinal ligamentsSpinal column

A method for treating stenosis in a spine comprises percutaneously accessing the epidural space in a stenotic region of interest, compressing the thecal sac in the region of interest to form a safety zonem, inserting a tissue removal tool into tissue in the working zone, using the tool to percutaneously reduce the stenosis; and utilizing imaging to visualize the position of the tool during at least a part of the reduction step. A tissue excision system for performing percutaneous surgery, comprises a cannula comprising a tissue-penetrating member having a distal end defining an aperture on one side thereof, an occluding member slidably received on or in the cannula and closing the aperture when the occluding member is adjacent the cannula distal end, means for engaging adjacent tissue via the aperture, and cutting means for resecting a section of the engaged tissue.

Owner:VERTOS MEDICAL

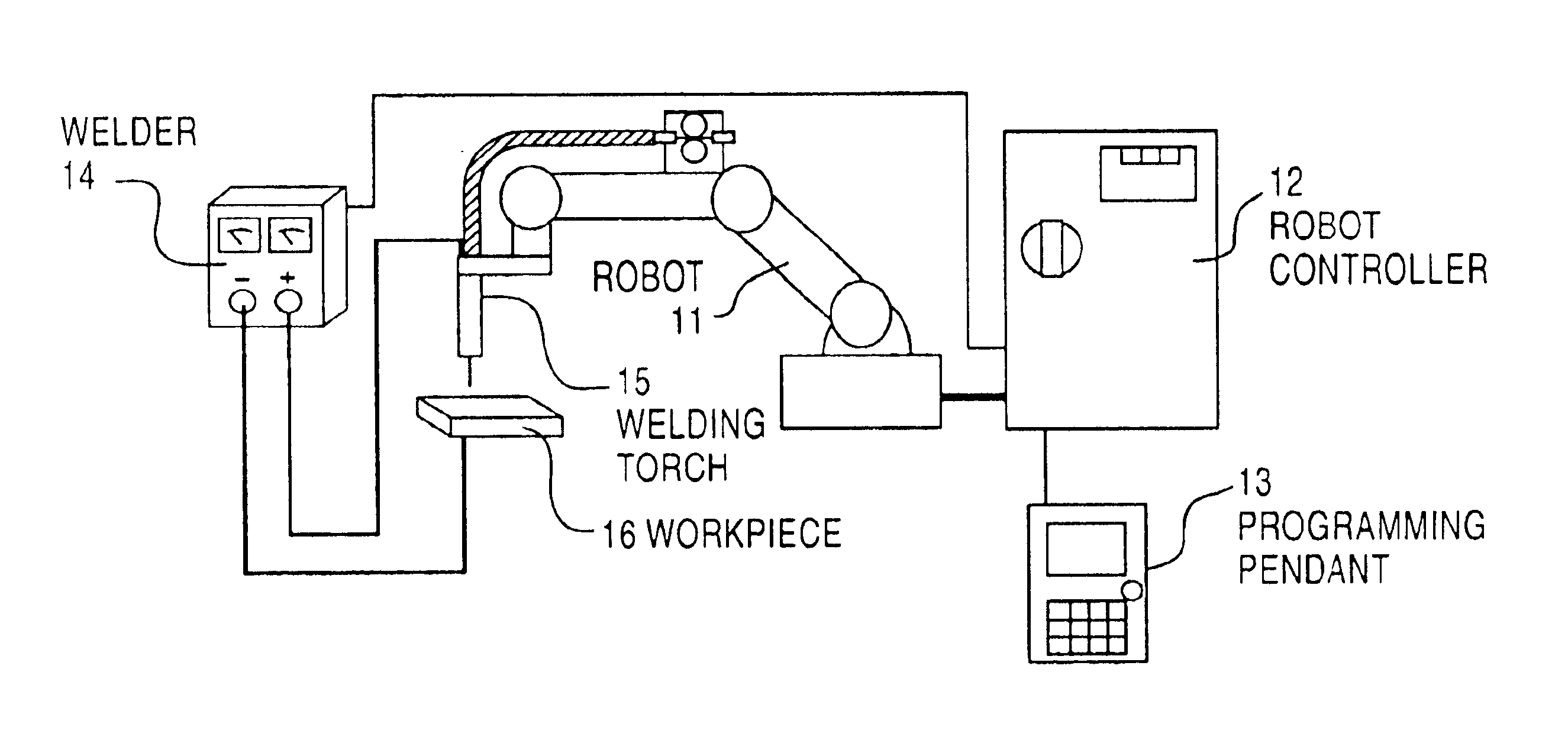

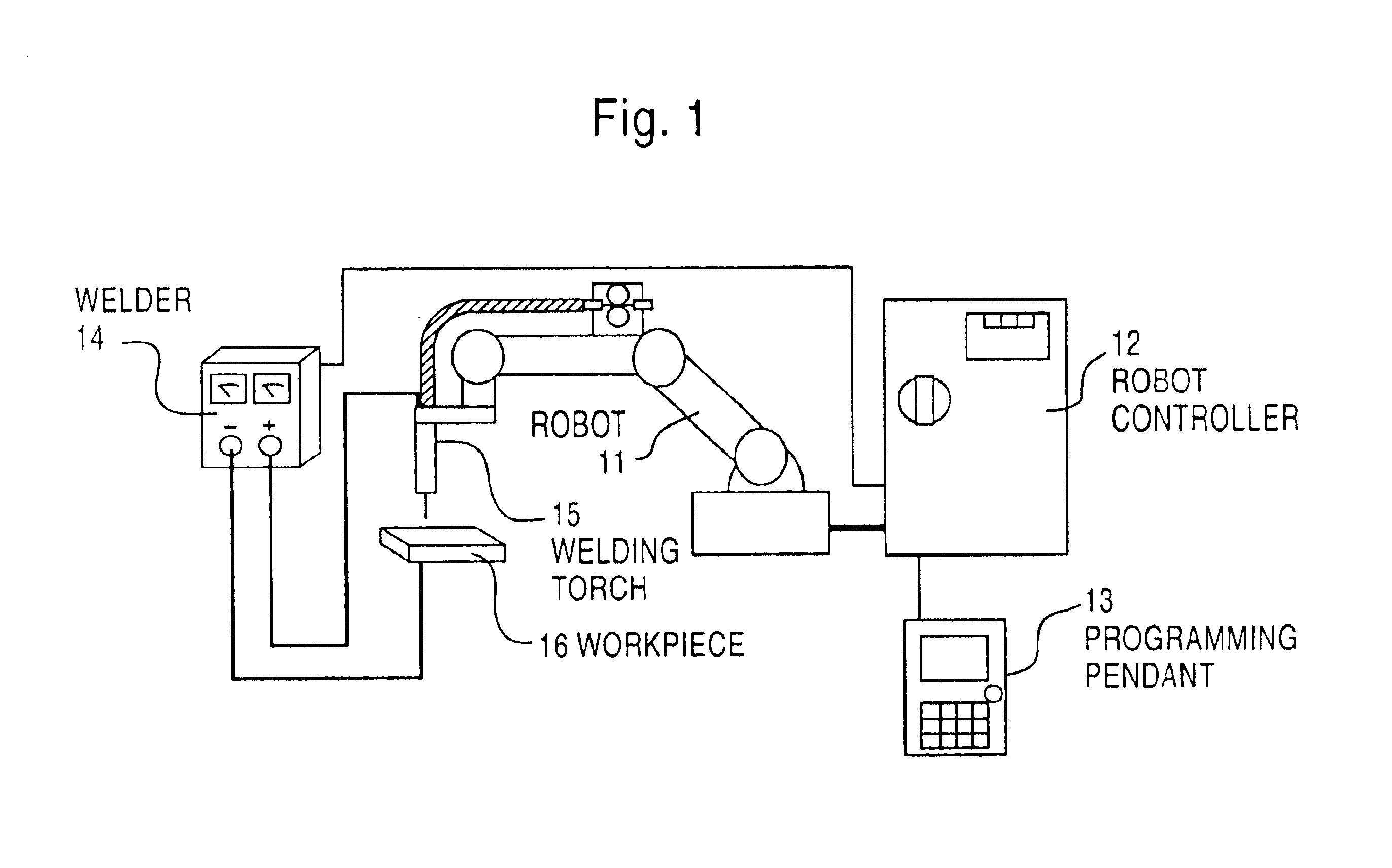

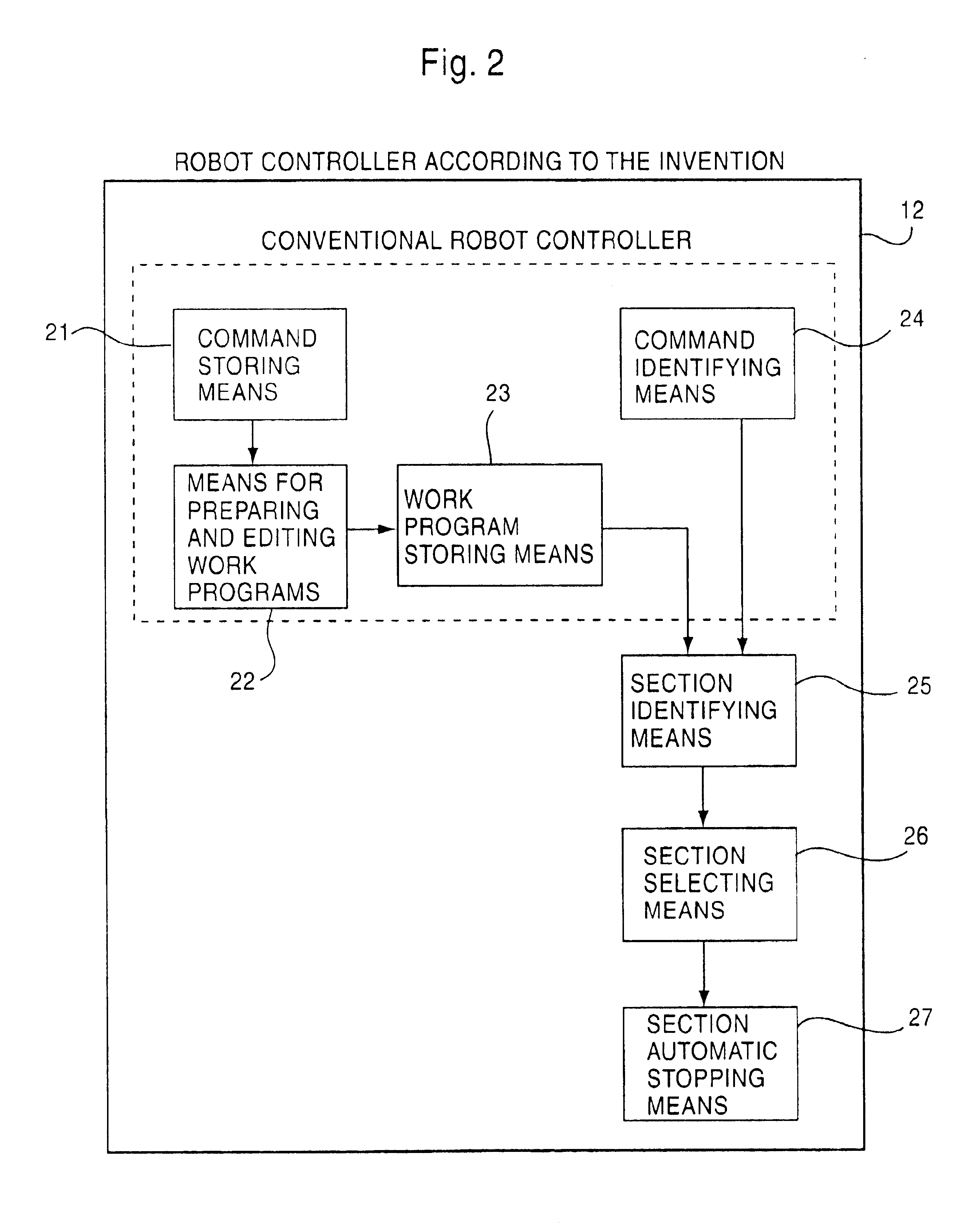

Robot controller

InactiveUS6853878B2Improve efficiencyShorten the timeProgramme-controlled manipulatorComputer controlProgram planningWork planning

A robot controller for teaching a robot with high efficiency. The robot controller including command storage unit (21) where a movement command and a work command are stored, command identifying unit (24) for discriminating between the movement and work commands, unit (22) for making / editing a series of work programs or discrete work programs by a combination of the commands, work program storage units (23) where the work programs are stored so as to control the robot according to the stored program, further including a work section identifying unit (25) for identifying a work section of the work program by way of the command identification unit (24) and work section automatic stopping unit (27) for automatically stopping or suspending the execution of the work program at the work section in a standby state when the work section identifying unit (25) identifies the work section during the execution of the work program.

Owner:YASKAWA DENKI KK

Spinal ligament modification devices

InactiveUS20060036271A1Prevent leakageUse minimizedSuture equipmentsSurgical needlesSpinal ligamentsSpinal column

A method for treating stenosis in a spine comprises percutaneously accessing the epidural space in a stenotic region of interest, compressing the thecal sac in the region of interest to form a safety zonem, inserting a tissue removal tool into tissue in the working zone, using the tool to percutaneously reduce the stenosis; and utilizing imaging to visualize the position of the tool during at least a part of the reduction step. A tissue excision system for performing percutaneous surgery, comprises a cannula comprising a tissue-penetrating member having a distal end defining an aperture on one side thereof, an occluding member slidably received on or in the cannula and closing the aperture when the occluding member is adjacent the cannula distal end, means for engaging adjacent tissue via the aperture, and cutting means for resecting a section of the engaged tissue.

Owner:VERTOS MEDICAL

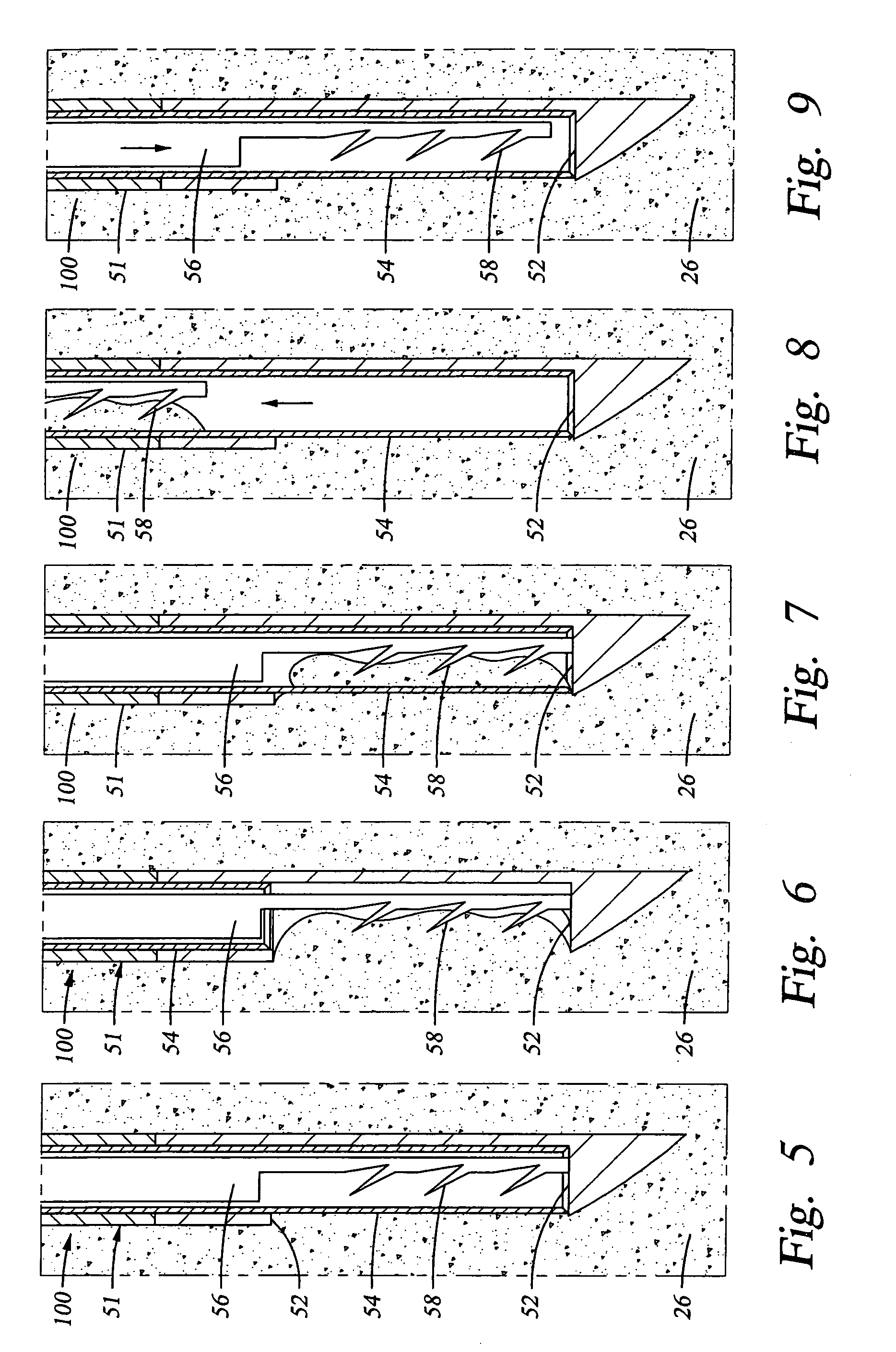

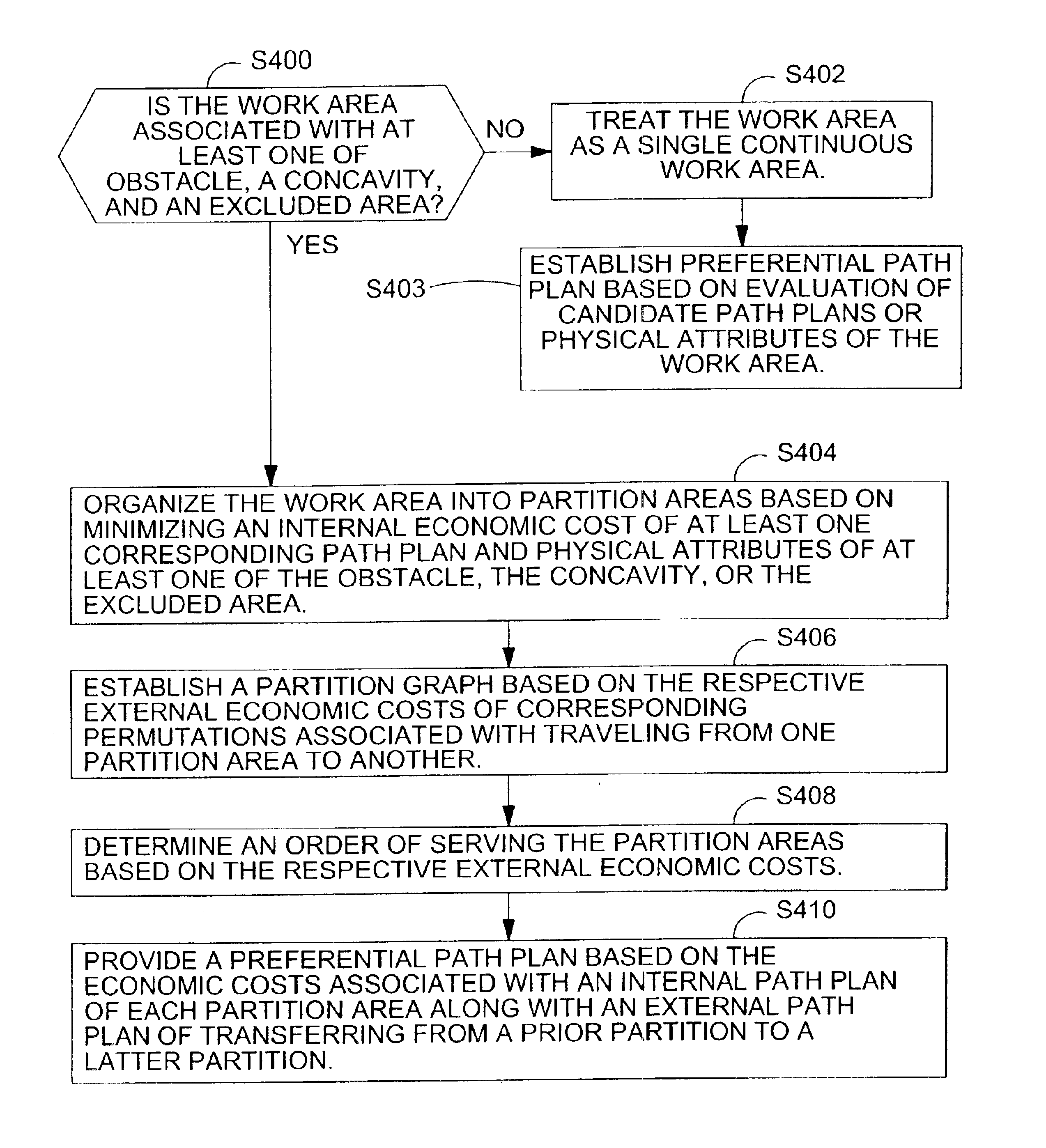

Method and system for determining an efficient vehicle path

ActiveUS6934615B2Instruments for road network navigationAnalogue computers for trafficPath planCost (economic)

A system and method for determining a path plan for a vehicle includes organizing a work area into partition areas based on at least one of an obstacle, a concavity, and an exclusion area associated with a work area. An external cost indicator is established for indicating the economic cost corresponding to the vehicle traversing from one partition area to another partition area for each possible permutation or potential combination of successive partition areas. The established external cost indicators are searched to determine a preferential order of traversing the partition areas. A preferential path plan is determined based on the internal path plan of each partition and a transfer path plan of transferring from a prior partition to a latter partition until each partition in the work area is traversed.

Owner:DEERE & CO

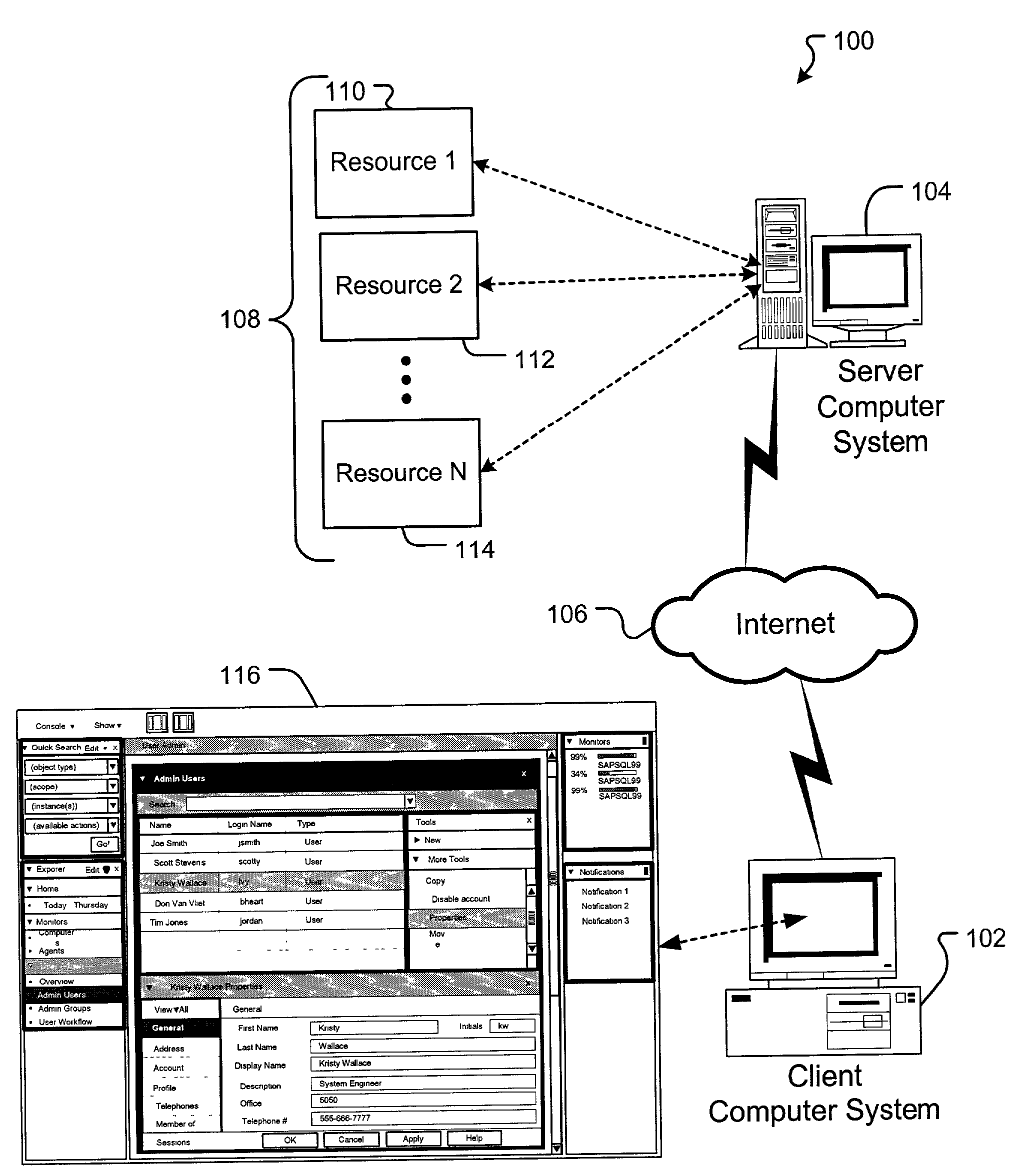

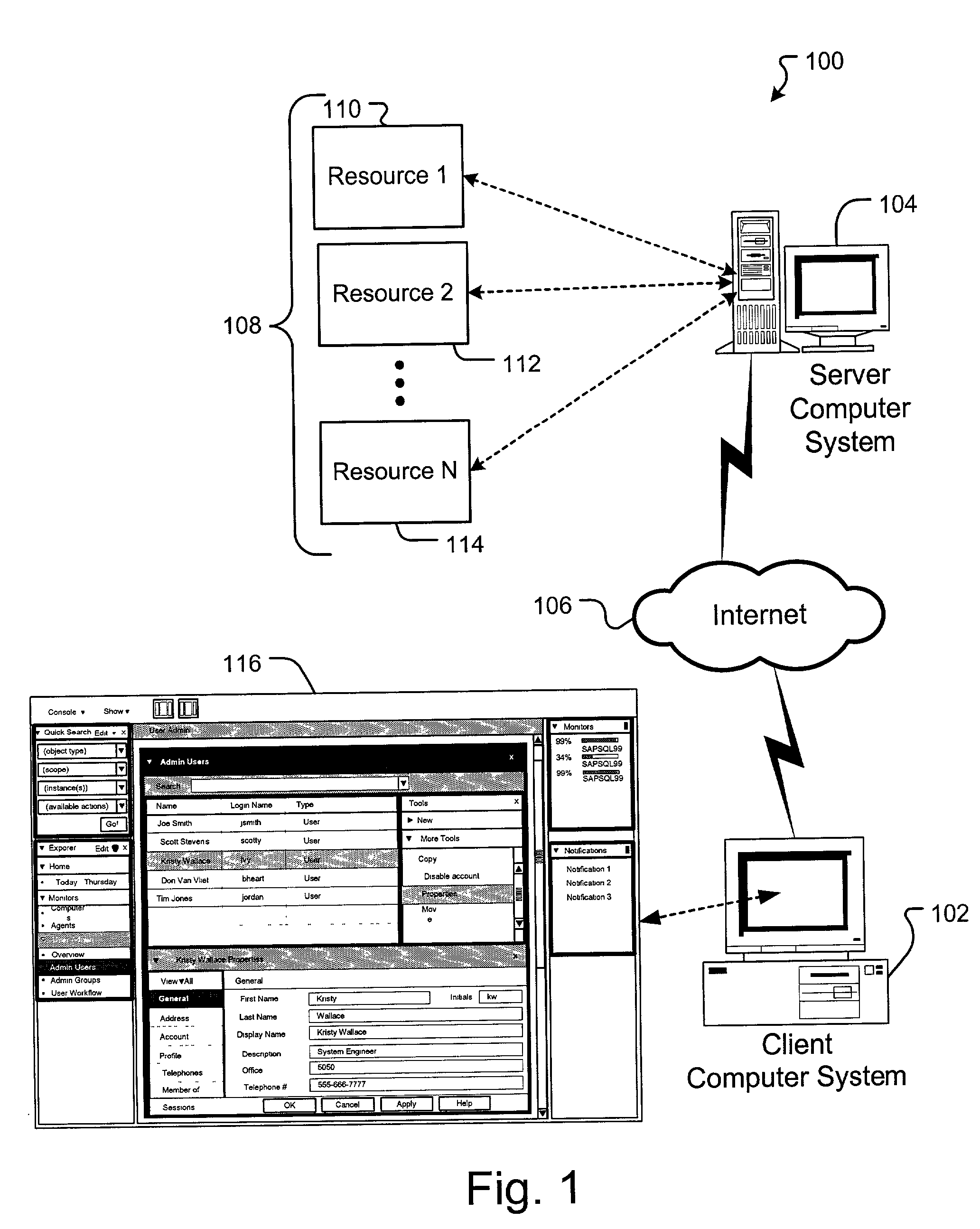

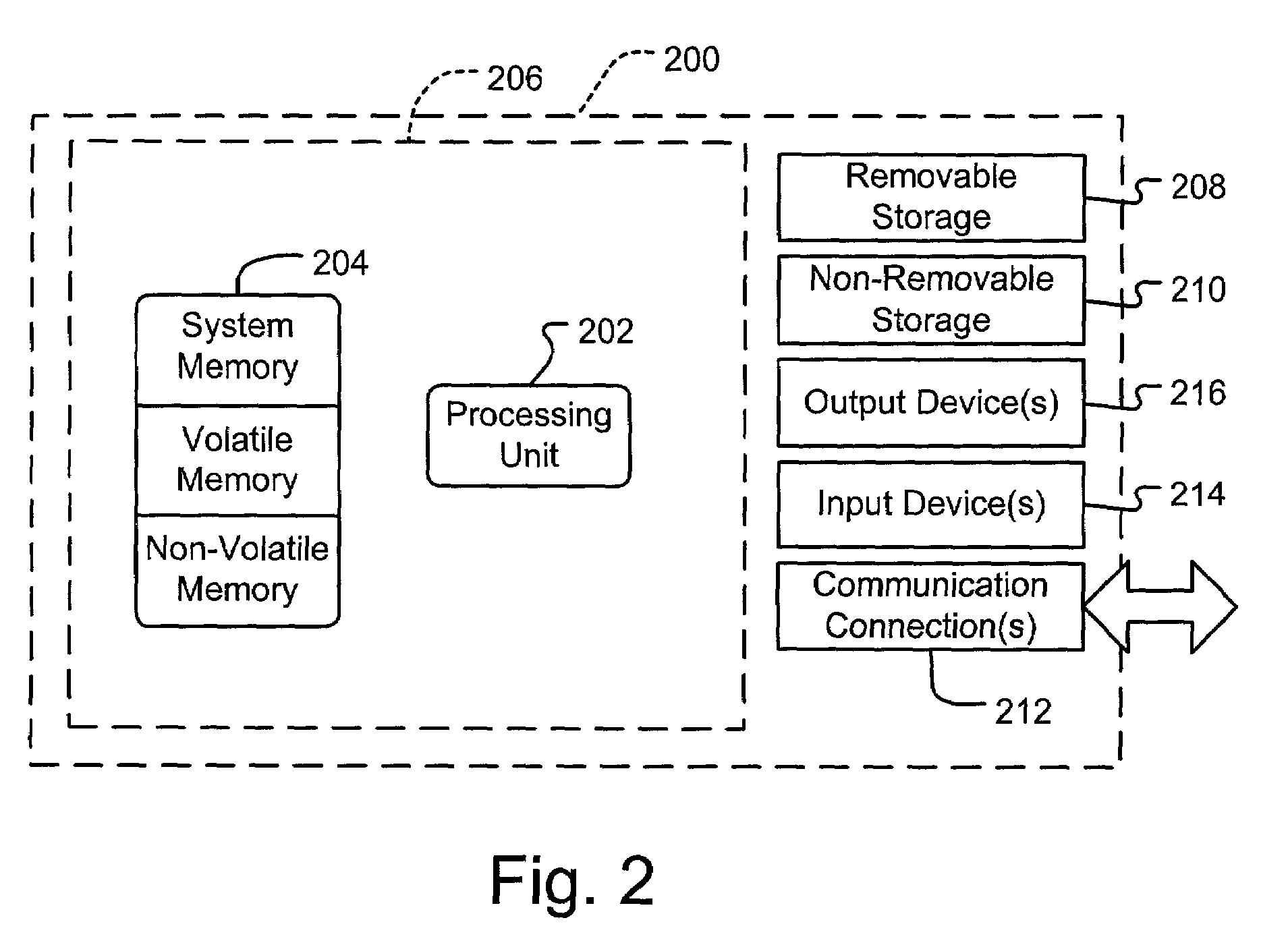

User interface for managing multiple network resources

InactiveUS6996778B2Reduce overheadEasy and higher-level operation optionData processing applicationsResource allocationGraphicsGraphical user interface

A method and system for displaying information related to a plurality of resources in a network environment. The system uses web technology to receive and store information related to back-end resources and to provide a framework by which client computer systems can manage the plurality of back-end resources in a uniform manner. In accordance with one method, a request is received to display object information from different network resources. In response, attribute and task information is retrieved from the appropriate different network resources and this information is displayed. A graphical user interface (GUI) displays information related to network resource objects. The GUI includes a console displaying a tool zone and a work zone. A module is displayed in the work zone having an object zone displaying a list of objects and a task zone displaying a list of tasks.

