Patents

Literature

2212results about How to "Reduce replacement frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

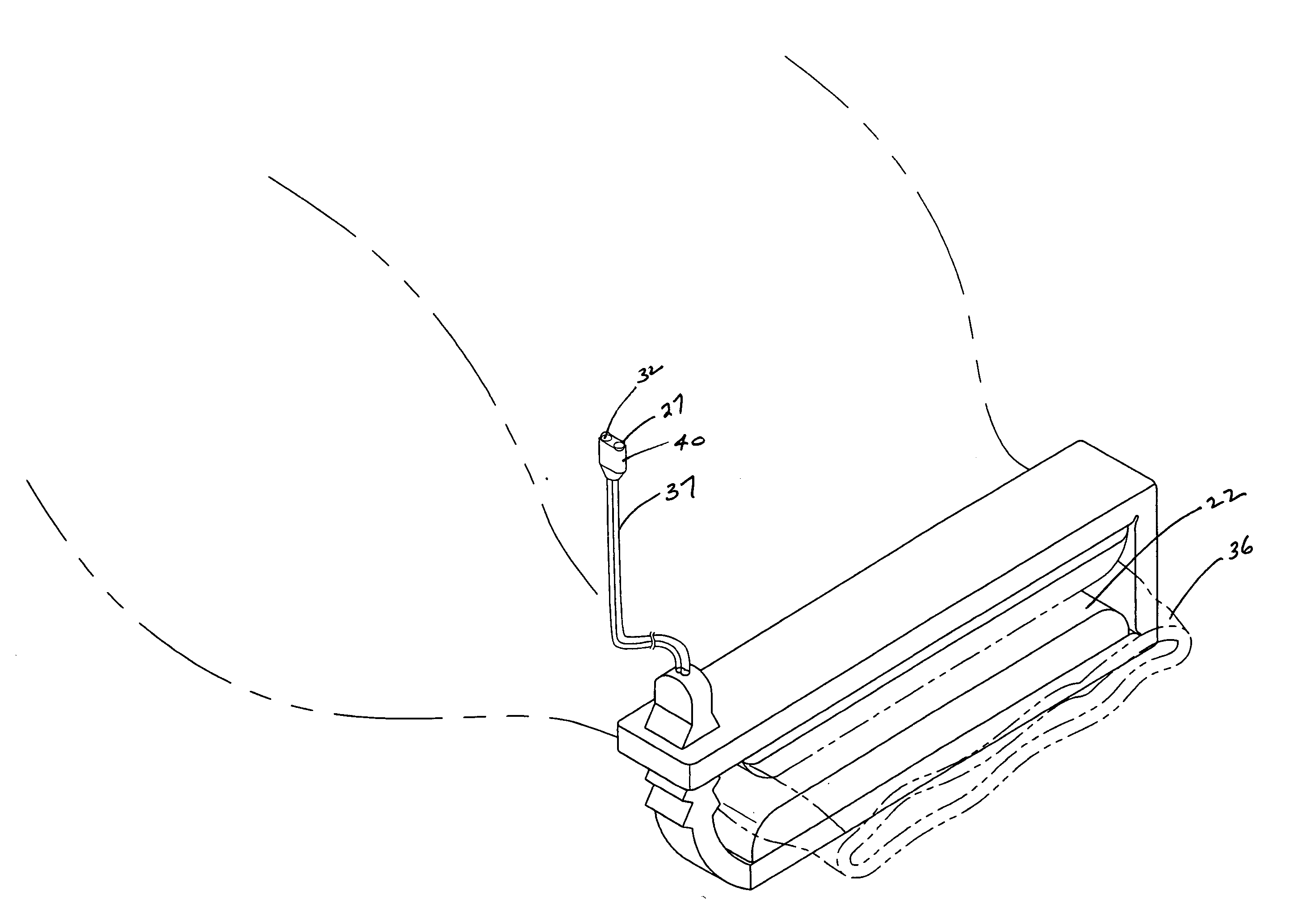

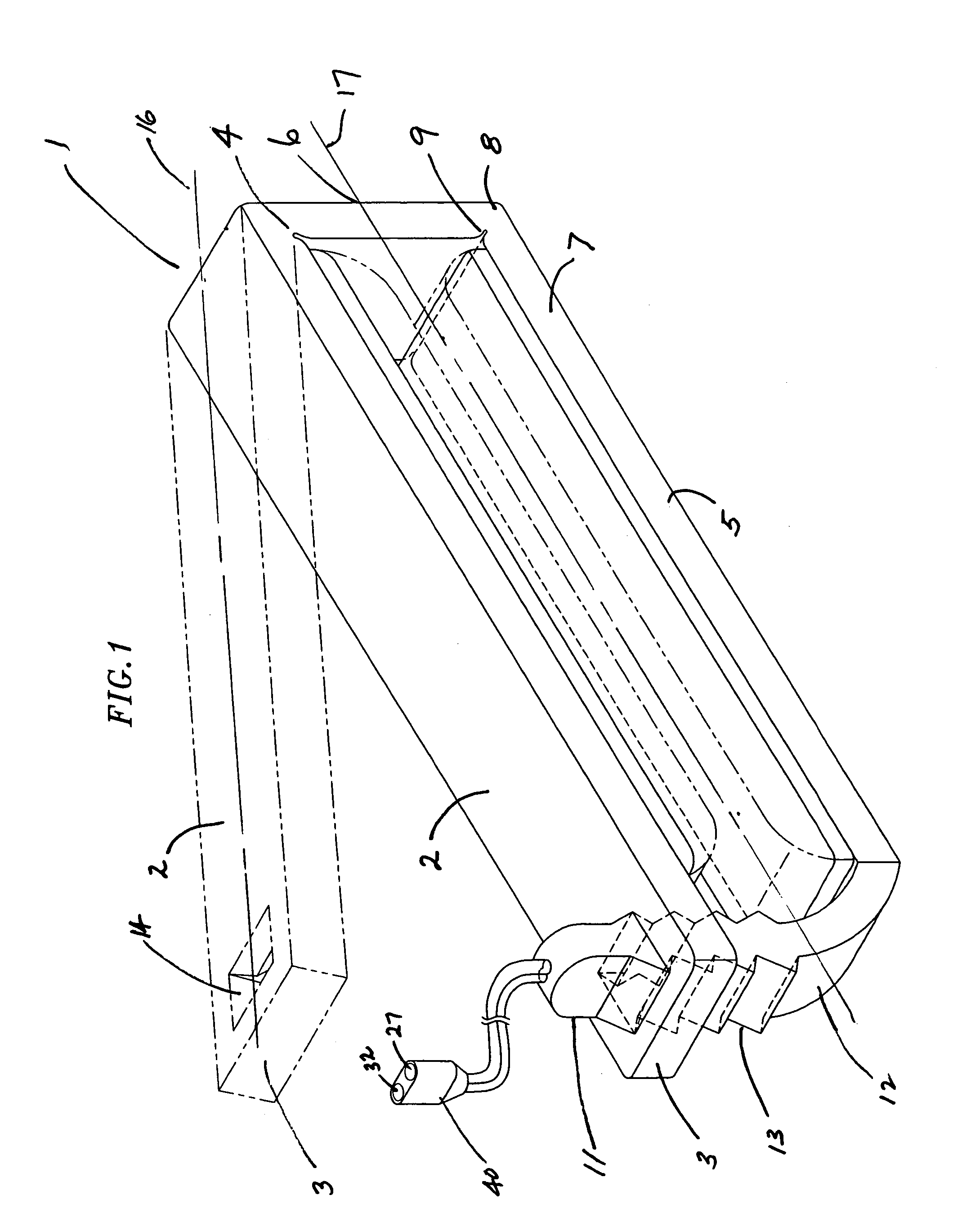

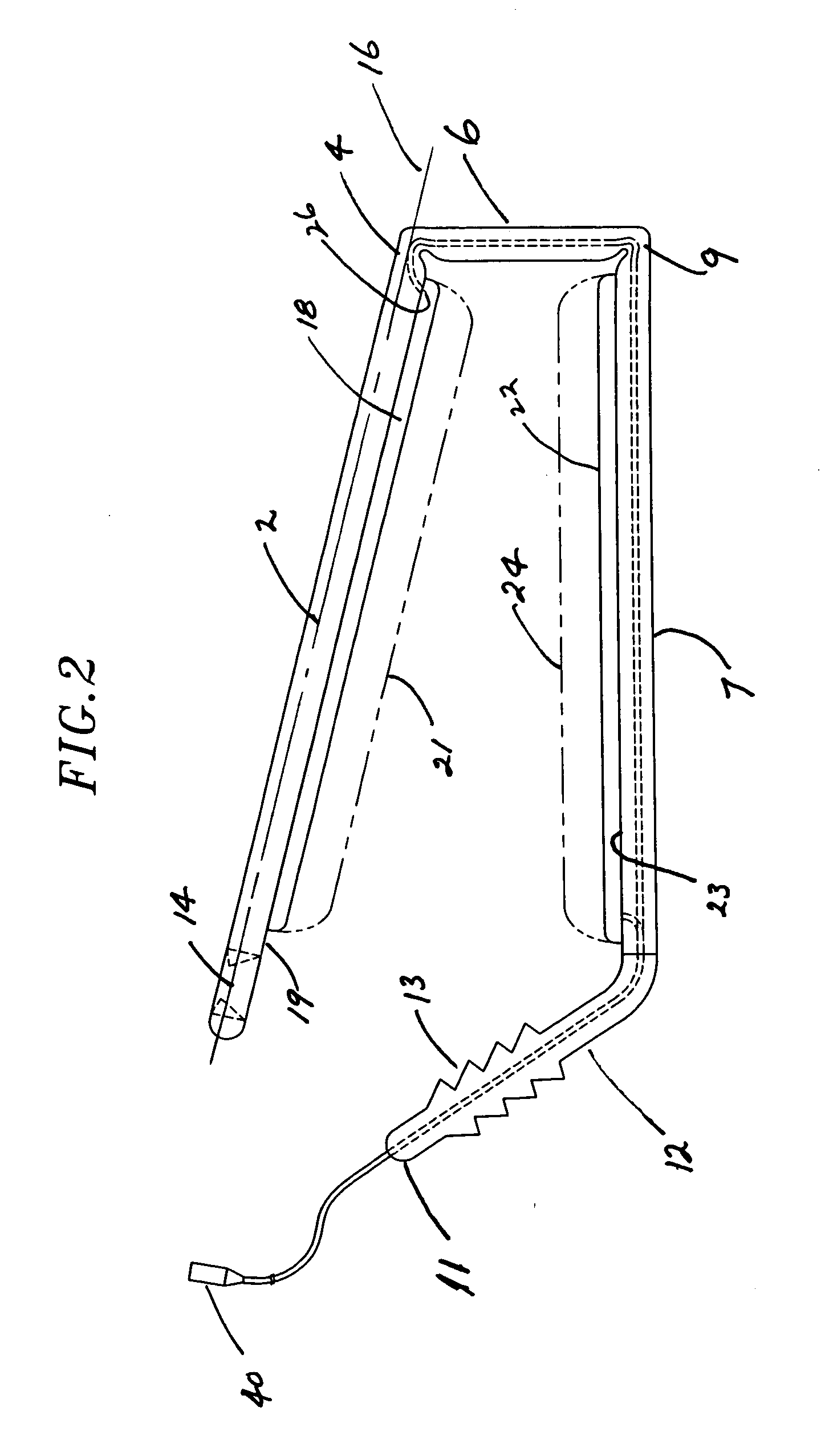

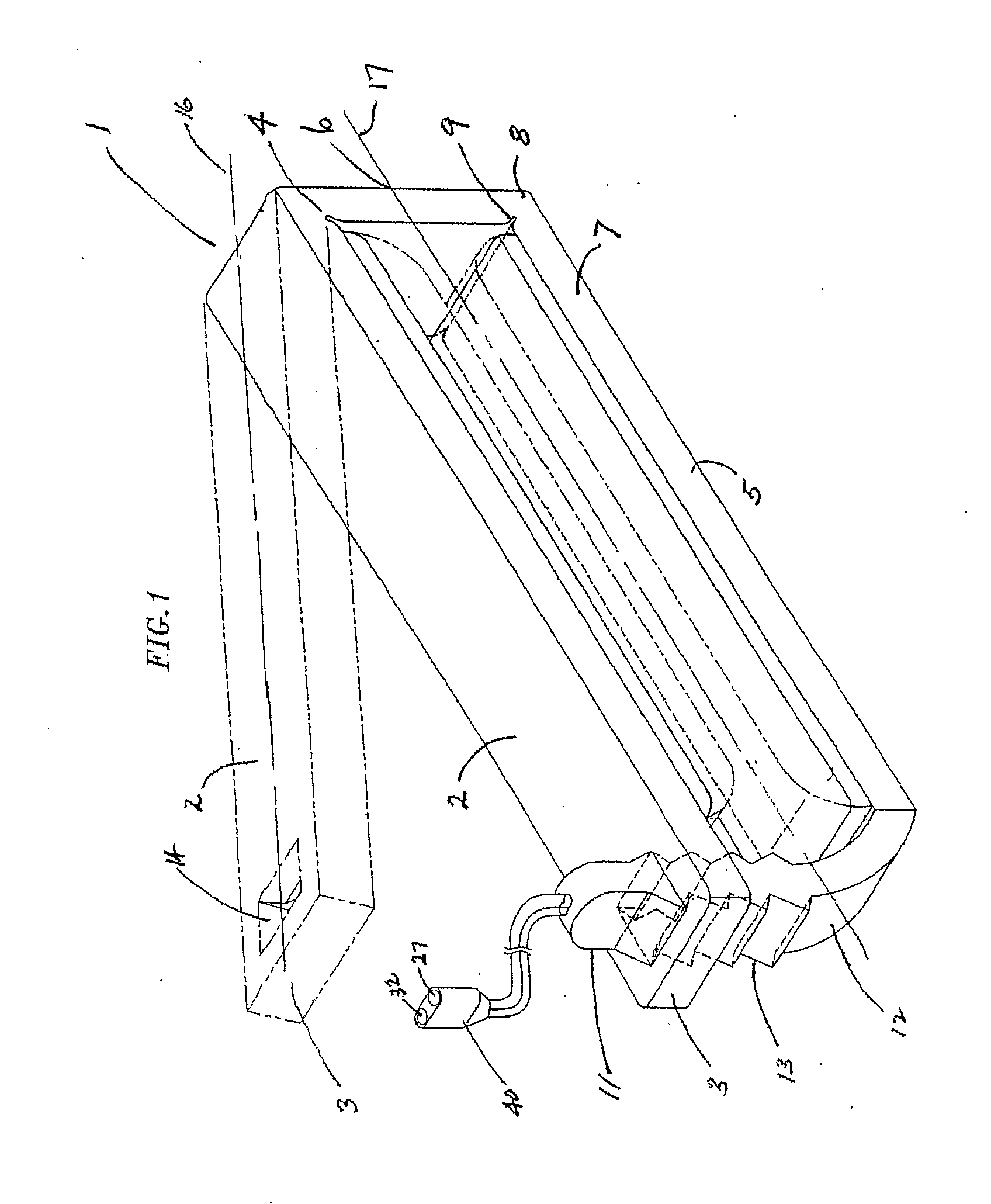

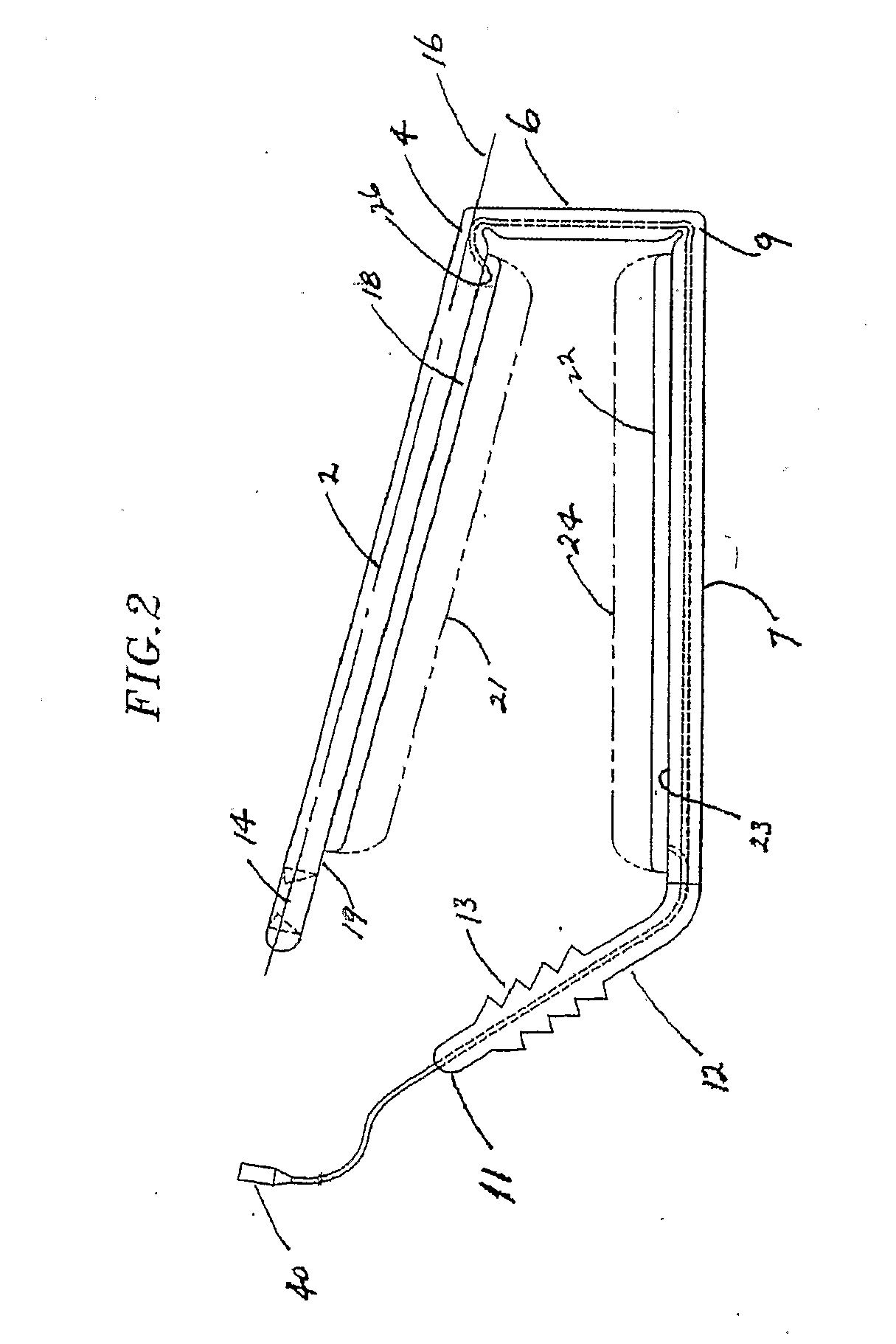

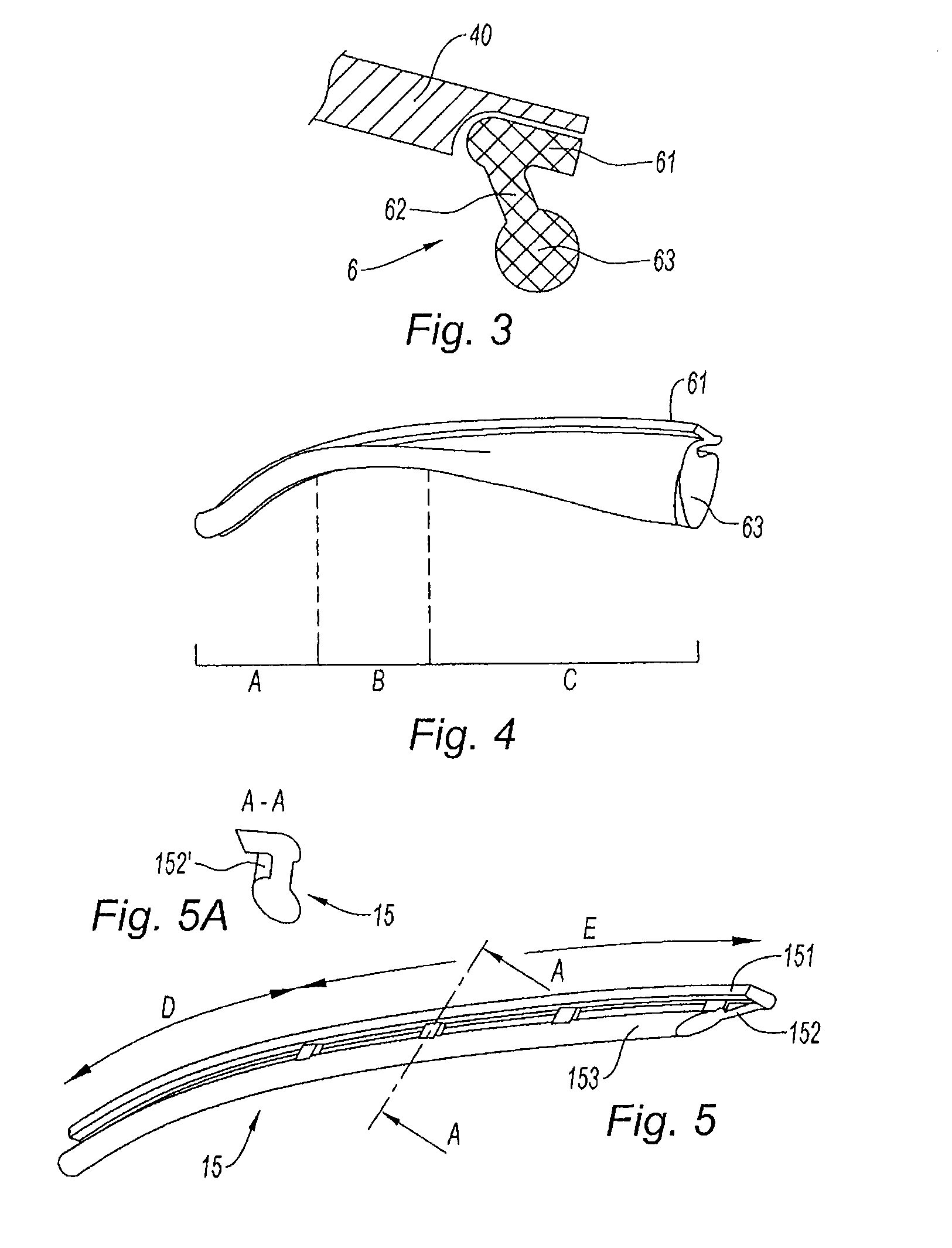

Clamp device to plicate the stomach

InactiveUS20070021761A1Reduce riskRigid enoughTubular organ implantsObesity treatmentStomach partStoma

A medical device for clamping the stomach in morbid obesity surgery consists of a silicone frame that is essentially U-shaped, having opposing legs self-hinged to a bight portion interconnecting the legs. The opposing legs have sufficient stiffness to permit limited bending and have inner surfaces that sealingly carry an inflatable balloon which can be selectively inflated or aspirated after the device has been clamped to the stomach to adjust the gastric restriction stoma. A flexible latch member carried by one of the legs has at least one serration which is inserted into a latch cavity of the opposing leg to lock the opposing legs in fixed spaced relationship. Lumens within the legs communicate with a fluid supply source and respective inflatable balloon for selective inflation or aspiration of the inflatable balloons.

