Patents

Literature

512results about How to "Energy optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

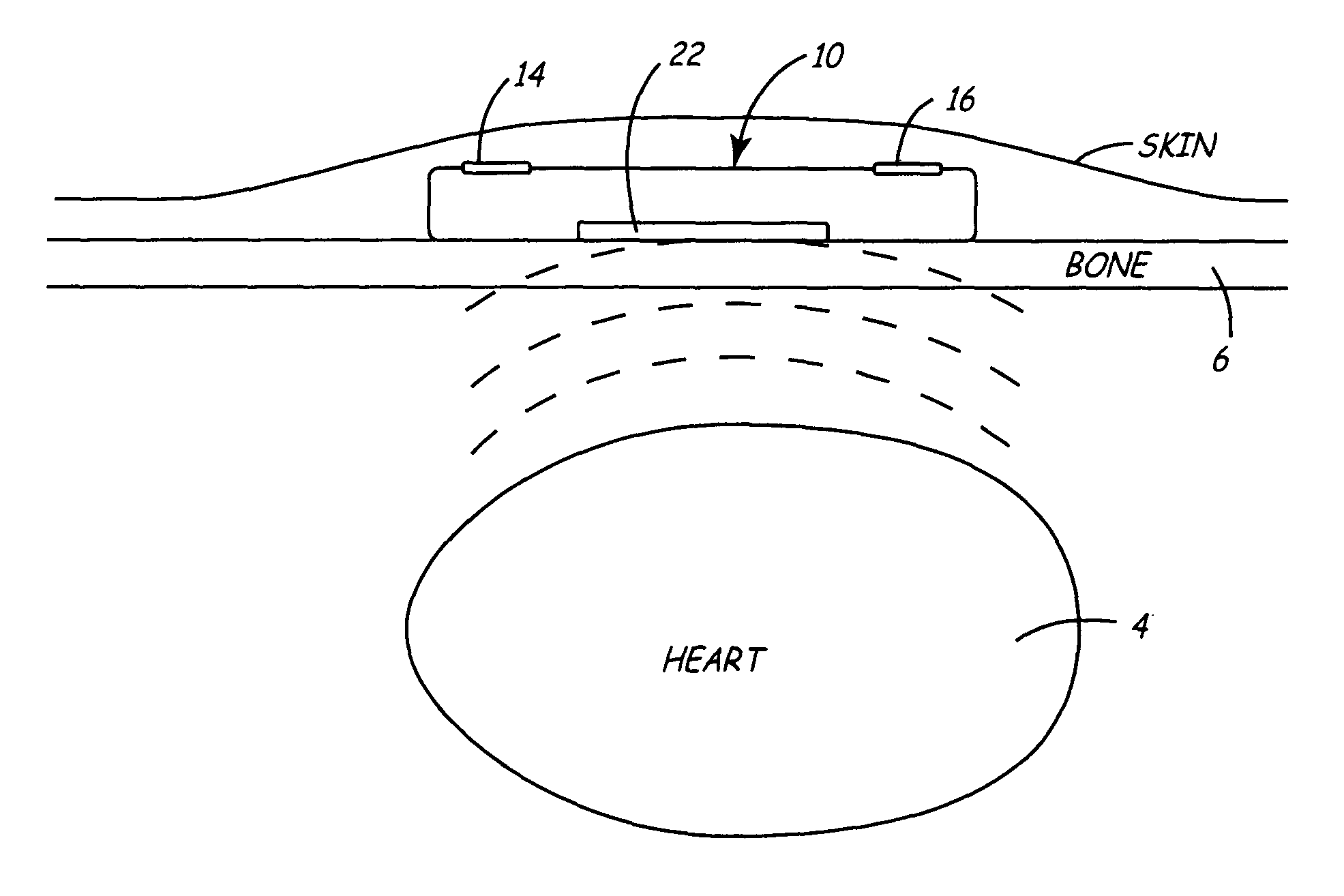

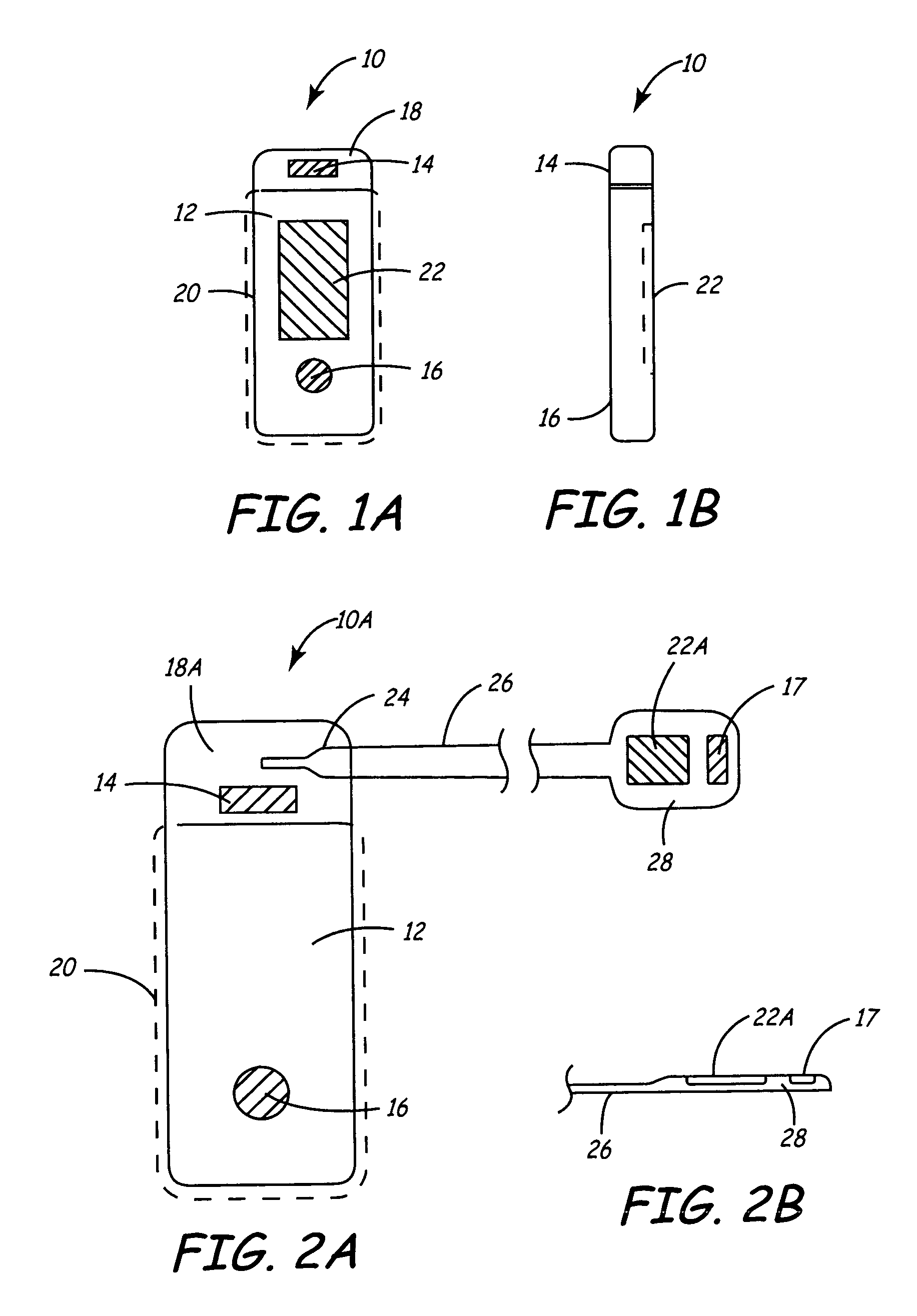

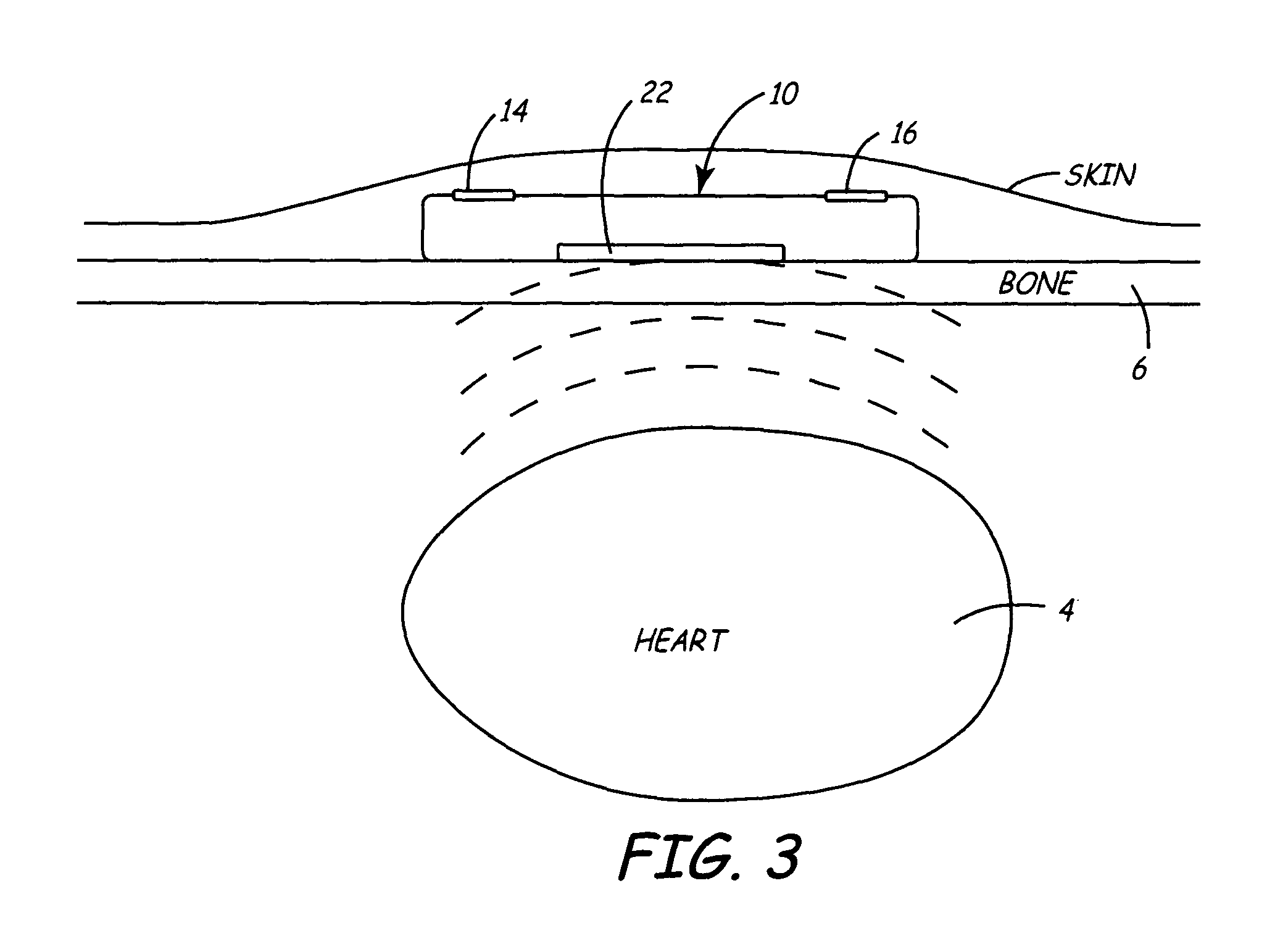

Method and apparatus for monitoring heart function in a subcutaneously implanted device

ActiveUS7035684B2Optimizing received energyRepeatability of measurement madeElectrocardiographyBlood flow measurement devicesElectricityLTM - Long-term memory

A minimally invasive, implantable monitor and associated method for chronically monitoring a patient's hemodynamic function based on signals sensed by one or more acoustical sensors. The monitor may be implanted subcutaneously or submuscularly in relation to the heart to allow acoustic signals generated by heart or blood motion to be received by a passive or active acoustical sensor. Circuitry for filtering and amplifying and digitizing acoustical data is included, and sampled data may be continuously or intermittently written to a looping memory buffer. ECG electrodes and associated circuitry may be included to simultaneously record ECG data. Upon a manual or automatic trigger event acoustical and ECG data may be stored in long-term memory for future uploading to an external device. The external device may present acoustical data visually and acoustically with associated ECG data to allow interpretation of both electrical and mechanical heart function.

Owner:MEDTRONIC INC

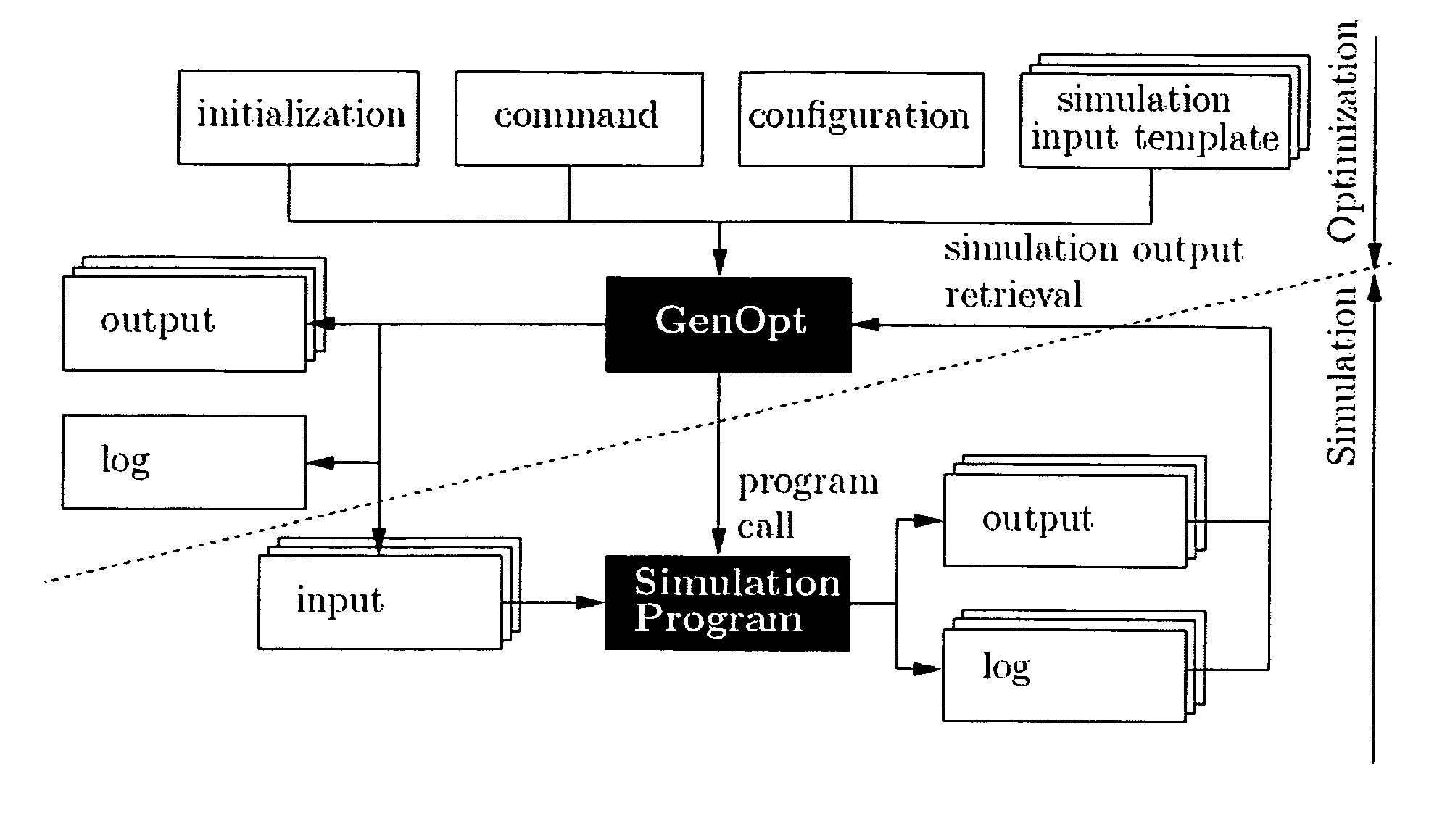

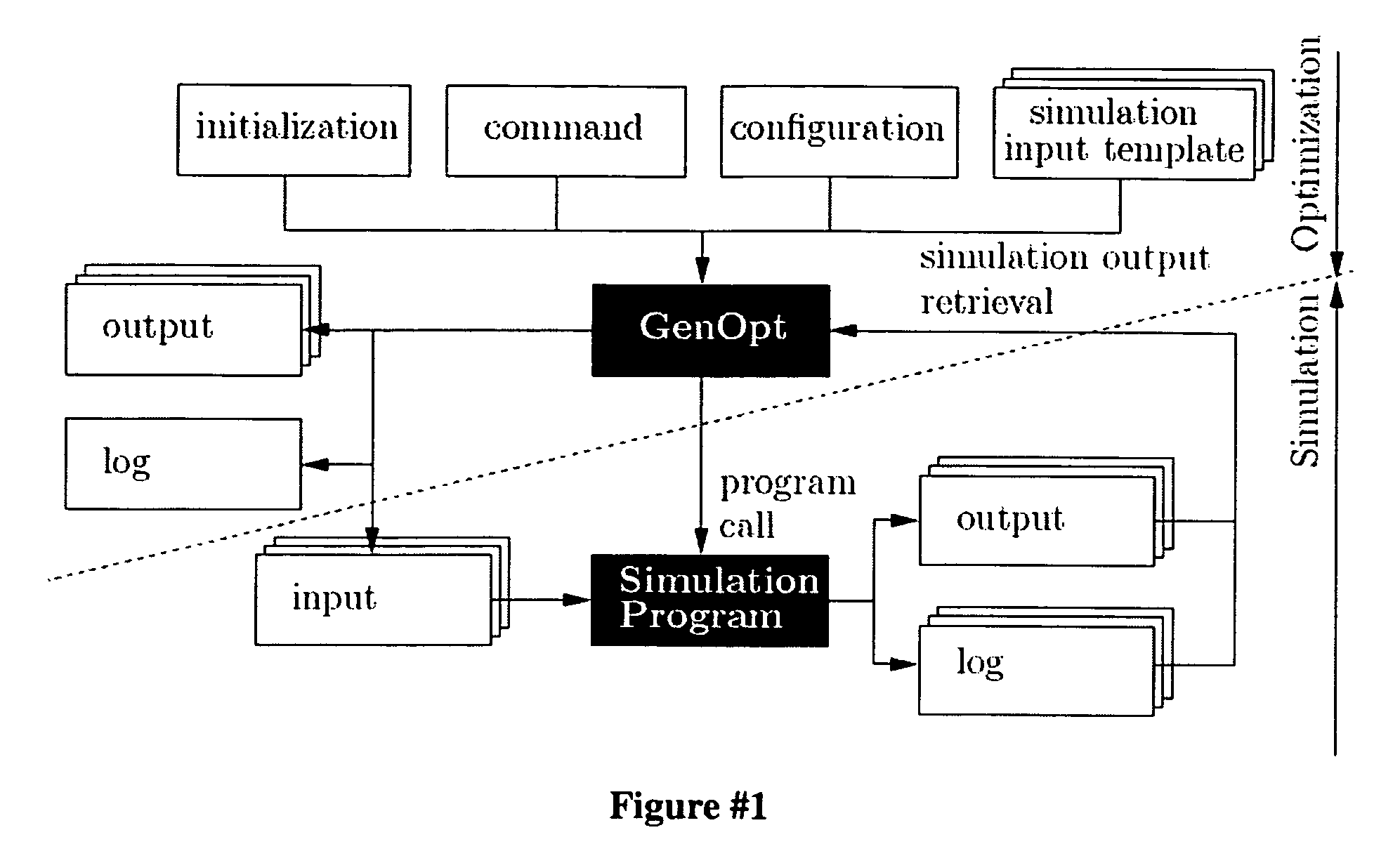

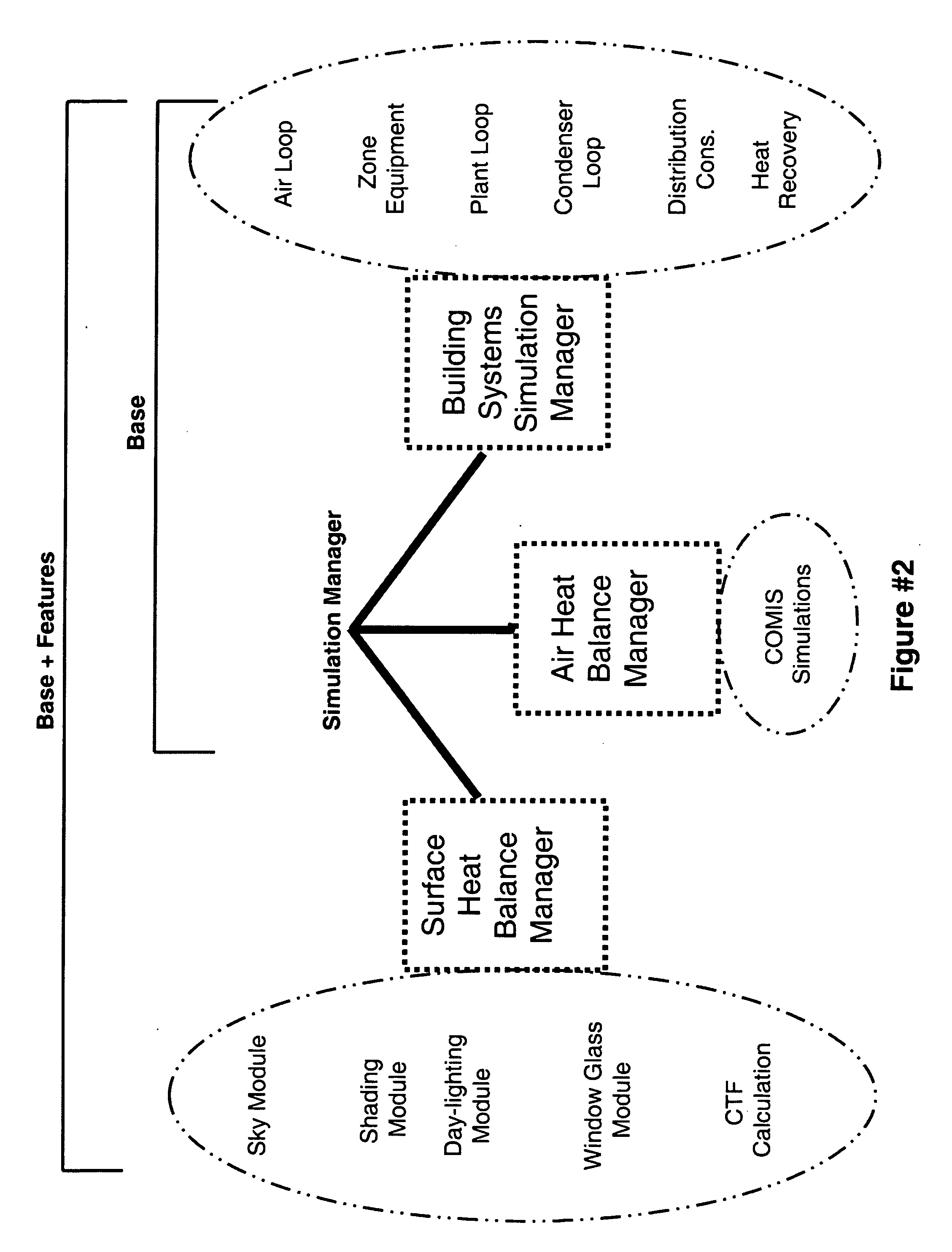

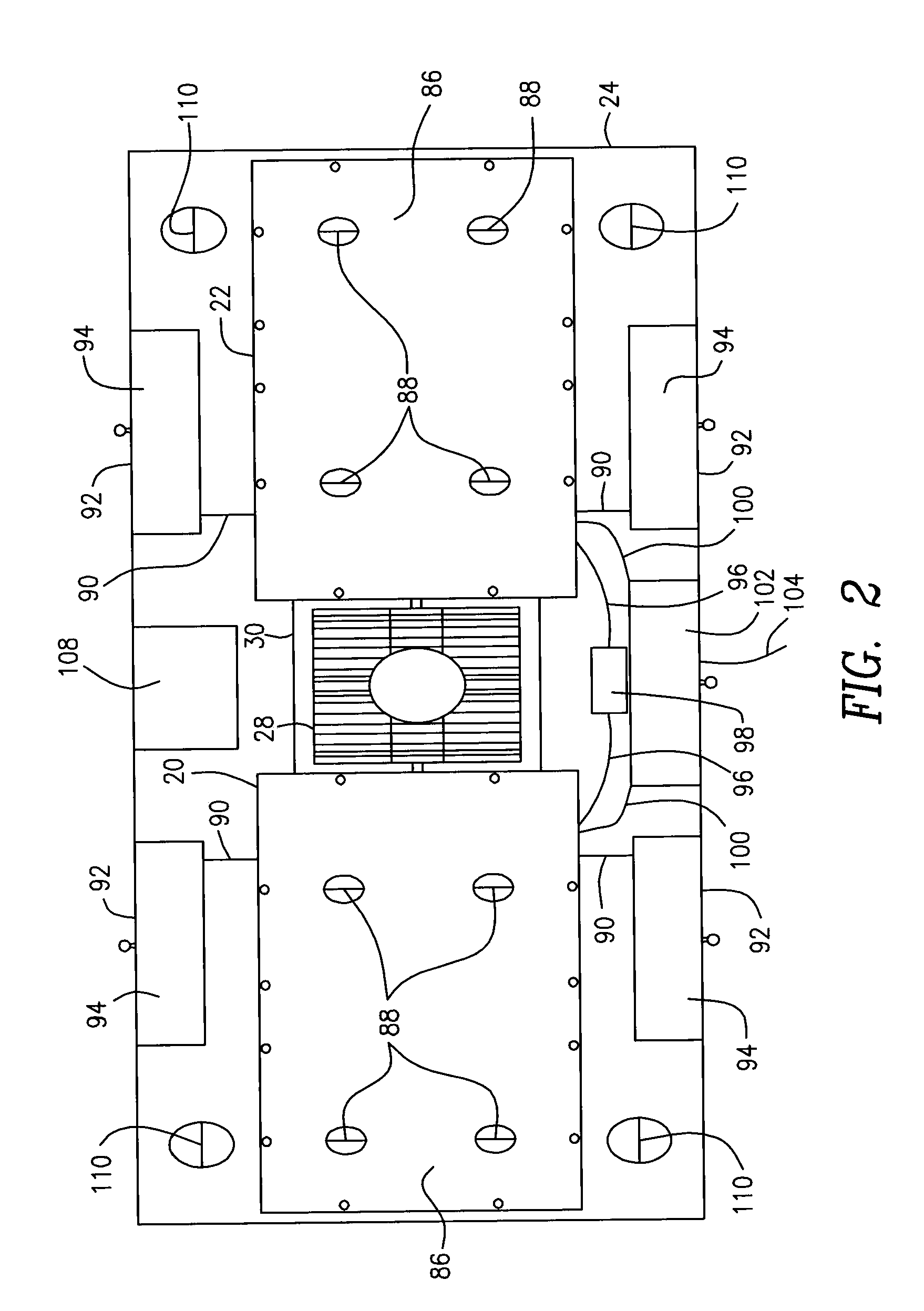

Real-time global optimization of building setpoints and sequence of operation

ActiveUS20070005191A1Operation efficiency can be improvedSimple and straightforward in implementationSampled-variable control systemsComputer controlReal-time dataMathematical model

A building heating / cooling system energy optimization method for a building having a heating / cooling system includes the steps of providing a mathematical model of the heating / cooling system, obtaining real-time weather information, reading the input water temperature (IWT), the output water temperature (OWT) and the supply air temperature (SA) output to the building, periodically transferring the IWT, the OWT and the SA to an optimization system which is operative to analyze the real-time data in coordination with the mathematical model by assigning at least three selected values in a range surrounding and including the current values of each of the IWT, the OWT and the SA and calculating the efficiency profile of the components of the heating / cooling system for each of the selected values, then cooperatively optimizing and selecting those values calculated to provide the highest efficiency profile, then periodically resetting the system values to those selected by the optimization system.