Owner:SERVICENOW INC

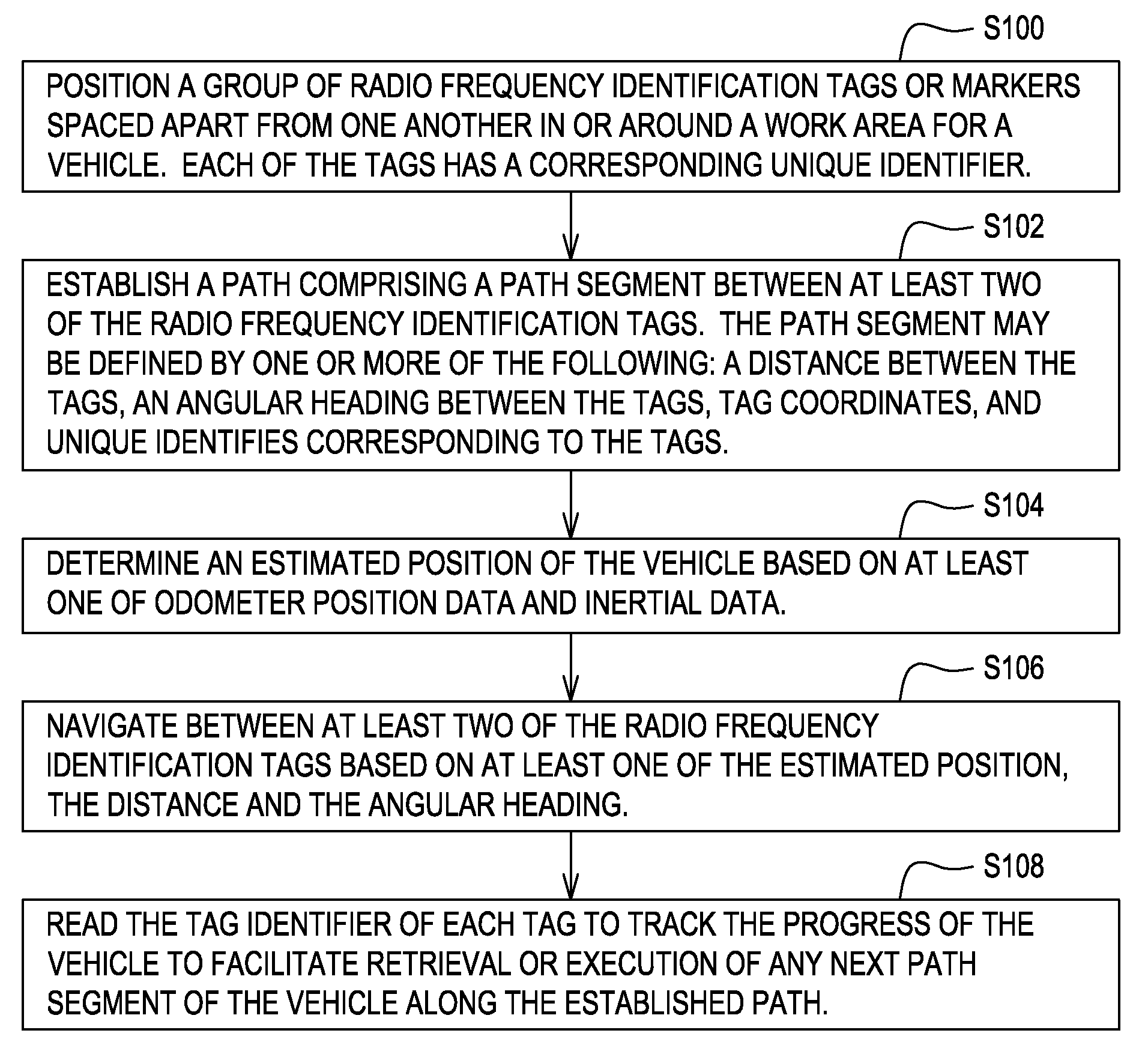

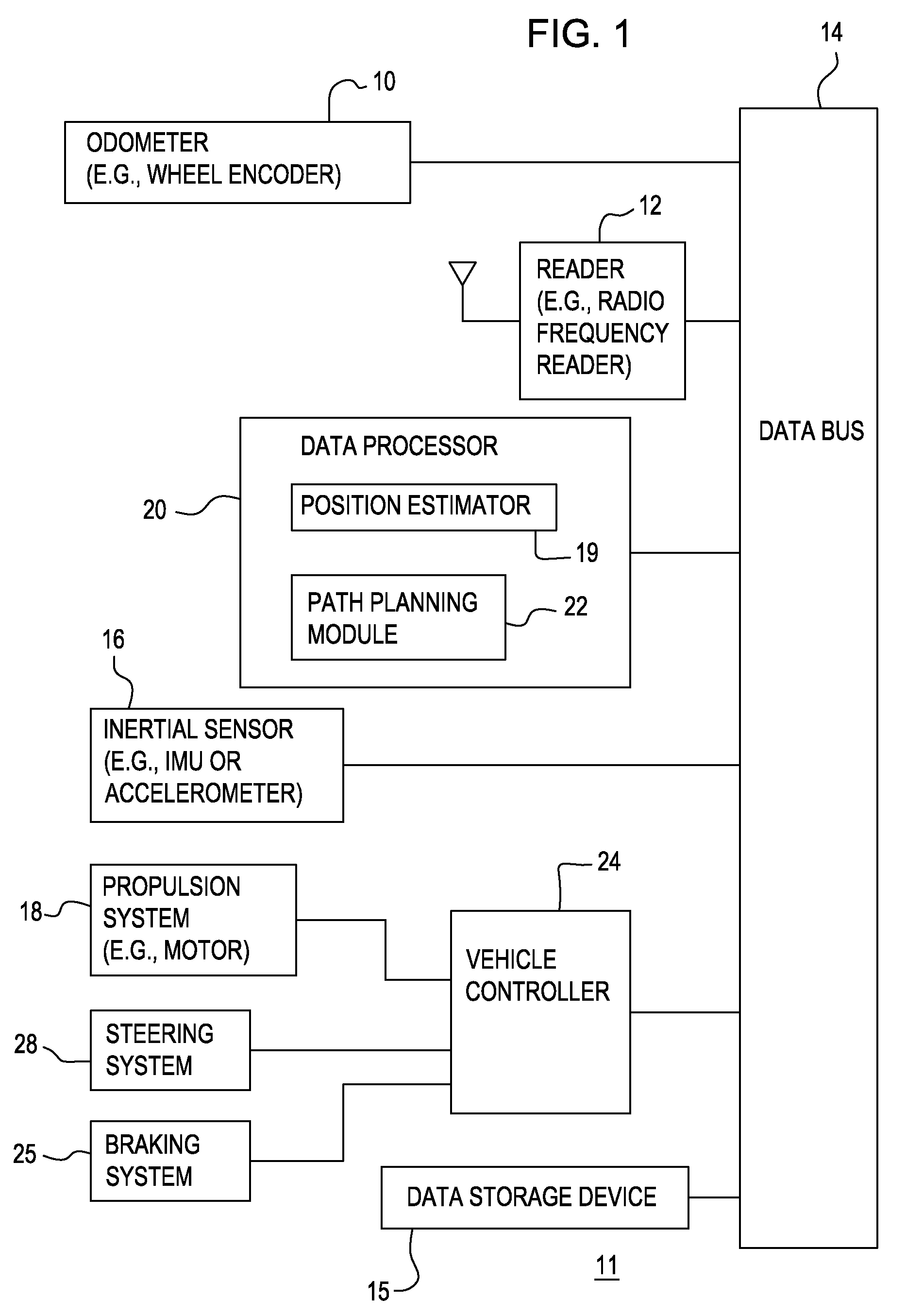

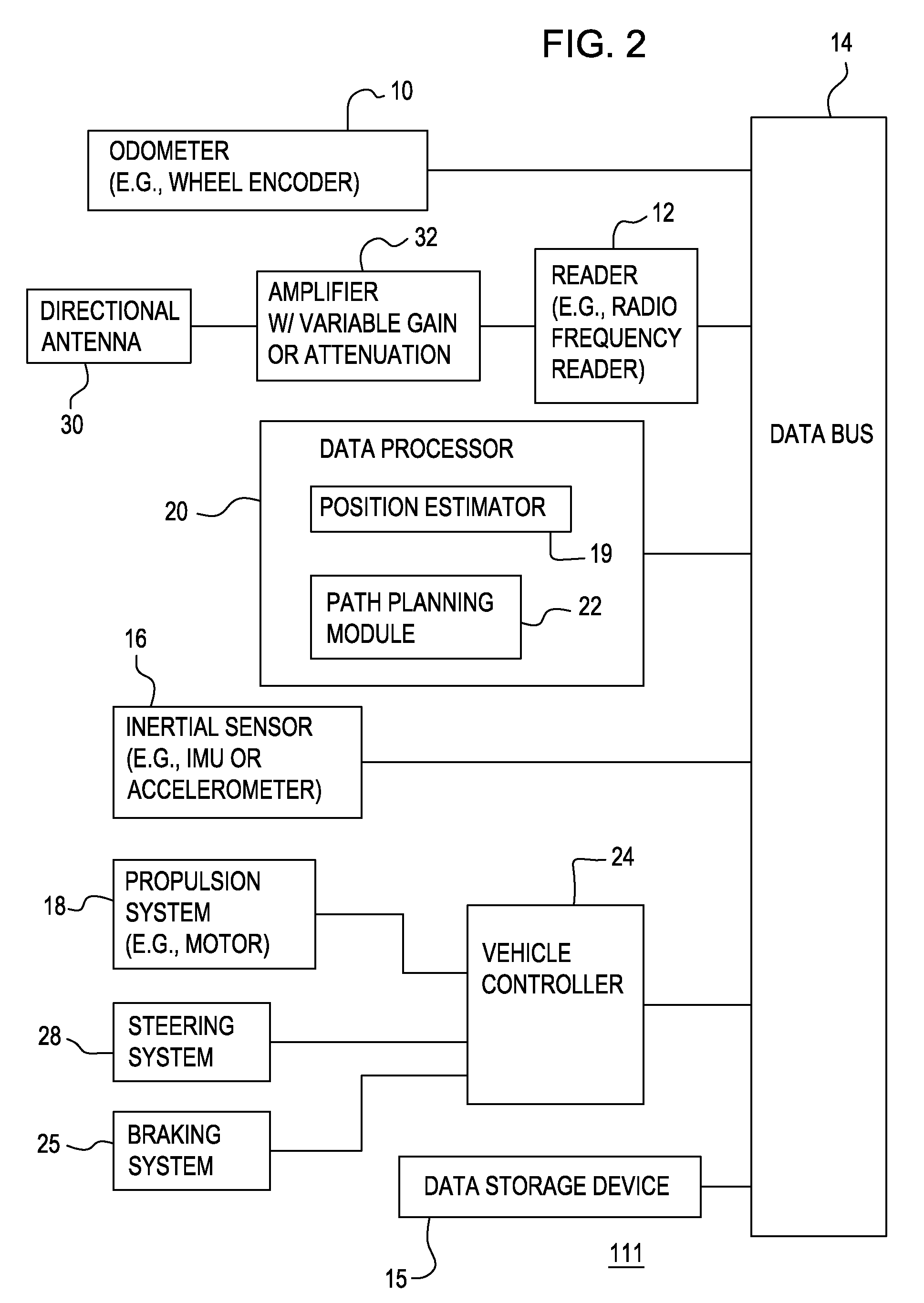

Method and system for determining a position of a vehicle

ActiveUS20100141483A1Road vehicles traffic controlSubscribers indirect connectionAccelerometer dataUnique identifier

Radio frequency identification tags are spaced apart from one another in or around a work area for the vehicle. Each of the tags has a corresponding unique identifier. A path planning module establishes a path comprising a path segment between at least two of the radio frequency identification tags. The path segment comprises at least one of a distance between the tags, an angular heading between the tags, and unique identifiers corresponding to the tags. A data processor determines an estimated position of the vehicle based on at least one of odometer data and accelerometer data. A vehicle controller navigates between at least two of the radio frequency identification tags based on the estimated position, the distance and the angular heading. A reader reads the tag identifiers of each tag to track the progress of the vehicle to facilitate execution of or retrieval of any next path segment of the vehicle along the established path.

Owner:DEERE & CO

Spinal ligament modification devices

InactiveUS20060184175A1Secure bootReduce stenosisSuture equipmentsSurgical needlesSpinal ligamentsSpinal column

A method for treating stenosis in a spine comprises percutaneously accessing the epidural space in a stenotic region of interest, compressing the thecal sac in the region of interest to form a safety zonem, inserting a tissue removal tool into tissue in the working zone, using the tool to percutaneously reduce the stenosis; and utilizing imaging to visualize the position of the tool during at least a part of the reduction step. A tissue excision system for performing percutaneous surgery, comprises a cannula comprising a tissue-penetrating member having a distal end defining an aperture on one side thereof, an occluding member slidably received on or in the cannula and closing the aperture when the occluding member is adjacent the cannula distal end, means for engaging adjacent tissue via the aperture, and cutting means for resecting a section of the engaged tissue.

