Patents

Literature

93 results about "Joint stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Joint Stress. Generic Name: aconitum napellus, arnica montana, calendula officinalis flowering top, hamamelis virginiana root bark/stem bark, hypericum perforatum, chickpea and toxicodendron pubescens leaf liquid Dosage Form: FOR ANIMAL USE ONLY Disclaimer: This drug has not been found by FDA to be safe and effective, and this labeling has not been approved by FDA.

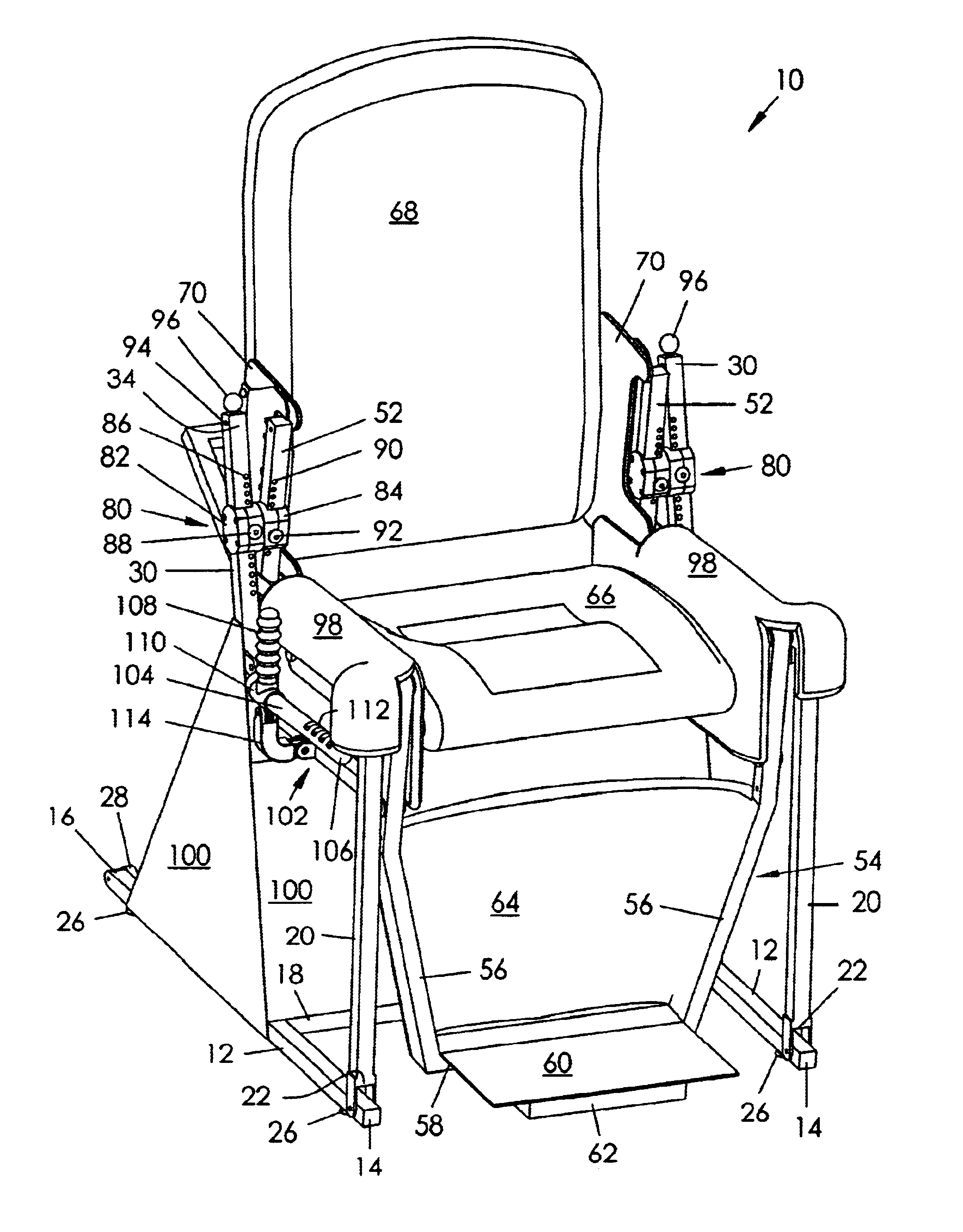

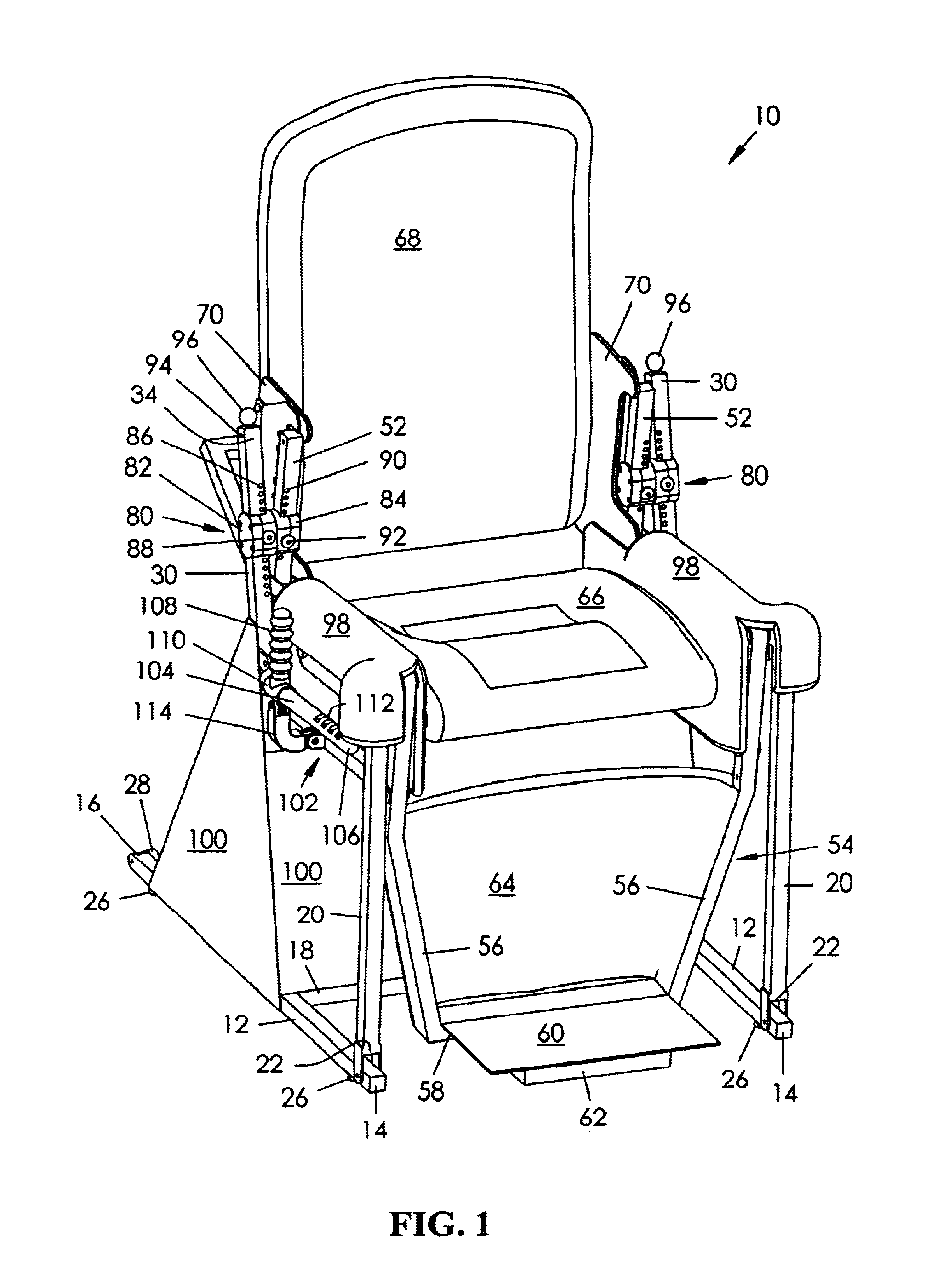

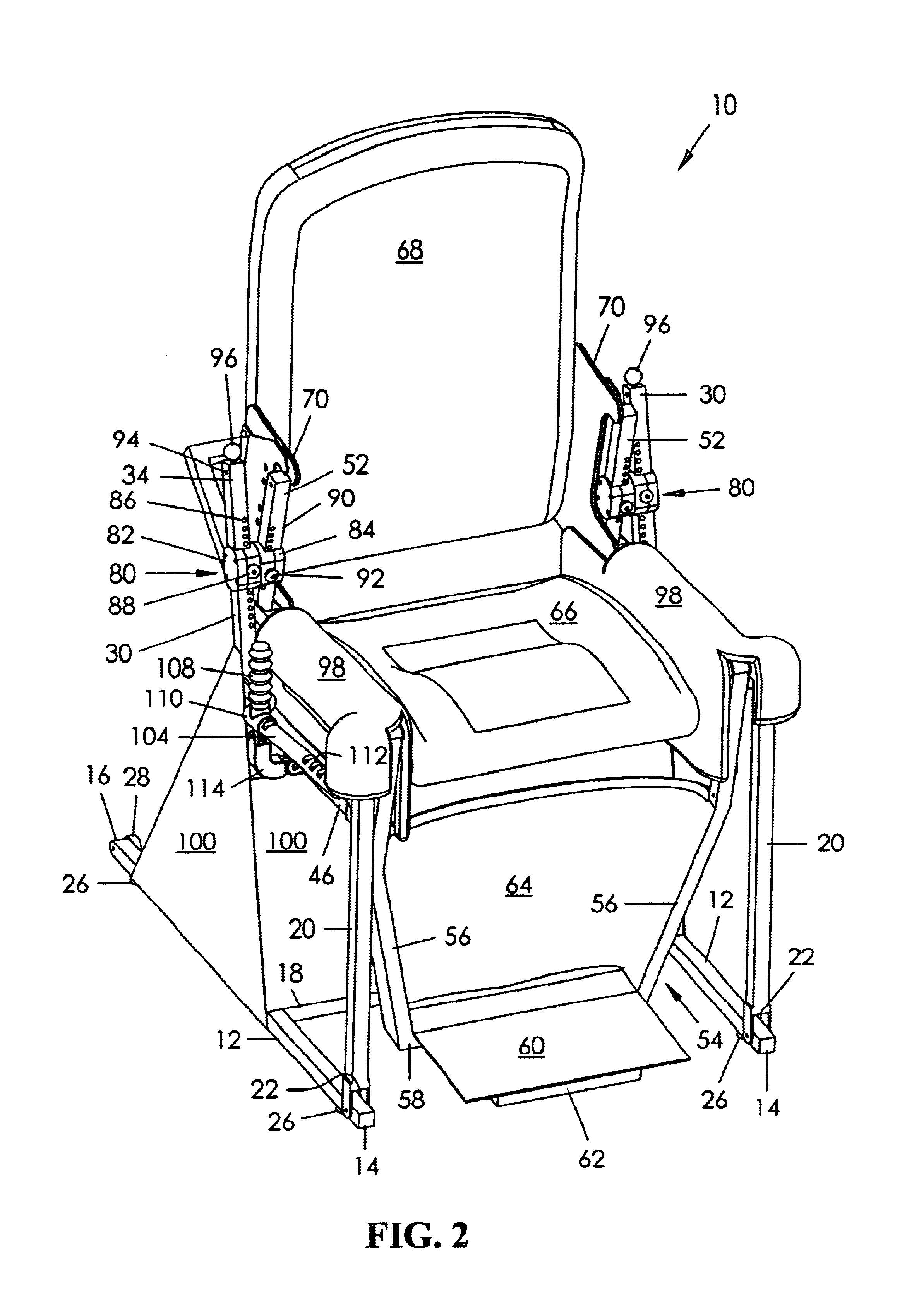

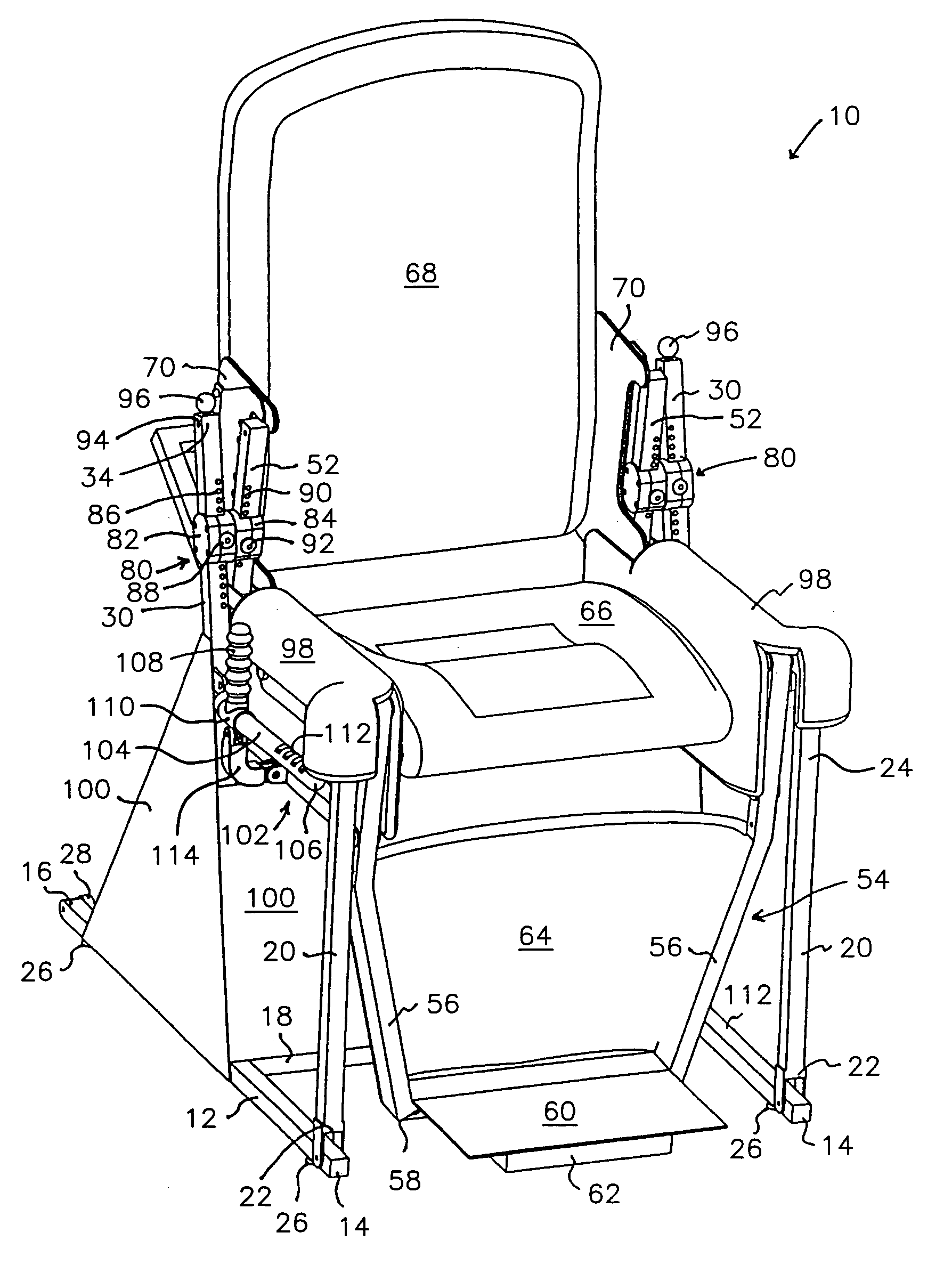

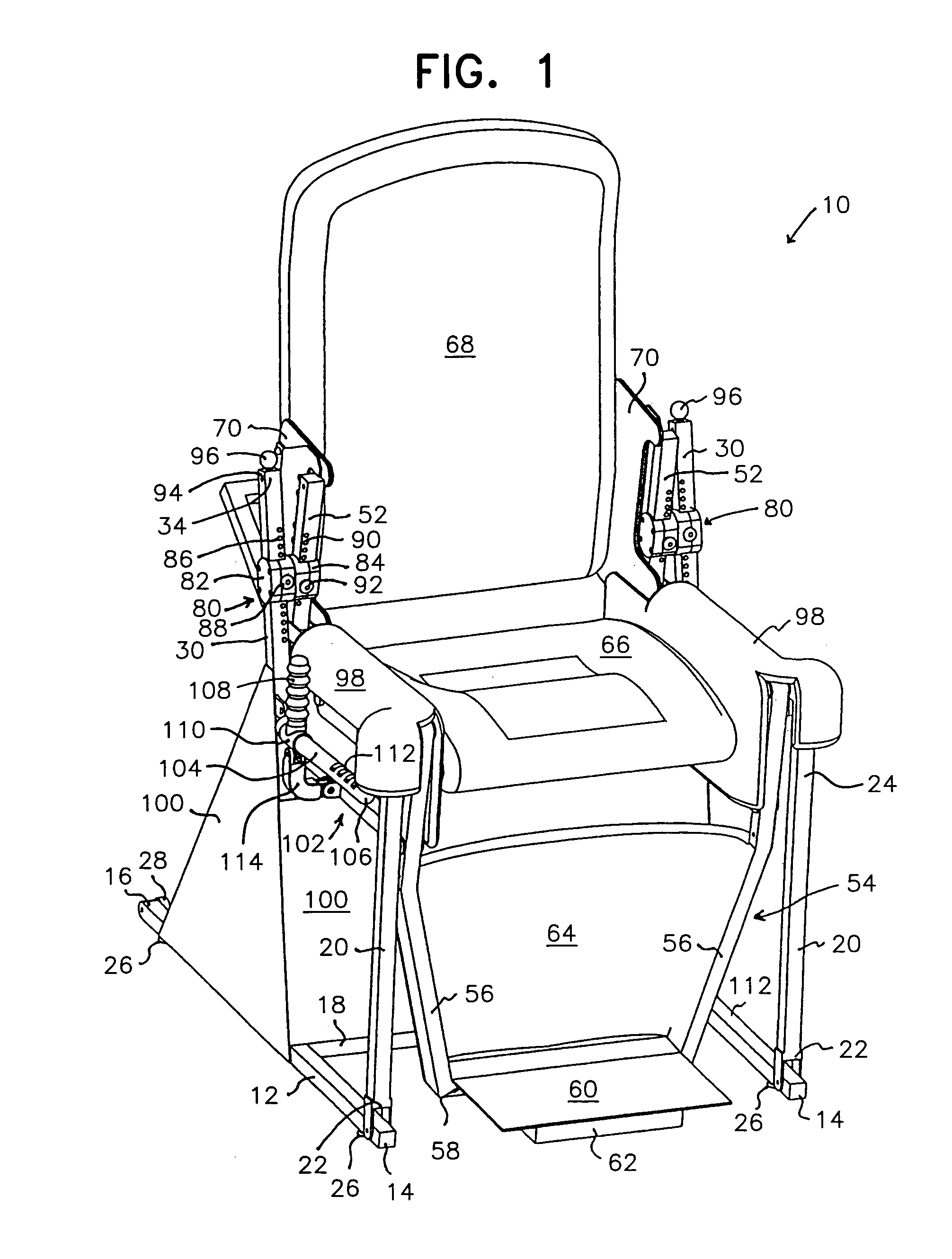

Low-resistance exercise and rehabilitation chair

InactiveUS6855098B2Easy to operateSmooth and low-resistance operation of apparatusOperating chairsDental chairsGear wheelEngineering

An exercise and rehabilitation chair includes a framework having lower frame members, pivotal front legs, and elongate rear legs. The chair includes a seat assembly having a seat bottom and seat back and upper arms, each upper arm being pivotally coupled at one end to a generally upstanding support arm and at an opposed end to a front leg. Bearing housings pivotally connect corresponding support arms and rear legs and establish a fulcrum about which the seat assembly may rotate. The bearing housings may be slidably positioned longitudinally along corresponding support arms and rear legs using pin fasteners or, alternatively, using motorized gear assemblies. The displacement of the fulcrum relative to a user's hips is adjustable for regulating the resistance of chair operation. A foot assembly is pivotally coupled to the front legs. All pivotal connections correspond anatomically to a user's joints for low joint stress and low-resistance exercise.

