Patents

Literature

1372results about How to "Avoid stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

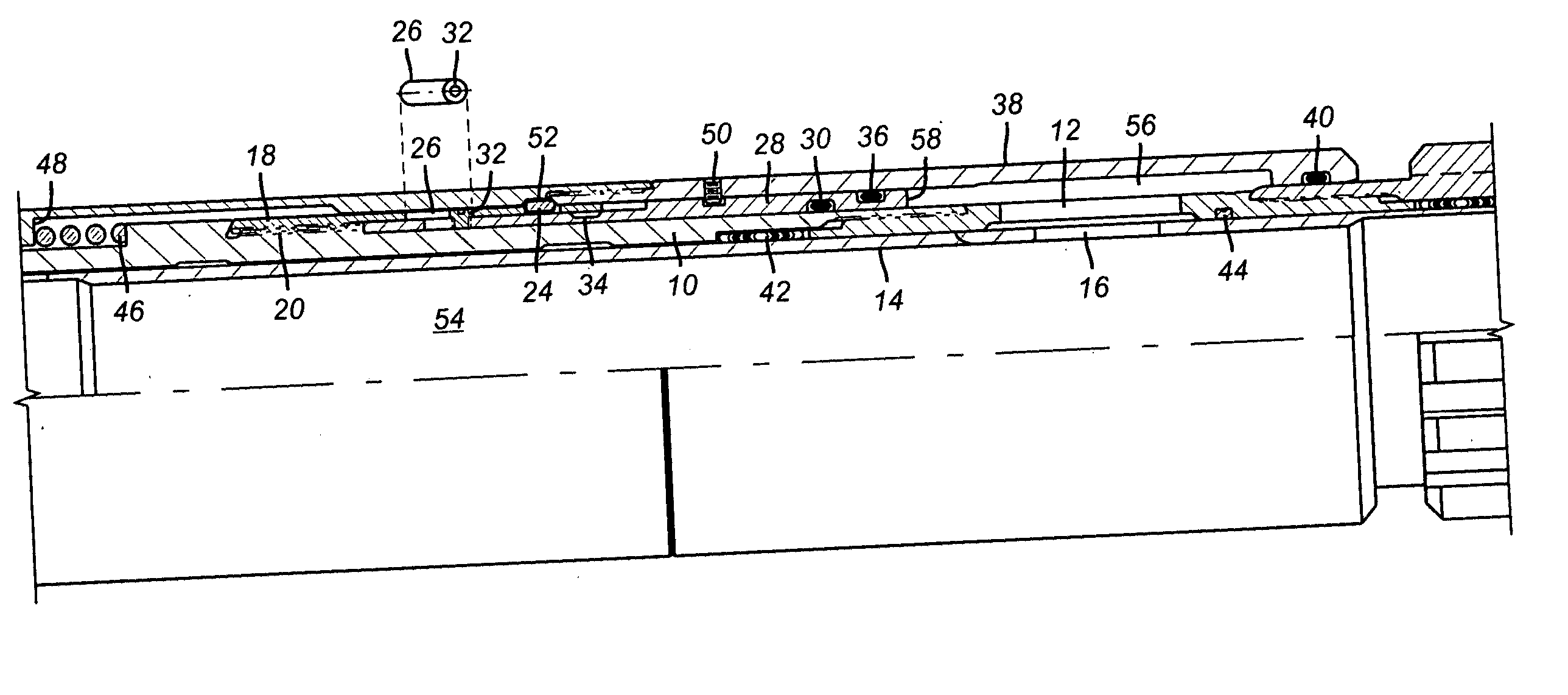

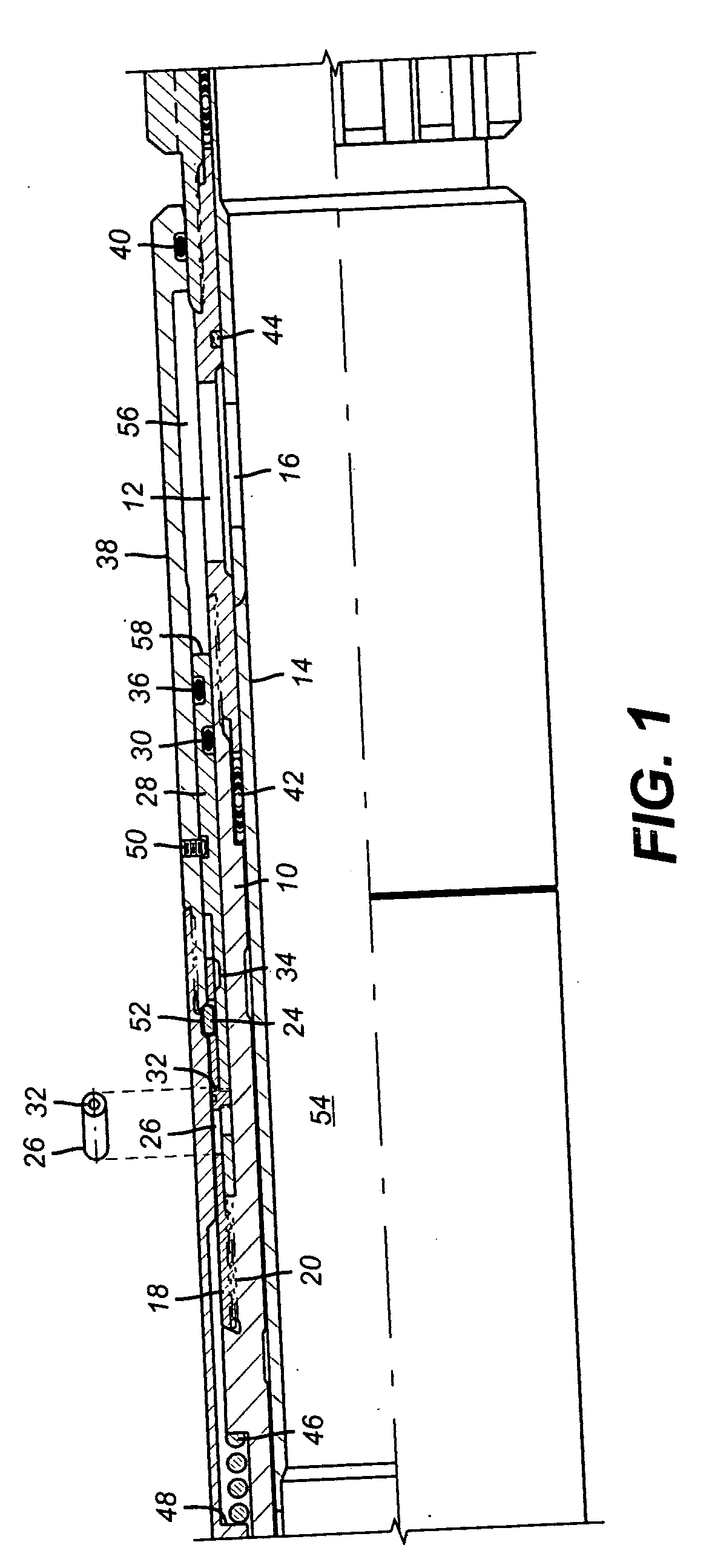

Lock mechanism for a sliding sleeve

ActiveUS20050126787A1Avoid stressRelieve stressFluid removalWell/borehole valve arrangementsPistonRelative motion

A locking device prevents stressing of other components used to hold tool portions against relative movement until a desired location is reached. A locking dog holds a first component, such as a sliding sleeve to a second component, such as a mandrel until pressure can move a piston and remove support for the dog. The same pressure that removes support for the dog to unlock the lock also forces a retainer, such as a shear pin that holds a sleeve to break to allow the sleeve to shift. The locking dog keeps stress off the shear pin when the locking dog is supported in the run in configuration. An alternative design uses a grease filled cavity to dampen shocks that could load a shear pin to the point of failure.

Owner:BAKER HUGHES INC

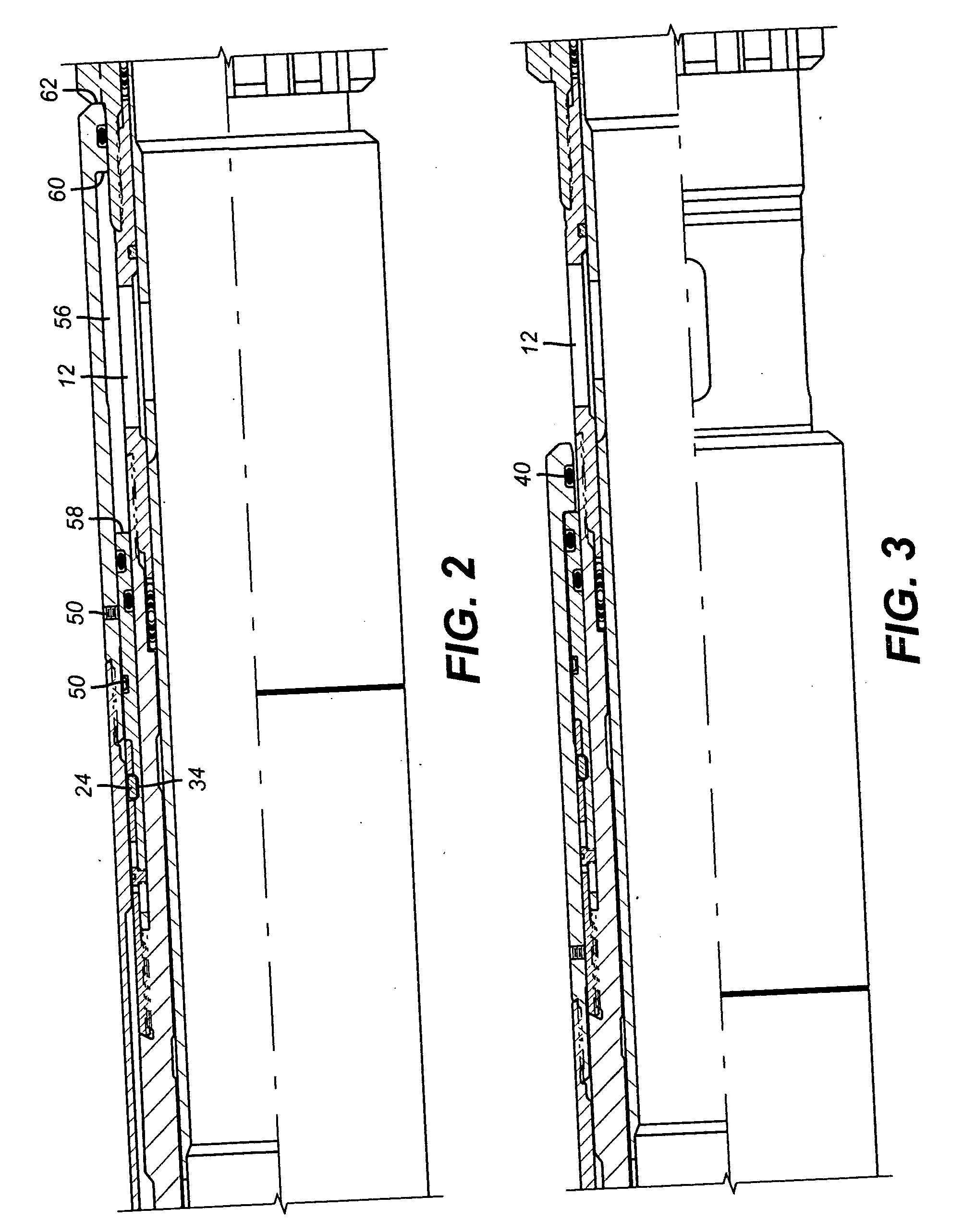

New flotation technique of lead zinc sulphur ore

The invention relates to a new technology for lead zinc sulfide ore floatation. Lead sulfide mineral is preferably carried out with mixed floatation in a neutral or weak alkali medium, then zinc floating and lead sulfur separation are carried out in a high alkali medium. The lead sulfide mineral is firstly floated to enter product, before zinc floating, lead sulfide mixed product is obtained, only pure zinc mineral enters slurry in a zinc floating work zone, thus being beneficial to zinc floatation and avoiding the operation method of heavy pulling and heavy stress; and lead tailing has no sulfur mineral, thus reducing useless poor circulation formed in zinc floating of the sulfur mineral, saving the beneficiation reagent and improving the sorting standard.

Owner:HUANGSHAPING MINING BRANCH HUNAN NONFERROUS METALS +2

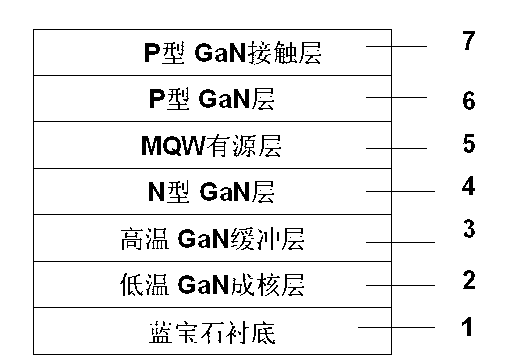

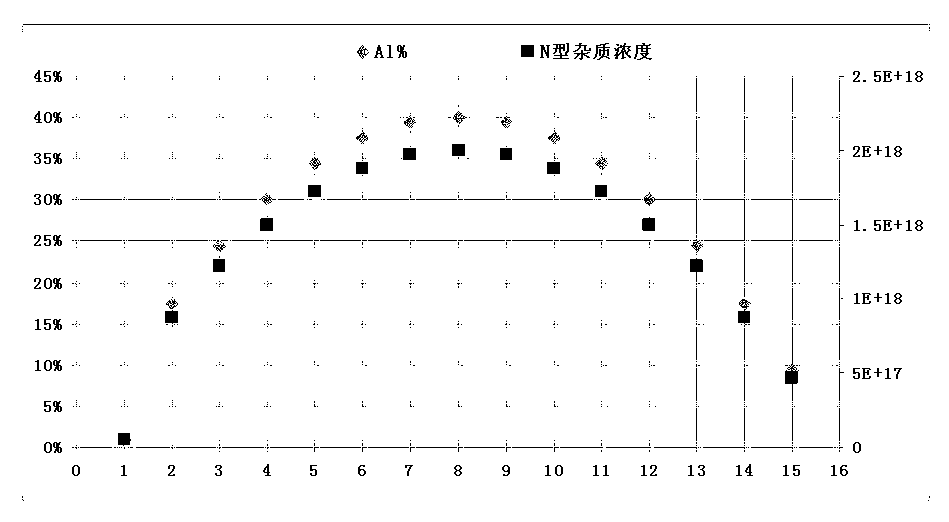

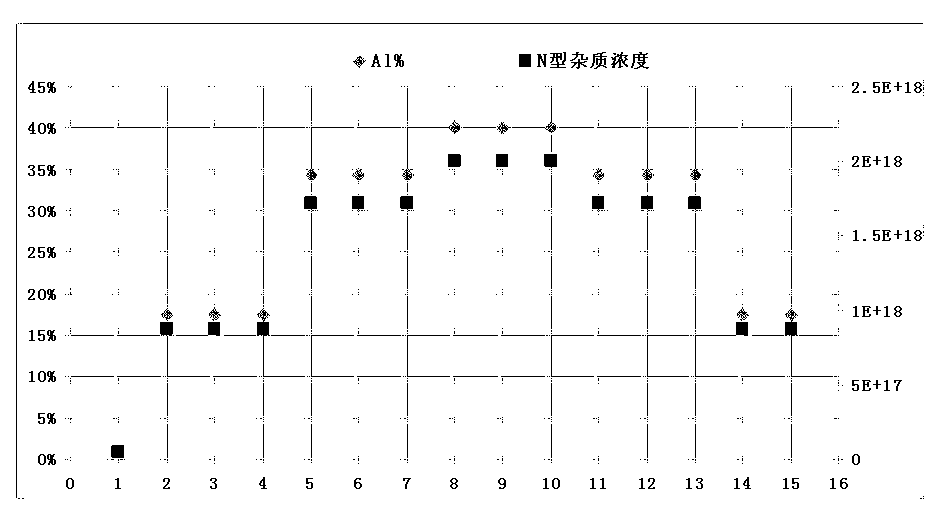

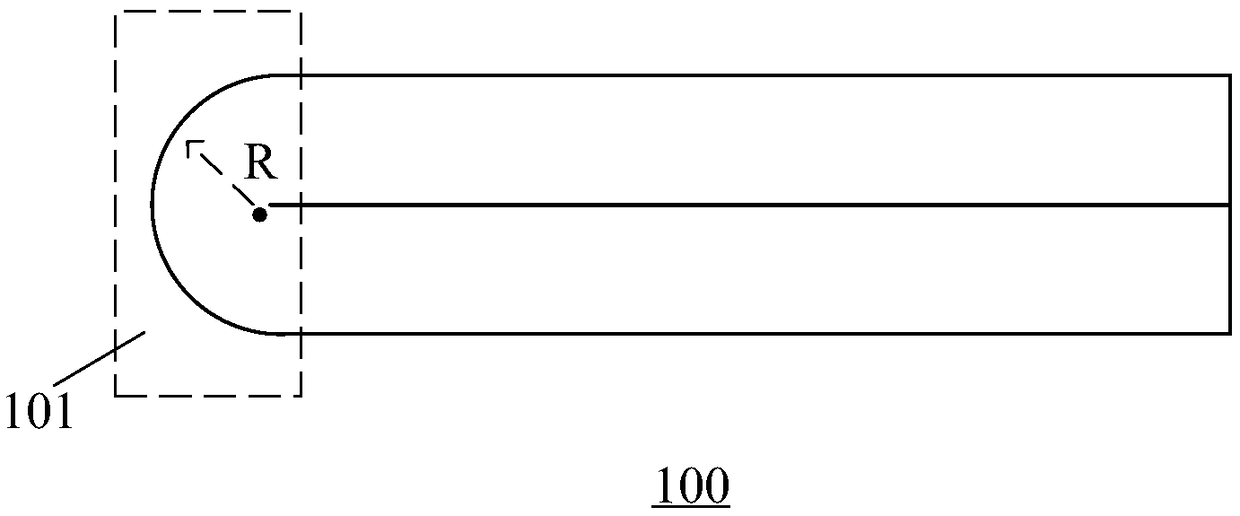

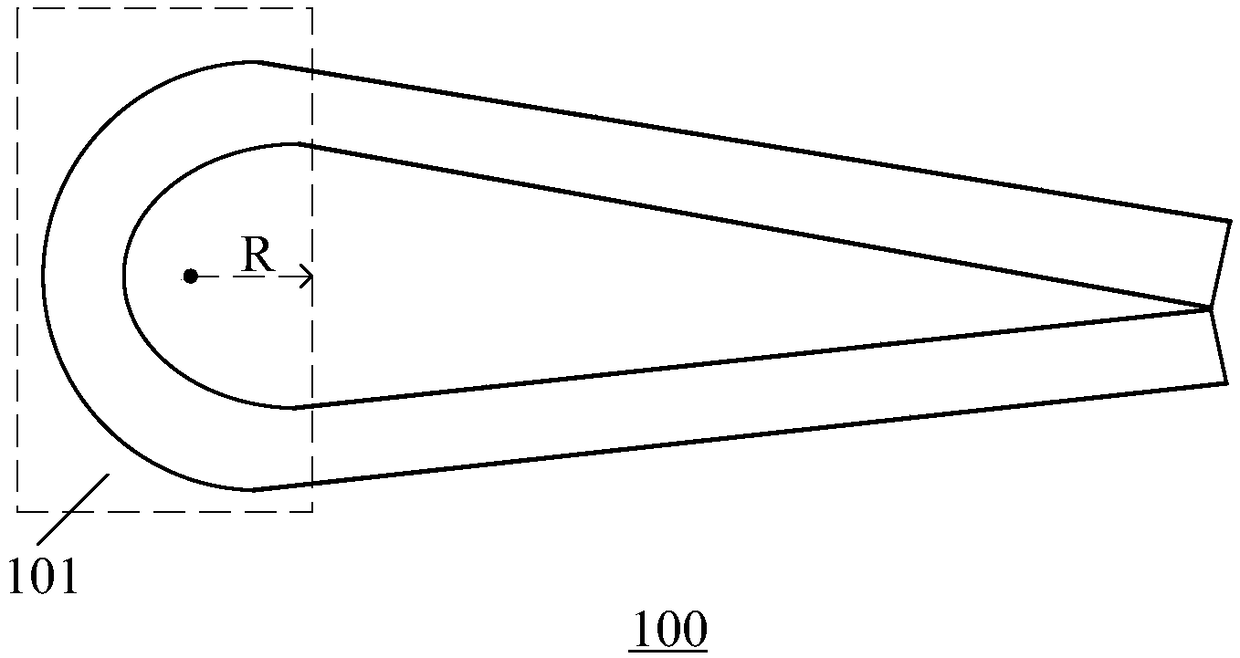

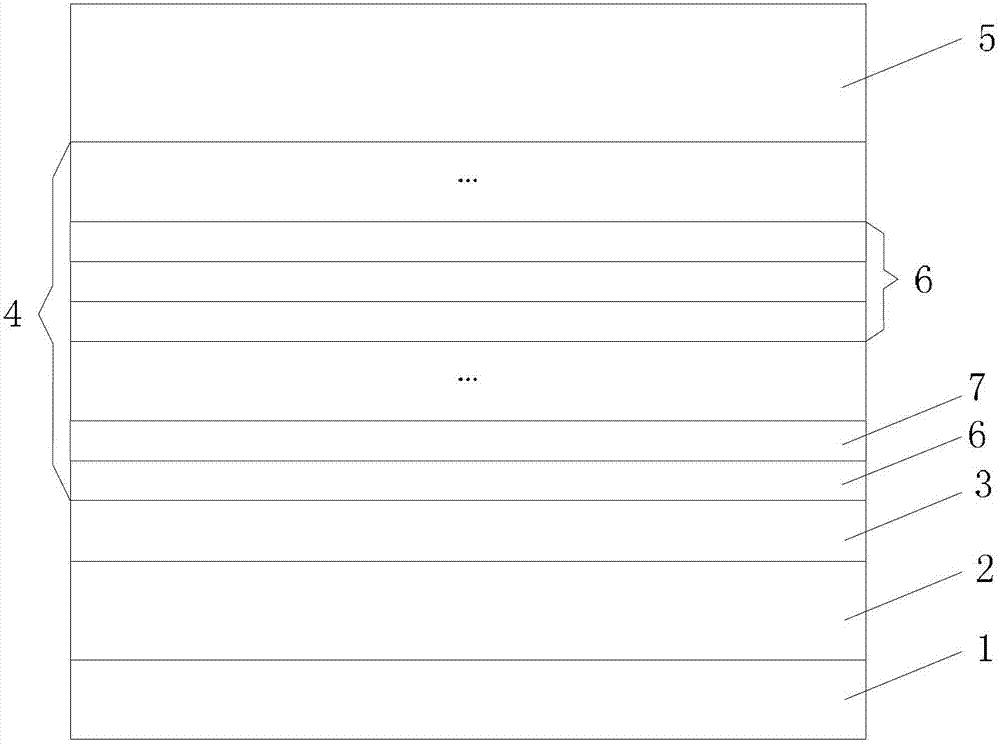

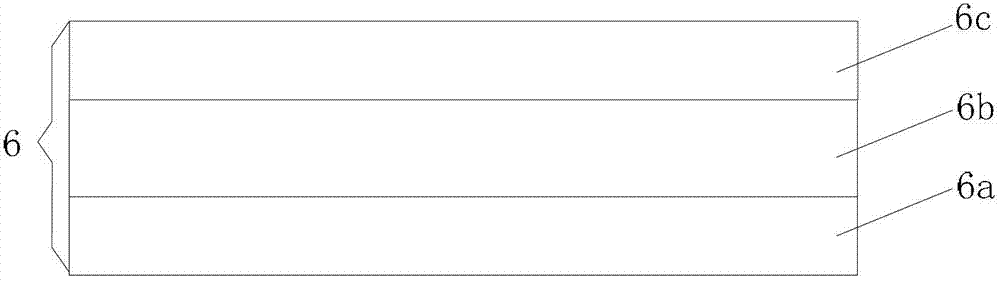

LED (light emitting diode) epitaxy structure and preparation method thereof

ActiveCN103236477AReduce dislocationAvoid warping effectSemiconductor devicesSemiconductor/solid-state device manufacturingCrystallographyLattice mismatch

The invention discloses an LED (light emitting diode) epitaxy structure and a preparation method thereof. The LED epitaxy structure successively comprises a substrate, a GaN nucleating layer, multiple pairs of superlattice buffer layers, an n-GaN layer, an MQW luminescent layer, a p-GaN layer and a p-type contact layer from bottom to top, wherein each superlattice buffer layer is formed by an AlGaN / n-GaN alternately stacked structure. The LED epitaxy structure is characterized in that Al(n) is defined to represent an Al component value in the nth pair of AlGaN / n-GaN superlattice buffer layer; N(n) represents the n-type impurity concentration value in the nth pair of AlGaN / n-GaN superlattice buffer layer; the variation trend of Al(n) is gradually lowered after being gradually raised; and the variation trend of N(n) is gradually lowered after being gradually raised. According to the LED epitaxy structure provided by the invention, lattice stress caused by lattice mismatch due to that a sapphire substrate and the GaN lattice are not matched can be effectively and fully released on a bottom layer growth section so as to greatly lower the warping of an epitaxial wafer in the whole high-temperature growth process and improve the wavelength concentricity and yield of the epitaxial wafer. Meanwhile, the GaN lattice quality is effectively improved, the lattice dislocation density is reduced, and the optical-electrical characteristic of the device is more stable.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