Owner:SLOUP CHARLES J +2

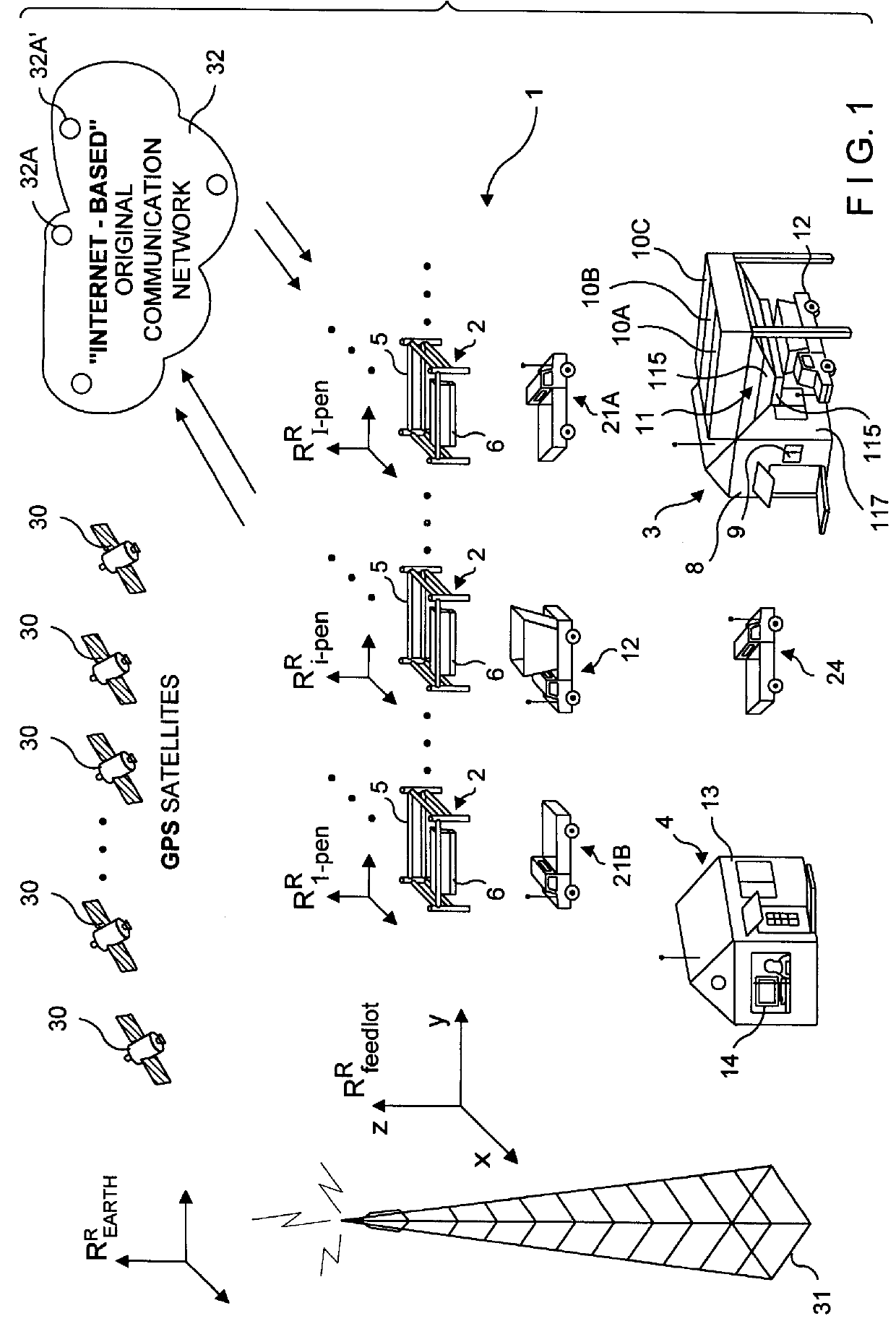

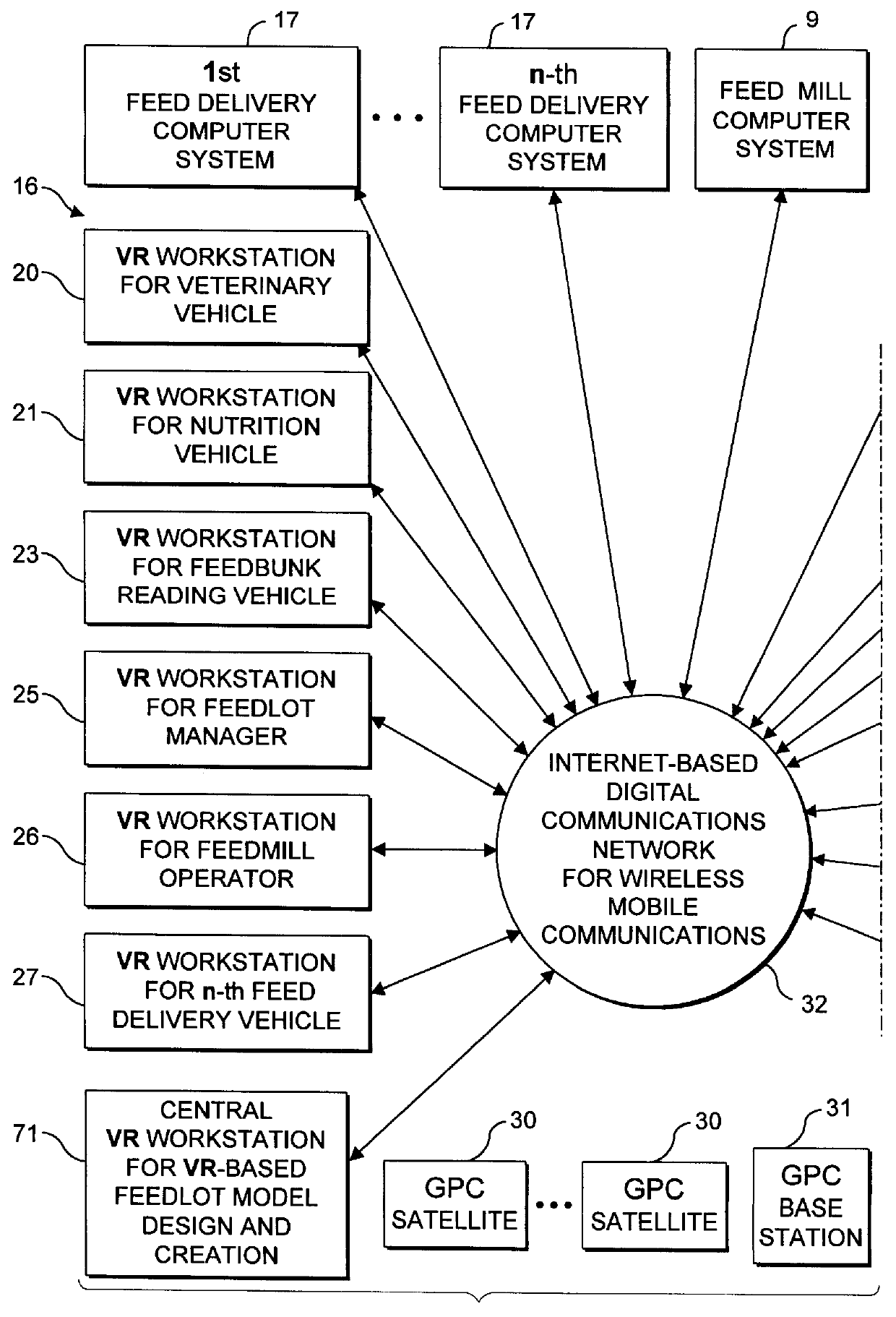

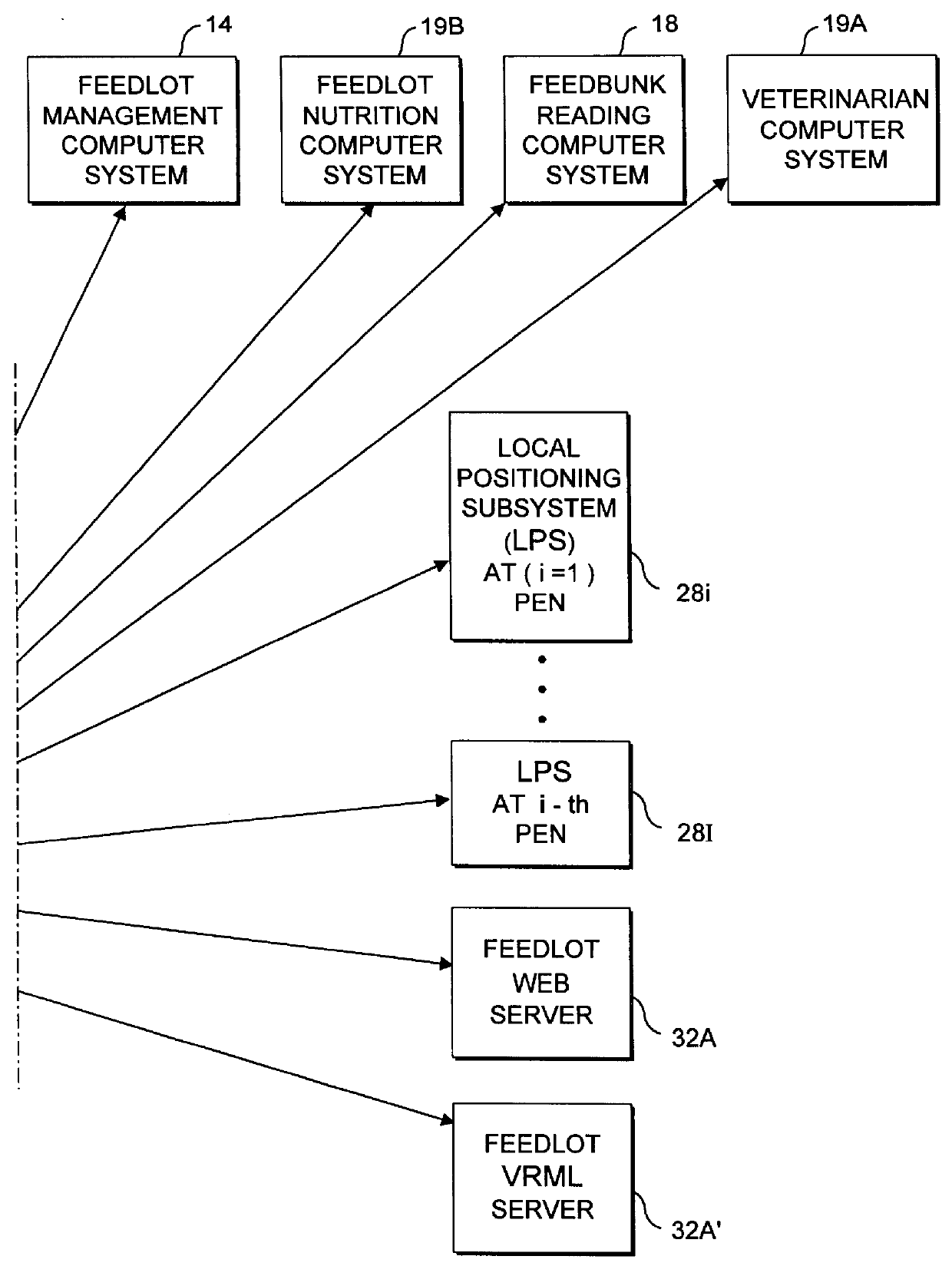

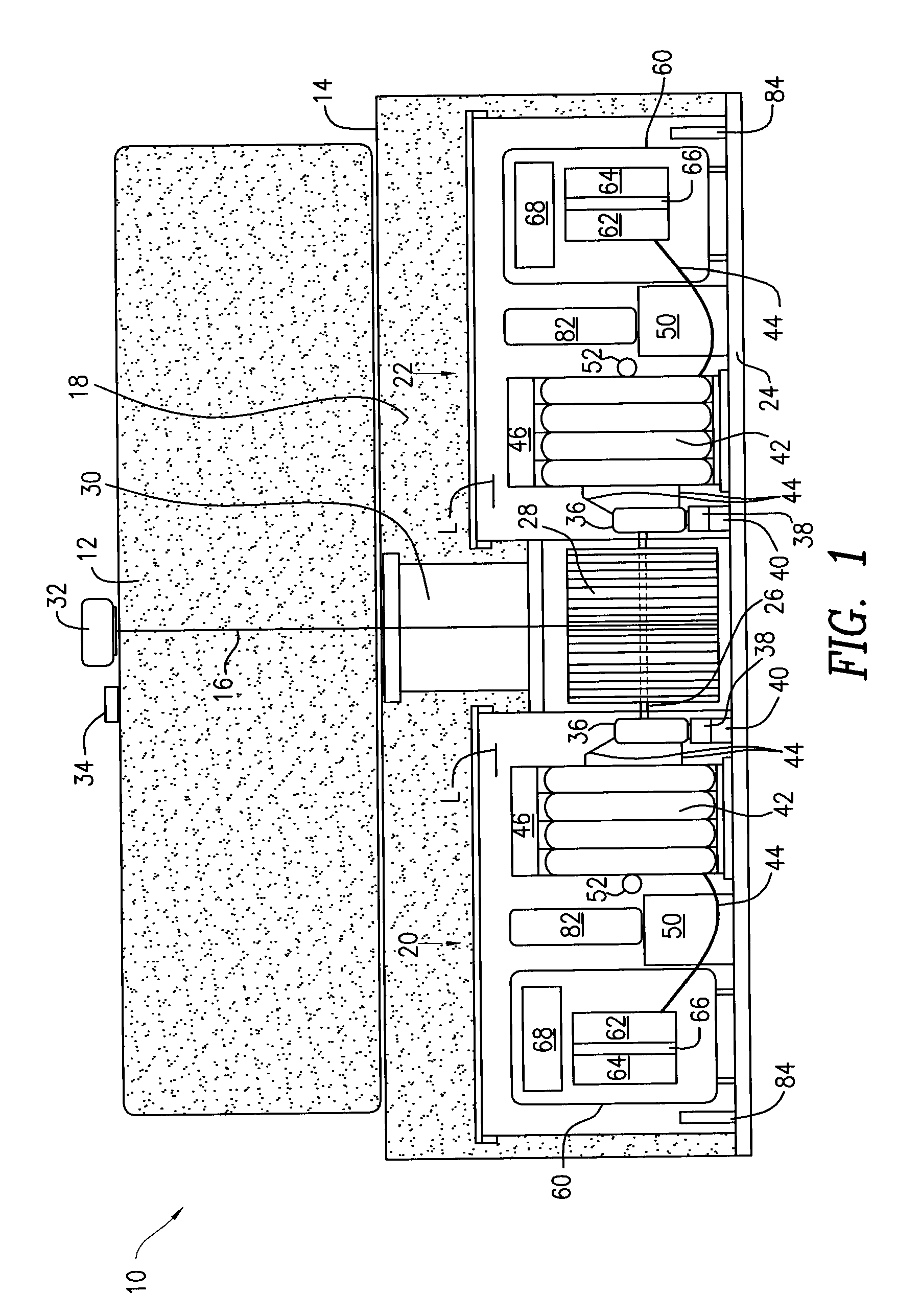

System for carrying out and managing animal feedlot operations using coordinate acquisition techniques

InactiveUS6032084AConvenient timeEnergy optimizationAnimal feeding devicesPosition fixationDelivery vehicleOn board

An animal feedlot management system is disclosed, wherein each feed delivery vehicle employed therein uses real-time virtual reality (VR) modelling and coordinate acquisition techniques supported upon an Internet-based (i.e., Cyberspace) communications platform in order to carry out various types of feedlot operations. Each feedlot vehicle has an on-board computer system which includes a VR subsystem, for accessing a VR database maintaining information representative of a VR model of the feedlot and the objects present therein (eg., tagged animals, pens, alley ways, feedbunks, buildings, vehicles, etc.

Owner:ANIMAL HEALTH INT

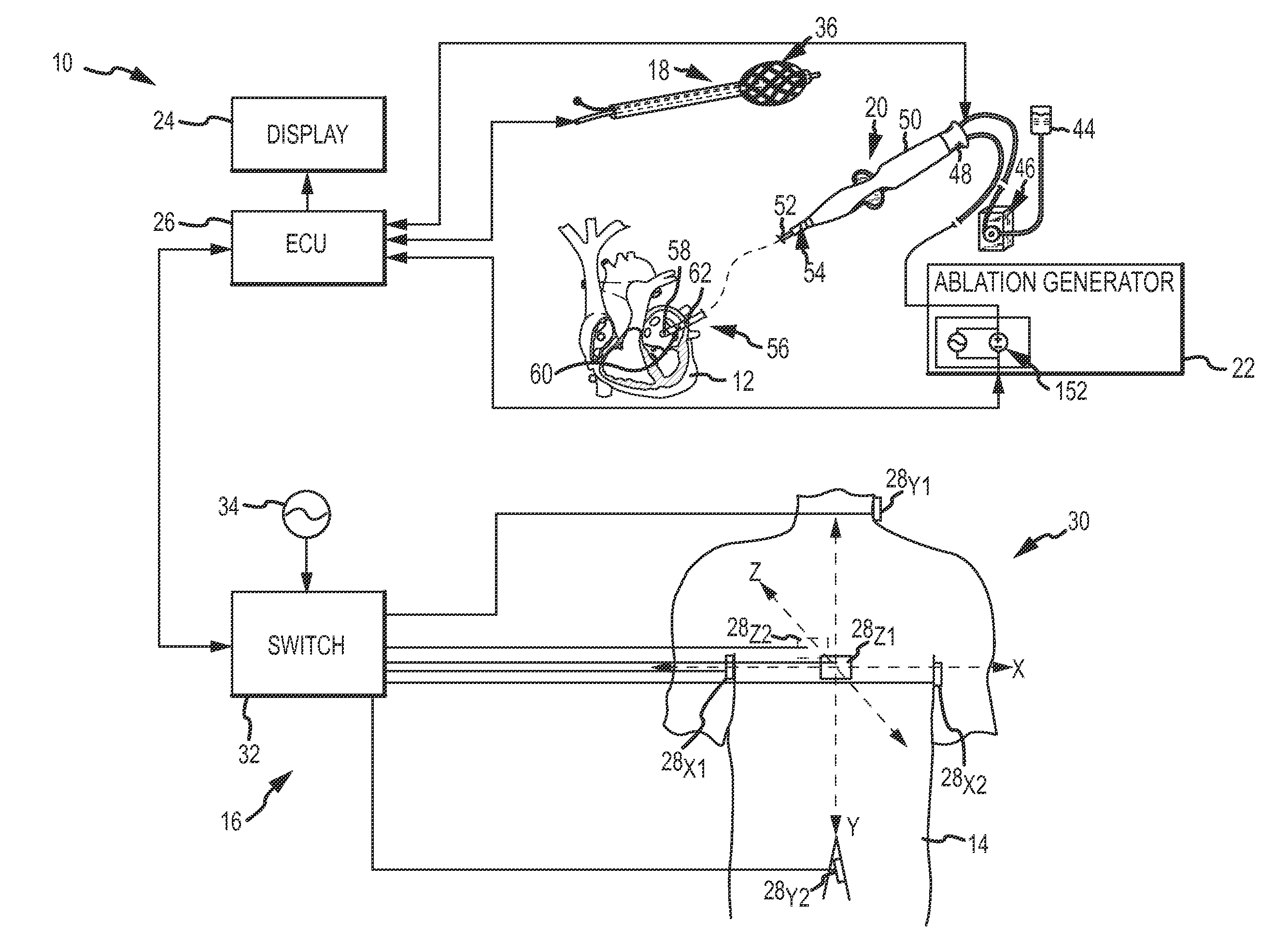

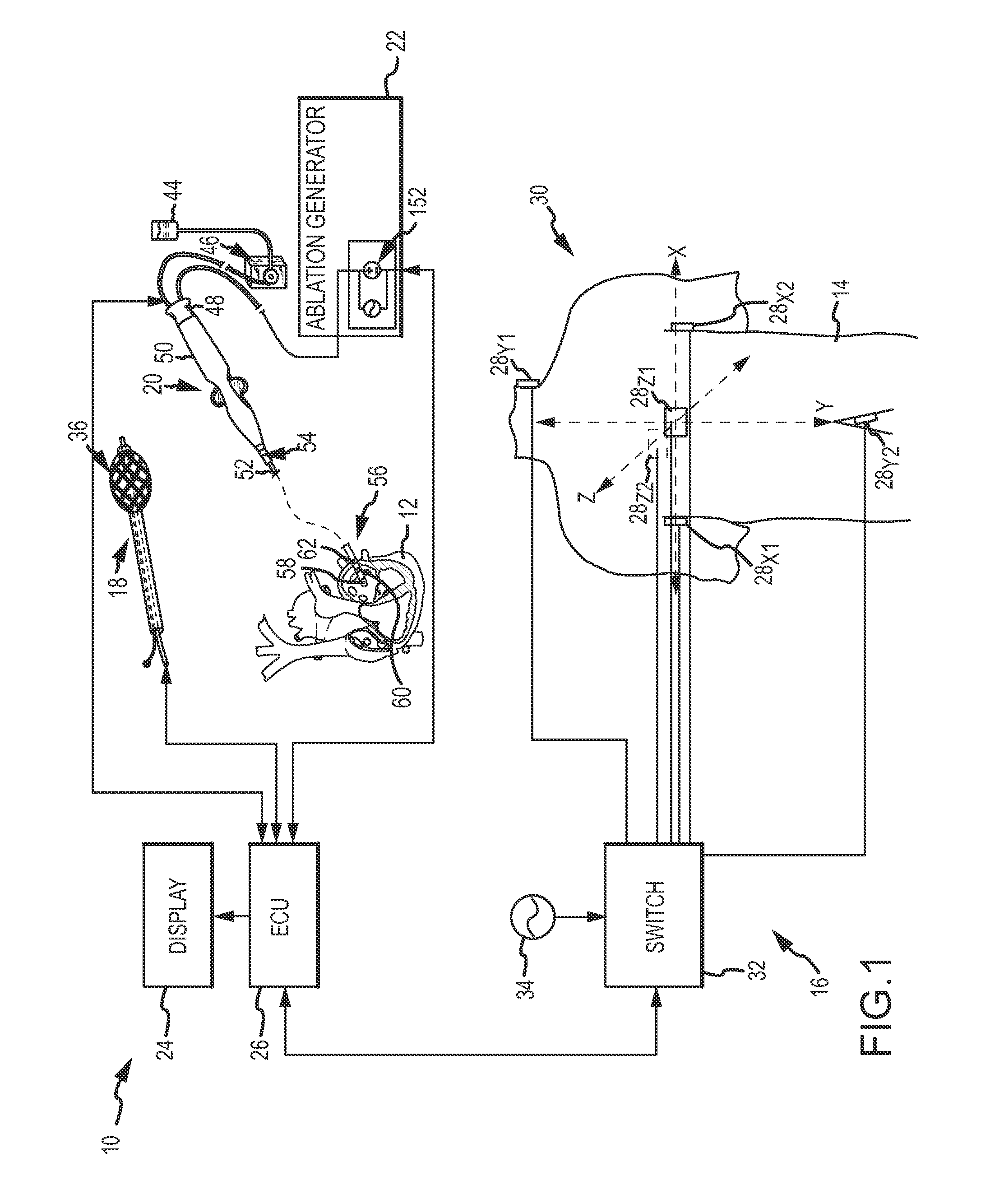

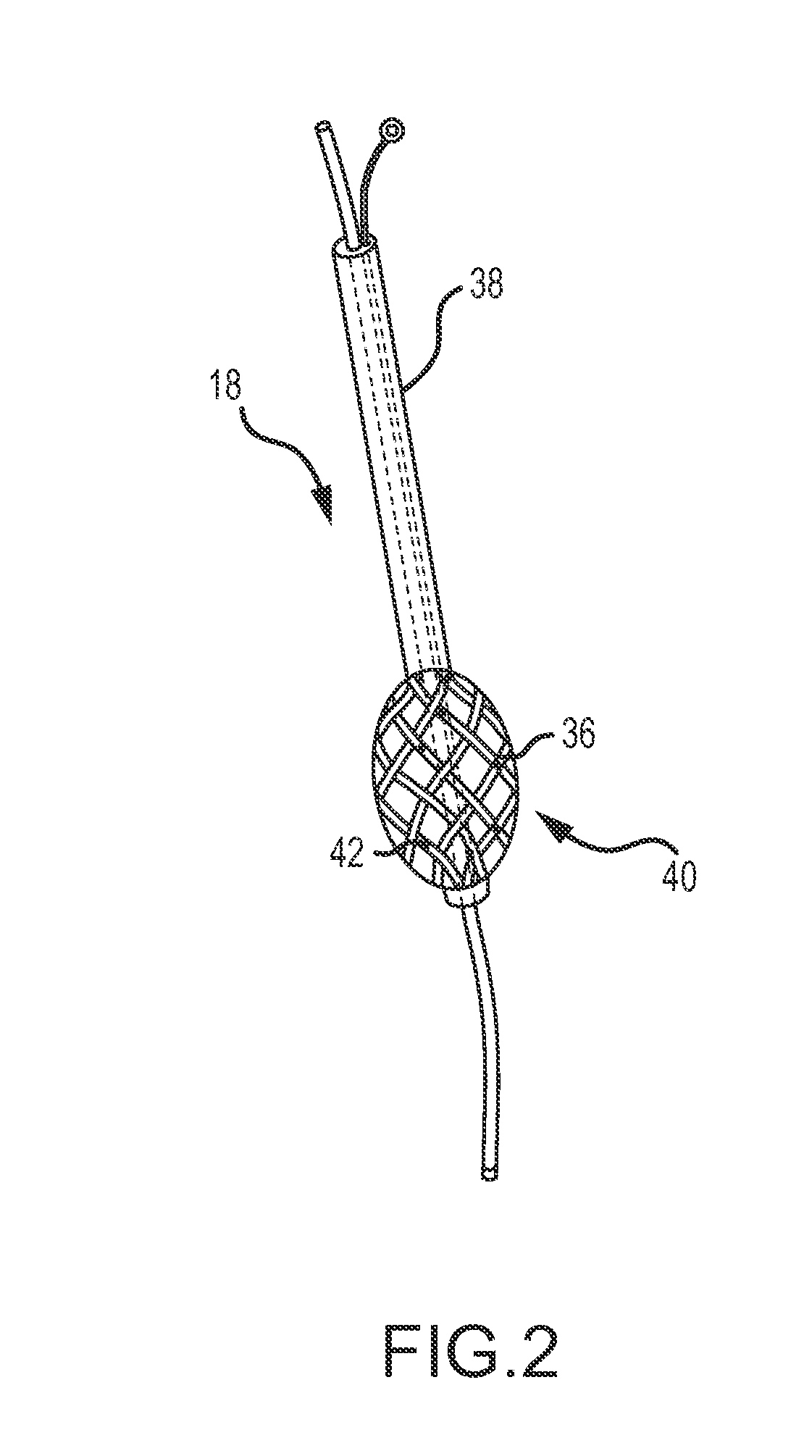

System for optimized coupling of ablation catheters to body tissues and evaulation of lesions formed by the catheters

ActiveUS20140364848A1Good curative effectOptimized application of energyCatheterDiagnostic recording/measuringProximateCoupling

A system for diagnosis or treatment of tissue in a body is provided. The system includes an ablation catheter having a deformable, elongate shaft having proximal and distal ends. The catheter further includes an ablation delivery member disposed proximate the distal end of the shaft and configured to deliver ablation energy to ablate the tissue. In one embodiment, the ablation delivery member comprises an ablation electrode and may also be configured to generate a signal indicative of electrical activity in the tissue. The catheter further includes one or more sensing electrodes disposed proximate the ablation delivery member. The sensing electrodes are configured to generate signals indicative of electrical activity in the tissue. The system further includes an electronic control unit configured to control delivery of ablation energy from the ablation delivery member responsive to one or more of the generated signals indicative of electrical activity in the tissue.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Nutritional supplements for healthy memory and mental function

InactiveUS20080213401A1Optimizing mental energyImprove mental functionBiocideNervous disorderMental functionsMental nerve

Owner:APPLIED COGNITIVE SCI

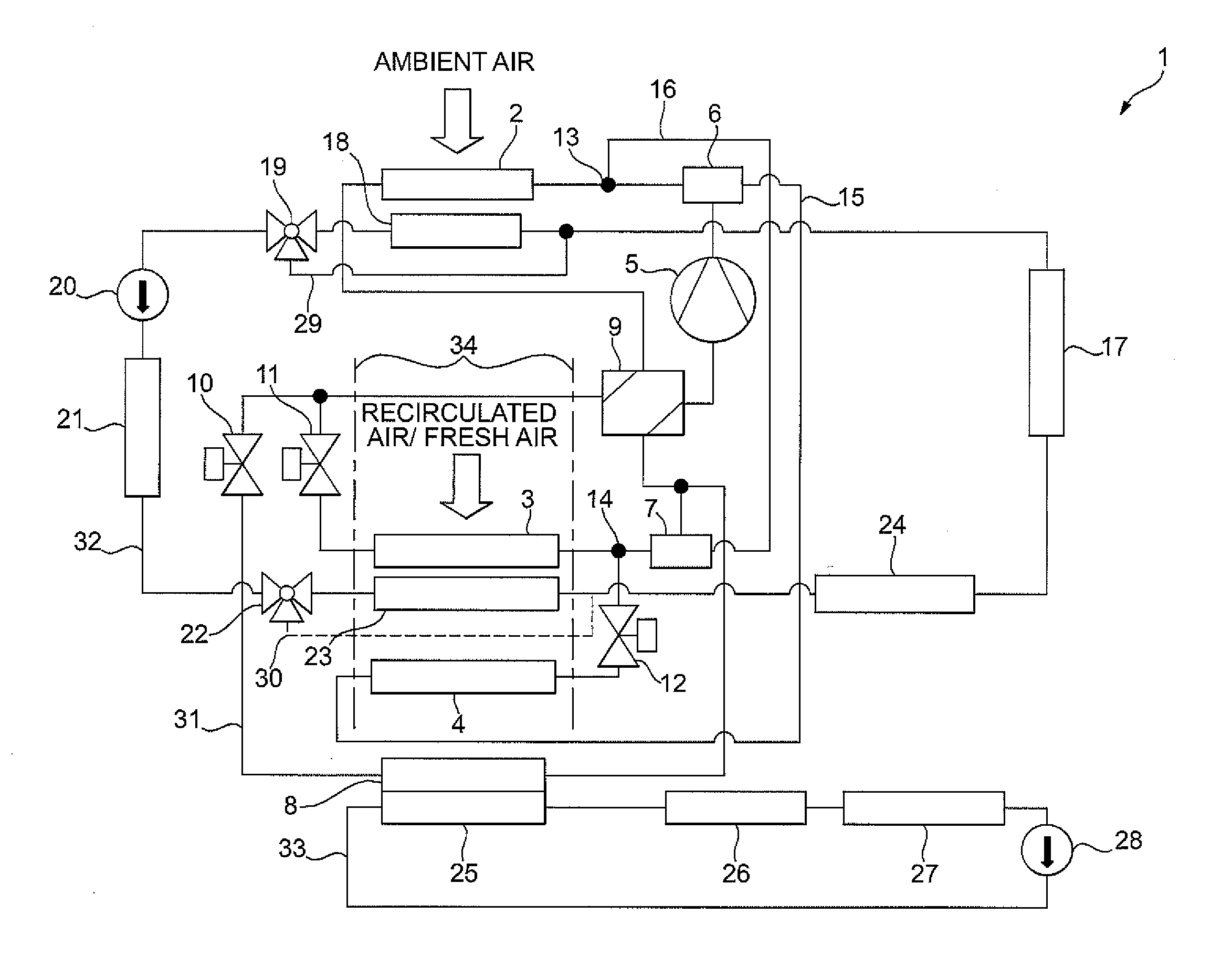

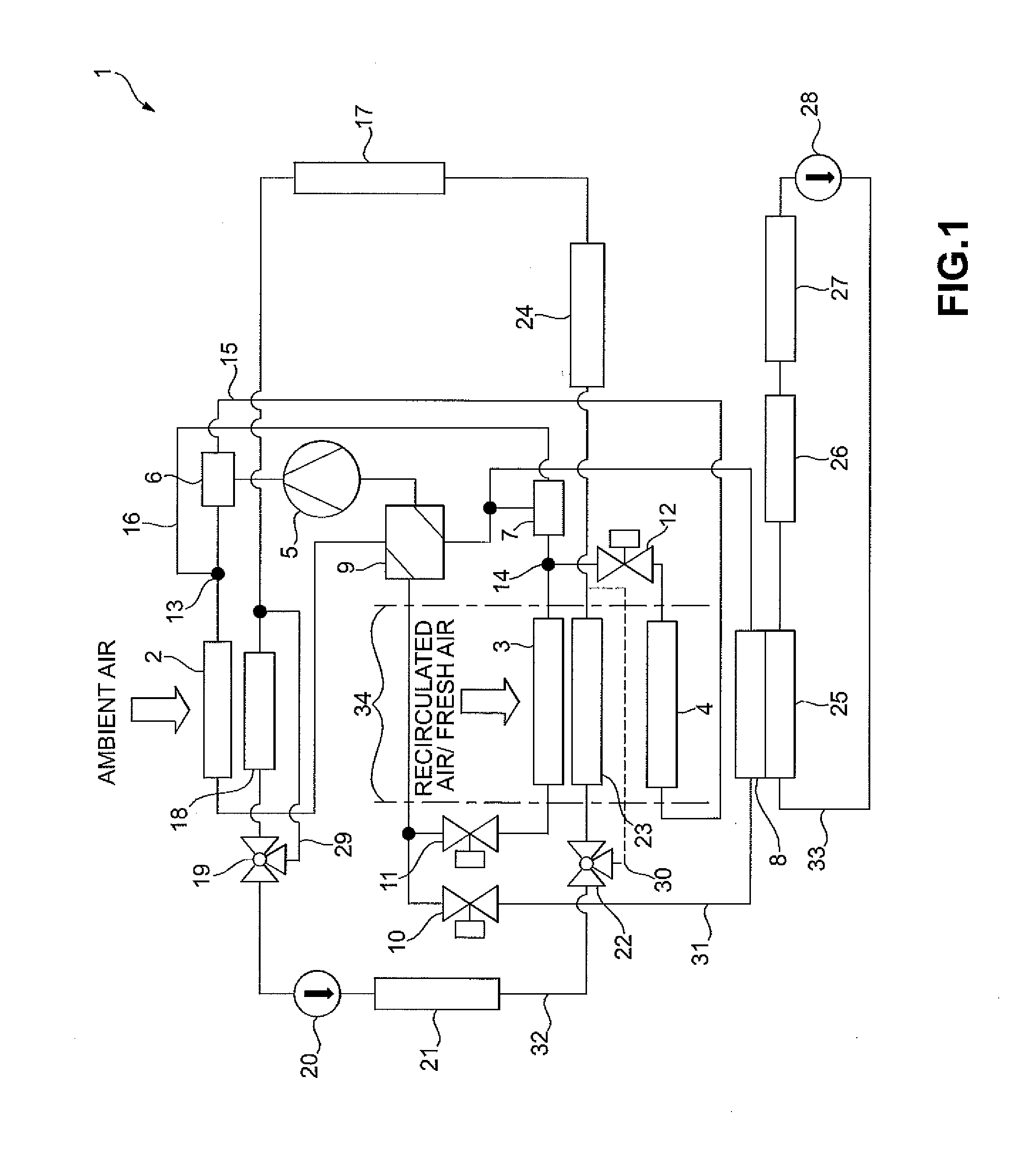

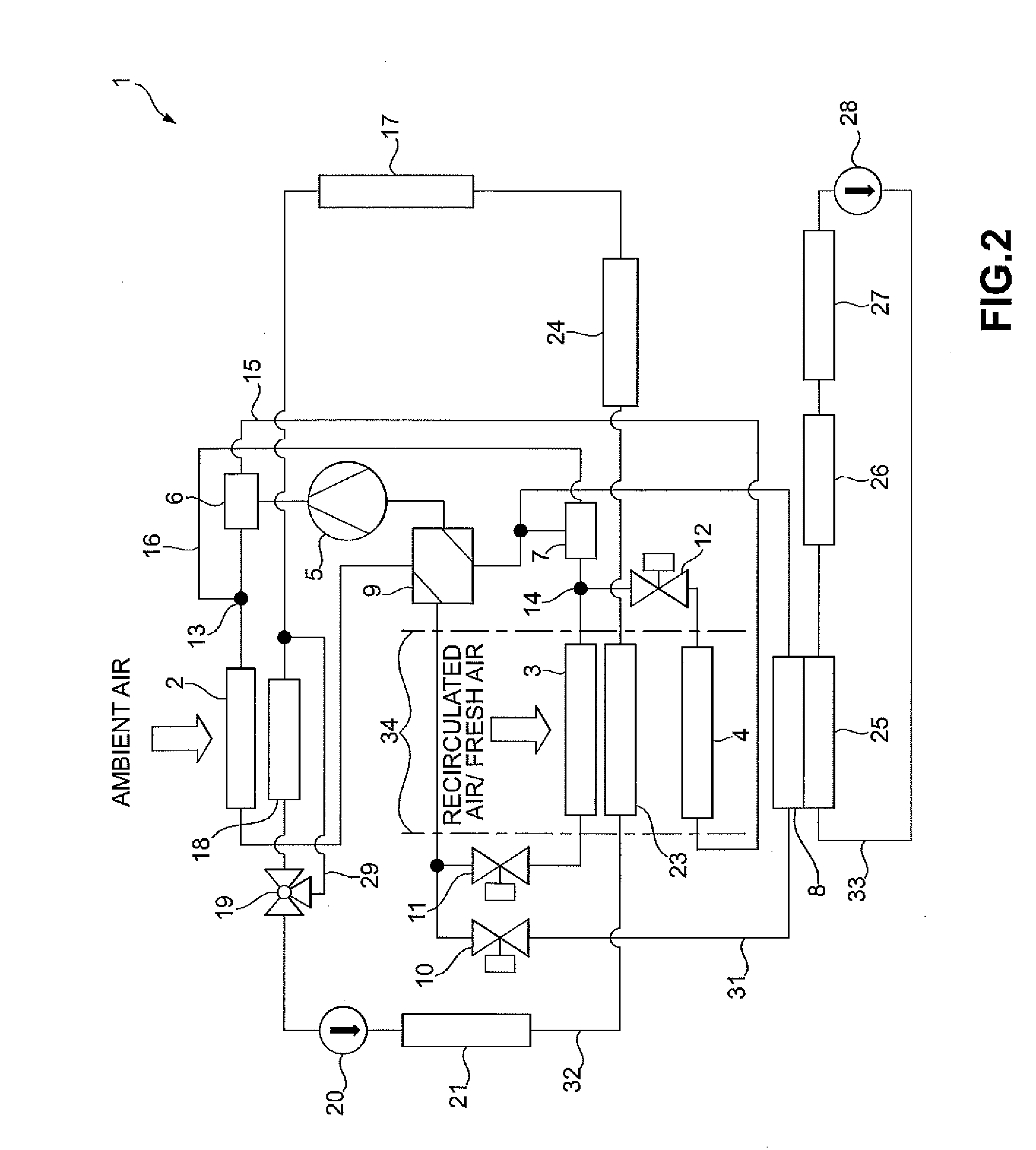

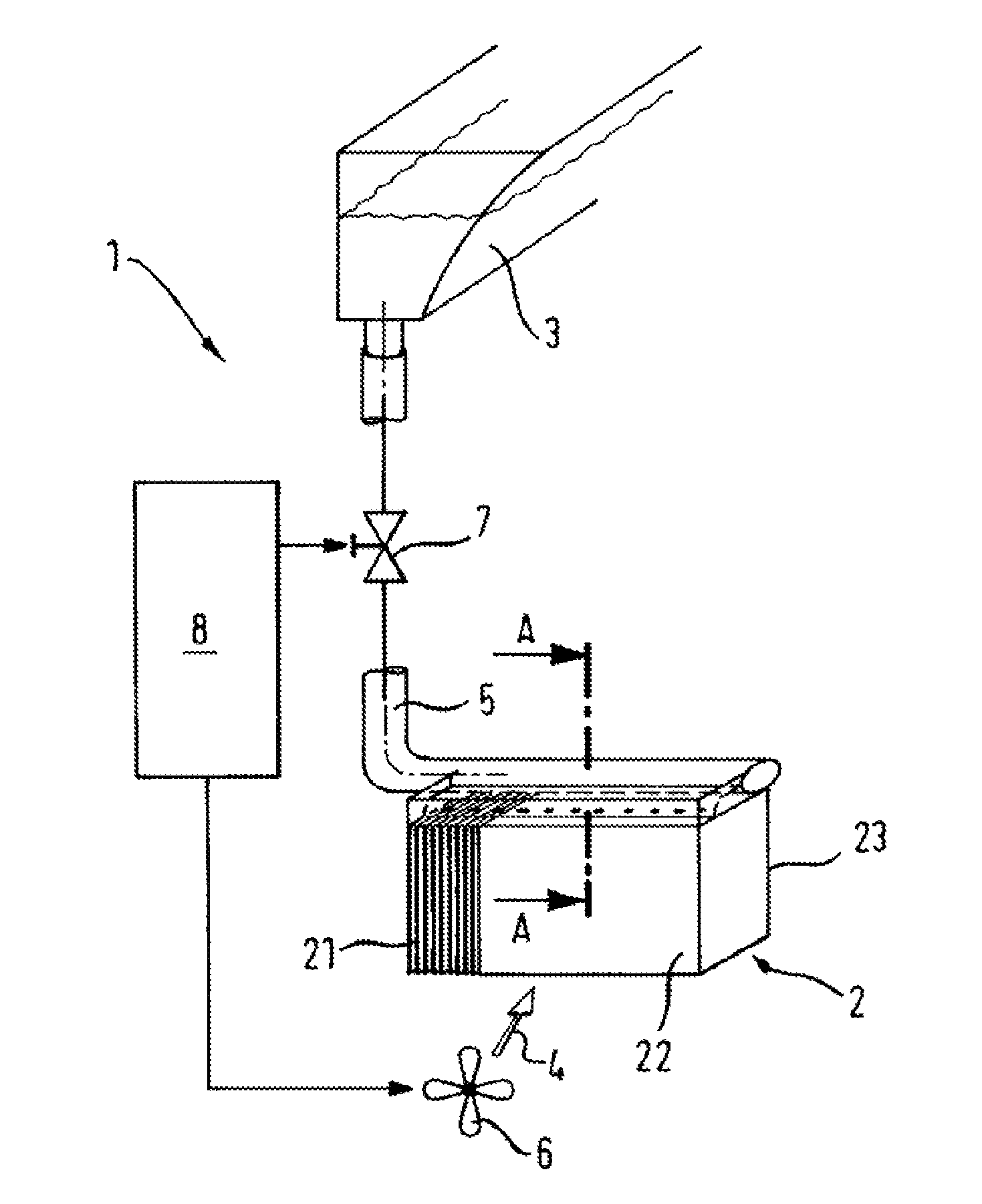

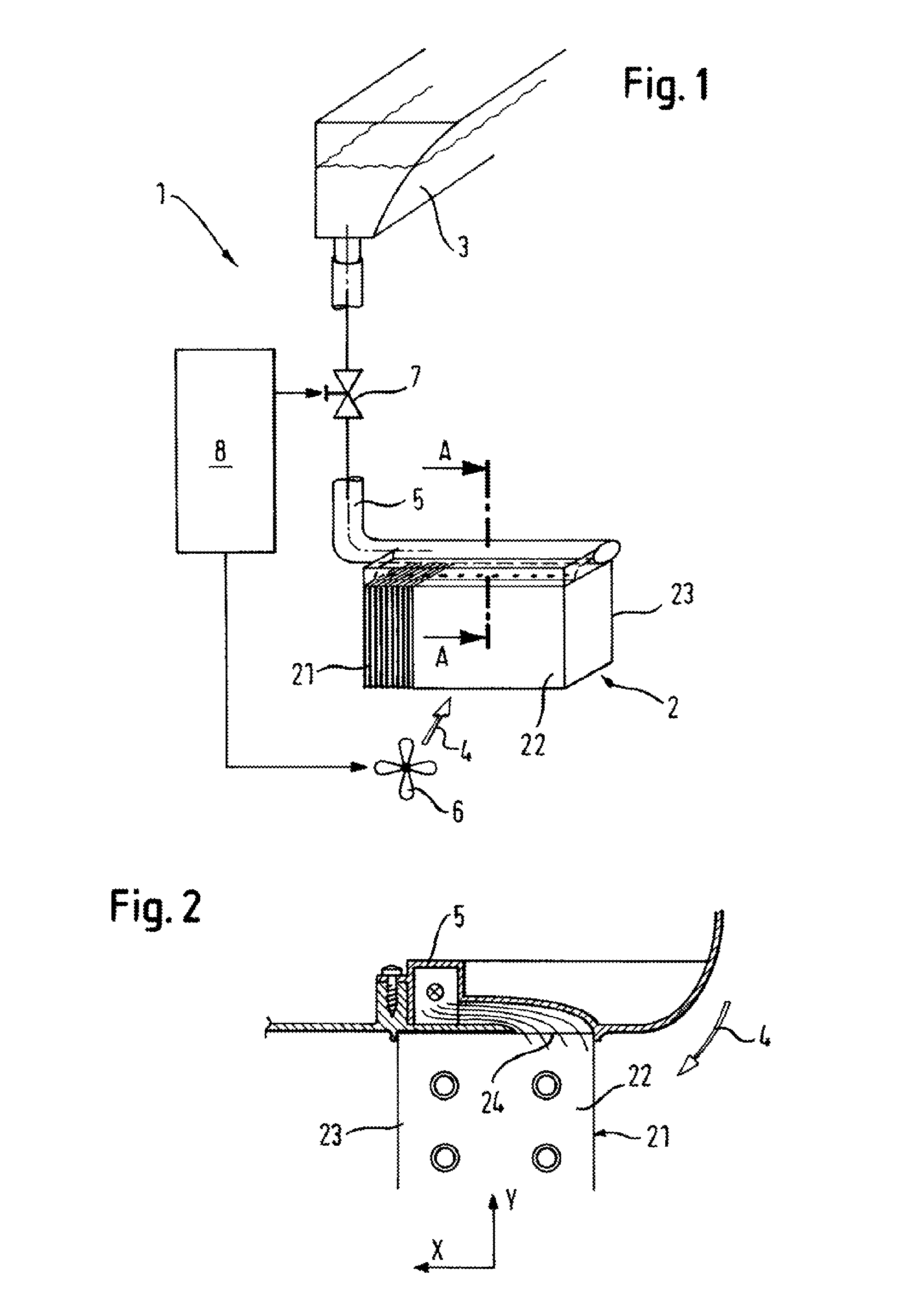

Method for operation of an HVAC system

ActiveUS20110174000A1Maximizes temperature gradientGuaranteed heat exchange effectLighting and heating apparatusVehicle heating/cooling devicesEngineeringHeating temperature

A method for operating an HVAC system includes the steps of adjusting a heating temperature of a heat exchanger disposed in a first flow passage, directing a first partial air mass flow through the first flow passage, directing a second partial air mass flow through a second flow passage, and directing the first partial air mass flow and the second partial air mass flow downstream of the first flow passage and the second flow passage, wherein the heating temperature of the heat exchanger required to at least one of achieve and maintain a desired climate in the passenger compartment of the vehicle is set as a maximum heating temperature for the heat exchanger, and wherein only an amount of energy required to at least one of achieve and maintain a desired climate in the passenger compartment of the vehicle is added to the HVAC system.