Owner:REITZ ALAN S +2

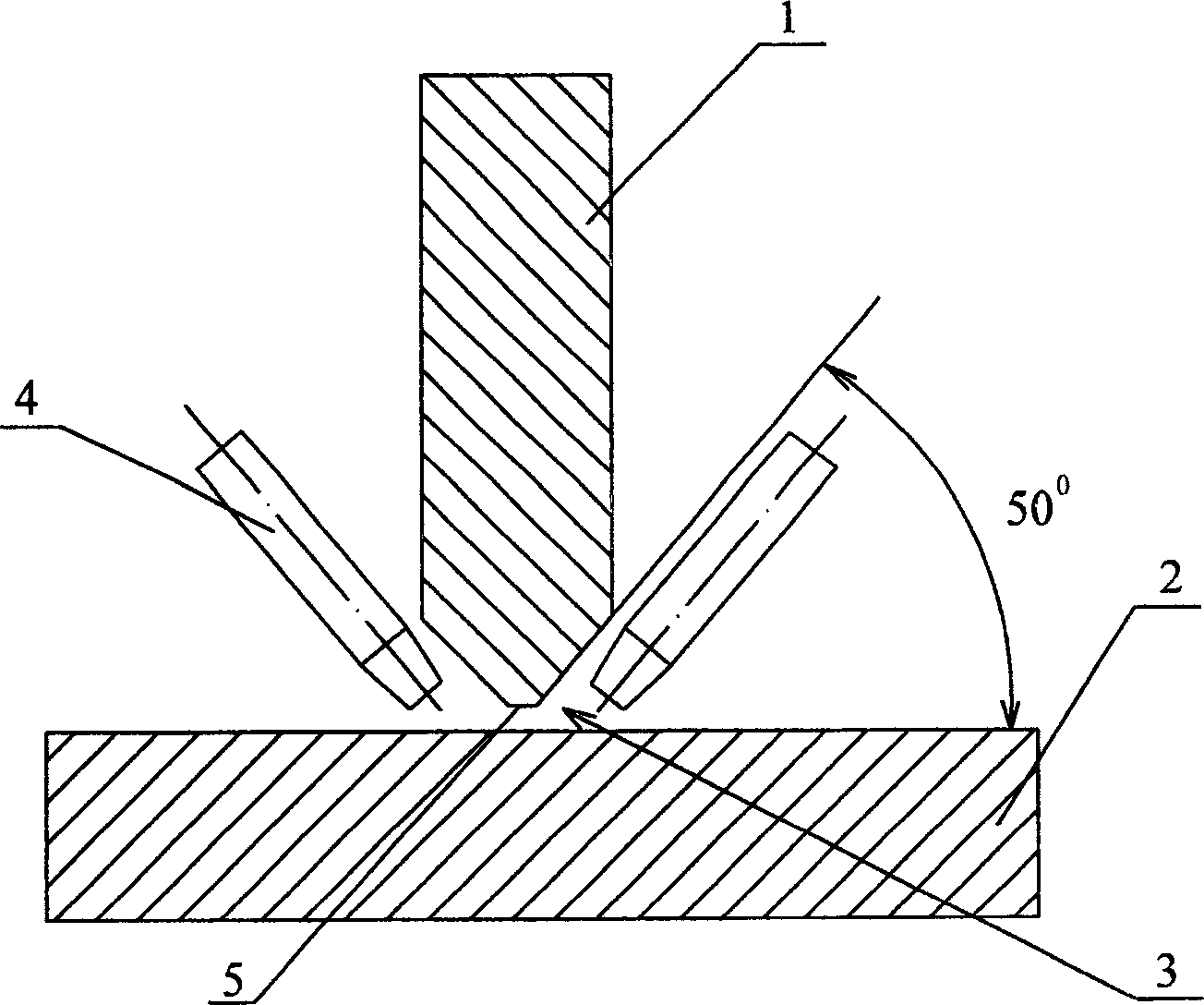

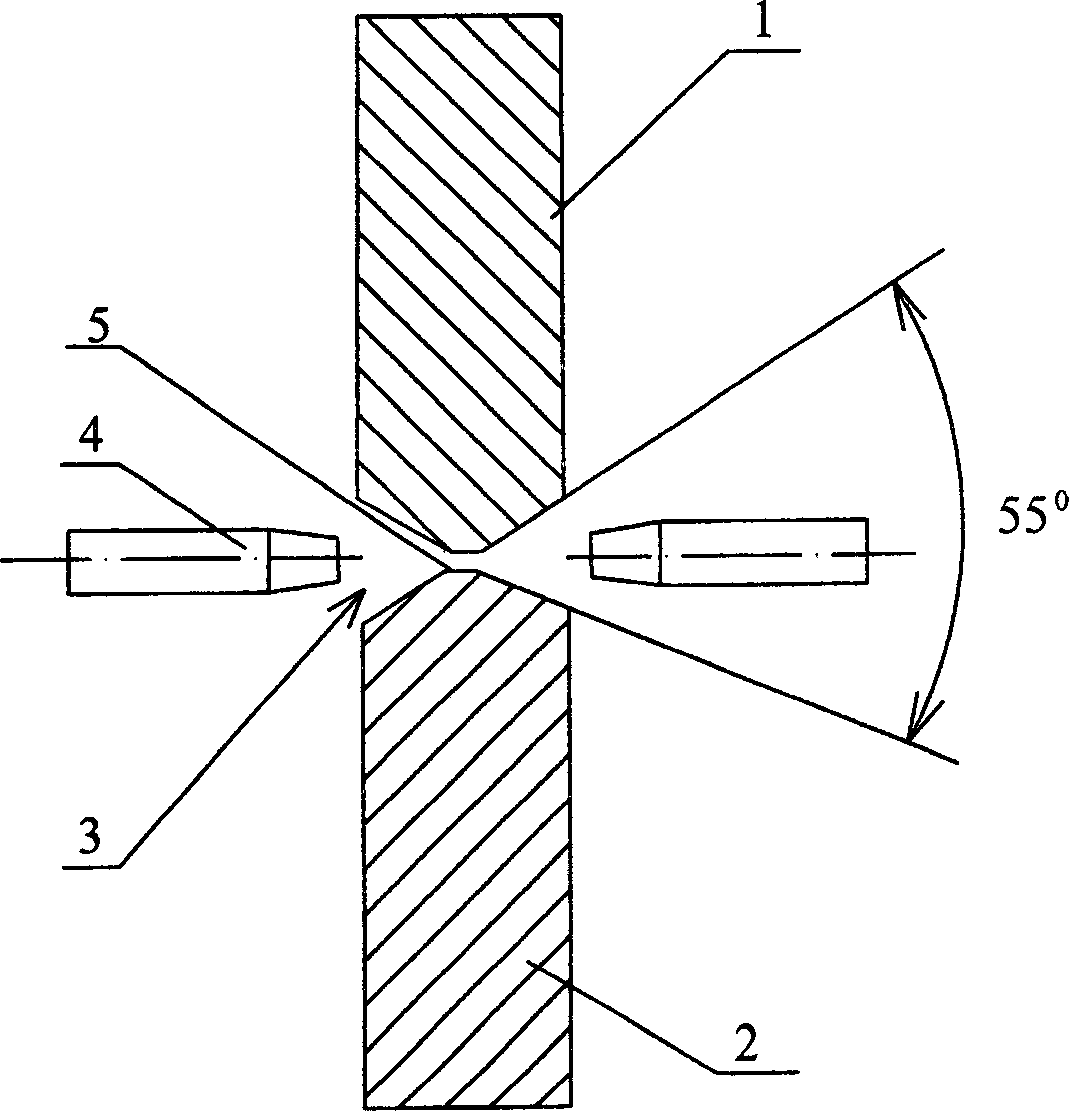

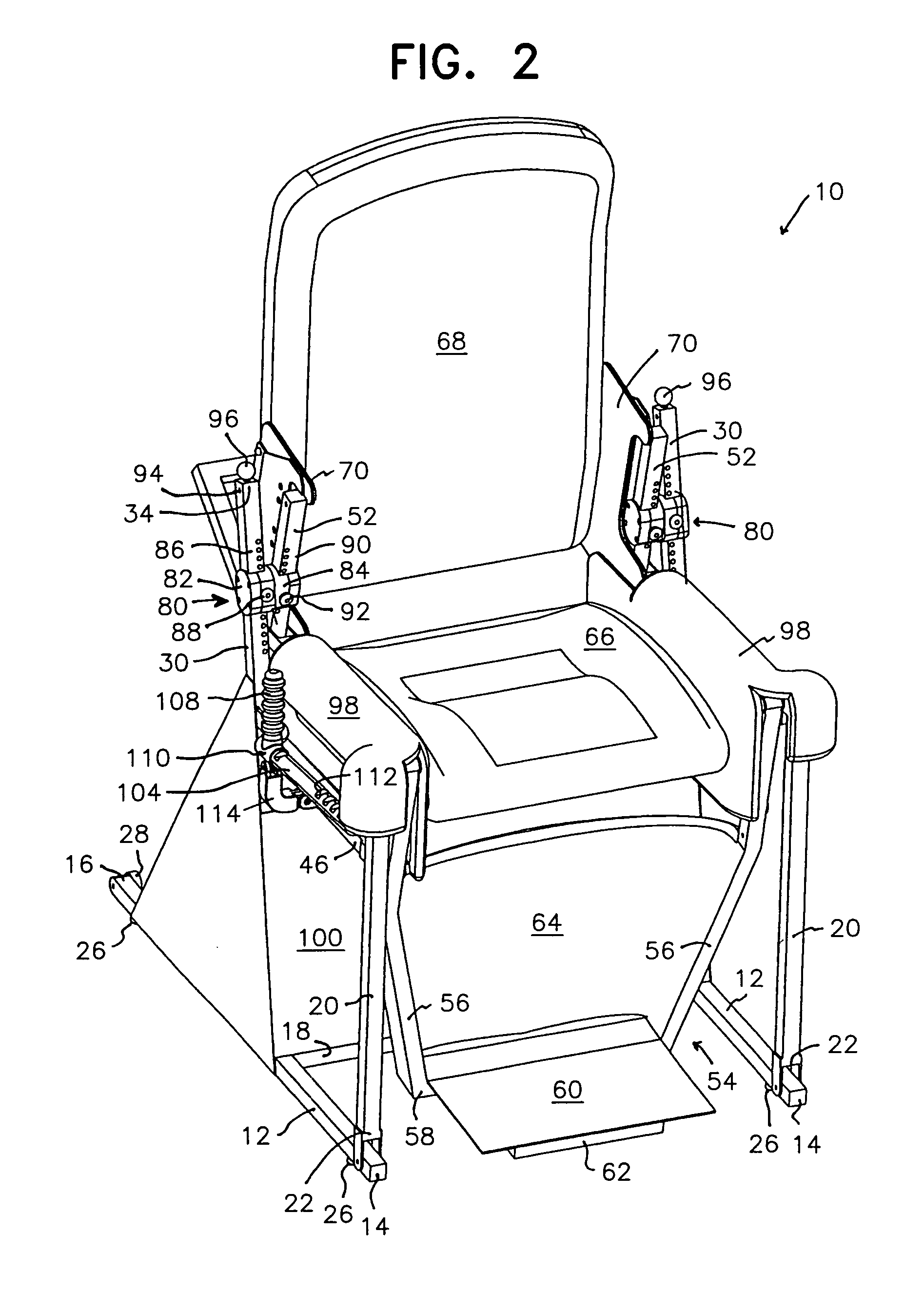

Double sides double arc welding method

ActiveCN1603045AReduce stressGuarantee welding qualityArc welding apparatusWorkpiece edge portionsJoint stressWelding deformation

The invention relates to a double side dual-arc welding method. It includes the following steps that the work-piece connection part waited for welding is made both sides welding groove; the both sides welding groove and its both sides surface is ground and cleaned out before the welding; the two independent electric arcs elicited by two welding guns of the two welding machines are conducted both sides dual-arc symmetry bottoming welding respectively at the both sides welding groove; after the bottoming welding, the two independent electric arcs are conducted both sides dual-arc filling welding respectively at the both sides welding groove. The invention avoids the carbon arc-air gouging back gouging process, simplifies the welding process, so that the automation welding can be realized. It avails to practice gas shielded welding, ensure the welding quality, reduce the welding deformation, and decrease joint stress. The method can apply to important metal structural parts welding.

Owner:渤海造船厂集团有限公司

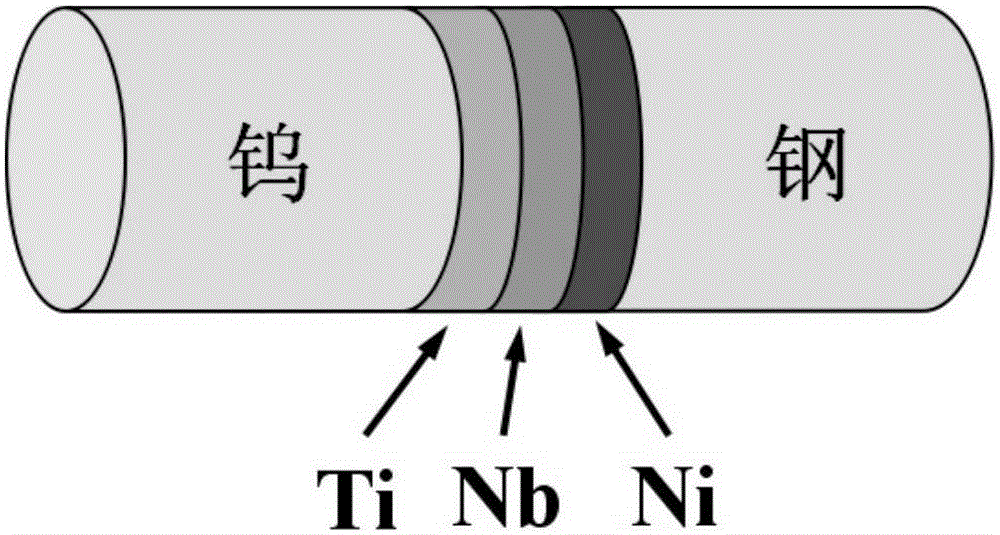

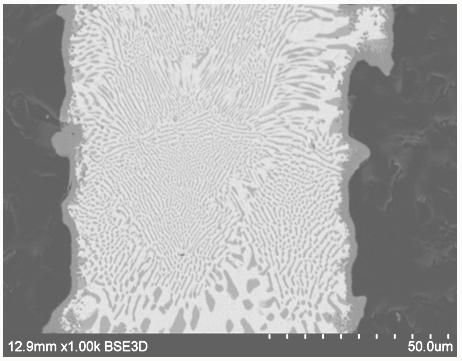

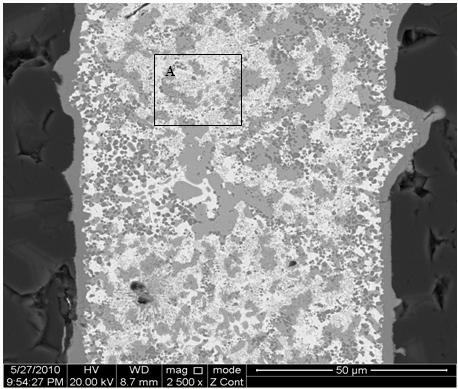

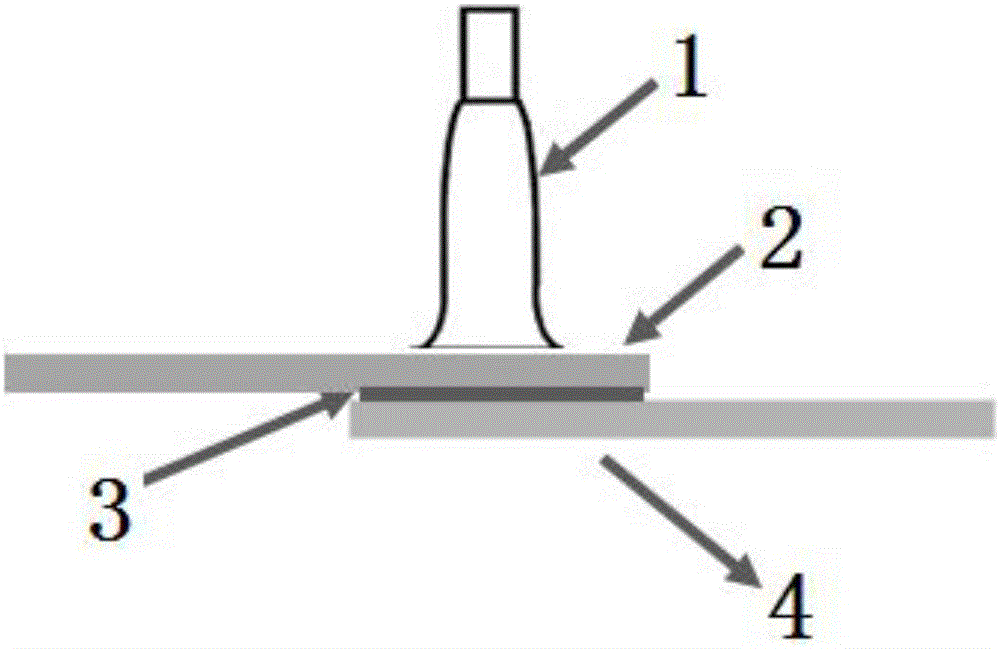

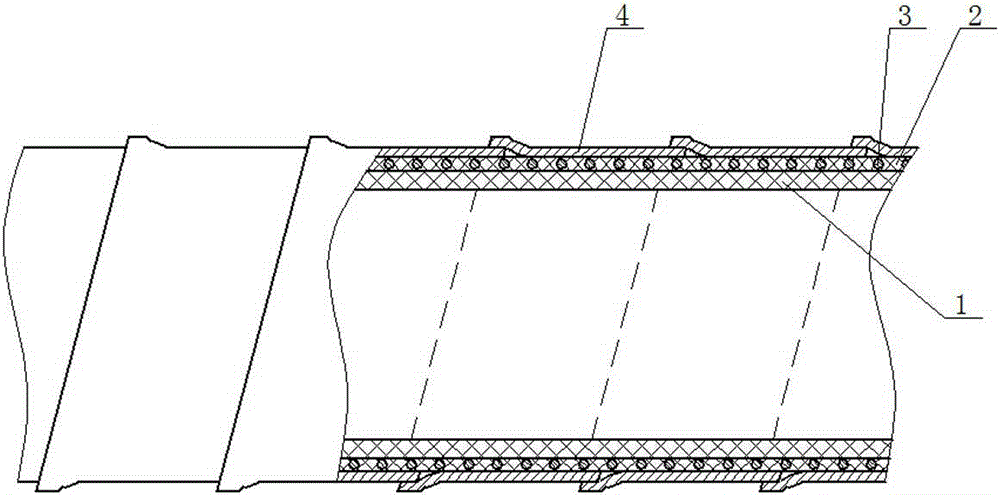

High-performance tungsten/steel composite material based on high-temperature application and preparation method thereof

ActiveCN105216394AHigh tensile strength at room temperatureImprove high temperature mechanical propertiesLaminationLamination apparatusNiobiumJoint stress

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

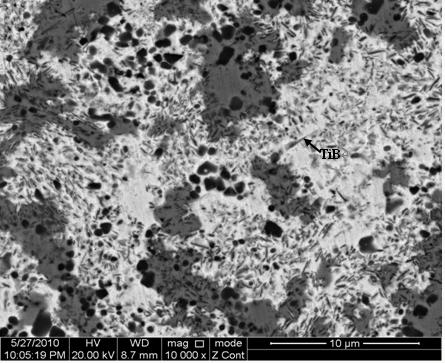

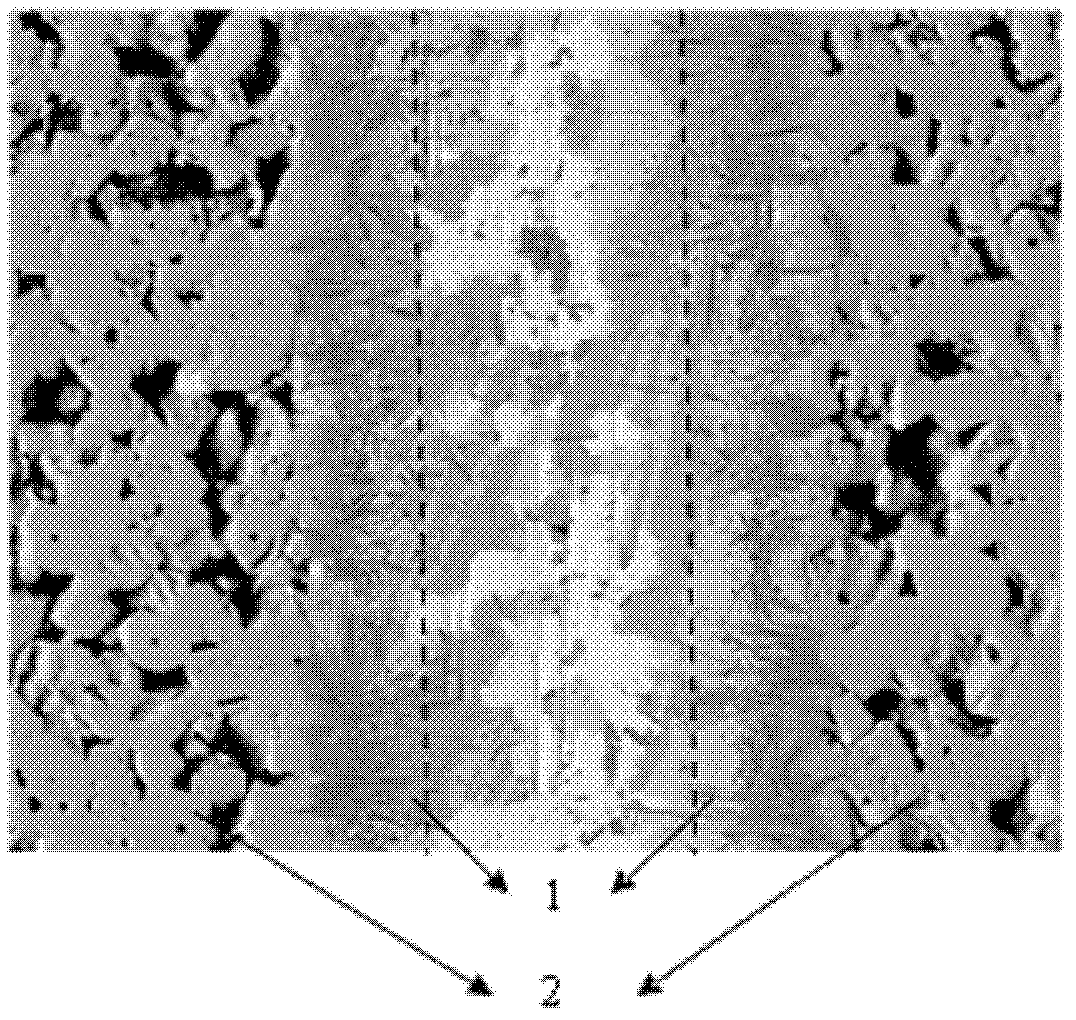

Method for improving strength of ceramic soldered joint by in-situ self-generated TiB whiskers

The invention discloses a method for improving the strength of a ceramic soldered joint by in-situ self-generated TiB whiskers, and relates to a preparation method for the ceramic soldered joint. The method solves the problems that a conventional ceramic activity soldering method has high joint stress and low strength and an enhancement phase in a method for directly adding the enhancement phase into an active solder is easy to segregate in the joint and is not easy to wet with matrix. The method comprises the following steps of: ball-milling Ag, Cu, TiB2 and TiH2 powder and mixing the ball-milled powder and adhesive uniformly, coating the mixture on a to-be-soldered surface of a ceramic piece to obtain a to-be-soldered piece, putting the to-be-soldered piece into a vacuum soldering furnace, and performing vacuum soldering treatment on the to-be-soldered piece to obtain the ceramic soldered joint of the in-situ self-generated enhancement phase. The in-situ self-generated TiB whiskers have good compatibility with the joint matrix and are distributed uniformly, and the compressive shearing strength of the ceramic soldered joint is 70 to 165MPa and is improved by 95 to 195 percent compared with the strength of a joint without the enhancement phase.

Owner:上海迪登科技发展有限公司

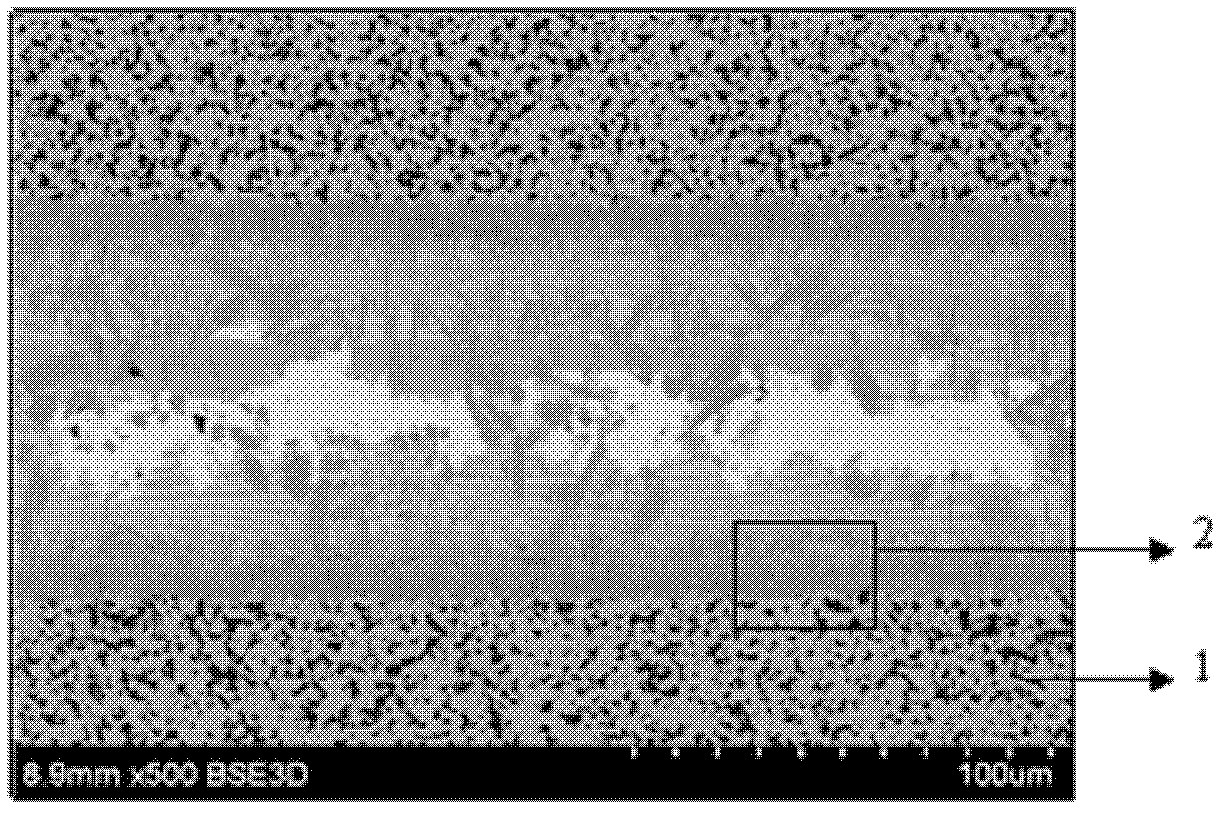

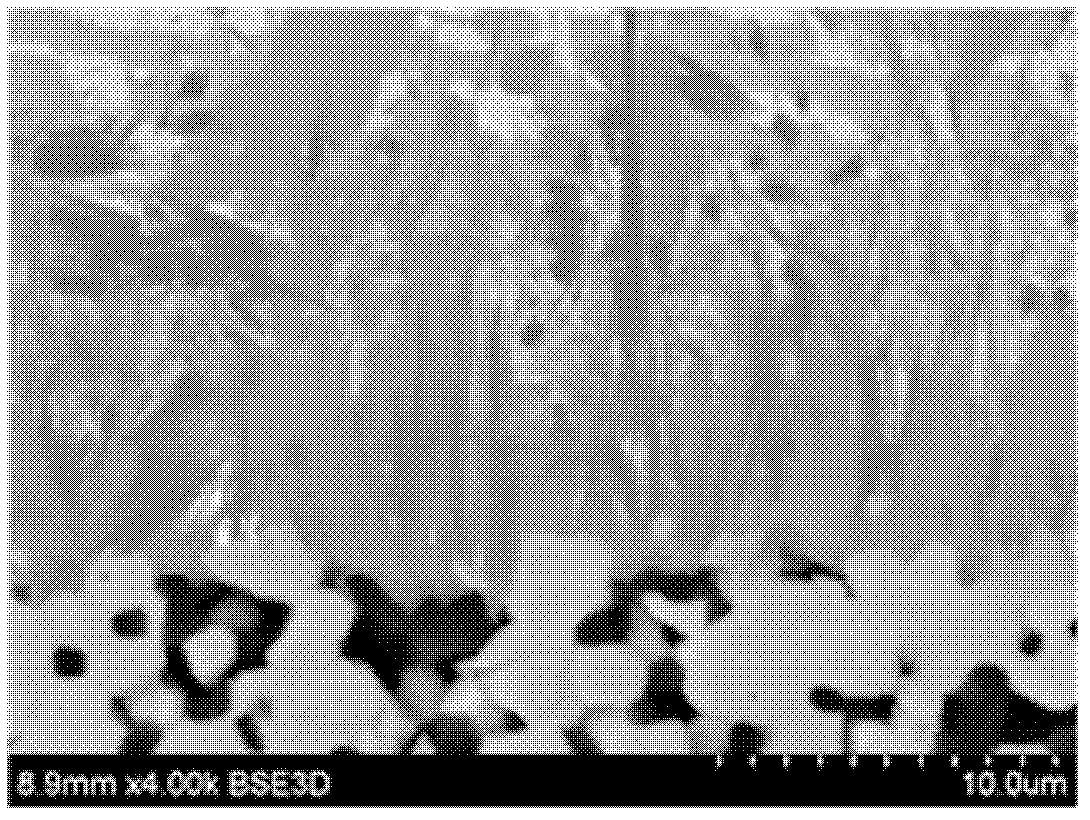

Brazing method for ZrB2-based material

ActiveCN102430829AStress reliefHigh strengthWelding/cutting media/materialsSoldering mediaThermal expansionUltimate tensile strength

A method for improving brazing connection strength of a ZrB2-based material relates to a brazing connecting method. The invention solves the problem that the brazing joint prepared by the method of active brazing filler metal with ZrB2-based material is low in strength, the remaining stress is large and reliability is not high caused by mismatching of thermal expansion coefficients of ceramic and metal. The brazing connecting method provided by the invention comprises the steps of: coating the composite brazing filler metal consisting of Ti powder and Ag-Cu eutecticpowder on the ZrB2-based material and connecting pieces which are to be connected on the ZrB2-based material; or placing the brazing filler metal foil consisting of Ti foil and Ag-Cu eutectic foil onthe ZrB2-based material and between the connecting pieces which are to be connected on the ZrB2-based material to form a piece to weld; placing the piece to a vacuum brazing furnace to weld so as to braze the ZrB2-based material. The method relieves the joint stress and improves the strength of the joint effectively. The shear strength of the brazing joint obtained by the method is 93.8MPa-112.3MPa and the strength of the joint is improved by 57-89%. The invention can be used to the field of brazing connection.

