Patents

Literature

10440 results about "Heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating systems are usually designed for a room temperature of 18-20 ºC, and that is for most cases sufficient. Elderly or sick persons may need a higher temperature to experience the same comfort as younger and healthy ones. The temperature difference vertically in a room should not be too great either.

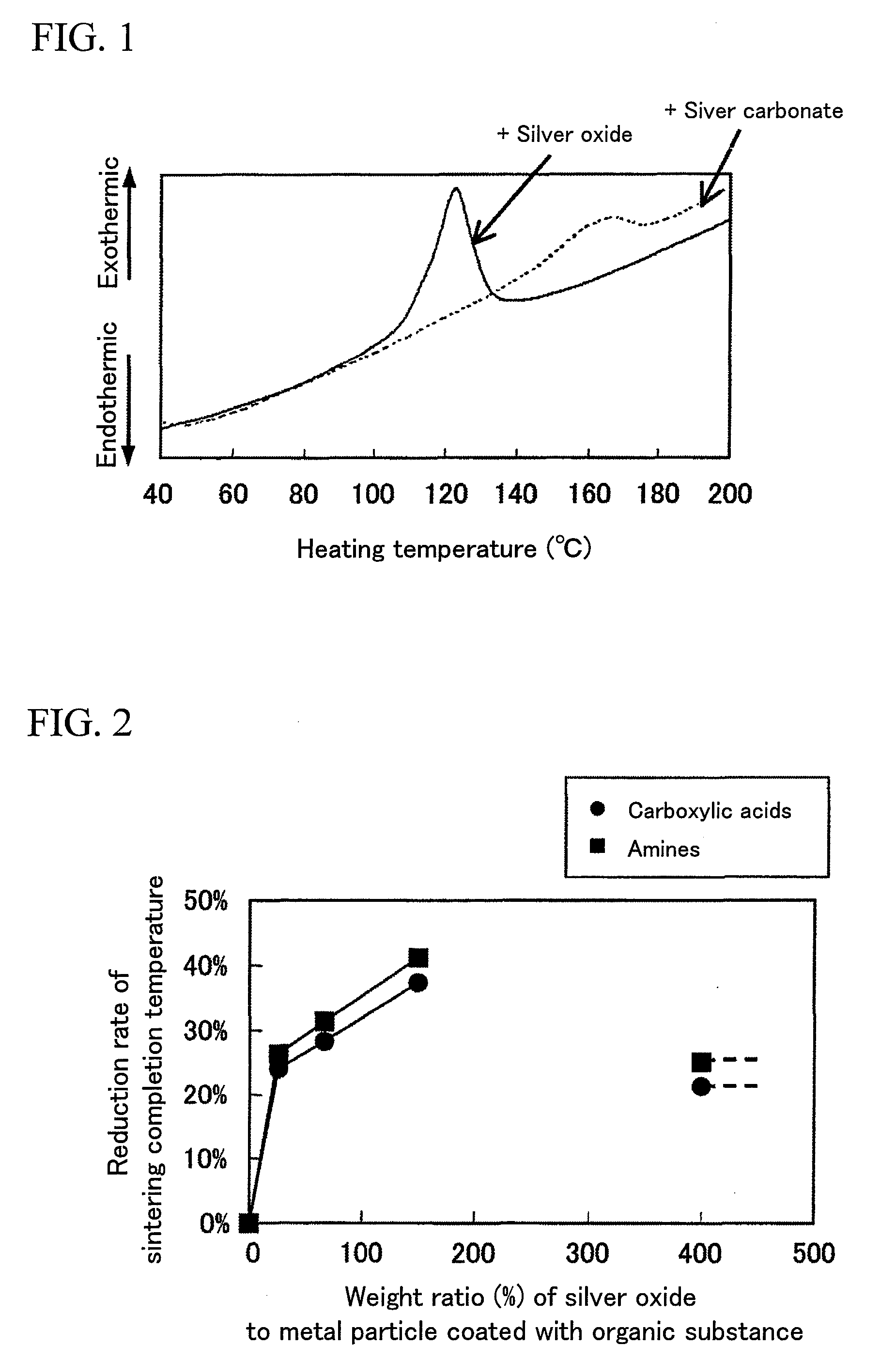

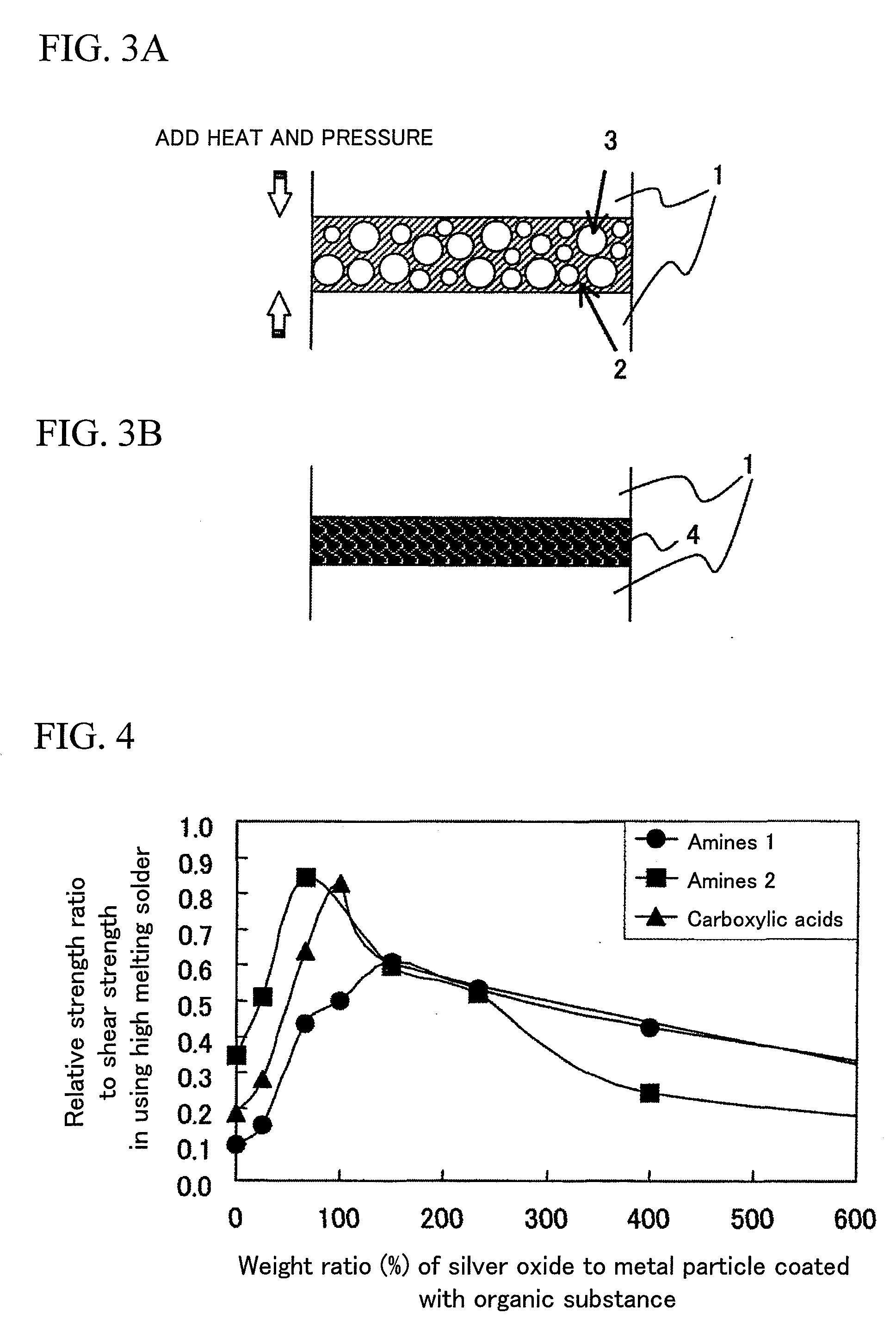

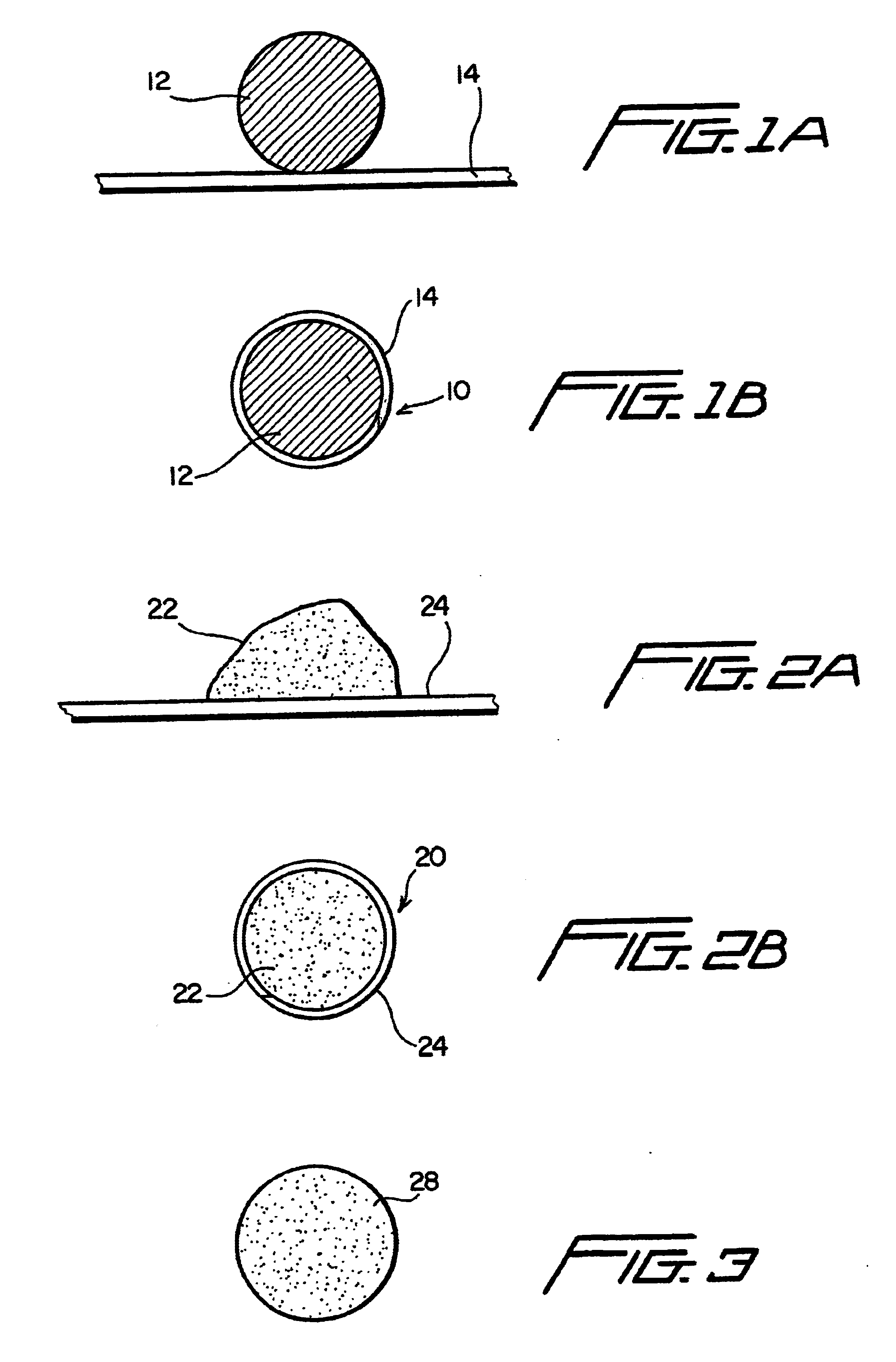

Conductive sintered layer forming composition and conductive coating film forming method and bonding method using the same

InactiveUS20080160183A1Low heating temperatureShorten heating timeSemiconductor/solid-state device detailsConductive materialHeating timeConductive coating

There is provided a conductive sintered layer forming composition and a conductive sintered layer forming method that can lower heating temperature and shorten heating time for a process of accelerating sintering or bonding by sintering of metal nano-particles coated with an organic substance. The conductive sintered layer forming composition may be obtained by utilizing a phenomenon that particles may be sintered at low temperature by mixing silver oxide with metal particles coated with the organic substance and having a grain size of 1 nm to 5 μm as compared to sintering each simple substance. The conductive sintered layer forming composition of the invention is characterized in that it contains the metal particles whose surface is coated with the organic substance and whose grain size is 1 nm to 5 μm and the silver oxide particles.

Owner:HITACHI LTD

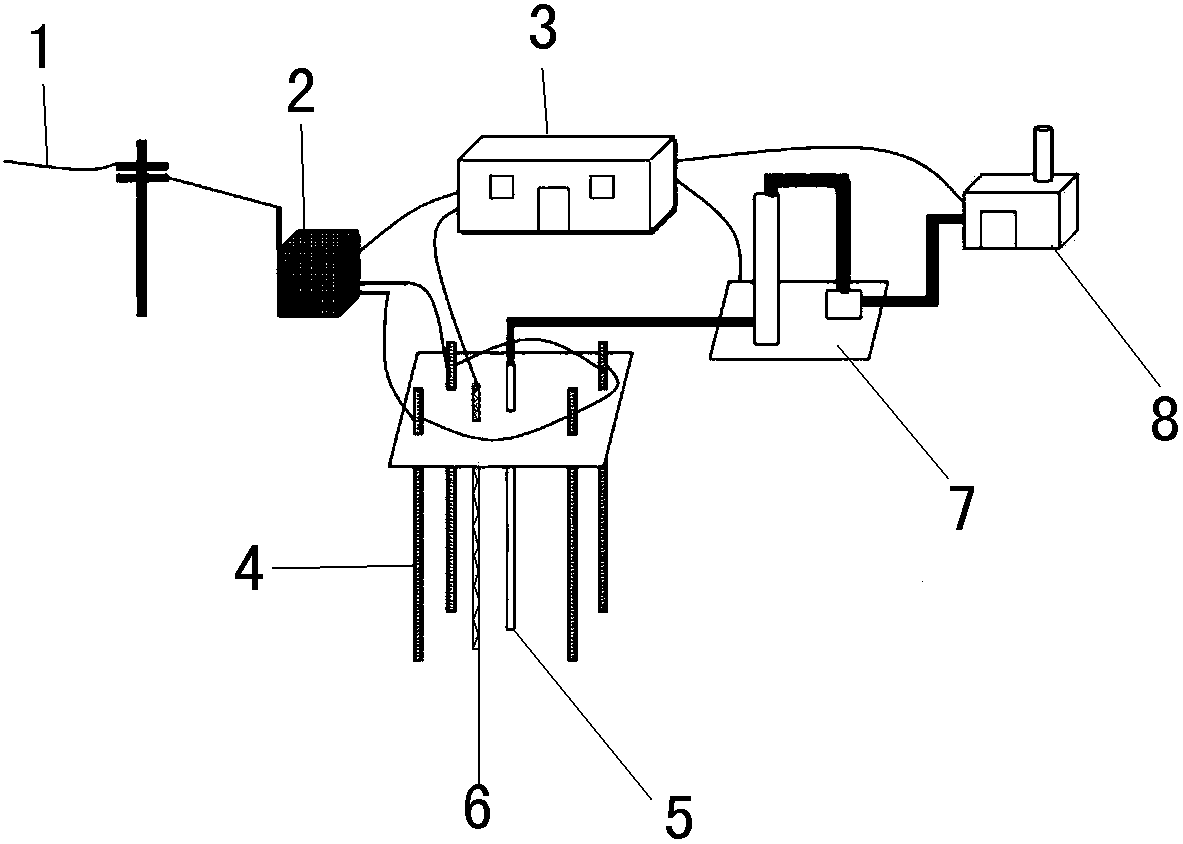

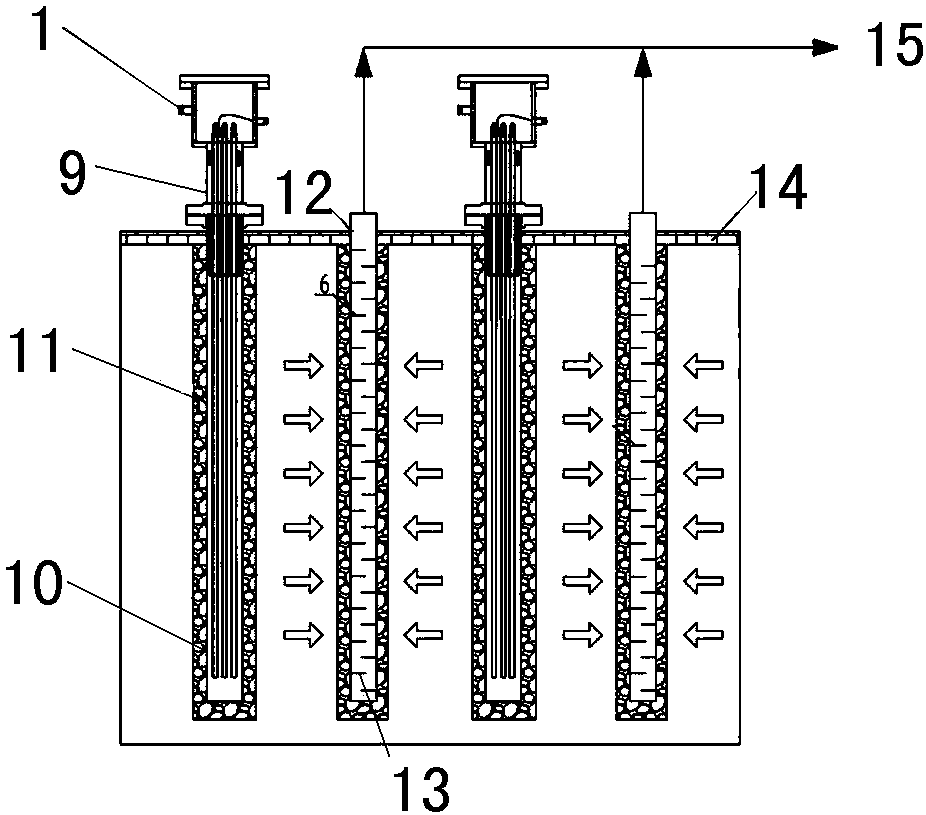

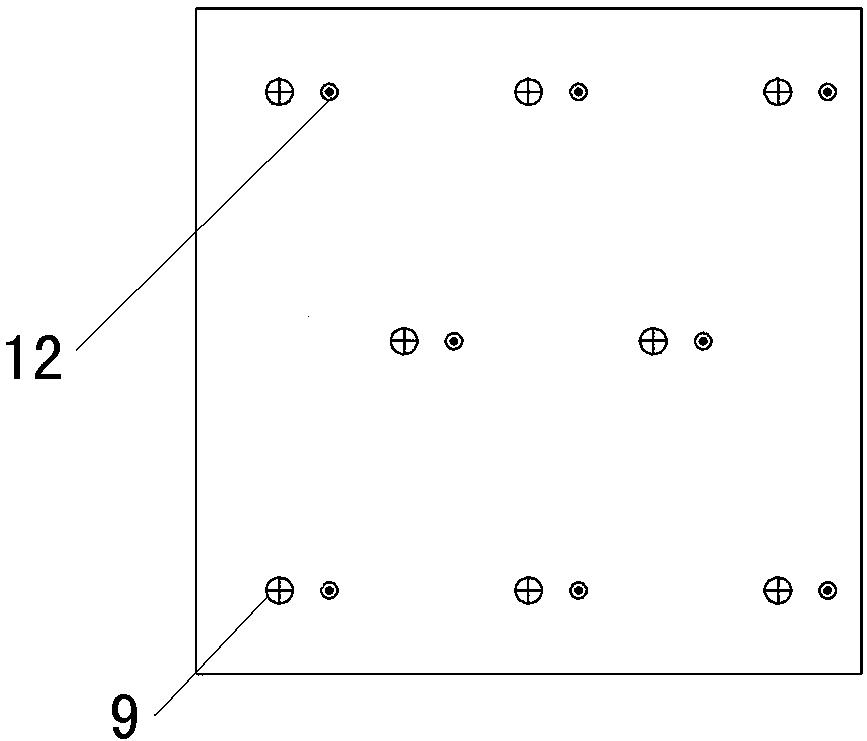

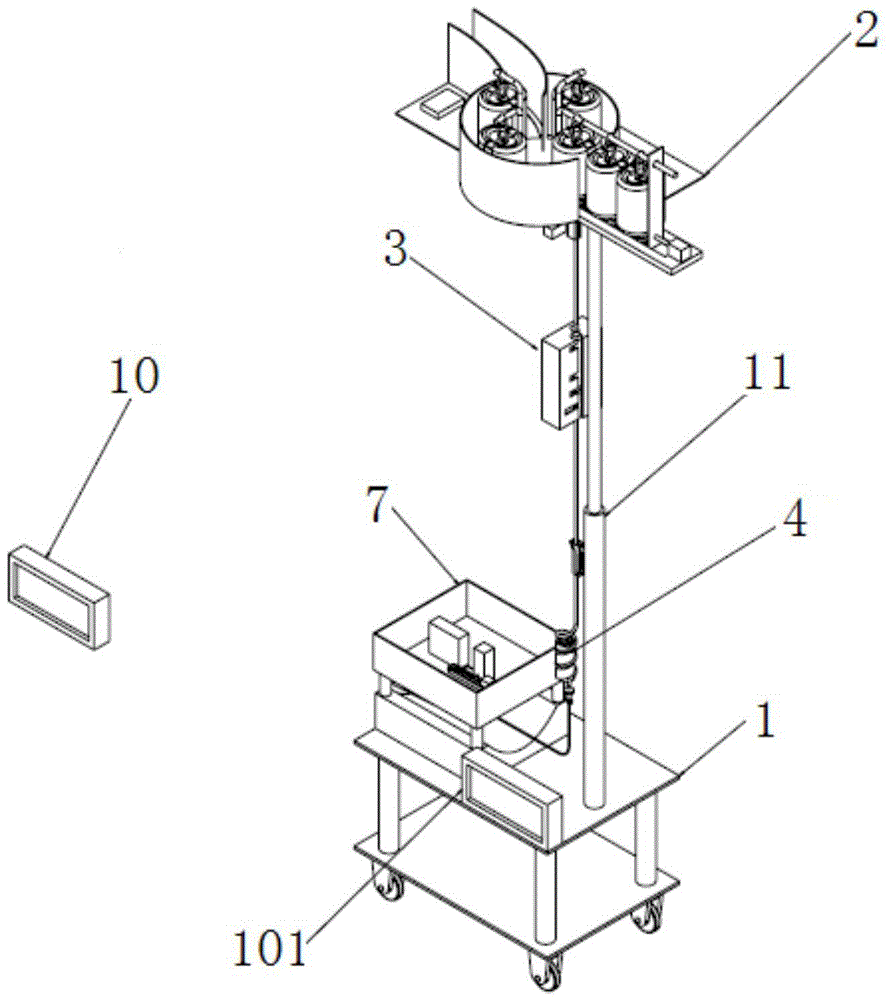

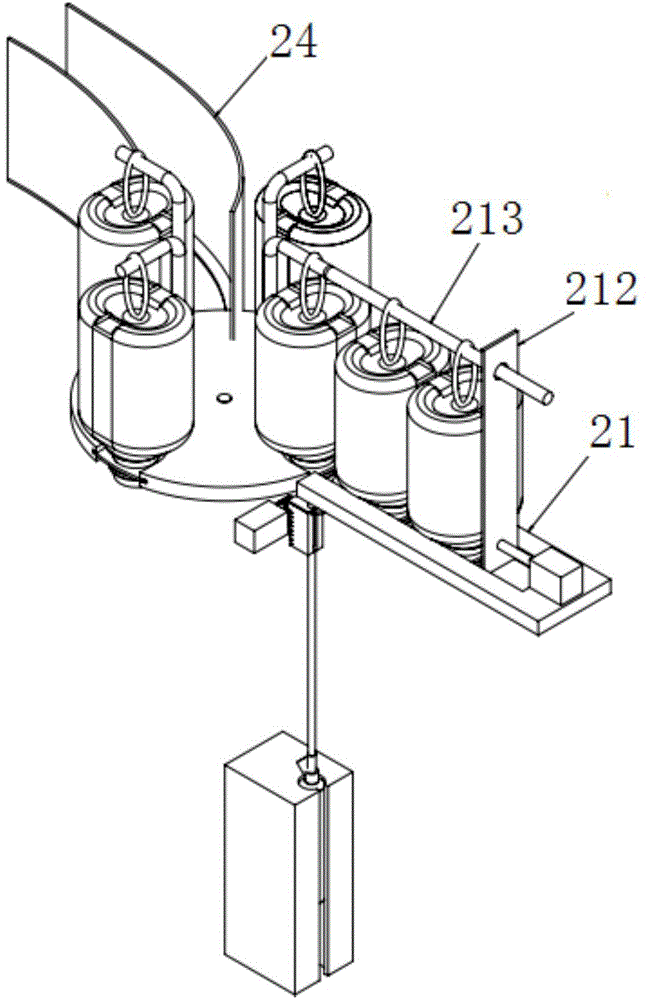

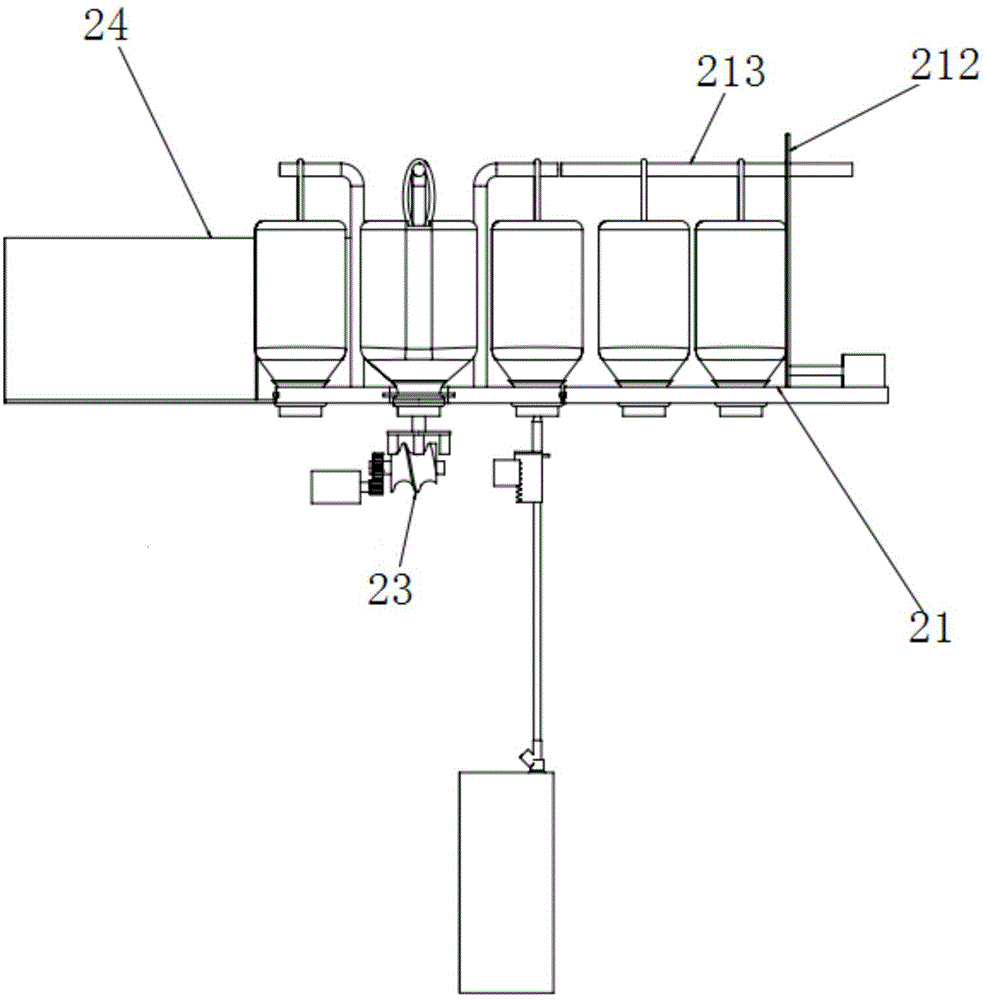

System for restoring organic contaminated soil through in-situ electrical heating and treatment method

ActiveCN108311535AUniversalPull out in timeCombination devicesContaminated soil reclamationTreatment effectSoil properties