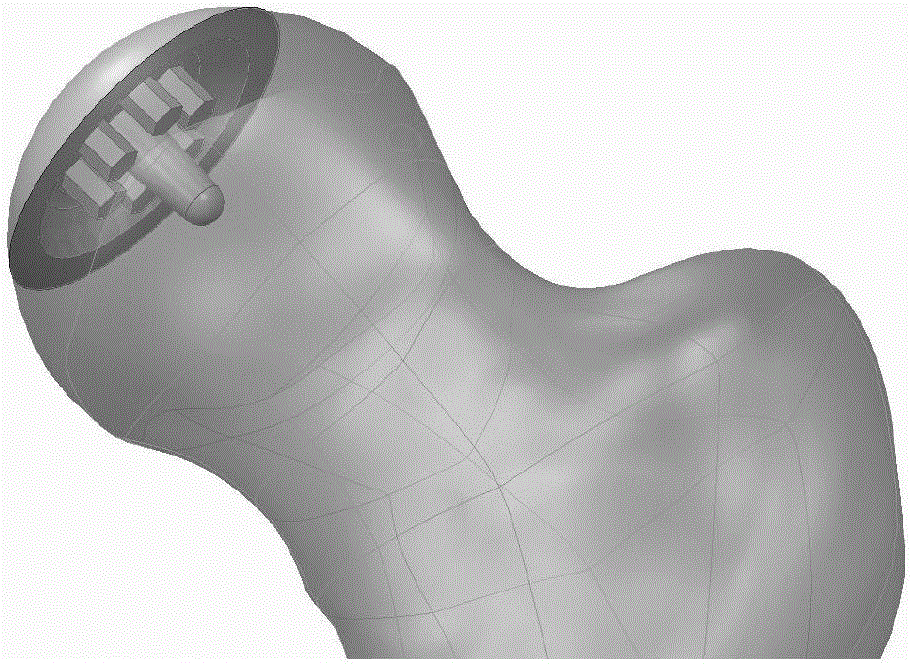

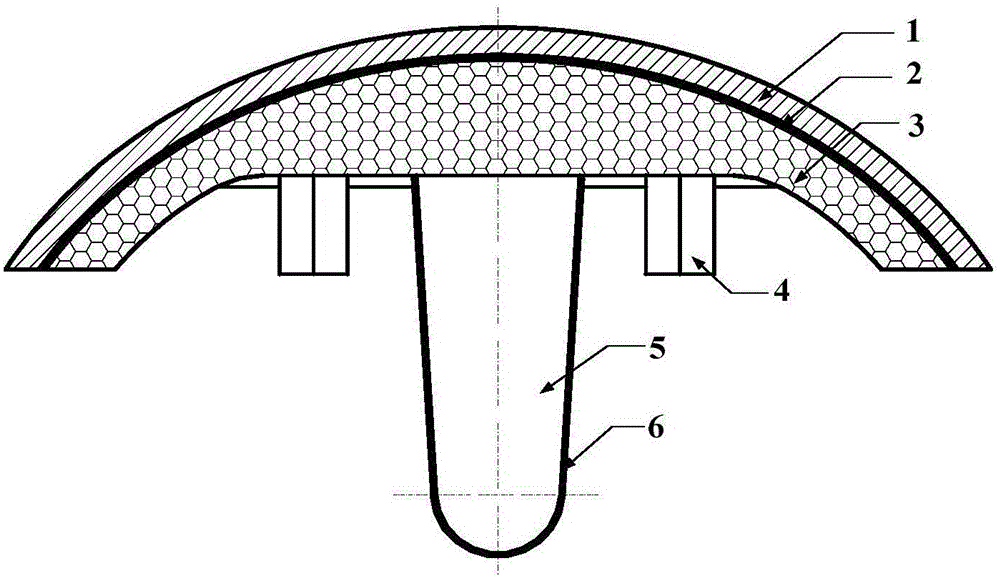

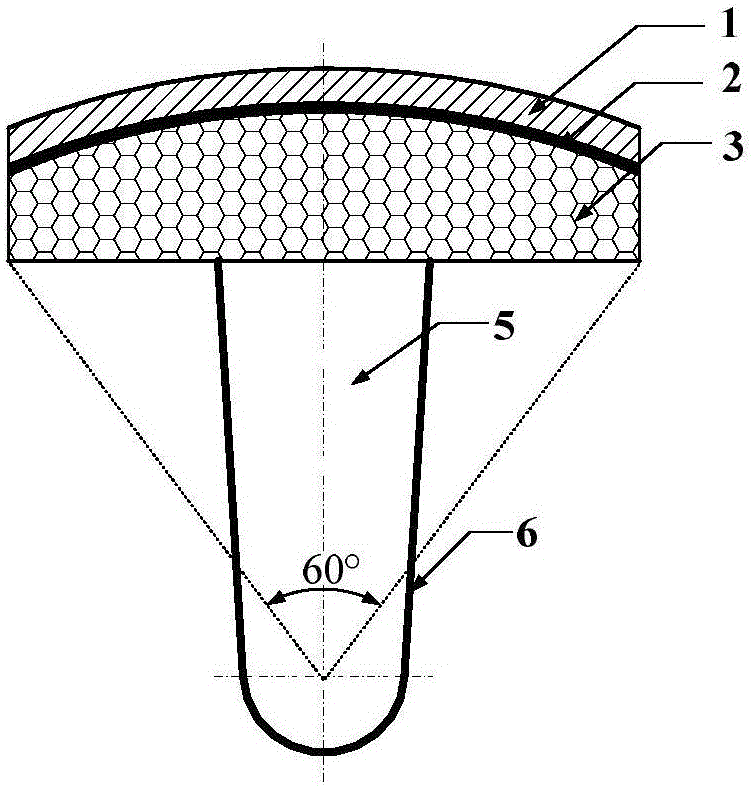

Biomimetic artificial hip joint with internal growth function

ActiveCN105105875AImprove tribological propertiesImprove fault toleranceJoint implantsHip jointsArticular surfacesBiomechanics

The invention discloses a biomimetic artificial hip joint with an internal growth function. The joint is composed of an artificial cartilage layer, an interface bonding layer and a porous bracket, wherein the artificial cartilage layer and the porous bracket have elliptic surfaces; the surface wrapping angle of the joint is 60-120 degrees; when the wrapping angle is 80-120 degrees, 3-6 convex columnar bodies, which are uniformly distributed, are designed on the inner surface of a prosthesis along the peripheral direction; a porous coating with biological activity is prepared on the outer surface of a femoral component and materials of the coating have gradient changes from inside to outside; the porous bracket is designed into a porous structure with gradient according to a finite element optimization result, and the pore diameter is 300-800 microns; the porosity is 20%-85%. According to the biomimetic artificial hip joint disclosed by the invention, bone mass and biomechanical characteristics of thigh bones can be kept to the greatest extent; the biomimetic artificial hip joint has good mechanical properties and tribological properties; the growth of bone cells is induced or promoted so as to guarantee effective interface bonding intensity between a prosthesis implantation material and a natural bone, the stability of the planted prosthesis is improved and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV

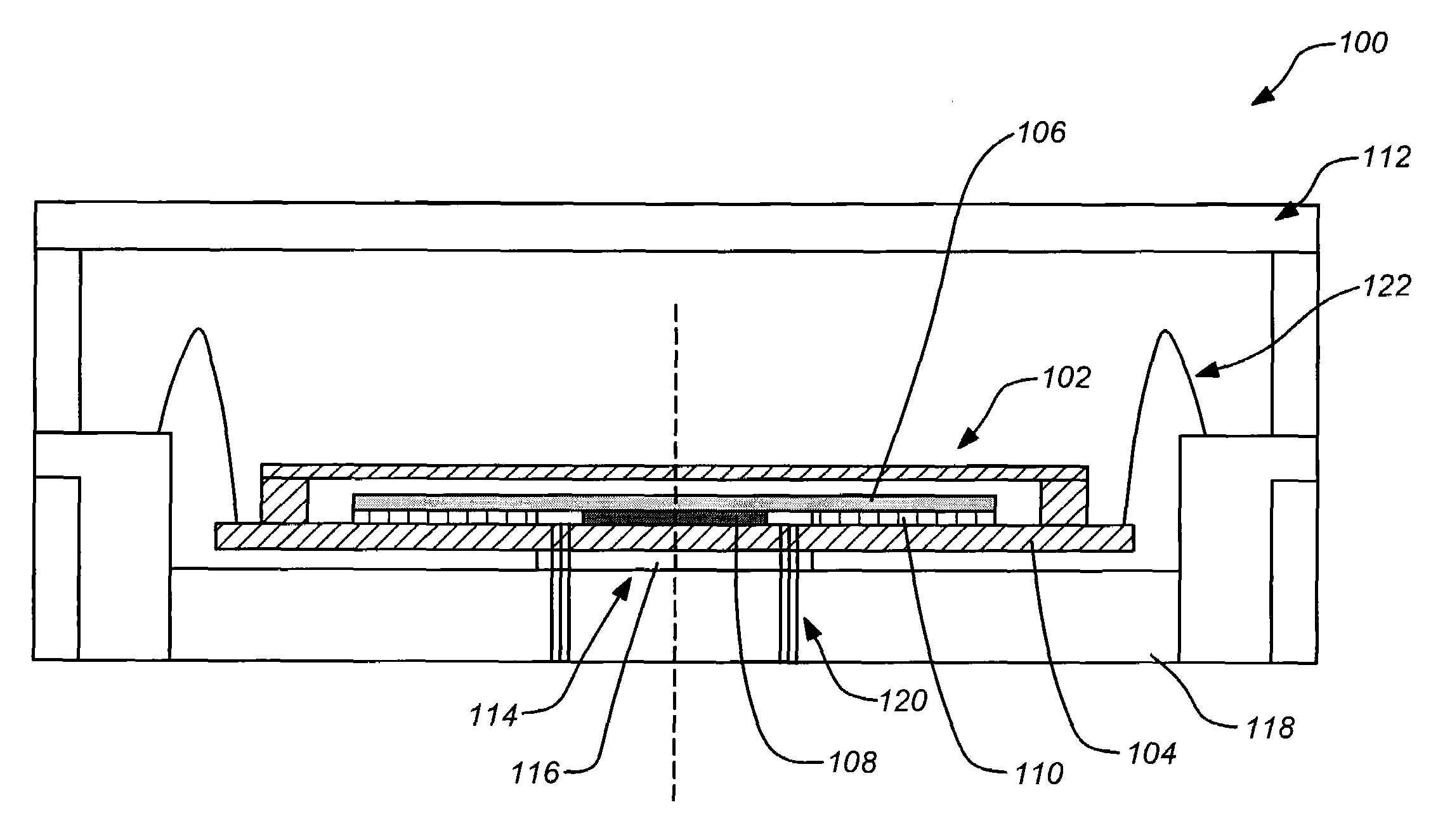

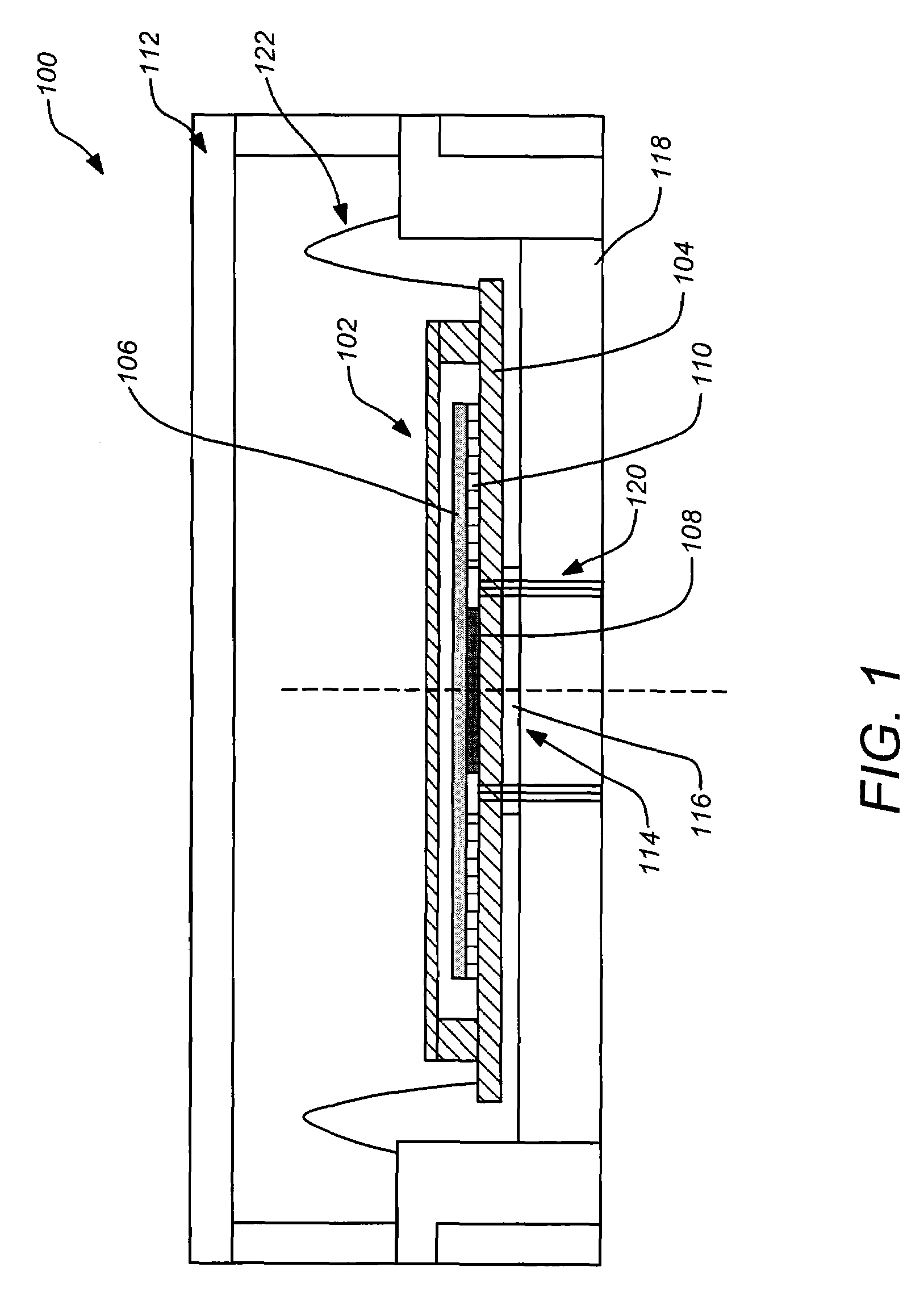

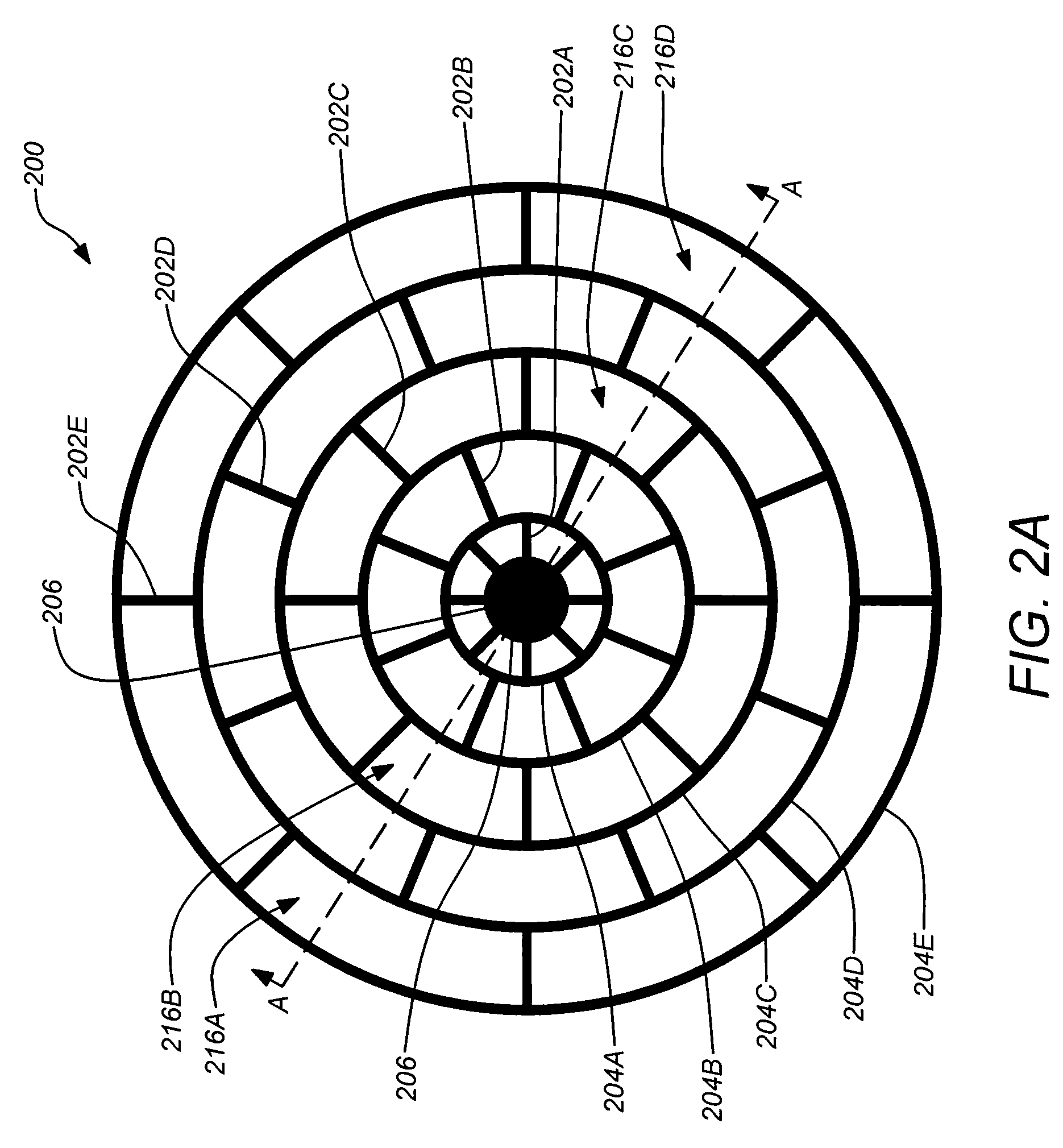

Planar resonator gyroscope central die attachment

ActiveUS20080295622A1Avoid stressReduce gradientMechanical apparatusAcceleration measurement using interia forcesThermal conductivityResonator

Packaging techniques for planar resonator gyroscopes, such as disc resonator gyroscopes (DRGs) are disclosed. A gyroscope die may be attached to its package substrate on a central disc area that is inboard of its embedded electrodes. This configuration eliminates contact of the die with the package substrate beneath the embedded electrodes allowing the internal electrode support structure to expand or contract freely without stress as its temperature changes. The central attachment can also be used diminish the package temperature gradients on the periphery of the die, if the thermal conductivity of the central disc attachment material is higher than the package substrate. Temperature gradients across the resonator also lead to thermoelastic damping asymmetry and rate drift. In addition, the electrical connections to the die may be formed by vertical vias within the central disc attachment area or by thin wirebonds to peripheral I / O pads on the gyro chip.

