Patents

Literature

545results about How to "Lower yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cosmetic and pharmaceutical foam

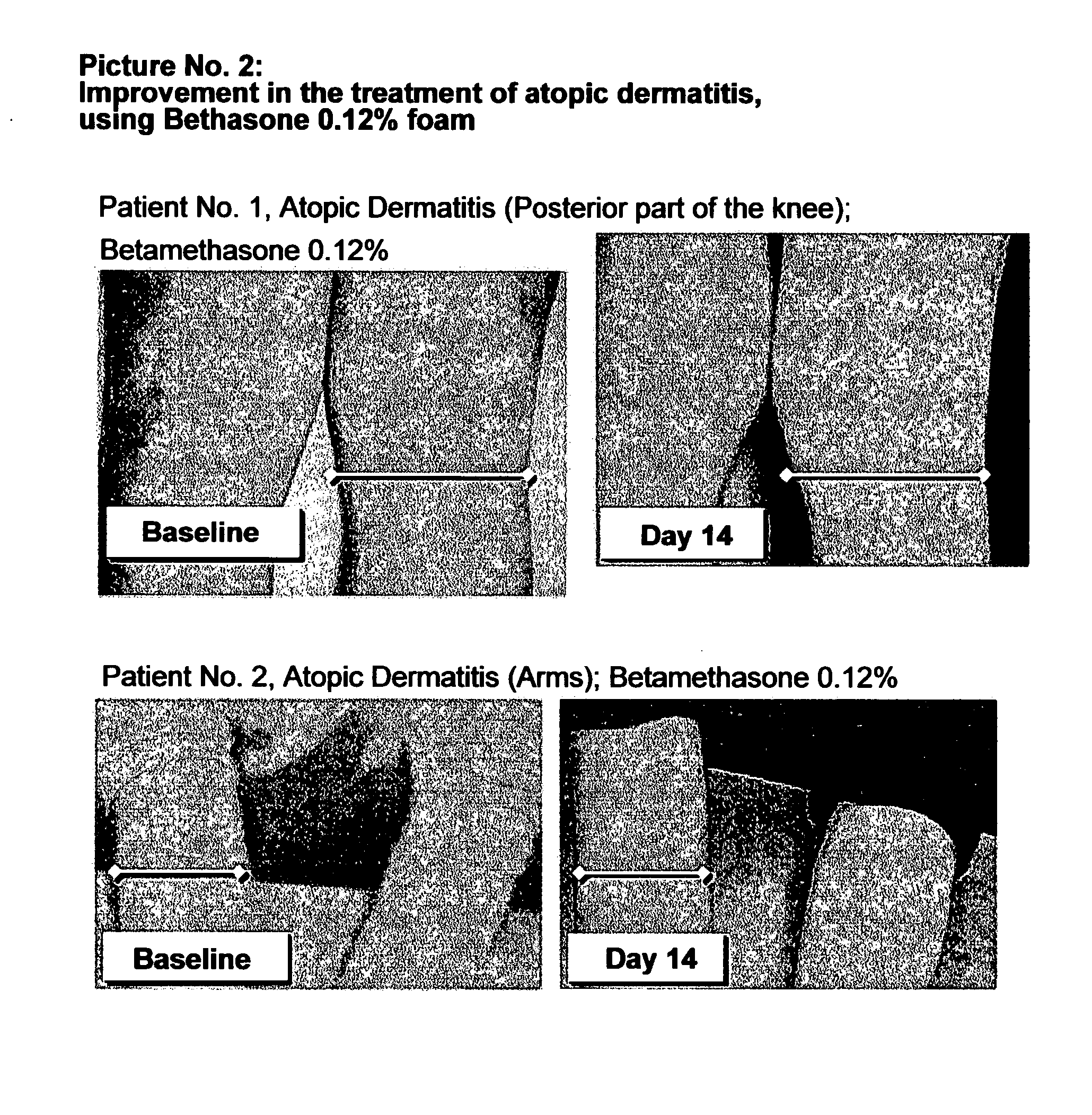

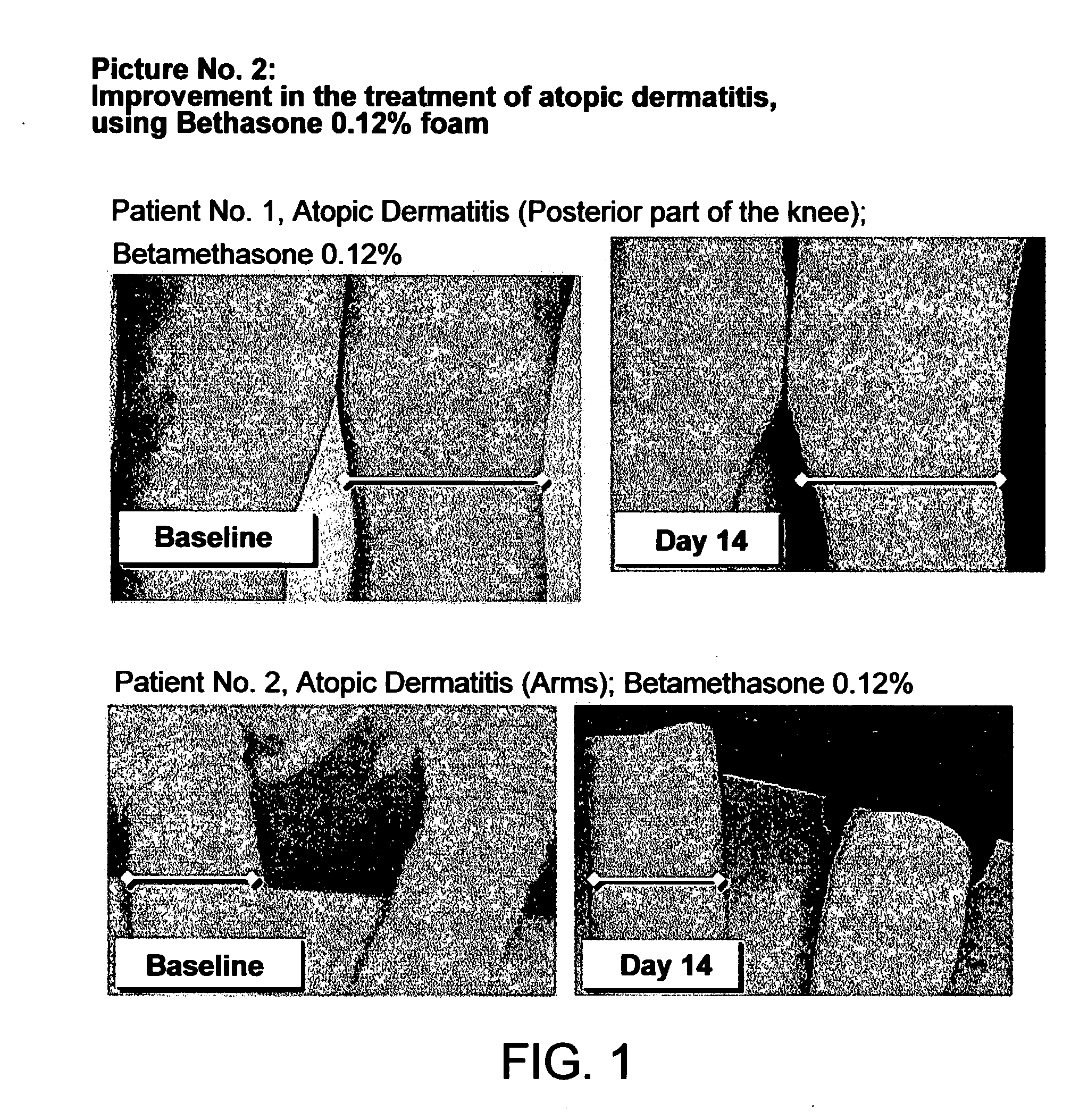

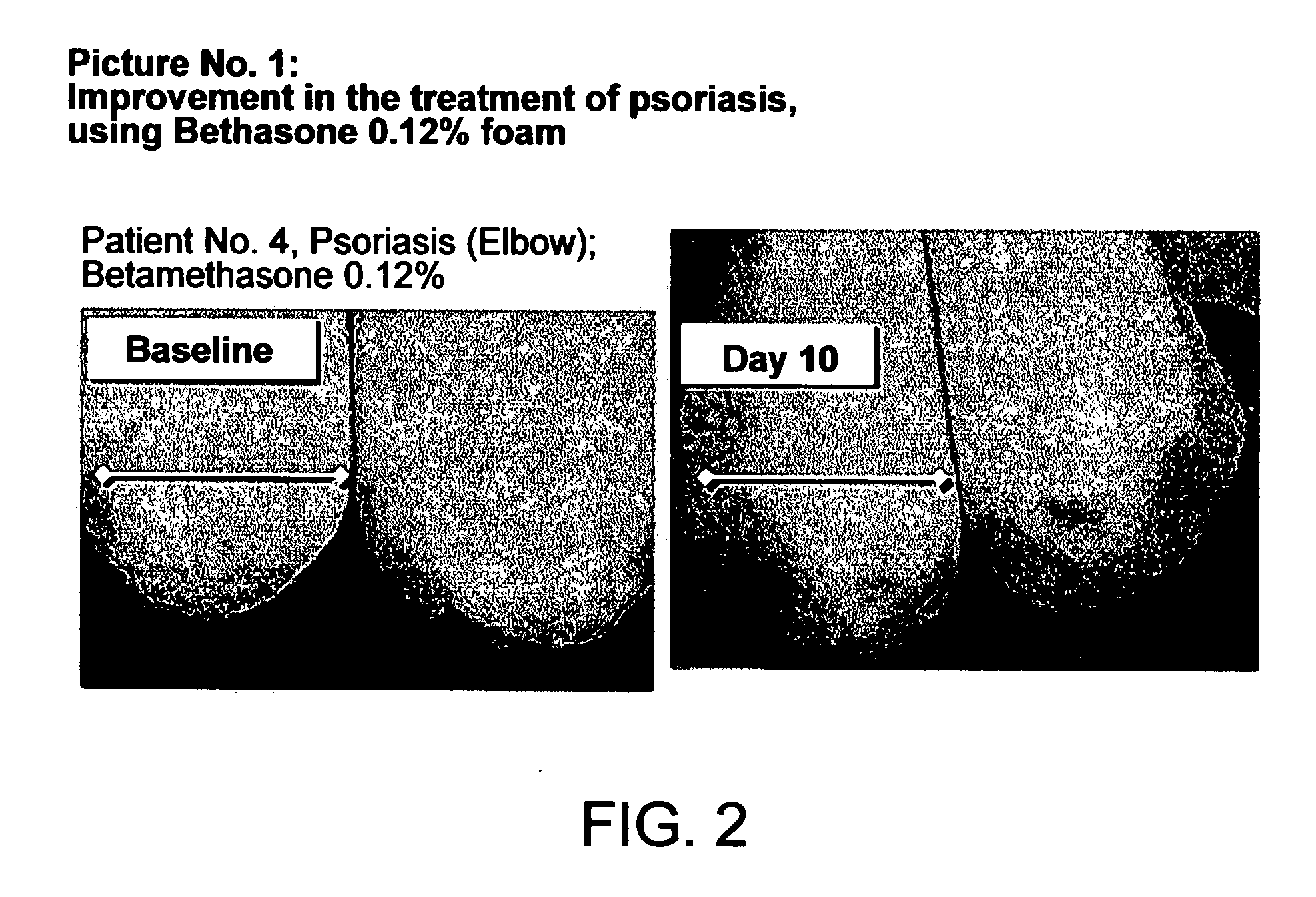

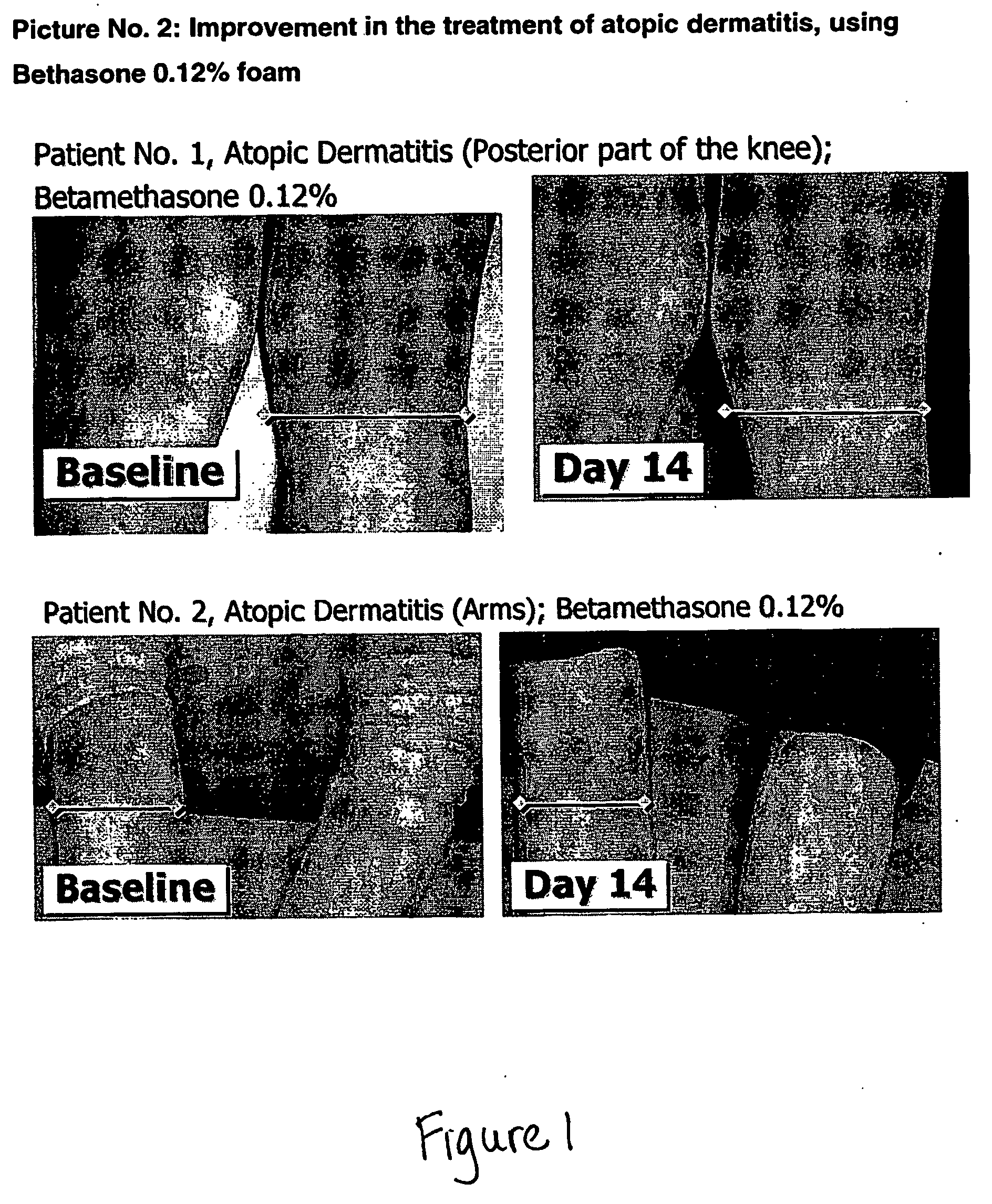

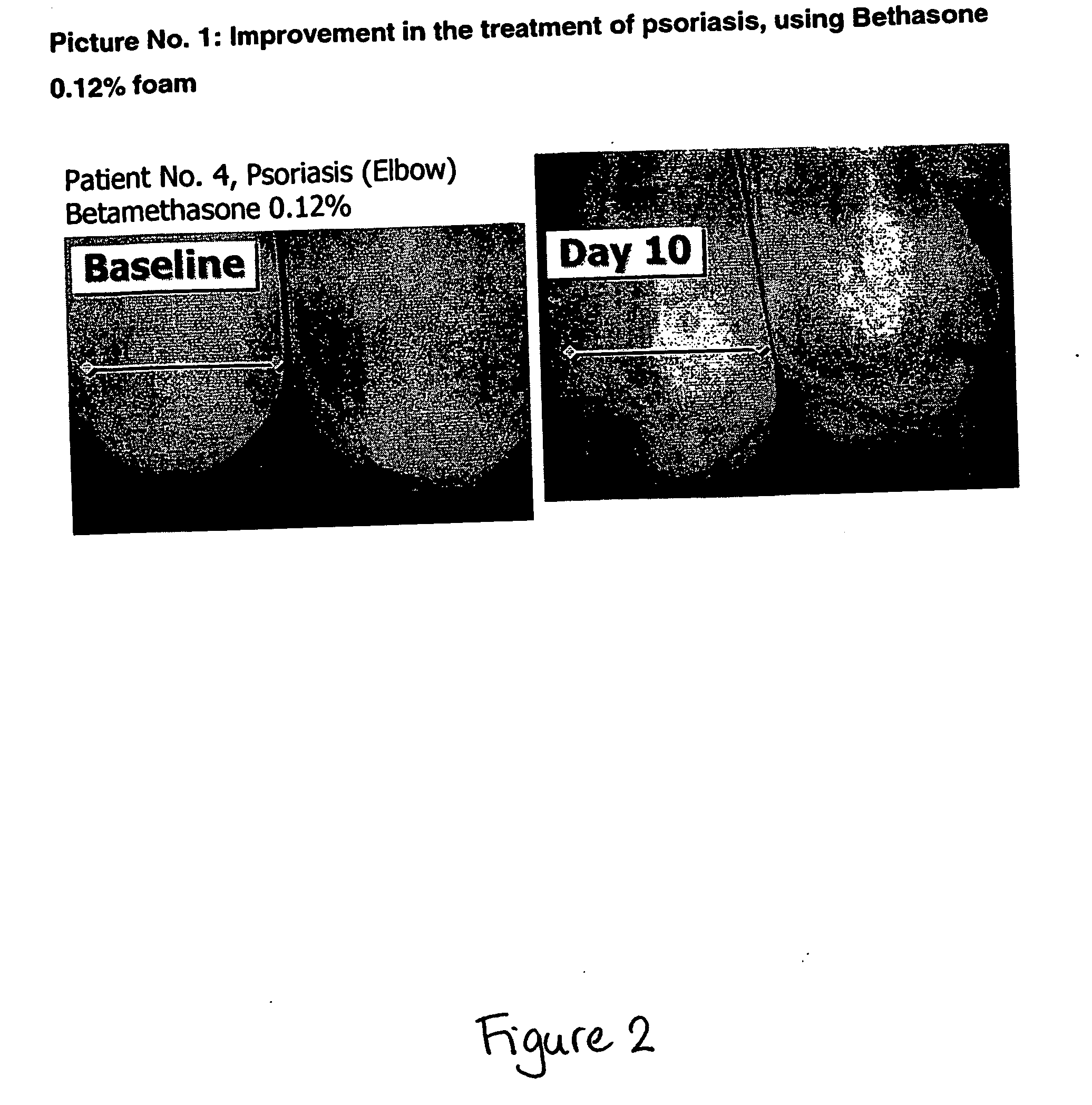

InactiveUS20080031907A1Efficient ConcentrationReduce sensitivityAntibacterial agentsBiocideAlcohol freeVegetable oil

The invention relates to uses of an alcohol-free cosmetic or pharmaceutical foam carrier comprising water, a hydrophobic solvent, a foam adjuvant agent, a surface-active agent and a water gelling agent as a flame retardant or flame resistant foam. The hydrophobic solvent is preferably mineral oil; medium chain triglycerides; isopropyl myristearate or octyl dodecanol, silicone oil or vegetable oil or mixtures thereof. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, also making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil-soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Cosmetic and pharmaceutical foam

InactiveUS20060140984A1Lower yield strengthRubbing easy and efficientCosmetic preparationsBiocideAlcohol freeAdjuvant

The invention relates to an alcohol-free cosmetic or pharmaceutical foam carrier comprising water, a hydrophobic solvent, a foam adjuvant agent, a surface-active agent and a water gelling agent. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Cosmetic and pharmaceutical foam with solid matter

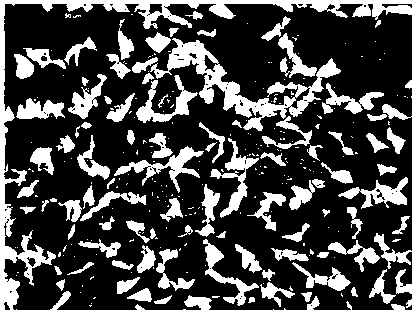

InactiveUS20050186147A1Good lookingLower yield strengthCosmetic preparationsAerosol deliveryMedicineSolvent

A foamable composition includes about 2 to about 30% by weight solid particles; about 2 to about 75% by weight hydrophobic solvent; about 10 to about 85% by weight water; about 0.1% to about 5% by weight surface-active agent; about 0.1% to about 5 wt % by weight stabilizer / gelling agent; and a liquefied or compressed gas propellant in a container, which upon release provides a breakable foam suitable for topical administration.