Owner:PHILLIPS EDWARD H

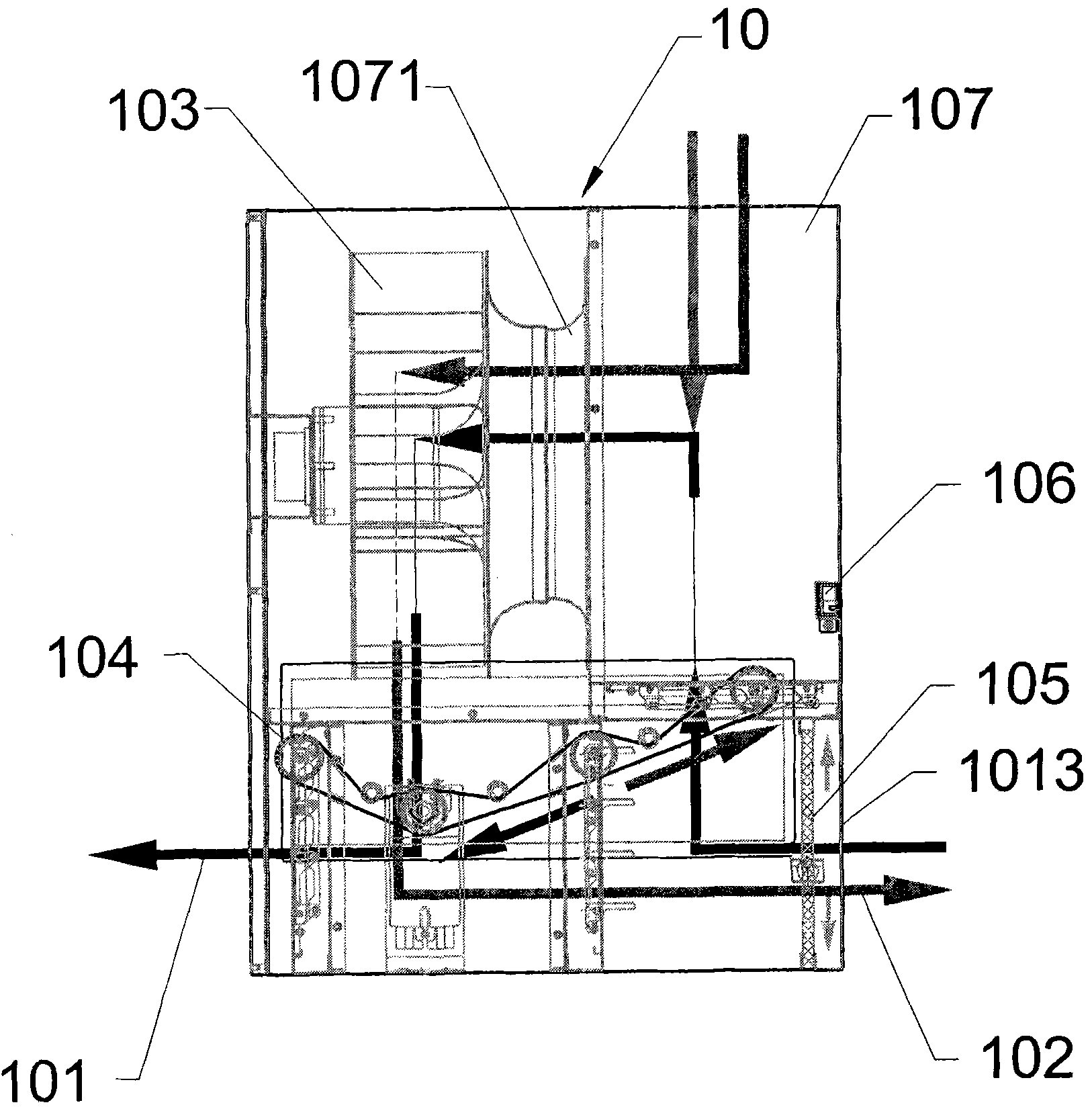

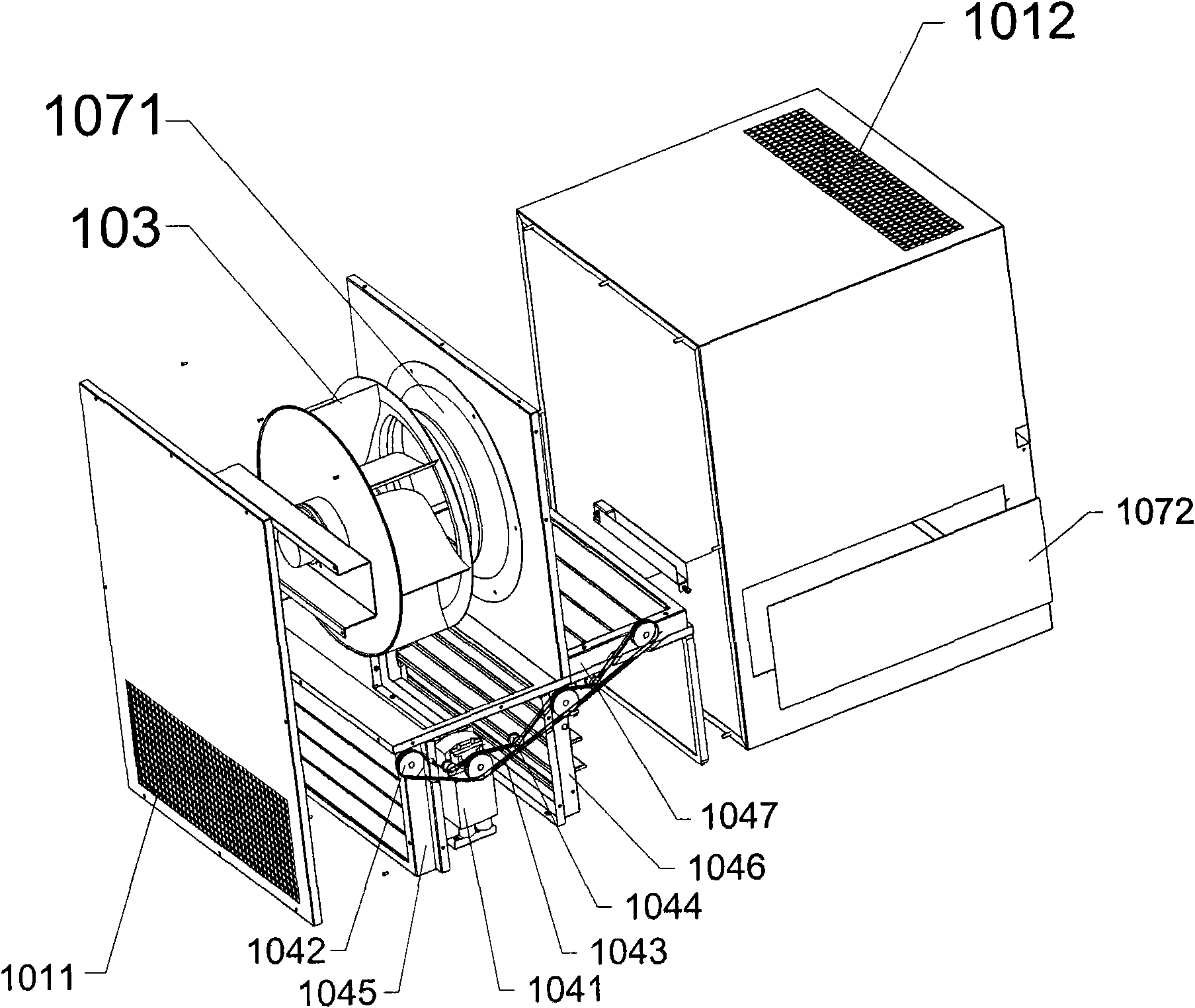

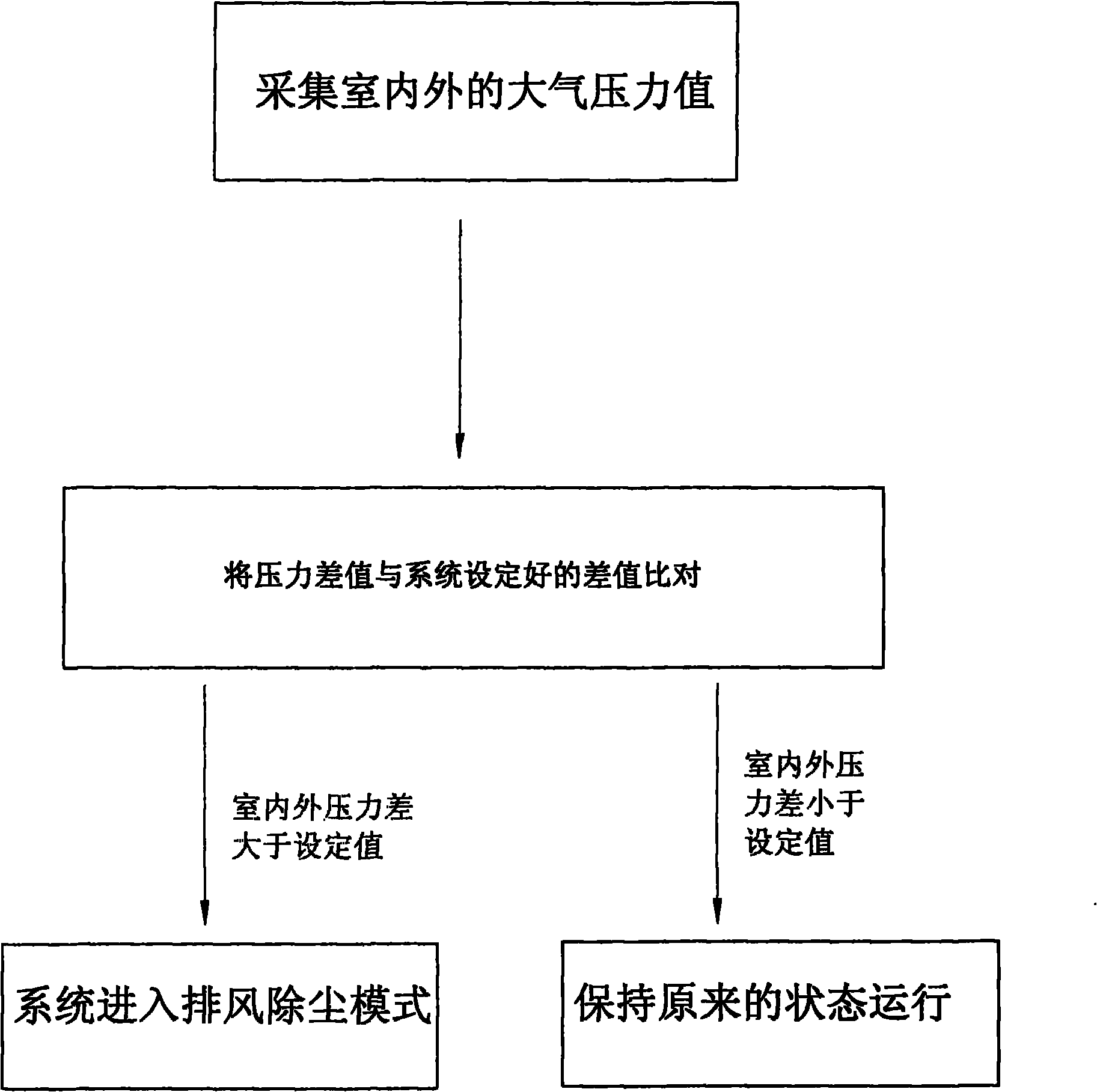

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

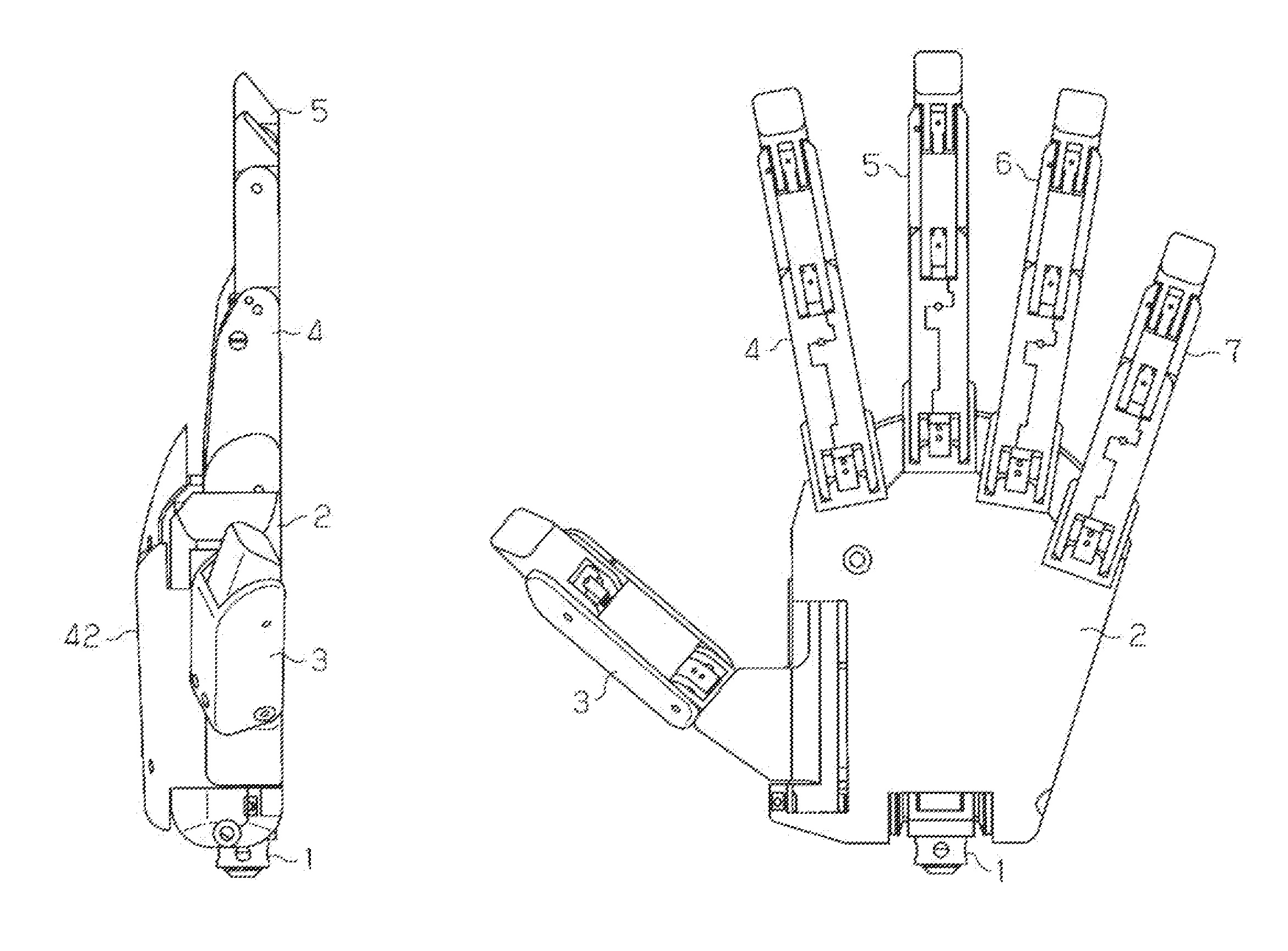

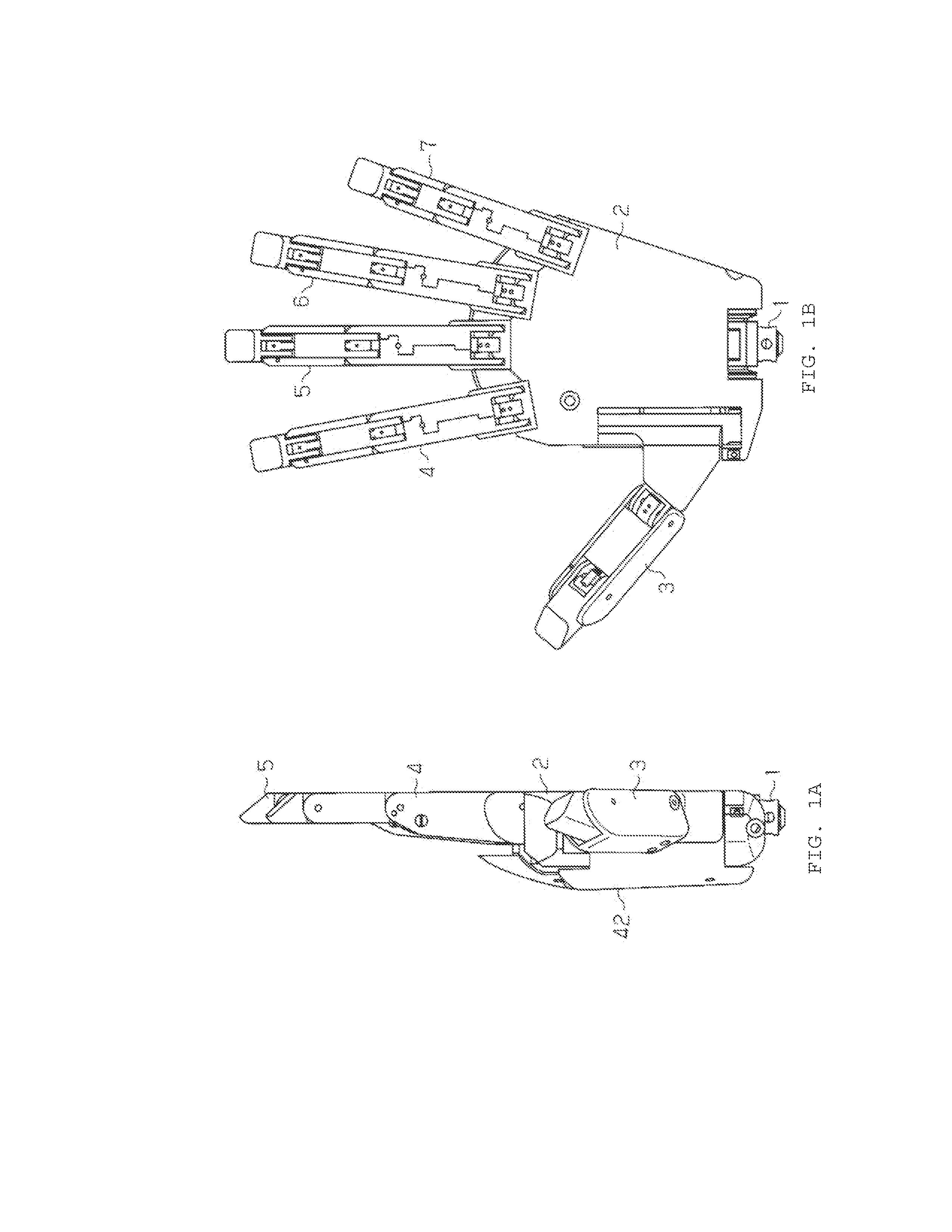

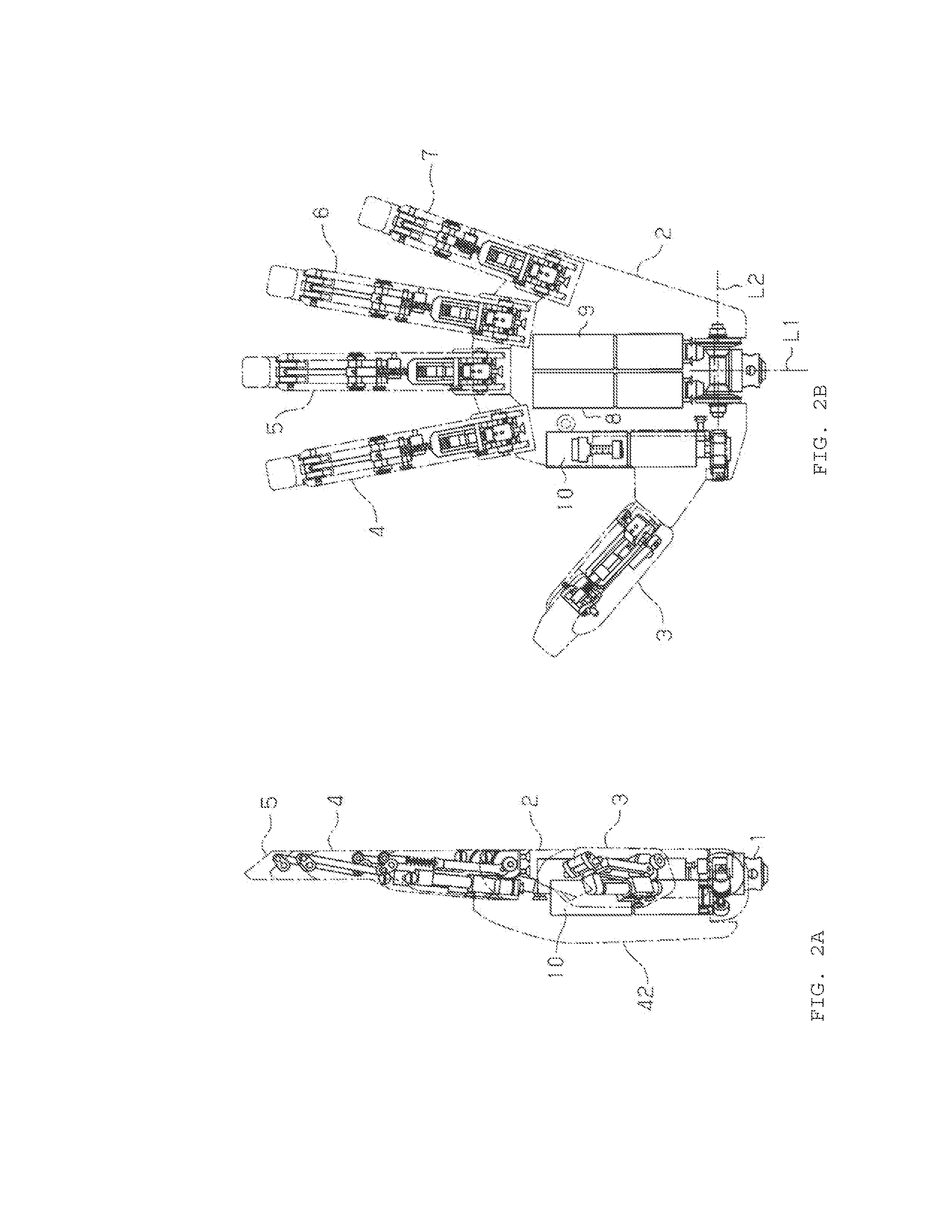

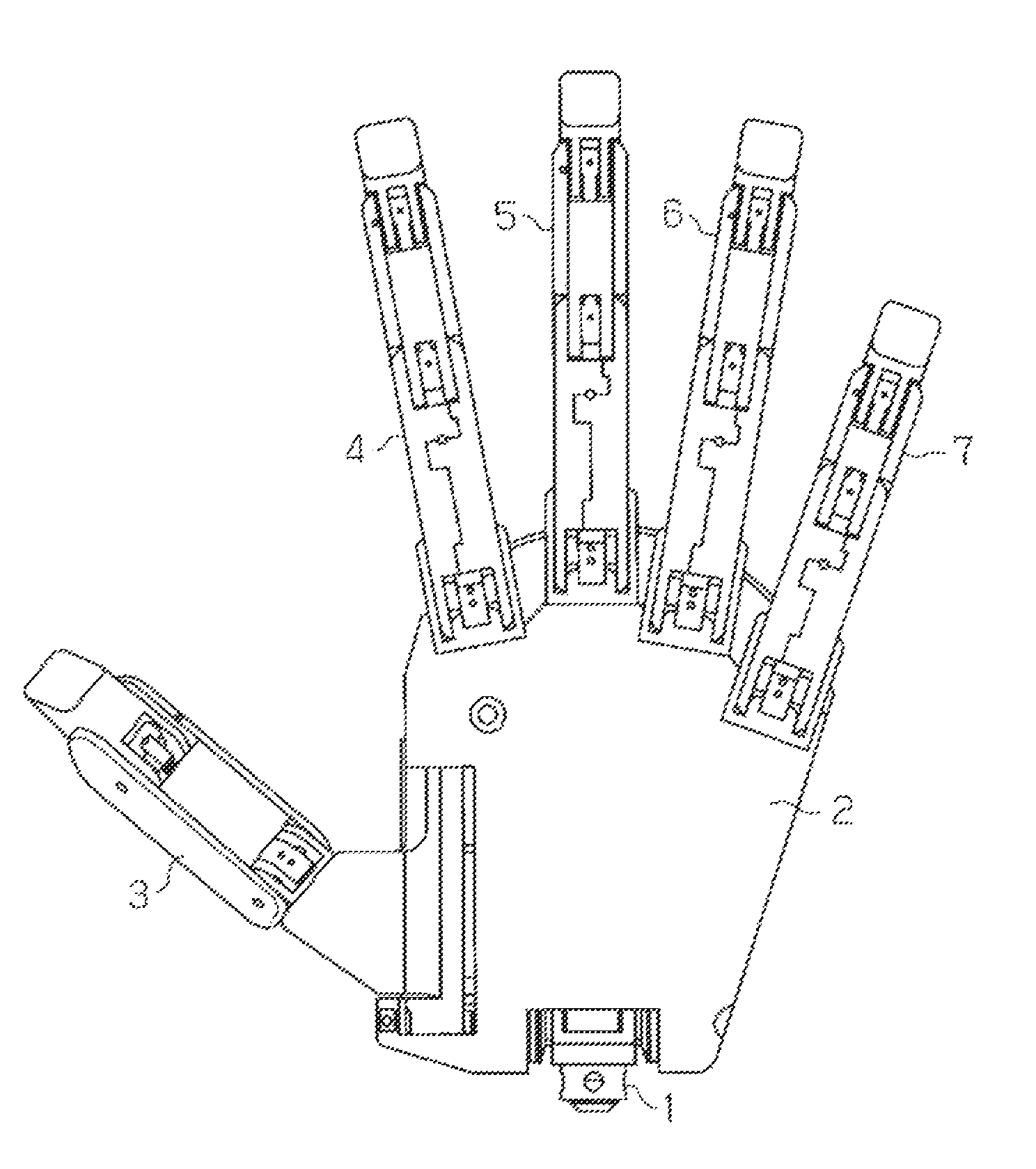

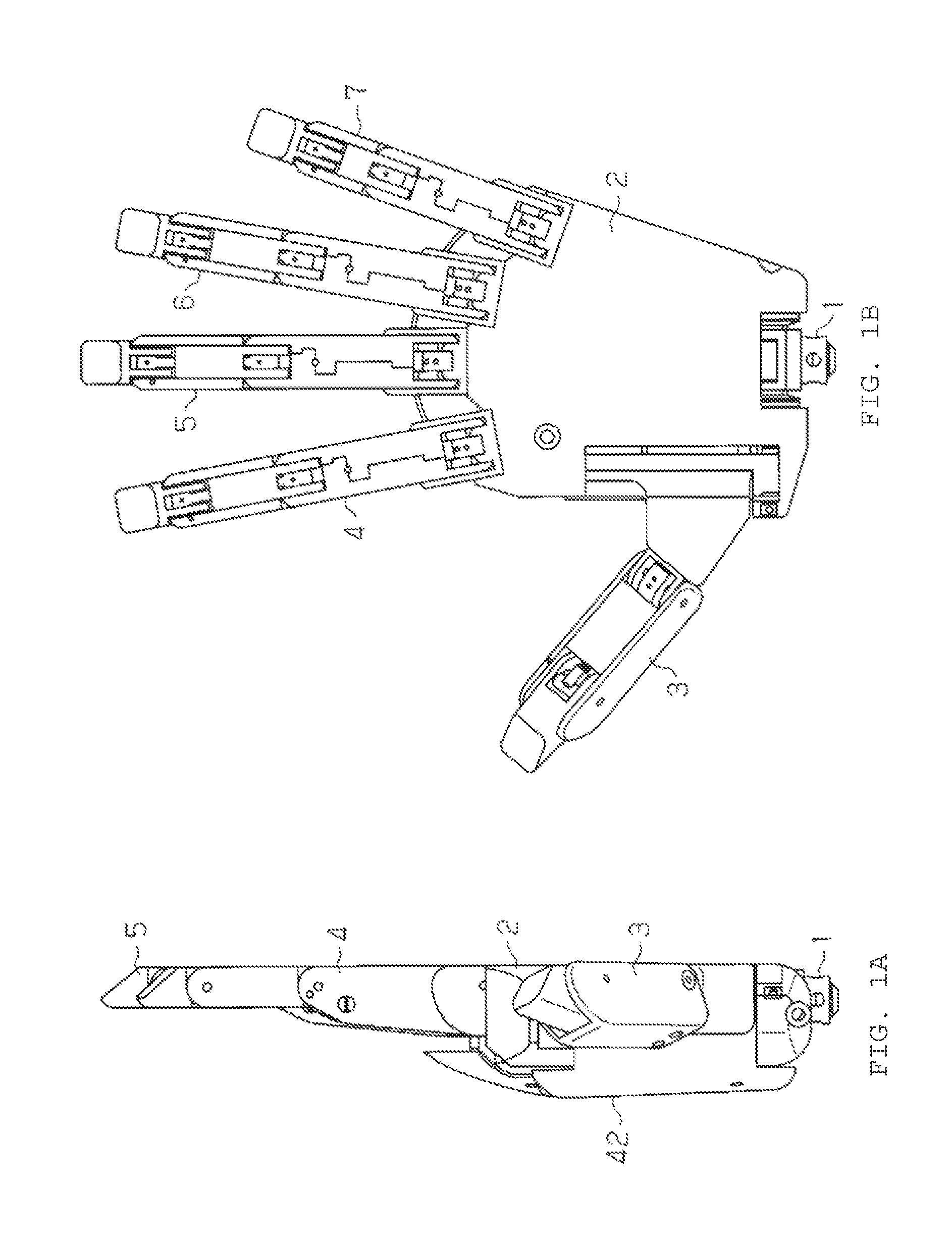

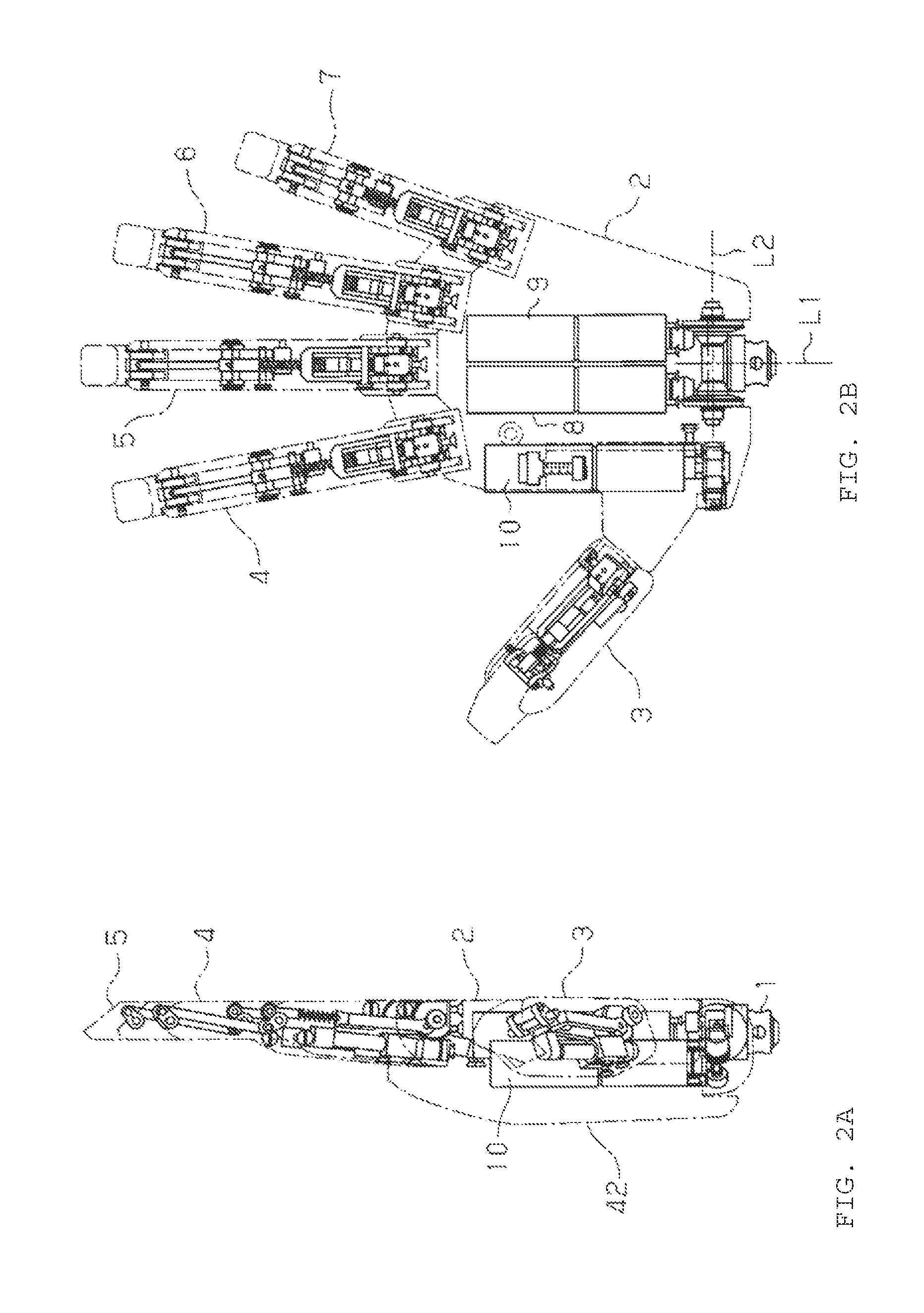

Humanoid electric hand

InactiveUS20130175816A1Easy maintenanceReduce weightGripping headsArtificial handsEngineeringSacroiliac joint

A humanoid electric hand includes a metacarpophalangeal joint and an interphalangeal joint. The interphalangeal joint bends or extends together with a bending or extending operation of the metacarpophalangeal joint, by linking a finger motor for driving a finger to a worm deceleration mechanism, an output gear of which moves rotationally to bend or extend the metacarpophalangeal joint, and by linking the metacarpophalangeal joint to the interphalangeal joint via a link mechanism.