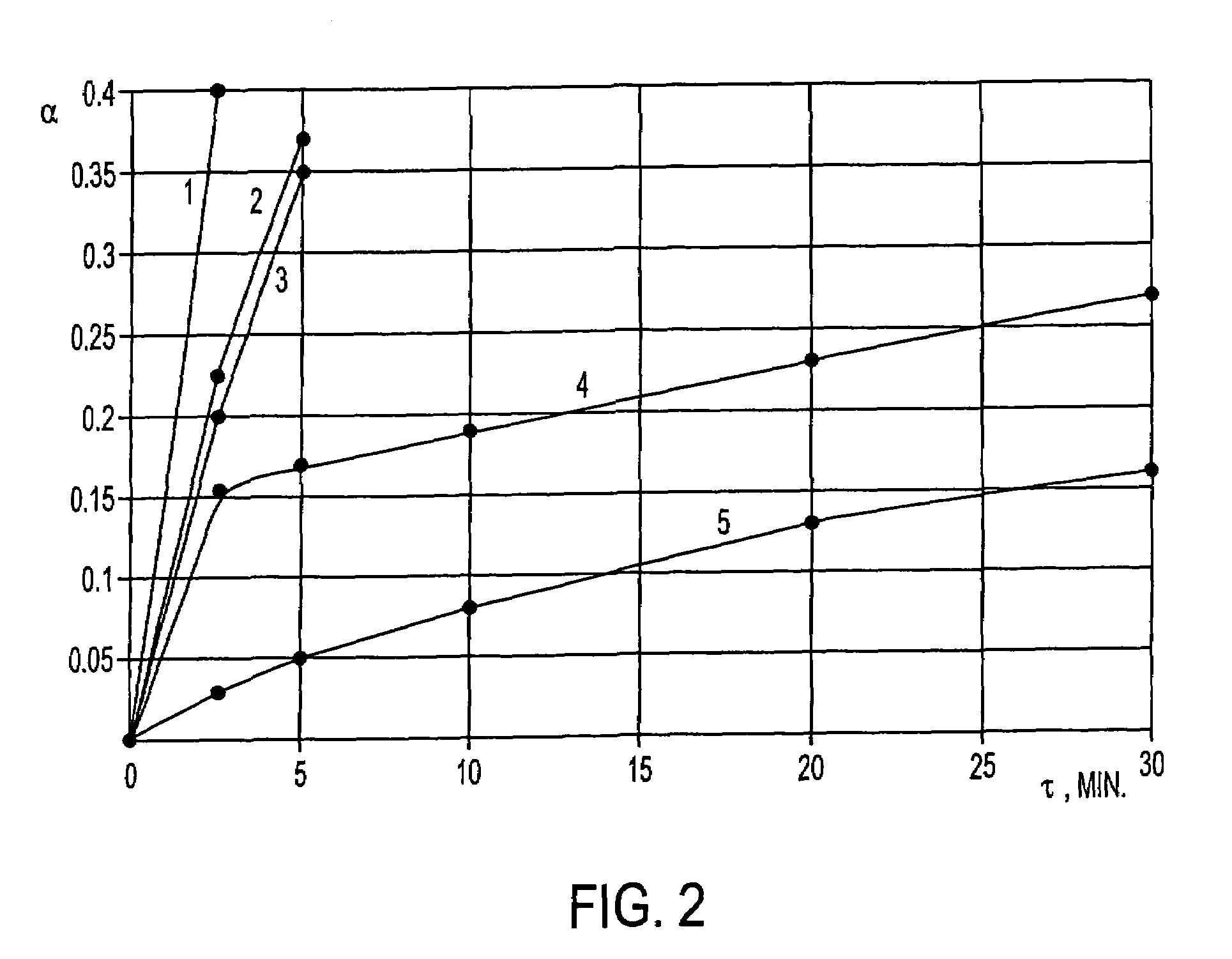

The invention provides a system for restoring organic contaminated soil through in-situ electrical heating. The system comprises an infrastructure technology, an electronic control system, a gas treatment system, a monitoring and data acquisition system and a repairing effect comprehensive assessment system. The infrastructure technology comprises heating well and extraction well construction, ground compaction and insulating layer construction technologies; heating wells are distributed on a contaminated site according to a triangle arrangement principle and a proximity principle, and the extraction well is arranged in the geometric center of the layout of the heating well; the gas treatment system is composed of a pre-cooling adsorption sledge, an extraction sledge and a treatment sledge, and is used for completing gas extraction and treatment and achieving the tail gas discharging requirement; and the repairing effect comprehensive assessment system evaluates the temperature risingeffect of the contaminated soil in the restoring process and the treatment effect of the contaminated soil. According to the system, the technological route is complete, the soil property applicability is wide, the heating temperature can reach 500 DEG C or above, and volatile and difficult-to-volatilize organic contaminant can be treated at the same time.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION +1

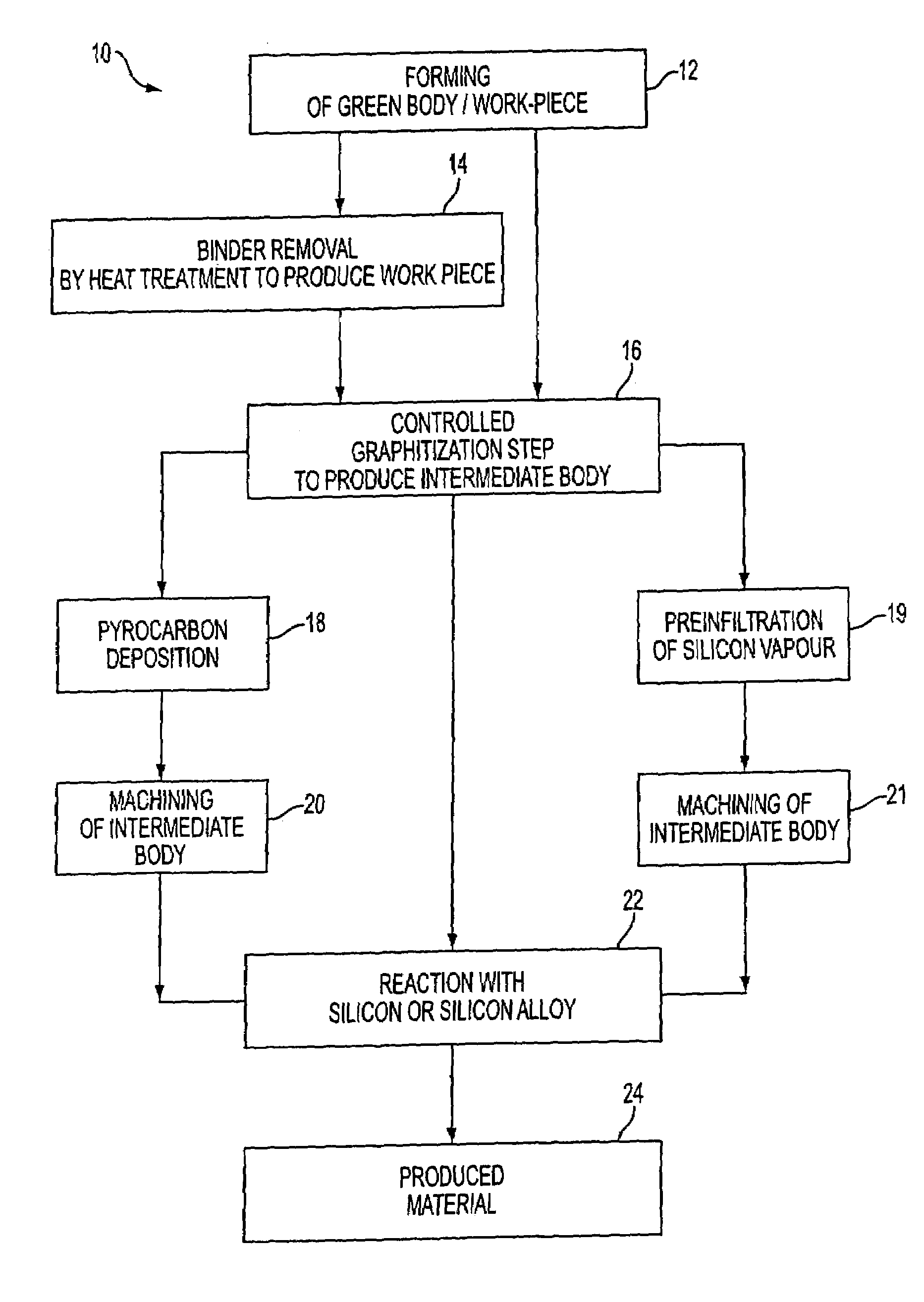

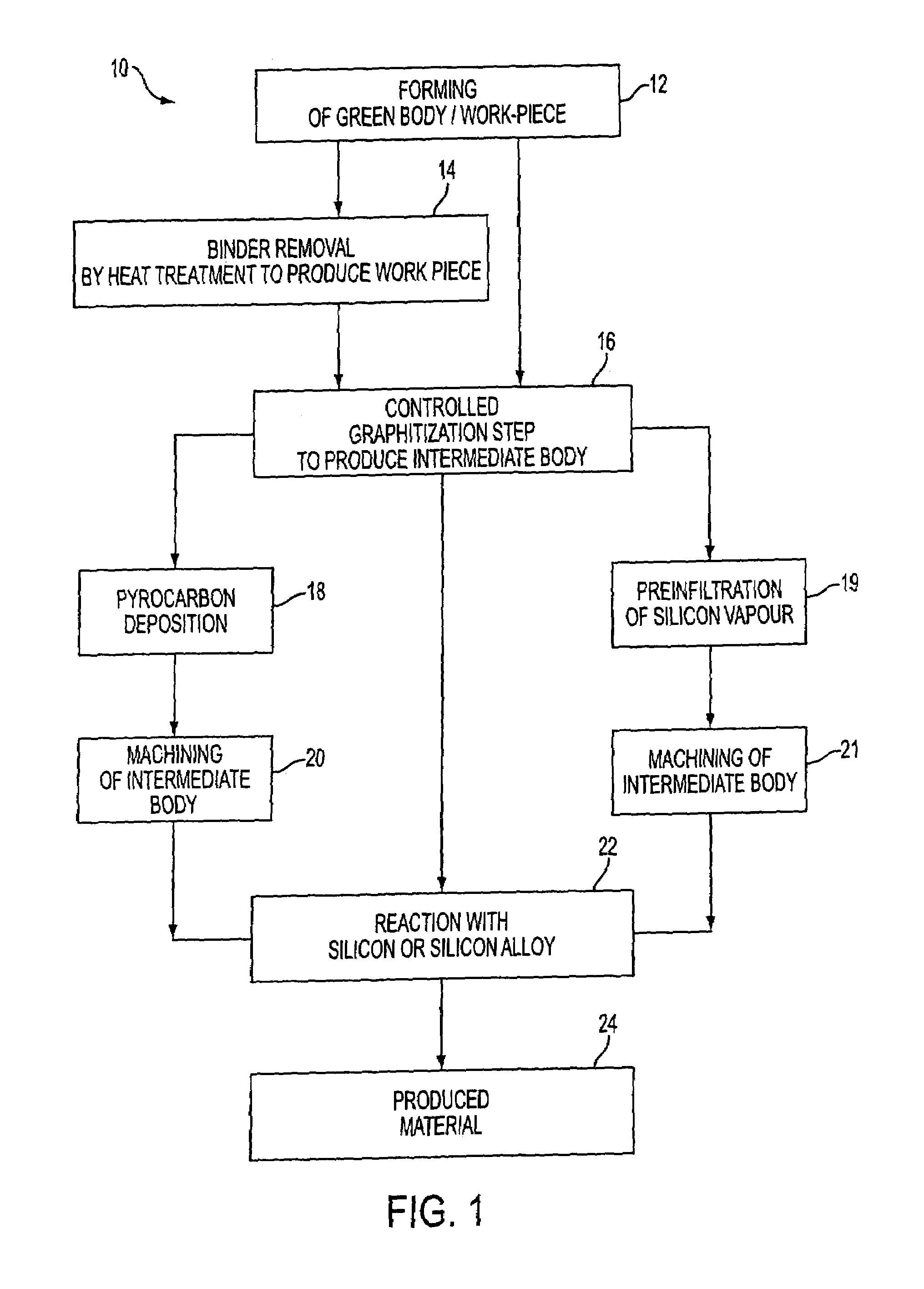

Method of manufacturing a diamond composite and a composite produced by same

InactiveUS7008672B2Simple production equipmentComplex shapeOther chemical processesNatural mineral layered productsHeating timeSilicon alloy

Owner:SKELETON TECH

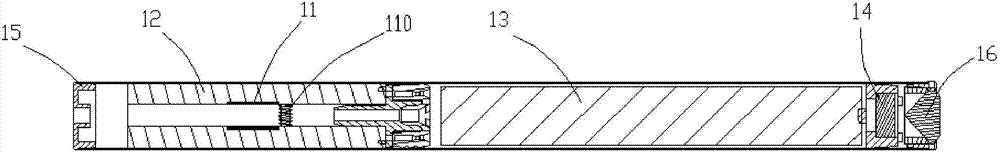

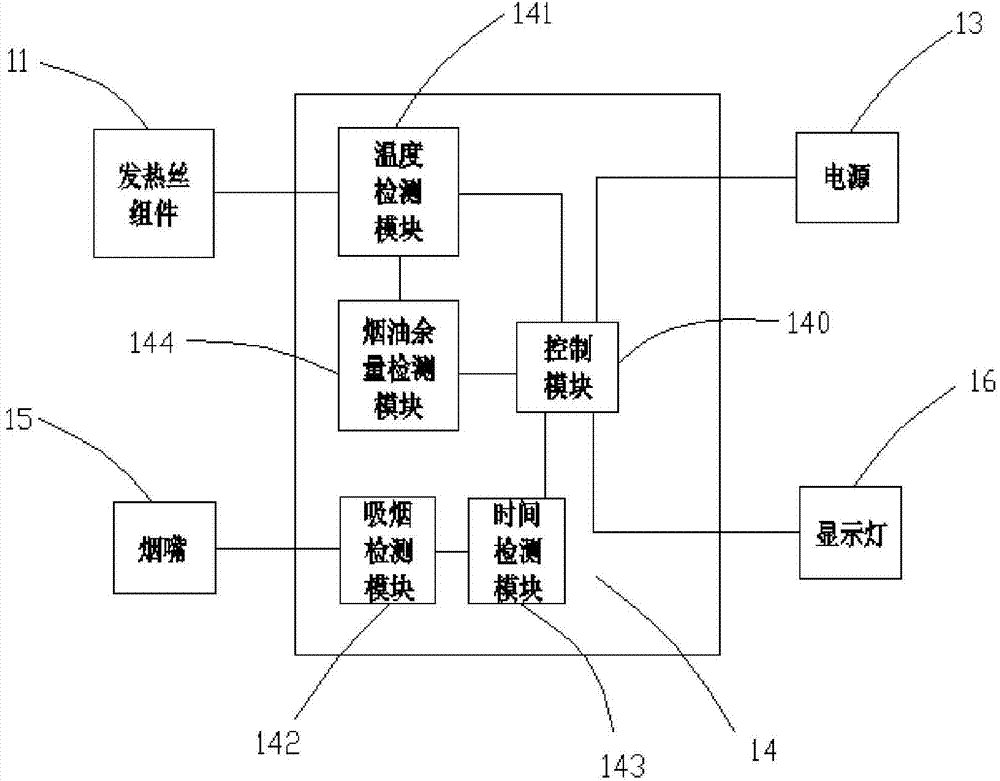

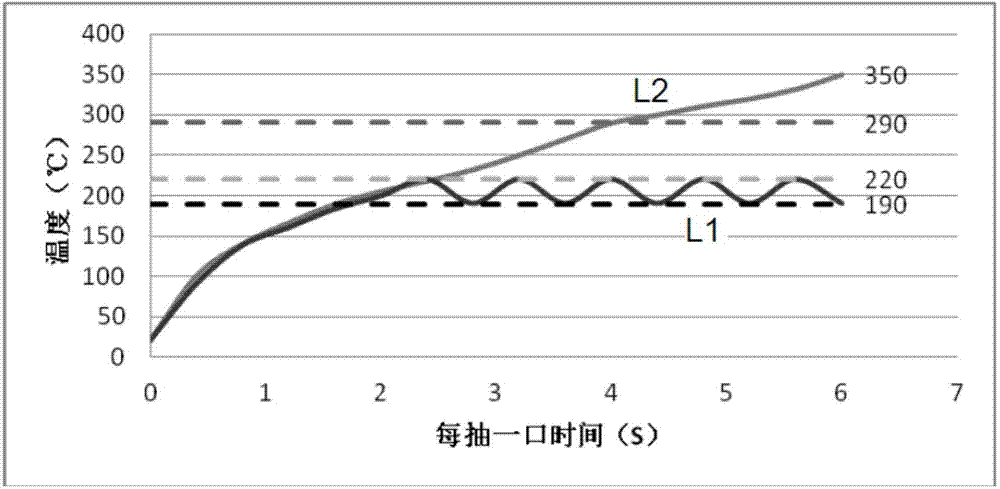

Electronic cigarette and control method thereof

ActiveCN104116138AAvoid burnt smellSave powerTobacco devicesOhmic-resistance heating detailsLower limitCurrent voltage

The invention provides an electronic cigarette and a control method thereof. The electronic cigarette comprises a heating wire assembly, a power source and a controller. The heating wire assembly is used for generating heat and comprises heating wires, wherein the resistance value of the heating wires changes along with the changes of temperatures. The power source is used for providing voltages for the heating wire assembly. The controller is electrically connected with the heating wire assembly and the power source and used for controlling the power source to output the voltages. The controller comprises a temperature detecting module which is used for detecting the resistance value of the heating wires to obtain the real-time temperature of the heating wire assembly, an upper limit heating temperature and a lower limit heating temperature are set in the temperature detecting module, the controller controls the power source to output a first voltage when the real-time temperature is smaller than or equal to the lower limit heating temperature and controls the power source to output a second voltage when the real-time temperature is larger than or equal to the upper limit heating temperature, the second voltage is smaller than the first voltage, and the controller controls the power source to keep outputting the current voltage when the real-time temperature is larger than the lower limit heating temperature and smaller than the upper limit heating temperature. The electronic cigarette and the control method thereof can ensure the taste consistency of the smoke of all times and save electric quantity.

Owner:SHENZHEN SMOORE TECH LTD

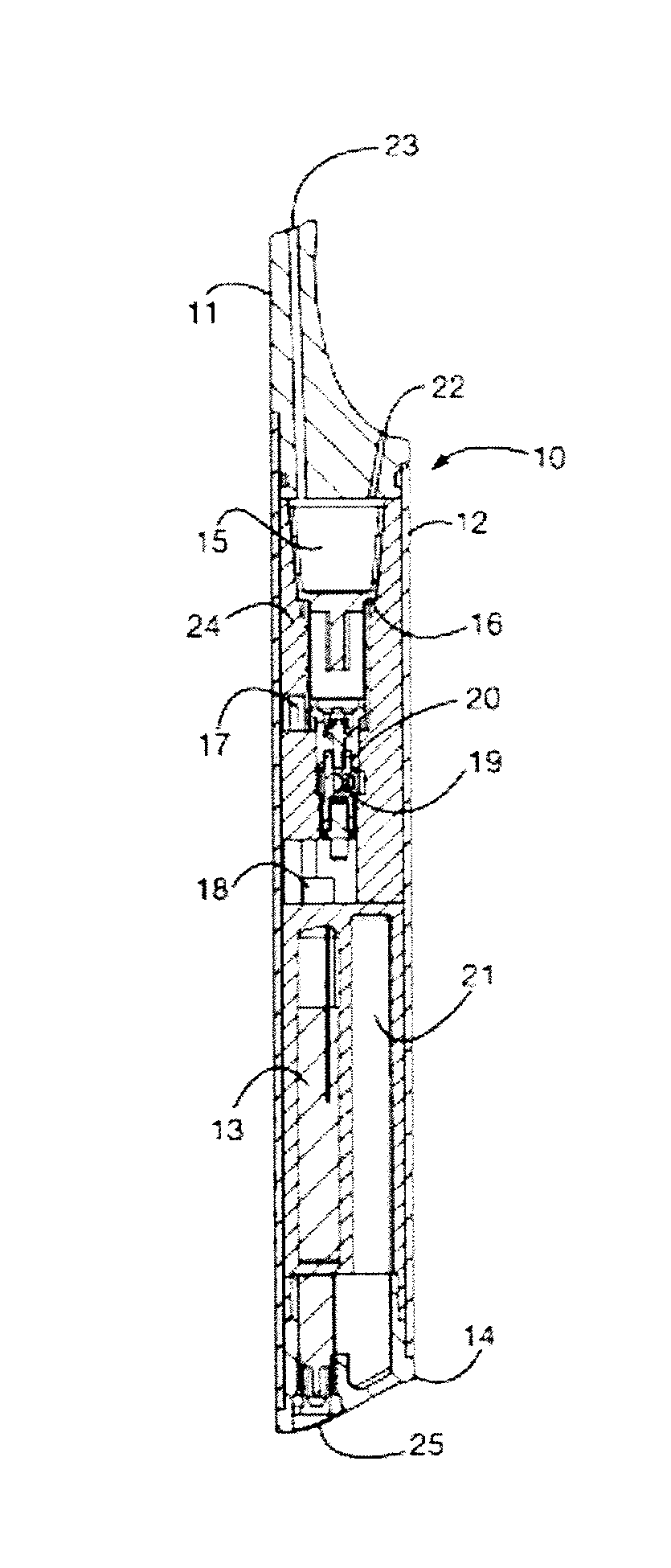

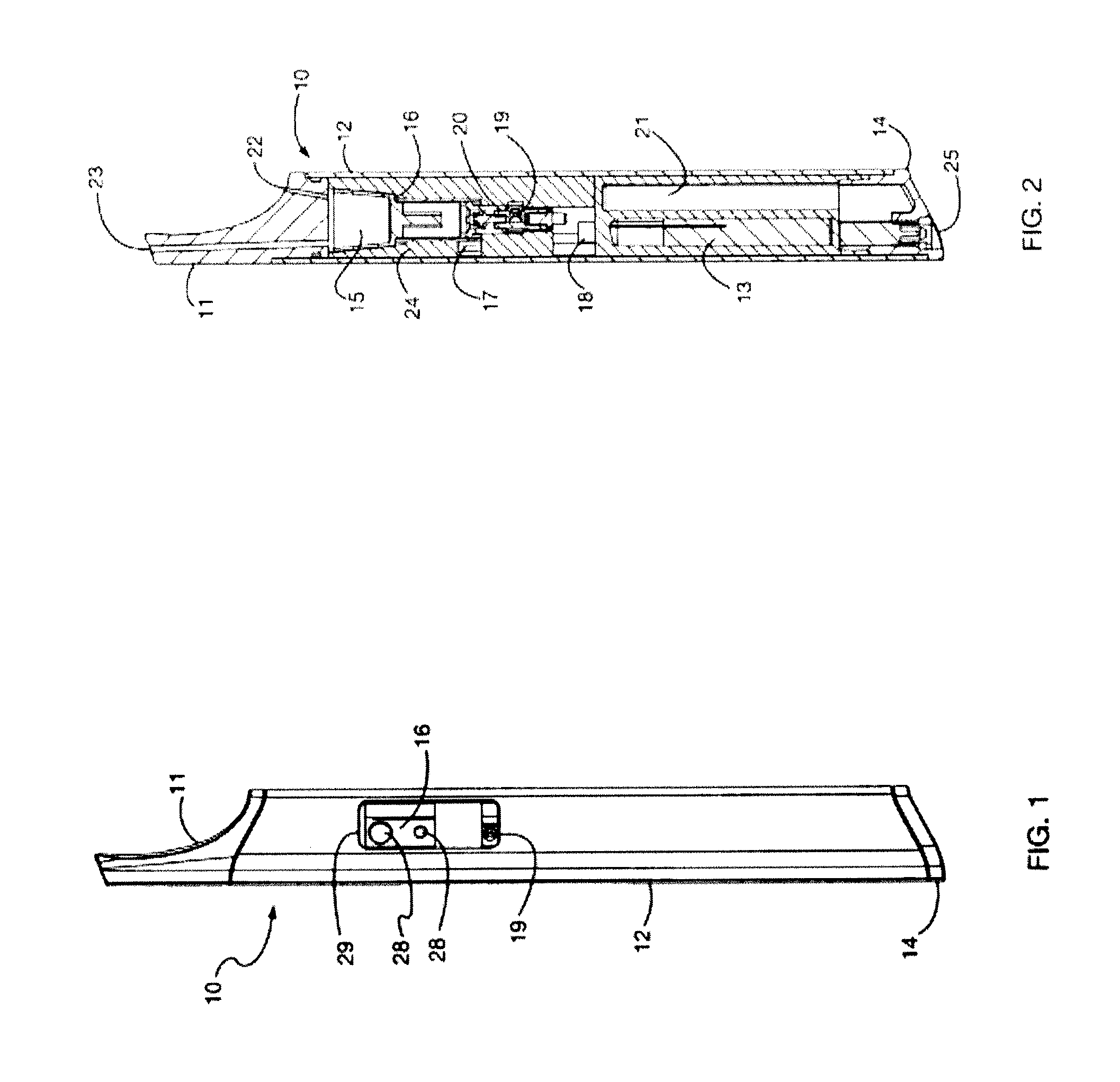

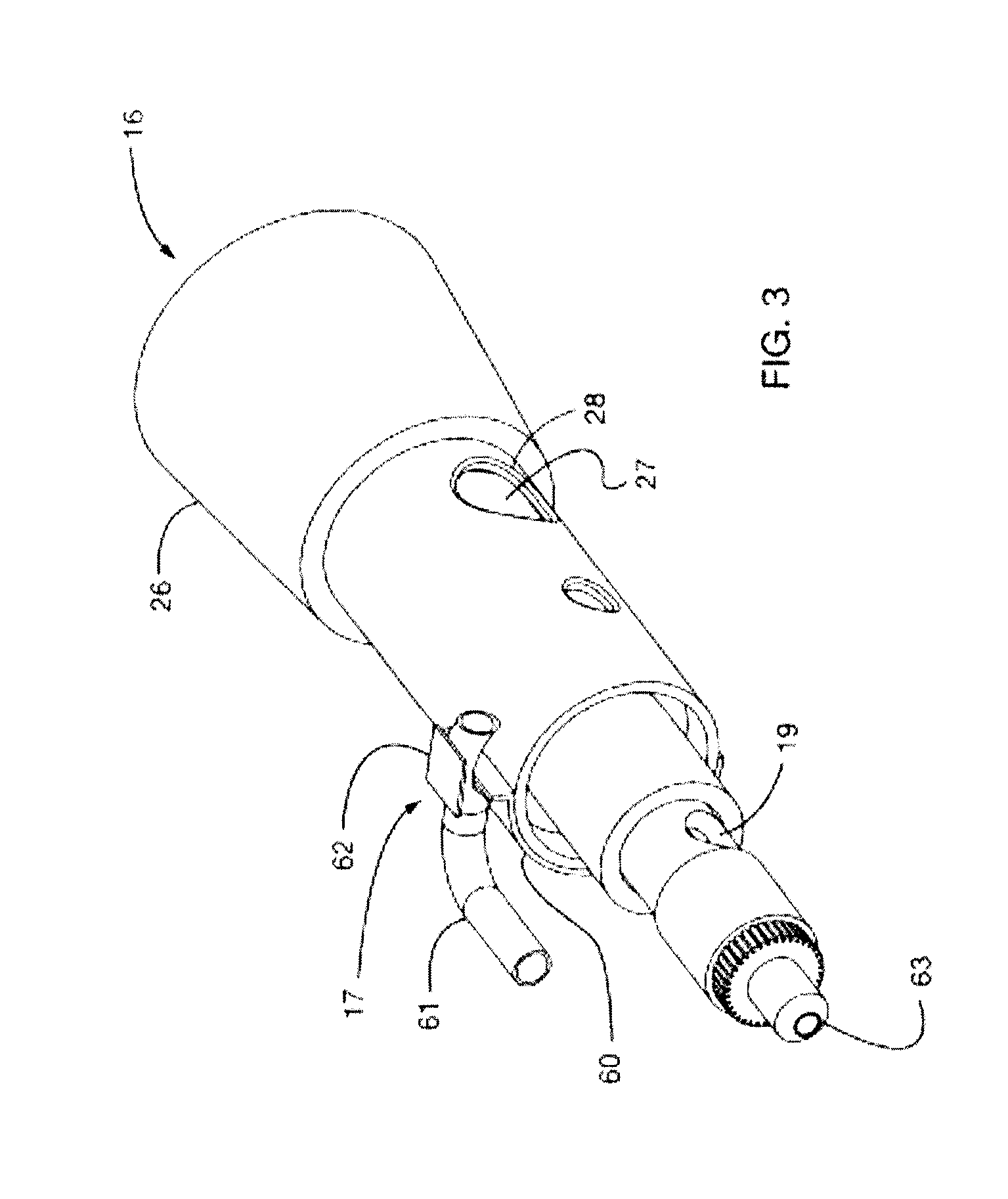

Electronic vaporization device

InactiveUS20160262459A1Avoid heatingEasy to insertRespiratorsBatteries circuit arrangementsVaporizationEngineering

Portable devices for generating an inhalable vapor that include an elongate cylindrical body that may have an oval cross-section, an oven configured to fit within the body and to hold a vaporizable material, a detachable mouthpiece covering the oven, a single-button interface comprising a single button that is configured to be pressed to begin heating, select a heating temperature, and turn off heating and one or more light emitting diode (LED) indicator configured to show information about the status of the device, including a user-selectable temperature setting.