Owner:THE BOEING CO

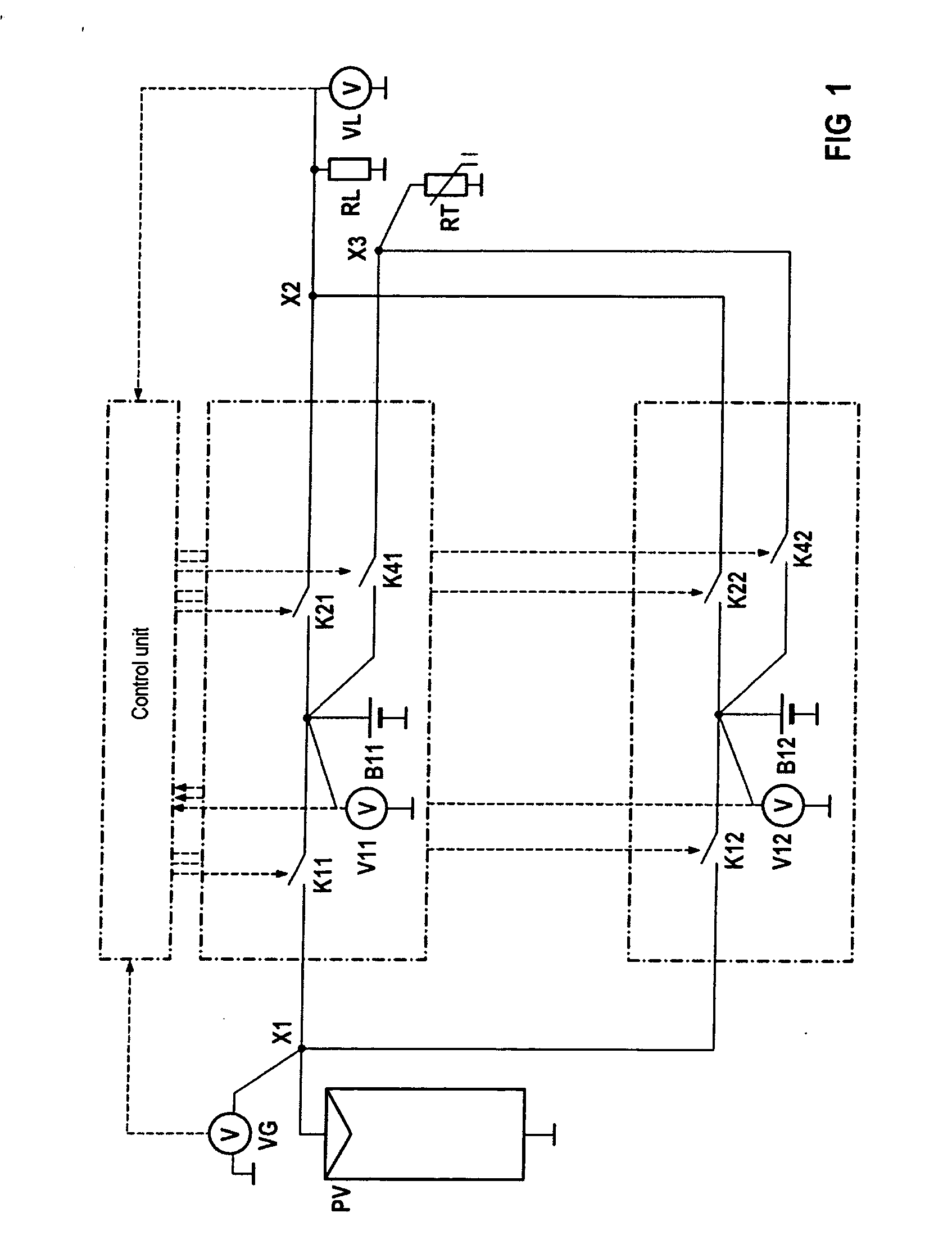

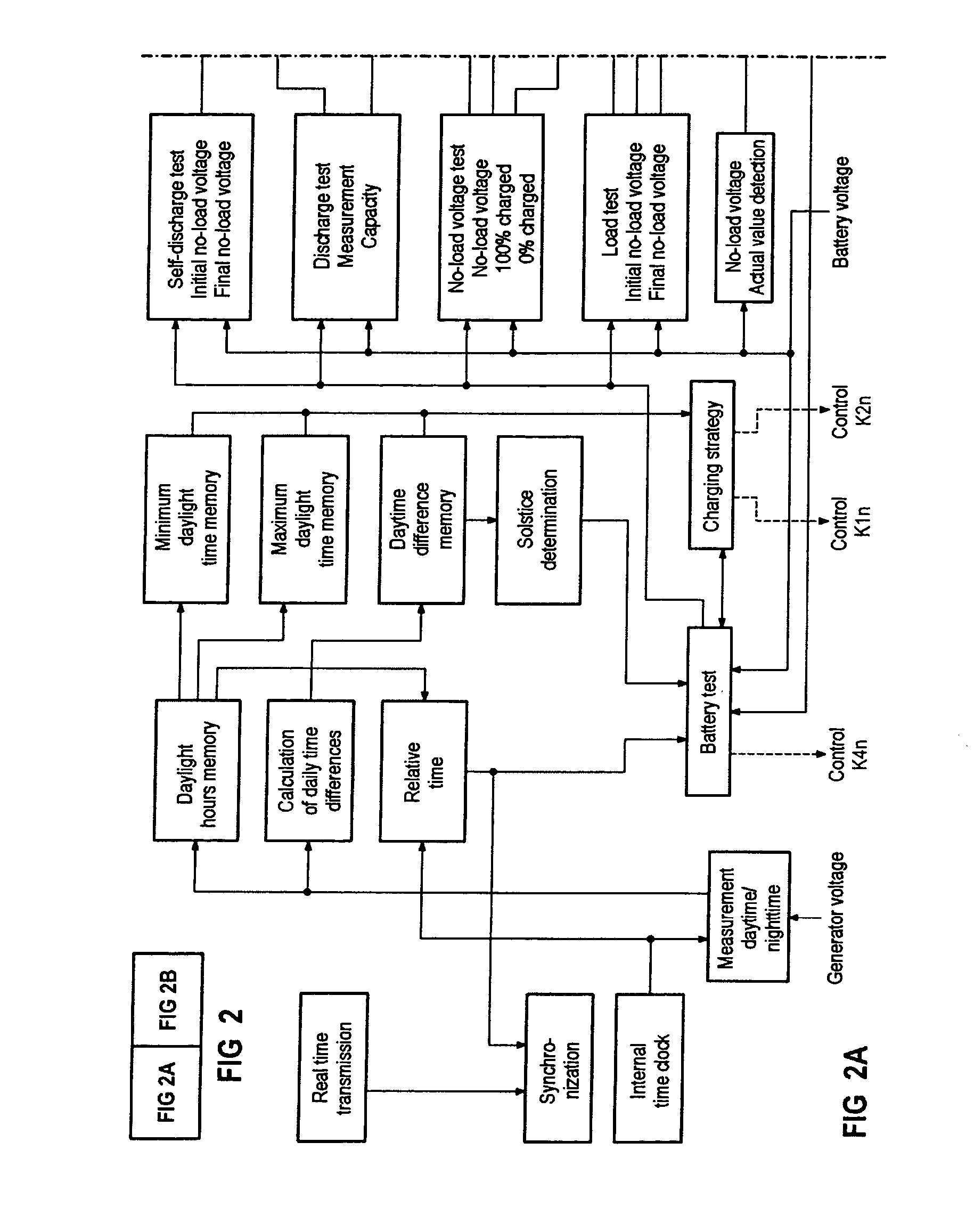

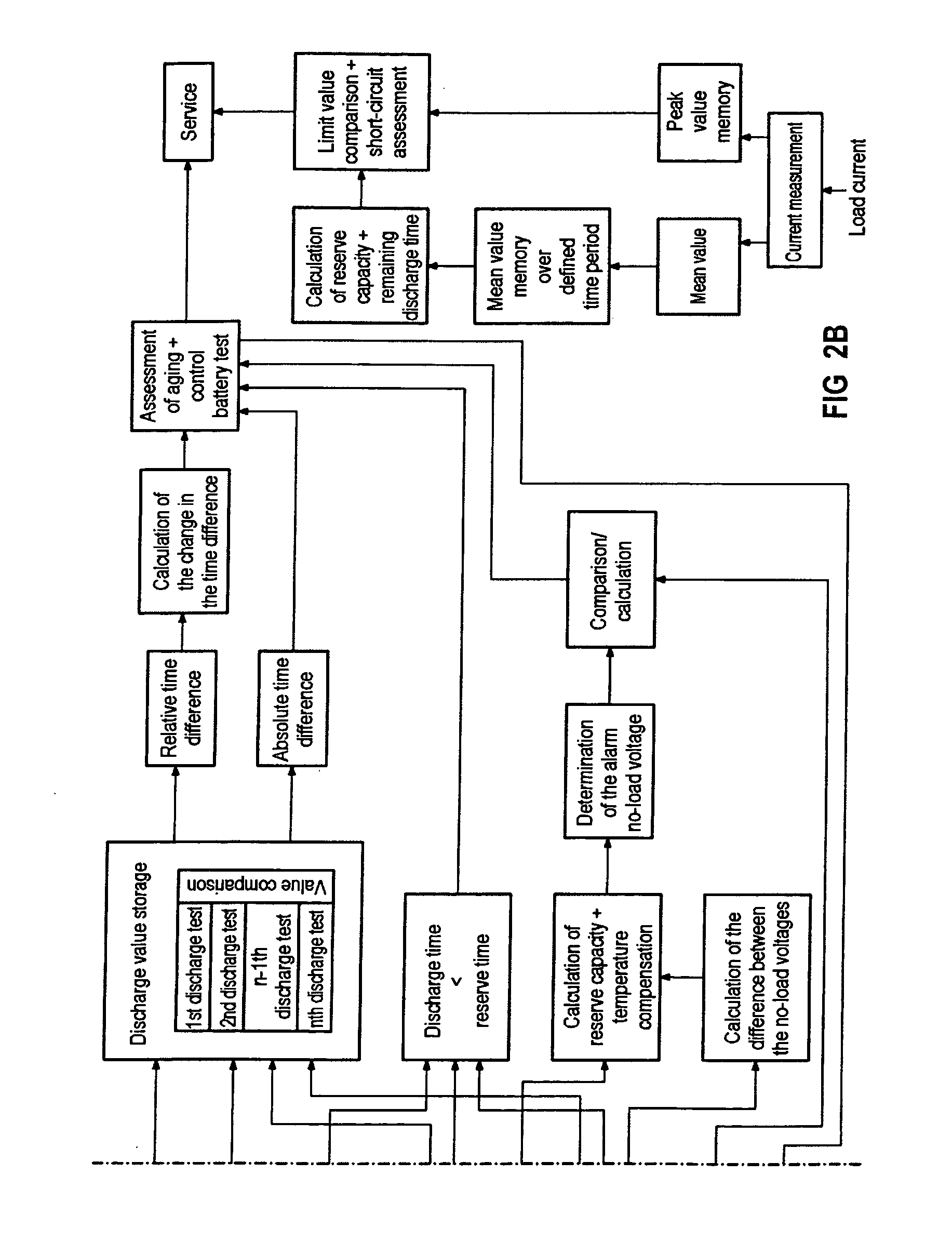

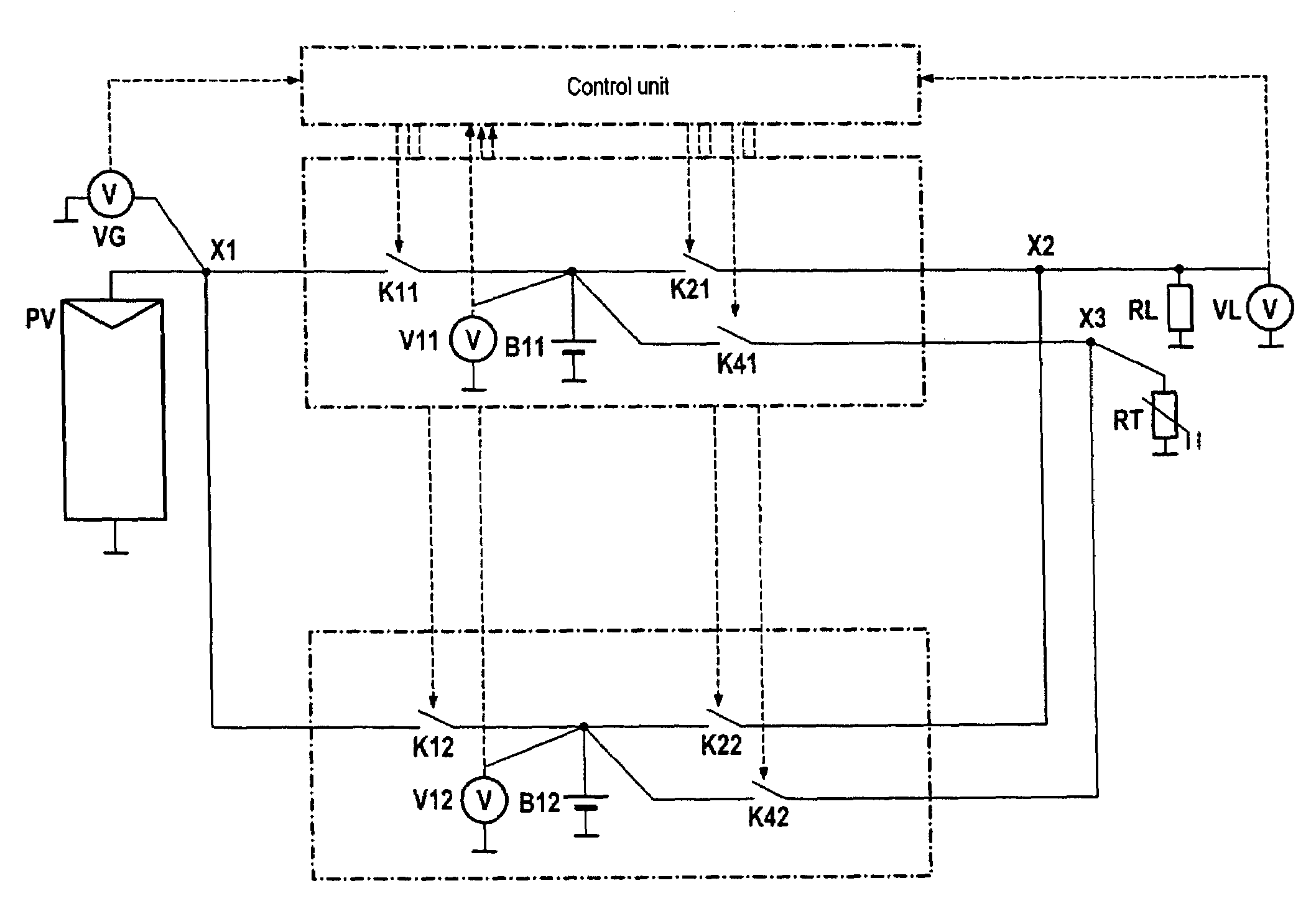

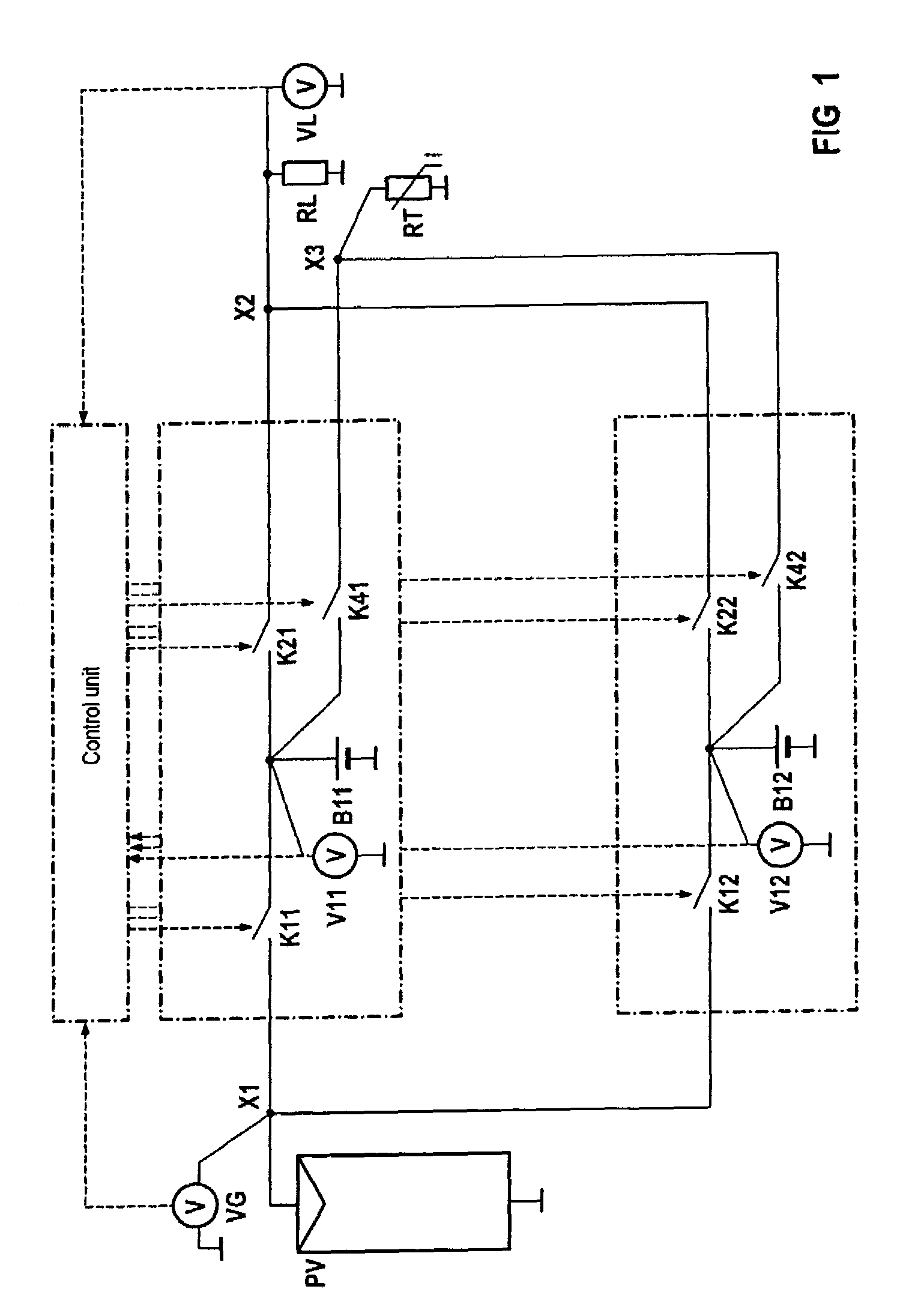

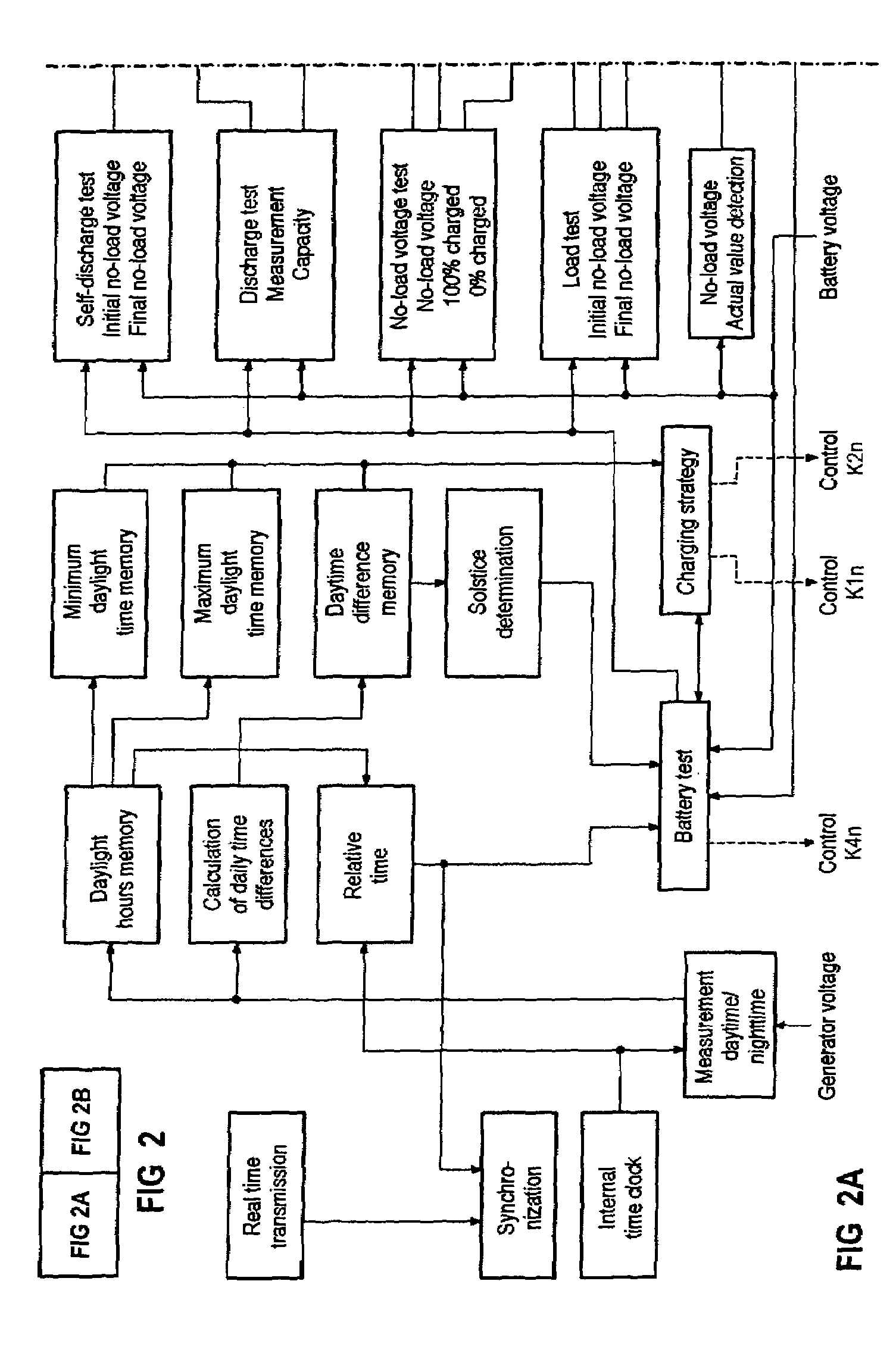

Method for assessment of the state of batteries in battery-supported power supply systems

InactiveUS20050007074A1Avoid stressBatteries circuit arrangementsMaterial analysis by electric/magnetic meansElectrical resistance and conductanceElectrical battery

After disconnection from the power supply system, a discharge characteristic of the no-load voltage is recorded automatically by means of a control unit across a discharge resistance during a stage-by-stage discharge cycle from a charged battery which is being operated for the first time on the power supply system. This stage-by-stage discharge cycle is repeated at times which can be defined, in order to record an instantaneous discharge characteristic of the no-load voltage, and an alarm no-load voltage is determined from the instantaneous discharge characteristic of the no-load voltage from a previously defined reserve time and from the final discharge voltage as determined in the first measurement, which alarm no-load voltage represents a measure of the energy which in each case still remains in the battery, and on reaching which during operation on the load, an alarm is produced for the operator of the power supply system.

Owner:SIEMENS AG

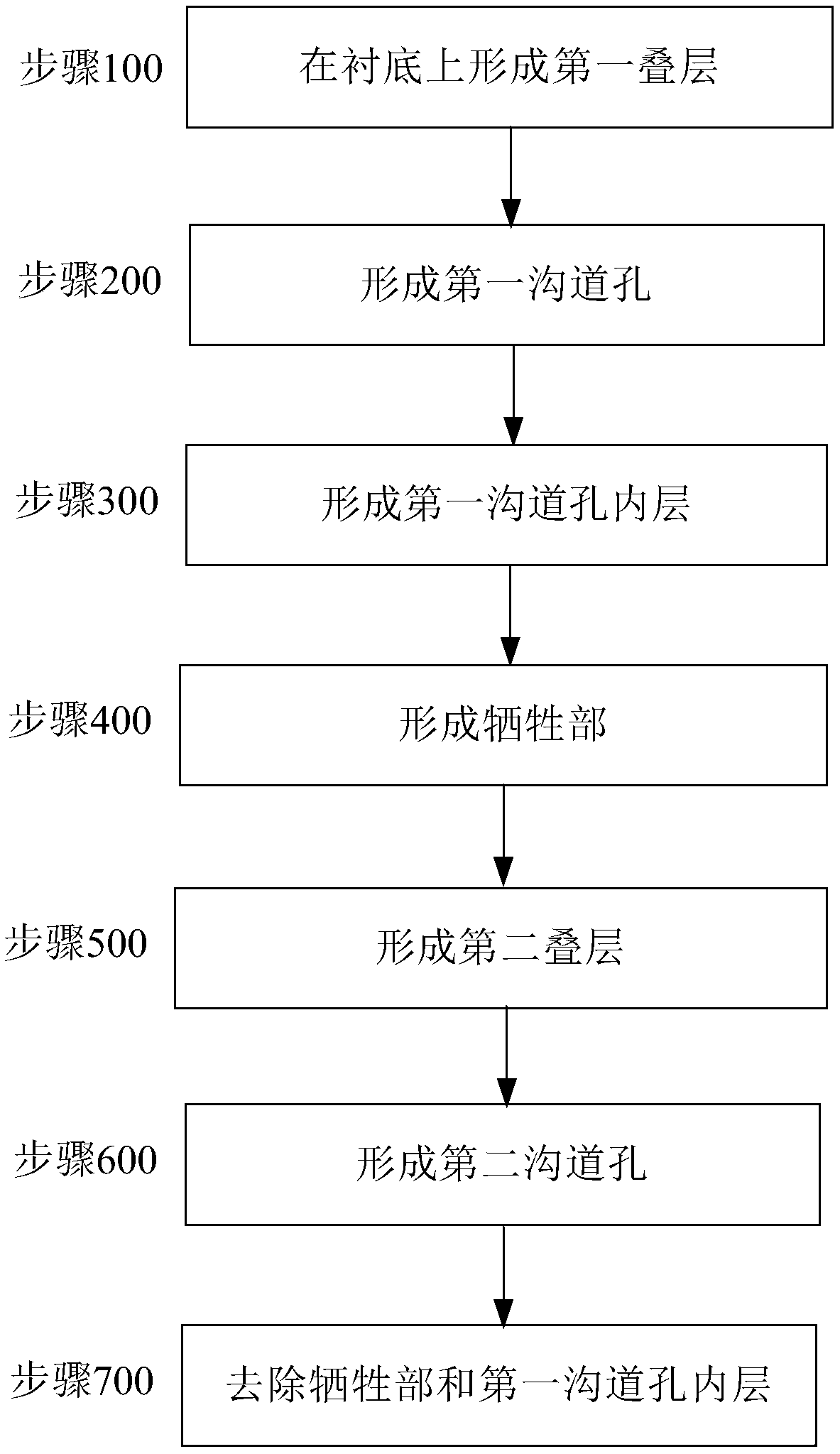

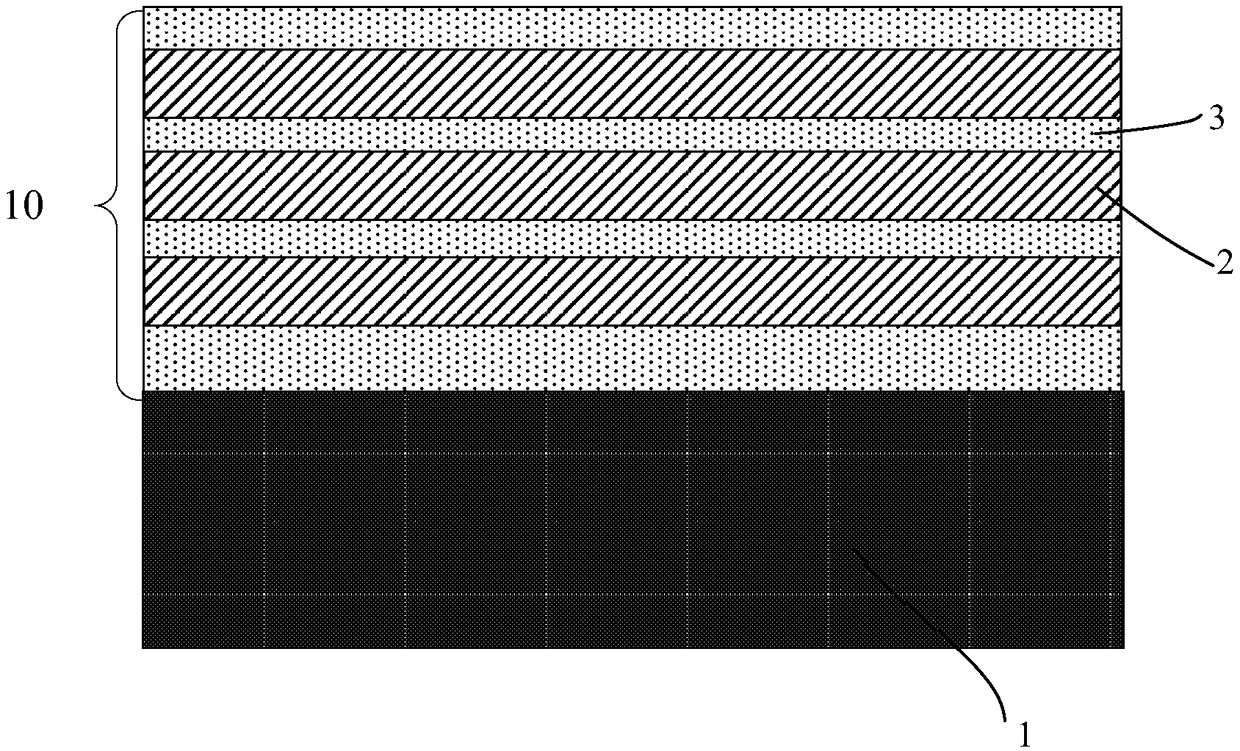

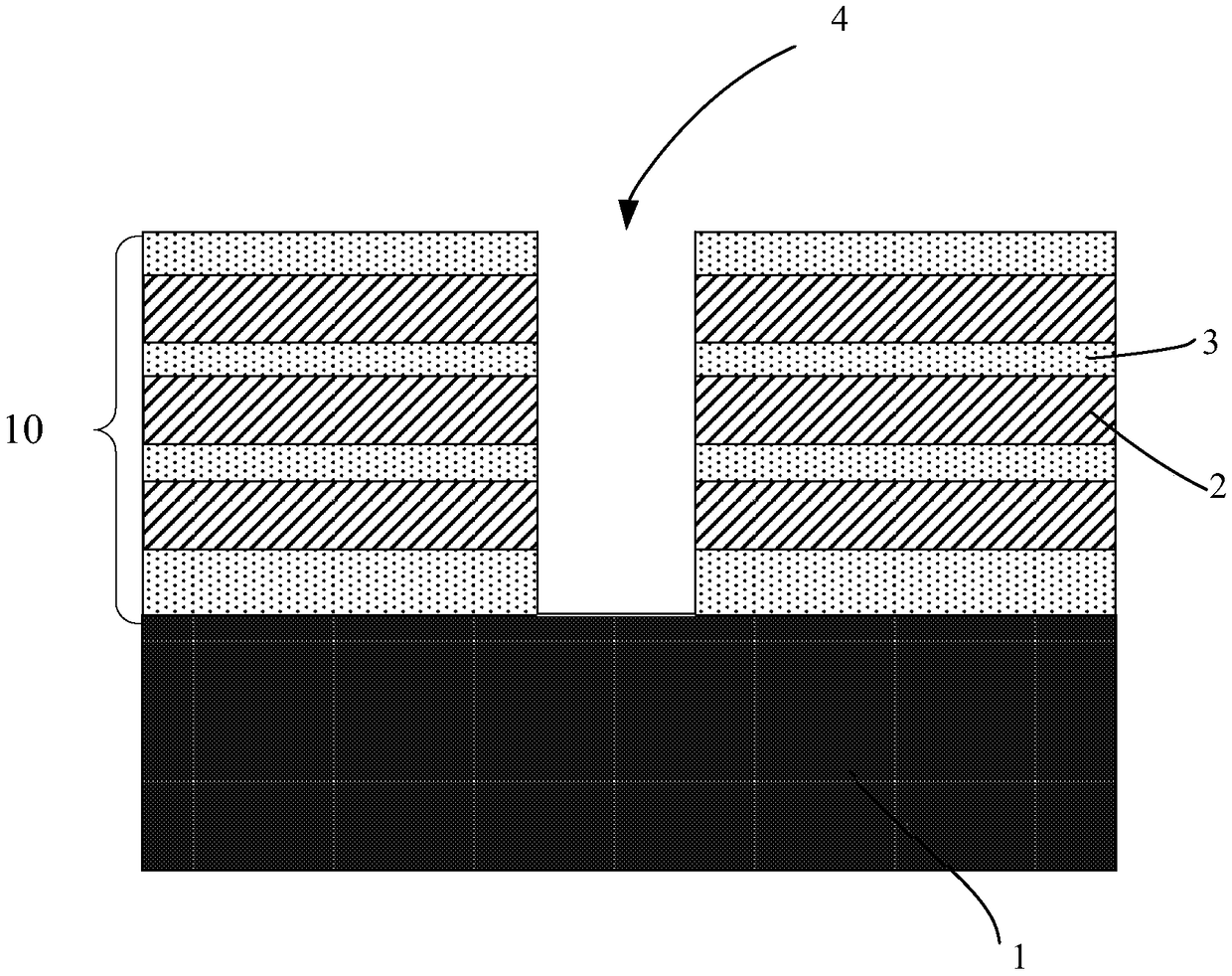

Preparation method of three-dimensional memory and preparation method of semiconductor structure