Owner:GIFU UNIVERSITY +1

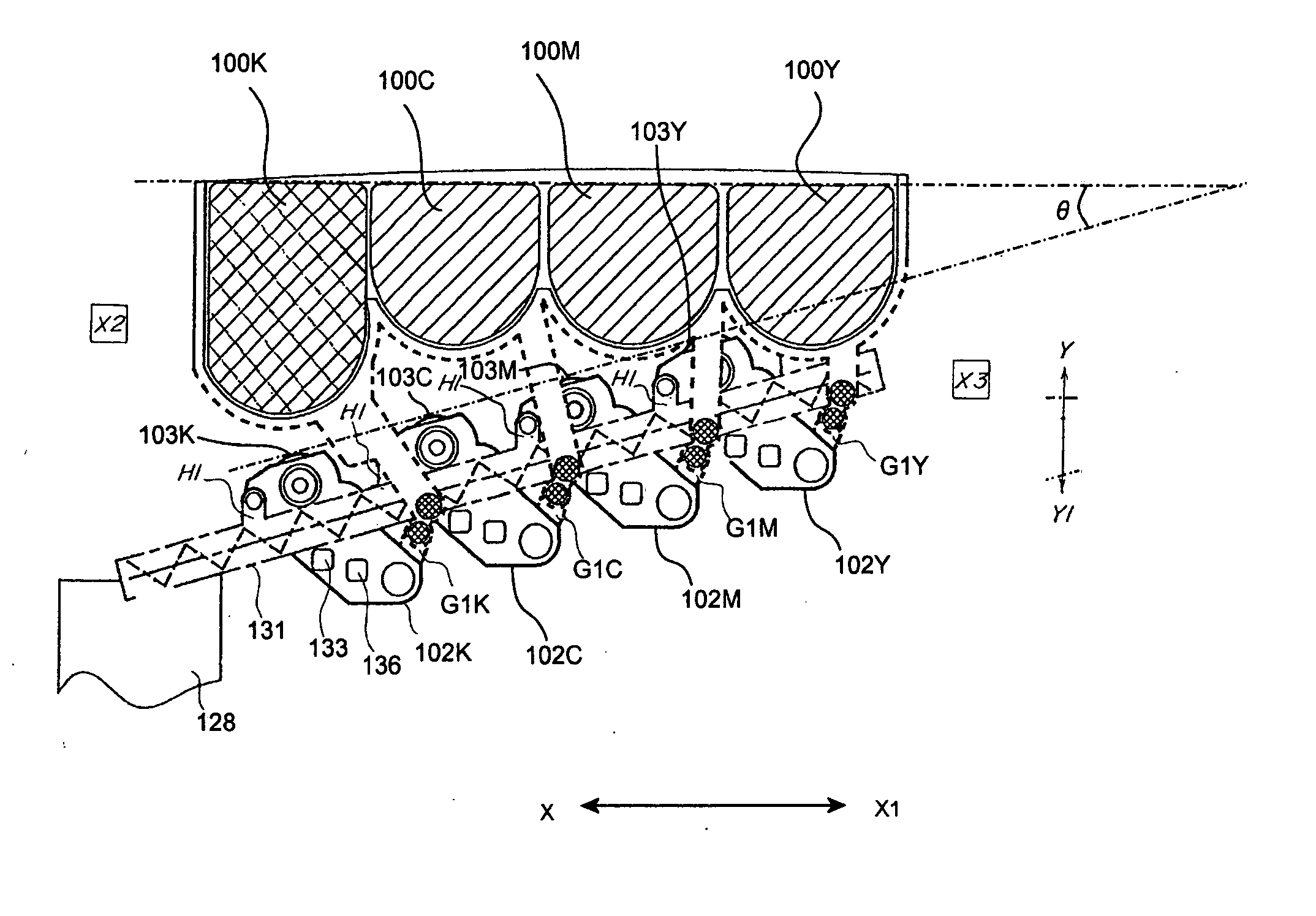

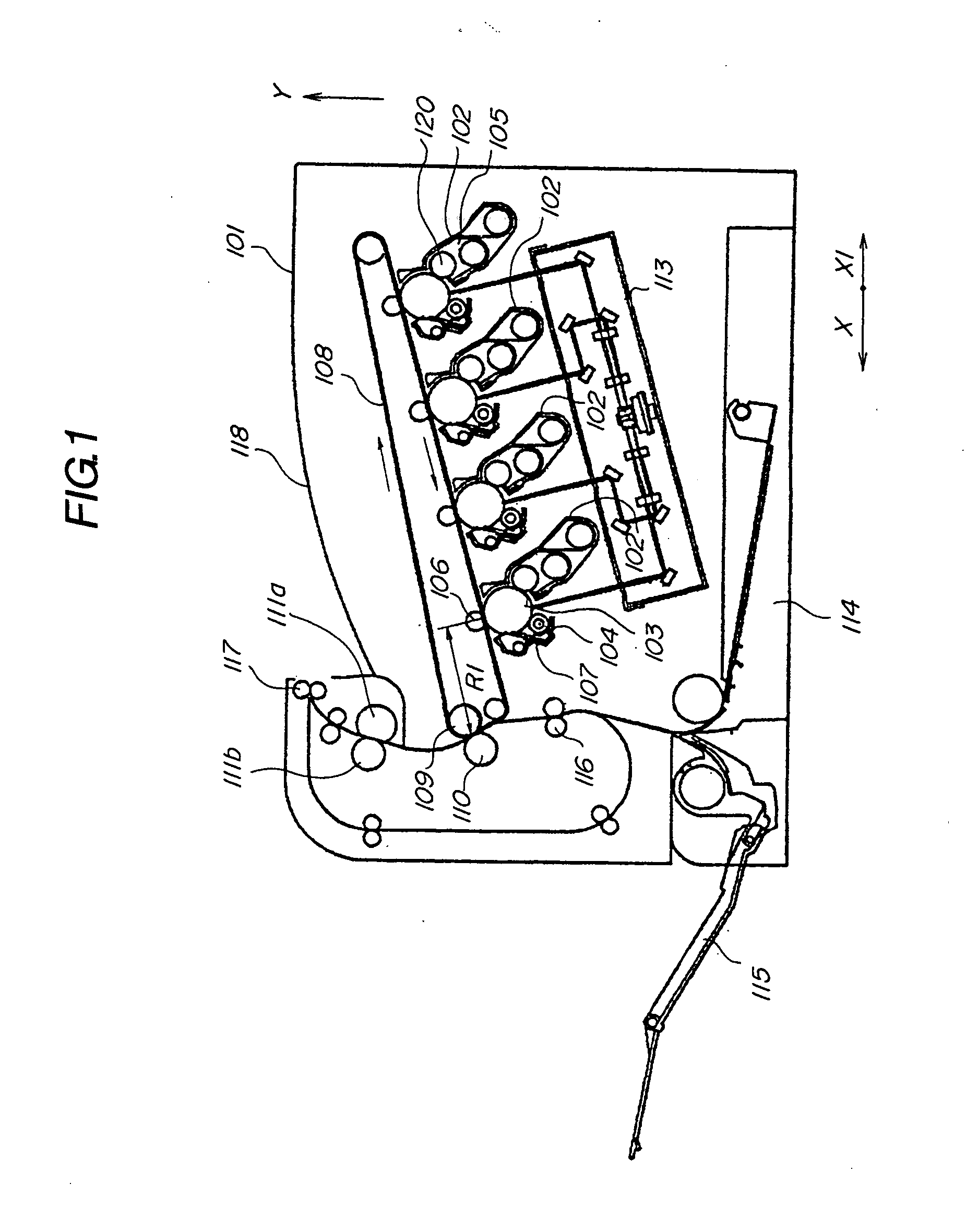

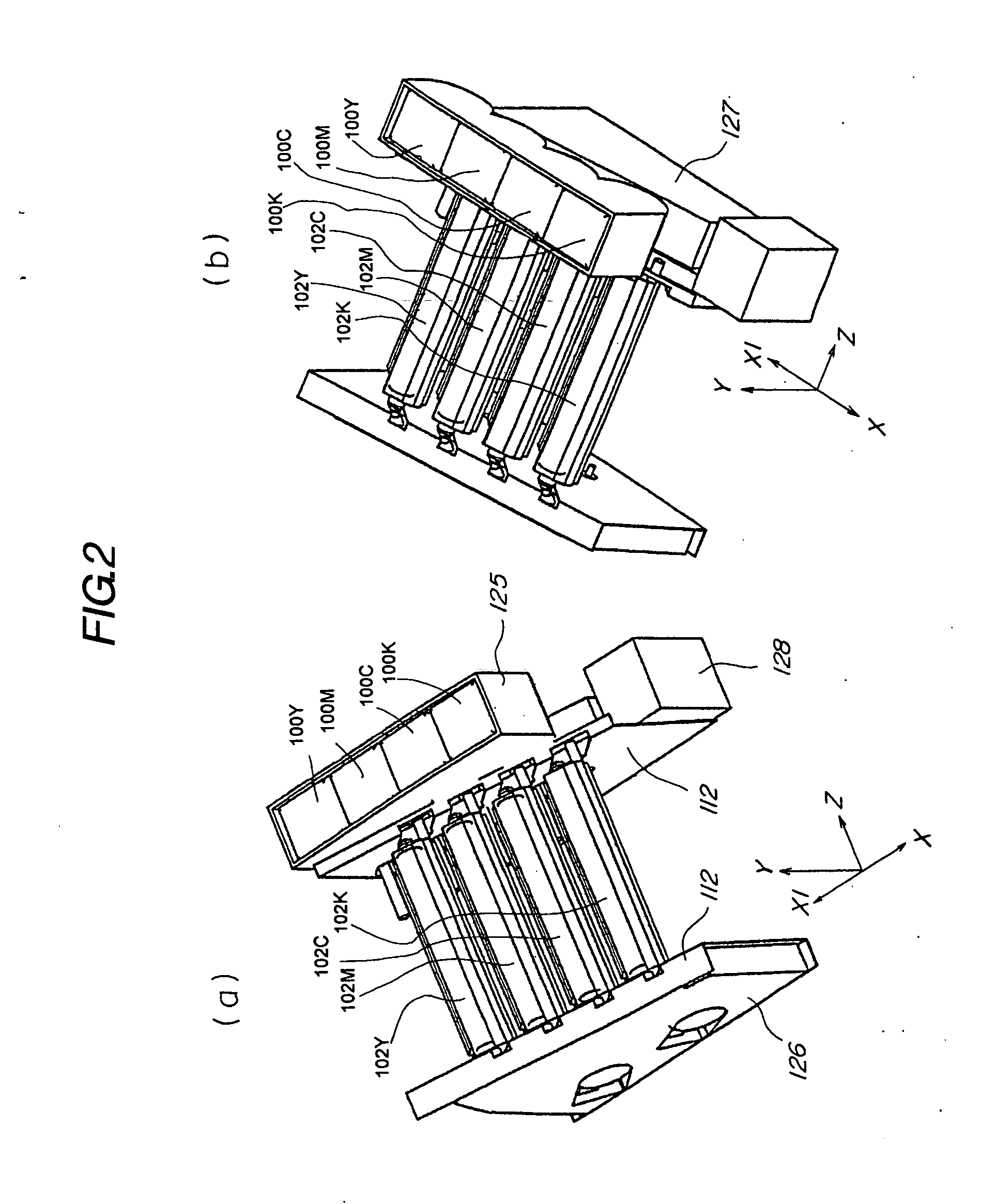

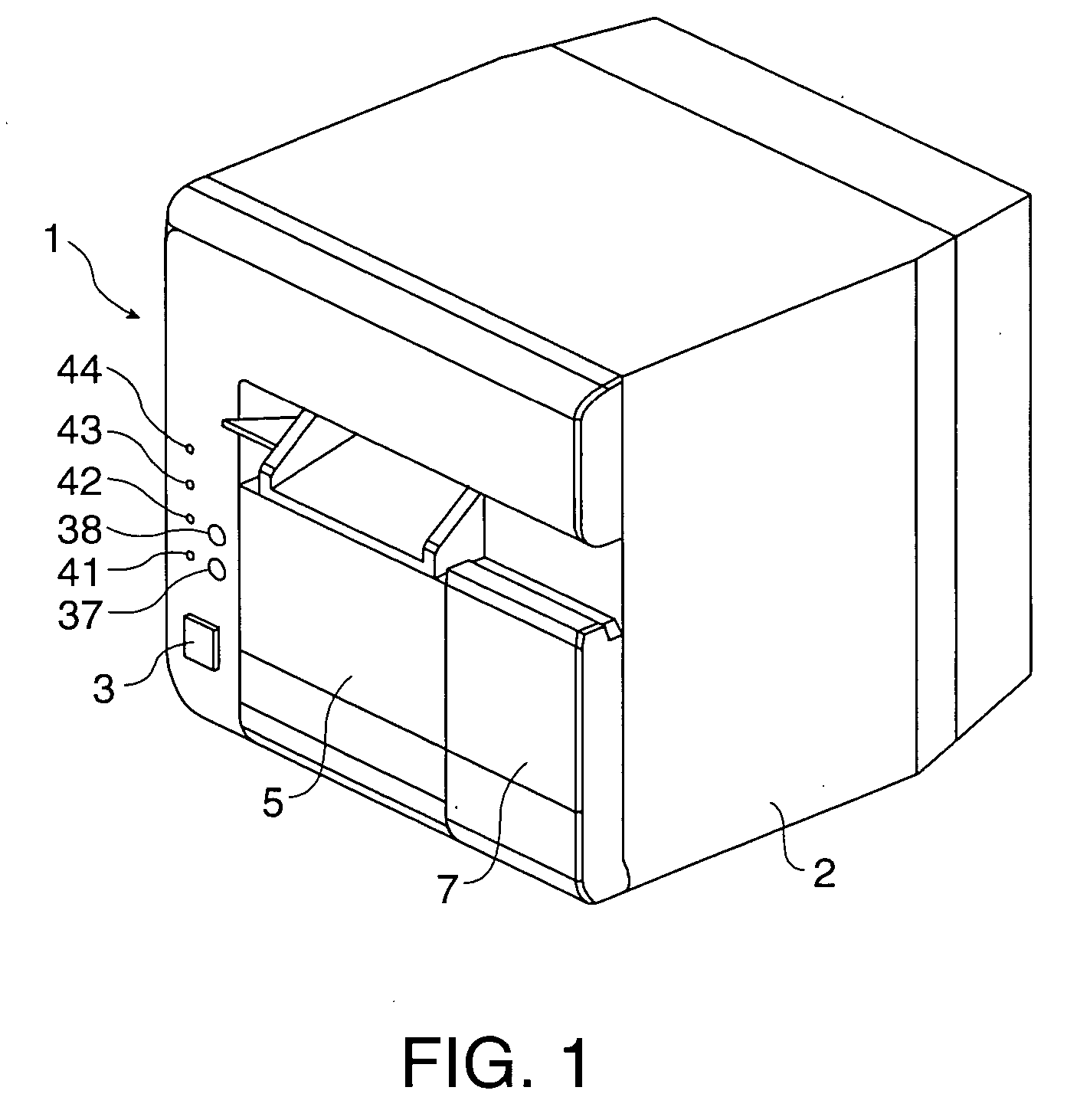

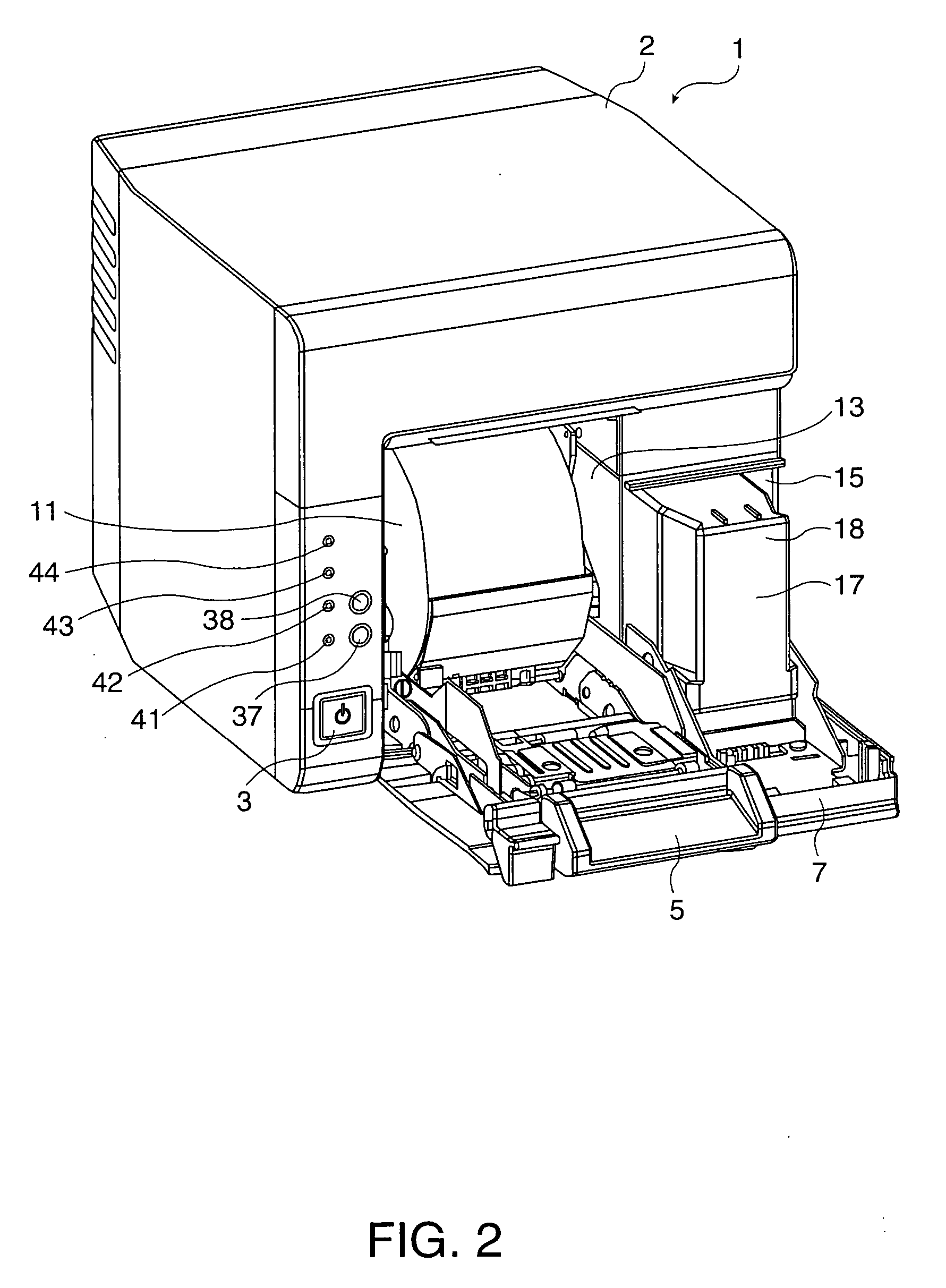

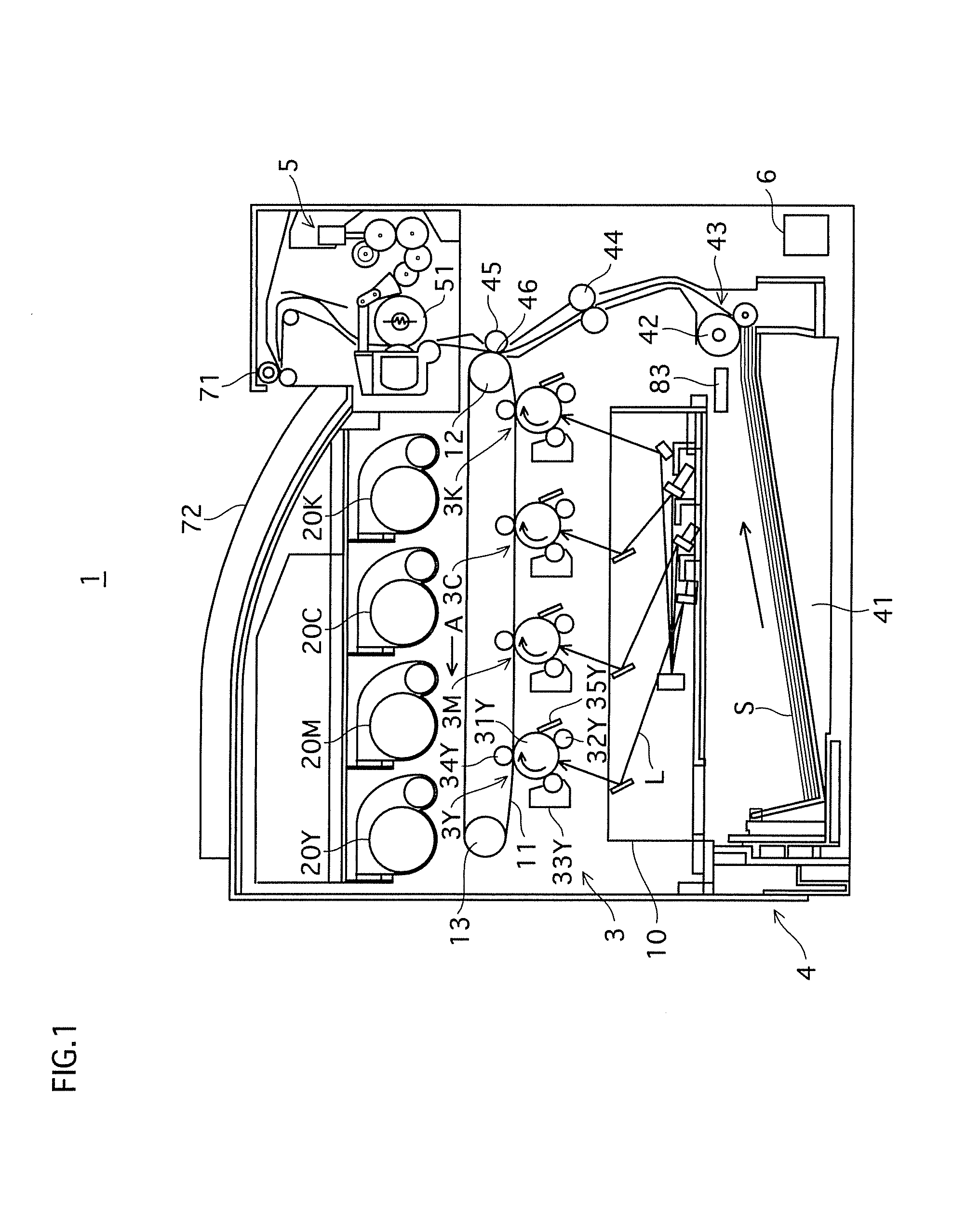

Image forming apparatus

InactiveUS20050281591A1Reduce replacement frequencyLow running costElectrographic process apparatusColor imageImage formation

An image forming apparatus includes a specific color image forming station for forming a black image and one or more non-specific color image forming stations for forming images of colors other than black, the photosensitive drum of the specific color image forming station is located vertically downward of the photosensitive drums of the non-specific color image forming stations, and the capacity of the black toner cartridge of the specific color image forming station is made larger than those of the toner cartridges of the non-specific color image forming stations. With this arrangement, the frequency of replacement of the black toner cartridge can be reduced without adversely affecting the size of an apparatus main body.

Owner:CANON KK

Clamp Device to Plicate the Stomach

Owner:PHILLIPS EDWARD H

Humanoid electric hand

InactiveUS8747486B2Reduce weightEasy maintenanceGripping headsArtificial handsEngineeringSacroiliac joint

Owner:GIFU UNIVERSITY +1

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

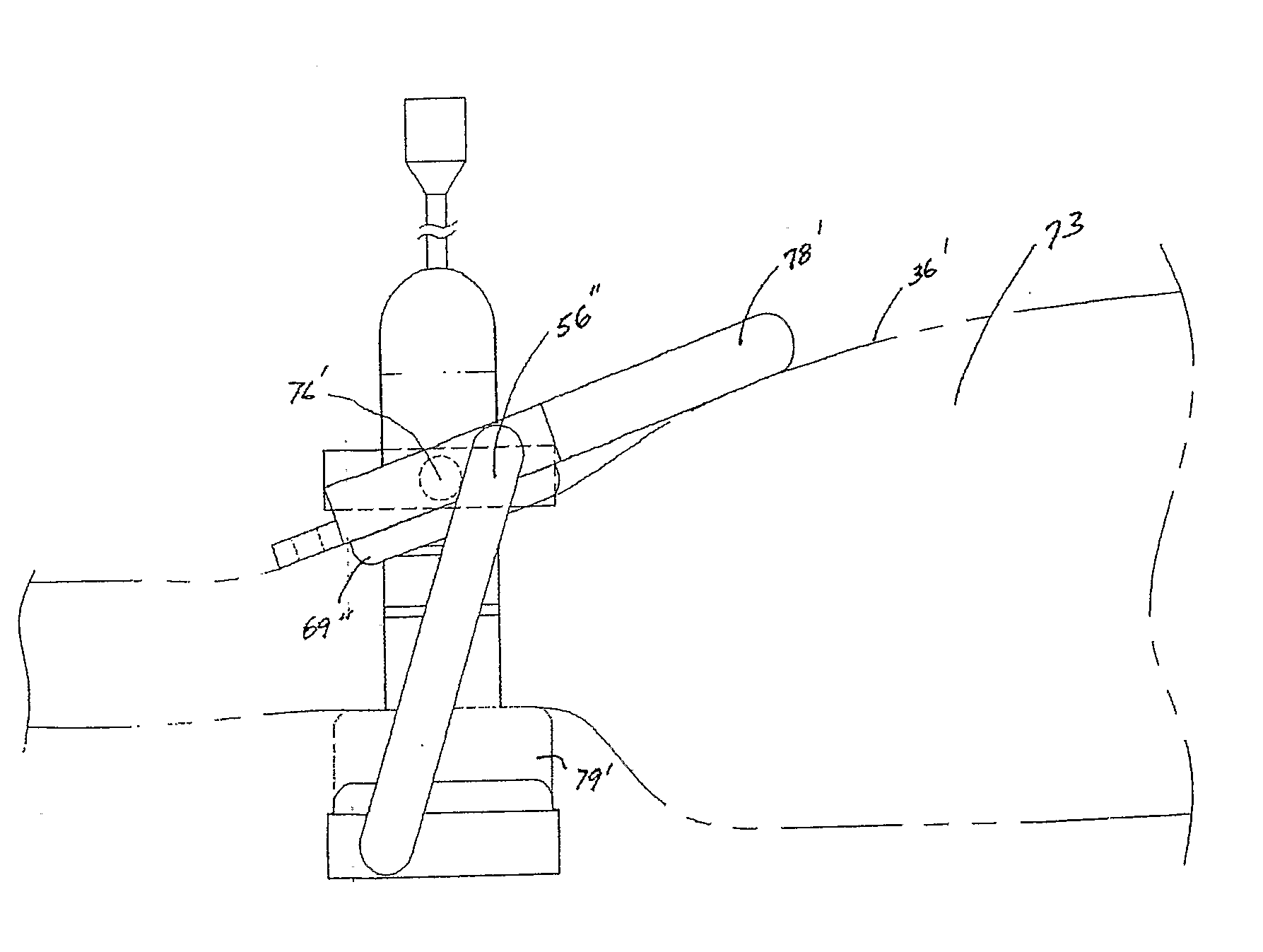

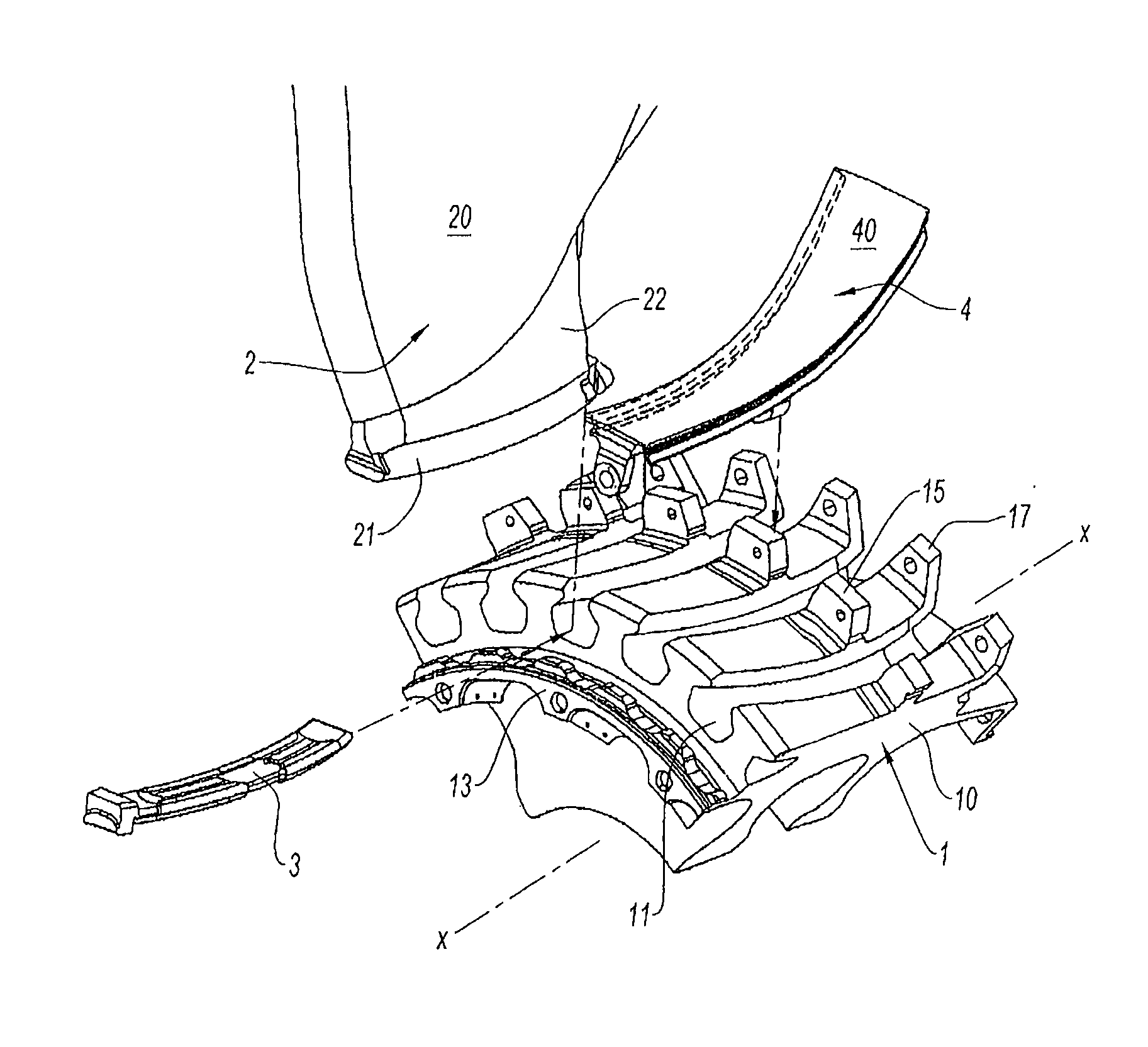

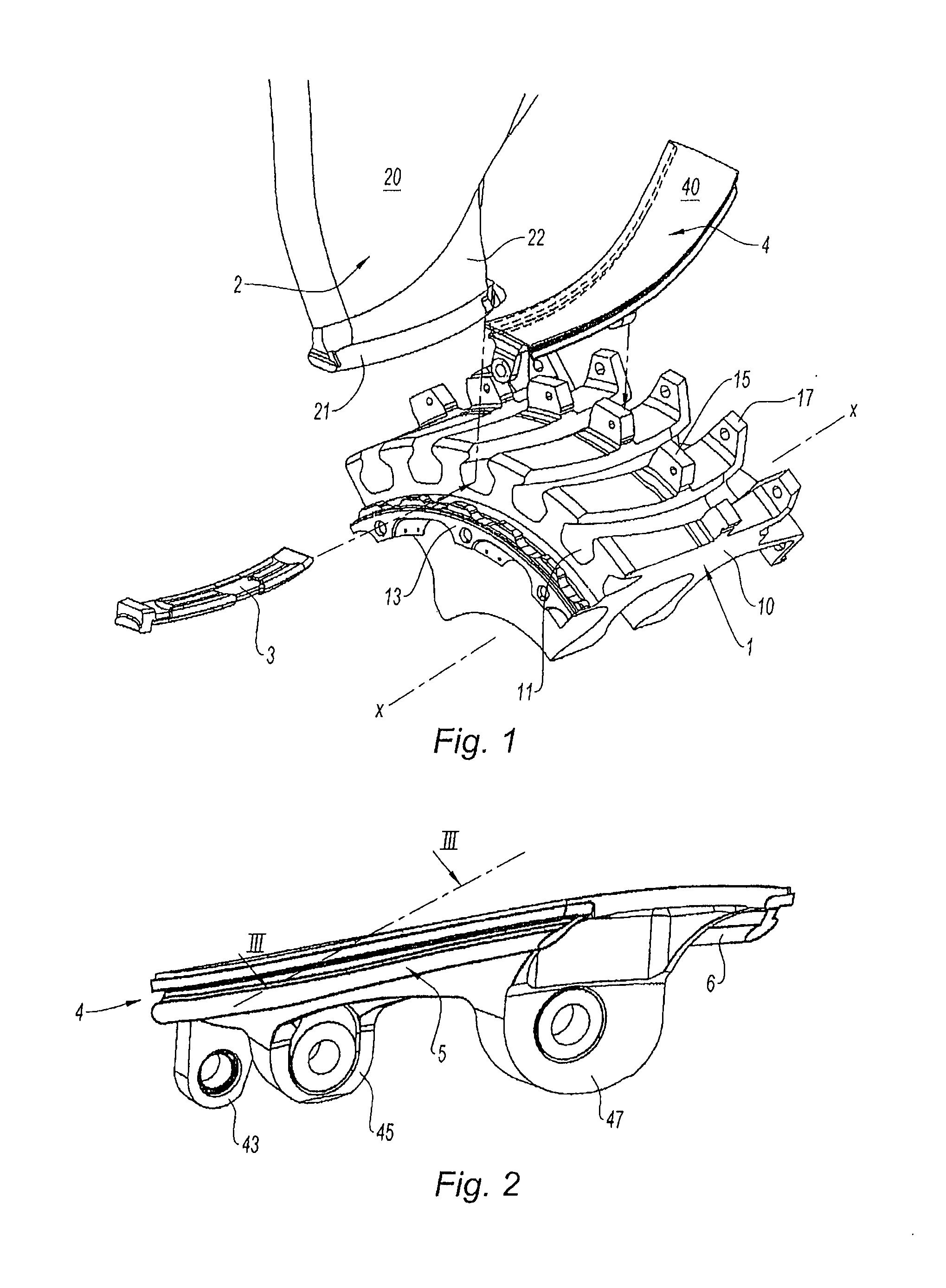

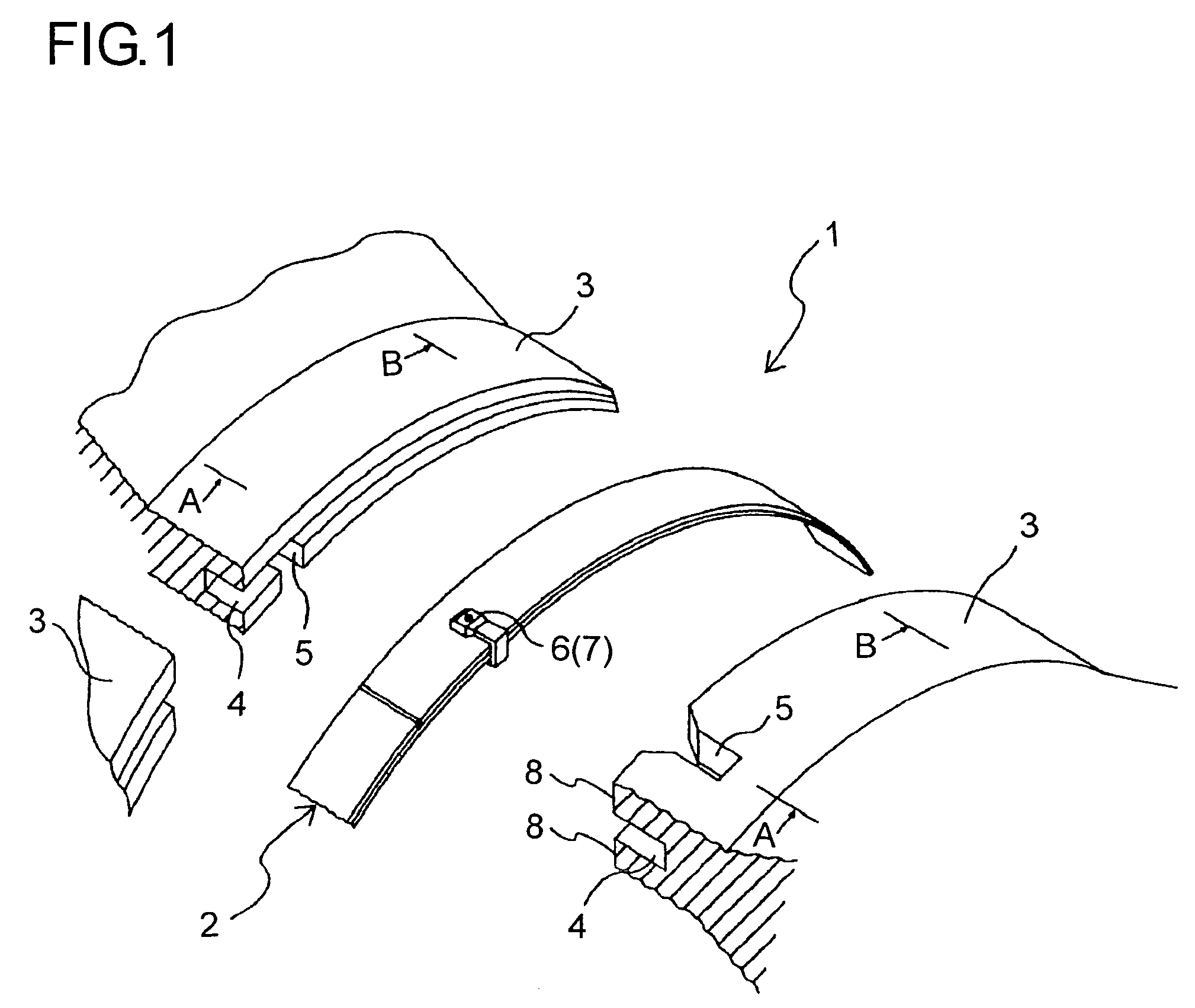

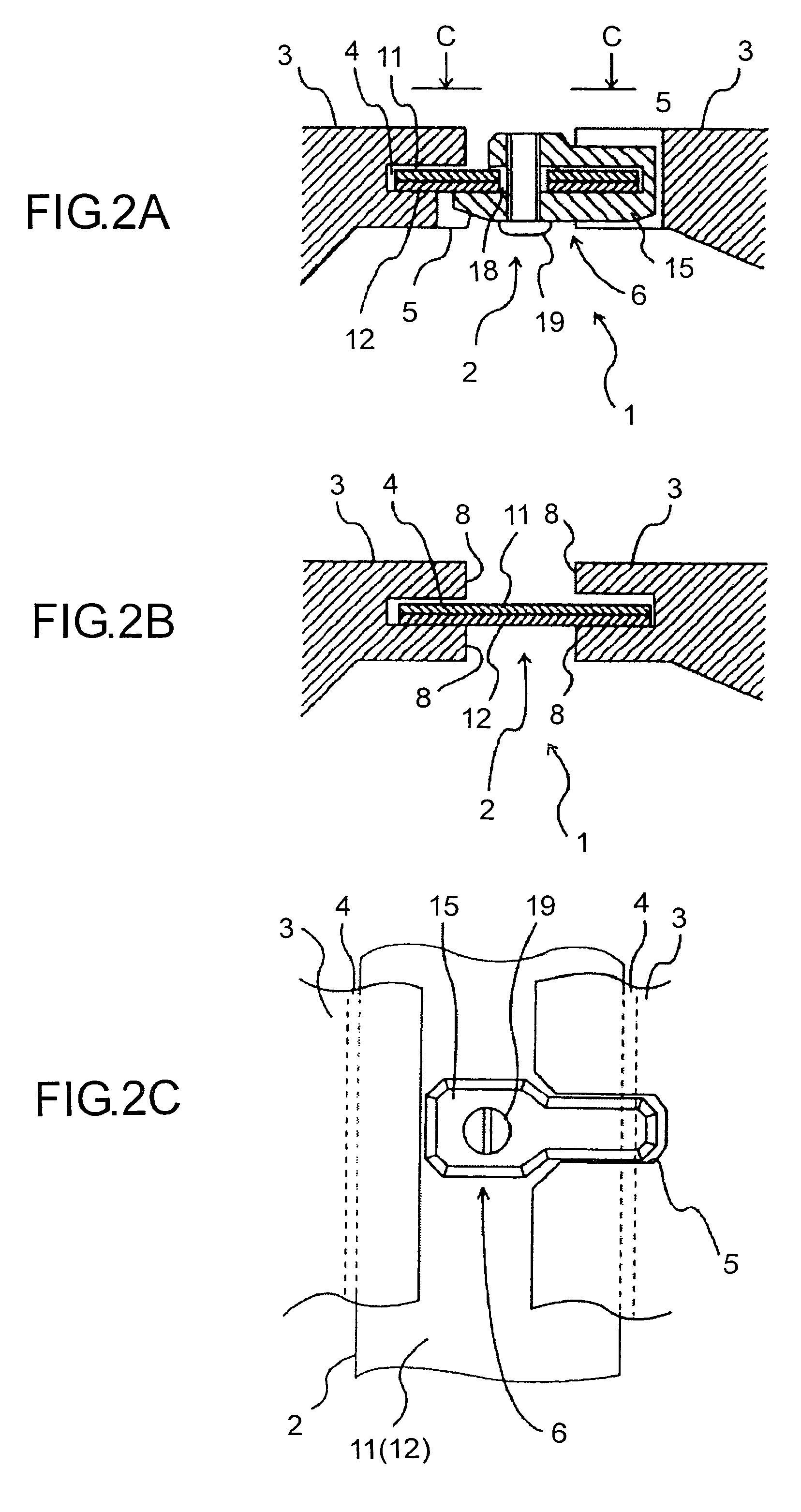

Platform seal in a turbomachine rotor, method for improving the seal between a platform and a turbomachine blade

ActiveUS20100150724A1Increase productionReduce replacement frequencyPropellersPump componentsElastomerEngineering