Owner:VERTOS MEDICAL

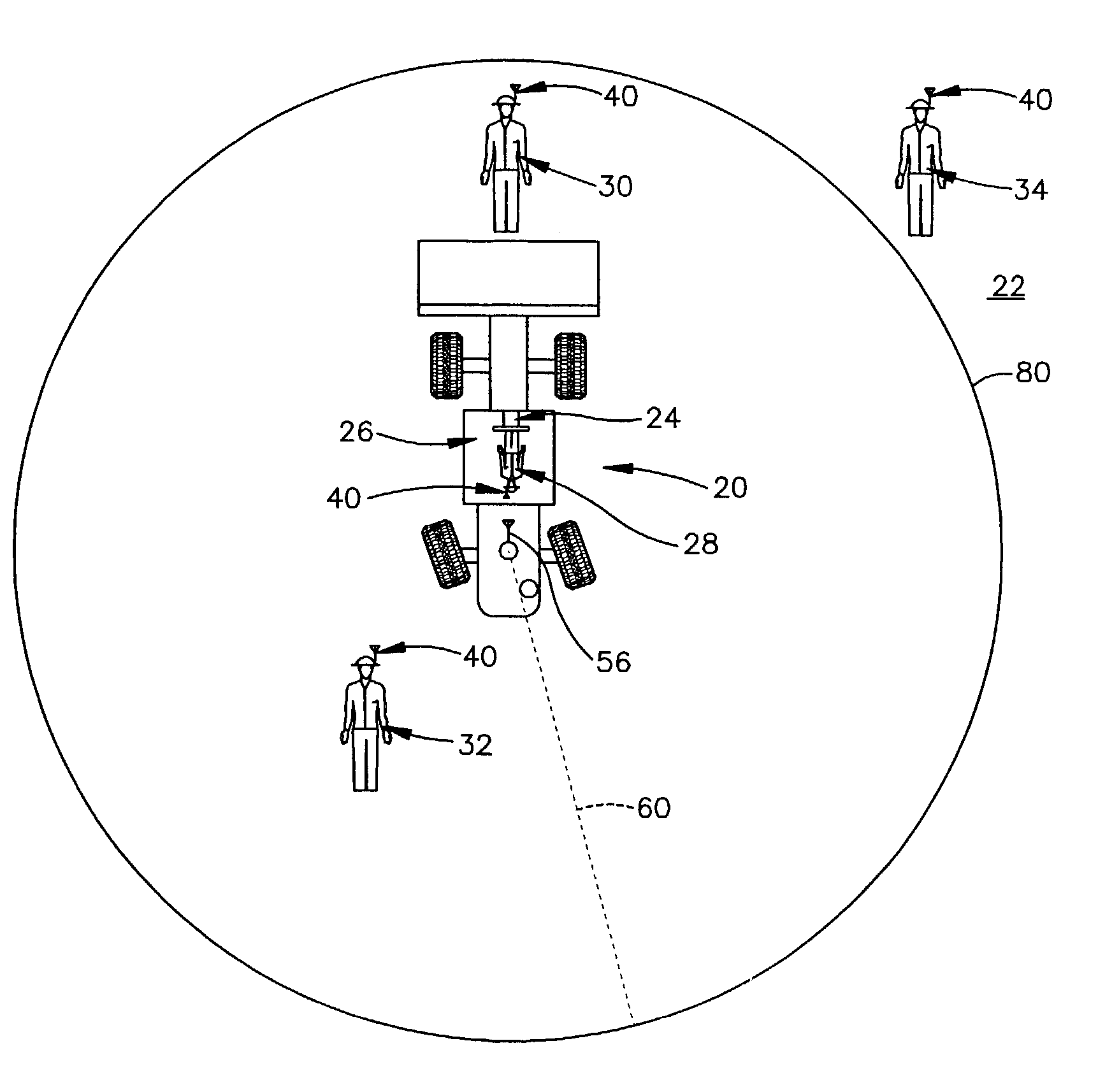

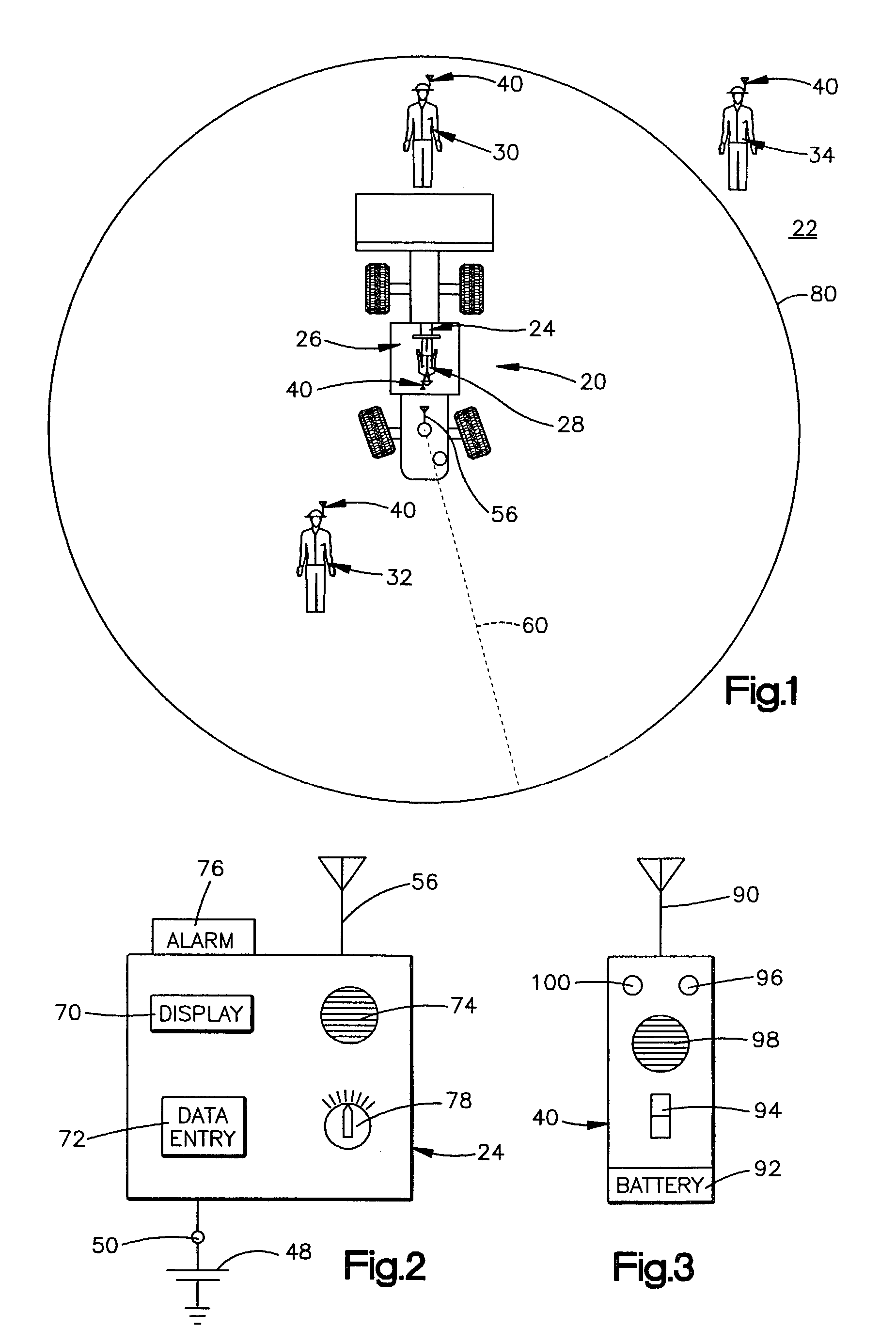

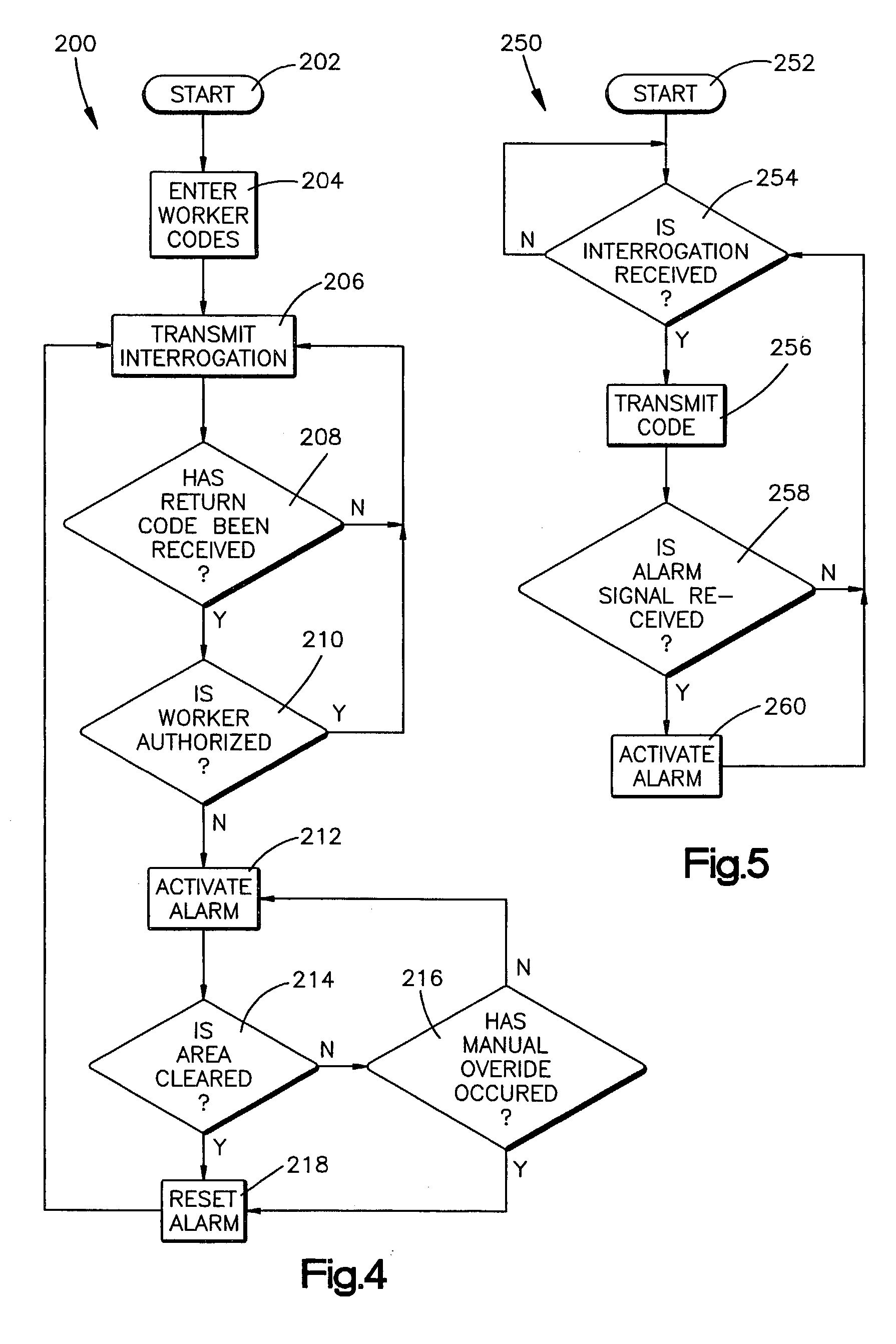

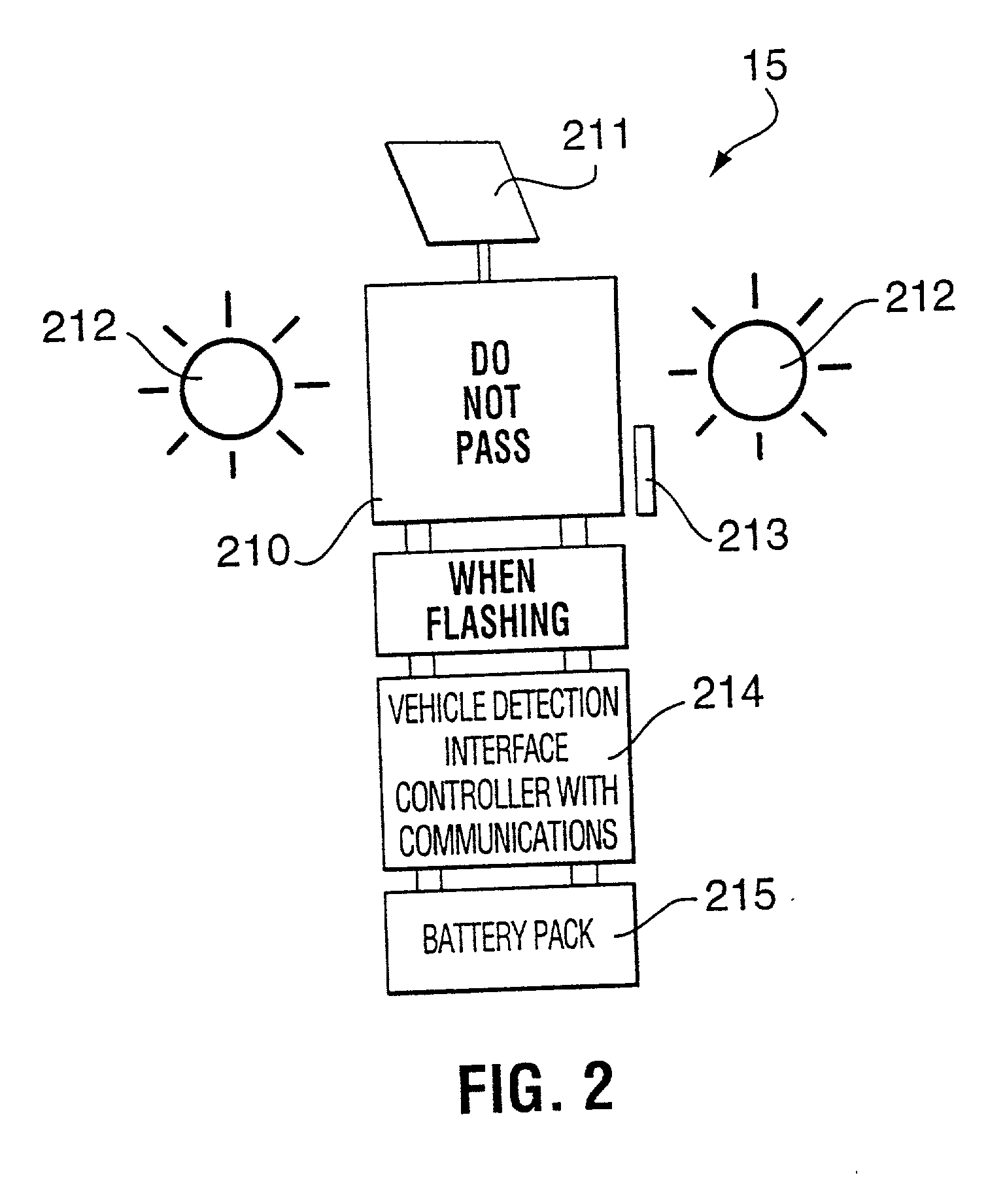

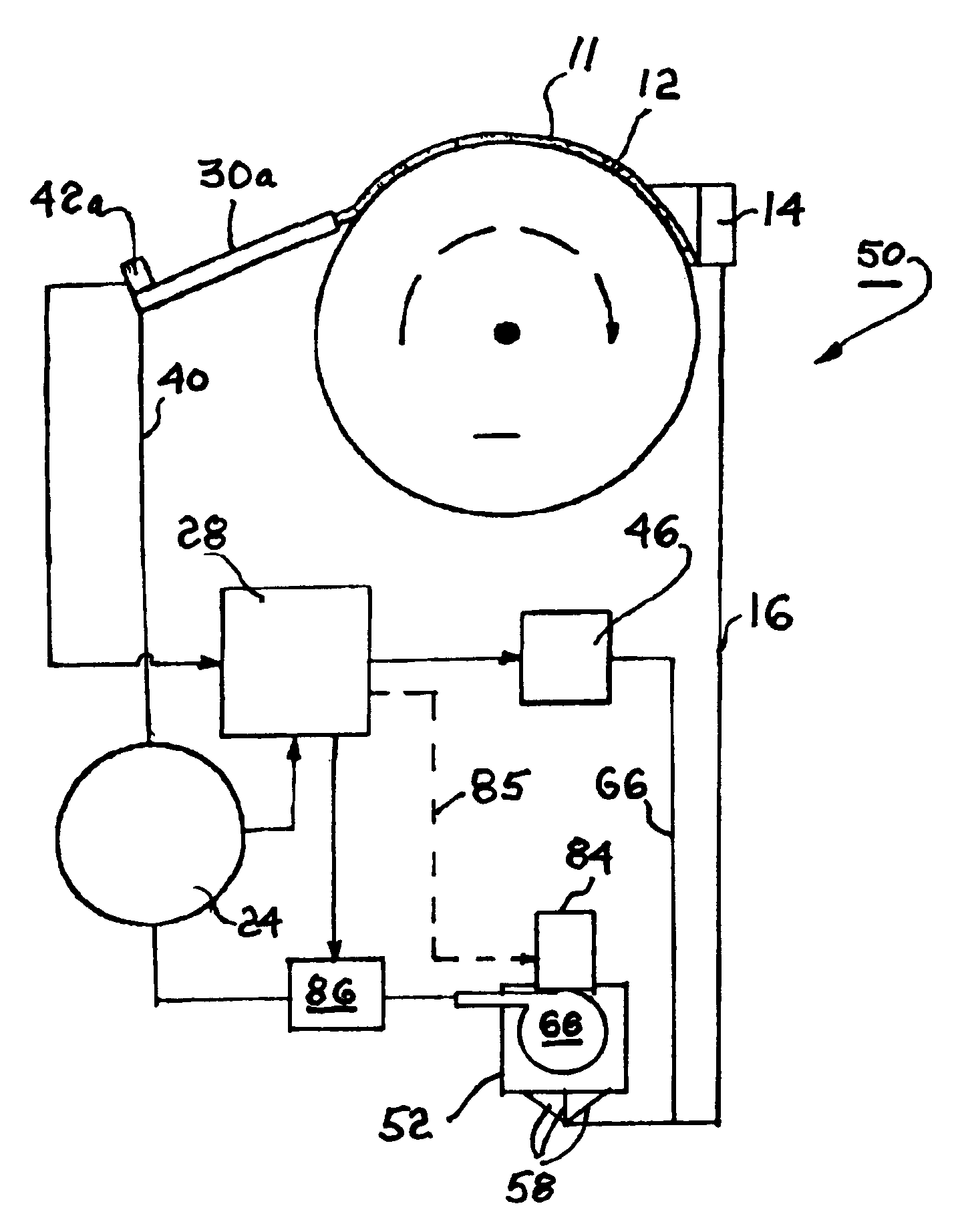

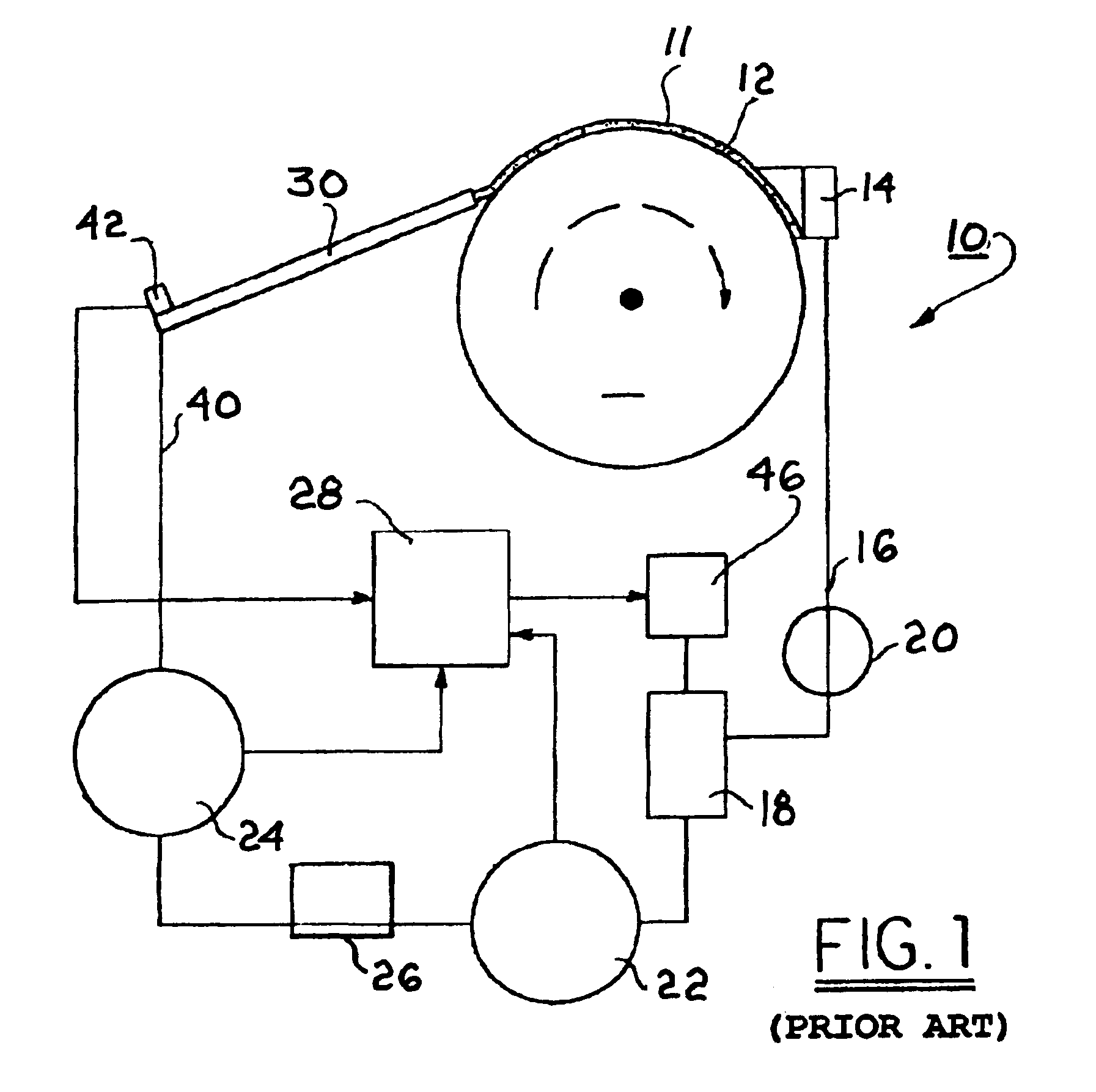

Method and apparatus for enhancing safety within a work zone

ActiveUS6963278B2Improve securityEngineering safety devicesElectric/electromagnetic visible signallingWork zoneIndustrial engineering

Owner:FRAME GARY M

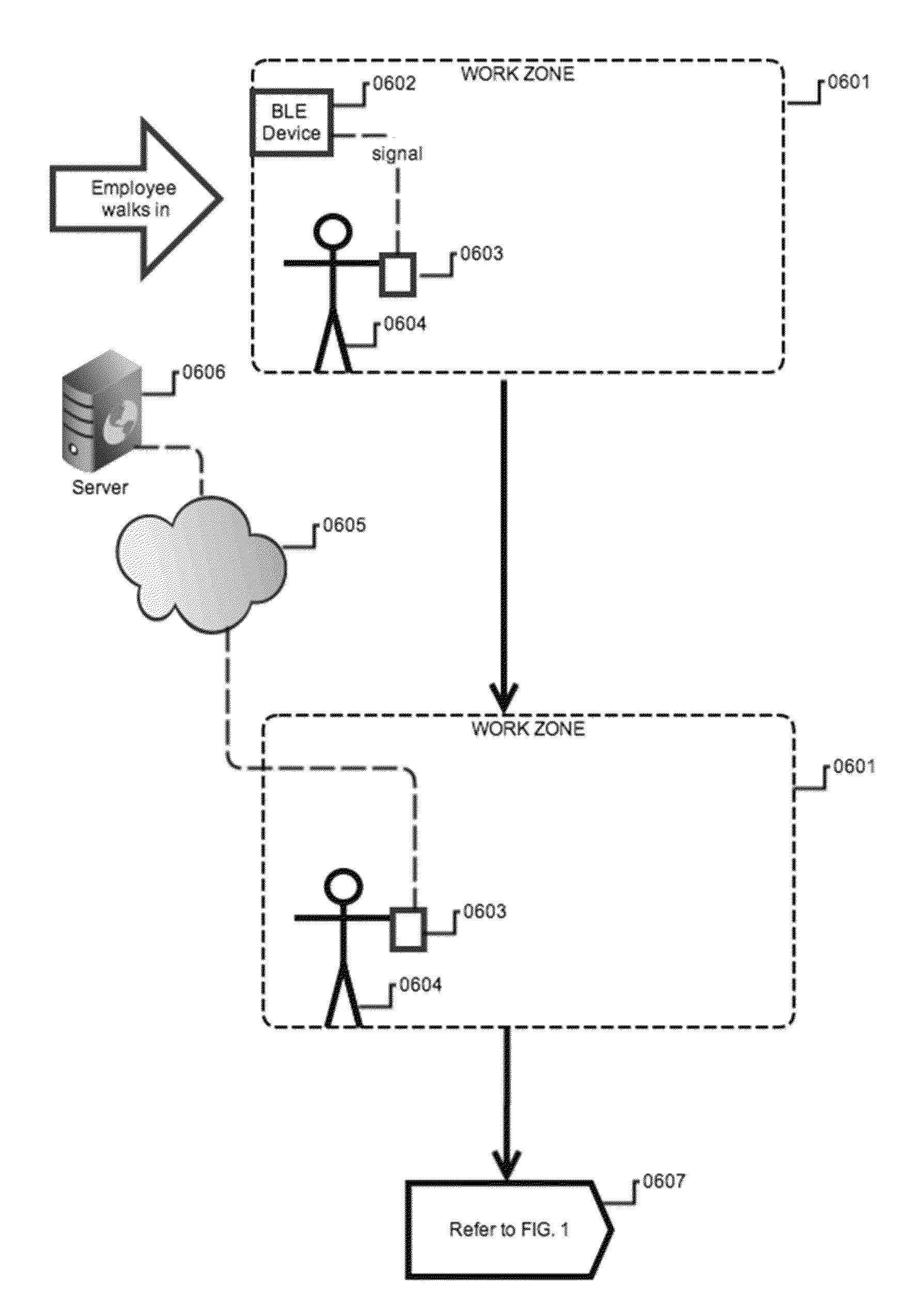

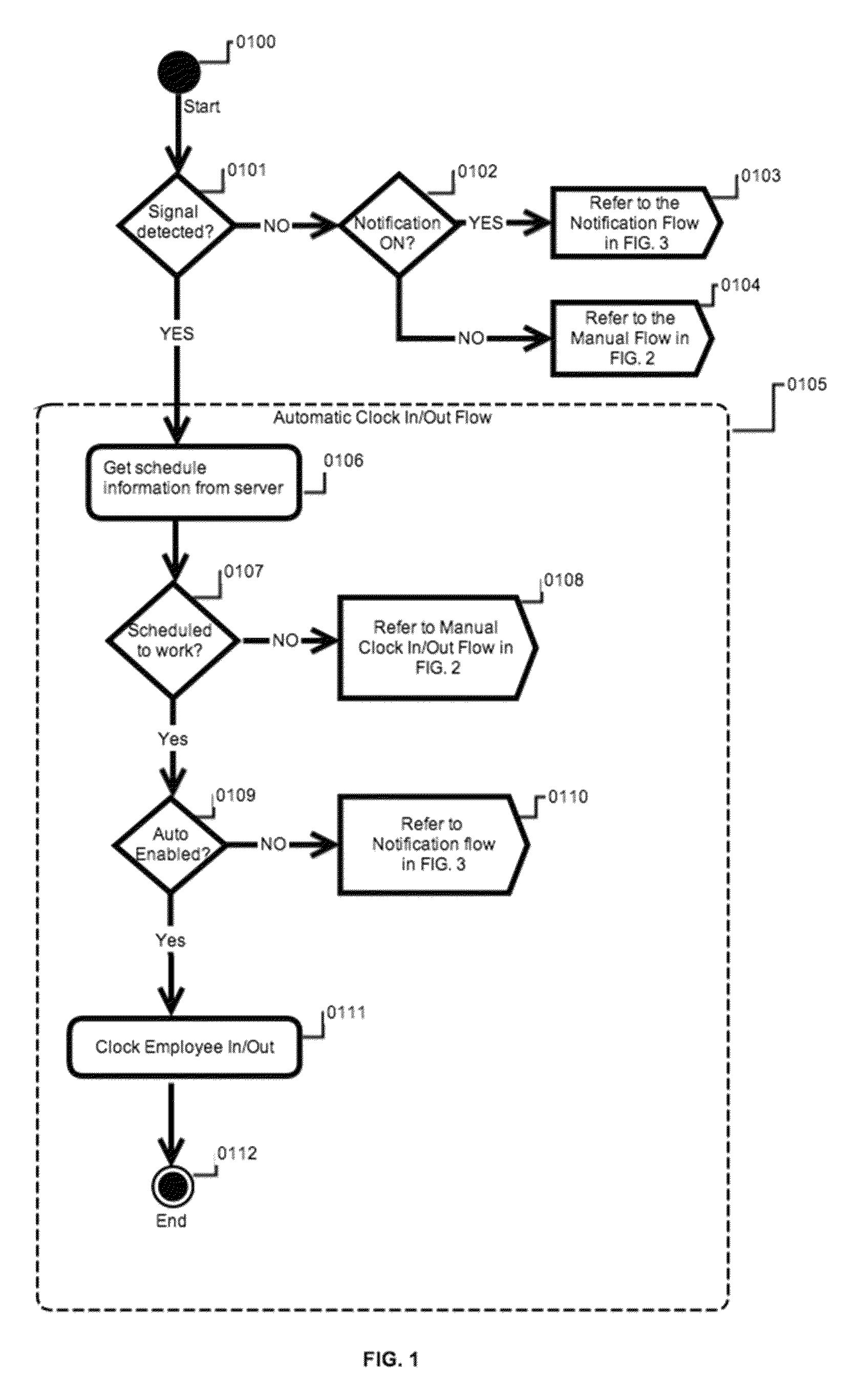

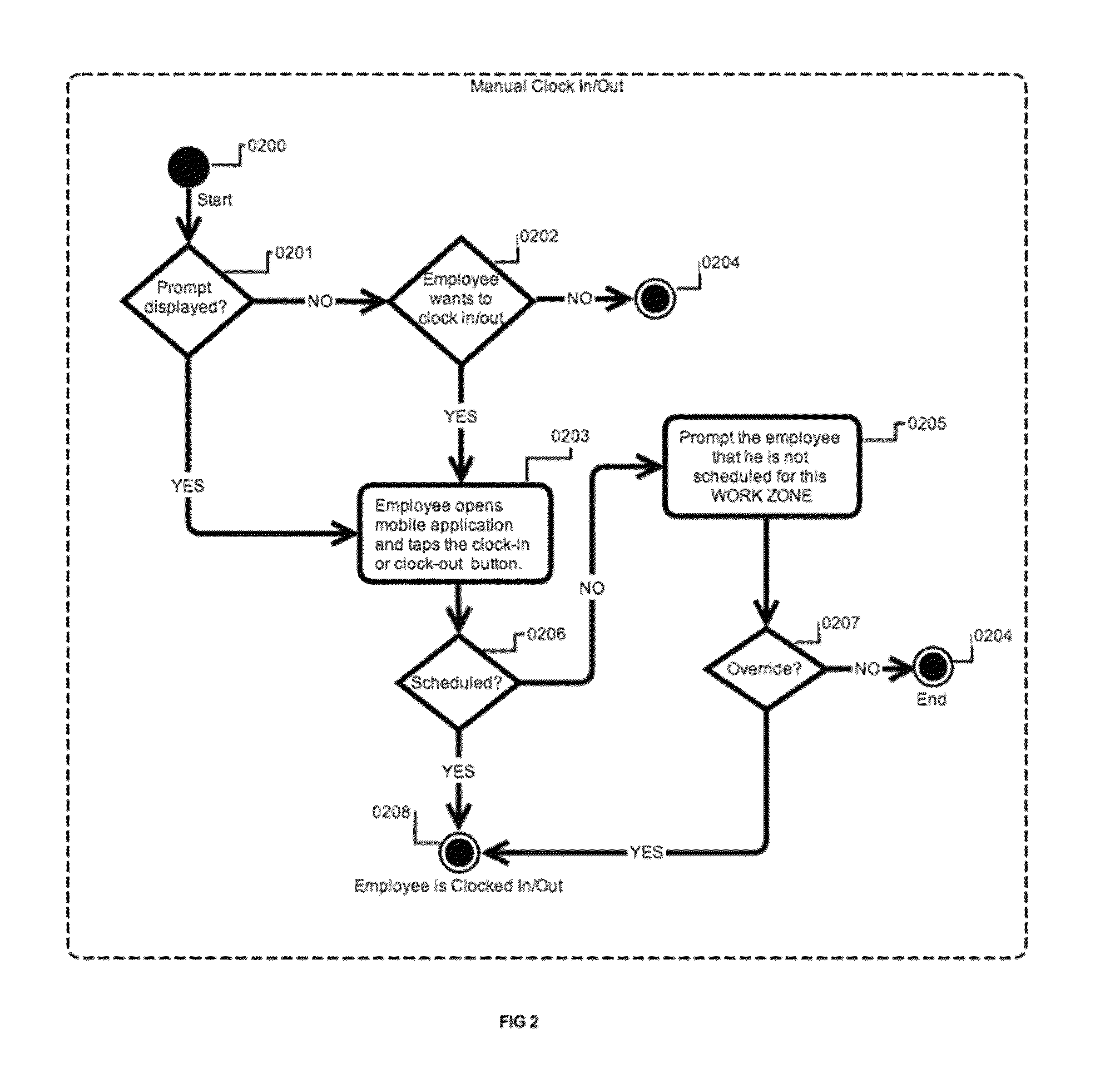

Method and system for time and location tracking

ActiveUS9020848B1High positioning accuracyImprove accuracyRegistering/indicating time of eventsFinanceLocation detectionLocation tracking

A method for tracking time and location of an employee based on a predefined schedule. This method may uses time tracking software installed on a mobile device to detect the presence (or lack of presence) of an electronic signal emitted by a NFC (near field communication), BLE (Bluetooth Low Energy), or other wireless device. The detection may trigger the mobile application to communicate to a server to determine if the employee is scheduled to work at a work zone, which may result in the mobile application clocking in / out the employee. Also, geofencing may be used in combination with scheduling to clock in / out employees when entering a geofenced area determined by the employer. These location detection embodiments of the present invention may be used individually or in combination to improve location accuracy. A supervisor may also use this system to review the timesheets, make changes and integrate the data into a Payroll system.

Owner:EZNOVA TECH

Ipsilateral Approach to Minimally Invasive Ligament Decompression Procedure

A method for treating stenosis in a spine of a patient having a median plane, wherein the spine includes a spinal canal having a posterior surface, a dural sac and an epidural space between the posterior surface and dural sac, the location of the stenosis determining a region of interest in the spine. In an embodiment the method comprises the steps of a) generating at least one view of a portion of the spinal canal in the region of interest; b) compressing the dural sac in the region of interest by injecting a fluid to form a safety zone and establish a working zone in the region of interest, the safety zone lying between the working zone and the dural sac; c) percutaneously accessing the epidural space in the region of interest on a first side of the median plane; d) inserting a tissue removal tool into tissue in the working zone on the first side of the median plane; e) using the tissue removal tool to percutaneously reduce the stenosis on the first side of the median plane; and f utilizing the at least one view to position the tissue removal too during at least a part of step d) and at least part of step e)

Owner:VERTOS MEDICAL

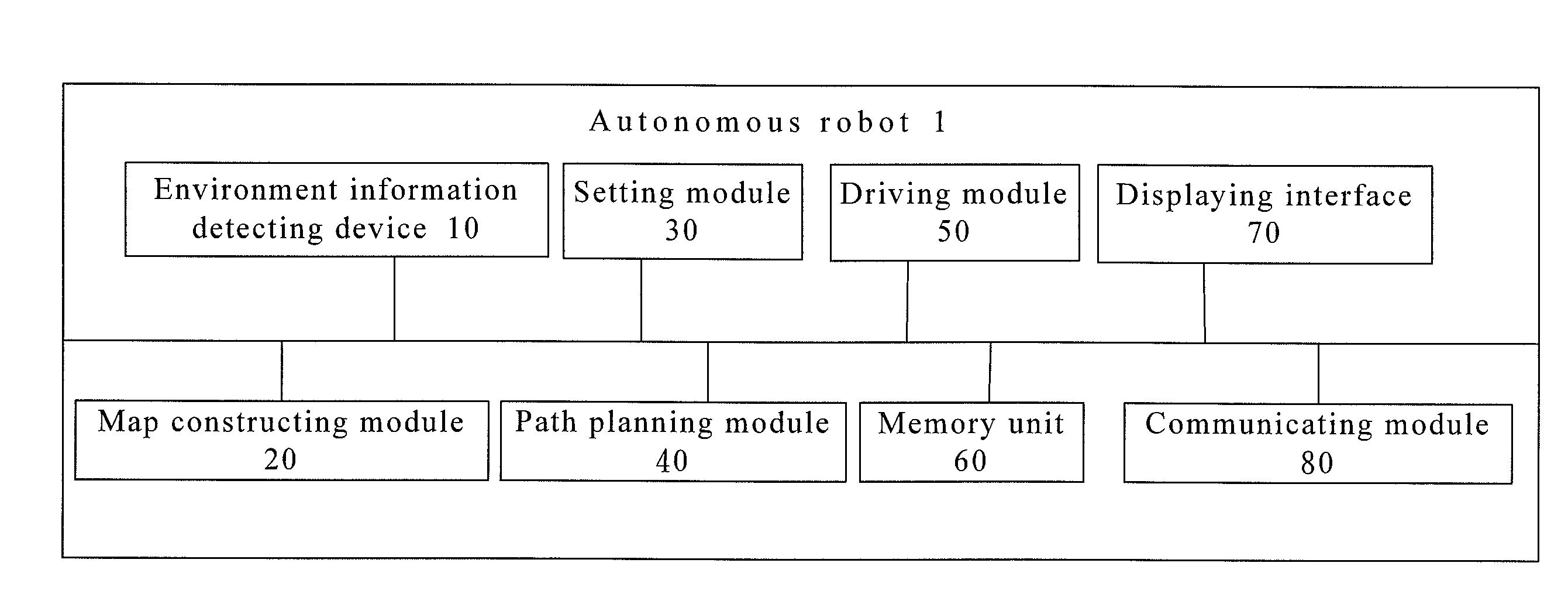

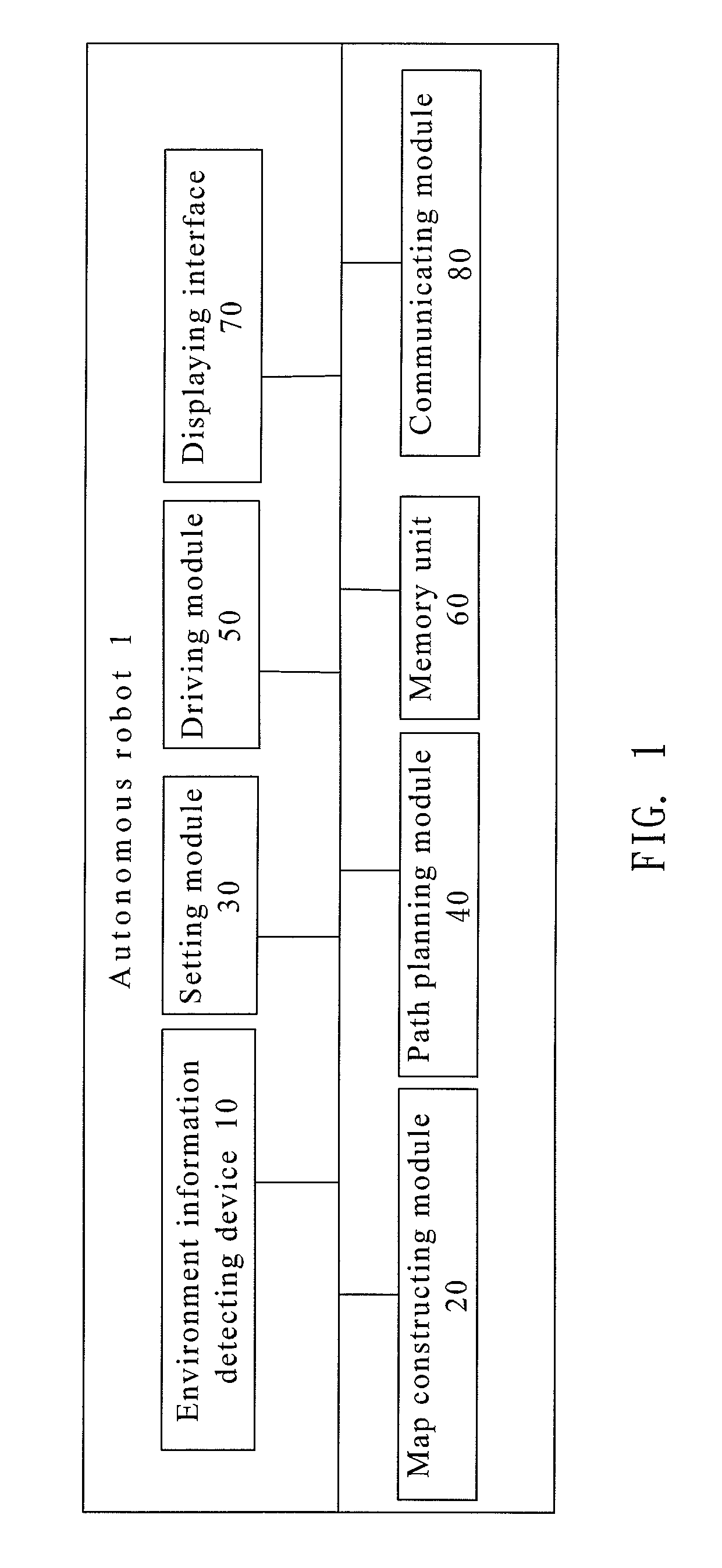

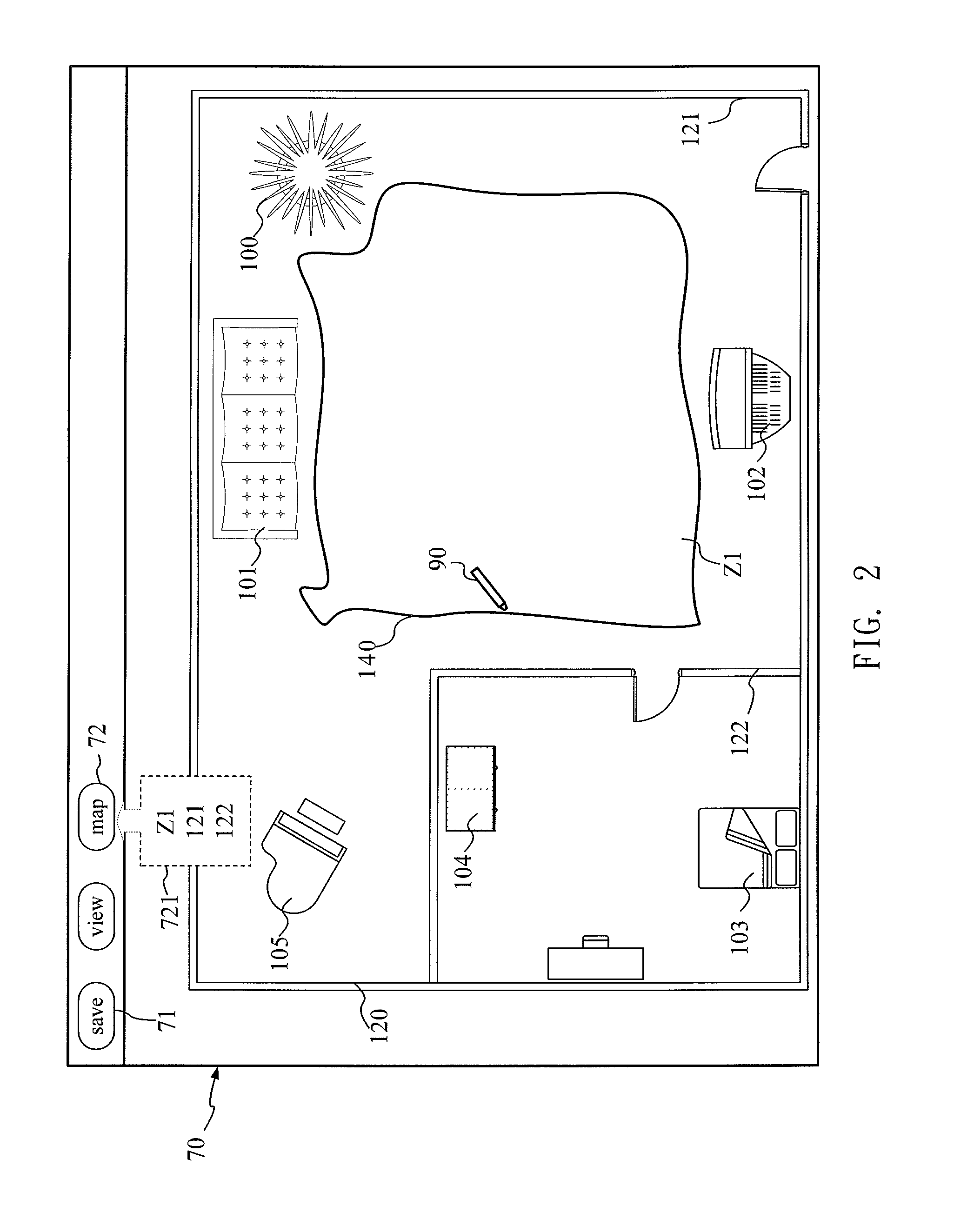

Autonomous Robot and A Positioning Method Thereof

InactiveUS20130024025A1Programme controlProgramme-controlled manipulatorElectricityArtificial intelligence

An autonomous robot and a positioning method thereof are disclosed. The autonomous robot includes an environment information detection device, a map construction module, a setting module, a path planning module, and a driving module. The environment information detection device is for detecting environment information about an environment where the autonomous robot is situated. An environment map is constructed based on the environment information detected by the environment information detection device. The setting module is used for setting a working boundary on the environment map. The path planning module is for planning a moving path in a working zone and is electrically connected to the setting module. The driving module for driving the autonomous robot to move along the moving path is electrically connected to the path planning module.