Owner:HANON SYST

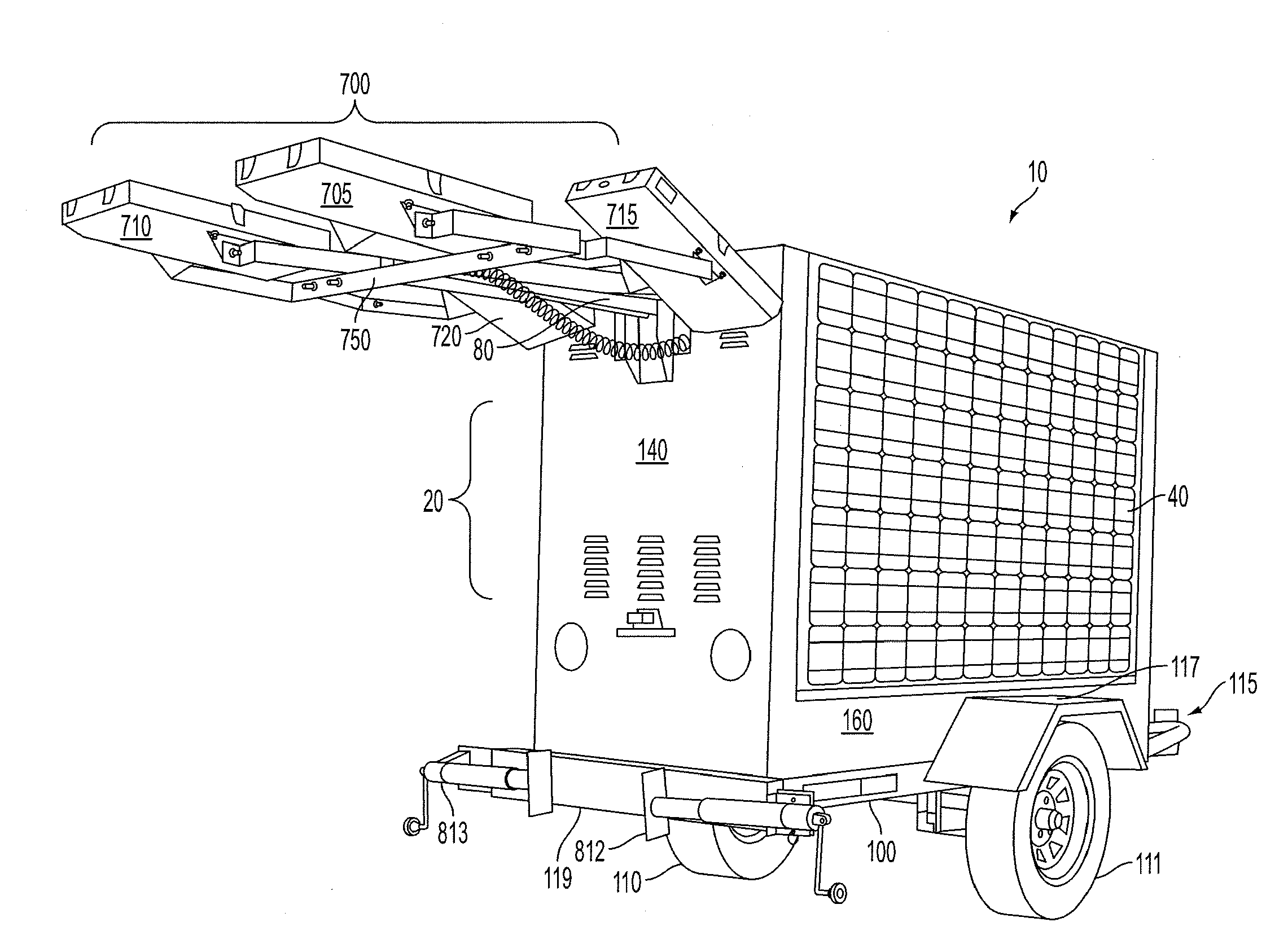

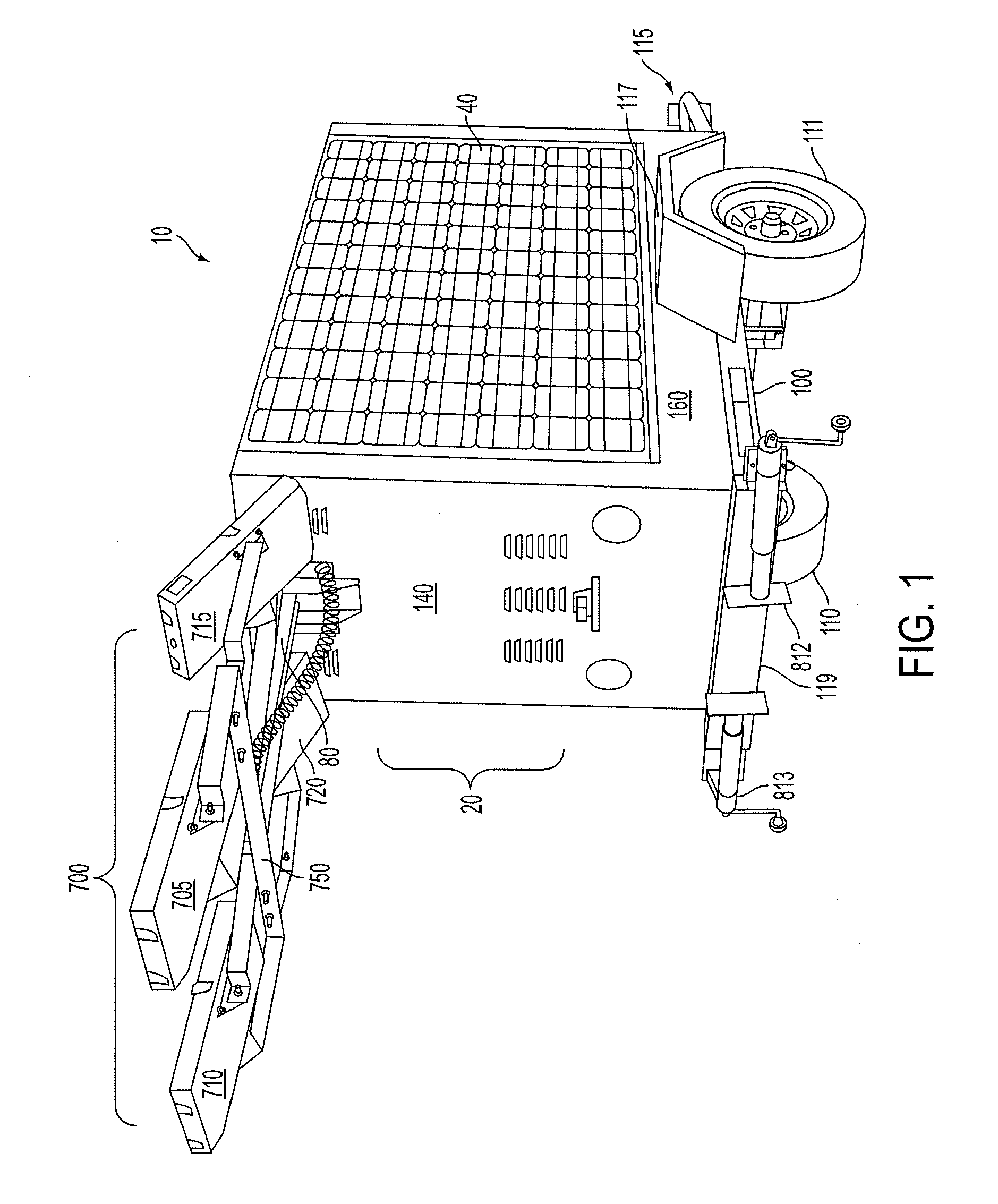

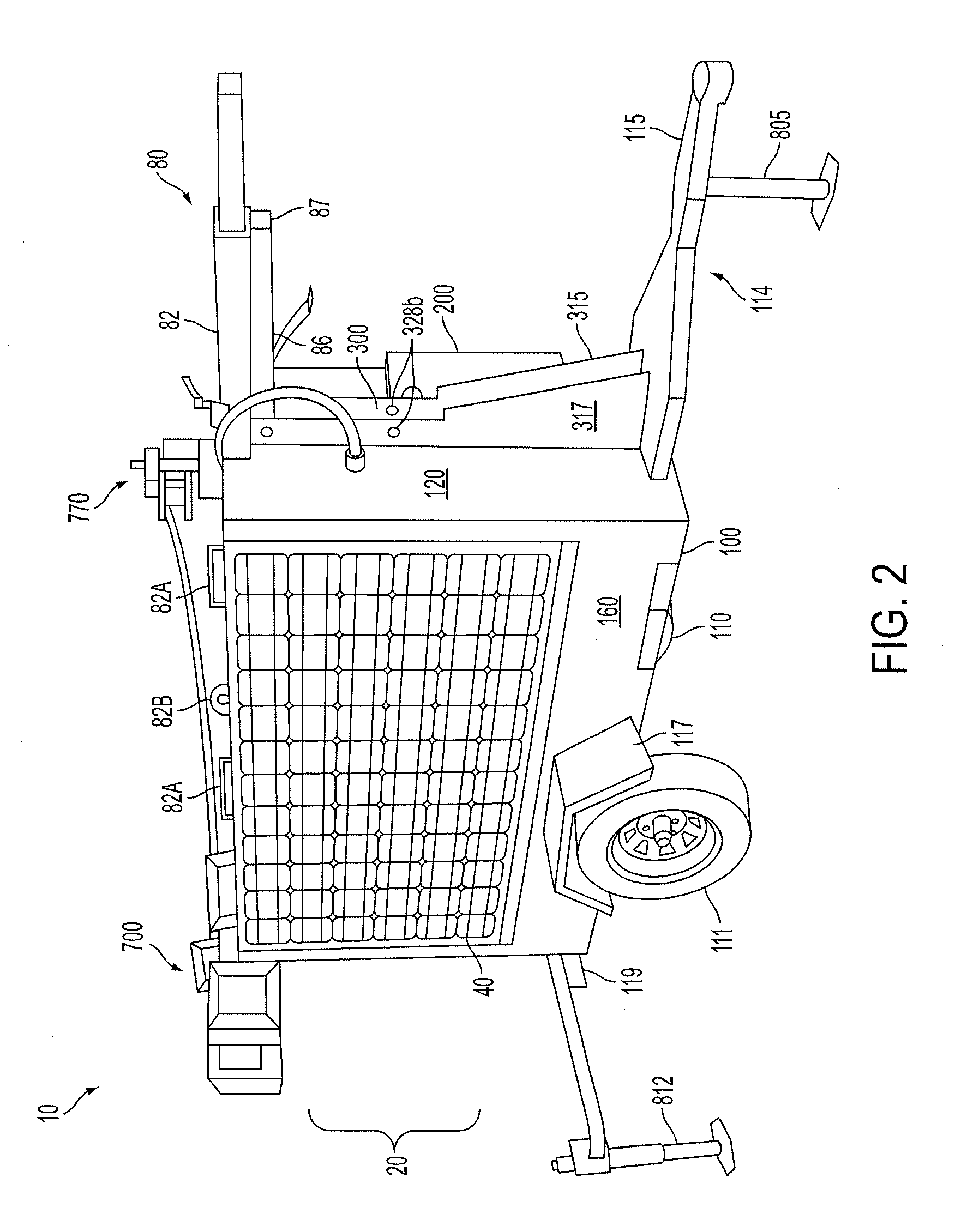

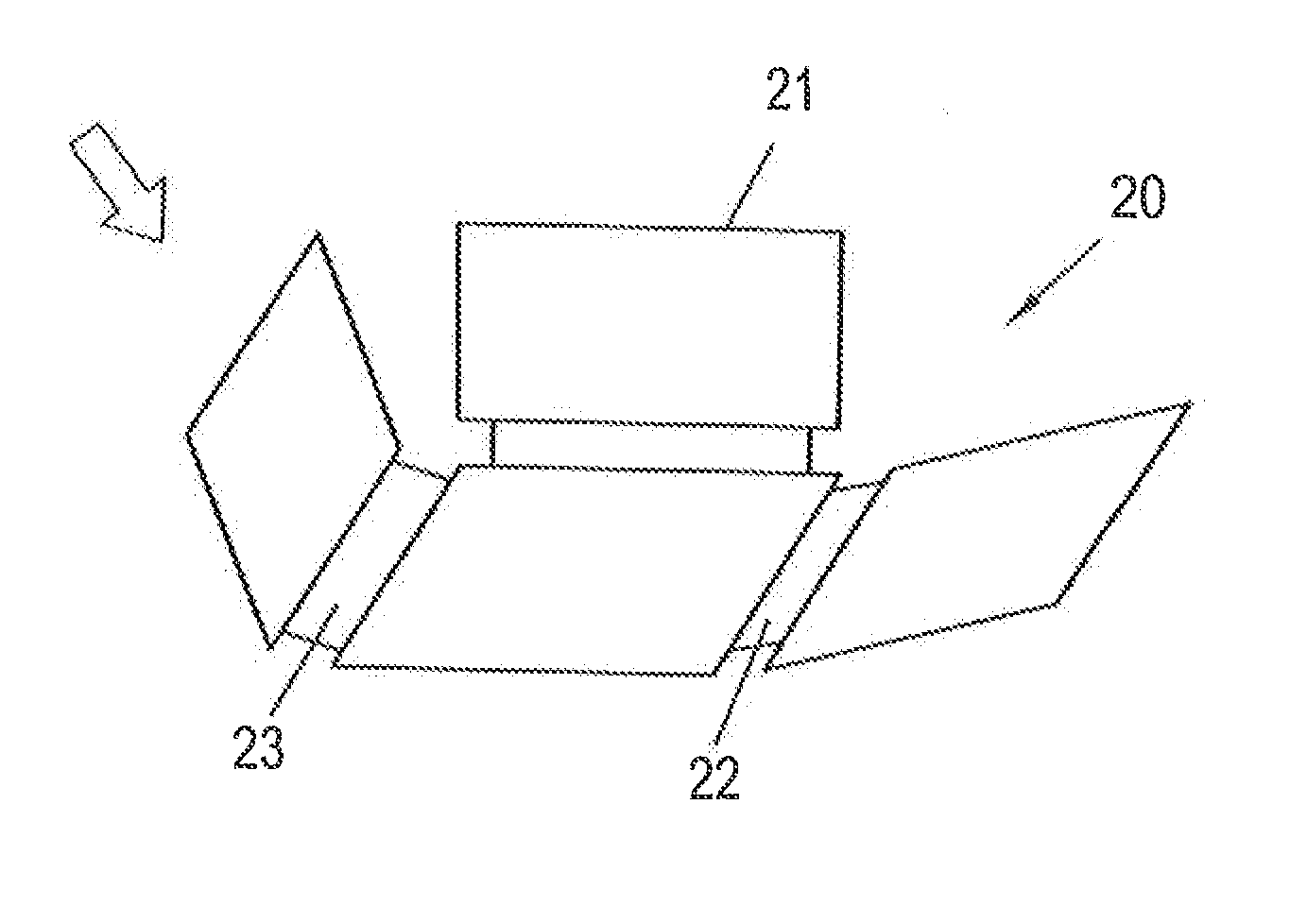

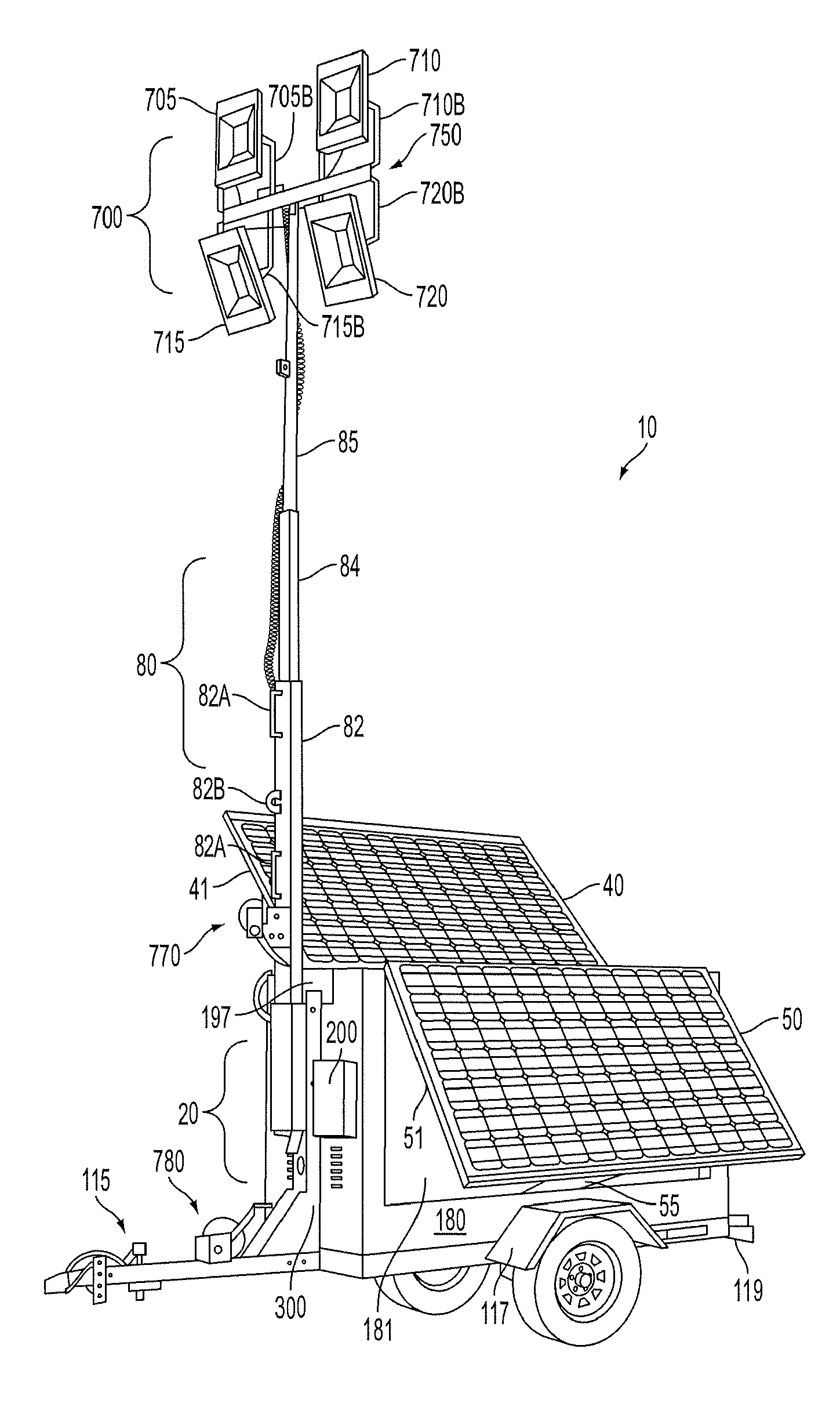

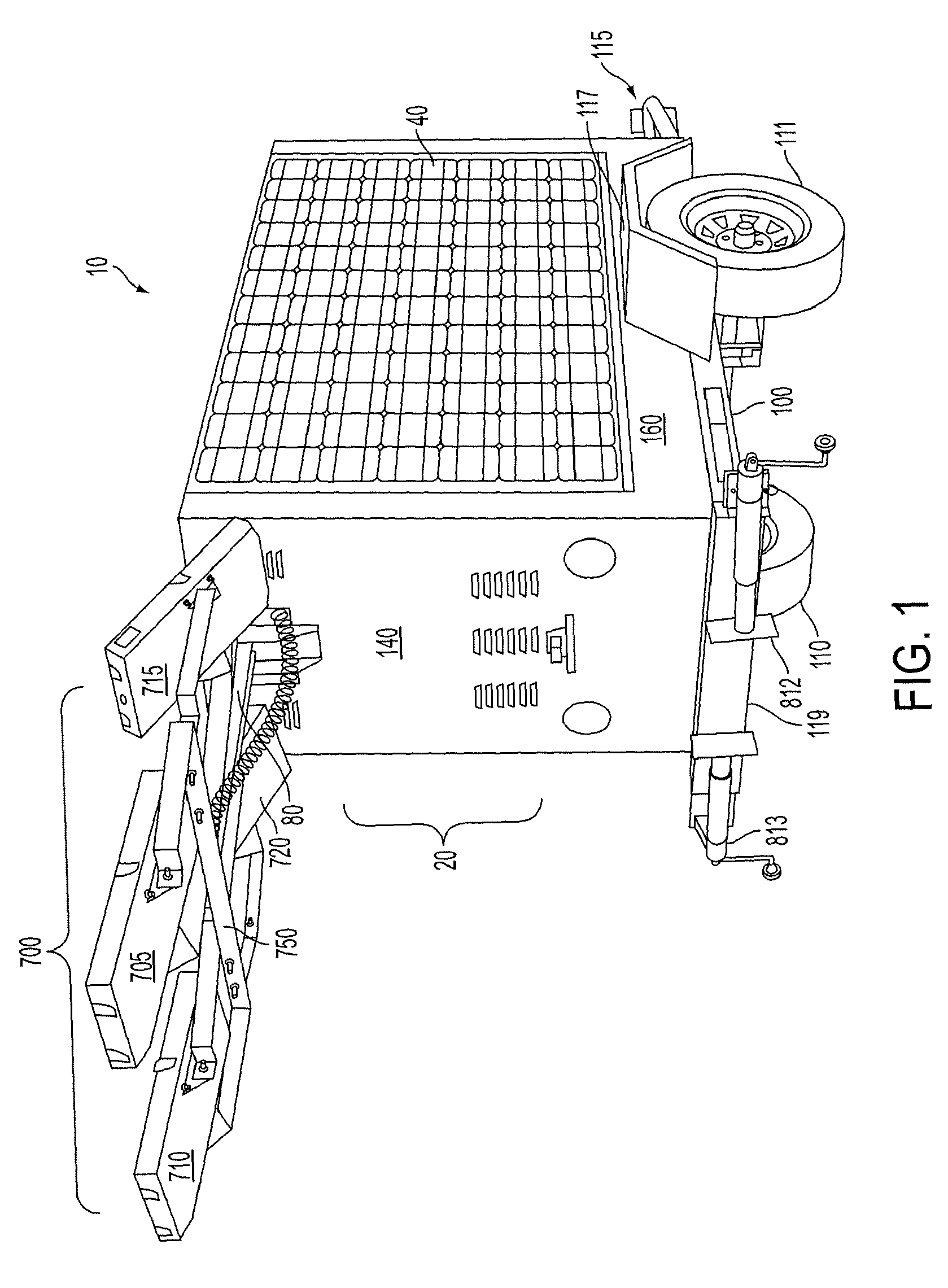

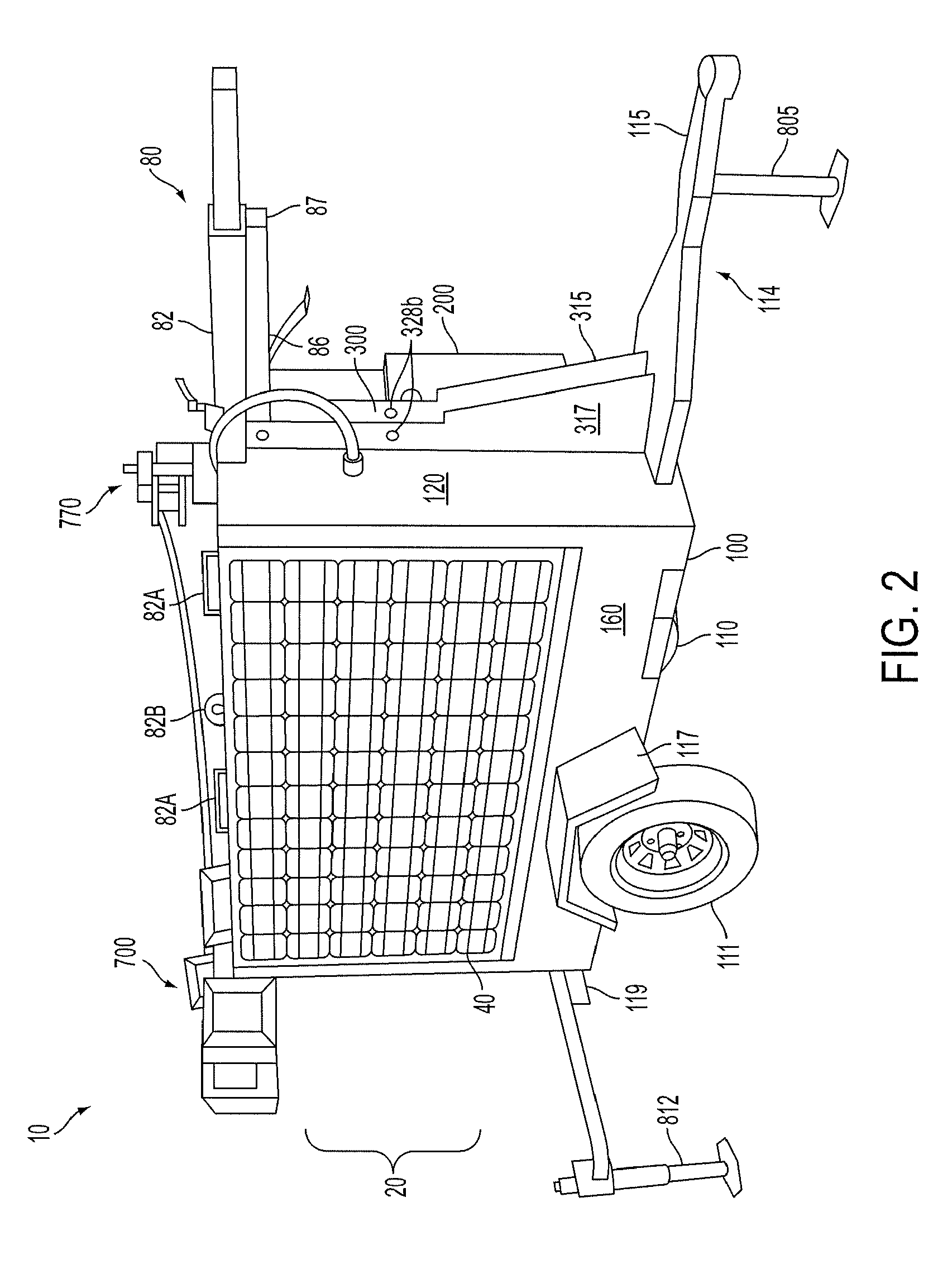

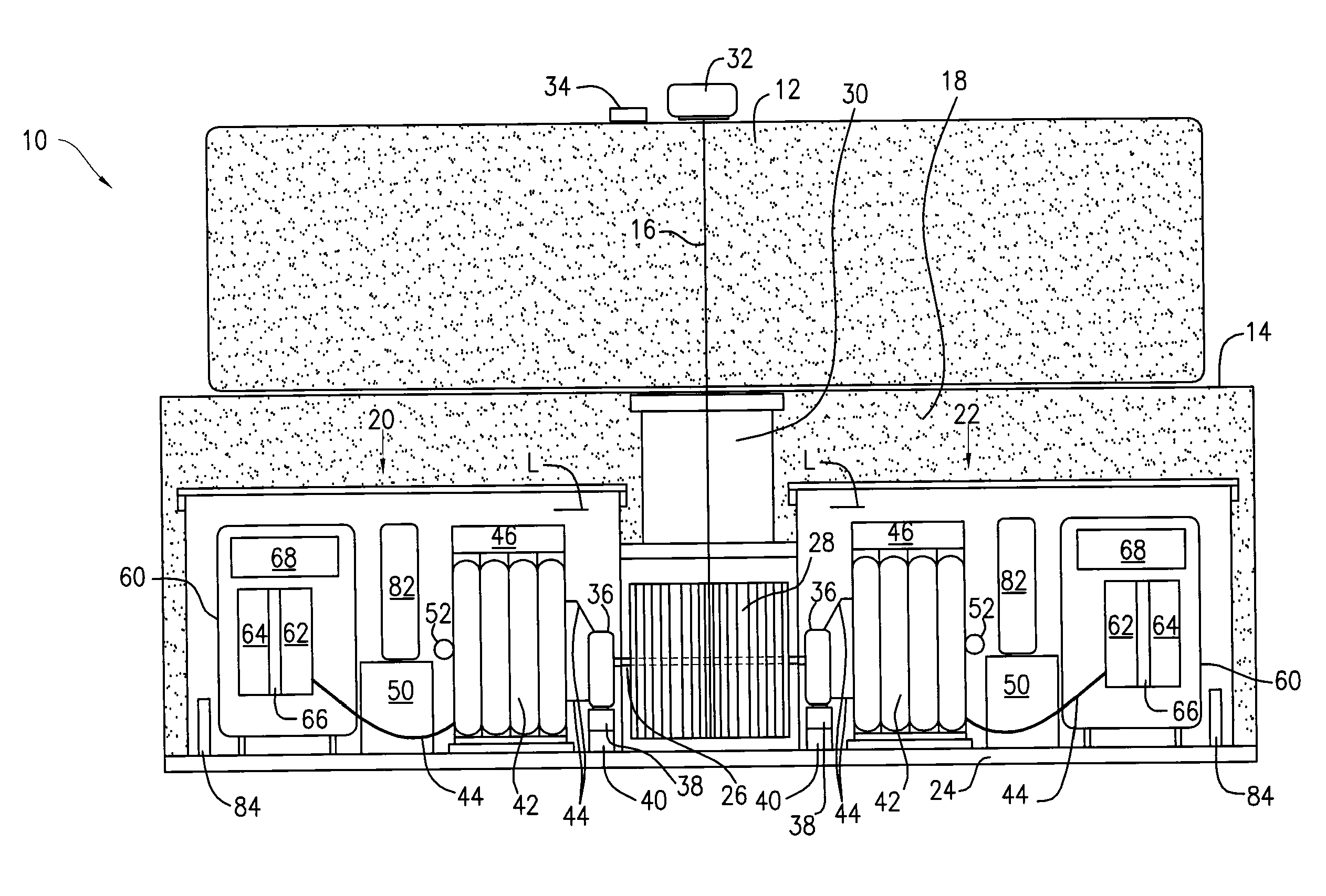

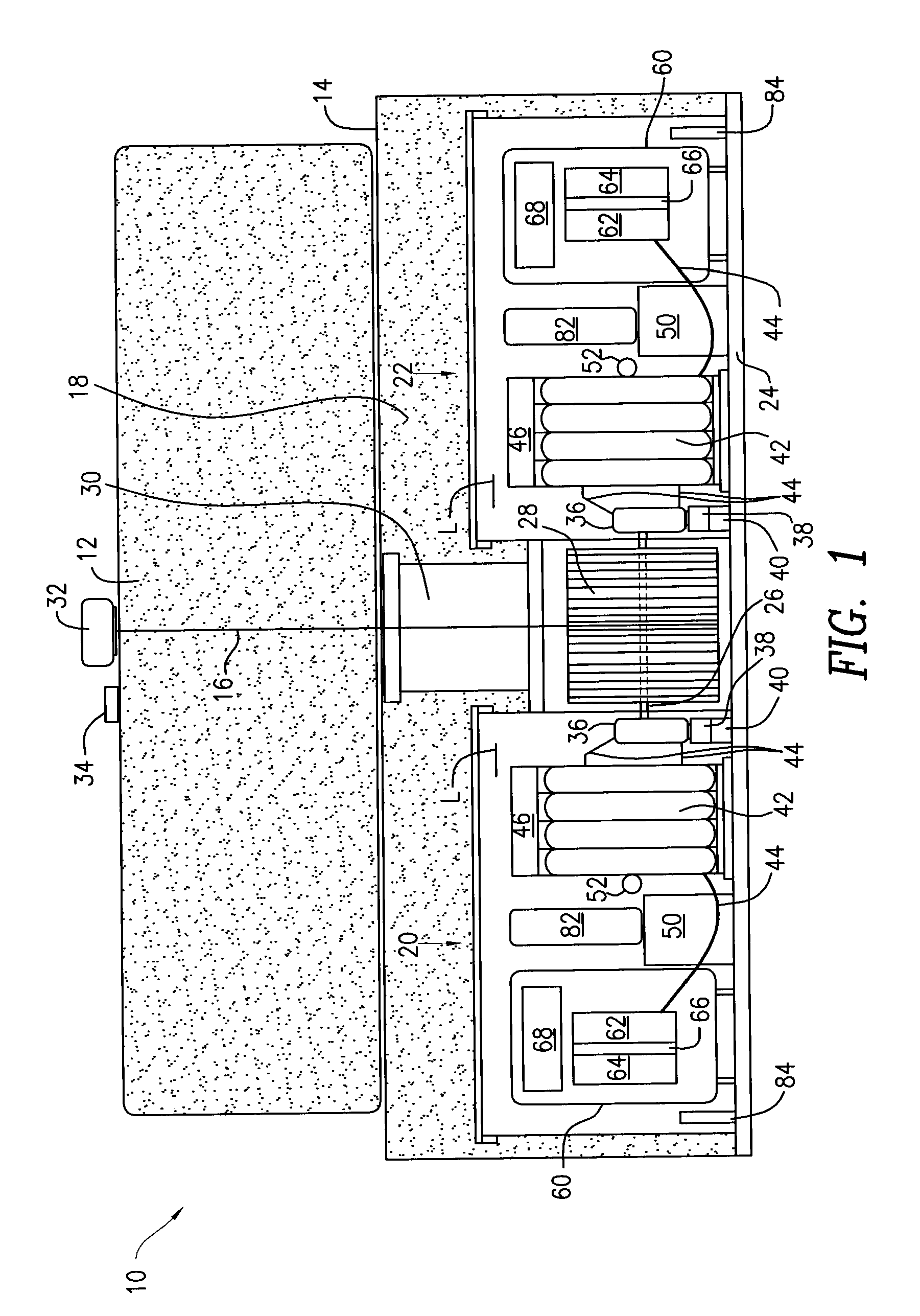

Mobile solar-powered light tower

ActiveUS20120201016A1Excellent and useful lightingRemove carbon emissionsMechanical apparatusLighting support devicesLight equipmentElectrical battery

Provided is a mobile lighting device that can derive power from a renewable energy source, such as solar power. The device can comprise a mobile base unit that can house one or more components of the device. The device further can comprise a solar power module associated with the mobile base unit that converts solar energy into electrical current. The device also can comprise a lighting module associated with the mobile base unit that is at least partially powered either directly or indirectly using the electrical current from the solar power module. The device further can comprise a solar power storage module, such as comprising one or more batteries, for storing energy and discharging as electrical current for powering the lighting module, which can be positioned atop a mast that can be extendable, pivotable, and / or rotatable. The invention also provides methods and systems for illuminating areas.