An elastomer material seal for an interleaved platform between two adjacent blades in a turbomachine rotor is disclosed. The seal is of elongate shape and includes transversely a contact part, an attachment part, and a flexible part between the attachment part and the contact part. The seal is noteworthy in that it further includes a local reinforcement of the flexible part, to avoid the tearing that would result from centrifugal forces on the seal. The local reinforcement of the flexible part includes at least one transverse rib on the flexible part.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

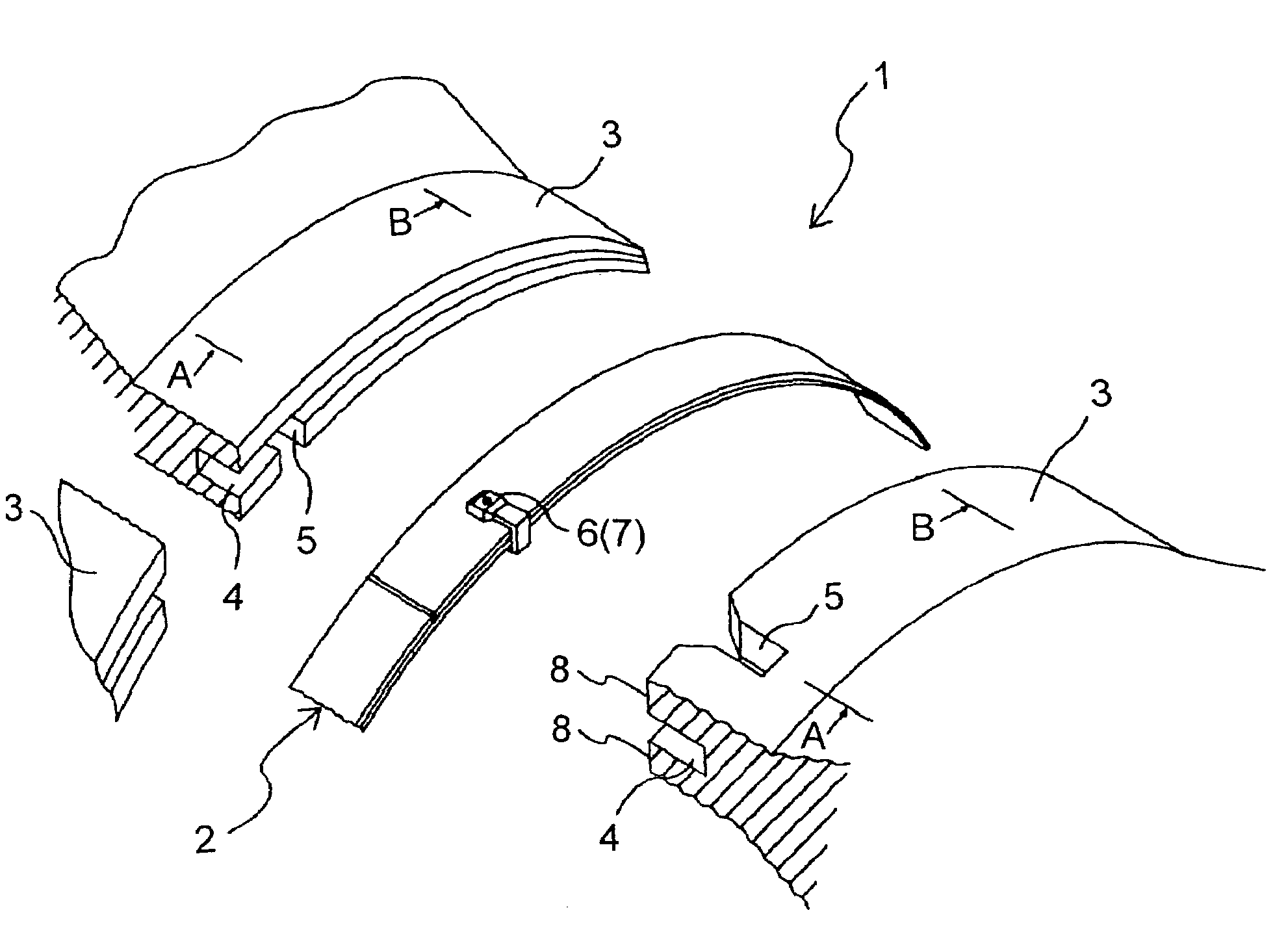

Gas turbine having a sealing structure

ActiveUS7549845B2Reduce replacement frequencyEasy to replacePropellersPump componentsEngineeringGas turbines

Owner:MITSUBISHI POWER LTD

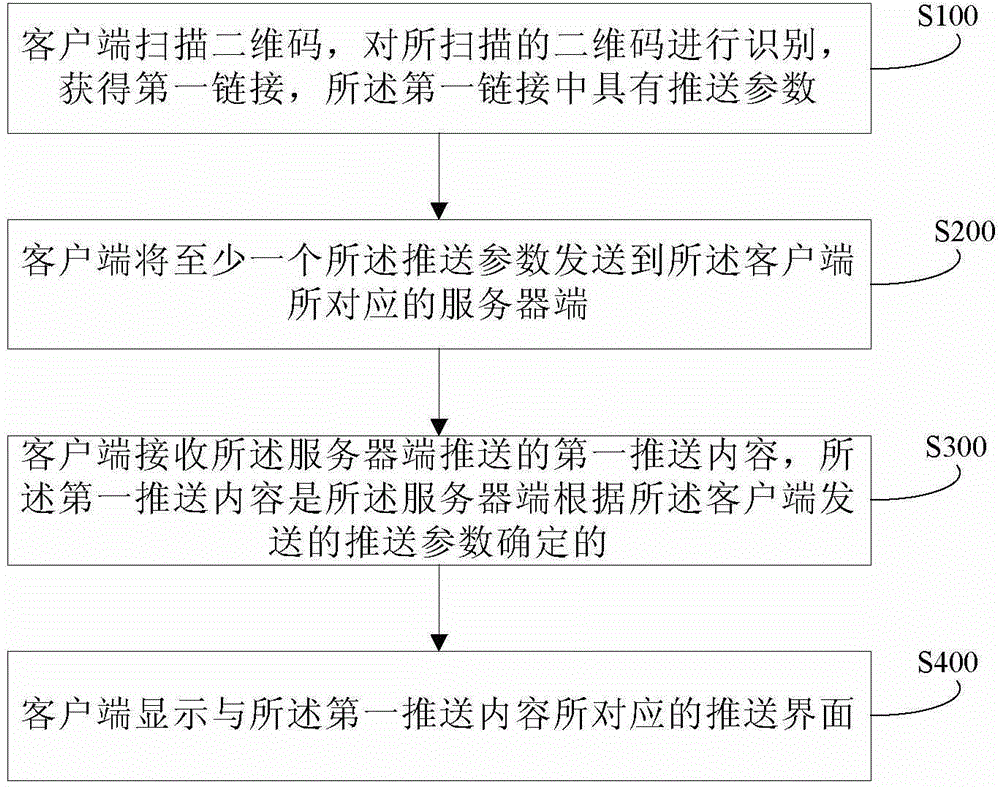

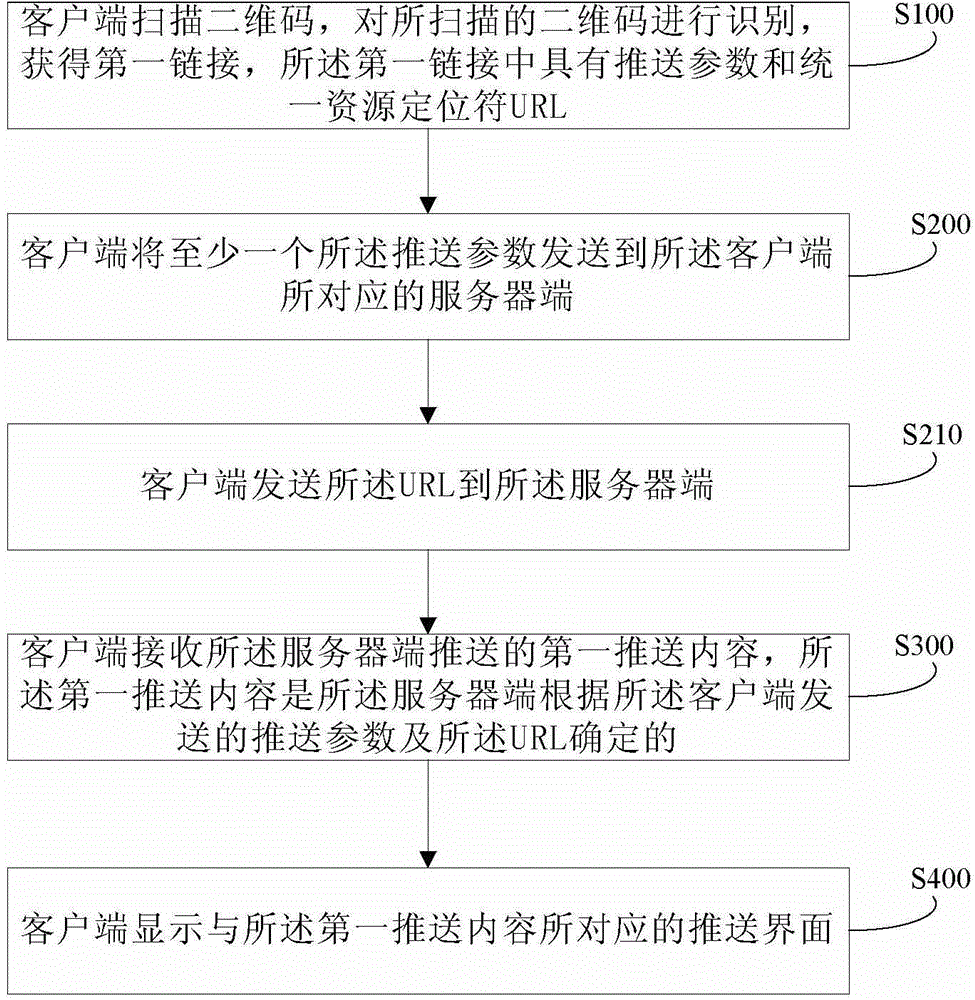

Two-dimension code processing method, client side, electronic equipment, server side and server

ActiveCN104660620AReduce the use of distinctionReduce replacement frequencyTransmissionSpecial data processing applicationsClient-sideServer-side

The embodiment of the invention provides a two-dimension code processing method, a client side, electronic equipment, a server side and a server. Website information is added into a prepared two-dimension code, and furthermore, push parameters are also increased. After different equipment scan the two-dimension code, the push parameters are sent to the server side. According to different push parameters, the server side judges and pushes different to-be-pushed content to the equipment, so that different equipment or software can acquire different information by scanning the same two-dimension code at different time.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD +1

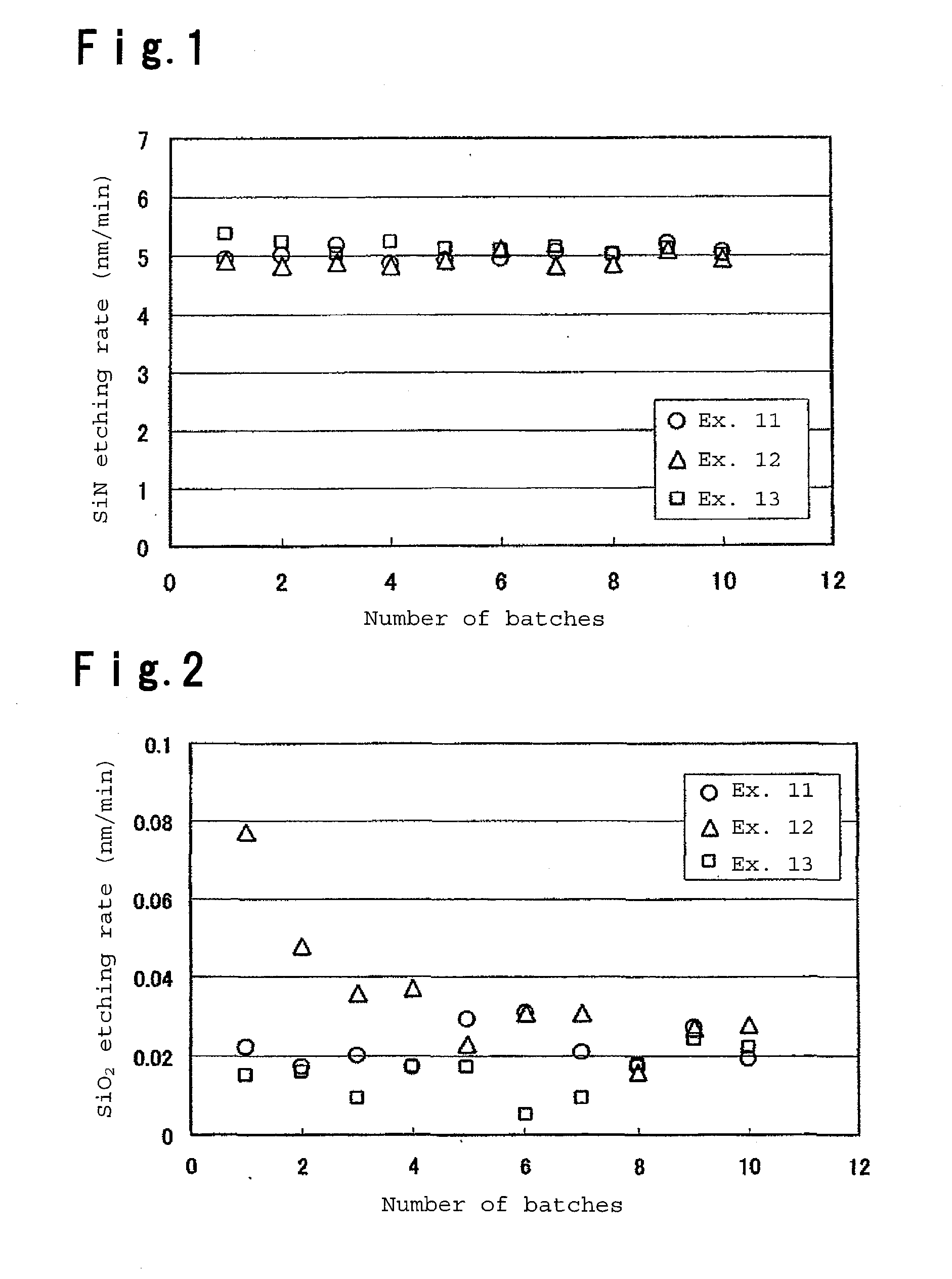

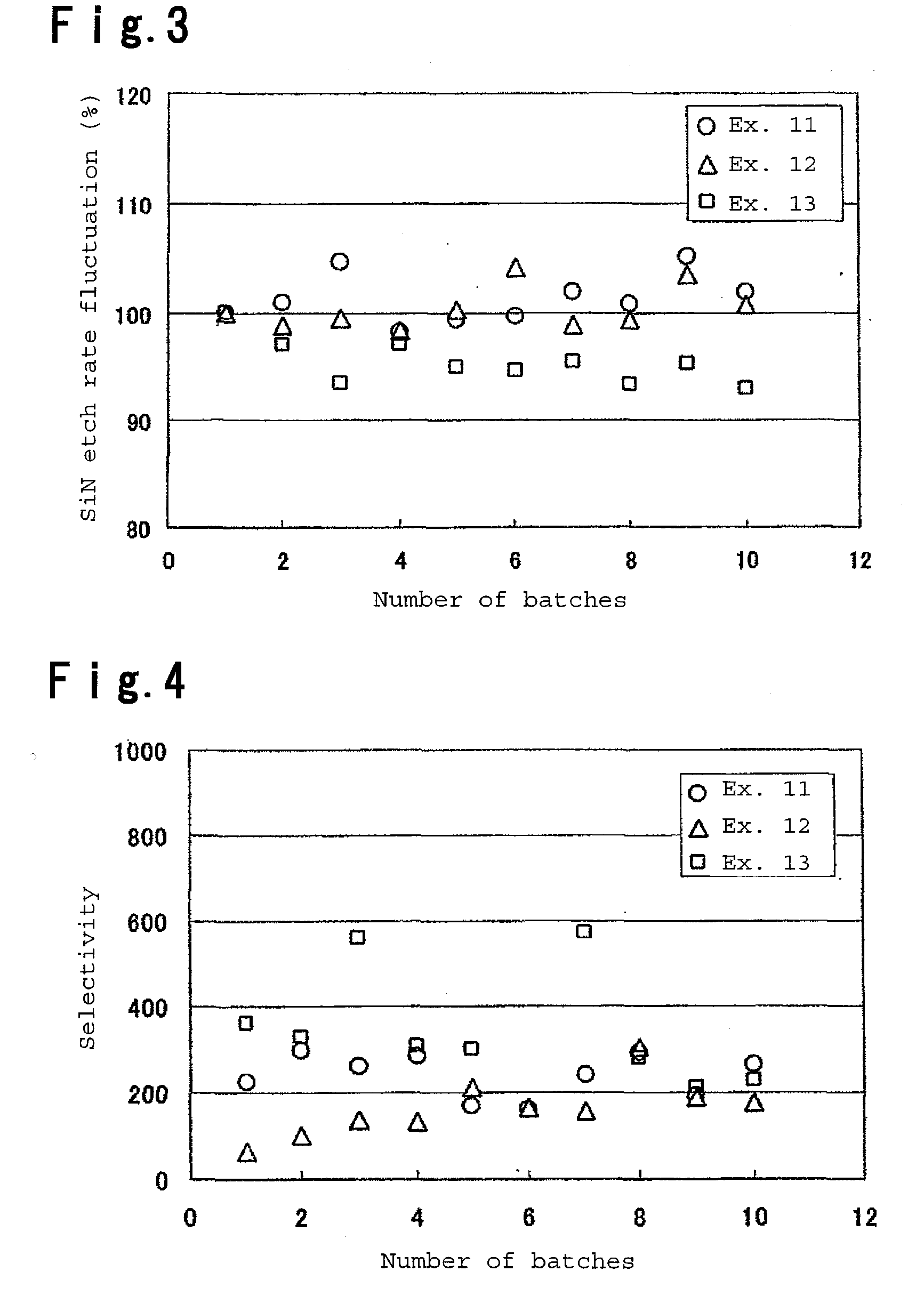

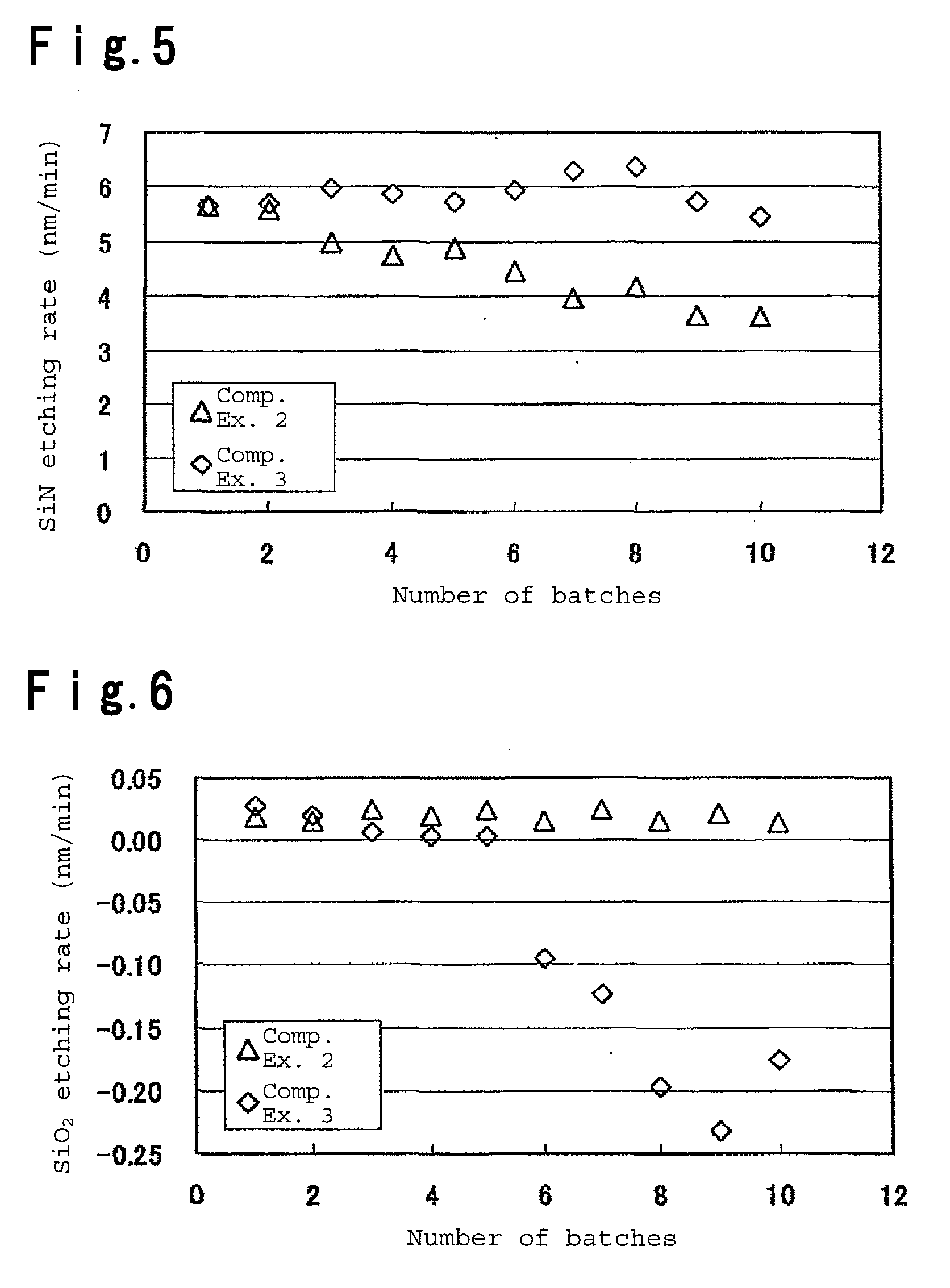

Etching method and etching composition useful for the method

InactiveUS20080203060A1High selectivityImprove productivityDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingSilicon oxide

In etching of silicon nitride with a phosphorus type, if etching is carried for a long time, silicon oxide tends to precipitate, and it has been impossible to constantly carry out the etching for a long period of time.By an etching method for silicon nitride using a composition comprising a phosphorus compound, a boron compound, a silicon compound and / or their fluorides thereof, there will be no precipitation of silicon oxide even when the composition is used for a long time. It is particularly preferred to further add nitric acid and / or a nitrate, whereby stability of selectivity will be increased.

Owner:TOSOH CORP

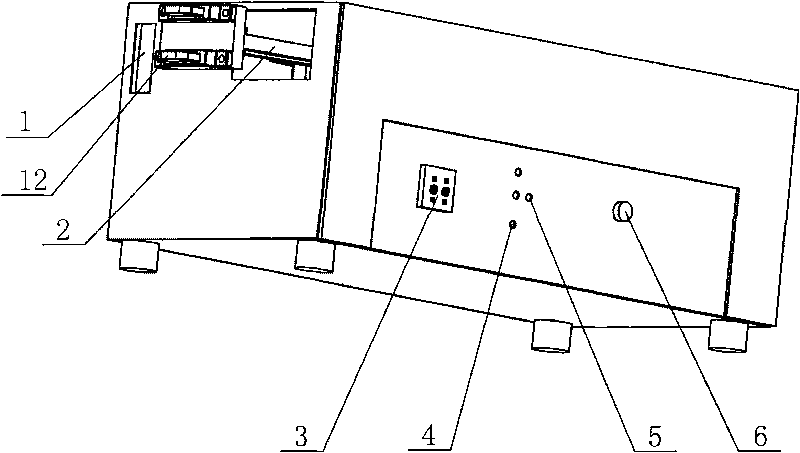

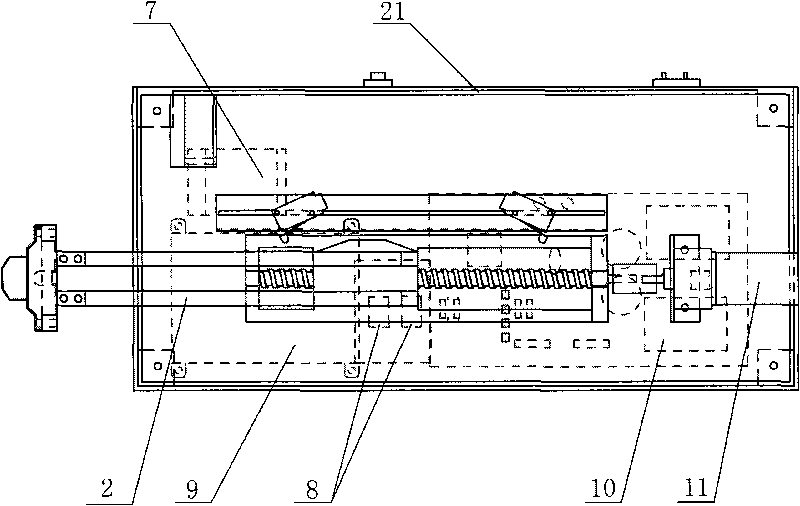

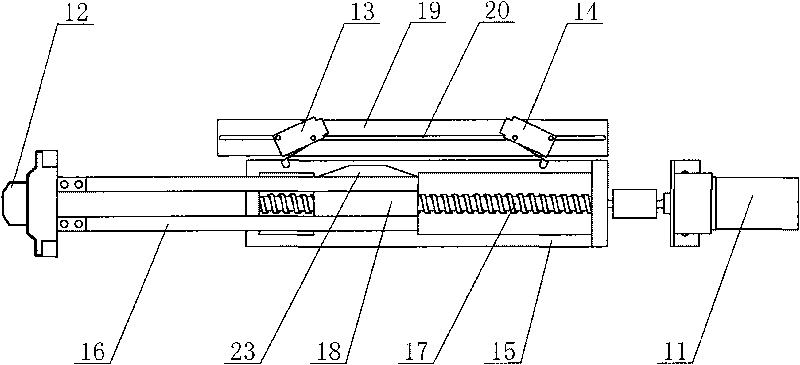

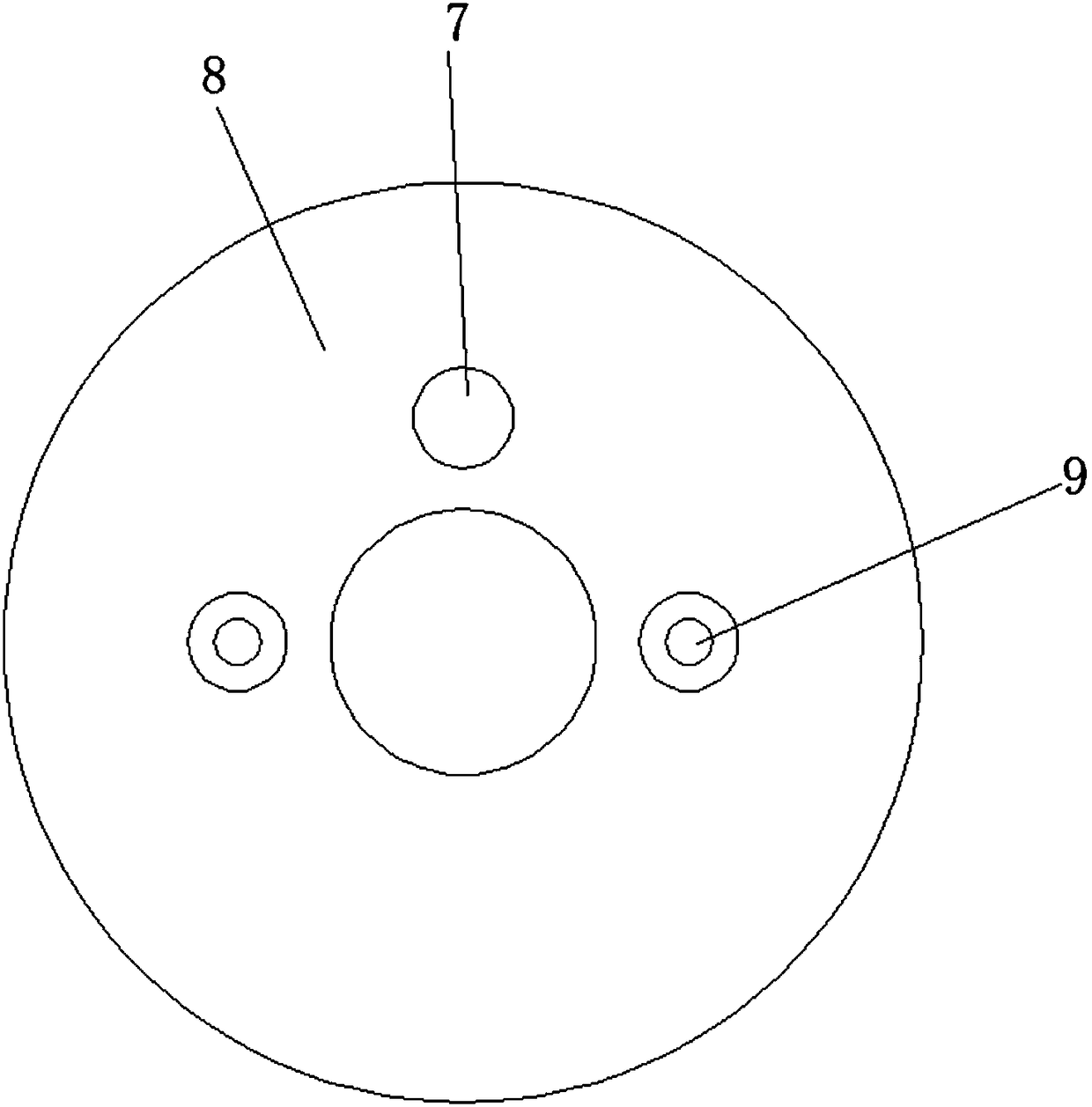

Special automatic charger for automatic guided vehicle

InactiveCN101694891ANo human intervention requiredDoes not take up working timeSecondary cells charging/dischargingDrive motorControl switch

The invention discloses a special automatic charger for an automatic guided vehicle. The charger comprises a casing body, a charging part and a control part, wherein the charging part and the control part are arranged inside the casing body. The charger is characterized by further comprising a connecting part connected with the guided vehicle; the connecting part includes a control switch component, a linear sliding rail module and a connector electrically connected with a charging interface of the guided vehicle; the linear sliding rail module includes a driving motor, a guiding frame, a sliding rail and a screw rod connected with the motor; and the control switch component includes an inductive element, a front limit switch and a rear limit switch, wherein the inductive element is disposed on the casing body, and the front limit switch and the rear limit switch contact and match with a connecting block. Besides, the control part is a control chip with software programs, a control end of the control part is respectively connected with the motor and a driving end of the charging part. By employing the control chip to control the connecting part, the special automatic charger is turned on and off timely, automatically finishes charging the AGV vehicle, reduces manpower input, sufficiently uses vehicle idle time to charge the vehicle, improves vehicle using efficiency and prolongs the service life of batteries.

Owner:HUAXIAO PRECISION SUZHOU

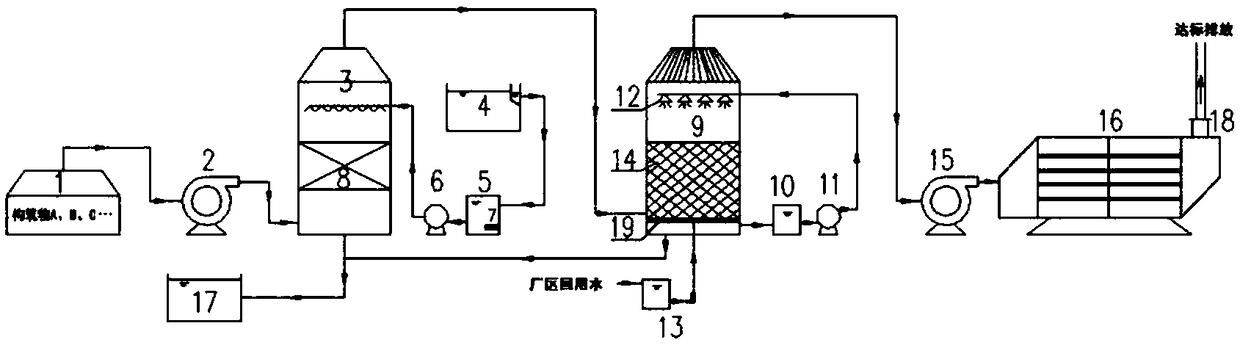

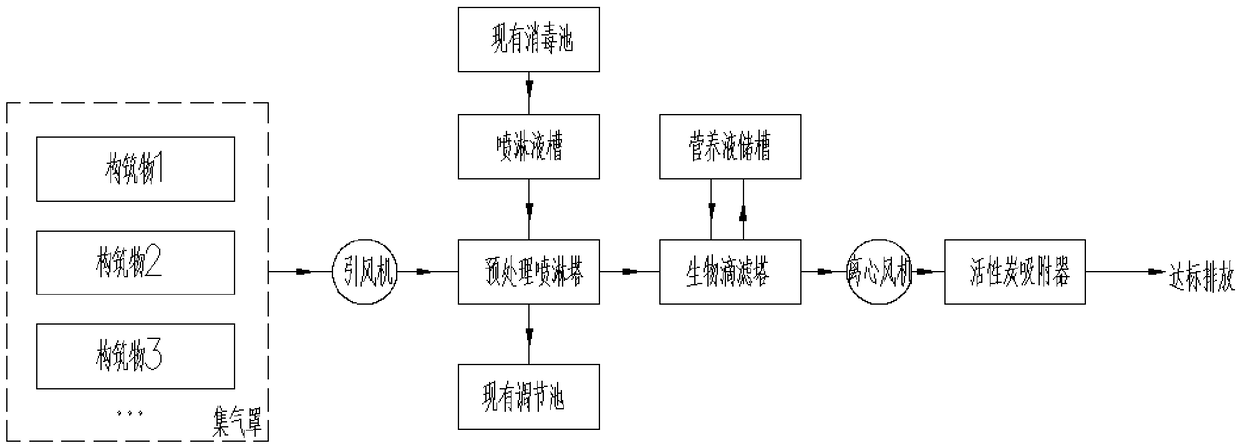

Sewage treatment plant odor collection and treatment system and method

PendingCN108854355AAvoid cloggingNo cloggingCombination devicesGas treatmentLiquid wasteSpray nozzle

The invention discloses a sewage treatment plant odor collection and treatment system and method. The system comprises a gas collecting cover, a draft fan, a pretreatment spraying tower, a sterilization pool, a biological drip filtering tower, a centrifugal fan, an active carbon adsorption device and a regulating pool, wherein the gas collecting cover is arranged above a building pool body radiating odor, and is communicated with the lower part of a pretreatment spraying tower through the draft fan; the sterilization pool is communicated with the upper part of the pretreatment spraying tower;waste liquid discharged from the bottom of the pretreatment spraying tower flows back to the regulating pool through a pipeline; the lower part of the biological drip filtering tower is communicated with the top of the pretreatment spraying tower through a pipeline; odor subjected to pretreatment enters the biological drip filtering tower; a group of spray nozzles are arranged on the top of the biological drip filtering tower and downwards and intermittently spray nutrition liquid; the active carbon adsorption device is communicated with the top of the biological drip filtering tower through acentrifugal fan and is used for performing further treatment on the waste gas treated in the biological drip filtering tower and then discharging the waste gas in a standard reaching way. The investment is saved; the occupied area is small; the equipment is simple; the deodorization efficiency is high; the pollution bearing load is high; the operation cost is low.