ActiveCN108831887AAdd depthEasy to shapeSolid-state devicesSemiconductor devicesSacrificial partSemiconductor structure

Owner:YANGTZE MEMORY TECH CO LTD

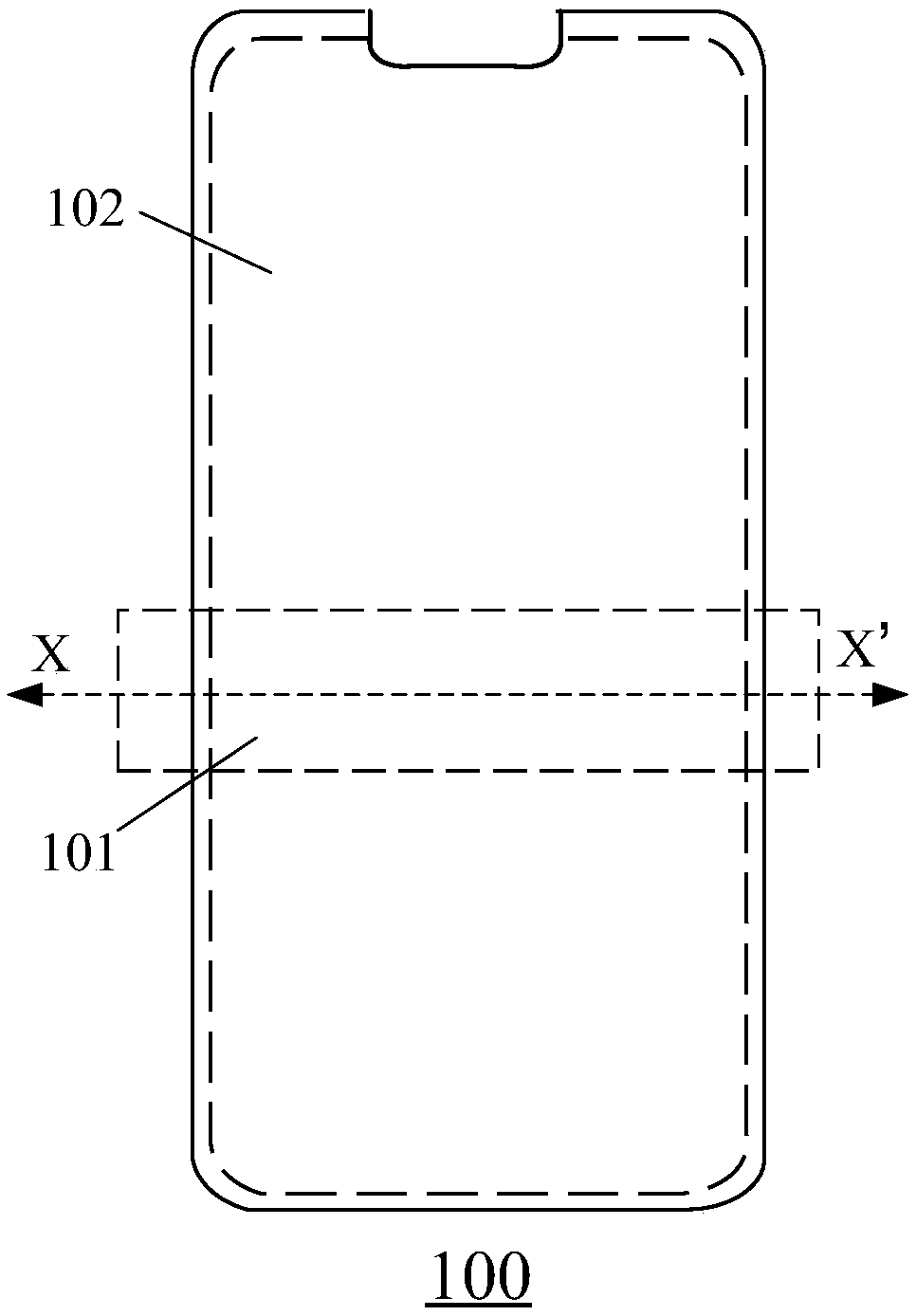

Display panel and display device

InactiveCN108922911AImprove bending performanceAvoid stressSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceHigh stress

The embodiment of the invention provides a display panel and a display device. An extra organic buffer layer is arranged on a substrate of the display panel; in a bent region, due to a concave-convexstructural design, the organic buffer layer comprises multiple "troughs" and "crests"; and devices having relatively large area proportions in a driving unit of the display panel are placed at the "crests" positions, thereby avoiding the problem of excessively high stress caused by the devices having the relatively large area proportions in bending operation. Meanwhile, all types of signal wires (patterned on a metal layer) with relatively low stress are arranged at the "troughs" positions. The devices and the signal wires are respectively arranged at the "troughs" positions and the "crests" positions of the organic buffer layer, so as to reduce the stress in the bent region.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Preparation method of low-stress and high-purity semi-insulating SiC single crystal

ActiveCN105821471AReduce stressQuality improvementPolycrystalline material growthFrom condensed vaporsGas phaseSeed crystal

The invention relates to a preparation method of a low-stress and high-purity semi-insulating SiC single crystal. The method includes the steps that synthesis of high-purity SiC powder is carried out, crystal growth is carried out with a physical vapor transport method, the concentration of shallow energy level impurities is reduced in the synthesis and crystal growth processes, a heat insulation material is subjected to high-temperature pretreatment, and boron impurities are prevented from being blended in; a silicon powder raw material and a carbon powder raw material are put into a graphite crucible with a coating for SiC synthesis; the obtained high-purity SiC powder is pretreated, seed crystals are fed, vacuumizing is carried out, high-purity argon or mixed gas of argon and hydrogen is introduced in to carry out crystal growth, then the temperature is rapidly lowered to enlarge point defects, and then the temperature is slowly lowered to the room temperature to eliminate stress. SiC crystal growth is carried out in an equilibrium state, so that the obtained crystal is small in stress, low in microtubule density and good in quality, and the resistivity on the area of the whole crystal is 108 ohm.cm or above. The method is small in preparation investment, high in safety and free of pollution.

Owner:SHANDONG UNIV

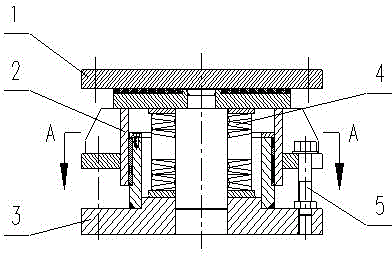

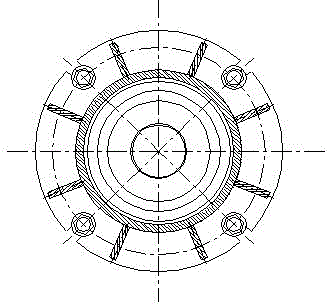

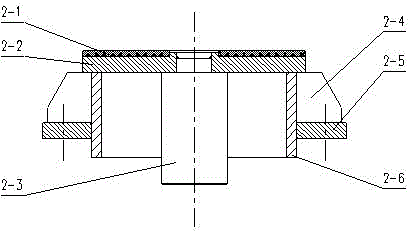

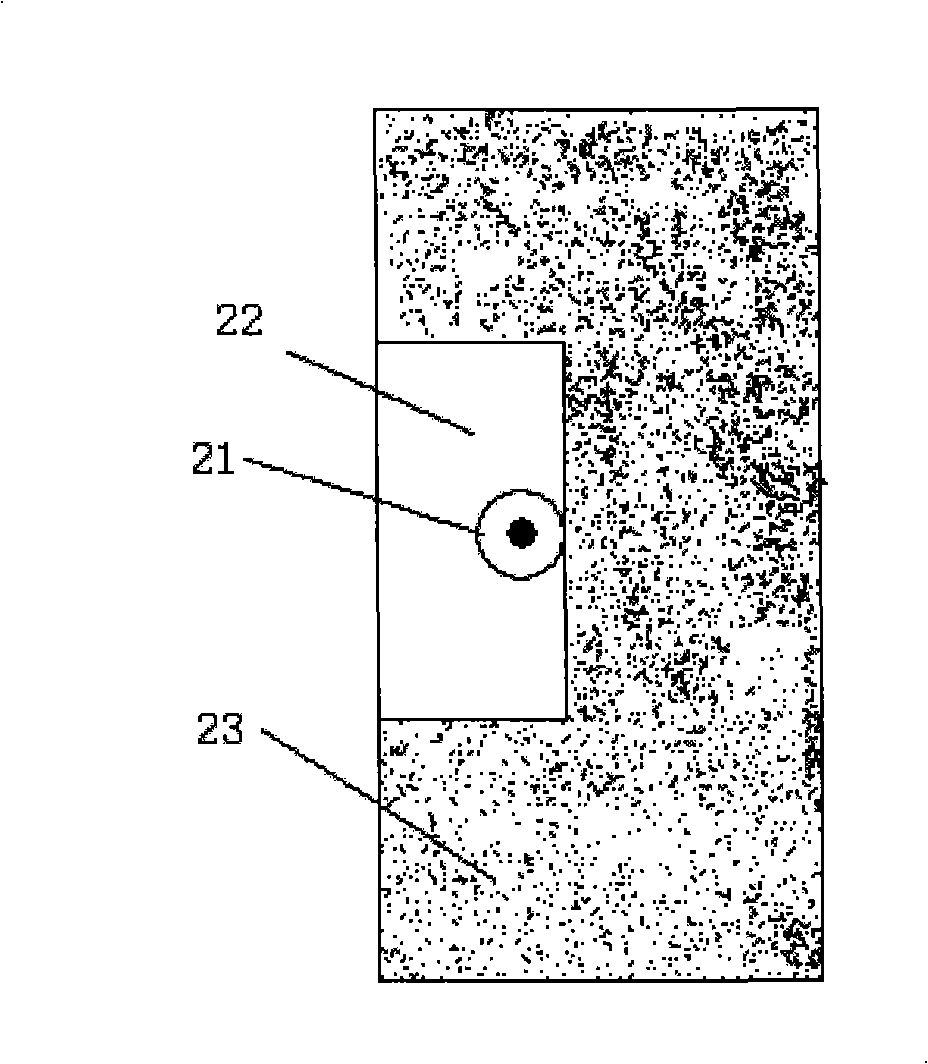

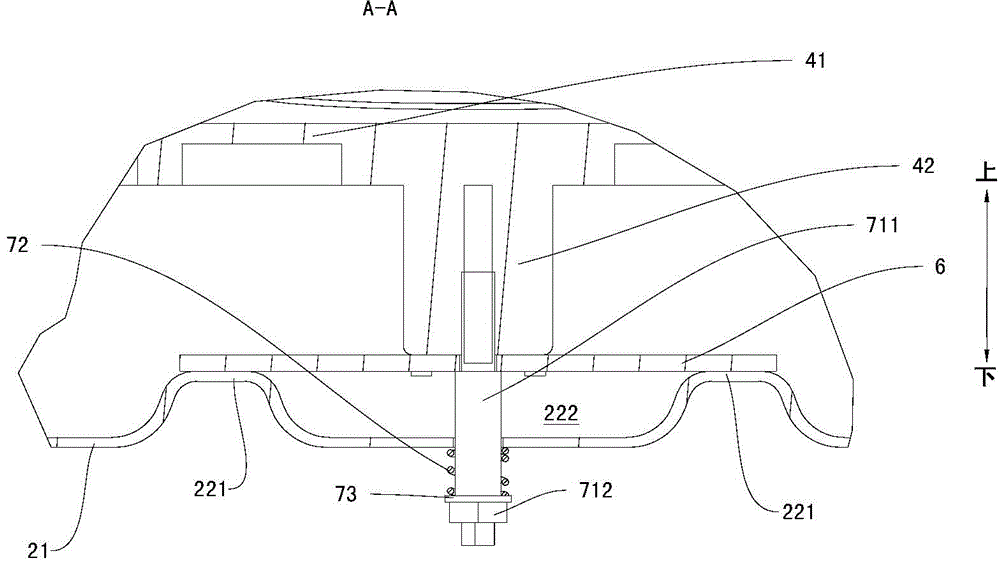

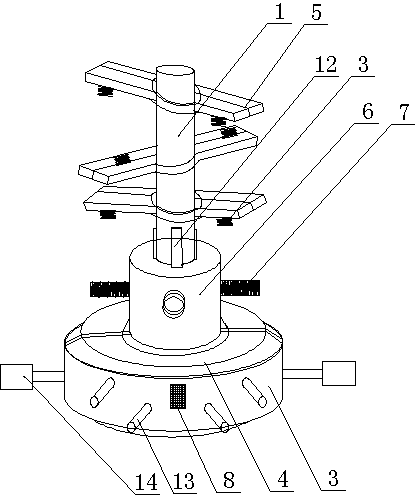

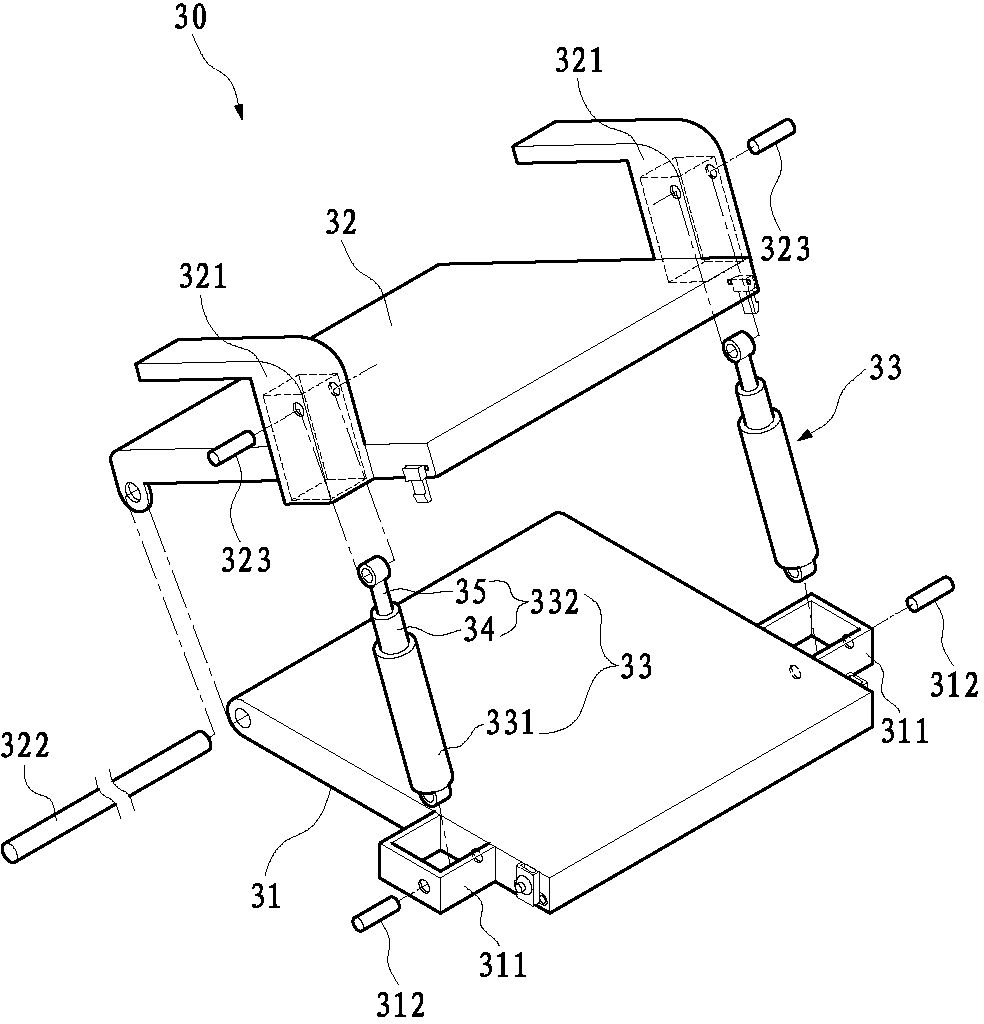

Three-dimensional elastic support

ActiveCN104676214AAvoid stressReduce vibrationPipe supportsBridge structural detailsThree-dimensional spaceSlide plate

The invention relates to a three-dimensional elastic support. The three-dimensional elastic support comprises a sliding plate, a top seat, a pedestal and a disk spring component, wherein the lower surface of the sliding plate is a smooth plane; the main body of the top seat is inverted cup-shaped; the sliding plate is positioned on a top plate of the top seat; the top plate is connected with a guide column which extends downwards; the main body of the pedestal is cup-shaped; an upper sleeve of the pedestal is cylindrical; the disk spring component sleeves the guide column, the upper end is supported against the top plate, and the lower end is supported against the bottom plate; an upper flange on the upper sleeve and a lower flange on the bottom plate are provided with threaded fastening members. The support has a simple, firm and durable structure and wide applicability; the requirement on free sliding in a three-dimensional space of a supported object can be met while complex change load is born; the supported object is also allowed to rotate around the normal of the supporting surface; the support is particularly suitable for supporting facilities and equipment under complex working conditions such as superimposed changeable load and multi-dimensional deformation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Grinder of bullet train tread cleaner and production method thereof

ActiveCN102432978AAvoid stressAvoid heat cracksOther chemical processesVehicle cleaningIron powderGraphite

The invention provides a grinder of a bullet train tread cleaner, wherein the grinder is made of a composite material; the composite materials comprises modified phenolic resin 6818, iron powder, copper fibres, steel fibres, sepiolite, potassium feldspar, graphite, cryolite and aluminium oxide; the invention further provides a production method of the grinder.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +1

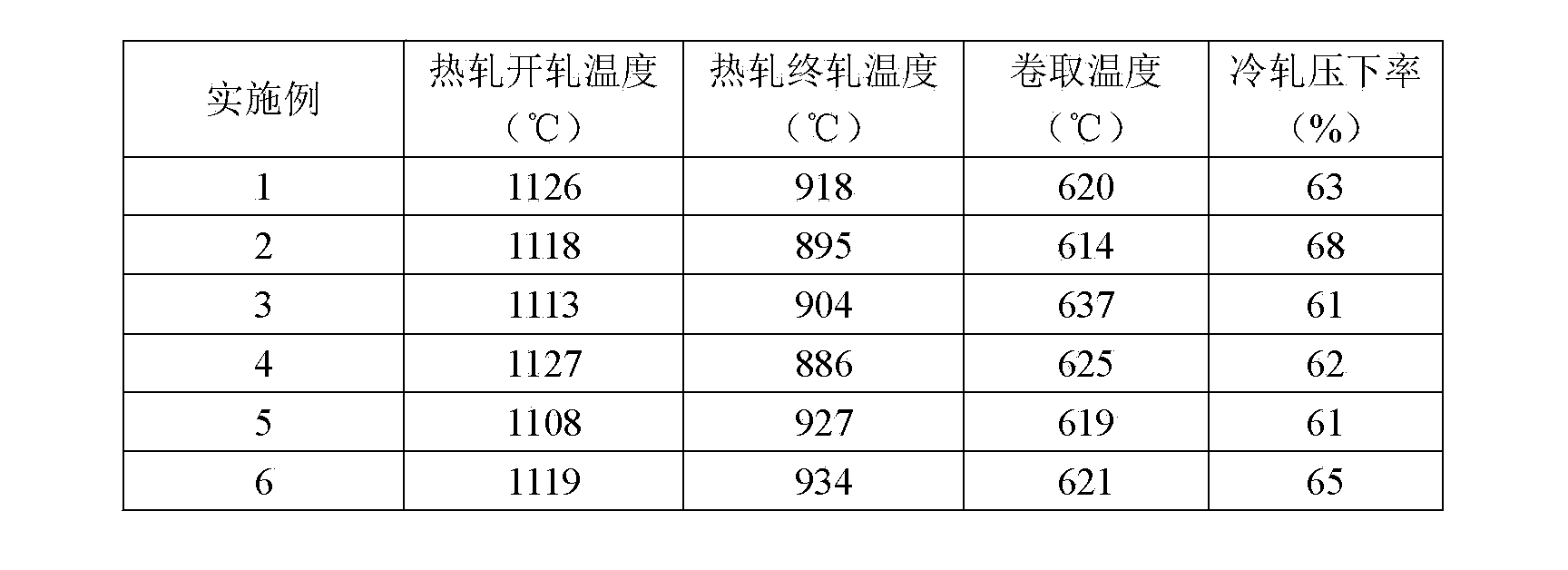

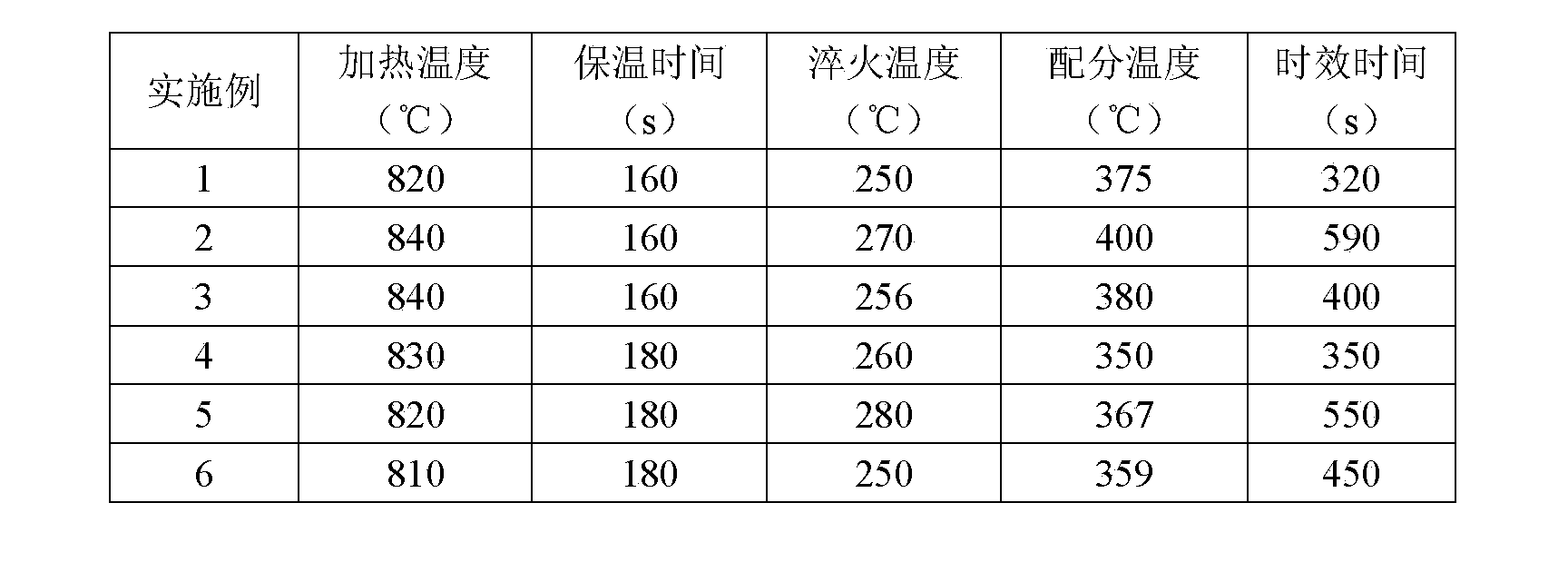

High-strength high-plasticity cold-rolled steel plate for automobiles and production method thereof

ActiveCN104278194AReduce equipment performance requirementsComply with reduction requirementsThermal insulationRoom temperature

The invention discloses a high-strength high-plasticity cold-rolled steel plate for automobiles and a production method thereof. The high-strength high-plasticity cold-rolled steel plate comprises, by weight, 0.25-0.35% of C, 0.8-1.2% of Si, 2.0-2.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, 0.5-1.0% of Al, 0.001-0.002% of B and the balance Fe and unavoidable impurities. The production method comprises smelting, continuous casting, hot rolling, pickling, cold rolling and continuous annealing. A continuous annealing heating temperature is in a range of 800-850 DEG C, thermal insulation time is in a range of 150-180s, a cooling rate is greater than or equal to 50 DEG C / s, a quenching temperature is in a range of 250-280 DEG C, a partition temperature is in a range of 350-400 DEG C, partition time is in a range of 300-600s and after partition, the product is cooled to a room temperature at a cooling rate greater than or equal to 50 DEG C / s.