Owner:JUUL LABS INC

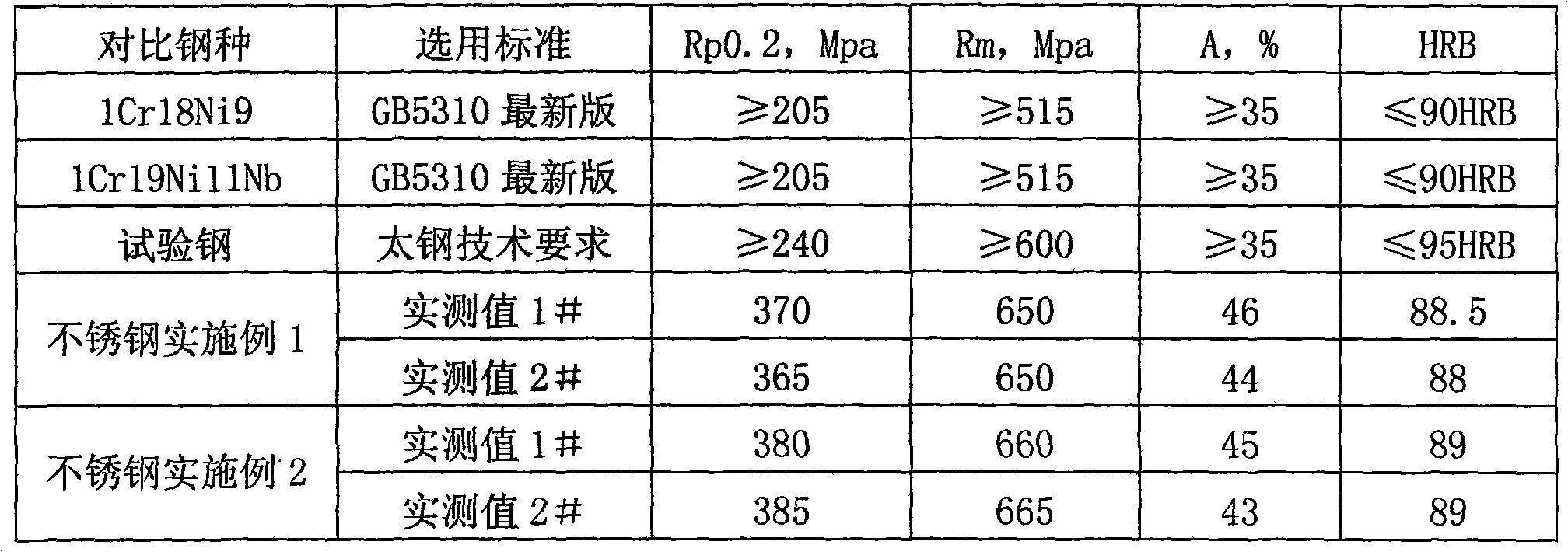

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

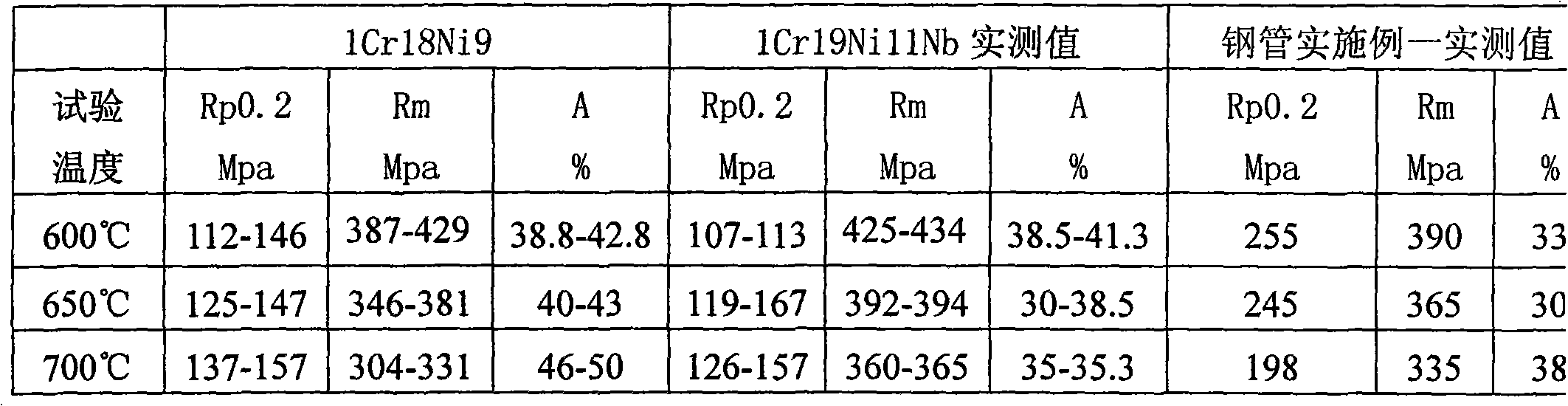

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

High speed laser scribing method of fragile material

InactiveUS20100089882A1Accelerate thermal stress scribingAvoid disadvantagesFine working devicesGlass severing apparatusLight beamOptoelectronics

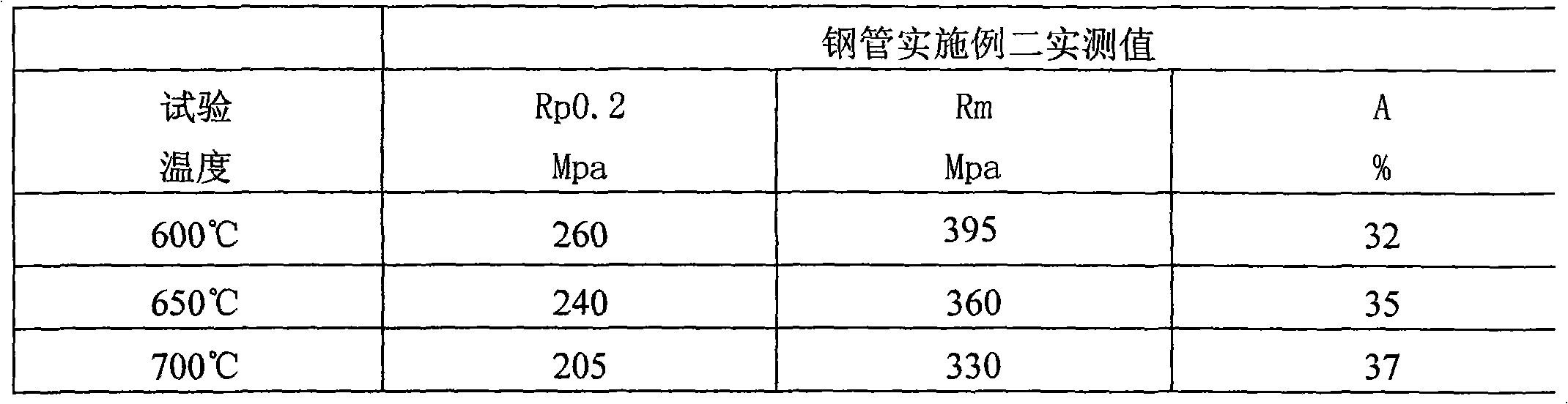

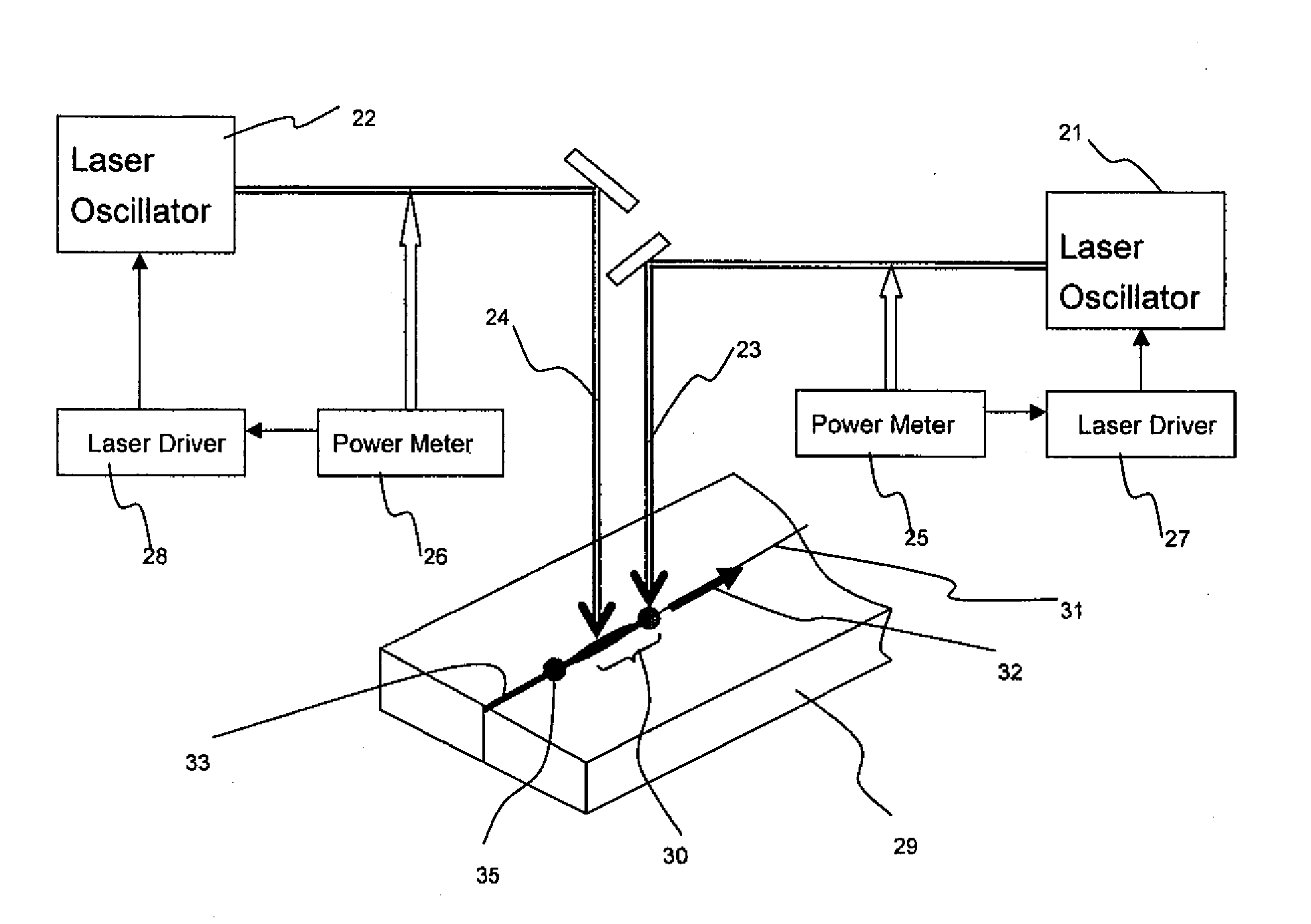

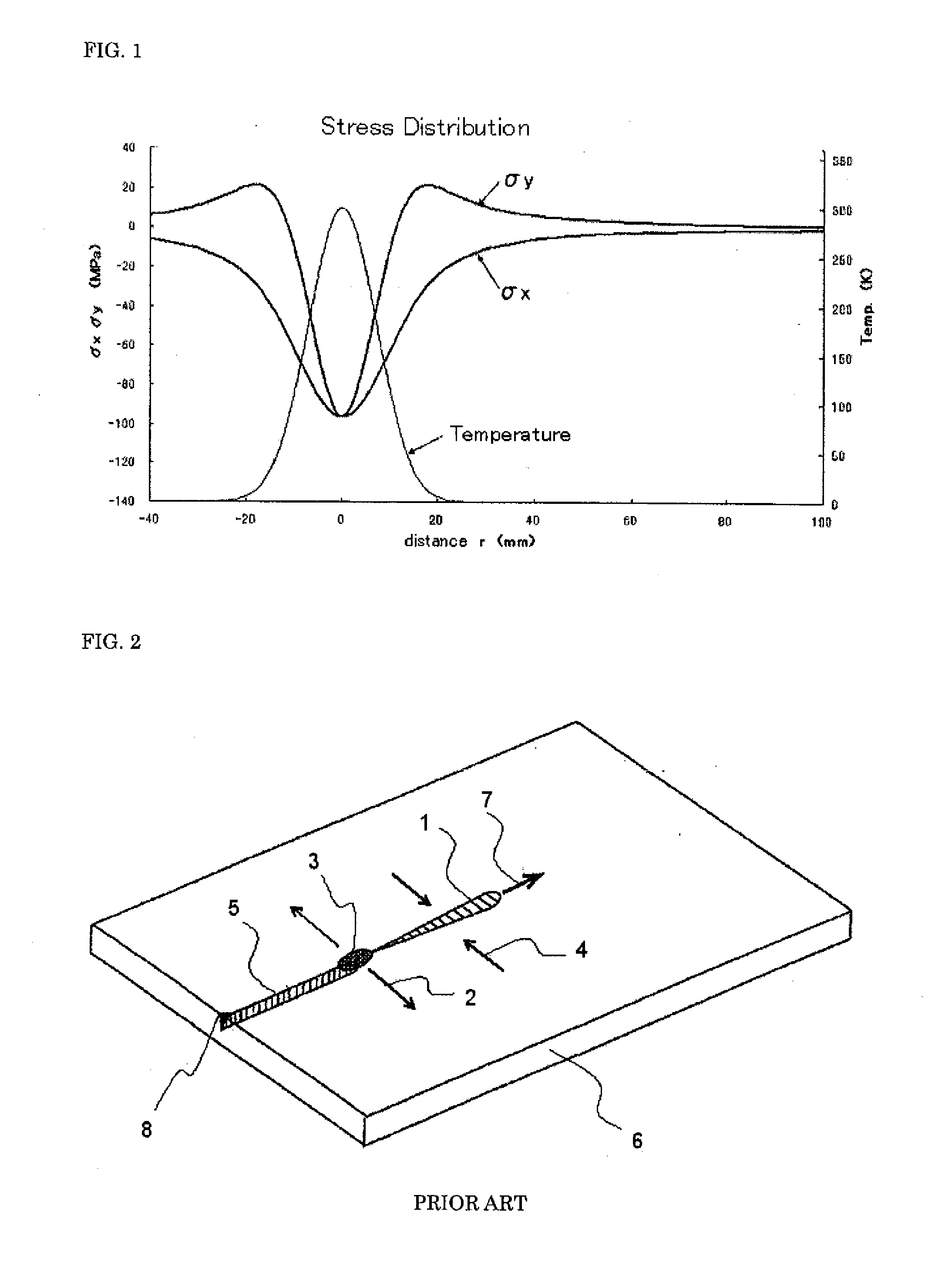

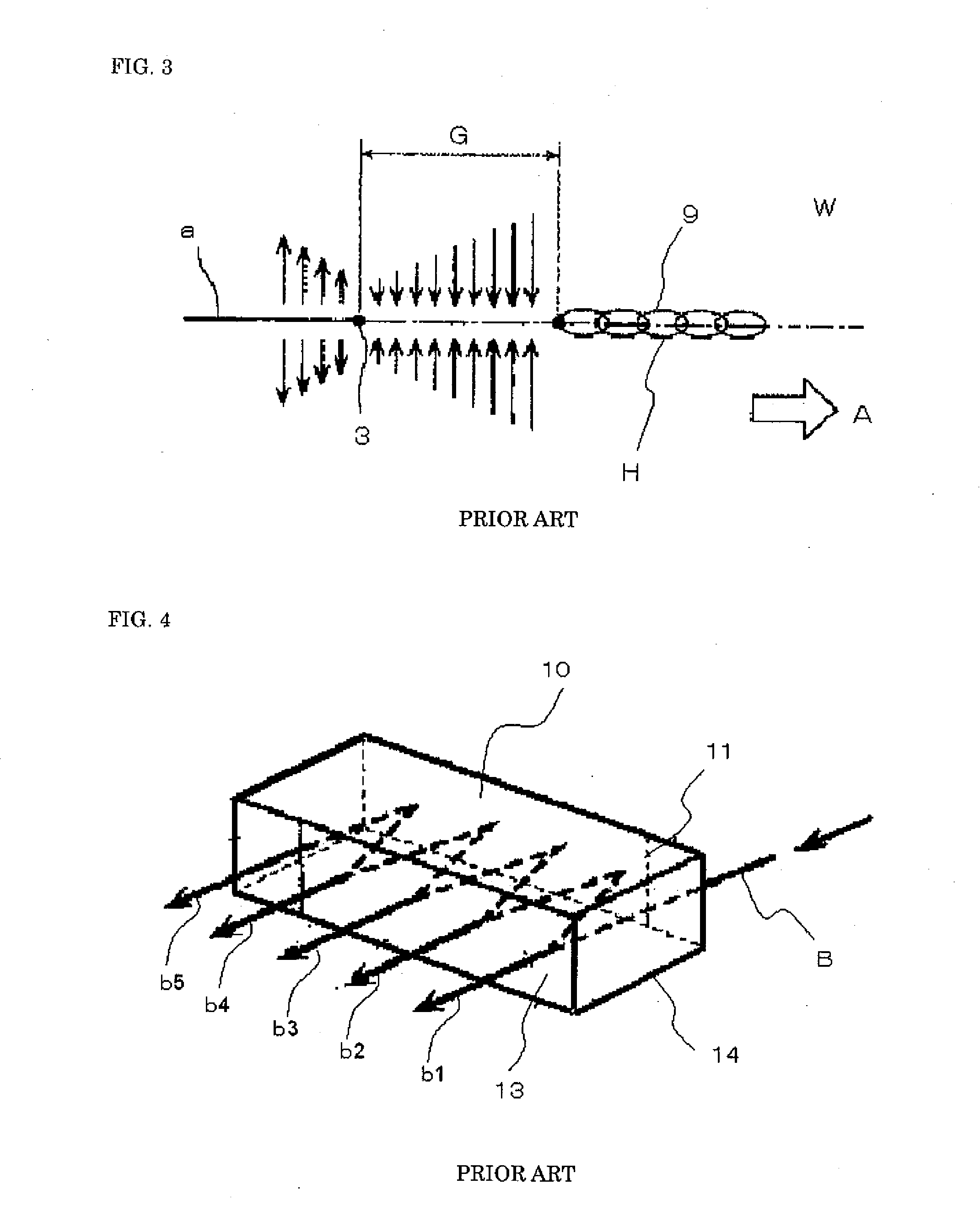

In a method for scribing fragile material, a laser beam is irradiated onto a work plate of the fragile material. The work plate is heated by absorption of the irradiated laser beam and generating thermal stress by the heating. The laser beam is formed by a plurality of laser beam groups arranged along a beam scanning direction on a same line, and the plurality of laser beam groups are divided into two groups. One takes charge of initial heating and rising up temperature of the work plate, and another takes charge of temperature holding of the work plate. The laser beam intensity corresponding to each of the laser beam groups is adjusted so as to obtain optimum values.By the method, it is possible to remarkably increase scribing speed of the work plate of the fragile materials without increasing heating temperature.

Owner:GLOBALY TECH CO LTD

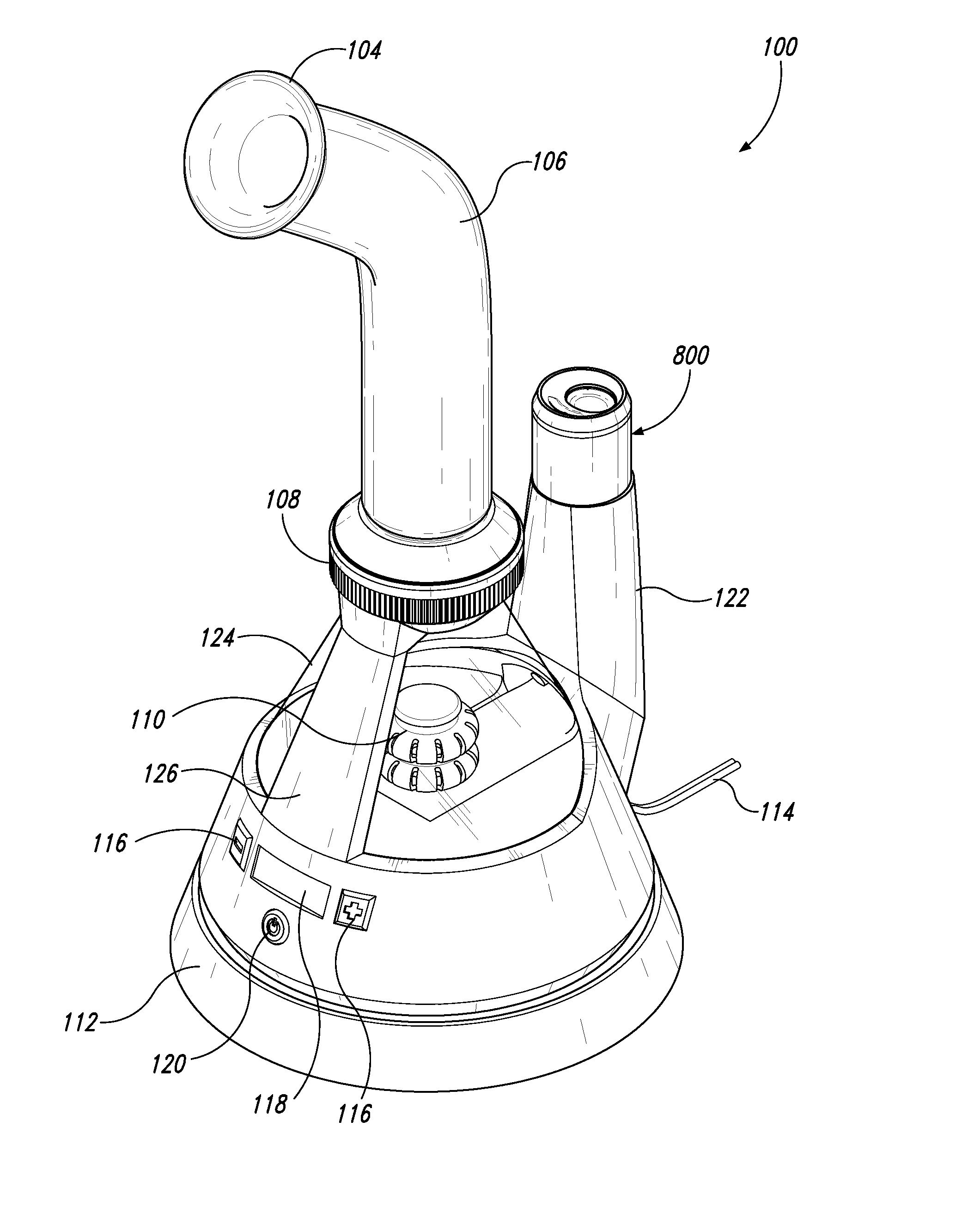

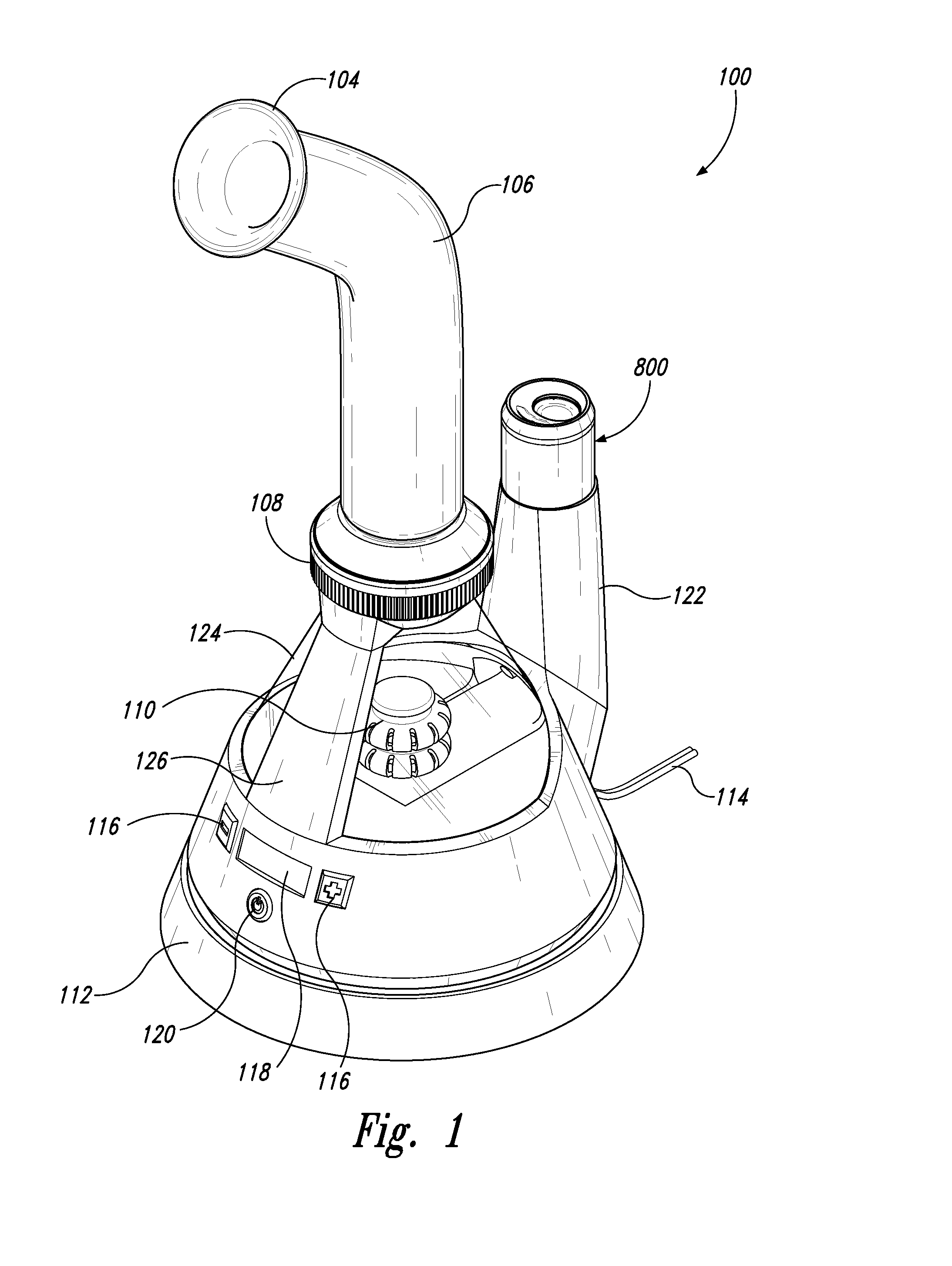

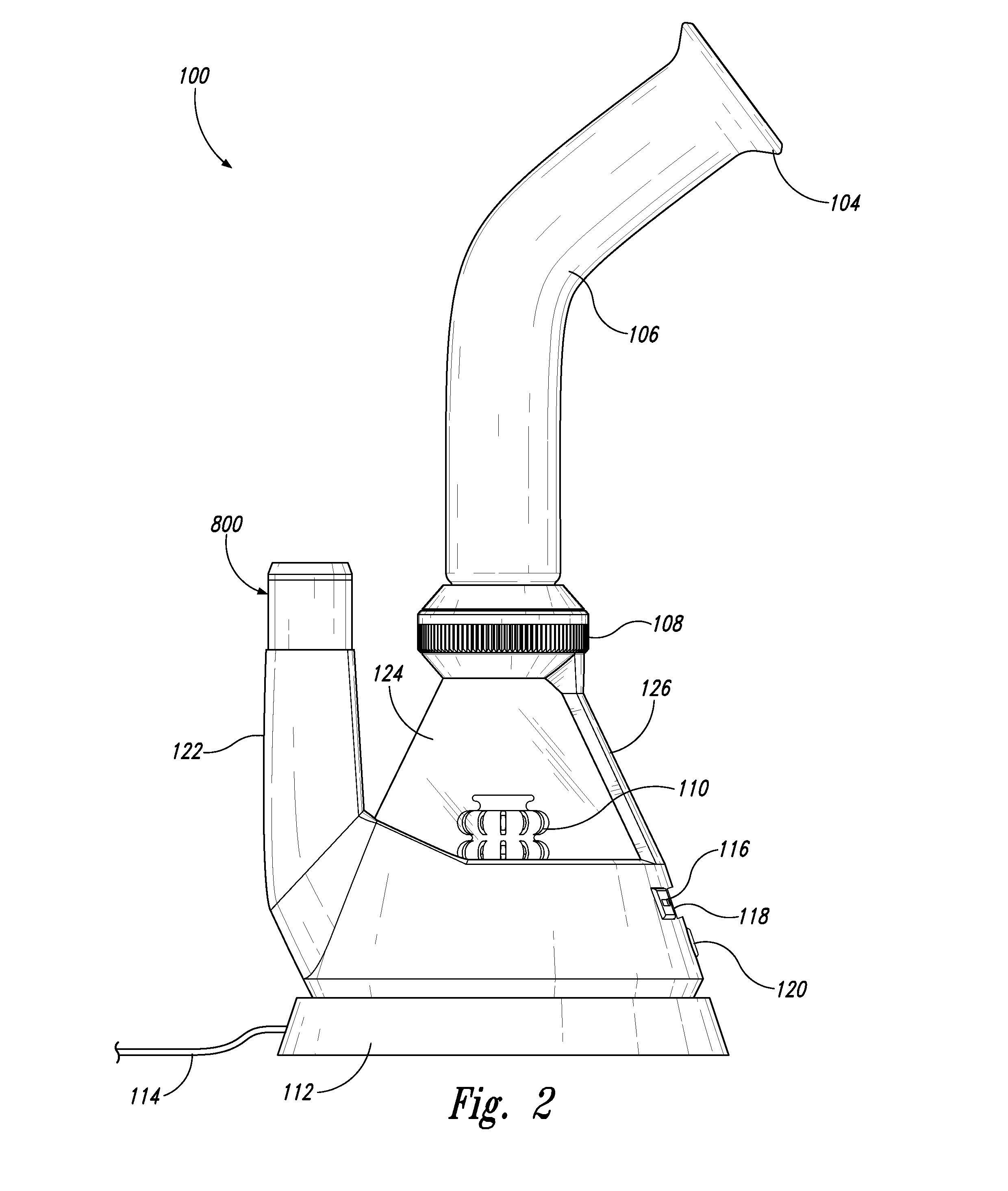

Electric Vapor Apparatus

A vapor apparatus for the pulmonary administration of combustible substances includes a vessel capable of holding liquids, a stem for holding a nail assembly, a nail assembly for heating the combustible substances, a user interface for determining heating temperature and heating duration, and an elongate neck for the user's mouth. Other embodiments include a remote interface, a removable neck, a percolator, and sensors for determining attributes of the combustible material. The vapor apparatus may further include a tool for sealing the combustible material and manipulating the combustible material. Fans can be added for forcing air through the apparatus.