Owner:HUBEI JUNJI WATER TREATMENT

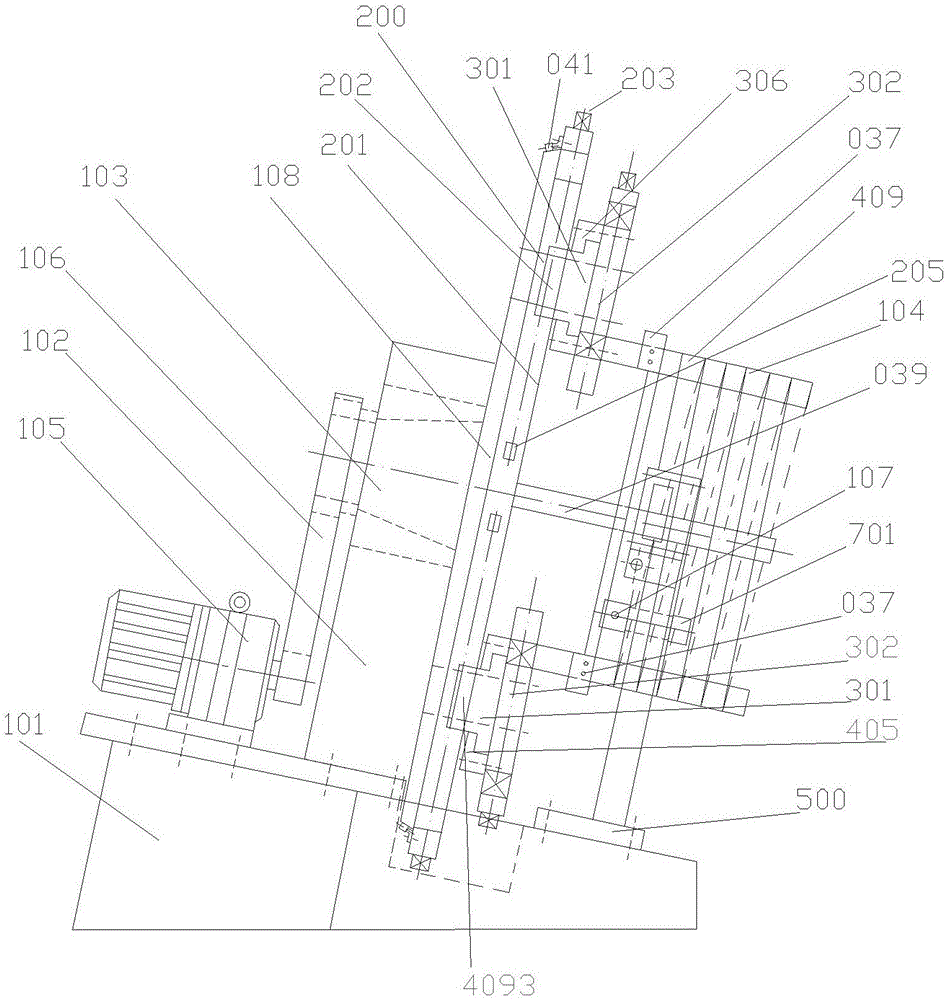

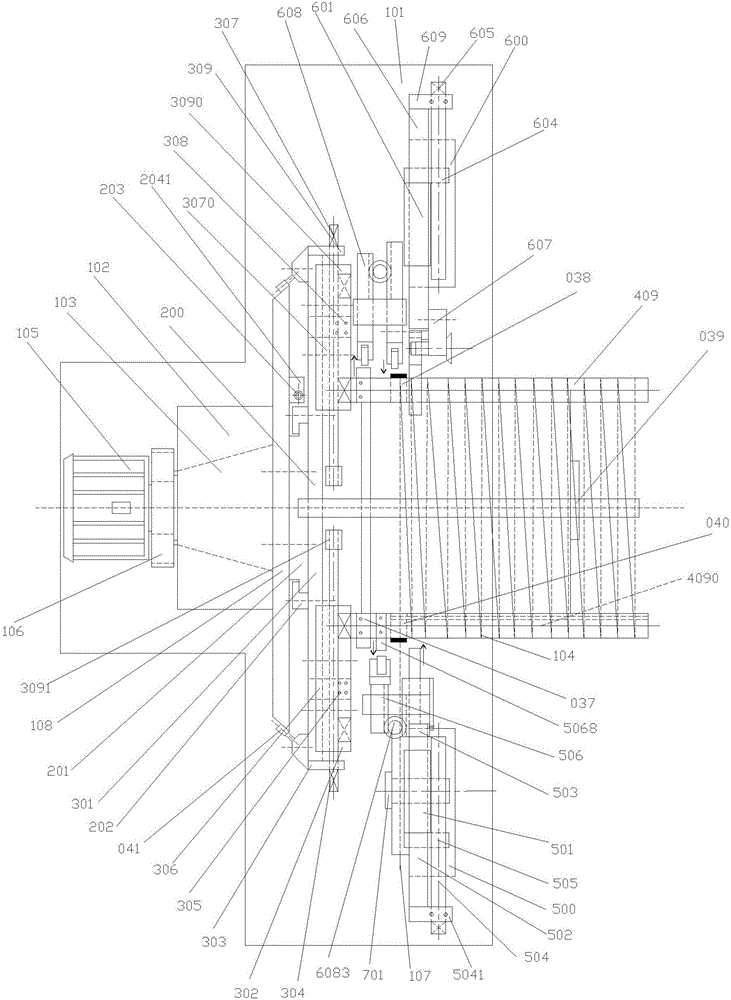

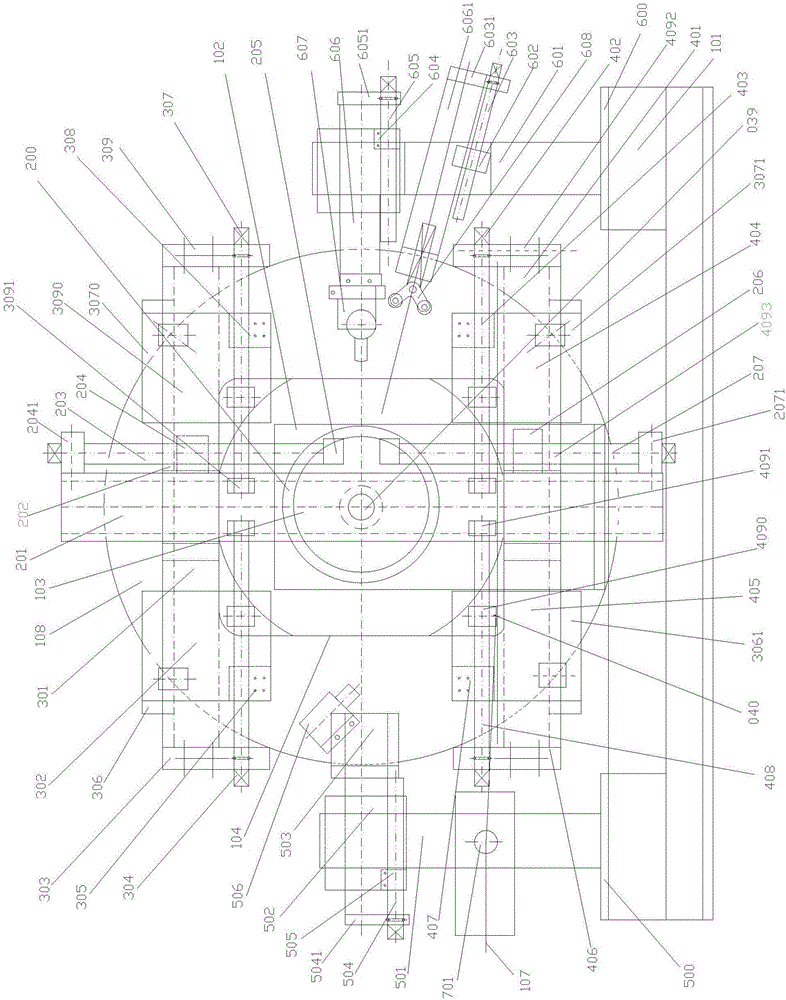

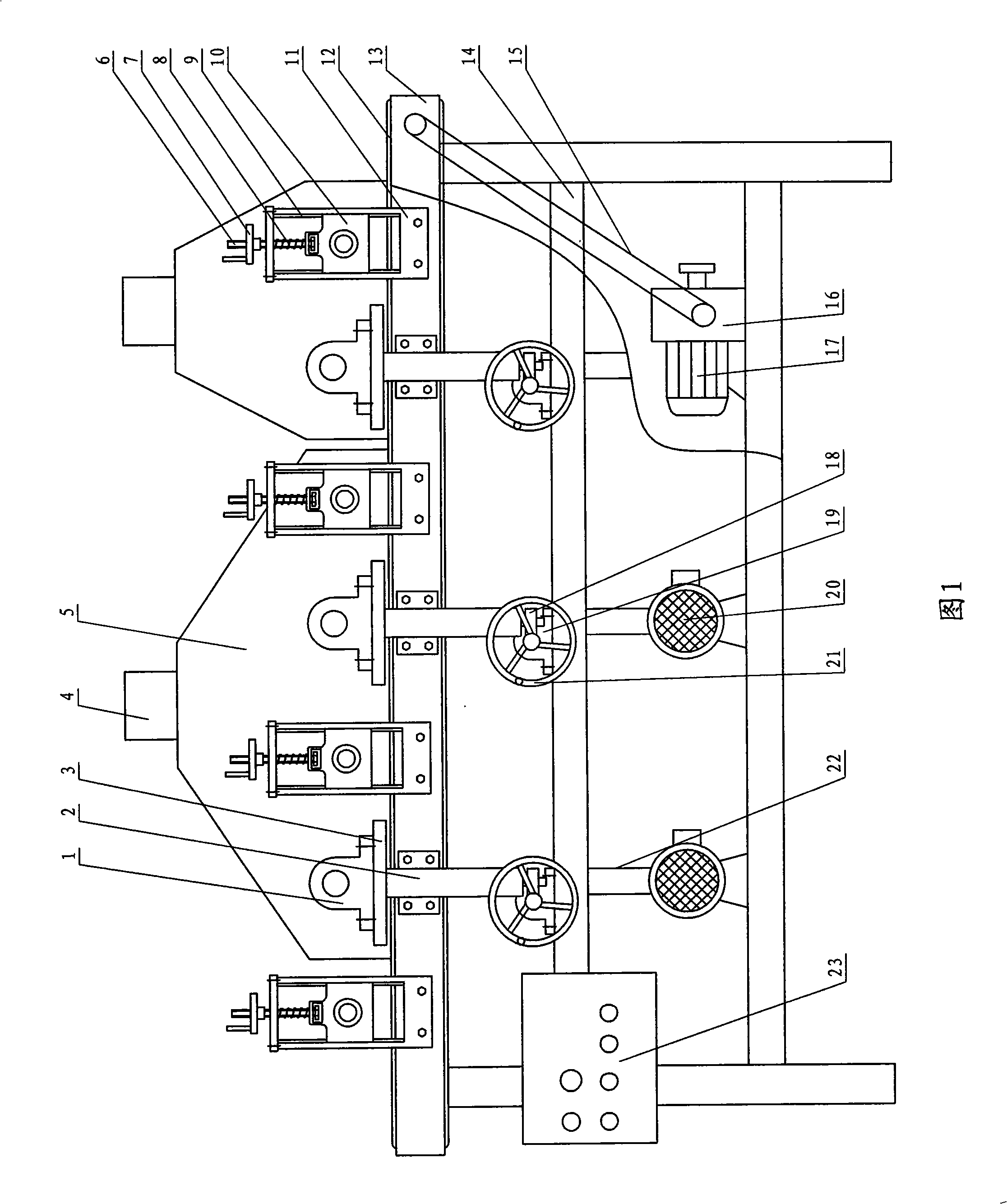

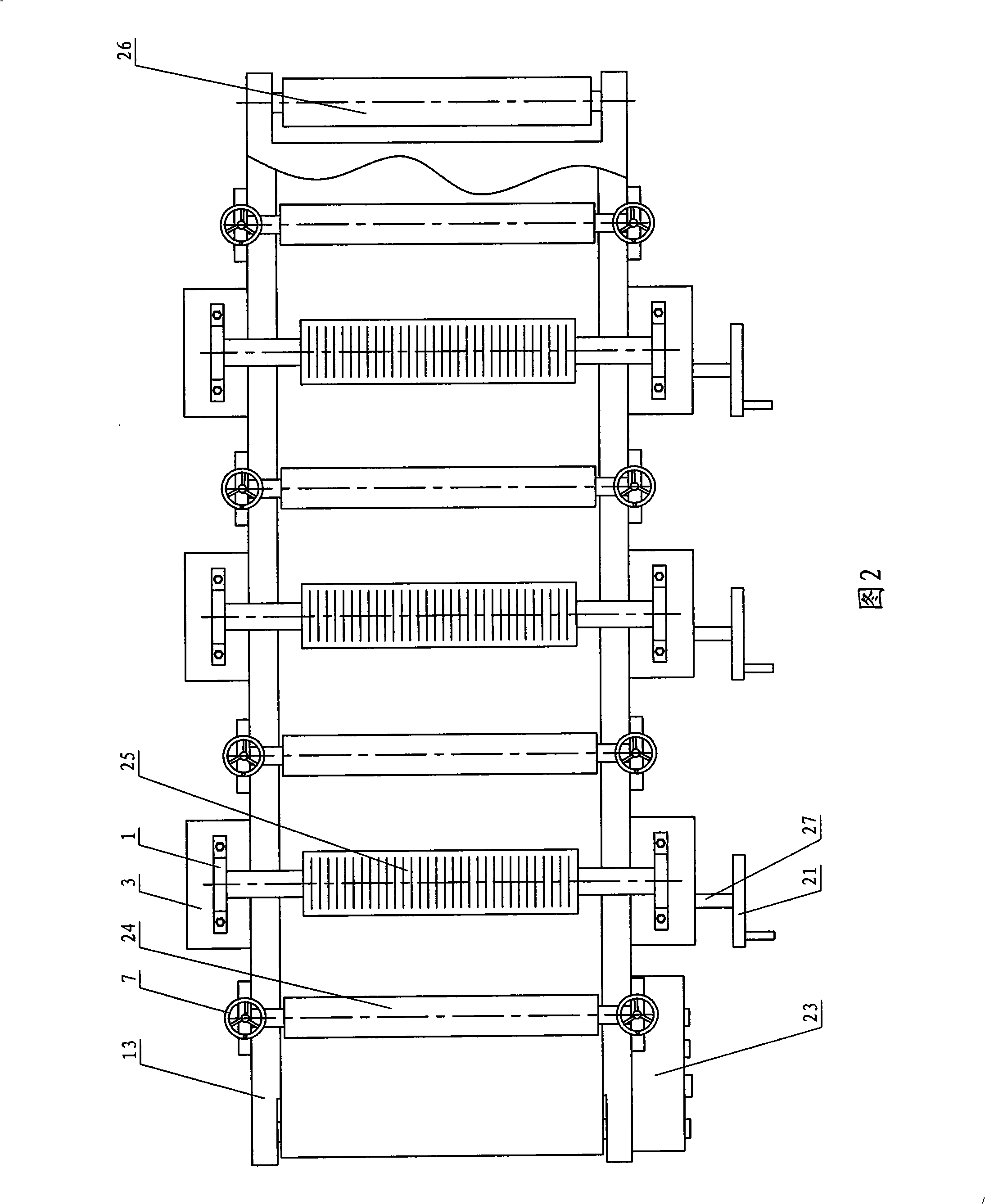

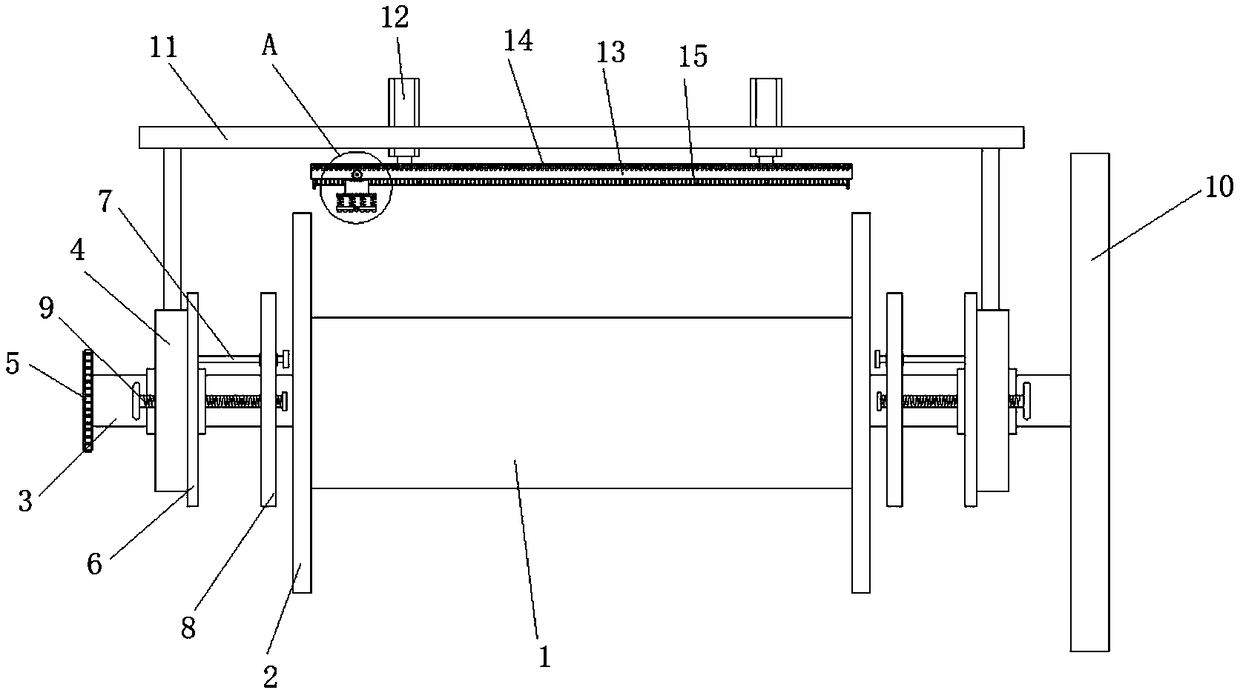

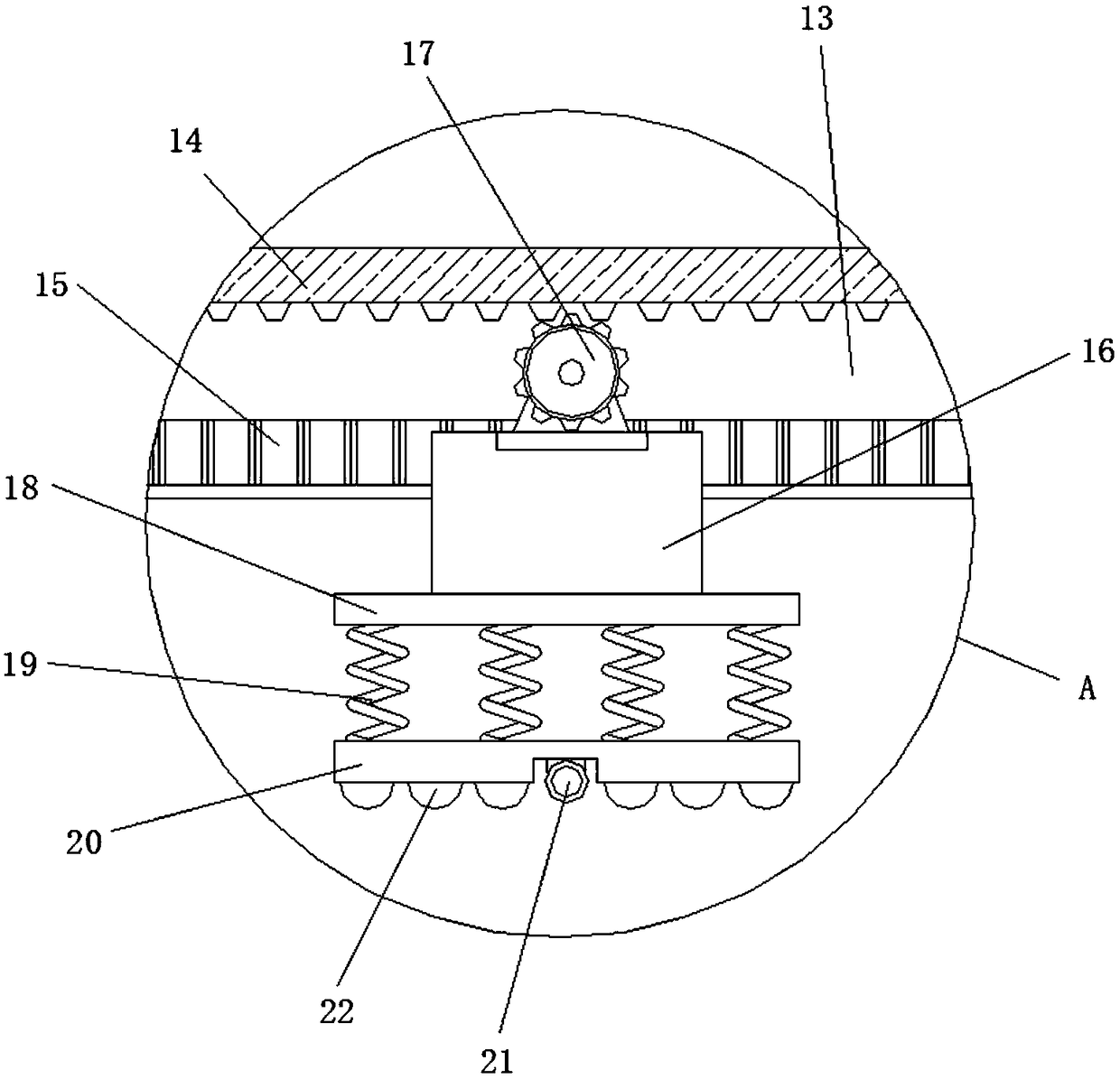

Spiral stirrup continuously and synchronously machining machine and machining method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

