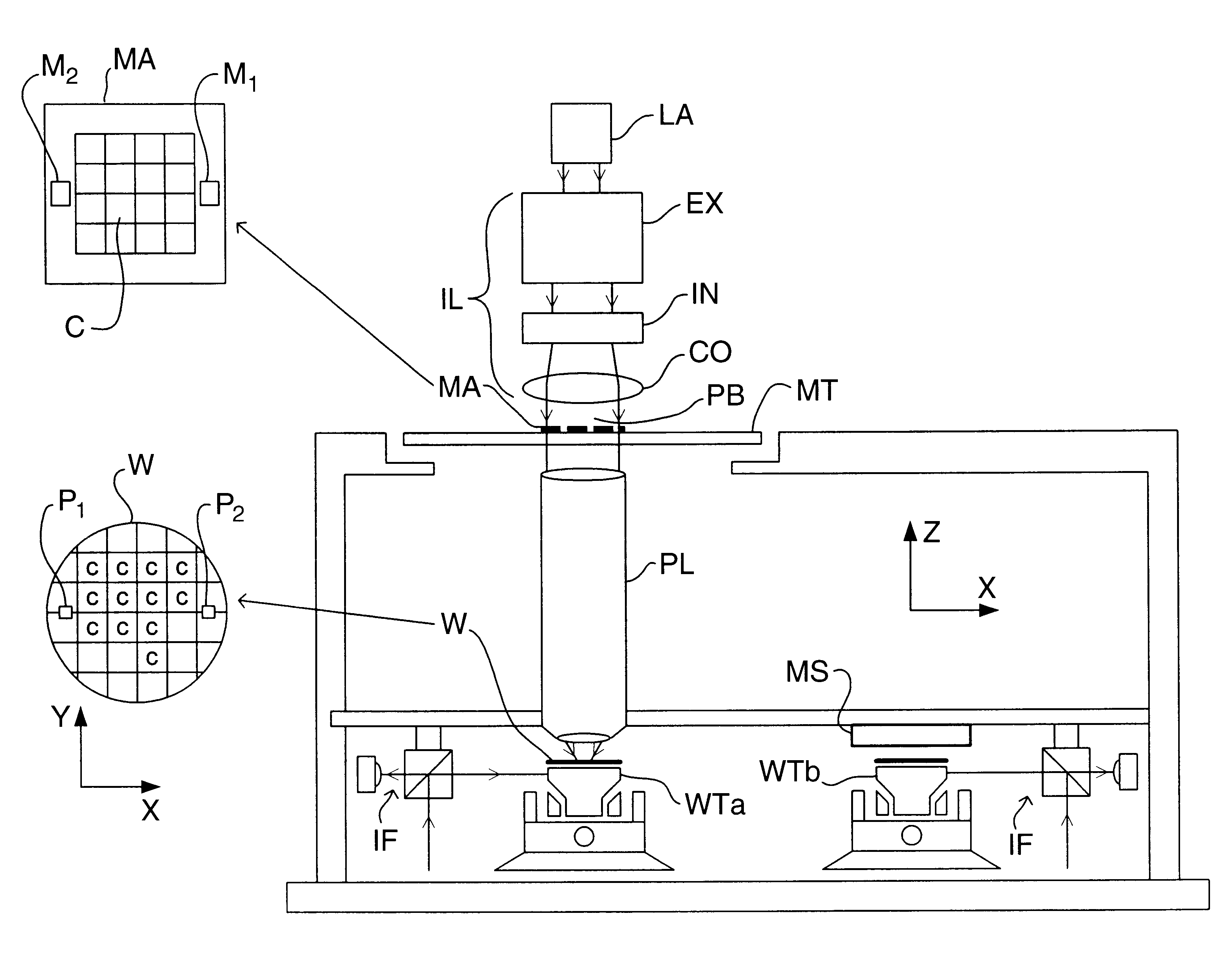

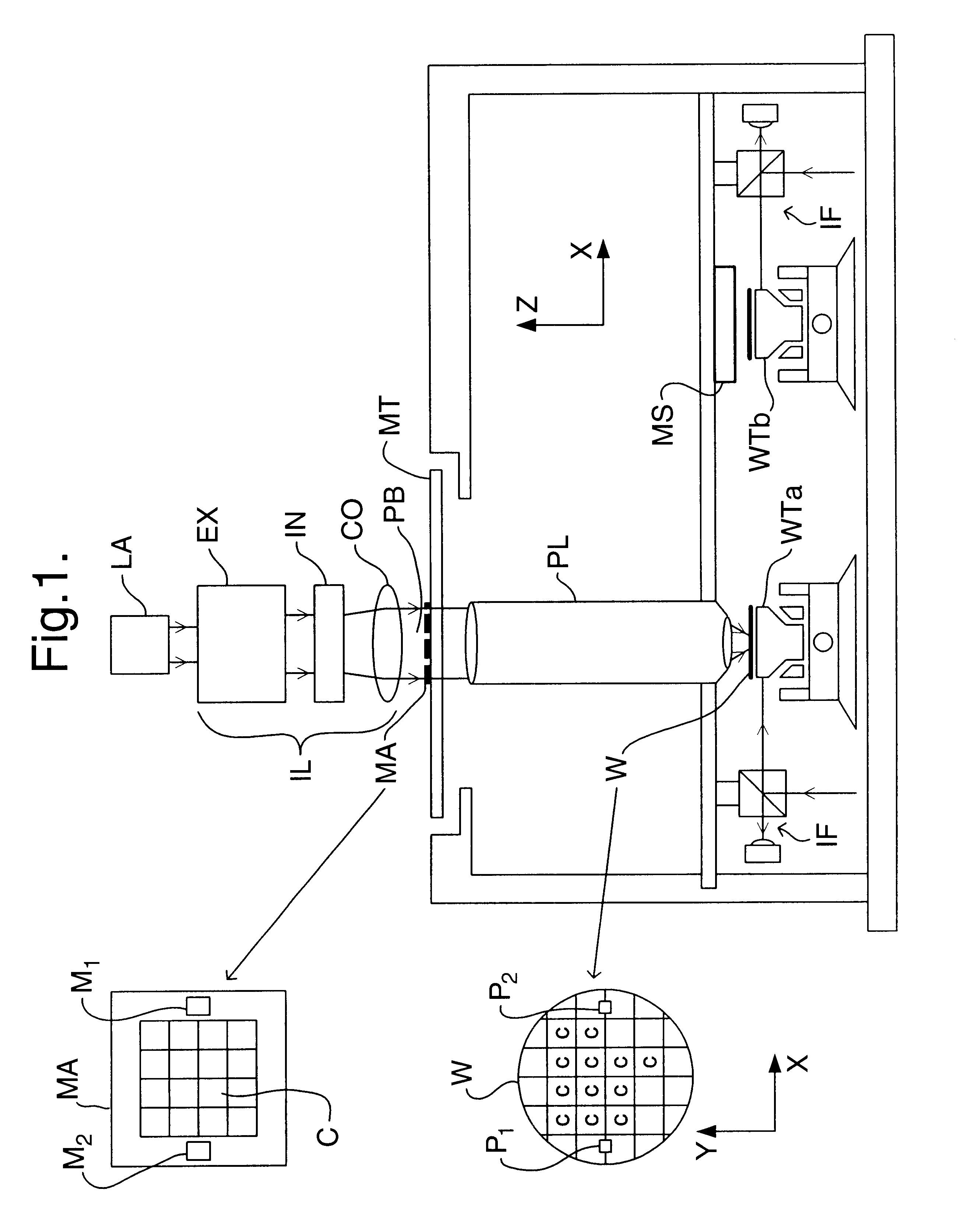

Crash prevention in positioning apparatus for use in lithographic projection apparatus

a positioning apparatus and lithographic projection technology, applied in the direction of engine lubrication, liquid/fluent solid measurement, radiation therapy, etc., can solve the problems of unusable whole apparatus, serious effects of any collision between tables, even a low speed on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