Owner:HARBIN INST OF TECH

Low-temperature welding method for sapphires

ActiveCN105364245ALow melting pointIncreased shear strengthSoldering apparatusEngineeringUltimate tensile strength

The invention relates to a welding method for sapphires, in particular to a low-temperature welding method for sapphires. The method solves the problems that in an existing welding technology for sapphires, welding temperature is high and component connection is likely to fail, and also solves the problems that in an existing low-temperature gluing method, joint strength is low and joint ageing is likely to occur. The method includes the steps that firstly, by mass, Bi2O3, B2O3, BaO, ZnO and SiO2 are weighed and mixed to obtain glass solder; secondly, the surfaces, to be welded, of sapphires are polished and then washed with acetone; thirdly, adhesive and the glass solder are mixed according to a volume ratio, and the sapphires are coated with the mixture; fourthly, the sapphires obtained in the third step are placed in an opposite contact mode and fixed through a clamp, and a connecting piece to be welded is obtained; fifthly, the connecting piece to be welded is welded. By means of the method, joint stress of sapphire components can be relieved, stability is good, and the joint ageing phenomenon can be avoided. The method is used for welding sapphires.

Owner:HARBIN INST OF TECH

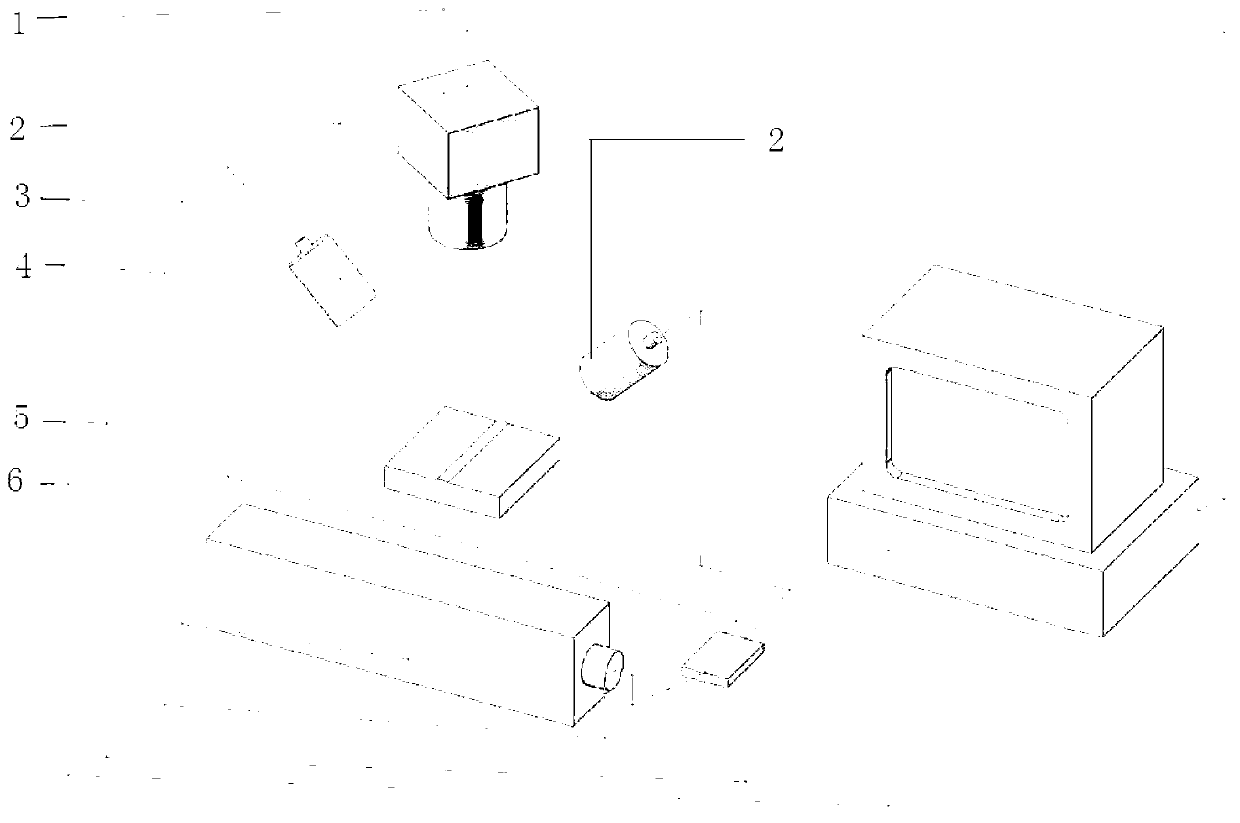

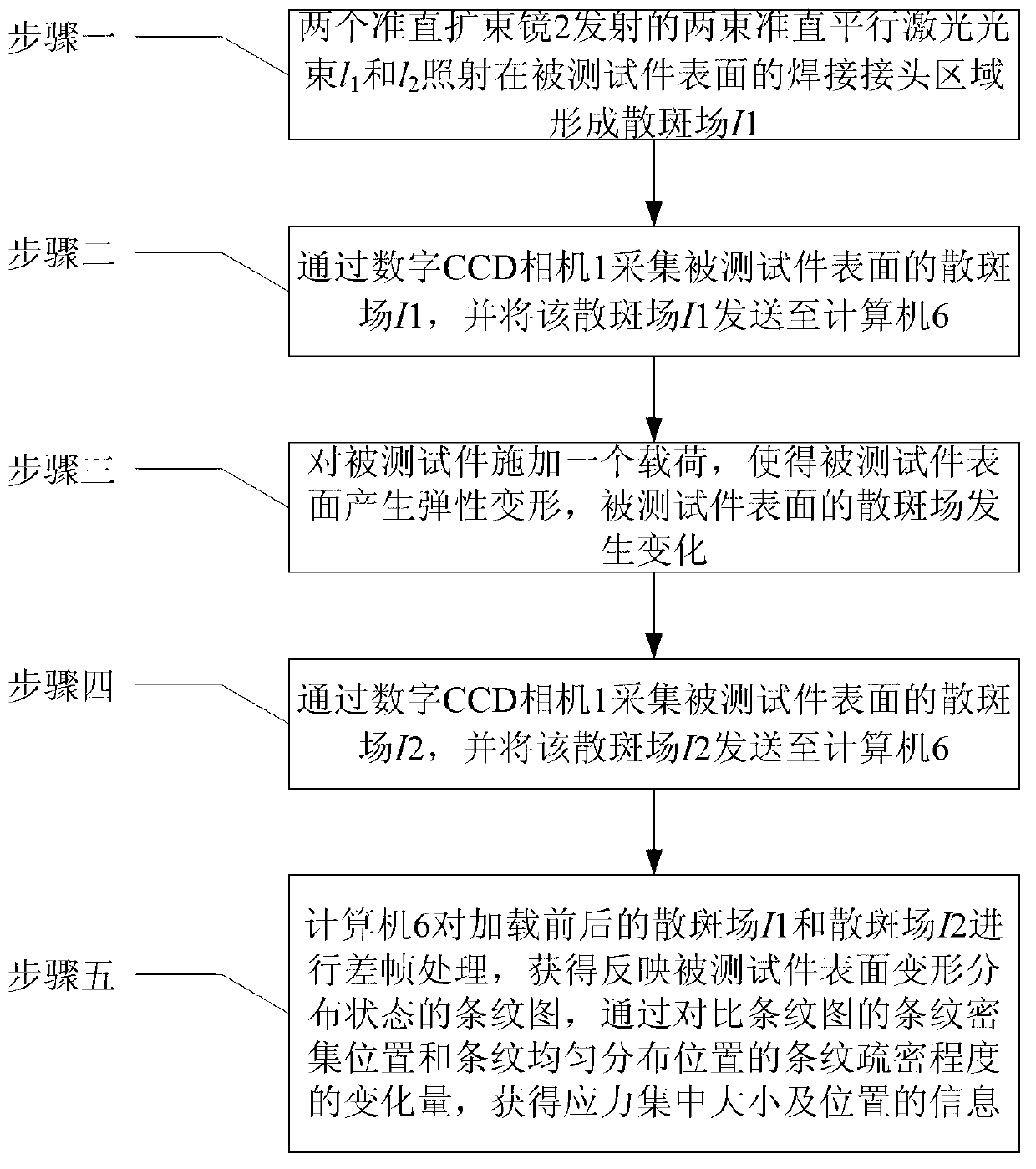

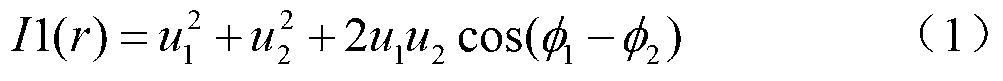

Soldered joint stress concentration testing device and stress concentration testing method based on laser speckle technology

InactiveCN103278272AIncrease flexibilityImprove accessibilityForce measurement by measuring optical property variationStress concentrationCcd camera

Owner:HARBIN INST OF TECH

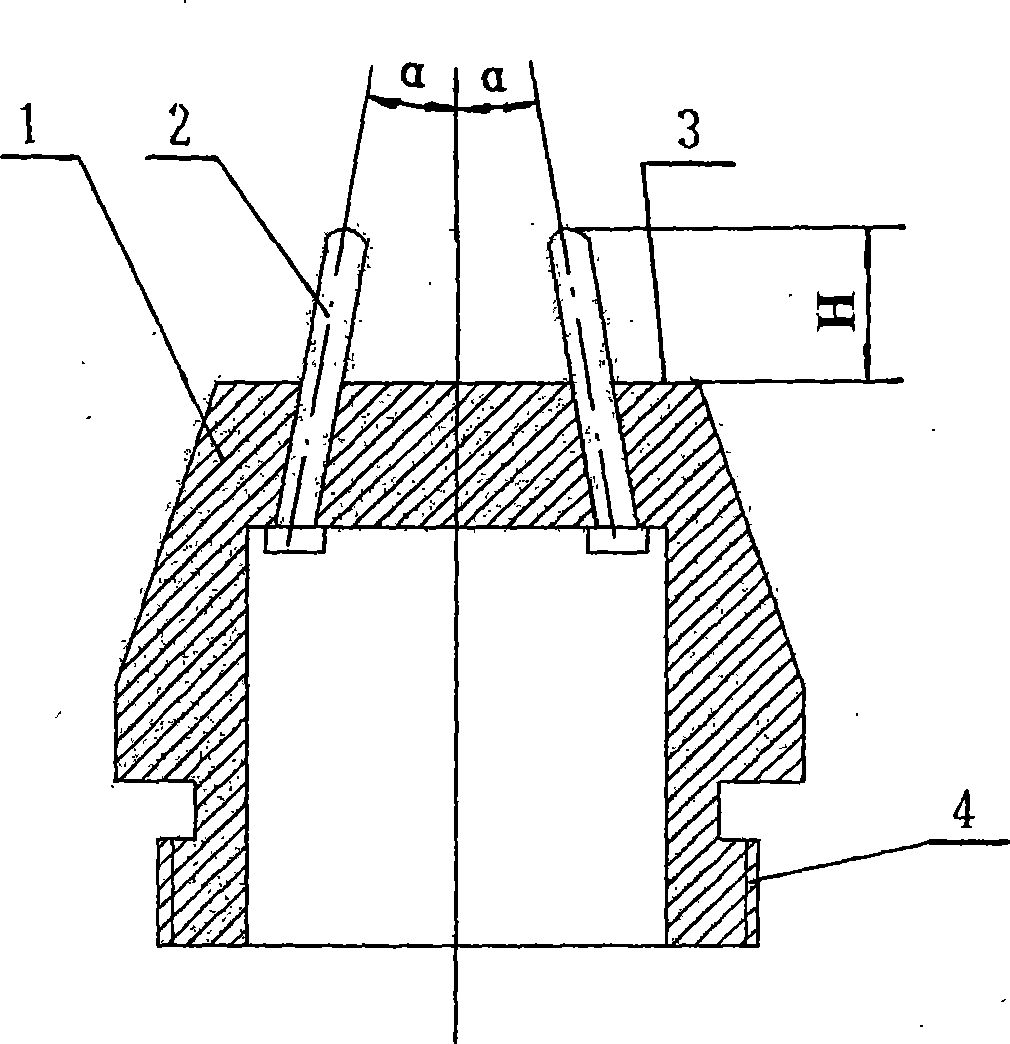

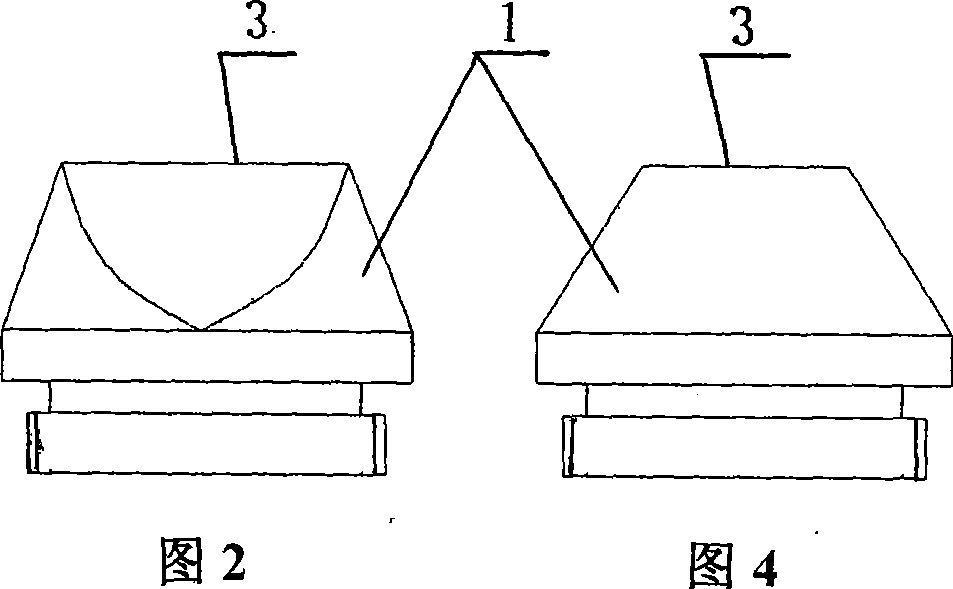

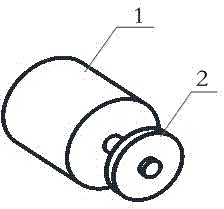

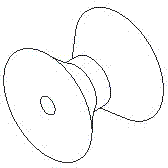

High-efficiency ultrasonic impact head for soldering joint stress release

InactiveCN101429588AImprove impact efficiencyIncrease impactNon-electric welding apparatusFatigue IntensityEconomic benefits

The invention relates to a high-efficient ultrasonic impact head for removing welding stress. The impact head comprises an impact head body and impact pins movably assembled in impact pinholes of the impact head body; two impact pins are symmetrically distributed on two side of a central axis, take the central axis as criteria and incline inwards to form an oblique angle alpha of between 2 and 5 degrees; each impact pin is of a cylindrical ball head shape; the diameter of each impact pin is between 5 and 8 mm; the length of each impact pin is between 30 and 35 mm; after each impact pin is arranged in the impact pin body, the length of the exposed part is required between 15 and 20 mm; and the lower part of the impact pin body is connected with an impact gun through screw thread. The impact head adopts two symmetric impact pins to simultaneously treat welding toes of two side of a weld joint, can remarkably improve the impact efficiency by 20 to 50 percent compared with a multi-pin impact head, improve the degree of the impact force, the impact strength, the removal of welding stress and the improvement of fatigue strength by more than 5 to 10 percent compared with the multi-pin impact head, has good impact effect, greatly improve the impact efficiency and stability in the treatment of a long aluminum alloy welding joint and has good economic benefit.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

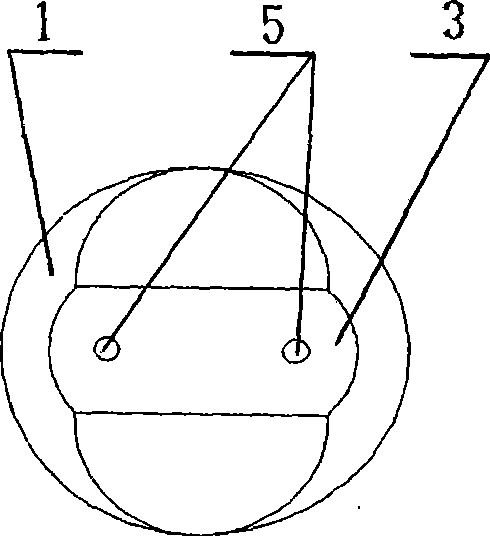

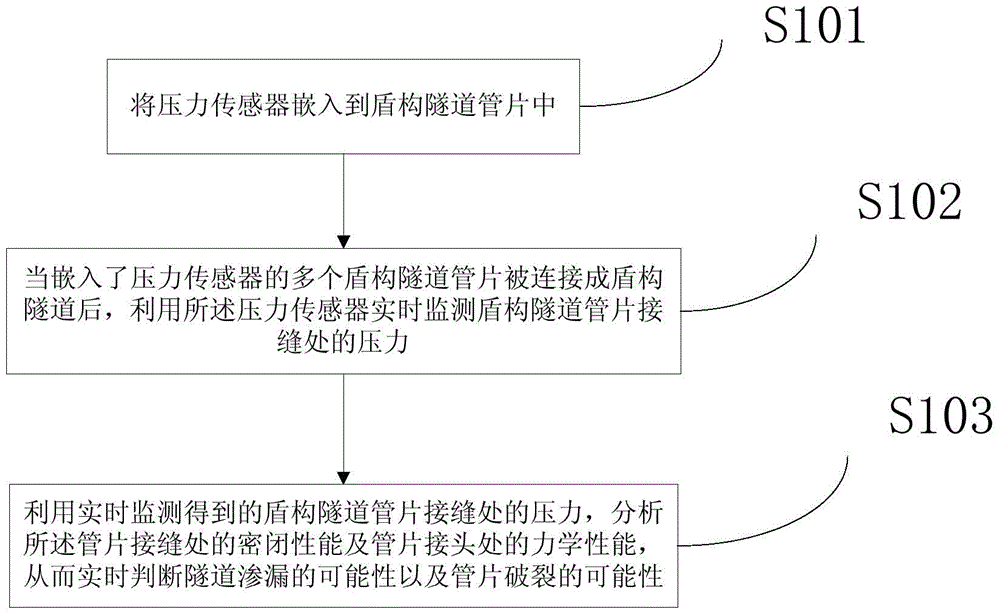

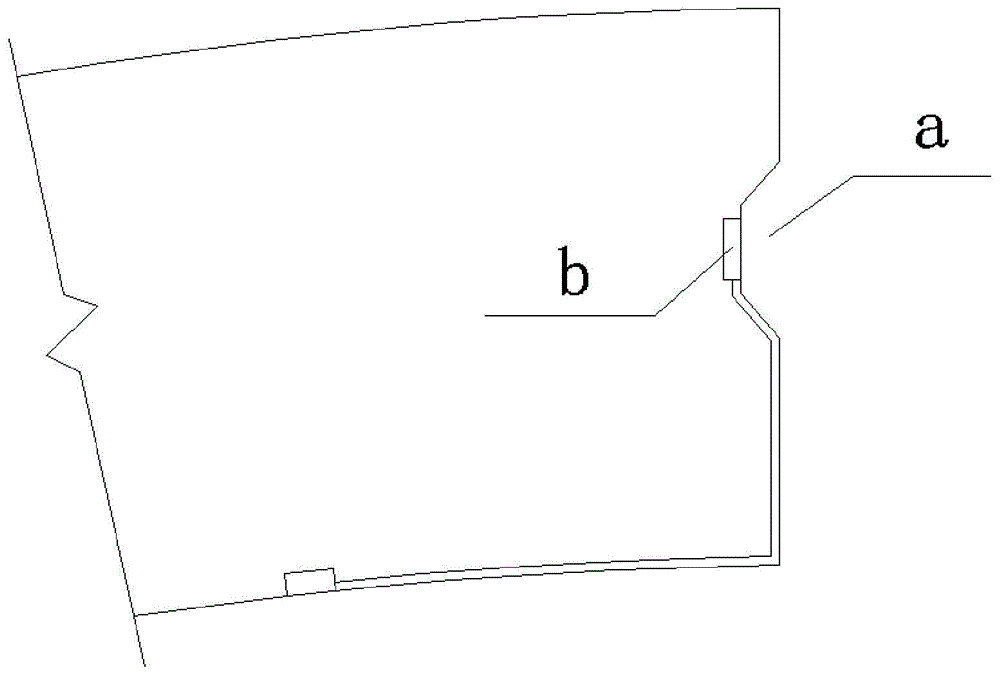

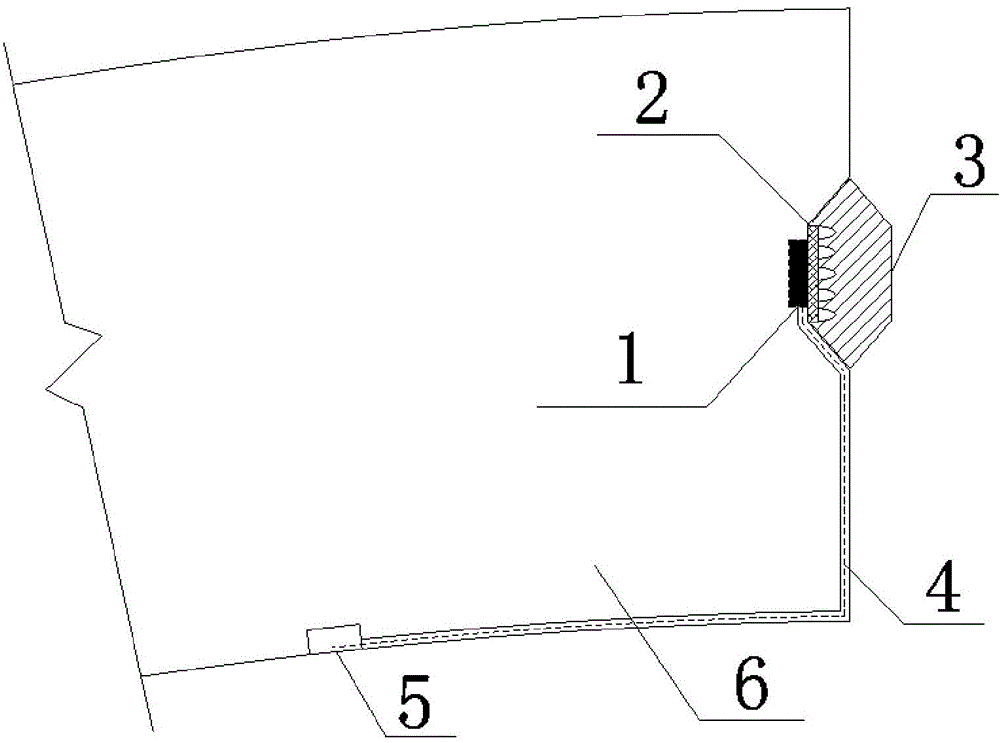

Shield tunnel segment joint stress in-situ measurement method

InactiveCN105987778ARealize in-situ monitoringNot corrosiveForce measurement by measuring optical property variationFiberGrating

The invention relates to a shield tunnel segment inner force monitoring method, in particular, a joint shield tunnel segment joint stress in-situ measurement method, and belongs to the crossing field of tunnel engineering field monitoring and construction technology. According to the method of the invention, a fiber grating pressure sensor is inserted into the interior of each segment, so that the sensors and the segments are connected together to form an integrated body to jointly bear a force; when the joint pressure of the segments is measured, a sheet rubber made of the same material with a rubber sealing strip of the corresponding shield segment is pasted on the outer surface of the corresponding fiber grating pressure sensor inserted into the segment, so that the correctness of load transfer can be ensured; the contact pressure of the rubber sealing strip at the joint of the shield segments is measured in real time, so that the stress condition of the joint of the shield segments in a tunnel construction and operation period can be determined, and the mechanical behavior and waterproof sealing performance of the shield segments can be analyzed, and therefore, the work condition of a shield liner joint can be evaluated. The joint shield tunnel segment joint stress in-situ measurement method of the invention has the advantages of high practicability and high effectiveness. With the method adopted, the stress state of the joint between the segments can be monitored in real time in situ, and the problem of difficulty in monitoring the inner force of the joint of the shield segments in the prior art can be solved.