Owner:RENEWABLE ENERGY HLDG

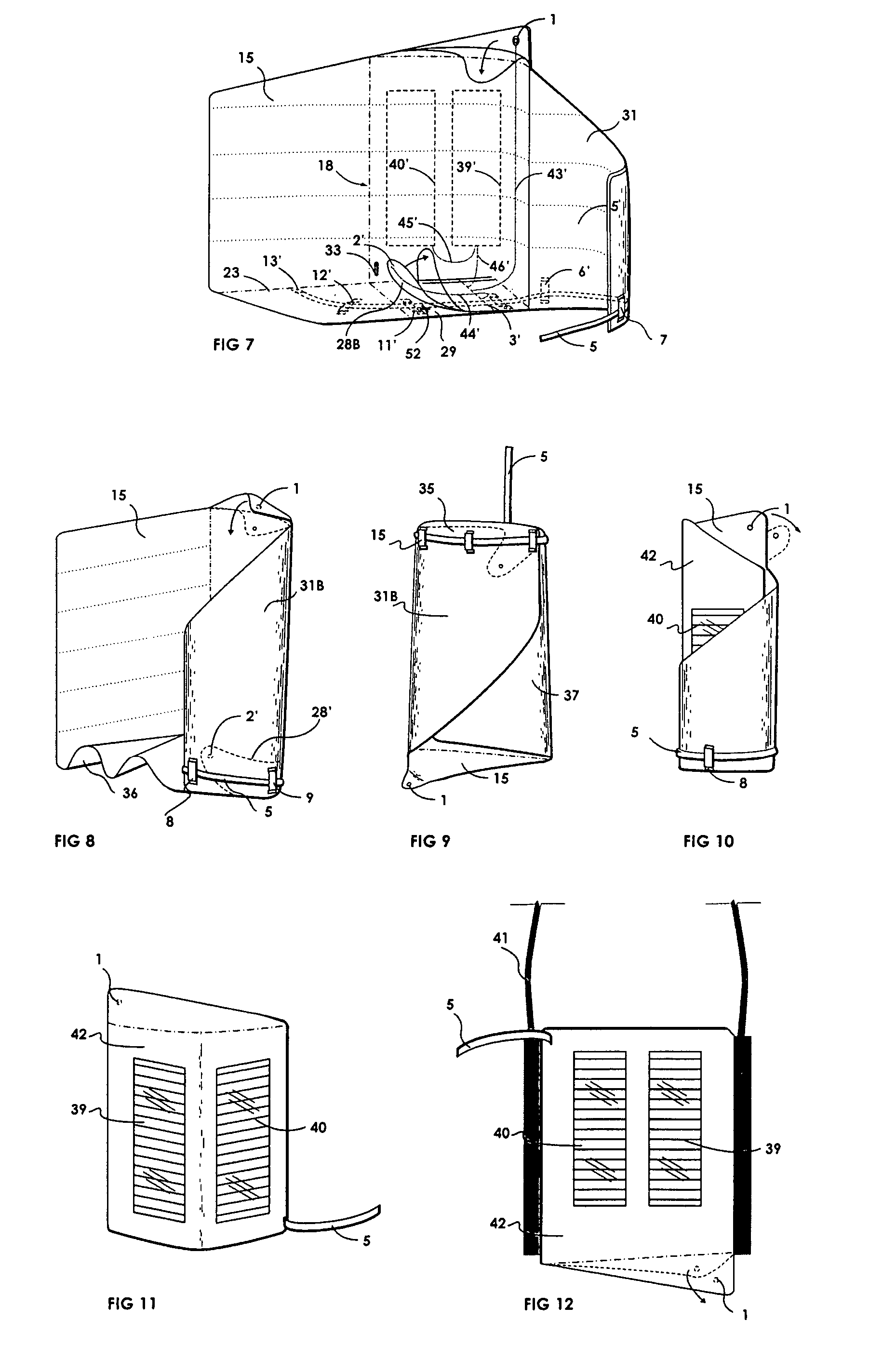

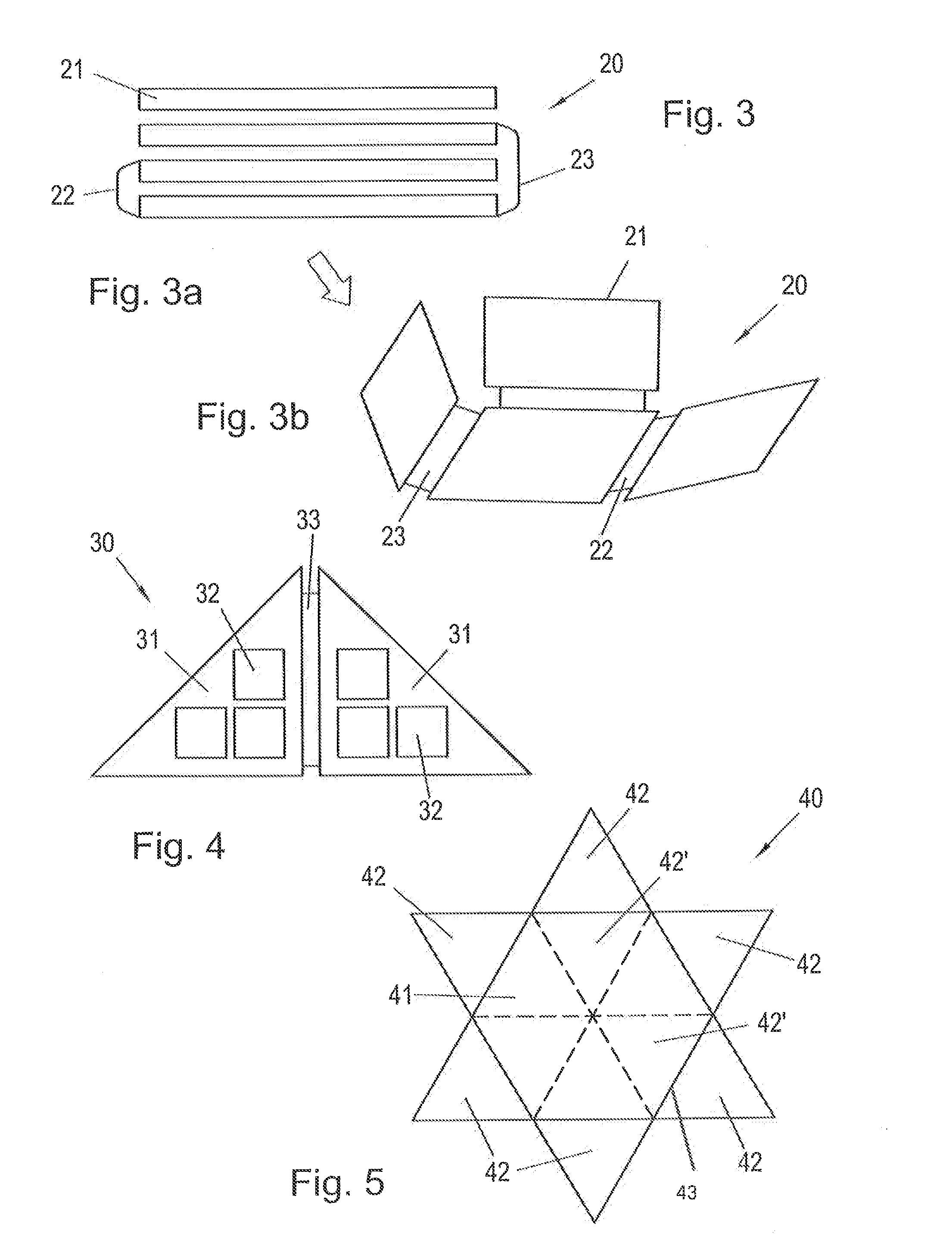

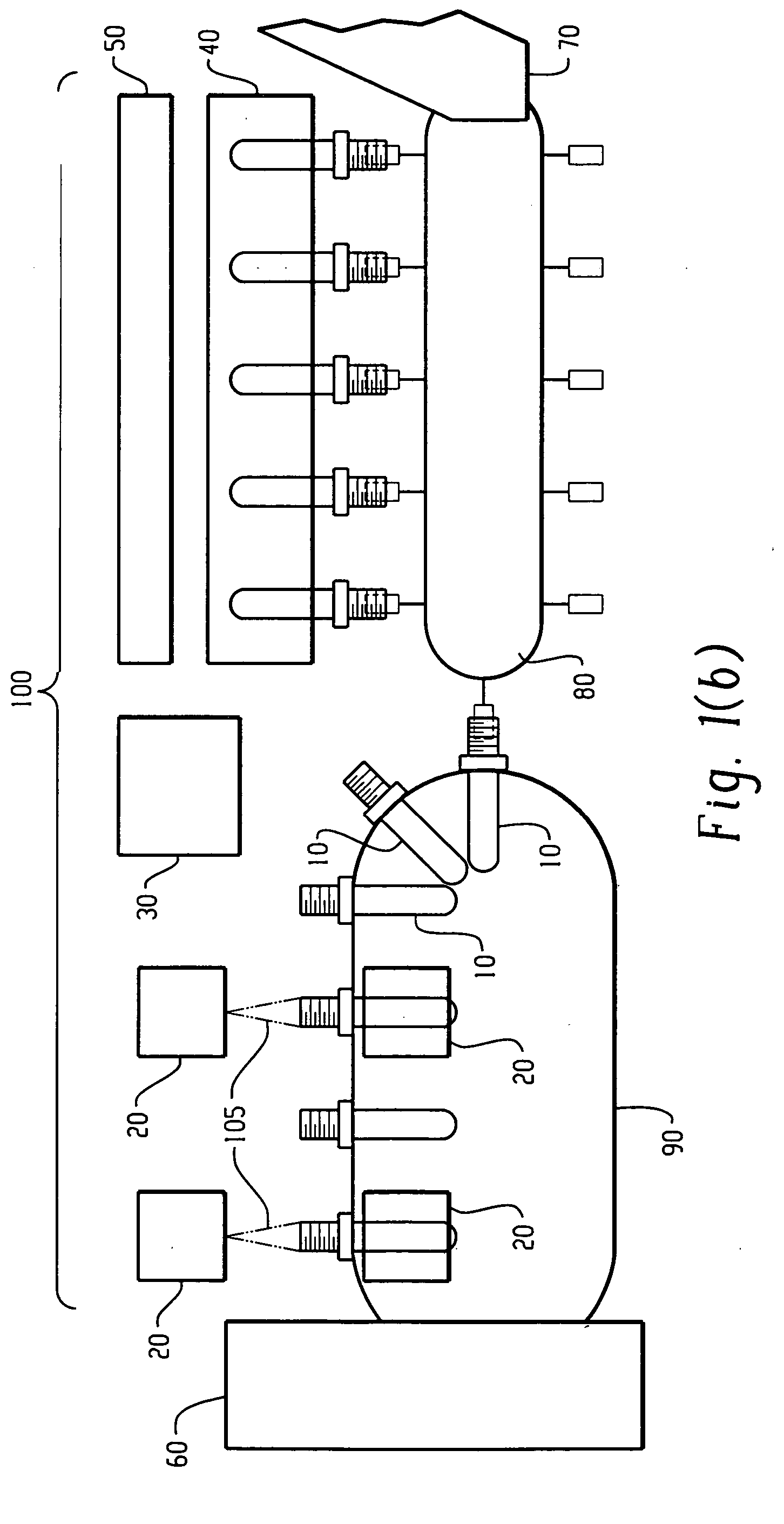

Portable lighting and power-generating system

ActiveUS7825325B2Energy optimizationImprove performanceBatteries circuit arrangementsLighting support devicesFiberManufacturing technology

A portable lighting system is disclosed. The portable lighting system includes at least one light-emitting source, a power-generating source, a power storage device, and a processing system for controlling and managing power-generated by the power-generating source that are all are integrated into a flexible-layered structure. The flexible-layered structure is a layered structure of woven or non-woven, natural or made-made fibers that have been joined using sewing, sonic-welding or heat lamination manufacturing techniques. Materials for the flexible-layered structure include woven textiles, non-woven materials, flexible plastics, natural leather materials, artificial leather materials, reflective flexible materials, opaque flexible materials, translucent flexible materials, light-diffusing materials, and specular reflective materials.

Owner:KENNEDY & VIOLICH ARCHITECTURE

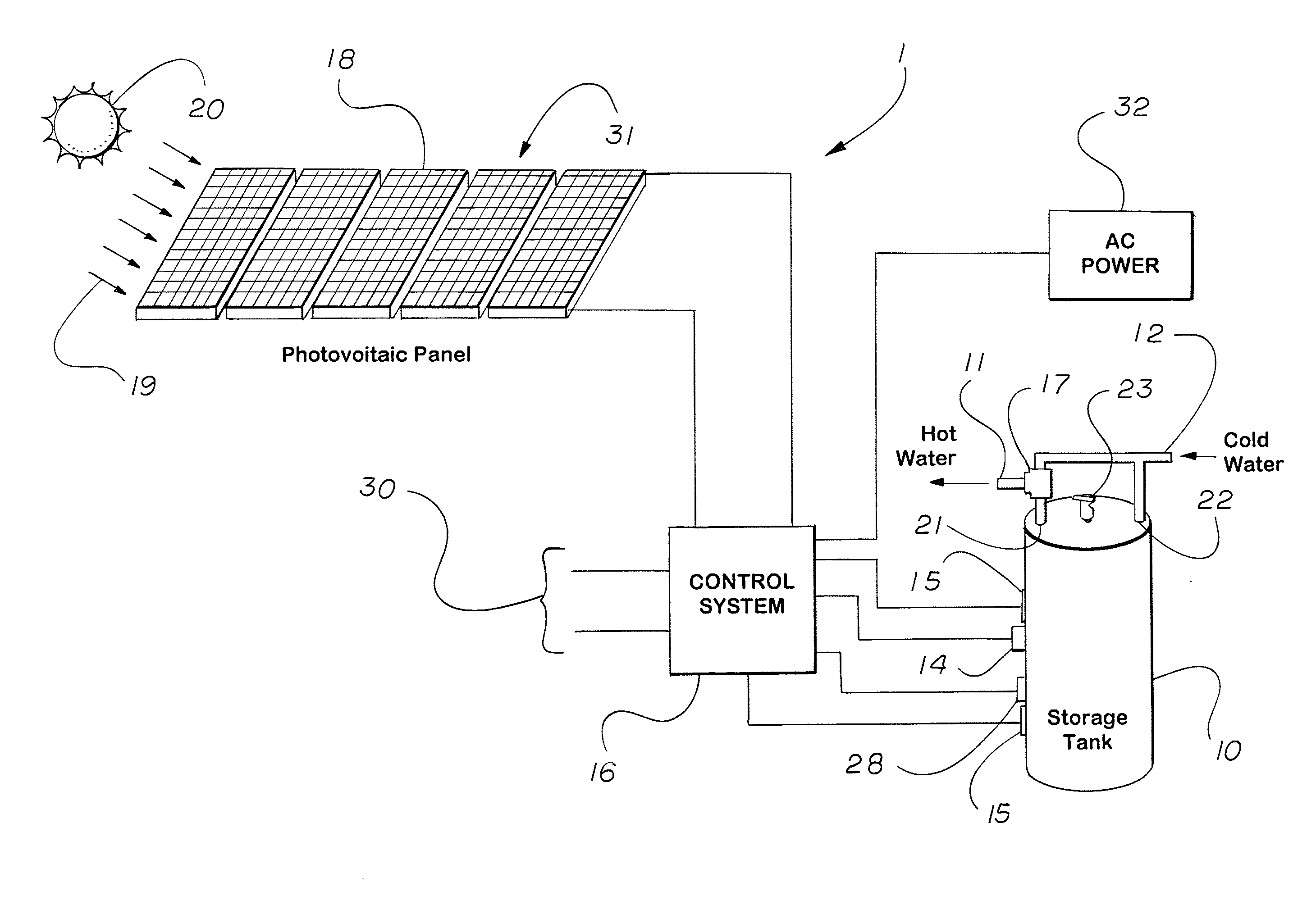

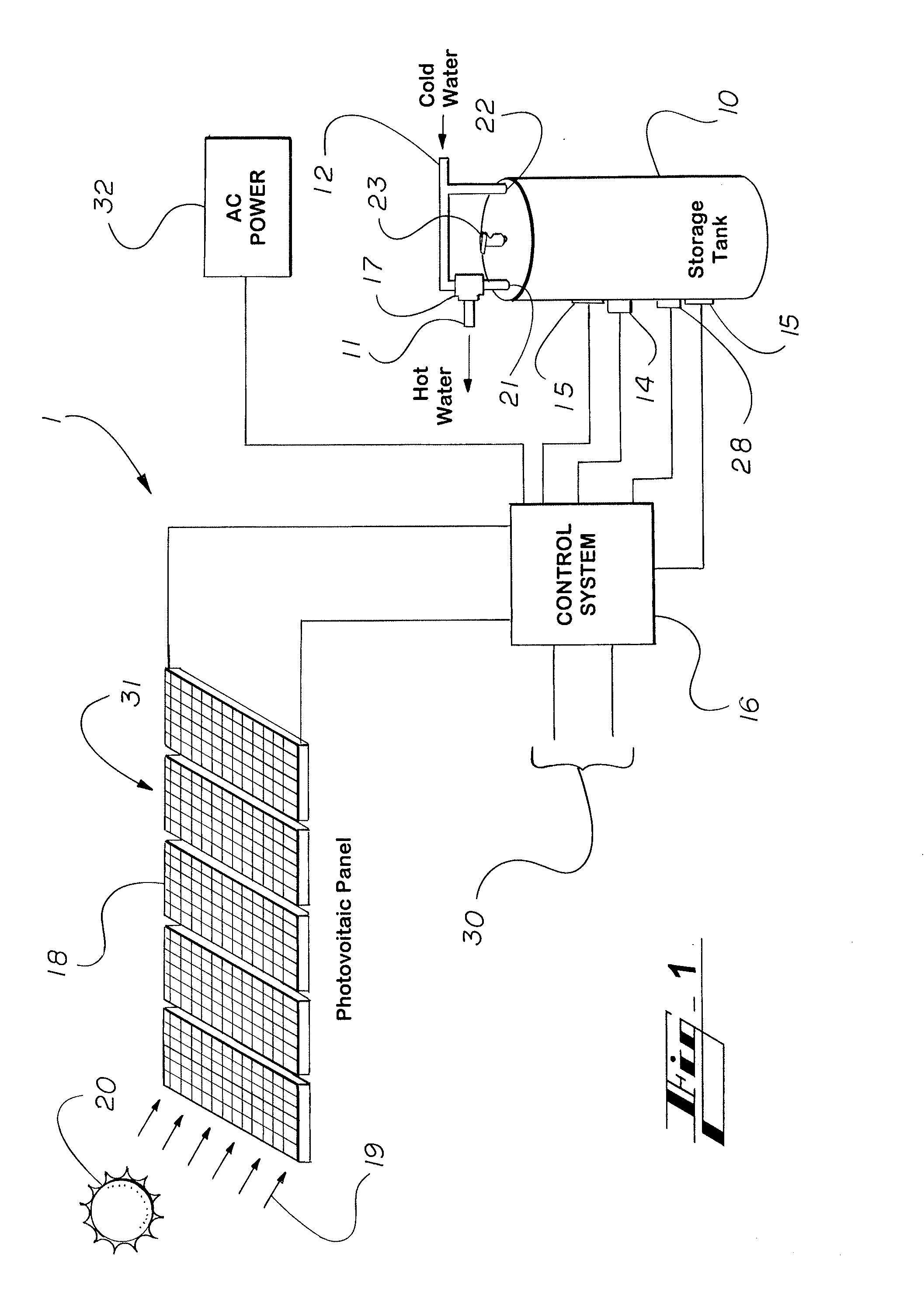

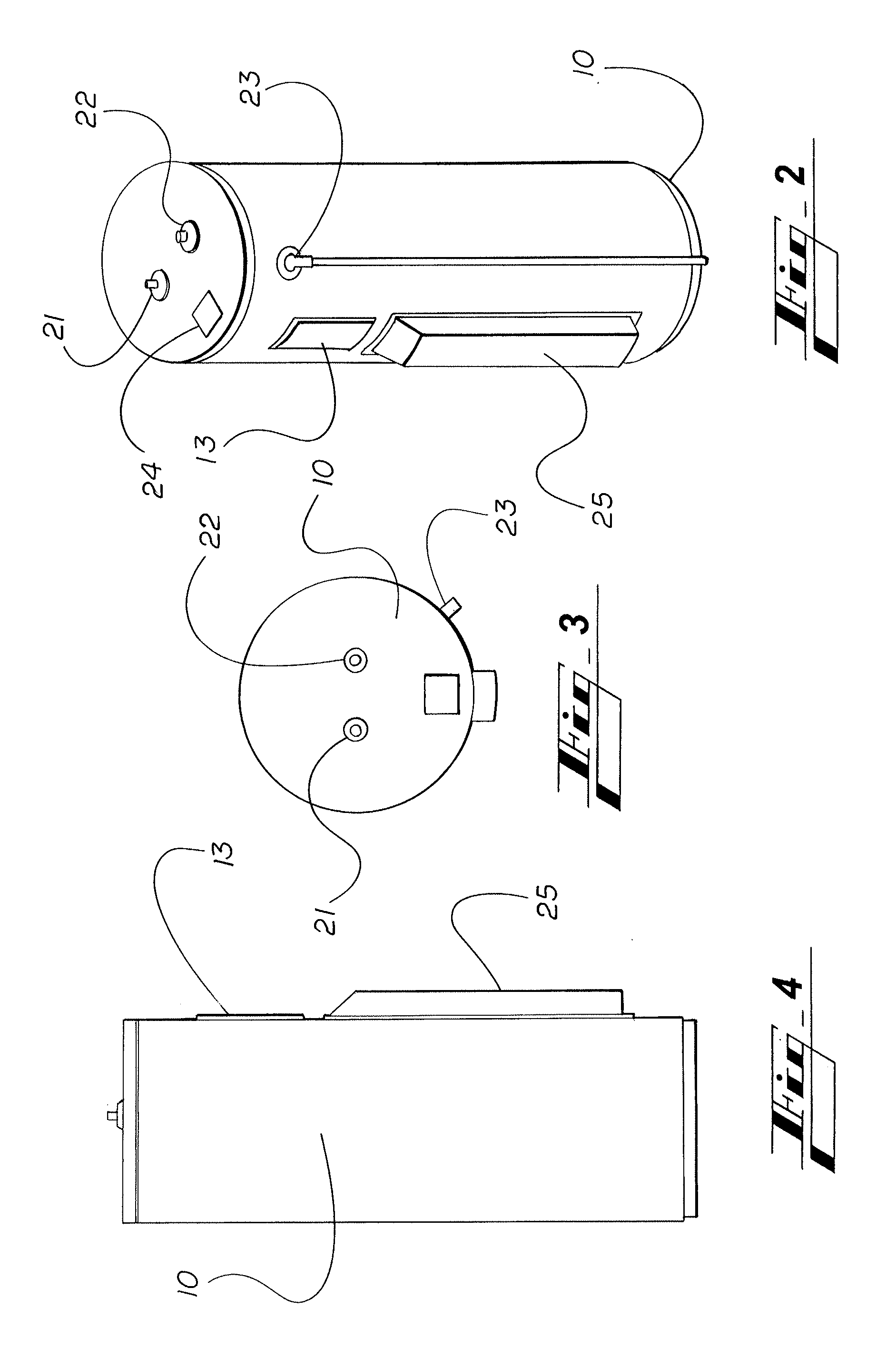

Solar Photovoltaic Water Heating System

InactiveUS20140153913A1Storage moreProlong lifeImmersion heating arrangementsCombined heat and power systemsEnergy transferLoad resistance

A solar photovoltaic water heating system is disclosed having a photovoltaic solar panel array, a storage tank containing water to be heated, a resistance heating element in the water to be heated. The water heating system matches the load resistance of the resistance heating element to the power that is available from the photovoltaic solar panel array in order to maximum energy transferred to the water in the storage tank.

Owner:ENERGY LAB

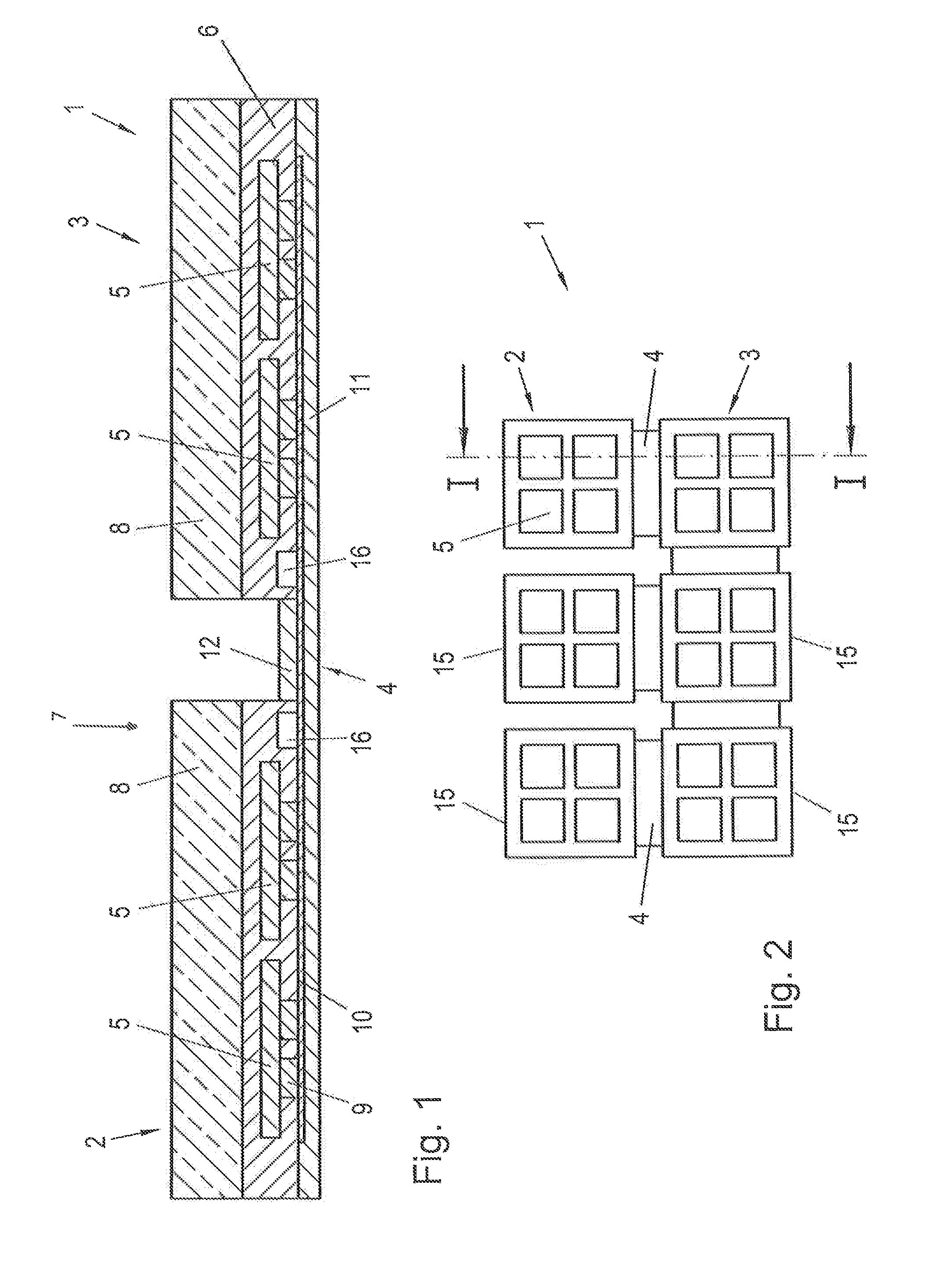

Photovoltaic module and use thereof

InactiveUS20150083191A1Easy wiringFacilitate electric couplingPV power plantsPhotovoltaic energy generationSolar cellElectrically conductive

In the case of a photovoltaic module which comprises a plurality of solar cells which are each coupled to an electrically conductive, structured layer for discharging the electrical energy generated in the solar cells, wherein at least two subregions of the photovoltaic module are coupled to one another via a flexible connecting region, provision is made for the solar cells to be coupled on the rear side of said solar cells to the electrically conductive, structured layer, and for the electrically conductive, structured layer to be integrated in a multilayered film arranged on the rear side of the solar cells, wherein the multilayered film forms the flexible connecting region between the at least two subregions of the photovoltaic module, as a result of which a photovoltaic module which can be tilted or folded can be made available.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AKTIENGES

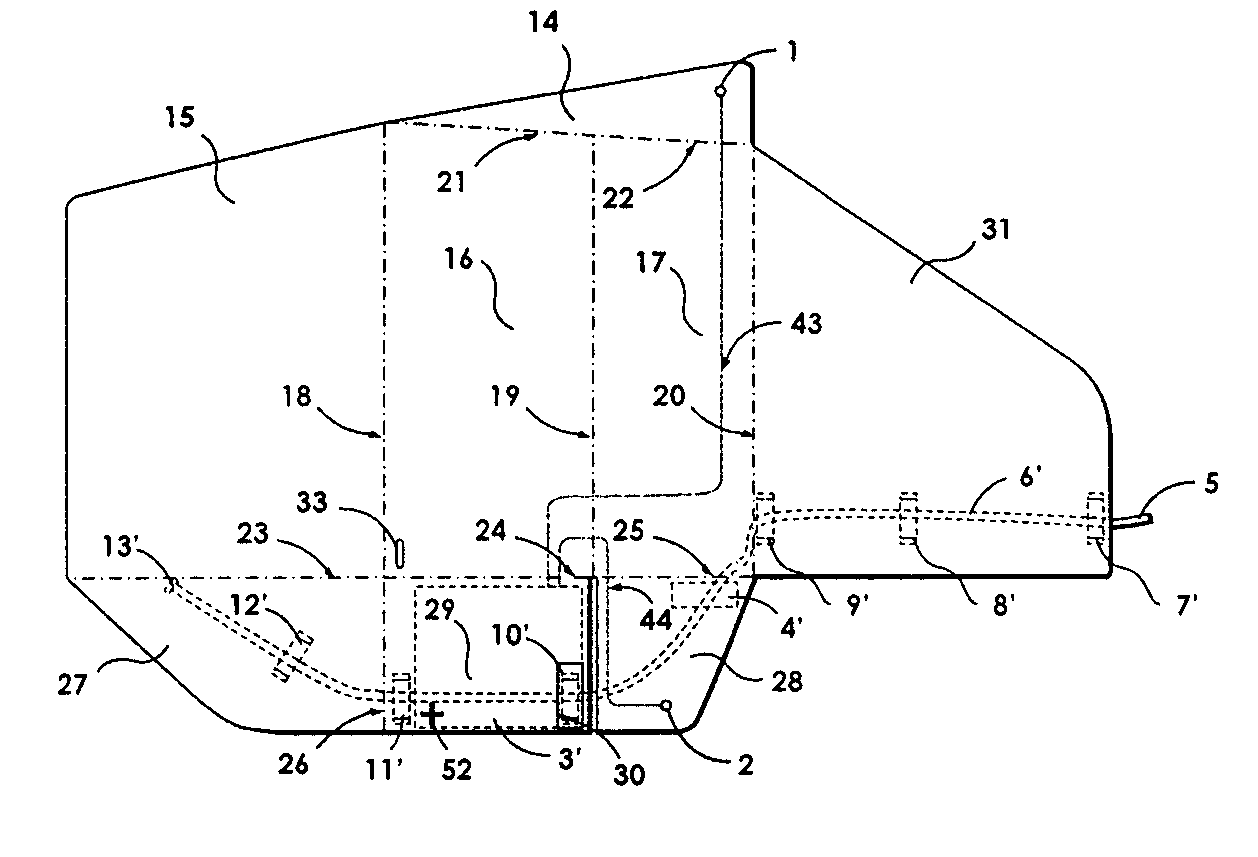

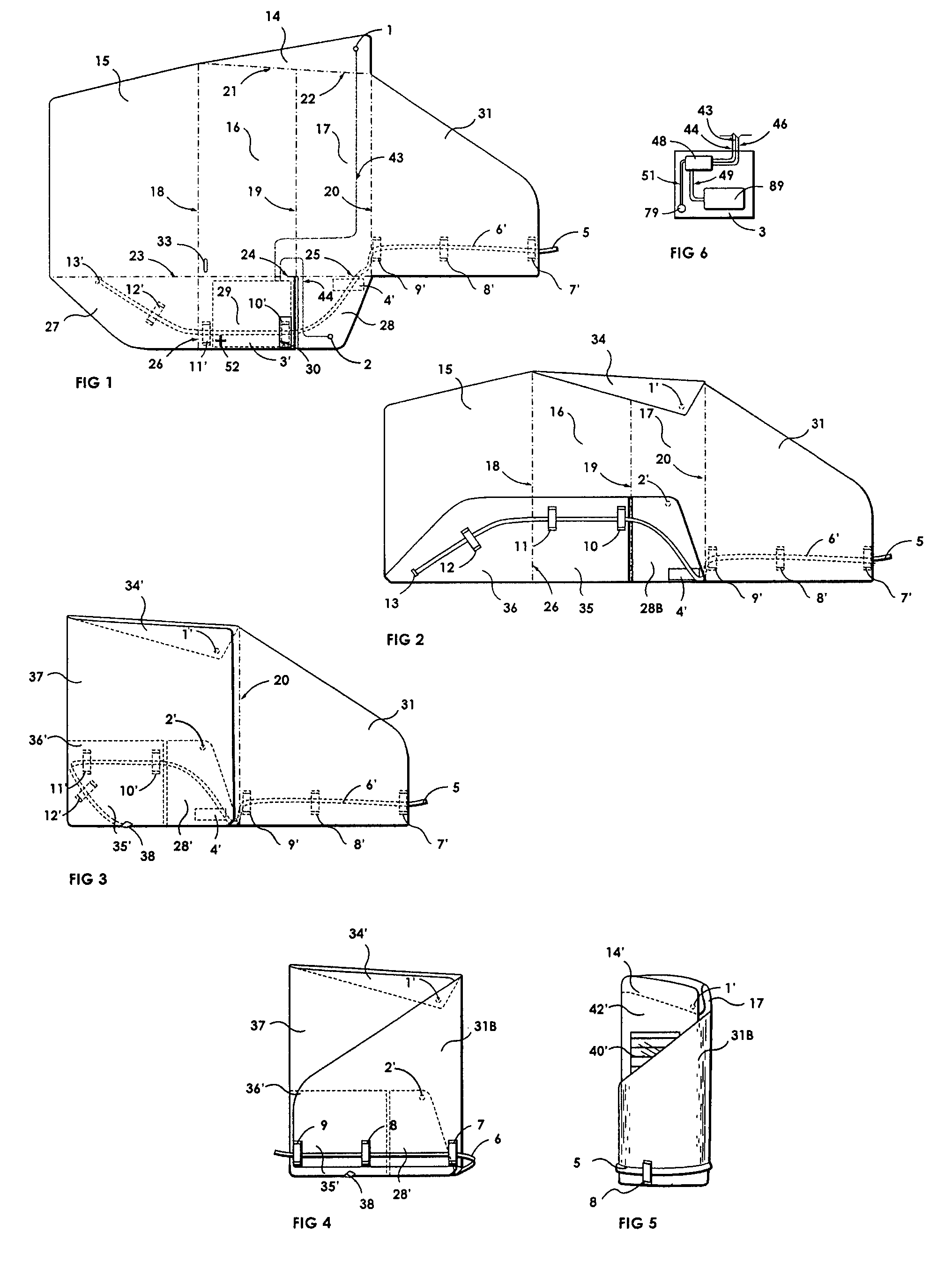

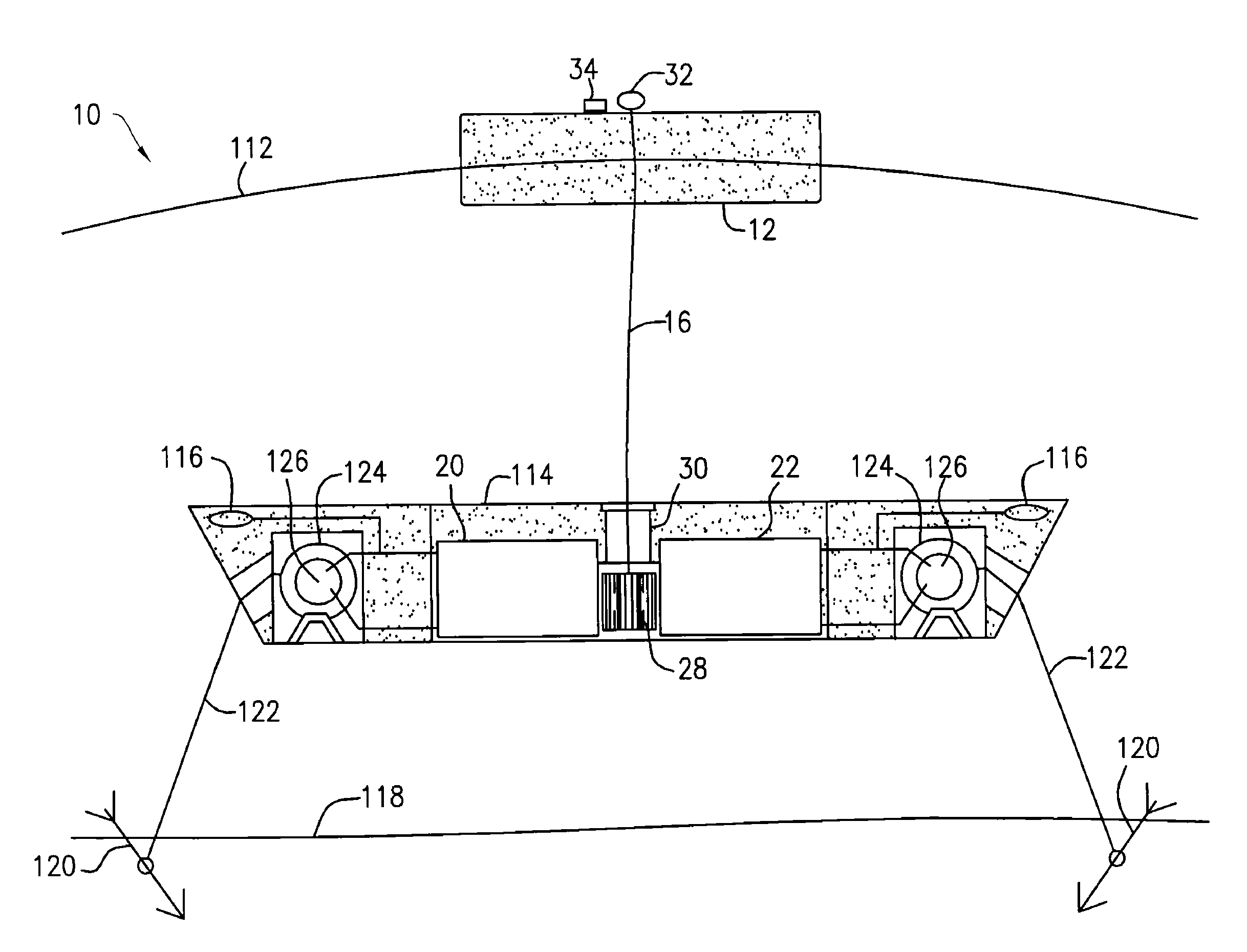

Wave energy harnessing device

ActiveUS8093736B2Increasing combined wave energy extraction efficiencyReducing kinematic and dynamic loadMachines/enginesEngine componentsWave shoalingResponse Frequency