Owner:ANGANG STEEL CO LTD

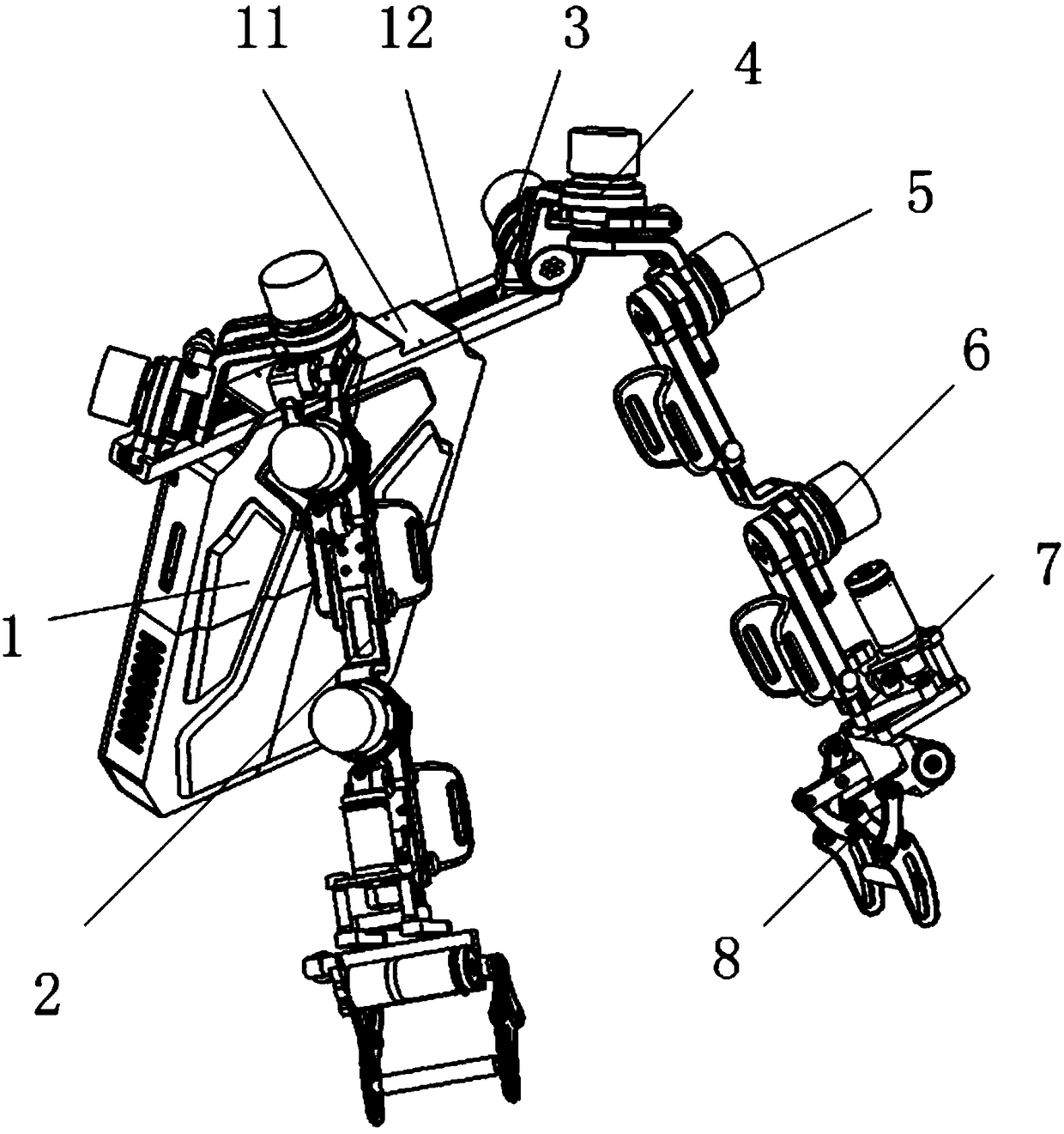

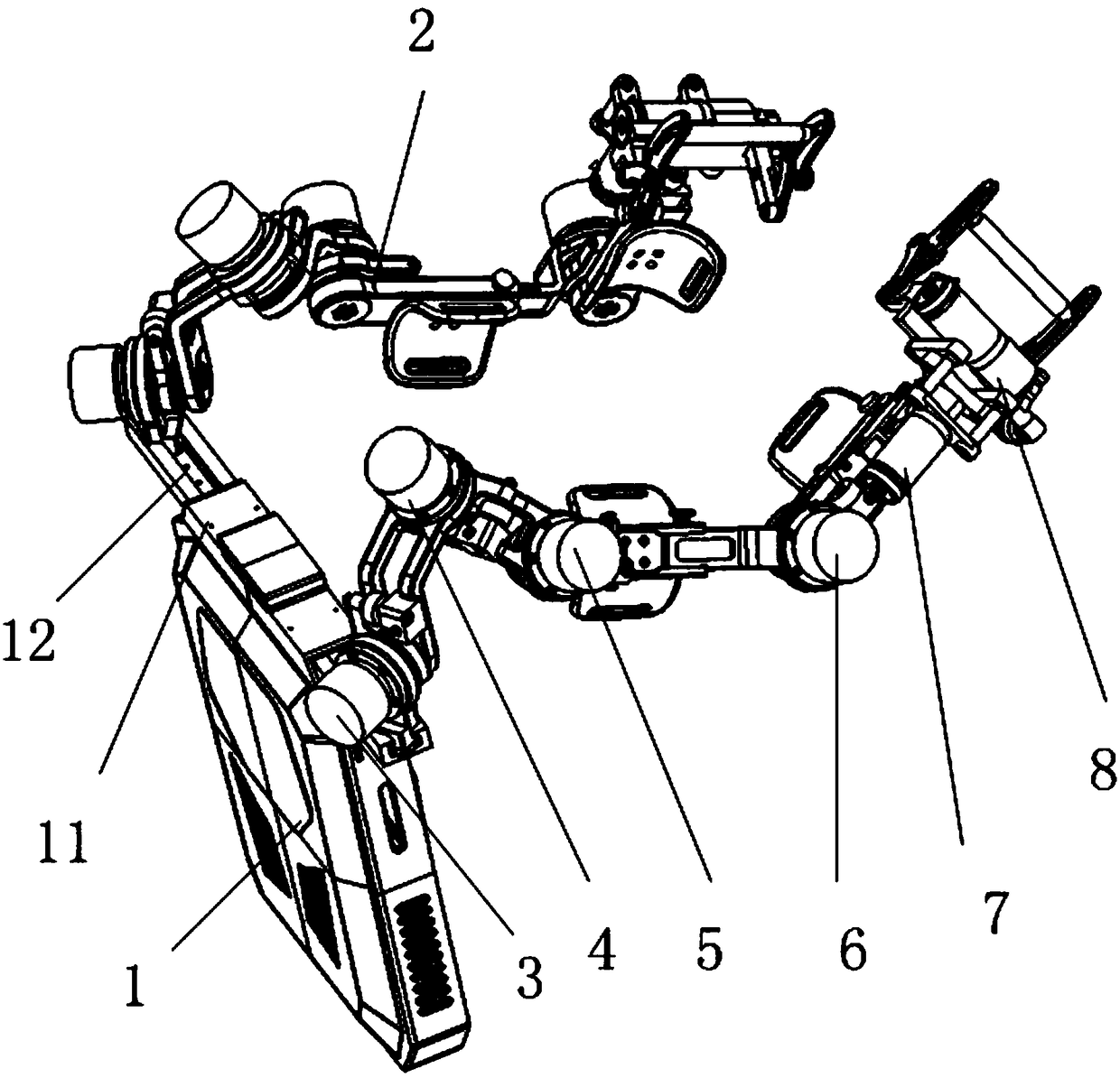

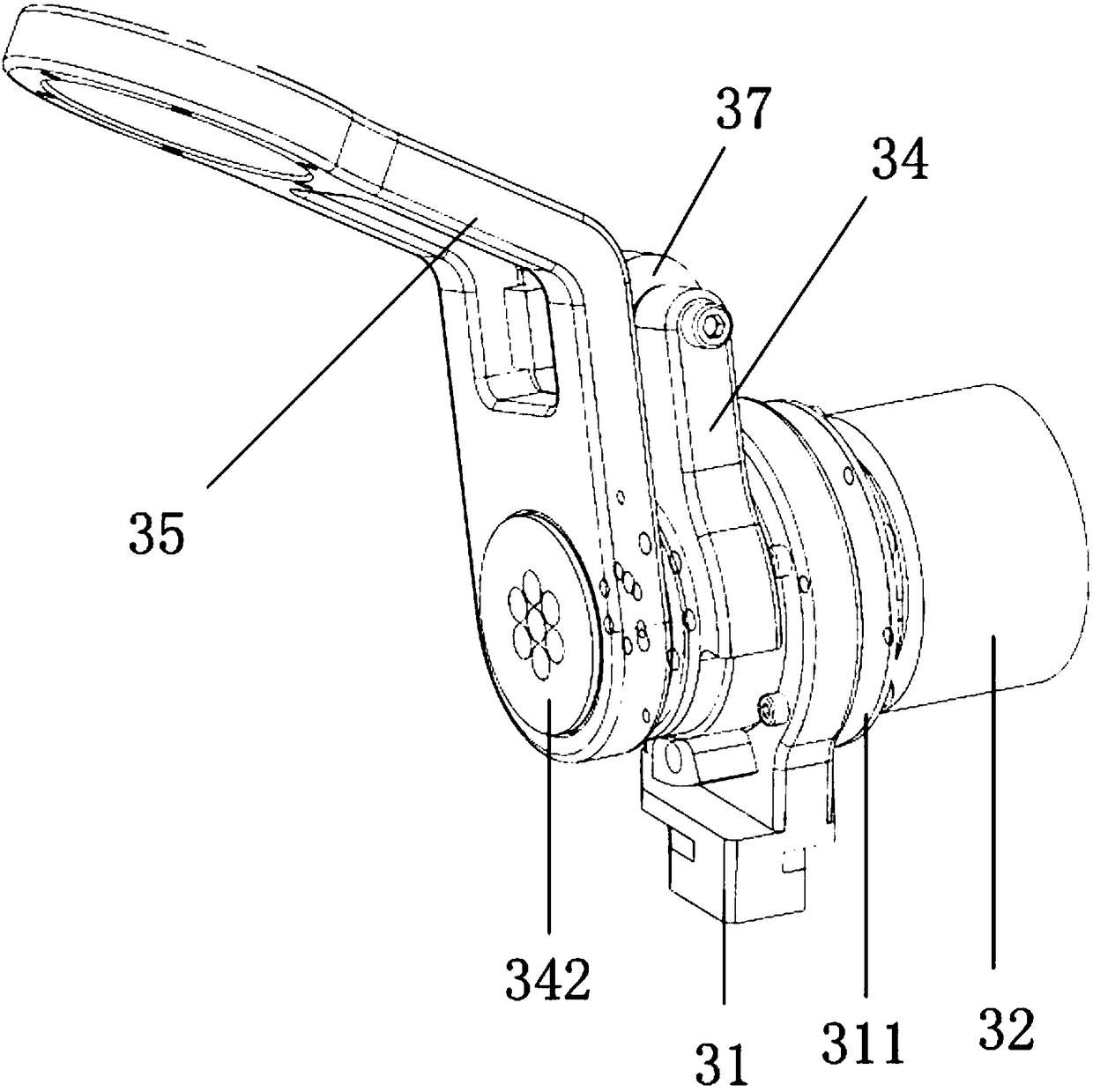

Rehabilitation mechanical arm and rehabilitation robot

PendingCN108144264ARealize rehabilitation trainingReduce volumeProgramme-controlled manipulatorChiropractic devicesJoint componentMedical equipment

The invention relates to a rehabilitation mechanical arm and a rehabilitation robot and relates to the field of medical equipment. The rehabilitation mechanical arm comprises a mechanical arm body formed by six rotary moving joints which are serially connected and is characterized in that the mechanical arm body comprise a shoulder joint component, an elbow joint component, a forearm rotating component and wrist moving component which are sequentially connected, the shoulder joint component comprises a first joint component, a second joint component and a third joint component, and the three rotary axes of the first joint component, the second joint component and the third joint component intersect at one point which is located at the rotation central point of the shoulder joint of a user.The rehabilitation robot comprises a back frame, a cantilever beam and the rehabilitation mechanical arm and is characterized in that one or a pair of the rehabilitation mechanical arms are arrangedon the back frame through the cantilever beam, and the first joint component is slidably connected to the cantilever beam. The rehabilitation mechanical arm and the rehabilitation robot are simple instructure, low in cost and simple to operate.

Owner:武汉沃森拓客科技有限公司

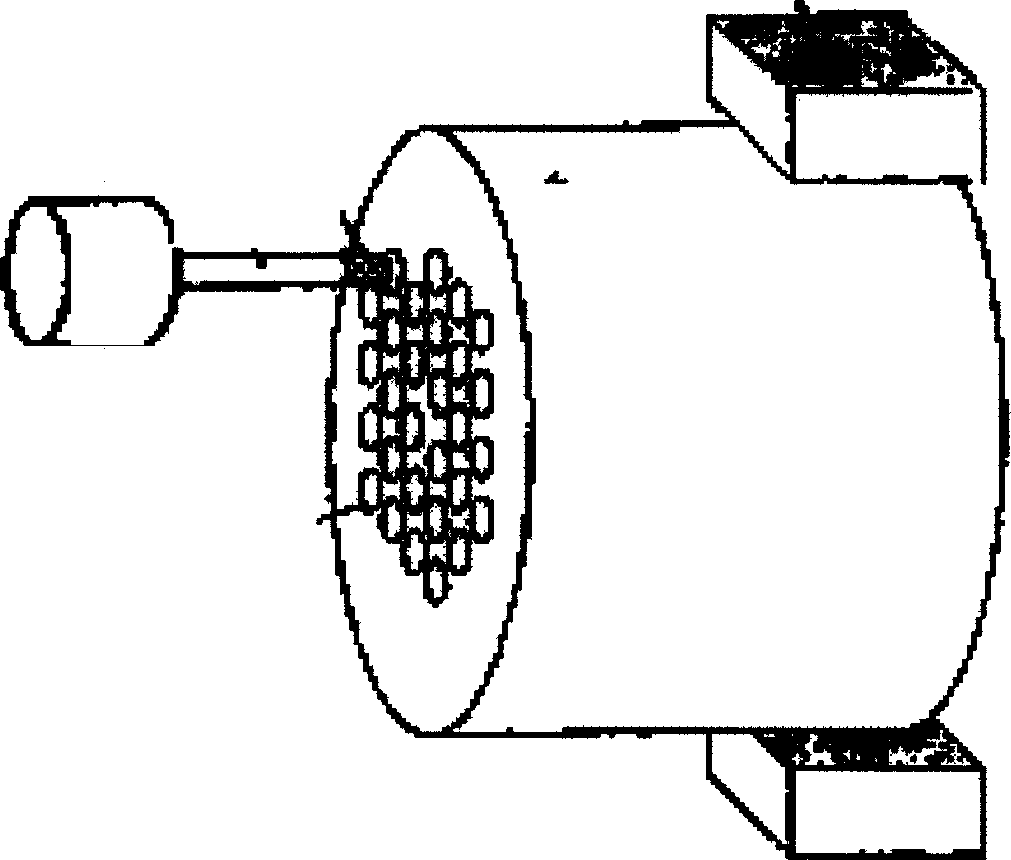

Method for preparing photon crystal optical fibre and apparatus therefor

ActiveCN1583617ASimple preparation procedureReduce lossGlass making apparatusGlass productionAtmospheric pressureMaterials science

The method is: Put many glass pipe in order to form a specific structure (photon crystal optical fibre prefab stick) in the glass cannula. The thin glass pipe is longer then the others. The equipment controls the pressure of photon-crystal optical fibre prefab stick. In another word is to vacuum the glass cannula, to input the thin glass pipe of 10 -1 mbar air.

Owner:FENGHUO COMM SCI & TECH CO LTD

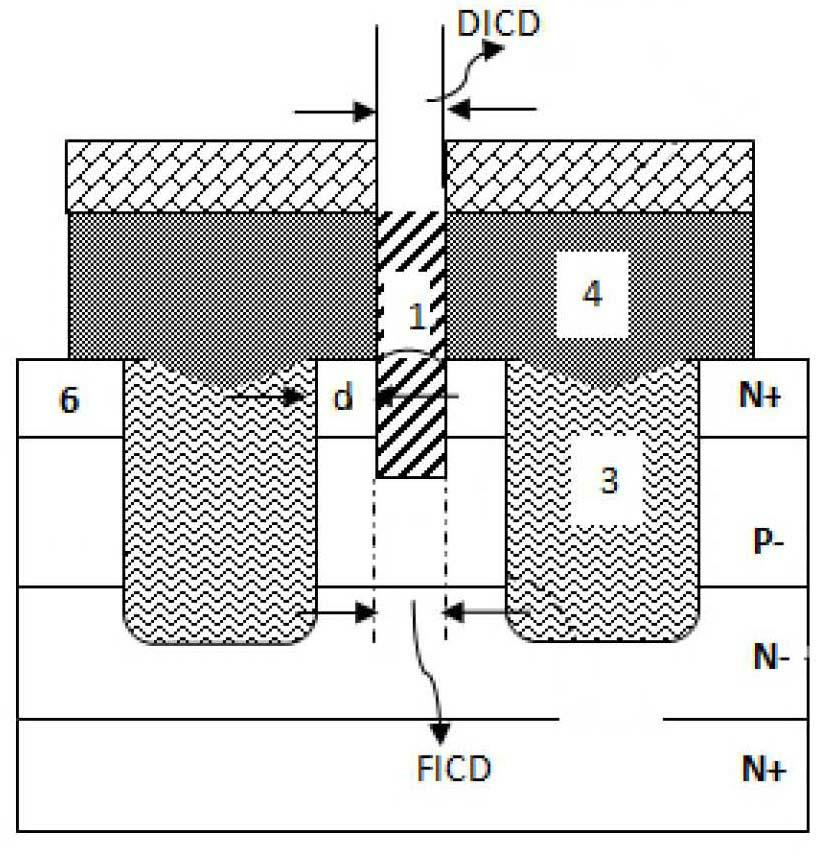

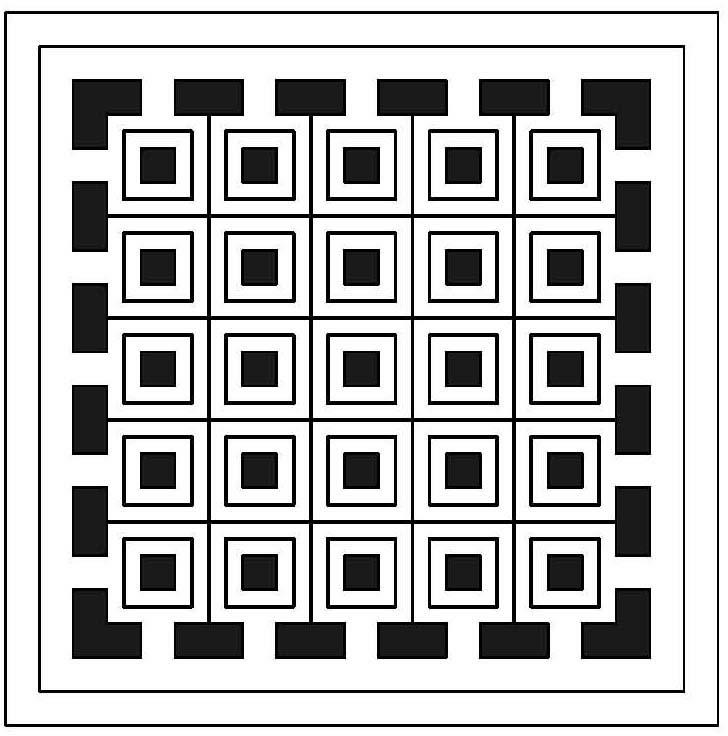

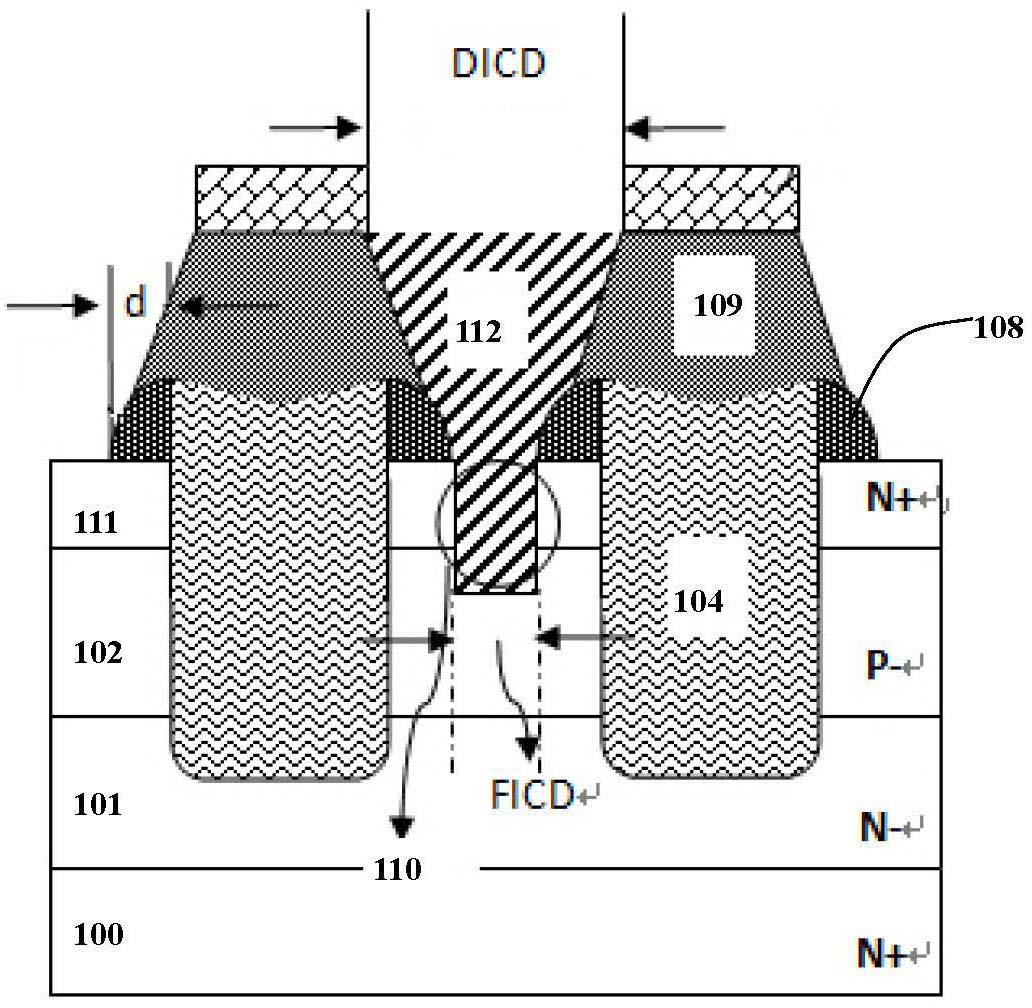

Trench MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) and manufacturing method thereof

ActiveCN102088035AReduced drain-source on-state resistanceReduce spacingSemiconductor/solid-state device detailsSolid-state devicesTrench mosfetEngineering

The invention provides a trench MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) and a manufacturing method thereof. The manufacturing method of the trench MOSFET comprises the following steps of: (1) preparing a heavily doped substrate; (2) forming a lightly doped epitaxial layer on the heavily doped substrate; (3) forming a lightly doped trap region on the lightly doped epitaxial layer; (4) forming a plurality of grid trenches penetrating through the lightly doped trap region and being in contact with the lightly doped epitaxial layer; (5) forming a heavily doped source region at the upper part of the lightly doped trap region and among the grid trenches; (6) forming a side wall on both sides of each grid trench; and (7) forming source electrode contact holes by self alignment of the side walls, wherein the top opening of each contact hole is greater than the bottom opening. The invention can further improve the density of unit cells of MOSFET, provides convenience for etching source electrode contact holes, and is favorable for metal filling of the source electrode contact holes.