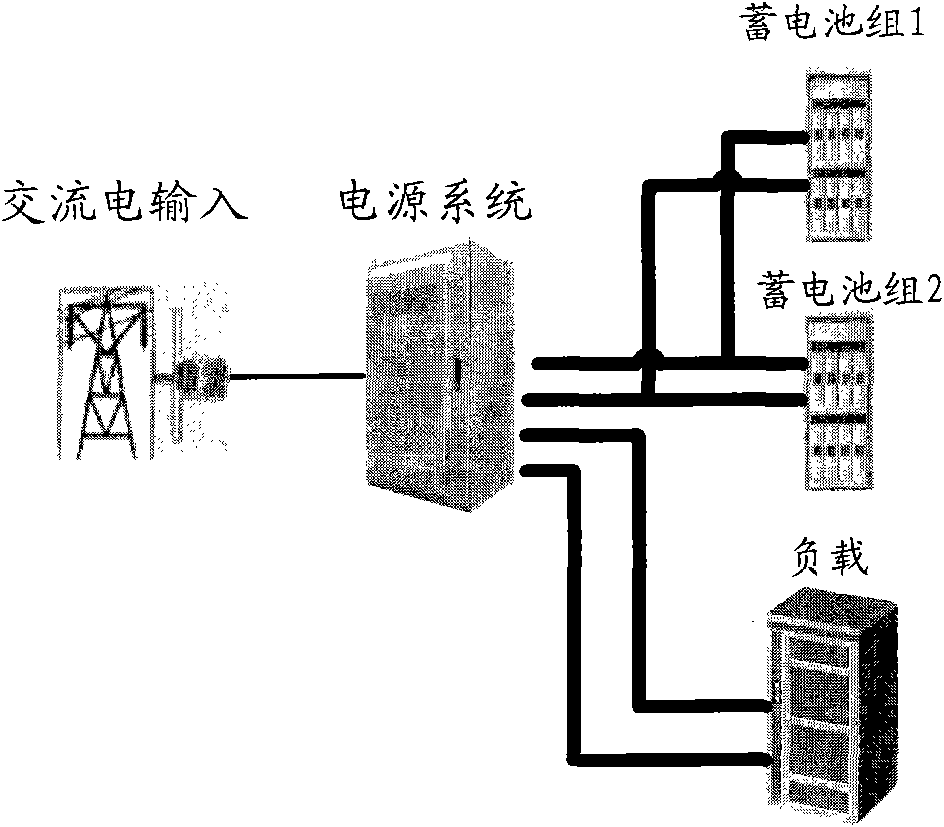

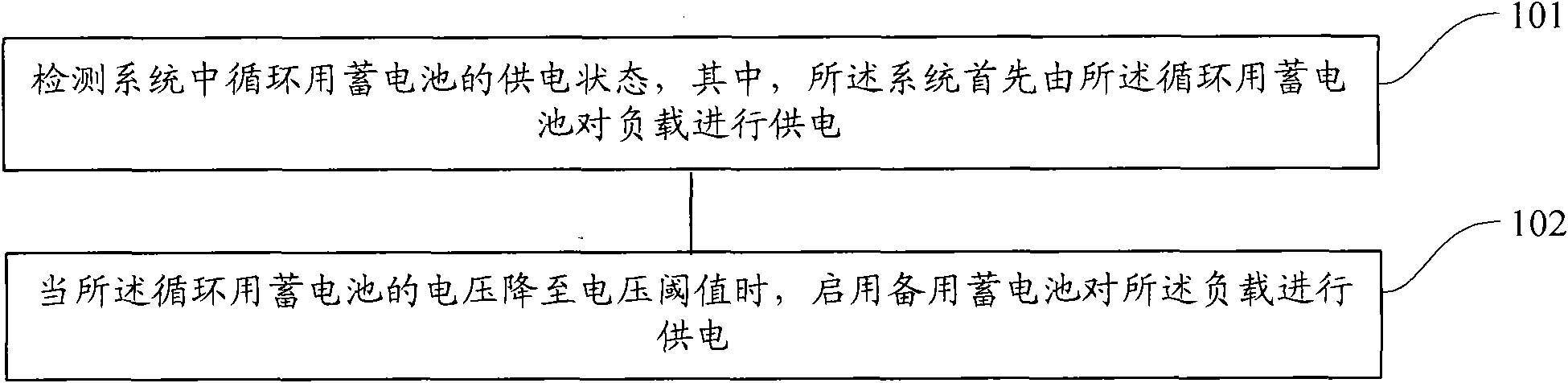

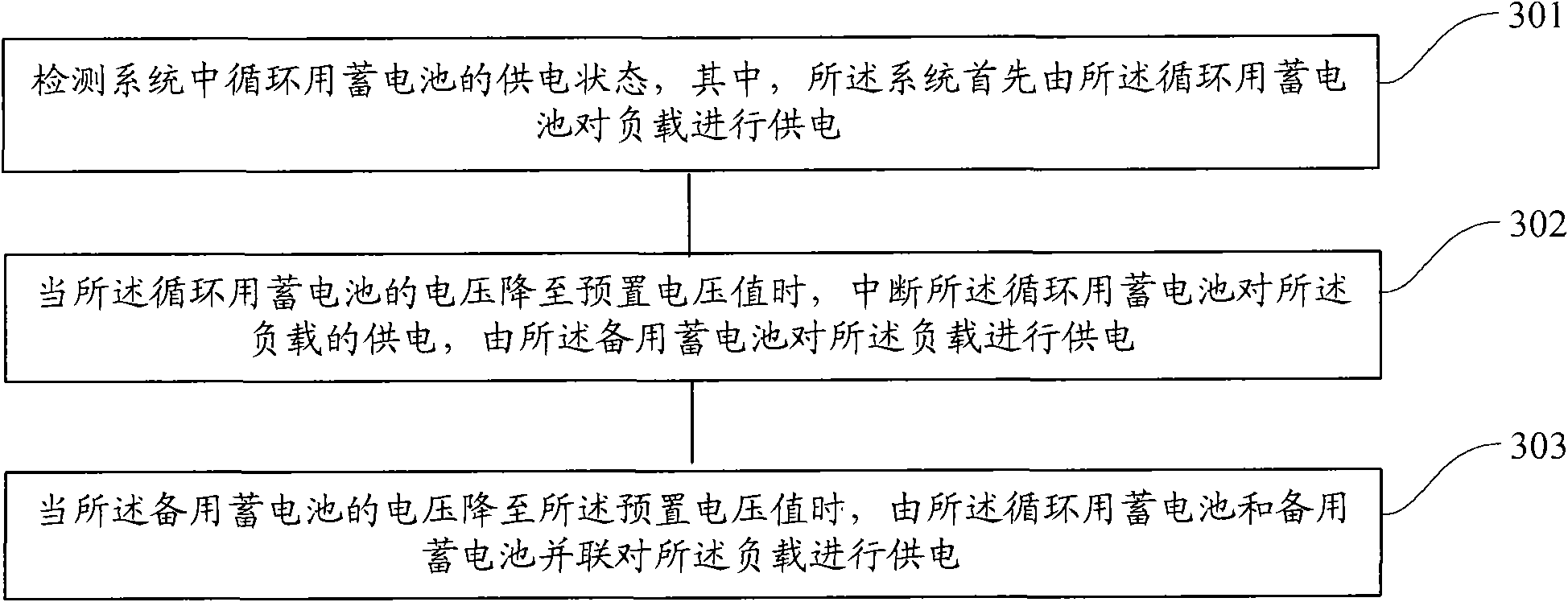

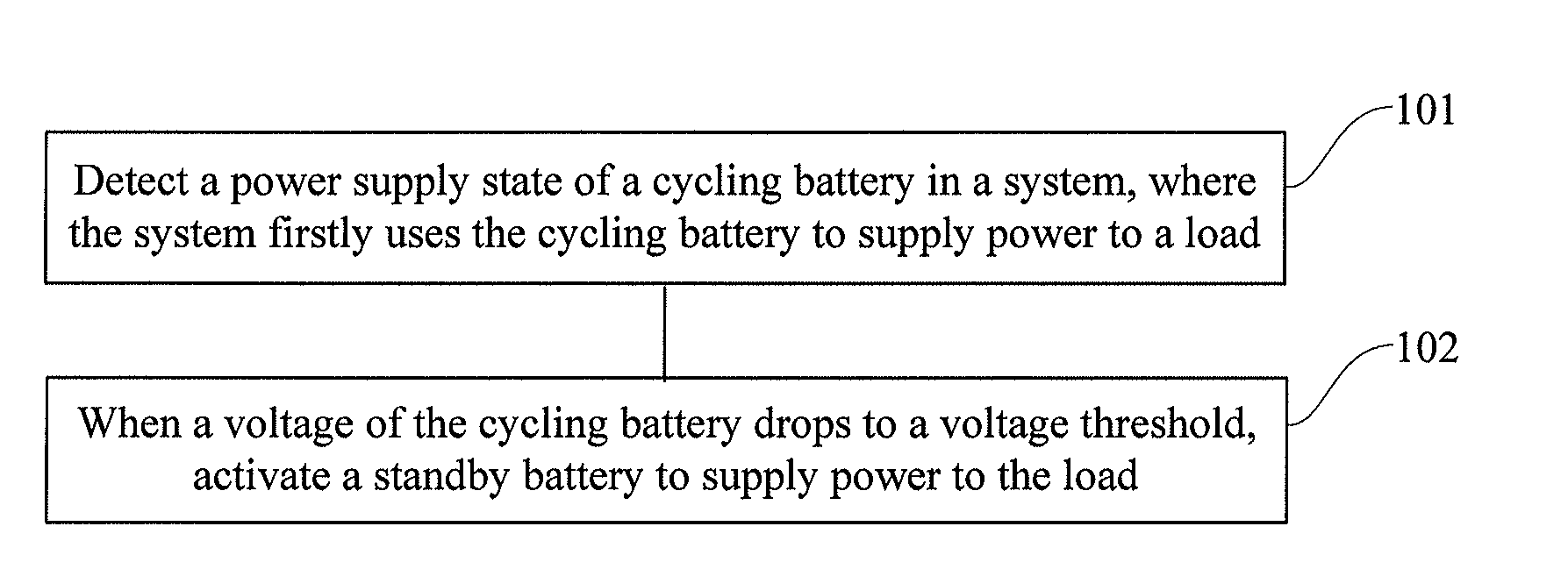

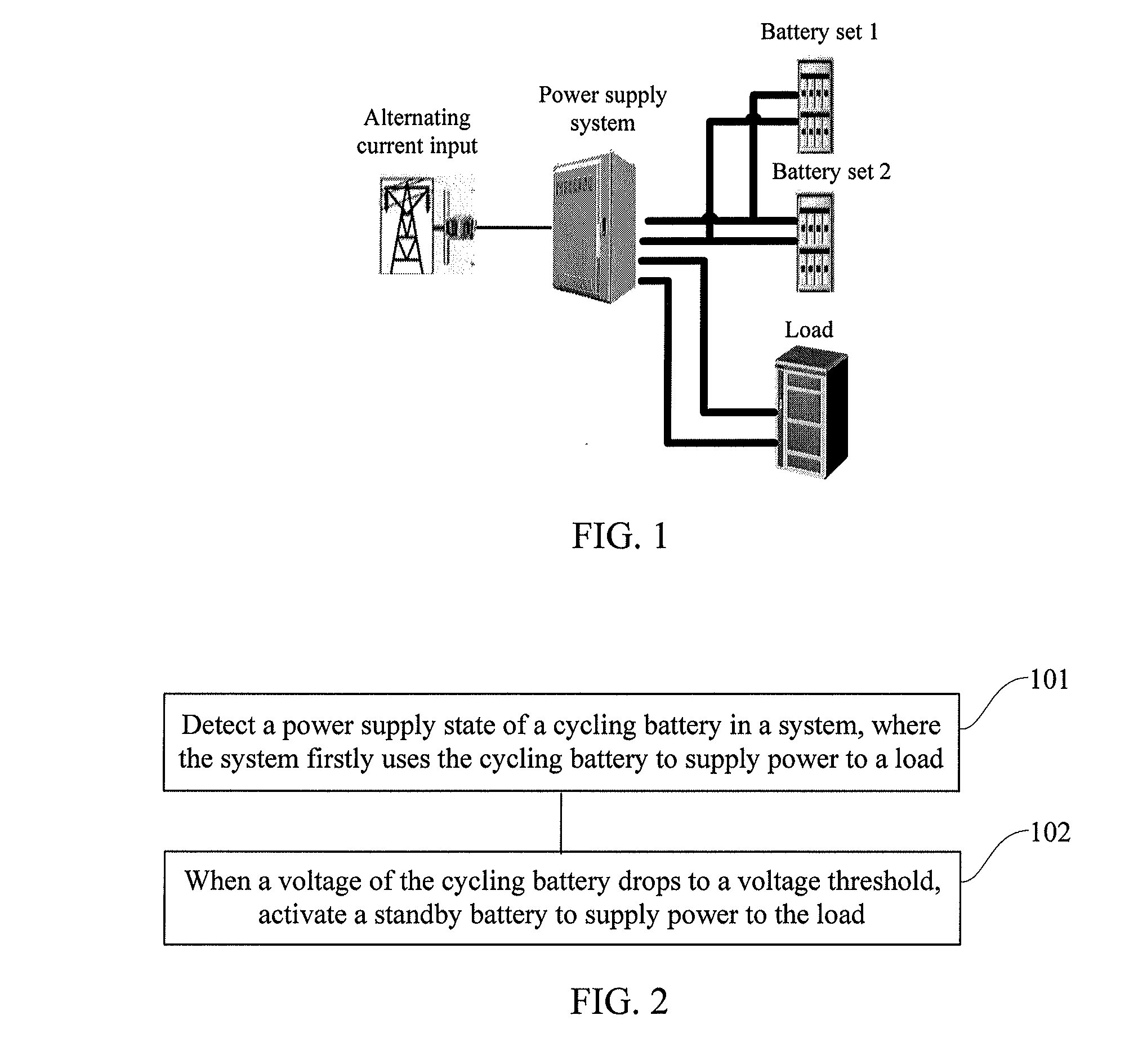

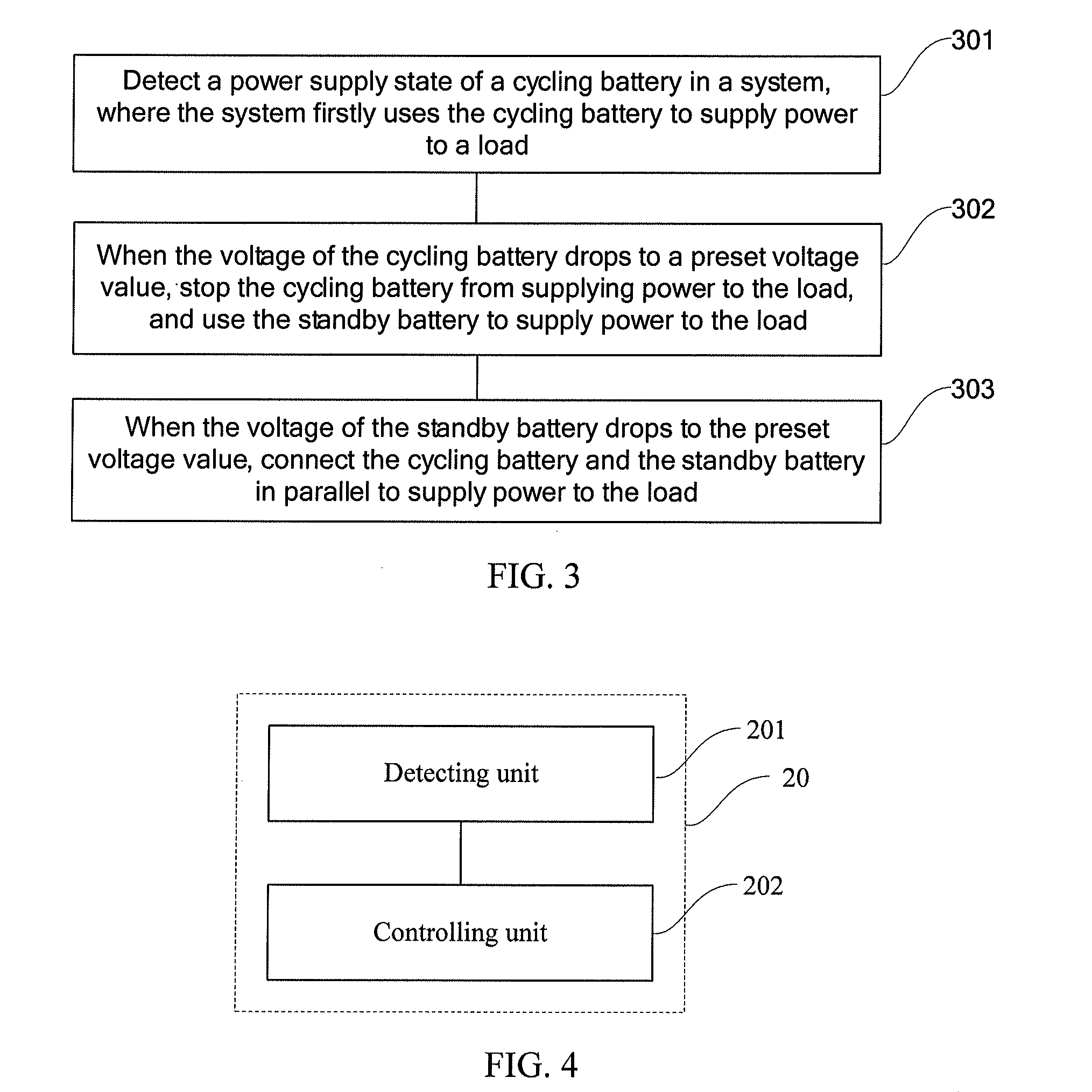

Power supply method, device and system for storage batteries

InactiveCN102148531AExtend your lifeIncrease profitBatteries circuit arrangementsPower network operation systems integrationVoltage

The embodiment of the invention discloses a power supply method, device and system for storage batteries, wherein the power supply method comprises the step as follows: the power supply state of a storage battery circularly used in a system is detected, wherein the system supplies power to a load through the storage battery circularly used firstly; when the voltage of the storage battery circularly used is reduced to a voltage threshold, a standby storage battery is started to supply power to the load. The embodiment can realize mixed application between different storage batteries.

Owner:HUAWEI TECH CO LTD

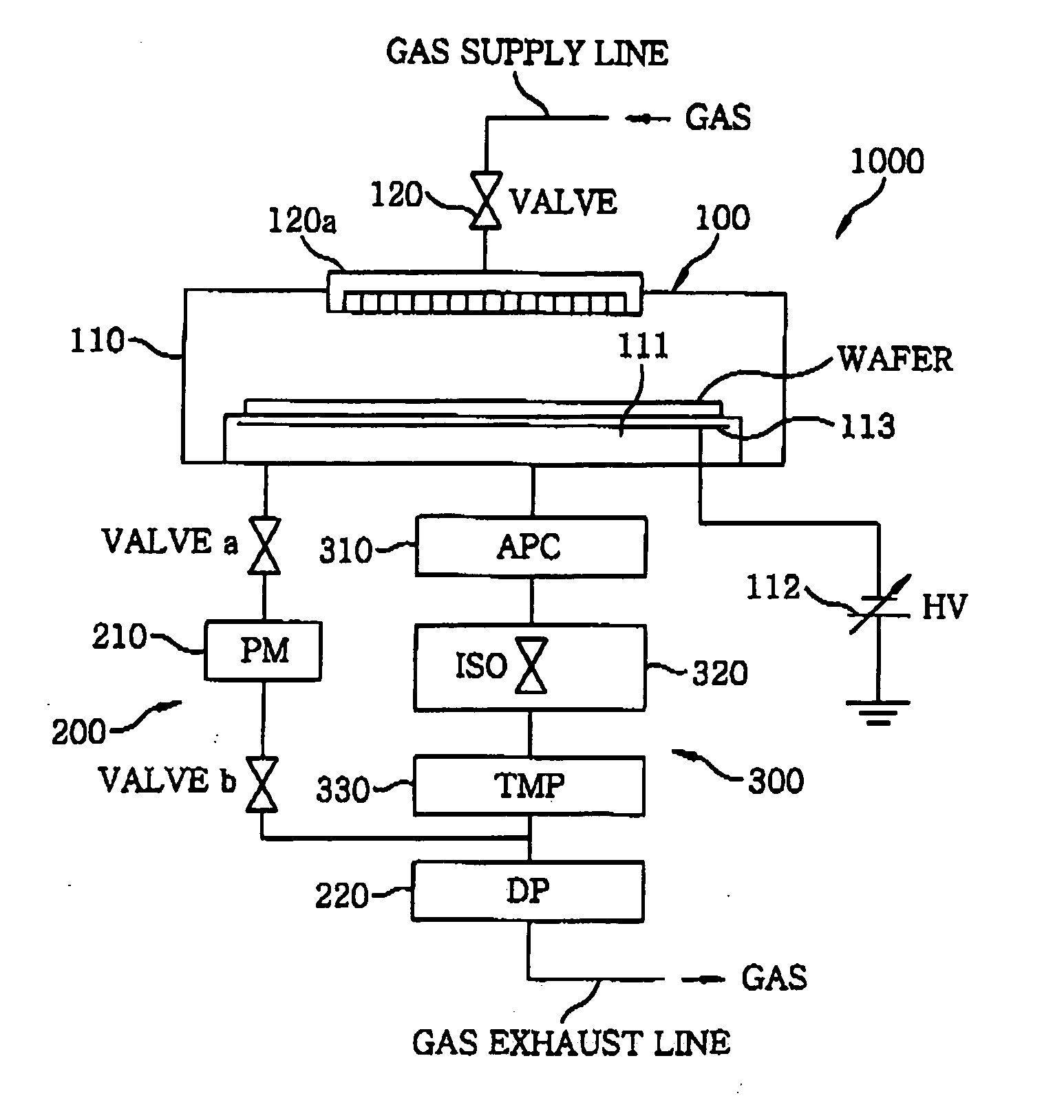

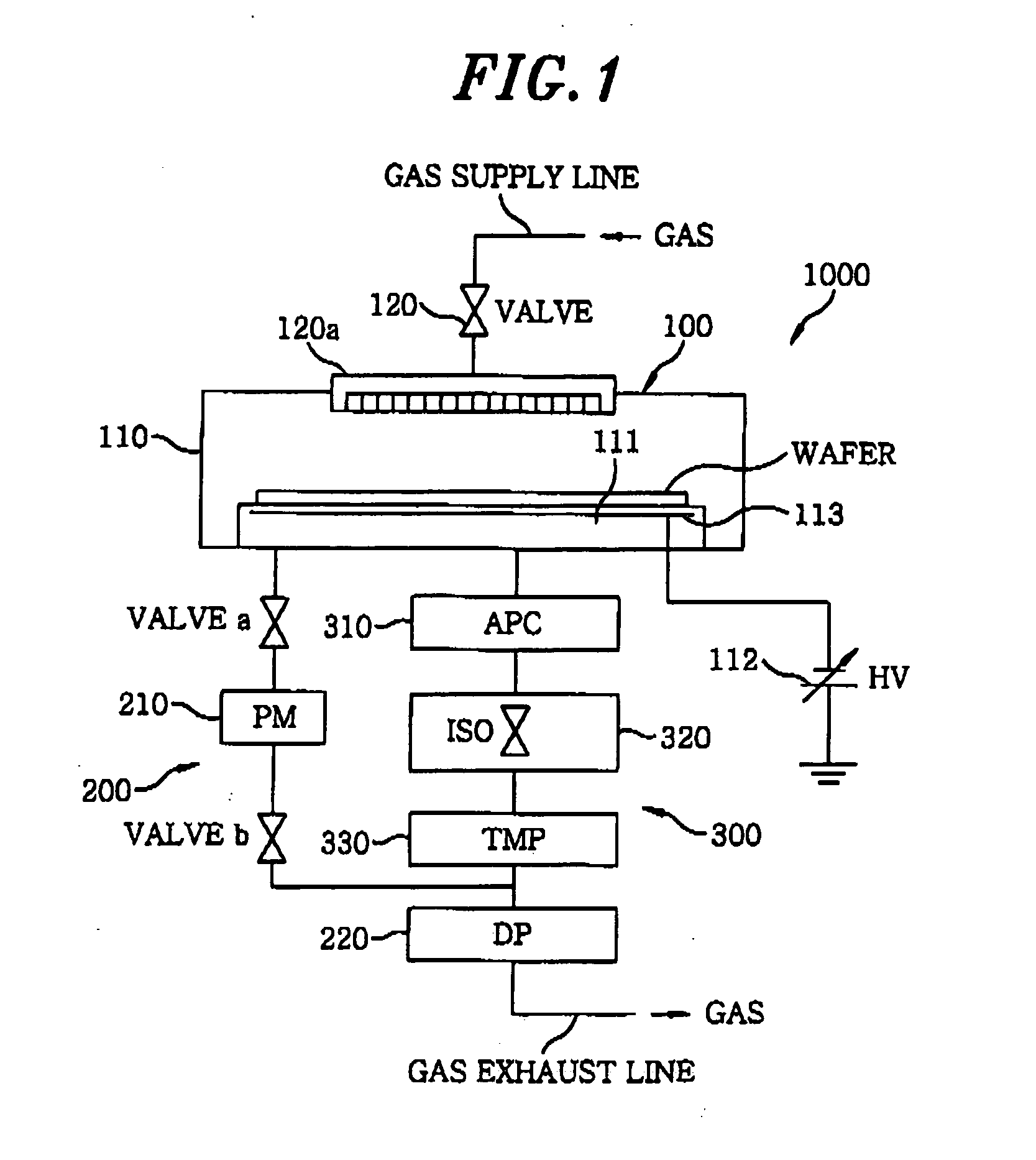

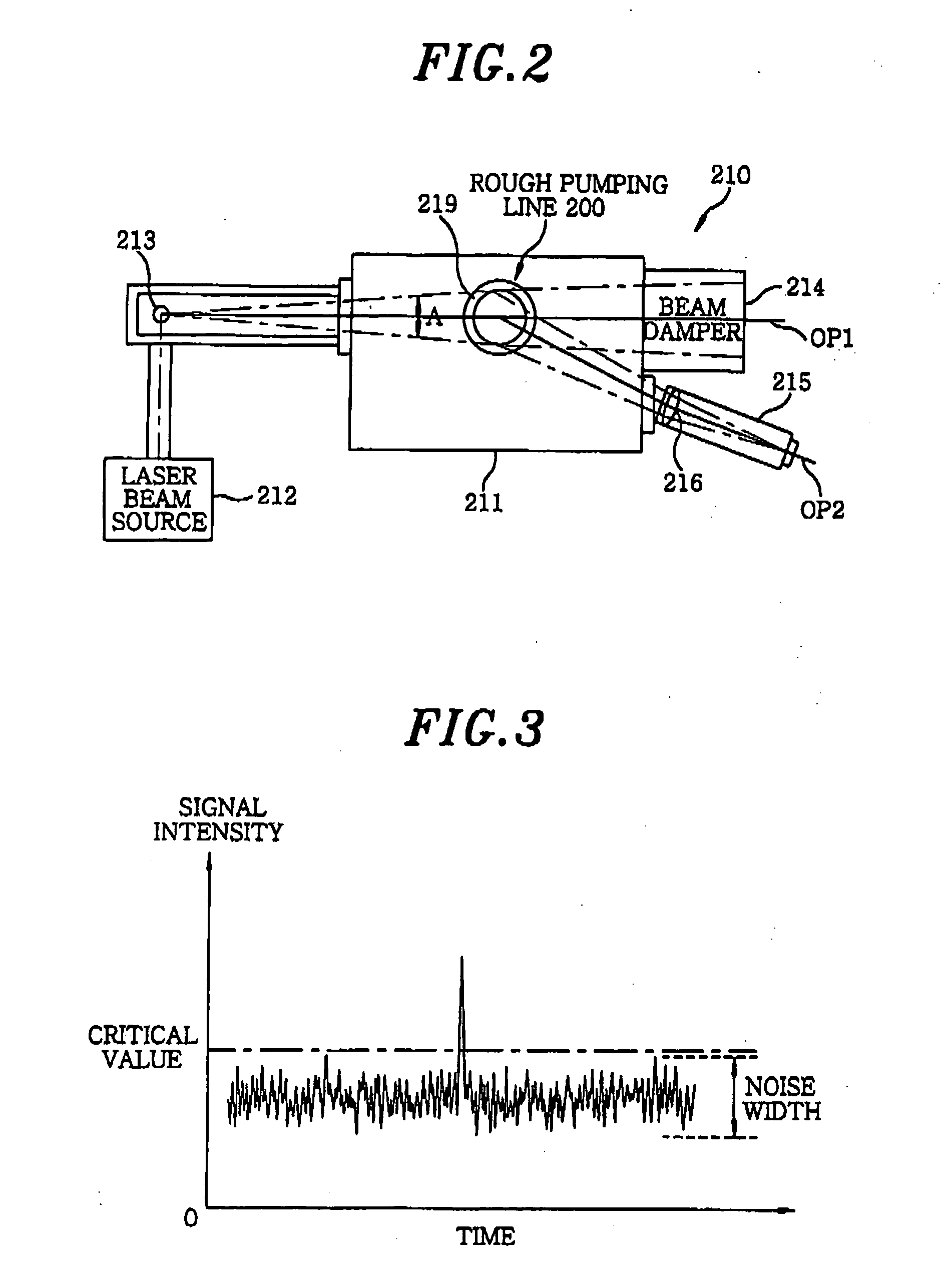

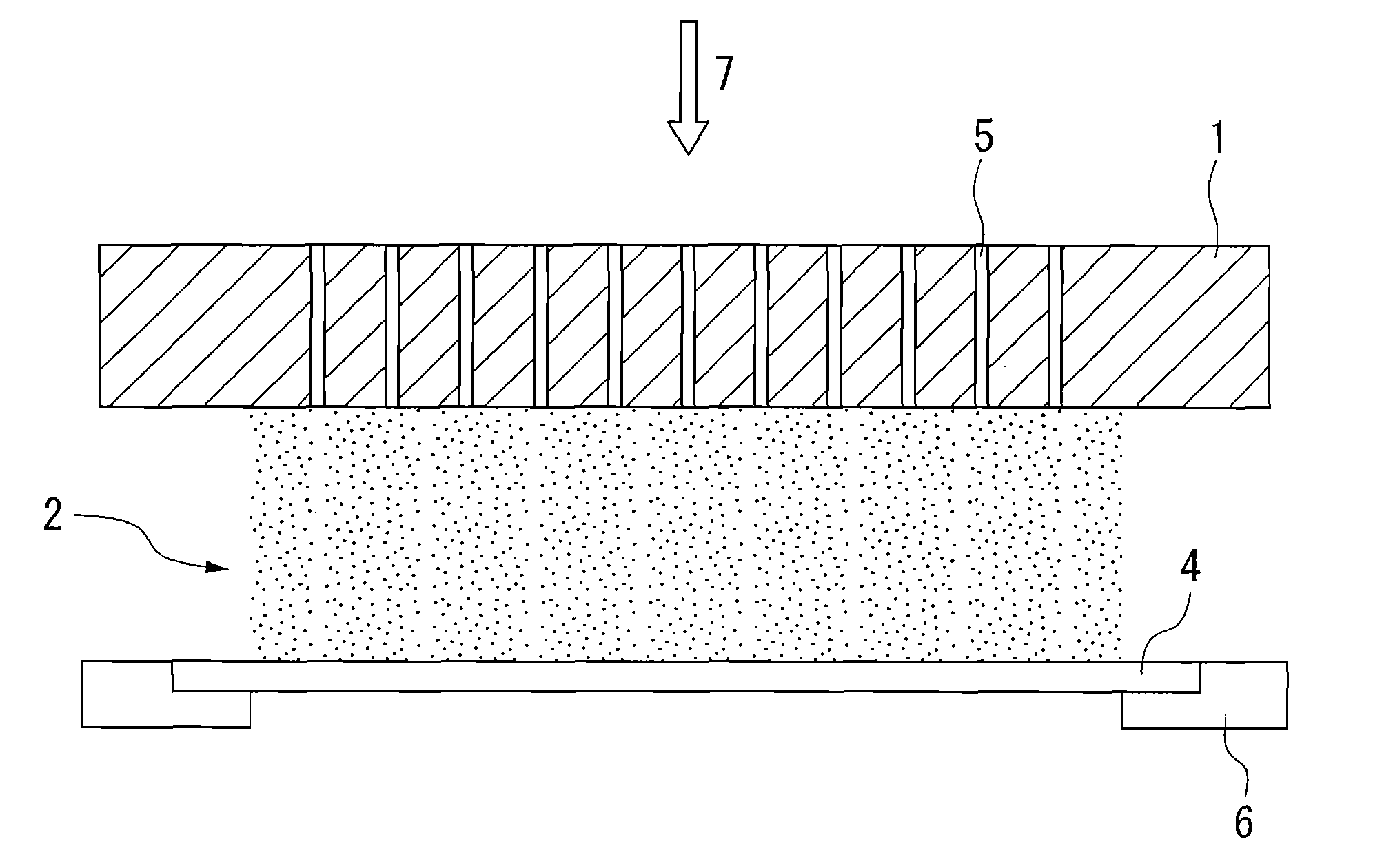

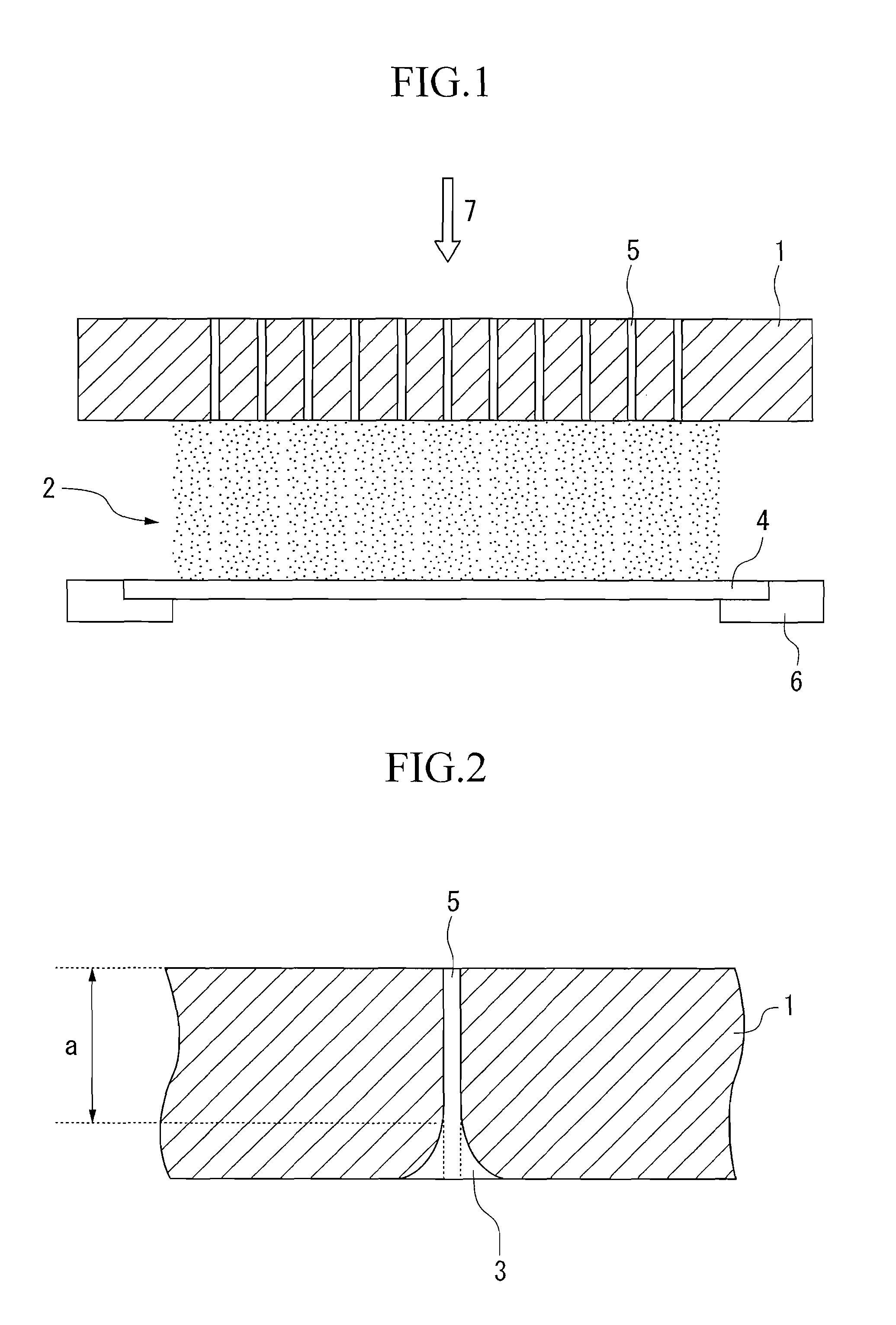

Vacuum apparatus including a particle monitoring unit, particle monitoring method and program, and window member for use in the particle monitoring

ActiveUS20050268694A1Improve the immunityPositively reducing frequency of replacementVehicle testingCombination enginesParticulatesShock wave

[Object]It is an object to provide a vacuum apparatus capable of evaluating its cleanness precisely by surely monitoring particles including deposits readily detached from the apparatus, and a particle monitoring method and program employed therein, and a window member for particle monitoring. [Constitution of the Invention]A semiconductor manufacturing apparatus 1000 includes a processing chamber 100 for performing a manufacturing processing on a wafer. A gas supply line for introducing a purge gas is connected to an upper portion of the processing chamber 100, a valve 120 being installed on the gas supply line. A rough pumping line 200 with a valve a is connected to a lower portion of the processing chamber 100. Installed on the rough pumping line 200 are a dry pump 220 for exhausting a gas in the processing chamber 100 and a particle monitoring unit 210 for monitoring particles between the valve a and the dry pump 220. In the semiconductor manufacturing apparatus 1000, after the valve 120 is opened, the purge gas is supplied to apply physical vibration due to shock wave in the processing chamber 100 so that deposits are detached therefrom to be monitored as particles.

Owner:TOKYO ELECTRON LTD

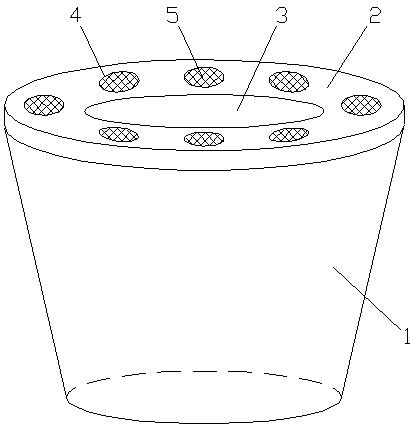

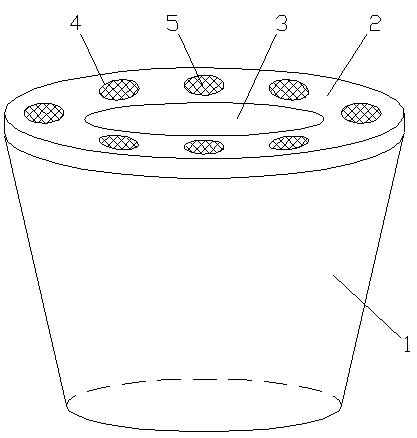

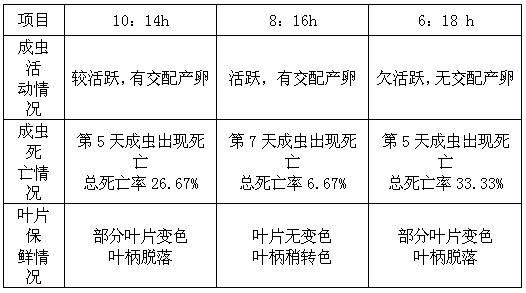

Insect breeding bottom and breeding method of gynaikothrips ficorum

The invention relates to an insect breeding bottom and a breeding method of gynaikothrips ficorum and belongs to the field of insect breeding and insect ecology. A bottom body is in a cone frustum shape with large top and small bottom and is in sealing match with a bottle cover, a magnifying glass is installed at the center of the bottle cover, a plurality of venting holes are evenly distributed on the bottle cover, and a filter screen is installed on the venting holes. The method utilizing the insect breeding bottom to breed the gynaikothrips ficorum comprises (1) collection of eggs, (2) hatching of the eggs, (3) breeding of nymphs and (4) breeding of imagoes. By using the breeding method, the hatching rate, survival rate and eclosion rate of the gynaikothrips ficorum are high, massive thrips of various insect states which are orderly in age and high in vigor can be obtained, and form changes and the whole life history of the gynaikothrips ficorum can be observed in real time.