Owner:CCNK LLC

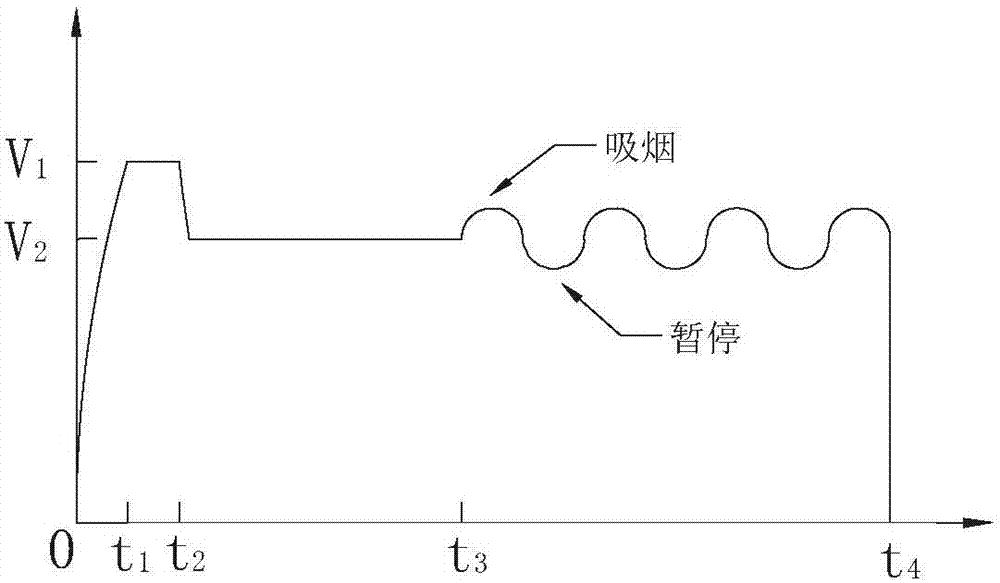

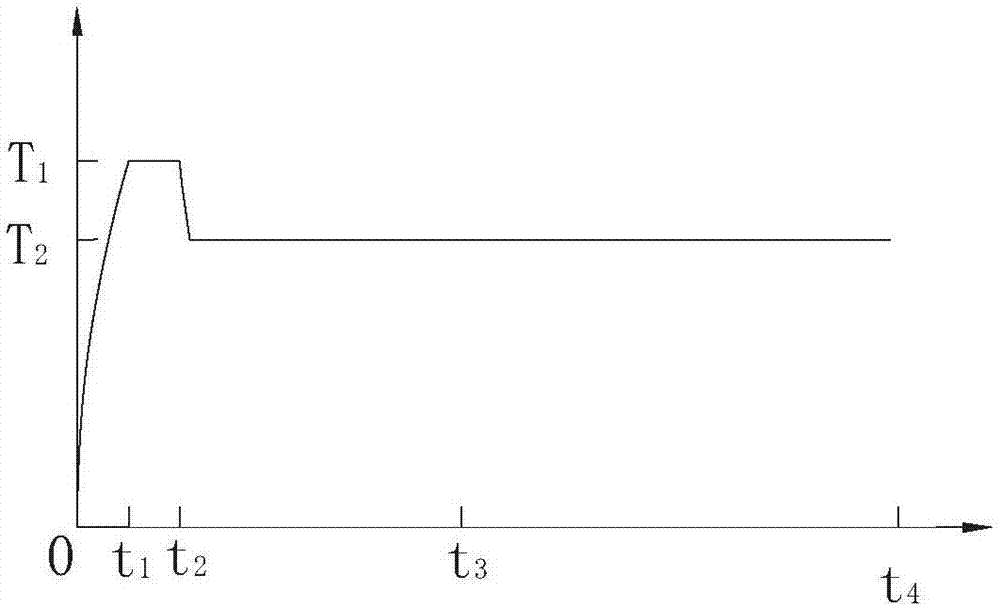

Heating method of electronic smoking set

The invention discloses a heating method of an electronic smoking set. The heating method comprises the following steps of a first heating device preheating stage before smoking, a second heating device preheating stage before smoking, a heat preservation stage during smoking, heat preservation stage pausing during smoking and smoking stage completion. The heating method has the advantages that the outer wall portion of a tobacco core and air flowing through the inside of the tobacco core are simultaneously preheated by adopting the method, a first heating device rapidly improves the temperature and exceeds normal heating temperature to make heat rapidly and evenly transferred to the inside of the tobacco core, the preheating time is short, and a user can be more quickly in a smoking state. During smoking, two heating devices can adjust voltage to keep constant temperature heating and ensure that sufficient smoke amount is produced in unit time, the user can smoothly smoke, the voltage can be also adjusted to keep constant temperature heating when smoking is paused, and the scorched flavor produced due to tobacco overburning in the tobacco core caused by temperature rise is avoided.

Owner:HUIZHOU HAPPY VAPING TECH LTD

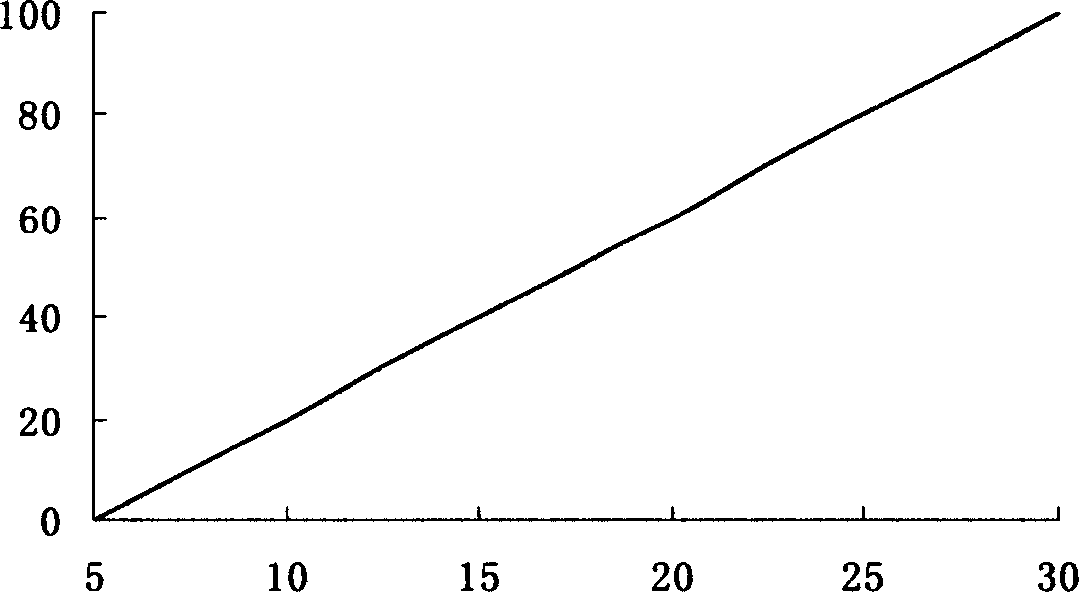

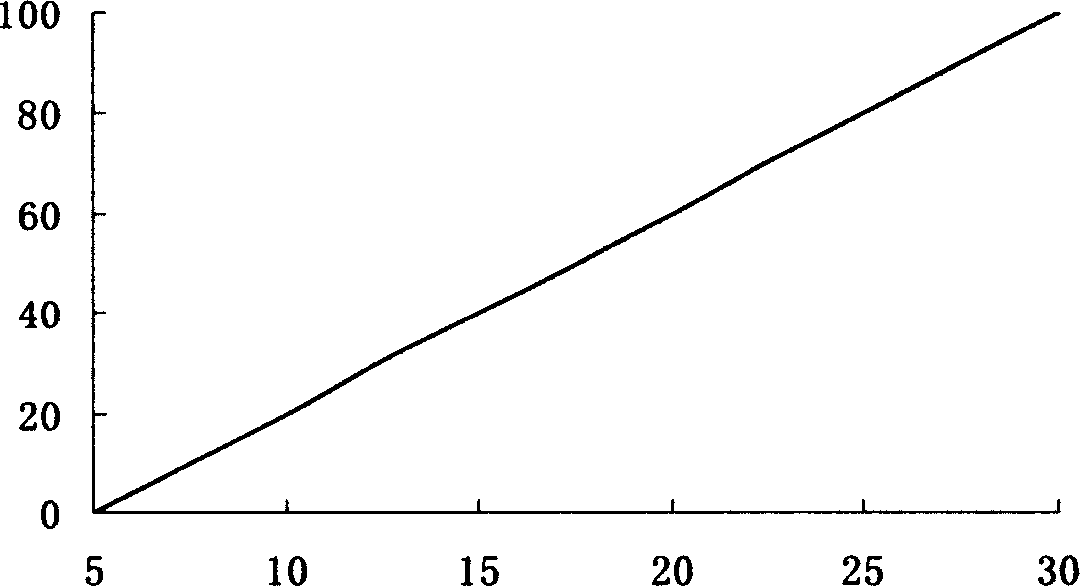

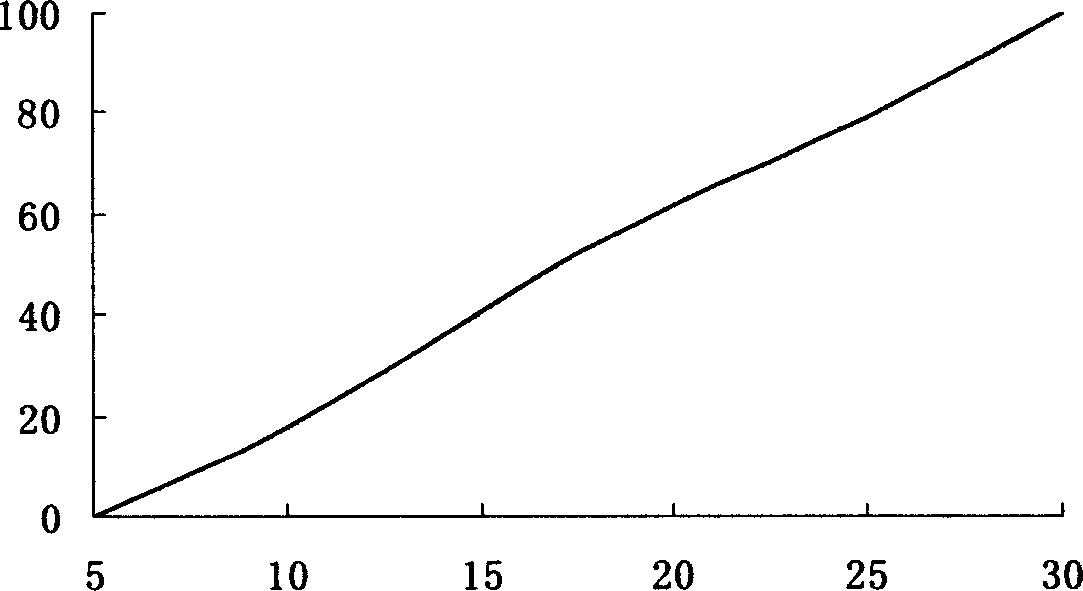

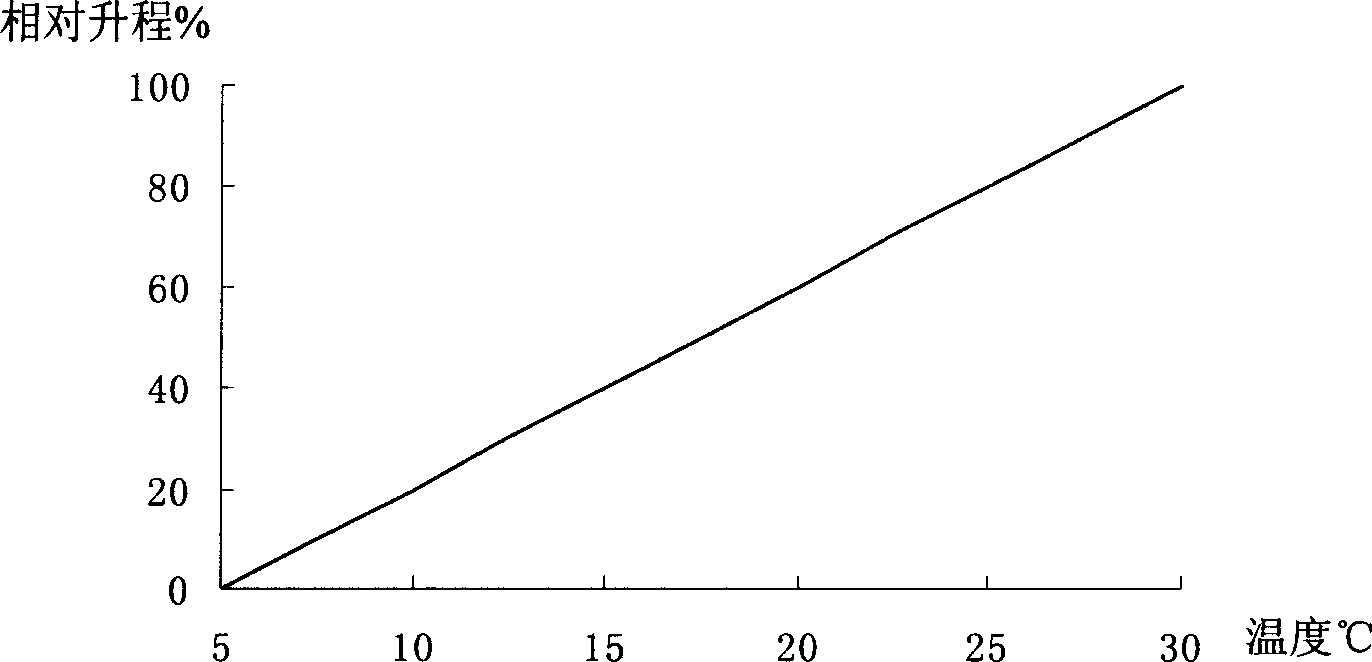

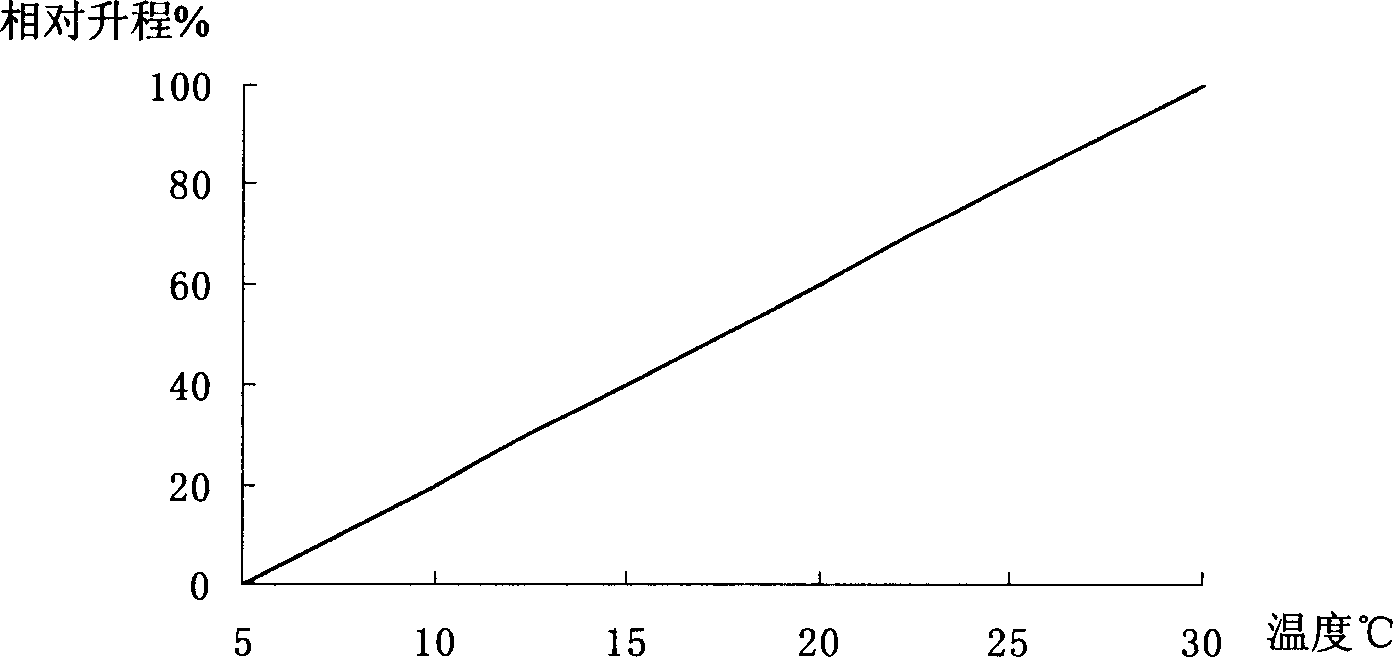

Wax dielectric for heating temperature control valve and its preparing method

InactiveCN1458241ALow pricePhysical stabilityHeating/cooling contact switchesMineral wax recovery/refiningTemperature controlDielectric

The present invention relates to wax dielectric for heating temperature control valve and its preparation process. The destination product is prepared with fluid wax, wax paste, soap wax, etc containing C9-C20 components and through decompression distillation in 5-20 deg.c fraction width, sweating of the fractions in the smelting point temperature as the ultimate temperature, equal weight ratio mixing, refining and other technological steps. The product may be used in heating temperature controlling valve for temperature control in 5-30 deg.c and has basically the same stroke each degree of temperature. The product may be also used in other automatic temperature controlling devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

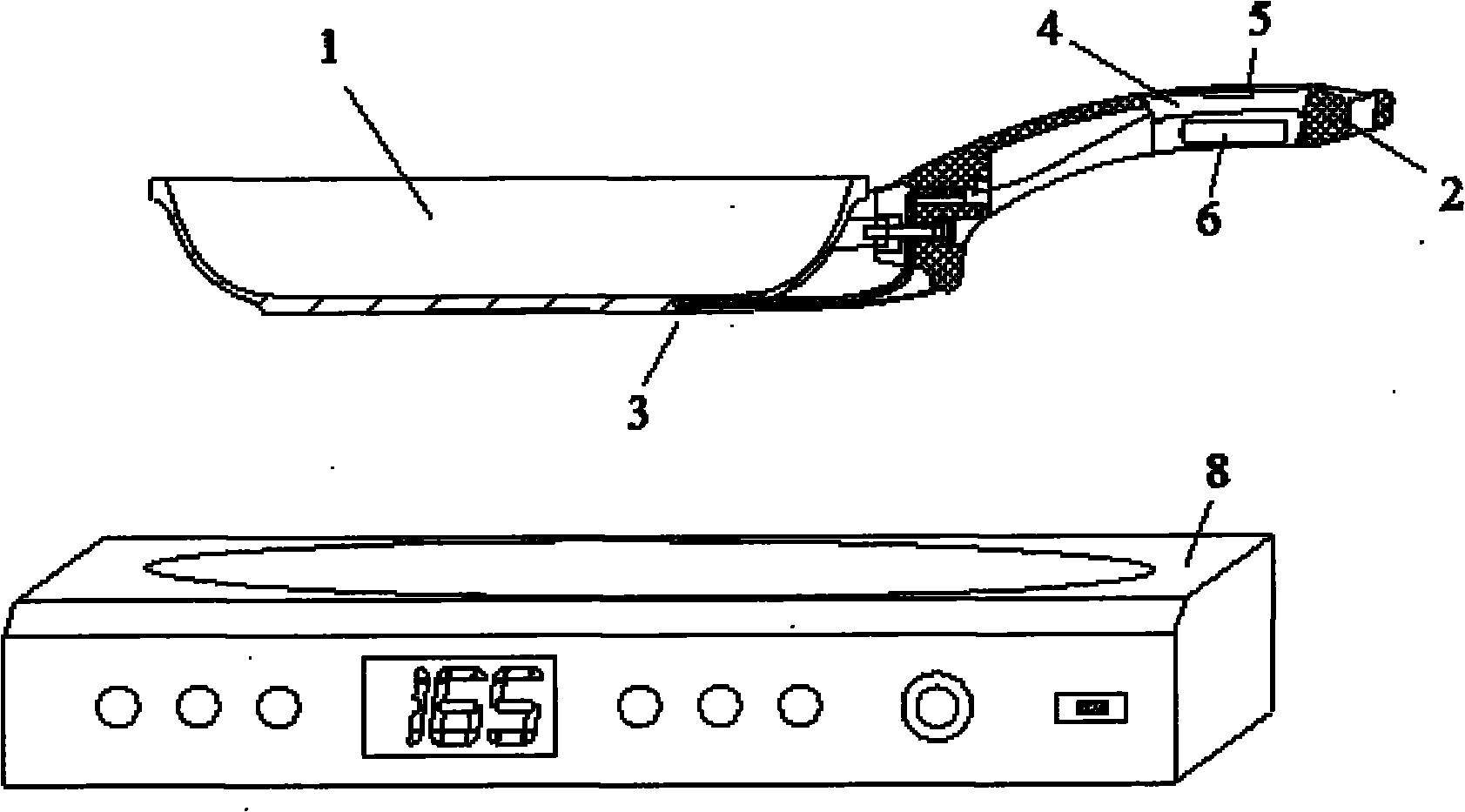

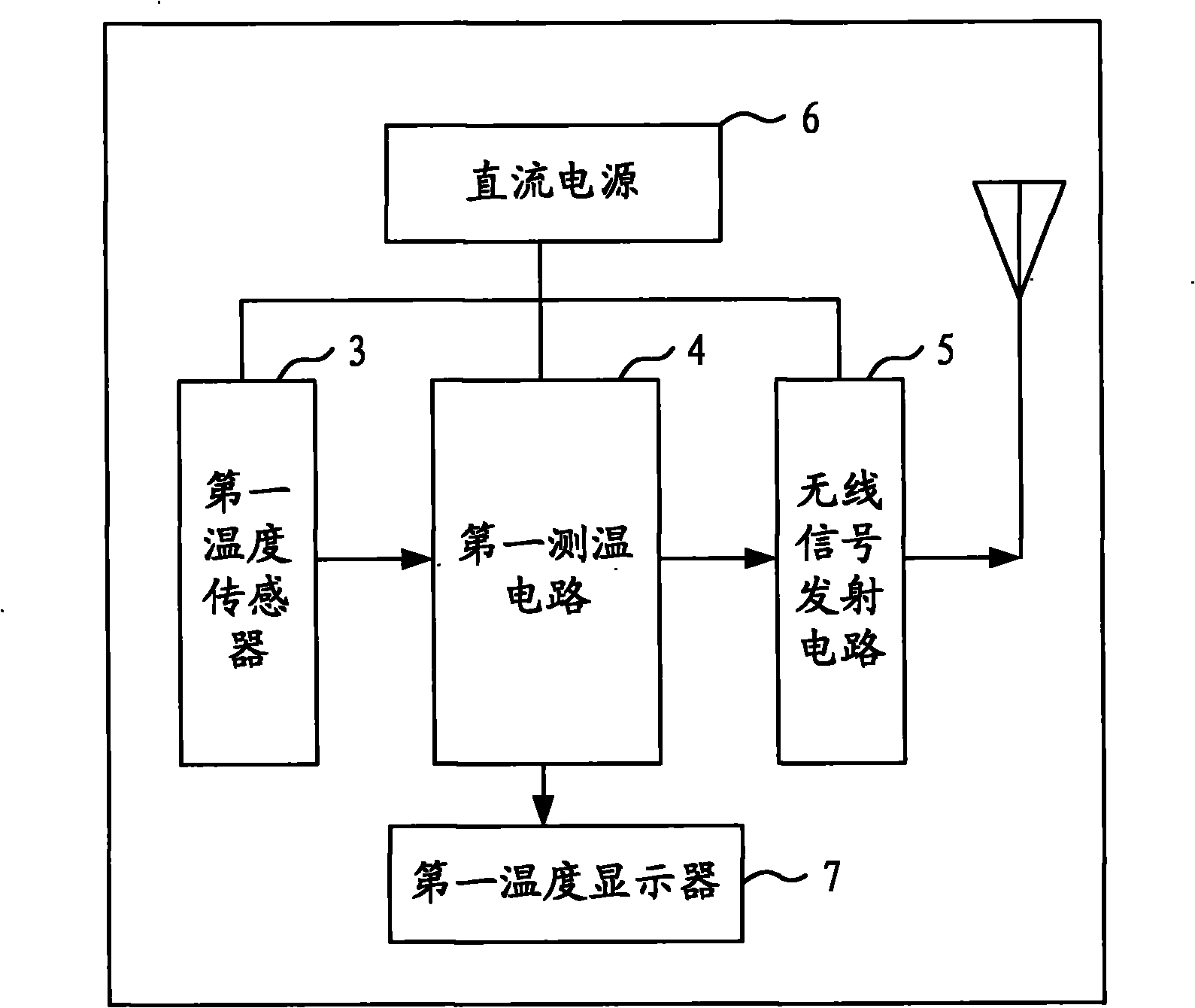

Electric cooker

InactiveCN101828856AControl heating temperatureStable temperatureDomestic stoves or rangesLighting and heating apparatusTemperature controlElectricity

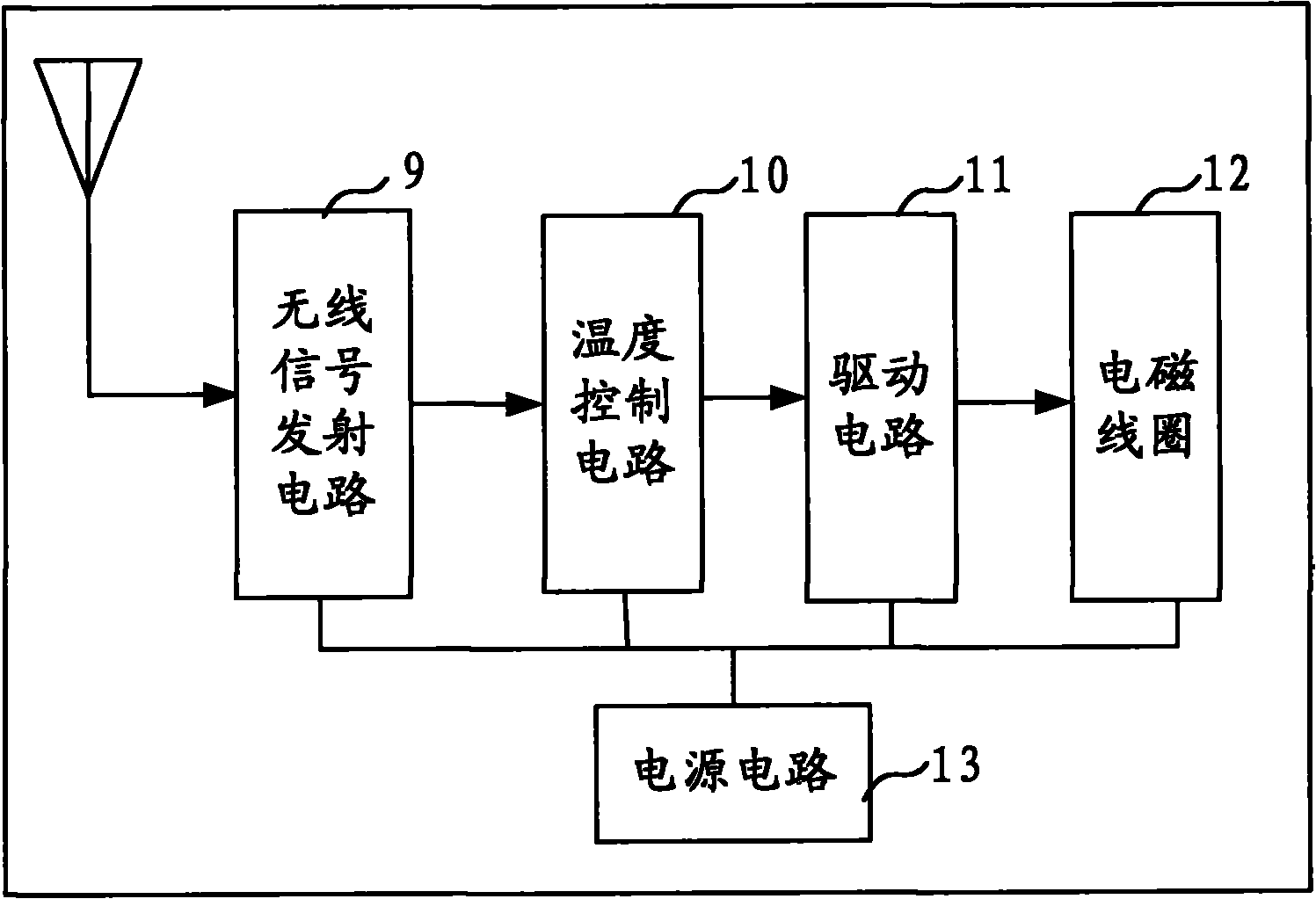

The invention discloses an electric cooker comprising a double-layer boiler body with a handle and an electromagnetic oven body, wherein the boiler body comprises a first temperature sensor, a first temperature measuring circuit, a wireless signal transmitting circuit and a direct-current power supply, and the electromagnetic oven body comprises a wireless signal receiving circuit, a temperature control circuit, a drive circuit, an electromagnetic coil and a power circuit. The invention adopts the technical scheme that the temperature sensor is arranged on the boiler body, the temperature control circuit receives temperature signals on the boiler body and controls the output power of the drive circuit according to the temperature signals of the boiler body so as to control the heating temperature of an electromagnetic oven, and then the precise temperature control on heated foods can be realized. In addition, the electromagnetic oven body also comprises a second temperature sensor and a second temperature measuring circuit; and the temperature control circuit can also receives the temperature signals of the electromagnetic oven body and controls the output power of the drive circuit according to the temperature signals of the electromagnetic oven body, thereby realizing the control on the heating temperature of the electromagnetic oven.