Owner:EMEME ROBOT

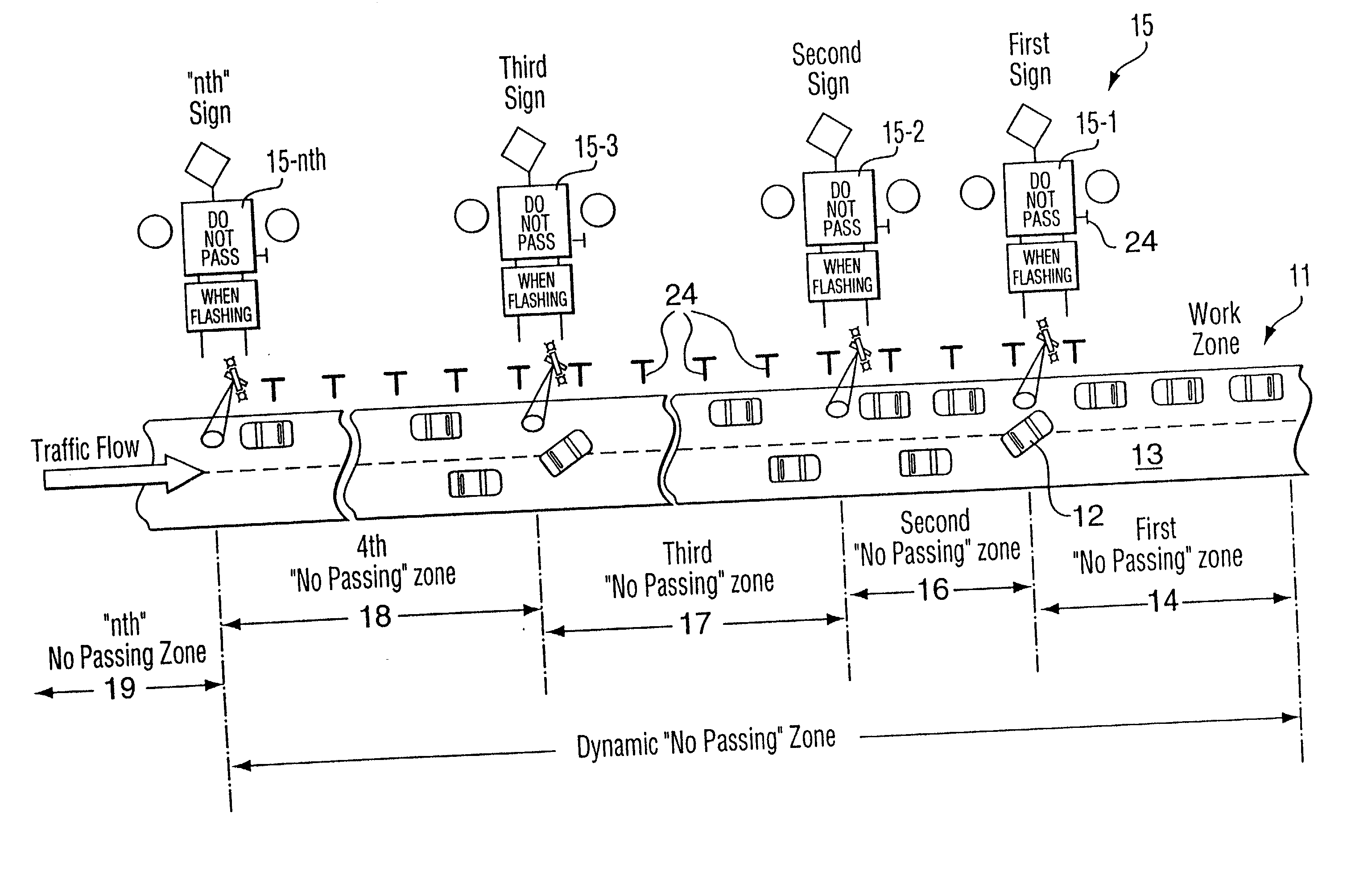

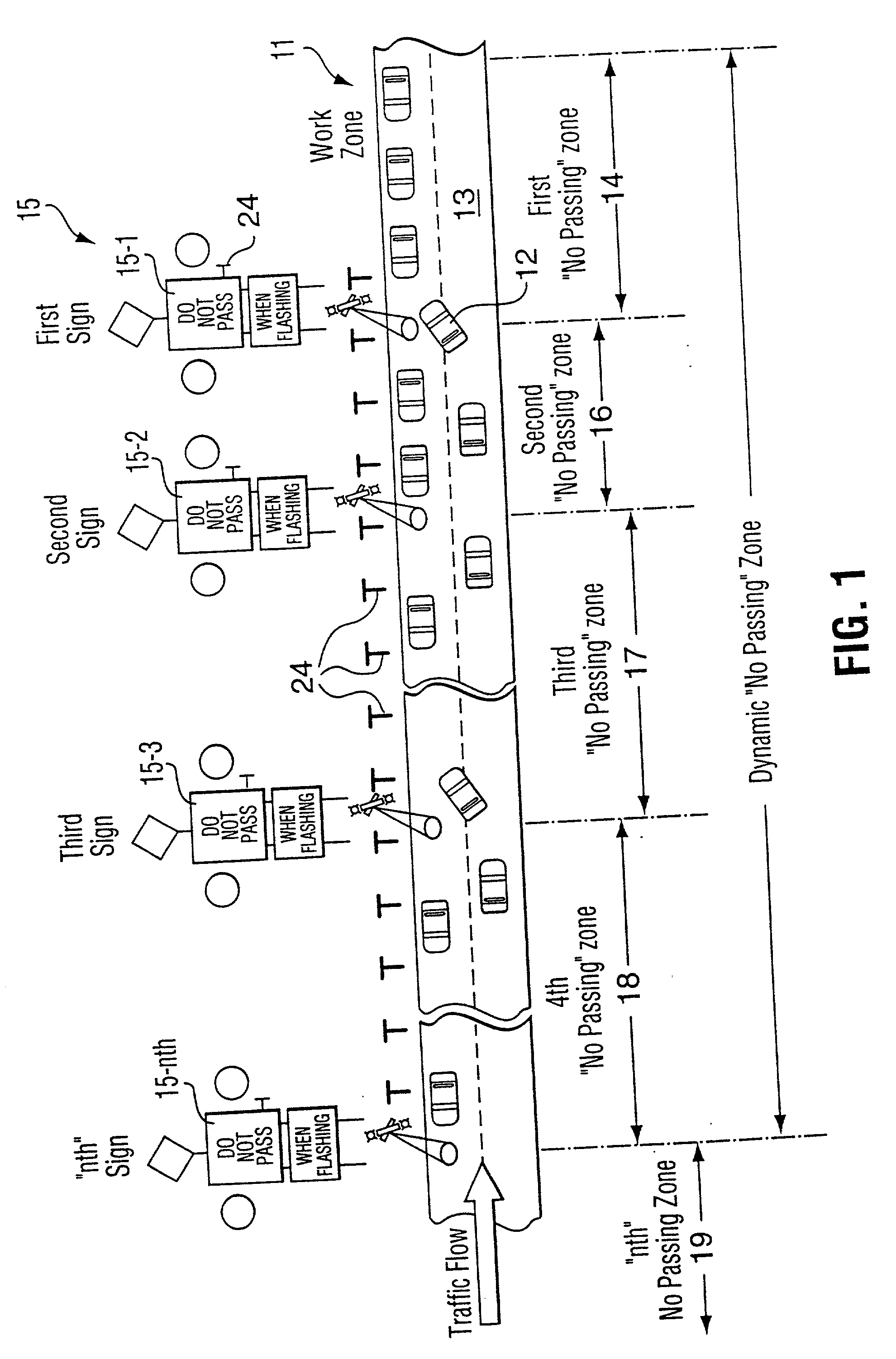

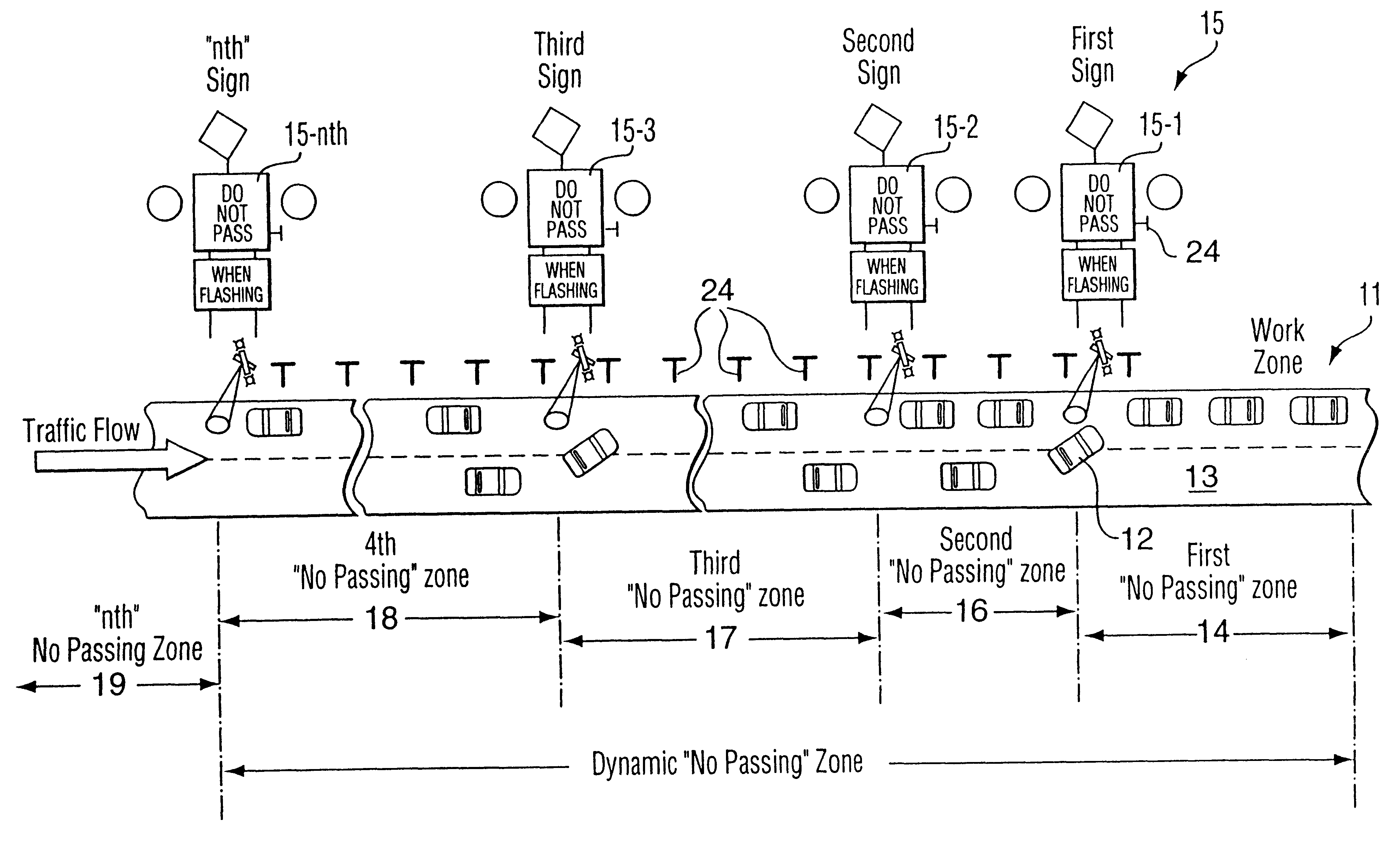

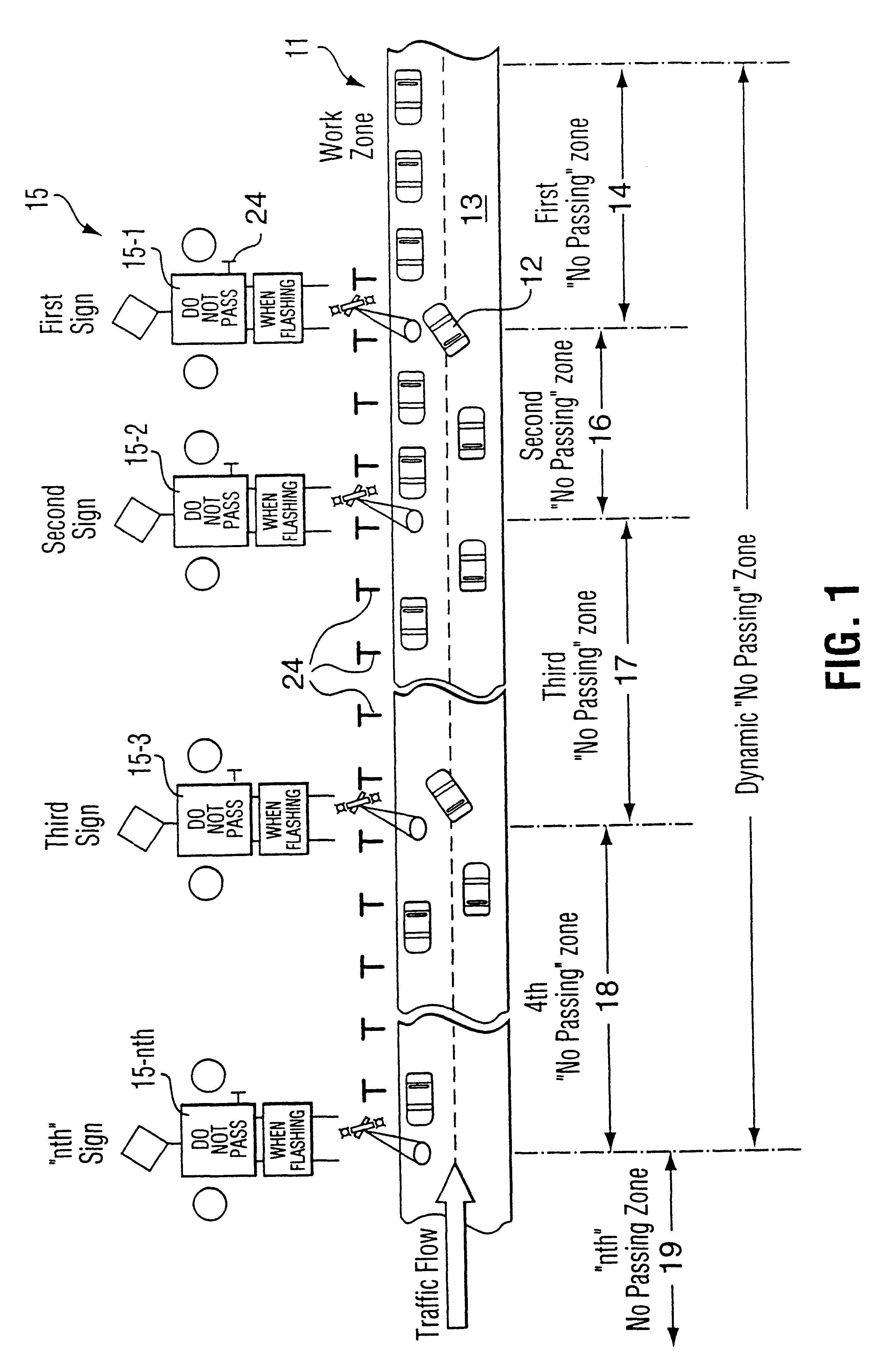

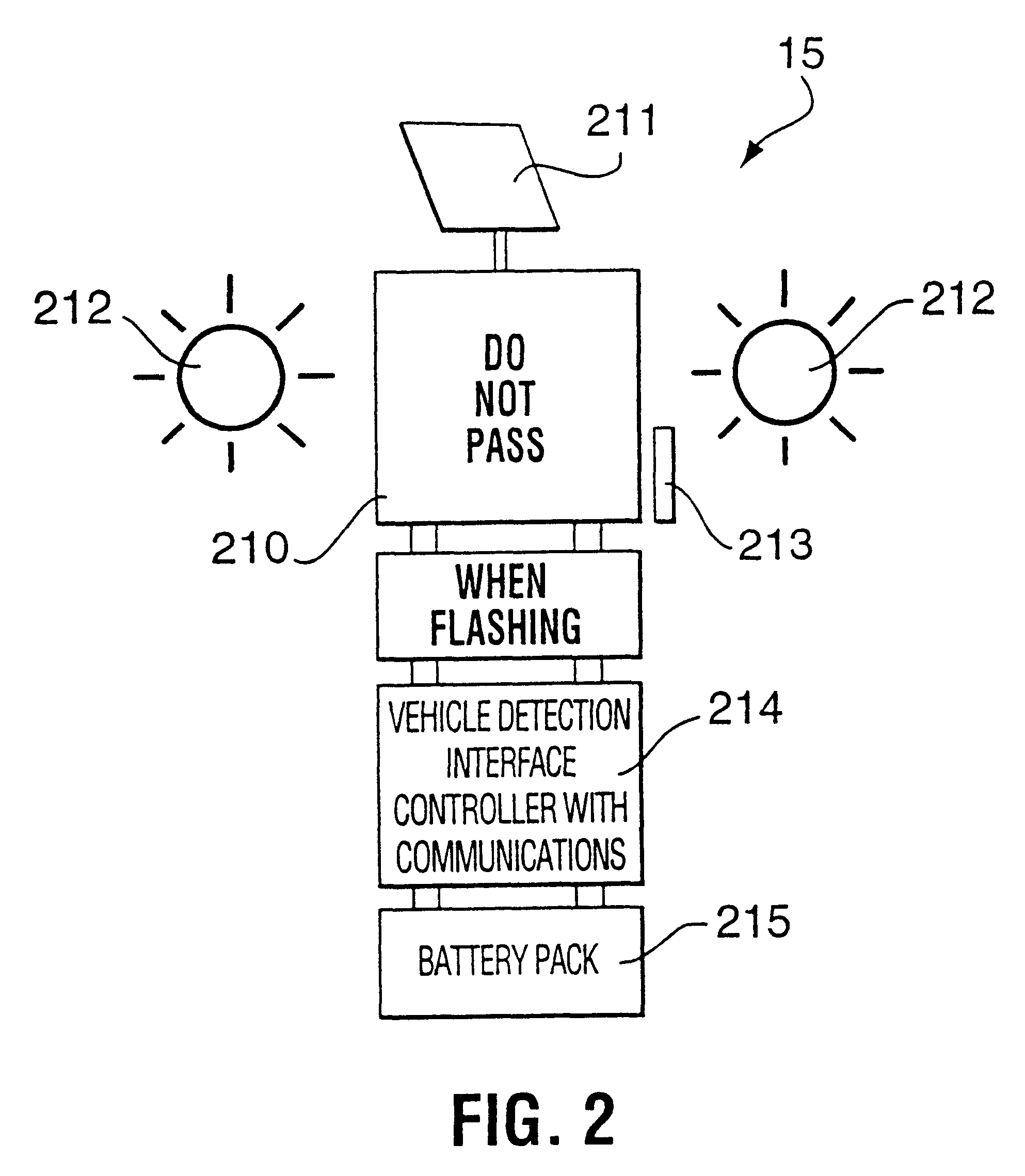

Dynamic work zone safety system and method

InactiveUS20020175831A1Avoid dangerPortable emergency signal deviceDetection of traffic movementTraffic signalEngineering

A novel dynamic work zone safety system and method of traffic control for a construction work zone are provided herein. The system includes at least two traffic signalling device which are positioned along a roadside immediately upstream of a point where traffic is diverted to a single lane. The traffic signalling devices selectively flash a suitable warning, e.g., "DO NOT PASS" or "MERGE LEFT" or "MERGE RIGHT", thereby to provide at least two "NO PASSING" or "MERGE LEFT" or "MERGE RIGHT" zones which is defined by the distance between the traffic signalling devices and the end of the work or construction zone. The "NO PASSING" or "MERGE LEFT" or "MERGE RIGHT" zones traffic signalling device and the end of the work or construction zone may thus be expanded or contracted. A plurality of spaced-apart sensors is disposed along the roadway both downstream of, and upstream of, the traffic signalling devices to detect and determine the length of traffic queues upstream of the traffic signalling devices, and provides signals which are representative of the length of the traffic queues. The processor receives the traffic queue signals and generates activation signals when the traffic queue reaches a predetermined length. It also generates a deactivation signal when the traffic queue is less than the predetermined length. This dynamically increases or decreases the "NO PASSING" or "MERGE LEFT" or "MERGE RIGHT" zone.

Owner:INTERNATIONAL ROAD DYNAMICS

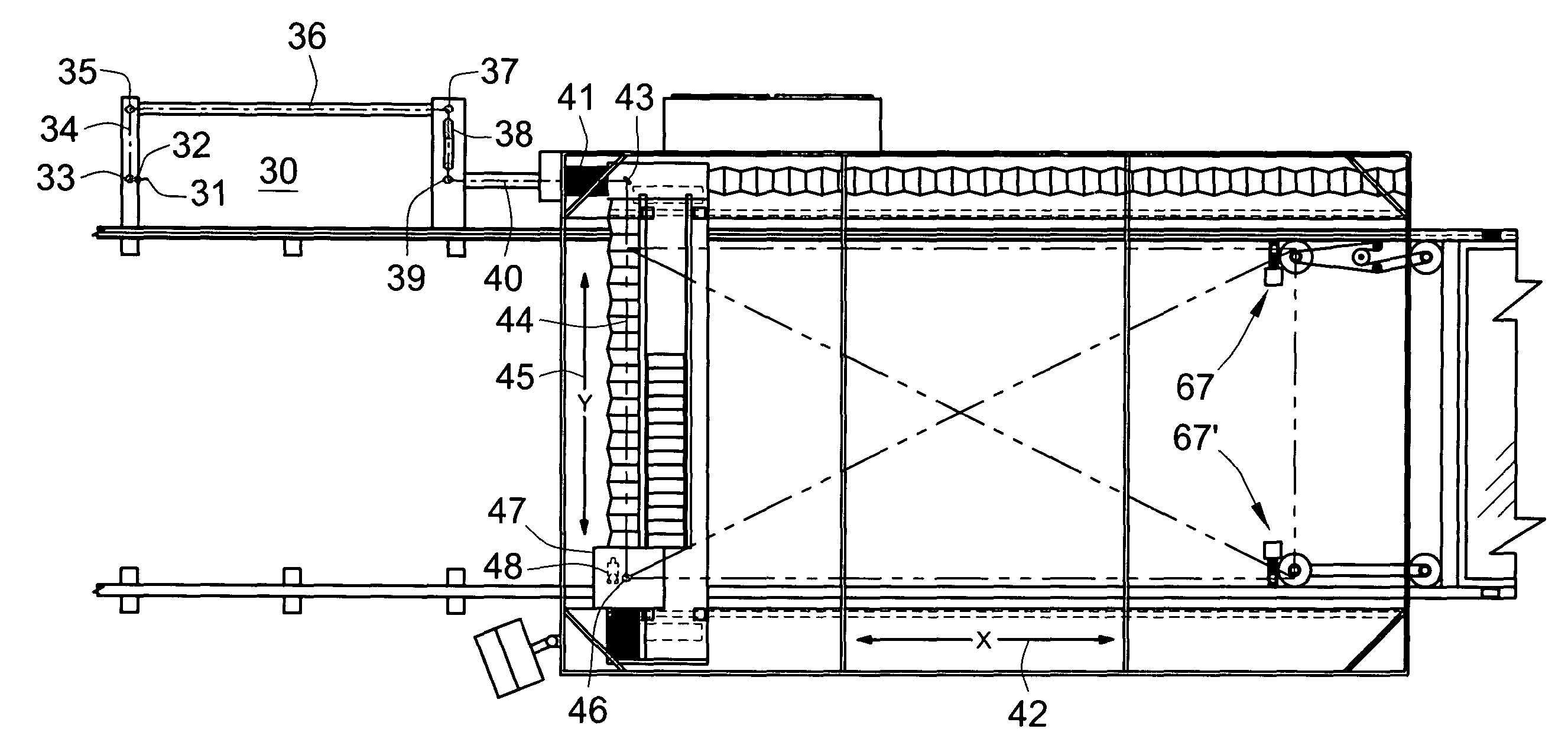

Machine and method for powder-based additive manufacturing

ActiveUS20150202687A1High precisionReduce manufacturing costManufacturing platforms/substratesArc welding apparatusEngineeringWork zone

Machine for the additive manufacture of a three-dimensional object by sintering or melting powder using a beam of energy acting on a layer of powder in a working zone, the said working zone being defined in the upper partof a build sleeve fixedly mounted in a chassis, in which sleeve the said object is manufactured, the said object being supported bya build plate which slides inside the said build sleeve when driven in vertical translation bythe head of an actuating cylinder placed along the central axis of the said sleeve. The build plate is positioned inside a transport container which is arranged removably between the said sleeve and the said actuating cylinder,the machine comprises means for moving the transport container (60) vertically into contact with the build sleeve andthe container is open at its top and at its bottom so that, when the actuating cylinder is actuated, the head thereof can transfer the said plate between the said transport container and the said build sleeve which forms a build envelope around the said plate.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