Owner:WILL SEMICON (SHANGHAI) CO LTD

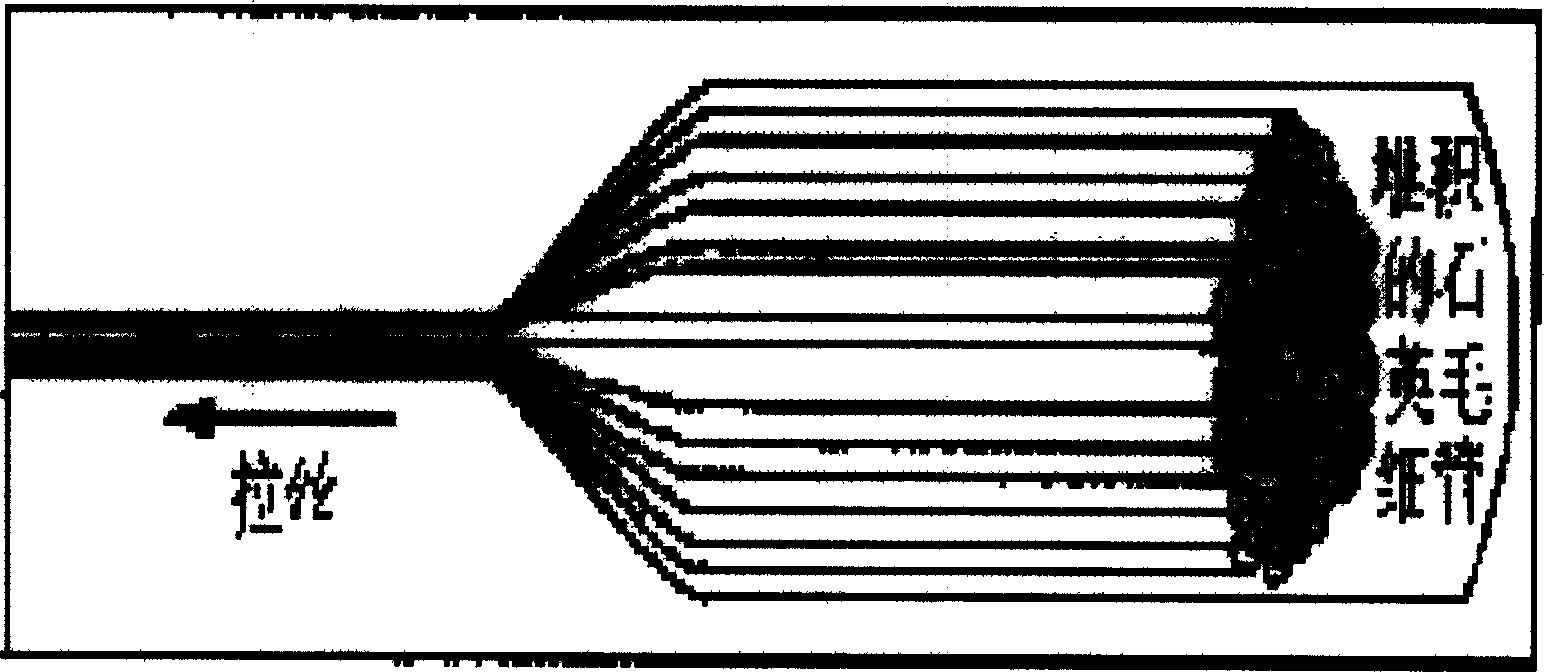

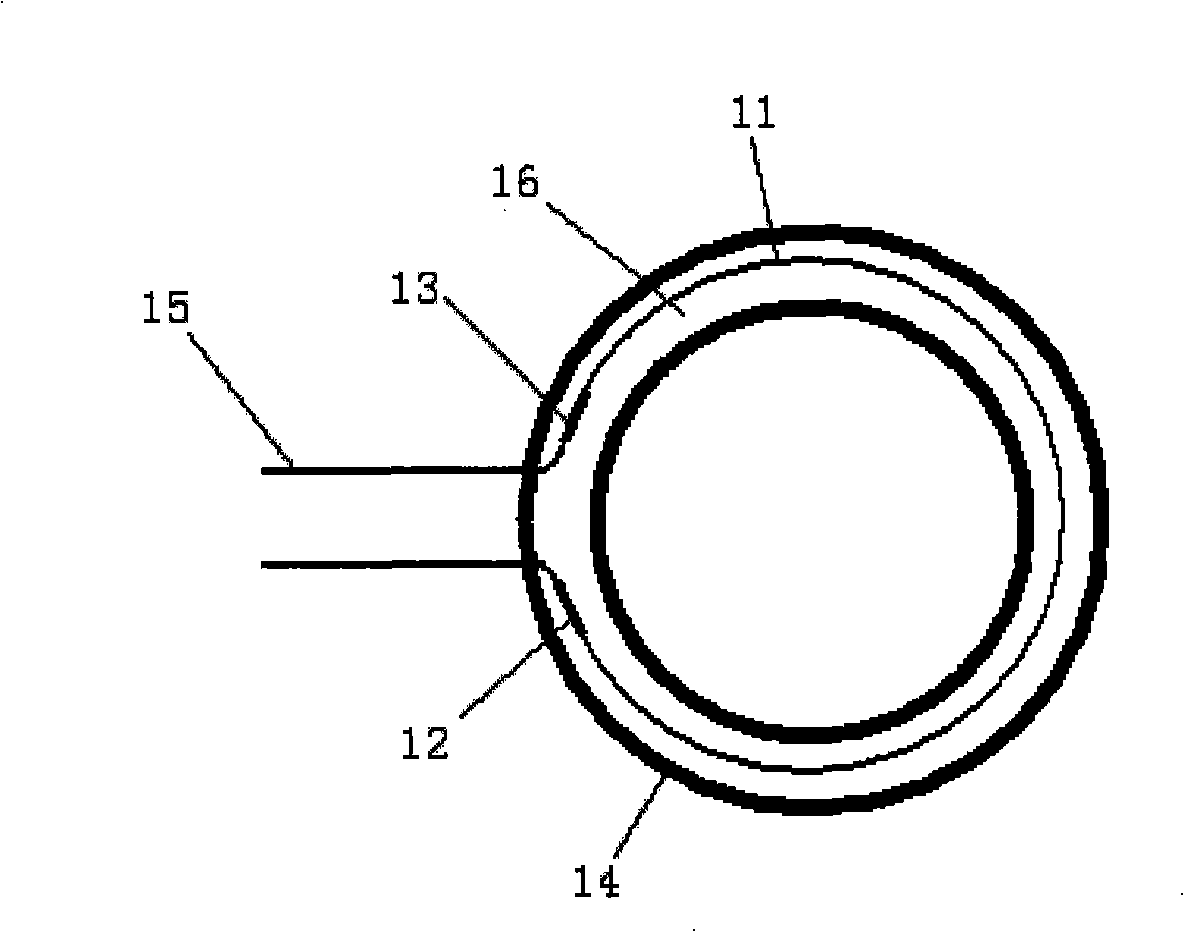

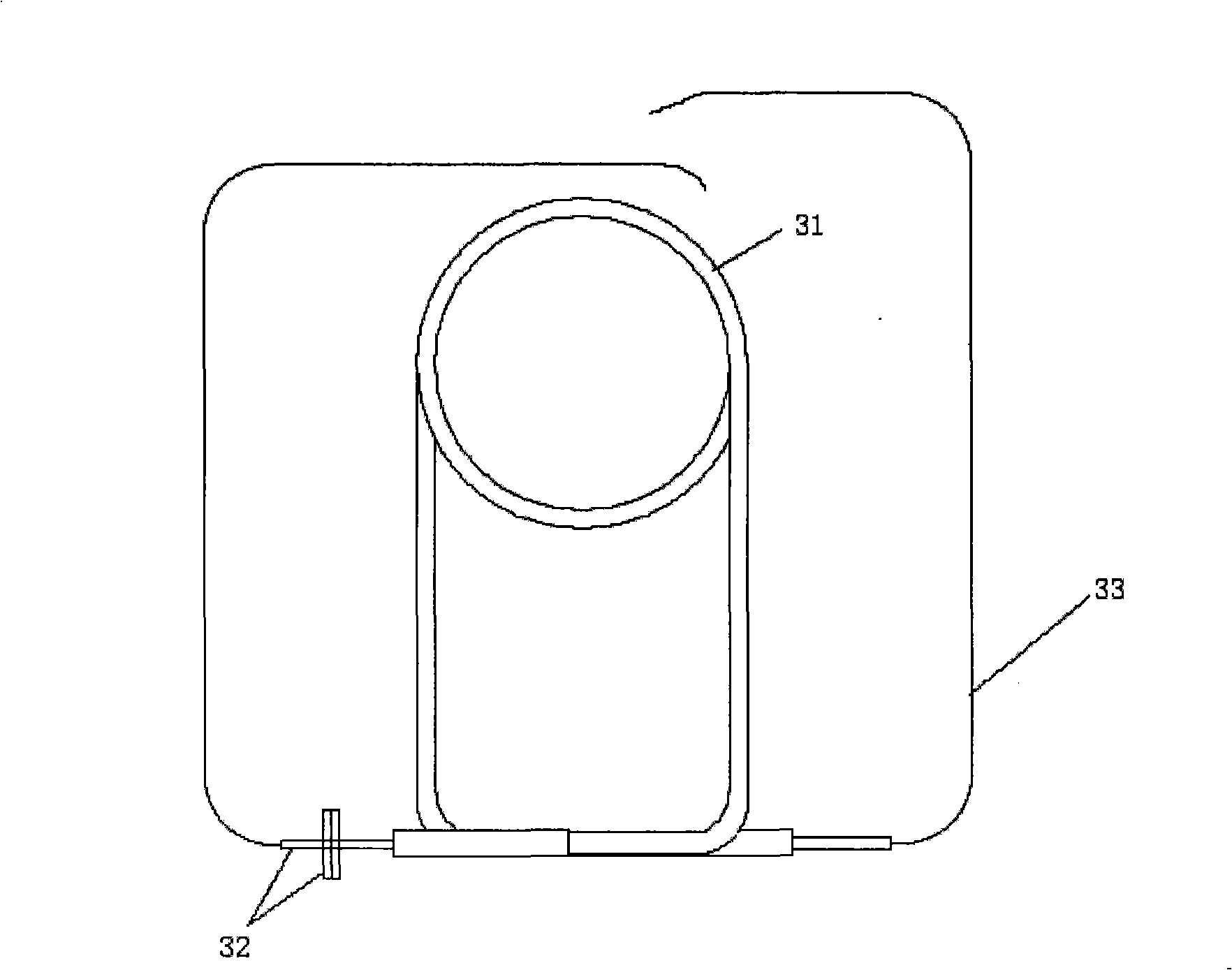

Method for manufacturing optical fiber current sensor sensitivity coil

ActiveCN101303373ASimple winding processEnsure stabilityCurrent/voltage measurementVoltage/current isolationEngineeringCurrent sensor

The invention discloses a method for preparing a sensor coil for an optical fiber current sensor, which comprises the steps that: (1) an annular coil frame is prepared with a relatively rough outer side surface, and an angle bracket is arranged on the outer side surface and the two sides of the angle bracket are both tangent with the coil frame; (2) the torsion of an optical fiber is removed to release stress; (3) the coil frame is fixed on the horizontal axis to ensure that the normal of the coil frame and the axes of the horizontal axis coincide and the horizontal axis of the coil frame is evenly rotated and fixed to fix the optical fiber on the coil frame; (4) symmetrical distributed points are chosen along the circumference direction of the coil frame to fix the optical fiber; (5) the two ends of the optical fiber are respectively provided with 1 / 4 wave plate and reflector and fixed on a bracket, the projection of the 1 / 4 wave plate and the reflector on the normal of the coil frame coincide and the end of the optical fiber provided with the 1 / 4 wave plate is connected with a polarization maintaining optical cable; (6) the coil is put into an incubator to remove stress introduced during the fixing process of the optical fiber; (7) the coil is fixed in a closed annular outer shell and sealed.

Owner:中国航天时代光电科技有限公司

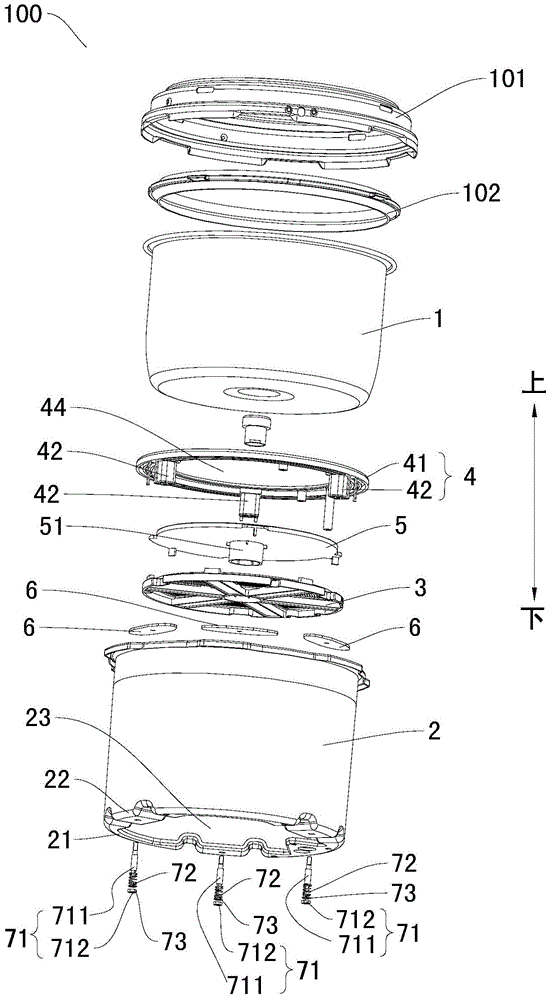

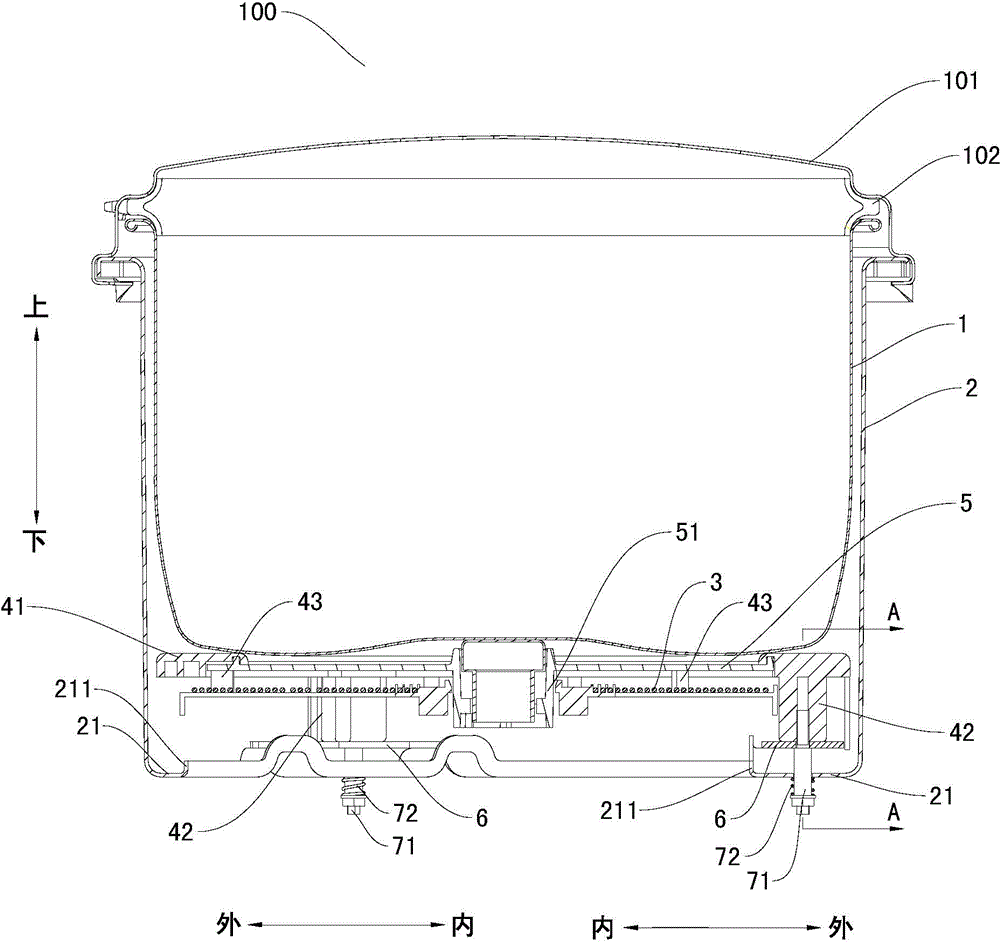

Pressure cooker

InactiveCN105310470AImprove structural strengthImprove securityPressure-cookersCooling effectEngineering

The invention discloses a pressure cooker which comprises an outer pot, annular supporting pieces, a coil disc, an air duct support and a fan. A turned edge extending inwards is arranged at the lower end of the outer pot. An opening in the bottom of the outer pot is defined by the turned edge. The turned edge is provided with a plurality of elastic pieces. The annular supporting pieces support the elastic pieces and can move in the vertical direction. The coil disc is arranged on the annular supporting pieces and located below the annular supporting pieces. The opening in the bottom is matched with the coil disc. The air duct support is arranged on the outer bottom wall of the outer pot. An outer annular protrusion protruding towards the coil disc is arranged on the upper surface of the air duct support. The width, in the radial direction, of the outer annular protrusion is matched with the width, in the radial direction, of the coil disc. An air duct with an air inlet and an air outlet is defined by the outer annular protrusion, the upper surface of the air duct support, the lower surface of the coil disc and the outer pot together. The fan is arranged at the air outlet. According to the pressure cooker, the coil disc is good in cooling effect, the outer pot is high in structural strength, and the pressure cooker is stably supported by an inner pot.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

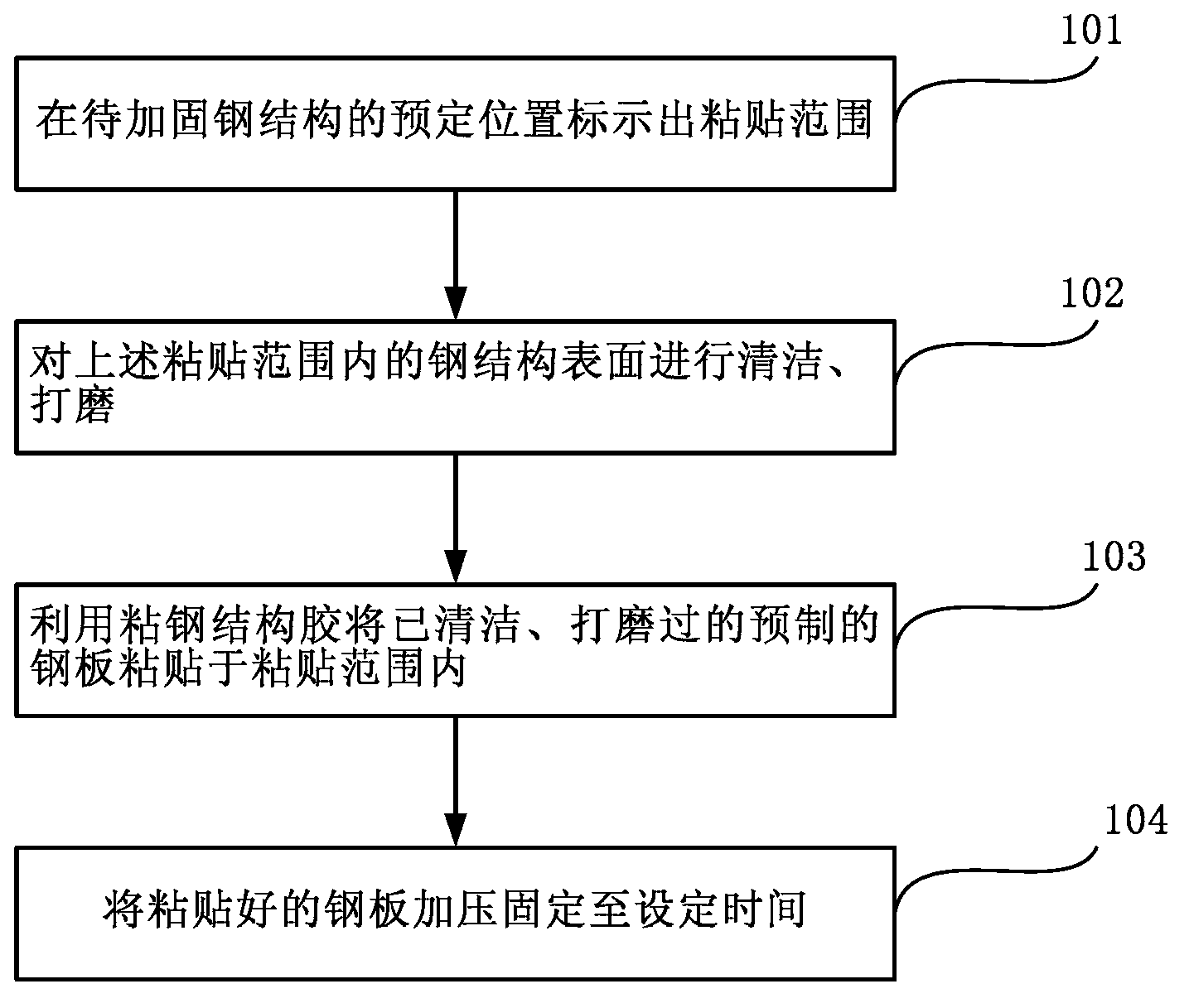

Steel-bonded reinforcement method for steel structure

ActiveCN102839824AEasy constructionAvoid deformationNon-macromolecular adhesive additivesBuilding repairsMetallurgyMaterials science

The invention discloses a steel-bonded reinforcement method for a steel structure. The steel-bonded reinforcement method comprises the following steps: marking a bonding range on the predetermined position of a steel structure to be reinforced; cleaning and grinding the surface of the steel structure within the bonding range; bonding the cleaned and grinded prefabricated steel plate within the bonding range by steel bonding glue; pressing and fixing the bonded steel plate to set time. The steel-bonded reinforcement method for the steel structure has the advantages that the construction is convenient, the reinforced steel structure is simple and light, the steel bonding proposals are flexible, and the reinforcement cost is economical and rational.

Owner:河北省建筑科学研究院有限公司 +1

Method for assessment of the state of batteries in battery-supported power supply systems

InactiveUS7400149B2Avoid stressBatteries circuit arrangementsElectrical testingRetention timeElectrical battery

After disconnection from the power supply system, a discharge characteristic of the no-load voltage is recorded automatically by means of a control unit across a discharge resistance during a stage-by-stage discharge cycle from a charged battery which is being operated for the first time on the power supply system. This stage-by-stage discharge cycle is repeated at times which can be defined, in order to record an instantaneous discharge characteristic of the no-load voltage, and an alarm no-load voltage is determined from the instantaneous discharge characteristic of the no-load voltage from a previously defined reserve time and from the final discharge voltage as determined in the first measurement, which alarm no-load voltage represents a measure of the energy which in each case still remains in the battery, and on reaching which during operation on the load, an alarm is produced for the operator of the power supply system.