Owner:CHINA RAILWAY SOUTH INVESTMENT GRP CO LTD +1

High-strength urban underground comprehensive pipe gallery

ActiveCN105926674AIncrease stiffnessImprove carrying capacityArtificial islandsUnderwater structuresEngineeringHigh intensity

The invention discloses a high-strength urban underground comprehensive pipe gallery. The high-strength urban underground comprehensive pipe gallery is characterized in that a top plate, a base plate and two side plates consisting of corrugated plates of which the outer sides and / or the inner sides are provided with protrusions are spliced to form a box-type pipe joint; the box-type pipe joints are spliced in the axial direction to form the comprehensive pipe gallery, wherein longitudinal beams are arranged at edges of the box-type pipe joints; cross beams are arranged at two ends of the top plates and / or the base plates in the axial direction of the box-type pipe joints; upright posts are arranged at two ends of the side plates; the cross beams and the upright posts are connected end to end to form a frame type framework; the top plates are arched; the direction of arched grains on the top plates are consistent with the extending direction of the pipe gallery; the top plates and the cross beams at two ends are combined to form a structure; the top plates apply the principles of joint stress of pipe and soil and a continuous arch bridge, and sheets of the top plates and backfill soil are collaboratively stressed; in addition, the direction of the arched grains on the sheets is consistent with the extending direction of the pipe gallery; in addition, the cross beams are arranged between adjacent top plates side by side in the extending direction of the pipe gallery; and except the cross beams at two ends of the pipe gallery, horizontal components of the top plates on the cross beams are offset leftwards and rightwards, so the bearing capacity of an overall structure is higher.

Owner:NANJING LIANZHONG CONSTR ENG TECH

Low-resistance exercise and rehabilitation chair

An exercise and rehabilitation chair and method includes pivotal front support legs, rigid rear legs, a seat assembly having a seat bottom and seat back and upper and lower arms, each upper and lower arm being pivotally coupled at a rearward end to a pivotal support arm rigid with a seat back and at a forward end to an upper end of a pivotal front leg. Bearing structures pivotally connect corresponding support arms and rear legs and establish a fulcrum about which the seat assembly may rotate. The bearing structures are simultaneously adjustable longitudinally along the pivotal support arms and rigid rear legs with displacement of the fulcrum relative to a user's hips regulating the resistance of chair operation. A foot assembly is pivotally coupled to the front legs and the forward ends of the upper and lower arms. All pivotal connections correspond anatomically to a user's joints for low joint stress and low-resistance exercise.

Owner:REITZ ALAN S +2

Ultrahigh molecular weight polyethylene dead-hard steel wire composite pipeline and manufacture method thereof

InactiveCN101230938AImprove pressure bearing capacityHigh impact strengthRigid pipesDiameter productPliability

The invention discloses a high strength steel wire composite pipeline of ultrahigh molecular weight polyethylene and the preparation method thereof, and steel wires are winded and arranged in the manner of being perpendicular to an axial line of a base tube, and the external walls of steel wires are wrapped with a sheet-shaped spiral winding radiation crosslinking polyethylene tension belt. A polyethylene hot melt adhesive is adopted among the steel wires, between the steel wires and the base tube and between the steel wires and the radiation crosslinking polyethylene tension belt to heat, so that the steel wires, the steel wires and the base tube, the steel wires and the radiation crosslinking polyethylene tension belt are bonded into a whole. The preparation method is that a tube of the ultrahigh molecular weight polyethylene is chosen as the base tube, and steel wires are winded and arranged in the manner of being perpendicular to the axial line of the base tube at the external wall of the base tube; at last, the radiation crosslinking polyethylene tension belt wraps on the steel wires of the external wall of the base tube in the manner of the spiral winding to integrate adhesively. The flexibility of a pipeline of the invention is good, and the phenomenon the joint stress intensively fractures can not appear. The cost is low, which is only one third of that of the prior composite pipe, and large diameter product can be manufactured according to requirements of users.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

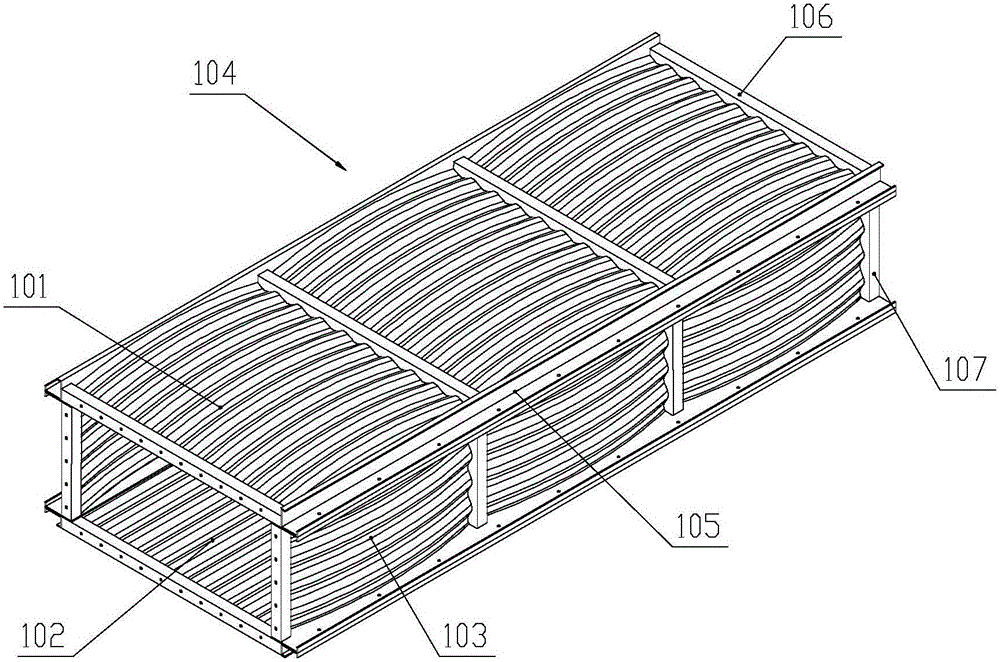

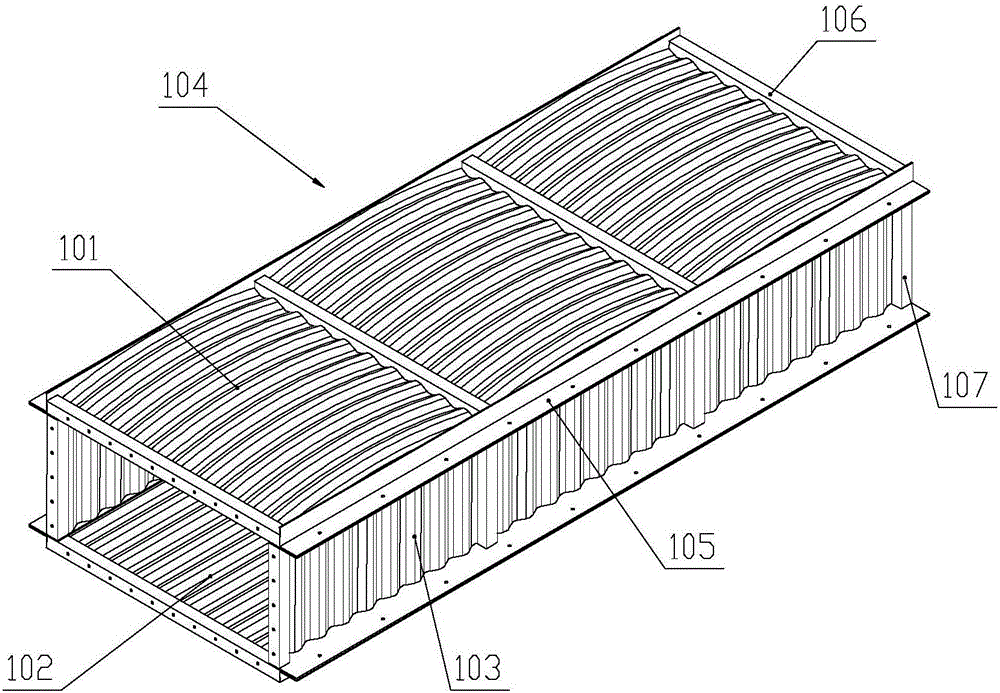

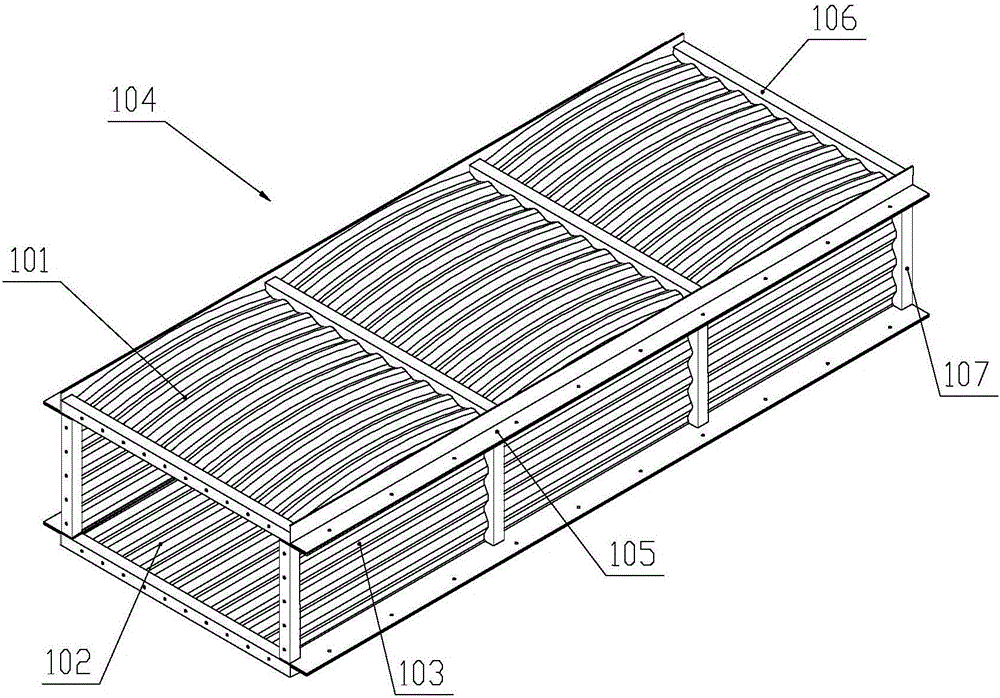

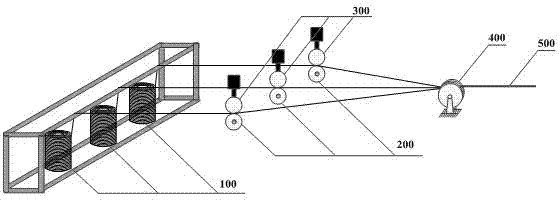

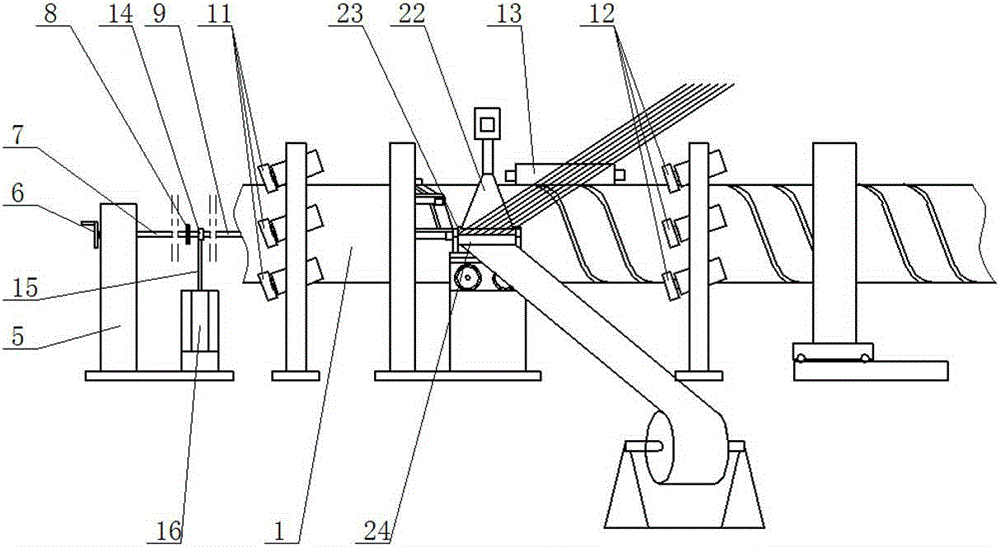

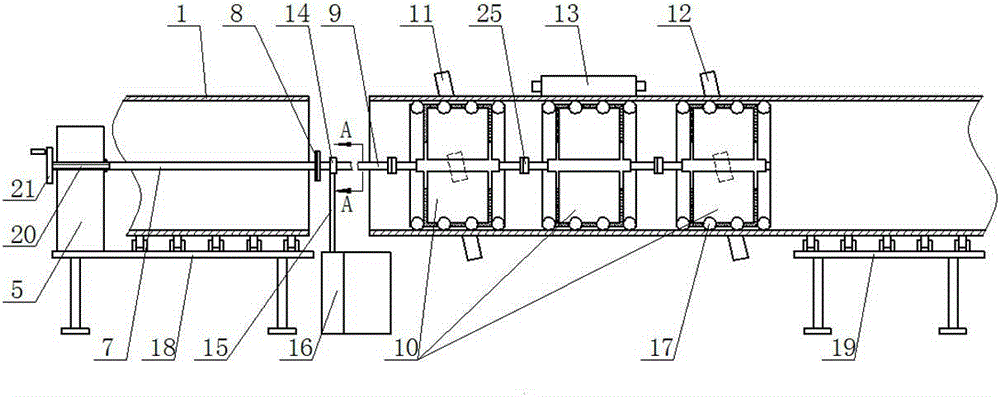

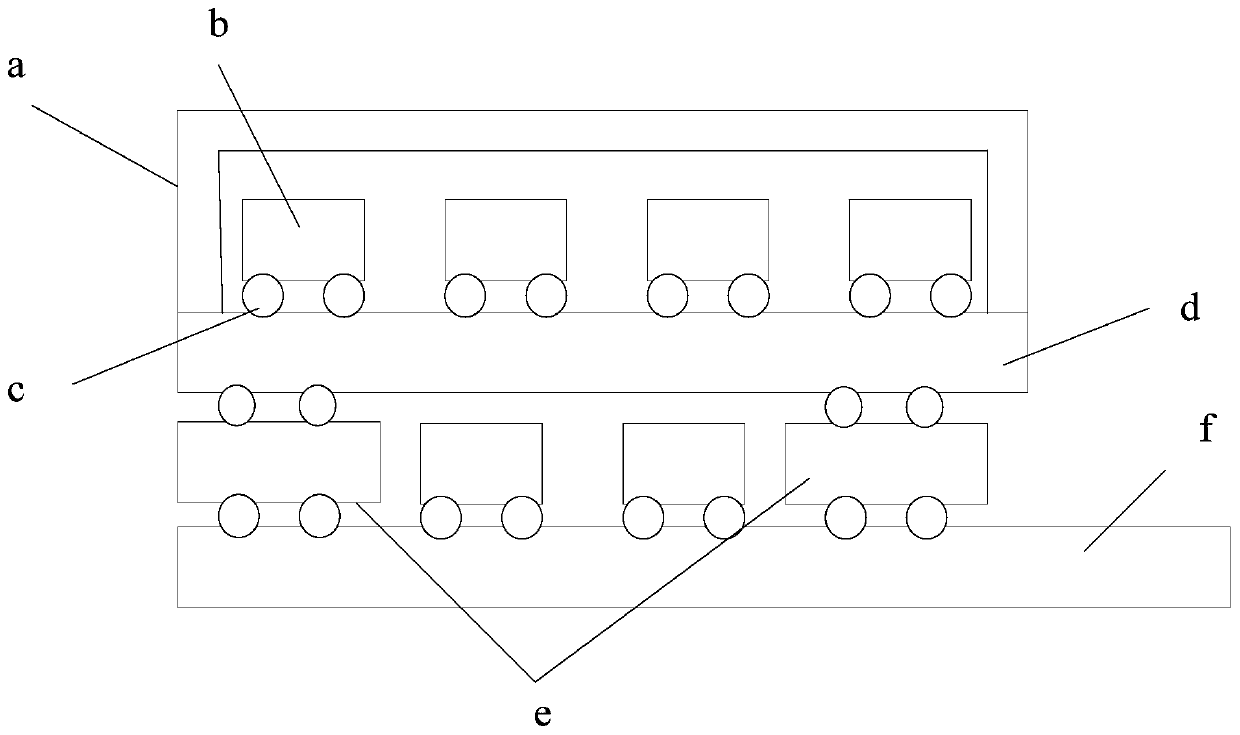

Silvalin plying device and method for improving mechanical properties of fiber reinforced composite materials

The invention provides a silvalin plying device and method for improving mechanical properties of fiber reinforced composite materials. The plying device comprises a silvalin releasing frame, a plying wheel and a damping type tension control device, wherein more than two precursor silvalin barrels are arranged on the silvalin releasing frame, concentric circular grooves for precursor silvalin plying are formed in the whole periphery of the plying wheel, the damping type tension control device comprises a tension control wheel and a pressing wheel, the tension control wheel comprises a damping control device and a tension wheel, the damping control device is connected with a wheel shaft of the tension wheel to control the rotation sped of the tension wheel, and the pressing wheel acts on precursor silvalin on the surface of the tension wheel adjustably. The silvalin plying method is simple in structure, is convenient to operate, overcomes the bottlenecks that part of fibers are twisted and are not uniform in length when a plurality of the precursor silvalin fibers are plied, and resolves the problems that due to the fact that the inside fibers are twisted and are not uniform in length after plying of the precursor silvalin fibers, the joint stress work performance of the fibers in a plied yarn is poor.

Owner:SOUTHEAST UNIV +1

Method suitable for underground storey adding of frame-structure independent foundation building

ActiveCN107035159AImprove stabilityExtended service lifeArtificial islandsBuilding repairsBasementJoint stress

The invention discloses a method suitable for underground storey adding of a frame-structure independent foundation building. The method solves the problem that basement storey adding in the prior art is severe in waste, and has the beneficial effects that waste of dismounting of pressed piles is reduced, and a new though is provided for underground storey adding of an existing building. The method includes the specific steps that earthwork above and around an independent foundation of the frame-structure building is excavated, and the independent foundation is exposed; a reaction frame and a jack are arranged on the top face of the independent foundation, and a precast pile is planted into the independent foundation through the reaction frame; the precast piles under all frame columns are connected in a pulling mode through rigid connecting parts to form a joint stress body; and a basement structure is constructed with the precast piles used as supporting columns of the basement structure.

Owner:SHANDONG JIANZHU UNIV +2

Double-steel tube-concrete combined structural pylon

InactiveCN101338550AReduced stiffening constructionSimple construction processBridge structural detailsCable stayedEngineering

A double-steel-tube concrete combined structure bridge tower pertains to a novel bridge tower structure applied in suspension bridge and cable-stayed bridge tower. In the double-steel-tube concrete combined structure bridge tower, each tower column consists of internal and external layers of steel tubes and concrete poured between the layers; the cross sections of the internal and external layers of steel tubes can be square, rectangular or polygonal, and the steel tubes are integrated with the concrete for joint stress, which can resist pressure and bending; the concrete is poured between the two layers of steel tubes to constrain the tube walls of the internal layer and the external layer of steel tubes, thus preventing the wall of the steel tube from bending; in order to ensure the mutual constraint between the steel tube and the concrete, one side of the walls of the internal layer and external layer of steel tubes close to the concrete is provided with a connector for shearing and pulling resistance. The present invention integrates the advantages of the concrete bridge tower and the steel bridge tower and has the advantages of high stability, high intensity and rigidity, light self-weight, good cracking resistance and easy construction, thus having a wide application prospect in the field of large-span bridge structure.

Owner:TSINGHUA UNIV

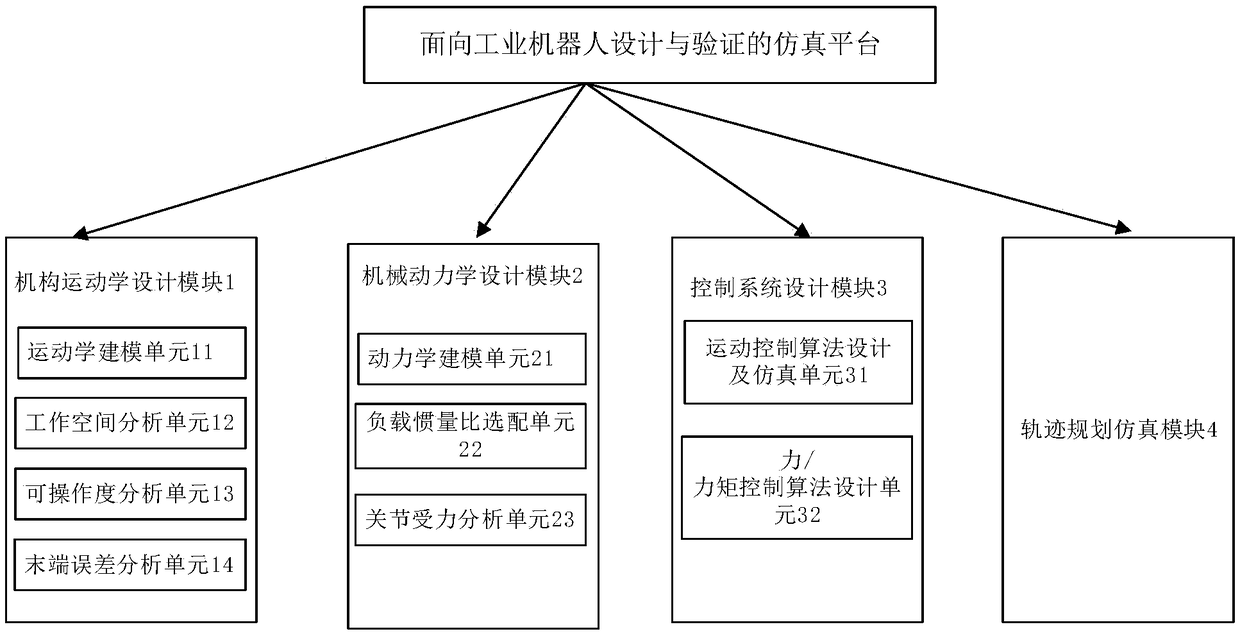

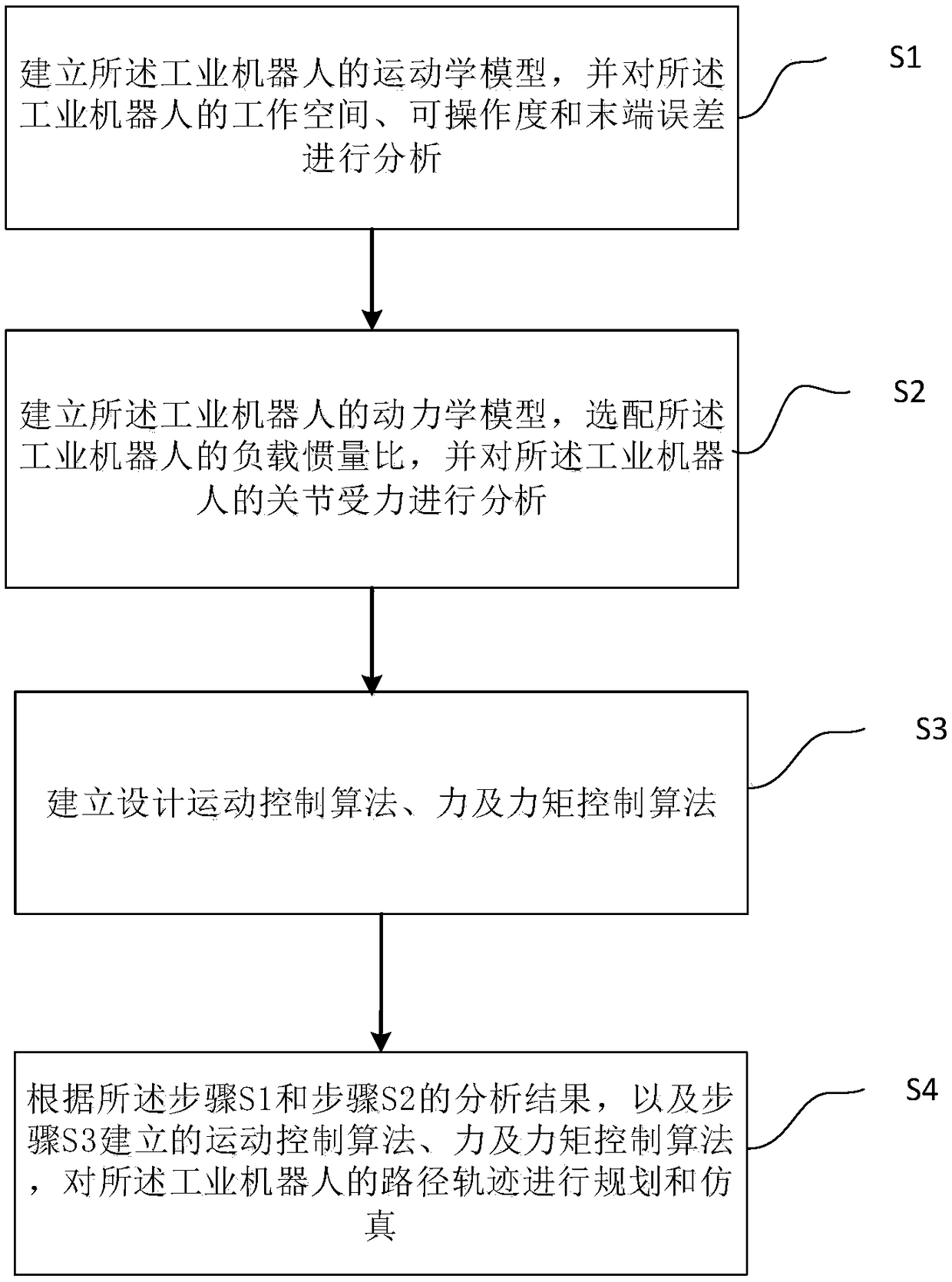

Industrial robot design and verification-oriented simulation platform and method

InactiveCN108595888ARealize integrated designImprove efficiencyGeometric CADProgramme-controlled manipulatorDynamic modelsControl system design

The invention provides an industrial robot design and verification-oriented simulation platform and method. The platform comprises a mechanism kinematics design module used for building a kinematics model of an industrial robot and performing analysis on working space, operability and end errors of the industrial robot, a mechanical dynamics design module used for building a dynamics model of theindustrial robot, selecting and configuring a load inertia ratio of the industrial robot and performing analysis on a joint stress of the industrial robot, a control system design module used for establishing a design motion control algorithm and a force and moment control algorithm, and a track planning simulation module used for performing planning and simulation on a path track of the industrial robot. The integrated design of the robot can be realized, so that the research development design efficiency and quality of the robot are effectively improved.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

Solder joint stress reduction structure and printed circuit board comprising same

InactiveCN102231944AReduce stressPrevent breakage etc.Printed circuit assemblingPrinted circuit detailsEngineeringJoint stress

The invention provides a solder joint stress reduction structure for reducing stress borne by a solder joint between a printed circuit board and a device welded on the printed circuit board. The solder joint stress reduction structure comprises an open slot. The open slot is formed on the printed circuit board and close to the device. The open slot can be positioned at a position close to an outer side of a corner of the device on the printed circuit board, or can be positioned at a position below the device on the printed circuit board. By arranging the solder joint stress reduction structure on the printed circuit board and close to the device, the stress borne by the solder joint between the device and the printed circuit board can be released or dispersed through the solder joint stress reduction structure, so that the stress borne by the solder joint is reduced; therefore, the phenomena that the solder joint is broken and the like are prevented. Moreover, the invention also provides the printed circuit board comprising the solder joint stress reduction structure.