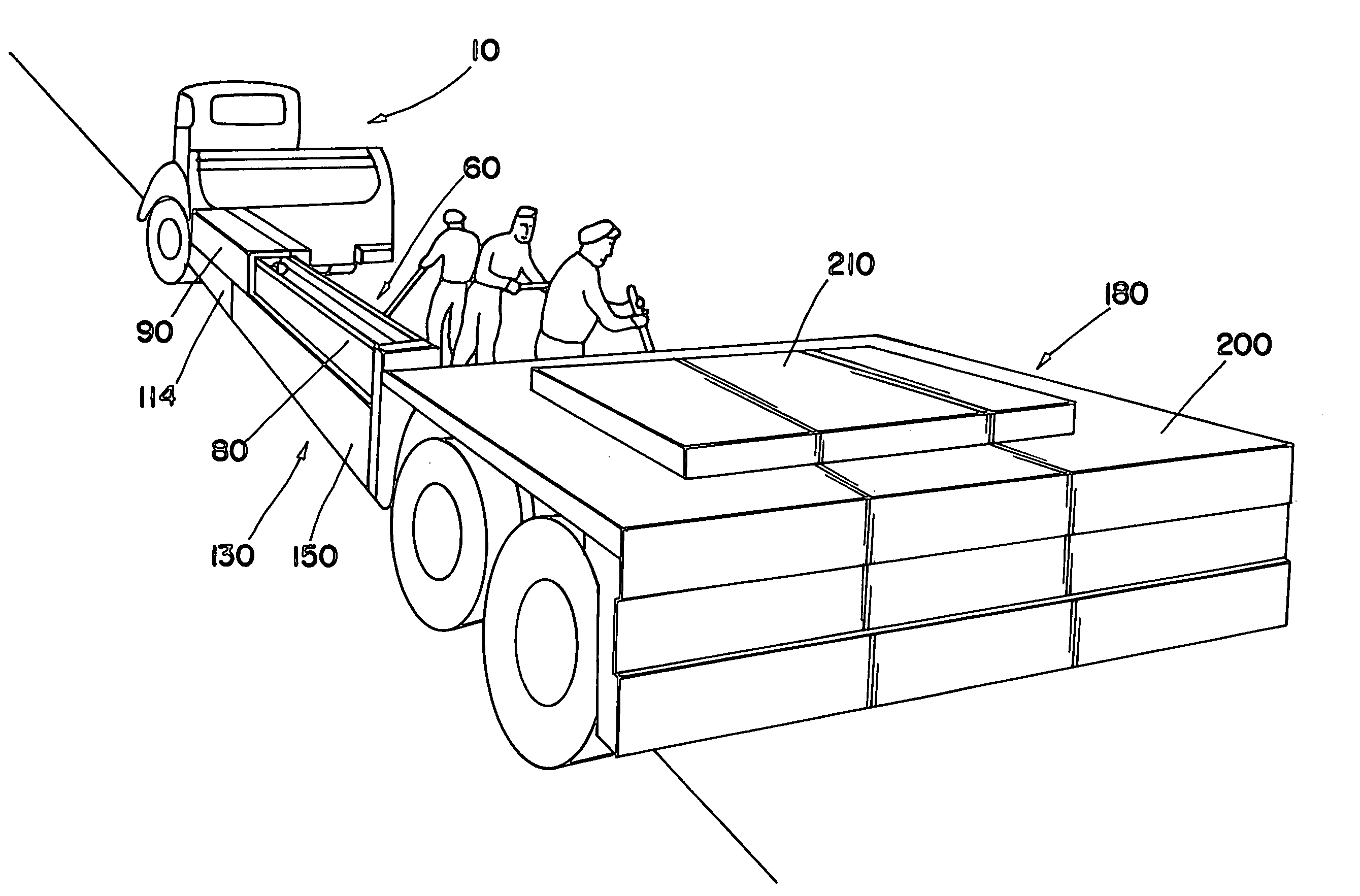

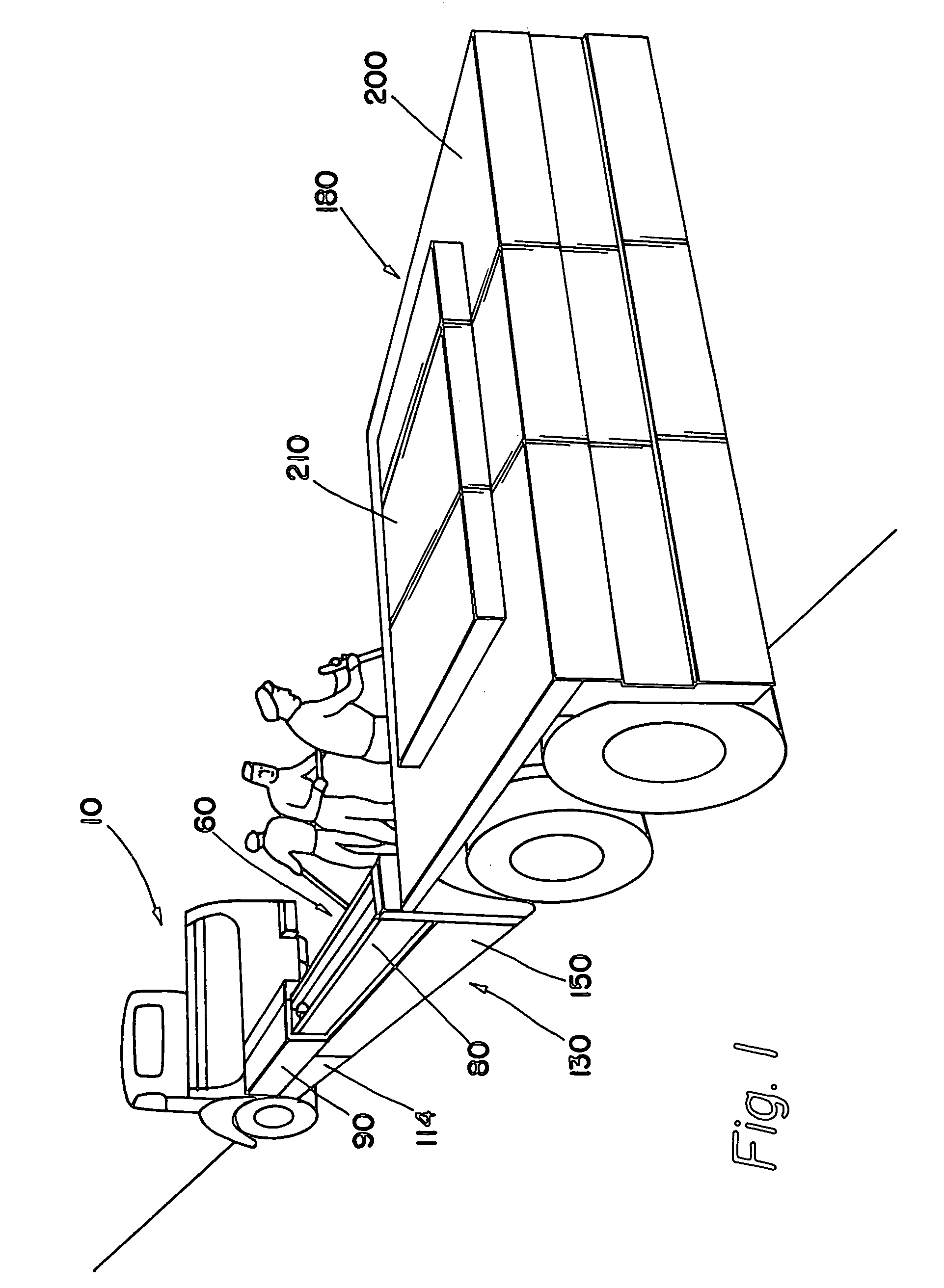

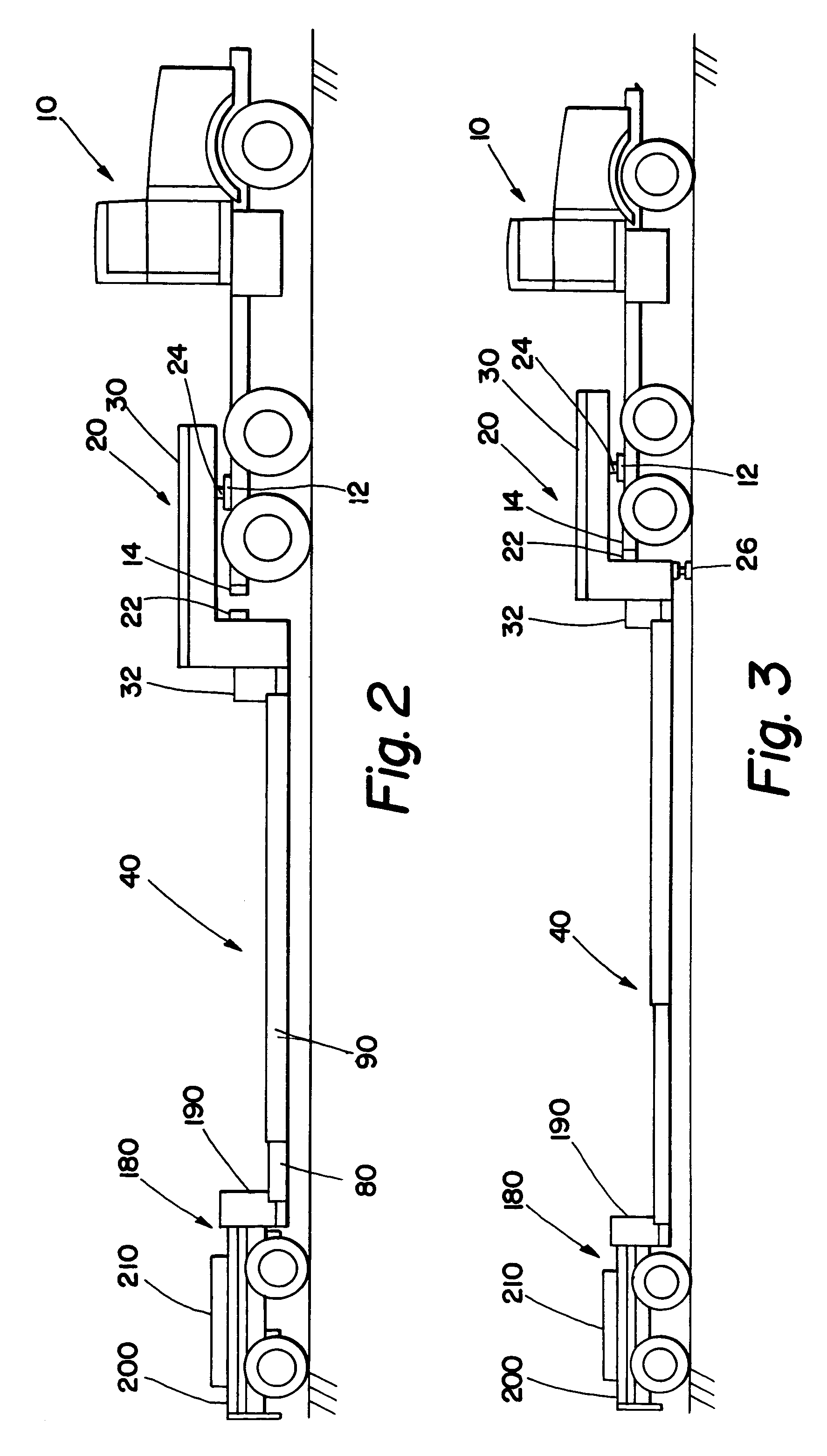

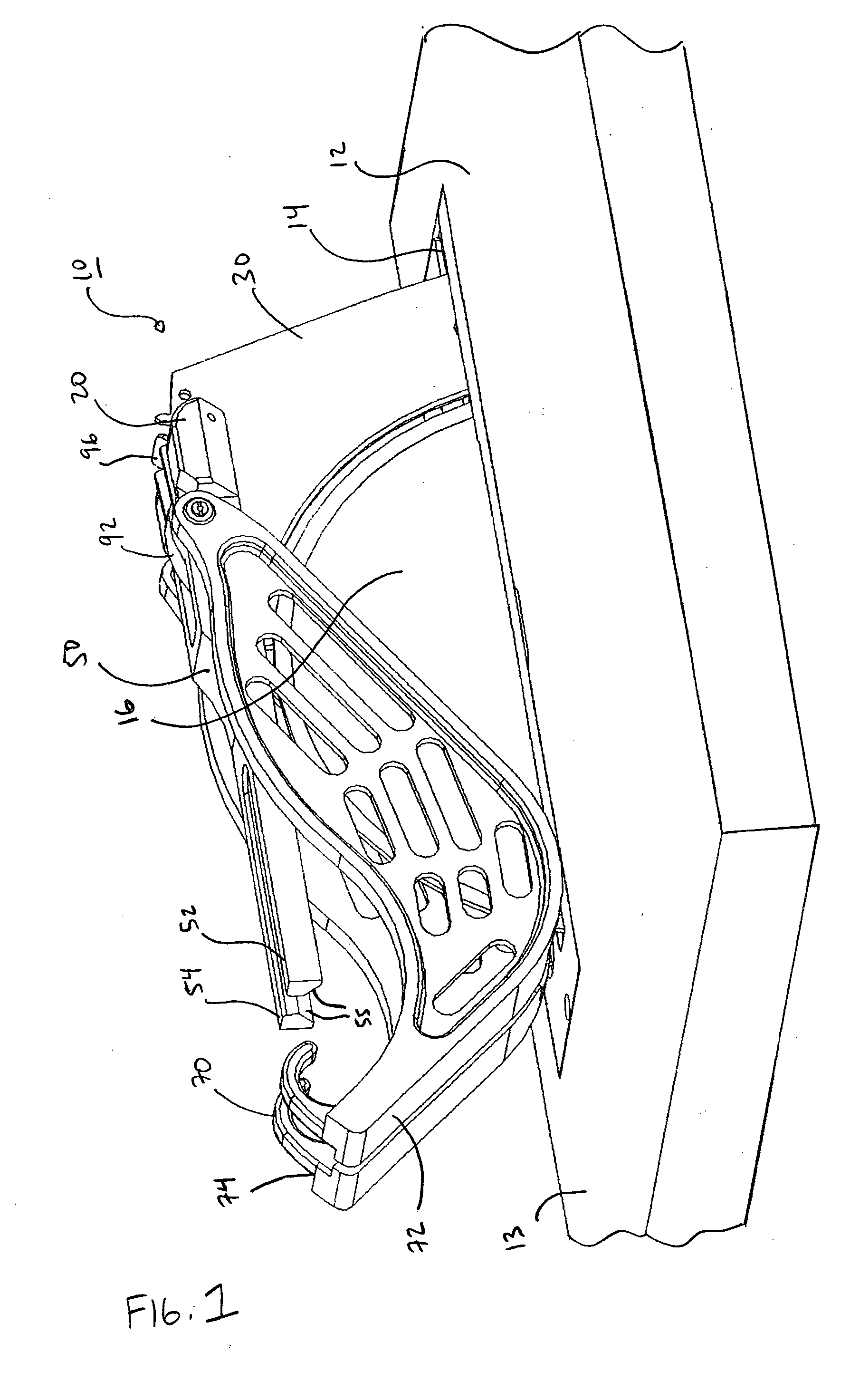

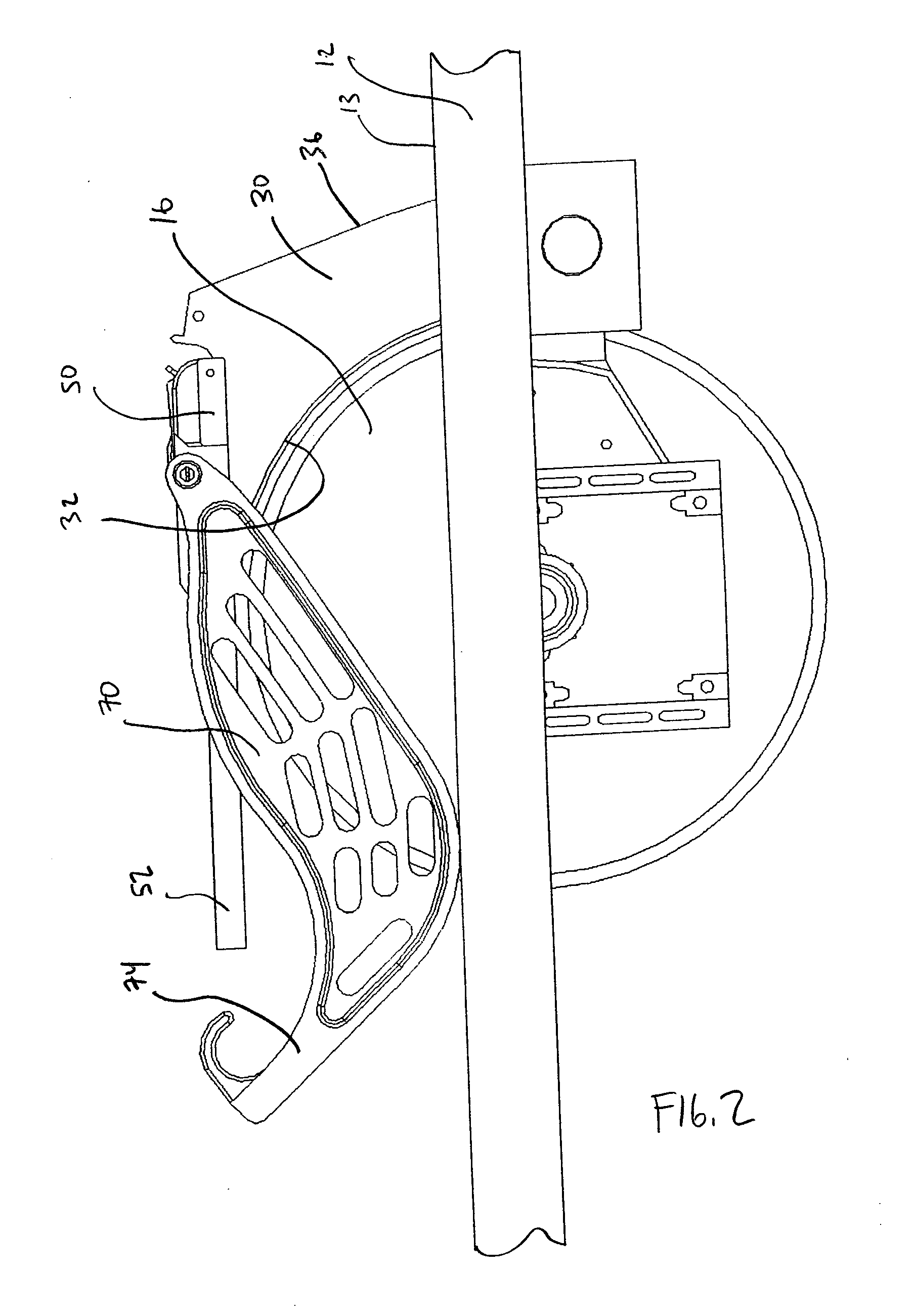

Mobile work zone protection device

A mobile work zone protection device includes a front carrier, a barrier beam assembly, and a rear carrier. In one embodiment, the barrier beam assembly includes two sets of telescoping beam structures. Each of these structures can rotate from one side of the device to the other, and thus can be deployed to create a safe work zone for roadway workers on either side of the device. The structure can also be left in the transit position to provide an enclosed safe work zone.

Owner:STATE OF CALIFORNIA DEPT OF TRANSPORTATION

Dynamic work zone safety system and method

InactiveUS6559774B2Controlling traffic signalsPortable emergency signal deviceTraffic signalEngineering

A novel dynamic work zone safety system and method of traffic control for a construction work zone are provided herein. The system includes at least two traffic signalling device which are positioned along a roadside immediately upstream of a point where traffic is diverted to a single lane. The traffic signalling devices selectively flash a suitable warning, e.g., "DO NOT PASS" or "MERGE LEFT" or "MERGE RIGHT", thereby to provide at least two "NO PASSING" or "MERGE LEFT" or "MERGE RIGHT" zones which is defined by the distance between the traffic signalling devices and the end of the work or construction zone. The "NO PASSING" or "MERGE LEFT" or "MERGE RIGHT" zones traffic signalling device and the end of the work or construction zone may thus be expanded or contracted. A plurality of spaced-apart sensors is disposed along the roadway both downstream of, and upstream of, the traffic signalling devices to detect and determine the length of traffic queues upstream of the traffic signalling devices, and provides signals which are representative of the length of the traffic queues. The processor receives the traffic queue signals and generates activation signals when the traffic queue reaches a predetermined length. It also generates a deactivation signal when the traffic queue is less than the predetermined length. This dynamically increases or decreases the "NO PASSING" or "MERGE LEFT" or "MERGE RIGHT" zone.

Owner:INTERNATIONAL ROAD DYNAMICS

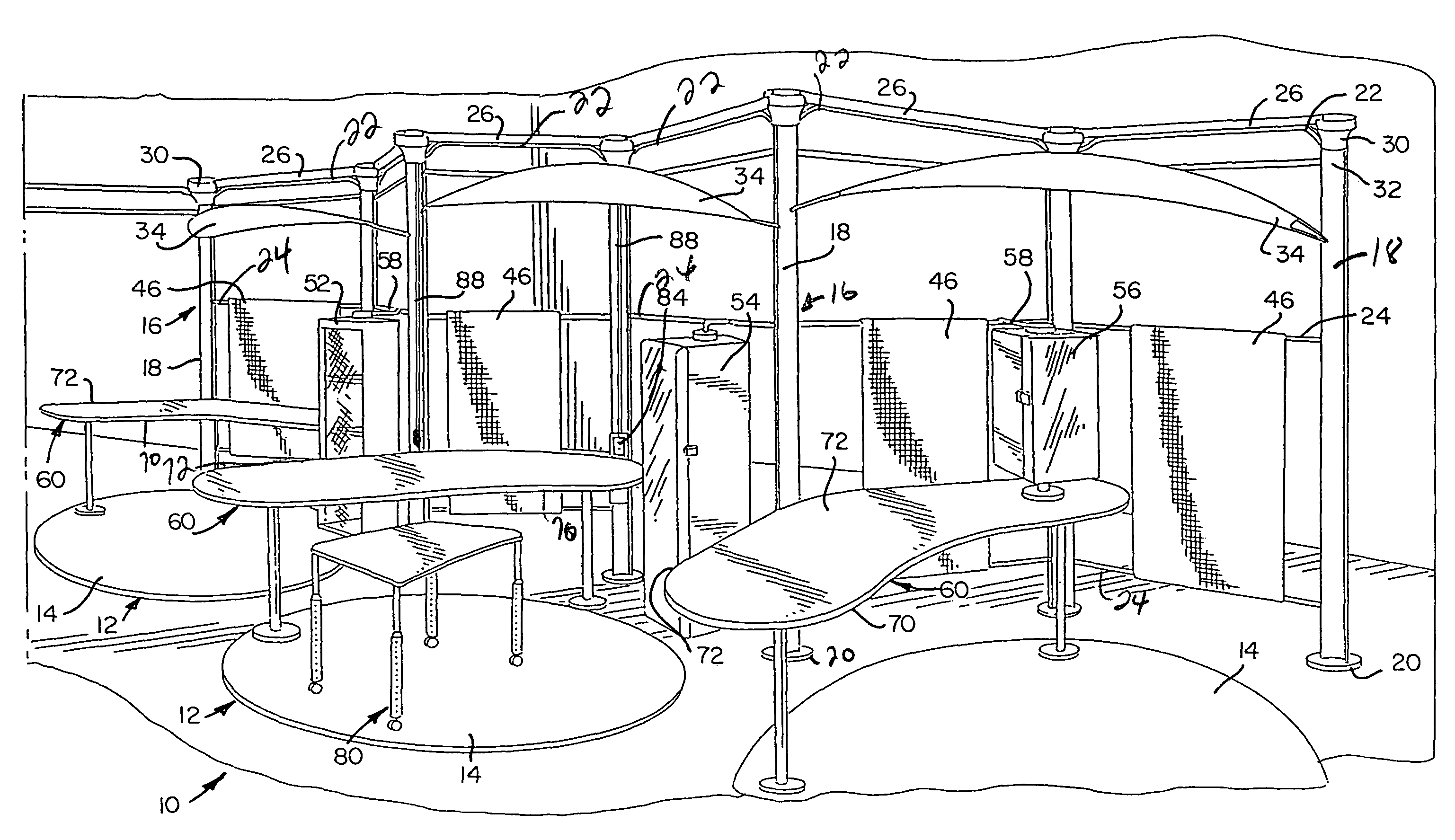

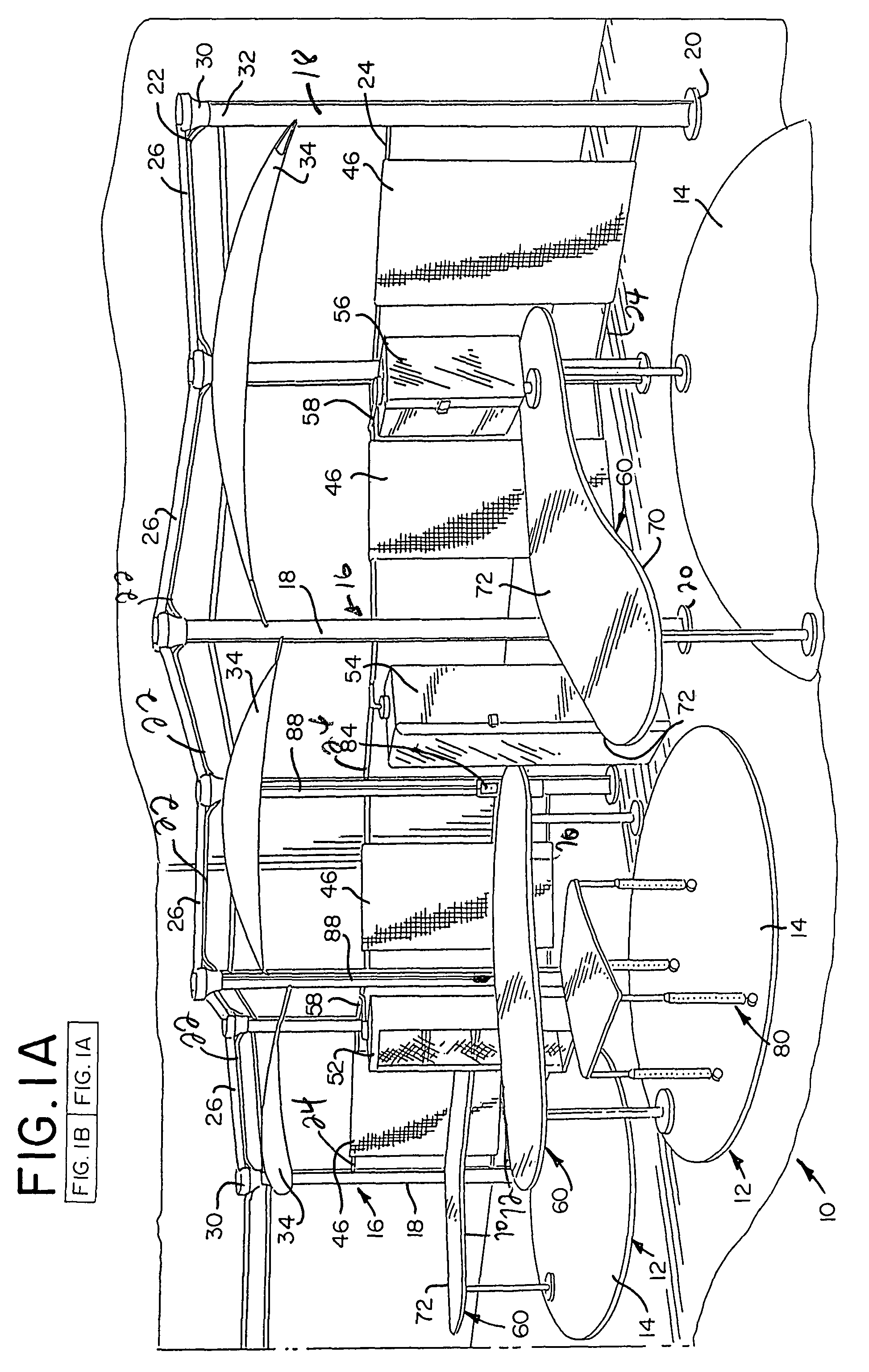

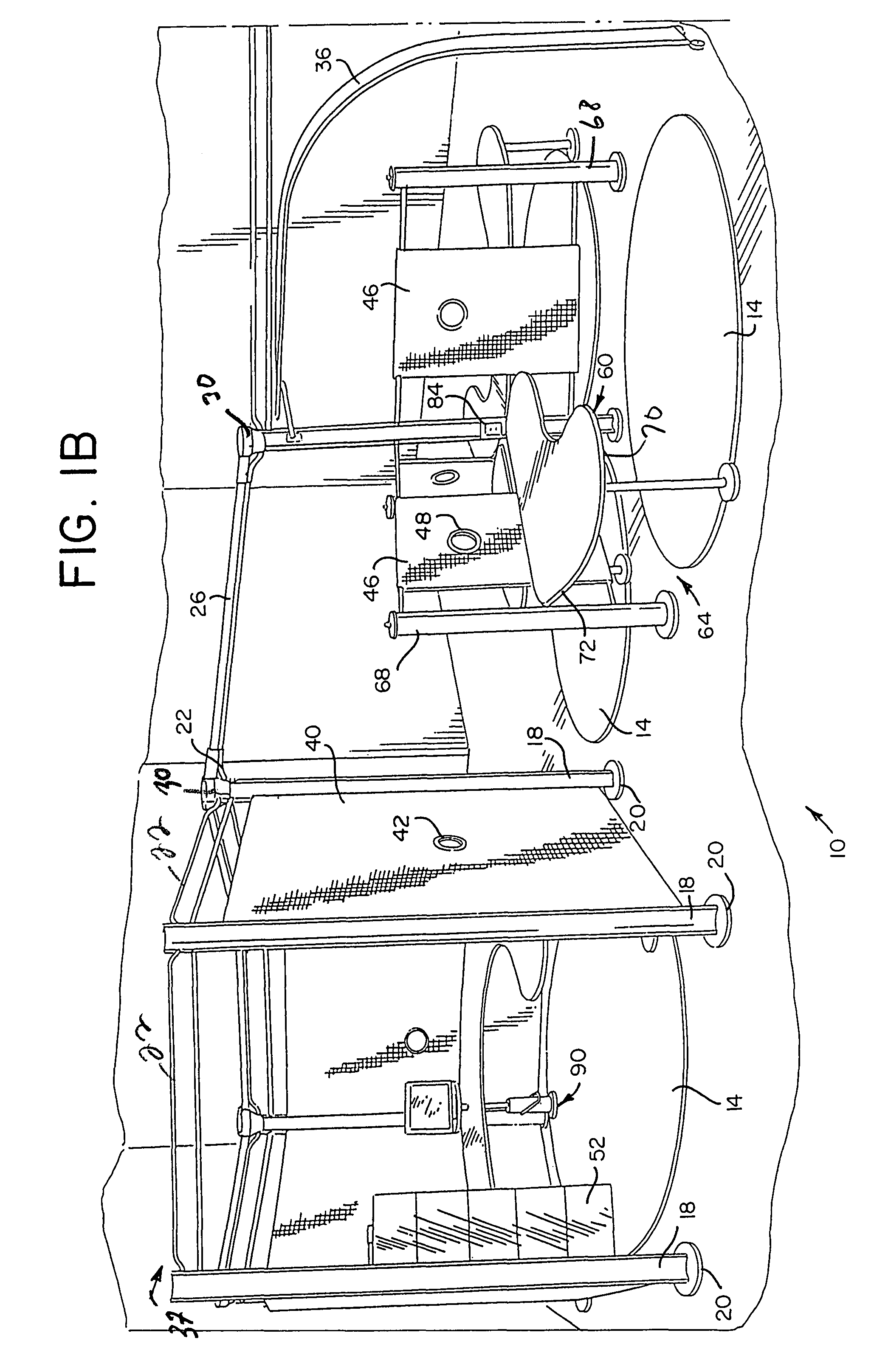

Work space management and furniture system

A system for defining a plurality of work zones within an otherwise open area. The system includes a framework formed from a plurality of spaced apart poles extending upward from a base surface. The poles are interconnected by a plurality of crossbeams at a height substantially above a standing user. At least some of the poles are adapted to provide a raceway for the delivery of utilities. The framework is capable of being arranged in a plurality of substantially non-linear patterns and includes an at least partially open area between adjacent poles.