Owner:SIEMENS AG

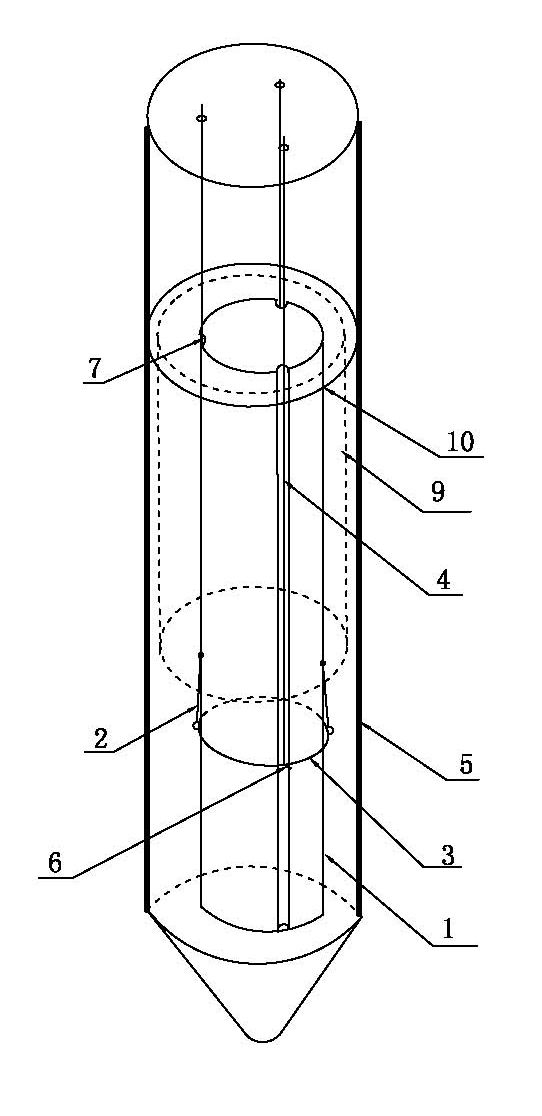

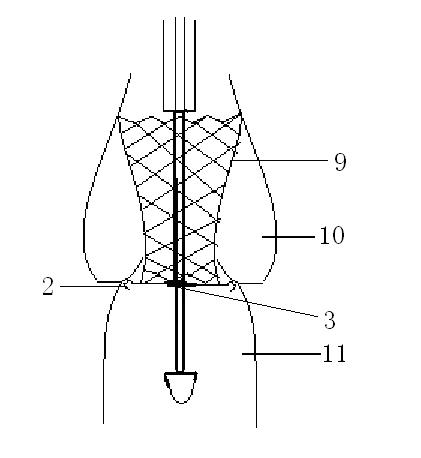

Percutaneous aortic valve replacement surgery conveying device with valve positioning function

ActiveCN101972177AIncrease success rateReduce surgical painHeart valvesPostoperative complicationMedical expenses

The invention relates to a percutaneous aortic valve replacement surgery conveying device with valve positioning function, which is characterized by comprising a conveying rod (1), a sheath pipe (5), a circular ring (3), positioning rods (2) and circular ring control cables (4), wherein the circular ring (3) is sheathed on the lower end of the percutaneous aortic valve replacement surgery conveying rod (1) and located in the conveying sheath pipe (5); the quantity of the positioning rods (2) is at least two, and one end of each positioning rod (2) is hinged with the conveying rod (1); and the quantity of the circular ring control cables (4) is at least two, the lower end of each circular ring control cable (4) is provided with a structure for supporting the circular ring (3), and the upper end of each circular ring control cable (4) stretches out of the human body along the axial direction of the conveying rod (1). The conveying device can play good auxiliary function on positioning the transplanted valve, increase the success rate of percutaneous aortic valve replacement surgery and reduce surgery difficulty and postoperative complications; the conveying device can also reduce surgery pain and risk for patients and decreases medical expenses.

Owner:孔祥清 +1

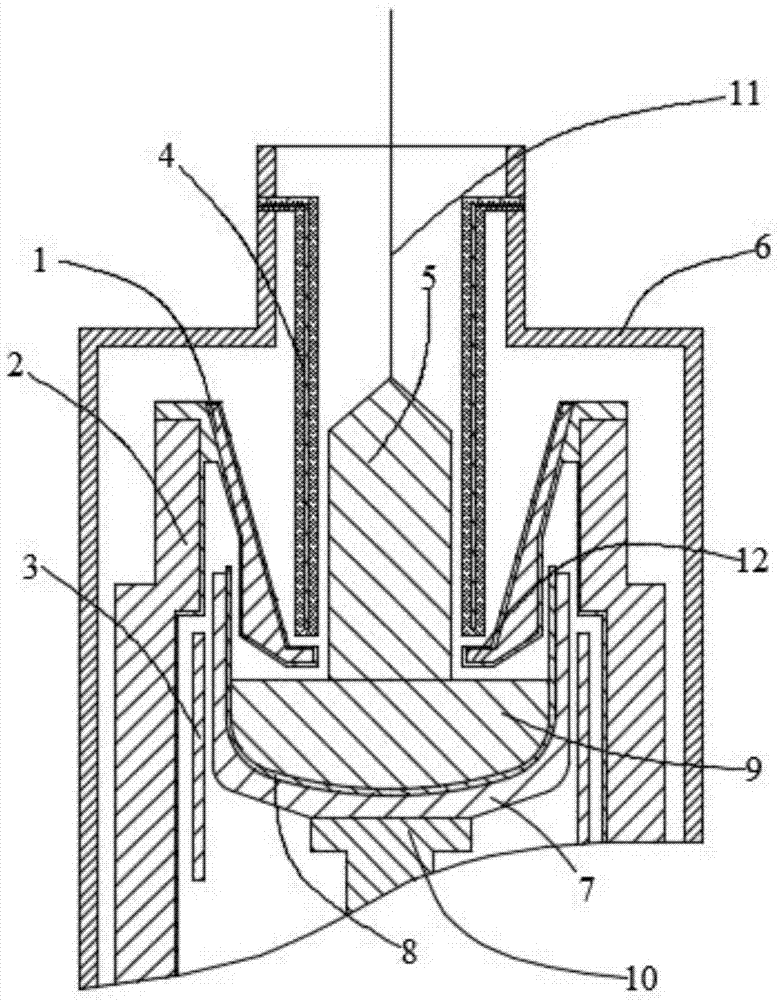

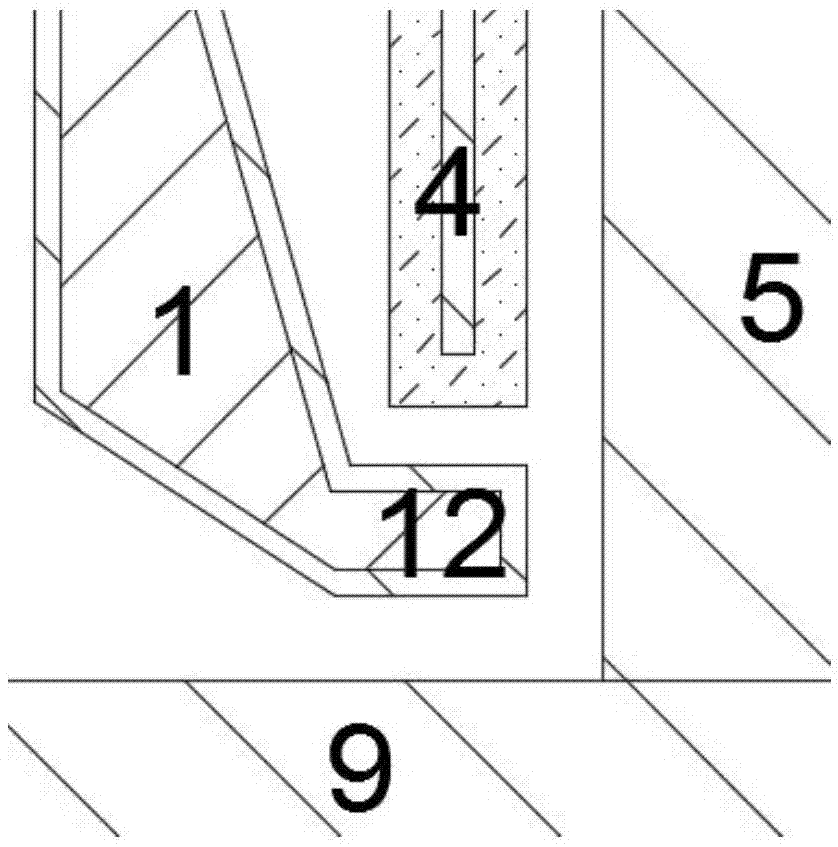

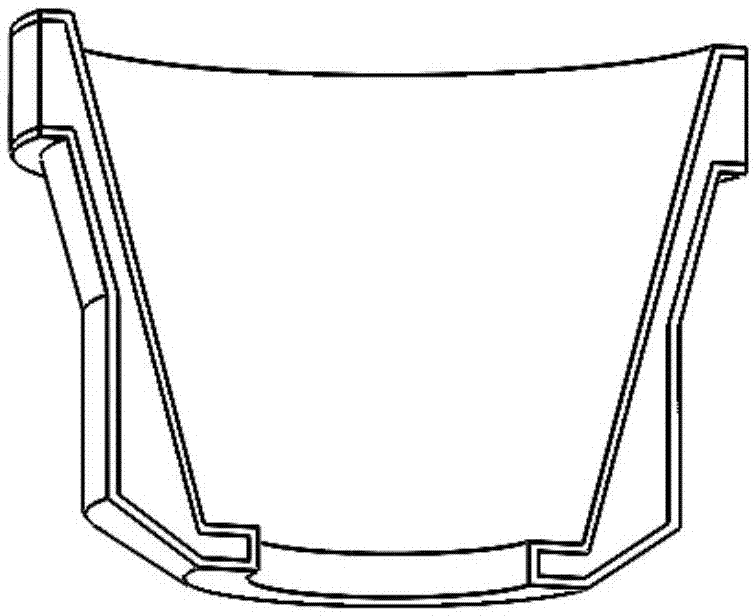

High-speed single crystal growth device

InactiveCN105442037AImprove cooling effectReduce heat dissipationPolycrystalline material growthBy pulling from meltHeat flowTriple point

The invention discloses a high-speed single crystal growth device which is characterized in that a guide cylinder is arranged above a crucible and the shape of the guide cylinder near a triple point is specially designed so as to control the direction of heat flow above a solidification interface; and a water jacket is arranged in the guide cylinder so as to reinforce the heat transfer of the crystal side. By designing the guide cylinder structure, the length of the water jacket extends to be near a solid-liquid interface. Compared with the conventional water jacket design, the heat dissipation capacity of the crystal side can be intensified greatly, and the crystal pulling speed is improved. The technical shortcoming that since the water jacket is too close to the solid-liquid interface, so that the concavity of the solid-liquid interface is increased is overcome, the flat solid-liquid interface shape can be achieved in the whole crystal pulling process, and the value of thermal stress in the crystal is controlled at a low level. Therefore, the high-speed single crystal growth device is favorable for quickly pulling high-quality single crystal.

Owner:XI AN JIAOTONG UNIV

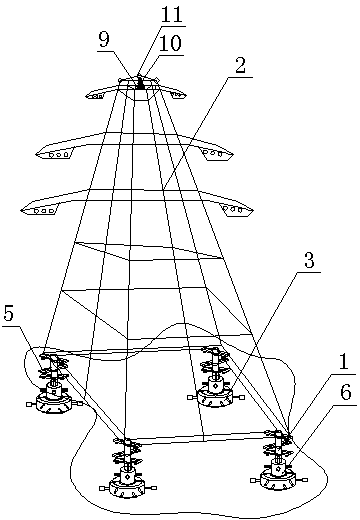

Earthquake self-adaptation-type pole and tower device

ActiveCN103437585AImprove performanceImprove structural stabilityFoundation engineeringTowersPower gridTower

The invention discloses an earthquake self-adaptation-type pole and tower device which comprises a pole and tower body, a self-adaptation-type positioning base and pieces of concrete tower footing. Supporting stand columns are arranged at the bottom of the pole and tower body. The self-adaptation-type positioning base and the pieces of concrete tower footing are laid underground. The self-adaptation-type positioning base comprises base plates and a plurality of layers of pole holding devices, wherein the lower portions of the base plates are precast on the pieces of concrete tower footing, and the pole holding devices are arranged in a spatial-crossing mode. Bearing positioning components of the supporting stand columns are arranged in the middles of the base plates. Self-reset springs are arranged on the peripheral sides of the bearing positioning components and / or the lower portions of the pole holding devices, and positioning reference modules are arranged in the pieces of concrete tower footing. A position collection module connected with a controller is arranged at the upper portion of the pole and tower body. The controller is connected with an alarming module. According to the earthquake self-adaptation-type pole and tower device, the self-adaptation-type positioning base and the pieces of concrete tower footing are laid underground in an embedded mode, the foundation intensity, the structural stability and the earthquake-proof capacity are improved, foundation cracking and uneven settlement are effectively prevented, the controller of the pole and tower body is utilized for collecting position information and timely giving an alarm, the early warning and the outage are carried out before the maximum damage of the disaster is reached, and large-area damage and power failures of a power grid are avoided.

Owner:STATE GRID CORP OF CHINA +1

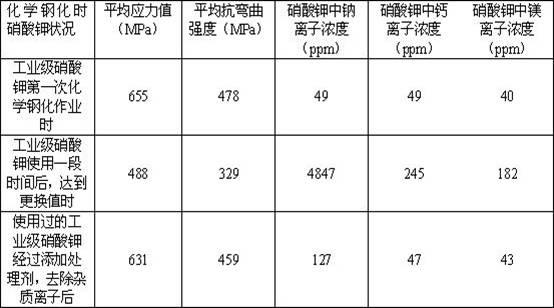

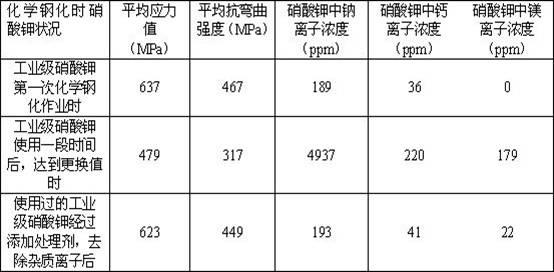

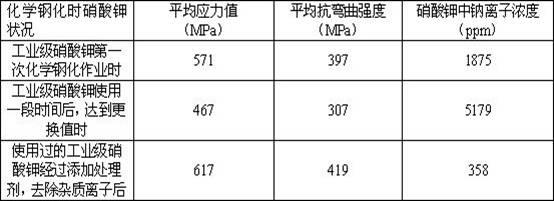

Method for removing potassium nitrate impurity ions on line in chemical tempering production

ActiveCN102515491AEasy stepsSimple processGlass tempering apparatusGlass productionImpurity ionsPotassium nitrate

The invention relates to a method for removing potassium nitrate impurity ions on line in chemical tempering production. The method implements the invention through the following steps in the mass chemical tempering operation: (1) the concentration of sodium, calcium and magnesium ions in molten potassium nitrate in a chemical tempering furnace is detected; when the glass stress and strength are lower than set values after a certain amount of chemical tempering, the tempering is stopped, and the concentration of the sodium, calcium and magnesium ions in the molten potassium nitrate in the furnace is recorded; (2) an appropriate amount of treated reagent (potassium pyroantimonate) is added in the potassium nitrate of which the tempering is stopped and simultaneously is stirred, so that the reaction is uniform and full; (3) the molten potassium nitrate obtained in the step (2) stands at constant temperature, so that the molten potassium nitrate reacts, is deposited and clarified thoroughly; and (4) after the molten potassium nitrate obtained in step (3) is fully clarified, the chemical tempering is re-started. The method can reduce the replacing frequency of the chemically tempered potassium nitrate, reduces the cost, improves the production efficiency, is simple in process and is convenient to implement.

Owner:GUANGDONG AVIC SPECIAL GLASS TECH

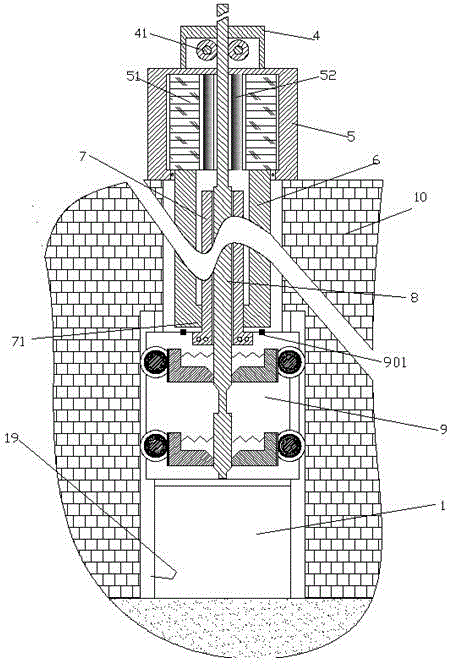

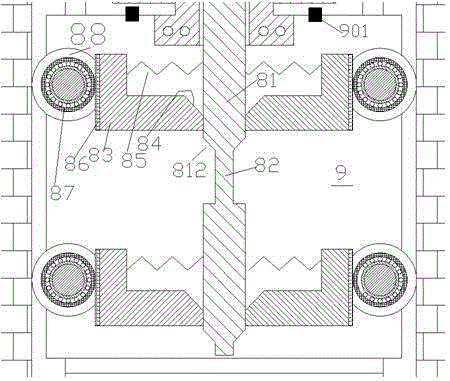

Water conservancy gate structure with high safety and use method thereof

The invention provides a water conservancy gate structure with high safety and a use method thereof. The device comprises a gate plate (9) for blocking a water channel opening (1). An external thread sleeve (7) is fixedly connected to the upper side of the gate plate (9) and used for stretching into the hollow portion of a rotary shaft (6) to be in threaded fit with an internal thread ring part (71) at the lower end, the upper end of the rotary shaft (6) is connected with a motor rotor (51) in a drive motor box (5) installed on a structure base body (10), and two roller bearing assemblies are installed on the land side of the gate plate (9) from top to bottom. Each roller bearing assembly comprises two bearing rollers (88) which are opposite in the horizontal direction and are rotationally installed on the left side and the right side of the gate plate (9) respectively.

Owner:舒泳军

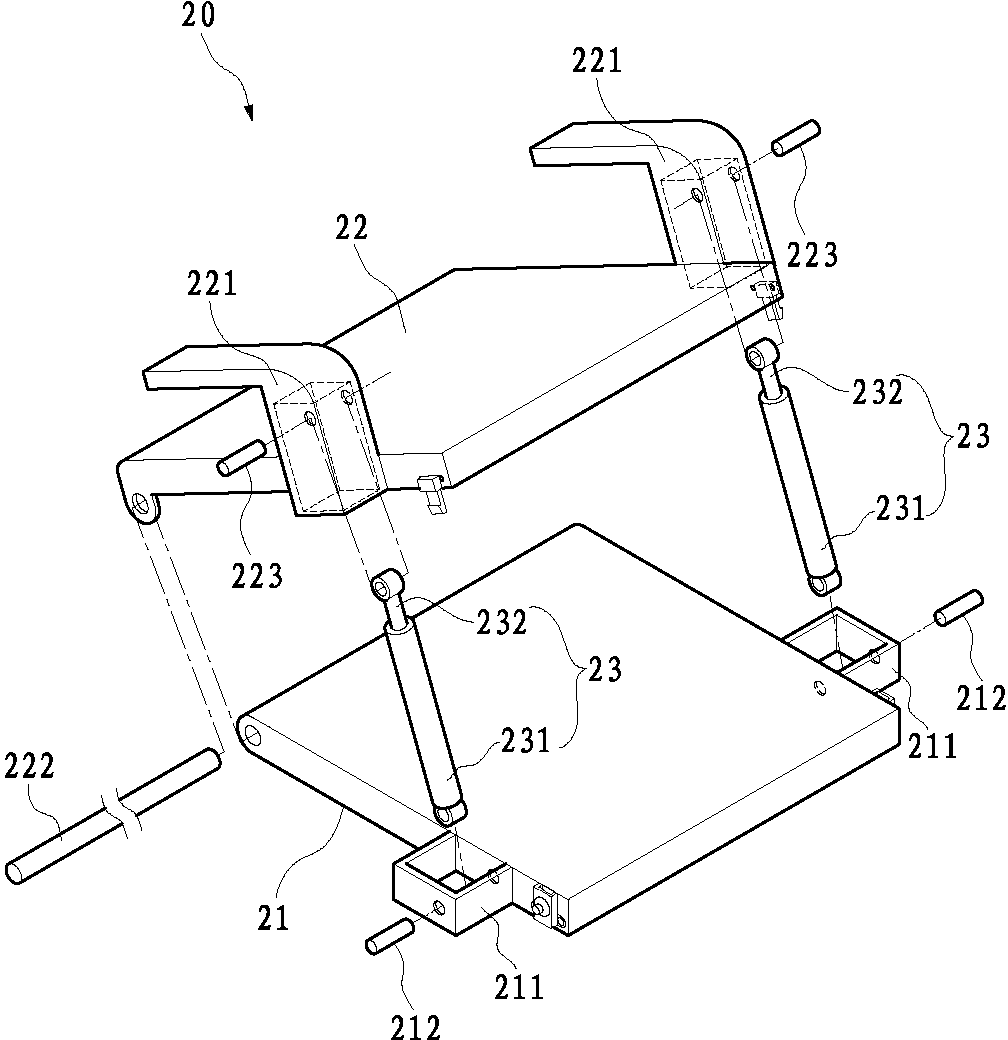

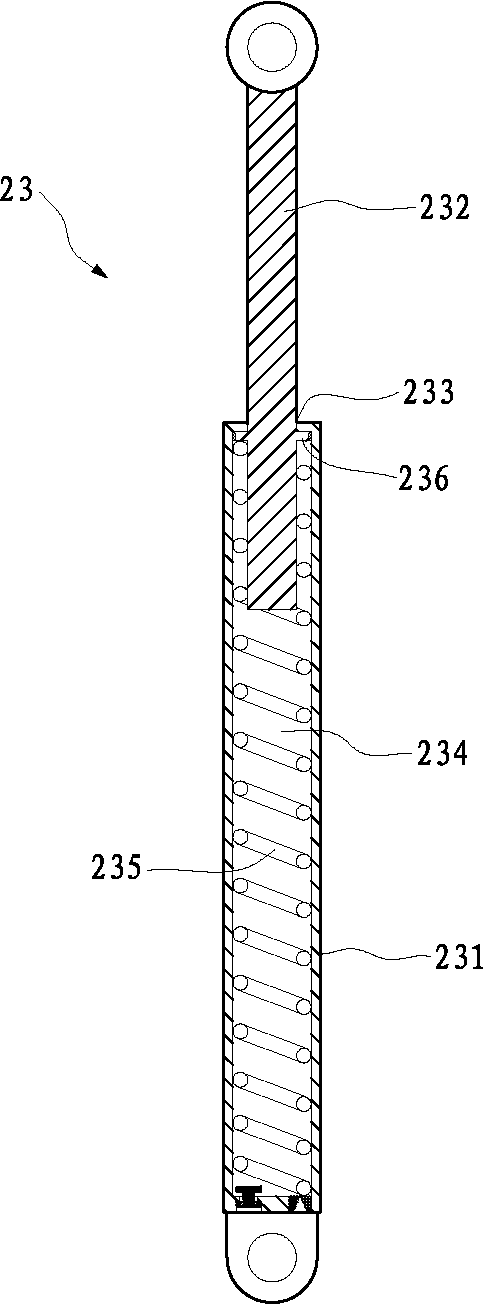

Getting-up auxiliary structure

The invention discloses a getting-up auxiliary structure which is applied on a chair. The structure comprises two telescopic supporting rods, a first seat body, and a second seat body. One ends of the two telescopic supporting rods are respectively hinged to one end of the fist seat body. The other ends of the two telescopic supporting rods are respectively hinged to one end of the second seat body. The other end of the first seat body and the other end of the second seat body are hinged to form an integral body. When the telescopic supporting rods are not influenced by any other external force, stress generated by elastic elements in the telescopic supporting rods can make the telescopic supporting rods in extending states, and a preset included angle is formed between the second seat body and the first seat body. When the telescopic supporting rods are under the force applied by the second seat body, the stress generated by the internal elastic elements can be overcome, the telescopic supporting rods are in folded states, and the second seat body and the first seat body are superposed. With the structure, a senior user can easily slowly sit down or get up, and a problem of falling and injury caused by waist and leg weakness is avoided.

Owner:谢光孚

Method for preparing multi-arc ion plating aluminium titanium chrome silicon yttrium nitride multi-component ultra-hard reaction film

InactiveCN101230448AQuality improvementGuaranteed repeatabilityVacuum evaporation coatingSputtering coatingAlloyTitanium

The invention relates to a method of preparing a multi-component super-hard reaction film for a multiple-arc ion-plated nitride of titanium, aluminum, chrome, silicon and yttrium. The method includes the following steps in sequence: the confirmation of the deposition technique and the design of the components of the target material (1); the preparation of a alloy target (2); the selection and pre-processing of a workpiece sample (3); the confirmation of the quantity of the electric arc source (4); the confirmation of the deposition technique (5); the acquirement of a transition layer (6); the processing of vacuum heating (7) and the rotation of the workpiece sample. The method confirms the variation range of the components of the Ti, Al, Cr, Si, Y elements in the complex Ti-Al-Cr-Si-Y alloy target and causes the super-hard reaction film of the (TiAlCrSiY)N to have the advantages of strong adhesive power (larger than or equal to 180 N) and high hardness (larger than or equal to HV3200).