Owner:HUAWEI TECH CO LTD

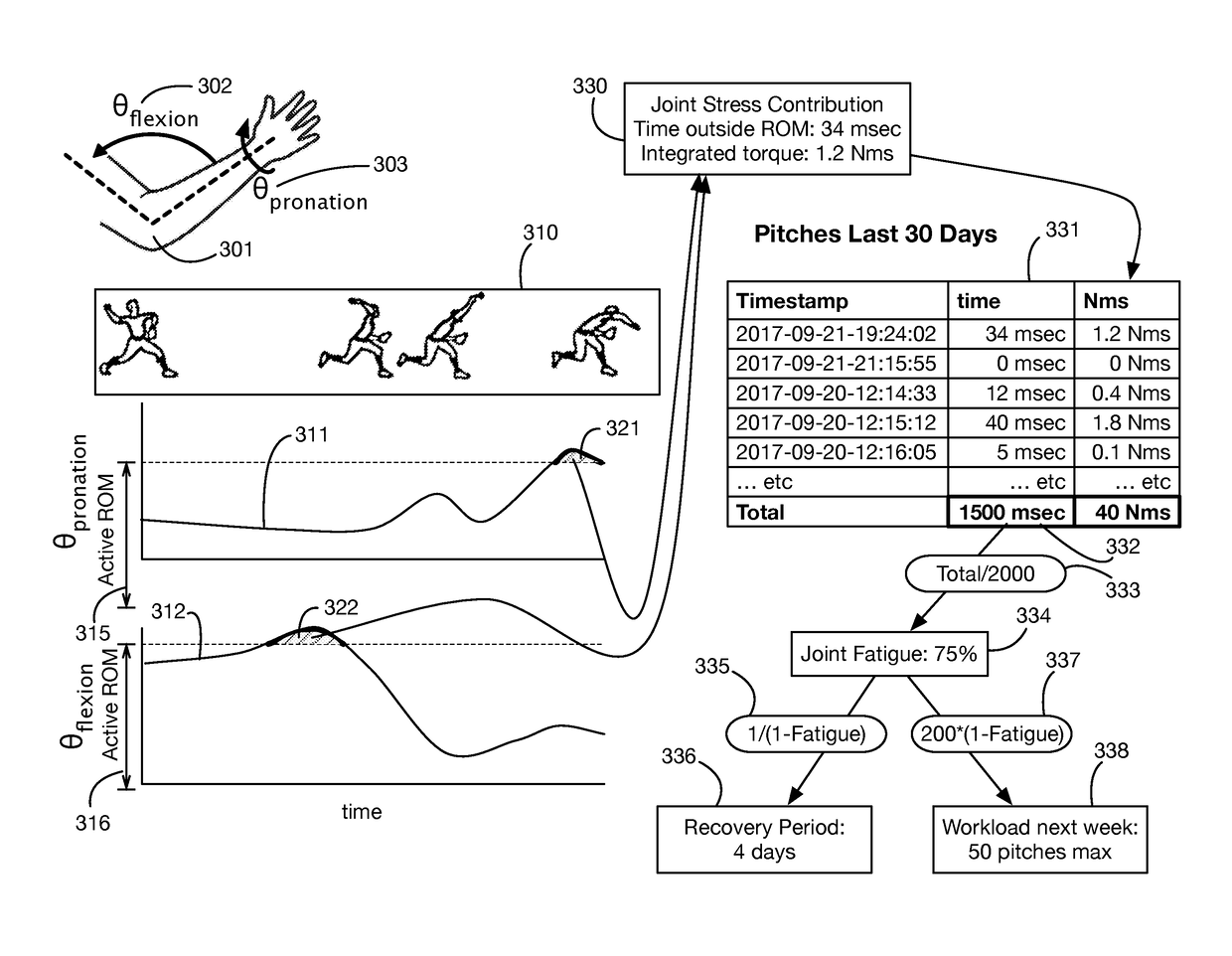

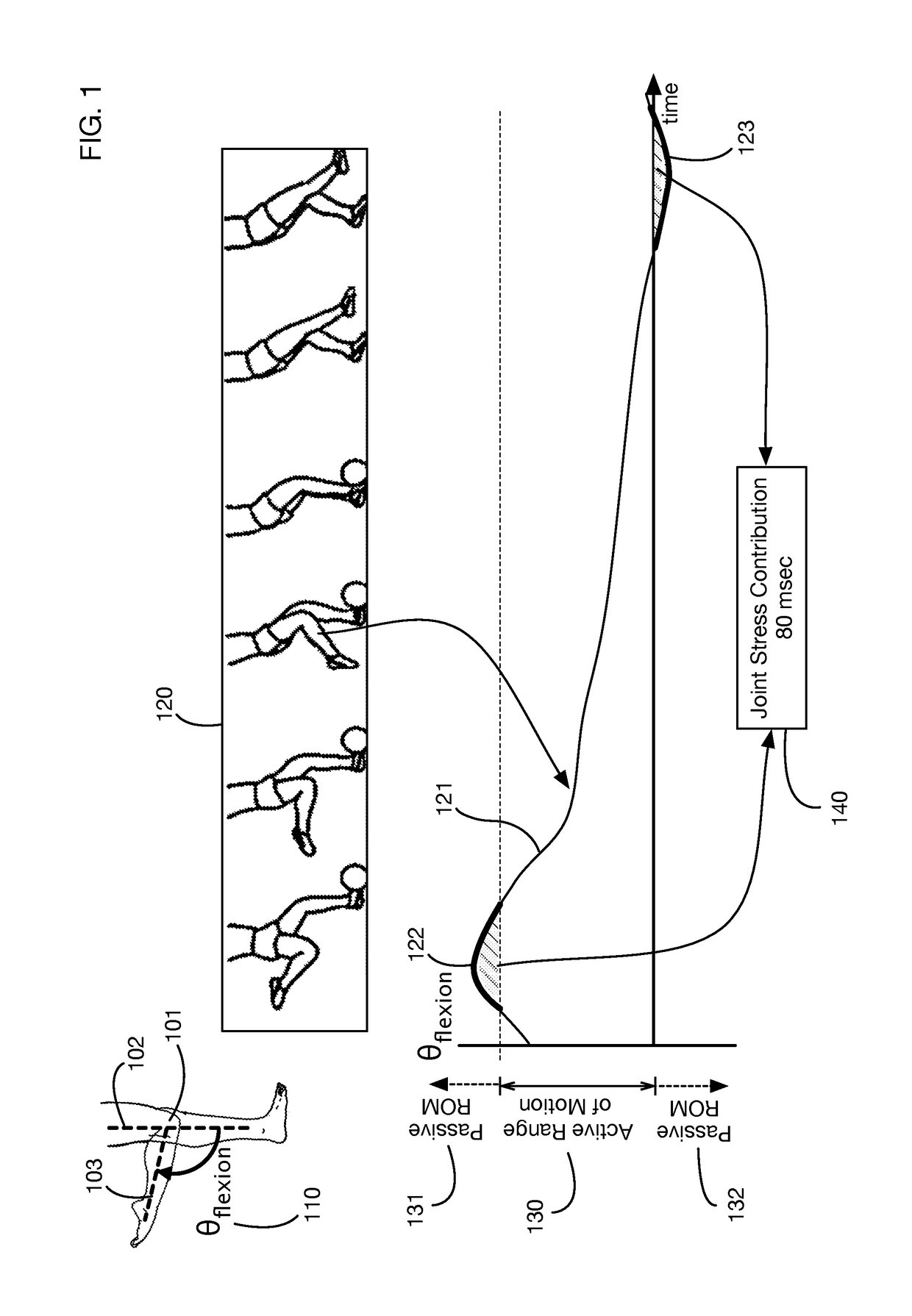

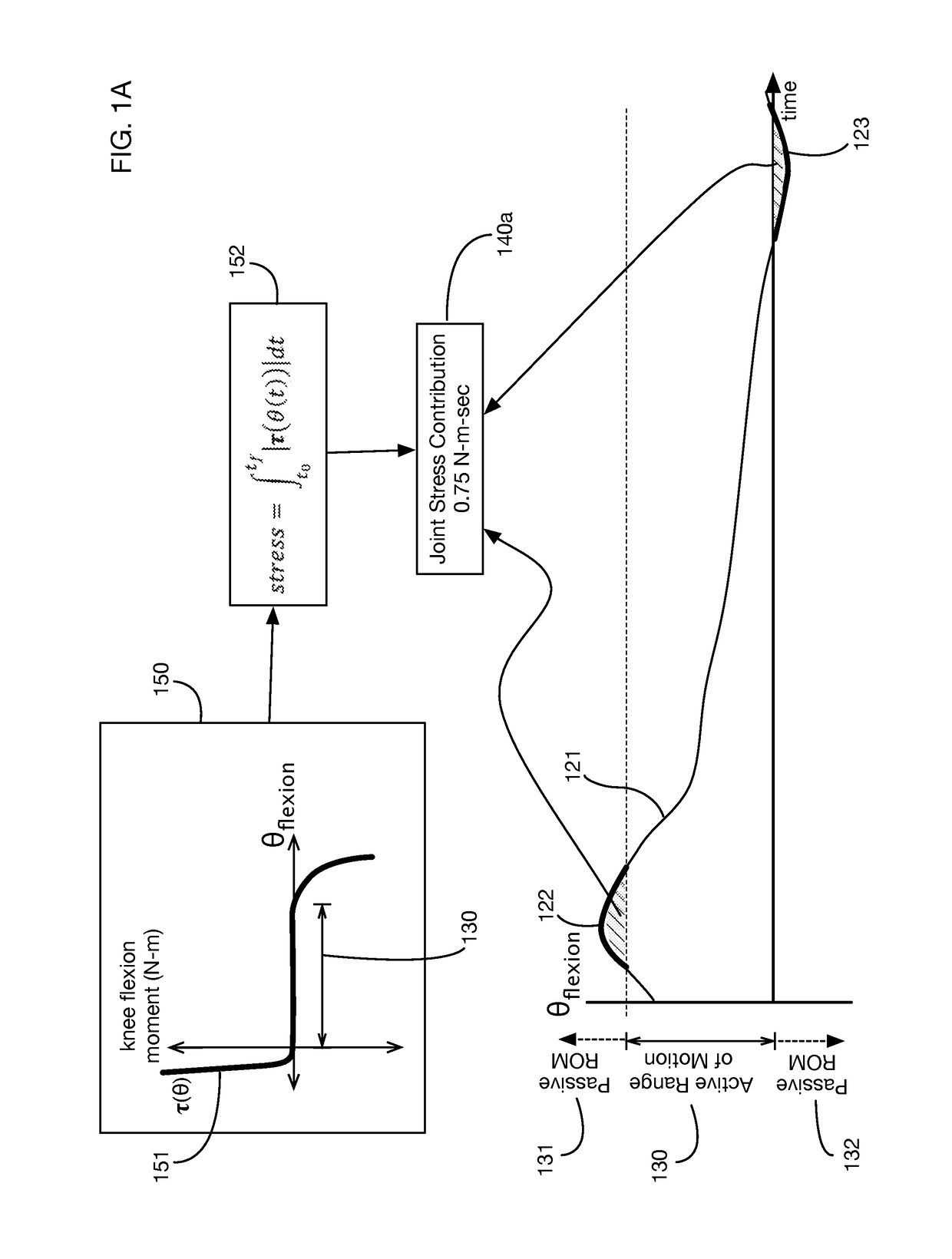

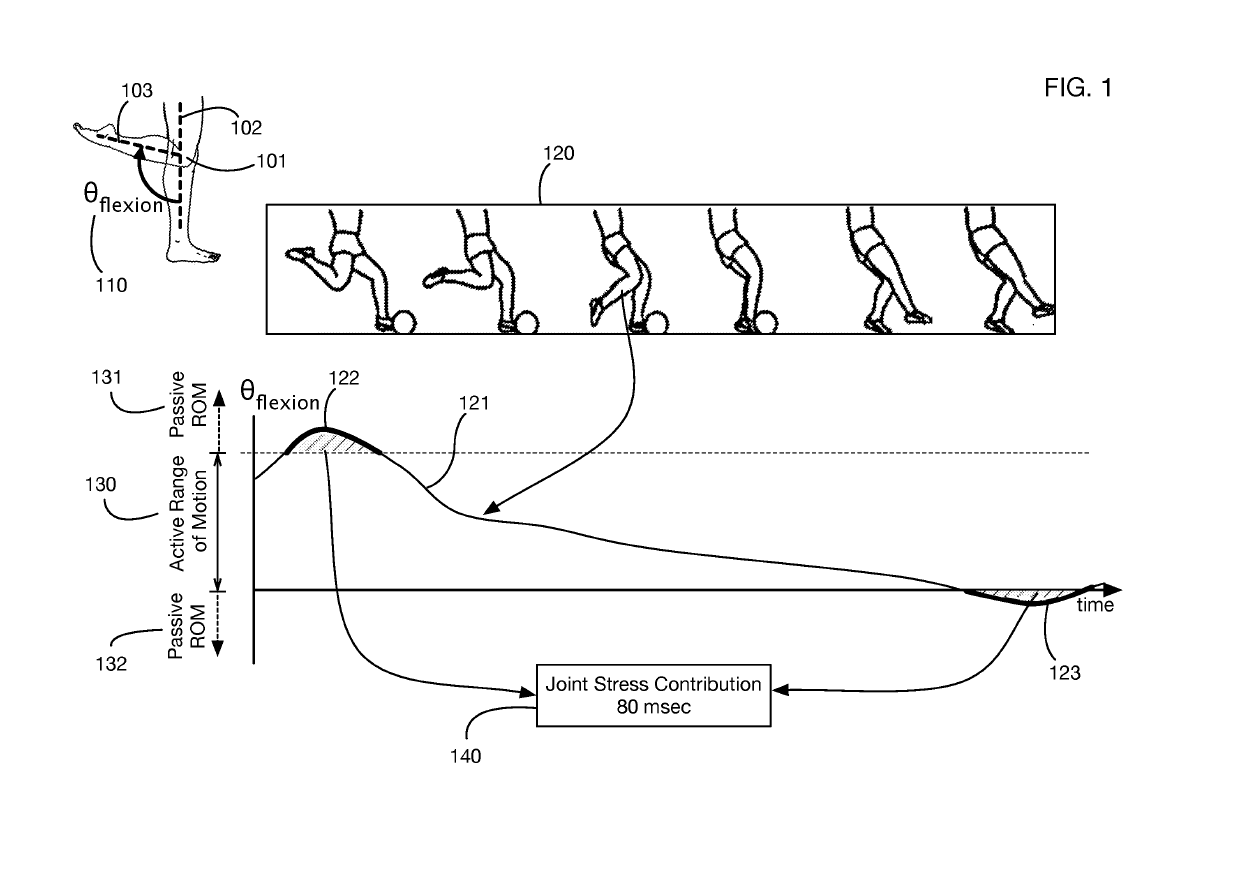

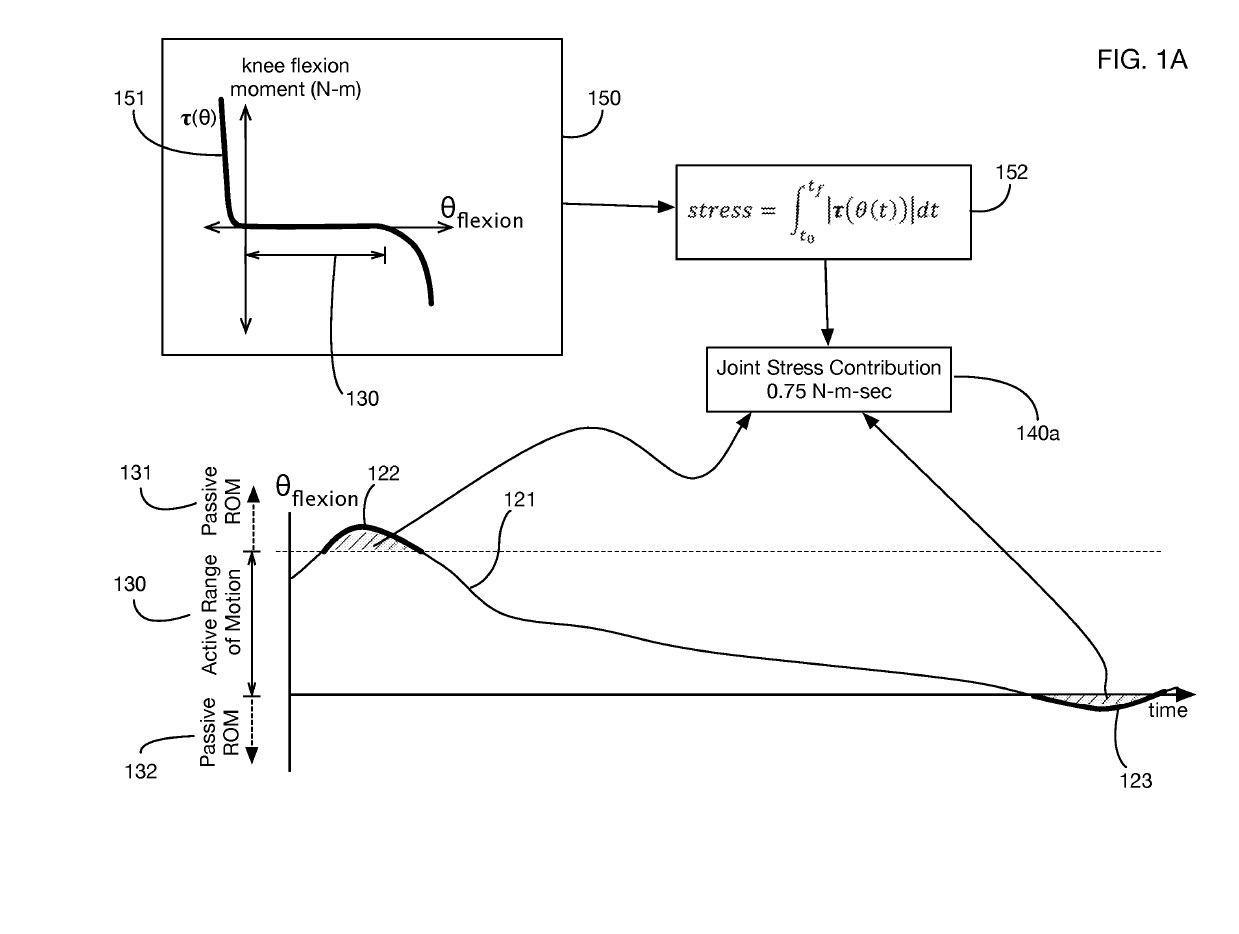

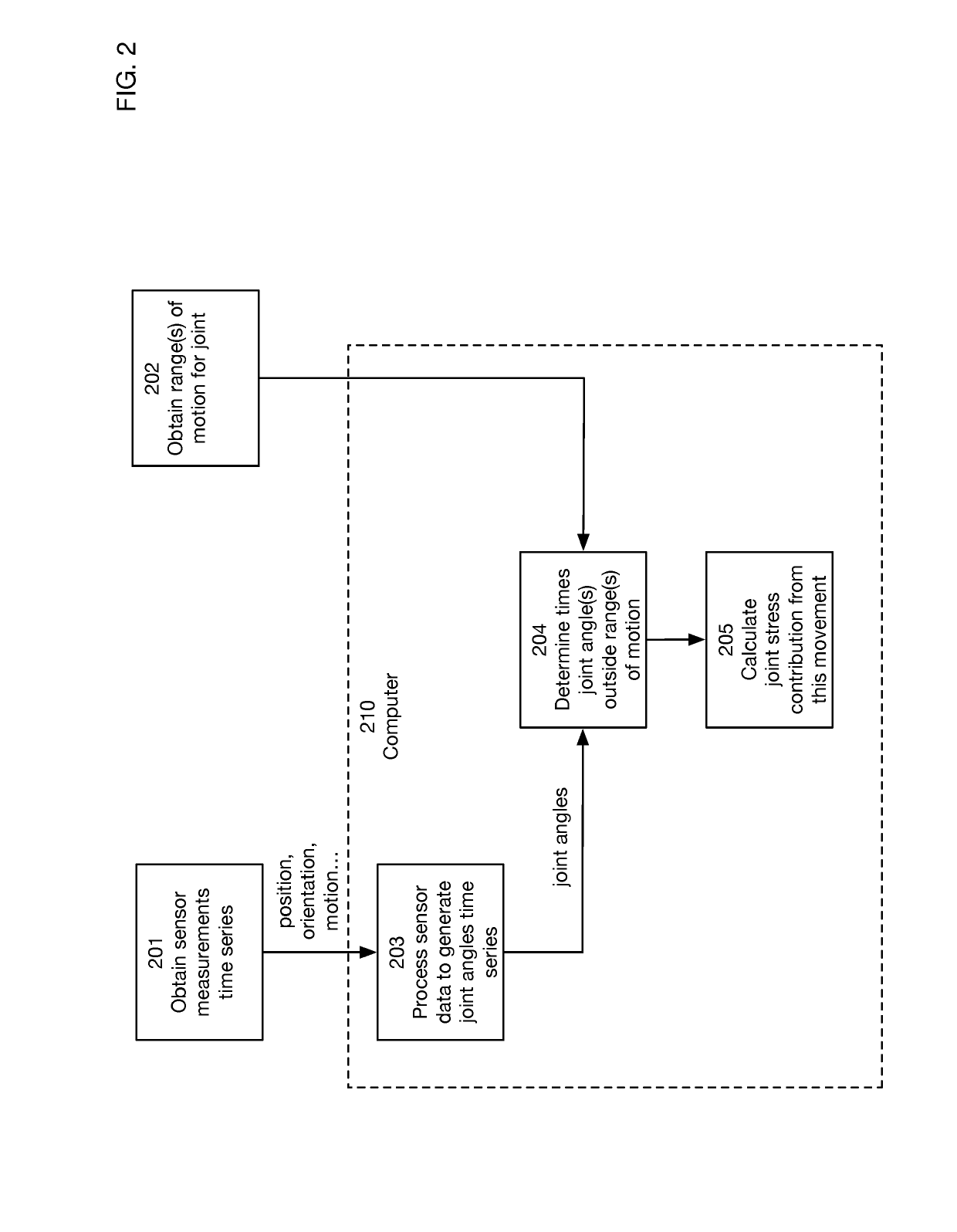

Method of determining joint stress from sensor data

A method of calculating the stress on a joint by determining when a joint angle is outside the normal range of motion for the joint. Applications include analysis of elbow joint stress for baseball pitchers, for example to mitigate the risk of injury to the ulnar collateral ligament (UCL). During a movement such as a baseball pitch, sensor data is collected to track the position, orientation, or motion of body segments; joint angles are derived from this sensor data. Joint angles are then compared to a range of motion, which may be measured for each individual. Joint stress contributions from movements that exceed the range of motion may be combined over time to calculate cumulative joint fatigue. This joint fatigue measure may for example be used for pitchers to quantify recovery periods (days off) and future workloads (such as maximum pitch counts).