Owner:MILLERKNOLL INC

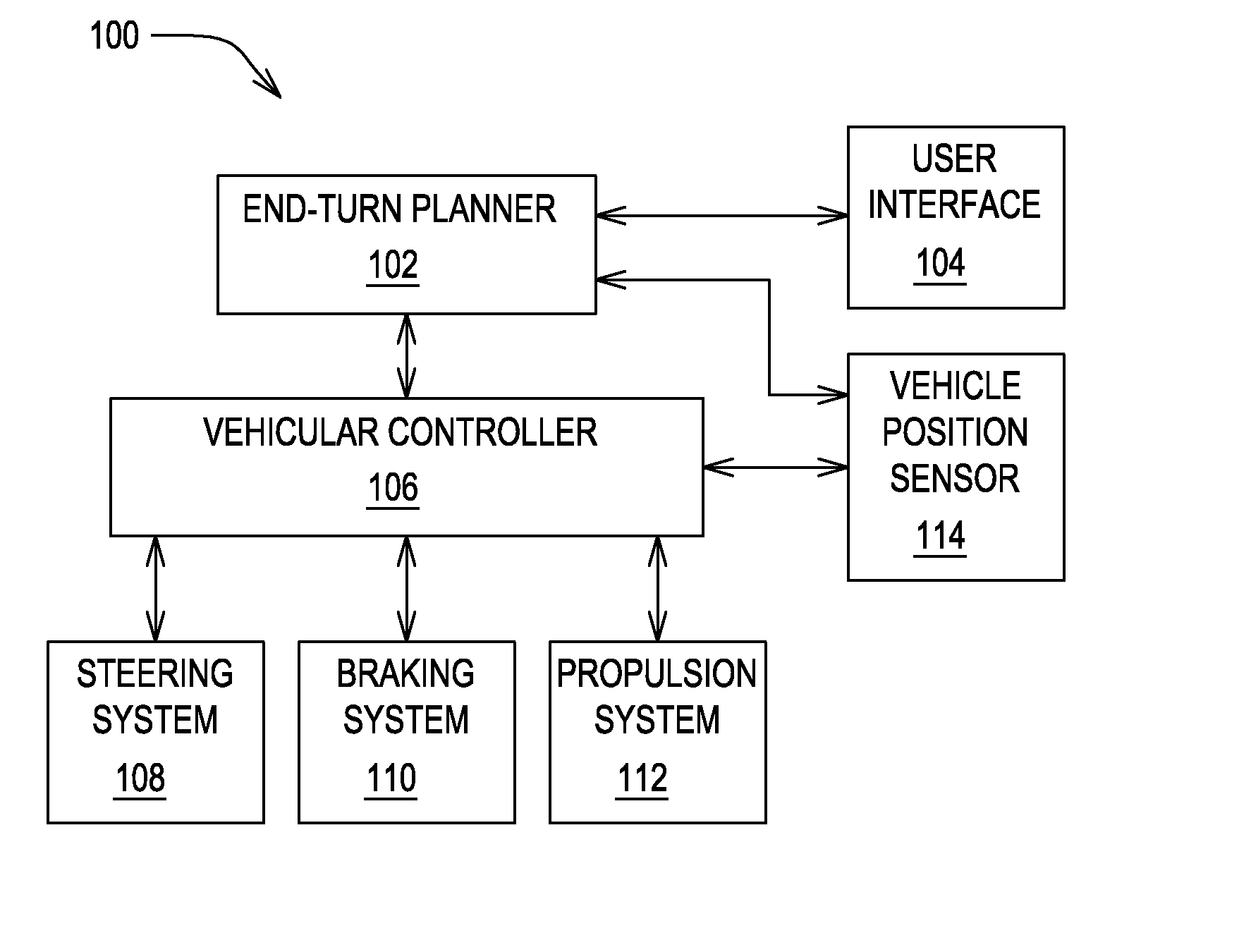

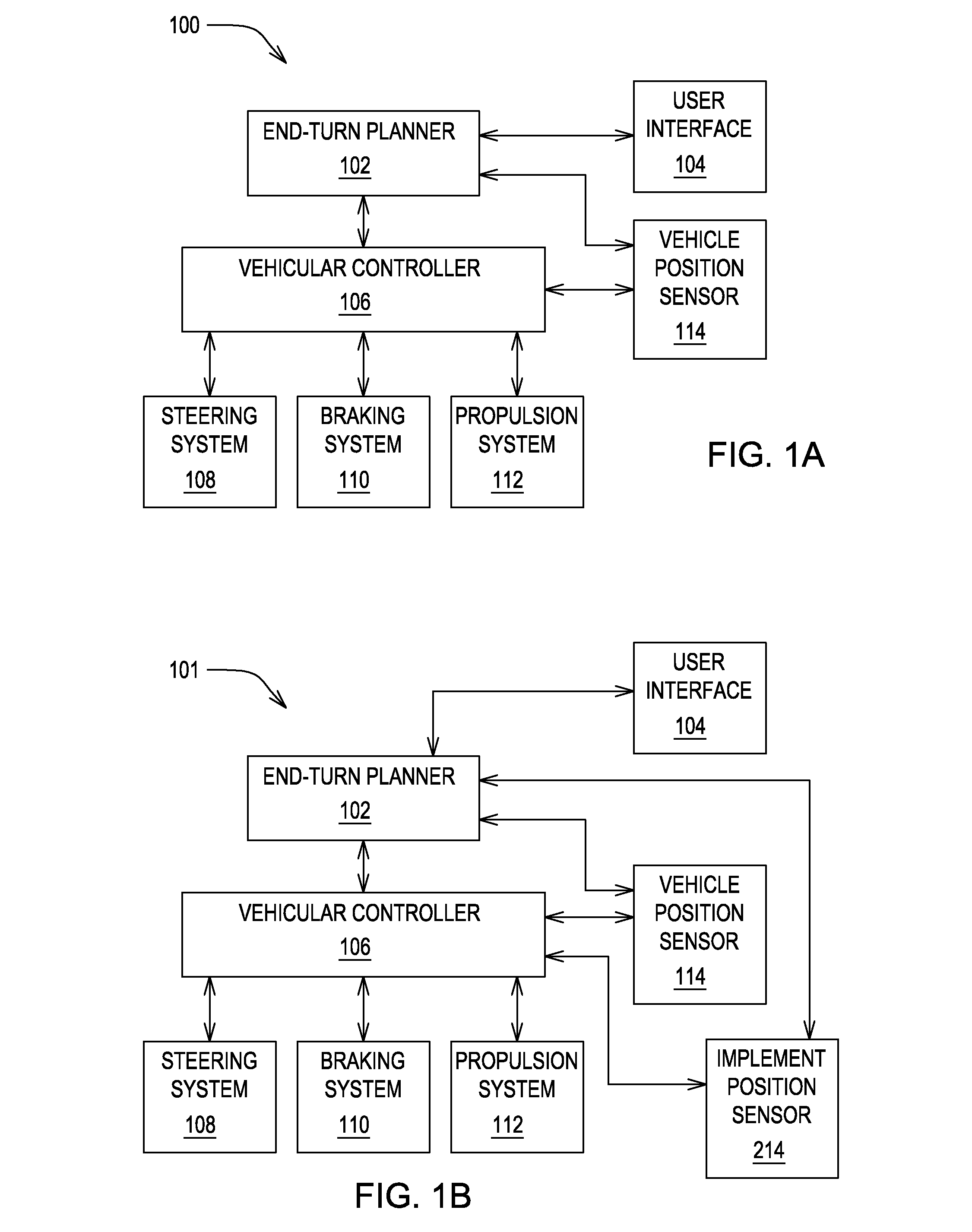

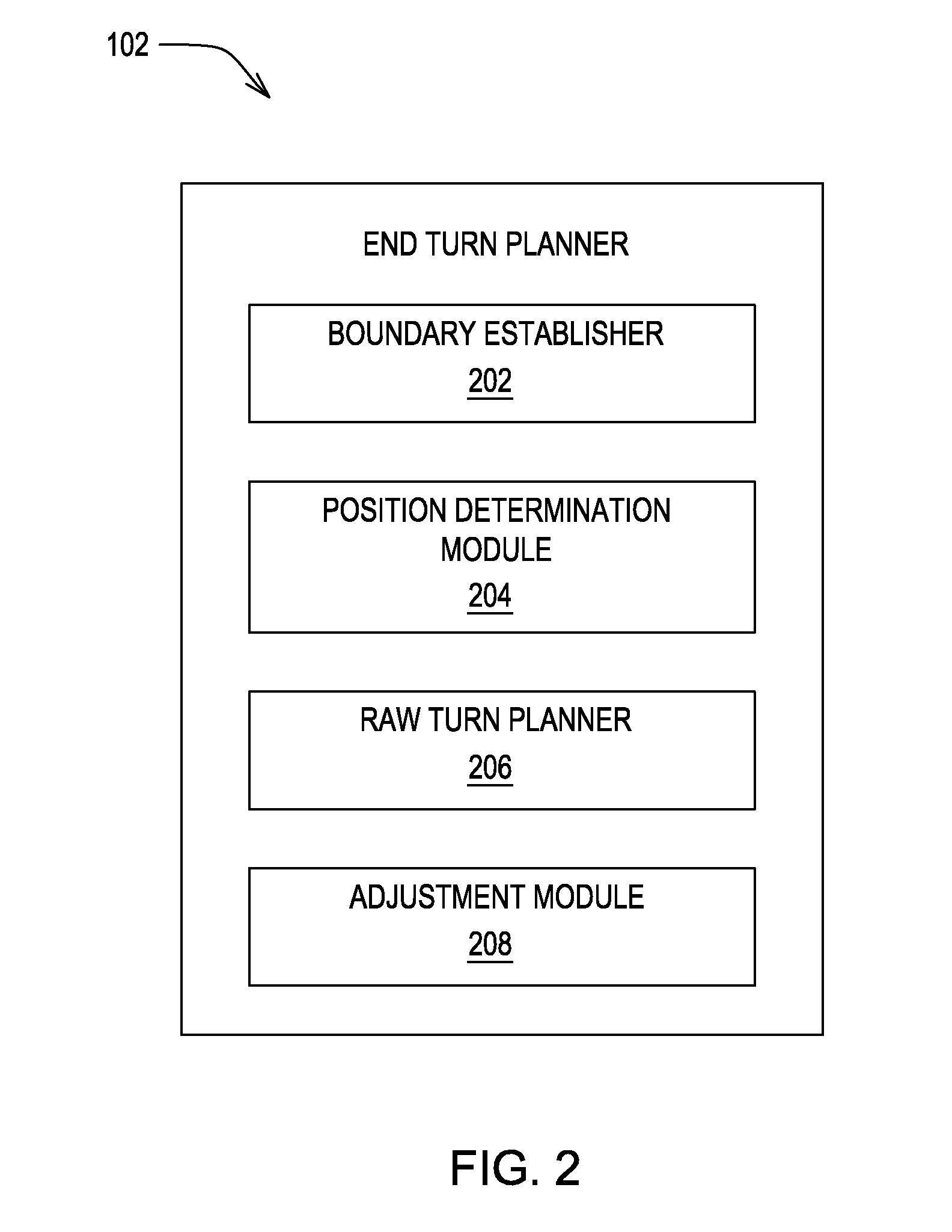

Method and system for generating end turns

ActiveUS20090037041A1External condition input parametersGuiding agricultural machinesEngineeringPosition sensor

A method and system for controlling a vehicle comprises a boundary establisher for establishing a boundary of a work area. A vehicle position sensor (e.g., a location-determining receiver) determines a position of the vehicle. A planner module plans a raw turn of a vehicle to be executed in accordance with a model turn pattern if the position of the vehicle has traversed the boundary. An adjustment module may adjust the raw turn of the vehicle to a compensated turn such that an implement coupled to the vehicle follows an implement path that substantially tracks the model turn pattern.

Owner:DEERE & CO

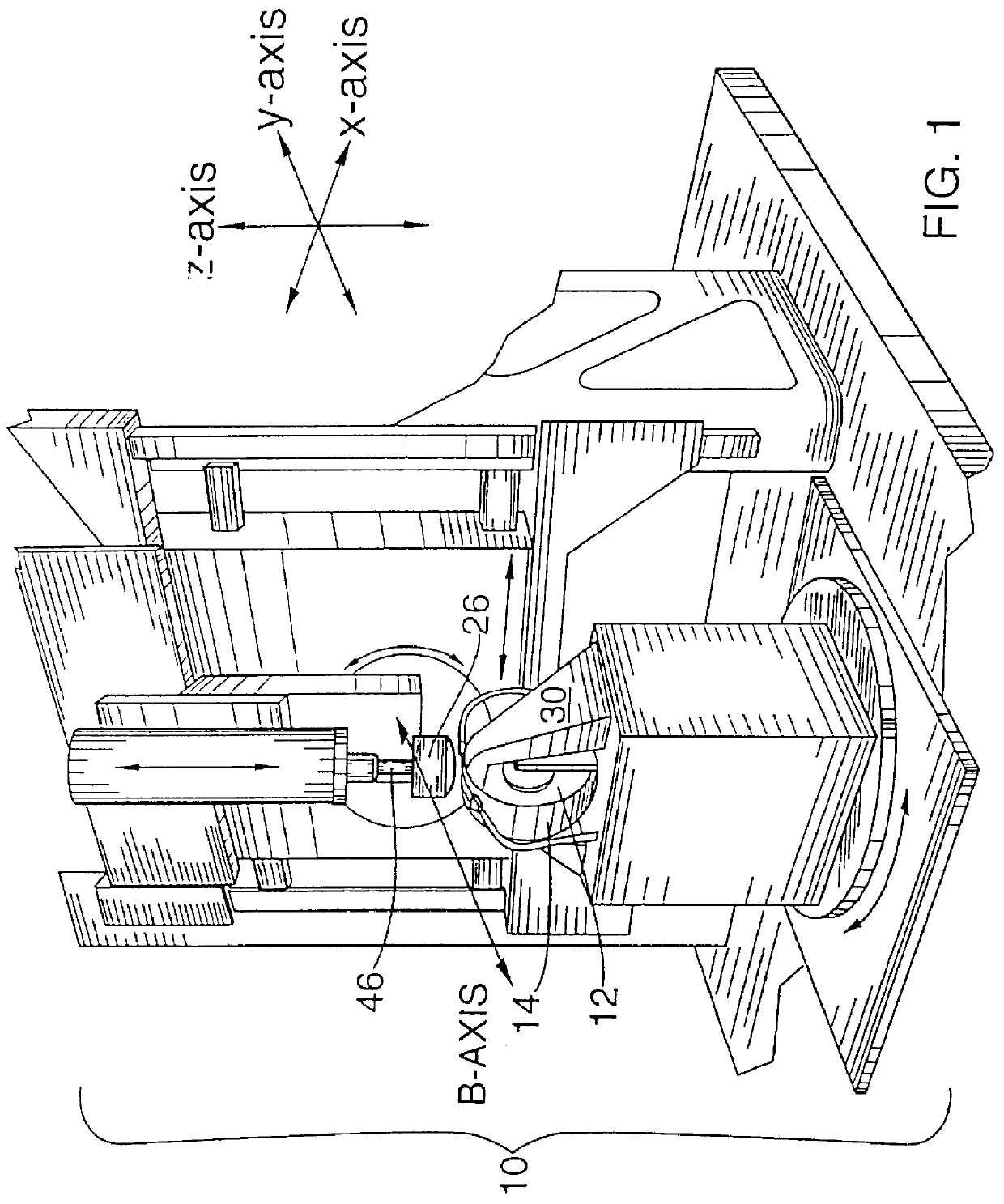

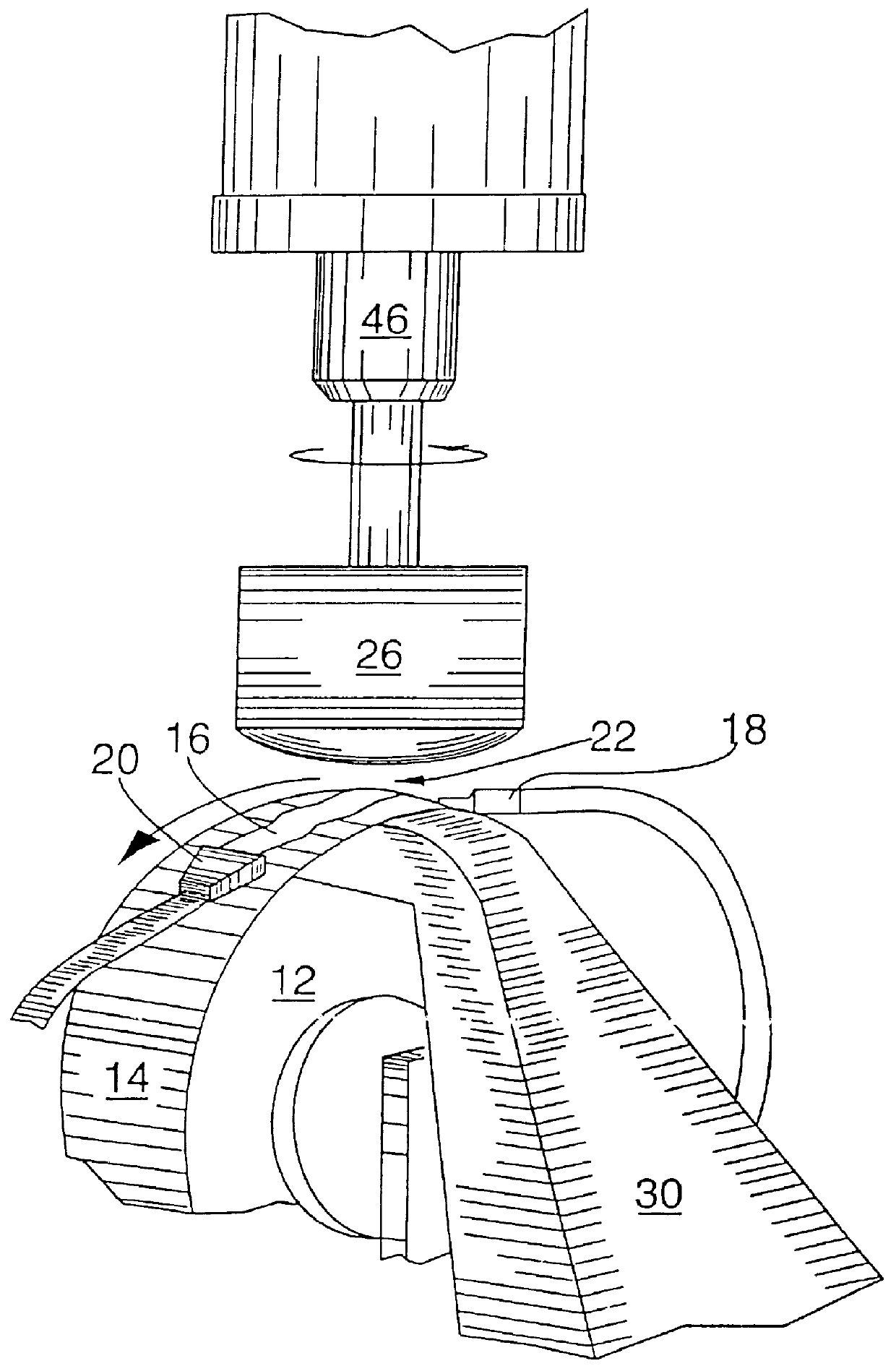

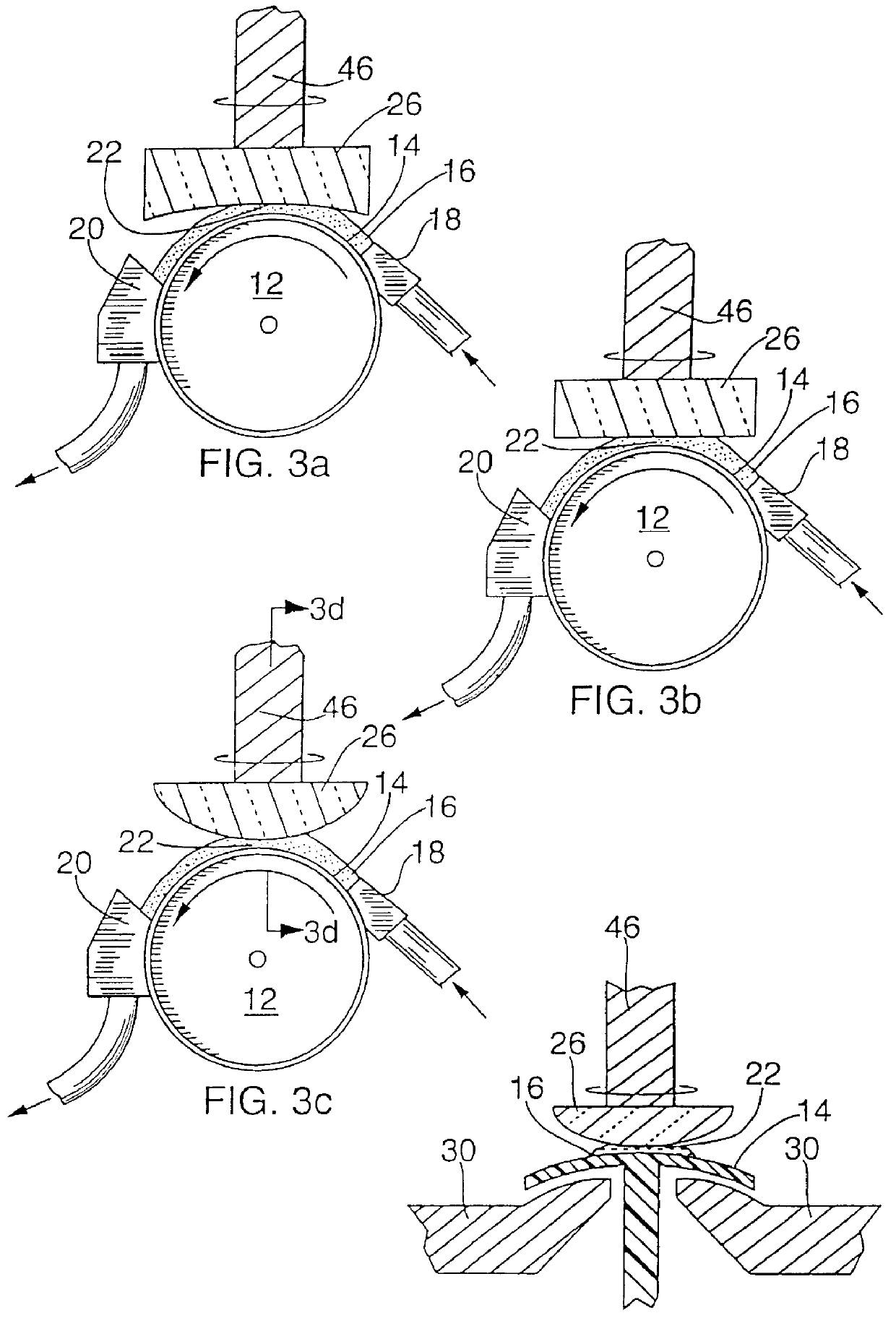

Deterministic magnetorheological finishing

InactiveUS6106380AConstantHigh viscosityEdge grinding machinesNanomagnetismMaterial removalMagnetorheological finishing

A method and apparatus for finishing a workpiece surface using MR fluid is provided wherein the workpiece is positioned near a carrier surface such that a converging gap is defined between a portion of the workpiece surface and the carrier surface; a magnetic field is applied substantially at said gap; a flow of stiffened MR fluid is introduced into said converging gap such that a work zone is created in the MR fluid to form a sub-aperture transient finishing tool for engaging and causing material removal at the portion of the workpiece surface; and the workpiece or the work zone is moved relative to the other to expose different portions of the workpiece surface to the work zone for predetermined time periods to selectively finish said portions of said workpiece surface to predetermined degrees.

Owner:QED TECH INT

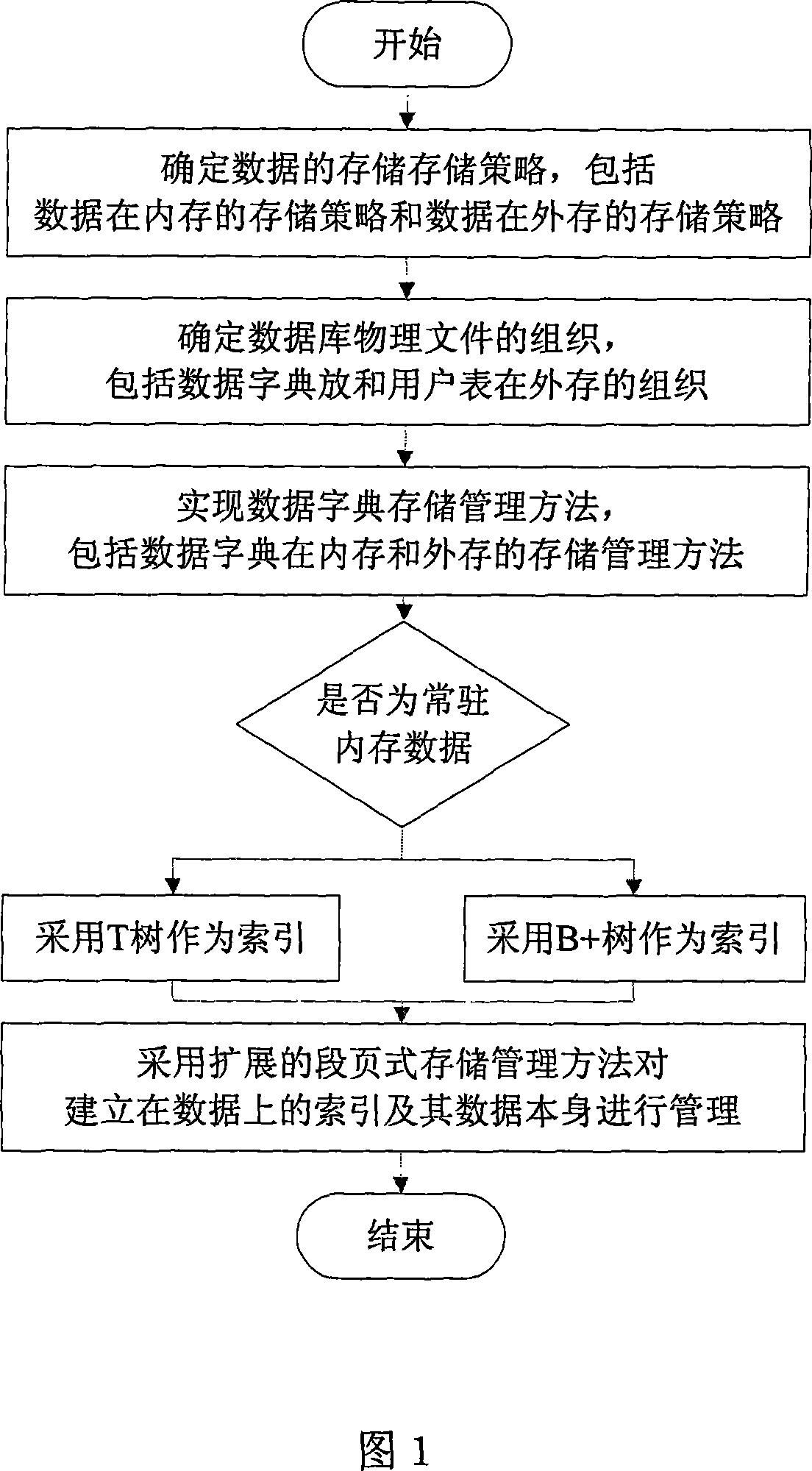

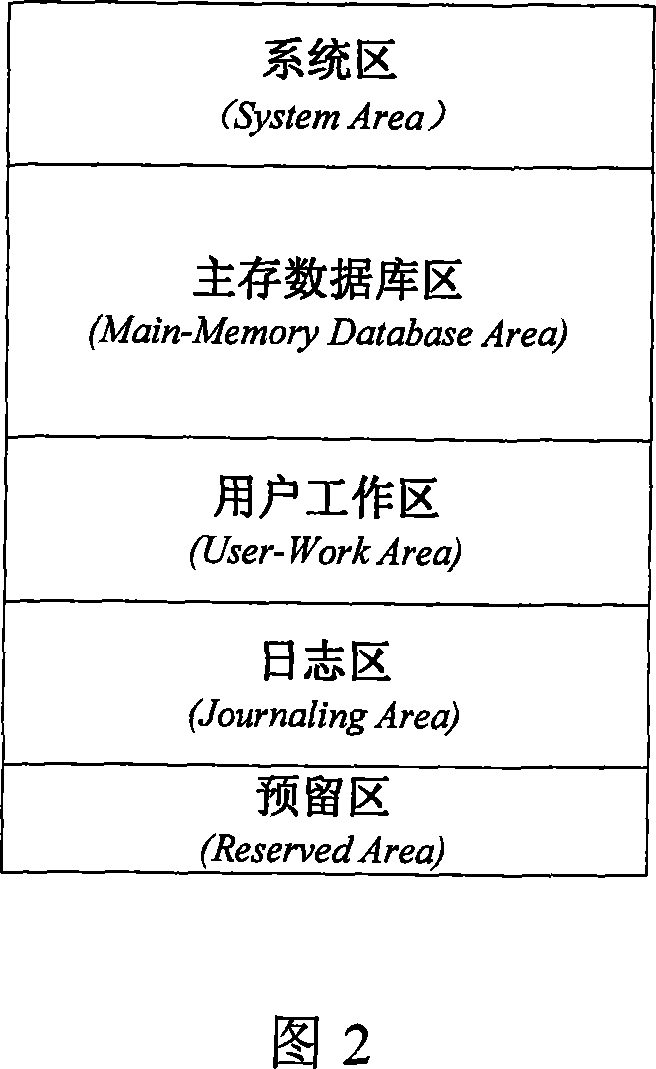

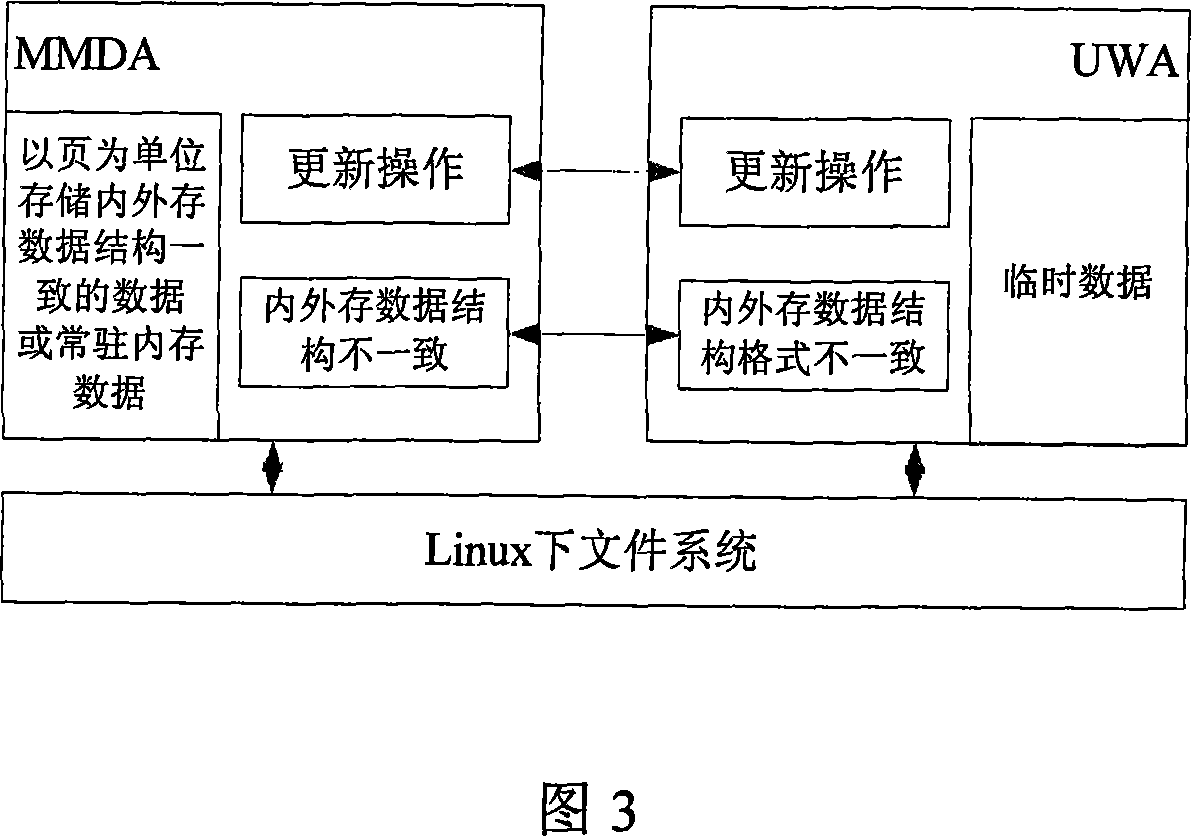

Embedded database storage management method

InactiveCN101055589AGuaranteed compactnessImprove loading speedSpecial data processing applicationsEmbedded databaseData access