Owner:SHENYANG UNIV

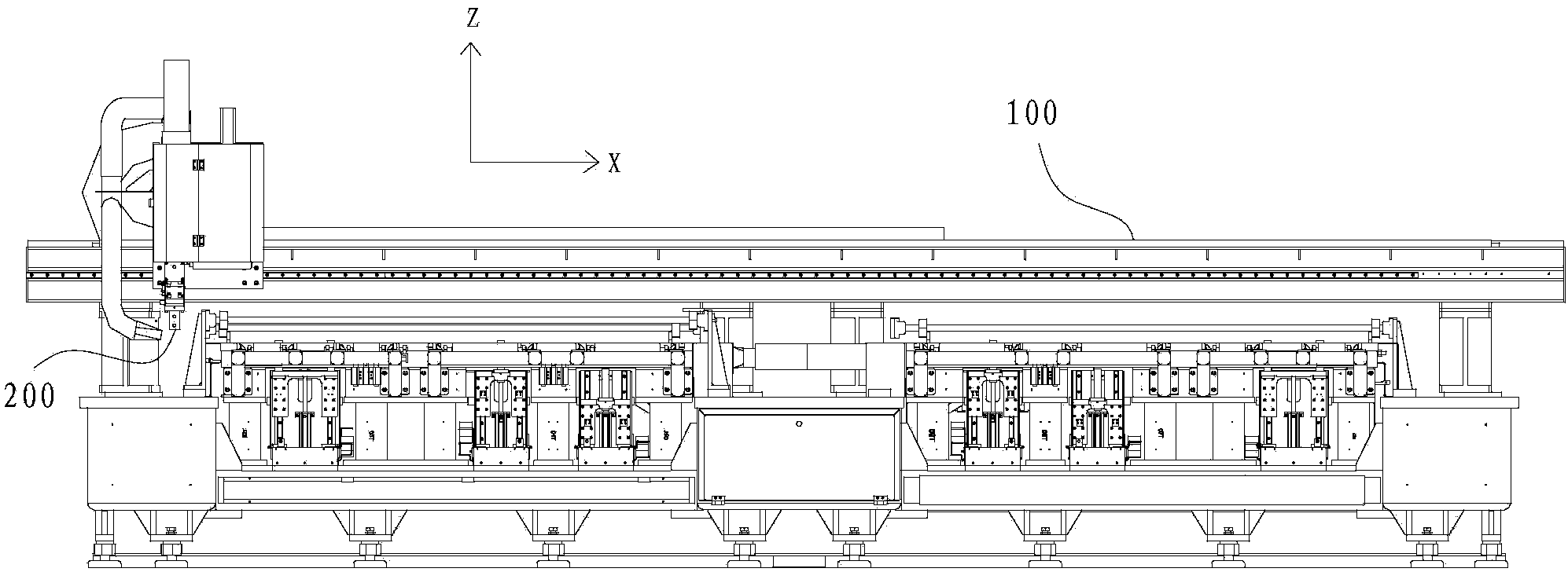

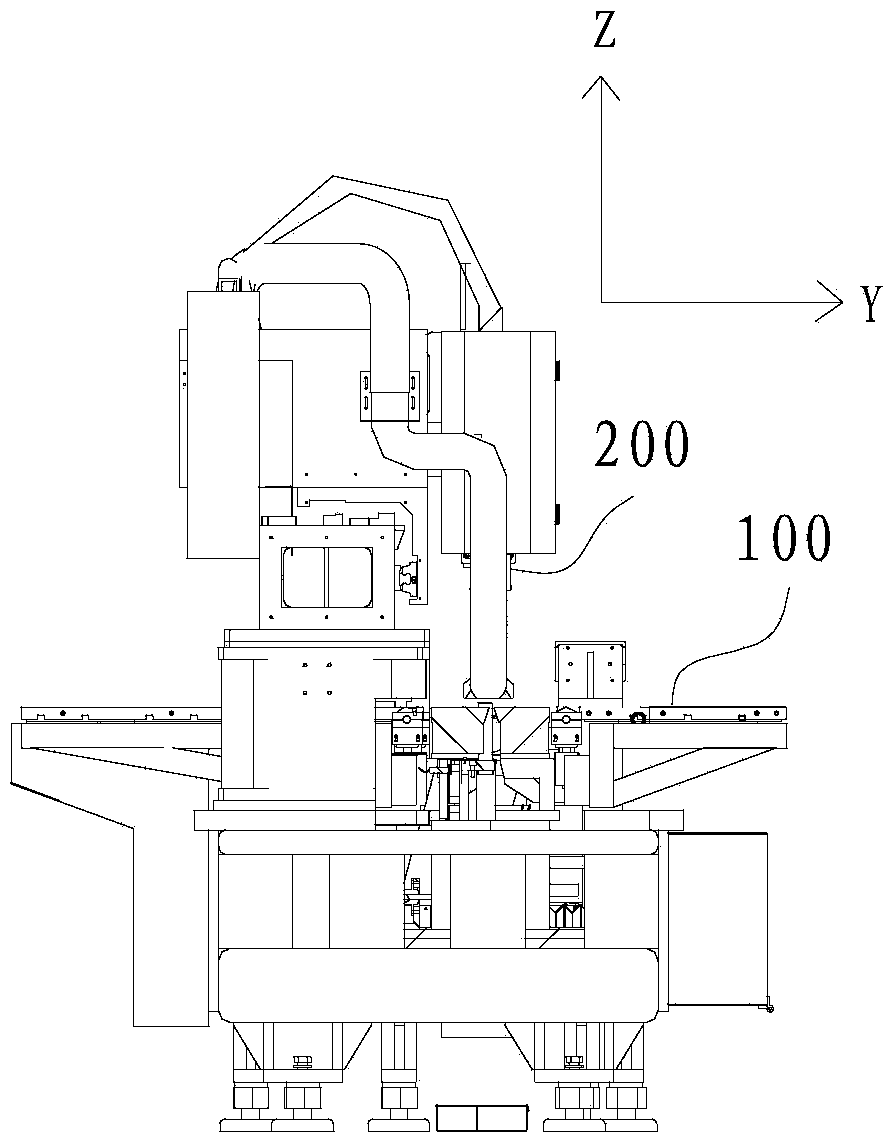

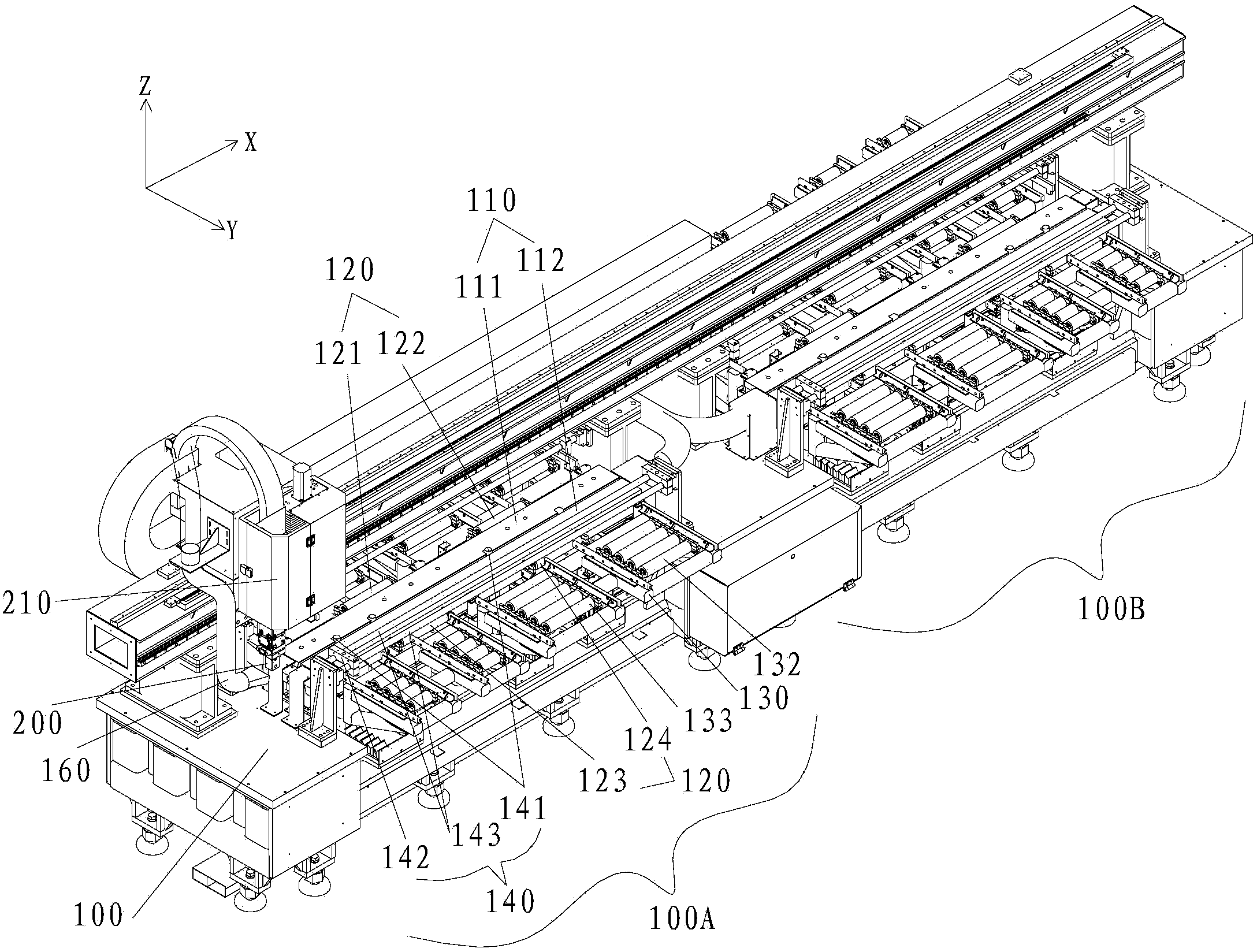

Tailored blank laser welding equipment and tailored blank laser welding method

ActiveCN104384716AAmple spaceWill not affect the activityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention discloses tailored blank laser welding equipment. A pressing mechanism of traditional tailored blank laser welding equipment is replaced through an electromagnetic platform; the structure is simple; a space above a plate to be welded is wide without influencing the movement of a welding head; downward pressure of the pressing mechanism of the traditional tailored blank laser welding equipment is replaced by sucking force generated by an electromagnet to achieve the purpose of plate fixation; the stress generated in the welding can be overcome to prevent a welding line from cracking; an indentation on the surface of the plate caused by the use of the pressing mechanism also can be prevented; and the condition of influence on the welding effect due to uneven stress is not generated. The invention further discloses a tailored blank laser welding method.

Owner:HANS LASER TECH IND GRP CO LTD

Epitaxial wafer of light-emitting diode (LED) and making method of epitaxial wafer

ActiveCN102760808ASlow down electronsReduced polarizationSemiconductor devicesMultiple quantumQuantum

The invention discloses an epitaxial wafer of a light-emitting diode (LED) and the manufacturing method of the epitaxial wafer and belongs to the technical field of diodes. The epitaxial wafer comprises a substrate layer, a buffer layer, an N-type layer, a multiple quantum well (MQW) layer and a P-type layer, wherein the substrate layer, the buffer layer, the N-type layer, the MQW layer and the P-type layer are sequentially covered on the substrate layer; the N-type layer is made of n-type doped GaN; the MQW layer comprises a plurality of quantum barrier layers and a plurality of quantum well layers which alternately grow with the quantum barrier layers; at least one of the quantum barrier layers comprises three sub-quantum barrier layers; a sub-quantum barrier layer positioned in the middle of the three sub-quantum barrier layers is made of n-type doped AlxInyGa[1-x-y]N, and the n-type doping concentration of the sub-quantum barrier layer is not greater than that of the N-type layer; and the other two sub-quantum barrier layers are made of non-doped GaN, wherein x is more than 0 and less than 1, and y is more than 0 and less than 1. According to the technical scheme, the electrostatic resistance of the LED can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Anticorrosive wear-resistant flexible ceramic powder coating

InactiveCN1743395AGood flexibilityImprove impact resistancePowdery paintsEpoxy resin coatingsEpoxyCeramic coating

The invention relates to an anticorrosive, wearproof flexible ceramic coating having A , B two components. It is characterized by: A component comprising epoxy resin, ceramic powder, pigment, solvent and additive. Its specific content is: using threeepoxy resins as film forming substance to improve anti-heat modification of coating layer, using silicon micropowder, titanium dioxide, lamprophyllite, titanium carbide, superfine zinc oxide as functional filler to increase wearproof and anticorrosion of coating layer, utilizing fibrous wollastonite to reinforce impact resistance of coating layer. B component is curing agent, phenol-amine compounds with long chain structure. It has outstanding properties of anticorrosion. wearproof, impact resiatance and sterilzing.

Owner:JIANGSU UNIV OF SCI & TECH

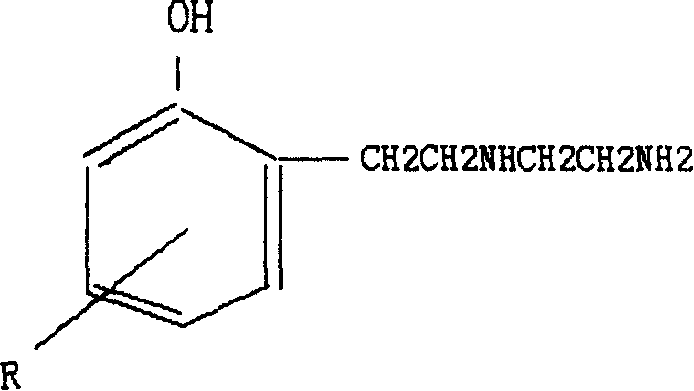

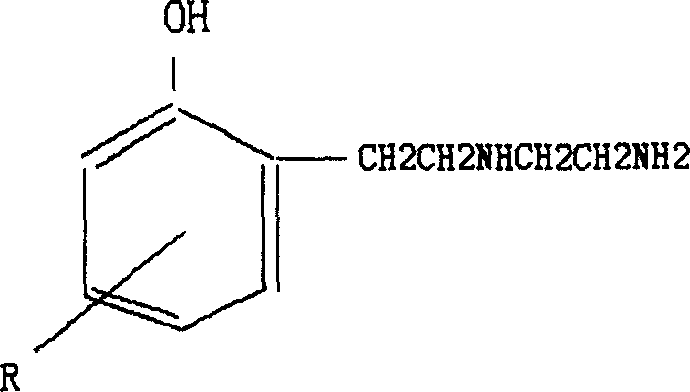

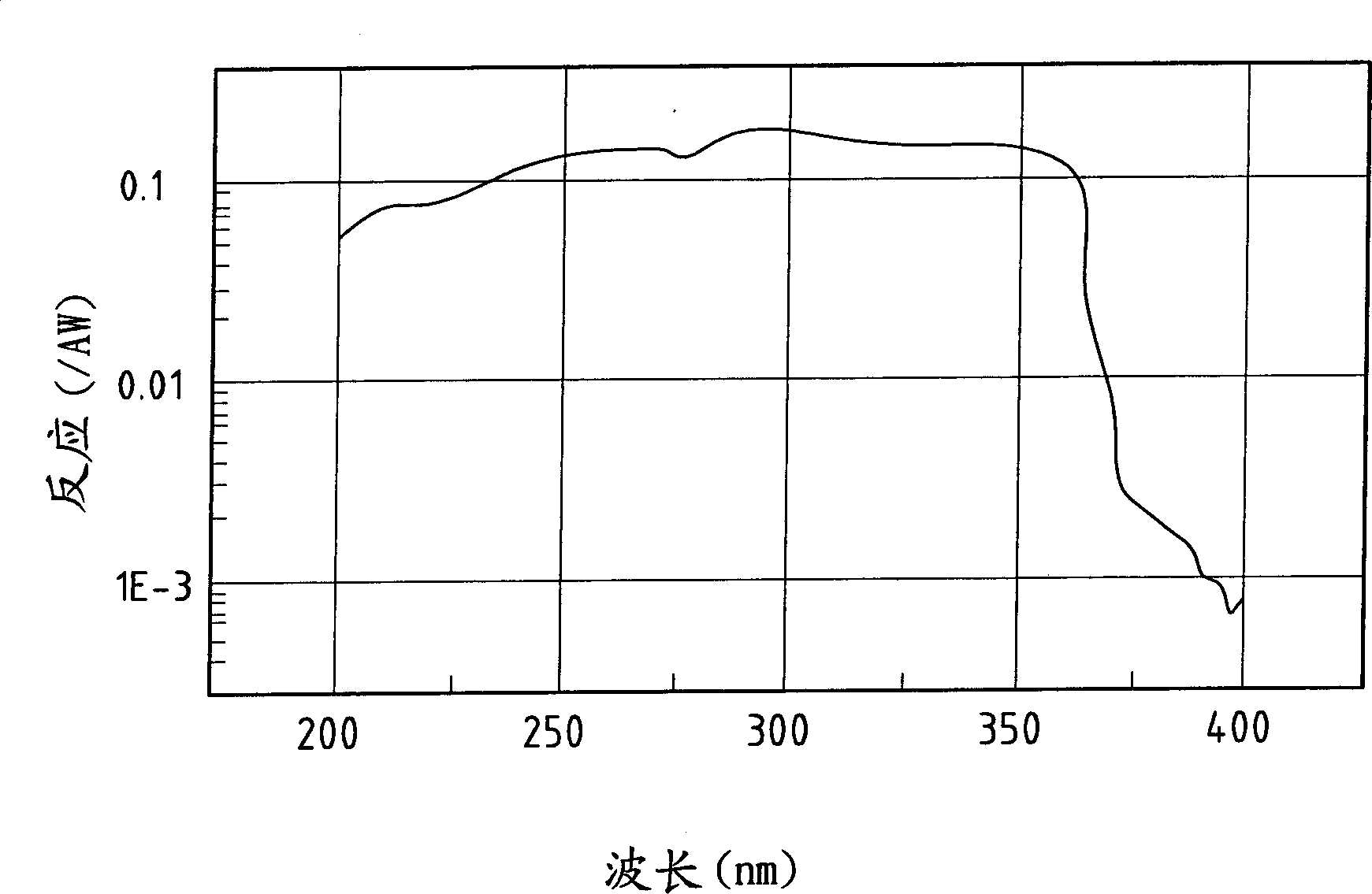

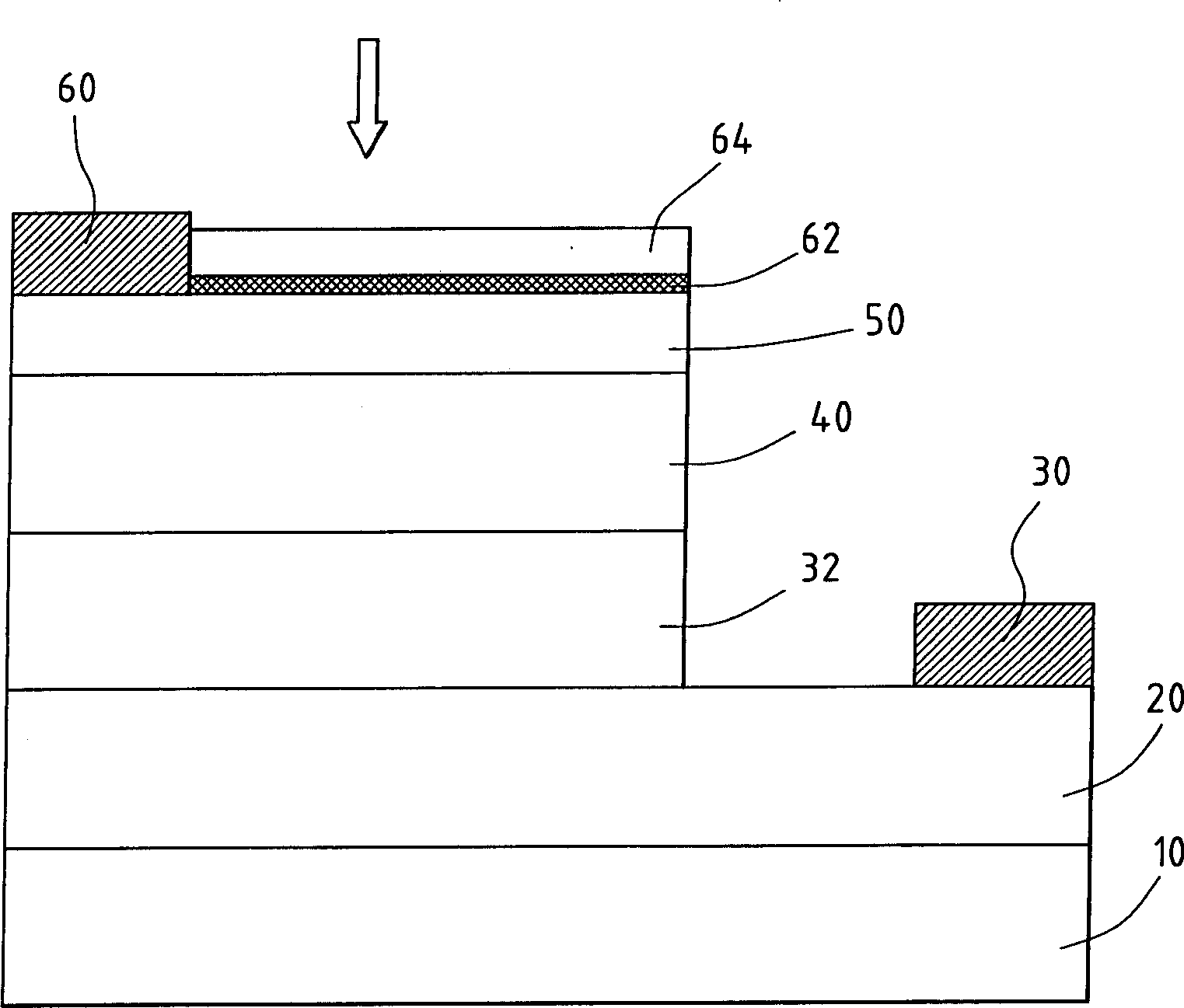

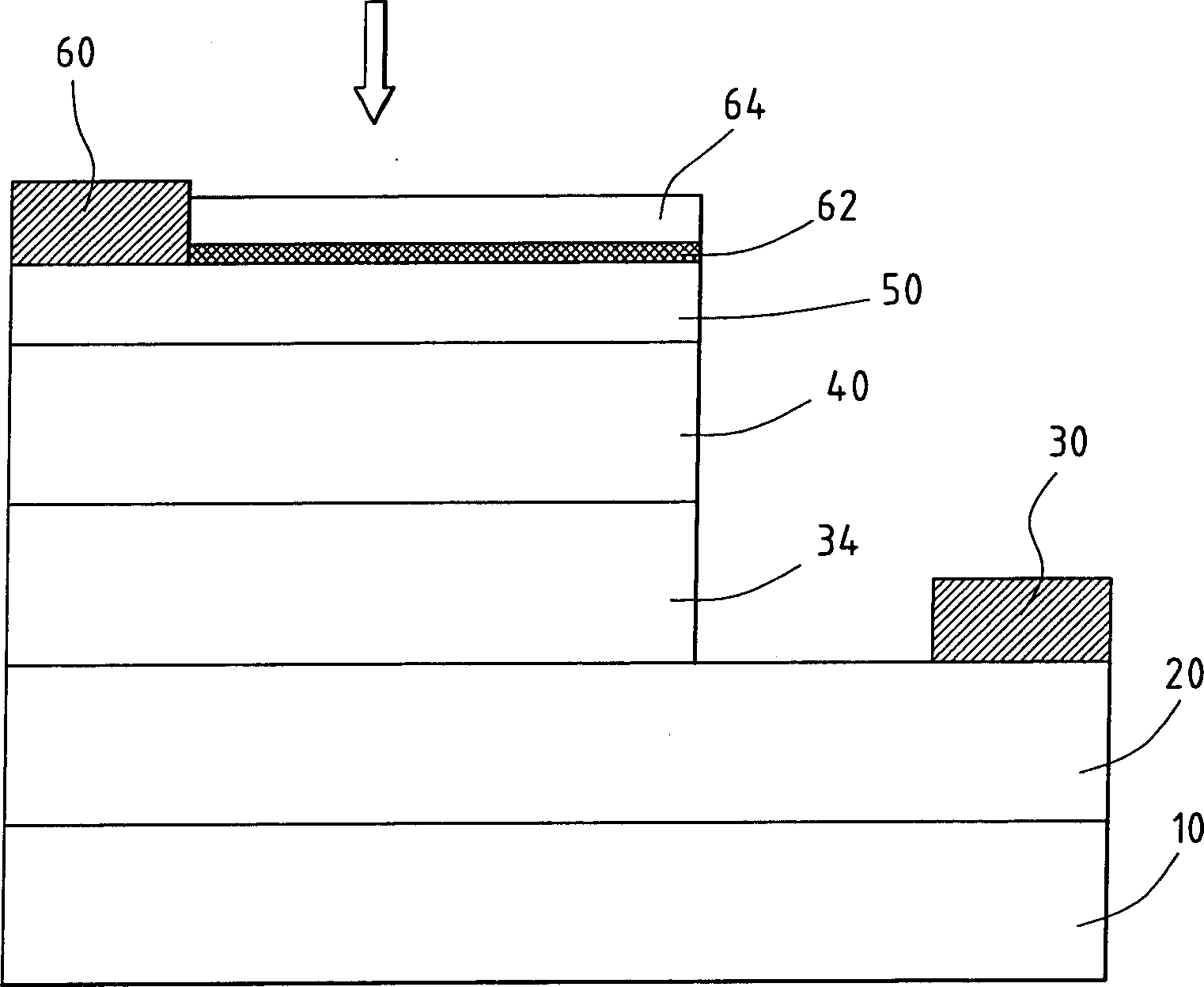

Ultra violet ray photo detector based on gallium nitride semiconductor

The invention provides a GaN semiconductor-based ultraviolet (UV) detector structure, from the substrate up, in sequence comprising n-type contact layer, light absorbing layer, light transmitting layer and p-type contact layer, all made of AlGaInN tetra-compound semiconductor material. By changing Al, Ga and In compositions of the semiconductor material, on one hand, these semiconductor layers can possess the needed energy gap, thus able to be specially sensitive to the optical reaction with respect to specific-wavelength UV; on the other hand, these semiconductor layers can possess matching crystal lattice constants, thus able to avoid the related problem of overlarge stress and simultaneously obtaining a UV detector with higher-quality crystal lattice structure. And the structure further comprises anode on the p-type contact layer, light transmitting Ohm contact layer and anti-reflecting layer as well as cathode on the n-type contact layer.

Owner:FORMOSA EPITAXY INCORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com