Owner:MINGLE DEV (SHENZHEN) CO LTD

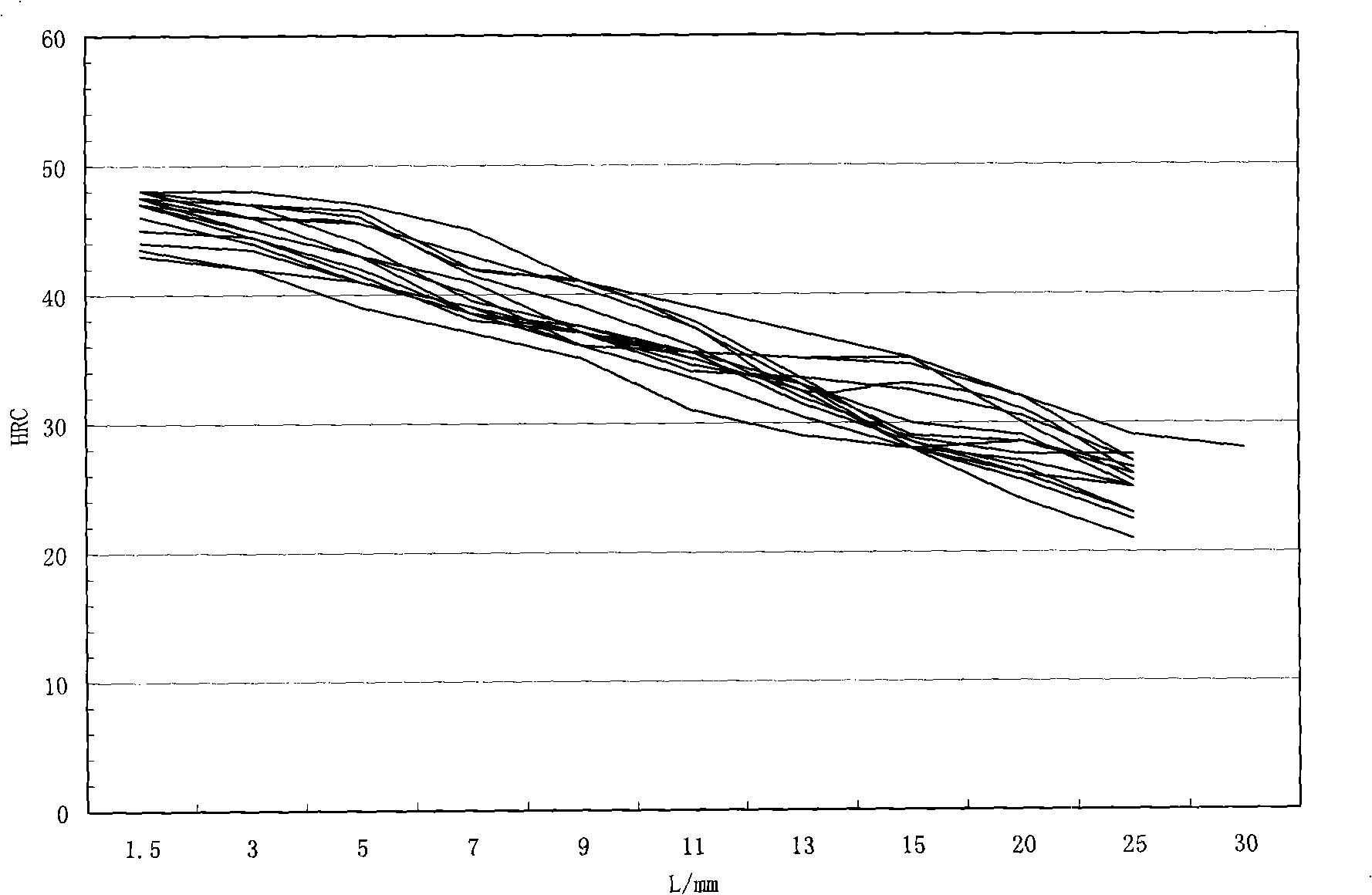

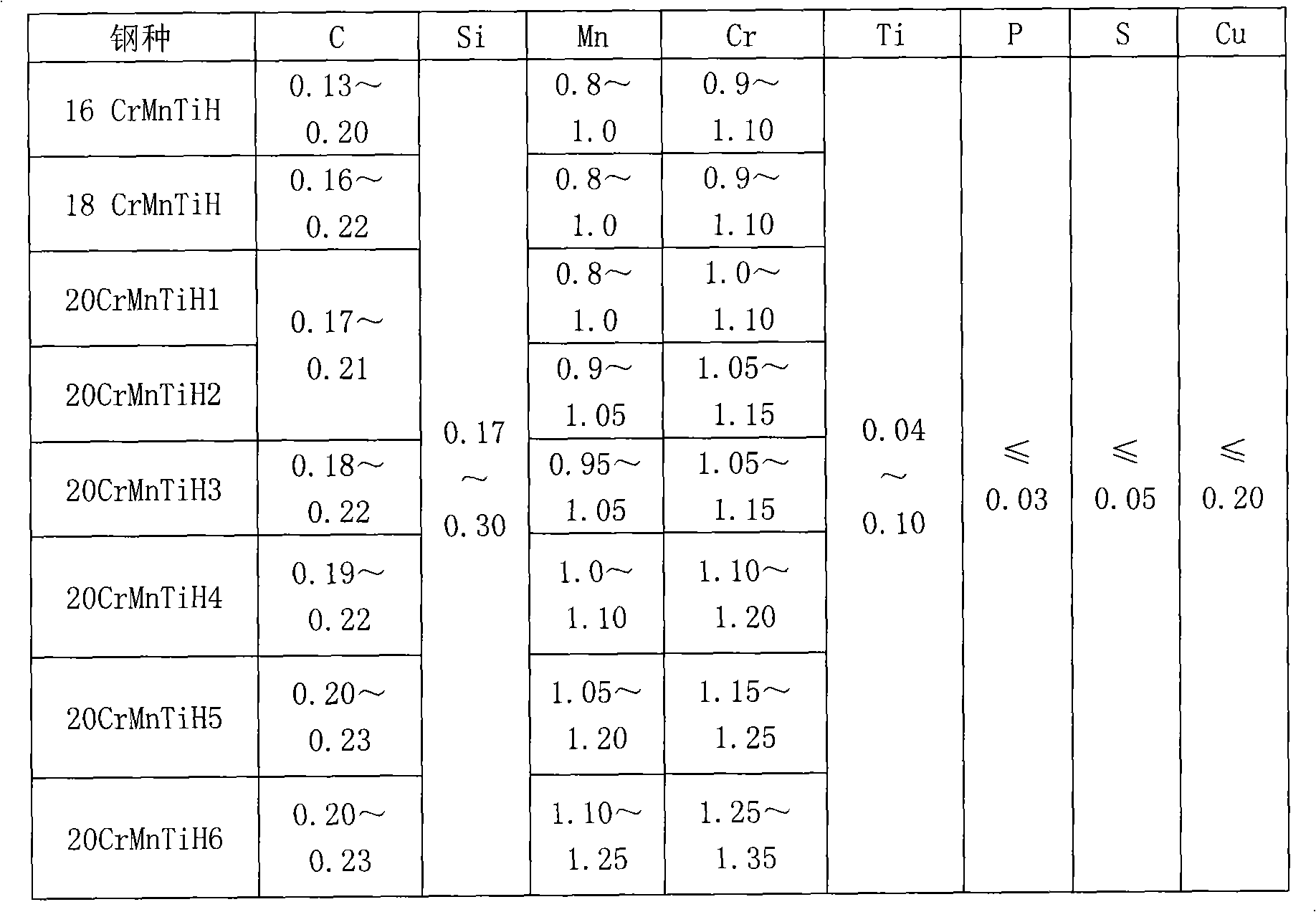

CrMnTi narrow hardenability strip pinion steels and method of manufacture

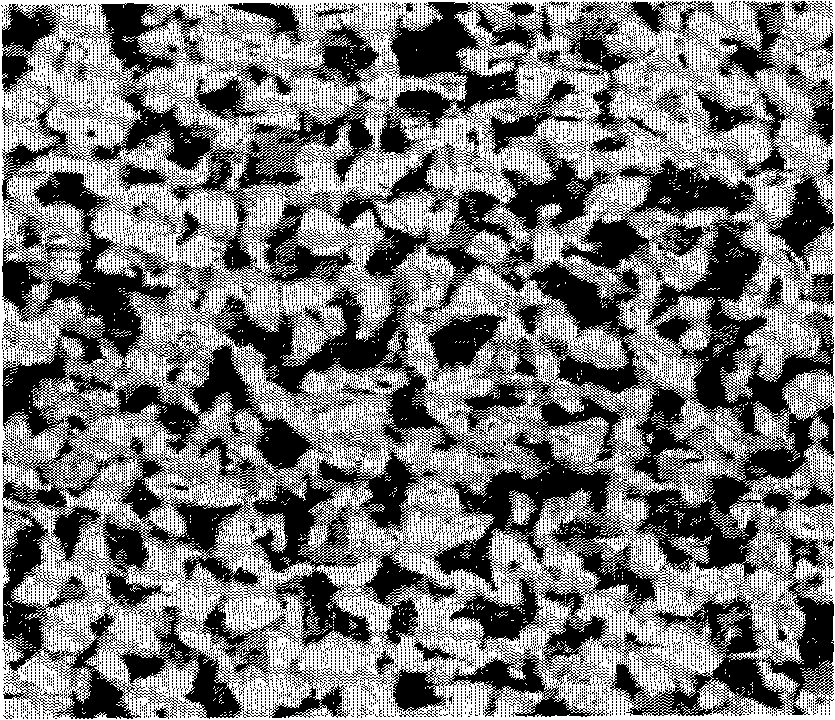

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

Aluminum titanate ceramic articles and methods of making same

ActiveUS7259120B2Reduced strengthLower firing temperatureInternal combustion piston enginesSilencing apparatusAlkaline earth metalRare earth

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:CORNING INC

Temerature sensitive medium for wax temperature controlling valve and its prepn process

The present invention is temperature sensitive medium for wax temperature controlling valve and its preparation process. The destination product is prepared with liquid paraffin containing C9-C20 components, cerate or other material and through decompression distillation, mixing, refining and other steps. During the mixing, partial commercial wax may be added to lower the production cost. The wax temperature controlling valve with the product of the present invention may be used in controlling temperature in 5-30 deg.c with the basically the same stroke each degree. The product of the present invention may be used in automatic temperature controlling device requiring homogeneous stroke, especially in heating temperature controlling valve.

Owner:CHINA PETROLEUM & CHEM CORP +1

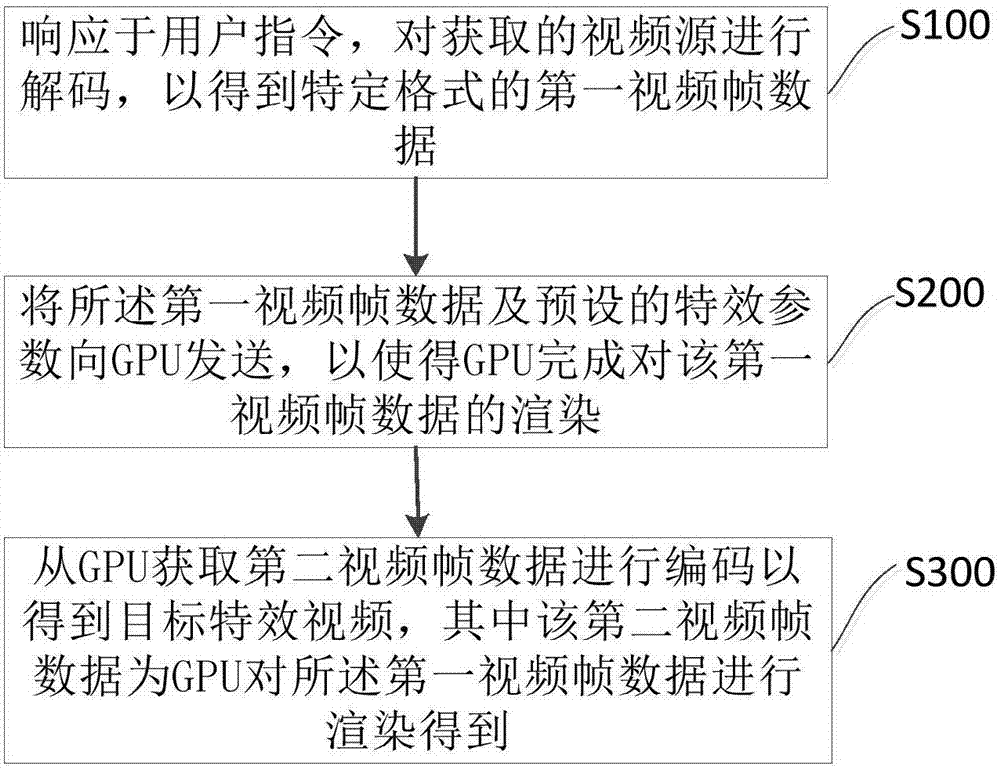

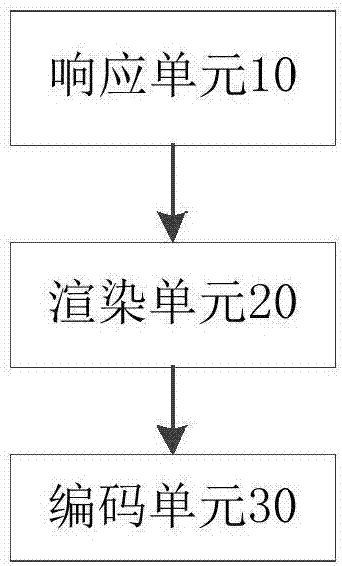

Video special effects rendering method, device and terminal

InactiveCN107277616AReduce total timeReduce occupancySelective content distributionGraphicsOccupancy rate

The invention provides a video special effects rendering method, device and terminal. The video special effects rendering method comprises the following steps: decoding a obtained video source in response to a user instruction to obtain a first video frame data in a particular format; sending the first video frame data and the preset special effects parameters to the GPU, so that the GPU completes the rendering of the first video frame data; and obtaining a second video frame data from the GPU and encoding to obtain a target special effects video, wherein the second video frame data is obtained by rendering the first video frame data by the GPU. According to the video special effects rendering method, the processing ability of the GPU for graphics is effectively utilized, the parallel computing capabilities of the GPU is utilized to speed up the rendering of video effects, and the duration of video rendering is shortened, so that the preview of the video rendering frames is high, the playback of the frames is smooth, and the occupancy rate of the CPU when rendering is reduced, therefore, the heating temperature of the mobile terminal is reduced.

Owner:广州猎游信息科技有限公司

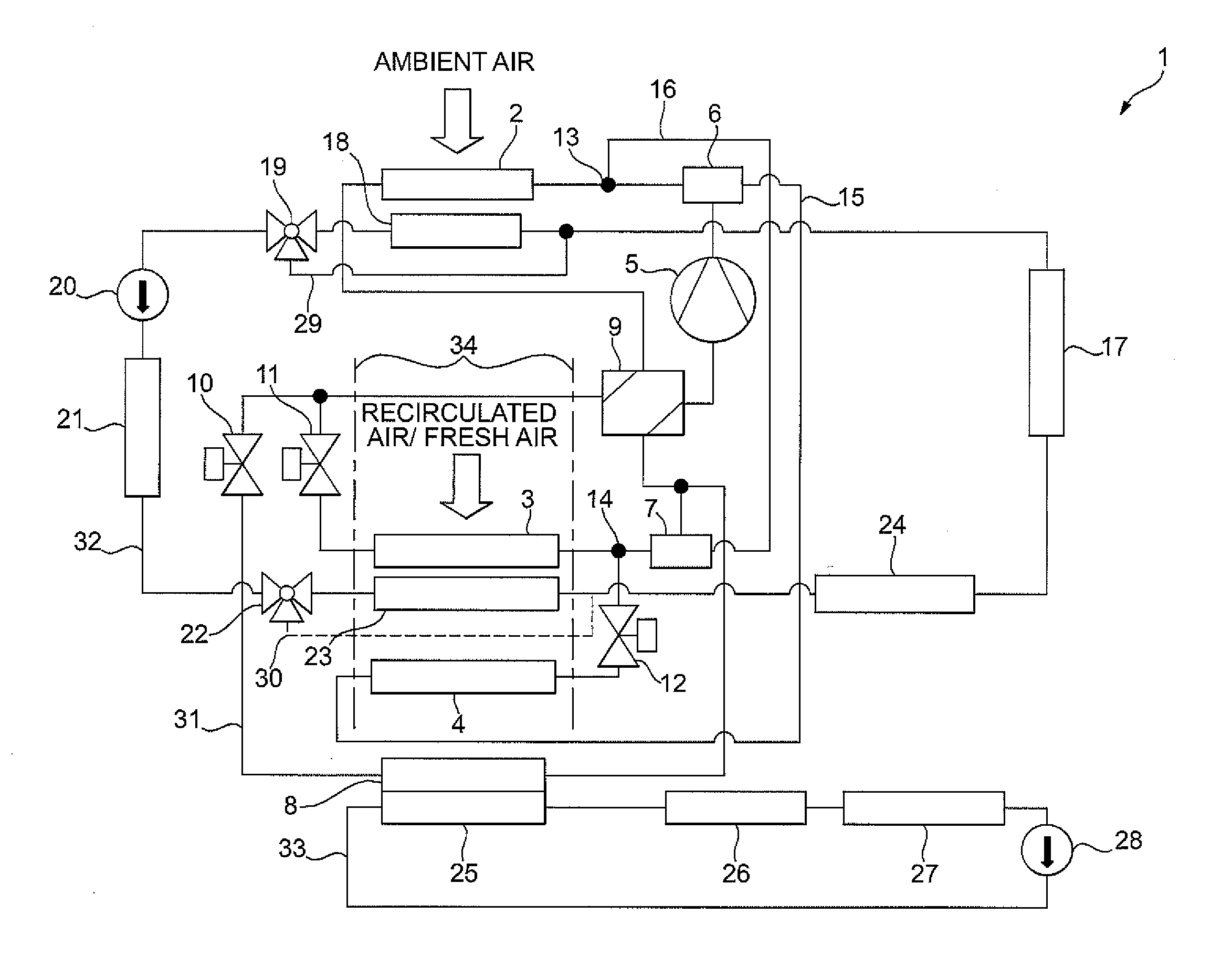

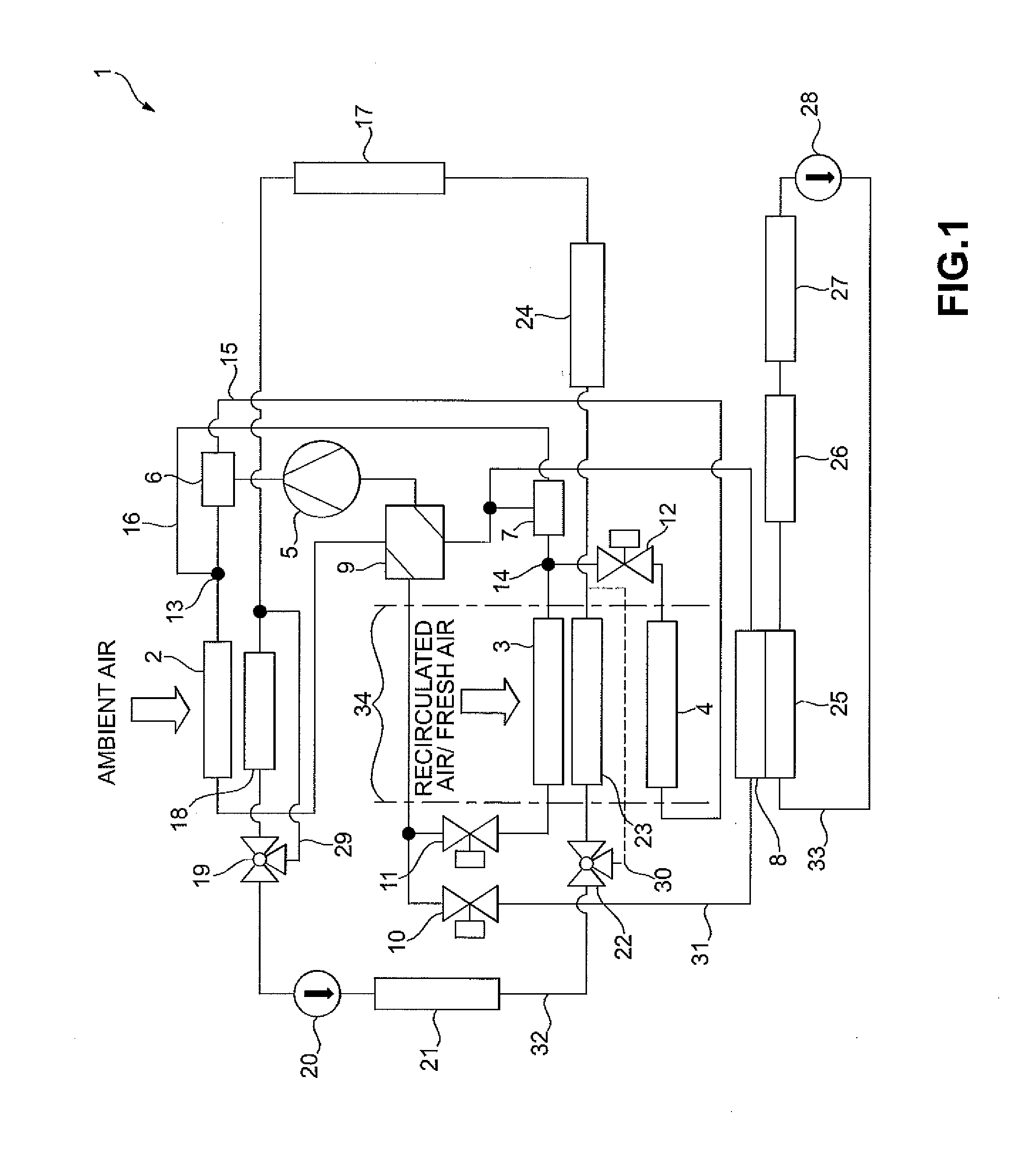

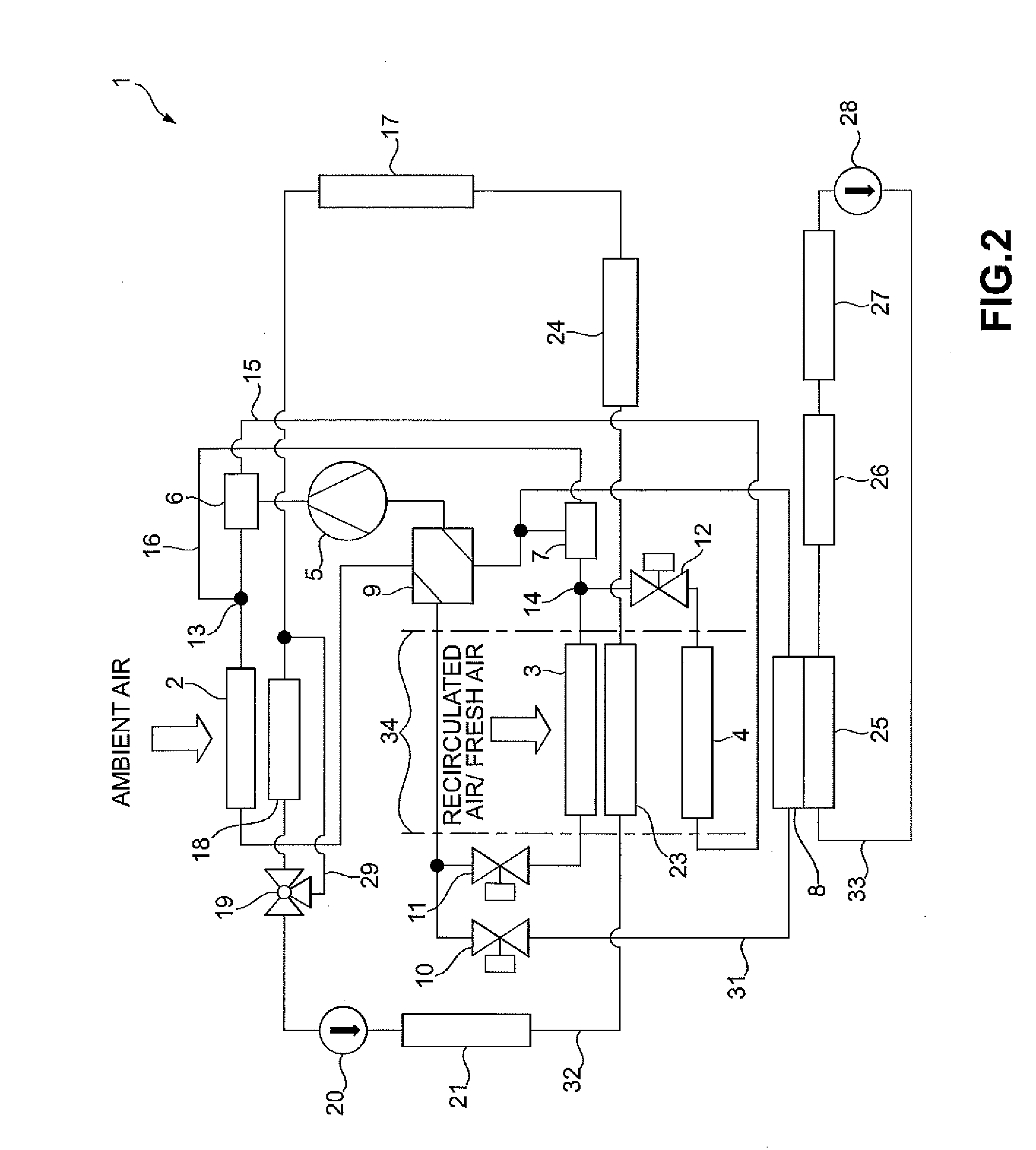

Method for operation of an HVAC system

ActiveUS20110174000A1Maximizes temperature gradientGuaranteed heat exchange effectLighting and heating apparatusVehicle heating/cooling devicesEngineeringHeating temperature

A method for operating an HVAC system includes the steps of adjusting a heating temperature of a heat exchanger disposed in a first flow passage, directing a first partial air mass flow through the first flow passage, directing a second partial air mass flow through a second flow passage, and directing the first partial air mass flow and the second partial air mass flow downstream of the first flow passage and the second flow passage, wherein the heating temperature of the heat exchanger required to at least one of achieve and maintain a desired climate in the passenger compartment of the vehicle is set as a maximum heating temperature for the heat exchanger, and wherein only an amount of energy required to at least one of achieve and maintain a desired climate in the passenger compartment of the vehicle is added to the HVAC system.