Owner:NEWLIGHT CAPITAL LLC

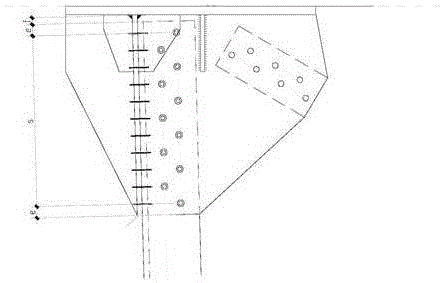

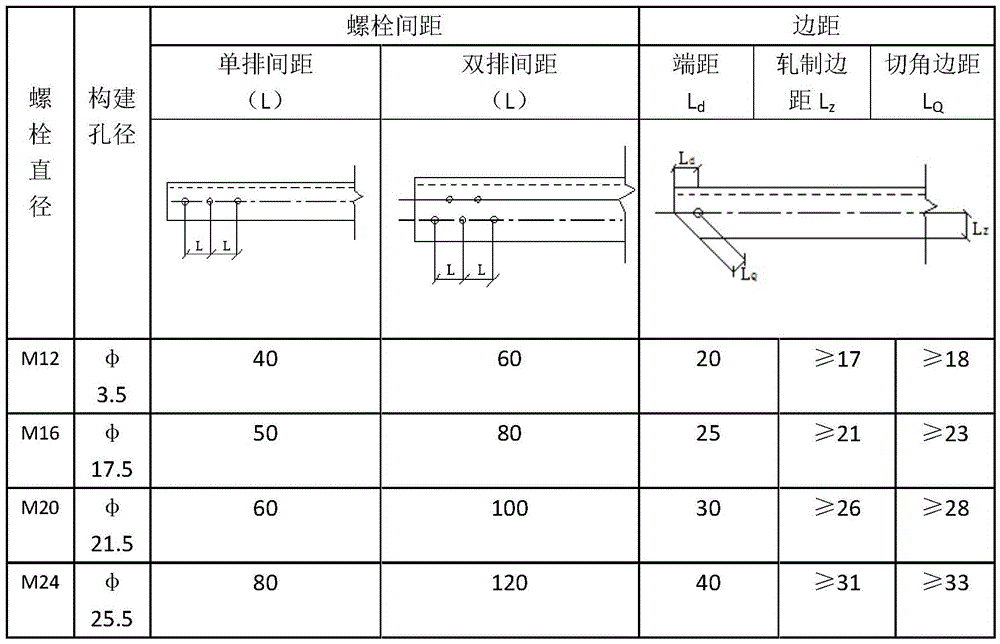

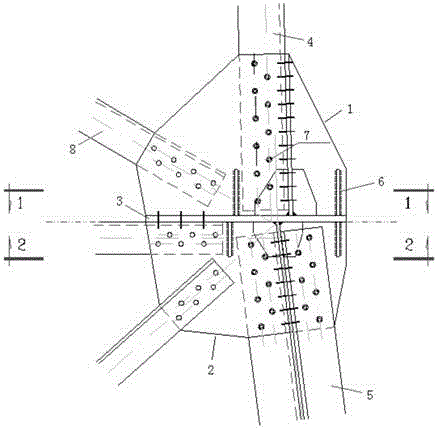

Power transmission line angle-steel tower single and double angle-steel transition joint design method

InactiveCN106703498AGood specificationImprove applicabilityTowersBuilding constructionsEngineeringTower

The invention provides a power transmission line angle-steel tower single and double angle-steel transition joint design method. Joints comprise a crisscross shoe plank on one side of single angle-steel, a crisscross shoe plank on one side of double angle-steel, a transition plate, a single angle-steel main material, the double angle-steel and stiffening plates; the design method comprises the steps of calculating shoe plank height, 2 calculating shoe plank thickness, 3 calculating shoe plank width, 4 calculating transition plate width and 5 calculating transition plate thickness. According to the method, influences of factors such as specifications of the angle-steel main material, the thicknesses of the shoe planks on the upper side and the lower side, and the thickness and width of a horizontal plate are comprehensively considered, the influences of different design parameters on joint stress are researched by building numerical simulation model and conducting entity experiments, design parameters corresponding to the angle-steel of different specifications are summarized according to researching and experimental data, a normative and systematic design method is provided, and a basis is provided for the power transmission line angle-steel tower single and double angle-steel transition joint design. Compared with the current design situation, the method has better normalization and engineering applicability.

Owner:CHINA ELECTRIC POWER RES INST +2

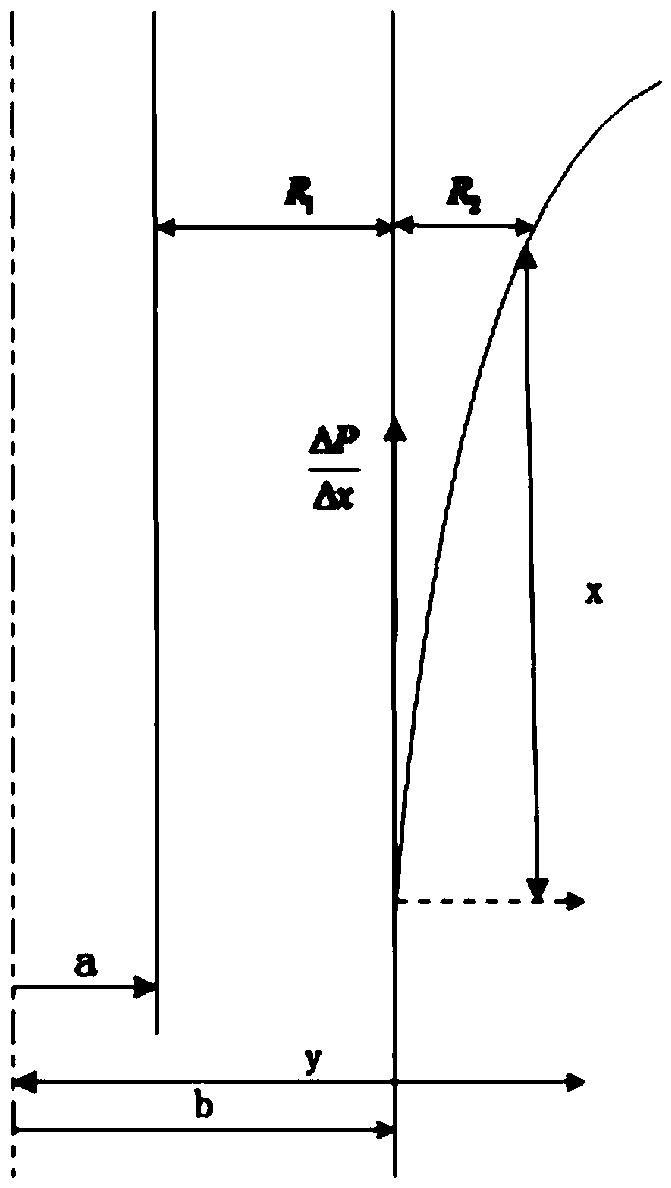

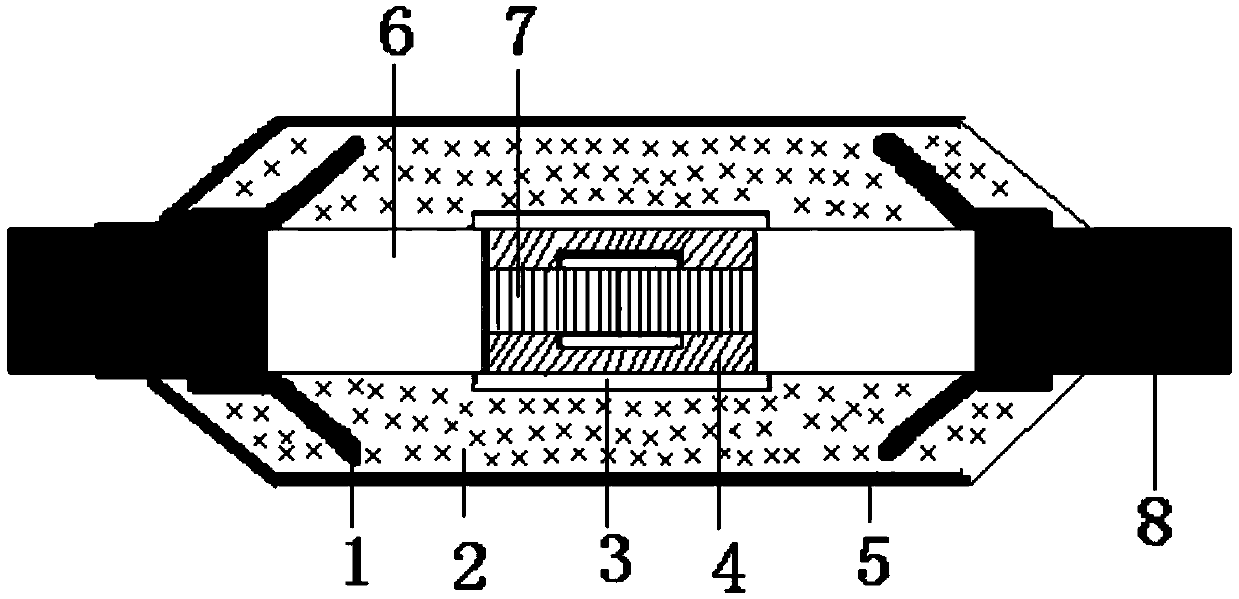

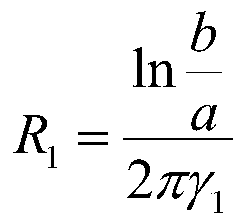

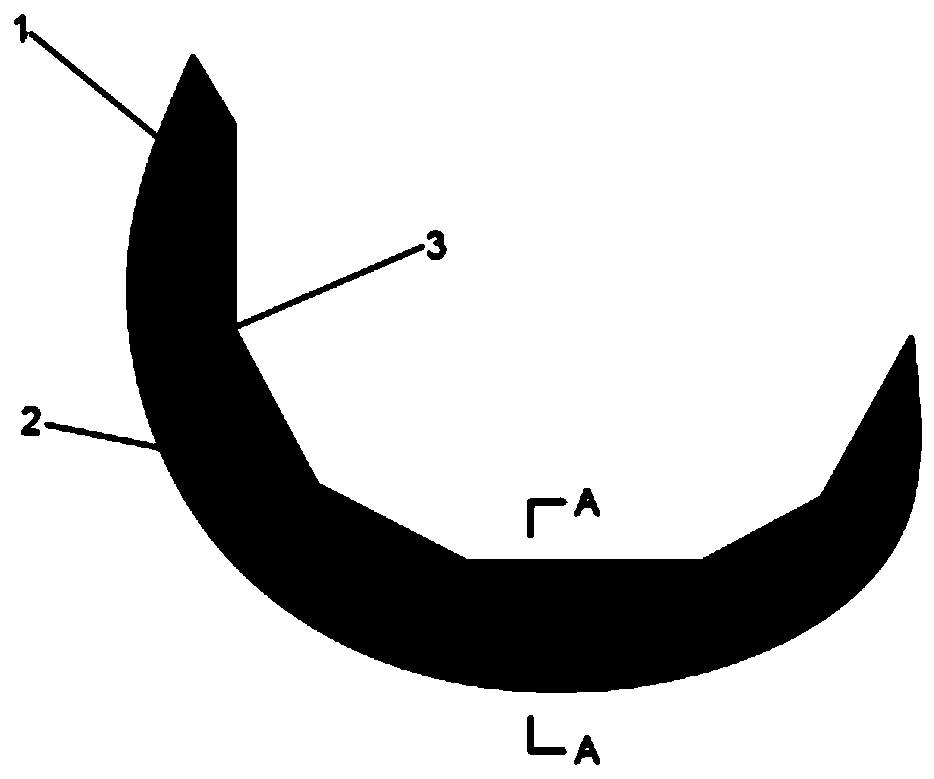

Design method of high-voltage DC cable intermediate joint stress cone

ActiveCN105514919AEnhanced Insulation ConductivityCable fittingsInsulation layerElectrical conductor

The invention provides a design method of a high-voltage DC cable intermediate joint stress cone. The method comprises the following steps: 1, determining the shielding radius a of a cable conductor, the outer-side radius b of cable insulation layer crosslinking polyethylene, resistance R1 of the cable insulation layer crosslinking polyethylene and resistance R2 of enhanced insulation silicone rubber; 2, calculating a ratio of electric potential of a P point at an interface between the insulation material of a cable insulation layer and the insulation material of enhanced insulation to conductor electric potential; and 3, calculating a vertical distance from the end portion of the stress cone to the root portion of the stress cone. According to the technical scheme provided by the invention, the tangential field intensity of the interface between the insulation materials is uniformly distributed according to conductivity of insulation materials of different high-voltage DC cable accessories.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

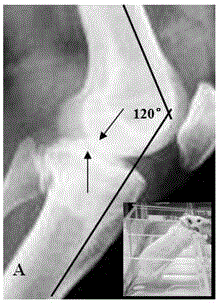

Rat-strain-knee-osteoarthritis model building method

The invention relates to a rat-strain-knee-osteoarthritis model building method. The rat-strain-knee-osteoarthritis model building method is combined with the primary-risk-factor joint acute or chronic biomechanics effect, the clinical strain-knee-osteoarthritis pathogenetic process is efficiently simulated, a novel animal model similar to the clinical knee-osteoarthritis pathogenesis is built, and in other words, experiment rats are only subjected to anterior cruciate ligament transection technology, but meniscuses of rats are not excised, and metabolic regulation and the stress effect of the rat knee joint micro-environment are highly kept; on the basis that a rat-knee-joint instable model is built, rats is in the forced upright bearing state at the same time, certain-strength running sport loads are fed, the joint stress effect is increased in a upslope-movement mode, a knee-joint-cartilage long-term strain is simulated, a knee osteoarthritis animal model is built, the model forming efficiency of the method and the rough time required by different-period molding of the knee osteoarthritis model are explored, and the basis is laid on further studying the mechanism and the treatment means of knee osteoarthritis.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

Method of determining joint stress from sensor data

A method of calculating the stress on a joint by determining when a joint angle is outside the normal range of motion for the joint. Applications include analysis of elbow joint stress for baseball pitchers, for example to mitigate the risk of injury to the ulnar collateral ligament (UCL). During a movement such as a baseball pitch, sensor data is collected to track the position, orientation, or motion of body segments; joint angles are derived from this sensor data. Joint angles are then compared to a range of motion, which may be measured for each individual. Joint stress contributions from movements that exceed the range of motion may be combined over time to calculate cumulative joint fatigue. This joint fatigue measure may for example be used for pitchers to quantify recovery periods (days off) and future workloads (such as maximum pitch counts).

Owner:NEWLIGHT CAPITAL LLC

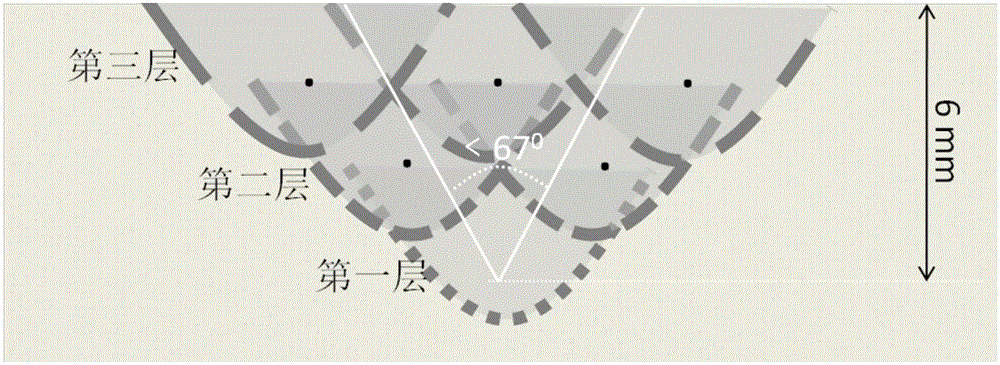

Method for controlling crack formation in heat affected zones in nickel-based alloy multi-layer laser filler wire welding

ActiveCN106077951AAvoid stress concentrationRepair looseWelding/soldering/cutting articlesLaser beam welding apparatusHeat-affected zoneThick plate

The invention discloses a method for controlling liquefied crack formation in heat affected zones in nickel-based alloy laser multi-layer filler wire welding. The method is mainly suitable for the welding process of welding and repair welding of nickel-based alloy laser filler wires with the thickness ranging from 3 mm to 12 mm. According to the method, the main principle is that joint stress distribution is changed, and the high-temperature dwell time of the heat affected zones of the overlapped positions is shortened, so that the crack formation rate is lowered. The welding method mainly comprises the following steps that firstly, the appropriate laser welding defocusing amount is determined, so that the fusion line of the cross section of each of weld joints is in a circular arc shape or an oval arc shape; and secondly, after the primary weld joint process is completed, in the secondary welding process, the heat affected zones generated in primary welding are made to be located in weld joint regions generated in the secondary welding process, and so on, the follow-up weld joints are treated. By the adoption of the welding method, under the same condition, the crack rate is lower compared with common laser filler wire repair welding or laser filler wire thick plate welding.