Owner:FOAMIX PHARMACEUTICALS LIMITED

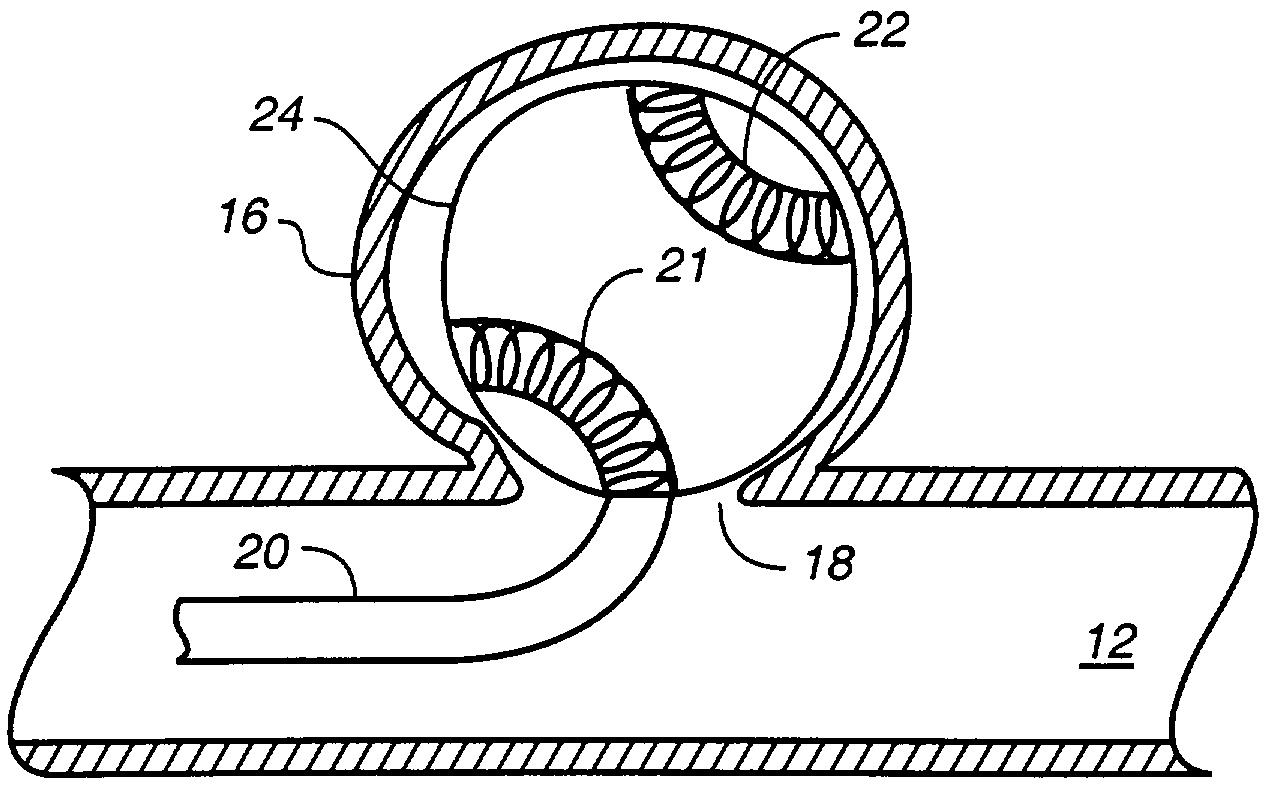

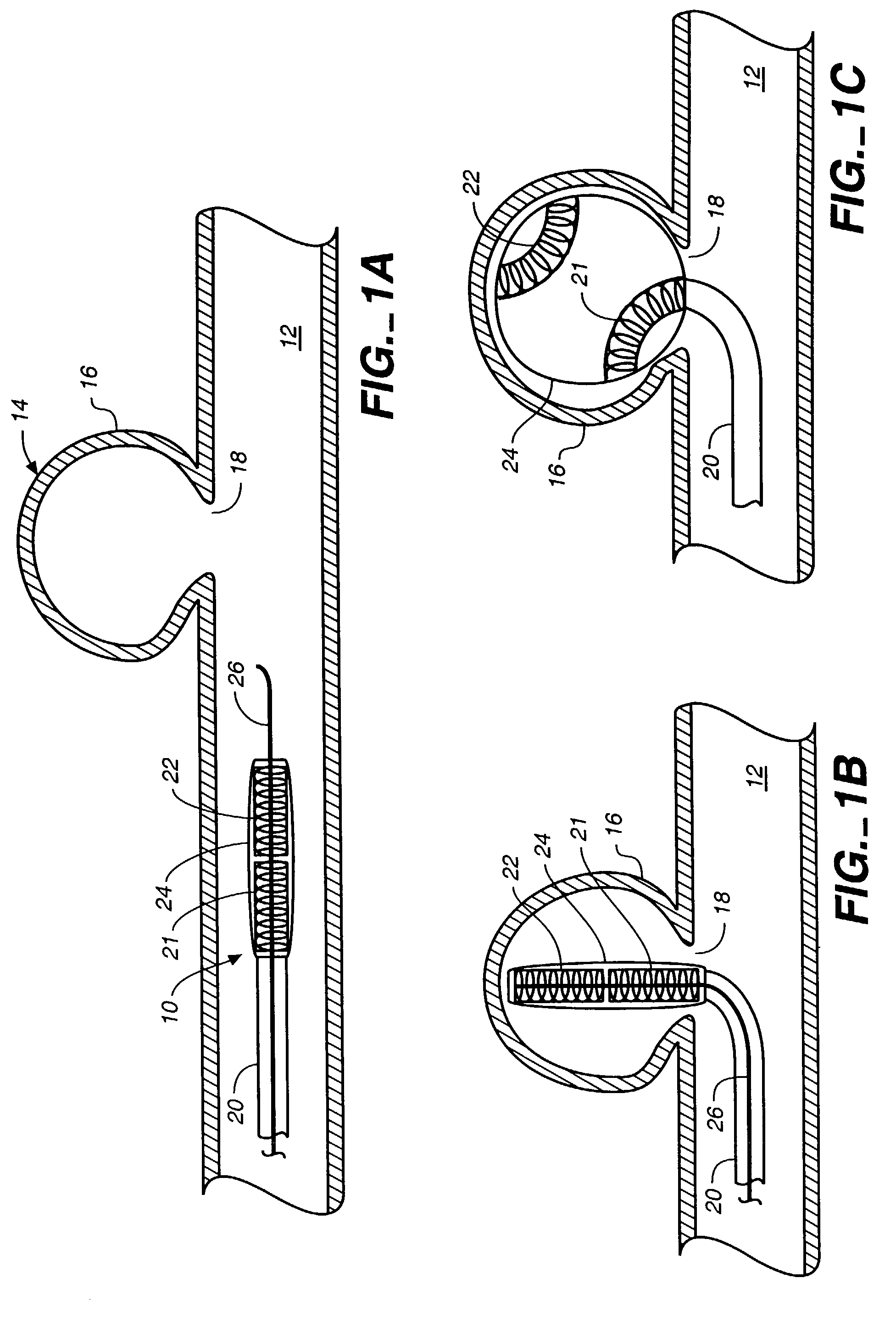

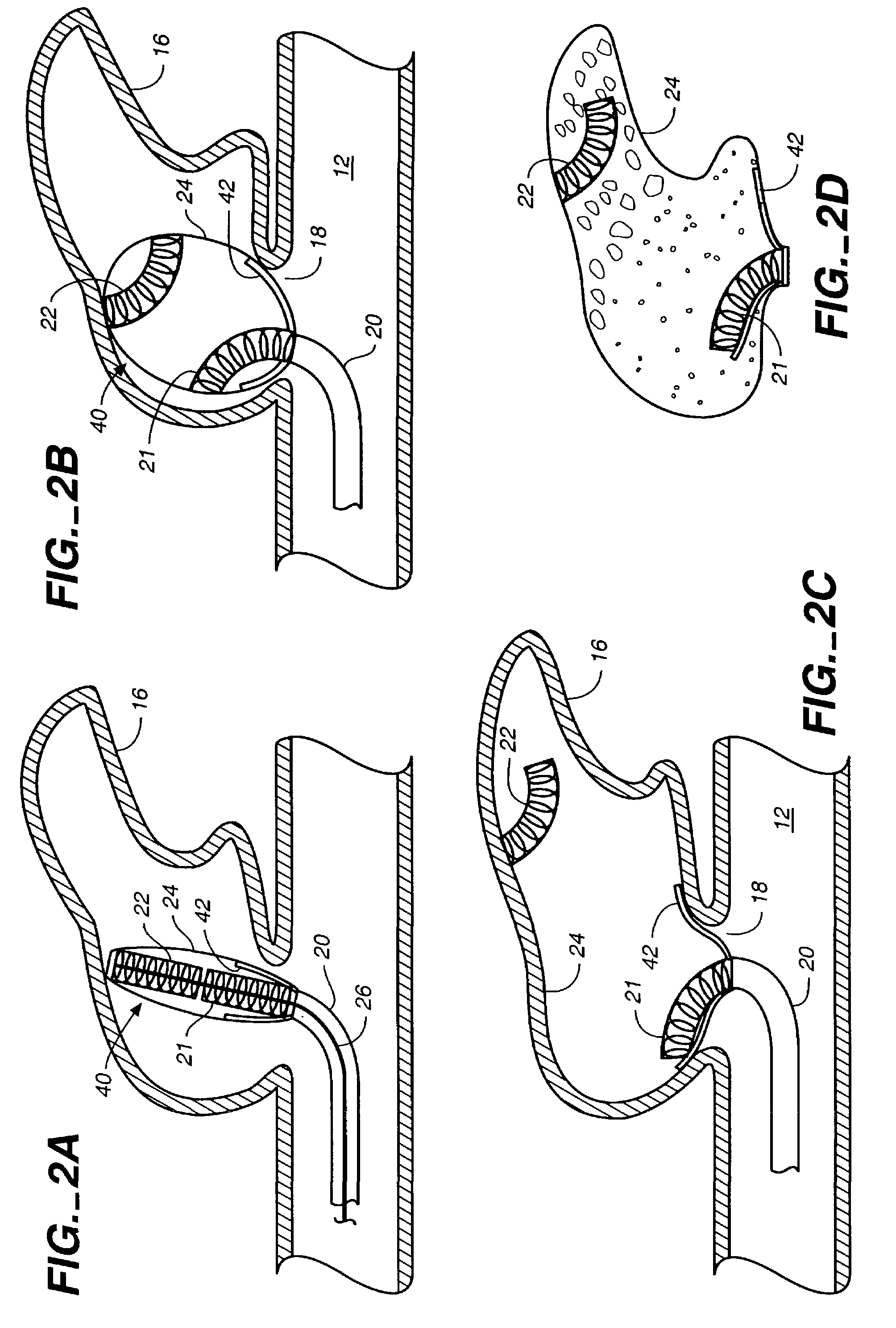

Expandable body cavity liner device

InactiveUS7695488B2Lower yield strengthEasy plastic deformationDilatorsCatheterAnterior Cerebral Artery AneurysmIliac Aneurysm

The present invention is an aneurysm treatment device for treating aneurysms of various shapes and sizes.

Owner:STRYKER CORP +1

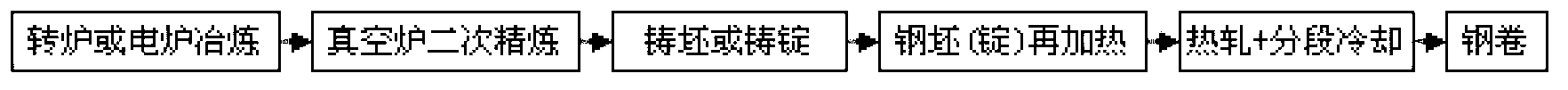

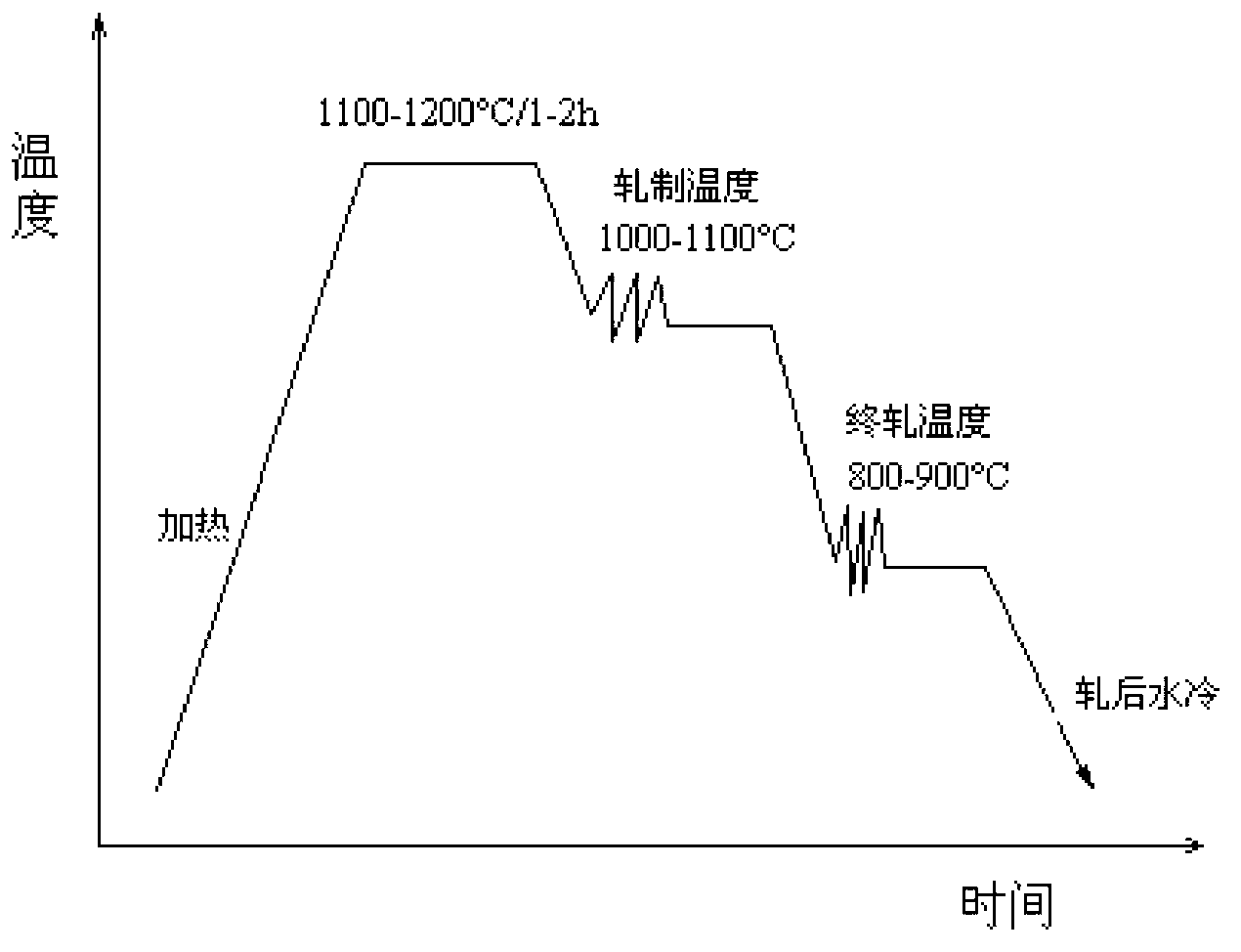

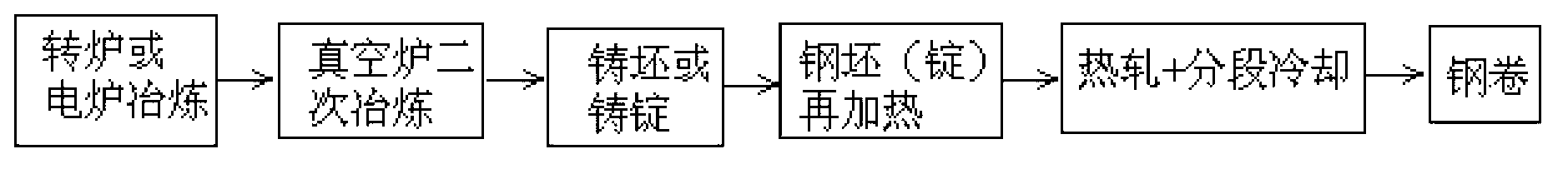

700MPa high strength hot rolling Q&P steel and manufacturing method thereof

ActiveCN103215516AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesAustenite grainChemical composition

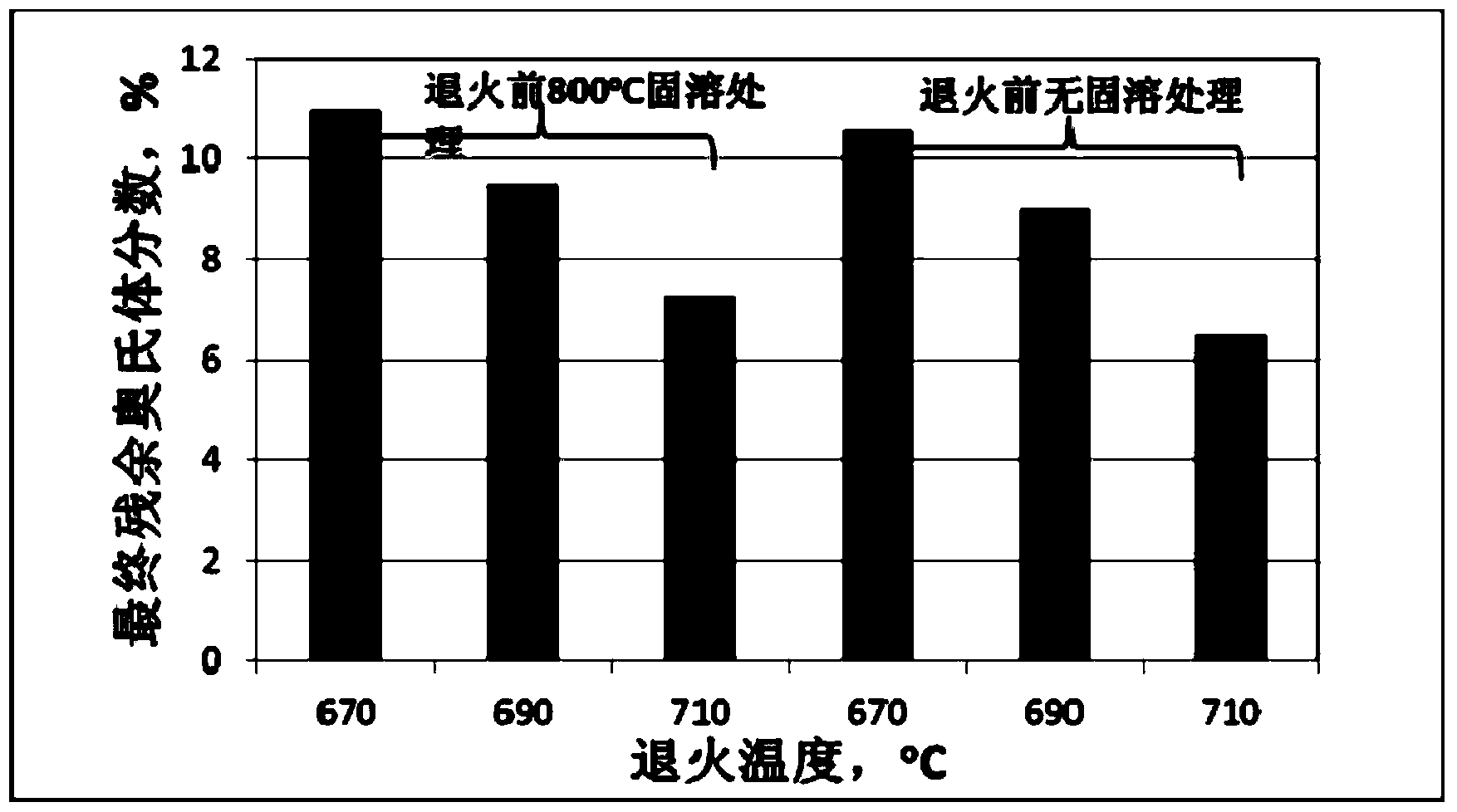

The invention relates to 700MPa high strength hot rolling Q&P steel and a manufacturing method thereof. The steel has the following chemical components in percentage by weight: 0.15-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.3-1.0% of Al, less than or equal to 0.0065% of N, 0.005-0.015% of Ti and the balance of Fe. The yield strength is greater than or equal to 70MPa, the strength of extension is greater than or equal to 1300MPa, and the ductility is greater than 10%. According to the invention, through a reasonable compound design, based on common C-Mn steel components, austenite crystal is refined by micro Ti treatment by improving the content of Si to inhibit separation of cementite, so that the austenite transformation kinetics in the air cooling process is accelerated by improving the content of Al. Meanwhile, a hot continuous rolling process is matched with a sectional cooling process, so that proeutectoid ferrite+martensite+retained austenite tissues are obtained. The cost of the alloy is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