A hydrokinetic device having a water surface float tethered to a submerged buoyant housing is provided with mechanisms for optimizing the amount of wave energy extracted from the waves by the device. Based on wave conditions, the optimization functionalities include controlling the depth of the housing to produce wave shoaling or storm avoidance, as well as to perform continuous phase control and load control for the purpose of matching the response frequency of the device to the frequency of the incident waves.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

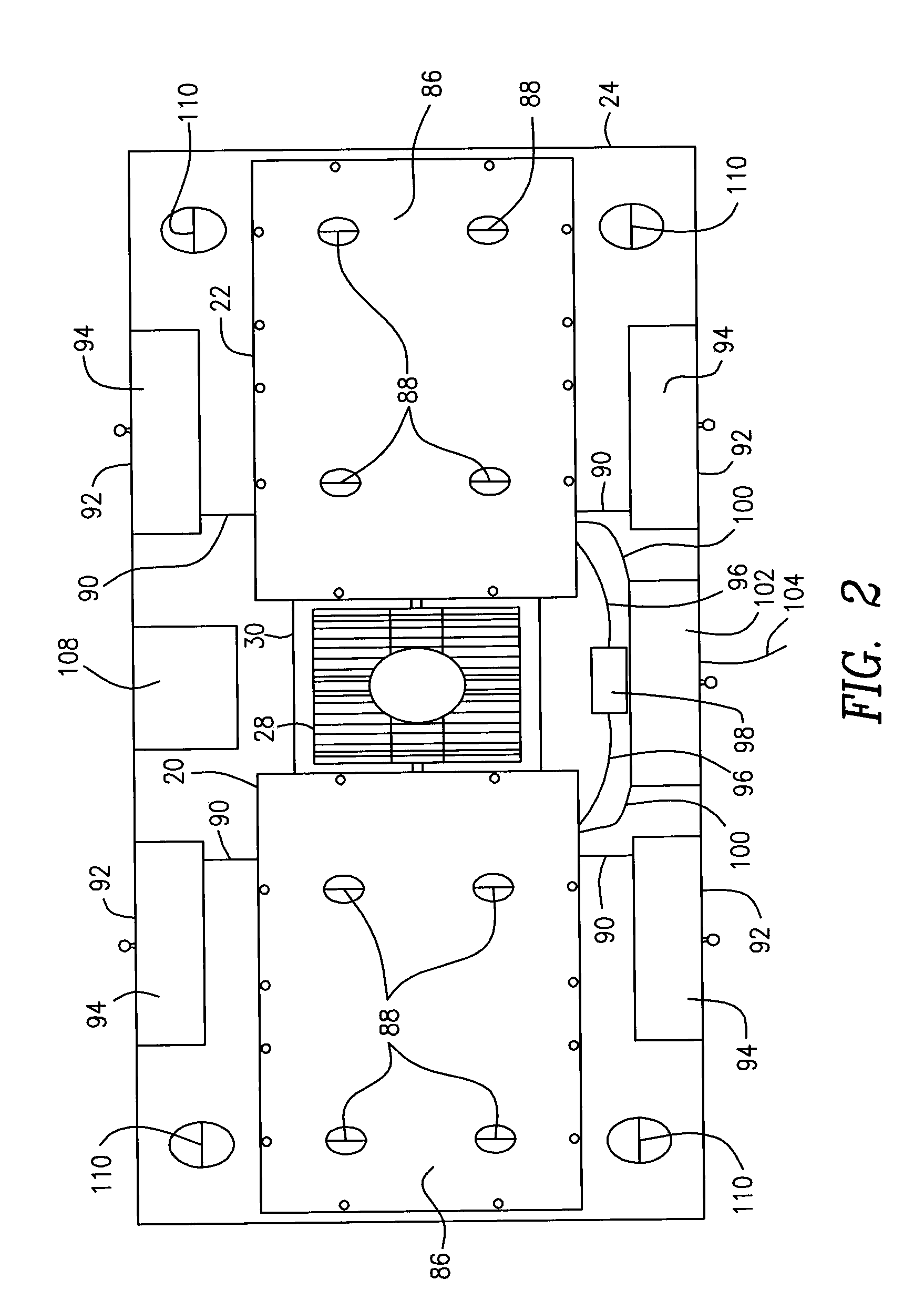

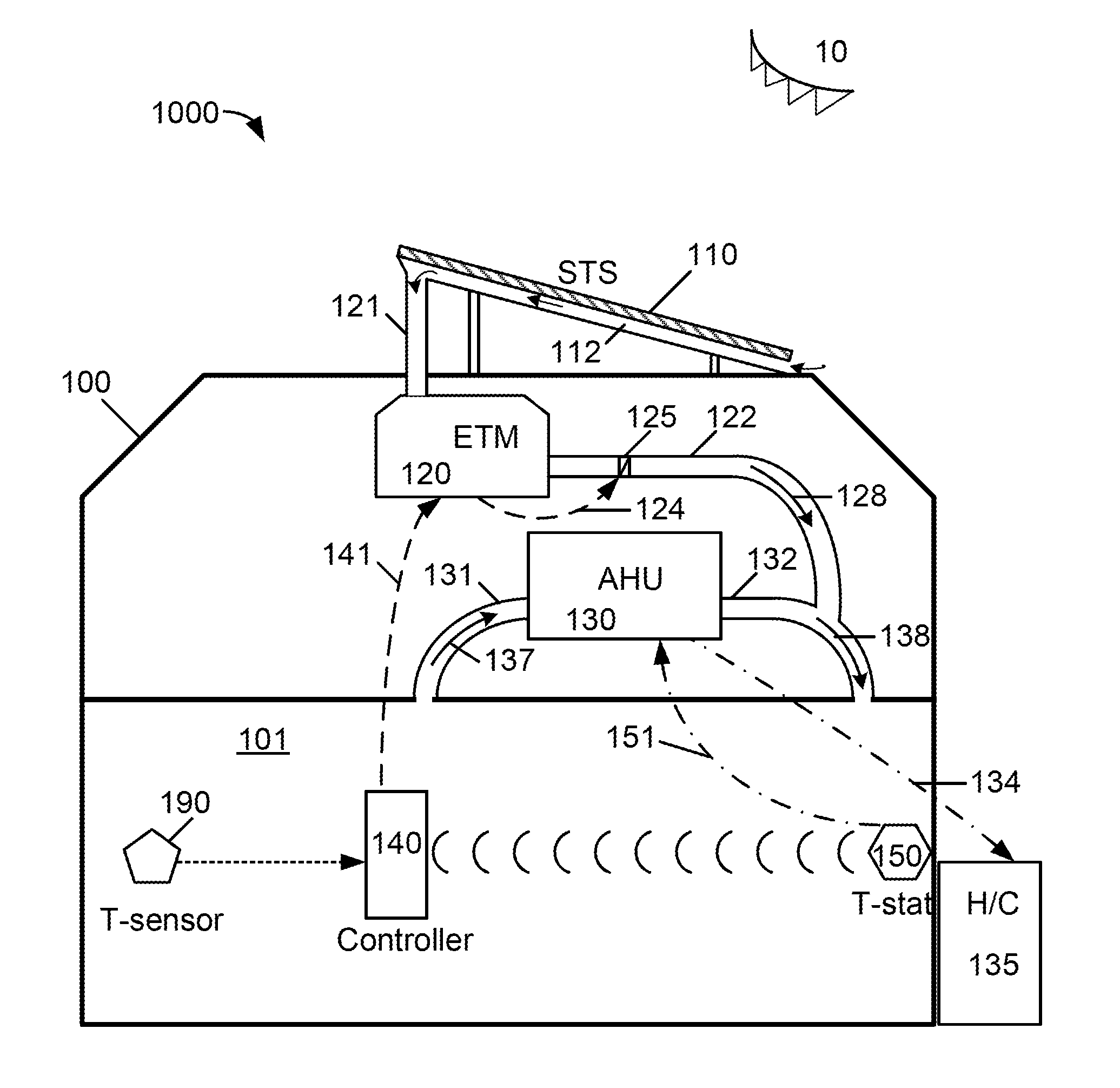

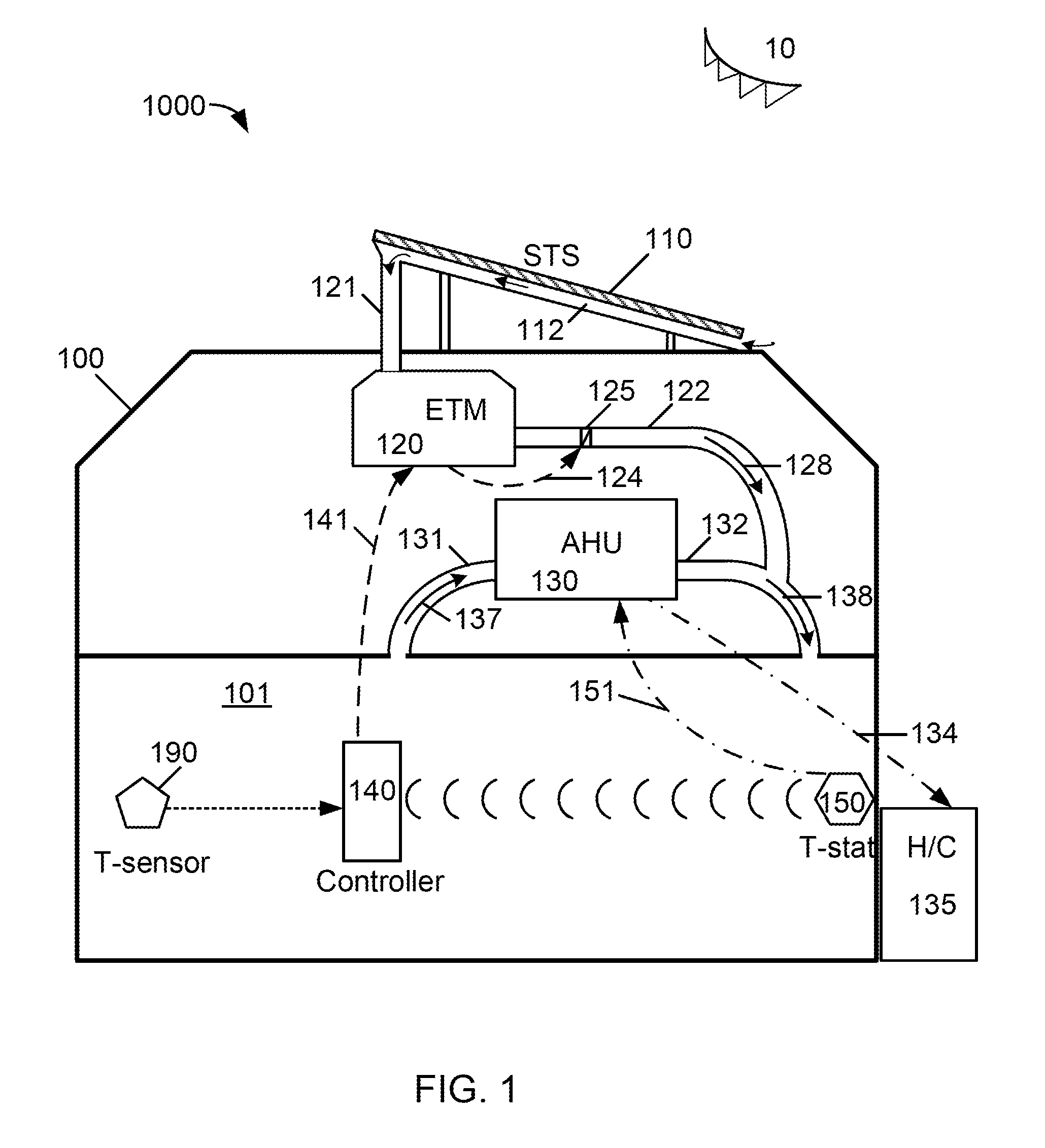

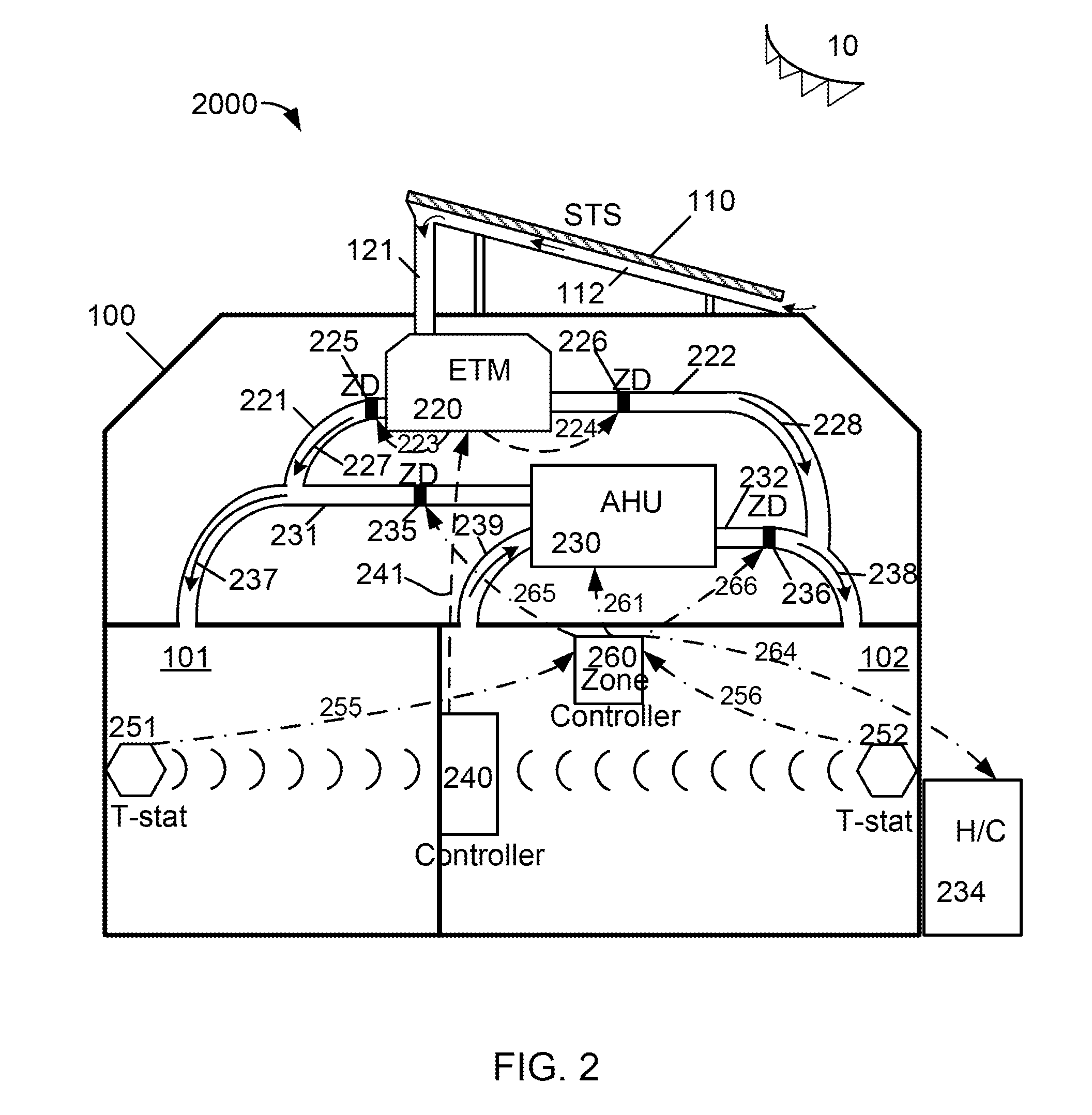

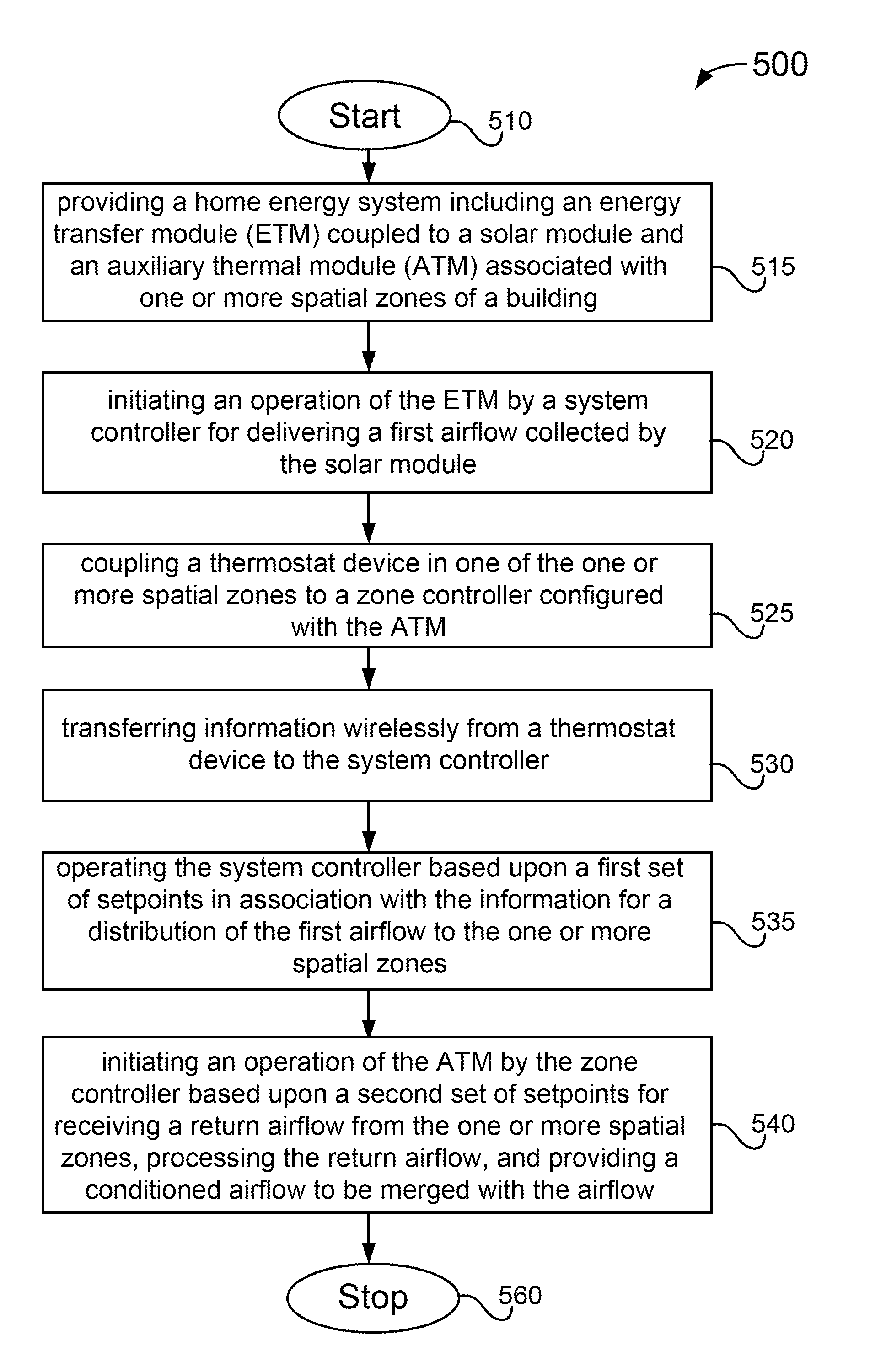

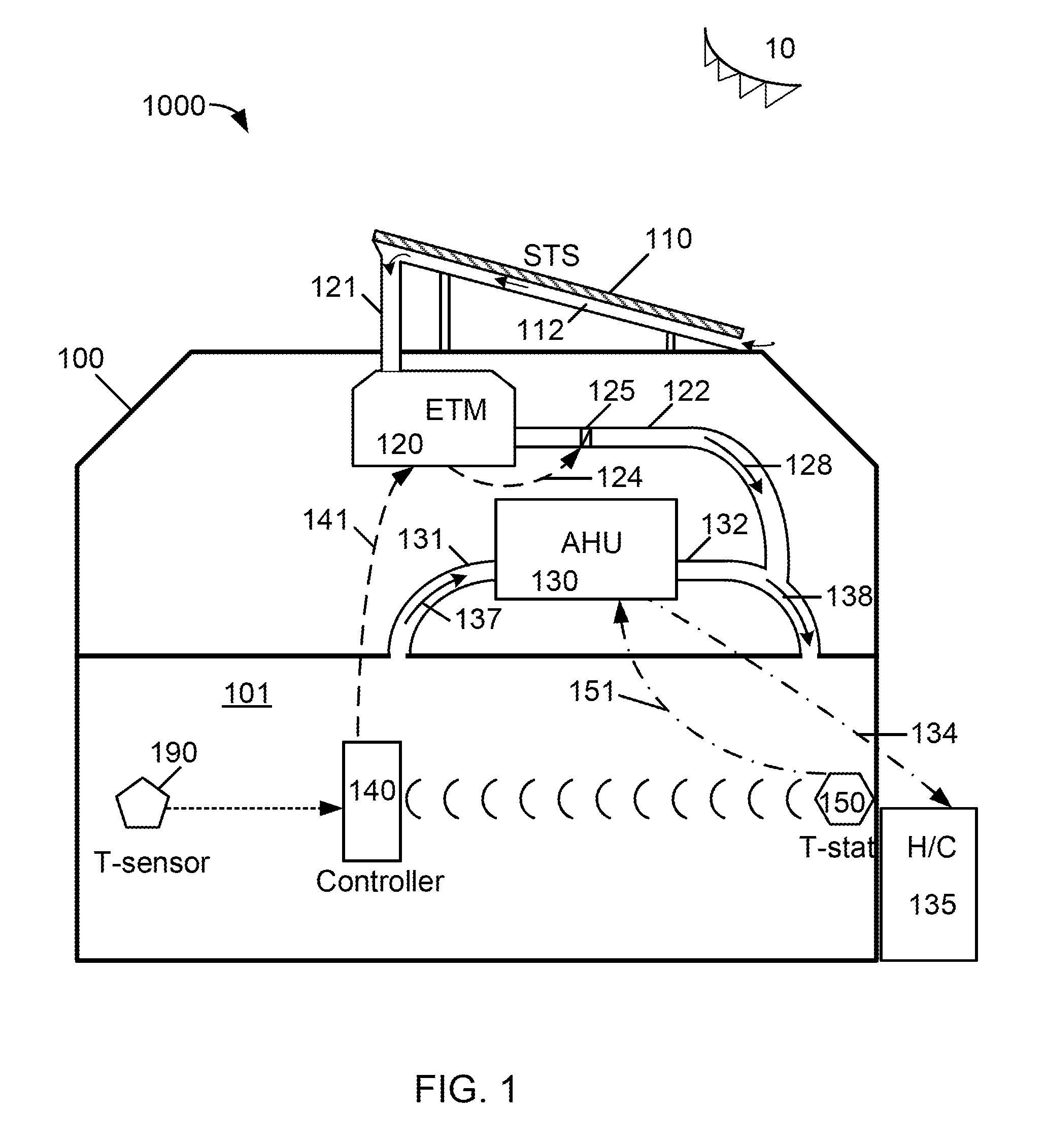

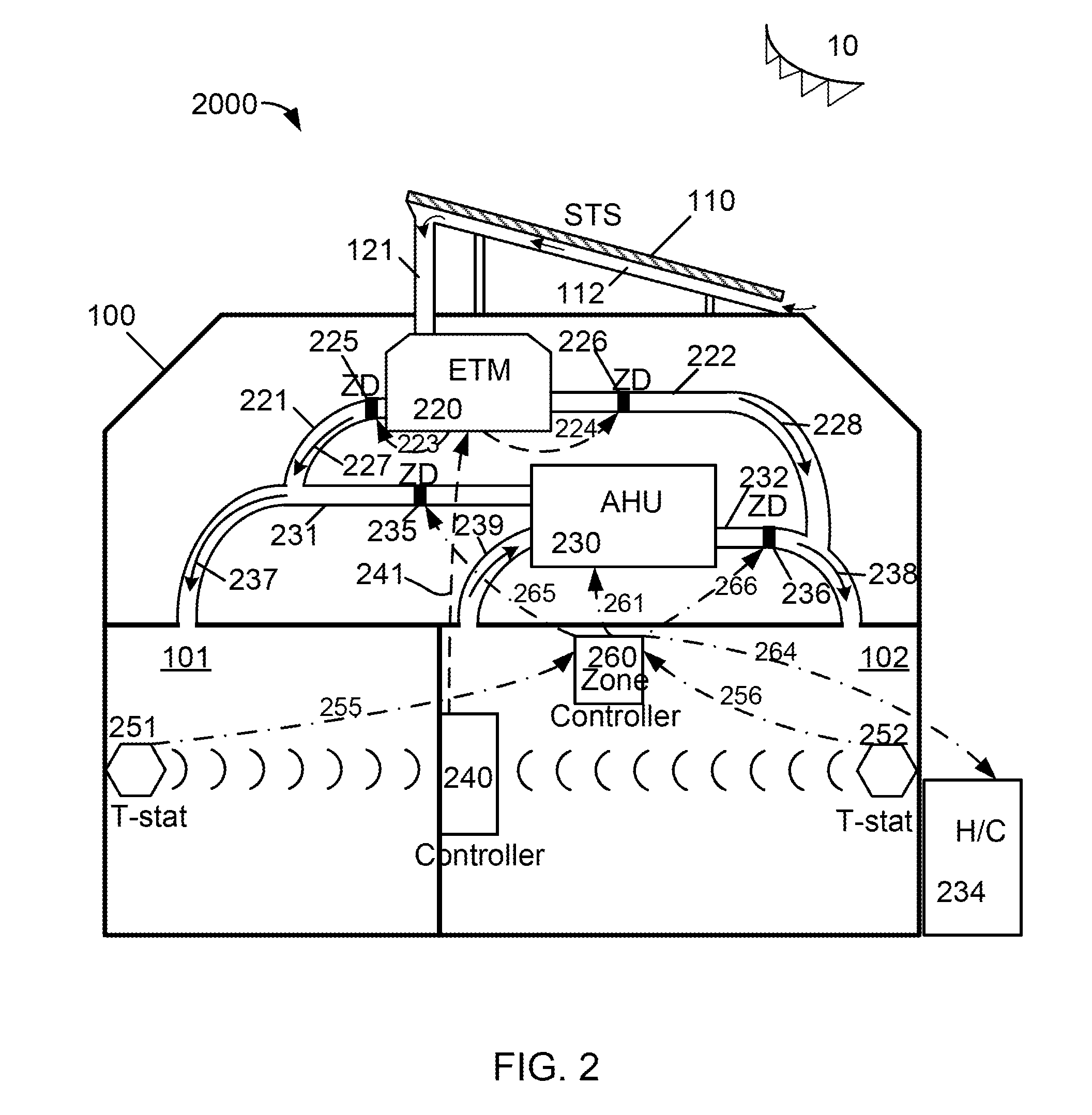

Method and system for healthy home zoning control configured for efficient energy use and conservation of energy resources

InactiveUS20110238223A1Eliminate conflictIncrease heatSolar heating energyMechanical apparatusEnergy transferThermostat

A system provides space conditioning zone control in a building for efficient energy use and conservation of energy resources. The system includes an energy transfer module coupled to a solar thermal system to receive a first airflow and an auxiliary thermal module coupled to the energy transfer module for processing a return airflow to provide a conditioned airflow for one or more spatial zones. The system further includes a zone controller coupled directly to the auxiliary thermal module and a thermostat in each spatial zone for operating the auxiliary thermal module. Furthermore, the system includes a master control module wirelessly communicated with each thermostat and configured to operate the energy transfer module. The master control module initiates a transfer of the first airflow based upon a first setpoint before the zone controller initiates a generation and transfer of the conditioned airflow based upon a second setpoint.

Owner:FTC SOLAR INC

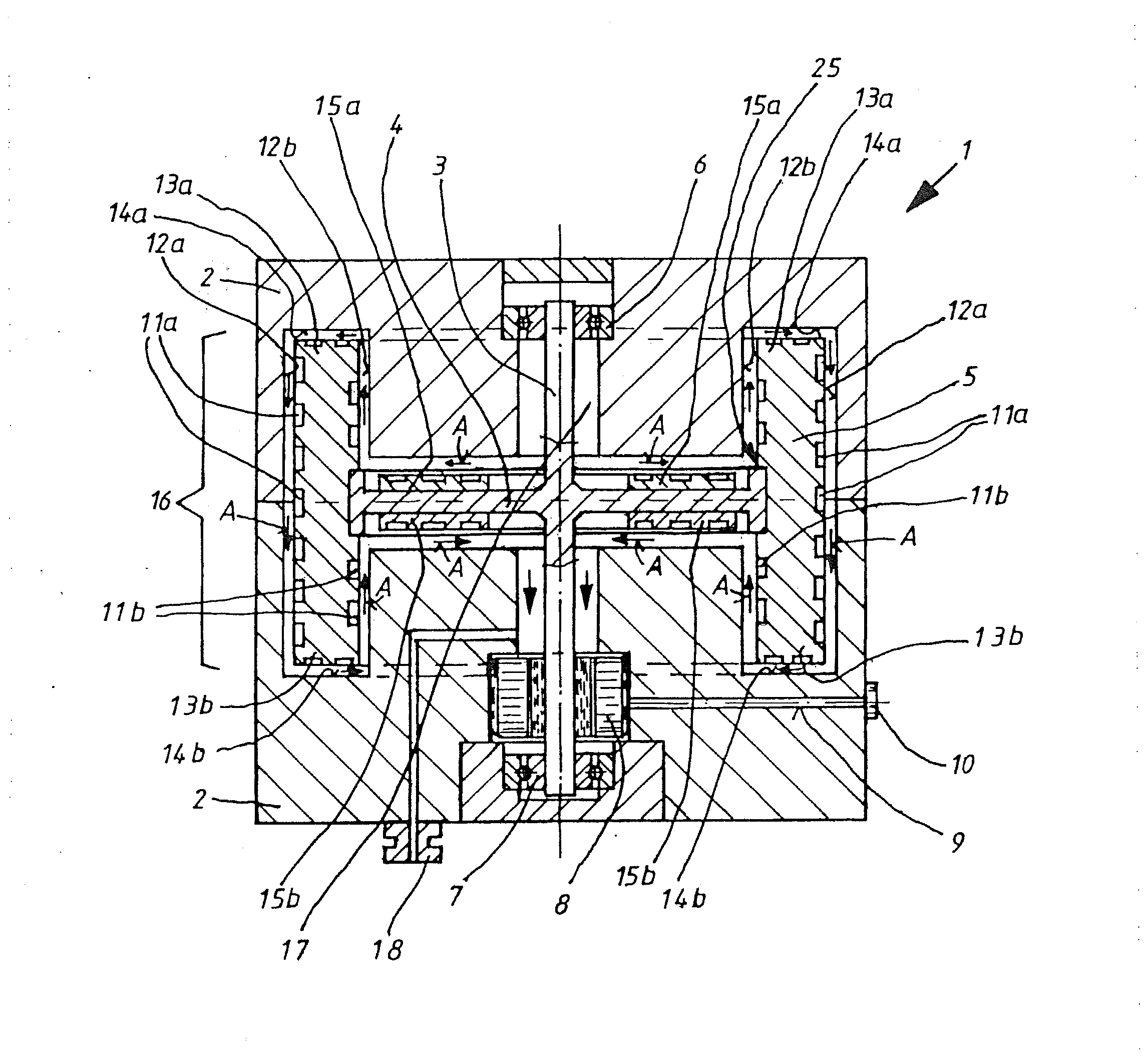

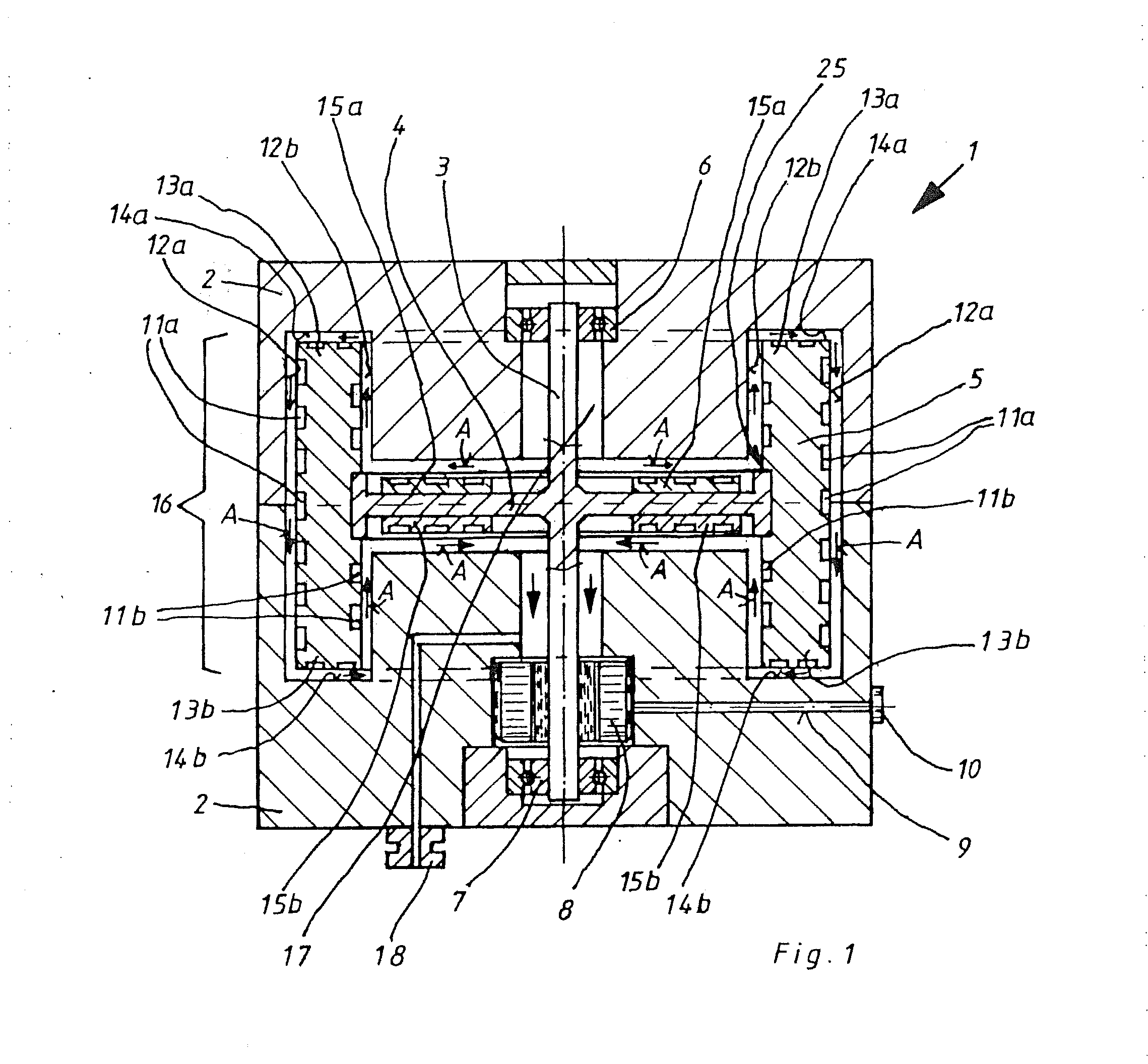

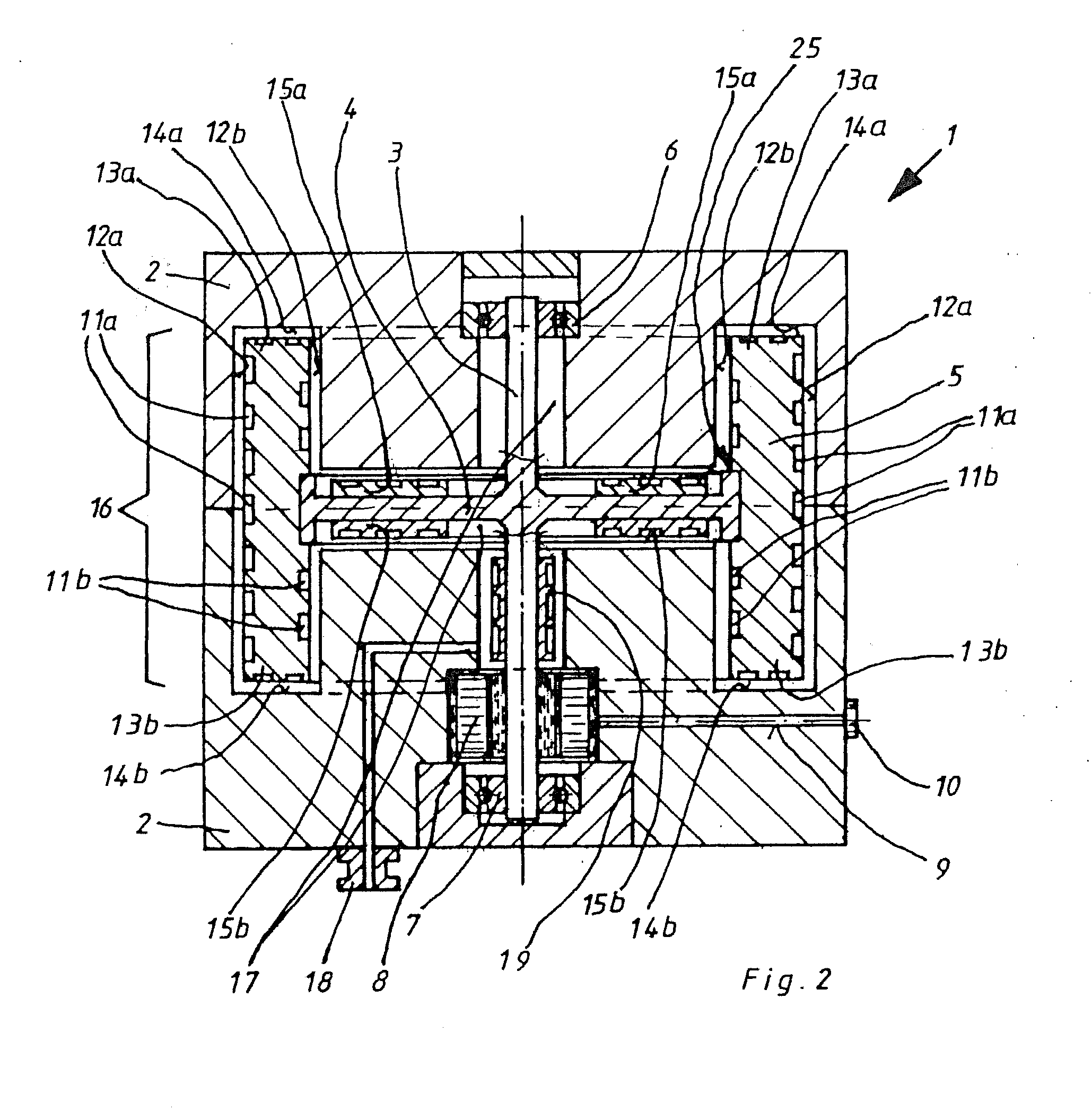

Method for removing lint from a heat exchanger of a domestic appliance and corresponding domestic appliance

InactiveUS8182612B2Clean thoroughlyThe process is simple and clearHollow article cleaningCompression machines with reversible cyclePlate heat exchangerEngineering

A method is provided for the removal from a heat exchange of lint that is generated during a drying process in a domestic appliance for laundry care. A rinsing fluid is run through the heat exchanger for cleaning and the rinsing fluid is deflected during a cleaning phase with the magnitude of deflection or the direction of deflection of the rinsing fluid being a function of the strength of an air flow that is applied to deflect the rinsing fluid. The rinsing fluid is thus run through various regions of the heat exchanger depending on the deflection.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Mobile solar-powered light tower

ActiveUS8833985B2Excellent and useful lightingEliminates the dependency on fossil fuelNon-electric lightingMechanical apparatusLight equipmentElectrical battery

Provided is a mobile lighting device that can derive power from a renewable energy source, such as solar power. The device can comprise a mobile base unit that can house one or more components of the device. The device further can comprise a solar power module associated with the mobile base unit that converts solar energy into electrical current. The device also can comprise a lighting module associated with the mobile base unit that is at least partially powered either directly or indirectly using the electrical current from the solar power module. The device further can comprise a solar power storage module, such as comprising one or more batteries, for storing energy and discharging as electrical current for powering the lighting module, which can be positioned atop a mast that can be extendable, pivotable, and / or rotatable. The invention also provides methods and systems for illuminating areas.