Owner:SHANGHAI JIAO TONG UNIV

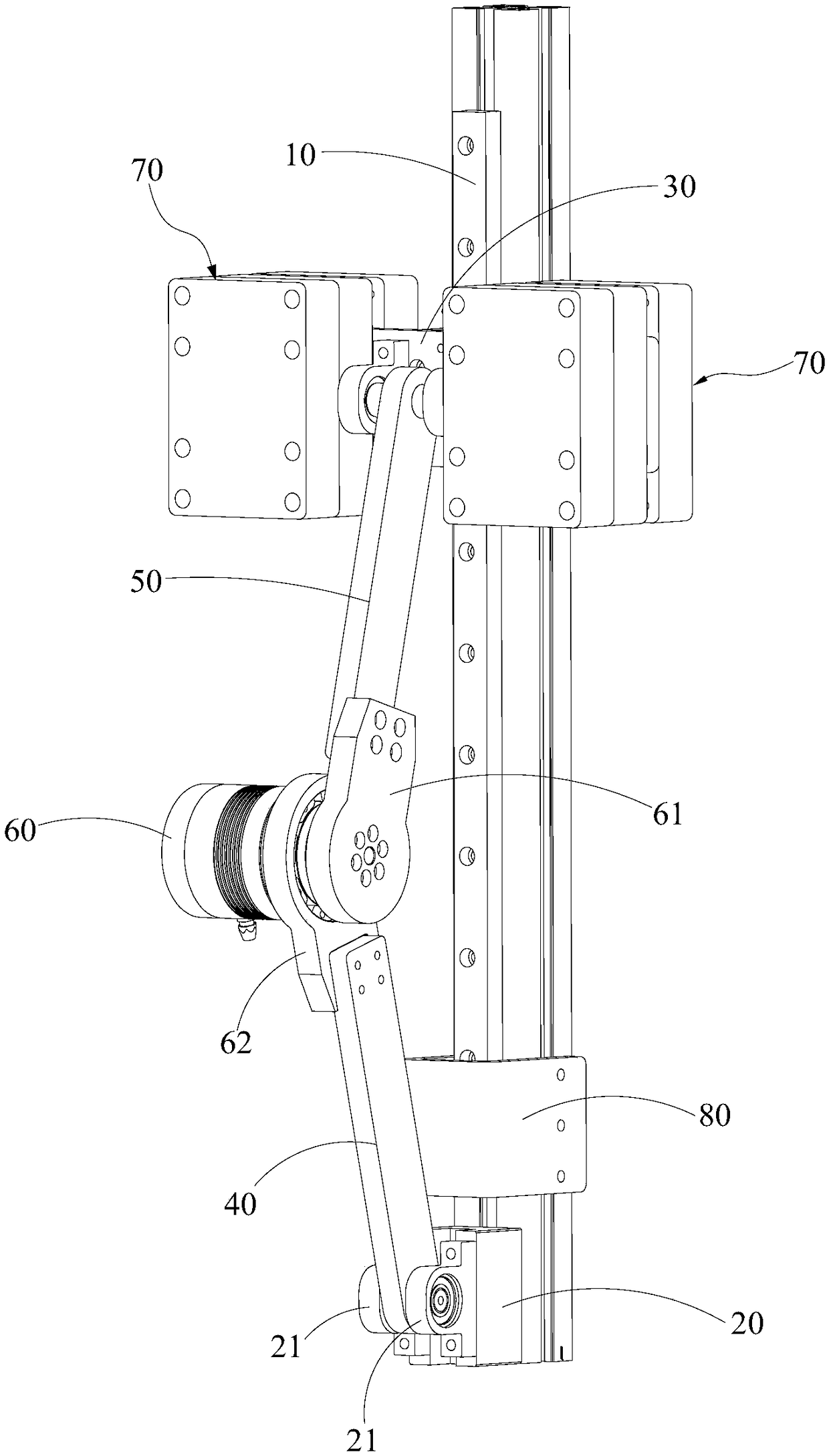

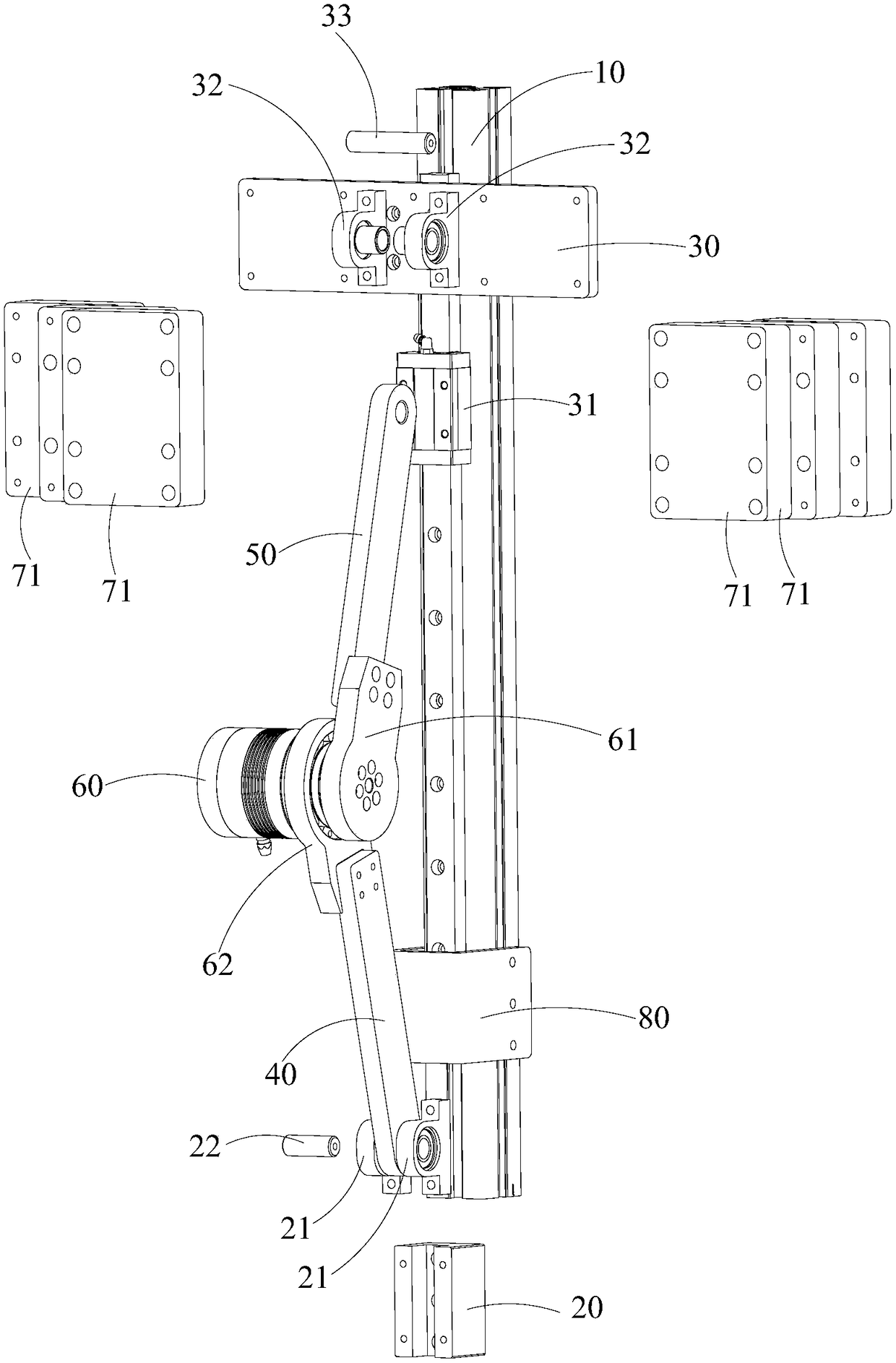

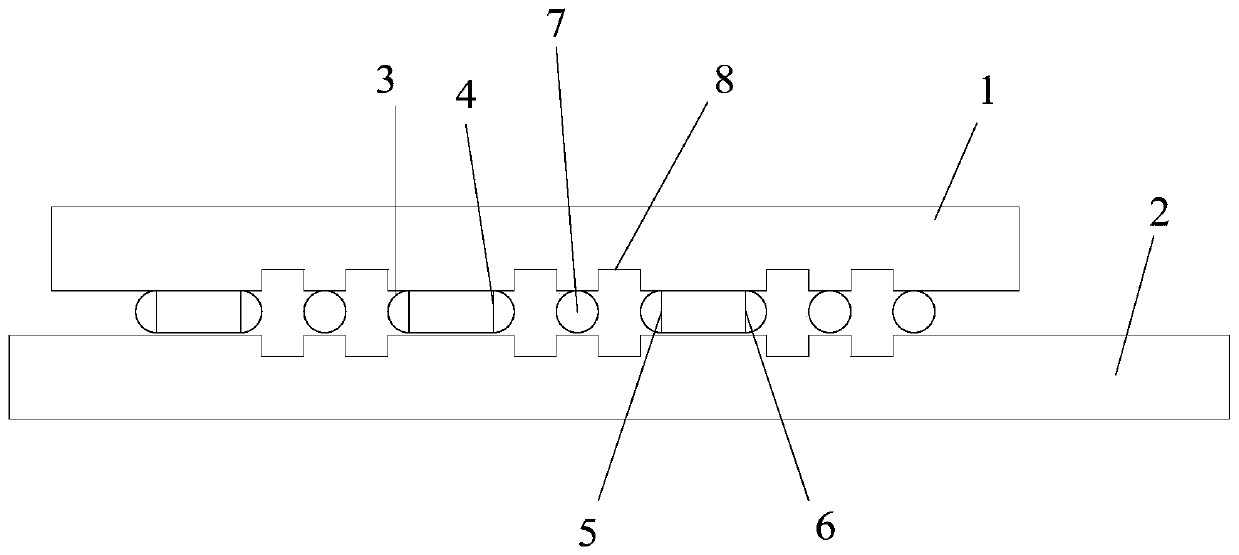

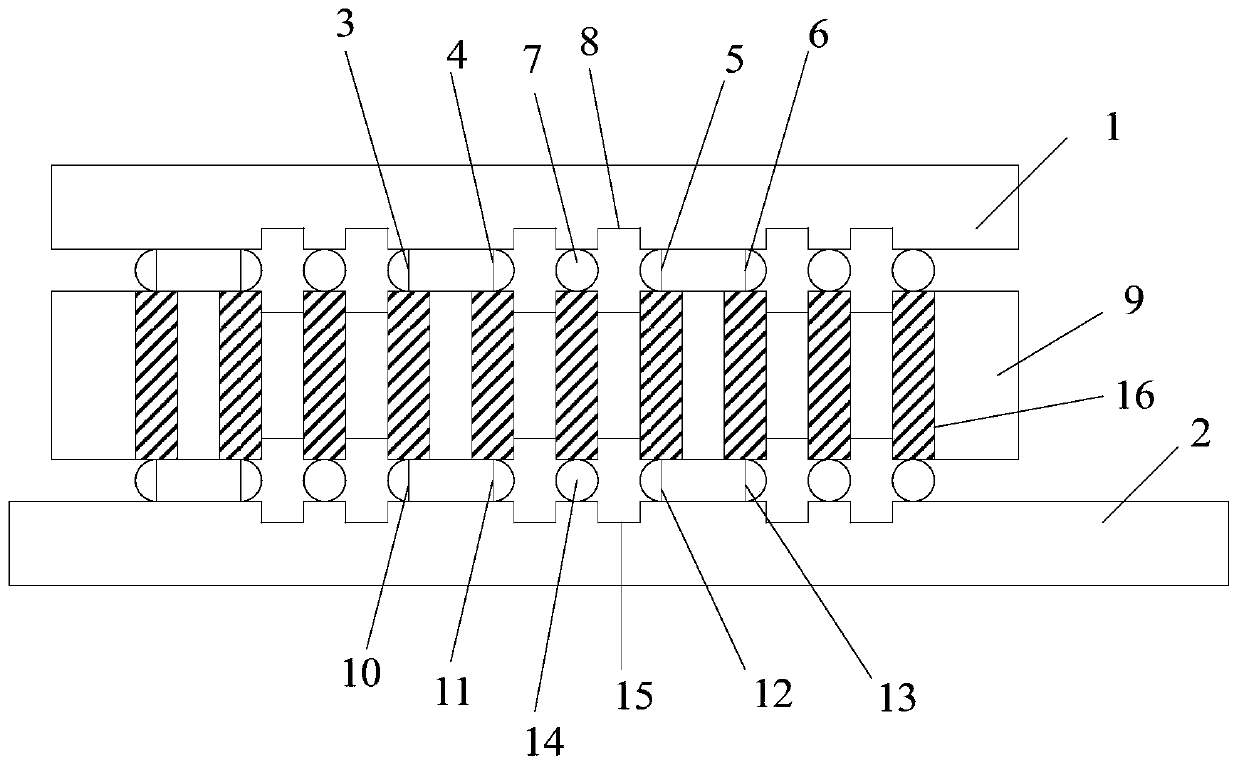

Humanoid robot movable joint stress testing device

ActiveCN108237557ASimple structureHigh degree of simulationProgramme-controlled manipulatorForce sensorsData processing systemHumanoid robot nao

The invention relates to the technical field of robots, and provides a humanoid robot movable joint stress testing device. The humanoid robot movable joint stress testing device comprises a vertically-arranged guide rail, a lower fixing block fixed to the bottom end of the guide rail, an upper fixing block arranged at the top end of the guide rail in a sliding manner, a lower connecting rod rotationally connected with the lower fixing block, an upper connecting rod rotationally connected with the upper fixing block, a joint module located between the lower connecting rod and the upper connecting rod and rotationally connected with the lower connecting rod and the upper connecting rod, and a data processing system which is in signal connection with the joint module. In the humanoid robot movable joint stress testing device, the joint module is used for transmitting torque to drive the upper connecting rod, the lower connecting rod and the upper fixing block to move on the guide rail, and the bending and stretching movement of a humanoid robot movable joint is simulated. In the motion process, the data processing system receives signals fed back by the joint module and conducts conversion, and then stress data of the movable joint can be obtained. The whole testing device is simple in structure, high in biofidelity, accurate and reliable in testing data and easy to operate.

Owner:UBTECH ROBOTICS CORP LTD

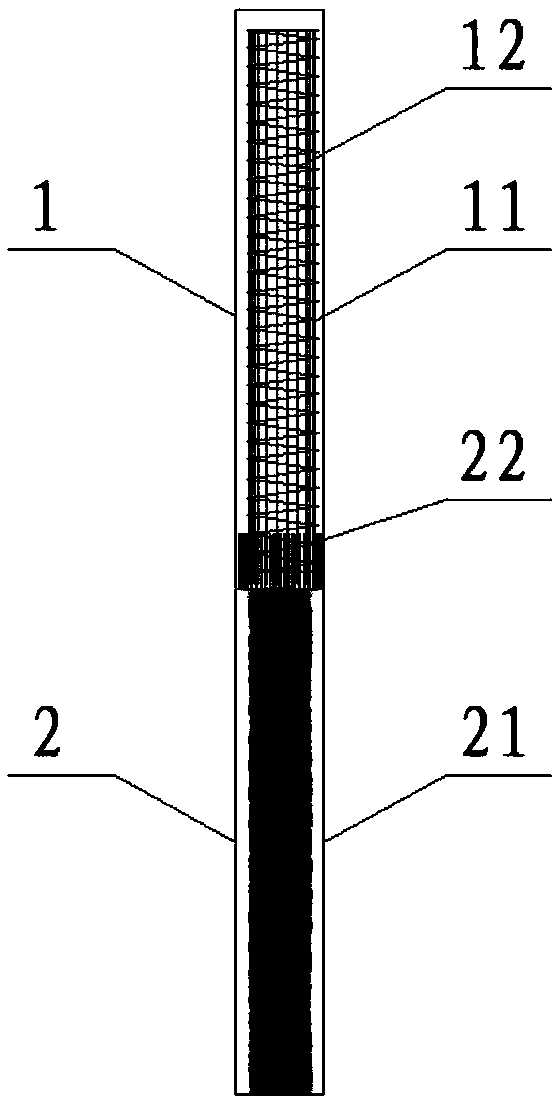

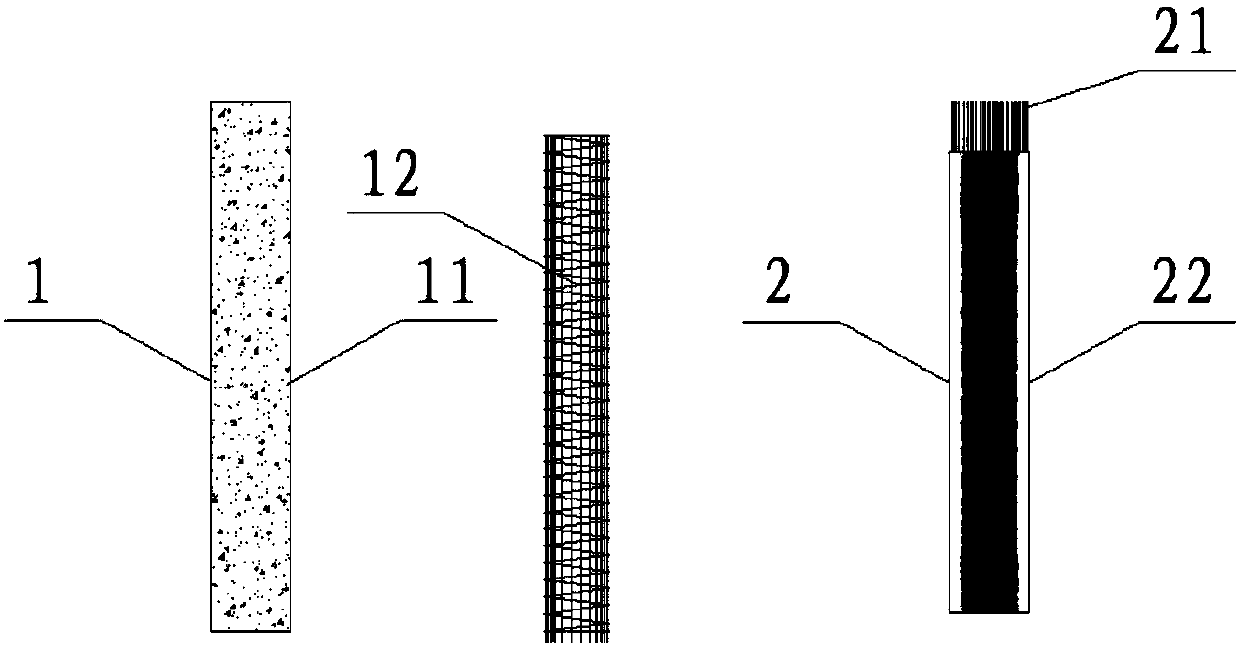

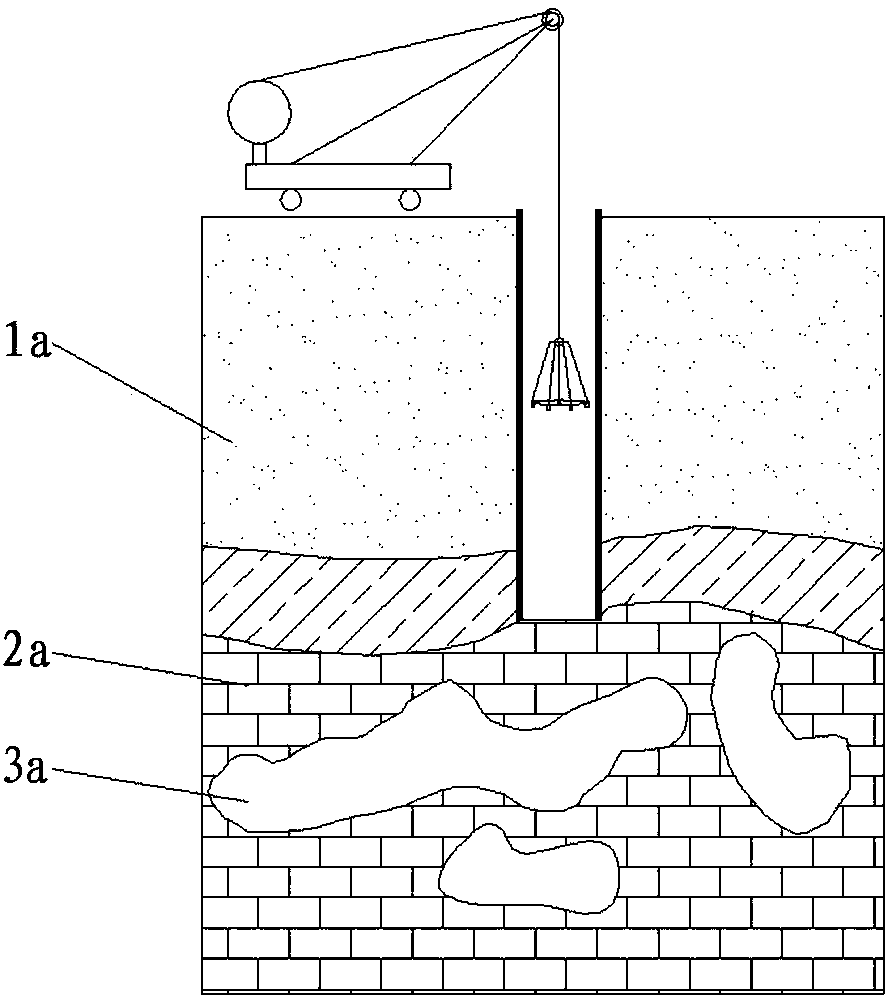

Cast-in-place prefabricated composite structure pile suitable for karst zone and construction method of cast-in-place prefabricated composite structure pile

The invention discloses a cast-in-place prefabricated composite structure pile suitable for a karst zone and a construction method of the cast-in-place prefabricated composite structure pile. The cast-in-place prefabricated composite structure pile comprises an upper pile section and a lower pile section, the upper pile section is a cast-in-place reinforced concrete grouting pile, the lower pile section is a prefabricated concrete tubular pile, the lower pile section penetrates a karst cave zone in a rock stratum, the upper pile section penetrates a non-karst-cave zone and is supported to theupper end of the lower pile section, and a pile foundation is jointly formed by combining the upper pile section and the lower pile section; in the construction process, an upper-layer non-karst-cavezone pile hole is constructed in a conventional method firstly, then a manual hole digging method or a rotary drilling rig is adopted for constructing a lower-layer karst cave zone pile hole, then theconcrete tubular pile is hoisted into the karst cave zone pile hole, a sealing ring is arranged between the top of the concrete tubular pile and the non-karst-cave zone pile hole, then a reinforcement cage of the reinforced concrete grouting pile is hoisted into the non-karst-cave zone pile hole, and cast-in-place grouting is carried out to obtain the overall pile foundation integrating the concrete tubular pile with the reinforced concrete grouting pile. According to the cast-in-place prefabricated composite structure pile and the construction method, the upper pile section and the lower pile section are combined to form an overall pile body to achieve joint stress, construction is convenient and quick, and the construction cost is low.

Owner:HUBEI UNIV OF TECH

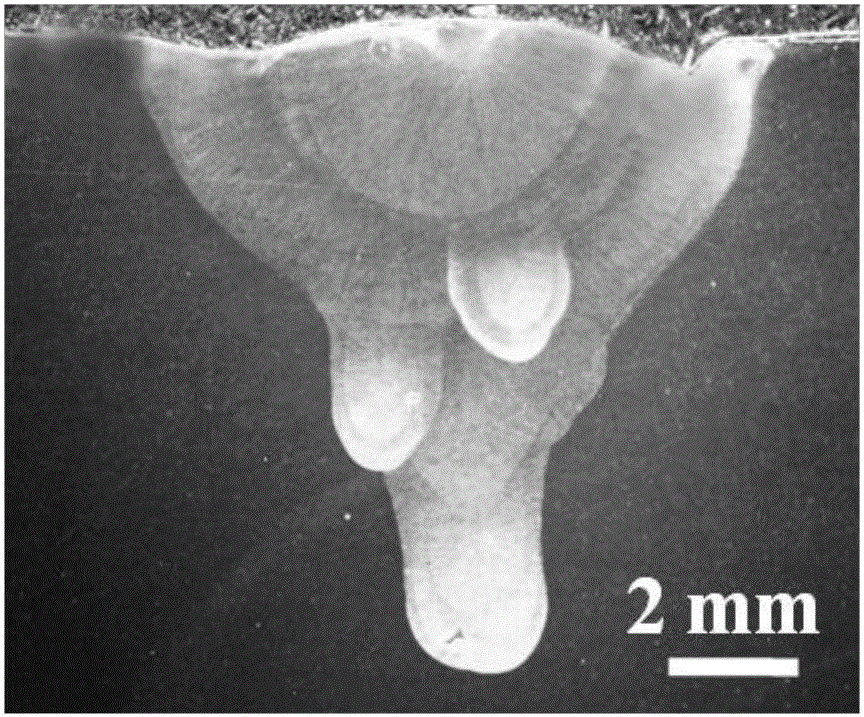

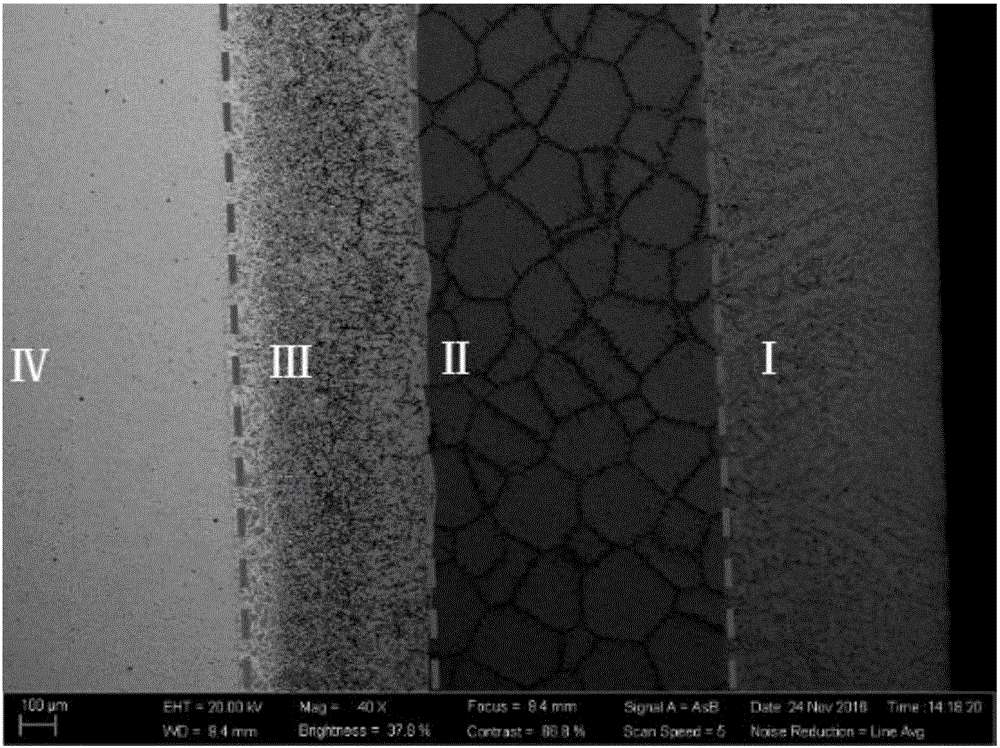

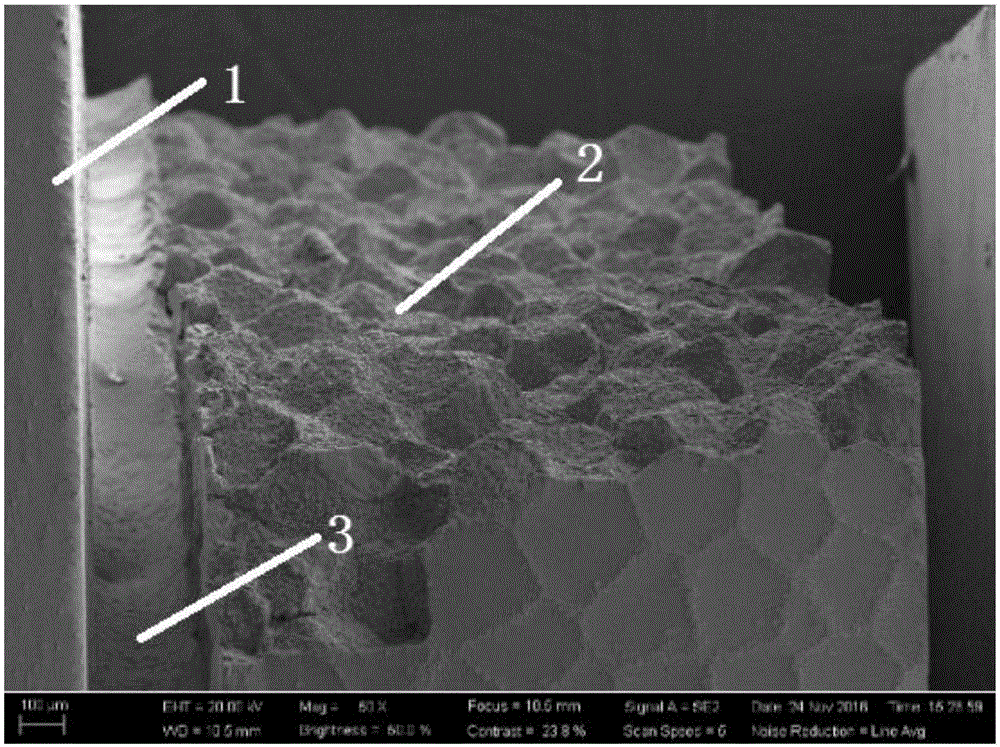

TIG welding method of Ti-based composite material and Ni-based alloy in lap joint with additional Cu middle layer

ActiveCN106735766AReduce performanceGrowth inhibitionArc welding apparatusTitanium matrix compositesLap joint

The invention relates to a TIG welding method of a Ti-based composite material and a Ni-based alloy in lap joint with an additional Cu middle layer in order to solve the problems that Ti / Ni dissimilar connection is difficult, the post-welded joint stress is large, and numerous brittle Ti-Ni phases exist due to complete melting of a welding area. The method includes the step that a TIG welded net structure TiBw / TC4 composite material and a high-temperature Ni-based alloy in lap joint with the additional Cu middle layer are adopted. On the one hand, stress in a Ti / Ni dissimilar joint is reduced, on the other hand, the Cu middle layer is low in melting point, completely melts and reacts with a base material on the two sides in the welding process, and accordingly, the number of formed brittle Ti-Ni phases such as Ti2Ni is decreased; and welding is conducted in a lap joint mode, the TiBw / TC4 composite material at the joint can be controlled to partially melt, and therefore, the high-strength Ti / Ni dissimilar joint of the layered structure can be obtained.

Owner:HARBIN INST OF TECH

Design and manufacturing method of polyether-ether-ketone bionic multilevel artificial joint

PendingCN110193926AAvoid ArtifactsAvoid stressAdditive manufacturing apparatusJoint implantsWear resistantJoint stress

The invention discloses a design and manufacturing method of a polyether-ether-ketone bionic multilevel artificial joint. The design and manufacturing method of the polyether-ether-ketone bionic multilevel artificial joint comprises the following steps of firstly, performing preoperative planning according to actual joint replacement, reconstructing a joint three-dimensional model of a patient, and performing mechanical analysis to obtain a joint stress distribution result; then according to the condition of the patient and the joint stress distribution result, designing the joint in a mode ofmodulus and strength, forming different modulus, strength and functional areas, and performing partition data processing on the final joint model according to the area requirements of different requirements, forming a process data packet containing 3D printing parameters; and leading the 3D printing process data packet into a 3D printer, controlling the 3D printing process, selecting different materials according to the result of the partition design, adopting multiple nozzles for simultaneous printing, and obtaining the required artificial joint by regulating and controlling different temperature and high-layer printing parameters. According to the method, the bionic multi-layer wear-resistant and bone-long-entry joint structure is designed, 3D printing is adopted for rapid manufacturing, and integrated design and production are formed.