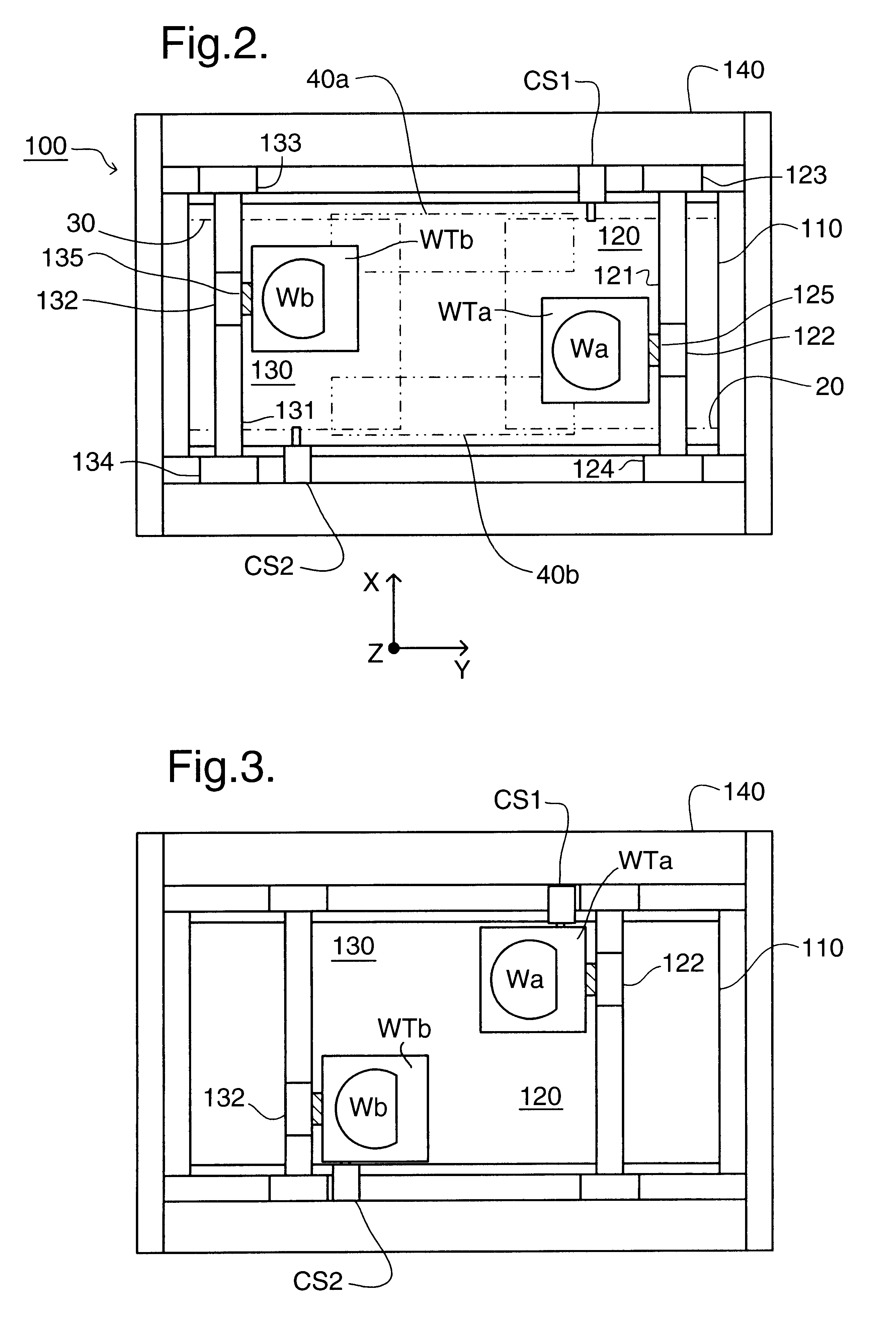

FIG. 2 shows the wafer stage 100 of the lithography apparatus of embodiment 1 in plan. The core of wafer stage 100 is formed by reference table, or stone, 110 which has a flat, level upper surface over which two wafer tables WTa, WTb can move. Wafer tables WTa and WTb are essentially identical and each includes a wafer holder (not shown) for respective wafers Wa, Wb and an air foot (air bearing) to support the table so that it can be moved essentially without friction over the reference table 110. The wafer tables are positioned by two drive units 120, 130, which are of a known H-drive arrangement. Each drive consists of an X-beam 121, 131 on which is mounted the stator of an X-linear motor which drives an X-slider 122, 132 longitudinally of the beam. Wafer tables WTa and WTb are kinematically coupled to respective ones of the X-sliders 122, 132 by releasable stage couplings 125, 135. Each end of each X-beam is mounted on a Y-slider 123, 124, 133, 134 which can be driven by Y-linear...

embodiment 2

A second embodiment of the invention is shown in FIGS. 10 to 13. In this embodiment the possibility of a crash is further reduced by providing the cable shuttles CS1', CS2' with drives so that they, rather than the drive units 120, 130, effect the transfer of the wafer tables between measurement and expose zones.

The first step in the transfer process in the second embodiment is the same as that in the first; the wafer tables WTa, WTb are moved into the labyrinth to engage cable shuttles CS1', CS2' respectively. In the second step, rather than being guided through the labyrinth by the drives 120, 130, coupling mechanisms 125, 135 are released to disengage the wafer tables WTa, WTb from drive units 120, 130. The wafer tables WTa, WTb are then driven through the labyrinth by cable shuttles CS1', CS2', as shown in FIG. 10. The first and second steps in the second embodiment can be carried out "on-the-fly" to reduce the time taken for the transfer. In this arrangement, the wafer tables W...

embodiment 3

In a third embodiment, shown in FIG. 14, the labyrinth arrangement is replaced by a revolving barrier or door 200. Otherwise, the third embodiment may be the same as either the first or second embodiment.

Revolving barrier 200 is mounted on a pivot 201 in the center of the reference table 110. To begin the transfer of wafer tables WTa, WTb, they are driven to diagonally opposite positions either side of pivot 201. The wafer tables WTa, WTb are then driven through the transfer zones 40a, 40b in synchronism with each other and the rotation of the barrier 200. In this embodiment, synchronization of the moving bodies during the transfer process is controlled by software. However, even in the event of a major failure, such as software error, unexpected power loss or interference, the revolving barrier 200 will always be between the two tables WTa, WTb preventing them coming into contact.

In an alternative arrangement the same effect is achieved with retractable barriers; one which projects...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com