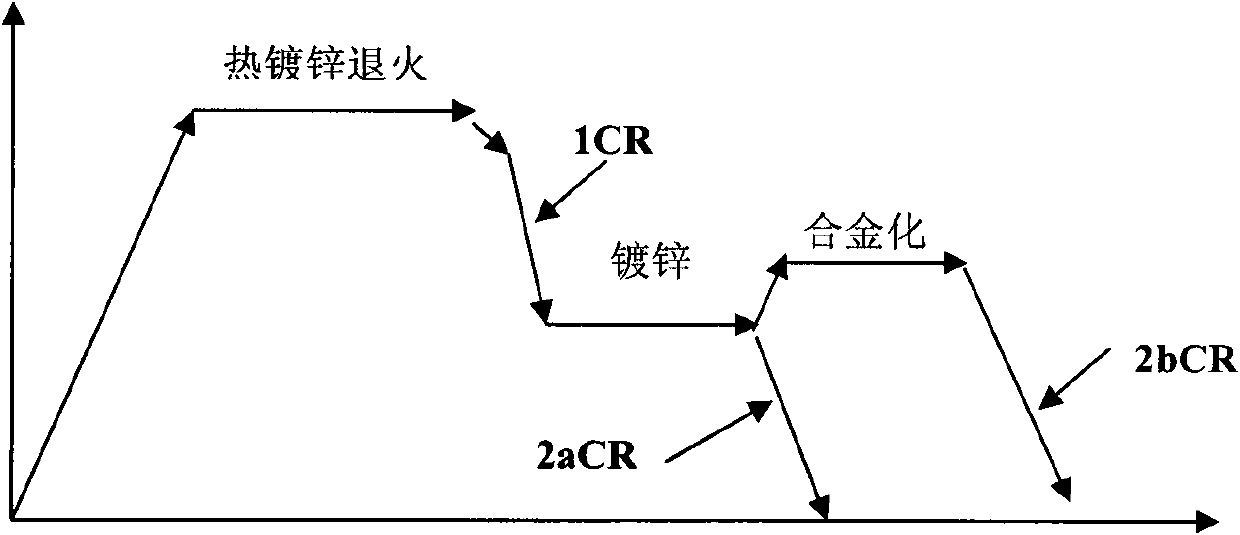

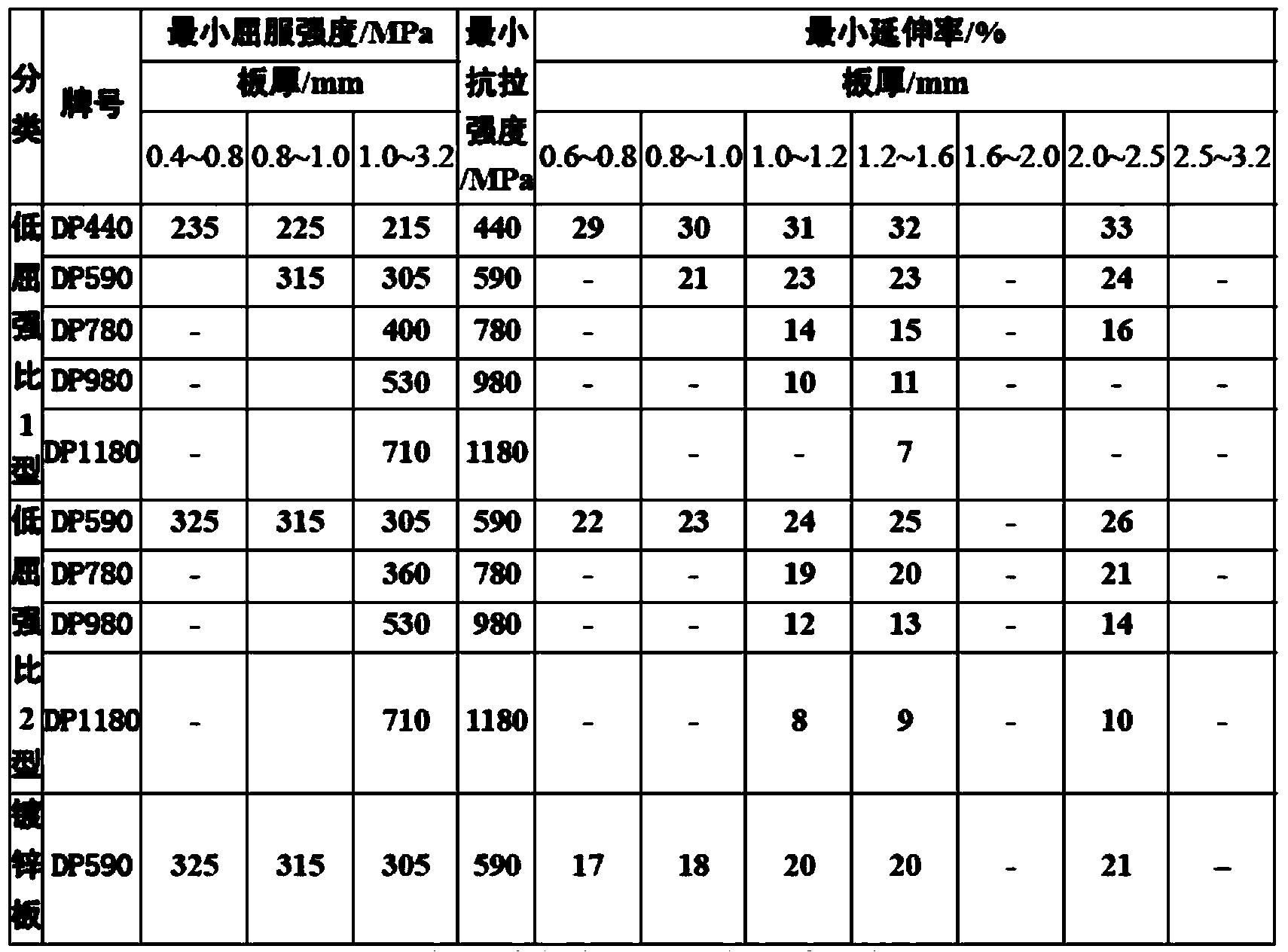

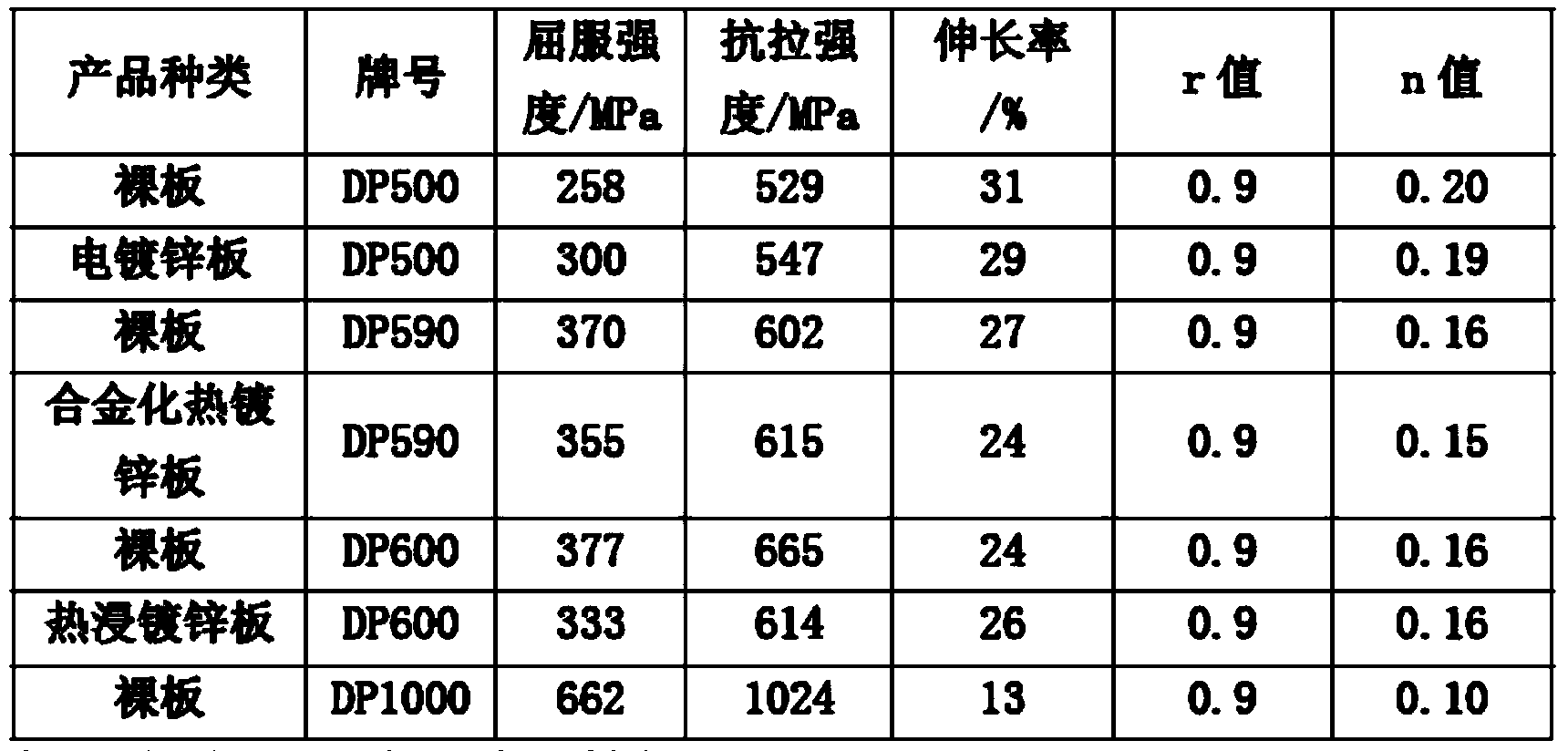

Cold-rolled galvanized duplex steel and manufacturing method thereof

ActiveCN102021482APlatability EliminationHigh strengthHot-dipping/immersion processesManufacturing convertersHigh rateOxygen

The invention relates to a cold-rolled galvanized duplex steel, wherein the substrate thereof comprises the following components by weight percentage: 0.08 to 0.18 wt.% of C, 0.50 to 1.50 wt.% of Si, 1.50 to 2.5 wt.% of Mn, 0.10 to 1.0 wt.% of Cr, 0.02 to 0.5 wt.% of Mo, 0.005 to 0.05 wt.% of Nb, 0.005 to 0.05 wt.% of Ti, 0.002 to 0.05 wt.% of T.Al, less than or equal to 0.02 wt.% of P, less thanor equal to 0.01 wt.% of S and less than or equal to 0.006 wt.% of N, and the balance of Fe. The manufacturing method thereof comprises the steps of: smelting in an oxygen top-blown convertor, refining in a heating steel ladle, continuously casting into a slab, and then conventionally hot rolling, pickling tandem rolling, galvanizing and annealing, wherein the critical annealing temperature is between 760 and 840 DEG C; the annealing is finished in the two-phase area of ferrite and austenite; 1CR section cooling has a cooling speed of 1 to 40 DEG C / S from the annealing temperature to the zincpool, putting the substrate into the zinc pool having a temperature of 450 to 465 DEG C so as to galvanize; and 2a CR section cooling has a cooling speed more than 3 DEG C / S. The steel of the invention has the advantages of high tensile strength, low yield ratio, capable of being press formed, excellent matching between strength and toughness, high rate of initially work-hardening and being free from yield extending.

Owner:BAOSHAN IRON & STEEL CO LTD

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

Two-phase automobile steel plate with low yield-strength ratio and high strength and production method of two-phase automobile steel plate

The invention discloses a two-phase automobile steel plate with low yield-strength ratio and high strength and a production method of the two-phase automobile steel plate, belonging to the technical field of steel for automobiles. The two-phase automobile steel plate comprises the following chemical components: 0.1-0.40wt% of C, 3.0-8.0wt% of Mn, less than or equal to 0.020wt% of P and less than or equal to 0.02wt% of S; on the basis, the two-phase automobile steel plate can be additionally provided with one or more of the following elements: 0.1-3.0wt% of Ni, 0.2-3.0wt% of Cr, 0.1-0.8wt% of Mo, 0.3-2.3wt% of Si, 0.5-2.0wt% of Cu, 0.0005-0.005wt% of B, 0.02-0.10wt% of Nb, 0.002-0.25wt% of [N], 0.05-0.25wt% of Ti, 0.02-0.25wt% of V, 0.015-0.060wt% of Al, 0.002-0.005wt% of RE (Rare Earth) and 0.005-0.03wt% of Ca. The two-phase automobile steel plate has the advantages that the two-phase automobile steel plate with low yield strength, high tension strength and favorable elongation can be produced through annealing within short time; the performance indexes of the two-phase automobile steel plate are as follows: two-phase steel with the tension strength of 980MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 22%, and two-phase steel with the tension strength of 1180MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 17%.

Owner:CENT IRON & STEEL RES INST

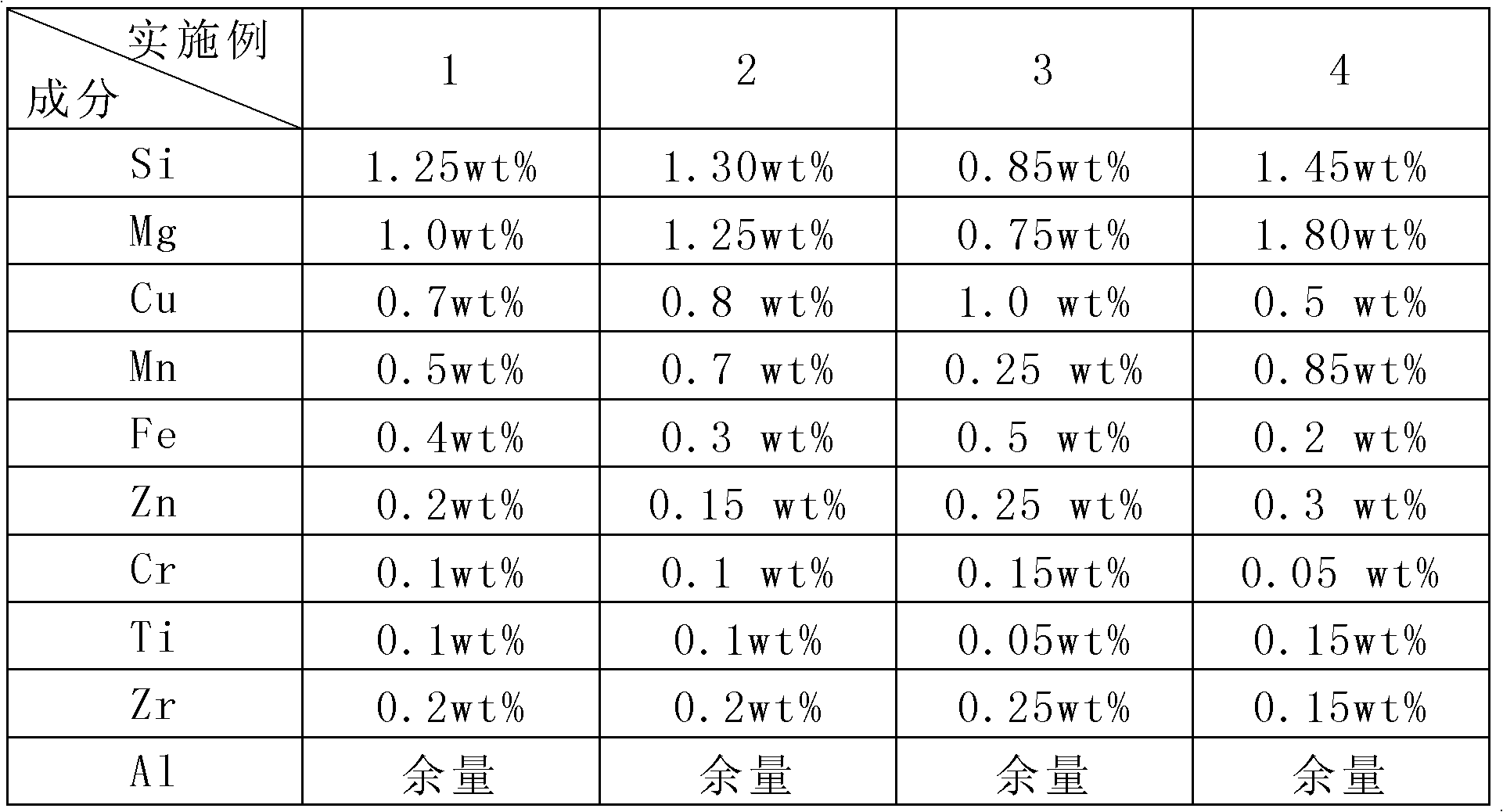

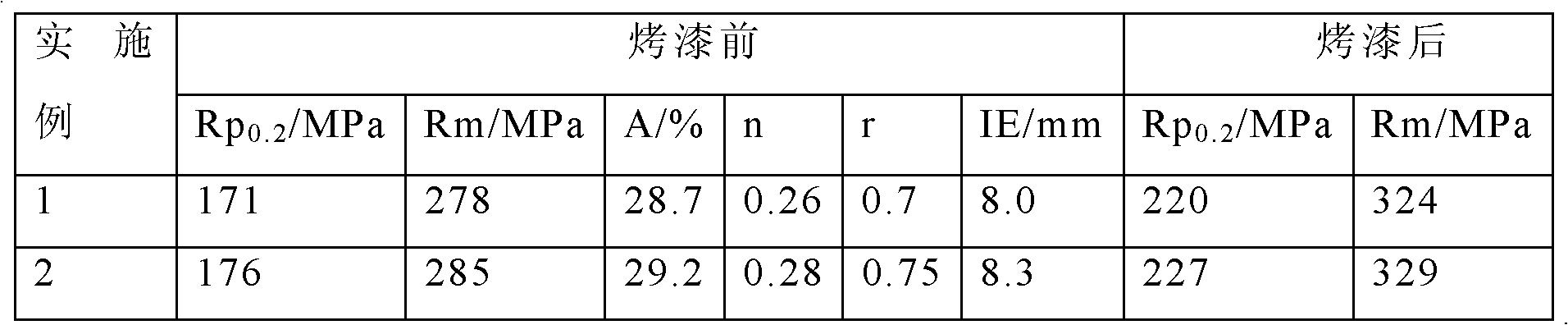

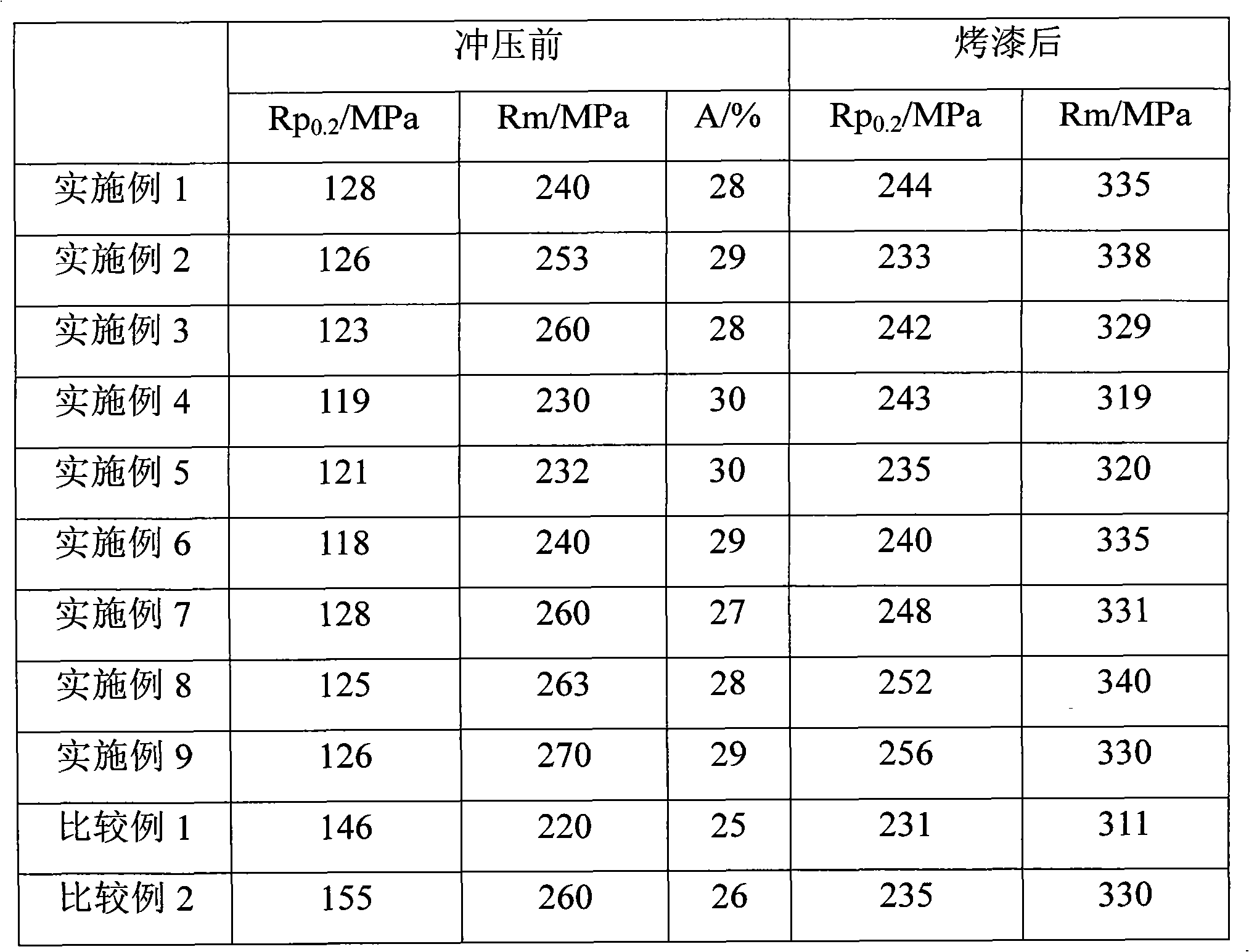

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

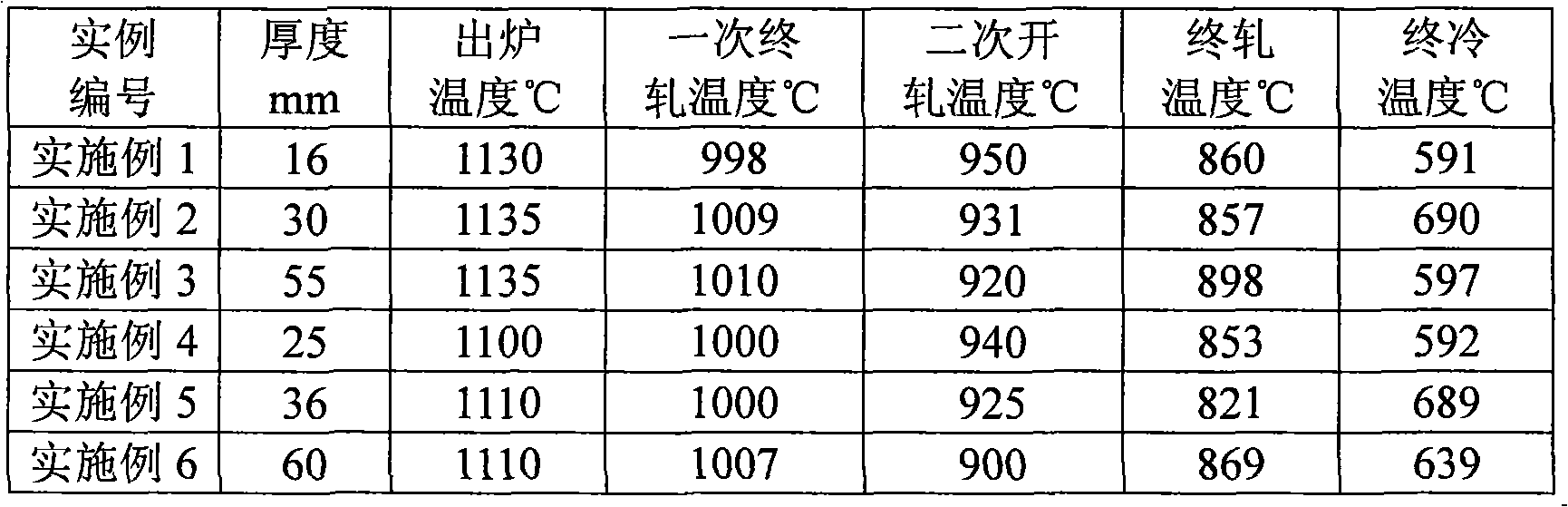

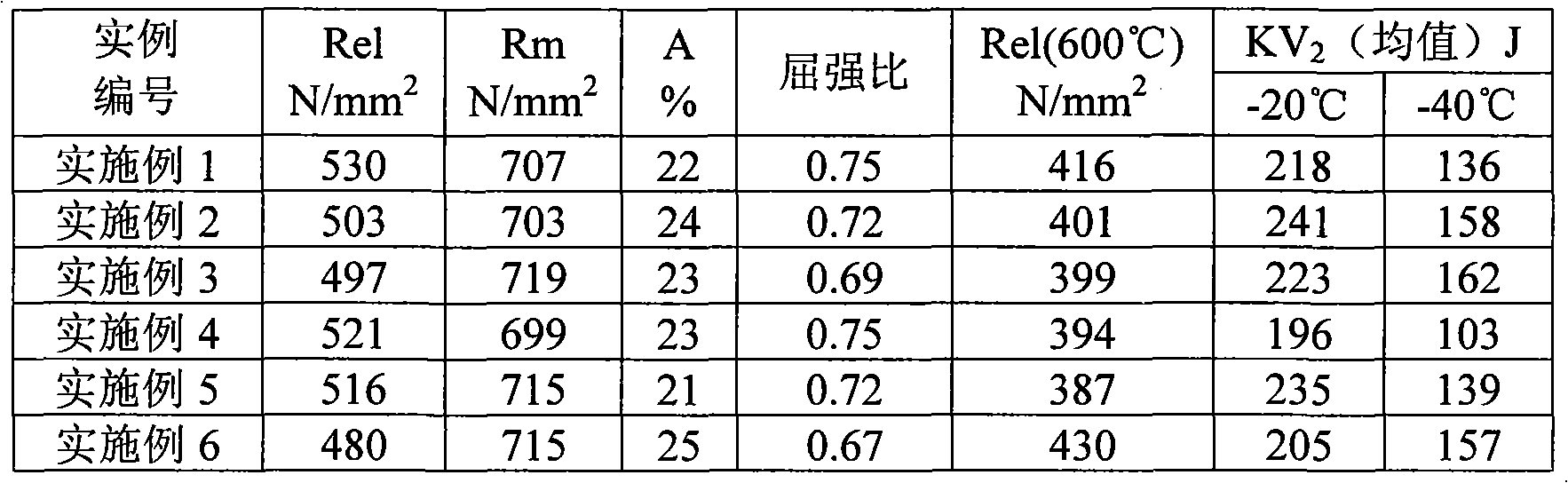

High-performance building structure refractory steel plates and manufacturing method thereof