Owner:INST OF PLANT PROTECTION FAAS

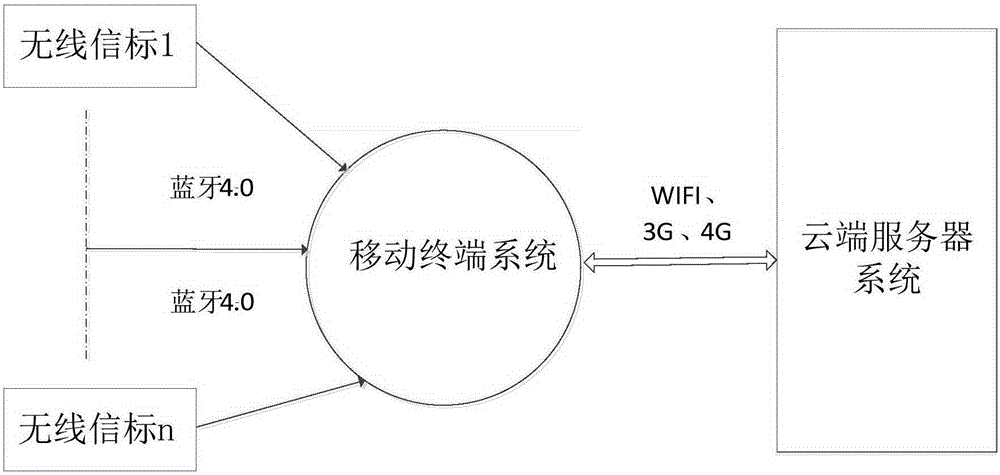

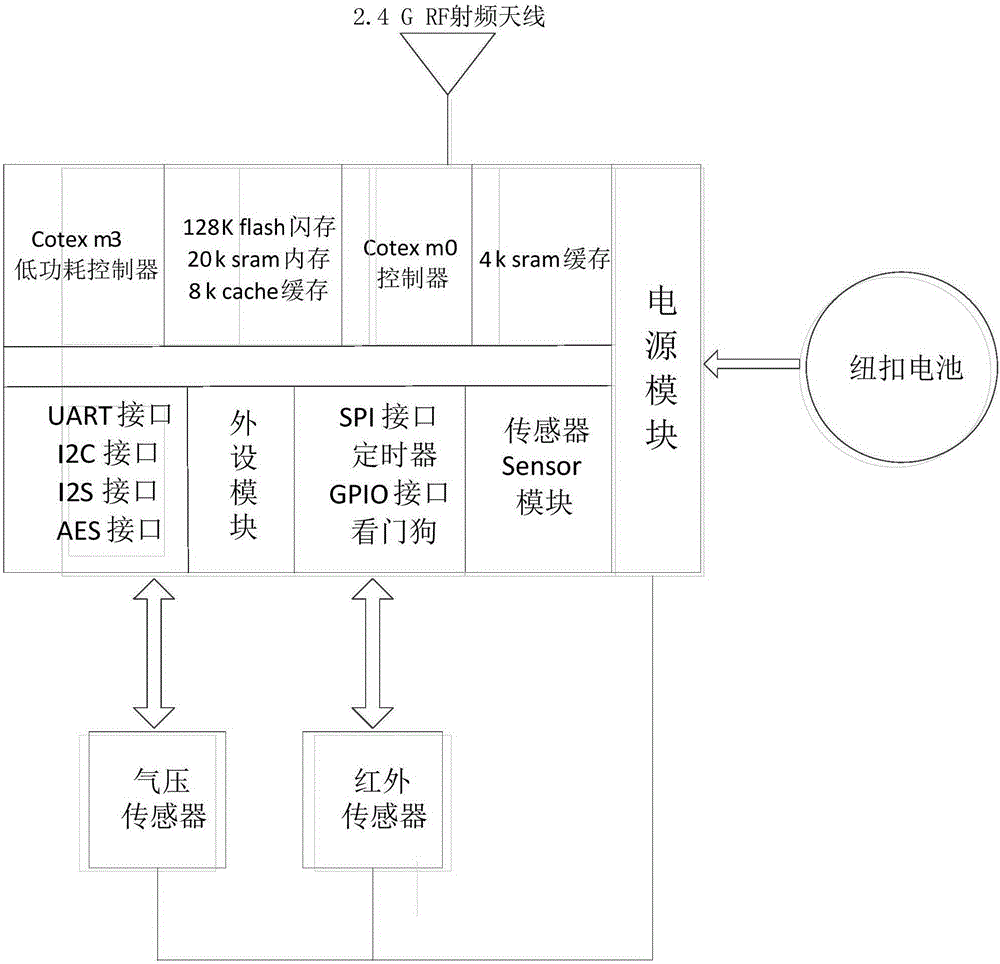

Indoor positioning system and method based on wireless beacons

InactiveCN105163386ALow costReduce replacement frequencyHigh level techniquesWireless communicationCombined methodRadio frequency signal

The invention provides an indoor positioning system and method based on wireless beacons. Based on a wireless beacon and inertial navigation combined method, information contents sent by the wireless beacons are added, and calibration data is included in each wireless beacon to realize real-time calibration, and therefore, the defects of instability of the single beacon and large accumulated errors of single initial navigation are solved and the accuracy of indoor positioning is improved. Each wireless beacon is integrated with an infrared sensor for sensing a moving object in real time, and only after the moving object is sensed, a radio-frequency signal is sent; in this way, the power consumption can be effectively reduced and the service time of the battery of the wireless beacon can be increased, and furthermore, the labor and material costs can be saved.

Owner:北京合众思壮时空物联科技有限公司 +1

Carbon and silicon carbide crucible and preparation process thereof

A carbon and silicon carbide crucible and preparation process thereof solve the problem that common crucibles are low in strength, poor in thermal shock resistance, short in service life and the like. The carbon and silicon carbide crucible is composited by carbon fibers and silicon carbide, and the preparation process comprises the steps of prefabrication, solidification, densification, purification, silicon socking, carbonization and molding. Thickness of the crucible can be obviously reduced, the strength and the thermal shock resistance of the crucible are improved, and service life of the crucible is prolonged. The carbon and silicon carbide crucible and the preparation process are suitable to use of high temperature furnaces, such as single crystal furnaces.

Owner:HUNAN JIUHUA CARBON HI TECH

Silicon electrode plate for plasma etching with superior durability

ActiveUS20070181868A1Reduce replacement frequencyElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon electrodeSingle crystal

This silicon electrode plate for plasma etching is a silicon electrode plate for plasma etching with superior durability including silicon single crystal which, in terms of atomic ratio, contains 3 to 11 ppba of boron, and further contains a total of 0.5 to 6 ppba of either or both of phosphorus and arsenic.

Owner:SUMCO CORP +1

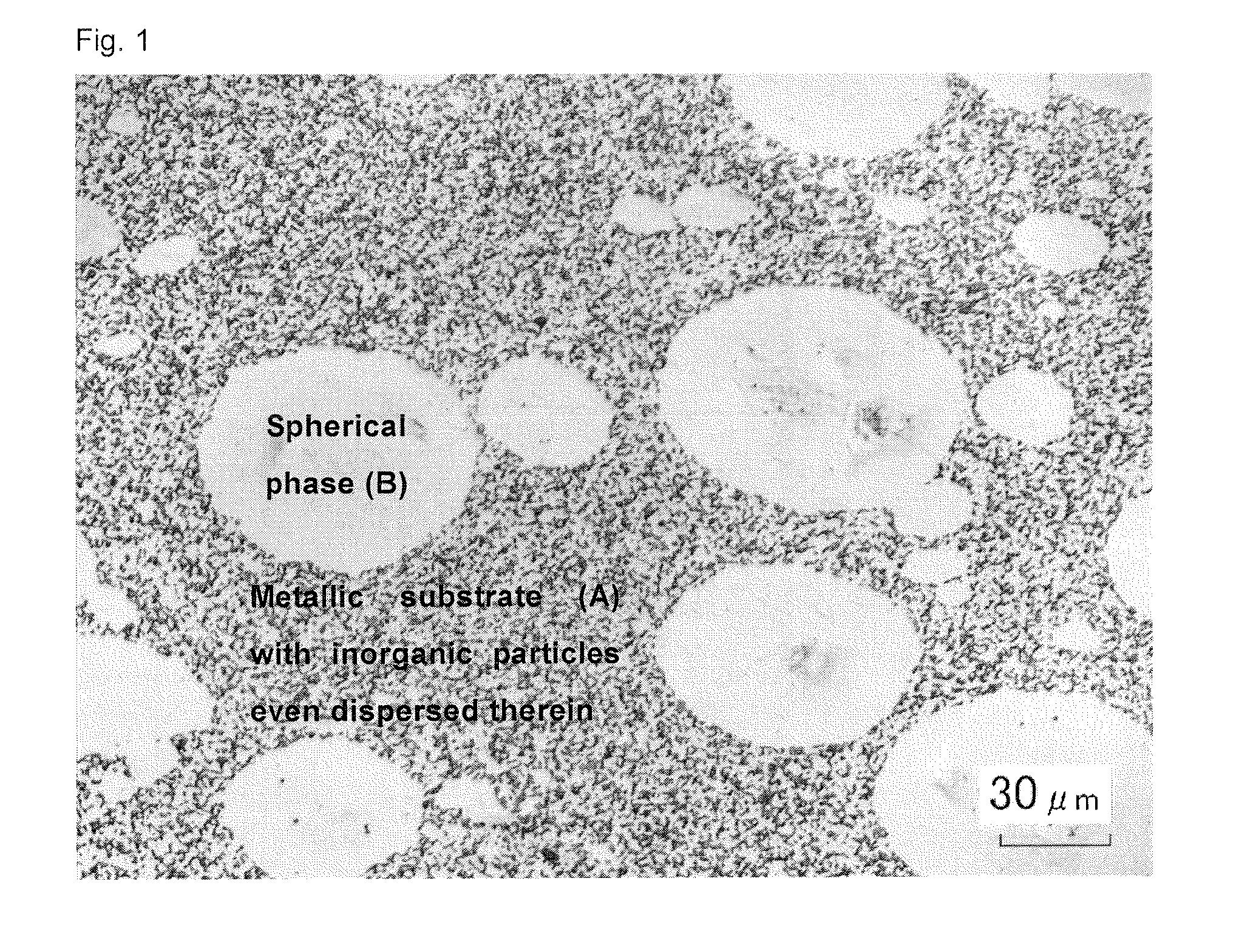

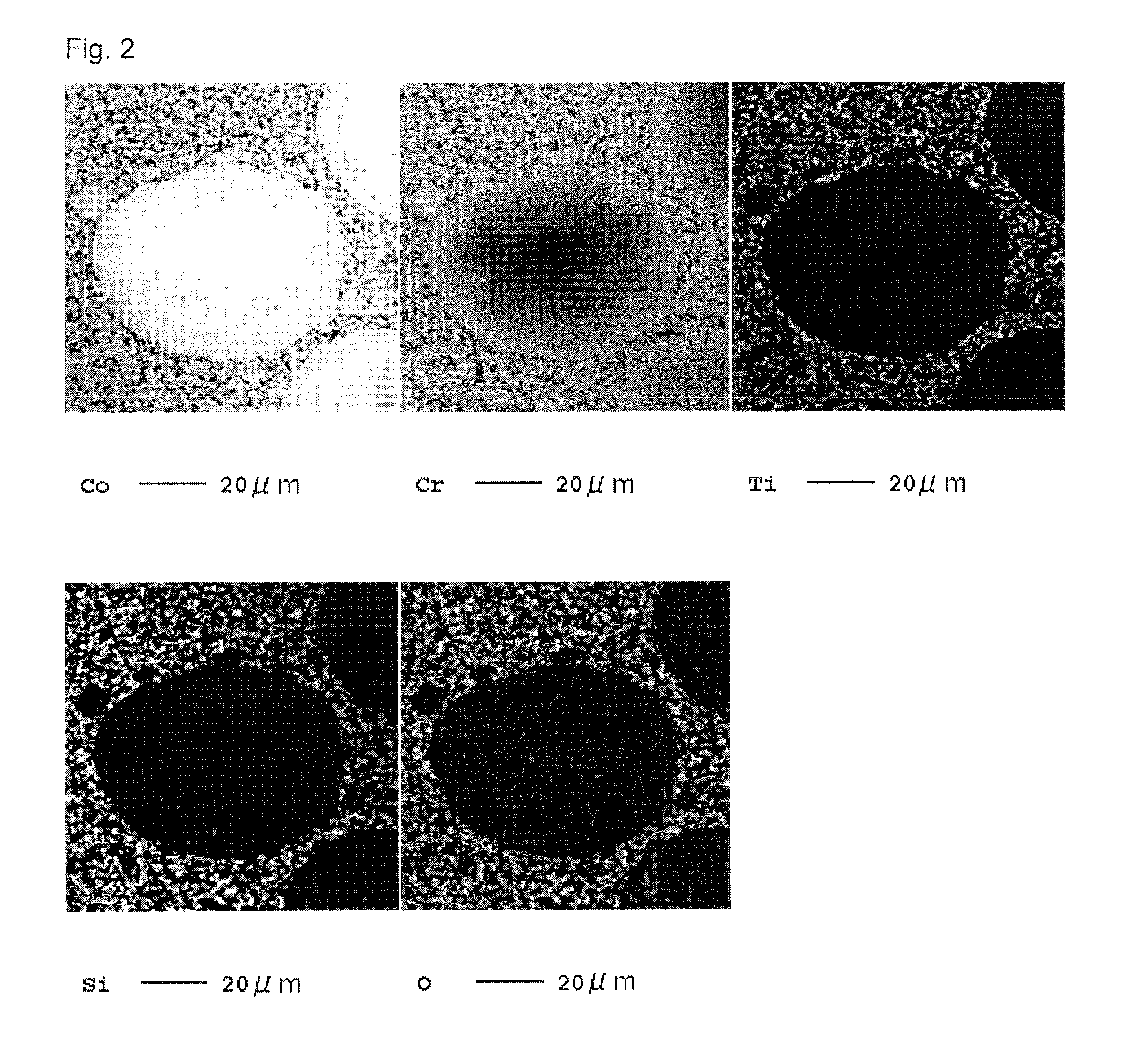

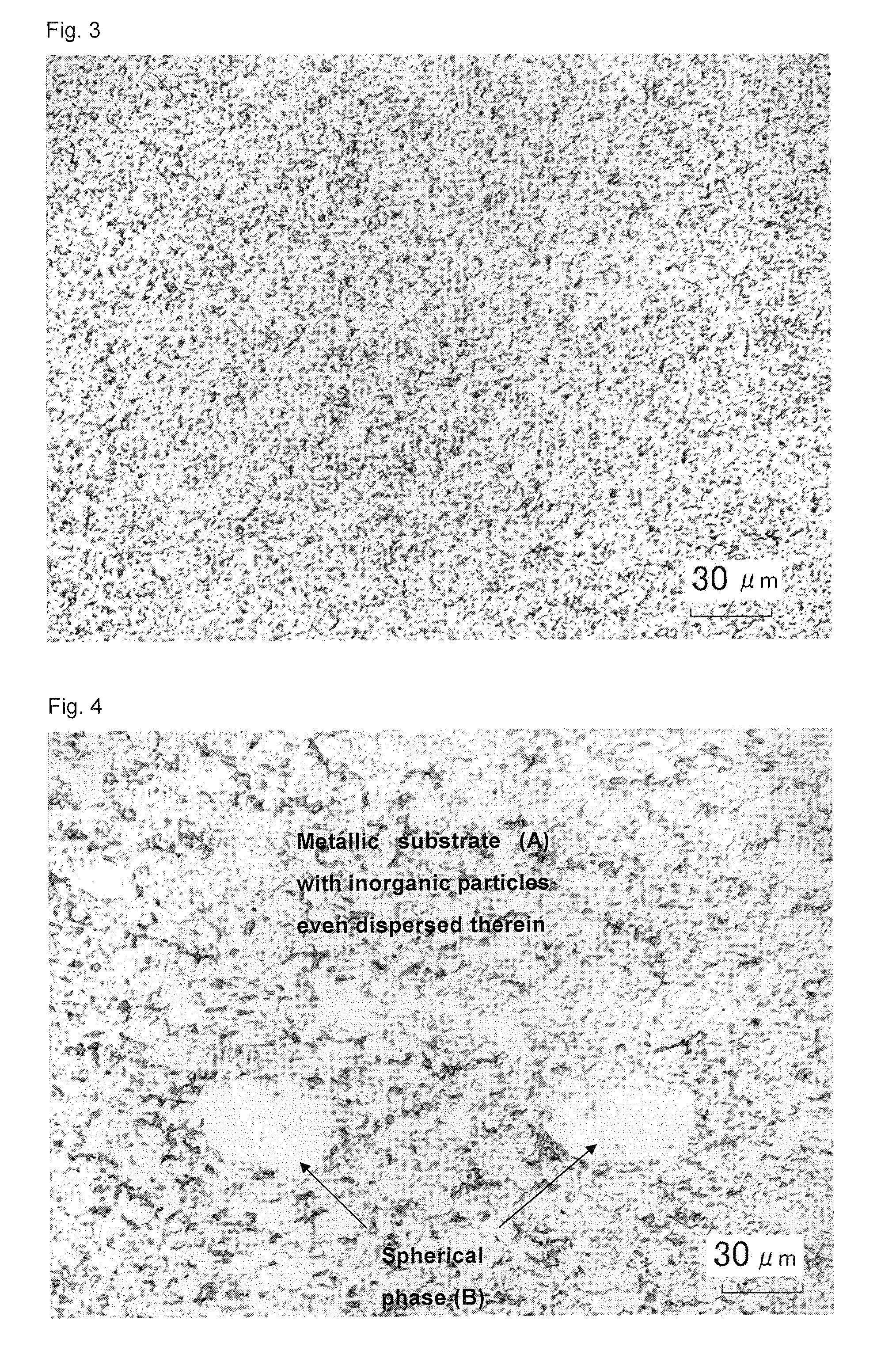

Ferromagnetic Material Sputtering Target

ActiveUS20120118734A1Improve featuresIncrease target densityCellsVacuum evaporation coatingSputteringLongest Diameter

Owner:JX NIPPON MINING& METALS CORP

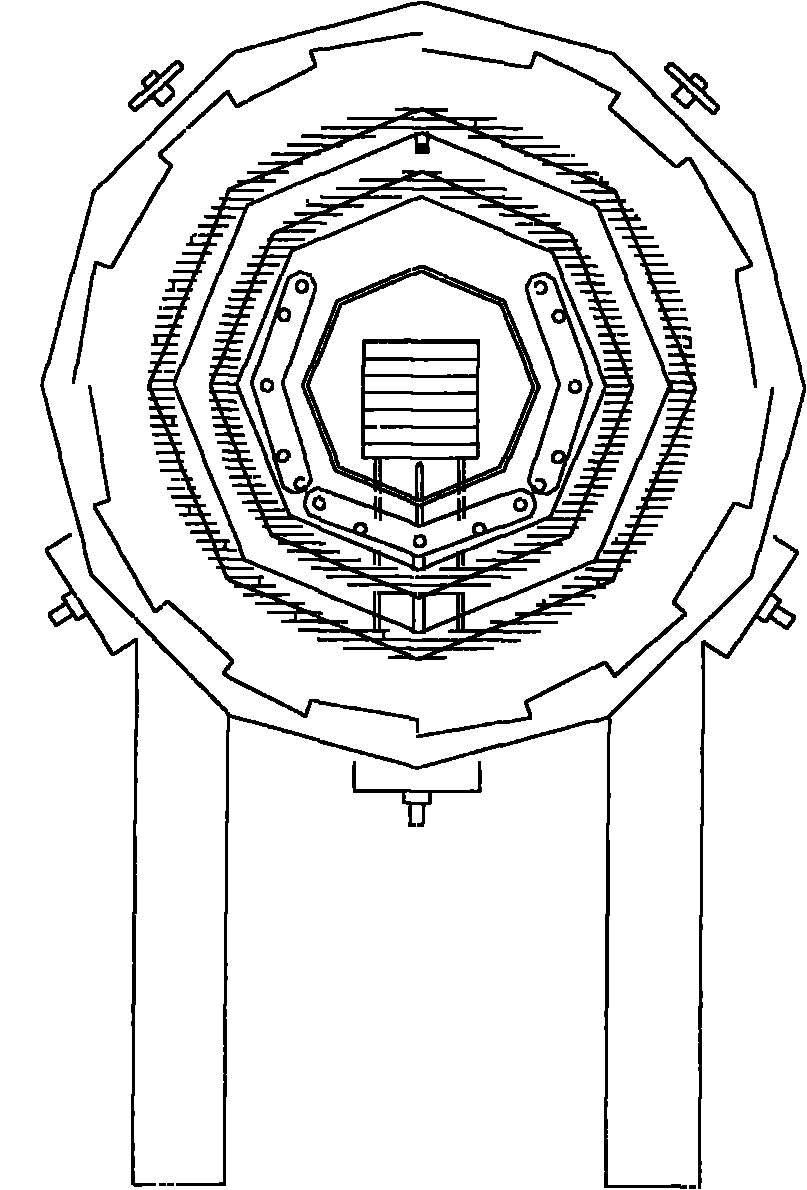

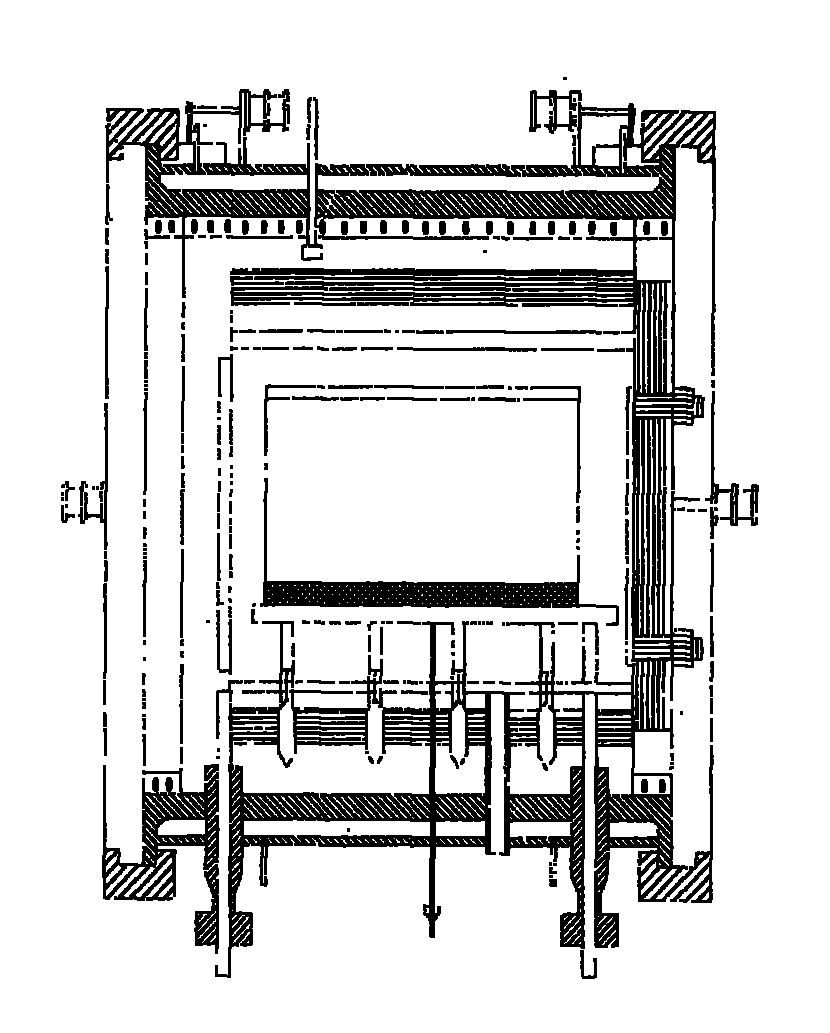

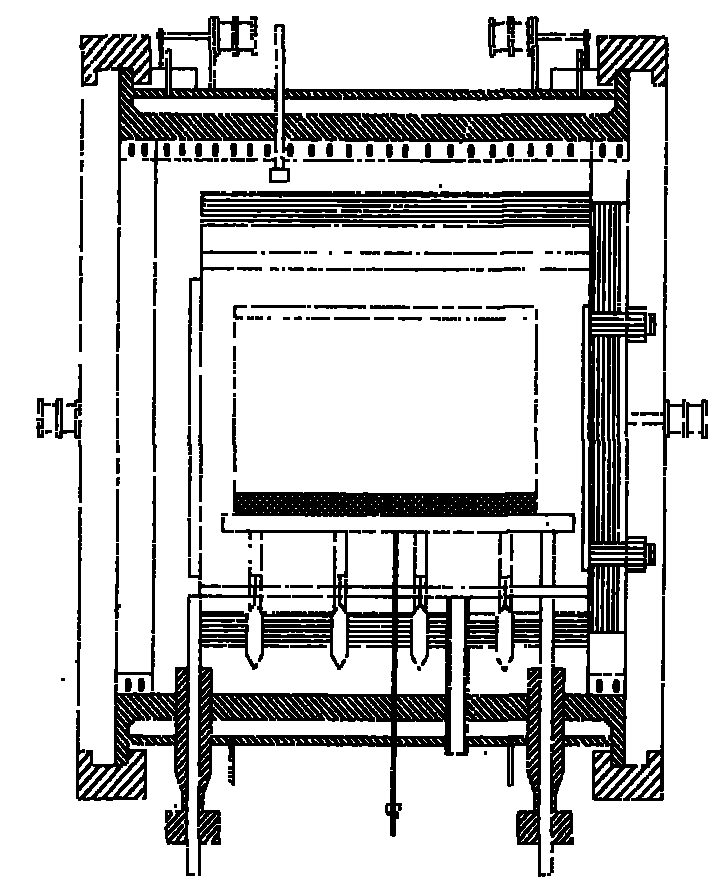

Pressure sintering furnace

InactiveCN101788226AAchieve elastic compressionSolve elastic compression problemsFurnace componentsMuffle furnacesCouplingDistribution system

The invention relates to a pressure sintering furnace used for producing hard alloys. The pressure sintering furnace comprises a furnace shell, a vacuum system, an air distribution system, a heating and thermal-insulating device, a compression system, a cooling system and a decompression device. The pressure sintering furnace is characterized in that the furnace shell is a horizontal cylinder provided with a double-wall water jacket, the furnace door on the furnace shell has a quick-opening hydraulic side-rotating structure, the furnace door of the furnace shell comprises a thermal-insulating door on the external layer of the furnace and a graphite door on the internal side of the furnace, the opening of the furnace door is controlled by a hydraulic locking device with a door-closing air cylinder, the door-closing air cylinder is provided with an elastic coupling device, and the thermal-insulating door of the furnace door is a boss thermal-insulating door. The pressure sintering furnace has stable performance and low cost and safety production can be realized by using the pressure sintering furnace, thus the uniformity of temperature field distribution in the furnace can be effectively improved and the qualification rate of products can be more than 90%.

Owner:ZHUZHOU CEMENTED CARBIDE EQUIP

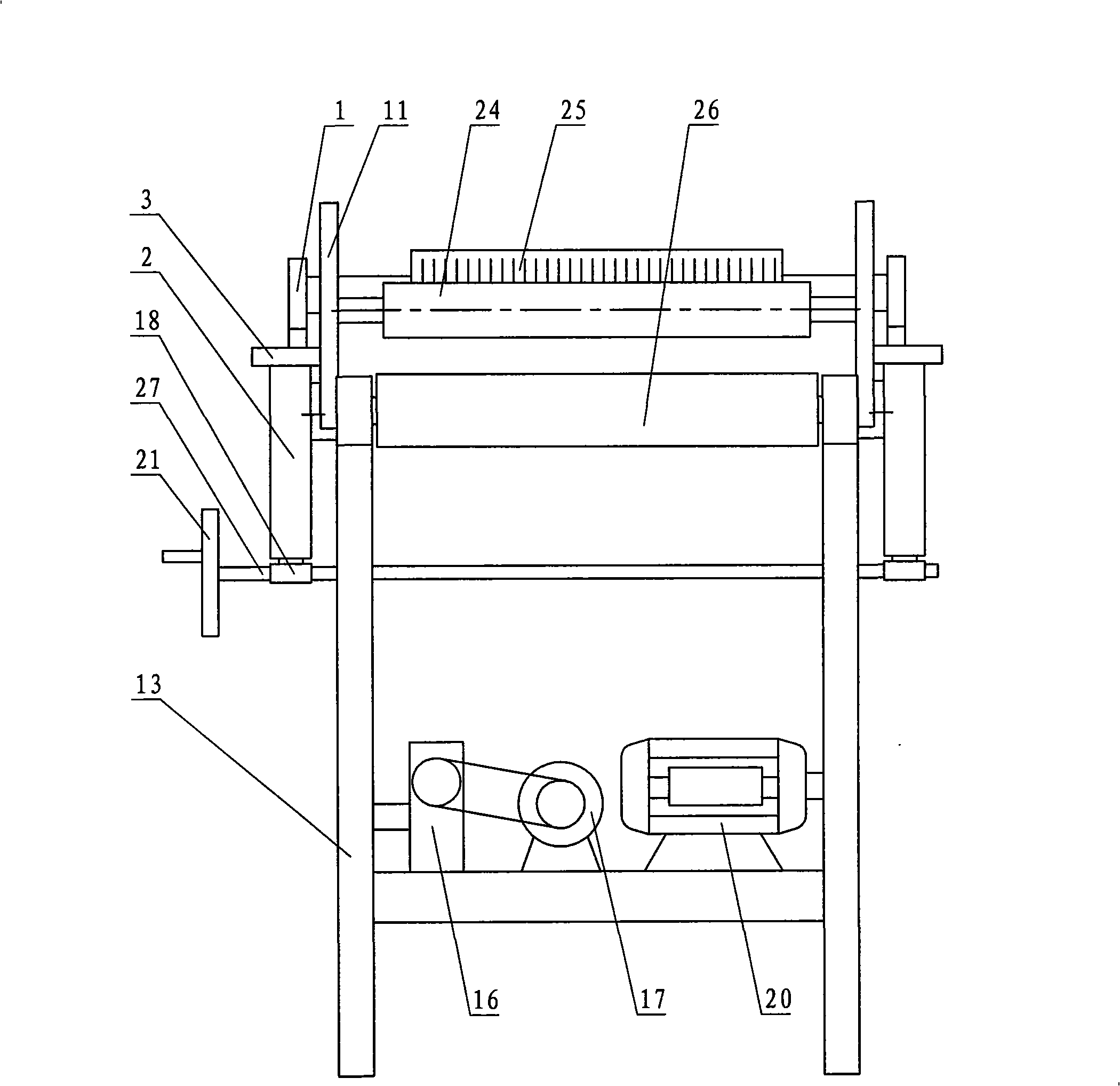

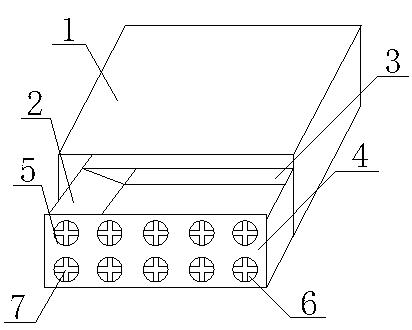

Wood block wiredrawing bench

InactiveCN101342669AThree-dimensional wood grain is smooth and obviousGood drawing effectPlane surface grinding machinesWood plankWork time

The invention relates to a board drawing mill. The board drawing mill is characterized in that the upper end face of a frame is provided with a board conveying system driven by a transmission motor which is arranged on the lower part of the frame. Pressing rolls and steel brushes are evenly arranged on the upper end face of the frame which is vertical to a conveyer belt. Each of the mounting rack of the pressing rolls and the steel brushes is provided with a controlling device which can adjust the distance between the pressing roll and the conveyer belt. The steel brushes are all driven by a steel brush motor which is fixedly arranged on the lower part of the frame. The board drawing mill has the advantages that the design is scientific and reasonable, the drawing mill can effectively shorten the work time and improve working efficiency, and the industrialization production of the board drawing mill is easily to be accomplished. The board drawing mill takes place the traditional manual drawing method, has good drawing effect, increases the meridian effect of the board surface, makes the thread much more stereoscopic, natural and so on.

Owner:SUNSHINE WOOD IND TIANJIN

PLC (planar lightwave circuit) splitter

The invention relates to the technical field of packaging of photoelectric devices, in particular to a PLC (planar lightwave circuit) splitter which comprises a casing, a box, a partition, a panel and holes. The casing is slidably connected with the box. The partition is disposed in the box. The holes are arranged on the panel of the box and are filled with sponge which is provided with cross apertures. The PLC splitter is simple in structure, practical and convenient. The PLC splitter can be examined and repaired only by drawing out the box due to the convenient drawer structure, and the use of the PLC splitter is greatly facilitated. PLC splitter components can be mounted in the box well, distribution of the components is reasonable, production is facilitated, influence by entering dust is relieved, the service life of the PLC splitter is prolonged, replacement frequency and using cost are lowered, and the PLC is convenient to apply and popularize.

Owner:CHANGZHOU LINKET ELECTRONICS TECH

Textile winding roller

ActiveCN108178025AInstalled and disassembledImprove replacement efficiencyFilament handlingYarnGear wheel

The invention discloses a textile winding roller comprising a winding roller body. The two ends of the winding roller body are both provided with limiting plates. The circle centers of the sides, faraway from each other, of the two limiting plates are each fixedly connected with one end of a supporting shaft. The end, far away from the corresponding limiting plate, of one supporting shaft is fixedly provided with a transmission gear. The transmission gear is meshed with an output shaft of a drive motor on a spinning machine. The end, far away from the limiting plate, of the other supporting shaft is fixedly connected with a supporting disk. The supporting disk is parallel to the corresponding limiting plate. The middle sections of the two supporting shafts are provided with supporting blocks through bearings. The textile winding roller is novel in design and convenient and rapid to use, the winding roller body is fixedly installed on a machine frame of the spinning machine through a connection mechanism, installation is firm, and disassembly is convenient and rapid; and a yarn carding device can tightly press the yarn during carding, so that the winding amount of a single windingroller body is improved, frequent replacement of the winding roller is avoided, and the work efficiency of the spinning machine is improved.