Owner:HANON SYST

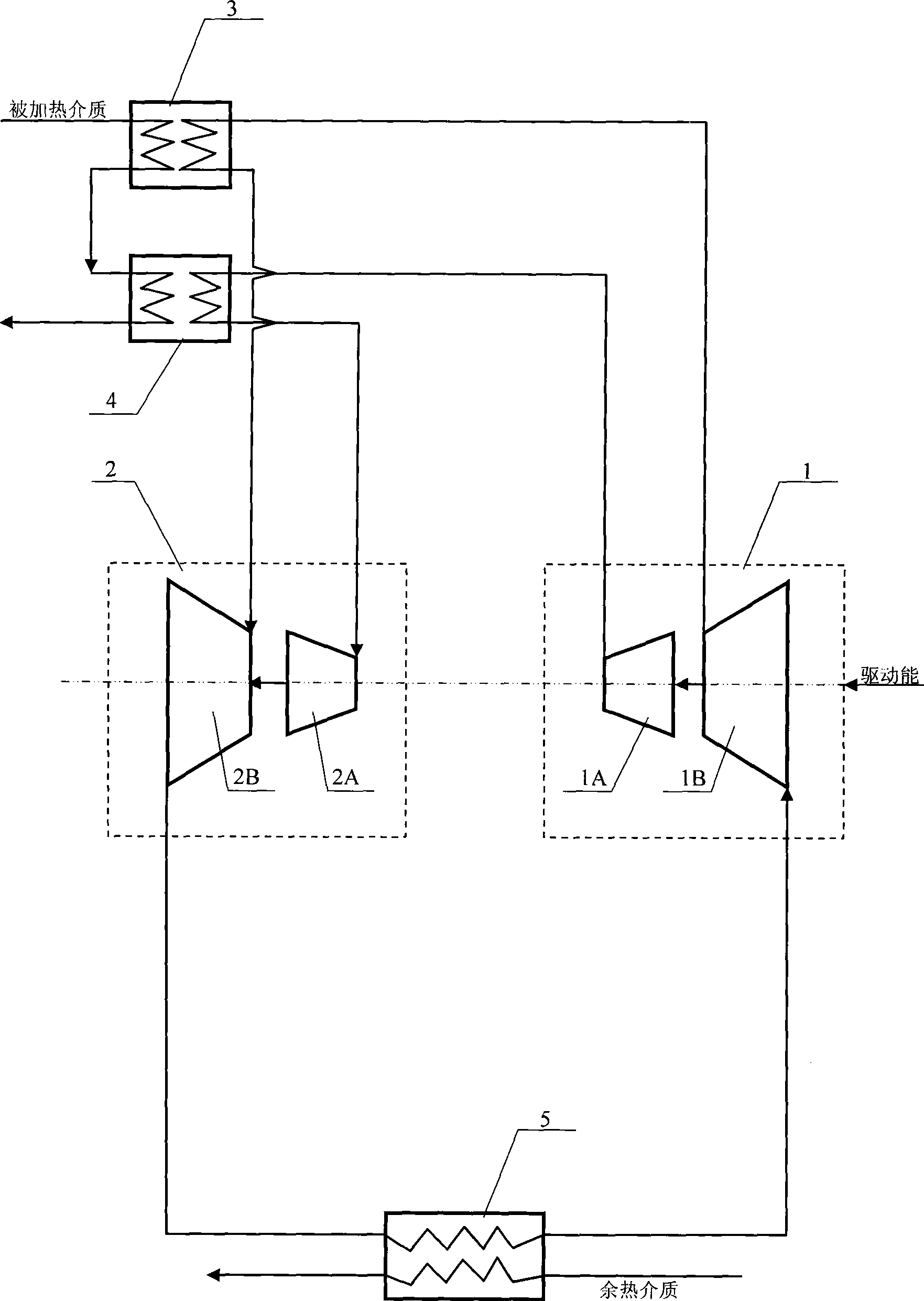

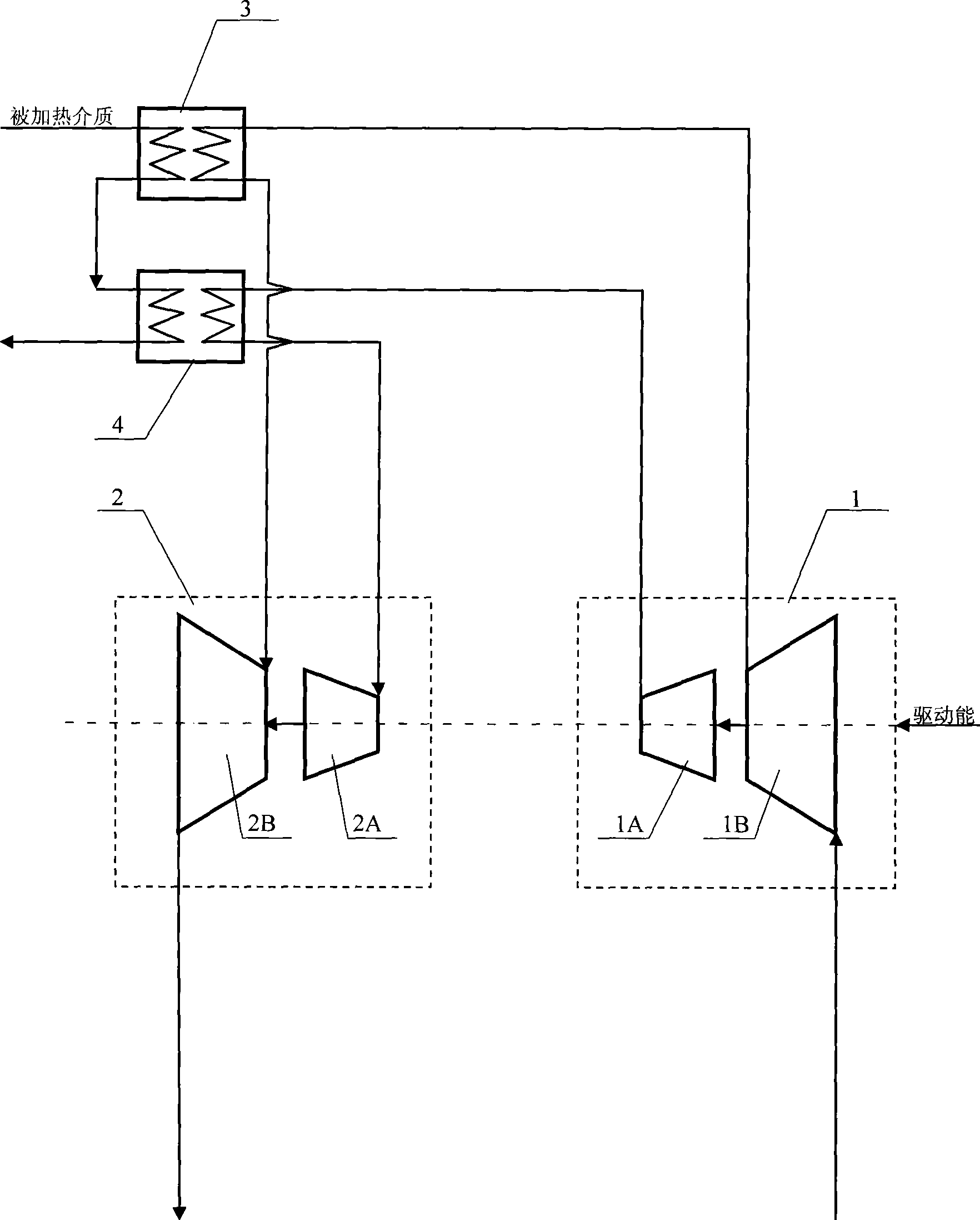

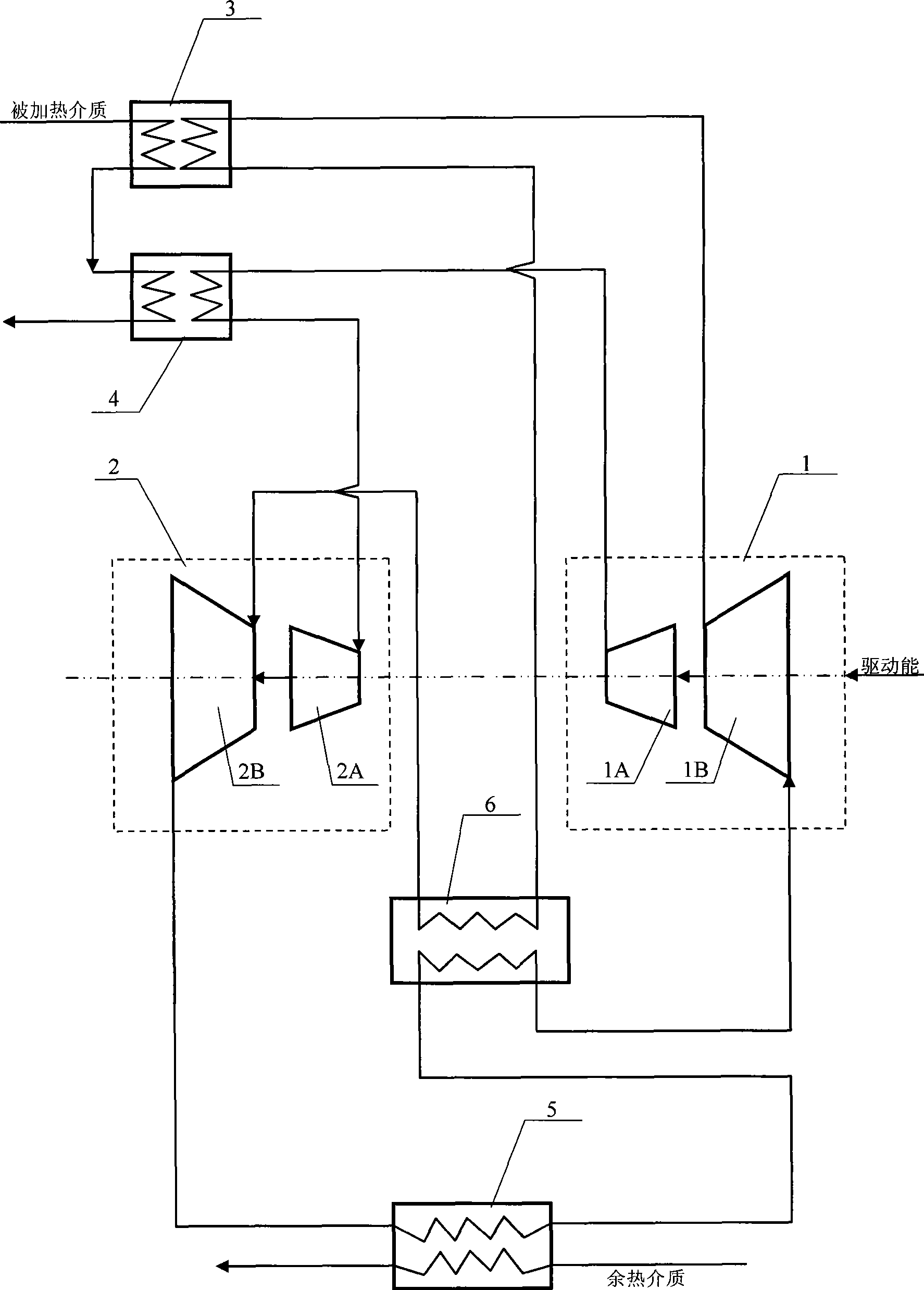

Segmented compression-segmented heat supply-segmented expansion gas compression type units

ActiveCN101504205AReduce power consumptionReduce the compression ratioCompression machines with non-reversible cycleSuperheatersPerformance indexEngineering

A subsection compression-subsection heat supply-subsection gas expanding compression type machine set belongs to the technical field of heat pumps / refrigeration, and consists of a compressor, an expander, a heat exchanger, a second heat exchanger and a low-temperature heat exchanger. Gas working substances absorbing heat from the low-temperature heat exchanger and raising temperature enter the compressor; after the gas working substances are compressed in a low pressure compression section, a part of the gas working substances are provided for the heat exchanger to complete the heating of a heated medium at an initial stage; the part of the gas working substances enter the expander and is expanded at a low pressure expansion section; the other part of the gas working substances are provided for the second heat exchanger to complete the heating of a second stage of the heated medium after continuously passing through the whole compression process and raising temperature, and enter the expander from an inlet of the high pressure expansion section of the expander for expanding; the gas working substances completing the expanding work flow through the low-temperature heat exchanger to absorb the heat and raise the temperature and enter the compressor; and a heat regenerator is added to form a regenerative machine set. The gas expanding compression type machine set reduces temperature difference of heat transmission and improves the performance index; when taken as a heat pump, the gas expanding compression type machine set is particularly suitable for occasions with high heating temperature and wide range; and when used for refrigeration, the gas expanding compression type machine set can reduce power consumption.

Owner:李华玉

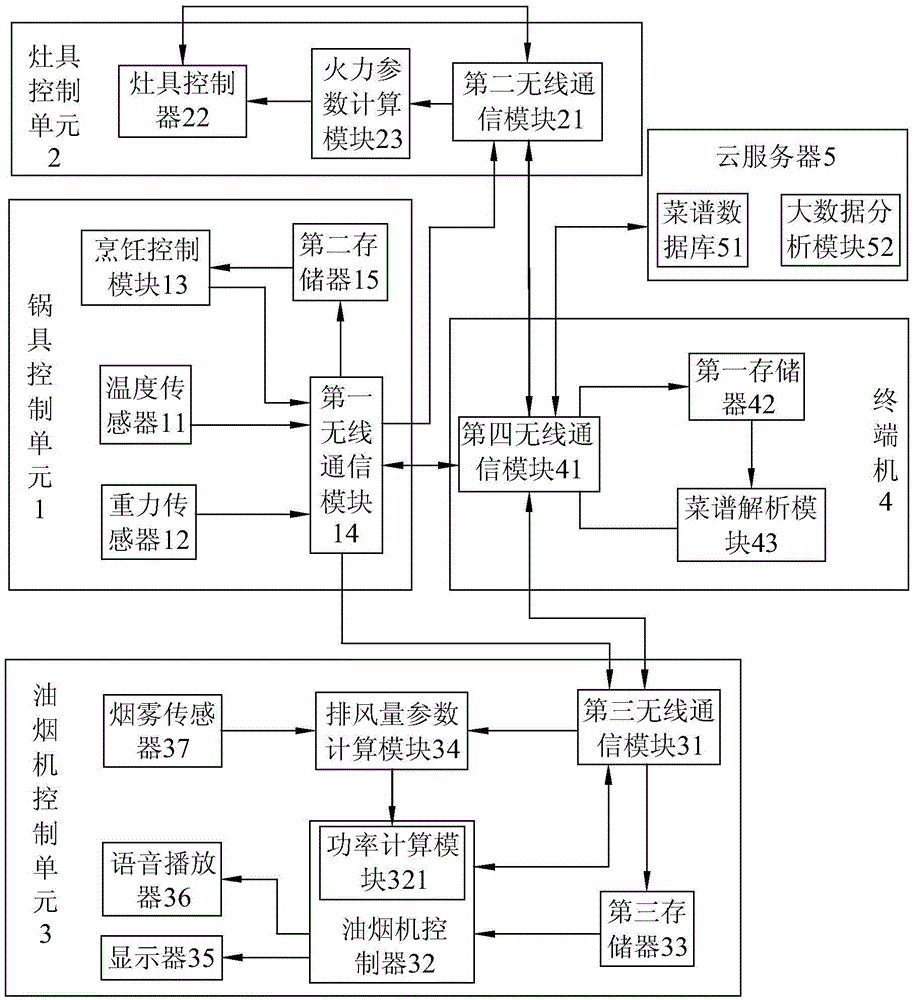

Intelligent cooking system and method

ActiveCN105652680AEnable direct communicationFine-tuning of firepowerComputer controlProgramme total factory controlControl engineeringControl cell

The invention relates to an intelligent cooking system. The intelligent cooking system comprises a pot control unit, a stove control unit and a range hood control unit, and the stove control unit and the range hood control unit are in communication with the pot control unit respectively. The intelligent cooking system further comprises a terminal and a cloud server. The terminal is in wireless communication with the pot control unit, the stove control unit, the range hood control unit and the cloud server. The invention further relates to an intelligent cooling method. The terminal can download cookbook data in the cloud server and transmit the date to the pot control unit so that cooking can be controlled. In the cooling process, the pot control unit can detect the weight of food placed in a pot and can also detect the heating temperature of the pot so that weight data and temperature data can be transmitted to the stove control unit and the range hood control unit, the fire power and the exhaust air rate can be flexibly and autonomously adjusted in real time, and the system can adapt to different food quantities. Meanwhile the terminal can be used for fine adjusting the fire power of a stove and the work power of a draught fan so that control over cooking can be more accurate.

Owner:ZHEJIANG AICHEN GRP CO LTD

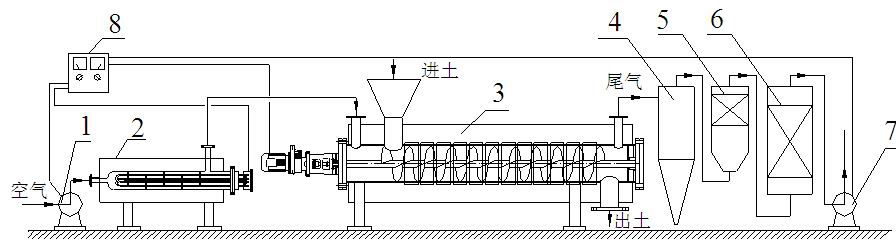

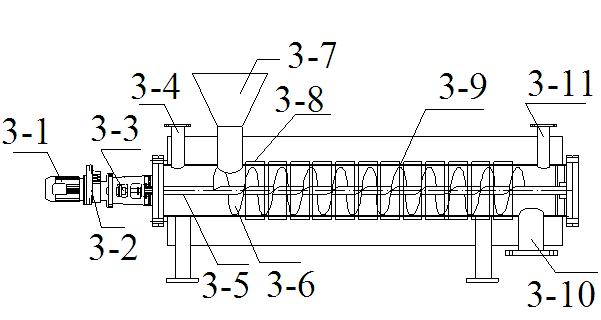

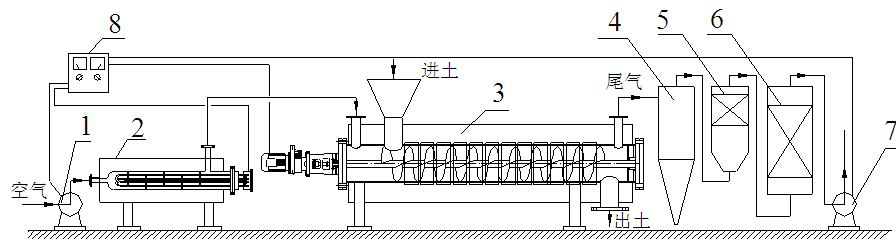

System for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption

ActiveCN101972773AEfficient repairRemediation of organic pollution is effectiveContaminated soil reclamationAgricultural engineeringCyclonic spray scrubber

The invention provides a system for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption, which comprises an air preheating system, a spiral stirring thermal desorption system, a tail gas treatment system and a control system, wherein the air preheating system consists of a blower and an air heater, the spiral stirring thermal desorption system consists of a spiral stirring thermal desorption device and a draft fan, the tail gas treatment system consists of a cyclone dust collector, a dehumidifier and an absorption tower, and the control system can realize the effective control of the rotation speed of a spiral stirrer, the air preheating temperature and the soil heating temperature. The system can be used for restoring soil contaminated by volatile / semi-volatile organic matters.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