ActiveCN101906585AMeet design needsMeet construction needsTemperature control deviceChemical compositionHeating time

The invention discloses high-performance building structure refractory steel plates and a manufacturing method thereof. The high-performance building structure refractory steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.12 percent of C, 0.05 to 0.50 percent of Si, 0.08 to 1.50 percent of Mn, 0.010 to 0.050 percent of Nb, 0.010 to 0.040 percent of Ti, 0.010 to 0.050 percent of Als, 0.20 to 0.60 percent of Cr, 0.20 to 0.40 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.0040 percent of N, less than or equal to 0.0020 percent of O and the balance of Fe and inevitable impurities. The production process of the high-performance building structure refractory steel plates is characterized in that: the steel blank heating temperature is 1,100 to 1,250 DEG C; the heating time is 60 to 110s / cm; two-stage controlled rolling is adopted; the final rolling temperature is kept between 800 and 900 DEG C; cooling is started 30 to 120 seconds later after final rolling; the final cooling temperature is kept between 500 and 750 DEG C; the steel plates are stacked quickly, cooled slowly and kept at a constant temperature; the stacking temperature is kept between 650 and 300 DEG C; and the temperature is kept for 10 to 24 hours. The plates have the characteristics of simple chemical components, low cost, and high refractability.

Owner:ANGANG STEEL CO LTD

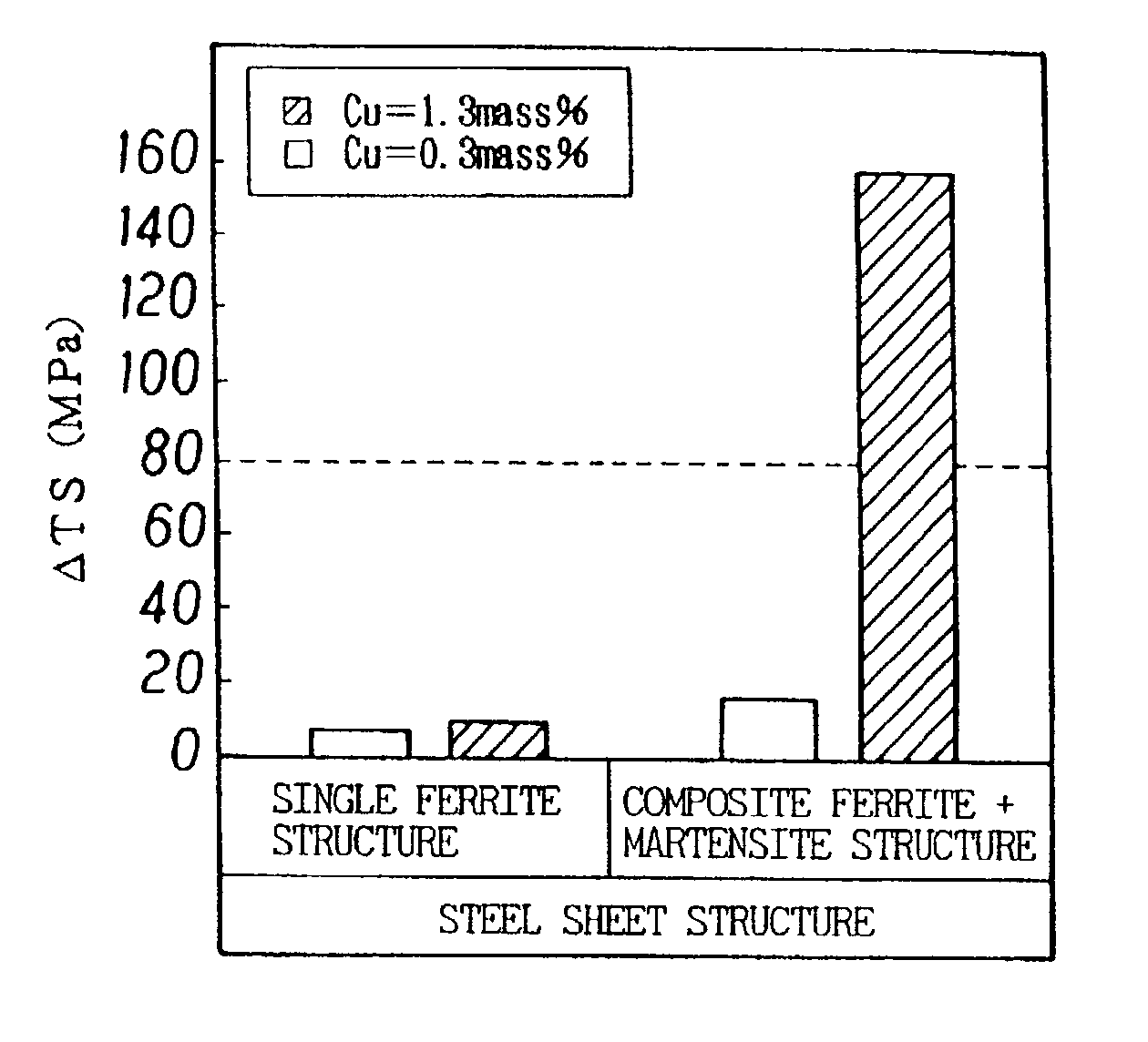

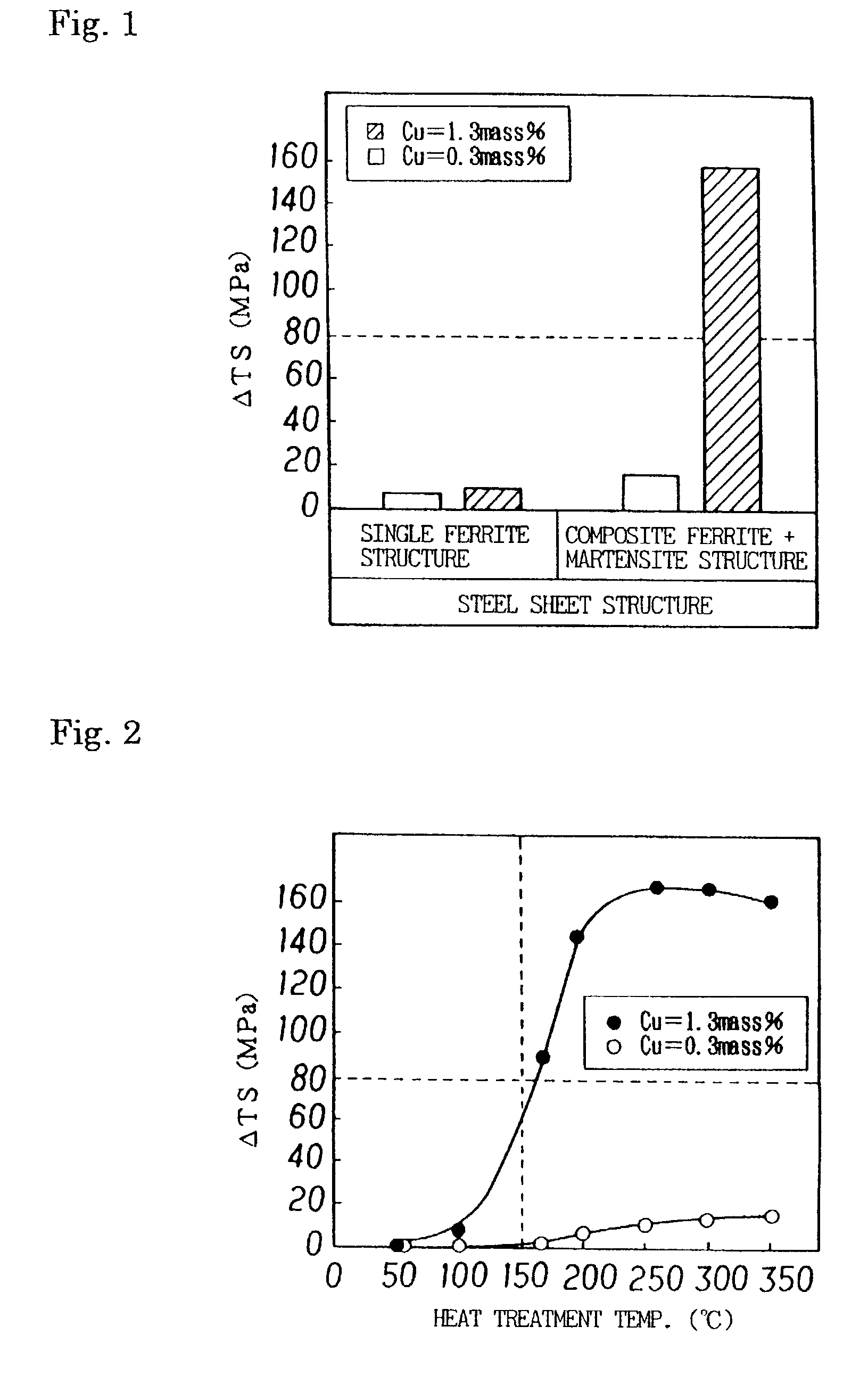

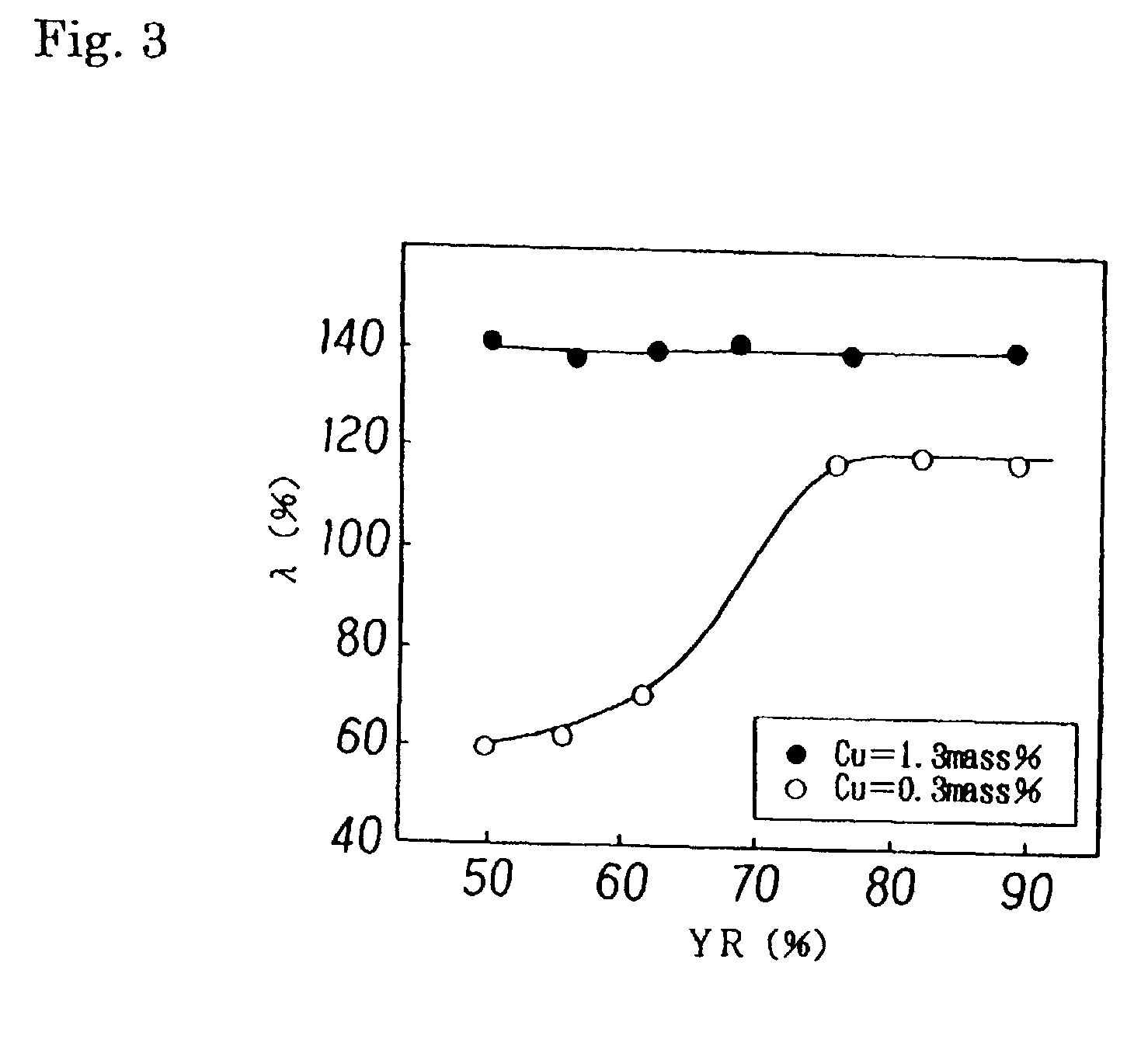

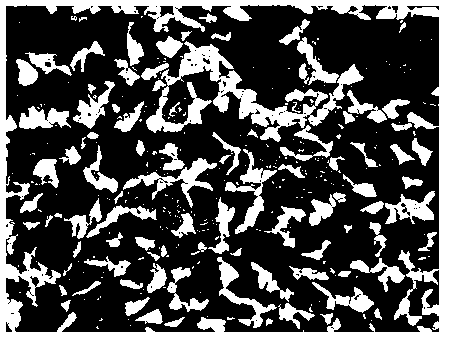

Hot rolled steel plate, cold rolled steel plate and hot dip galvanized steel plate being excellent in strain aging hardening characteristics, and method for their production

InactiveUS20030111144A1Improve stamping formabilityGood strainHot-dipping/immersion processesFurnace typesSheet steelChemical composition

The present invention provides a steel sheet having a chemical composition comprising 0.15% or less C, 2.0% or less Si, 3.0% or less Mn, P, S, Al and N in adjusted amounts, from 0.5 to 3.0% Cu, or one or more of Cr, Mo and W in a total amount of 2.0% or less, and having a composite structure comprising ferrite and martensite having an area ratio of 2% or more. The steel sheet is in the form of a high-strength hot-rolled steel sheet, a high-strength cold-rolled steel sheet, or a hot-dip galvanized steel sheet. There is thus available a steel sheet excellent in press-formability and in strain age hardening property as represented by a DELTATS of 80 MPa or more.