Owner:RENEWABLE ENERGY HLDG

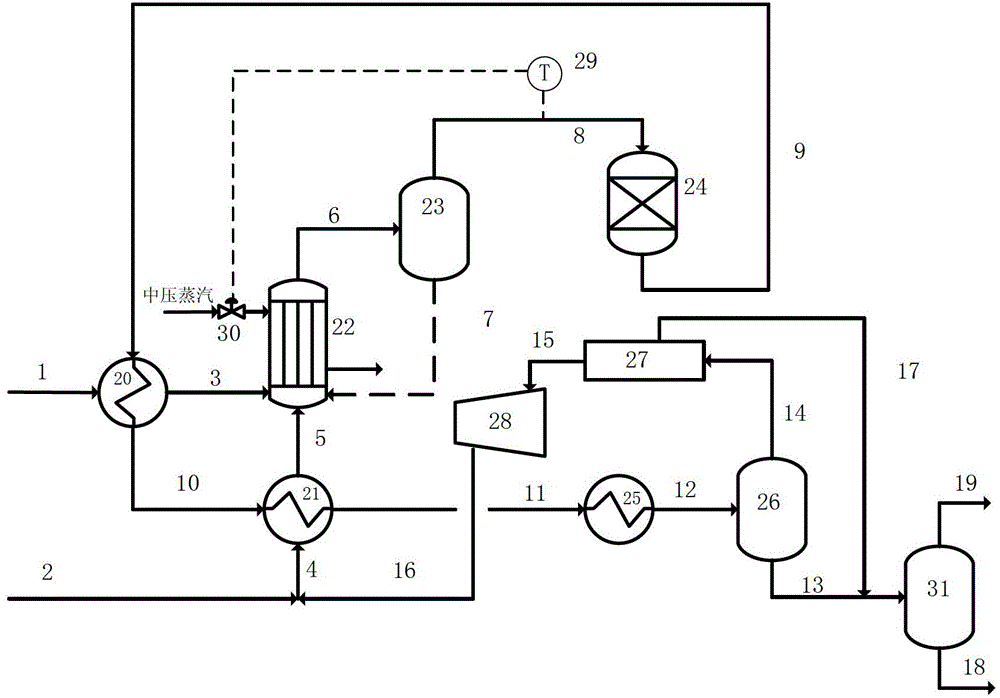

Method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen

ActiveCN102942446ALow costReduce heating effectOrganic compound preparationEnergy inputGas phaseProduct gas

The invention relates to a method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen. The method comprises the steps of: recycling hydrogen in the gas phase of a product by using a pressure swing adsorption (PSA) device and then increasing the pressure for recirculating; heating the mixed gas of acetic ester, circulated hydrogen and fresh hydrogen by using reaction heat; heating the preheated raw material gas by medium-pressure steam and then importing into a reactor so as to realize high acetic ester conversion rate and high ethanol selectivity in the presence of a catalyst; and carrying out gas-liquid separation on the product gas obtained via the reaction, and liquefying and separating the reaction principal product ethanol, a small amount of byproducts and unreacted acetic ester to obtain an initial product. According to the method, hydrogen is recycled and recirculated via PSA so that the use of the raw material hydrogen can be greatly reduced, the reaction raw materials are preheated by fully utilizing the reaction heat so that the energy consumption of the heating and the cooling is decreased, the flow is simple and the control is simple and convenient.

Owner:DATANG INT CHEM TECH RESINST

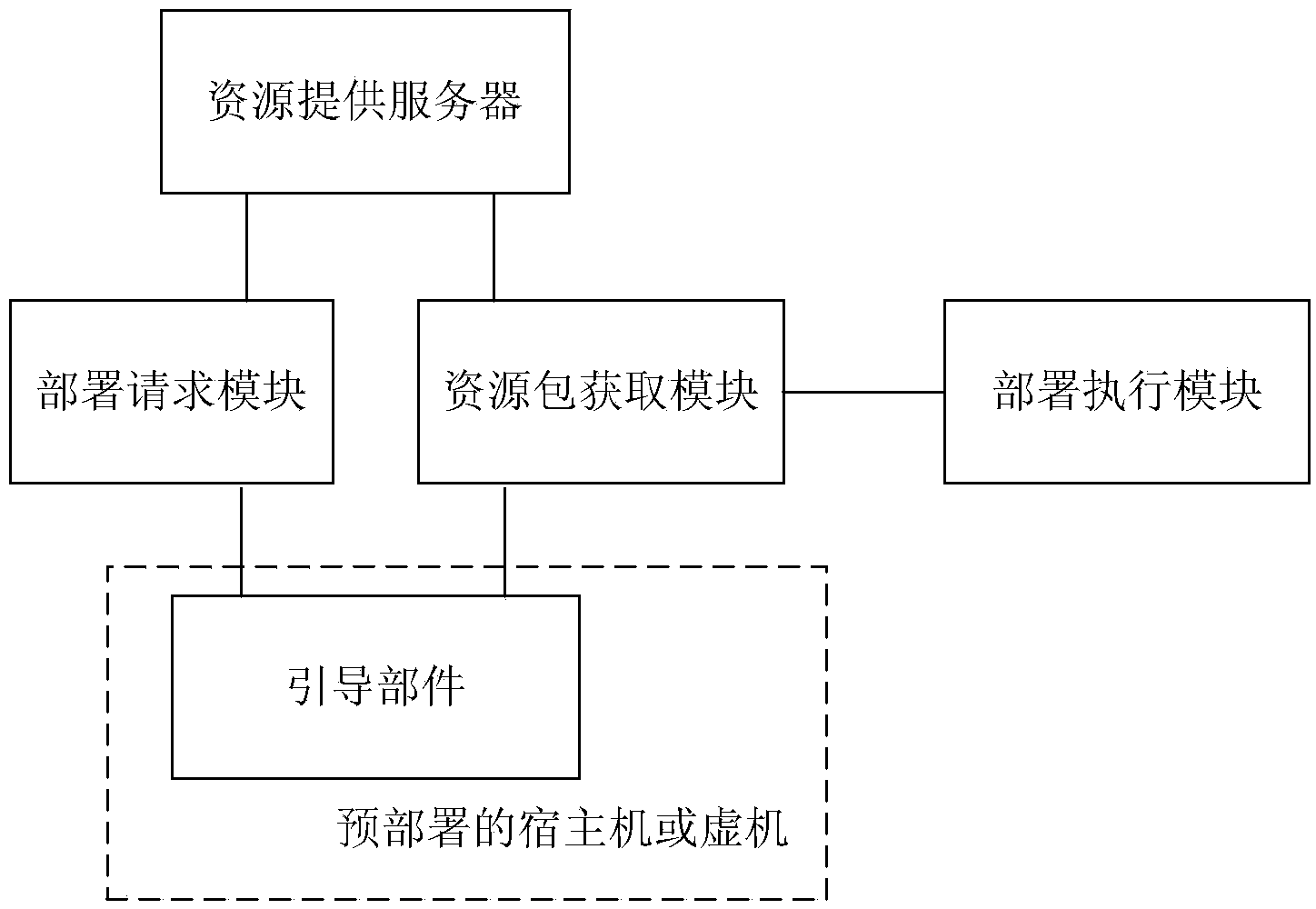

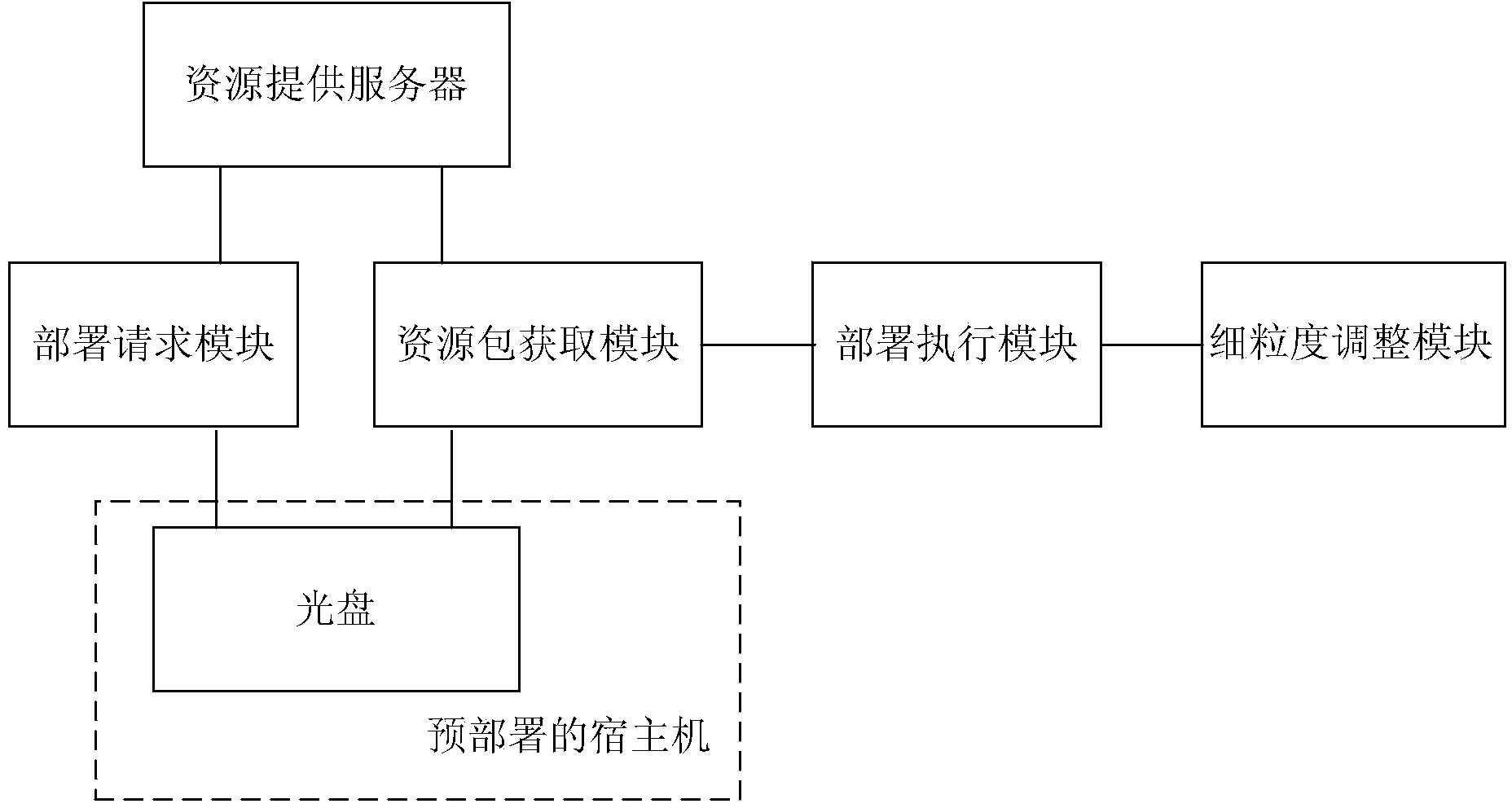

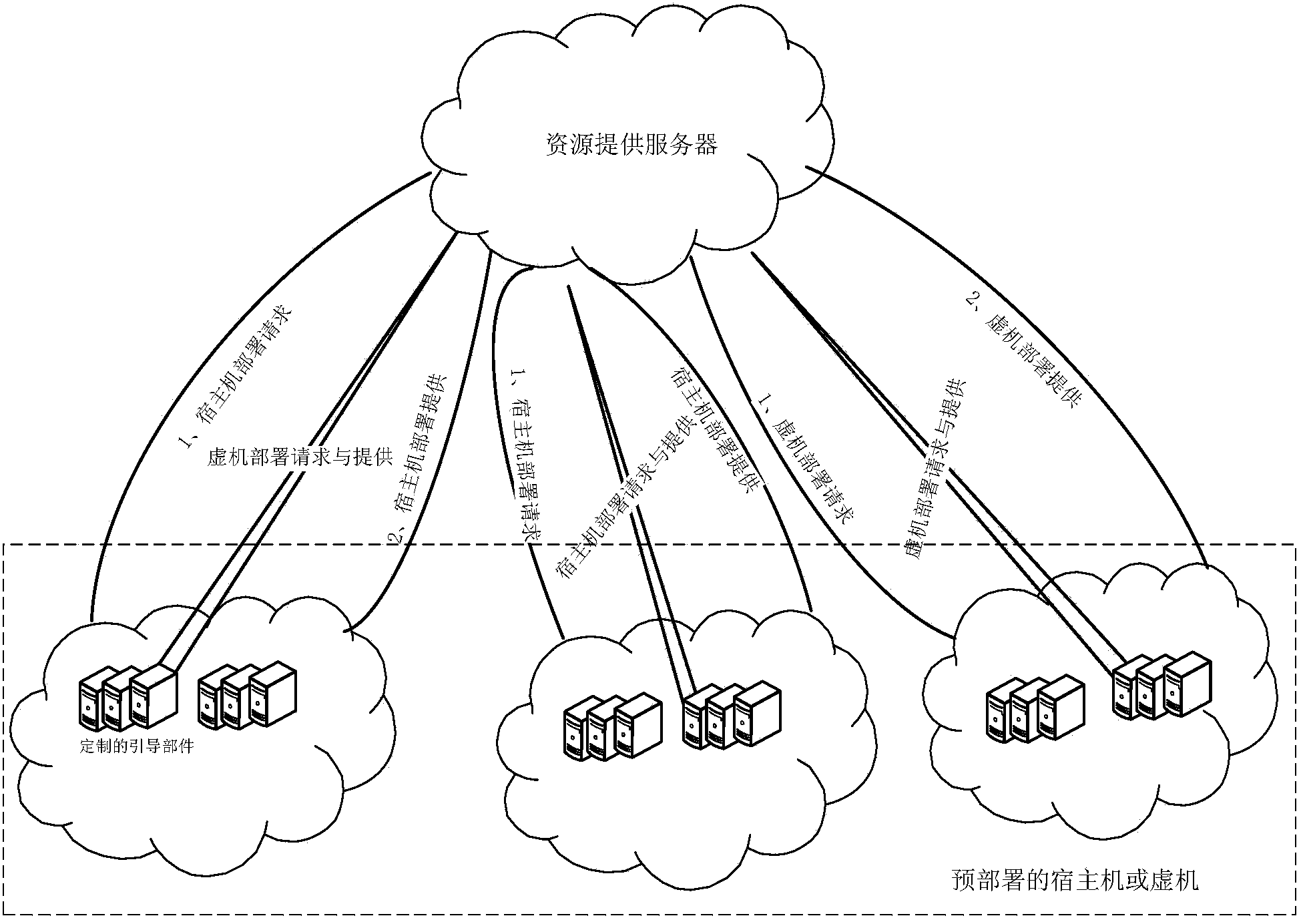

One-key deployment method and device for cloud system

ActiveCN103458002AFast one-click deploymentPlay a guiding roleData switching networksOperational systemApplication software

The invention relates to a one-key deployment method and device for a cloud system. The one-key deployment method for the cloud system comprises the steps that a resource providing server is set up in the cloud computing environment at first; an installation resource package and a DHCP service are set up in the resource providing server, wherein the installation resource package comprises configuration files of a pre-deployed host machine or virtual machine, and an installation package and an additional application software package of an operating system; the installation resource package of the resource providing server is obtained from the cloud environment in the nodes of the pre-deployed host machine or virtual machine through guide files comprising kernel guide information and installation paths; one-key deployment is conducted on the content in the obtained installation resource package, and the operating system and the application environment of the host machine or virtual machine are installed. According to the one-key deployment method and device for the cloud system, the operating system and the application environment of the host machine or virtual machine can be deployed in a unification, centralization, speediness and one-key mode.

Owner:CEC CYBERSPACE GREAT WALL

Wave energy harnessing device

ActiveUS20100025993A1Increasing combined wave energy extraction efficiencyReducing kinematicMachines/enginesSafety/regulatory devicesWave shoalingResponse Frequency

A hydrokinetic device having a water surface float tethered to a submerged buoyant housing is provided with mechanisms for optimizing the amount of wave energy extracted from the waves by the device. Based on wave conditions, the optimization functionalities include controlling the depth of the housing to produce wave shoaling or storm avoidance, as well as to perform continuous phase control and load control for the purpose of matching the response frequency of the device to the frequency of the incident waves.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

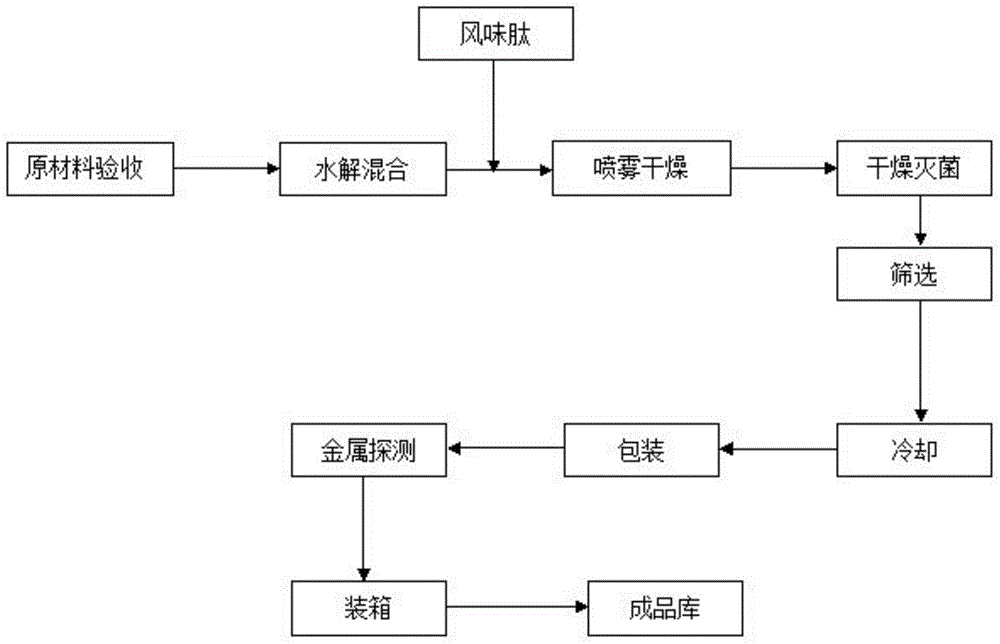

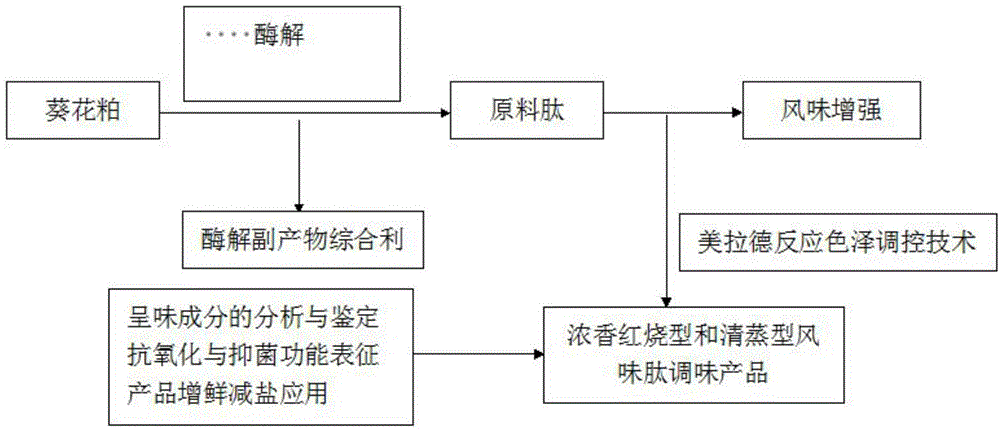

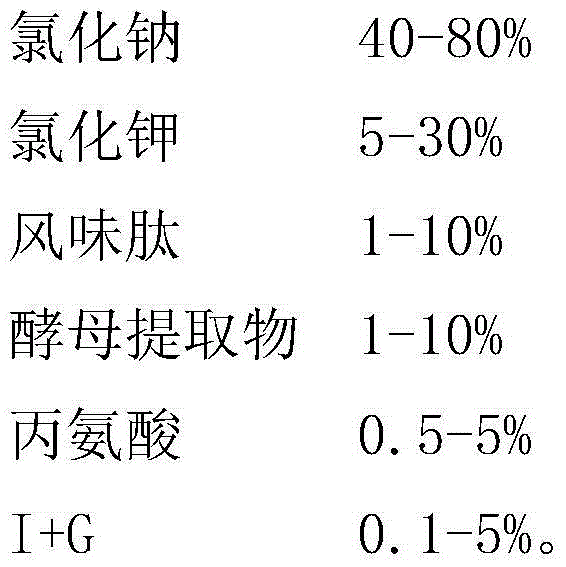

Flavored low-sodium seasoning salt

ActiveCN104643006AHigh nutritional valuePromote emptyingYeast food ingredientsFood ingredient functionsPotassiumYeast cell extract

The invention provides flavored low-sodium seasoning salt. The flavored low-sodium seasoning salt is characterized by being prepared from the following raw materials in percentage by weight: 40 to 80% of sodium chloride, 5 to 30% of potassium chloride, 1 to 10% of flavored peptide, 1 to 10% of a yeast extract, 0.5 to 5% of alanine, and 0.1 to 5% of I+G. The flavored low-sodium seasoning salt can reduce the use quantity of salt but remain the salt taste, thus the intake of sodium can be reduced; the salt is technically reduced; in addition, the fresh is increased; with the adoption of the salt, aginomoto can be saved, and the health can be conditioned.

Owner:安徽强旺生物工程有限公司

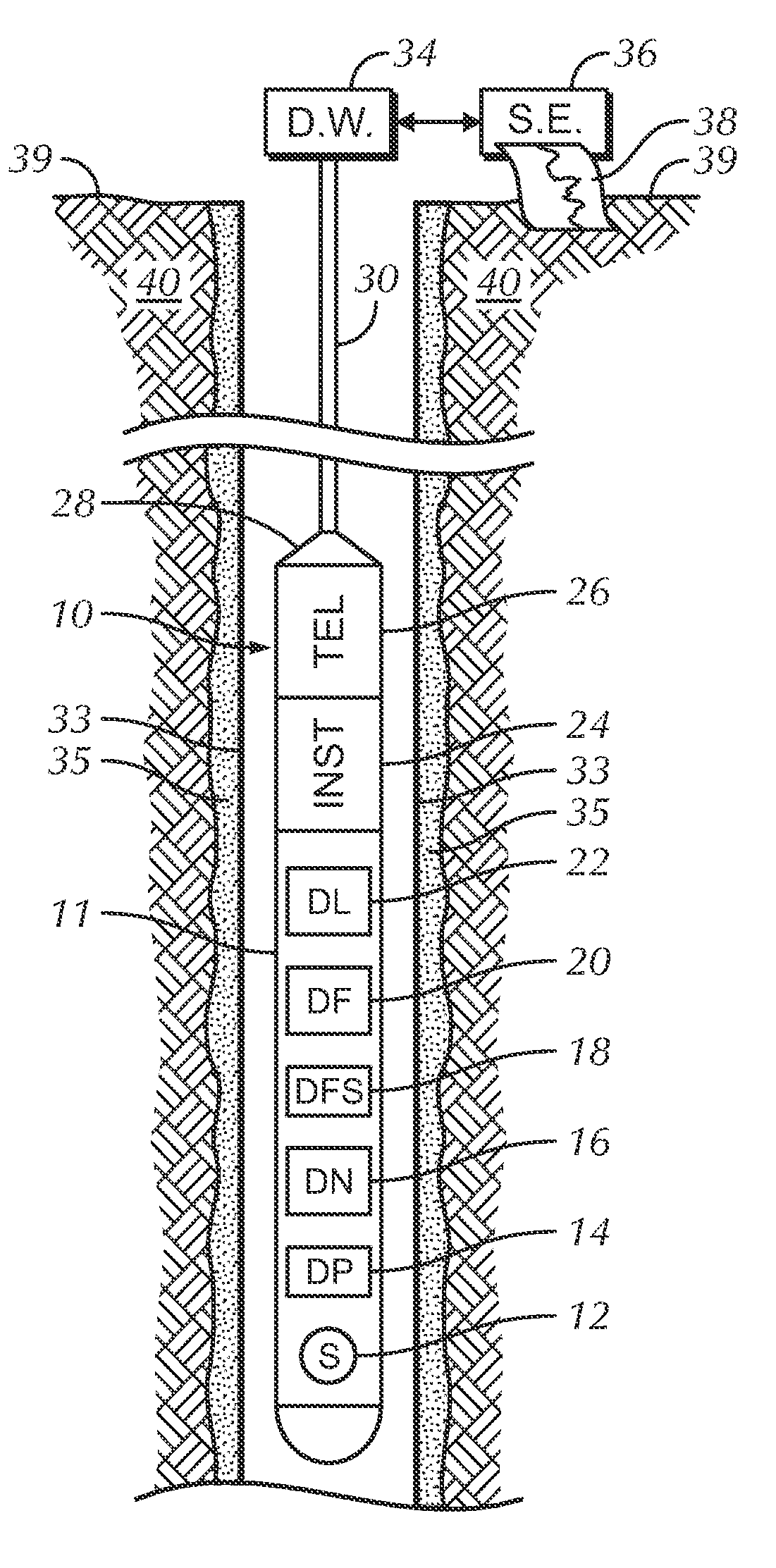

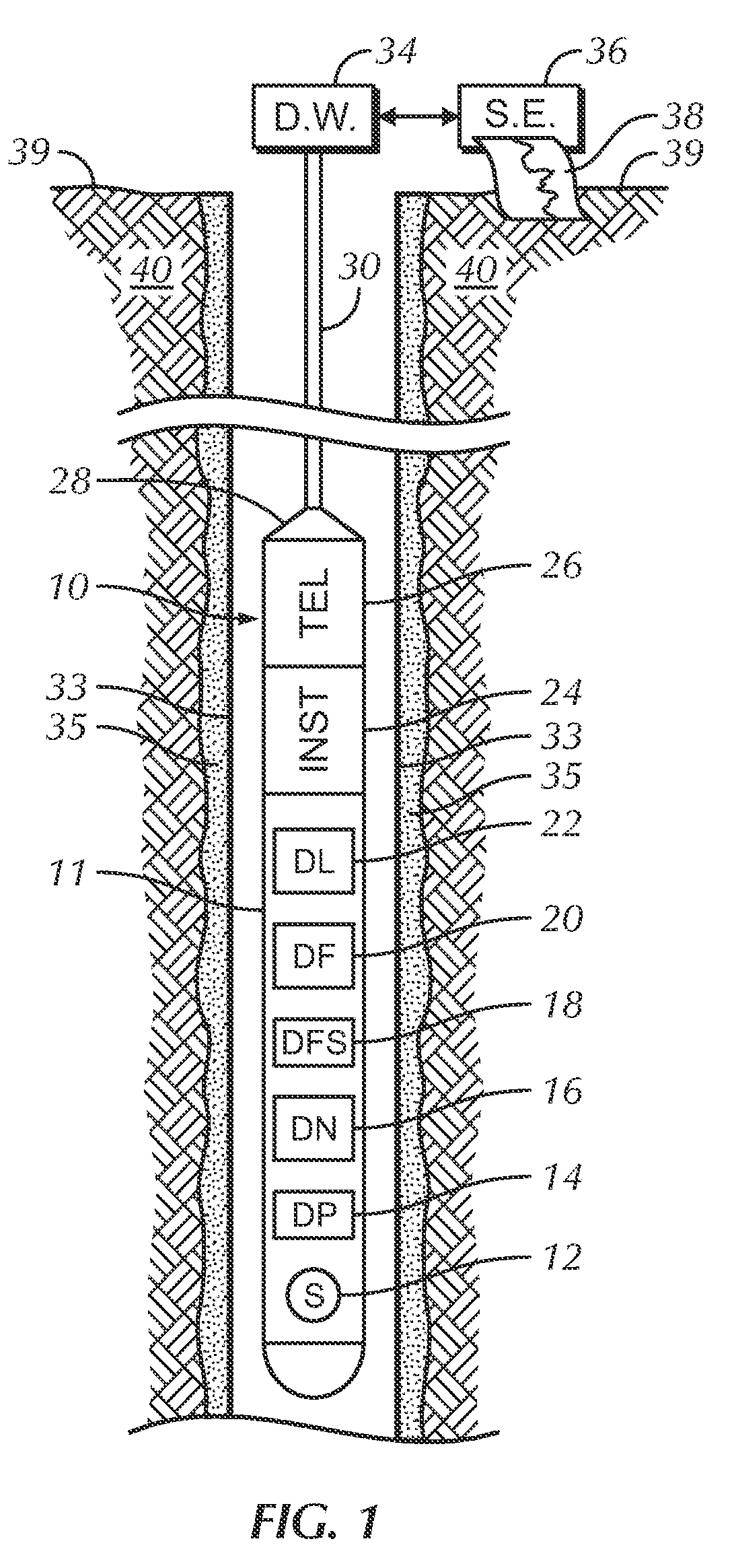

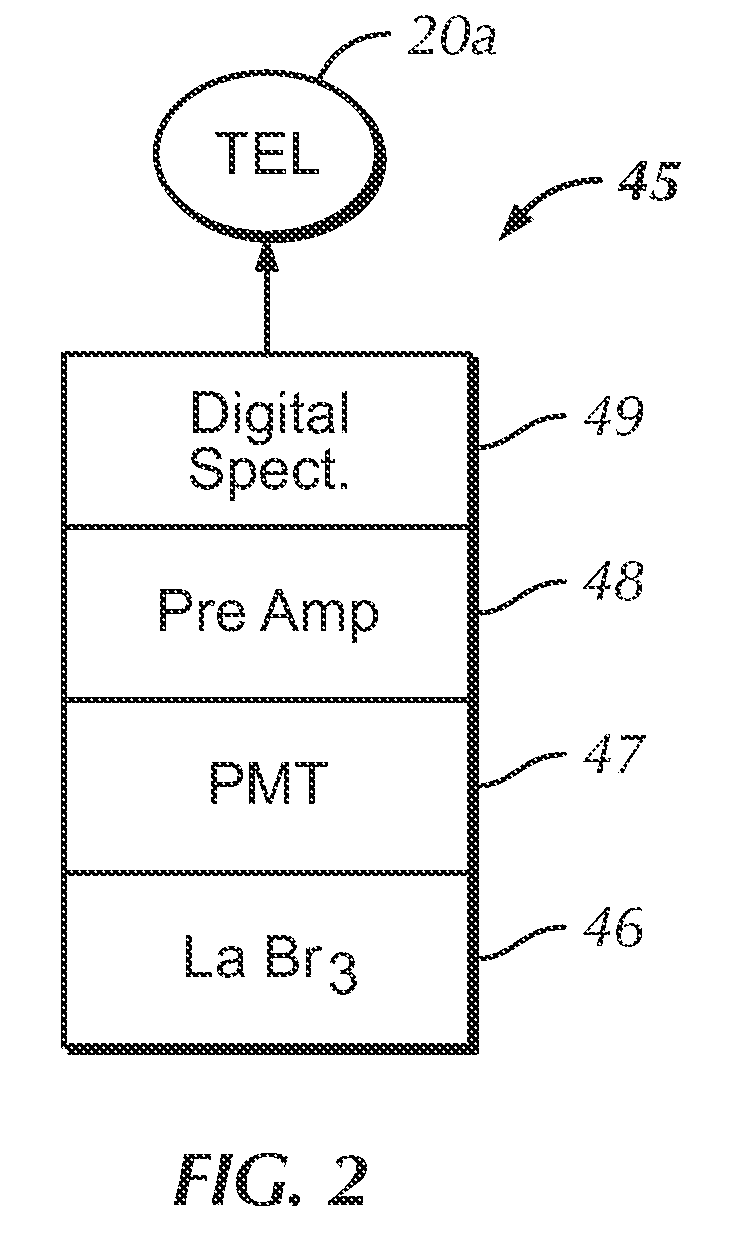

Borehole measurements using a fast and high energy resolution gamma ray detector assembly

ActiveUS7999220B2Energy optimizationFast emission timeRadiation pyrometrySpectrum investigationDead timePulse height

A gamma ray detector assembly for a borehole logging system that requires the measure of gamma radiation with optimized gamma ray energy resolution and with fast emission times required to obtain meaningful measurements in high radiation fields. The detector assembly comprises a lanthanum bromide (LaBr3) scintillation crystal and a digital spectrometer that cooperates with the crystal to maximize pulse processing throughput by digital filtering and digital pile-up inspection of the pulses. The detector assembly is capable of digital pulse measurement and digital pile-up inspection with dead-time less than 600 nanoseconds per event. Pulse height can be accurately measured (corrected for pile-up effects) for 2 pulses separated by as little as 150 nanoseconds. Although the invention is applicable to virtually any borehole logging methodology that uses the measure of gamma radiation in harsh borehole conditions, the invention is particularly applicable to carbon / oxygen logging.

Owner:WEATHERFORD TECH HLDG LLC

Method and system for healthy home zoning control configured for efficient energy use and conservation of energy resources

InactiveUS8660708B2Eliminate conflictIncrease heatSolar heating energyMechanical apparatusEnergy transferThermostat

A system provides space conditioning zone control in a building for efficient energy use and conservation of energy resources. The system includes an energy transfer module coupled to a solar thermal system to receive a first airflow and an auxiliary thermal module coupled to the energy transfer module for processing a return airflow to provide a conditioned airflow for one or more spatial zones. The system further includes a zone controller coupled directly to the auxiliary thermal module and a thermostat in each spatial zone for operating the auxiliary thermal module. Furthermore, the system includes a master control module wirelessly communicated with each thermostat and configured to operate the energy transfer module. The master control module initiates a transfer of the first airflow based upon a first setpoint before the zone controller initiates a generation and transfer of the conditioned airflow based upon a second setpoint.