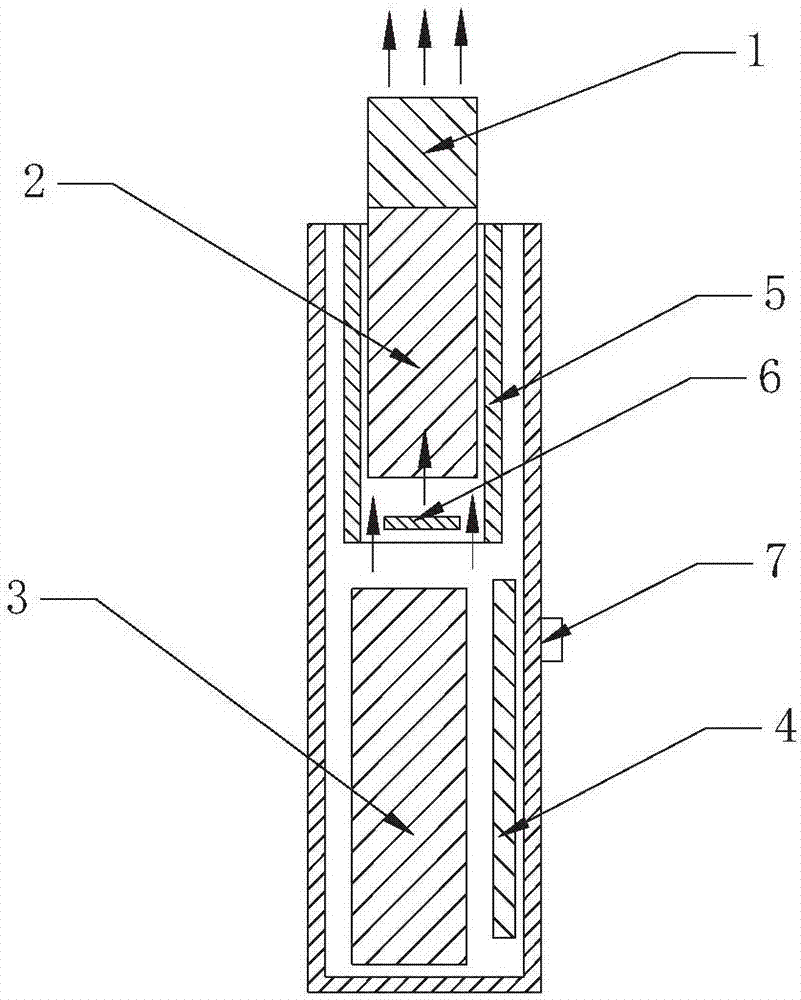

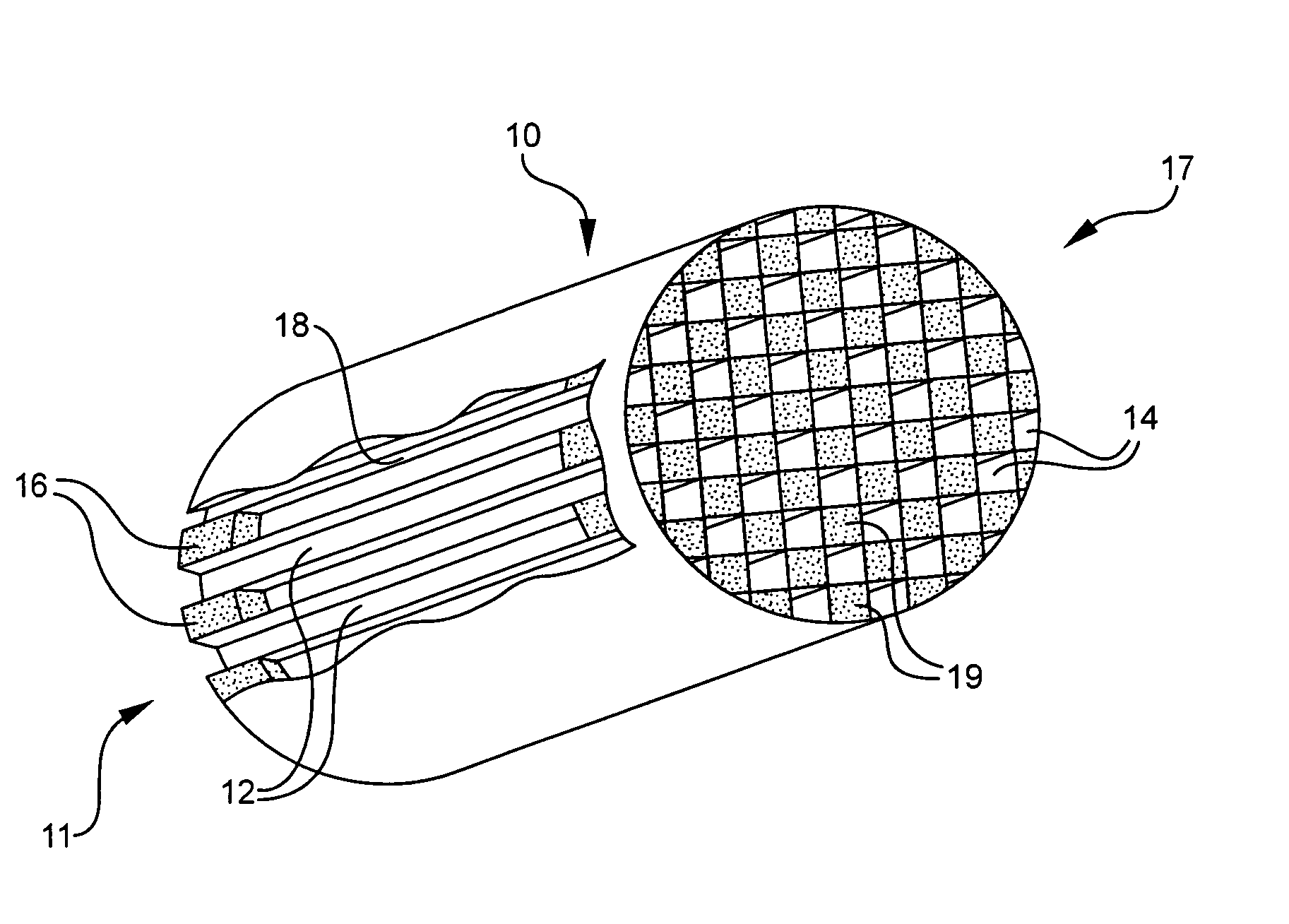

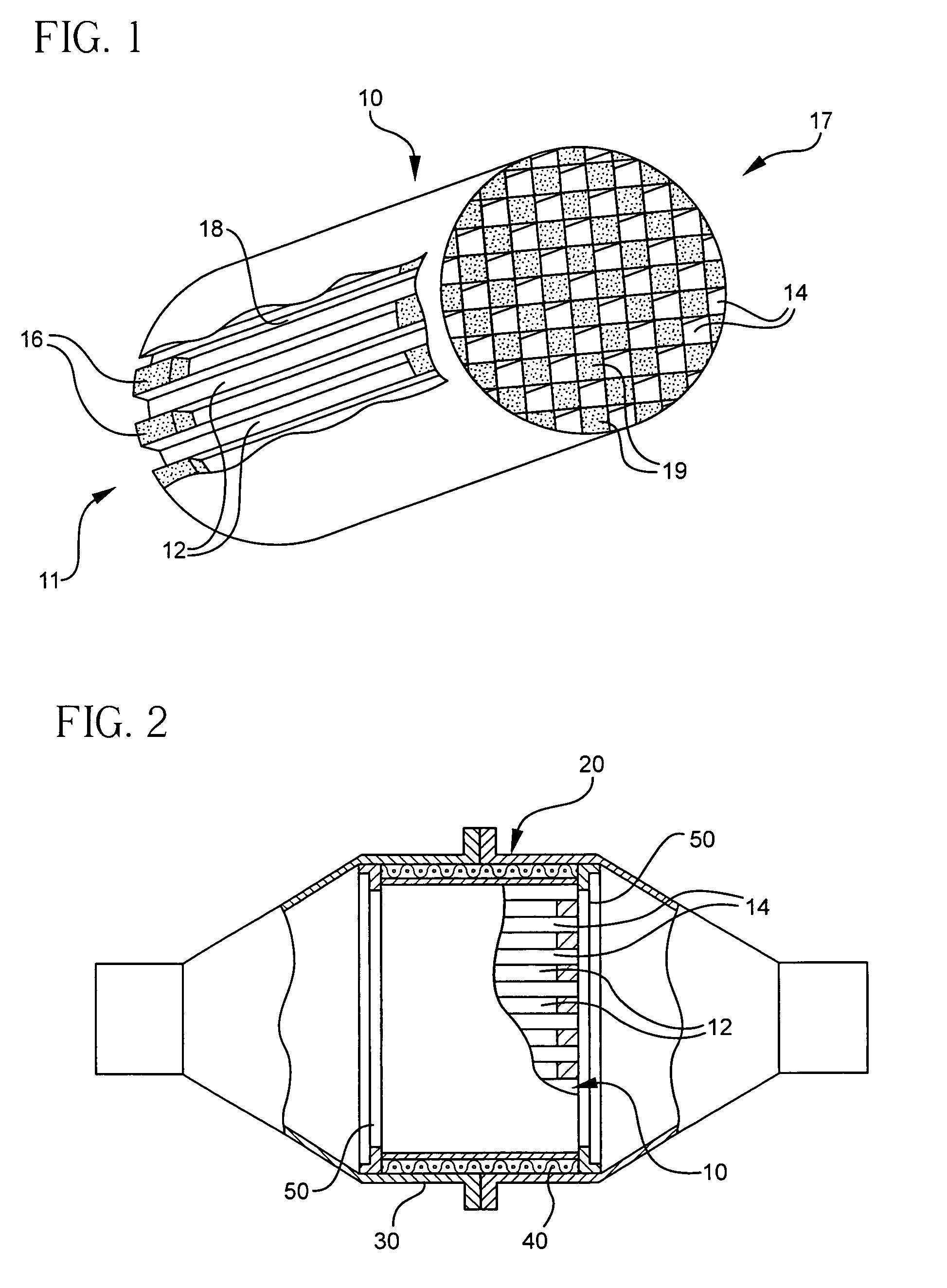

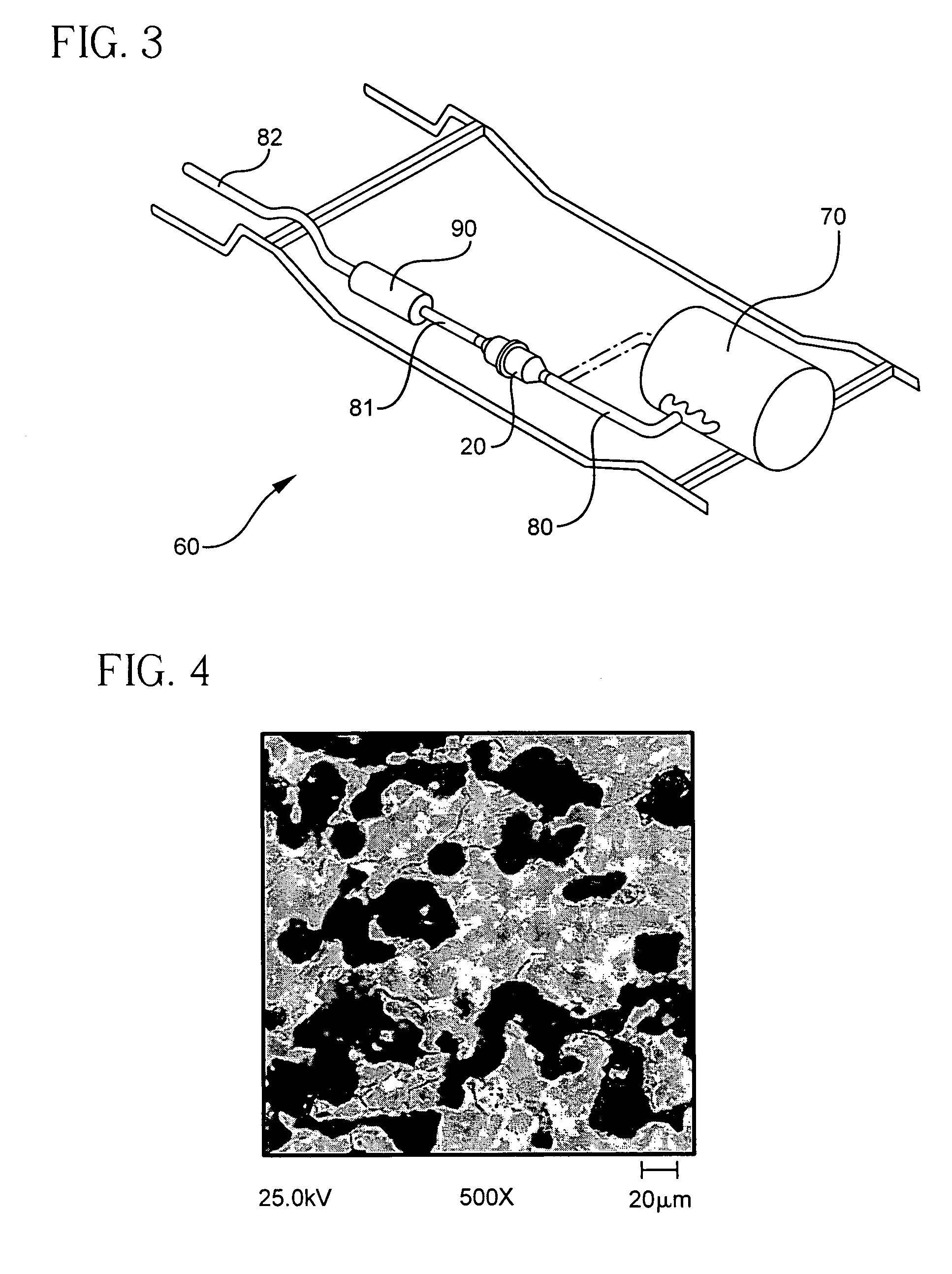

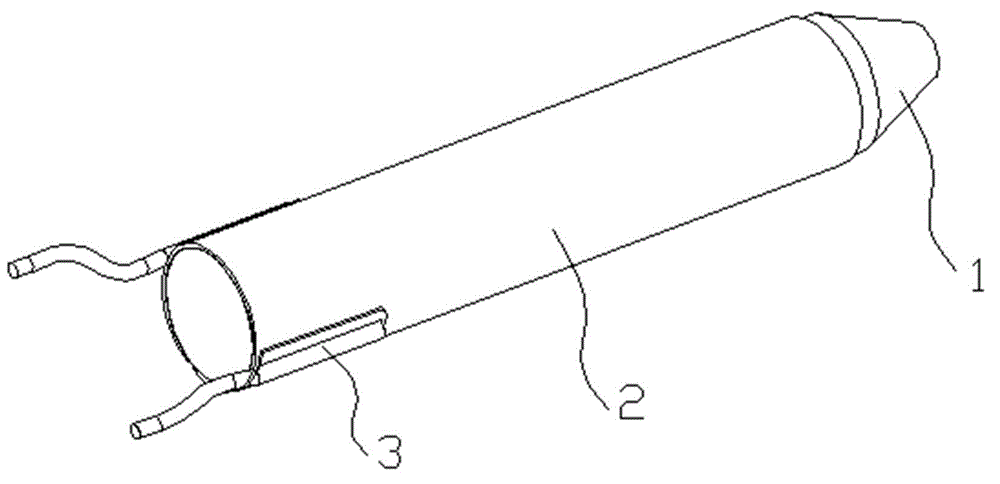

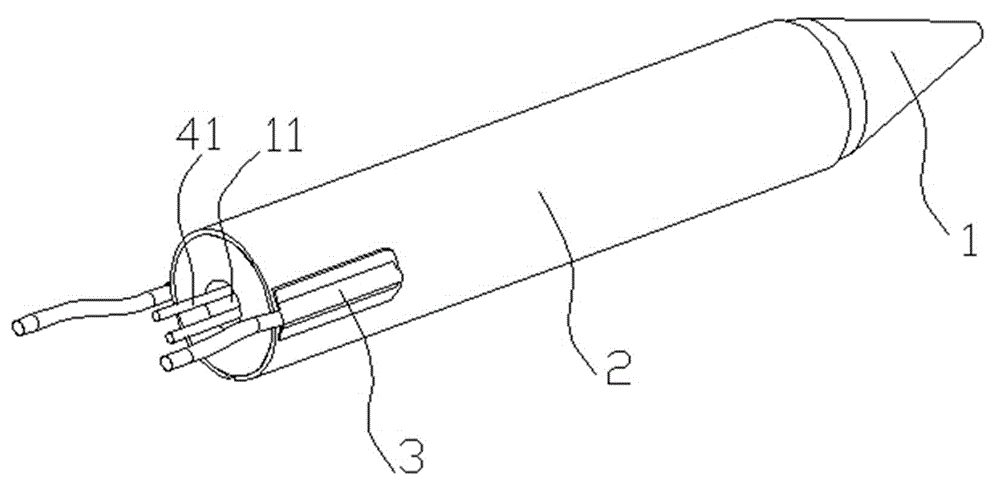

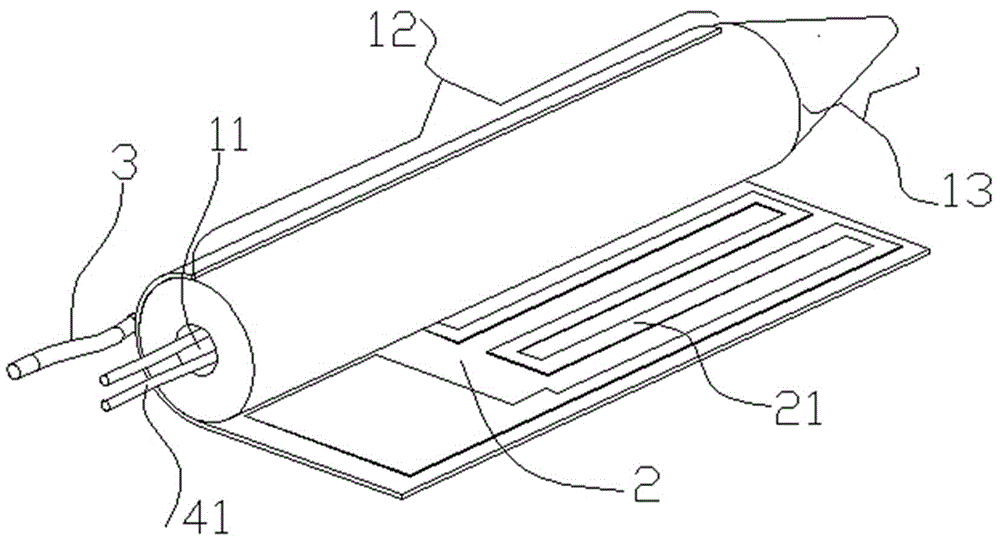

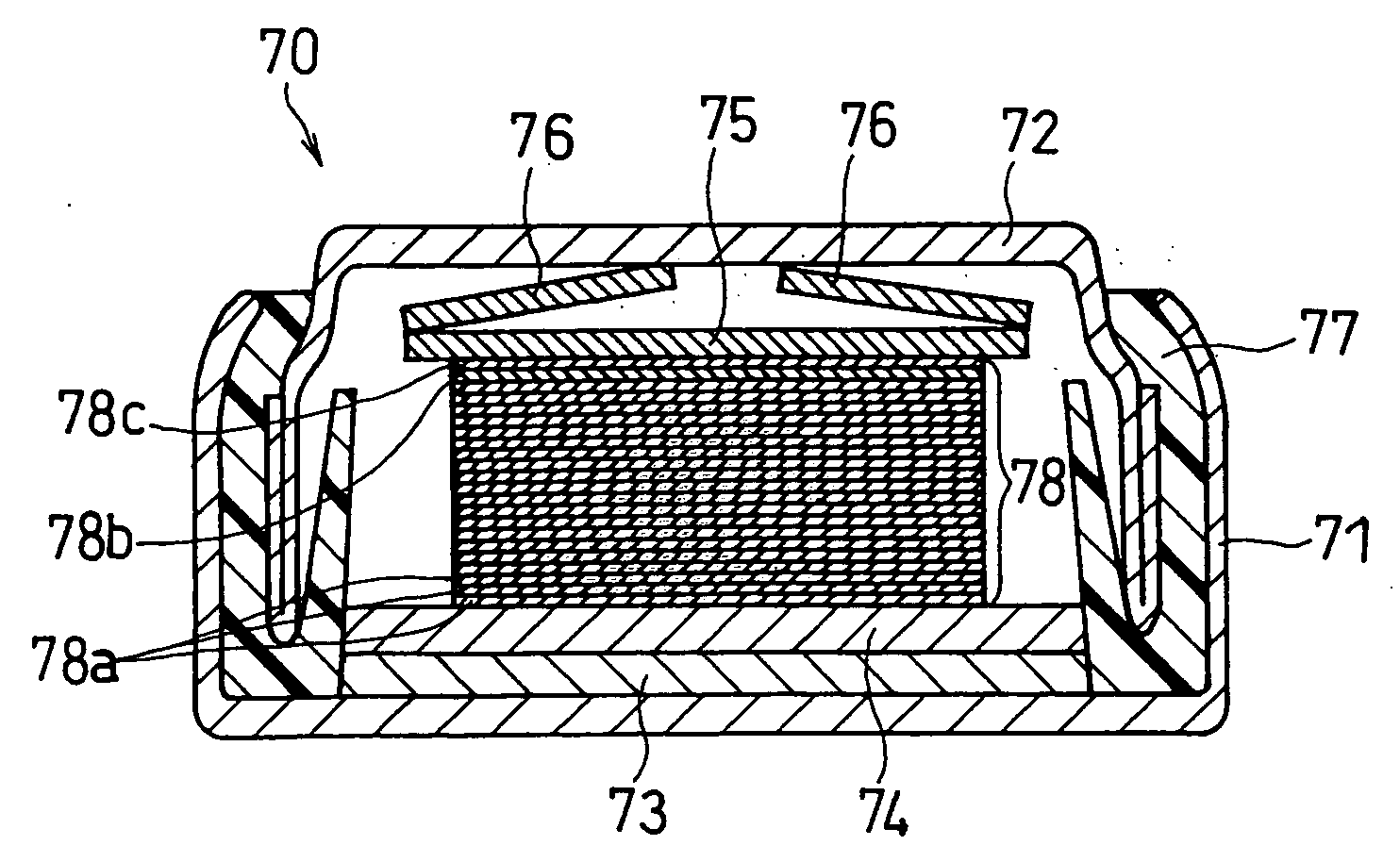

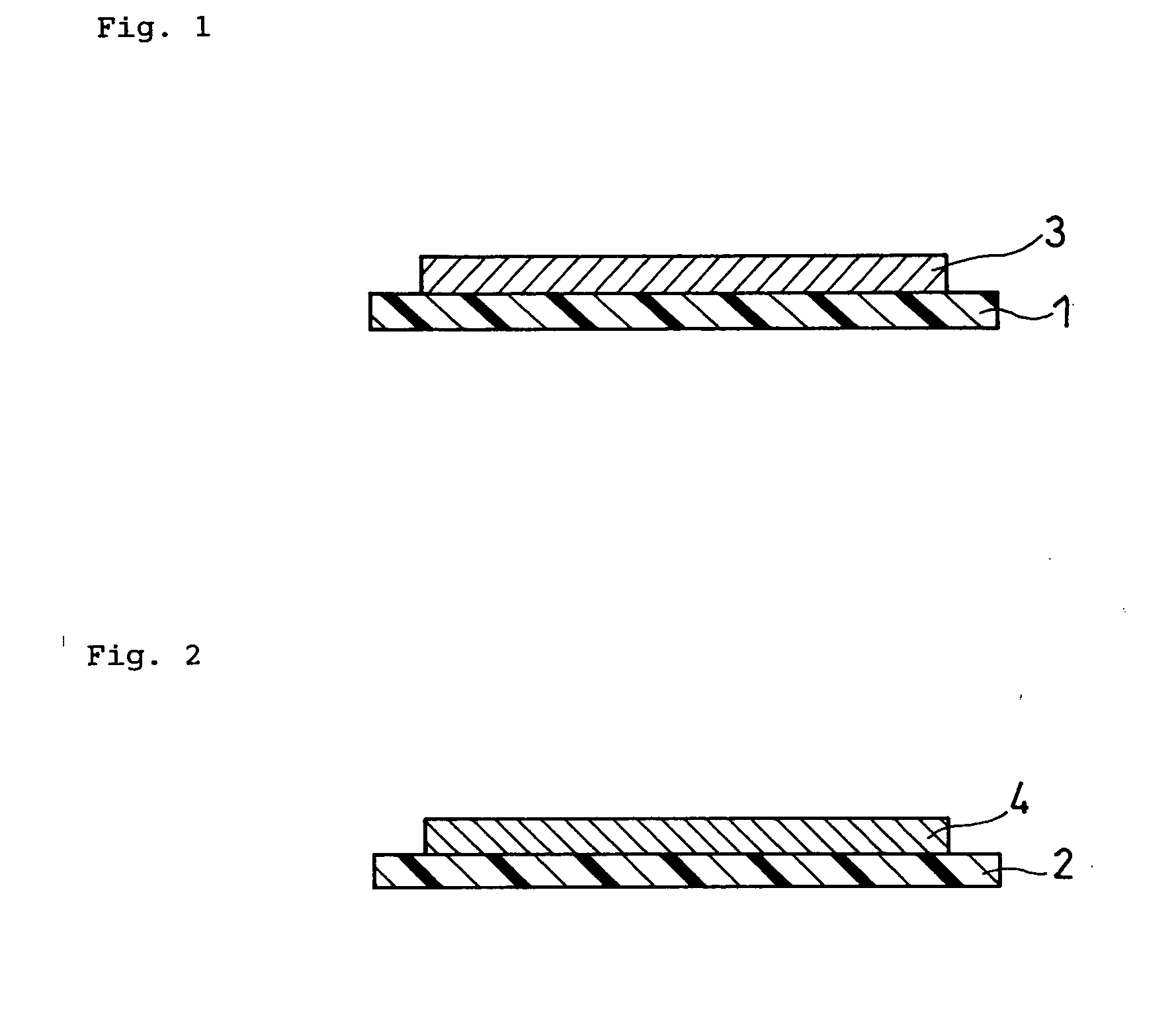

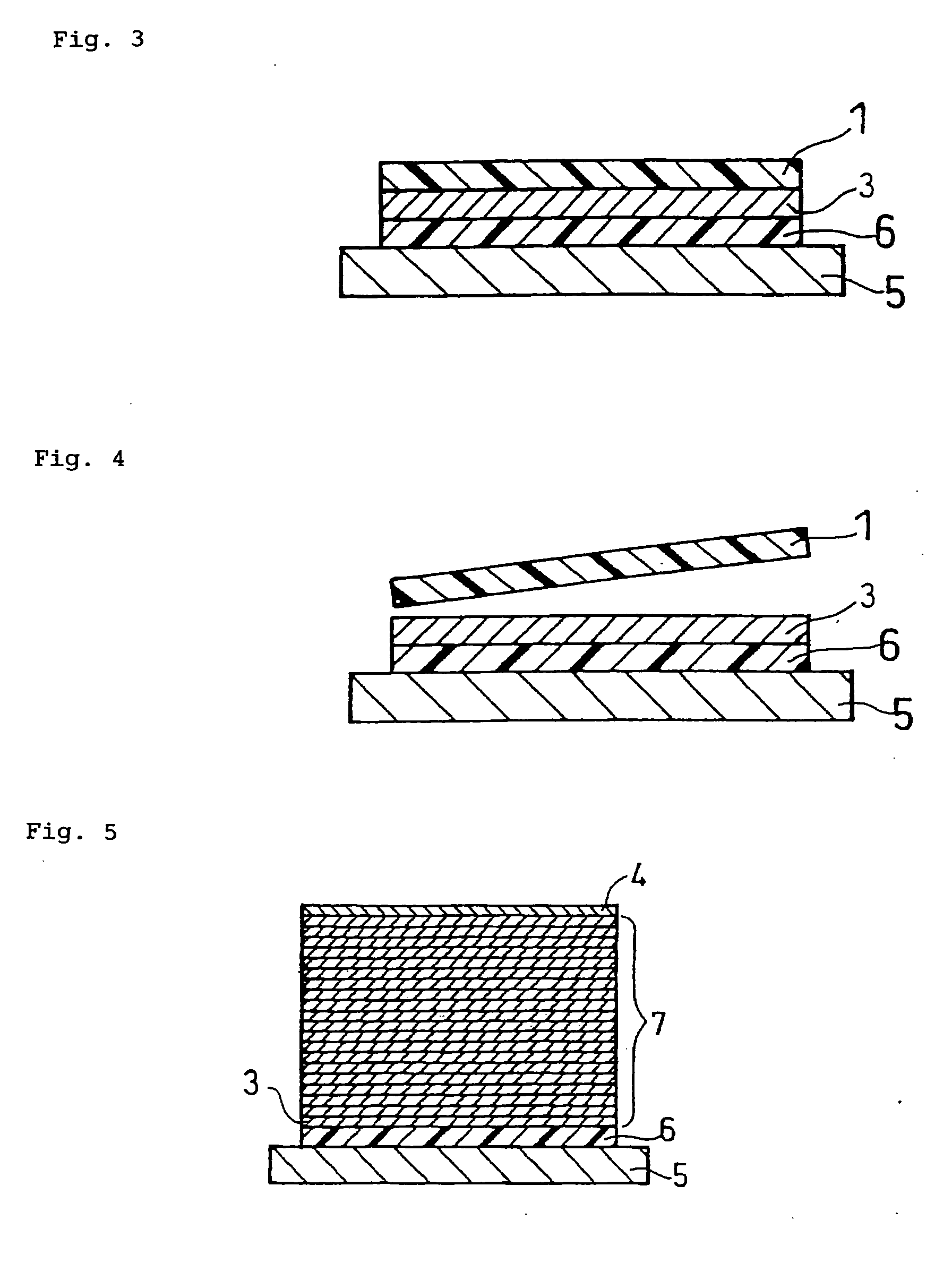

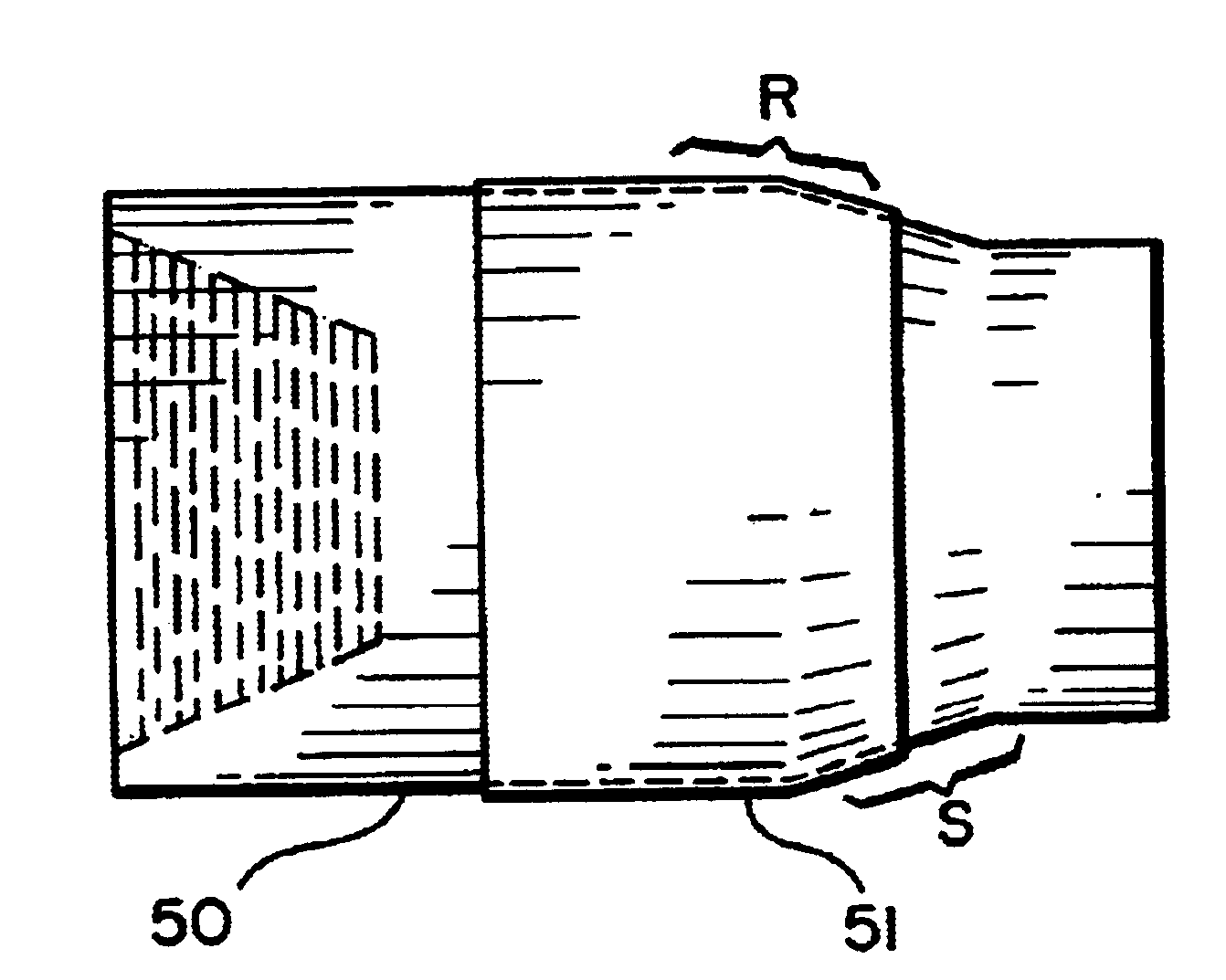

Electronic cigarette smoking set heater with low-temperature heating function

InactiveCN104799438AHigh control precisionRealize closed-loop controlTobacco devicesInsulation layerClosed loop

The invention discloses an electronic cigarette smoking set heater with a low-temperature heating function. The electronic cigarette smoking set heater comprises a core rod (1), an insulation layer (2), anode and cathode pins (3) and a temperature sensor (4), wherein the insulation layer (2) wraps the outer surface of the core rod (1) in a sintering manner; the anode and cathode pins (3) are connected with the insulation layer (2) which wraps the outer surface of the core rod (1); the temperature sensor (4) is embedded in a blind hole (11) which is formed in the tail end of the core rod (1); the rear end of the temperature sensor (4) is connected with pins (41) which extend out of the blind hole (11). The electronic cigarette smoking set heater can be conveniently inserted into core parts of tobacco products for heating; meanwhile, the temperature sensor can be embedded into the core part of the heater for realizing closed-loop control on temperatures; the control precision of an electronic cigarette smoking set heater with a low-temperature heating function on the heating temperature of the tobacco products can be improved.

Owner:云南云智数字科技有限公司

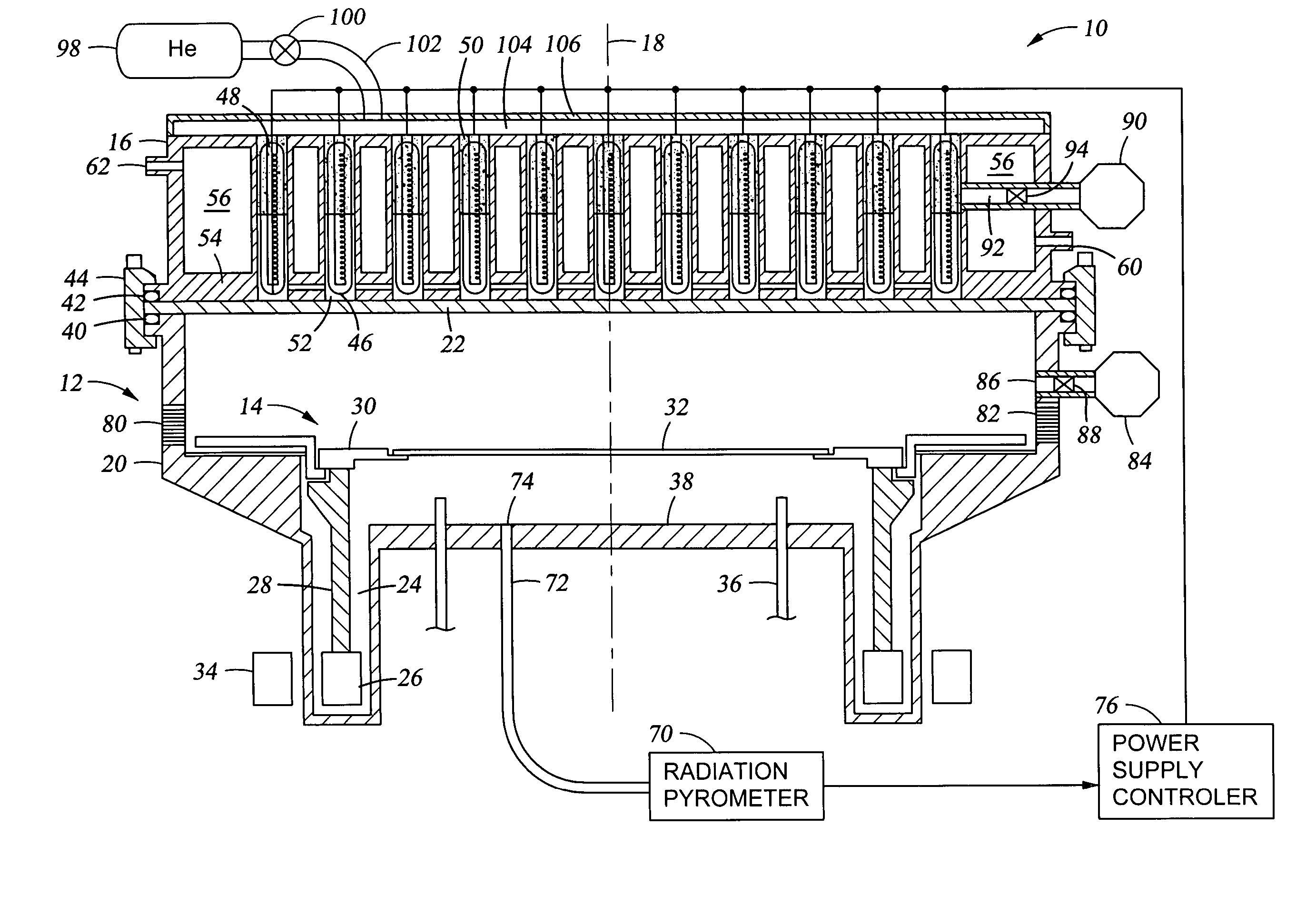

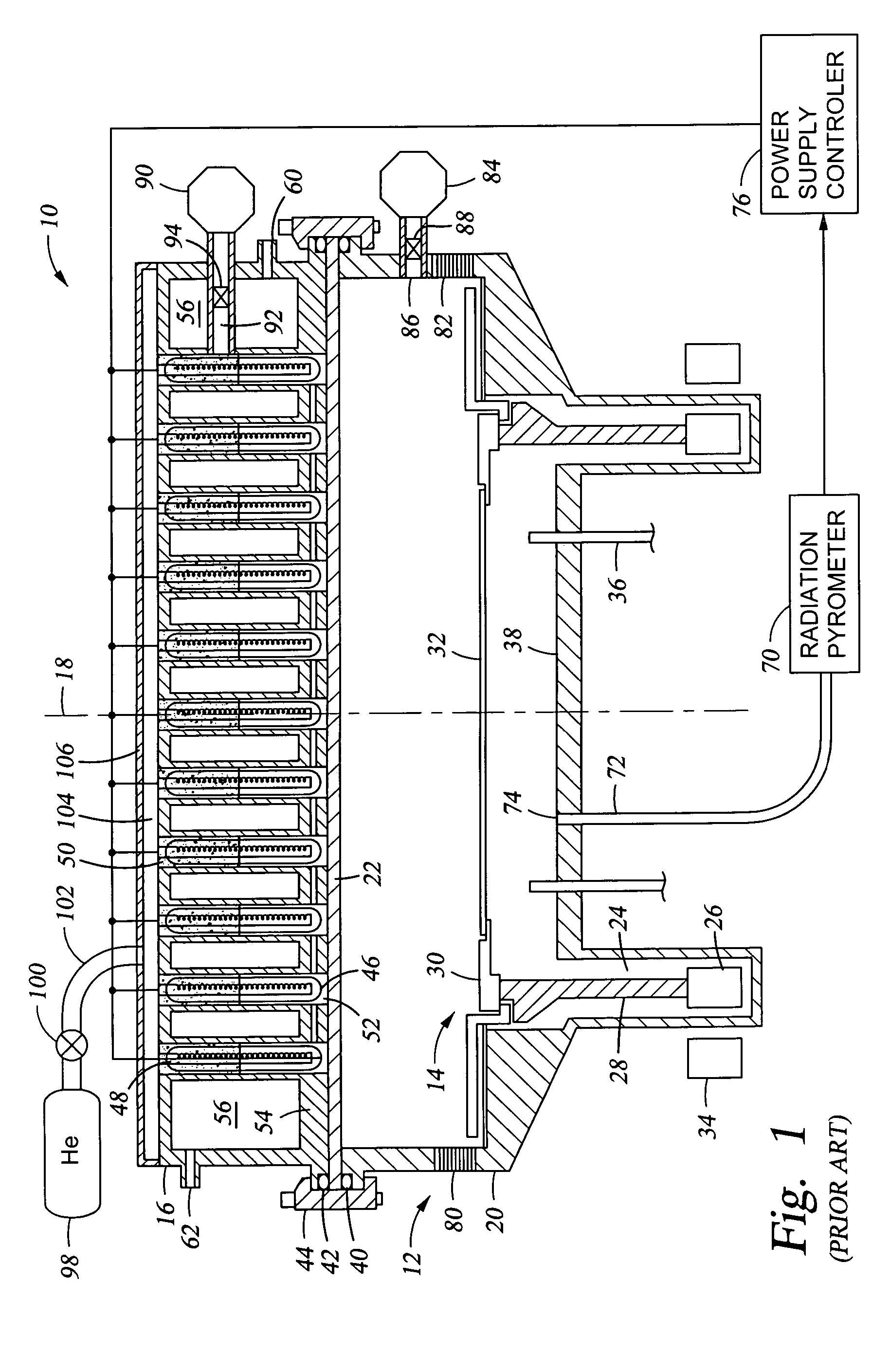

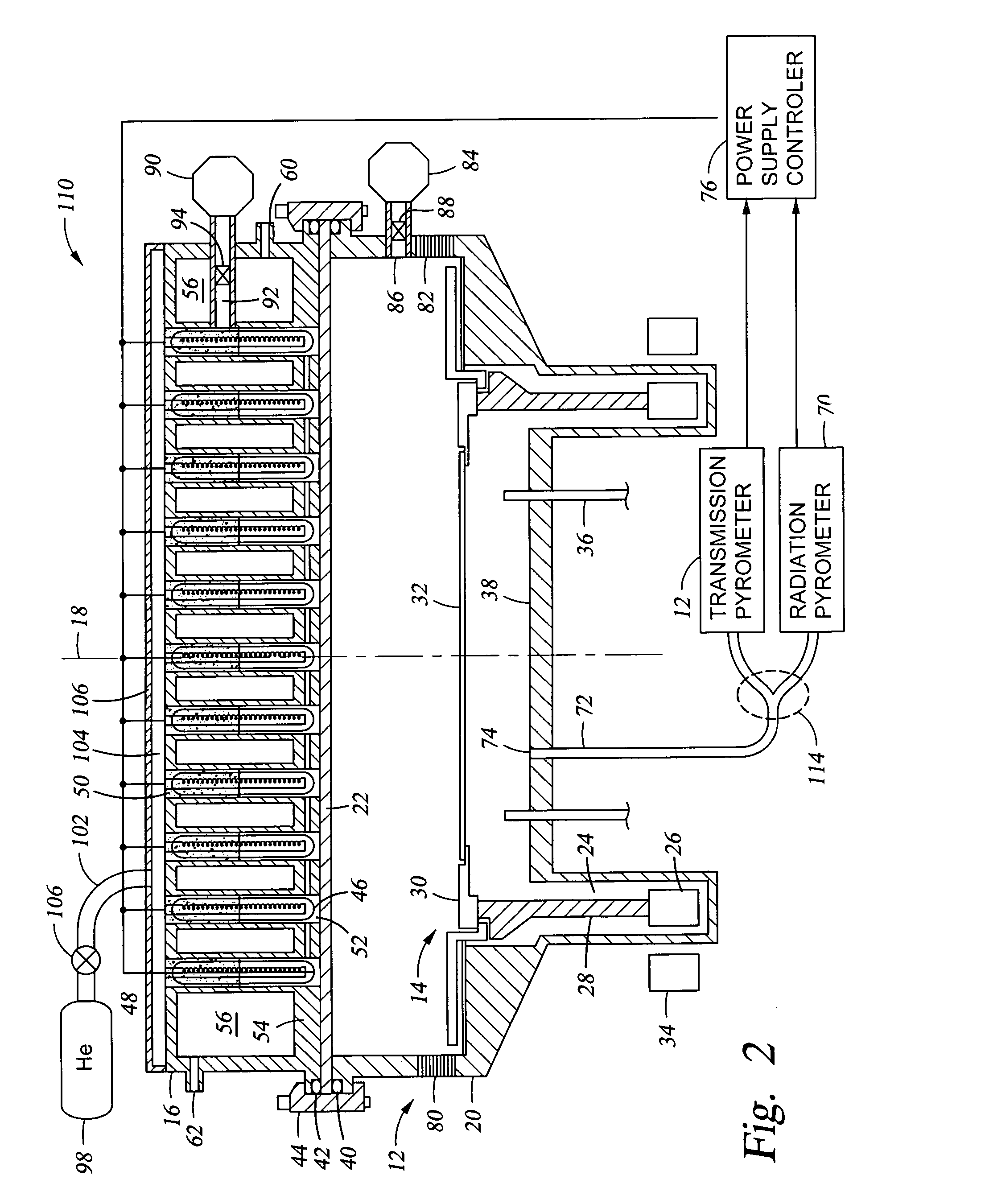

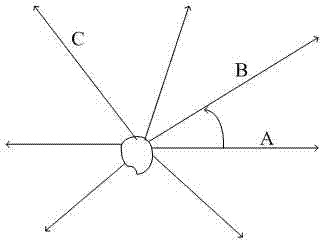

Method and apparatus for low temperature pyrometry useful for thermally processing silicon wafers

A rapid thermal processing (RTP) system including a transmission pyrometer monitoring the temperature dependent absorption of the silicon wafer for radiation from the RTP lamps at a reduced power level. A look-up table is created relating unnormalized values of photodetector photocurrents with wafer and radiant lamp temperatures. A calibrating step measures the photocurrent with known wafer and lamp temperatures and all photocurrents measured thereafter are accordingly normalized. The transmission pyrometer may be used for closed loop control for thermal treatments below 500° C. or used in the pre-heating phase for a higher temperature process including radiation pyrometry in closed loop control. The pre-heating temperature ramp rate may be controlled by measuring the initial ramp rate and readjusting the lamp power accordingly. Radiation and transmission pyrometers may be included in an integrated structure with a beam splitter dividing radiation from the wafer.