Owner:JFE STEEL CORP

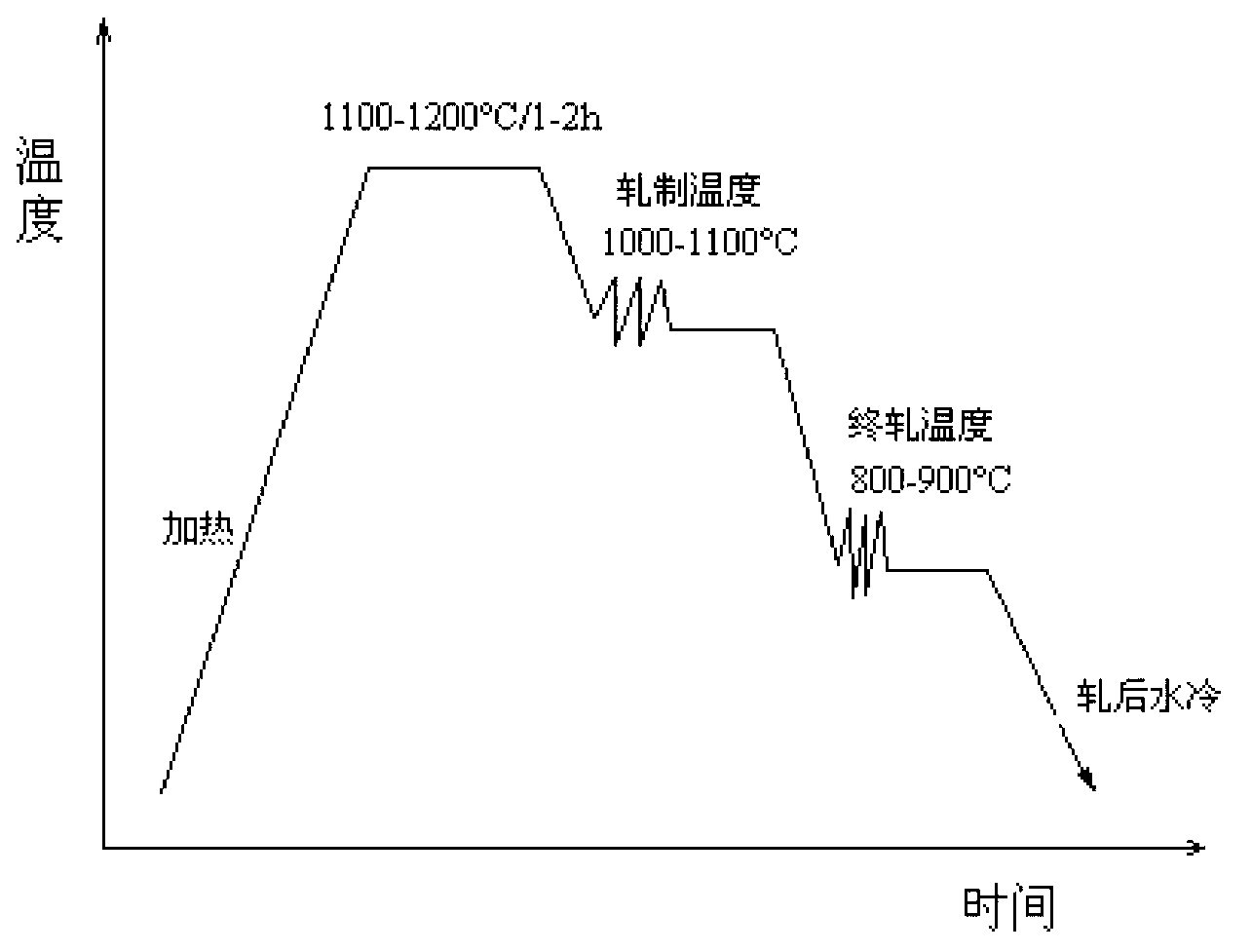

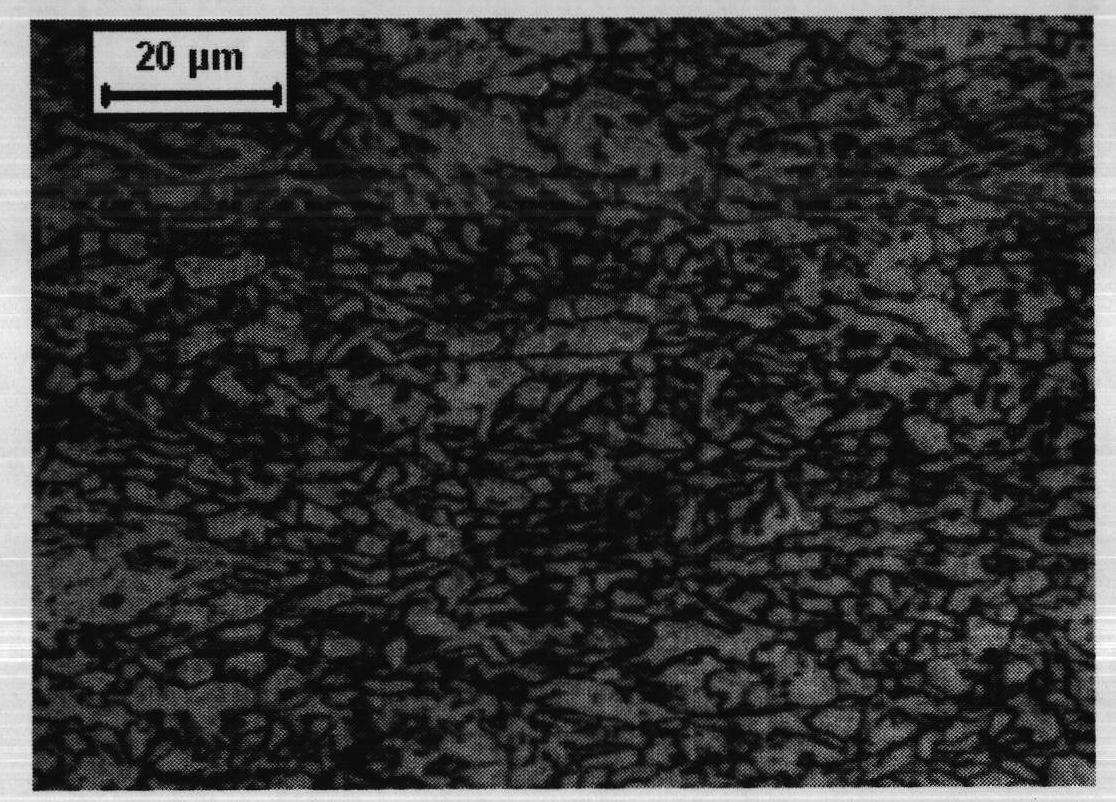

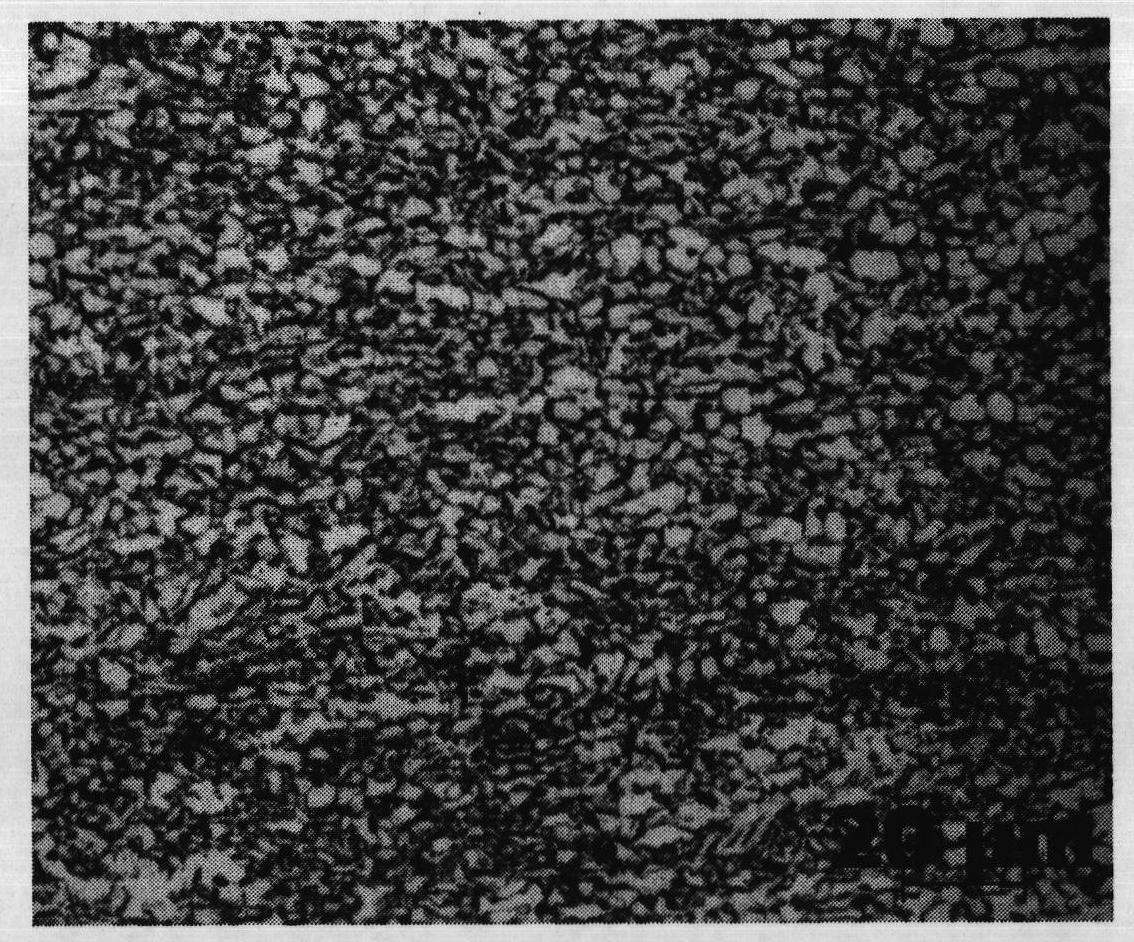

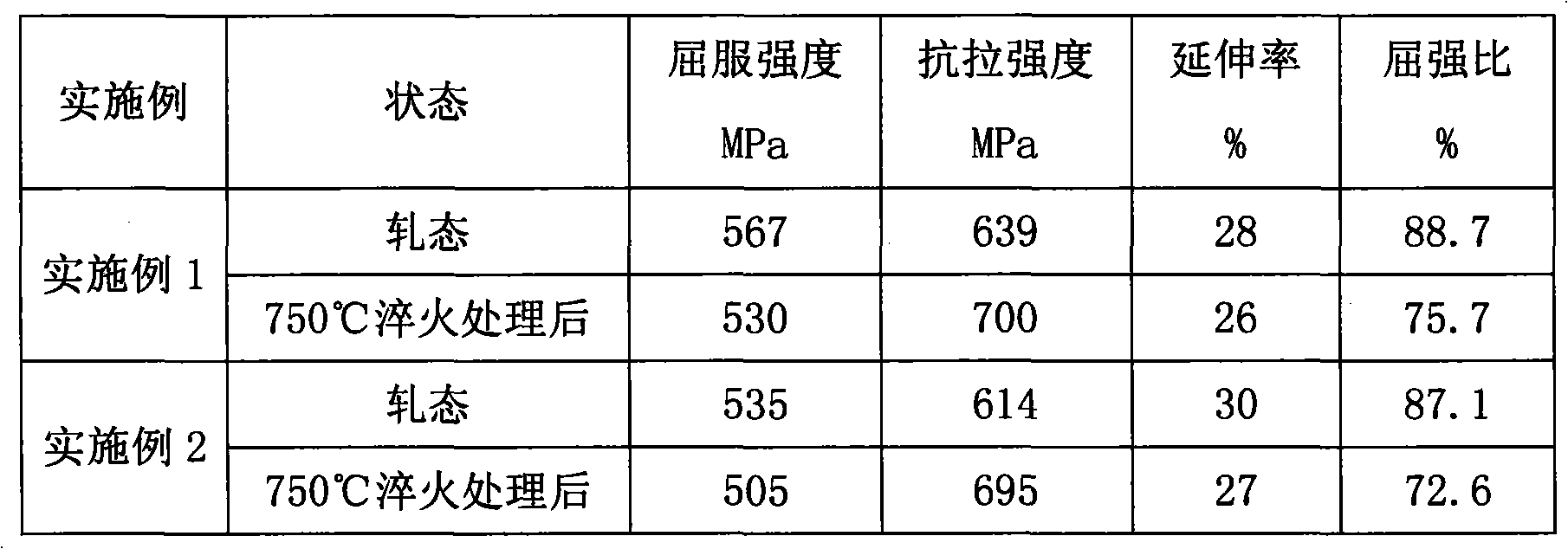

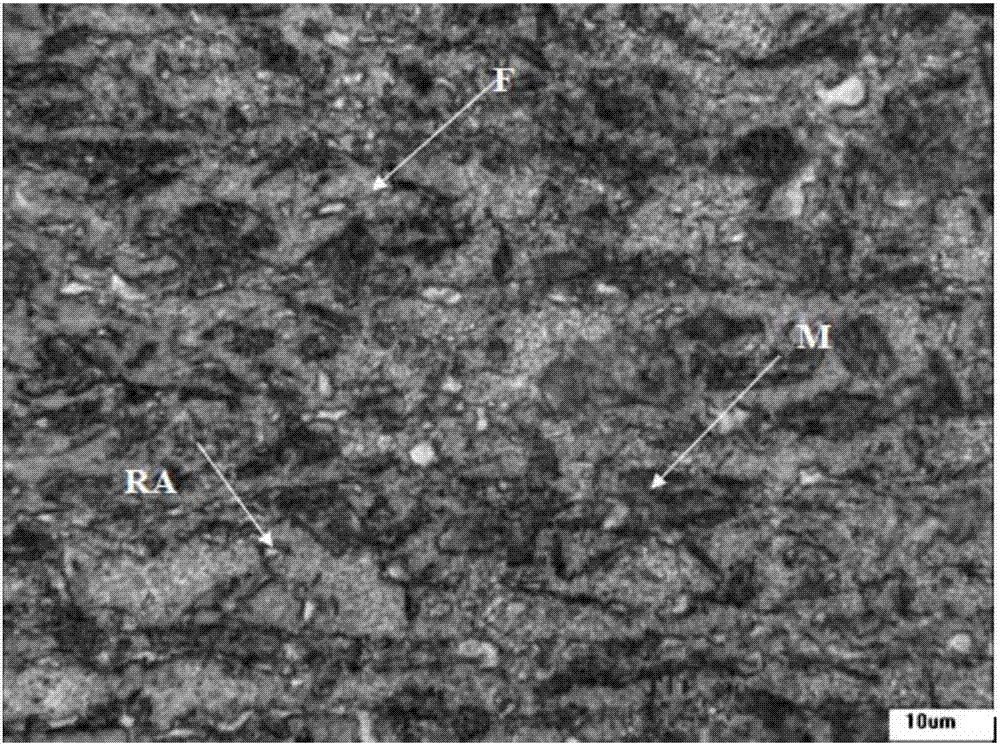

Low-yield-ratio high-strength hot-rolled Q&P steel and manufacturing method thereof

The invention relates to low-yield-ratio high-strength hot-rolled Q&P steel and a manufacturing method thereof. The steel comprises the chemical components of 0.20-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.02-0.08% of Al, no more than 0.006% of N, 0.005-0.015% of Ti, and balance of Fe and unavoidable impurities. According to the invention, through low-cost component design, on a basis of common C-Mn steel, Si content is increased such that cementite precipitation is inhibited, and austenite grains are micronized through micro-Ti treatment. Also, with a combination of hot continuous rolling process and sectioned cooling process, a structure comprising proeutectoid ferrite, martensite, and residual austenite is obtained. The yield strength is lower than 700MPa, a tensile strength is higher than 1000MPa, a yield ratio is 0.50-0.60, and alloy cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

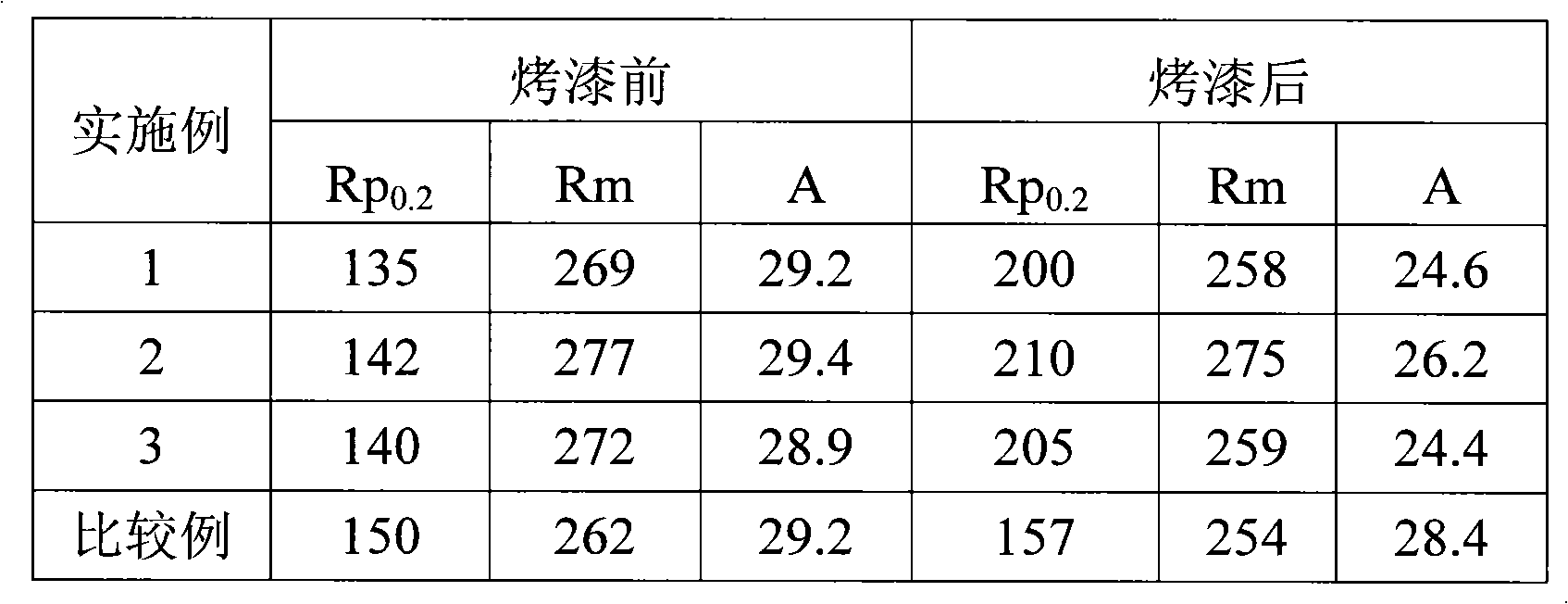

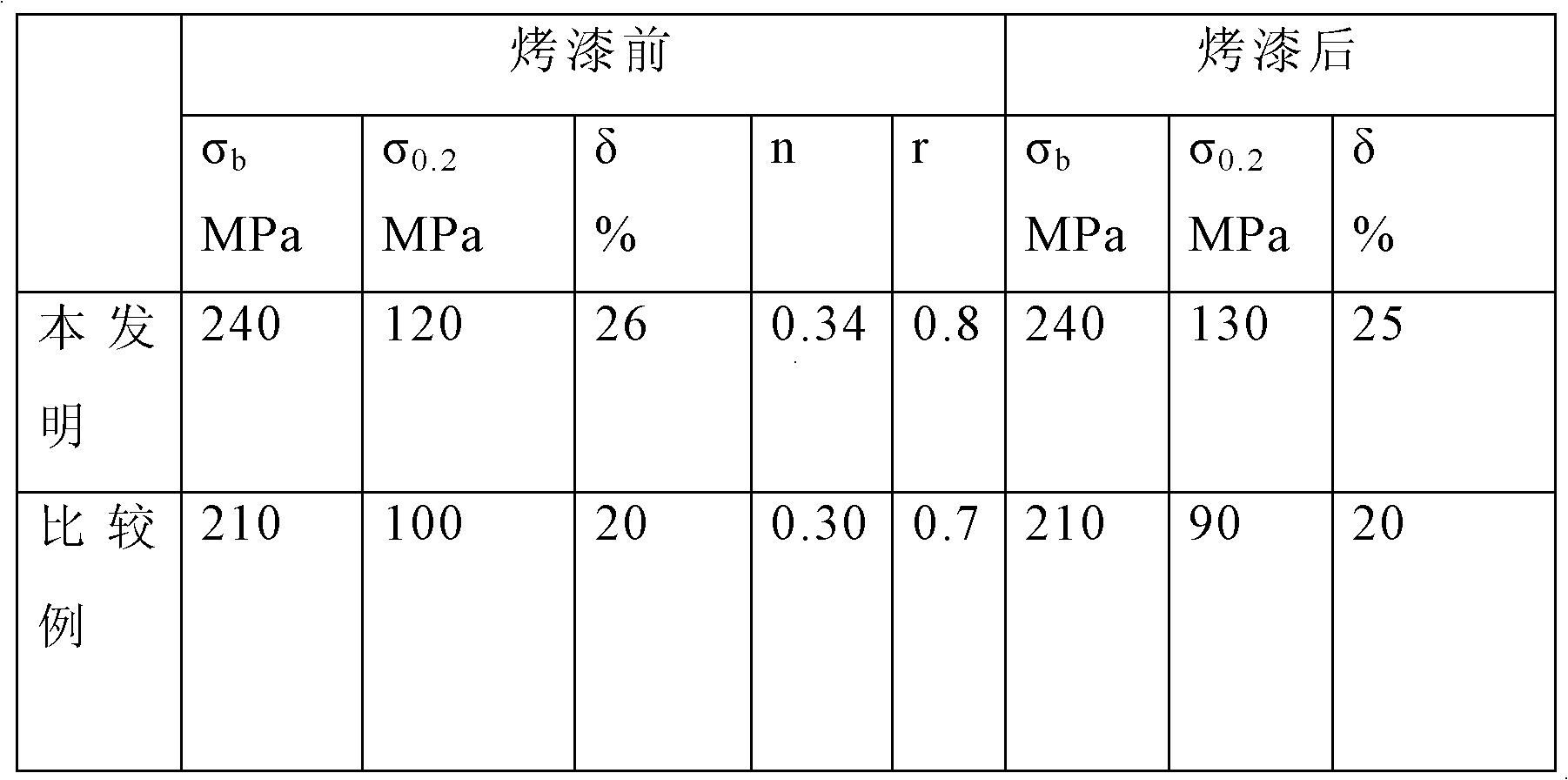

Car body aluminum alloy plate and manufacturing method thereof

InactiveCN103173661ALower yield strengthExcellent formabilityUltimate tensile strengthBake hardening

The invention provides a high-strength brake hardening car body aluminum alloy plate and a manufacturing method thereof, and belongs to the technical field of aluminum alloy. The aluminum alloy has the component characteristic that a Zn element is added on the basis of the conventional AL-Mg-Si-Cu quaternary alloy, so that the alloy has higher brake hardening performance; and interaction, strengthening-phase separation process and the like among solute elements are reasonably adjusted through reasonable pre-ageing process optimization control, and therefore, a novel car material Al-Mg-Si-Cu-Zn quinary aluminum alloy with excellent comprehensive performances is successfully developed. By adding the element Zn, the aluminum alloy material disclosed by the invention has the performance characteristic of being low in yield strength, good in plasticity and conductive to stamping and forming a car covering piece before baking finish; and after baking finish is finished, the yield strength is greatly improved, the tensile strength is high and the bake hardening performances are high.