A storage mamagement method of embedded database,includes that: (1) the storage strategy of data in the memory is that: if logic structure accords with physical structure, the structure is into a divided system area, a main storage database area, a user working area, a log area and a preformed area; the storage strategy of data in the external memory is that: logic structure is divided into a database table, a segment and a database block; physical structure includes a physical file and a physical block; (2) the physical file organization of database is that: a data dictionary is placed at the heading, a user table since then; (3) the memory management of data dictionaryin the external memory is that: the described information of physical file is stored in the file header, denotative definition kind and attribute definition kind adopt a three section type storage form; data dictionary adopt a page type memory management method in the memory; (4) a permanent memory data is stored using T tree and a a permanent external memory data is stored using B+ tree; data and its index are managed using a extended segment memory management method. The invention improves the utilization rate of memory space, and accelerate the speed of data to access.

Owner:BEIHANG UNIV

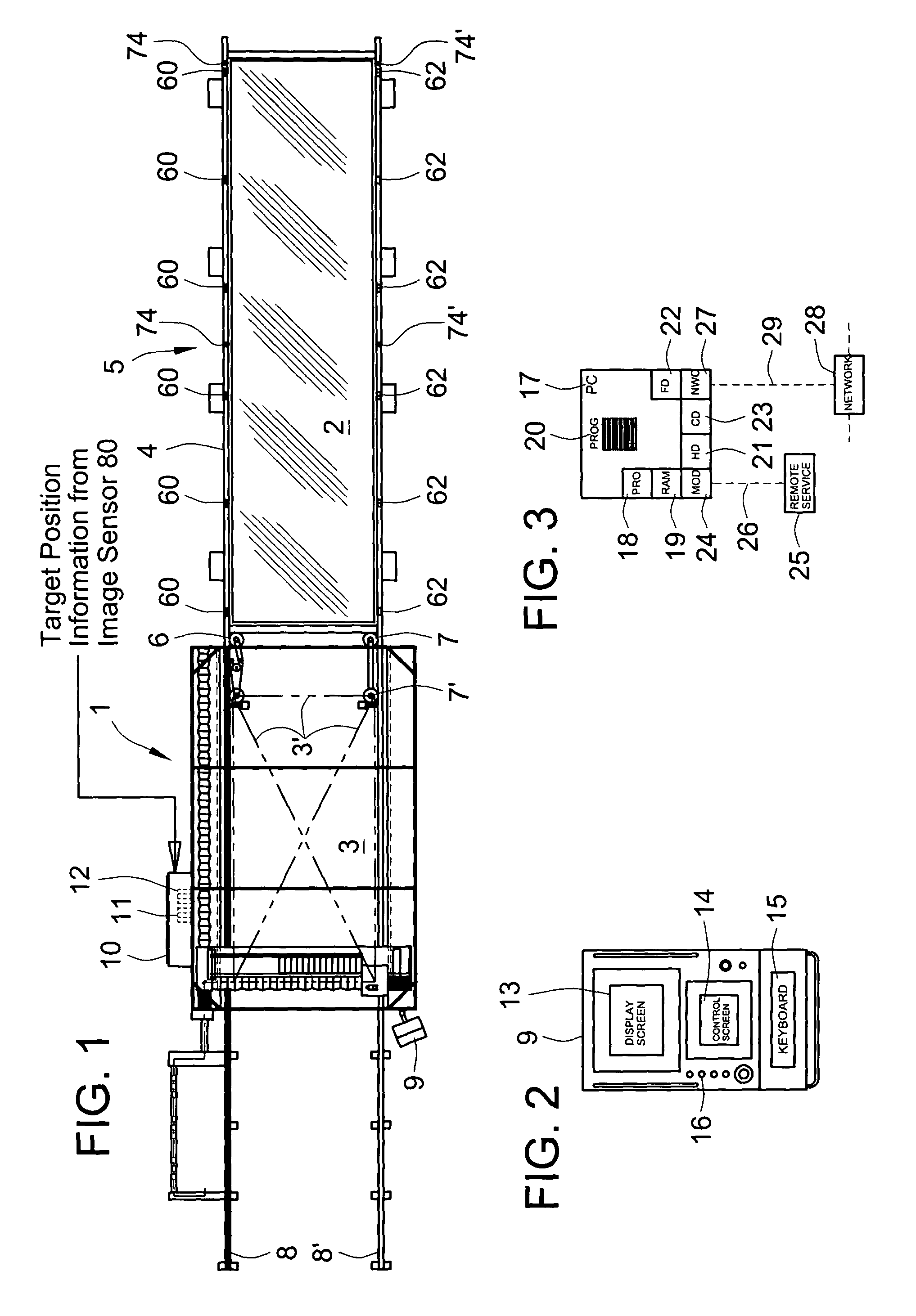

Laser machine tool with image sensor for registration of workhead guidance system

A computer controlled laser machine tool is provided wherein the machine tool work zone is smaller than the size of the workpiece that can be processed. The machine tool has an apparatus to register the workhead guidance system to the workpiece without requiring a hole in the workpiece. The machine tool is adapted with an image sensor, a form of a digital camera, to measure the position of targets etched in or affixed to the surface of the workpiece. Registration of the workhead guidance system relative to the workpiece is checked before and after the workpiece support is indexed.

Owner:W A WHITNEY

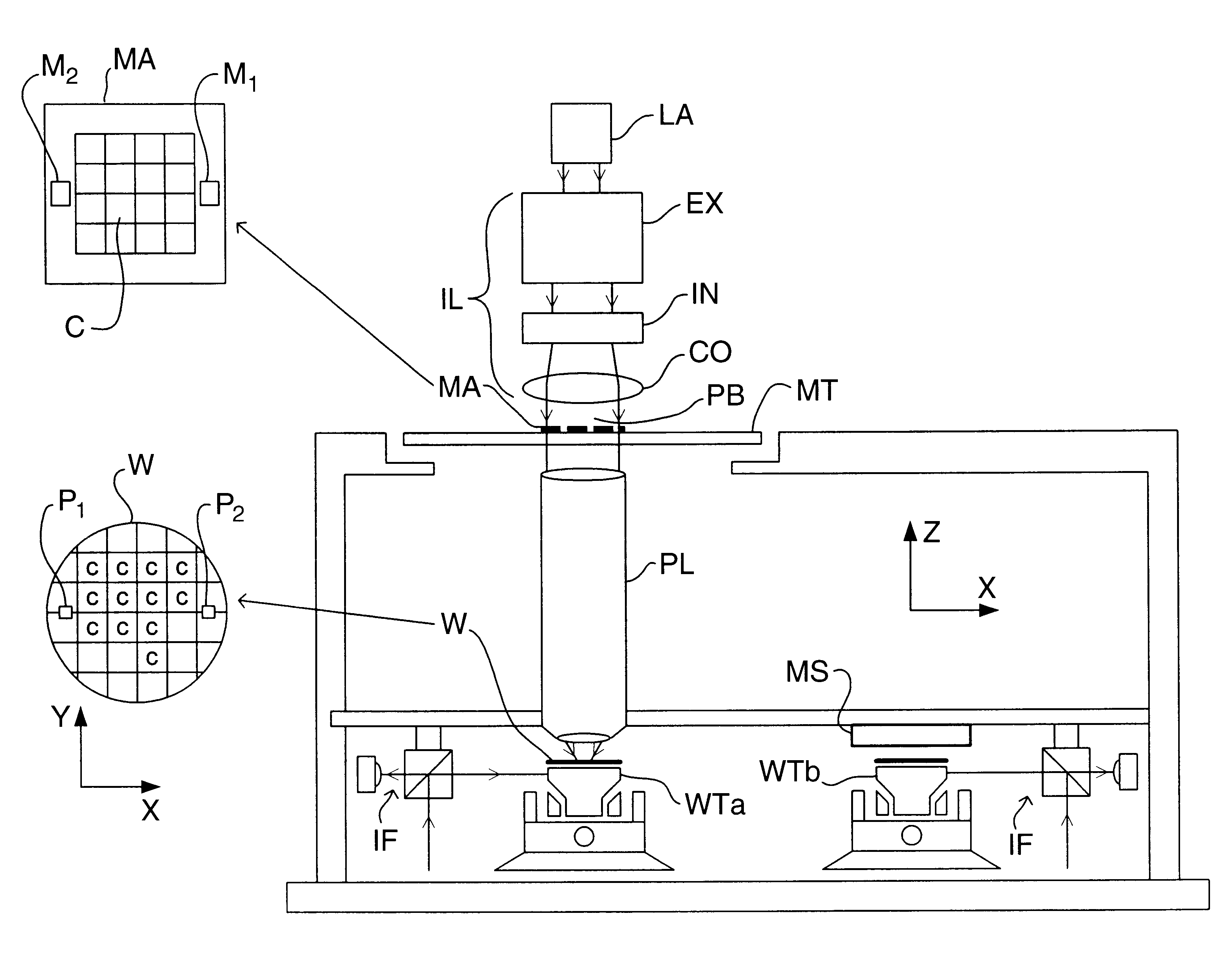

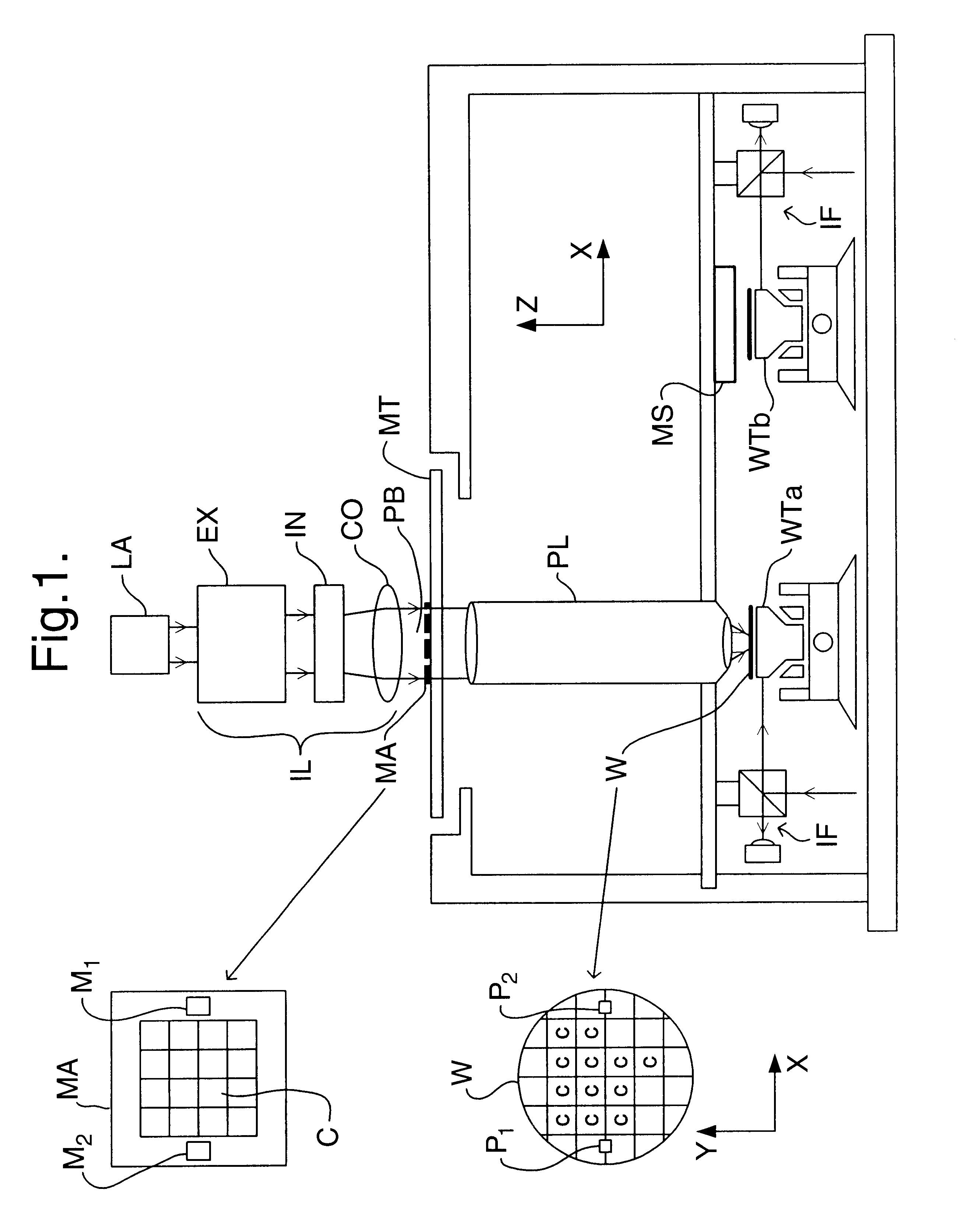

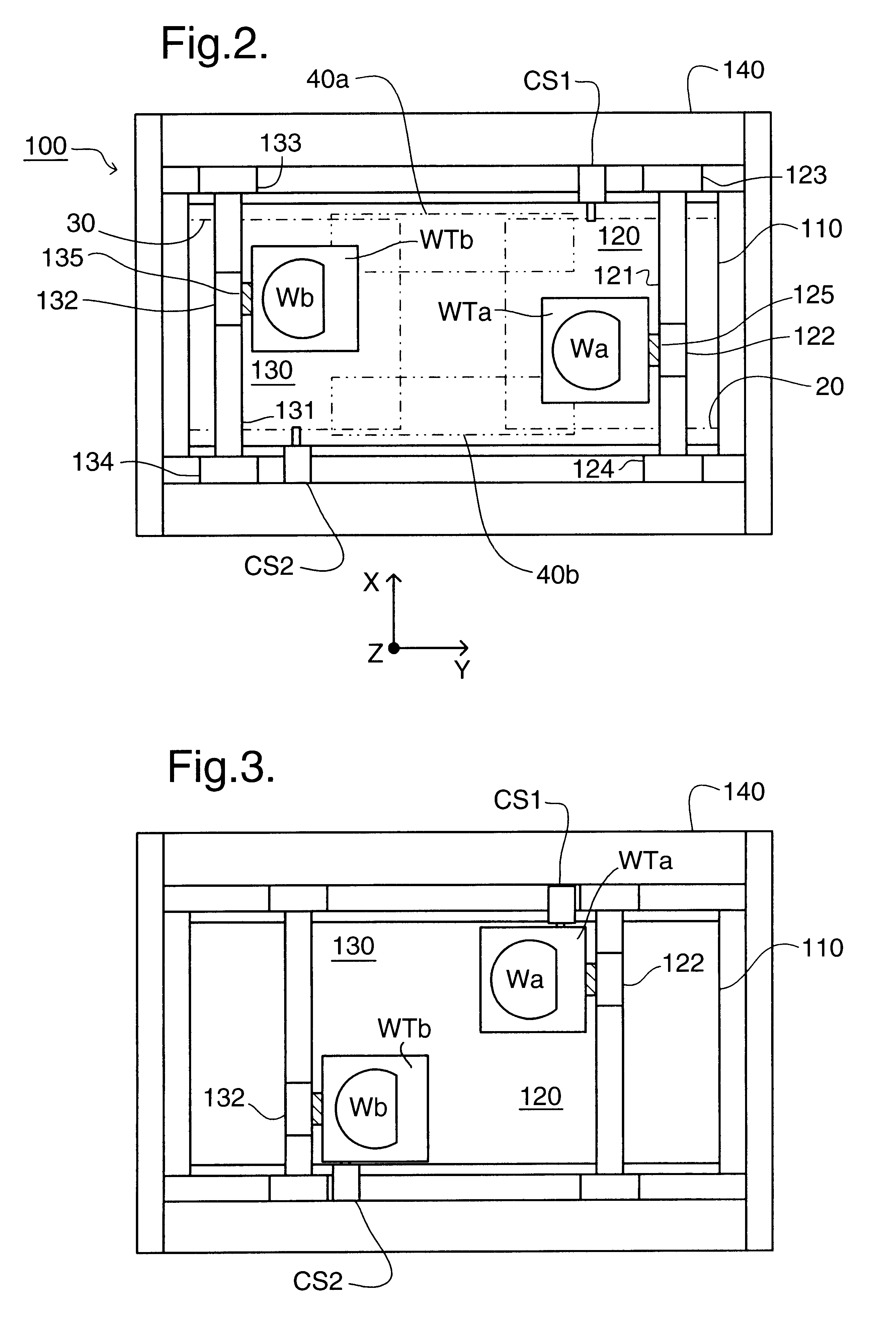

Crash prevention in positioning apparatus for use in lithographic projection apparatus

InactiveUS6498350B2Avoid collisionElectric discharge tubesThermometers using material expansion/contactionEngineeringPlanographic printing

In a multi-table lithographic apparatus in which substrate tables may be exchanged between a first working zone where substrates are loaded onto and removed from the table and a second working zones where wafers are exposed, collision prevention means are provided to prevent collisions between tables in the exchange process. The collision prevention means may be formed of a labyrinth or a revolving door. The exchange process may be controlled by shuttles, optionally including drive means, that are interlinked so that the tables can only be exchanged between zones together.

Owner:ASML NETHERLANDS BV

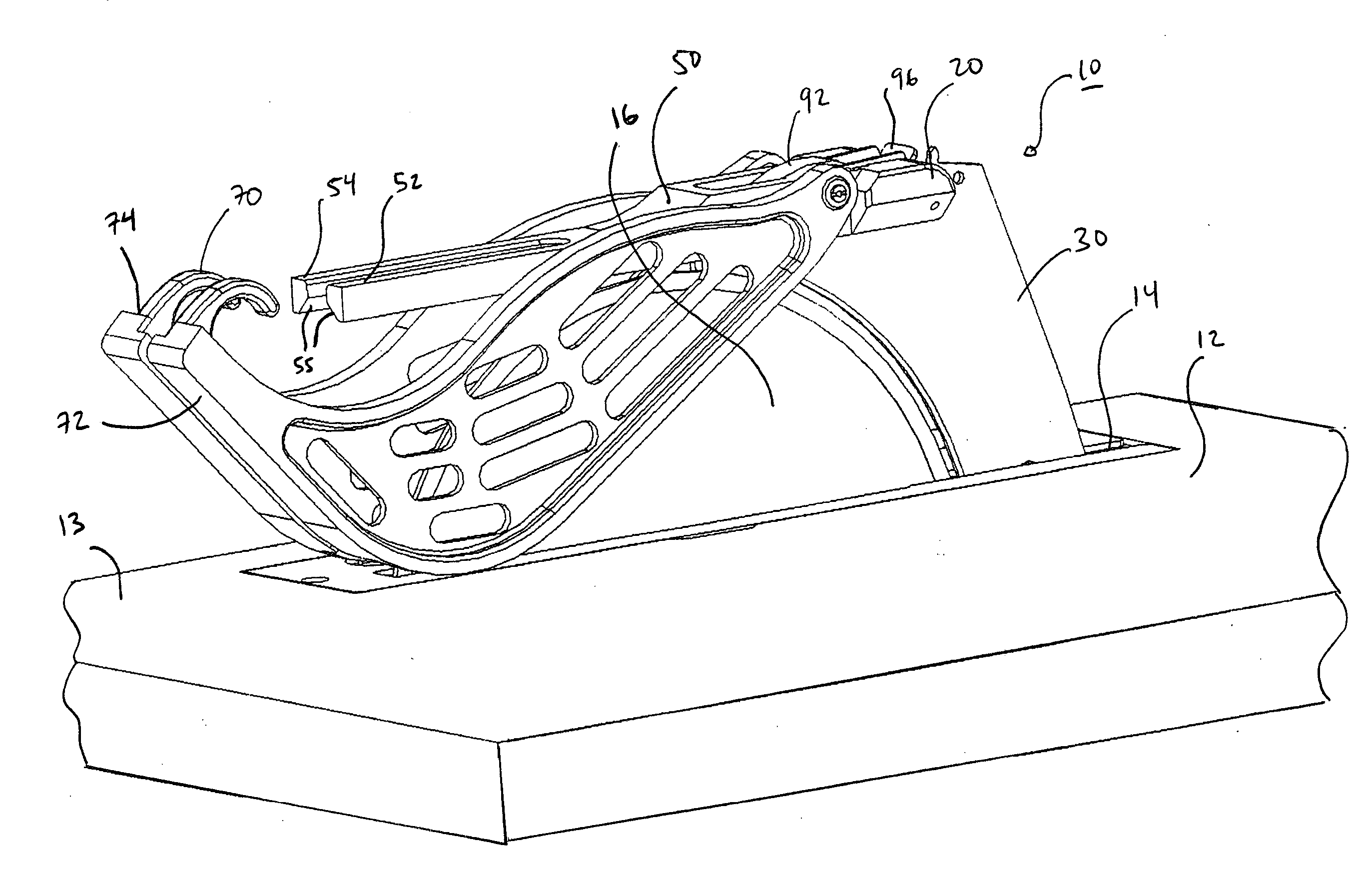

Percutaneous Devices for Separating Tissue, Kits and Methods of Using the Same

The disclosure describes devices for separating a first tissue from a second tissue at a surgical site, comprising, a hollow body having a distal end and a proximal end, wherein the distal end further comprises an upper separation member extendable laterally from hollow body at a first angle; an inner member slidably disposed within the hollow body, wherein the distal end of the inner member has a lower separation member extendable laterally from inner member at a second angle, wherein the upper separation member and the lower separation member have a first configuration and a second configuration into a tissue in the working zone on the first lateral side of the median plane. Additionally, methods for using the device and kits containing the device are disclosed.

Owner:VERTOS MEDICAL

Table saw guard

An improved riving knife / guard assembly for a table saw allows the guard to be removed and attached without the use of any tools, provides a clear view of the work zone, blade and workpiece, and is easily adjustable to accommodate different size workpieces and cutting angle. The assembly includes a riving knife extending upward from the table substantially coplanar with the saw blade and a guard that releasably attaches to the riving knife with a rotatable latch with the guard at least partially surrounding the saw blade.

Owner:EASTWATY FAIR COMPANY LIMITED OF TRIDENT CHAMBERS

Delivery system for magnetorheological fluid

A magnetorheological fluid delivery system includes a mixing and tempering vessel. Fluid is admitted to the vessel via a plurality of tangential ports, creating a mixing of the fluid in the vessel and promoting homogeneity. Fluid may be reconstituted in the vessel by metered addition of carrier fluid. A fixed-speed centrifugal pump disposed in the vessel pressurizes the system. Fluid is pumped through a magnetic-induction flowmeter and a magnetic flow control valve having solenoid windings whereby MR fluid is magnetically stiffened to restrict flow. A closed-loop feedback control system connects the output of the flowmeter to performance of the valve. A nozzle having a slot-shaped bore dispenses MR fluid for re-use in the work zone. A planar-diaphragm flush-mounted pressure transducer at the entrance to the nozzle and flowmeter inferentially measure relaxed viscosity and provide signals to a computer for dispensing metered amounts of carrier fluid into the mixing vessel to assure correct composition of the reconstituted fluid as it is dispensed.