Owner:安徽海洋网业有限公司

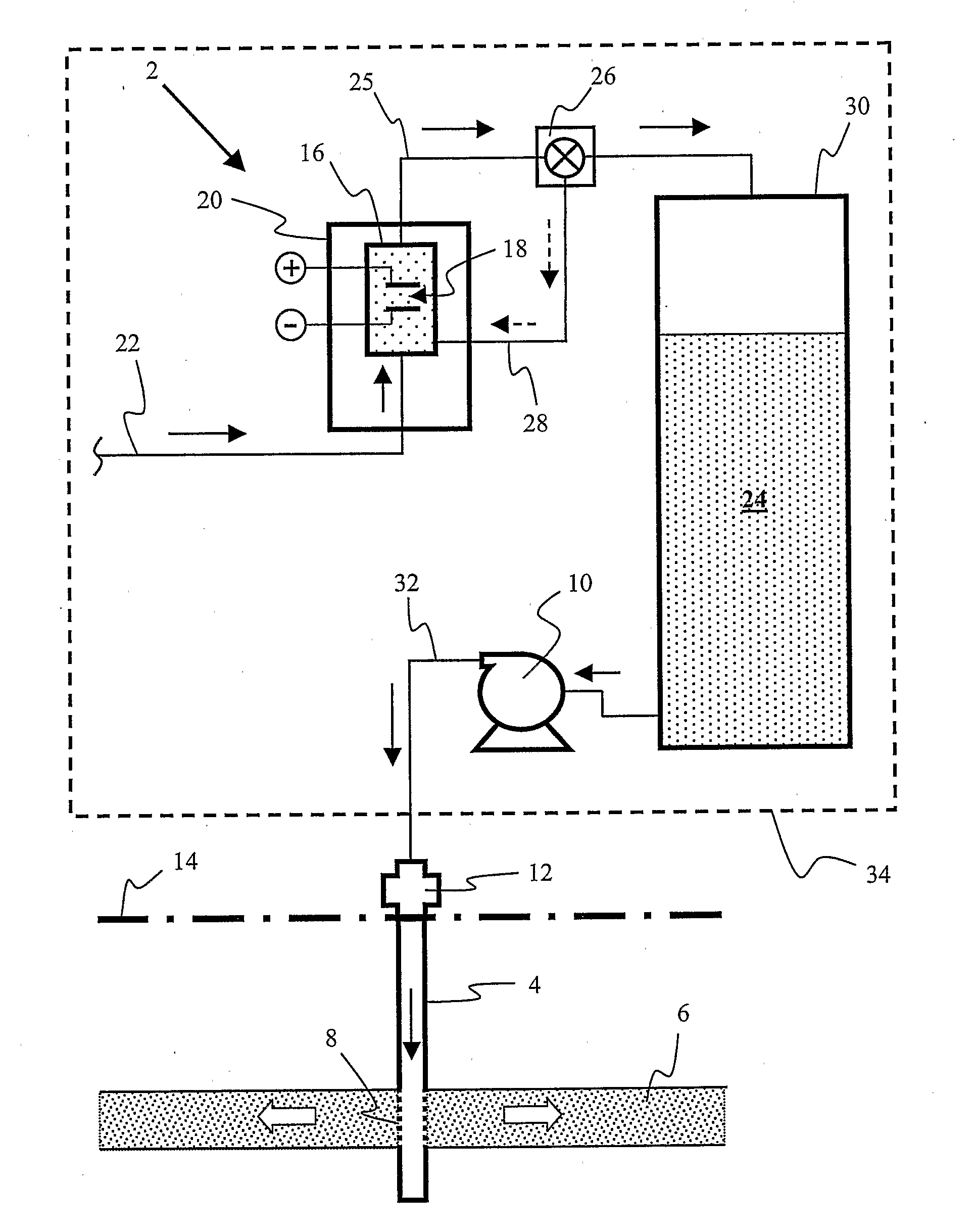

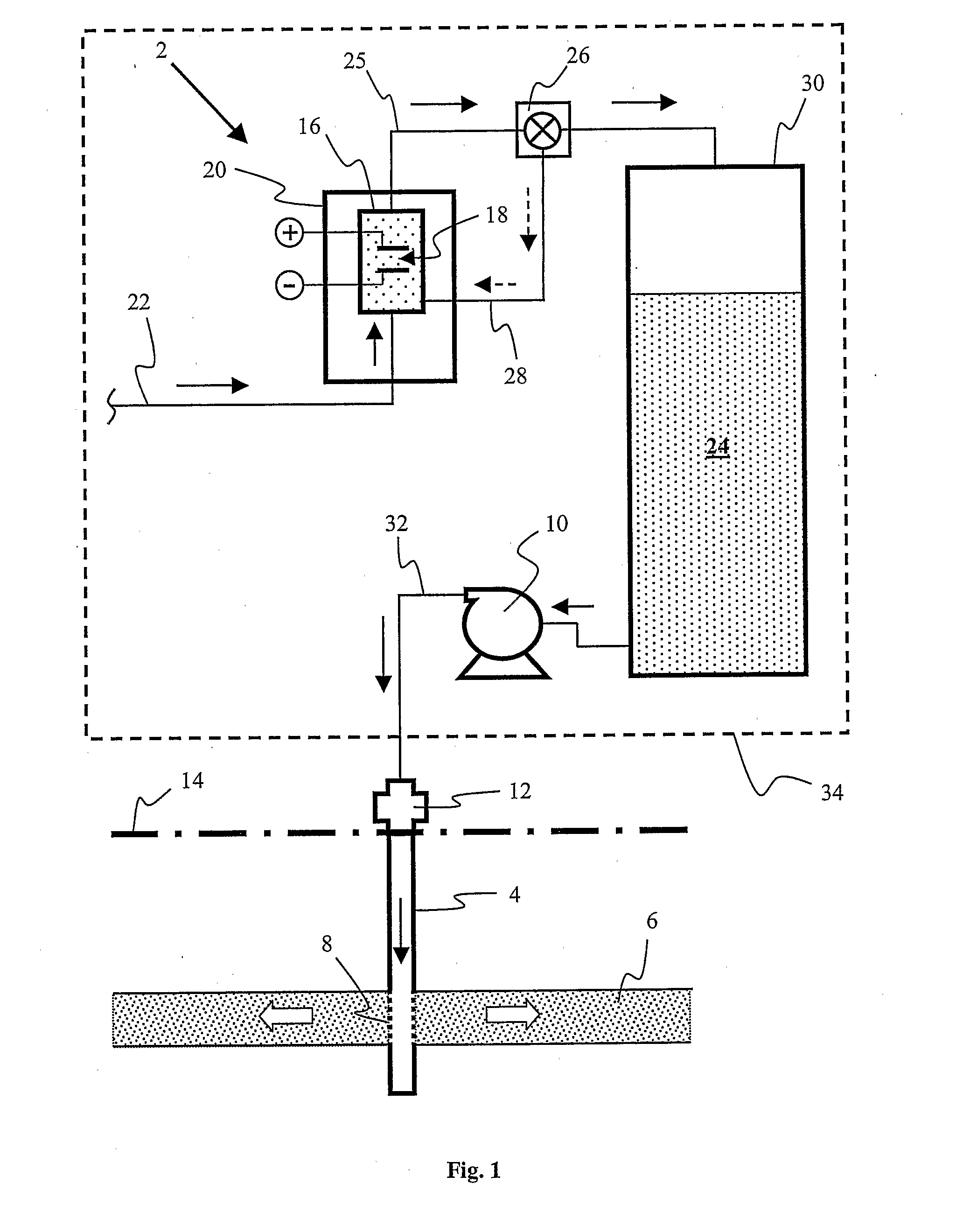

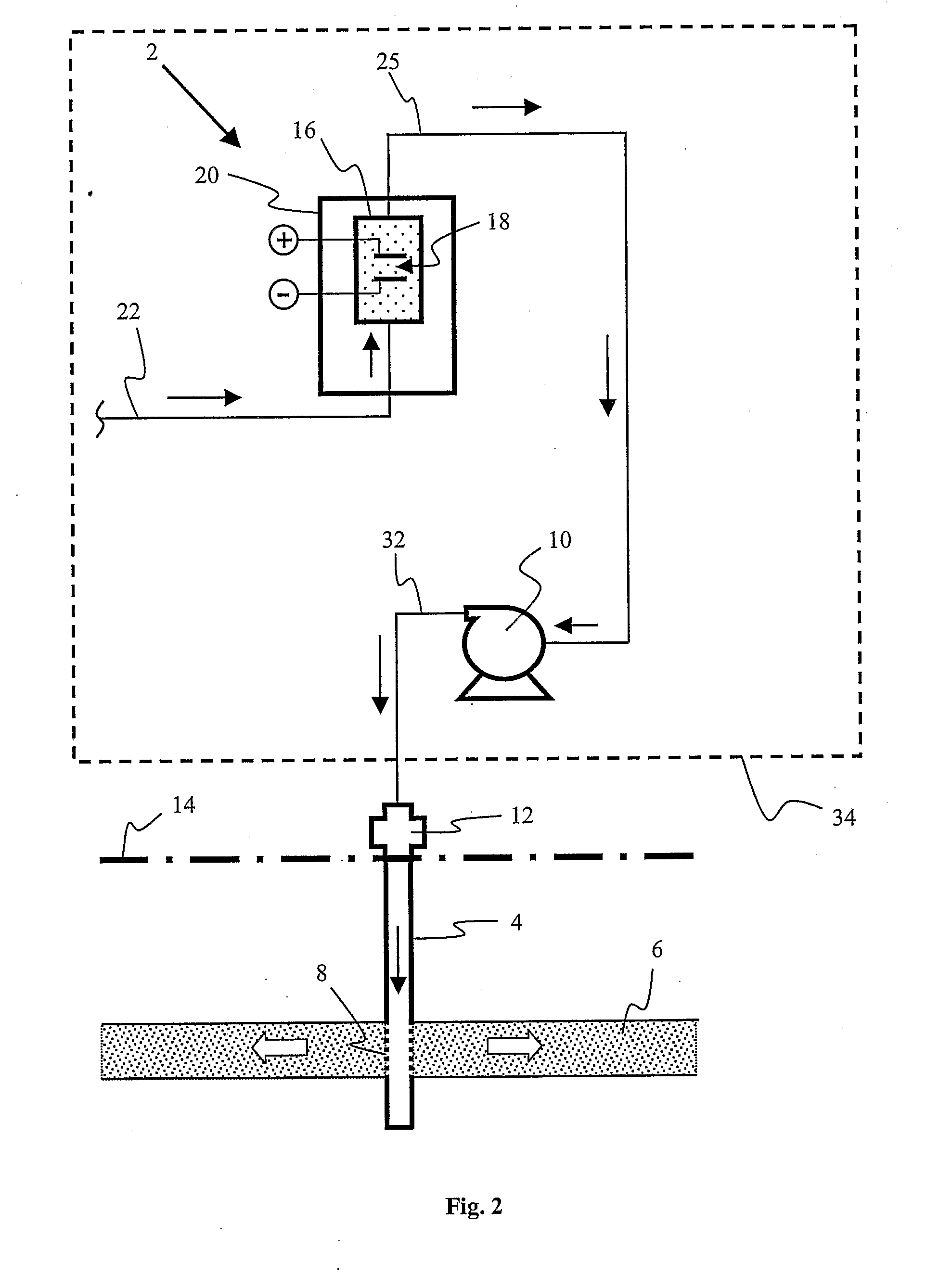

Method and a device for destructing organic material in injection water and use of injection water for generation of destructive hydroxyl radicals

ActiveUS20090301717A1Simple and inexpensive and efficientShort lifeDrilling rodsMachines/enginesElectrolysisSource material

A method and a device (2) for destruction of organic material in injection water for an injection well (4), in which a means (10) for introduction of water in the injection well (4), and at least one electrochemical cell (16) with associated operating means are used for in situ electrolytic generation from water of at least short-lived, free hydroxyl radicals. The distinctive characteristic of the invention is that it comprises the following steps: (A) to connect the at least one electrochemical cell (16) to the injection well (4); and (B) by means of said operating means, to conduct the injection water through said cell (16) for in situ generation of at least free hydroxyl radicals from the injection water, insofar as free hydroxyl radicals immediately destruct organic material that they engage in the injection water. The invention also comprises use of water, which is to be injected into an injection well (4), as a source material for in situ electrolytic generation of said hydroxyl radicals for immediately destruction of organic material in the injection water.

Owner:SEABOX

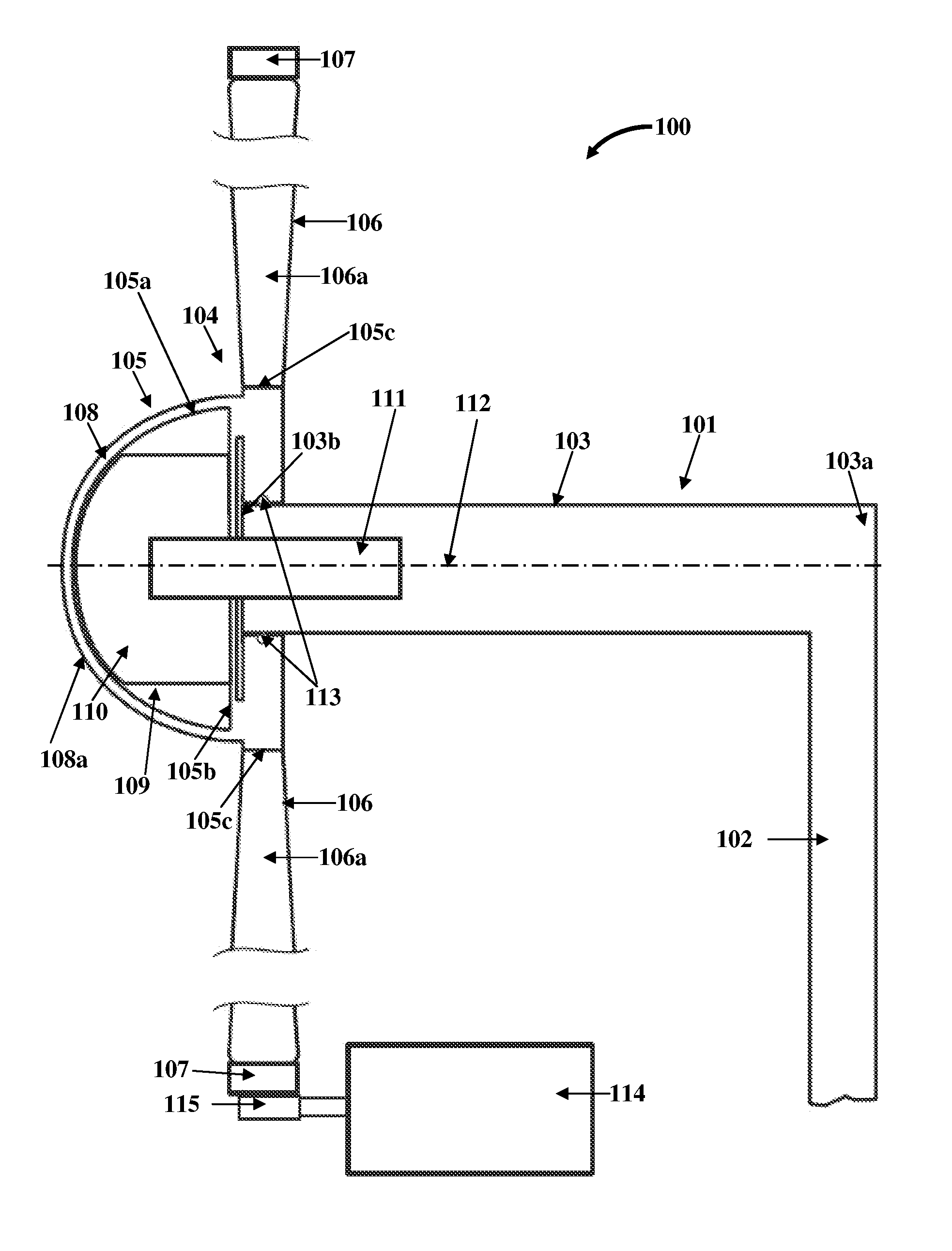

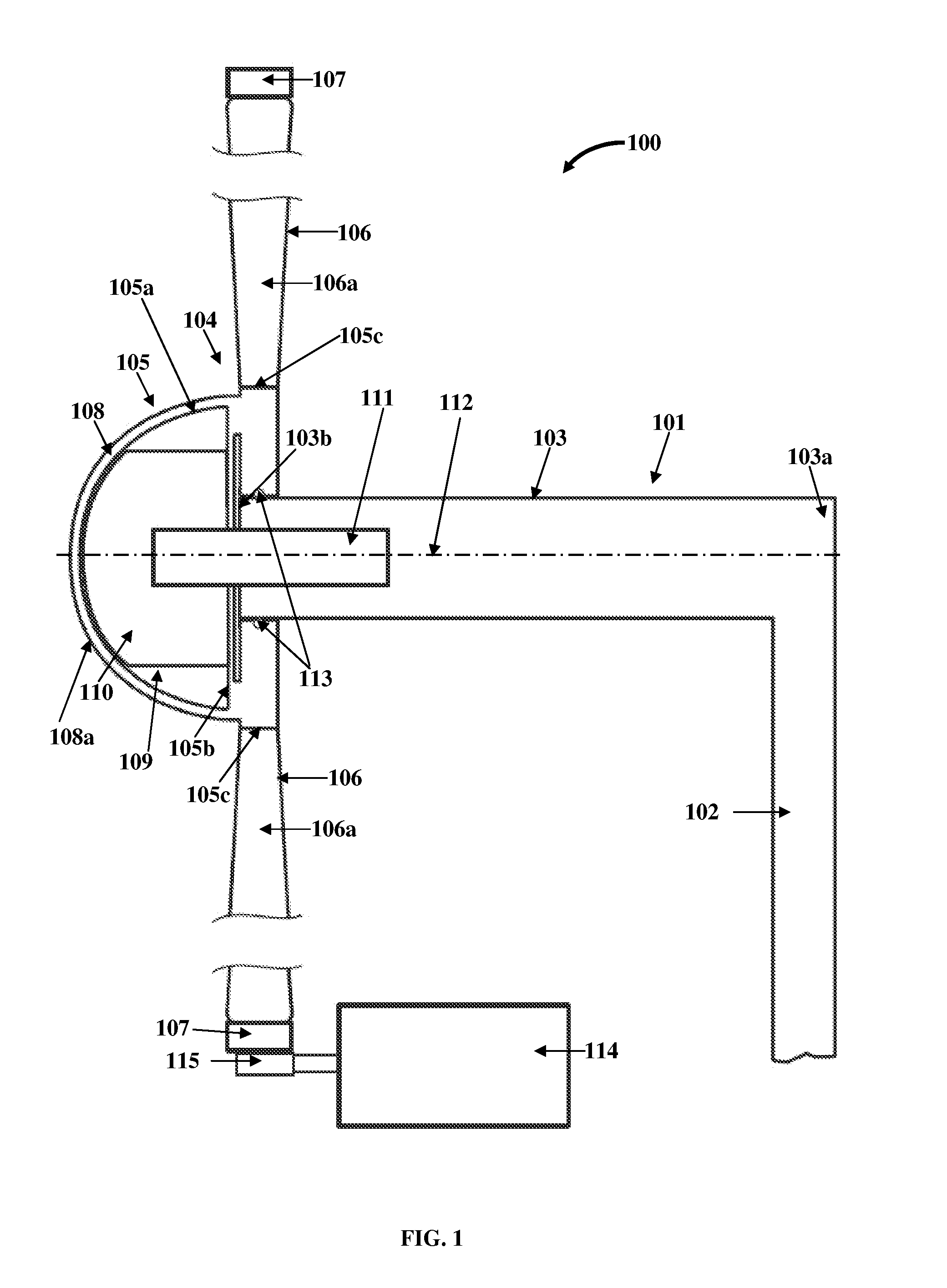

Hybrid Horizontal Axis Energy Apparatus

ActiveUS20110215587A1Improve efficiencyHigh energyWind motor with solar radiationWind energy with electric storageElectricityMechanical energy

A hybrid horizontal axis energy apparatus comprising a frame and a rotor assembly rotatably connected to the frame is provided. A drive mechanism is rigidly attached on the rotor assembly and is in engageable communication with an adjacent drive mechanism of an adjacent rotor assembly for rotating the adjacent rotor assembly. One or more solar devices, rigidly attached to the rotor assembly, produce electrical energy. A motor is electrically connected to the solar devices and rotates the rotor assembly about a horizontal axis of the frame on receiving the electrical energy produced by the solar devices. An electrical generator, in engageable communication with the rotor assembly via the drive mechanism, converts mechanical energy produced by the rotation of the rotor assembly to electrical energy. The rotation of the rotor assembly removes light attenuating particles from the solar devices housed on the rotor assembly, thereby increasing efficiency of the solar devices.

Owner:LEE WILLIAM EDWARD +1

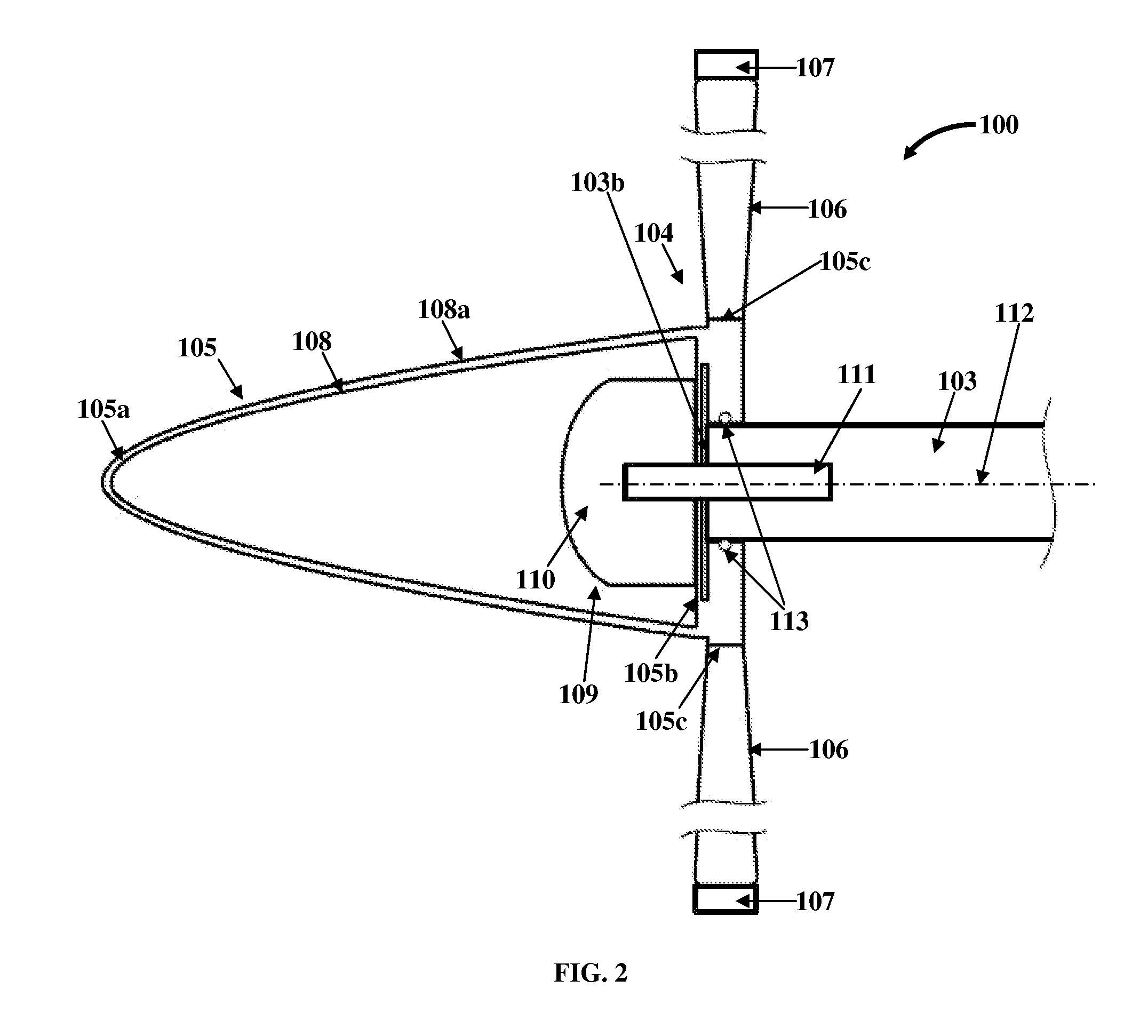

Cleaning device, inkjet printer, and an inkjet printer cleaning method

InactiveUS20070035574A1Suppressing ink wasteInk waste can be suppressedPrintingComputer printingInk printer

A cleaning mechanism for cleaning a print head in an inkjet printer with the print head having ink nozzles for discharging ink including a drive control unit which operates the cleaning mechanism at a first process level or a second process level that consumes less ink than the first process level; a timer which counts the elapsed time passed in which the print head is in a no-printing state; and a process selection unit responsive to a predetermined input cleaning command for selecting the first process level when the no-printing state has continued for less than a predetermined time or the second process level when the no-printing state has continued for greater than the predetermined time, based on the value of the timer when the predetermined input cleaning command is received. The predetermined input cleaning command can be received from a cleaning button or from a host computer. The drive control unit operates the cleaning mechanism at the process level selected by the process selection unit according to the predetermined input cleaning command.

Owner:SEIKO EPSON CORP

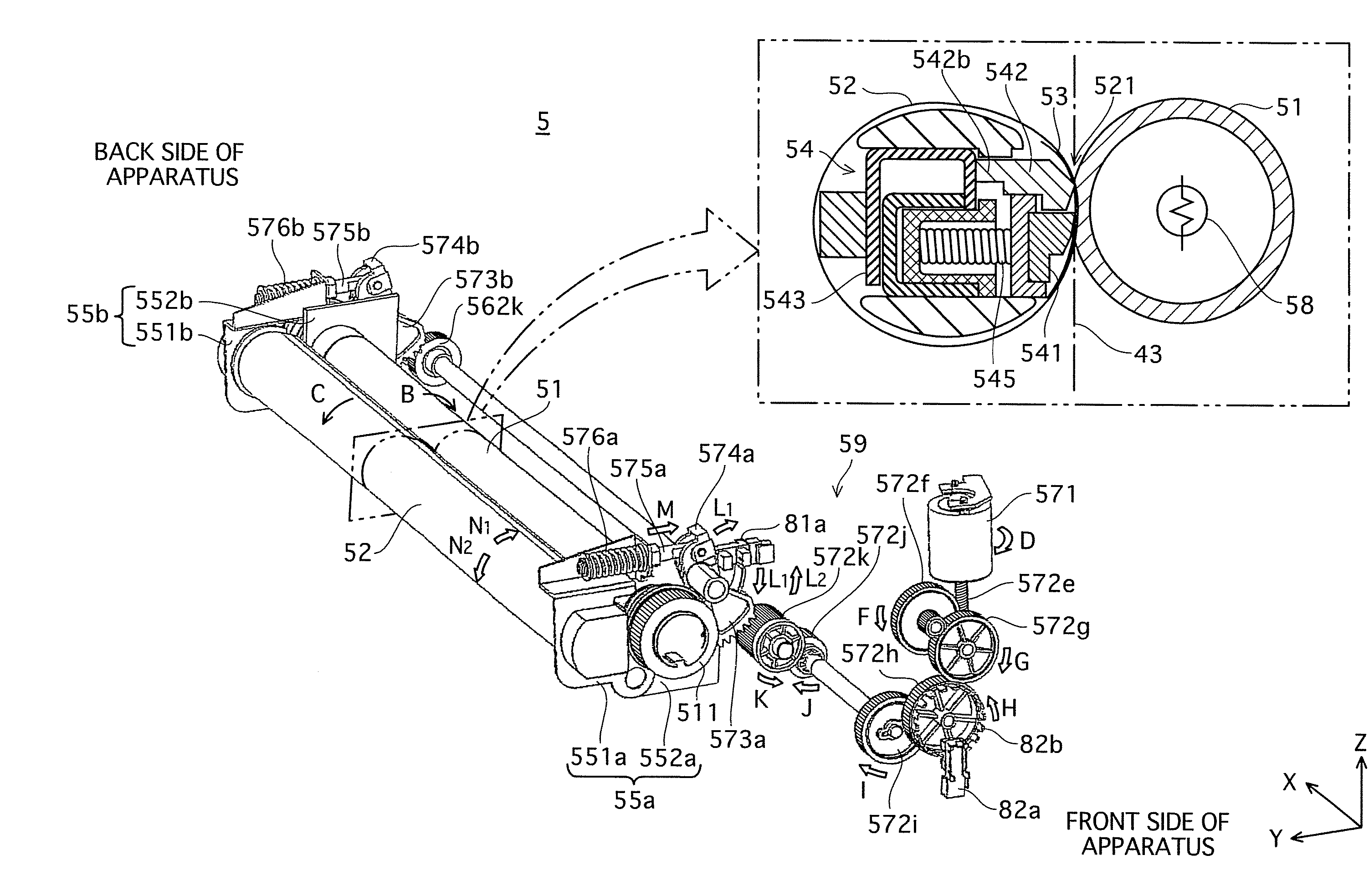

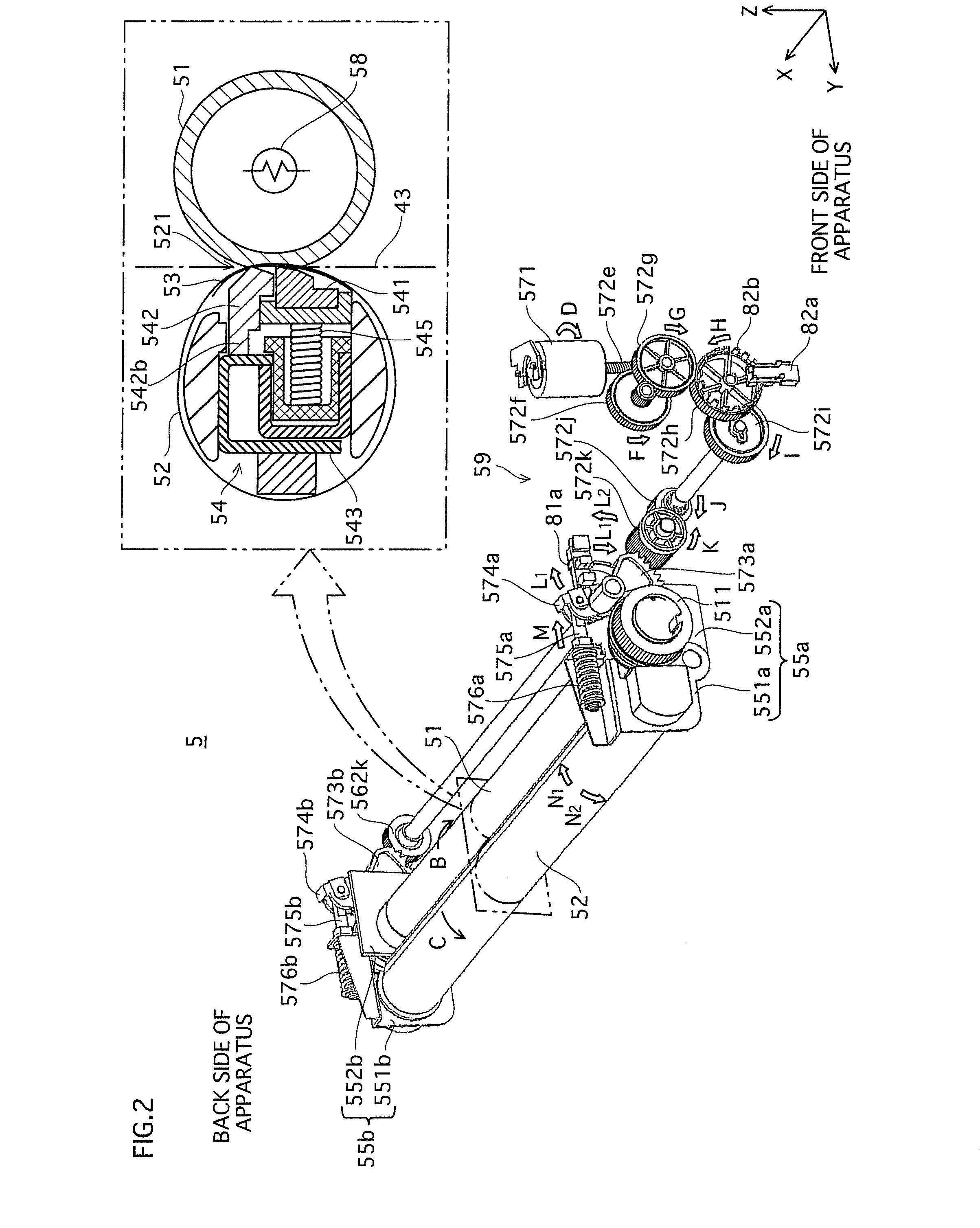

Fixing apparatus in which a fixing nip is secured by a pressure belt and a fixing roller, and image formation apparatus that includes the fixing apparatus

InactiveUS20090052925A1Reduce pressure areaAvoid it happening againElectrographic process apparatusImage formationEngineering

A belt-nip system fixing apparatus or an image formation apparatus including the fixing apparatus reduces the frequency of replacing a pressure belt or a sliding sheet. In accordance with a sheet measurement in a roller axis direction, the fixing apparatus or image formation apparatus switches a pressure distribution in the roller axis direction between a low-pressure load distribution in which pressure is greatest at a center pressure switching projection (542b) of a hard pad (542), and pressure gradually lessens towards pressure switching projections (543c) near the ends of the hard pad (542), and the pressure in a range of 216 [mm] in a center in the roller axis direction is greater than or equal to a necessary pressure for fixing (a predetermined value Nm) while the pressure in other projections near the ends is below the predetermined value Nm, and a high-pressure load distribution in which the pressure throughout the total area in the roller axis direction equals or exceeds the predetermined value Nm.

Owner:KONICA MINOLTA BUSINESS TECH INC

Method, device, and system for supplying power from batteries

InactiveUS20120293002A1Increase profitExtended standby lifeBatteries circuit arrangementsPower network operation systems integrationElectrical batteryEngineering

A method for supplying power from batteries includes: detecting a power supply state of a cycling battery in a system, where the system firstly uses the cycling battery to supply power to a load; and when a voltage of the cycling battery drops to a voltage threshold, activating a standby battery to supply power to the load.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com