Owner:FTC SOLAR INC

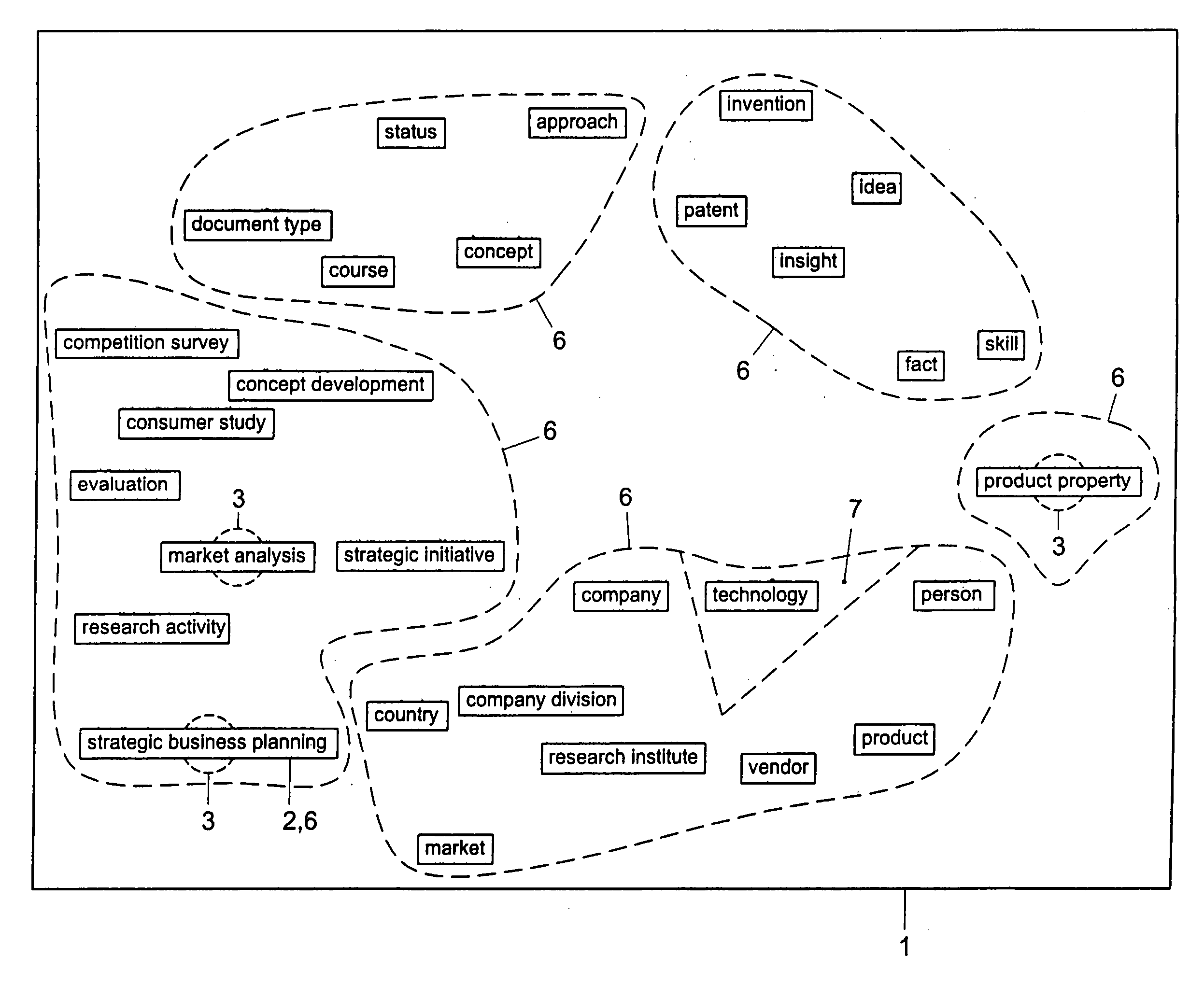

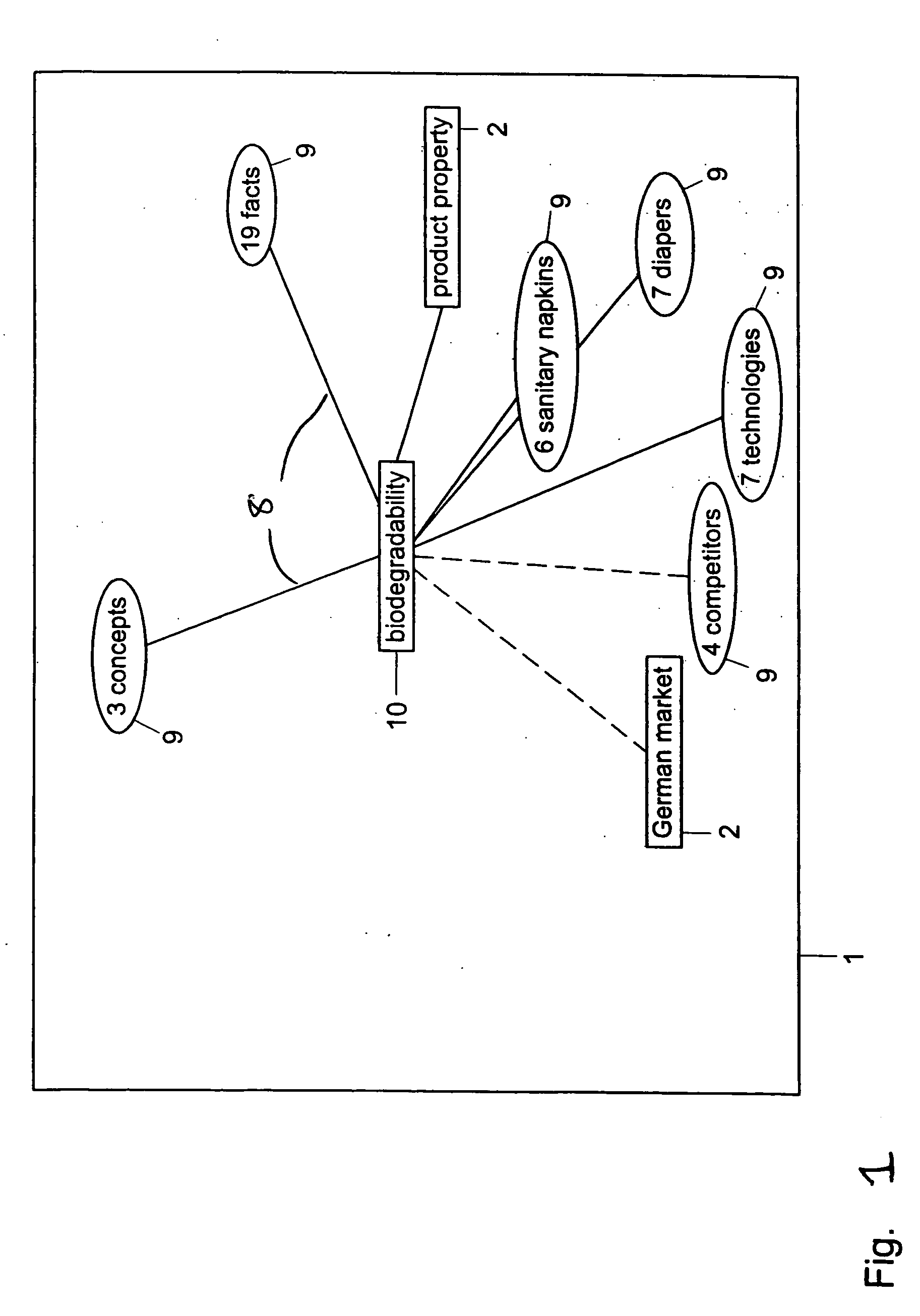

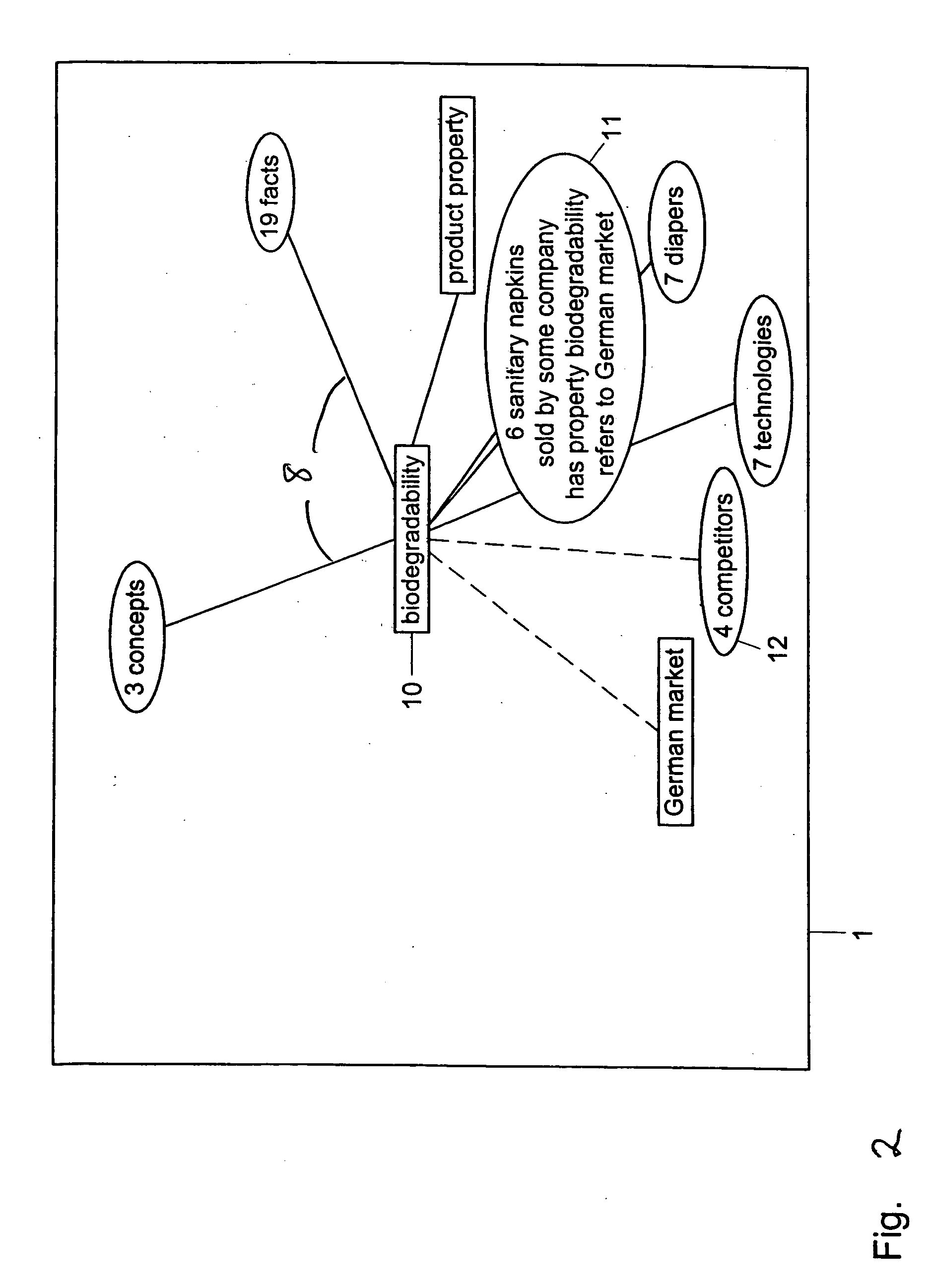

Methods and systems for providing a visualization graph

ActiveUS20050114802A1Energy optimizationPrecise positioningDigital data information retrievalDigital data processing detailsData mining

A visualization graph is provided on a computer. Data corresponding to a plurality of entities is stored, wherein a semantic net includes the entities and wherein the entities are linked to each other by a plurality of relations. In response to a query with respect to an entity selected from the plurality of entities, providing a visualization graph representing the results of the query, representing a plurality of entities having a common relation as a first node on the visualization graph. In response to a predetermined stimulus causing the entities comprised at the first node to be displayed, and in response to a further predetermined stimulus causing the graph to restructure so that the node replaces the displayed entities.

Owner:SAP AG

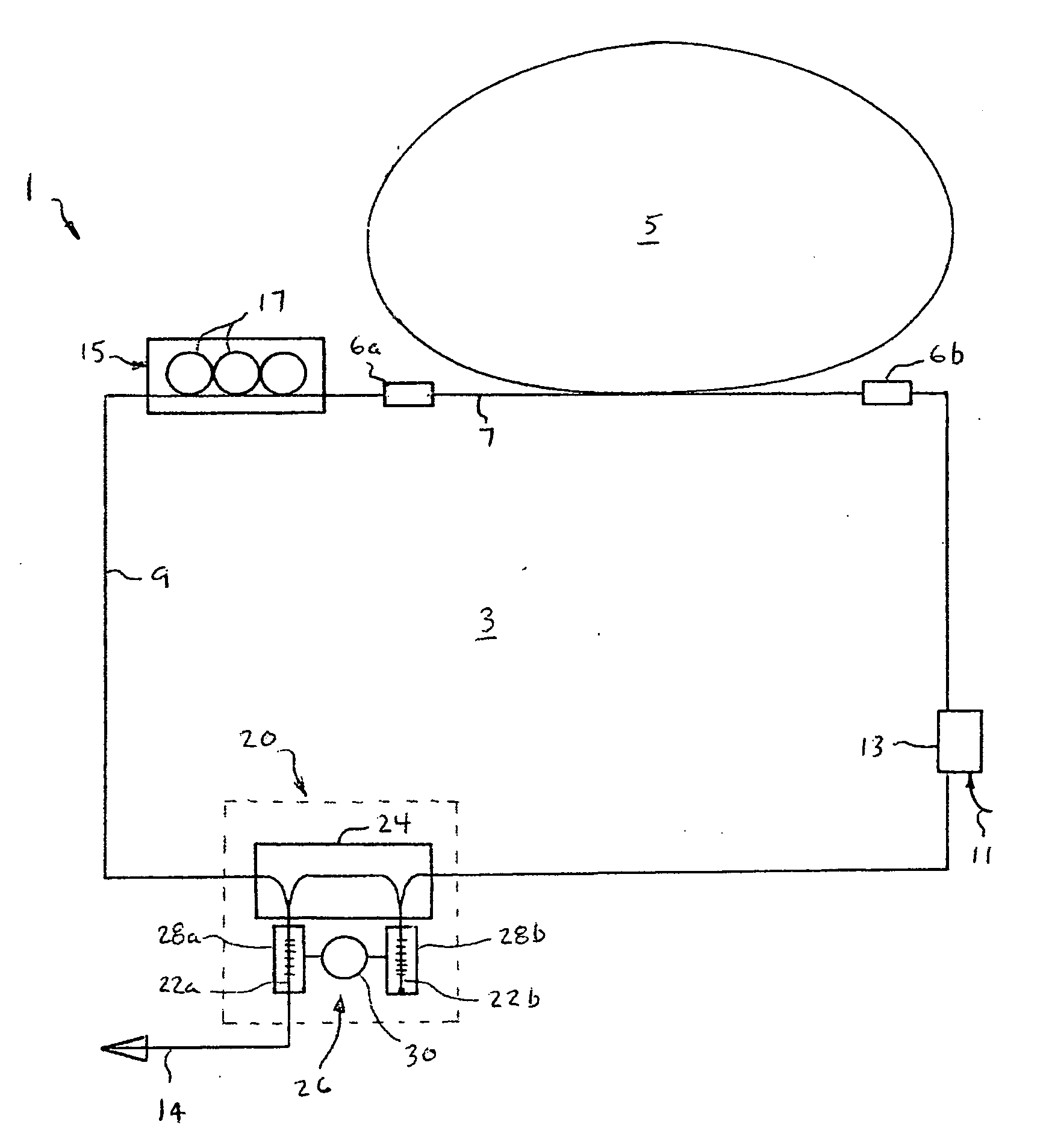

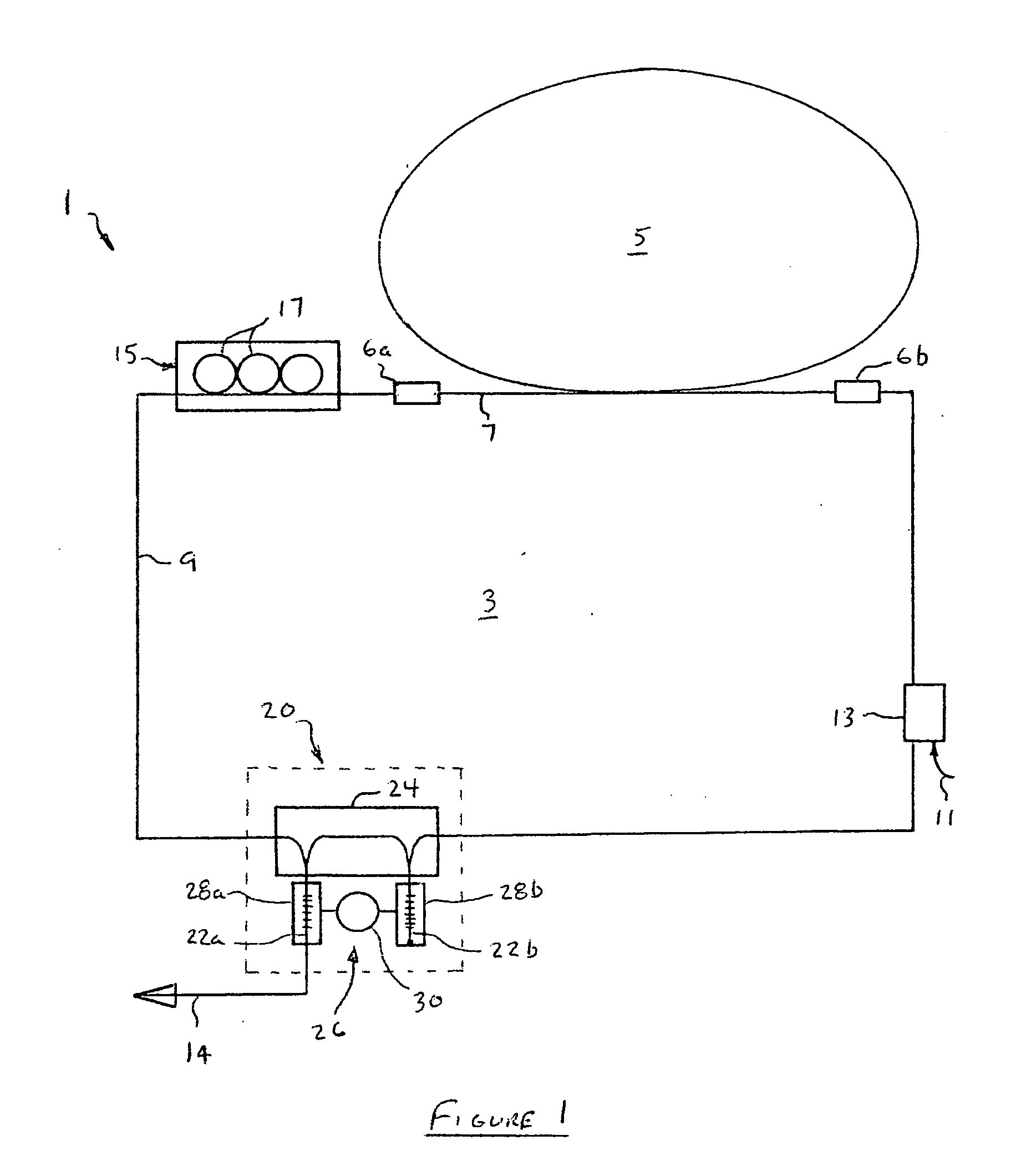

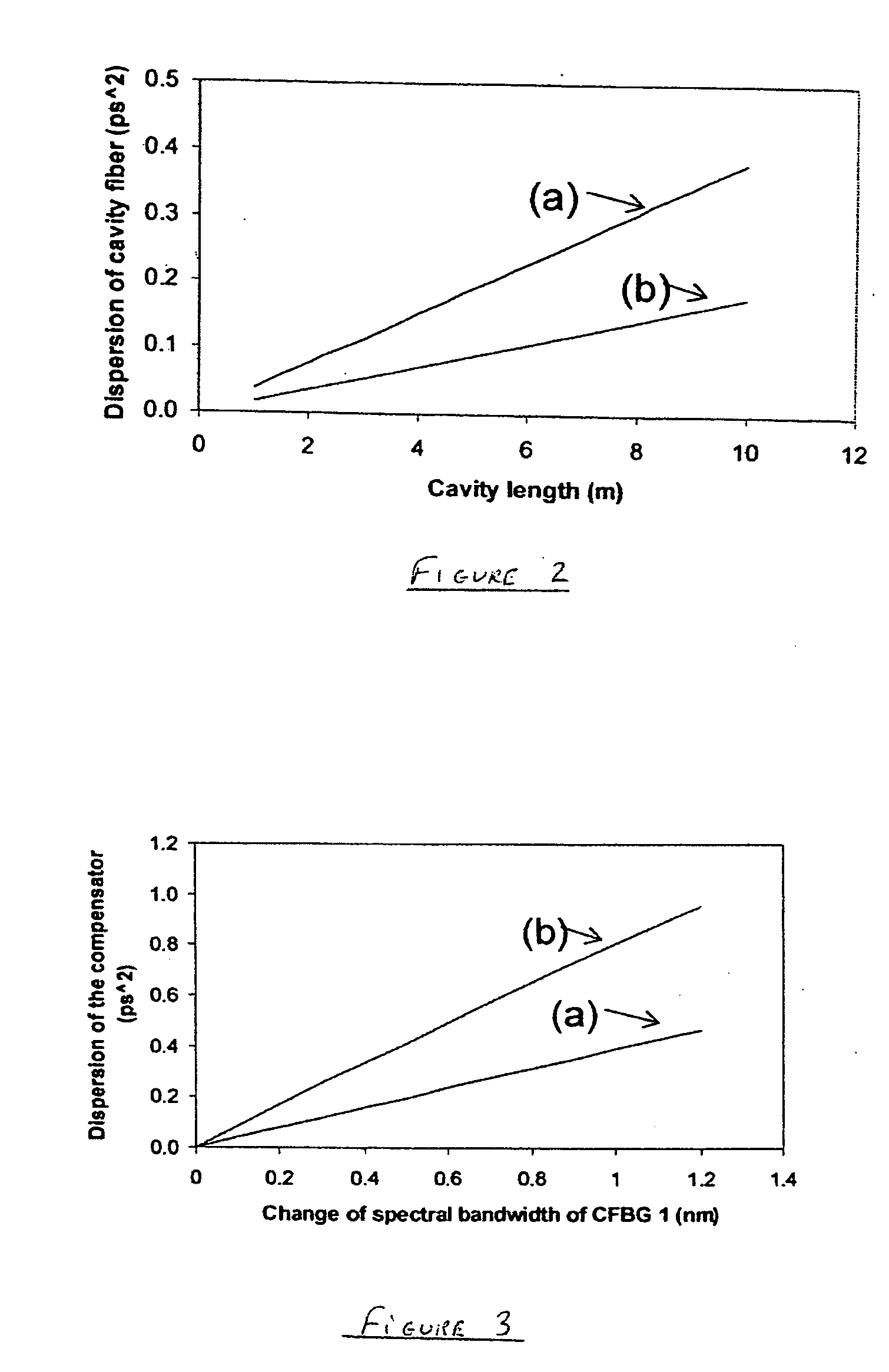

High energy, ultrashort pulse ring fiber laser having a linear dispersion compensator with chirped Bragg gratings

InactiveUS20080025348A1Easily adjustFreedom misalignmentLaser using scattering effectsLight sourceErbium

A high energy, ultra short pulse ring fiber laser is provided that includes a passively mode locked, all optical fiber laser formed from a closed loop of optical fiber doped with erbium or other rare earth metal, a pump light source optically coupled to the loop of optical fiber, and a linear dispersion compensator that includes a pair of chirped Bragg gratings with substantially equal but opposite sign dispersion. The difference in dispersion between the pair of chirped Bragg gratings is adjusted so that it is substantially equal and opposite to the dispersion generated in the loop of optical fiber. The linear dispersion compensator includes a tuner which can individually stretch or compress the pair of chirped fiber Bragg gratings such that one of the gratings can be adjusted to cancel out the dispersion of the ring laser cavity, while the other grating is adjusted to eliminate third order dispersion of the cavity.

Owner:CORNING INC

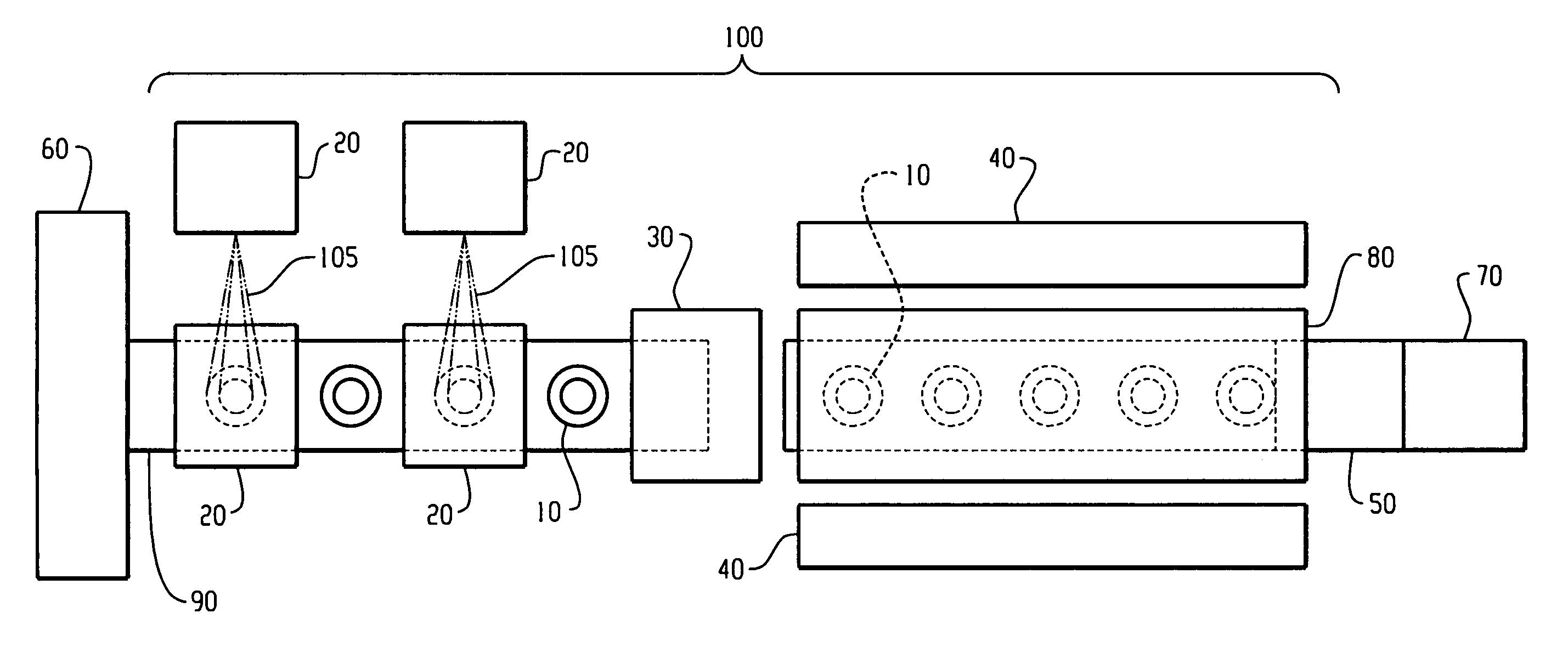

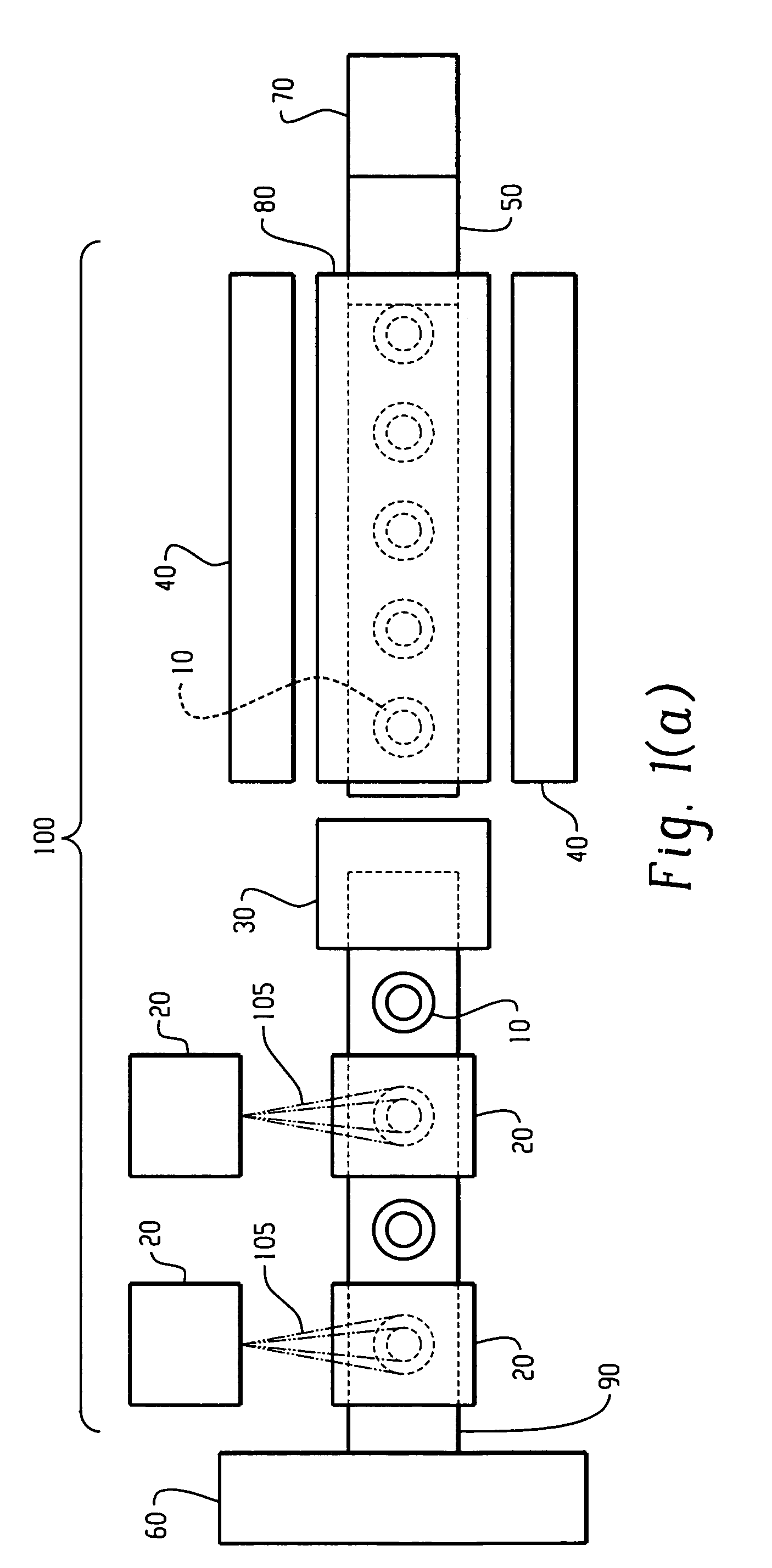

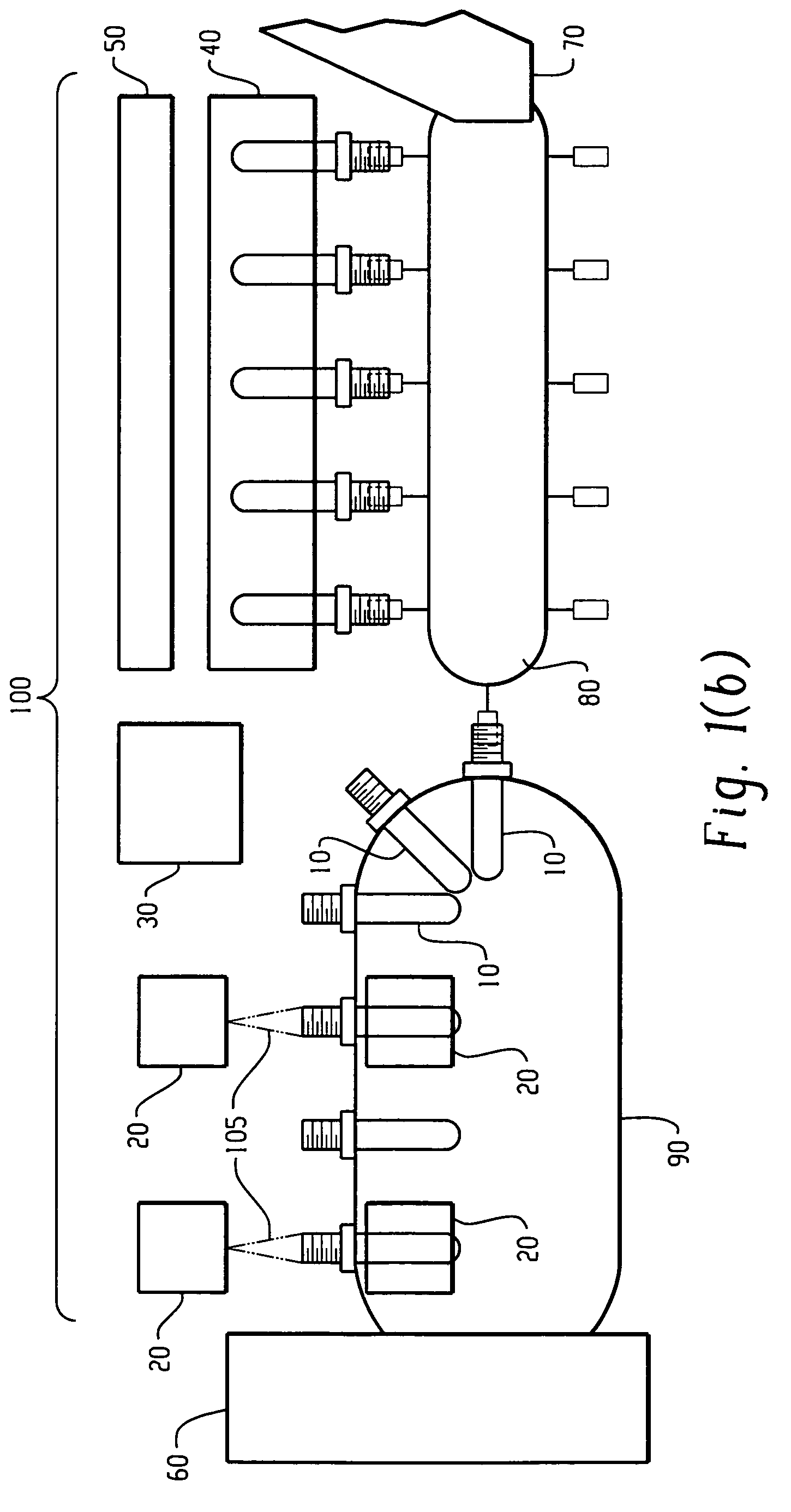

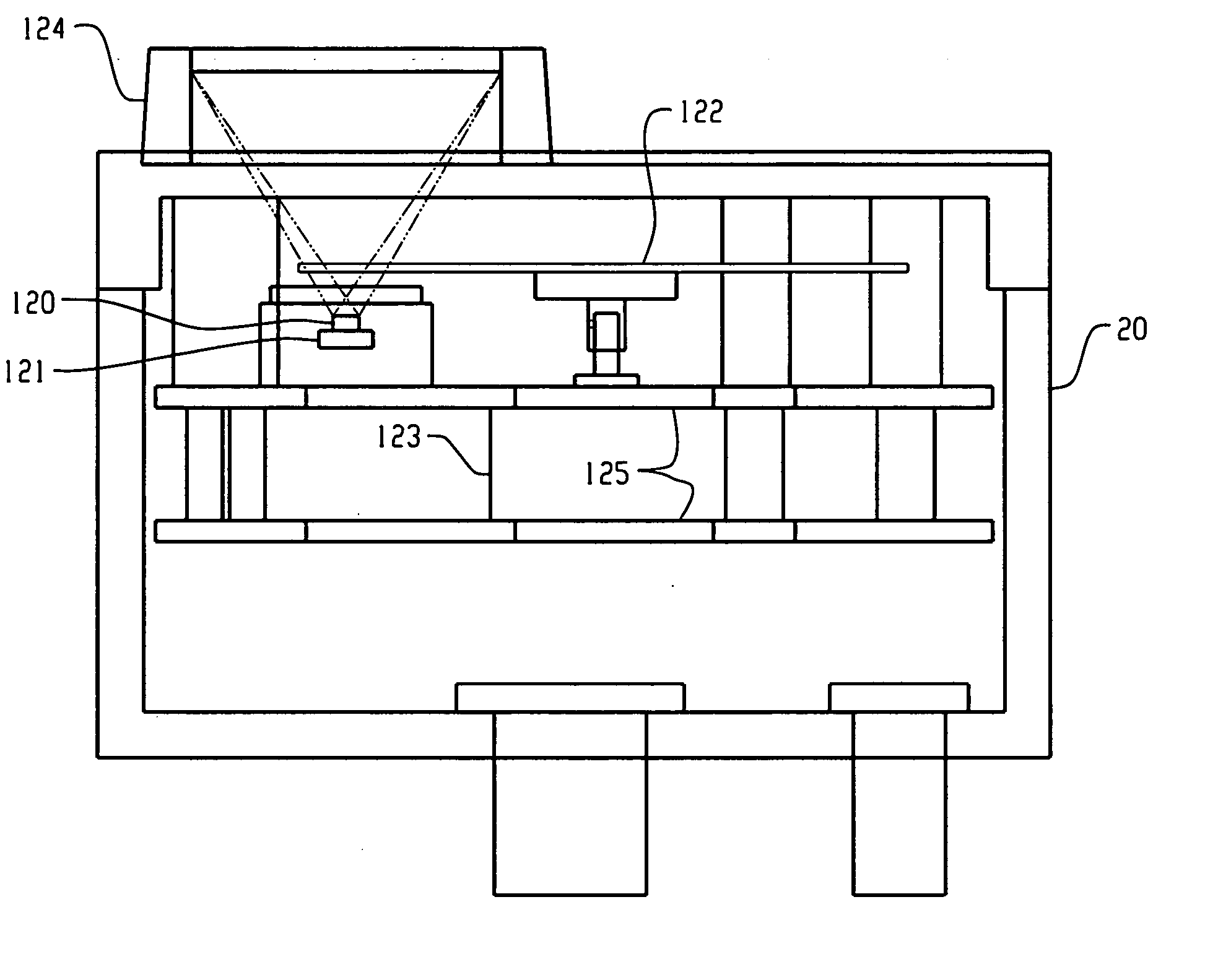

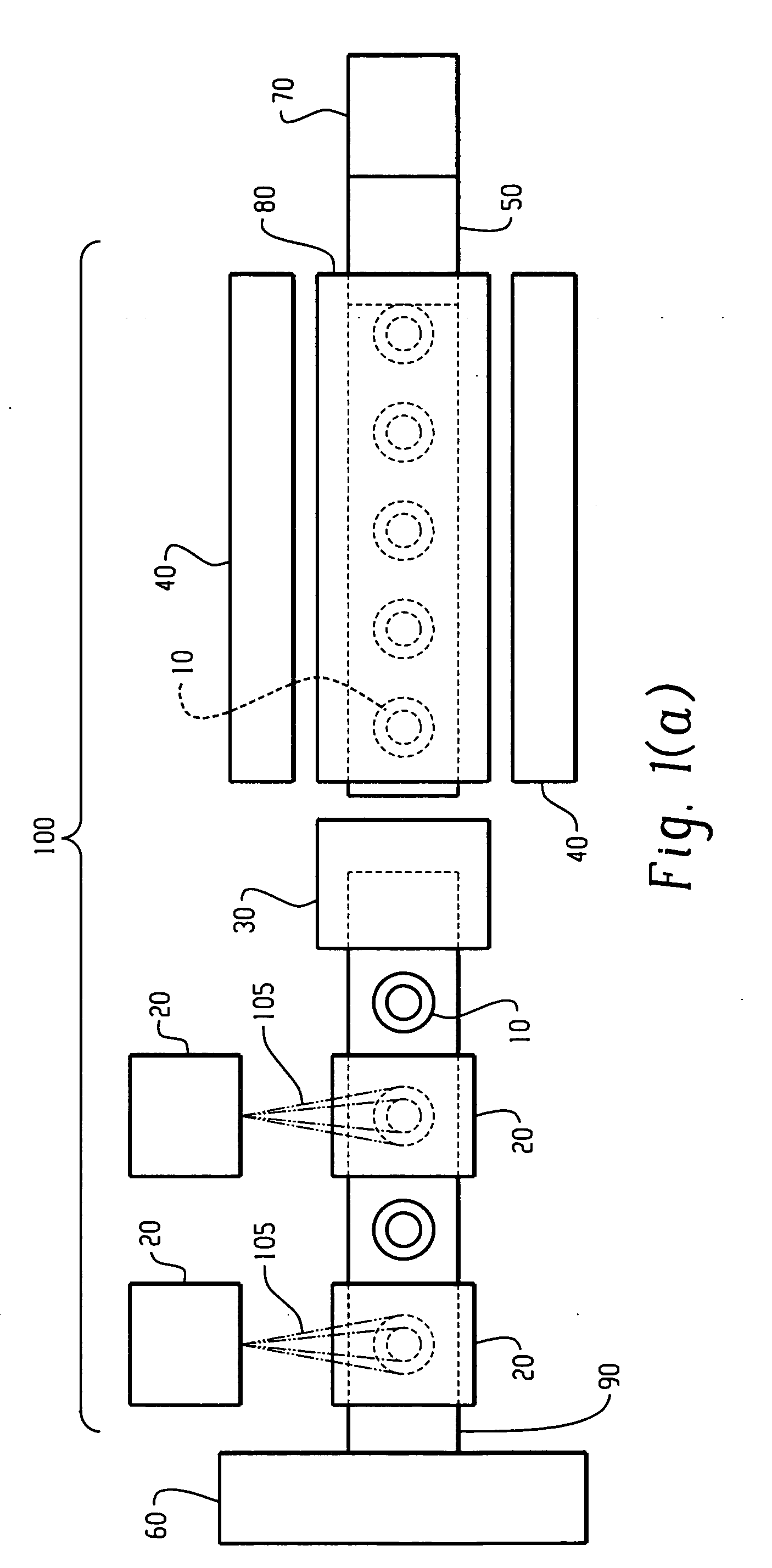

Method and apparatus for the measurement and control of both the inside and outside surface temperature of thermoplastic preforms during stretch blow molding operations

ActiveUS7220378B2Eliminate needEnergy optimizationRadiation pyrometryAuxillary shaping apparatusBlow moldingControl system

A stretch blow molding system that condition preforms such that the temperature distribution within the cross-section of each preform is optimized prior to blow molding operations is provided. The system has a temperature measurement and control system capable of directly monitoring both the outside as well as inside surface temperature of preforms at different stages of transport throughout the thermal conditioning section of the system.