Owner:APPLIED MATERIALS INC

High strength cold-rolled plate with excellent formability and production method thereof

The invention provides a high strength cold-rolled plate with excellent formability, containing: no more than 0.0040% of C, 0.02-0.15% of Si, 0.20-1.00% of Mn, 0.02-0.09% of P, 0.015-0.06% Ti, 0.01-0.05% of Nb, and the rest being Fe. The production method comprises: smelting, continuous casting, hot-rolling, cold rolling and continuous annealing, wherein the heating temperature of the hot-rolled billet is 1170-1270 DEG C, the finishing temperature of hot-rolling is 850-960 DEG C, and the coiling temperature is 650-760 DEG C; the cold rolling reduction percent is 60-82%; the annealing temperature is 760-880 DEG C, the thermal insulation time is 60-210s, the slow-cooling segment temperature is 630-700 DEG C, and the fast-cooling exit temperature is 300-500 DEG C; and the levelling elongationrate is 0.5-1.0%. The high strength steel plate containing phosphorus of the invention has the features of low carbon, microalloying and purity. The steel added with a certain amount of Nb and Ti hashigher plasticity. Using relevant rolling and annealing technique, the indexes of performance of the steel achieves the demand of high strength automobile stamping parts.

Owner:ANGANG STEEL CO LTD

High-strength cold rolling transformation induced plasticity steel plate and preparation method thereof

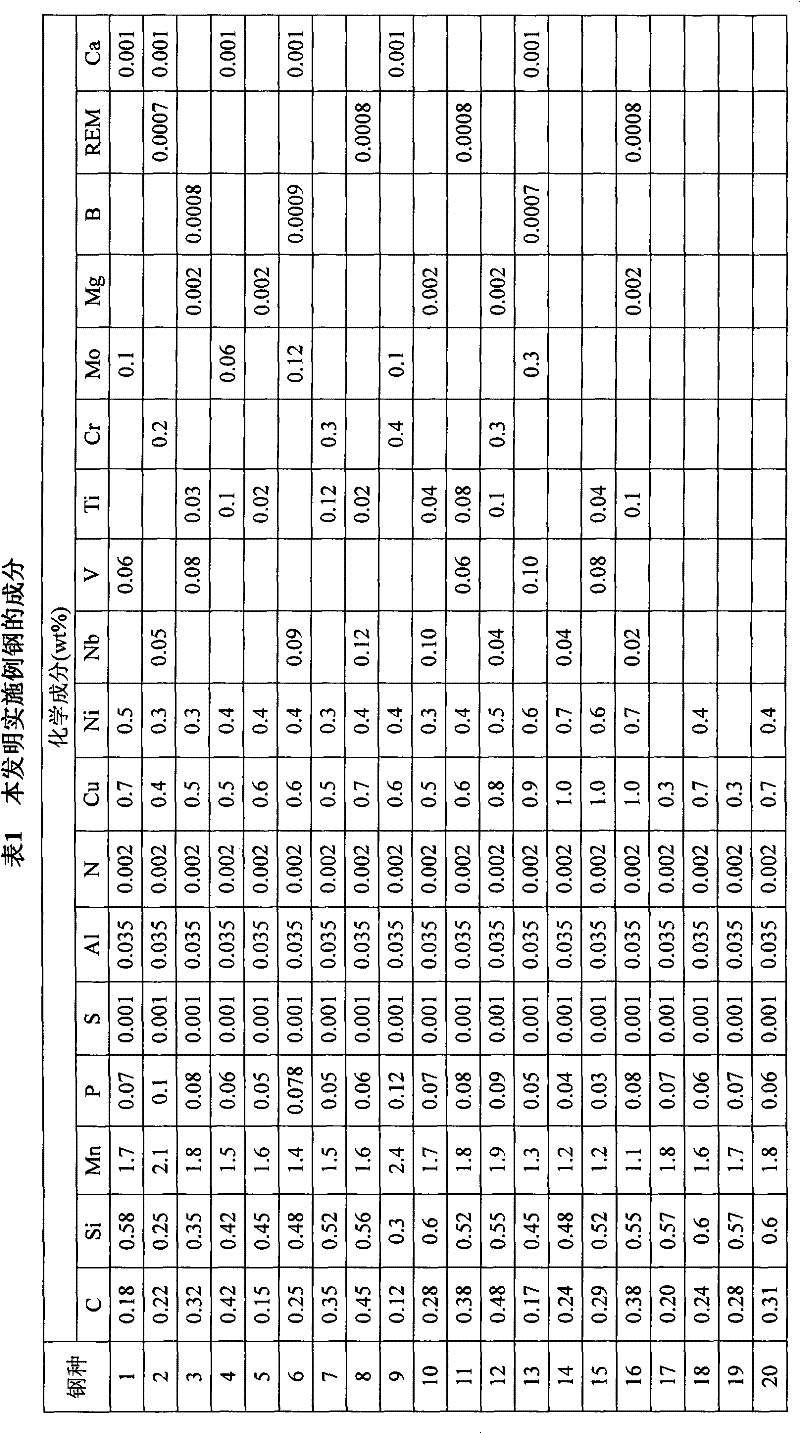

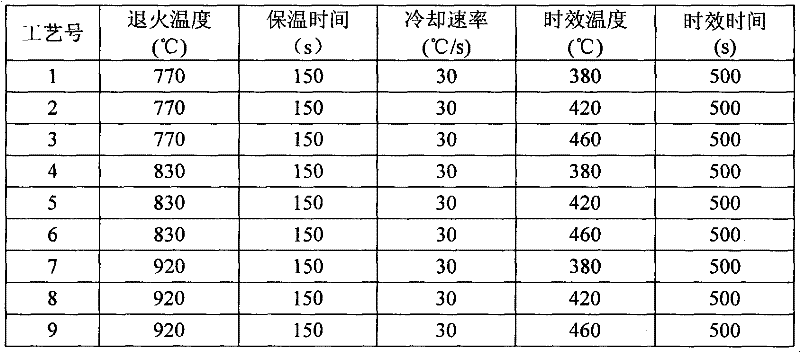

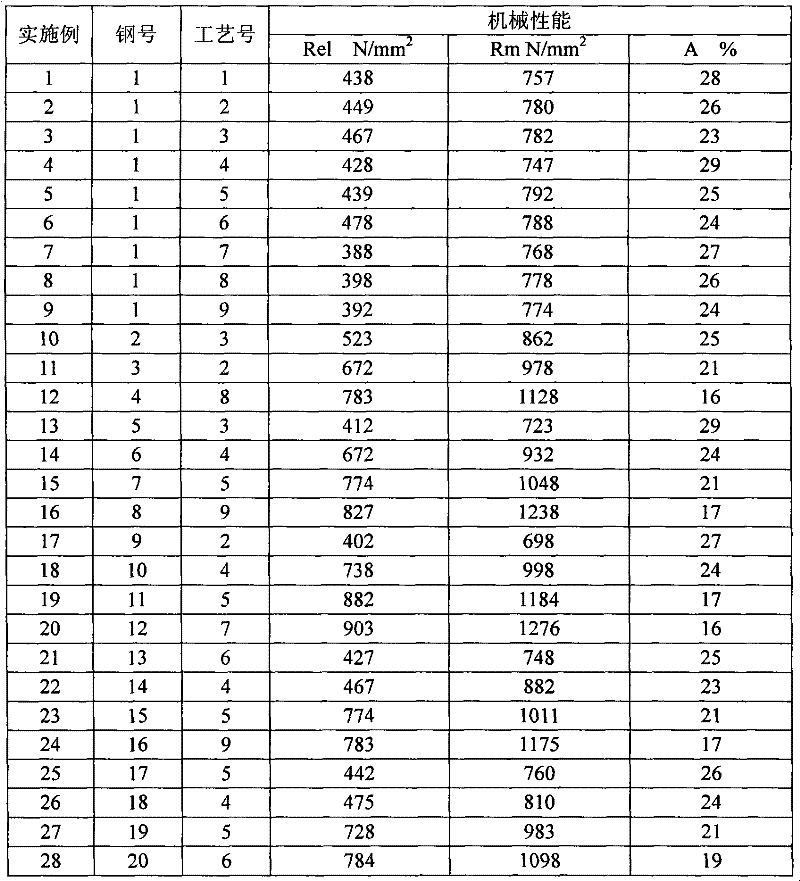

InactiveCN102409235ASolve Surface Quality IssuesSolve the blockageTemperature control deviceFurnace typesSheet steelRoom temperature

The invention provides a high-strength cold rolling transformation induced plasticity steel plate and a preparation method thereof. The high-strength cold rolling transformation induced plasticity steel plate comprises the following components by weight percentage: 0.1%-0.5% of C, 0.1%-0.6% of Si, 0.5%-2.5% of Mn, 0.02%-0.12% of P, less than or equal to 0.02% of S, 0.02%-0.5% of Al, less than or equal to 0.01% of N, 0.1%-1.0% of Cu and the rest Fe. The preparation method comprises the following steps of: (a) refining molten steel meeting a component condition, and casting into a blank; (b) rolling, wherein the heating temperature is 1,100-1,250 DEG C, the heat preservation time is 1-4h, the initial rolling temperature is 1,100 DEG C, the final rolling temperature is 750-900 DEG C, the coiling temperature is less than 700 DEG C, the thickness of a hot rolled steel plate is 2-4mm, and the cold rolling accumulated pressing amount is 40-80%; and (c) continuous annealing, wherein the annealing temperature is 700-Ac3+50 DEG C, the heat preservation time is 30-360s, the cooling speed is 10-150 DEG C / s, the aging temperature is 250-600 DEG C, the aging time is 30-1,200s, and the hot roller steel plate is cooled at the speed of 5-100DEG C / s to be at the room temperature. The steel plate disclosed by the invention has the bending strength of 380-1,000 MPa, tensile strength of 680-1,280 MPa and elongation of 15-30%.

Owner:ANGANG STEEL CO LTD

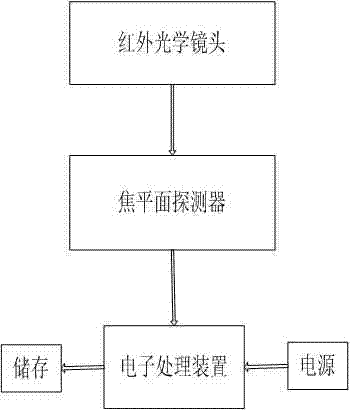

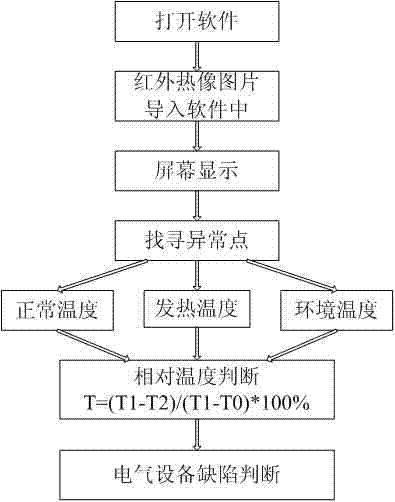

Infrared image automatic fault identifying method for high-voltage equipment

ActiveCN102928742AAutomatic identification of red hot faultsRadiation pyrometryFault locationImaging processingTemperature difference

The invention discloses an infrared image automatic fault identifying method for high-voltage equipment. Firstly, electric equipment in need of detection is selected and a temperature image of the electric equipment is obtained; secondly, a heating point, heating a point temperature T1 and a normal phase temperature T2 of the electric equipment are obtained through processing of the temperature image; thirdly, a relative temperature is calculated in combination with an environment reference temperature T0 to judge a running condition and fault information of the electric equipment. In the infrared image automatic fault identifying method for the high-voltage equipment, the running condition and the fault information of the electric equipment on a high-voltage transmission wire are monitored on the basis of an infrared image processing technology, a temperature heating abnormal point is detected according to an infrared temperature image processing technology, a heating temperature, a normal temperature, an environment temperature and the relative temperature of an abnormal point are calculated and then the running condition and the fault information of the electric equipment are automatically judged according to a relative temperature difference judging method; in this case, quick on-line detection of the running condition of the electric equipment is realized.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

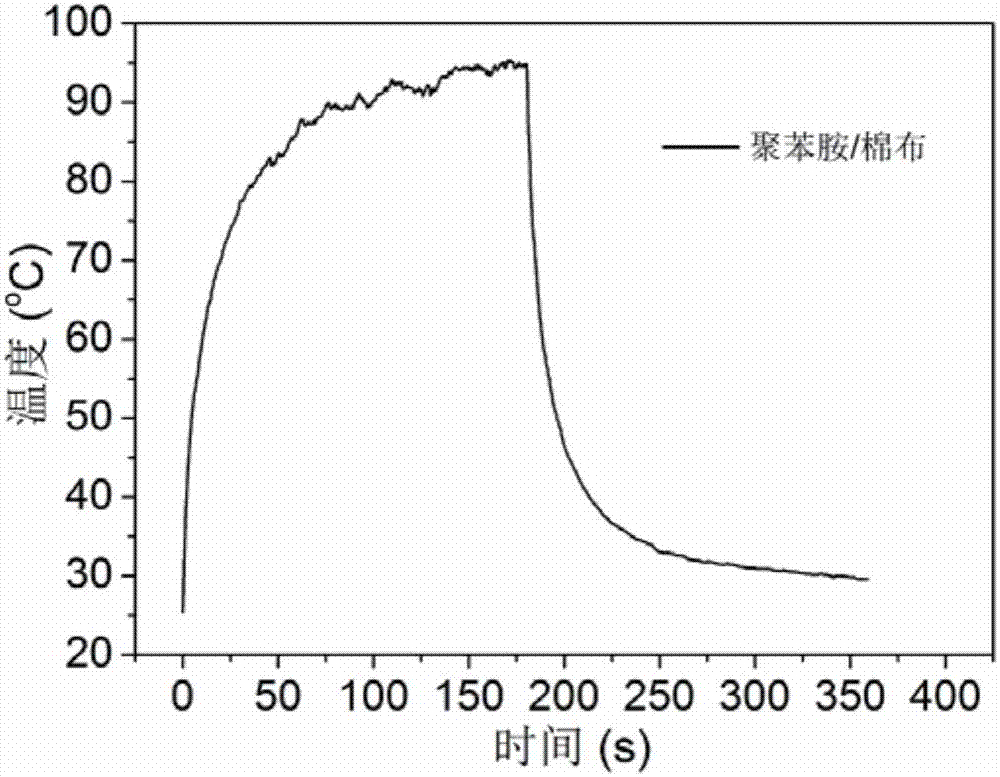

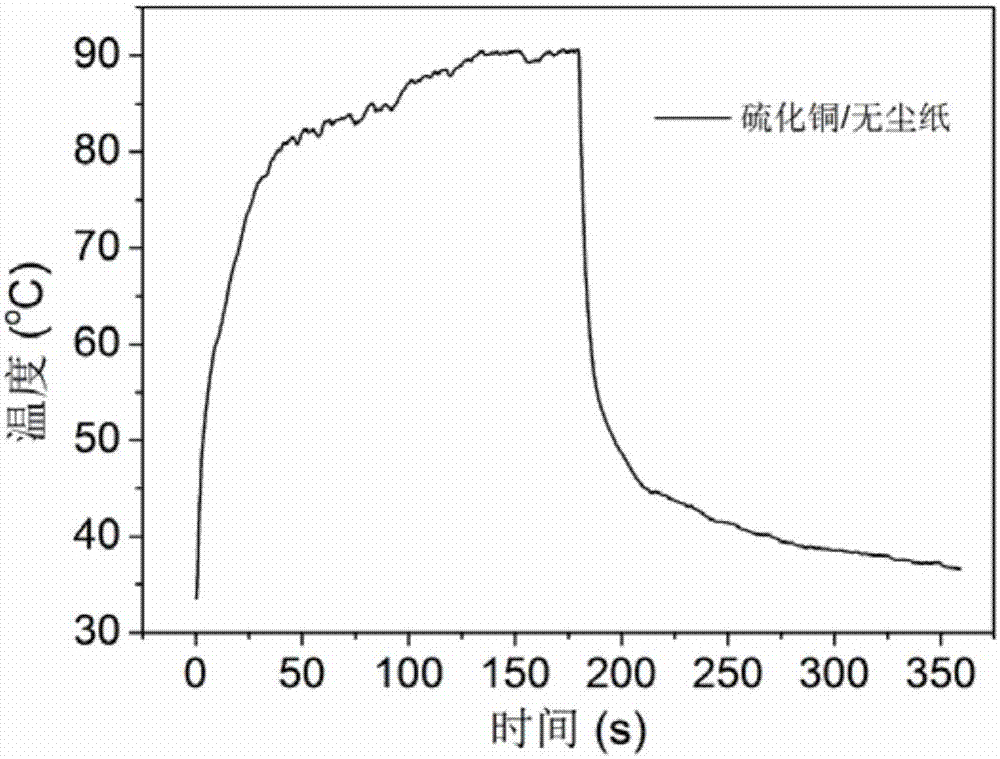

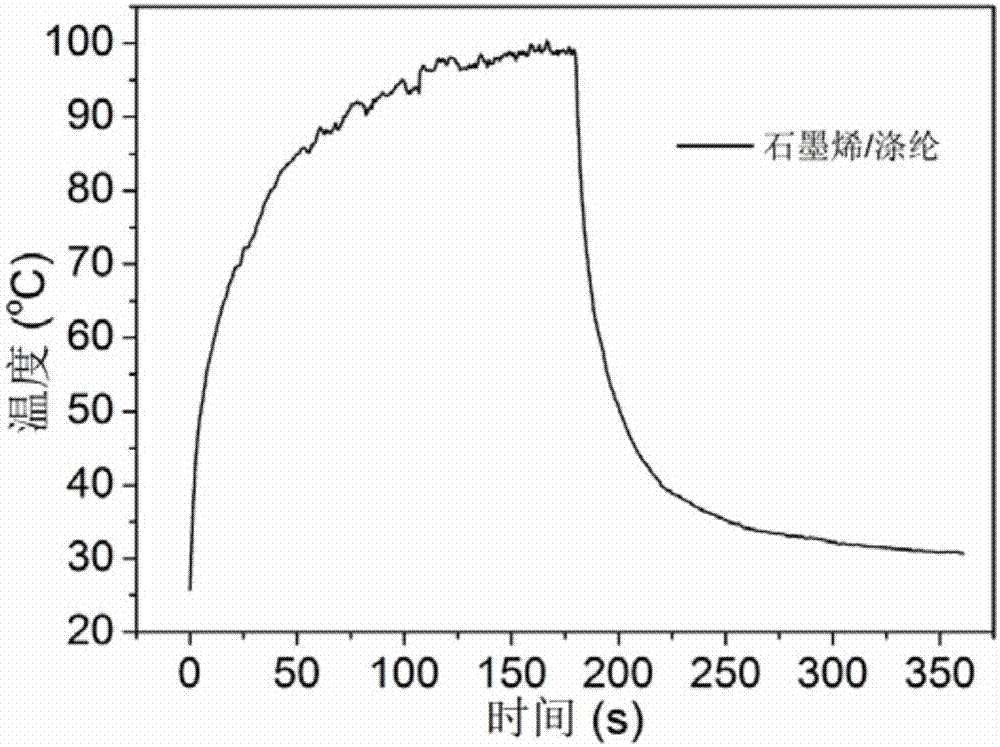

Method for preparing photothermal conversion textile

InactiveCN106958141AImprove photothermal efficiencyImprove mechanical propertiesVegetal fibresAnimal fibresPhotothermal conversionEngineering

The invention relates to a method for preparing a light-to-heat conversion fabric. The light-to-heat conversion fabric uses the fabric as a matrix to attach photothermal nanomaterials to the surface of the fabric matrix. The method includes the following steps: dispersing the photothermal nanomaterials into a solvent to obtain light thermal nanometer material dispersion liquid; uniformly distributing the photothermal nanometer material dispersion liquid on the fabric substrate; drying to obtain light heat conversion fabric. The invention expands the photothermal nano-material from the solution to the surface of the fabric, has the characteristics of rapid temperature rise and high temperature rise, greatly improves the application range, simple operation, mild conditions, low cost, and the obtained photothermal conversion fabric has high photothermal efficiency , with good mechanical properties, it is expected to have great application value in the fields of winter heating, a new generation of solar thermal insulation clothing, new solar heating equipment and new solar desalination.

Owner:DONGHUA UNIV

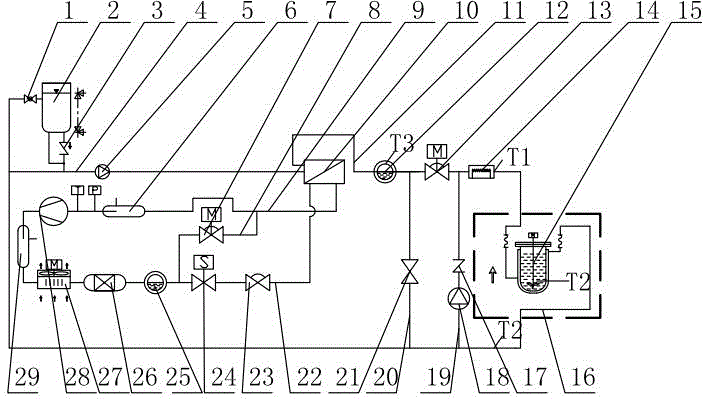

High-heat-discharge-quantity refrigerating and heating temperature control system for reaction kettle

ActiveCN103983041ACompact structureReasonable structureMechanical apparatusEfficient regulation technologiesExpansion tankVapor–liquid separator

The invention relates to a high-heat-discharge-quantity refrigerating and heating temperature control system for a reaction kettle. The high-heat-discharge-quantity refrigerating and heating temperature control system comprises a reaction kettle, wherein one end of the reaction kettle is sequentially connected with a heating pipe, an electric proportioning regulating valve, a first cold storage tank and an evaporation heat exchanger through a fourth pipeline, the output end of the evaporation heat exchanger is sequentially connected with a first circulation pump, a first one-way valve, an expansion tank and an exhaust valve through a first pipeline, the exhaust valve is connected to the other end of the reaction kettle through a fifth pipeline, the two ends of the evaporation heat exchanger are connected with a refrigerating machine, the refrigerating machine is structurally characterized in that one end of the evaporation heat exchanger is sequentially connected in series with a gas-liquid separator, a compressor, an oil separator, a condenser, a drying filter, a second cold storage tank, an electromagnetic valve and an expansion valve through a third pipeline, the outer end of the expansion valve is connected with the other end of the evaporation heat exchanger through an eighth pipeline, the refrigerating machine is positioned between the electromagnetic valve and the second cold storage tank and is connected with the third pipeline through the second pipeline, and an electronic expansion valve is arranged on the second pipeline. The work reliability is good.

Owner:WUXI GUANYA REFRIGERATION TECH

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

Method for producing solid state battery

A method for producing a solid state battery including the steps of: (a) obtaining an active material slurry; (b) obtaining a solid electrolyte slurry; (c) obtaining a current collector slurry; (d) forming an active material green sheet and a solid electrolyte green sheet; (e) laminating the solid electrolyte green sheet on one surface of the active material green sheet to form a first green sheet group, and forming a current collector green sheet layer on the other surface of the active material green sheet to form a second green sheet group; (f) heating the second green sheet group at not less than 200° C. and not greater than 400° C. in an oxidizing atmosphere; and (g) baking the second green sheet group having heated in the step (f) in a low oxygen atmosphere at a baking temperature higher than the heating temperature in the step (f) to obtain a laminate.

Owner:PANASONIC CORP

Intelligent infusion device

ActiveCN104784771AMonitor drop rateRealize automatic integrationFlow monitorsLiquid temperatureAutomatic control

The invention discloses an intelligent infusion device. The intelligent infusion device comprises an infusion bottle control mechanism, a puncture outfit mechanical arm mechanism, an infusion liquid dynamic monitoring mechanism, an infusion liquid temperature control mechanism, an automatic needle plugging and unplugging mechanism, a central control station and a central control unit. The central control unit corresponds to the puncture outfit mechanical arm mechanism, the liquid dynamic monitoring mechanism, the liquid temperature control mechanism and the automatic needle plugging and unplugging mechanism. The intelligent infusion device has the advantage that automatic integration in the infusion process can be achieved, which is concretely embodied in that an infusion bottle can be automatically changed; infusion dripping speed, flowing speed and liquid bubbles are monitored, the infusion dripping speed and flowing speed are controlled, and the bubbles are eliminated in time; in the infusion process, an infusion tube is heated, and heating temperature is automatically controlled; through control of mechanical arms, automatic needle plugging and unplugging are achieved; the central receiver controls controllers of all units, so that control over all stages in the infusion process is achieved.

Owner:深圳文健医疗科技有限公司

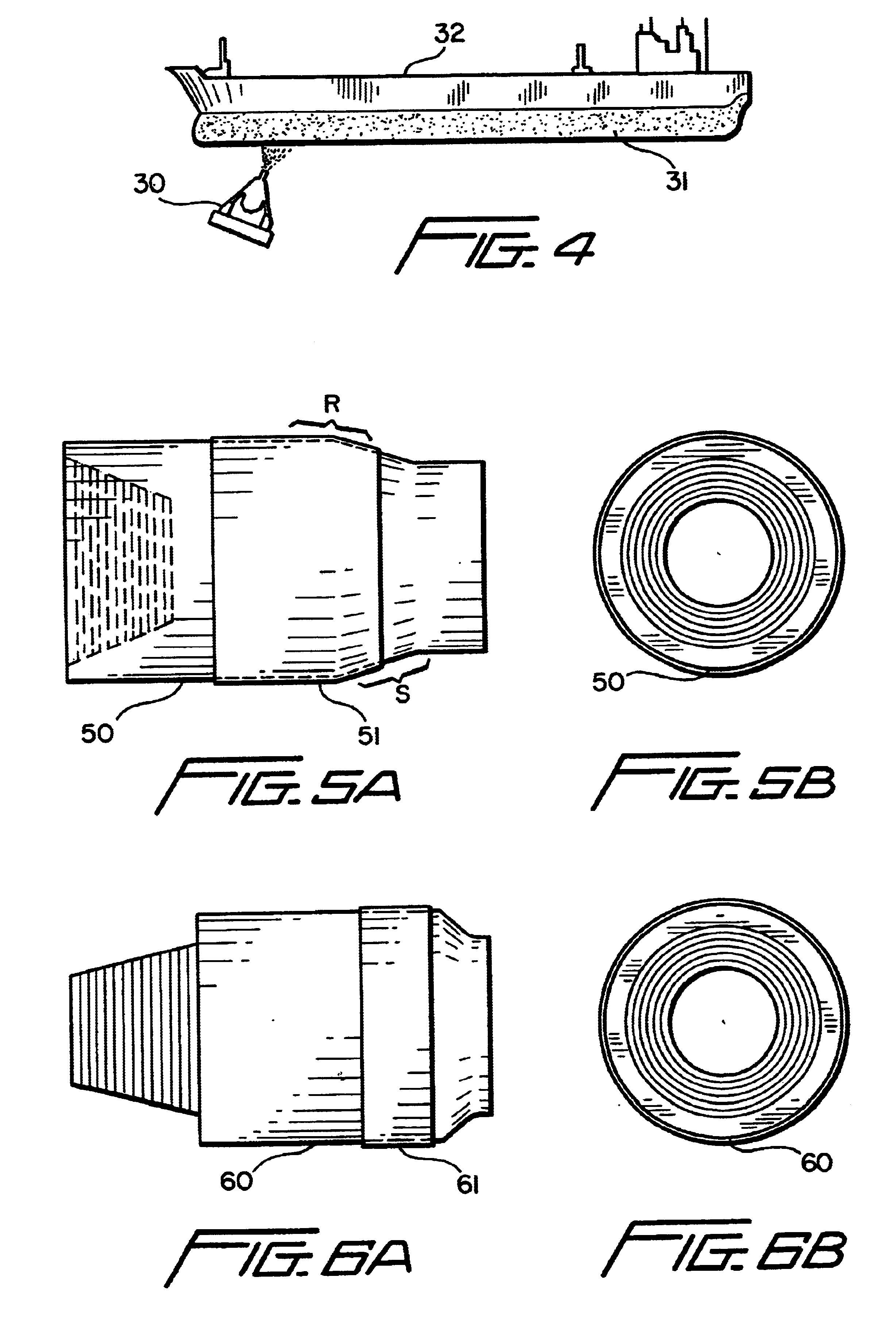

Methods for using a laser beam to apply wear-reducing material to tool joints

InactiveUS6861612B2Low heating temperatureExtremely wear resistant claddingElectric discharge heatingVacuum evaporation coatingMetallurgyLaser beams

A method for applying wear reducing material to a tool joint useful in a wellbore in drilling operations, the method, in at least certain aspects, including positioning the tool joint adjacent laser beam apparatus, delivering wear-reducing material to a location on the tool joint to which the wear-reducing material is to be applied, heating the wear-reducing material with the laser beam apparatus to a temperature not exceeding its melting temperature so that the wear-reducing material is welded to the tool joint; in one particular aspect, using a defocused laser beam to achieve desired heating temperatures; and, in one aspect, defocusing the laser so no plasma is formed.

Owner:MCCLUNG GUY L III

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com