PLC (planar lightwave circuit) splitter

A technology of optical splitter and box body, applied in the direction of fiber mechanical structure, etc., can solve the problems of short service life, easy failure, high replacement frequency, etc., achieve reasonable component distribution, prolong service life, practical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

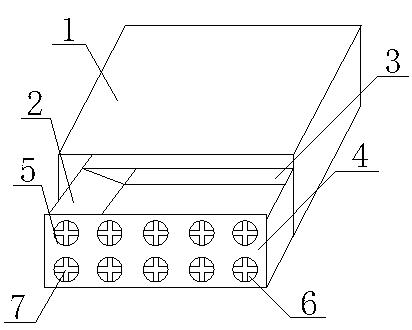

[0011] Such as figure 1 It is a structural schematic diagram of the present invention, a PLC optical splitter, including a housing 1, a box body 2, a partition 3, a panel 4, a hole 5, a sponge 6 and a cross-shaped opening 7, and the housing 1 is slidably connected to the box body 2, A partition 3 is arranged inside the box body 2, and a hole 5 is arranged on the panel 4 of the box body 2, and a sponge 6 is filled in the hole 5, and a cross-shaped opening 7 is arranged on the sponge 6.

[0012] When in use, the shell 1 is slidingly connected to the box body 2, and the inside of the box body 2 is separated by a partition 3, so that the distribution of the optical splitter components is relatively reasonable. There are holes 5 on the front panel 4 of the box body 1, and the sponge 6 is filled in In the hole 5, the sponge 6 has a cross-shaped opening 7, which can prevent dust from entering the box body 2. This kind of PLC optical splitter is simple in structure, practical and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com