Owner:PRESSCO IP LLC

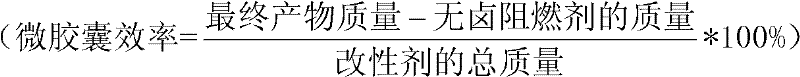

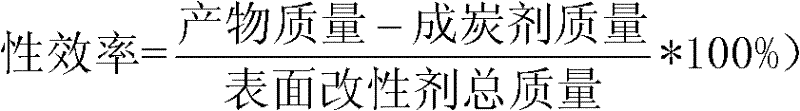

Preparation method of microencapsulated gradient halogen-free flame retardant system

InactiveCN102516603AEvenly dispersedLiquidMicroballoon preparationMicrocapsule preparationPolymer scienceMoisture

The invention relates to a preparation method of a microencapsulated gradient halogen-free flame retardant system. The preparation method comprises the steps of: mixing a phosphorus-series flame retardant with an inorganic flame retardant according to a certain ratio to obtain a microencapsulated halogen-free flame retardant, then carrying out surface modification on a charring agent, and then mixing the microencapsulated halogen-free flame retardant, a phosphorus-containing organic flame retardant and surface-modified charring agent according to a certain ratio to obtain the microencapsulated gradient halogen-free flame retardant system. By using the system, distributed gradient flame retarding is realized, the flame retardancy of a polymer material is greatly improved, the defect that compatibility between the flame retardant and the polymer is poor is solved, the migration of the halogen-free flame retardant from the polymer matrix under high-temperature and moisture conditions is significantly reduced, and the long-term storage of a flame-retardant polymer material is facilitated. The method has the characteristics of simple process, convenience for operation, environmental friendliness, and lower cost. The obtained flame retardant system has good flame retarding effect and wide application field.

Owner:JILIN UNIV

Process method for preparing cold brewing tea by ice crystallization cell wall breaking

InactiveCN101669553AInhibit peroxidationImprove solubilityPre-extraction tea treatmentData controlDrinking habits

The invention discloses a method for preparing cold brewing tea by ice crystallization treatment. The method comprises the following steps: putting fresh tea leaves in a low-temperature environment below 40 DEG C below zero for ice crystallization; putting the tea leaves subjected to the ice crystallization treatment into a vacuum container; slubbing the tea leaves in the vacuum container; heatingthe vacuum container at a heating temperature of between 70 and 100 DEG C; and stirring the tea leaves in the heated vacuum container until the tea leaves are dried. The ice crystallization process,which is adopted for replacing the conventional withering process, can change the conventional process depending on human experience control into data control and significantly improve the product consistency; the ice crystallization cooperated with the enzymatic oxidation of vacuum negative pressure isolated environment oxygen can avoid the problem of peroxided sensitive substances in the tea leaves; the adoption of an ice crystallization wall breaking process combined with vacuum evaporation dewatering drying can avoid the problem of reoxidation in the drying process; the tea prepared by theice crystallization wall breaking process has better solubility in cold water; the cold water brewing tea prepared by the ice crystallization wall breaking process can improve tea drinking habits ofhuman beings; and the adoption of the cold water brewing tea can save a large amount of energy for boiling water. The method can also be used for preparing cold water brewing beverages by using otherplants to conventionally be soaked in water for drinking, such as ginseng leaves, ginkgo leaves, chrysanthemums, green plums, olives and the like, thereby providing a new idea for enriching markets.

Owner:苏少宁

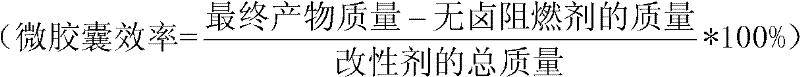

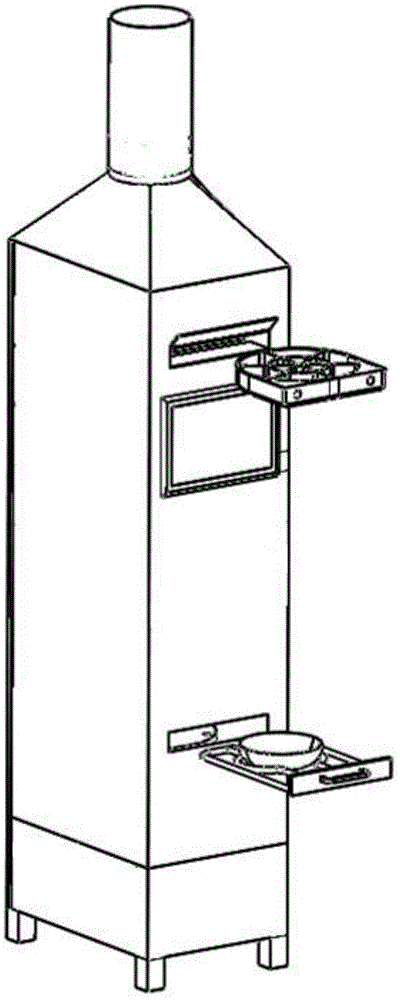

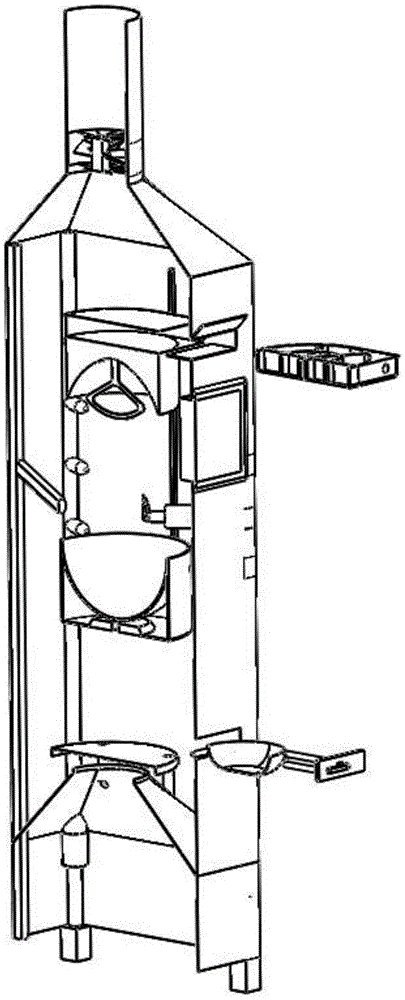

Cooking robot

ActiveCN105459127ARealize standardization, unification and diversificationQuality assuranceManipulatorCooking vessel constructionsAutomatic controlControl system

The invention belongs to the field of automatic and intelligent control of household appliances, and discloses a cooking robot. The cooking robot comprises a machine body as well as a charging mechanism, a feeding mechanism, a control system, a cooking mechanism and a dish collecting mechanism, wherein the control system is respectively connected to the charging mechanism, the feeding mechanism, the cooking mechanism and the dish collecting mechanism, and controls each mechanism to work. The cooking robot disclosed by the invention uses a customized one-off dish raw material containing device, all dish raw materials are respectively packaged respectively according to a menu formula in a plant, and the whole cooking process is controlled by virtue of the automatic control system, so that a great deal of manpower and material resources can be saved, and therefore, the cooking robot has a wide application space and a good market prospect.

Owner:QINGDAO FEAST ROBOT CO LTD

Apparatus for kinetic energy storage

ActiveUS20140125171A1Improve efficiencyCheap componentMechanical propulsion powerVehicular energy storageEnergy recoveryVacuum pump

An apparatus for kinetic energy storage includes an electrical machine operable at least in one of motor mode and generator mode, and at least one energy recovery system for an intermediate storage of a produced kinetic energy and which converts the kinetic energy into an electrical energy, with, the at least one energy recovery system having at least one flywheel body formed as a rotor, and a stator and with at least one of the rotor and the stator being formed as at least one vacuum pump stage.

Owner:PFEIFFER VACUUM GMBH

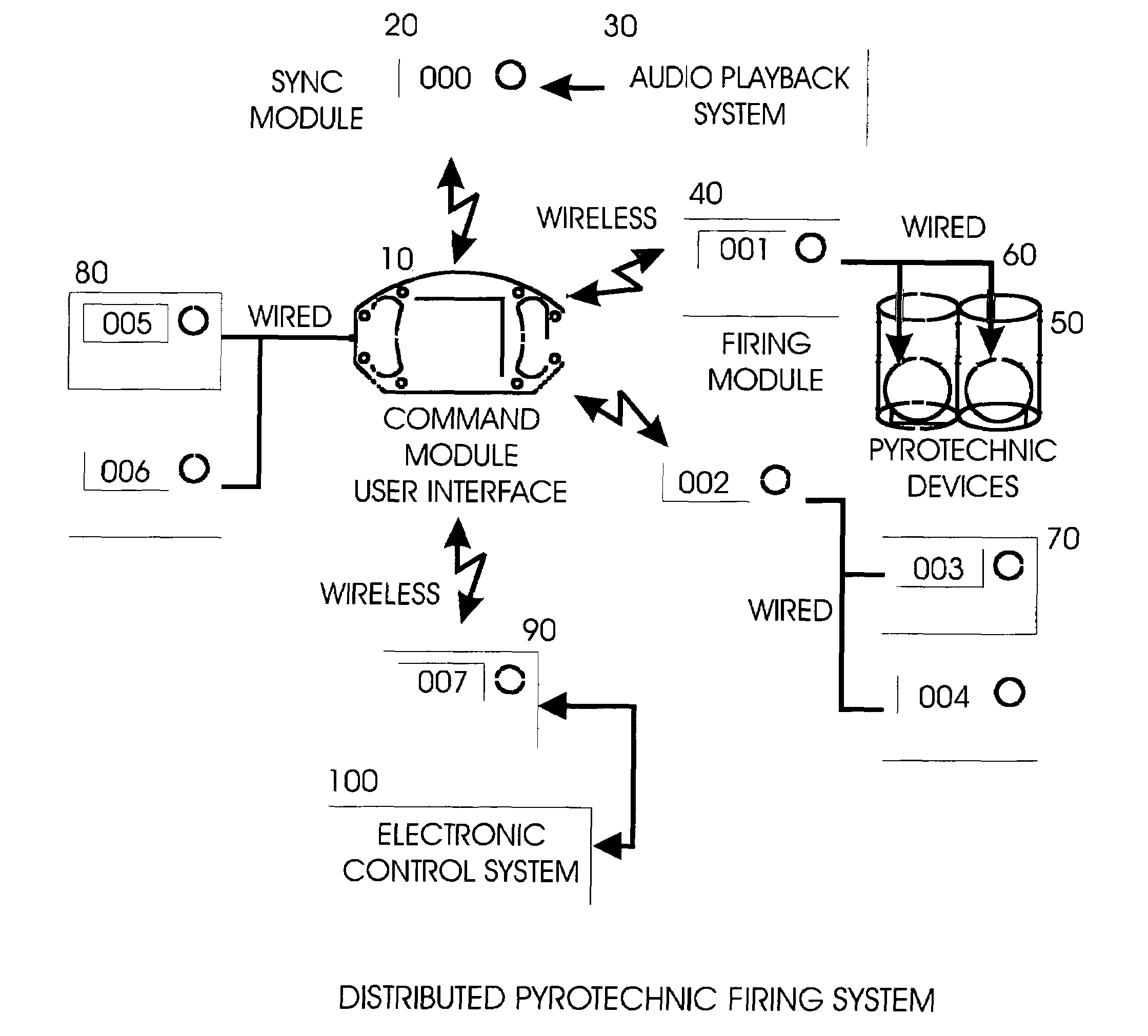

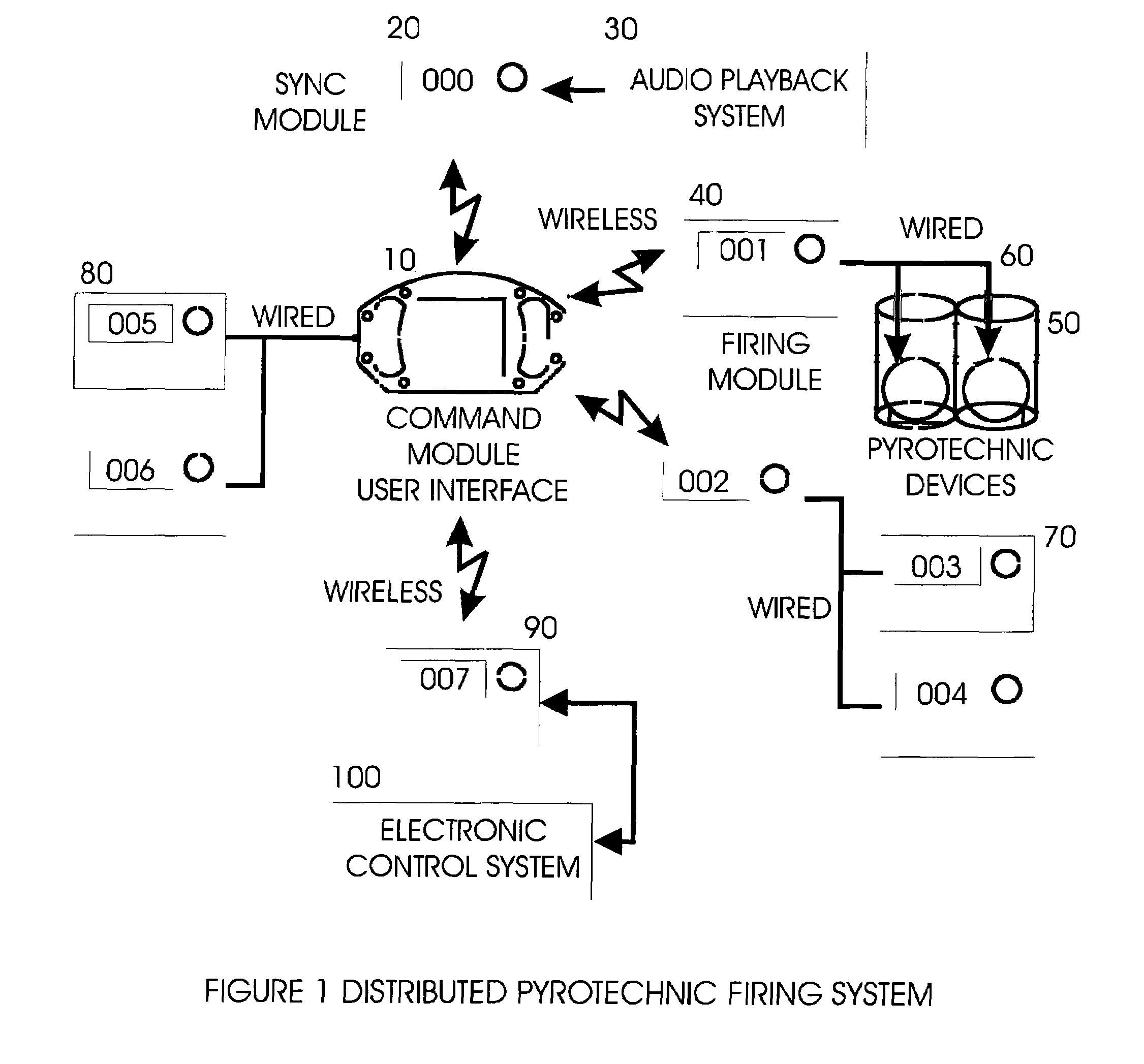

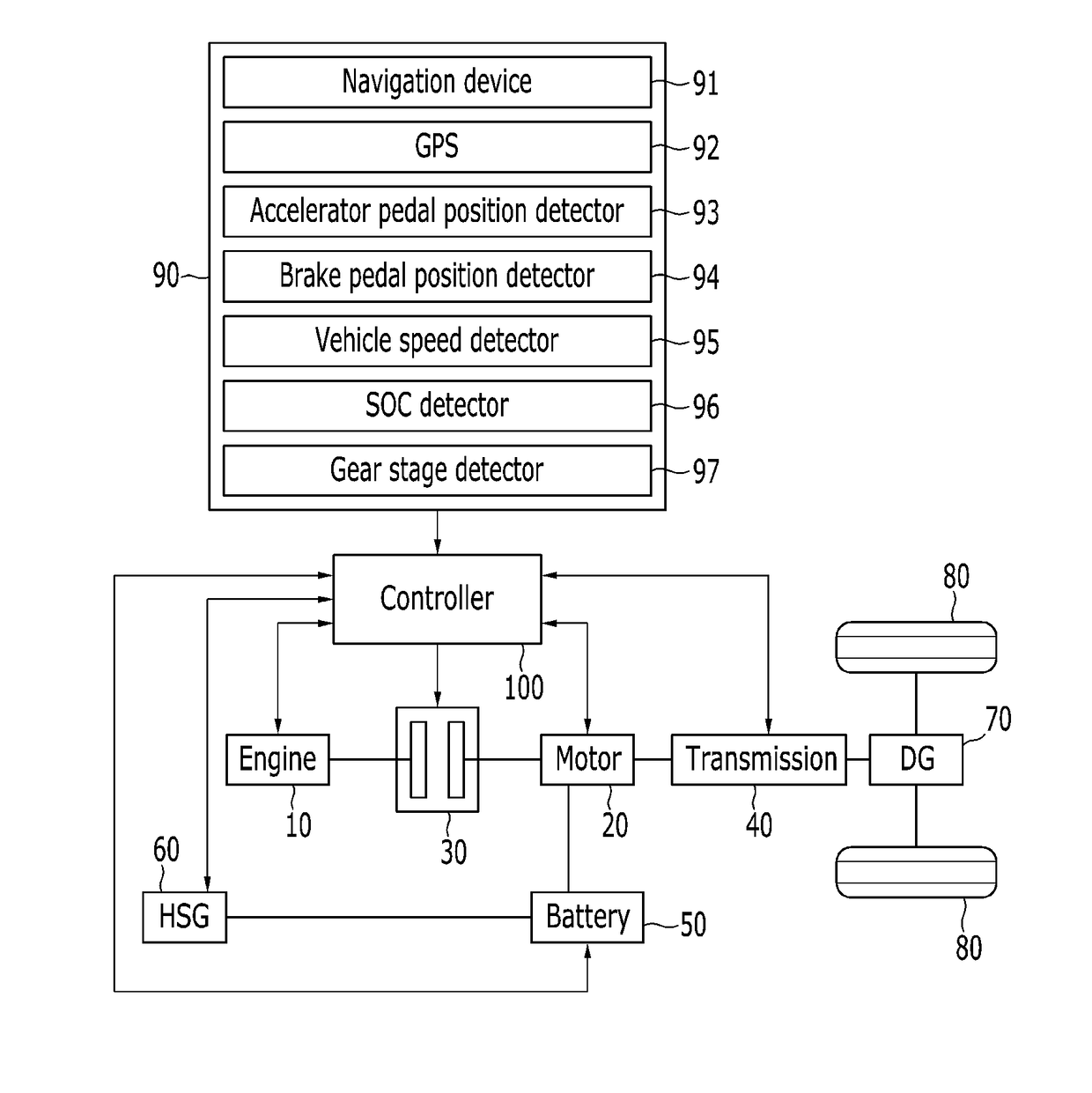

System and method for zero latency distributed processing of timed pyrotechnic events

ActiveUS7493859B2Energy optimizationZero delayAmmunition projectilesIncandescent ignitionMaster controllerLatency distribution

A method for achieving zero, or near zero, latency timed pyrotechnic events by utilizing distributed processing is presented. A list of timed events may be used to synchronize a pyrotechnic firing sequence with music or other external events. This list is distributed over a series of embedded microprocessors. Each microprocessor is then synchronized to a master controller clock, and enabled such that each processor may then fire independently as required by the master list. This distributed process removes the split-second timing requirement from the main controller enabling the achievement of zero latency and providing significantly more timing events to be processed simultaneously while alleviating problems such as wireless radio interference delays. Each module is capable of forwarding information to other modules, which may be a position that prevents wireless communication directly with the master controller.

Owner:BIRKET IP HLDG INC

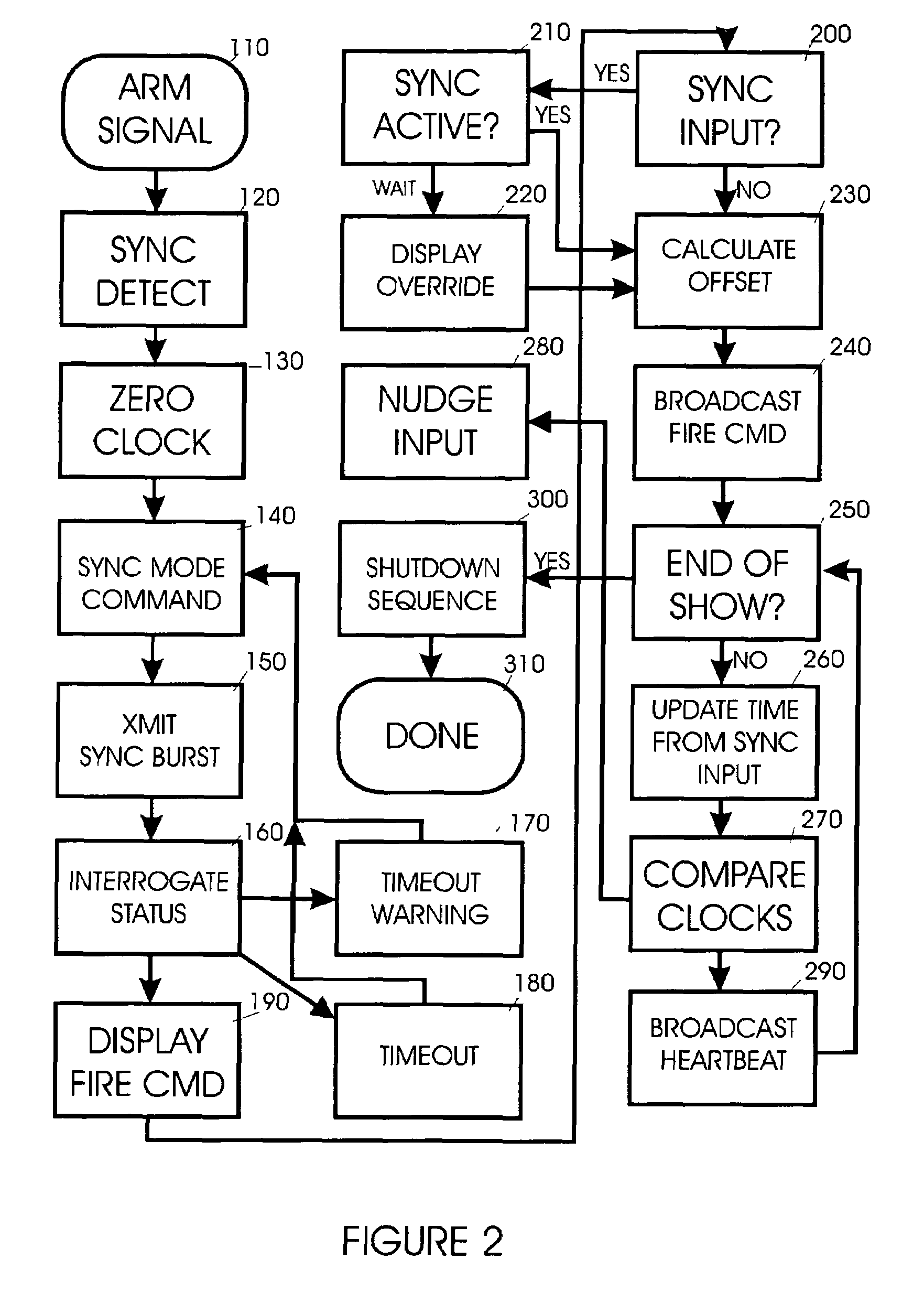

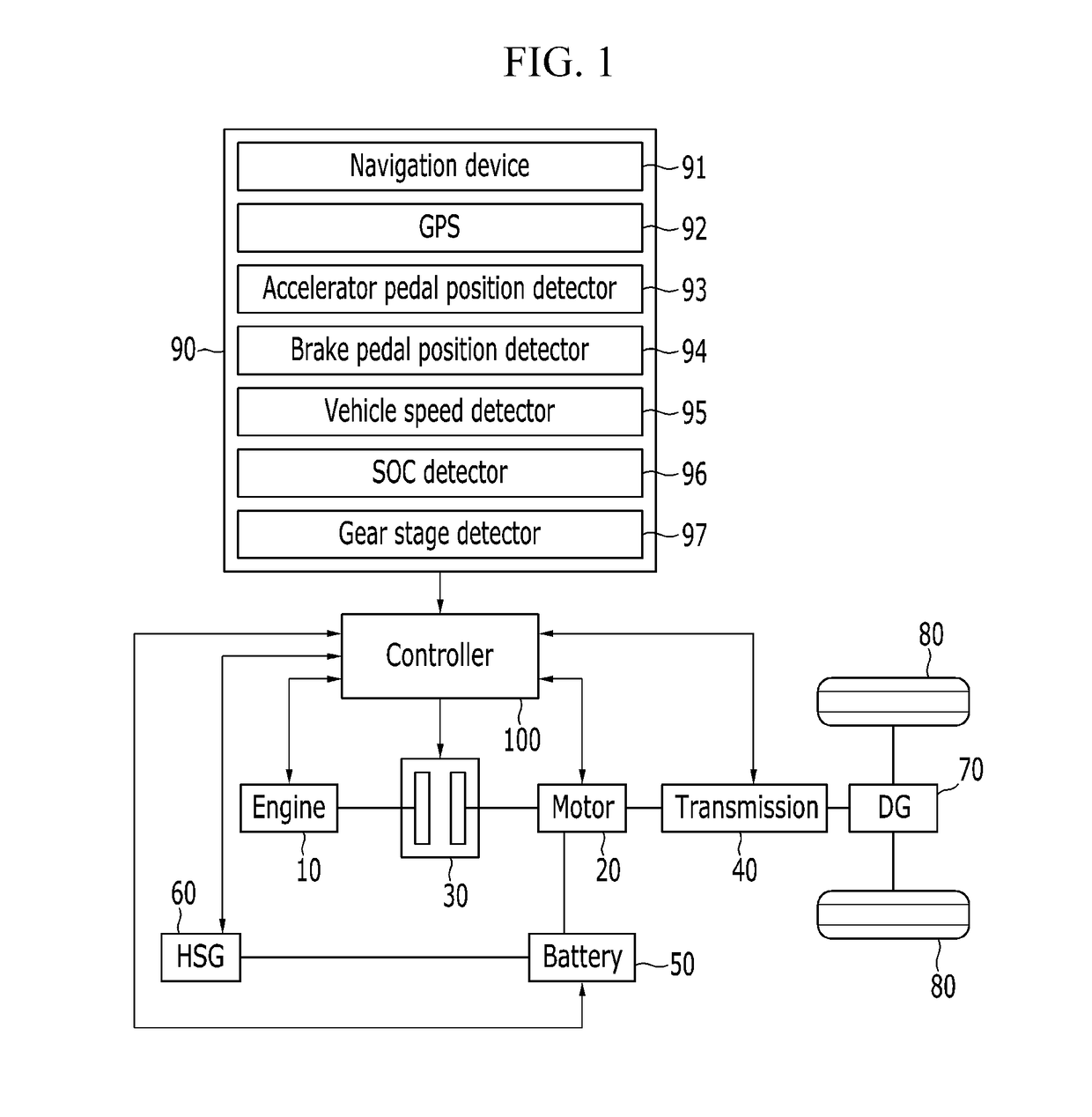

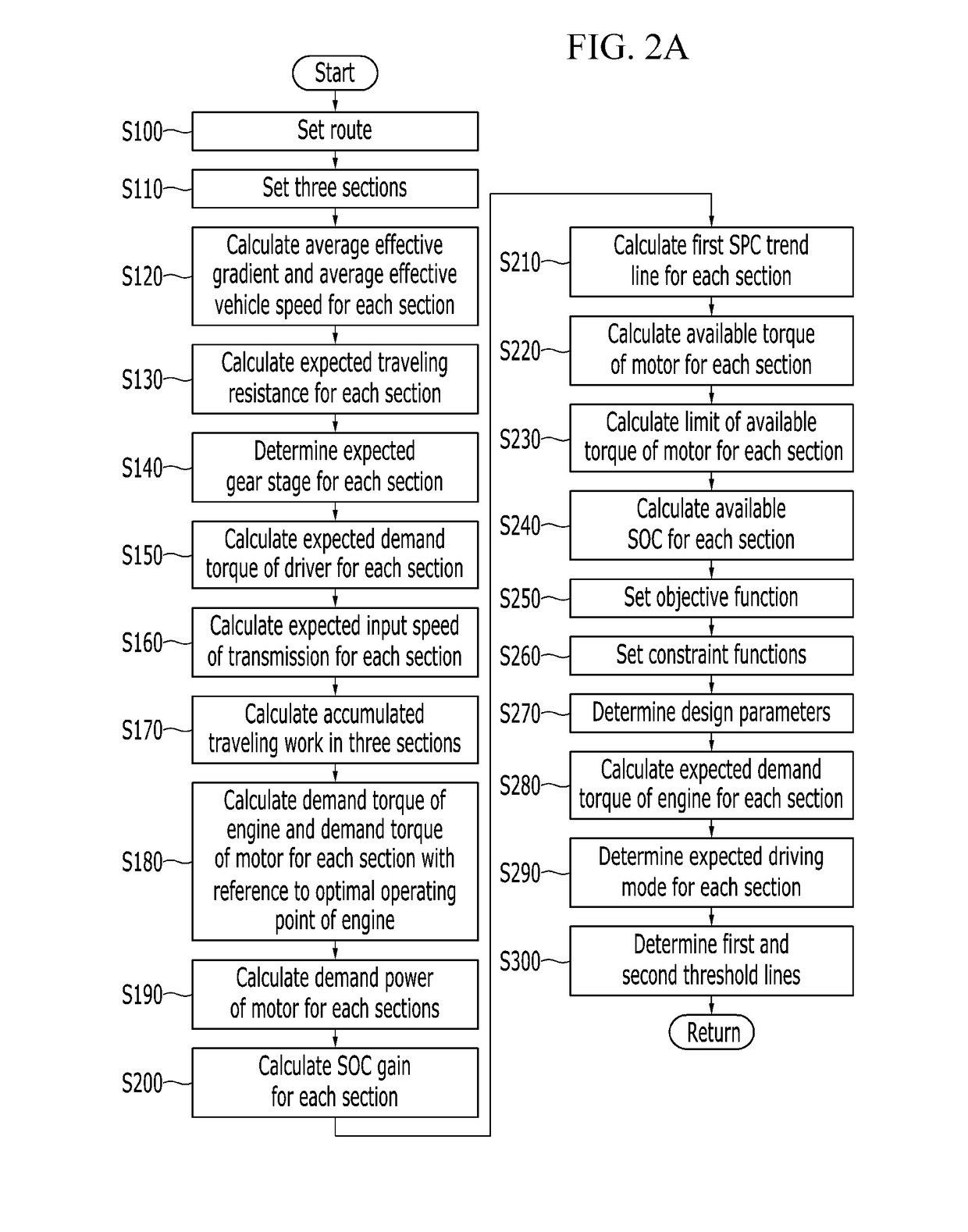

Method and apparatus for controlling hybrid electric vehicle

ActiveUS20170096134A1Mode switching can be preventedReduce communication loadHybrid vehiclesInstruments for road network navigationState of chargeEngineering

Owner:HYUNDAI MOTOR CO LTD +1

Method and apparatus for the measurement and control of both the inside and outside surface temperature of thermoplastic preforms during stretch blow molding operations

ActiveUS20050146065A1Minimize maintenance timeOptimize performanceRadiation pyrometryAuxillary shaping apparatusTemperature measurementEngineering

A stretch blow molding system that condition preforms such that the temperature distribution within the cross-section of each preform is optimized prior to blow molding operations is provided. The system has a temperature measurement and control system capable of directly monitoring both the outside as well as inside surface temperature of preforms at different stages of transport throughout the thermal conditioning section of the system.

Owner:PRESSCO IP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com