Owner:UNIV OF SCI & TECH BEIJING +1

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

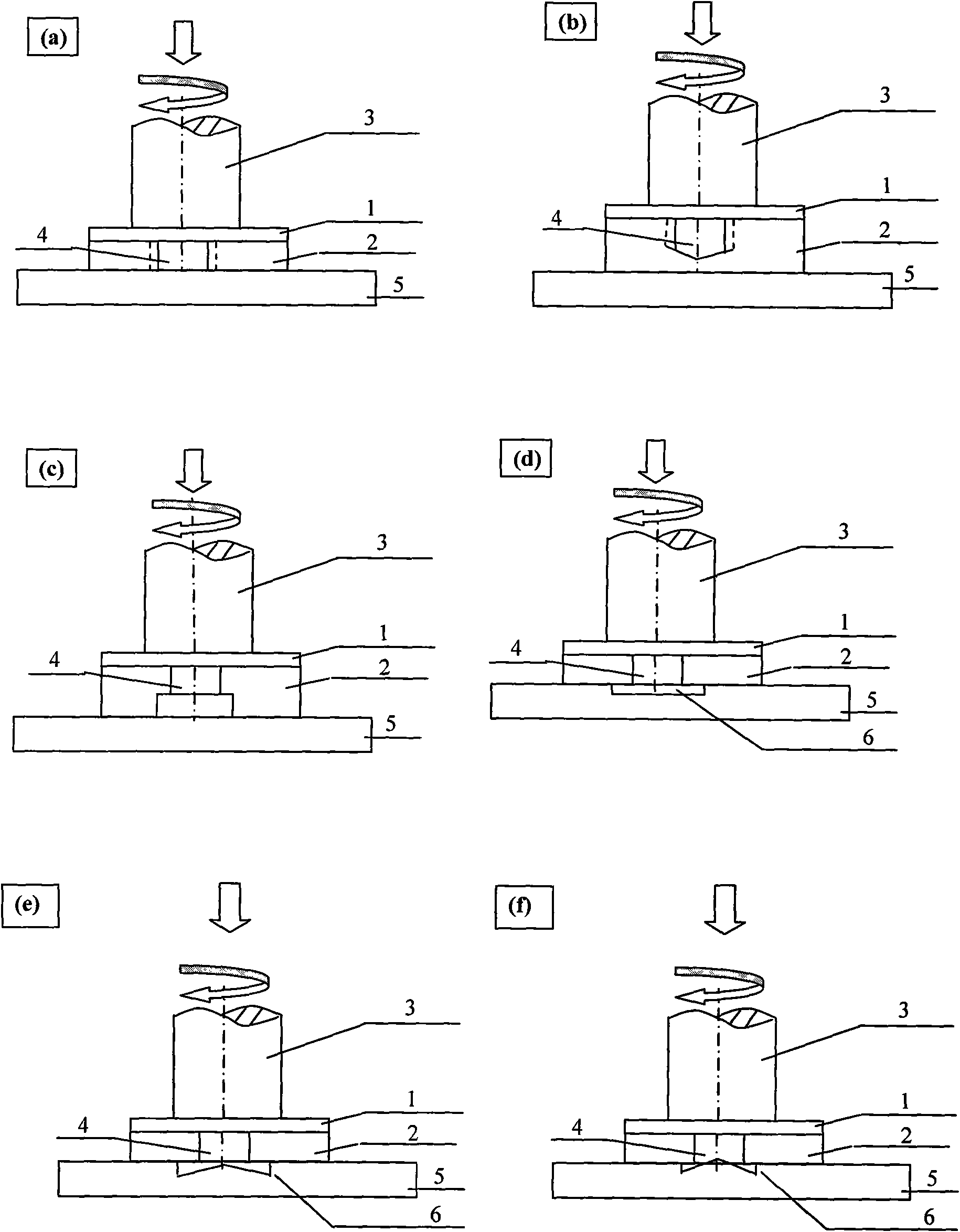

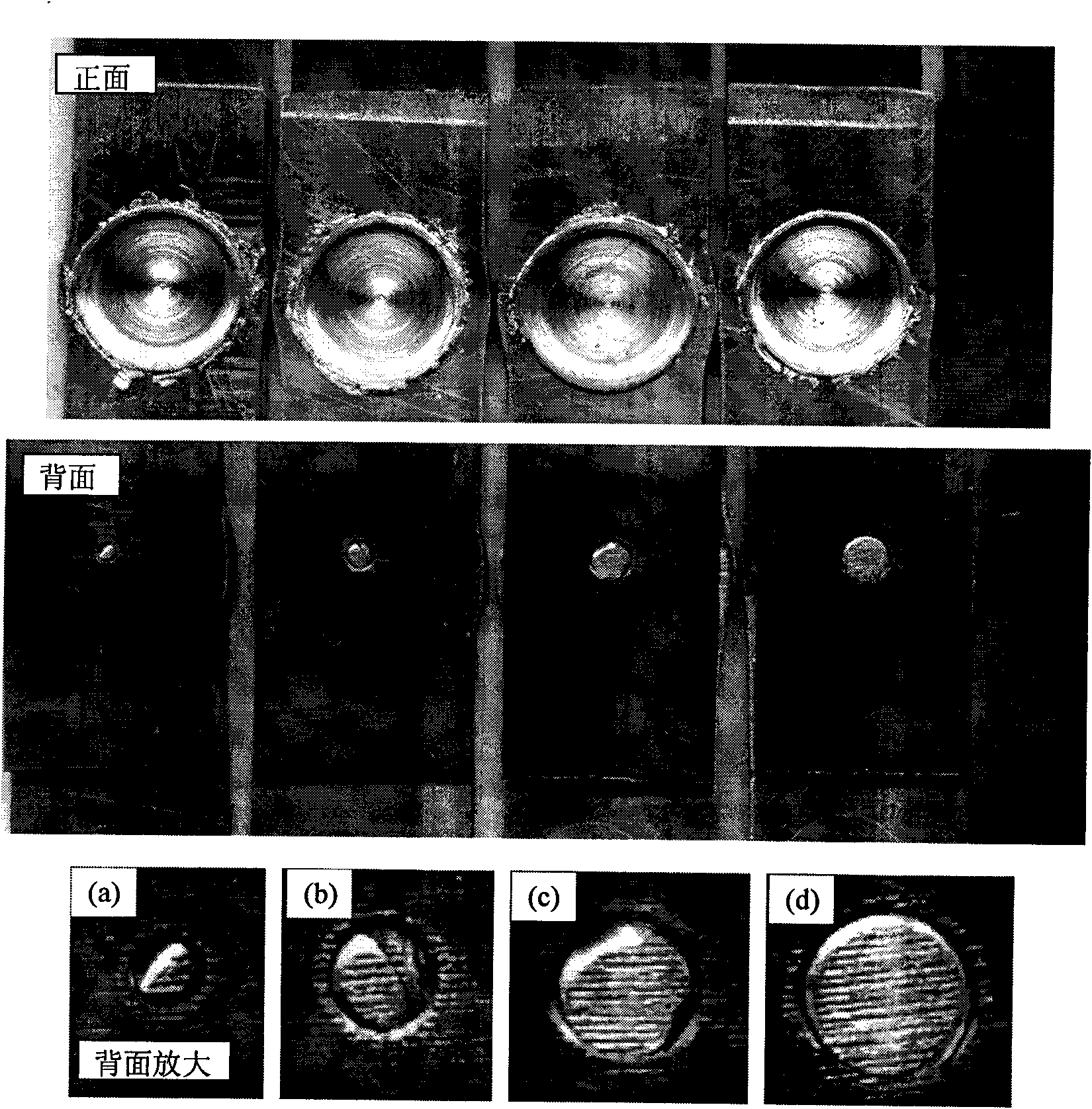

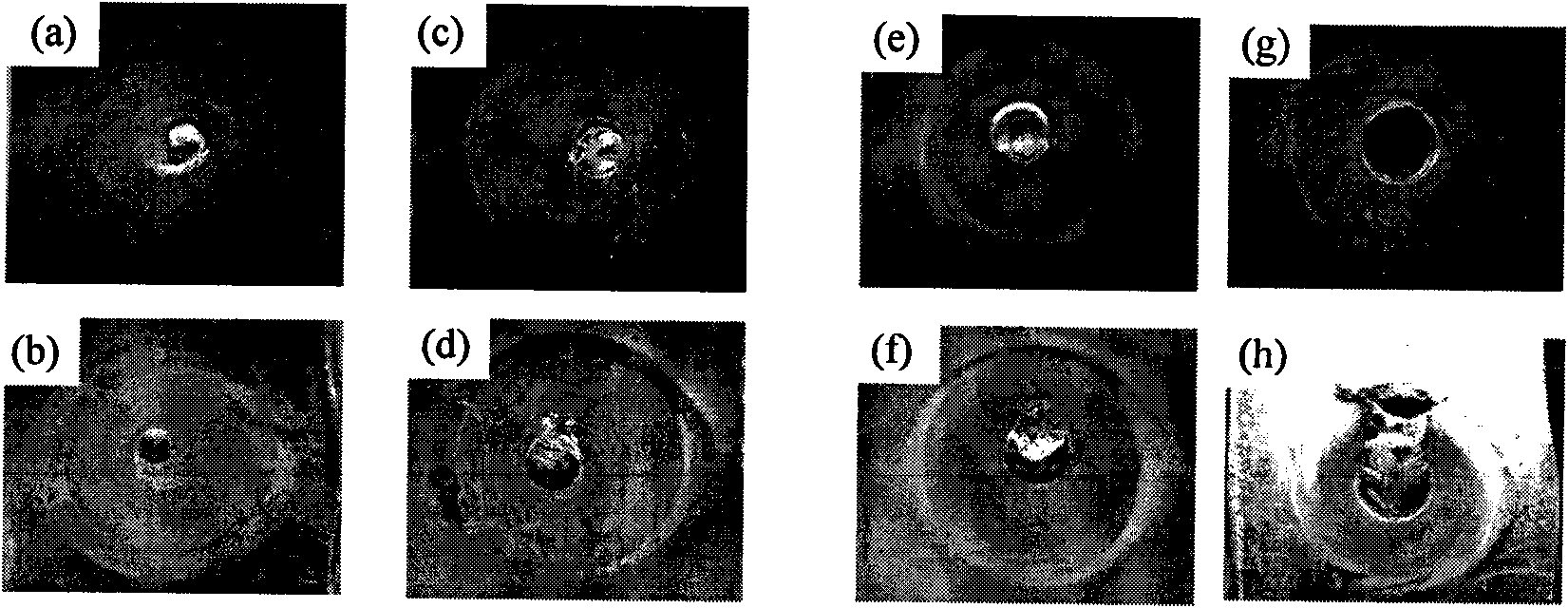

Embedded stirring friction spot welding method

InactiveCN101670482AAvoid wear and tearImprove flatnessNon-electric welding apparatusKeyholeMagnesium

The invention relates to an embedded stirring friction spot welding method which can be used for the overlapping spot welding of heterogeneous or homogeneous metal and is particularly suitable for theoverlapping between aluminum or magnesium and a harder heterogeneous metal material. The method comprises the following procedures: firstly, drilling on a harder second base material in advance and tapping in a hole or respectively drilling two coaxial holes with unequal diameters on both surfaces of the harder second base material; adopting a subplate with a glenoid die on light holes with equaldiameters; then assembling in an overlapping form and demanding that an aluminum plate is arranged above the harder second base material and the hole of the harder second base material, which has a small diameter, is arranged at the upper side; starting a pin-free type stirring head to rotate and leading the pin-free type stirring head to be in contact with the surface of an upper base material;limiting the press depth of the stirring head within 0.25-1 mm or so without penetrating through the welding interface; rubbing for several seconds and then rotatably extruding an upper plate into thehole of a harder lower plate to finish welding. Compared with the traditional stirring friction spot welding technology, the method prevents the abrasion of the hard second base material on a tool, prolongs the service life of the tool, has no keyhole on a joint and has smooth appearance.

Owner:XI AN JIAOTONG UNIV

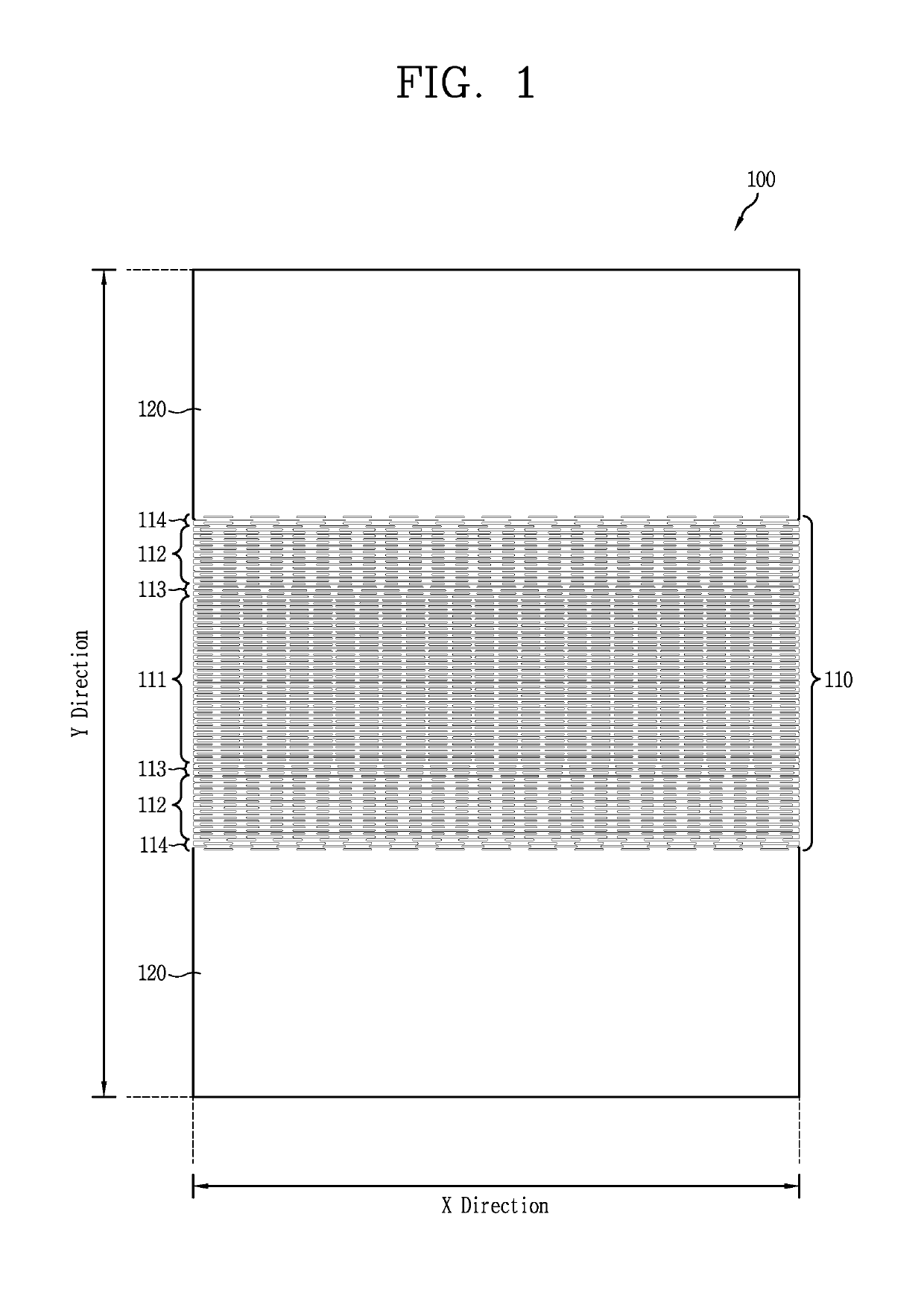

Flexible display unit and mobile terminal having the same

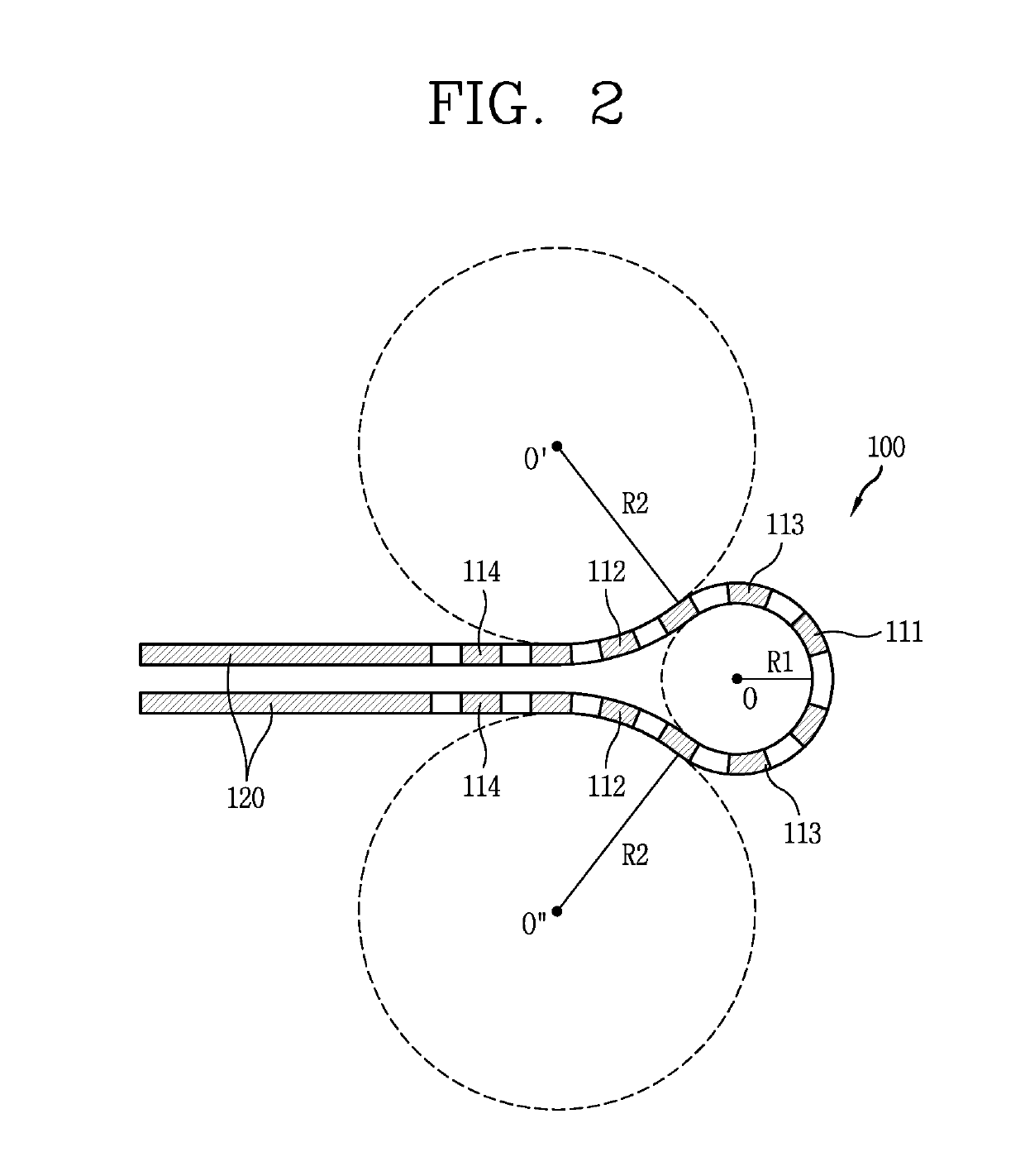

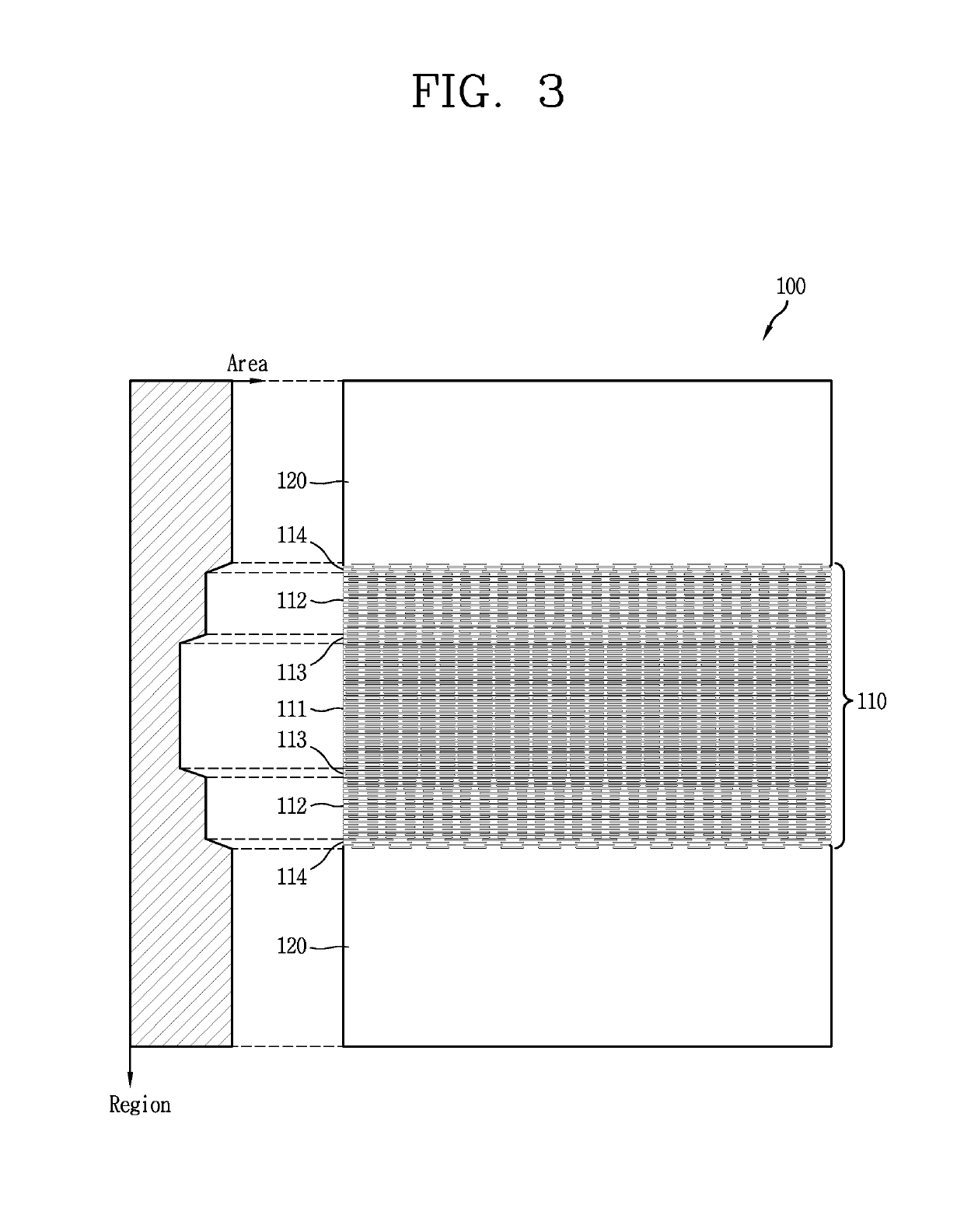

ActiveUS20190132947A1Lower yield strengthLarge strainCircuit bendability/stretchabilityDigital data processing detailsDisplay deviceEngineering

A flexible display unit is disclosed including a flexible display, and a flexible frame coupled to the flexible display, the flexible frame including a first rigid portion, a second rigid portion, and a flexible portion located between the first and second rigid portions and configured to permit the frame to be bent, the flexible portion including a first region including a first plurality of holes having a first size, and a second region including a second plurality of holes having a second size, wherein the first size is greater than the second size, the first region is positioned closer to a center axis of the flexible frame than the second region, and an area of the first plurality of holes within a portion of the first region is greater than an area of the second plurality of holes within a portion of the second region having the same area.