Owner:XI AN JIAOTONG UNIV +1

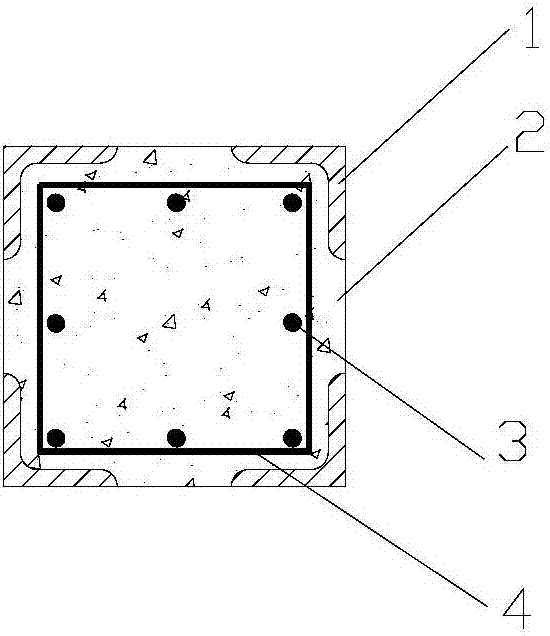

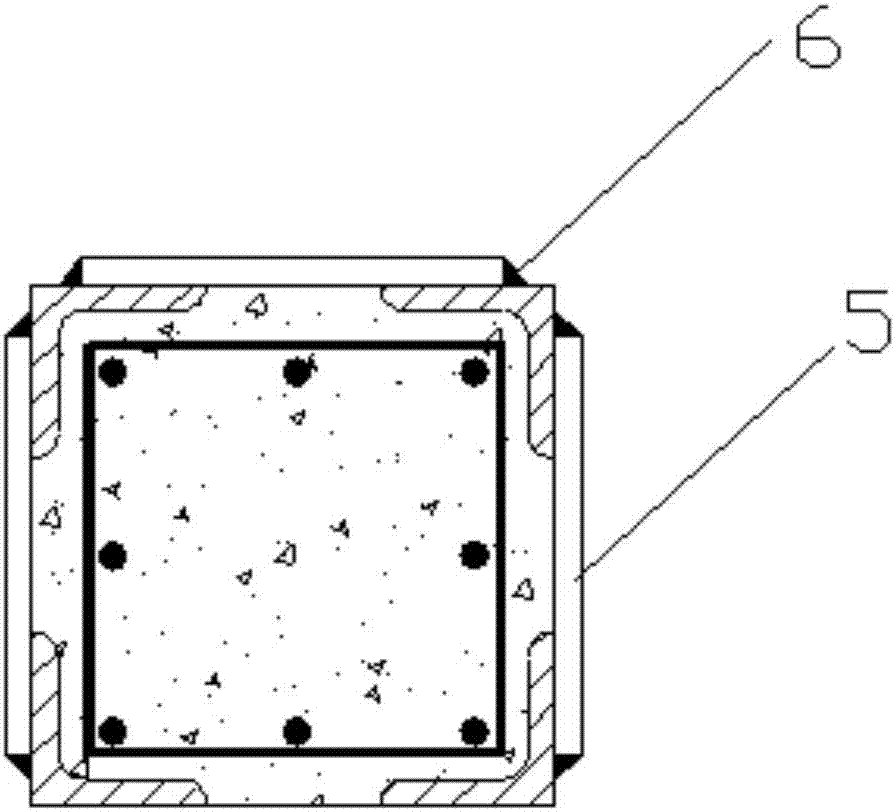

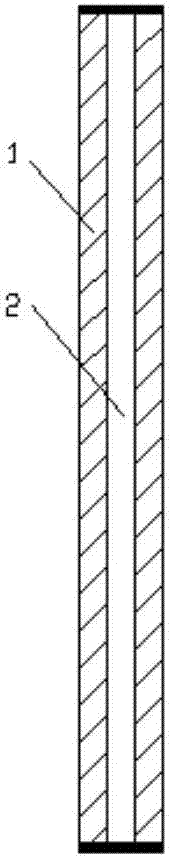

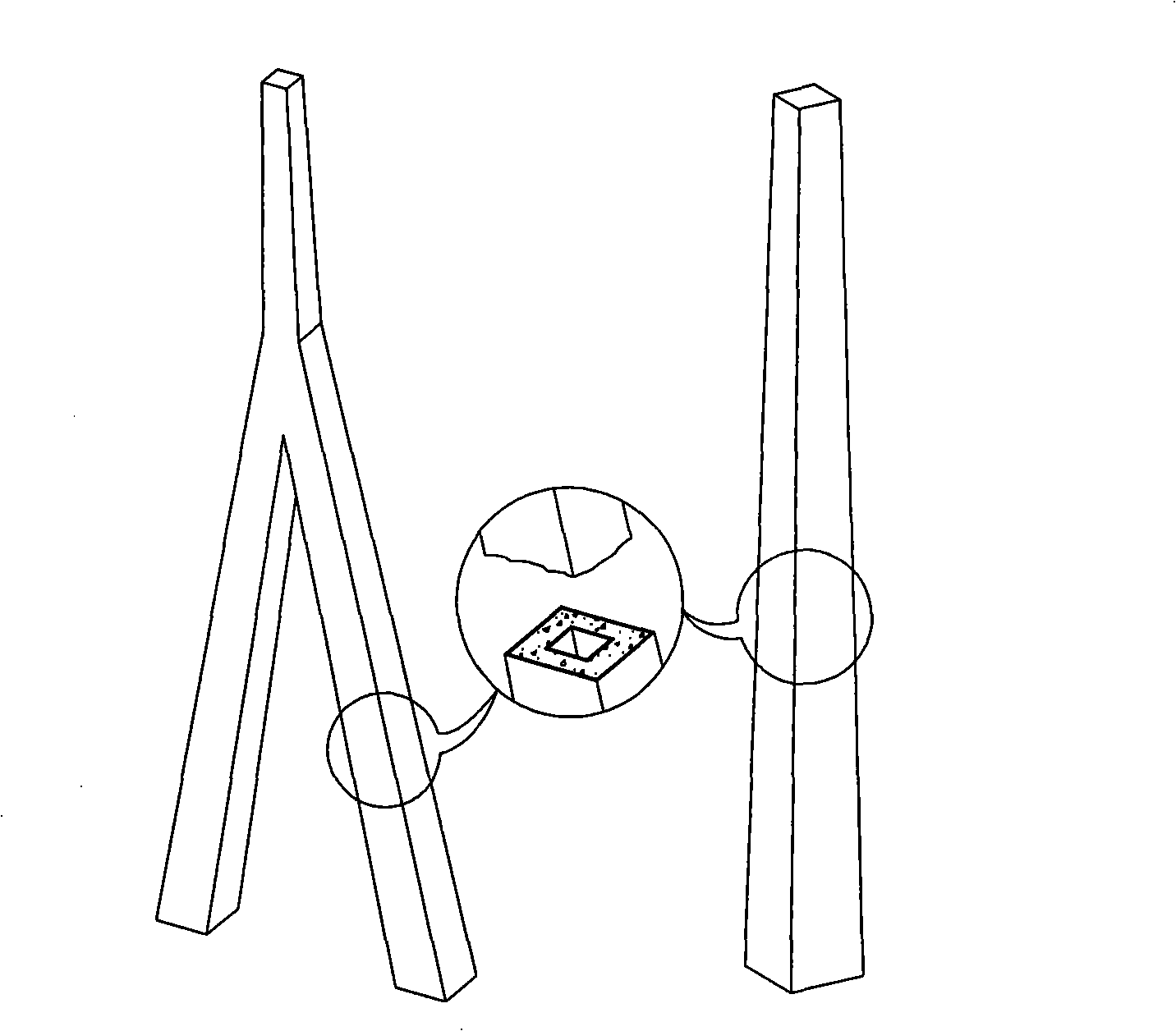

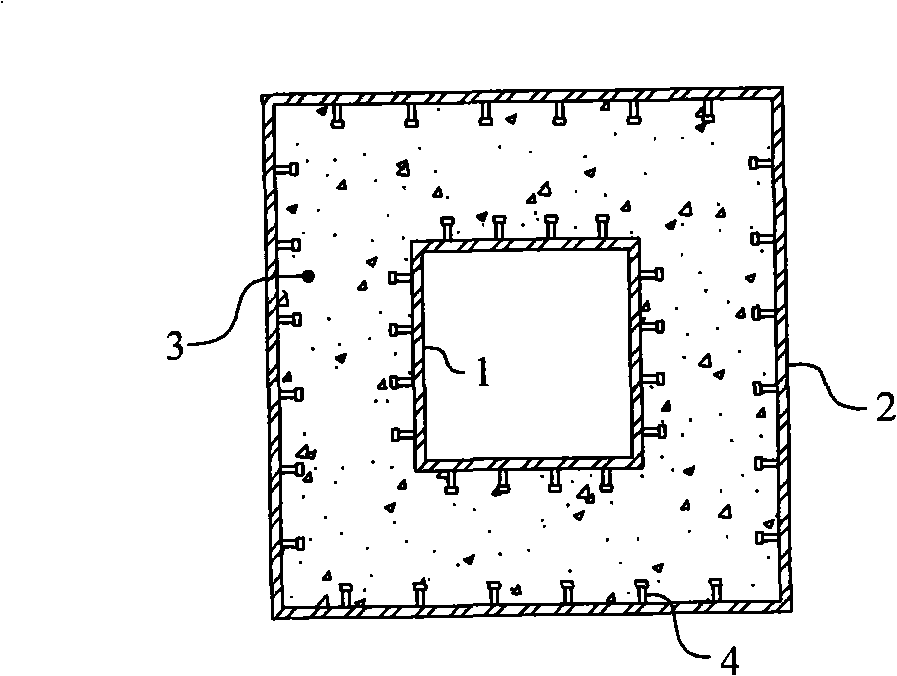

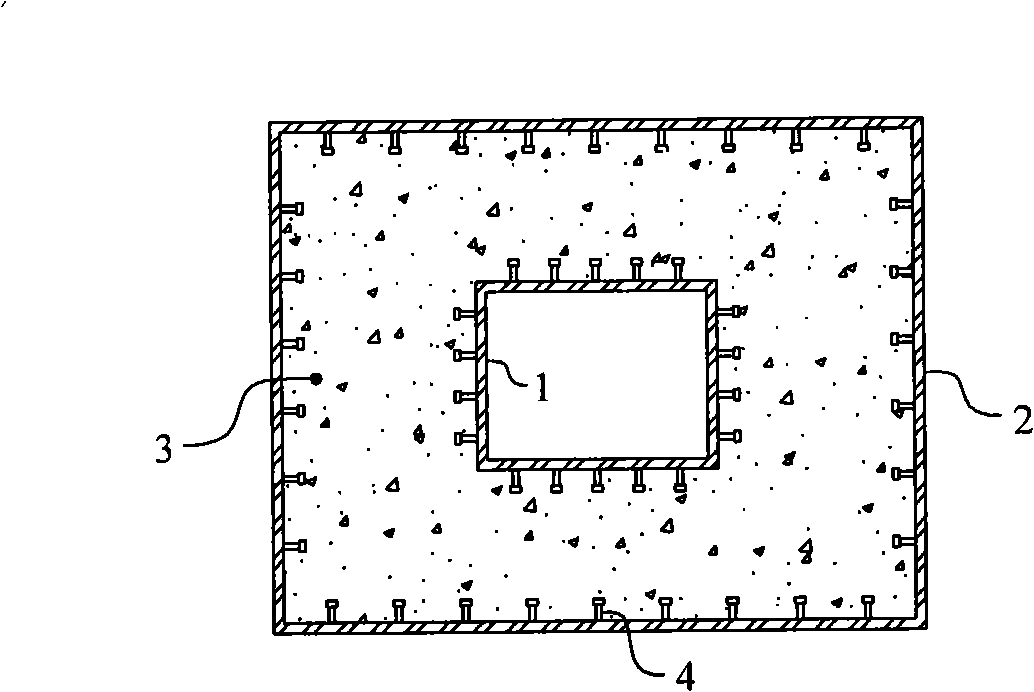

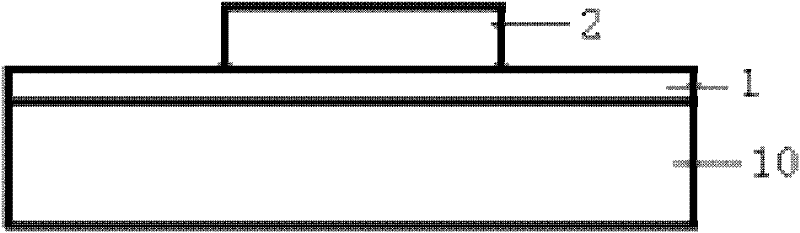

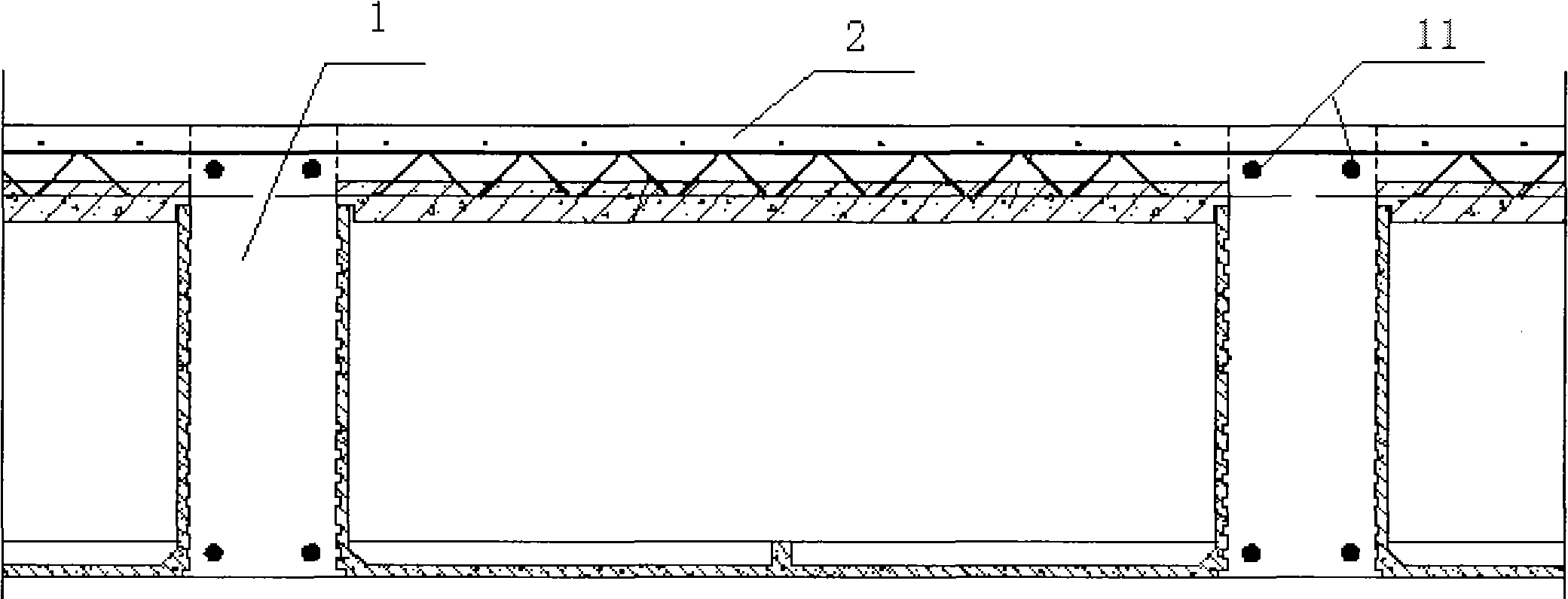

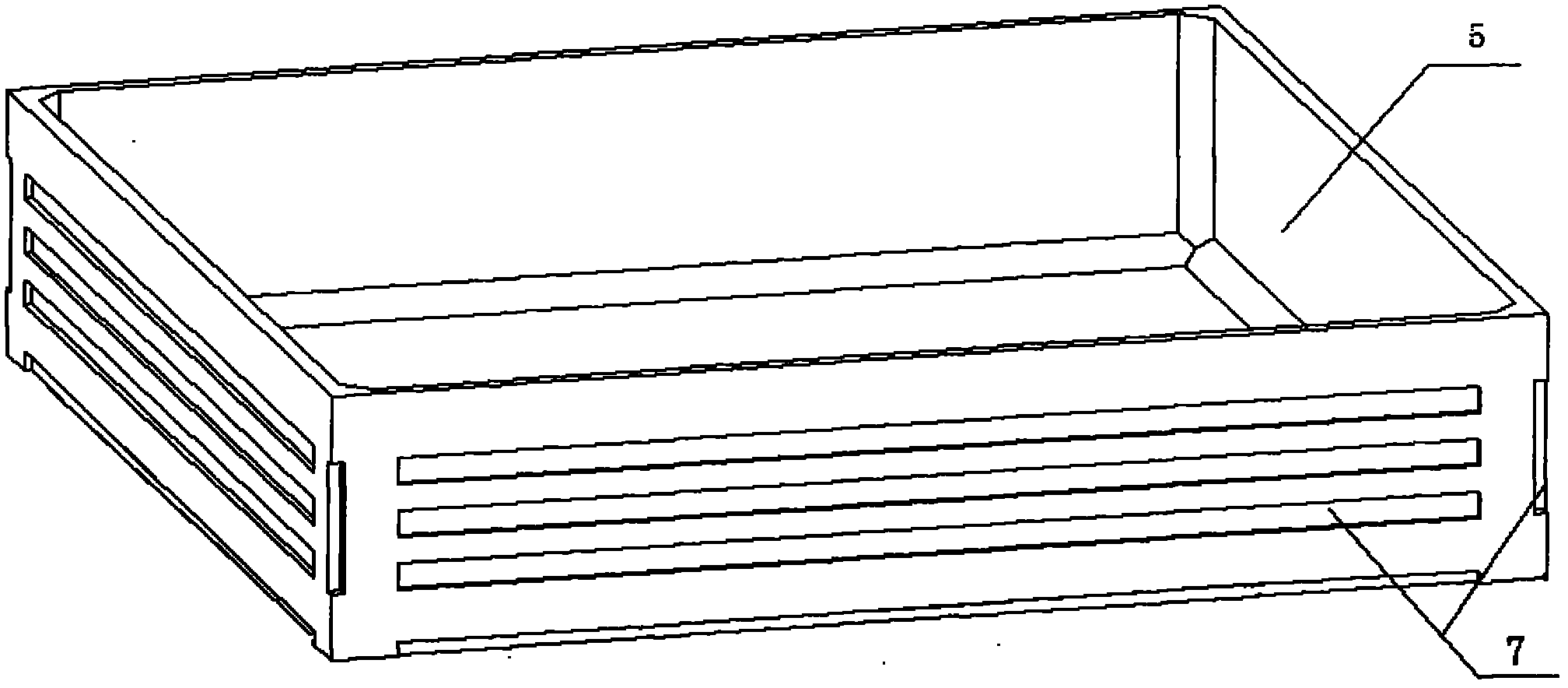

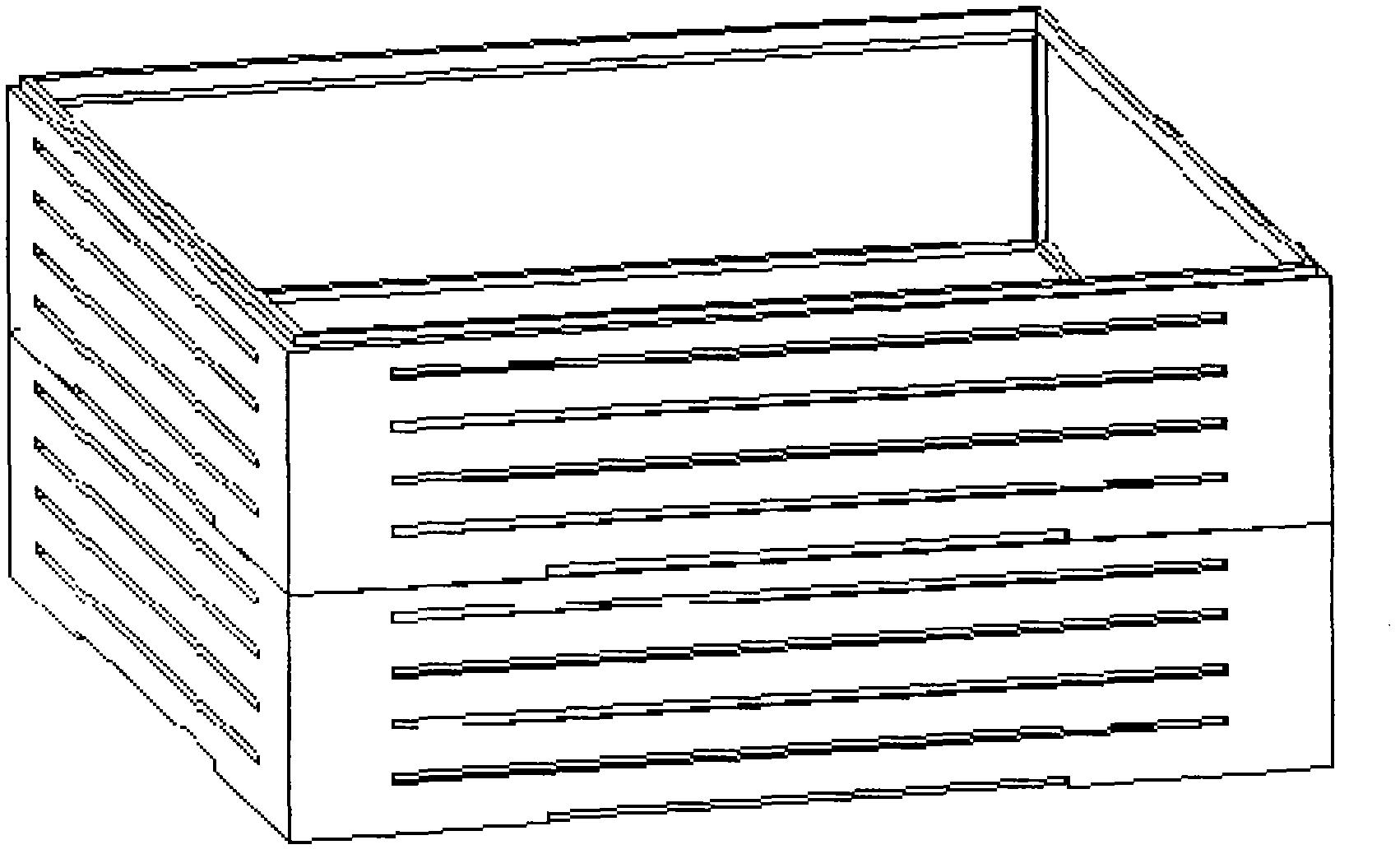

Assembled monolithic concrete ribbed hollow floor slab

InactiveCN102094481AHigh hollow rateLight weightFloorsForms/shuttering/falseworksFloor slabReinforced concrete

The invention relates to a floor slab, in particular to an assembled monolithic concrete ribbed hollow floor slab with combination of prefabrication and casting in place and joint stress, which comprises reinforced concrete rib beams (1), a reinforced concrete overlapping layer (2) and assembled box dies (3); each reinforced concrete rib beam is formed by casting in place between the adjacent assembled box dies; the reinforced concrete overlapping layer is formed by casting in place above the assembled box dies; each assembled box die (3) comprises a lattice reinforced composite slab (4) and an open box (5), and each lattice reinforced composite slab is a top slab of the open box (5); and protruding steel bars (6) are arranged in the lattice reinforced composite slabs (4), the protruding steel bars protrude into the peripheral rib beams for anchoring, longitudinal stressed steel bars (11) in the rib beams are hooked, and the rib beams (1) and the lattice reinforced composite slabs (4) are jointly stressed. The structural height of the floor slab can be greatly reduced, and higher using space for a building can be provided under the situation of same storey height.

Owner:辛崇安

Steel framed HMWPE (high molecular weight polyethylene) composite pipe, manufacturing method thereof and composite equipment

ActiveCN105202281AGood flexibilityReduce stressFlexible pipesTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a steel framed HMWPE (high molecular weight polyethylene) composite pipe, a manufacturing method thereof and composite equipment. According to the steel framed HMWPE composite pipe, material strength and composite bonding strength are very high; pipe flexibility is good, and the pipe can be bent with topographical change for laying, can be resistant to ground settlement to a certain extent and is not prone to cracking; meanwhile, the toughness is good, pipe joint stress can be greatly reduced, one-way steel wire winding and inner pipe rotation are only required during manufacturing, the diameter of a carbon spring steel wire is 0.5 mm-3 mm, an HMWPE sheet protection layer (4) is arranged on the periphery of a high molecular weight linear low-density polyethylene bonding layer (2), the molecular weight of the HMWPE sheet protection layer (4) is 800,000-950,000 units, the HMWPE sheet protection layer (4) is formed by spirally winding and shrinking HMWPE sheets after thermal stretch processing, edges of adjacent HMWPE sheets after winding are in mutual overlap joint, the overlap joint width is 20 mm-40 mm, the thickness of each HMWPE sheet is 2 mm-5 mm, and the width of each HMWPE sheet is 200 mm-800 mm.

Owner:刘嵩

Printed circuit board assembly and terminal

ActiveCN110312363AIncrease the gapPrevent electromigrationMagnetic/electric field screeningCross-talk/noise/interference reductionElectromagnetic shieldingPrinted circuit board

The invention provides a printed circuit board assembly and a terminal. The printed circuit board assembly includes a first printed circuit board, and a second printed circuit board electrically connected with the first printed circuit board by at least four solder joints, wherein the at least four solder joints includes a first solder joint, a second solder joint, a third solder joint and a fourth solder joint, the first solder joint is in communication with the second solder joint, the third solder joint is in communication with the fourth solder joint, at least one solder joint and / or at least one printed circuit board cavity are disposed between the second solder joint and the third solder joint, and the printed circuit board cavity is a recess structure recessed from a surface of a printed circuit board toward the inside. The printed circuit board assembly is advantaged in that the stress on individual solder joints can be scattered, moreover, electromagnetic shielding is providedfor signals of inner solder joints, on the basis of maintaining the scattered solder joint stress and the electromagnetic shielding ability, the gap among the solder joints is enhanced, the space forscaling powder evaporation is improved, and thereby the level of resistance to electromigration is further improved.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com