Owner:QED TECH INT

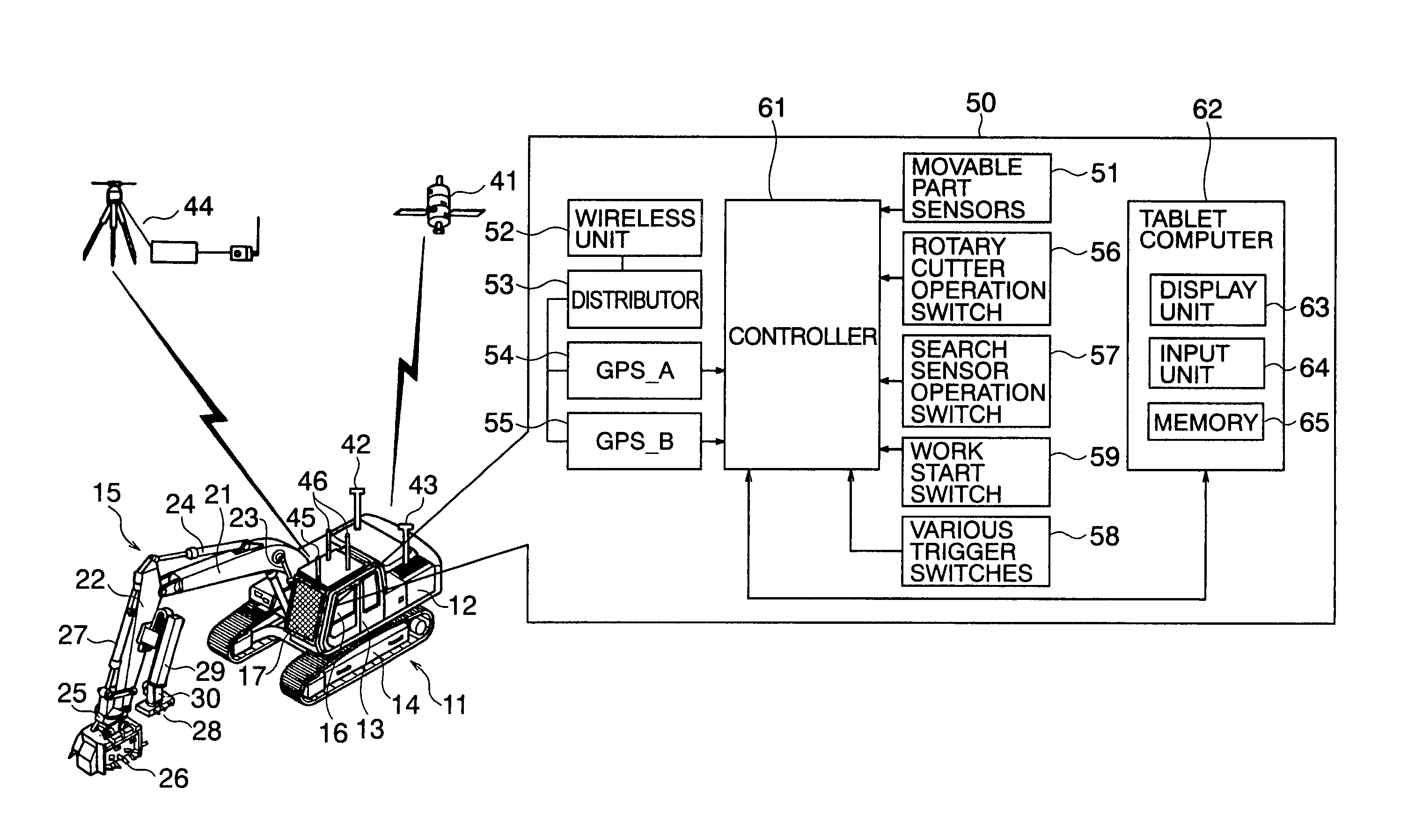

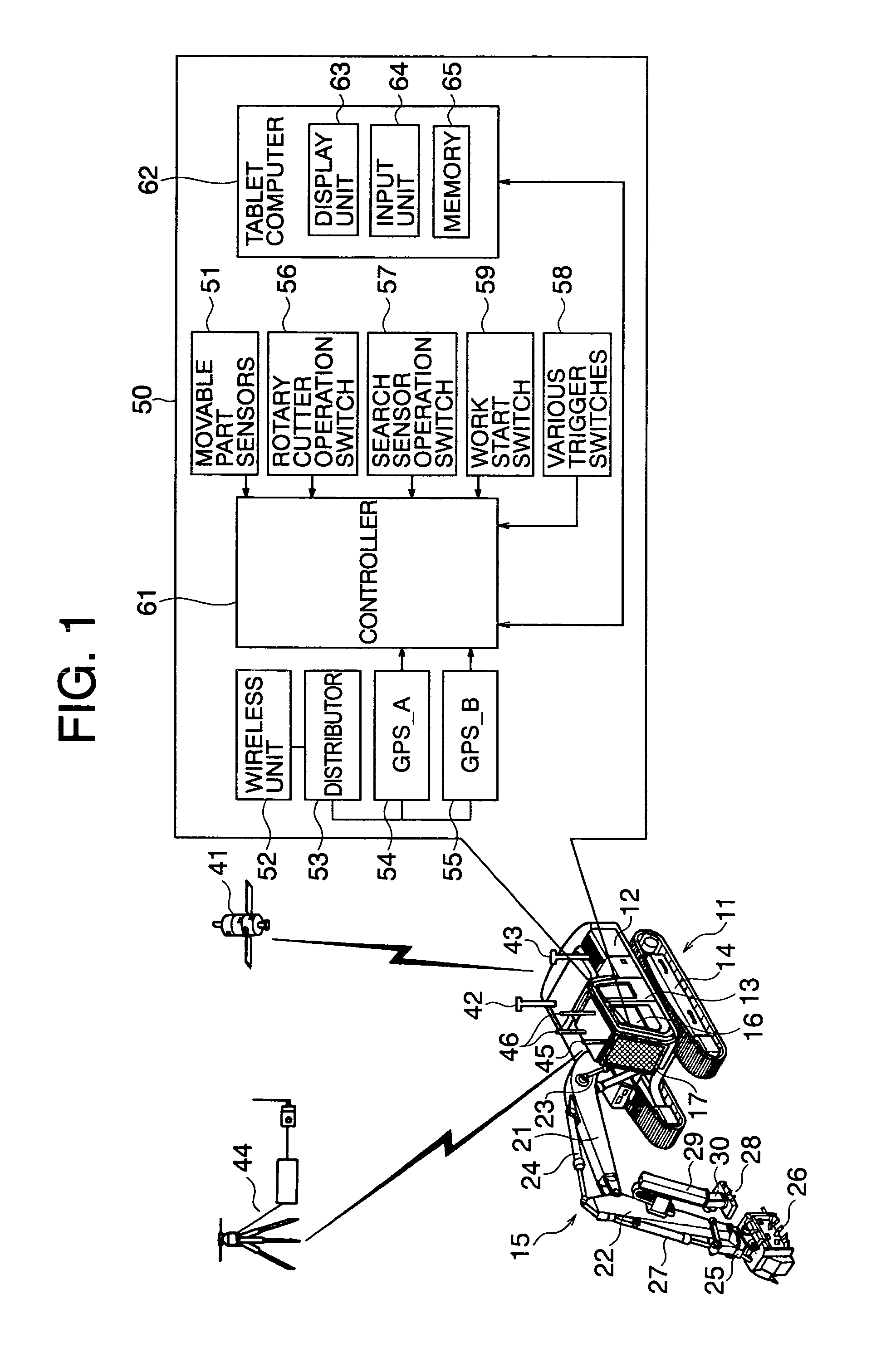

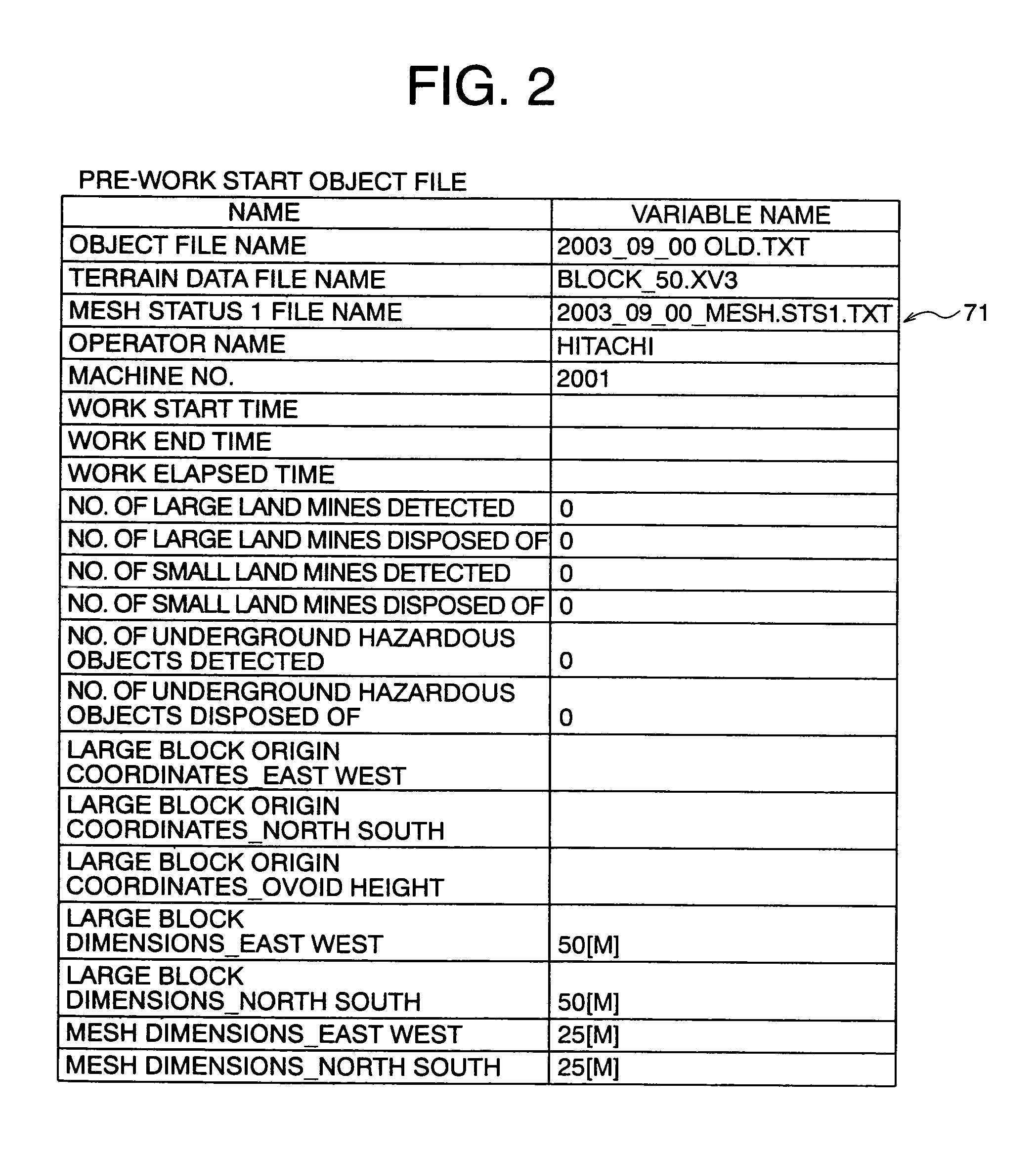

Work area setting and managing system

InactiveUS20070195011A1Increase flexibilityGood general applicabilityDefence devicesTelemetry/telecontrol selection arrangementsTablet computerWork zone

A work area setting and managing system which enables a operator to plan and manage work in a work area and set and store the work area at just the mobile work machine side at the work site is provided. The system is applied to a mobile work machine 11 performing land mine disposal work in the work area and provided with a GPS 3D position finding system and a tablet computer 62 having a display unit 63, input unit 64, and memory 65. This system is provided with a first means for displaying a work monitor screen 90 on a screen of the display unit, a second means for displaying a symbol of the mobile work machine on the work monitor screen based on positional coordinates of an attachment of the mobile work machine obtained by the GPS 3D position finding system, and a third means for preparing a work area based on an input operation of a operator using as the origin the symbol displayed on the work monitor screen and displaying a work area block model showing the work area.

Owner:NIHON KENKI CO LTD

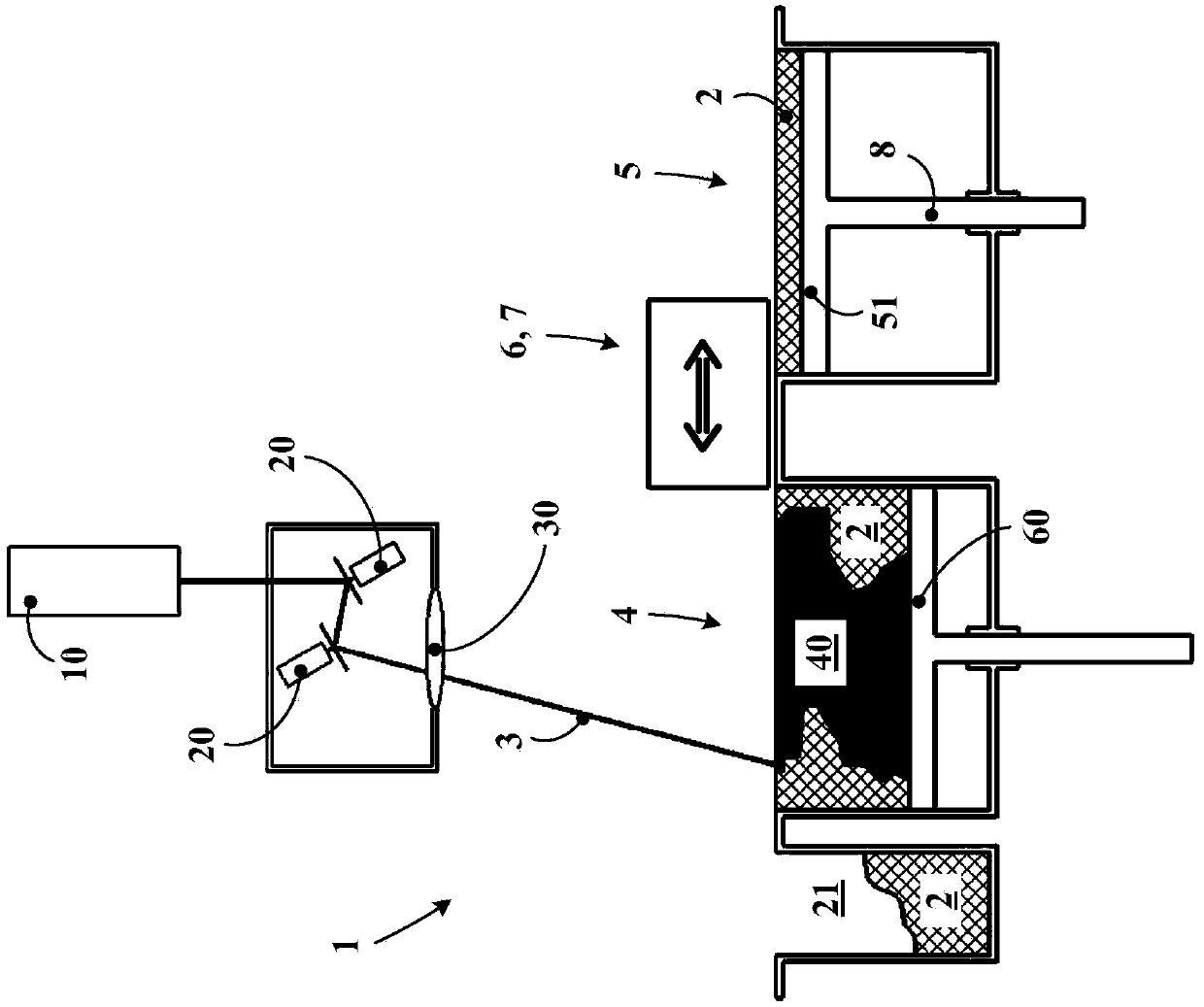

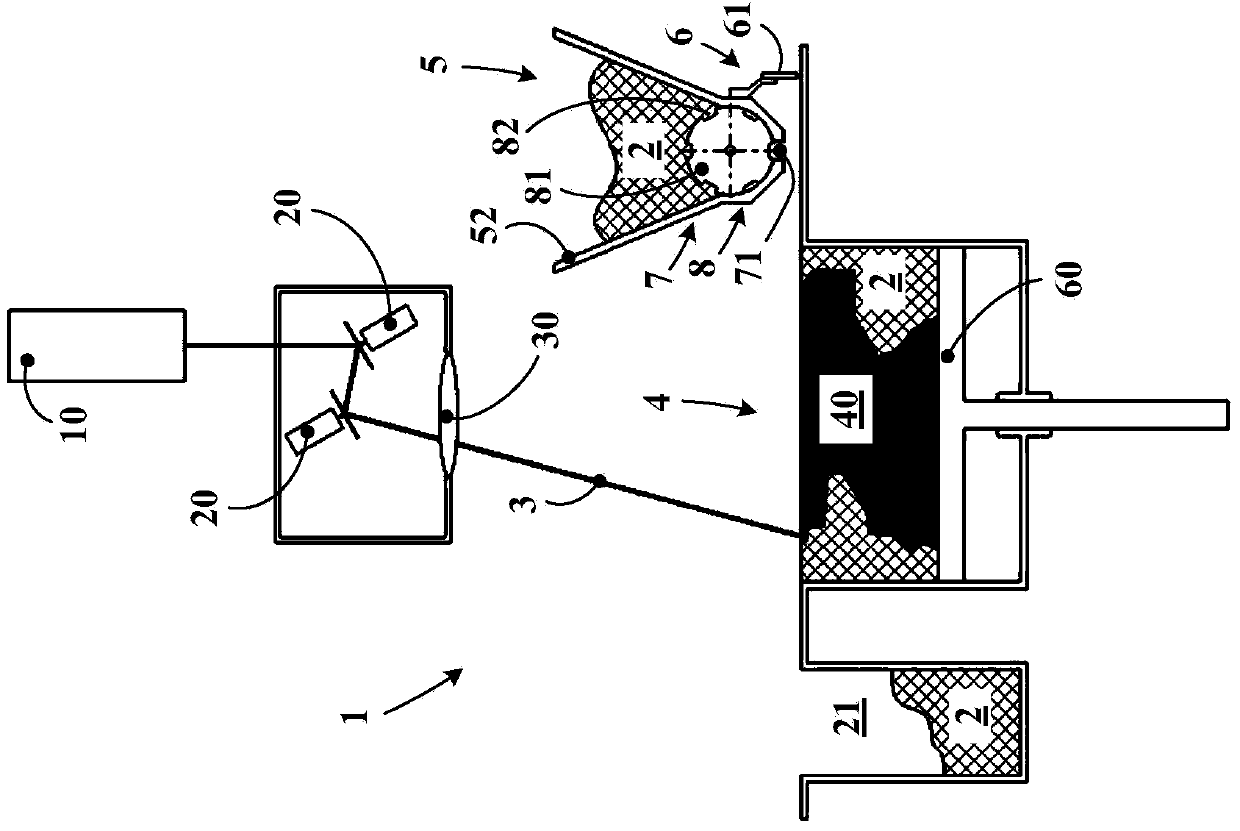

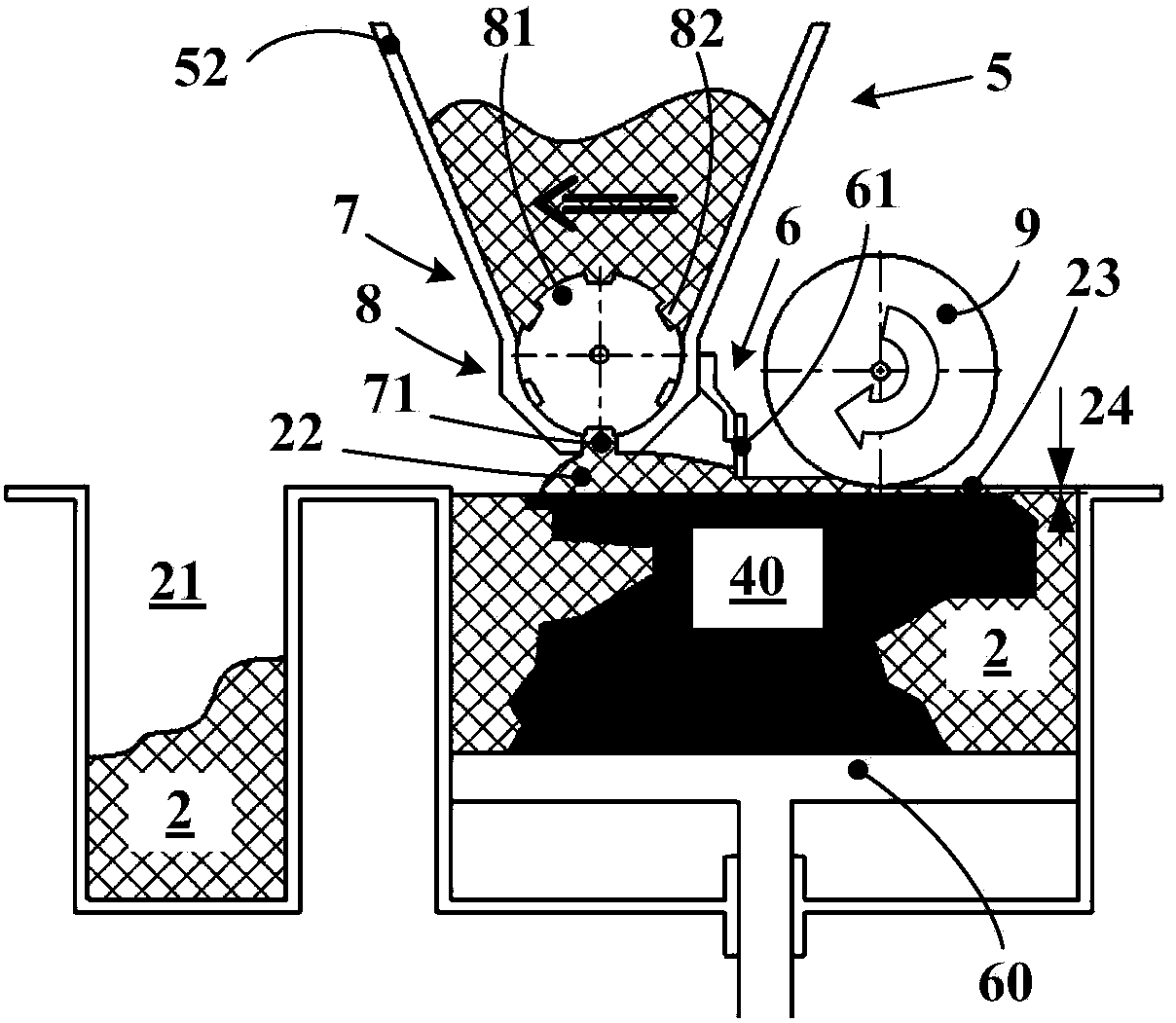

Machine and process for powder-based additive manufacturing

ActiveCN104010750AImprove uniformityManufacturing enclosuresPretreated surfacesProcess engineeringMechanical engineering

The invention in particular relates to a machine (1) for additive manufacturing that frits or melts powder (2) using an energy beam (3) acting on a powder layer (23) in a working zone (4), said machine comprising a device for producing a layer of said powder, said device comprising: means (5) of storing the powder; means (6) for distributing the powder, which means is able to travel over the working zone in order to distribute the powder in a layer (23) having a final thickness (24) tailored to the additive manufacturing; feeding means (7) able to transfer the powder from the storage means (5) to the distributing means (6); and dosing means (8) able to control the amount of powder transferred from the storage means (5) to the distributing means (6), said machine being characterised in that: the storing means (5) are located above the working zone (4); the feeding means (7) are gravitational feeding means; and the feeding means (7) and the dosing means (8) are able to move with the distributing means (6).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

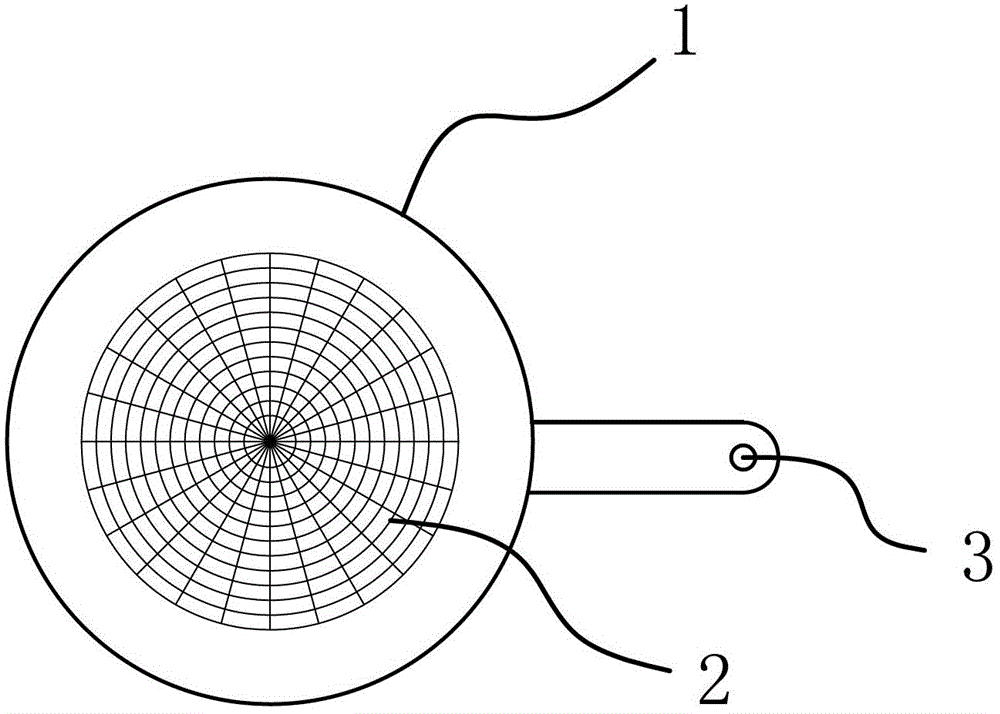

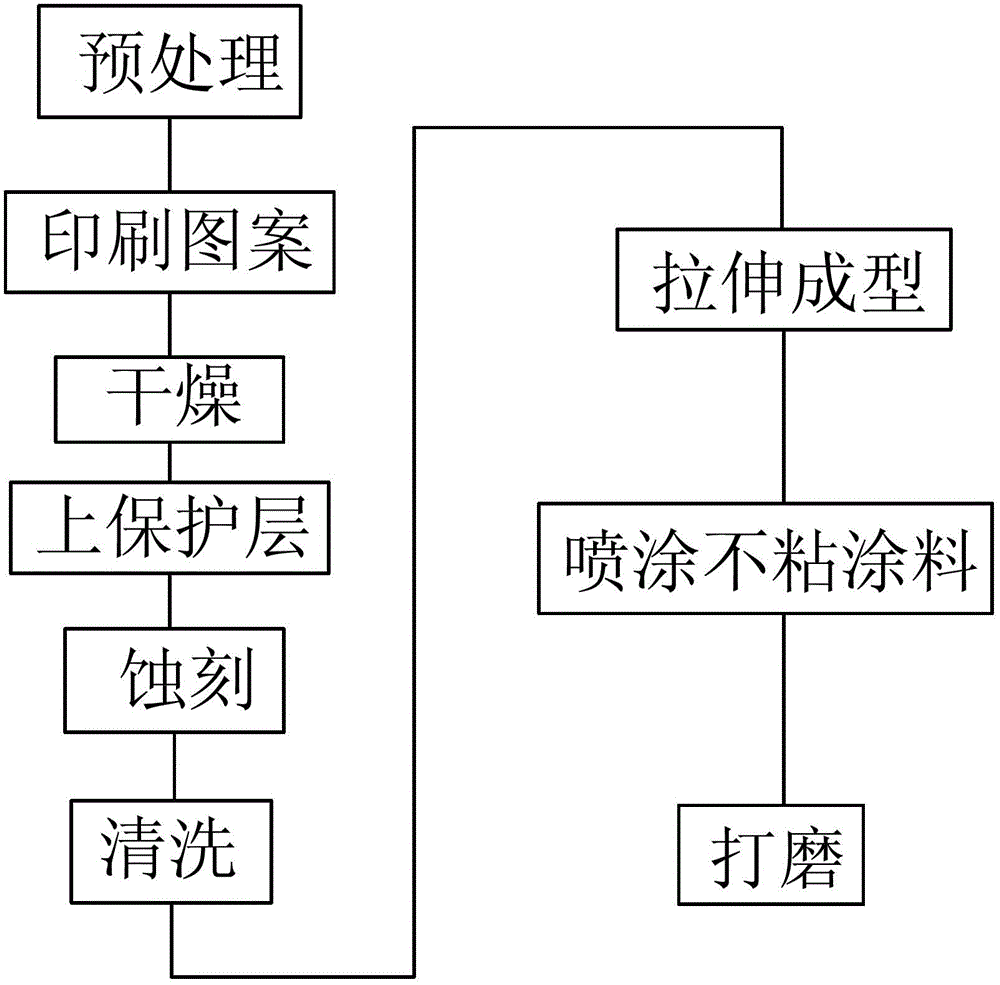

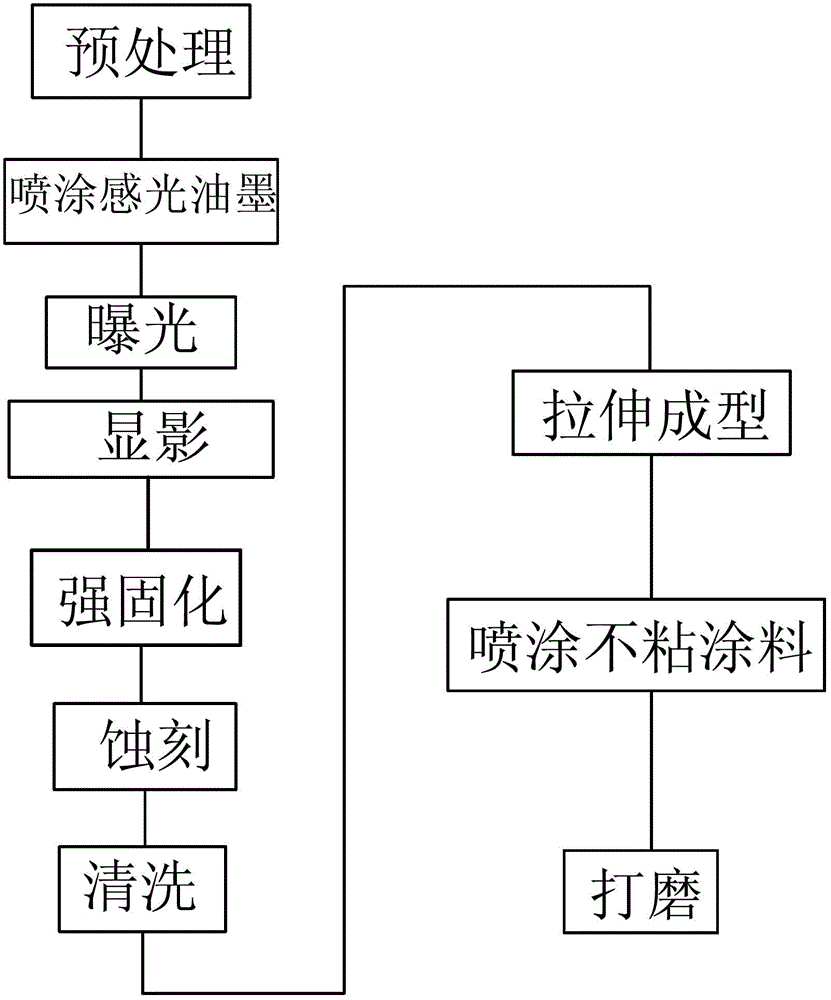

Method for manufacturing stainless steel or compound steel non-stick pan

InactiveCN103142132AAvoid electroplating and other processesOvercoming serious pollution and other problemsCooking vesselsSurface patternEtching

The invention provides a method for manufacturing a stainless steel or compound steel non-stick pan and belongs to the technical field of non-stick pan manufacturing technique. The method solves the technical problems that the non-stick performance of a non-stick pan in the prior art is poorer and pollution can be easily caused. The method comprises the following steps that a, surface pattern treatment: concave-convex lines with preset patterns are formed in a preset zone on the surface of a stainless steel plate through a chemical etching, graving or rolling depression method; b, drawing forming: the stainless steel plate body is drawn to form a pan body, and the preset zone is positioned in the working zone of a formed pan body; c, spraying of non-stick coating: non-stick coating is sprayed to the preset zone on the inner surface of the pan body, so that the non-stick coating is coated on the preset zone on the inner surface of the pan body; d, polishing: the preset zone on the inner surface of the pan body is subjected to mechanical polishing, the non-stick coating on the convex surfaces of the concave convex lines is removed, and the non-stick coating on the concave surfaces of the concave convex lines is retained. The method for manufacturing the stainless steel or compound steel non-stick pan has the advantages of durability and good non-stick property.

Owner:ZHEJIANG BAHE KITCHENWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com