Owner:LG ELECTRONICS INC

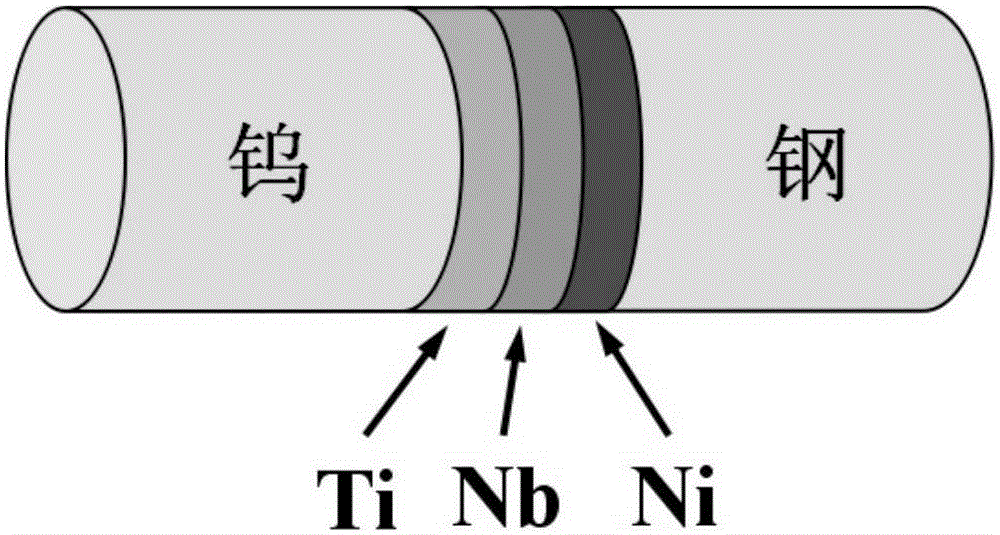

High-performance tungsten/steel composite material based on high-temperature application and preparation method thereof

ActiveCN105216394AHigh tensile strength at room temperatureImprove high temperature mechanical propertiesLaminationLamination apparatusNiobiumJoint stress

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

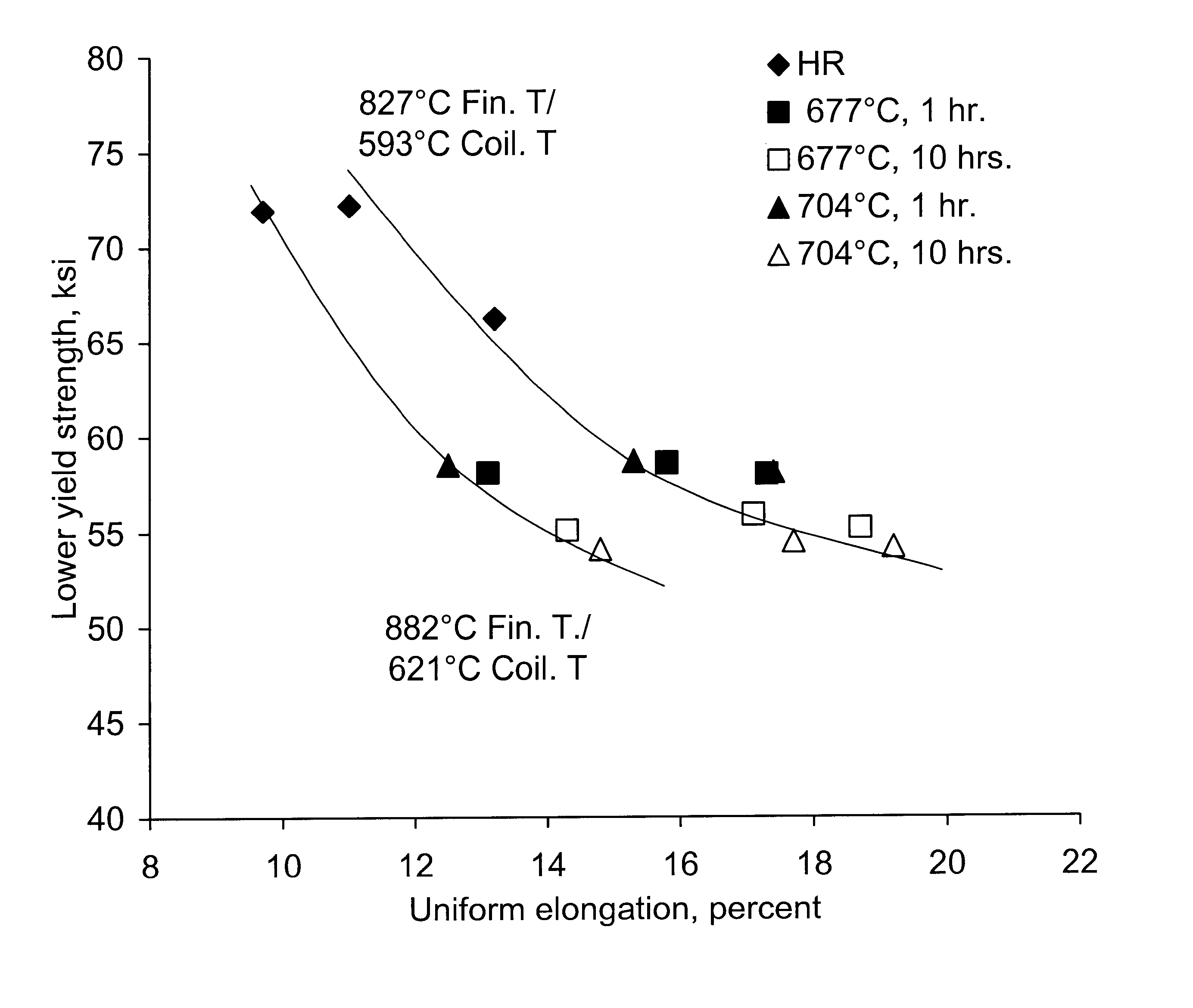

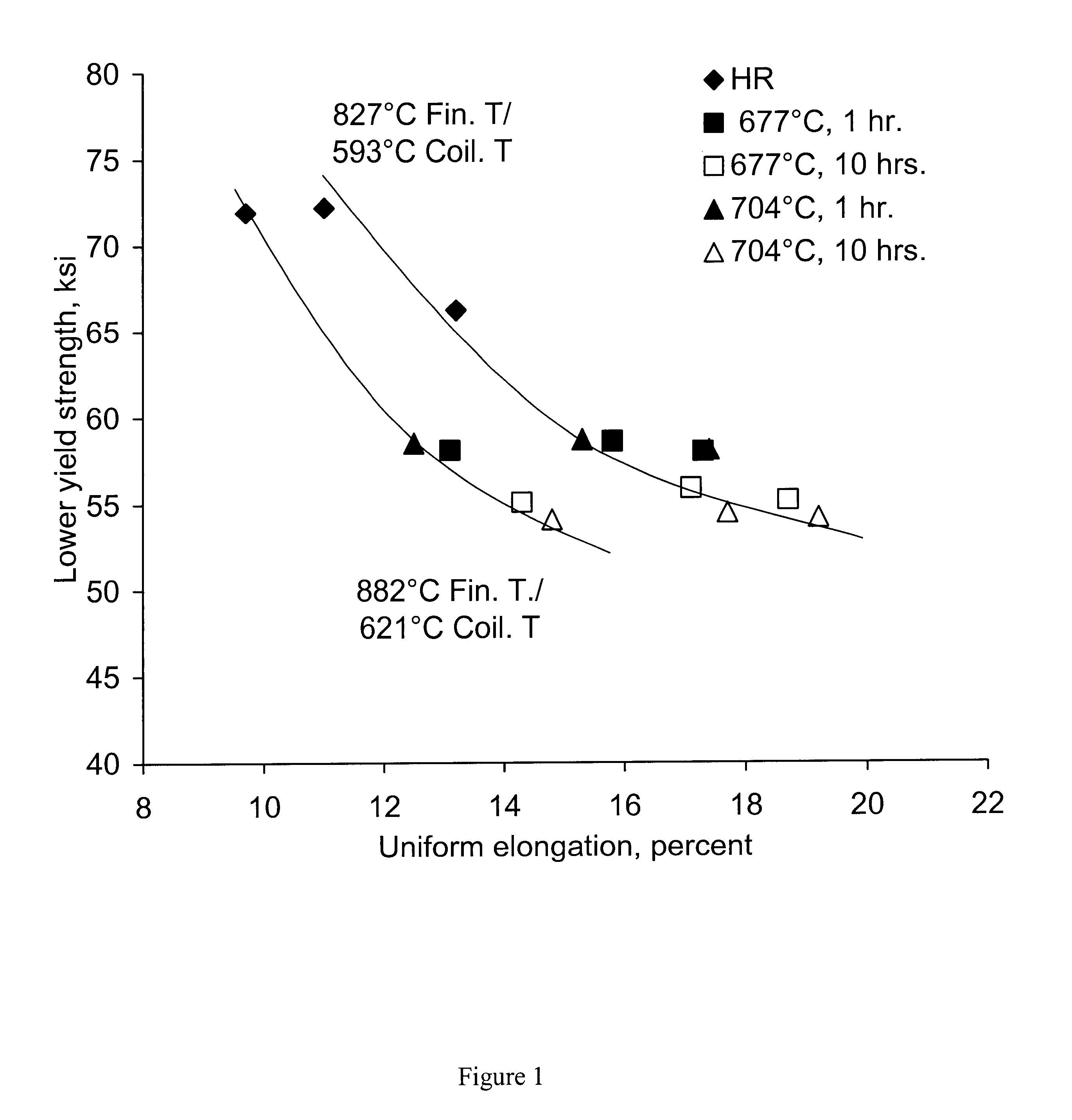

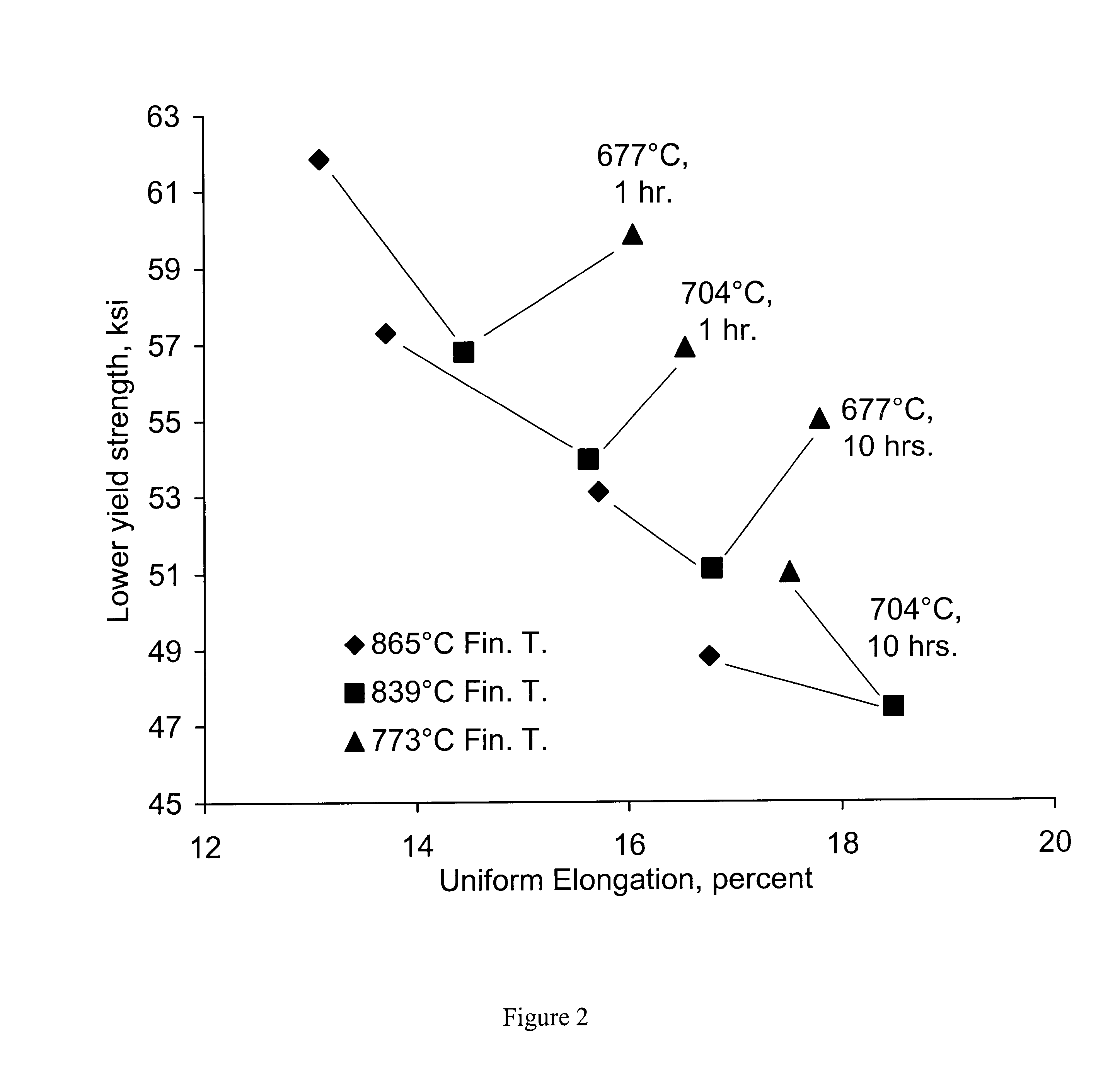

Medium carbon steel sheet and strip having enhanced uniform elongation and method for production thereof

A method is provided for producing medium carbon steel sheet and strip with enhanced uniform elongation for deep drawing applications. In one embodiment, a steel slab containing carbon 0.30 / 0.70%, manganese 0.75 / 2.0%, silicon up to 1.0% max., total aluminum 0.020 / 0.10%, the balance iron and incidental impurities is hot rolled to strip at a finishing temperature within the range of 839° C. (1542° F.) to 773° C. (1424° F.) and spheroidize annealed at a temperature below the A1 temperature. In a second embodiment, a steel slab containing 0.40 minimum / 0.70% maximum carbon, 0.50 / 1.50% manganese, up to 1.0% silicon, 0.020 / 0.10% total aluminum, the balance iron and incidental impurities is hot rolled, cold rolled and spheroidize annealed, with various combinations of manganese and silicon within the above ranges providing lower yield strength at levels of 60 ksi, 70 ksi, and 80 ksi with minimum 14% uniform elongation.

Owner:NITED STATES STEEL CORP

Aluminum alloy material with high bake hardening capability for 6-series automobile bodies

InactiveCN101985707AHigh bake hardening propertiesLower yield strengthSolution treatmentNatural aging

The invention provides an aluminum alloy material with high bake hardening capability for 6-series automobile bodies, which comprises the following components: 0.50-1.00wt% of Si, 0.60-1.30wt% of Mg, 0.01-0.30wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, less than or equal to 0.15wt% of Ti, 0.05-0.25wt% of Fe and the balance of Al. After the material is formed by casting, the material is treated by homogenizing annealing, hot rolling, cold rolling, solution treatment and then natural aging. Before stamping, the yield strength of the material is lower than 130MPa; and after baking, the yield strength of the material is greater than 230MPa, and the tensile strength of the material is greater than 310MPa. The material has higher bake hardening ability, and simultaneously, the forming property of the material meets the using requirements, thus the material is an ideal material for manufacturing automobile bodies.

Owner:苏州有色金属研究院有限公司

Impact stage low carbon steel hot-rolled sheet and mfg. method thereof

InactiveCN1752261ALower yield strengthLow yield ratioTemperature control deviceMetal rolling arrangementsAlloyConductor Coil

A hot-rolled low-carbon steel sheet for punching contains proportionally C, Mn, S, P, Si, Al, Fe, Cr, B, Ti and Nb. Its preparing process includes such steps as heating to 1100-1150 deg.C, primary rolling, water cooling, fine rolling, winding, recrystallizing at 600-700 deg.C and annealing. Its advantages are high deep punching performance, plasticity, tension strength, and elongation percentage, and low yield strength.

Owner:YANSHAN UNIV

Aluminum alloy for vehicle body plate and method for manufacturing same

The invention provides an aluminum alloy used on an automotive body board, and a manufacture method thereof. The aluminum alloy has the components as follows: Si is 0.8 to 1.5wt percent, Fe is 0.05 to 0.20wt percent, Cu is 0.01 to 0.11wt percent, Mn is 0.02 to 0.1.wt percent, Mg is 0.51 to 0.7wt percent, Cr is 0.1wt percent, Zn is 0.25wt percent, Ti is 0.15wt percent, rare-earth Ce is 0.01 to 0.2wt percent, and the other weight percentage is composed of Al. The invention has the technology that the Al is added in a resistance furnace first; master alloys that are AlSi20, AlCu50, AlMn10, AlCr5, and Al-5Ce are added and stirred when the Al is melted down and the temperature of fused mass is 740 to 760 DEG C; the Mg, and the Zn are added when the temperature of the fused mass is reduced by 720 to 730 DEG C, and then the beating and refining are performed; Al-5Ti-B is added in and stirred when the temperature reaches 730 to 740 DEG C, and then the mixture is stood for 10 to 25 minutes, and is casted and molded in a cast iron die; then aluminum alloy cast ingot is processed through homogenization treatment, and rolled into thin slabs; the thin slabs are processed through water quench after solution treatment, so that finished products are obtained. The aluminum alloy has better roasting hardening capacity, has lower yield strength and higher plasticity before punching, facilitates for punching and molding, and has increased yield strength after roasting hardening so as to satisfy the shock resistance request of the automotive body board.

Owner:CHINA ALUMINUM INT ENG CORP

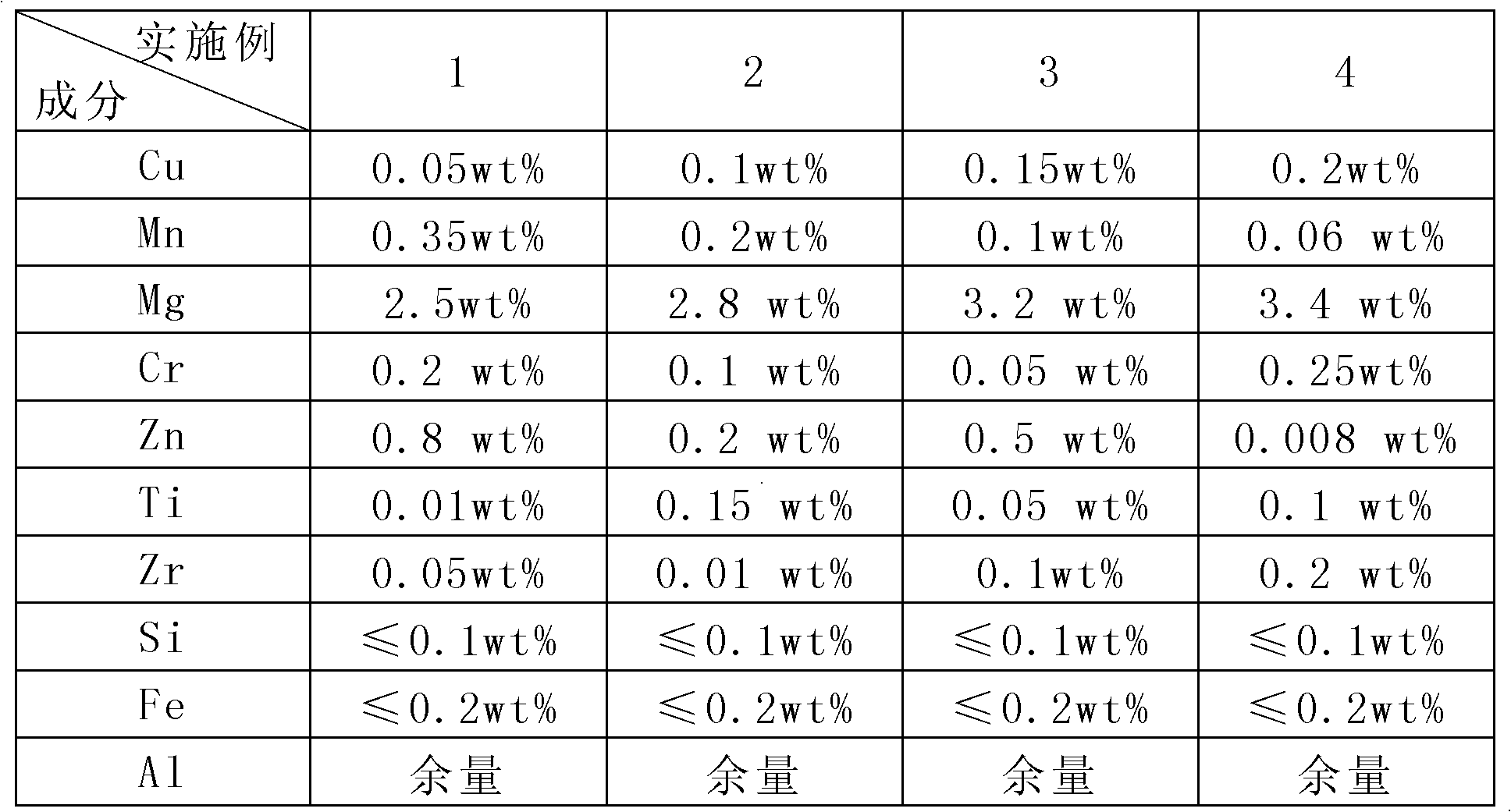

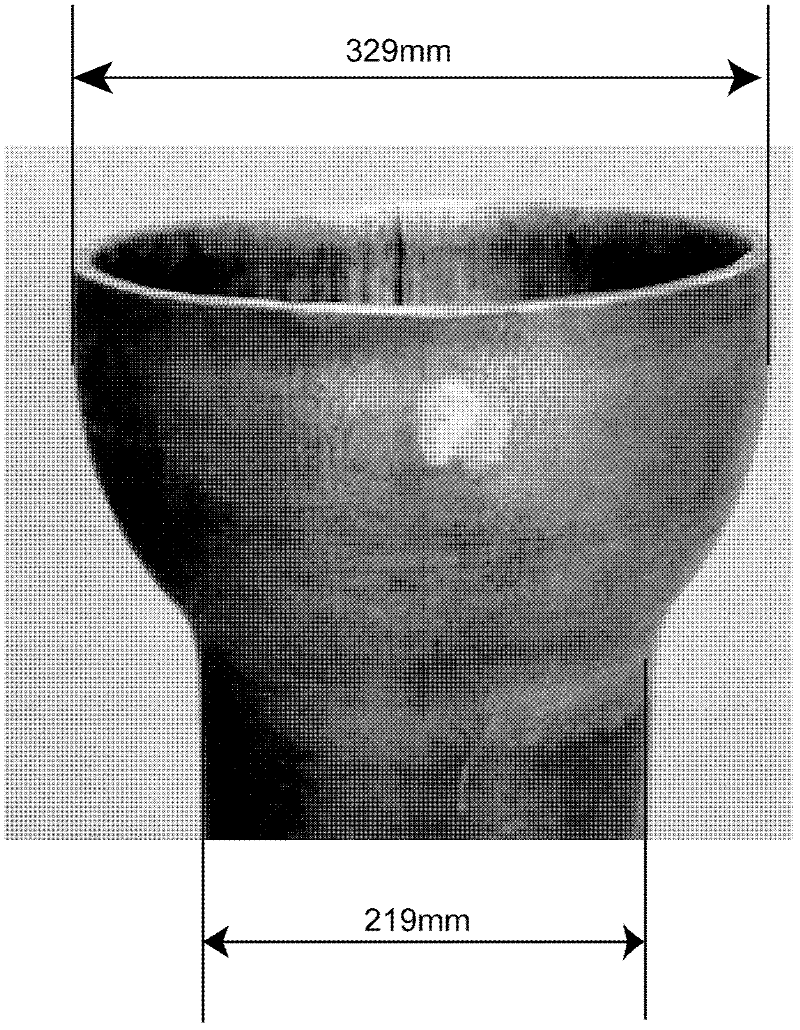

Al-Mg alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880803AImprove corrosion resistance and plasticityGood impact resistanceMg alloysAluminium alloy

The invention provides Al-Mg alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the problem that the existing 5754 series alloys have poor strength and impact resistance. The alloys comprise the following components in percentage by weight: 0.001-0.25wt% of Cu, 0.05-0.35wt% of Mn, 2.5-3.5wt% of Mg; 0.005-0.25wt% of Cr, 0.008-0.8wt% of Zn, 0.01-0.15wt% of Ti, 0.001-0.2wt% of Zr, not more than 0.2wt% of Si, not more than 0.3wt% of Fe and the balance Al. The alloys have the advantages of good impact resistance and plasticity and strong feasibility, and the manufacturing method has the advantage of realizing the aims of energy conservation and emission reduction in the process of machining.

