Method for removing potassium nitrate impurity ions on line in chemical tempering production

A technology of chemical tempering and impurity ions is applied in the field of potassium nitrate treatment, which can solve the problem of too fast replacement frequency of potassium nitrate, and achieve the effects of improving machine utilization rate and production capacity, simple steps and operations, and avoiding stress and poor strength products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

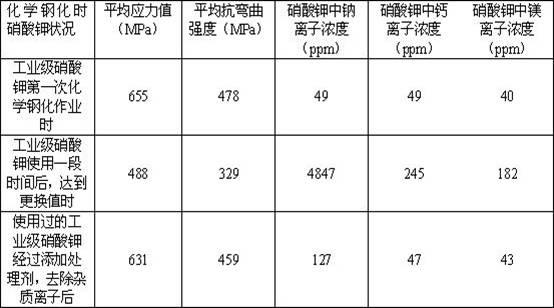

[0038] Add a certain amount of industrial-grade haifa brand potassium nitrate (purity ≥ 99.4%) into the chemical tempering furnace, set the heating temperature at 350°C, and melt the potassium nitrate. The heating time depends on the amount of potassium nitrate added and the heating power. After complete melting, set the temperature at the temperature required for chemical toughening production, such as 420°C, and keep it at a constant temperature for 48 hours. Then batch tempering production operations, the above-mentioned process is the existing chemical tempering production process; during the production operation, potassium nitrate samples are taken to detect the concentration of sodium, calcium, and magnesium ions, and the frequency is once for each batch of operations. Concentrations of calcium and magnesium ions. At the same time, each batch of chemically tempered products is also tested for stress and strength, and the test data is recorded. When the stress value is l...

Embodiment 2

[0049] Take analytical grade potassium nitrate as an example (purity ≥ 99.5%) instead of industrial pure potassium nitrate, and add it into the chemical tempering furnace. The steps refer to the implementation case 1 for comparison.

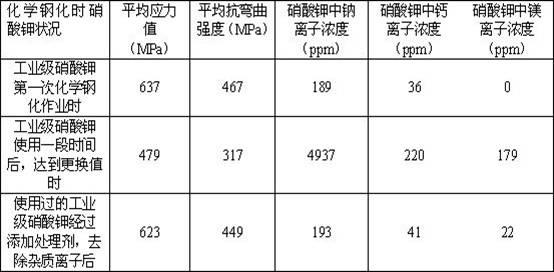

[0050] For the convenience of comparative strength and stress, the following experiments were done respectively with reference to Example 1:

[0051] Ordinary float soda-lime-silicate glass is also used as the test glass, and the 100*100*0.7mm test pieces are ground and cleaned, and put into the chemical tempering furnace in batches. Time 4 hours, after chemical tempering, soak in water and clean, use ORIHARA (ORIHARA) stress optics to test its stress, use a universal material testing machine to test 3-point bending, calculate its bending strength when it breaks, and take samples to test Record chemical Potassium nitrate contains the concentration of sodium ions, calcium ions and magnesium ions during tempering. For the purpose of comparison, th...

Embodiment 3

[0062] Take another manufacturer’s industrial grade potassium nitrate as an example (purity ≥ 99.0%) instead of haifa industrial pure potassium nitrate, and add it into the chemical tempering furnace. The operation steps refer to Example 1 for comparison.

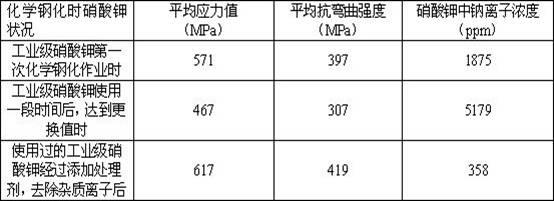

[0063] For the convenience of comparative strength and stress, the following experiments were done respectively with reference to Example 1:

[0064] Ordinary float soda-lime-silicate glass is also used as the test glass, and the 100*100*0.7mm test pieces are ground and cleaned, and put into the chemical tempering furnace in batches. Time 4 hours, after chemical tempering, soak in water and clean, use ORIHARA (ORIHARA) stress optics to test its stress, use a universal material testing machine to test 3-point bending, calculate its bending strength when it breaks, and take samples to test Record chemical Potassium nitrate contains sodium ion concentration during tempering. For the purpose of comparison, the chemical temperi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com