Owner:ZHEJIANG GKO IND CO LTD

Steel for high-expansion-rate petroleum casing and method for manufacturing petroleum casing

InactiveCN102517511ALower yield strengthHigh deformation strengthening rateDrilling rodsFurnace typesSteel platesSteel tube

The invention discloses steel for a high-expansion-rate petroleum casing and a method for manufacturing the petroleum casing, which relates to an iron-based alloy. The petroleum casing consists of the raw material elements in percentage by mass: 0.03-0.25 percent of C, 0.3-2.5 percent of Si, 0.5-4.0 percent of Mn, 0-0.5 percent of Cr, less than or equal to 0.02 percent of S, less than or equal to0.02 percent of P and the balance of Fe; one, two or three of 0.01-0.12 percent by mass of Nb, 0.01-0.06 percent by mass of Ti and 0.01-0.12 percent by mass of V can be added; a steel pipe blank or asteel plate is manufactured by smelting; and a high-expansion-rate seamless petroleum casing is manufacturing with the steel pipe blank by using a seamless pipe molding technology and a high-expansion-rate seamed petroleum casing is manufactured by adopting straight slit resistance welding with the steel plate. The expansion rate of the manufactured petroleum casing is more than or equal to 30 percent, and the defects of low expansion rate and high cost of the conventional expandable casing for an oil-gas well are overcome.

Owner:HEBEI UNIV OF TECH

Hot-rolling double-phase weather-resistant steel plate and mfg. method thereof

InactiveCN1752260ALower yield strengthHigh tensile strengthTemperature control deviceDouble phaseDual-phase steel

A hot-rolled dual-phase steel plate with high mechanical performance, cold processibility, weldability and weatherability contains proportionally Fe, C, P and Cu, and is prepared through heating raw plate to 1100-1250 deg.C, hot rolling, cooling to 400-650 deg.C, and winding or fast cooling. Its structure is composed of ferrite and martensite.

Owner:YANSHAN UNIV

Soft tin-plate of hardness HR30T 51+/-3 and its making process

ActiveCN1888113ALower yield strengthReduce hardnessRoll mill control devicesFurnace typesHardnessTin plating

The soft tin-plate of hardness HR30T 51+ / -3 consists of C not more than 0.005 wt%, Mn 0.20-0.30 wt%, Al 0.03-0.06 wt%, Si not more than 0.03 wt%, Ti 0.03-0.06 wt%, P not more than 0.012 wt%, S not more than 0.015 wt%, N not more than 0.003 wt%, O not more than 0.004 wt%, and Fe and inevitable impurities for the rest. Its production process includes the following steps: smelting steel, continuous casting and rolling, hot rolling, acid pickling and rolling, continuous annealing, flattening and tin plating.

Owner:BAOSHAN IRON & STEEL CO LTD

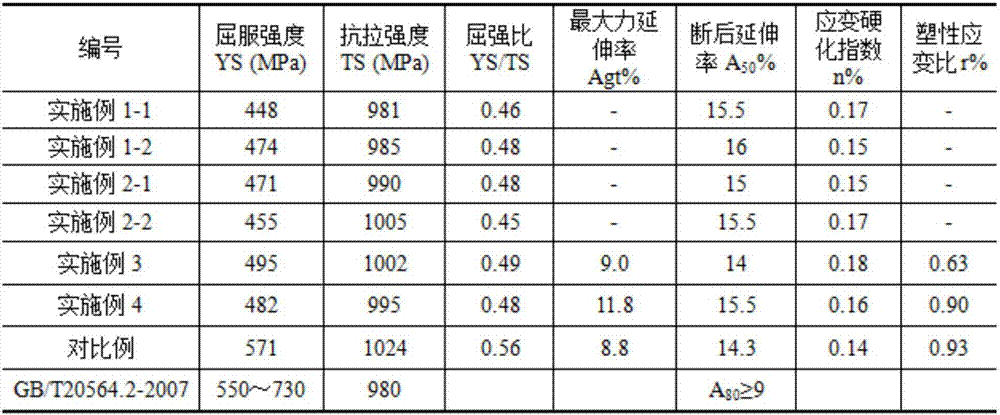

Ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and manufacturing method thereof

The invention discloses ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and a manufacturing method of the ultralow yield ratio 980 MPa-grade cold rolling two-phase steel, and belongs to the technical field of two-phase steel. Chemical components of the steel comprise, by weight, 0.13-0.18% of C, 0.3-0.6% of Si, 1.7-2.4% of Mn, 0.03-0.06% of Als, 0-0.05% of Nb, 0.3-0.5% of Cr and the balance Fe and inevitable impurities. In composition design, the composite strengthening way mainly comprising phase transformation strengthening and combining solid solution strengthening, refined crystalline strengthening, phase change strengthening and precipitation strengthening is adopted, the cold rolling two-phase steel plate can be used as an automobile anti-collision part, a structural part and an inner plate material. The steel has the advantages that DP980 has the ultralow yield ratio YS / TS which is smaller than 0.50, good ductility A50 which is larger than or equal to 14%, the high n value, the small mechanical property fluctuation range, the low process sensitivity and other property characteristics, can reduce springback after stamping and is beneficial to follow-up deep processing of the automobile industry.

Owner:CENT IRON & STEEL RES INST

Steel used for solid expandable casing of oil and gas well and manufacturing method of expandable casing

ActiveCN101805871APerformanceHigh elongationTemperature control deviceMetal rolling arrangementsAlloyUltimate tensile strength

The invention relates to a steel used for a solid expandable casing of an oil and gas well and a manufacturing method of the expandable casing, which are applied to prepare the expandable casing of the oil and gas well in oil and gas industry. The steel alloy material used for the solid expandable casing of the oil and gas well comprises the following components in percentage by mass: 0.1-0.3% of C, 1.5-3.5% of Mn, 1-2.5% of Si, 0.1-3% of Al, less than or equal to 0.010% of P, less than or equal to 0.005 % of S, 0.003-0.010% of Ca, less than or equal to 0.0007% of N and the balance of Fe. The preparation method comprises the steps of vacuum melting, continuous casting and homogenizing annealing; hot rolled plate coils are prepared via controlling rolling and cooling, and the hot rolled plate coils are used for producing straight seam resistance welded steel pipes; and expandable pipe materials can be obtained via two stages of isothermal heat treatment. Threads are processed at both ends of each steel pipe. The invention has the effects that the expandable casing has the characteristics of high uniform elongation, high plasticity, low yield strength, low yield ratio and the like before expansion, and has high strength, enough plasticity, good welding seam quality and performance after expansive deformation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

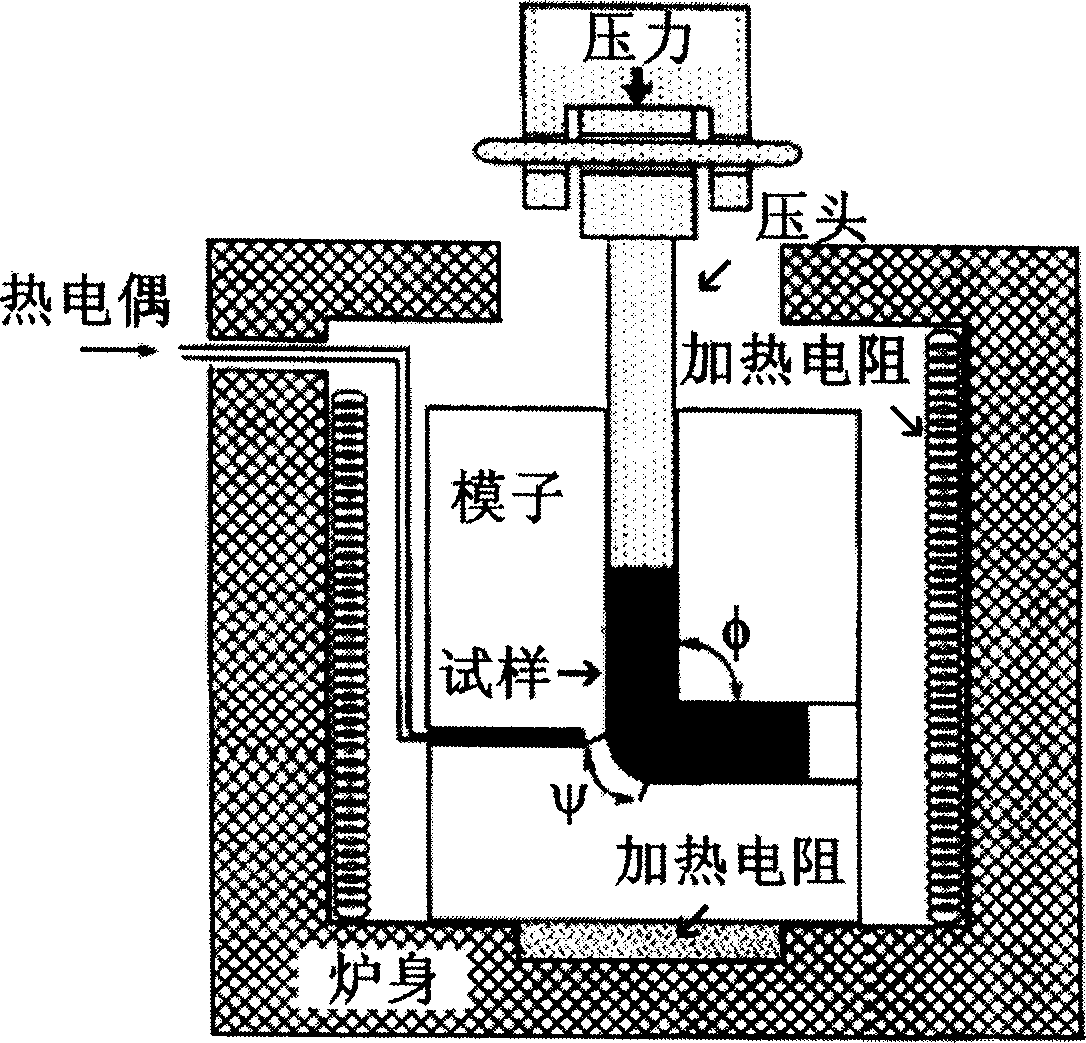

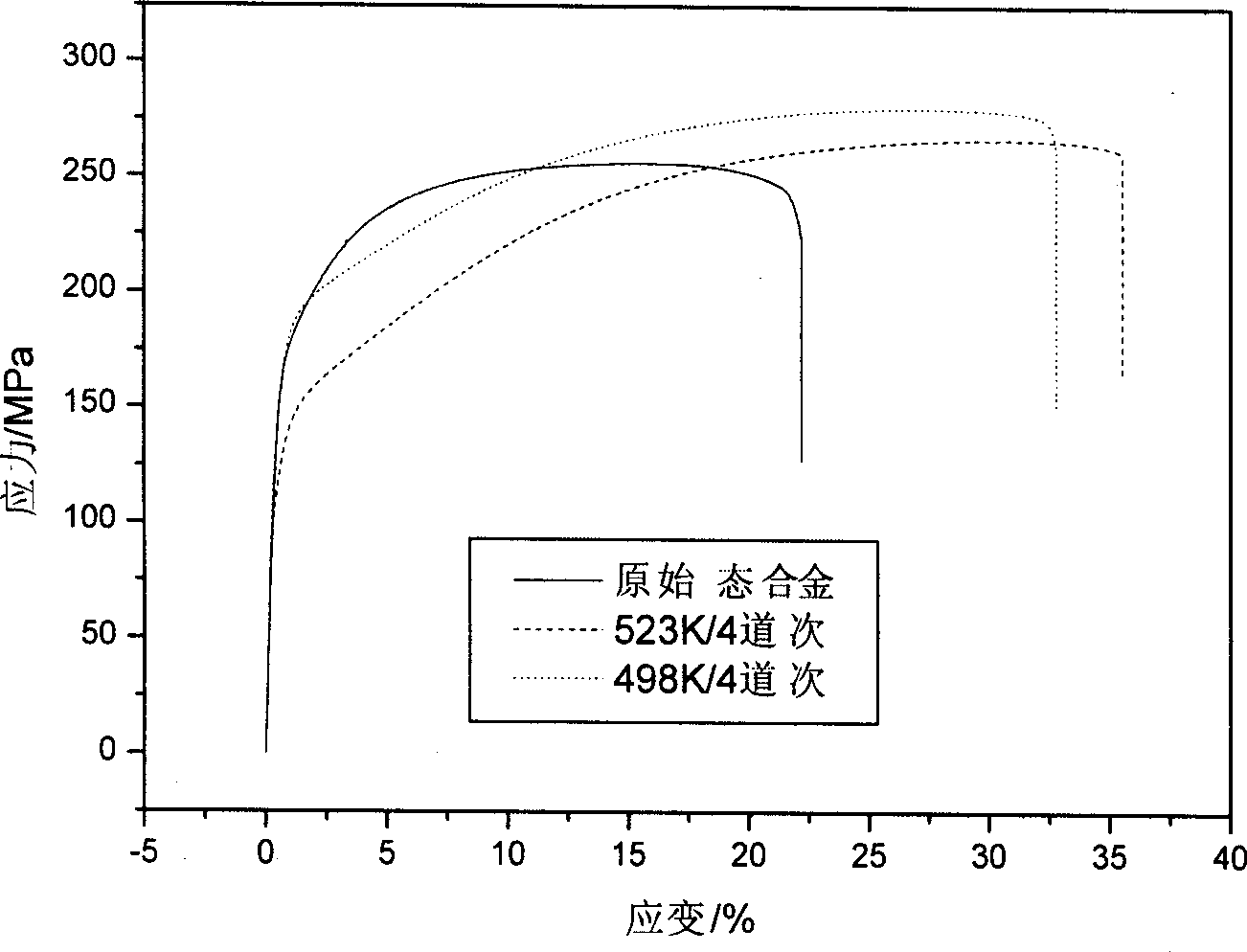

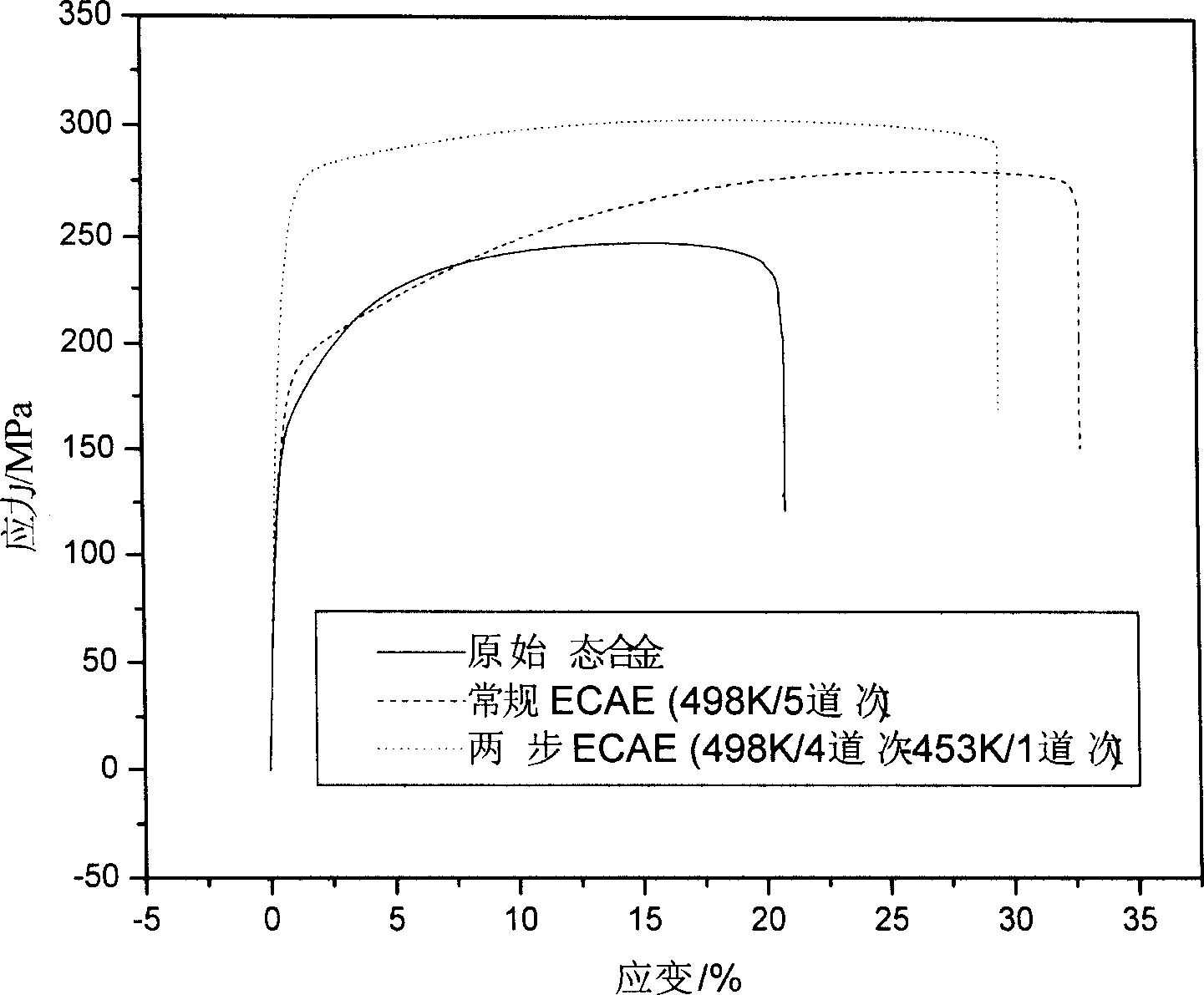

Method for extrusion two-step equal channel angle of magnesium alloy

InactiveCN1792487AGrain refinementImprove organizational structureExtrusion control devicesEqual channel angular extrusionMaterials processing

A two-step squeeze method with equal channel angle for Mg-alloy includes such steps as designing equi-channel squeezing die set, regulating deformation speed and temp to find out the lowest temp for non-crack deformation, equichannel squeezing by 2-4 passes, lowering the deformation temp, and squeezing by 4-8 passes. Its advantage is high strength and toughness.

Owner:FENGYANG L S NET FORMING CO LTD

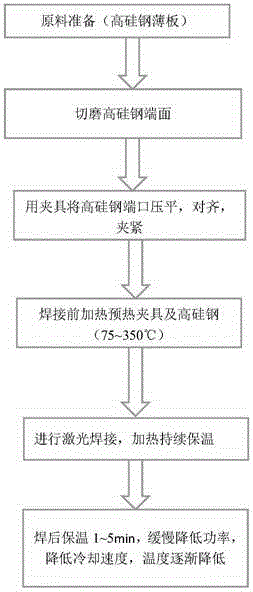

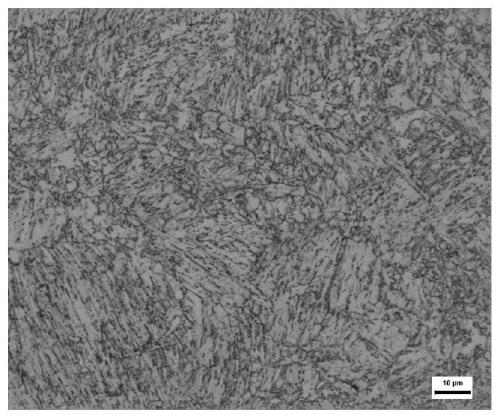

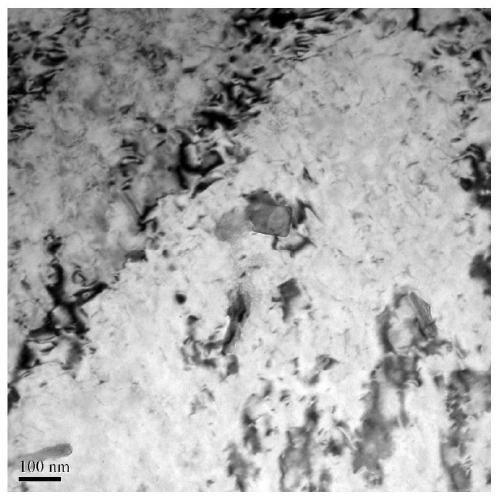

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

690MPa-stage anti-seismic fire-proof weather-proof building structure steel and preparing method thereof

The invention discloses 690MPa-stage anti-seismic fire-proof weather-proof building structure steel and a preparing method thereof. The steel comprises, by weight percent, 0.05 to 0.10% of C, 0.01 to0.30% of Si, 1.0 to 1.4% of Mn, 0 to 0.01% of P, 0 to 0.002% of S, 0.01 to 0.5% of Mo, 0.01 to 0.05% of Nb, 0.01 to 0.03% of Ti, 0 to 0.06% of V, 0.4 to 1.0% of Cr, 0.3 to 0.4% of Cu, 0.3 to 0.4% of Ni, 0 to 0.003% of B, 0.001 to 0.08% of N and the balance Fe and inevitable impurities. The preparing method comprises the steps of steel making, refining, continuous casting, steel blank heating, two-stage controlled rolling and controlled cooling and heat treatment. On the premise that the use property meets GB / T 19879 building structure steel plate needs, the yield strength is larger than or equal to 706 MPa, the yield ratio is smaller than or equal to 0.849, DNH coefficient is larger than or equal to 6.5%, at the temperature of 600 DEG C, heat preservation is carried out for one to three hours, the yield strength is not lower than 2 / 3 at the room temperature, meanwhile, the anti-seismic fire-proof weather-proof needs are met, and the property is excellent.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com